Patents

Literature

30results about How to "Increase or" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

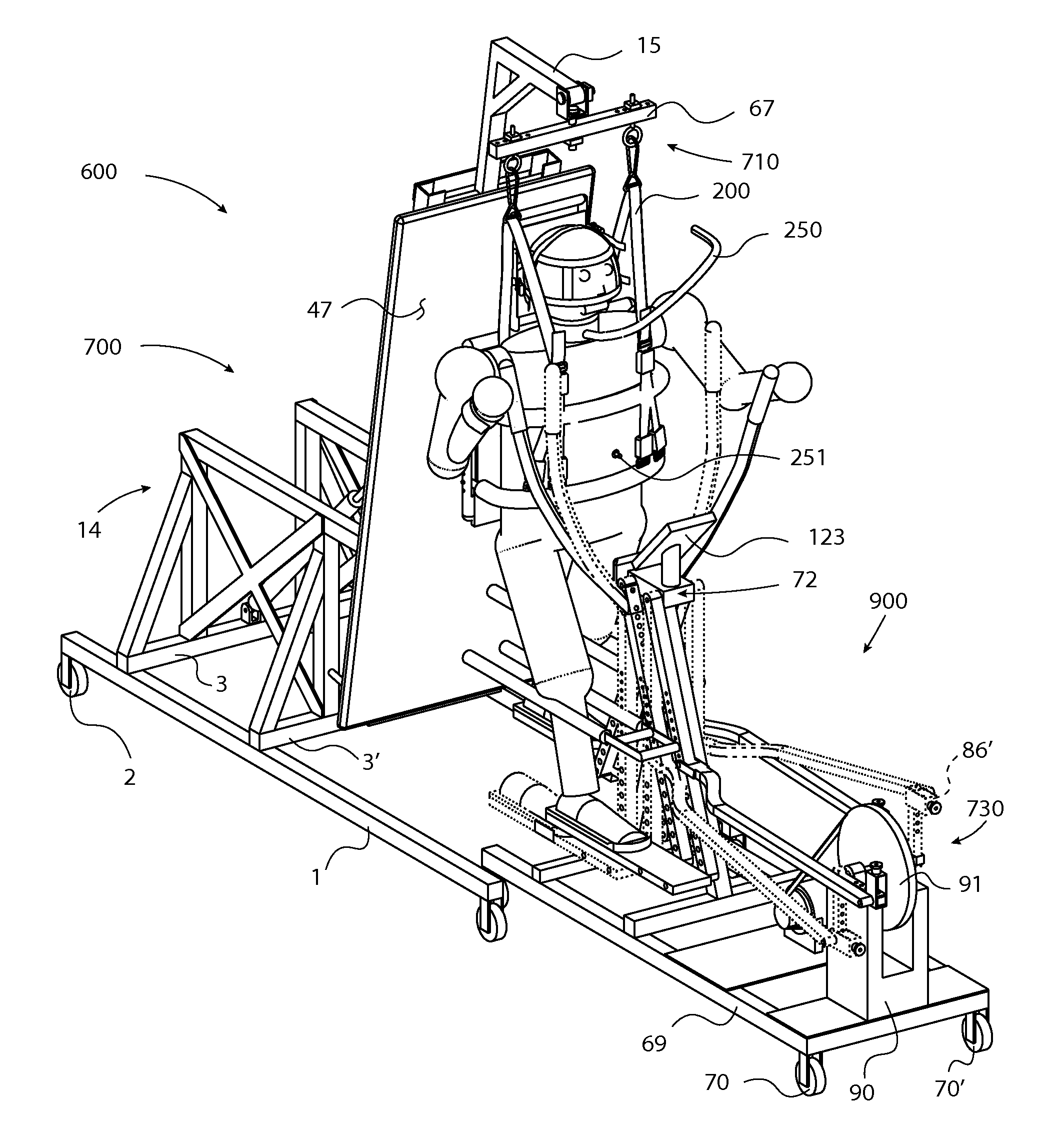

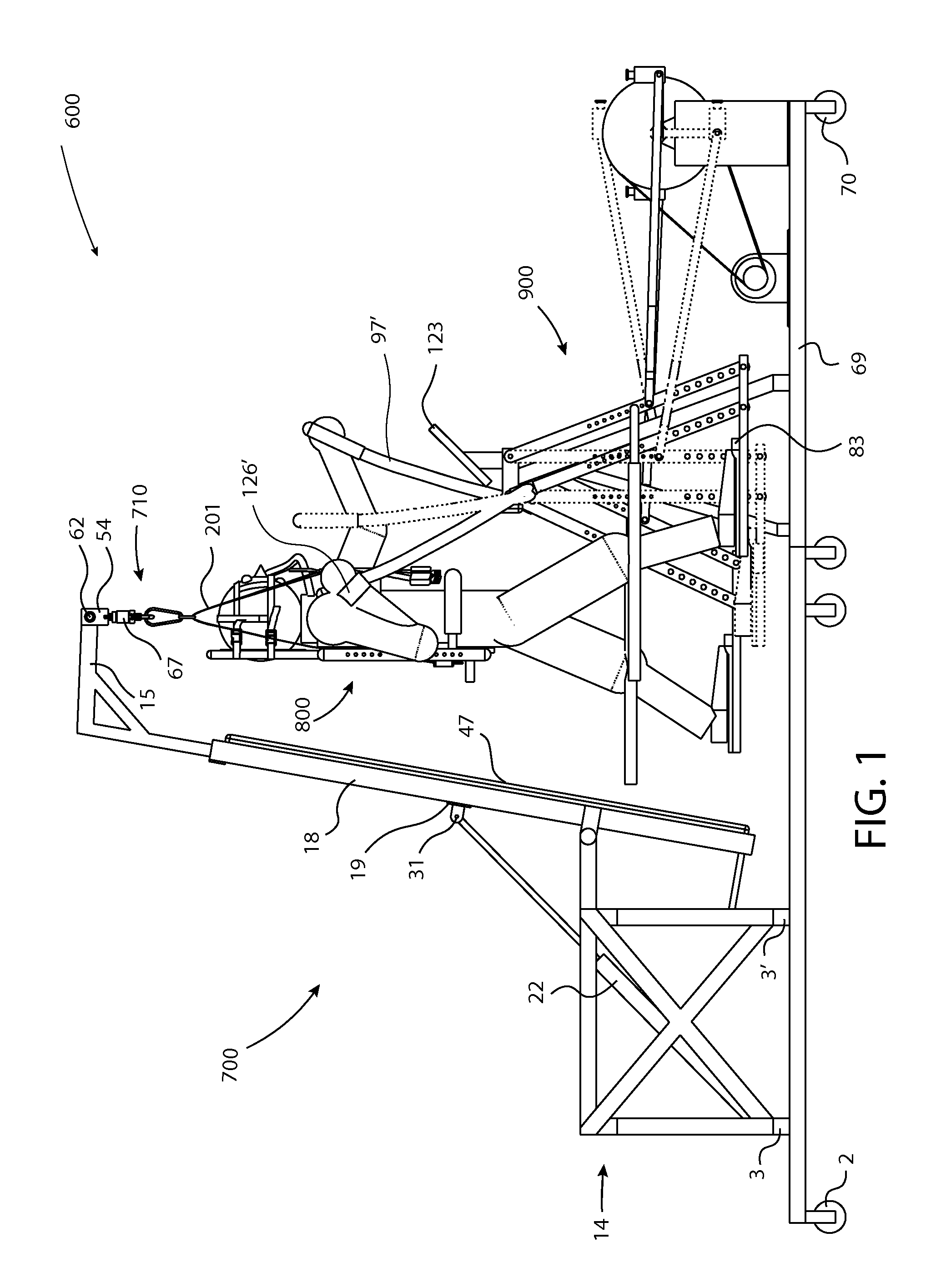

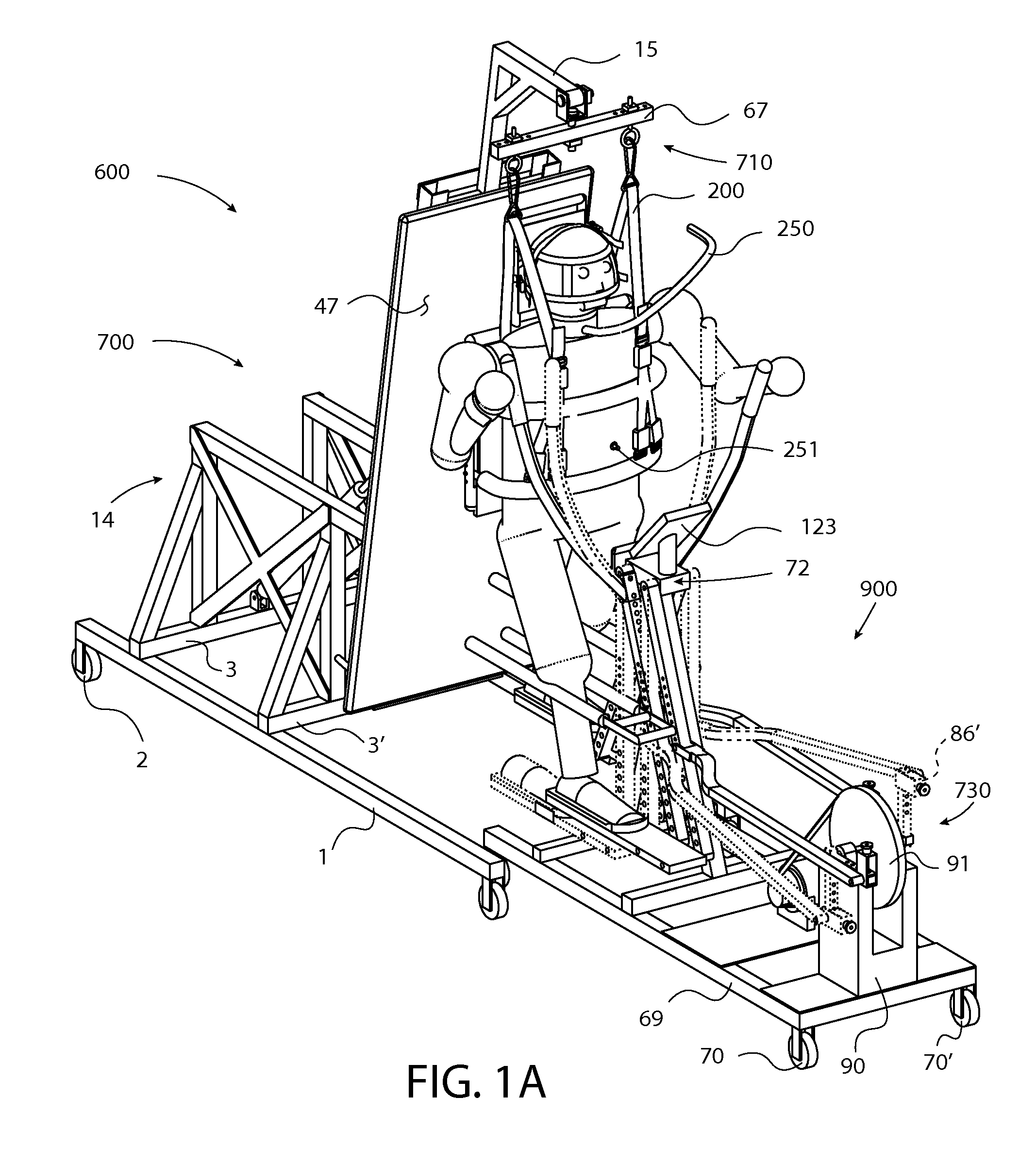

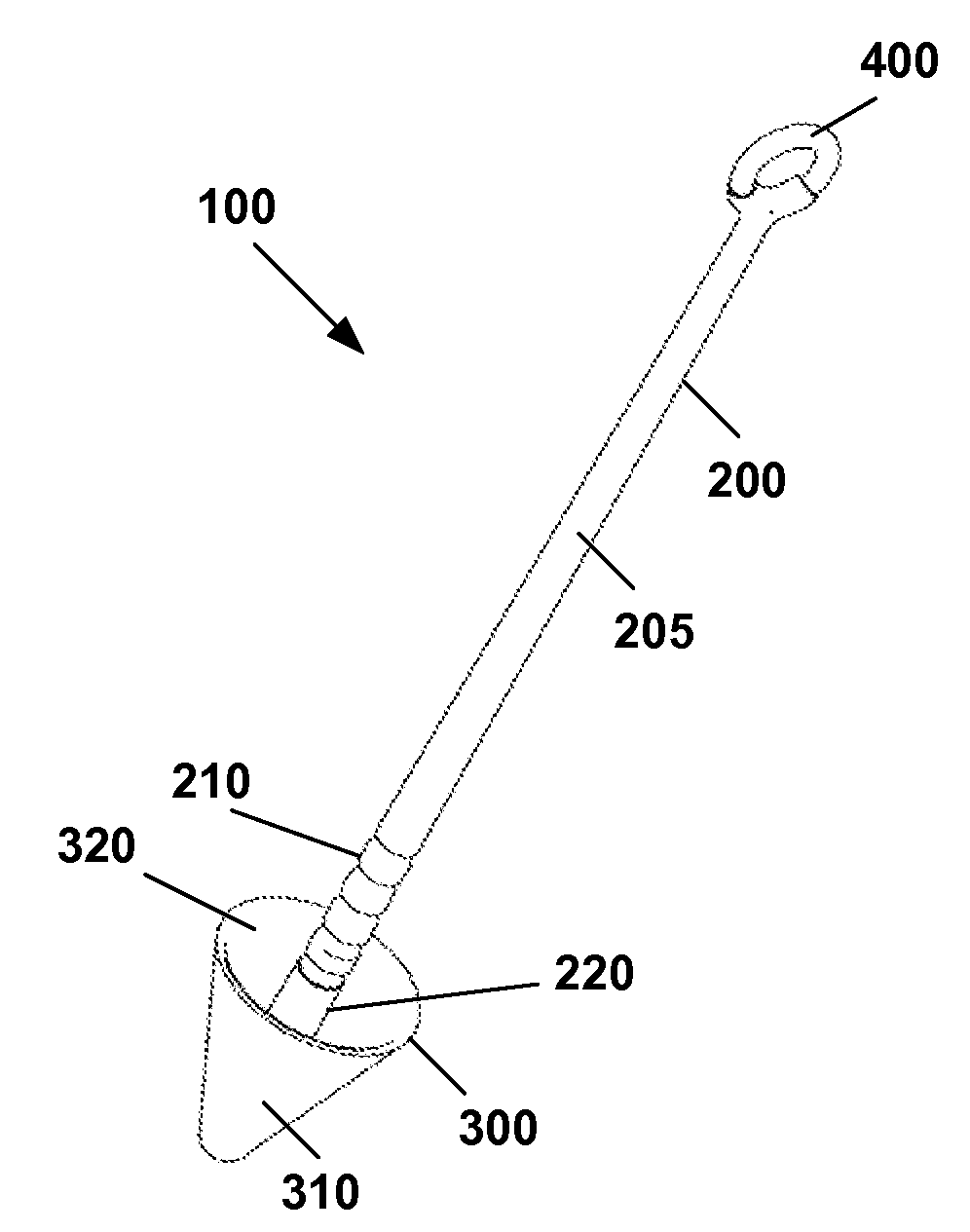

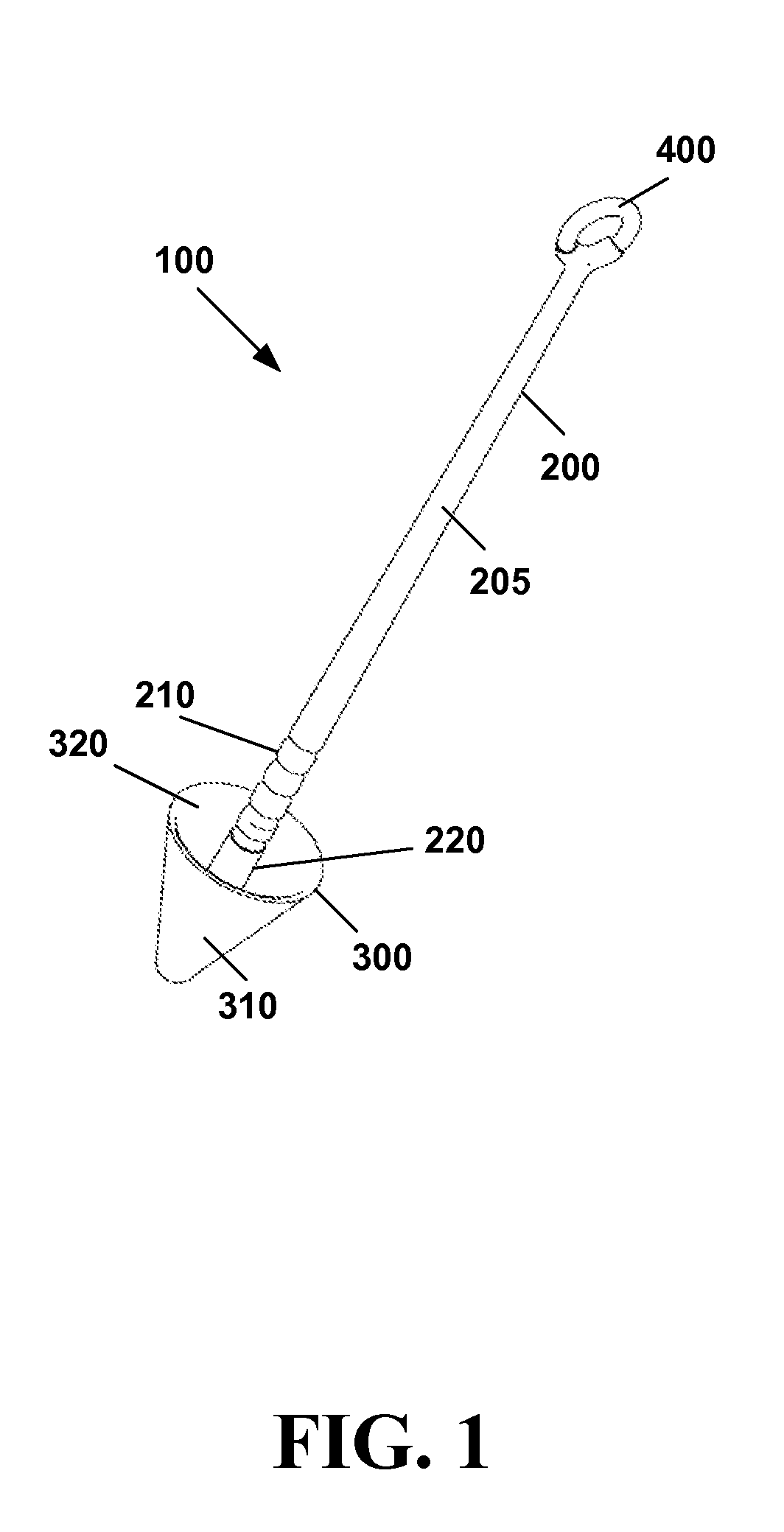

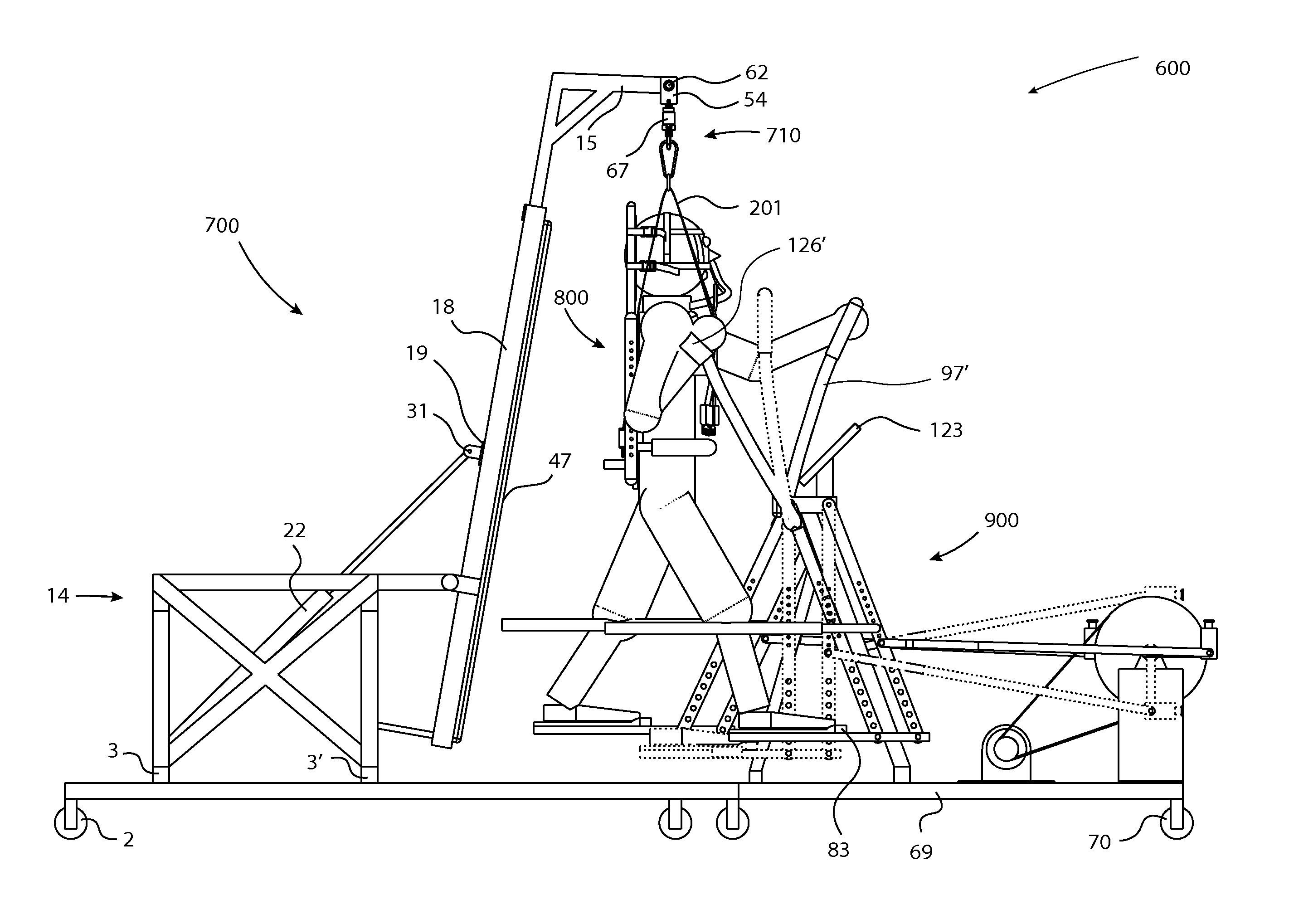

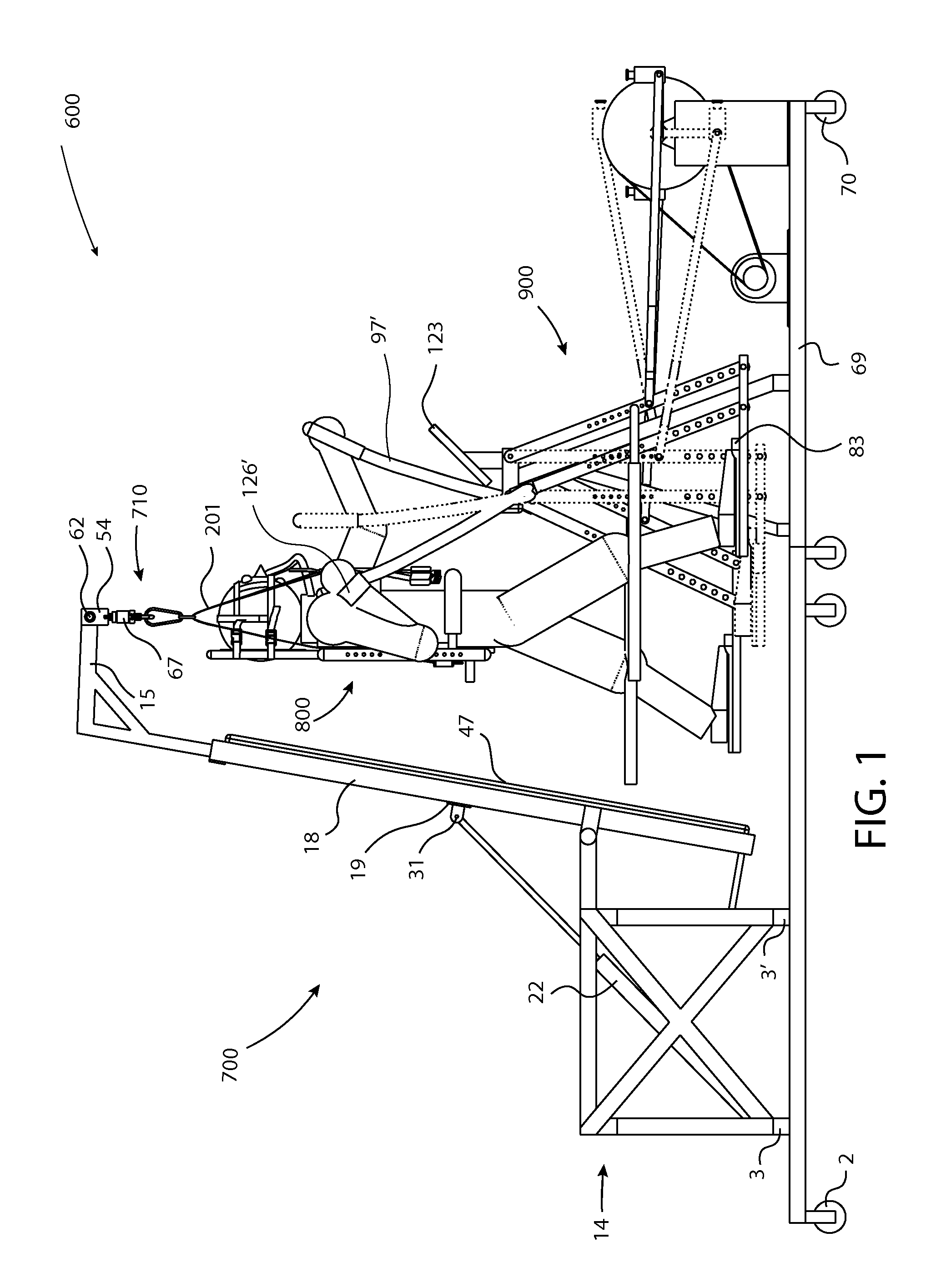

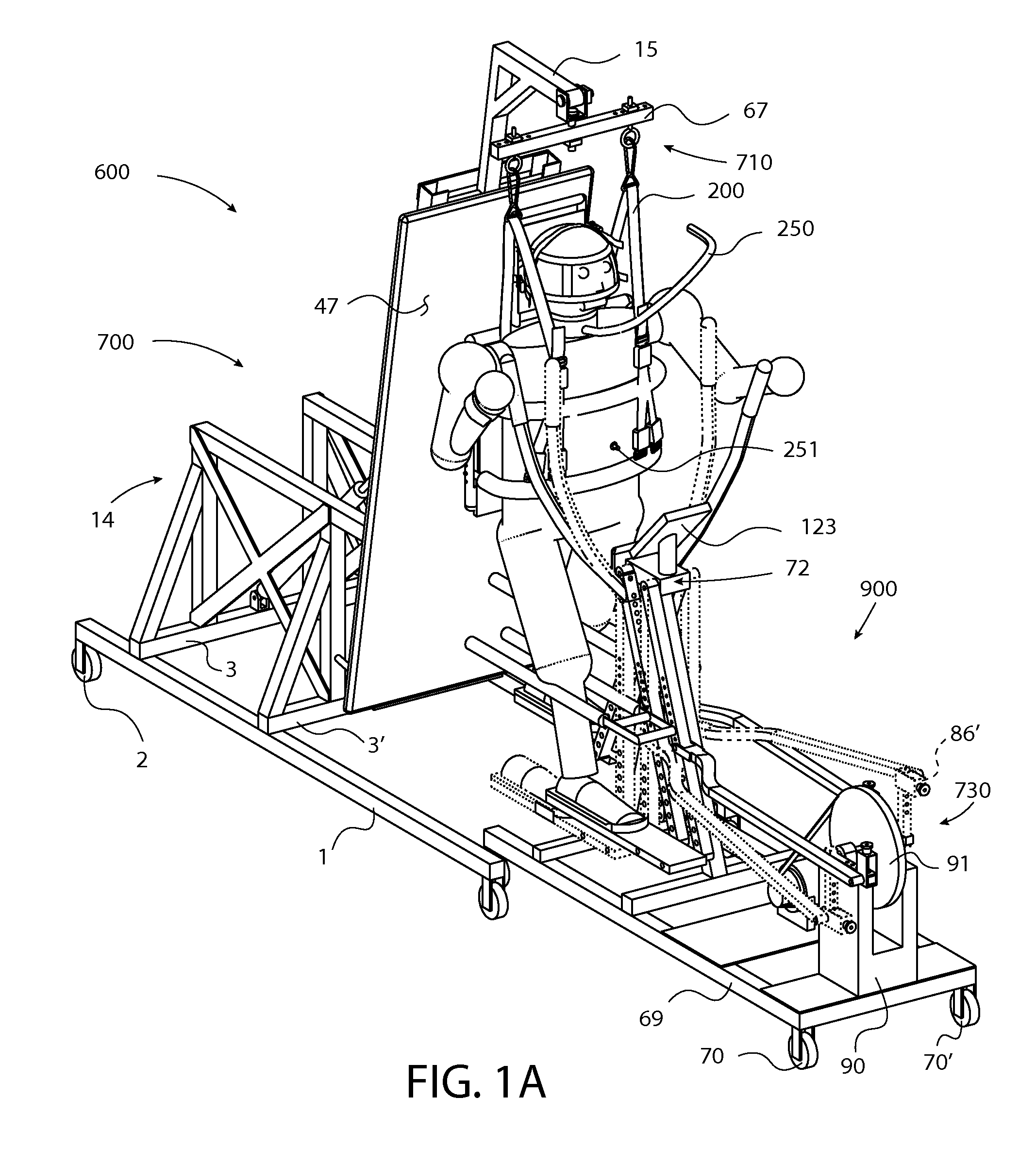

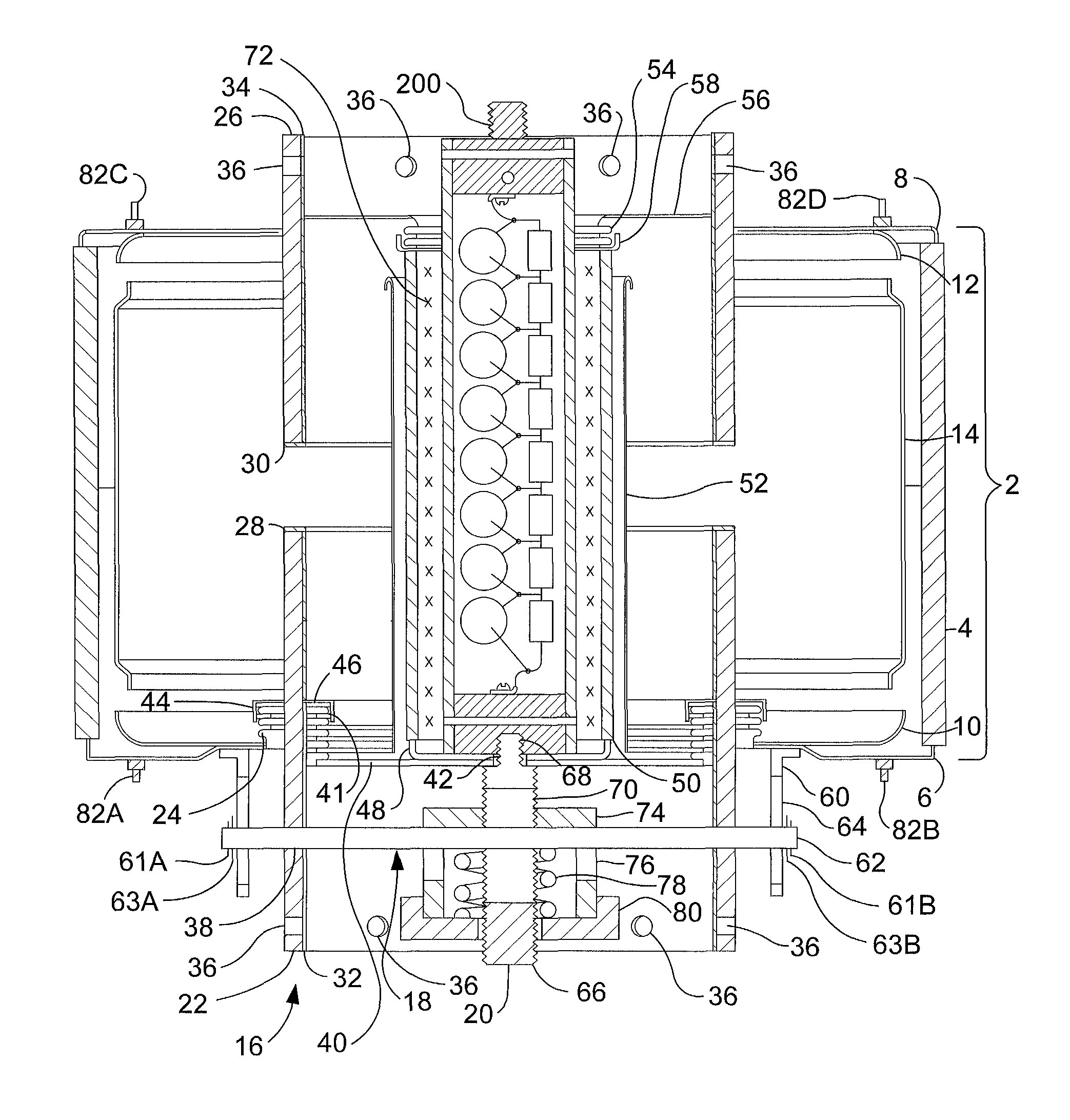

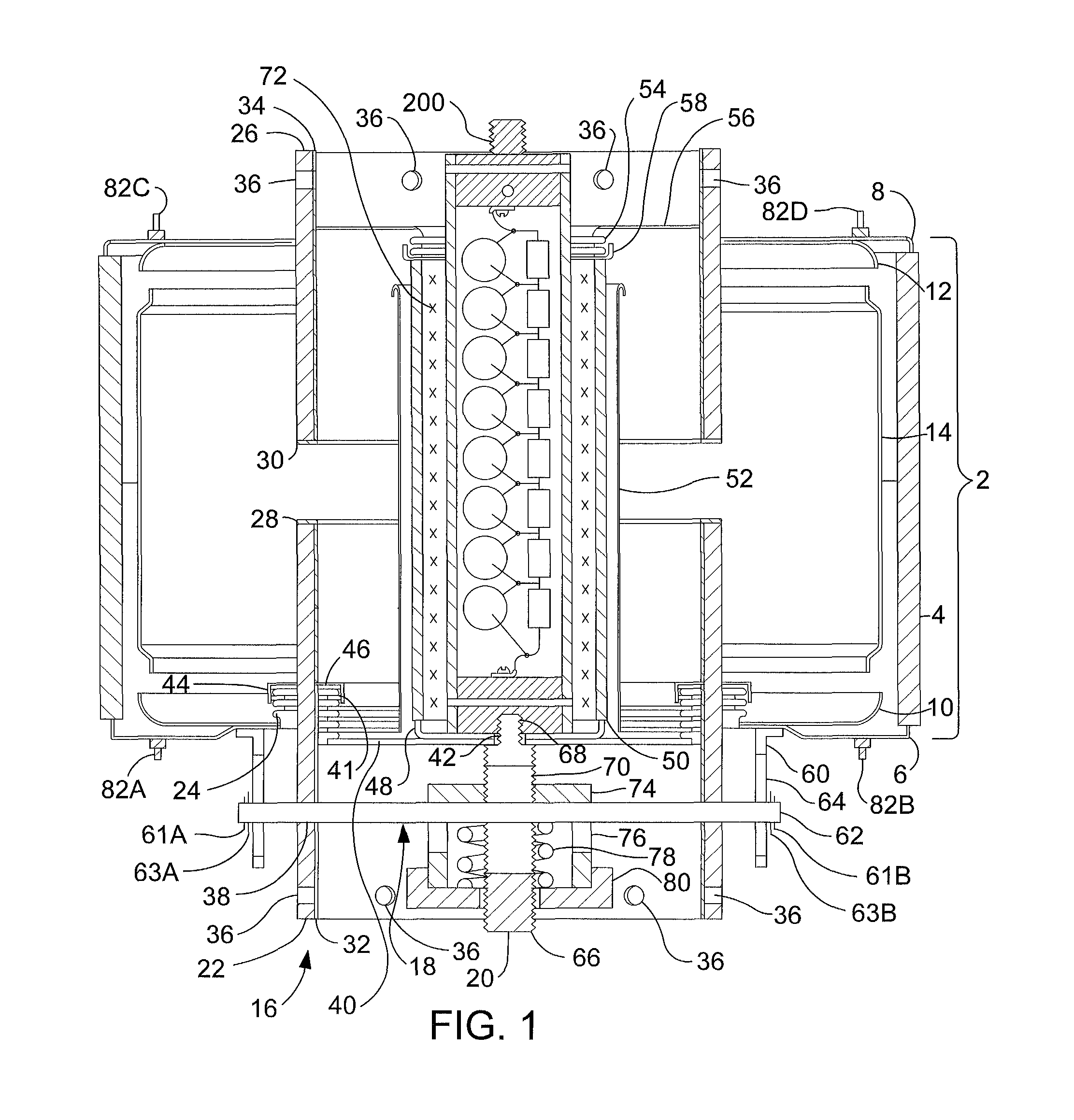

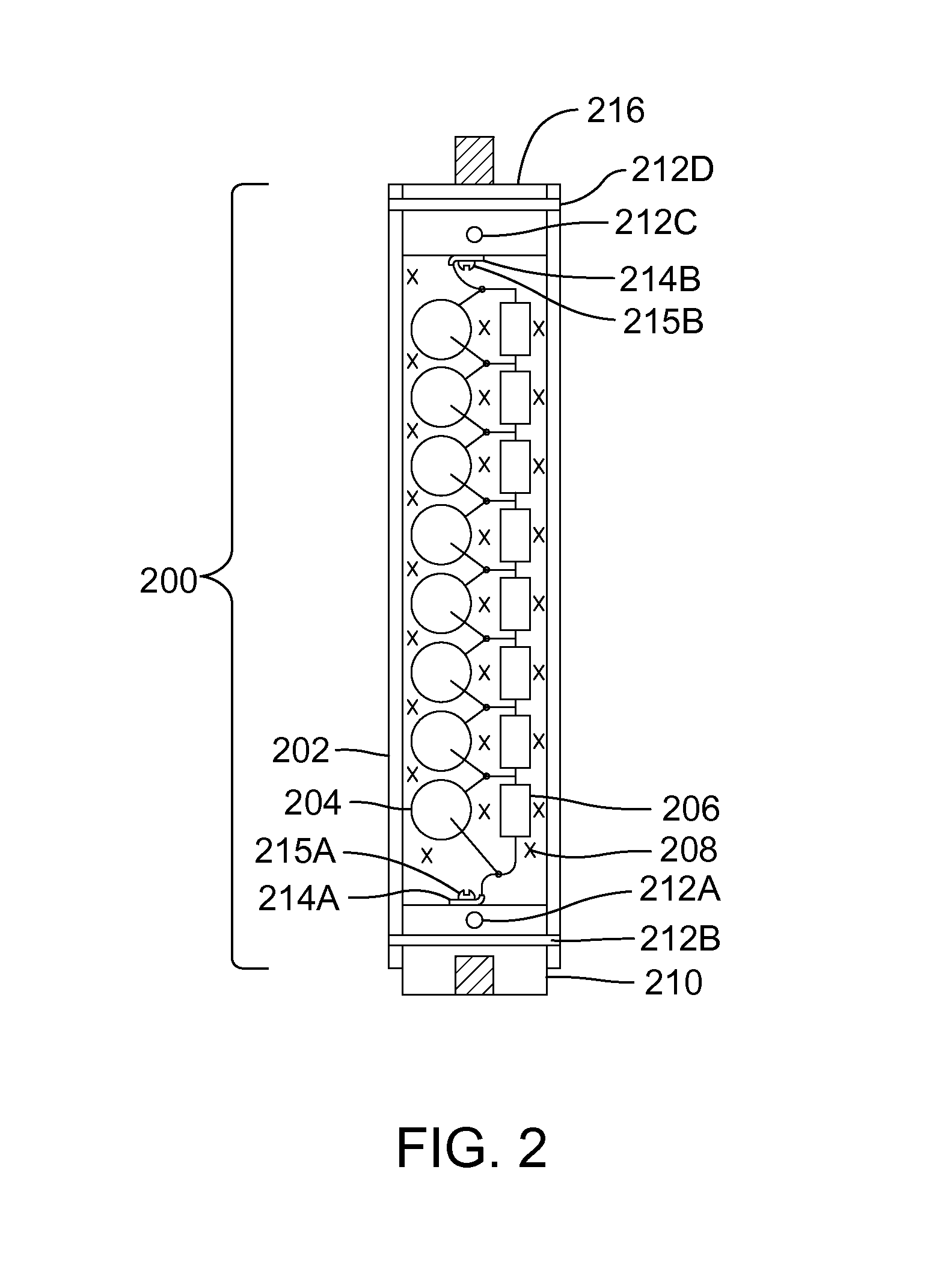

Motorized air walker and suspension system for paralyzed persons

ActiveUS20150250675A1Increase orAccommodate a gait of the patientChiropractic devicesWalking aidsEngineeringUse walkers

A system for patient rehabilitation is disclosed. The system includes a first movable frame including an articulating bed, wherein the bed is configured to be selectively articulated to an inclined position, a suspension system, wherein the suspension system is disposed within the articulating bed and is selectively adjustable to accommodate varying patient height, a harness, wherein the harness is selectively engageable with the suspension system, wherein the harness is selectively adjustable to accommodate varying patient sizes, a second movable frame including a walker, wherein the walker includes a pair of legs and a motor, wherein approximation of the two movable frames permits the patient to easily utilize the walker from the bed. A method of using the system for patient rehabilitation is also disclosed.

Owner:KALINOWSKI EUGENE

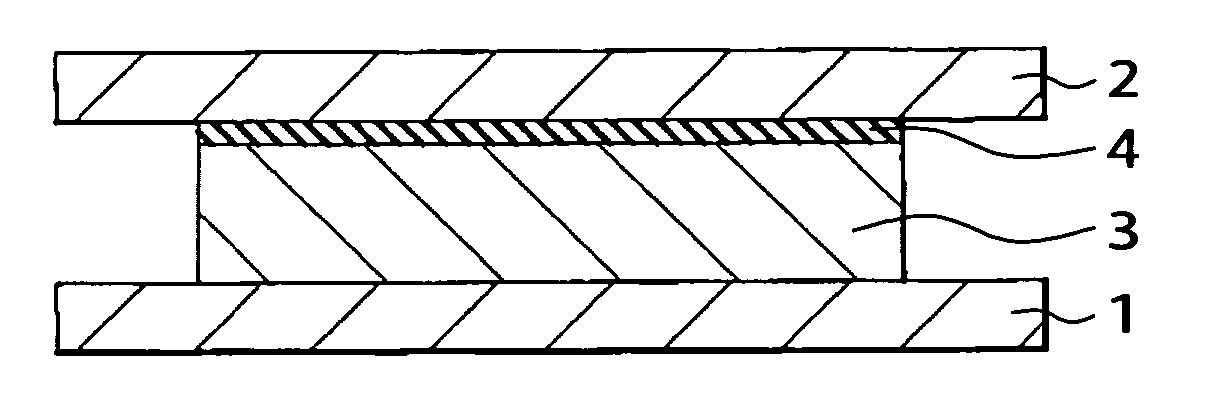

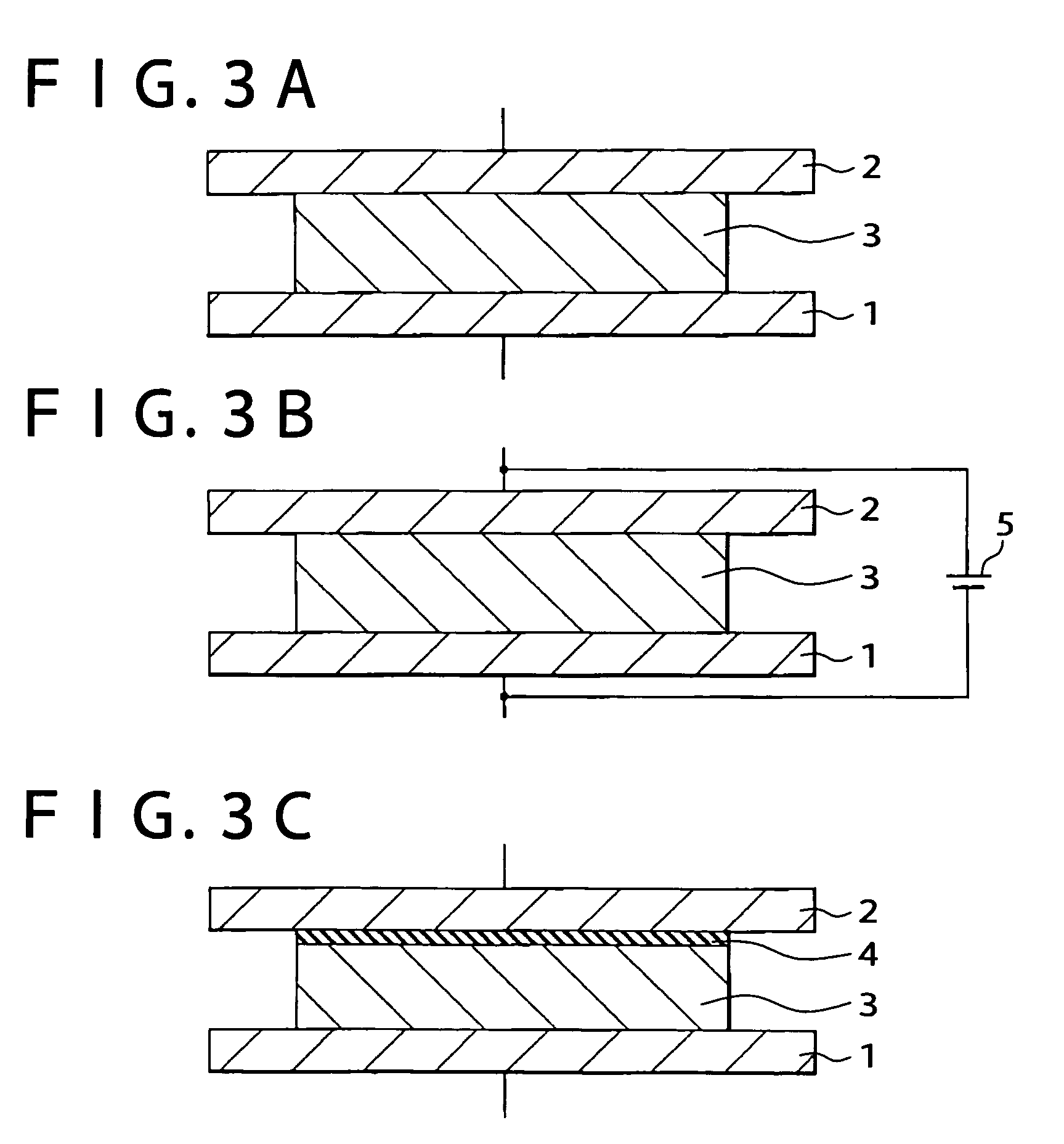

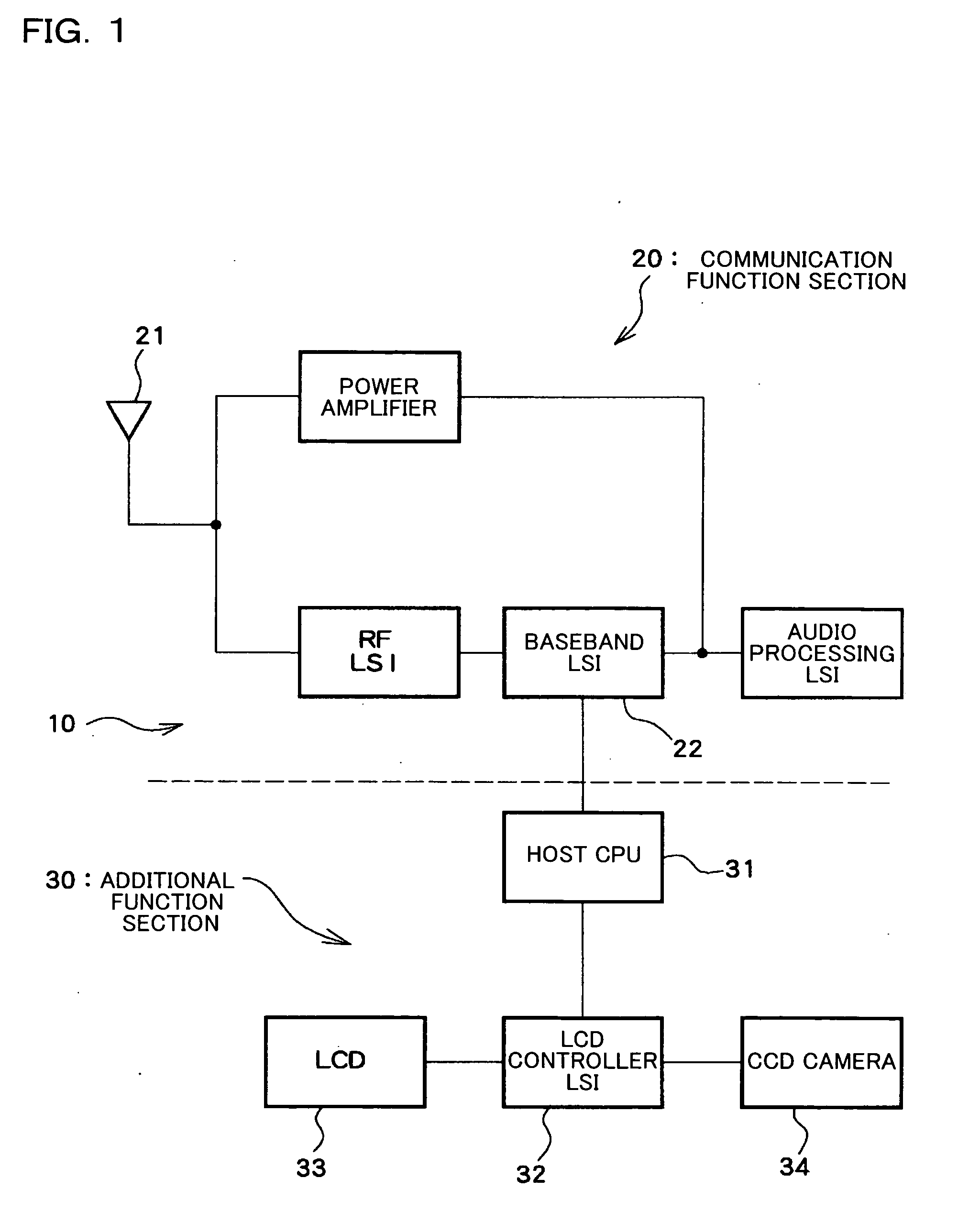

Storage device

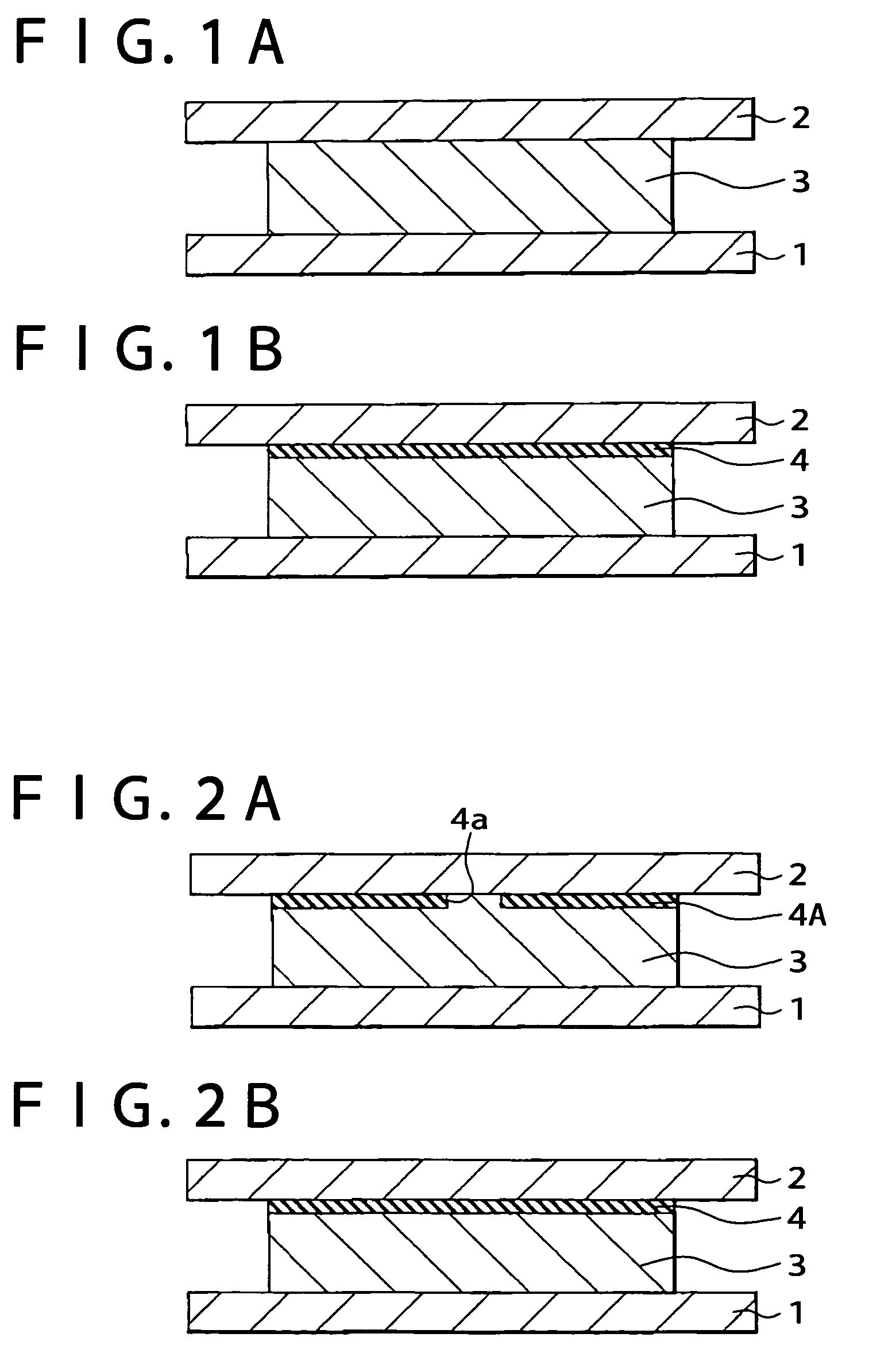

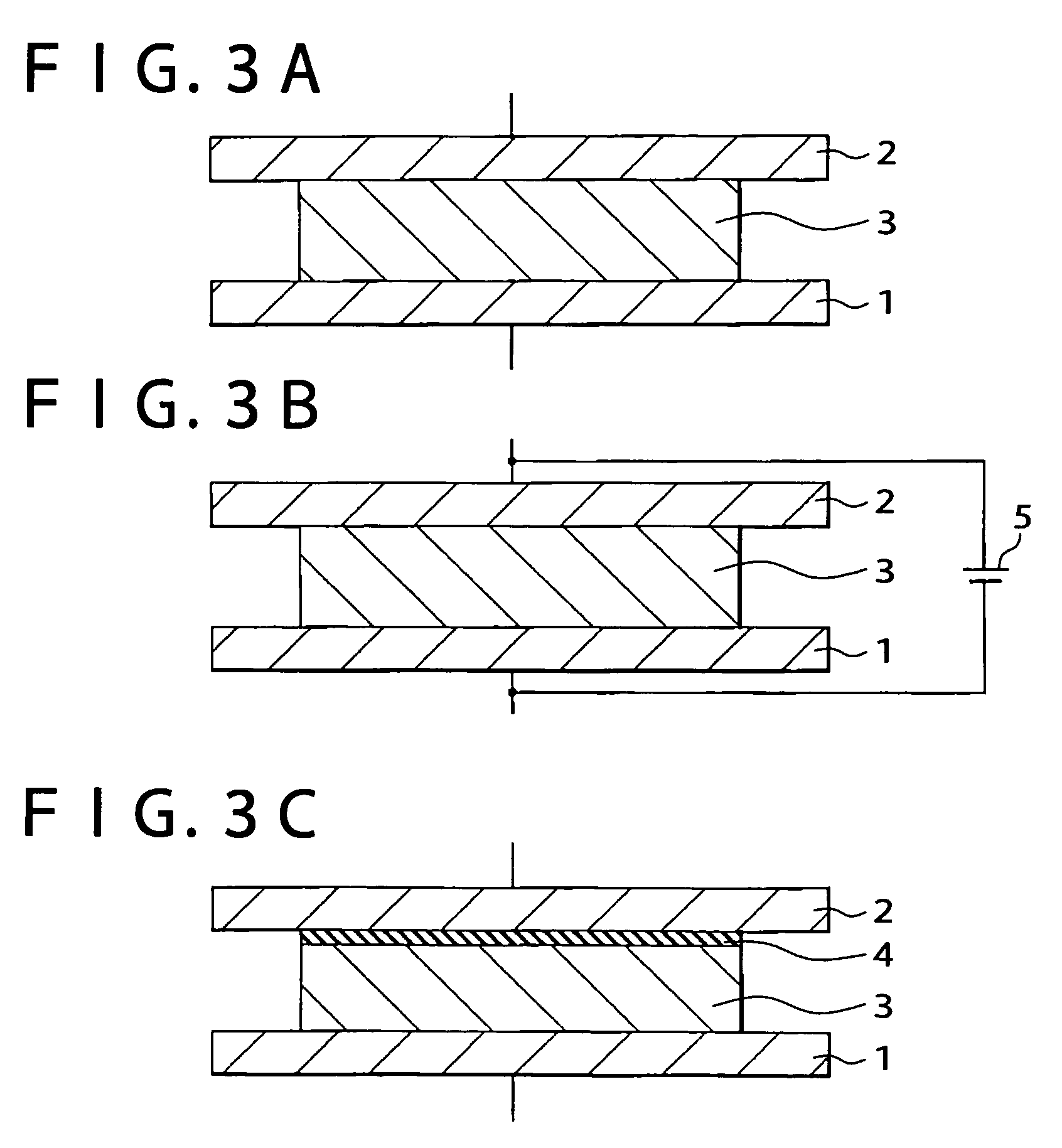

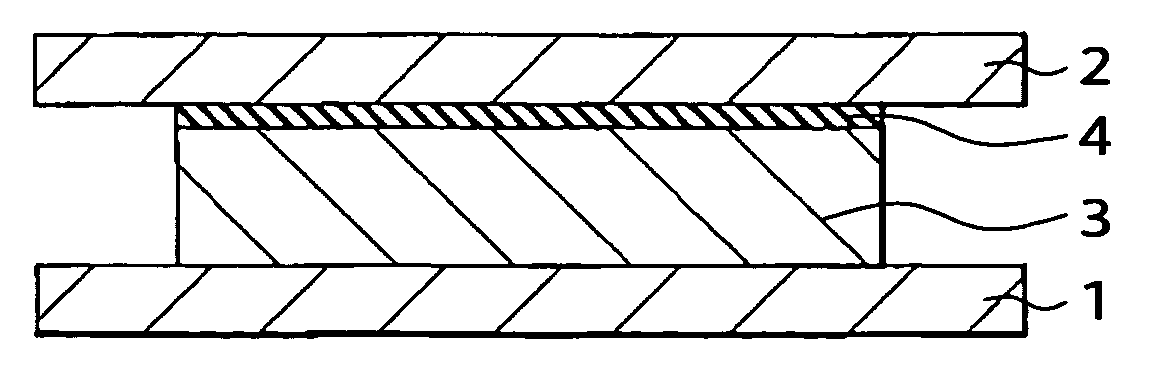

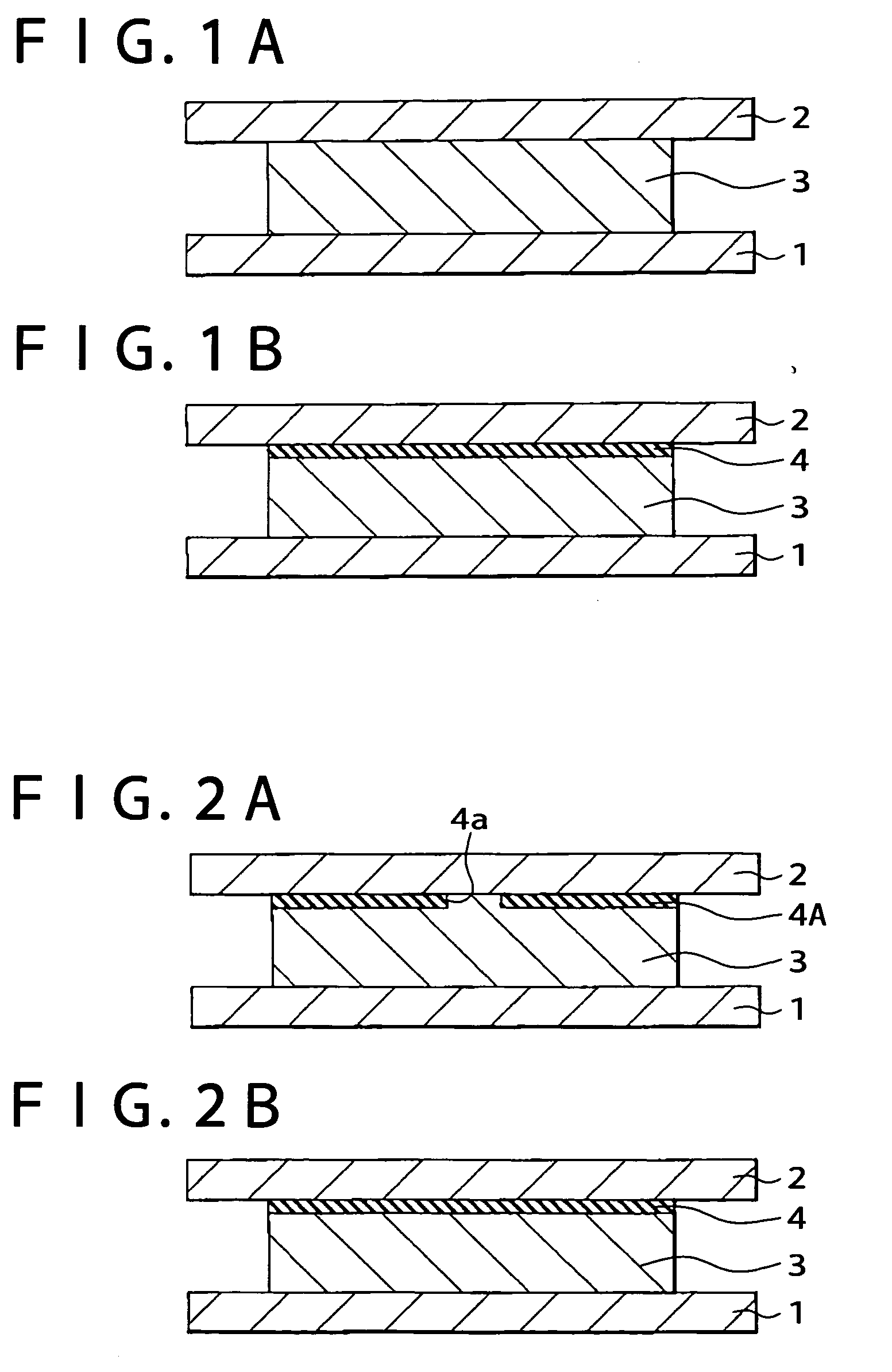

ActiveUS7126152B2Increase orProcess stabilitySolid-state devicesRead-only memoriesEngineeringOxidation reduction

Owner:SONY CORP

Storage device

ActiveUS20050121697A1Increase or decrease areaProcess stabilitySolid-state devicesRead-only memoriesElectric fieldOxidation reduction

A storage device includes a first electrode, a second electrode facing the first electrode, an inter-electrode material layer provided between the first electrode and the second electrode, and a voltage application unit applying a predetermined voltage to the first and the second electrodes. Furthermore, an oxidation-reduction active material changeable into an electrode reaction inhibition layer by applying voltages to the first and the second electrodes is contained in a region that is covered by an electric field, the electric field being generated when the voltage is applied, and the electrode reaction inhibition layer is either formed along an interface region between the second electrode and the inter-electrode material layer, or changes an area thereof, or disappears depending on an application condition of the voltage to the first and the second.

Owner:SONY CORP

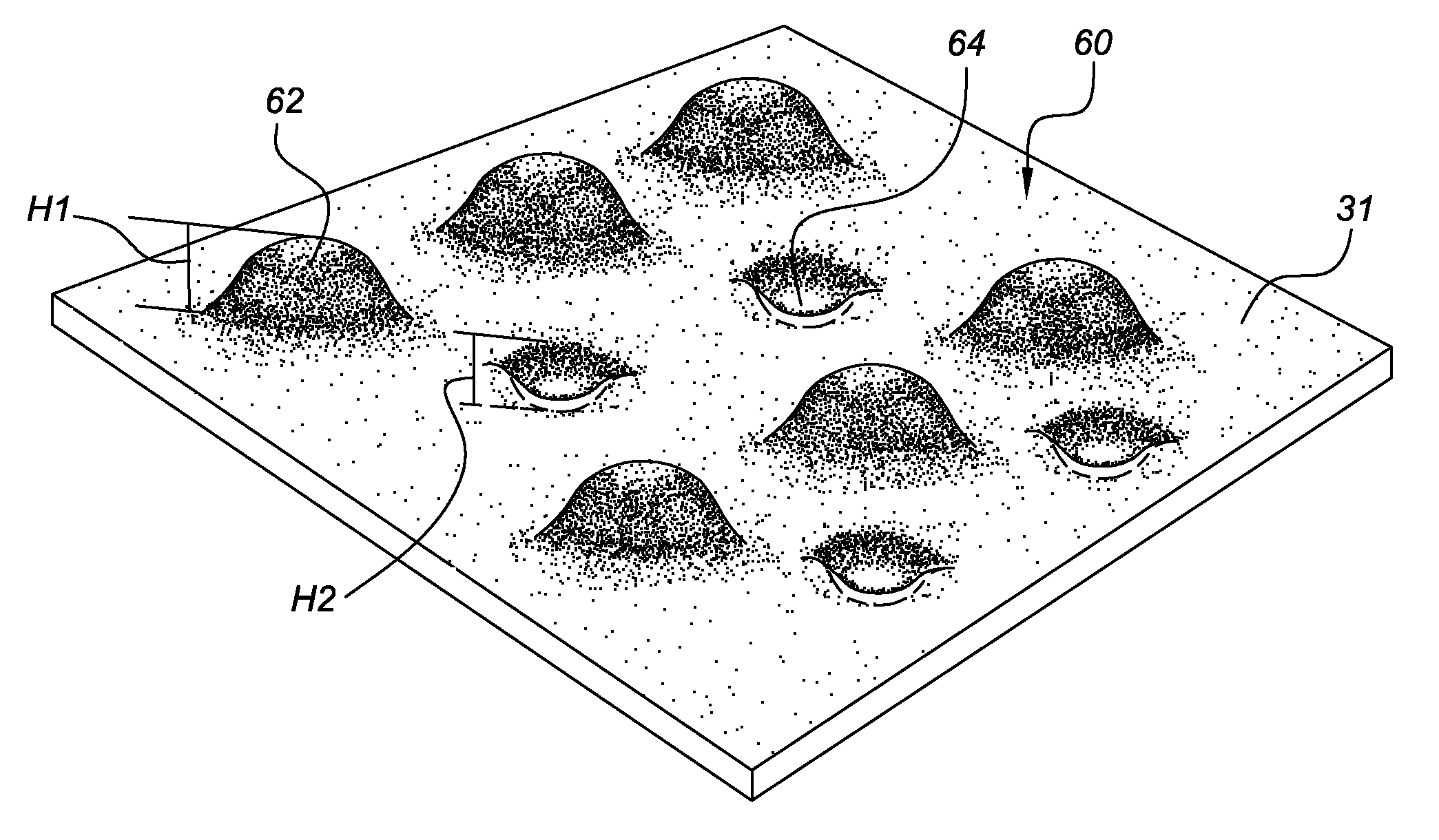

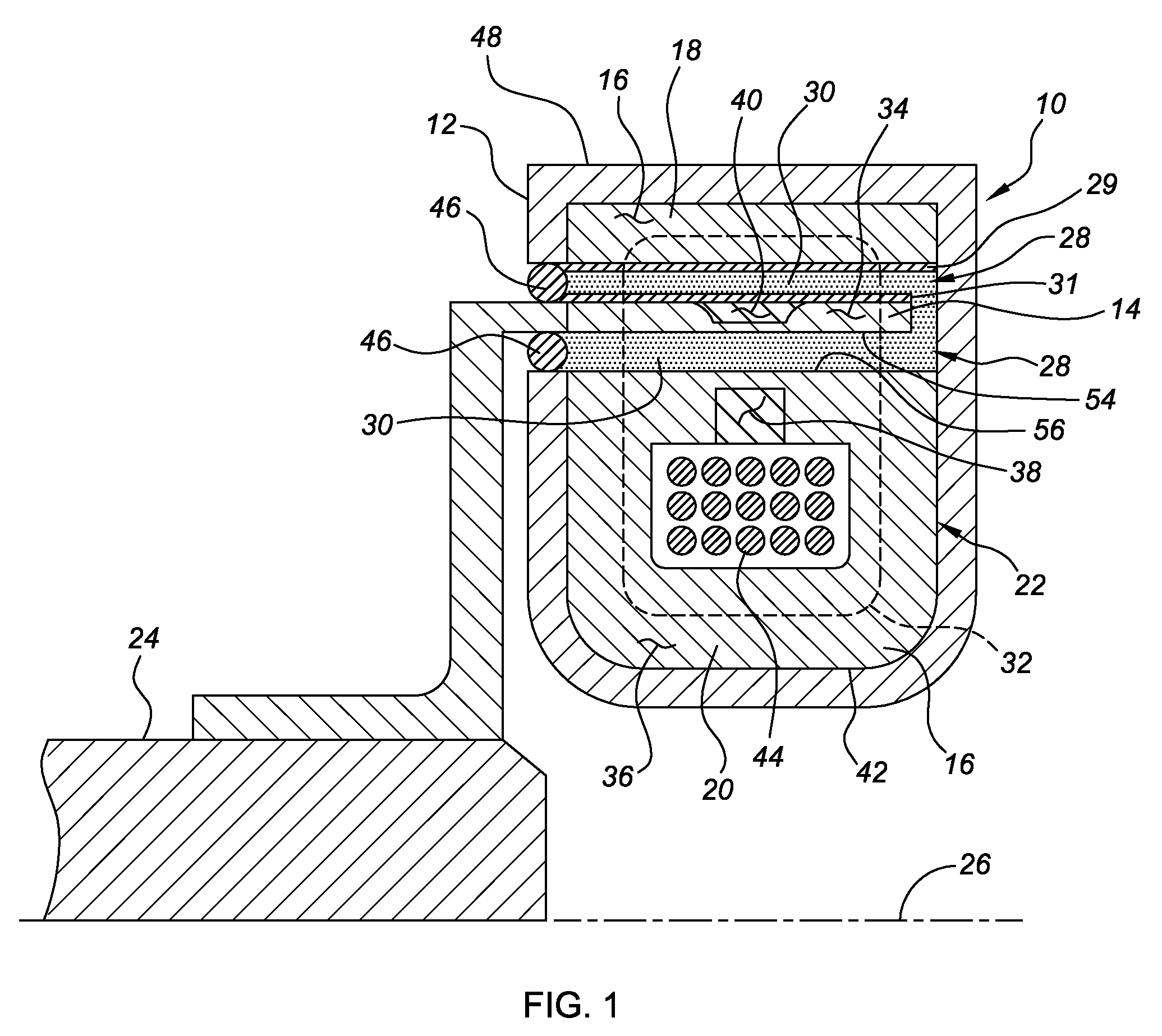

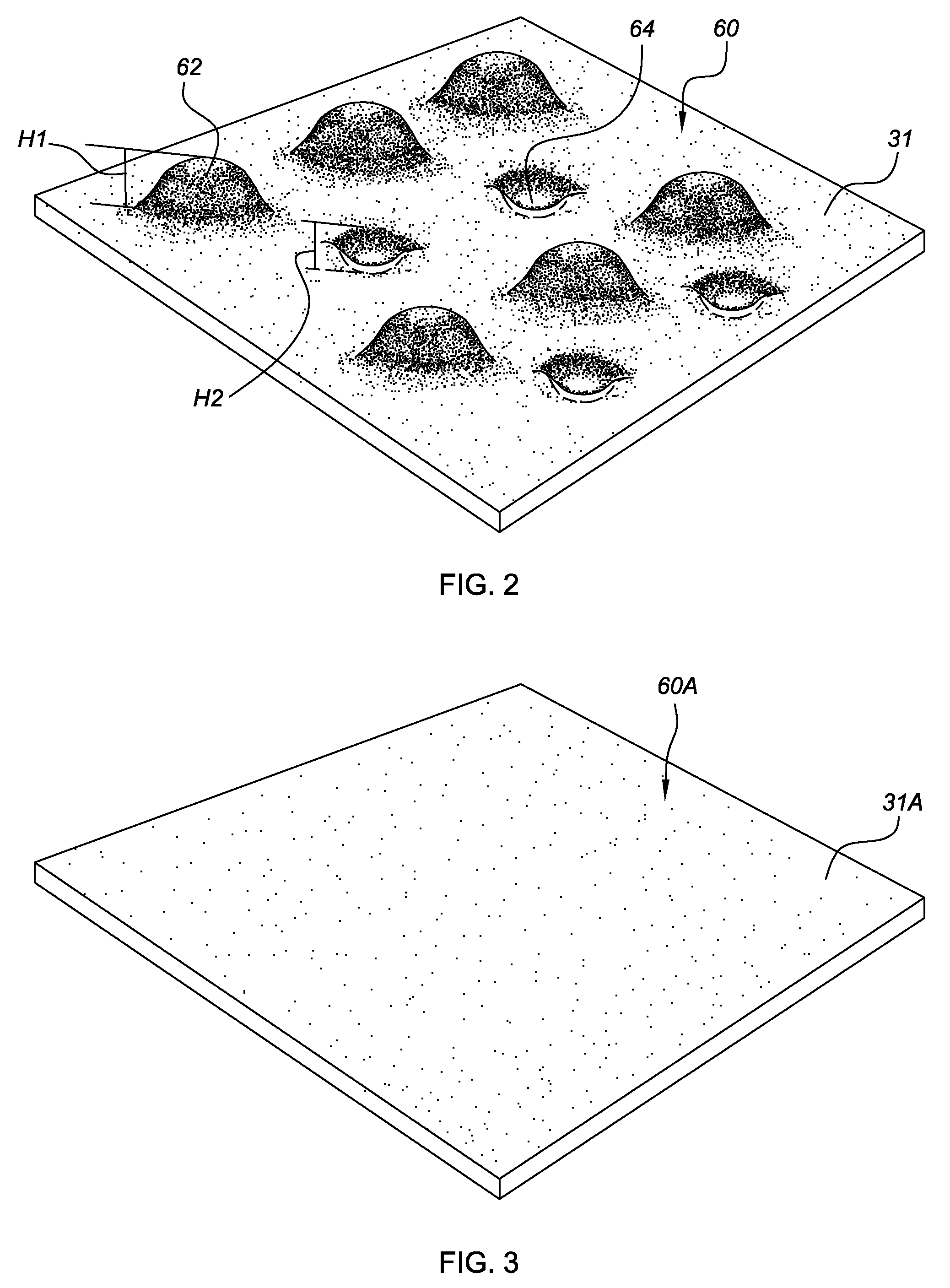

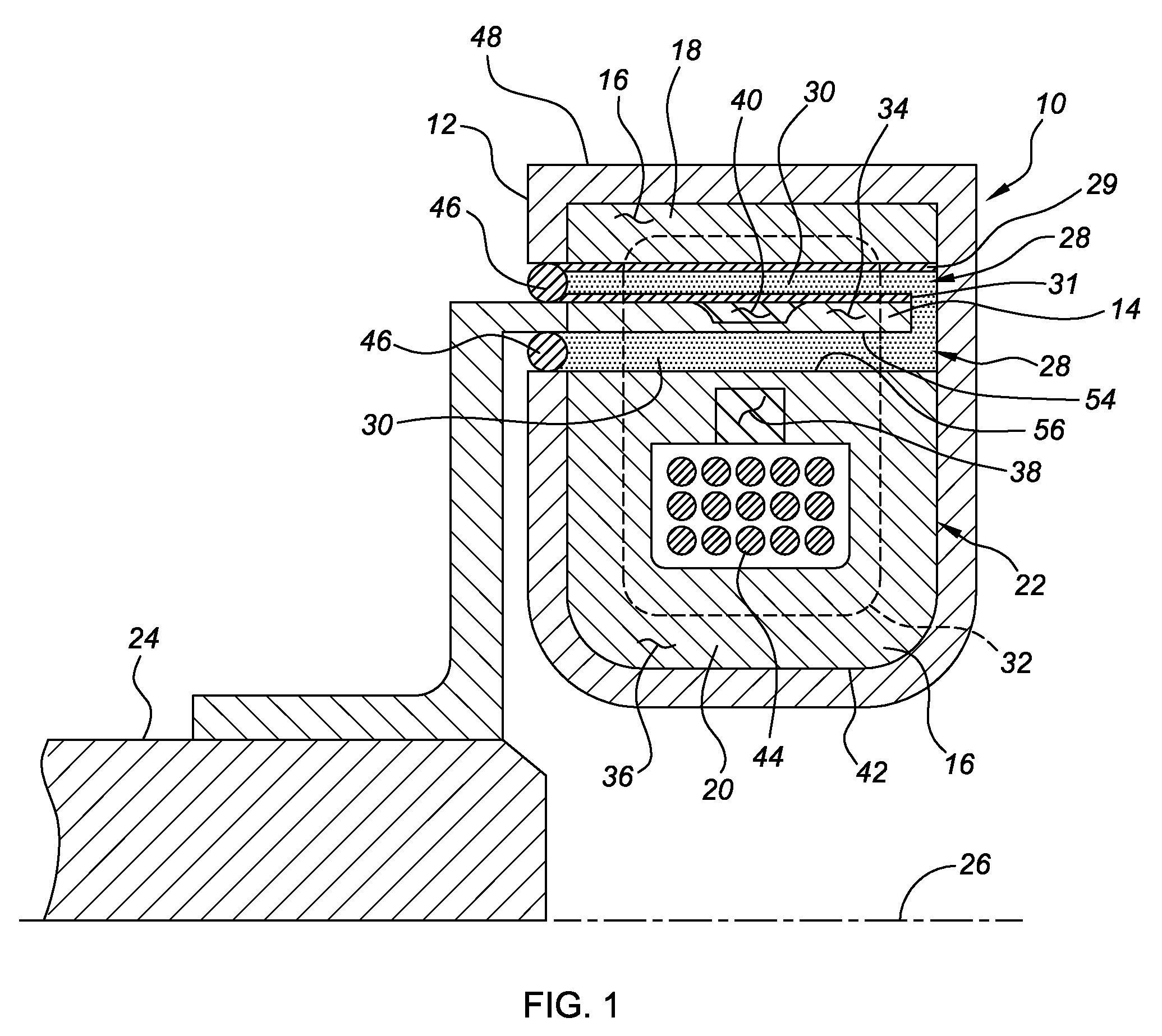

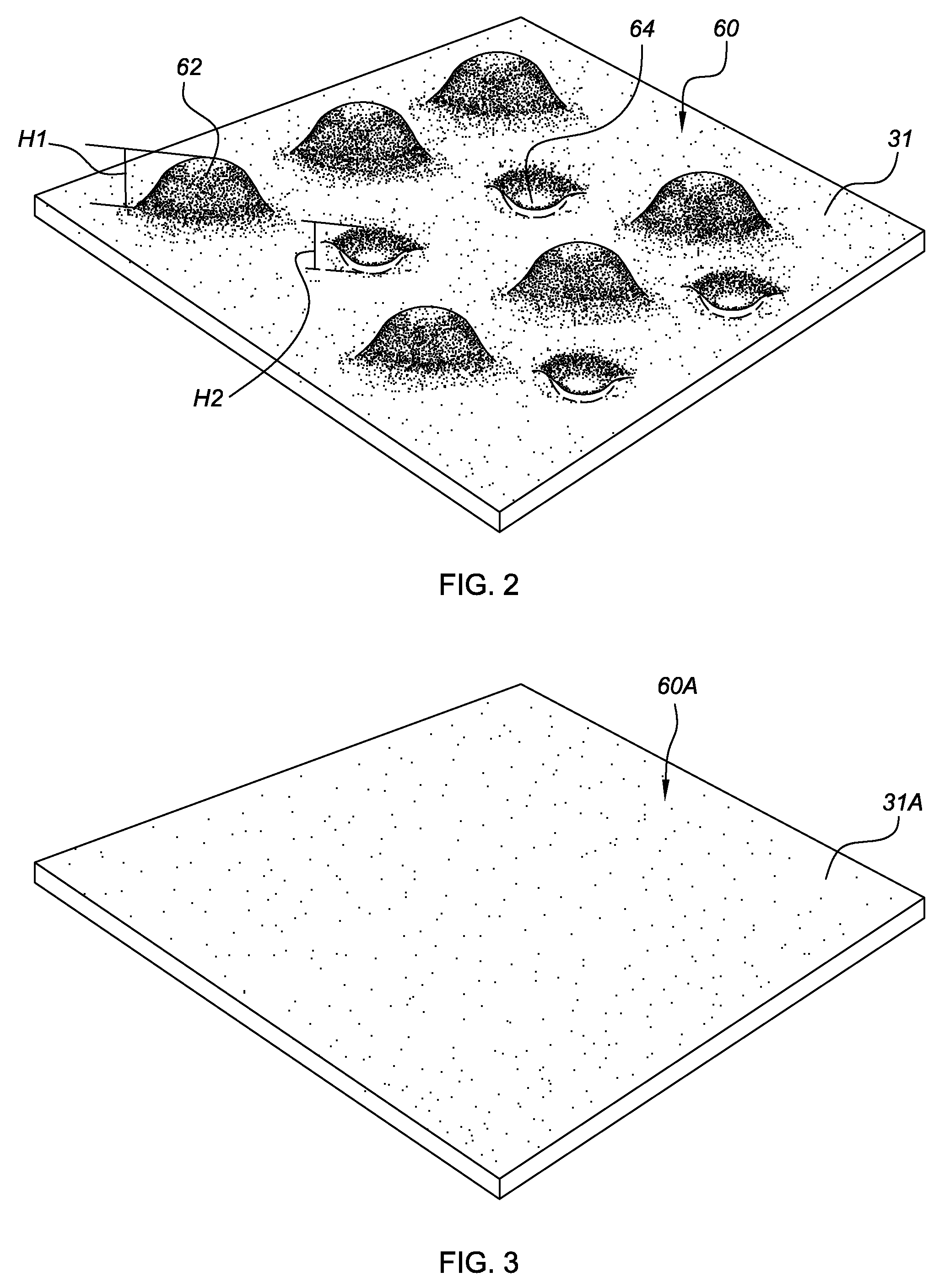

Apparatus with active material surface in contact with rheological fluid and method of enhancing performance thereof

InactiveUS8056687B2Increased torque capacityOverheating of the stator and/or rotor is avoidedSpringsNon-rotating vibration suppressionEngineeringSurface geometry

An apparatus is provided having an active material forming a surface thereof in contact with a rheological fluid. The active material is controllable to vary a surface geometry thereof between a rough or nonsmooth surface geometry to increase drag, and achieve an increase in stress transmitted through the fluid, when a field is applied, while allowing a smooth surface geometry and an associated reduction in stress transmitted through the fluid when the field is removed. A method of enhancing performance of an apparatus that includes a rheological fluid is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

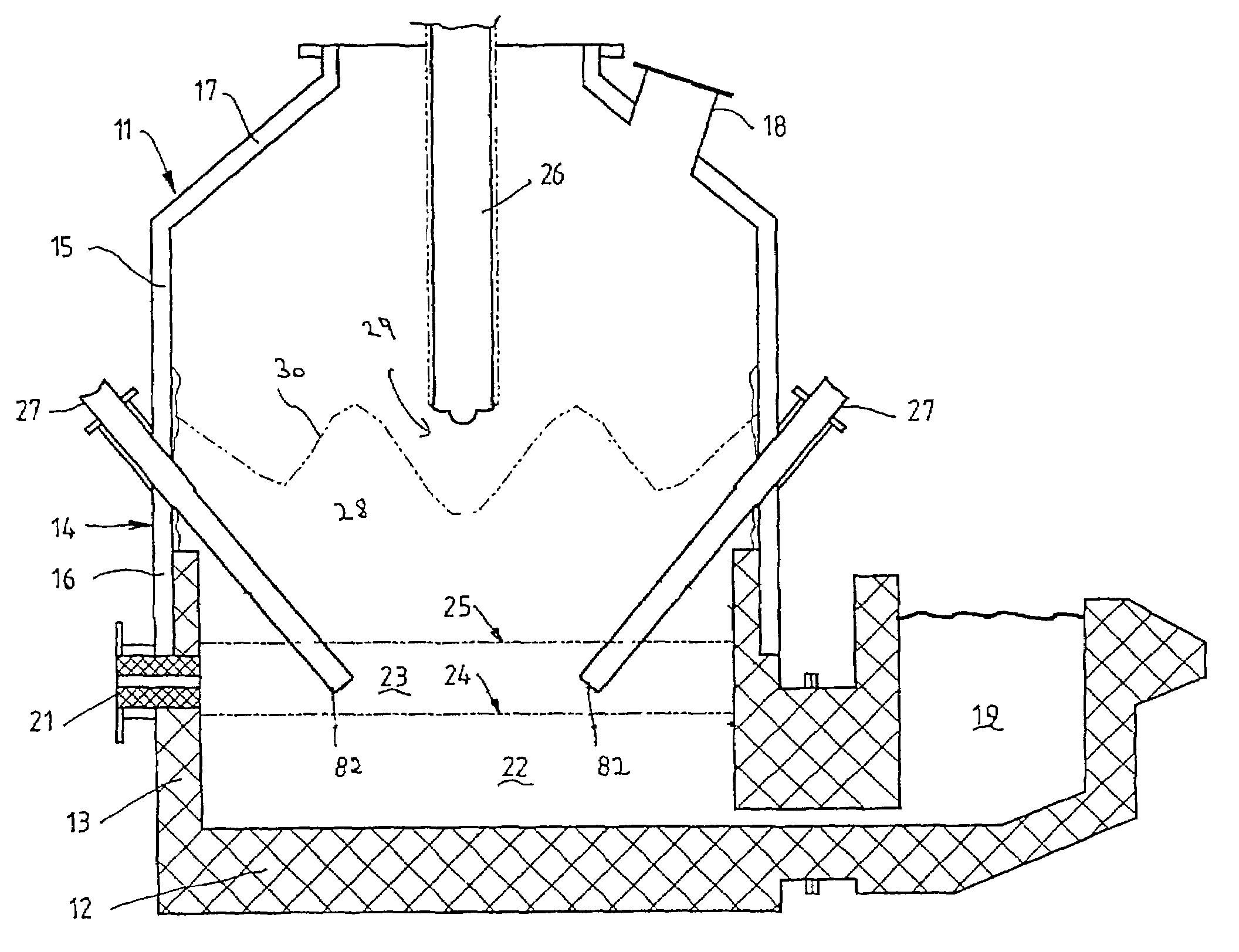

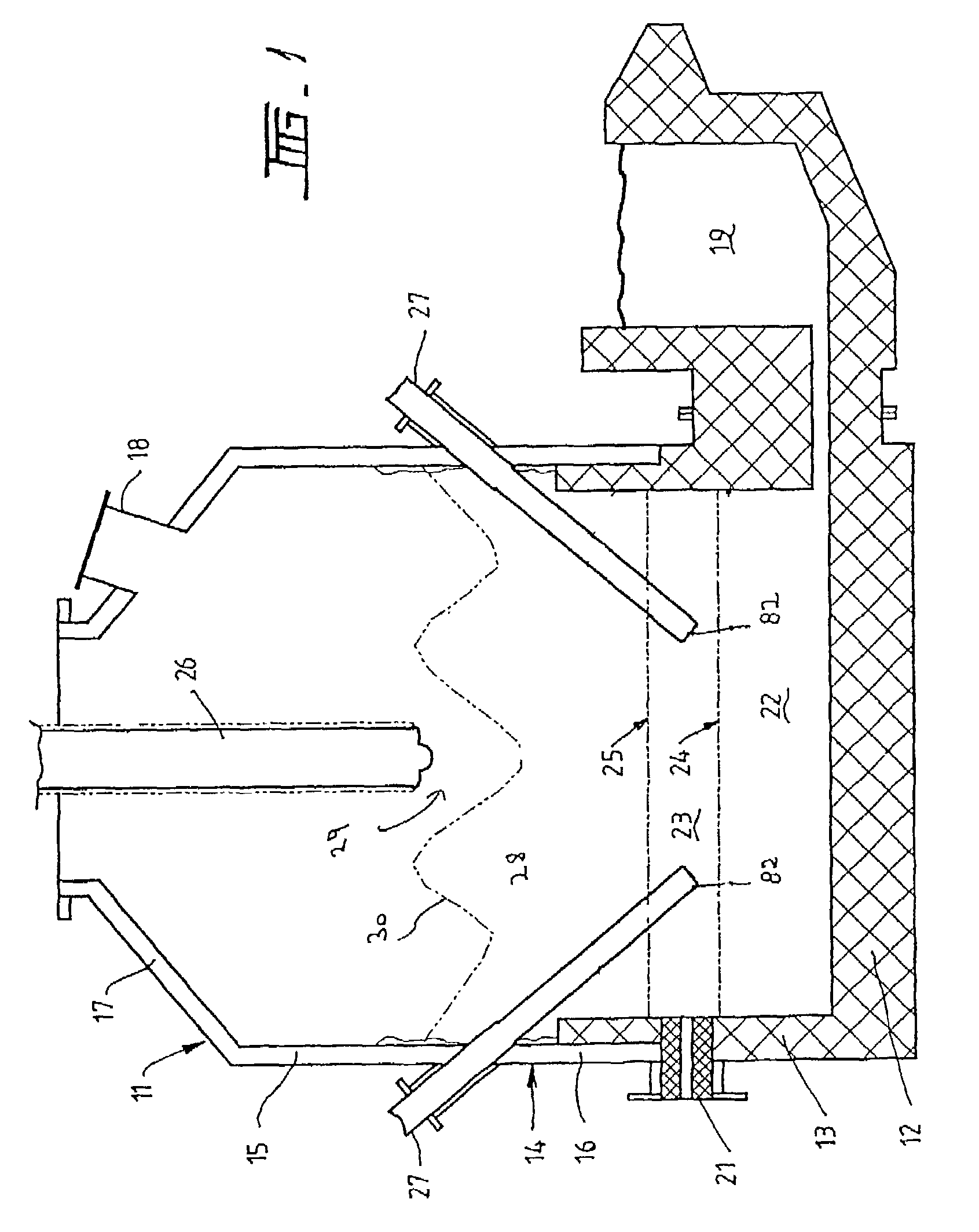

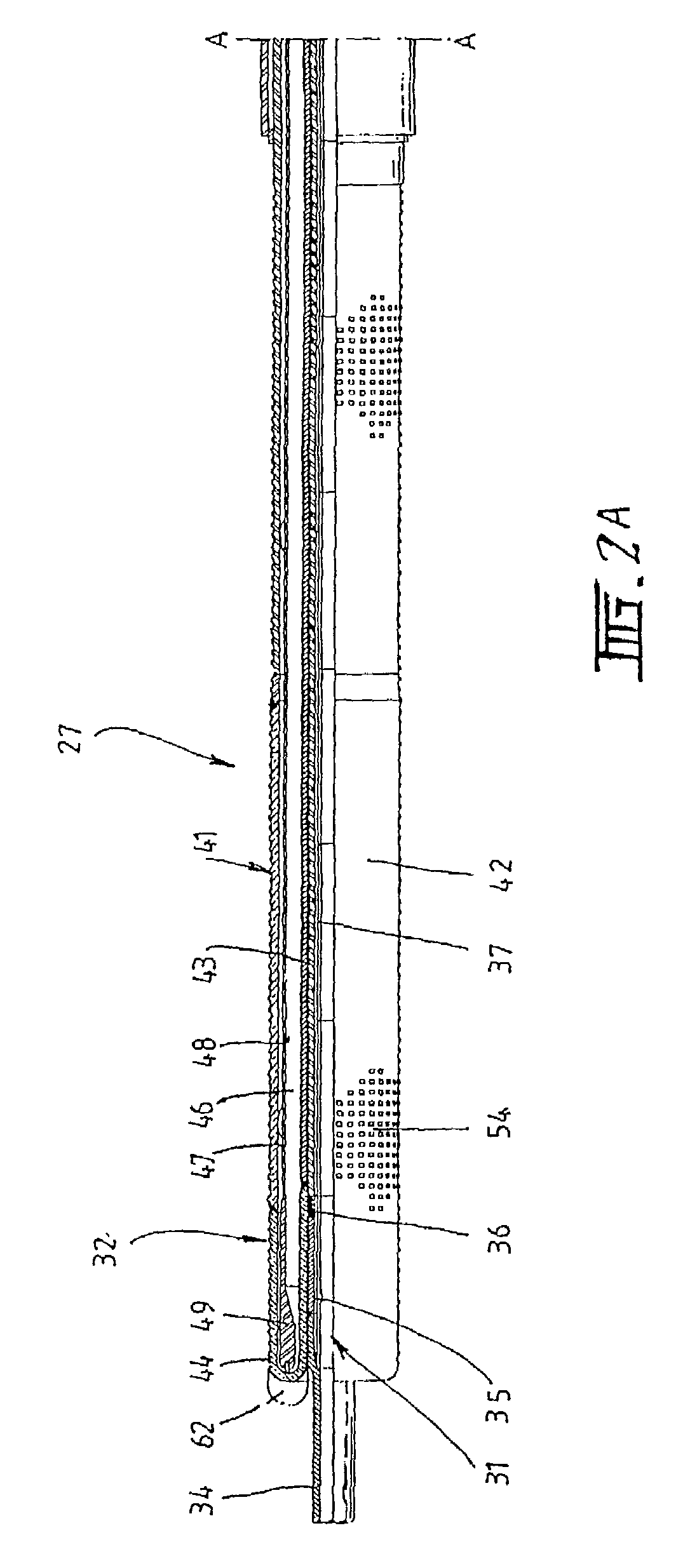

Direct smelting process and apparatus

InactiveUS6989042B2Increase exposurePromote oxidationShaft furnaceGas emission reductionSmelting processMolten bath

A molten-bath based direct smelting process and apparatus for producing metals from a ferrous material is disclosed. The process includes injecting feed materials being solid material and carrier gas into a molten bath at a velocity of at least 40 m / s through at least one downwardly extending solids injection lance having a delivery tube of internal diameter of 40–200 mm that is located so that a central axis of an outlet end of the lance is at an angle of 20 to 90 degrees to a horizontal axis. The feed materials injection generates a superficial gas flow of at least 0.04 Nm3 / s / m2 within the molten bath at least in part by reactions of injected material in the bath. The gas now causes molten material to be projected upwardly as splashes, droplets and streams and form an expanded molten bath zone, with the gas flow and the upwardly projected molten material causing substantial movement of material within the molten bath and strong mixing of the molten bath. The feed materials are selected so that, in an overall sense, the reactions of the feed materials in the molten bath are endothermic. The process also includes injecting an oxygen-containing gas into an upper region of the vessel via at least one oxygen gas injection lance and post-combusting combustible gases released from the molten bath.

Owner:TATA STEEL

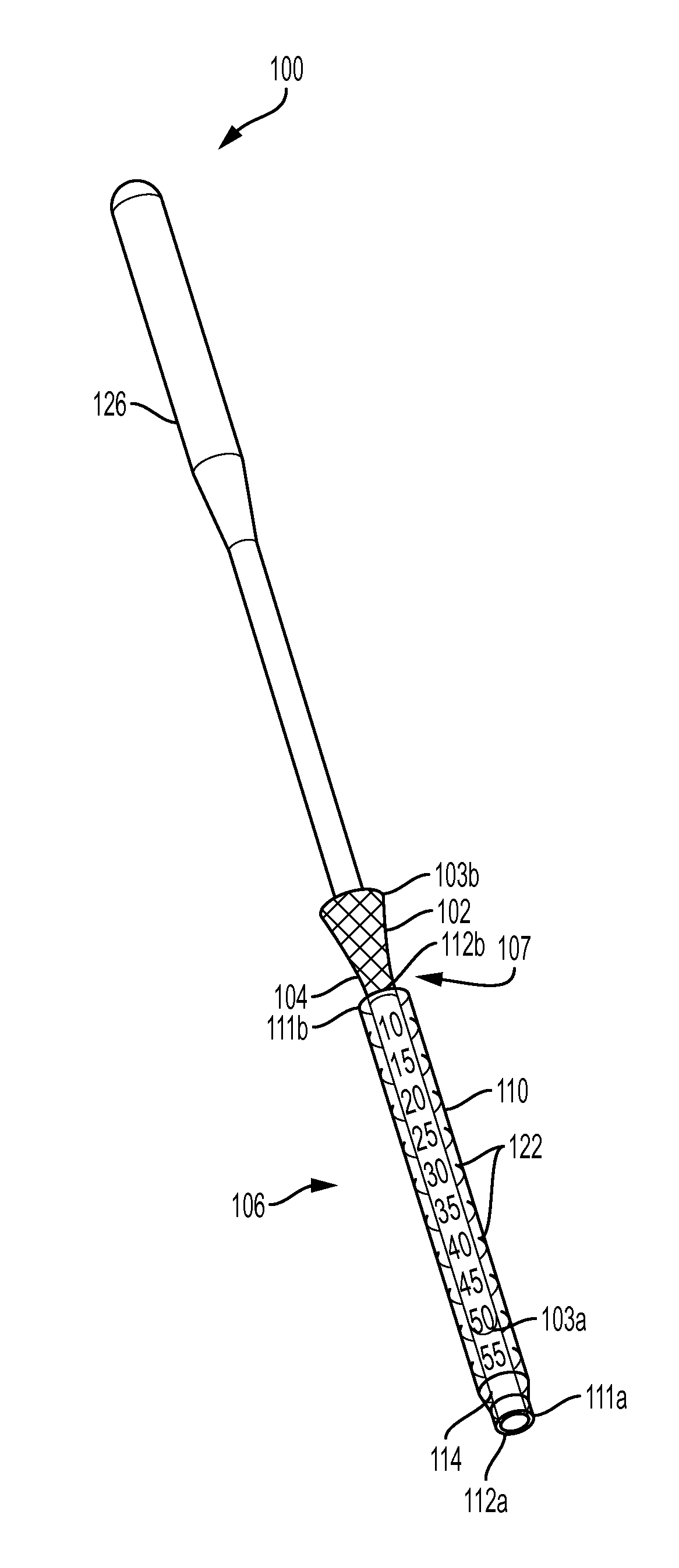

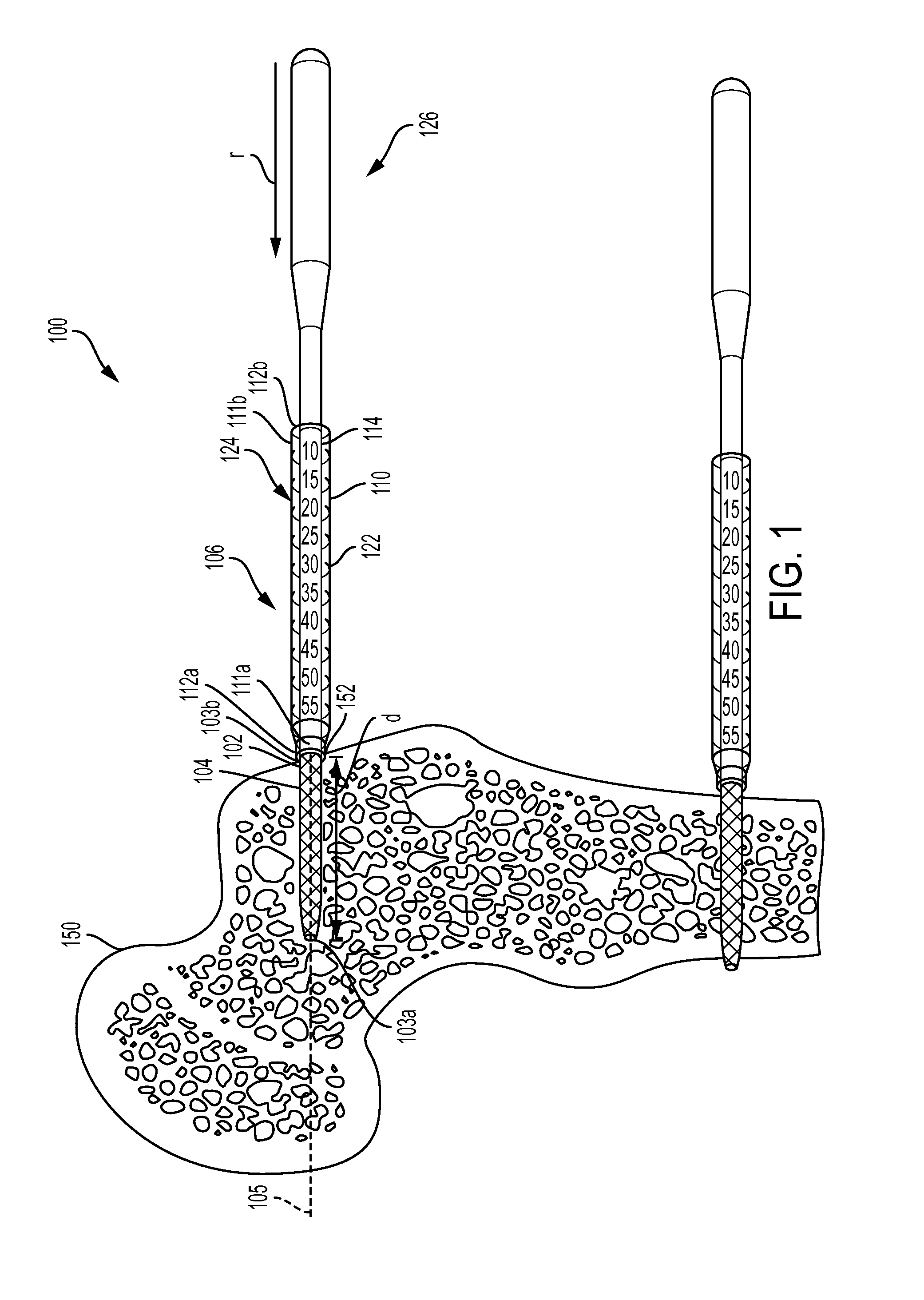

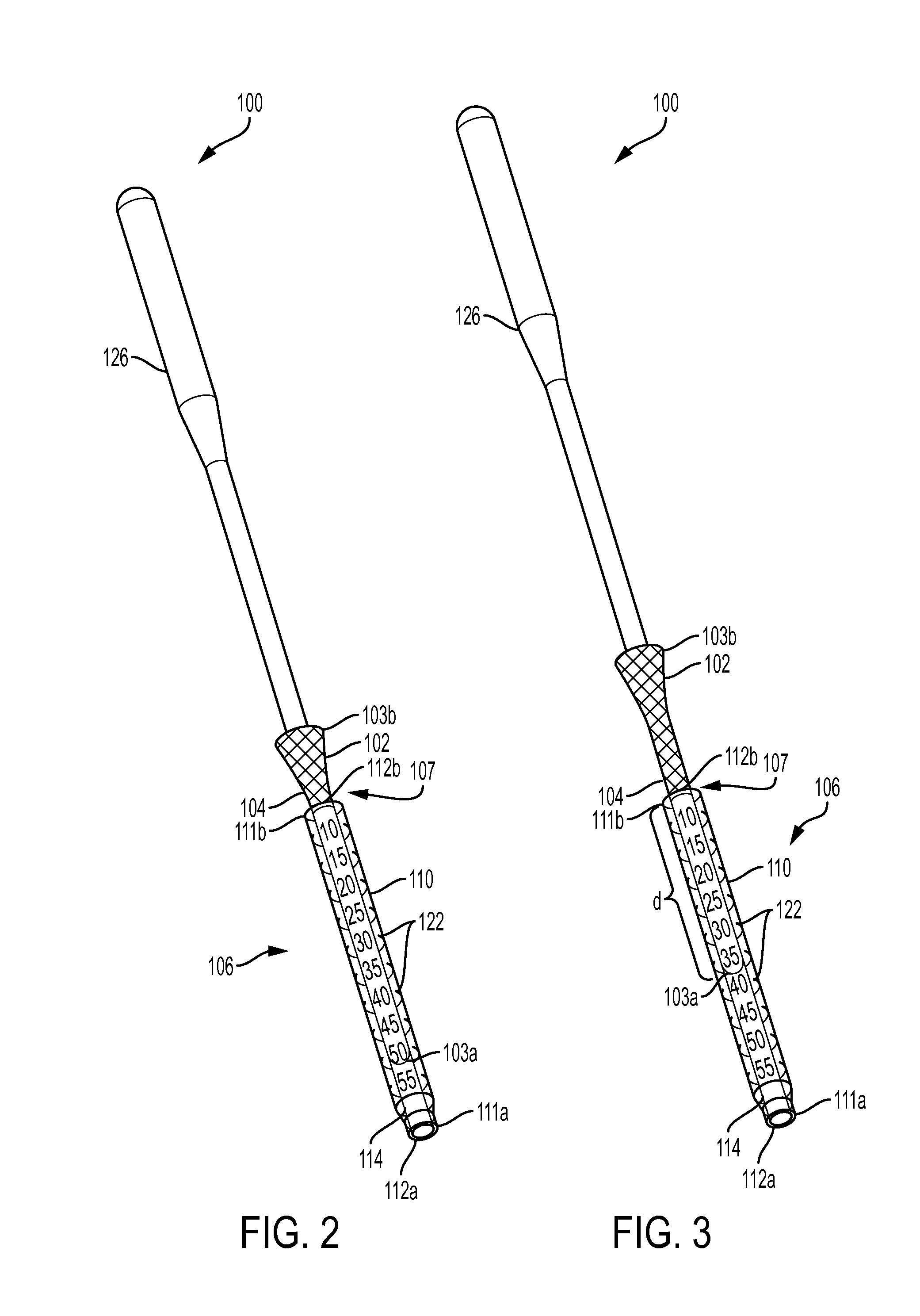

Woven retention devices, systems, packaging, and related methods

InactiveUS20160074084A1Increase orSuture equipmentsInternal osteosythesisBiomedical engineeringFastener

A system for preparing and inserting a woven retention device into bone is provided. The system includes a woven retention device having a distal end, a proximal end for receiving a fastener, and a sleeve body between the distal and proximal ends. A longitudinal axis extends between the distal and proximal ends. The system also includes a measuring device surrounding at least a portion of the woven retention device and defining a cutting position at which the woven retention device is to be cut for insertion into a hole in the bone. The measuring device measures a distance from the distal end of the woven retention device to the cutting position. The woven retention device is movable relative to a least a portion of the measuring device that defines the cutting position such that the woven retention device can be cut to a desired size.

Owner:WOVEN ORTHOPEDIC TECH

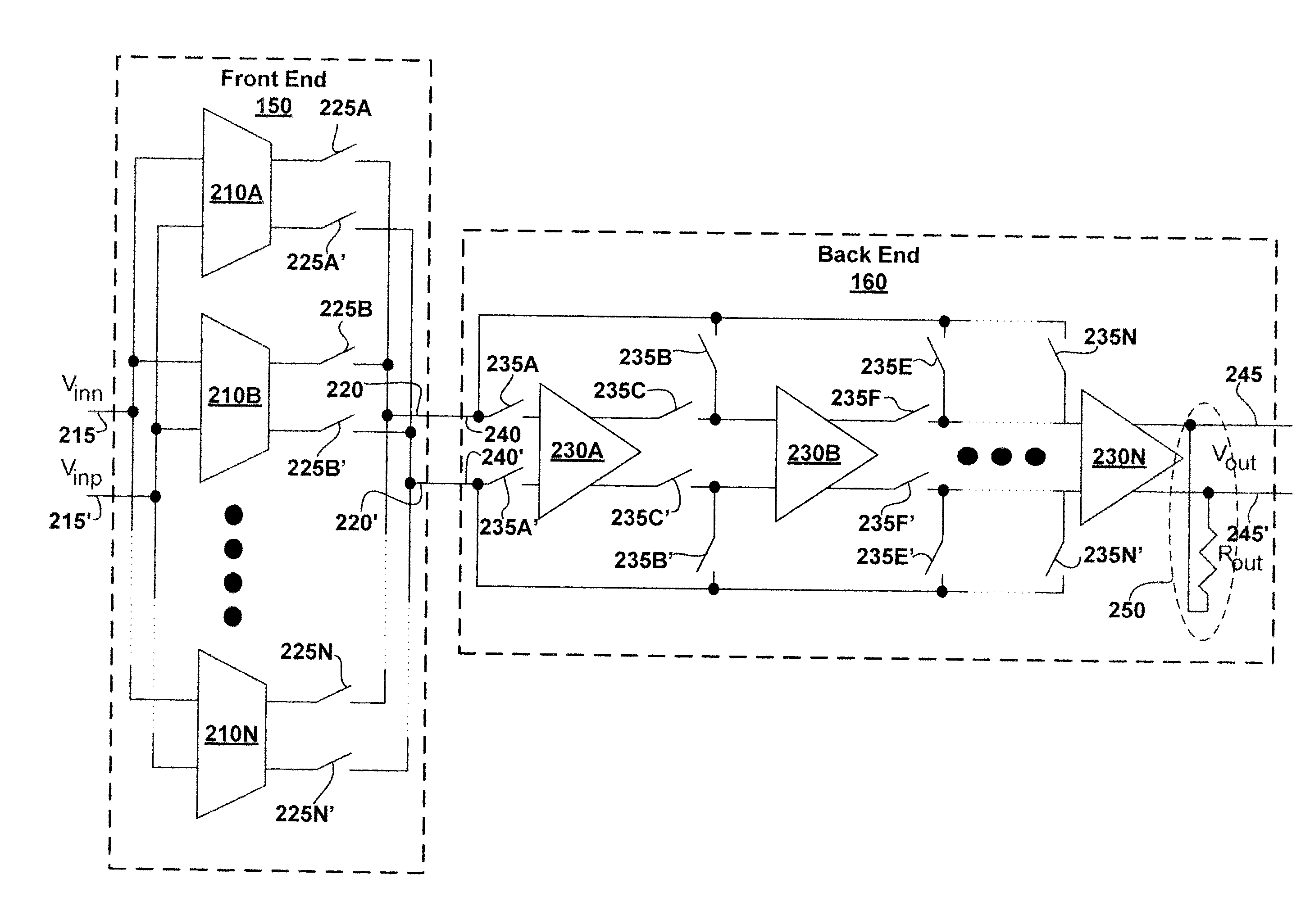

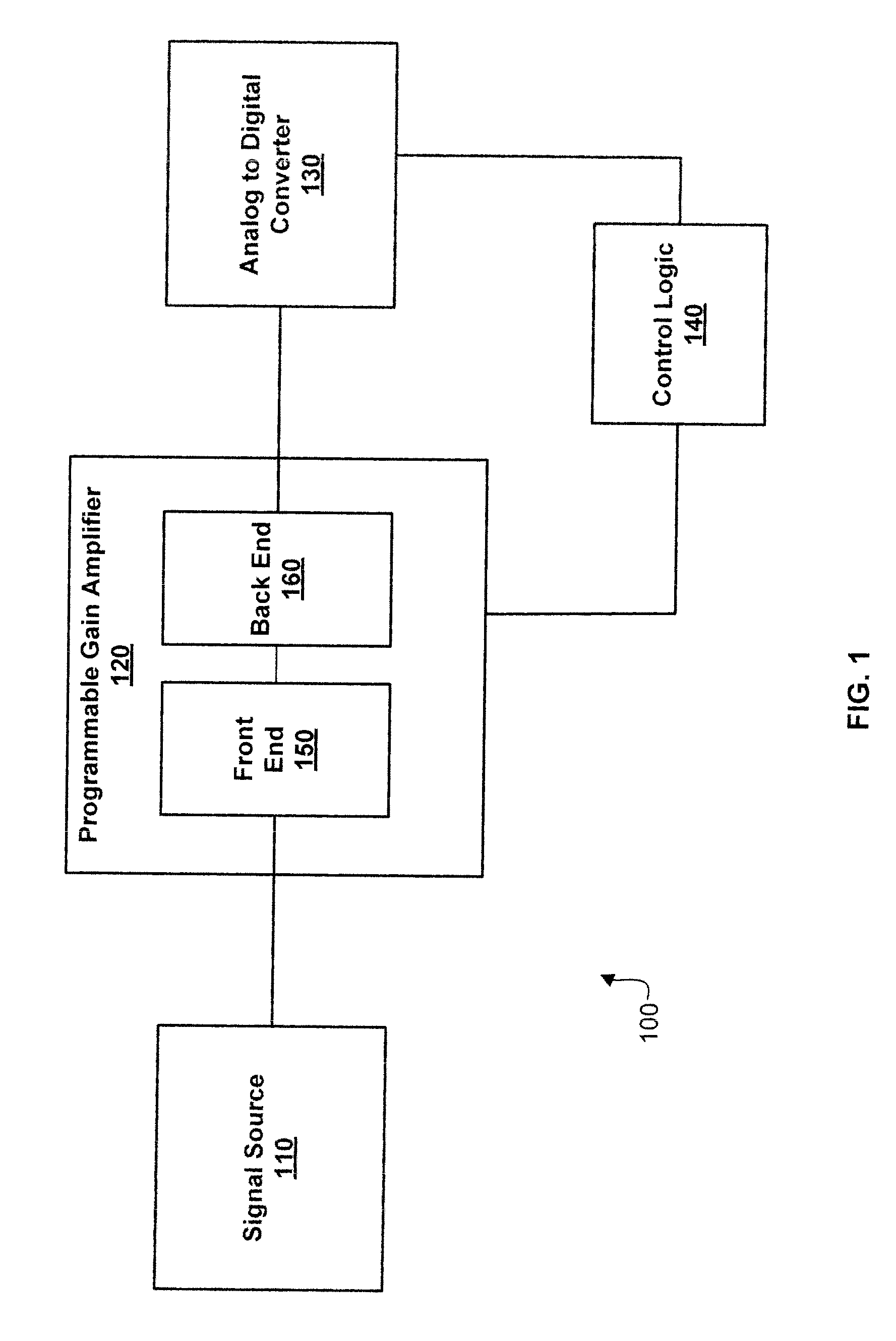

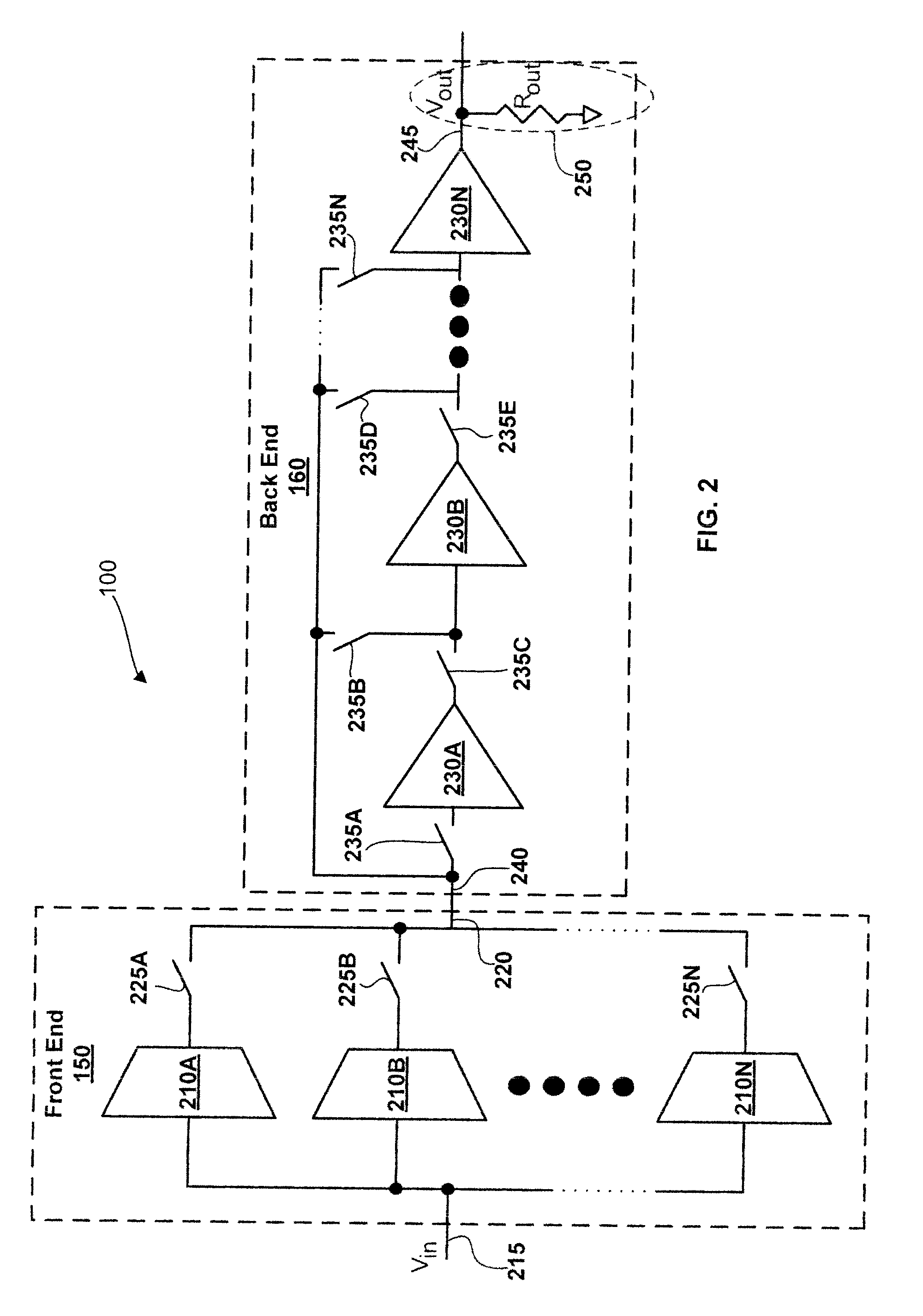

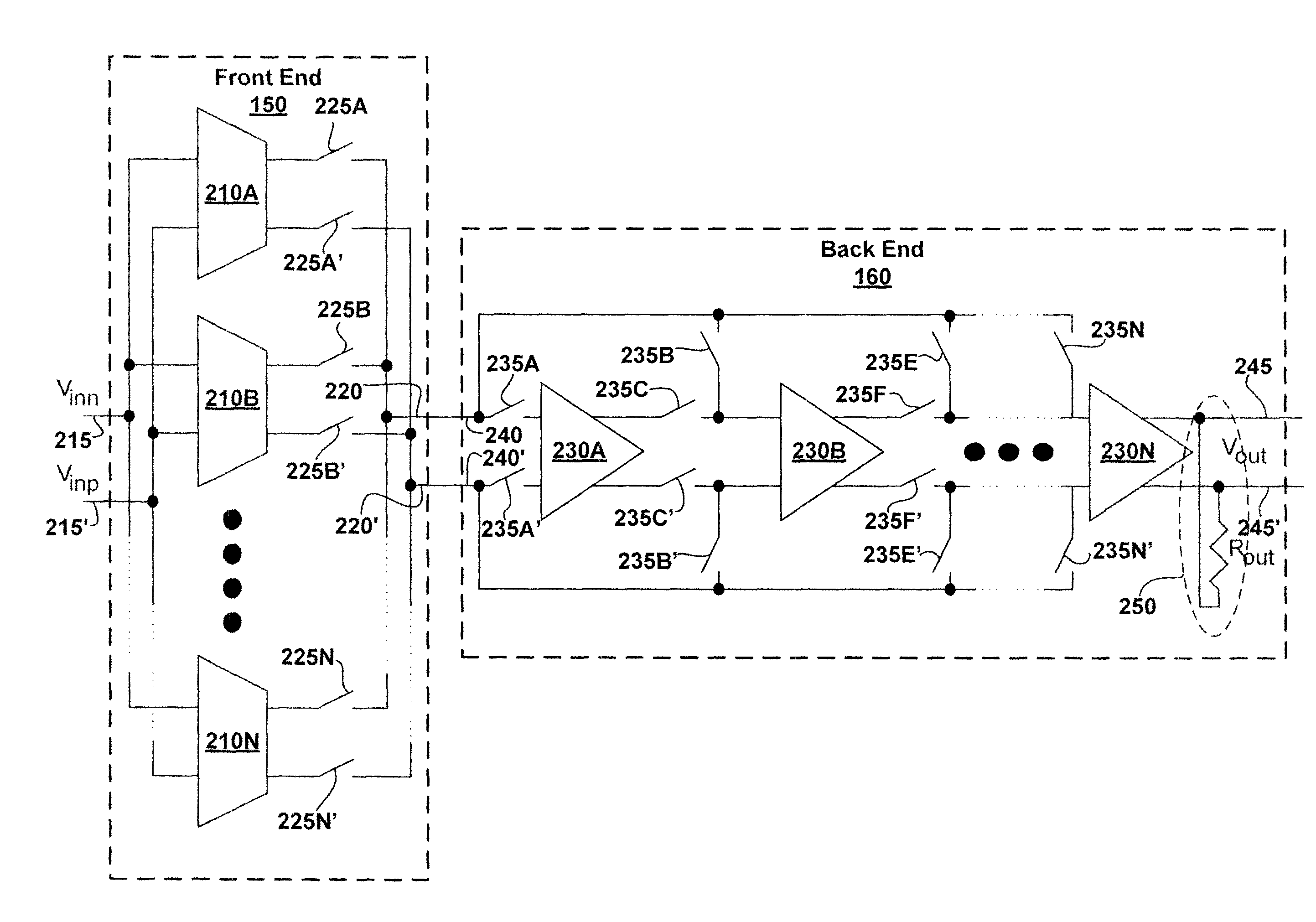

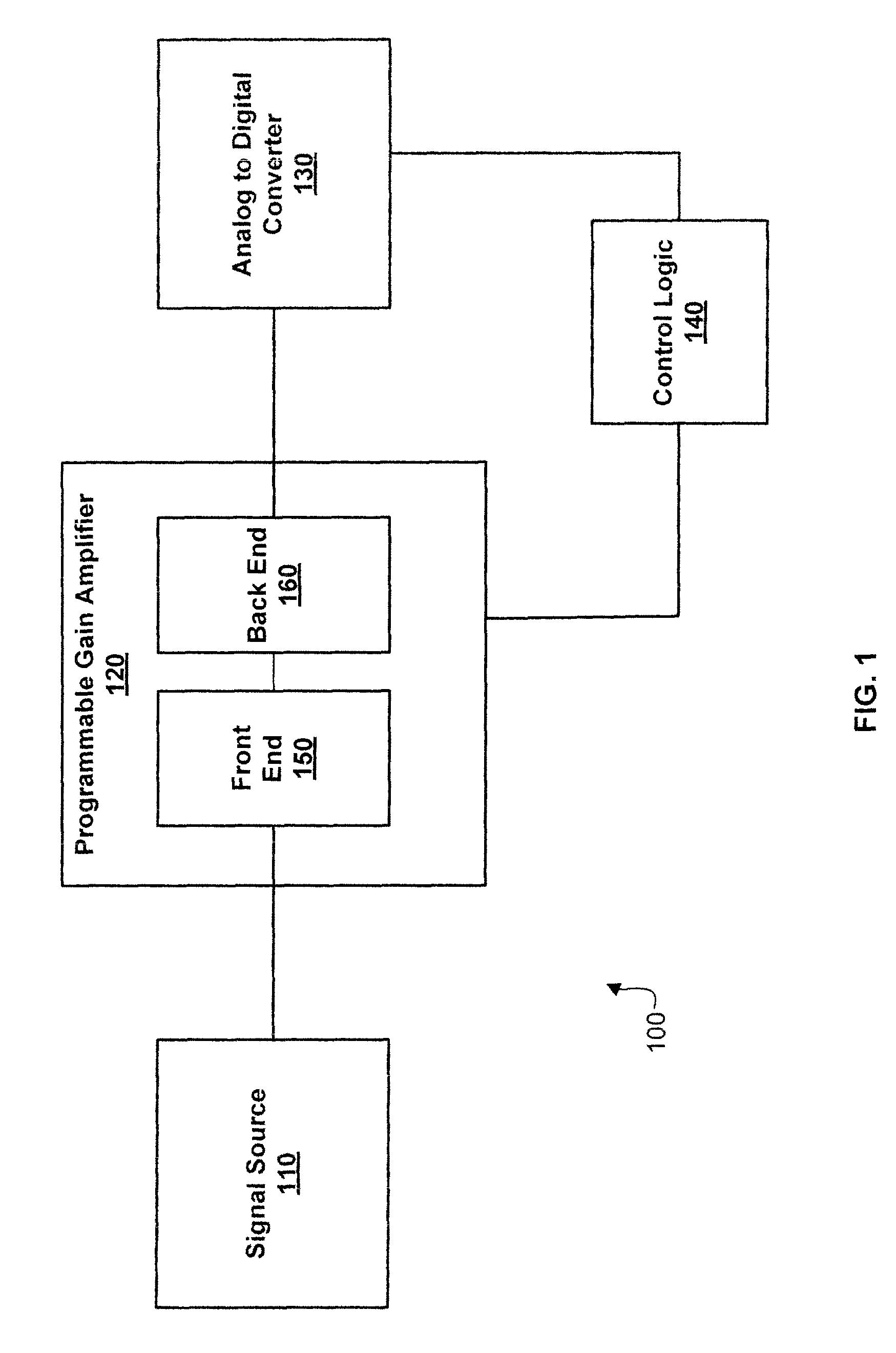

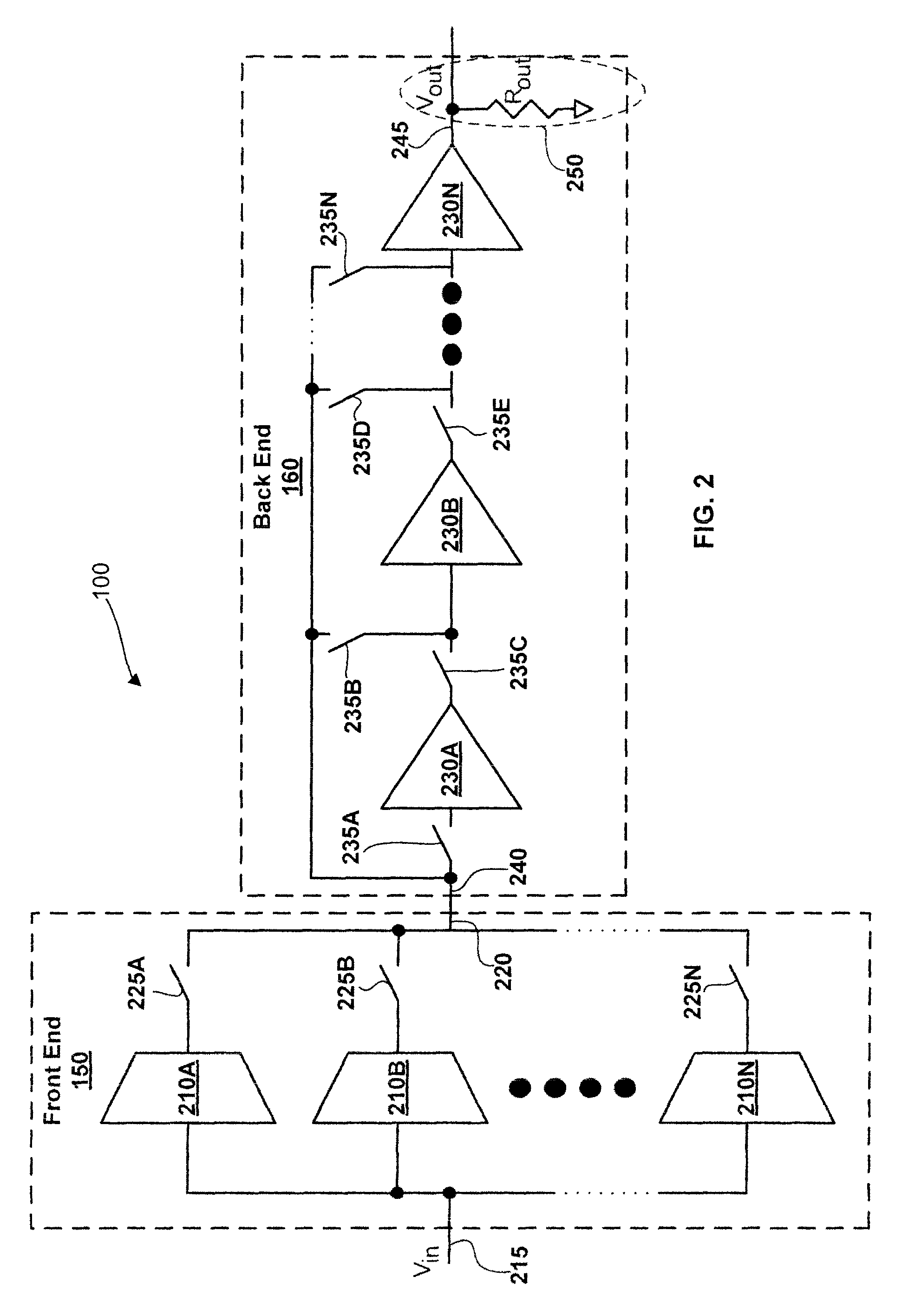

Programmable Gain Amplifier and Transconductance Compensation System

InactiveUS20100117734A1Noise minimizationIncrease orGated amplifiersAmplifier modifications to raise efficiencyEngineeringControl circuit

A programmable gain amplifier (PGA) system comprises selectable parallel transconductors in a front end, independently selectable serial amplification circuits in a back end. The back end is configured to receive an output of the front end and may include a plurality of current or voltage mode amplifiers in series. The PGA system also includes control circuitry to select a gain configuration for the PGA by selecting selectable components in the front and back ends. The PGA system may additionally include control circuitry configured to change the transconductance of one or more of the front end transconductors such that the gain configurations of the PGA are independent of variations such as those due to temperature and fabrication. The PGA system may be used between a signal receiver and an analog to digital converter.

Owner:AVAGO TECH INT SALES PTE LTD

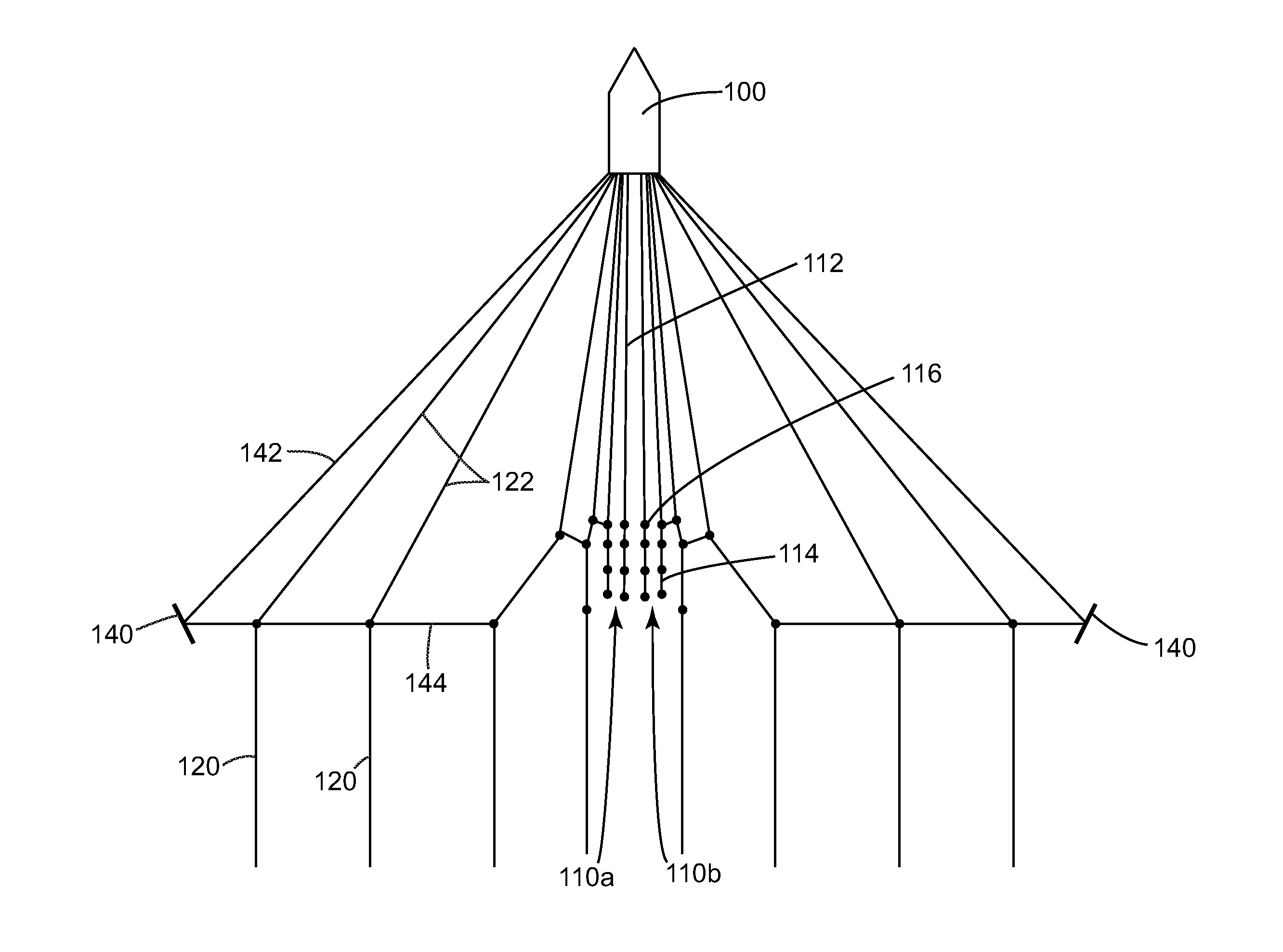

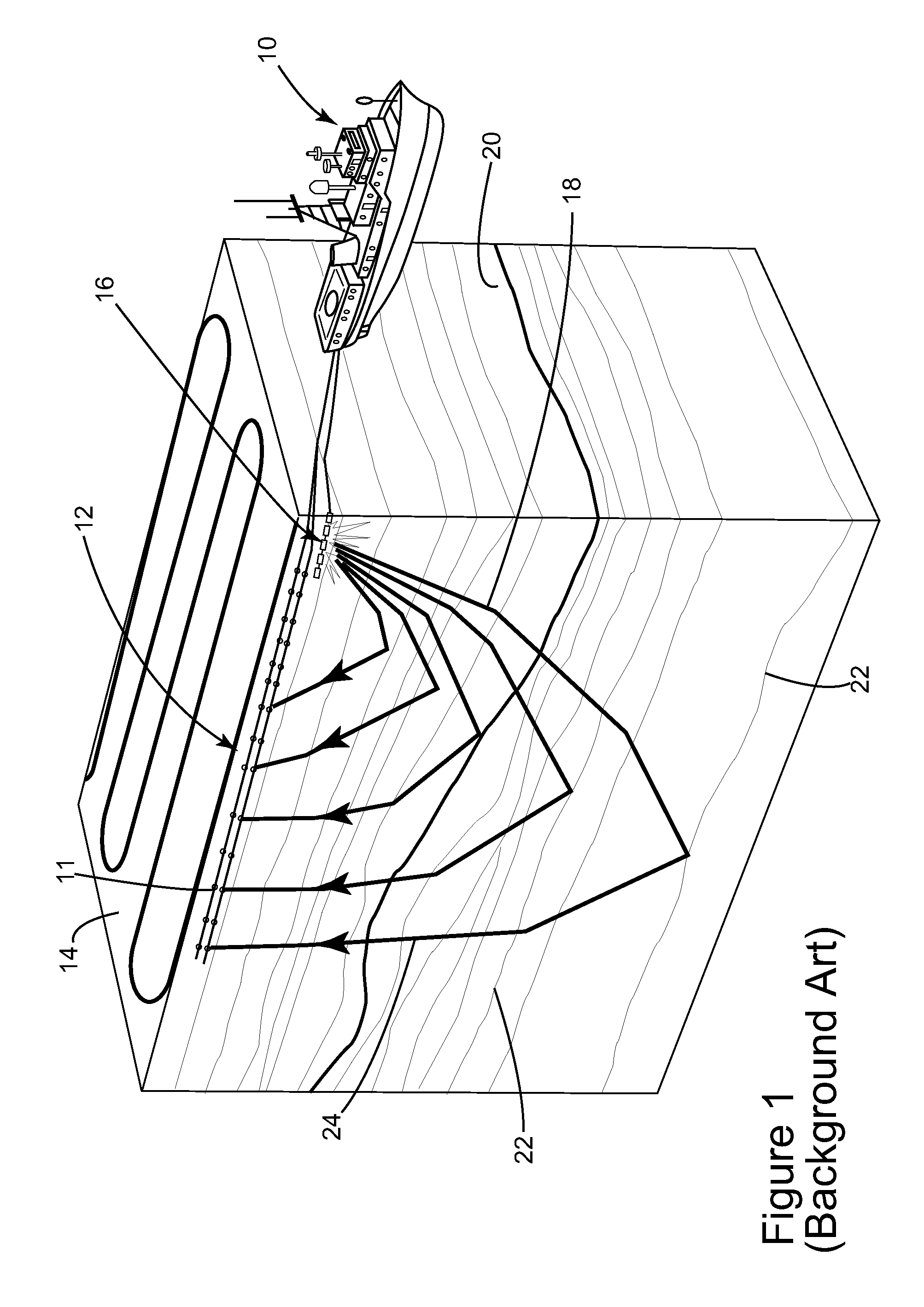

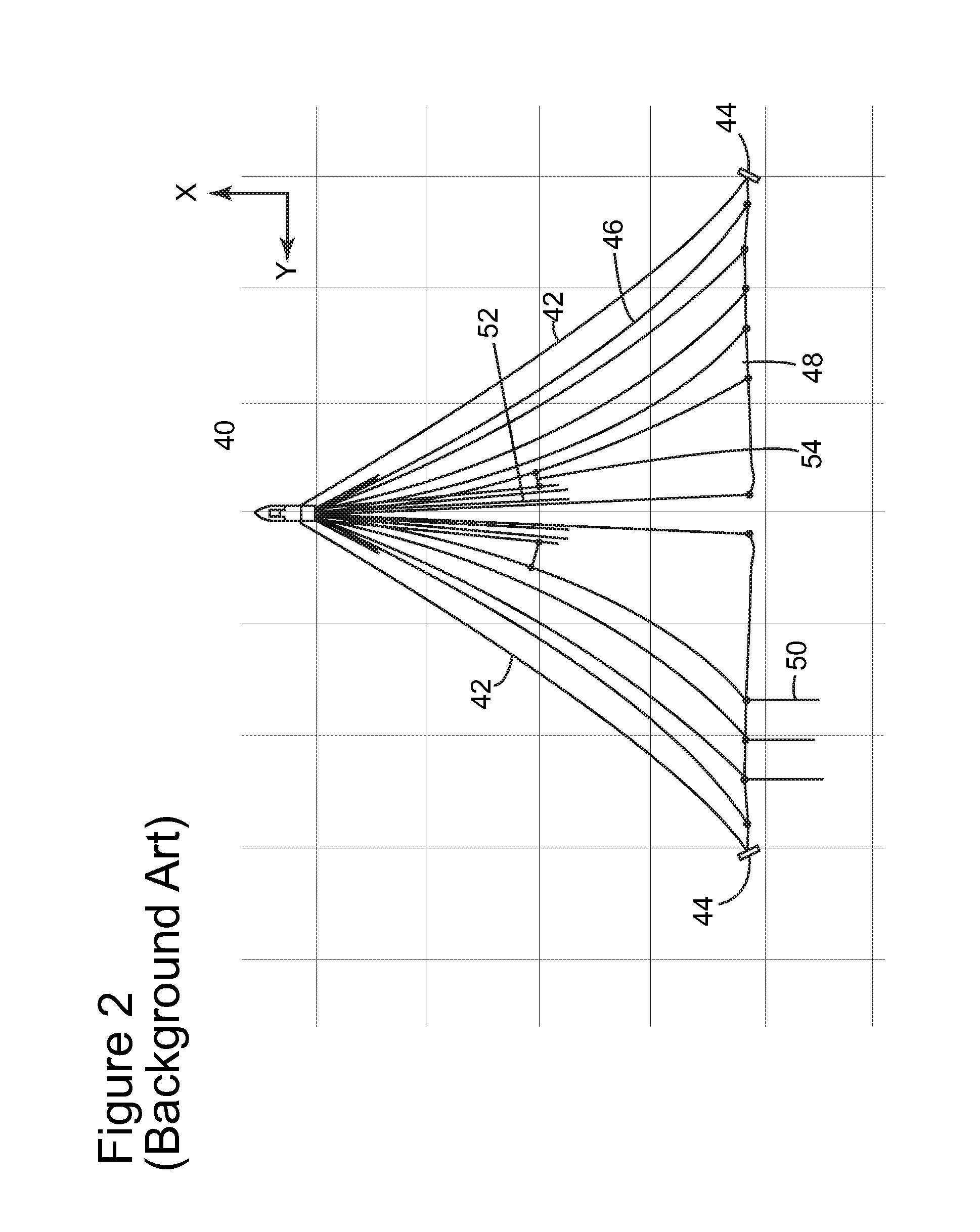

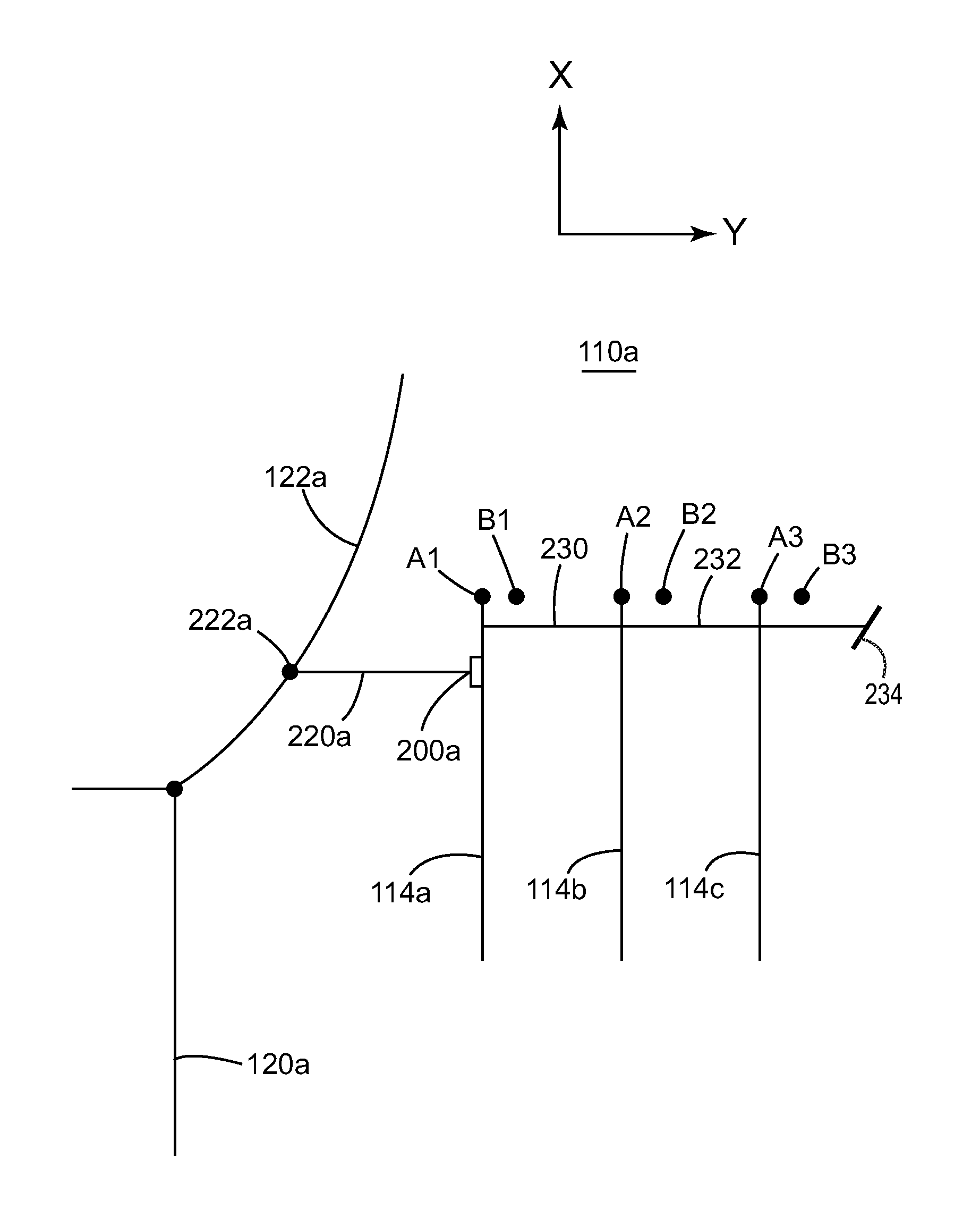

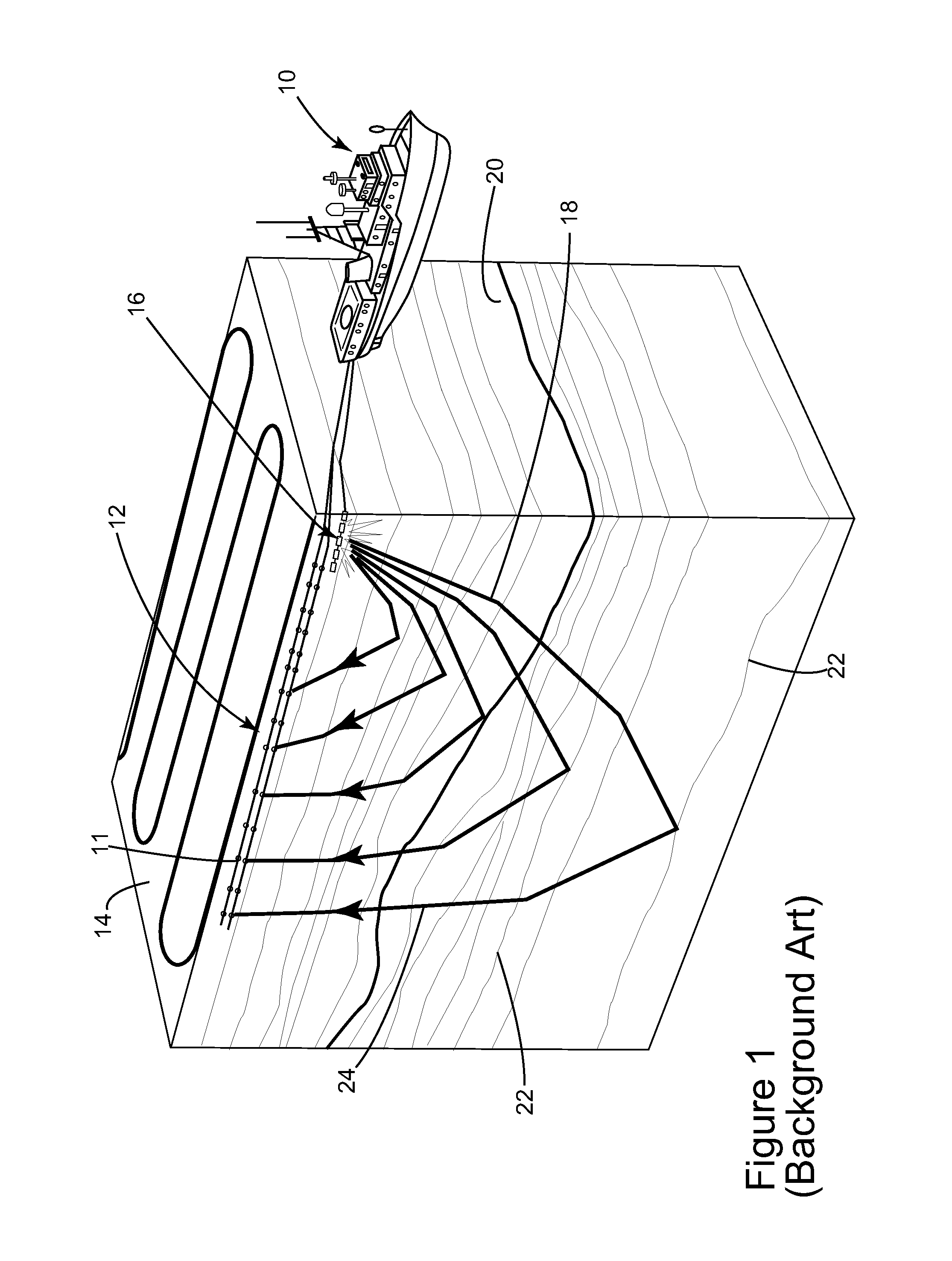

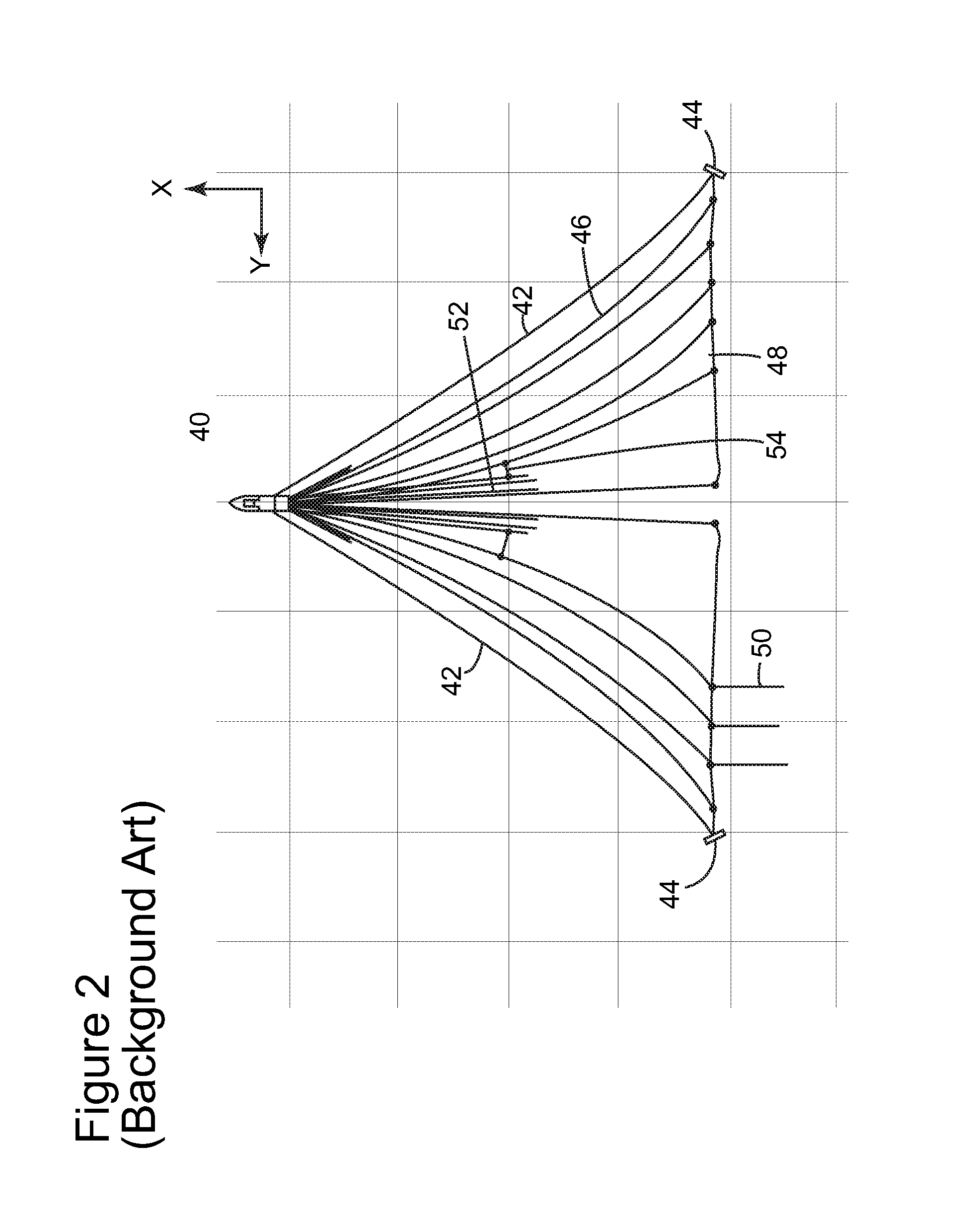

Steerable source systems and method

ActiveUS20130070557A1Length be controlIncreaseTowing/pushing equipmentSeismology for water-covered areasEngineeringAcoustic wave

A marine acoustic source system for generating an acoustic wave in a body of water. The marine acoustic source system includes a first marine acoustic source array having first and second external source sub-arrays, each sub-array including one or more individual source elements; a first actuator device connected to the first external source sub-array; and a first rope connecting the first actuator device to a first lead-in that is configured to connect to a head of a streamer. The first actuator device is configured to control a length of the first rope in order to control a position of the first source array relative to the streamer.

Owner:SERCEL SAS

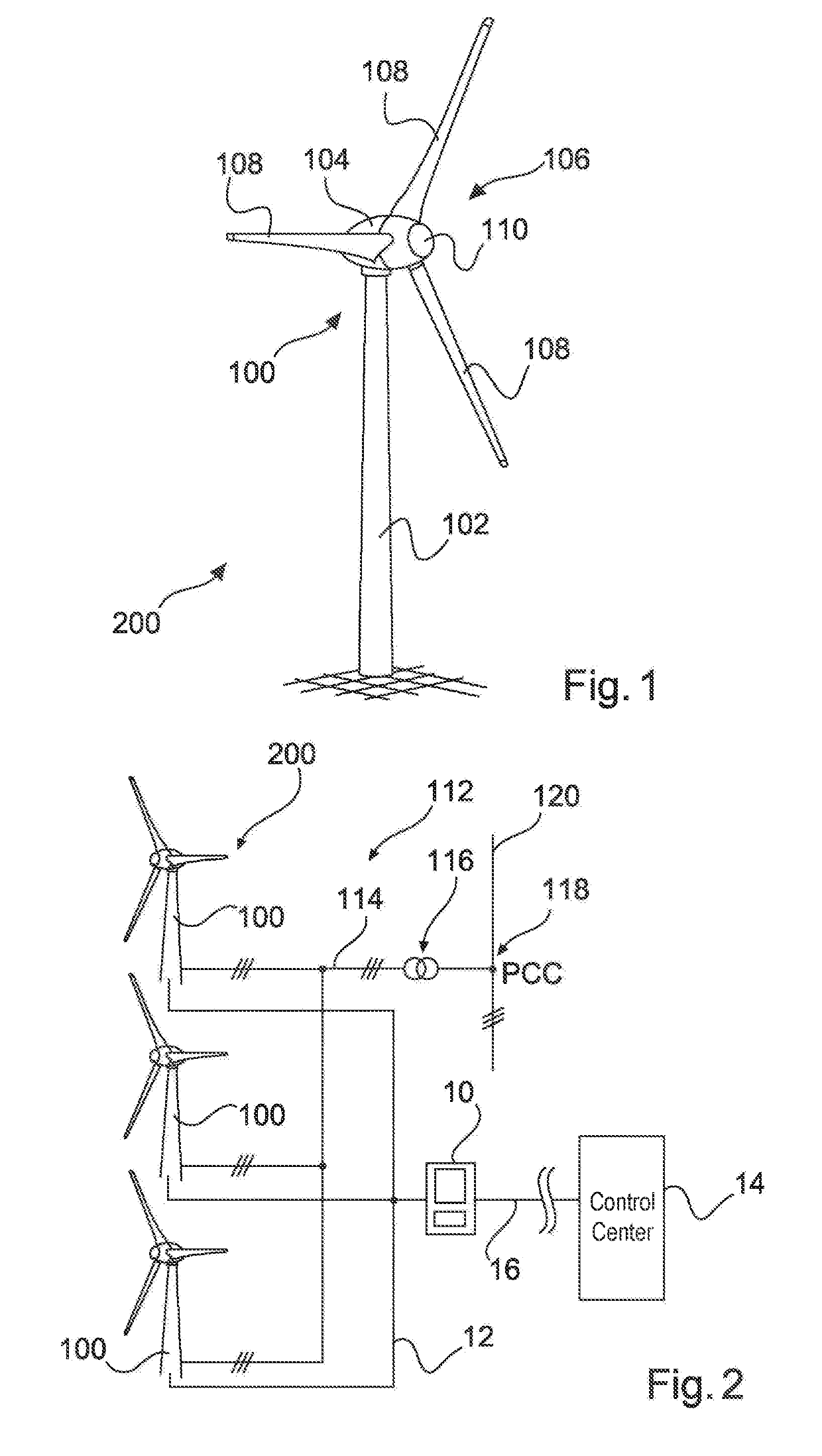

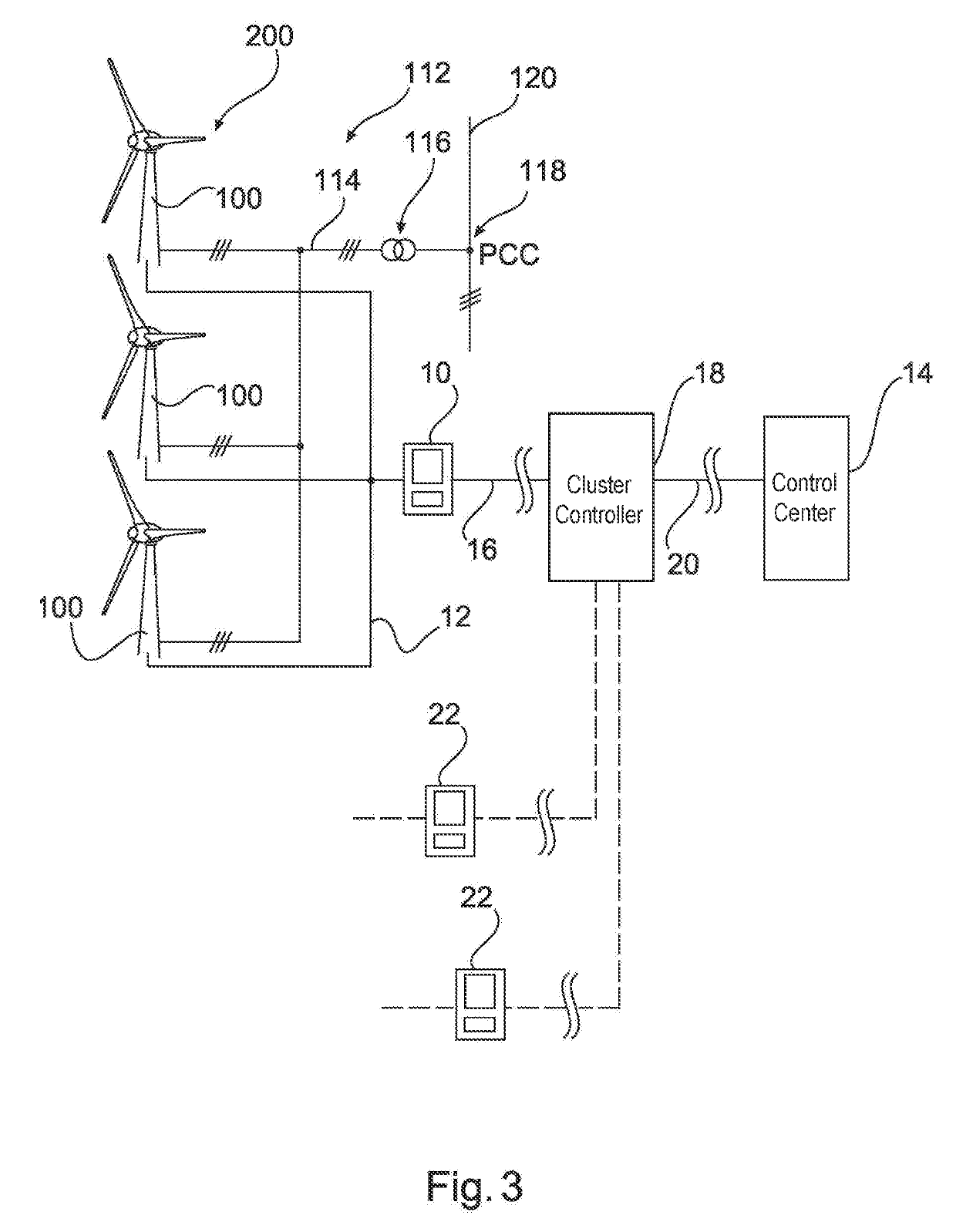

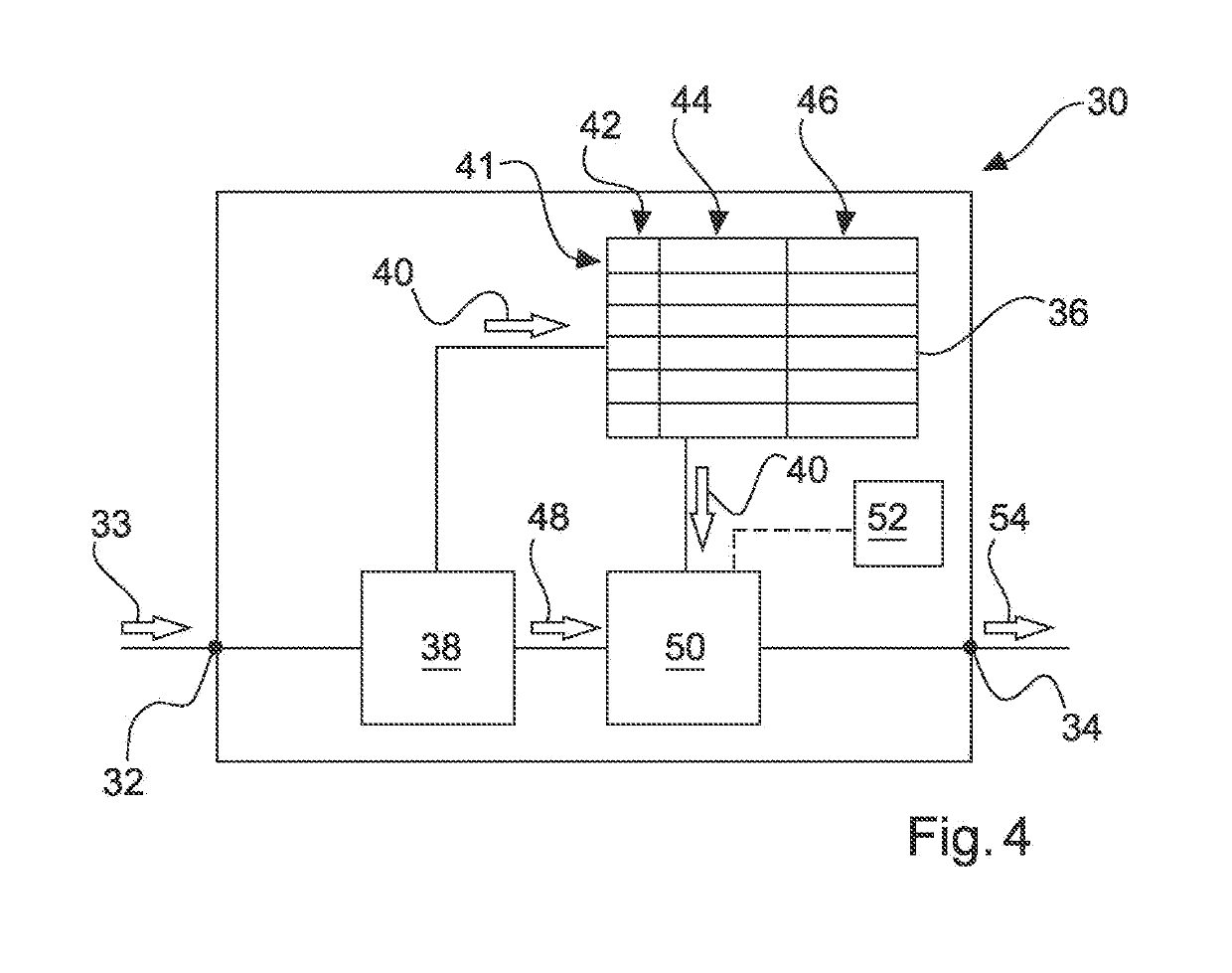

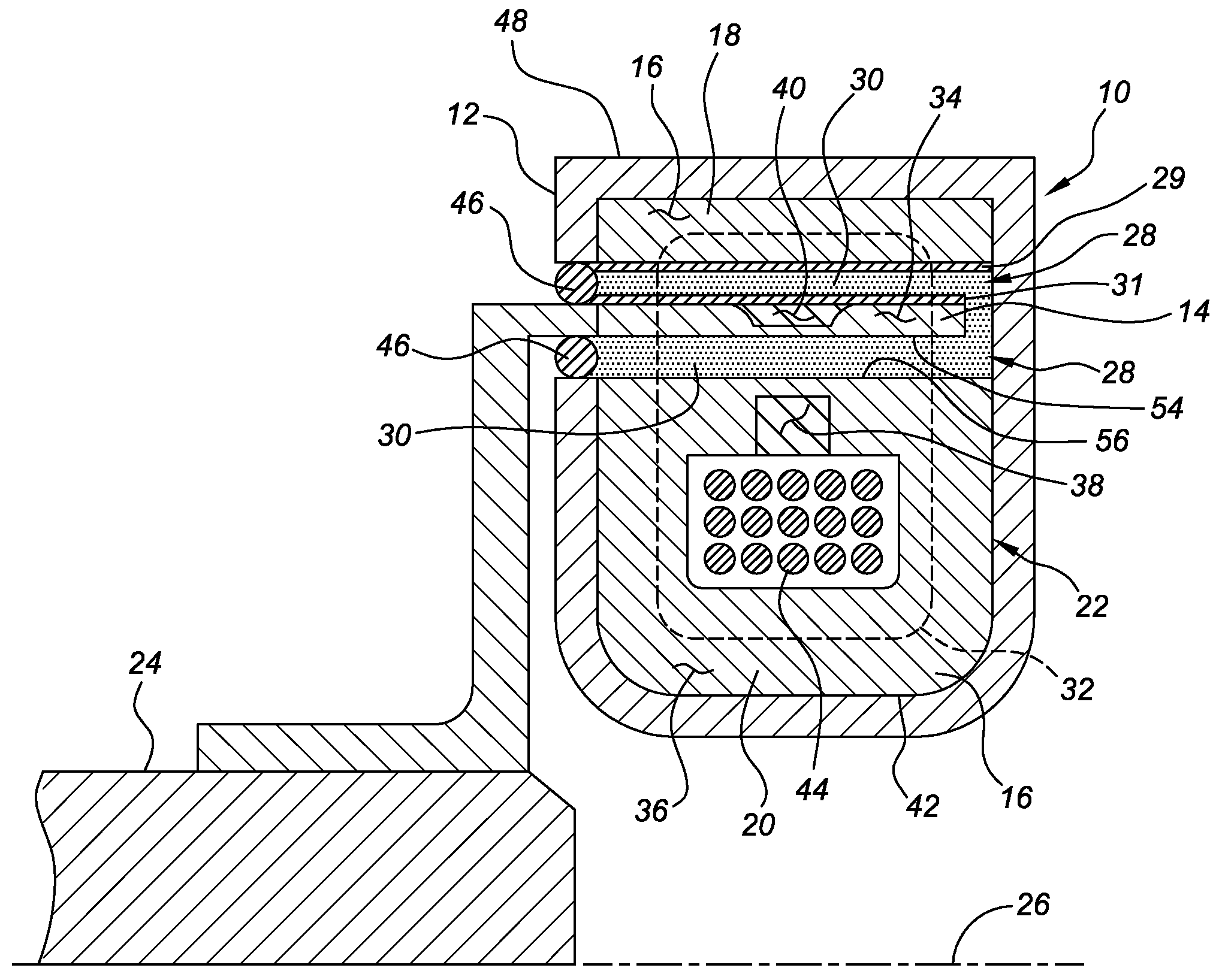

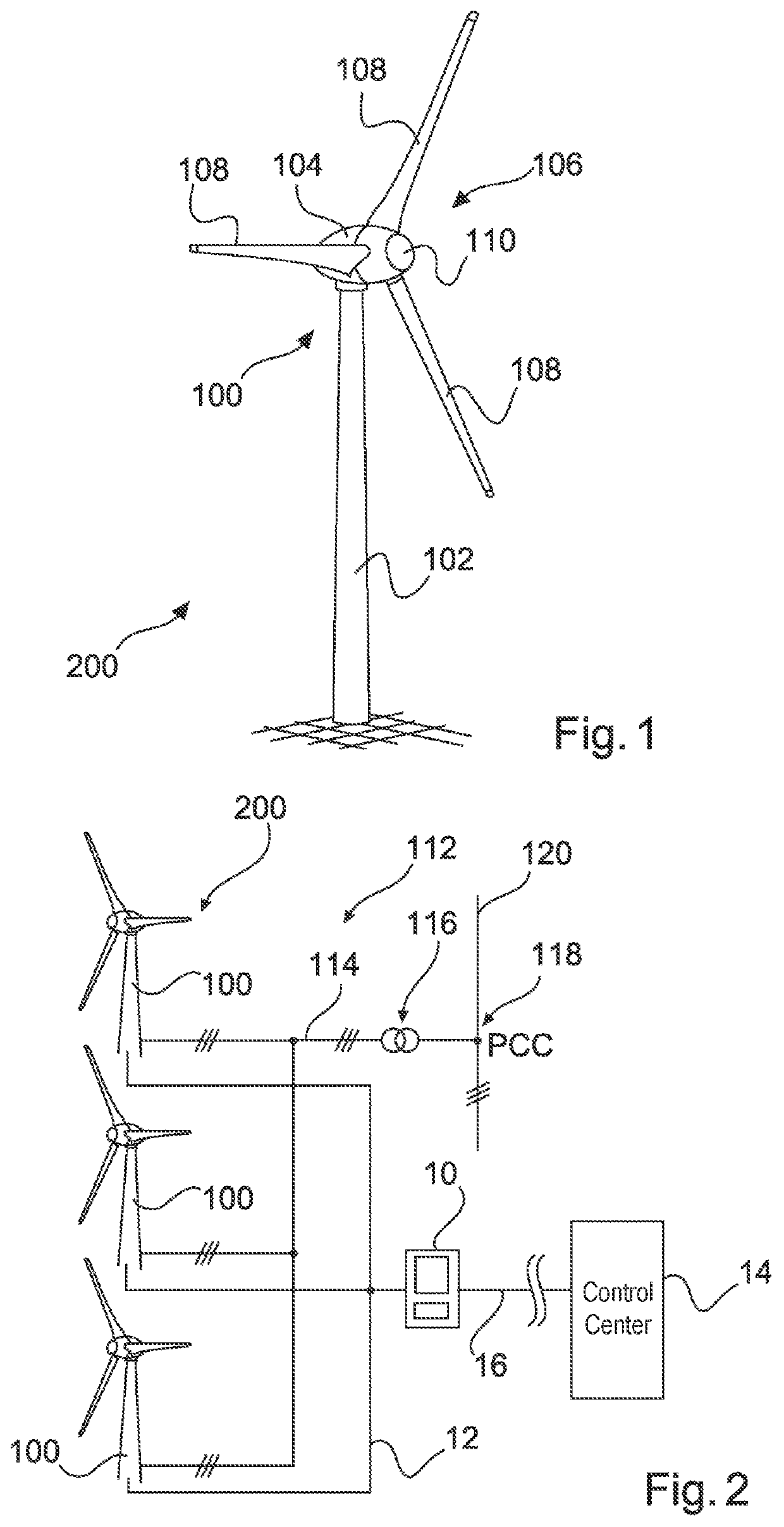

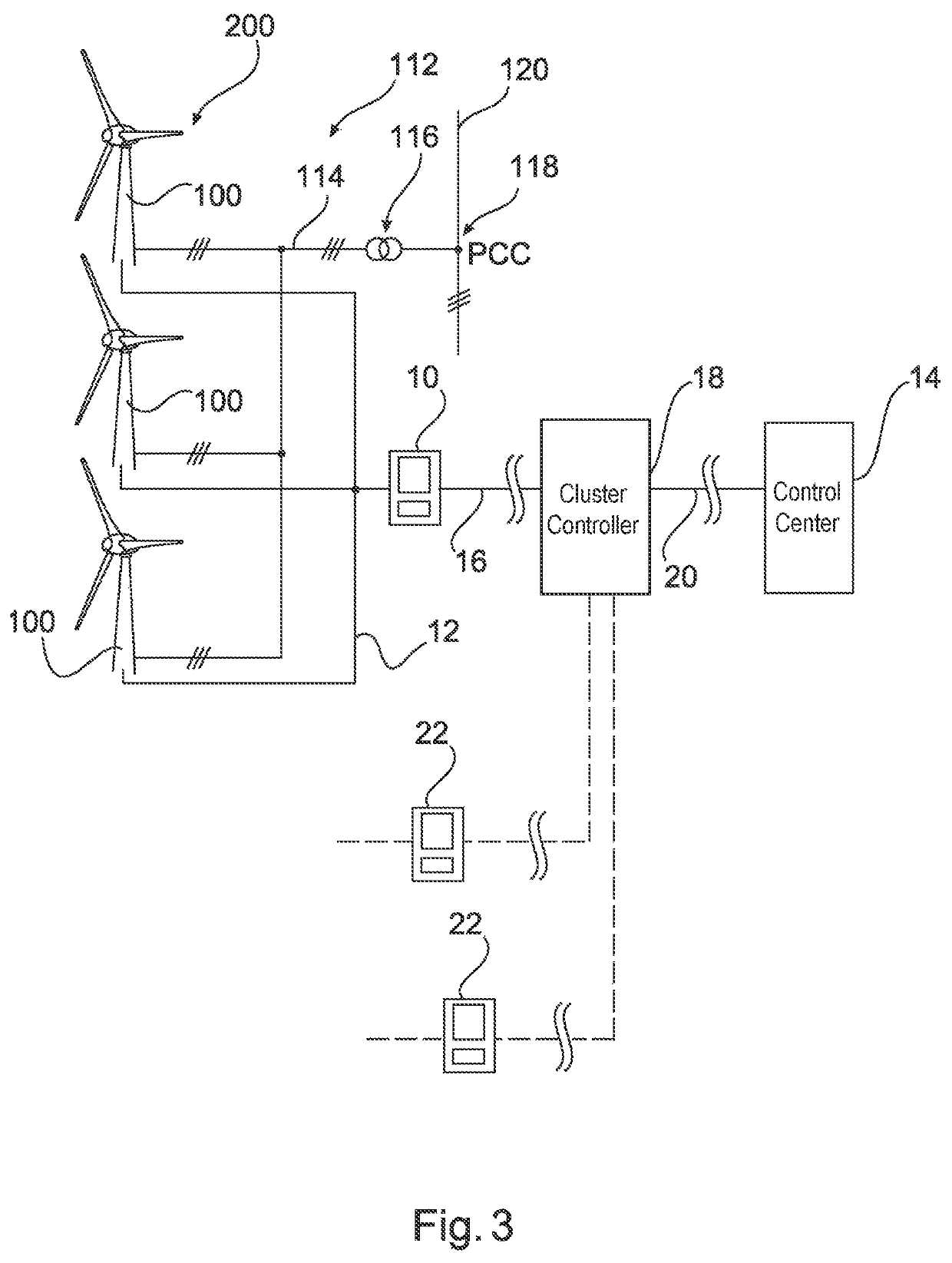

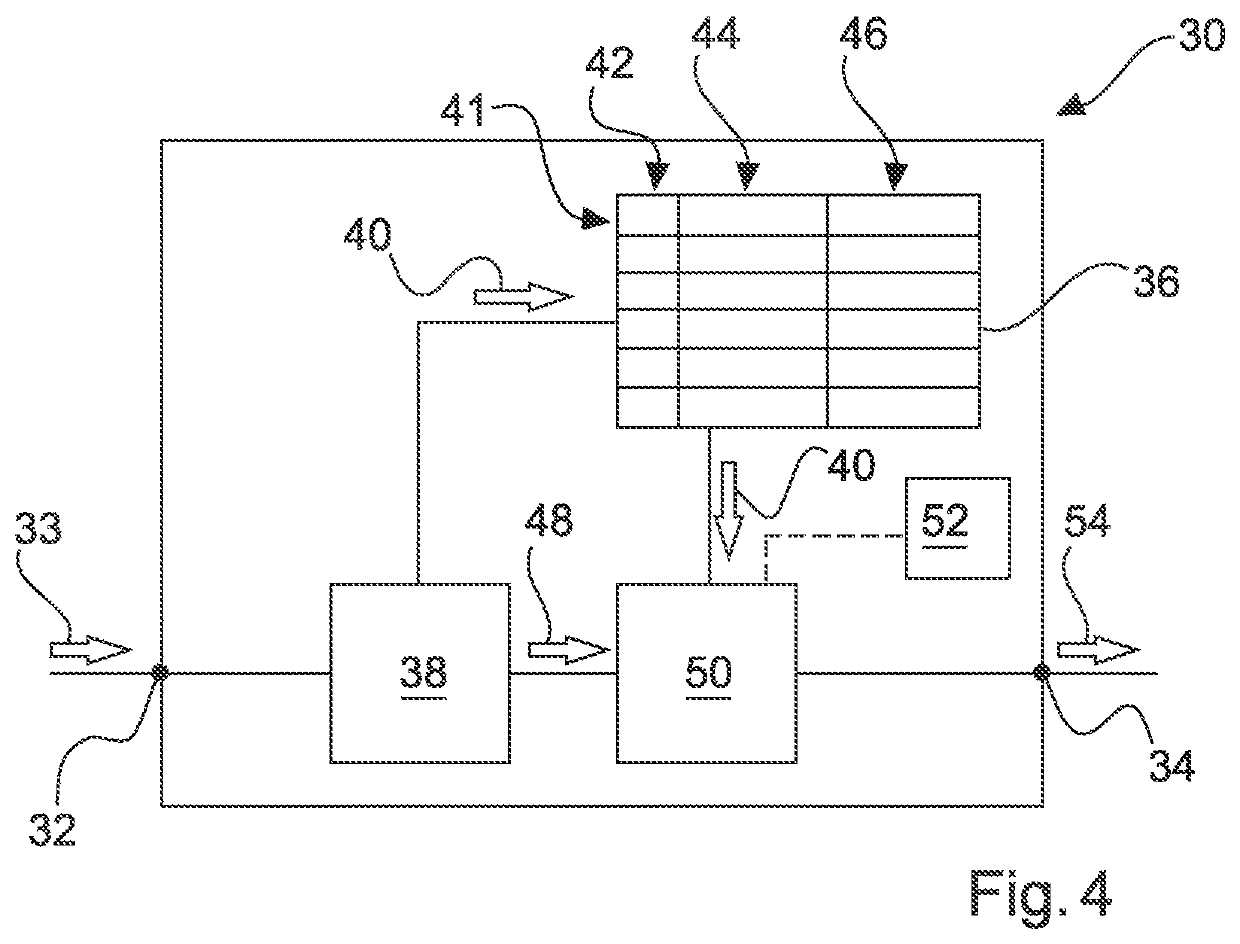

Method for sending a controller setpoint for a power generator, device therefor and system containing the same

ActiveUS20190178229A1Increase orImprove accuracyWind motor controlSingle network parallel feeding arrangementsNetwork packetEngineering

Provided is a method, device and system for outputting a controller setpoint for at least one power generator that is at least one wind power installation, at least one windfarm, or a cluster controller. The method includes receiving, over a data input, a data packet including a current setpoint and a plurality of future setpoints, storing the future setpoints of the received data packet in a memory, and outputting, over a data output, the current setpoint as the controller setpoint. If after the expiration of a predefined time period from the reception of the data packet, no further data packet is received, a first setpoint of the stored plurality of future setpoints is output over the data output as a next controller setpoint.

Owner:WOBBEN PROPERTIES GMBH

Apparatus with active material surface in contact with pheological fluid and method of enhancing performance thereof

InactiveUS20090032353A1Improve performanceReduce surface roughnessSpringsNon-rotating vibration suppressionEngineeringSurface geometry

An apparatus is provided having an active material forming a surface thereof in contact with a rheological fluid. The active material is controllable to vary a surface geometry thereof between a rough or nonsmooth surface geometry to increase drag, and achieve an increase in stress transmitted through the fluid, when a field is applied, while allowing a smooth surface geometry and an associated reduction in stress transmitted through the fluid when the field is removed. A method of enhancing performance of an apparatus that includes a rdeological fluid is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

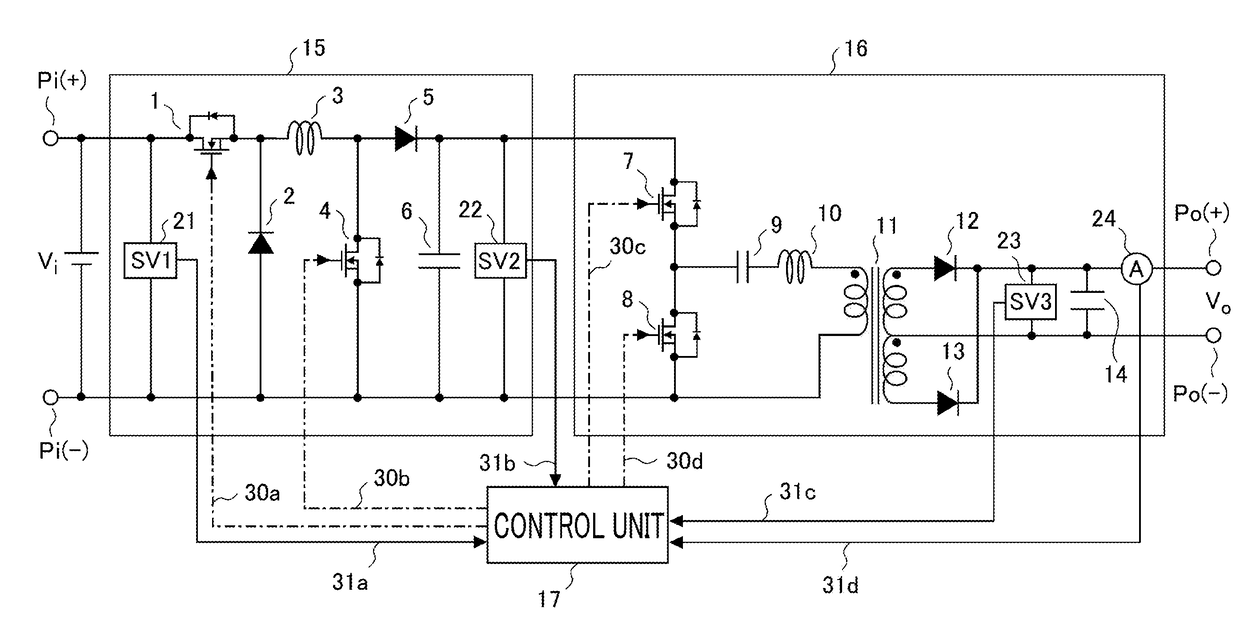

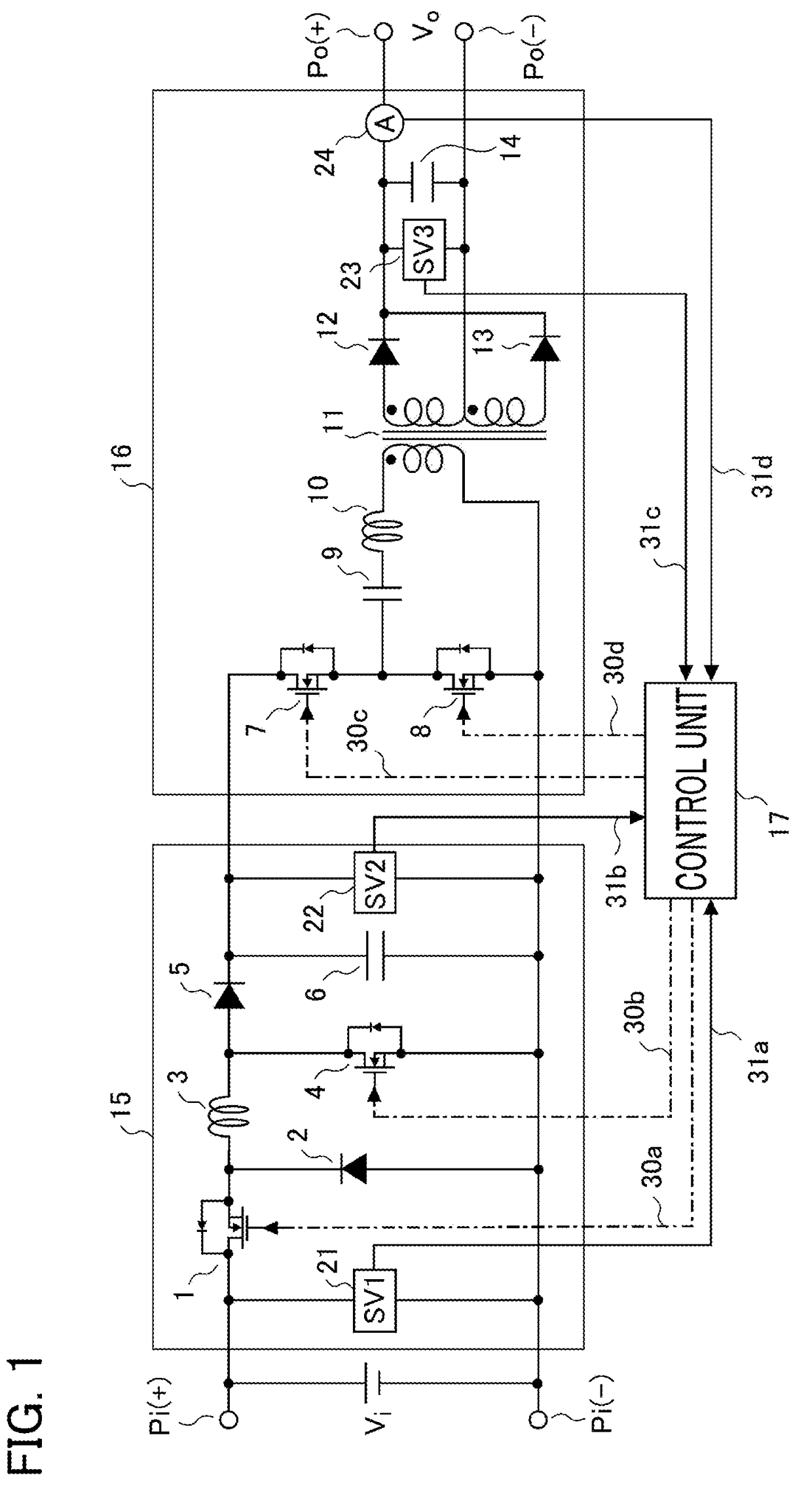

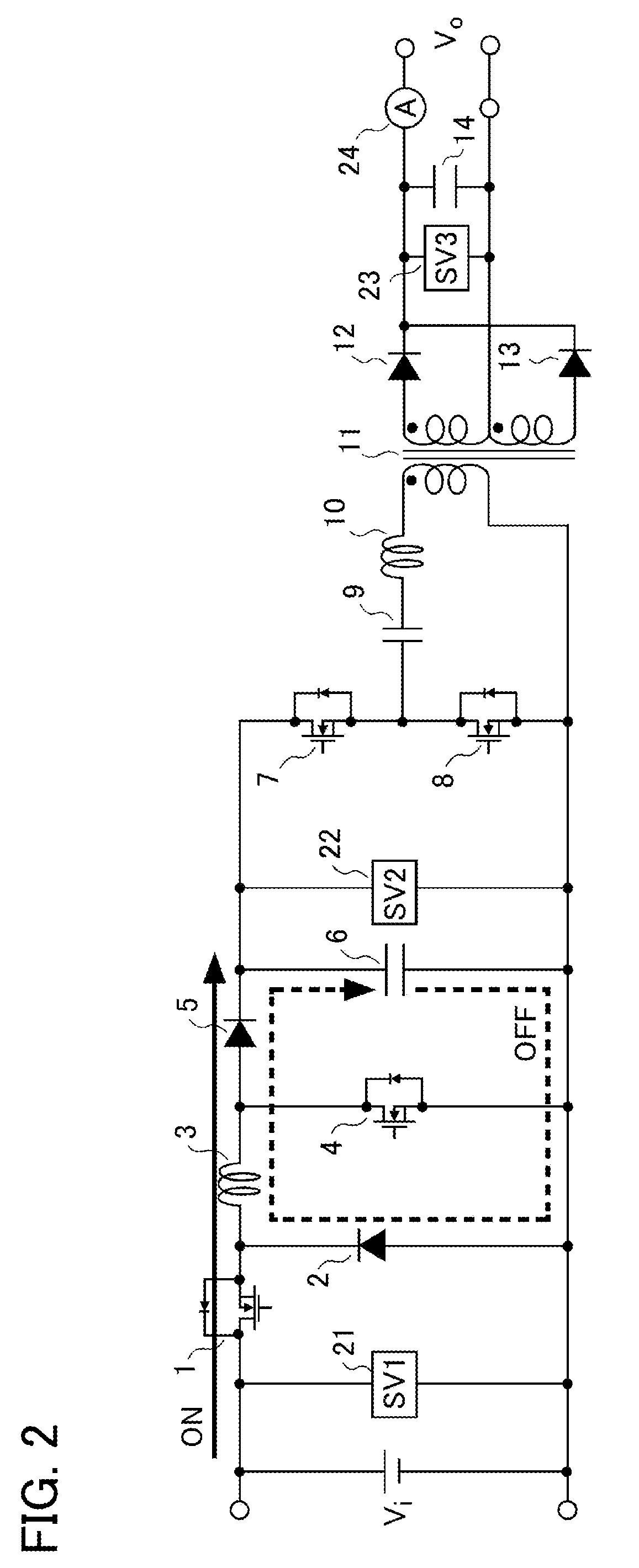

Power converter

ActiveUS20180041108A1Low costHigh efficiencyEfficient power electronics conversionApparatus with intermediate ac conversionEngineeringVoltage ratio

An electric power converter is provided, at low costs and in high efficiency, which also enables voltage conversion to be capable of dealing with sharp load variation, even when input voltage and output current ranges are wide. The converter includes a non-isolated buck-boost converter circuit for outputting a DC voltage by increasing or decreasing a voltage being inputted into the circuit, an isolated converter circuit for outputting a DC voltage to a load by inputting a DC voltage outputted from the non-isolated buck-boost converter circuit, and a control unit for controlling the non-isolated buck-boost converter circuit and the isolated converter circuit, whereby the control unit adjusts using only the non-isolated buck-boost converter circuit, by performing the control of a buck-boost voltage ratio between the voltage inputted thereinto and an output voltage of the isolated converter circuit, so as to make the output voltage coincident with its target value.

Owner:MITSUBISHI ELECTRIC CORP

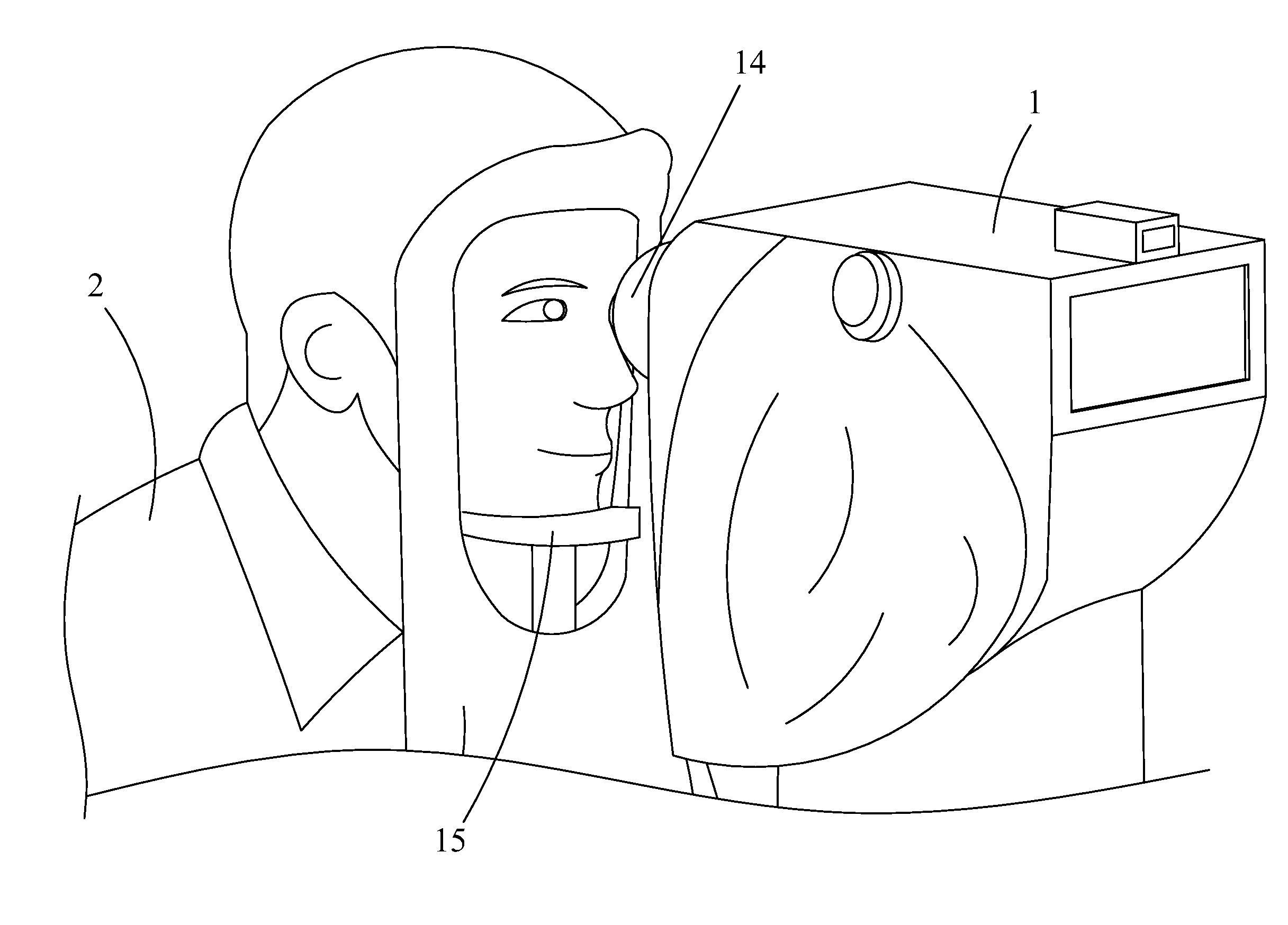

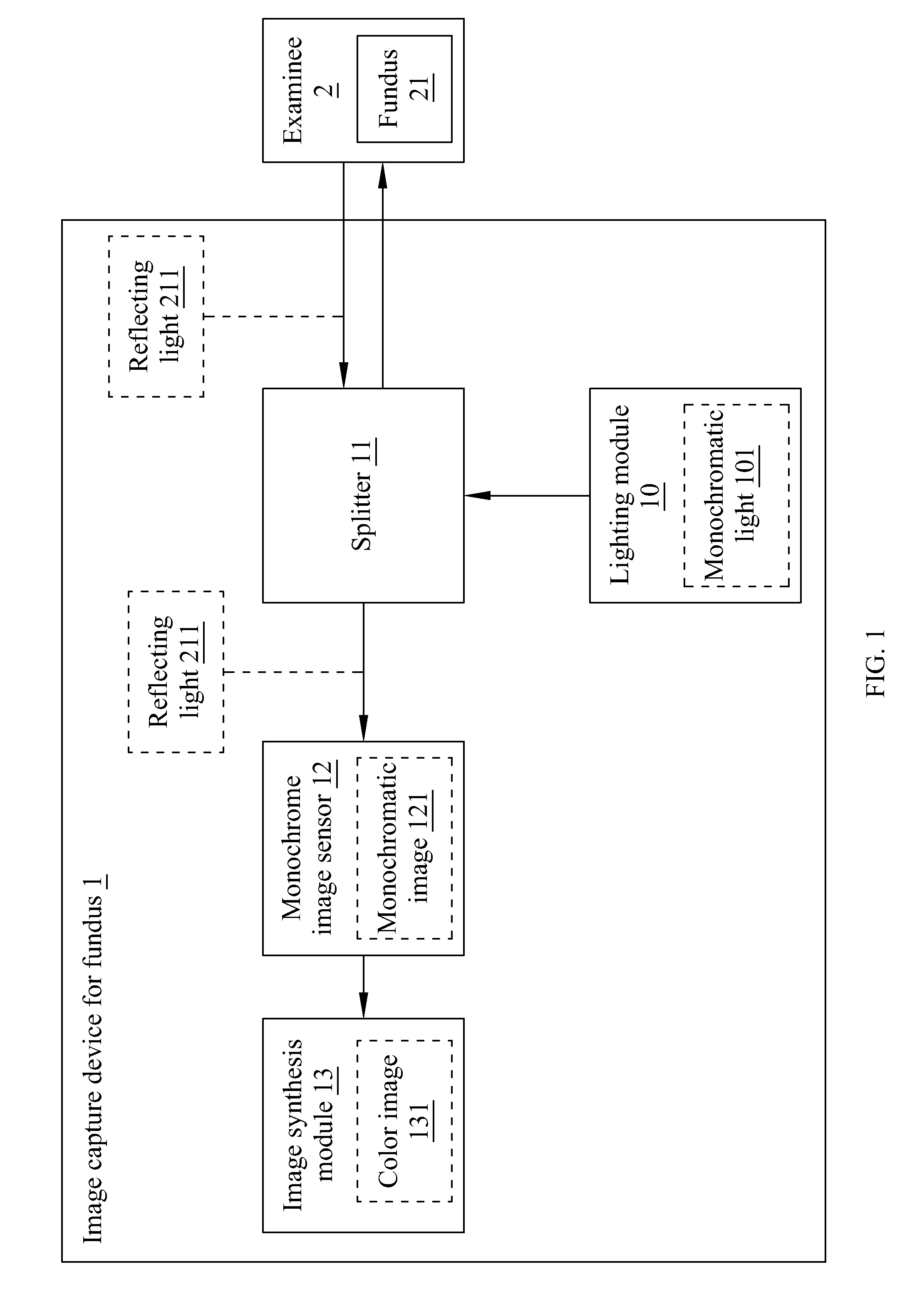

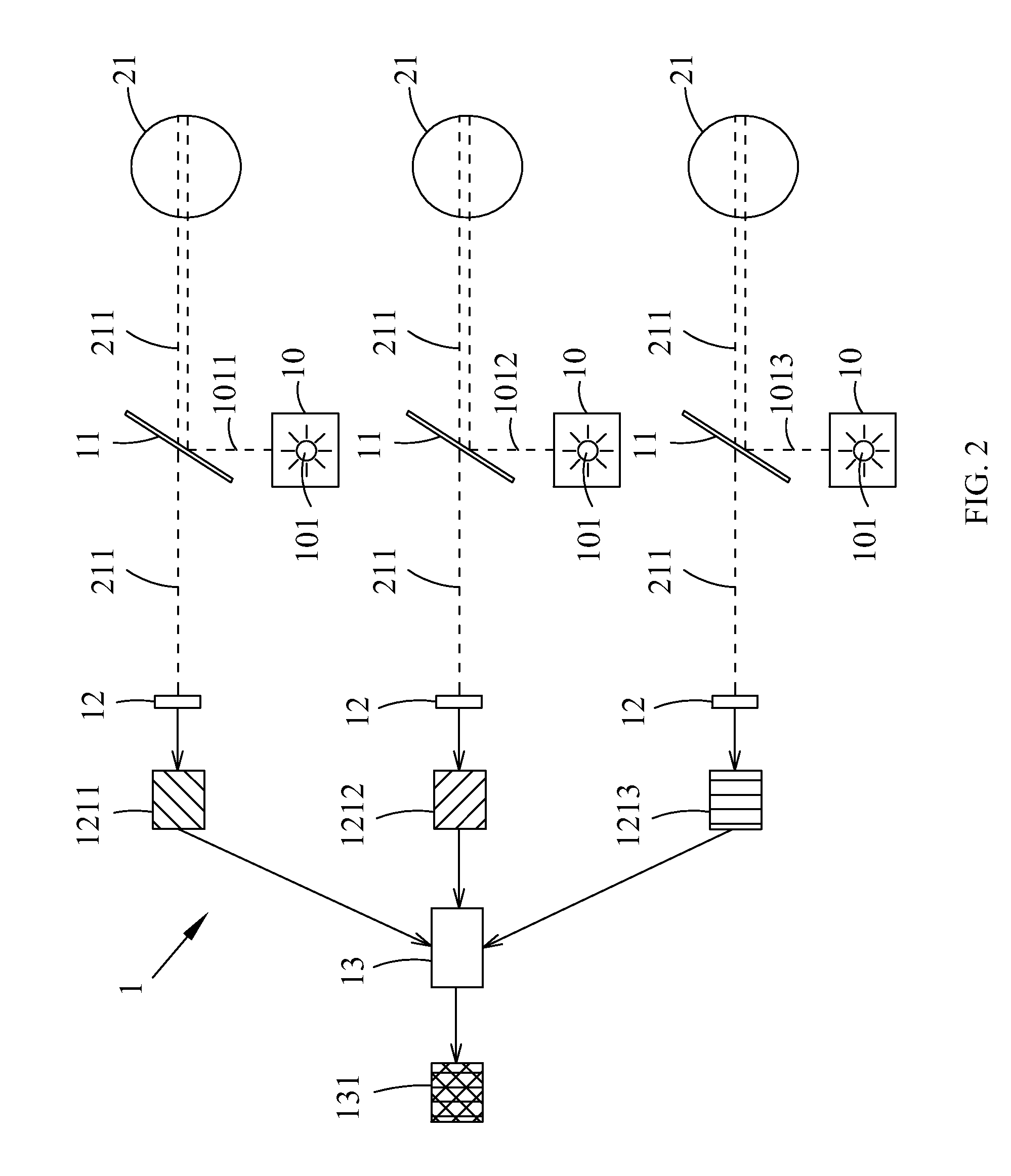

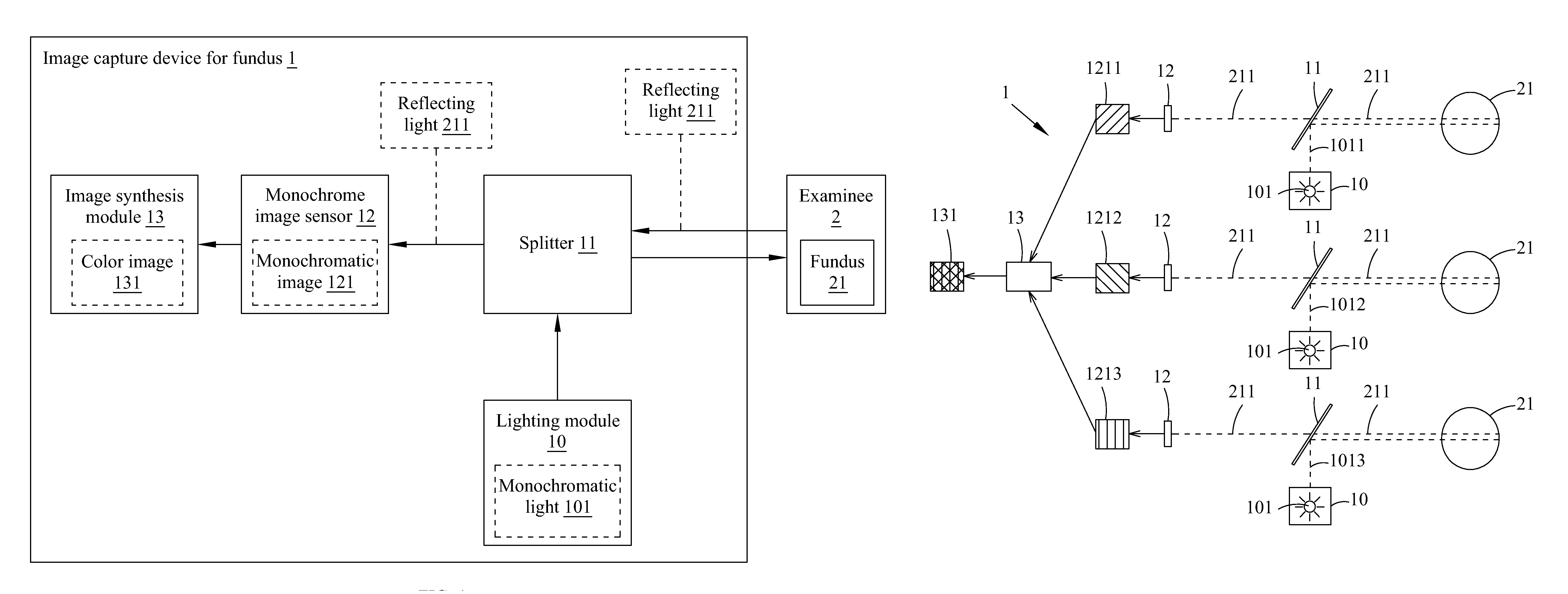

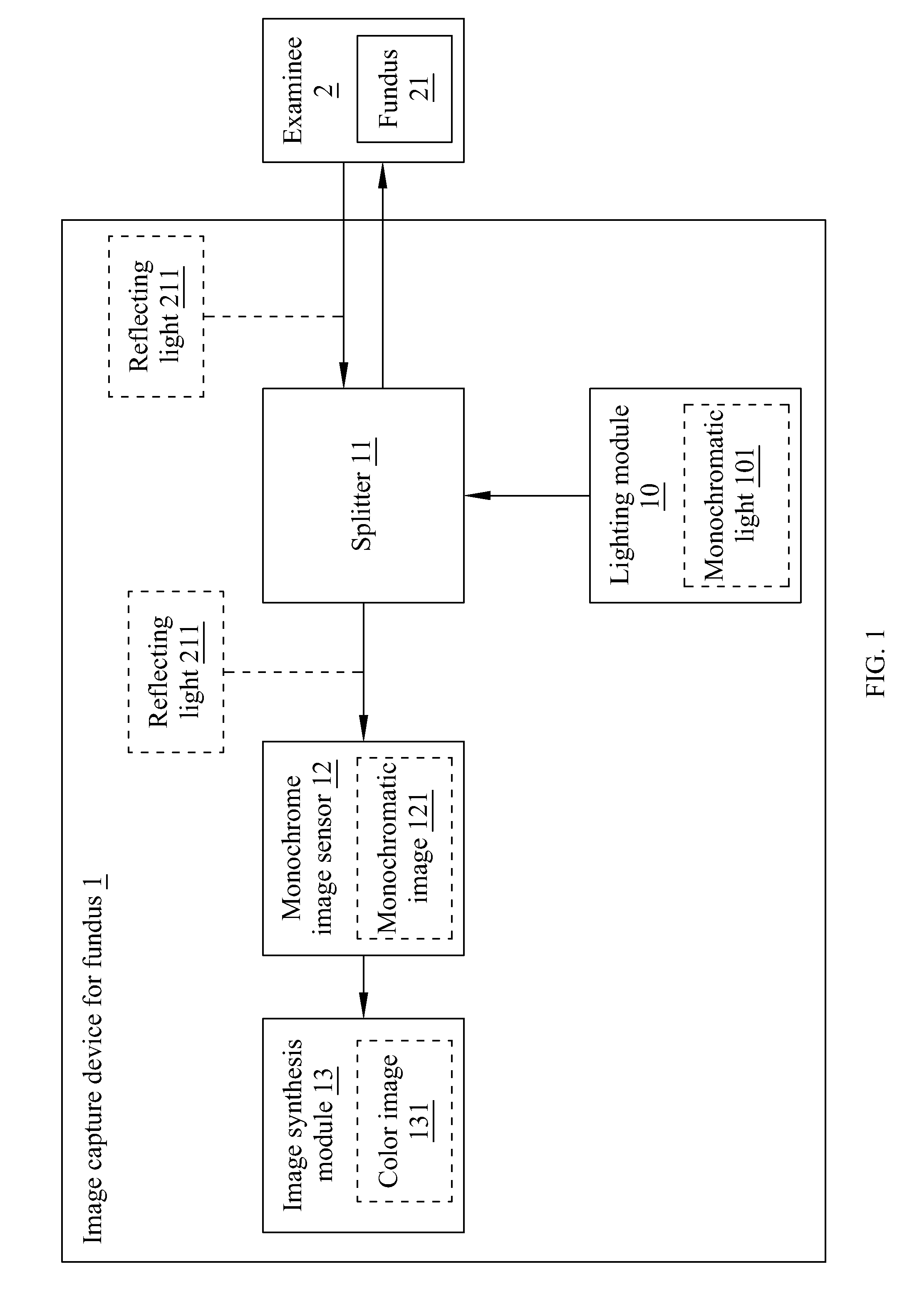

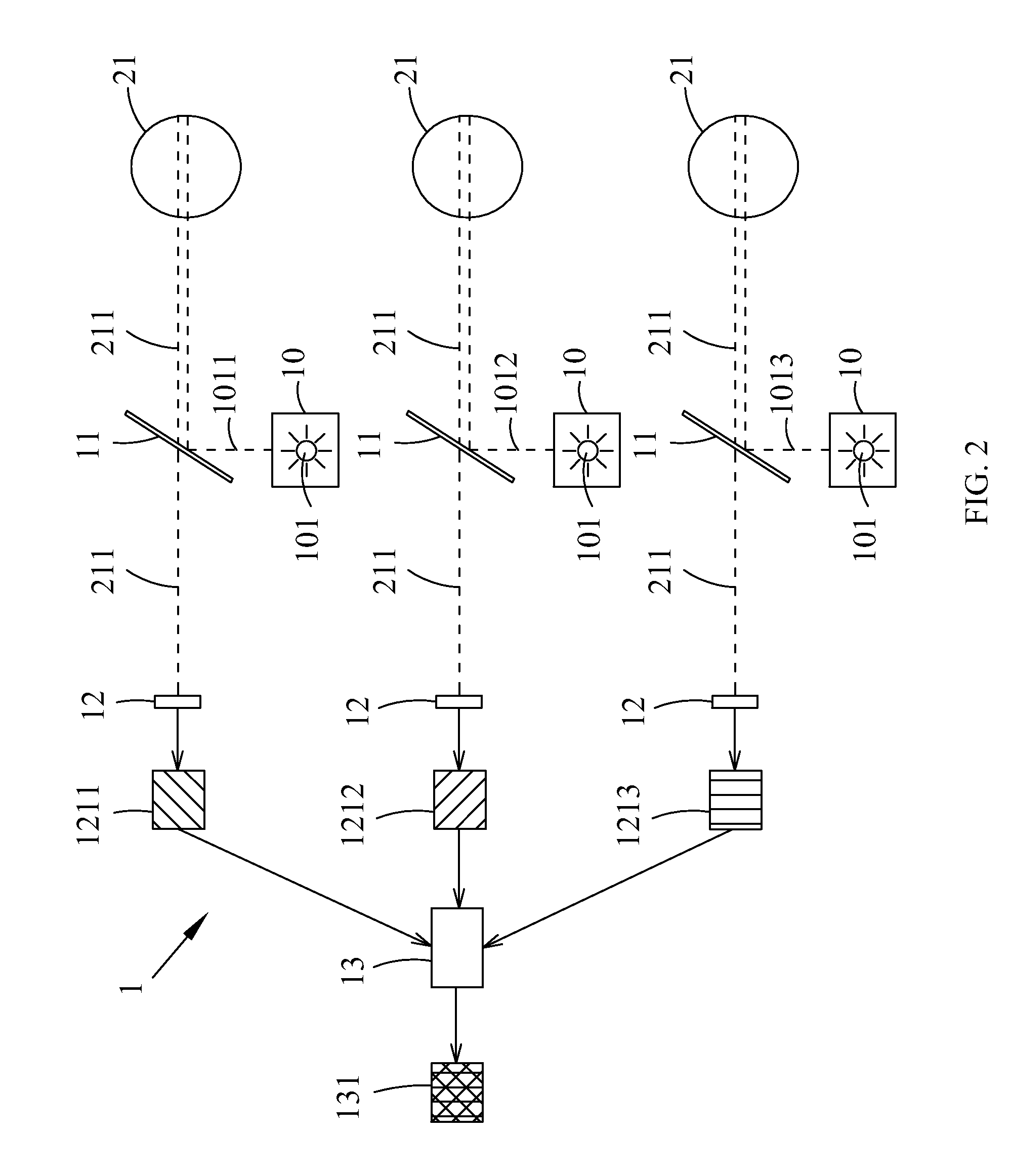

Image capture device for fundus and imaging method thereof

This invention discloses an image capture device for fundus and an imaging method thereof. The image capture device includes a lighting module, a splitter, a monochrome image sensor and an image synthesis module. The lighting module emits plurality beams of monochromatic light. The splitter is disposed on a light path of the lighting module. The splitter reflects the plurality beams of the monochromatic light to a fundus of an examinee and forms a plurality of reflecting light respectively through reflection of the fundus. The monochrome image sensor receives the plurality beams of the reflecting light and produces a monochromatic image corresponding to each beam of the monochromatic light. The image synthesis module receives each of the monochromatic images and synthesizes each monochromatic image into a color image. By such arrangements, the invention provides good quality fundus imaging and reduces costs.

Owner:ALTEK BIOTECH

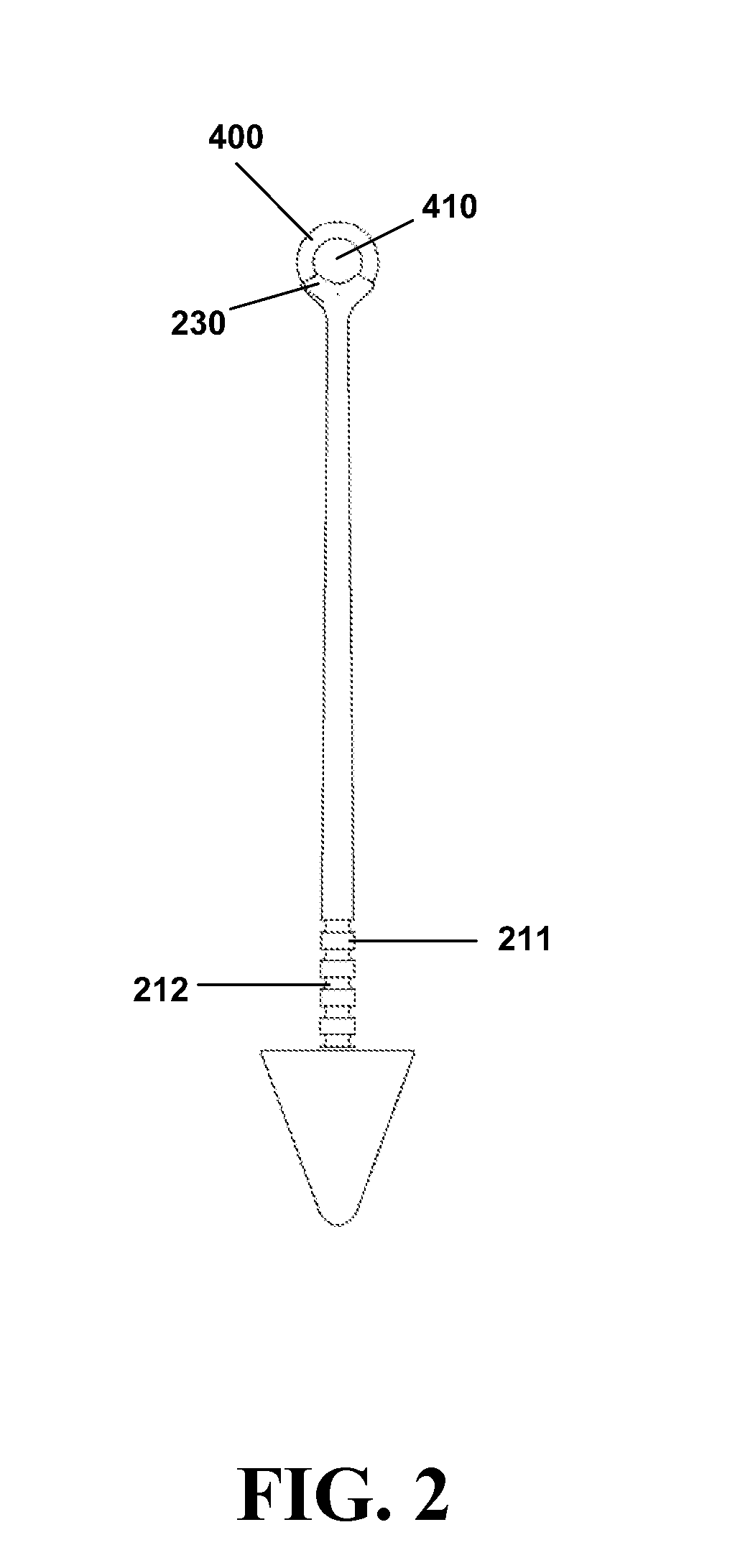

Drizzle device

InactiveUS20070210593A1Facilitates both the drizzling of liquids and the extracting of dregsIncrease orLiquid surface applicatorsLifting devicesDrizzleEngineering

A device that facilitates both the drizzling of liquids and the extracting of small food items from hard to reach container corners and the like is disclosed. The device is comprised of a pivoting ladle-like cone connected to a flexible shaft protruding from the center of the cavity of the cone.

Owner:FUSIONBRANDS LLC

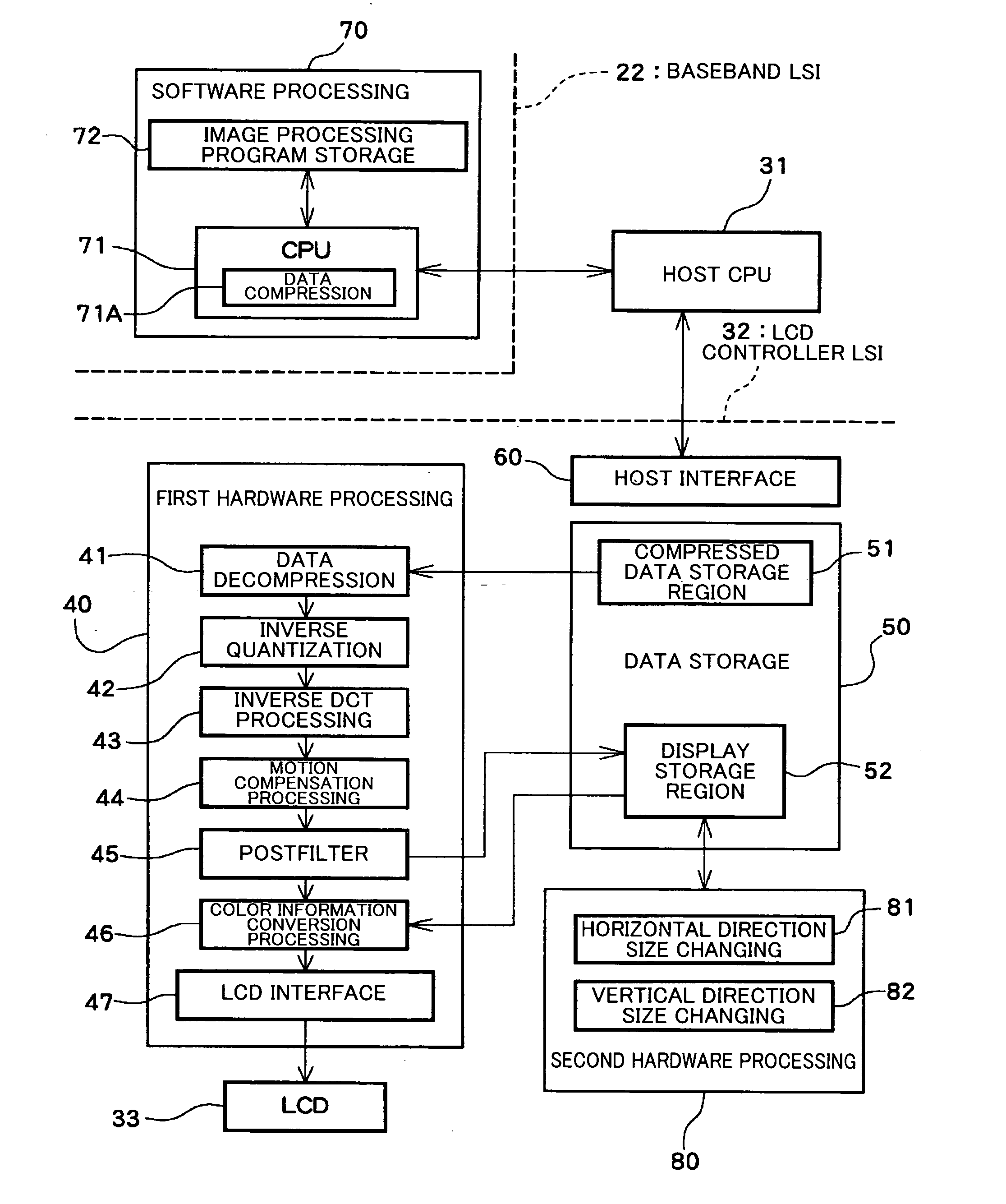

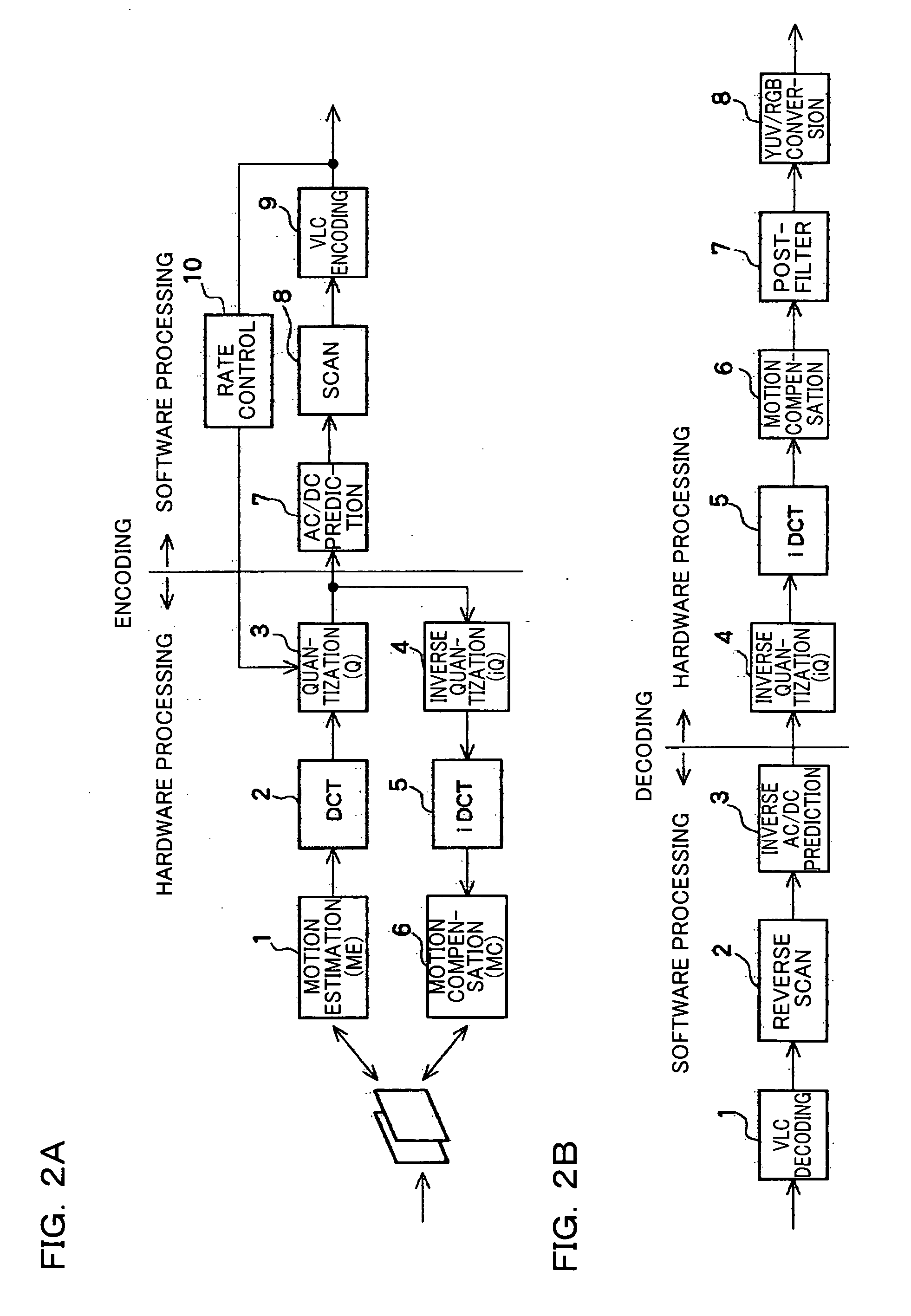

Method and device for changing image size

InactiveUS20050008259A1Increased and reduced in sizeReduce image qualityTelevision system detailsGeometric image transformationSize changeComputer vision

A method of changing an image size includes changing a size of the original image at least in a horizontal direction by interpolating data in an interpolation pixel between predetermined pixels in each of the unit areas of the original image according to a set horizontal increasing scale factor. Each of the unit areas includes a plurality of first boundary pixels arranged along a vertical virtual boundary line between two of the unit areas adjacent in the horizontal direction in the frame. In the image size changing step, the interpolation pixel is set between pixels other than the first boundary pixels.

Owner:SEIKO EPSON CORP

Motorized air walker and suspension system for paralyzed persons

ActiveUS9421144B2Increase orAccommodate a gait of the patientChiropractic devicesWalking aidsEngineeringUse walkers

Owner:KALINOWSKI EUGENE

Toroidal vacuum interrupter for modular multi-break switchgear

ActiveUS8466385B1Increase contactEffective interruptionHigh-tension/heavy-dress switchesAir-break switchesContact pressureModularity

A toroidal vacuum switch / interrupter for modular switchgear is disclosed. The toroidal vacuum module includes a coaxial moving contact drive rod system, which includes a nonconductive tube inside of a moving insulating cylinder. A contact drive rod system drives a contact system. The contact configuration allows the center contact rod to extend completely through the vacuum envelope to drive successive series connected modules. A system of capacitors and resistors is provided in the insulated portion of the contact drive rod, which extends through the module to connect to and balance the voltage between any series connected vacuum modules. A mechanical adjustment system provides contact pressure and a means to adjust out tolerance build-up within the vacuum module to provide the contacts with a uniform set point. This allows multiple vacuum modules to be connected together in series combinations and provides for simultaneous operation of the contacts in each module.

Owner:GLASER MICHAEL DAVID

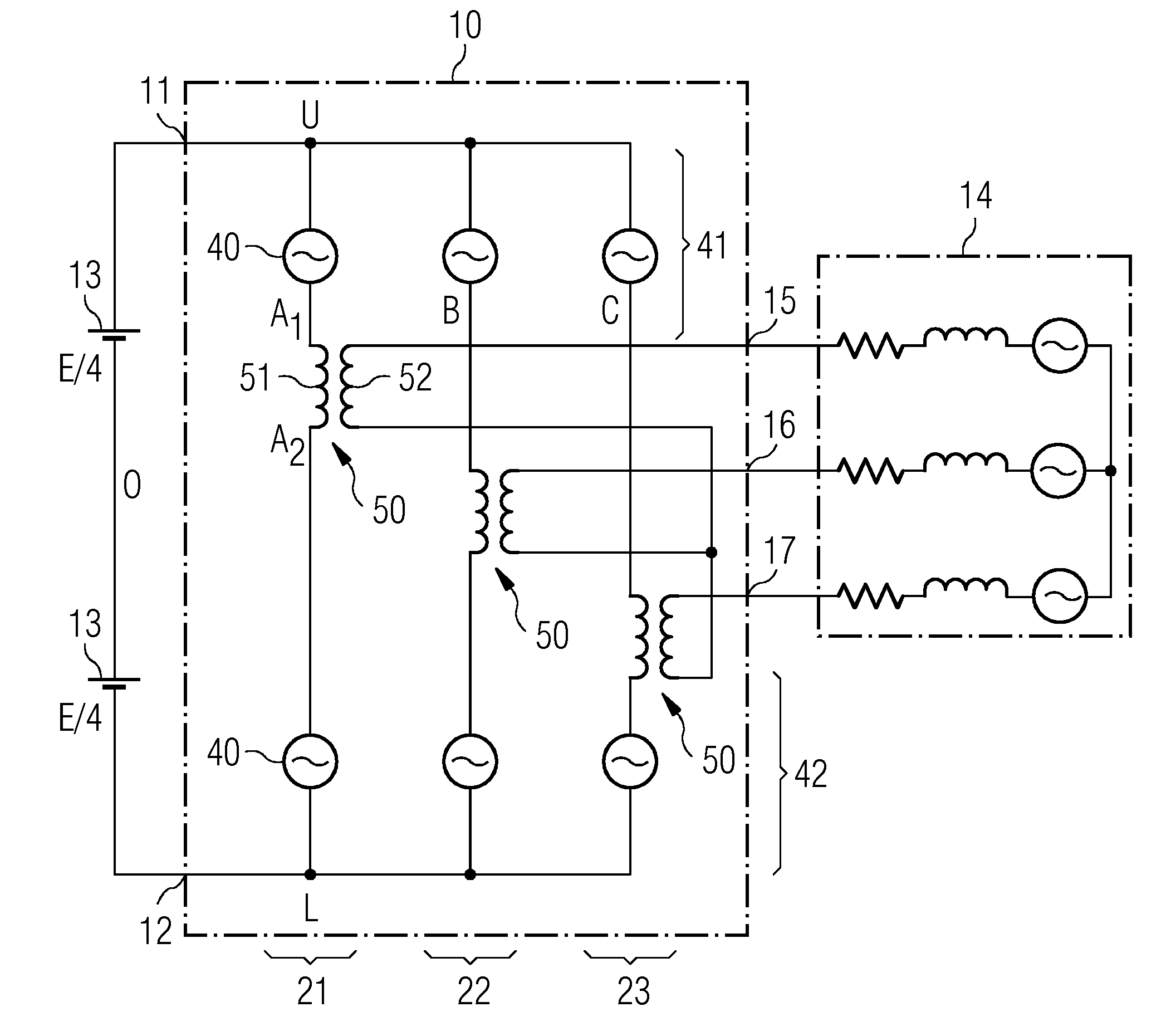

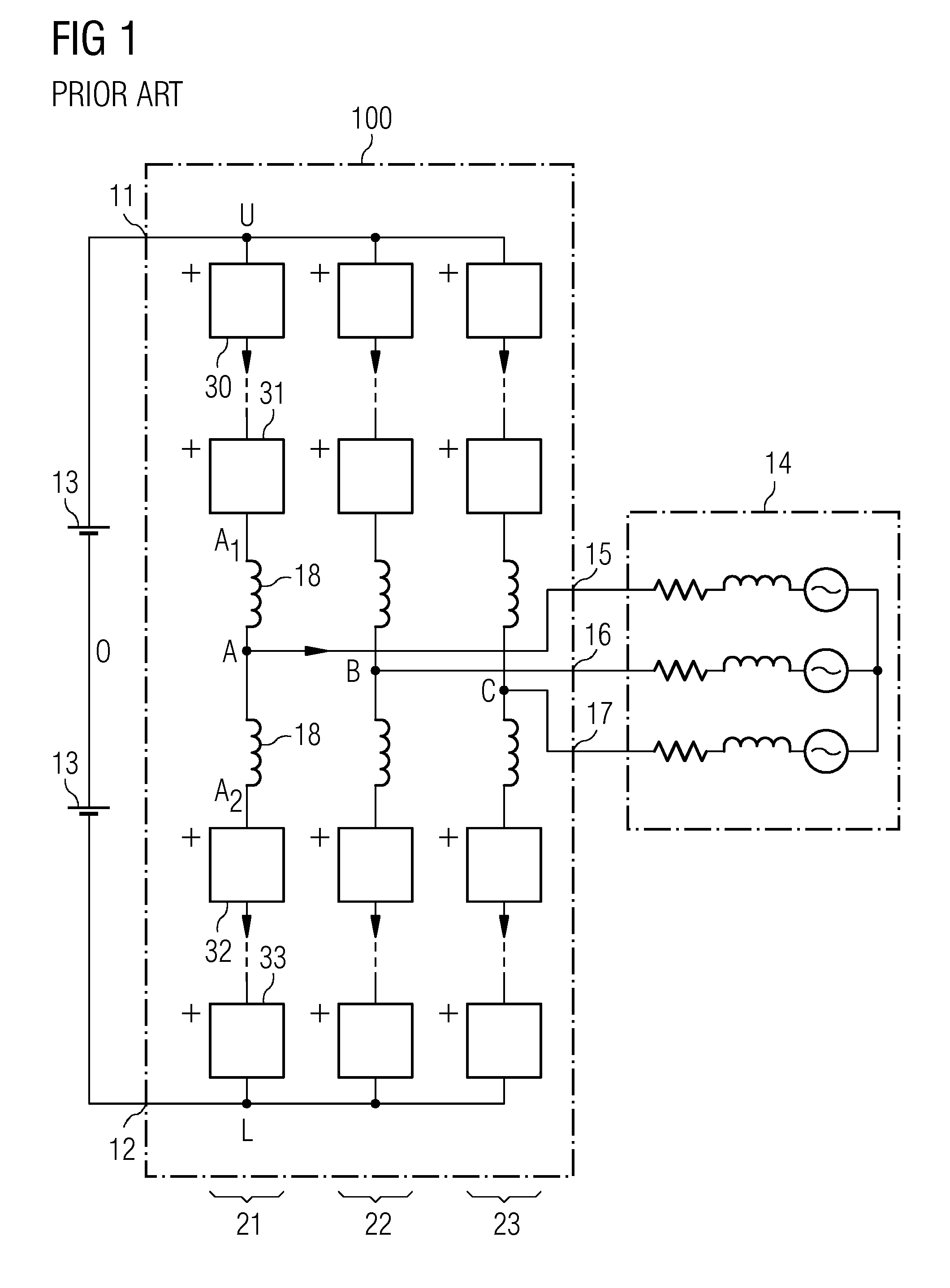

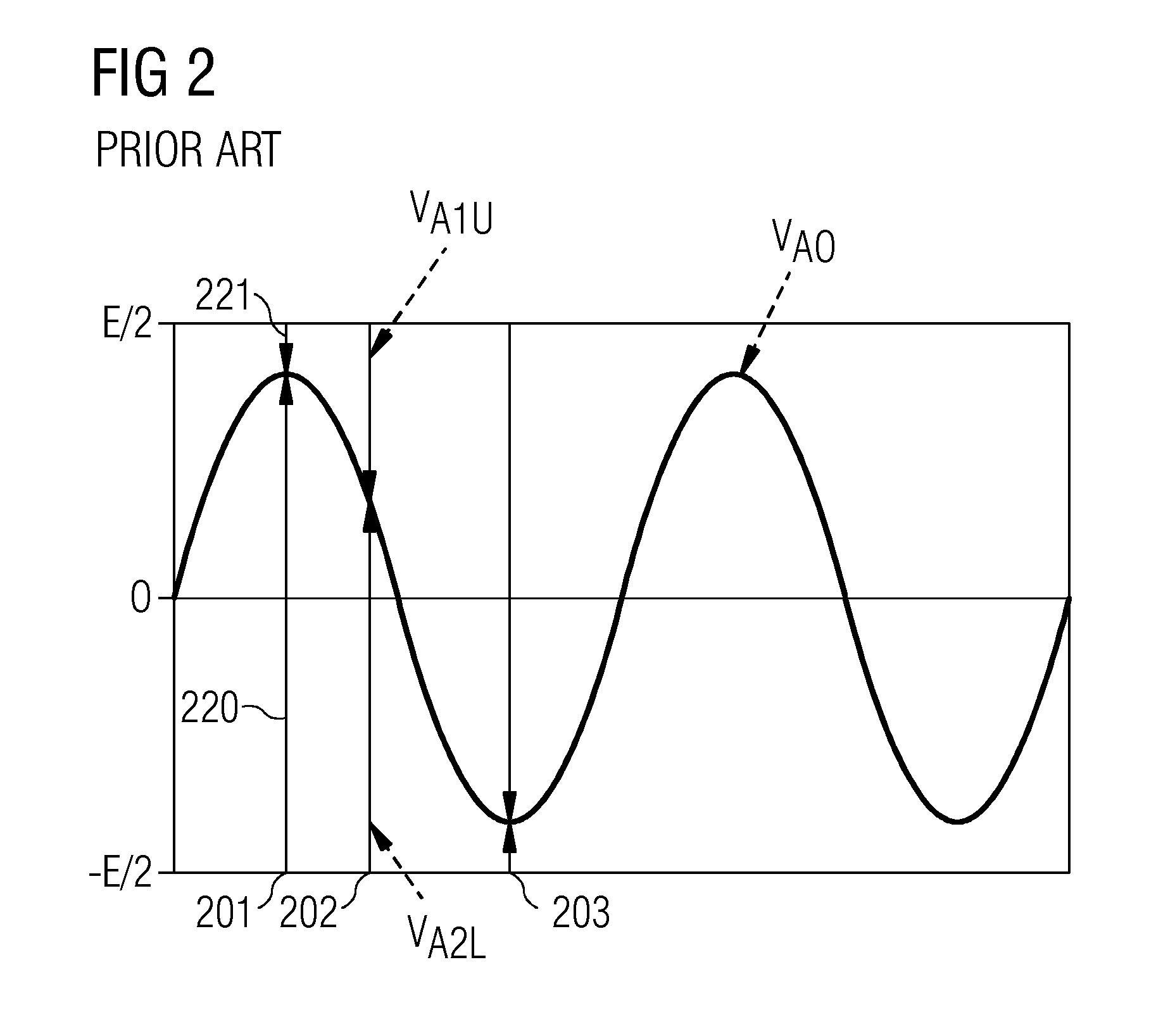

Multilevel Converter

A multilevel converter for performing a DC to AC or an AC to DC voltage conversion as provided. The multilevel converter has a first DC terminal and a second DC terminal, a first converter arm and a second converter arm, wherein each converter arm comprises at least one converter cell, at least one AC terminal and an electric component. The first converter arm, the electric component and the second converter arm are connected in series between the first DC terminal and the second DC terminal. The electric component is connected between the first converter arm and the second converter arm.

Owner:SIEMENS AG

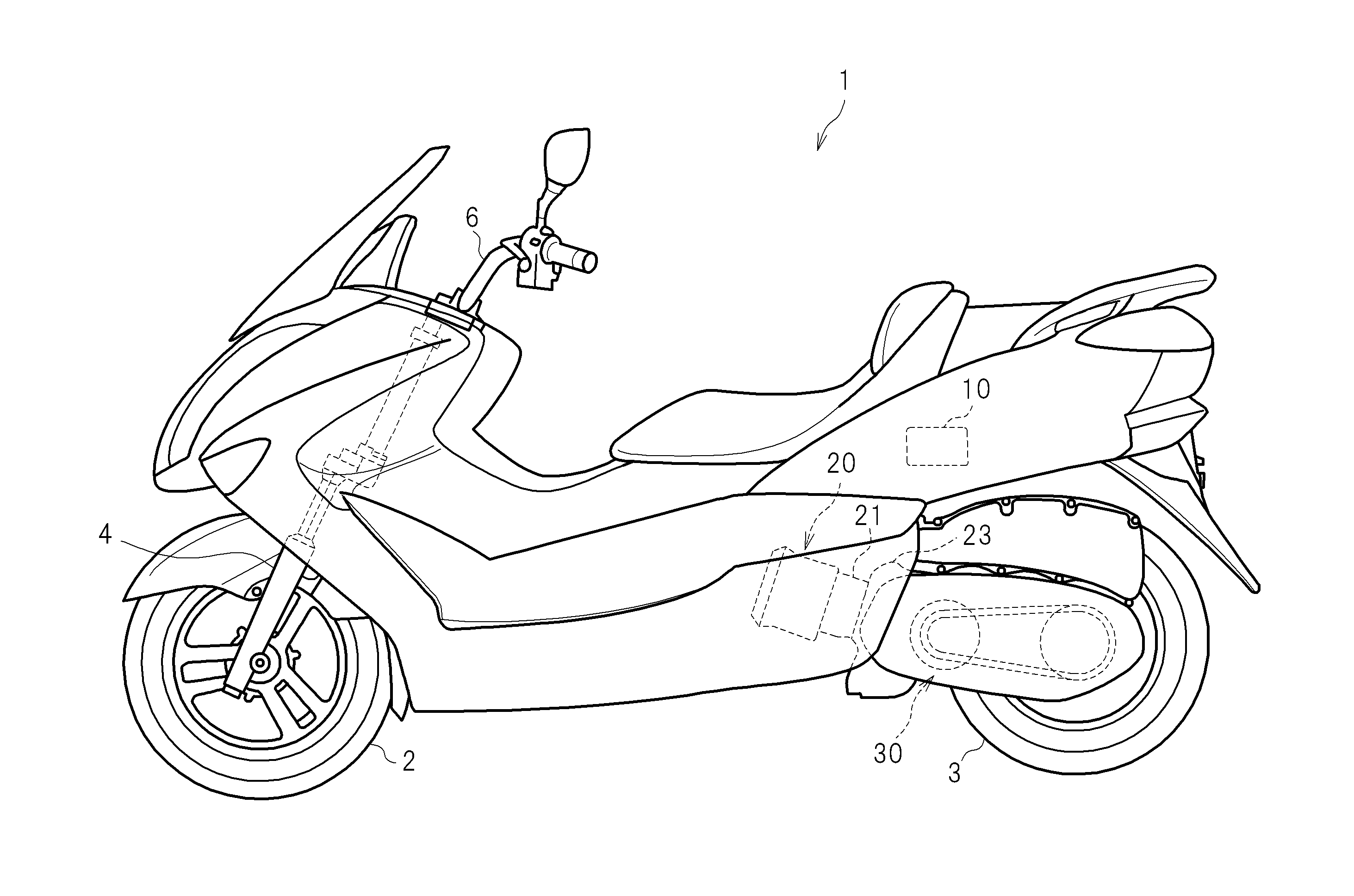

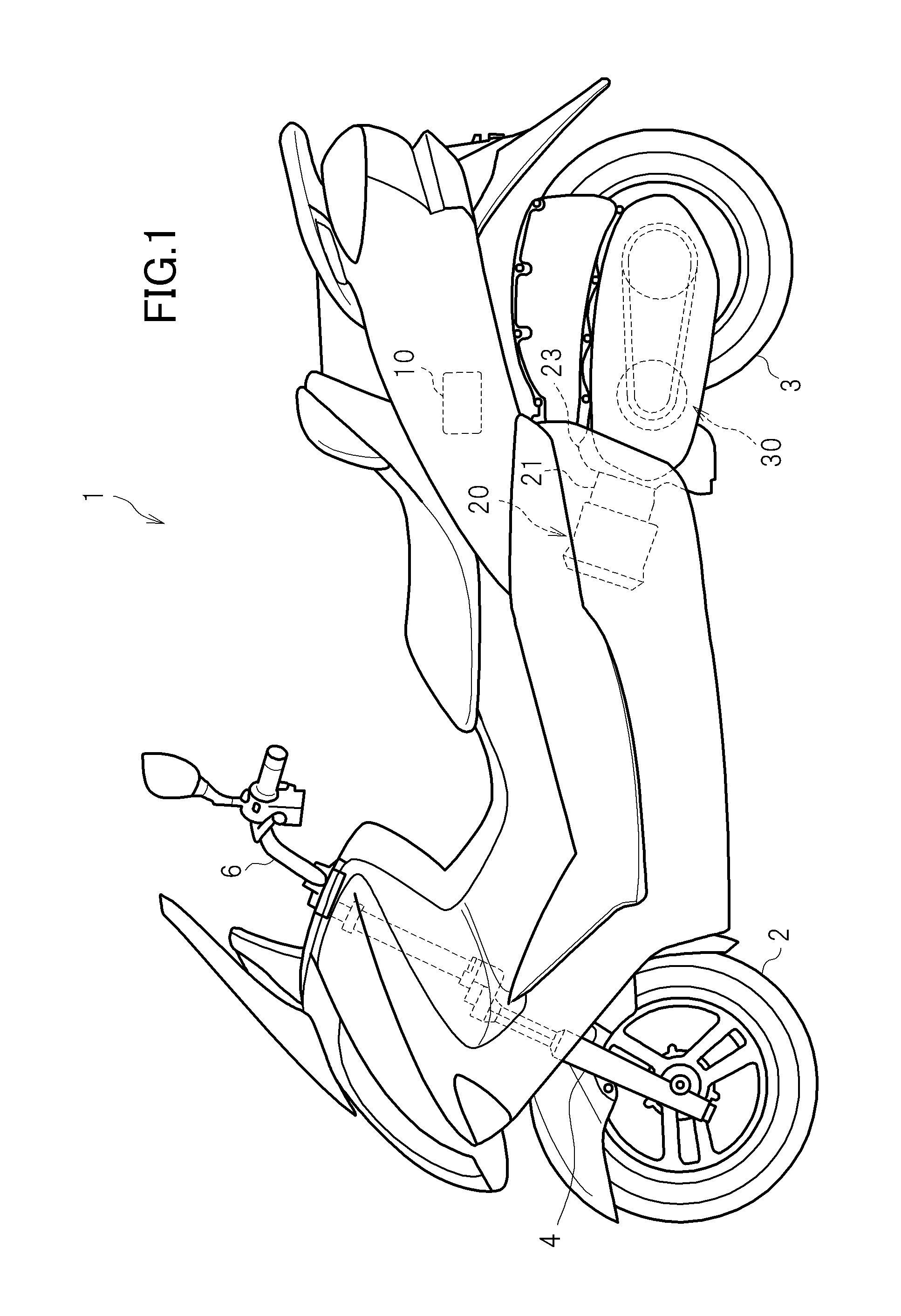

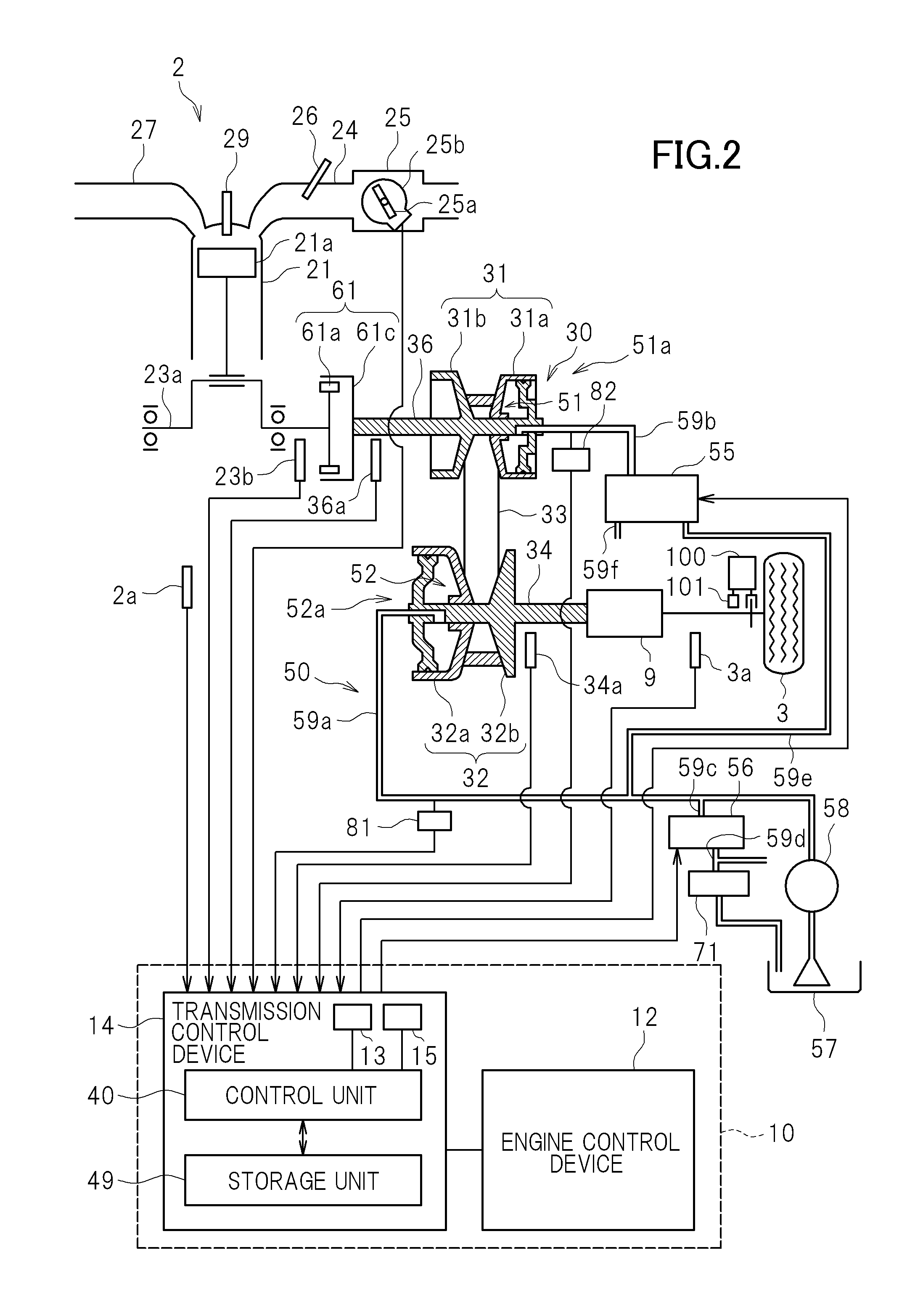

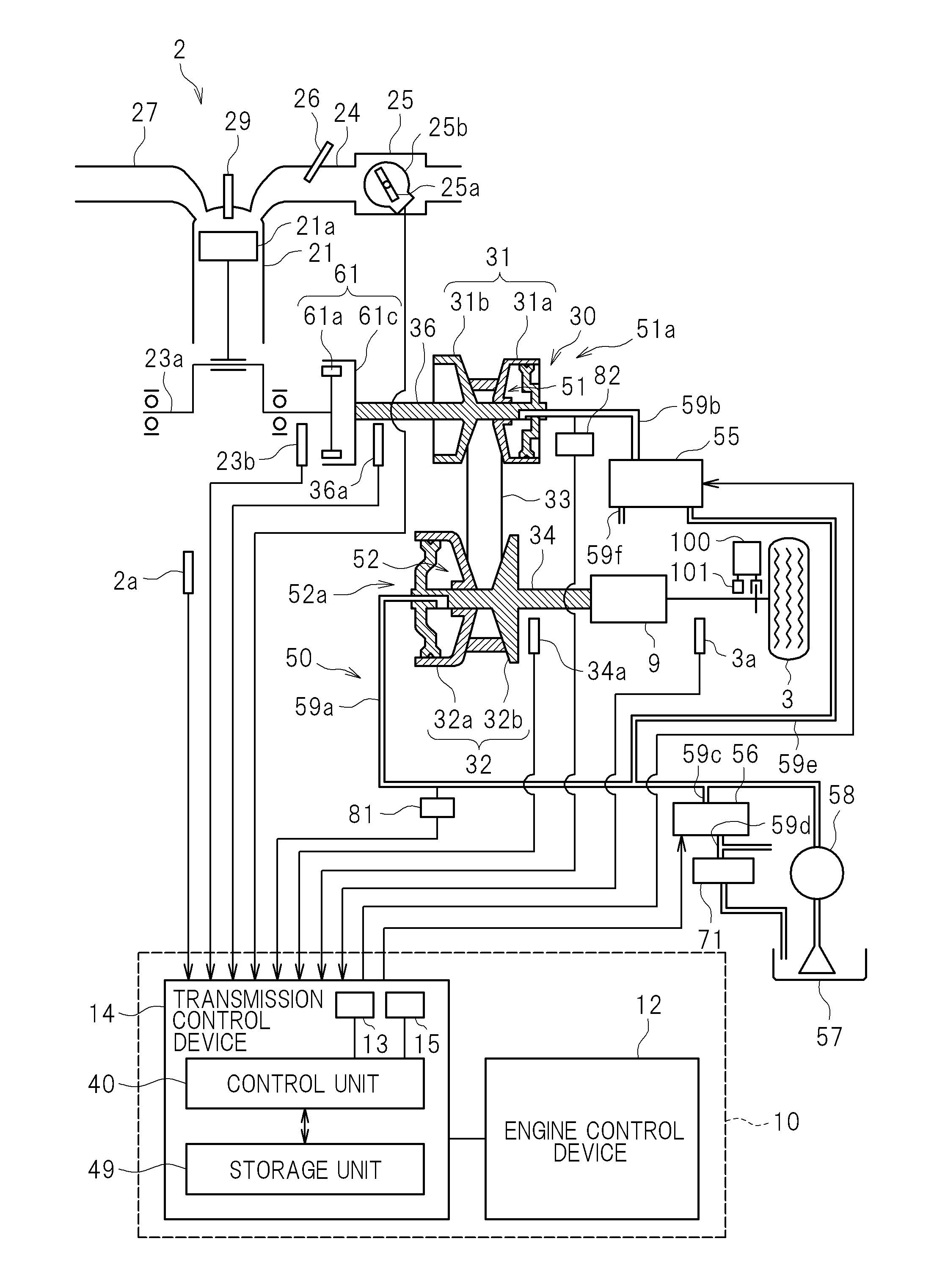

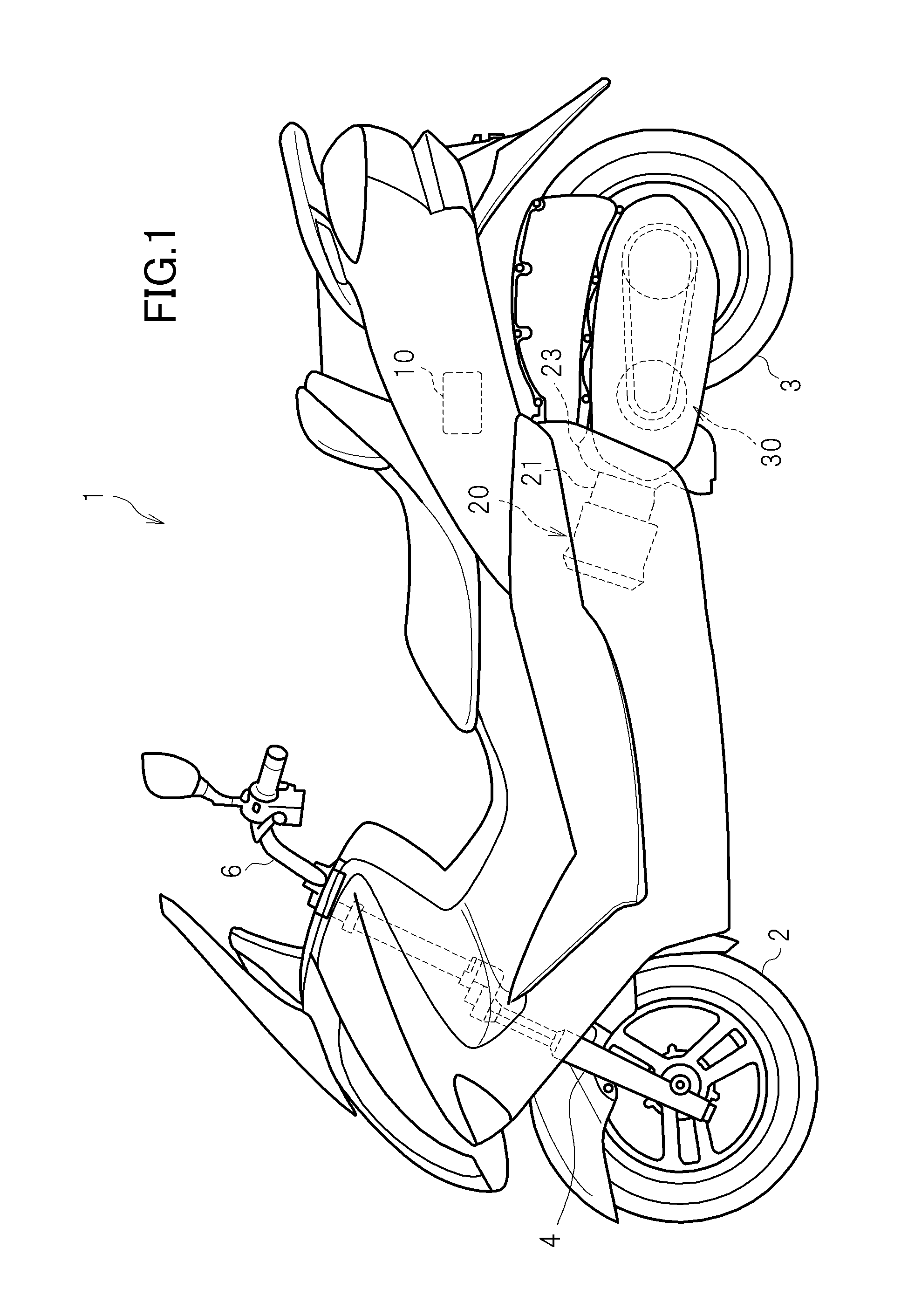

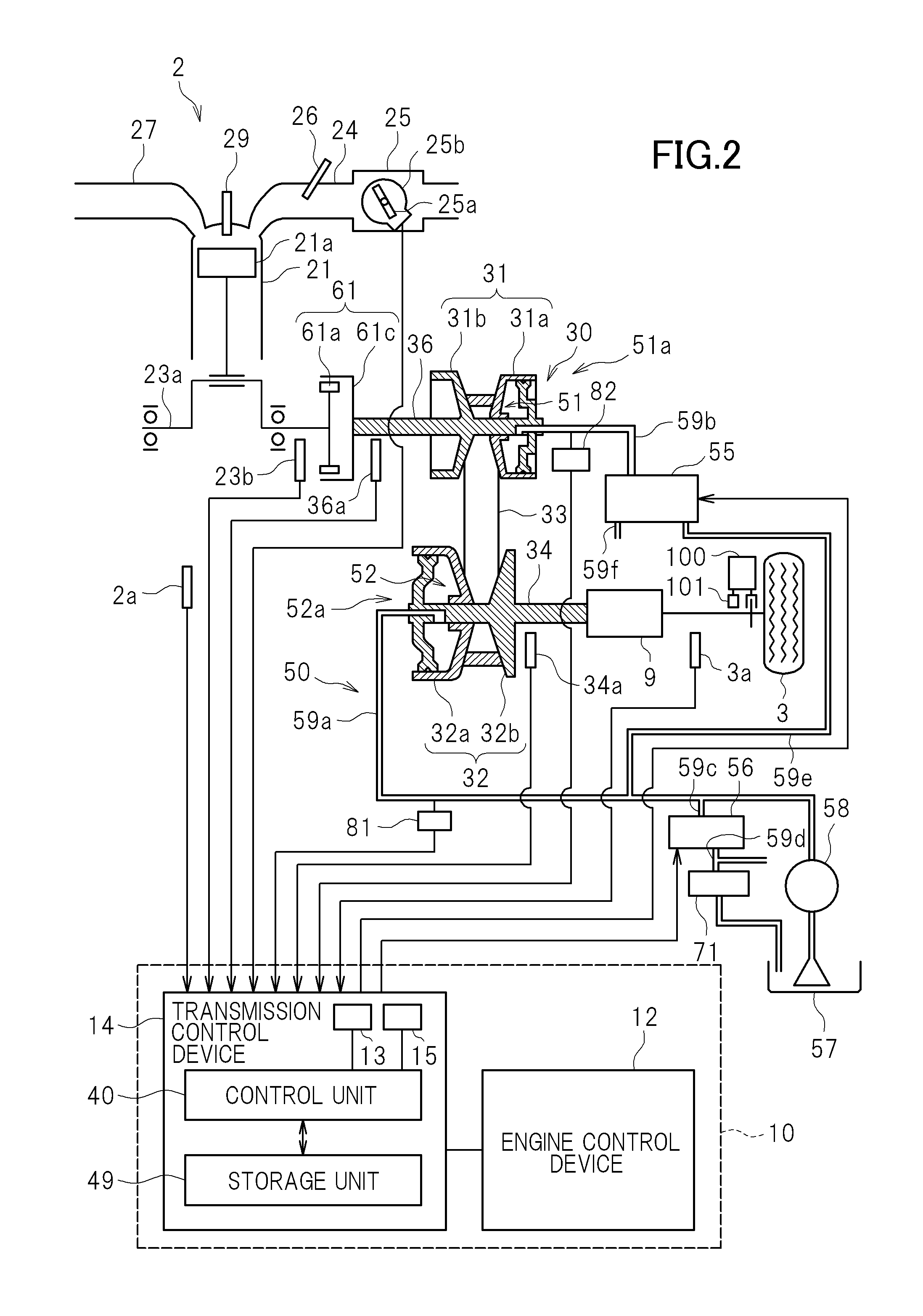

Vehicle and method for controlling the same

InactiveUS20120264566A1Increase clamping forcePrevent slippingGearingGear vibration/noise dampingDrive wheelTorque transmission

A vehicle and a method for controlling the vehicle are capable of preventing slip of a belt of a continuously variable transmission at an appropriate timing. A control unit included in the vehicle includes a state information obtaining unit that obtains information indicating a state of a torque damping mechanism provided on a torque transmission path between a second pulley of a continuously variable transmission and a drive wheel, and a clamping force changing processing unit that changes the clamping forces of the first pulley of the continuously variable transmission and the second pulley, based on the state of the torque damping mechanism.

Owner:YAMAHA MOTOR CO LTD

Vehicle and method for controlling the same

InactiveUS8753248B2Prevent slippingIncrease clamping forceGearingGear vibration/noise dampingDrive wheelTorque transmission

A vehicle and a method for controlling the vehicle are capable of preventing slip of a belt of a continuously variable transmission at an appropriate timing. A control unit included in the vehicle includes a state information obtaining unit that obtains information indicating a state of a torque damping mechanism provided on a torque transmission path between a second pulley of a continuously variable transmission and a drive wheel, and a clamping force changing processing unit that changes the clamping forces of the first pulley of the continuously variable transmission and the second pulley, based on the state of the torque damping mechanism.

Owner:YAMAHA MOTOR CO LTD

Steerable source systems and method

A marine acoustic source system for generating an acoustic wave in a body of water. The marine acoustic source system includes a first marine acoustic source array having first and second external source sub-arrays, each sub-array including one or more individual source elements; a first actuator device connected to the first external source sub-array; and a first rope connecting the first actuator device to a first lead-in that is configured to connect to a head of a streamer. The first actuator device is configured to control a length of the first rope in order to control a position of the first source array relative to the streamer.

Owner:SERCEL SAS

Wave energy conversion device and dual-axial wave energy conversion device

PendingUS20220220931A1Reduce and increase lengthIncrease orMagnetic circuit rotating partsMachines/enginesEngineeringWave power

A wave energy conversion device includes a permanent magnet generator, a first driving component and a second driving component. The permanent magnet generator includes a stator structure and a rotor structure. The stator structure includes a stator body. The rotor structure includes a rotor body. The rotor body is disposed inside the stator body in a swinging manner or in a rotatable manner. The first driving component is coupled to the rotor structure. The second driving component is coupled to the stator structure. The wave energy conversion device of the present invention requires a low speed / angle of a swinging / rotating movement of the rotor body relative to the stator body to generate electricity, which facilitates electricity generation from wave energy.

Owner:FLH ENERGY TECH LTD

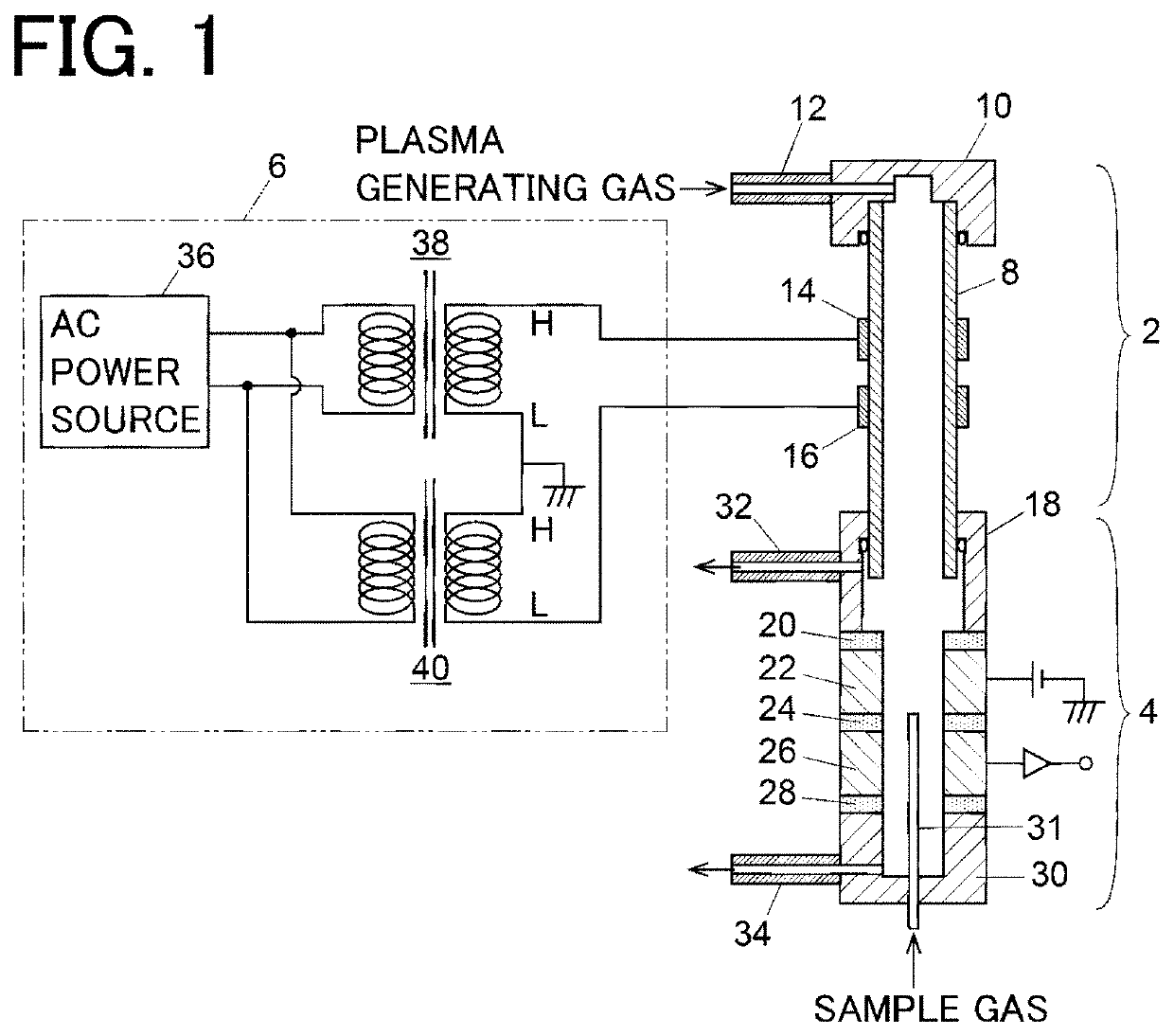

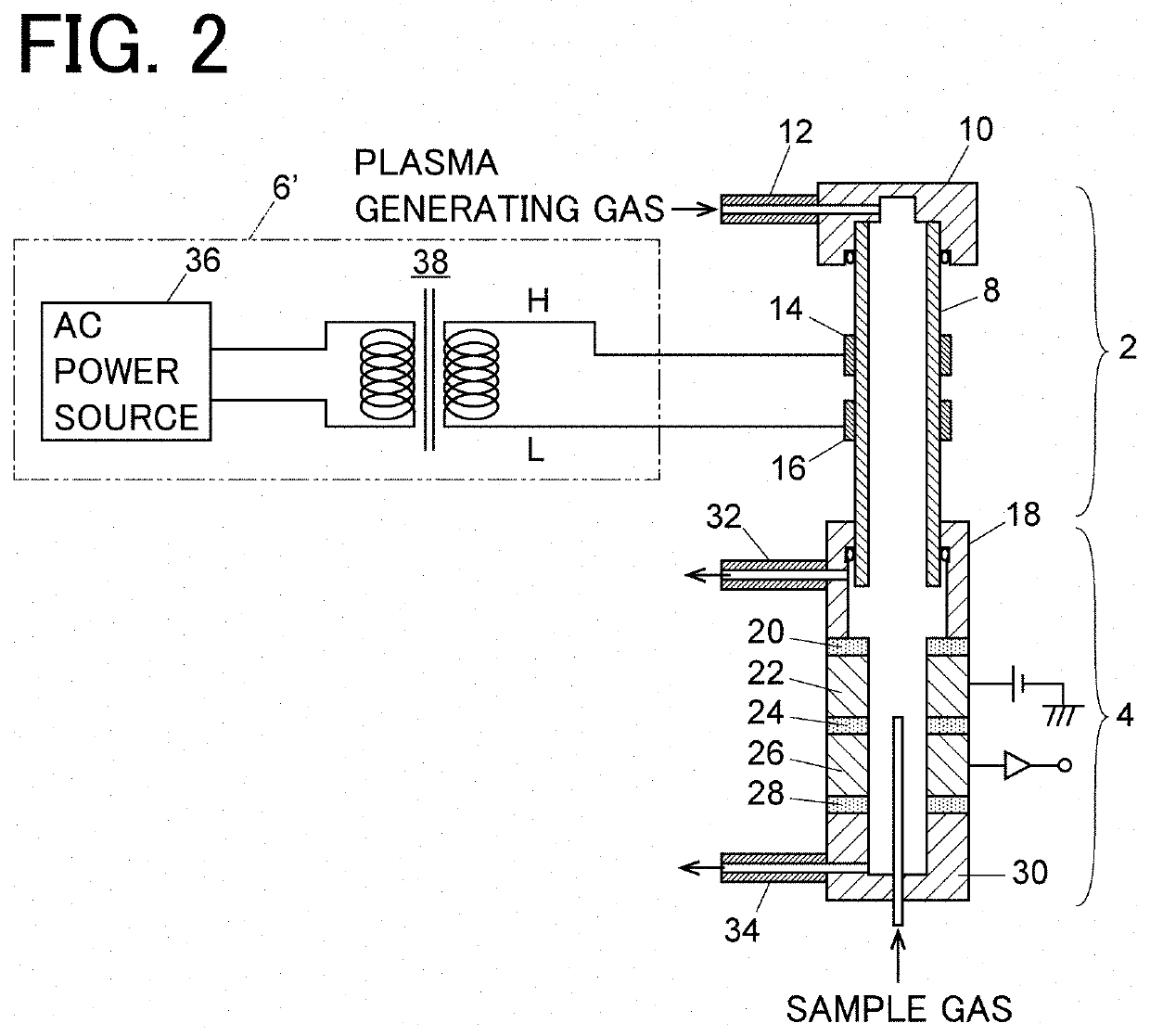

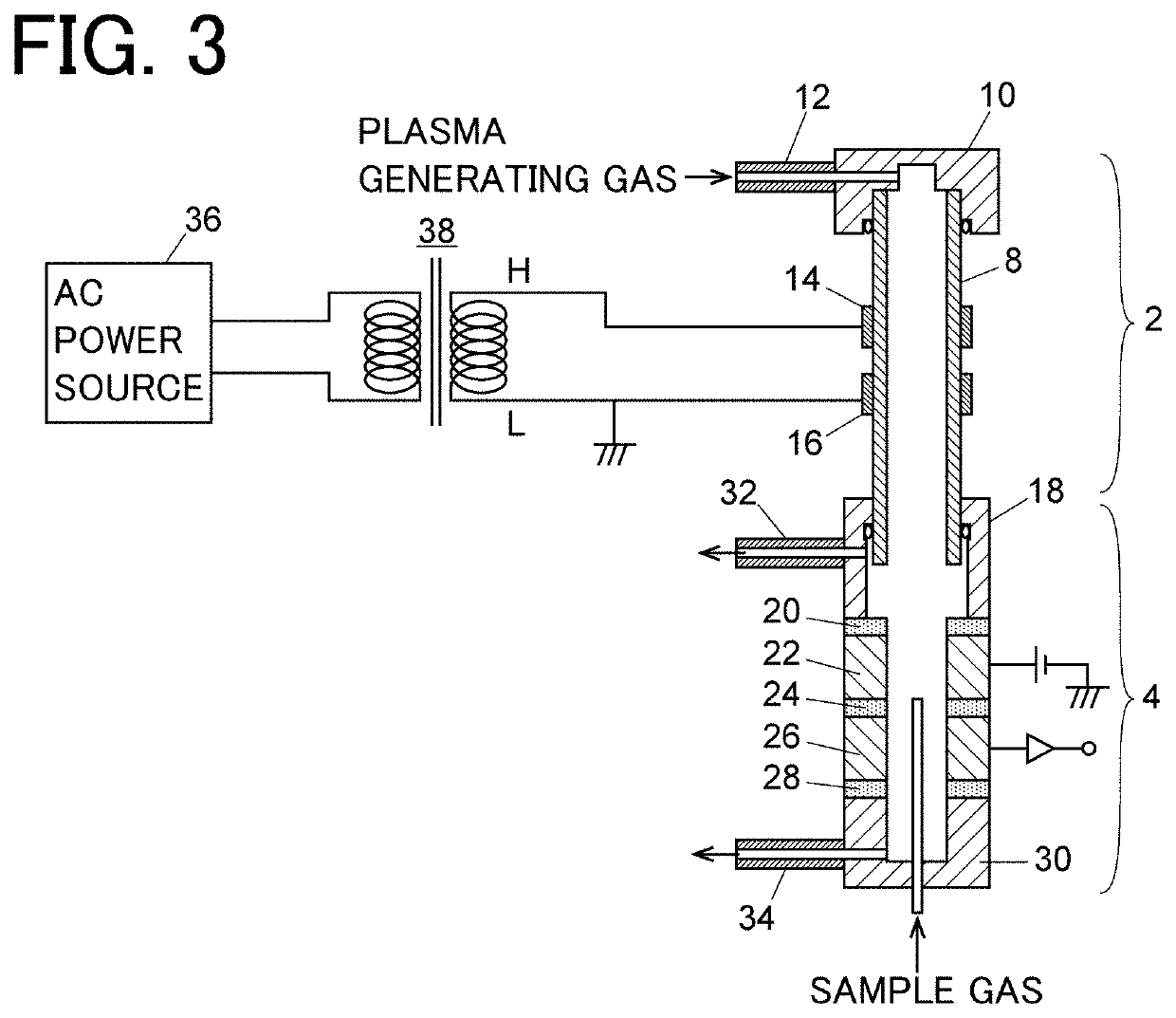

Dielectric barrier discharge ionization detector

ActiveUS20200236772A1Potential differenceCreeping dischargeComponent separationPlasma techniquePotential differenceVoltage source

A BID includes: a discharger (2) including a dielectric pipe (8) and a pair of electrodes (14, 16) attached on an outer wall of the dielectric pipe, the pair of electrodes (14, 16) being arranged at a distance from each other in a direction along a central axis of the dielectric pipe (8), the discharger (2) being arranged so that plasma generating gas is introduced from a first end of the dielectric pipe (8) and configured to generates dielectric barrier discharge inside the dielectric pipe (8) to generate plasma; a detection section (4) including a sample gas introduction section (31) and a collection electrode (26) for collecting ions, the detection section (4) being configured to ionize components in the sample gas using light emitted from the plasma generated in the discharger (2) and to detect the generated ions by collecting them using the collection electrode (26); and a voltage supply (6; 6′) for generating a potential difference between the pair of electrodes (14, 16).

Owner:SHIMADZU CORP +1

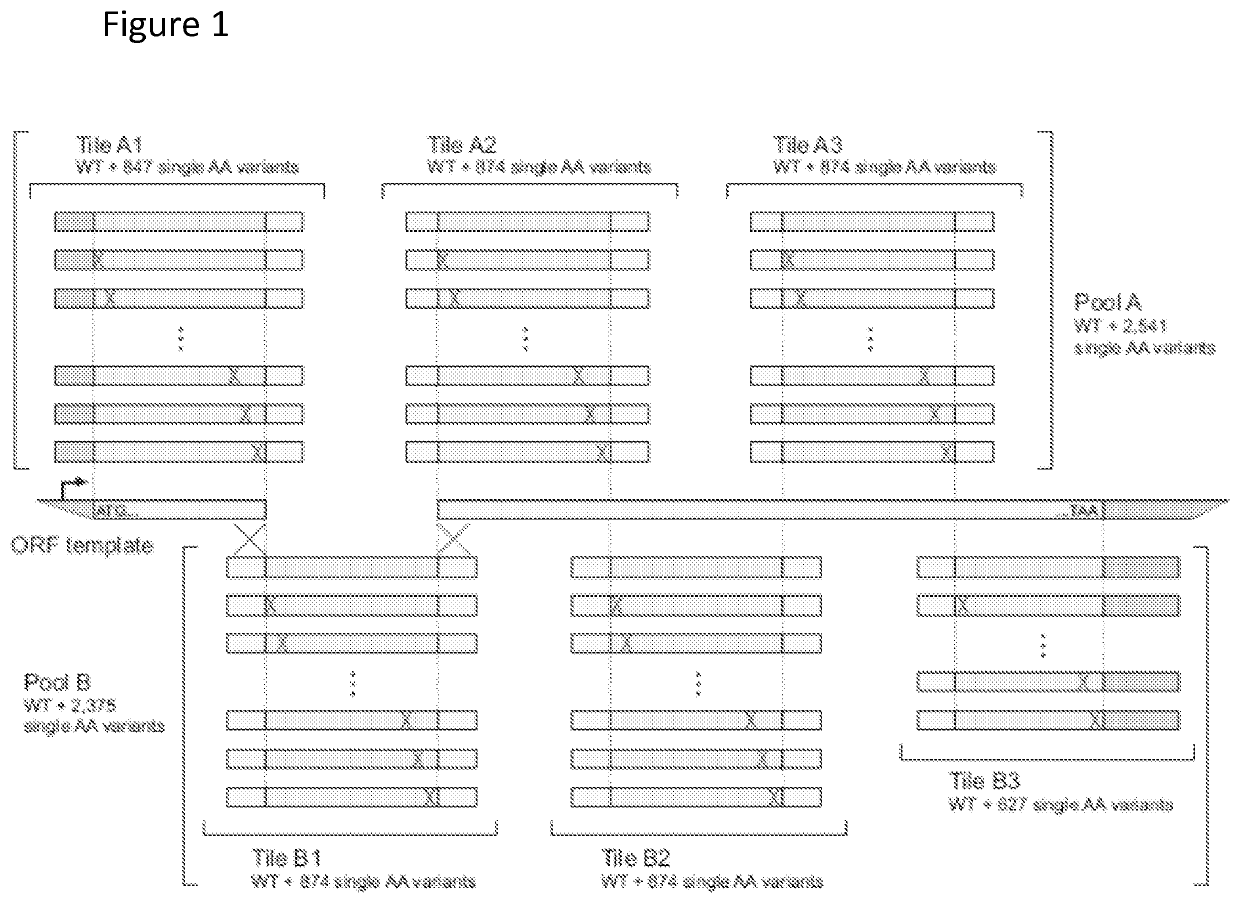

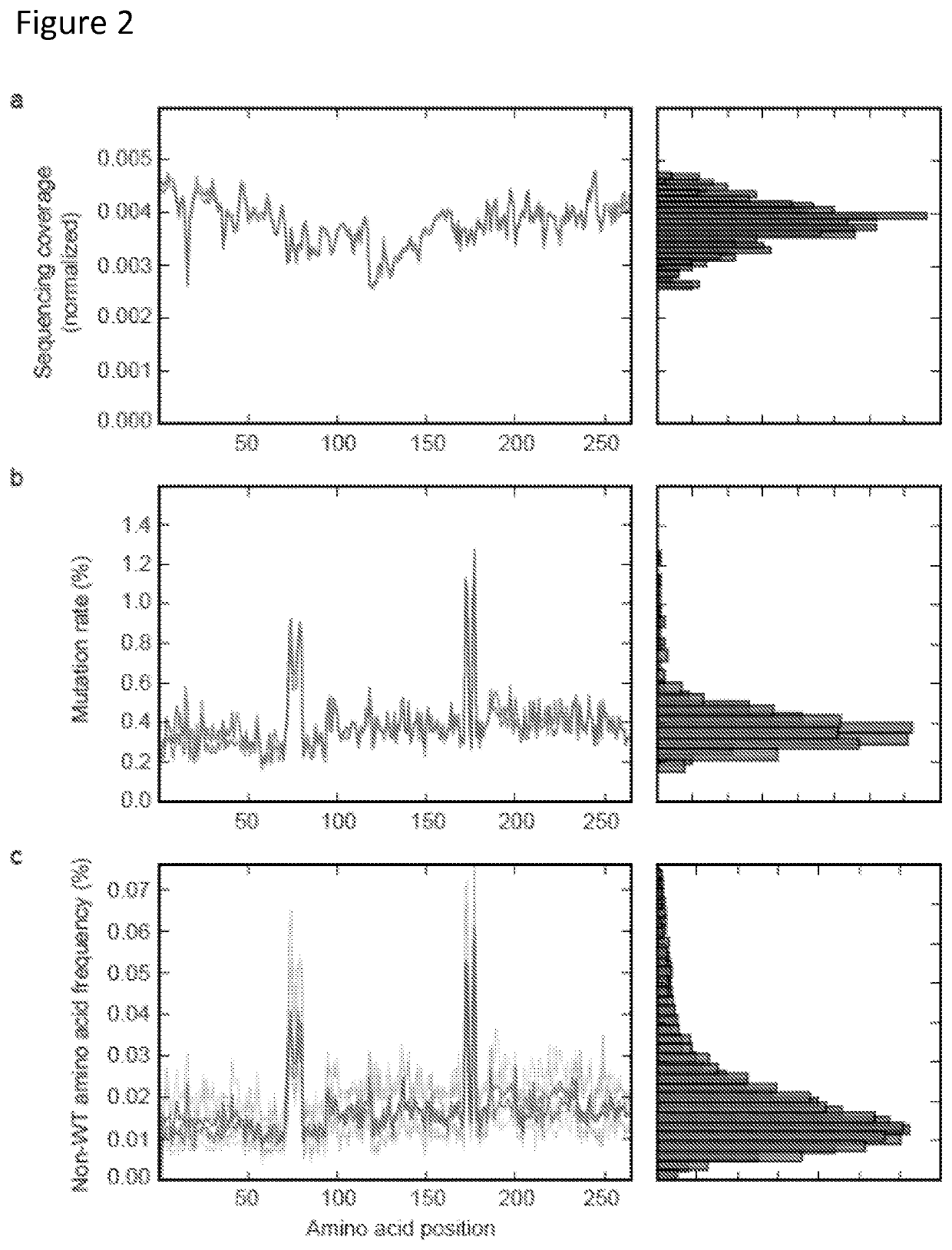

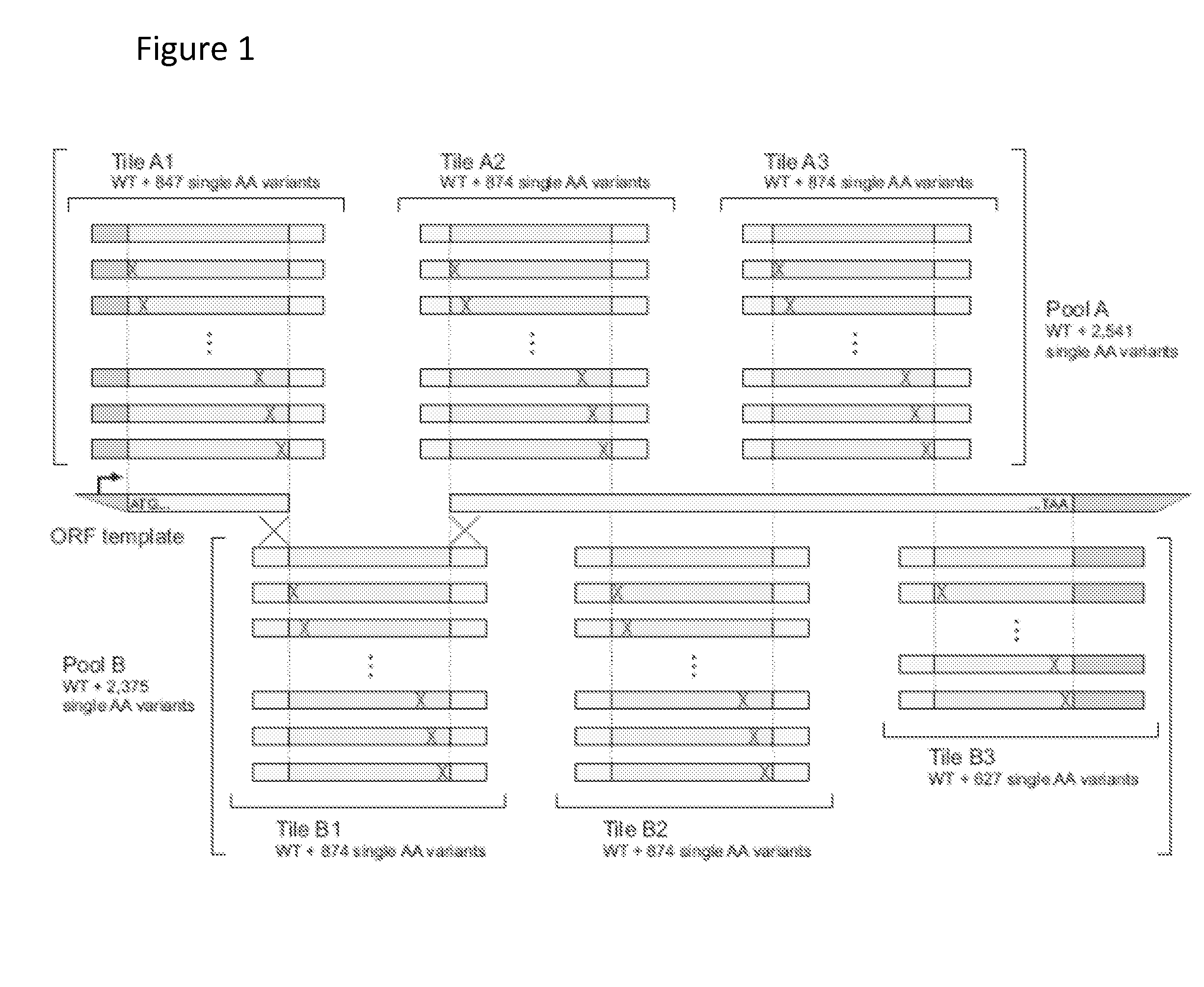

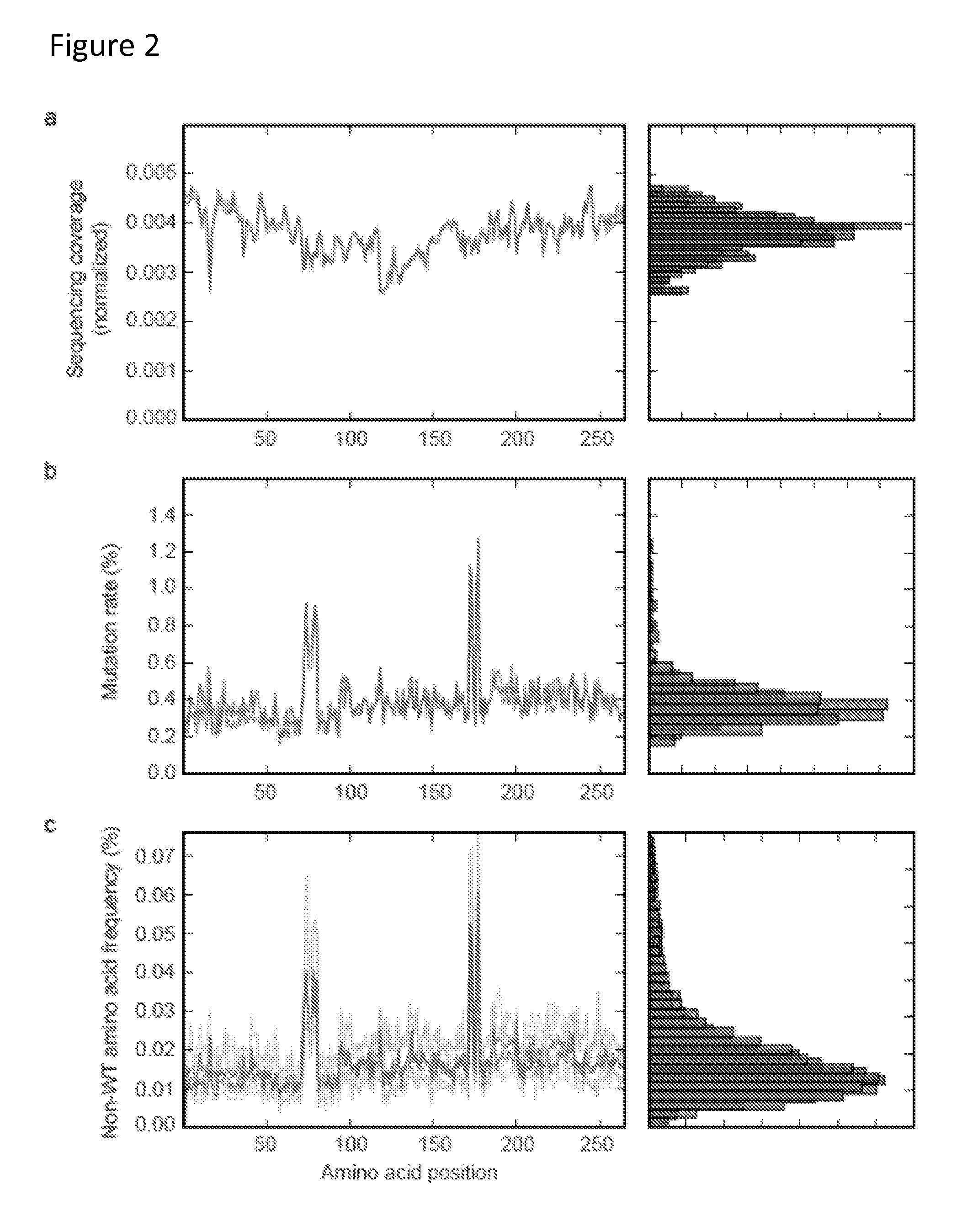

Methods for generating pools of variants of a DNA template

ActiveUS11274295B2Increase and decrease sensitivityIncrease orVector-based foreign material introductionDNA preparationEnvironmental agentA-DNA

The invention provides methods for generating pools of variants of DNA templates, and methods of using pools of variants to identify sequences involved in conferring sensitivity or resistance to environmental factors.

Owner:THE BROAD INST INC

Method for sending a controller setpoint for a power generator, device therefor and system containing the same

ActiveUS10900466B2Increase orImprove accuracyWind motor controlSingle network parallel feeding arrangementsData packControl engineering

Provided is a method, device and system for outputting a controller setpoint for at least one power generator that is at least one wind power installation, at least one windfarm, or a cluster controller. The method includes receiving, over a data input, a data packet including a current setpoint and a plurality of future setpoints, storing the future setpoints of the received data packet in a memory, and outputting, over a data output, the current setpoint as the controller setpoint. If after the expiration of a predefined time period from the reception of the data packet, no further data packet is received, a first setpoint of the stored plurality of future setpoints is output over the data output as a next controller setpoint.

Owner:WOBBEN PROPERTIES GMBH

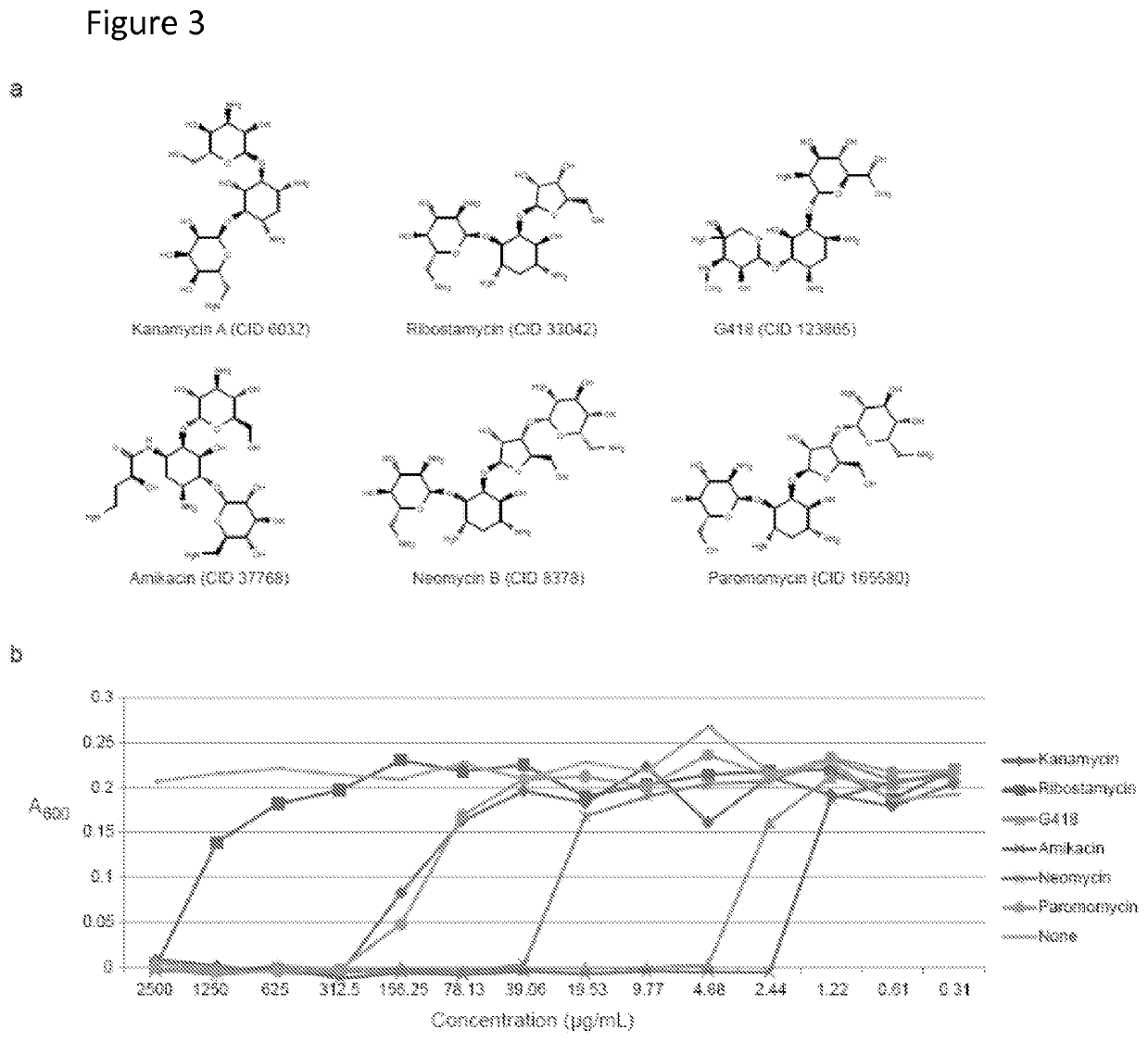

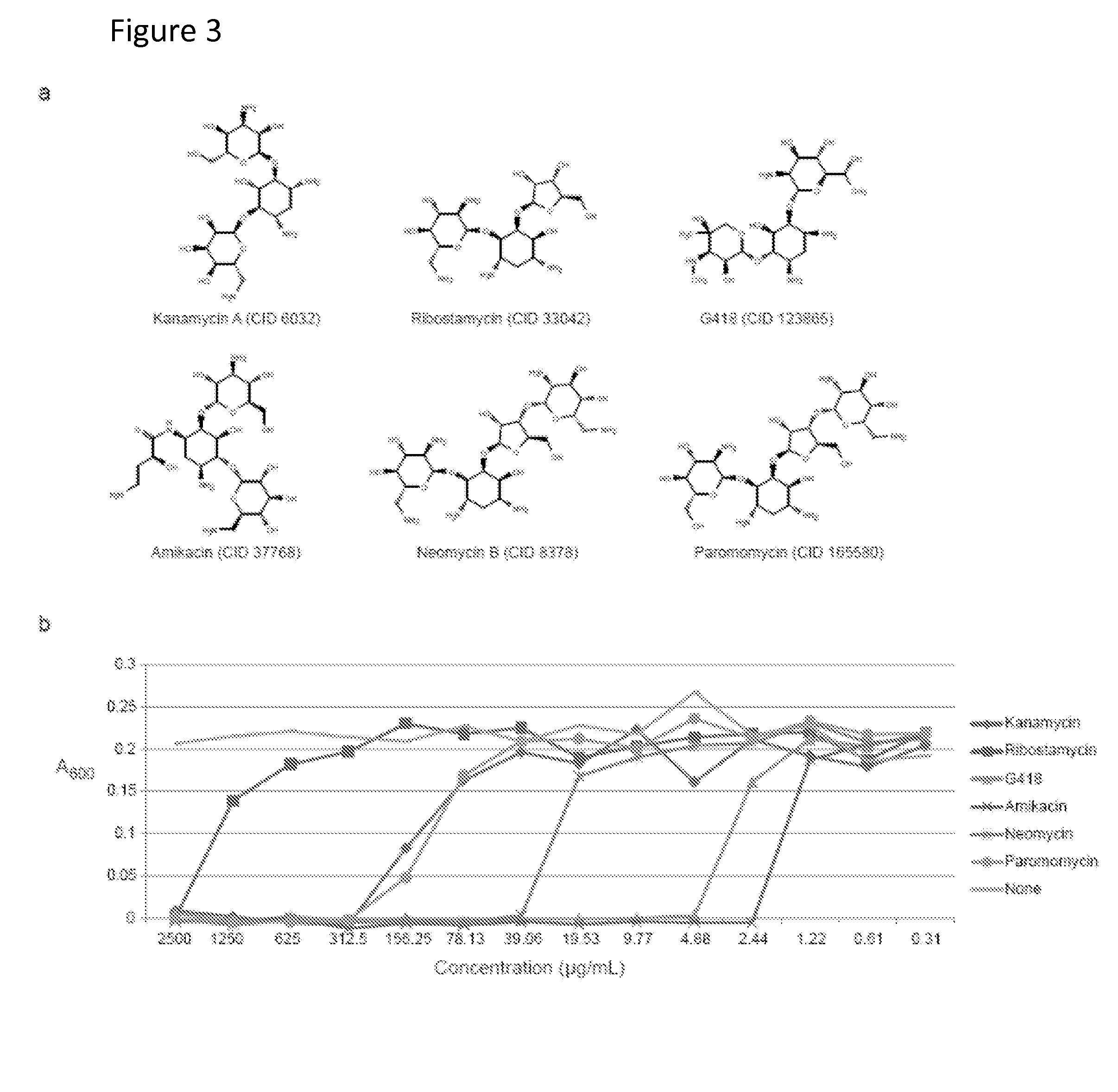

Method of treating bacterial infections

ActiveUS10828316B2Solve the antibacterial effect is not goodLow toxicityAntibacterial agentsBiocideTrimethoprimNucleotide

The present invention relates to a composition comprising a first compound which is a nucleoside analogue capable of inhibiting a bacterial colonisation or infection of a subject; a second compound which is capable of decreasing mitochondrial toxicity of said nucleoside analogue and surprisingly enhance the antibacterial effect of the combination; and a third compound capable of decreasing the concentration in bacteria of nucleosides and / or nucleotides known to compete with nucleoside analogues. The first compound may be AZT, FdUrd, 5-fluorouracil, BrdUrd, IdUrd, didanosine or gemcitabine; the second compound may be uridine or a uridine-comprising compound; and the third compound may be trimethoprim or a compound comprising trimethoprim, such as trimethoprim-sulfa.

Owner:ULTUPHARMA AB

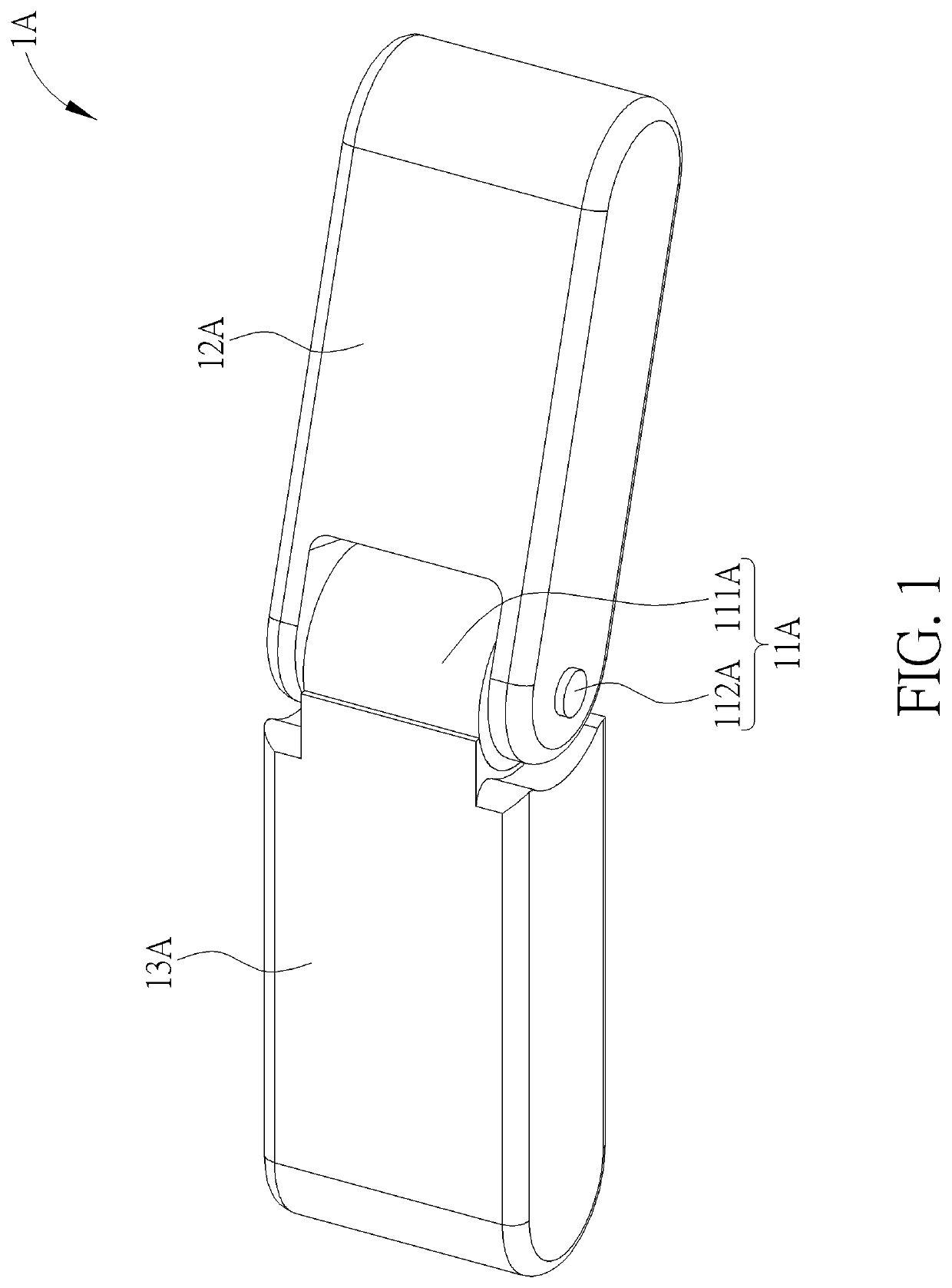

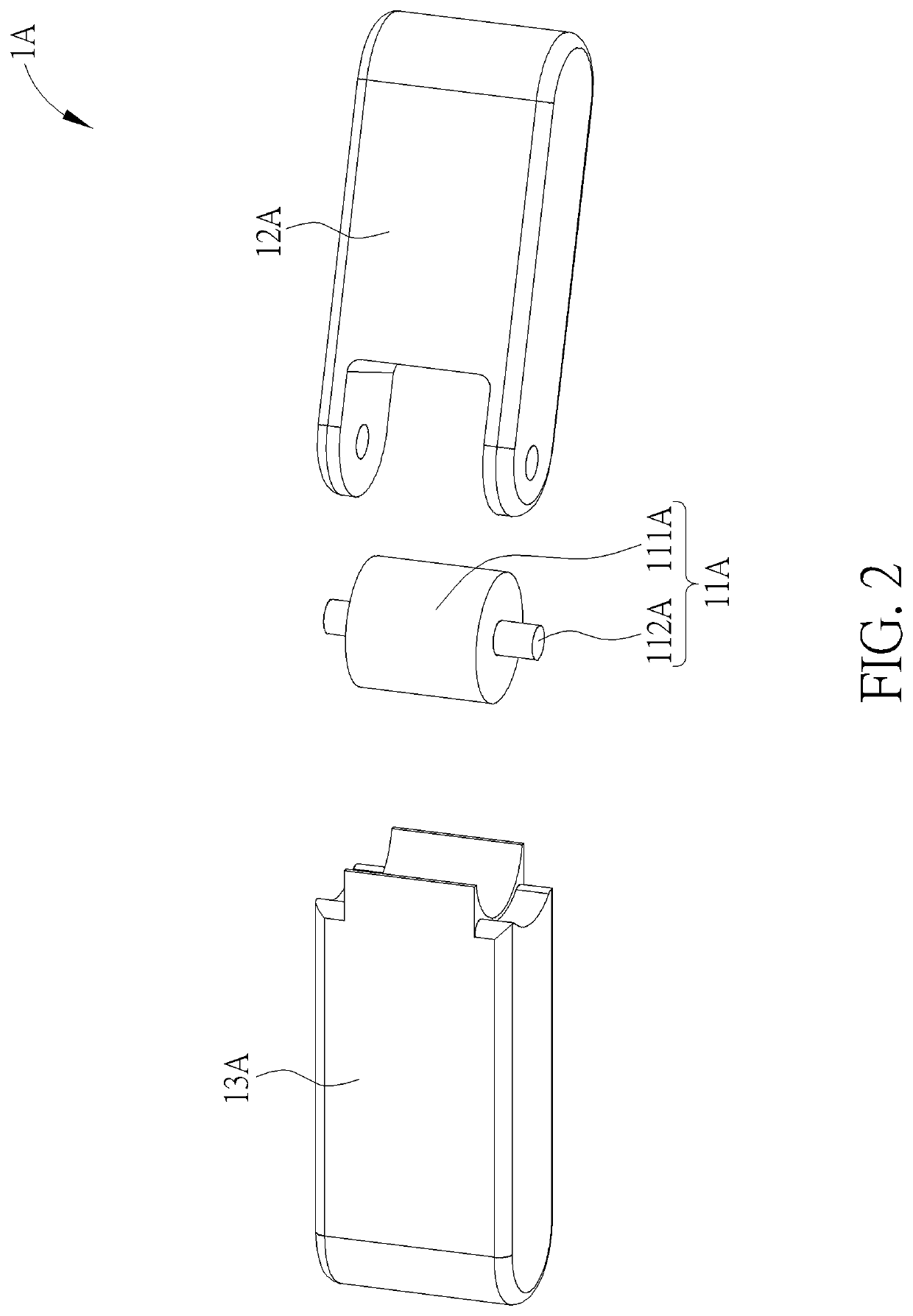

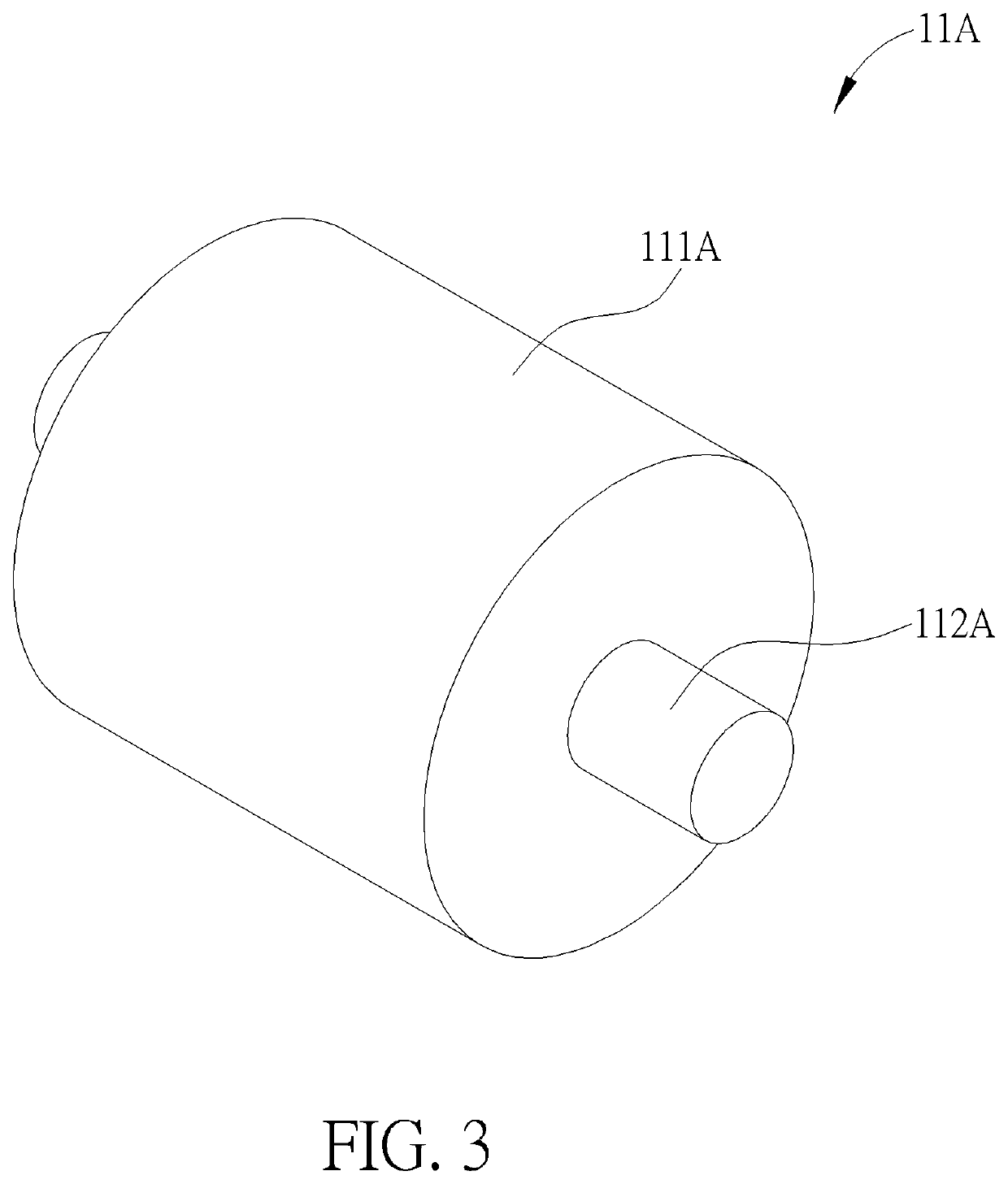

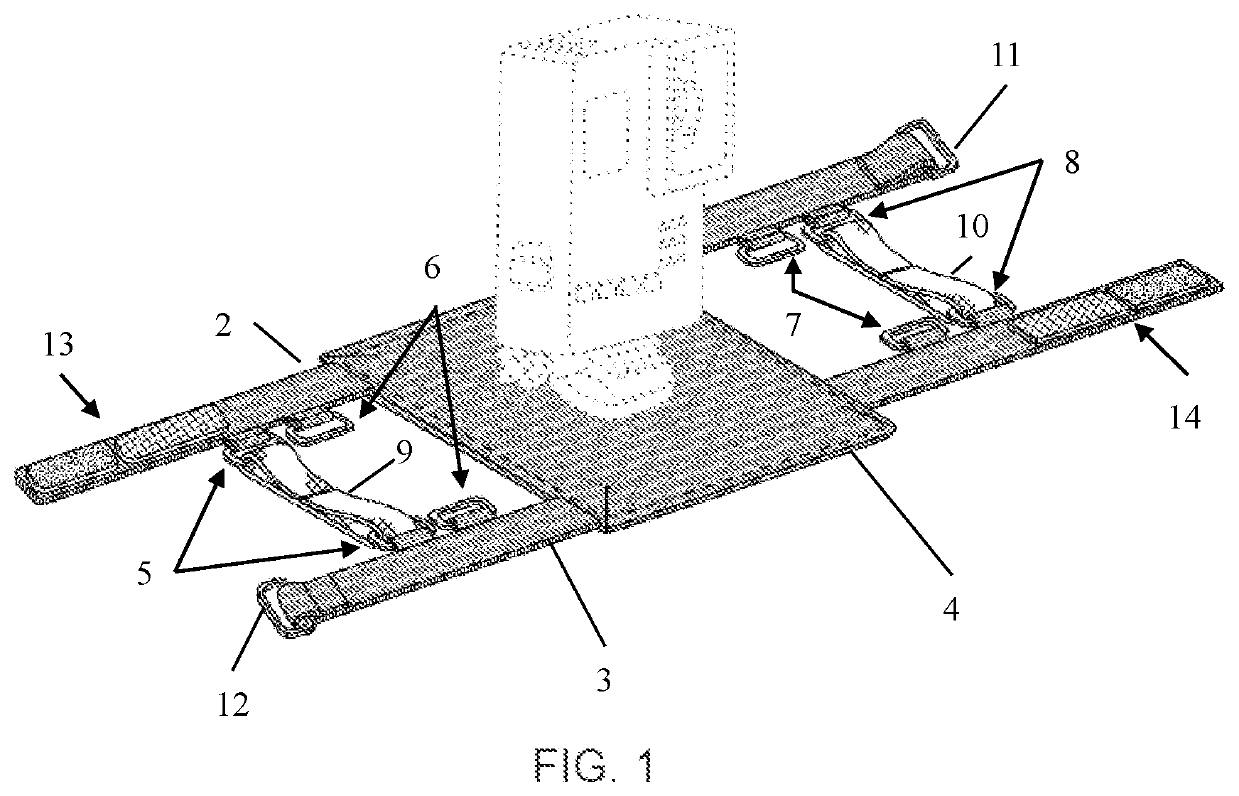

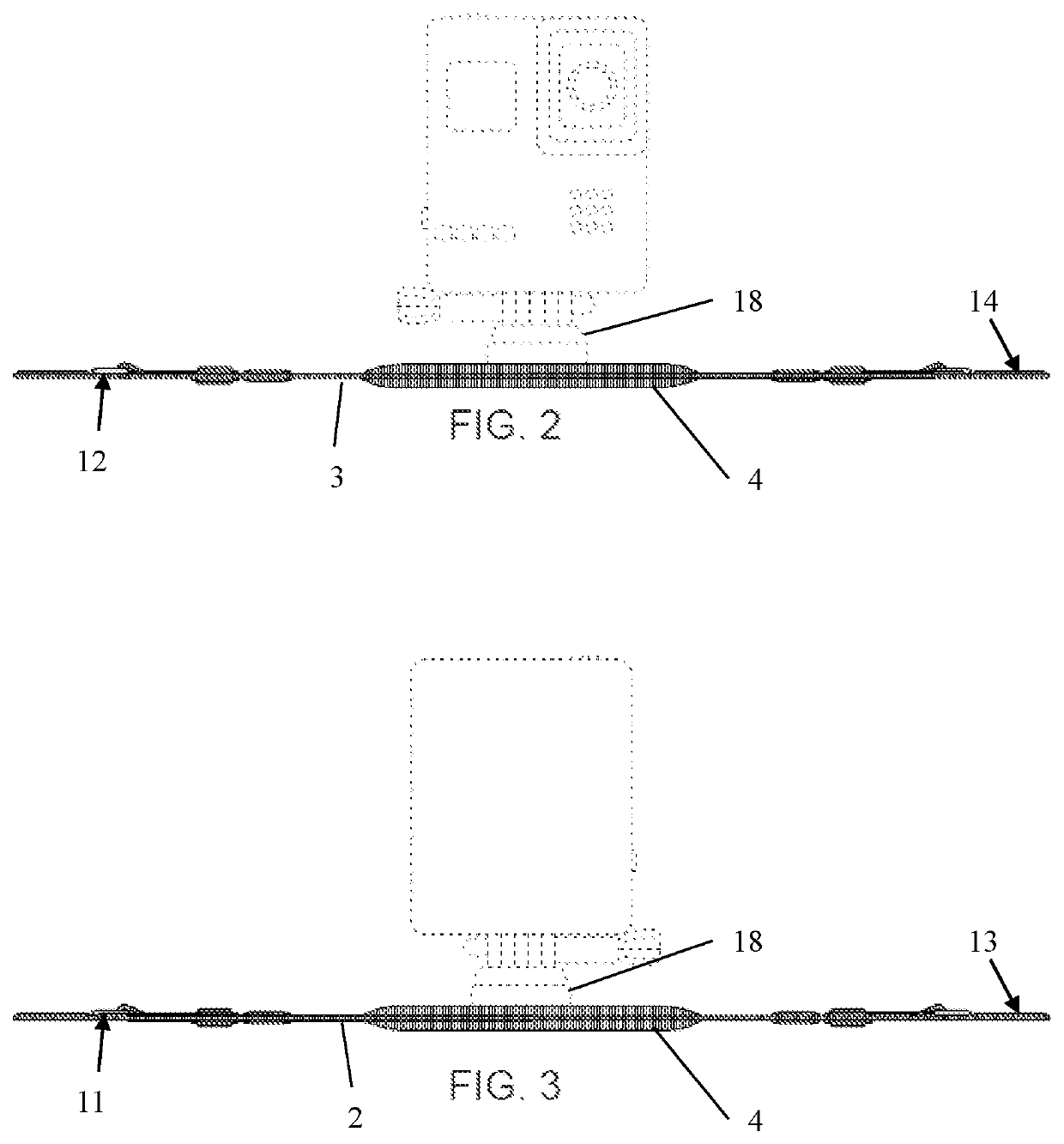

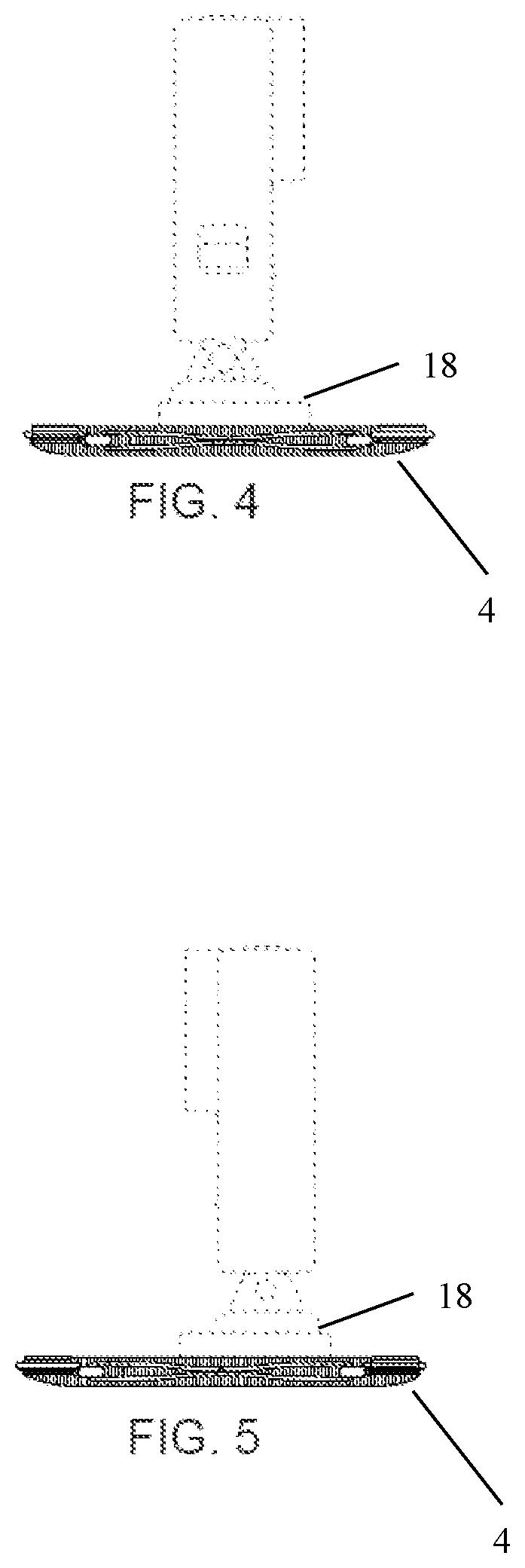

Device Mount

InactiveUS20220243870A1Improve comfortStable supportStands/trestlesOther apparatusComputer hardwareMobile camera

An apparatus for holding a portable electronic device, such as a cellular phone, smart phone, camera, or other digital media device, that may be strapped or otherwise secured to an animal's head, such as a dog. A first and second parallel strap systems, connected by a central square or rectangular pad, and having a plurality of inner facing and complimentary loops on the inner side of the first and second parallel straps, providing for one or more adjustable perpendicular straps. The top surface of the central square or rectangular pad is further comprised of an attached mount which provides connection means for attaching an electronic device such as a camera or smartphone. The inner facing complimentary loops on each opposing parallel strap provide adjustment means making the device adaptable to a variety of sizes and to provide better fitment.

Owner:BALEWA TROY HAFEEZ

Image capture device for fundus and imaging method

This invention discloses an image capture device for fundus and an imaging method thereof. The image capture device includes a lighting module, a splitter, a monochrome image sensor and an image synthesis module. The lighting module emits plurality beams of monochromatic light. The splitter is disposed on a light path of the lighting module. The splitter reflects the plurality beams of the monochromatic light to a fundus of an examinee and forms a plurality of reflecting light respectively through reflection of the fundus. The monochrome image sensor receives the plurality beams of the reflecting light and produces a monochromatic image corresponding to each beam of the monochromatic light. The image synthesis module receives each of the monochromatic images and synthesizes each monochromatic image into a color image. By such arrangements, the invention provides good quality fundus imaging and reduces costs.

Owner:ALTEK BIOTECH

Methods for Generating Pools of Variants of a DNA Template

ActiveUS20150203838A1Increase and decrease sensitivityIncrease orLibrary screeningDirected macromolecular evolutionA-DNABioinformatics

The invention provides methods for generating pools of variants of DNA templates, and methods of using pools of variants to identify sequences involved in conferring sensitivity or resistance to environmental factors.

Owner:THE BROAD INST INC

Programmable gain amplifier and transconductance compensation system

InactiveUS7956689B2Noise minimizationIncrease orGated amplifiersAmplifier modifications to raise efficiencyPower flowEngineering

A programmable gain amplifier (PGA) system comprises selectable parallel transconductors in a front end, independently selectable serial amplification circuits in a back end. The back end is configured to receive an output of the front end and may include a plurality of current or voltage mode amplifiers in series. The PGA system also includes control circuitry to select a gain configuration for the PGA by selecting selectable components in the front and back ends. The PGA system may additionally include control circuitry configured to change the transconductance of one or more of the front end transconductors such that the gain configurations of the PGA are independent of variations such as those due to temperature and fabrication. The PGA system may be used between a signal receiver and an analog to digital converter.

Owner:AVAGO TECH INT SALES PTE LTD

New method of treating bacterial infections

ActiveUS20180325934A1Solve the antibacterial effect is not goodLow toxicityAntibacterial agentsPharmaceutical delivery mechanismTrimethoprimNucleotide

The present invention relates to a composition comprising a first compound which is a nucleoside analogue capable of inhibiting a bacterial colonisation or infection of a subject; a second compound which is capable of decreasing mitochondrial toxicity of said nucleoside analogue and surprisingly enhance the antibacterial effect of the combination; and a third compound capable of decreasing the concentration in bacteria of nucleosides and / or nucleotides known to compete with nucleoside analogues. The first compound may be AZT, FdUrd, 5-fluorouracil, BrdUrd, IdUrd, didanosine or gemcitabine; the second compound may be uridine or a uridine-comprising compound; and the third compound may be trimethoprim or a compound comprising trimethoprim, such as trimethoprim-sulfa.

Owner:ULTUPHARMA AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com