Patents

Literature

61results about How to "Simple hardware requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

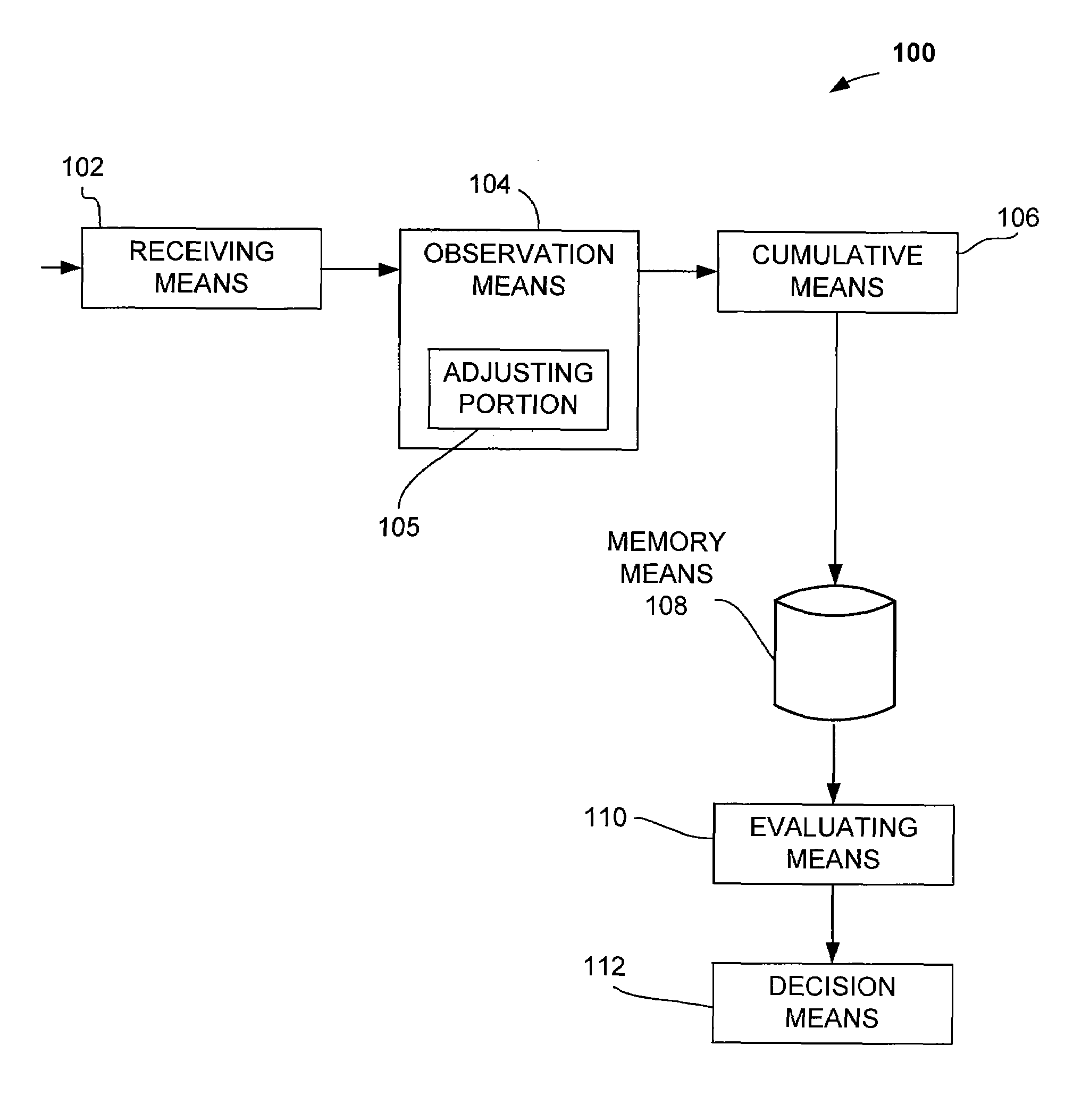

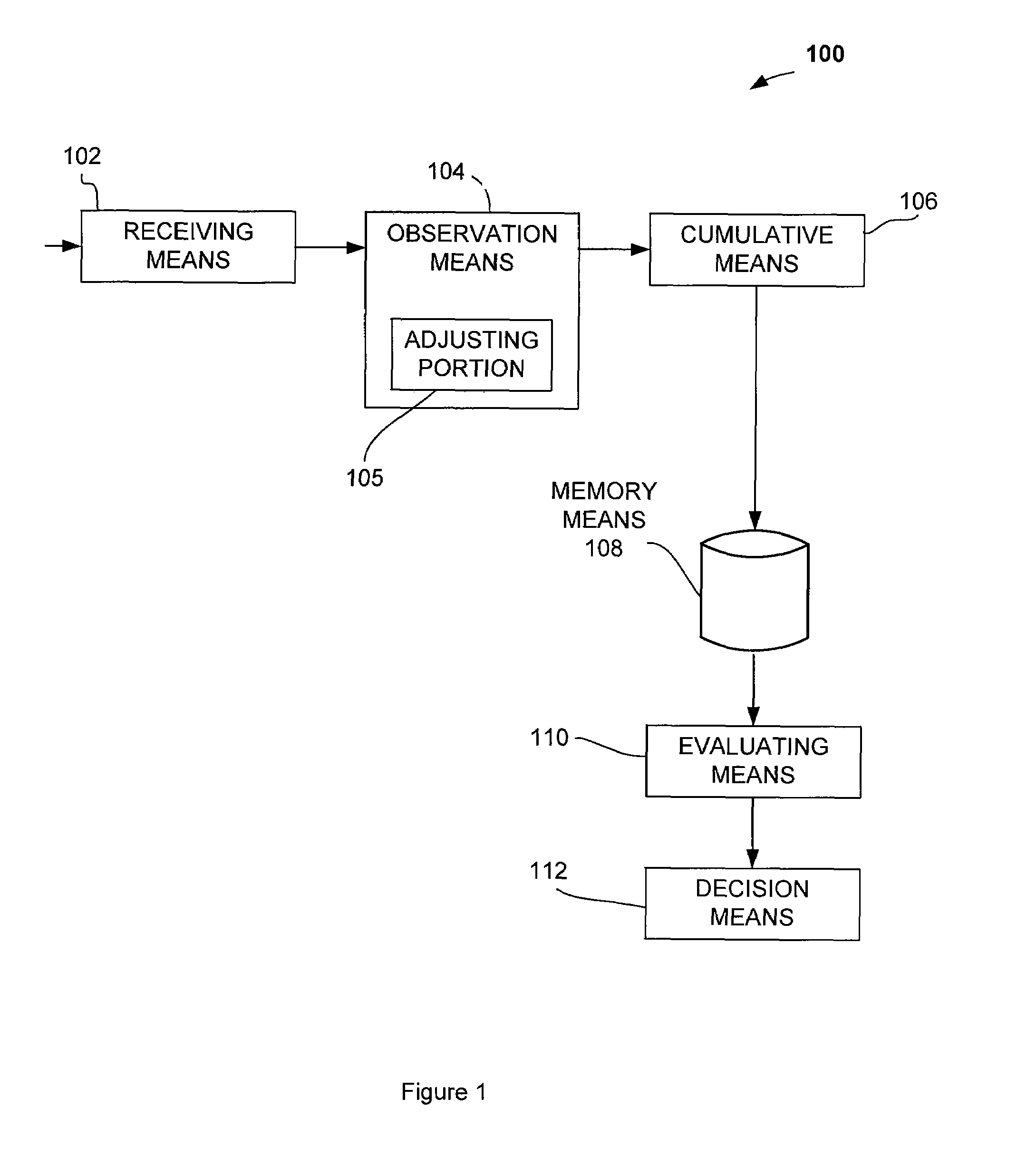

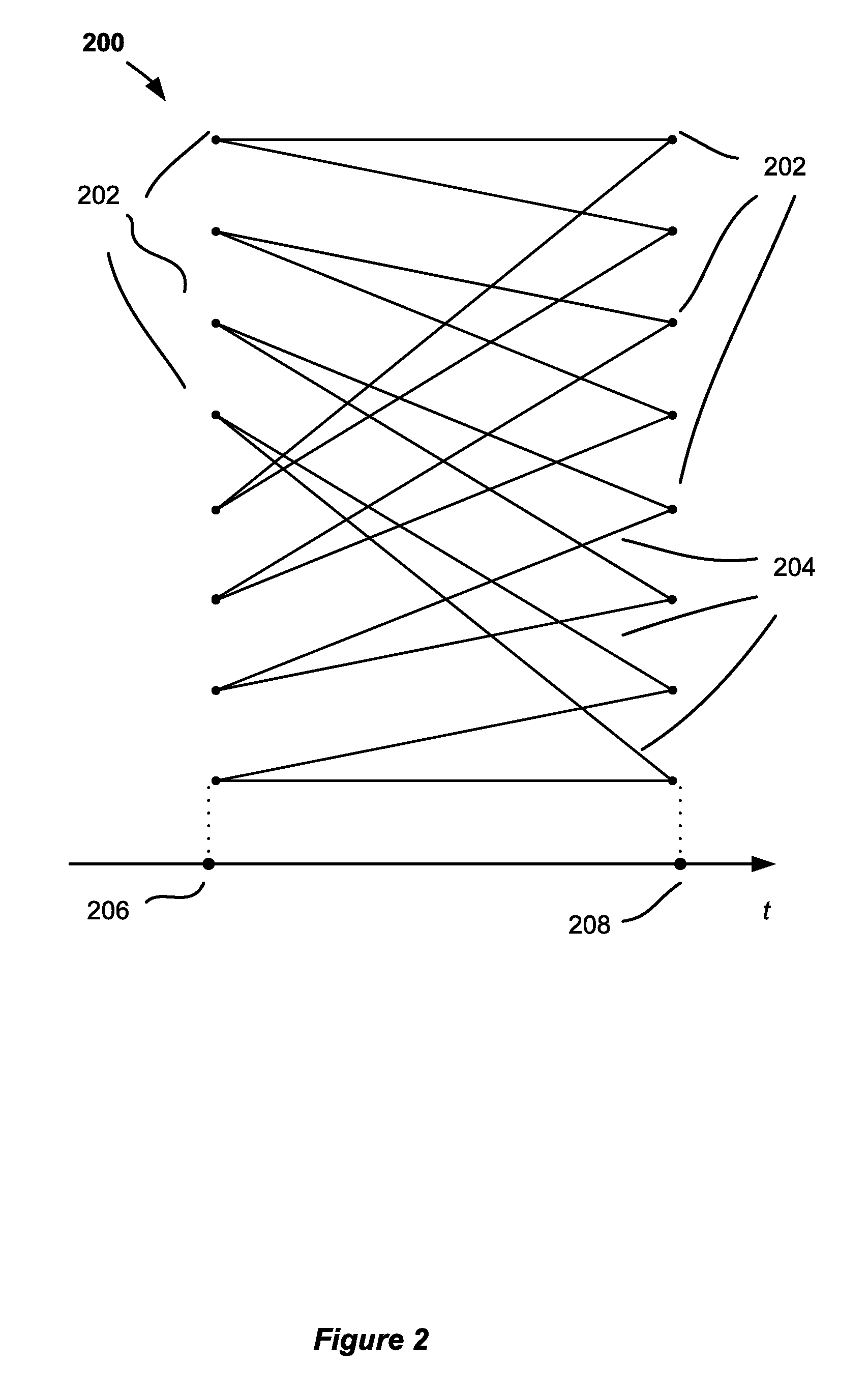

Scheme for blocking the use of lost or stolen network-connectable computer systems

ActiveUS6925562B2Easy to tamper withMaximum flexibilityDigital data processing detailsUser identity/authority verificationCommunication interfaceTrusted hardware

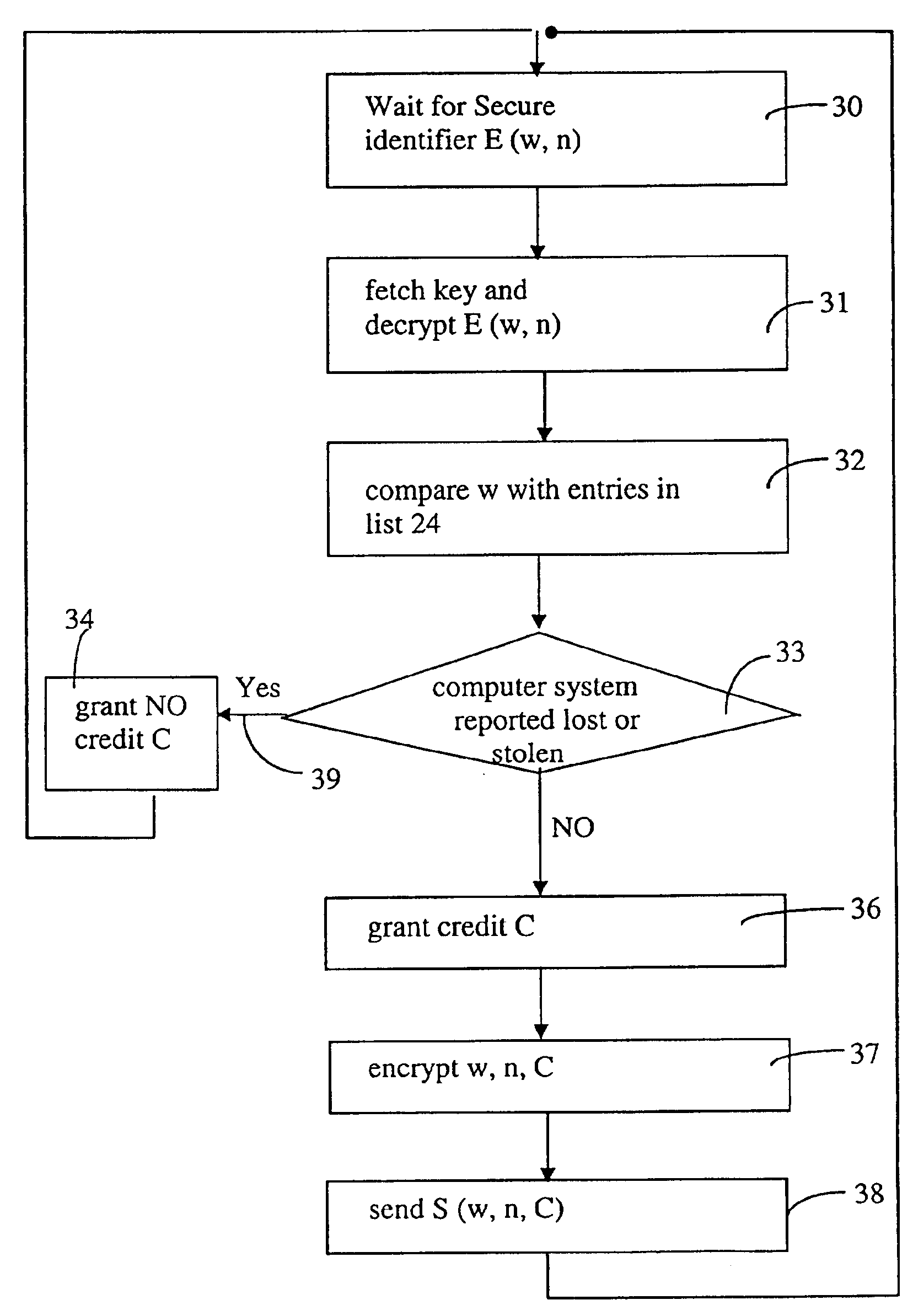

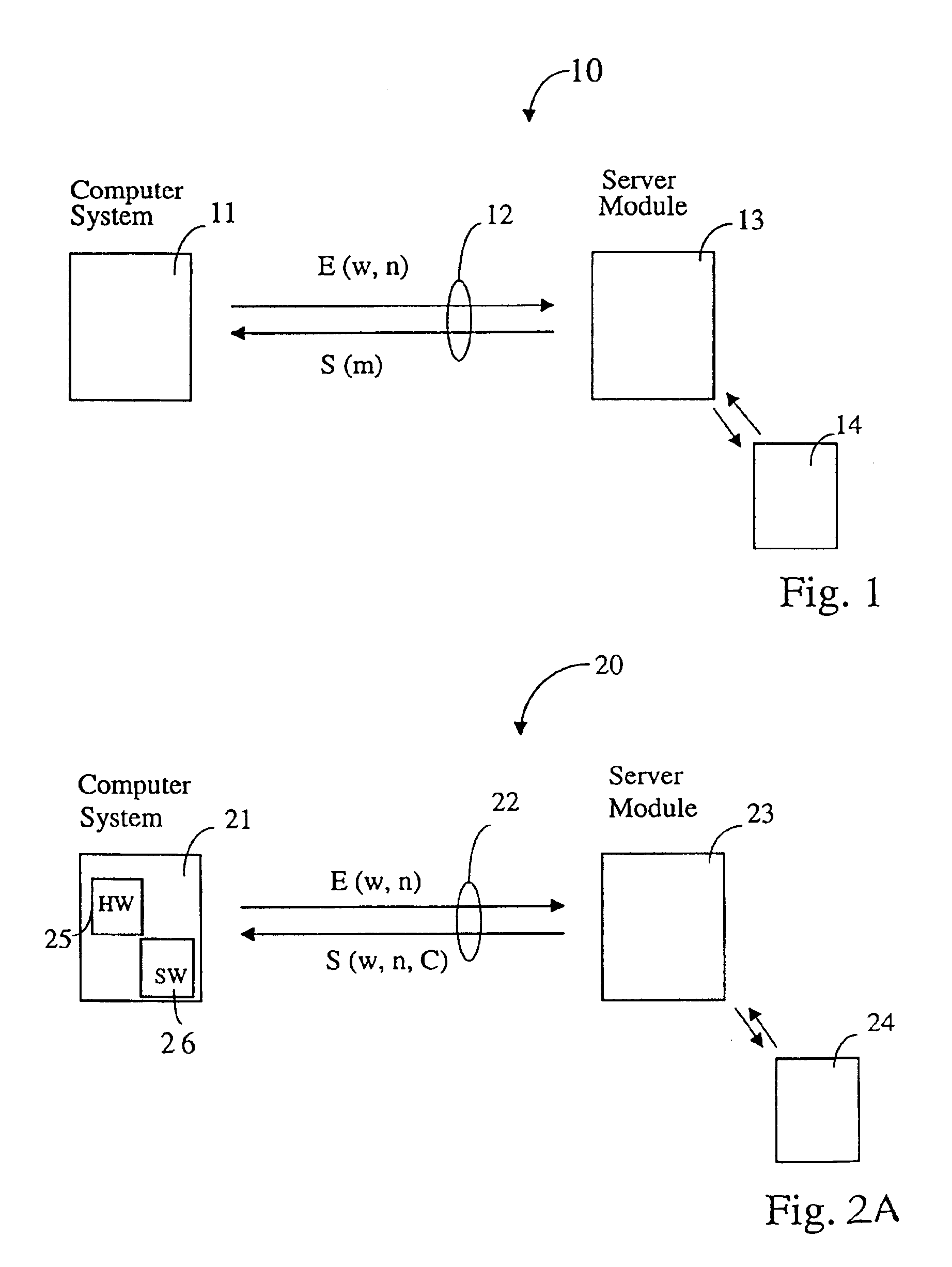

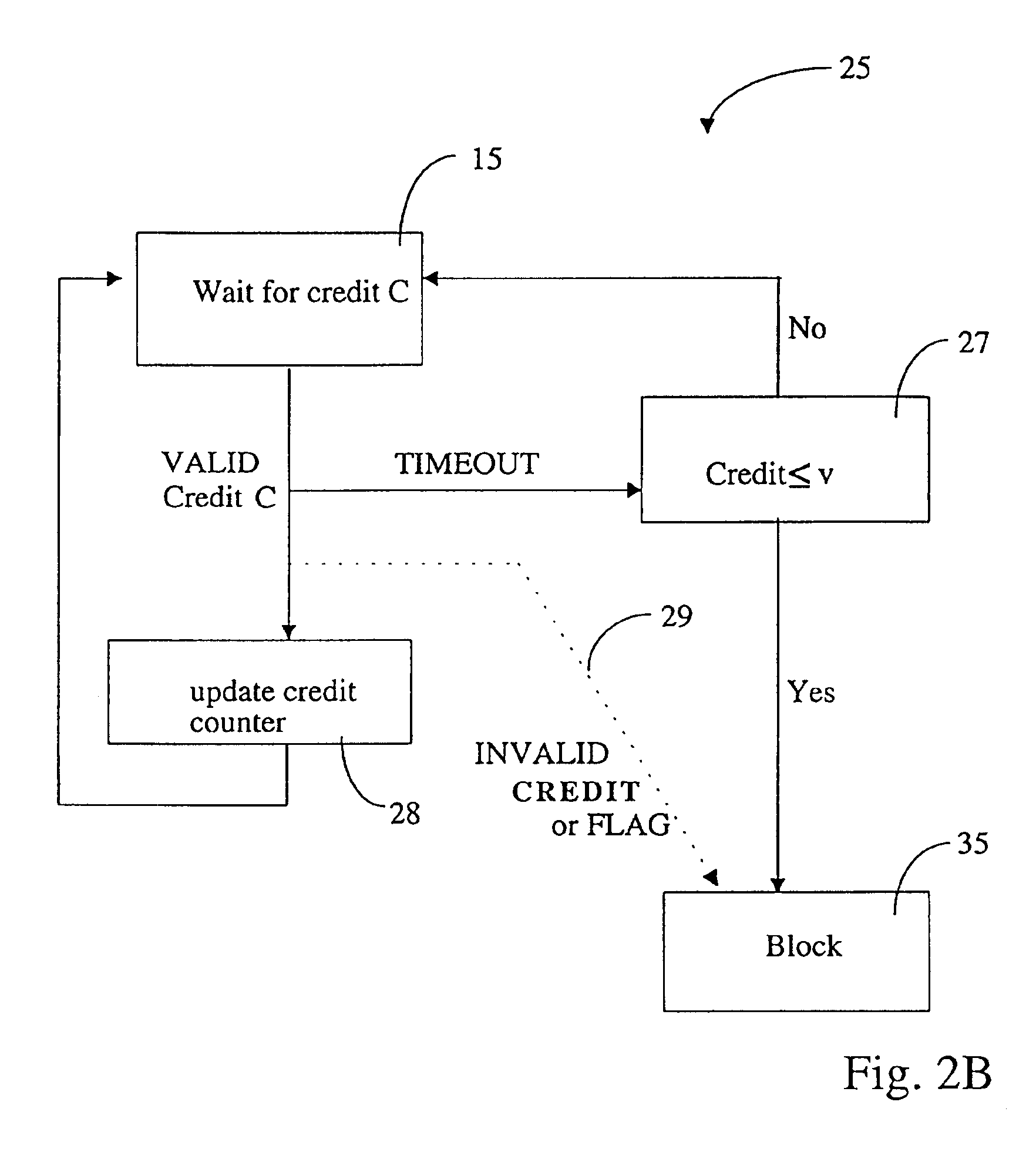

Scheme for switching a computer system (21), which is connectable via a communication interface and a network (22) to a server module (23), into a special mode of operation. The computer system (21) comprises a software component (26) for sending an identifier (w) assigned to the computer system (21) via the communication interface and the network (22) to the server module (23). In response, the software component (26) receives a token (S), issued by the server module (23), whereby the token (S) comprises a credit (C). In addition, the computer system (21) comprises a trusted hardware component (25) storing the identifier (w) and comprising a credit counter (44) with a credit which is automatically exhaustible step-by-step, and which is updateable with the credit (C) received from the server module (23). The computer system (21) has a trigger unit for switching the computer system (21) into the special mode of operation, e.g. a mode where the computer system (21) is of limited use to a user, if the credit of the credit counter is exhausted.

Owner:TREND MICRO INC

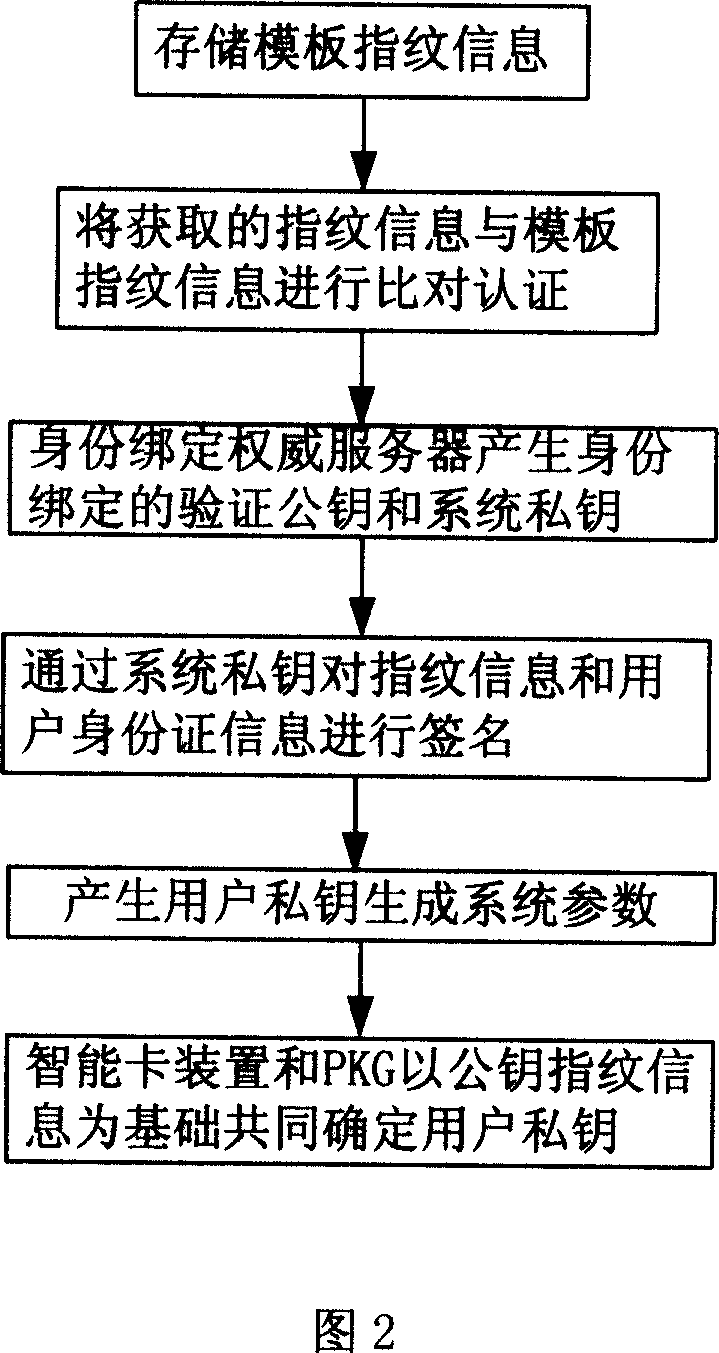

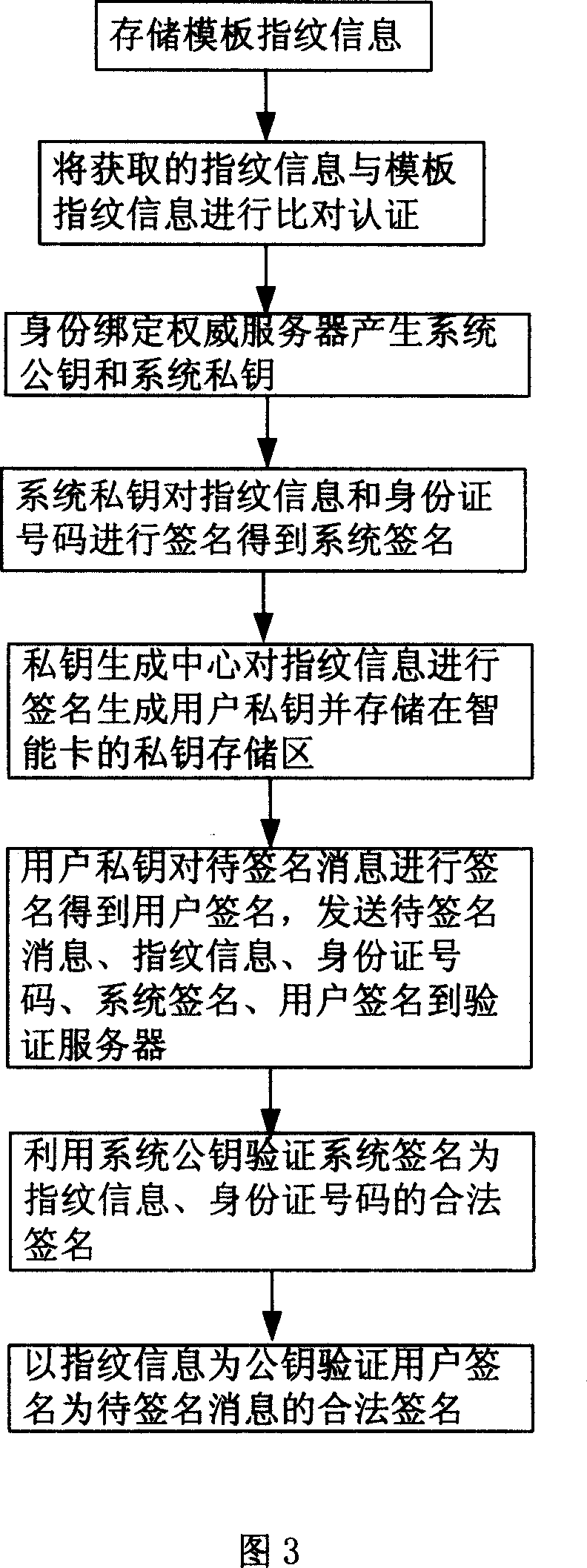

Public key infrastructure system, local safety apparatus and operation method

InactiveCN1921384ALess investmentSolve the management complexityPublic key for secure communicationUser identity/authority verificationE-commerceKey generator

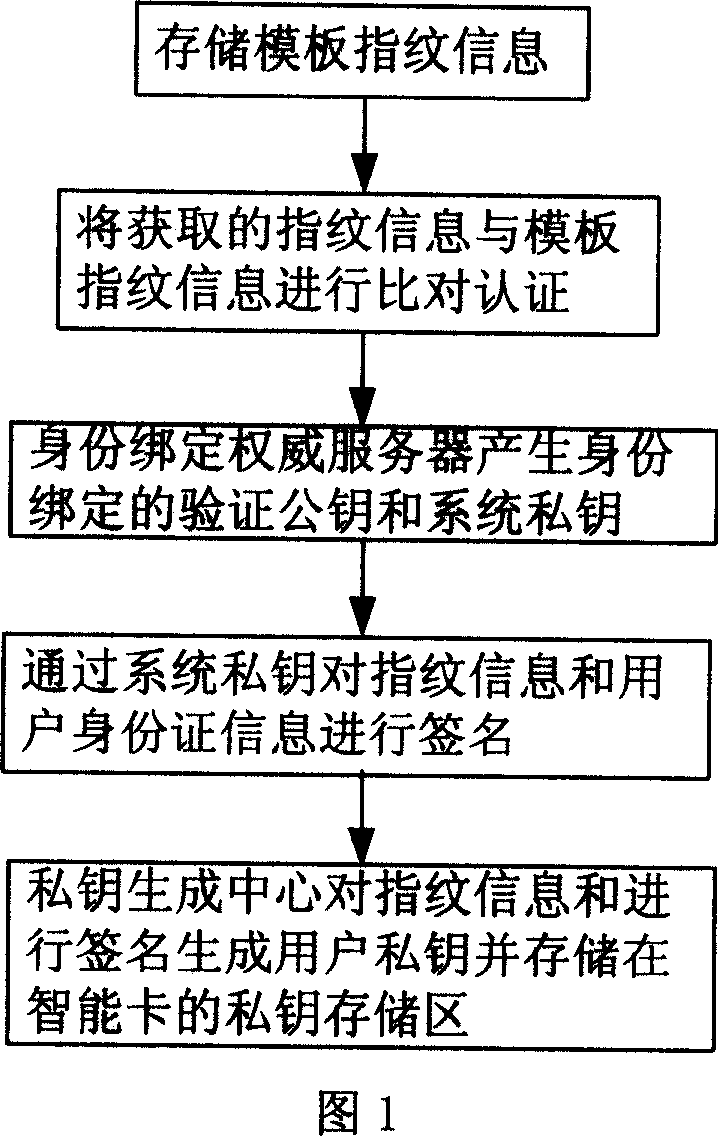

The invention relates to a public key basic device, local safety device and operation method. Wherein, it comprises that user via local safety device obtains the biology character information; the identification bond authority server generates the system private key not obtained by user, and generates identification bond system parameter as the system public key to be published; the local safety device via the system private key signs the user biology character information IDU and real identification information to obtain the system sign; the uses biology character information as public key, the private key generator via the biology character information signs to generate user private key, to be stored in local safety device. The invention also provides a relative public key basic device identification system and device. And the electric business platform can be used in mobile communication, etc.

Owner:SHANGHAI JIAO TONG UNIV +1

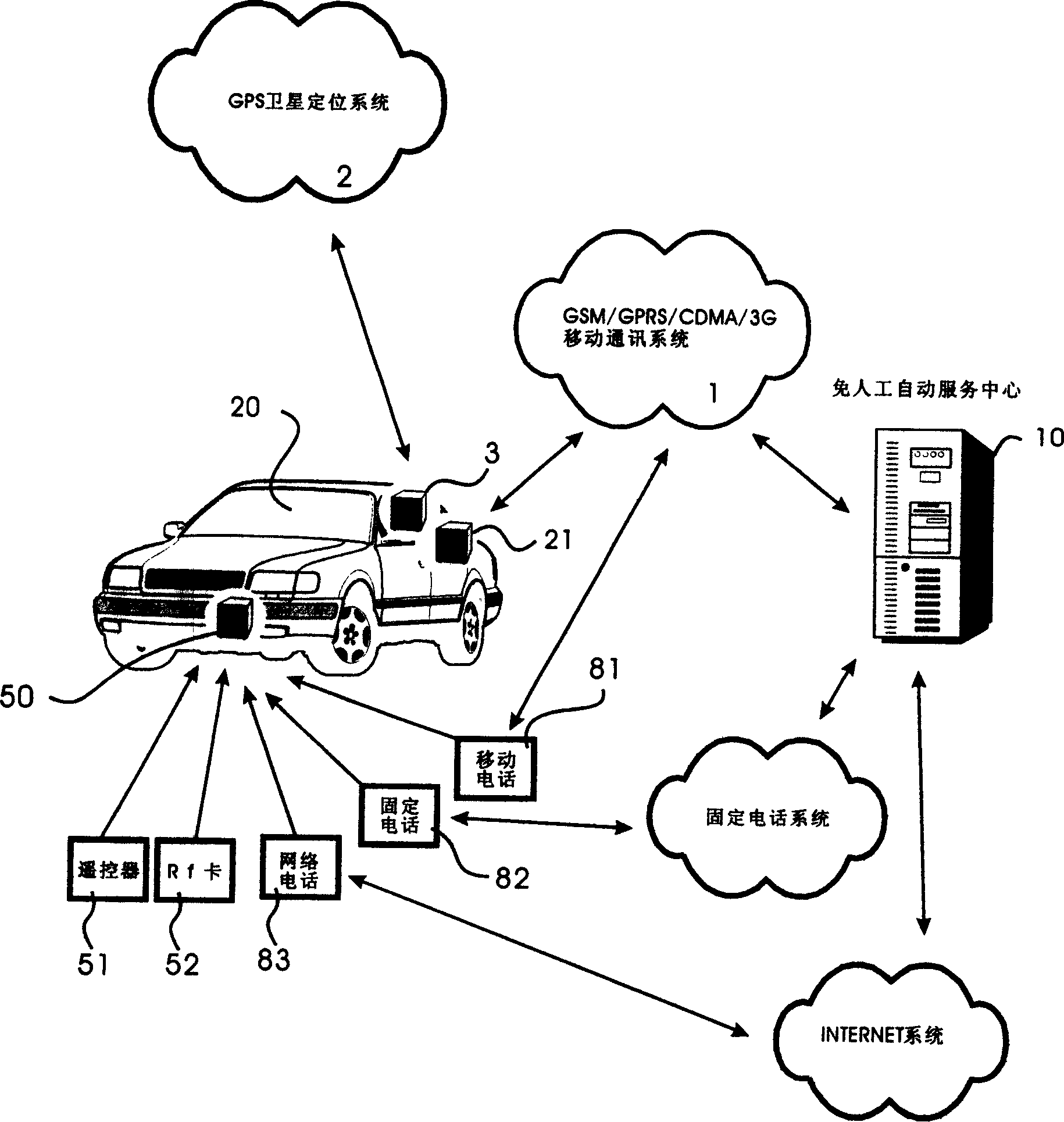

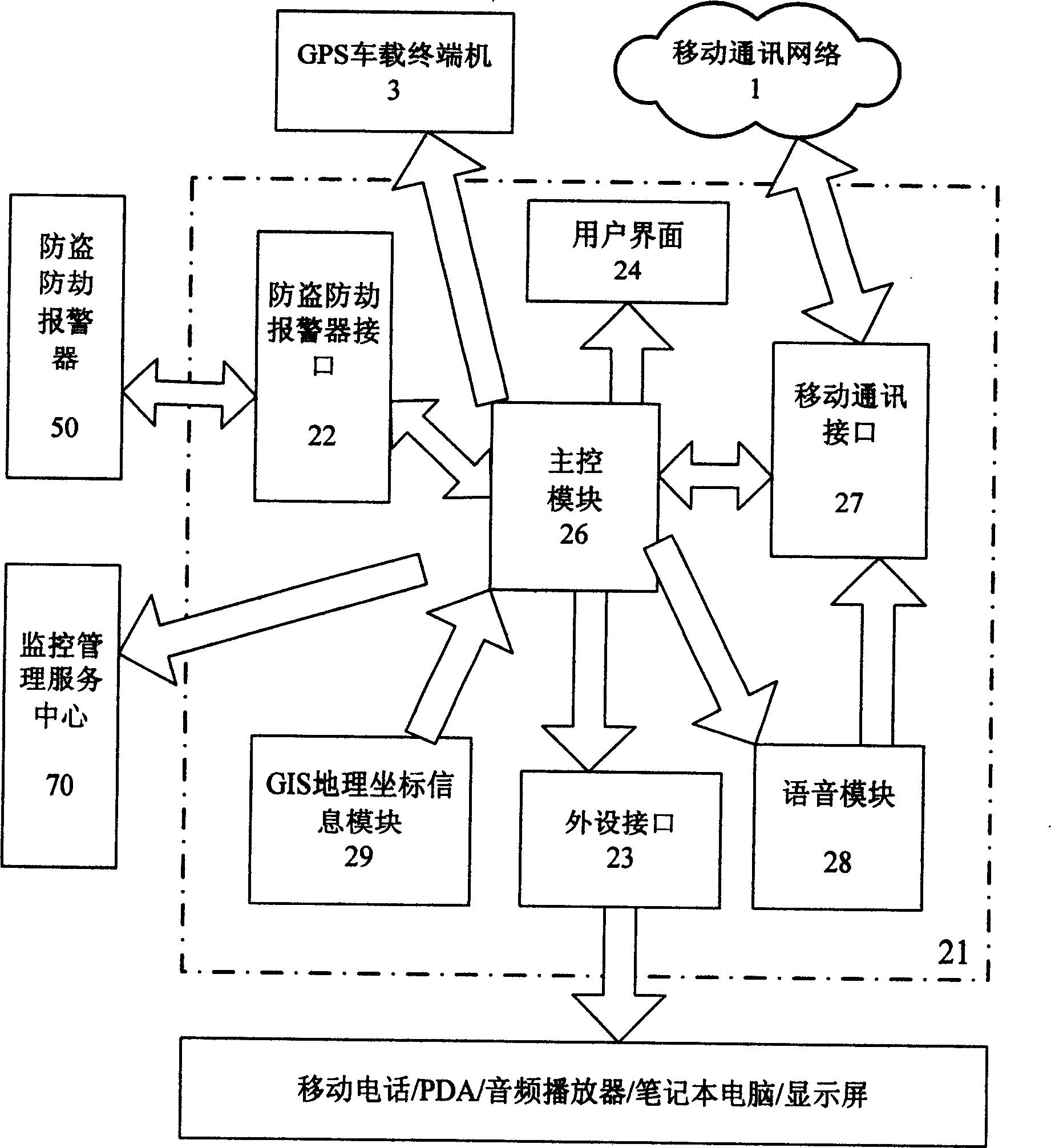

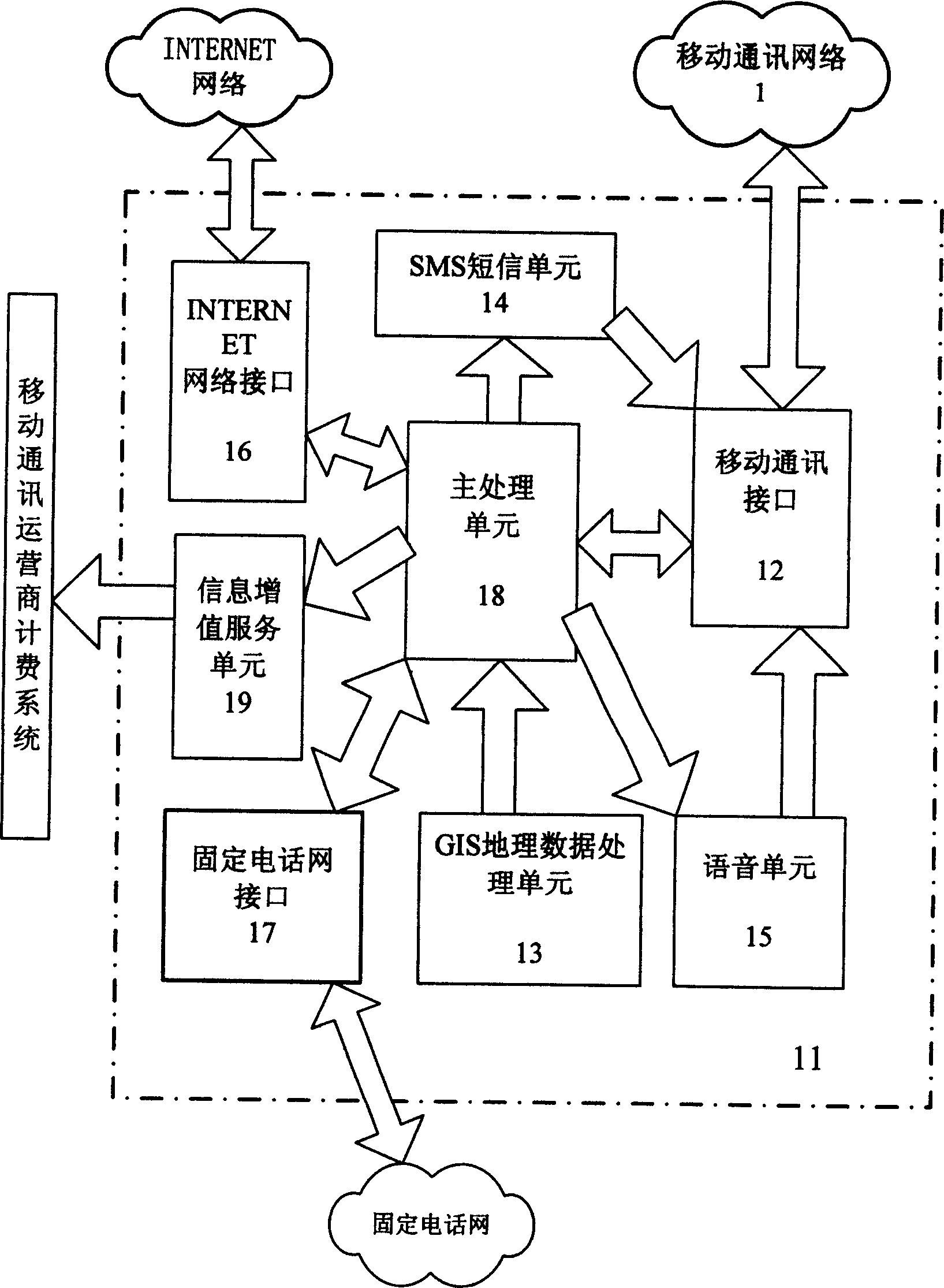

Manpower-free automatic service center type automobile network anti-theft and anti-robbery monitoring alarm and satellite positioning system

InactiveCN1604608ARemote Monitoring SecurityRealize automatic mutual data exchangeTelephonic communicationAlarmsThird generationGSM

This is the manual-free automatic service center style auto network anti-theft anti-robbery monitoring alarm and satellite positioning system. It based on GSM / GPRS / CDMA / 3G and other mobile communication network, telecom network, Internet network, GPS, GIS, data-character switch processing, character and voice switch processing, data storage and connection processing and so on. It builds the complete network manual-free automatic service center. The system vehicle-carrying host in this invention can compliant with any existing vehicle-carrying burglar alarm, and can real-time view / send various information of vehicle by any communication network remotely. It can also use the intelligent voice platform of this system send words, voice, image, picture and other system information and attached added value service information to various communication terminal of system user.

Owner:深圳市赛利达实业发展有限公司

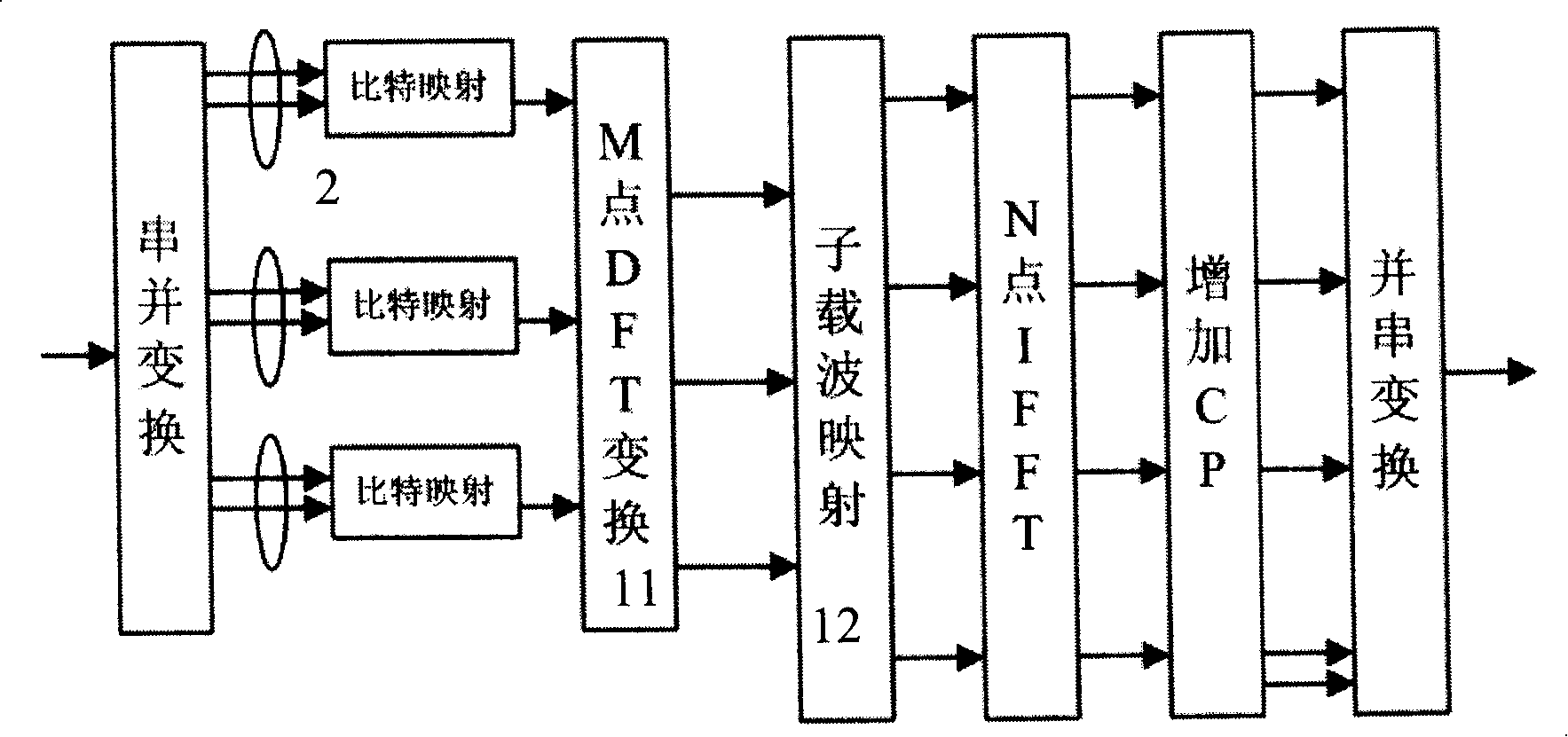

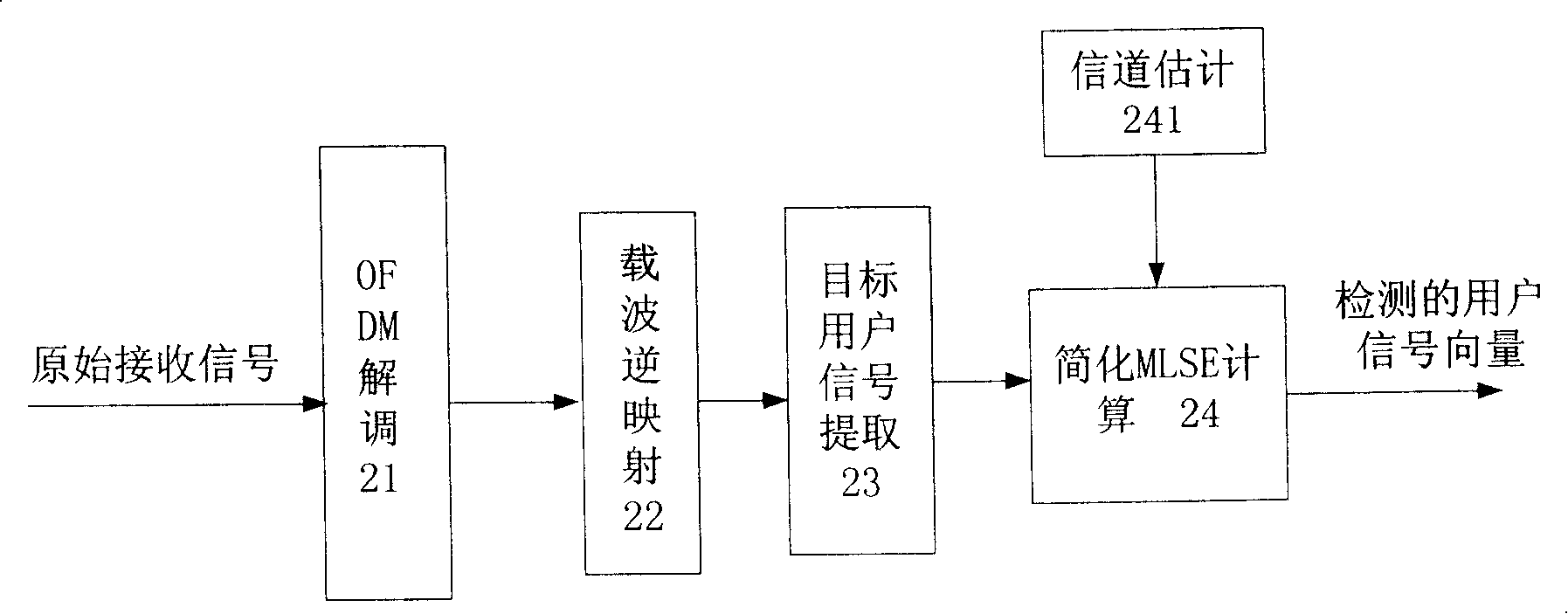

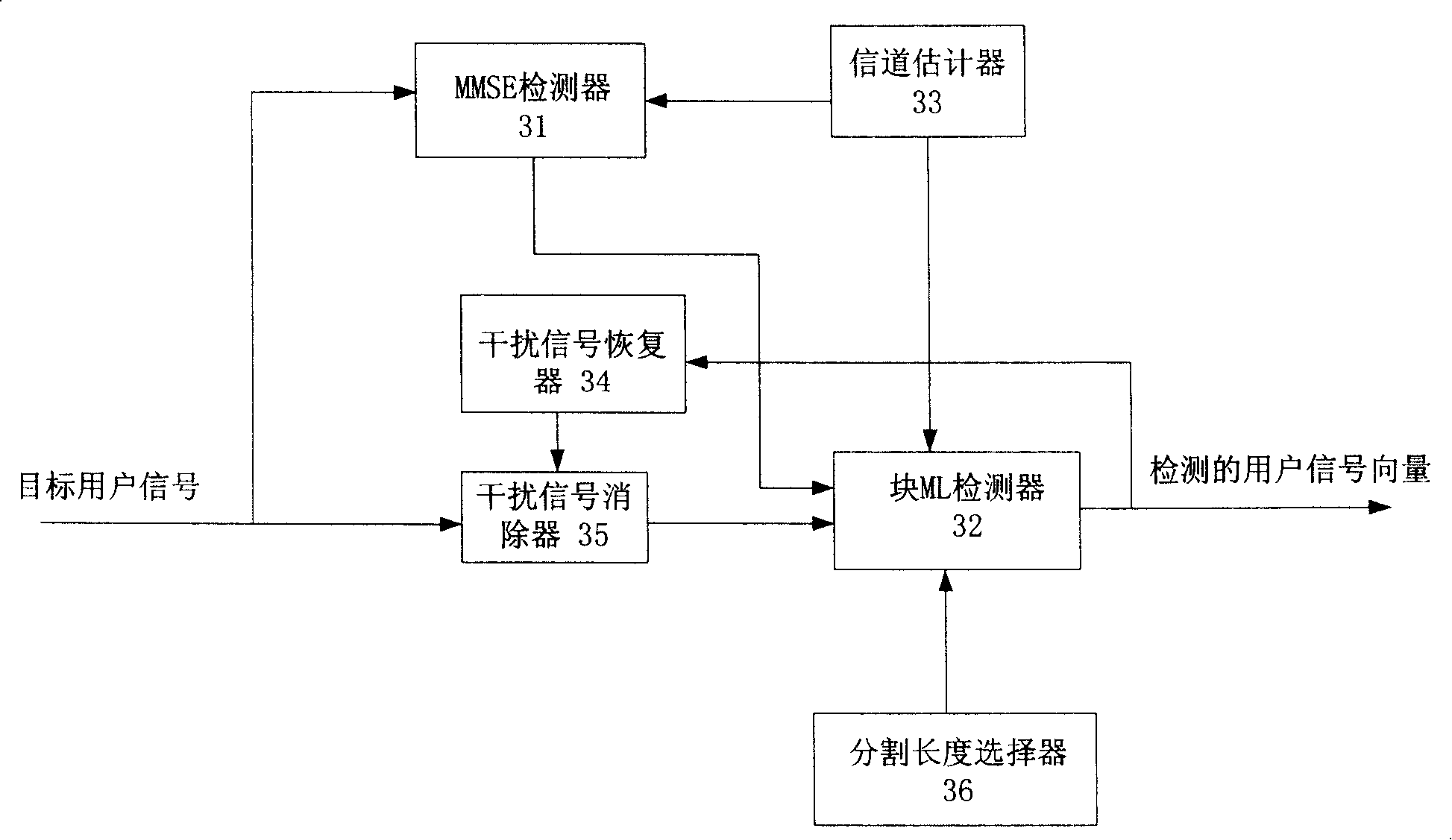

A multi-level mixing detection method and its device

InactiveCN101170317AReduce complexityReduced performance gainBaseband system detailsRadio transmission for post communicationRound complexityLow complexity

The invention relates to a multi-grade mixing checking method and a device. The method includes the steps of: estimating the value according to the channel and generating the preliminary sequence from user signals according to digital wave filtering rules; expanding the preliminary sequence peripherally for the combination of the sequence aggregate to be judged; traversing the aggregate and selecting the maximum likelihood sequence with user information according to the maximum likelihood principle and taking the sequence as the checking result; wherein, the device also sets a digital wave filter for pretreatment before the ML checker. The method and the device replace the direct MLSE treatment of user information with the result of digital wave filtering, thus greatly lowering the complication of MLSE arithmetic, being superior to digital wave filtering in performance, and ensuring the given performance gaining. Under the high complication of MLSE arithmetic, the method and device can simplify the concrete realization of MLSE checking, which is favorable for actual application.

Owner:ZTE CORP

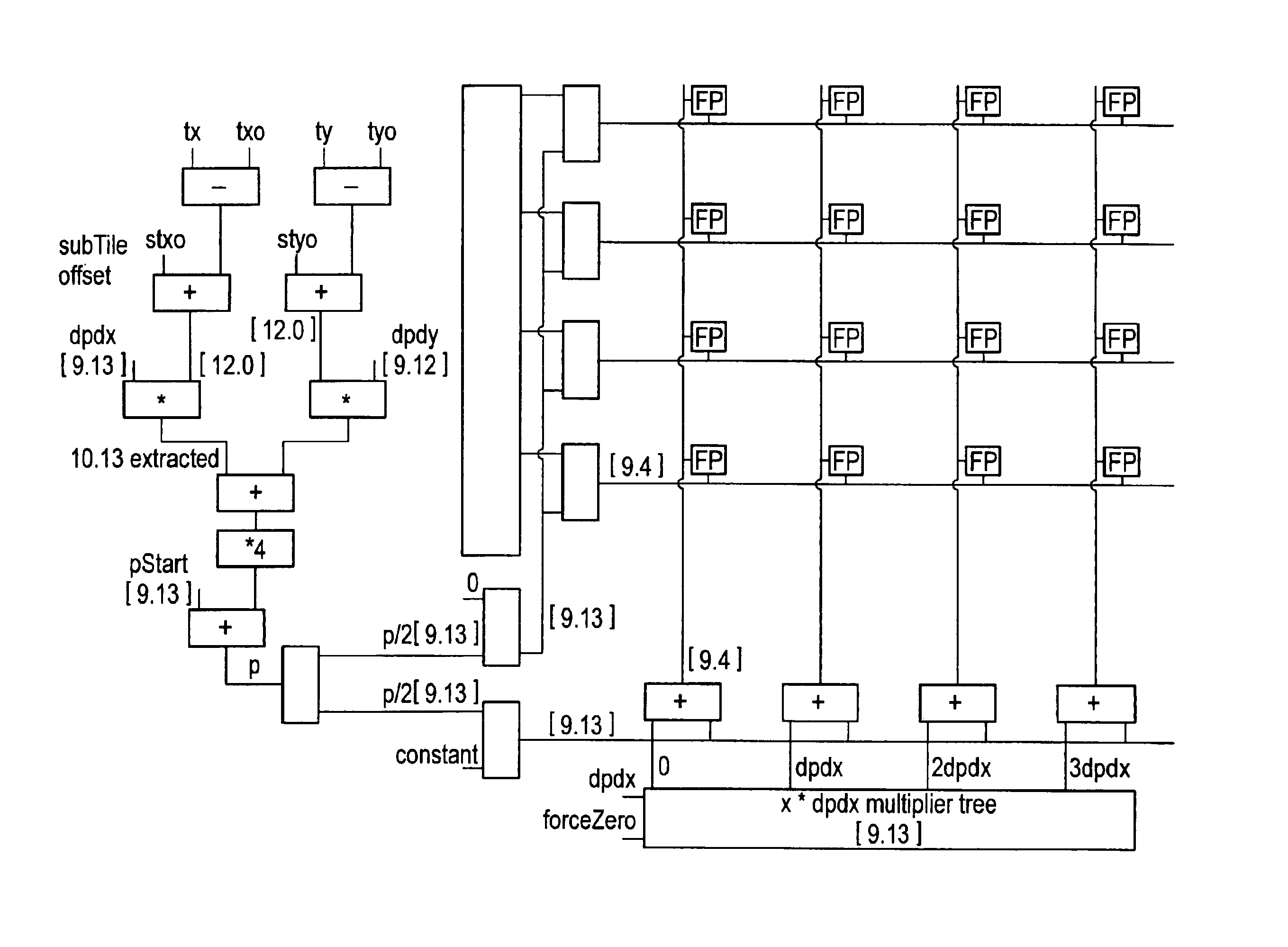

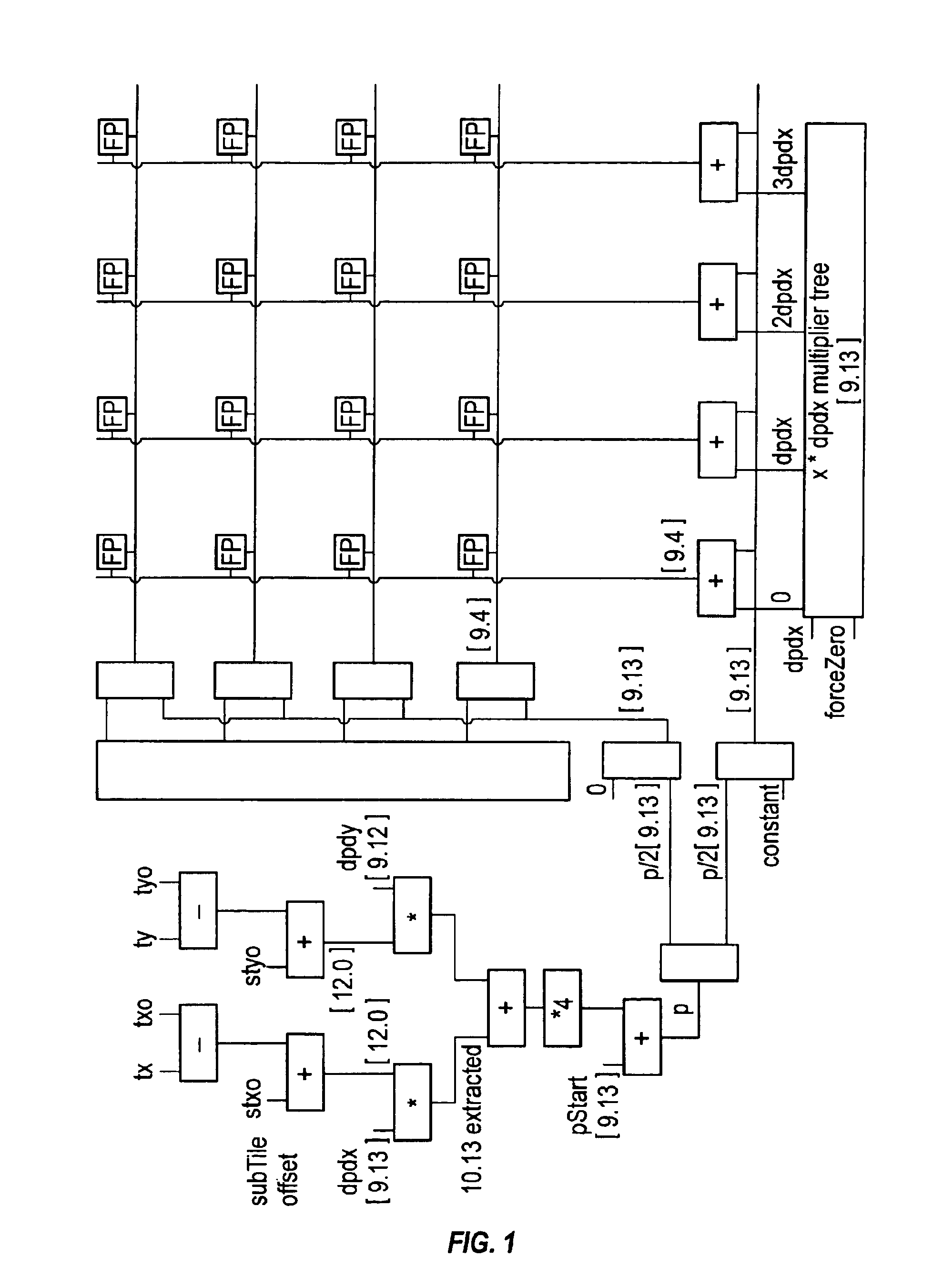

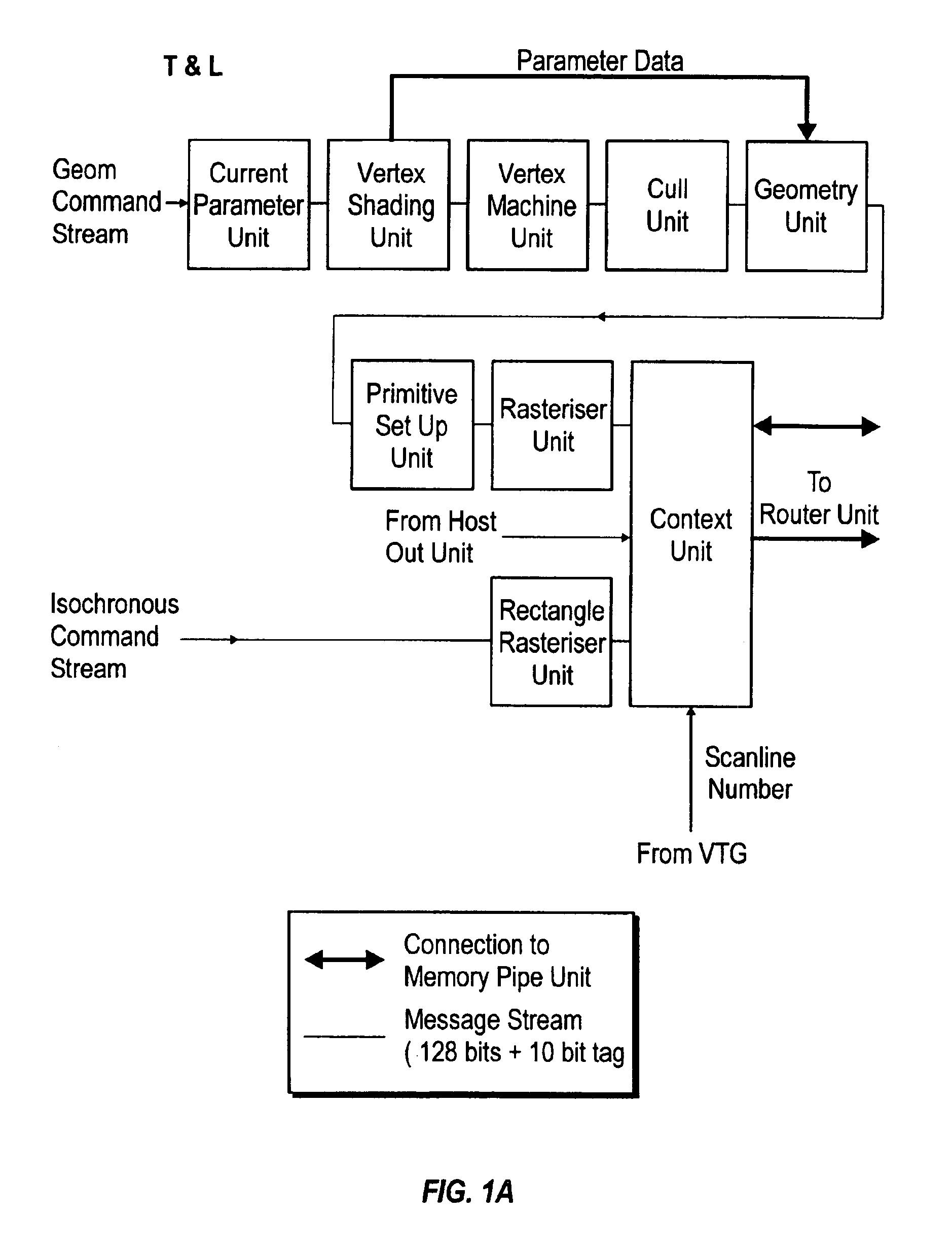

Tile relative origin for plane equations

InactiveUS6900800B2Rapid assessmentSimple hardware requirements3D-image rendering3D modellingMembership testingClassical mechanics

Patch-parallelized plane equation evaluation, for triangle membership testing, is performed with reduced dynamic range by referencing x and y coordinates to a base location which is (for each patch) in or near the patch.

Owner:XUESHAN TECH INC

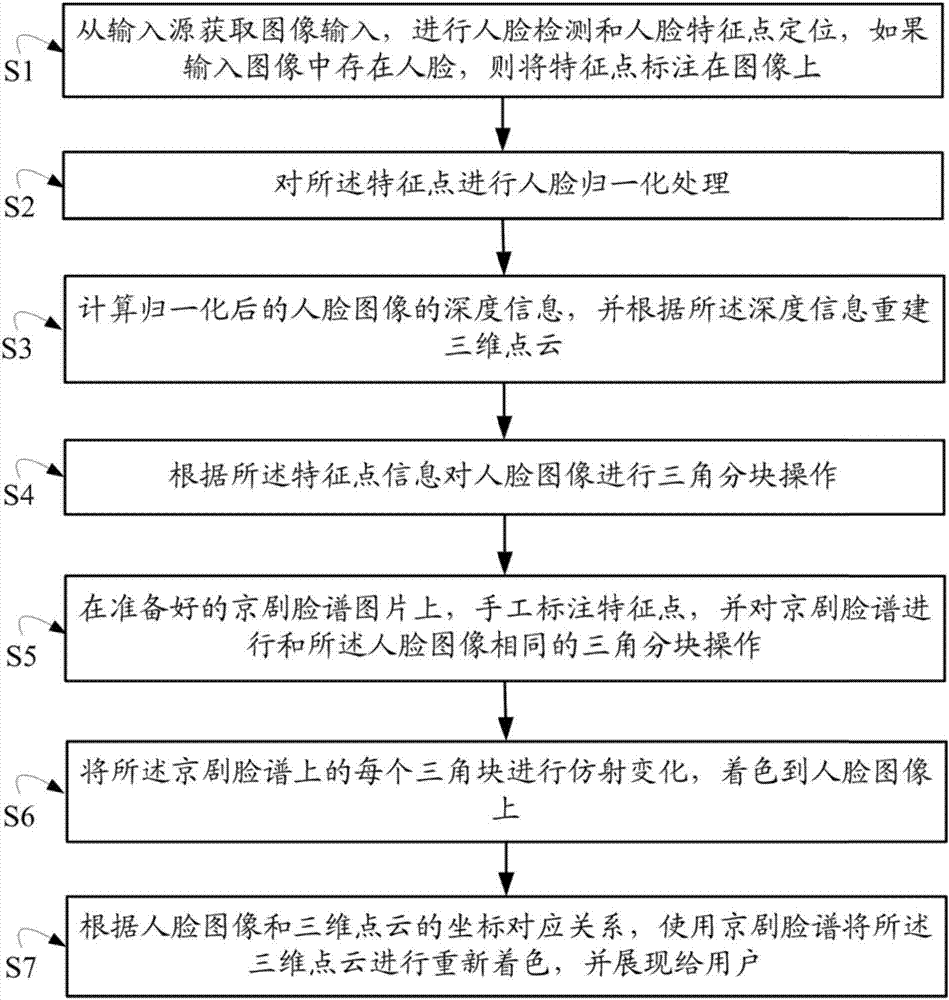

Automatic making up method of three-dimensional Beijing opera facial makeup

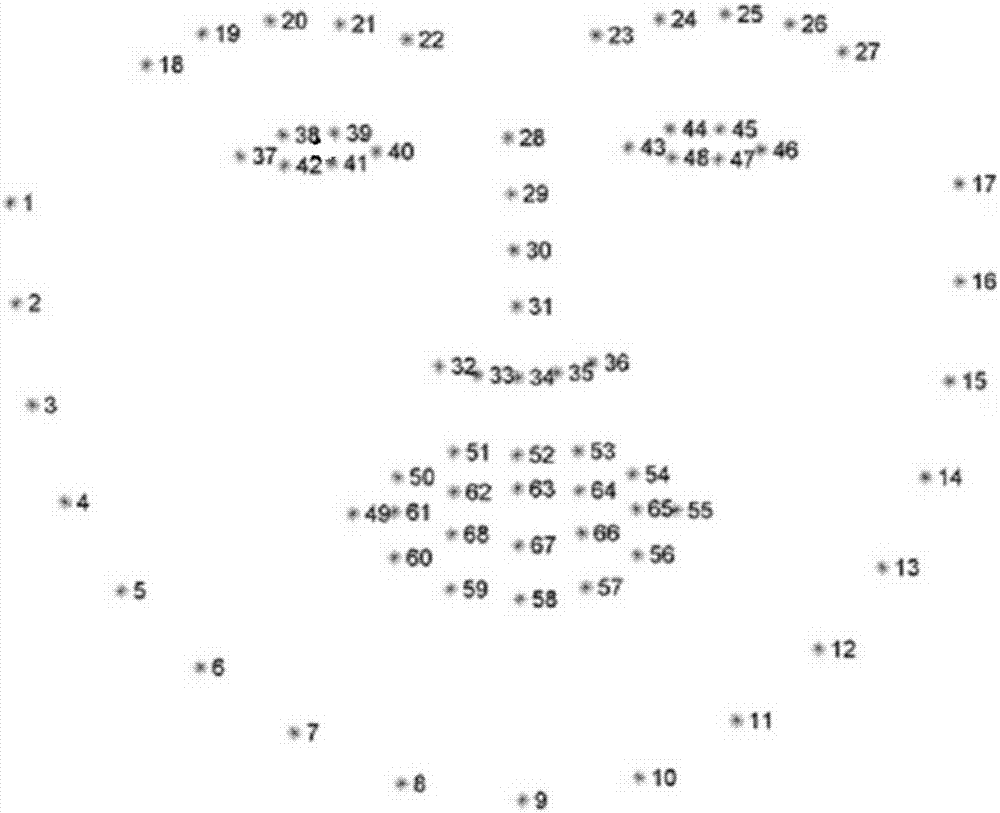

ActiveCN106952221AShow effect is goodEasy to makeGeometric image transformationCharacter and pattern recognitionPattern recognitionFace detection

The invention discloses an automatic making up method of a three-dimensional Beijing opera facial makeup. The method comprises steps of acquiring image input from an input source, carrying out face detection and face feature point positioning and marking the feature points on an image; carrying out face normalization processing on the feature points, calculating depth information of the normalized face image and according to the depth information, reconstructing three-dimensional point cloud; according to the feature point information, carrying out triangular blocking operation on the face image; manually marking the feature points on a prepared Beijing opera facial makeup picture, and carrying out the triangular blocking operation on the Beijing opera facial makeup; coloring the face image with each triangular block on the Beijing opera facial makeup; and using the Beijing opera facial makeup to recolor the three-dimensional point cloud, and displaying the result to a user. According to the invention, by calculating the coordinates of the face feature points and the face three-dimensional mode, and using the technology related to computer vision and image processing, a Beijing opera facial makeup with manually pre-marked feature points is drawn on the three-dimensional model of the target face.

Owner:SUN YAT SEN UNIV

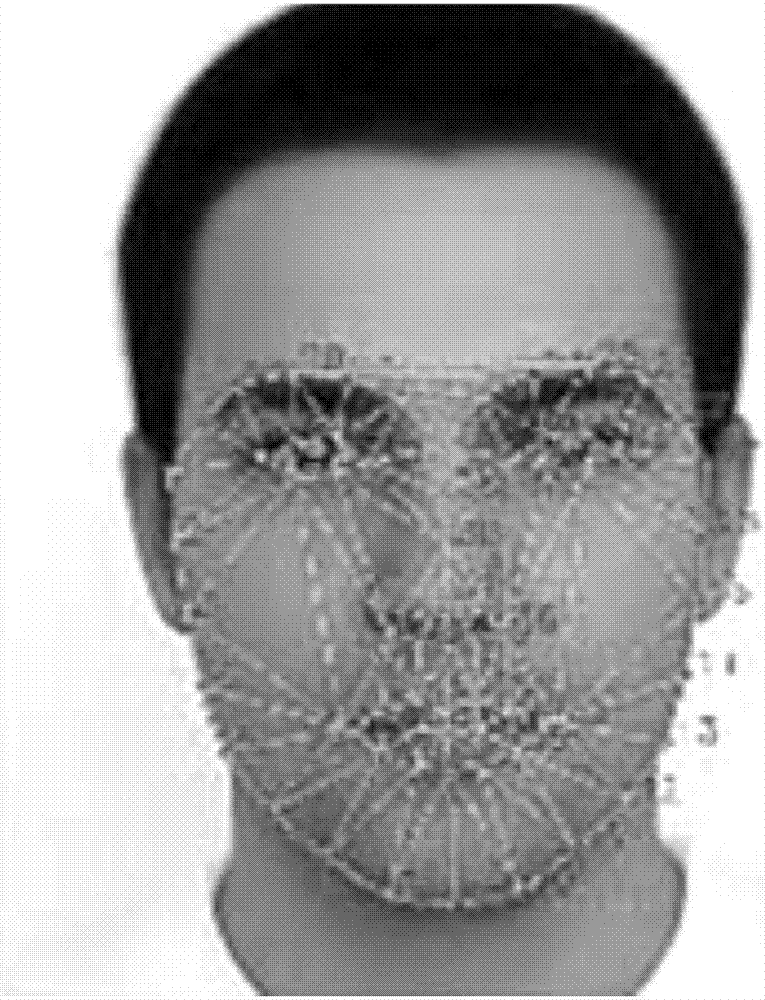

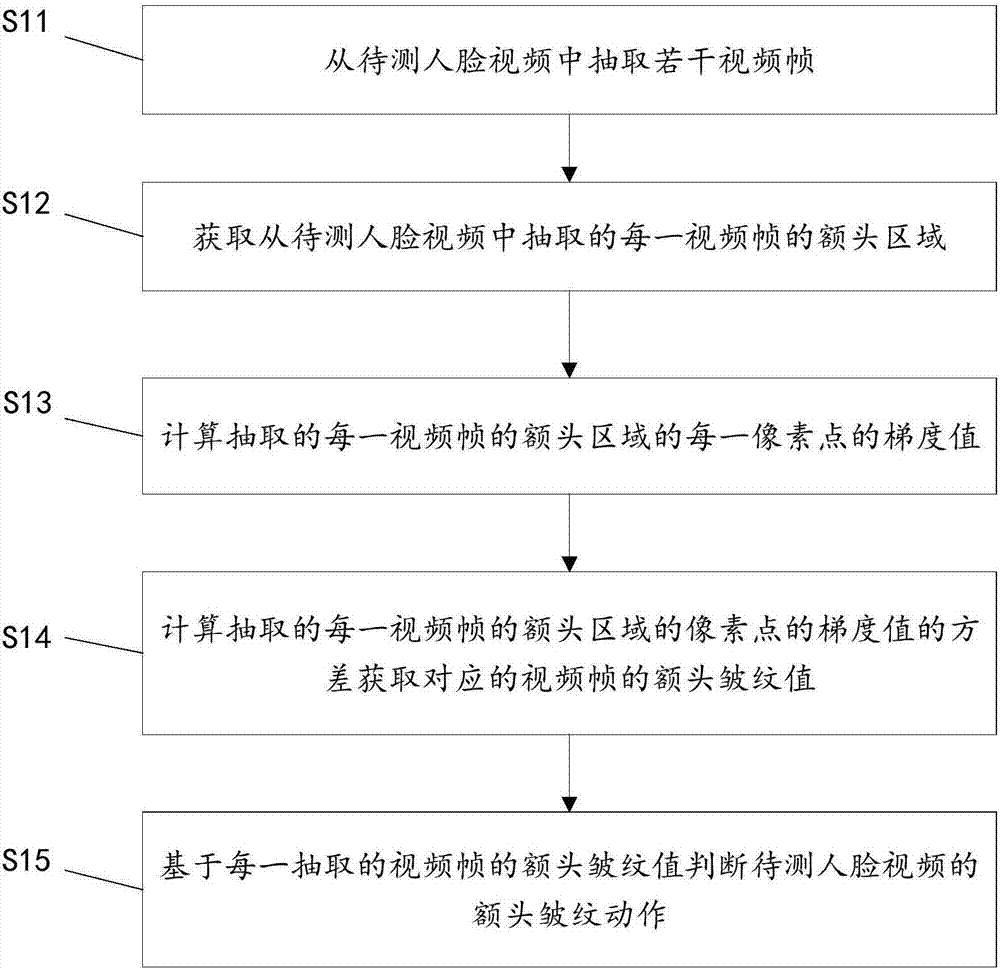

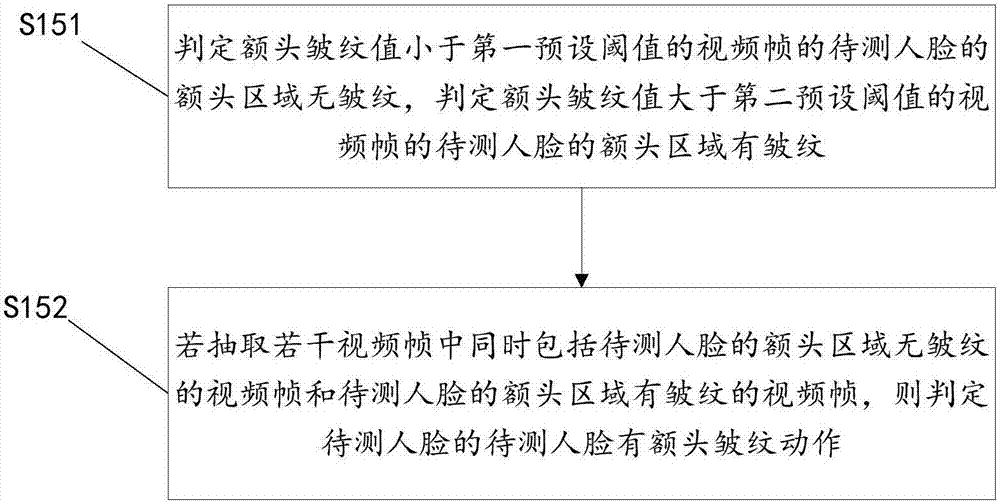

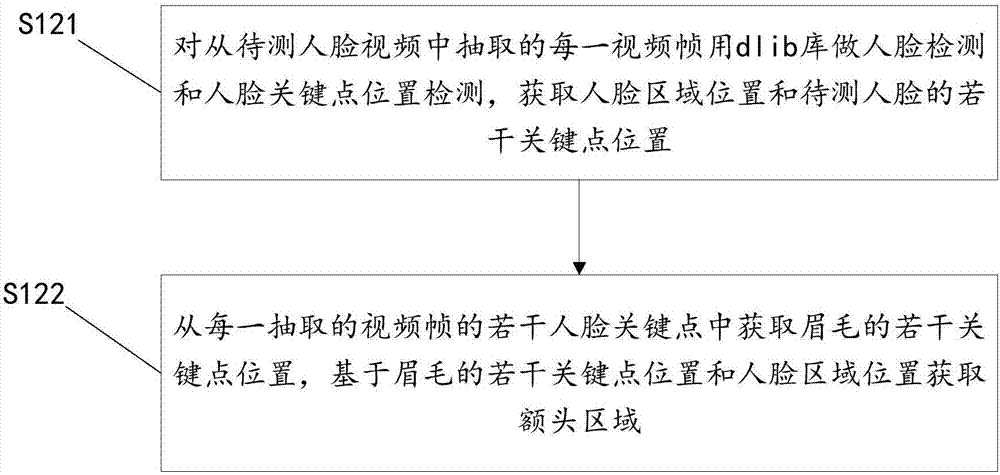

Forehead wrinkle motion detection method and device and living body recognition method and system

ActiveCN107330370ASimple hardware requirementsSimple calculationSpoof detectionPattern recognitionWrinkle skin

The invention discloses a forehead wrinkle motion detection method, which comprises the steps of extracting a plurality of video frames from a face video to be detected; acquiring a forehead region of each video frame extracted from the face video to be detected; calculating a gradient value of each pixel of the forehead region in each extracted video frame through an edge detection operator; calculating a variance of the gradient value of each pixel of the forehead region in each extracted video frame to obtain a corresponding forehead wrinkle value of the video frame; and judging a forehead wrinkle motion of the face video to be detected based on the forehead wrinkle value of each extracted video frame. Correspondingly, the invention further discloses a forehead wrinkle motion detection device. The forehead wrinkle motion detection method and device are simple in calculation and high in efficiency.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

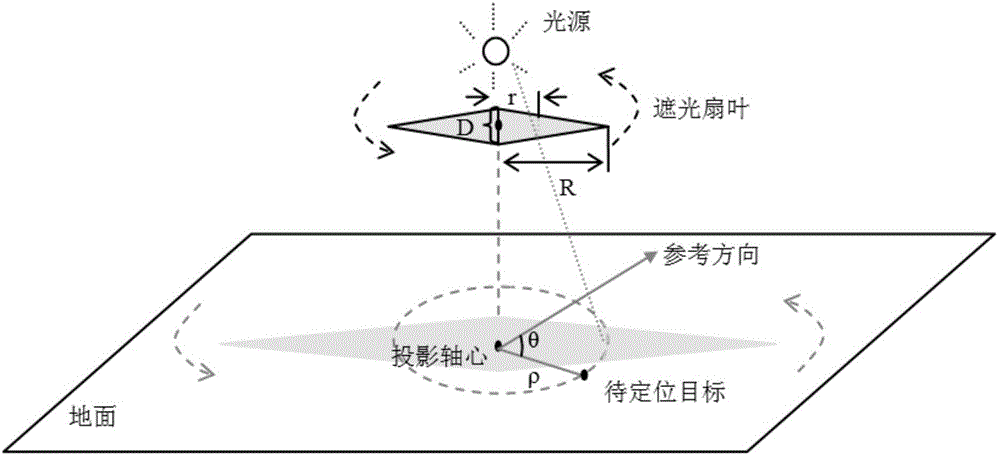

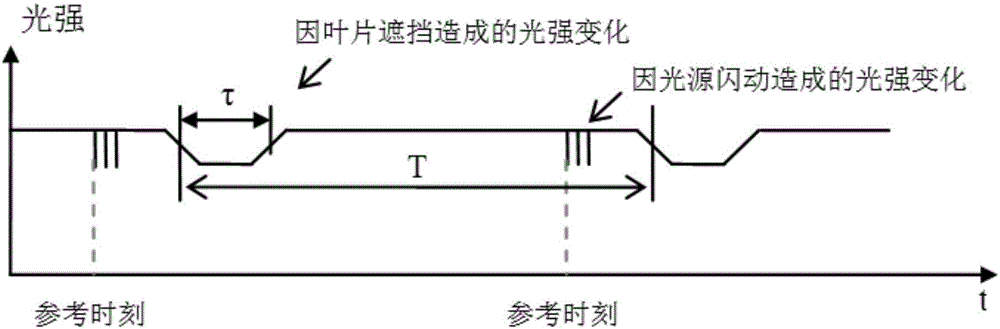

Indoor positioning method based on light pattern

InactiveCN105866736ASimple hardware requirementsHigh positioning accuracyImage analysisPosition fixationLight signalDeflection angle

The invention discloses an indoor positioning method based on a light pattern. The method comprises the following steps: 1, arranging a light pattern emission apparatus; 2, detecting light signals of an object to be positioned; and 3, positioning the position of the object to be positioned, and obtaining a distance rho from the object to be positioned to a flabellum rotating shaft and a deflection angle theta of the object to be positioned relative to a datum line. According to the invention, through improving composition and arrangement of a light pattern emission apparatus, corresponding measurement parameters of a conventional indoor positioning method based on a light pattern and the like, compared to the prior art, the method provided by the invention has the following advantages: the problem of not high indoor positioning precision can be effectively solved, the indoor positioning method can realize centimeter-grade positioning precision, the quantity of positioning objects is large, and the positioning scope is wide. Besides, the indoor positioning method does not have high requirements for hardware functions of the positioning objects, and the application scope can be greatly expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

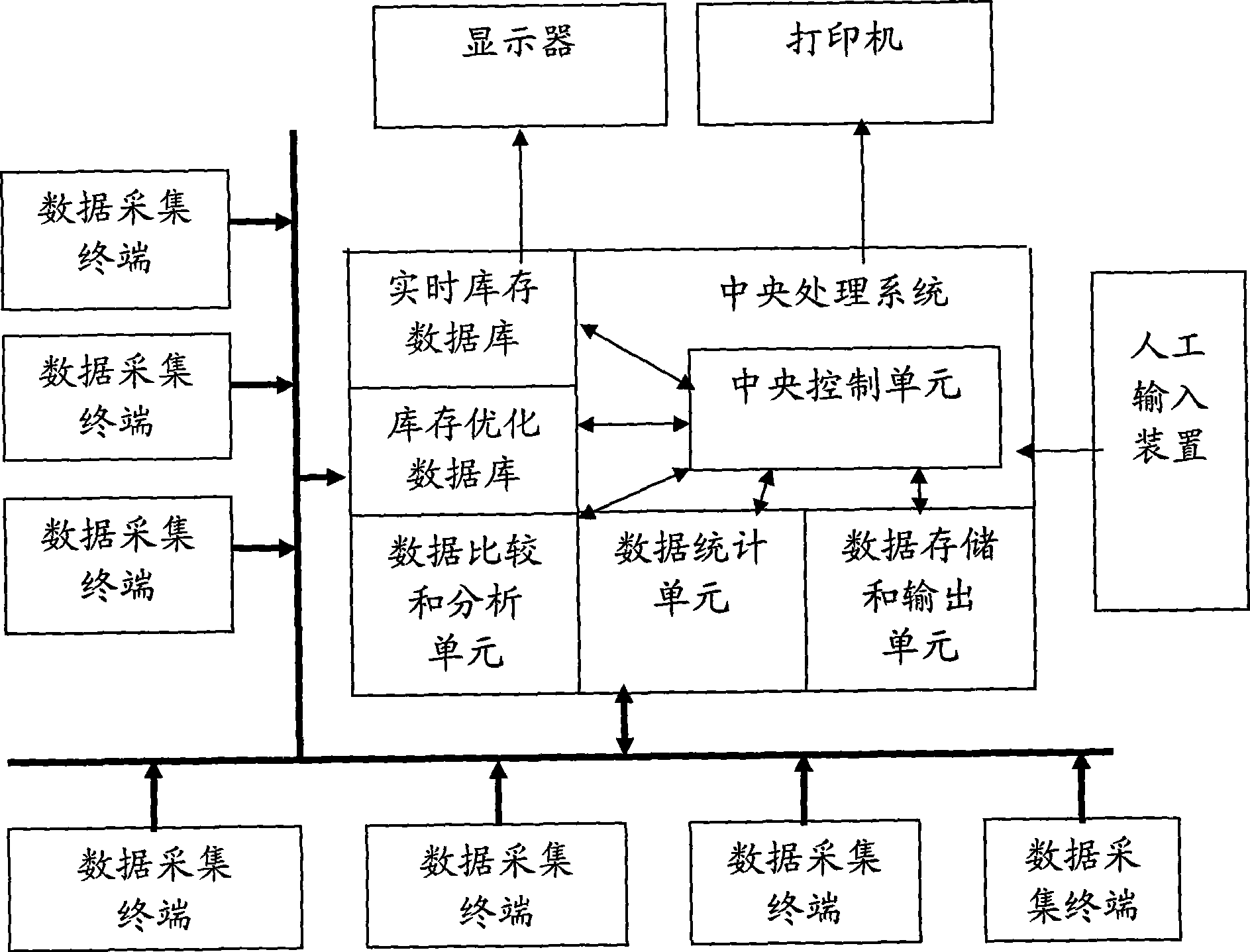

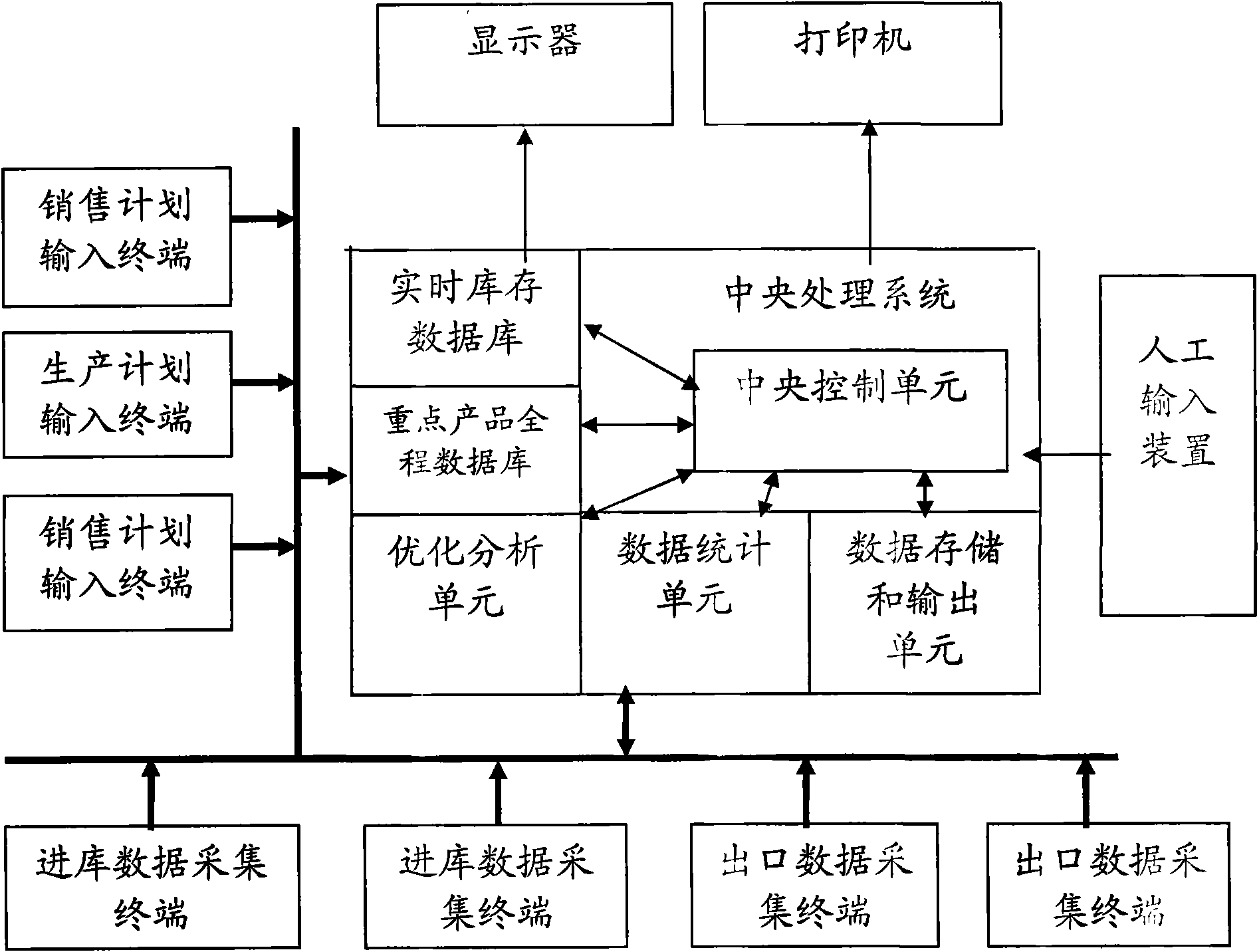

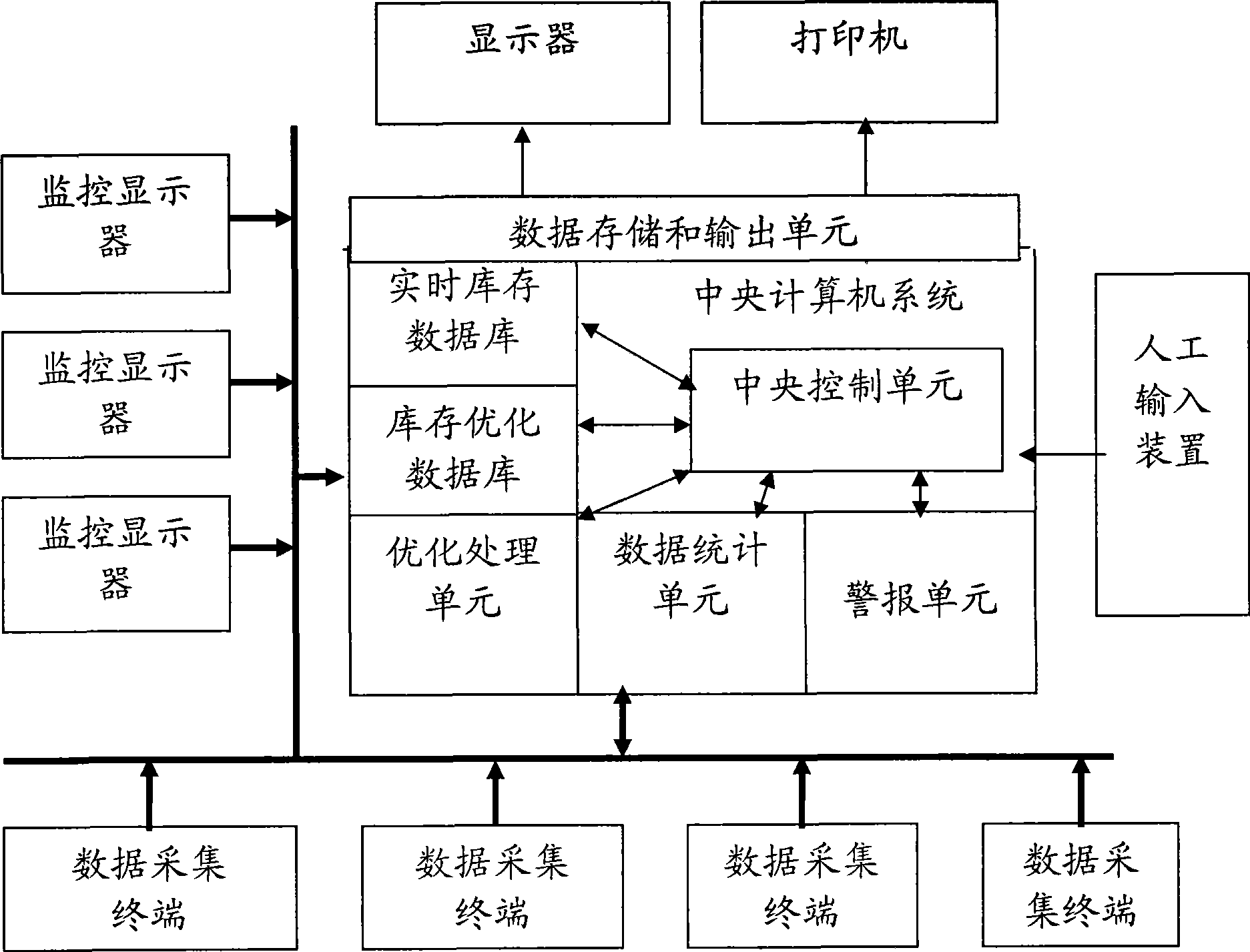

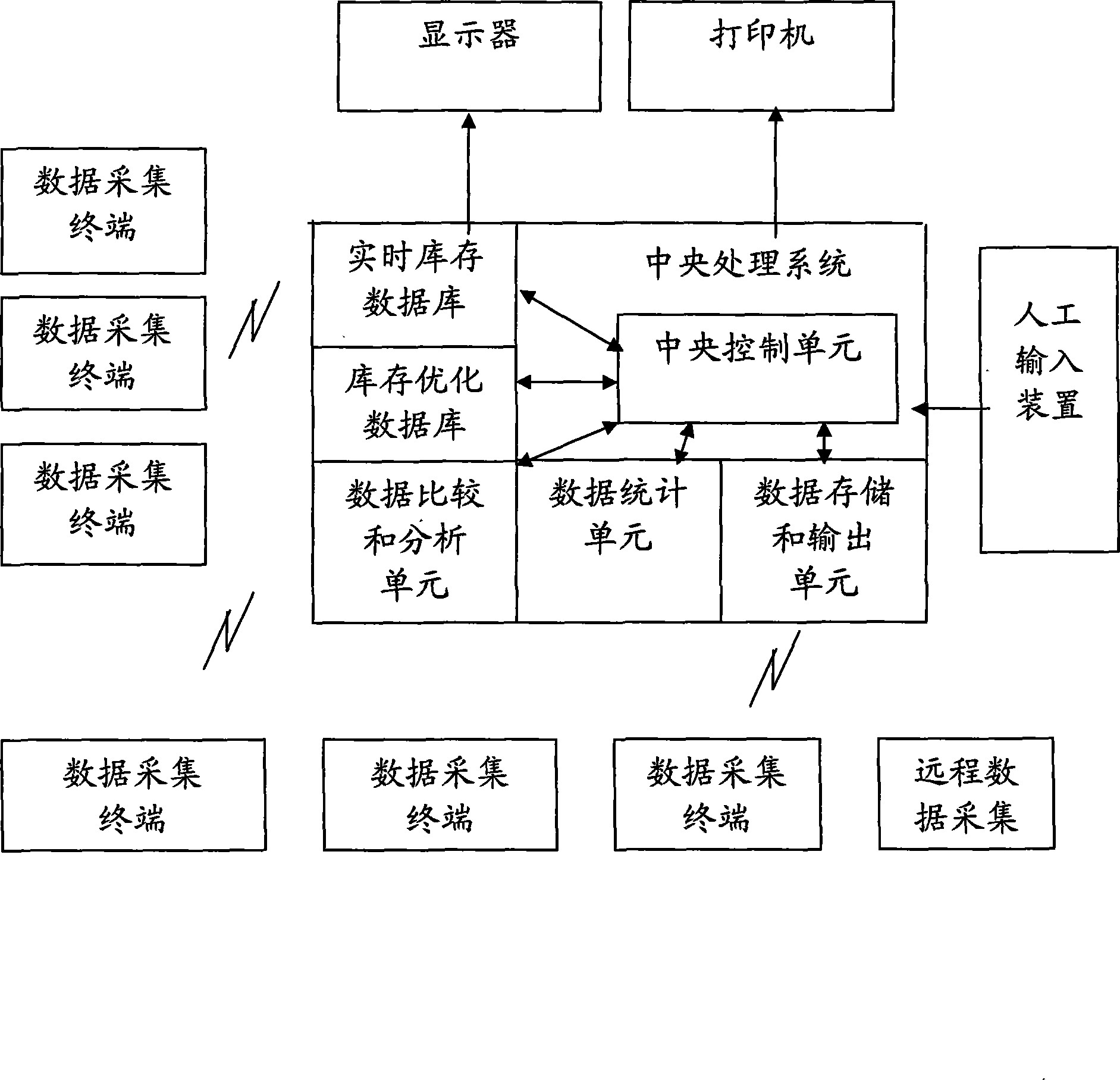

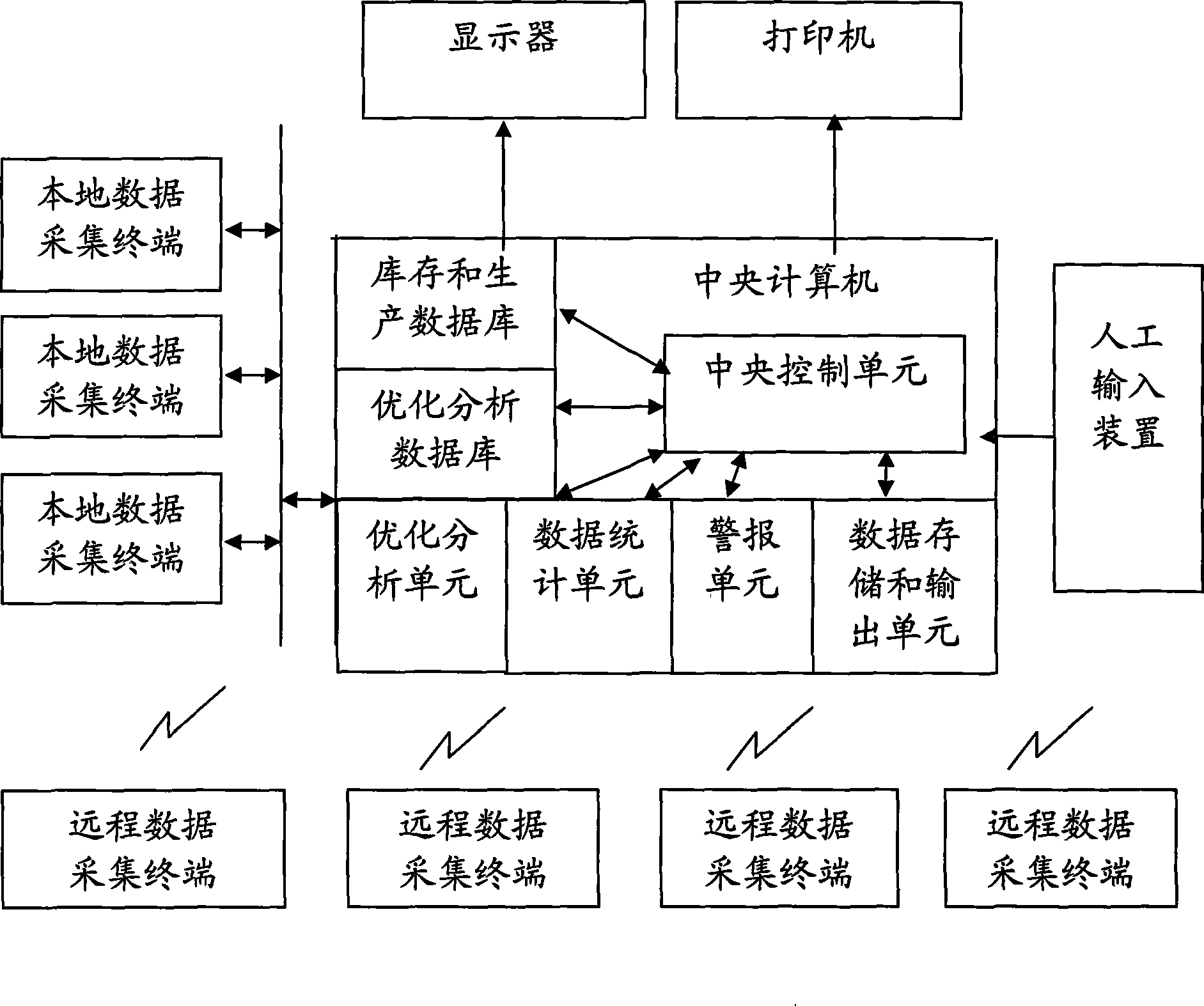

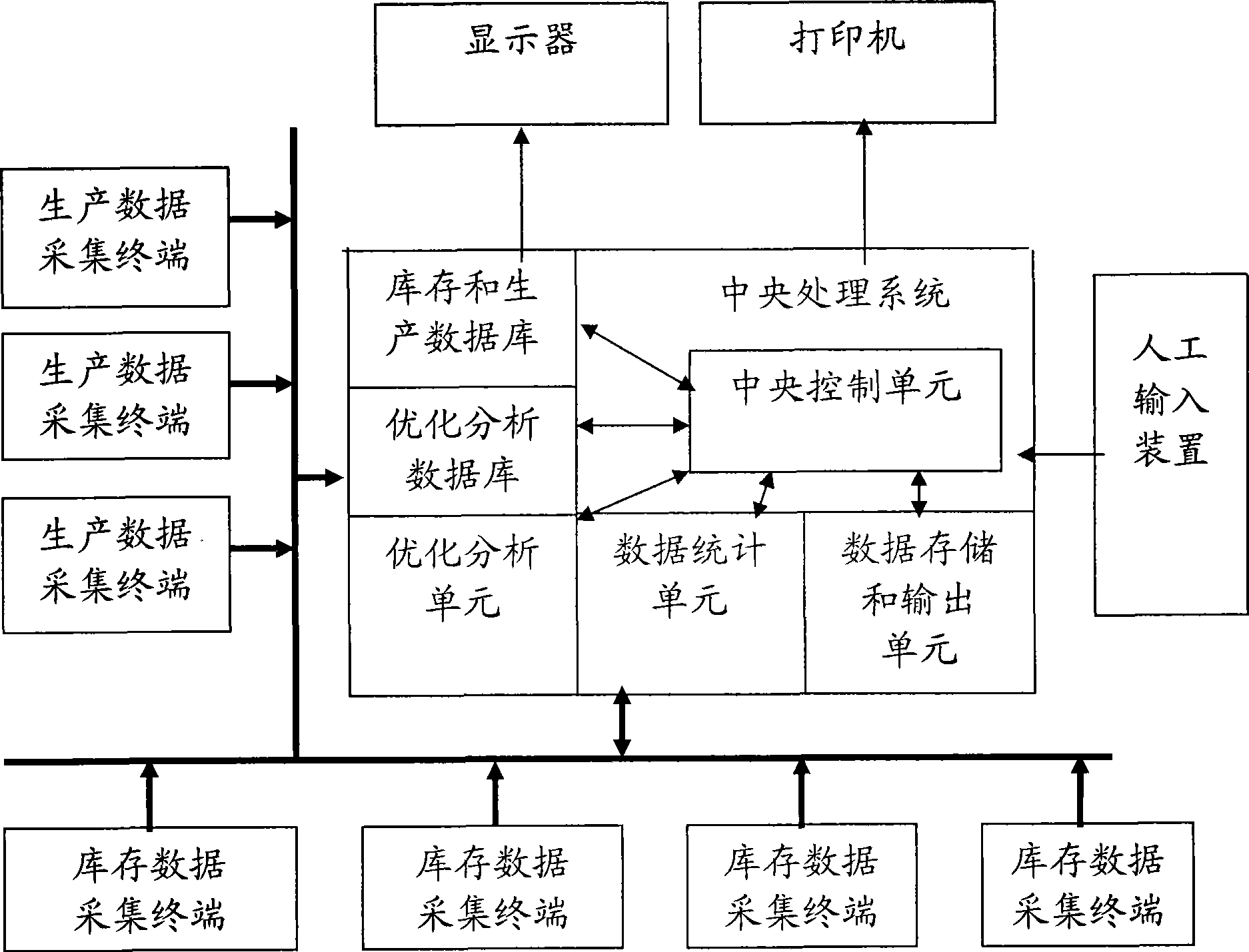

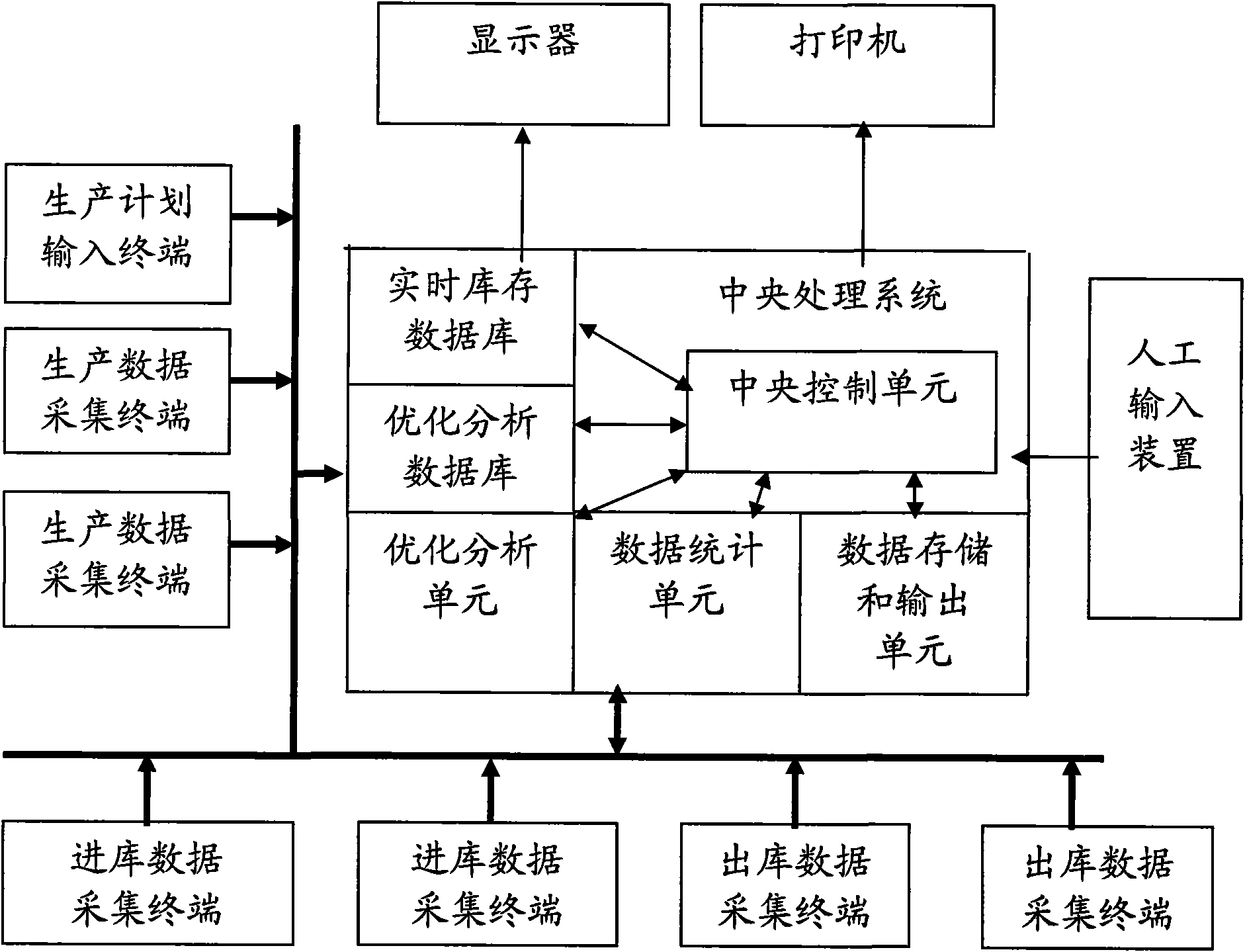

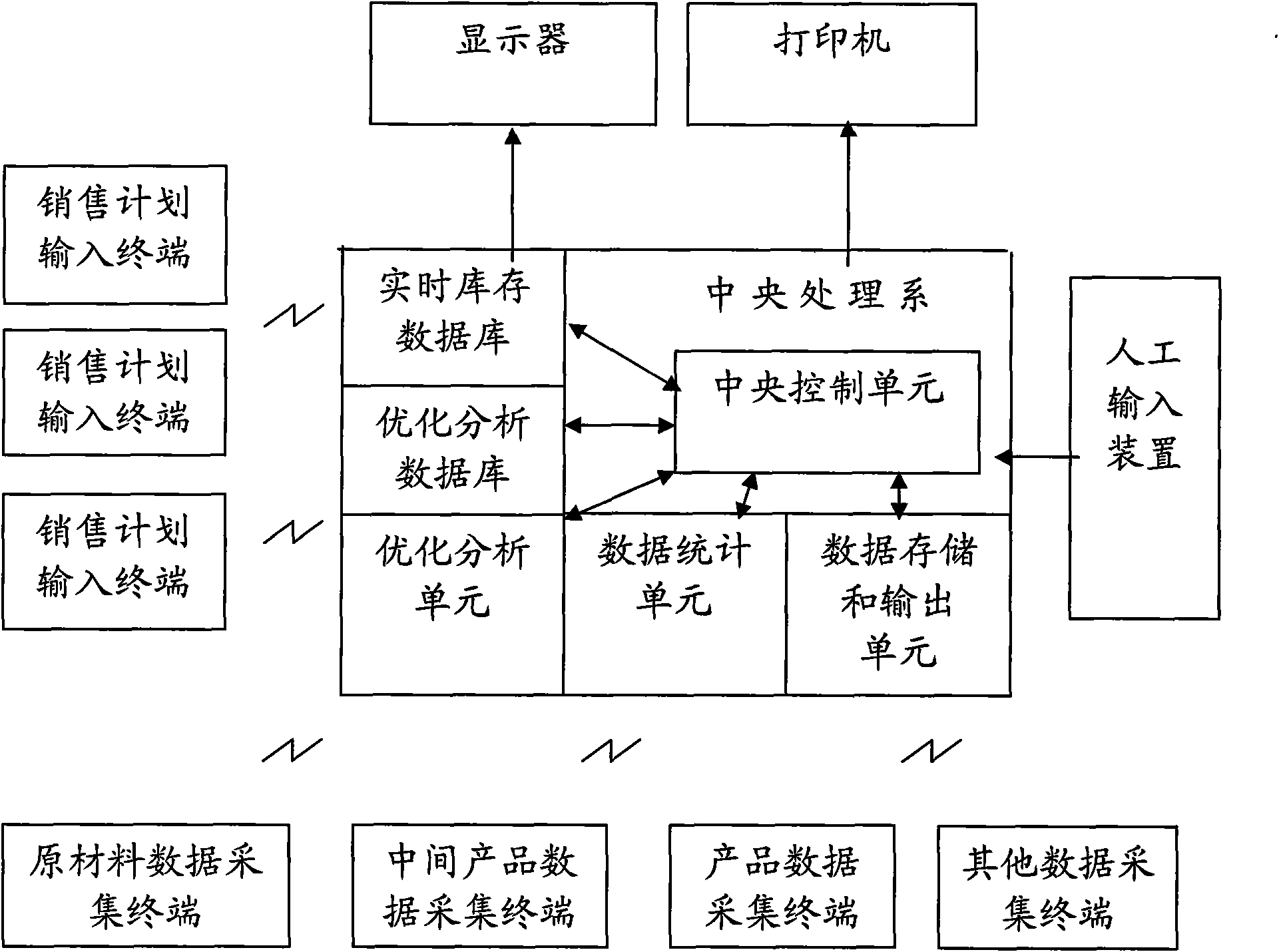

Computer storage management system

InactiveCN101441732AImprove management levelAdaptableLogisticsTotal factory controlData acquisitionData store

The invention relates to a computer warehouse management system, which mainly comprises a central processing system and a data acquisition terminal exchanging data with the central processing system, wherein the data acquisition terminal acquires warehouse in / out data of various goods, which is sent into the central processing system; the central processing system counts, analyzes and stores the warehouse in / out data; and the central processing system is provided with a real-time inventory database and an inventory optimization database, as well as a data statistics unit, a data comparing-analyzing unit, a data storing-outputting unit, a manual input device and a central control unit. The system not only can realize the acquisition and statistics of warehouse data but also can optimize and control the inventory mode, inventory level and inventory time of the goods according to the management states of enterprises, alarms for optimization problems, and is favorable for raising the operating management level of the enterprises on the whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

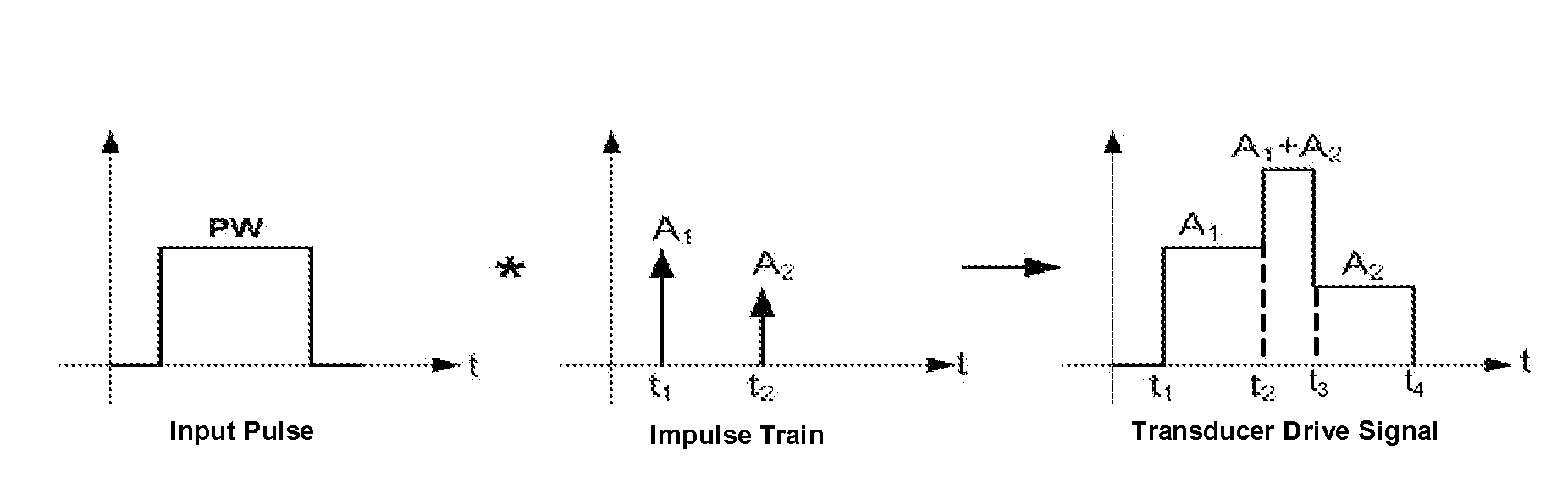

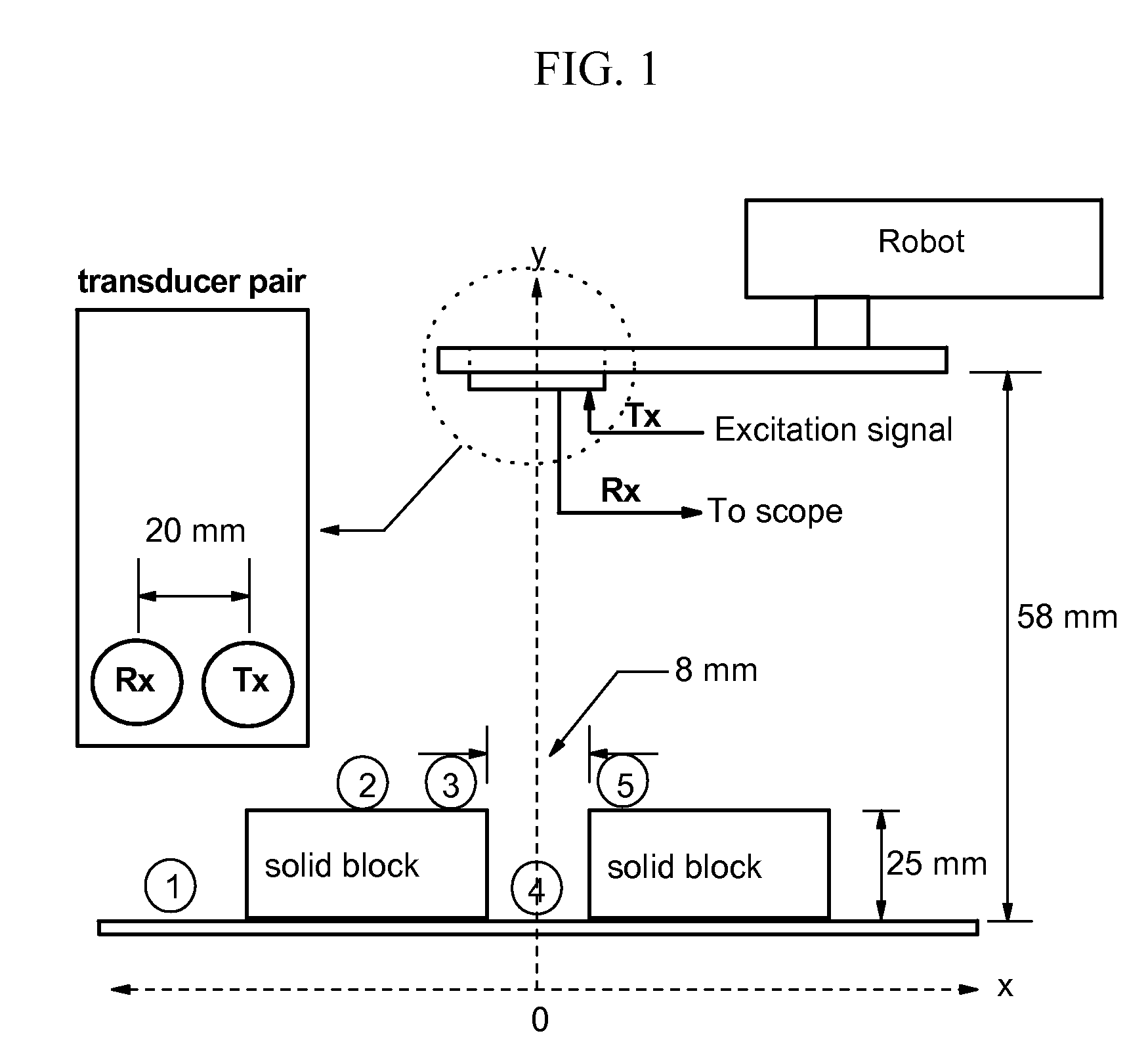

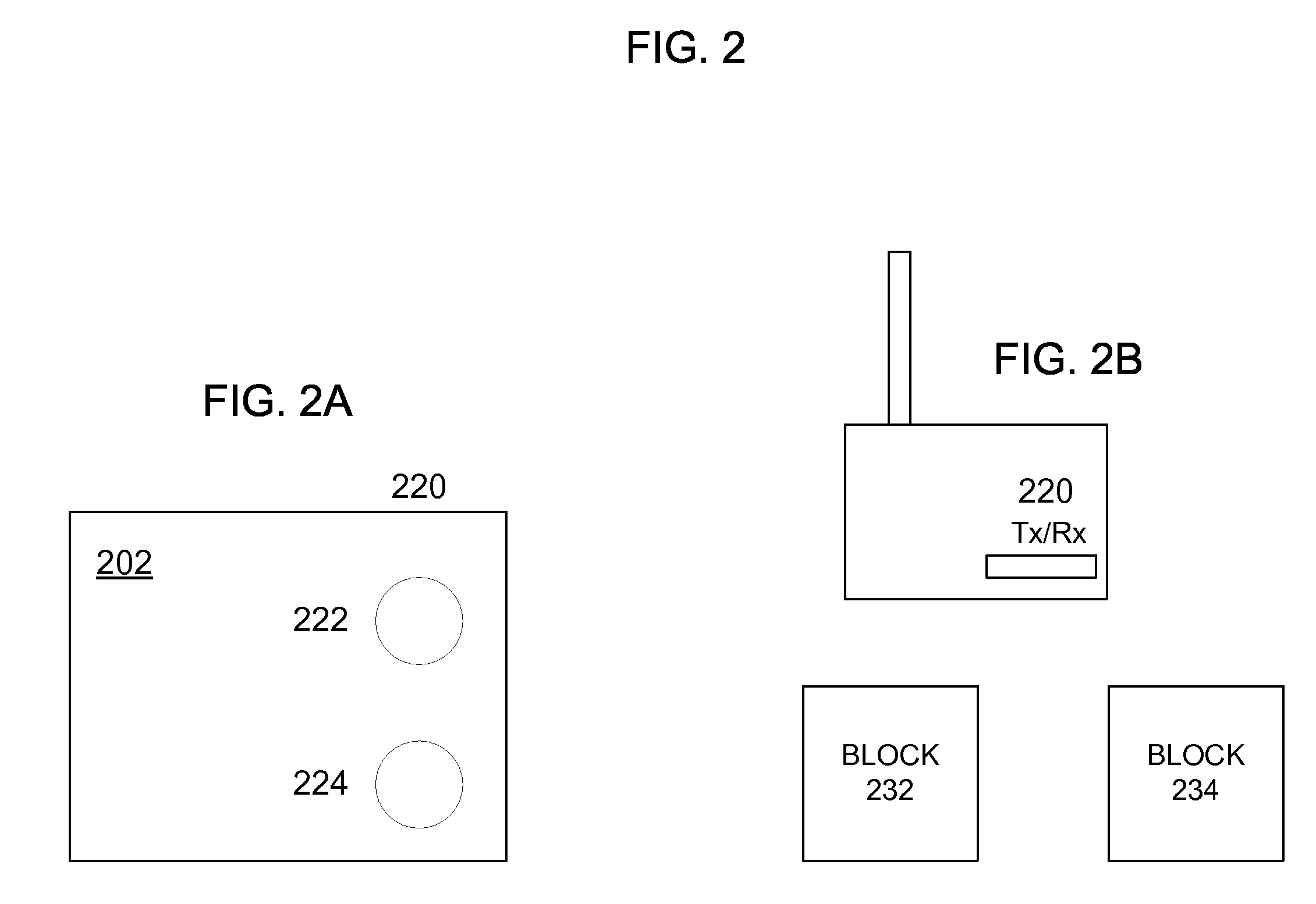

System and method for pressure wave transmission and measurement

InactiveUS7492668B2Improved spatial detection resolutionHigh frequencyWave based measurement systemsTransmissionTransducerEngineering

A system and method for measurement are disclosed which may include providing an input command signal; convolving the input command signal with a plurality of impulse signals to produce a transducer drive signal; and activating a first pressure transducer with the drive signal to transmit a pressure wave output from the transducer.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

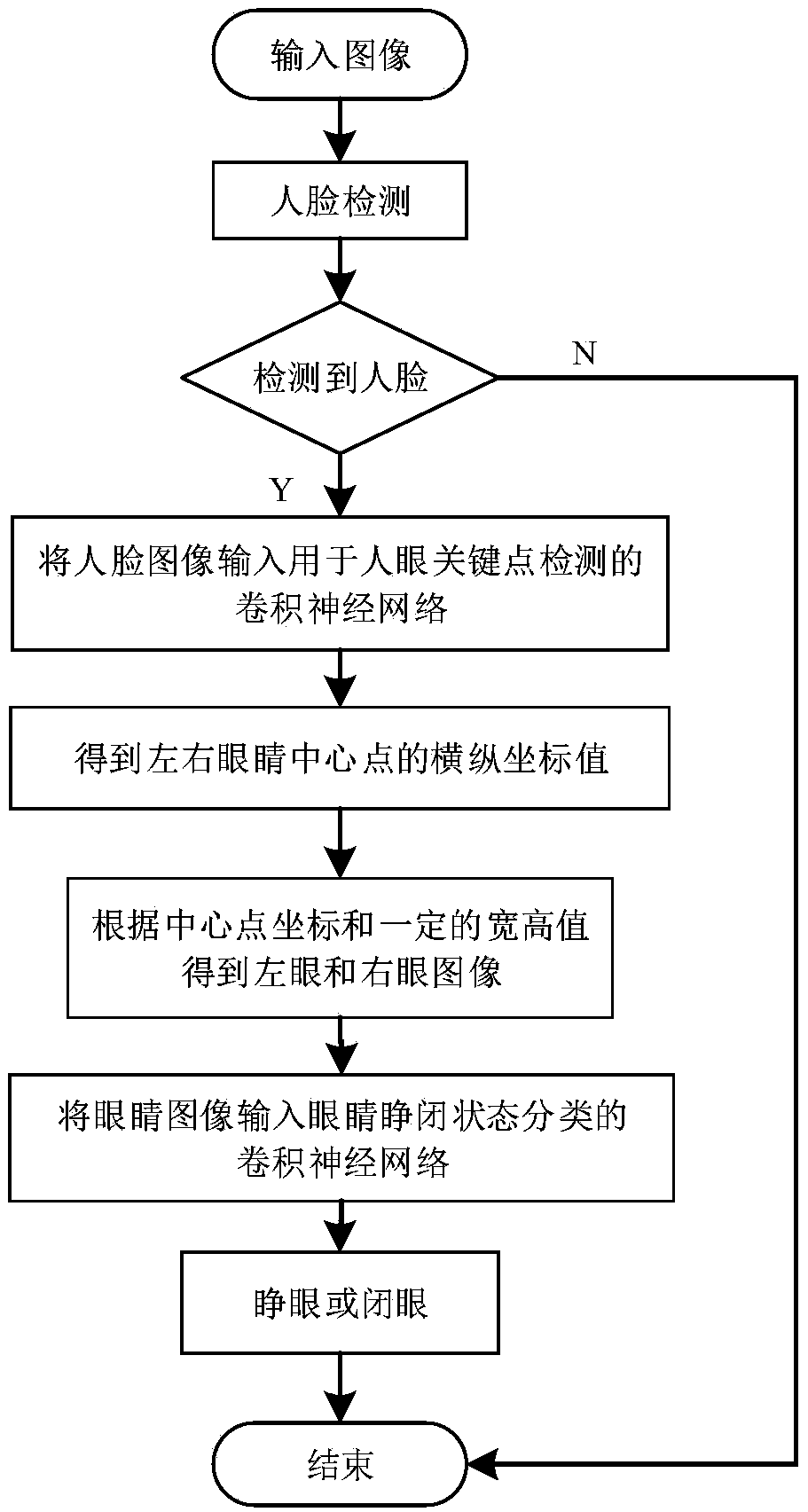

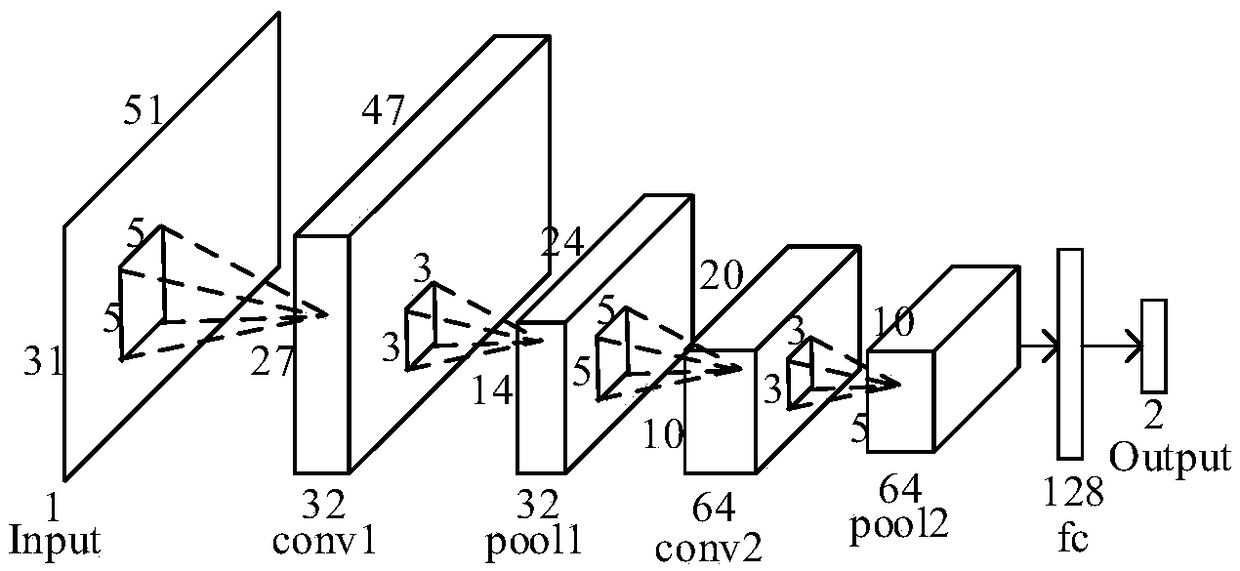

Deep learning-based eye opening and closing state detection method

ActiveCN108614999AImprove accuracyImprove robustnessCharacter and pattern recognitionNeural architecturesLearning basedSingle image

The invention discloses a deep learning-based eye opening and closing state detection method. A single image is directly processed, as long as a face is detected on the image, the position of an eye center point can be detected, and an eye area image is thus obtained. The eye opening and closing state classification accuracy is high, strong robustness is achieved for illumination changes, scene changes, face rotation, tilt and other posture changes, the operating speed is quick, the real-time performance requirements in actual application can be met, the hardware requirements are simple, and large-scale promotion is easy.

Owner:GUIZHOU UNIV

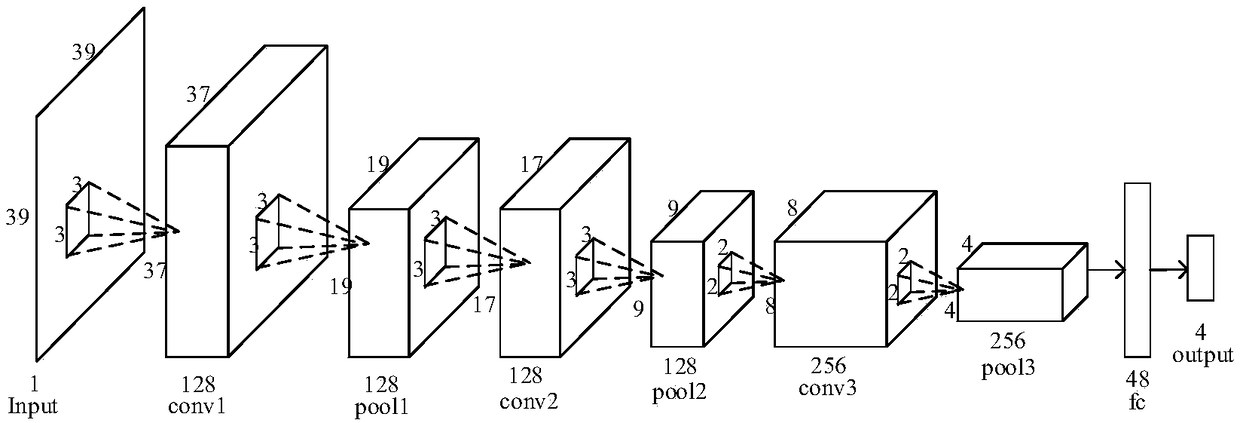

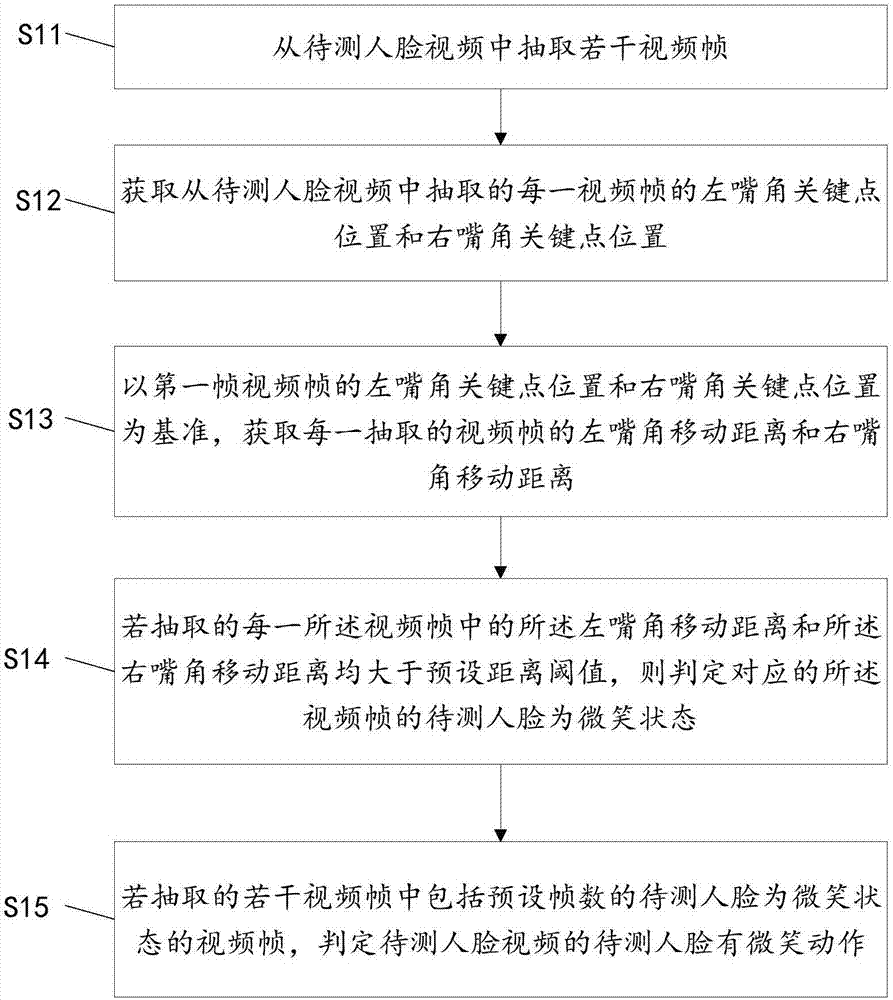

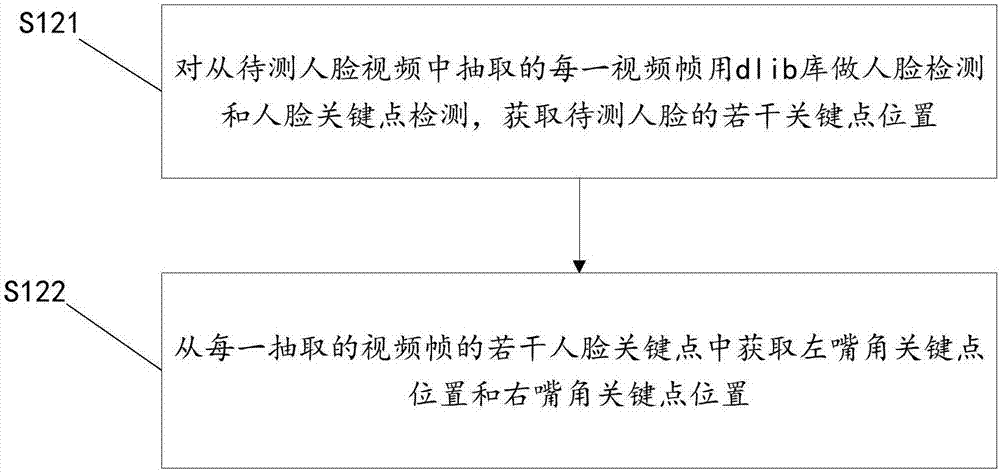

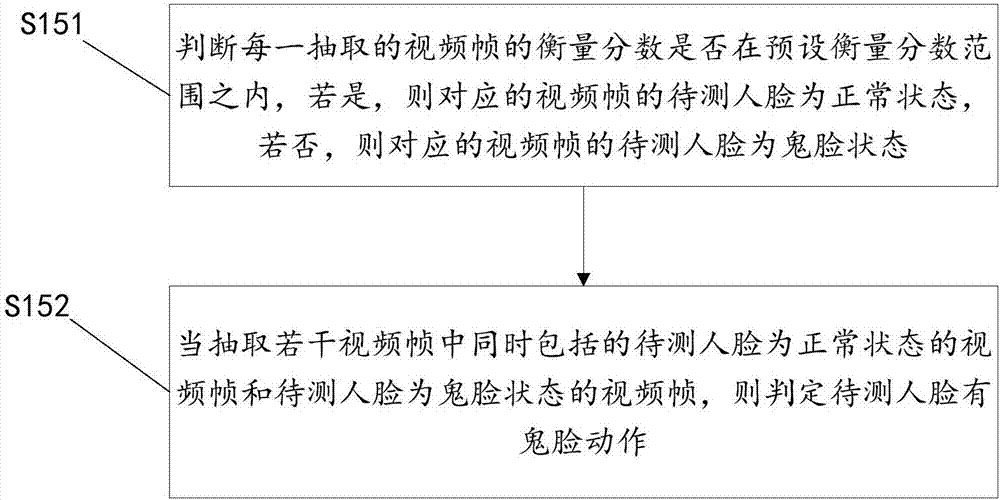

Smile motion detection method and device and in vivo recognition method and system

InactiveCN107368777ASimple hardware requirementsSimple calculationSpoof detectionIn vivoComputer science

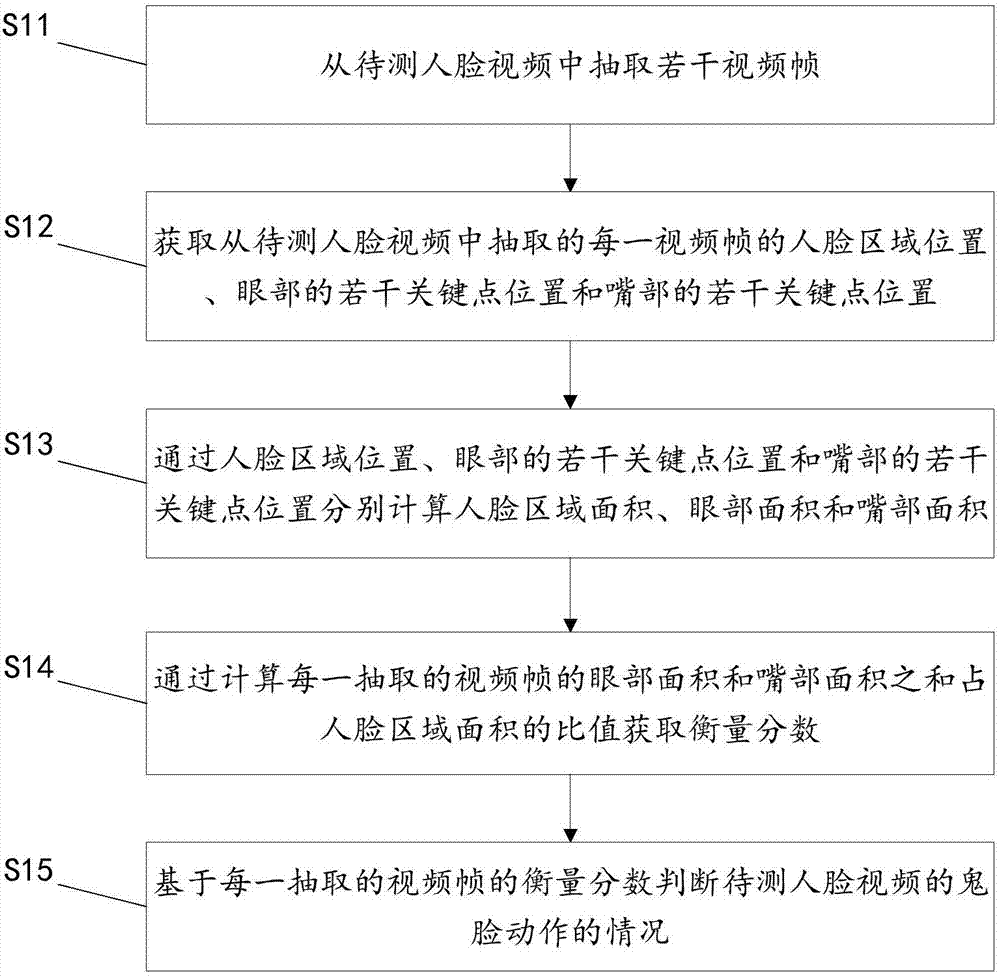

The invention discloses a smile motion detection method, and the method comprises the steps: extracting a plurality of video frames from a to-be-detected human face video, wherein the extracted video frames comprise a first video frame of the to-be-detected human face video; obtaining the positions of key points at left and right mouth corners of each extracted video frame in the to-be-detected human face video; taking the positions of key points at left and right mouth corners of the first video frame as the reference, and obtaining the moving distances of the left and right mouth corners in each extracted video frame; determining that a to-be-detected human face in a video frame with the moving distances of the left and right mouth corners being greater than a preset distance threshold value is in a smiling state; and determining that the to-be-detected human face is smiling if a plurality of extracted video frames comprises a preset number of video frames with the to-be-detected human face being in a smiling state. Correspondingly, the invention also discloses a smile motion detection device. The method is simple in calculation, and is high in efficiency.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

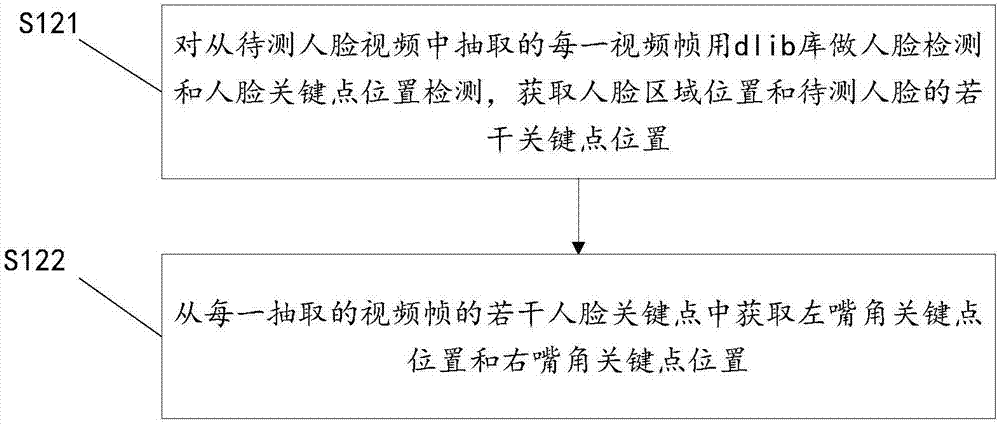

Grimacing detection method and device and method and system for living body recognition

InactiveCN107358155ASimple hardware requirementsSimple calculationAcquiring/recognising facial featuresSpoof detectionPattern recognitionLiving body

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

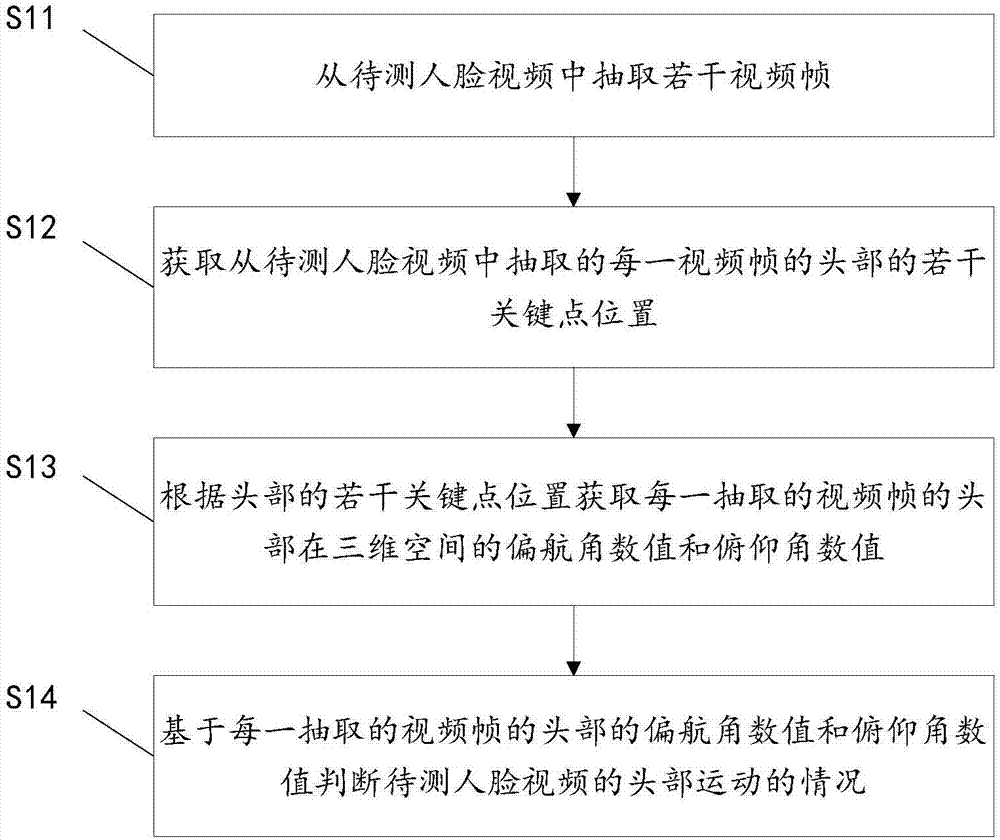

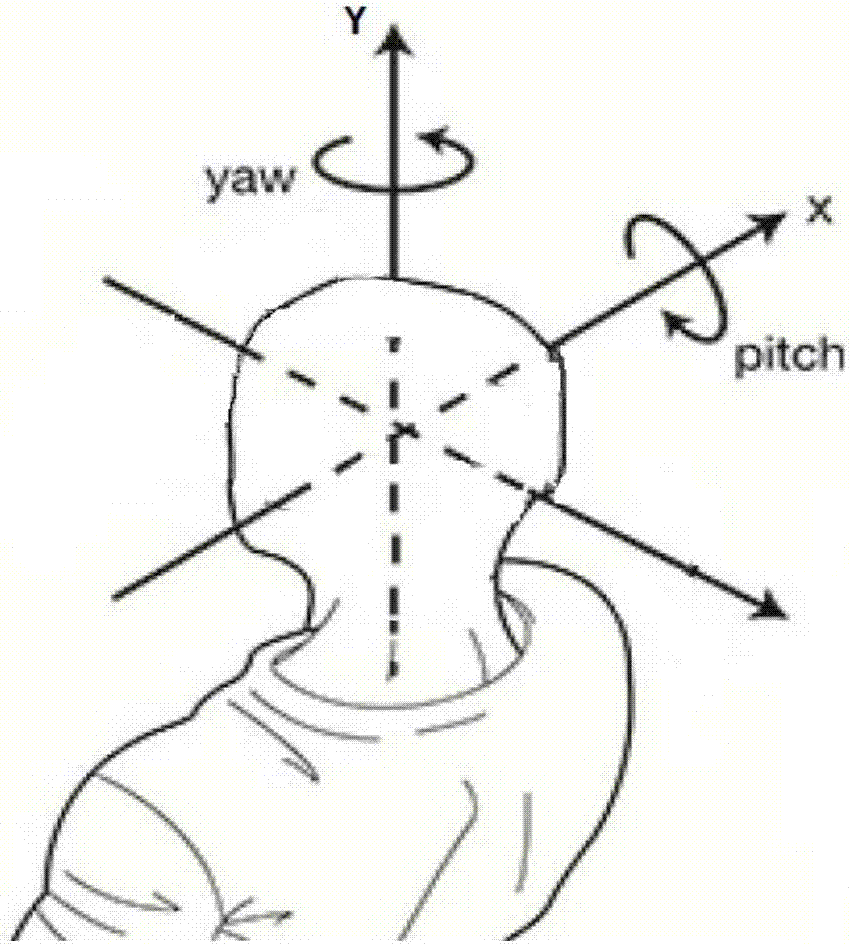

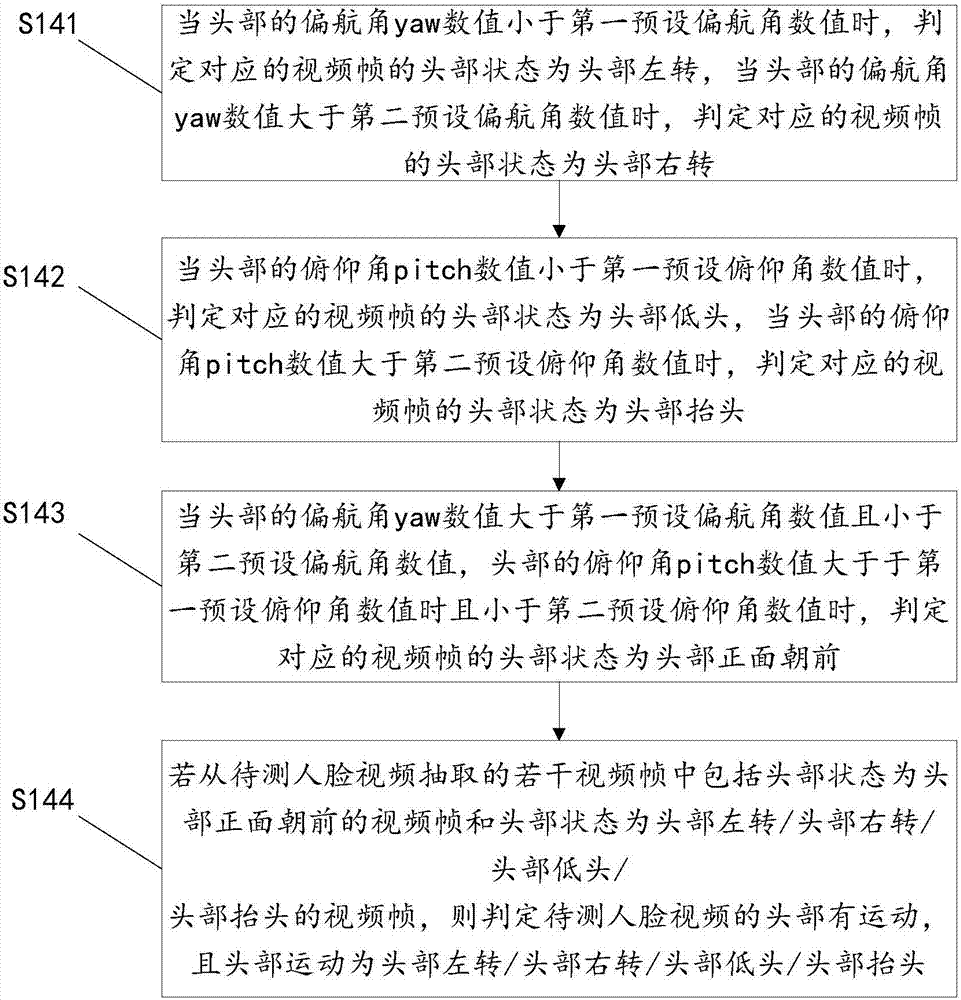

Head movement detection method and device and living body recognition method and system

InactiveCN107358154ASimple hardware requirementsSimple calculationCharacter and pattern recognitionHead movementsThree-dimensional space

The invention discloses a head movement detection method, which comprises the steps of extracting a plurality of video frames from a human face video to be detected; acquiring a plurality of key point positions of the head in each of the video frames extracted from the human face video to be detected; acquiring a yaw angle value and a pitch angle value of the head in each of the extracted video frames in the three-dimensional space according to the plurality of key point positions of the head; and judging a movement condition of the head in the human face video to be detected based on the yaw angle value and the pitch angle value of the head in each of the extracted video frames. Correspondingly, the invention further discloses a head movement detection device. The head movement detection method and device disclosed by the invention are simple in calculation, high in efficiency and low in requirement for hardware equipment.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Computer operation management system of production enterprises

InactiveCN101593309AConvenient and timely connection statusLow costCo-operative working arrangementsLogisticsData acquisitionData store

The invention relates to a computer operation management system of production enterprises, mainly comprising a central processing system and remote data collection terminals performing data exchange with the central processing system. The remote data collection terminals comprise a raw material data collection terminal, an intermediate product data collection terminal, a production data collection terminal, a marketing plan input terminal, a production plan input terminal and a purchase plan input terminal; the central processing system is provided with a real-time inventory database and a key product whole course database, and a data statistics unit, an optimization analysis unit, a data storage and the like. The invention only can not realize collection and statistics of storage data, but also perform comprehensive monitoring of storage situation of the whole course covering production, supply and sales with respect to key products in the enterprise, judge whether the operation situation is normal, and alarm when abnormality appears, thus being favorable for enhancing the operation management level of the enterprise as a whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

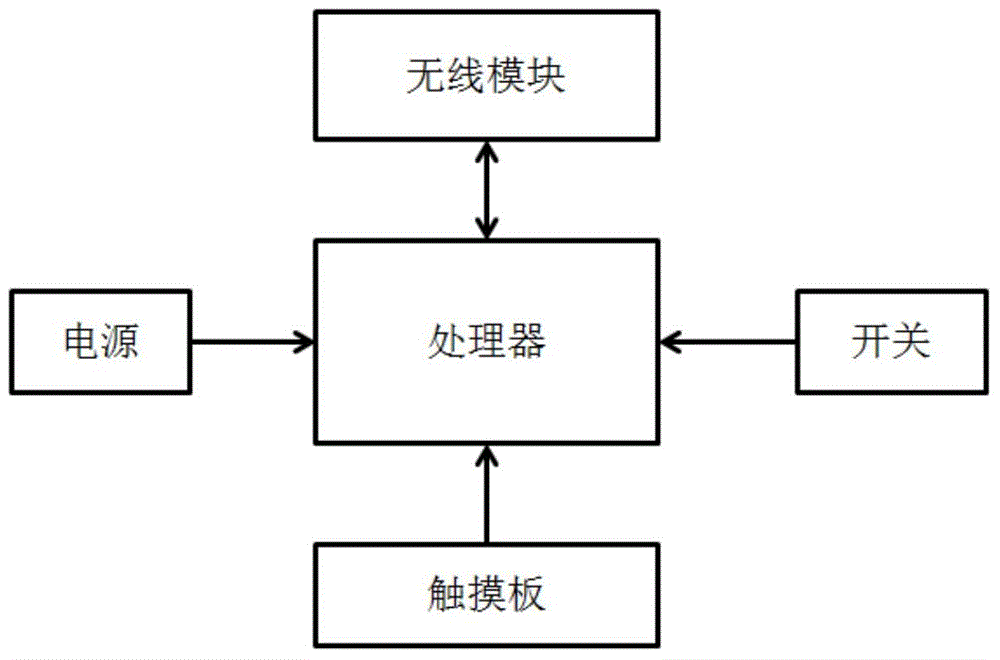

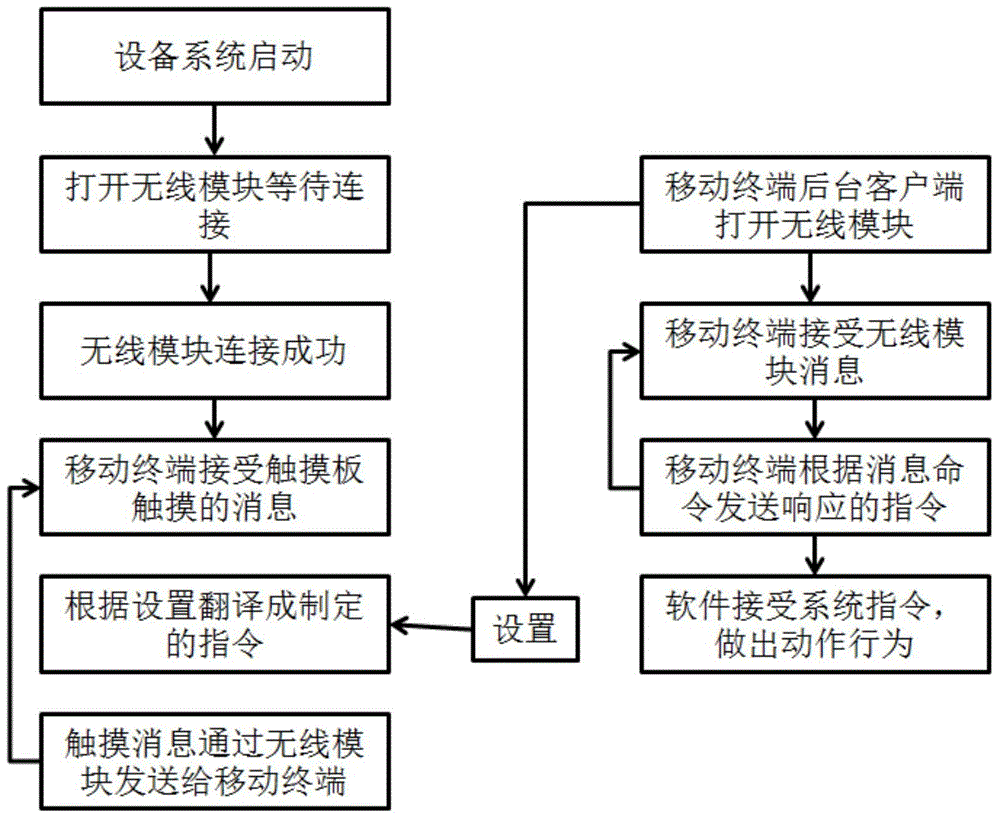

Wireless type intelligent terminal control equipment and controlling method thereof

InactiveCN104636017AEasy to operateEasy to carryInput/output processes for data processingElectricityControl system

The invention discloses wireless type intelligent terminal control equipment and a controlling method thereof and belongs to the field of application of mobile terminals. The wireless type intelligent terminal control equipment comprises a touch controller and a terminal controlling module, wherein the touch controller consists of a hardware circuit module, a touch board and a switch, the hardware circuit module consists of a power supply, a wireless module, a processor and a switch module, and the power supply provides electricity for a system; a wireless module and a control client are arranged in a mobile terminal; a control system of the control equipment is used for setting the touch board by virtue of the control client of the mobile terminal and defining a working mode, the processor is used for carrying out processing according to the defined working mode to obtain a control command, the mobile terminal is used for receiving the control command, translating the control command to obtain a corresponding instruction and calling SDK provided by a mobile terminal system, the mobile terminal system is used for simulating and sending the corresponding instruction, and the corresponding instruction is used for carrying out operation on application software needed to be controlled.

Owner:ANHUI UNIVERSITY

Optimized management system for enterprise stock

The invention relates to an enterprise inventory optimization management system, which mainly comprises a central computer system, a plurality of data gathering terminals and a plurality of monitoring displays, wherein the central computer system and the data gathering terminals are connected through signals, the data gathering terminals gather database-in and database-out data which feed various goods to the central computer system, the central computer system is used to numerate, analyze and store the database-in and database-out data, and is provided with a real time inventory database and an inventory optimization database. The enterprise inventory optimization management system can achieve the gathering and the numerating of inventory data, and can optimize and control inventory mode, inventory quantity and inventory time of goods according to an enterprise operation state, generates warning signals through a warning unit when optimization problems appear, and alarms through a display and / or a warning device, and the warning signals are simultaneously fed to a monitoring display to display. The enterprise inventory optimization management system has reasonable structure, which is beneficial for improving enterprise operation management level from integral body.

Owner:BEIJING AOTENGXUNDA SCI & TECH

Remote computer storage administrating system

InactiveCN101251910AImprove management levelAdaptableCo-operative working arrangementsData acquisitionOptimization problem

The invention relates to a remote computer storehouse management system which mainly comprises a central processing system and a remote data collection terminal made data exchange with the central processing system. The remote data collection terminal is provided with a wireless transmitting and receiving module, the central processing system is provided with a supporting wireless transmitting and receiving module, stock-in / out data is statisticized, analyzed and stored, the central processing system is provided with a real-time inventory database, an inventory optimization database, a data statistics unit, a data comparison and analysis unit, a data storage and output unit, a manual input device and a central control unit. The system can not only realize the collection and the statistics of the inventory data, but also can optimize and control the inventory mode, the inventory level and the inventory time of the goods according to the operation state of the enterprise, alarms when the optimization problem appears, and contributes to improving the operation management level of the enterprise on the whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

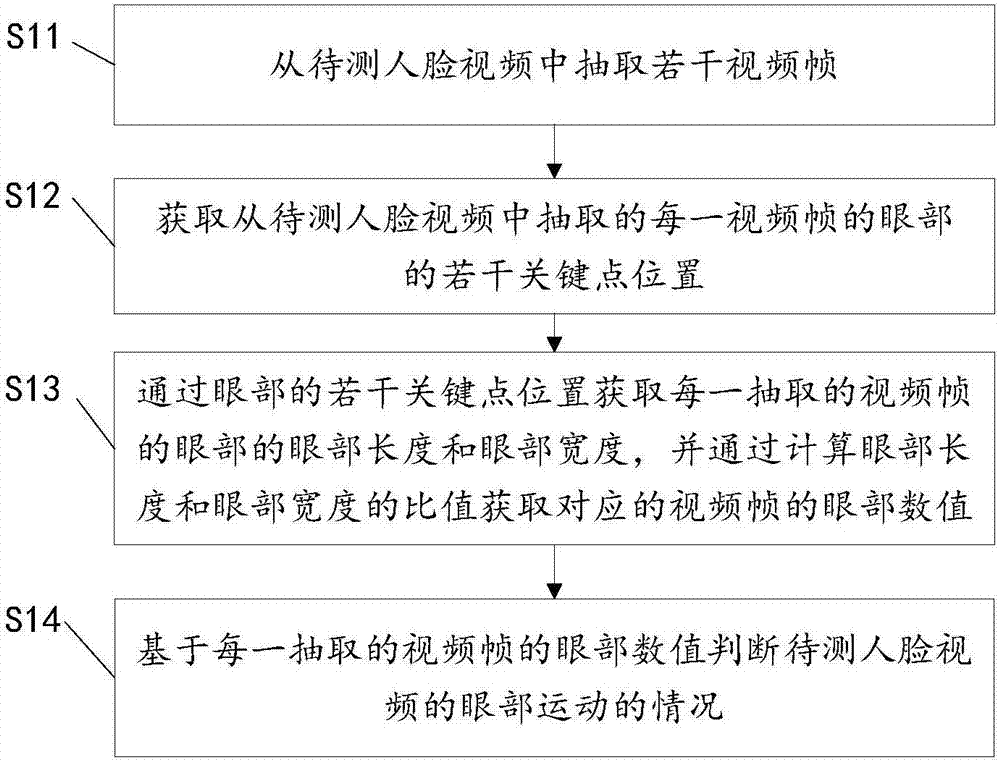

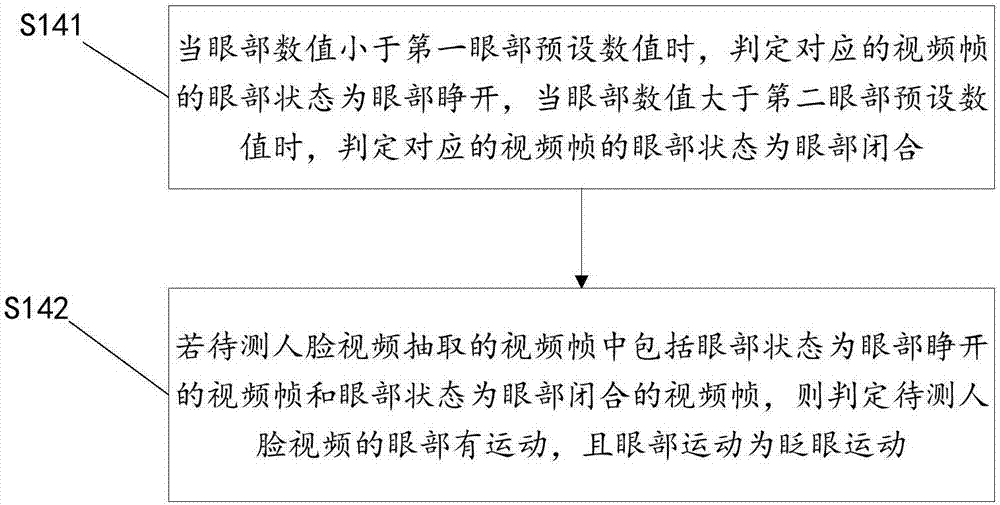

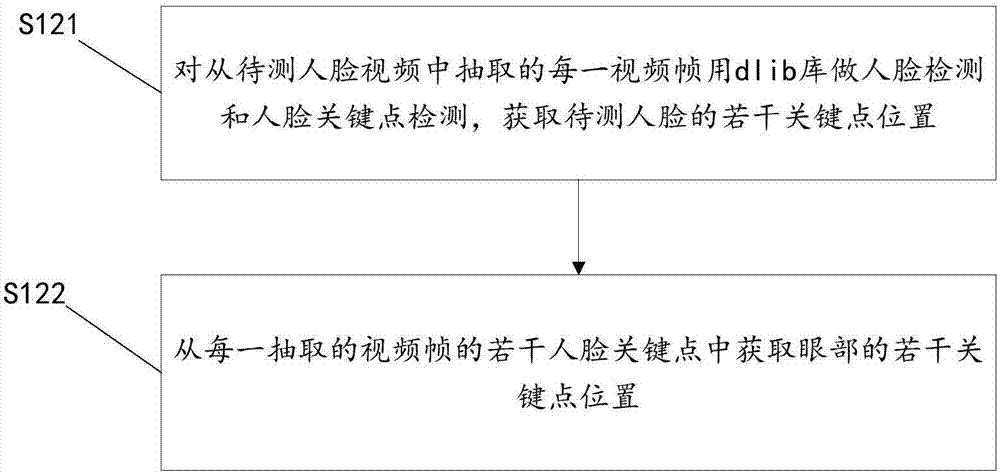

Eye movement detection method and device and living body recognition method and system

InactiveCN107358151AImprove accuracySimple calculationCharacter and pattern recognitionLiving bodyComputer science

The invention discloses an eye movement detection method, which comprises the steps of extracting a plurality of video frames from a human face video to be detected; acquiring a plurality of key point position of the eye in each of the video frames extracted from the human face video to be detected; acquiring the eye length and the eye width of the eye in each of the extracted video frames according to the plurality of key point positions of the eye, and acquiring an eye value of the corresponding video frame through calculating the ratio of the eye length and the eye width; and judging a movement condition of the eye in the human face video to be detected based on the eye value of each of the extracted video frames. Correspondingly, the invention further discloses an eye movement detection device. The eye movement detection method and device disclosed by the invention are simple in calculation, high in efficiency and low in requirement for hardware equipment.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

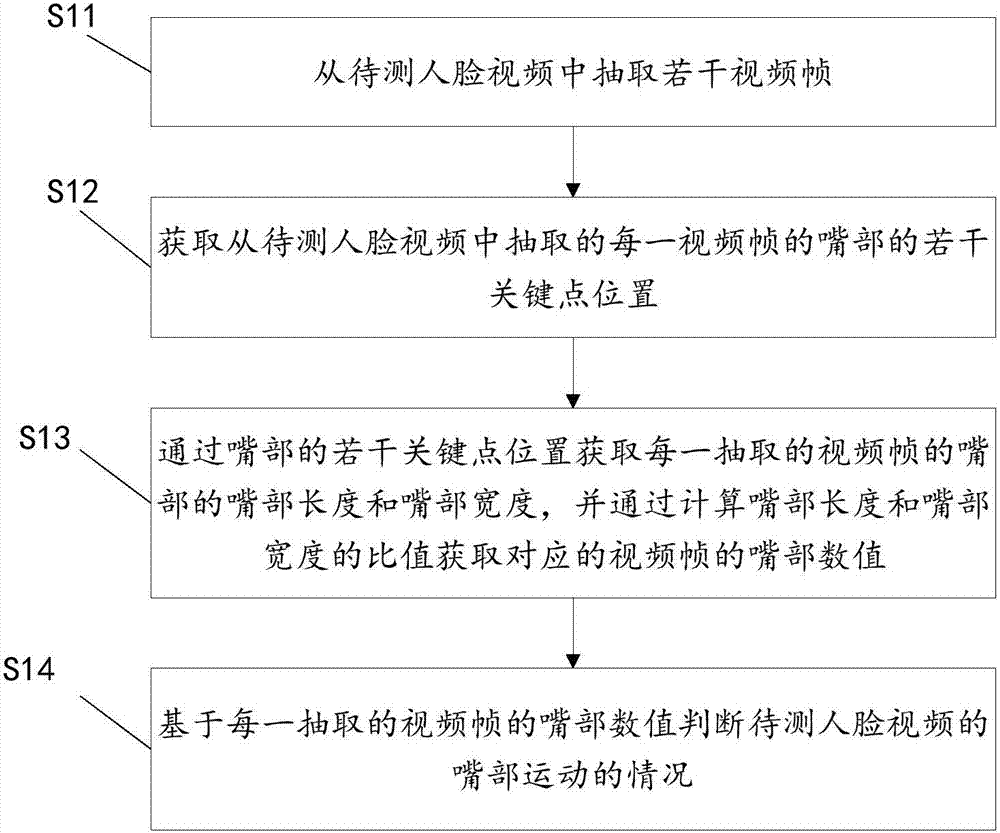

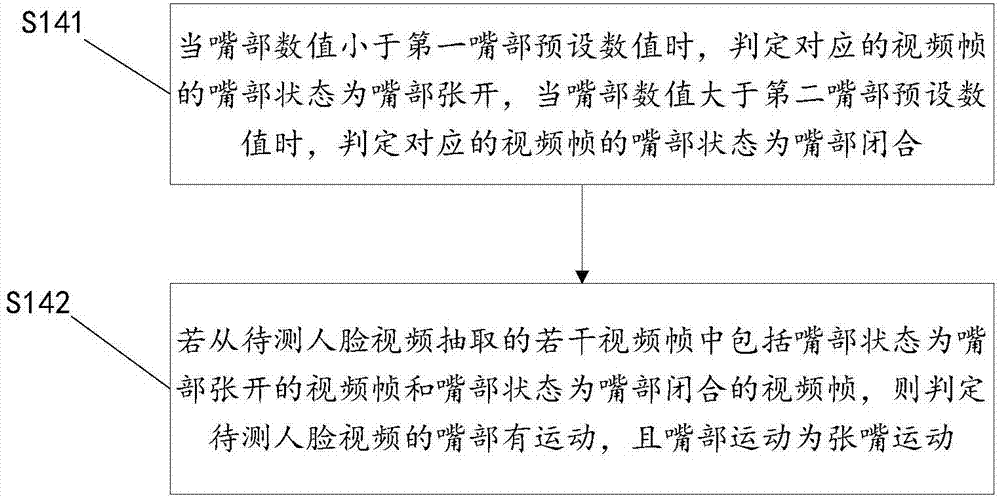

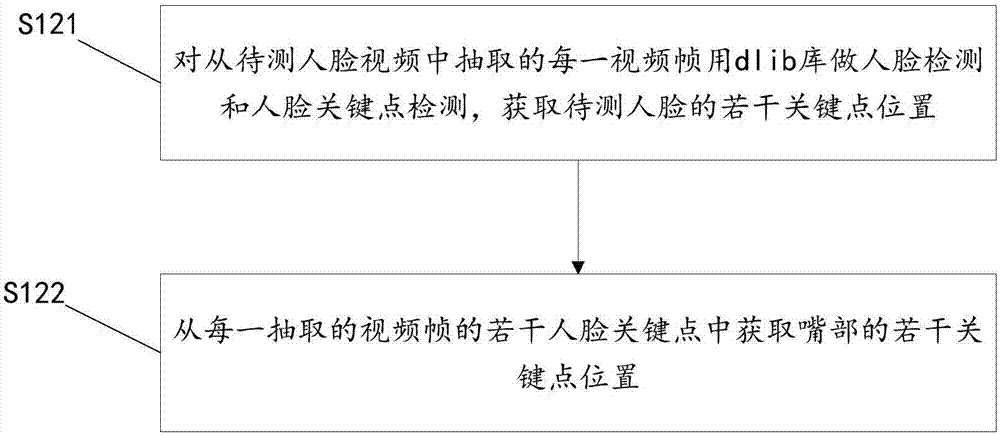

Mouth movement detection method and device and living body recognition method and system

InactiveCN107358153ASimple hardware requirementsSimple calculationCharacter and pattern recognitionPattern recognitionCrucial point

The invention discloses a mouth movement detection method, which comprises the steps of extracting a plurality of video frames from a human face video to be detected; acquiring a plurality of key point positions of the mouth in each video frame extracted from the human face video to be detected; acquiring the mouth length and the mouth width of the mouth in each extracted video frame according to the plurality of key point positions of the mouth, and acquiring a mouth value of the corresponding video frame through calculating the ratio of the mouth length and the mouth width; and judging a movement condition of the mouth in the human face video to be detected based on the mouth value of each extracted video frame. Correspondingly, the invention further discloses a mouth movement detection device. The mouth movement detection method and device are simple in calculation and high in efficiency.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

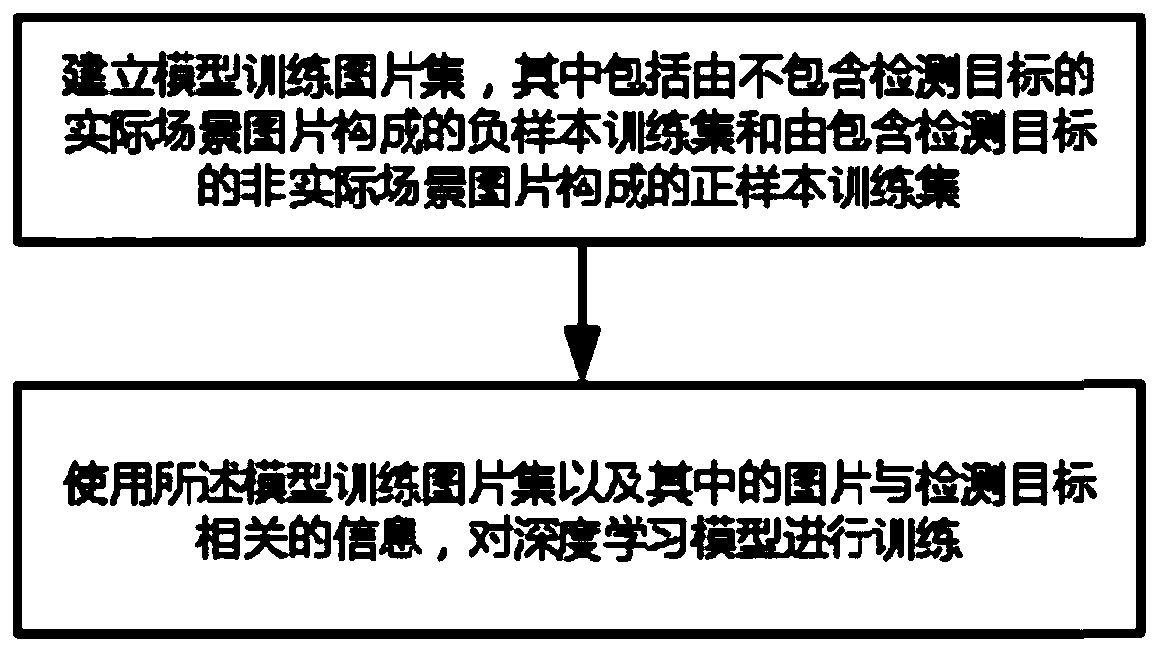

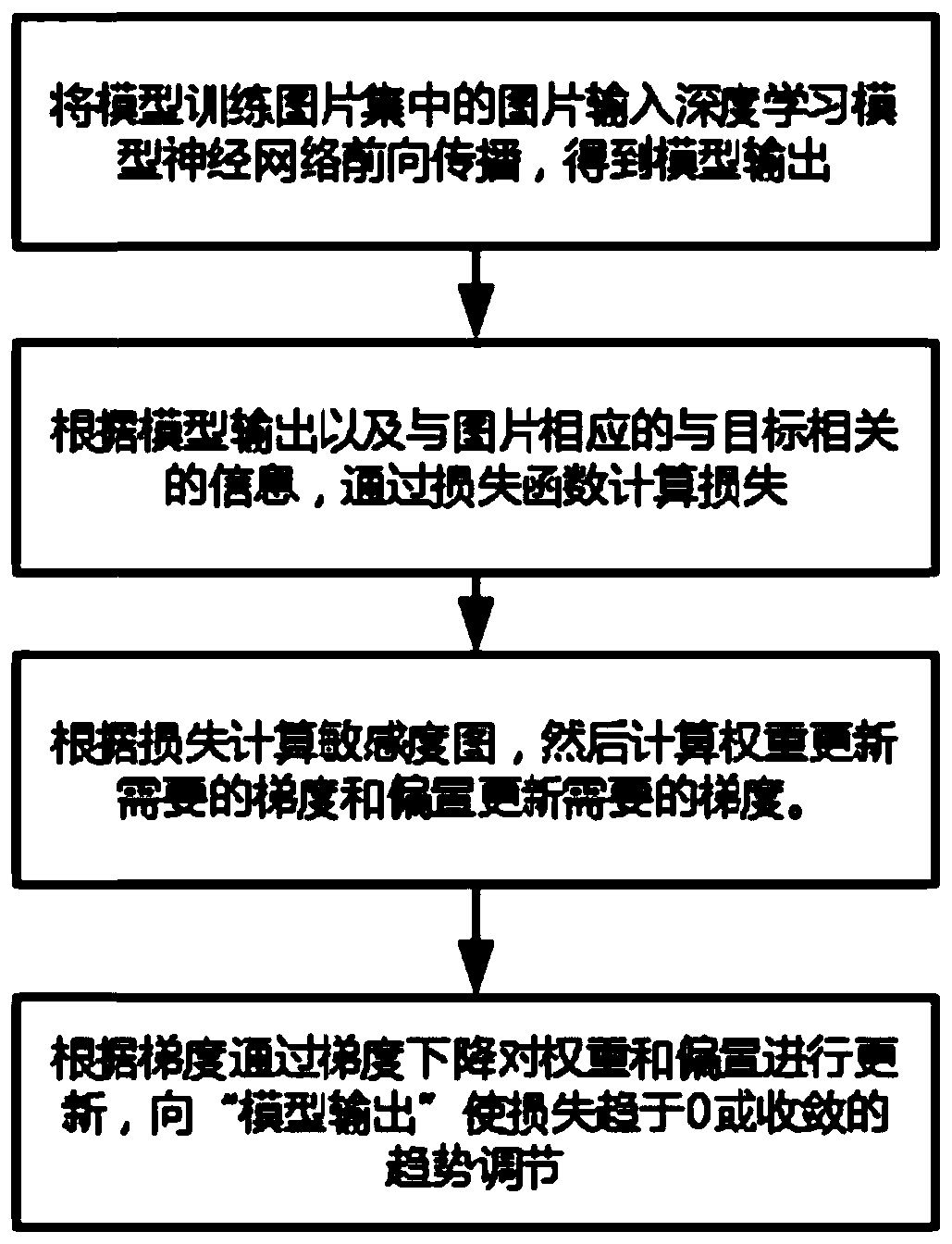

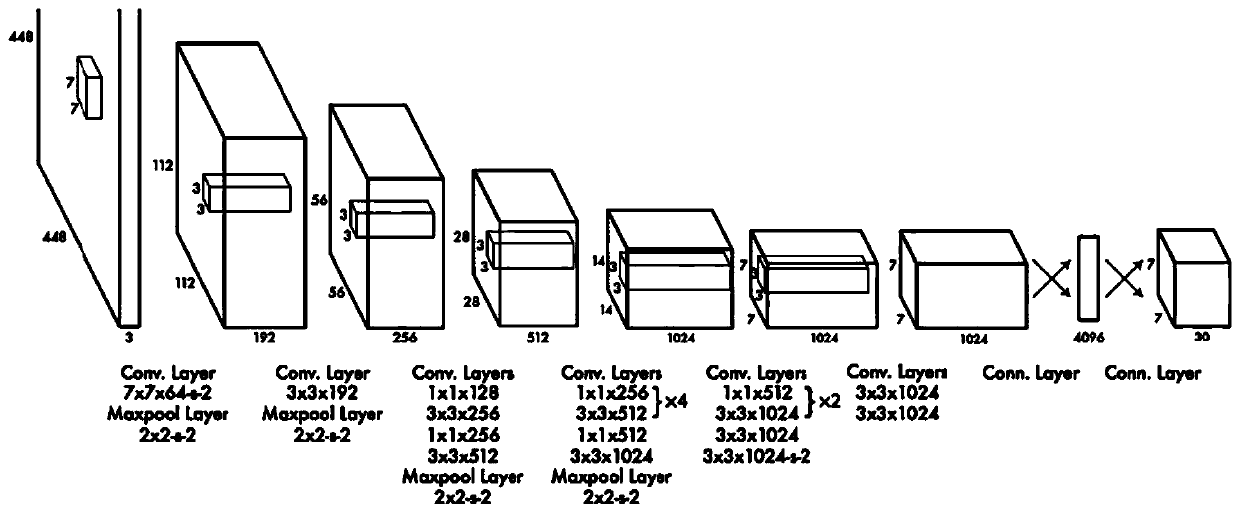

Target detection deep learning model training method and target detection method

InactiveCN109978036AReduce false detection rateImprove robustnessCharacter and pattern recognitionNeural architecturesPositive sampleFalse detection

The invention discloses a method for training a deep learning model in target detection based on deep learning, which comprises the following steps of: establishing a model training picture set whichcomprises a negative sample training set consisting of actual scene pictures which do not contain a detection target and a positive sample training set consisting of non-actual scene pictures which contain the detection target; and training a deep learning model by using the model training picture set and the information related to the detection target and the pictures in the model training picture set. According to the method, the loss of the background picture is considered when the loss is calculated, so that the false detection rate of the model on the background in an actual detection scene is greatly reduced. Strong robustness is provided for illumination change and scene change. The operation speed is high, real-time operation detection can be carried out on the CPU, and stability and high efficiency are achieved; hardware requirements are simple, and large-scale popularization is easy.

Owner:华瑞新智科技(北京)有限公司

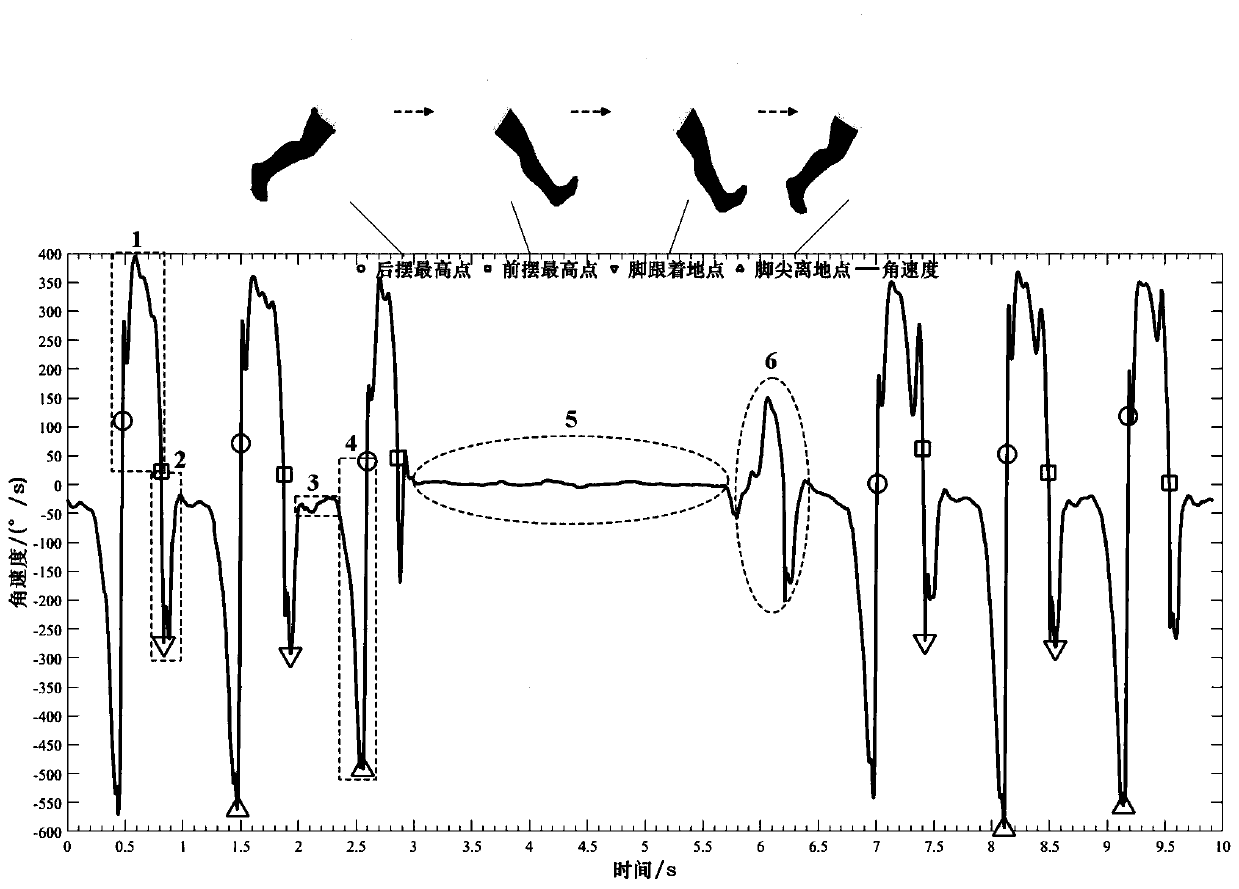

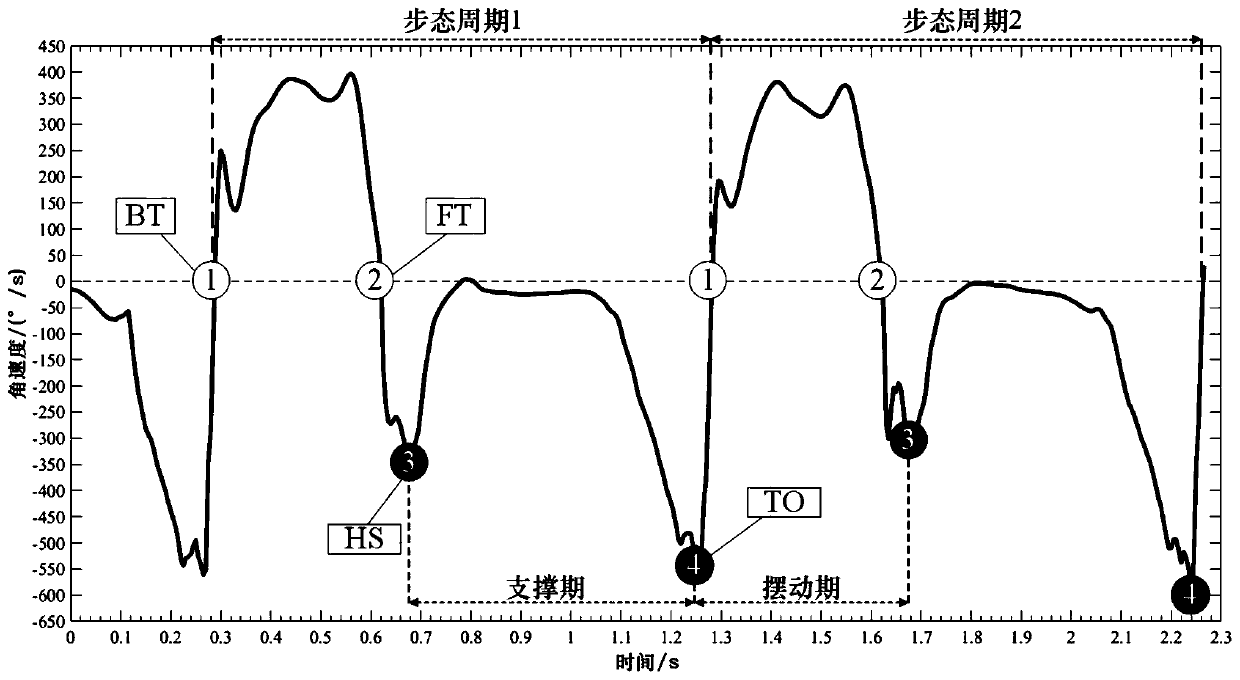

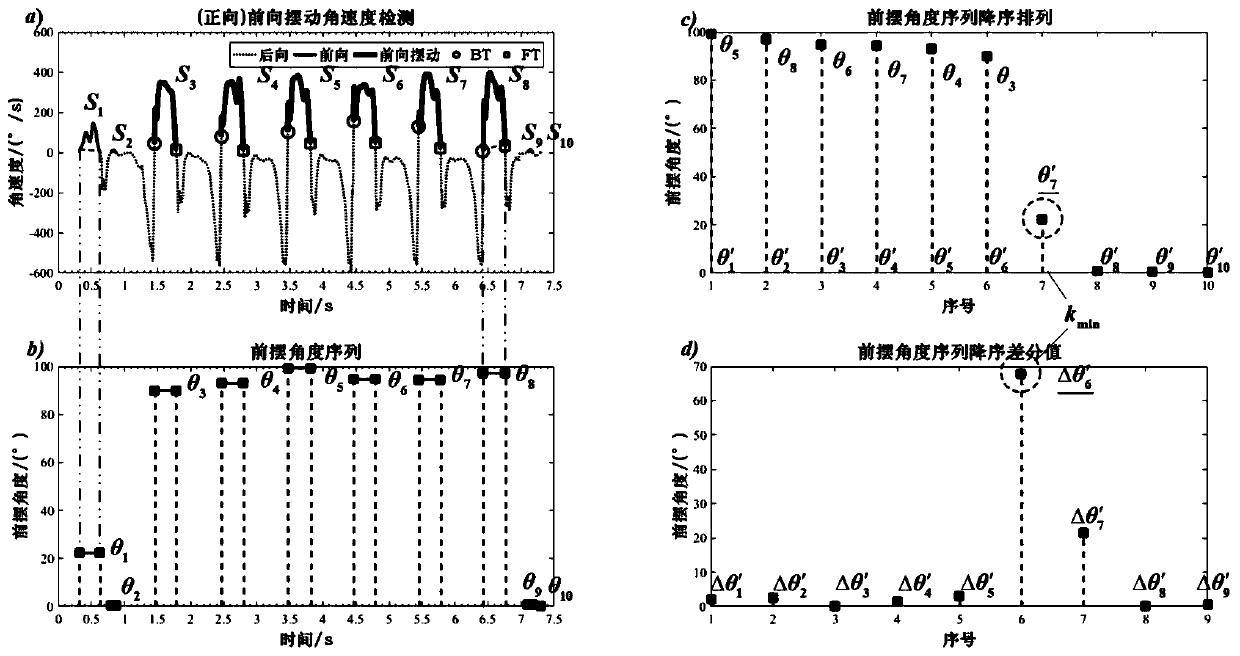

Gait phase analysis method for segmented local peak detection

ActiveCN109998551ASimple hardware requirementsImprove robustnessDiagnostic recording/measuringSensorsHeel contactAngular velocity

The invention provides a gait phase analysis method for segmented local peak detection, and relates to the field of gait analysis, in particular to a gait phase analysis method related to the foot angular velocity. The gait phase analysis method for segmented local peak detection is disclosed to solve the problem that a double-peak detection method used for gait phase division according to inertial data is poor in self-adaptability. The method is technically characterized by comprising the two steps that pitch angular velocity data of a foot in a gait movement is obtained; according to movement characteristics of a swing stage and a landing stage in the gait movement, the non-forward swing angular velocity is segmented by extracting the forward swing angular velocity. Local extreme valuesare extracted to replace a traditional peak detection method, and extraction of information of two key points including a heel contact point and a toe-off point during the gait movement is achieved. The method can be applied to the field of gait analysis.

Owner:山东昌达自动化技术有限公司

Computer remote production management system

InactiveCN101464972AConvenient and timely connection statusLess squeezeLogisticsAnalysis dataData acquisition

The invention relates to a remote production management system for a computer, which mainly comprises a central computer, a plurality of local data acquisition terminals and a plurality of remote data acquisition terminals, wherein, the central computer is connected with various local data acquisition terminals through cables and is in communication connection with the remote data acquisition terminals through a wireless base station, inhouse and outhouse data and product data during manufacture of various goods are transmitted through various remote data acquisition terminals and local data acquisition terminals received by the wireless base station and the cables, the inhouse and outhouse data and the production data are counted, analyzed and stored, the central computer is provided with a stock, a production database and an optimal analysis database and is also provided with a data statistical unit, an optimal analysis unit, a data storage and output unit, a manual input device and a central control unit; therefore, the system not only can realize acquisition and statistics of the storage data, but also can optimize and control stock modes, stock quantity and stock time of the goods according to the enterprise management condition, the remote production management system can alarm when an optimization problem occurs, so that the system is favorable to enhance the operation management level of the enterprise on the whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

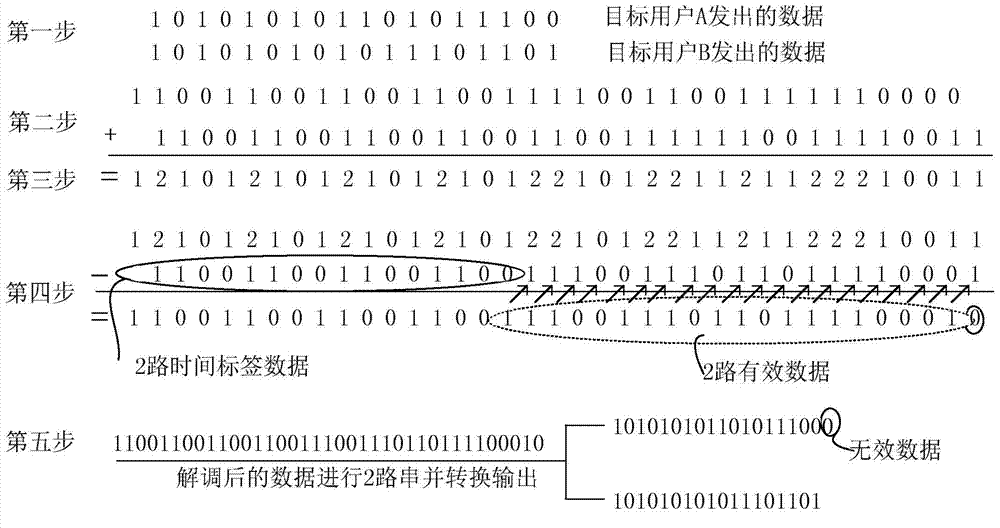

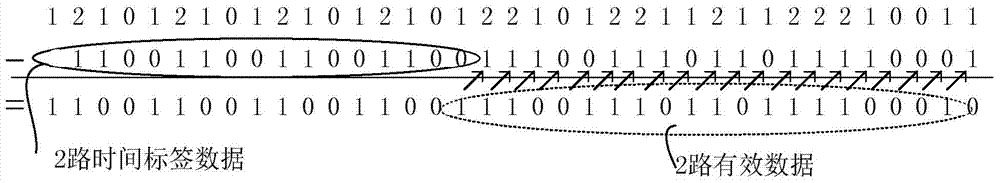

Satellite relay method utilizing time labels to achieve multi-target user support

ActiveCN104301025ASimple hardware requirementsReduce in quantityRadio transmissionHigh level techniquesDislocationVIT signals

The invention provides a satellite relay method utilizing time labels to achieve multi-target user support. The satellite relay method comprises the steps that (1) N target users add the K-bit time labels into the respective L-bit relay data heads to be transmitted, and the N target users are controlled to sequentially stagger (1 / N)-bit cycle time to sequentially transmit data; (2) a relay satellite receives N electromagnetic wave superimposed signals and forwards the N electromagnetic wave superimposed signals to a ground station; (3) the receiving end of the ground station performs judgment demodulation according to the detection judgment cycle of a (1 / N)-bit cycle, so that (N*L+N*K+N-1)-bit data are obtained through demodulation; (4) according to prior information of the time labels, N channels of data are sequentially figured out based on dislocation subtraction; (5) the data figured out is subjected to N-channel parallel conversion and is output, and then the data transmitted by the N target users respectively are restored. According to the satellite relay method, relay satellite resources are utilized in an optimized mode; besides, the satellite relay method has the advantages that hardware requirements are simplified, the number of terminals is reduced, system weight is reduced, and power consumption is lowered.

Owner:SHANGHAI SATELLITE ENG INST

Trellis-based lock detector

ActiveUS7675987B2Simple hardware requirementsData representation error detection/correctionCarrier regulationPattern recognitionTime index

Owner:QUASONIX

Enterprise stockpile and production management system

InactiveCN101464970AConvenient and timely connection statusLess squeezeLogisticsAnalysis dataData acquisition

The invention relates to an enterprise stock and production management system, which mainly comprises a central processing system, a stock data acquisition terminal and a production data acquisition terminal, wherein, the data acquisition terminal collects inhouse and outhouse data and product data during manufacture for feeding various goods into the central processing system respectively, the inhouse and outhouse data and the product data during manufacture are counted, analyzed and stored through the central processing system, the central processing system is provided with a real-time stock, a product database during manufacture and an optimal analysis database and is also provided with a data statistical unit, an optimal analysis unit, a data storage and output unit, a manual input device and a central control unit; therefore, the system not only can realize acquisition and statistics of the storage data and the real-time production data, but also can optimize and control stock modes, stock quantity, stock time and a manufacturing process of goods according to the enterprise management condition, the enterprise stock and production management system can alarm when an optimization problem occurs, so that the system is favorable to enhance the production operation management level of the enterprise.

Owner:BEIJING AOTENGXUNDA SCI & TECH

Enterprise production control system

InactiveCN101593307AConvenient and timely connection statusLess squeezeCo-operative working arrangementsLogisticsAnalysis dataBusiness management

The invention relates to an enterprise production control system, mainly comprising a central processing system and data collection terminals performing data exchange with the central processing system. The data collection terminals comprise an input data collection terminal, an output data collection terminal, a production input terminal and a production data collection terminal, and are used for collecting relevant data of various cargoes and sending the relevant data to the central processing system; the central processing system is used for performing statistics, analysis and storage of the relevant data, and is provided with a real-time inventory database and an optimal analysis database, and is additionally provided with a data statistics unit, an optimal analysis unit, a data storage and output unit, an artificial input device and a central control unit. The system can not only realize collection and statistics of storage data, but also optimize and control the inventory manner, inventory quantity and inventory time of the cargoes according to the business condition of the enterprises, thus being capable of alarming when optimization problem appears and favorable for enhancing the business management level of the enterprises as a whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

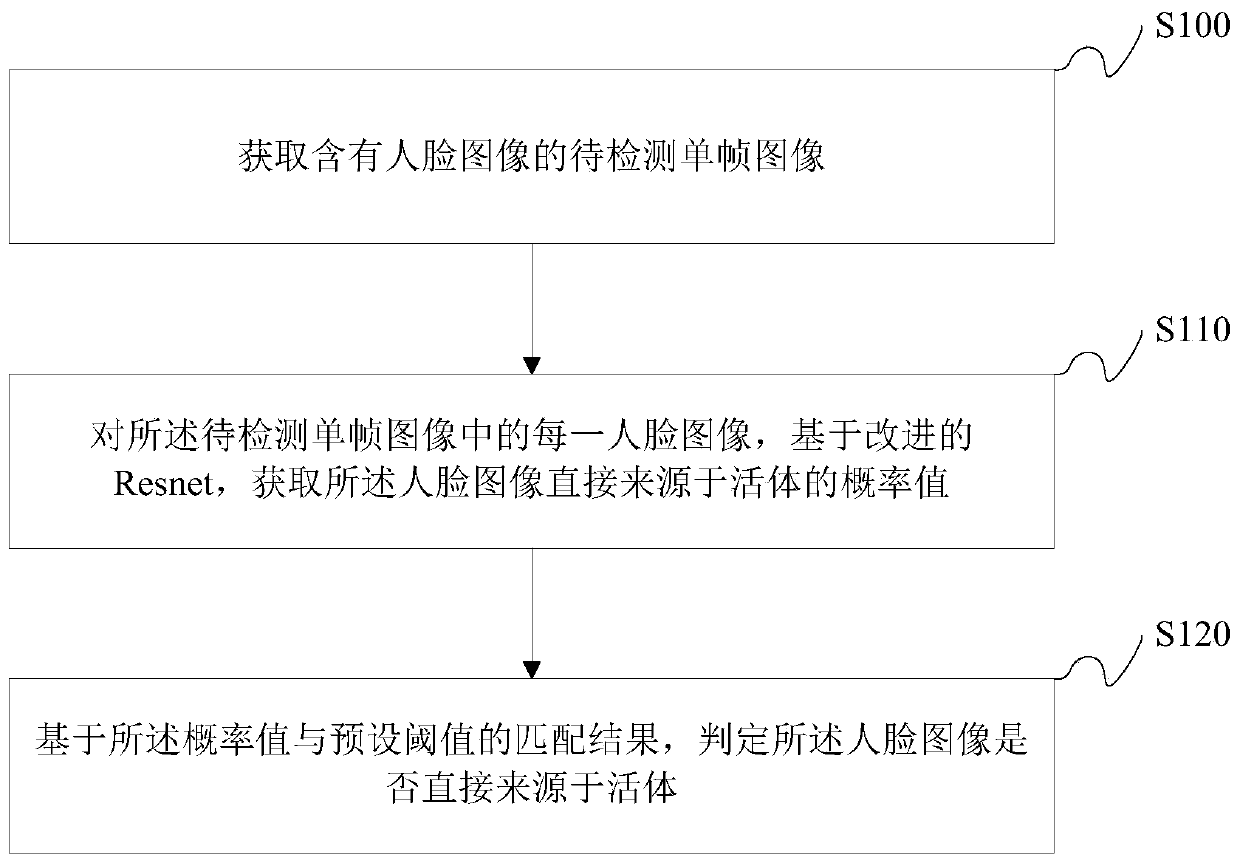

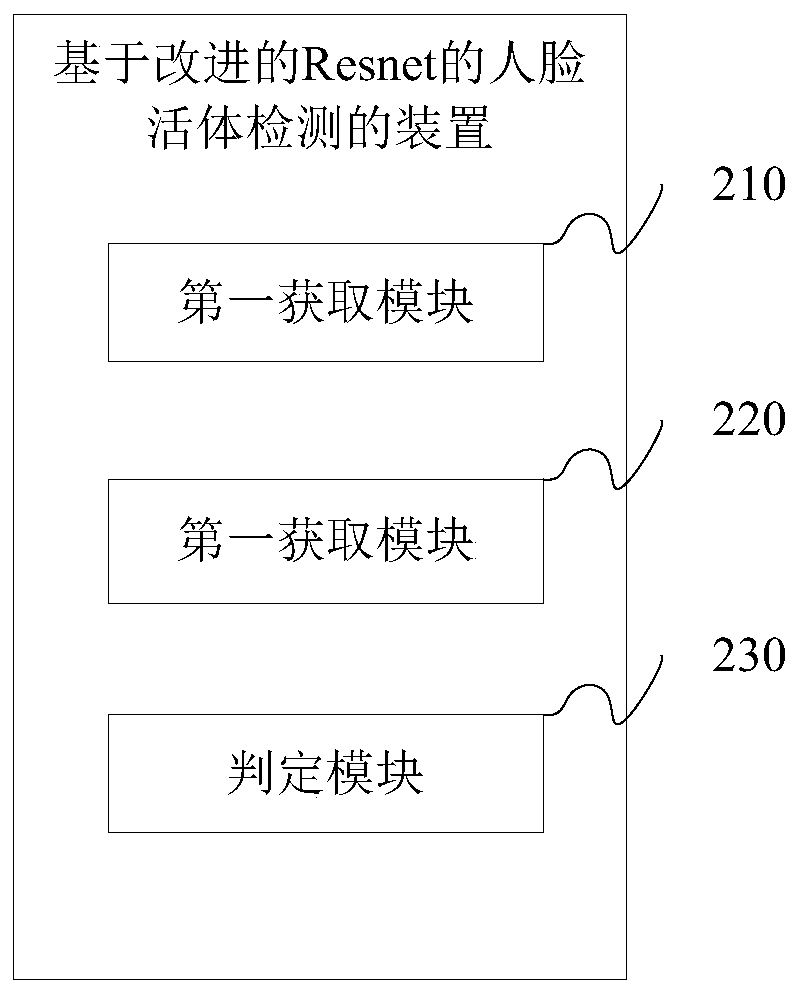

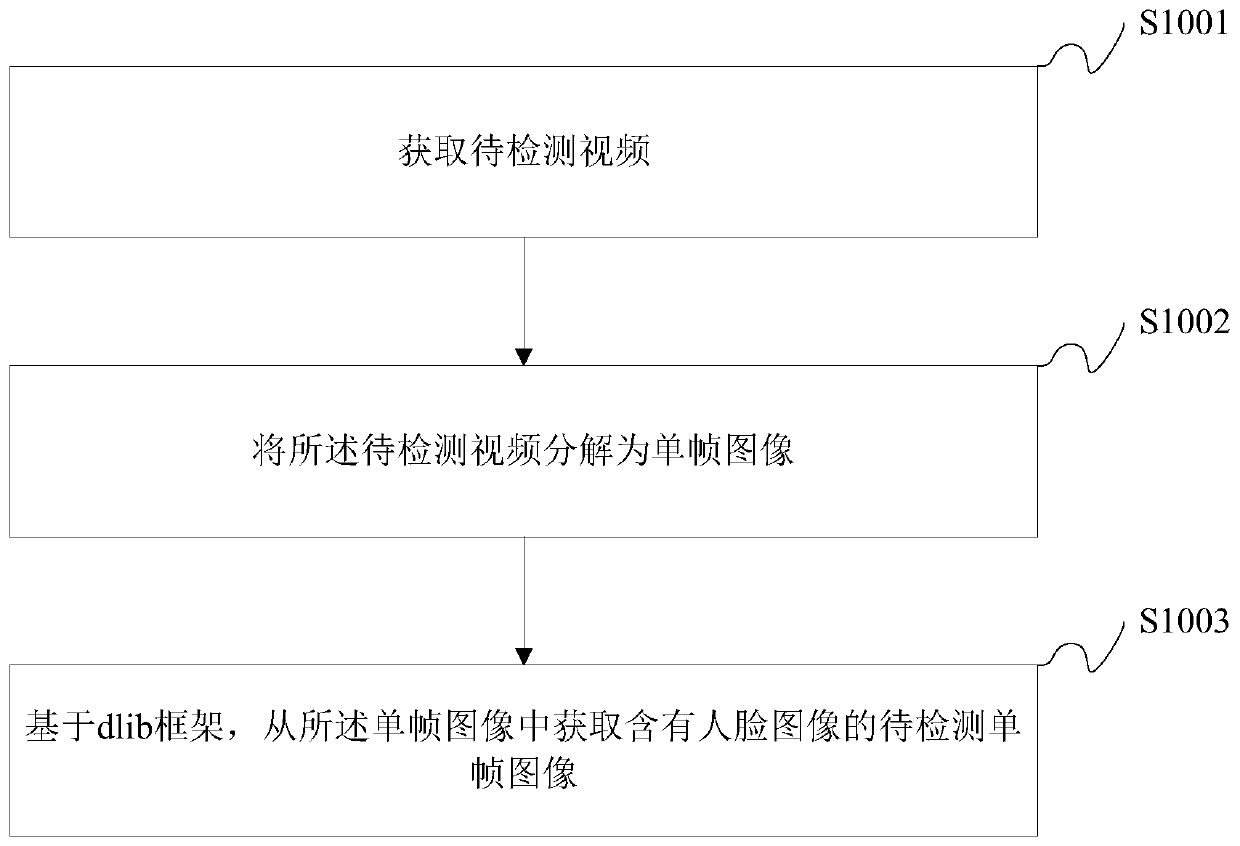

Improved Resnet-based human face in-vivo detection method and related equipment

PendingCN110059542ASimple hardware requirementsHigh precisionSpoof detectionPattern recognitionIn vivo

The invention discloses an improved Resnet-based human face in-vivo detection method and related equipment, and relates to the field of in-vivo detection, and the method comprises the steps: obtaininga to-be-detected single-frame image containing a human face image; for each face image in the to-be-detected single-frame image, based on an improved Resnet, obtaining a probability value of the faceimage directly coming from a living body; and judging whether the face image is directly from a living body based on a matching result of the probability value and a preset threshold value. Accordingto the method, the accuracy of human face in-vivo detection is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Remote computer inventory management system of production enterprises

InactiveCN101593314AConvenient and timely connection statusLess squeezeCo-operative working arrangementsLogisticsAnalysis dataData acquisition

The invention relates to a remote computer inventory management of production enterprises, mainly comprising a central processing system and data collection terminals performing data exchange with the central processing system. The data collection terminals are used for collecting relevant data of various cargoes and sending the relevant data to the central processing system and comprise a raw material data collection terminal, an intermediate product data collection terminal, a production data collection terminal and a marketing plan input terminal; the central processing system is provided with a real-time inventory database and an optimization analysis database, and is additionally provided with a data statistics unit, an optimization analysis unit, a data storage and output unit, an artificial input device and a central control unit. The system can not only realize collection and statistics of storage data, but also optimize and control the inventory manner, inventory quantity and inventory time of the cargoes according to the business condition of the enterprise, thus being favorable for enhancing the business management level of the enterprises as a whole.

Owner:BEIJING AOTENGXUNDA SCI & TECH

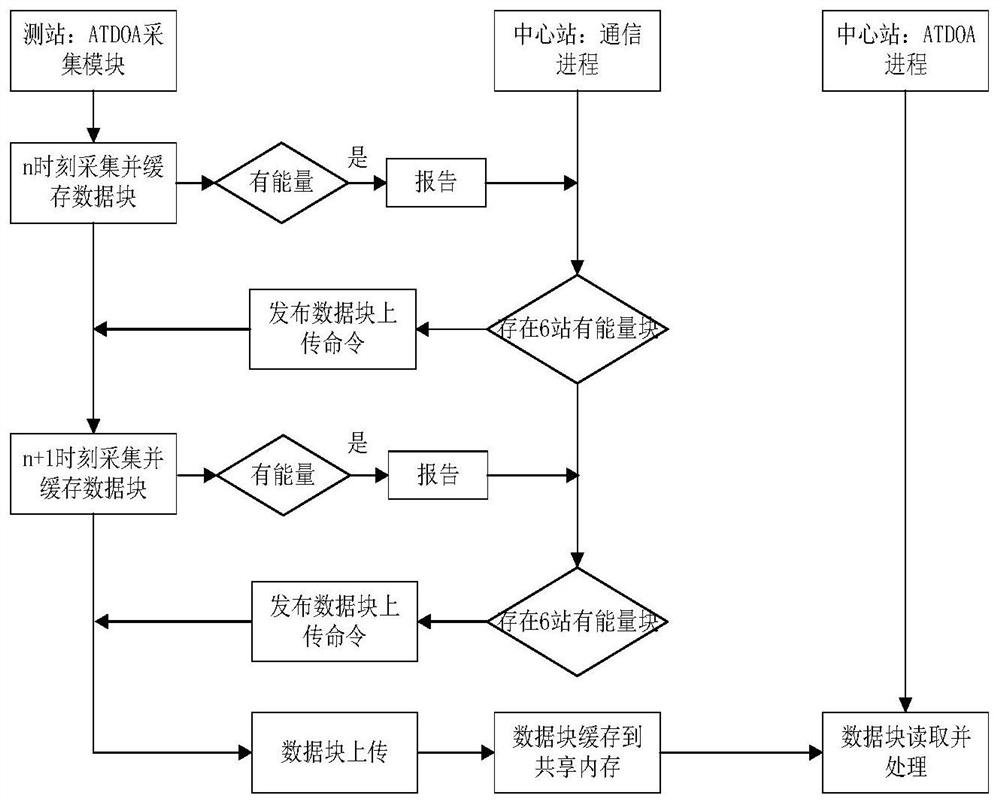

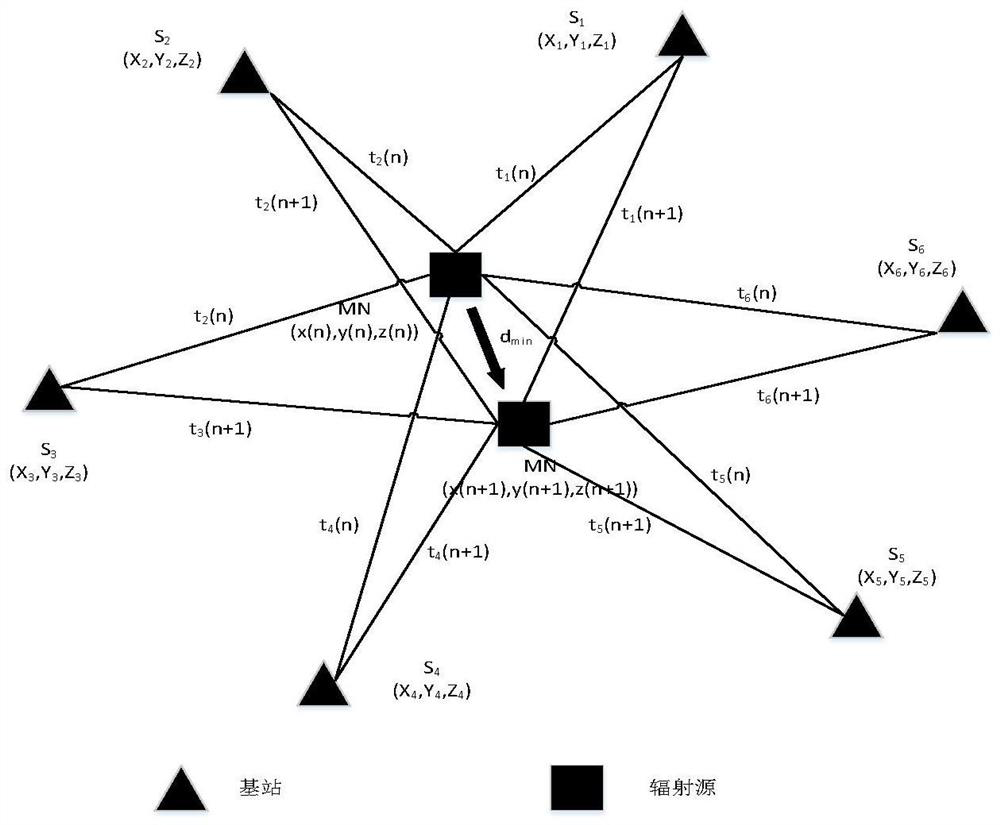

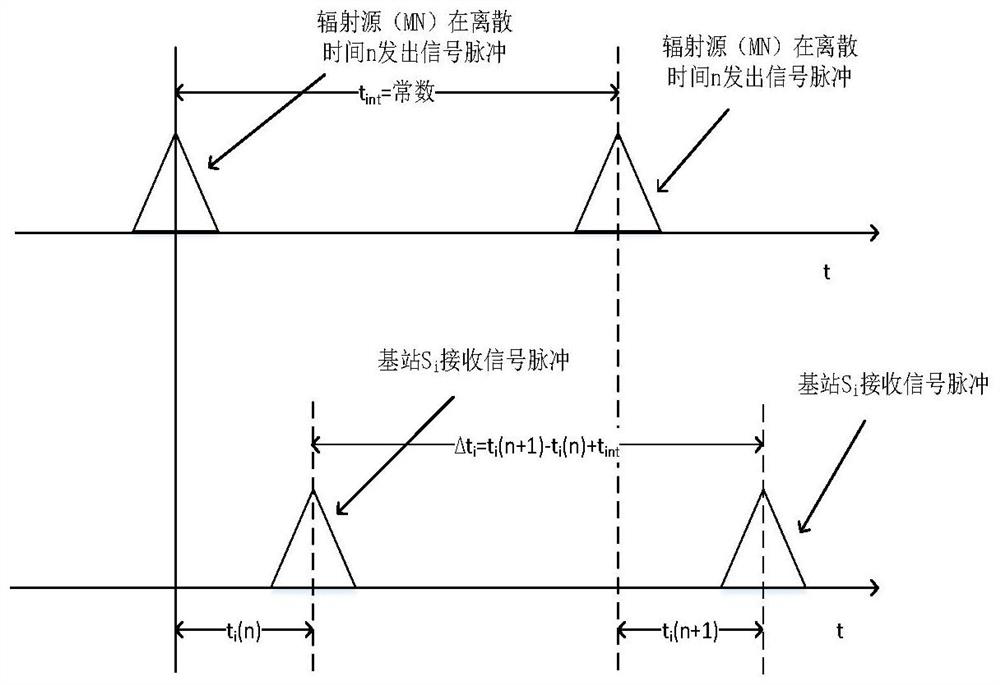

Frequency spectrum detection system positioning method based on ATDOA algorithm

PendingCN113391267AOvercoming costly problemsGuaranteed positioning accuracyPosition fixationFrequency spectrumAlgorithm

The invention discloses a frequency spectrum detection system positioning method based on an ATDOA algorithm, and the method comprises the steps: at least six base stations are deployed in a three-dimensional space to carry out the positioning monitoring of a radiation source, the coordinates of the radiation source are obtained, the positions of the base stations is fixed and known, and clocks are allowed to be asynchronous among the base stations; the radiation source sends sound pulses at a fixed frequency, can be measured by a monitoring station and moves within a monitoring range at a relatively high speed. The problem of clock synchronization is solved for a monitoring system applying a TDOA algorithm for positioning. An ATDOA algorithm is applied to frequency spectrum monitoring, and the ATDOA algorithm comprises the steps of identifying the frequency of signals sent by a radiation source, obtaining the time difference of the signals sent by the radiation source received by a plurality of observation stations twice, distributing tasks of the observation stations and a central station in the process, and solving obtained data information through a genetic algorithm. Therefore, strict clock synchronization required by the TDOA method is avoided, the positioning precision of the system is effectively improved, and the positioning power consumption is reduced.

Owner:XIAN UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com