Patents

Literature

60results about How to "Easily correlated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Document knowledge management apparatus and method

InactiveUS20050154690A1Efficient processingEasily correlatedDigital computer detailsUnstructured textual data retrievalPart of speechGraphics

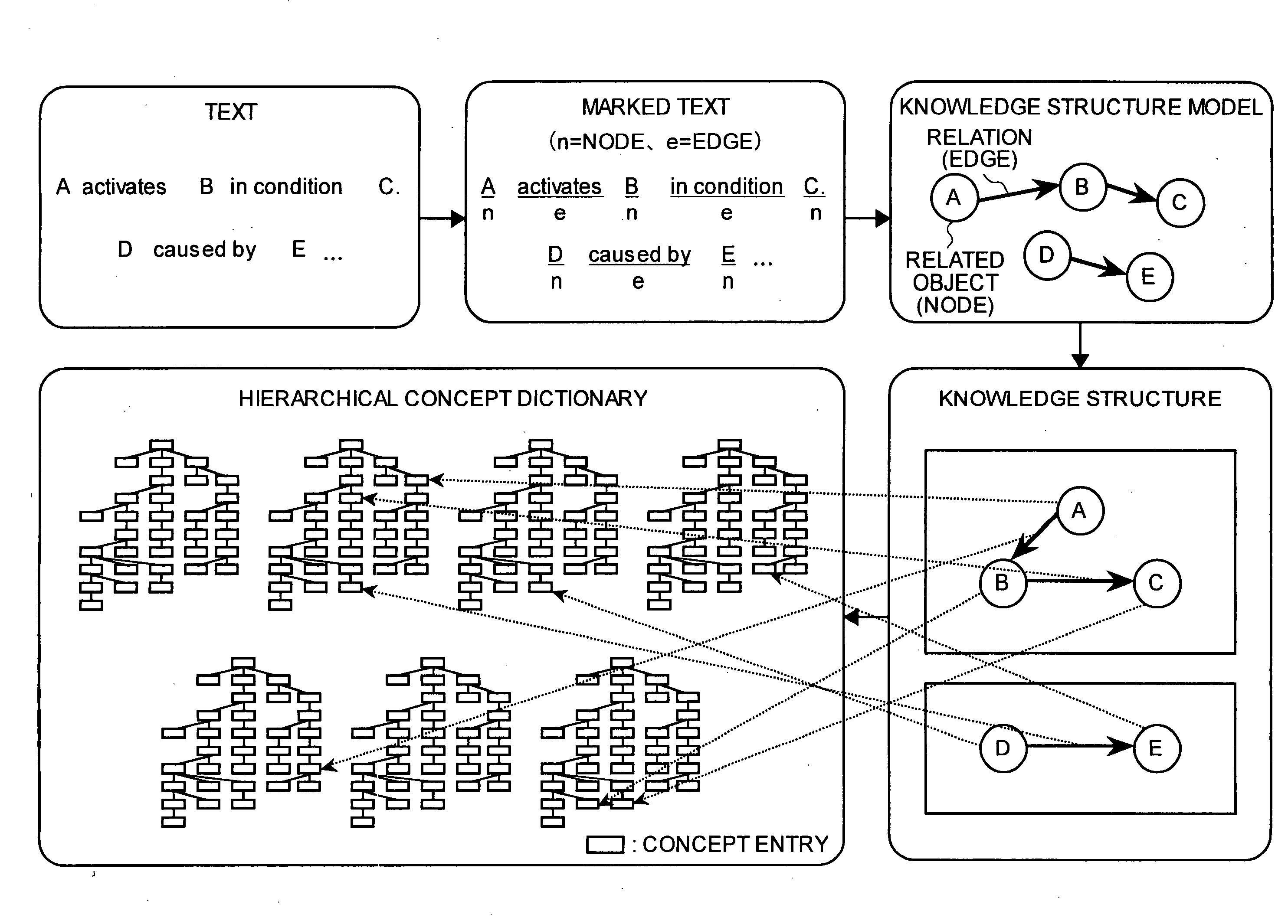

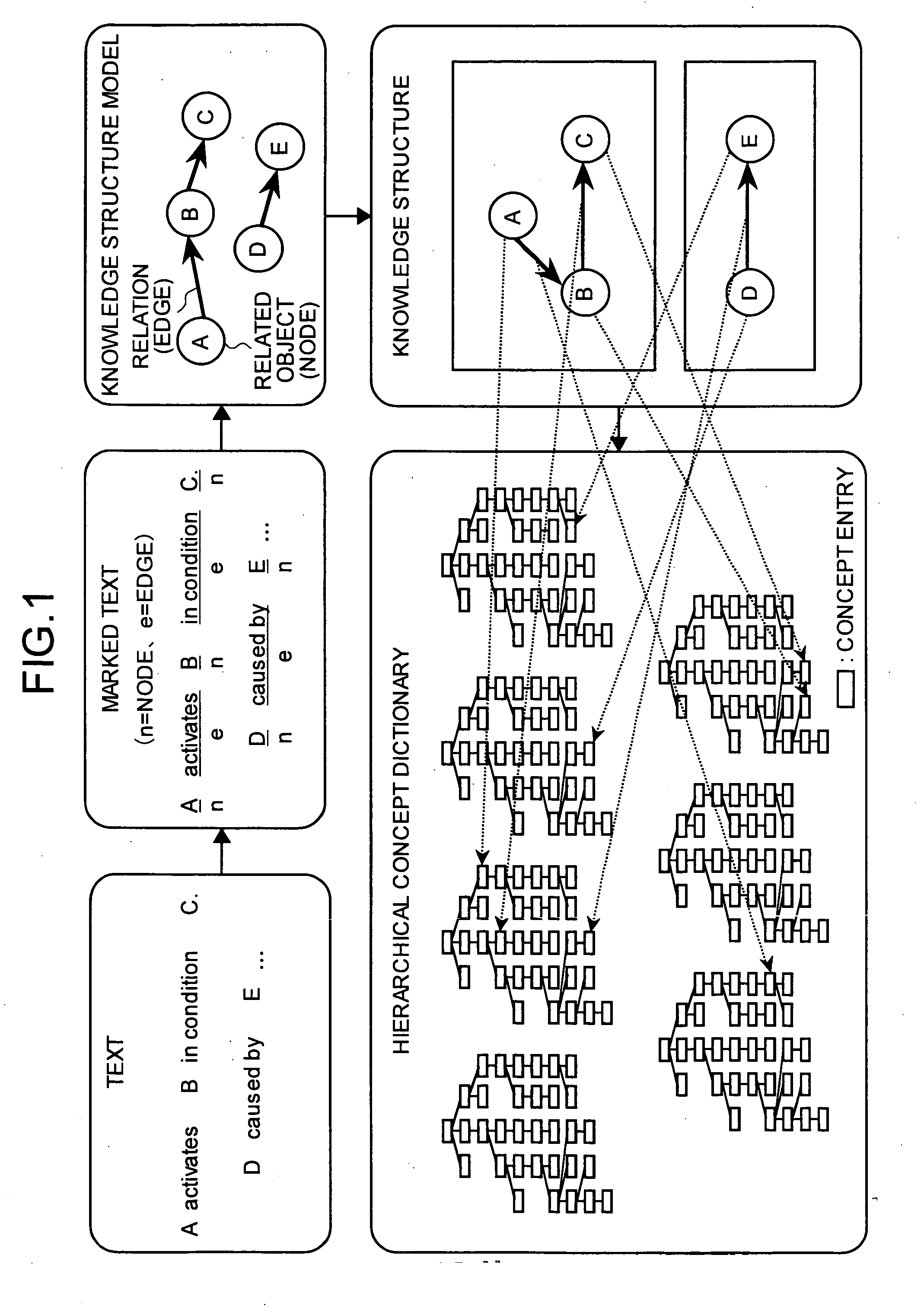

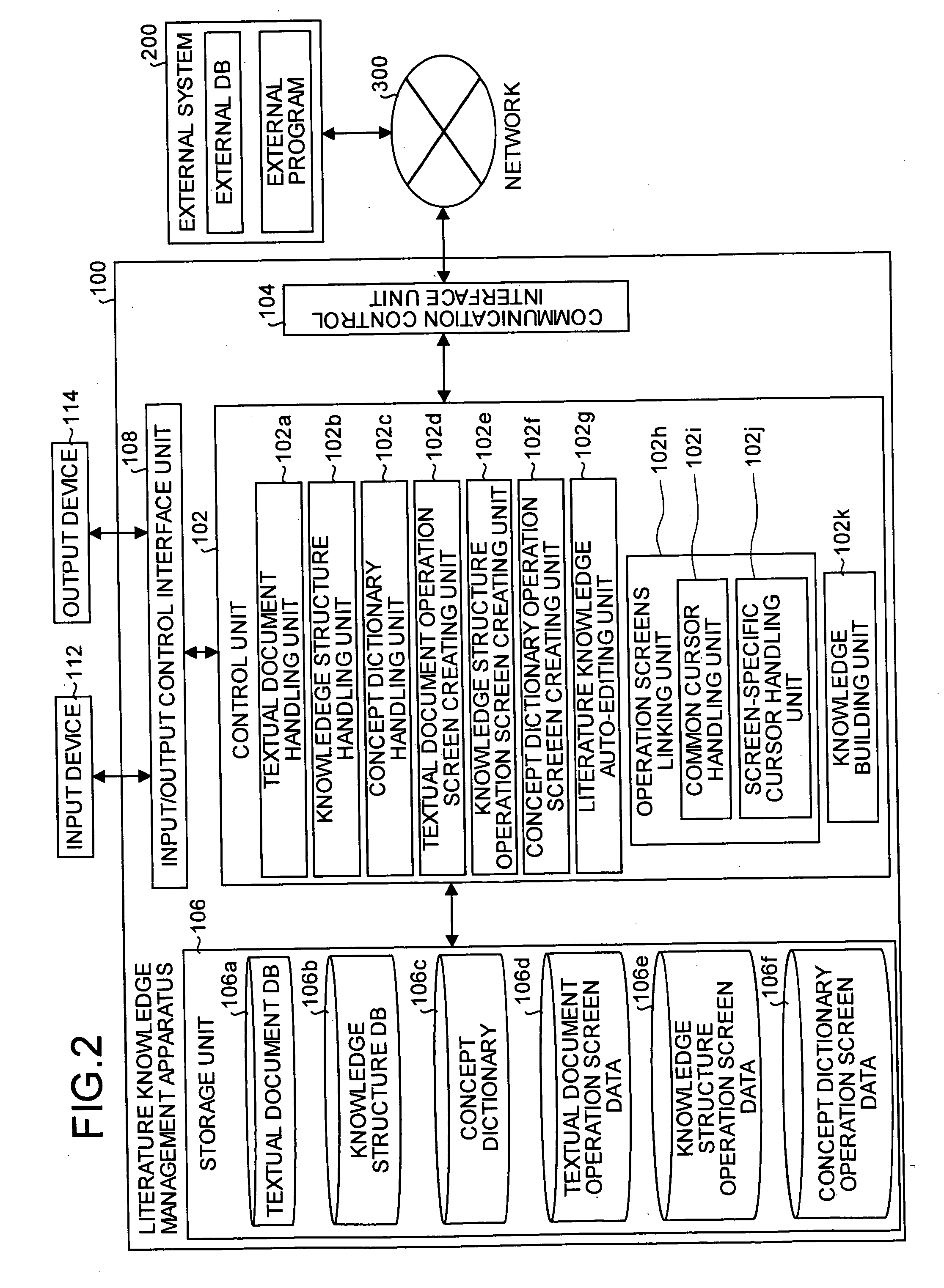

In the present invention, a textual document is syntactically analyzed and knowledge is constructed from a single word or plural words. The knowledge is then marked, from the broken down knowledge (represented by the underscores in FIG. 1) or from a part-of-speech, as a related object (node) or a relation (edge) (represented by ‘n’ or ‘e’ shown in FIG. 1). In other words, in the present invention a textual document is treated as knowledge constructed from a single word or plural words. The knowledge extracted from the textual document is structured to form a knowledge structure (such as a graph structure constituted from nodes and edges). At least one link can be established between each of the knowledge structure elements and a semantically closest concept entry in a hierarchical concept dictionary.

Owner:CELESTAR LEXICO SCI

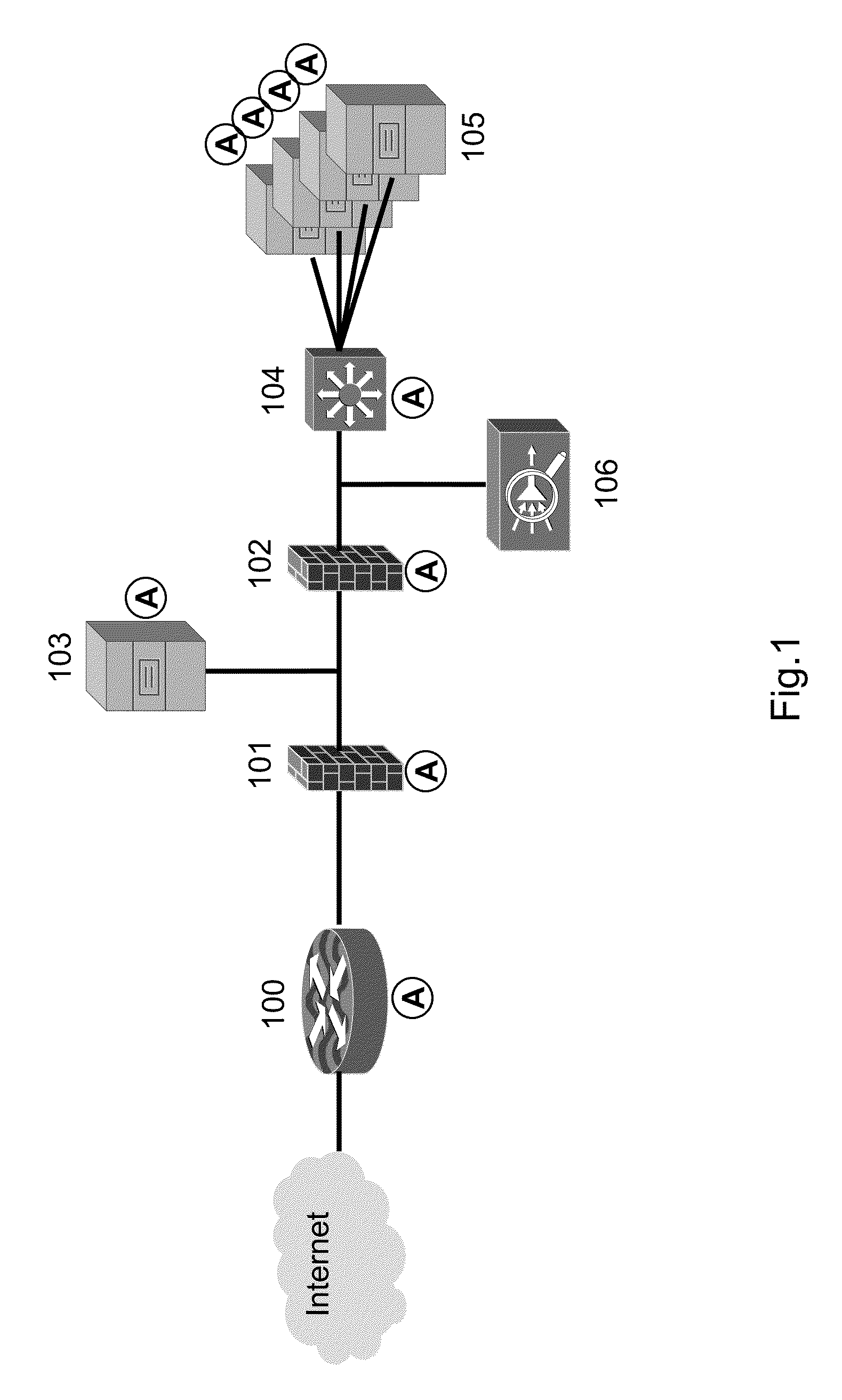

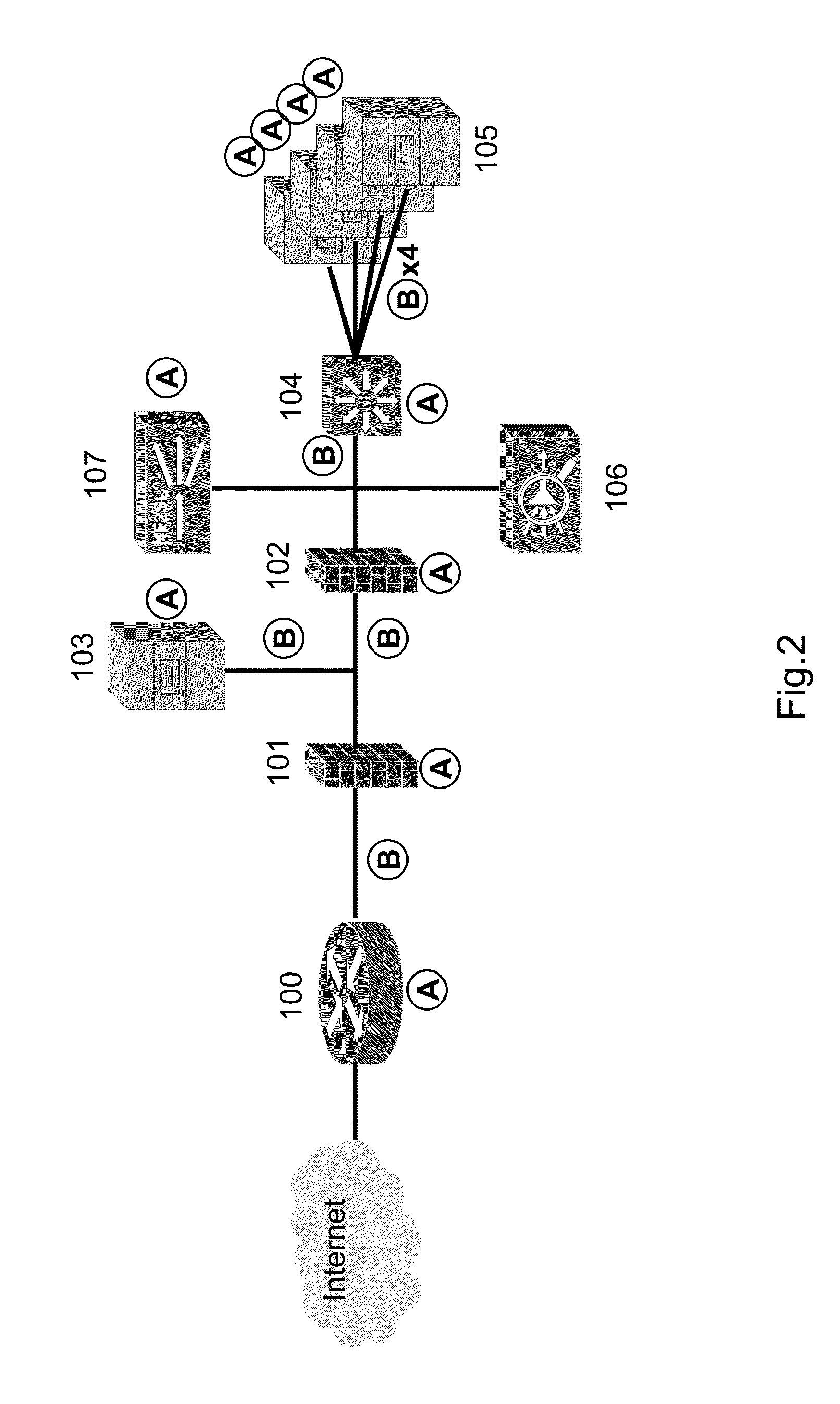

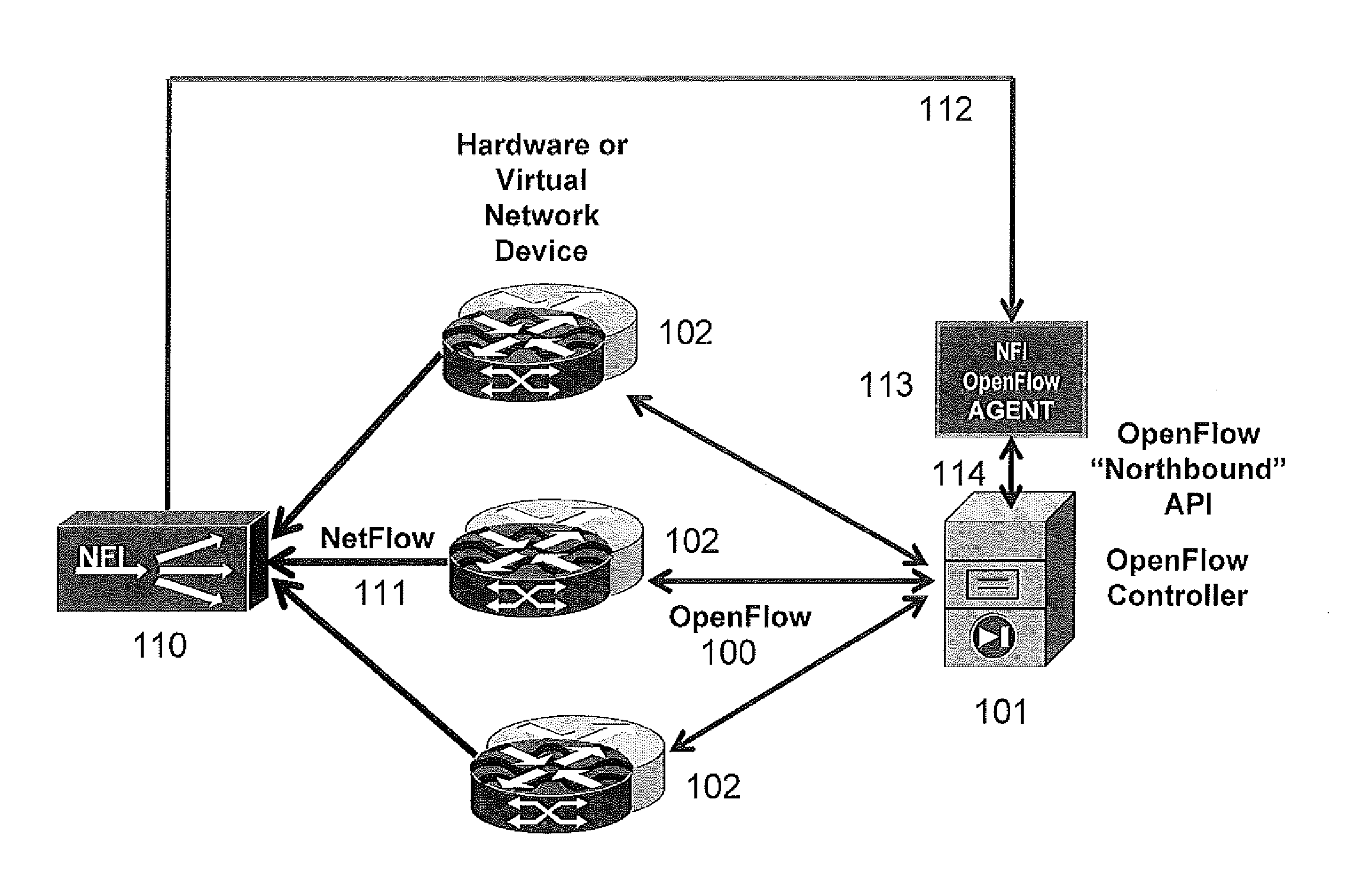

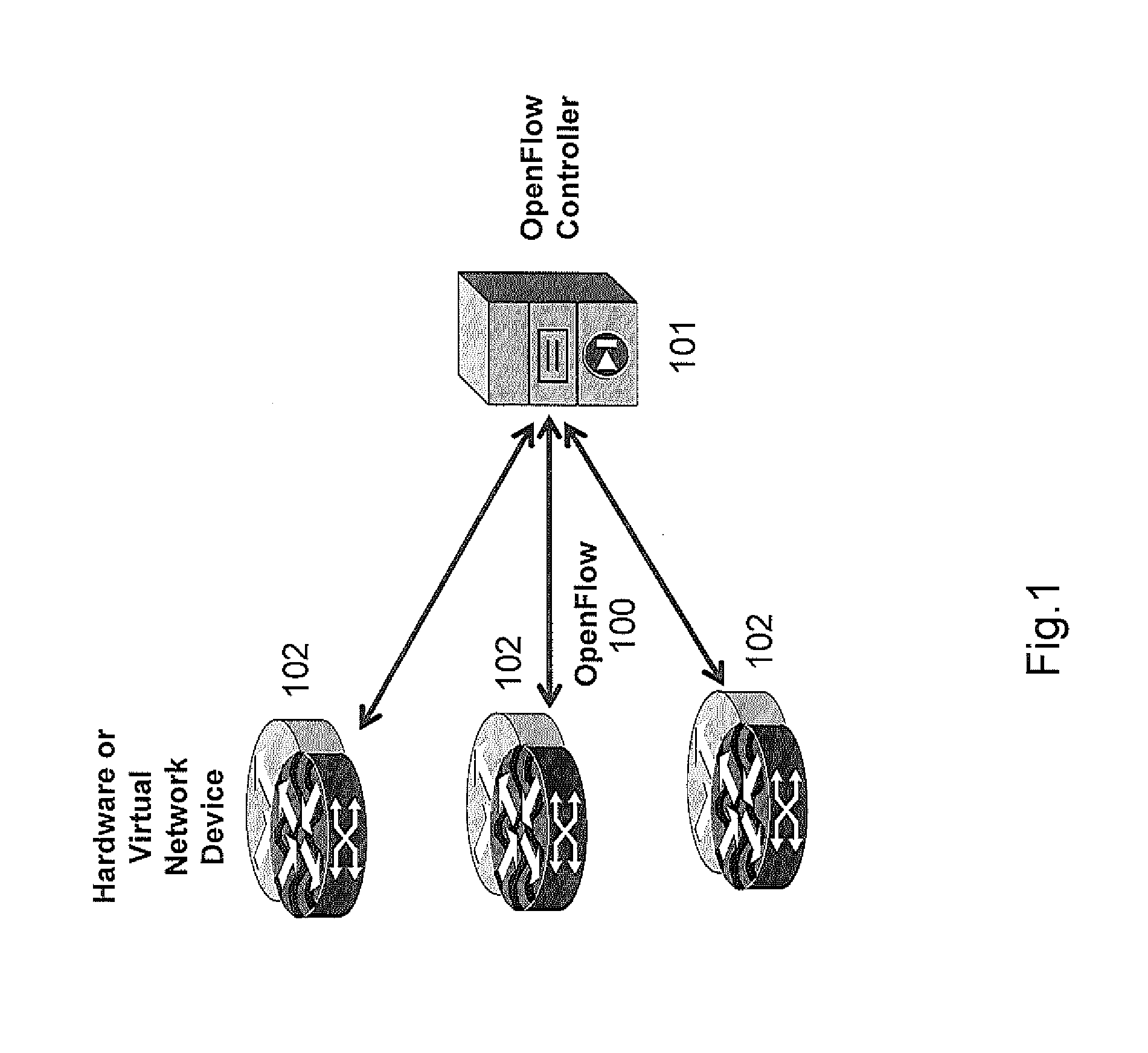

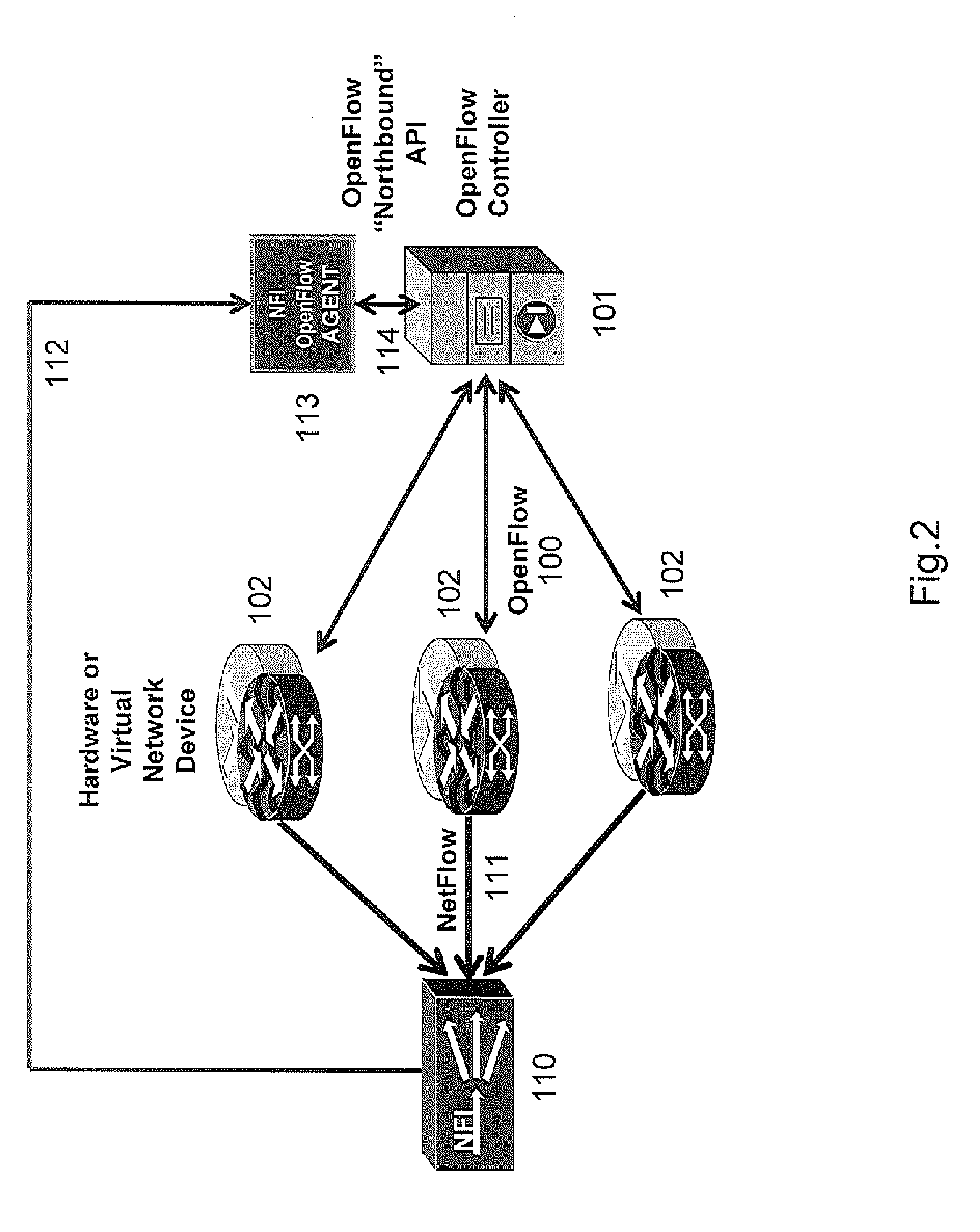

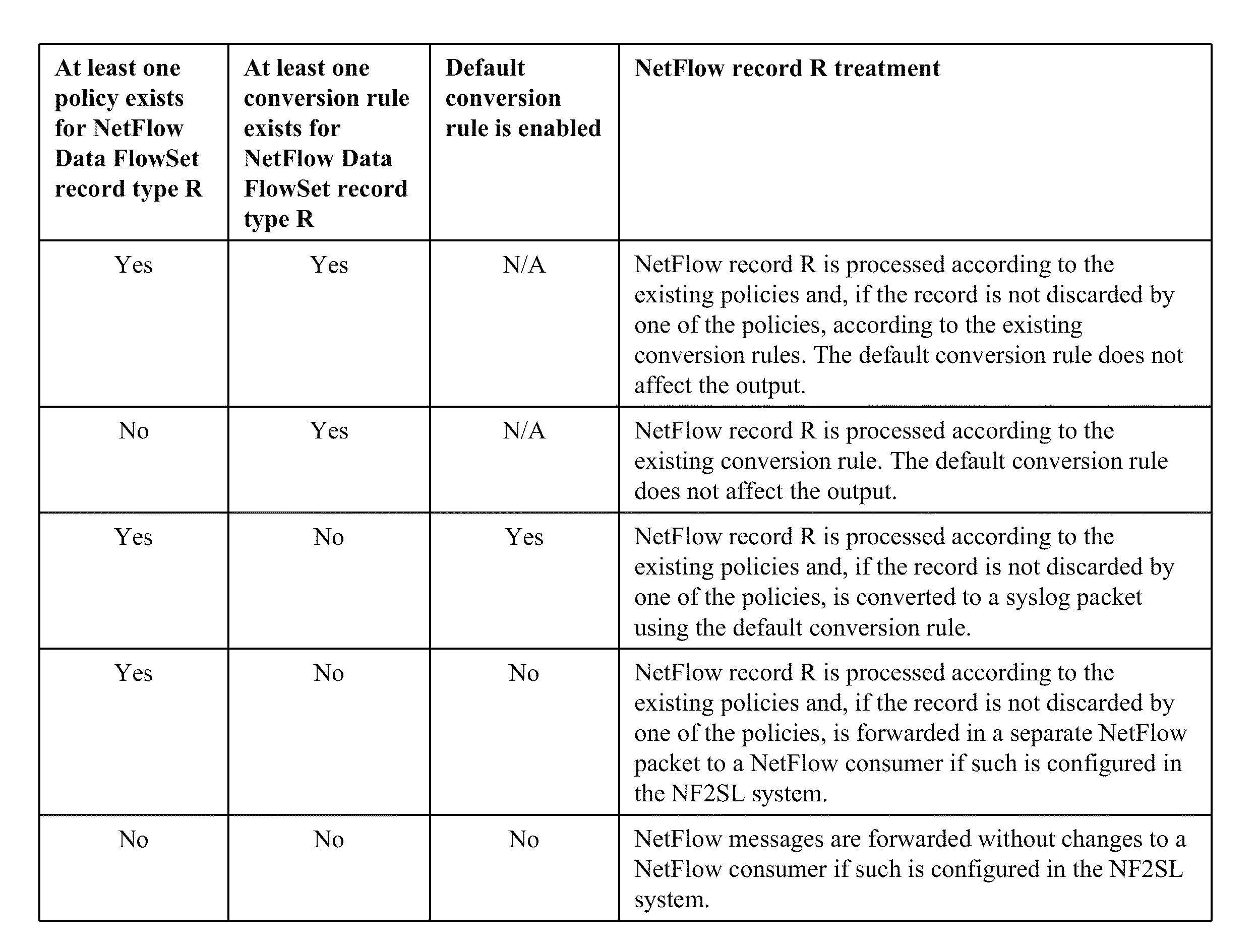

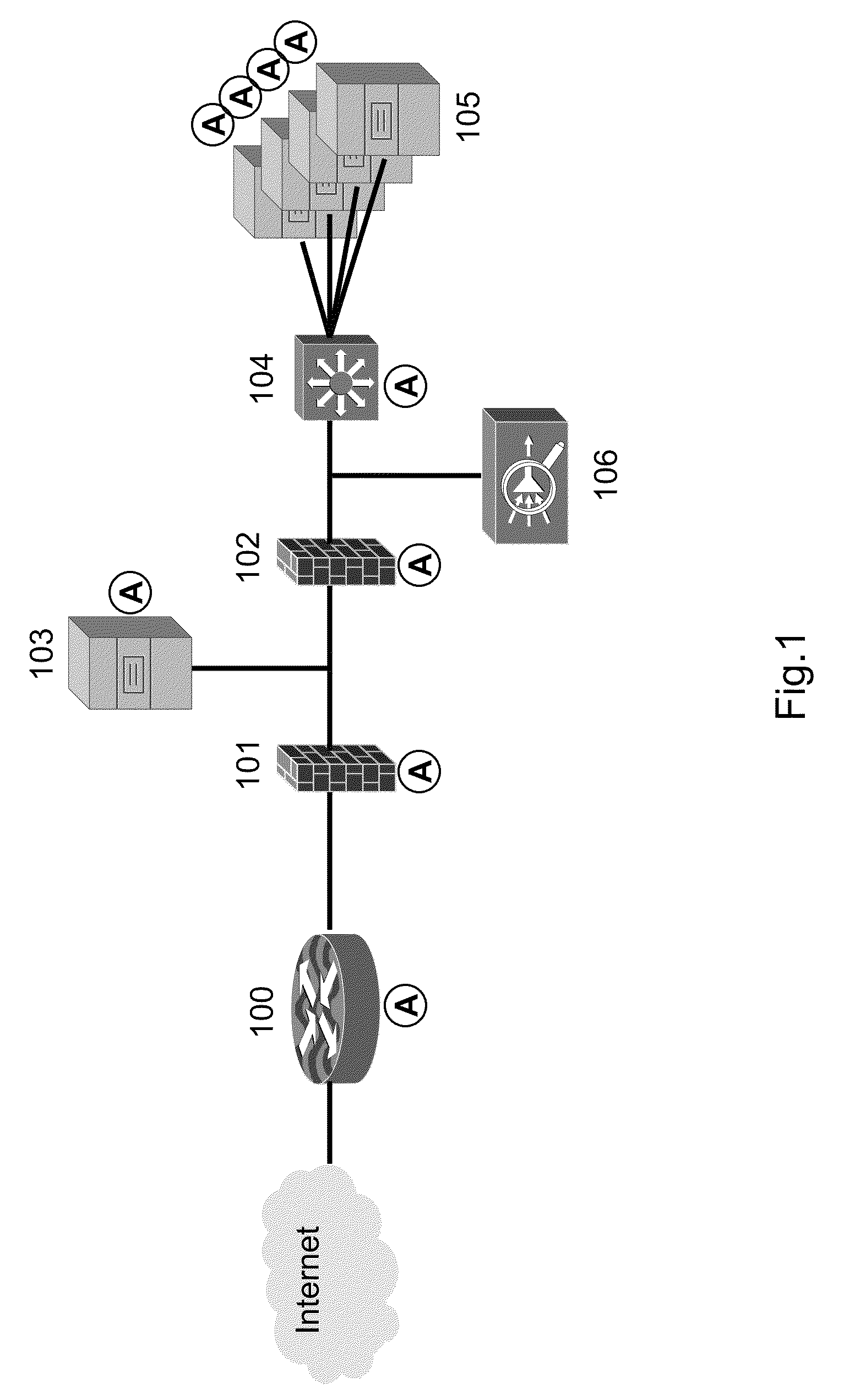

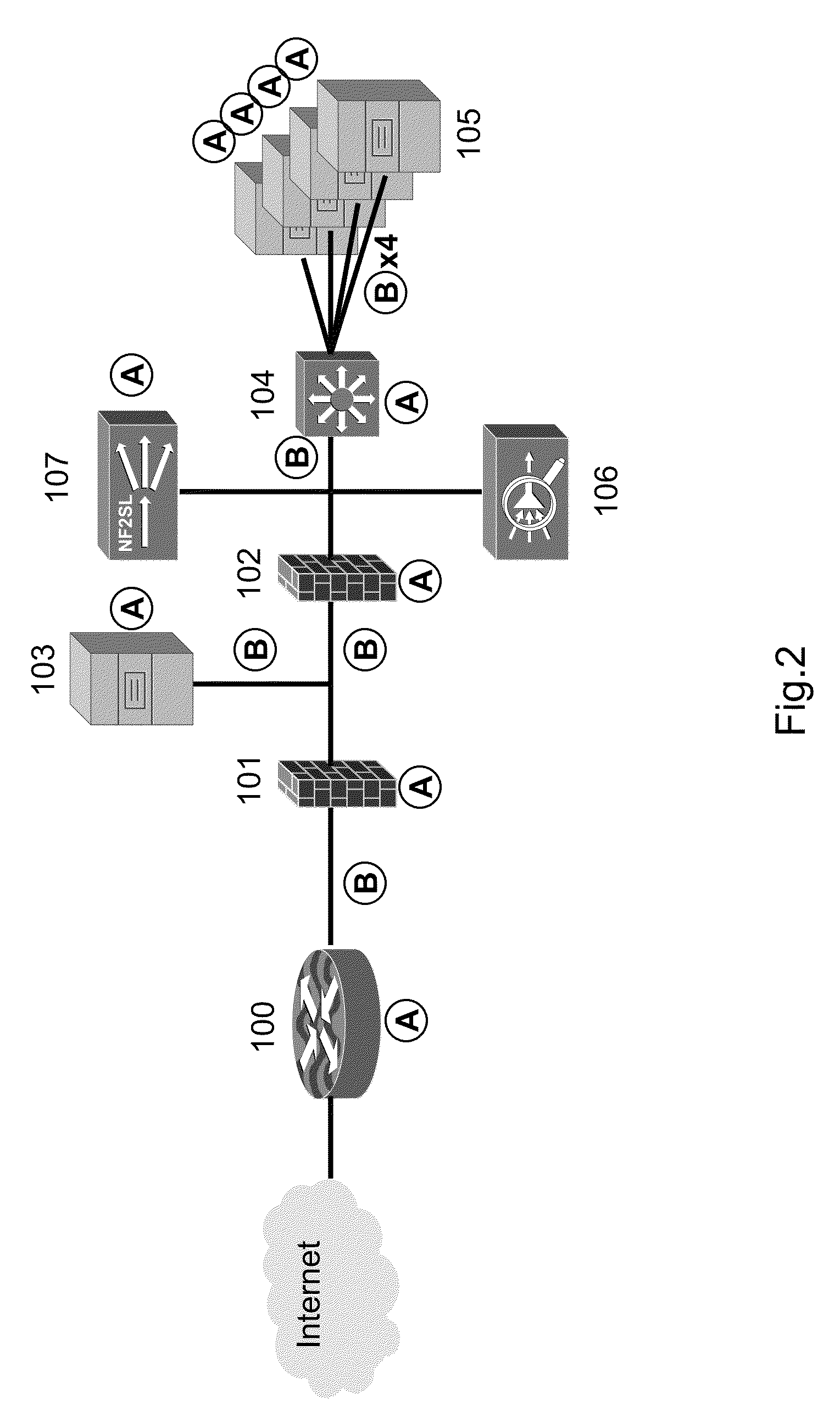

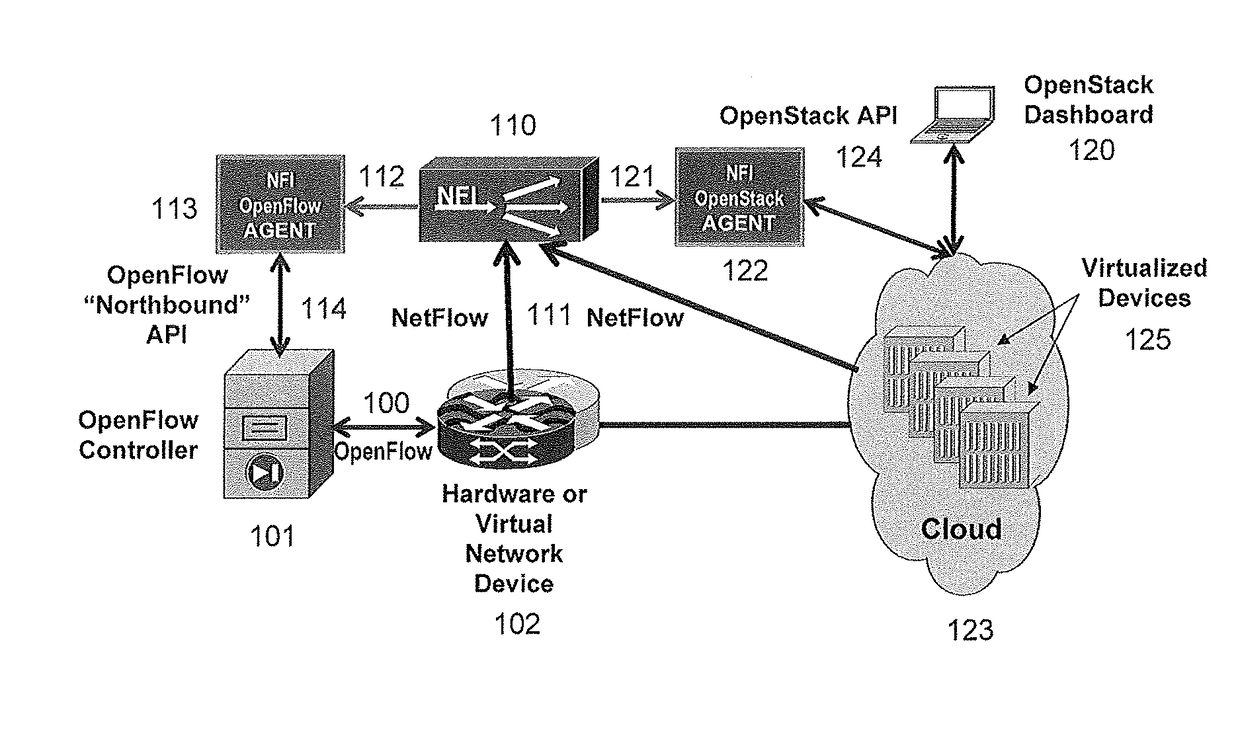

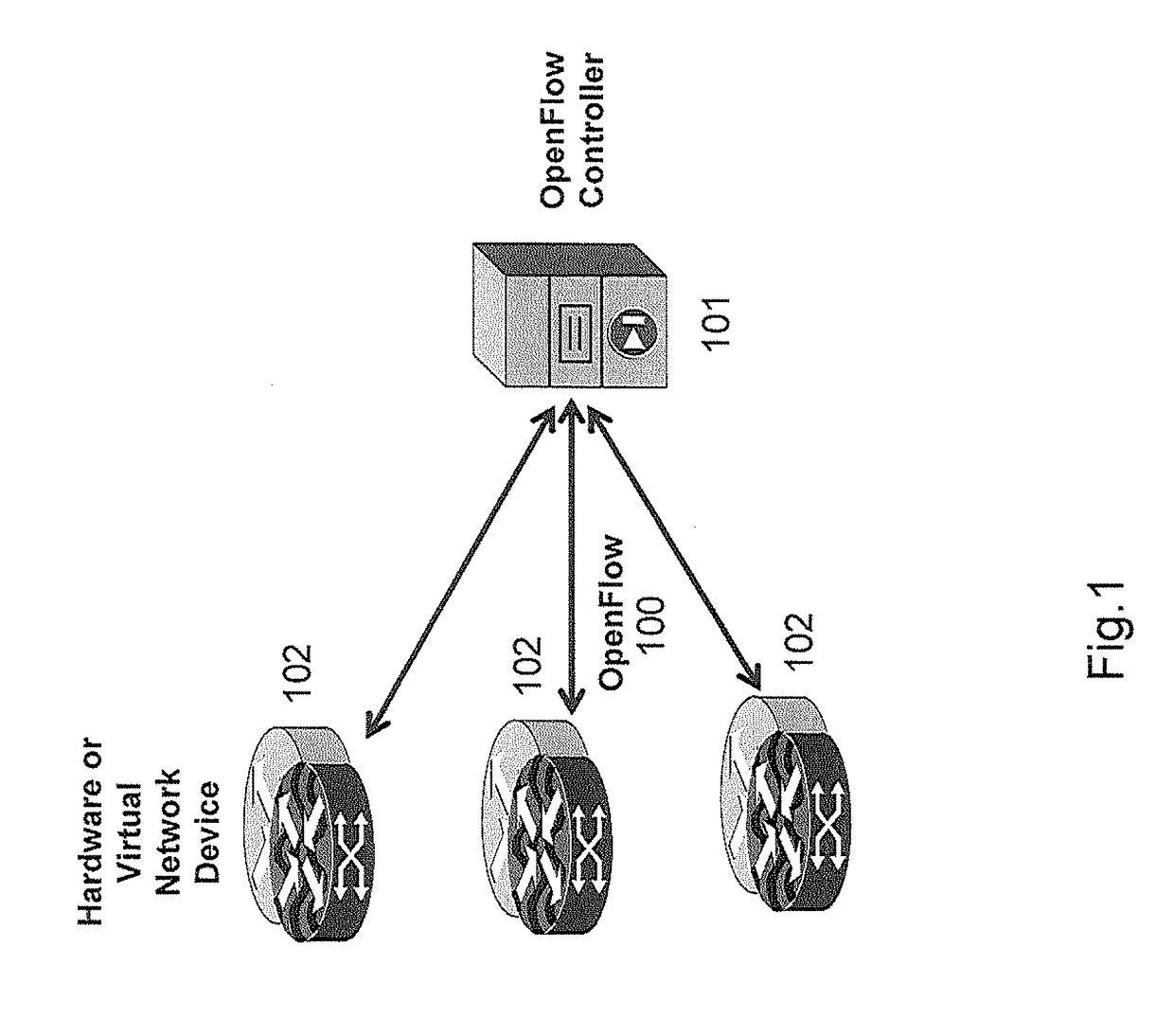

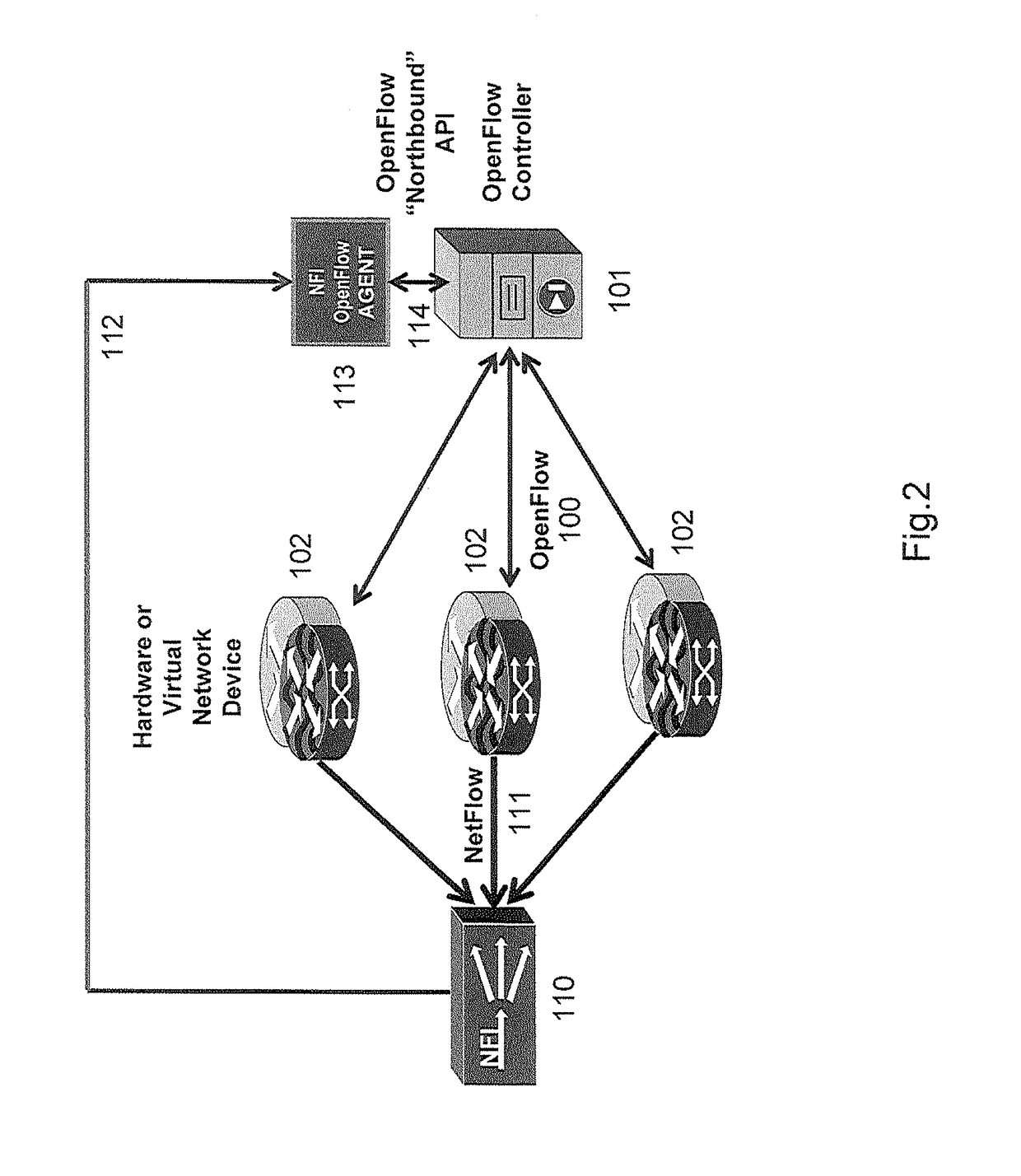

Streaming Method and System for Processing Network Metadata

ActiveUS20130117847A1Problem can be addressedEasily correlatedMemory loss protectionError detection/correctionTemplate basedSoftware modules

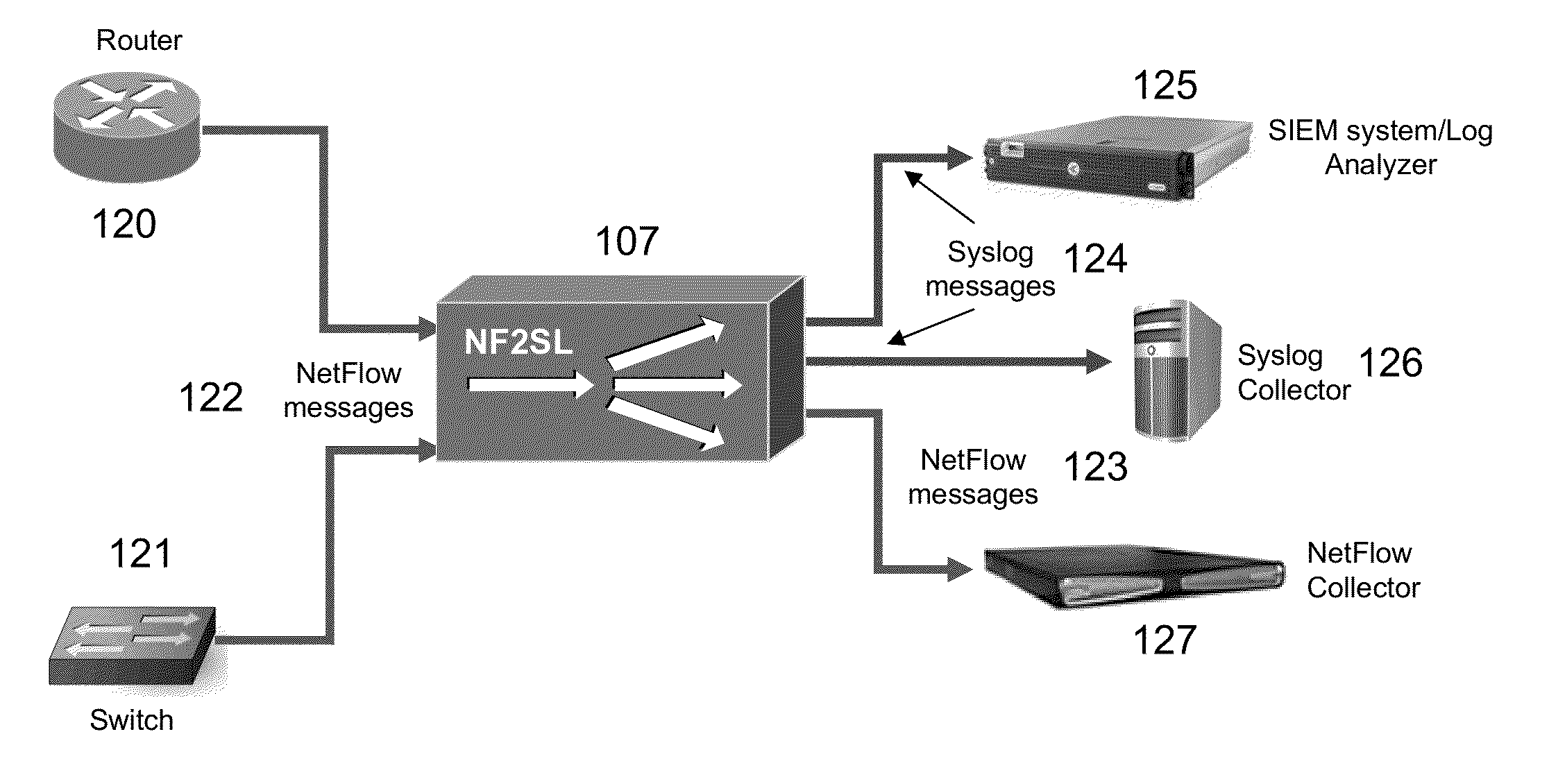

A method and system for processing network metadata is described. Network metadata may be processed by dynamically instantiated executable software modules which make policy-based decisions about the character of the network metadata and about presentation of the network metadata to consumers of the information carried by the network metadata. The network metadata may be type classified and each subclass within a type may be mapped to a definition by a unique fingerprint value. The fingerprint value may be used for matching the network metadata subclasses against relevant policies and transformation rules. For template-based network metadata such as NetFlow v9, an embodiment of the invention can constantly monitor network traffic for unknown templates, capture template definitions, and informs administrators about templates for which custom policies and conversion rules do not exist. Conversion modules can efficiently convert selected types and / or subclasses of network metadata into alternative metadata formats.

Owner:NETFLOW LOGIC

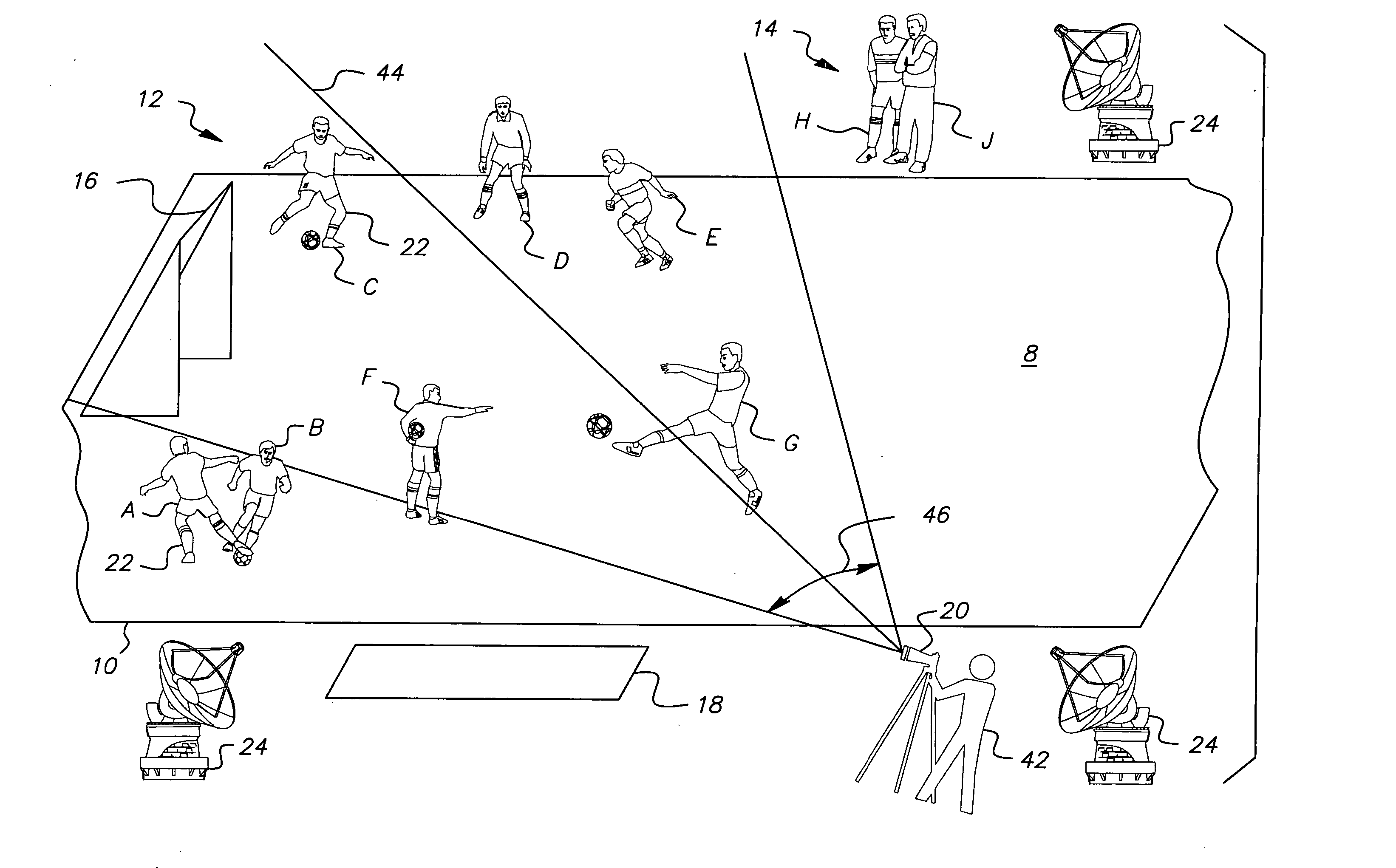

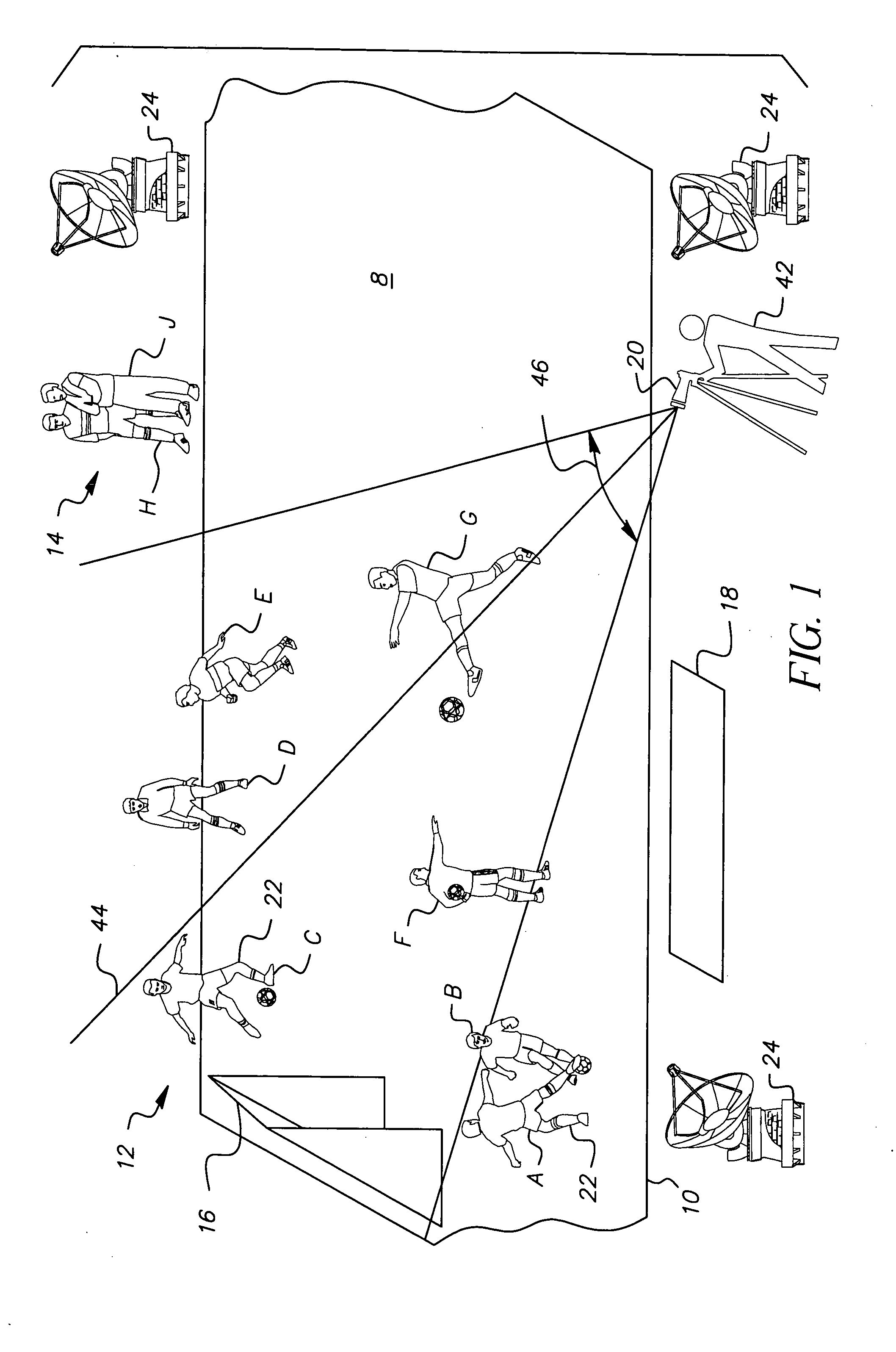

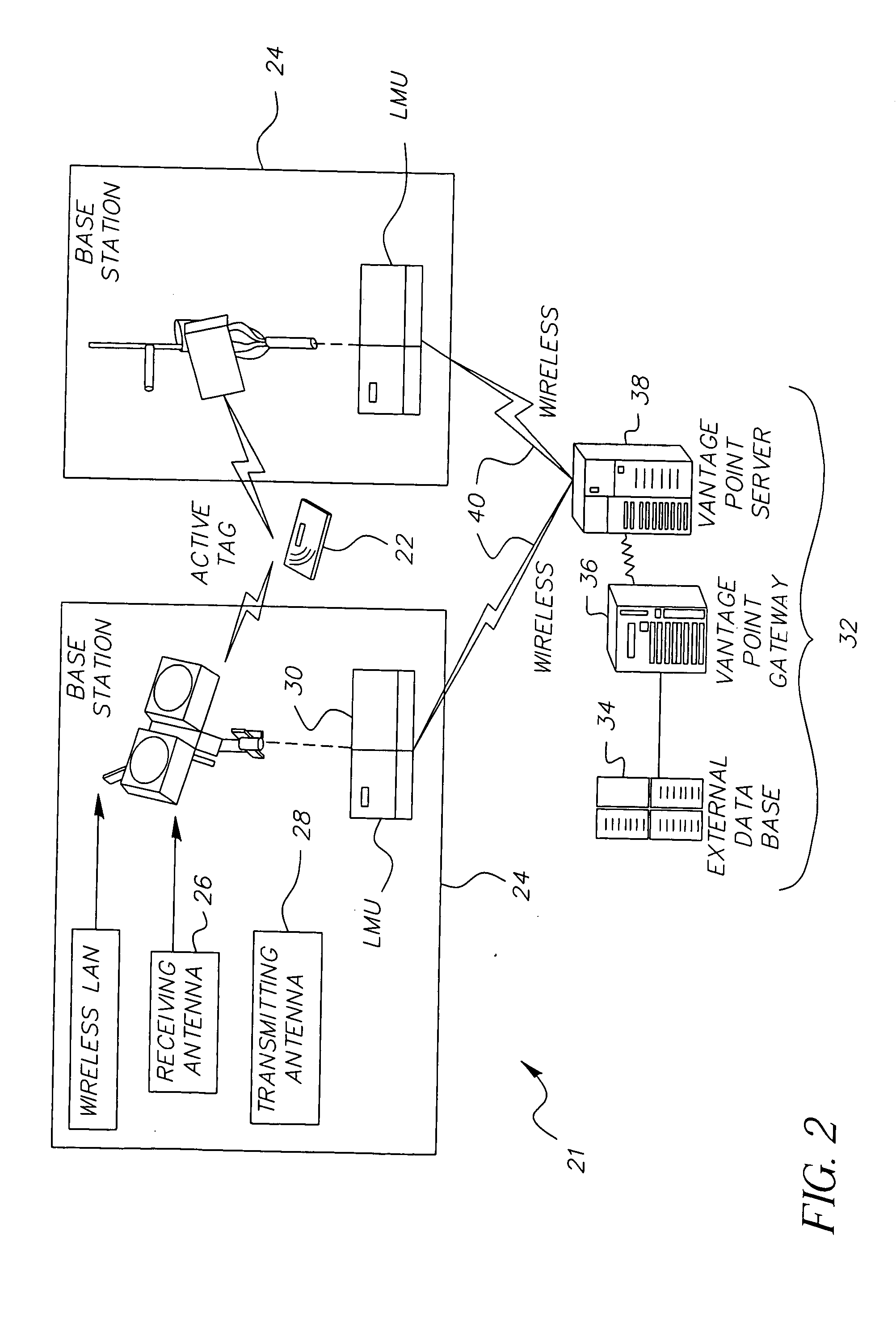

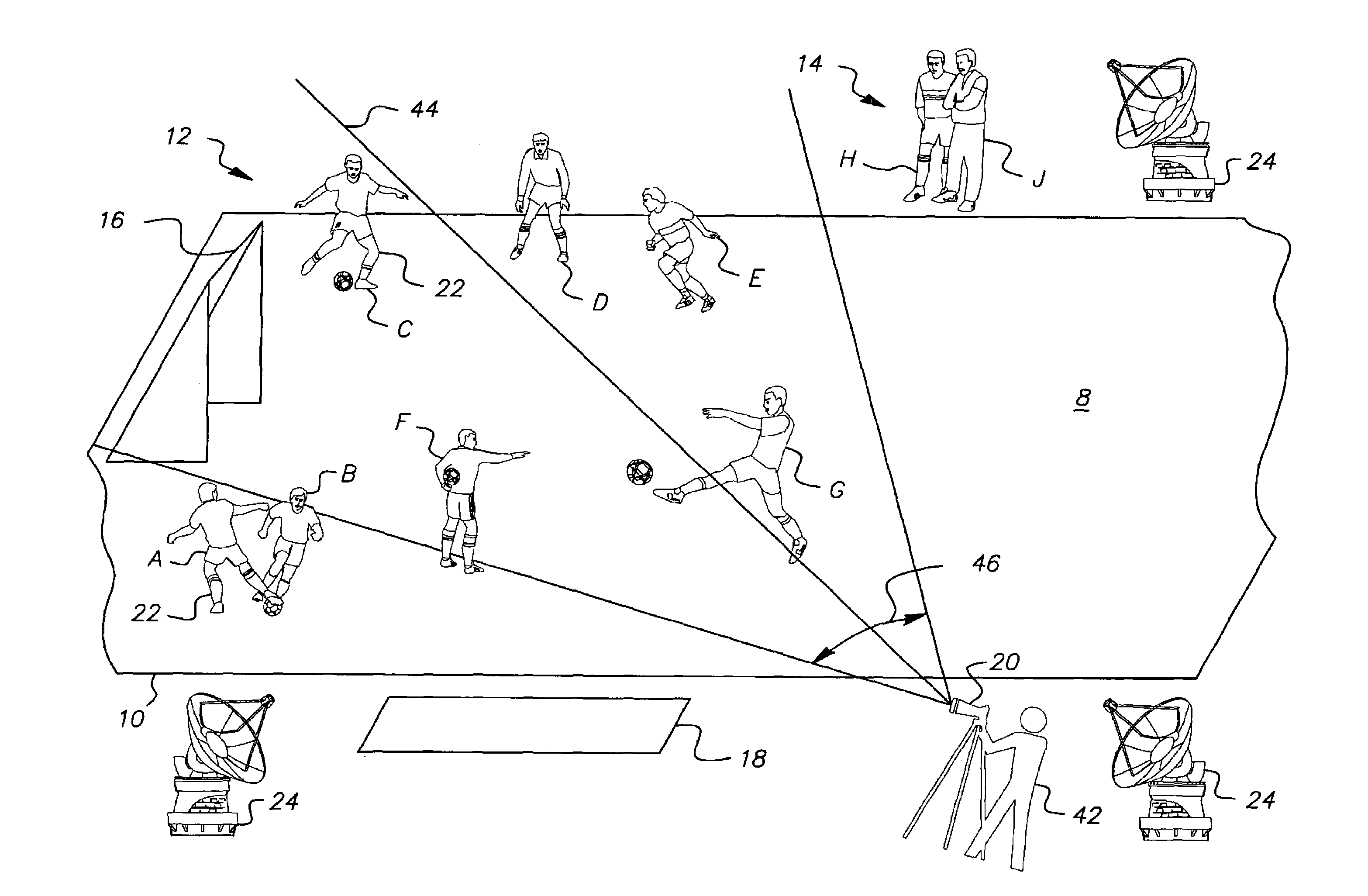

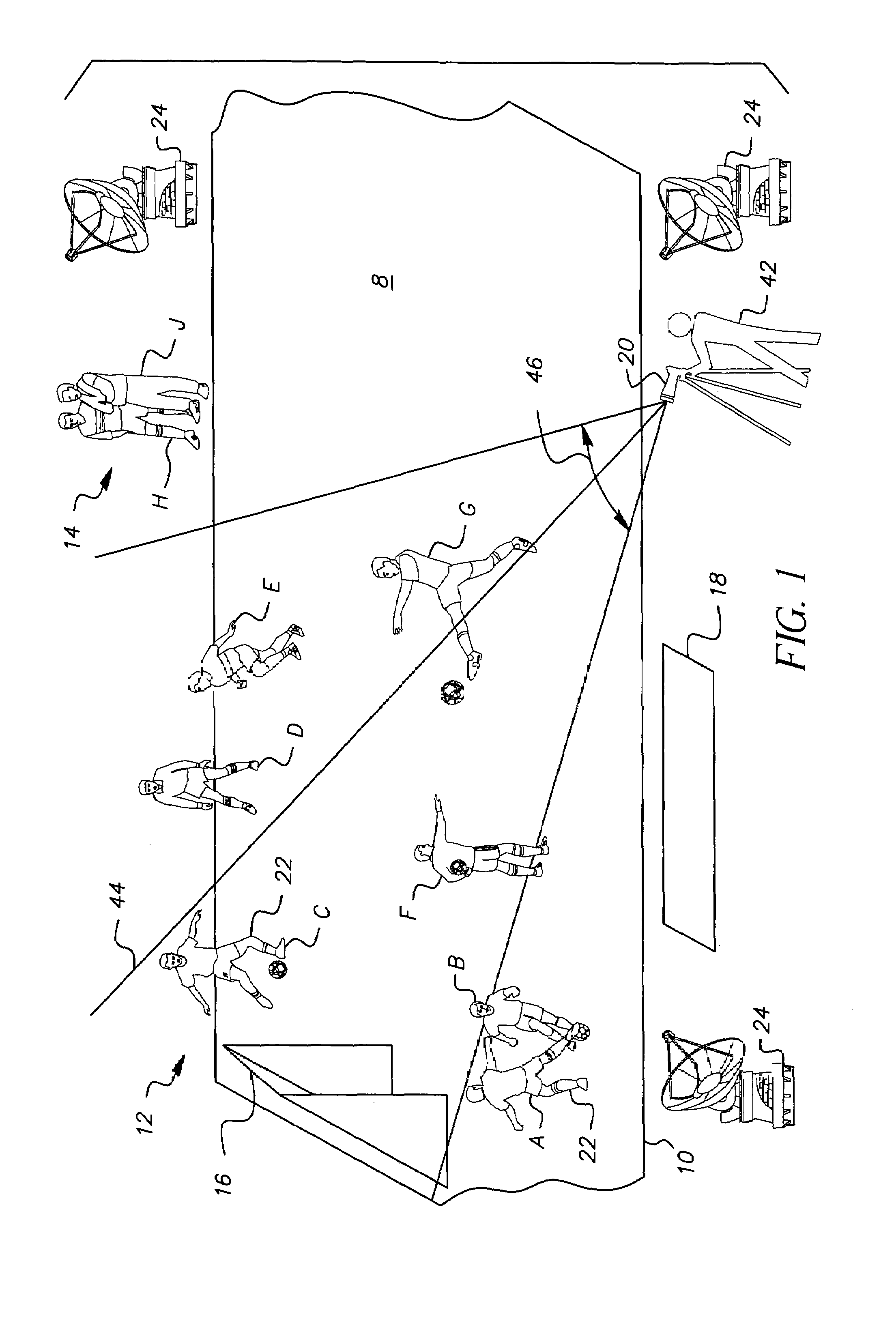

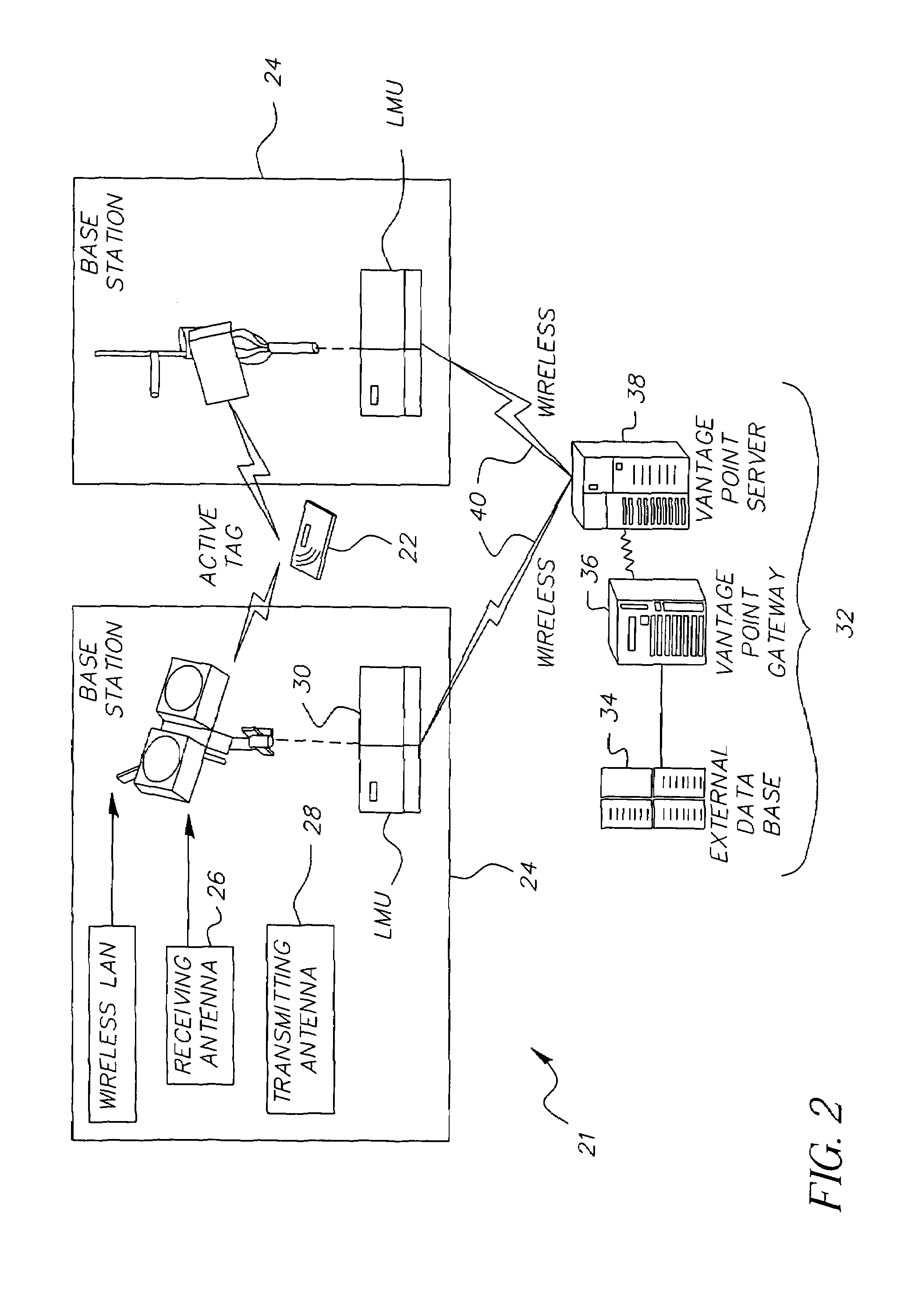

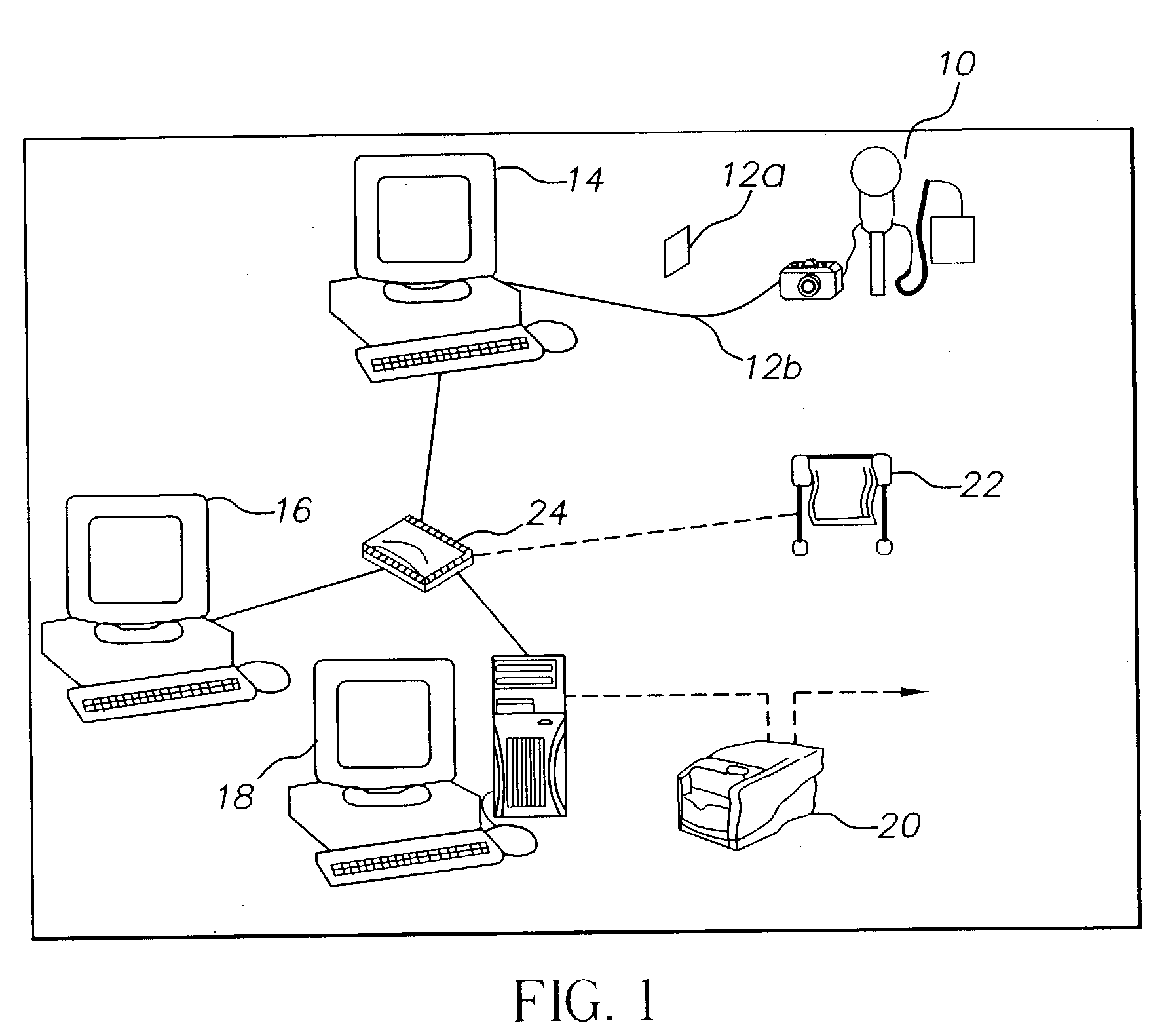

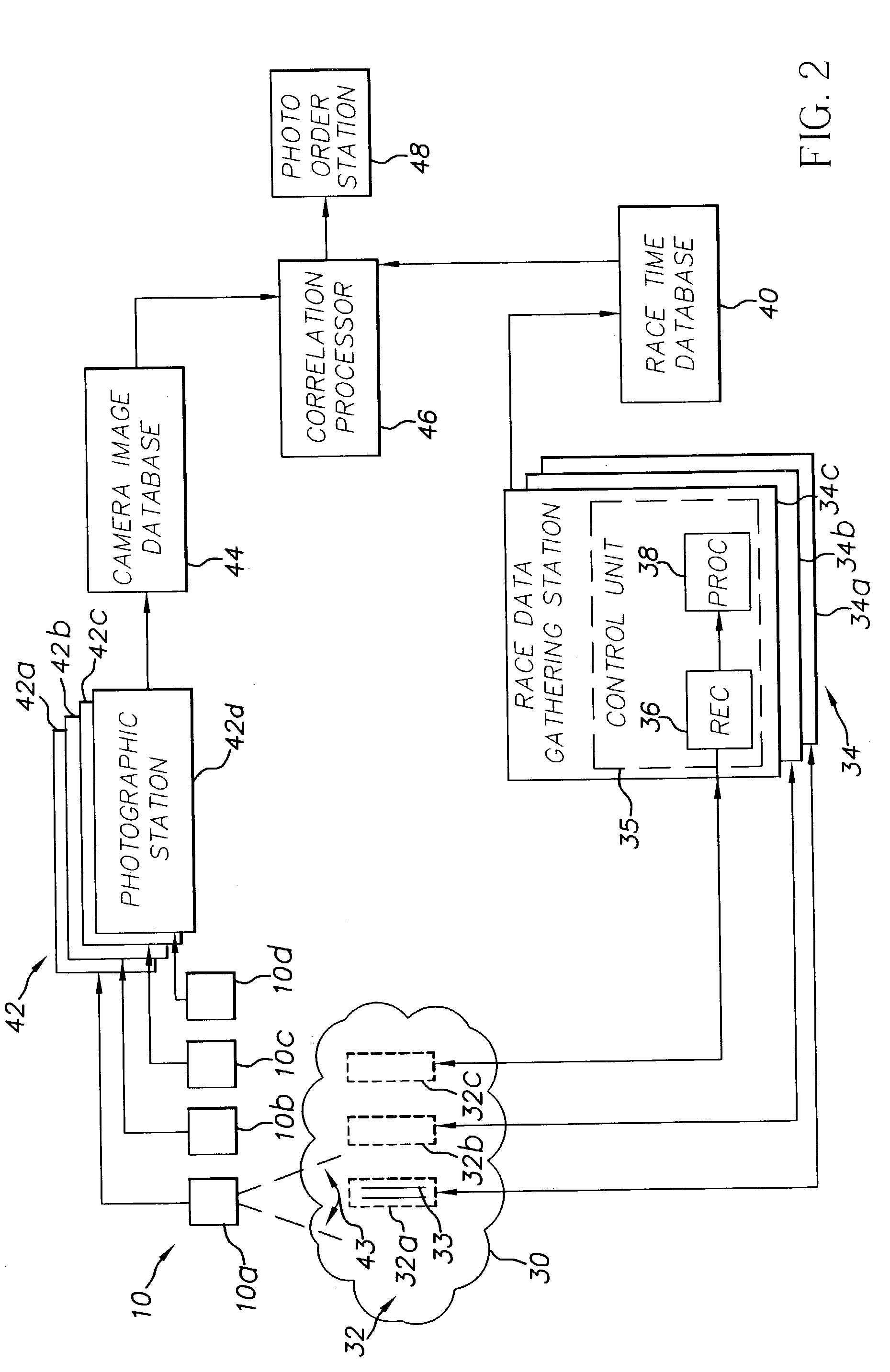

Correlating captured images and timed 3D event data

ActiveUS20050093976A1Easily correlatedEasily identifyTelevision system detailsColor television detailsImage captureVideo camera

A method for correlating tracking data associated with an activity occurring in a three-dimensional space with images captured within the space comprises the steps of: (a) locating a camera with respect to the three-dimensional space, wherein the camera at a given location has a determinable orientation and field of view that encompasses at least a portion of the space; (b) capturing a plurality of images with the camera and storing data corresponding to the images, including a capture time for each image; (c) capturing tracking data from identification tags attached to the people and / or objects within the space and storing the tracking data, including a tag capture time for each time that a tag is remotely accessed; (d) correlating each image and the tracking data by interrelating tracking data having a tag capture time in substantial correspondence with the capture time of each image, thereby generating track data corresponding to each image; (e) utilizing the track data to determine positions of the people and / or objects within the three dimensional space at the capture time of each image; and (f) utilizing the location and orientation of the camera to determine the portion of the space captured in each image and thereby reduce the track data to a track data subset corresponding to people and / or objects positioned within the portion of space captured in each image.

Owner:KODAK ALARIS INC

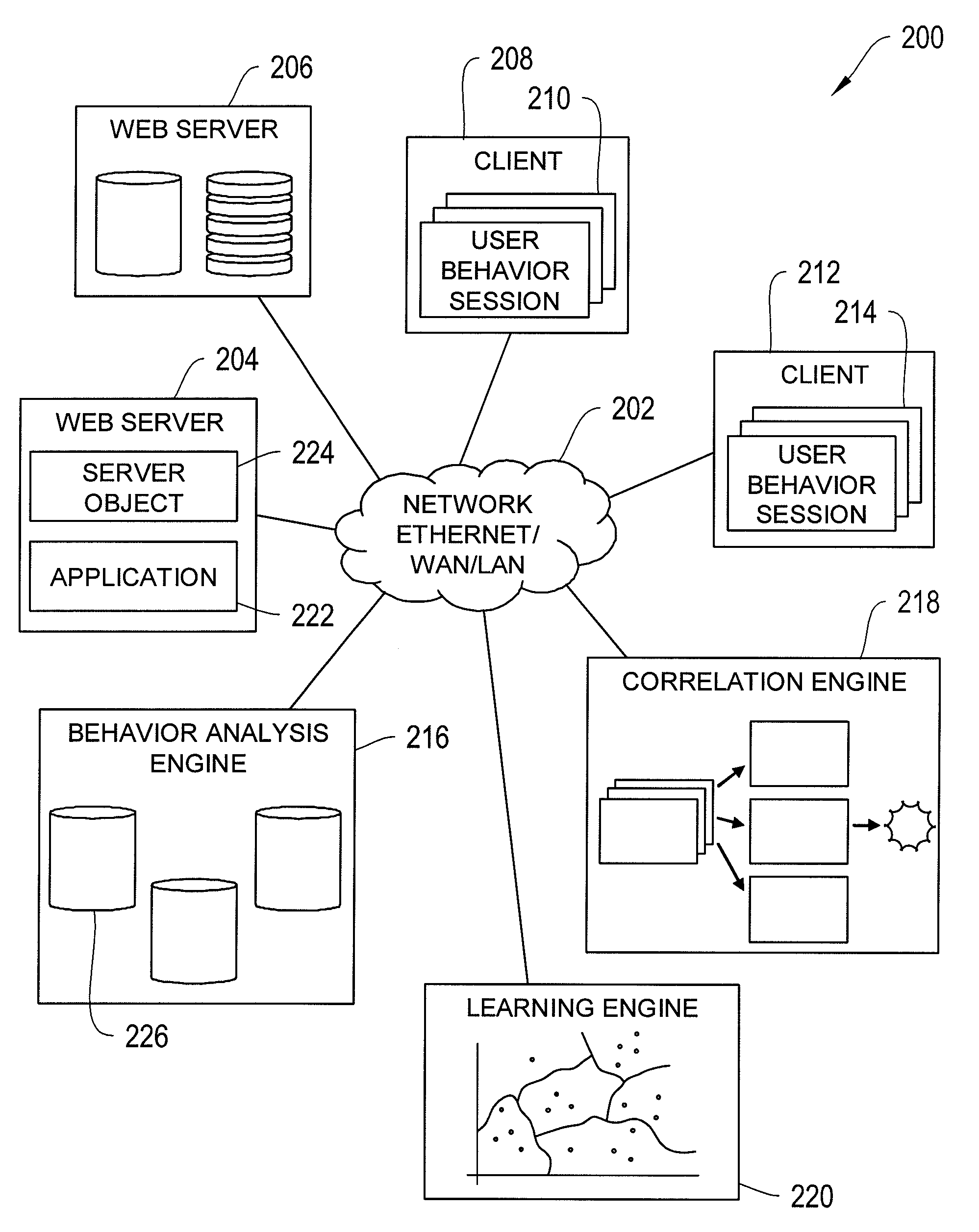

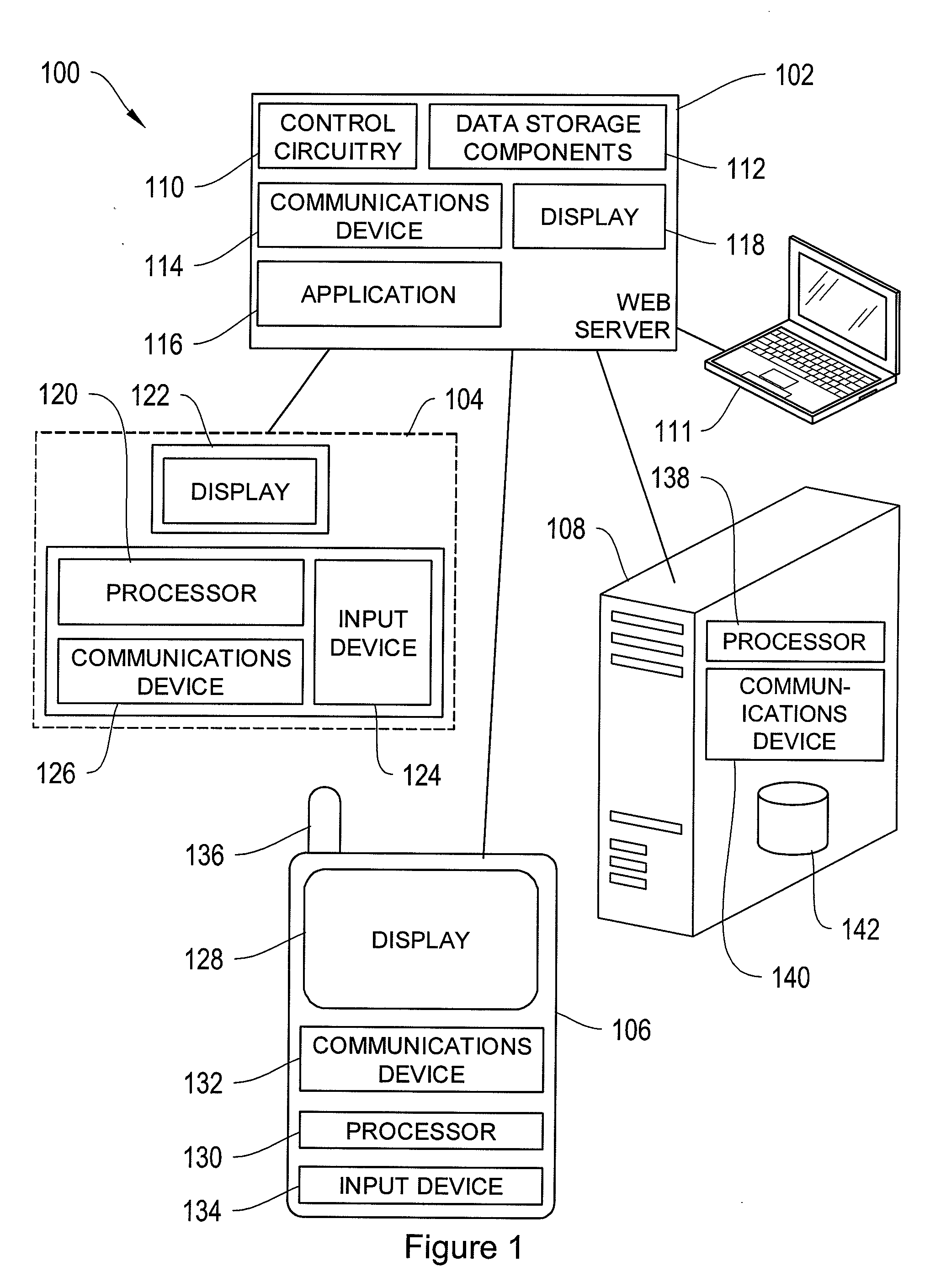

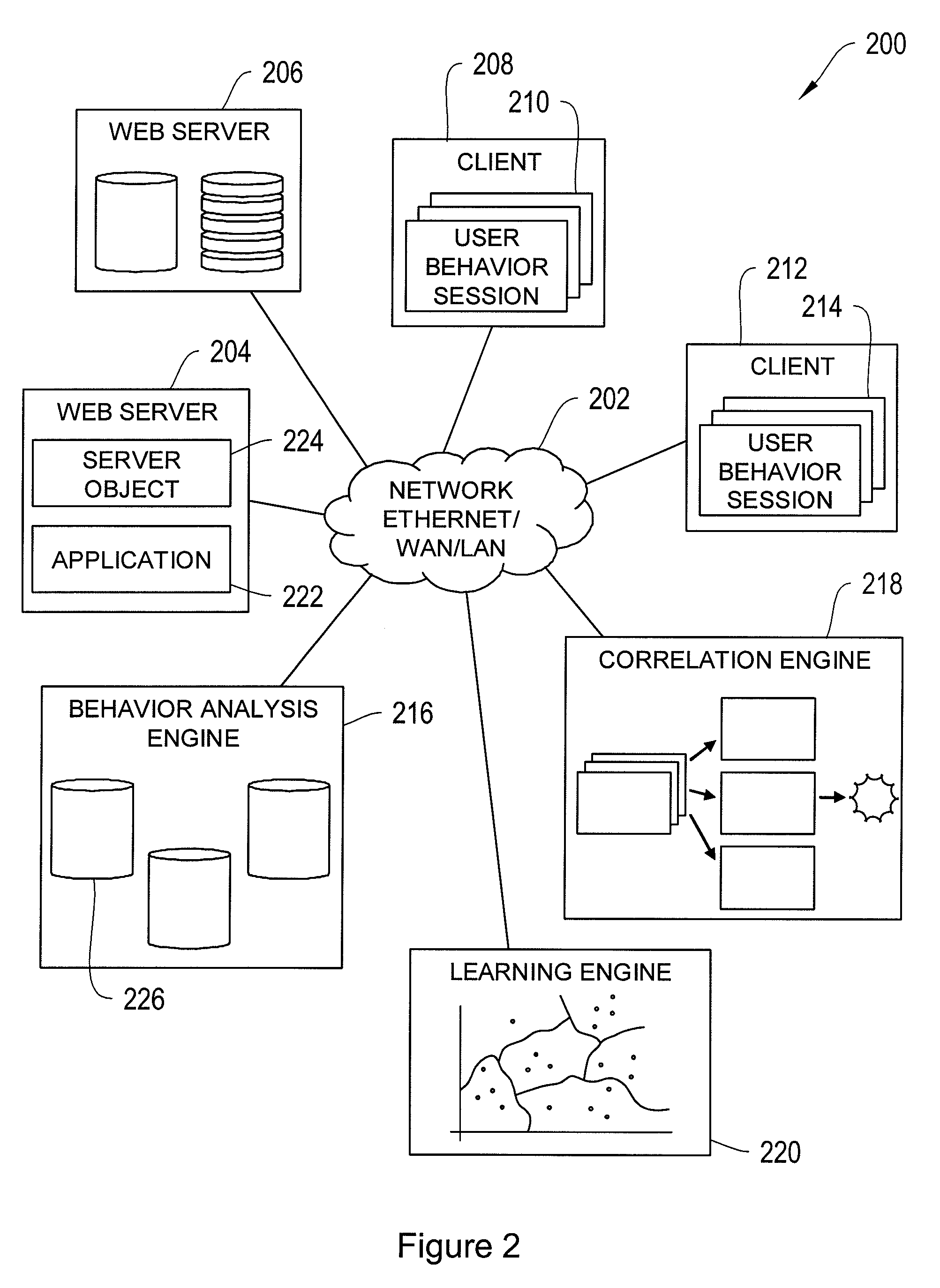

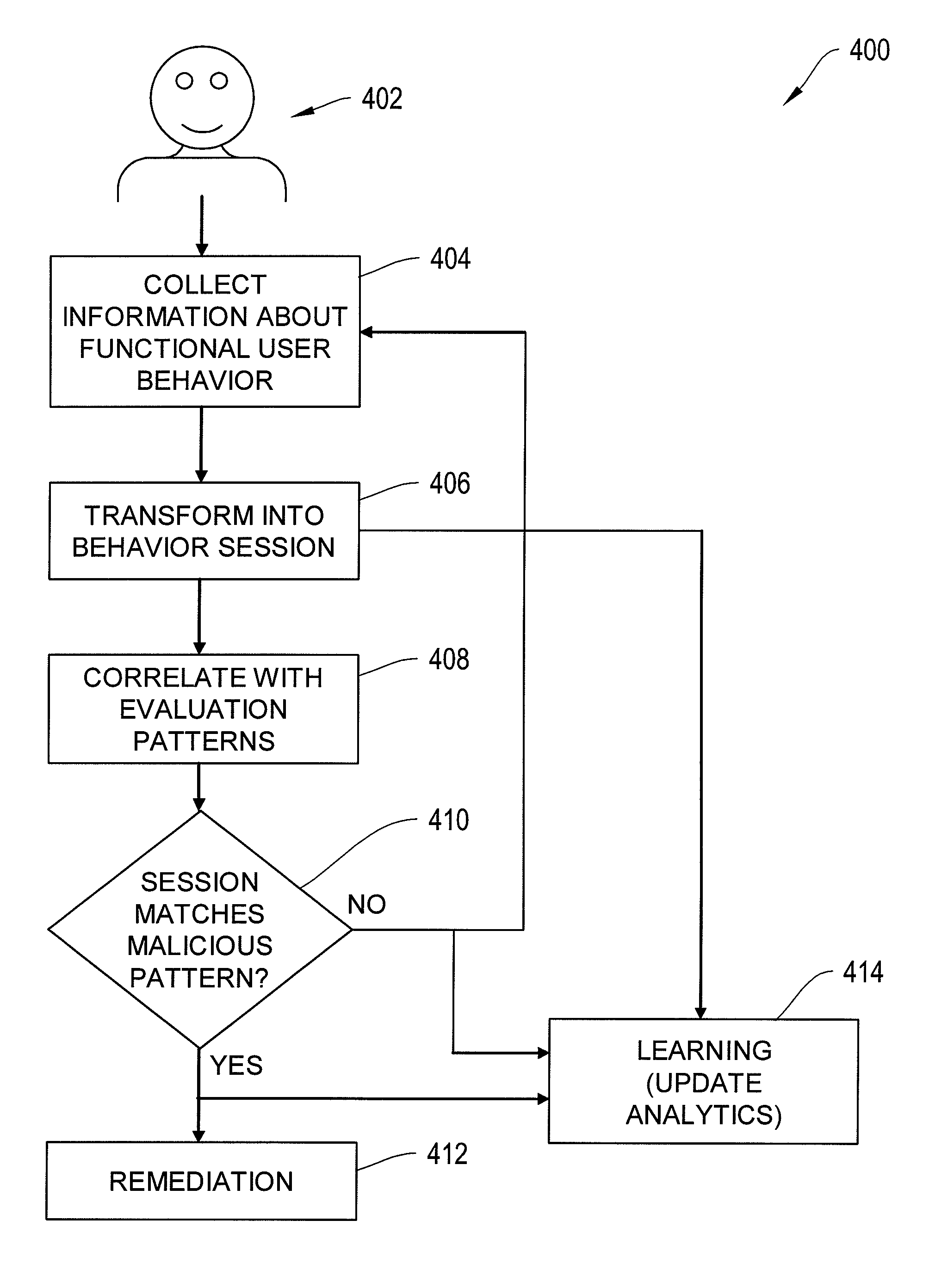

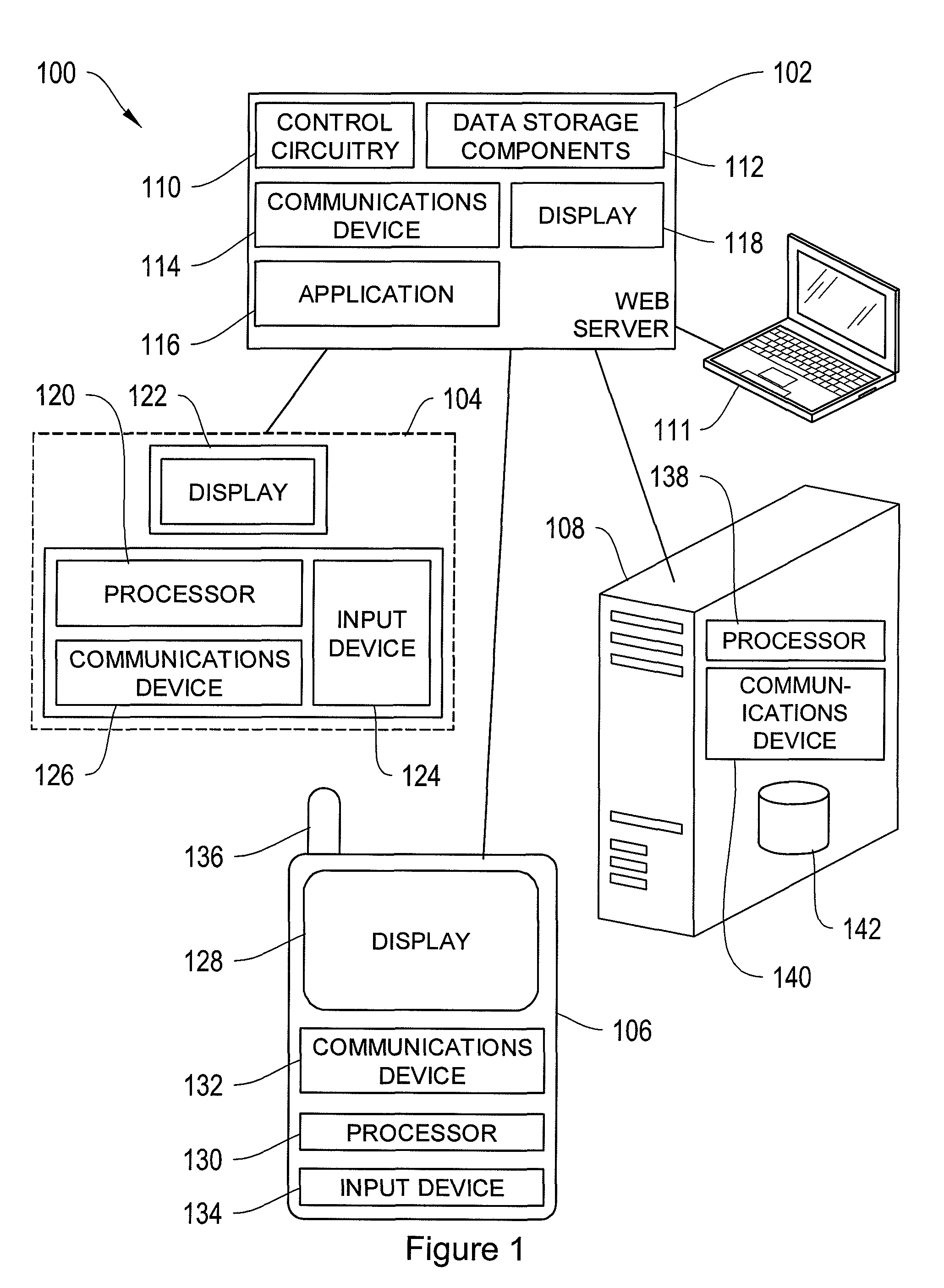

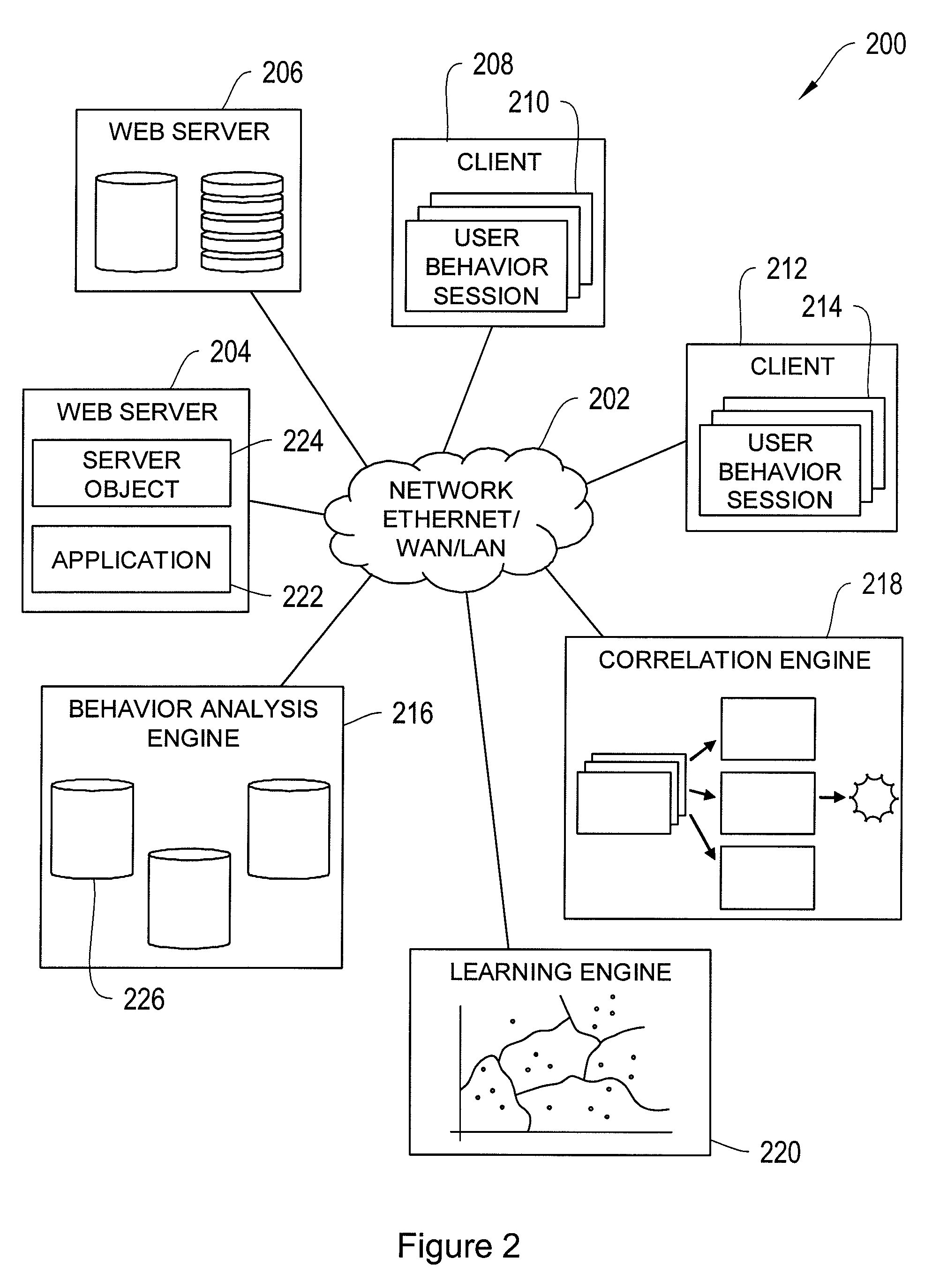

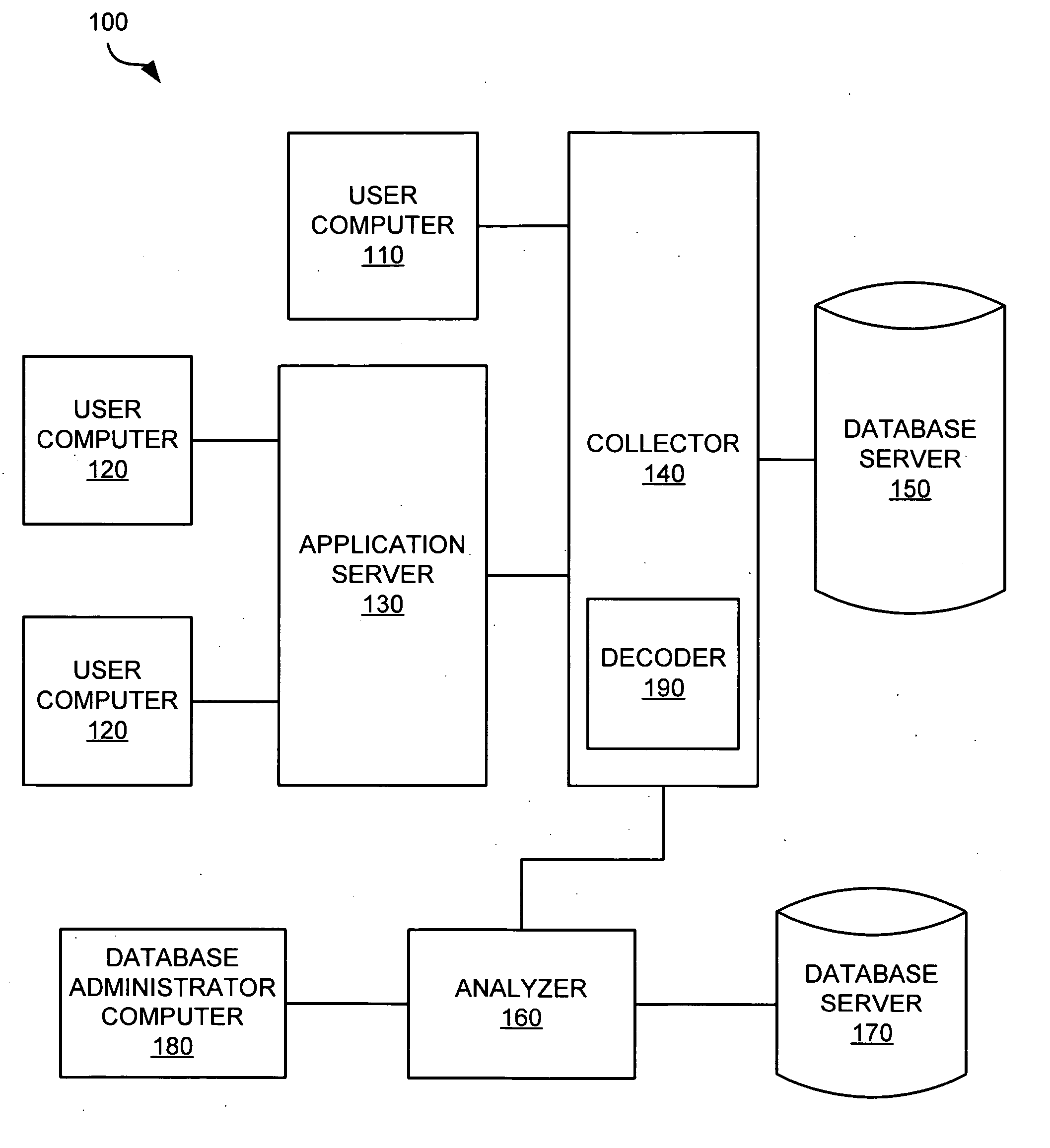

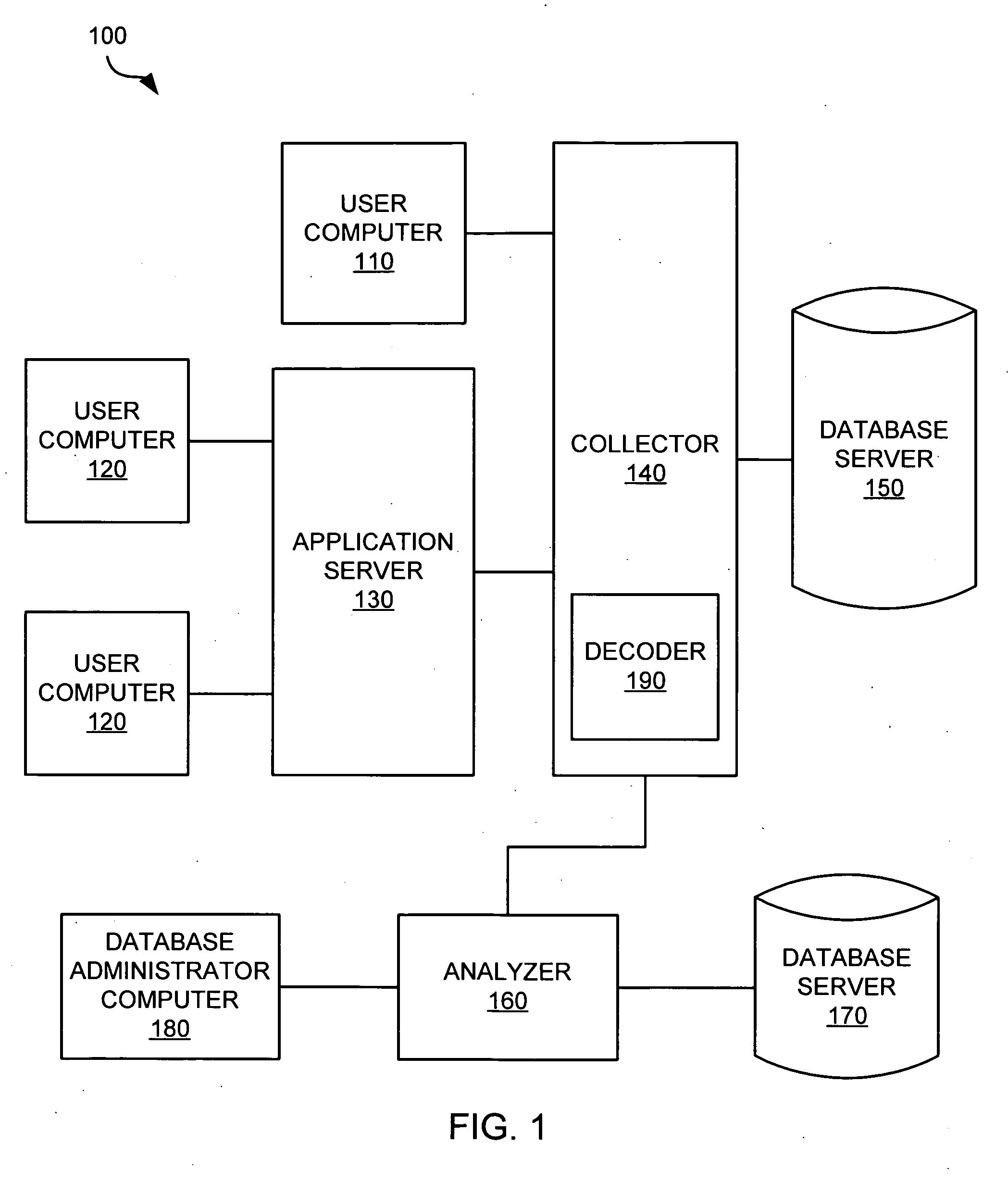

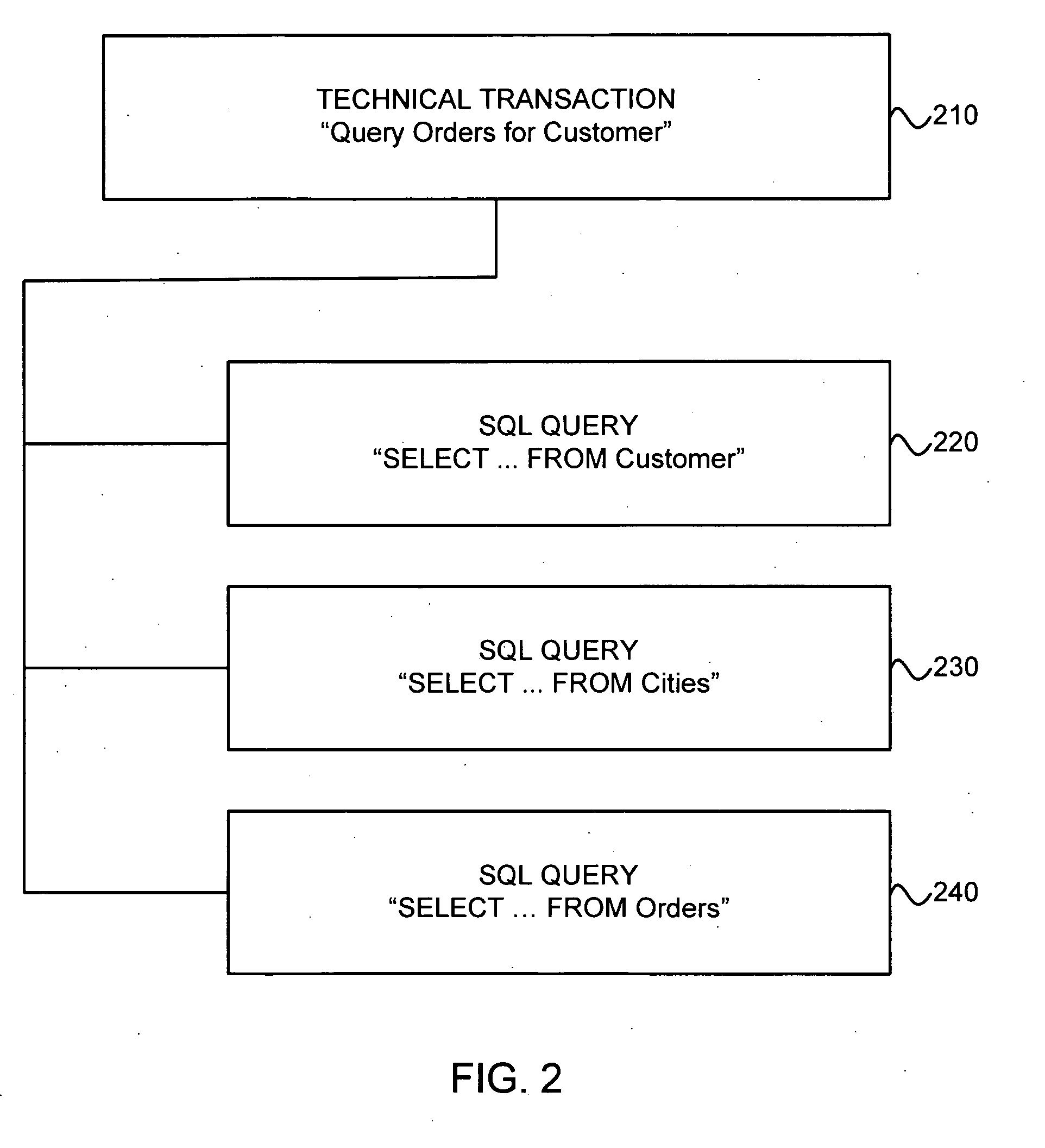

Systems and Methods for Application-Level Security

InactiveUS20100299292A1Easily correlatedReduce settingsMemory loss protectionError detection/correctionInternet privacyBehaviour pattern

A system and method for application-level security is disclosed. Application-level security refers to detecting security threats from functional user behavior. Information about functional user behavior is transformed into a behavior session. The behavior session is transformed into a behavior pattern. The behavior pattern is correlated with evaluation patterns to detect potential security threats. Behavior patterns are collected over time to improve analysis.

Owner:XYBERSHIELD INC

Streaming Method and System for Processing Network Metadata

InactiveUS20140075557A1Easy to deployImprove system throughputMemory loss protectionError detection/correctionInternet trafficTemplate based

An improved method and system for processing network metadata is described. Network metadata may be processed by dynamically instantiated executable software modules which make policy-based decisions about the character of the network metadata and about presentation of the network metadata to consumers of the information carried by the network metadata. The network metadata may be type classified and each subclass within a type may be mapped to a definition by a unique fingerprint value. The fingerprint value may be used for matching the network metadata subclasses against relevant policies and transformation rules. For template-based network metadata such as NetFlow v9, an embodiment of the invention can constantly monitor network traffic for unknown templates, capture template definitions, and informs administrators about templates for which custom policies and conversion rules do not exist. Conversion modules can efficiently convert selected types and / or subclasses of network metadata into alternative metadata formats.

Owner:NETFLOW LOGIC

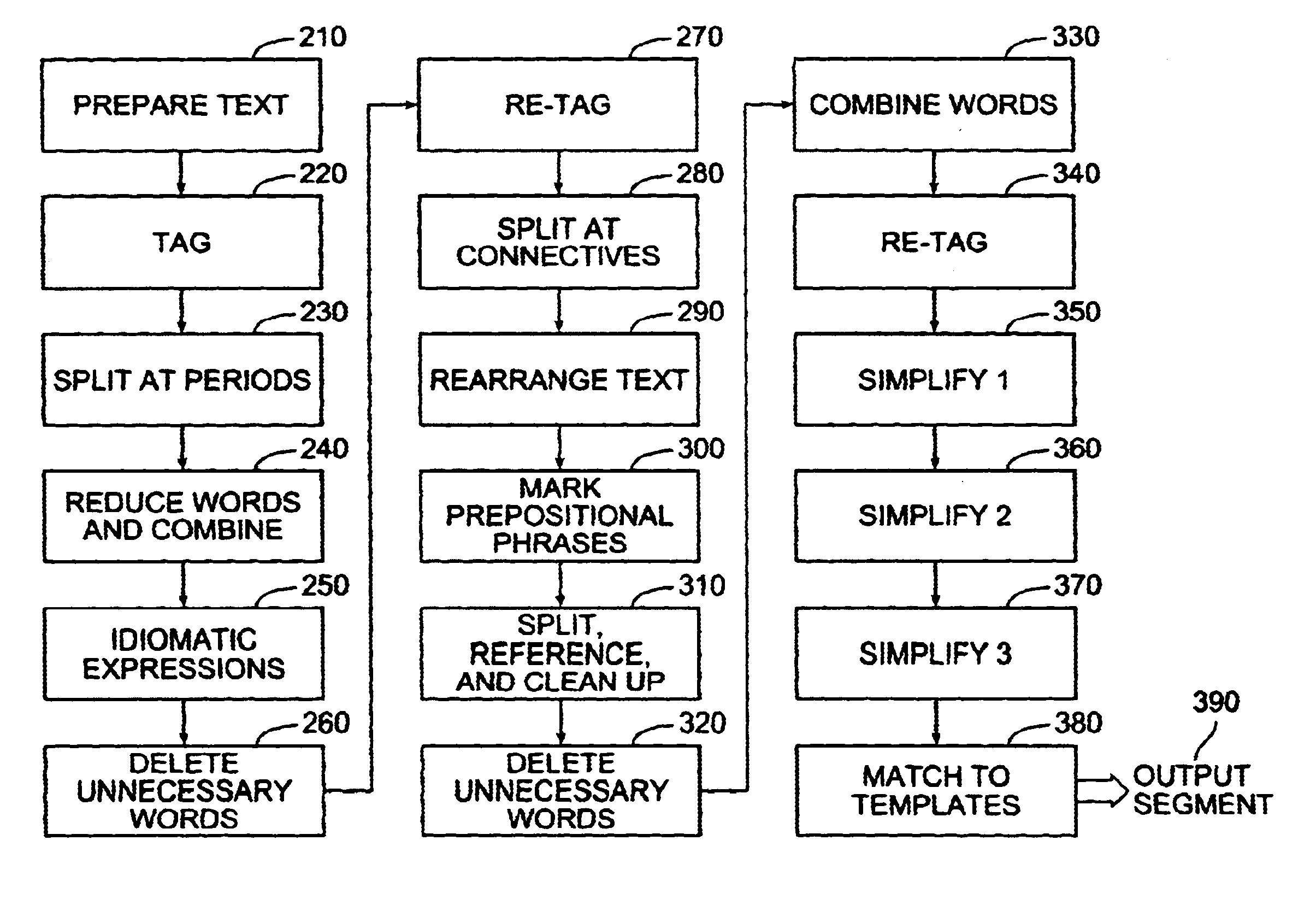

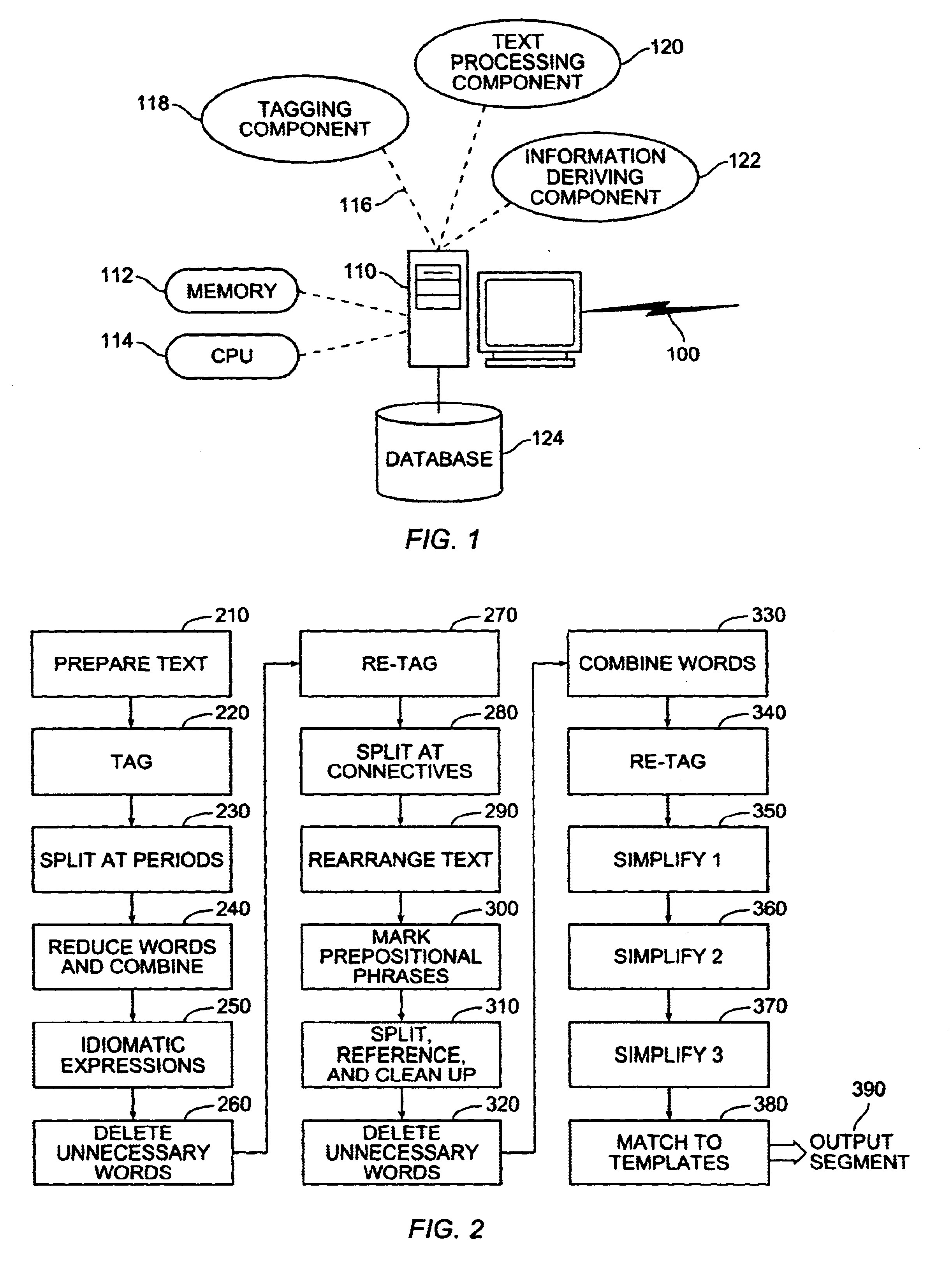

Method and system for text analysis based on the tagging, processing, and/or reformatting of the input text

InactiveUS6658377B1Improve accuracyEasily correlatedNatural language data processingSpecial data processing applicationsInformation retrievalNatural language

A method and system are provided for text analysis. A computer is used to analyze, parse, and manipulate natural language text according to a series of specific steps. Text is decomposed into small, homogenous segments that can be readily correlated to one another, to quantitative data, or to a knowledge database. The segments generated at the completion of the text analysis can then be further processed, for example, by a computer to derive statistical information, to generate a report, or to build a knowledge database.

Owner:BCS SOFTWARE LLC

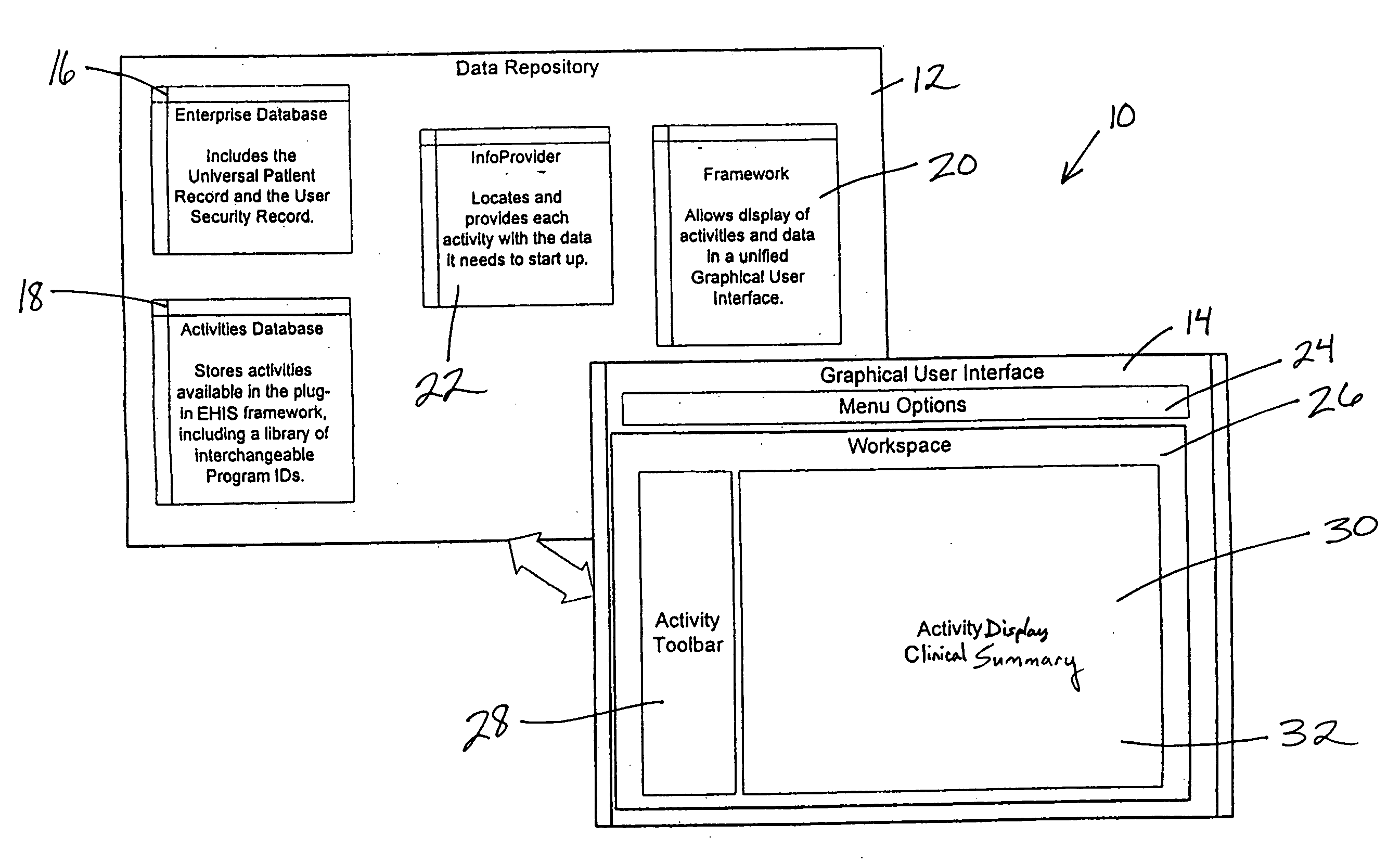

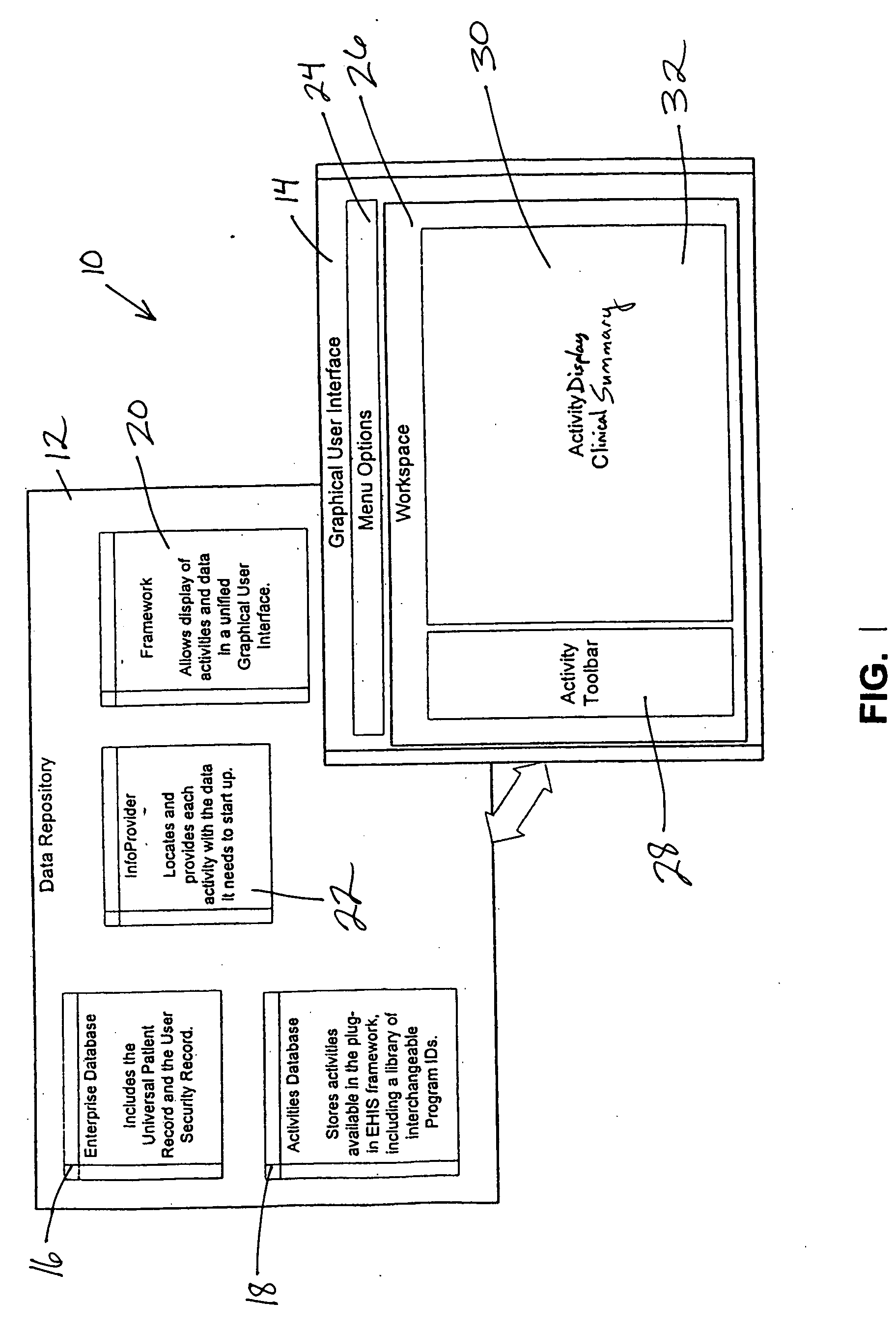

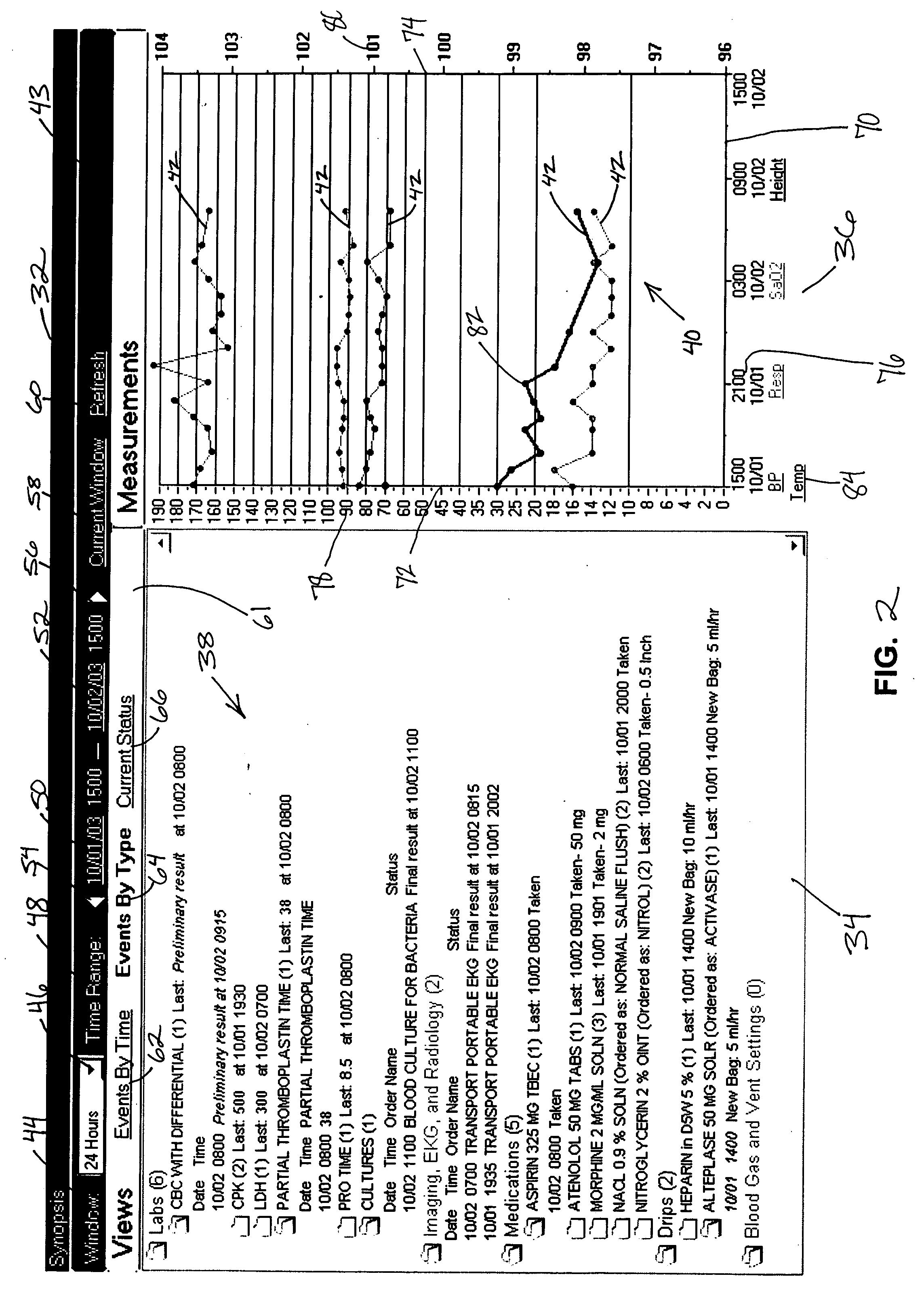

System and method for providing a clinical summary of patient information in various health care settings

InactiveUS20060080140A1Highly configurableMore and more conditionMedical report generationPatient personal data managementData displayGraphics

A system and method for providing a clinical summary of patient data in a health care setting. The system and method comprises a graphical user interface in communication with a health information system for accessing patient data. The graphical user interface is capable of displaying a clinical summary of patient data in a summary window in a textual format and a graphical format. The system and method further comprises a user record allowing a user to specify and configure the patient data displayed in the summary window. The user record includes configuration and security settings for selectively controlling the display of the user-specified patient data, and a user can select from the displayed patient data, access additional information about the selected patient data, generate detailed reports including the selected patient data, and generate graphical representations including the selected patient data.

Owner:EPIC SYST CORP (US)

Correlating captured images and timed 3D event data

ActiveUS7327383B2Easily correlatedEasy to associateTelevision system detailsColor television detailsThree-dimensional spaceEvent data

A method for correlating tracking data associated with an activity occurring in a three-dimensional space with images captured within the space comprises the steps of: (a) locating a camera with respect to the three-dimensional space, wherein the camera at a given location has a determinable orientation and field of view that encompasses at least a portion of the space; (b) capturing a plurality of images with the camera and storing data corresponding to the images, including a capture time for each image; (c) capturing tracking data from identification tags attached to the people and / or objects within the space and storing the tracking data, including a tag capture time for each time that a tag is remotely accessed; (d) correlating each image and the tracking data by interrelating tracking data having a tag capture time in substantial correspondence with the capture time of each image, thereby generating track data corresponding to each image; (e) utilizing the track data to determine positions of the people and / or objects within the three dimensional space at the capture time of each image; and (f) utilizing the location and orientation of the camera to determine the portion of the space captured in each image and thereby reduce the track data to a track data subset corresponding to people and / or objects positioned within the portion of space captured in each image.

Owner:KODAK ALARIS INC

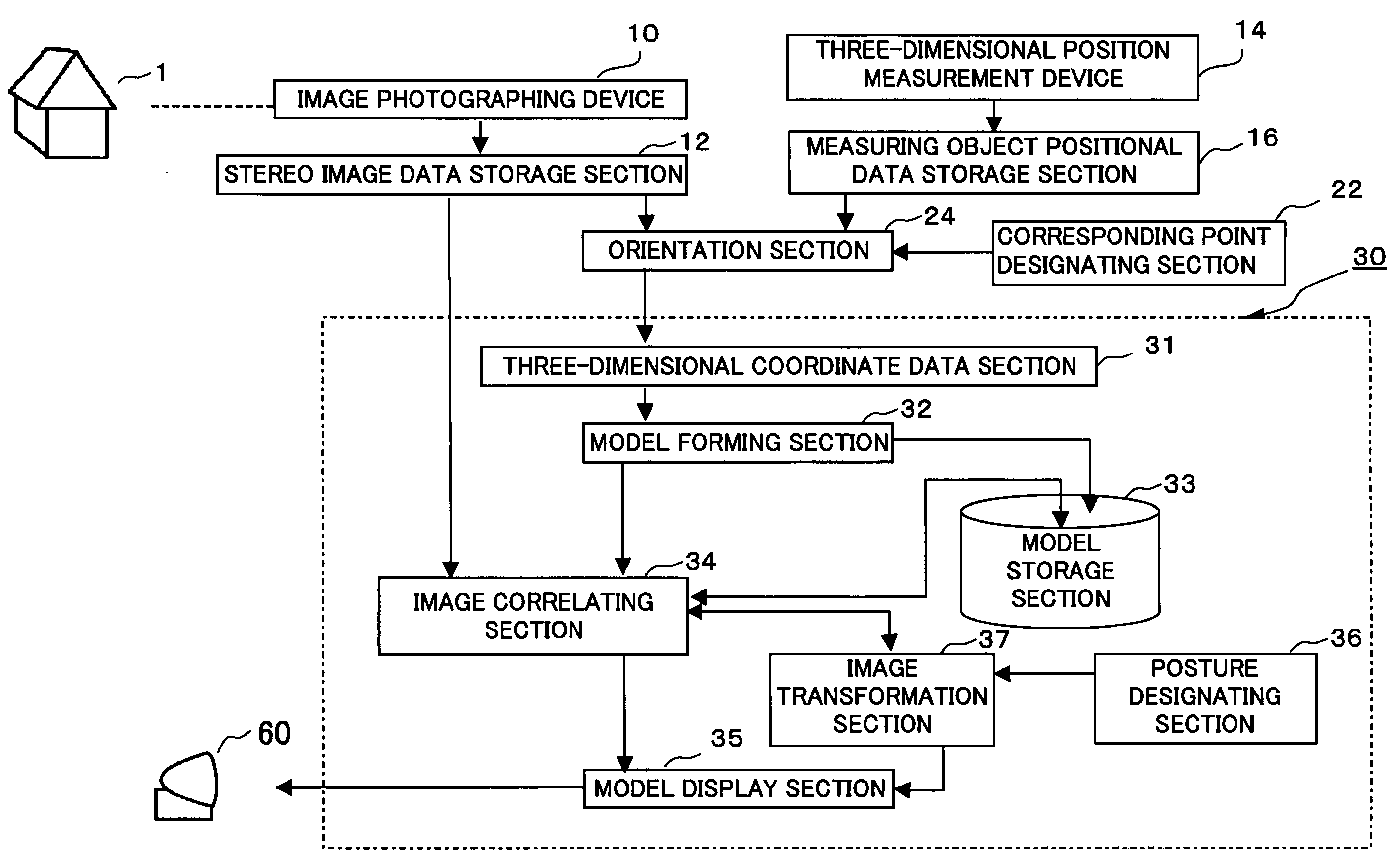

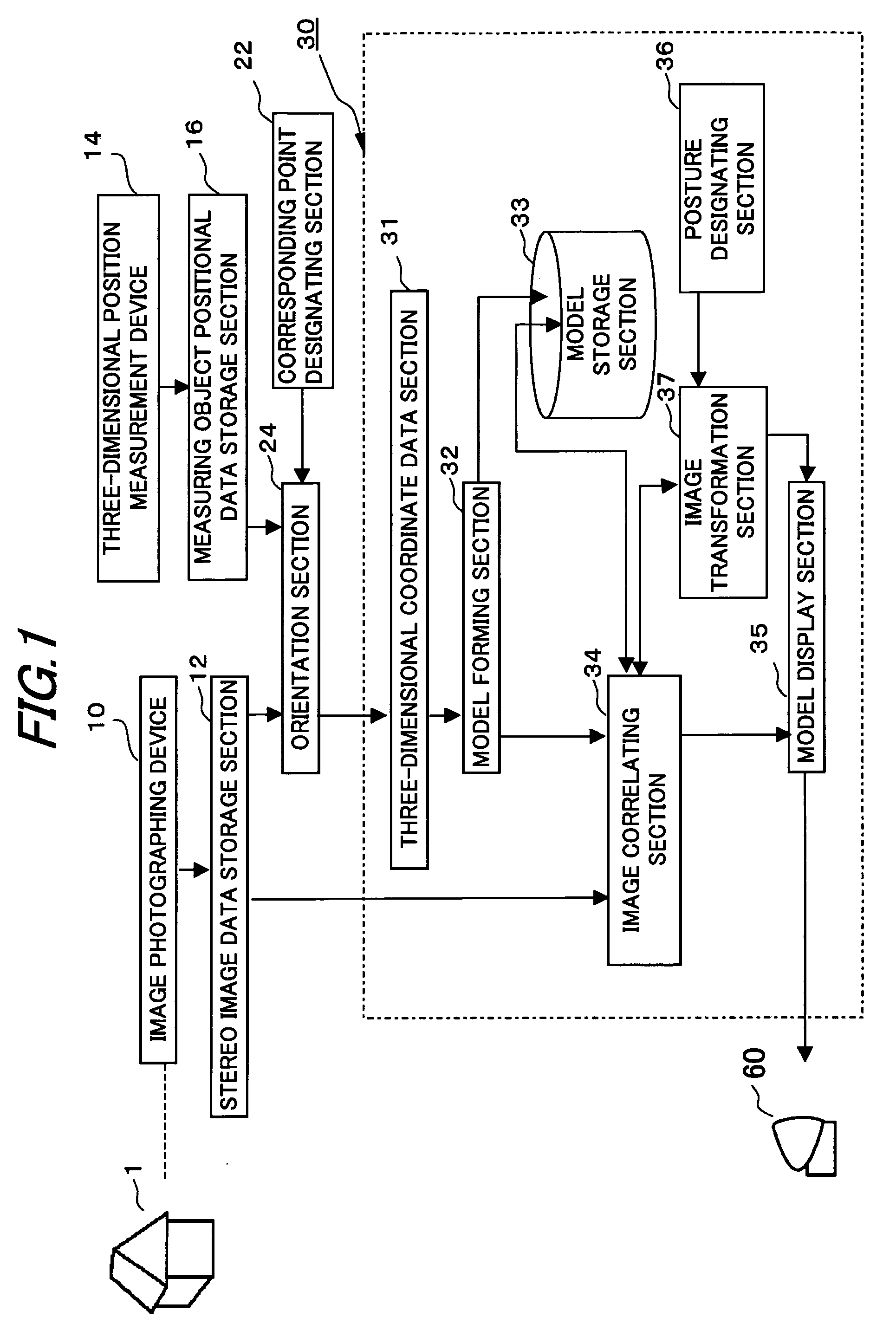

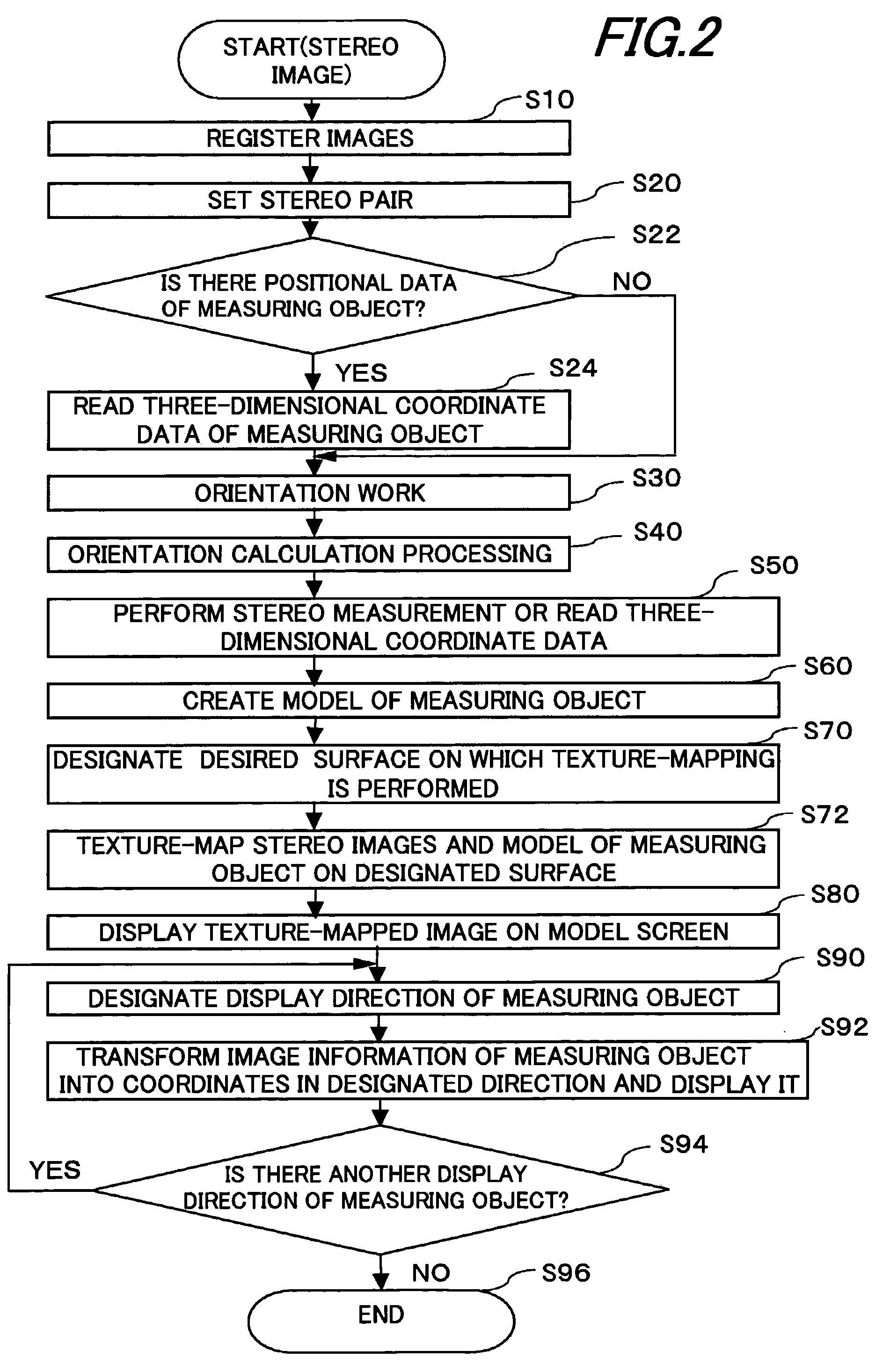

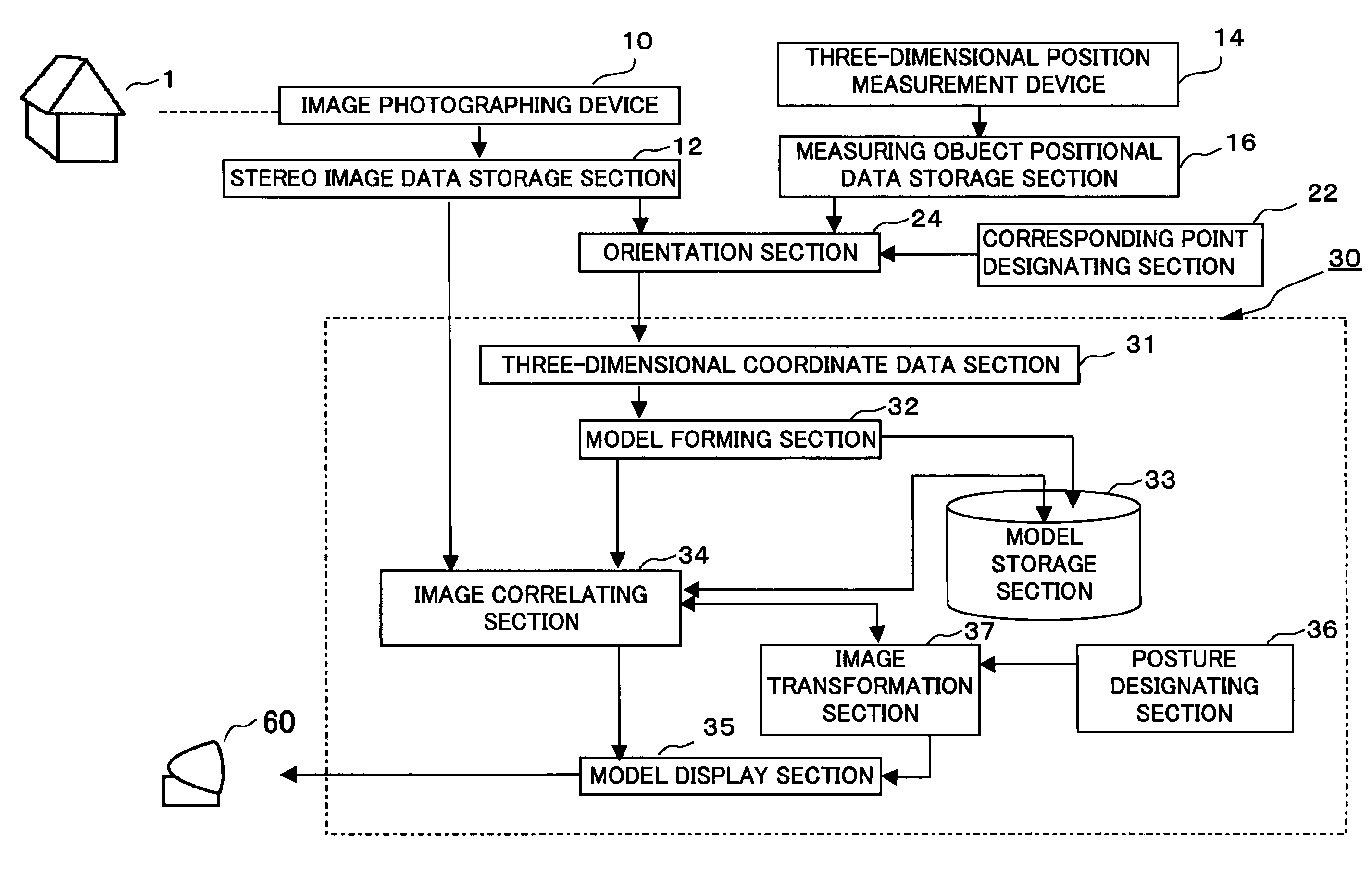

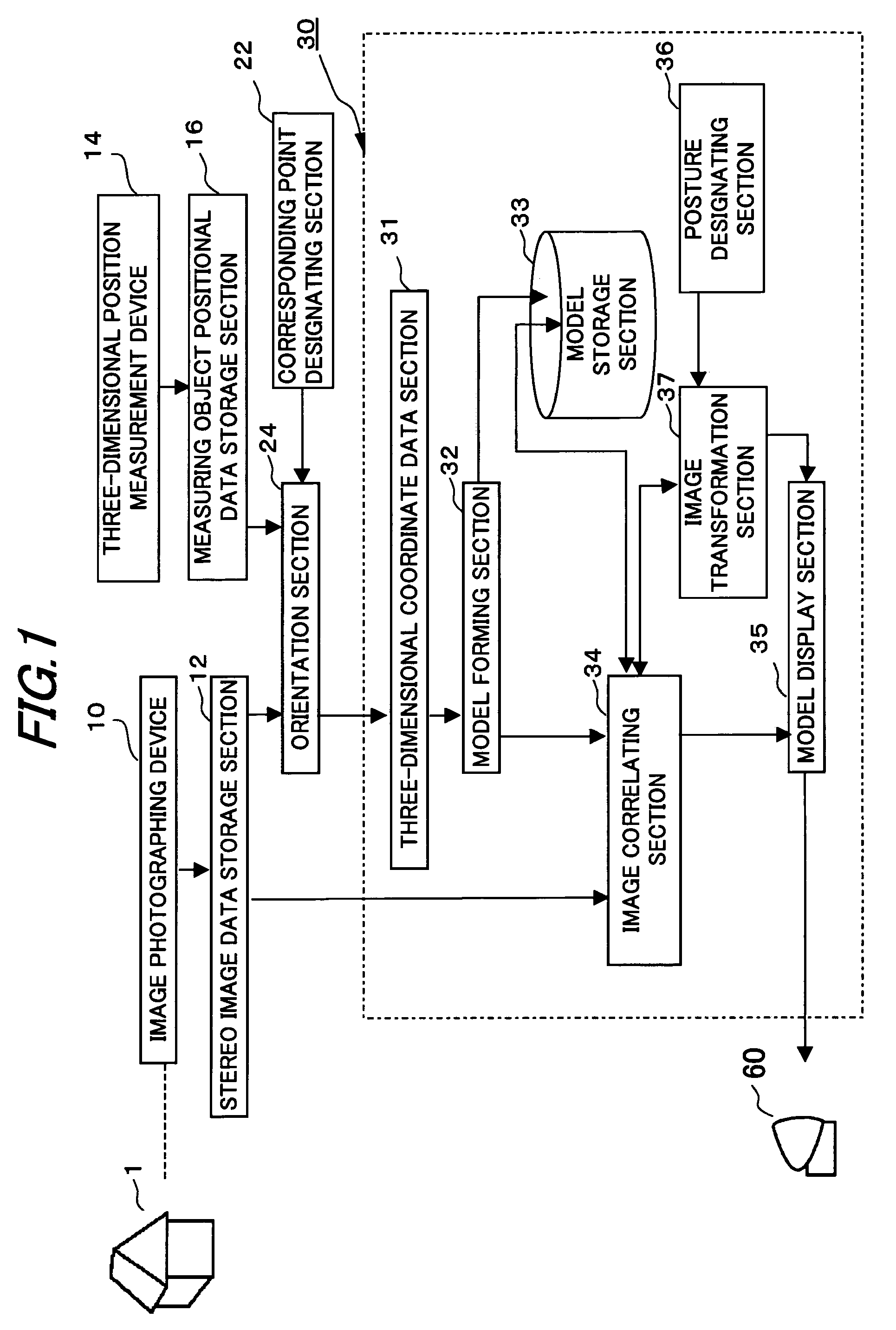

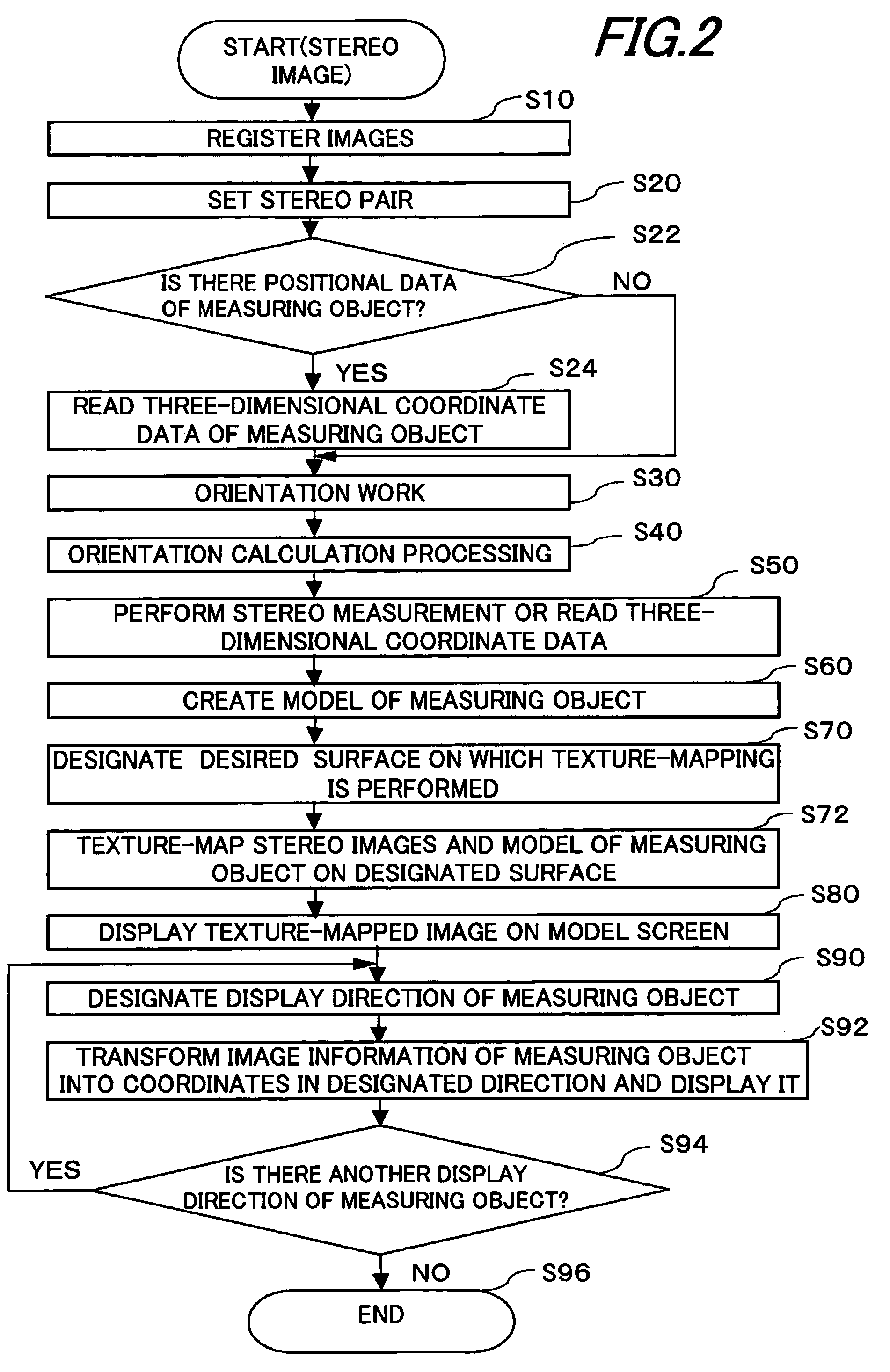

Three-dimensional image display apparatus and method

ActiveUS20050151839A1Easily recognizeEasily determineImage enhancementImage analysisStereo imageObject store

A three-dimensional image display apparatus is provided that can integrate and visualize 3D measurement data obtained from a stereo image with an image of a measuring object to which stereoscopic texture is applied. The apparatus includes: an orientation section 24 for finding relationship as to corresponding points in a stereo image of a measuring object 1 based on the position and the tilt at which the stereo image was photographed; a three-dimensional coordinate data section 31 for obtaining three-dimensional coordinate data on the corresponding points of the measuring object 1 based on the relationship as to the corresponding points found by the orientation section 24; a model forming section 32 for forming a model of the measuring object 1 based on the three-dimensional coordinate data on the corresponding points; an image correlating section 34 for correlating the stereo image of the measuring object stored in the stereo image data storage section 12 and the model formed by the model forming section 32, using the relationship as to the corresponding points found by the orientation section 24; and a model display section 35 for displaying an image of the measuring object 1 to which stereoscopic texture is applied, using the stereo image correlated with the model by the image correlating section 34.

Owner:KK TOPCON

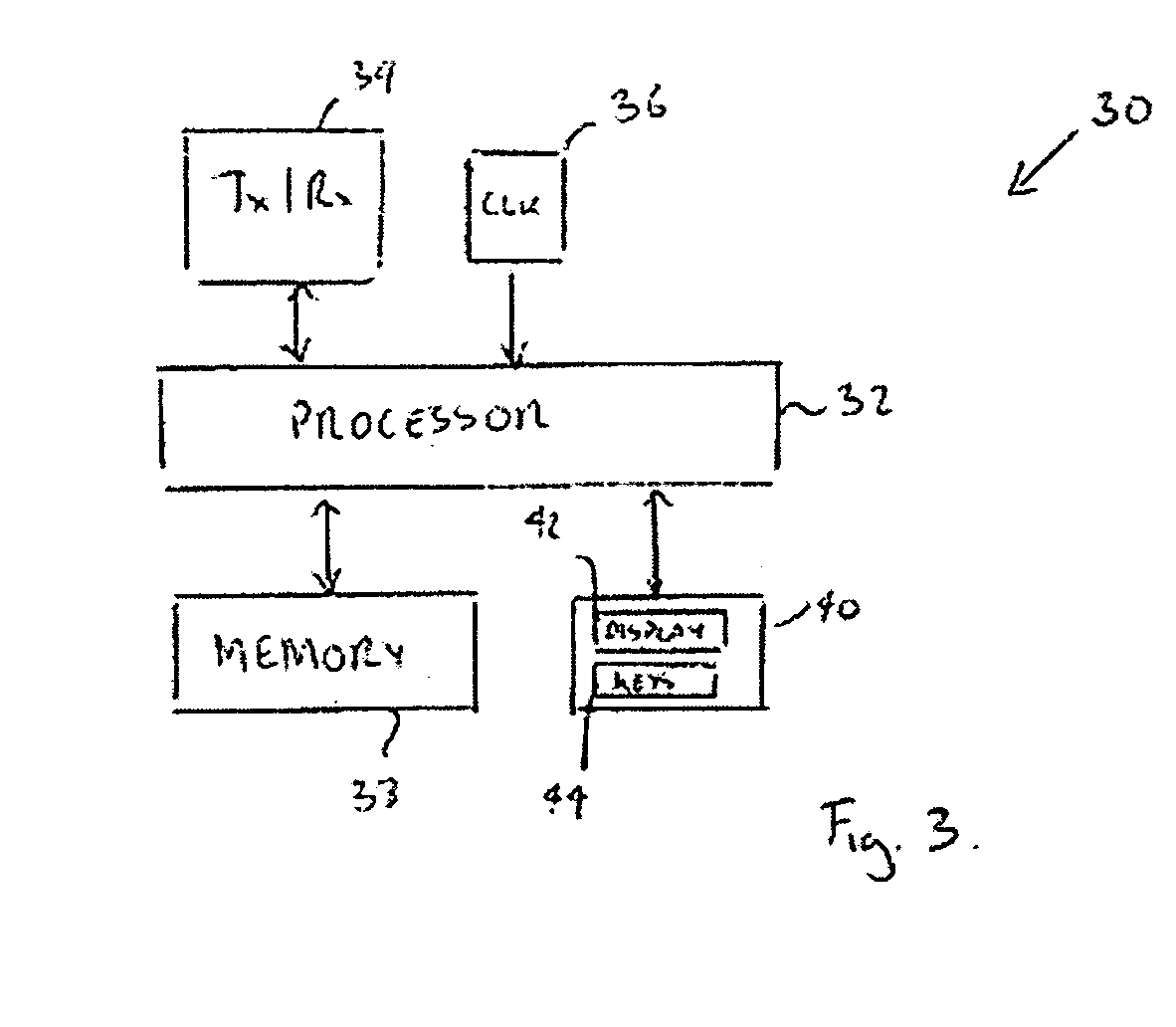

Wireless location privacy

InactiveUS20060165100A1Position can be determinedAccurate locationData switching by path configurationWireless commuication servicesTransceiverComputer science

A method for combating the tracking of a mobile transceiver, the mobile transceiver forming a node in a wireless communication network which has at least one other node, the method comprising the steps for enabling, until a first time, the transmission of a radio packet that depends upon a first anonymous address; calculating, dependent on a privacy level for the mobile transceiver, a second time; enabling, from the second time, the transmission of a radio packet that depends upon a second anonymous address; and disabling, between the first time and the second time, the transmission of a radio packet that depends upon either the first anonymous address or the second anonymous address.

Owner:NOKIA CORP

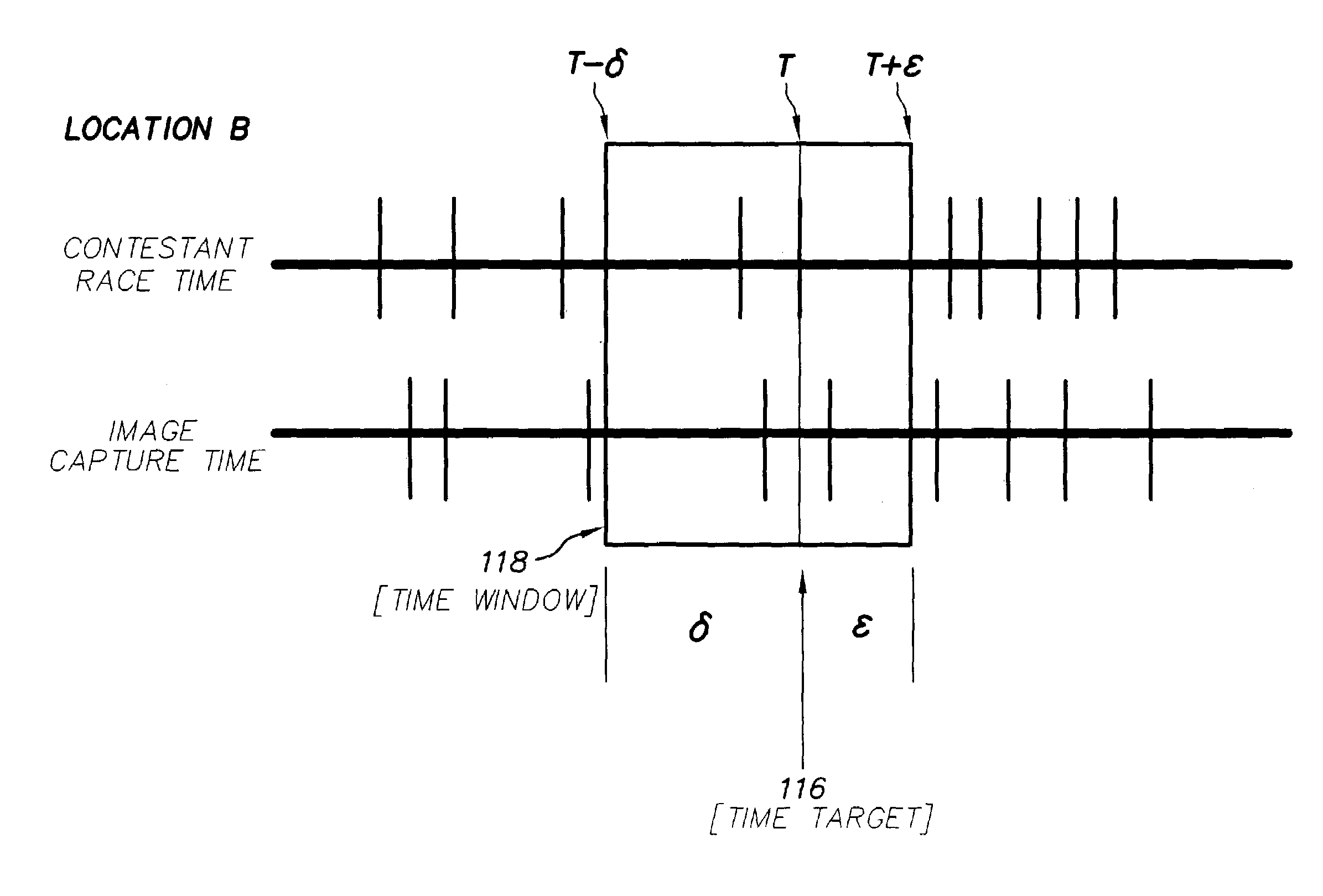

Correlating captured images and timed event data

ActiveUS7158689B2Easily correlatedEasily identifyTelevision system detailsRegistering/indicating time of eventsImage databaseImage capture

A method for correlating asynchronously captured event data associated with a timed activity and images associated with the events comprises the steps of: (a) capturing a plurality of images and storing the images and data corresponding to the images, including a time of image capture for each image, in an image database; (b) gathering data from one or more events associated with the timed activity and storing event data, including a time of occurrence of each event, in an event database; and (c) correlating the images and the event data in the databases by generating a time-based window that interrelates event data in the event database having a time of occurrence within the window with images in the image database having a time of capture within the window.

Owner:KODAK ALARIS INC

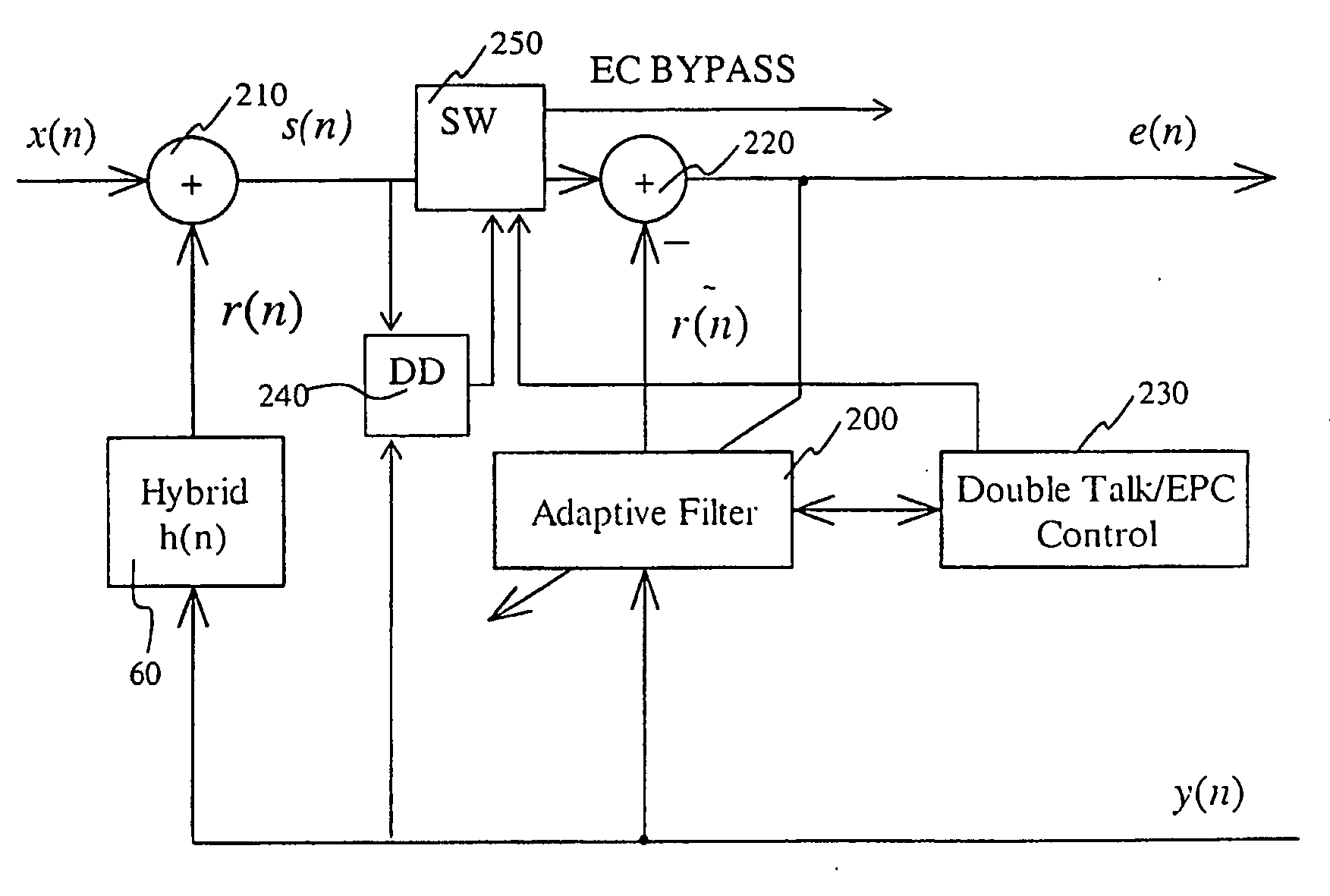

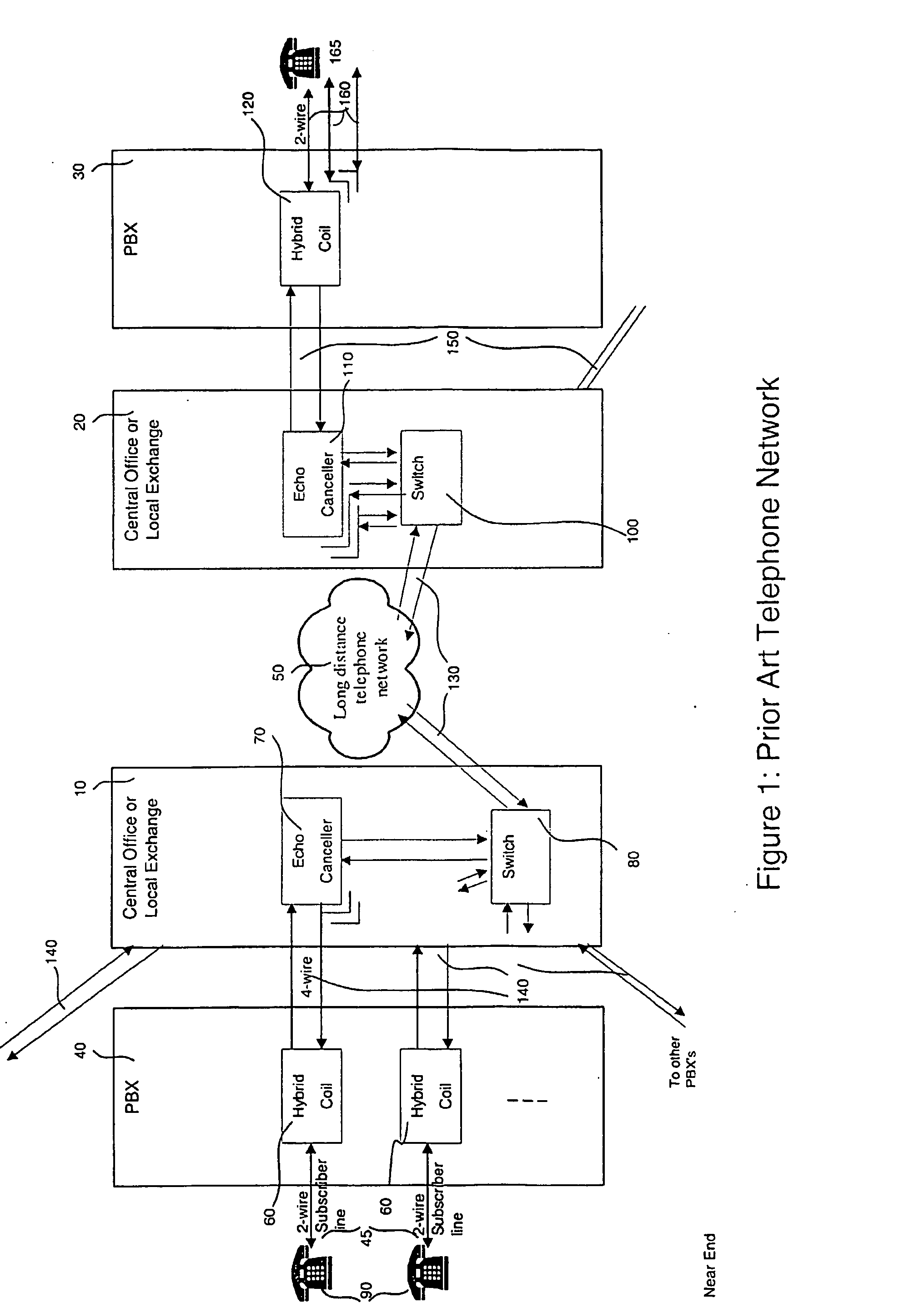

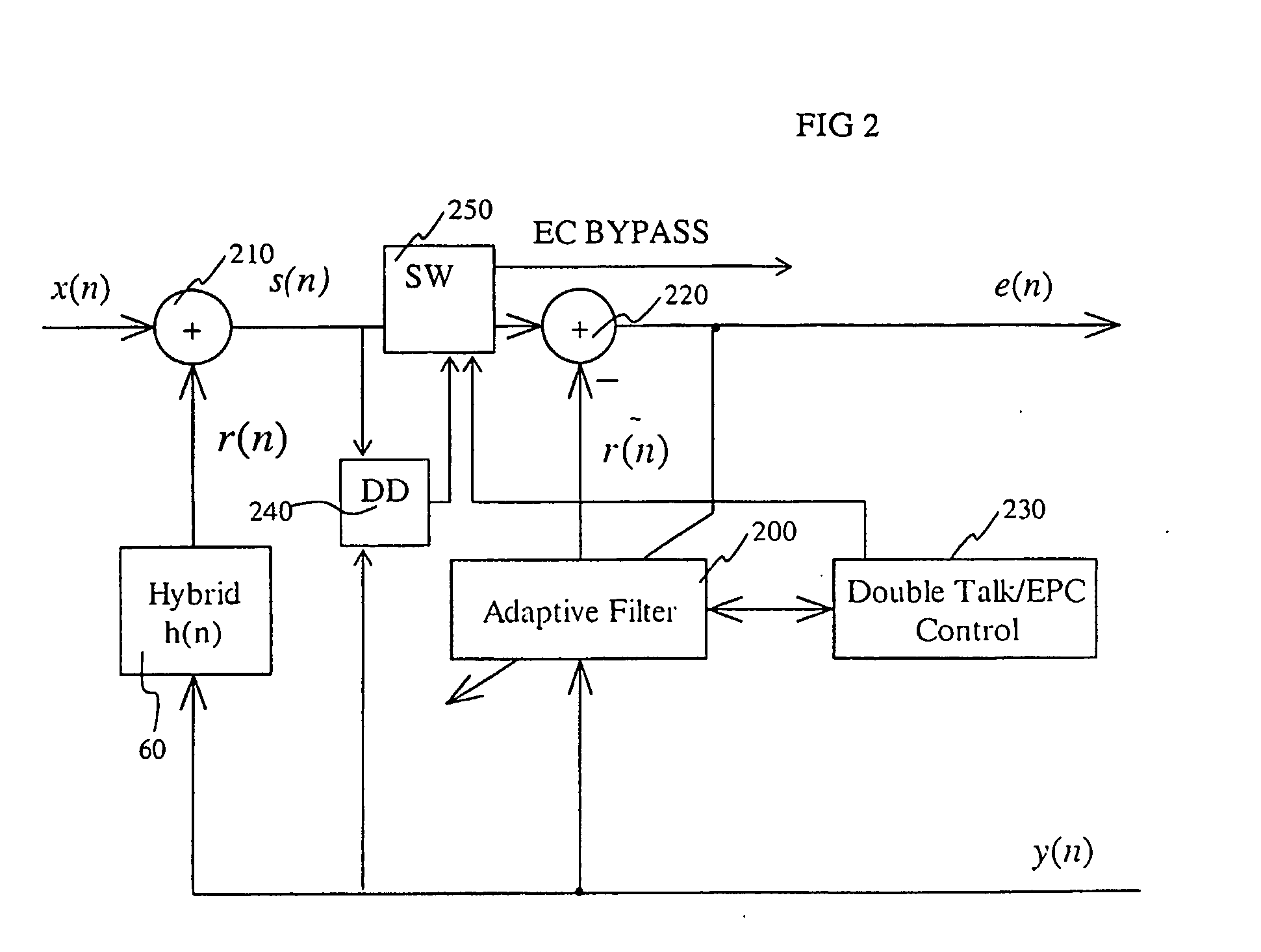

Echo detector having correlator with preprocessing

InactiveUS20060140392A1Reduce the amount of calculationReduce in quantityTwo-way loud-speaking telephone systemsLine-transmissionNarrow rangePeak value

An echo detector correlates between an incoming signal an echo signal to determine echo delay. A preprocesssor extracts a characteristic pattern such as a binary pattern derived by thresholding an averaged power of each signal. This pattern is down sampled then used for the correlation, and delay is deduced from peaks in the correlation. Advantages include reduced computational load, or larger correlation window size, because the characteristic pattern is easier to correlate. The quantising can enhance the correlation peaks, and the averaging can limit the number of transitions, to give more robustness to noise. An echo canceller has a coarse echo delay estimator and a fine echo delay estimator. The coarse estimated delay is used to adjust a delay detection range of a fine delay detector having a narrow range. The output of the fine detector is used to adjust or suppress the adaptive echo canceller.

Owner:TECTEON

Systems and methods for application-level security

InactiveUS8356001B2Easily correlatedReduce settingsMemory loss protectionError detection/correctionInternet privacyApplication software

Owner:XYBERSHIELD INC

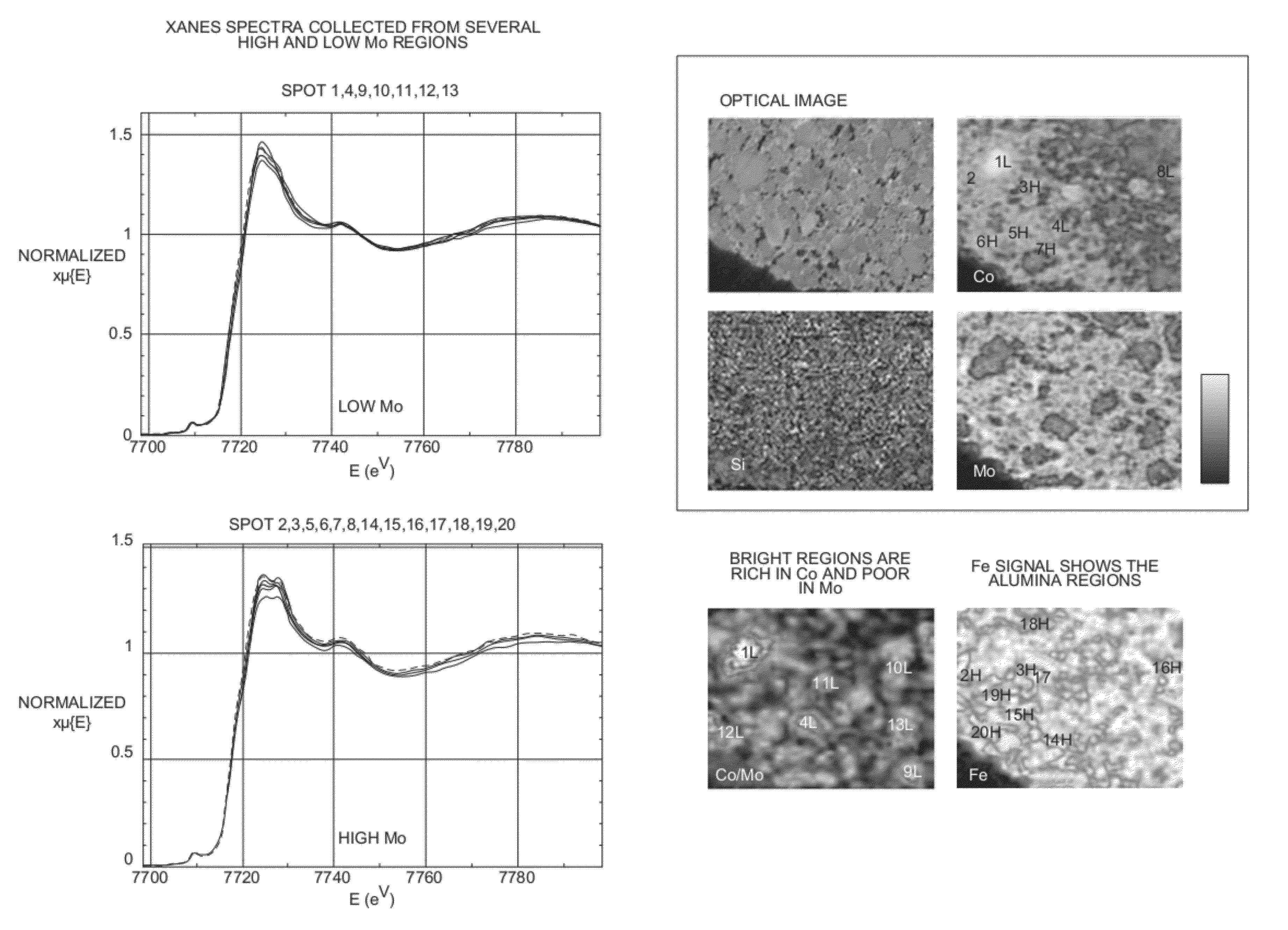

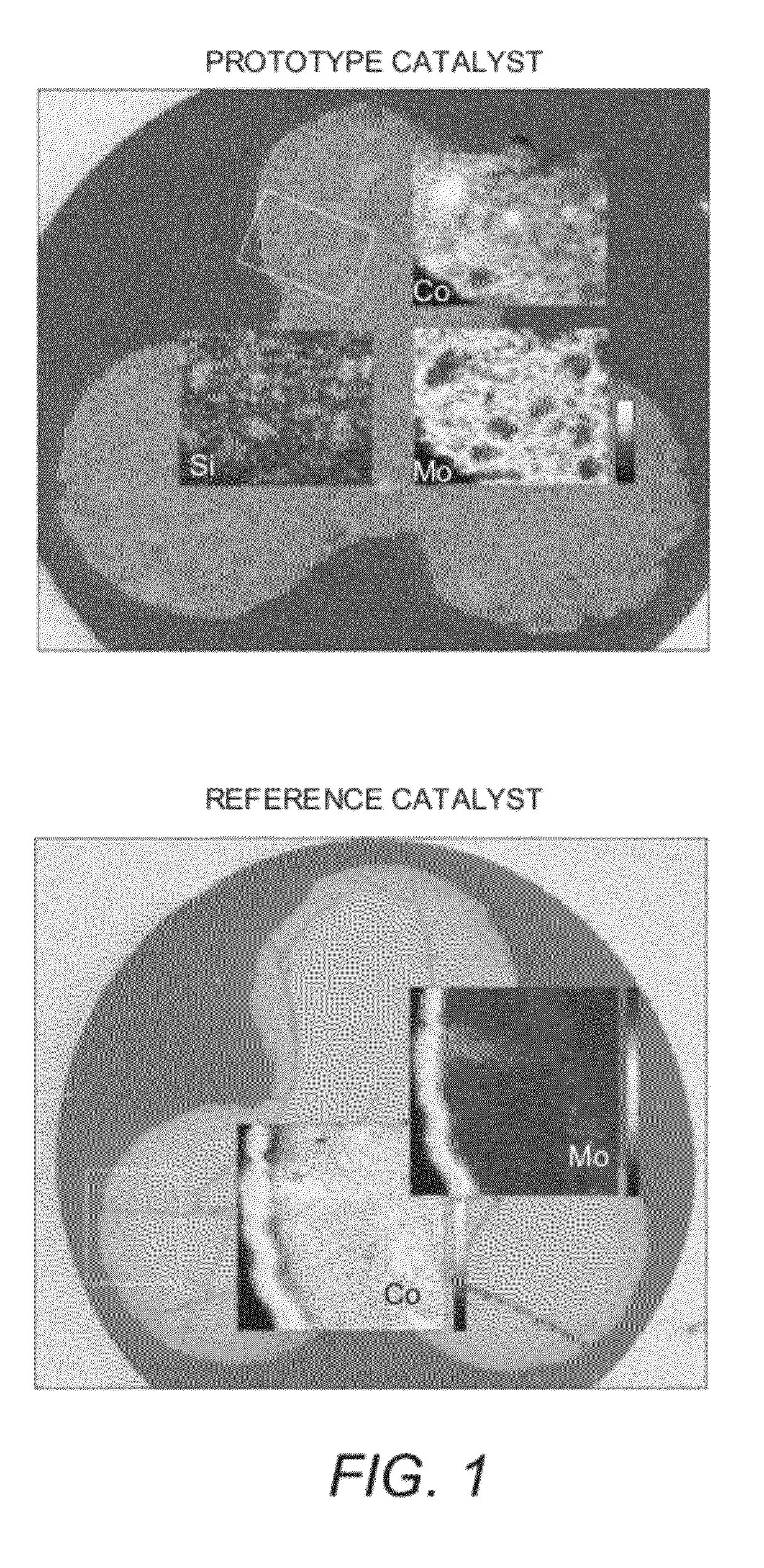

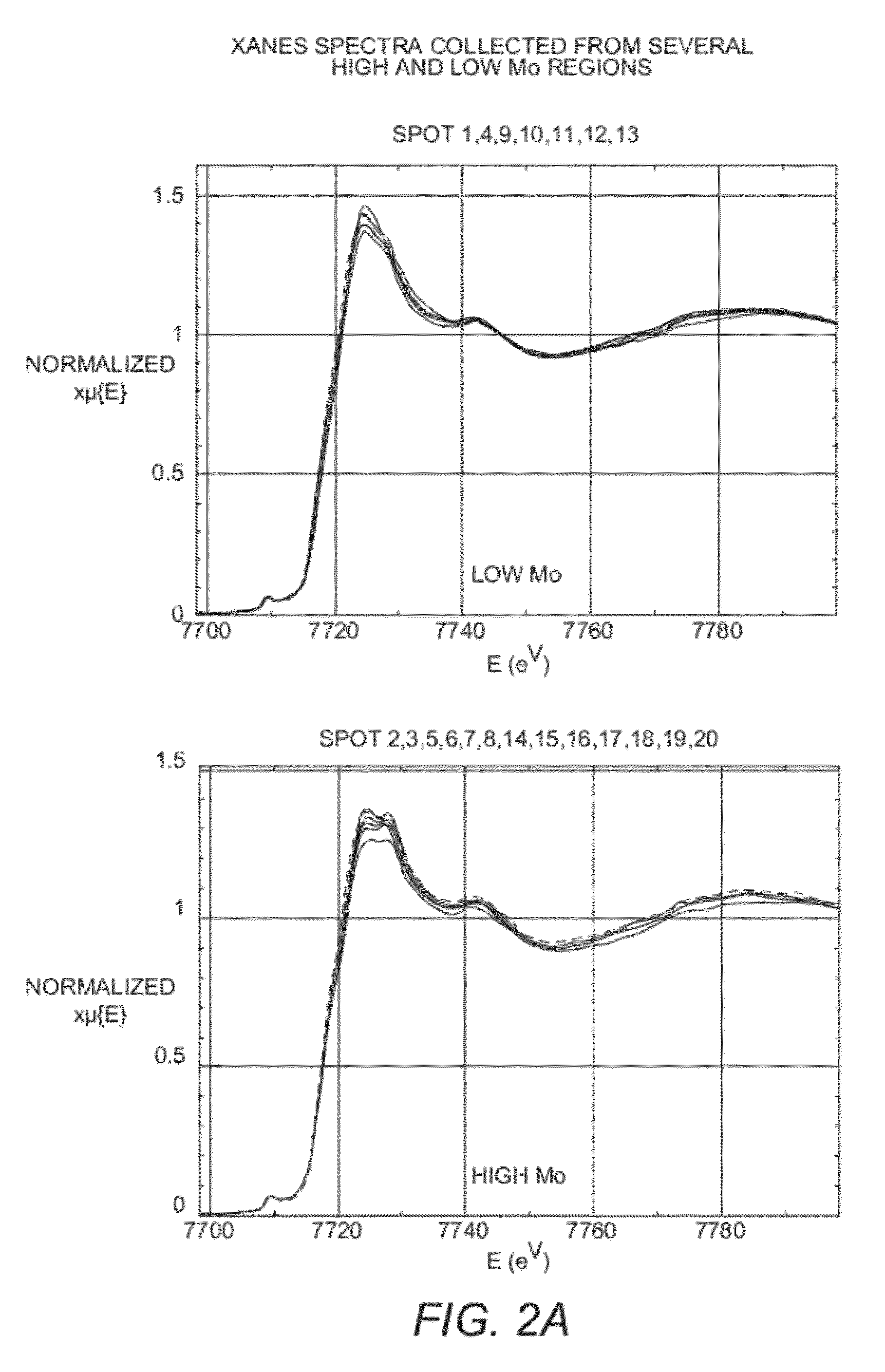

Solid material characterization with x-ray spectra in both transmission and fluoresence modes

InactiveUS20120321039A1Efficient analysisGood mechanical integrityX-ray spectral distribution measurementMaterial analysis using wave/particle radiationSoft x rayX-ray absorption spectroscopy

Methods are disclosed utilizing synchrotron X-ray microscopy including x-ray fluorescence and x-ray absorption spectra to probe elemental distribution and elemental speciation within a material, and particularly a solid that may have one or more elements distributed on a solid substrate. Representative materials are relatively homogeneous in composition on the macroscale but relatively heterogeneous on the microscale. The analysis of such materials, particularly on a macroscale at which their heterogeneous nature can be observed, provides valuable insights into the relationships or correlations between localized concentrations of elements and / or their species, and concentrations of other components of the materials. Sample preparation methods, involving the use of a reinforcing agent, which are advantageously used in such methods are also disclosed.

Owner:UOP LLC

Streaming method and system for processing network metadata

ActiveUS9392010B2Problem can be addressedEasily correlatedMemory loss protectionError detection/correctionInternet trafficTemplate based

A method and system for processing network metadata is described. Network metadata may be processed by dynamically instantiated executable software modules which make policy-based decisions about the character of the network metadata and about presentation of the network metadata to consumers of the information carried by the network metadata. The network metadata may be type classified and each subclass within a type may be mapped to a definition by a unique fingerprint value. The fingerprint value may be used for matching the network metadata subclasses against relevant policies and transformation rules. For template-based network metadata such as NetFlow v9, an embodiment of the invention can constantly monitor network traffic for unknown templates, capture template definitions, and informs administrators about templates for which custom policies and conversion rules do not exist. Conversion modules can efficiently convert selected types and / or subclasses of network metadata into alternative metadata formats.

Owner:NETFLOW LOGIC

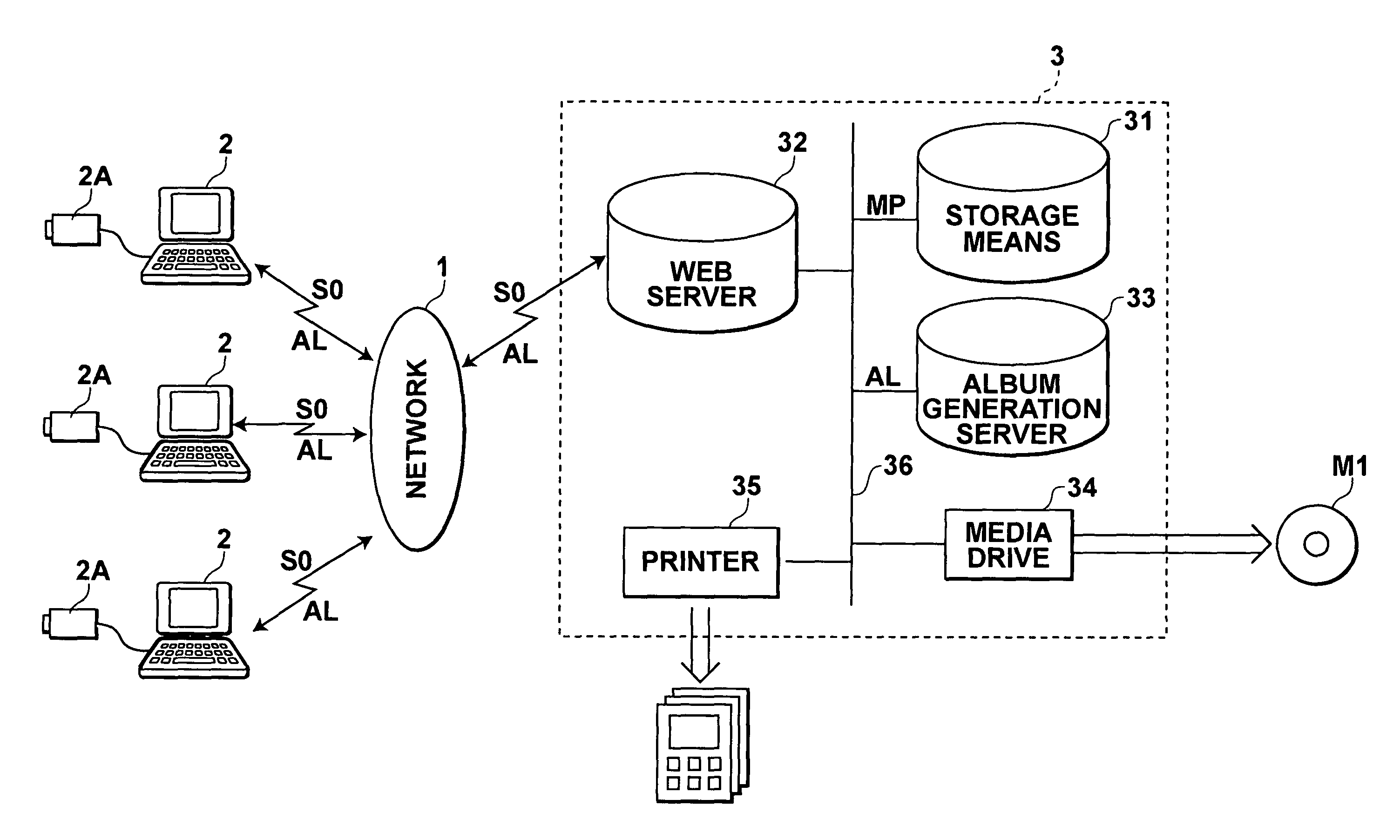

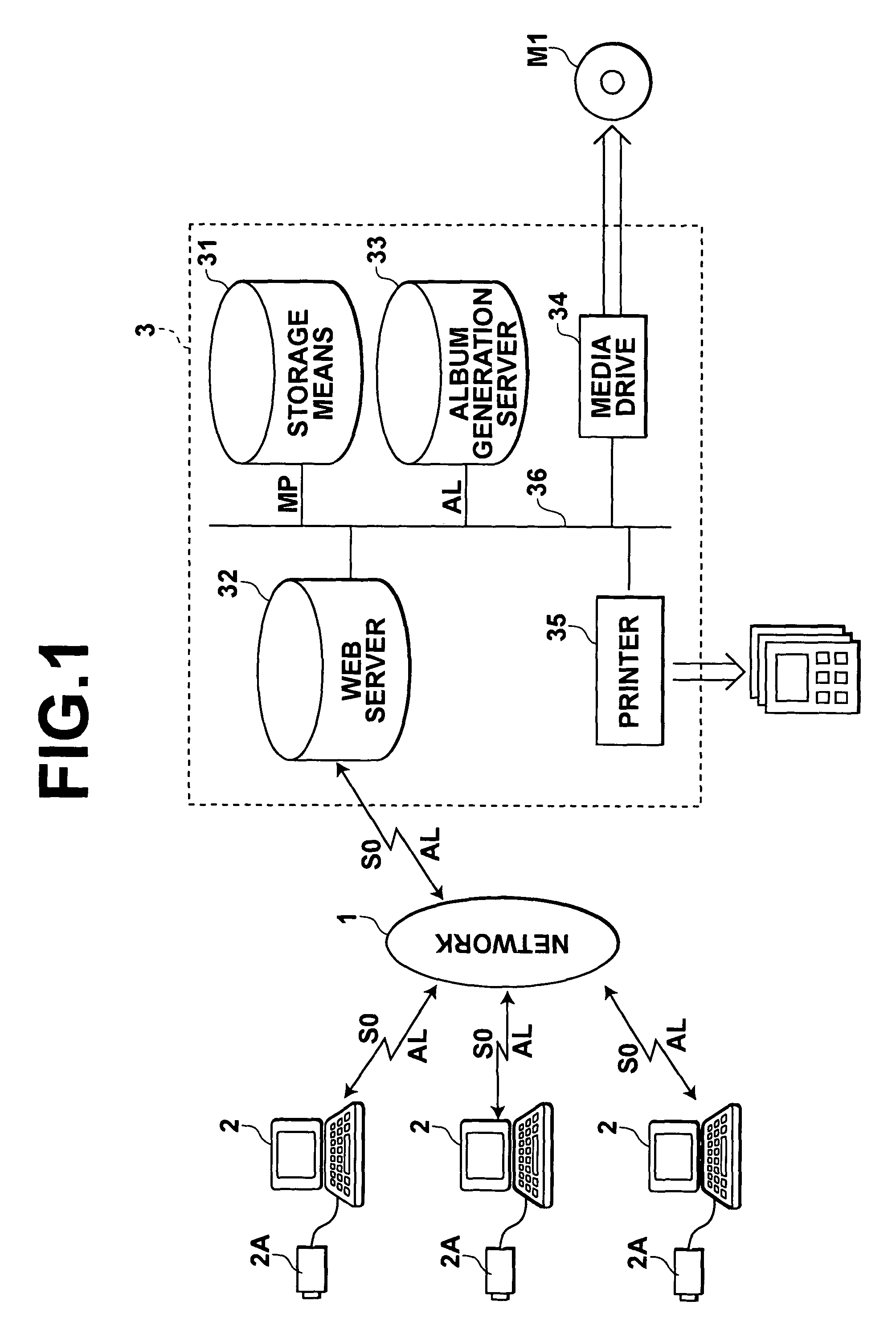

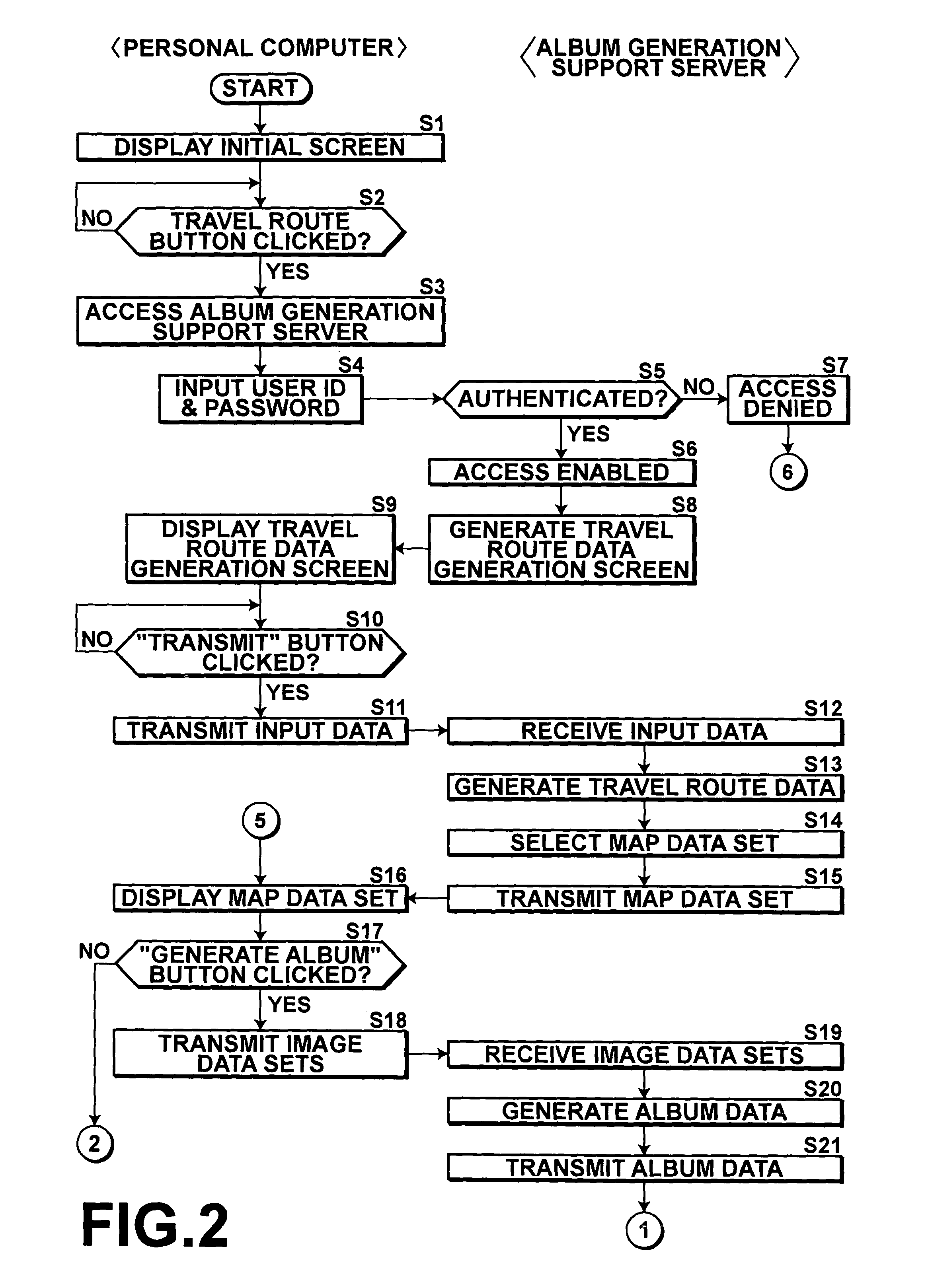

Method, apparatus, and computer program for generating albums

ActiveUS7281021B2Accurate dataEasily correlatedInstruments for road network navigationData processing applicationsData setUser input

Correlation between images and photography locations thereof is facilitated when generating an album of images photographed during a trip. Map data sets are stored in a storage means of an album generation support server. A user accesses the album generation support server from a personal computer to request album generation. Screens for transmitting image data sets and for prompting input of data that specifies a travel route are displayed at the personal computer. The user inputs data regarding a departure point, a departure time, a final destination, etc., and transmits the image data sets to the album generation support server. An album generation server generates travel route data representing the user's travel route based on the input data, estimates locations along the travel route where the image data sets were photographed based on time data attached thereto, and generates album data by correlating the image data sets with a map.

Owner:FUJIFILM CORP

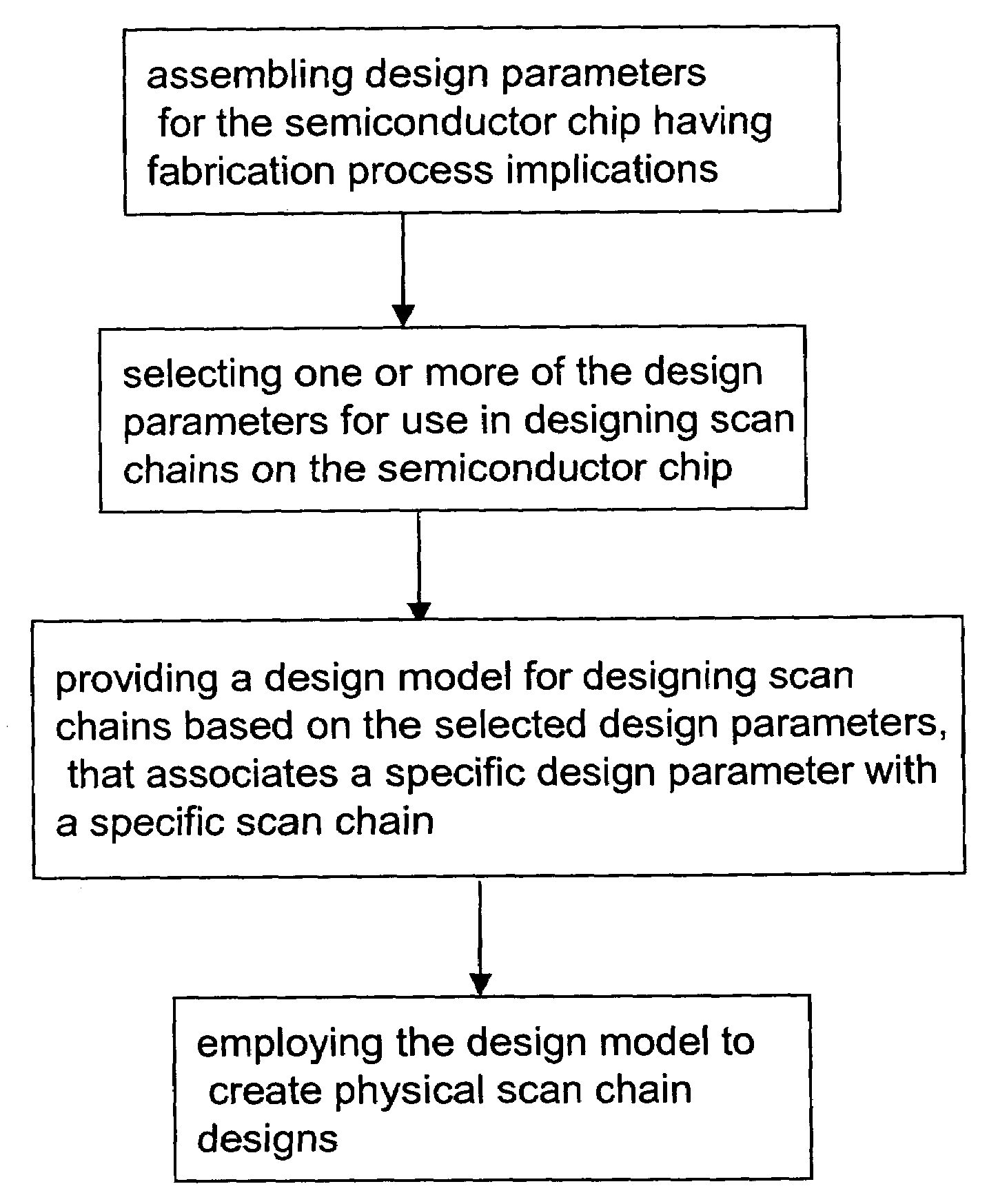

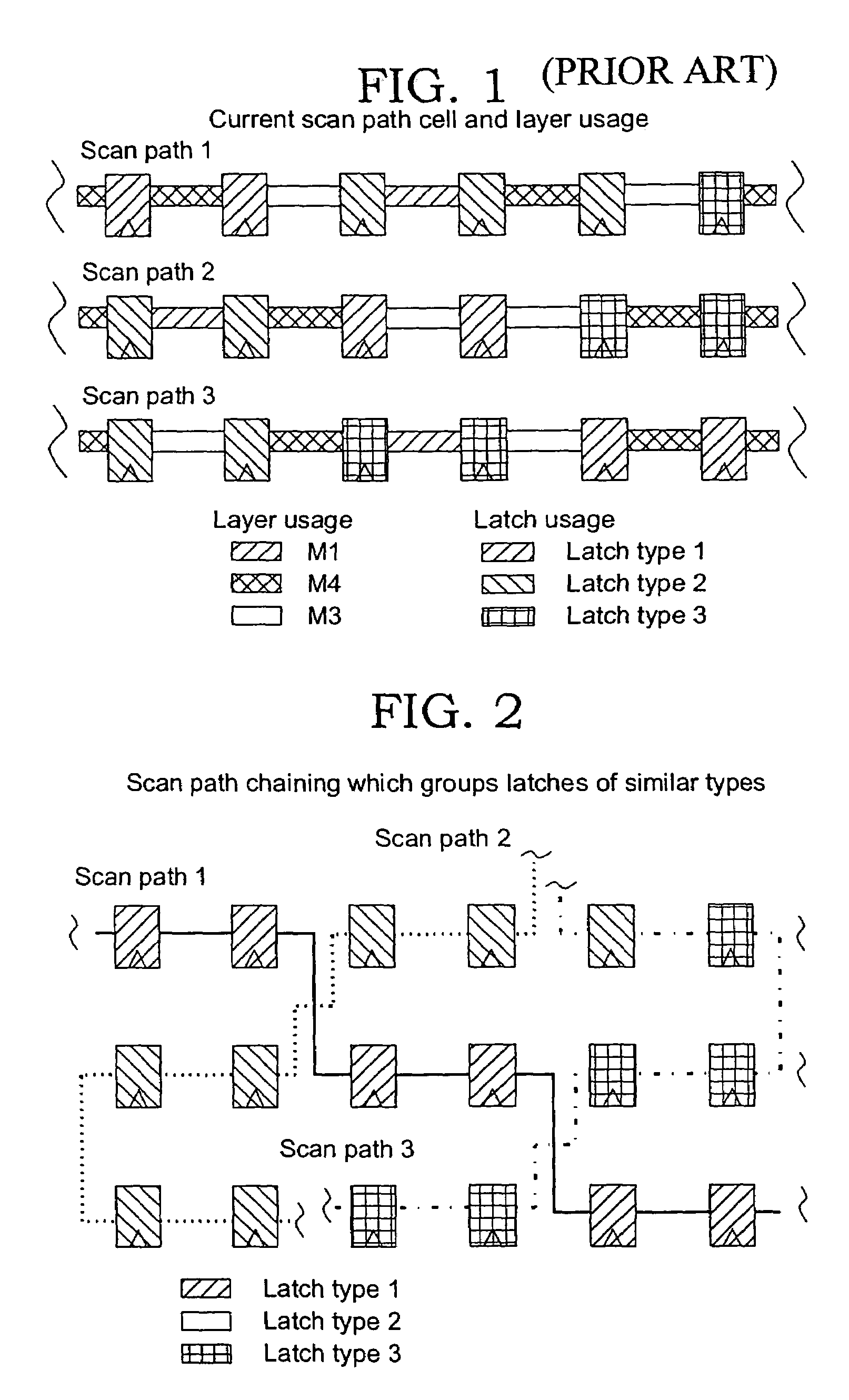

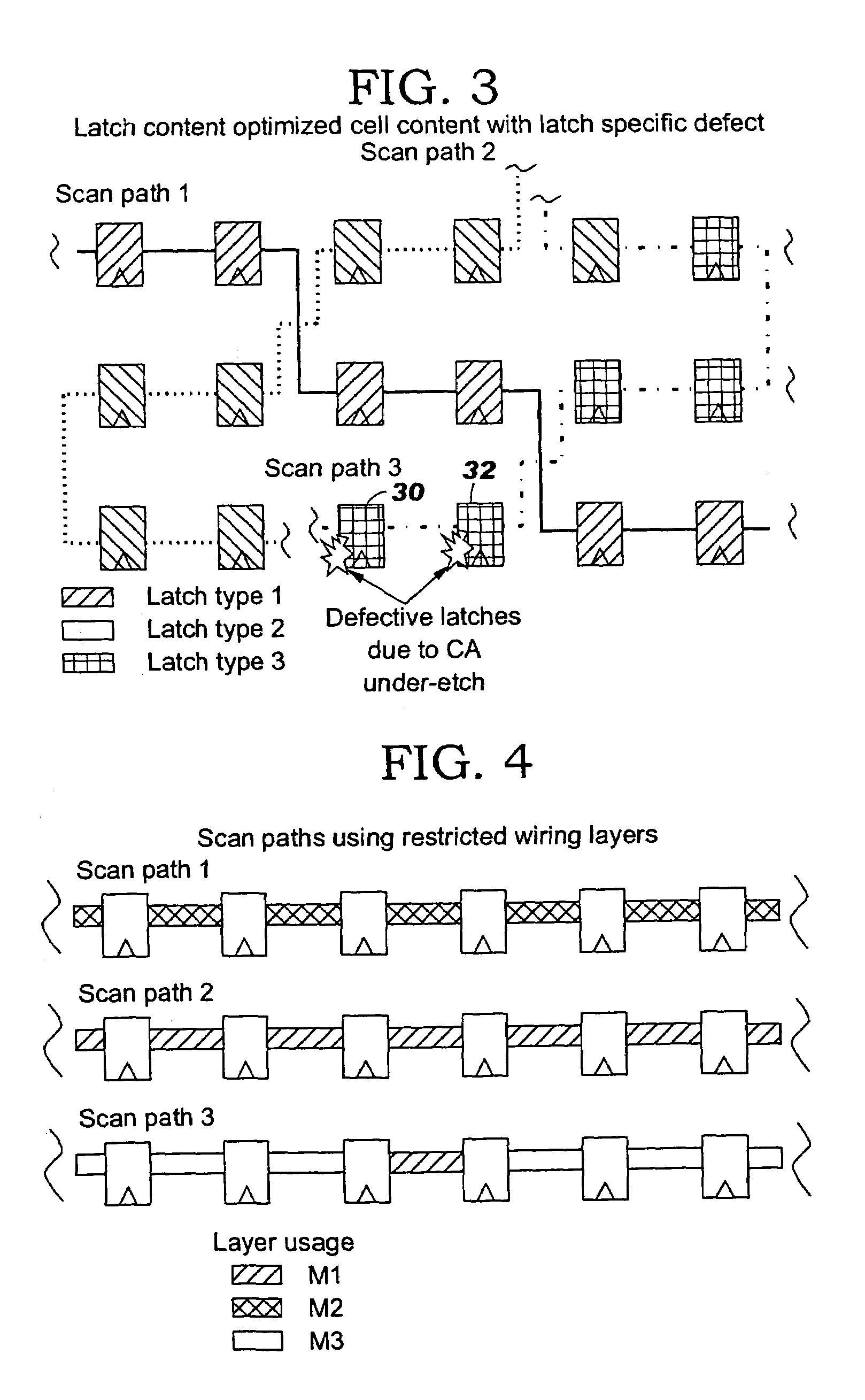

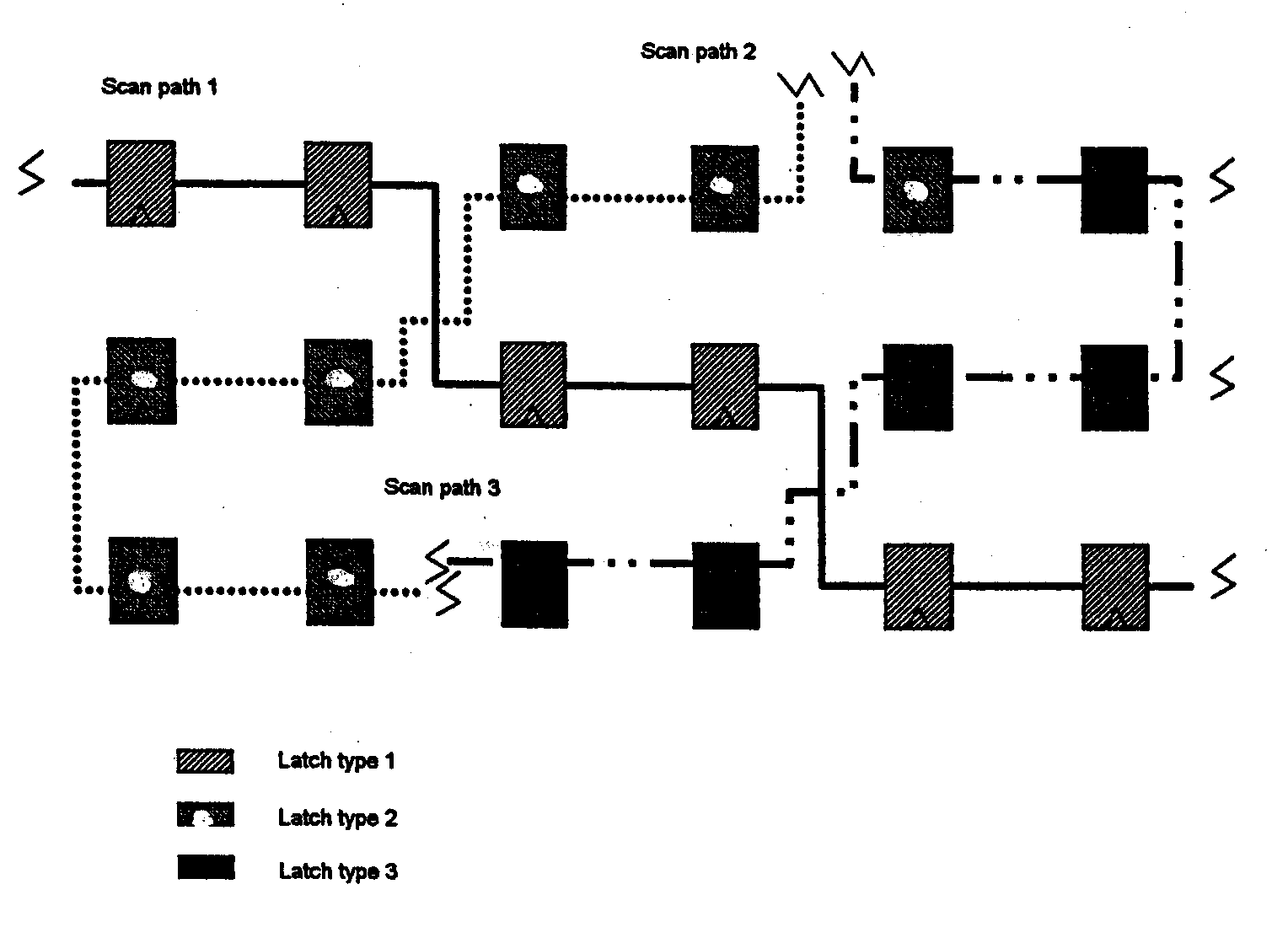

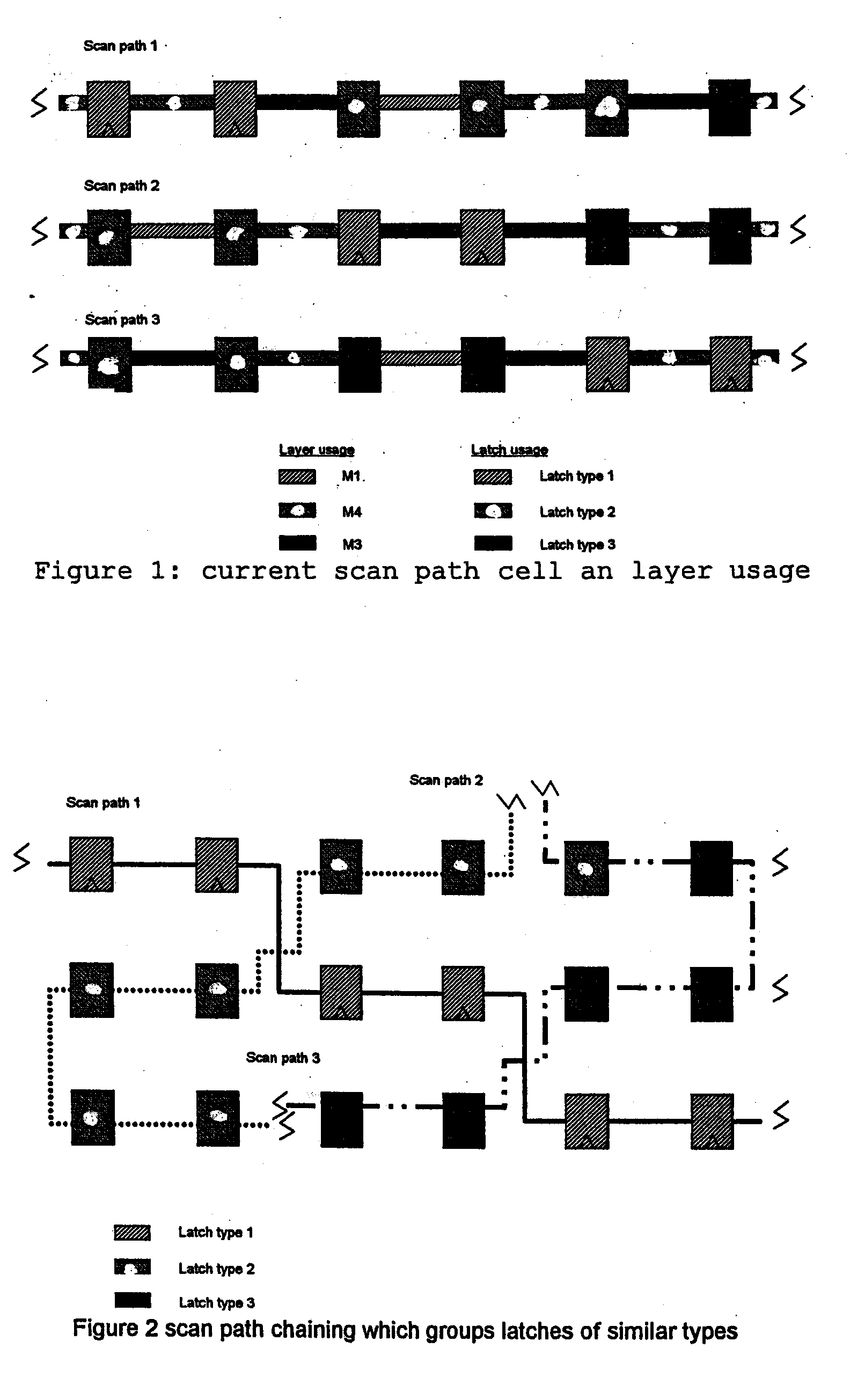

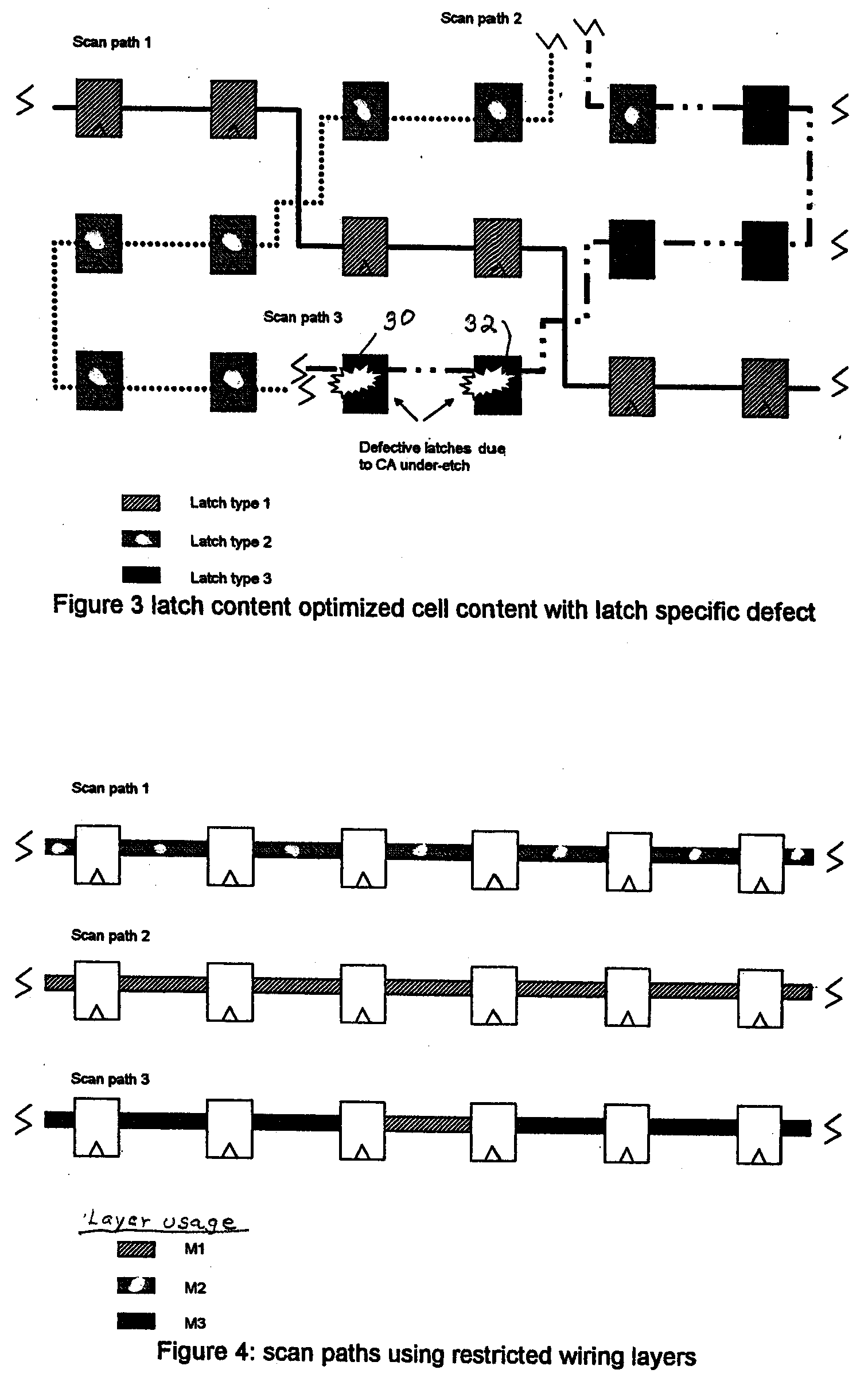

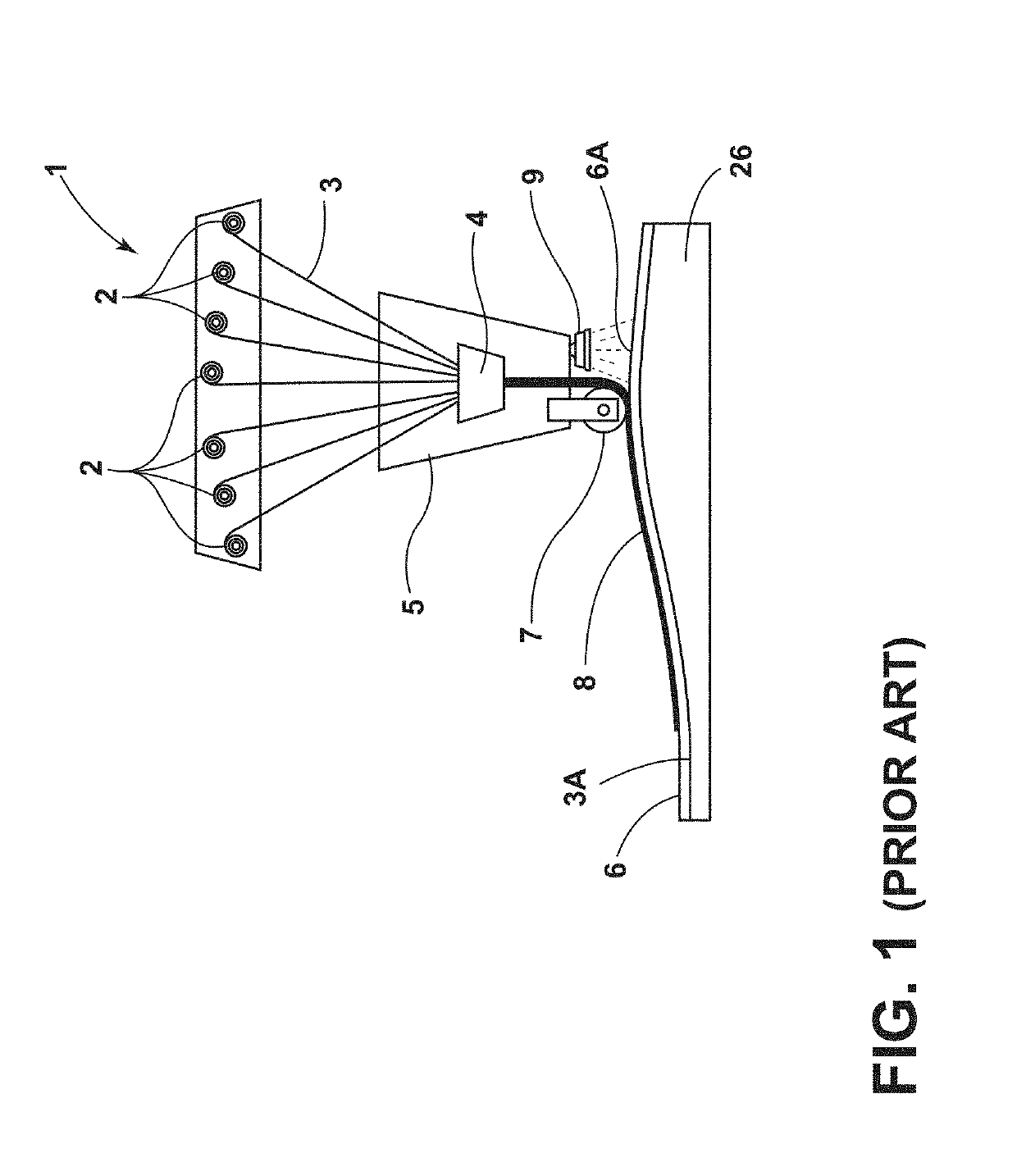

Designing scan chains with specific parameter sensitivities to identify process defects

InactiveUS7194706B2Easily correlatedImprove availabilitySemiconductor/solid-state device testing/measurementElectronic circuit testingProbable CaseEngineering

A method is disclosed for designing scan chains in an integrated circuit chip with specific parameter sensitivities to identify fabrication process defects causing test fails and chip yield loss. The composition of scan paths in the integrated circuit chip is biased to allow them to also function as on-product process monitors. The method adds grouping constraints that bias scan chains to have common latch cell usage where possible, and also biases cell routing to constrain scan chain routing to given restricted metal layers for interconnects. The method assembles a list of latch design parameters which are sensitive to process variation or integrity, and formulates a plan for scan chain design which determines the number and the length of scan chains. A model is formulated of scan chain design based upon current state of yield and process integrity, wherein certain latch designs having dominant sensitivities are chosen for specific ones of the scan chains on the chip. The model is provided as input parameters to a global placement and wiring program used to lay out the scan chains. Test data on the chip is then analyzed to determine and isolate systematic yield problems denoted by attributes of a statistically significant failing population of a specific type of scan chain.

Owner:IBM CORP

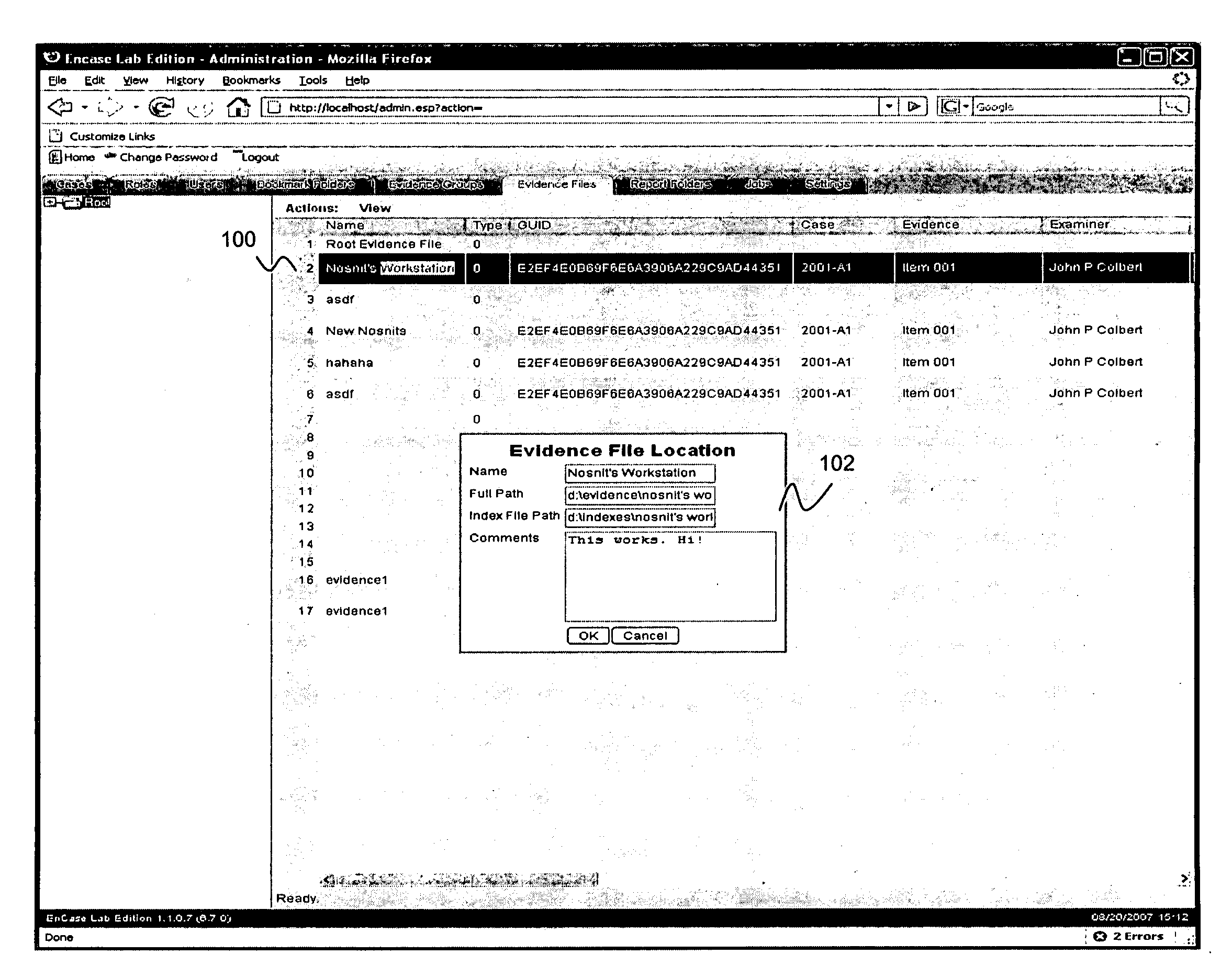

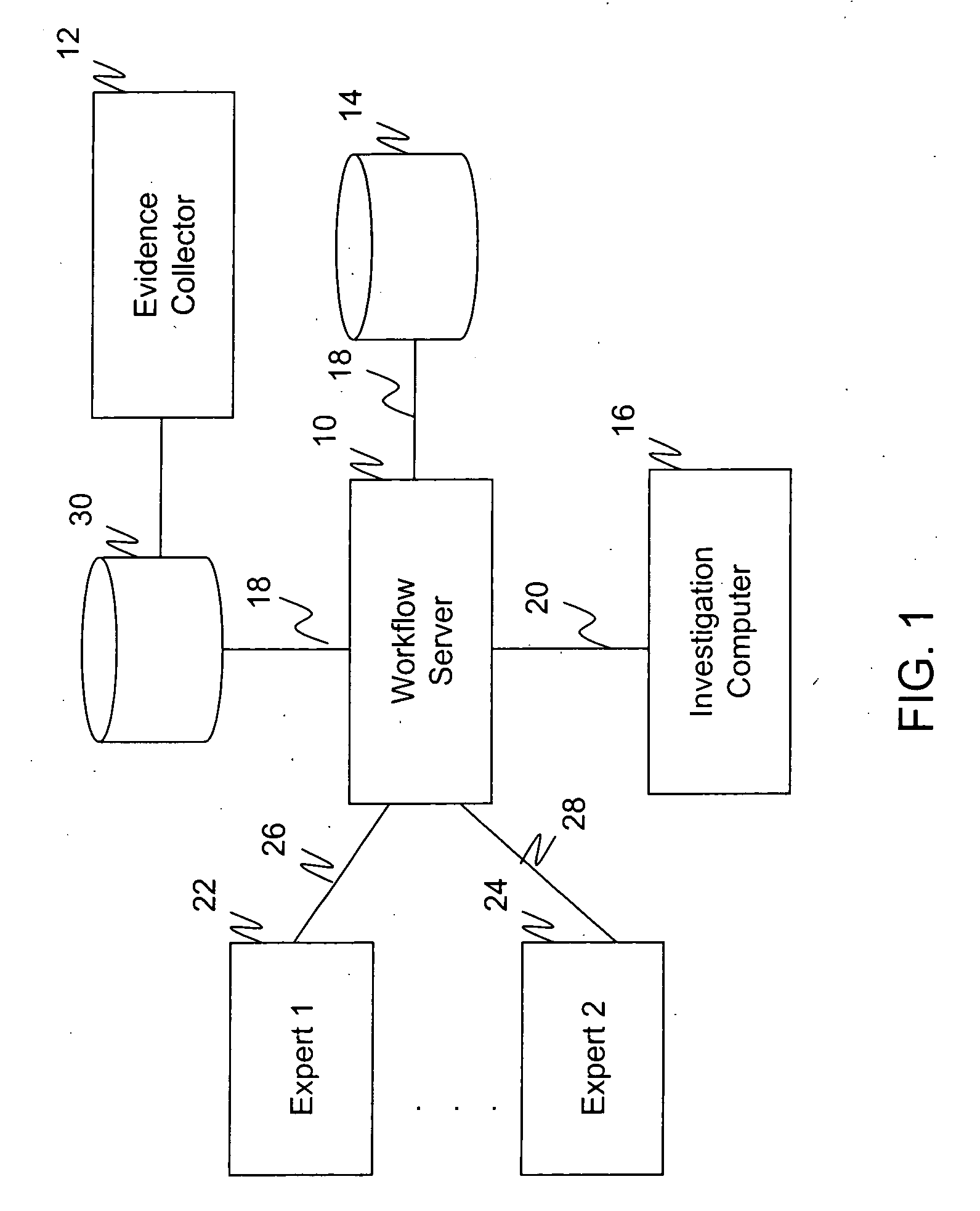

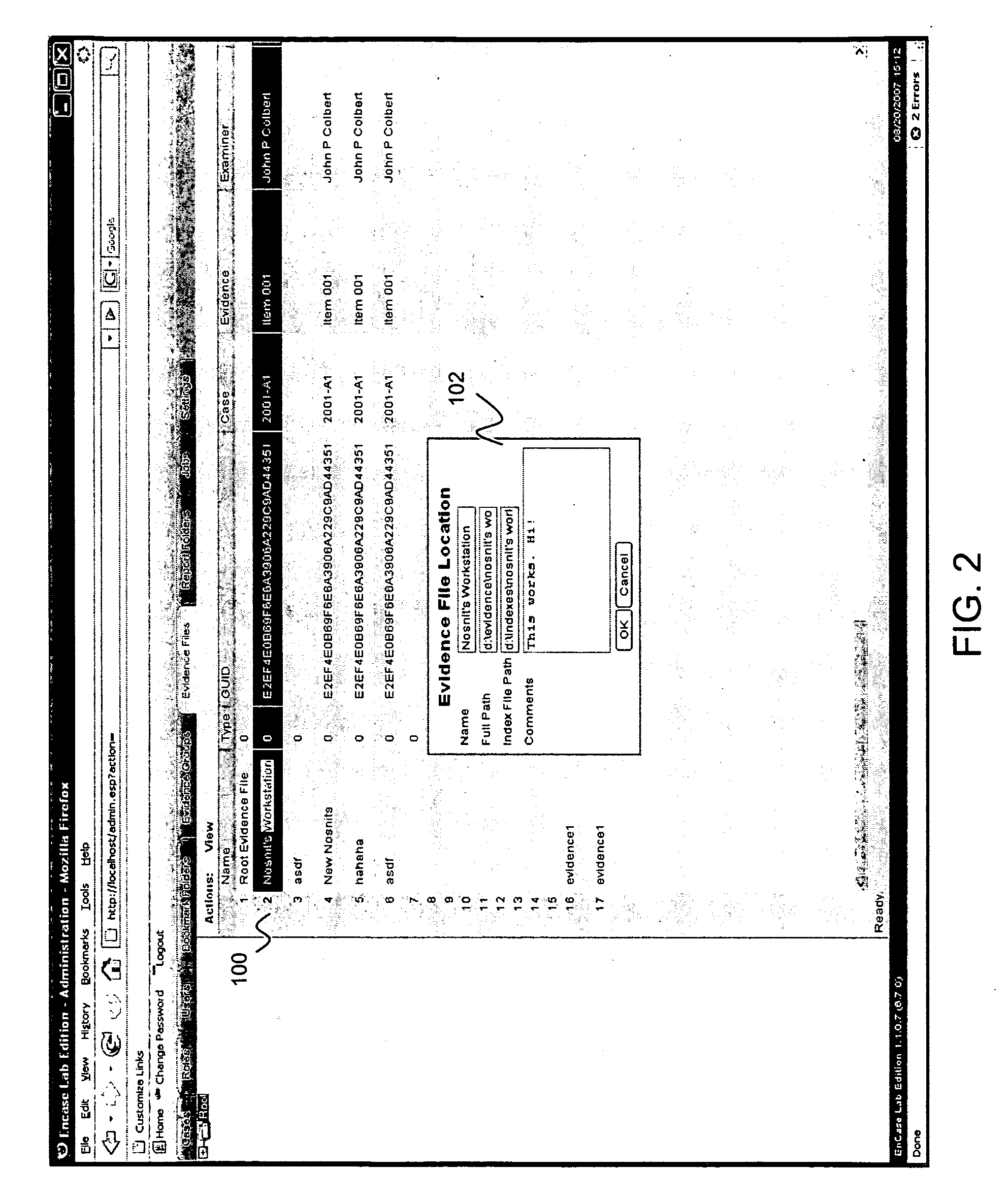

Workflow collaboration in a forensic investigations system

InactiveUS20090171961A1Effective distributionEasily correlatedResourcesSpecial data processing applicationsWorkflowAnnotation

A system and method for centralized workflow collaboration that invokes the skills of different experts to carry out investigation of forensic evidence data and generate a forensic report. A centralized workflow system stores attributes, annotations, reports, and other information associated with collected forensic evidence data. The attributes associated with the evidence data are used to narrow the evidence data without actually reviewing the contents of the evidence, and to assign the review of the contents of the narrowed evidence to experts who are deemed to have the qualifications necessary to perform the review. The assignment of a workflow task to a particular expert may be manual or automatic. The generating of workflow tasks may also be automatic in response to evidence processing.

Owner:GUIDANCE SOFTWARE

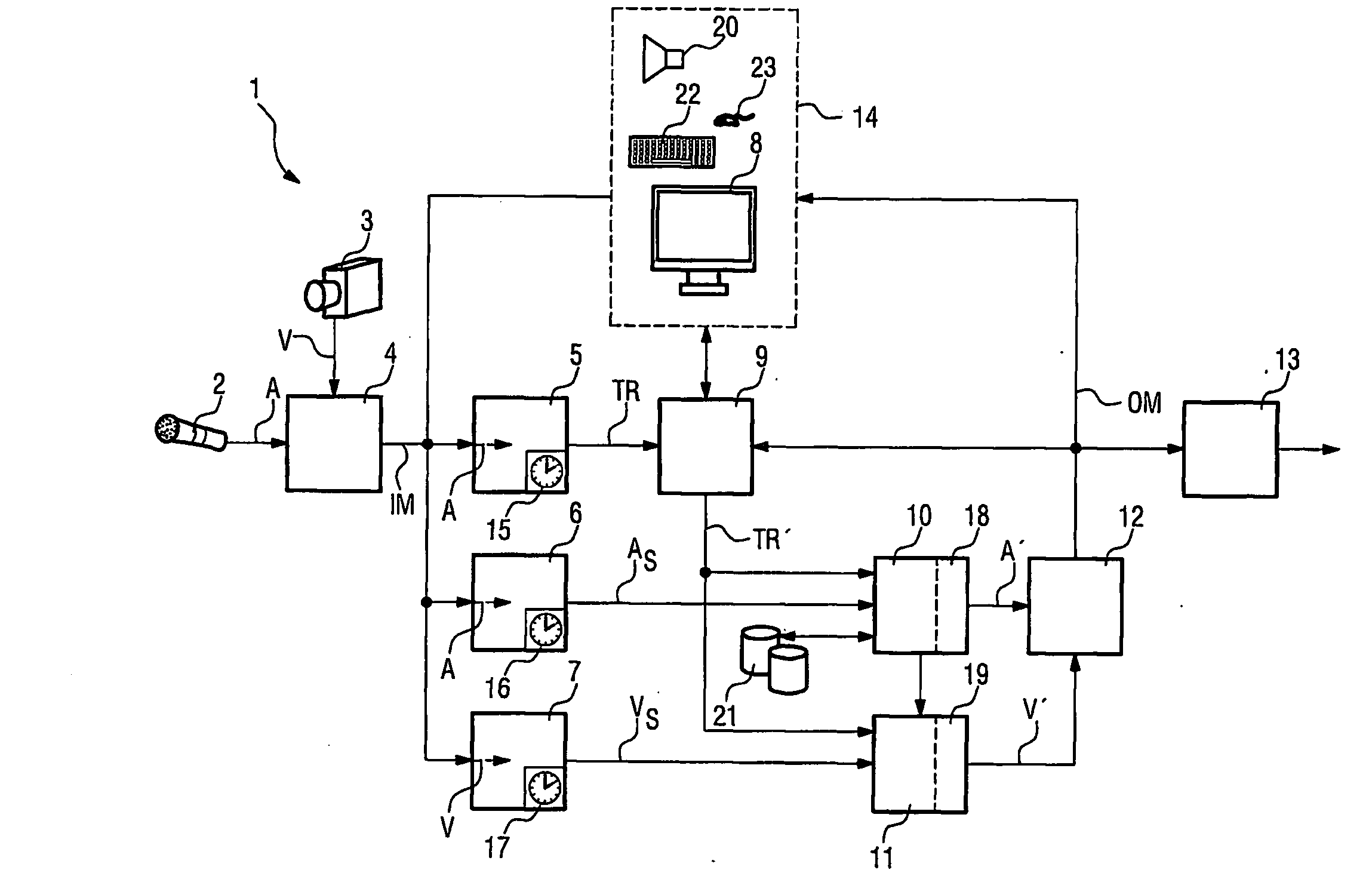

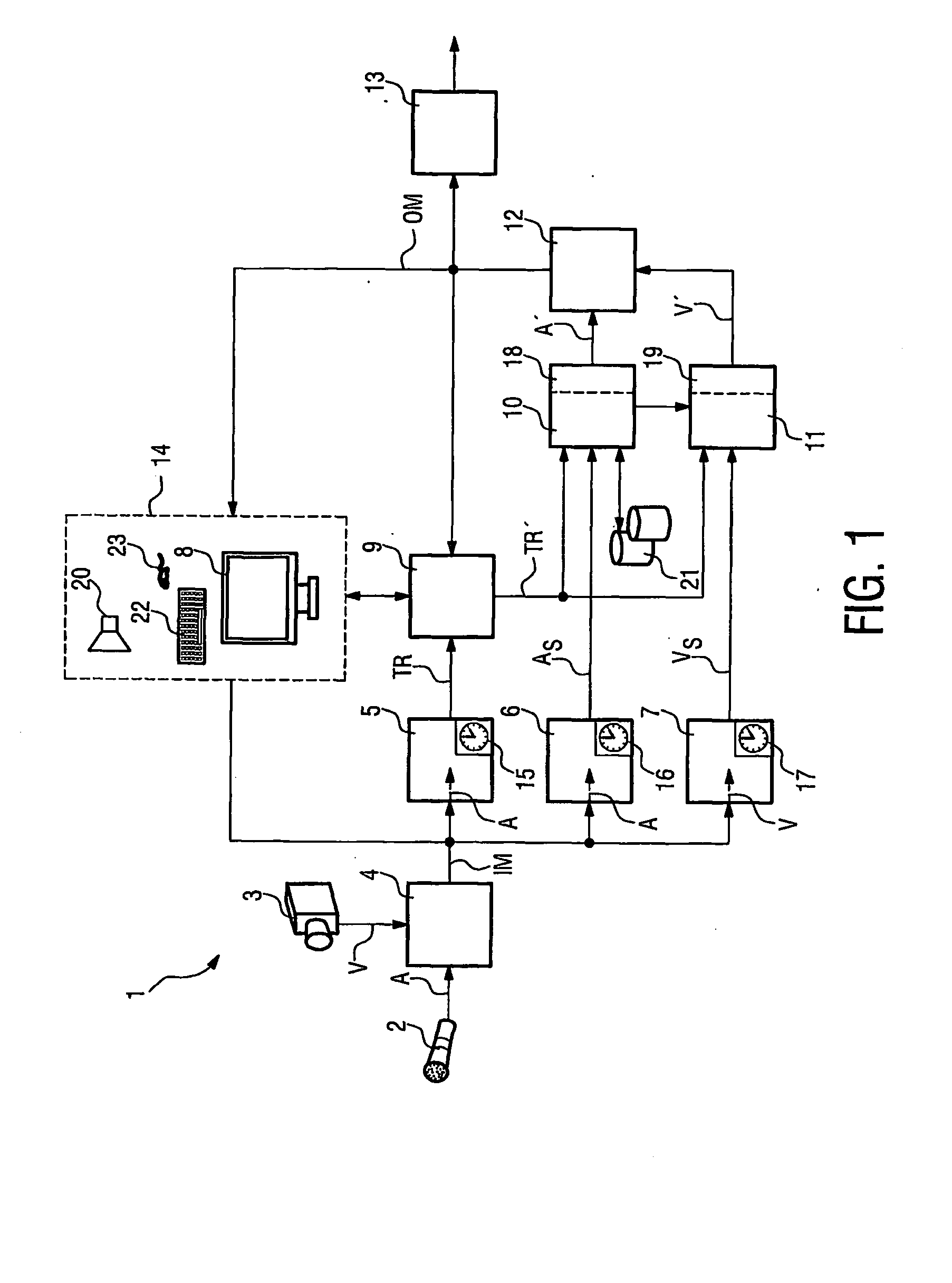

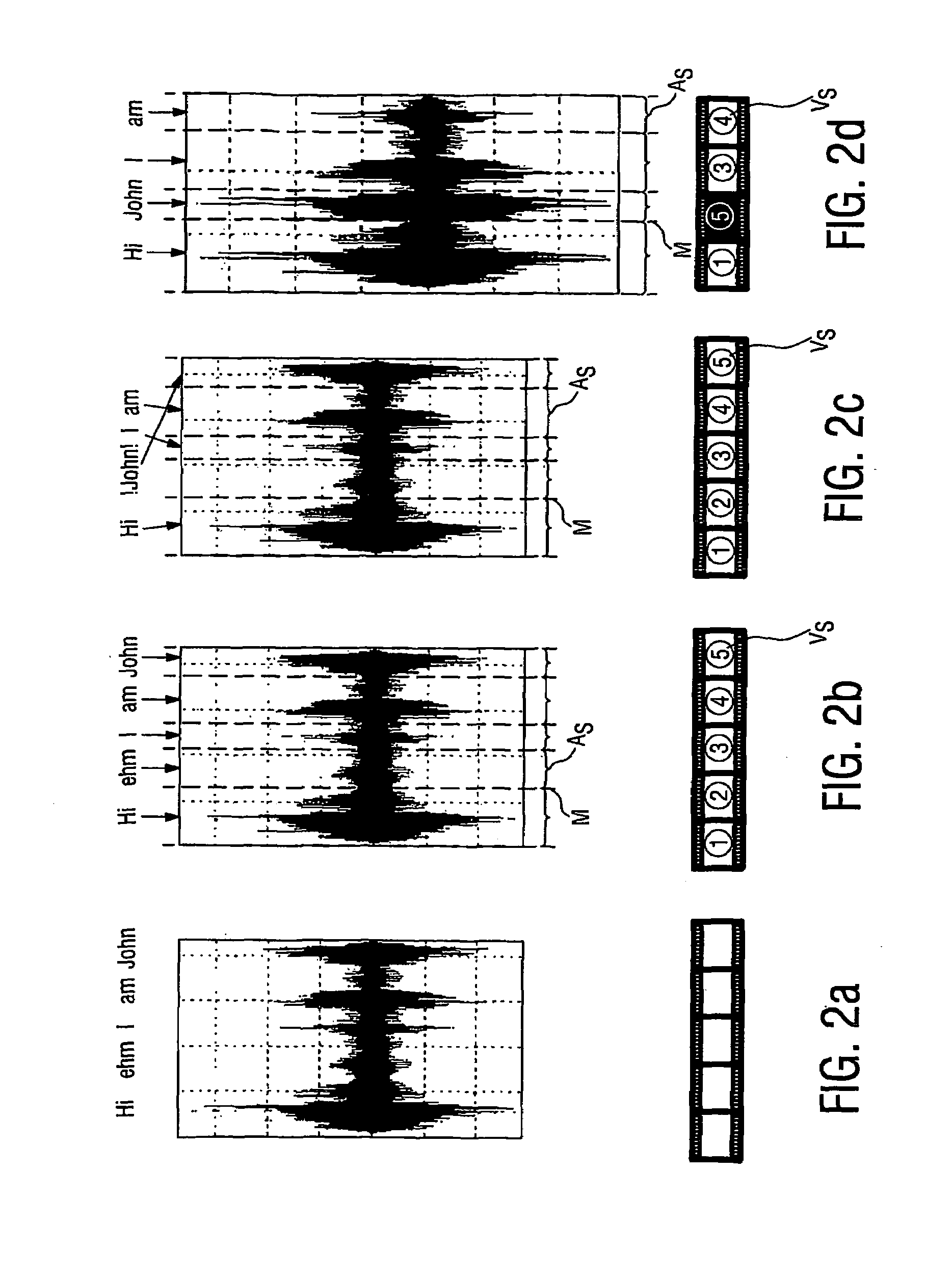

Method of and System for Modifying Messages

InactiveUS20080275700A1Easily and intuitively modifyingSuitableElectronic editing digitised analogue information signalsBuying/selling/leasing transactionsSpeech sound

The invention describes a method of and a system for modifying an input message (IM) containing audio content, which method comprises the steps of converting the audio content (A) of the input message (IM) into elements of a text representation (TR), segmenting the audio content (A) of the input message (IM) into constituent phonetic elements (As), correlating to the text representation (TR), rendering the text representation (TR) in a form suitable for editing the text representation (TR) in accordance with editing input, and altering the correlating phonetic elements (As) of the audio content (A) in accordance with the edited text representation (TR′) so as to give a modified audio content (A′) of an output message (OM).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

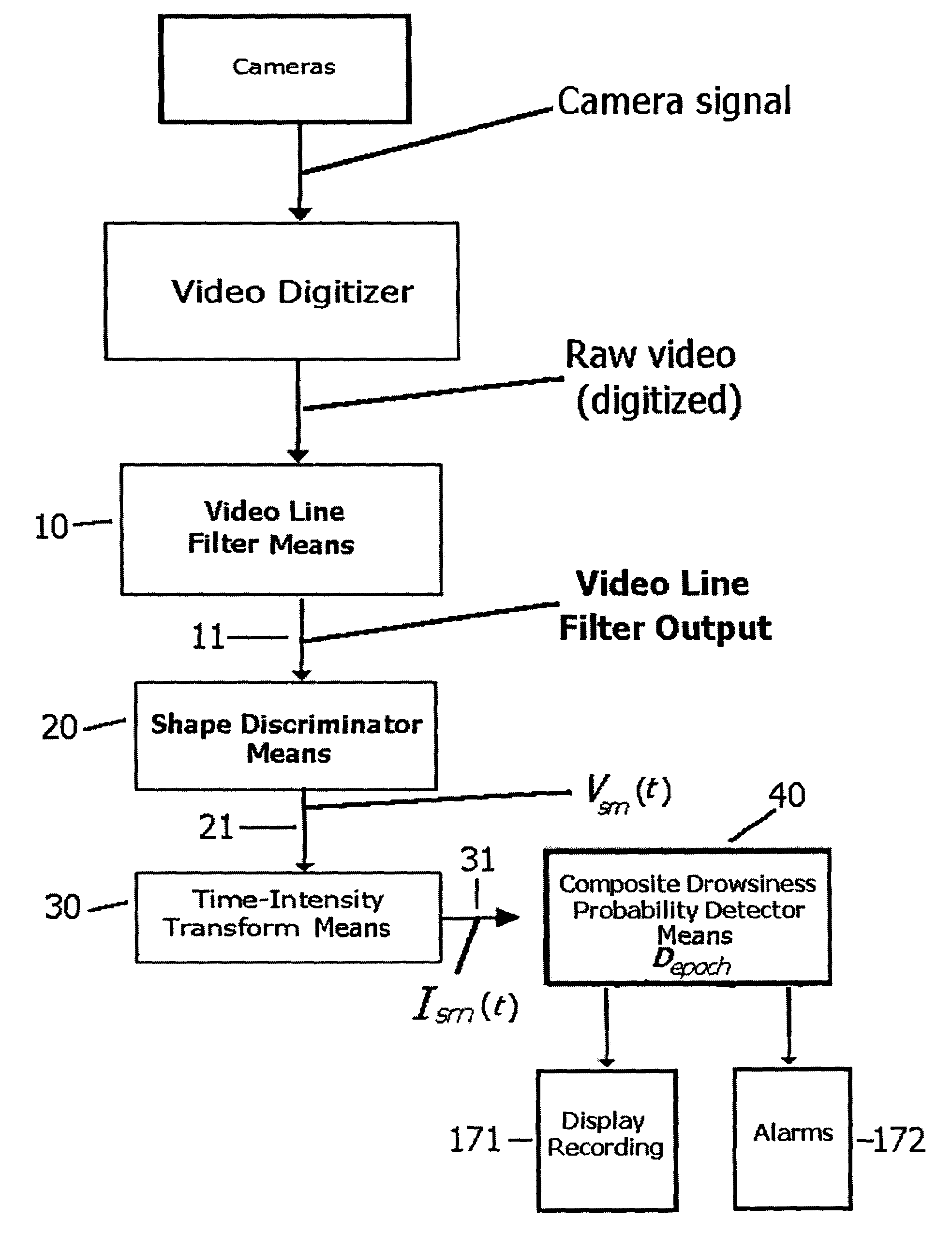

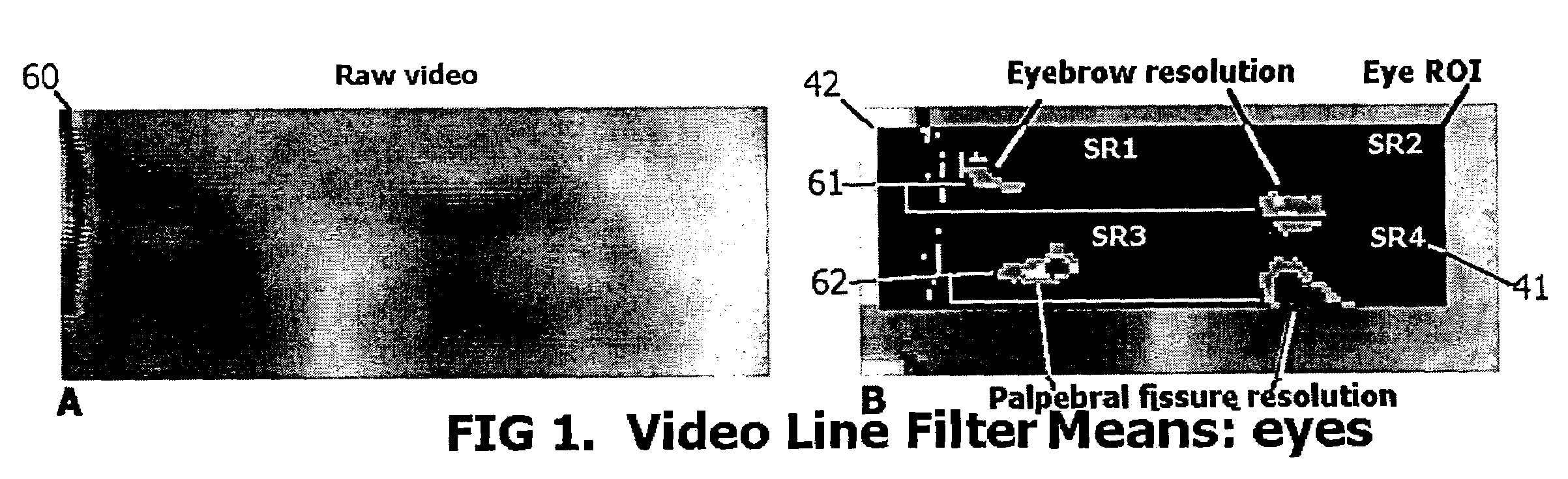

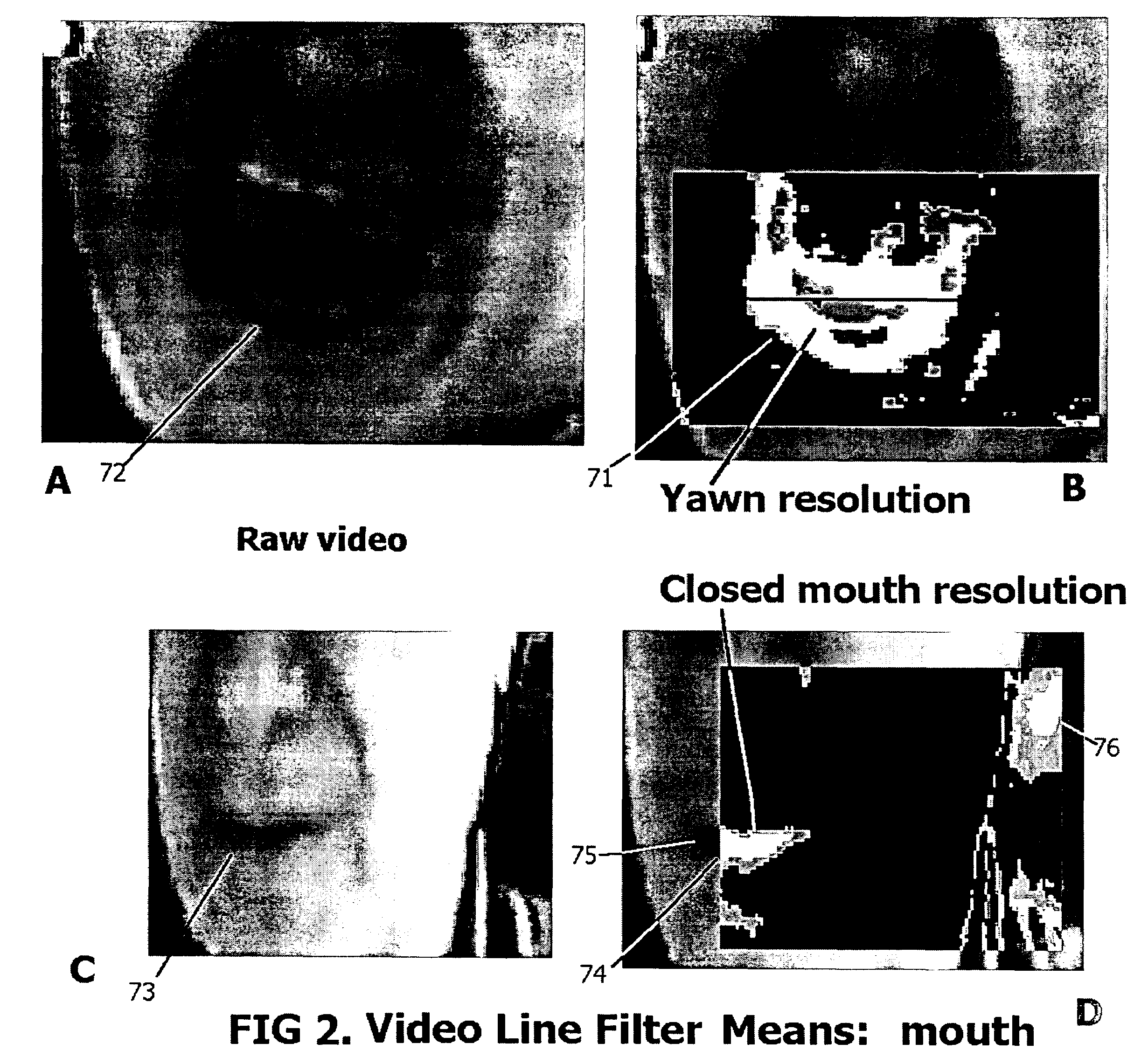

Method and apparatus for detection of drowsiness and quantitative control of biological processes

InactiveUS7336804B2High accuracy of resultsImprove accuracyImage analysisCharacter and pattern recognitionPattern recognitionVideo monitoring

The present invention is directed to a real-time automated video cognizer that functions as a facial video processor for detecting drowsiness in operators of motorized vehicles, including the use of a video cognizer to provide pattern recognition and control signal generation during monitoring of macroscopic or microscopic biological processes. More specifically, the present invention accepts input from a video monitoring system that continuously captures the operator's facial images; employing three sequential means of processing the digitized video information to extract the position and configuration of drowsy-relevant facial features and numerically processes this information to yield a quantitative estimate of drowsiness probability in each epoch of monitoring. The means of the present invention are noninvasive, do not restrict driver movement or performance, provide increased measurement reliability for actual driver behavior, and include the capability of generating or triggering suitable alarms when drowsiness occurs.

Owner:STEFFIN MORRIS

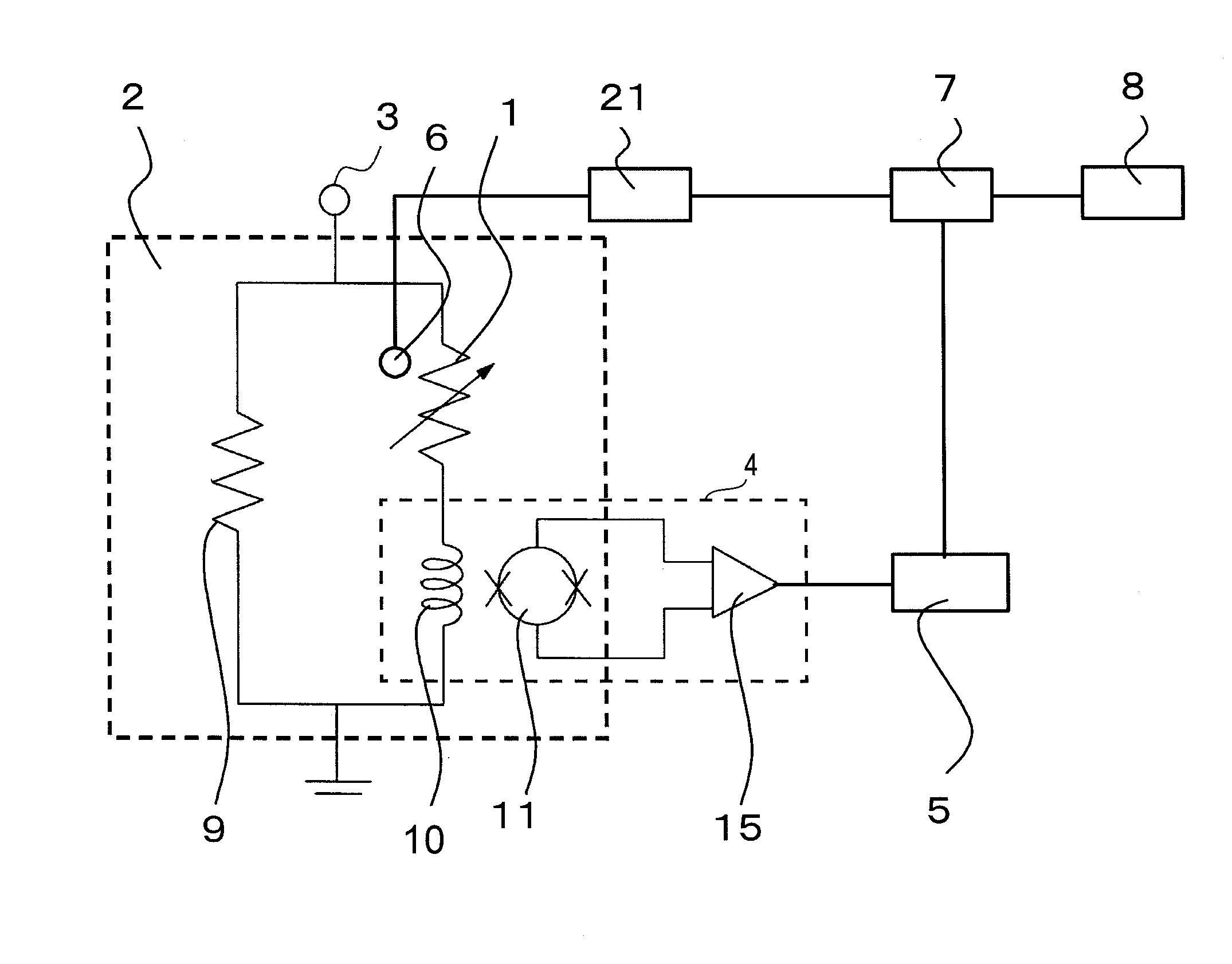

Radiation analyzer and method for analyzing radiation

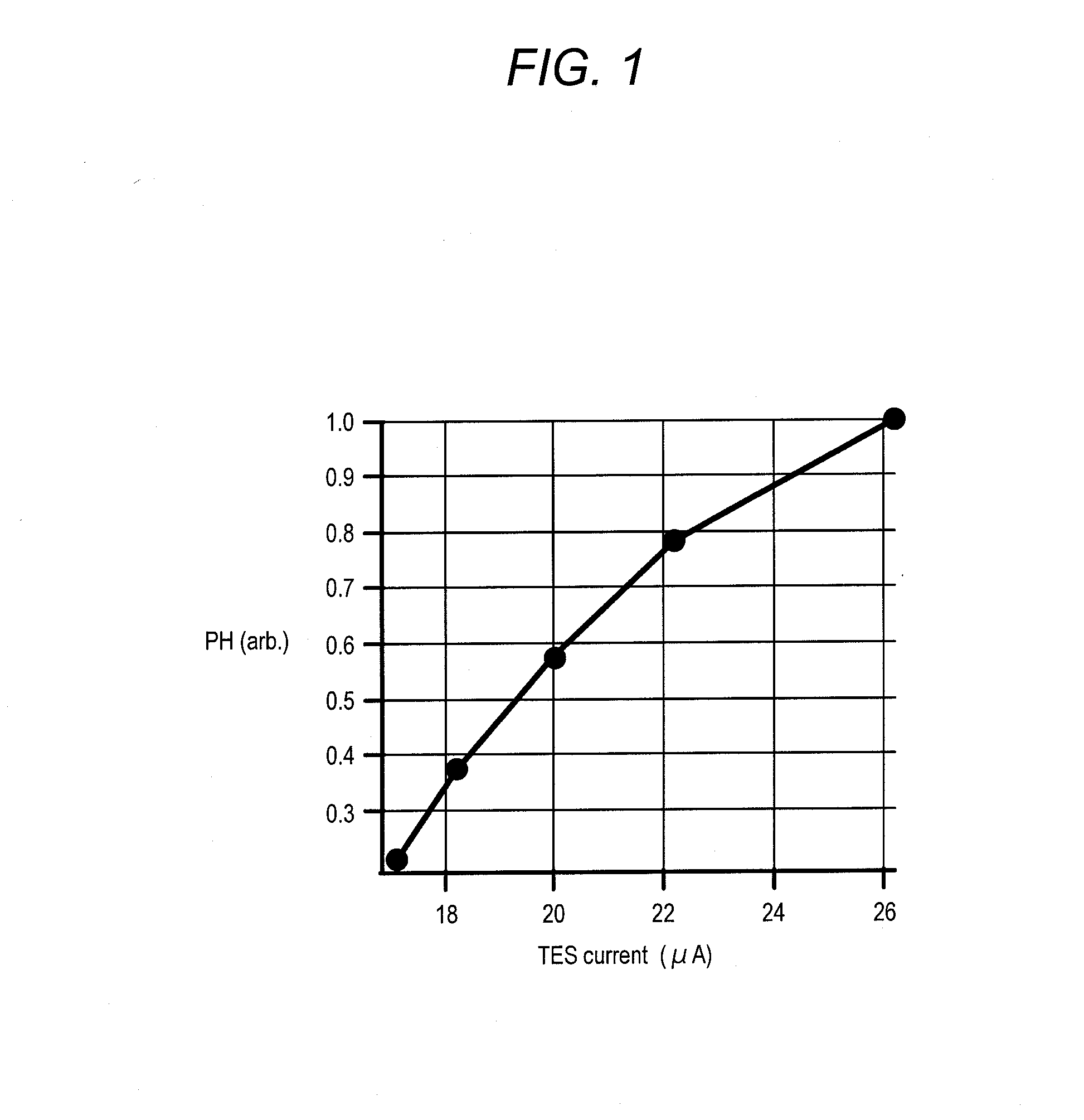

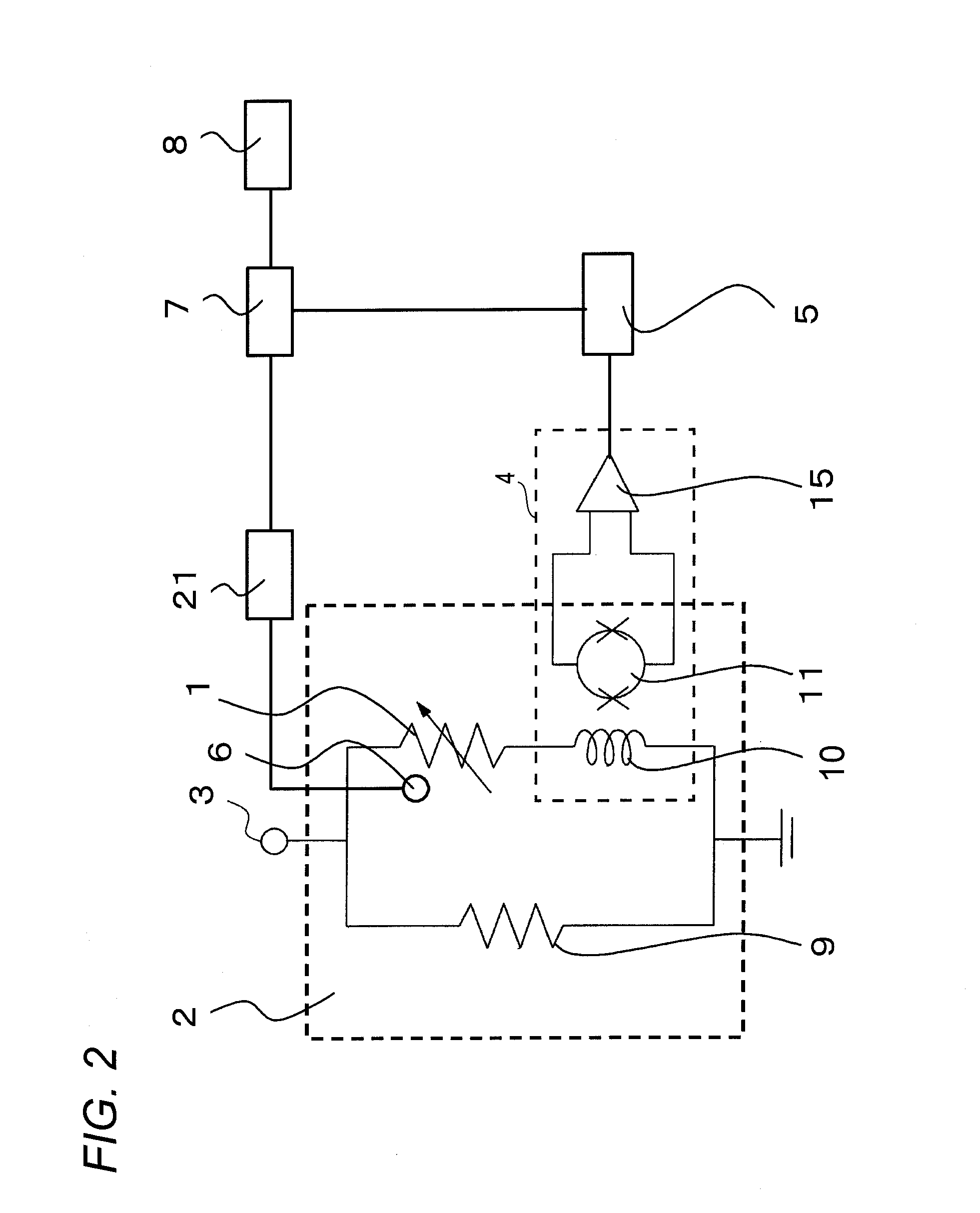

ActiveUS20140048717A1Improved energy resolutionAccurate SensitivityMaterial analysis using wave/particle radiationMaterial analysis by optical meansPower flowTransition edge sensor

A radiation analyzer includes: a transition edge sensor (TES) that detects radiation; a current detection mechanism that detects a current flowing in the TES; a peak analyzing unit that measures a peak value based on the current detected by the current detection mechanism; a first heater that heats the TES to keep a constant temperature; a sensitivity correction operating unit that corrects sensitivity of the TES based on a relation obtained in advance between an output of the first heater and a peak value measured by the peak analyzing unit.

Owner:HITACHI HIGH TECH SCI CORP

Designing Scan Chains With Specific Parameter Sensitivities to Identify Process Defects

InactiveUS20060026472A1Improve availabilityImproves process defect monitoringSemiconductor/solid-state device testing/measurementElectronic circuit testingProbable CaseEngineering

A method is disclosed for designing scan chains in an integrated circuit chip with specific parameter sensitivities to identify fabrication process defects causing test fails and chip yield loss. The composition of scan paths in the integrated circuit chip is biased to allow them to also function as on-product process monitors. The method adds grouping constraints that bias scan chains to have common latch cell usage where possible, and also biases cell routing to constrain scan chain routing to given restricted metal layers for interconnects. The method assembles a list of latch design parameters which are sensitive to process variation or integrity, and formulates a plan for scan chain design which determines the number and the length of scan chains. A model is formulated of scan chain design based upon current state of yield and process integrity, wherein certain latch designs having dominant sensitivities are chosen for specific ones of the scan chains on the chip. The model is provided as input parameters to a global placement and wiring program used to lay out the scan chains. Test data on the chip is then analyzed to determine and isolate systematic yield problems denoted by attributes of a statistically significant failing population of a specific type of scan chain.

Owner:IBM CORP

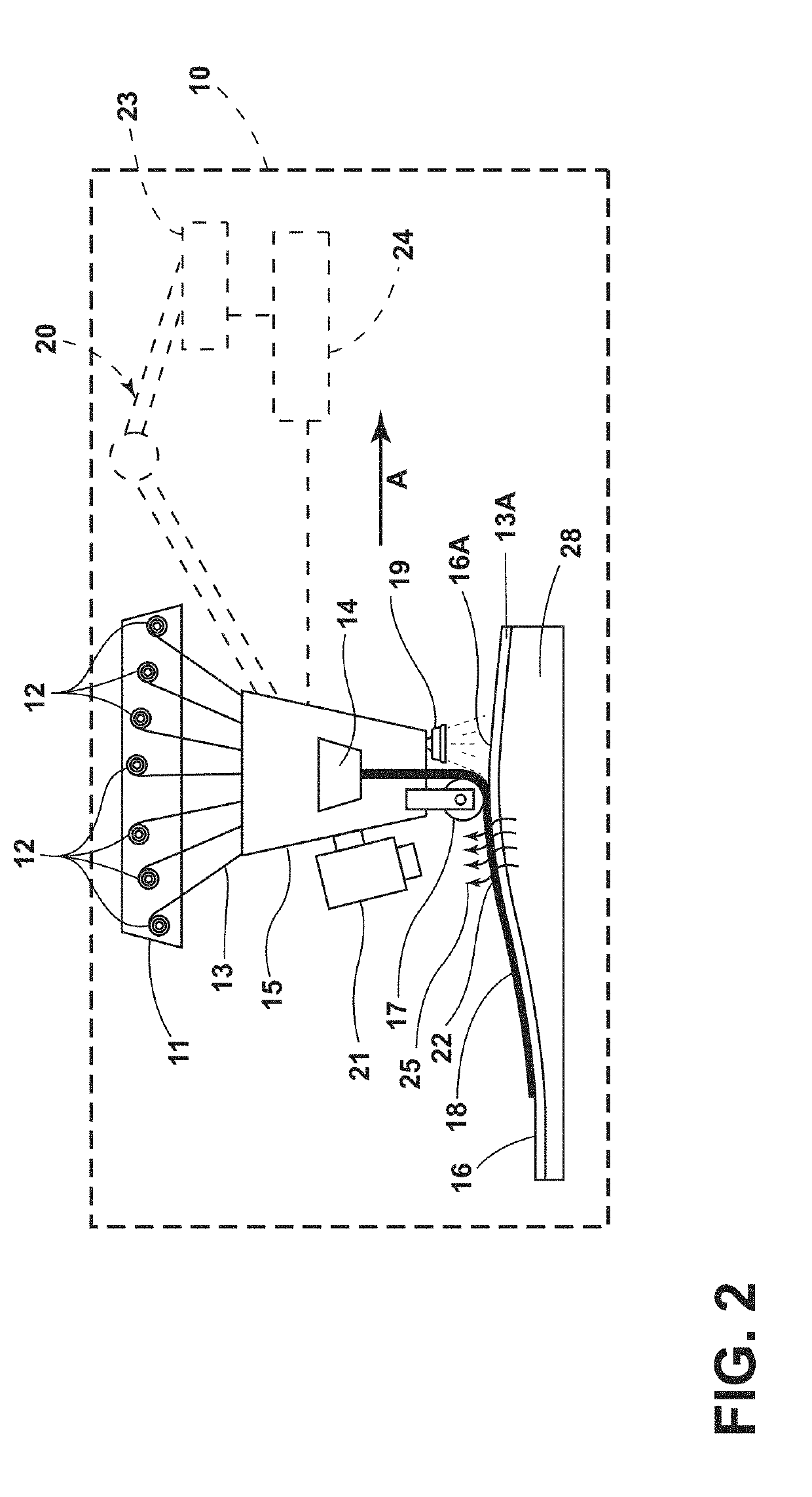

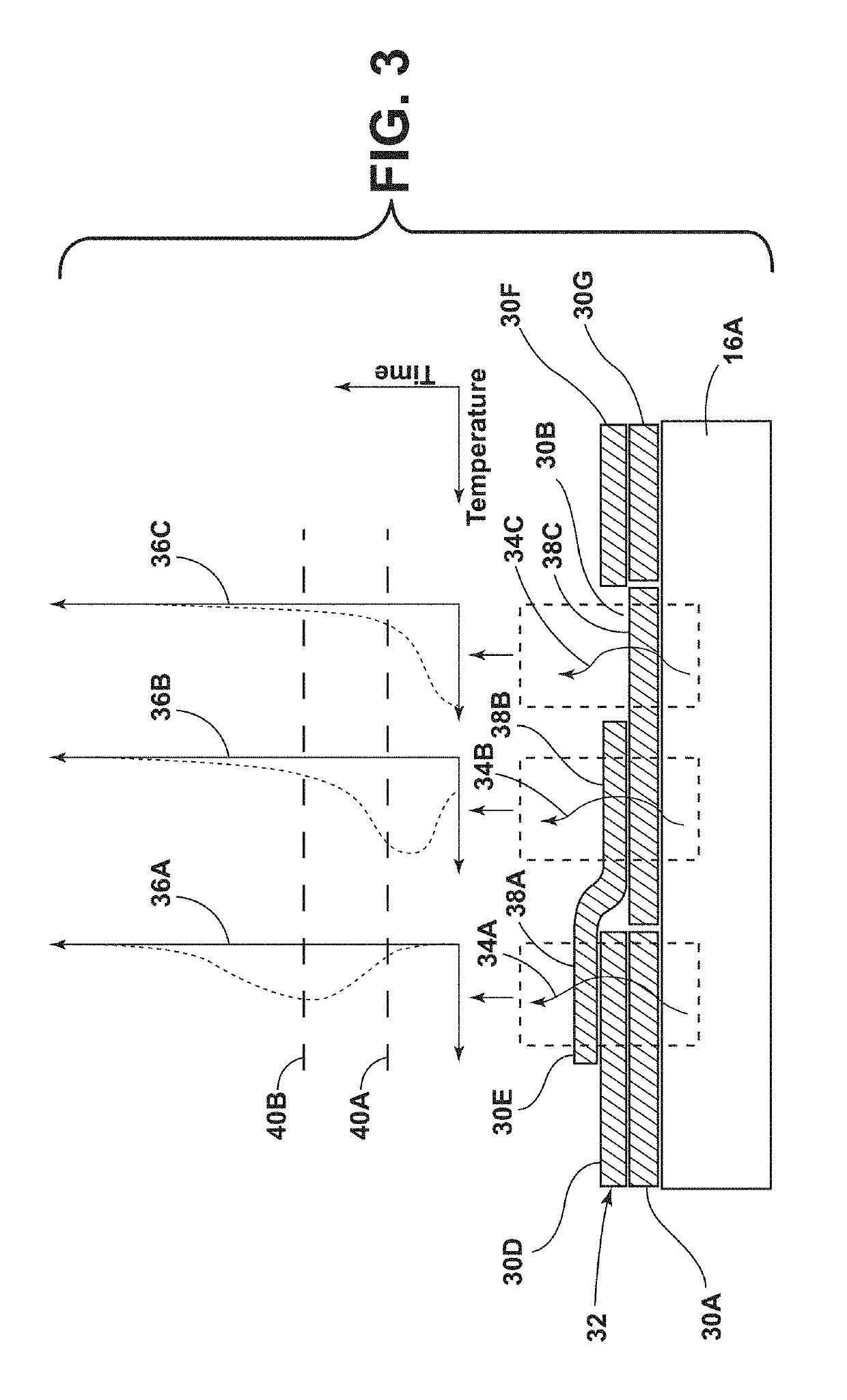

Method and means to analyze thermographic data acquired during automated fiber placement

ActiveUS20190318444A1Easily correlatedImprove the level ofTelevision system detailsImage enhancementFiberTime delays

A method of detecting defects in a composite structure includes applying heat to a surface of a composite structure. Thermographic images or frames captured by a moving camera may be utilized to corm temporally aligned images that include temperature data (pixals) from a plurality of frames, wherein the pixals comprise data captured at a simple (uniform) time delay from the time at which heat was applied. The temporally aligned thermographic data for the surface region may include variations due to differences in thermal transients caused by defects in the composite structure. The variations in the thermographic data may be utilized to detect one or more defects in the composite structure.

Owner:NASA

Generation of names related to organization actions

InactiveUS20060190480A1Easy to monitorEasily correlatedOffice automationResourcesCommunication interfaceData treatment

A system for generating names related to organization actions performed with applications includes a communications interface and a processor. The communications interface receives data sent between an application and a server in response to a user interacting with the application. The processor processes the data to determine an organization action performed with the application. The processor generates a name related to the organization action based on the data.

Owner:ESI SOFTWARE LTD

Breathing movement measurements and apparatus

InactiveUS20030220570A1Easily correlatedReduce inconvenienceBlood flow measurement devicesMedical automated diagnosisMedicineMovement measurement

A method and apparatus for measuring breathing movements and determining breathing patterns, by measuring the simultaneous movement of a plurality of points of a human subject, such that a breathing pattern may be determined based on data obtained in a single acquisition. The method provides a symmetry breathing pattern parameter.

Owner:REMO EHF

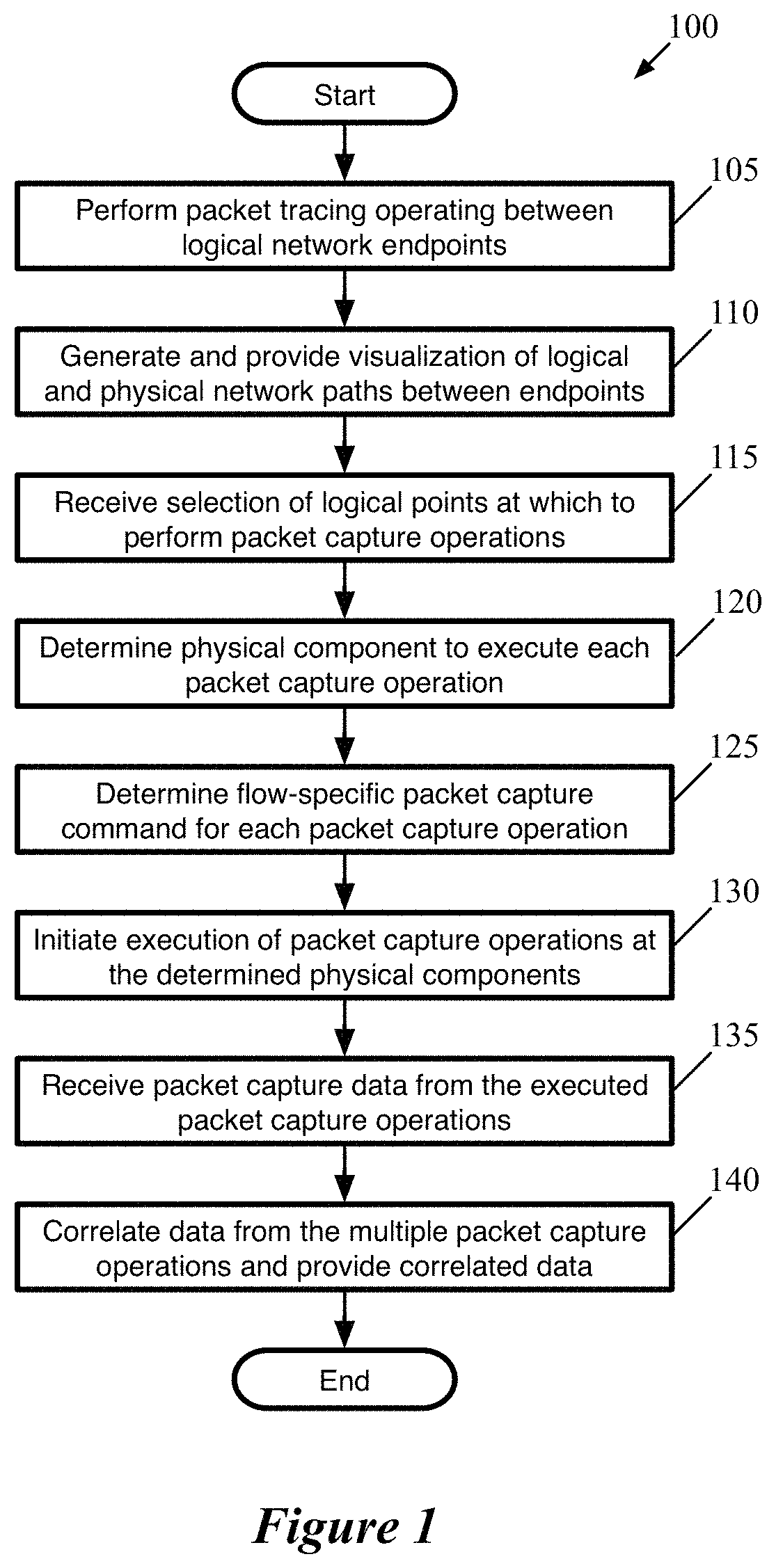

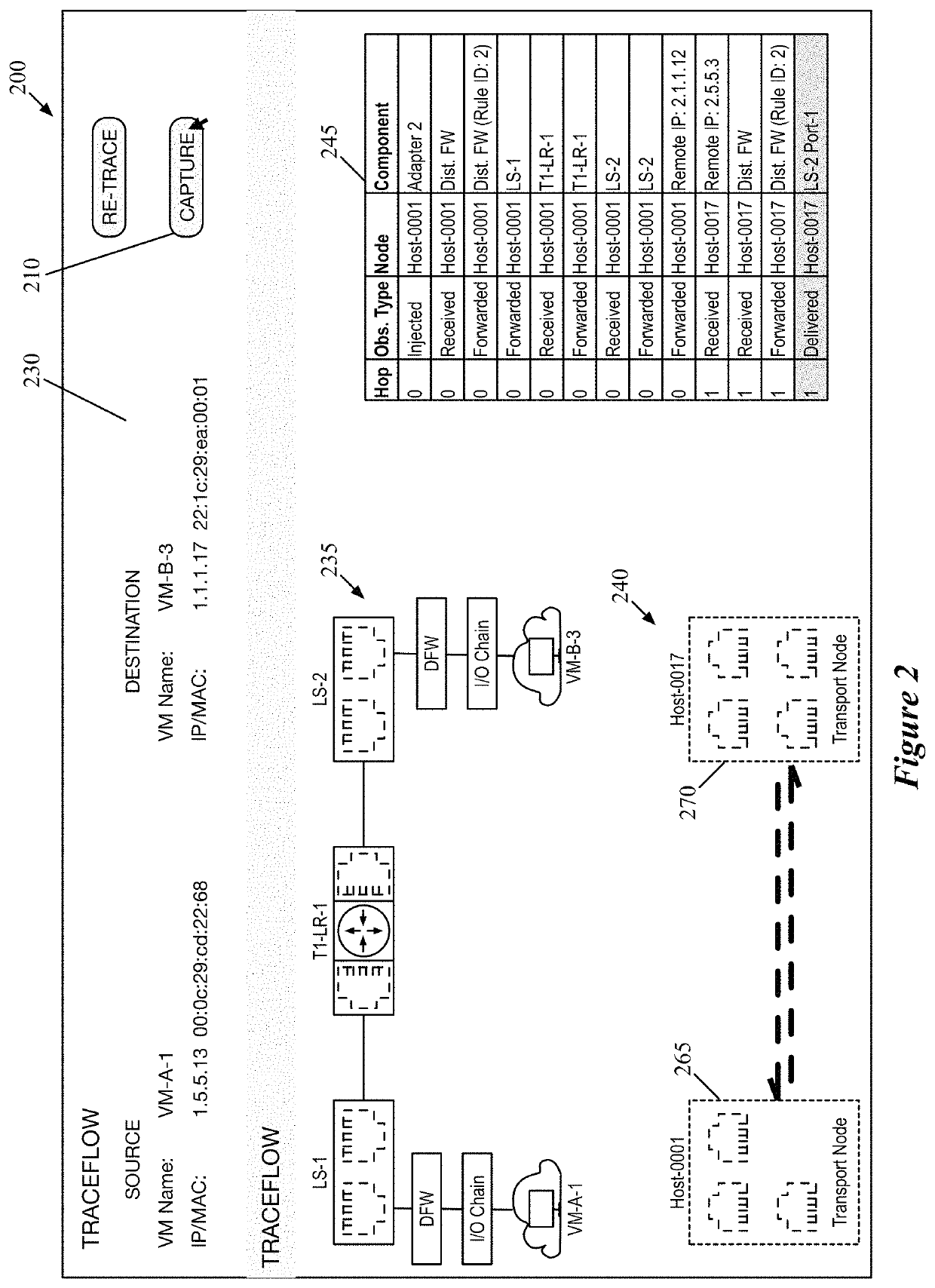

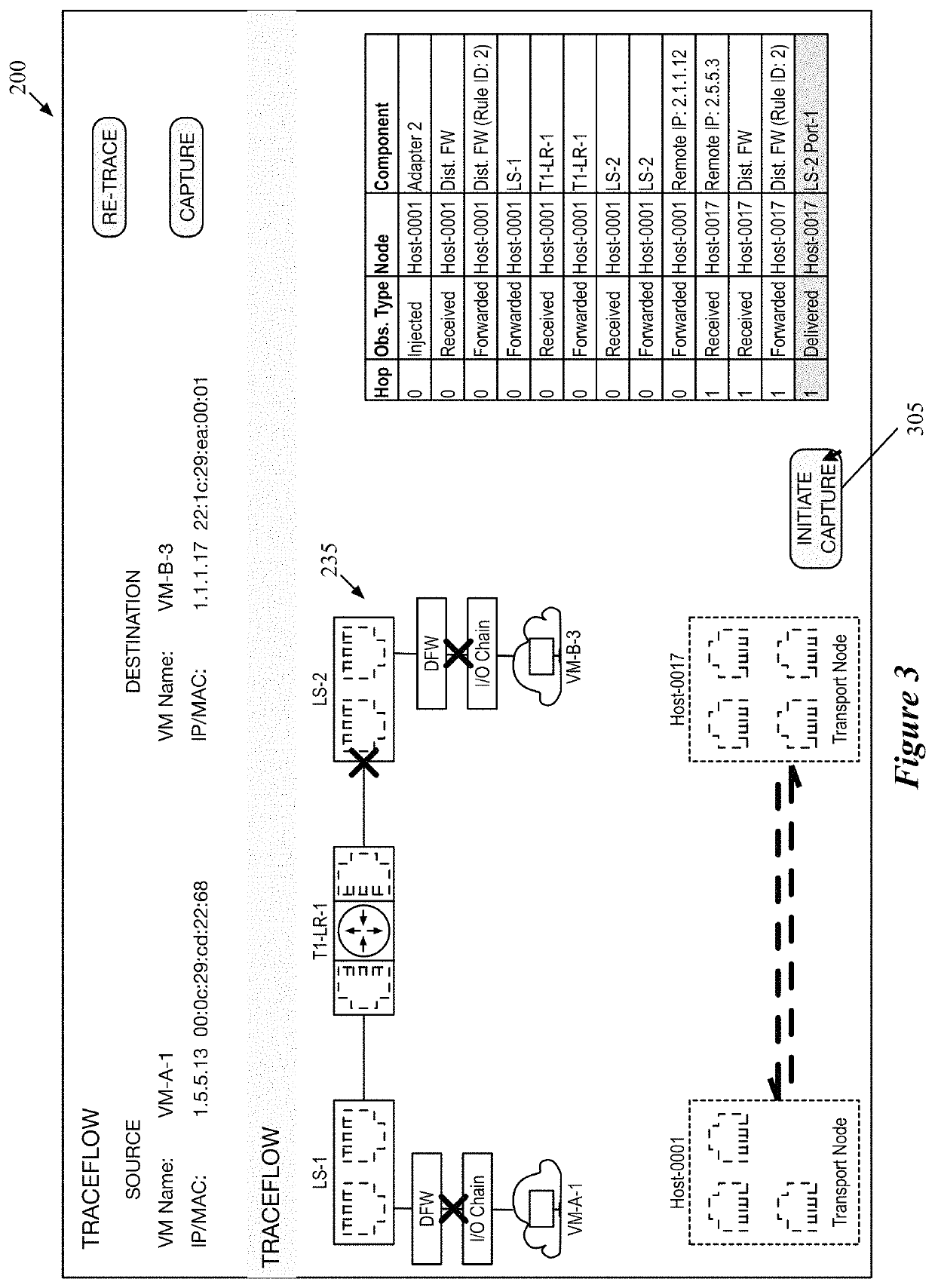

Using packet tracing tool to automatically execute packet capture operations

ActiveUS10608887B2Limits numberCorrelation between the various packet captures easierData switching networksData packData stream

Some embodiments provide a method that performs a packet tracing operation for a particular data flow between endpoints of a logical network to generate a representation of logical network components along a path between the endpoints. In response to a selection of at least two of the logical network components, the method automatically generates separate packet capture operations for execution by physical components that implement each of the selected logical network components. The method uses packet header information to correlate packet data from the separate packet capture operations.

Owner:NICIRA

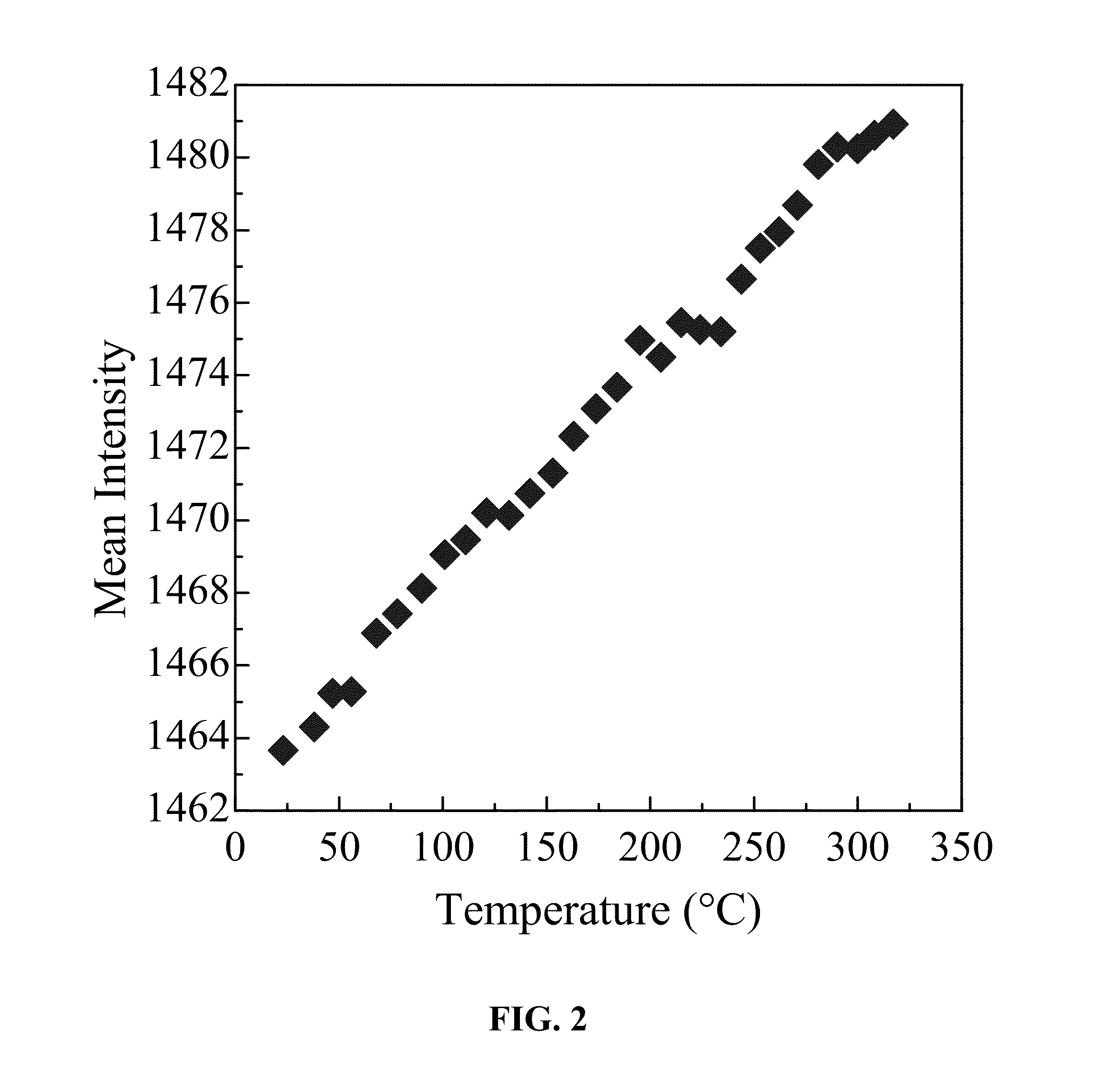

High spatial resolution non-contact temperature measurement

InactiveUS20130340127A1Easy to integrateEasily correlatedElectric discharge tubesThermometers using weight distributionImage resolutionTemperature measurement

Advantageous systems, methods, and computer-readable media for temperature measurement of a sample, using new temperature measurement and mapping techniques, are provided. The technique employs a temperature sensitive electron signal in a scanning electron microscope (SEM) and provides both high spatial resolution and non-contact temperature measurement capabilities no existing technique can adequately combine. This technique thus adds a new capability—temperature measurement and mapping—to the collection of existing SEM capabilities.

Owner:RENESSELAER POLYTECHNIC INST

Streaming method and system for processing network metadata

ActiveUS9860154B2Problem can be addressedEasily correlatedPlatform integrity maintainanceData switching networksTemplate basedImproved method

An improved method and system for processing network metadata is described. Network metadata may be processed by dynamically instantiated executable software modules which make policy-based decisions about the character of the network metadata and about presentation of the network metadata to consumers of the information carried by the network metadata. The network metadata may be type classified and each subclass within a type may be mapped to a definition by a unique fingerprint value. The fingerprint value may be used for matching the network metadata subclasses against relevant policies and transformation rules. For template-based network metadata such as NetFlow v9, an embodiment of the invention can constantly monitor network traffic for unknown templates, capture template definitions, and informs administrators about templates for which custom policies and conversion rules do not exist. Conversion modules can efficiently convert selected types and / or subclasses of network metadata into alternative metadata formats.

Owner:NETFLOW LOGIC

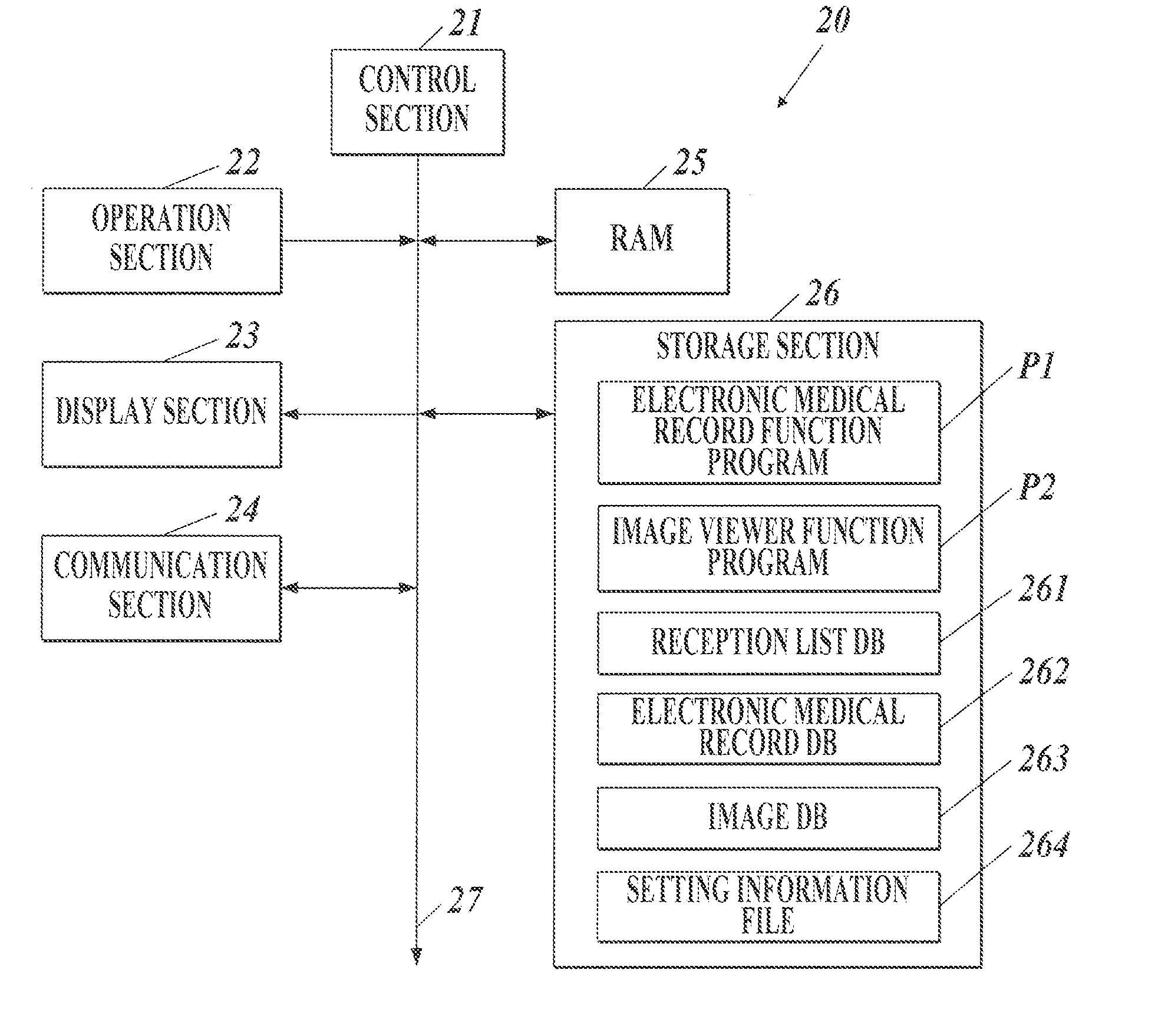

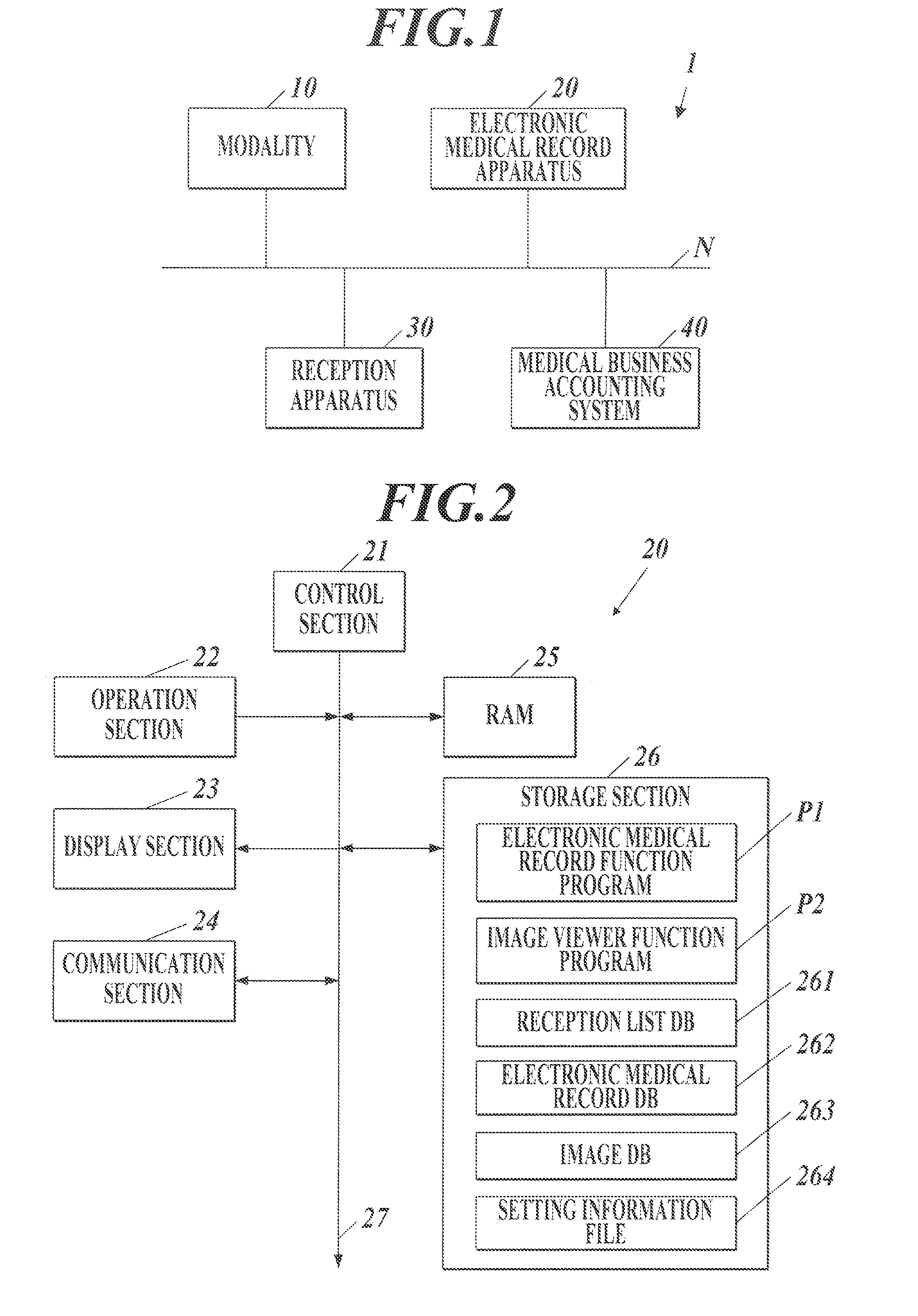

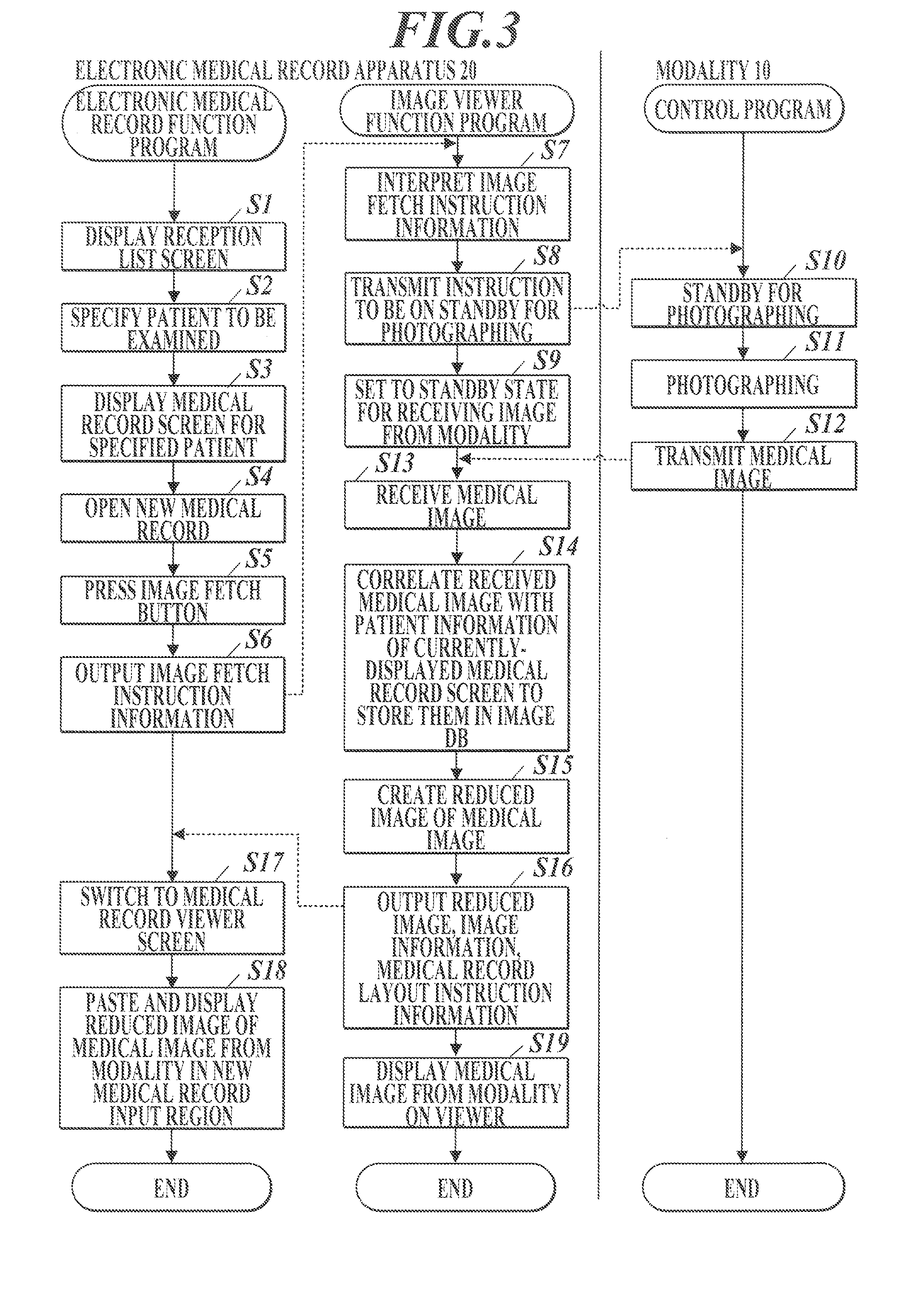

Electronic medical record apparatus and recording medium

ActiveUS20140172458A1Easily correlatedImprove efficiencyData processing applicationsMedical imagesMedical recordElectronic medical record

An electronic medical record apparatus is connected to an image generation apparatus which performs photographing to generate a medical image. The electronic medical record apparatus includes: a storage member; a patient specifying member to receive an input of specifying a patient to be examined; a display member to display a medical record screen for displaying electronic medical record information pertaining to the specified patient; a fetch instruction member, provided on the medical record screen, to receive an instruction to fetch the generated medical image; a control member to cause the storage member to store the medical image transmitted from the image generation apparatus so that the medical image is correlated with patient information of the patient whose medical record screen is currently displayed in the display member, when the fetch instruction member receives the instruction to fetch the medical image.

Owner:KONICA MINOLTA INC

Three-dimensional image display apparatus and method

ActiveUS7746377B2Easily correlatedSimplify workImage enhancementImage analysisObject basedComputer graphics (images)

A three-dimensional image display apparatus is provided that can integrate and visualize 3D measurement data obtained from a stereo image with an image of a measuring object to which stereoscopic texture is applied. The apparatus includes: an orientation section for finding relationship as to corresponding points in a stereo image of a measuring object; a three-dimensional coordinate data section for obtaining three-dimensional coordinate data on the corresponding points of the measuring object; a model forming section for forming a model of the measuring object based on the three-dimensional coordinate data on the corresponding points; an image correlating section for correlating the stereo image of the measuring object stored in the stereo image data storage section and the model formed by the model forming section; and a model display section for displaying an image of the measuring object to which stereoscopic texture is applied.

Owner:KK TOPCON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com