Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Good transportation safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Difenoconazole emulsible powder

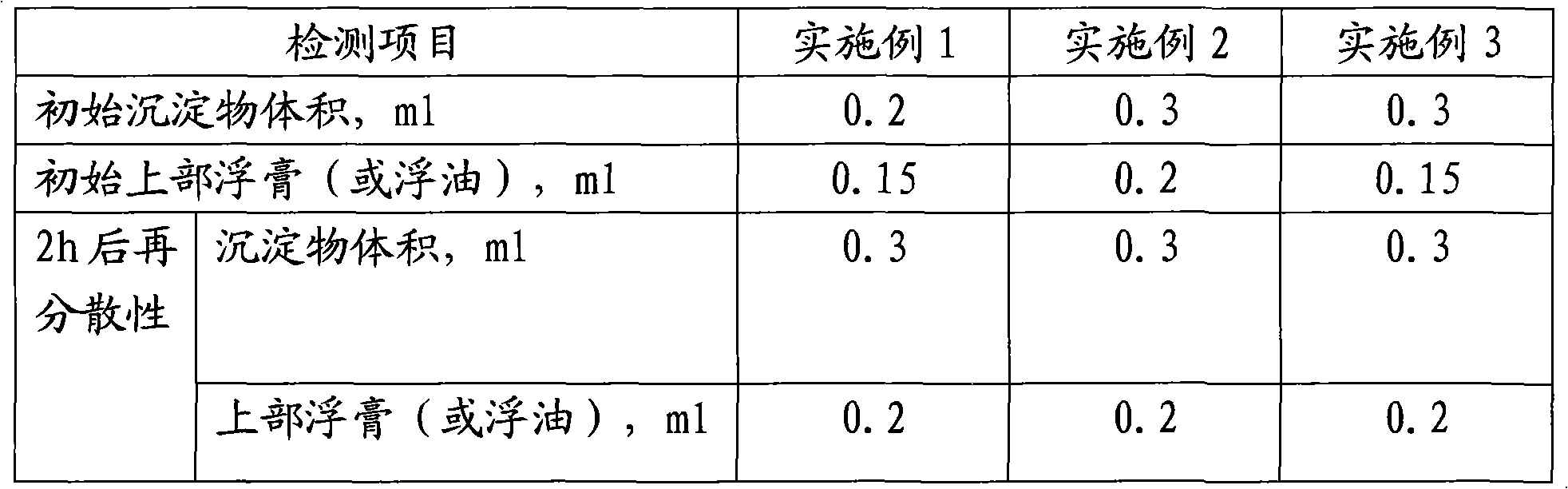

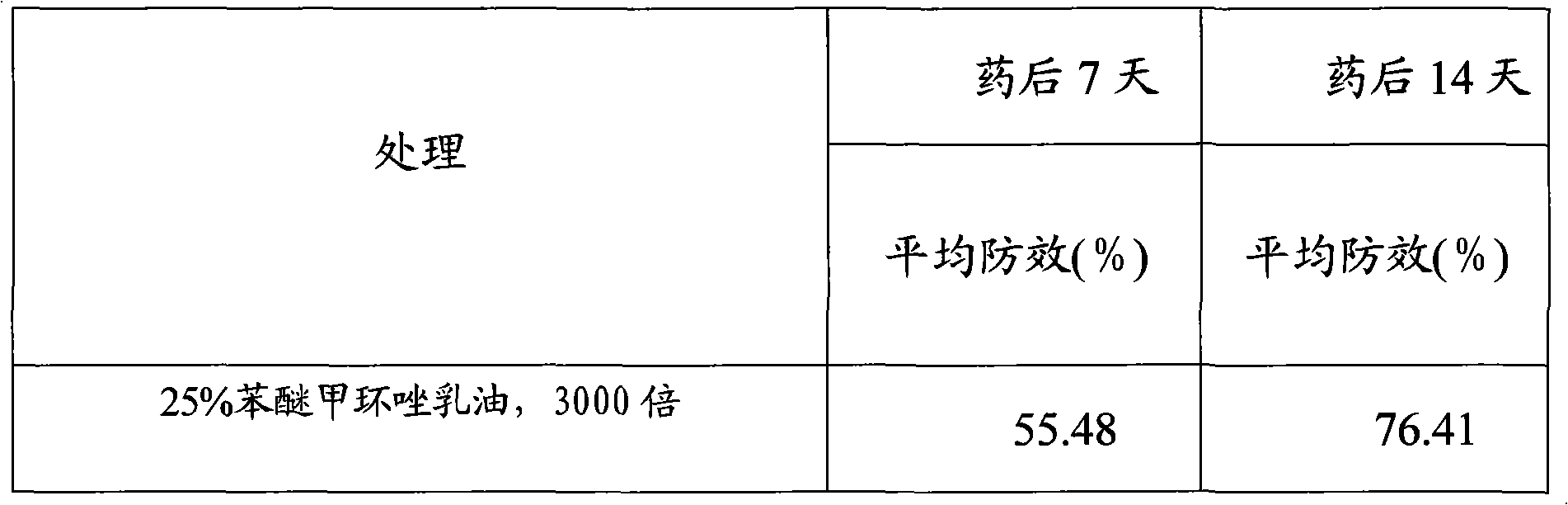

The invention relates to difenoconazole emulsible powder, which is agricultural germicide taking original difenoconazole as effective constituents and the dosage form is emulsible powder; the emulsible powder is constituted by the following constituents in percentage by the mass fraction: 5-60% of difenoconazole, 0-5% of solvent, 0.5-10% of dispersing agent, 0.5-30% of emulsifier, 0-8% of wetting agent, 0.1-5% of suspending agent and the balance of carrier. The optimized dispersing agent is sodium lignosulfonate or the dispersing agent MF; the emulsifier is difenoconazole emulsifier or the combination of pesticide emulsifier 500 or pesticide emulsifier 600 and pesticide emulsifier 700; the wetting agent is lauryl sodium sulfate or wetting agent JFC; the suspending agent is carboxymethyl cellulose or xanthan gum; the carrier is pot clay and white carbon black. Tests prove that the pesticide effect of emulsible powder in the invention corresponds to that of difenoconazole missible oil, and the contained organic solvent is far less than the missible oil and emulsion in water, thus having little contamination on the environment and good storage and transportation safety.

Owner:JIANGSU FENGDENG PESTICIDE

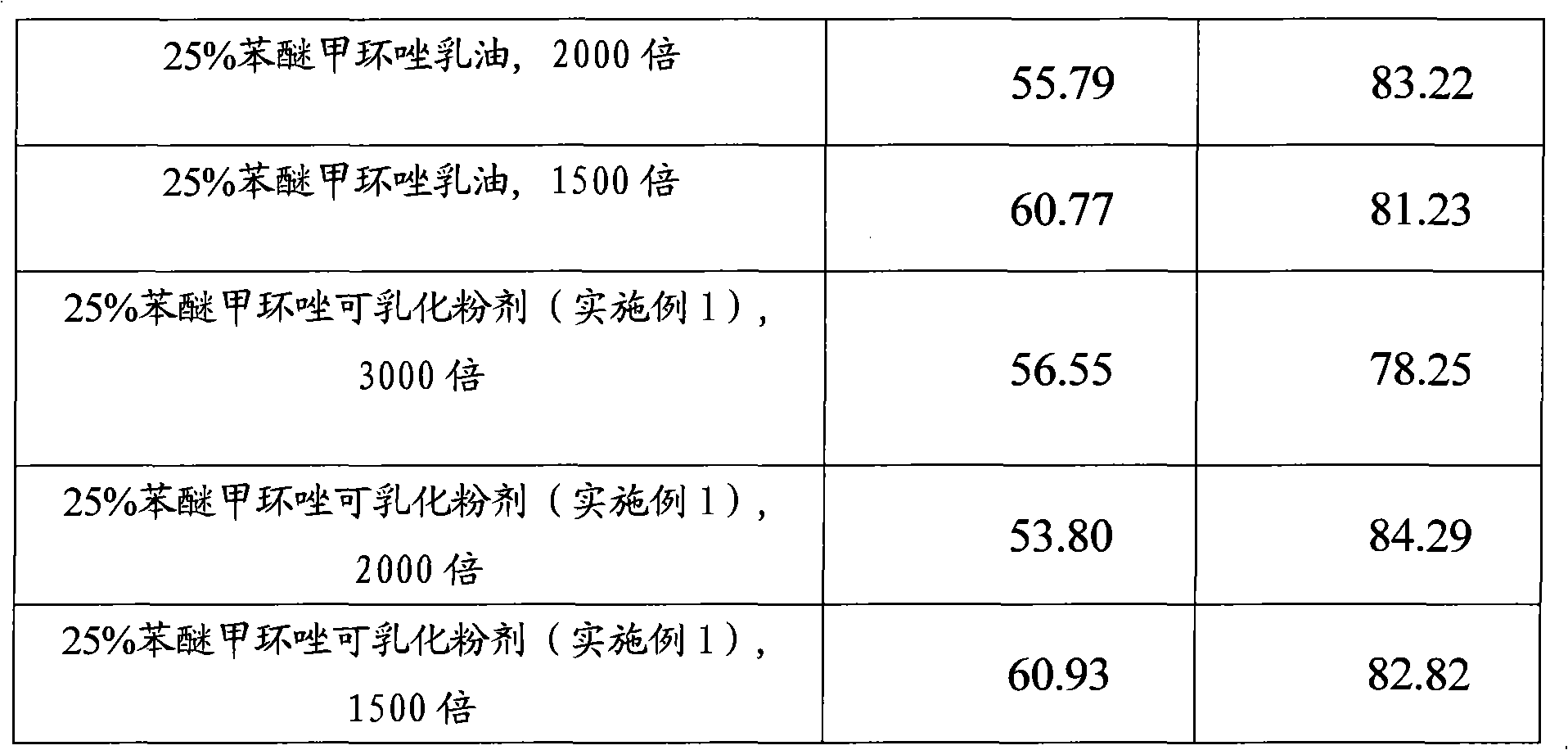

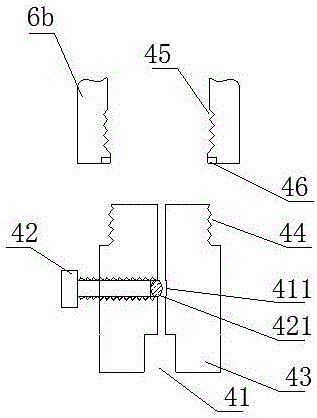

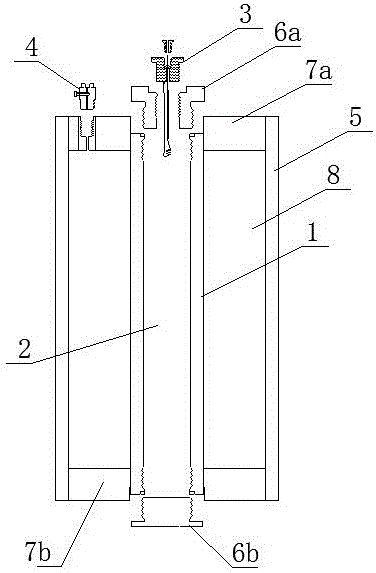

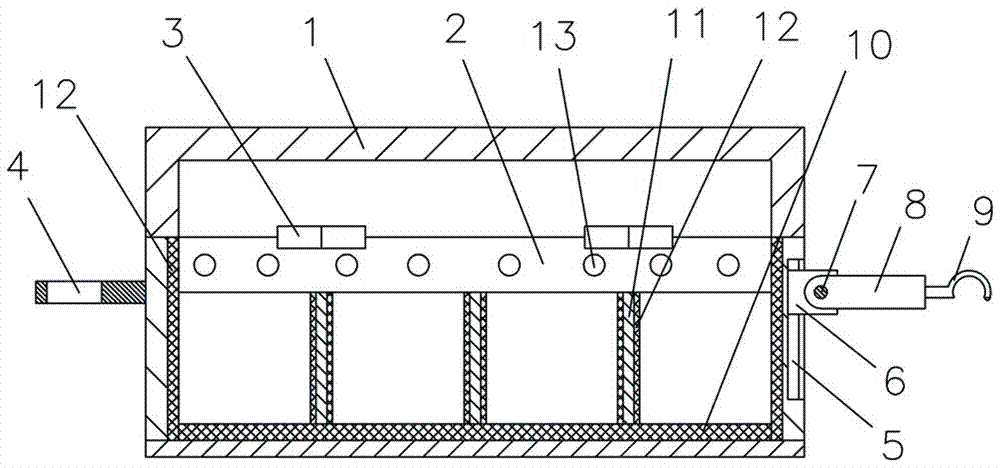

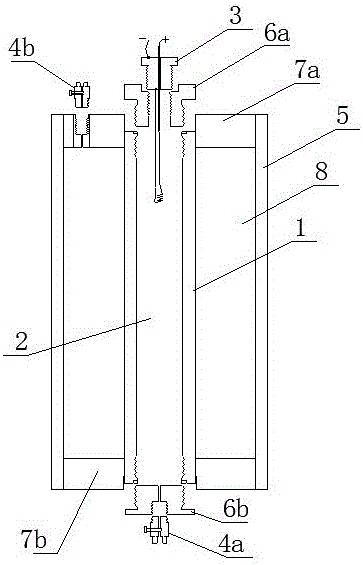

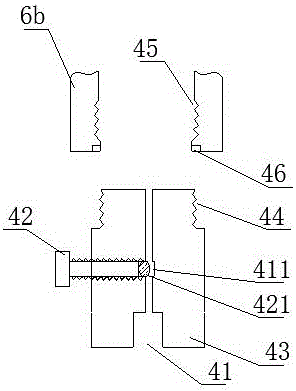

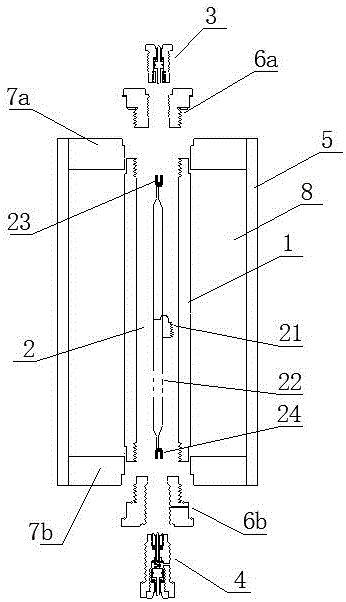

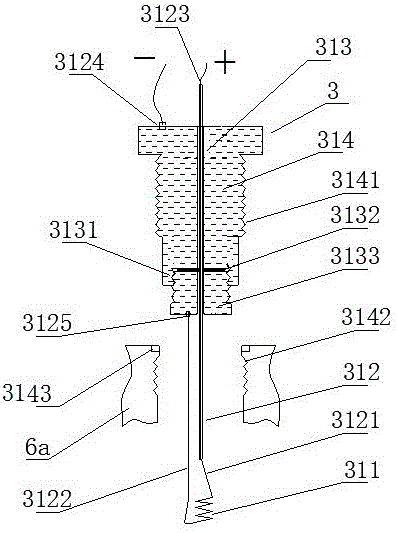

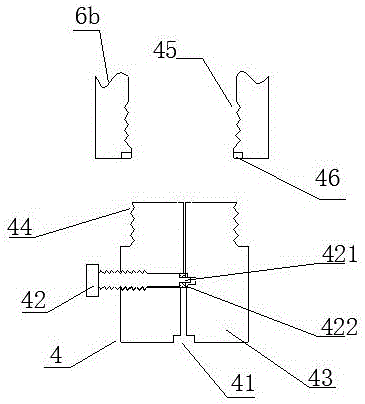

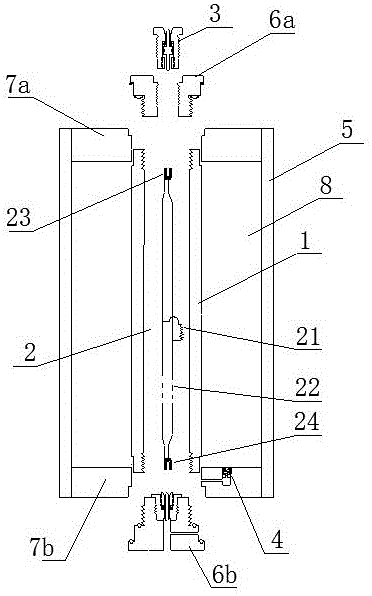

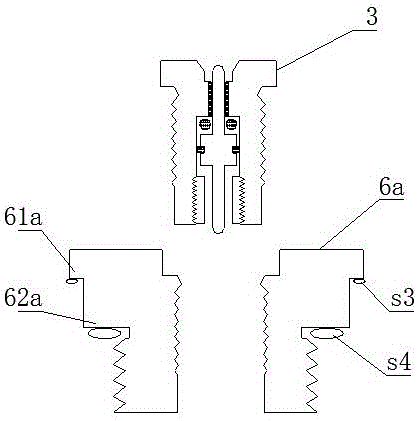

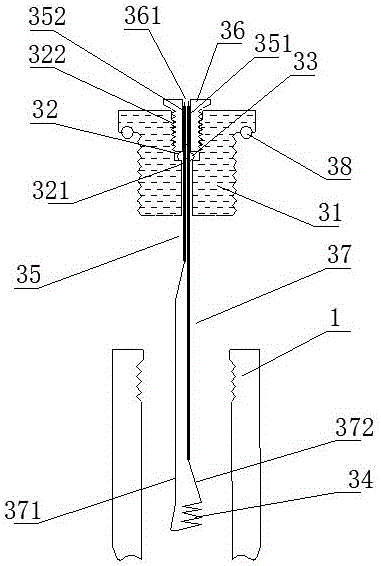

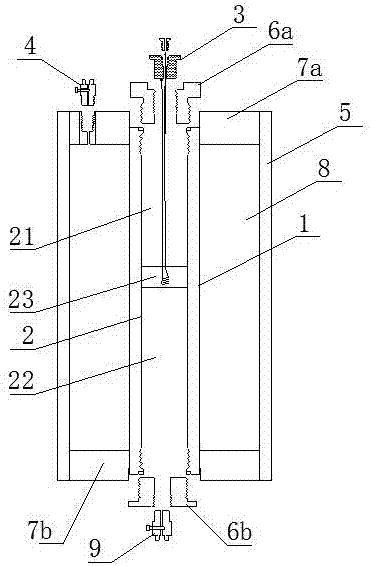

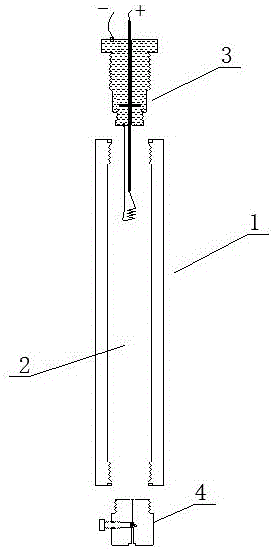

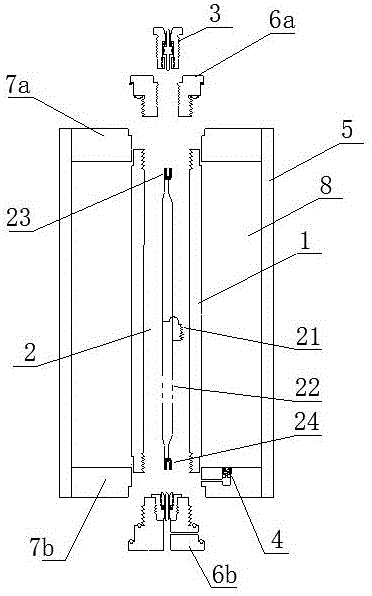

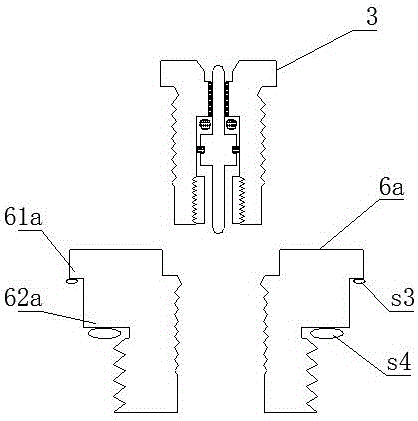

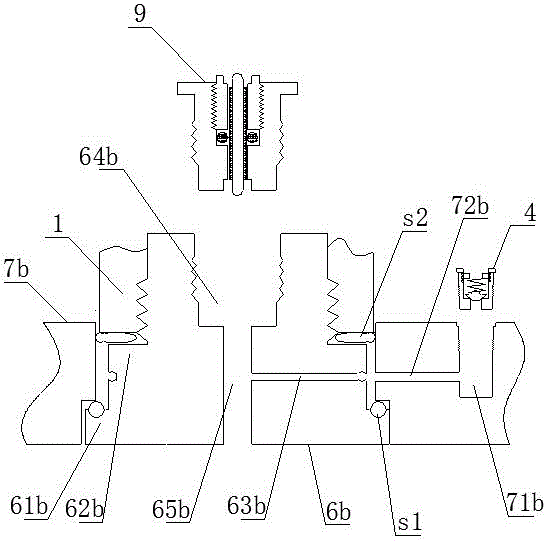

Gas-inflating-and-locking-integrated gas blaster

InactiveCN106643314AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesCheck valvesEngineeringLiquid carbon

The invention discloses a gas-inflating-and-locking-integrated gas blaster. The gas-inflating-and-locking-integrated gas blaster comprises an inner tube, an inner-tube filling cavity, an ignition mechanism, an inner-tube gas inflating mechanism and an outer tube. The inner-tube filling cavity is formed in the inner tube, a first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner tube in a sealed mode respectively, the outer tube is arranged on the outer layer of the inner tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, the ignition mechanism and the inner-tube gas inflating mechanism are installed on the first sealing inner cover or the second sealing inner cover, and an outer-tube gas inflating mechanism is installed on the first sealing outer cover or the second sealing outer cover; a sealed cavity between the inner tube and the outer tube is an outer-tube filling cavity, the inner-tube filling cavity is filled with supercritical oxygen and carbonaceous organic materials, and the outer-tube filling cavity is filled with liquid easy-to-gasify materials such as liquid carbon dioxide or liquid nitrogen. The gas-inflating-and-locking-integrated gas blaster has the advantages that the manufacturing cost is low, the mixing uniformity of reaction materials is high, the heat releasing efficiency is high, the transportation safety is good, and the blasting power is large.

Owner:郭远军

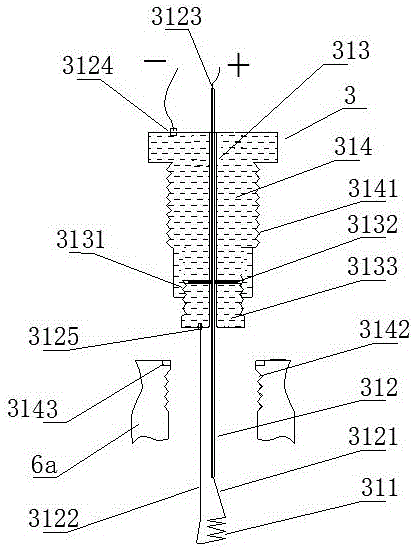

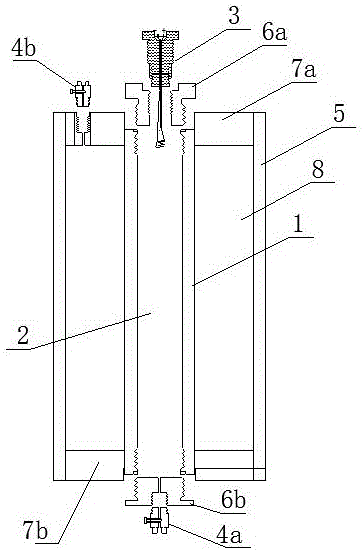

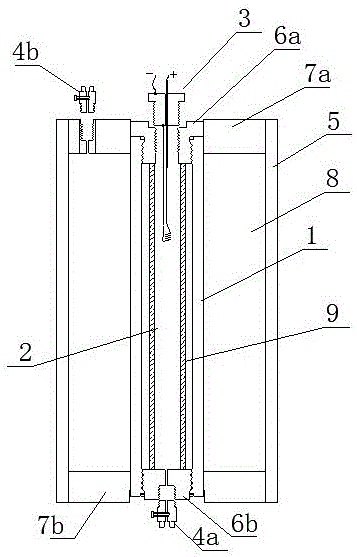

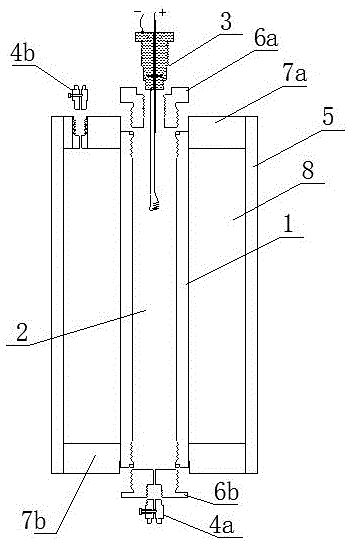

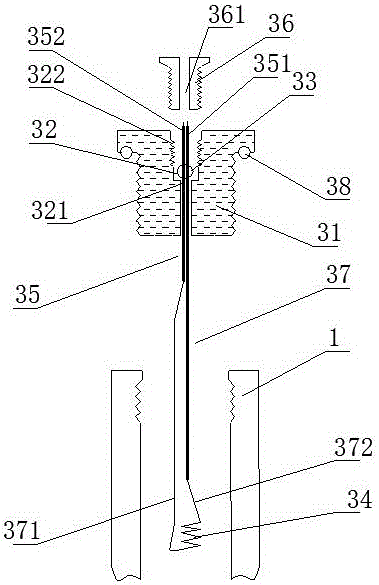

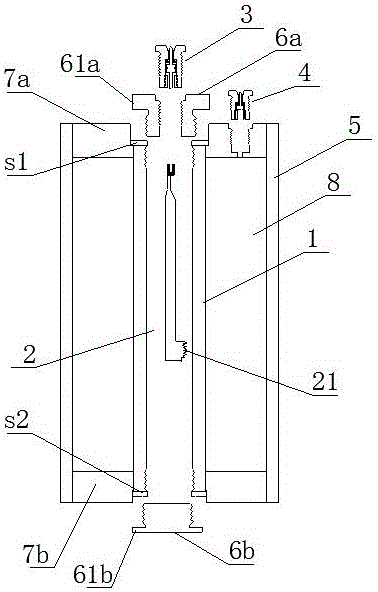

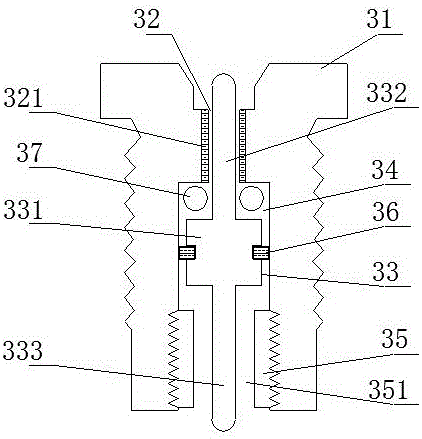

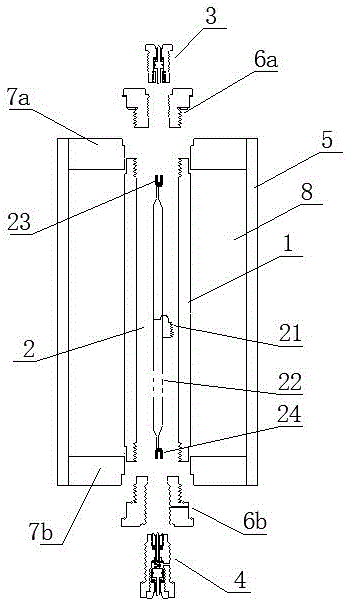

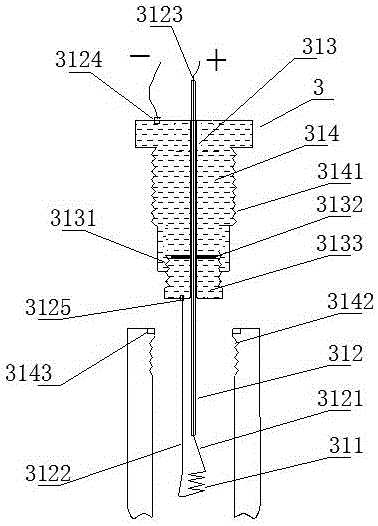

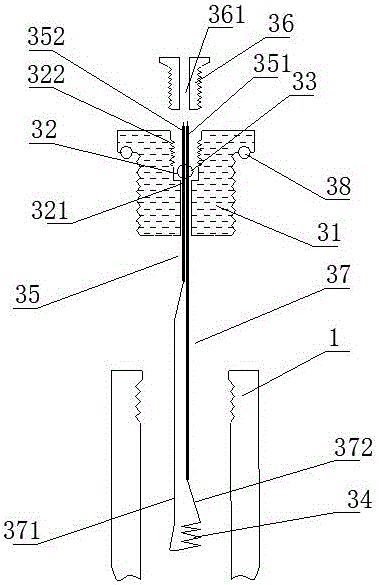

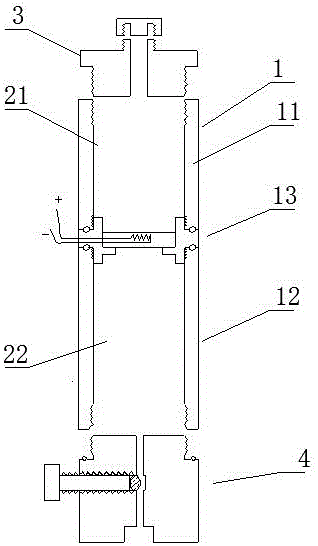

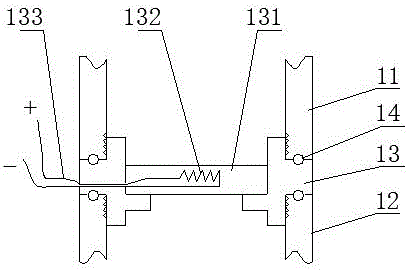

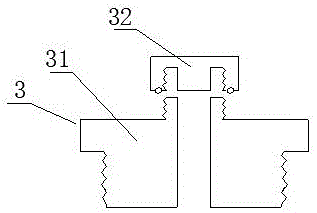

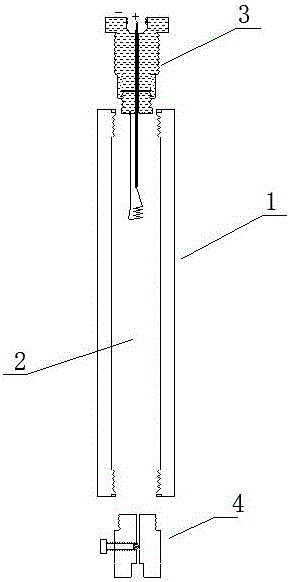

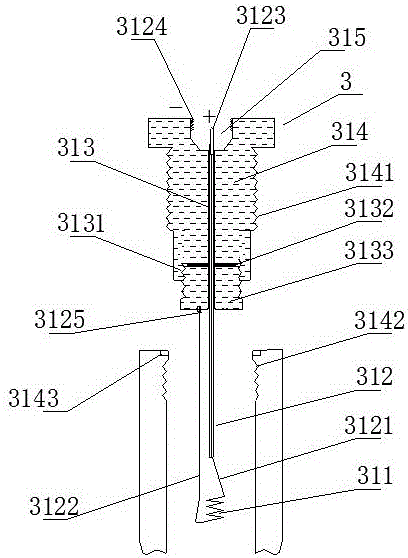

Inflation and ignition integrated gas blaster

PendingCN106931838AReduce mixReduce production processBlasting cartridgesCheck valvesHeating efficiencyNitrogen gas

The invention discloses an inflation and ignition integrated gas blaster. The inflation and ignition integrated gas blaster comprises an inner pipe, an inner pipe filling cavity, an inflation and ignition mechanism, an inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; the two ends of the inner pipe are in sealed connection with a first inner sealing cap and a second inner sealing cap correspondingly; the first inner sealing cap and the second inner sealing cap are connected through a connecting piece; the outer pipe is arranged outside the inner pipe; a first outer sealing cap and a second outer sealing cap are connected between the inner pipe and the outer pipe in a sealed mode; the inflation and ignition mechanism is installed on the first inner sealing cap; the first outer sealing cap is provided with the inflation mechanism; a sealed cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer pipe filling cavity is filled with liquid carbon dioxide, liquid nitrogen or other liquid substances liable to gasify. The inflation and ignition integrated gas blaster has the advantages of being low in manufacturing cost, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

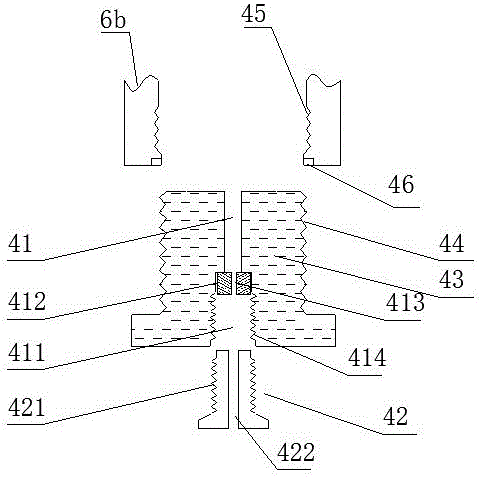

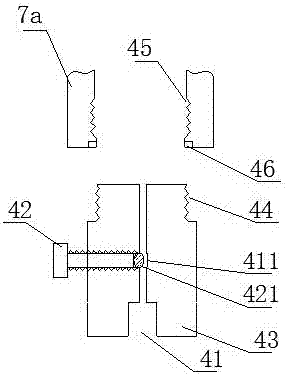

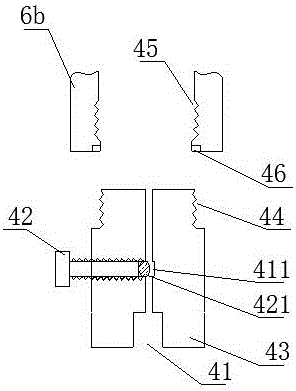

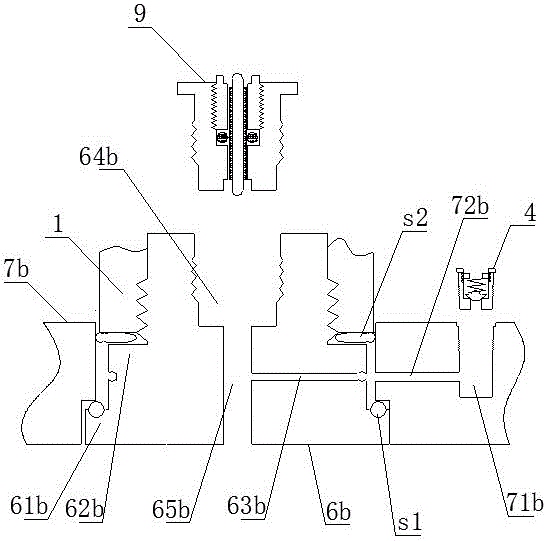

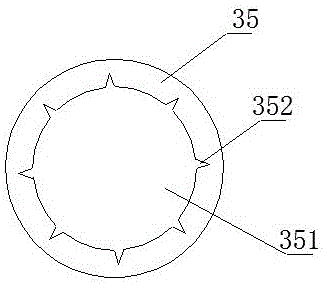

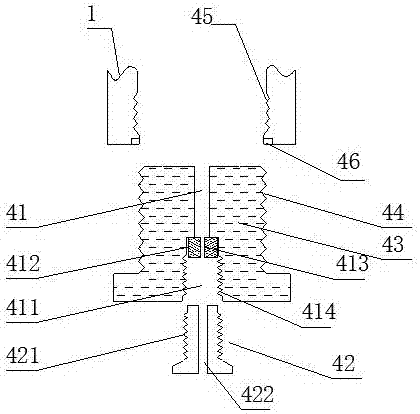

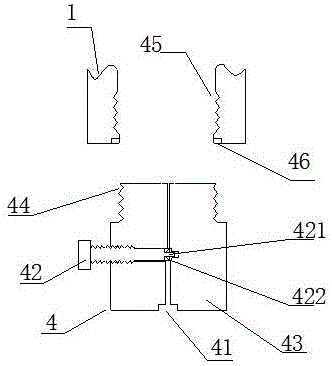

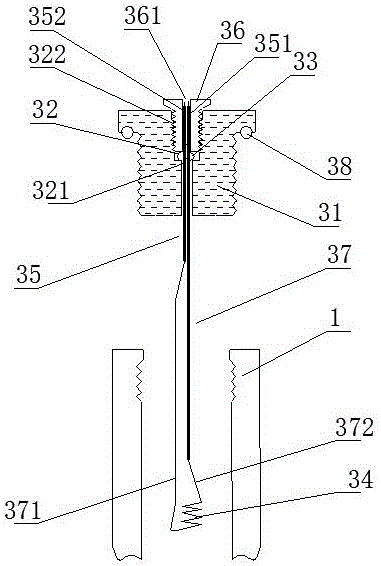

Plug-in type gas blaster

PendingCN106595397AUniform responseAdequate responseBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a plug-in type gas blaster. The plug-in type gas blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube gas inflation mechanism and an outer tube. The inner tube is internally provided with the inner tube filling cavity. A first sealed inner cover and a second sealed inner cover are connected to the two ends of the inner tube in a sealed manner correspondingly. The outer tube is arranged on the outer layer of the inner tube. A first sealed outer cover and a second sealed outer cover are connected between the inner tube and the outer tube in a sealed manner. The ignition mechanism and the inner tube gas inflation mechanism are mounted on the first sealed inner cover or the second sealed inner cover. The first sealed outer cover or the second sealed outer cover is provided with an outer tube gas inflation mechanism. A seal cavity formed between the inner tube and the outer tube is an outer tube filling cavity. The inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter. The outer tube filling cavity is filled with liquid matter easy to gasify such as liquid carbon dioxide or liquid nitrogen. The plug-in type gas blaster has the beneficial effects of being low in manufacturing cost, high in reaction material mixing uniformity, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

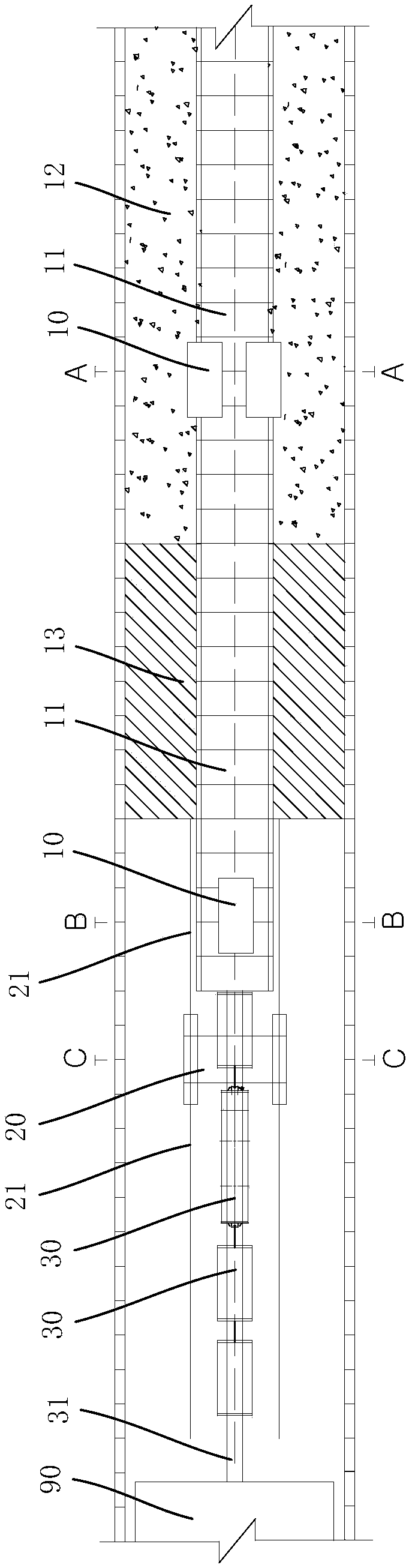

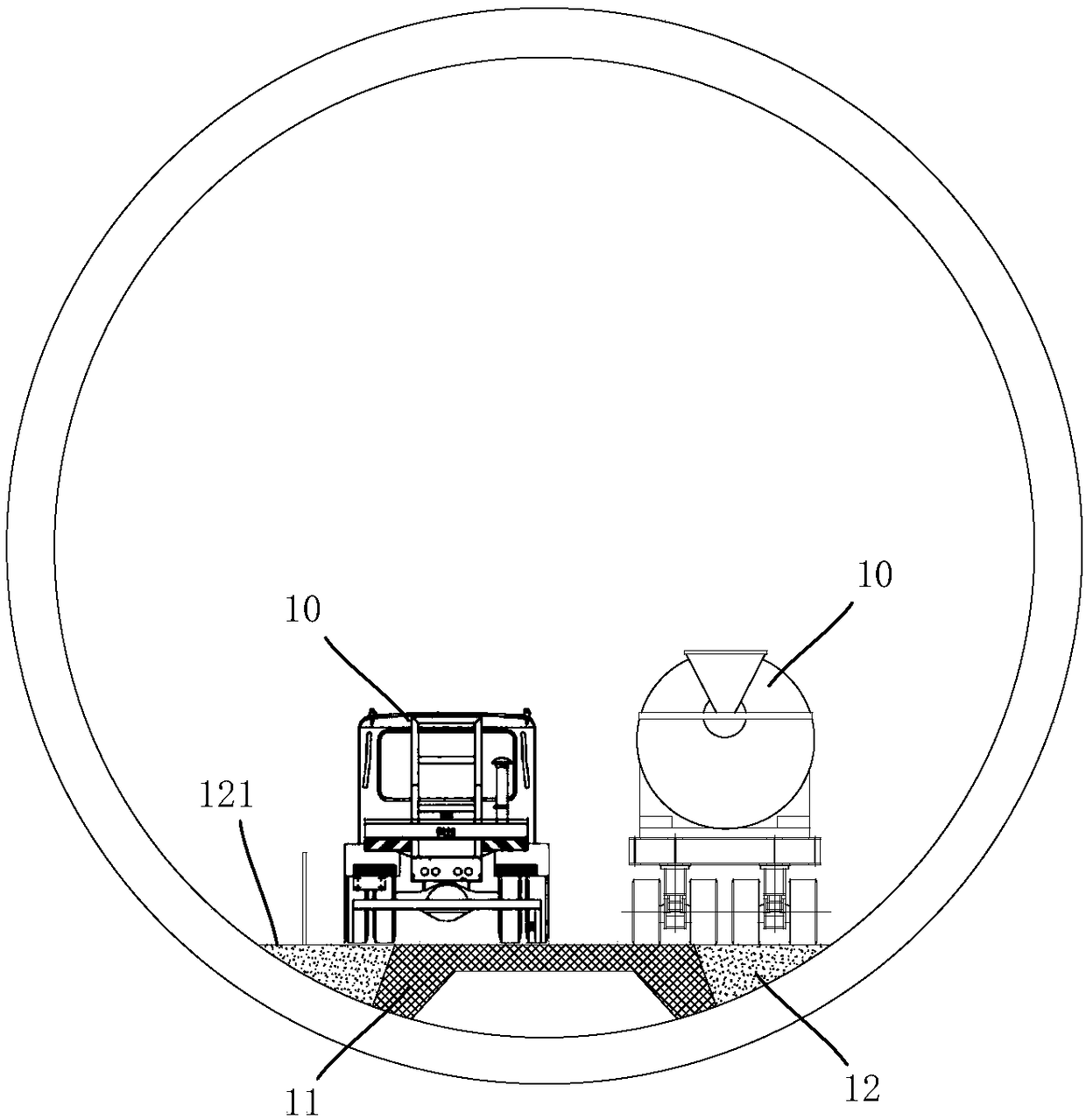

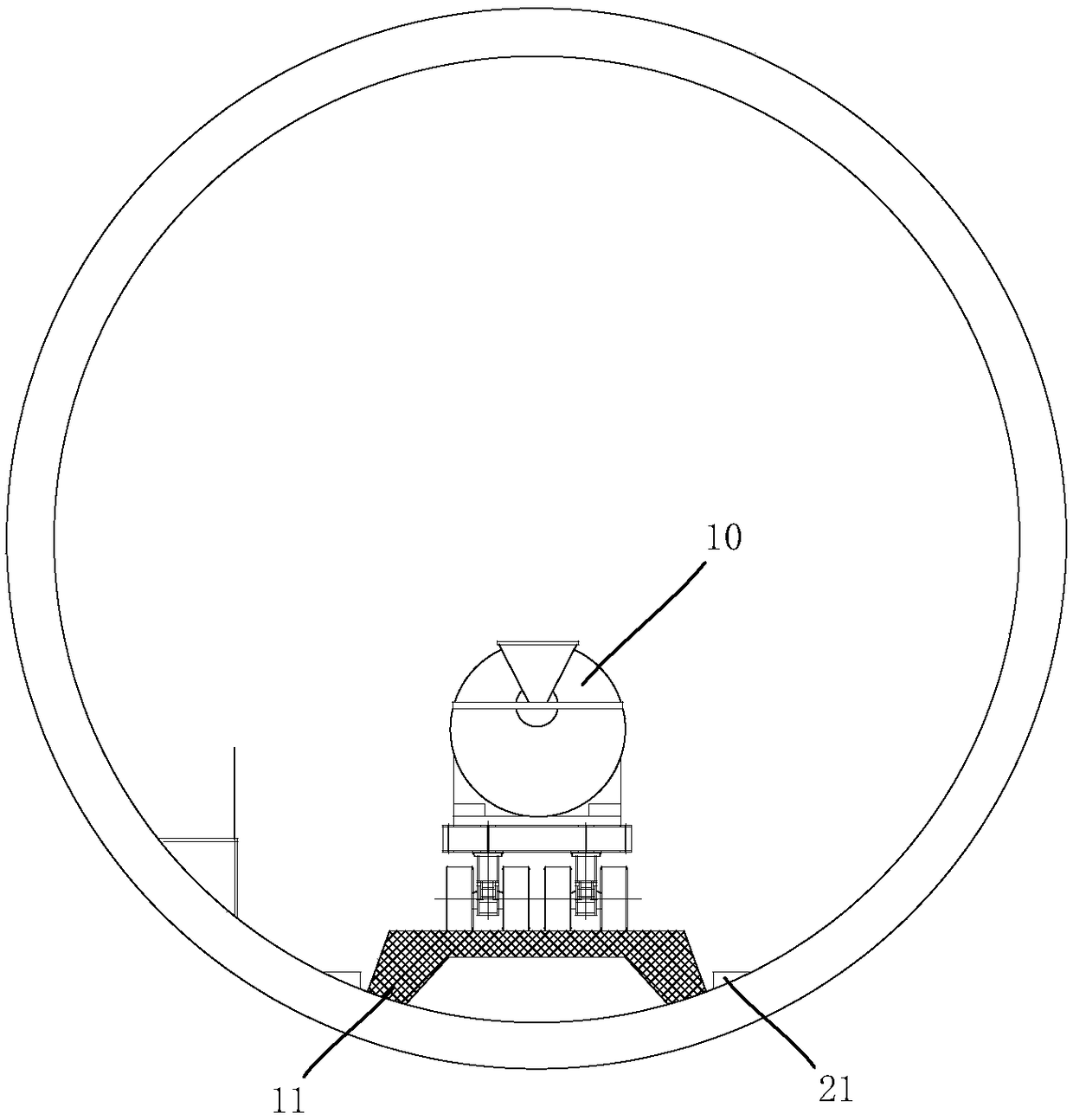

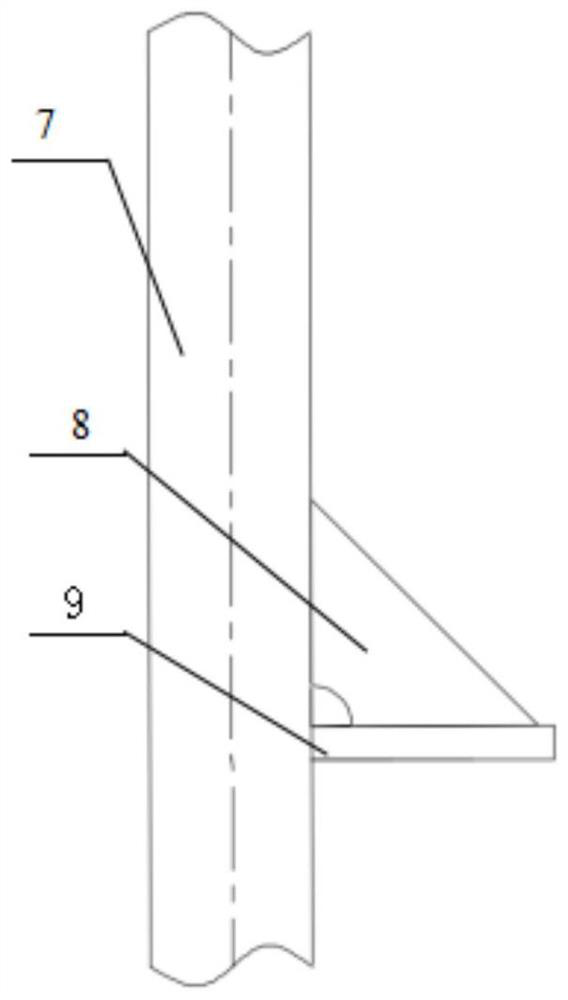

Transporting method and structure for tunnel construction through shield method

ActiveCN108590745ARealize the combinationGood transportation safetyUnderground chambersTunnel liningVehicle frameMode of transport

The invention relates to a transporting method and structure for tunnel construction through a shield method. The transporting method comprises the steps that a locomotive rail is laid on a segment atthe bottom in a tunnel, and one end of the locomotive rail extends into a shield vehicle frame; a pi-shaped piece is erected on the part, close to the other end of the locomotive rail, of the segmentat the bottom in the tunnel and extends to the position close to a working well, and a plane is formed in the top surface of the pi-shaped piece; a construction material is transported from the working well into the tunnel through a car travelling on the plane of the pi-shaped piece; the construction material on the car is hoisted to a rail locomotive travelling on the locomotive rail; and the construction material is transported into the shield vehicle frame through the rail locomotive. The transporting method and structure for tunnel construction through the shield method have the beneficial effects that car transporting and rail locomotive transporting are combined, the advantages of the two transporting modes are exerted, and the transporting difficult problems under the small-clearance and large-slope working condition are solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

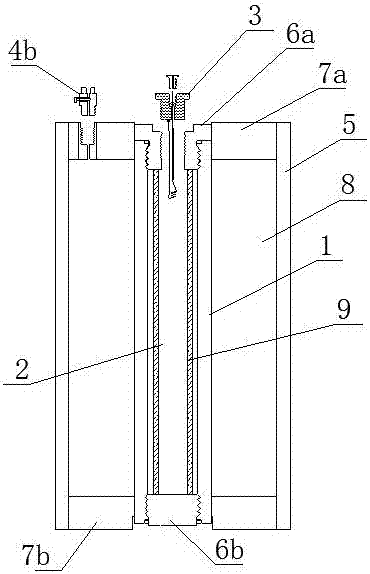

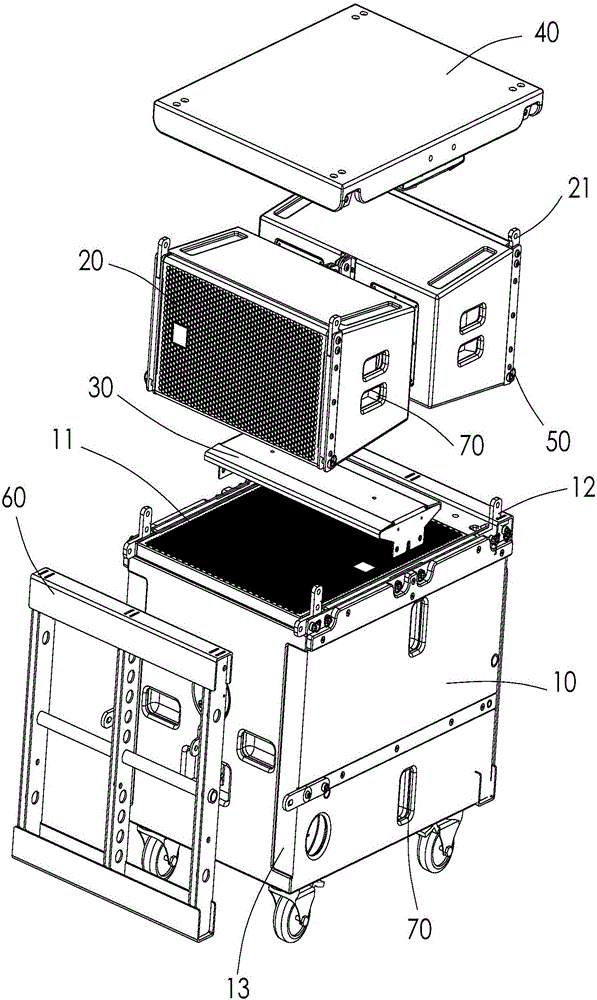

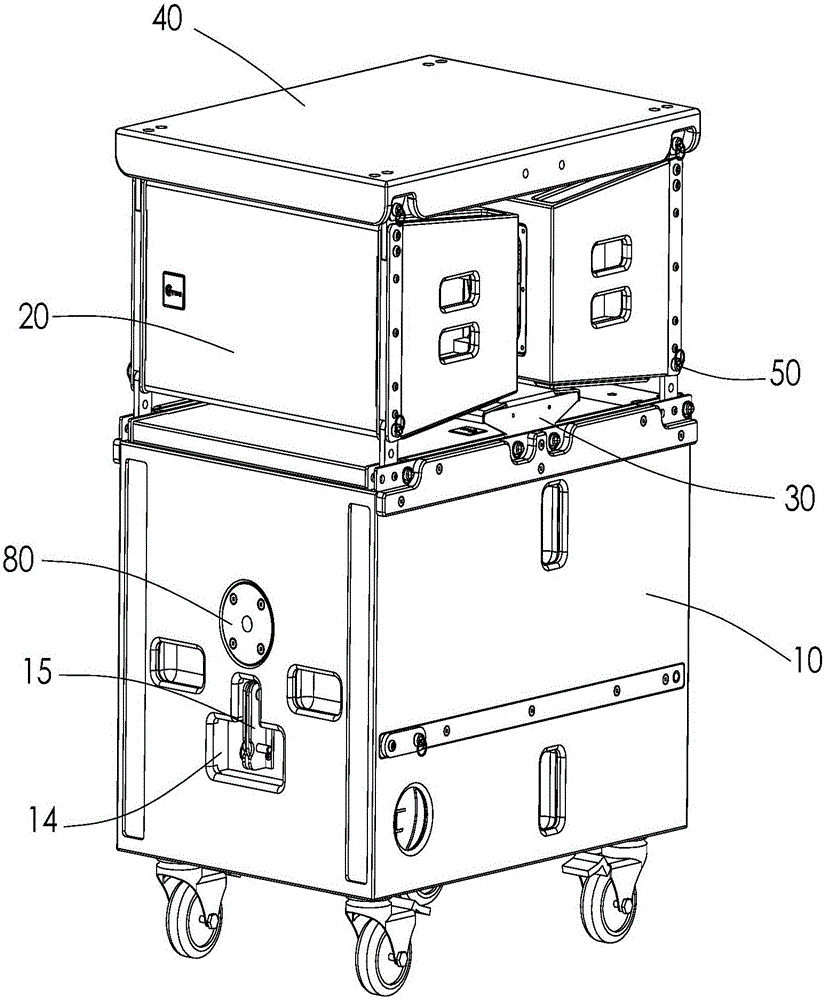

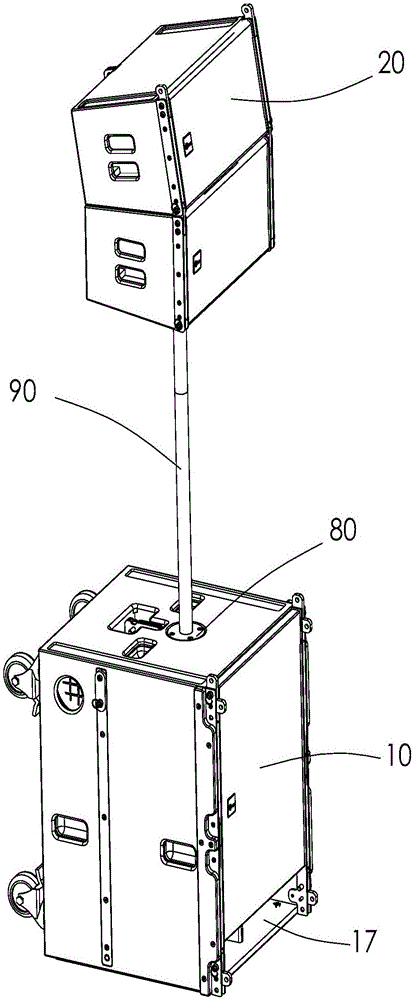

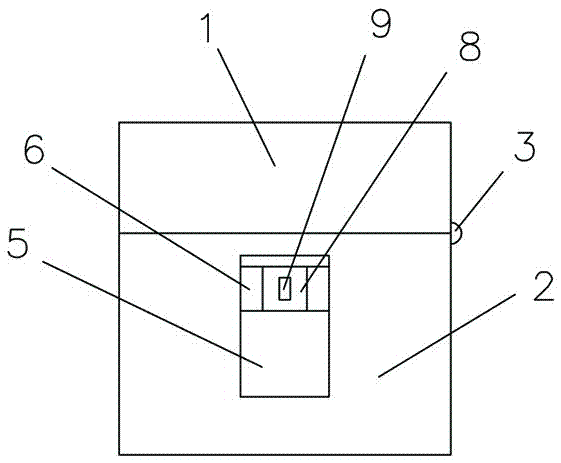

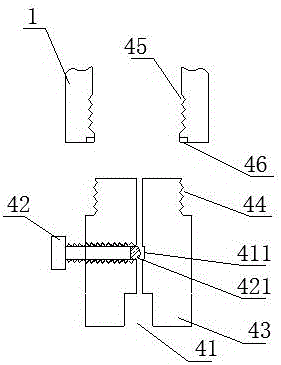

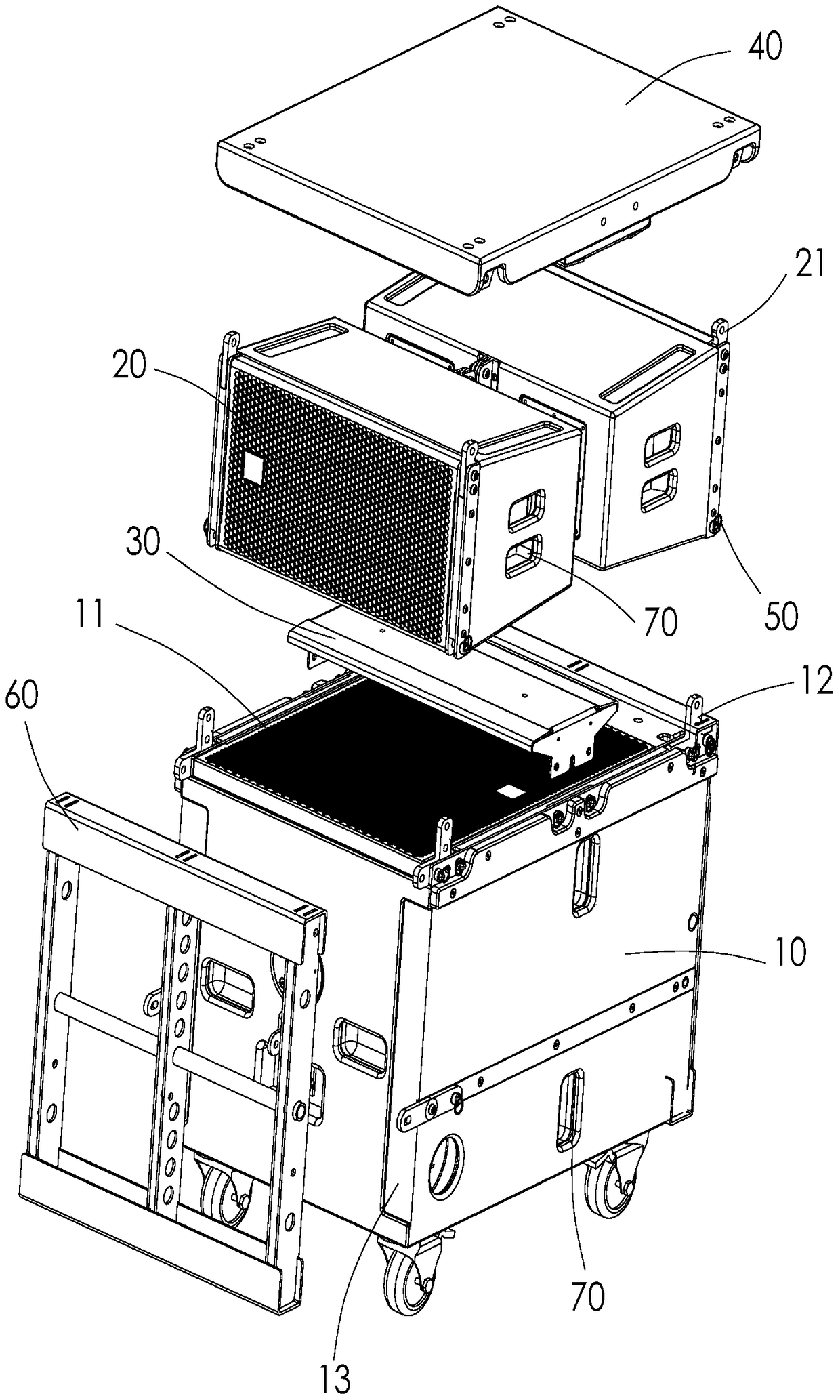

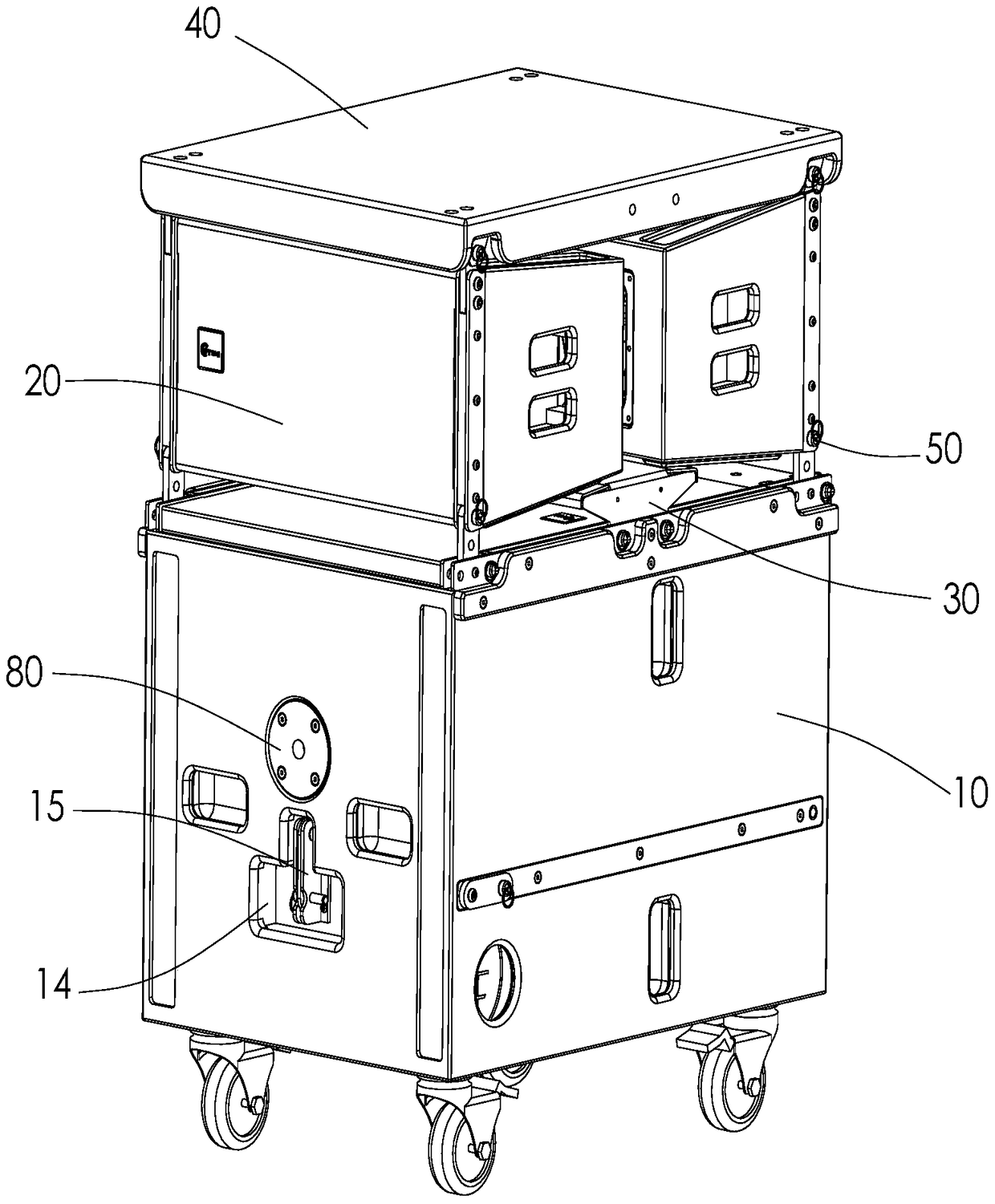

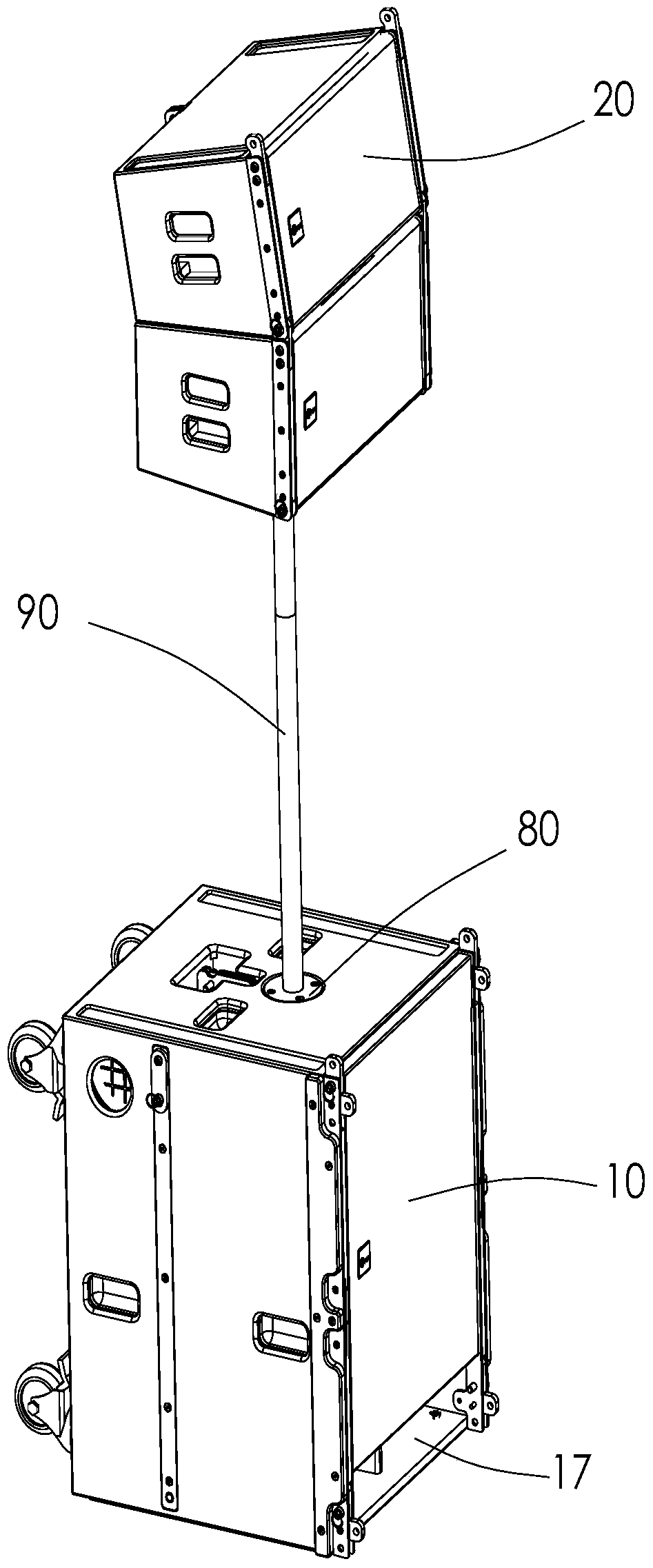

Integrated sound box combination

ActiveCN105142051APrevent crashGood transportation safetyTransducer casings/cabinets/supportsEngineeringTransportation safety

The invention provides an integrated sound box combination comprising a large sound box and multiple small sound boxes. The large sound box is provided with a sound generating surface. The integrated sound box combination also comprises first plug pins, a supporting plate and a cover plate. The multiple small sound boxes are arranged above the sound generating surface of the large sound box. The large sound box is provided with multiple first connecting members along the edge of the large sound box. The supporting plate is detachably installed above the sound generating surface of the large sound box. The small sound boxes are supported on the supporting plate, and one side of each small sound box is detachably connected with the first connecting members via the first plug pins. The cover plate covers the multiple small sound boxes and the cover plate and the multiple small sound boxes are detachably fixed. According to the integrated sound box combination, multiple small sound boxes are detachably installed on the large sound box via the first plug pins so that the small sound boxes can be stacked on the large sound box to be transported; the bottom ends of the small sound boxes are supported by the supporting plate so that crashing of the small sound boxes to the sound generating hole of the large sound box can be prevented; and finally the cover plate is packaged on the small sound boxes so that transportation safety performance is great.

Owner:GUANGZHOU YME TECH CO LTD

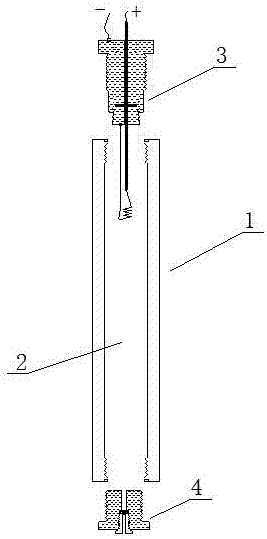

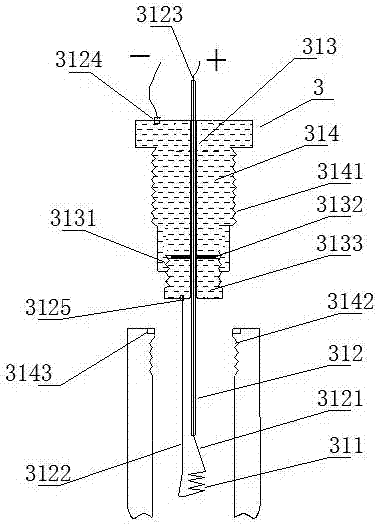

Inflation and ignition integrated air blaster

InactiveCN106643324AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses an inflation and ignition integrated air blaster. The inflation and ignition integrated air blaster comprises an inner tube, an inner tube filling cavity, an inner tube inflation and ignition head, an outer tube inflation head and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner correspondingly; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the inner tube inflation and ignition head is mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer tube filling cavity is filled with liquid easy-to-gasify matter such as liquid carbon dioxide and liquid nitrogen. The inflation and ignition integrated air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

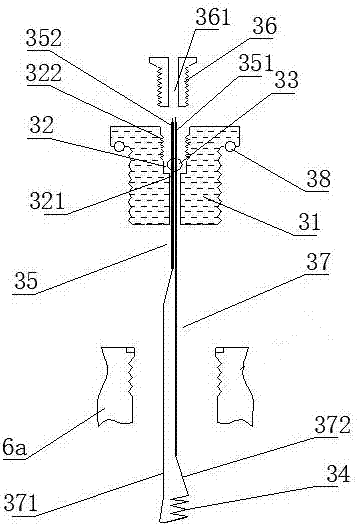

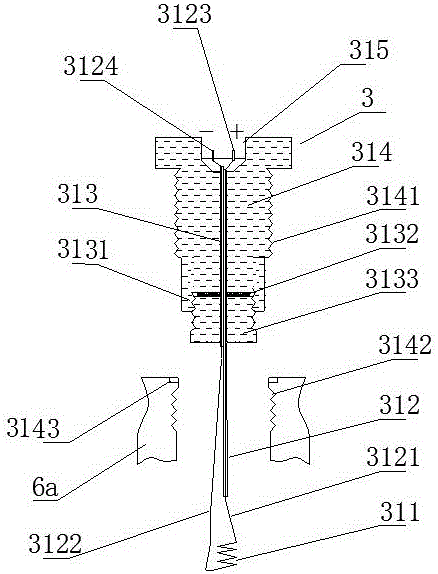

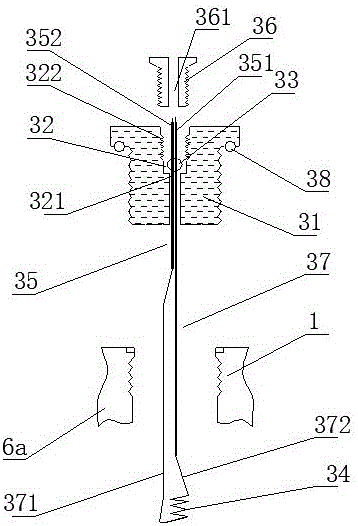

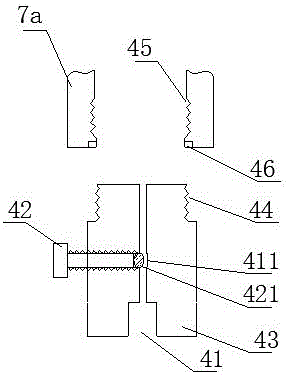

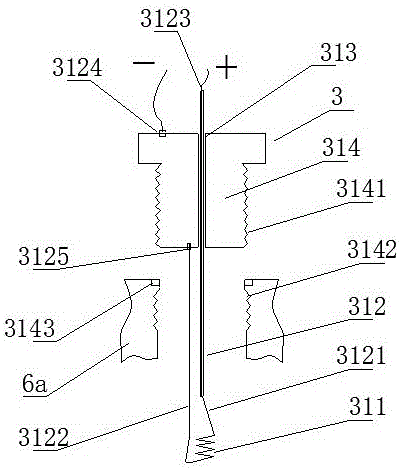

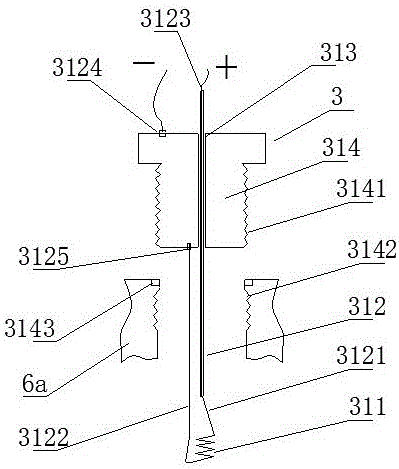

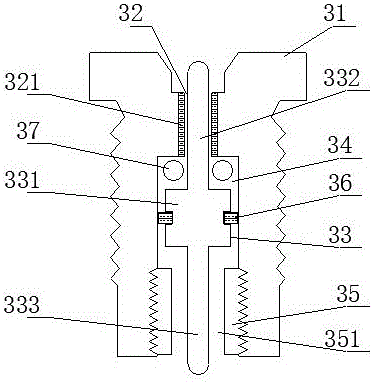

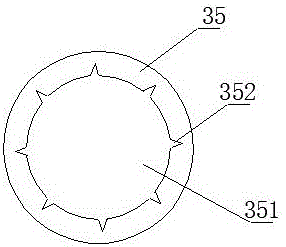

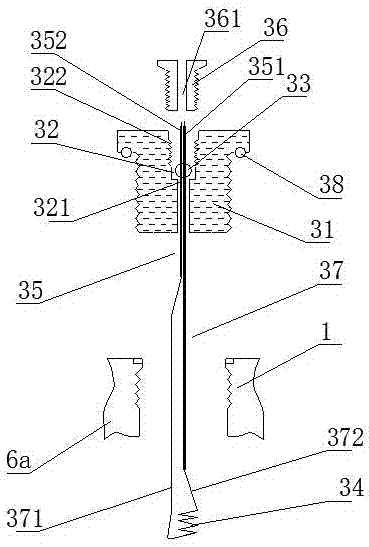

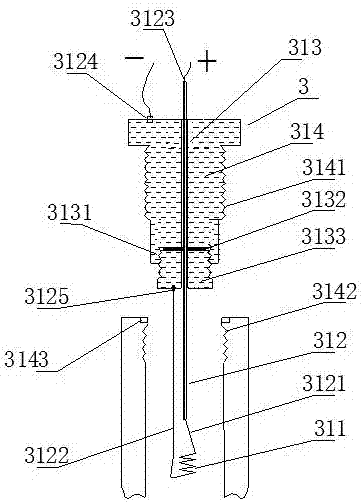

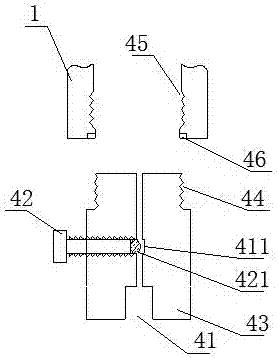

Air inflation and ignition integrated blaster and fracturing device

The invention discloses an air inflation and ignition integrated blaster and a fracturing device. The air inflation and ignition integrated blaster comprises a tube body, a filling cavity located in the tube body, as well as an air inflation and ignition head and a cover body respectively located at the two ends of the tube body, wherein the filling cavity is filled with supercritical oxygen and a reductive simple substance; the air inflation and ignition head comprises a plugging substrate, an air inflation hole, a sealing ball valve, a conductive contact and an electric heating wire; the air inflation hole penetrates through the plugging substrate; a sealing shrink mouth is formed in the lower part of the air inflation hole; the sealing ball valve is mounted above the sealing shrink mouth; the conductive contact penetrates through the sealing ball valve and is fixedly connected with the sealing ball valve in a clamping manner; the spherical surface of the lower part of the sealing ball valve is a rough surface; the degree of tightness of the sealing ball valve is adjusted by a sealing locking screw; a contact window, through which the conductive contact penetrates, is formed in the middle of the sealing locking screw; the conductive contact is connected with the electric heating wire by a wire; and a connecting piece is connected between the plugging substrate and the cover body. The air inflation and ignition integrated blaster has the advantages that a powder filling process is simple, the safety is high, the mixing uniformity of materials is high, and the end of the blaster is prevented from flying out.

Owner:郭远军

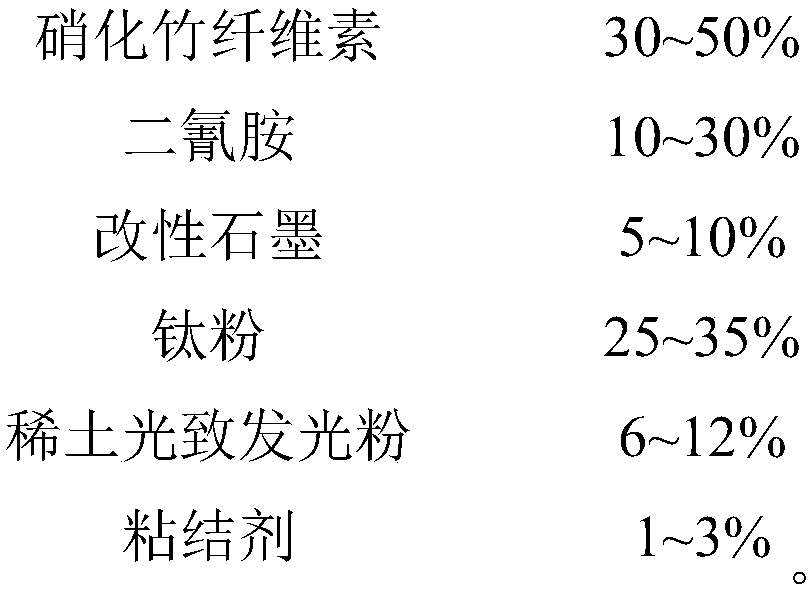

Low-sensitivity environment-friendly firework chemical and preparation method thereof

The invention relates to a low-sensitivity environment-friendly firework chemical and a preparation method thereof, and belongs to the technical field of civil entertainment fireworks. The preparationmethod comprises the steps: weighing nitrocellulose, dicyandiamide, modified graphite, titanium powder, rare earth photoluminescent powder and a binder; dissolving dicyandiamide in hot water to prepare a dicyandiamide solution, loading the dicyandiamide solution into a sprinkling can, and sprinkling the dicyandiamide solution onto uniformly laid modified graphite; turning over the modified graphite powder while sprinkling, and ensuring uniform spraying; and after completion of sprinkling, drying to obtain dicyandiamide / modified graphite powder; dropwise adding an adhesive into uniformly mixedtitanium powder and rare earth photoluminescent powder, kneading uniformly, sieving and drying to obtain the luminous granulation powder; and mixing nitrocellulose, the dicyandiamide / modified graphite powder and the luminous granulation powder, and granulating to obtain the low-sensitivity environment-friendly firework chemical. The low-sensitivity environment-friendly firework chemical providedby the invention is low in sensitivity and excellent in production, storage and transportation safety performance; raw materials are easily available and the cost is low; and the setting-off process is smokeless, sulfur-free, green and environment-friendly.

Owner:江西吉润花炮新材料科技有限公司

Sectionalized brick transportation case

InactiveCN107985754AAvoid collision damageImprove protectionContainers preventing decayContainers to prevent mechanical damageBrickEngineering

The invention relates to the field of tunnel brick transportation equipment, in particular to a sectionalized brick transportation case. The sectionalized brick transportation case comprises a case cover and a case body, wherein the case cover and the case body are rotationally installed in a matching manner through screw threads, a connecting ring is arranged at the left end of the case body, a sliding groove is perpendicularly formed in the right end of the case body, a sliding block is installed in the sliding groove in a slideable and matching manner, a connecting rod is rotationally installed in the sliding block through a rotating shaft, and a hook matched with the connecting ring is arranged at the outer end of the connecting rod; a plurality of side holes used for ventilation are symmetrically formed in the two sides of the case body, a plurality of separation plates which are installed in a mutually vertically crossed manner are arranged in the case body, and the case body space is separated into a plurality of square grooves matched with tunnel bricks in size; and a rubber pad is arranged at the bottom of the case body, and the inner walls of the separation plates and theinner wall of the case body are provided with protection pads used for protecting the tunnel bricks. The sectionalized brick transportation case is convenient to operate and safe to transport and hasgood use and popularization value.

Owner:刘艺鹏

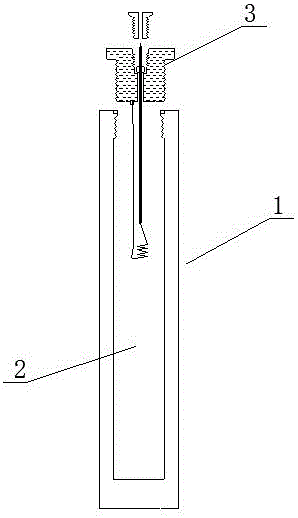

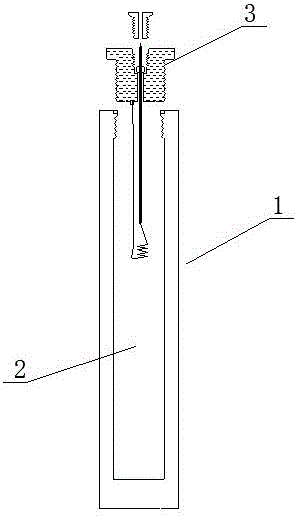

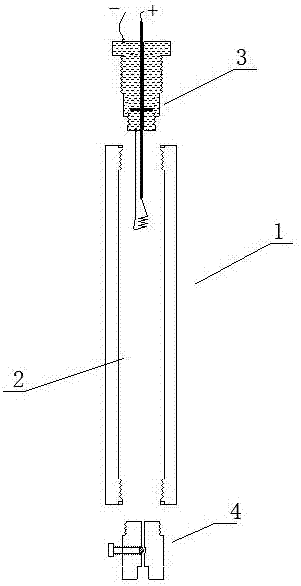

Air blaster

PendingCN106643327AReduce mixReduce production processBlasting cartridgesCheck valvesTransport securityNitrogen gas

The invention discloses an air blaster. The air blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube inflation mechanism and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner respectively; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the ignition mechanism and the inner tube inflation mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matters; and the outer tube filling cavity is filled with such liquid easy-to-gasify matters as liquid carbon dioxide and liquid nitrogen. The air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

Gas blasting device

InactiveCN106767183AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a gas blasting device which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, a first inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is arranged in the inner pipe; the two ends of the inner pipe are in sealing connection with a first inner sealing cover and a second inner sealing cover; the first inner sealing cover and the second inner sealing cover are connected through a connecting piece; the outer pipe is arranged on the outer layer of the inner pipe; a first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe in a sealing manner; the ignition mechanism and the first inflation mechanism are mounted on the first inner sealing cover; a second inflation mechanism is mounted on the first outer sealing cover; the sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matters; the outer pipe filling cavity is filled with liquid easy gasifying materials such as liquid carbon dioxide or liquid nitrogen. The gas blasting device has the advantages that the manufacture cost is low, the heat release efficiency is high, the transport security is good and the blast power is high.

Owner:郭远军

Gas blasting machine convenient to inflate

InactiveCN106643318AReduce wall thicknessReduce weightBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses a gas blasting machine convenient to inflate. The gas blasting machine comprises an inner pipe, an inner pipe filling cavity, a first inflating conductive head, a second inflating conductive head and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are connected to between the inner pipe and the outer pipe; the inner pipe is in clearance fit with the first sealing outer cap and the second sealing outer cap; the outer pipe is in sealing connection with the first sealing outer cap and the second sealing outer cap; the first sealing inner cap is in sealing connection with the first sealing outer cap, and the second sealing inner cap is in sealing connection with the second sealing outer cap; the first inflating conductive head is mounted in the first sealing inner cap, and the second inflating conductive head mounted in the second sealing inner cap; and an outer pipe filling cavity is formed between the inner pipe and the outer pipe. The gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in homogeneity degree of reacting materials, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Ejector pin sealing type gas blasting machine

PendingCN106643321AReduce mixReduce production processBlasting cartridgesExplosivesNitrogen gasEngineering

The invention discloses an ejector pin sealing type gas blasting machine which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, an inner pipe inflating mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; two ends of the inner pipe are hermitically connected with a first sealing inner cover and a second sealing inner cover respectively; the outer pipe is arranged on the outer layer of the inner pipe; a first sealing outer cover and a second sealing outer cover are hermitically connected between the inner pipe and the outer pipe; the ignition mechanism and the inner pipe inflating mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer pipe inflating mechanism is mounted on the first sealing outer cover or the second sealing outer cover; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbonaceous organic materials; and the outer pipe filling cavity is filled with liquid gasification-liable substances such as liquid carbon dioxide or liquid nitrogen. The ejector pin sealing type gas blasting machine has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, high transportation safety and high blasting power.

Owner:郭远军

Inflating type gas blasting machine

PendingCN106643319AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesEngineeringMechanical engineering

The invention discloses an inflating type gas blasting machine. The inflating type gas blasting machine comprises an inner pipe, an inner pipe inflating conductive head, an outer pipe inflating head and an outer pipe, wherein a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are respectively connected between the inner pipe and the outer pipe; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe inflating conductive head is arranged at the shaft center part of the first sealing inner cap; a first radial air hole in the radial direction is formed in the second sealing inner cap; a second mounting cavity and an axial through hole which communicate with each other are formed in the shaft center part of the second sealing inner cap; the axial through hole penetrates through the first radial air hole; a conductive connection head is mounted in the second mounting cavity; a first radial air hole in the radial direction is formed in the second sealing outer cap; and the outer pipe inflating head is arranged on the inner side surface of the second sealing outer cap. The inflating type gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

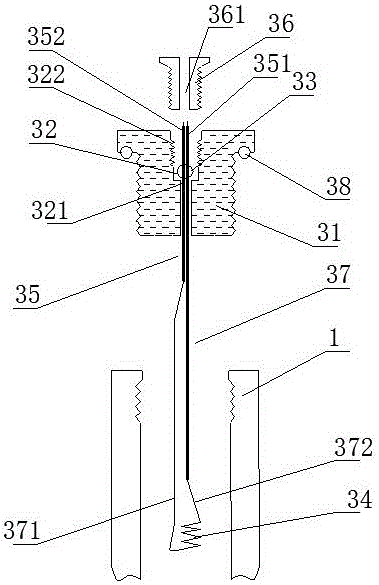

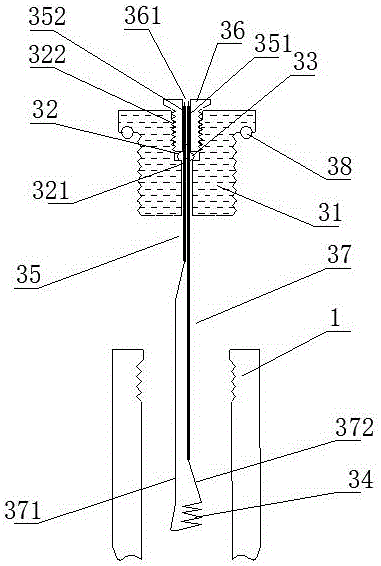

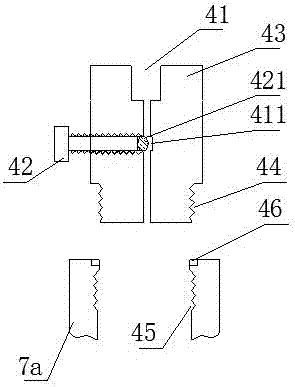

Inflating and igniting integrated initiator and cracking device

The invention discloses an inflating and igniting integrated initiator and a cracking device. The initiator comprises a housing, a filling cavity located in the housing and an inflating and igniting head connected at one end of the housing. Supercritical oxygen and a carbon-containing organic matter or a reductive elementary substance fill the filling cavity. The inflating and igniting head comprises a plugging base body, an inflating hole, a sealed ball valve, a conductive joint and a sealed locking screw. The inflating hole penetrates through the plugging base body from top to bottom, a sealed shrunk port is formed in the lower portion of the inflating hole, the sealed ball valve is mounted above the sealed shrunk port, the conductive joint penetrates through the sealed ball valve and is fixedly locked on the sealed ball valve, the lower spherical surface of the sealed ball valve is a non-smooth surface, an internal thread is arranged in the upper port of the inflating hole, the internal thread is in threaded connection to the sealed locking screw, a joint window for penetrating through the conductive joint is formed in the middle portion of the sealed locking screw, and the conductive joint is connected to an electric heating wire through a wire. The initiator disclosed by the invention has the advantages of being simple in filing process, good in safety, high in material mixing uniformity, low in manufacturing cost of inflating and igniting structure and good in sealing property.

Owner:郭远军

Dual supercritical state gas detonator

InactiveCN106871731AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesExplosivesDetonatorDetonation

The invention discloses a dual supercritical state gas detonator. The dual supercritical state gas detonator comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation ignition head, an outer pipe inflation head and an outer pipe. The inner pipe is internally provided with the inner pipe filling cavity. A first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner pipe in a sealing manner correspondingly. The outer layer of the inner pipe is provided with the outer pipe. A first sealing outer cover and a second sealing outer cover are connected between the inner pipe and the outer pipe in a sealing manner. A sealing cavity formed by the inner pipe, the outer pipe, the first sealing outer cover and the second sealing outer cover is an outer pipe filling cavity. The outer pipe filling cavity is filled with liquid carbon dioxide or liquid nitrogen. The inner pipe filling cavity comprises a first inner cavity and a second inner cavity which are sealed and isolated through a thermoplastic sheet. The first inner cavity and the second inner cavity are filled with supercritical oxygen and supercritical state alkane correspondingly. The dual supercritical state gas detonator has the beneficial effects that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high, the transporting safety is good, and the detonation power is high.

Owner:郭远军

Inflation lead integral gas blasting device

InactiveCN106643320AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesLiquid stateNitrogen

The invention discloses an inflation lead integral gas blasting device. The device comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation electric conducting head, an outer pipe inflation head and an outer pipe; the inner pipe filling cavity is in the inner pipe; two ends of the inner pipe are tightly connected with a first sealing inner cover and a second sealing inner cover; the outer layer of the inner pipe is the outer pipe; a first sealing outer cover and a second sealing outer cover are tightly connected between the inner pipe and the outer pipe; the inner pipe inflation electric conducting head is mounted on the first sealing inner cover or the second sealing inner cover; the outer pipe inflation head is mounted on the first sealing outer cover or the second sealing outer cover; an outer pipe filling cavity is a sealing cavity between the inner pipe and the outer pipe; an electric heating wire is mounted in the inner pipe filling cavity; supercritical oxygen and carbon-contained organic matters are filled in the inner pipe filling cavity; and such liquid-state gasified matters as liquid-state carbon dioxide or liquid-state nitrogen are filled in the outer pipe filling cavity. The inflation lead integral gas blasting device has the advantages of low production cost, high mixing uniformity of reaction materials, high heat releasing efficiency, good transportation safety and high blasting power.

Owner:郭远军

Gas filling and locking integrated detonator and fracturing device

The invention discloses a gas filling and locking integrated detonator and a fracturing device. The gas filling and locking integrated detonator comprises a shell, a filling cavity, an ignition mechanism and a gas filling mechanism. The filling cavity is formed in the shell. The shell is connected with the sealing ignition mechanism and the gas filling mechanism. The filling cavity is filled with supercritical oxygen and carbonaceous organic materials or reducibility elementary substances. The gas filling mechanism comprises a gas filling hole, a gas filling locking valve rod and a gas filling valve seat. The gas filling valve seat penetrates through the gas filling hole in the axial direction. A gas locking cavity is formed in the upper portion of the gas filling hole. A rubber sealing pipe valve is installed at the bottom of the gas locking cavity. A pipe valve through hole is formed in the center of the rubber sealing pipe valve. An internal thread is arranged on the inner wall of an edge opening of the gas locking cavity. The side edge of the gas filling locking valve rod is provided with an external thread matched with the internal thread. A gas filling through hole is formed in the axis position of the gas filling locking valve rod. The gas filling and locking integrated detonator and the fracturing device have the advantages that manufacturing cost is low, reaction material mixing uniformity is high, heat release efficiency is high and transporting safety is good.

Owner:郭远军

Gas detonation device convenient to inflate

PendingCN106595400AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesDetonationEngineering

The invention discloses a gas detonation device convenient to inflate. The gas detonation device comprises an inner pipe, an inner pipe filling cavity, a first inflation conductive head, a second inflation conductive head and an outer pipe. The inner pipe filling cavity is formed in the inner pipe, a first inner sealing cover and a second inner sealing cover are connected to the two ends of the inner pipe in a sealed mode correspondingly, and the outer pipe is arranged outside the inner pipe. A first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe. The inner pipe is in clearance fit with the first outer sealing cover and the second outer sealing cover, and the outer pipe is connected with the first outer sealing cover and the second outer sealing cover in a sealed mode. The first inner sealing cover and the second inner sealing cover are connected with the first outer sealing cover and the second outer sealing cover in a sealed mode correspondingly. The first inflation conductive head and the second inflation conductive head are mounted on the first inner sealing cover and the second inner sealing cover correspondingly, and an outer pipe filling cavity is located between the inner pipe and the outer pipe. The gas detonation device has the advantages of being low in manufacturing cost, high in reaction material mixing uniformity, high in heat releasing efficiency, good in transporting safety and high in detonation power.

Owner:郭远军

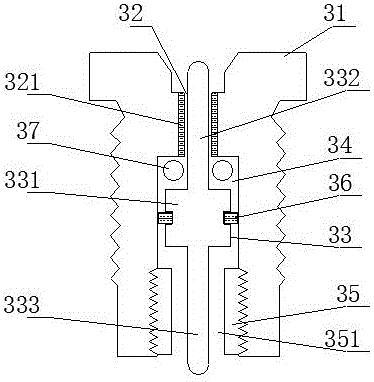

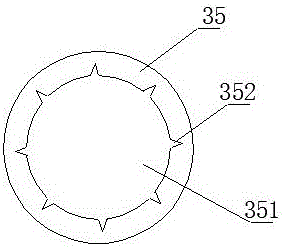

Thimble sealed type trigger and cracking device

InactiveCN106595398AAvoid safety hazardsReduce mixingBlasting cartridgesExplosivesEngineeringThermal efficiency

The invention discloses a thimble sealed type trigger and a cracking device. The thimble sealed type trigger comprises a shell, a filling cavity, an ignition mechanism and an air inflation mechanism. The inside of the shell is the filling cavity, and the shell is connected with the sealed ignition mechanism and the air inflation mechanism. The filling cavity is filled with supercritical oxygen and carbonaceous organic material or elementary substance with reductibility. The air inflation mechanism comprises an air inflation hole, a valve rod and an air inflation valve seat. The middle of the air inflation hole is an air locking cavity, and the valve rod is movably installed in the air locking cavity through a thread structure. An ejector header and an ejector header sealed ring are installed at the top of the valve rod, and the ejector header is sleeved with the ejector header sealed ring. The thimble sealed type trigger and the cracking device have the advantages that manufacturing cost is low, mixing uniformity of reaction materials is high, heat releasing efficiency is high, and conveying safety is good.

Owner:郭远军

Inflation and ignition integrated gas blaster igniter and cracker

InactiveCN106643328AReduce wall thicknessReduce weightBlasting cartridgesExplosivesRough surfaceEngineering

The invention discloses an inflation and ignition integrated gas blaster igniter and a cracker. The integrated gas blaster igniter comprises a shell, a filling cavity in the shell and an inflation and ignition head connected to one end of the shell, wherein the inflation and ignition head comprises a plugging base body, an inflation hole, a seal ball valve, a conductive contact and a seal lock screw; the inflation hole penetrates through the plugging base body from top to bottom, a seal necking hole is formed at the lower part of the inflation hole, the seal ball valve is installed above the seal necking hole, the conductive contact penetrates through and is fixedly clamped on the seal ball valve, the lower ball surface of the seal ball valve is a rough surface, an internal threaded hole is formed at the upper part of the inflation hole and is in threaded connection with the seal lock screw, a contact window through which the conductive contact penetrates is formed in the middle of the seal lock screw, and the conductive contact is connected with the heating wire via a lead. The integrated gas blaster igniter and the cracker have the advantages of simple powder charging process, good safety, high mixing uniformity, as well as low manufacturing cost and good sealing property of the inflation and ignition structure.

Owner:郭远军

Assembly-type lead sealing gas blaster detonator and fracturing device

InactiveCN107062997AAvoid burnsAvoid explosionBlasting cartridgesChemical industryDetonatorRubber ring

The invention discloses an assembly-type lead sealing gas blaster detonator and a fracturing device. The assembly-type lead sealing gas blaster detonator comprises a shell, a filling cavity, an ignition mechanism and a gas filling mechanism. A filling cavity is formed in the shell. The shell is connected with the sealing ignition mechanism and the gas filling mechanism. The ignition mechanism comprises an electric heating wire, a guide wire, a guide wire through hole and a sealing base body. The electric heating wire is connected with the guide wire. The guide wire through hole is formed in the axis portion of the sealing base body. The guide wire penetrates through the guide wire through hole through an insulating layer outer coat. An internal thread hole is formed in one end of the guide wire through hole, and an inner sealing rubber ring is installed at the bottom of the internal thread hole. The internal thread hole is matched with a perforation screw, and a perforation hole is formed in the axis of the perforation screw. The guide wire penetrates through the inner sealing rubber ring and the perforation screw. The perforation screw is matched with the internal thread hole to compress the inner sealing rubber ring, so that the guide wire hole is sealed. The assembly-type lead sealing gas blaster detonator and the fracturing device have the advantages that manufacturing cost is low, reaction material mixing uniformity is high, heat release efficiency is high and transportation safety is good.

Owner:郭远军

Fluid type igniter for gas blaster, and fracturing device

InactiveCN106595402AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesChemical industryElectricityCoupling

The invention discloses a fluid type igniter for a gas blaster, and a fracturing device. The igniter comprises a casing and a filling cavity located in the casing; the casing comprises a first sub-joint, a second sub-joint and a coupling head; the filling cavity comprises a reducing agent filling cavity and an oxidizing agent filling cavity; the reducing agent filling cavity is formed in the first sub-joint, and the oxidizing agent filling cavity is formed in the second sub-joint; two ends of the coupling head are in threaded and sealed connection with one end of the first sub-joint and one end of the second sub-joint or are seamlessly welded at one end of the first sub-joint and one end of the second sub-joint; the other end of the first sub-joint is connected with a liquid filling nozzle, and the other end of the second sub-joint is connected with an inflation mechanism; an isolation thermoplastic piece is mounted in the middle of the coupling head; and an electric heating wire is packaged in the isolation thermoplastic piece and is led out of the casing through a wire. The igniter has the advantages that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high and the transportation safety is good.

Owner:郭远军

Opposite-inflatable air blasting device

InactiveCN106643317AReduce mixReduce production processBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses an opposite-inflatable air blasting device. The device comprises an inner pipe, an inner pipe inflatable conductive head, an outer pipe inflatable head and an outer pipe, the two ends of the inner pipe are connected with a first seal inner cover and a second seal inner cover in a sealed mode respectively, the outer pipe is arranged on the outer layer of the inner pipe, the first seal outer cover and the second seal outer cover are connected between the inner pipe and the outer pipe, a seal cavity formed between the inner pipe and the outer pipe is an outer pipe filling cavity, the inner pipe inflatable conductive head is arranged at the axial core of the first seal inner cover, a first radial air hole is formed in the second seal inner cover in the radial direction, the axial core of the second seal inner cover is provided with a second installation cavity and an axial through hole which are communicated with each other, the axial through hole penetrates through the first radial air hole, a conductive connector is installed in the second installation cavity, the first radial air hole is formed in the second seal outer cover in the radial direction, and an outer pipe inflatable head is arranged on the inner side face of the second seal outer cover. The device has the advantages of being low in manufacturing cost, high in heat release efficiency, good in transport safety and large in blast power.

Owner:郭远军

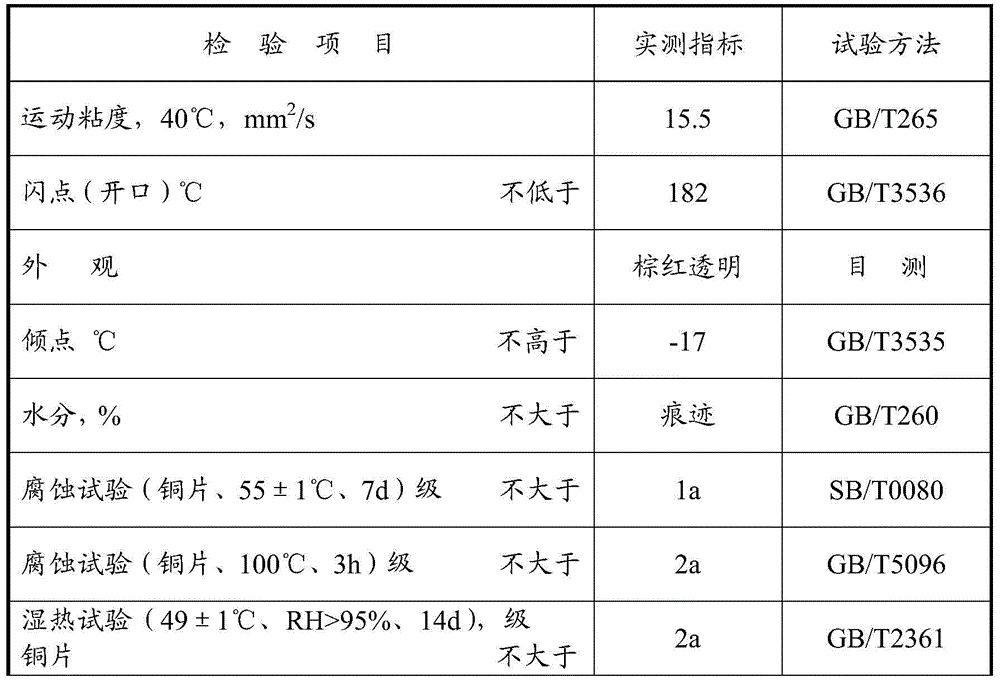

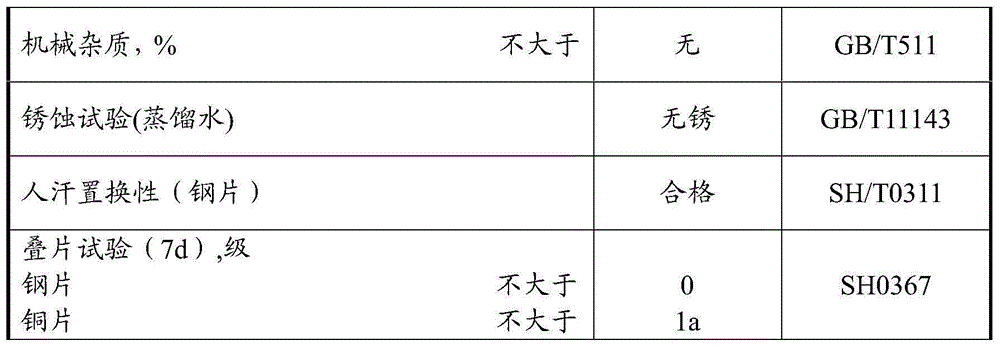

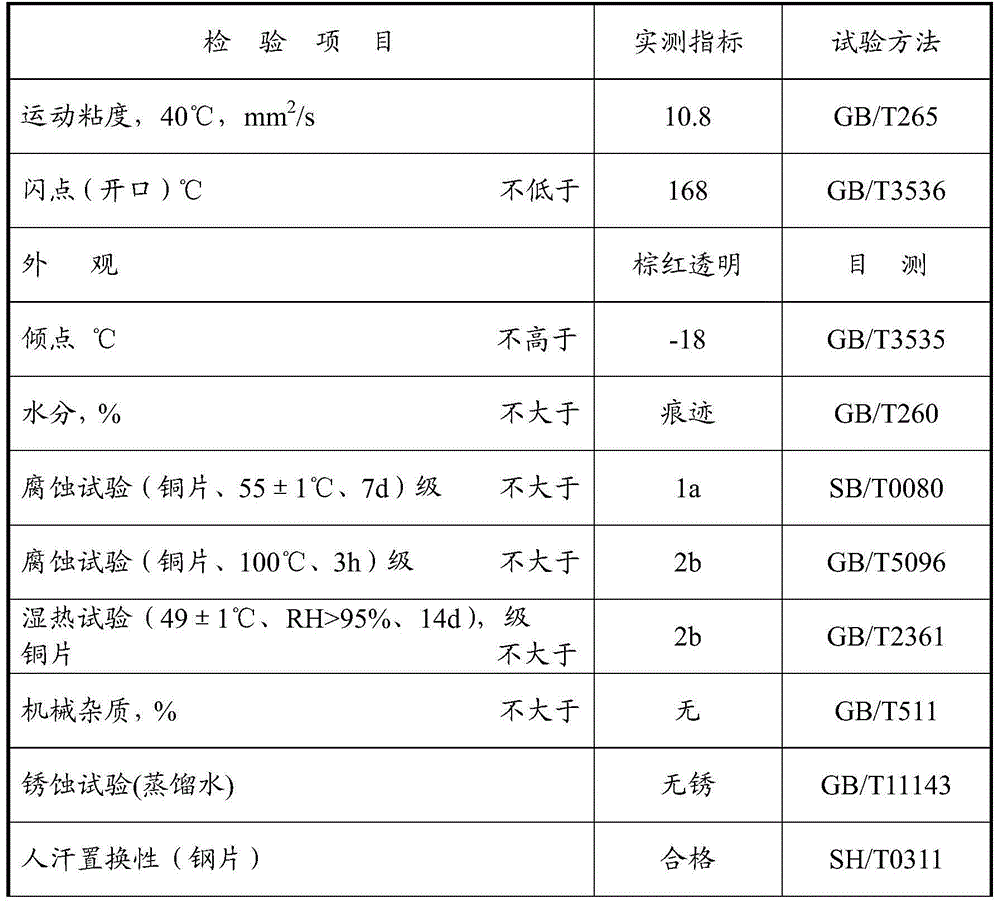

Application of biodiesel in preparation of biodegradable rust preventing oil

The invention discloses an application of biodiesel in preparation of biodegradable rust preventing oil. According to the biodegradable rust preventing oil prepared by using biodiesel as the raw material, tests of product physical and chemical indexes and practical applications by equipments and workpieces in actual working conditions prove that the biodegradable rust preventing oil is comparable or even surpasses the traditional mineral-oil-based rust preventing oil in performances.

Owner:NINGBO LANRUN ENERGY TECH

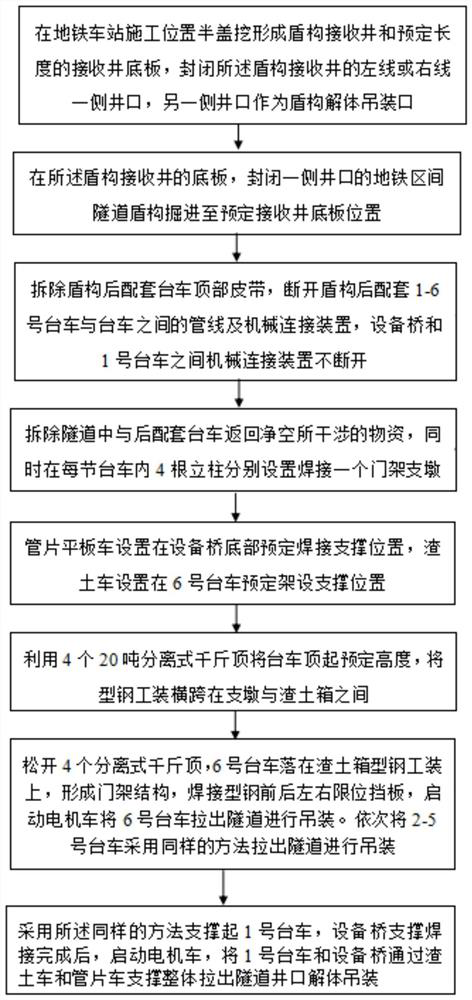

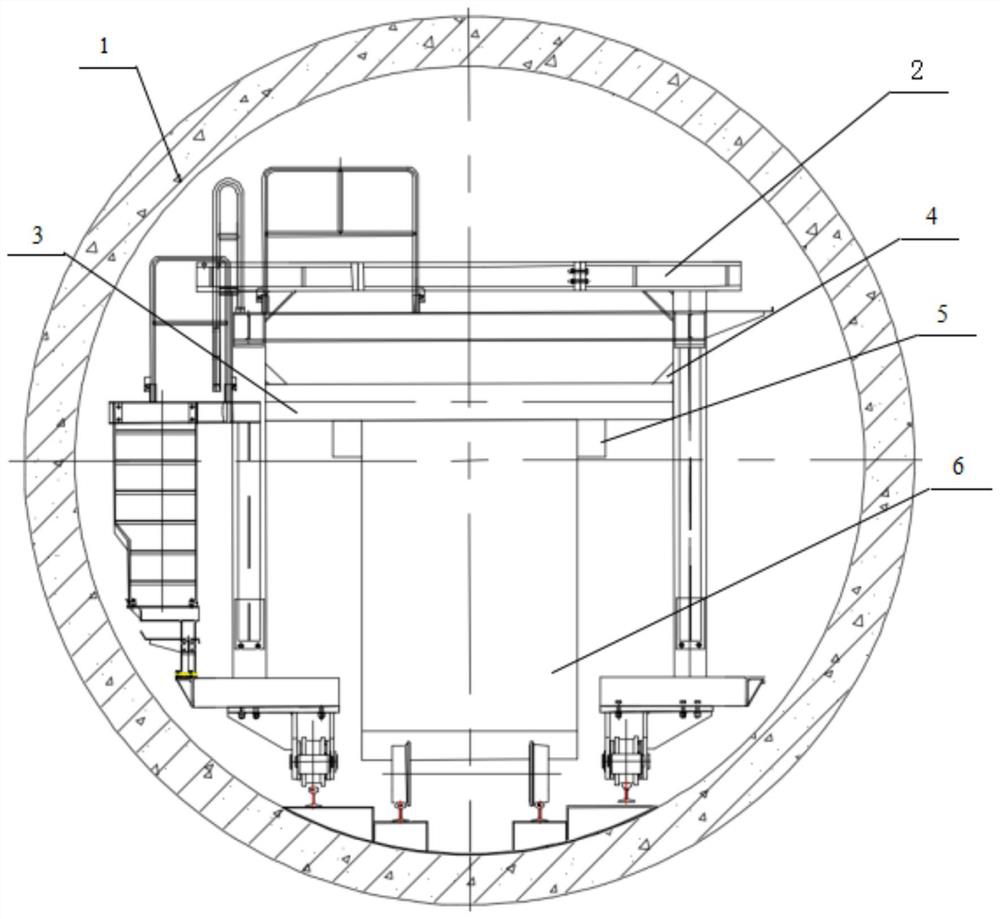

Construction method for tunnel return of matched trolley after low-gravity-center dragging shield

ActiveCN114033398AThere is no need to consider the problem of extra weight and extra weightLower center of gravityMining devicesHydro energy generationArchitectural engineeringJackscrew

The invention relates to the technical field of shield construction, in particular to a construction method for tunnel return of a matched trolley after low-gravity-center dragging shield. The construction method comprises: S1, a receiving well and a receiving well bottom plate are formed; S2, tunneling to a receiving well bottom plate is performed; S3, trolleys are disconnected, and an equipment bridge and the first trolley are not disconnected; S4, a trolley stand column buttress is arranged at the position of a trolley stand column; S5, a segment flat car is arranged at the bottom of the equipment bridge, and a slag car is arranged at the supporting position of the sixth trolley; S6, a profile steel tool stretches across the position between a buttress and a muck box; S7, a jack is loosened, the sixth trolley is pulled out of a tunnel to be hoisted, and the second to fifth trolleys are sequentially pulled out and hoisted; and S8, the first trolley and the equipment bridge are pulled out of the tunnel wellhead to be disassembled and hoisted. The method is low in gravity center and good in transportation safety, the profile steel tool cross beam can be repeatedly used, construction is convenient, the trolley balance weight problem does not need to be considered, and the construction efficiency is improved. The method is mainly applied to tunnel return construction of the matched trolley after low-gravity-center dragging shield.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Threaded twist joint type initiator and cracking device

PendingCN106643326AAvoid burnsAvoid explosionBlasting cartridgesCheck valvesElectric heatingElectricity

The invention discloses a threaded twist joint type initiator and a cracking device. The threaded twist joint type initiator comprises a housing, a filling cavity, an ignition mechanism and an inflation mechanism, wherein the filling cavity is formed in the housing, the housing is connected to and seal the ignition mechanism and the inflation mechanism, and the filling cavity is filled with supercritical oxygen and a carbon-containing organic matter or a reductive single element; the ignition mechanism comprises an electric heating wire, a wire, a perforated hole of the wire, a sealed base body and a thread hole slot; the electric heating wire is connected to the wire, the thread hole slot is located in the upper portion of the perforated hole of the wire, a positive electrode contact pin is mounted at the axis of the thread hole slot, the positive electrode contact pin and the sealed base body are insulative, the surrounding edge of the thread hole slot is a negative electrode connecting thread, the bottom end of the perforated hole of the wire is an internal threaded hole, an internal sealing rubber ring is mounted in the bottom of the internal threaded hole, the internal threaded hole is matched with a perforated screw, and the wire penetrates through the internal sealing rubber ring and the perforated screw. The initiator disclosed by the invention has the advantages of being low in manufacturing cost, high in mixing uniformity of reaction materials, high in heat release efficiency, good in transporting safety and stable in connection of the wire.

Owner:郭远军

All-in-one speaker combination

ActiveCN105142051BPrevent crashGood transportation safetyTransducer casings/cabinets/supportsEngineeringTransportation safety

The integrated speaker combination includes a large speaker and multiple small speakers. The large speaker has a sound output surface. The integrated speaker combination also includes a first pin, a support plate and a cover plate. The multiple small speakers are arranged on the sound output surface of the large speaker. Above, the large speaker is provided with a plurality of first connectors along its edge, the support plate is detachably installed above the sound surface of the large speaker, the small speaker is supported on the support plate, and one side of the small speaker passes through the first The bolt is detachably connected to the first connecting piece; the cover plate is arranged above the multiple small sound boxes and is detachably fixed to the multiple small sound boxes. In the integrated speaker combination of the present invention, a plurality of small speakers are detachably installed on the large speaker through the first bolt, so that the small speakers can be stacked on the large speaker for transportation; the bottom of the small speakers is supported by a support plate to prevent the small speakers from The speaker crashes the sound hole of the large speaker; finally, the cover plate is packaged on the small speaker, which has good transportation safety performance.

Owner:GUANGZHOU YME TECH CO LTD

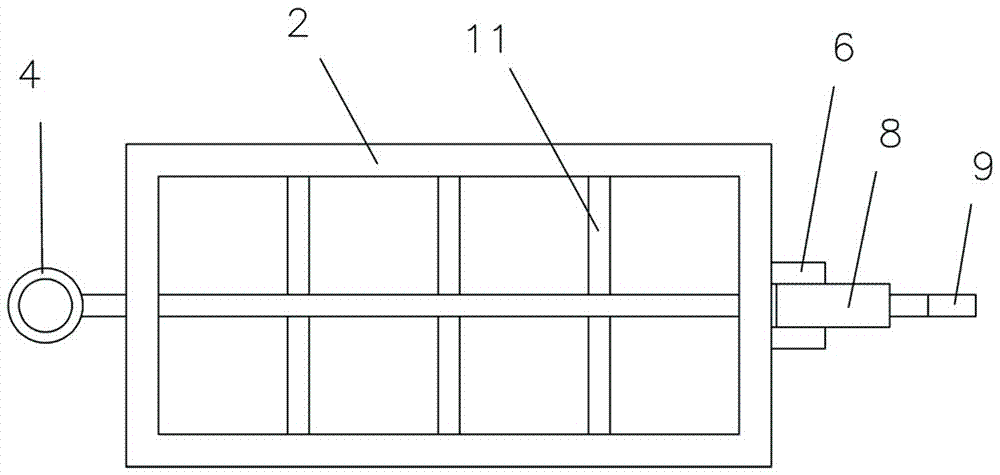

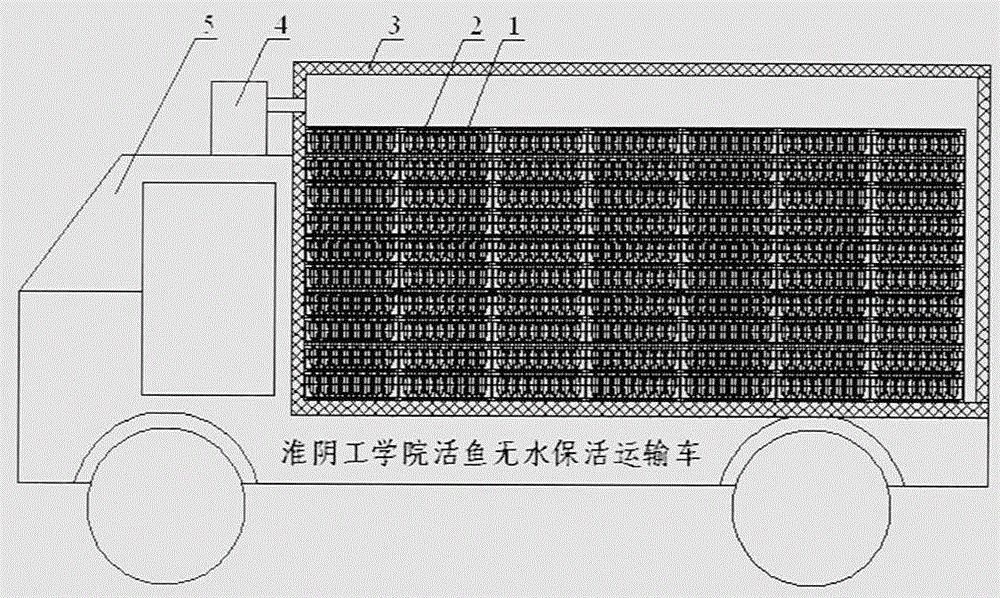

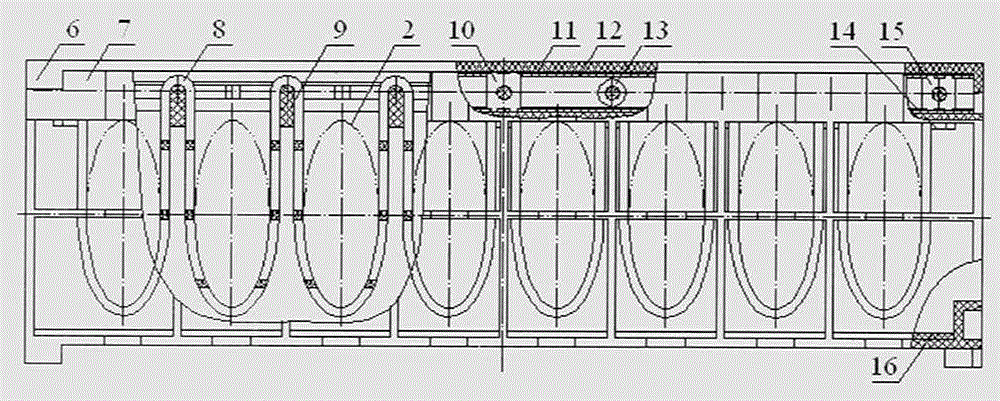

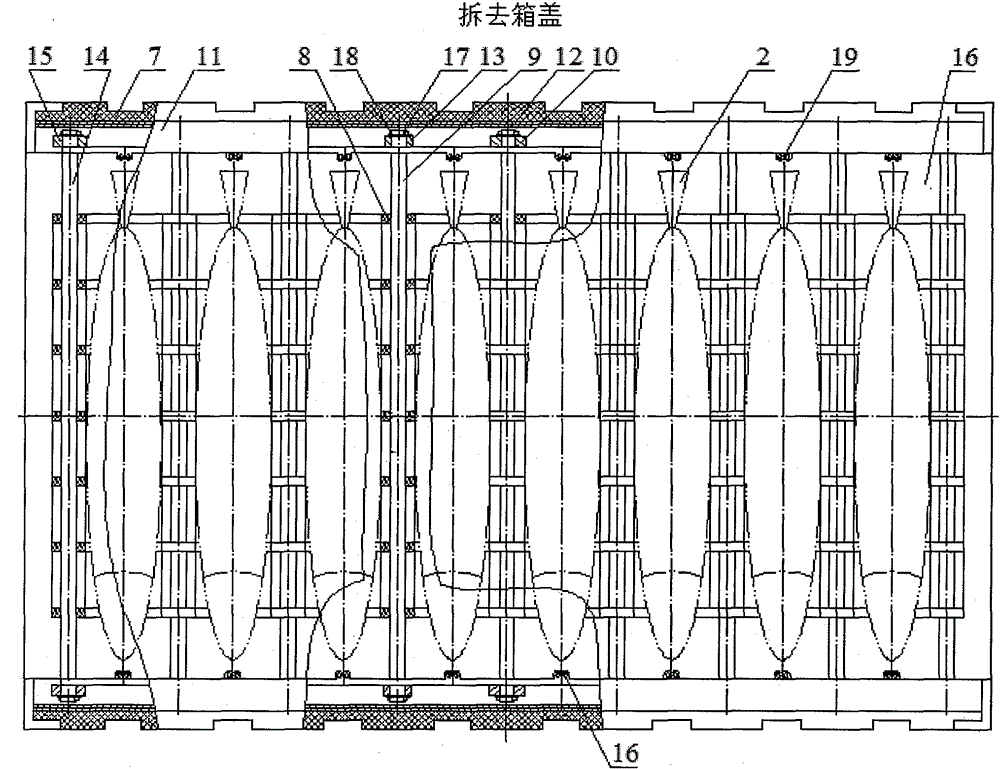

Fish box and method for transporting live fish vertically without water

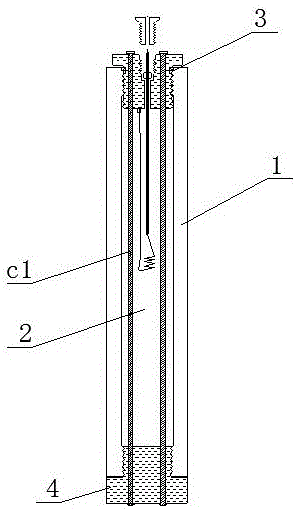

InactiveCN103858812BLess chance of mechanical damageGood securityPisciculture and aquariaFishing netEngineering

The invention discloses a live fish vertically placing water-free life-keeping conveying fish box and a live fish vertically placing water-free life-keeping conveying method. Live fishes (2) are contained in fish nets (8); the fish nets (8) are hung to inner supporting rods (9) and end supporting rods (14) and are respectively linked with the corresponding supporting rods; the two ends of the end supporting rods (14) and the two ends of the inner supporting rods (9) are supported on a box body (7); a box cover (6) is covered on the box body (7); certain minimum distance is formed between adjacent inner supporting rods (9); certain minimum distance is formed between each end supporting rod (14) and the adjacent inner supporting rod (9); due to the minimum distance, the fish nets on the two sides of the fishes (2) are approximately parallel and are kept to have certain distance to prevent the bodies of the live fishes (2) from being inclined, the live fishes (2) are placed in the fish box (1) without water, and the fish box (1) is placed in a refrigeration box (3) of a refrigeration vehicle (5), so that the live fishes (2) are kept alive and are conveyed without water. The fish box is used for keeping the fished alive and conveying the fishes without water, and the squeezing hurt to the fishes and death of the fishes in a water-free life-keeping conveying process of the live fishes are reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com