Patents

Literature

51results about How to "The pores are evenly distributed and connected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of medical porous metal implant material

ActiveCN103740964AImproved biosafety and biocompatibilityOptimizing Process ConditionsProsthesisUreaImplant material

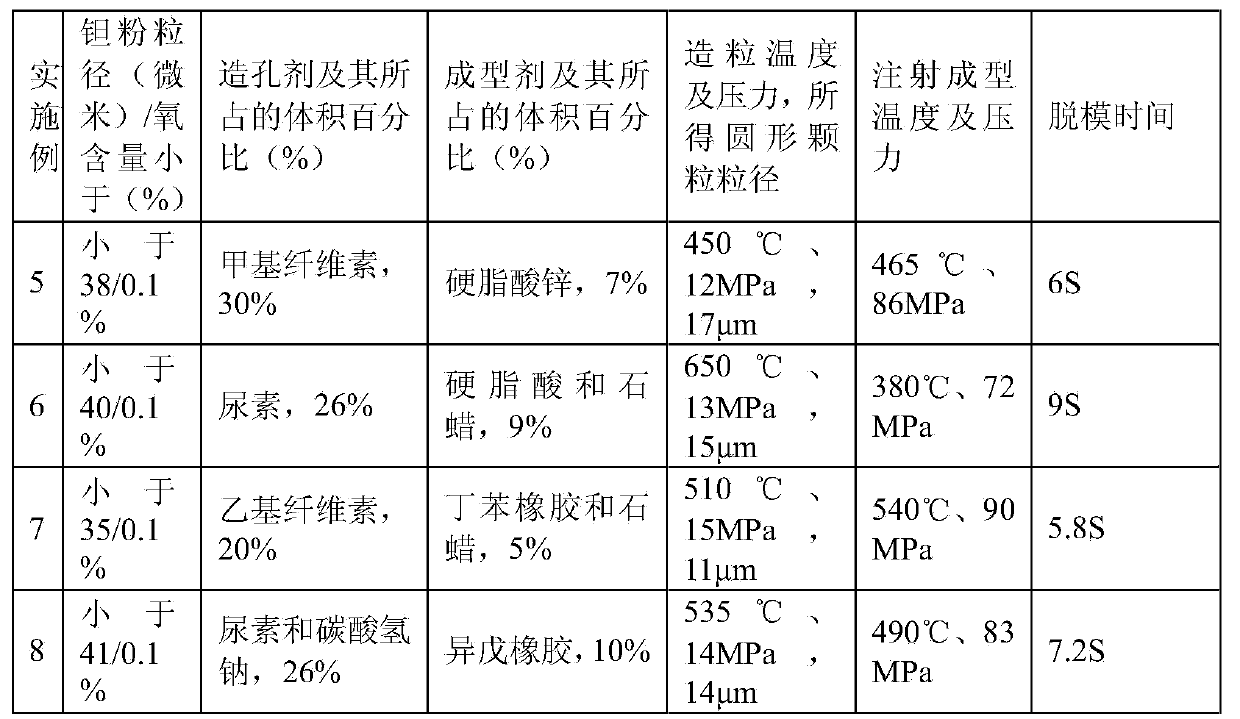

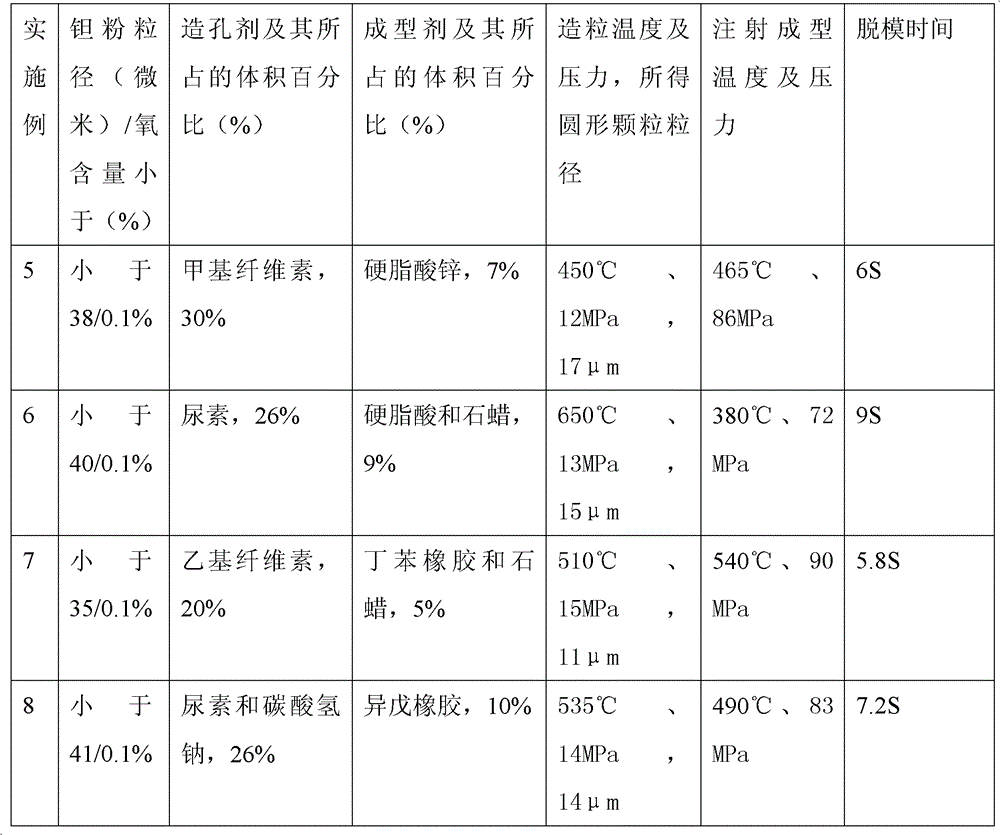

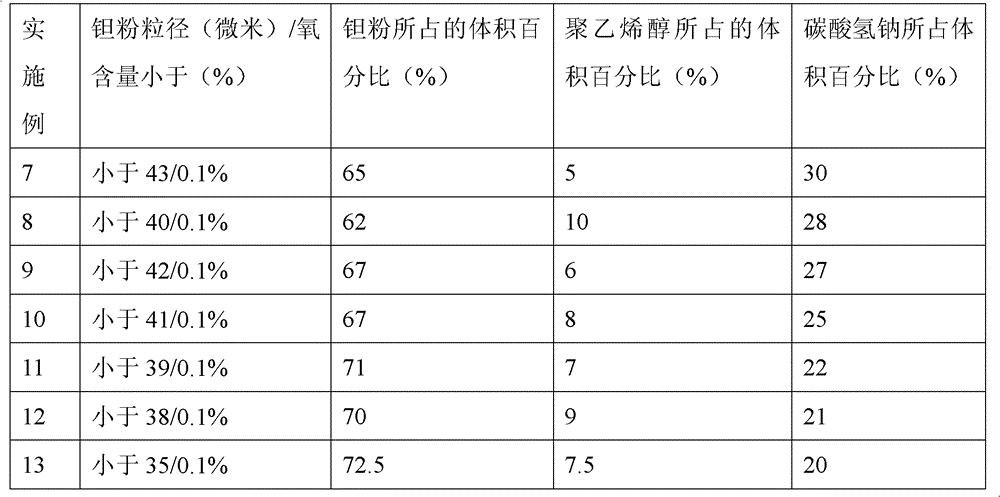

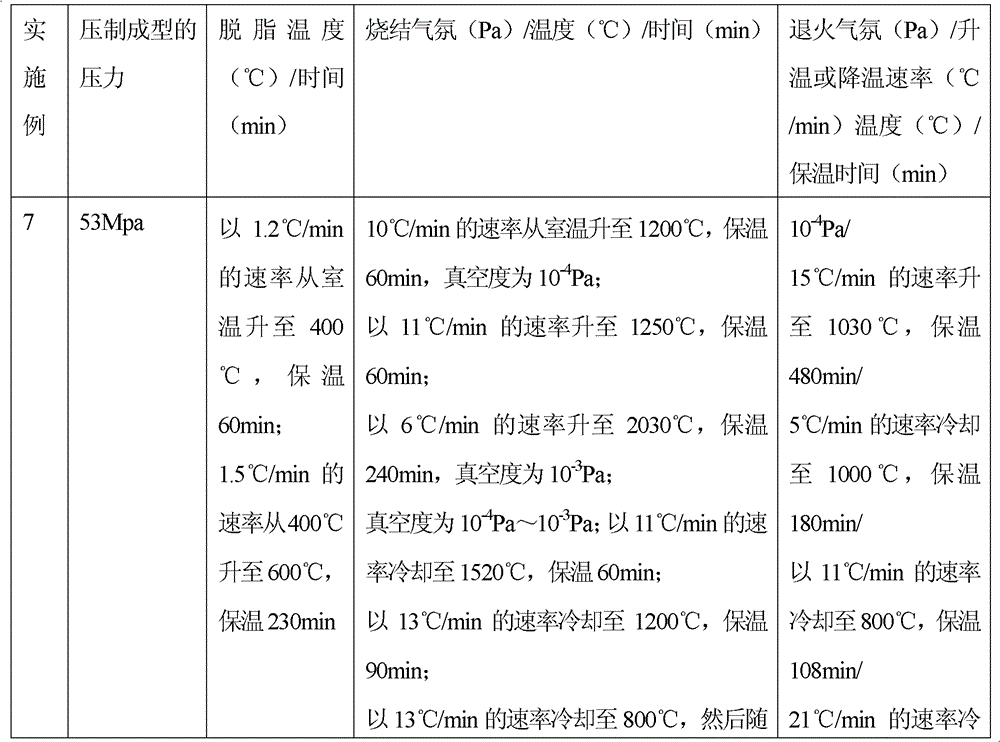

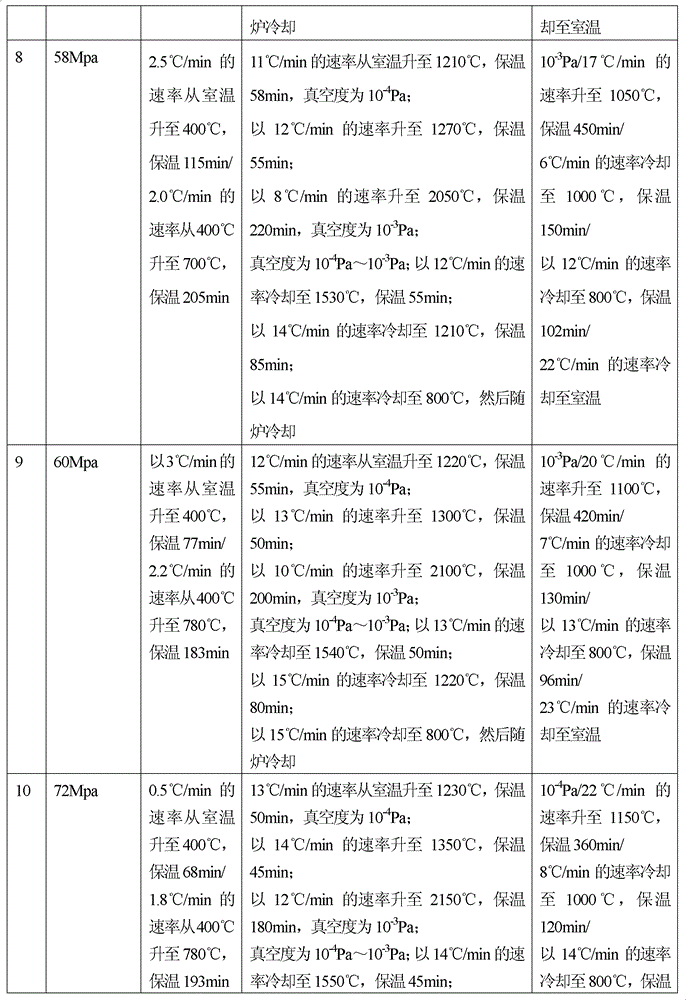

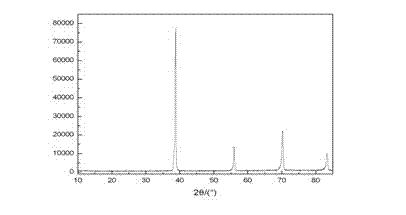

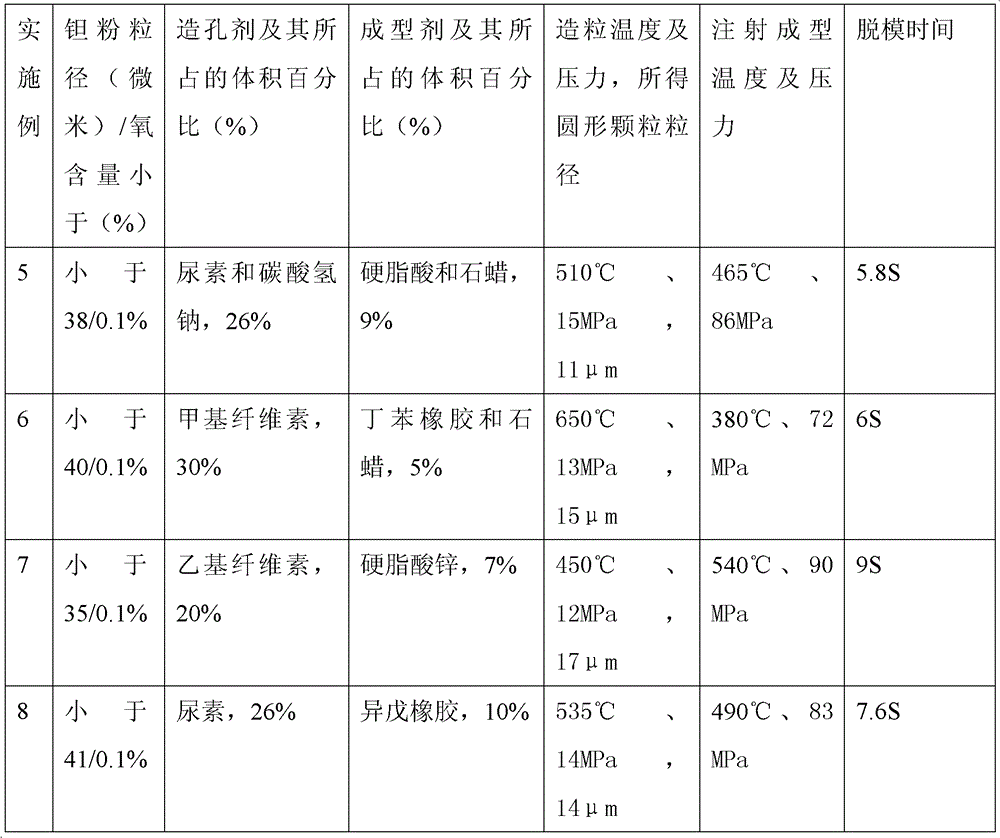

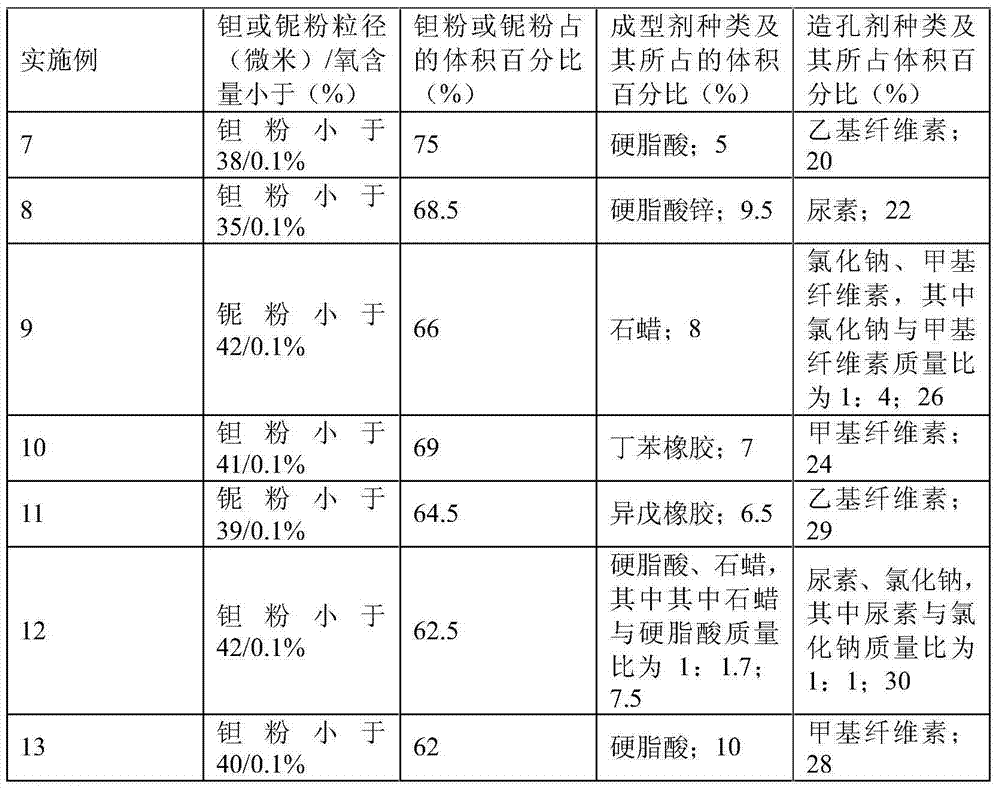

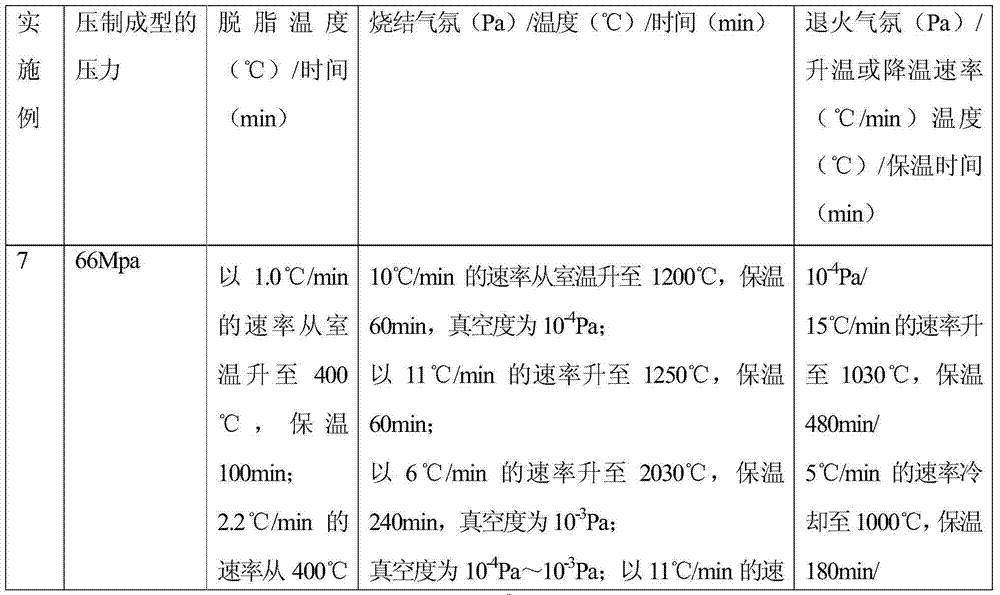

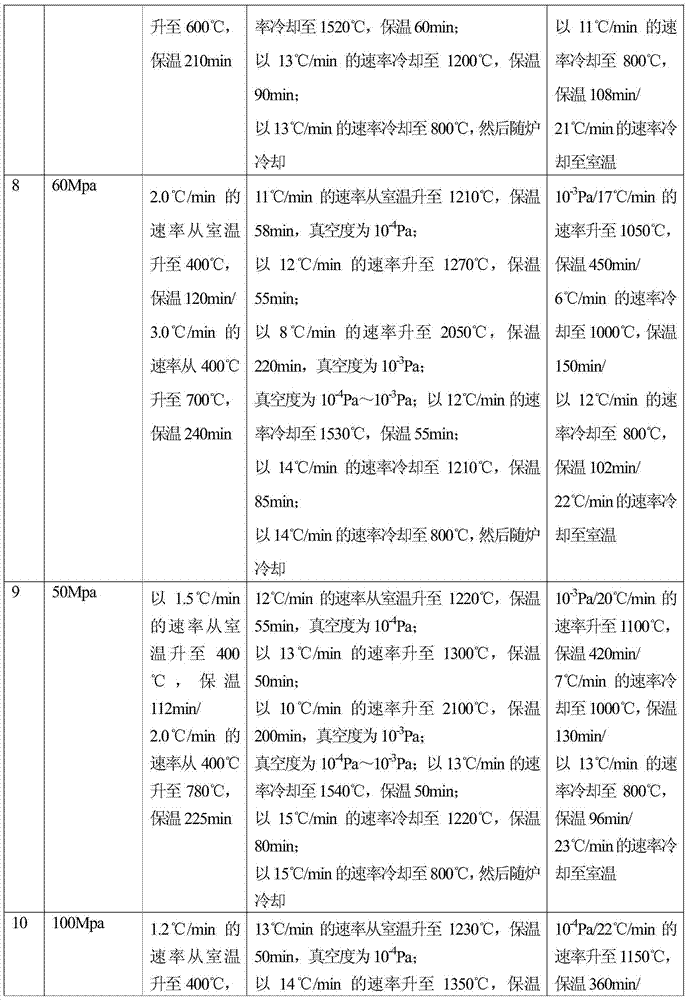

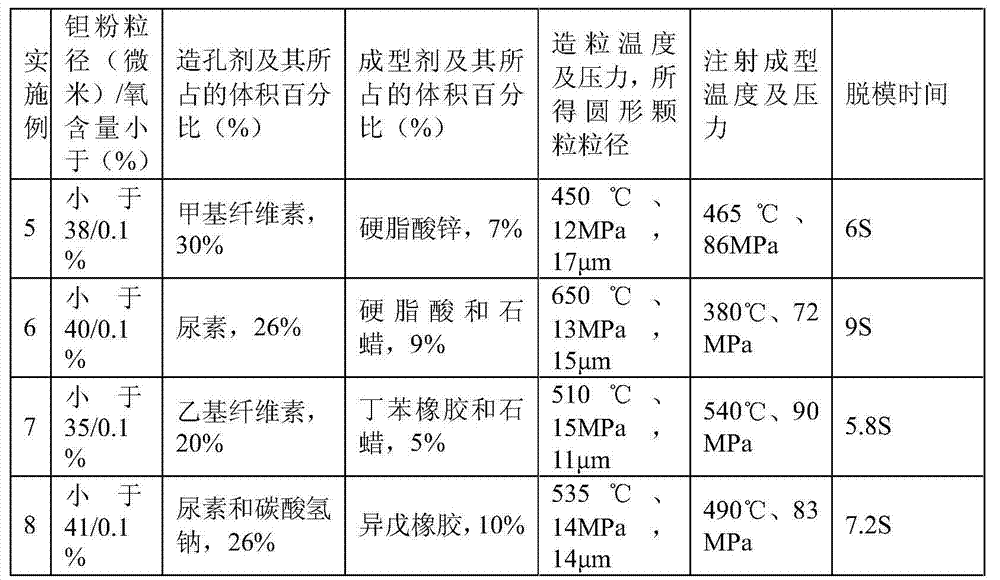

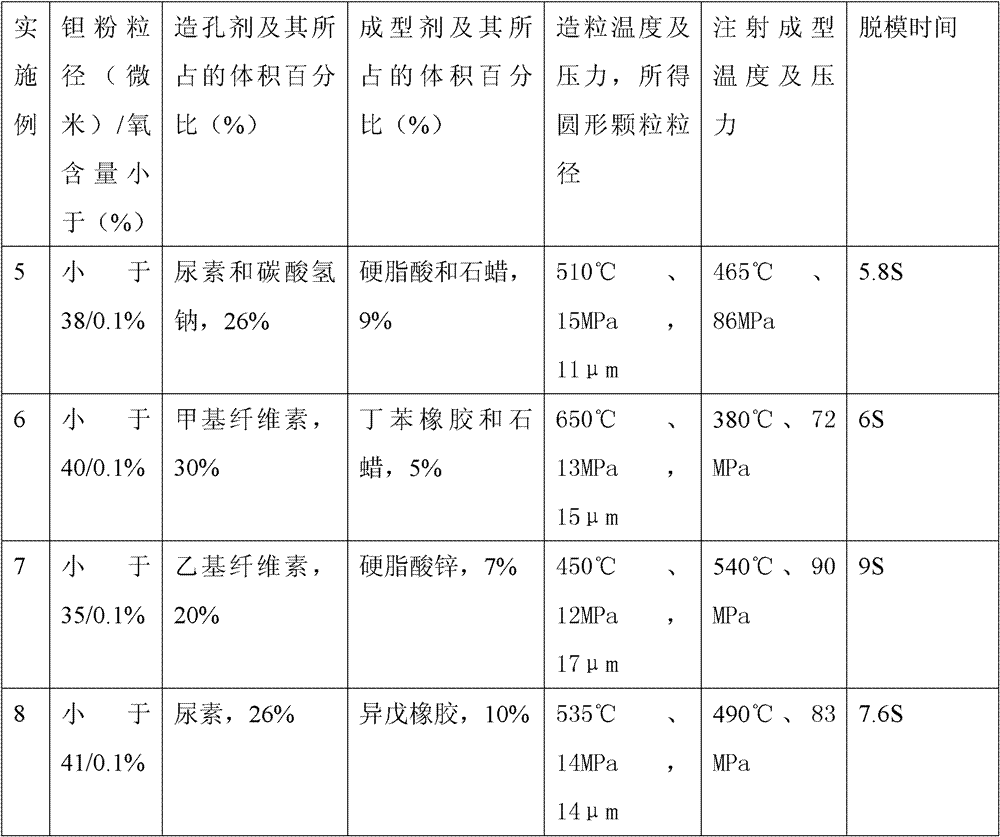

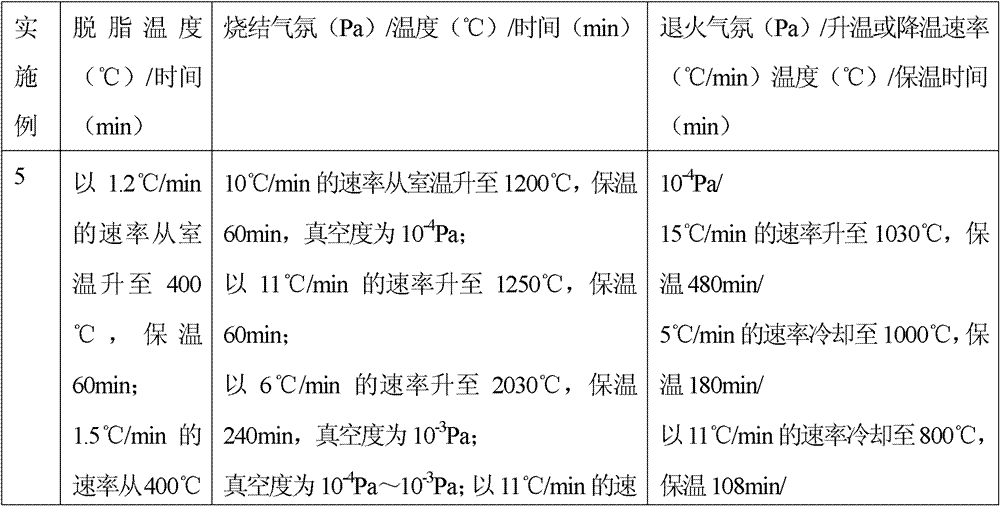

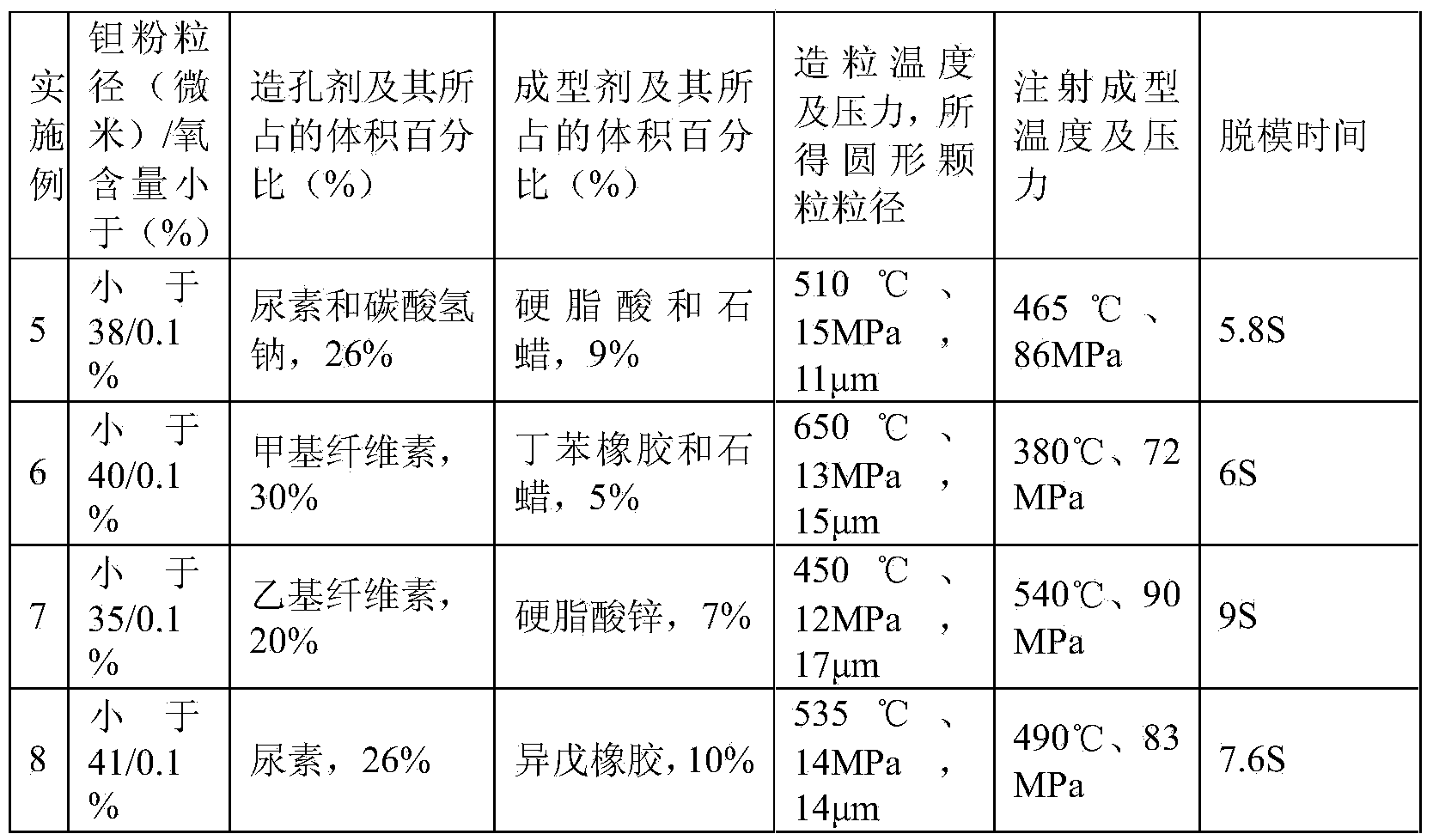

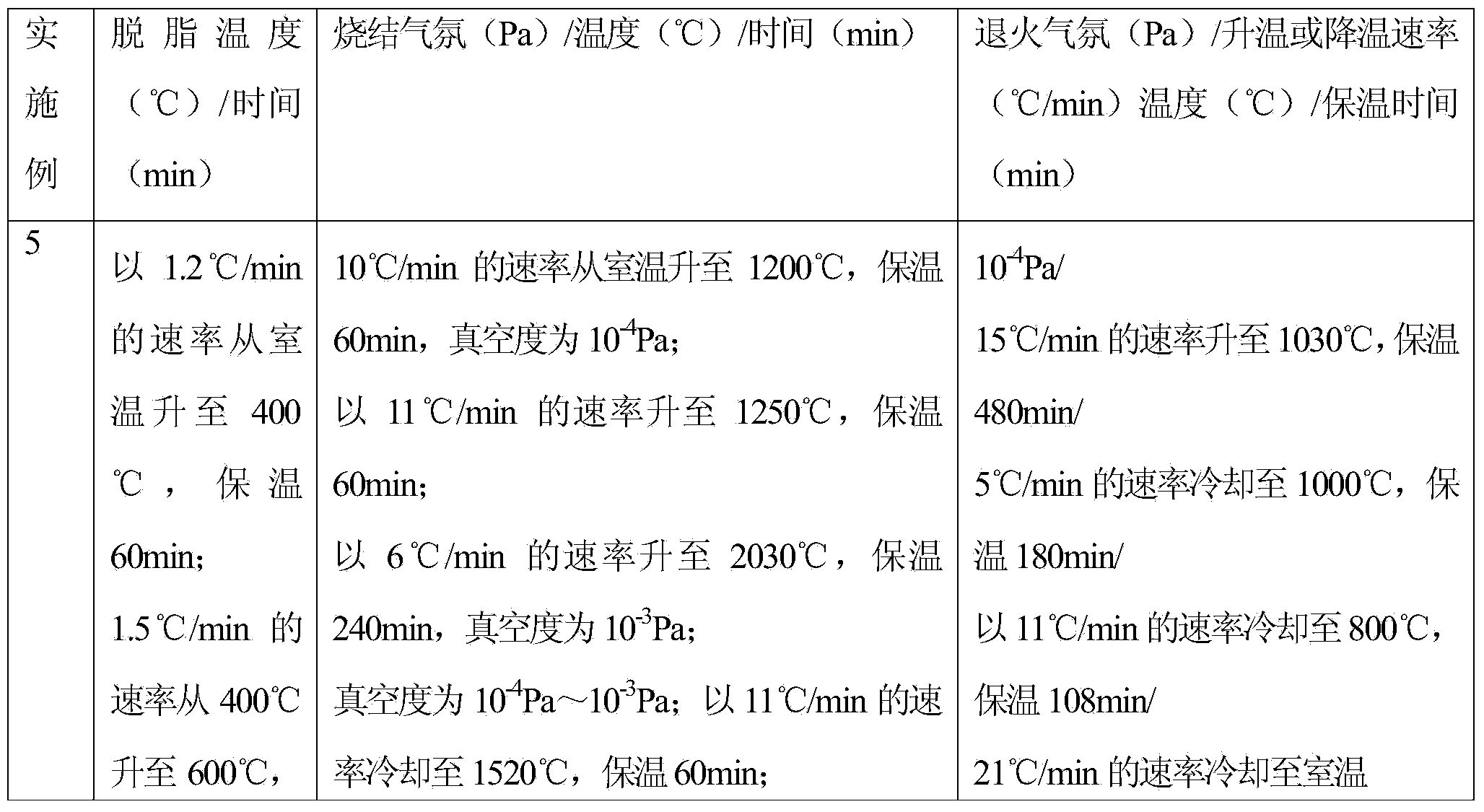

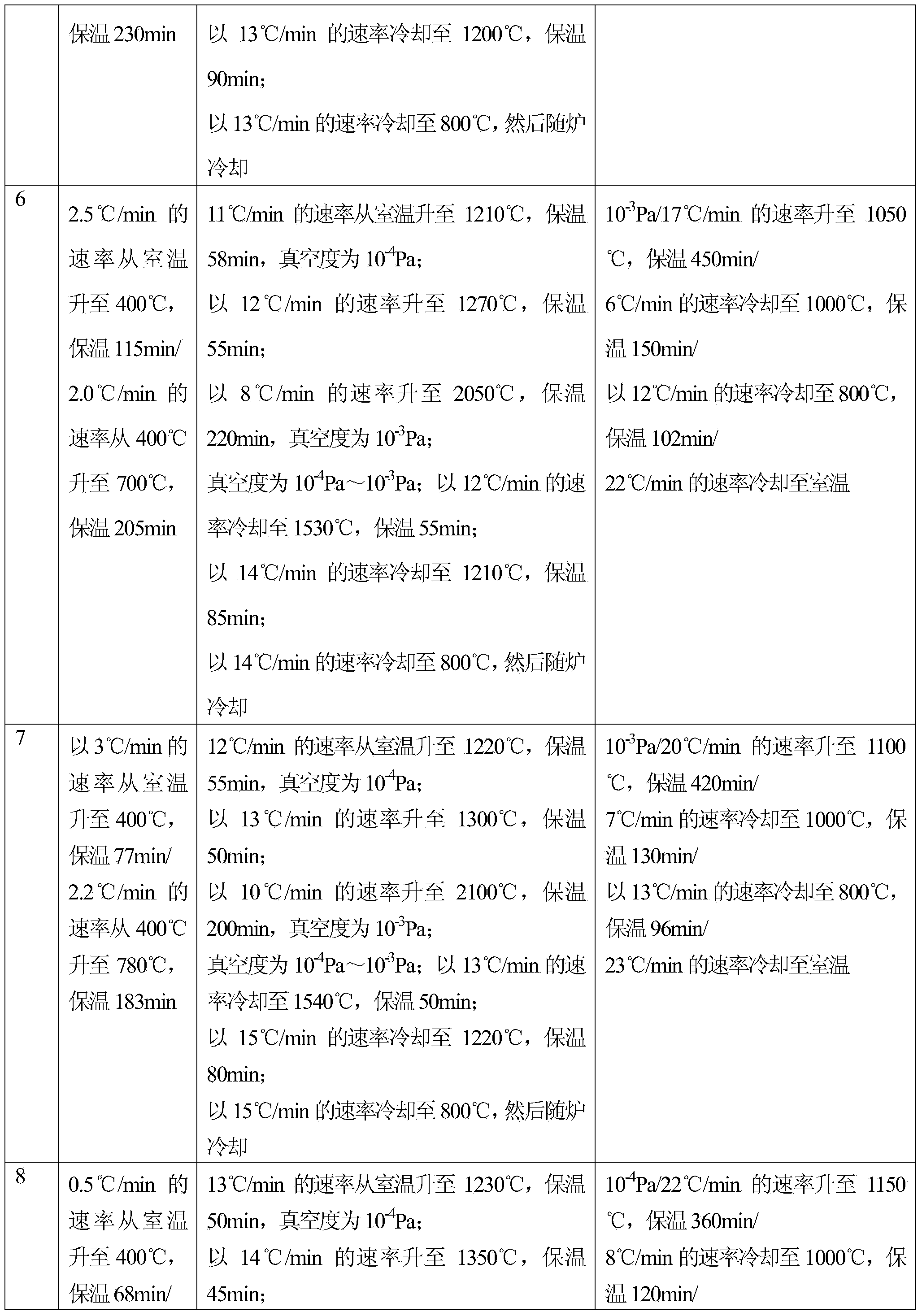

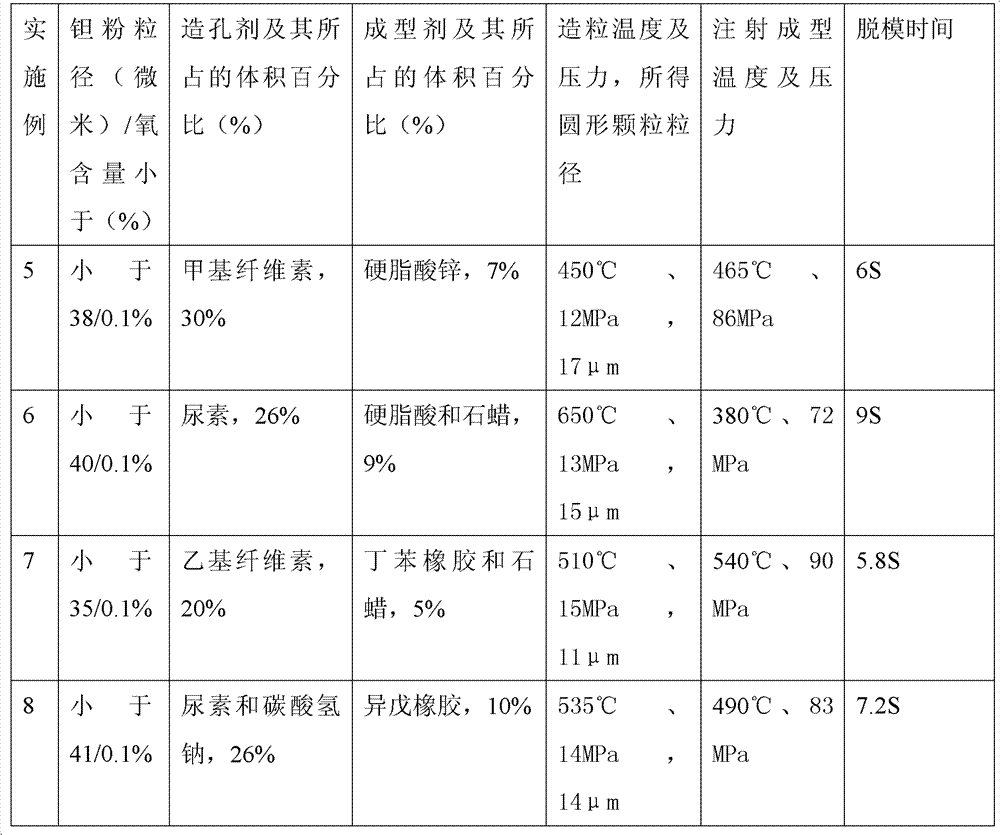

The invention relates to a preparation method of a medical porous metal implant material. The method comprises the following steps: mixing tantalum powder with a pore former and a forming agent so as to form mixed powder; and performing granulation, injection mould forming, demoulding, degreasing, sintering and heat treatment on the mixed powder so as to prepare the medical porous metal implant material capable of replacing a dentale tissue, wherein the pore former is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyecellulose; the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; the degreasing process is performed under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.5 DEG C / minute to 3 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out heat preservation for 60 to 240 minutes; the sintering process and the heat treatment process are effectively improved. Thus, the mechanical property of the prepared medical porous metal implant material is greatly improved. As a result, the prepared medical porous metal implant material is very suitable for replacement of the dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

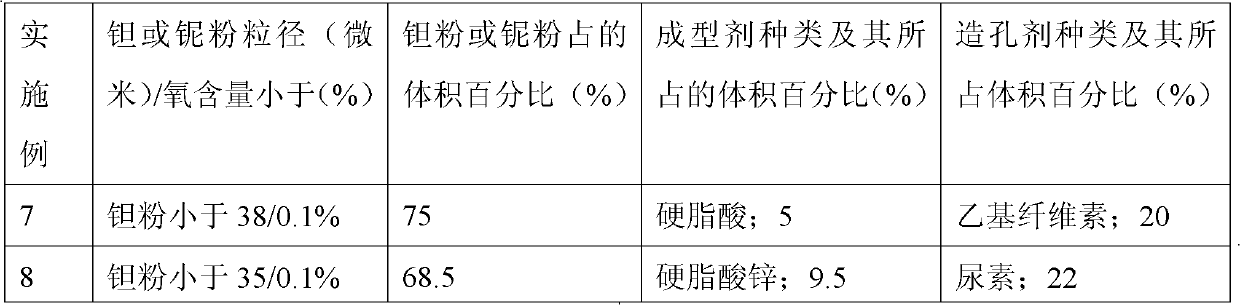

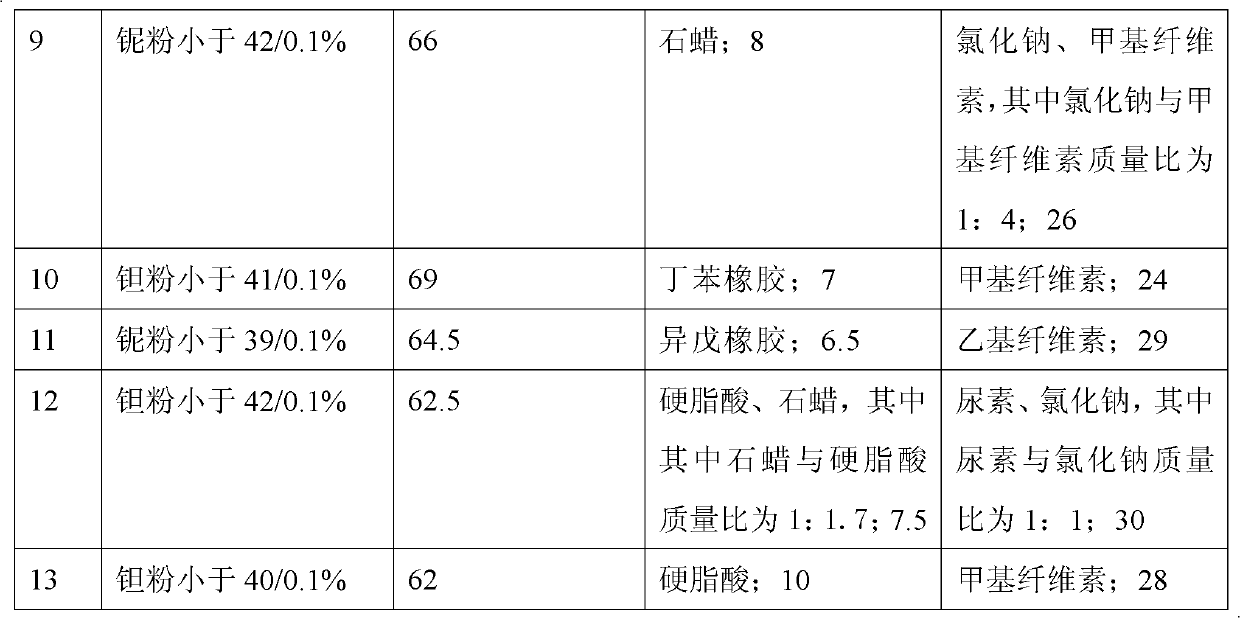

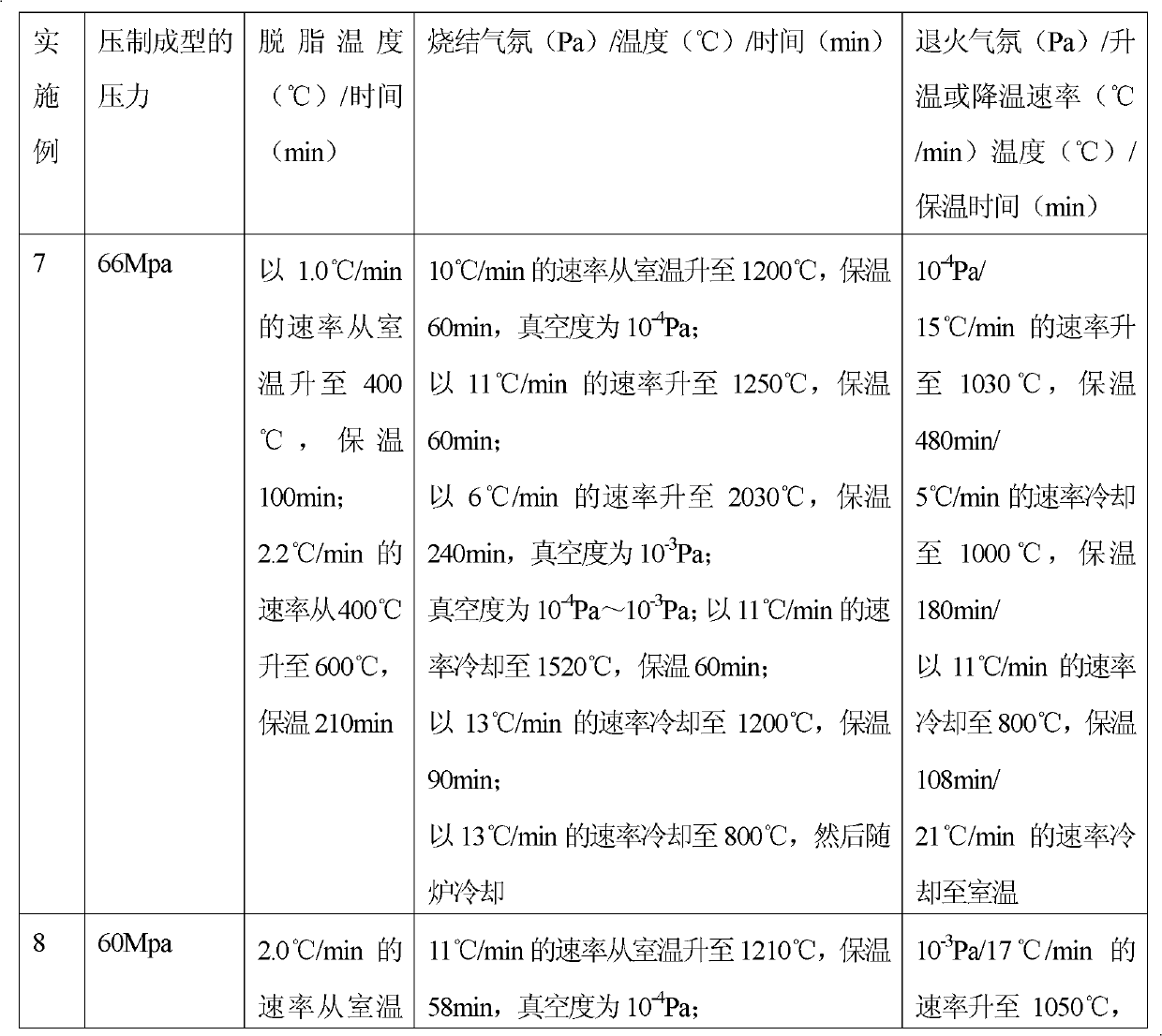

Preparation method of medical porous metal material substituting for dental bone

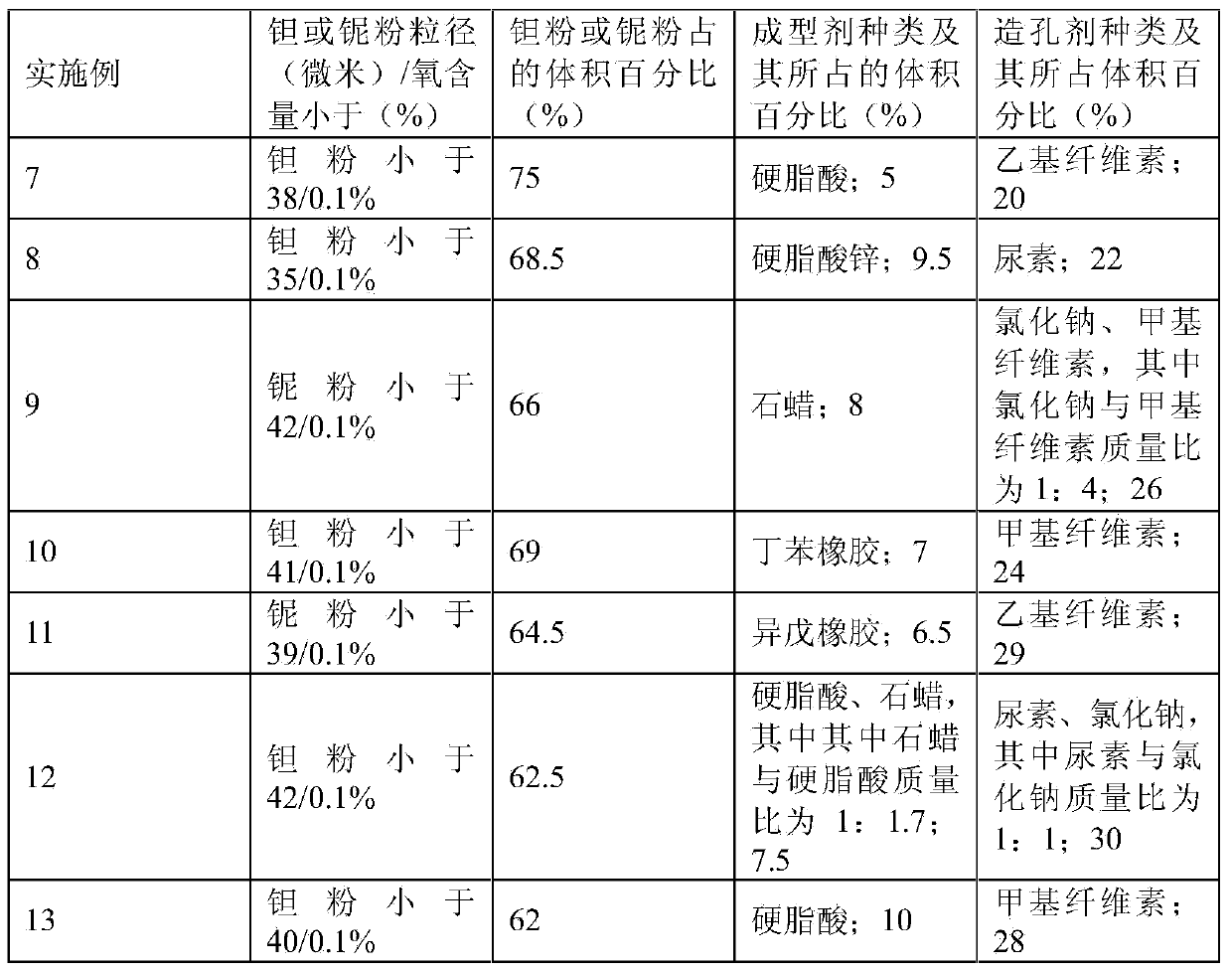

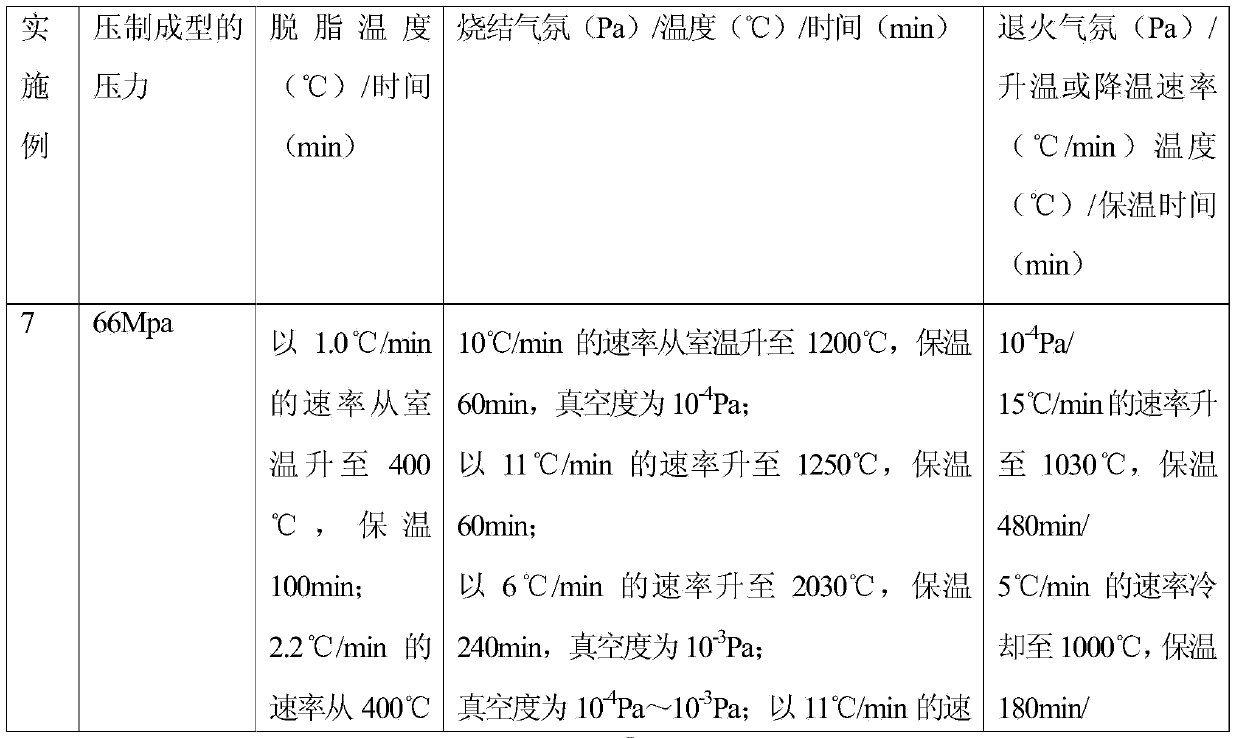

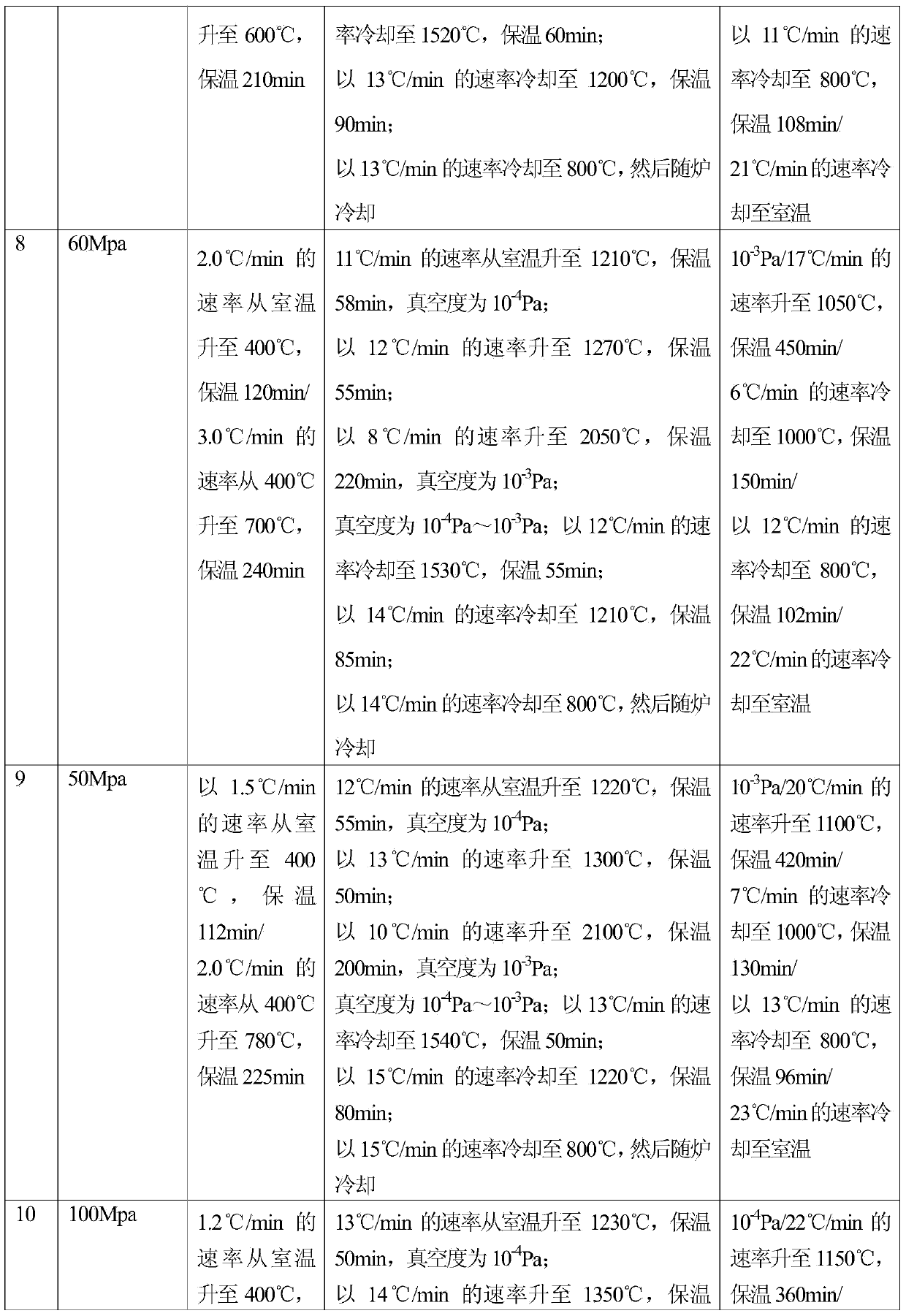

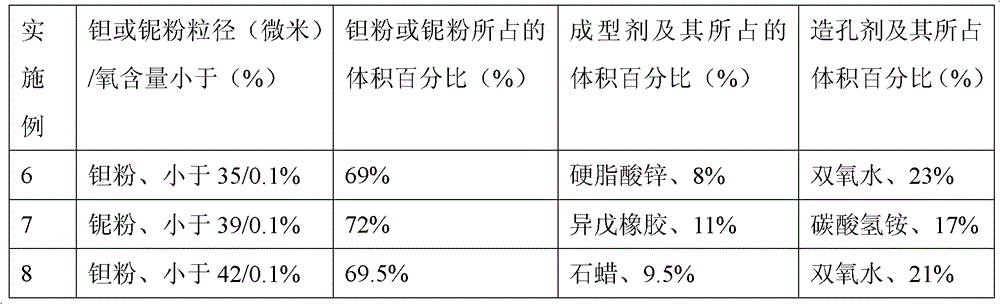

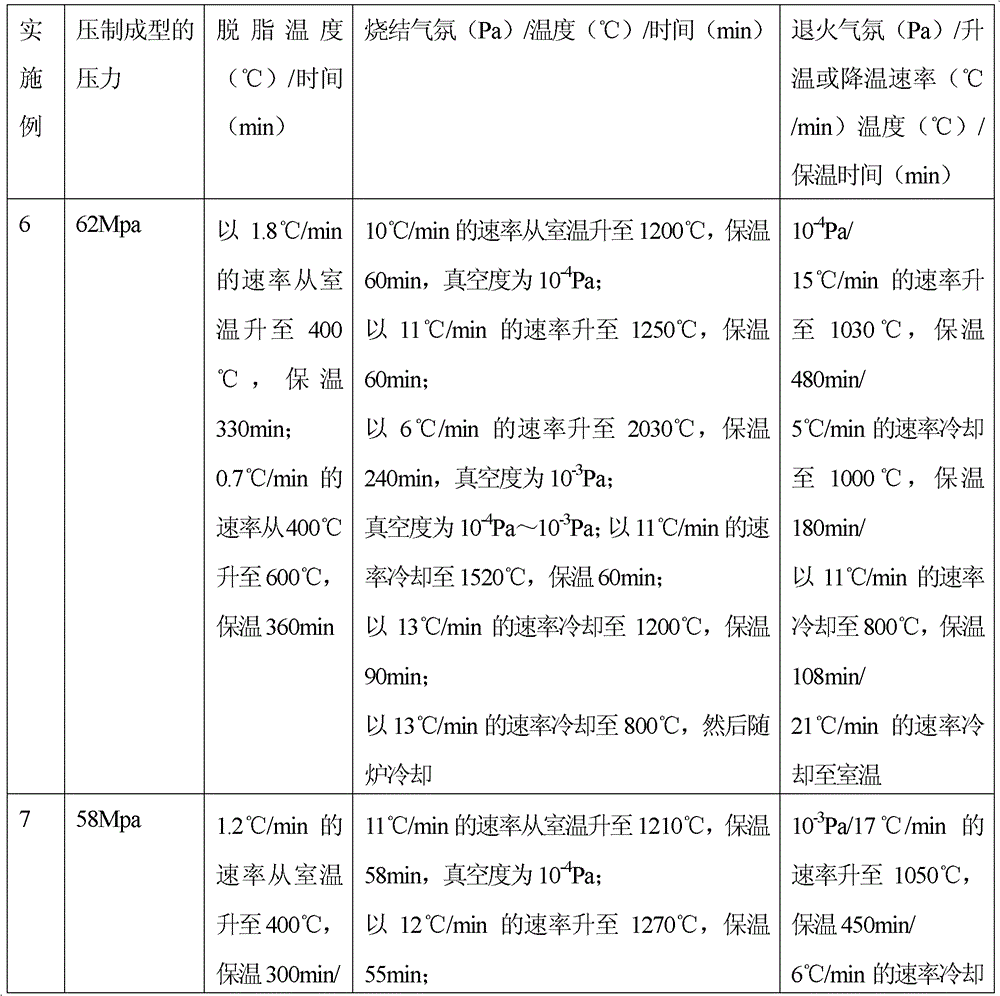

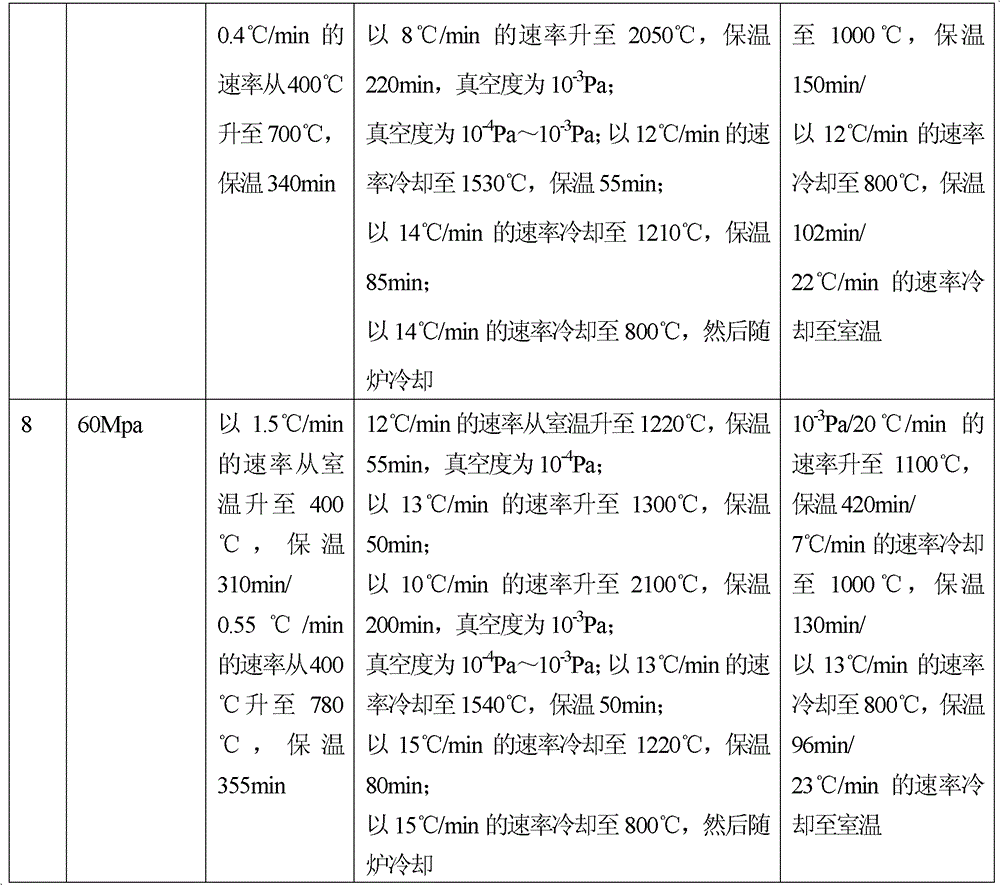

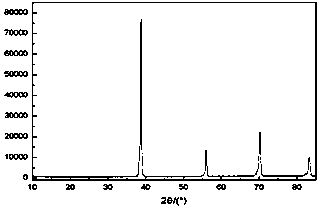

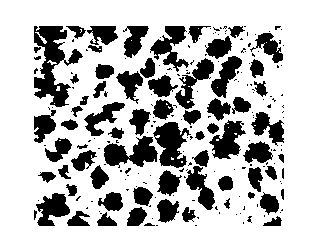

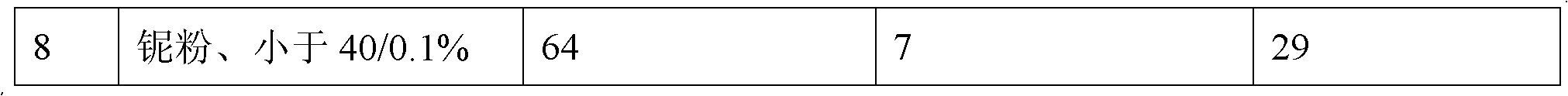

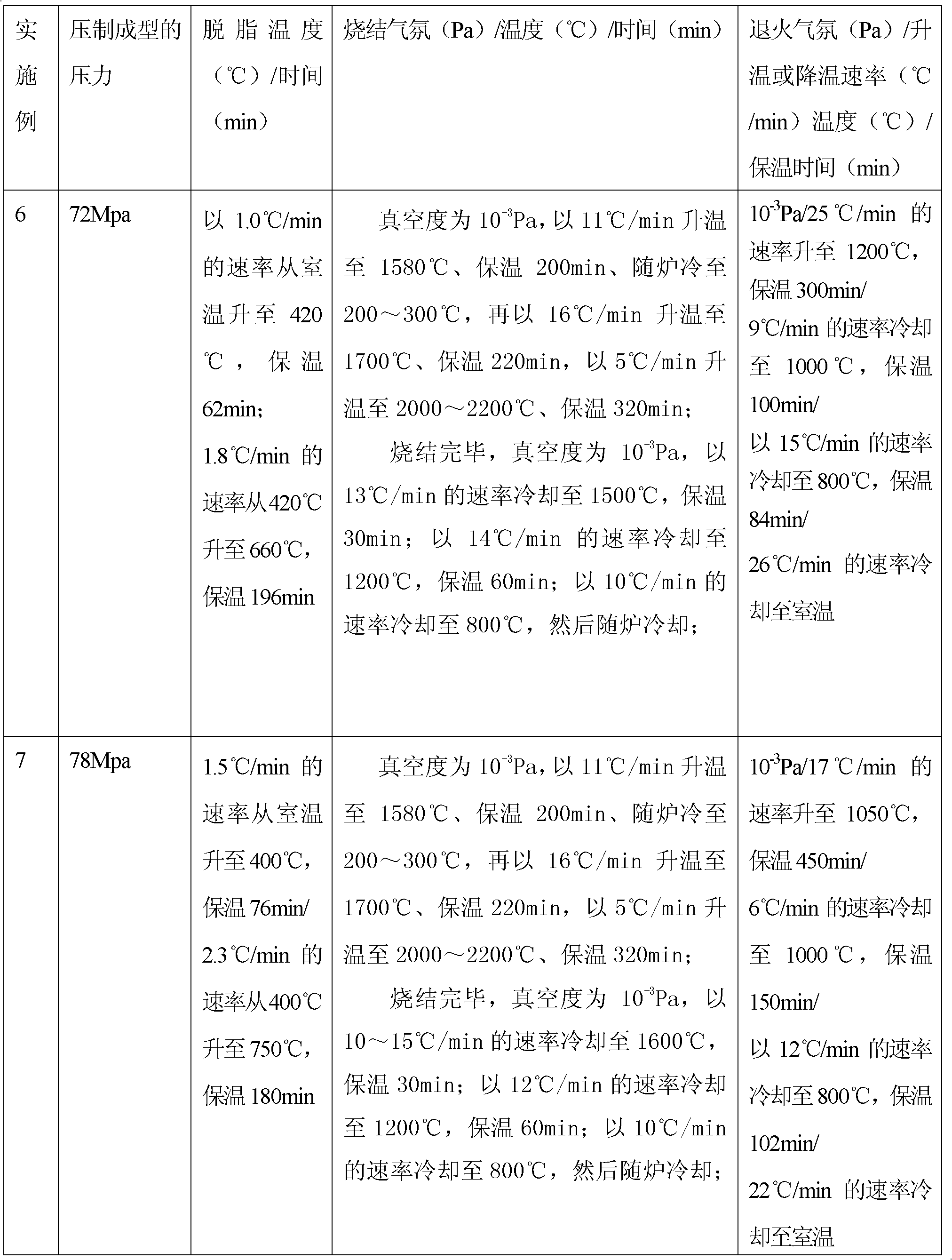

The invention relates to a preparation method of a medical porous metal material substituting for a dental bone. The preparation method comprises the steps of mixing tantalum powder, a pore-forming agent and a forming agent to form mixed powder, and further pressing the powder into an organic foam body for forming, degreasing, sintering, cooling and performing heat treatment to prepare a porous tantalum material, wherein the press-forming pressure is 50-100Mpa, the pore-forming agent is one or more of urea, sodium chloride, ethyl cellulose and methyl cellulose, and the forming agent is one or more of stearic acid, zinc stearate, paraffin wax and synthetic rubber. According to the preparation method provided by the invention, tests prove that in the final porous tantalum material, the impurity content can be lower than 0.2%, the density can achieve 11.67-13.34g / cm<3>, the porosity can achieve 20-30%, and the pore diameter can achieve 5-30mu m; the elastic modulus can achieve 4.5-6.0Gpa, the bending strength can achieve 110-130Mpa, and the compressive strength can achieve 100-130Mpa. The porous tantalum material provided by the invention is very suitable for the medical implant material substituting for the dental bone.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implanting material

ActiveCN102796899AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePolyvinyl alcohol

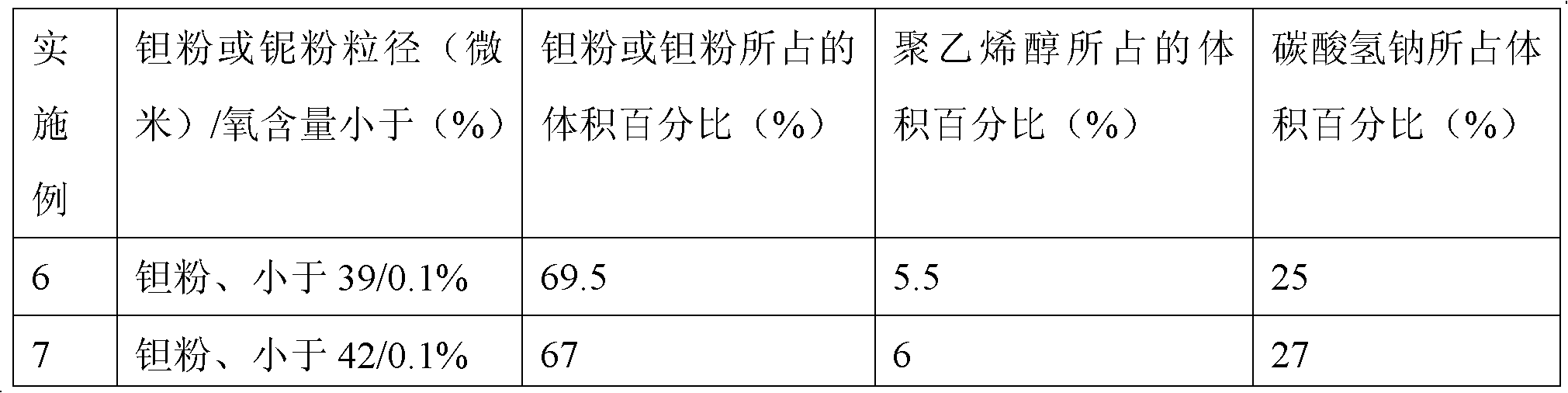

The invention discloses a preparation method of a medical porous metal implanting material. The preparation method comprises the steps of: mixing tantalum powder, pore-forming agent and forming agent to mixed powder; and carrying out granulation, mould-injection forming, demoulding, degreasing, sintering and heat treatment to obtain the medical porous metal implanting material which is used for replacing tooth bone tissues, wherein the pore-forming agent comprises one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyl cellulose; the forming agent comprises one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; and the degreasing process comprises the steps of: gradually raising the temperature to 400-800 DEG C at a speed of 0.5-3 DEG C / min, introducing in argon to form protection atmosphere and holding the temperature for 60-240min. According to the preparation method provided by the invention, the sintering and heat treatment steps are effectively improved, so that the mechanical property of a prepared porous tantalum material is greatly improved and the porous tantalum material is particularly suitable for serving as a medical implanting material for replacing the tooth bone tissues of human body.

Owner:CHONGQING RUNZE PHARM CO LTD

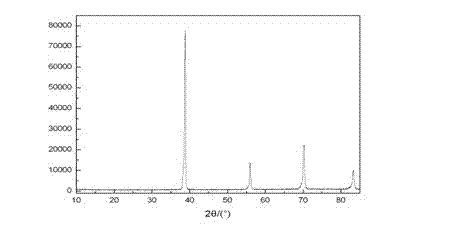

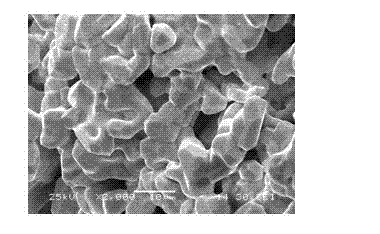

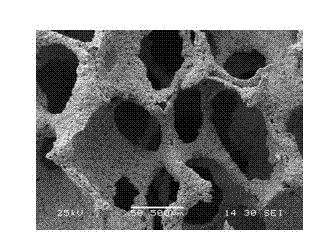

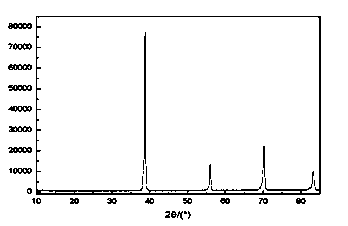

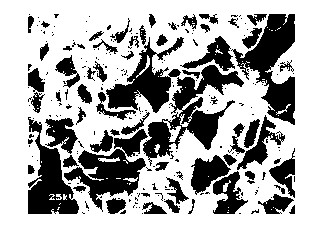

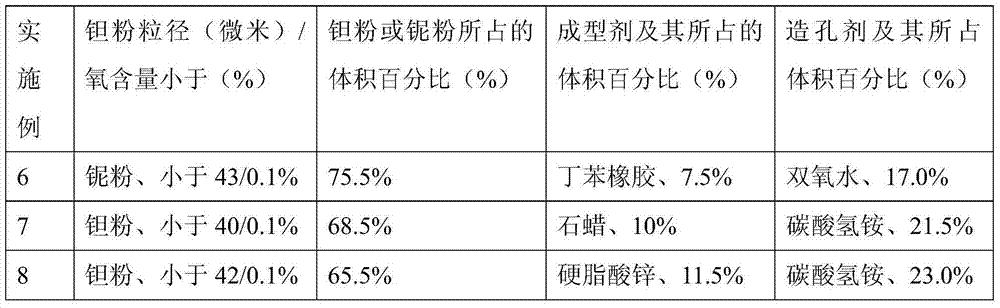

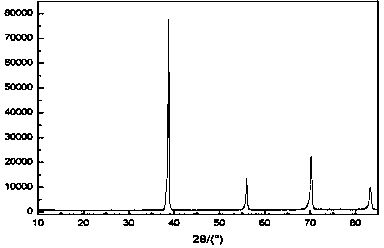

Preparation method for medical metal implant material porous niobium

The invention provides a preparation method for a medical metal implant material porous niobium. According to the invention, a solution prepared from ethyl cellulose which is used as an organic binder and anhydrous ethanol which is used as a dispersant and mixed powder prepared from starch and niobium powder which has an average particle size of less than 43 mu m and oxygen content of less than 0.1% are used to prepare niobium powder slurry which is casted and dipped into an organic foam; the organic foam is dried and then is subjected to degreasing under the protection of an inert gas atmosphere and to sintering in vacuum so as to prepare a porous sintered body, sintered niobium powder particles mutually have a sintering neck structure, and after annealing in vacuum and normal post-treatment, porous niobium is prepared; wherein, the content of starch in the mixed powder of metallic niobium powder and starch is 5 to 10%. The medical metal implant material porous niobium prepared in the invention has excellent bio-compatibility and bio-safety; meanwhile, the porous niobium has a sintering neck structure, which enables mechanical properties of the porous niobium like ductility, etc., to be improved; the invention provides a good method for convenient and effective application of porous niobium in the field of medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

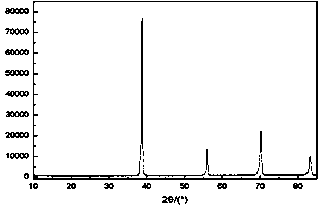

Medical porous tantalum material for replacing dentale and preparation method thereof

ActiveCN102793945AGood biocompatibilityHigh biosecurityTissue regenerationProsthesisSodium bicarbonatePolyvinyl alcohol

The invention discloses a medical porous tantalum material for replacing dentale and a preparation method thereof. The material is prepared by mixing tantalum powder, polyvinyl alcohol and sodium hydrogen carbonate to form mixed powder, pressing the mixed powder to an organic foam body, molding, degreasing, sintering, cooling and performing heat treatment; and pressure adopted for pressing molding is 50 to 100MPa, the pore diameter of the formed medical porous tantalum material is 30 to 50 microns, and the porosity is 30 to 38 percent. The porous tantalum is prepared by adopting a pure physical die pressing method, so that the impurity content of the final porous tantalum material is extremely low, and biocompatibility and bio-safety are effectively improved; by testing, the impurity content of the material can be lower than 0.2 percent, the density can reach 10.34 to 11.67g / cm<3>, the porosity can reach 30 to 38 percent, and the pore diameter can reach 30 to 50 microns; and the elastic modulus can reach 4.5 to 6.0GPa, the bending strength can reach 120 to 130MPa, and the compressive strength can reach 100 to 140MPa. The porous tantalum is very suitable to be used as a medical implant material for replacing the dentale.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical metal implant material porous tantalum

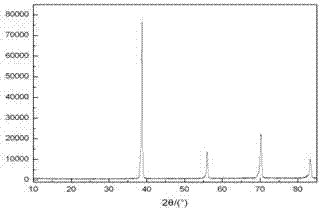

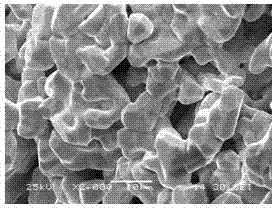

The invention relates to a preparation method of medical implant material porous tantalum. The preparation method comprises the following steps: preparing tantalum powder slurry from a solution prepared from ethyl cellulose and anhydrous ethanol and tantalum powder, pouring into an organic foam body, soaking till pores of the organic foam body are filled with the tantalum powder slurry, then drying to remove a dispersant in the organic foam body poured with the tantalum powder slurry, performing degreasing treatment under a protective atmosphere of inert gas to remove an organic binder and the organic foam body, sintering in a vacuum state to prepare a porous sintered body, further annealing in the vacuum state, and performing conventional post-treatment to prepare the porous tantalum, wherein the average particle size of the tantalum powder is less than 10mu m, and the oxygen content is less than 0.1%. The porous tantalum medical implant material prepared by the preparation method provided by the invention has great biocompatibility and relatively good mechanical properties, and is particularly suitable for being used as the medical implant material for coupling members at wounds or defects of shoulder bone, skull and facial bone tissues. Simultaneously, the preparation method has the advantages of simple process and easiness in control; and the whole preparation process has no harm, no pollution, no toxic and harmful dust and no side effects against a human body.

Owner:CHONGQING RUNZE PHARM CO LTD

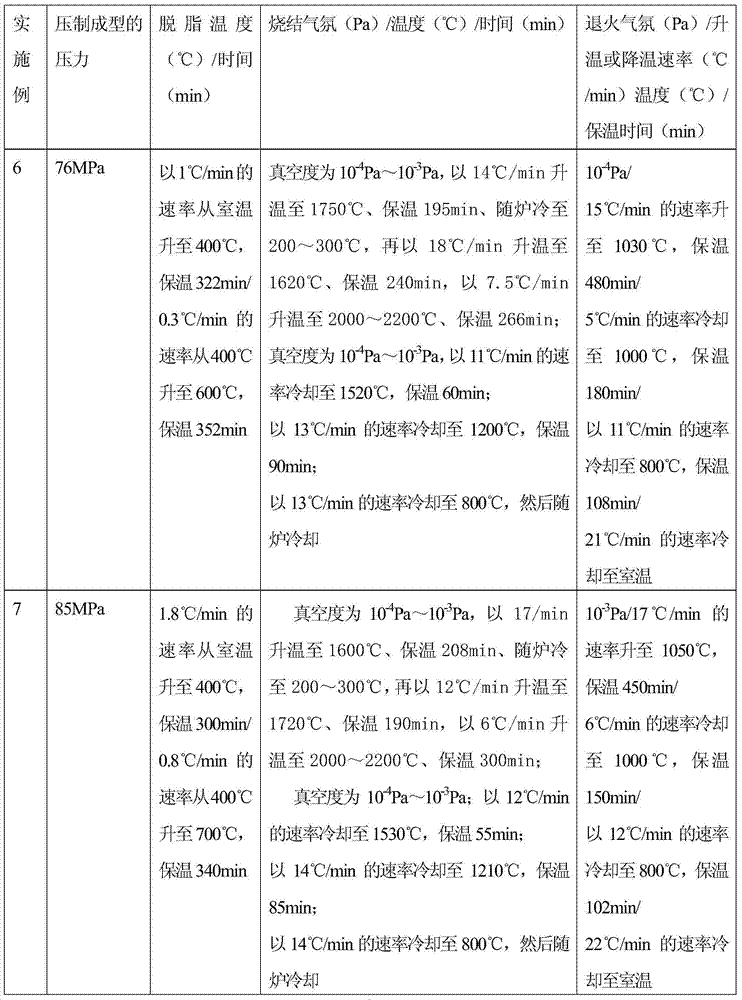

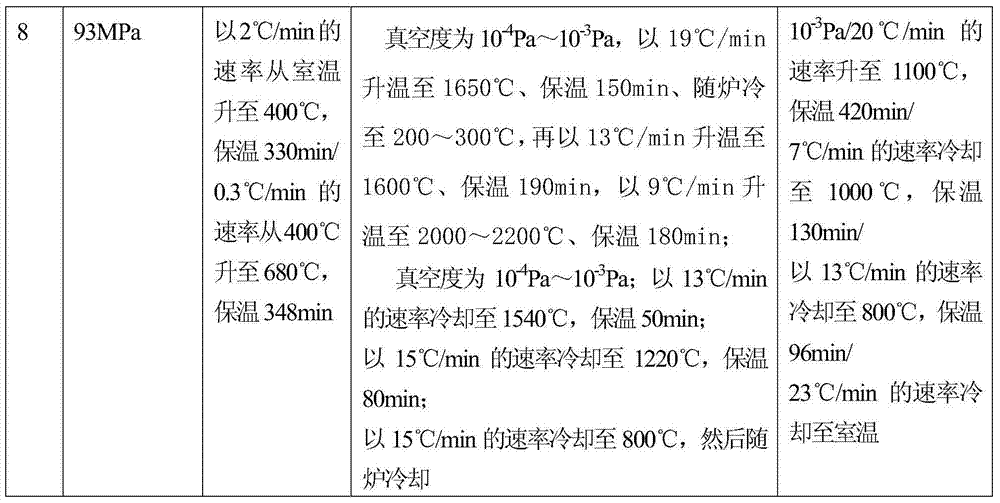

Medical porous metal material for replacing weight-bearing bone tissues and preparation method of medical porous metal material

ActiveCN102796904AGood biocompatibilityHigh biosecurityTissue regenerationProsthesisStearic acidAmmonium Hydrogen Carbonate

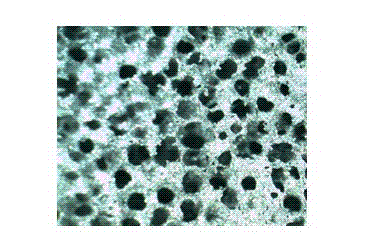

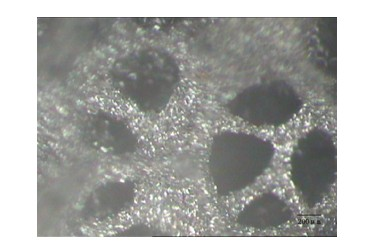

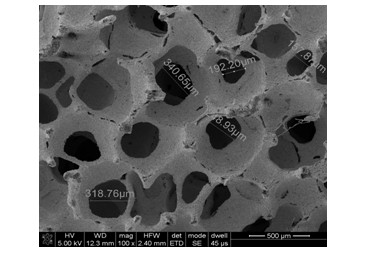

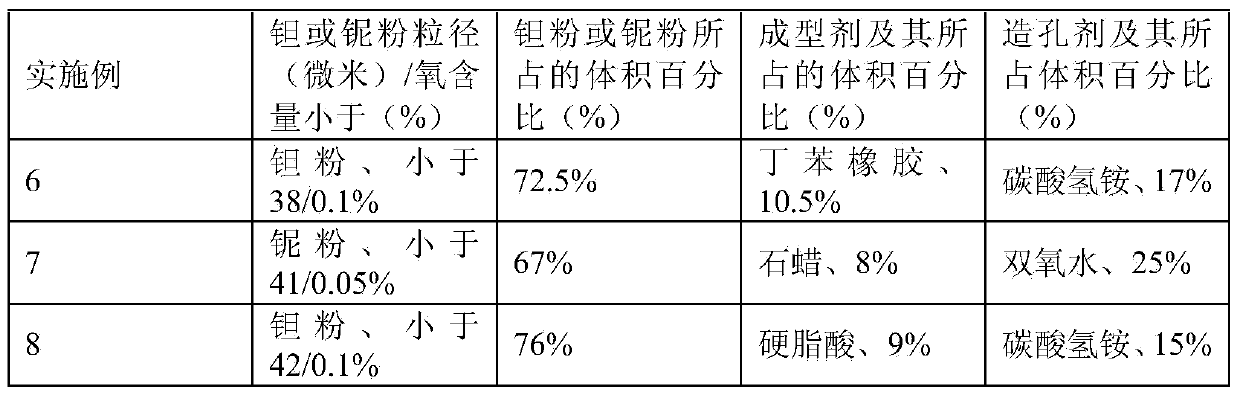

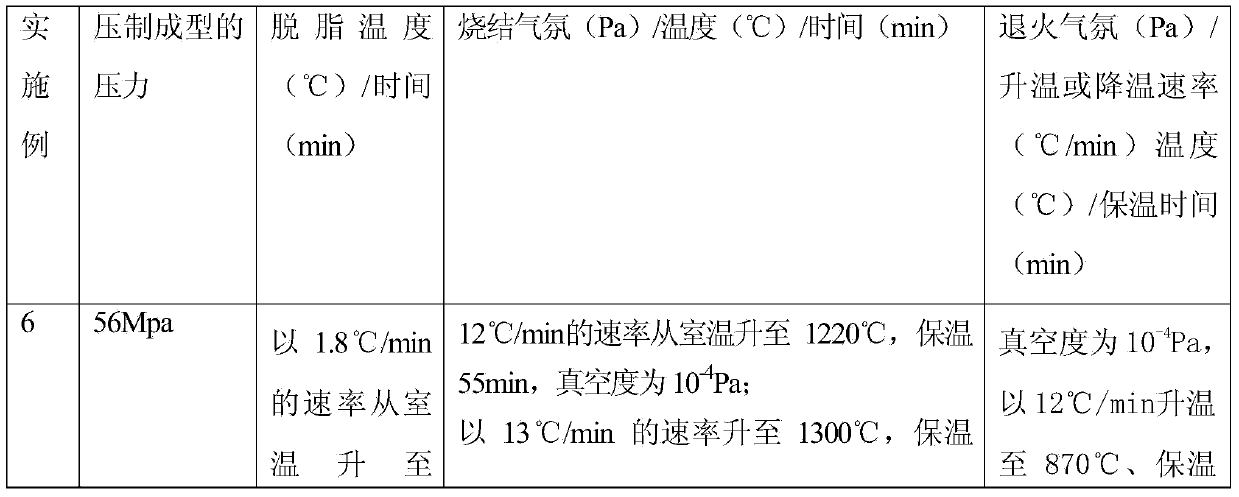

The invention discloses a medical porous metal material for replacing weight-bearing bone tissues and a preparation method of the medical porous metal material. The preparation method of the medical porous metal material comprises the following steps of: mixing tantalum powder with a pore creating material and a forming agent, and then pressing the mixed powder in an organic foam; performing forming, degreasing, sintering, cooling and heat processing to prepare the medical porous metal material; the pressure adopted in the process of press forming is 50-100 MPa, the temperature is gradually raised to 400-800 DEG C at a speed of 0.3-2 DEG C per minute in the degreasing process, argon is introduced in to form protective atmosphere, and the temperature is preserved for 300-360 minutes; the pore creating material is ammonium hydrogen carbonate or hydrogen peroxide, the forming agent is one or more of stearic acid, zinc stearate, wax and synthetic resin, and the formed medical porous tantalum material has the pore diameter of 100-500 microns, the porosity degree of 55-65%, the elastic modulus of 3.8-4.2 Gpa and the elongation percentage of 9.3-10.7%. Through the preparation method of porous tantalum disclosed by the invention, the final content of impurity in the porous tantalum material is very low, and simultaneously the contradiction that the medical porous tantalum material for replacing a weight-bearing site requires larger porosity and also requires good mechanical property is efficiently solved.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of porous tantalum serving as medical metal implant material

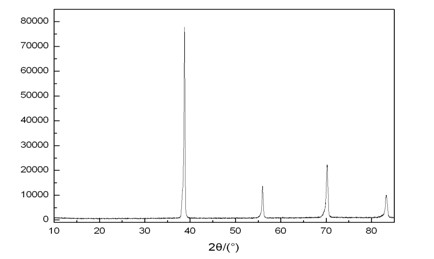

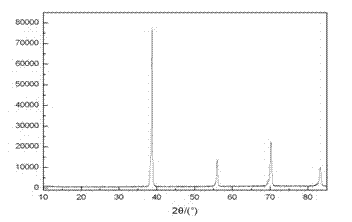

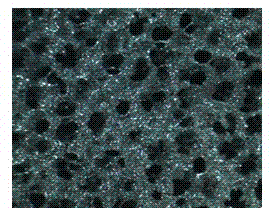

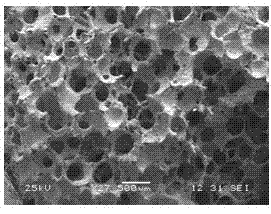

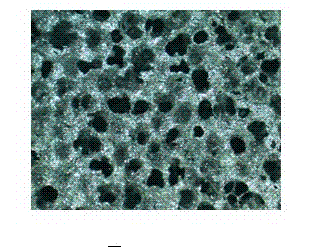

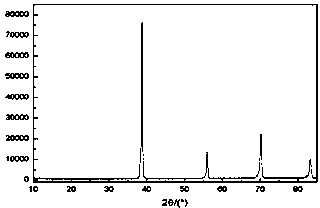

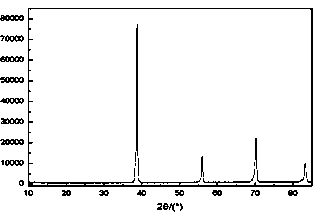

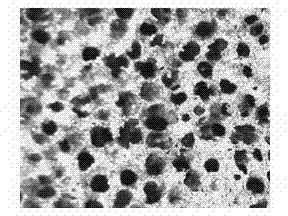

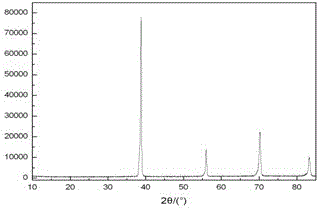

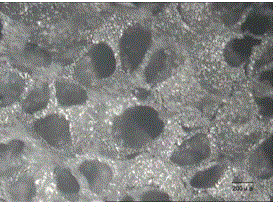

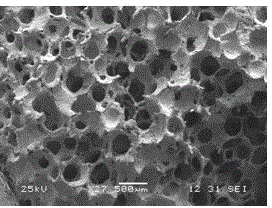

ActiveCN102462861AThe pores are evenly distributed and connectedThe modulus of elasticity does not affectProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention relates to a preparation method of porous tantalum serving as a medical metal implant material. An organic binder and a dispersant are mixed to prepare solution, the solution is mixed with mixed powder of starch and tantalum metal powder to prepare tantalum powder slurry, the tantalum powder slurry is poured into an organic foam body for impregnation until pores of the organic foam body are completely filled with the tantalum powder slurry, the dispersant in the organic foam body with the tantalum powder slurry is removed via drying, the organic binder and the organic foam body are removed via degreasing treatment in the protective atmosphere of inert gases, a porous sintered body is prepared via sintering under vacuum conditions, the sintered pure tantalum powder is stacked to form a foam skeleton, sintered neck structures are formed among the tantalum powder particles, and the porous tantalum can be prepared after vacuum annealing and conventional post-processing; and the organic binder adopts polyvinyl alcohol, and the dispersant adopts distilled water. The prepared medical implant porous tantalum material has excellent biocompatibility and safety and also has good mechanical properties and ductility, and is particularly suitable for use as a medical implant material for parts of a human body under relatively light loads.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implant material

A preparation method of a medical porous metal implant material includes steps of mixing solution, prepared by starch which serves as an organic binder and distilled water which serves as a dispersant, with niobium powder of the average particle size smaller than 43 mu m and oxygen content lower than 0.1% to prepare niobium slurry, pouring the niobium slurry into an organic foam body, impregnating the organic foam body until holes of the organic foam body are filled with the niobium slurry, drying and removing the dispersant, removing the organic binder and the organic foam body in a degreasing manner under the protection atmosphere of inert gas, producing a porous sintered body by vacuum sintering, and finally preparing porous niobium after vacuum annealing and conventional post-treatments, wherein the mass percentage concentration of starch solution ranges from 2% to 6%. The porous niobium of the medical metal implant material, which is prepared by the preparation method, has excellent biological compatibility and safety. Meanwhile, since the porous niobium has the sintered neck structure, mechanical properties such as ductility and the like of the porous niobium are improved, and the preparation method is good and convenient for practical application of the porous niobium in medical metal implanting.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical metal implanted material porous niobium

The invention relates to a preparation method of a medical implanted material porous niobium. The preparation method comprises the following steps: 1, preparing a niobium powder slurry from a solution prepared with ethyl cellulose as an organic binder and waterless ethanol as a dispersant and niobium powder with the average particle size of less than 38mum and the oxygen content of less than 0.1%, wherein the mass percentage concentration of the obtained ethyl cellulose waterless ethanol solution is 2-4%; 2, casting the niobium powder slurry into an organic foam; 3, drying to remove the dispersant in the organic foam casted with the niobium powder slurry; 4, degreasing in an inert gas atmosphere; 5, sintering under vacuum conditions to prepare a porous sinter, wherein there is a sintering neck structure between each two sintered niobium powder particles; and 6, annealing under vacuum conditions, and carrying out routine post-processing to obtain the porous niobium. A medical metal implanted material porous tantalum prepared in the invention has the advantages of superior biological compatibility and superior biological safety; and the porous tantalum has the sintering neck structure, so mechanical properties of ductility and the like of the medical metal implanted material porous tantalum are improved, thereby good methods are provided for the convenient and effective application of the porous tantalum in the medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

ActiveCN102796898AUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusParaffin waxSodium bicarbonate

The invention discloses a method for preparing a medical porous metal implant material. The method comprises the following steps of: mixing tantalum powder, a pore forming agent and a forming agent to obtain mixed power, wherein the pore forming agent is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethylcellulose, and the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin wax and synthetic rubber; pelletizing; injecting into a mould and forming; demoulding; degreasing, namely gradually raising temperature to 400 to 800 DEG C at the speed of 0.5 to 3 DEG C / min, introducing argon to form protective atmosphere and preserving heat for 60 to 240 minutes; sintering; and performing thermal treatment, namely raising temperature to 800 to 900 DGE C at the speed of 10 to 20 DEG C / min under the vacuum degree of 10<-4> to 10<-3> Pa, preserving heat for 240 to 480 minutes, cooling to 400 DEG C at the speed of 2 to 5 DEG C / min, preserving heat for 120 to 300 minutes, and cooling to room temperature along with a furnace, and finally, the medical porous metal implant material for replacing dentale tissues can be obtained. Through tests, the prepared porous tantalum material is very suitable to be used as the medical implant material for replacing dentale tissues.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical metal implant material multi-hole niobium

Disclosed is a method for preparing medical metal implant material multi-hole niobium. A solution is obtained by adopting polyvinyl alcohol as an organic binding agent and distilled water as a dispersing agent, and mixed with mixed powder of starch and niobium powder with the mean grain size smaller than 43 micrometers and the oxygen content smaller than 0.1% to obtain a niobium powder sizing agent which is poured into an organic foamed body, then, the niobium powder sizing agent is dried, the dispersing agent in the organic foamed body with the poured niobium sizing agent is removed, under the inert gas shielding atmosphere, the ungrease treatment is carried out to remove the organic binding agent and the organic foamed body, sintering is carried out in vacuum to obtain a multi-hole sintering body, and then annealing in the vacuum and conventional postprocessing are carried out to obtain the multi-hole niobium. In the mixed powder of the metal niobium powder and the starch, the content of the starch is 5-10%. The obtained medical metal implant material multi-hole niobium has excellent biological compatibility and biological safety, meanwhile, the multi-hole niobium is of a sintering-neck structure, the mechanical performance like the malleability of the multi-hole niobium is improved, and according to the method, the multi-hole niobium can be conveniently and effectively implanted into medical metal.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical implant material porous niobium

ActiveCN103520768AImprove mechanical propertiesImprove ductilityProsthesisBiocompatibility TestingSlurry

A preparation method of a medical implant material porous niobium comprises the following steps: preparing ethyl cellulose as an organic binder and absolute ethanol as a dispersant into a solution; mixing the solution with mixed powder composed of starch and niobium powder with the mean particle diameter of less than 43 microns and the oxygen content of less than 0.1% to prepare niobium powder slurry; pouring; dipping in an organic foam; drying, degreasing in an inert gas atmosphere; sintering under vacuum to obtain a porous sintered body having sintering neck structures between the sintered niobium powder particles; and annealing under vacuum; and performing conventional posttreatment to obtain the porous niobium, wherein in the mixed powder of the metal niobium powder and the starch, the starch content is 5-10%. The prepared medical metal implant material porous niobium has excellent biocompatibility and bio-safety; the porous niobium has the sintering neck structures, so that the ductility and other mechanical properties of the porous niobium are improved; and a very good method is provided for convenient and effective application of the porous niobium to medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal material substituting for load-bearing bone tissue

ActiveCN103740966ASuitable for preparationGood biocompatibilityProsthesisParaffin waxFlexural strength

The invention relates to a preparation method for preparing a medical porous metal material substituting for a load-bearing bone tissue. The preparation method comprises the steps of mixing tantalum powder, a pore-forming agent and a forming agent, and further pressing mixed powder into an organic foam body for forming, degreasing, sintering, cooling and performing heat treatment, wherein the press-forming pressure is 50-100Mpa, in the degreasing process, heating is gradually performed to 400-800 DEG C at the rate of 0.3 DEG C / min-2 DEG C / min, argon gas is introduced to constitute a protective atmosphere and heat preservation is performed for 300min-360min, the pore-forming agent is ammonium hydrogen carbonate or hydrogen peroxide, and the forming agent is one or more of stearic acid, zinc stearate, paraffin wax and synthetic resin; heating to 800-900 DEG C at the rate of 10-20 DEG C / min under 10<-4>Pa-10<-3>Pa, performing heat preservation for 240-480min, further cooling to 400 DEG C at the rate of 2-5 DEG C / min, performing heat preservation for 120-300min, and then cooling to room temperature along with a furnace. The test proves that the impurity content is lower than 0.2%, the density achieves 6.67-8.34g / cm<3>, the porosity achieves 50-60%, the pore diameter achieves 150-450mu m, the elastic modulus can achieve 4.5-6.0Gpa, and the bending strength can achieve 100-120Mpa.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method for medical porous metal material for replacing dentale

ActiveCN102796892BGood biocompatibilityHigh biosecurityTransportation and packagingMetal-working apparatusPowder mixtureFlexural strength

A preparation method for a medical porous metal material for dental bone replacement: mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, press-forming the powder into an organic foamed body, then degreasing, sintering, cooling, and performing a heating process to produce the porous tantalum material. The pressure used during the press-forming is 50 to 100 Mpa. The pore-forming agent is one of or a combination of urea, sodium chloride, ethyl cellulose, and methyl cellulose. The forming agent is one of or a combination of stearic acid, zinc stearate, paraffin, and synthetic rubber. Measurements show that the porous tantalum material prepared using the preparation method has an impurity concentration lower than 0.2%. The density reaches 11.67 to 13.34 g / cm3, the porosity reaches 20% to 30%, and the pore diameter reaches 5 to 30 mum. The elastic modulus reaches 4.5 to 6.0 Gpa, the bending strength reaches 110 to 130 Mpa, and the compressive strength reaches 100 to 130 Mpa. The porous tantalum prepared using the method is applicable as a medical implant material for dental bone replacement.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical implant material multi-hole tantalum

The invention provides a method for preparing medical implant material porous tantalum. The method includes the steps that a solution prepared from ethyl cellulose which is used as an organic binding agent and absolute ethyl alcohol which is used as a dispersing agent combines with mixed powder of starch and metal tantalum powder to prepare tantalum powder slurry, the tantalum powder is poured into organic foams, soaked until holes of the organic foams are filled with the tantalum powder slurry, and dried to remove the dispersing agent in the organic foams into which the tantalum powder slurry is poured, ungrease treatment is conducted under the inert gas shielding atmosphere to remove the organic binding agent and the organic foams, vacuum sintering is conducted to obtain porous sintering bodies, on a foam framework which is formed by stacking sintered pure tantalum powder, sintering neck structures exist among the tantalum powder particles, and then vacuum annealing and conventional after-treatment are conducted to obtain the porous tantalum. The medical implant porous tantalum material prepared from the method has good biocompatibility, safety, mechanical property and malleability and is especially suitable for being used as the medical implant material for human body parts with low bearing capacity.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal material substituting for dental bone

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implant material

ActiveCN103740964BUniform tissueOrganizational stabilityProsthesisSodium bicarbonatePolyvinyl alcohol

The invention relates to a preparation method of a medical porous metal implant material. The method comprises the following steps: mixing tantalum powder with a pore former and a forming agent so as to form mixed powder; and performing granulation, injection mould forming, demoulding, degreasing, sintering and heat treatment on the mixed powder so as to prepare the medical porous metal implant material capable of replacing a dentale tissue, wherein the pore former is one or more of sodium bicarbonate, urea, sodium chloride, methylcellulose and ethyecellulose; the forming agent is one or more of polyvinyl alcohol, stearic acid, zinc stearate, paraffin and synthetic rubber; the degreasing process is performed under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.5 DEG C / minute to 3 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out heat preservation for 60 to 240 minutes; the sintering process and the heat treatment process are effectively improved. Thus, the mechanical property of the prepared medical porous metal implant material is greatly improved. As a result, the prepared medical porous metal implant material is very suitable for replacement of the dentale tissue.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method for medical metal implant material porous niobium

InactiveCN102475903BImprove mechanical propertiesImprove ductilityProsthesisSlurryMechanical property

The invention provides a preparation method for a medical metal implant material porous niobium. According to the invention, a solution prepared from ethyl cellulose which is used as an organic binder and anhydrous ethanol which is used as a dispersant and mixed powder prepared from starch and niobium powder which has an average particle size of less than 43 mu m and oxygen content of less than 0.1% are used to prepare niobium powder slurry which is casted and dipped into an organic foam; the organic foam is dried and then is subjected to degreasing under the protection of an inert gas atmosphere and to sintering in vacuum so as to prepare a porous sintered body, sintered niobium powder particles mutually have a sintering neck structure, and after annealing in vacuum and normal post-treatment, porous niobium is prepared; wherein, the content of starch in the mixed powder of metallic niobium powder and starch is 5 to 10%. The medical metal implant material porous niobium prepared in the invention has excellent bio-compatibility and bio-safety; meanwhile, the porous niobium has a sintering neck structure, which enables mechanical properties of the porous niobium like ductility, etc., to be improved; the invention provides a good method for convenient and effective application of porous niobium in the field of medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal material capable of replacing weight-bearing bone tissue

ActiveCN103740961BUniform tissueOrganizational stabilityProsthesisFlexural strengthMechanical property

The invention relates to a preparation method of a medical porous metal material capable of replacing a weight-bearing bone tissue. The method comprises the following steps: mixing tantalum powder with a pore-forming agent and a molding agent; pressing mixed powder into an organic foaming body; molding, degreasing, sintering and cooling; and performing heat treatment, wherein carrying out the degreasing under the conditions of gradually heating to 400 DEG C to 800 DEG C according to the speed rate of 0.3 DEG C / minute to 2 DEG C / minute, forming a protective atmosphere in an argon leading-in mode and carrying out the heat preservation for 300 to 360 minutes; and carrying out the sintering at 10<-4>Pa to 10<-3>Pa under the conditions of gradually heating to 1500 DEFG C to 1800 DEG C at the speed rate of 10 DEG C / minute to 20 DEG C / minute, carrying out the heat preservation for 120 to 240 minutes, cooling to 200 DEG C to 300 DEG C along with a furnace, then gradually heating to 1500 DEG C to 1800 DEG C at the speed rate of 10 DEG C / minute to 20 DEG C / minute, carrying out the heat preservation for 180 to 240 minutes, heating to 2000 DEG C to 2200 DEG C according to the speed rate of 5 DEG C / minute to 10 DEG C / minute and carrying out the heat preservation for 120 to 360 minutes. By testing, the content of impurities in the material is below 0.2%; the density of the material can reach 5.00g / cm<3> to 6.67g / cm<3>; the porosity of the material can reach 60% to 70%; the pore diameter of the material can reach 200 mu m to 400 mu m; the elasticity modulus of the material can reach 3.8Gpa to 4.2Gpa; the bending strength of the material can reach 125Mpa to 150Mpa; the compressive strength of the material can reach 72Mpa to 90Mpa. Thus, the contradiction that the medical porous metal material for replacing the weight-bearing bone tissue is required to have the large porosity and the good mechanical property is effectively solved.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

A preparation method for a medical porous metal implant material comprising mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, then granulating, injecting into a mold for forming, demolding, degreasing, sintering, and performing a heating process to produce the medical porous metal implant material for dental bone tissue replacement; the pore-forming agent is one or multiple of sodium bicarbonate, urea, sodium chloride, methyl cellulose, and ethyl cellulose, and the forming agent is one or multiple of polyvinyl alcohol, stearic acid, zinc stearate, paraffin, and synthetic rubber; the degreasing process comprises: gradually increasing the temperature to 400 to 800°C at a speed of 0.5 to 3°C / min, introducing argon gas to form a protective atmosphere, and maintaining the temperature for 60 to 240 minutes. Measurements show that the porous tantalum material prepared using the method has an impurity concentration lower than 0.2%. The density reaches 11.67 to 13.34 g / cm3, the porosity reaches 20% to 30%, and the pore diameter reaches 12 to 25 mum. The elastic modulus reaches 4.5 to 6.0 Gpa, the elongation rate reaches 12.0% to 13.8%, the bending strength reaches 120 to 150 Mpa, and the compressive strength reaches 90 to 110 Mpa.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical metal implant material multi-hole niobium

Disclosed is a method for preparing medical metal implant material multi-hole niobium. A solution is obtained by adopting polyvinyl alcohol as an organic binding agent and distilled water as a dispersing agent, and mixed with mixed powder of starch and niobium powder with the mean grain size smaller than 43 micrometers and the oxygen content smaller than 0.1% to obtain a niobium powder sizing agent which is poured into an organic foamed body, then, the niobium powder sizing agent is dried, the dispersing agent in the organic foamed body with the poured niobium sizing agent is removed, under the inert gas shielding atmosphere, the ungrease treatment is carried out to remove the organic binding agent and the organic foamed body, sintering is carried out in vacuum to obtain a multi-hole sintering body, and then annealing in the vacuum and conventional postprocessing are carried out to obtain the multi-hole niobium. In the mixed powder of the metal niobium powder and the starch, the content of the starch is 5-10%. The obtained medical metal implant material multi-hole niobium has excellent biological compatibility and biological safety, meanwhile, the multi-hole niobium is of a sintering-neck structure, the mechanical performance like the malleability of the multi-hole niobium is improved, and according to the method, the multi-hole niobium can be conveniently and effectively implanted into medical metal.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implant material

ActiveCN102475902BImprove mechanical propertiesImprove mechanical properties such as ductilityProsthesisNiobiumSlurry

A preparation method of a medical porous metal implant material includes steps of mixing solution, prepared by starch which serves as an organic binder and distilled water which serves as a dispersant, with niobium powder of the average particle size smaller than 43 mu m and oxygen content lower than 0.1% to prepare niobium slurry, pouring the niobium slurry into an organic foam body, impregnating the organic foam body until holes of the organic foam body are filled with the niobium slurry, drying and removing the dispersant, removing the organic binder and the organic foam body in a degreasing manner under the protection atmosphere of inert gas, producing a porous sintered body by vacuum sintering, and finally preparing porous niobium after vacuum annealing and conventional post-treatments, wherein the mass percentage concentration of starch solution ranges from 2% to 6%. The porous niobium of the medical metal implant material, which is prepared by the preparation method, has excellent biological compatibility and safety. Meanwhile, since the porous niobium has the sintered neck structure, mechanical properties such as ductility and the like of the porous niobium are improved, and the preparation method is good and convenient for practical application of the porous niobium in medical metal implanting.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical metal implanted material porous niobium

ActiveCN102475905BImprove mechanical propertiesImprove mechanical properties such as ductilityProsthesisCellulosePorous tantalum

Owner:CHONGQING RUNZE PHARM CO LTD

Medical porous metal material for replacing dentale and preparation method thereof

ActiveCN102793946BGood biocompatibilityHigh biosecurityTissue regenerationProsthesisSodium bicarbonateVacuum pressure

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of porous niobium for medical implant material

ActiveCN103520768BImprove mechanical propertiesImprove ductilityProsthesisNiobiumBiocompatibility Testing

A preparation method of a medical implant material porous niobium comprises the following steps: preparing ethyl cellulose as an organic binder and absolute ethanol as a dispersant into a solution; mixing the solution with mixed powder composed of starch and niobium powder with the mean particle diameter of less than 43 microns and the oxygen content of less than 0.1% to prepare niobium powder slurry; pouring; dipping in an organic foam; drying, degreasing in an inert gas atmosphere; sintering under vacuum to obtain a porous sintered body having sintering neck structures between the sintered niobium powder particles; and annealing under vacuum; and performing conventional posttreatment to obtain the porous niobium, wherein in the mixed powder of the metal niobium powder and the starch, the starch content is 5-10%. The prepared medical metal implant material porous niobium has excellent biocompatibility and bio-safety; the porous niobium has the sintering neck structures, so that the ductility and other mechanical properties of the porous niobium are improved; and a very good method is provided for convenient and effective application of the porous niobium to medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical porous metal implant material

ActiveCN103691004BUniform tissueOrganizational stabilityProsthesisSodium bicarbonatePolyvinyl alcohol

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of porous tantalum serving as medical metal implant material

ActiveCN102462861BThe pores are evenly distributed and connectedThe modulus of elasticity does not affectProsthesisPolyvinyl alcoholBiocompatibility Testing

The invention relates to a preparation method of porous tantalum serving as a medical metal implant material. An organic binder and a dispersant are mixed to prepare solution, the solution is mixed with mixed powder of starch and tantalum metal powder to prepare tantalum powder slurry, the tantalum powder slurry is poured into an organic foam body for impregnation until pores of the organic foam body are completely filled with the tantalum powder slurry, the dispersant in the organic foam body with the tantalum powder slurry is removed via drying, the organic binder and the organic foam body are removed via degreasing treatment in the protective atmosphere of inert gases, a porous sintered body is prepared via sintering under vacuum conditions, the sintered pure tantalum powder is stacked to form a foam skeleton, sintered neck structures are formed among the tantalum powder particles, and the porous tantalum can be prepared after vacuum annealing and conventional post-processing; and the organic binder adopts polyvinyl alcohol, and the dispersant adopts distilled water. The prepared medical implant porous tantalum material has excellent biocompatibility and safety and also has good mechanical properties and ductility, and is particularly suitable for use as a medical implant material for parts of a human body under relatively light loads.

Owner:CHONGQING RUNZE PHARM CO LTD

Preparation method of medical porous metal implanting material

ActiveCN102796899BUniform tissueOrganizational stabilityTransportation and packagingMetal-working apparatusSodium bicarbonatePowder mixture

A preparation method for a medical porous metal implant material comprising mixing tantalum powder, a pore-forming agent, and a forming agent into a powder mixture, then granulating, injecting into a mold for forming, demolding, degreasing, sintering, and performing a heating process to produce the medical porous metal implant material for dental bone tissue replacement; the pore-forming agent is one or multiple of sodium bicarbonate, urea, sodium chloride, methyl cellulose, and ethyl cellulose, and the forming agent is one or multiple of polyvinyl alcohol, stearic acid, zinc stearate, paraffin, and synthetic rubber; the degreasing process comprises: gradually increasing the temperature to 400 to 800°C at a speed of 0.5 to 3°C / min, introducing argon gas to form a protective atmosphere, and maintaining the temperature for 60 to 240 minutes; Effective improvements to the sintering and heating process steps substantially enhance the mechanic properties of the produced porous tantalum material, thereby enabling the material to be very suitable as a medical implant material for human dental bone tissue replacement.

Owner:CHONGQING RUNZE PHARM CO LTD

Method for preparing medical implant material multi-hole tantalum

ActiveCN103463674BImprove mechanical propertiesImprove mechanical properties such as ductilityProsthesisBiocompatibility TestingSlurry

The invention provides a method for preparing medical implant material porous tantalum. The method includes the steps that a solution prepared from ethyl cellulose which is used as an organic binding agent and absolute ethyl alcohol which is used as a dispersing agent combines with mixed powder of starch and metal tantalum powder to prepare tantalum powder slurry, the tantalum powder is poured into organic foams, soaked until holes of the organic foams are filled with the tantalum powder slurry, and dried to remove the dispersing agent in the organic foams into which the tantalum powder slurry is poured, ungrease treatment is conducted under the inert gas shielding atmosphere to remove the organic binding agent and the organic foams, vacuum sintering is conducted to obtain porous sintering bodies, on a foam framework which is formed by stacking sintered pure tantalum powder, sintering neck structures exist among the tantalum powder particles, and then vacuum annealing and conventional after-treatment are conducted to obtain the porous tantalum. The medical implant porous tantalum material prepared from the method has good biocompatibility, safety, mechanical property and malleability and is especially suitable for being used as the medical implant material for human body parts with low bearing capacity.

Owner:CHONGQING RUNZE PHARM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com