Patents

Literature

40 results about "Partial graph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

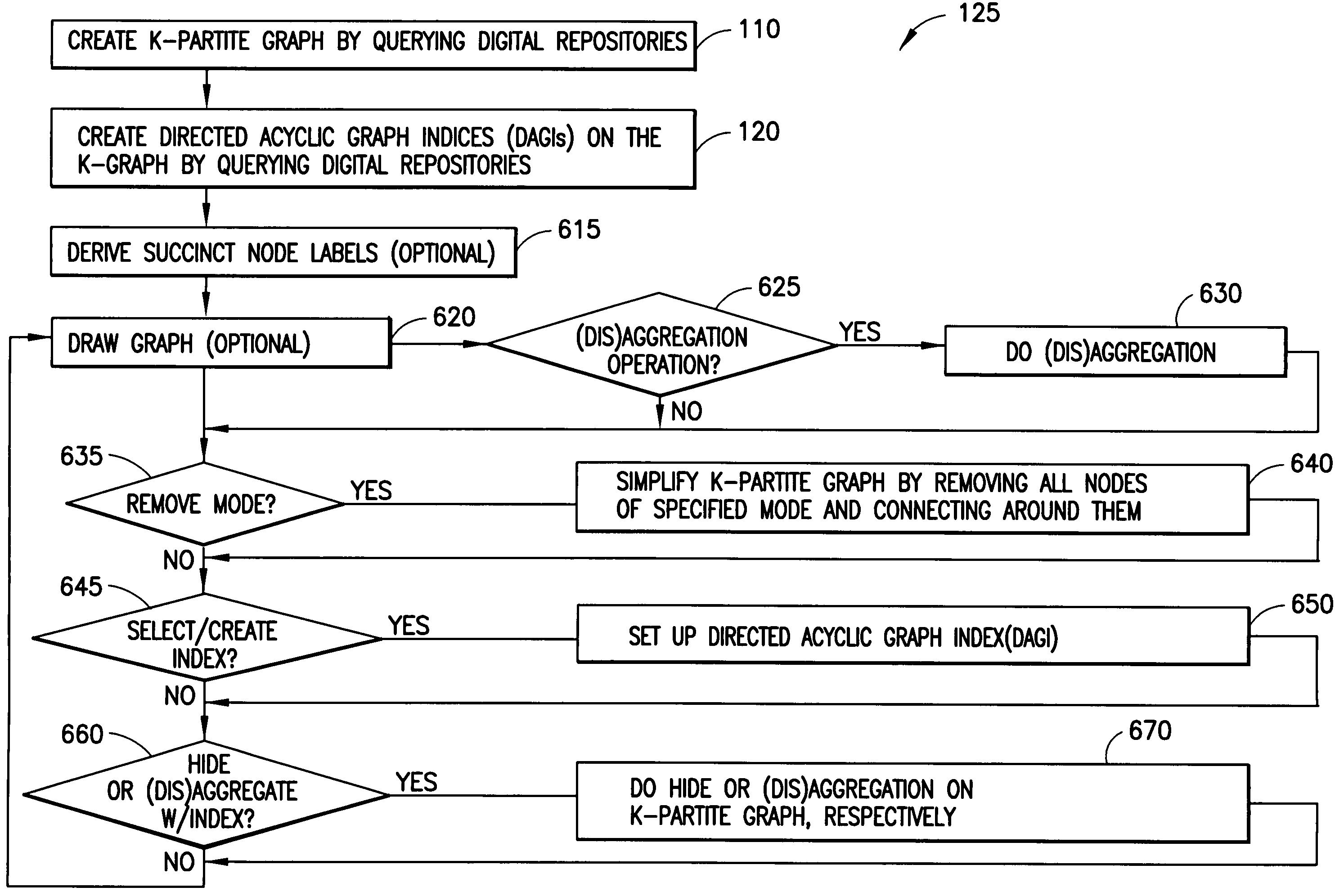

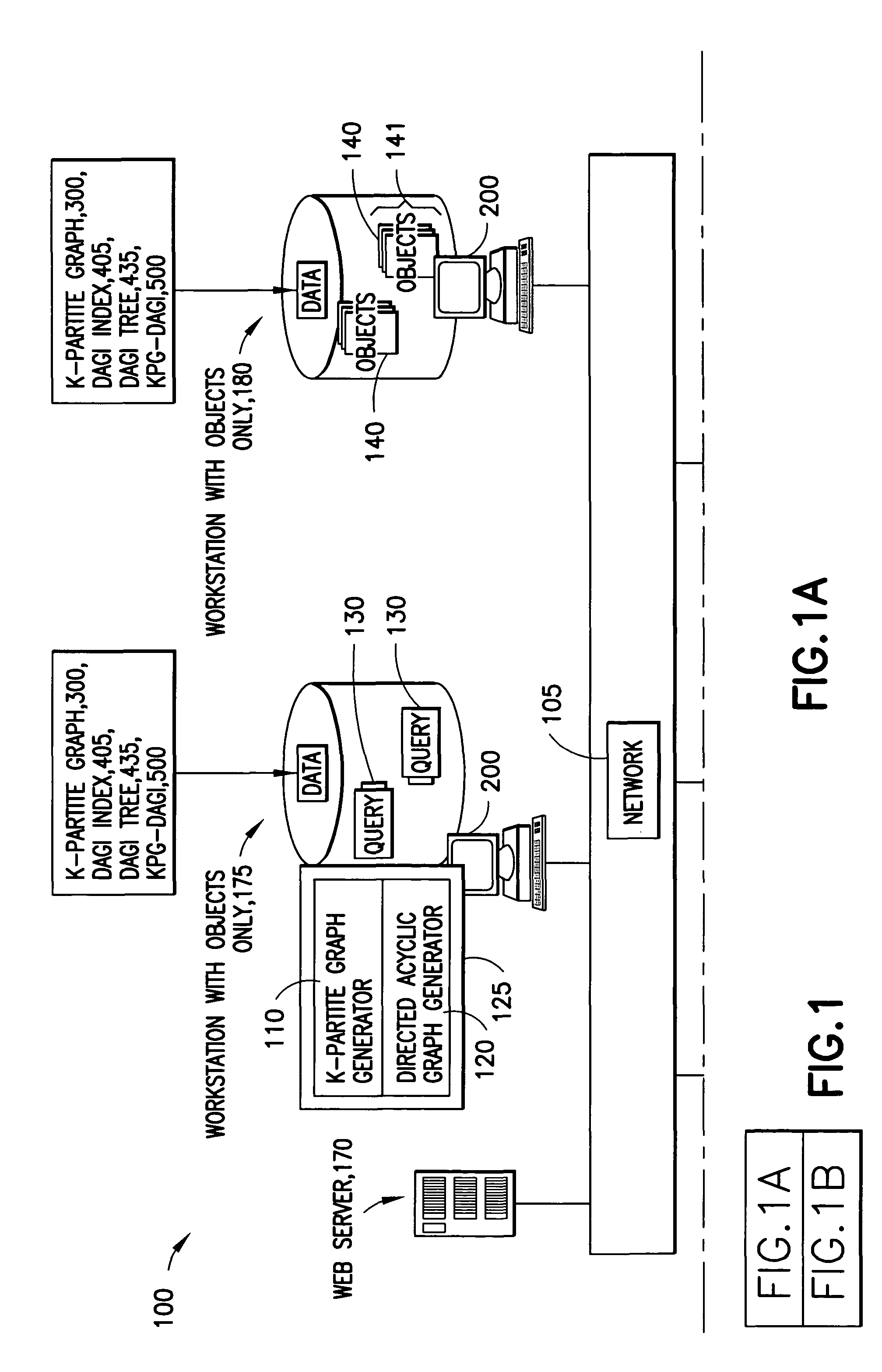

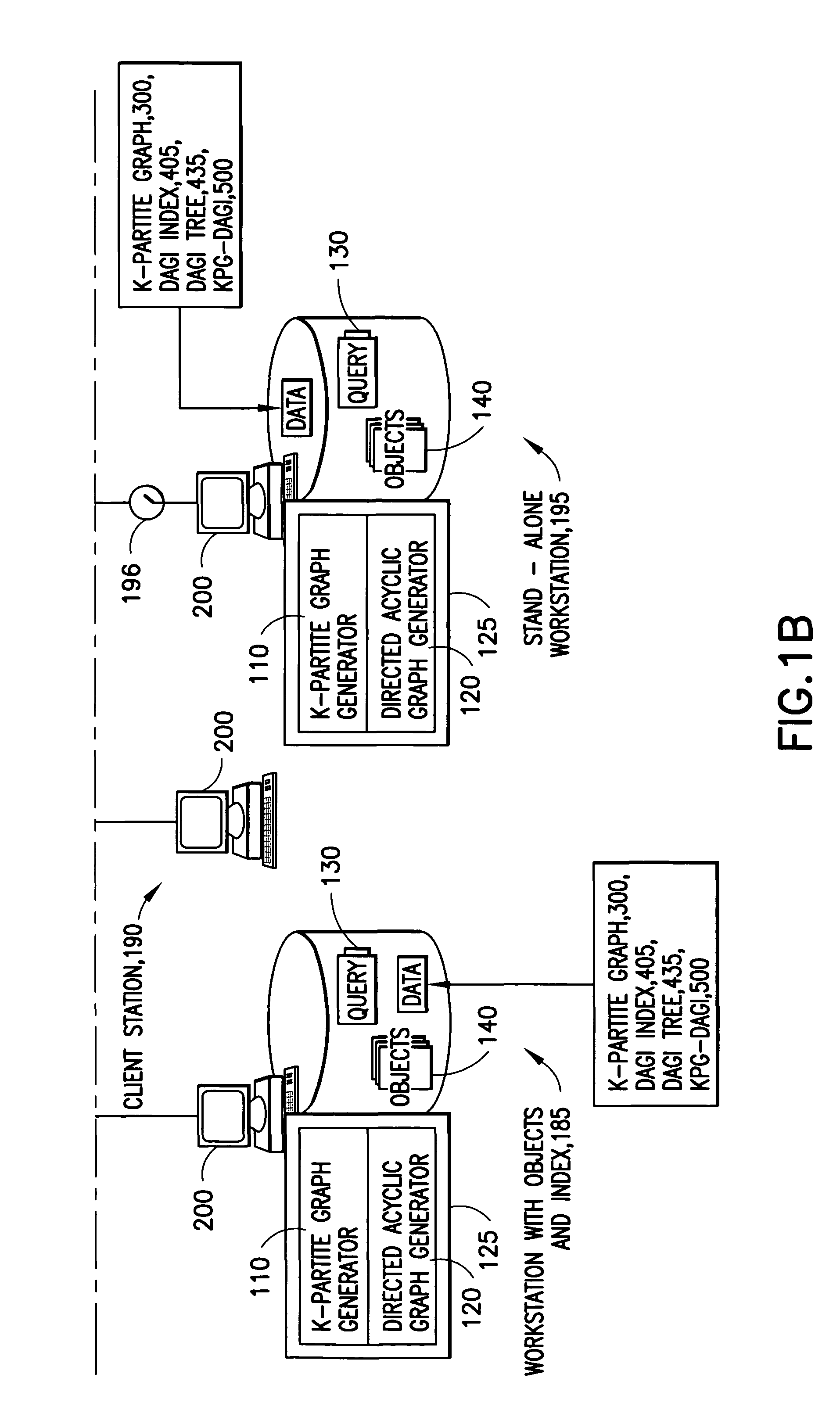

System and method for simplifying and manipulating k-partite graphs

InactiveUS7805440B2Sampled-variable control systemsData processing applicationsTheoretical computer scienceMultiple category

The system has a collection of a plurality of objects. Each object defines a node in a k-partite graph, such that, the nodes can be divided into a number of mutually exclusive sets such that all of the nodes are in exactly one of the sets; further edges occur only between nodes in different sets; The system also has a simplification process that aggregates one or more of the nodes into one or more categories and identifies a category node corresponding to each category. The category node inherits the mode and the edges of all the nodes in the respective category. Further, the system contains Directed Acyclic Graphs Indices (DAGIs) whose nodes may have a 1-1 mapping with the nodes in the k-partite graph. These indices can be used to aggregate and hide nodes in the k-partite graph. Aggregation occurs by selecting one or more non-leaf nodes in the DAGI and aggregating all descendent nodes. Hiding occurs by selecting some set of DAGI nodes, thus selecting some corresponding set of nodes in the k-partite graph, and requesting this set of nodes be hidden which effectively removes them from further consideration until they are restored by explicit request.

Owner:INT BUSINESS MASCH CORP

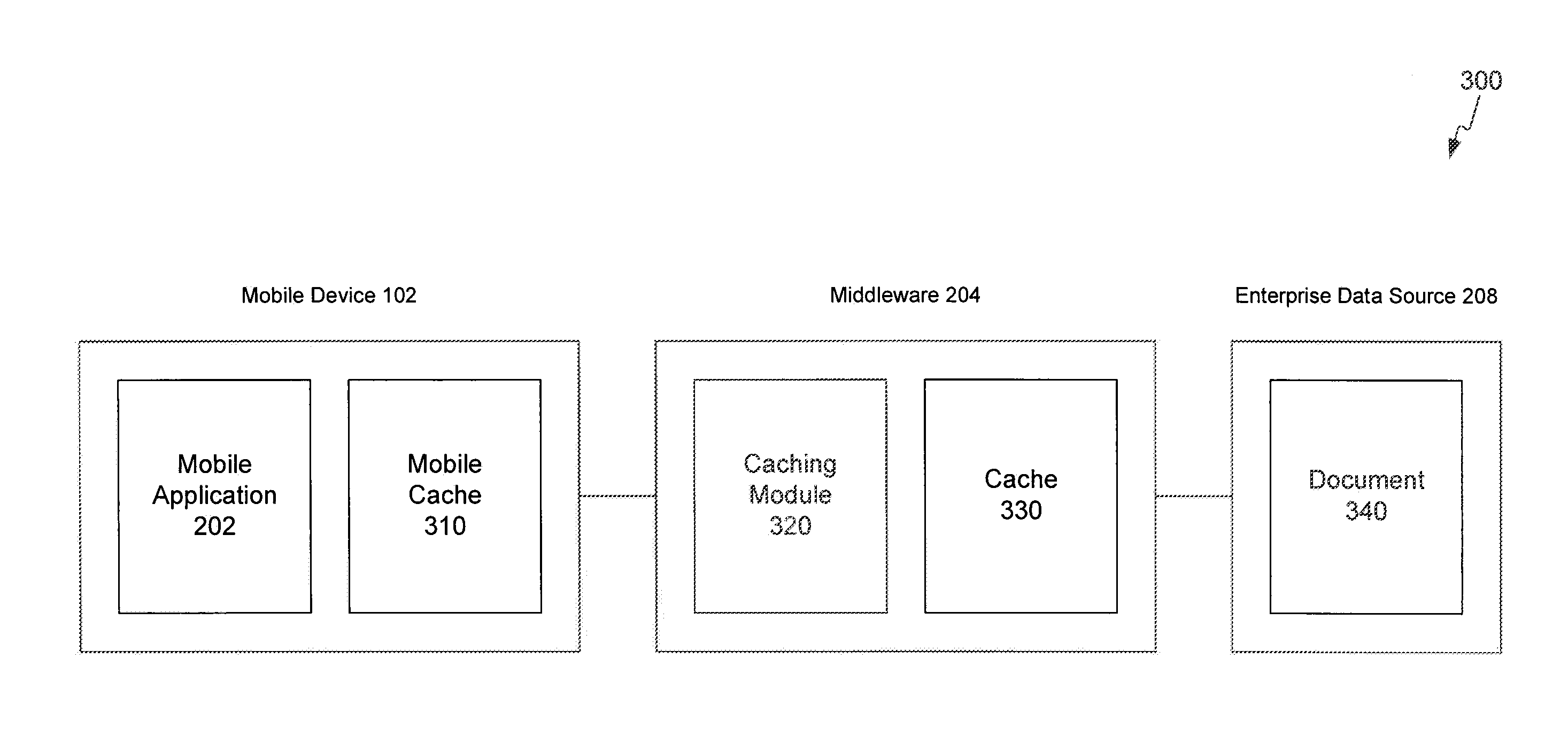

Cache conflict detection

ActiveUS20130318055A1Memory architecture accessing/allocationDigital data processing detailsAlgorithmApplication software

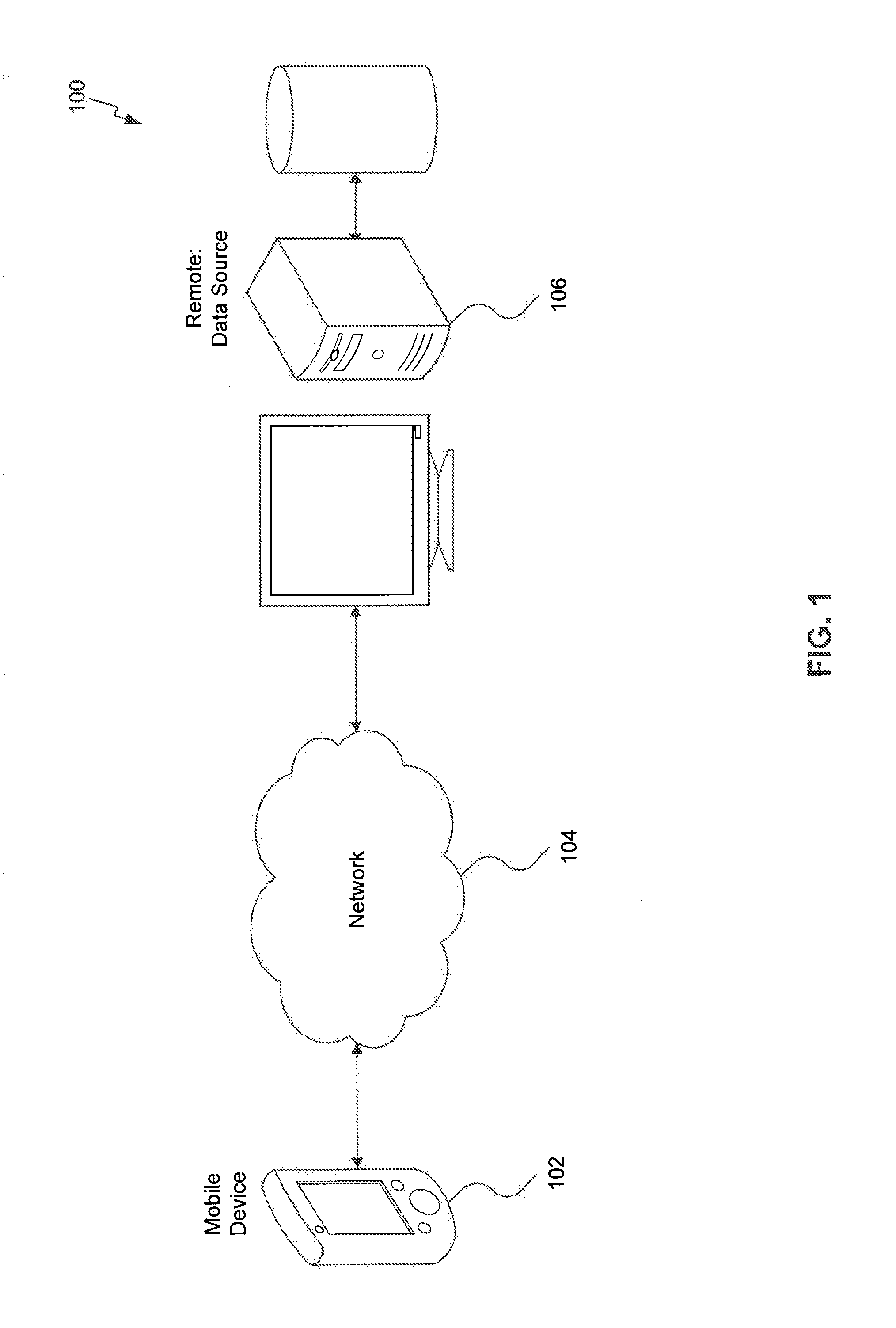

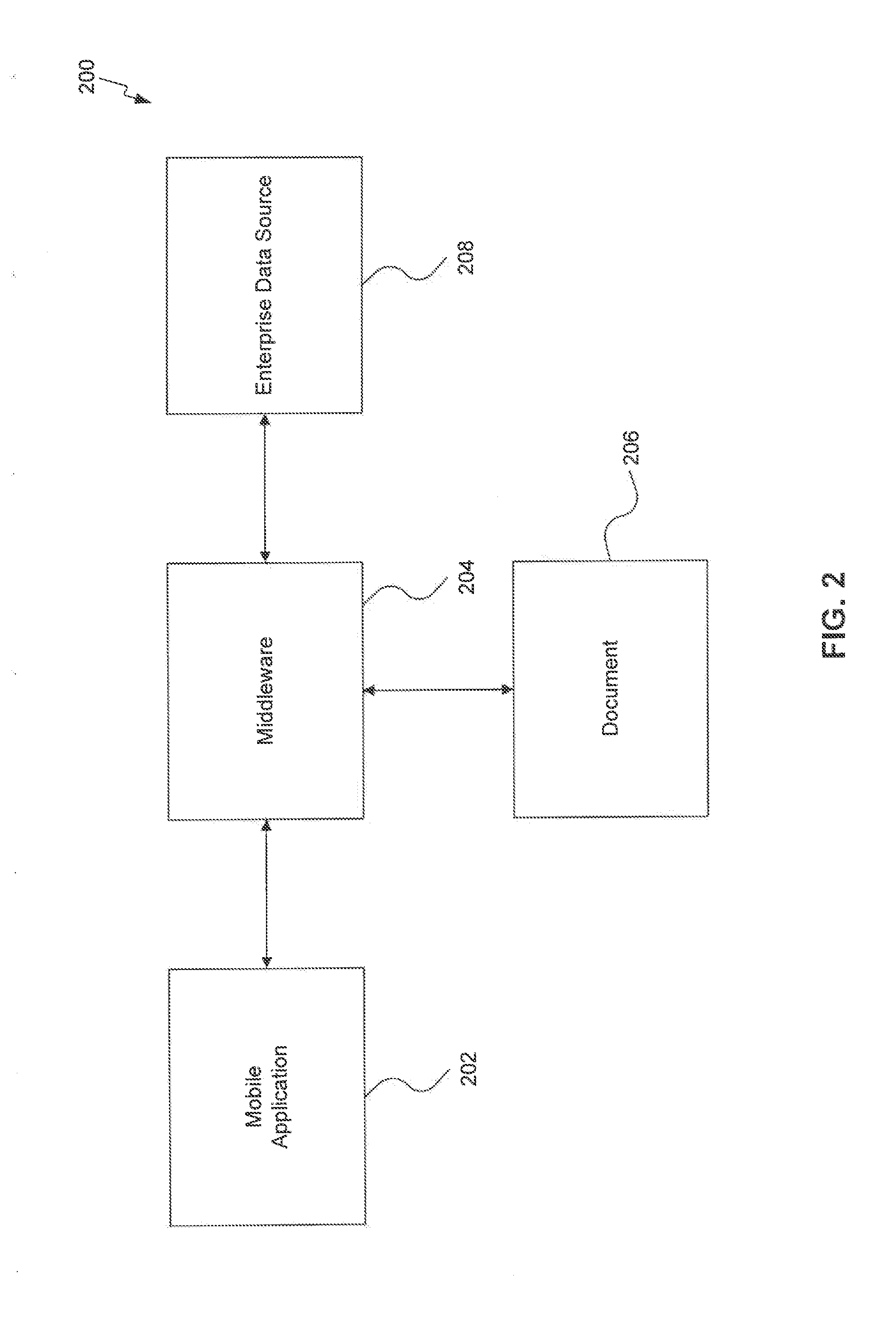

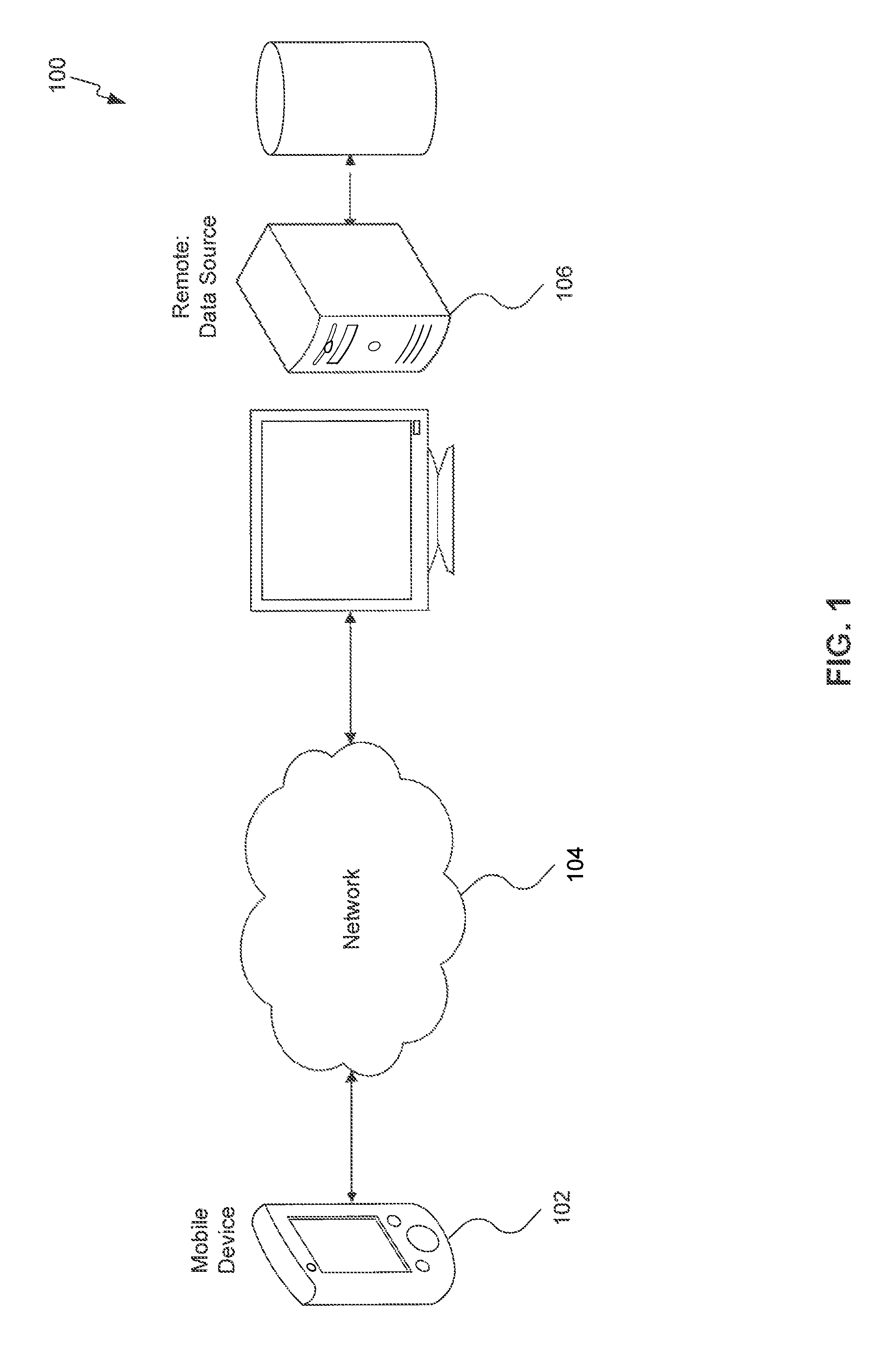

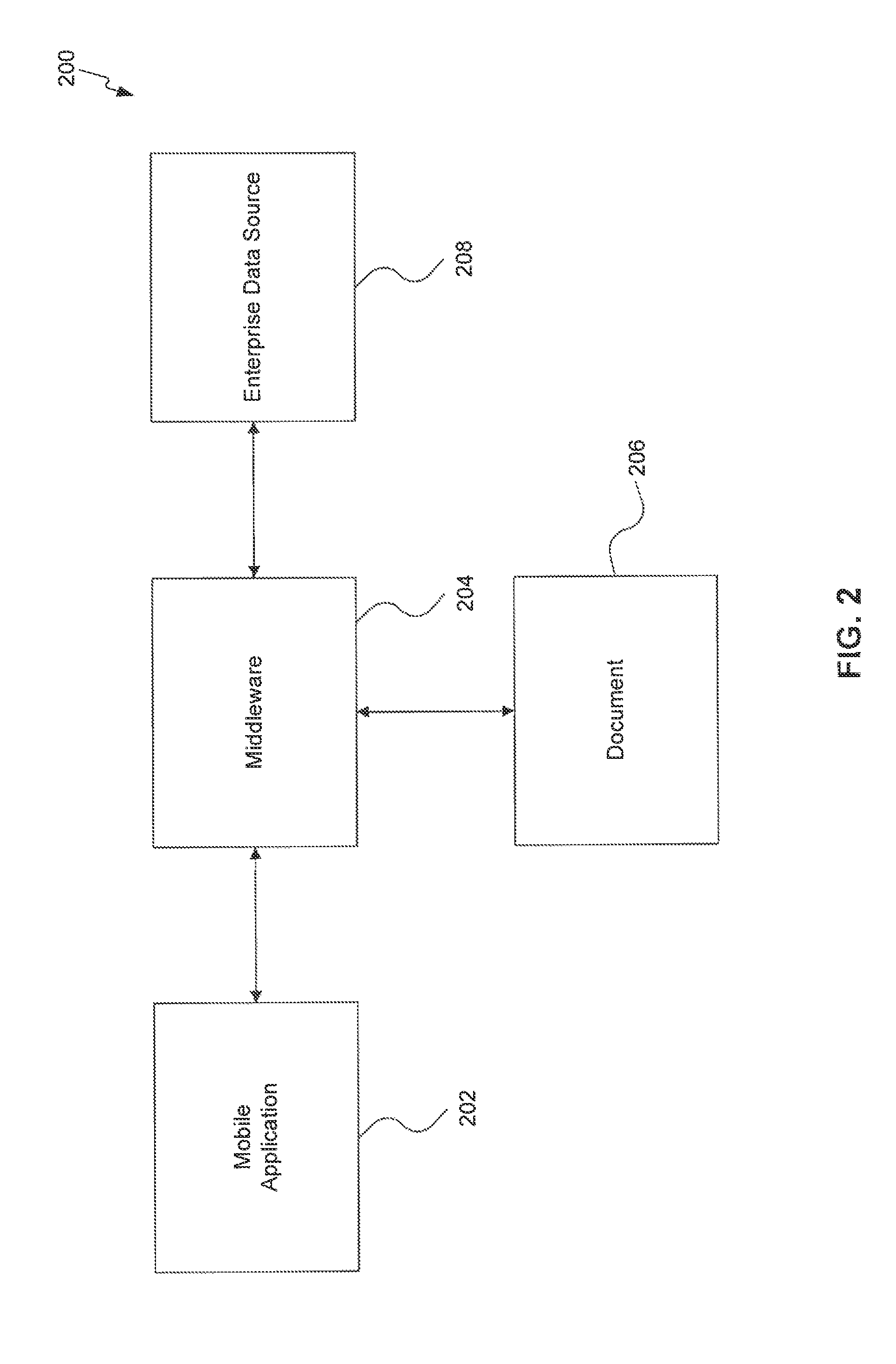

Methods, systems, and computer program products for cache conflict detection are provided. A computer-implemented method may include providing a partial graph of data to an application executing on a mobile device where the partial graph is derived from a document comprising a graph of data having a plurality of nodes, receiving a modified partial graph from the application where the modified partial graph includes one or more changes to the partial graph, and determining a document version used to derive the partial graph is no longer a most recent version of the document.

Owner:SYBASE INC

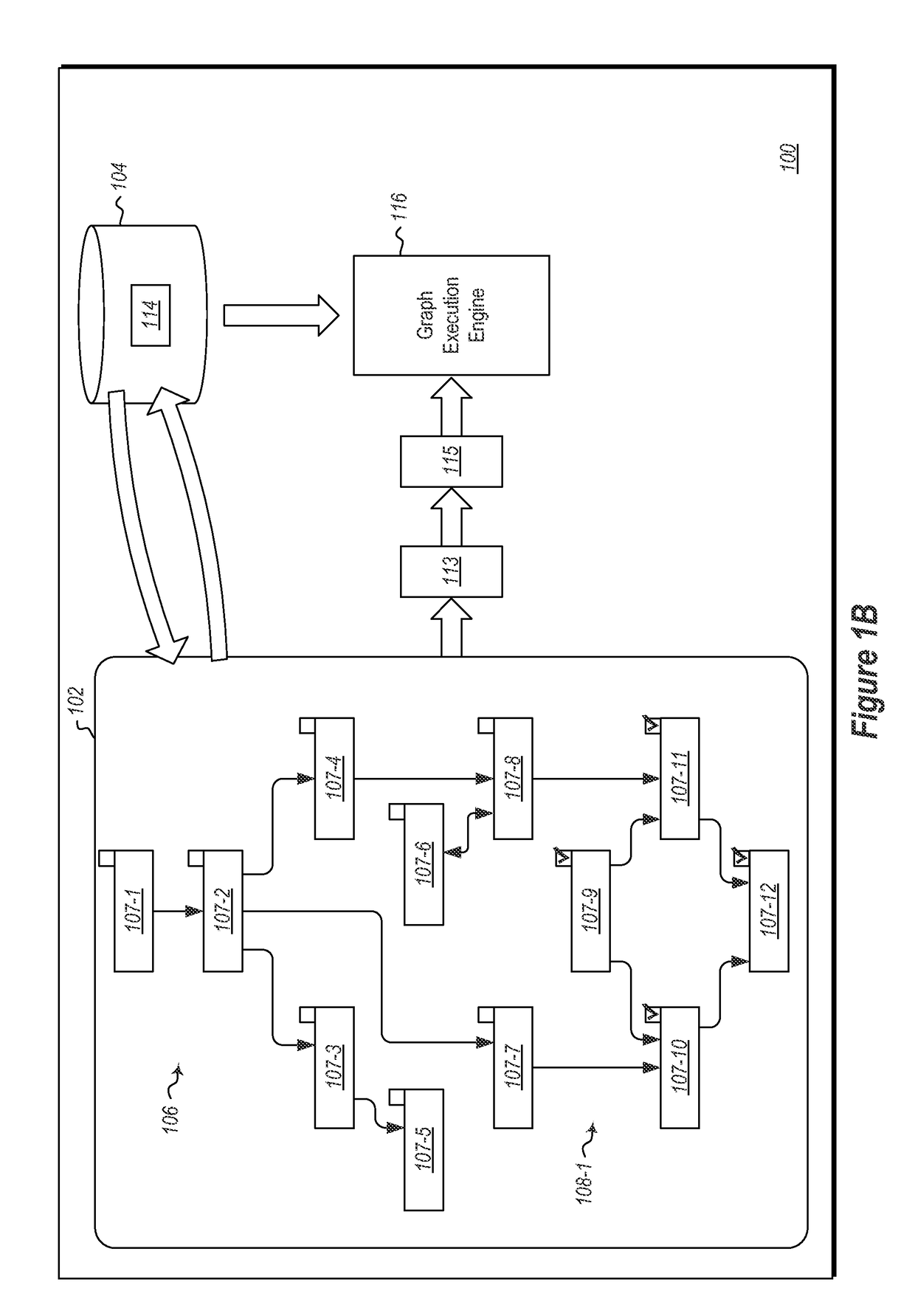

Interface for defining user directed partial graph execution

ActiveUS10108321B2Error detection/correctionExecution for user interfacesGraphicsTheoretical computer science

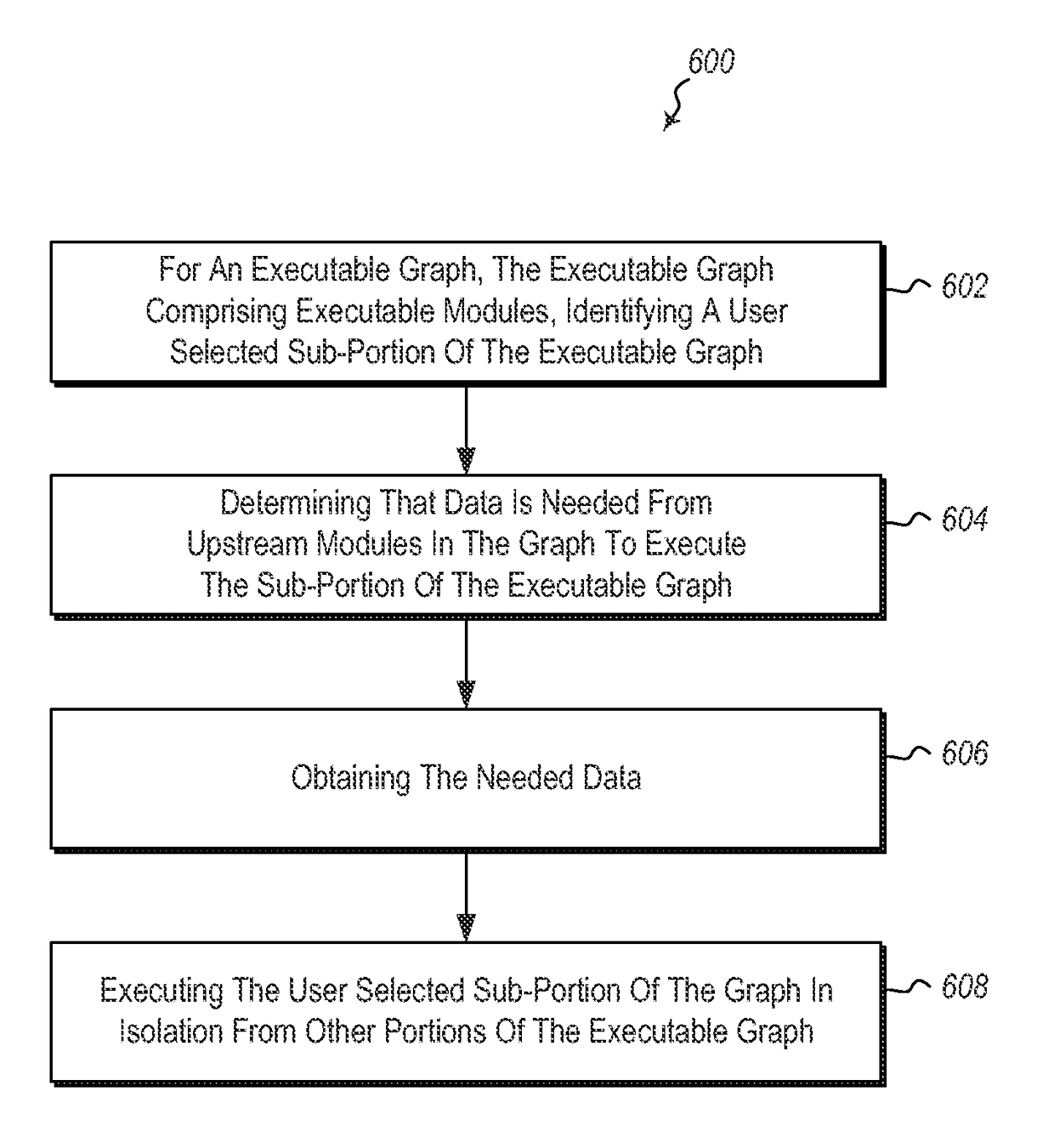

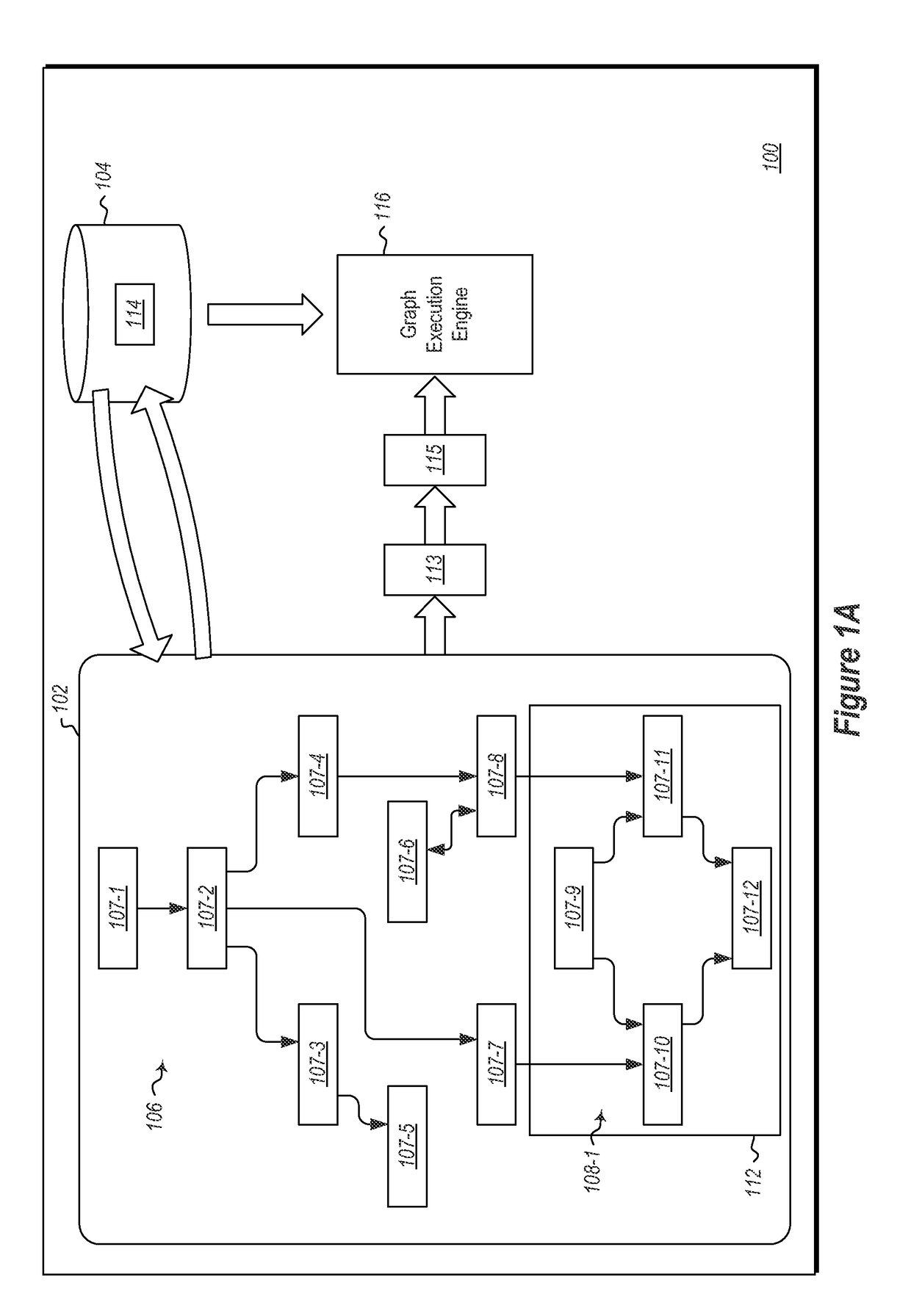

Executing a user defined portion of an executable graph. The method includes providing to a user a graphical representation of an executable graph, the executable graph comprising executable modules. The method further includes receiving from the user a selection of a sub-portion of the executable graph. The method further includes executing the user selected sub-portion of the graph in isolation from other portions of the executable graph.

Owner:MICROSOFT TECH LICENSING LLC

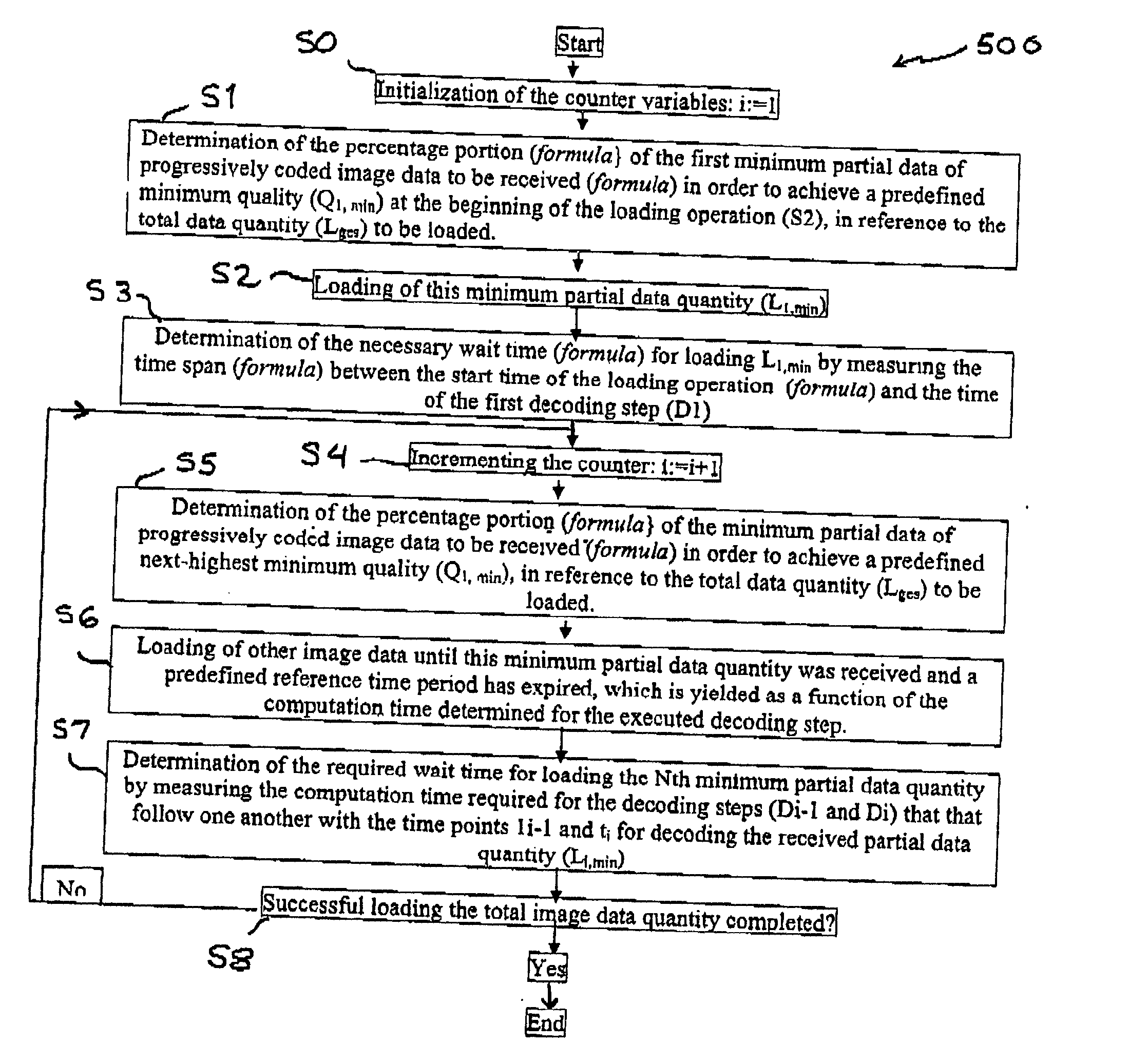

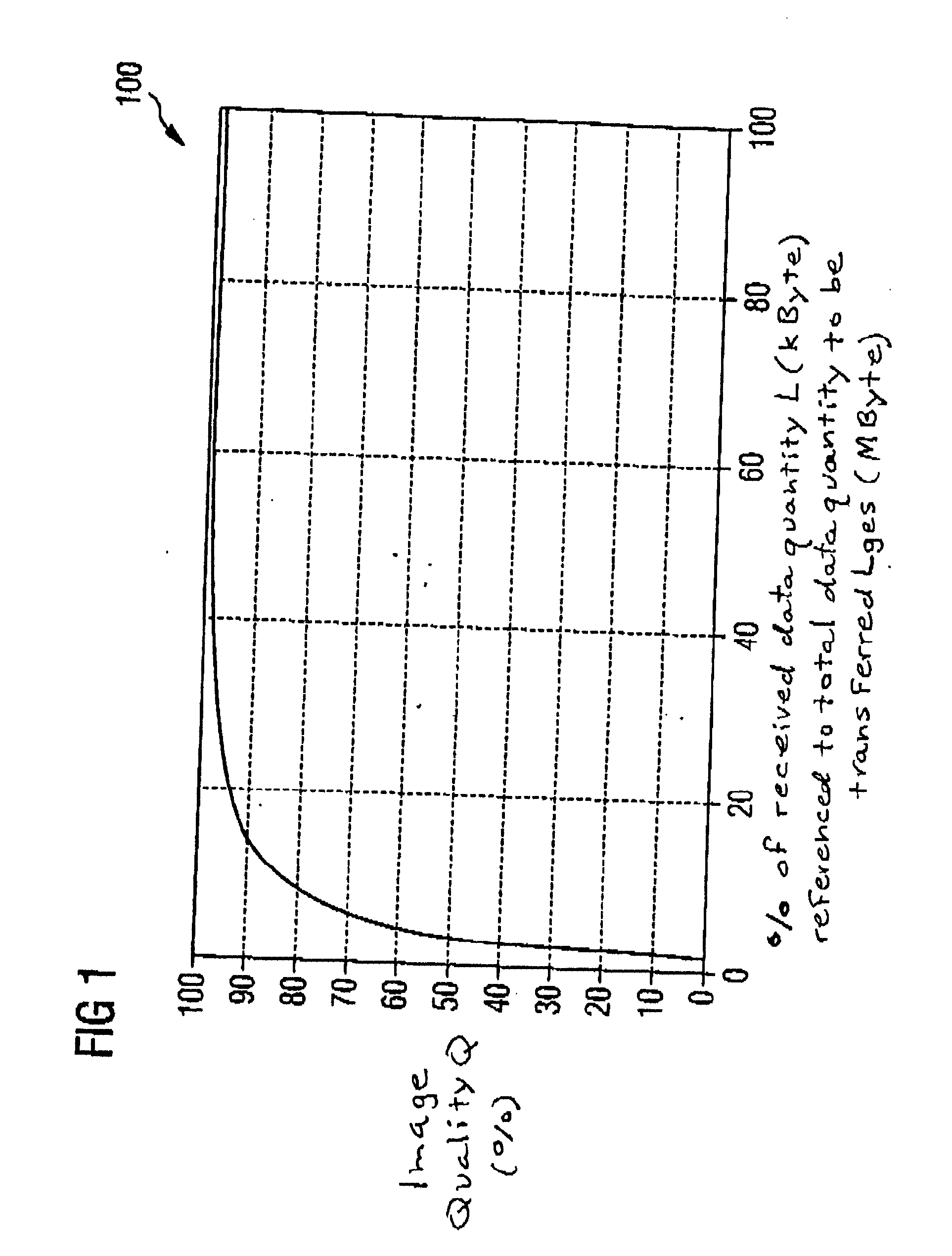

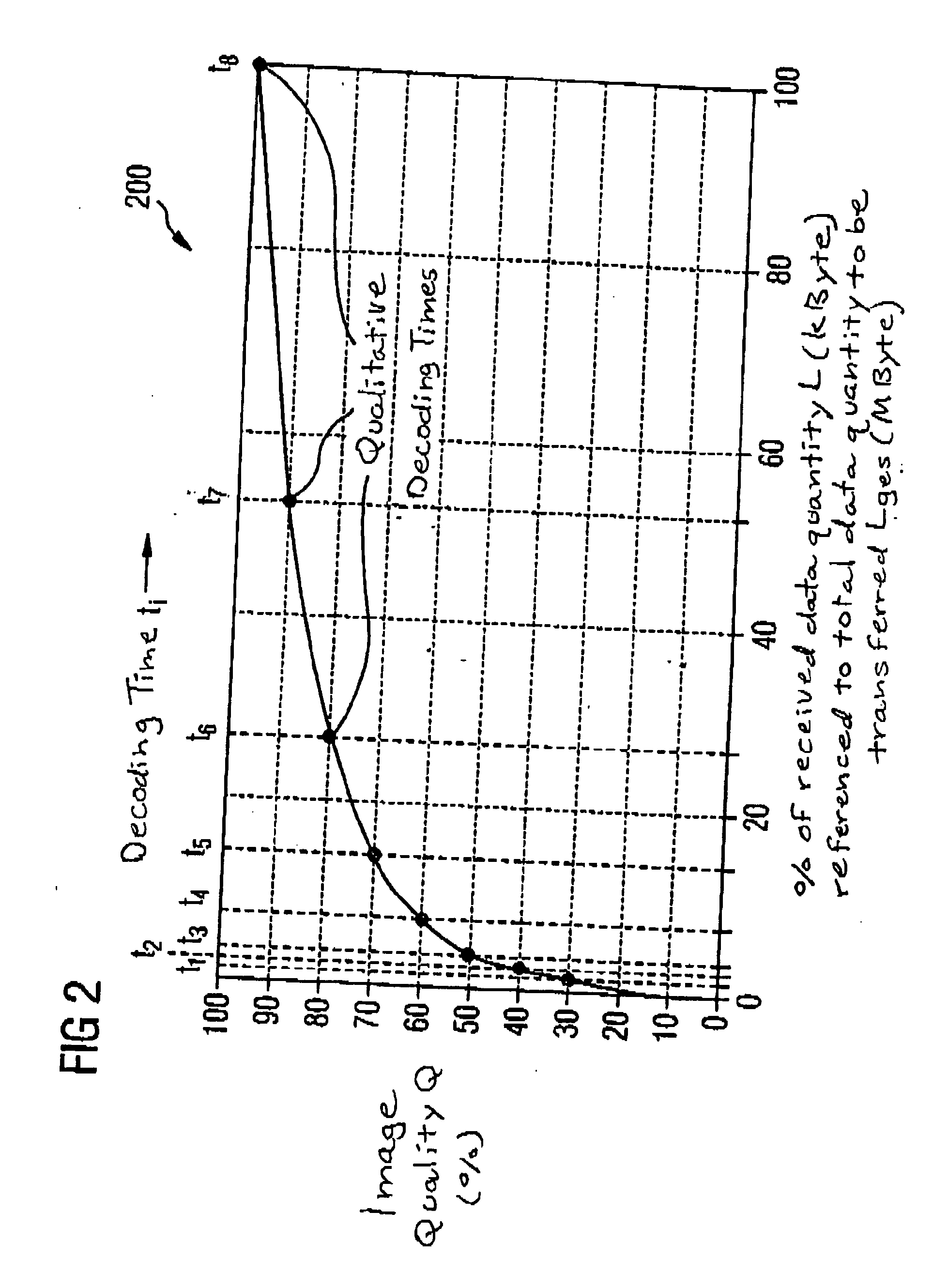

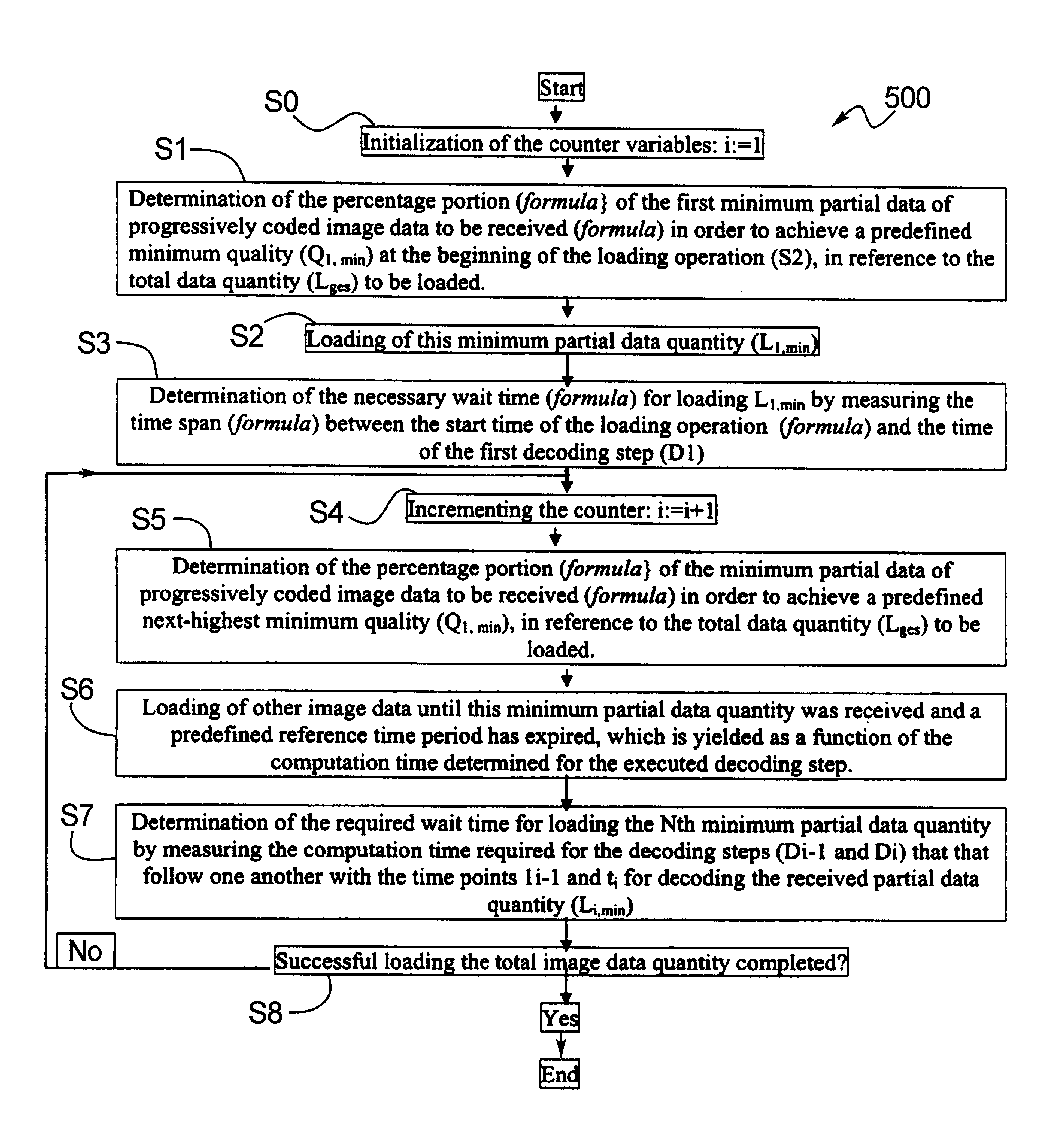

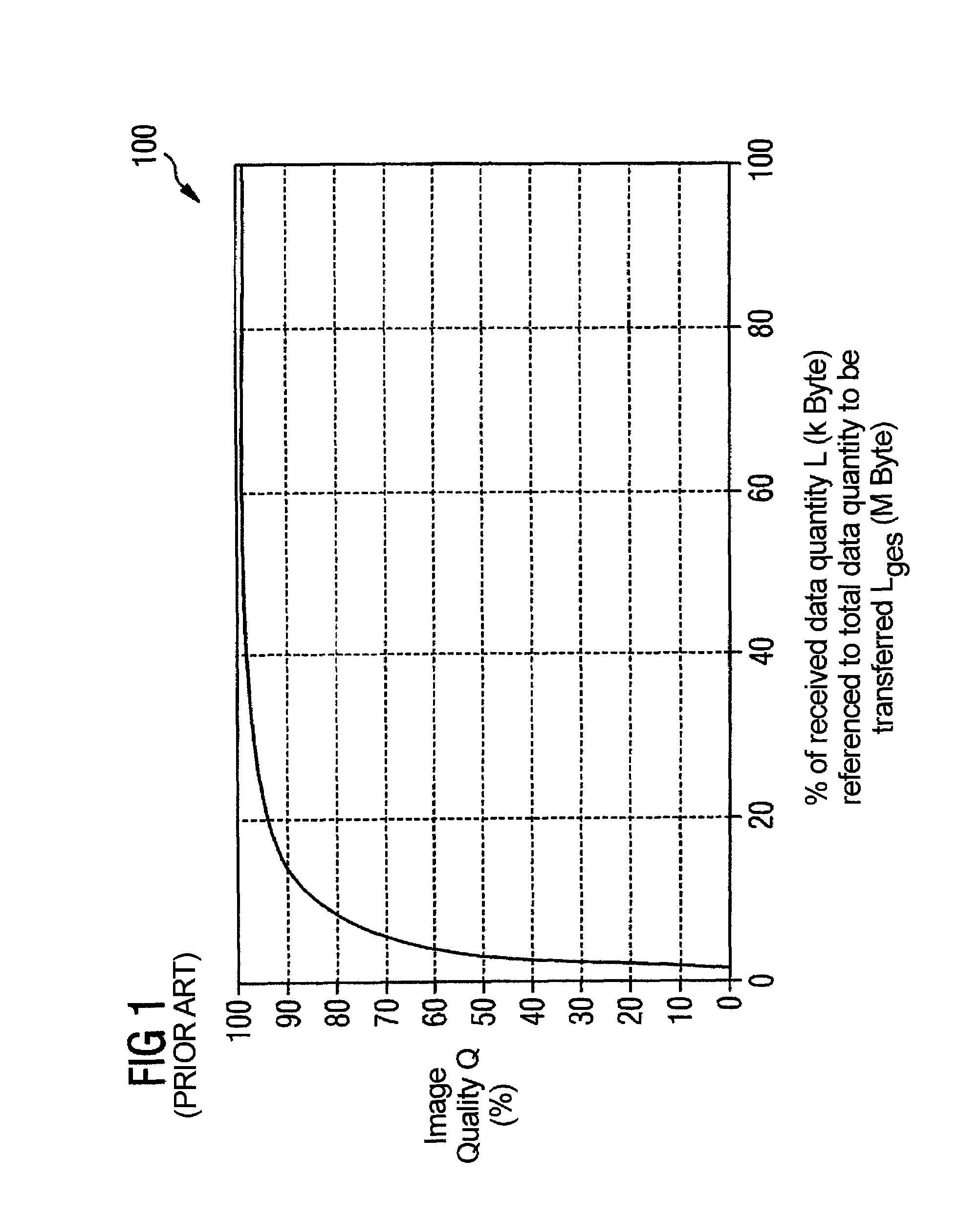

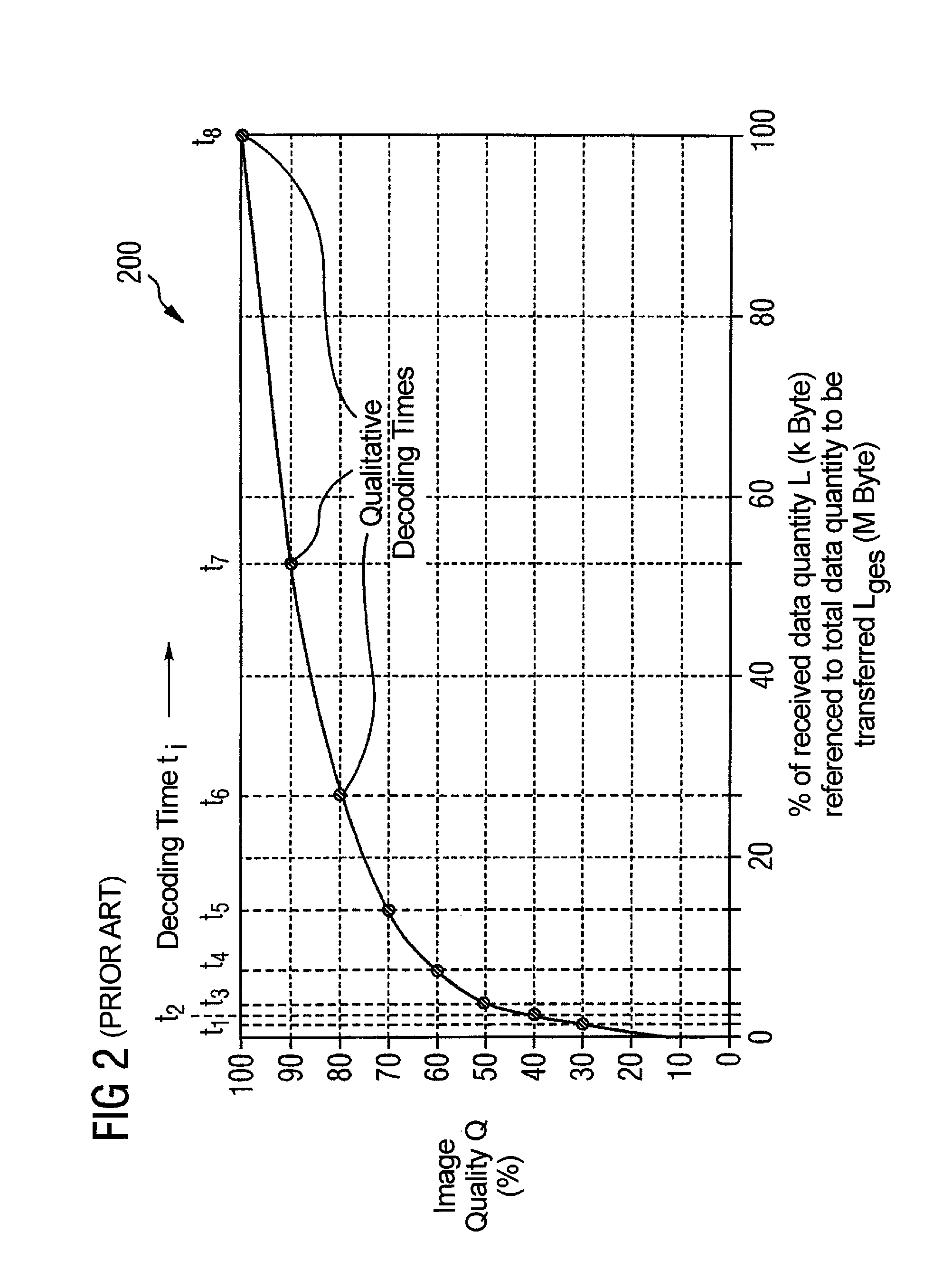

Process and functional unit for the optimization of displaying progressively coded image data

InactiveUS20050008234A1Easy to downloadImage codingCharacter and pattern recognitionGraphicsImage resolution

In a process and unit for gradual decoding, archiving and graphic display of progressively decoded image data, time intervals between the time points of consecutive decoding steps, during which network users receive ever more refined image resolution when downloading image data from a central network server to the client computer using transferred and decoded partial data quantities ΔLi as preview images, are generated with abbreviated time spans that are optimized with respect to minimization of system usage by the decoding system. For this purpose, the receiving data rates for transfer of the individual partial data quantities, which are taken into account through improvements generated by the individual decoding steps of a quality metric showing the degree of image resolution and the temporary usage of the decoding system upon determination of the decoding time points. The wait times between the time points of directly consecutive decoding steps are calculated using statistical image quality parameters of received partial image data in such a manner that the decoding steps which do not lead to a perceptible improvement in the quality of a reconstructed image are suppressed.

Owner:SIEMENS HEALTHCARE GMBH

Methods for finger biometric processing and associated finger biometric sensors

A method for processing a plurality of biometric fingerprint images corresponding to parts of a fingerprint, the method accounting for uncertainty in the alignment of the parts. The method includes generating a respective estimated transformation between each pair of partial biometric fingerprint images, and generates a respective uncertainty for each estimated transformation. A graph structure called logical fingerprint biometric image graph may be associated with the above data wherein the partial images correspond to nodes and the estimated transformations and their respective uncertainty correspond to edges. The logical fingerprint biometric image graph is readily used for subsequent accurate matching in either touch sensor applications or slide sensor applications.

Owner:AUTHENTEC

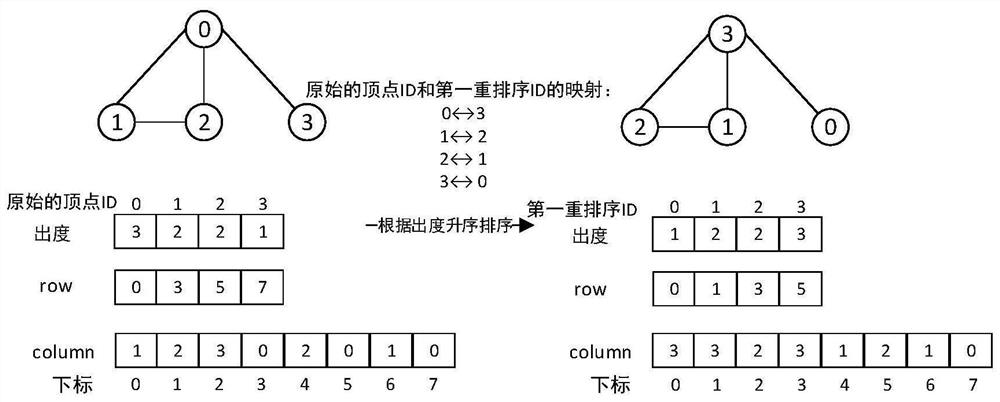

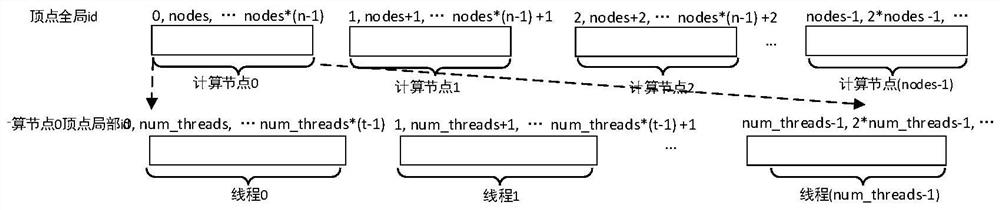

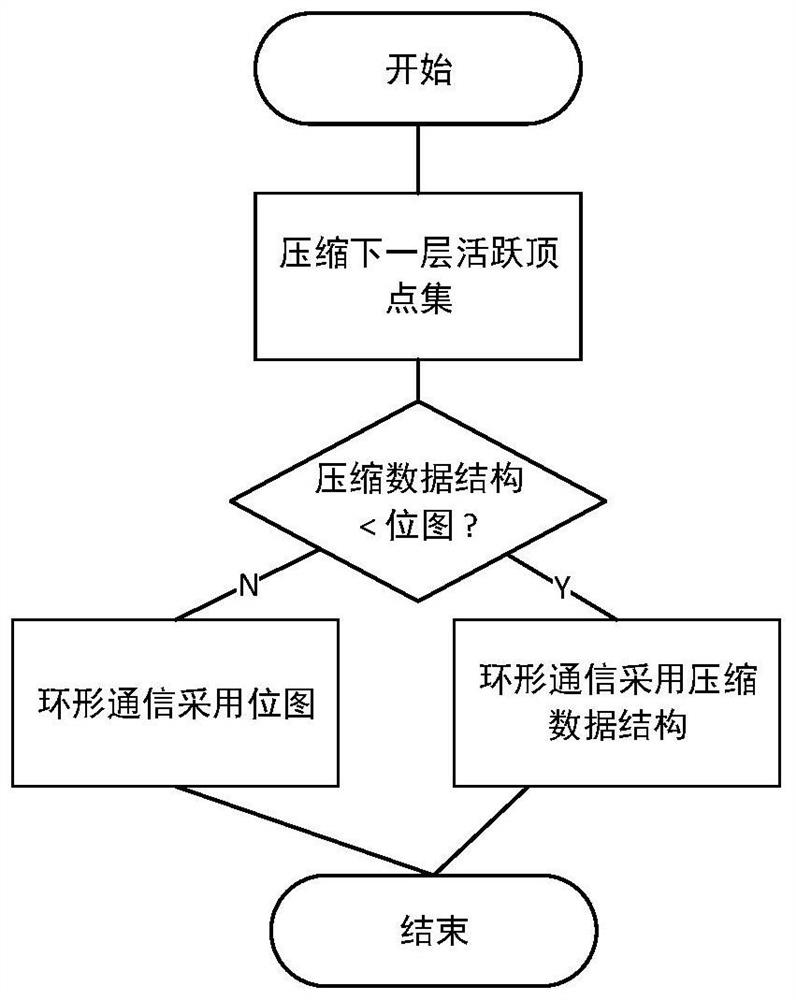

Graph data processing method applied to distributed computing node cluster and medium

ActiveCN111737540AReduce the amount of data transferredReduce trafficOther databases indexingOther databases queryingComputational scienceData compression

The embodiment of the invention provides a graph data processing method, which comprises the following steps of: S1, obtaining graph data containing a plurality of vertexes, sorting the vertexes according to the descending order of the vertexes, and taking a sorting serial number as a first resorting ID; S2, sequentially distributing the vertexes of the graph data to each distributed computing node in a distributed computing node cluster in a polling manner according to the first reordering ID and preset granularity; S3, traversing the obtained partial graph data by the computational nodes byusing a hybrid BFS algorithm, and obtaining a local next-layer active vertex set by each computational node after each layer is traversed; S4, after each layer is traversed, performing loop communication between adjacent computing nodes to transmit a local next-layer active vertex set, and determining the compression mode of the local next-layer active vertex set to be transmitted this time beforethe local next-layer active vertex set is transmitted after partial-layer traversal. According to the invention, vertex IDs are subjected to reordering, data compression and loop communication through the out-degree of the vertexes, and the communication efficiency is improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Process for cleaning high-precision screen printing plates

The invention relates to a process for cleaning high-precision screen printing plates, which comprises the steps of: 1 rapidly taking down a screen printing plate in one minute after printing, and collecting residual silver paste on the screen printing plate in two minutes; 2 simultaneously wiping the front side and the back side of the screen printing plate with non-woven fabric wetted in a TM plate washing agent along the direction of mesh stretching angles; 3 after the both sides of the screen printing plate are cleaned by the TM washing agent, simultaneously wiping the front and the back sides of graphics fields with non-woven fabric wetted in a DM plate washing agent along the direction of mesh stretching angles, 4 checking graphs with lights, if partial graphs are invisible, simultaneously wiping the front and the back sides of the field with non-woven fabric wetted in the DM plate washing agent along the direction of mesh stretching angles, until the graphs are visible, wherein the whole wiping process is not more than ten minutes; and 5 after the screen plating plate is wiped clean, drying the screen printing plate with an ion blower gun. The process can rapidly clean the high-precision screen printing plates completely, and is quite effective to plates with high-precision screen printing silver paste that is difficult to be cleaned, has low cleaning cost, and guarantees the normal production.

Owner:TIANJIN ZHONGHUAN HI TECH

Process and functional unit for the optimization of displaying progressively coded image data

InactiveUS7409096B2Easy to downloadImage codingCharacter and pattern recognitionGraphicsImaging quality

In a process and unit for gradual decoding, archiving and graphic display of progressively decoded image data, time intervals between the time points of consecutive decoding steps, during which network users receive ever more refined image resolution when downloading image data from a central network server to the client computer using transferred and decoded partial data quantities ΔLi as preview images, are generated with abbreviated time spans that are optimized with respect to minimization of system usage by the decoding system. For this purpose, the receiving data rates for transfer of the individual partial data quantities, which are taken into account through improvements generated by the individual decoding steps of a quality metric showing the degree of image resolution and the temporary usage of the decoding system upon determination of the decoding time points. The wait times between the time points of directly consecutive decoding steps are calculated using statistical image quality parameters of received partial image data in such a manner that the decoding steps which do not lead to a perceptible improvement in the quality of a reconstructed image are suppressed.

Owner:SIEMENS HEALTHCARE GMBH

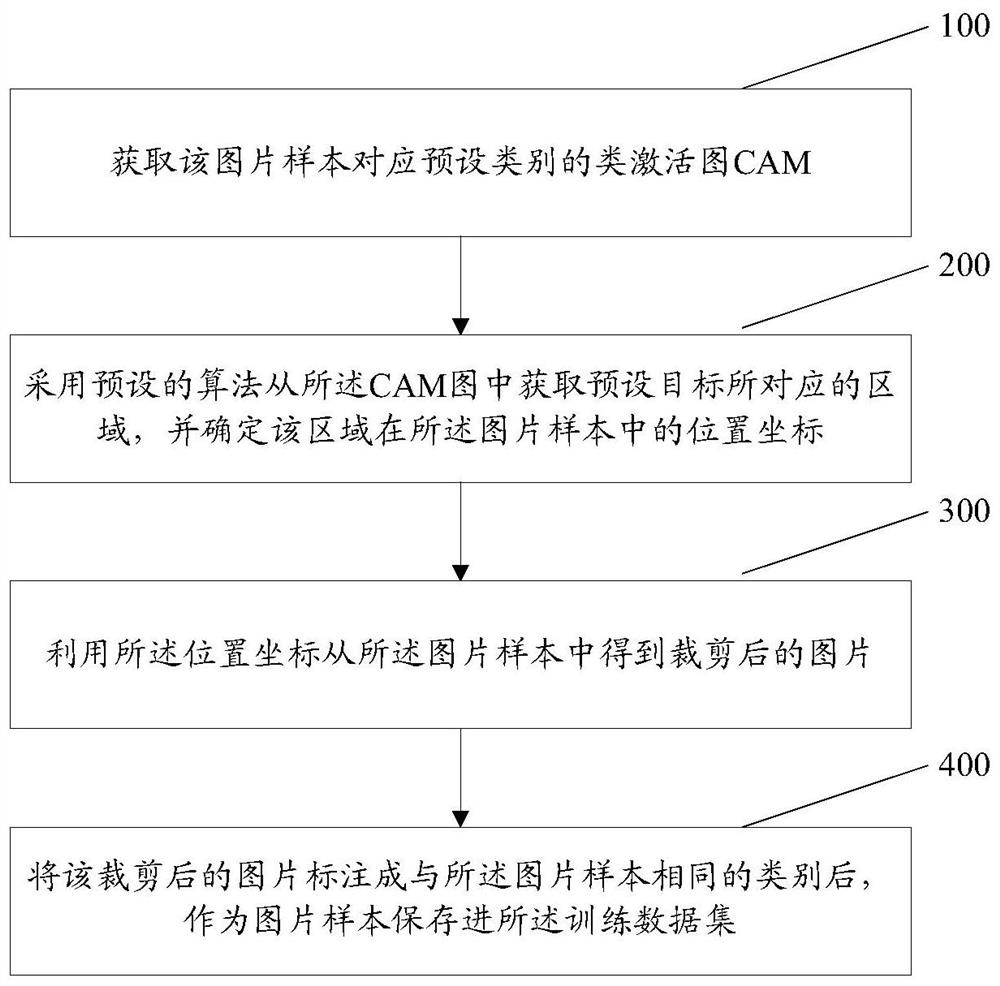

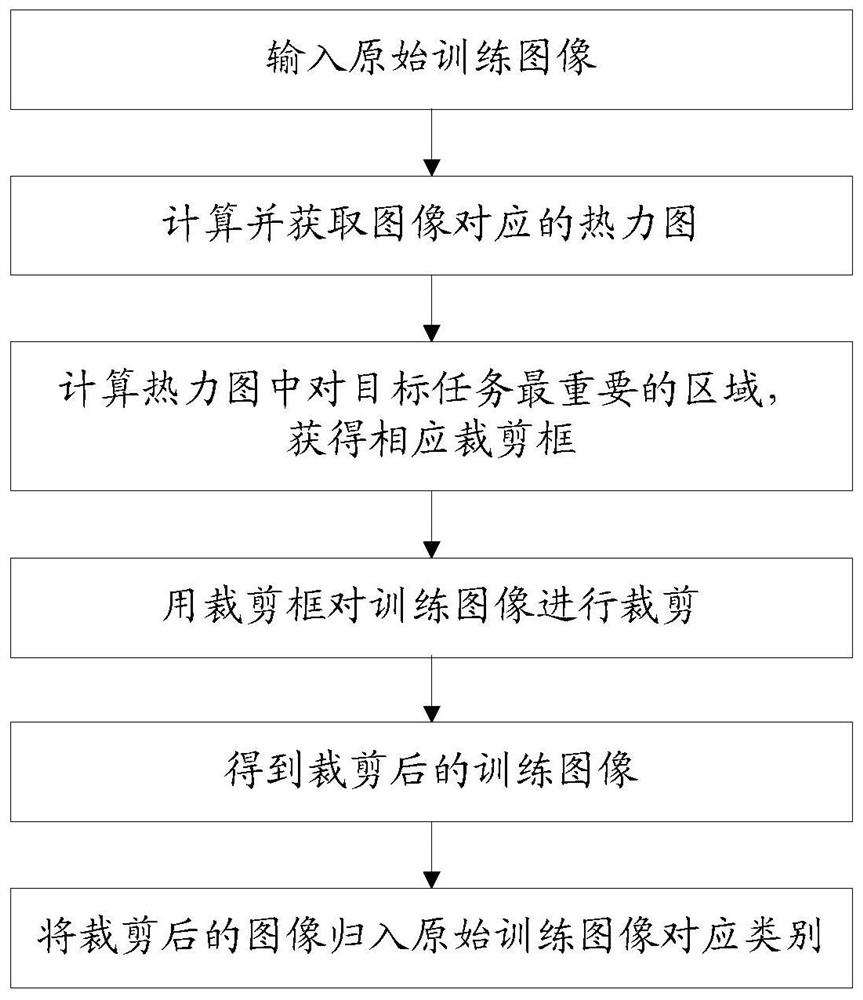

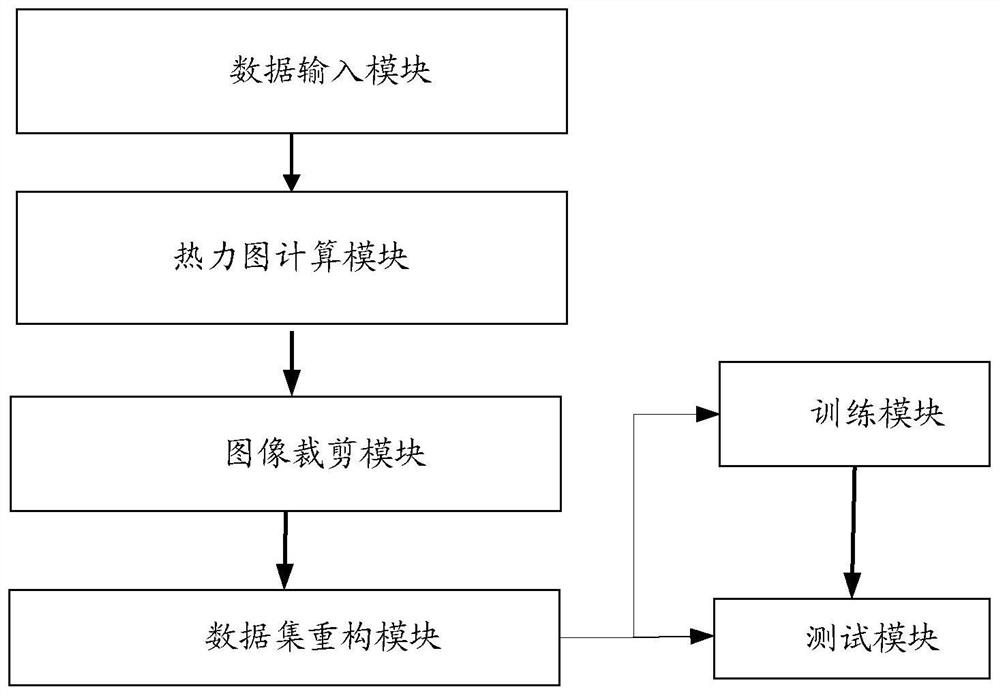

Data set expansion and training method and device of an image classification model

The embodiment of the invention discloses a data set expansion and training method and device of an image classification model, the image classification model is realized based on a convolutional neural network, and the data set expansion method comprises the following steps: for each picture sample in at least part of picture samples in a training data set of the image classification model, respectively executing the following operations: obtaining a class activation graph CAM of a preset class corresponding to the picture sample; obtaining an area corresponding to a preset target from the CAM graph by adopting a preset algorithm, and determining a position coordinate of the area in the picture sample; obtaining a cut picture from the picture sample by utilizing the position coordinates; and labeling the cut picture as the same category as the picture sample, and storing the picture sample into the training data set. According to the scheme of the invention, in the training process of the image classification model, effective training data set samples can be added.

Owner:TSINGHUA UNIV

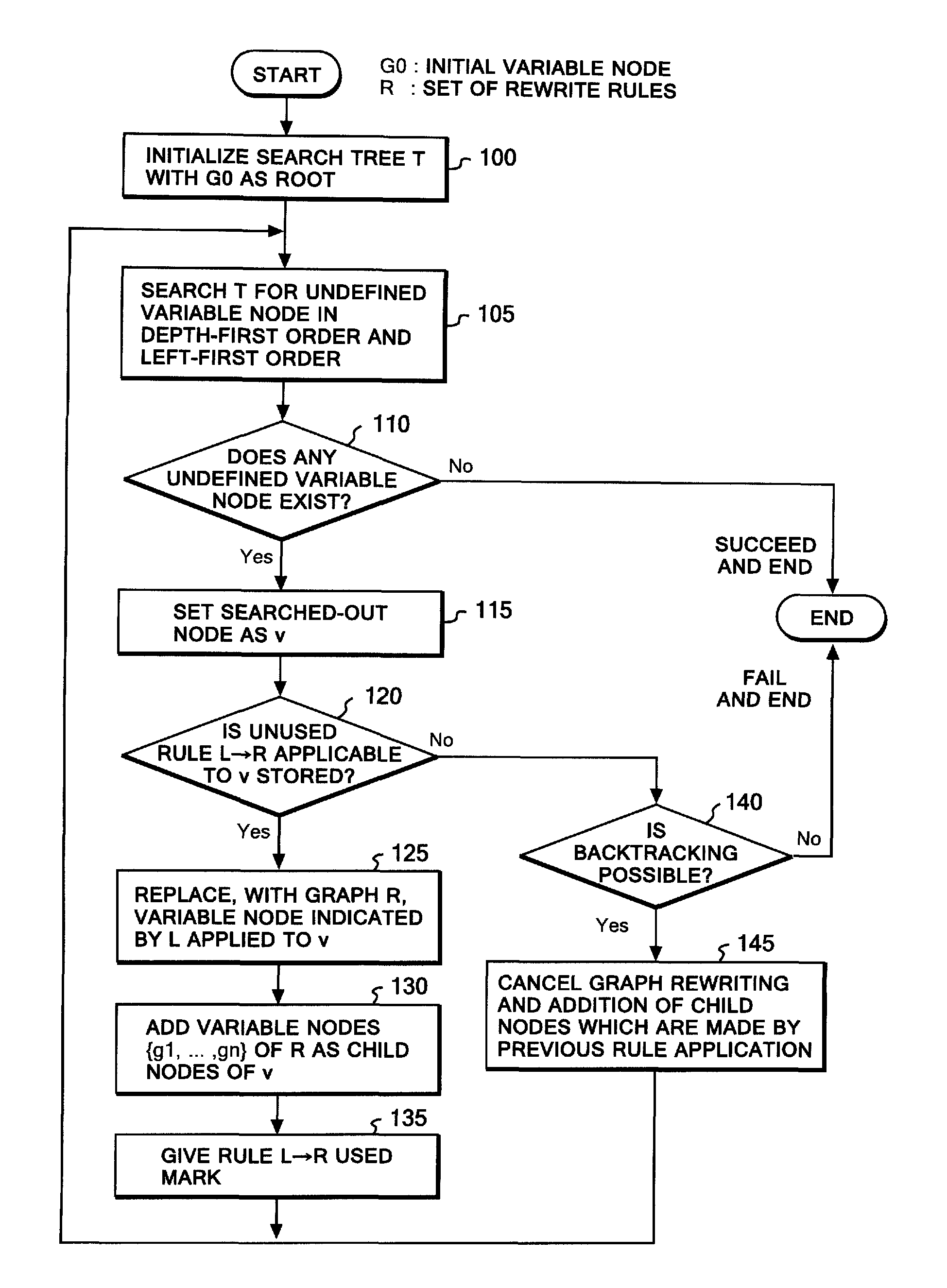

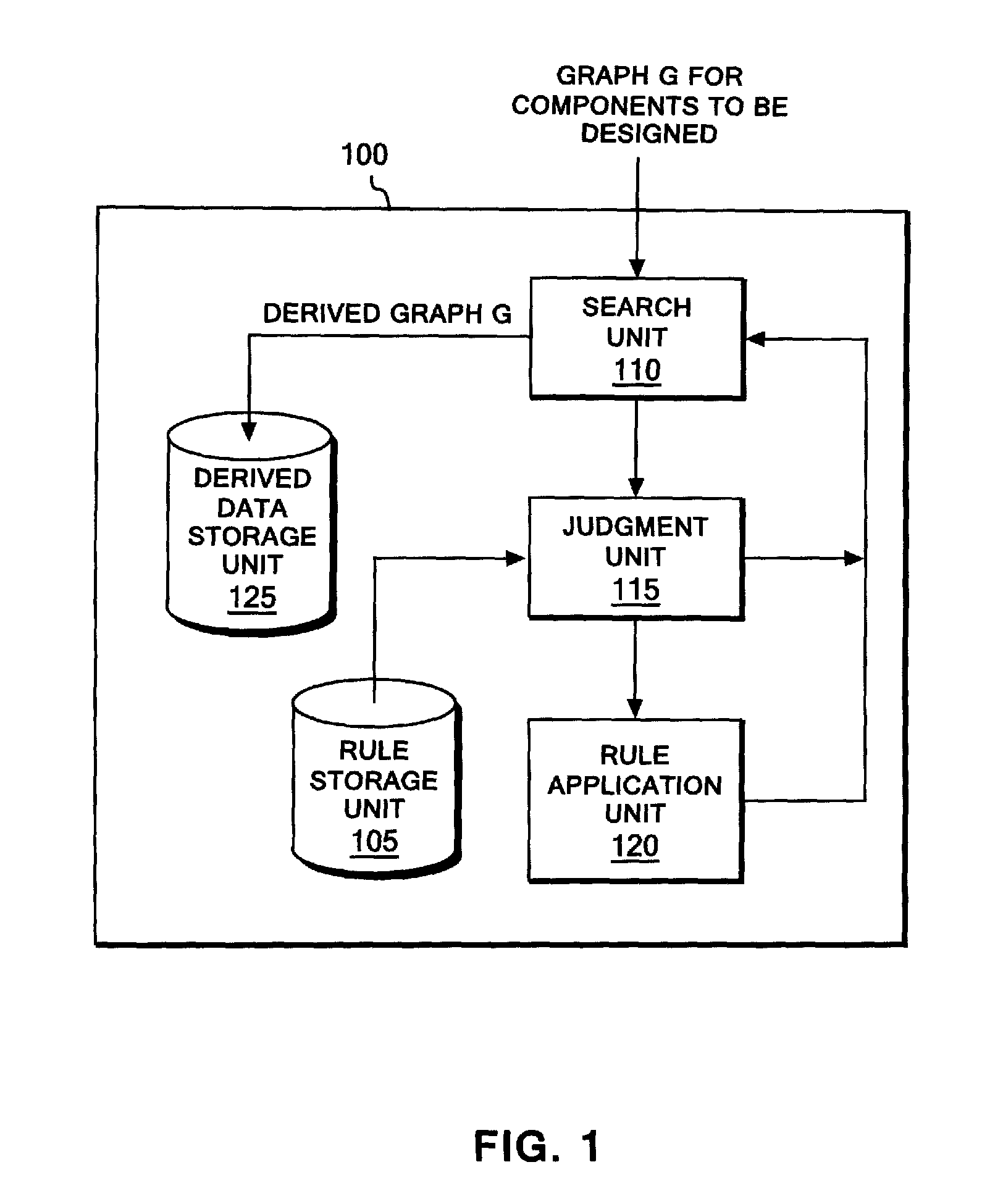

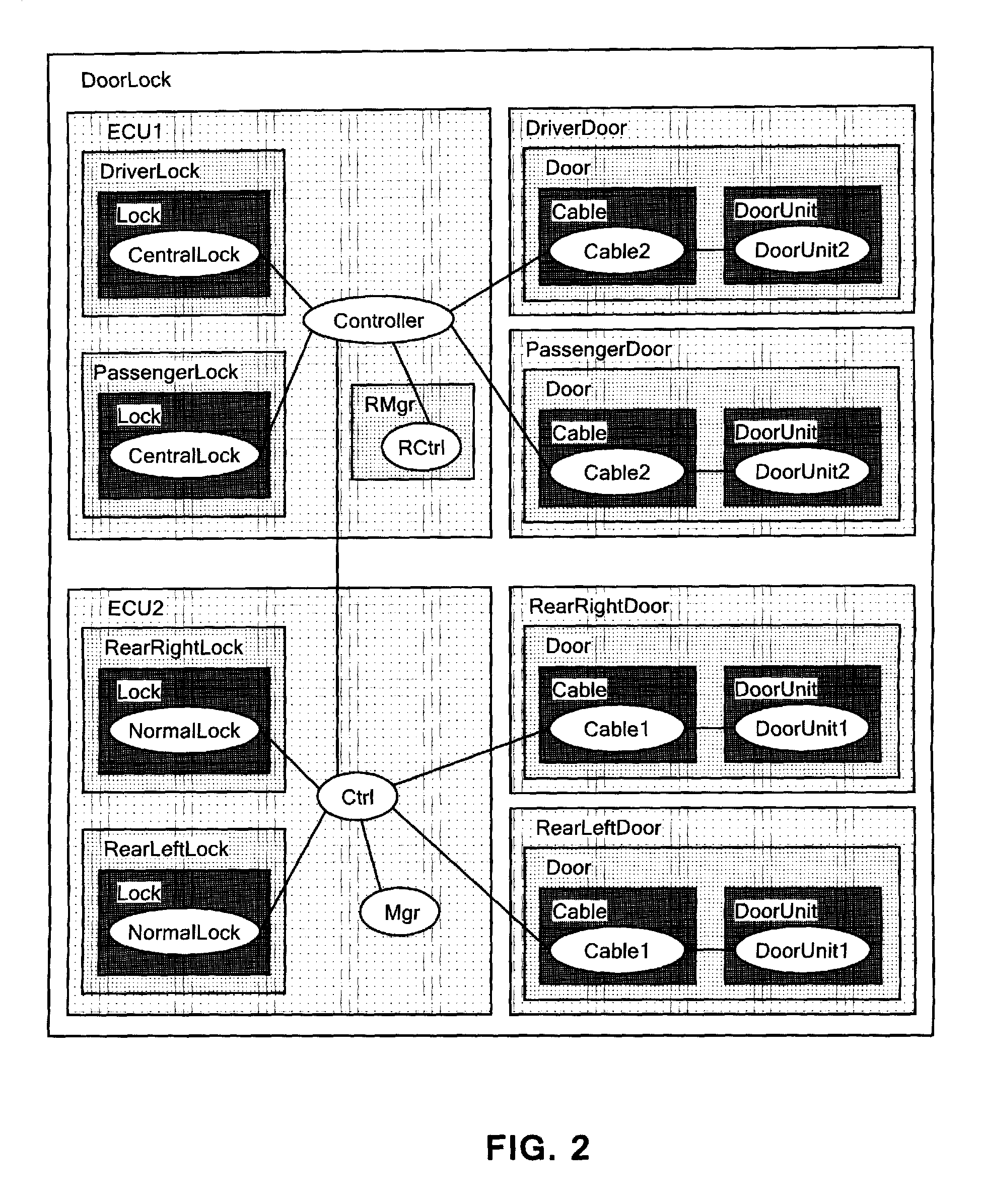

Automatic designing system, automatic designing method and automatic designing program for automatically designing architecture for system components

InactiveUS8396823B2Efficient reuseSimple methodGeometric CADDigital data processing detailsLevel structureTheoretical computer science

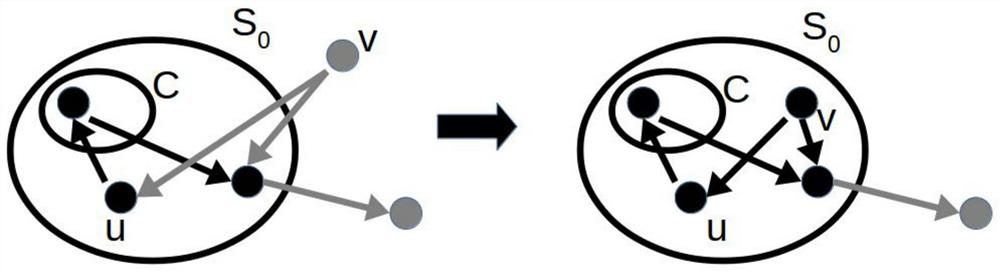

An automatic designing system includes: a rule storage unit storing sets of rewrite rules for rewriting variable nodes of a hierarchically structured graph in a design architecture for the system; a search unit sequentially determining variable nodes as application targets for the rewrite rules by searching the graph, including components in the design architecture for the system to be designed, using a search tree; a judgment unit judging whether the rewrite rule is applicable to the determined variable node; and a rule application unit replacing the determined variable node with a partial graph, including at least one of fixed and variable nodes, according to the rewrite rule, in response to a judgment that the rewrite rule is applicable. The search unit performs the searching until an undefined variable node no longer exists in the graph to be designed, and performs backtracking on condition that no variable node is found.

Owner:INT BUSINESS MASCH CORP

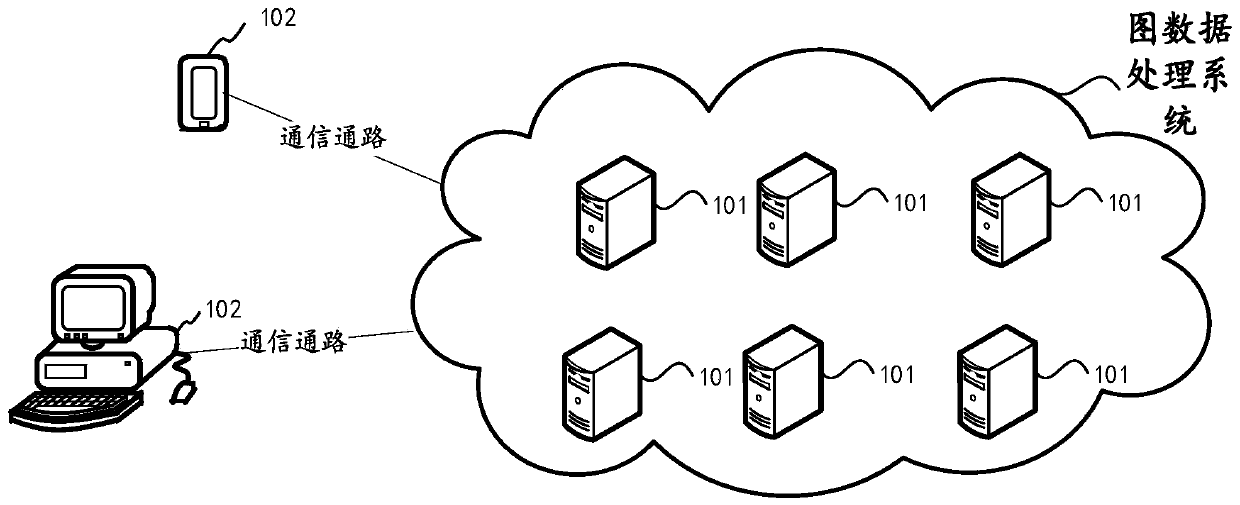

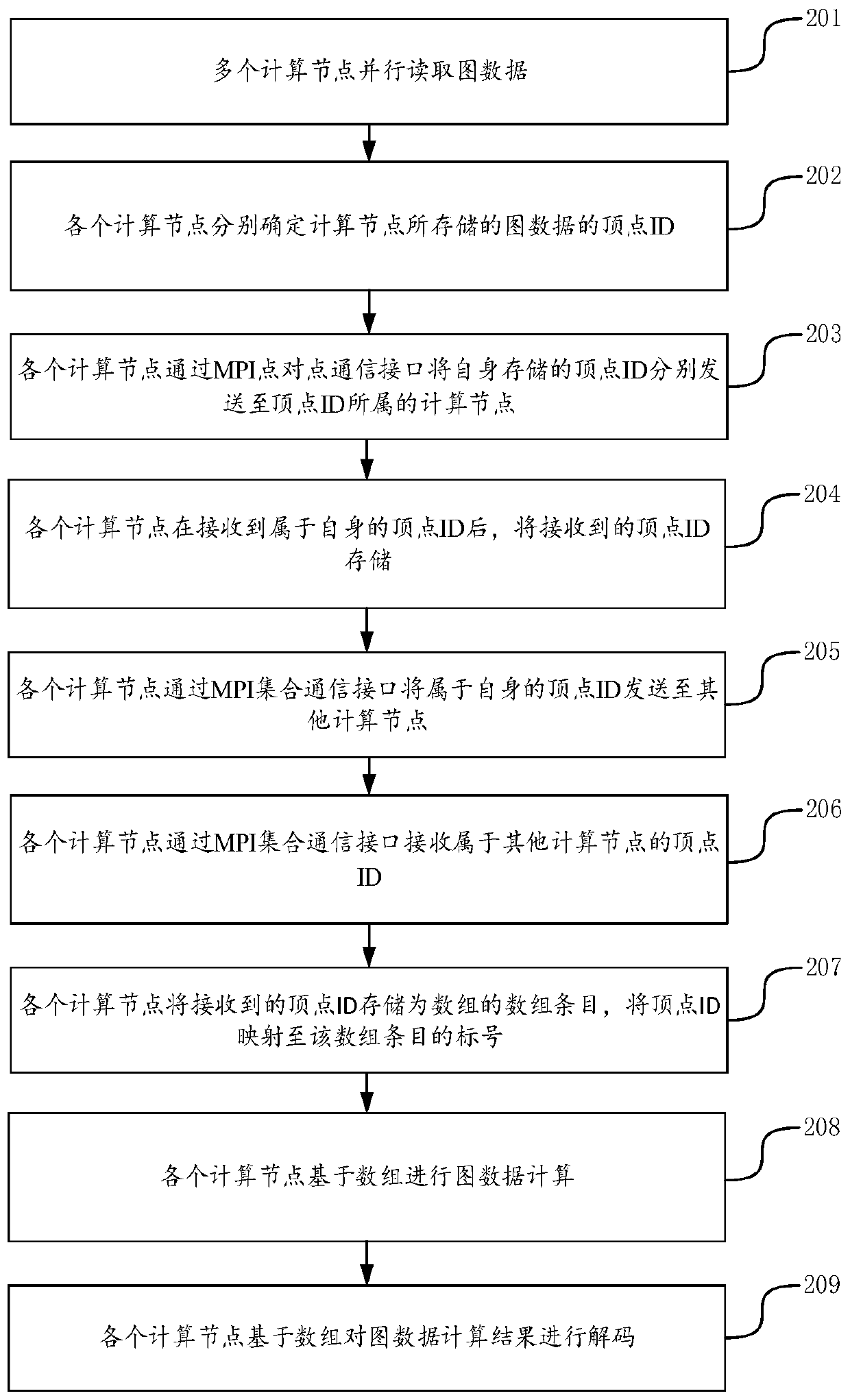

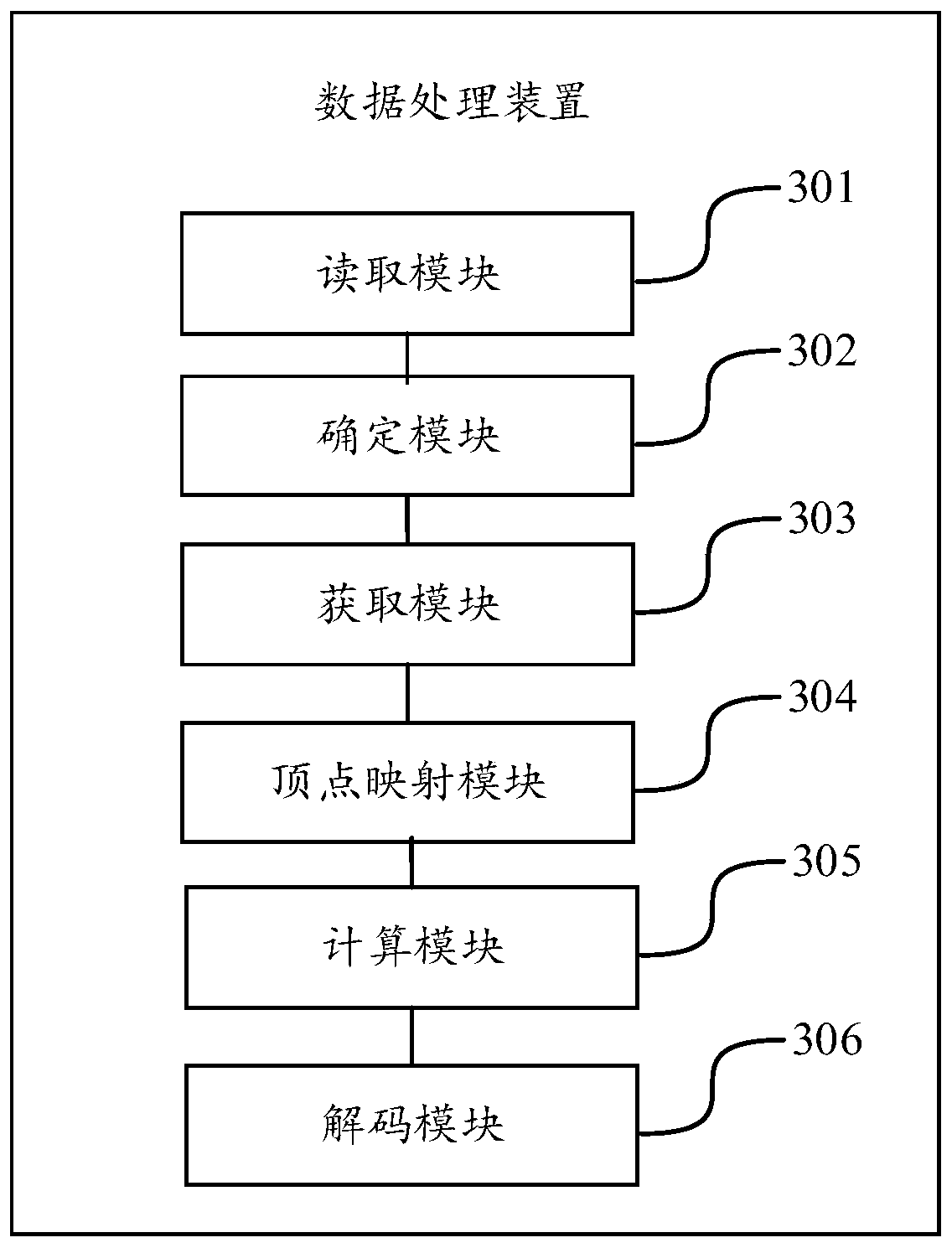

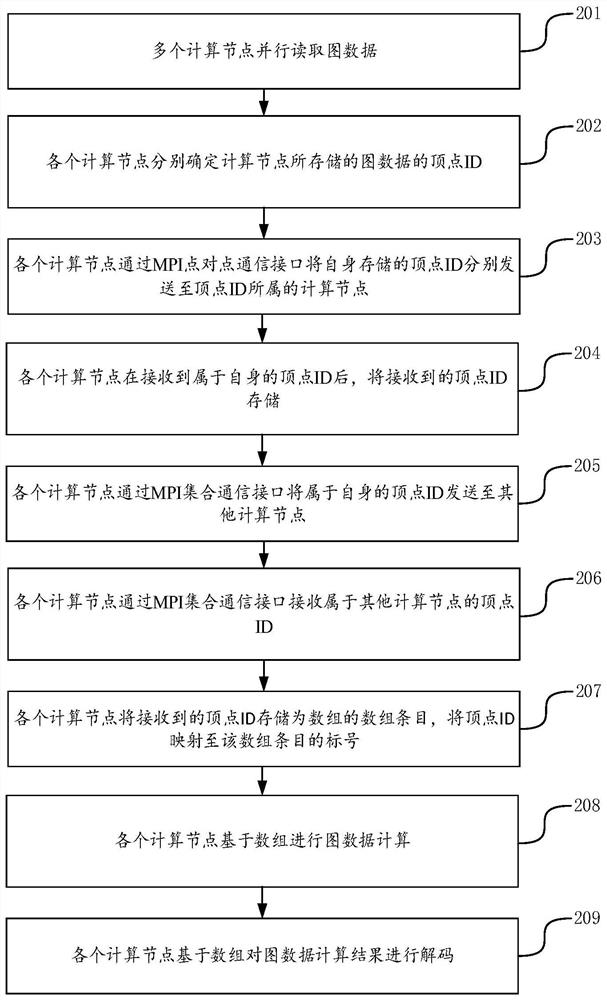

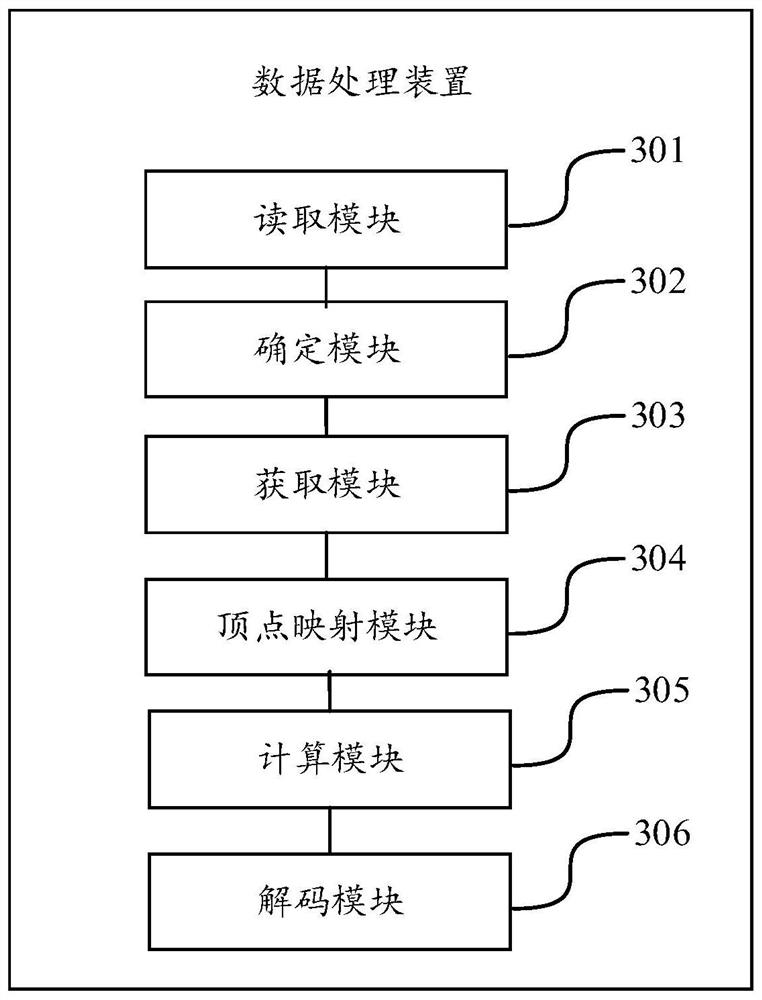

Data processing method, data processing system, computer equipment and storage medium

ActiveCN110769050AImprove execution efficiencyReduce trafficTransmissionData processing systemComputer network

The invention discloses a data processing method, a data processing system, computer equipment and a storage medium, and belongs to the technical field of graph calculation. The embodiment of the invention provides a method. A data processing system with a distributed architecture is adopted; partial graph data is stored by each computing node in the data processing system. In a coding phase, primary aggregation is carried out at each computing node, interaction of vertex IDs between the computing nodes is carried out to complete second aggregation;; through the two aggregation processes, allthe computing nodes can store full-amount vertex IDs, decoding can be completed without communication in the decoding stage, the overall communication traffic can be reduced, and the algorithm execution efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Device and system for shard creation

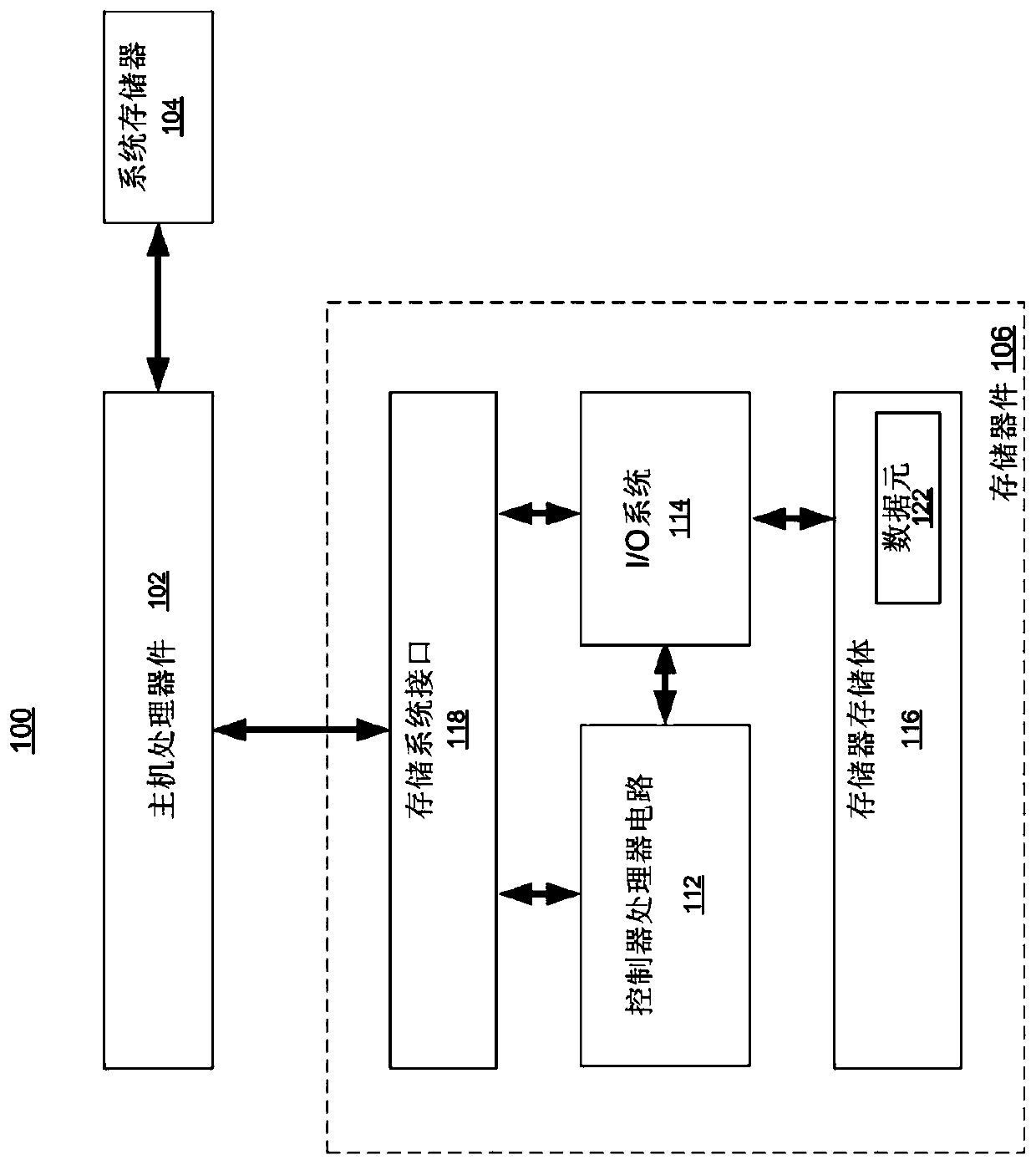

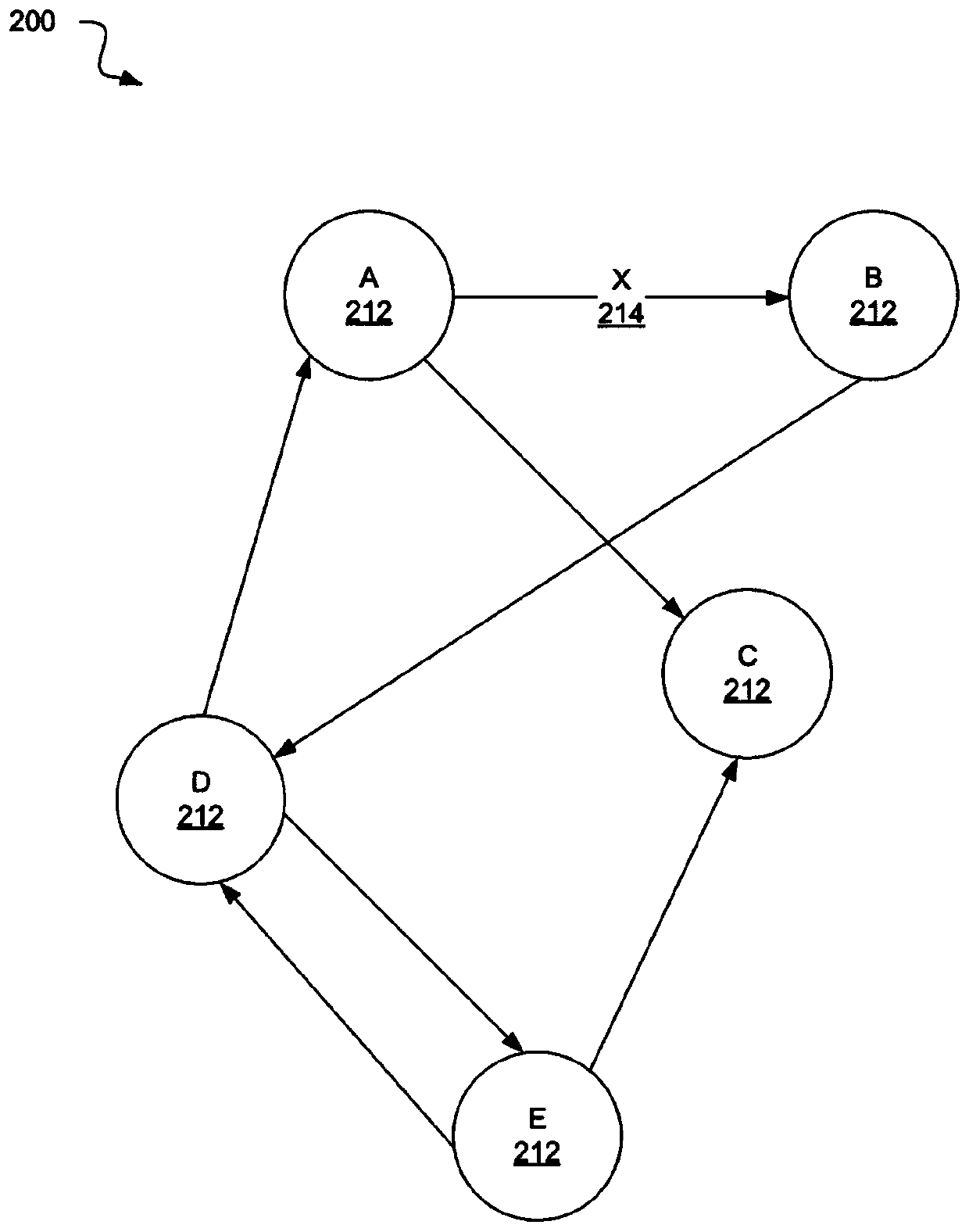

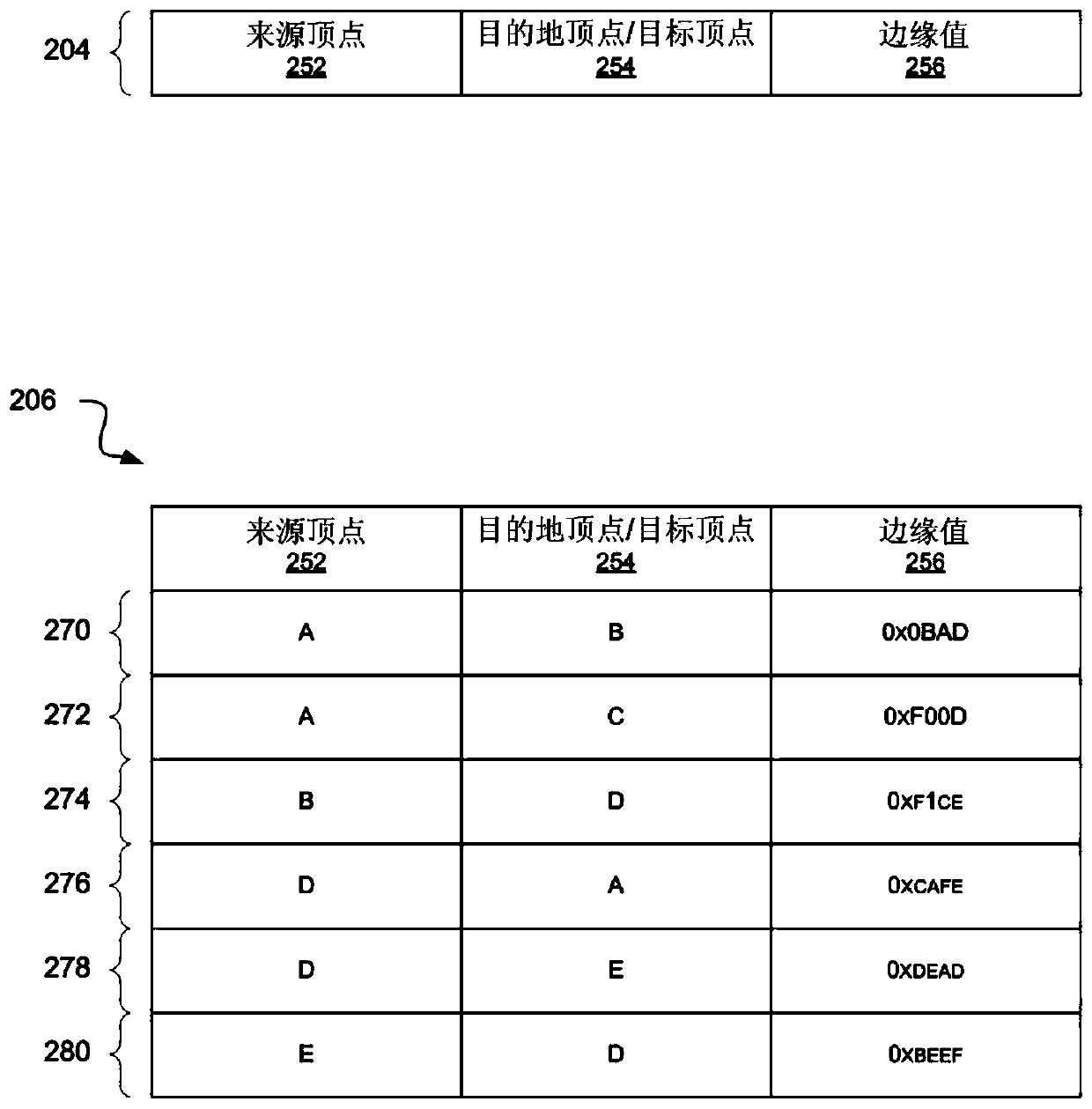

According to one general aspect, a shard creation device may include a host processor interface circuit configured to communicate data and commands with an external host processor circuit. The devicemay include a controller processor circuit configured to merge graph data elements into merged dynamic shards, wherein the merged dynamic shards include the same number of graph data elements. The device may include a non-volatile memory configured to store data in an at least a partial graph structure, wherein the graph structure includes data elements that each include vertexes and an edge, andwherein sub-portions of the data elements are grouped into shards. A shard creation system is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

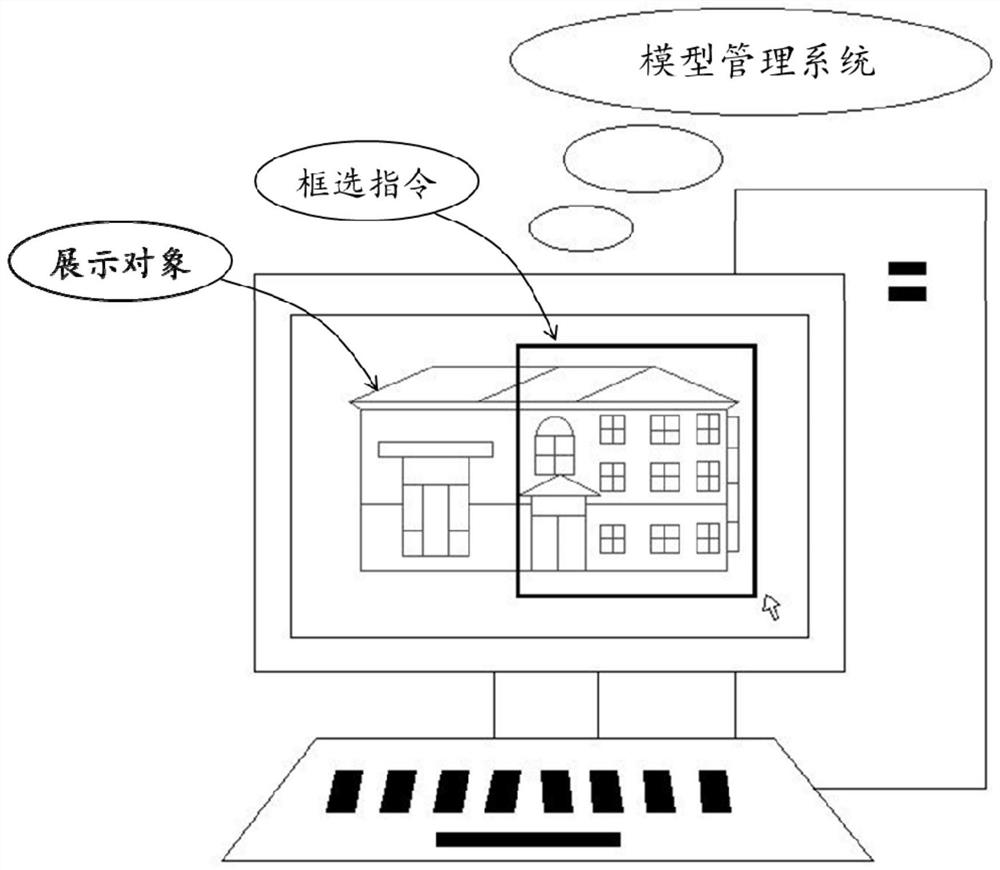

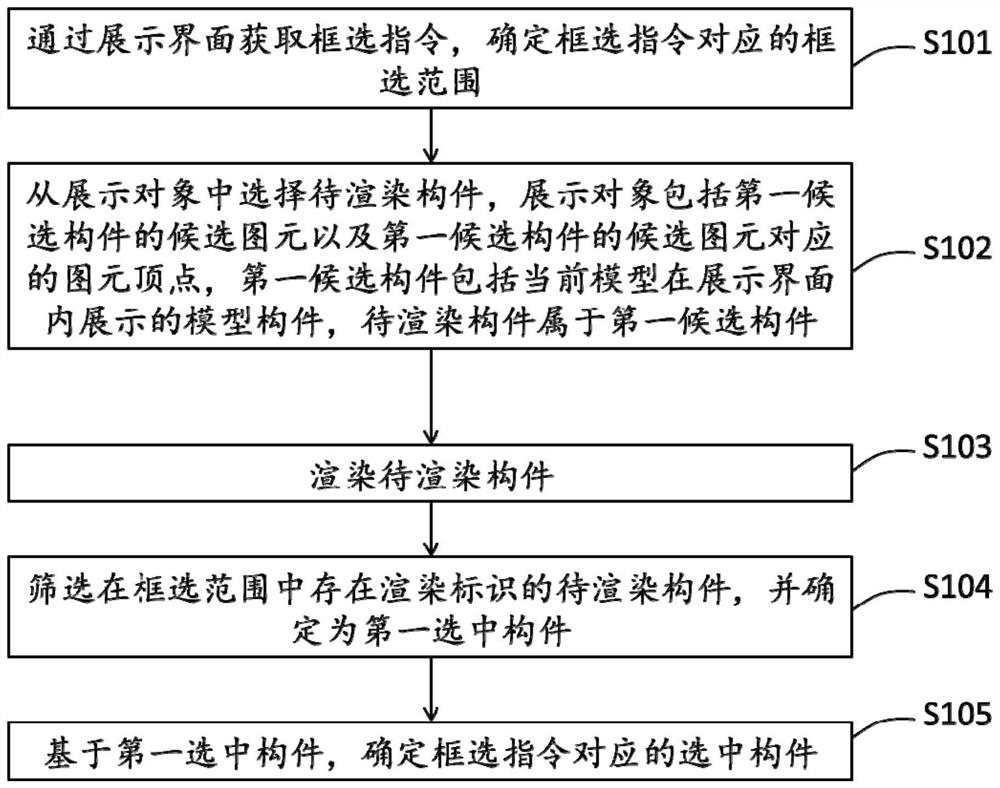

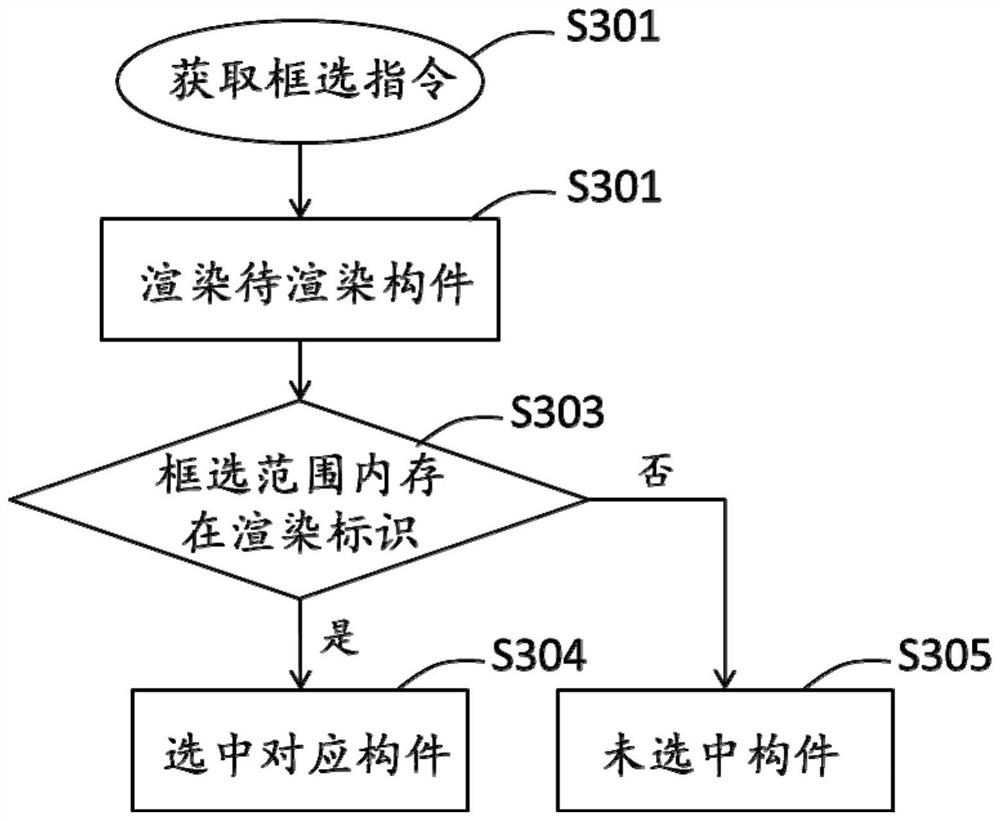

Model management method and device and electronic equipment

ActiveCN112257134AShorten the timeImprove the efficiency of frame selection operationsGeometric CADSpecial data processing applicationsModel managementAlgorithm

The invention provides a model management method and device and electronic equipment, and the method comprises the steps: rendering of a first candidate component in a display object, and determininga first selected component through judging whether a rendering identification exists in a frame selection range or not; determining a second selected component by judging whether partial primitive vertexes corresponding to candidate primitives of the second candidate component are within the frame selection range or not; and determining a third selected component by judging whether all primitive vertexes corresponding to the candidate primitives of the third candidate component are within the box selection range or not. Rendering identifier judgment and primitive vertex judgment are combined to determine the selected component, so that the complexity of primitive vertex judgment is simplified, and the time for executing component selection is shortened.

Owner:久瓴(上海)智能科技有限公司

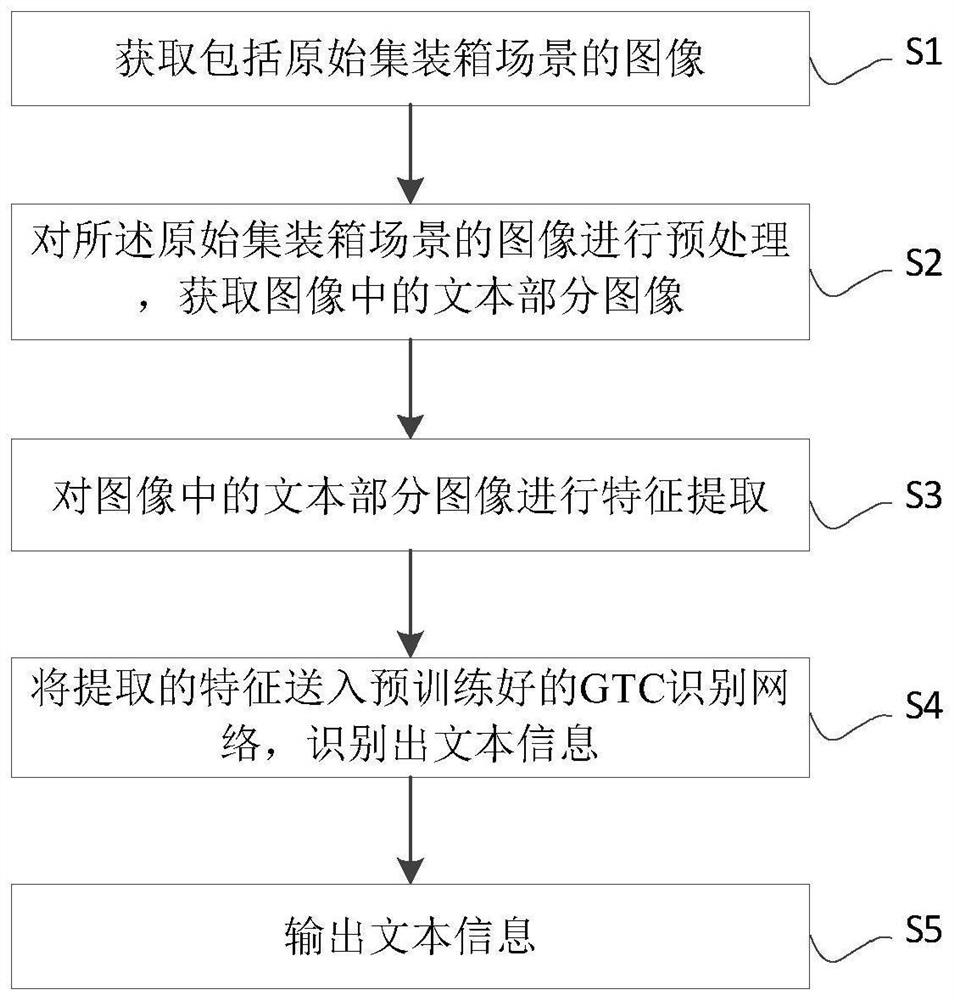

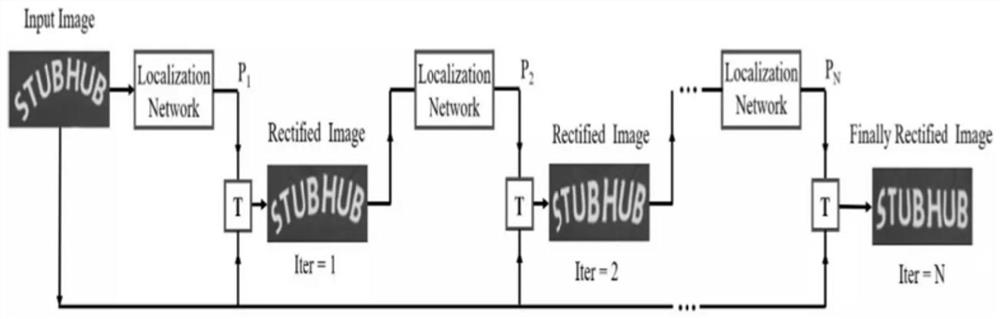

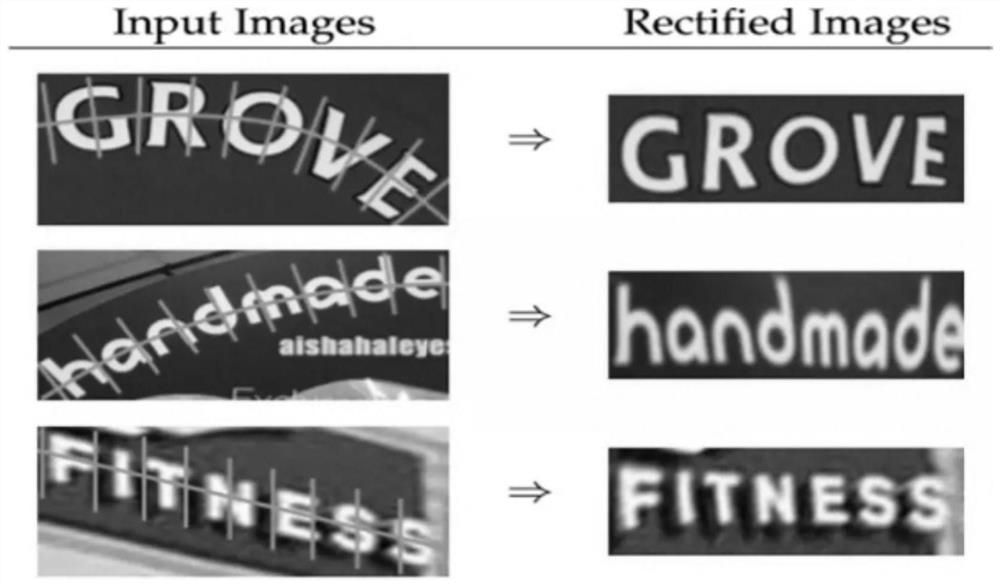

Graph neural network container text recognition method based on attention mechanism

PendingCN112801095AHigh speedCharacter and pattern recognitionNeural architecturesText recognitionFeature extraction

The invention provides a graph neural network container text recognition method based on an attention mechanism. The method comprises the following steps of: S1, obtaining an image including an original container scene; S2, preprocessing the image of the original container scene to obtain a text part image in the image; S3, performing feature extraction on the text part image in the image; S4, sending extracted features to a pre-trained GTC recognition network, and recognizing text information; and S5, outputting the text information. According to the method, the processed image is input into a designed iteration correction network, the image is iteratively corrected through the same correction network, the recognition result is obtained through the GTC recognition network, and an advanced recognition effect in the world is achieved. Compared with the speed of an attention-based method, the speed of the method of the invention is greatly increased.

Owner:GUANGDONG UNIV OF TECH

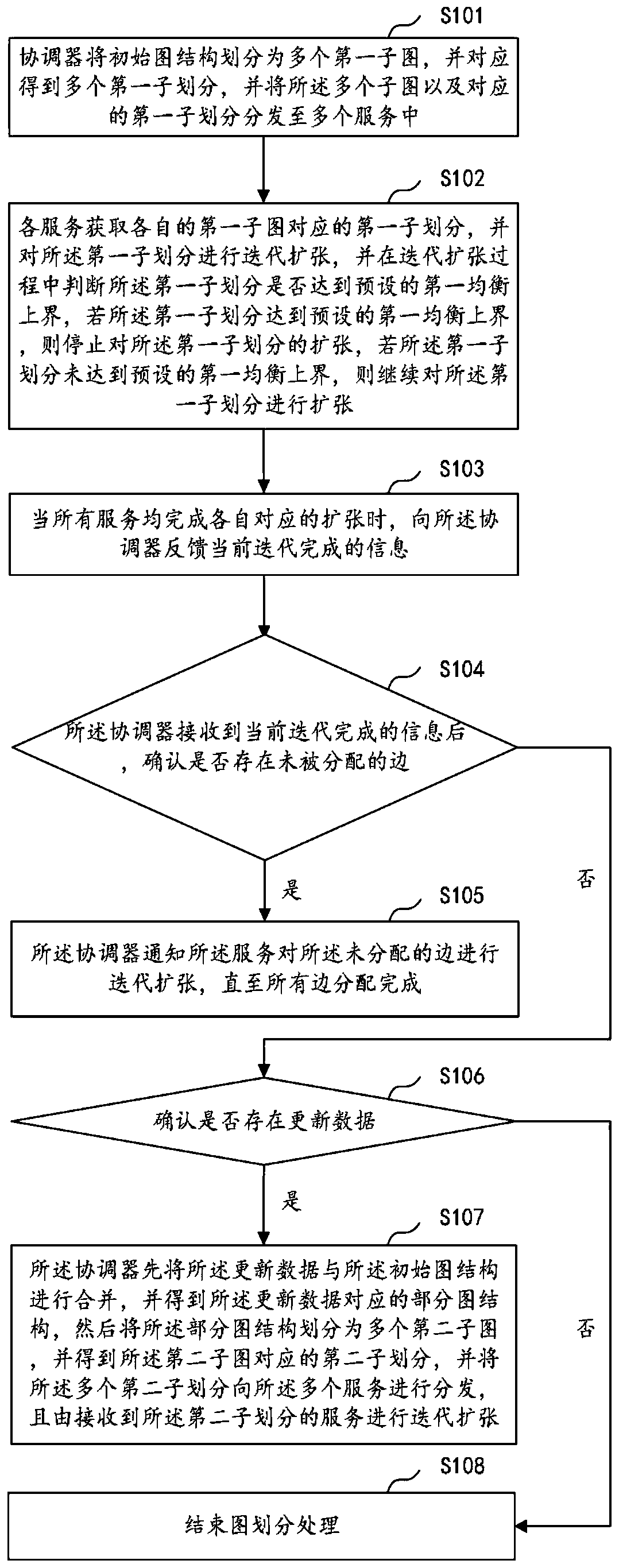

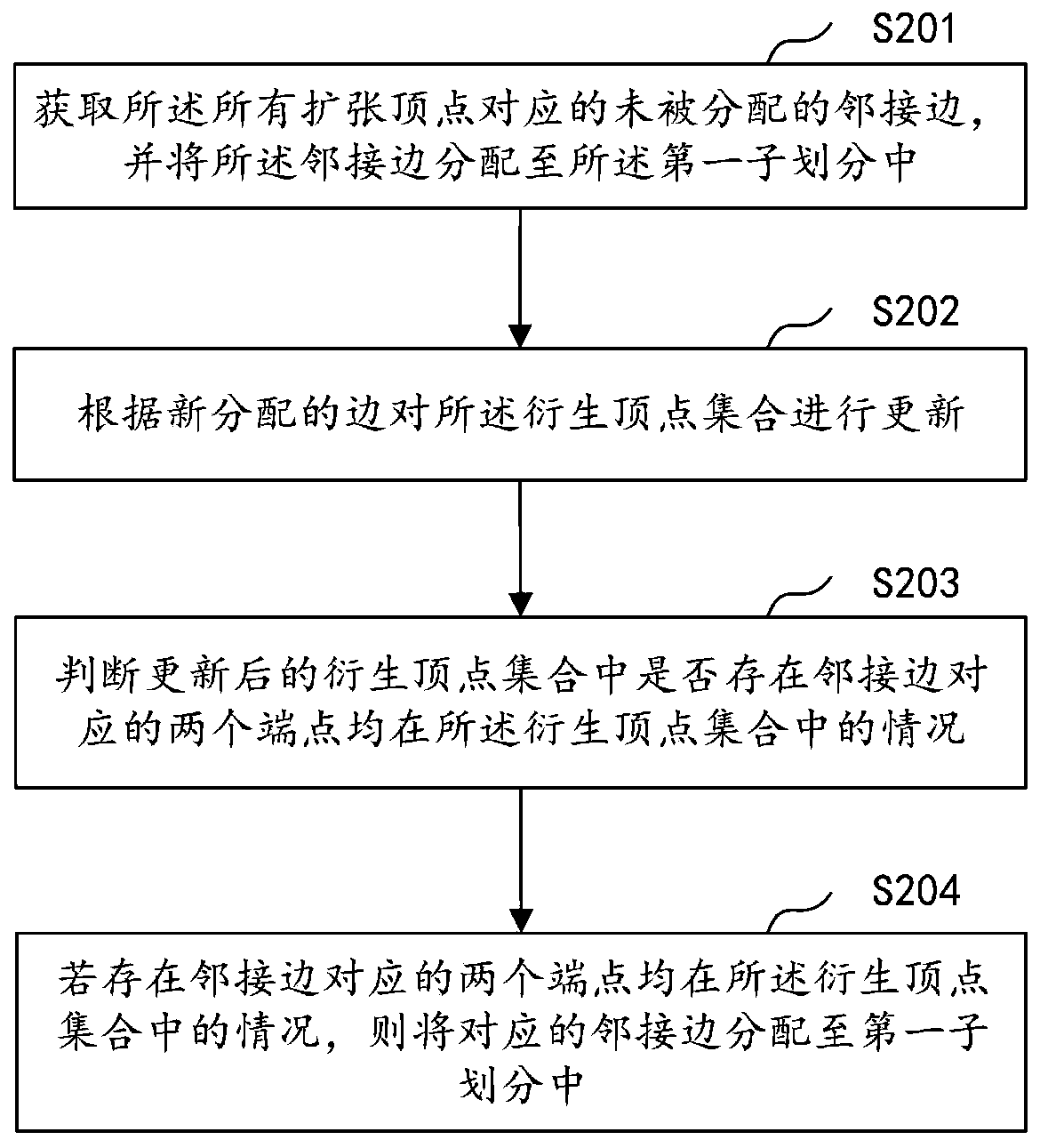

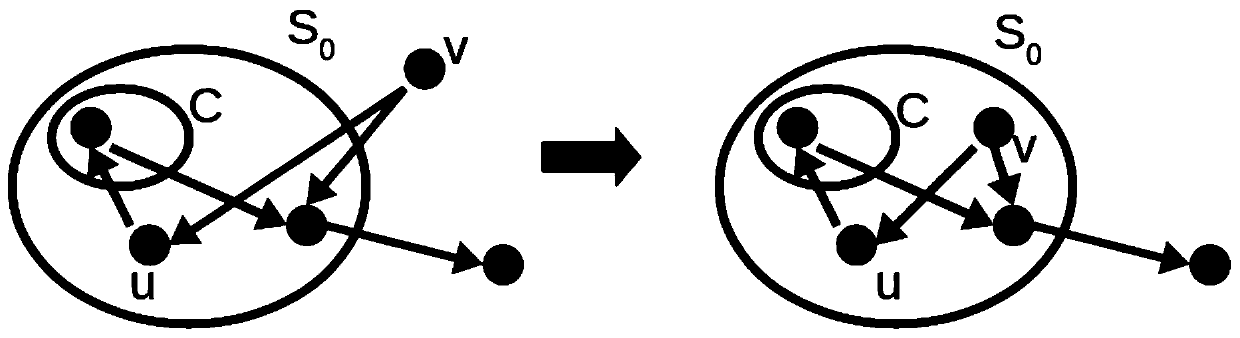

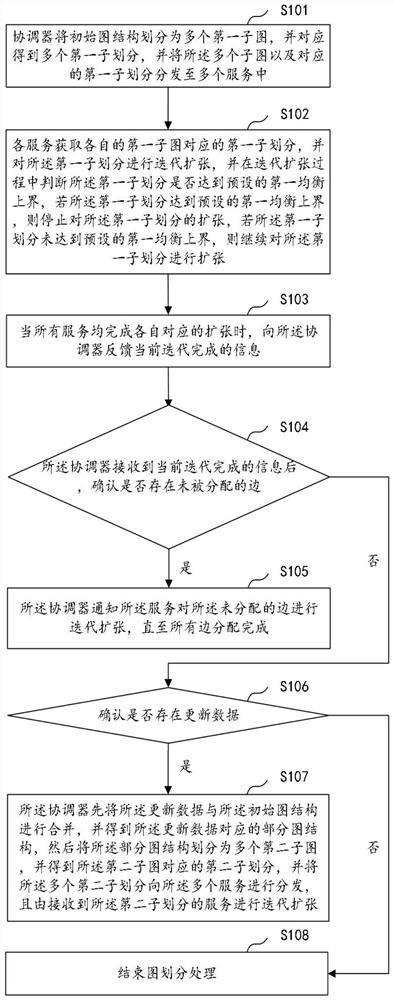

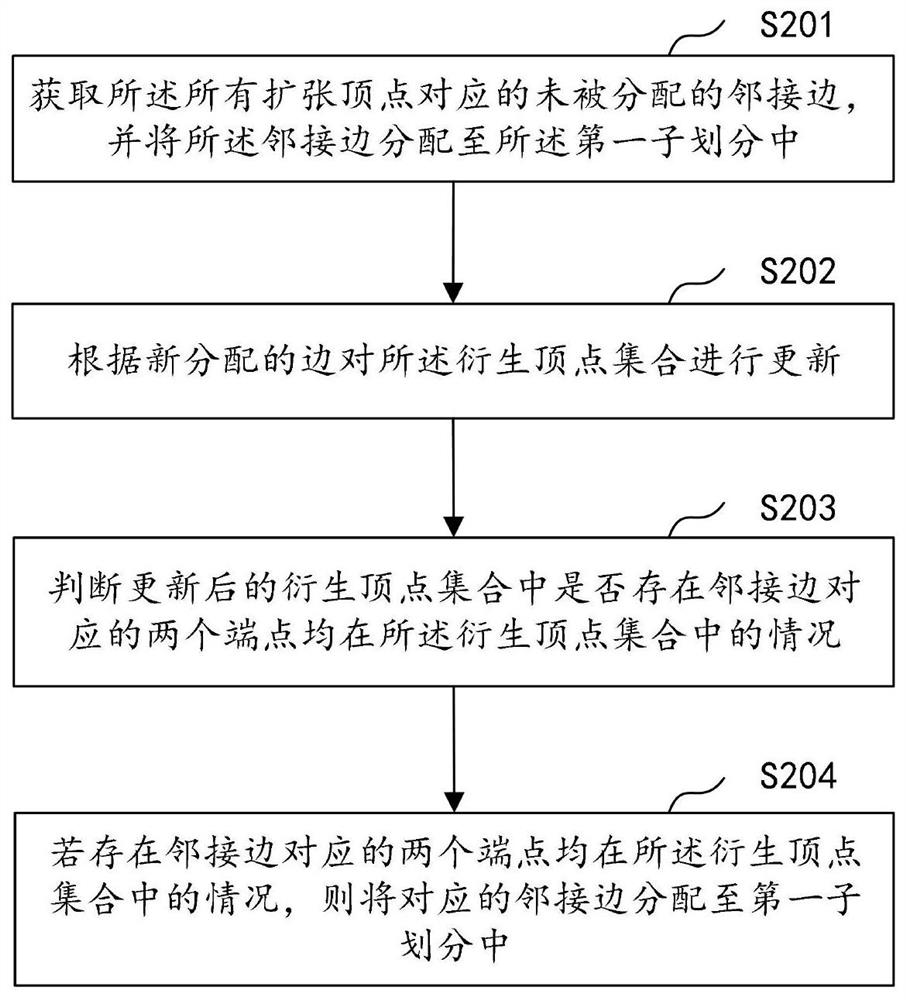

Bounded incremental graph partition method and system

ActiveCN111538867AReduce computational overheadThe division results are balancedOther databases indexingSpecial data processing applicationsAlgorithmTheoretical computer science

The invention discloses a bounded incremental graph partition method and system. The method comprises the following steps of: partitioning an initial graph structure into a plurality of first sub-graphs by a coordinator to correspondingly obtain a plurality of first sub-partitions, and distributing the first sub-partitions to a plurality of workers; performing iterative expansion on the obtained first sub-partitions by each worker, and judging whether the first sub-partitions reach a preset equilibrium upper bound or not in the iterative expansion process, and if the first sub-partitions reachthe preset equilibrium upper bound, stopping expansion of the first sub-partitions; confirming whether update data exists or not by the coordinator; and if update data exists, combining the update data with the initial graph structure to obtain an updated partial graph structure, then partitioning the partial graph structure into a plurality of second sub-graphs and corresponding second sub-partitions, distributing the second sub-partitions to the workers, and performing iterative expansion by the workers receiving the second sub-partitions. According to the method and system, the calculationoverhead during distributed graph partition can be reduced, and the partition result is more balanced.

Owner:SHENZHEN INST OF COMPUTING SCI

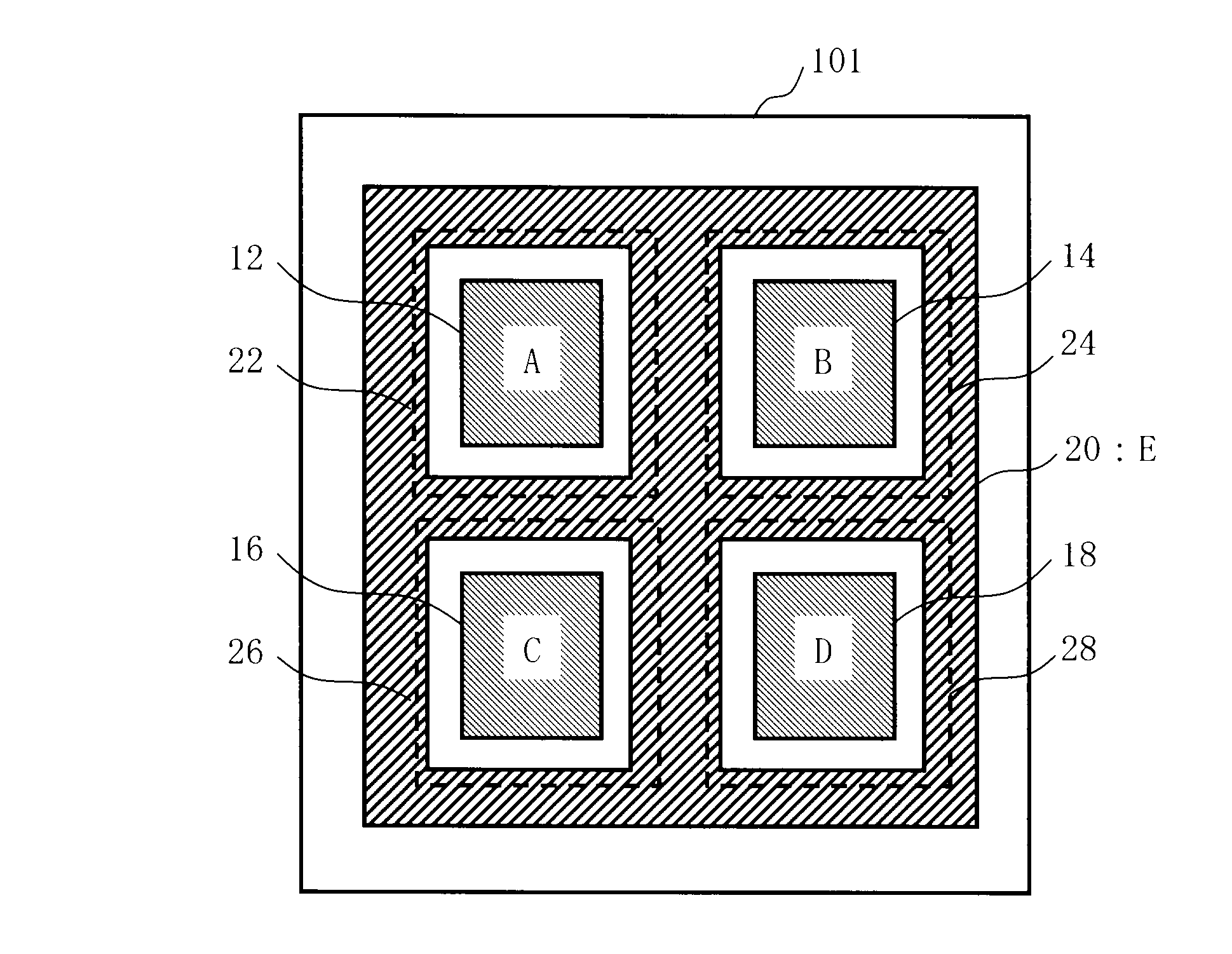

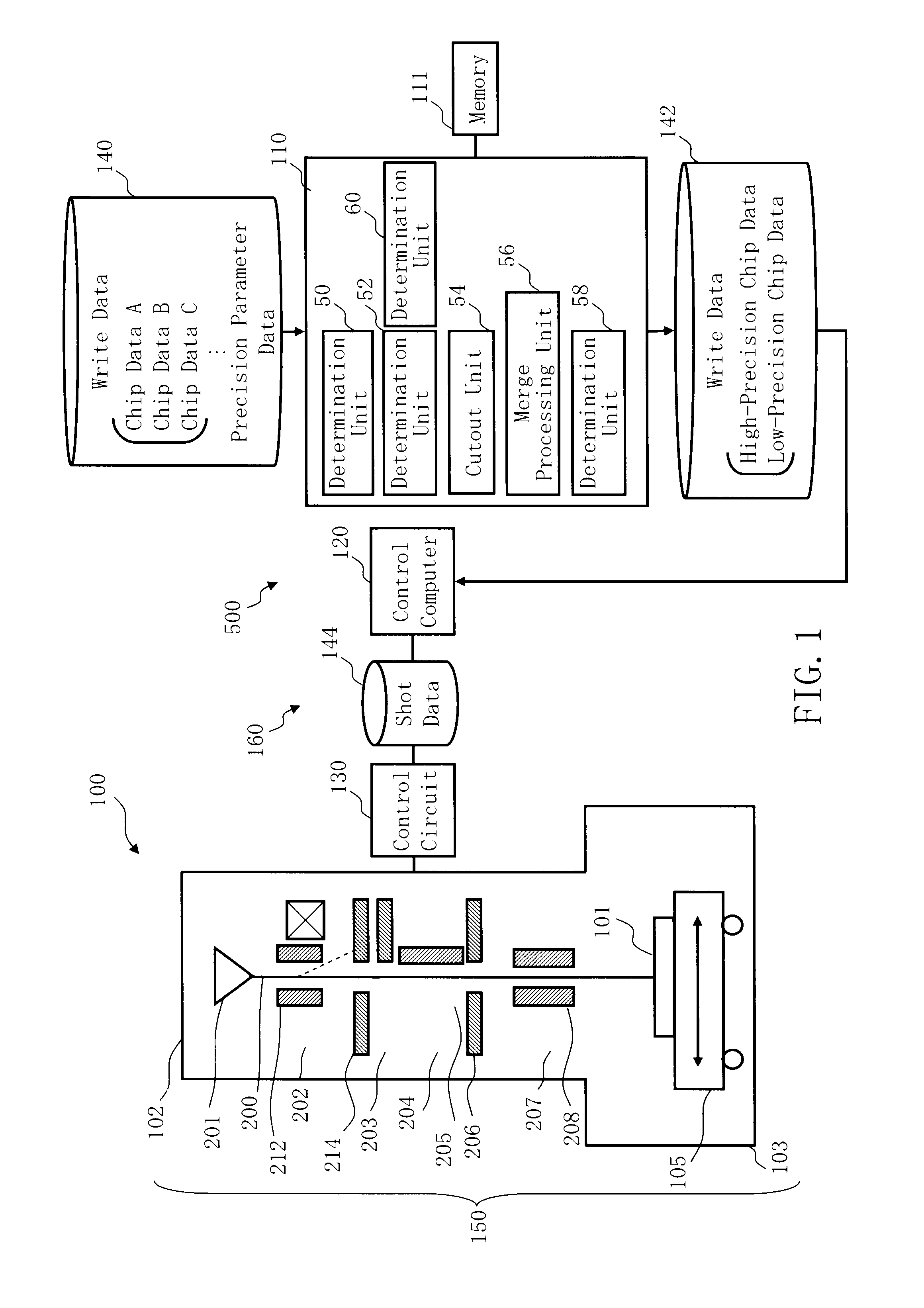

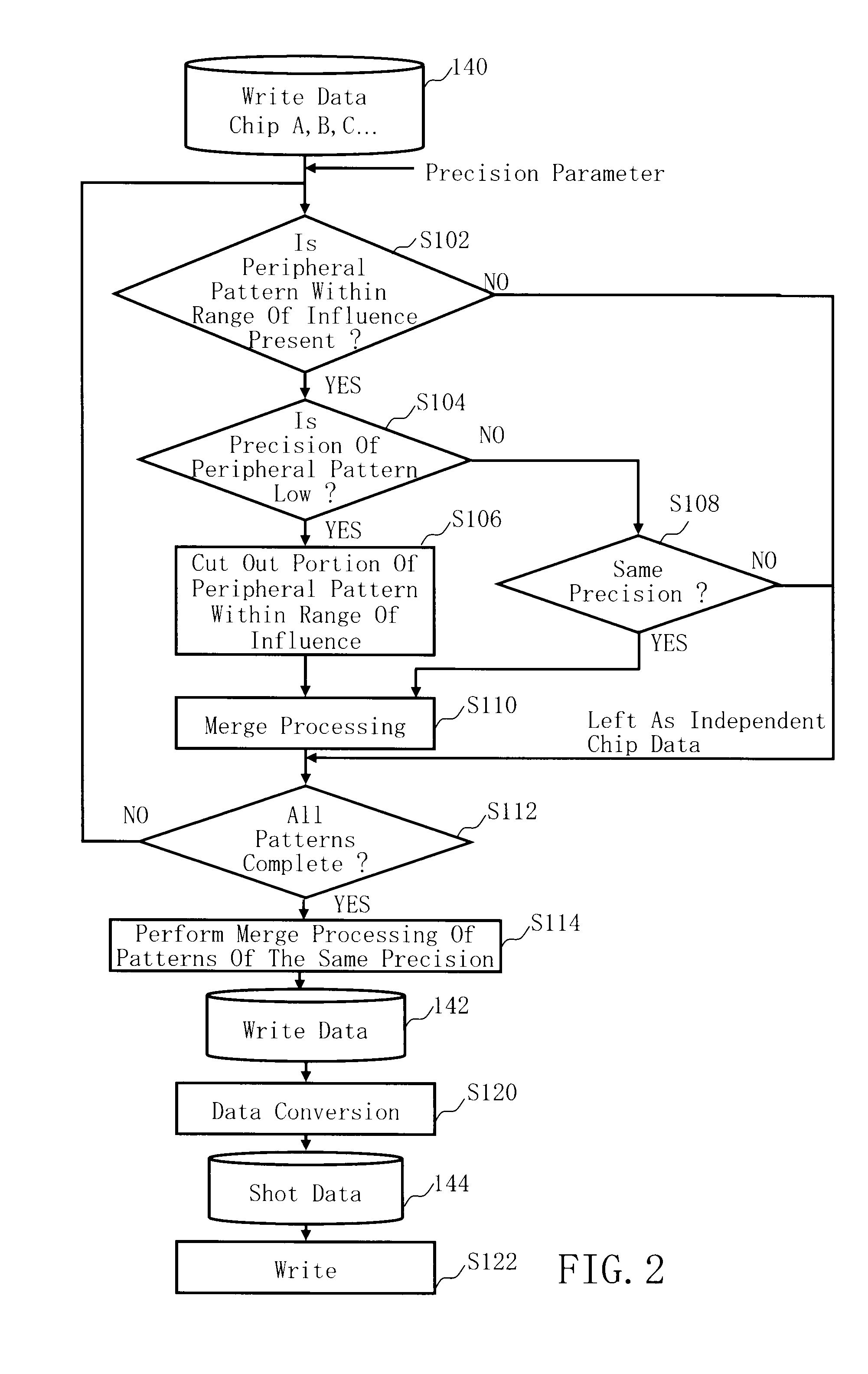

Charged particle beam writing apparatus, write data creation method and charged particle beam writing method

ActiveUS20110286319A1Electron beam carrier recordingElectric discharge tubesMolecular physicsCharged particle beam

A charged particle beam writing apparatus according to an embodiment, includes a storage device configured to store write data which is to be written by using a charged particle beam and in which a plurality of patterns with different writing precision is defined; a cutout unit configured to read data of each pattern from the storage device and to cut out a partial pattern, among a pattern, in the plurality of patterns, whose writing precision is on a low-precision side, positioned within a range of influence of a proximity effect from a region edge of a pattern, in the plurality of patterns, whose writing precision is on a high-precision side; a merge processing unit configured to perform merge processing of a cut-out partial pattern on the low-precision side and the pattern on the high-precision side; and a pattern writing unit configured to write a pattern obtained by the merge processing and a remaining partial pattern on the low-precision side remaining without being merged with the pattern on the high-precision side to a target object by using the charged particle beam under different writing conditions based on data of the pattern obtained by the merge processing and data of the remaining partial pattern.

Owner:NUFLARE TECH INC

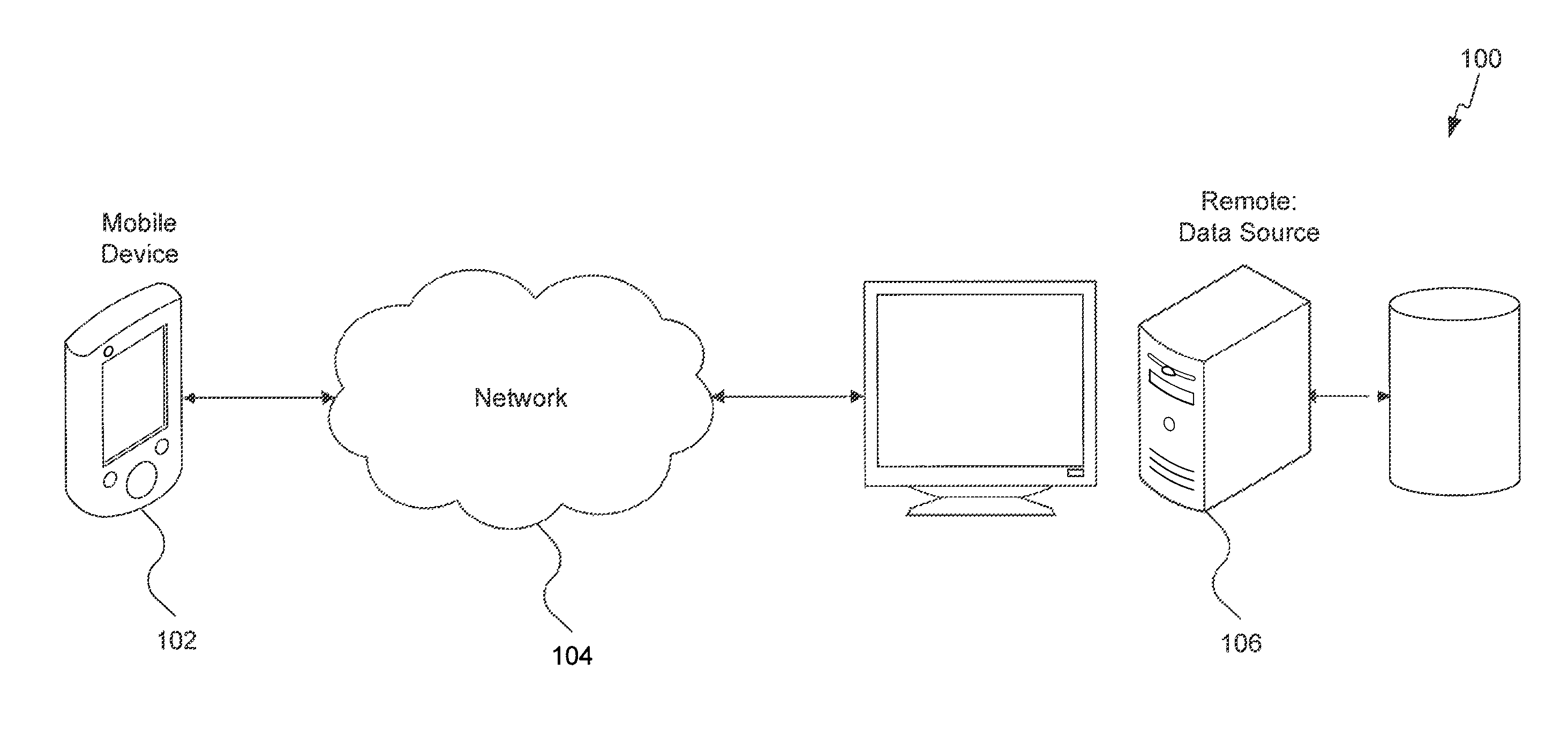

Composite graph cache management

ActiveUS8874682B2Digital data processing detailsDatabase distribution/replicationGraphicsData source

Methods, systems, and computer program products for synchronizing data between a mobile application and an enterprise data source are provided. A computer-implemented method may include receiving a request for data from an application executing on a mobile device, receiving a document including the requested data from a data source where the document represents a graph of data having a plurality of nodes, and providing a partial graph of data to the application where the partial graph is derived from the received document and at least includes the requested data.

Owner:SYBASE INC

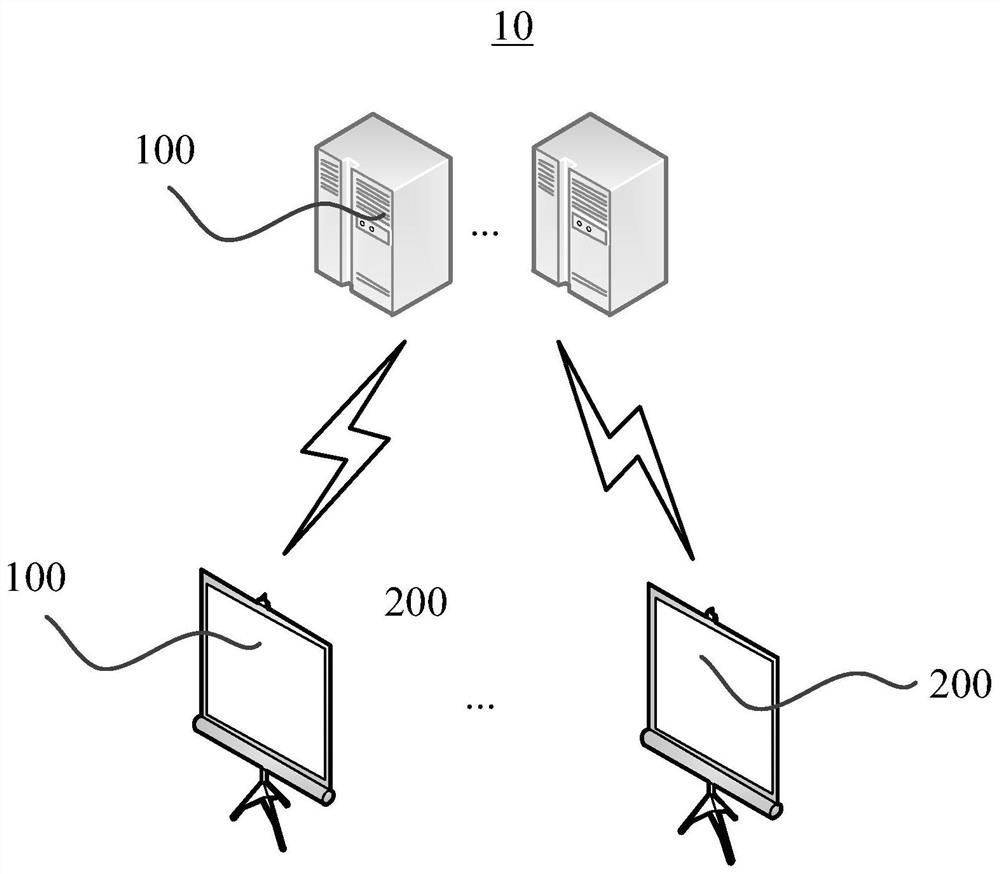

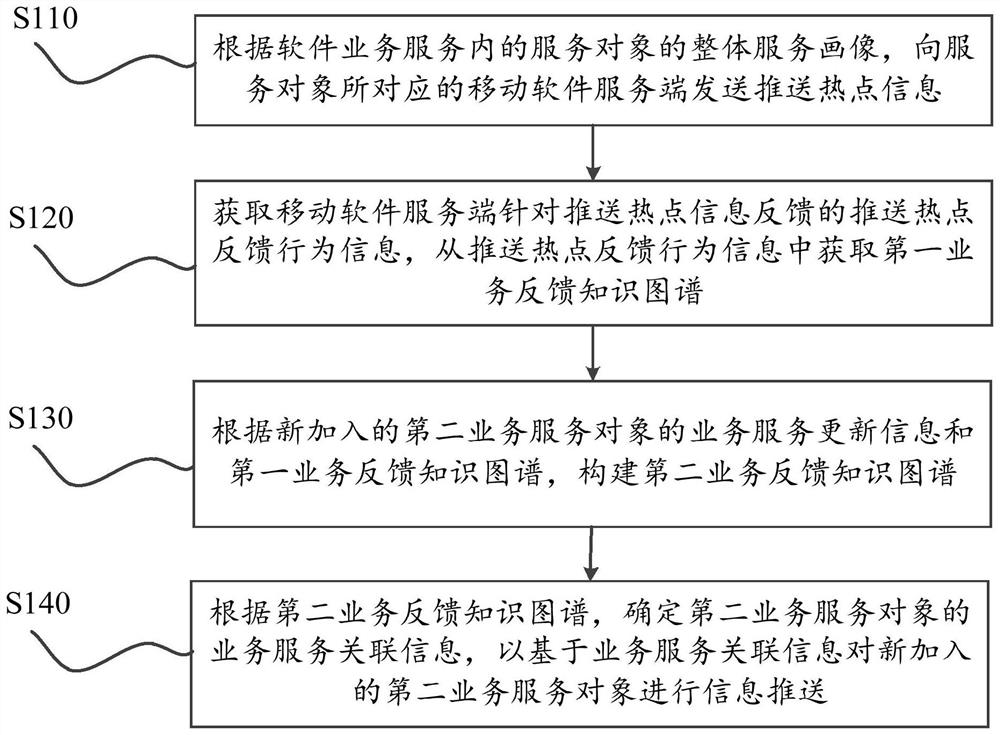

Information cloud computing pushing method combining big data portraits and digital content server

InactiveCN112685007AEnhance detailsMeet the needs of efficient analysis and pushDigital data information retrievalRequirement analysisDigital contentKnowledge graph

The embodiment of the invention provides an information cloud computing pushing method combining big data portraits and a digital content server, and aims to solve the problems that the cloud computing pressure for computing business service association vectors of all entities in a whole business feedback knowledge graph is relatively high, and the requirement of efficient analysis pushing cannot be met. A second business feedback knowledge graph is constructed on the basis of a second business service object and an existing first business feedback knowledge graph, that is, part of graph content of the first business feedback knowledge graph involved when business service associated information of the second business service object is determined, so that information details are increased, cloud computing pressure is reduced, the cloud computing efficiency of the business service associated information of the second business service object is higher, and the requirement for efficient analysis and pushing is better met.

Owner:凌清华

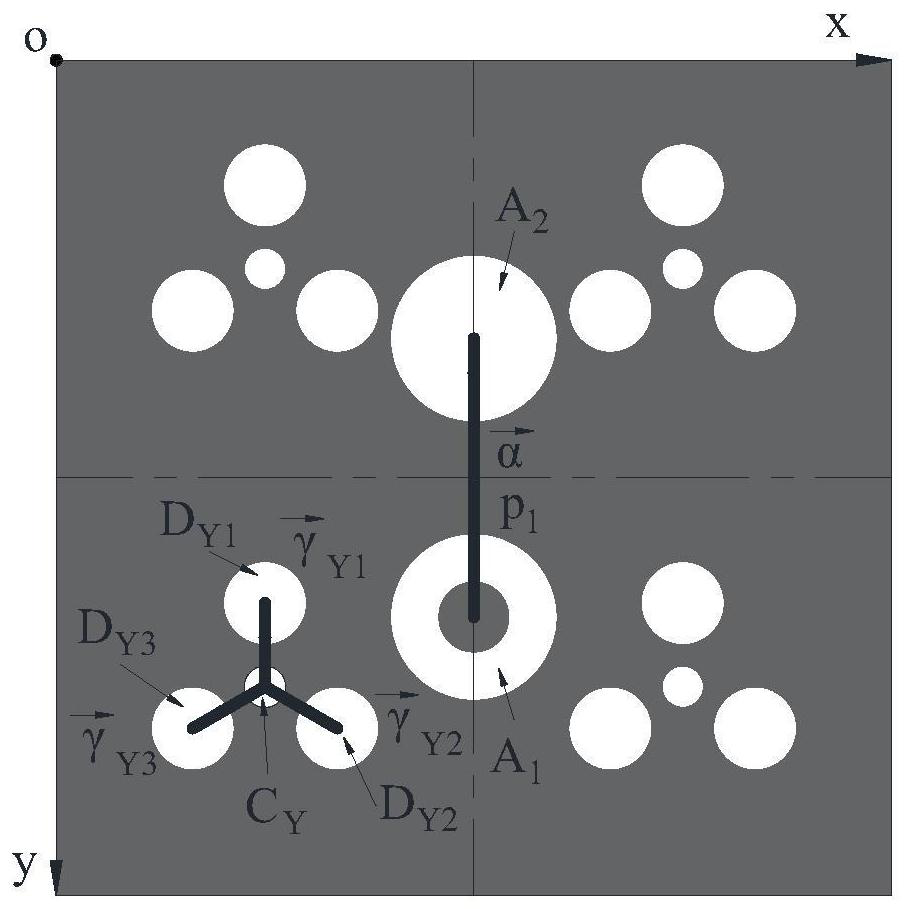

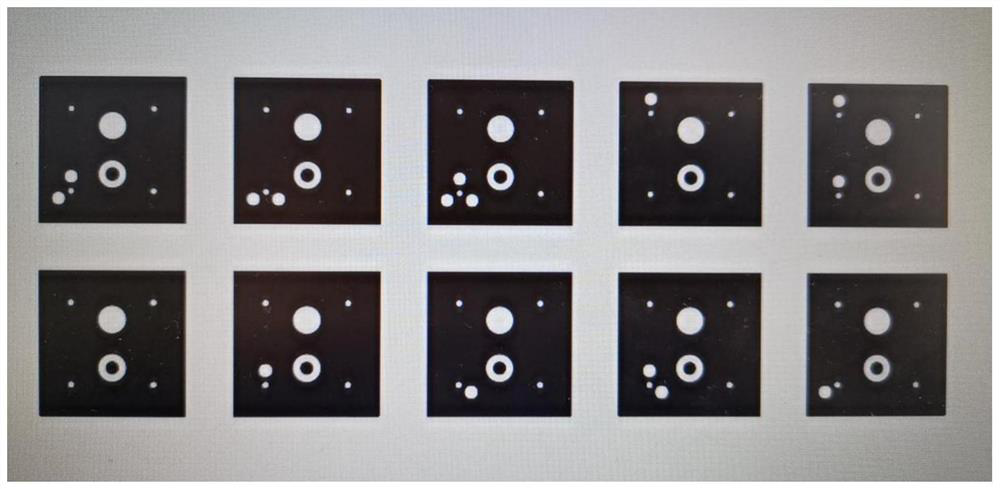

Method for decoding parallelogram coded mark based on graphic geometrical relationship

ActiveCN113129397AIncrease flexibilityIncrease capacityImage enhancementImage analysisGraphicsAlgorithm

The invention discloses a method for decoding parallelogram coded mark based on a graphic geometrical relationship, the parallelogram coded mark is composed of a parallelogram background pattern and a coding pattern, the coding pattern is arranged in the parallelogram background pattern and comprises a positioning pattern, a directional pattern and a coding combination pattern, the directional pattern and the positioning pattern are used for judging the direction of the parallelogram coding mark; and the coding combination pattern is used for coding four vertexes of the coding mark. The coding pattern in the parallelogram coding mark provided by the invention can automatically judge the relative rotation direction of the detected target and the camera in the processes of camera calibration, three-dimensional data splicing and the like, and the flexibility is improved; the positions of the patterns of the constituent parts are distinguished through a graph geometrical relationship and a vector product method, and the robustness is high; according to a decoding method, the decoding accuracy is greatly improved; the invention has the advantages of high efficiency and high decoding speed, and can realize real-time decoding.

Owner:HEFEI UNIV OF TECH

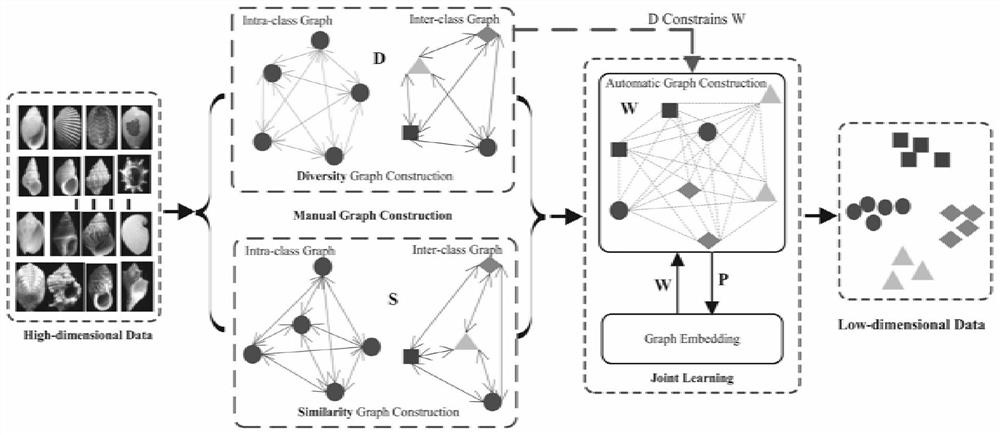

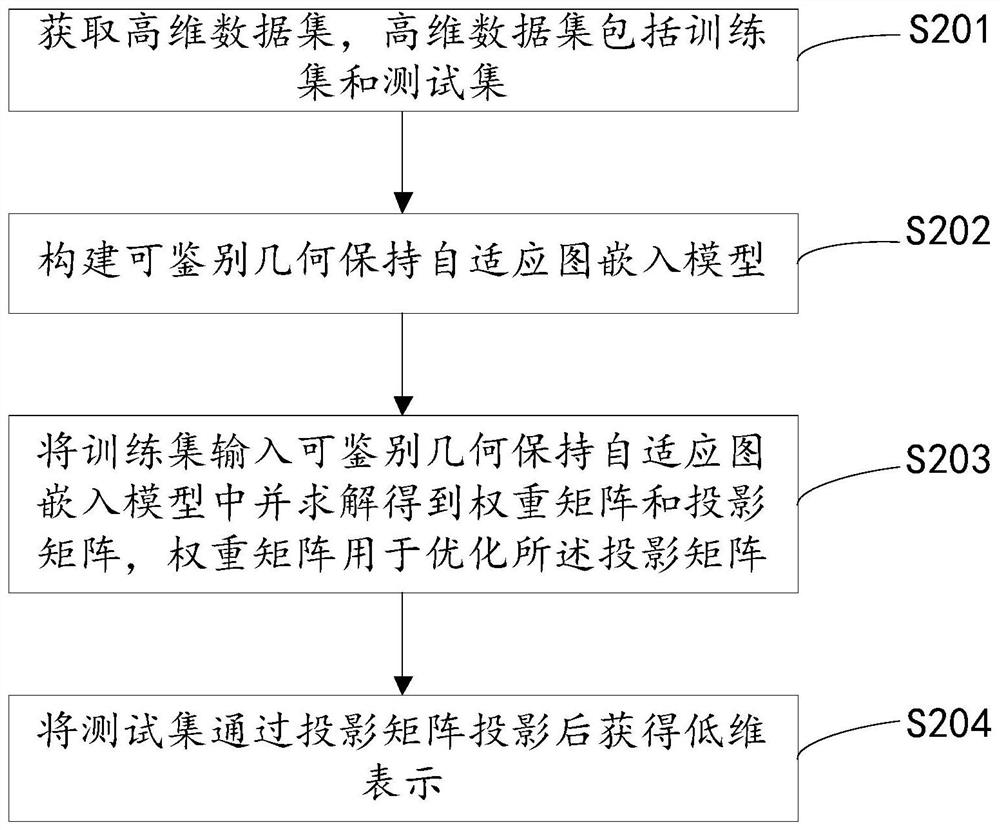

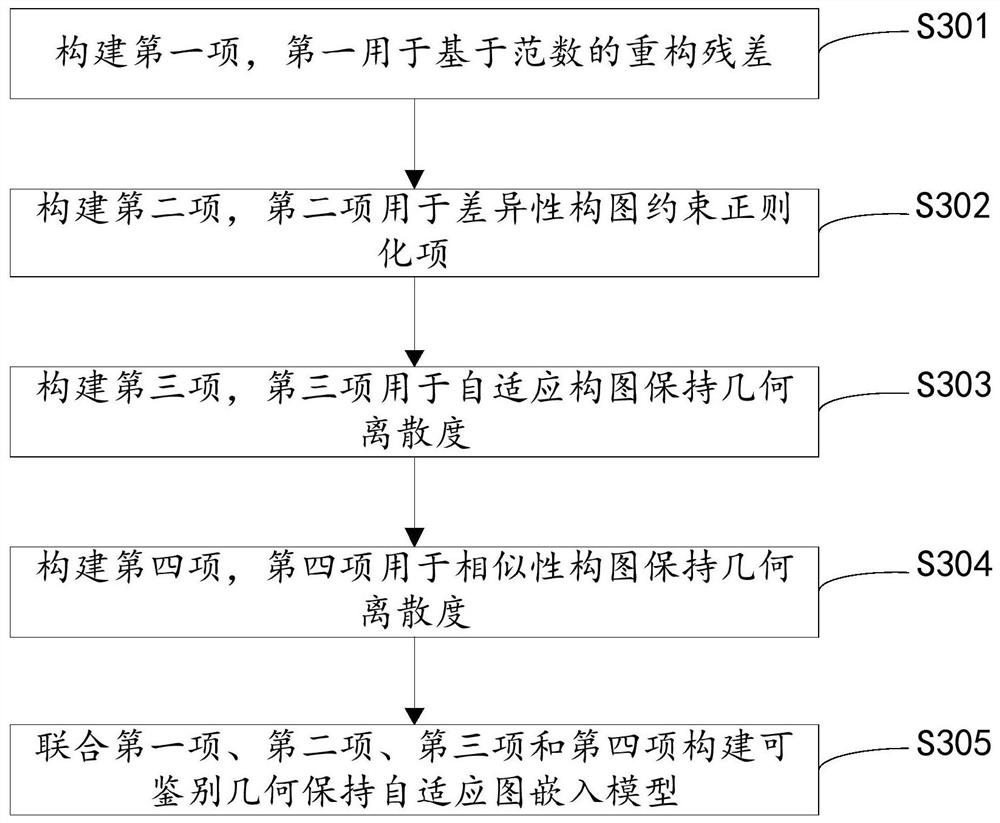

Identifiable geometry preserving adaptive graph embedding method and device, equipment and medium

The invention relates to the technical field of pattern recognition, and discloses an identifiable geometry preserving adaptive graph embedding method, a device, equipment and a medium, the method comprises the following steps: obtaining a high-dimensional data set, the high-dimensional data set comprising a training set and a test set, the training set further comprising corresponding category information; constructing an identifiable geometry preserving adaptive graph embedding model; inputting the training set into the identifiable geometry preserving adaptive graph embedding model, and solving to obtain a weight matrix and a projection matrix, wherein the weight matrix is used for optimizing the projection matrix; and projecting the test set through the projection matrix to obtain low-dimensional representation. The method solves the problem that the structure information reflected by an existing graph embedding method is unsuitable for data, unreliable or insufficient due to the fact that the existing graph embedding method cannot adapt to different data samples in a partial graph composition mode.

Owner:JIANGSU UNIV

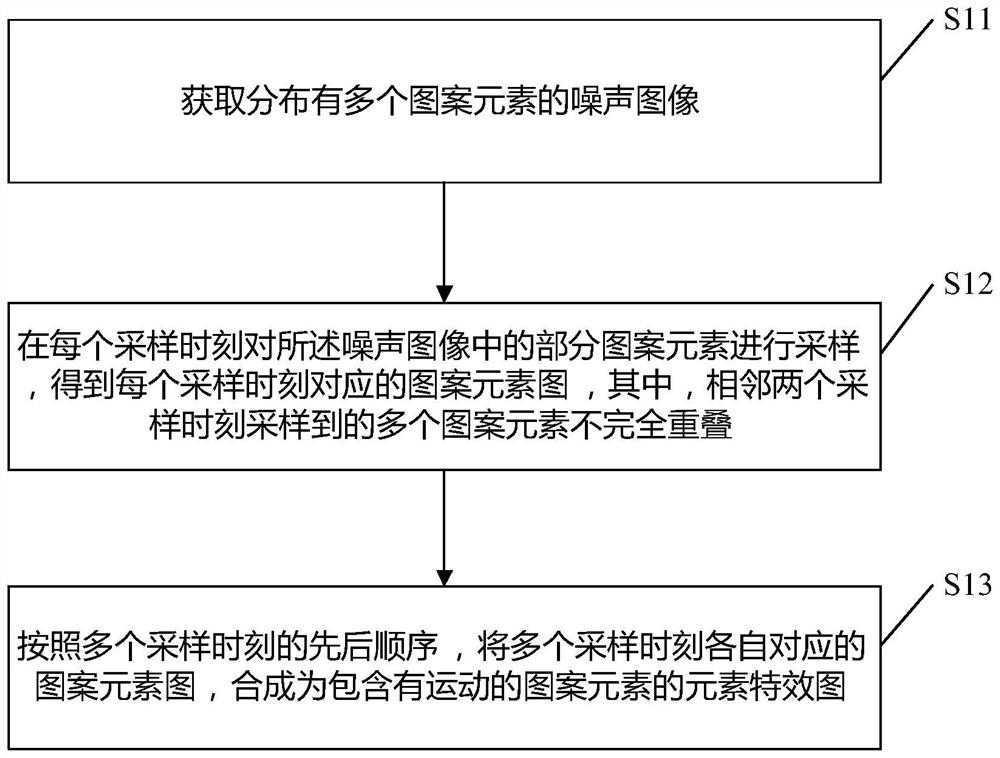

Image processing method and device, electronic equipment, medium and program product

PendingCN114387194ARealize the effect of movementImage enhancementImage analysisImaging processingAlgorithm

The invention relates to an image processing method and device, electronic equipment, a medium and a program product. The method comprises the following steps: acquiring a noise image on which a plurality of pattern elements are distributed; part of pattern elements in the noise image are sampled at each sampling moment, a pattern element graph corresponding to each sampling moment is obtained, and a plurality of pattern elements sampled at two adjacent sampling moments are not completely overlapped; and according to the sequence of the plurality of sampling moments, synthesizing the pattern element diagrams corresponding to the plurality of sampling moments into an element special effect diagram containing moving pattern elements. According to the invention, the noise image distributed with the plurality of pattern elements is directly sampled to obtain the pattern element graph, so that the special effect of pattern element movement can be added to the to-be-processed image by using the pattern element graph; the problems that the special effect of pattern element movement added to the to-be-processed image needs to depend on a corner detection algorithm and the special effect is easy to lose are solved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

A Bounded Incremental Graph Partitioning Method and System

ActiveCN111538867BReduce computational overheadThe division results are balancedOther databases indexingSpecial data processing applicationsAlgorithmOperations research

The invention discloses a method and system for dividing a bounded incremental graph. The method includes: the coordinator divides the initial graph structure into a plurality of first subgraphs, correspondingly obtains a plurality of first subdivisions, and distributes the first subdivisions to multiple services; The partition is iteratively expanded, and during the iterative expansion process, it is judged whether the first sub-division reaches the preset equilibrium upper bound, and if the first sub-division reaches the preset equilibrium upper bound, the expansion of the first sub-division is stopped; the coordinator Confirm whether there is updated data; if there is updated data, first merge the updated data with the initial graph structure to obtain an updated partial graph structure, and then divide the partial graph structure into multiple second subgraphs, and the corresponding second subgraphs Partition, distribute the second sub-partition to the service, and perform iterative expansion by the service that receives the second sub-partition. The invention can reduce the calculation overhead when the distributed graph is divided, and make the division result more balanced.

Owner:SHENZHEN INST OF COMPUTING SCI

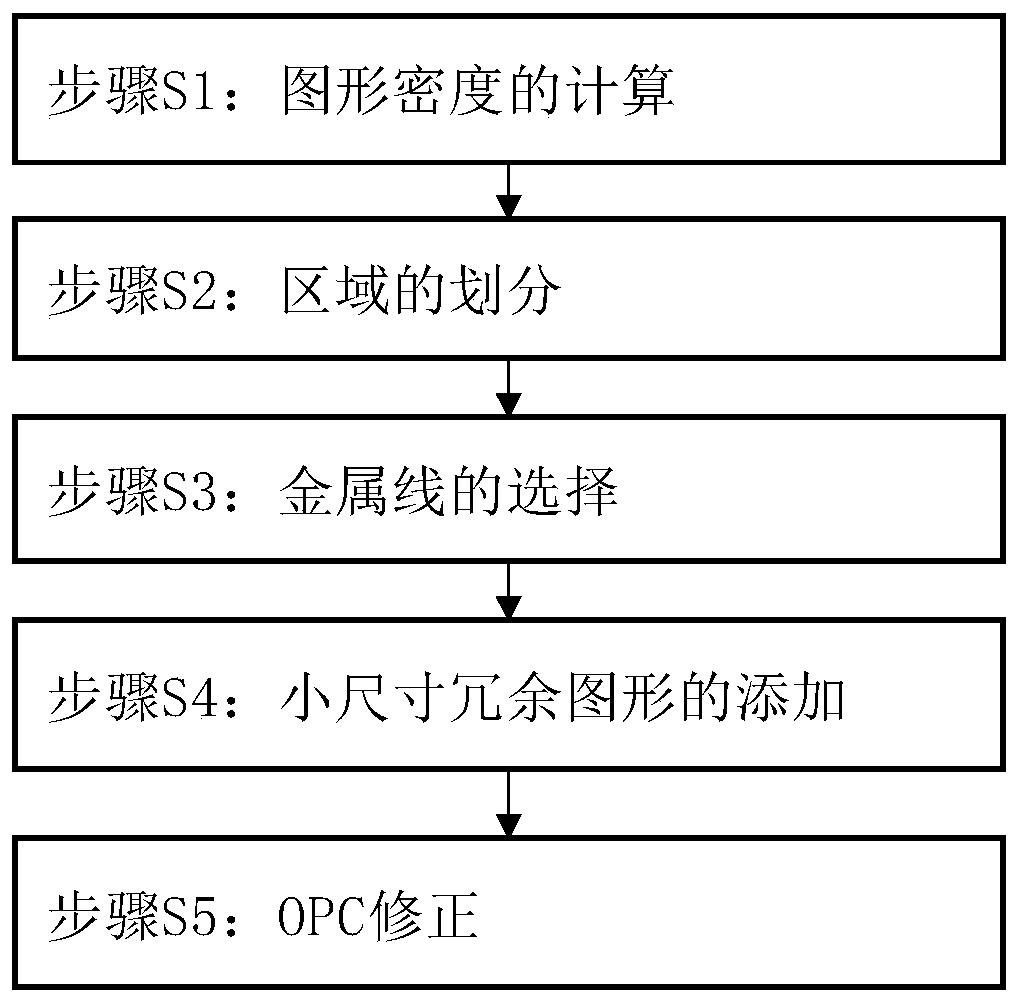

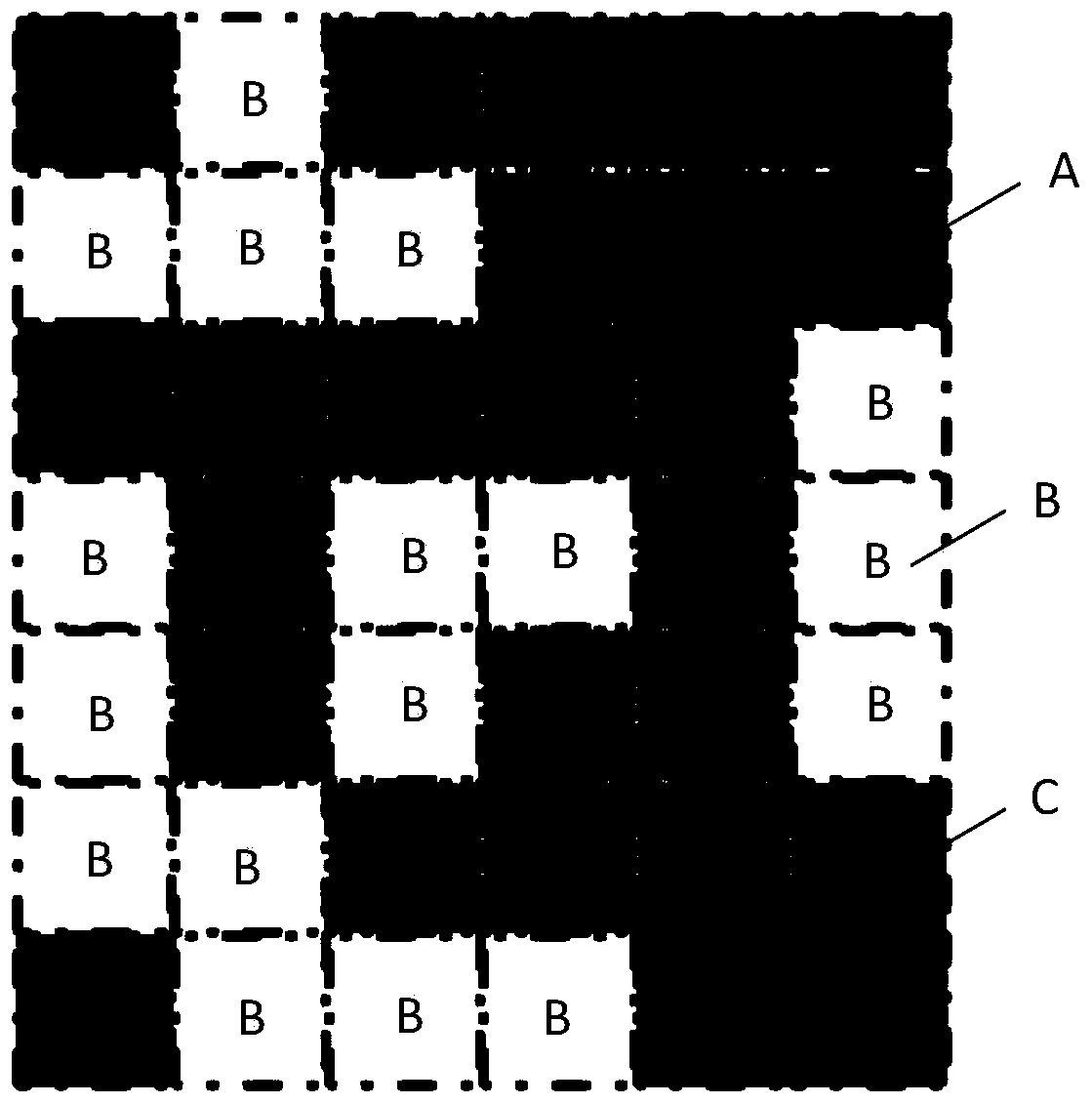

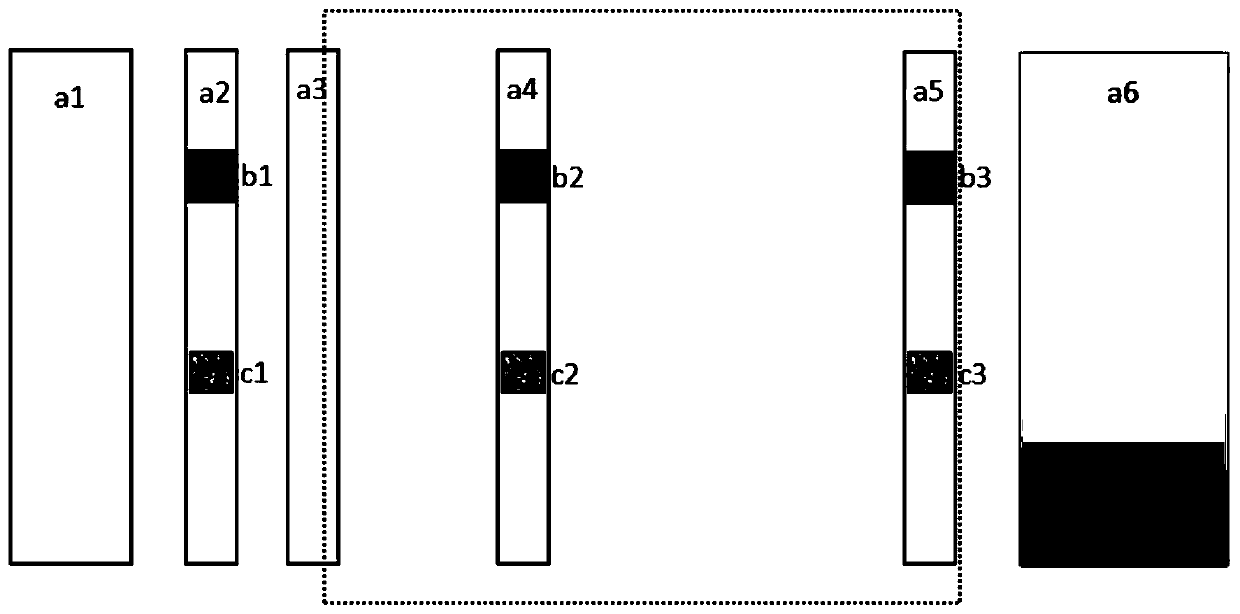

A Method for Adding and Processing Small-sized Redundant Graphics of Metal Line Layer

ActiveCN106444273BHigh densityExpanding the photolithography process windowOriginals for photomechanical treatmentGraph sizeGraphics

The invention discloses an addition and processing method of small-size redundant graphs for metal wire layers. The method comprises the steps of dividing the original layout into a plurality of regions according to a design rule, calculating the graph density of the metal wire layers in the regions, dividing all the regions of the original layout into a first graph density region, a second graph density region and a third graph density region according to the graph density, selecting metal wires meeting addition conditions of the small-size redundant graphs from the regions, adding the small-size redundant graphs for the selected different metal wires located in the first graph density region, the second graph density region and the third graph density region according to the graph size and the quantity, merging the small-size redundant graphs to the original main graph of the metal wire layers in the original layout, and performing optical proximity correction. The method can really realize a change from isolated metal wires to dense metal wires and can achieve purposes of increasing a photolithographic technology window of the selected partial metal wires and improving the selected partial graph density.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

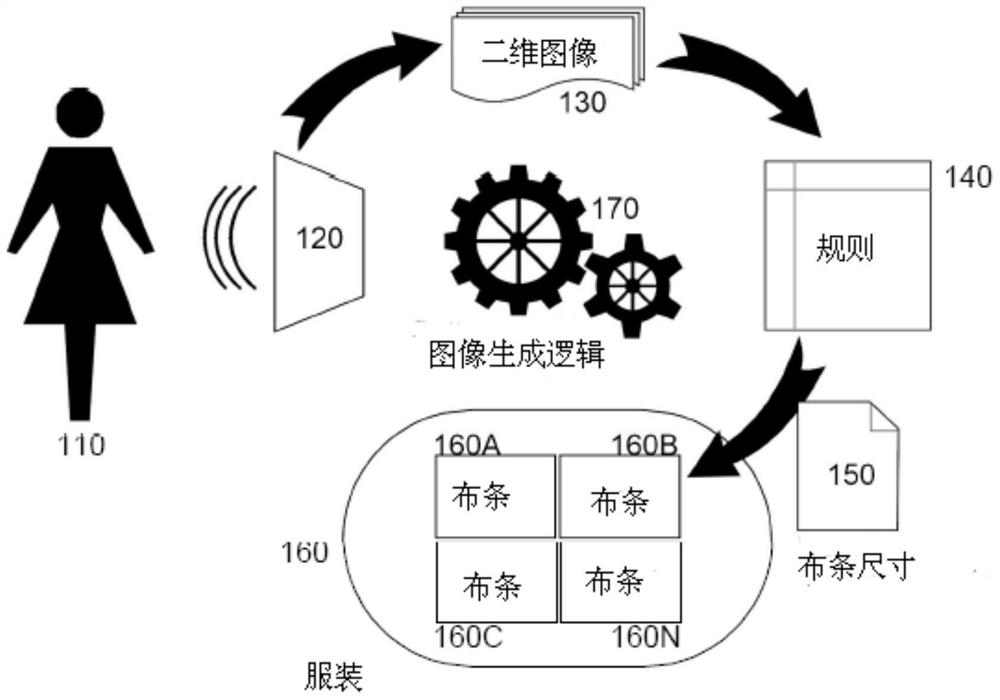

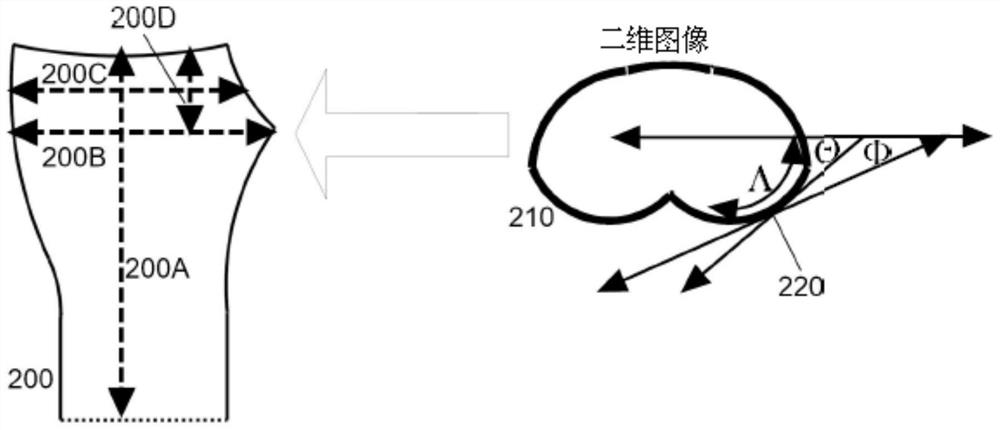

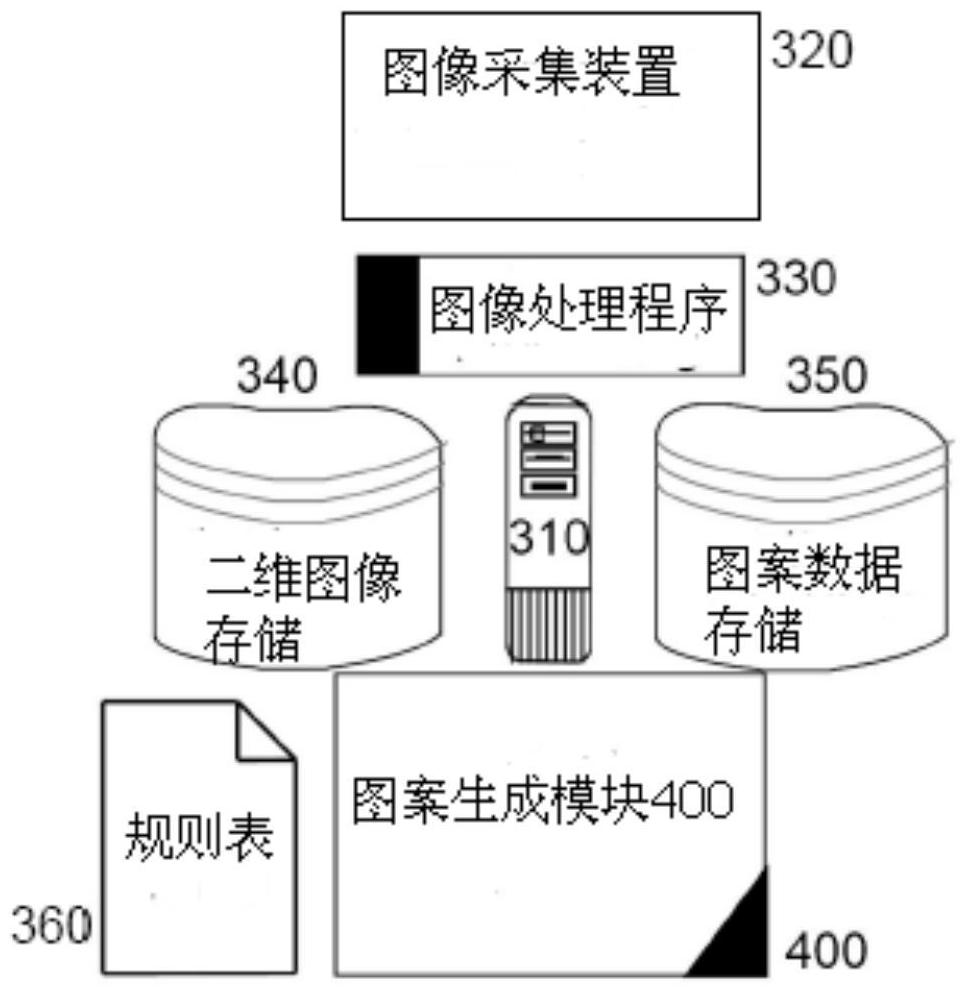

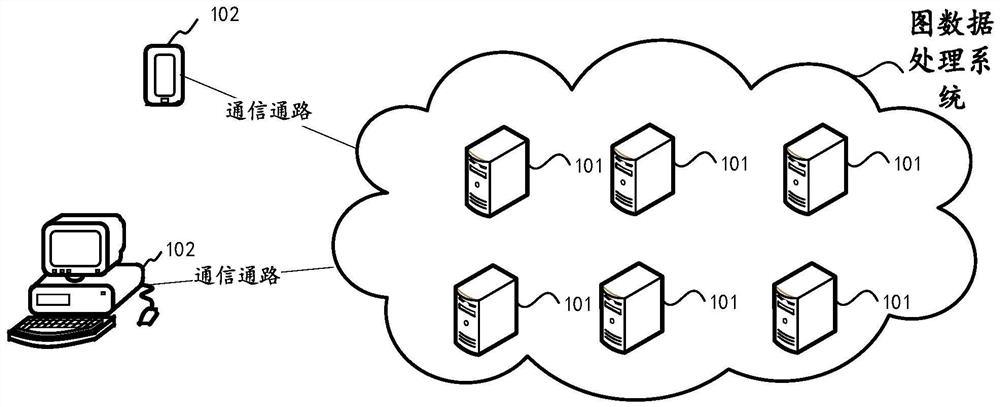

Making Garment Patterns Using Two-Dimensional Images of Human Body

Embodiments of the present invention provide a computer-aided method, system and computer program code product for pattern drafting in the field of apparel. In one embodiment of the present invention, a pattern making method includes: acquiring a series of different two-dimensional images of the human body from the storage of the computer; selecting cloth strips of partial patterns of clothing by the processor of the computer; a processor of a computer making metric calculation rules for said selected strip of said two-dimensional image; acquiring a measurement value of said two-dimensional image by said processor of said computer; and said processing by said computer The device generates a measurement value for the selected cloth strip by using the acquired measurement value according to the created metric calculation rule.

Owner:共鸣有限责任公司

Data processing method, data processing system, computer equipment and storage medium

ActiveCN110769050BImprove execution efficiencyReduce trafficTransmissionData processing systemCalculation technique

The application discloses a data processing method, a data processing system, computer equipment, and a storage medium, which belong to the technical field of graph computing. In the method provided by the embodiment of the present application, by using a data processing system with a distributed architecture, each computing node in the data processing system stores part of the graph data, and in the encoding stage, each computing node performs an aggregation first, and then calculates Interaction of vertex IDs between nodes to complete the second aggregation. Through the above two aggregation processes, each computing node can store a full amount of vertex IDs. In the decoding stage, decoding can be completed without communication, which can reduce The overall communication volume improves the efficiency of algorithm execution.

Owner:TENCENT TECH (SHENZHEN) CO LTD

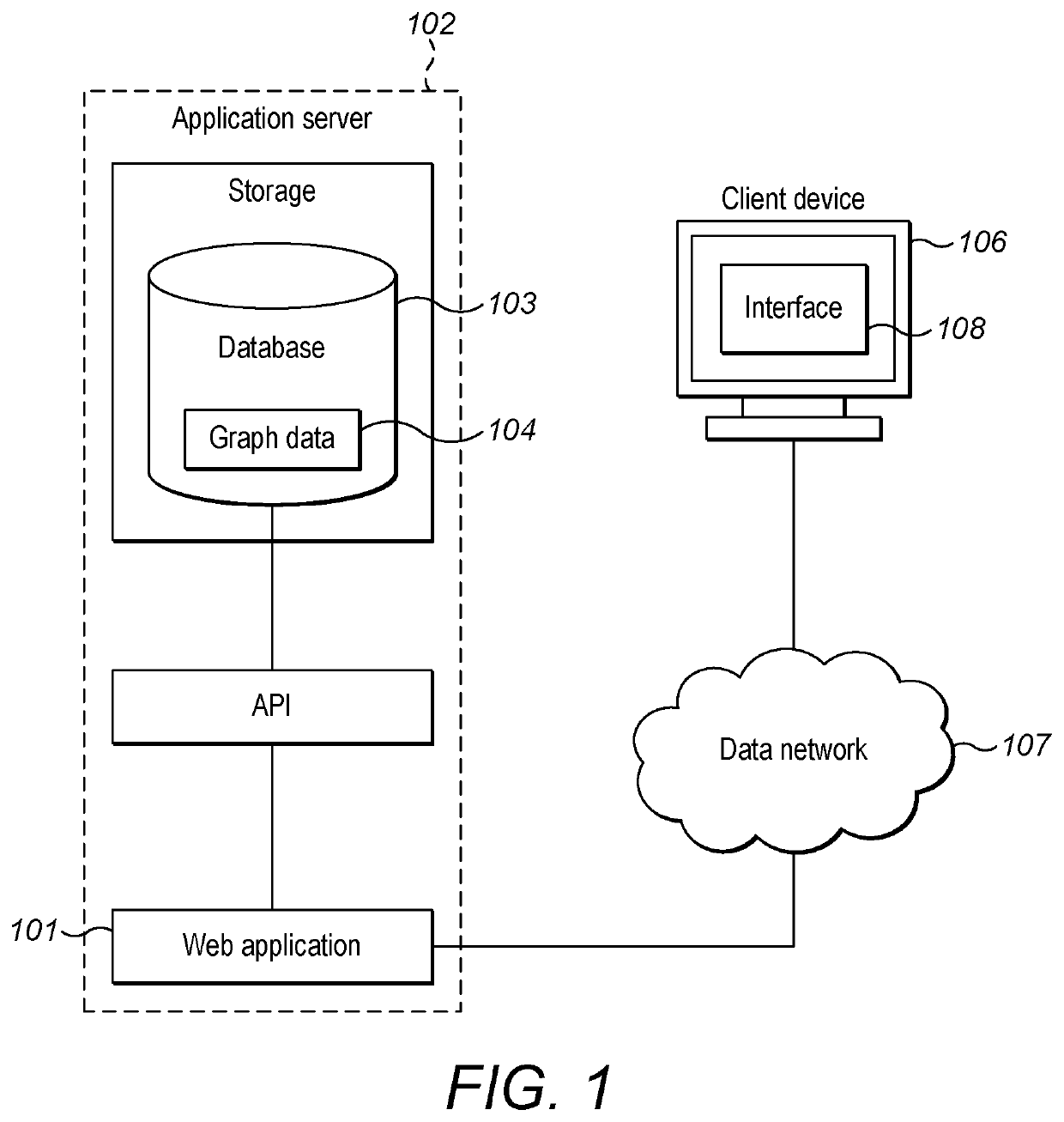

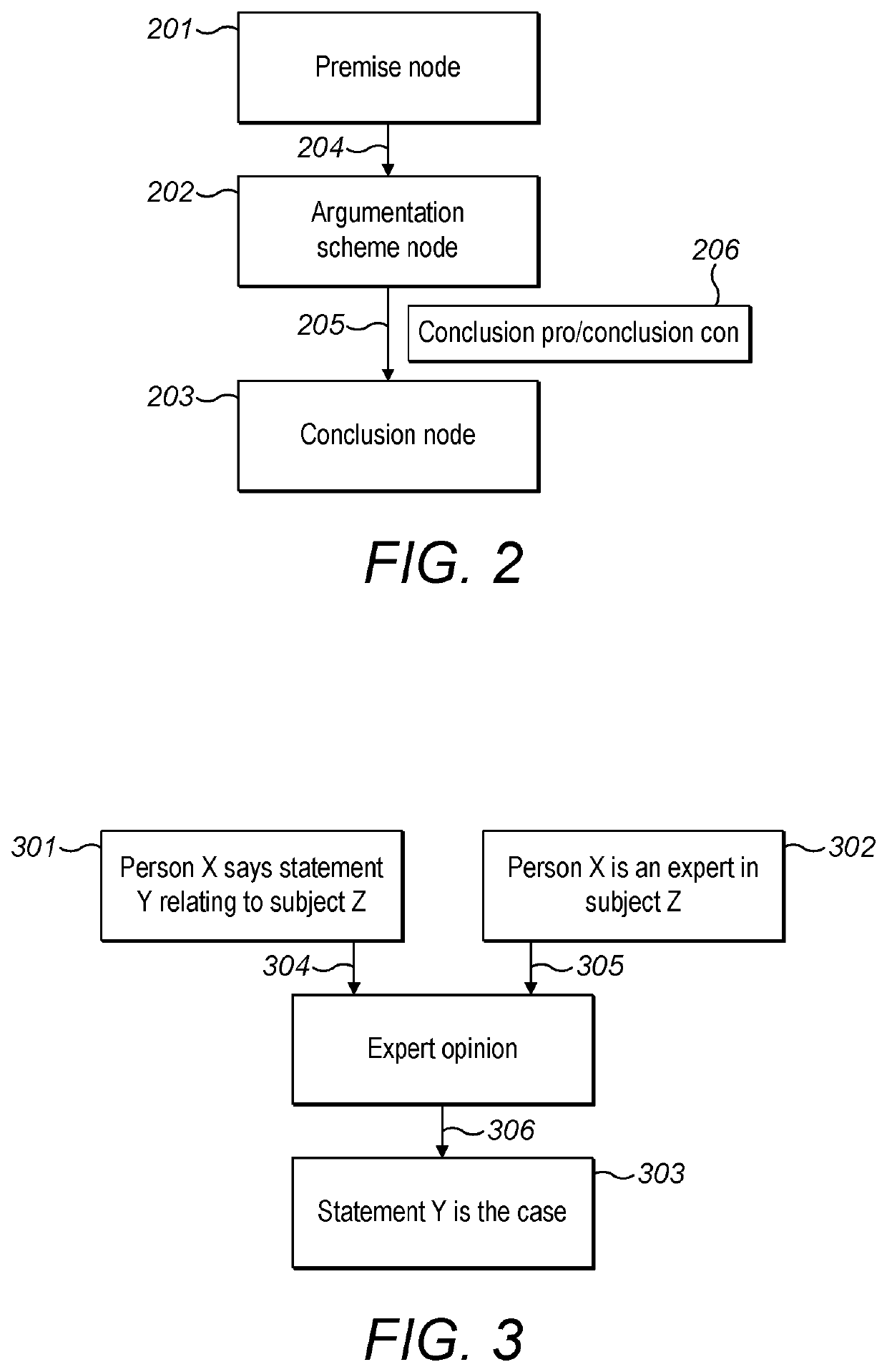

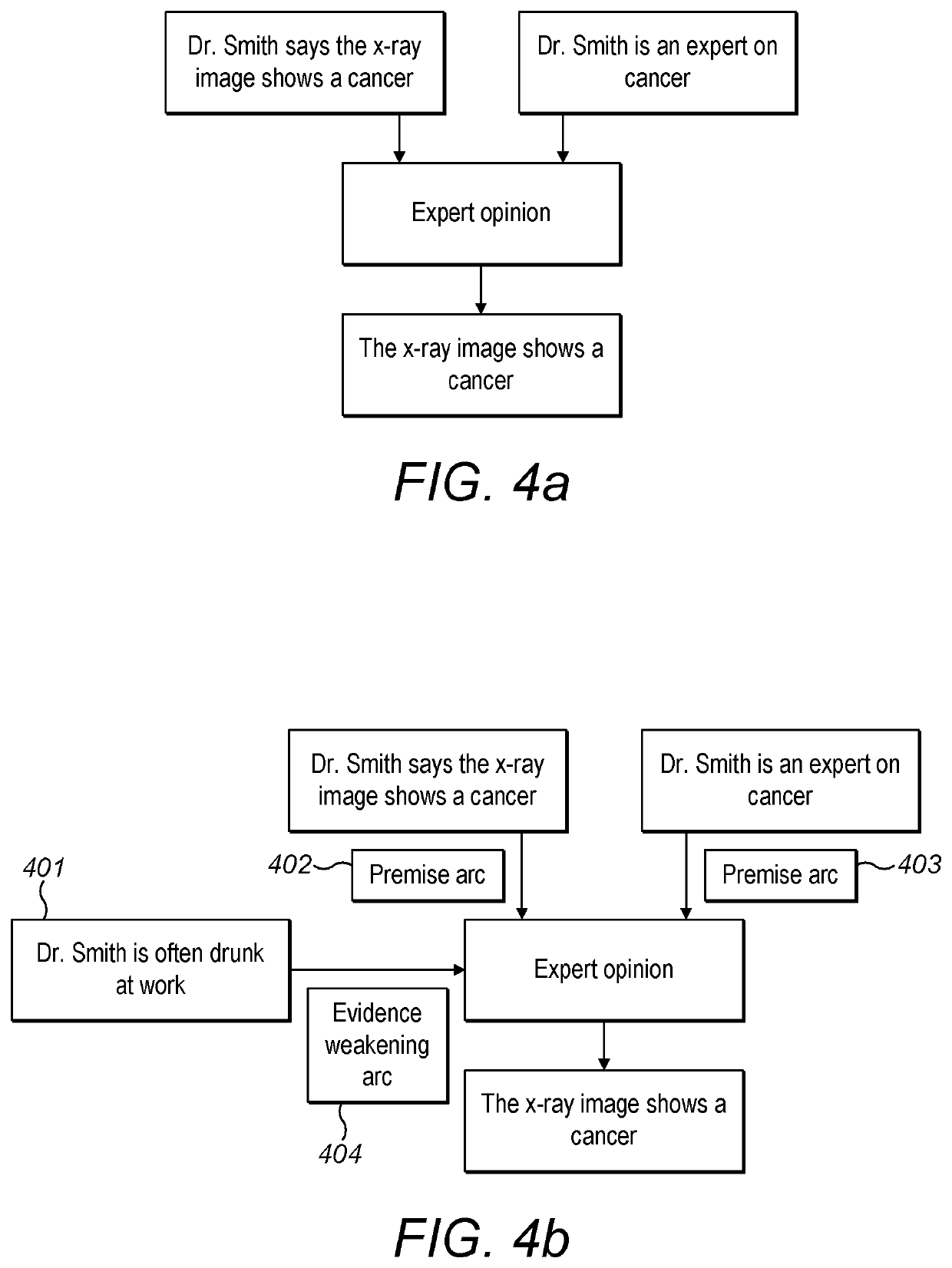

Defeasible reasoning system

PendingUS20220180229A1Readily representedEasy to understandMathematical modelsKnowledge representationDefeasible reasoningGraphics

A computing system for enabling a user to interact with graphical representations of defeasible reasoning. The system comprises a server device on which is running an application; memory storage on which is stored graph data defining a plurality of argument graphs, each argument graph comprising a plurality of nodes, said plurality of nodes comprising: at least a first premise statement node, connected via a first arc to at least a first argumentation scheme node, connected via a second arc to at least a first conclusion statement node, and optionally one or more evidence statement nodes connected via one or more arcs to the argumentation scheme node. The system further comprises at least one client device, wherein said application is operable to access the graph data and communicate at least part of the graph data to the client device.

Owner:PLUMLEY JULIAN ASHTON

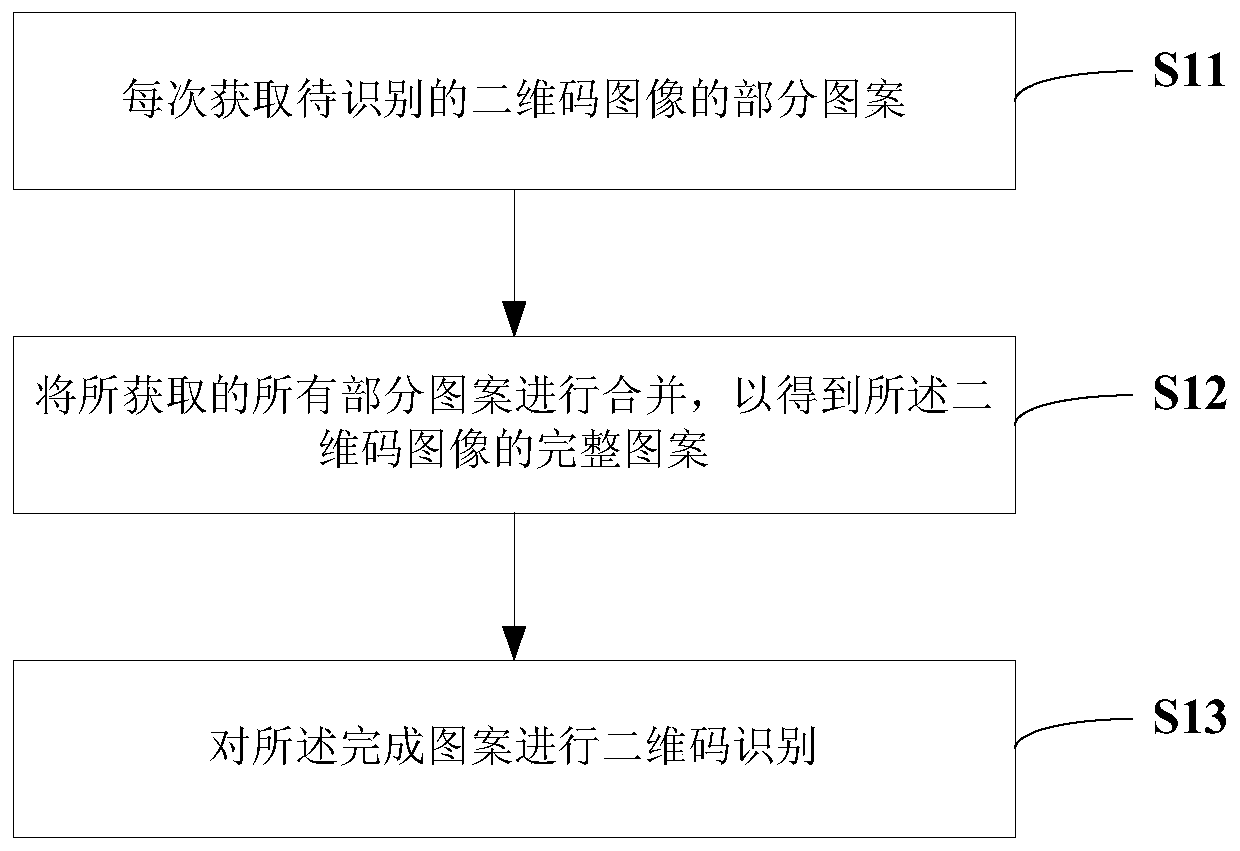

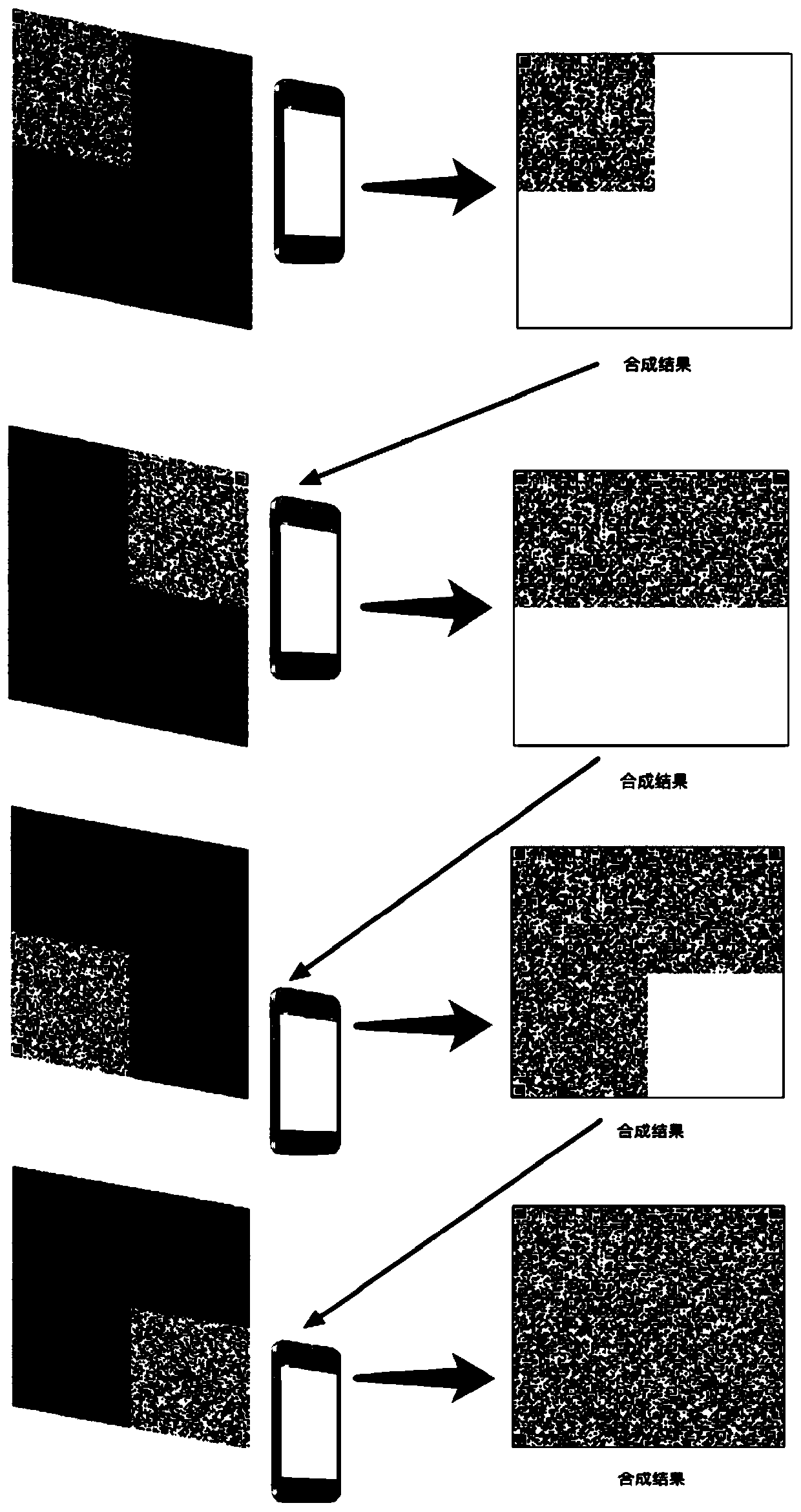

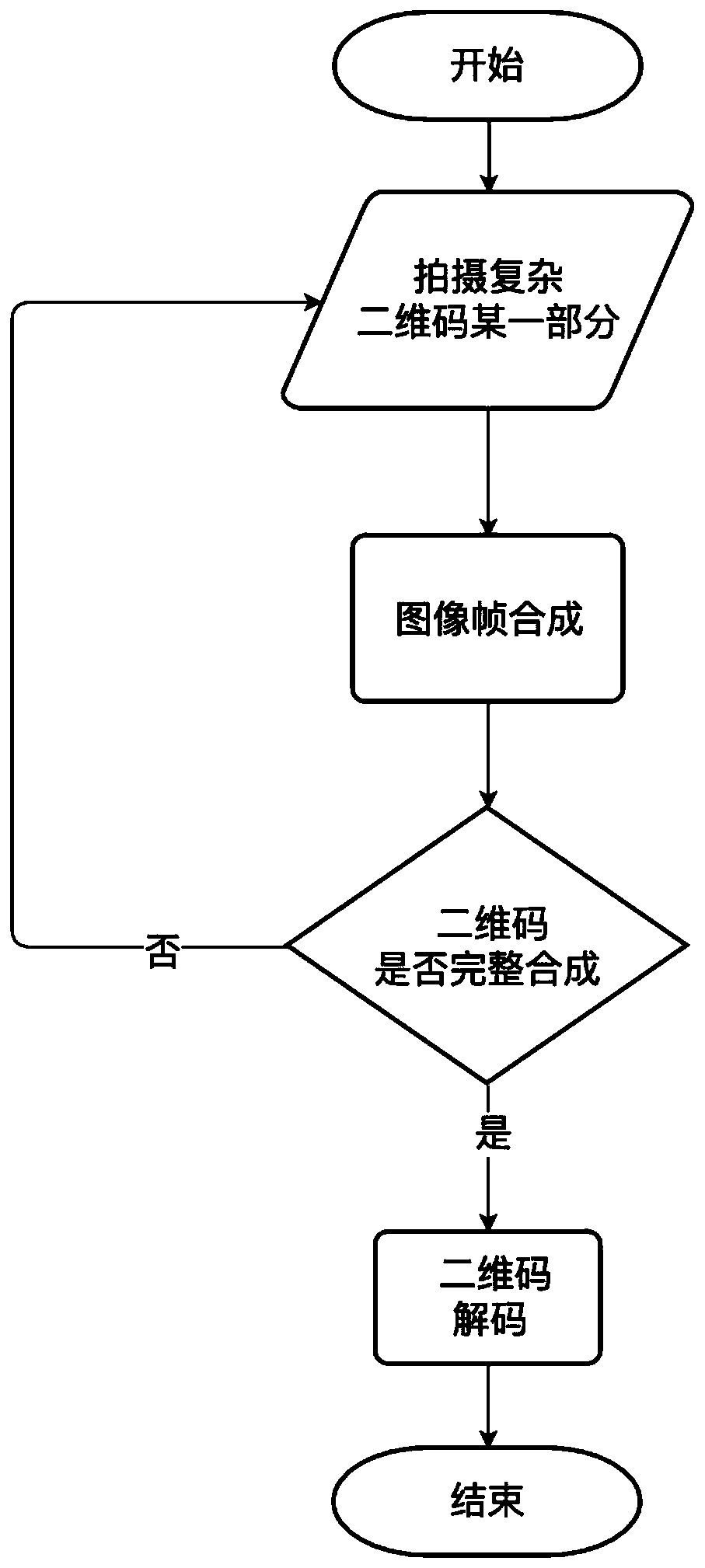

Complex two-dimensional code recognition method and system, medium and equipment

PendingCN110728161AImprove the recognition success rateSensing by electromagnetic radiationAlgorithmReliability engineering

The invention provides a complex two-dimensional code recognition method and system, a medium and equipment. The complex two-dimensional code identification method comprises the following steps: acquiring a partial pattern of a to-be-identified two-dimensional code image each time; combining all the obtained partial patterns to obtain a complete pattern of the two-dimensional code image; and performing two-dimensional code recognition on the completed pattern. According to the invention, the recognition success rate of the complex two-dimensional code is improved.

Owner:TIANYI ELECTRONICS COMMERCE

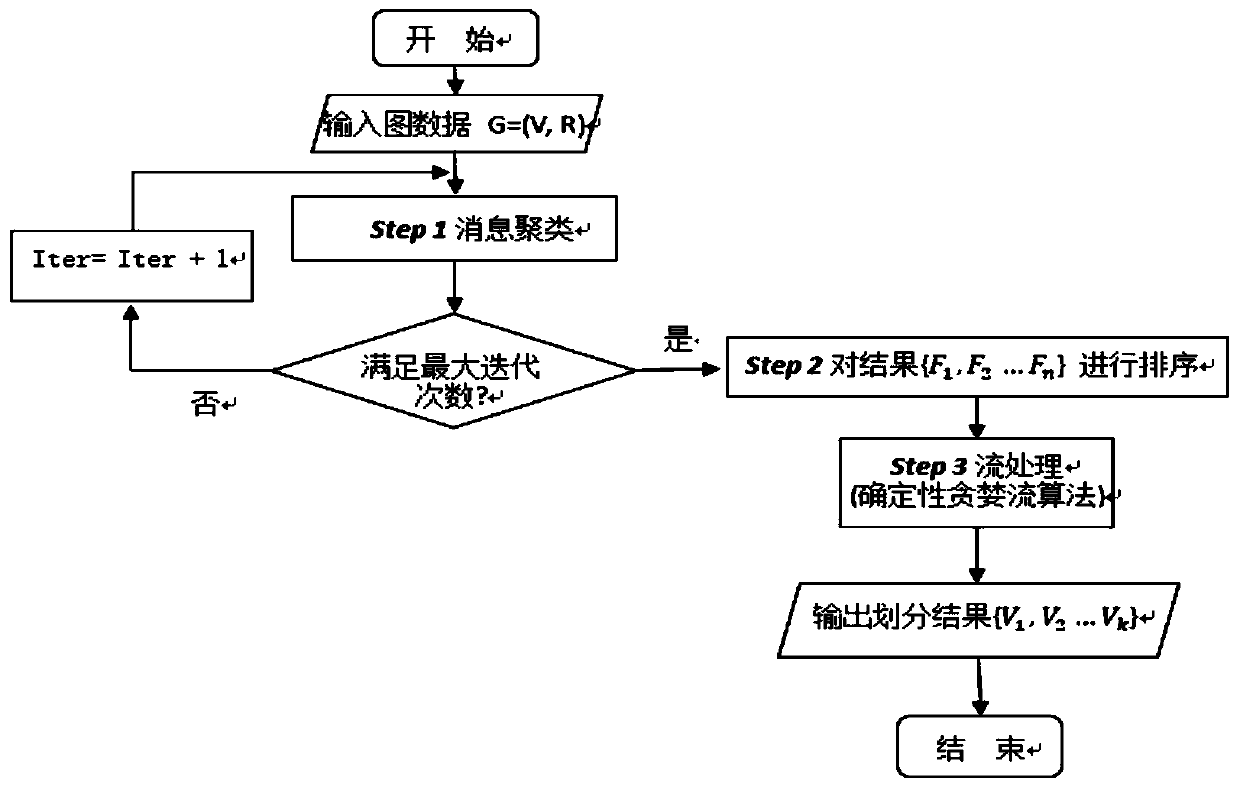

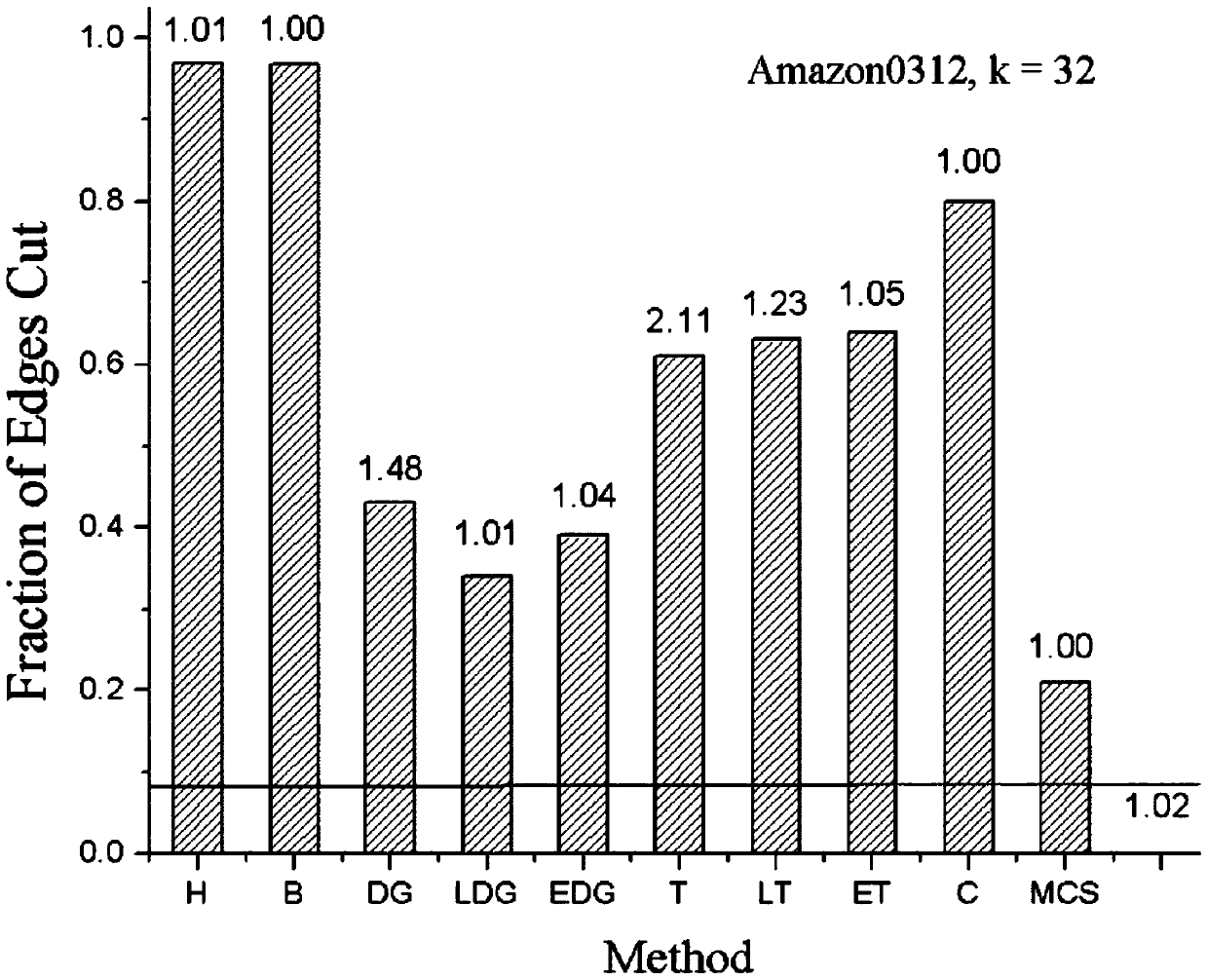

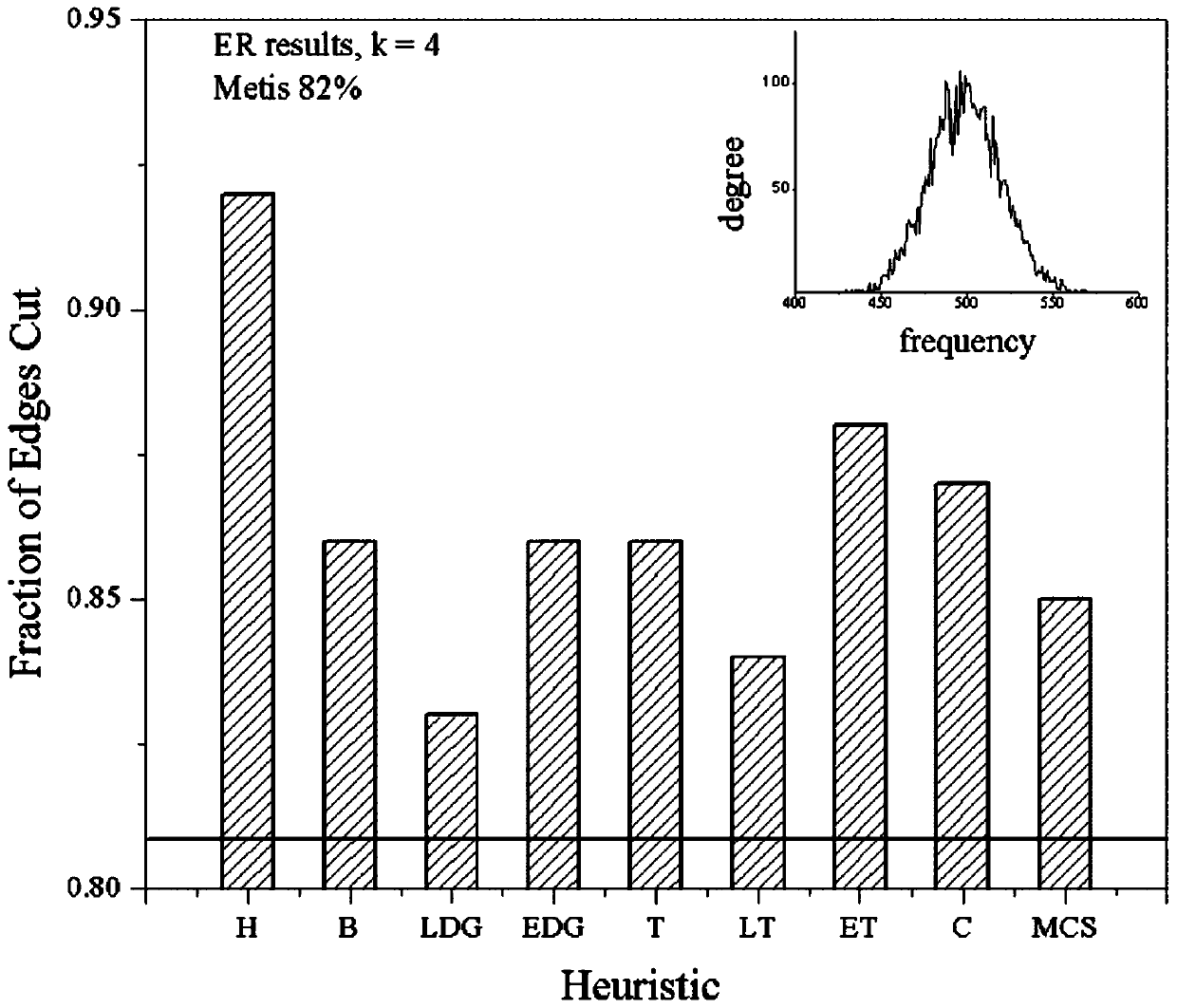

A Streaming Balancing Graph Partitioning Method Oriented to Memory Computing

InactiveCN106970779BRealize discoverySuitable for preprocessing workResource allocationConcurrent instruction executionConcurrent computationTheoretical computer science

The invention discloses a stream type equilibrium diagram division method and belongs to the field of parallel diagram calculation. According to an algorithm, for a characteristic of power-law distribution of most diagrams in reality, firstly an original input diagram is quickly subjected to community detection under a constraint condition; secondly communities are sorted; and finally vertexes are allocated to a specified processing unit in sequence according to a deterministic greedy flow algorithm. Compared with a conventional division algorithm, the division quality and the division efficiency are greatly improved. The stream type equilibrium diagram division method is suitable for task division in parallel computing of large-scale networks of power-law distribution.

Owner:CHONGQING UNIV

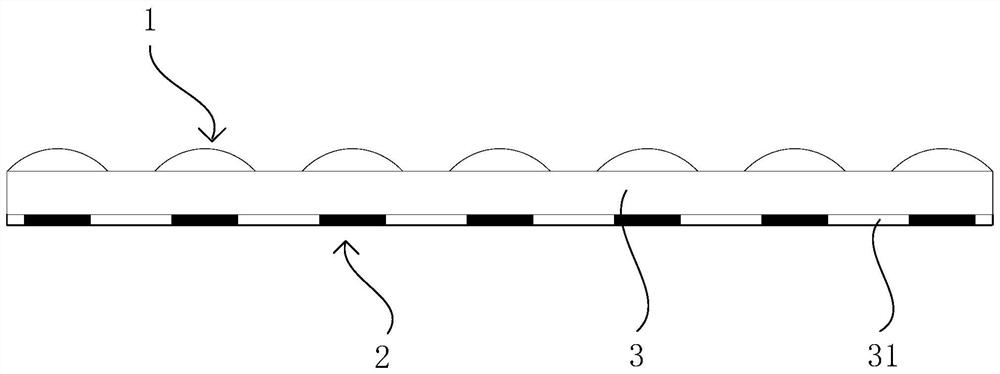

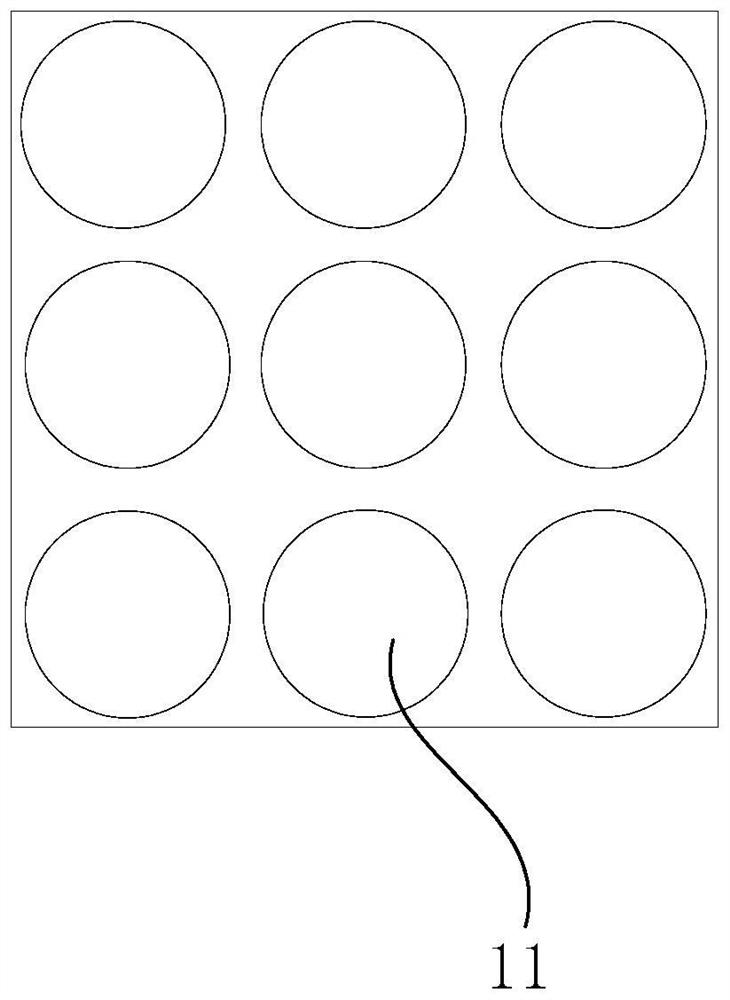

Optical imaging film

The invention provides an optical imaging film, which comprises an imaging layer and a micro image-text layer; the imaging layer comprises a plurality of imaging structures which are periodically distributed; the micro image-text layer comprises a plurality of micro image-texts which are periodically distributed, and the micro image-texts are arranged corresponding to the imaging structure, so that the optical imaging film forms a target image with an amplification effect; the micro image-texts are partial graphs of the target image, and the plurality of micro image-texts can form a complete graph consistent with the target image. Compared with a traditional optical imaging film, the optical imaging film provided by the invention has the beneficial effect that a larger Moire image can be displayed.

Owner:SHINE OPTOELECTRONICS KUNSHAN CO LTD

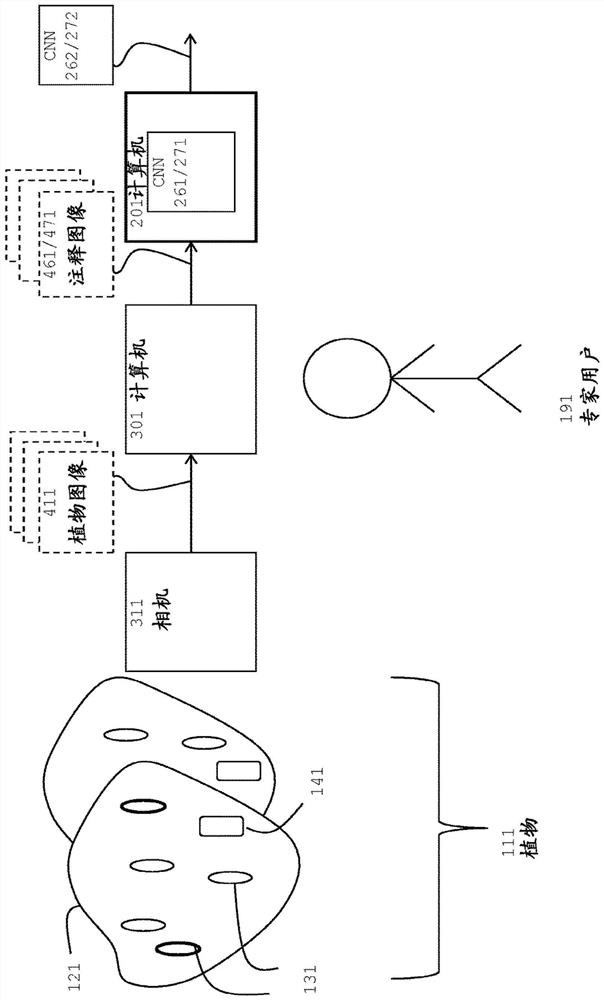

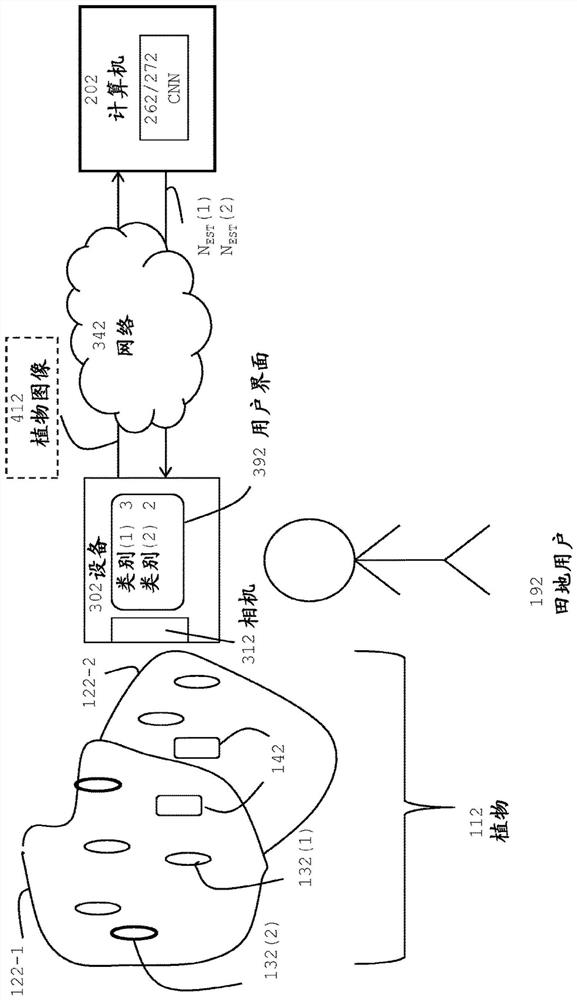

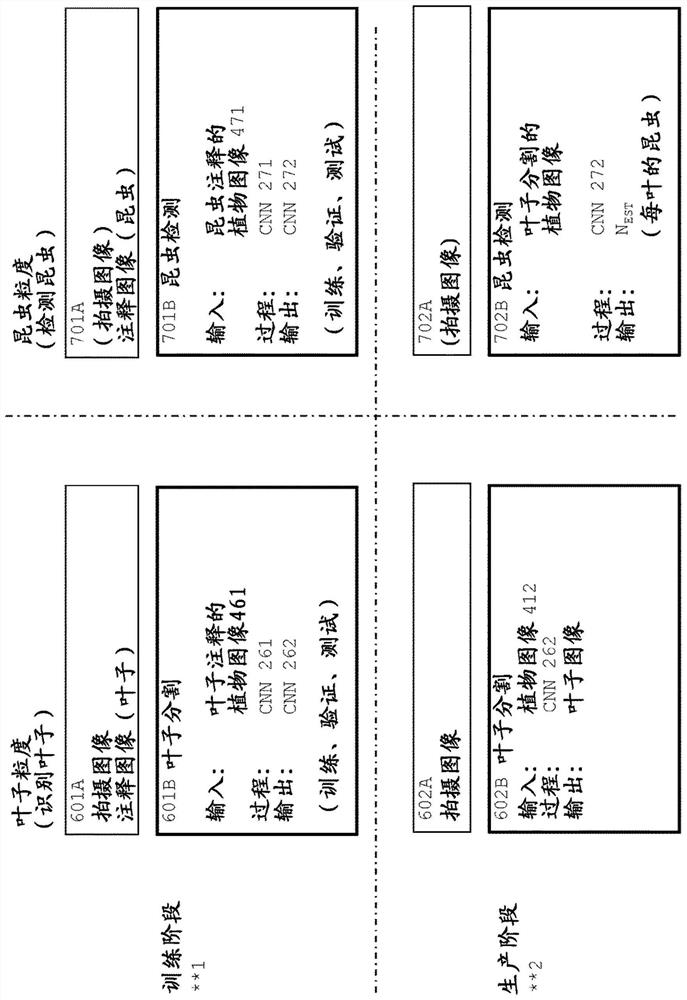

Quantifying objects on plant by estimating number of objects on plant portion, such as leaf, through convolutional neural network providing density map

Quantifying plant infestation is performed by estimating the number of biological objects (132) on a portion (122) of a plant (112). A computer (202) receives a plant image (412) captured from a specific plant (112). A computer (202) derives a portion image (422) showing a portion of a plant using a first convolutional neural network (262 / 272). The computer (202) segments the partial image into tiles and processes the tiles into a density map using a second network. The computer (202) combines the density maps into a combined density map at the size of the partial image and integrates pixel values into an estimated number of objects of the partial image. Object categories (132 (1), 132 (2)) may be distinguished to fine-tune quantization to identify category-specific countermeasures.

Owner:BASF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com