Method for preparing efficient probiotic preparation from macrofungi bacterial liquid (mycoplasm)

A high-efficiency, bacterial preparation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fungi, etc., can solve the problems of low stability of bacterial activity and low therapeutic effect, so as to improve the effect of health care and treatment, The production process is simple and the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

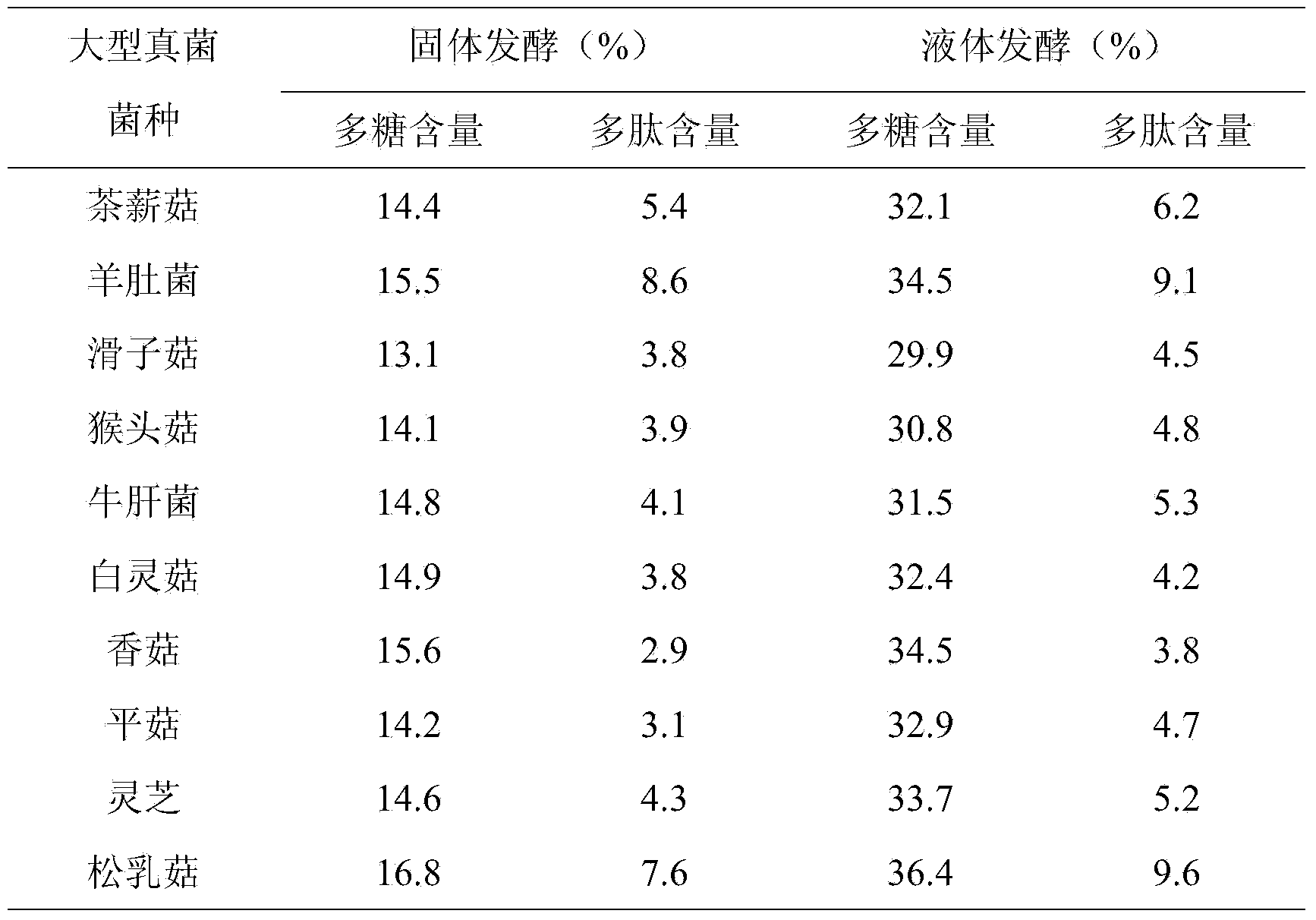

[0028] Example 1 Comparison of the active components of different kinds of macrofungus hyphae fermentation bacteria / bacteria liquid

[0029] 1. Materials

[0030] Large-scale fungal strains: tea mushroom, morel, slide mushroom, Hericium erinaceus, boletus, Bailing mushroom, shiitake mushroom, oyster mushroom, golden mushroom, ganoderma lucidum, Yunzhi, Cordyceps, Poria cocos, bamboo fungus, Pine milk mushroom and other slant strains are preserved by Hunan Minkang Biotechnology Research Institute.

[0031] Liquid medium: 1.5g corn steep liquor, 0.15g ammonium nitrate, 0.4g sodium carboxymethylcellulose, 1.5g glucose, K 2 HPO 4 0.02g, MgSO 4 ·7H 2 O0.05g, distilled water to 100mL, pH6.5.

[0032] Solid medium: solid matrix (40% bran, 30% corn bran, 10% soybean meal, 10% puffed corn, 10% oil bran), nutrient solution (0.5% corn steep liquor, 1% glucose, (NH 4 ) 2 NO 3 0.3%, K 2 HPO 4 0.05%, MgSO 4 ·7H 2 (00.1%, the balance is water, pH6.0-6.5) is 55% of the mass of the...

Embodiment 2

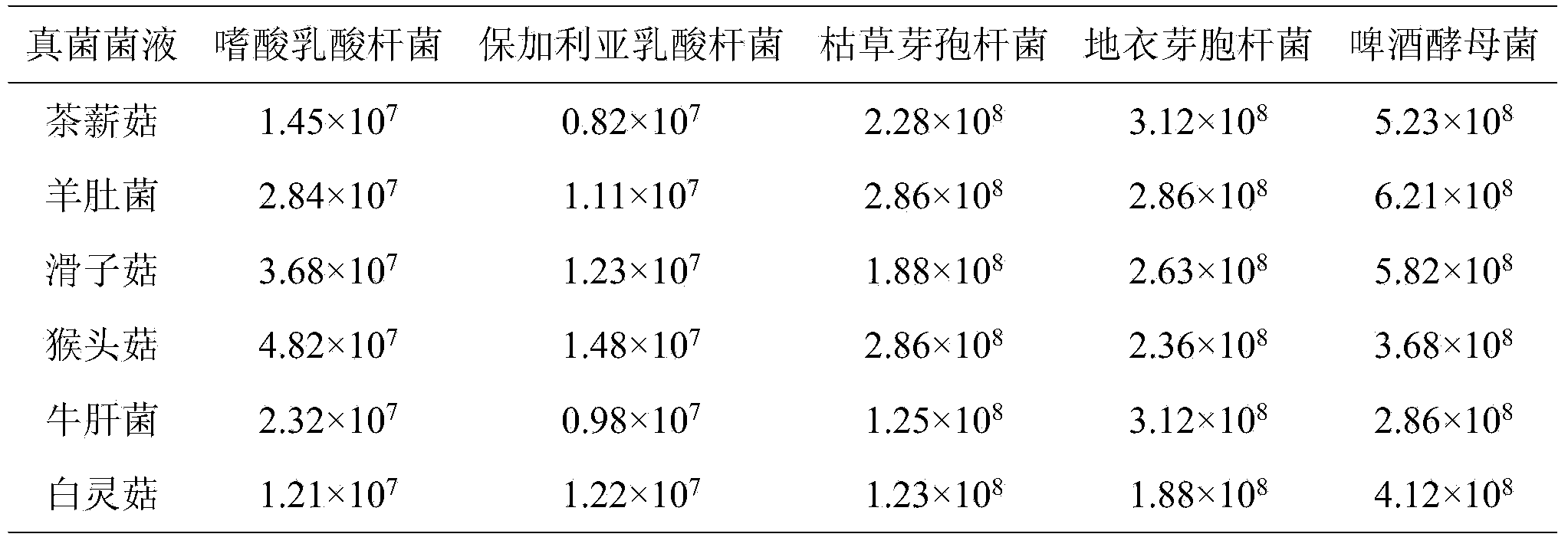

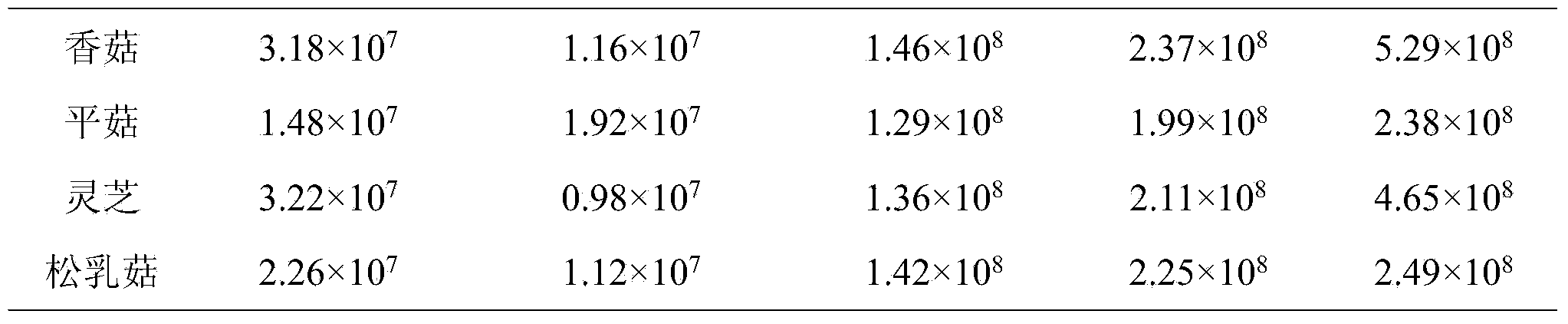

[0043] Example 2 The cultivation test of probiotics by macrofungus bacterium liquid preparation medium

[0044] 1. Materials

[0045] (1) Probiotic strains: Lactacidophilus, Lactobacillus bulgaricus, Bacillus subtilis, B. lichenifofmis, Saccharomycesbayanus.

[0046] (2) Culture medium: the fungal liquid fermentation product (culture liquid and mycelium) that embodiment 1 produces, milk homogenizer homogenate, compound enzyme (0.5~1.5% of cellulase, 1.0%~3.0% of pectinase, protease 1.5-3.0%) enzymolysis, 80 ℃ ultrasonic extraction for 40min, four layers of gauze filtration; take the filtrate, add 2% glucose, 1.5% corn steep liquor, 1% peptone (such as 100mL filtrate, add 2g glucose, 1.5g corn steep liquor, 1g peptone), put it in a Erlenmeyer flask, and sterilize at 121°C for 20min.

[0047] 2. Method

[0048] (1) Secondary inoculation culture: Inoculate 2-5% aerobic probiotic single strain liquid culture composite strains (Bacillus licheniformis: Bacillus subtilis: Saccharo...

Embodiment 3

[0055] Example 3 Determination of antibacterial activity of edible and medicinal fungal mycelia fermentation broth and its cultured probiotics to pathogenic bacteria

[0056] 1. Method: take the liquid cultures of 9 kinds of fungal hyphae in Table 3 respectively, after grinding, enzymatic hydrolysis, ultrasonic treatment and sterilization, secondarily inoculate and cultivate compound probiotics according to the method of Example 2, fungal mycelium The solution and its cultured probiotics were filtered separately (wherein the concentration of the bacterial solution contained about 2% dry bacterial substance, and the bacterial concentration of the probiotic solution was 1.5×10 9 cfu / mL) for spare; use the agar plate culture method to streak inoculate pathogenic bacteria (Escherichia coli C44103, Salmonella C26112, Pasteurella C44-1, Streptococcus 01026), place Oxford cups respectively, and add 50 μL bacterial plasma / bacterial liquid to each cup , cultivated at 37°C for 24h, meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com