Patents

Literature

33results about How to "Efficient blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bridge construction equipment

InactiveCN107336352AAutomatic control and automatic stirring workEfficient blankingDischarging apparatusCement mixing apparatusArchitectural engineeringFuselage

The invention discloses a bridge construction equipment, which comprises a fuselage, feet fixed on the left and right sides of the bottom of the fuselage, and a feeding part that is rotatably installed on the top of the fuselage. The first cavity in the first cavity is provided with a second cavity in the fuselage on the right side of the first cavity, and a motor is fixed in the fuselage between the second cavity and the first cavity, and the tail end on the left side of the motor cooperates with The first cone runner extending into the first cavity is connected, the first cavity on the left top of the first cone runner is meshed with the second cone runner, and the top surface of the second cone runner is fixed with a The rotating shaft is extended upwards, and the extended tail end of the top of the rotating shaft is fixedly connected with the bottom of the feeding part; the invention has a simple structure, is small and light, can realize automatic concrete mixing, and improves construction efficiency.

Owner:张迪超

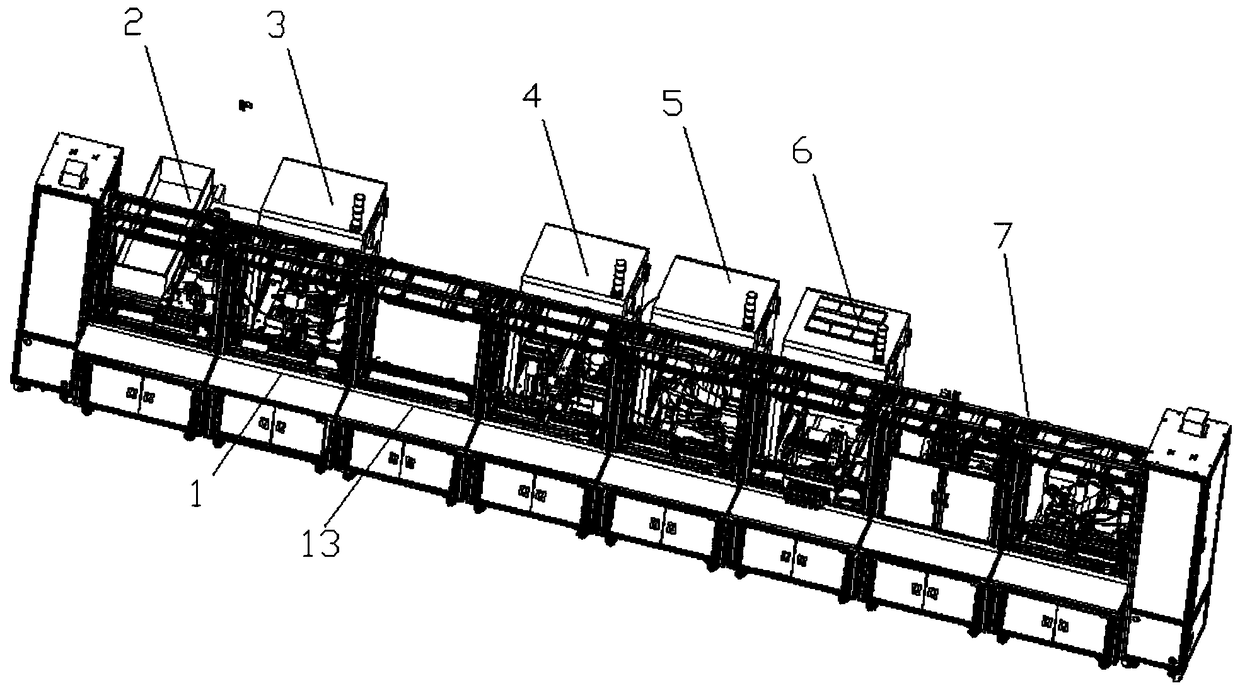

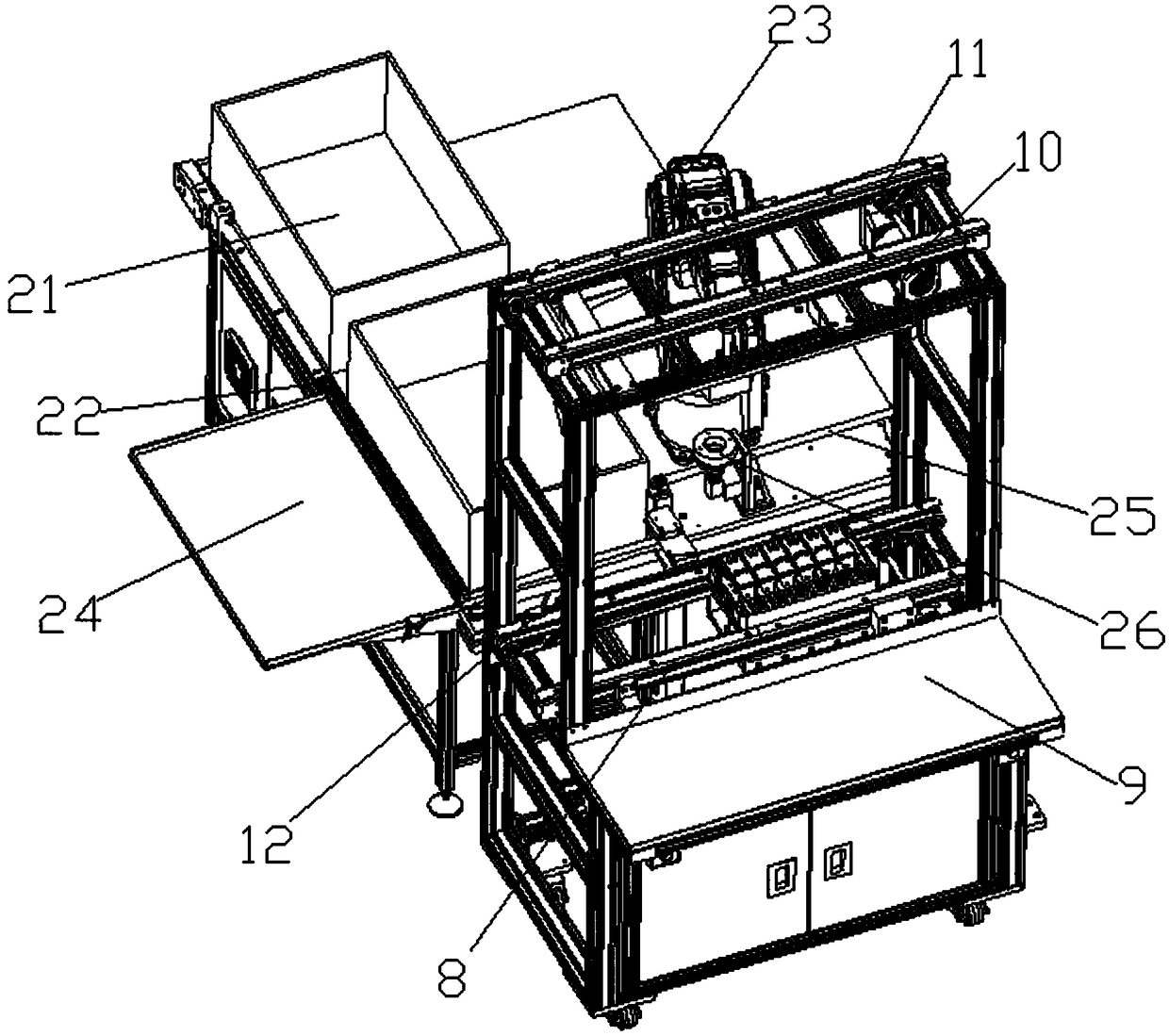

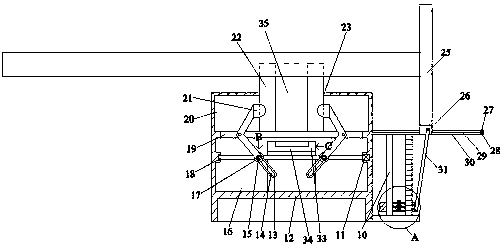

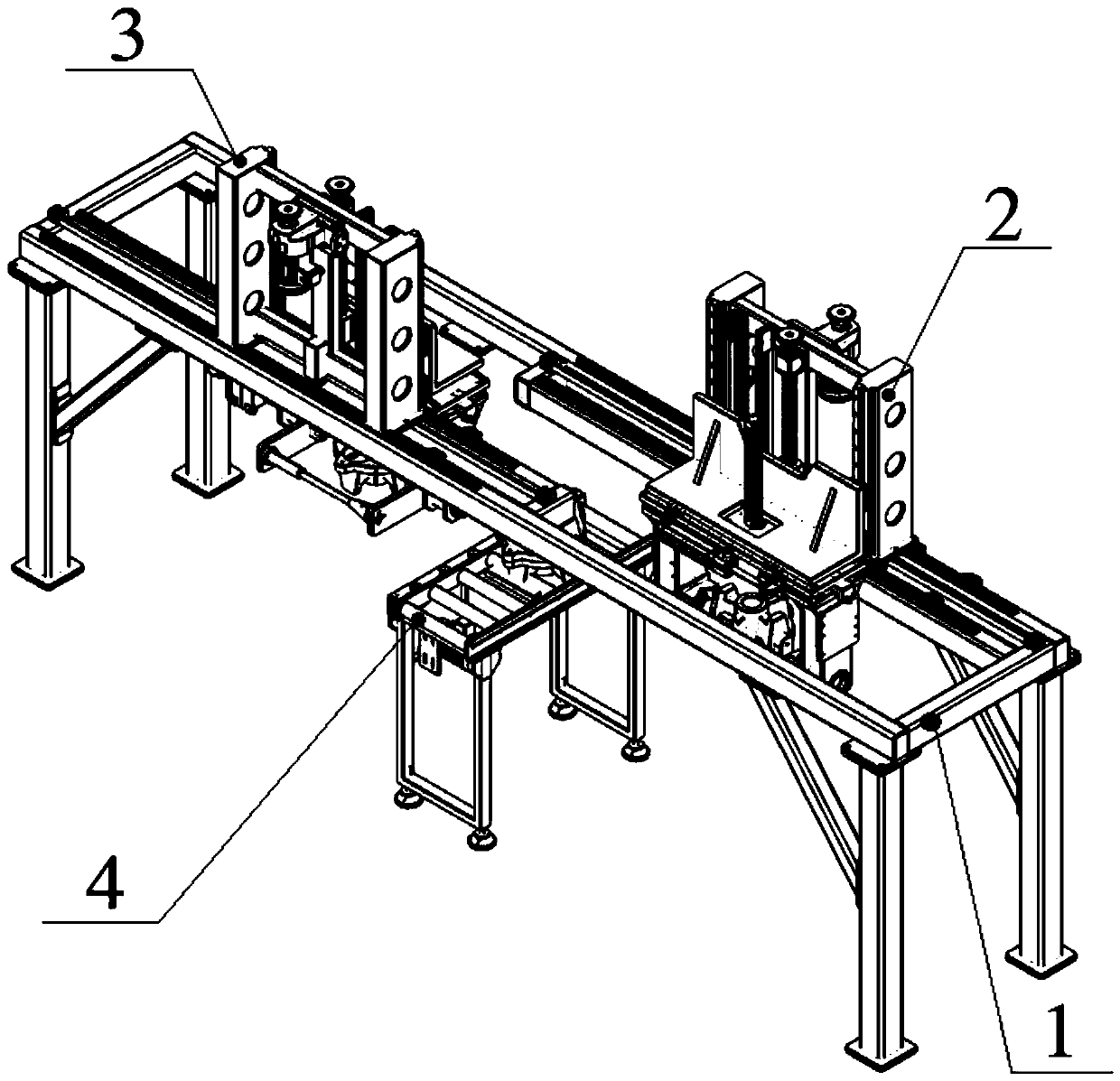

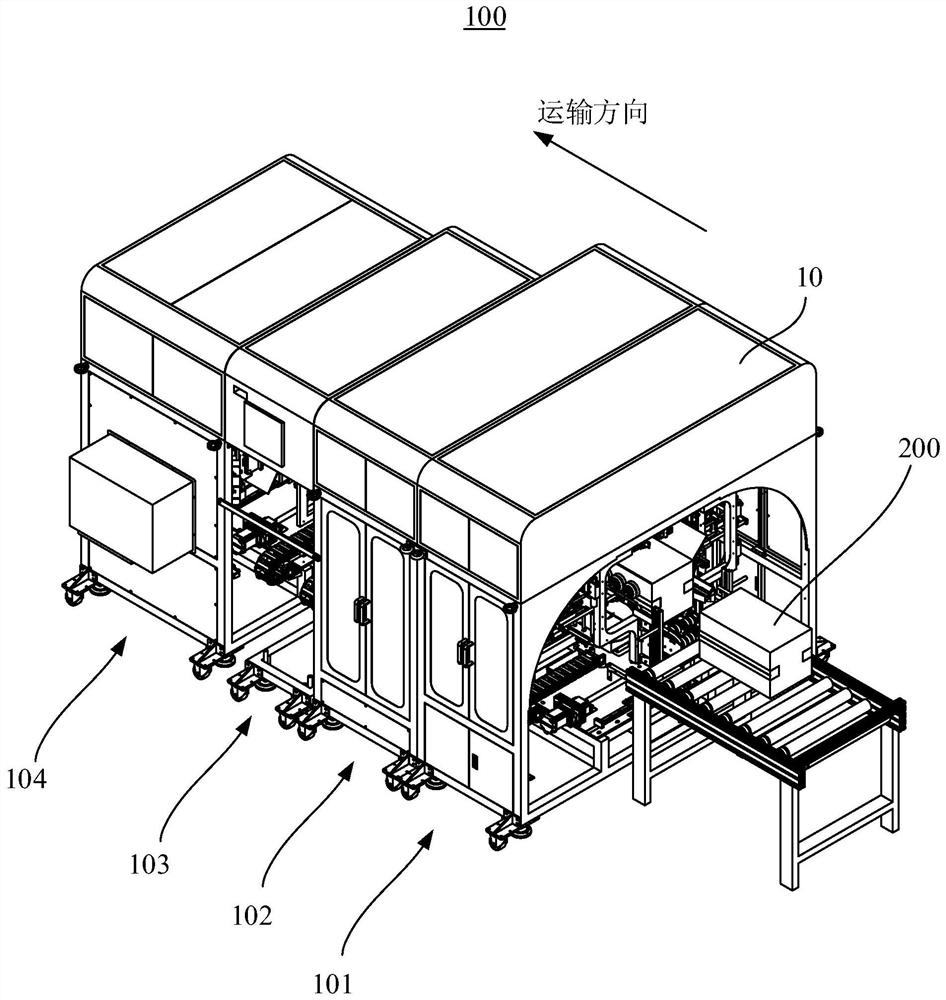

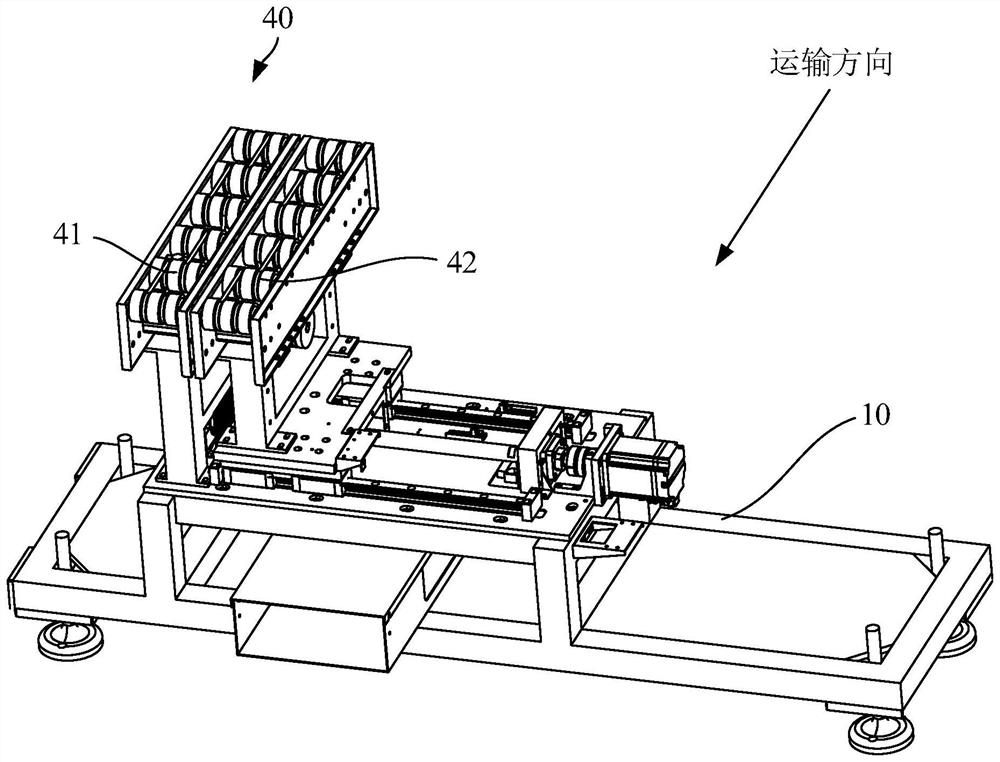

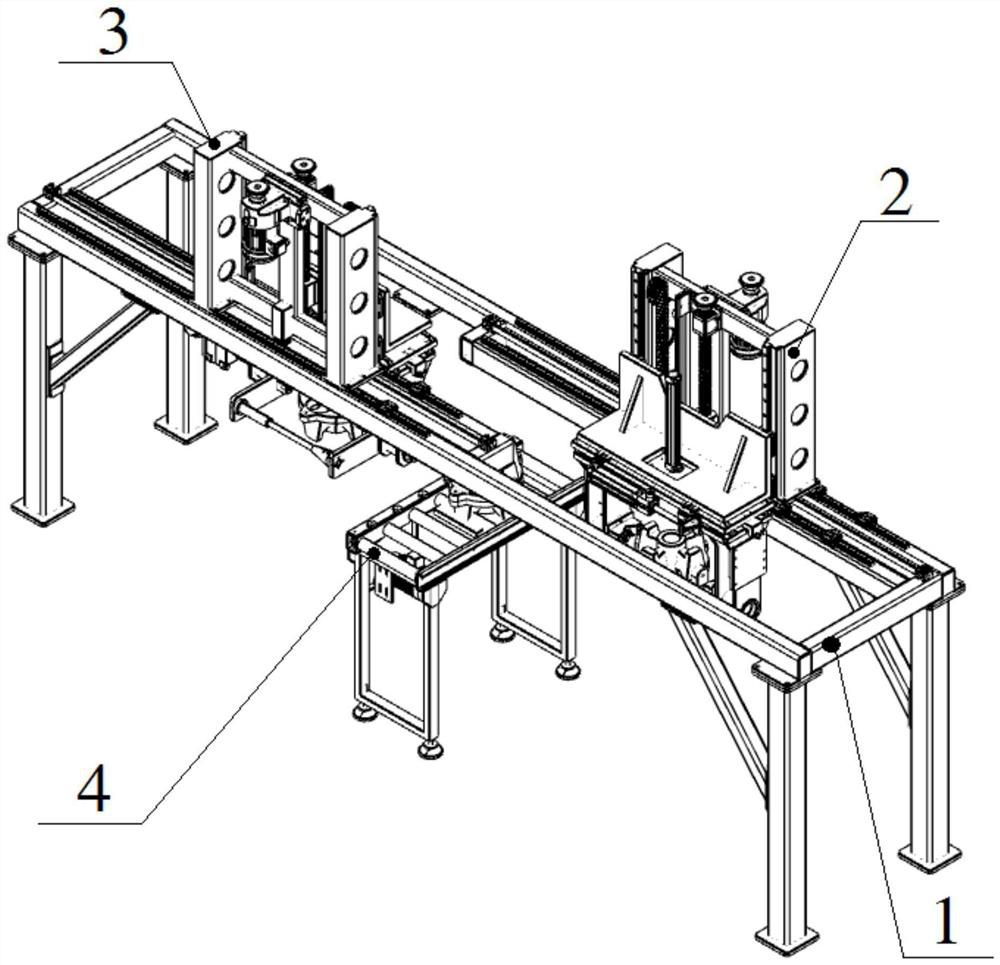

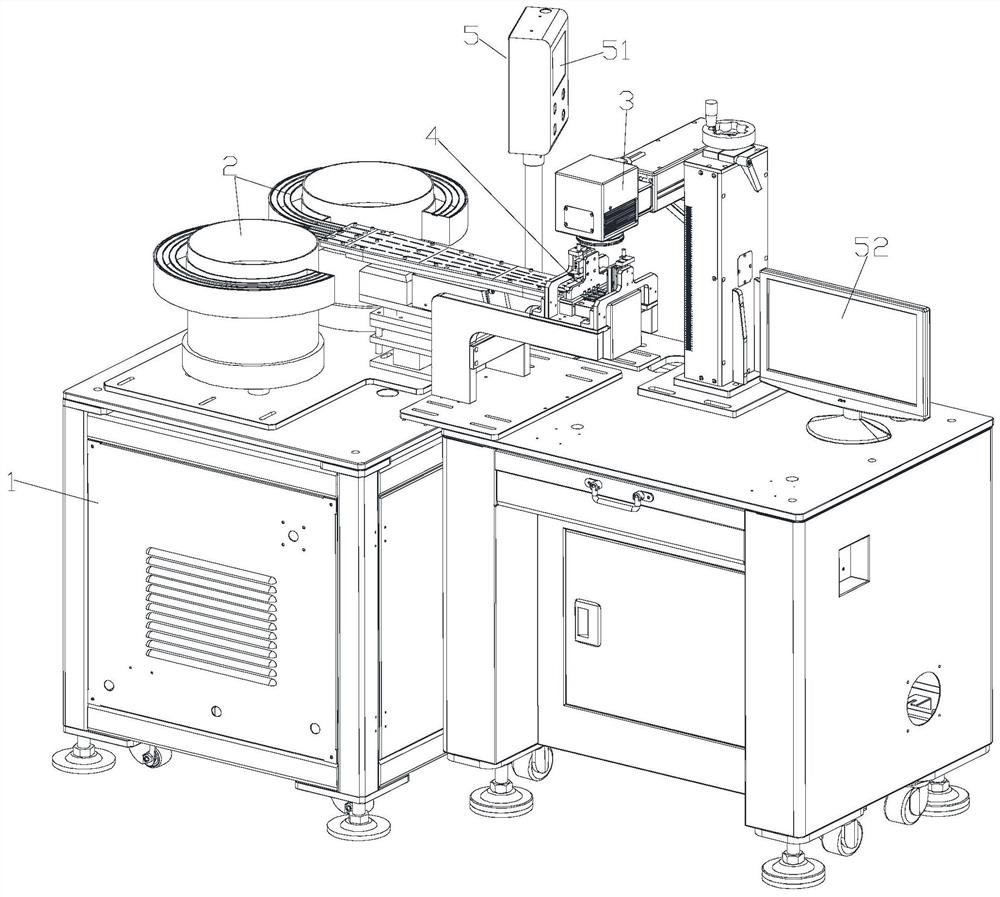

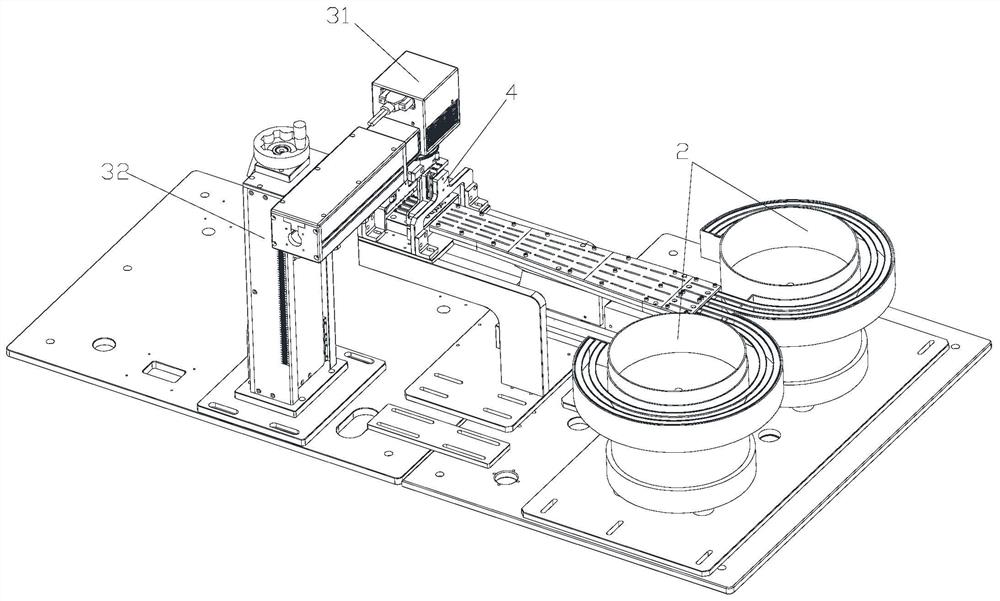

Collector assembly packaging whole line

PendingCN108820754AGood materialImprove assembly efficiencyControl devices for conveyorsDe-stacking articlesManipulatorEngineering

The invention discloses a collector assembly packaging whole line which comprises a shell automatic feeding mechanism, a PCB storing mechanism, an automatic screw locking mechanism, an automatic uppercover closing mechanism, a function testing mechanism 6 used for detecting whether a collector is qualified or not, and a labeling mechanism, wherein the automatic shell feeding mechanism, the PCB storing mechanism, the automatic screw locking mechanism and the automatic upper cover closing mechanism are sequentially arranged. The PCB storing mechanism comprises a PCB dividing disc feeding mechanism and a PCB four-axis manipulator arranged on one side of the PCB dividing disc feeding mechanism and used for grabbing and storing PCBs, and the PCB dividing disc feeding mechanism comprises PCB dividing discs stored in a stacked mode and used for storing the PCBs, a PCB dividing disc support used for storing the PCB dividing discs, and a PCB flowing support used for moving the dividing disc onthe bottommost layer to one side of the PCB four-axis manipulator. A PCB pushing air cylinder used for pushing the dividing disc on the upper layer is arranged on one side of the PCB dividing disc support. The PCBs are efficiently fed, and the assembling efficiency is improved accordingly.

Owner:苏州德尔富自动化科技有限公司

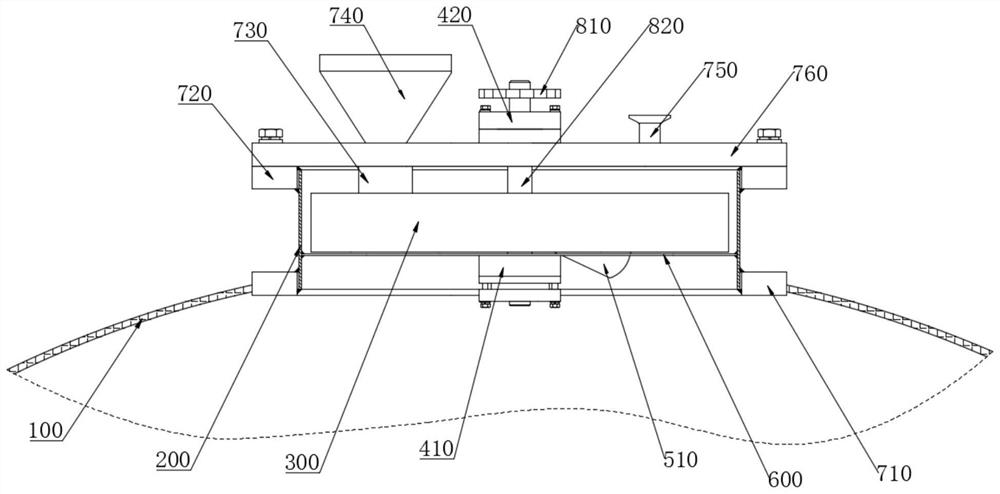

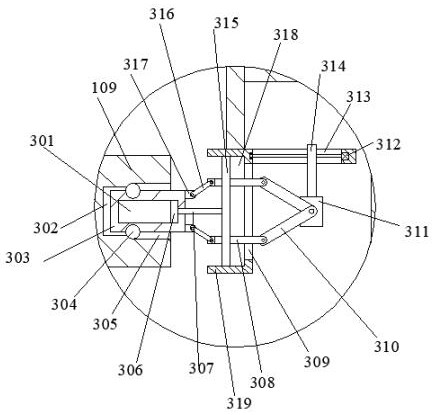

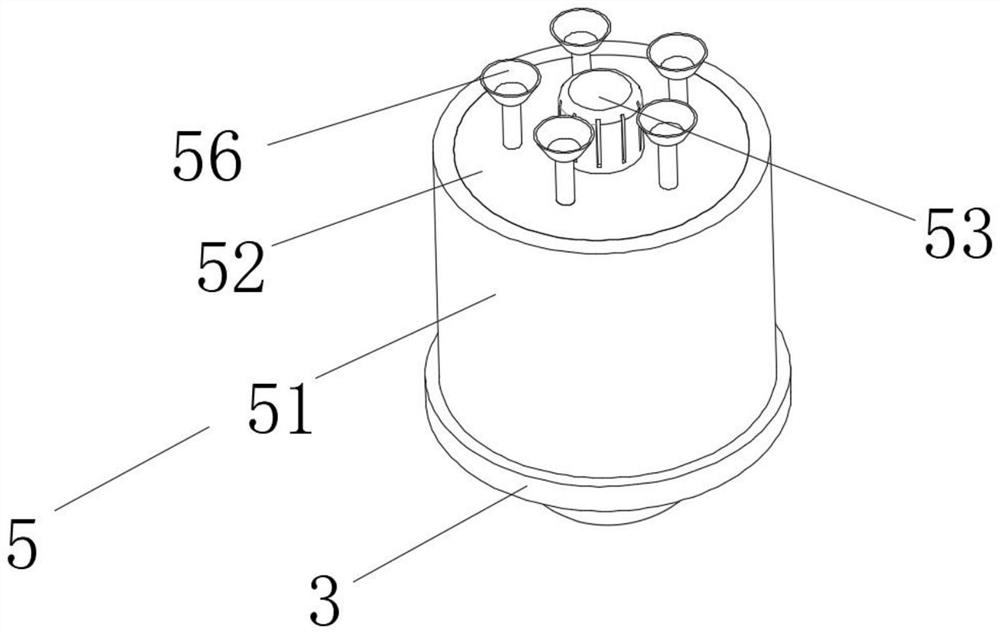

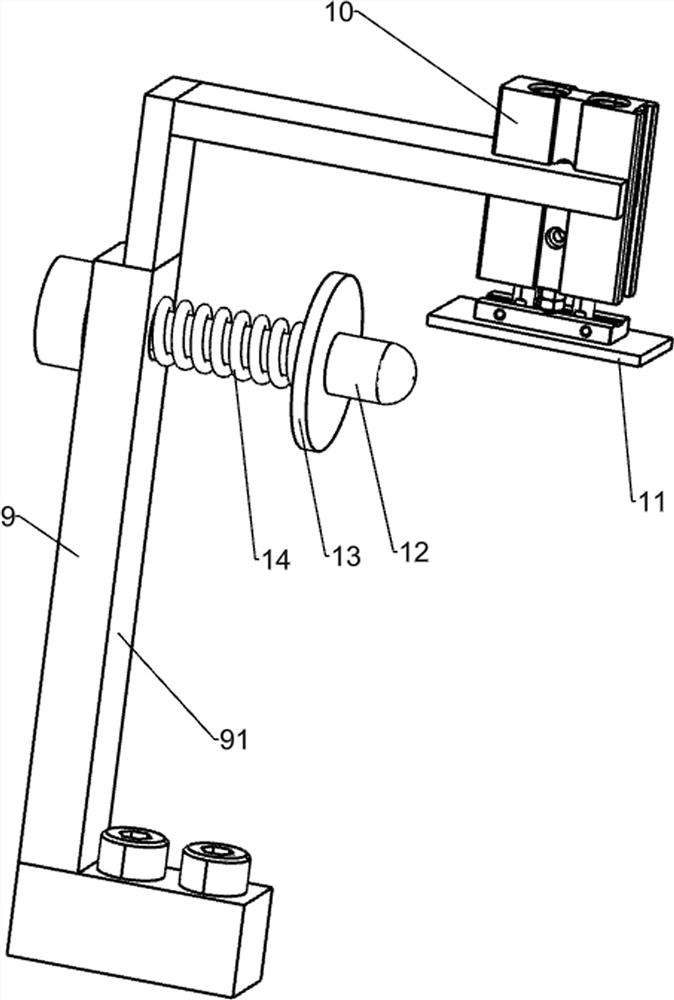

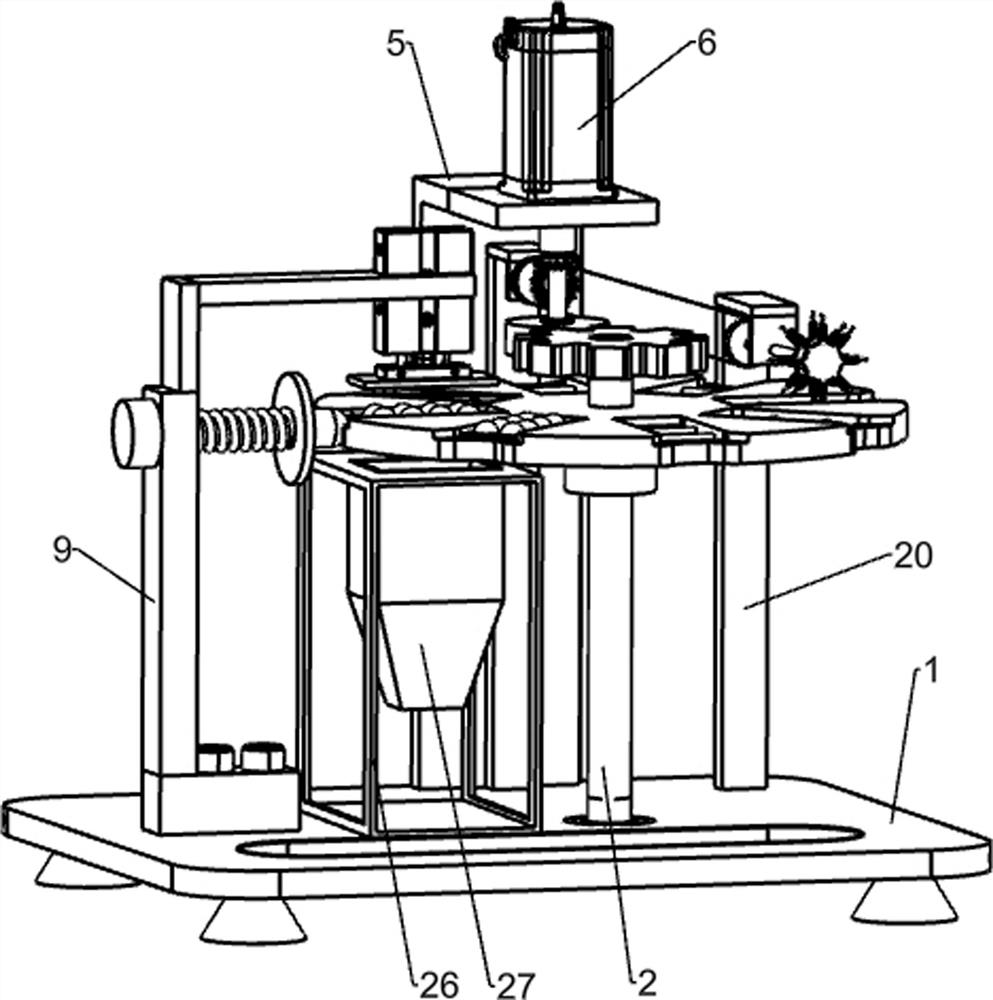

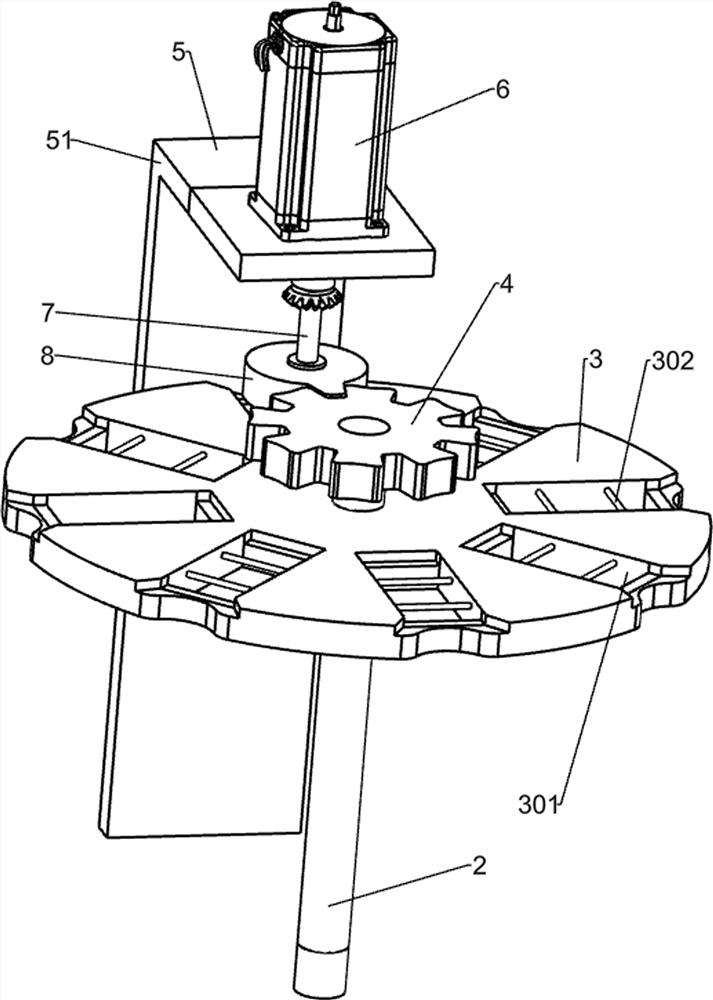

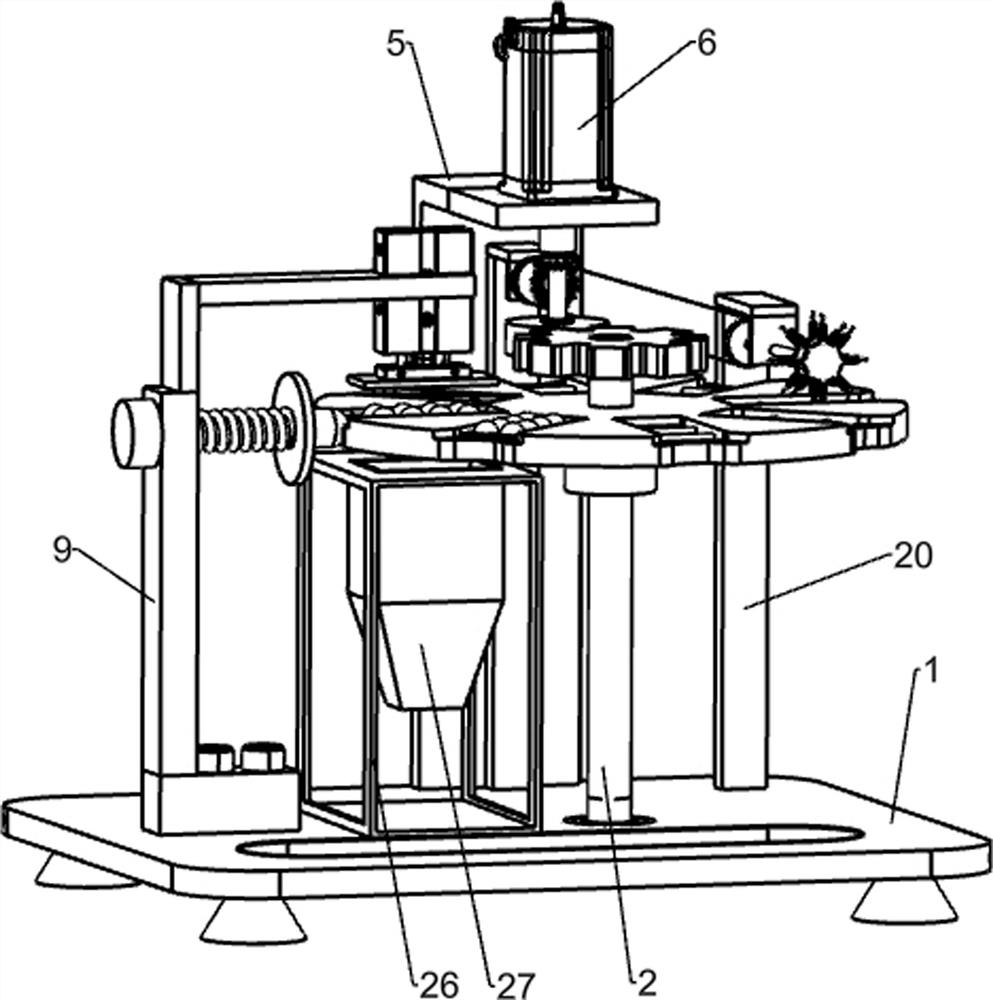

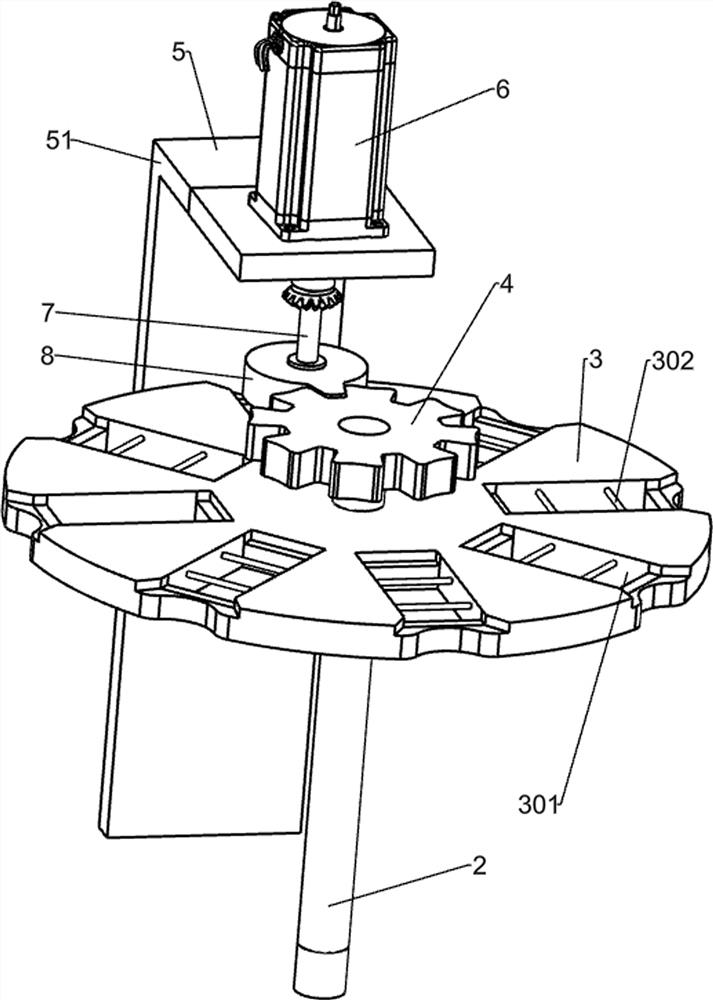

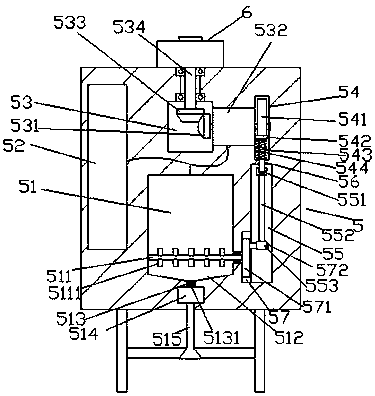

Novel vertical shaft type rotary blanking mode and blanking device

PendingCN114408617AAvoid shear damageIntegrity guaranteedLoading/unloadingControl engineeringMechanical engineering

The invention discloses a novel vertical shaft type rotary discharging mode and a discharging device.The discharging device comprises a discharging assembly used for receiving materials and an intermittent transmission assembly used for providing intermittent rotation power input for the discharging assembly. The discharging assembly is driven by the intermittent transmission assembly to intermittently rotate to collect materials, discharging is carried out at the position of the limiting opening through the automatic opening and closing assembly, continuous discharging can be achieved, and the problem that the materials with large viscosity are accumulated and blocked in the discharging device can be effectively solved through the vertical discharging mode; the discharging device is suitable for most kinds of solid materials in traditional Chinese medicine, food and health care product industries, quantitative, efficient and stable discharging is guaranteed, in addition, the vertical discharging mode facilitates internal cleaning of the discharging device, shearing damage to the materials in the discharging process of a traditional rotary discharging valve can be avoided, the integrity of the materials is indirectly guaranteed, and the discharging efficiency of the discharging device is improved. And the material benefit is improved.

Owner:SHANGHAI UNIWIN PHARMA MACHINERY

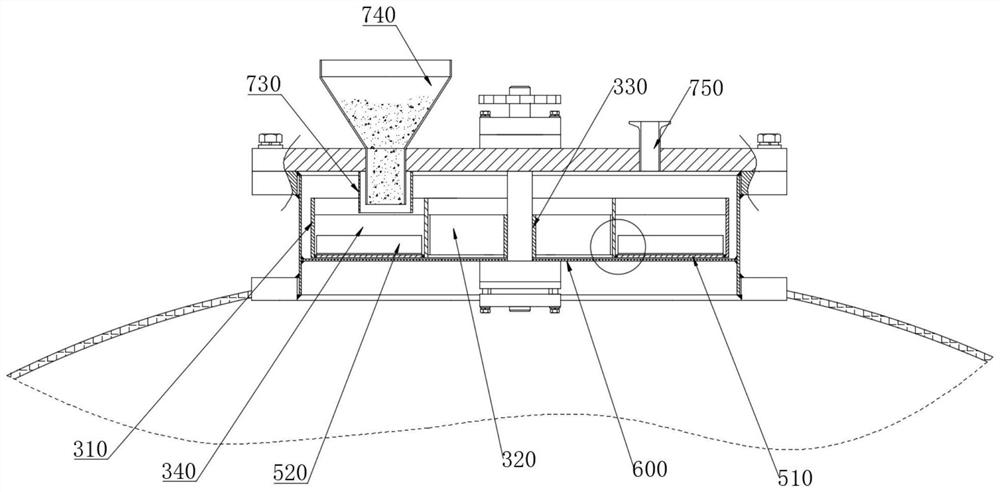

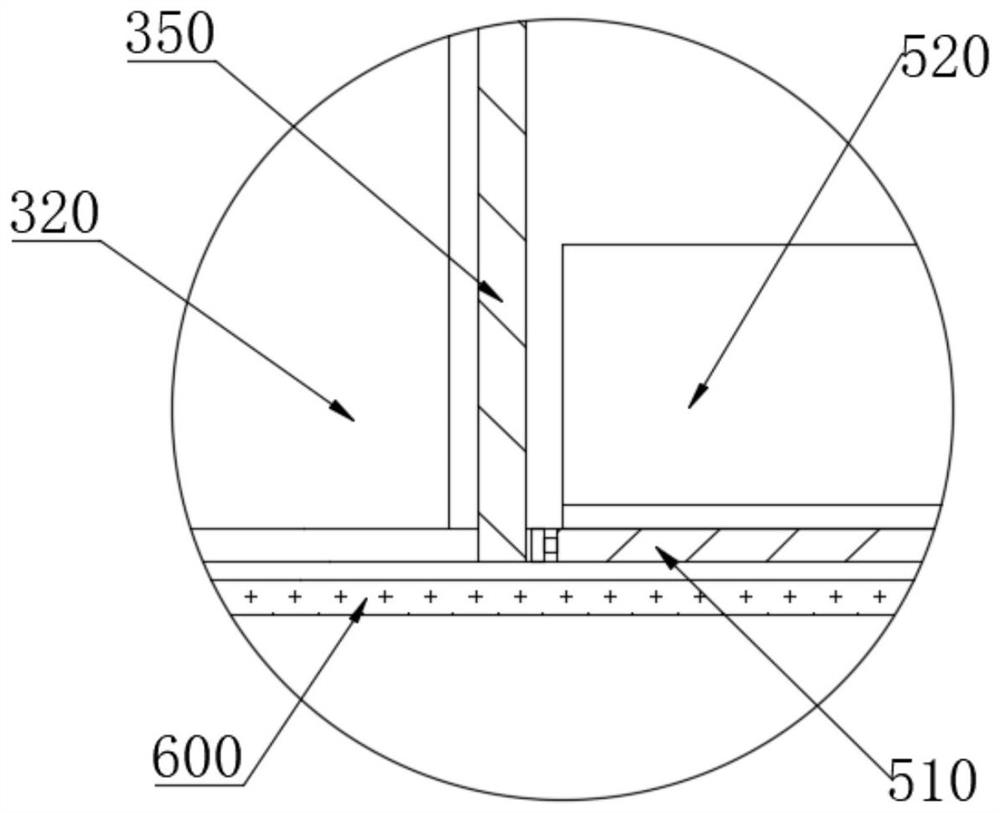

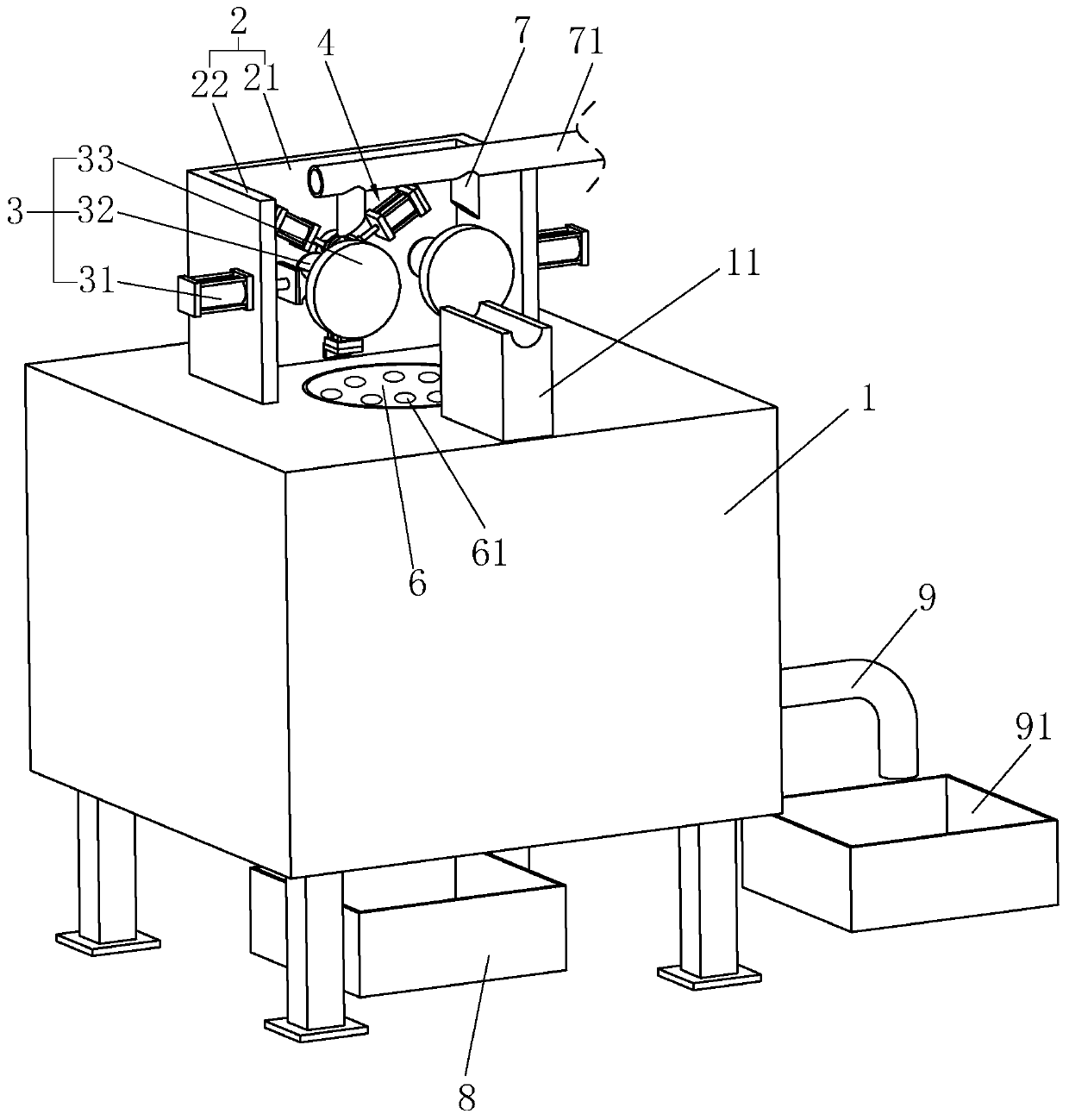

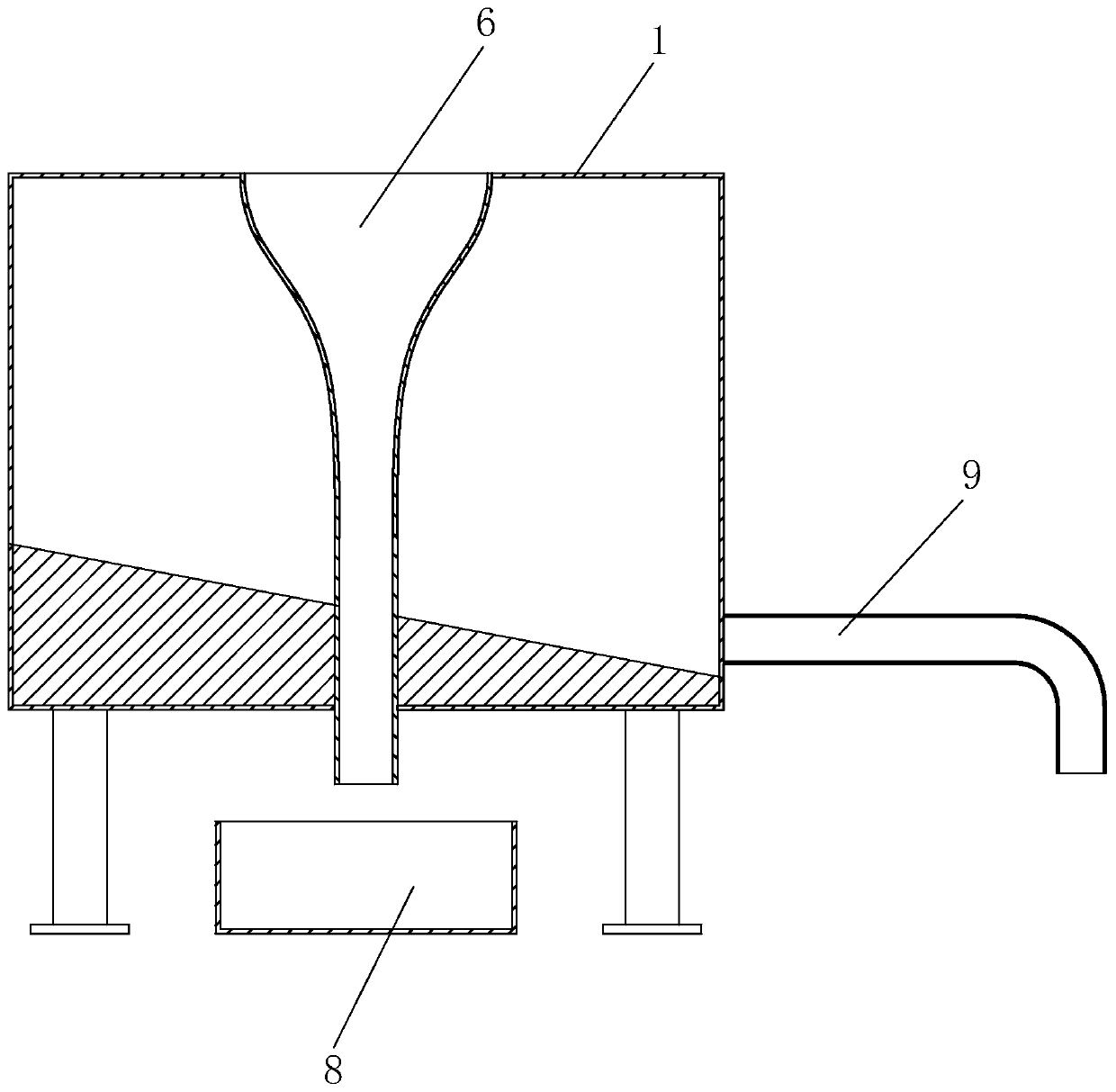

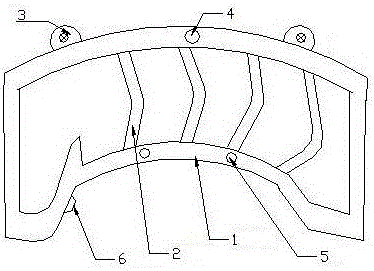

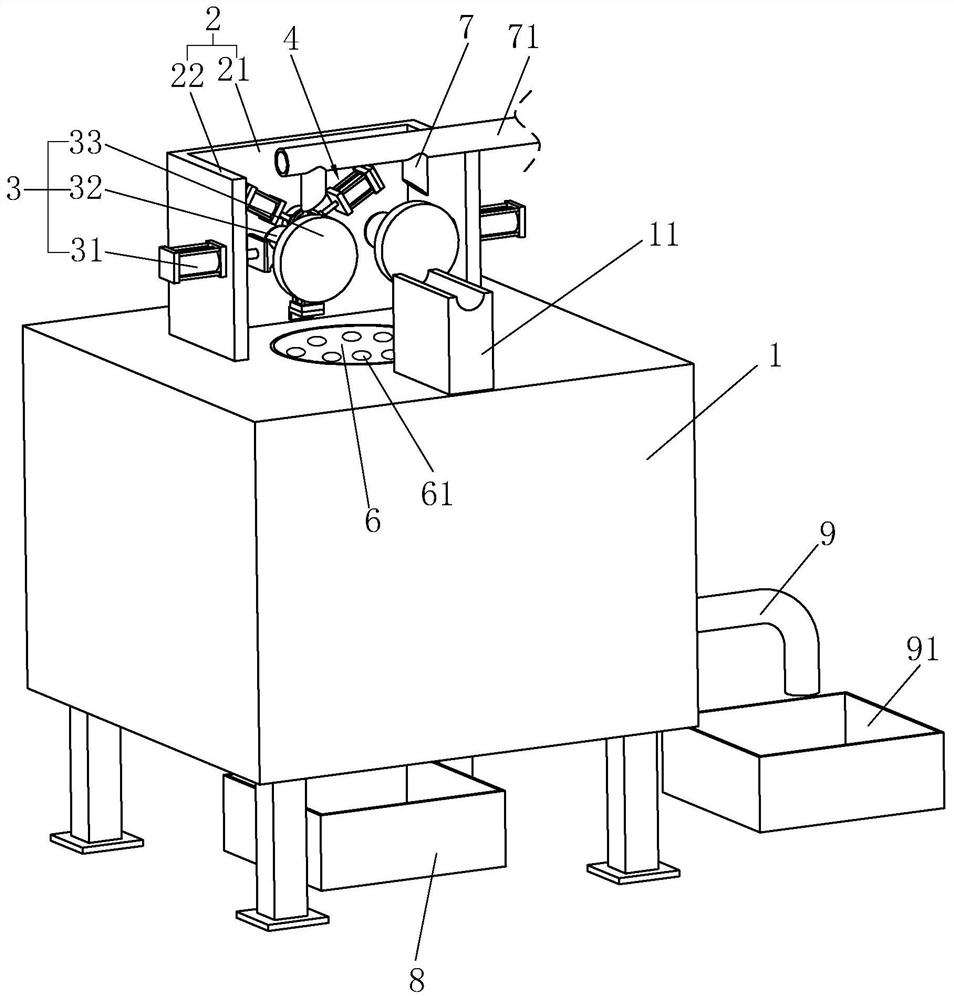

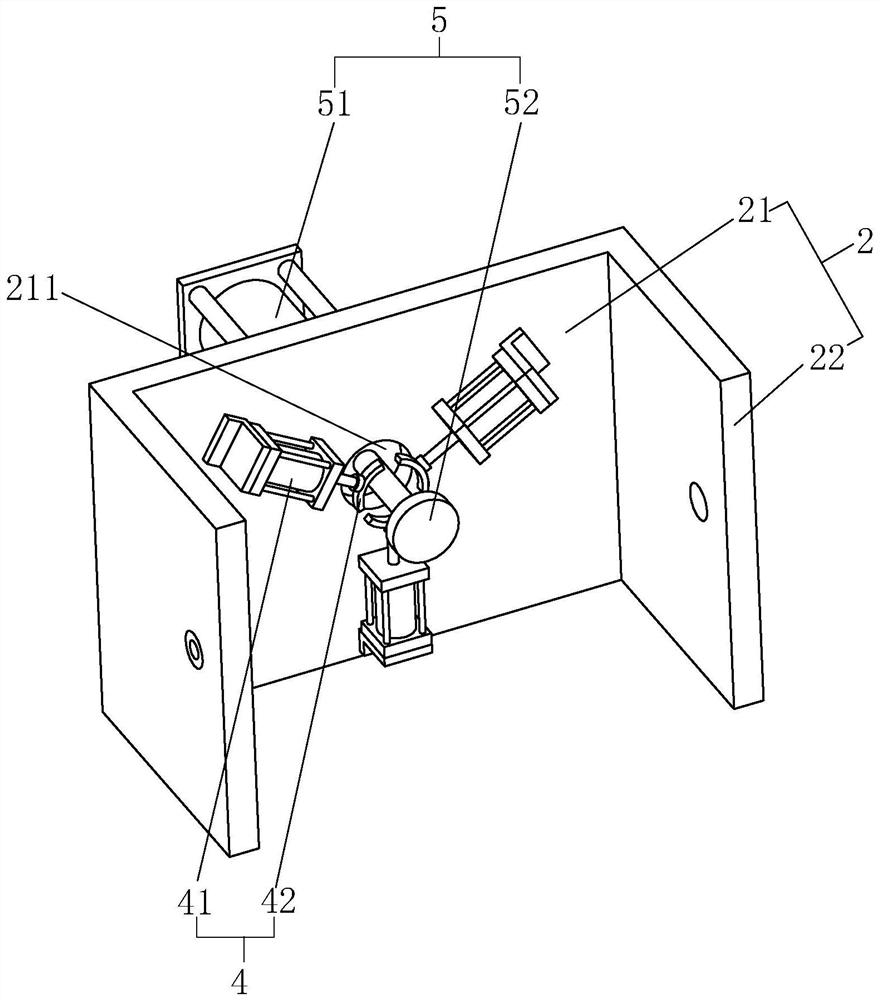

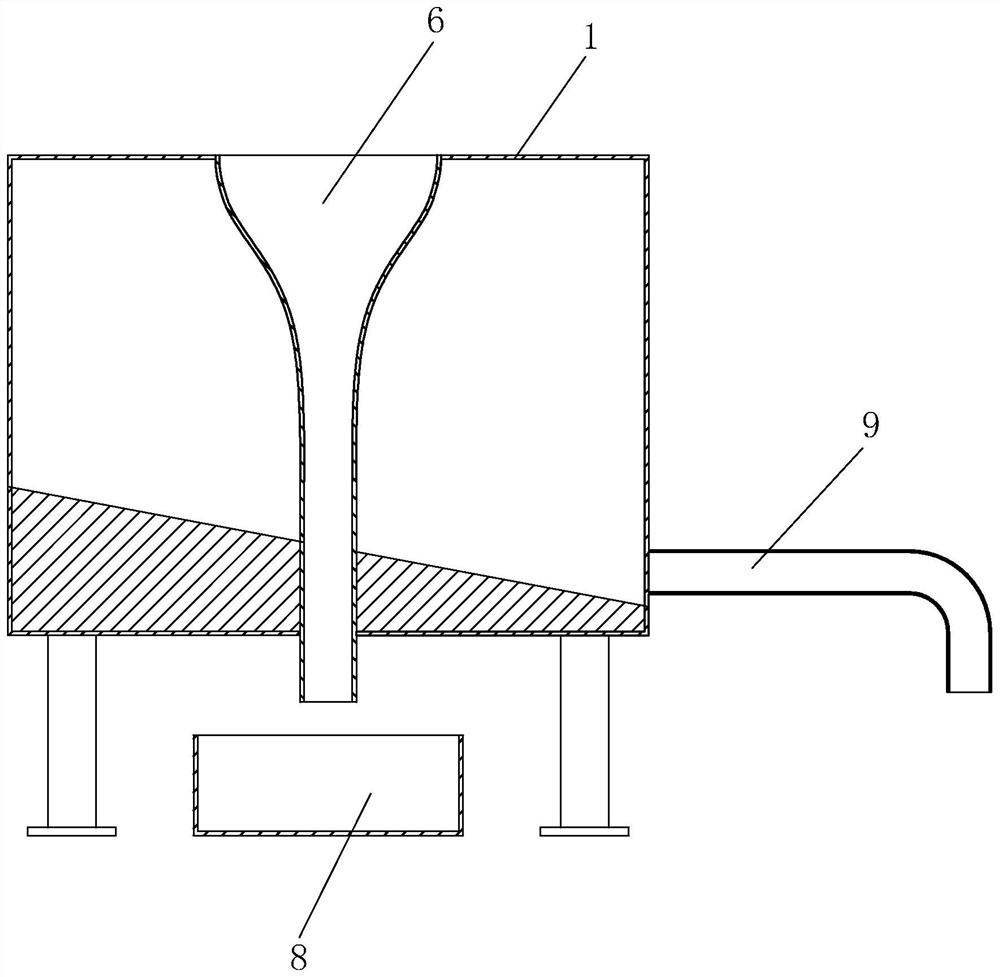

Overflow-free concrete stirrer material falling device

InactiveCN108724466AEfficient blankingAccurate and efficient blankingSold ingredients supply apparatusButt jointMaterial flow

The invention relates to an overflow-free concrete stirrer material falling device, and belongs to the technical field of equipment. The overflow-free concrete stirrer material falling device comprises a material falling hopper, a baffle, a guiding rail and a servo motor. The overflow-free concrete stirrer material falling device is powered by the servo motor, thus continuity of the opening and closing states of a material falling opening is achieved, the opening and closing degree of the material falling opening can be adjusted at will from 0% to 100%, and the material flowing speed can be controlled better. The opening and closing degree of the material falling opening is determined by the specific concrete component and the number of required materials, and thus the problem of blockageof the material falling opening is solved fundamentally; and through butt joint of the stirring connection material hopper and the stirrer material falling opening servo motor, the material falling speed is increased, the situation that the opening and closing degree of the material falling opening is controlled manually by an operator is avoided, the more efficient effect is achieved, the production efficiency of a stirrer is improved, and the production cost is saved.

Owner:XUZHOU ZHONGLIAN CONCRETE CO LTD

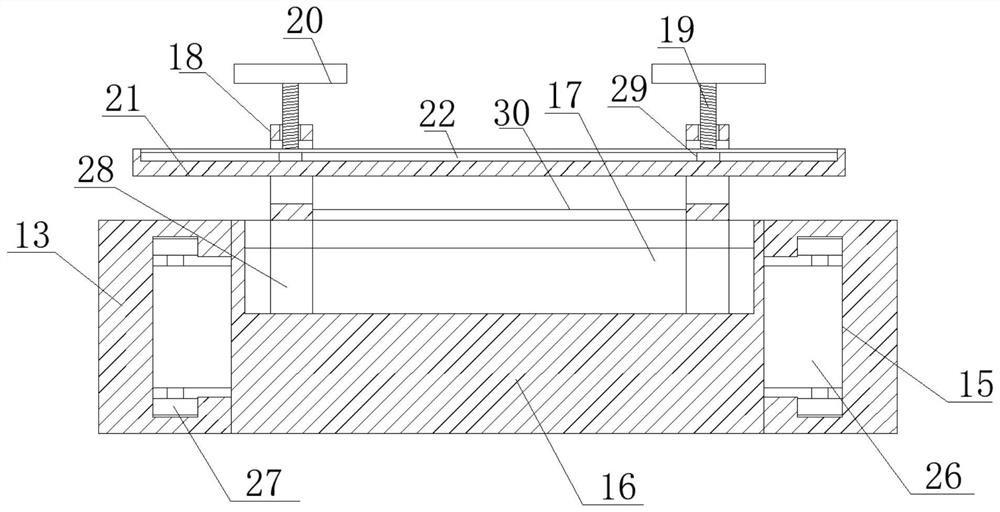

Stamping die for conveniently adjusting distance

The invention discloses a stamping die for conveniently adjusting distance. The stamping die for conveniently adjusting the distance comprises a side box, wherein a transmission inner cavity is arranged in the side box, an intermediate cavity is arranged in the upper end wall of the transmission inner cavity in a communicating mode, a top cavity is arranged in the upper end wall of the intermediate cavity in a communicating mode, an open cavity is arranged in the upper end wall of the top cavity in a communicating mode, a lower die is clamped in the open cavity, a through discharging cavity isarranged in the lower die, the lower die abuts against the lower end wall of the top cavity, a linkage fixing device for stably fixing the lower die is arranged in the transmission inner cavity, themiddle cavity and the top cavity, and a low side plate is fixedly arranged on the right end face of the side box. The stamping die is simple in structure, the size and distance can be conveniently adjusted during workpiece stamping, efficient stamping and machining of workpieces are achieved, the lower die is convenient to mount and replace and the structural intensity is improved as a connectionrod, a cam and other structures are used, and waste materials are discharged more efficiently and quickly.

Owner:山东力创模具股份有限公司

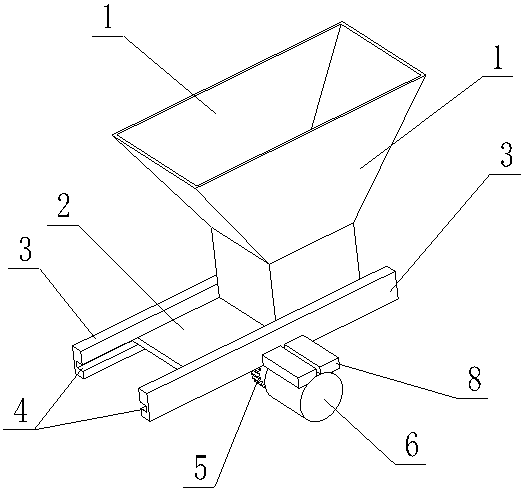

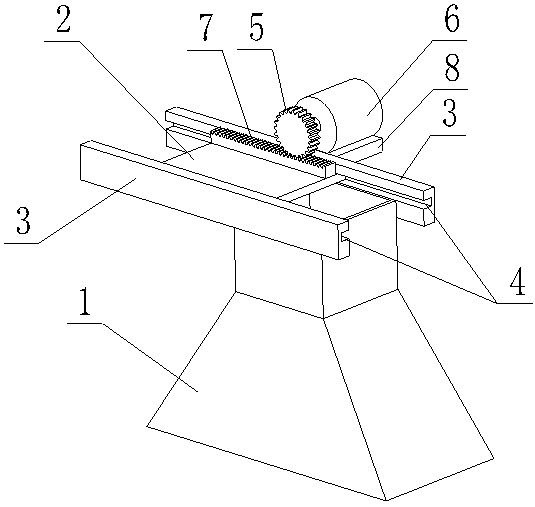

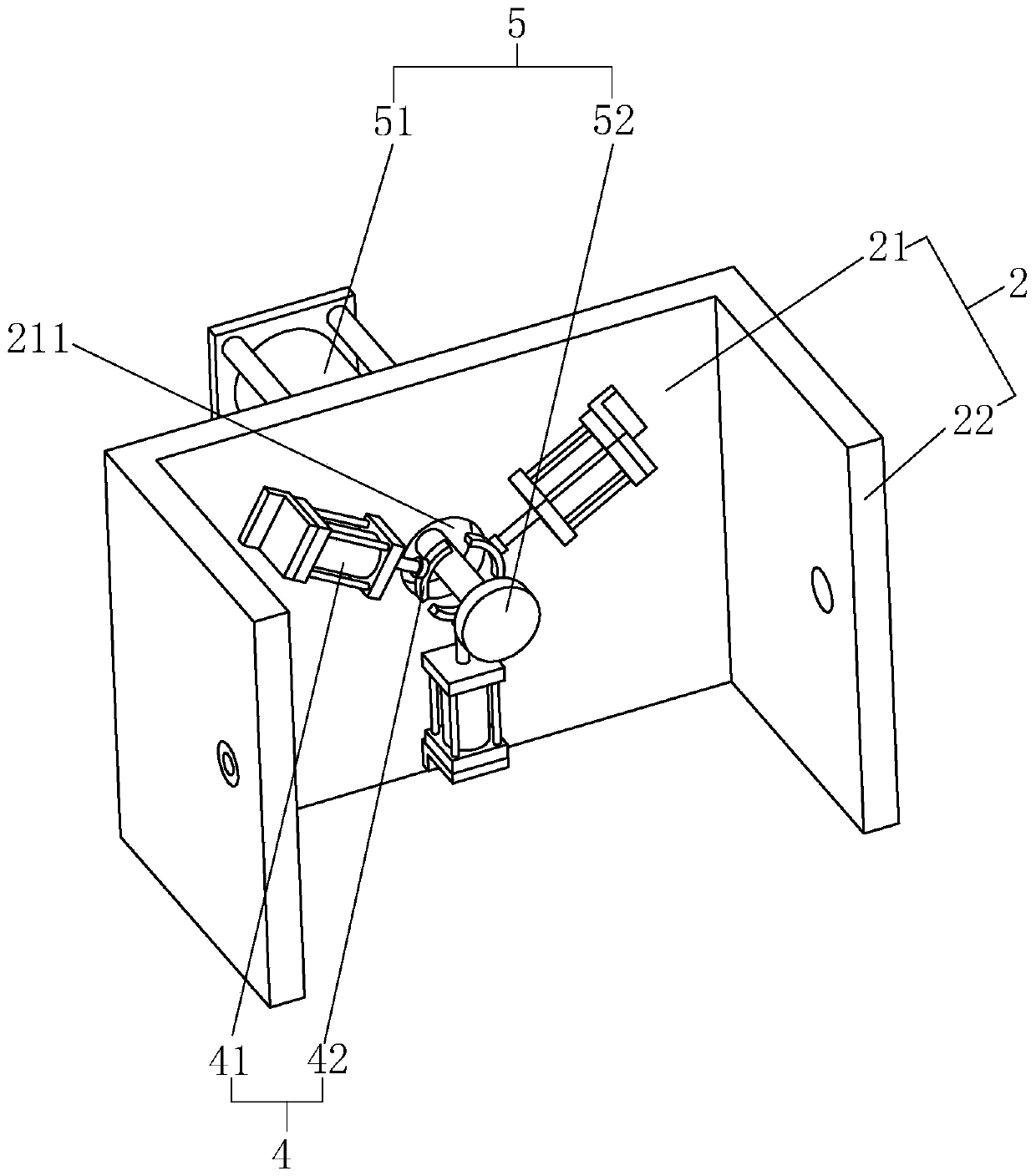

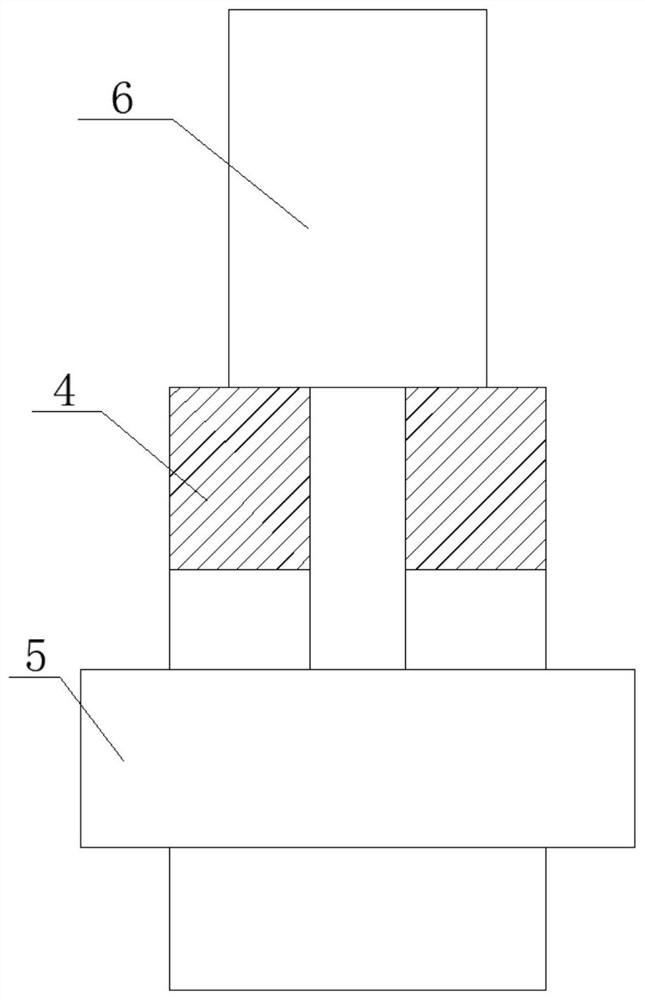

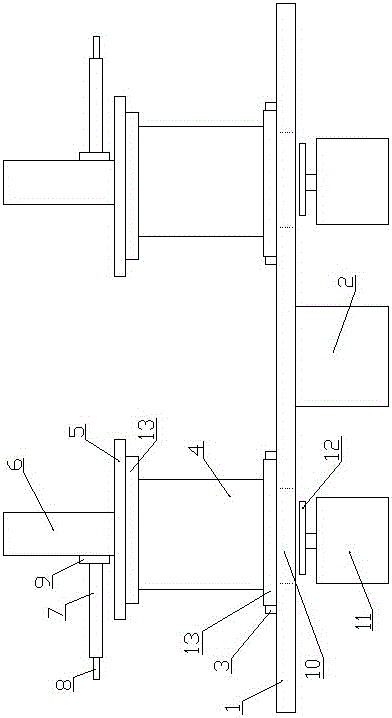

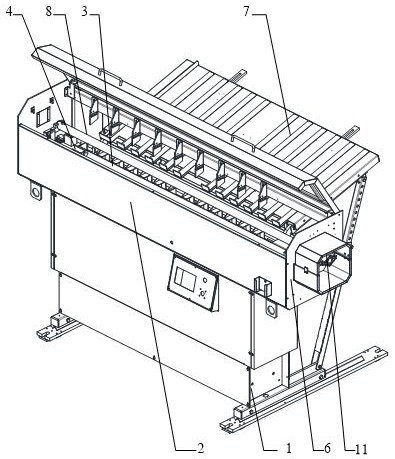

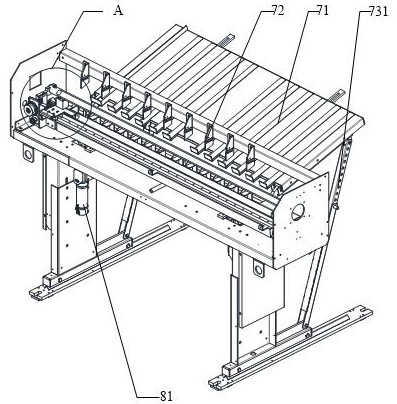

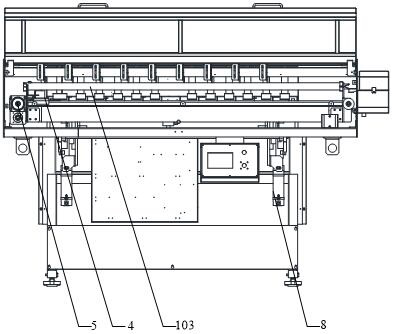

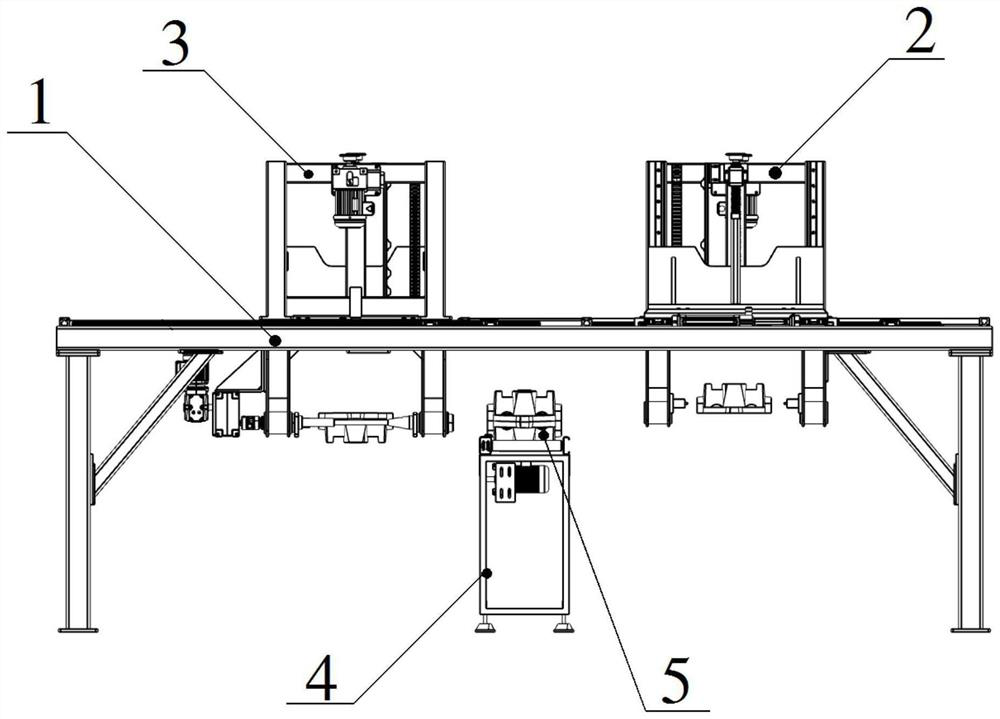

High-efficiency flat milling machine

ActiveCN110732712AImprove feeding efficiencyEfficient blankingWork clamping meansMilling equipment detailsFeed driveMachine

The invention relates to a high-efficiency flat milling machine. The key point of the technical scheme is a high-efficiency flat milling machine, the high-efficiency flat milling machine comprises a machine body, a supporting frame is fixedly arranged on the surface of the machine body, a group of processing components which are facing each other to flat milling a workpiece are fixedly arranged onthe supporting frame, a plurality of clamping parts which are used for clamping the workpiece are fixedly arranged on the supporting frame, the clamping parts and the processing components are located at a side face adjacent the supporting frame, the supporting frame is fixedly provided with a feeding part, the feeding part comprises a feeding driving cylinder which is fixed with the supporting frame and a taking magnet which is fixed with a piston rod of the feeding driving cylinder, the piston rod of the feeding driving cylinder is located in the middle of the two groups of the processing components and is perpendicular to a connecting line between the two groups of the processing components, a shrinkage groove is arranged at the position where the supporting frame is directly facing the taking magnet, the groove depth of the shrinkage groove is larger than the thickness of the taking magnet, the machine body is fixedly provided with a temporarily placed table for temporarily placing workpieces, and the temporarily placed table is located in the front of the feeding driving cylinder, so that the effect that the processing efficiency is improved is achieved.

Owner:天津宇仁金属制品有限公司

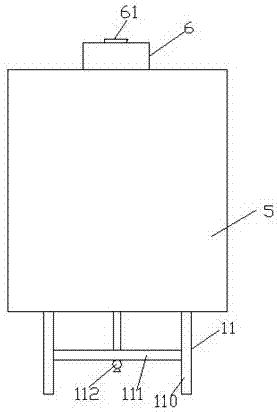

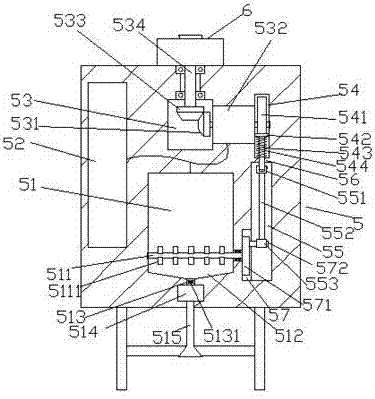

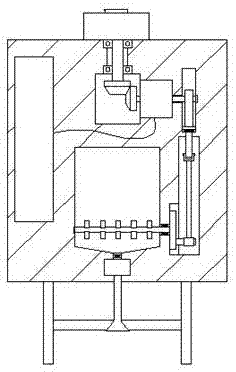

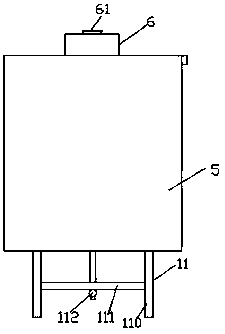

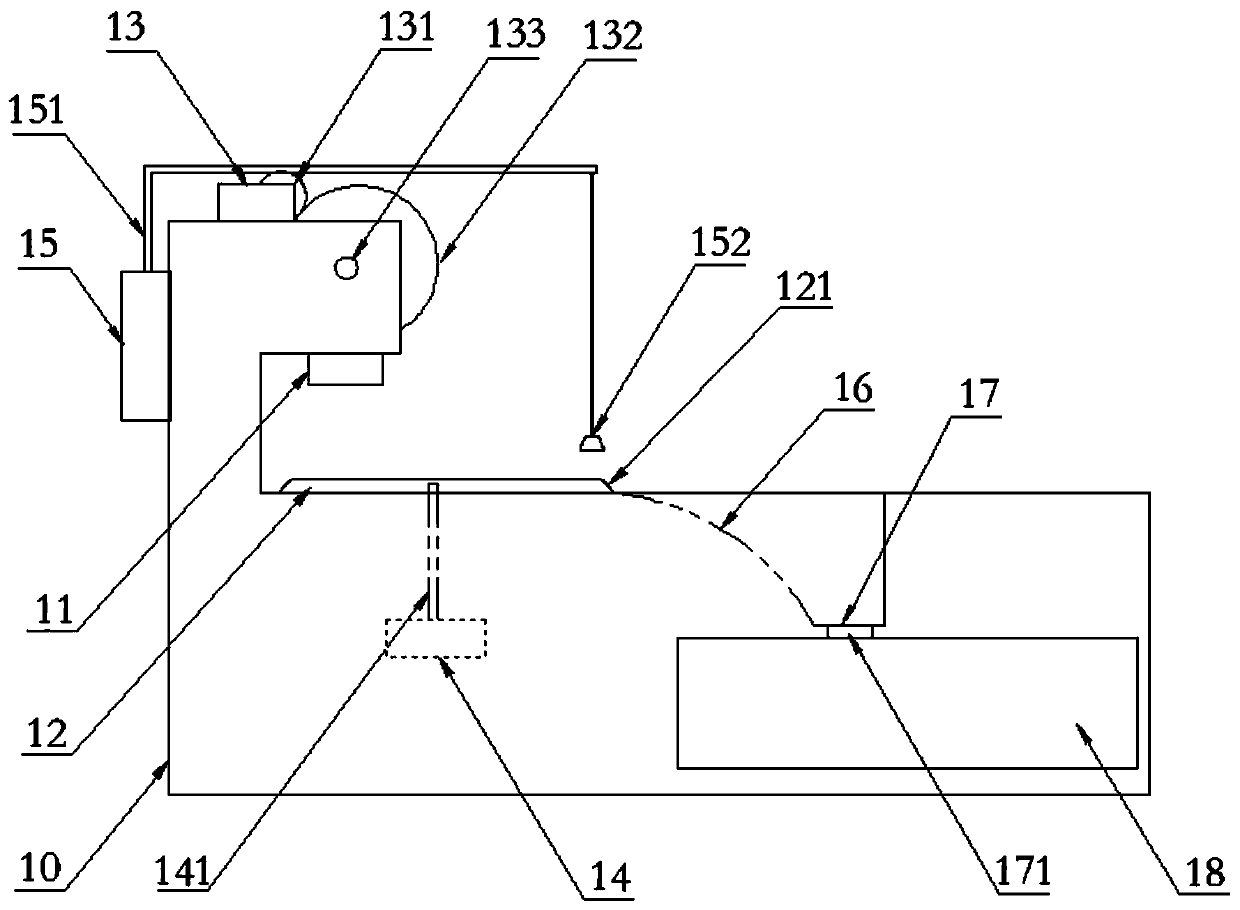

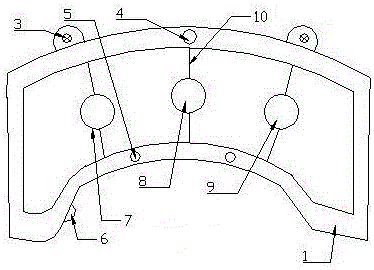

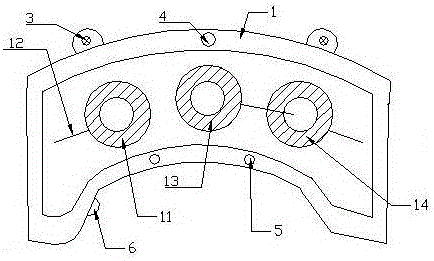

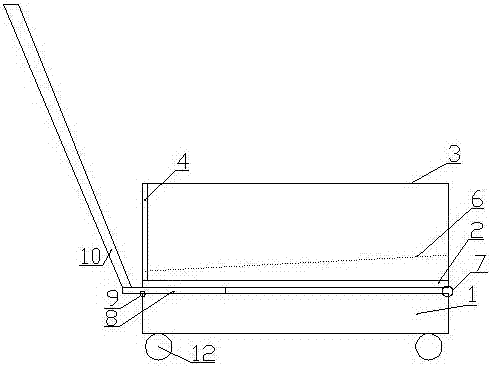

Small bridge construction equipment

InactiveCN108081455AAutomatic control and automatic stirring workEfficient blankingDischarging apparatusCement mixing apparatusArchitectural engineeringBuilding construction

The invention discloses small bridge construction equipment which comprises an equipment body, vertical feet fixed on left and right sides of the bottom of the equipment body and a feeding portion rotatably mounted at the top of the equipment body. A concrete cavity is arranged in the equipment body, a first cavity is arranged in the equipment body above to concrete cavity, a second cavity is arranged in the equipment body on the right side of the first cavity, a motor is fixedly arranged in the equipment body between the second cavity and the first cavity, the tail end of the left side of themotor is in matched connection with a first bevel runner extending into the first cavity, a first bevel runner is connected in the first cavity at the top of the left side of the first bevel runner in a meshed manner, a rotating shaft extending upwards is fixedly arranged on the top face of the second bevel runner, and the extending tail end of the top of the rotating shaft is fixedly connected with the bottom of the feeding portion. The small bridge construction equipment is simple in structure, compact, light, convenient and capable of realizing automatic concrete mixing, and construction efficiency is improved.

Owner:惠安县通联机械研发中心

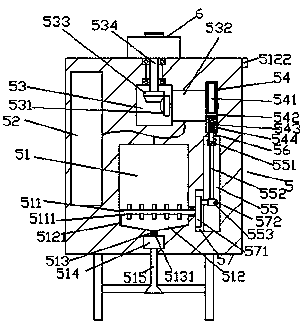

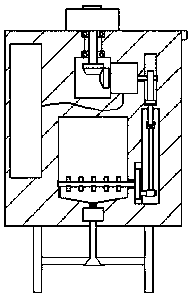

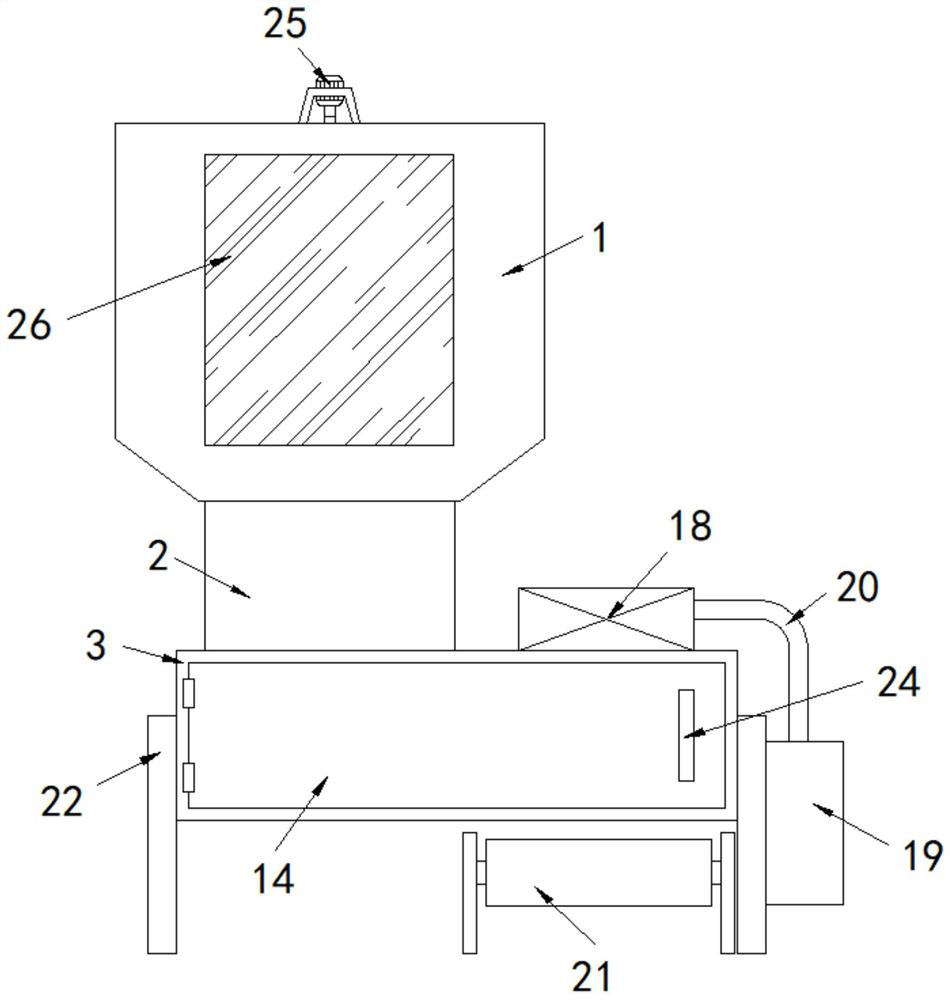

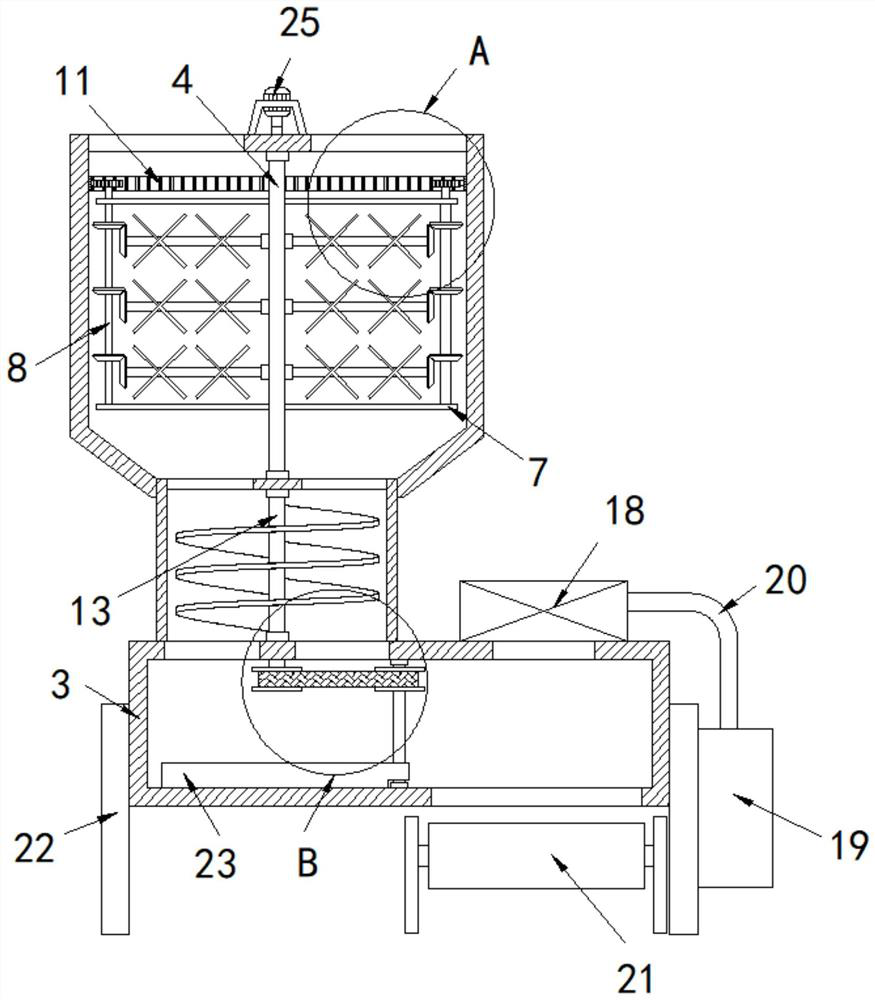

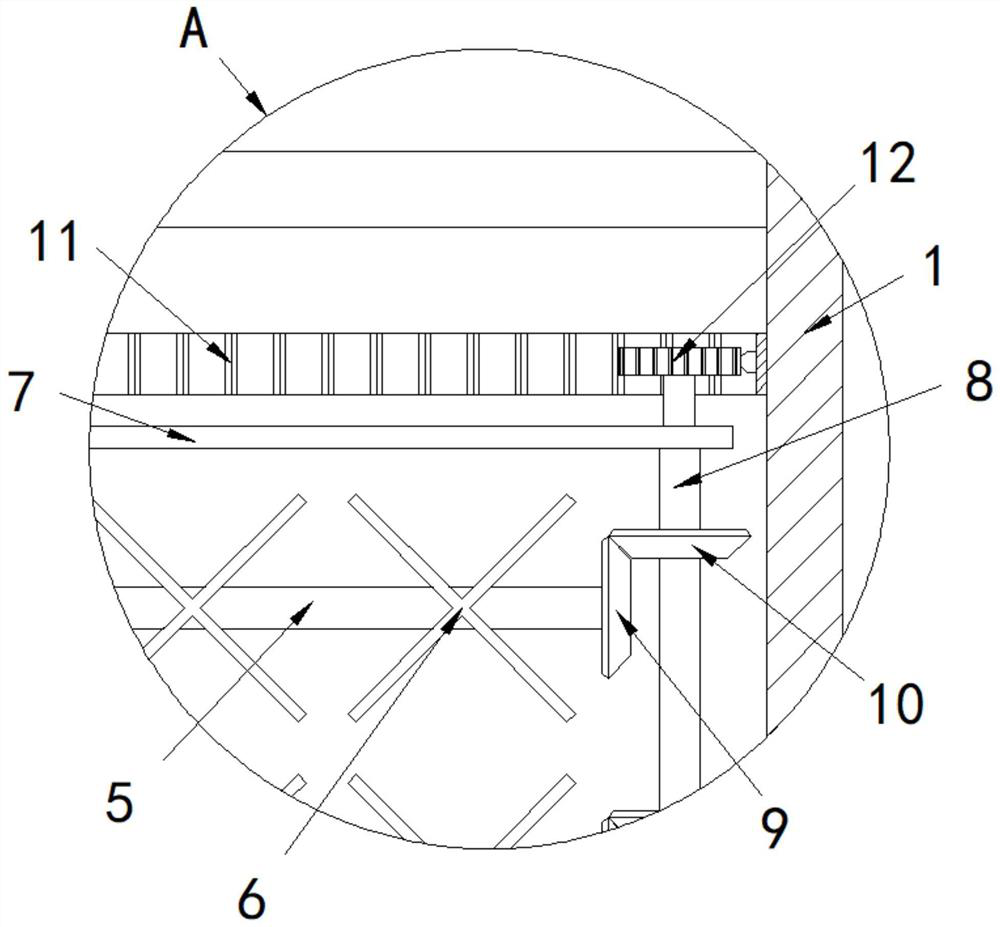

Clinker discharging device for cement production

ActiveCN113522451AFully and evenly crushedEfficient blankingGrain treatmentsEngineeringClinker (cement)

The invention relates to the technical field of cement production, and discloses a clinker discharging device for cement production. The clinker discharging device comprises a storage bin, a conveying shell and a discharging box, the conveying shell is fixedly arranged at the lower end of the storage bin, the discharging box is fixedly arranged at the lower end of the conveying shell, and a first rotating rod is rotatably arranged in the storage bin; second rotating rods are sequentially and rotationally arranged on the two sides of the rod wall of the first rotating rod from top to bottom, a plurality of cross-shaped rods are fixedly arranged on the rod walls of the multiple second rotating rods, transverse rods fixedly sleeve the rod walls of the two ends of the first rotating rod, and third rotating rods are arranged between the two ends of the two transverse rods; and the two ends of the two third rotating rods are rotationally connected with the corresponding transverse rods through first rolling bearings correspondingly, and first bevel gears fixedly sleeve one ends of the outer sides of the multiple second rotating rods correspondingly. According to the clinker discharging device for cement production, efficient discharging can be carried out, and materials can be evenly and fully smashed.

Owner:HEFEI CEMENT RES DESIGN INST

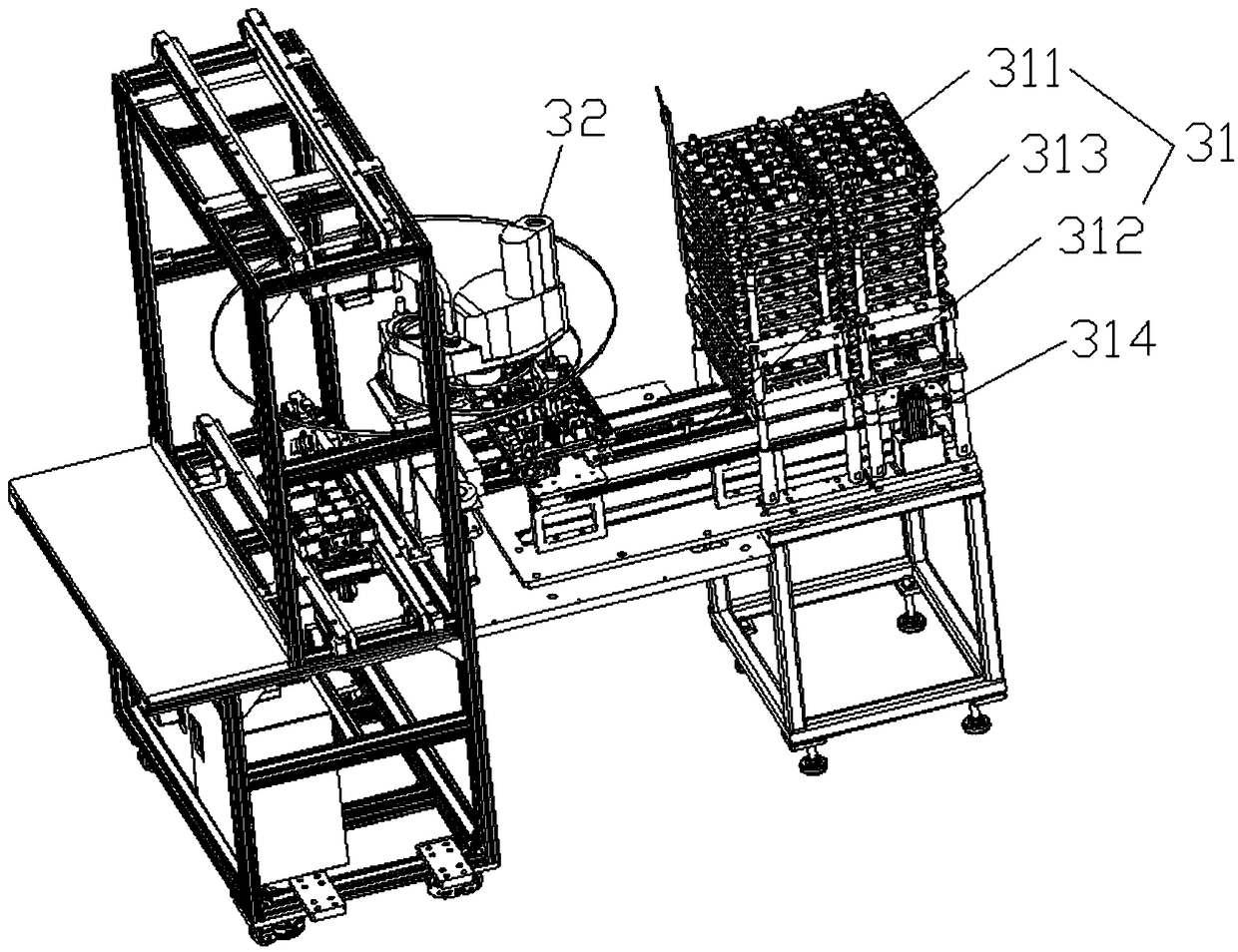

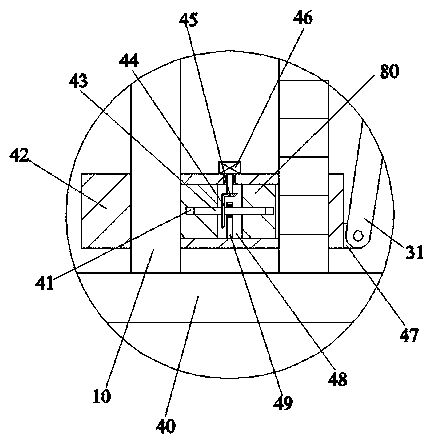

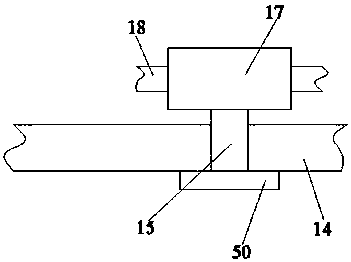

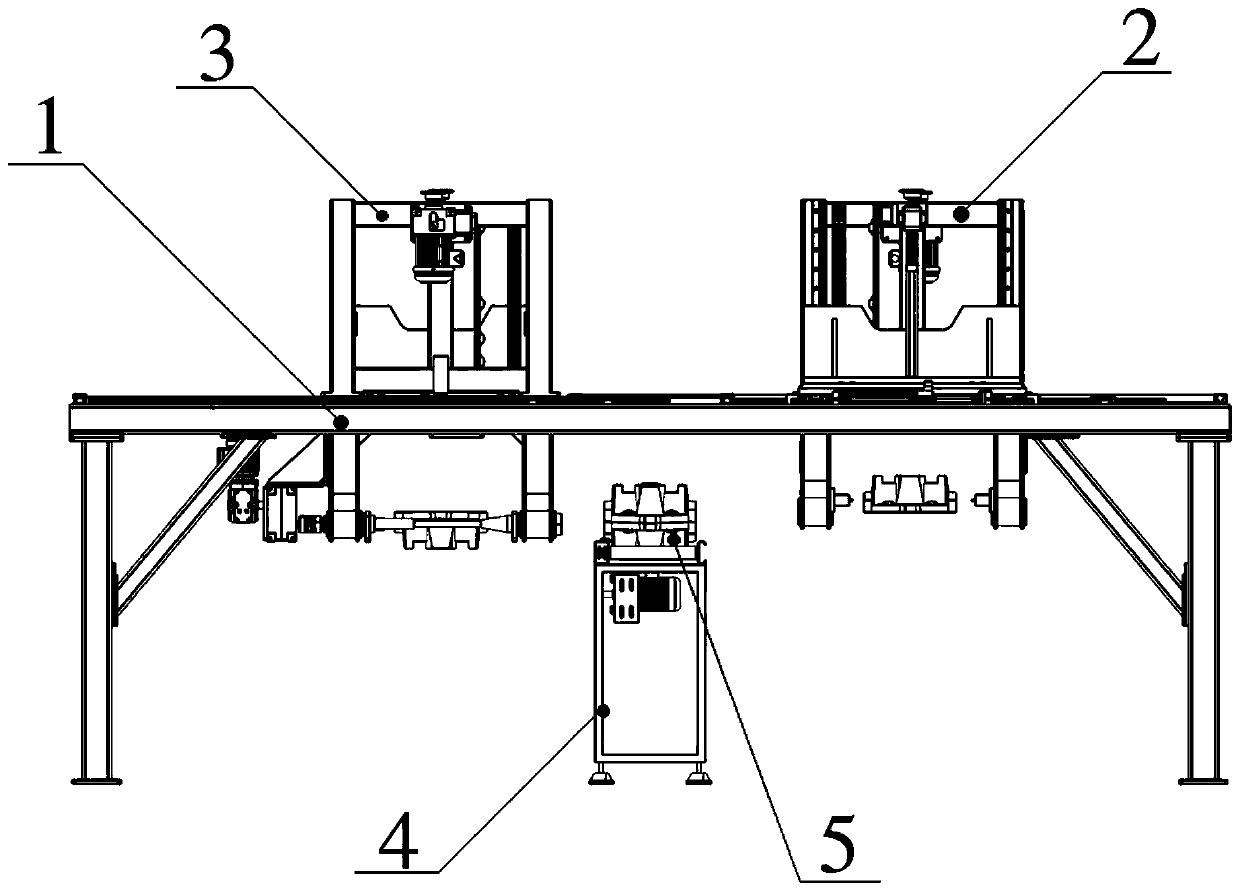

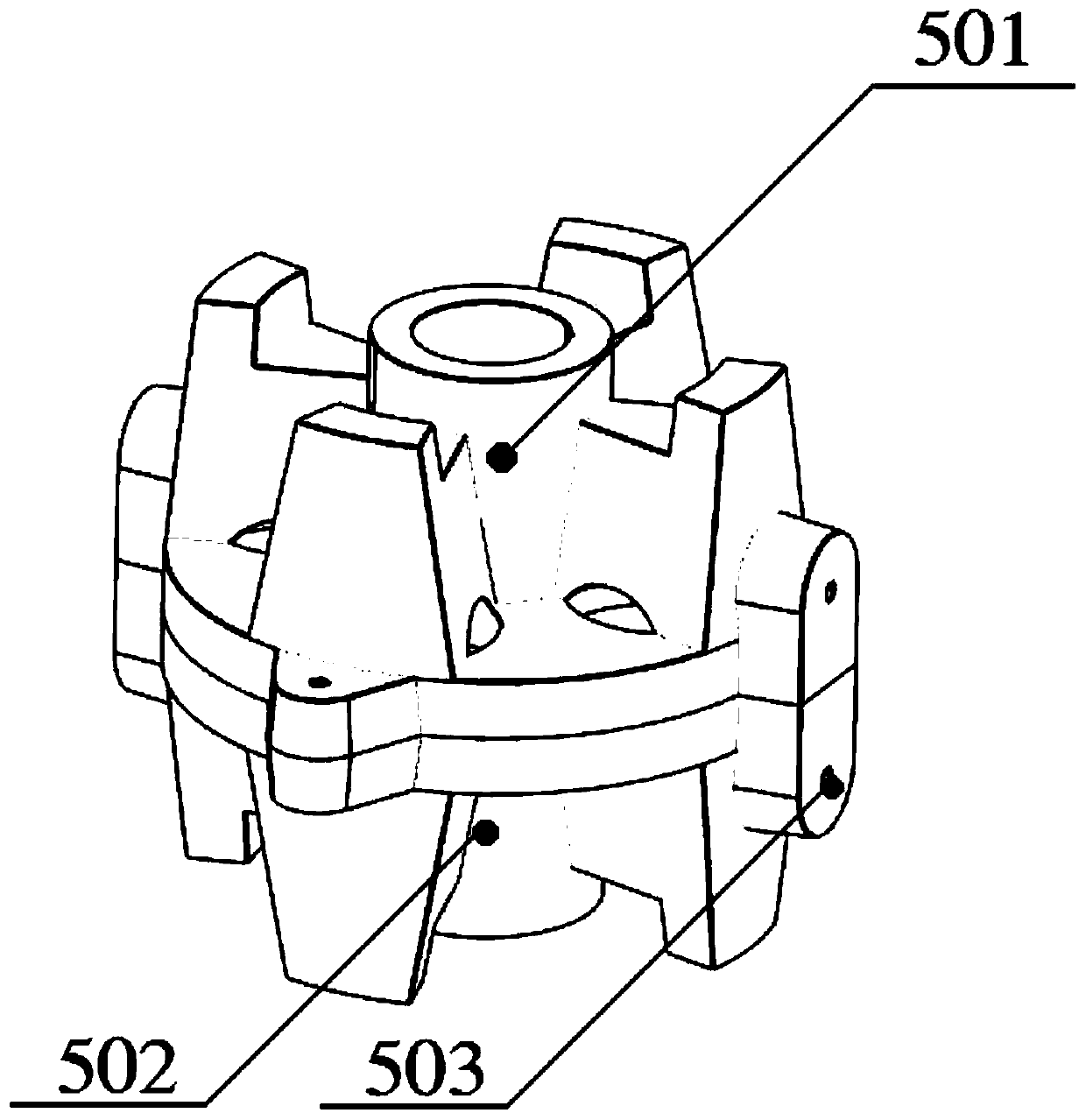

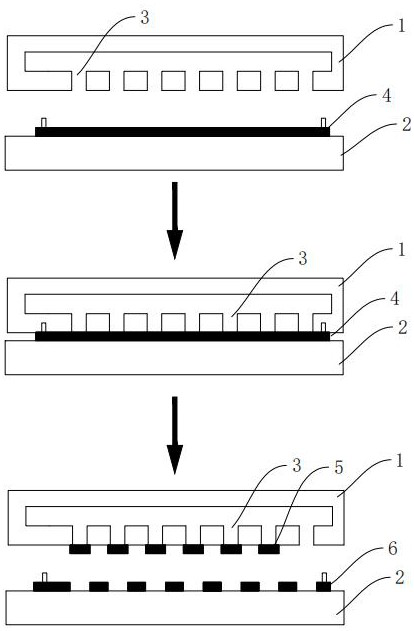

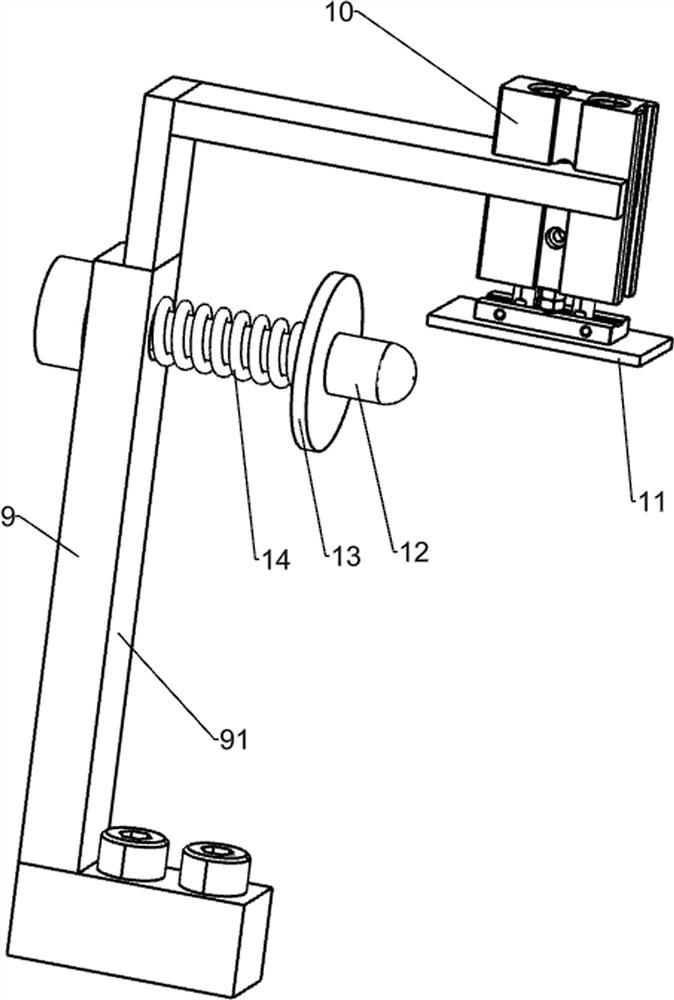

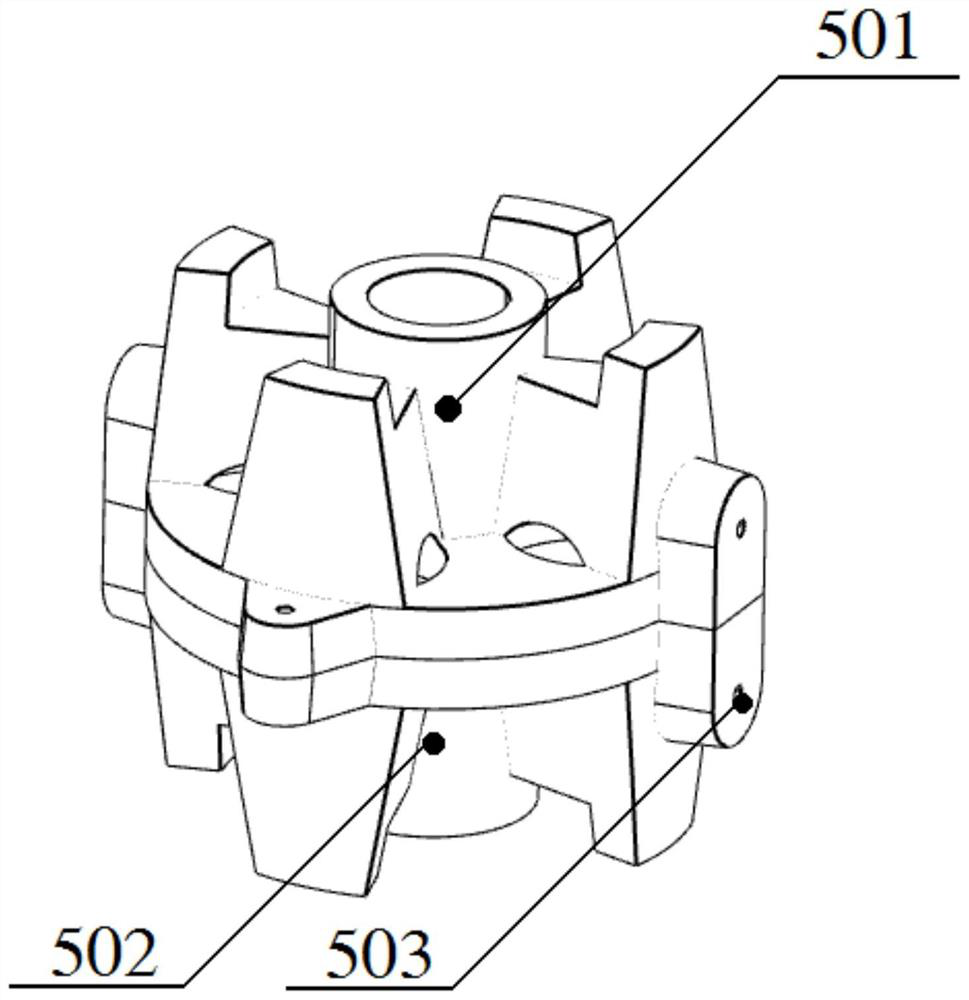

Blanking device suitable for delivery and mold closing of multi-size molds

ActiveCN111531152AReduce labor intensityDegree of reductionMould handling equipmentsEngineeringSteel ball

The invention provides a blanking device suitable for delivery and mold closing of multi-size molds. The blanking device comprises a mounting rack, an upper mold manipulator, a lower mold manipulatorand a roller conveying line, wherein the roller conveying line is arranged in an opening below the mounting rack; the roller conveying line is used for conveying a steel ball mold; the steel ball moldis formed by an upper mold and a lower mold; a steel ball is stored between the upper mold and the lower mold; the upper mold manipulator is slidably arranged on one side of the mounting rack; the lower mold manipulator is slidably arranged on the other side of the mounting rack; the upper mold manipulator is used for clamping the upper mold for blanking and mold closing; the lower mold manipulator is used for clamping the lower mold for overturning, blanking and mold closing. The blanking device is reasonable in design and fast in motion, the whole process of mold opening, blanking and moldclosing can be completed, the labor intensity and the working danger level of operators are effectively reduced, the blanking efficiency is improved, a problem of material adhesion is solved, and meanwhile, the blanking device has applicability.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST +1

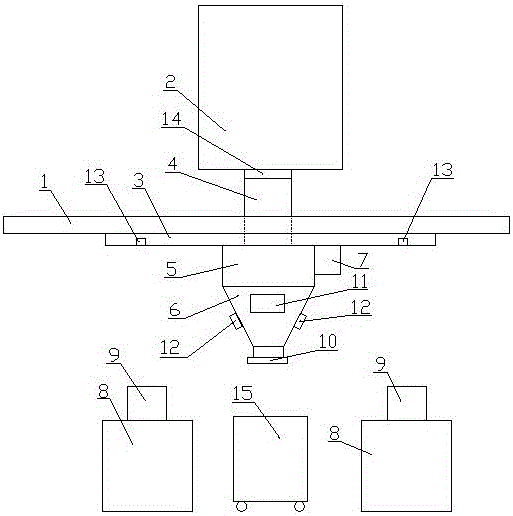

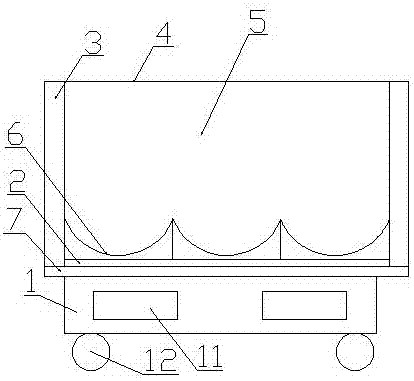

Movable discharging apparatus for storage battery grid lead paste

InactiveCN106531958AEfficient blankingEfficient and fast completion of blankingLead-acid accumulator electrodesElectrode collector coatingDrive motorEngineering

The invention aims to provide a movable discharging apparatus for storage battery grid lead paste. The movable discharging apparatus comprises a top plate, wherein lead paste and paste machine is arranged above the top plate; a transversely slidable sliding track is formed in the bottom of the top plate; a material outlet pipe used for discharging mixed paste is arranged at the bottom of the lead paste and paste machine; the bottom end of the material outlet pipe passes through the top plate to extend in the sliding track; a slidable sliding cover is arranged at the bottom of the sliding track; the material outlet pipe extends on the top of the sliding cover for receiving the lead paste; a discharging hopper used for taking the lead paste is connected at the bottom of the sliding cover; a driving motor for providing driving power is arranged on the right side of the sliding cover; two pasting machines are arranged at the left end and the right end below the sliding track; and a material receiving hopper for receiving the discharged material is arranged on the top of each pasting machine. By adoption of the movable discharging apparatus, material discharging can be completed efficiently and rapidly, so that the movable discharging apparatus is applicable to production.

Owner:TIANNENG BATTERY WUHU

Terminal cover injection mold with automatic discharging function

The invention aims to provide a terminal cover injection mold with an automatic discharging function. The terminal cover injection mold with the automatic discharging function comprises a movable mold body and a fixed mold body. The movable mold body is located on the left side, and the fixed mold body is located on the right side. An installation block is arranged at the bottom of the fixed mold body. Sliding rails are arranged at the front end and the rear end of the bottom of the installation block and stretch leftwards to the space below the movable mold body. A collecting box with the top being open is arranged below the two sliding rails and slides below the sliding rails. An installation column is arranged in the middle of the bottom of the movable mold body. The installation column and the collecting box are connected through a connecting column. The collecting box is located below the fixed mold body when the movable mold body and the fixed mold body are assembled. After injection molding of a terminal cover is completed, the movable mold body moves leftwards, the collecting box is driven to move leftwards to be located between the movable mold body and the fixed mold body, then materials are ejected out and discharged to fall into the collecting box, the collecting box is a meshed box and is connected with an air blowing pipe for rapid cooling, and an openable plate which can be opened for material collection is arranged at the bottom of the collecting box; and after the materials are ejected out, the movable mold body moves rightwards, and the collecting box is driven to move rightwards to be located below the fixed mold body.

Owner:WUHU WANHUA PLASTIC PROD

Punching machine capable of achieving efficient discharging

The invention discloses a punching machine capable of achieving efficient discharging. The punching machine capable of achieving efficient discharging comprises a machine tool. A first motor is arranged on the machine tool. The first motor is connected with a crankshaft in a driving mode. A connecting rod is connected to a rotary shaft of the crankshaft. An upper die base is connected to the connecting rod. The first motor drives the upper die base to reciprocate in the longitudinal direction through the connecting rod. A lower die base is arranged on the machine tool and is located below theupper die base, and one end of the lower die base is aligned to a punching station of the upper die base. A second motor is further arranged on the machine tool and is connected to the center of the lower die base in a driving mode. When the upper die base is aligned to one end of the lower die base to complete punching once, the second motor drives the lower die base to rotate, and the lower diebase drives a punched workpiece to leave the punching station. According to the punching machine capable of achieving efficient discharging, the lower die base rotates to enable the two ends of the lower die base to alternately leave the punching station to bring punched workpieces on the lower die base away from the punching station, and thus, efficient discharging of the workpieces is achieved.

Owner:广东虹瑞智能设备股份有限公司

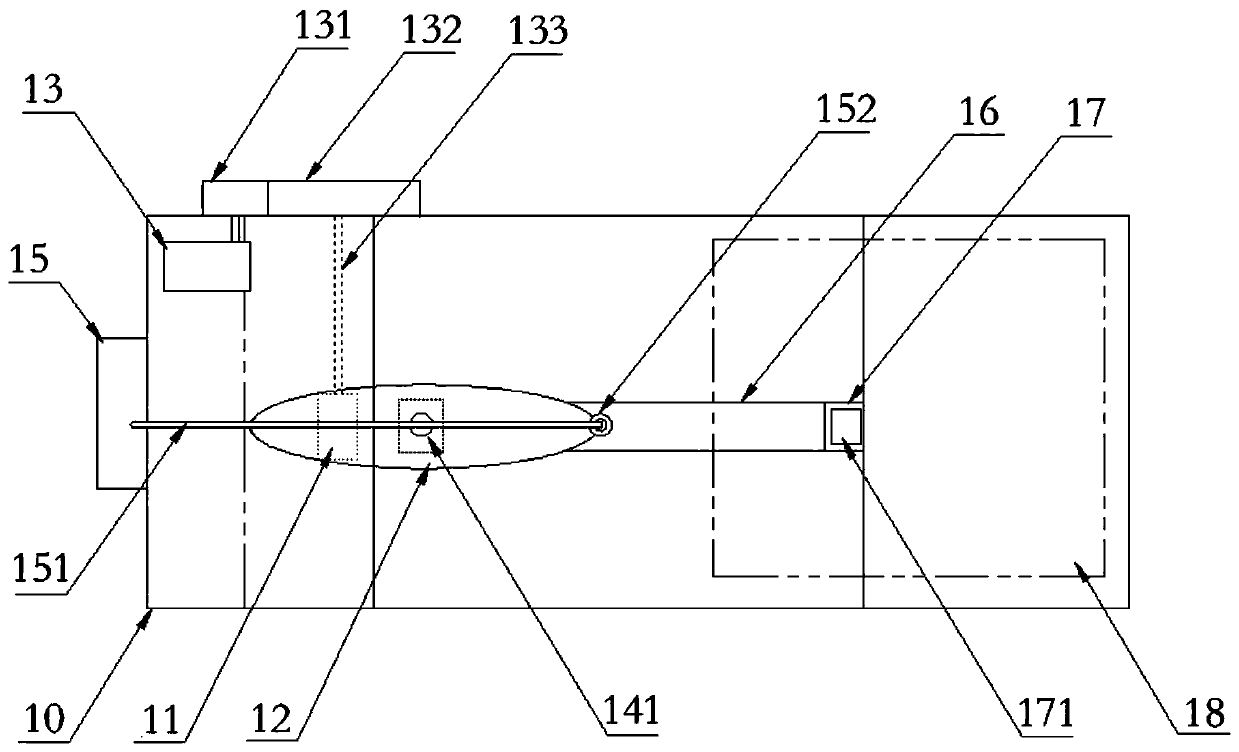

Blanking method for FPCA plate die cutting, die cutting method and die cutting device

PendingCN113199558AReduce workloadPrecise positioningInsulating layers/substrates workingMetal working apparatusSuction forceStructural engineering

The invention discloses a blanking method for FPCA plate die cutting. The blanking method comprises the following steps that an upper die with suction holes moves away from a lower die, and meanwhile products adsorbed to the upper die is separated from the lower die; each product is sucked by at least one suction hole, and the multiple products formed through one-time die cutting are correspondingly sucked by all the suction holes in the upper die at the same time; material receiving discs are moved and positioned to the lower die, and the lower die drives the material receiving discs to move towards the upper die till the material receiving discs is attached to the upper die; and after the material receiving discs are attached to the upper die, suction force generated by the suction holes to the products is canceled, so that each product freely falls into a material frame of the corresponding material receiving disc. The invention further discloses a die cutting method and a die cutting device using the blanking method. The product loading operation is rapidly and efficiently completed, and the labor cost is reduced.

Owner:FOREWIN FPC SUZHOU

Metal material machining device

InactiveCN113182606ASatisfy fixationReduce investmentMetal sawing devicesMeasurement/indication equipmentsMetallic materialsMaterials processing

The invention discloses a metal material machining device, and relates to the field of metal materials. The metal material machining device comprises a fixed bottom plate, wherein supporting vertical rods are vertically and downwards welded to the bottom face of the fixed bottom plate; a control panel is obliquely welded to one side edge of the fixed bottom plate; a fixed top block is welded to the top face of the fixed bottom plate; an extrusion plate is horizontally arranged on the inner side edge of the fixed top block; a pushing and pressing air cylinder is connected to the top face of the fixed top block through a bolt; bottom sleeve rods are vertically and upwards welded to the top face of the fixed bottom plate; extending vertical rods are vertically and upwards inserted into the top ends of the bottom sleeve rods; a top box body is horizontally welded to the side edge between the extending vertical rods; and extending side rods are vertically and downwards welded on the bottom surface of the top box body. According to the device provided by the invention, the design is integrated, the structure is simple, operation is convenient, product discharging is faster and more efficient by adopting the intelligent automatic measuring and cutting procedure, meanwhile, labor input is greatly reduced in a more time-saving and labor-saving mode, and the requirement for market development is met.

Owner:宿迁小鲤工业设计有限公司

A turret blanking die

Owner:江苏诚益达智能科技有限公司

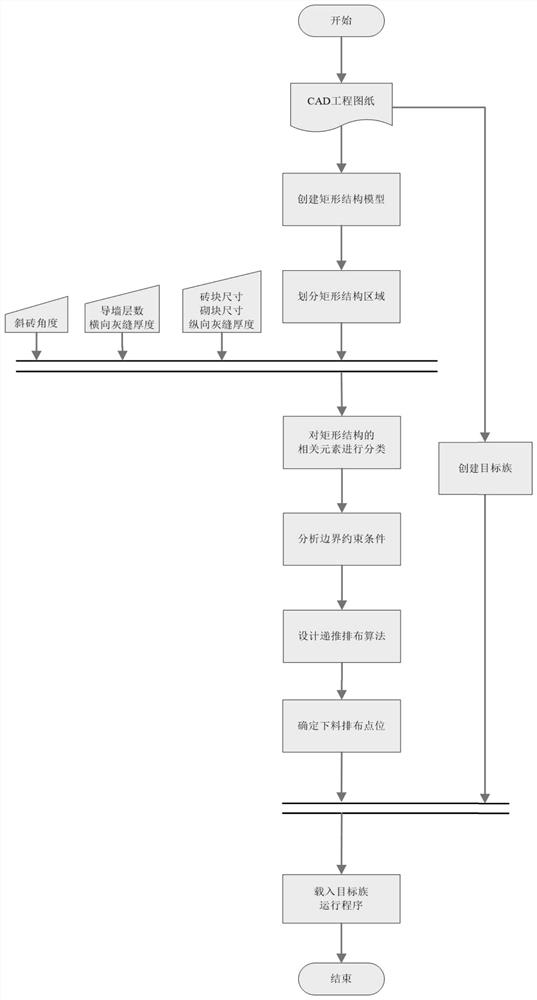

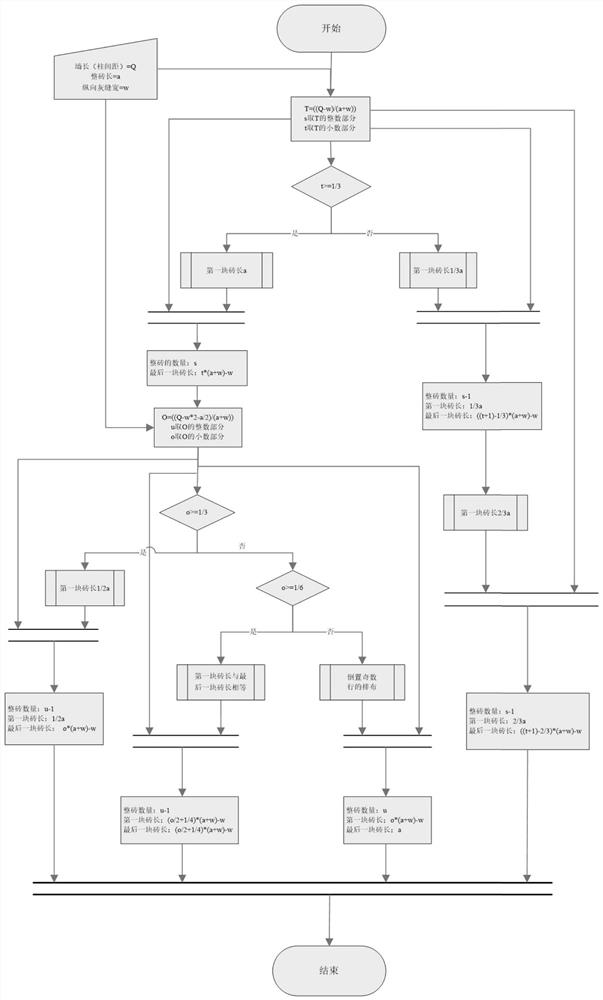

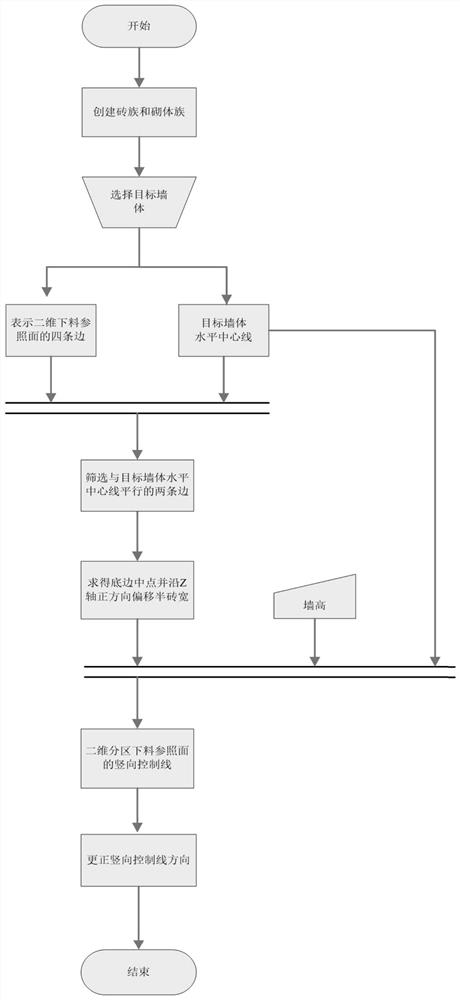

Rectangular structure subarea blanking fine arrangement method

PendingCN114065350AEfficient creation methodAccurate creation methodGeometric CADForecastingMaterials preparationBatch processing

The invention relates to the technical field of building construction, and discloses a rectangular structure subarea blanking refined arrangement method which mainly comprises the steps of creating a target primitive, and dividing a rectangular structure into a plurality of areas; analyzing parameter information of the rectangular structure, and dividing parameterized elements, non-parameterized elements and adaptive elements of the rectangular structure; defining boundary constraint conditions of the rectangular structure; designing a recursive arrangement algorithm; determining blanking arrangement point positions of all the areas; and loading a target group into a visual programming platform, operating a program and finishing blanking work of the rectangular structure. Based on the visual programming platform, programming is carried out by utilizing a computer language, and a corresponding function of an application interface of the visual programming platform is called, so that standardized blanking of the rectangular structure is quickly realized, and the method is used for accurately guiding site construction. The material utilization rate and the construction site blanking efficiency can be remarkably improved, factory batch processing material preparation and construction site fine management are facilitated, and green and sustainable development of the building industry is promoted.

Owner:江西中煤建设集团有限公司 +2

Thick copper wire pay-off device with feeding and discharging functions

InactiveCN105118571AGuided delivery is smoothEfficient and fast loading and unloading and unloadingCable/conductor manufactureCopper wireEngineering

The invention discloses a thick copper wire pay-off device with feeding and discharging functions. A placement plate with a rotation motor to rotate is arranged for arranging two thick copper wire roller to release wires; a left side is a work station and is used for releasing wire; once the wire releasing by the work station is finished, the placement plate is rotated for 180 degrees to rotate the thick copper wire roller from the right side to the left side to perform work wire releasing; then the material discharging is performed on the thick copper wire which is rotated to the right side and finishes the wire releasing, the material feeding is performed then after the material discharging is done and the new thick copper wire roller is installed; a magnetic guiding ring is set through a rotation shaft to perform guiding, which enables the guiding conveying to be smoother; and a pushing-up air cylinder is arranged to perform height adjustment on the thick copper wire coil roller to release the wire. The invention is simple in structure and easy to operate, can perform material feeding, material discharging and wire releasing on the thick copper wire and is applicable to the production.

Owner:WUHU SHUNCHENG ELECTRONICS

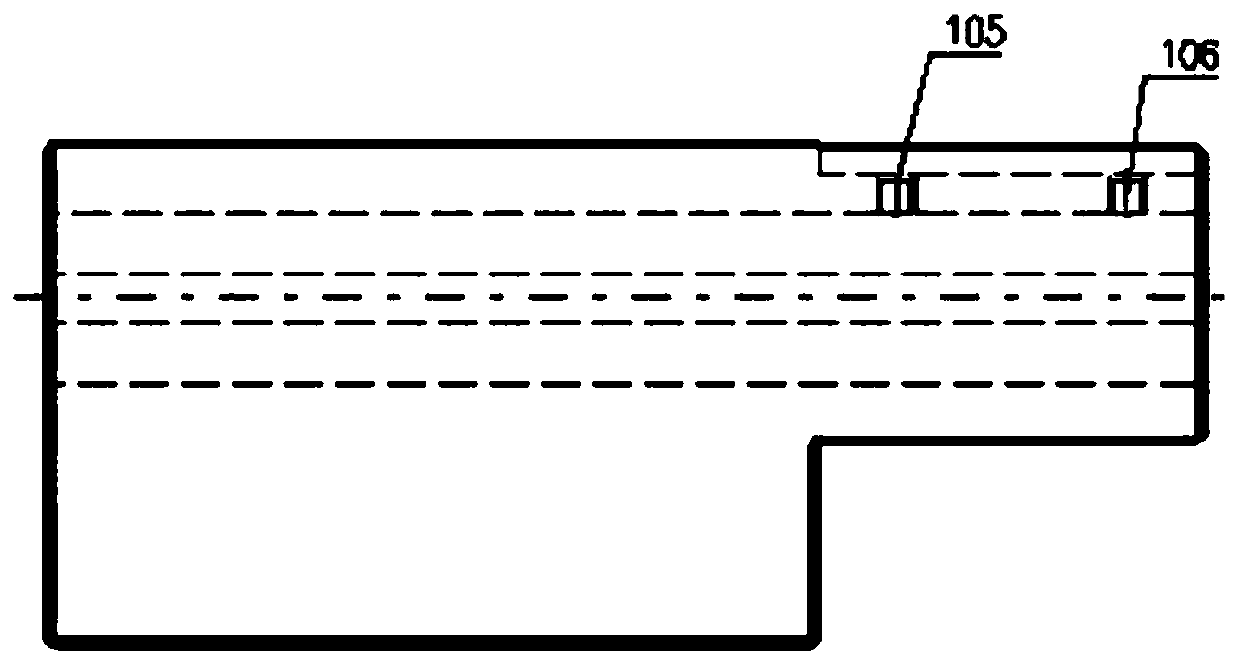

Dry-type short bar type automatic feeder

PendingCN114310437AEfficient blankingReasonable designMetal working apparatusStructural engineeringMachine

The invention belongs to the technical field of automatic feeder equipment, and provides a dry-type short bar type automatic feeder which comprises a rack, a feeder case, a pipe groove, a feeding trolley, a feeding rod, a driving device and a machine head, a discharging port is formed in the machine head, a bar braking device is arranged on one side of the feeder case, and a driving device is arranged on the other side of the feeder case. The feeding side of the bar braking device inclines towards the pipe groove, a feeding lifting unit is arranged below the pipe groove, a material shifting unit is arranged on the side, facing the bar braking device, of the feeding lifting unit, and a secondary feeding unit connected with a feeding trolley in a clutch mode is arranged on the feeding lifting unit. The secondary feeding unit comprises a clutch mechanism, an ejector rod is arranged at the transmission end of the clutch mechanism, and the length of the ejector rod is larger than that of the feeding rod. The device is reasonable in design, simple in structure, low in cost, high in applicability and suitable for large-scale popularization, bars with special-shaped sizes can be fully machined, and the production and machining efficiency can be improved.

Owner:山东新景机械有限公司

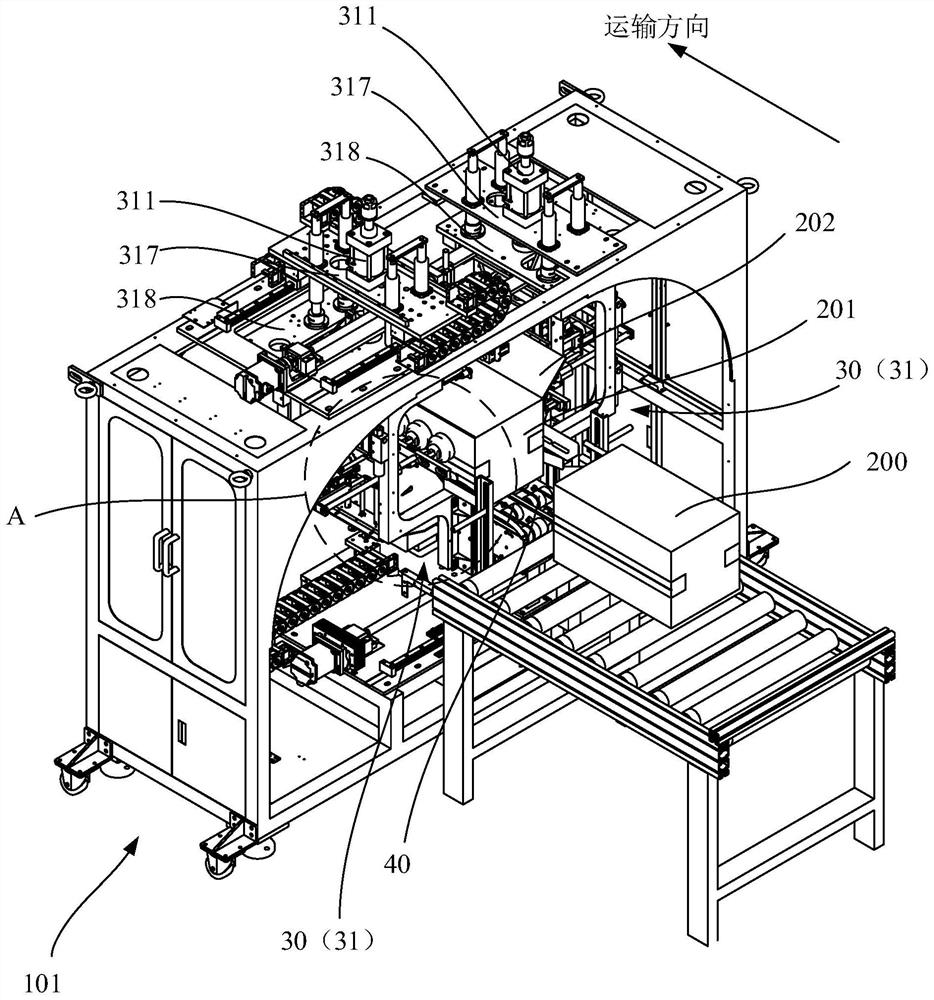

Unpacking and taking-out equipment and control method

PendingCN114476277AImprove unpacking efficiencyLabor savingUnpacking by cuttingStructural engineeringMachine

The invention discloses box opening and taking-out equipment and a control method, and the box opening and taking-out equipment comprises a rack; the detection device is connected to the rack and is used for acquiring the size information of the box body; the box opening and pushing-out device comprises a box opening assembly and a pushing-out assembly which are movably connected to the machine frame, the detection device is electrically connected with the box opening assembly and the pushing-out assembly, and the box opening assembly moves relative to the machine frame according to the size information of the box body to open the box body. And the push-out assembly moves relative to the rack according to the size information of the box body and pushes out the materials in the box body. According to the technical scheme, the box opening and taking-out equipment saves occupied space and is high in working efficiency.

Owner:HANS LASER TECH IND GRP CO LTD

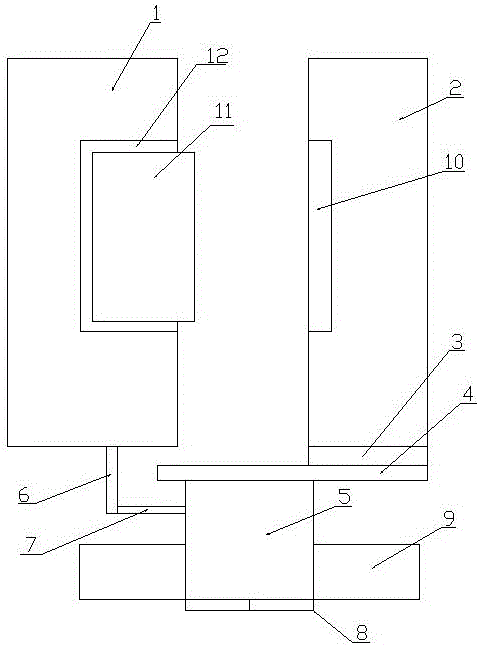

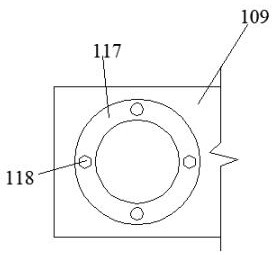

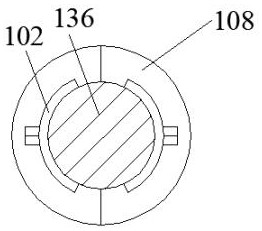

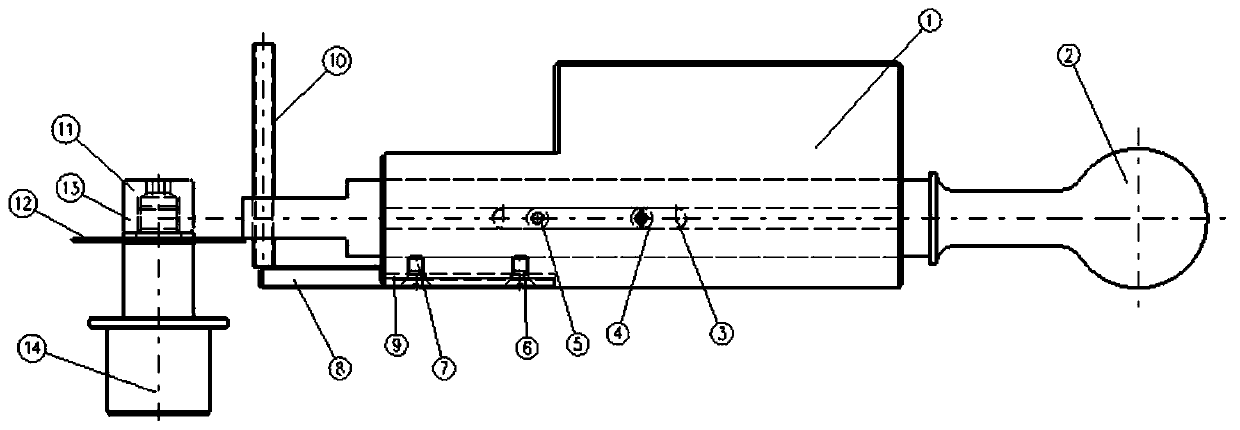

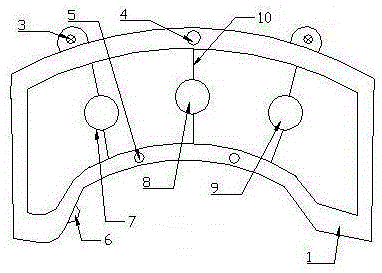

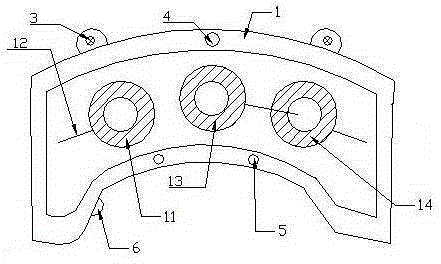

A forced feeder for a tablet press and its working method

The invention belongs to the technical field of tablet application in a tablet press, and specifically discloses a forced feeder for a tablet press, which consists of a casing, a feeding tube arranged on the casing, and a feeding tube arranged on the upper side of the feeding tube. It is composed of a material sieve and a crushing component arranged inside the casing. A kind of beneficial effect of the forced feeder used for tablet press of the present invention is: 1, through three rotating shafts and agitating teeth replacing the tablet raw material distribution structure of the traditional structure, the tablet raw material is pulverized twice, ensuring There is no blockage during the tableting process; 2. In the guide tube of the semi-vacuum tableting machine, three rotating shafts and stirring teeth are used to effectively ensure the continuity, stability and uniformity of the falling of the drug material, and improve the quality of the tableting process. the quality of. The invention has the advantages of reasonable design, stable working state, efficient feeding and crushing, and easy popularization.

Owner:XINGHUA CITY XIANGHE PHARMA MACHINERY

Mulberry leaf essence (extract) extraction production processing equipment and production method thereof

PendingCN114857891AReasonable structureReduce manual involvementDrying gas arrangementsDrying machines with non-progressive movementsElectric machineryEngineering

The invention discloses mulberry leaf essence (matter) extraction production processing equipment and a production method thereof.The mulberry leaf essence (matter) extraction production processing equipment comprises a base, supporting plates are fixedly installed on the two sides of the top of the base, a cutting structure is fixedly installed in the middles of the supporting plates, the cutting structure comprises a cutting barrel, and a top plate is fixedly installed on the top of the cutting barrel; and a driving motor is fixedly mounted at the top of the top plate. Bolts are fixedly installed on the outer surface of the cutting barrel, annular plates are fixedly installed on the two sides of the bolts, and the annular plates penetrate through the two sides of the supporting plate and extend to the outer surface. A drying structure is fixedly mounted in the middle of the top end of the base and comprises a drying oven, and grooves are formed in the two sides of the top end of the drying oven. And during smashing, the design of the multiple feeding openings can have the characteristic of efficient discharging, the time is well controlled during smashing, essence protection liquid is added for essence protection, and essence is prevented from being wasted.

Owner:嘉兴源升堂健康科技有限公司

A rotary blanking device for table tennis production

The invention relates to a blanking device, in particular to a rotary blanking device for table tennis production. The invention provides a rotary blanking device for table tennis production that automatically blanks and automatically cleans up remaining waste. A rotary blanking device for table tennis production includes: a workbench, on which a first rotating shaft is rotatably connected; A slot, a plurality of bearing rods are connected in the placement slot, and a spur gear is fixedly connected to the side of the first rotating shaft close to the circular disk; the intermittent rotating mechanism is arranged on the side of the workbench away from the first rotating shaft. The invention can make the produced table tennis material tray rotate to the right below the pressing mechanism through the intermittent rotating mechanism, and the table tennis material can be blanked through the pressing mechanism, so that the blanking speed of the table tennis material can be improved.

Owner:聊城一明五金科技有限公司

Rotary discharging device for table tennis ball production

The invention relates to a discharging device, in particular to a rotary discharging device for table tennis ball production. The invention provides the rotary discharging device for table tennis ballproduction, which is capable of automatically discharging and automatically cleaning residual wastes. The rotary discharging device for table tennis ball production comprises a workbench, a first rotating shaft is rotationally connected to the workbench, a circular disc is installed on the first rotating shaft, eight containing grooves are formed in the circumferential wall of the circular disc,a plurality of bearing rods are connected into the containing grooves, and a straight gear is fixedly connected to the side, close to the circular disc, of the first rotating shaft; the rotary blanking device also comprises an intermittent rotating mechanism which is arranged on the side, away from the first rotating shaft, of the workbench. According to the invention, the produced table tennis ball tray can be rotated to the position under the pressing mechanism through the intermittent rotating mechanism, table tennis ball materials can be discharged through the pressing mechanism, and therefore the discharging speed of the table tennis ball materials can be increased.

Owner:聊城一明五金科技有限公司

Unloading device suitable for taking and closing multi-size molds

ActiveCN111531152BReduce labor intensityDegree of reductionMould handling equipmentsEngineeringSteel ball

The invention provides a blanking device suitable for taking and closing molds of multiple sizes, comprising: an installation frame, an upper mold manipulator, a lower mold manipulator and a roller conveying line; the roller conveying line is arranged on the The middle part is vacant at the bottom, and the roller conveying line is used to transport the steel ball mold. The steel ball mold is composed of an upper mold and a lower mold, and steel balls are stored between the upper mold and the lower mold; the upper mold manipulator slides Installed on one side of the installation frame; the lower mold manipulator is slidably installed on the other side of the installation rack; The manipulator of the lower mold is used to grip the lower mold, turn over the material and close the mold; the present invention is reasonable in design and fast in movement, and can complete the whole process of mold opening, blanking and mold closing, effectively reducing the labor intensity and The degree of work danger improves the cutting efficiency, solves the problem of material adhesion, and has applicability at the same time.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST +1

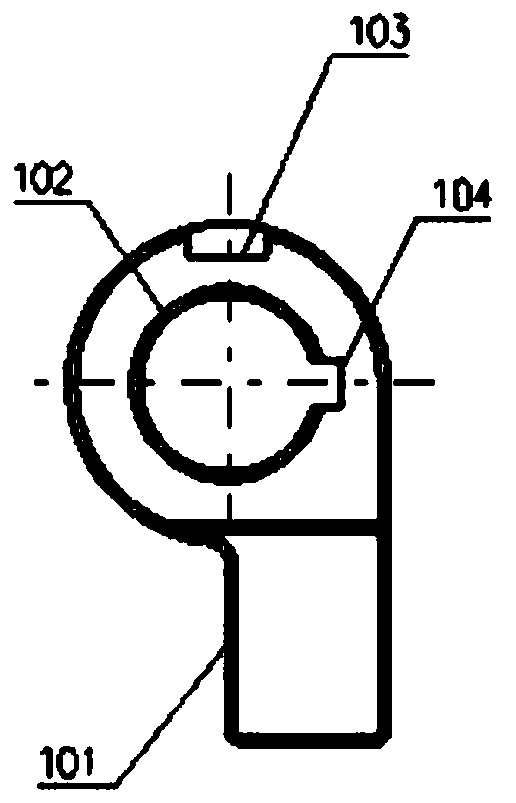

Aluminum sealing pipe blanking device and using method thereof

The invention relates to an aluminum sealing pipe blanking device and a using method thereof. The aluminum sealing pipe blanking device comprises a transmission shaft driving a slitting cutter, used for cutting an aluminum sealing pipe, to rotate. The aluminum sealing pipe blanking device further comprises a fixture body which is fixed to a lathe saddle and used for providing supporting for the aluminum sealing pipe, a push rod which is arranged in the fixture body, is in sliding fit with the fixture body and is used for manually adjusting the distance between the aluminum sealing pipe and theslitting cutter, and a positioning block which is arranged at the lower end of the fixture body and used for providing supporting positioning for the aluminum sealing pipe. The using method comprisesthe following specific steps of S1, flat key installing, S2, gasket adjusting, S3, push rod assembling, S4, fixture body fastening, S5, cutter installing, S6, rotary shaft starting, and S7, speed adjusting and cutting. The aluminum sealing pipe blanking device achieves efficient blanking of the aluminum sealing pipe, has the advantages of being convenient and quick to operate, good in size consistency, capable of relieving labor intensity and improving the production efficiency, high in sealing performance and automation degree, small in size and high in safety, and meanwhile, is low in manufacturing cost and suitable for middle and small-sized enterprises.

Owner:安徽天航机电有限公司

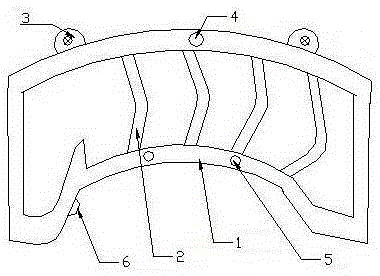

Forced feeder used for tablet press and work method thereof

The invention belongs to the technical field of tabletting application of a tablet press and particularly discloses a forced feeder used for a tablet press. The forced feeder consists of a shell, a material guide pipe arranged on the shell, a feeding sieve opening formed in one side of the upper part of the material guide pipe and a material pressing pulverizing assembly arranged in the shell. The forced feeder used for the tablet press has the advantages that 1, three transmission shafts and stirring teeth replace a traditional tablet raw material separating structure, carry out secondary pulverizing operation on tablet raw materials and ensure that no blocking phenomena occur in the tabletting process; and 2, through utilizing the three transmission shafts and stirring teeth in the semi-vacuum material guide pipe of the tablet press, the feeding continuity, stability and evenness of the drug raw materials are effectively ensured, and the tabletting quality is improved. The forced feeder is reasonable in design, stable in work states, efficient in feeding and pulverizing and easy to popularize.

Owner:XINGHUA CITY XIANGHE PHARMA MACHINERY

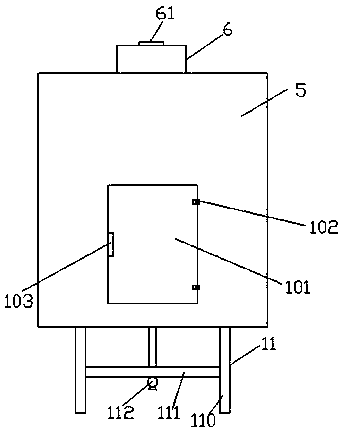

Industrial fabric transfer tooling

ActiveCN105366170BSmooth feedingEfficient blankingContainers for annular articlesDischarging meansEngineeringTruck

The object of the present invention is to provide a kind of industrial cloth transfer tool, on the base, there is a placement cavity consisting of a bottom plate, two side plates and a baffle, and a concave placement block whose height gradually increases from left to right is set in the placement cavity To place the wound industrial cloth, so that the industrial cloth in the shape of a letter can be placed, which is very stable, and the upper side of the middle plate can be pushed down by the handle to make the left side of the bottom plate go up, so that the industrial cloth can be unloaded, which is very efficient; And the bottom of the base is equipped with universal wheels for transfer, and the right side of the base is provided with a socket for forklift fork transfer, which is very convenient; the structure of the invention is simple and easy to operate, and can safely and stably transfer industrial cloth, and the material is quickly unloaded, suitable for in production.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

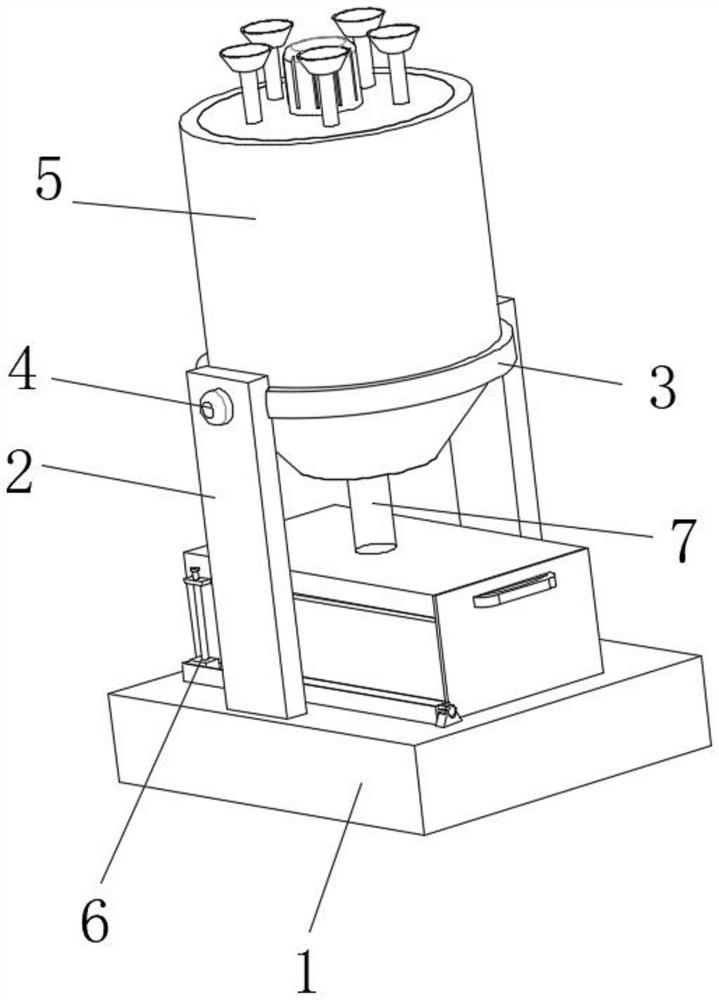

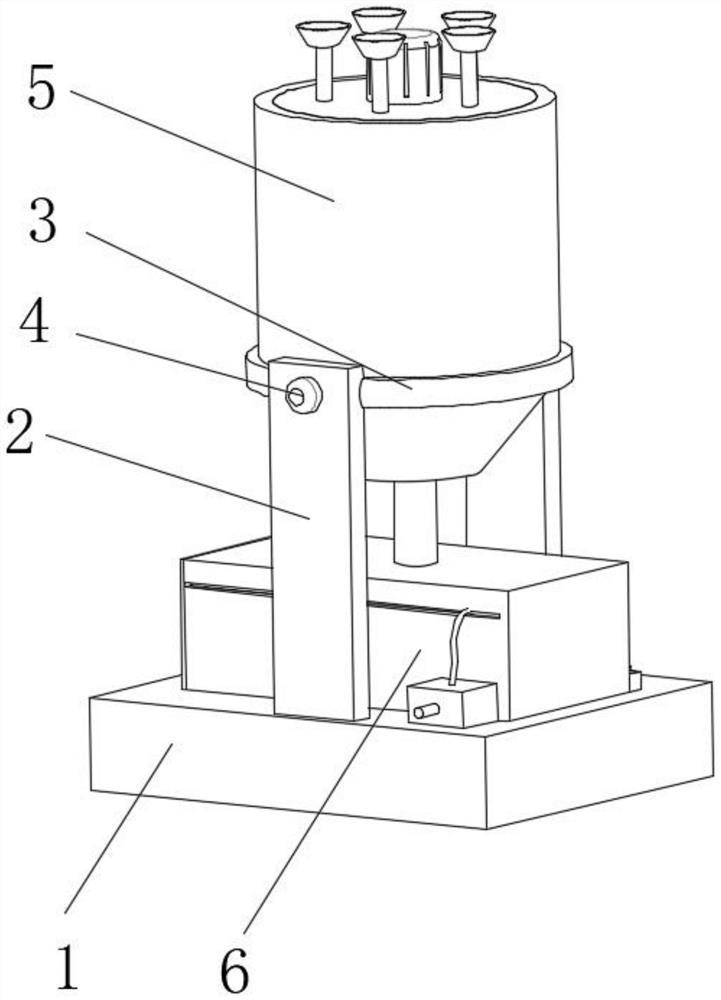

Bridge construction device quick to use

InactiveCN108086159AAutomatic control and automatic stirring workEfficient blankingBridge erection/assemblyCement mixing apparatusArchitectural engineeringFuselage

The invention discloses a bridge construction device quick to use. The bridge construction device quick to use comprises a machine body, standing feet fixed to the left side and the right side of thebottom of the machine body and a feeding part rotationally installed at the top of the machine body. A concrete cavity is formed in the machine body. A first cavity is formed in the portion, above theconcrete cavity, in the machine body. A second cavity is formed in the portion, on the right side of the first cavity, in the machine body. A motor is fixedly arranged in the portion, between the second cavity and the first cavity, in the machine body. A first bevel runner extending into the first cavity is in cooperating connection with the tail end of the left side of the motor. A second bevelrunner is in engaged connection with the portion, at the top of the left side of the first bevel runner, in the first cavity. A rotary shaft extending upwards is fixedly arranged on the top face of the second bevel runner. The extending tail end at the top of the rotary shaft is fixedly connected with the bottom of the feeding part. The bridge construction device quick to use is simple in structure, small, exquisite, light, convenient to use and capable of achieving automatic concrete even stirring work and improving construction efficiency.

Owner:惠安县通联机械研发中心

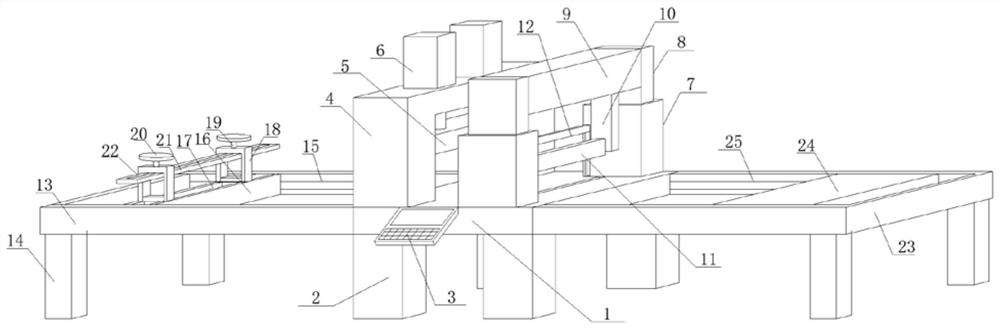

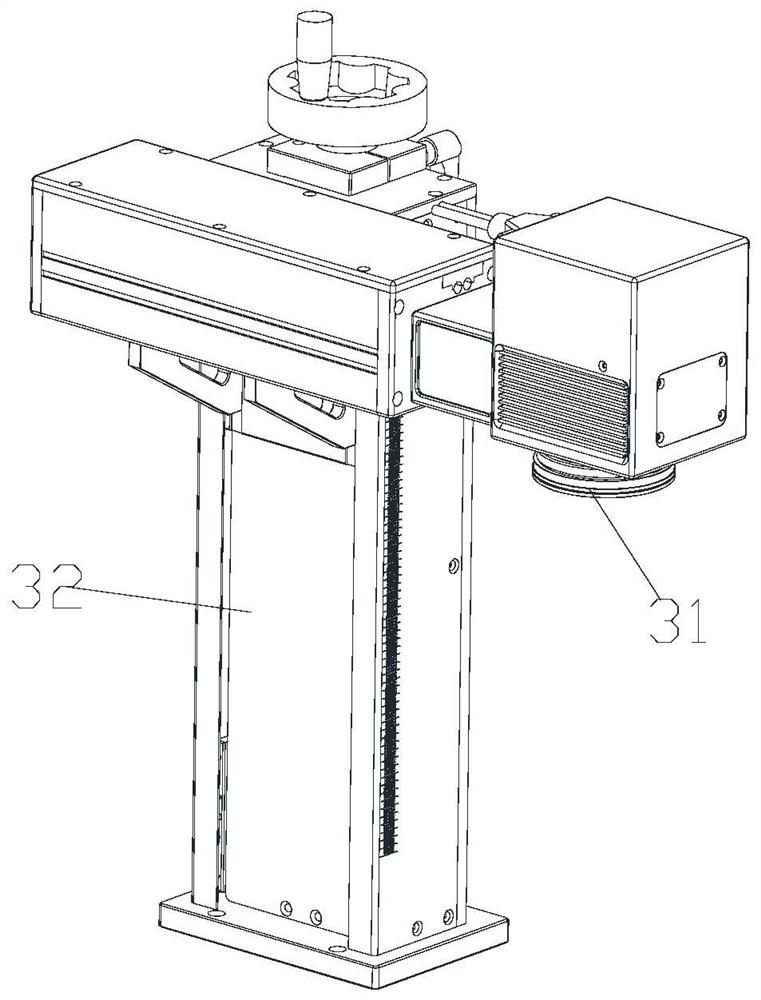

Rapid marking equipment based on vibration disc discharging

PendingCN112676698ASave human effortSimple structureControl devices for conveyorsLaser beam welding apparatusEngineeringMachine

The invention discloses rapid marking equipment based on vibration disc discharging. The rapid marking equipment based on vibration disc discharging comprises a machine platform, a vibration disc discharging device and a marking device and further comprises a marking auxiliary device, the vibration disc discharging device and the marking device are arranged on the machine platform, the marking auxiliary device is arranged on the machine platform and is located between the vibration disc discharging device and the marking device, the marking auxiliary device comprises a jig plate, a material pressing mechanism, an air blowing mechanism and a material blocking mechanism, a first conveying channel communicating with the vibration disc discharging device is formed in the jig plate, the material pressing mechanism is matched with a workpiece in the first conveying channel and used for tightly pressing the workpiece, the air blowing mechanism is installed on the material pressing mechanism, matched with the workpiece in the first conveying channel and used for blowing the workpiece after marking is completed, the material blocking mechanism is installed behind the material pressing mechanism, located at the discharging end of the first conveying channel and used for carrying out limitation on the workpiece, and a marking working area of the marking device is located between the material pressing mechanism and the material blocking mechanism. The equipment is simple in structure, convenient to operate, efficient in production, high in speed and saves cost and manpower.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

High-efficiency milling and flattening machine

ActiveCN110732712BImprove feeding efficiencyEfficient blankingWork clamping meansMilling equipment detailsFeed driveMachine

The invention relates to a high-efficiency flat milling machine. The key point of the technical scheme is a high-efficiency flat milling machine, the high-efficiency flat milling machine comprises a machine body, a supporting frame is fixedly arranged on the surface of the machine body, a group of processing components which are facing each other to flat milling a workpiece are fixedly arranged onthe supporting frame, a plurality of clamping parts which are used for clamping the workpiece are fixedly arranged on the supporting frame, the clamping parts and the processing components are located at a side face adjacent the supporting frame, the supporting frame is fixedly provided with a feeding part, the feeding part comprises a feeding driving cylinder which is fixed with the supporting frame and a taking magnet which is fixed with a piston rod of the feeding driving cylinder, the piston rod of the feeding driving cylinder is located in the middle of the two groups of the processing components and is perpendicular to a connecting line between the two groups of the processing components, a shrinkage groove is arranged at the position where the supporting frame is directly facing the taking magnet, the groove depth of the shrinkage groove is larger than the thickness of the taking magnet, the machine body is fixedly provided with a temporarily placed table for temporarily placing workpieces, and the temporarily placed table is located in the front of the feeding driving cylinder, so that the effect that the processing efficiency is improved is achieved.

Owner:天津宇仁金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com