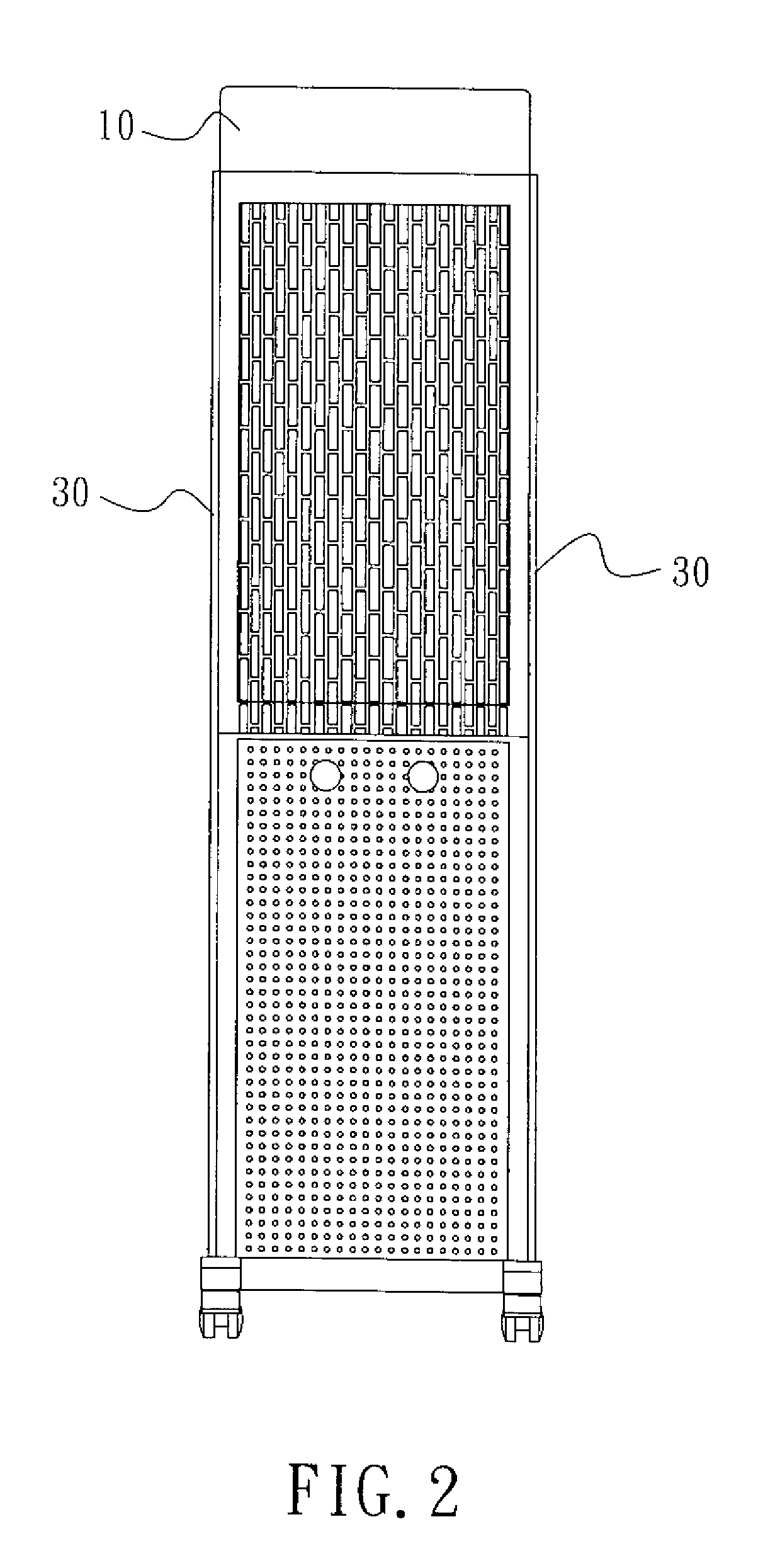

Patents

Literature

37results about How to "Ensure Lighting Safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

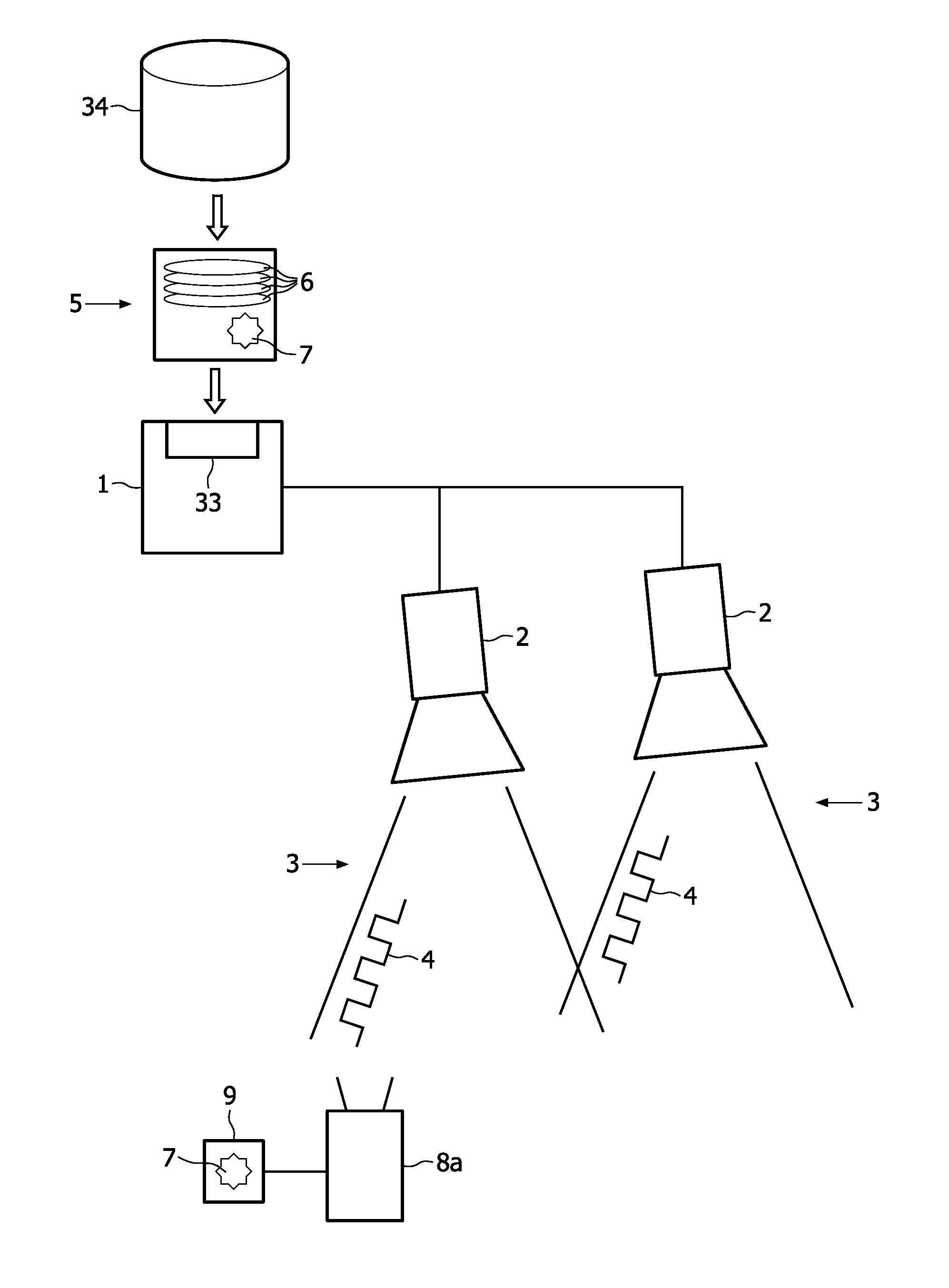

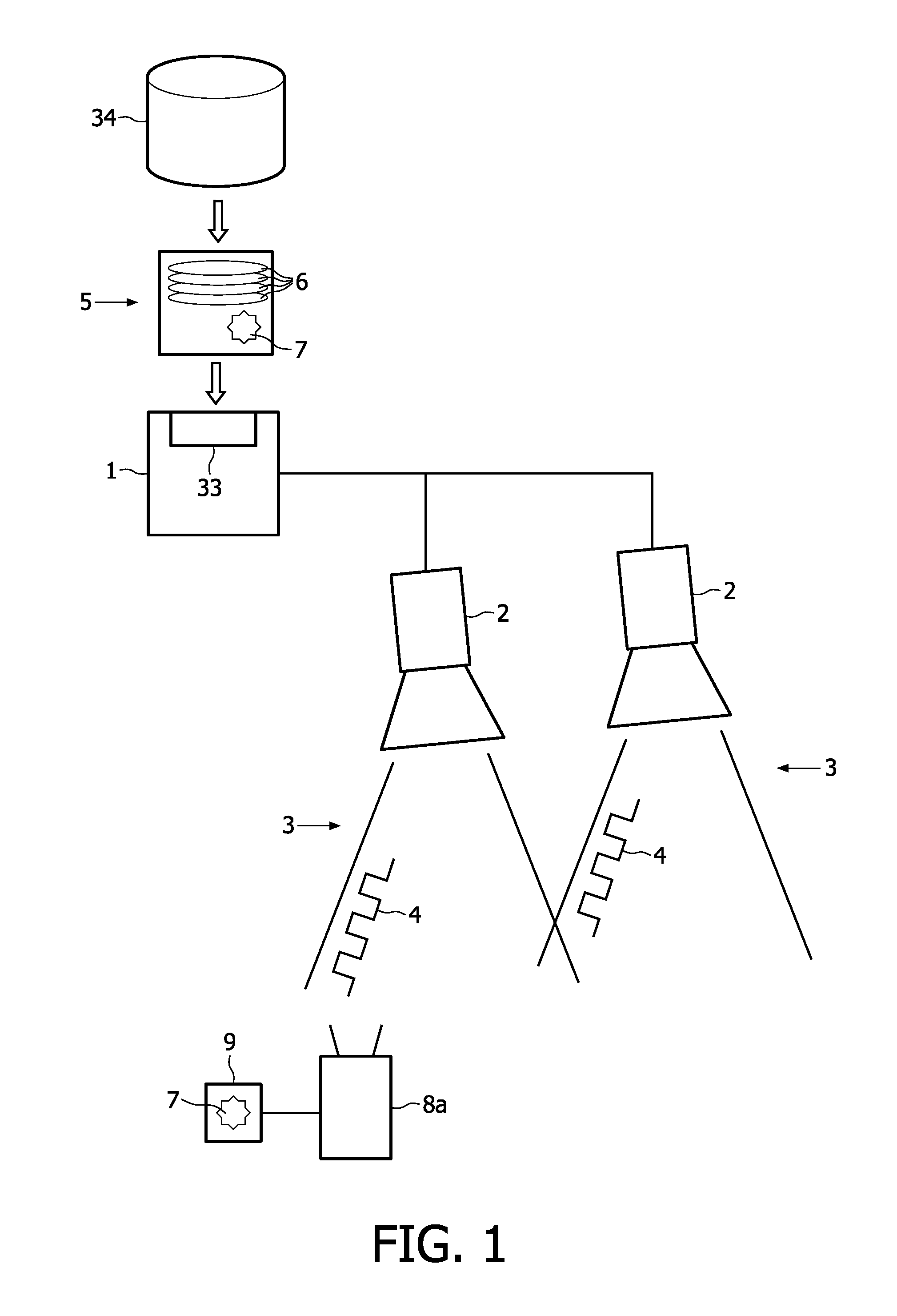

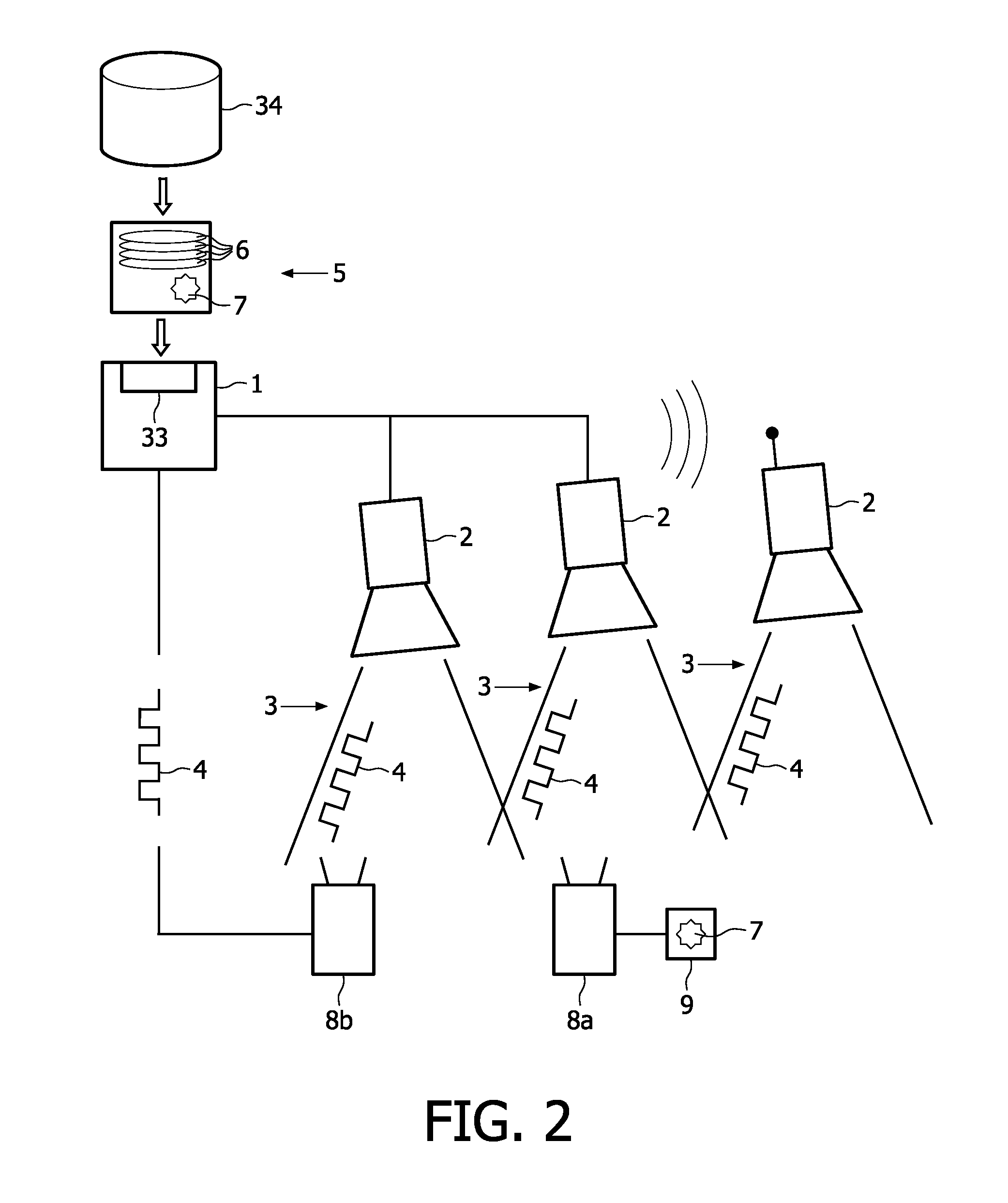

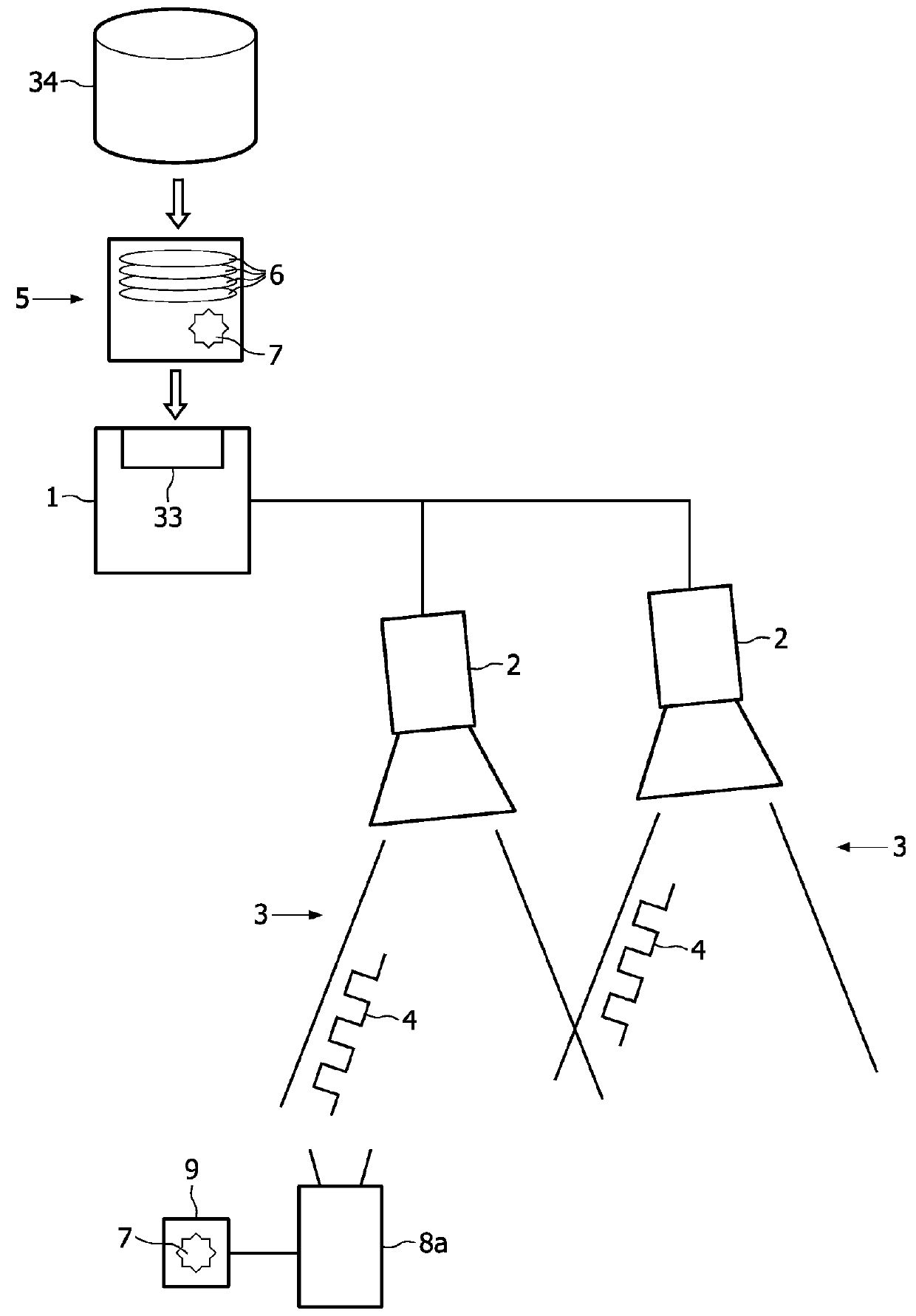

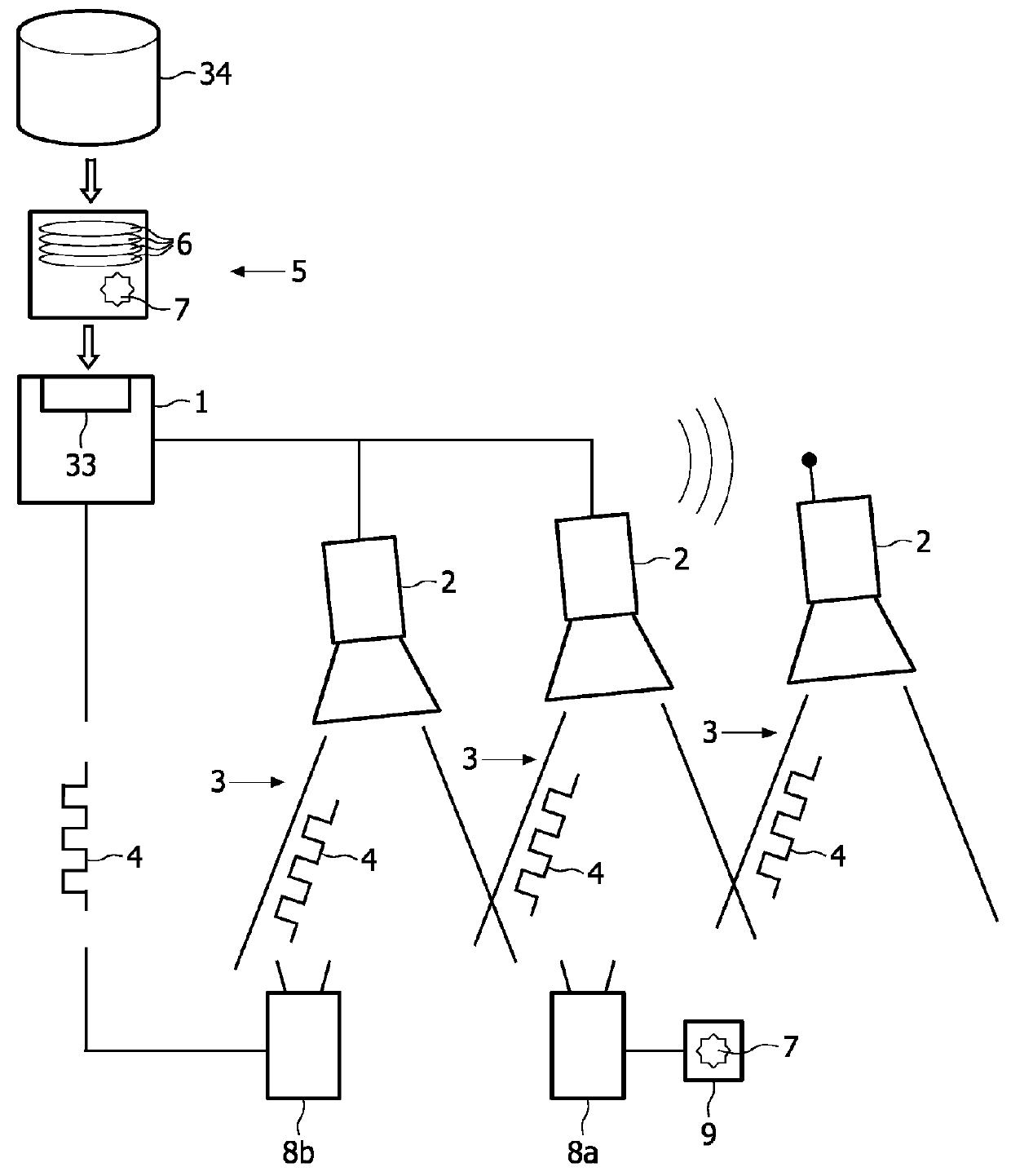

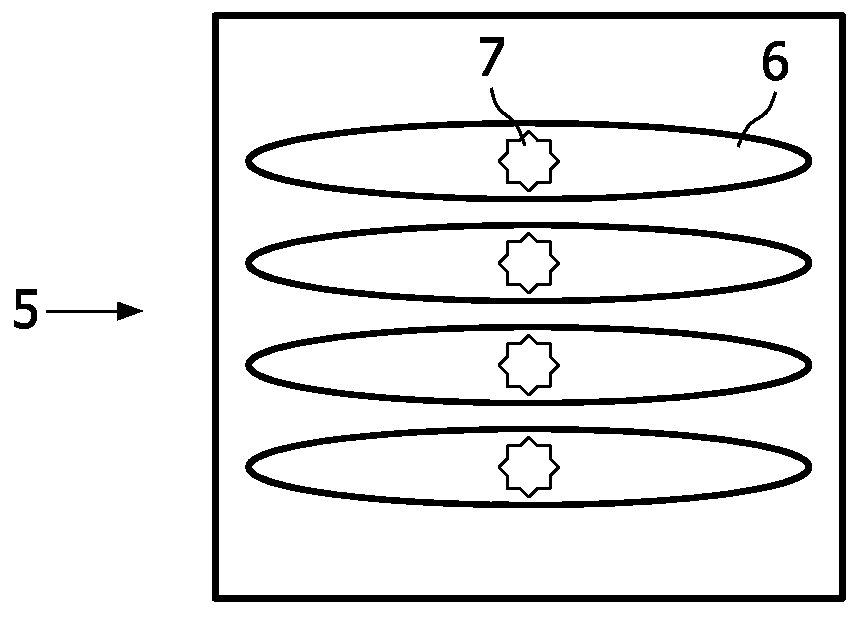

Lighting system and method for operating a lighting system

ActiveUS20100309016A1Direct monitoringEnsure Lighting SafetyElectric signal transmission systemsElectrical apparatusEffect lightLight beam

A lighting system and a method for a operating a lighting system, enabling to obtain an identification tag (7) comprised in lighting design data (5) directly from an output beam (3), i.e. from the emitted light of the at least one lighting unit (2). It is thus possible to trace any unauthorized distribution of a lighting design by monitoring the emitted light without the need to directly access the controller or any other part of the lighting system.

Owner:SIGNIFY HLDG BV

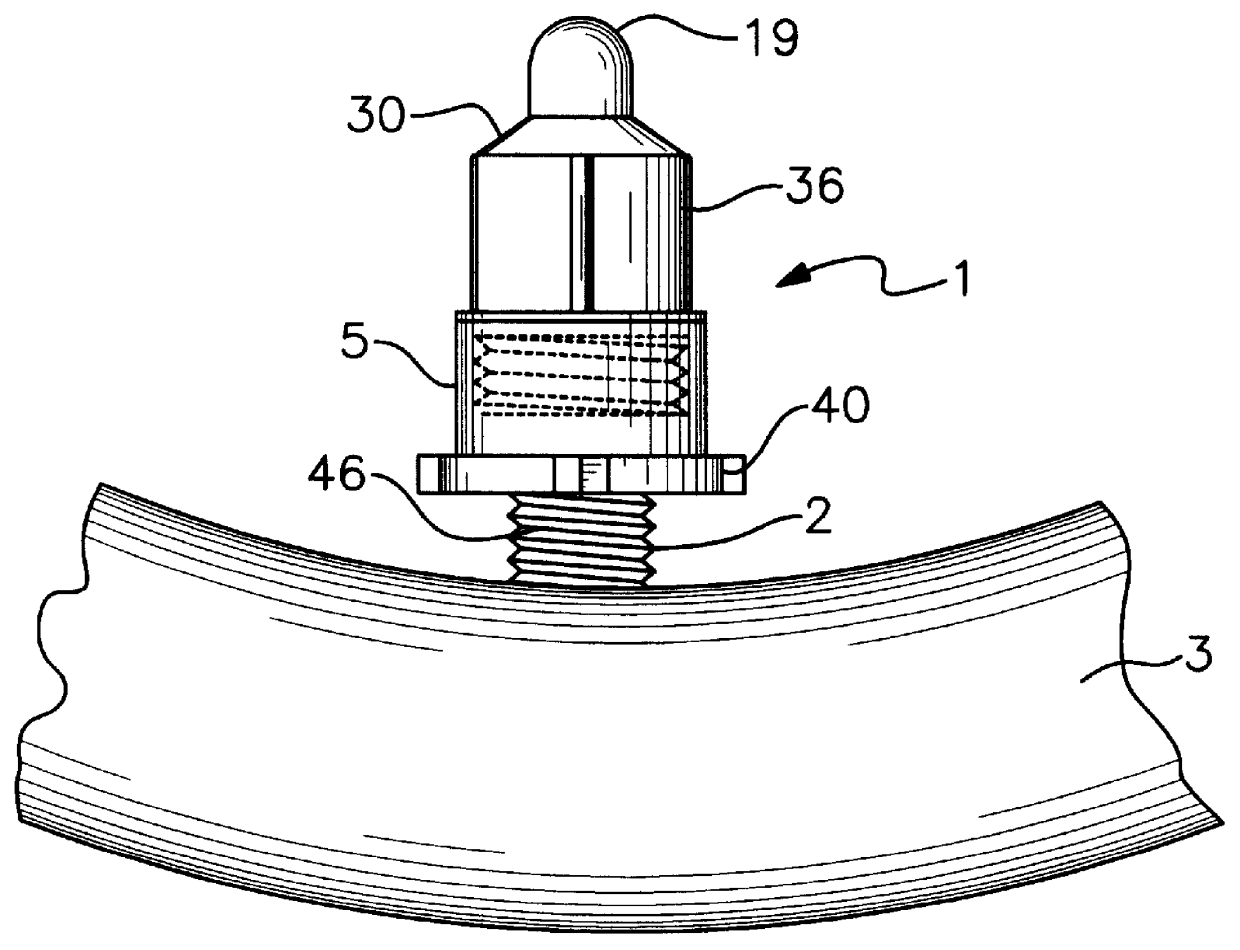

Waterproof valve stem safety light for vehicles

InactiveUS6070997AImproved vehicle safety lightEnsure Lighting SafetyOptical signalLighting heating/cooling arrangementsEngineeringValve stem

A symmetrical safety light for wheeled vehicles is turned on by relative rotation of a removable plug in a housing that pushes a battery in the housing against the resistance of a spring. The light is turned off by relative rotation of the components in the opposite direction, which allows the spring to push the battery out of contact with a conductor from the light.

Owner:STREET GLOW

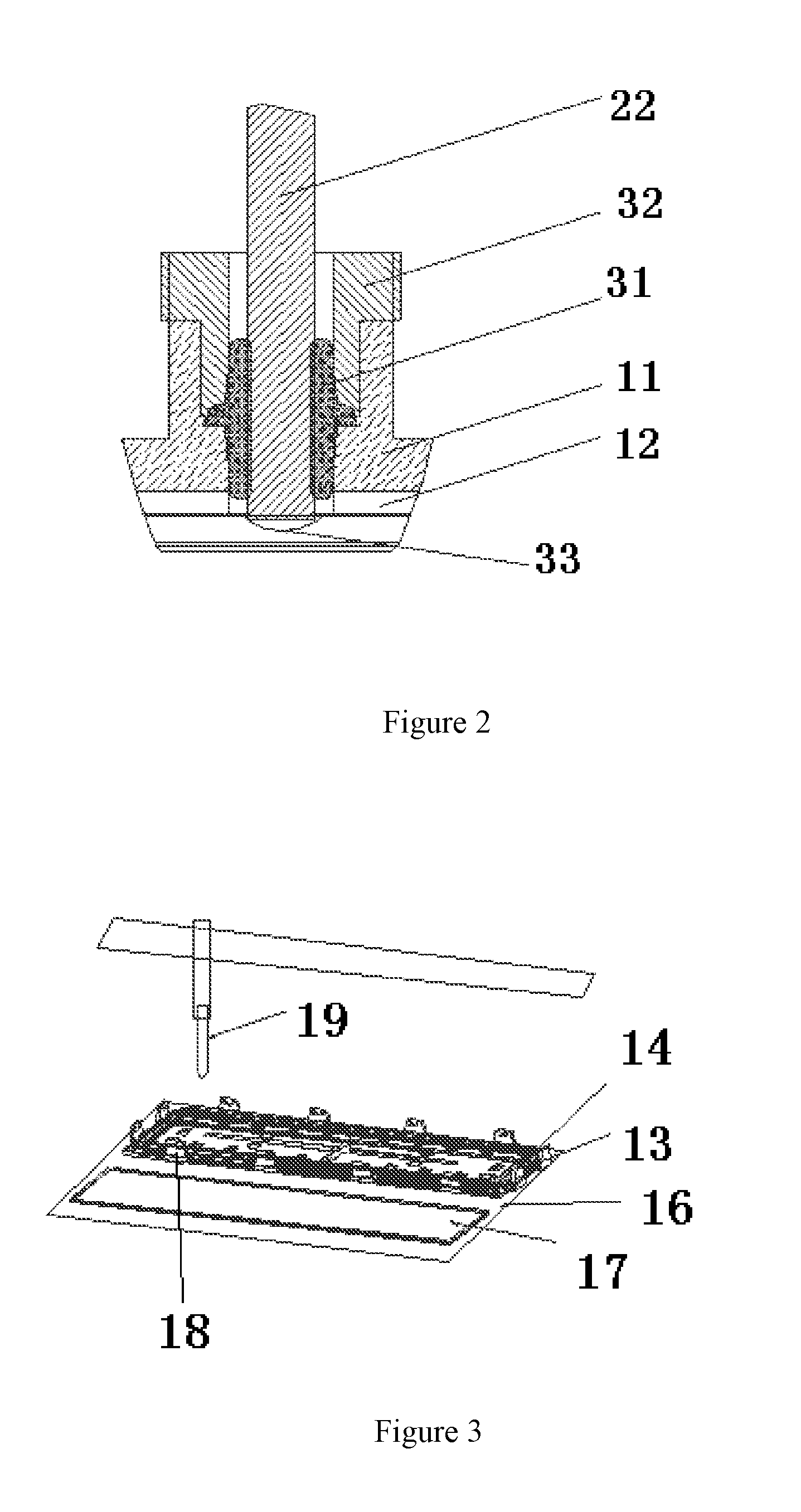

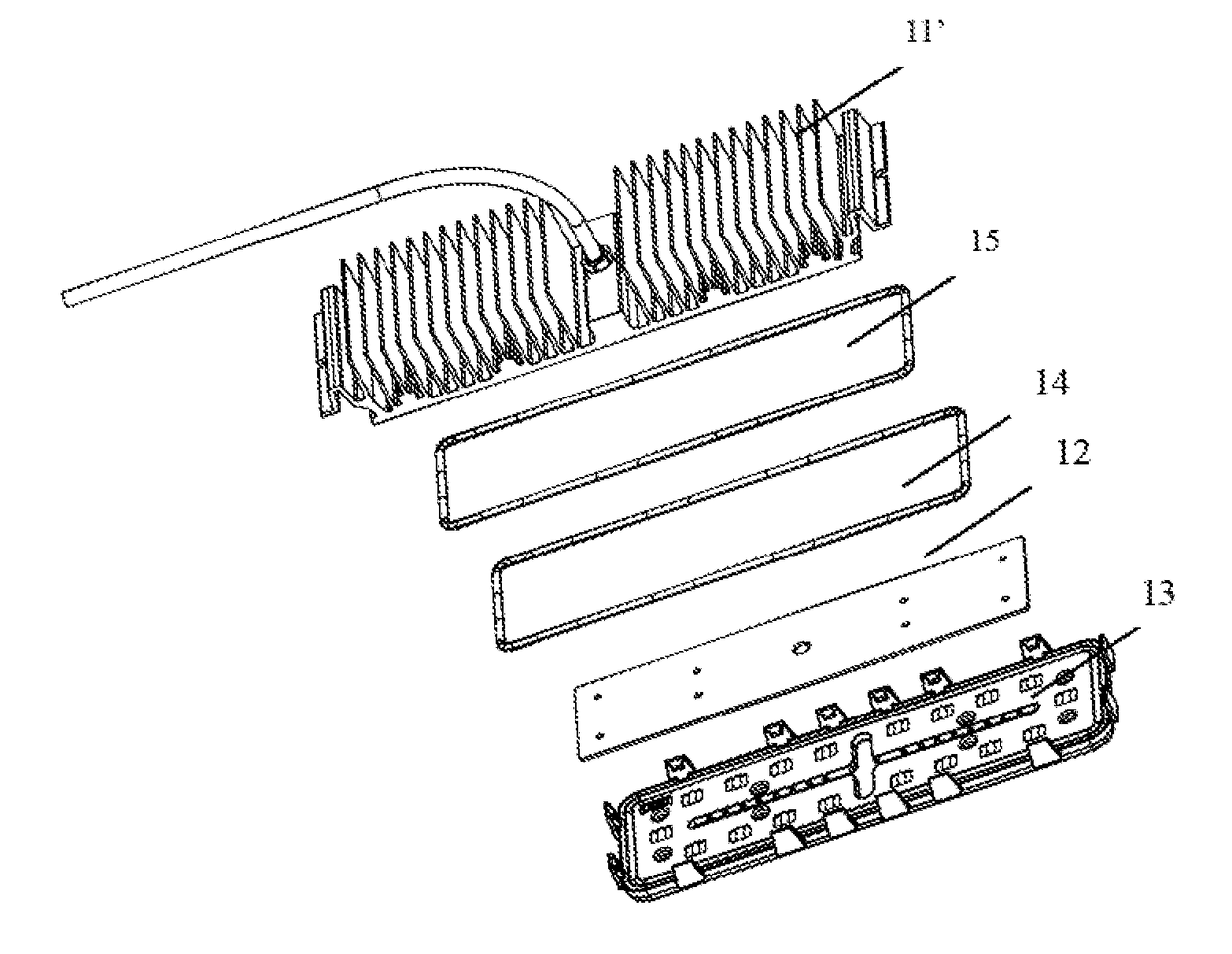

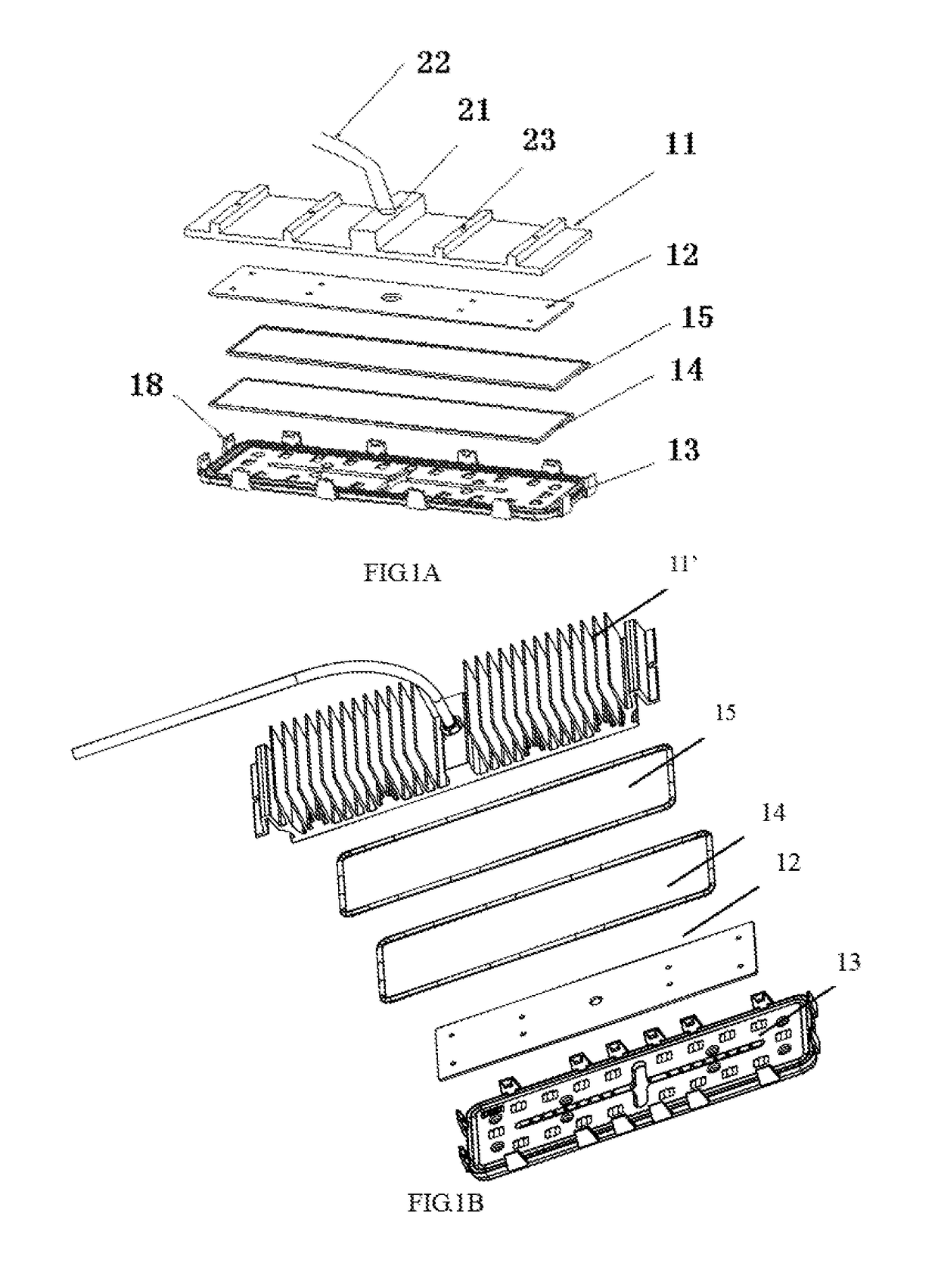

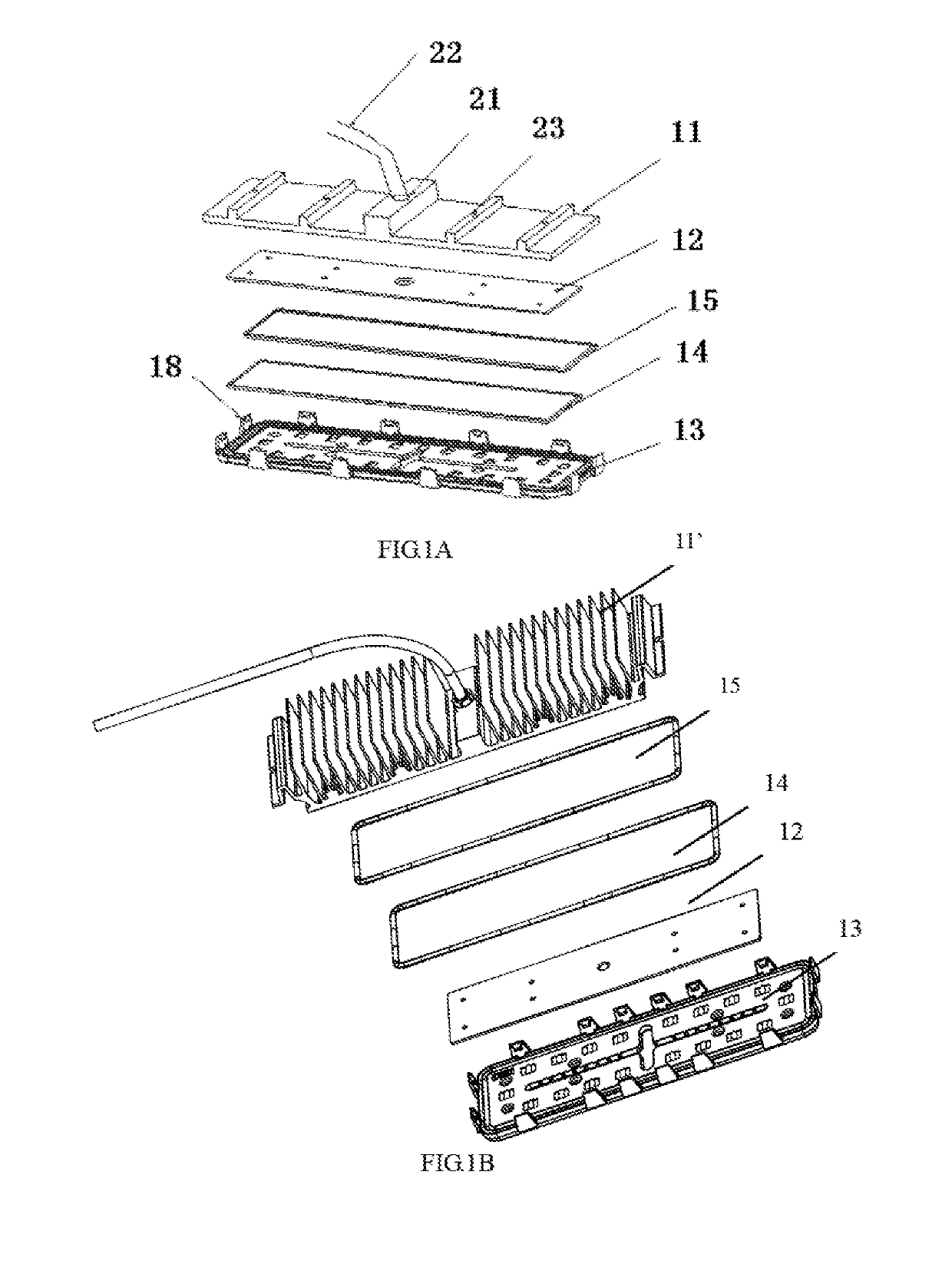

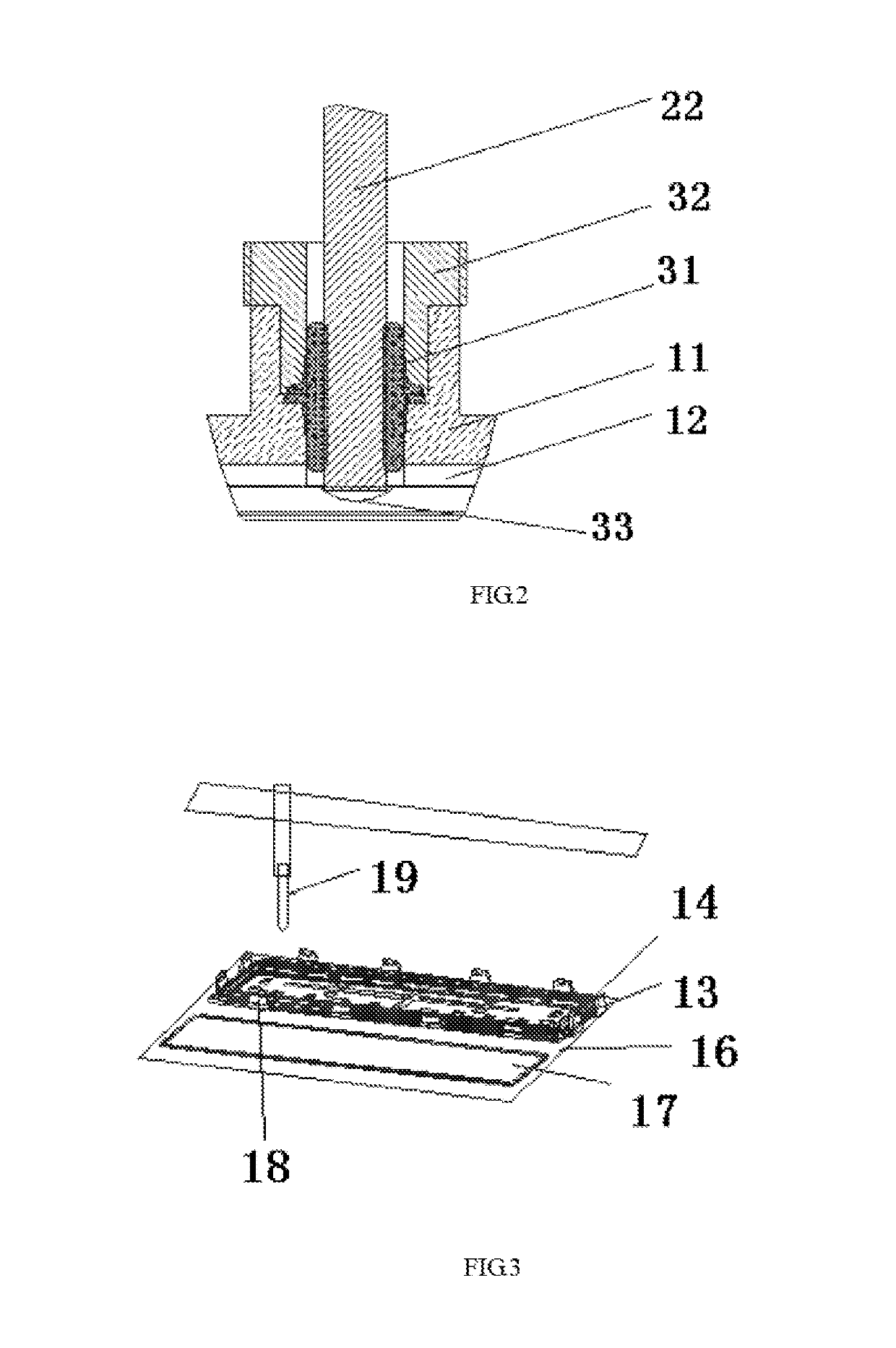

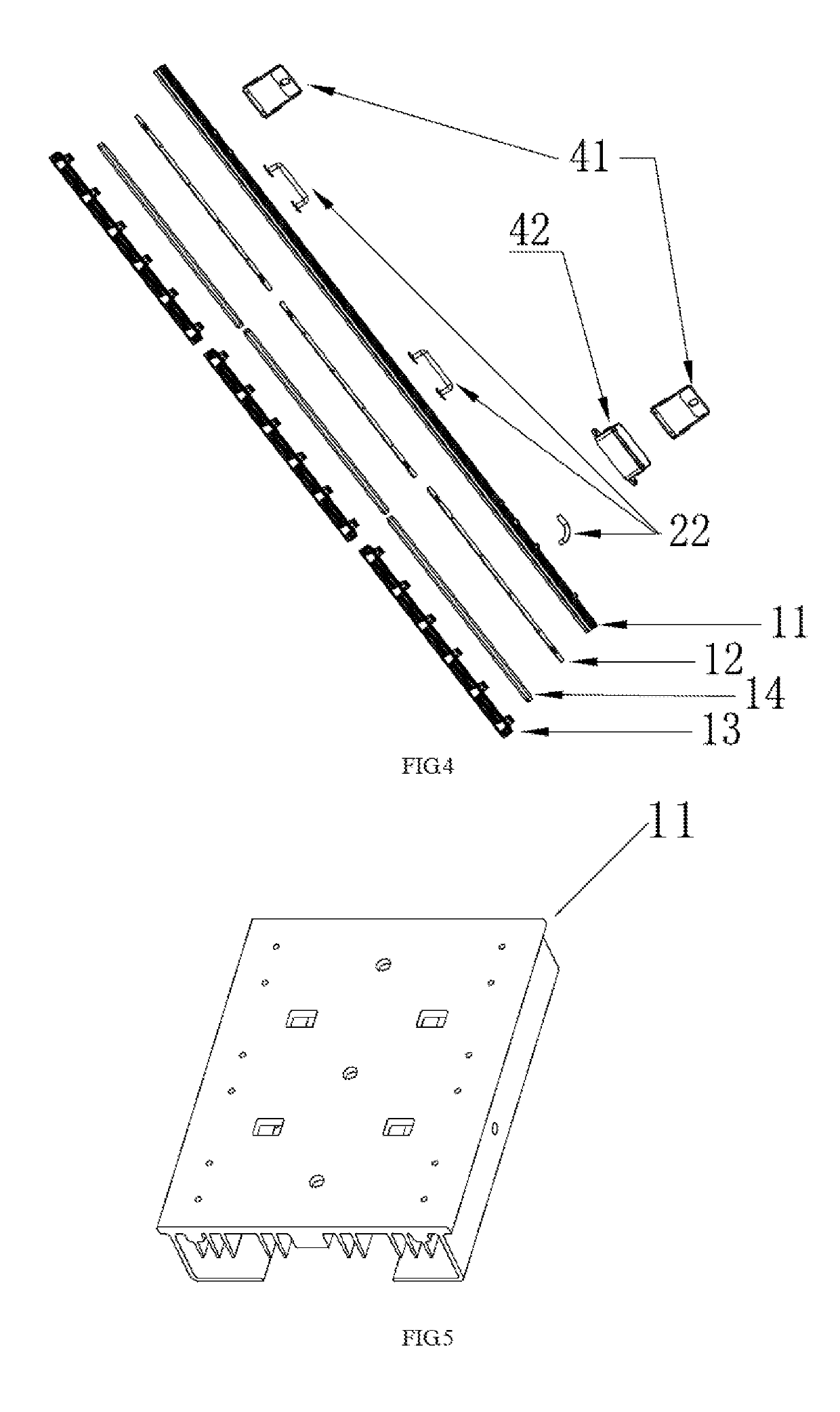

LED Module Sealing Technology

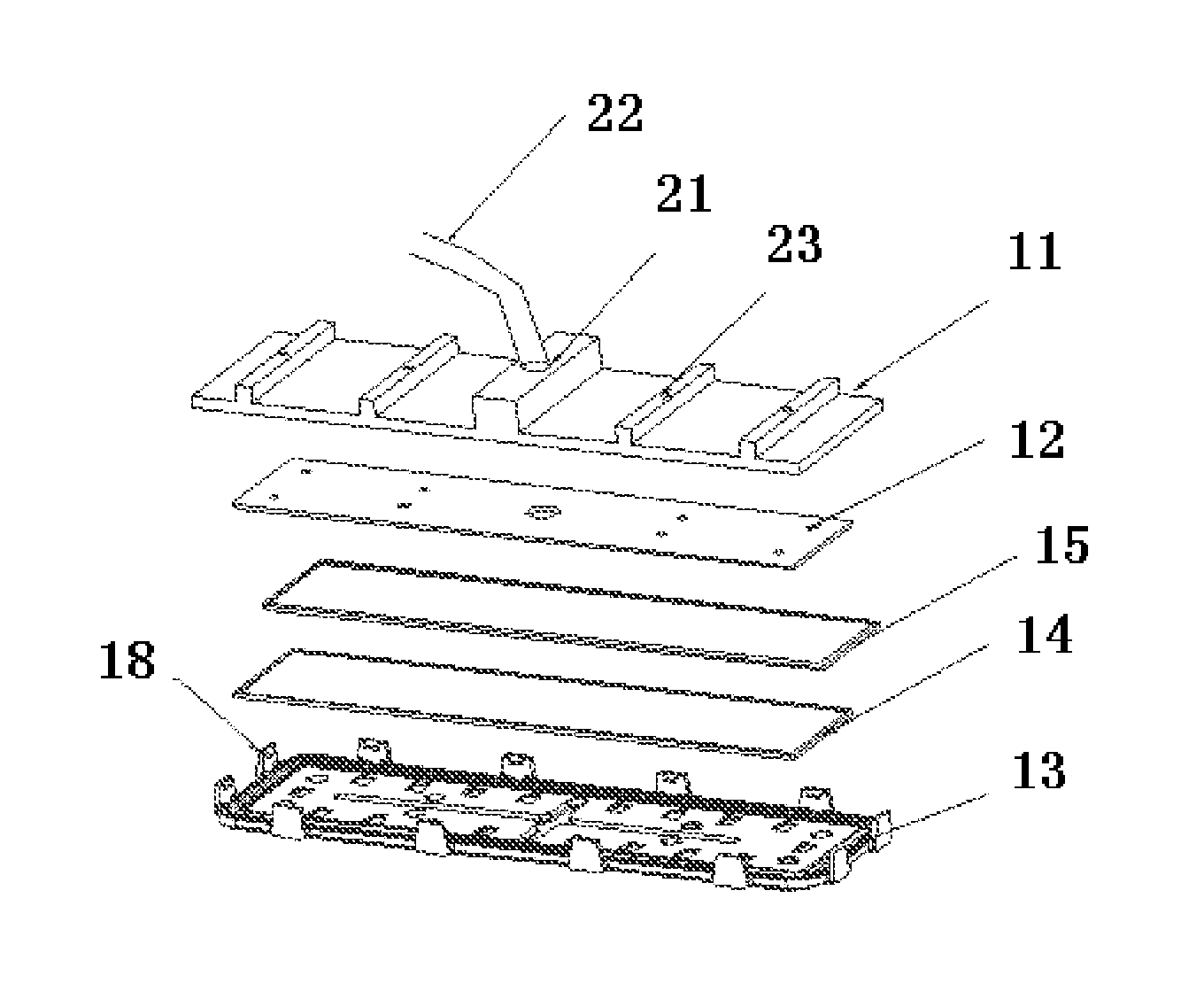

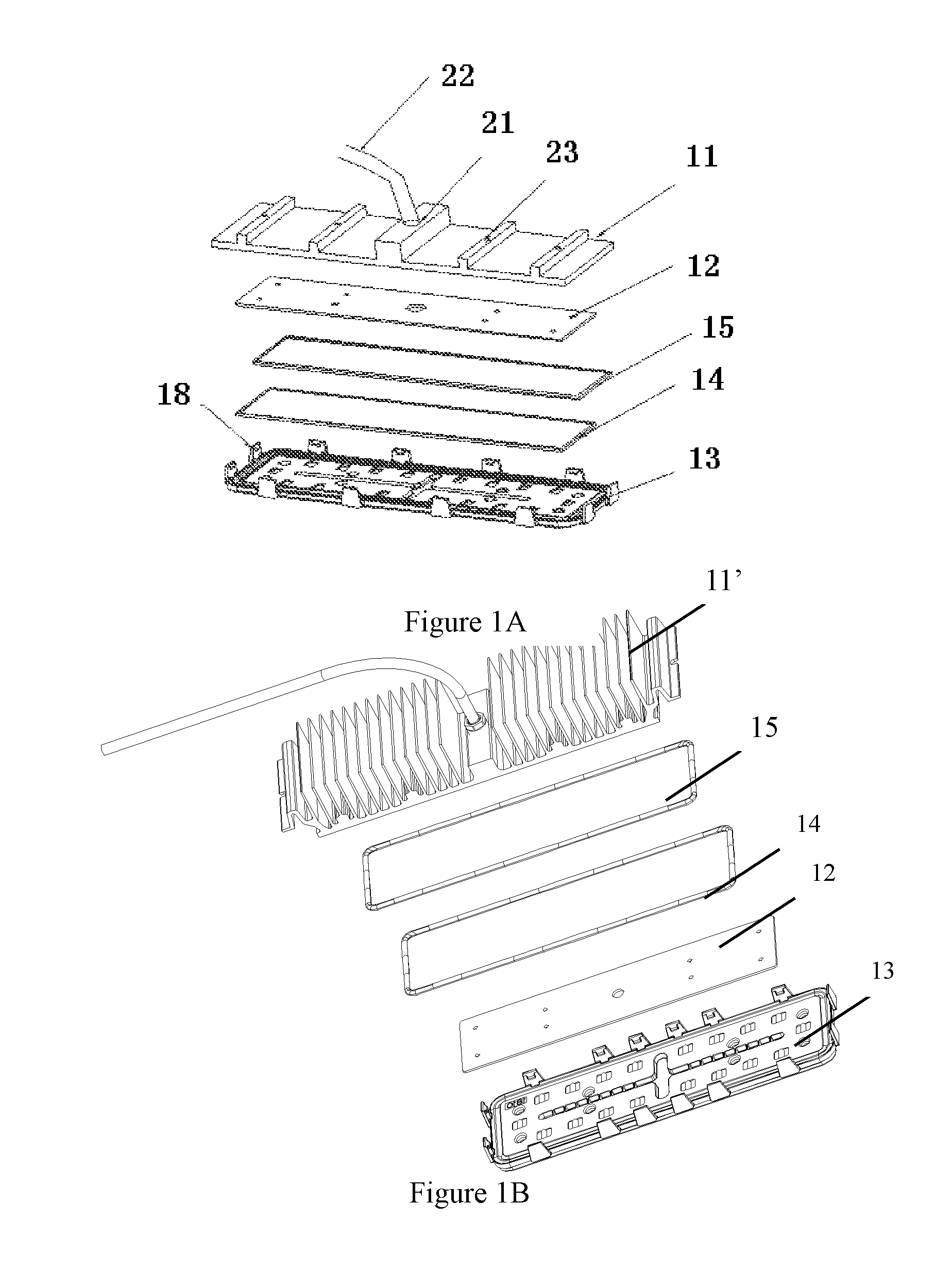

ActiveUS20150128409A1Easy to useReduce the amount requiredPlanar light sourcesPipesWater vaporEngineering

A sealing process of LED modules includes a waterproof wire put through a wire-through hole of a heat sink to be connected with a positive-negative solder joints on a PCB board, which are subjected to glue sealing treatment. A waterproof sealing process is operated between the waterproof wire and wire-through hole. The PCB board is fixed on the heat sink. One sealing ring is placed into a groove. A ring of liquid silica gel is evenly applied along the other groove. The heat sink installed with the PCB board and the waterproof wire are inversely buckled on the lens set which is fixed with the solid silica gel ring and liquid silica gel. At least two waterproof sealing rings are used to isolate an LED chip from the outside so as to prevent all water vapor or other harmful gases from corroding the chip and the PCB

Owner:HANGZHOU HPWINNER OPTO CORP

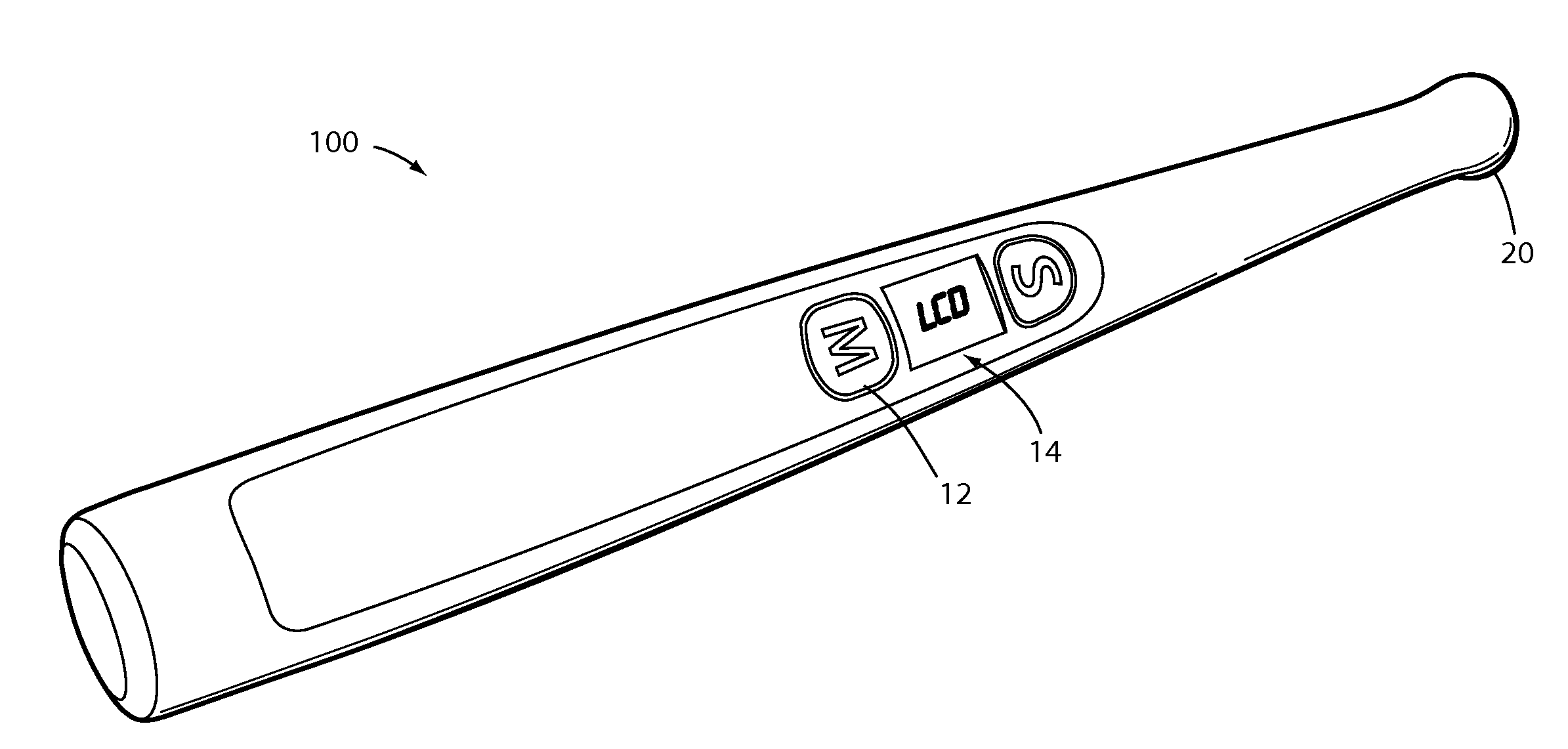

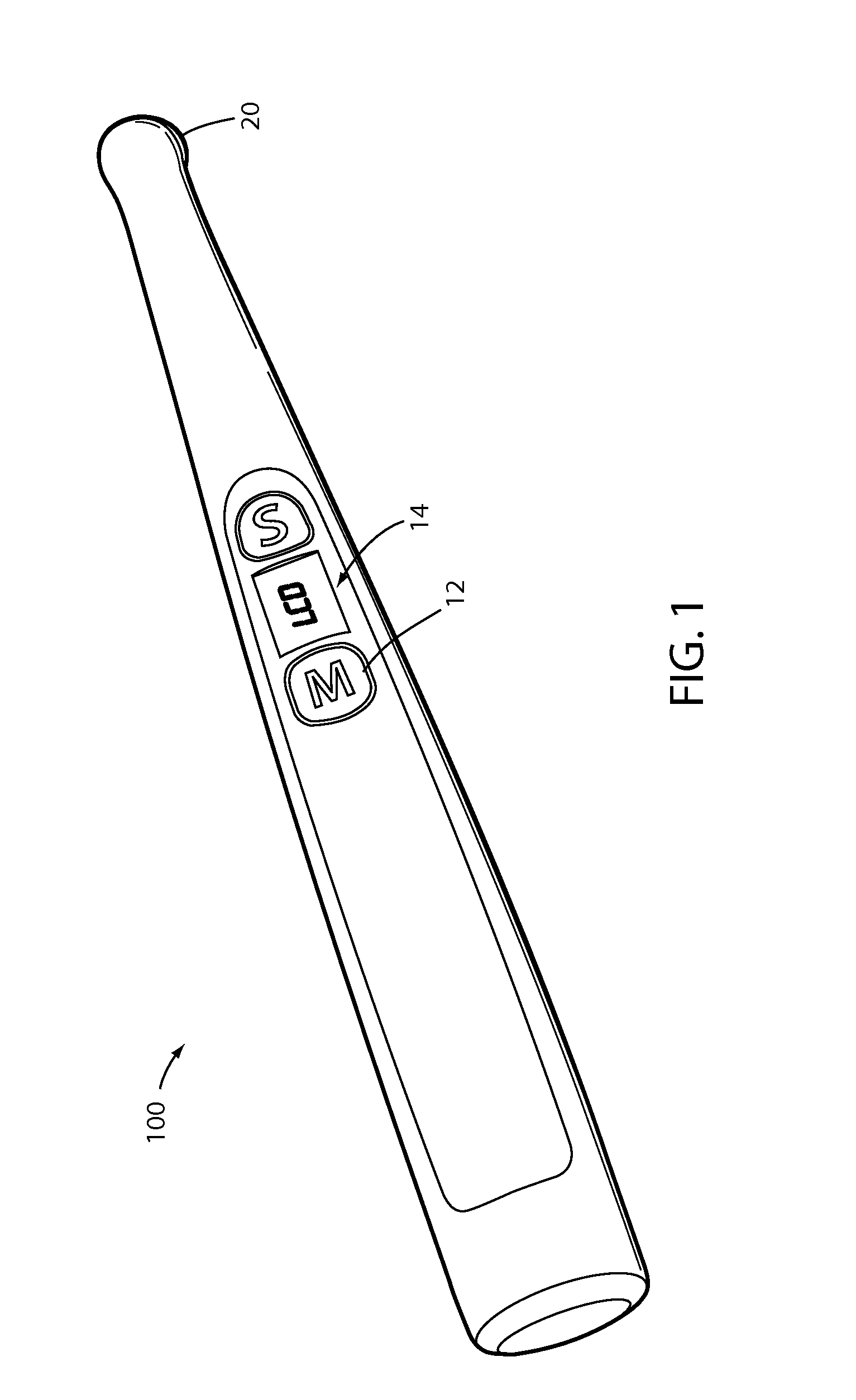

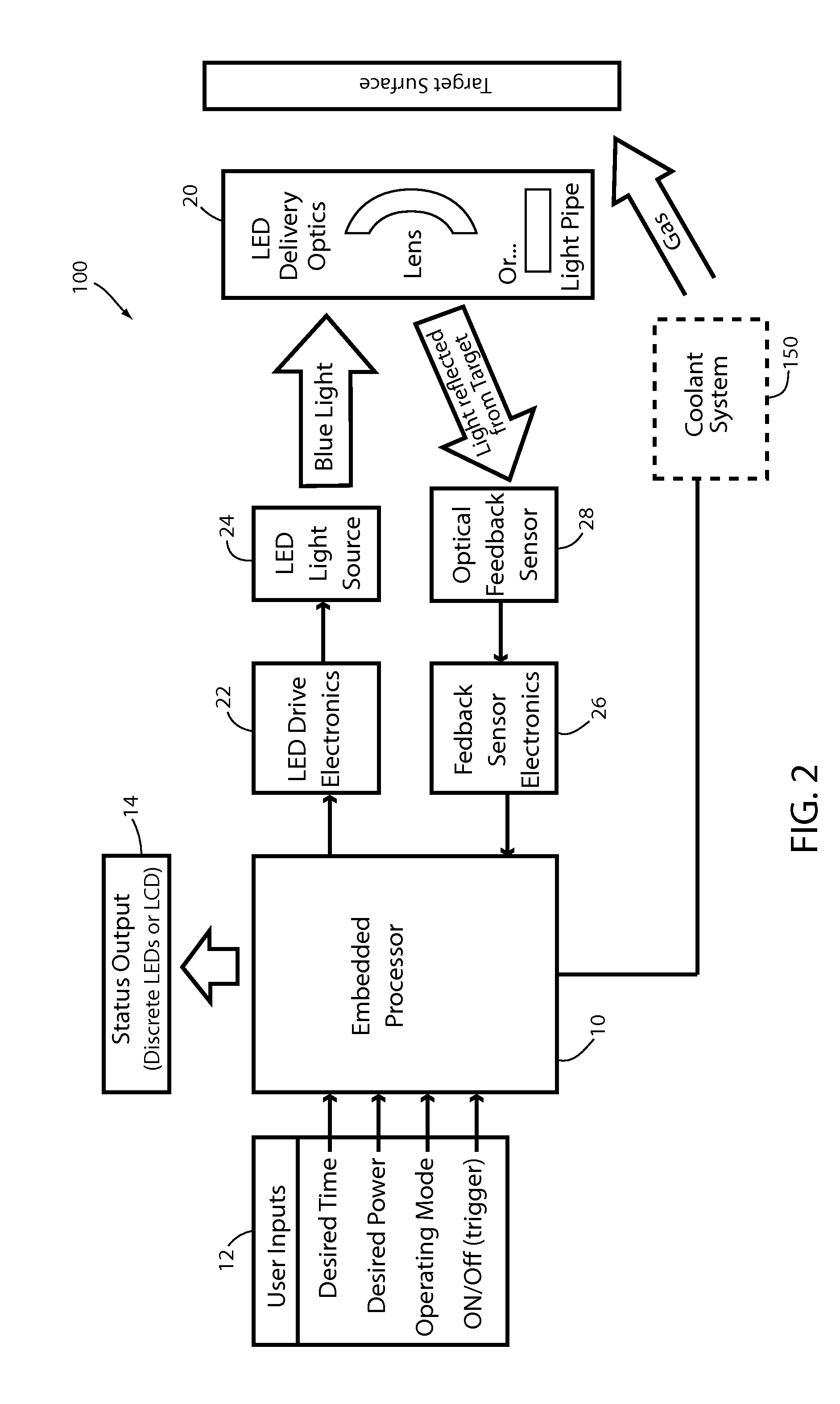

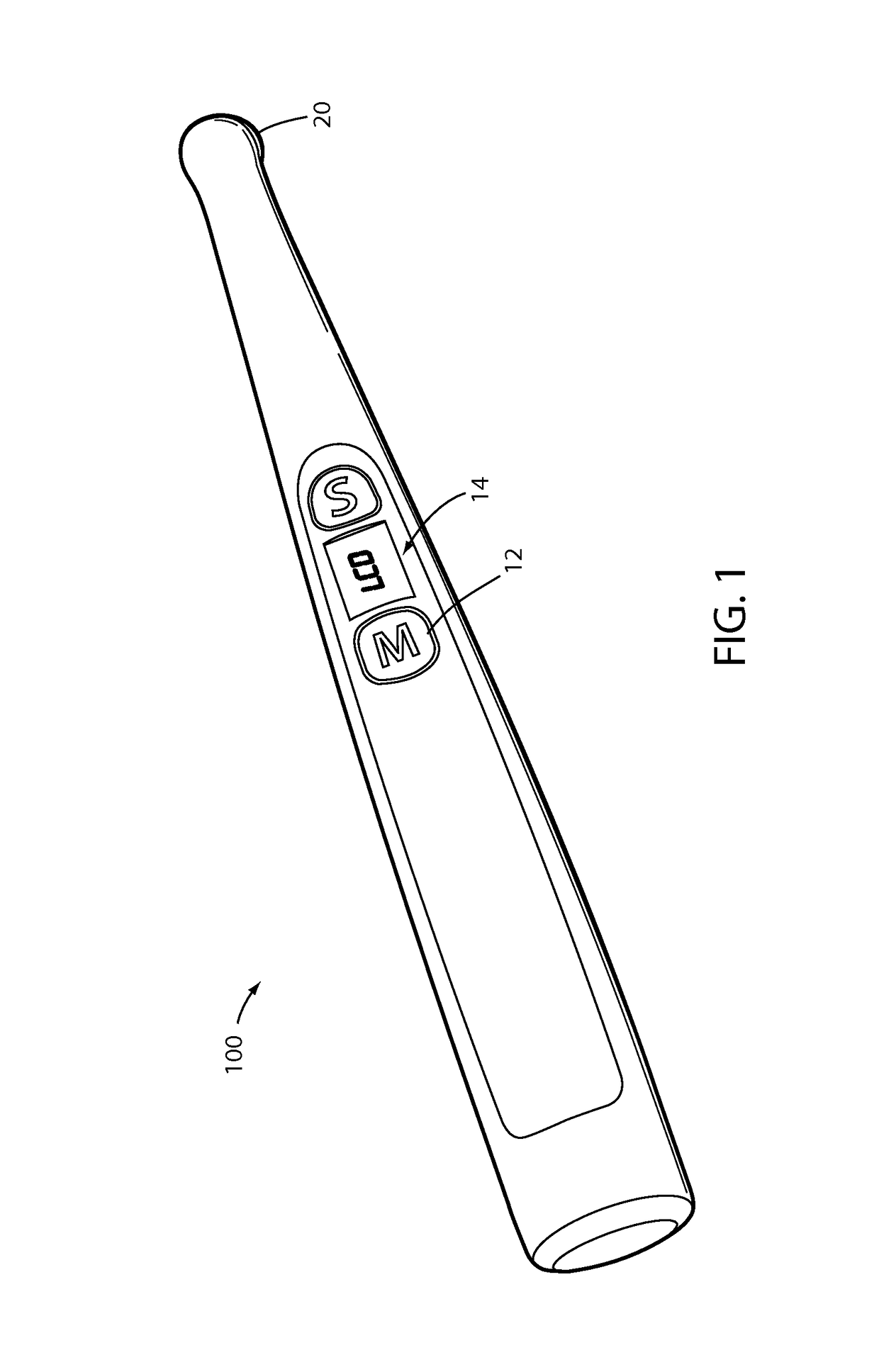

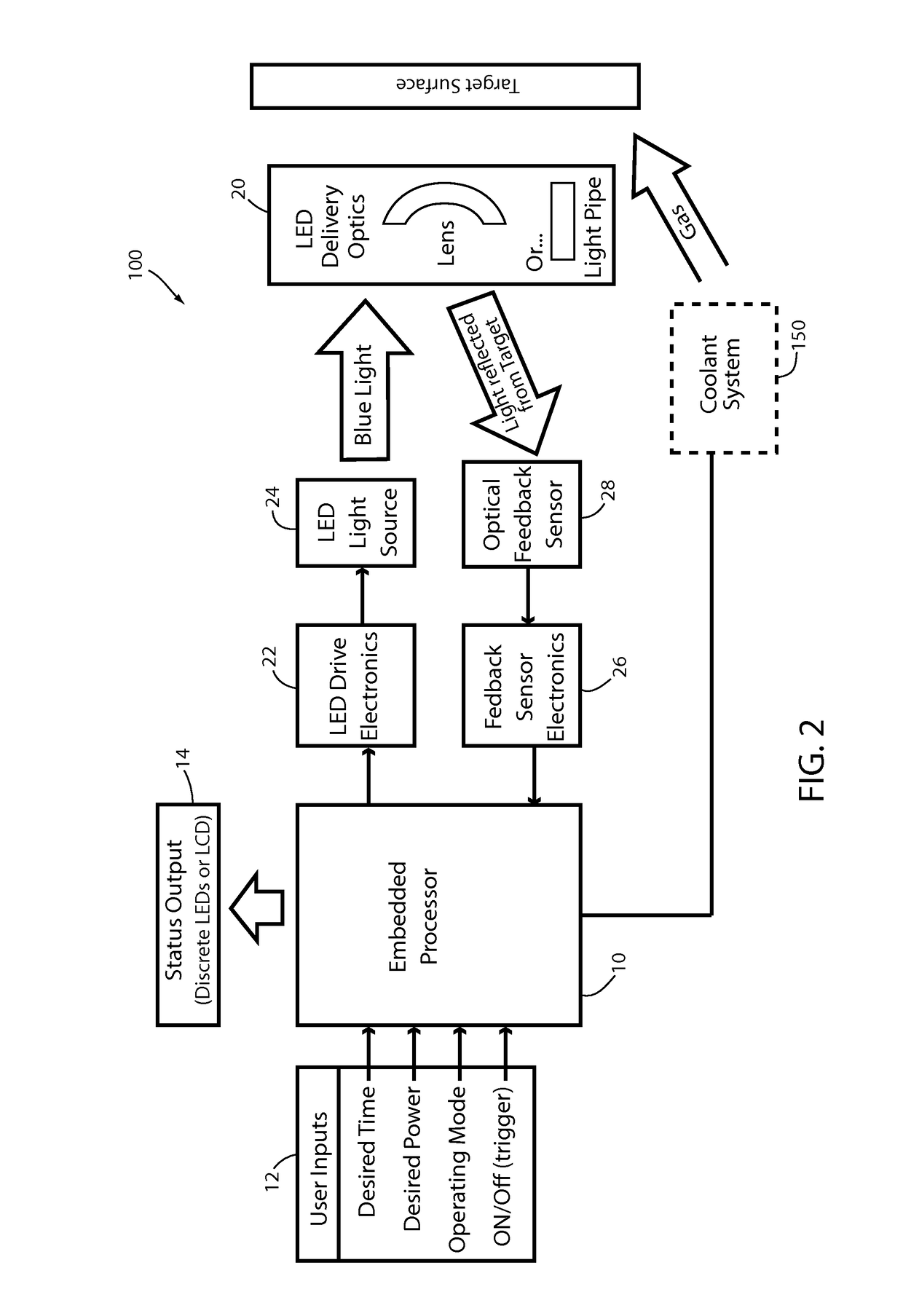

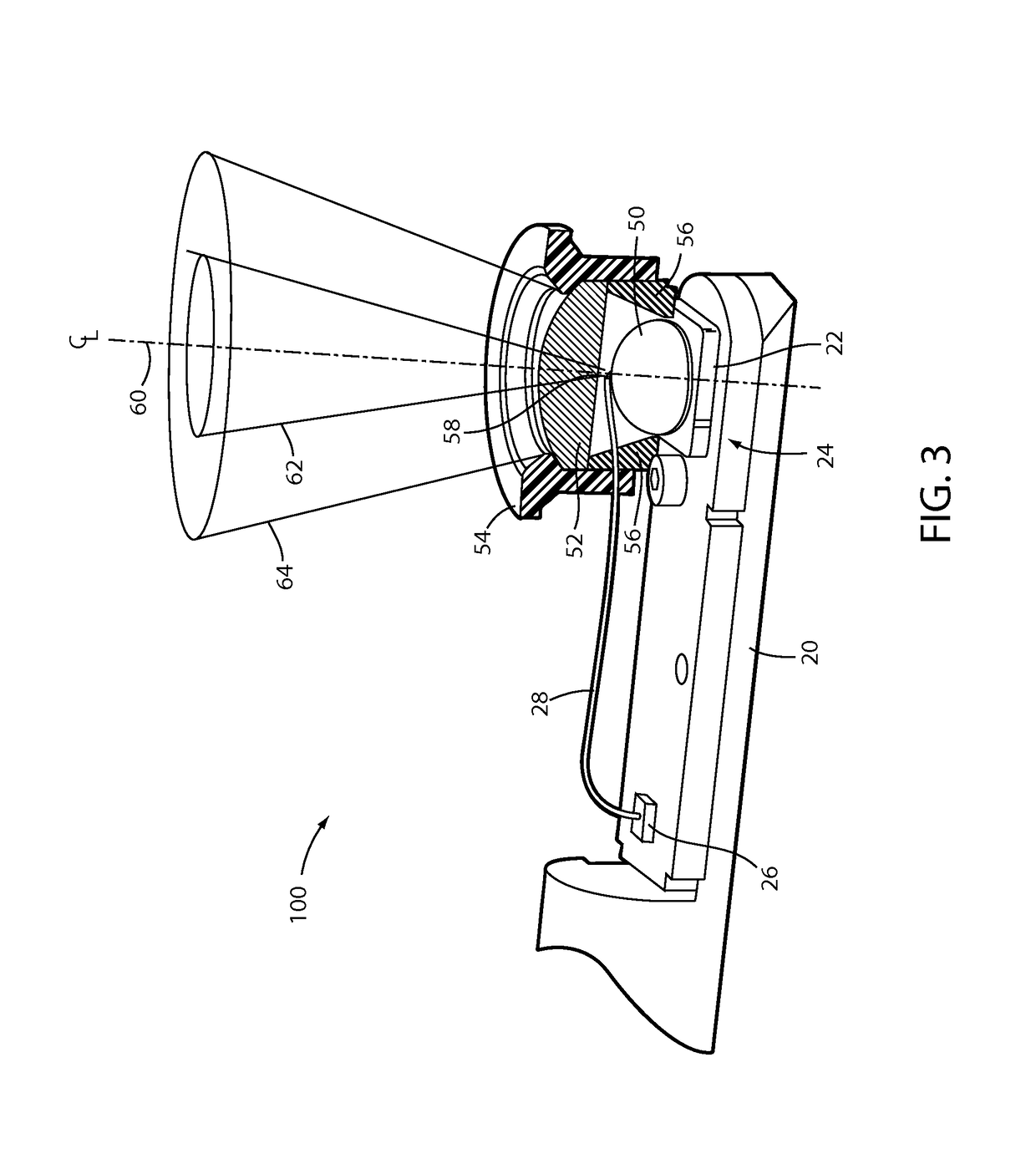

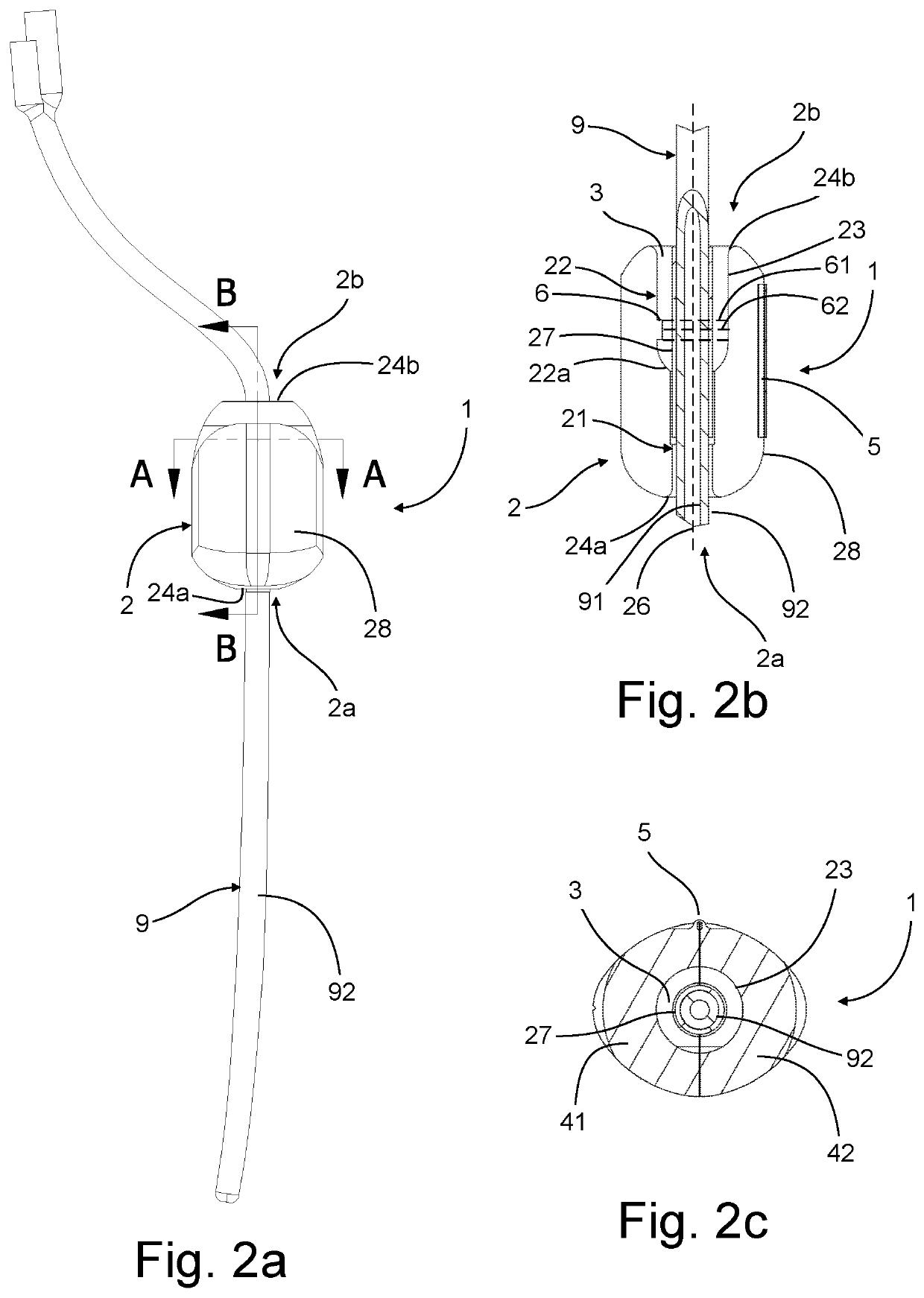

Dental curing light

ActiveUS20160074144A1Quality improvementGood precisionDental toolsBoring toolsClosed loopDental Curing

An optical sensor for an instrument to form a closed-loop curing instrument that is configured to manage the quantity of delivered energy to a curable material, including a composite restoration for a tooth. The closed-loop curing instrument is configured to analyze a signal indicative of the light reflecting from the curable material, and to adjust light output based on the analysis.

Owner:GARRISON DENTAL SOLUTIONS

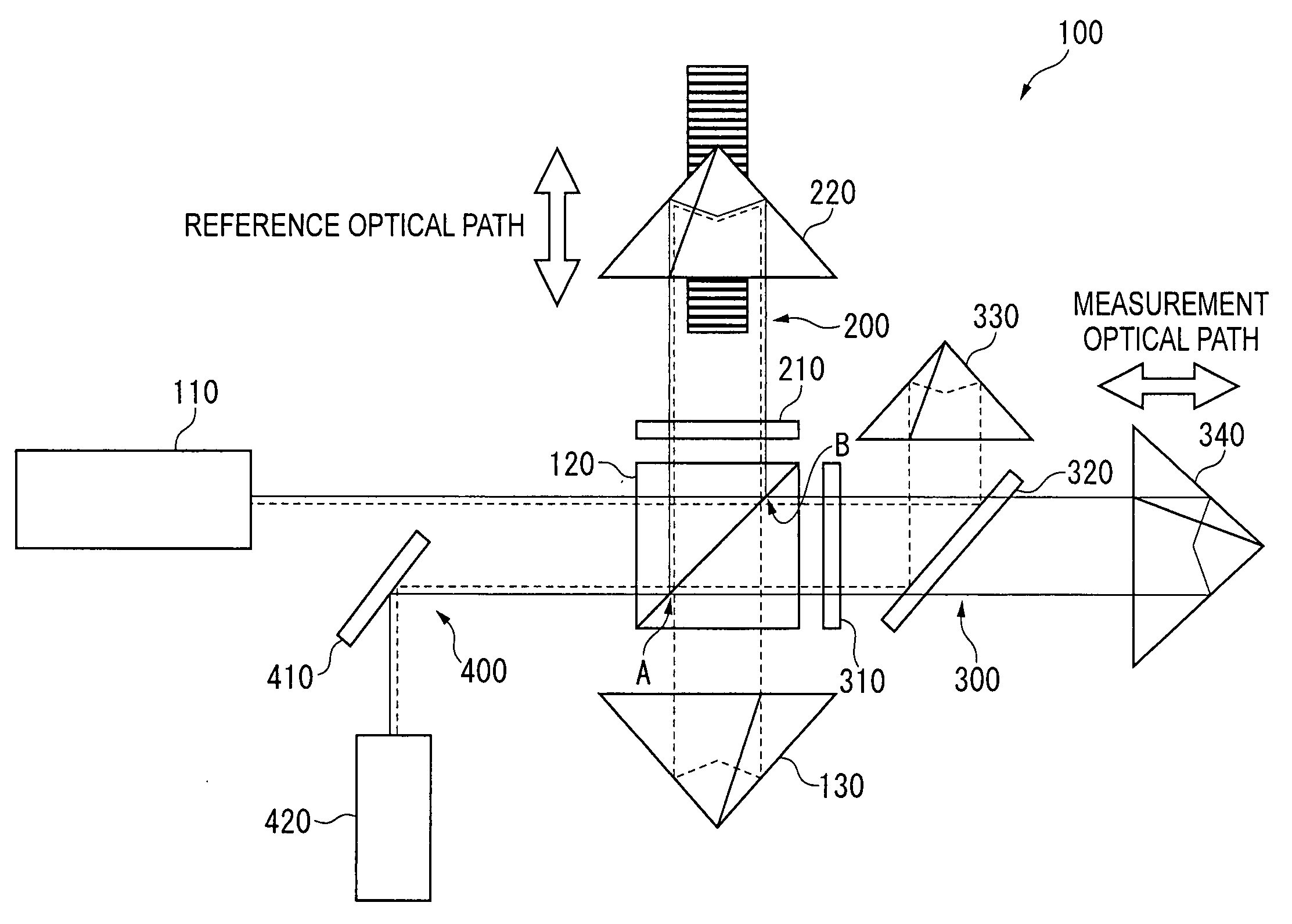

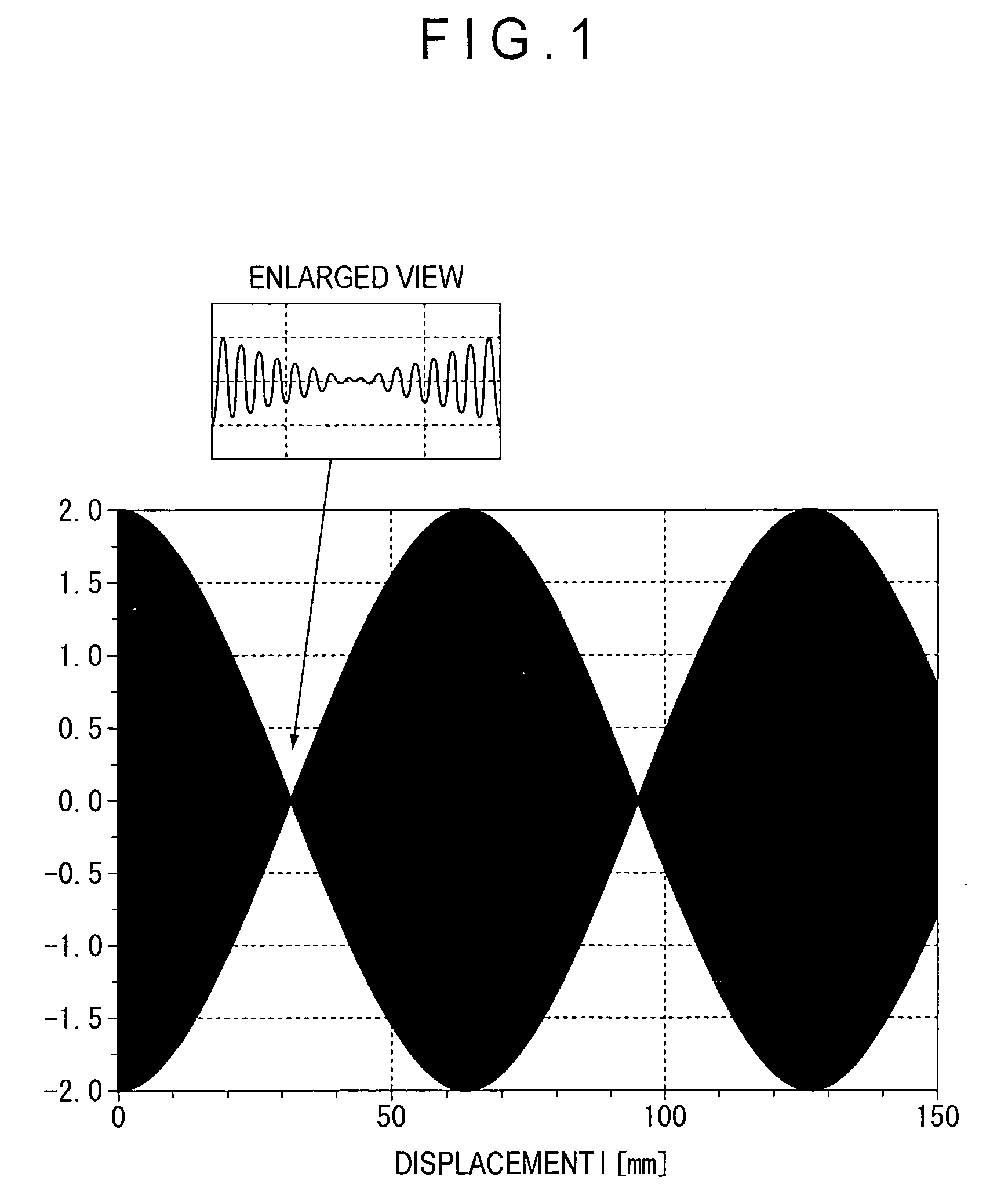

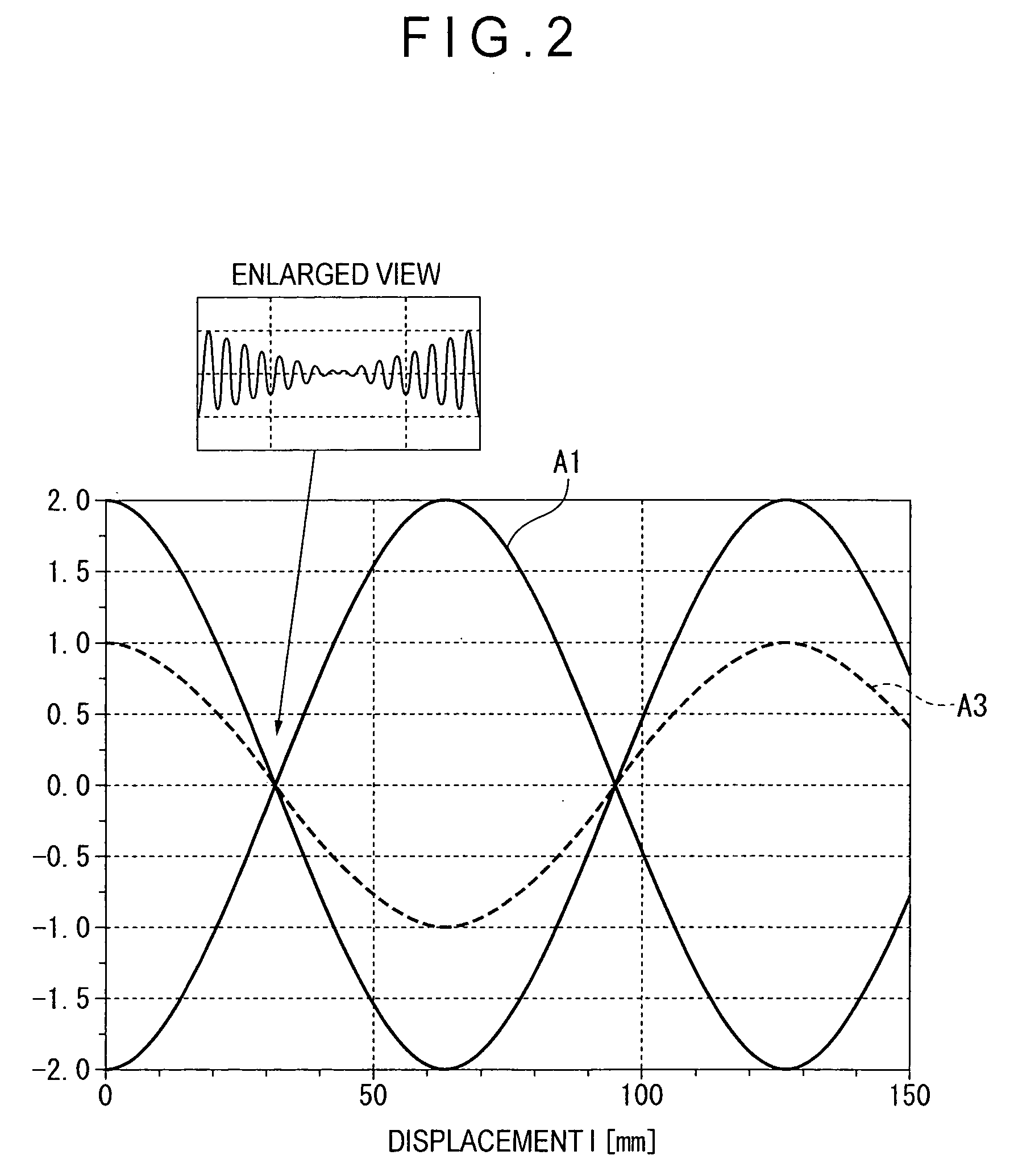

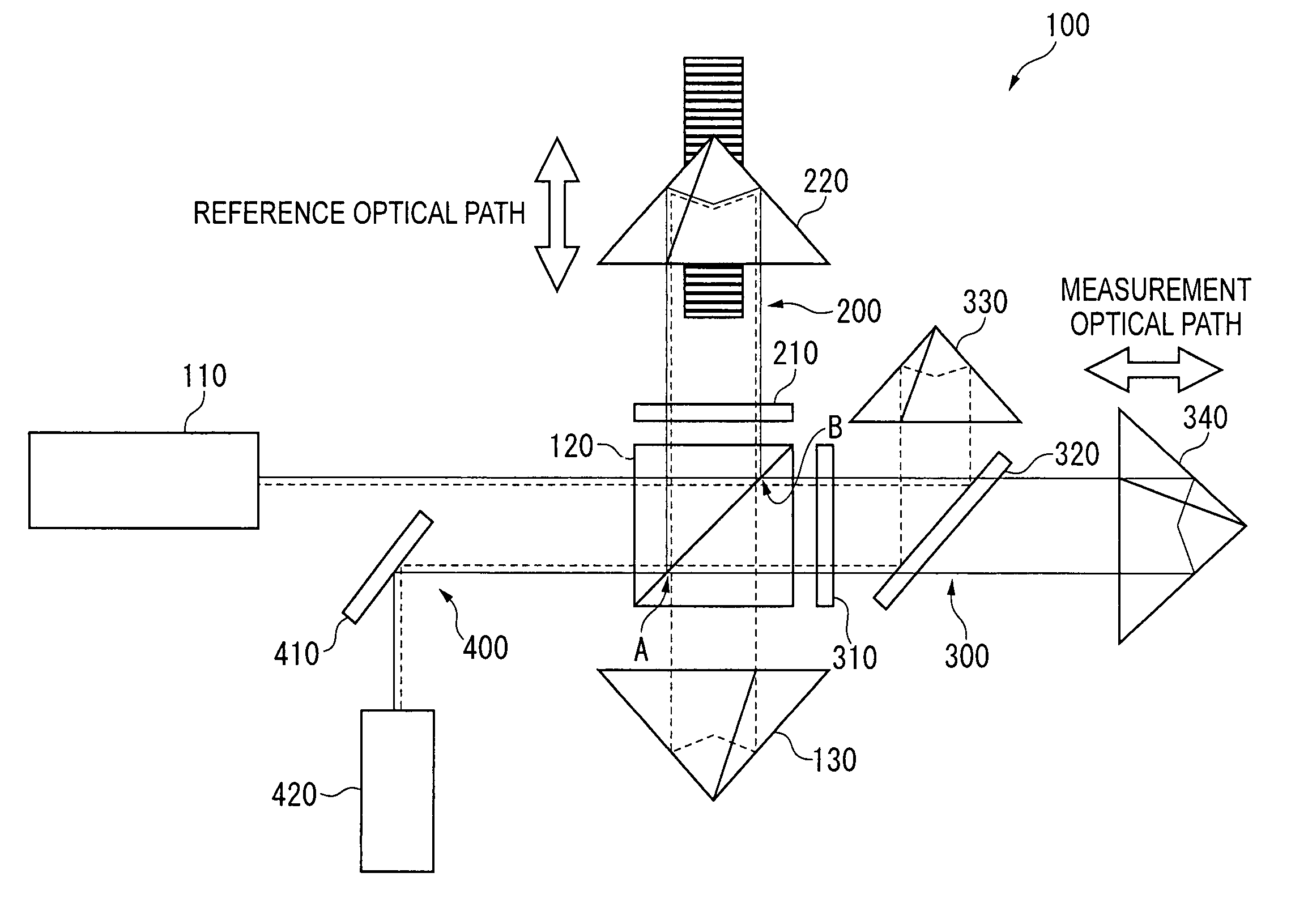

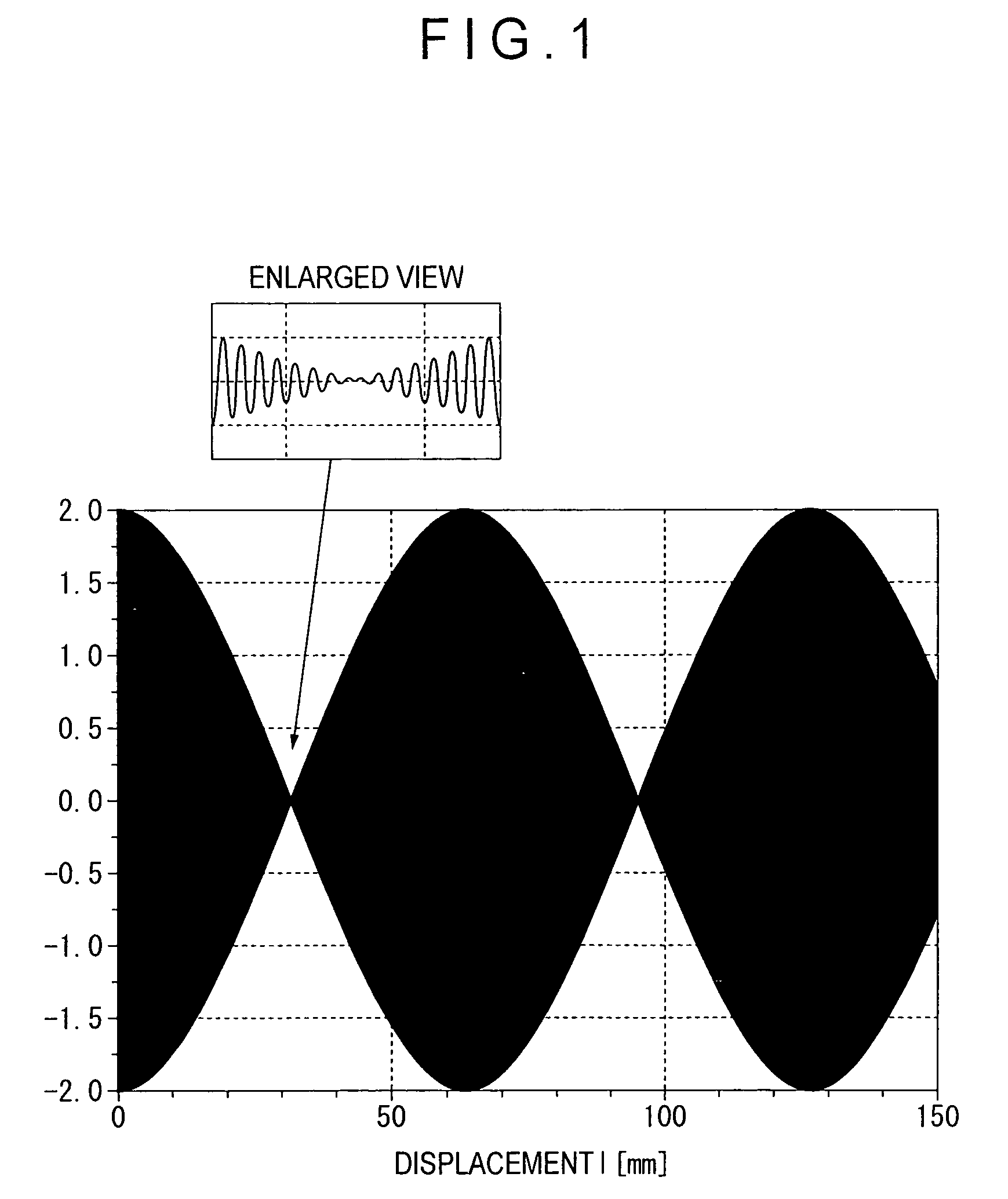

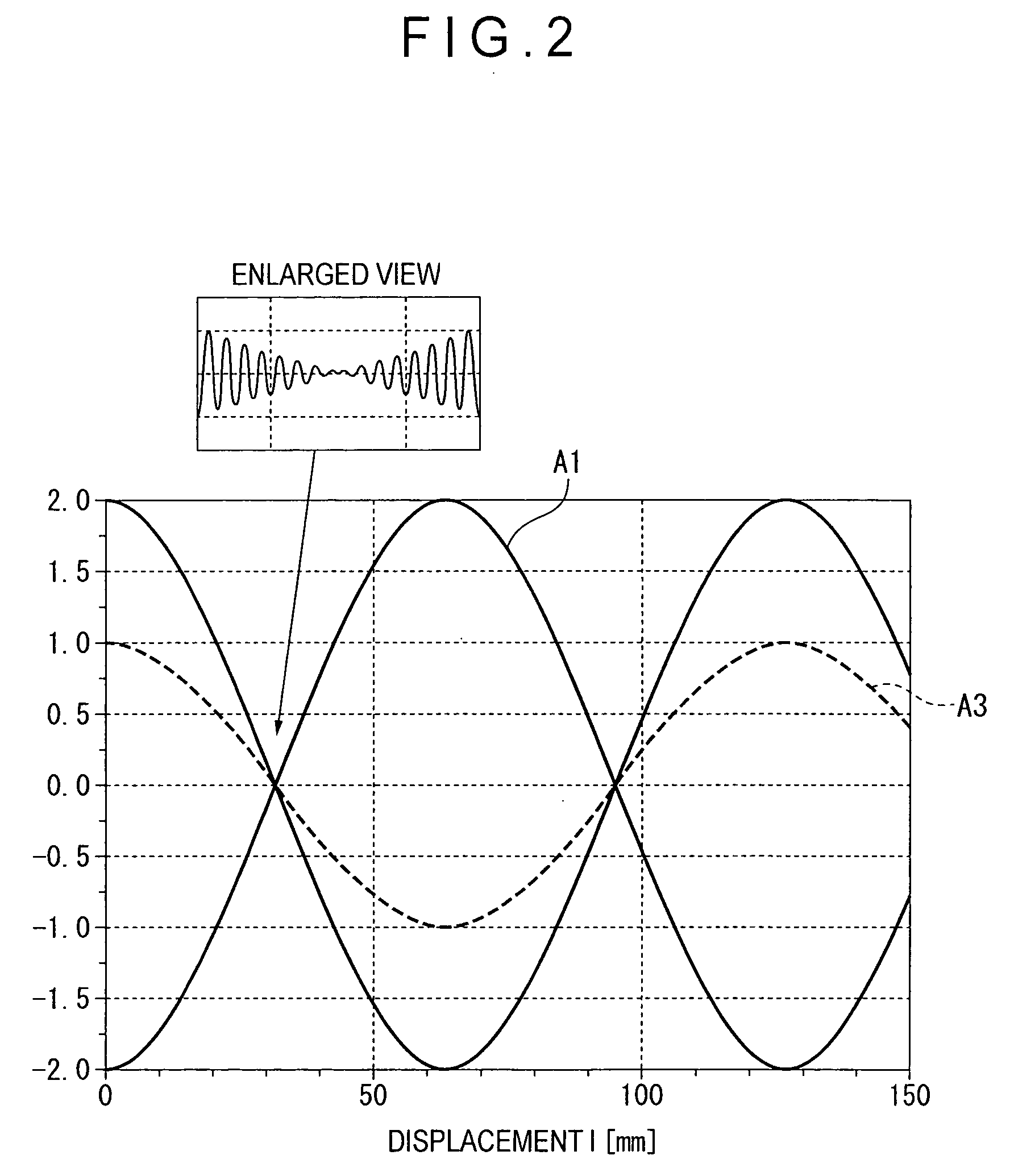

Displacement measuring instrument and displacement measuring method

ActiveUS20100027026A1Easy and accurate calculationAccurate displacementInterferometersUsing optical meansBeam splitterMeasuring instrument

A laser interferometric measuring instrument includes: a light source that emits a laser beam of 1064 nm and another laser beam of 532 nm; a polarizing beam splitter; a dichroic mirror that splits a long-wavelength laser beam provided in a measurement optical path; a long-wavelength corner cube that reflects the split laser beam; a measurement corner cube that is displaceable along the measurement optical path; a reference corner cube that is displaceable along a reference optical path; a optical path changing unit that changes an optical path length of the long-wavelength laser beam; a phase detector that outputs interference signals; a sum signal computer that calculates a sum signal; a displacement controller that displaces the reference corner cube so as not to change a phase of the sum signal; a reference displacement detector that detects a displacement of the reference corner cube; and a measurement displacement computer that calculates a displacement of the measurement corner cube.

Owner:MITUTOYO CORP

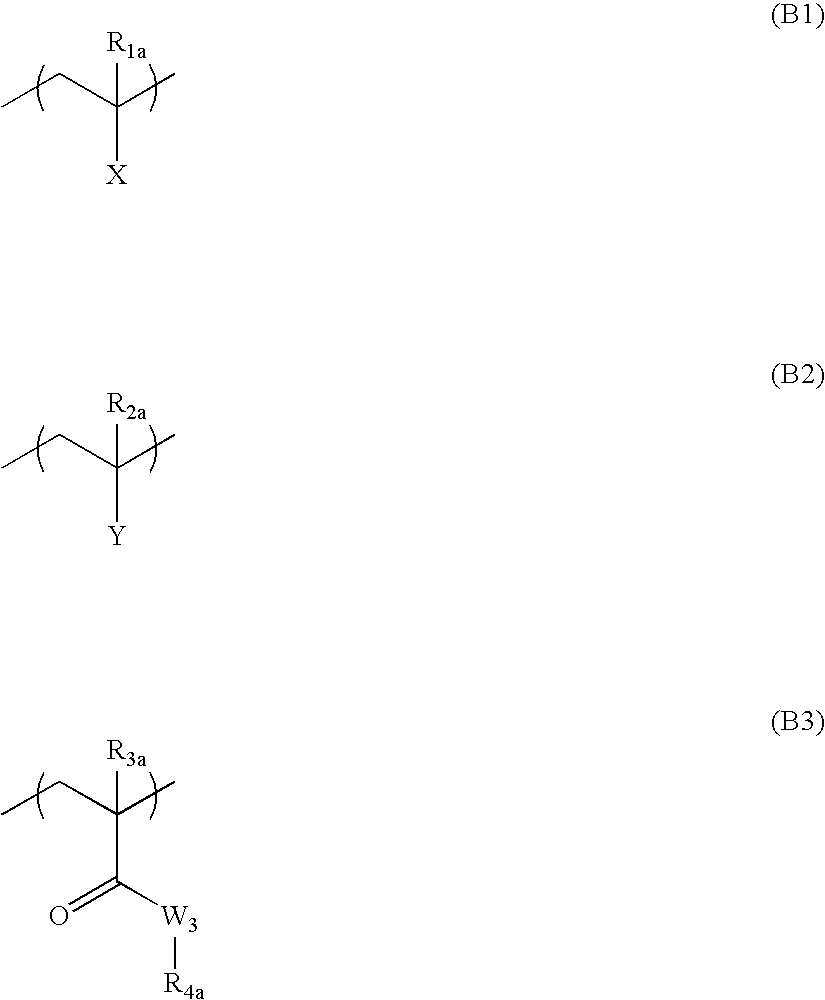

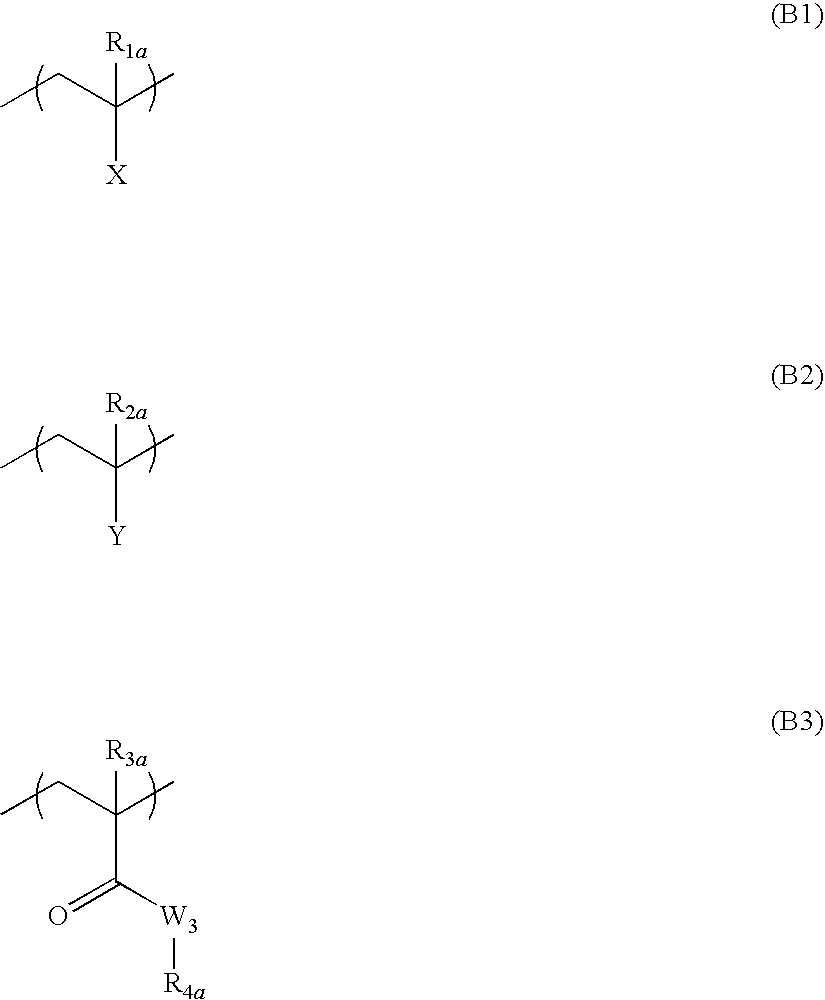

Photosensitive lithographic printing plate

ActiveUS20060188814A1Excellent in safe light stabilityHigh definitionSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersArylDouble bond

A photosensitive lithographic printing plate comprising a hydrophilic support and a photopolymerizable photosensitive layer containing: (i) a sensitizing dye having an absorption maximum in a wavelength range of from 360 to 450 nm; (ii) a hexaarylbisimidazole compound; (iii) an addition polymerizable compound having an ethylenically unsaturated double bond; (iv) a binder polymer; and (v) a mercapto compound represented by the following formula (1) as defined herein.

Owner:FUJIFILM HLDG CORP +1

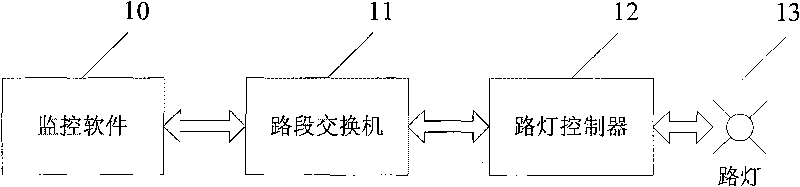

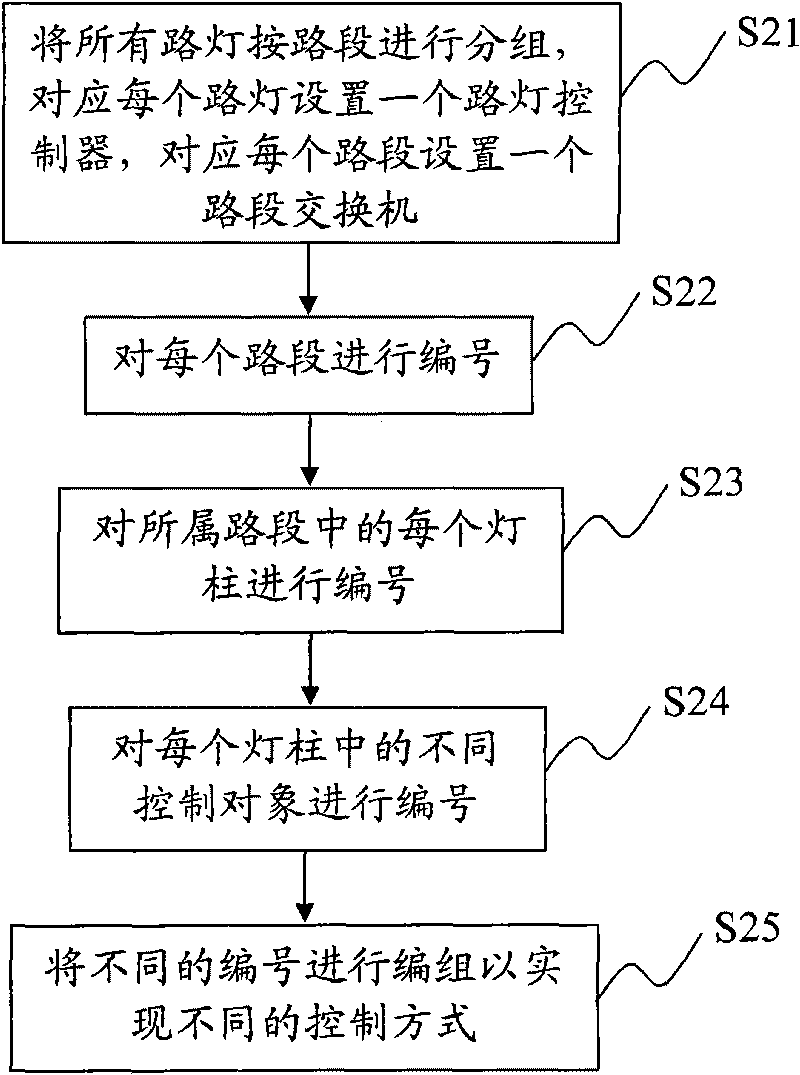

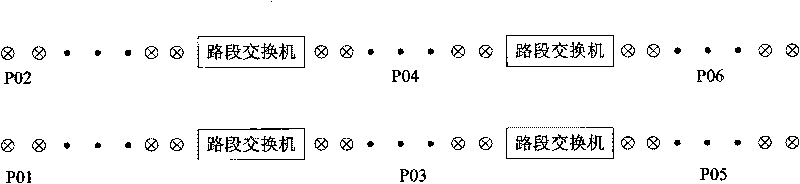

Method for controlling street lamps capable of being controlled by marshalling at random

InactiveCN101702857AEnsure Lighting SafetyFlexible and convenient operationElectric light circuit arrangementEnergy efficient lightingControl mannerEngineering

The invention provides a method for controlling street lamps capable of being controlled by marshalling at random, comprising the following steps of; grouping all street lamps according to road sections, arranging a street lamp controller corresponding to each lamp post and arranging a road section exchanger corresponding to each road section; numbering for each road section; numbering for each lamp post in the belonged road section; numbering for different control objects in each lamp post; and marshalling for the different numbers so as to realize different control ways. The method for controlling street lamps capable of being controlled by marshalling at random can be used for marshalling for the road sections and the street lamps at random according to the requirements of users, thereby controlling different road sections and street lamps. The method has higher flexibility and can save electric energy of an urban public illuminating system on the basis of ensuring the safety of roadway illumination.

Owner:NINGBO AUPUL TELECOMM EQUIP +1

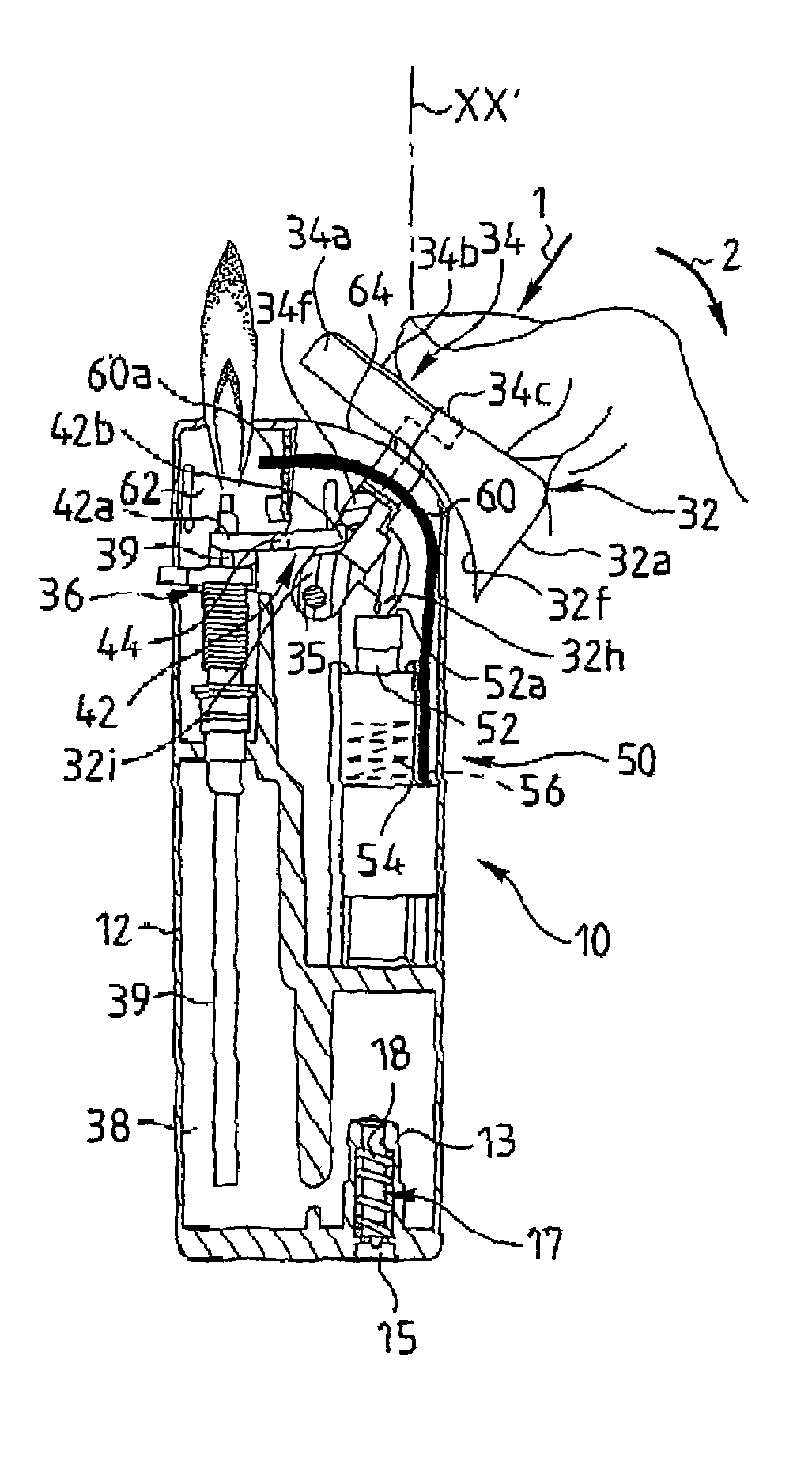

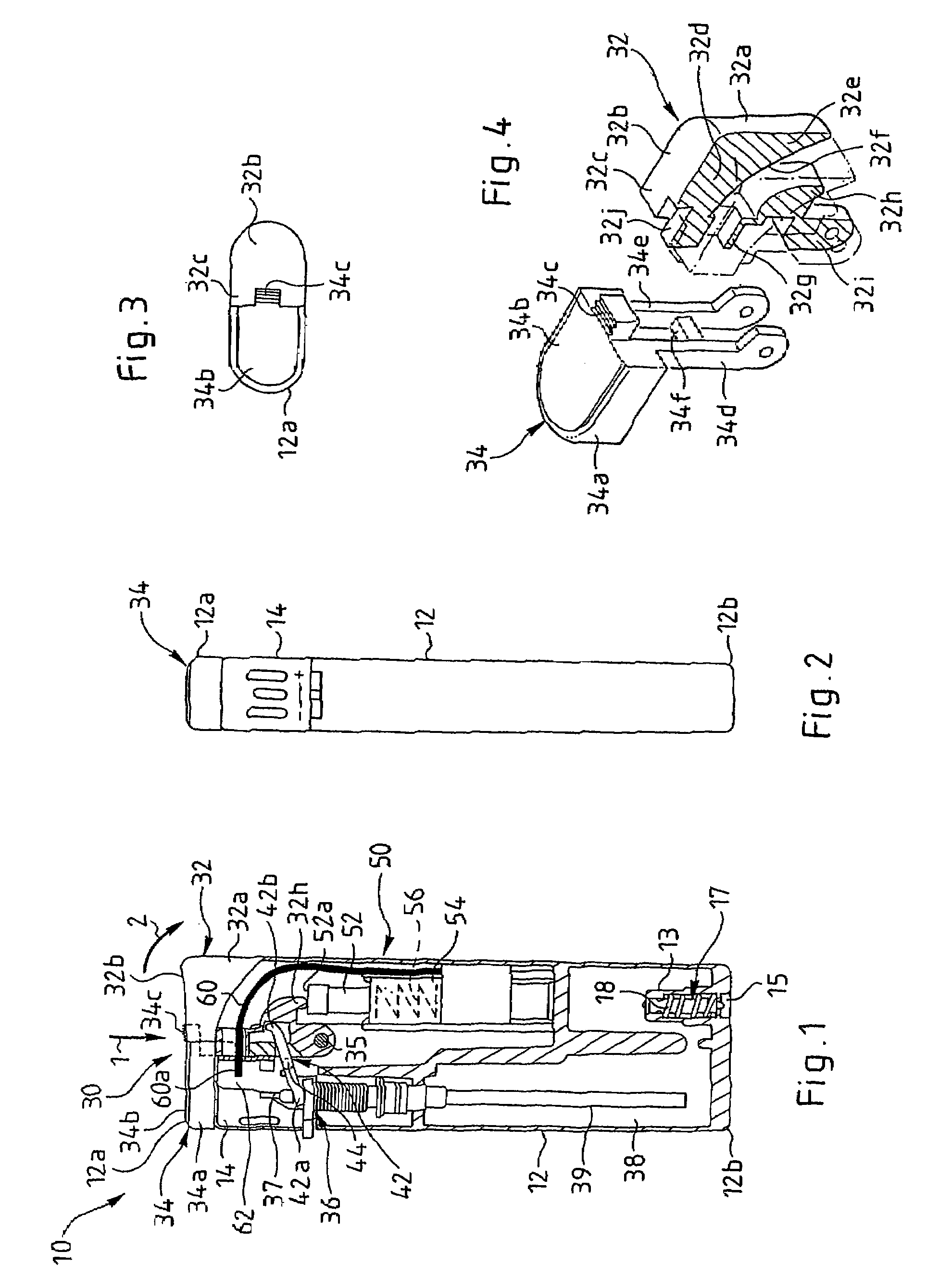

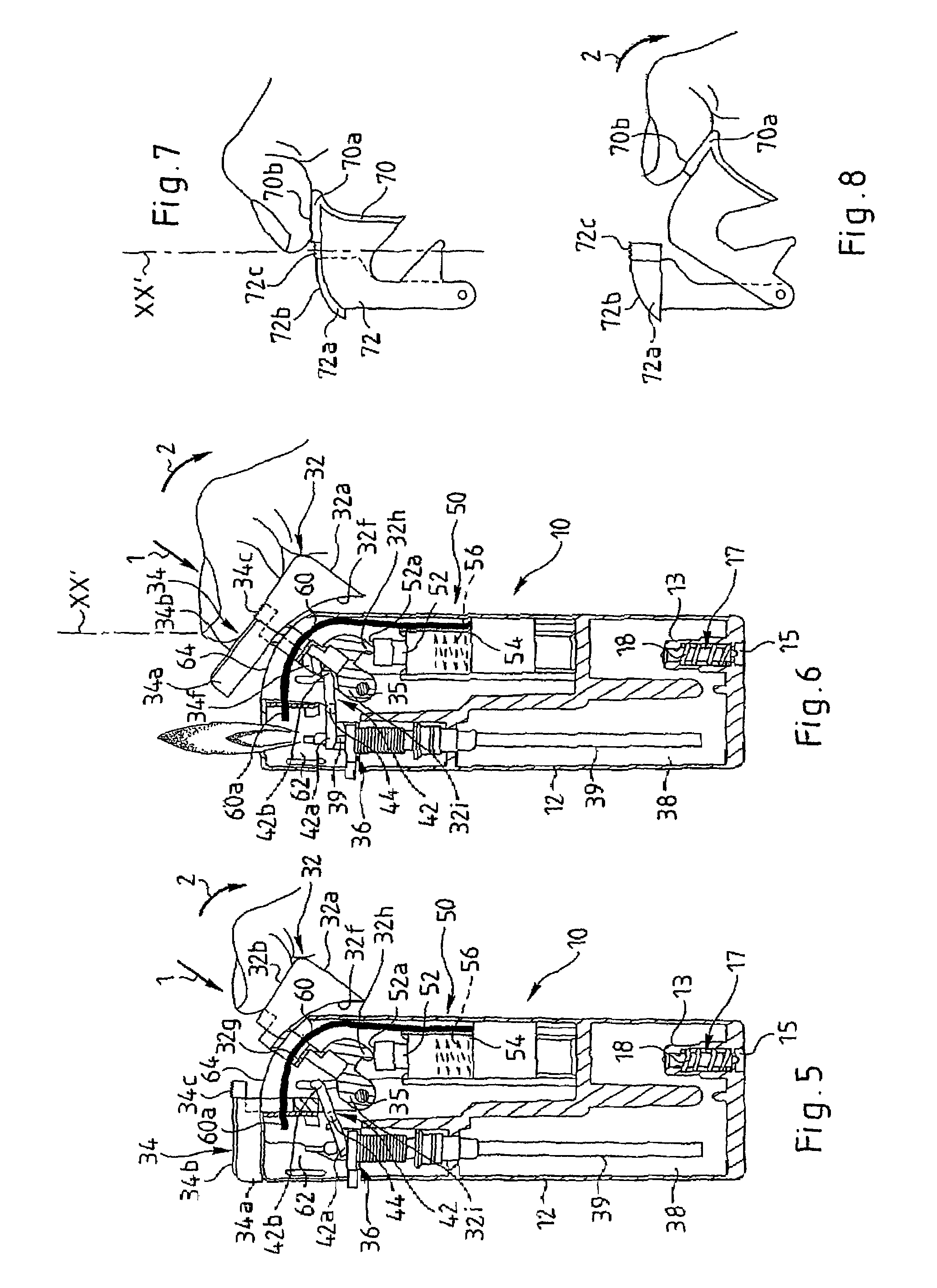

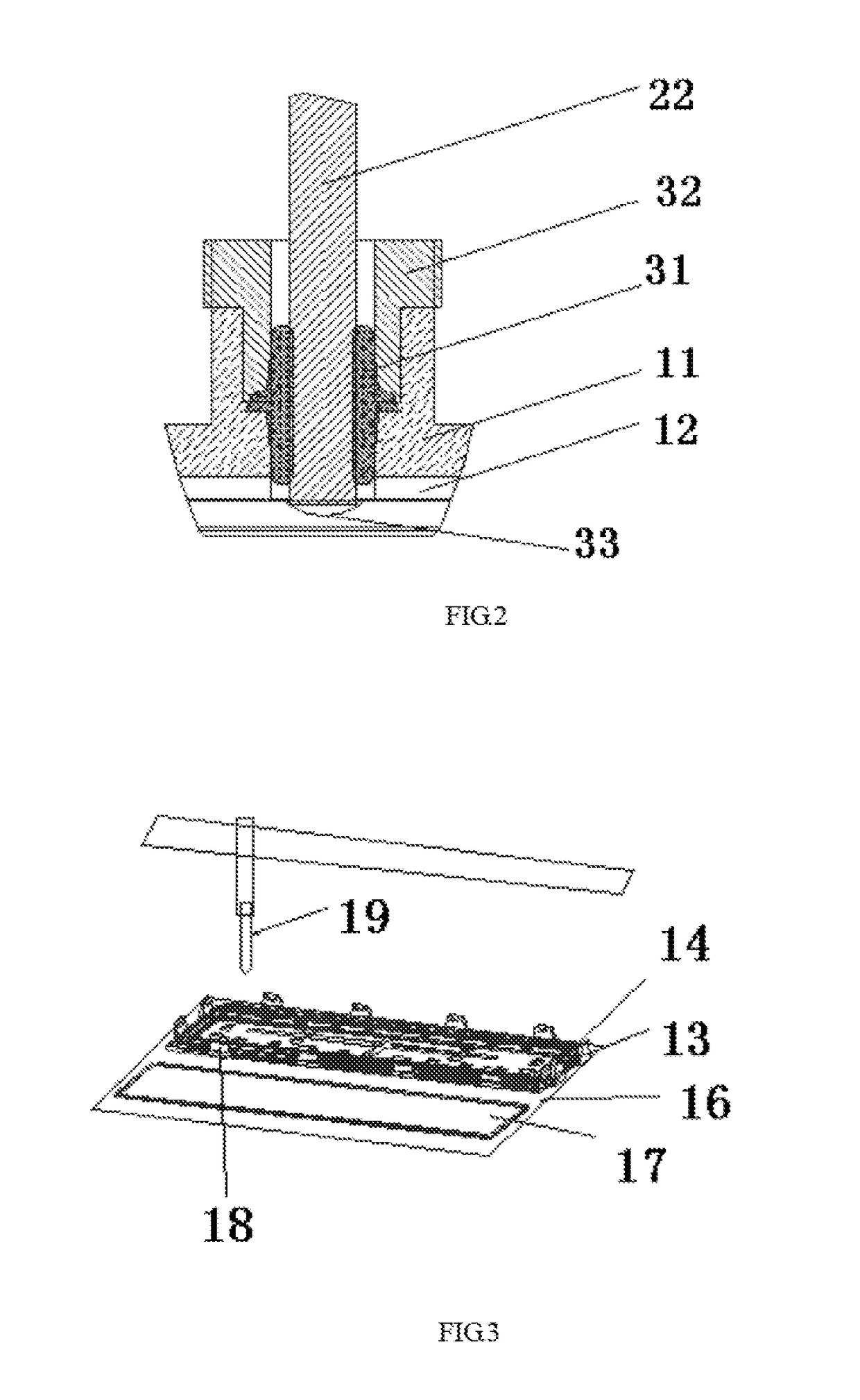

Piezoelectric lighter with increased security

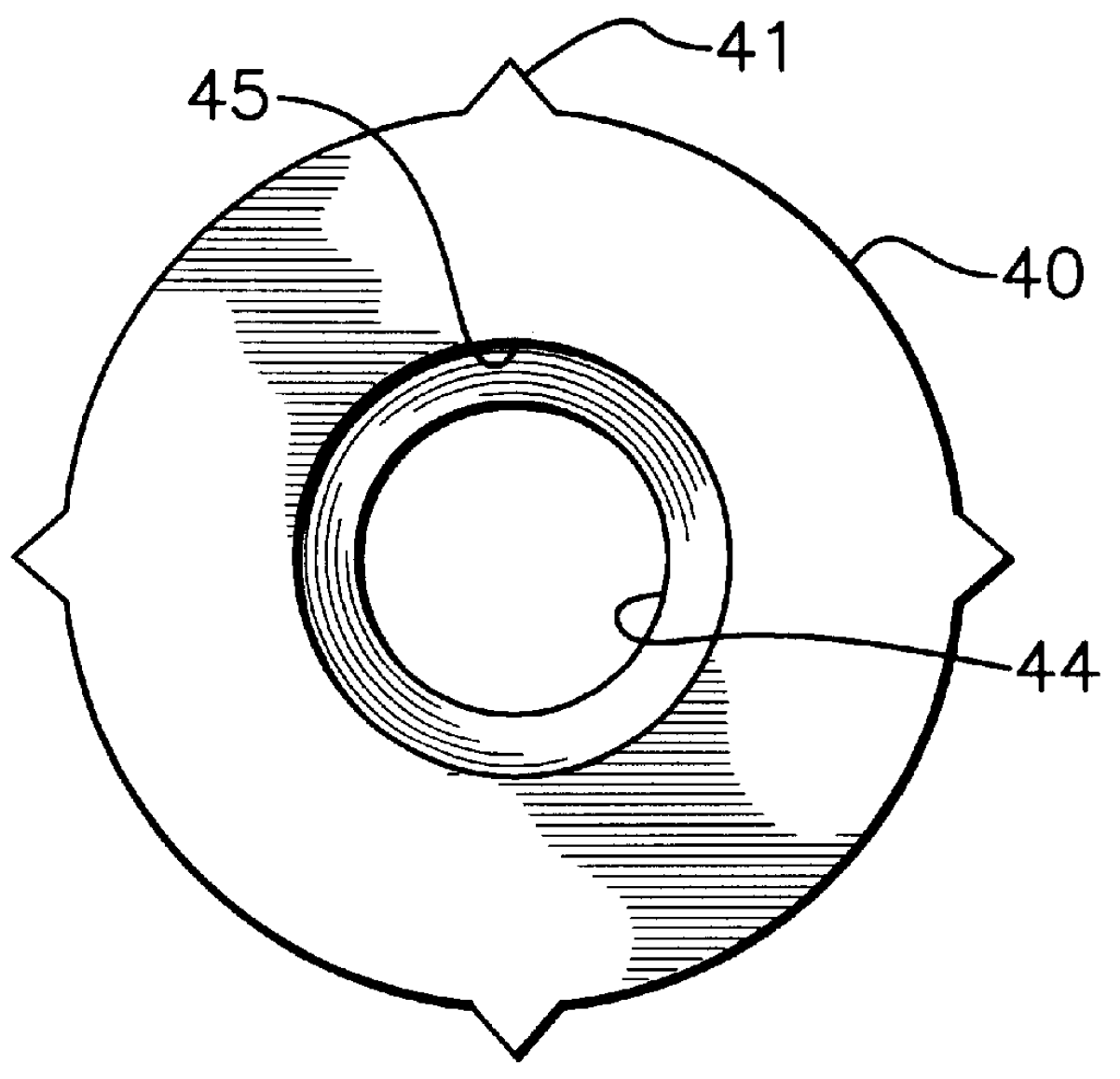

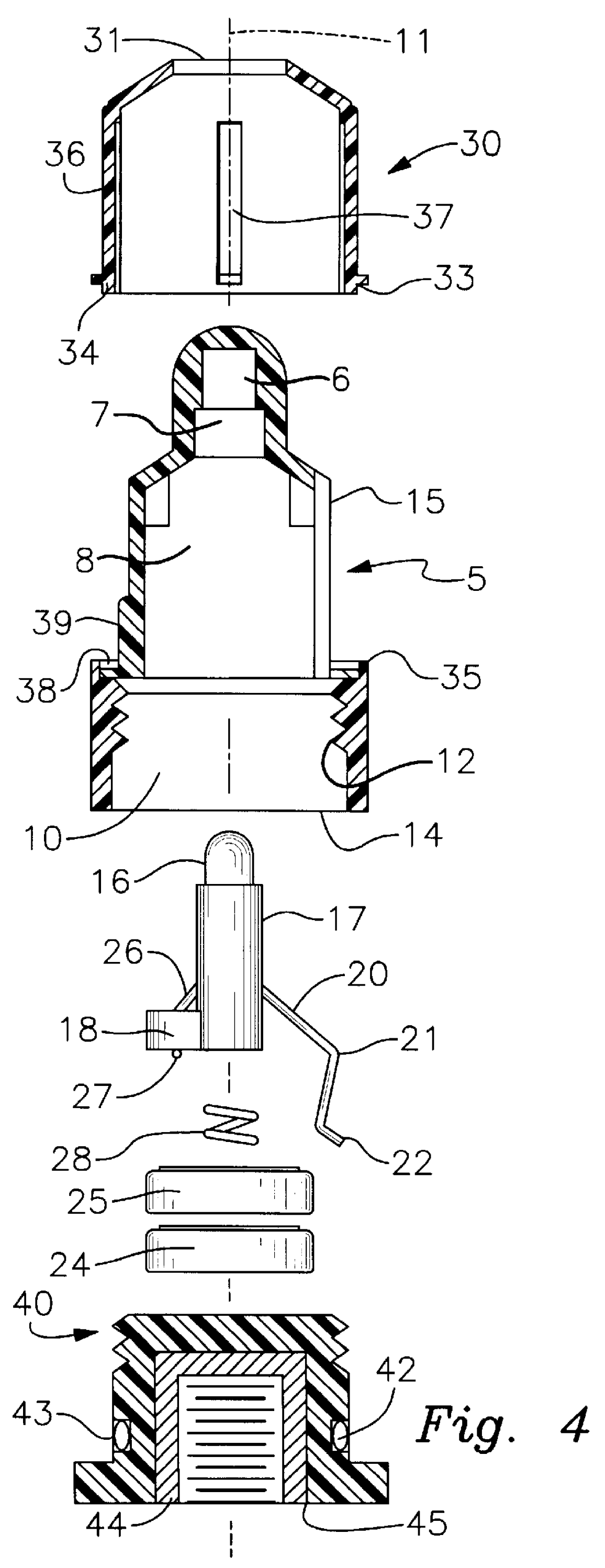

InactiveUS7641471B2Increase safetyEnsure Lighting SafetyBurnersIncandescent ignitionElectricityAerospace engineering

A piezoelectric type of lighter, with a flame generation device (30), including a gas jet release mechanism (36) and a piezoelectric mechanism for generation of a spark (50), characterized in that the lighter includes two actuators (32, 34) which are displaced following a pivoting movement under the action of a force applied by a user, between a first position called rest position and a second position called the active position, whereby at least one of the actuators, called the first actuator, can be displaced independently of the second actuator and acts on at least one of the mechanisms, called the first mechanism. The lighter can produce a flame from the lighter when the two actuators have been pivoted.

Owner:POLLYCONCEPT HLDG

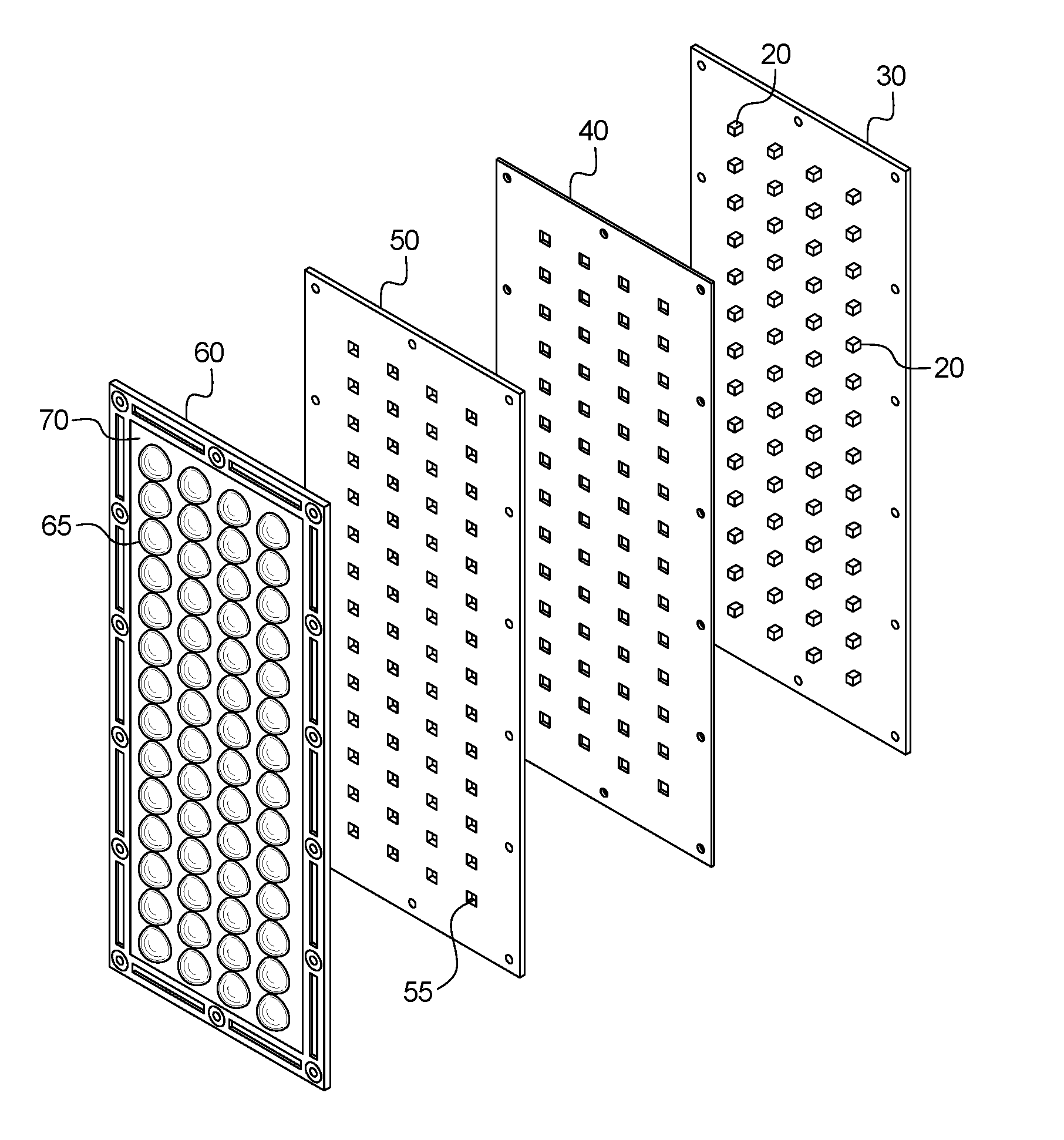

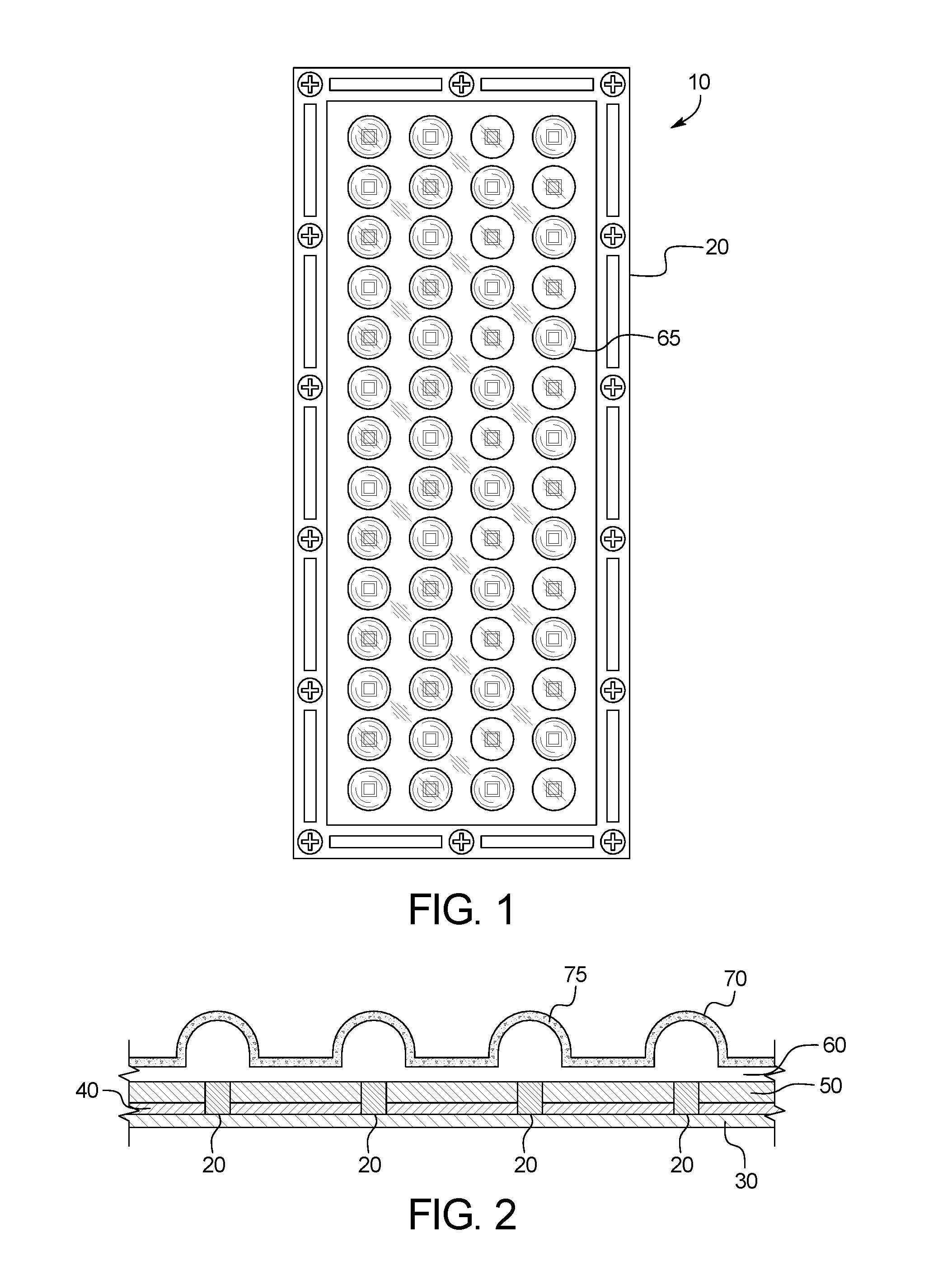

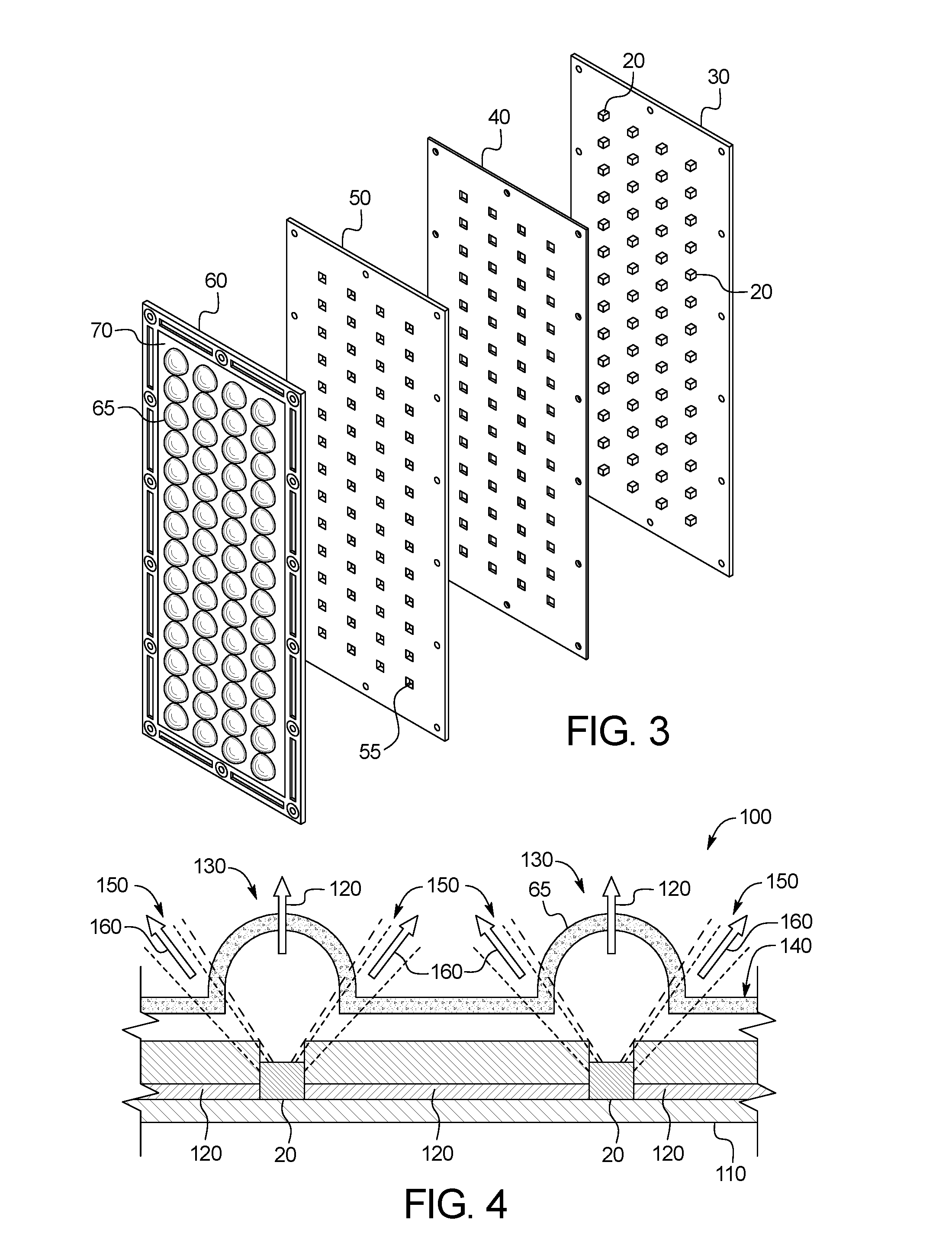

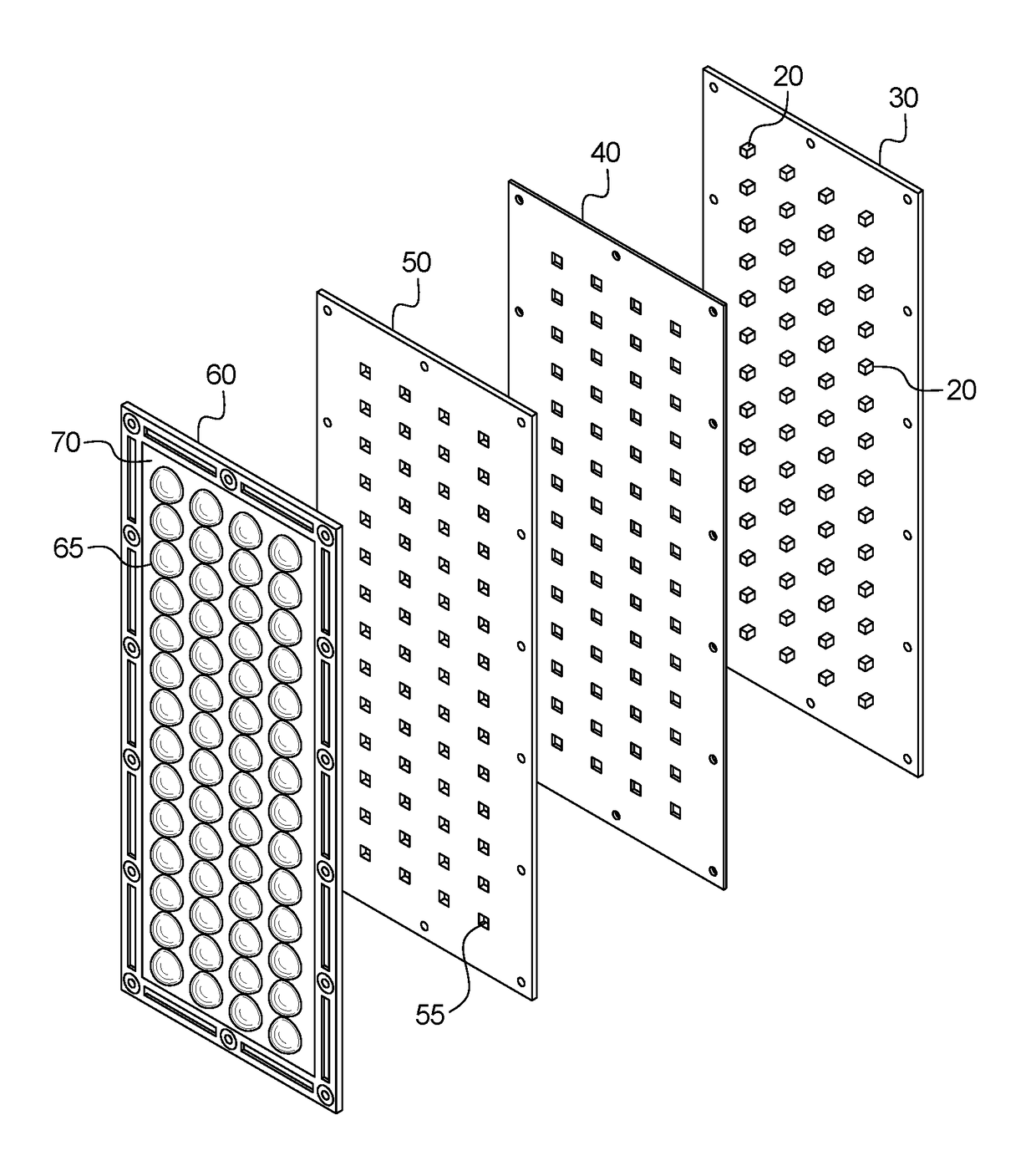

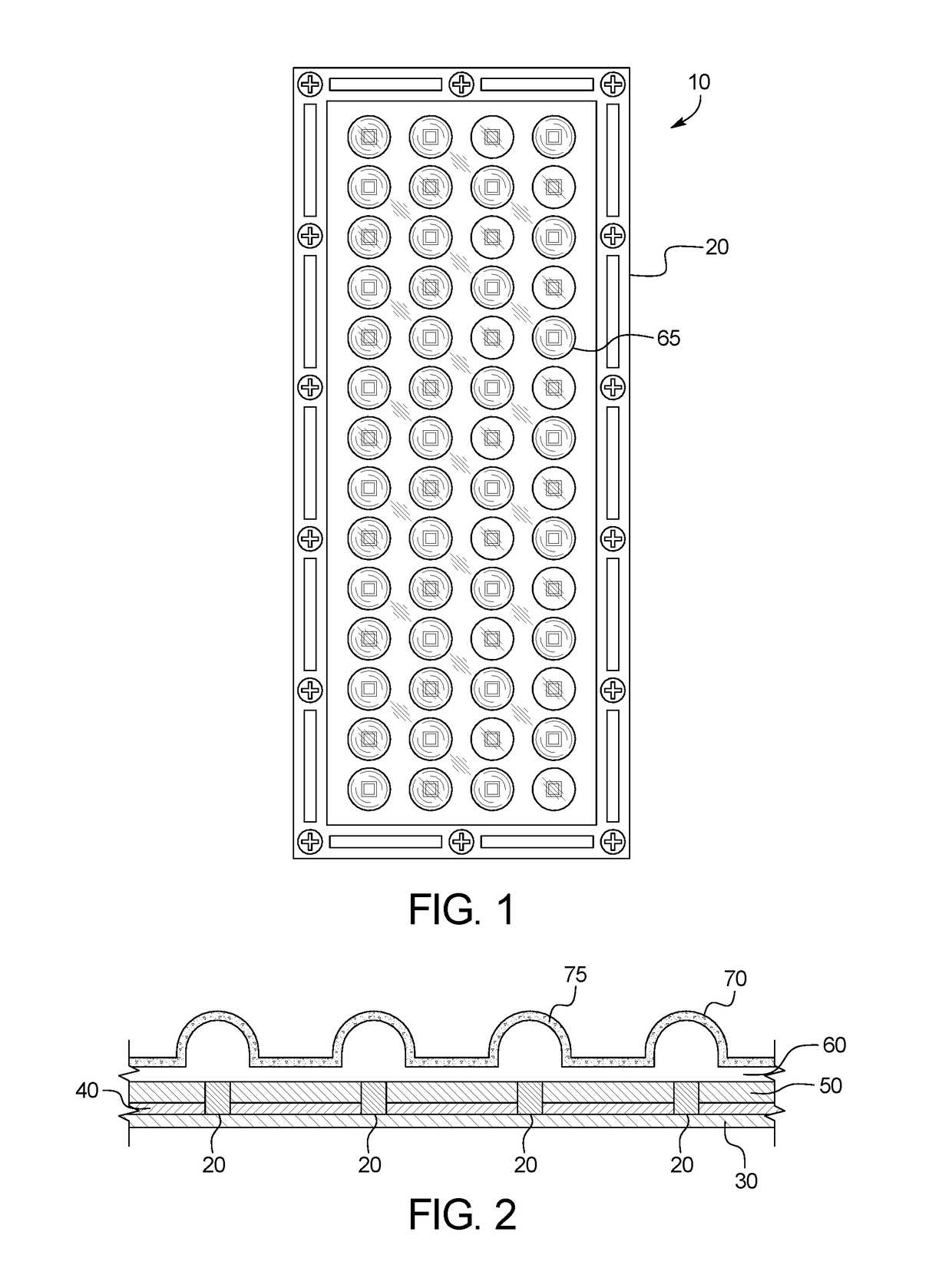

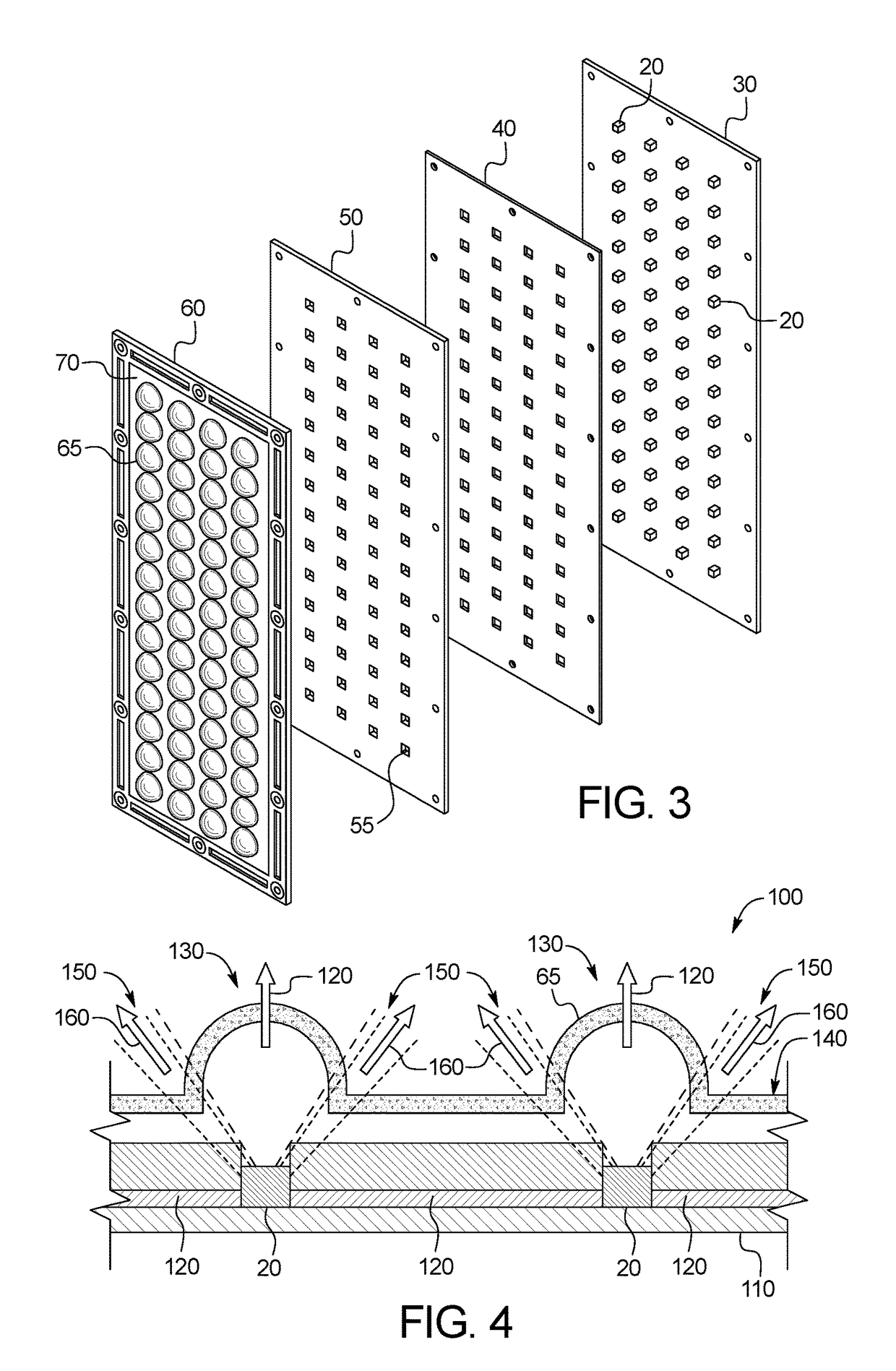

Reduced glare LED light device

InactiveUS20160320016A1Reduce glareFull optical control of lightPlanar light sourcesGlobesLight beamHigh intensity

A device for providing light including: a housing; an array of a plurality of LED lights mounted to the housing, wherein, when active, each LED emits a highest intensity beam of light along a primary axis and emits a lower intensity beam of light along a secondary axis; a lens mounted to the housing, the lens including an optic element corresponding to each of the plurality of LED lights, each optic element intersected by the primary axis of the corresponding LED light; and a translucent edge-light diffusing layer located between two or more of the plurality of LED lights, the edge diffusing layer is not intersected by the primary axis and is intersected by the secondary axis of the LED lights.

Owner:DEDICK CORY D

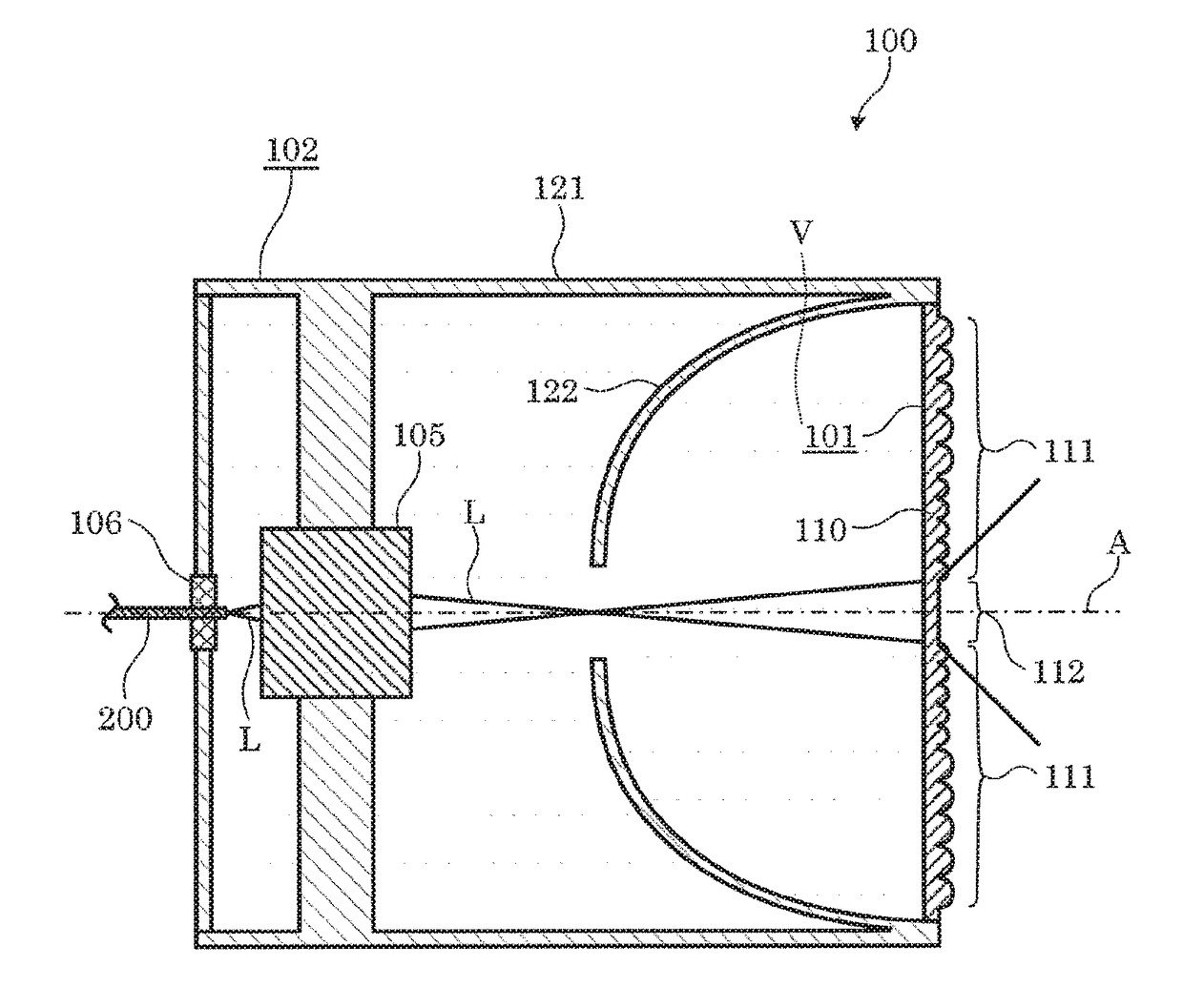

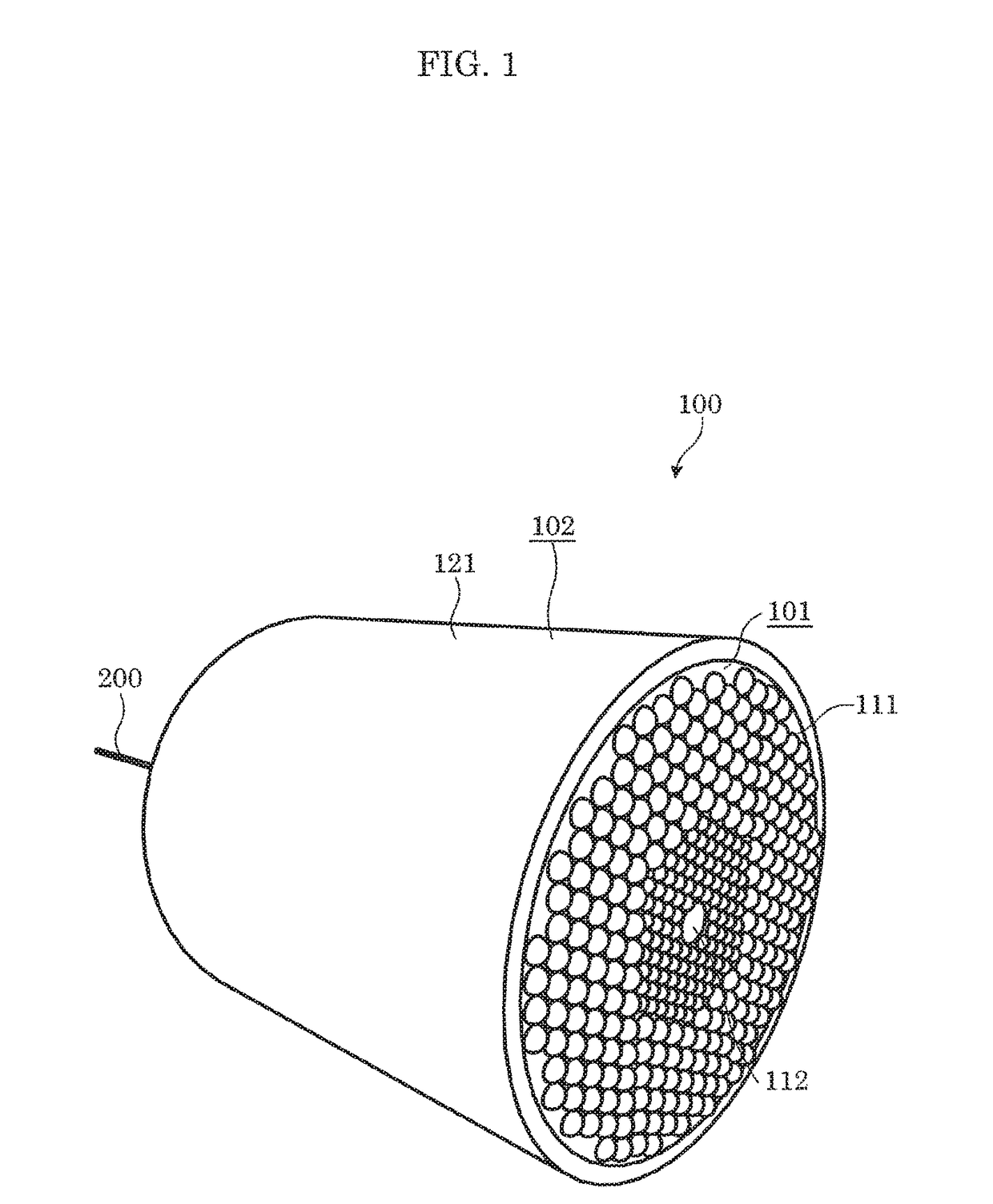

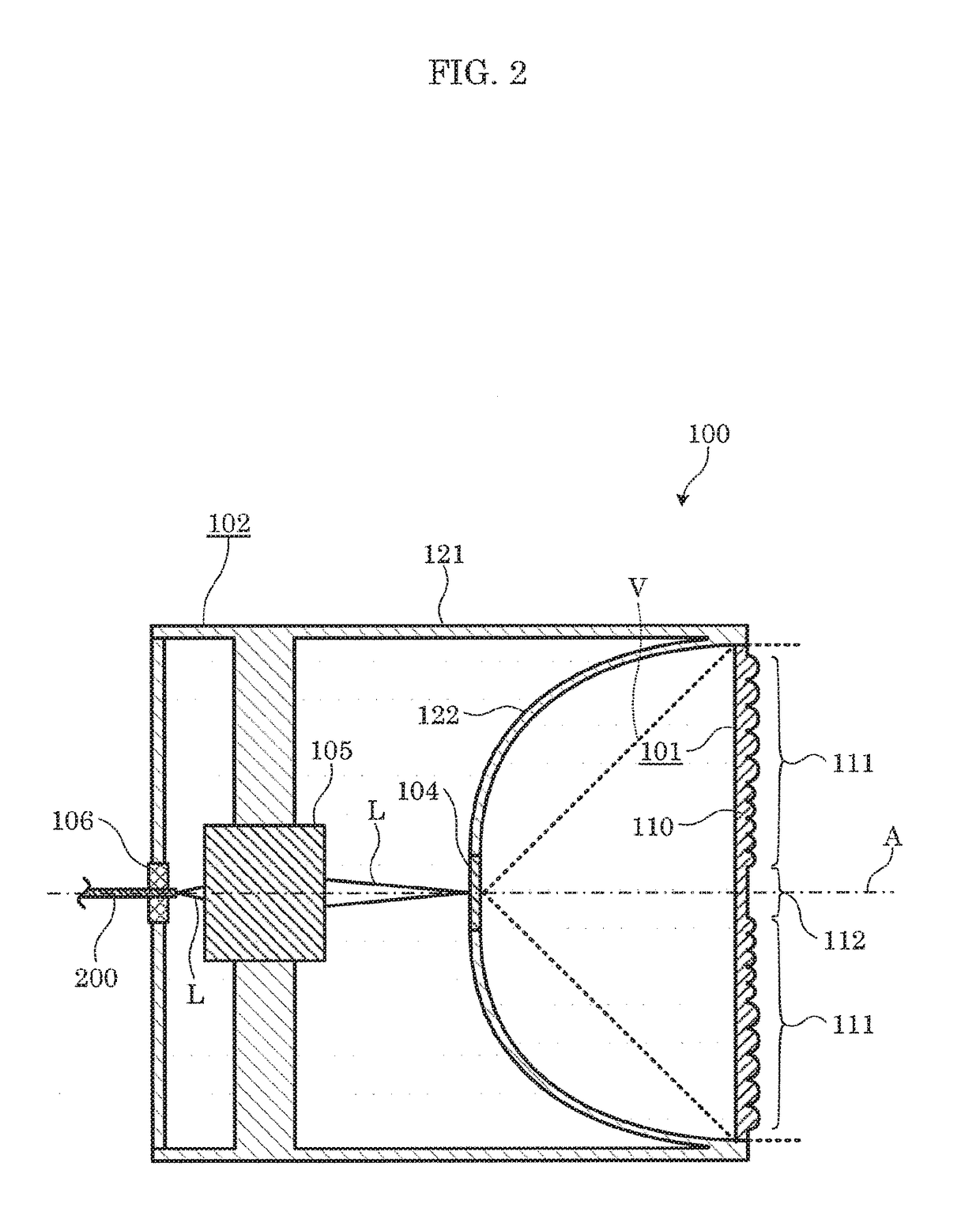

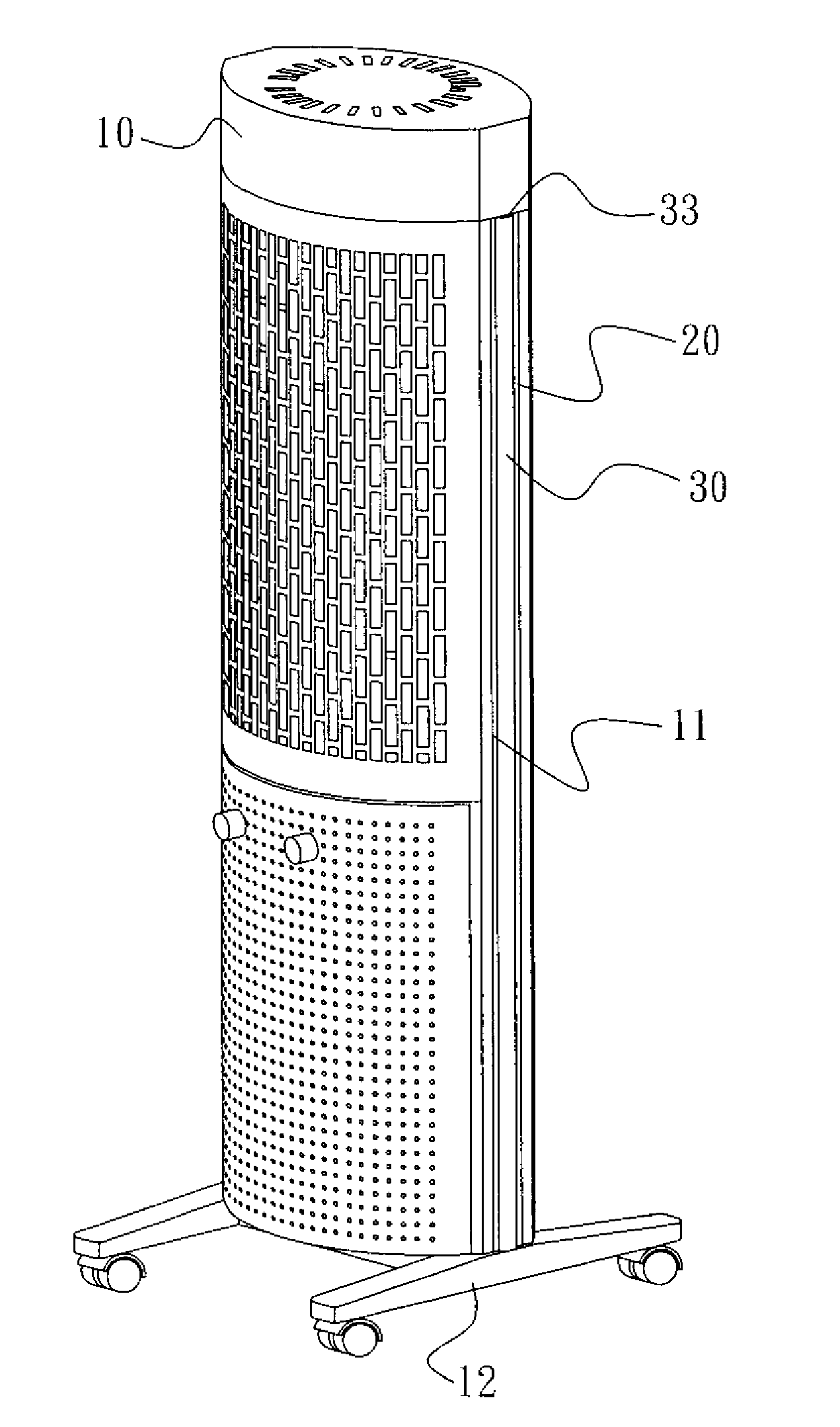

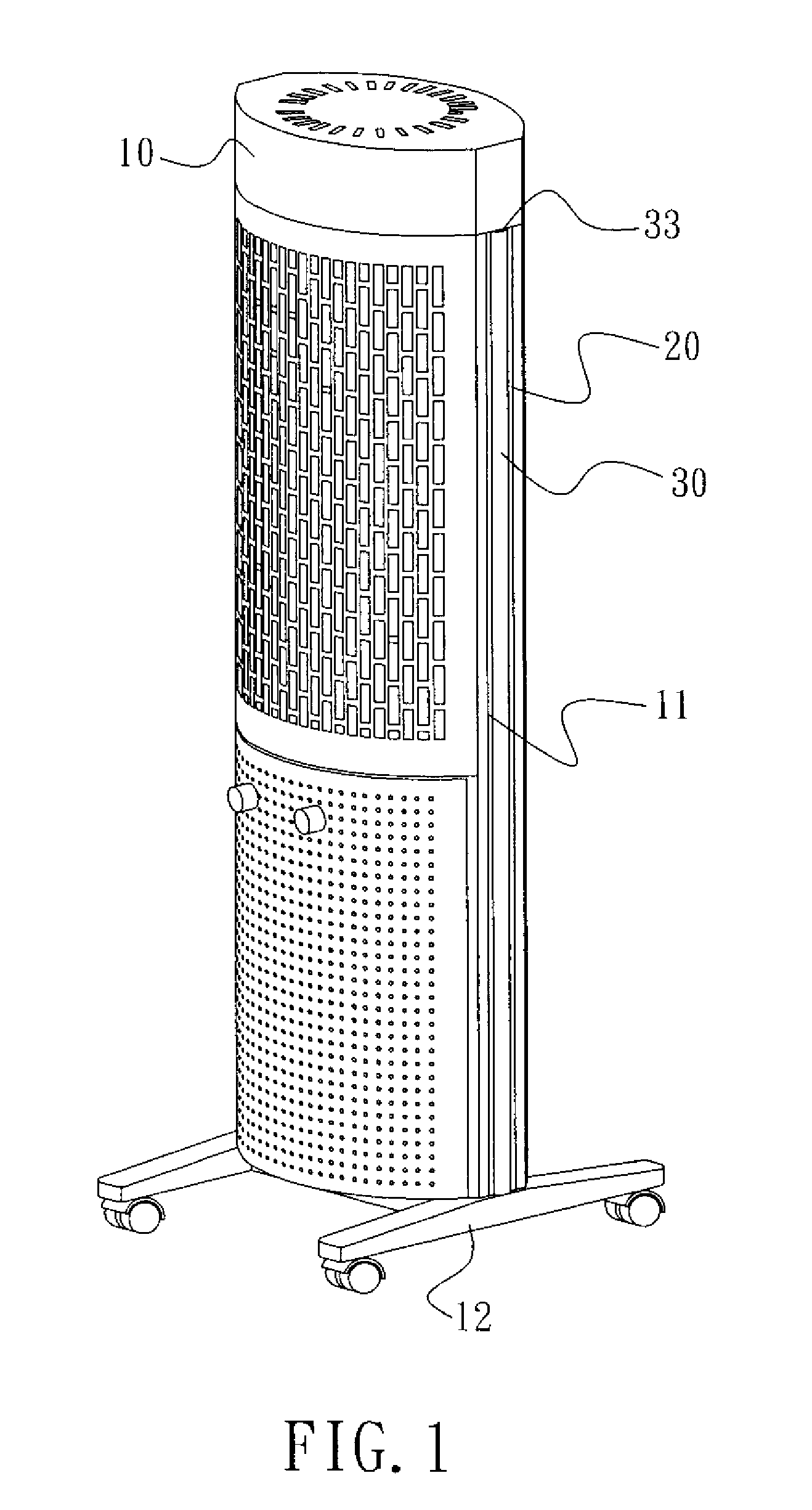

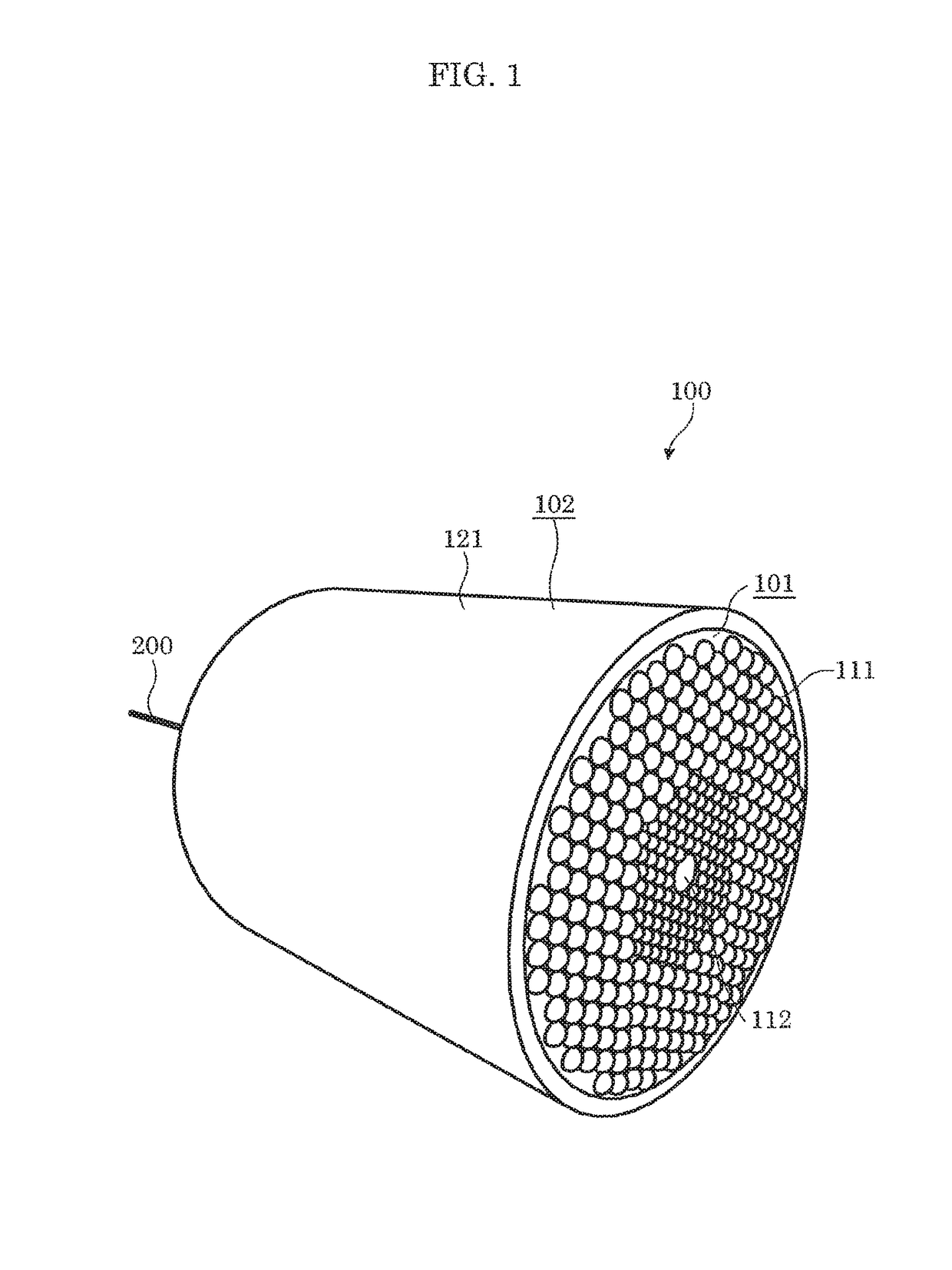

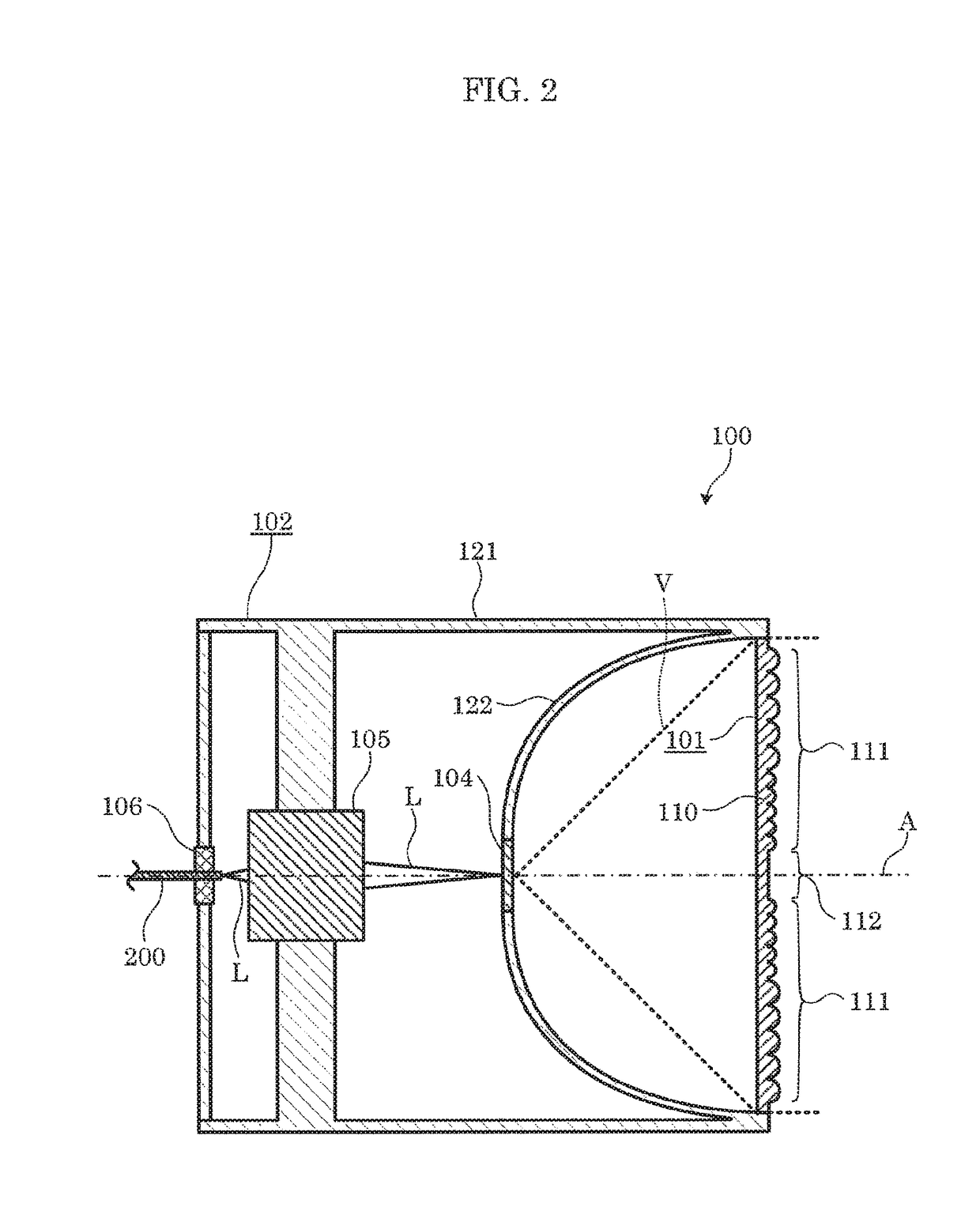

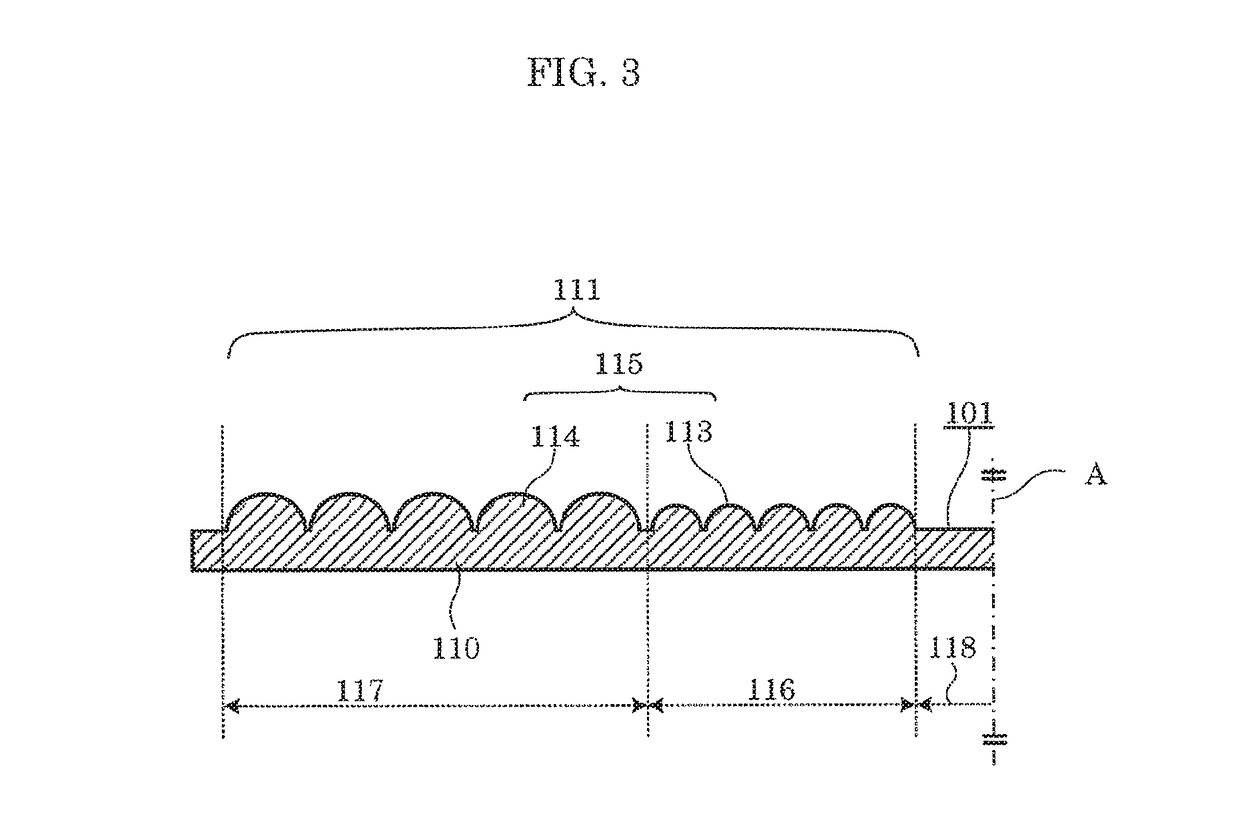

Lighting apparatus

ActiveUS20170108182A1Improve securityLarge structureLighting applicationsMechanical apparatusDistribution controlLight equipment

A lighting apparatus having laser light as a light source is provided. The lighting apparatus includes: a light-emitter which radiates light of a wavelength different from a wavelength of the laser light; and a lens including a light distribution controlling structure that controls distribution of the light radiated from the light-emitter. The lens is disposed opposite a laser light entry side of the lighting apparatus. The light-emitter is disposed between the lens and the laser light entry side. The lens integrally includes, along an optical axis of the laser light, a light-dispersing structure configured to disperse the laser light.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Dental curing light

ActiveUS10159548B2Quality improvementGood precisionBoring toolsDental prostheticsClosed loopDental Curing

An optical sensor for an instrument to form a closed-loop curing instrument that is configured to manage the quantity of delivered energy to a curable material, including a composite restoration for a tooth. The closed-loop curing instrument is configured to analyze a signal indicative of the light reflecting from the curable material, and to adjust light output based on the analysis.

Owner:GARRISON DENTAL SOLUTIONS

LED Module Sealing Technology

ActiveUS20170373483A1Prevent moisture intrusionEasy to useCoupling device detailsGas-tight/water-tight arrangementsWater vaporEngineering

A sealing process of LED modules, comprising: (1) a waterproof wire goes through a wire-through hole of a heat sink to be connected with a positive-negative solder joints on a PCB board, wherein the positive-negative solder joint and the position that the waterproof wire going through are subjected to glue sealing treatment, and a waterproof sealing process is operated between the waterproof wire and the wire-through hole; (2) fix the PCB board on the heat sink; (3) place one sealing ring into one of the grooves; (4) apply evenly a ring of liquid silica gel along the other groove of the lens set and the amount of the liquid silica gel is limited to completely sticking the solid silica gel sealing ring; (5) the heat sink installed with the PCB board and the waterproof wire as processed in step (2) is inversely buckled on the lens set which is set with the solid silica gel ring and the liquid silica gel as processed in step (4), so as to fix the heat sink entirety and the lens set. At least two waterproof sealing rings are used for completely isolating an LED chip from the outside so as to prevent all water vapor or other harmful gases from corroding the chip and the PCB, and the sealing rings are firmer when being compared with thin film sealing; the service life is longer and the guarantees to the sealing performance between the lens set and the heat radiation frame are realized.

Owner:HANGZHOU HPWINNER OPTO CORP

Reduced glare LED light device

InactiveUS9989212B2Full controlSignificant reduction in glarePlanar light sourcesMechanical apparatusLight beamHigh intensity

A device for providing light including: a housing; an array of a plurality of LED lights mounted to the housing, wherein, when active, each LED emits a highest intensity beam of light along a primary axis and emits a lower intensity beam of light along a secondary axis; a lens mounted to the housing, the lens including an optic element corresponding to each of the plurality of LED lights, each optic element intersected by the primary axis of the corresponding LED light; and a translucent edge-light diffusing layer located between two or more of the plurality of LED lights, the edge diffusing layer is not intersected by the primary axis and is intersected by the secondary axis of the LED lights.

Owner:DEDICK CORY D

Atmospheric heater

InactiveUS20100006556A1Enhance atmospheric lighting effectEnhancement of atmospheric lighting effectAir heatersOhmic-resistance heatingAtmospheric airEngineering

An atmospheric heater has opposite side walls each forming a groove for receiving a retention rail with an opening of the retention rail exposed to receive and retain a fogged light-transmitting tube, which is spaced from a bottom wall of the retention rail to define a first channel. A circuit board that carries light-emitting diodes is fixed inside the tube and opposite to the tube wall where light is given off to thereby form a second channel between the circuit board and the tube wall. Heat emitted from the heater travels through the first and second channels for penetrating vertically in a down-to-up direction to generate a chimney effect for heat dissipation in order to prevent the light-emitting diodes from over-heating and burnout during the operation thereof and also provide a dim lighting effect on opposite sides of the heater.

Owner:GRAND HALL ENTERPRISE COMPANY

Lamp

PendingCN107906381AEnsure Lighting SafetyImprove overall senseLighting heating/cooling arrangementsGas-tight/water-tight arrangementsEngineeringPhysics

The embodiment of the invention discloses a lamp. A line type lamp cylinder comprises a lamp body and a lampshade connected to the opening portion of the lamp body. Opposite bearing tables are arranged on the two side walls, in the axial direction of the line type lamp cylinder, of the lamp body correspondingly. A protruding portion is arranged on the side wall of one side, away from the lampshade, of each bearing table in the axial direction of the line type lamp cylinder. A gap is spaced between each protruding portion and the corresponding bearing table. A light source module comprises a heat dissipating plate with the two sides assembled in the gaps, and a light source module arranged on one side, facing the lampshade, of the heat dissipating plate. A spring piece connected with the grounding end of an input line is arranged on the side, away from the lampshade, of the heat dissipating plate. Piercing portions extending to the heat dissipating plate are arranged at the two ends ofthe spring piece correspondingly. The piercing portions pierce the surface layers of the protruding portions. The distance from the ends, close to the heat dissipating plate, of the piercing portionsis smaller than the distance between the two points of contact between the protruding portions and the heat dissipating plate and contact between the protruding portions and the piercing portions. Thelamp in the embodiment solves the technical problems that a lamp at the present stage is unreliable in grounding and poor in integrity.

Owner:ZOPOISE TECH

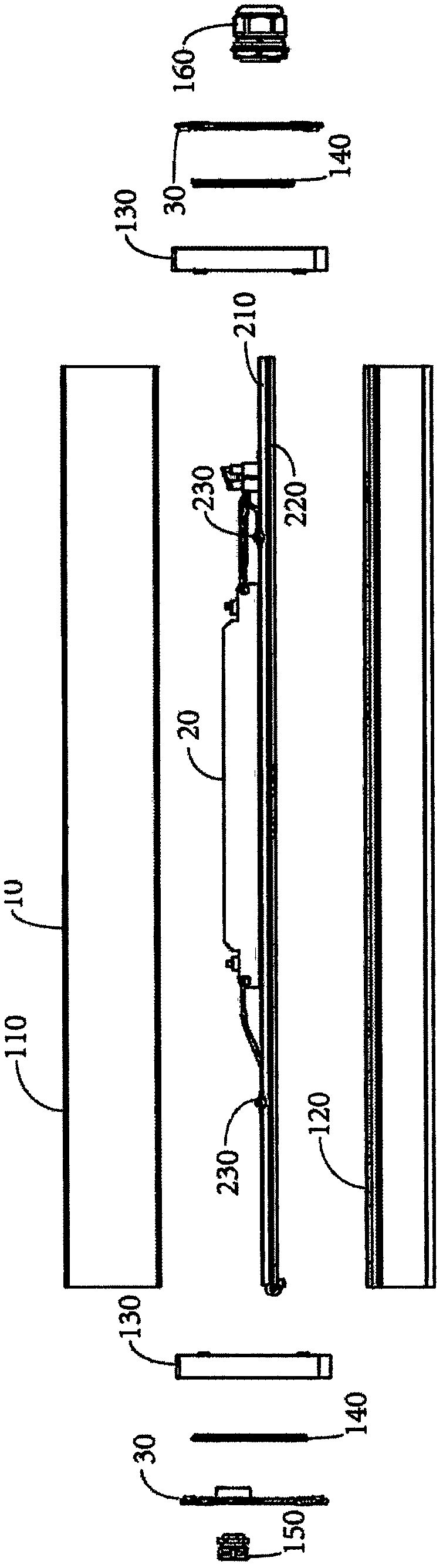

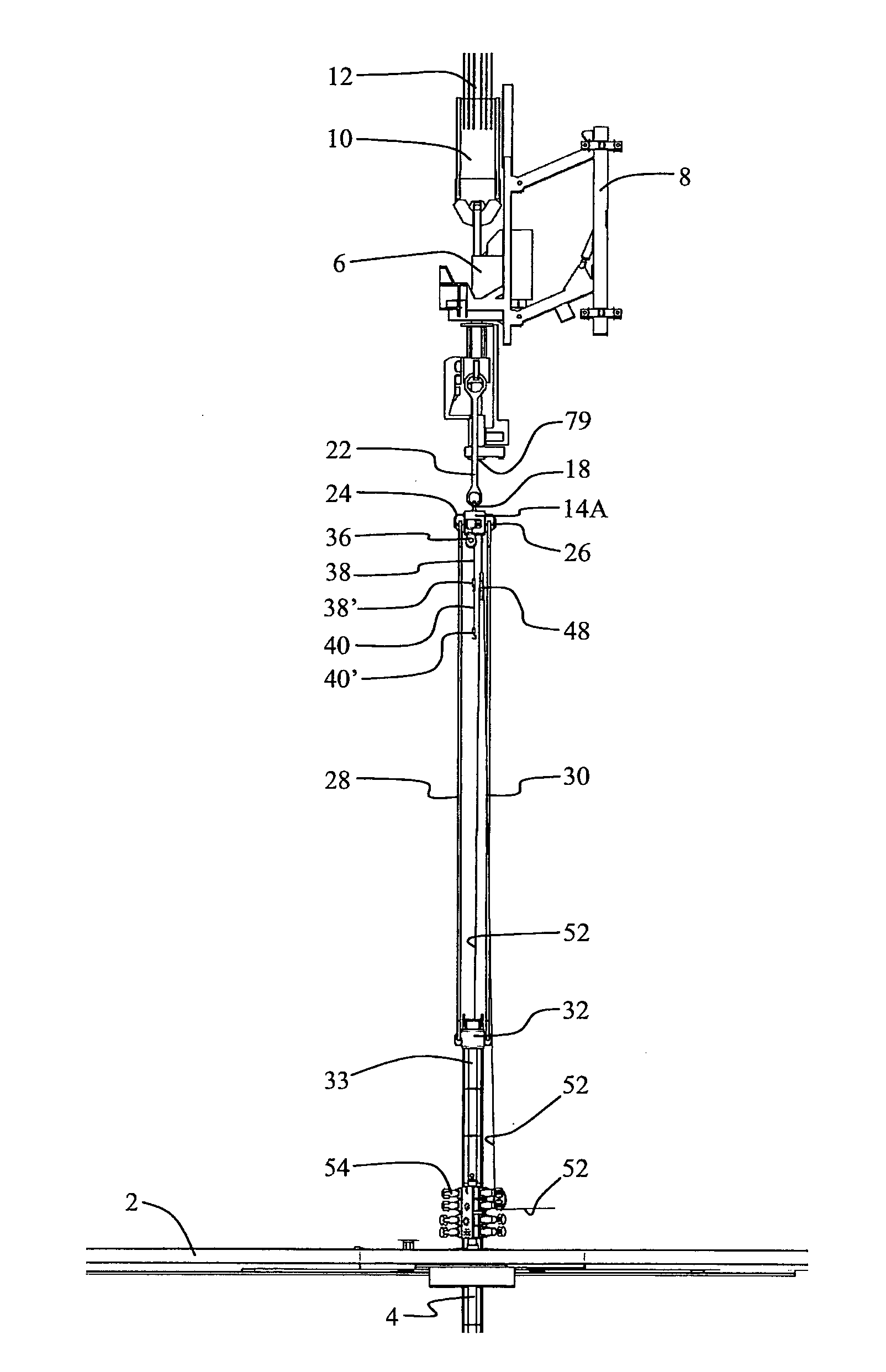

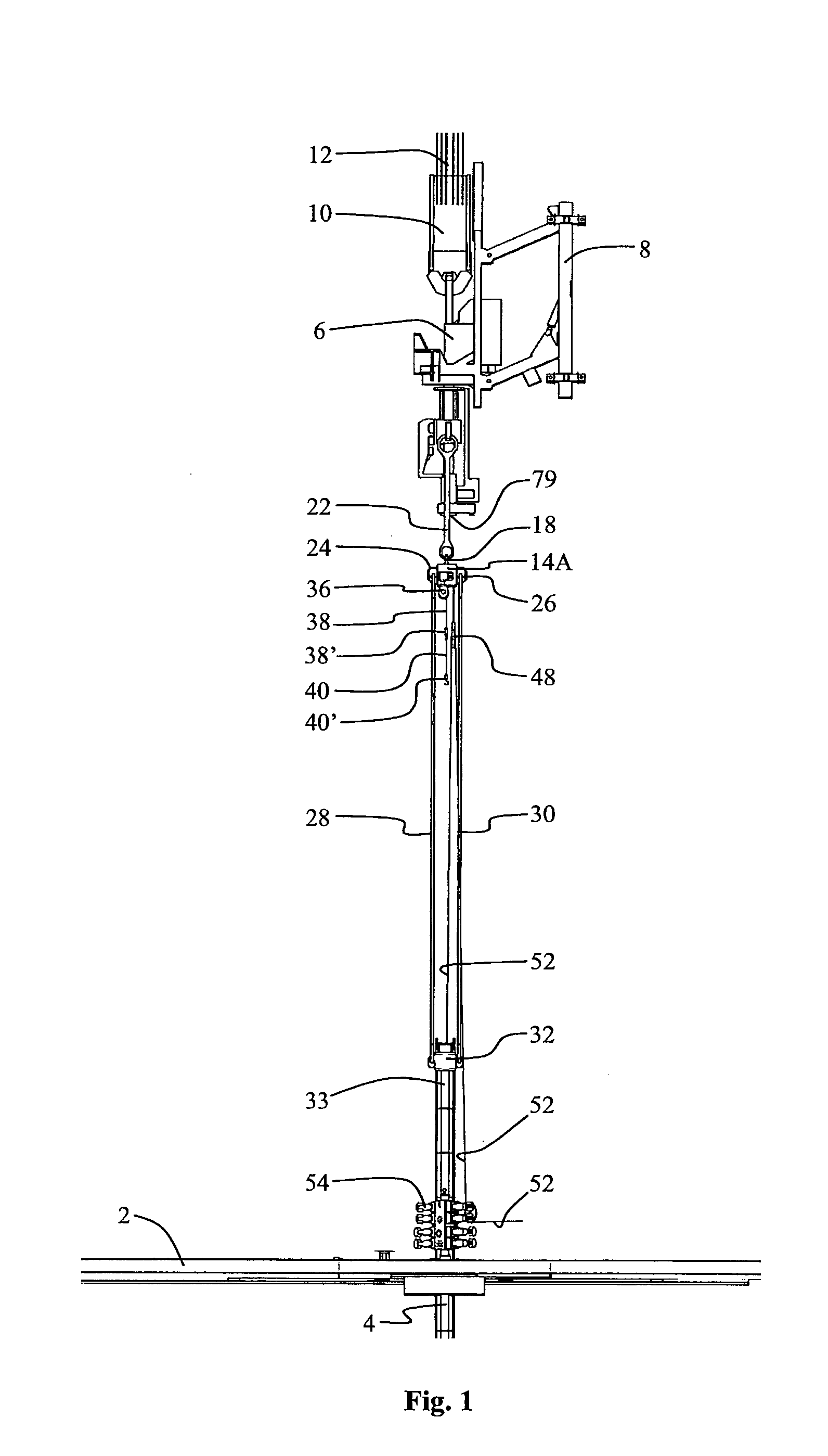

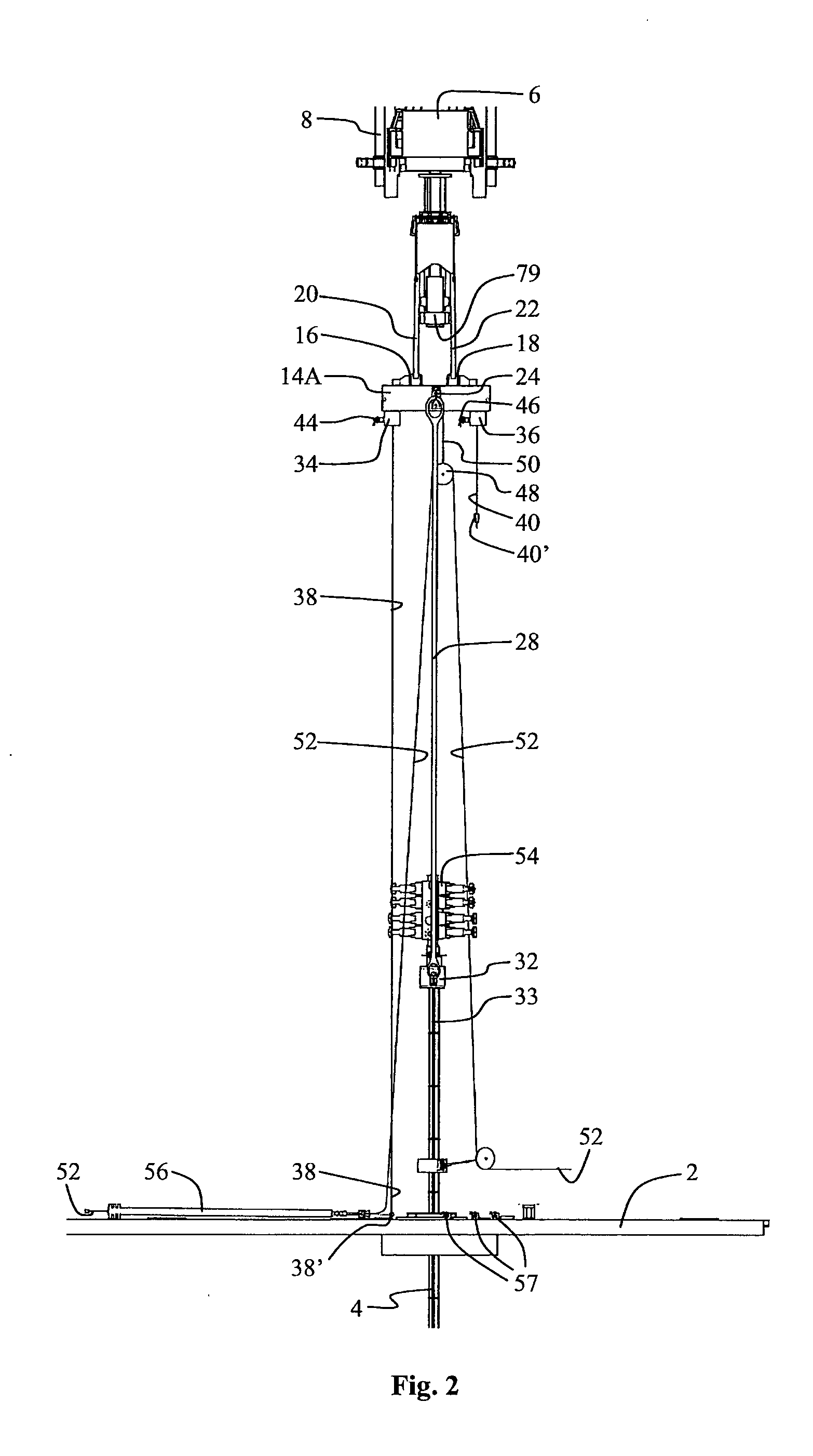

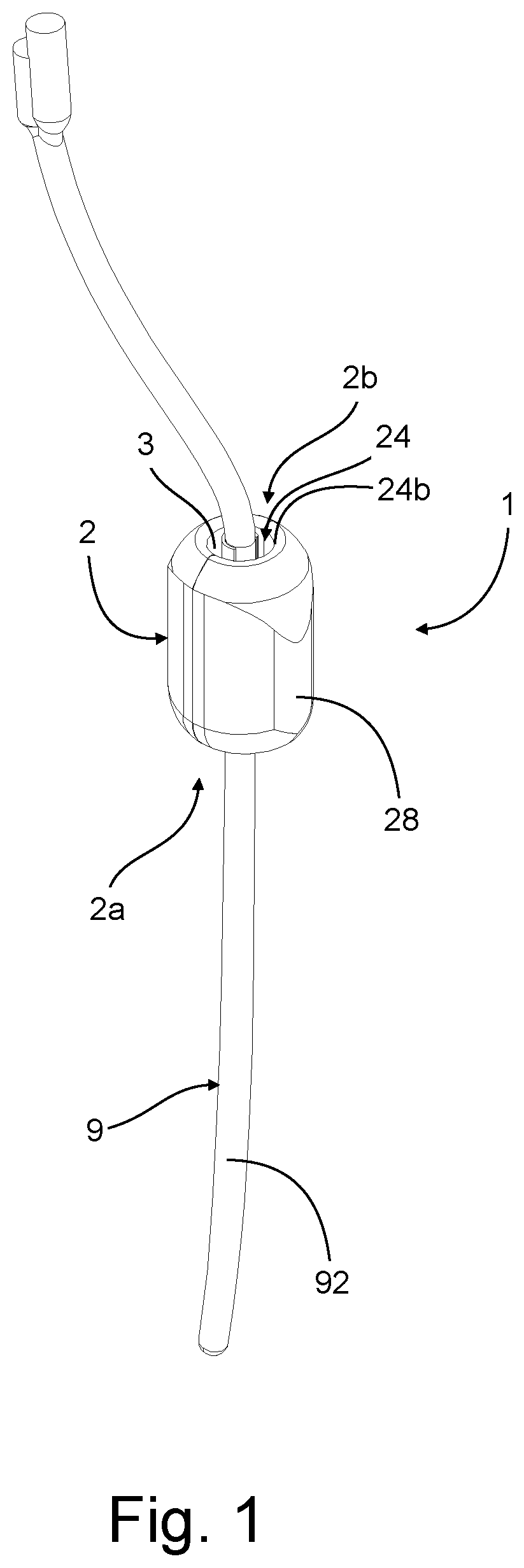

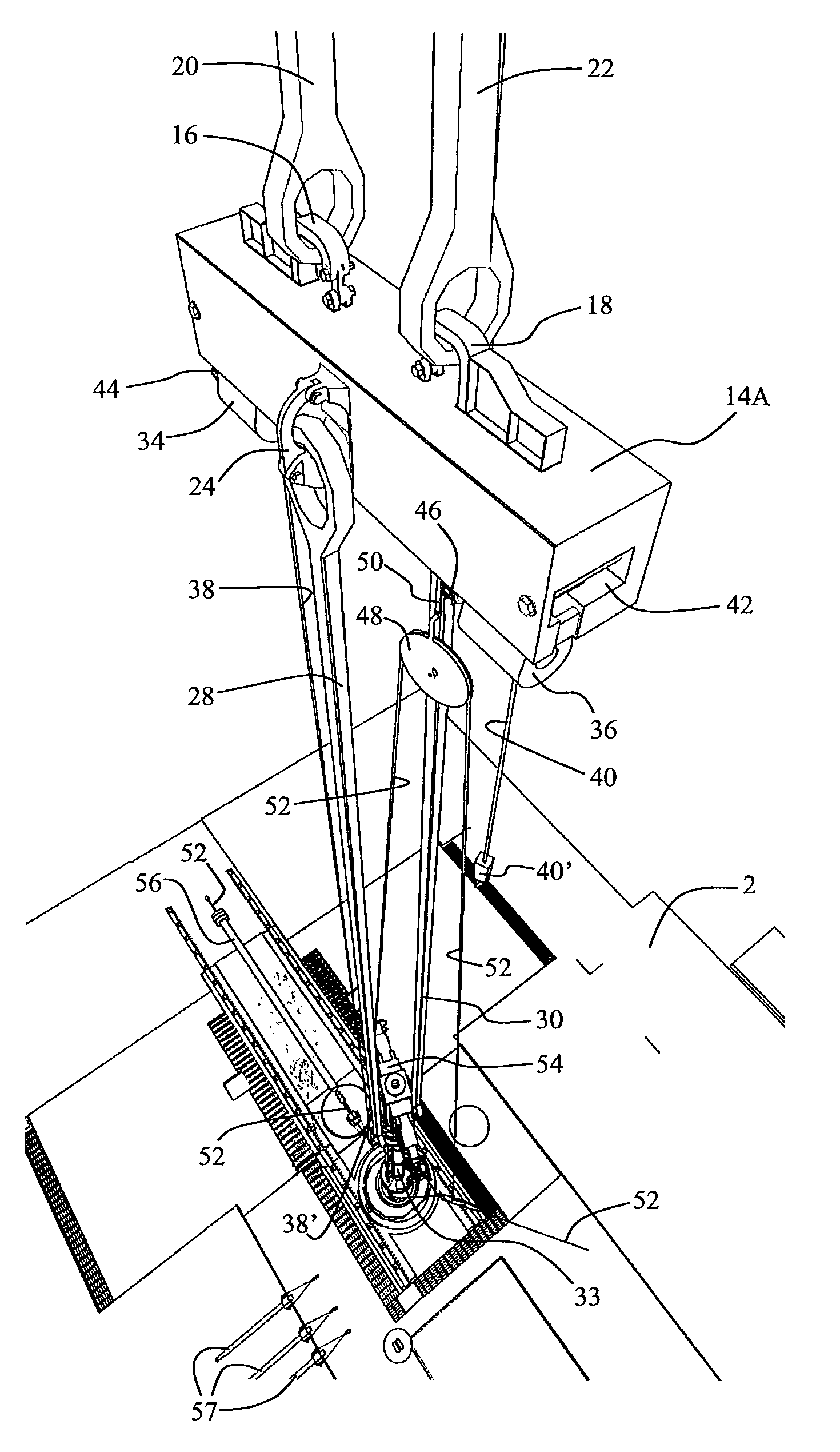

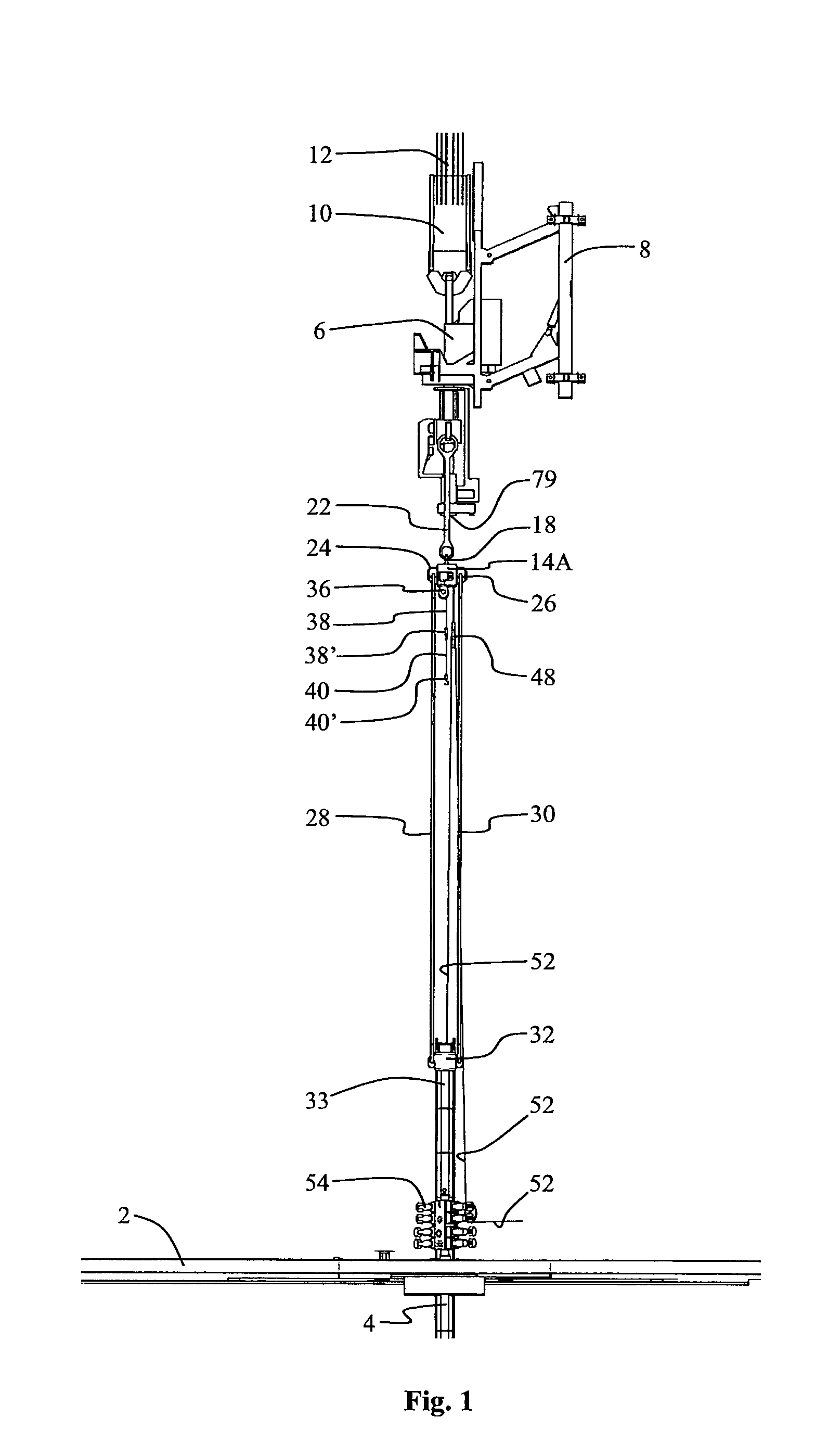

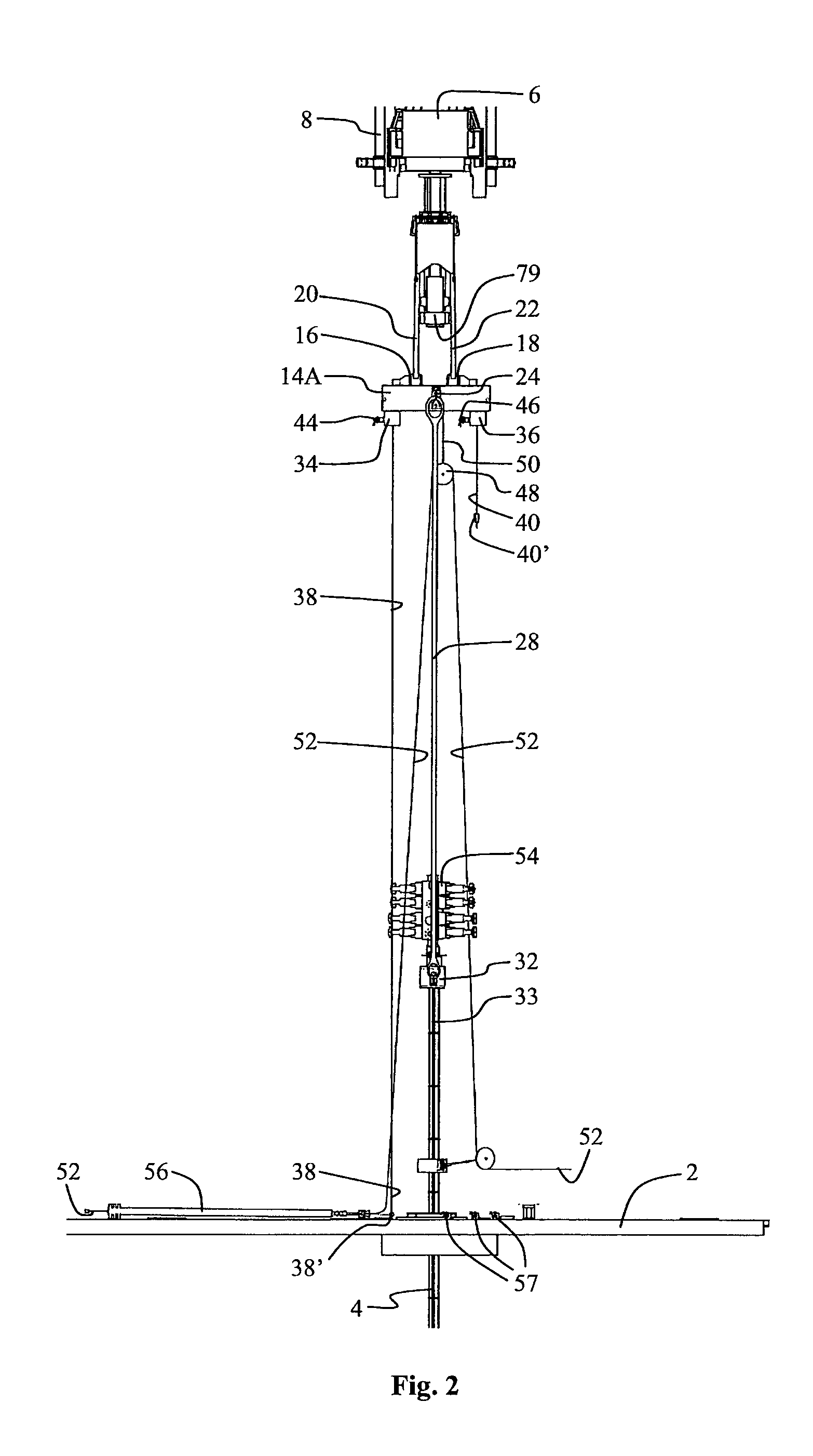

Device, Method and Use for Transfer of Equipment for a Wireline Operation in a Well

ActiveUS20110253385A1Reduce disadvantagesSimple and flexible and compact and cheapDrilling rodsFluid removalTop driveRemote control

Device for transfer of equipment for a wireline operation in a well connected to a drilling derrick via a top drive. The device comprises a beam structured for releasable connection to said top drive; wherein the beam is structured in a manner allowing it to extend, when in its position of use, transversely relative to a centre line between the top drive and the well; wherein the beam is provided with at least one hoisting device with a lifting line for vertical movement of said equipment; wherein a support point for the lifting line is connected to the beam and is structured so as to be movable in the longitudinal direction of the beam, whereby said equipment may be moved horizontally relative to said centre line; and wherein said hoisting device and support point are structured for remote-controlled operation.

Owner:QUALITY INTERVENTION

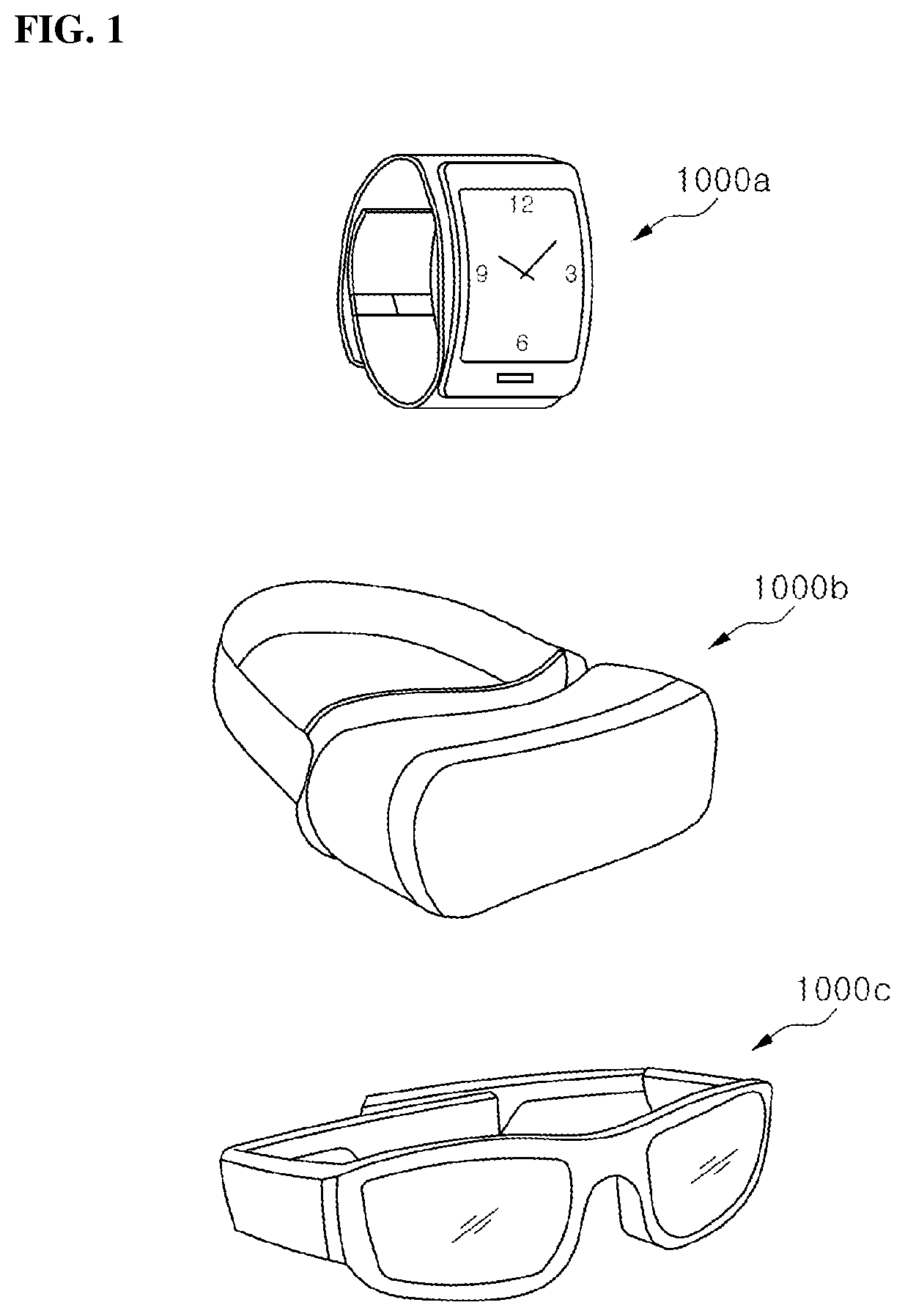

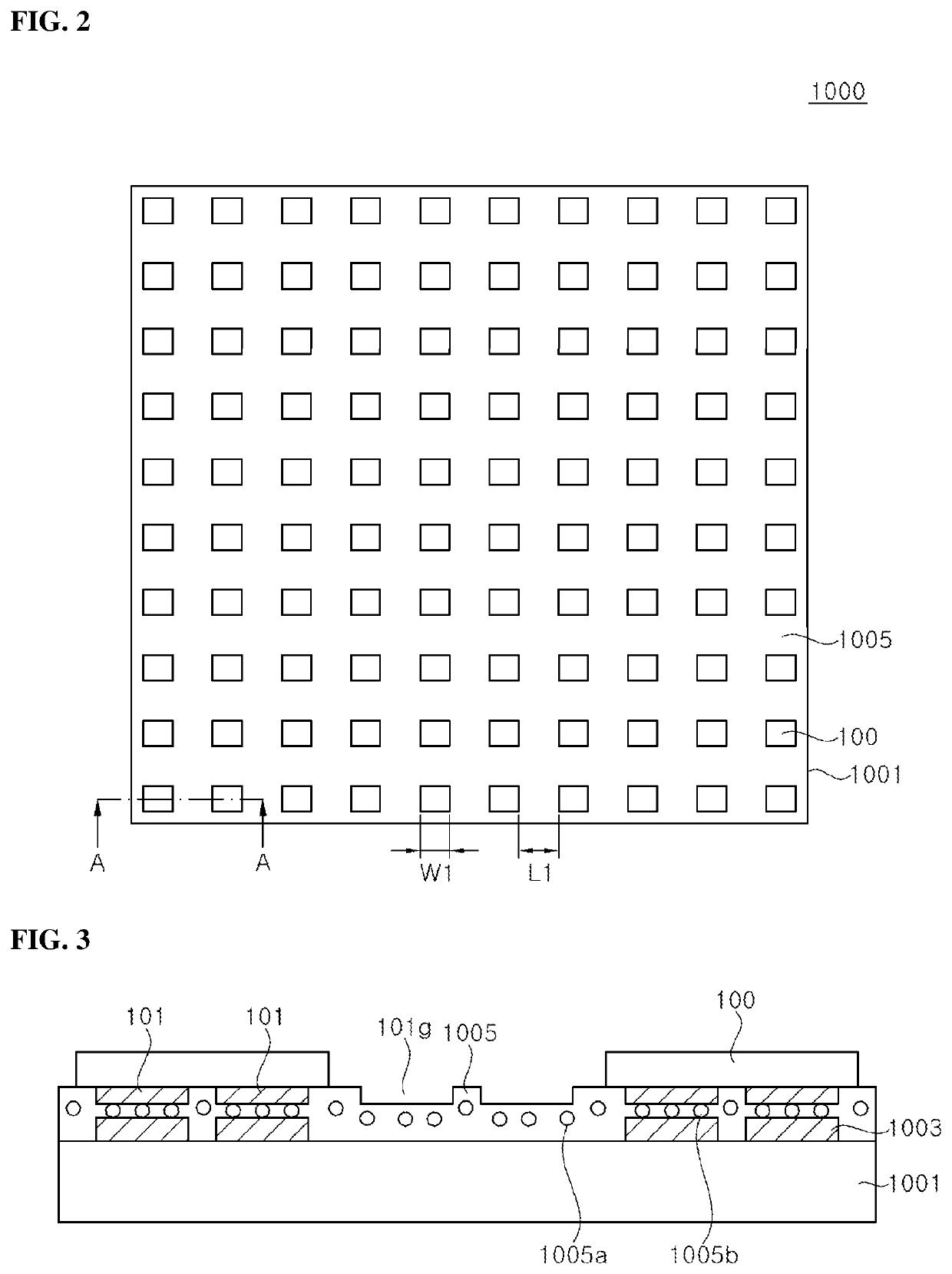

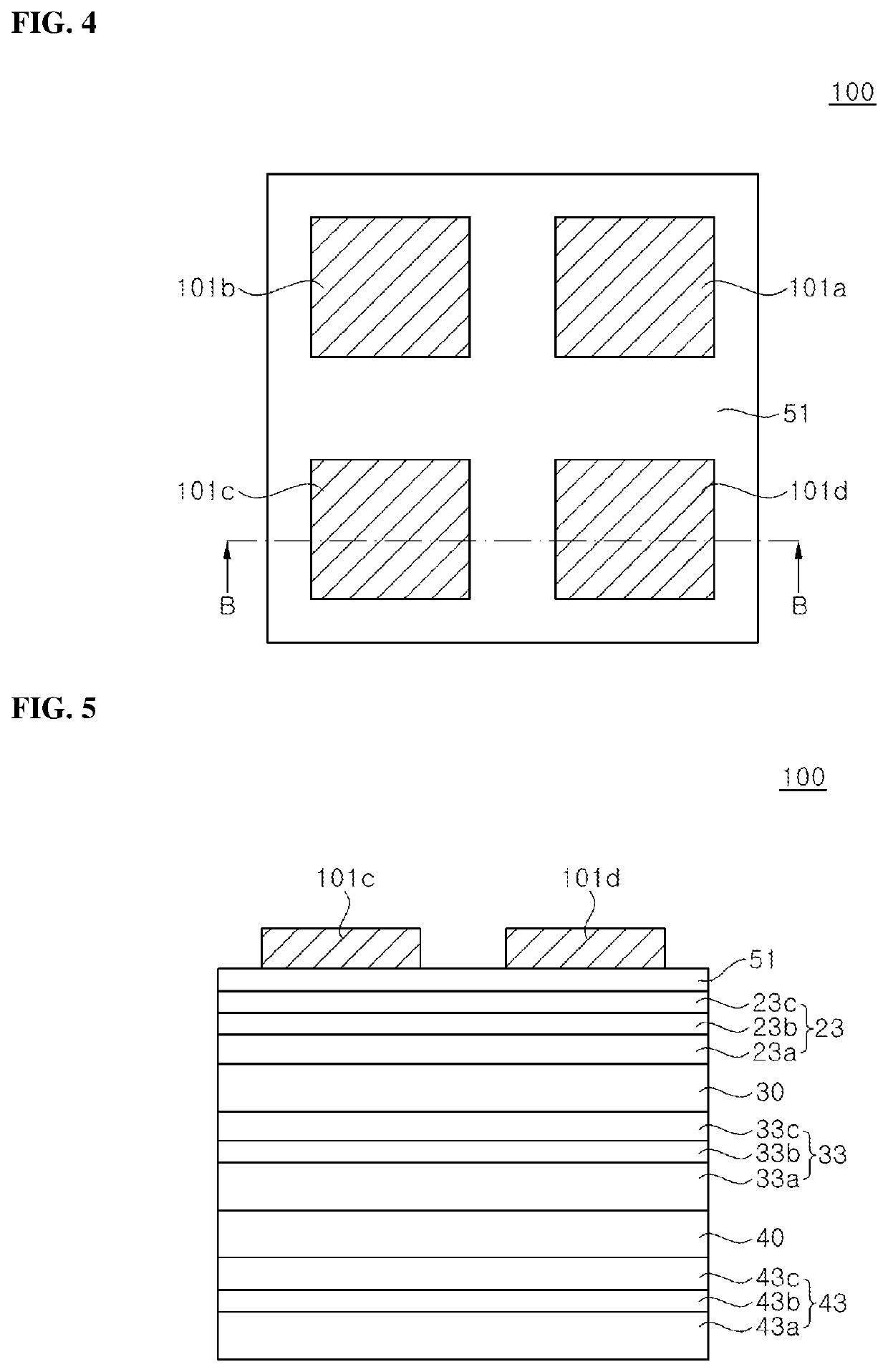

LED display panel, LED display apparatus having the same and method of fabricating the same

ActiveUS20200343227A1Safe transferIncrease the areaSolid-state devicesNon-linear opticsLED displayEngineering

A display panel including a circuit board having pads, light emitting devices electrically connected to the pads and arranged on the circuit board, each light emitting device having a first surface facing the circuit board, and a buffer material layer disposed between the circuit board and the light emitting devices to fill a space between the circuit board and the light emitting devices, in which the buffer material layer is disposed under the first surfaces of the light emitting devices

Owner:SEOUL VIOSYS CO LTD

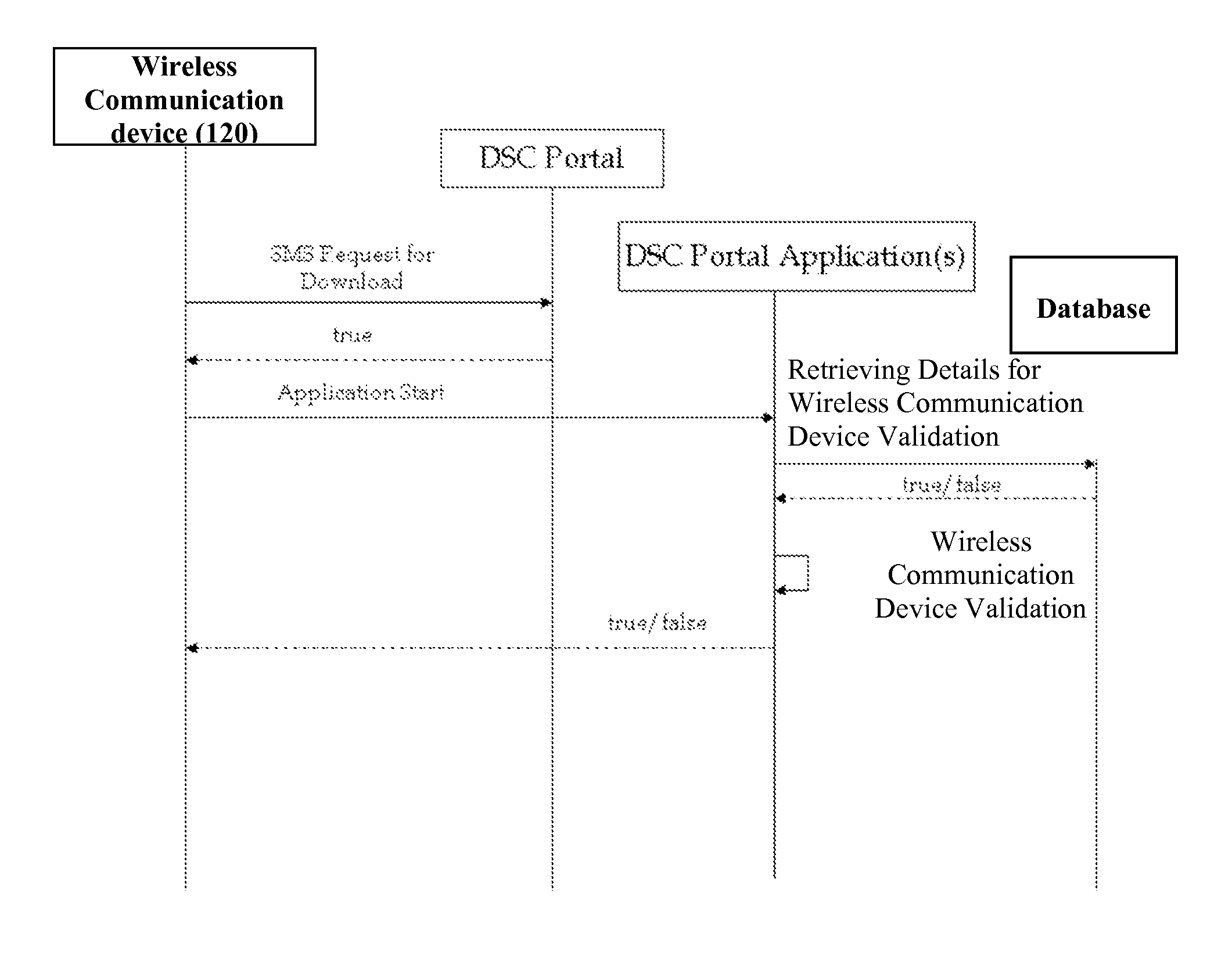

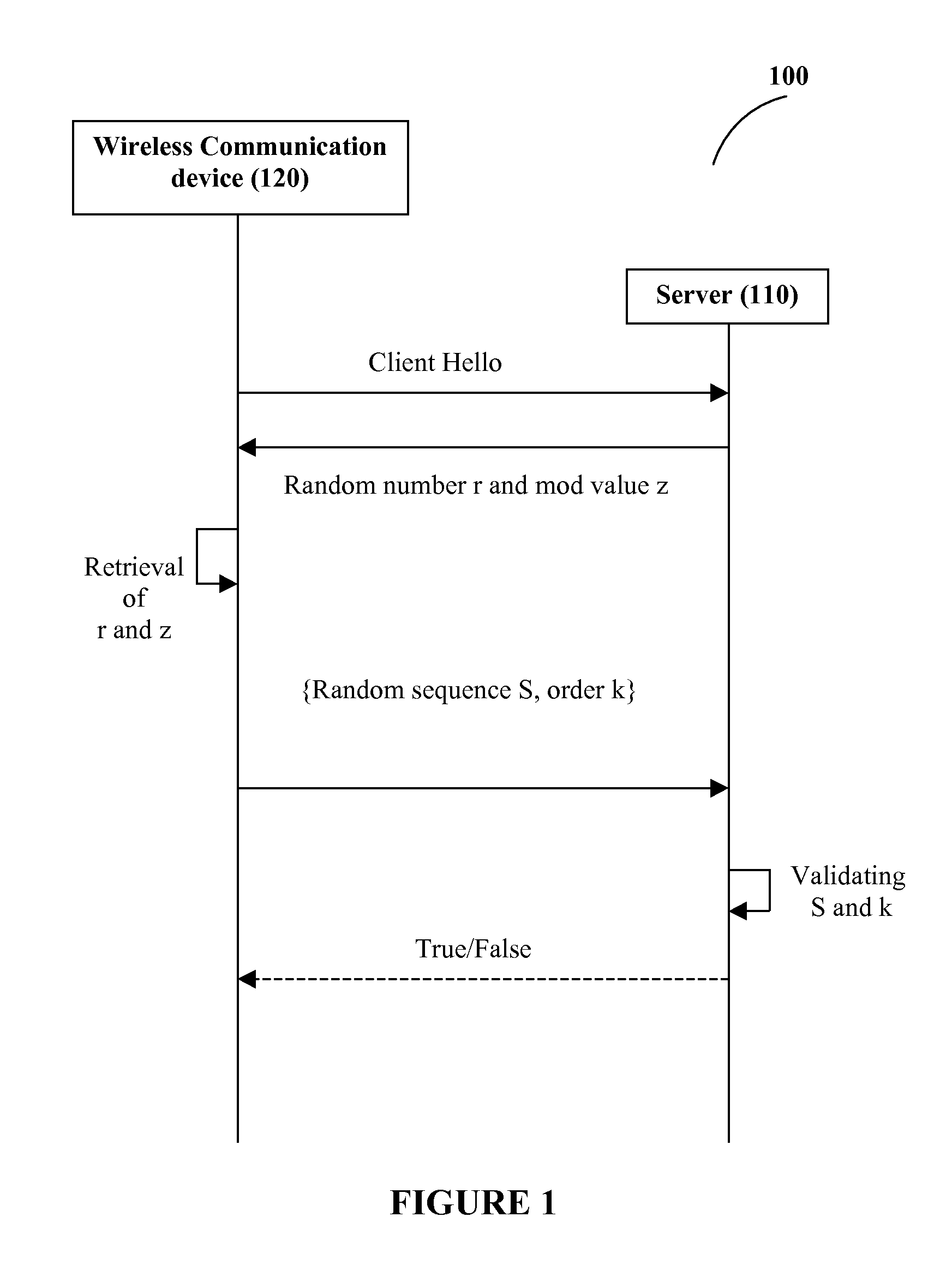

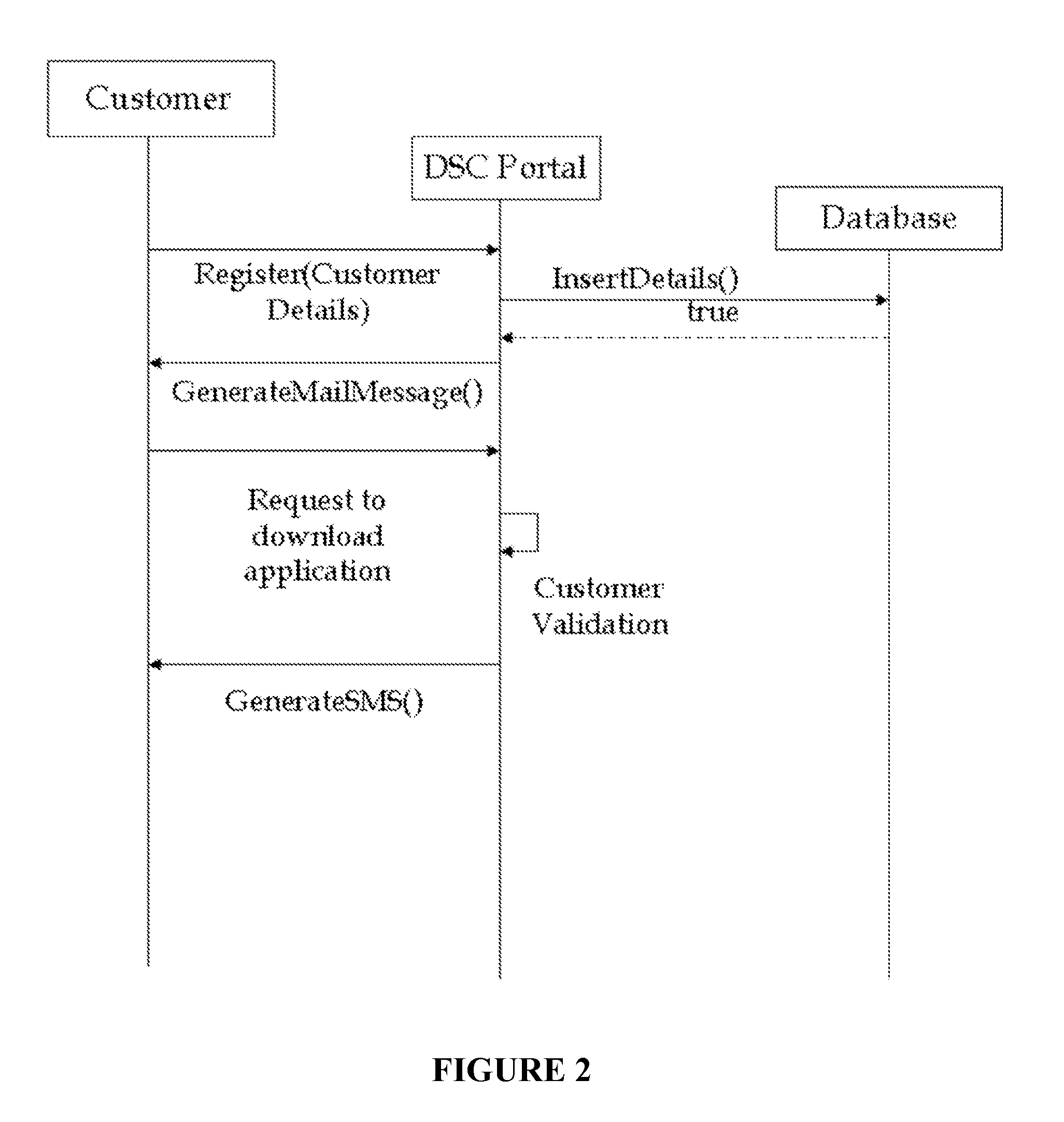

System and method for a secure synchronization between a wireless communication device and a server

ActiveUS20110164751A1Light weightImprove performanceSynchronising transmission/receiving encryption devicesSecret communicationComputer hardwareRound complexity

The present invention provides a system and method for designing secure synchronization protocols in mobile communication by using Deterministic Random Number Generator (DRNG) through linear operators without using multi-precision integers. It also provides an efficient way to generate a huge size collection of pseudorandom numbers with a less computational complexity and DRSG is designed for mobile and wireless communications and also the said DRSG algorithm is a lightweight algorithm. The generated sequence has a lot of applications in Mobile computation and Information security. The invention provides a securely transfer of registry and provision of consumer details over the communication network and also provide a light weight security with better performance in comparison to the lower layer chip level security provided by 2G, 3G or 4G applications.

Owner:TATA CONSULTANCY SERVICES LTD

A Sterilisation Device for Sterilising a Section of a Catheter Tube and a Method for Sterilising a Section of a Catheter Tube

PendingUS20220152243A1Improve sterilization effectEnsure Lighting SafetyCatheterRadiationBiomedical engineeringGeneral surgery

A sterilisation device for sterilising a section of a catheter tube includes a casing including a proximal end, a distal end, an attachment portion, a sterilisation chamber, and a through hole extending through the attachment portion and the sterilisation chamber, the through hole having a distal opening positioned at the distal end of the casing and leading into the sterilisation chamber, the attachment portion being configured to retain a section of a catheter tube in the through hole; and at least one light source configured to emit germicidal light into the sterilisation chamber of the casing. A diameter of the distal opening of the through hole is greater than a diameter of the through hole at the attachment portion, so that when the catheter tube is retained in the through hole, an air gap is formed between the sterilisation chamber at the distal opening and the catheter tube.

Owner:VIOBAC APS

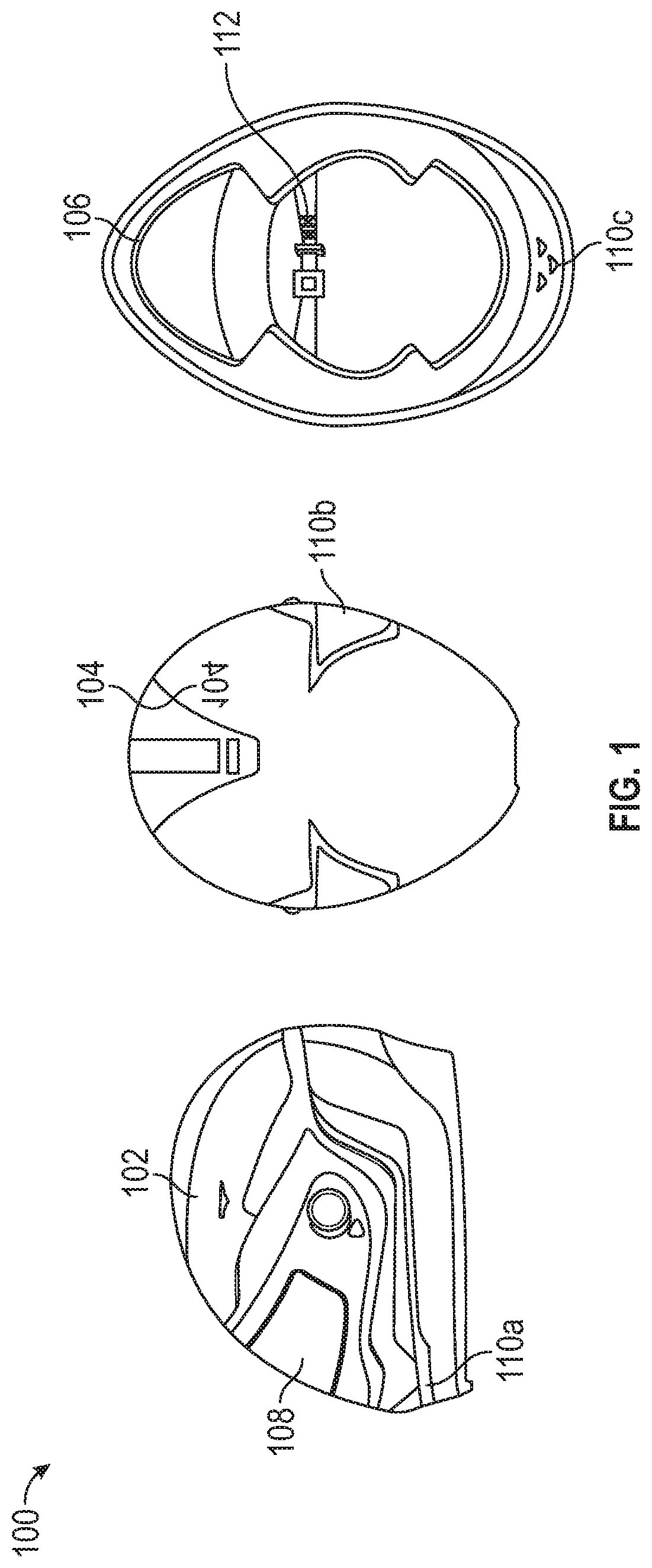

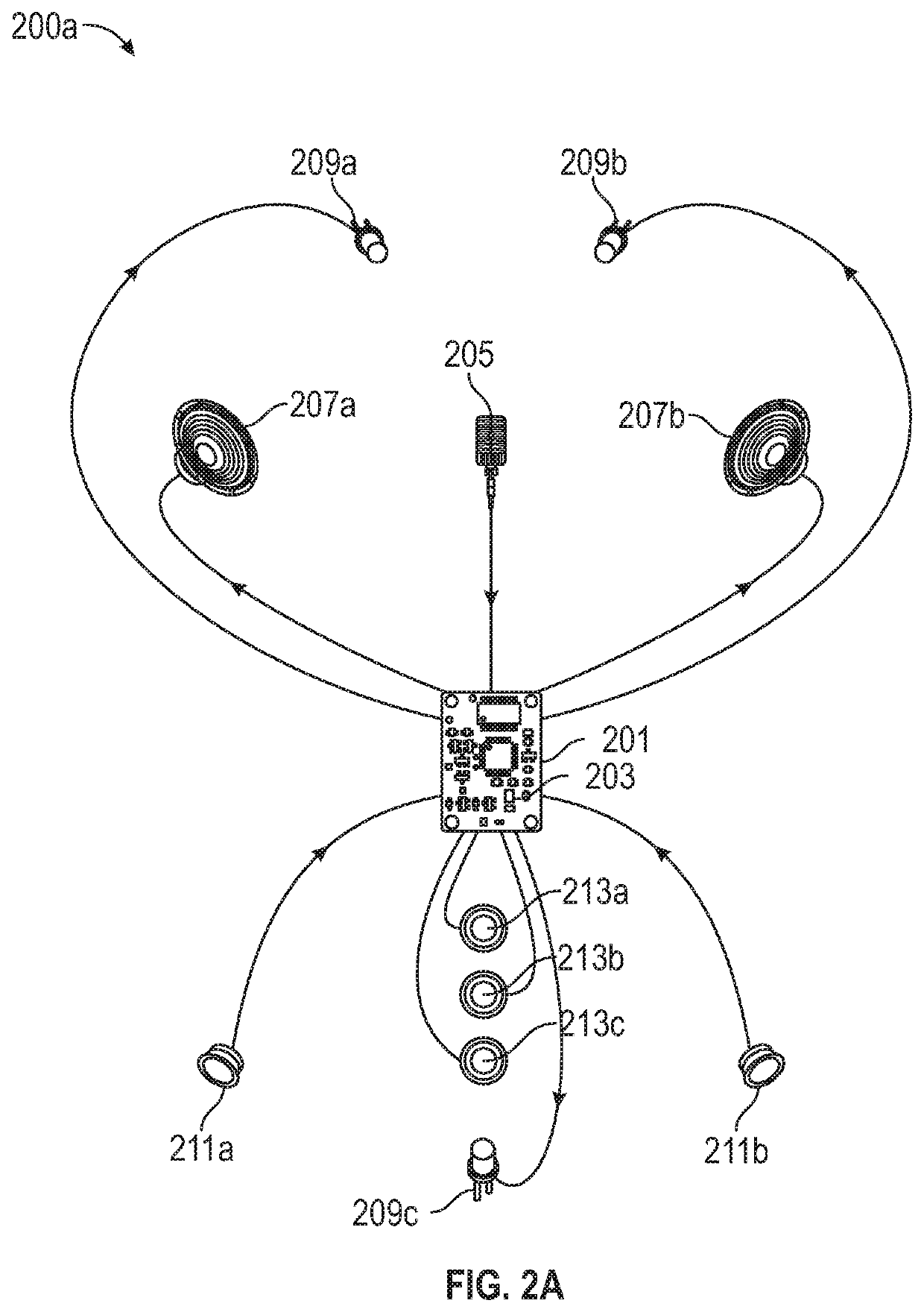

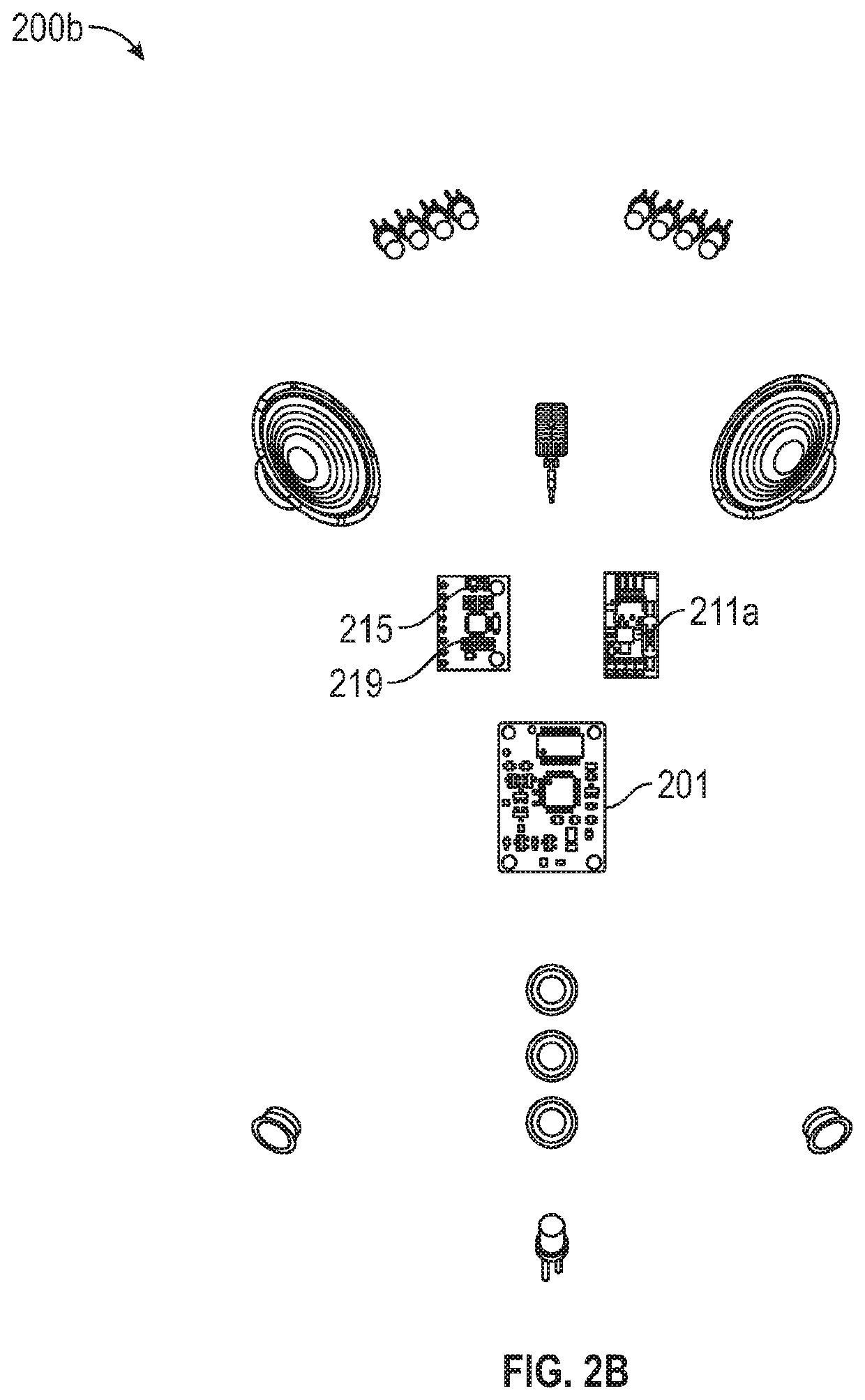

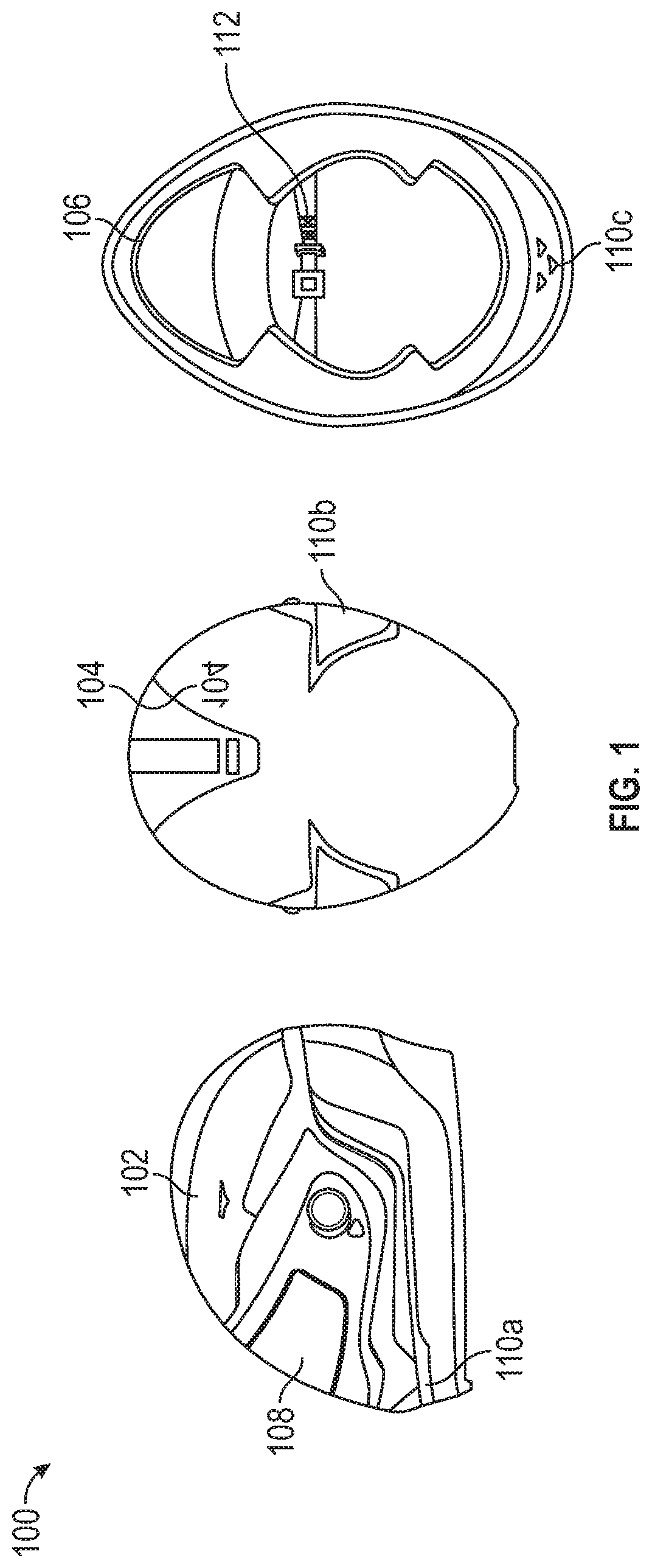

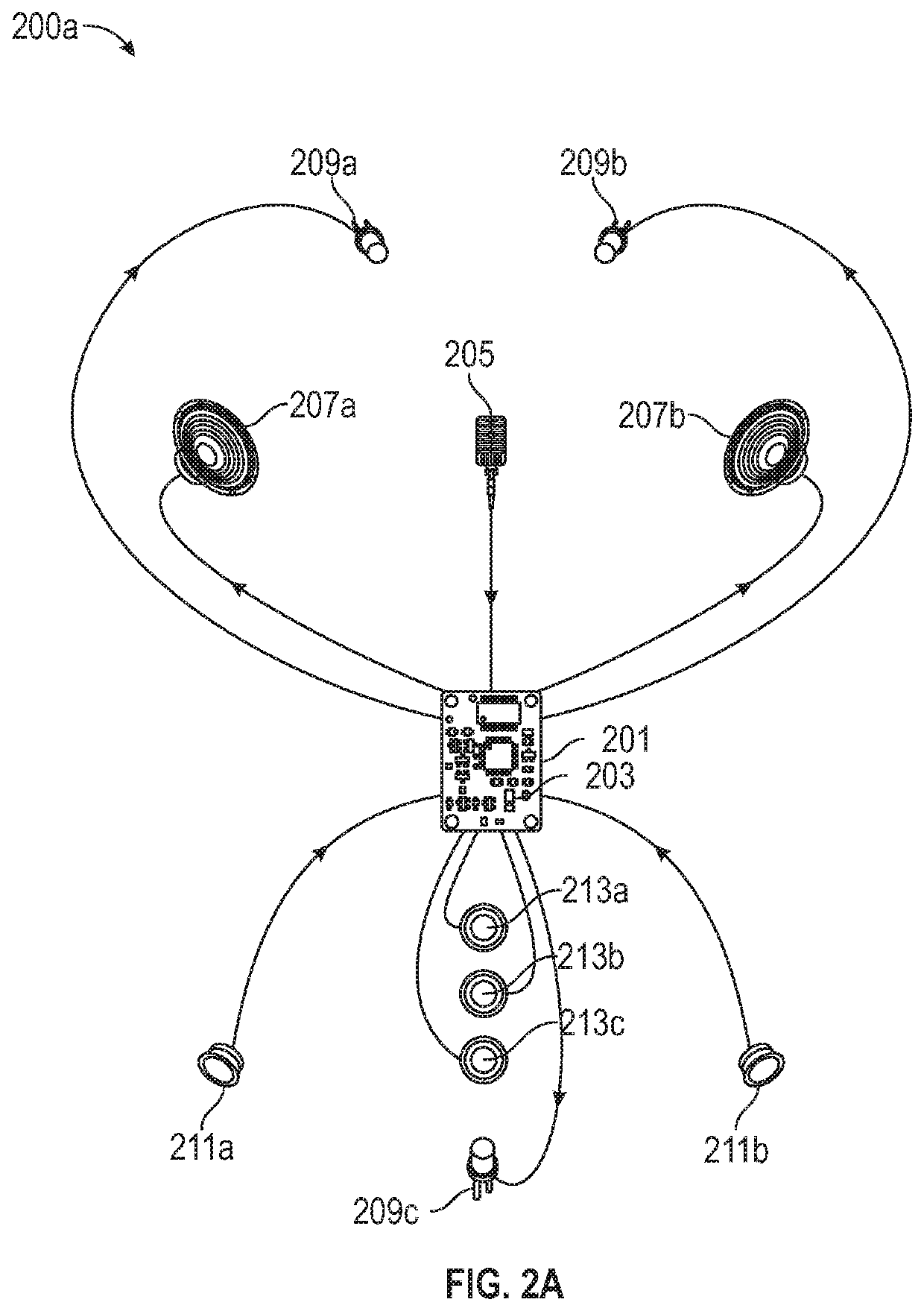

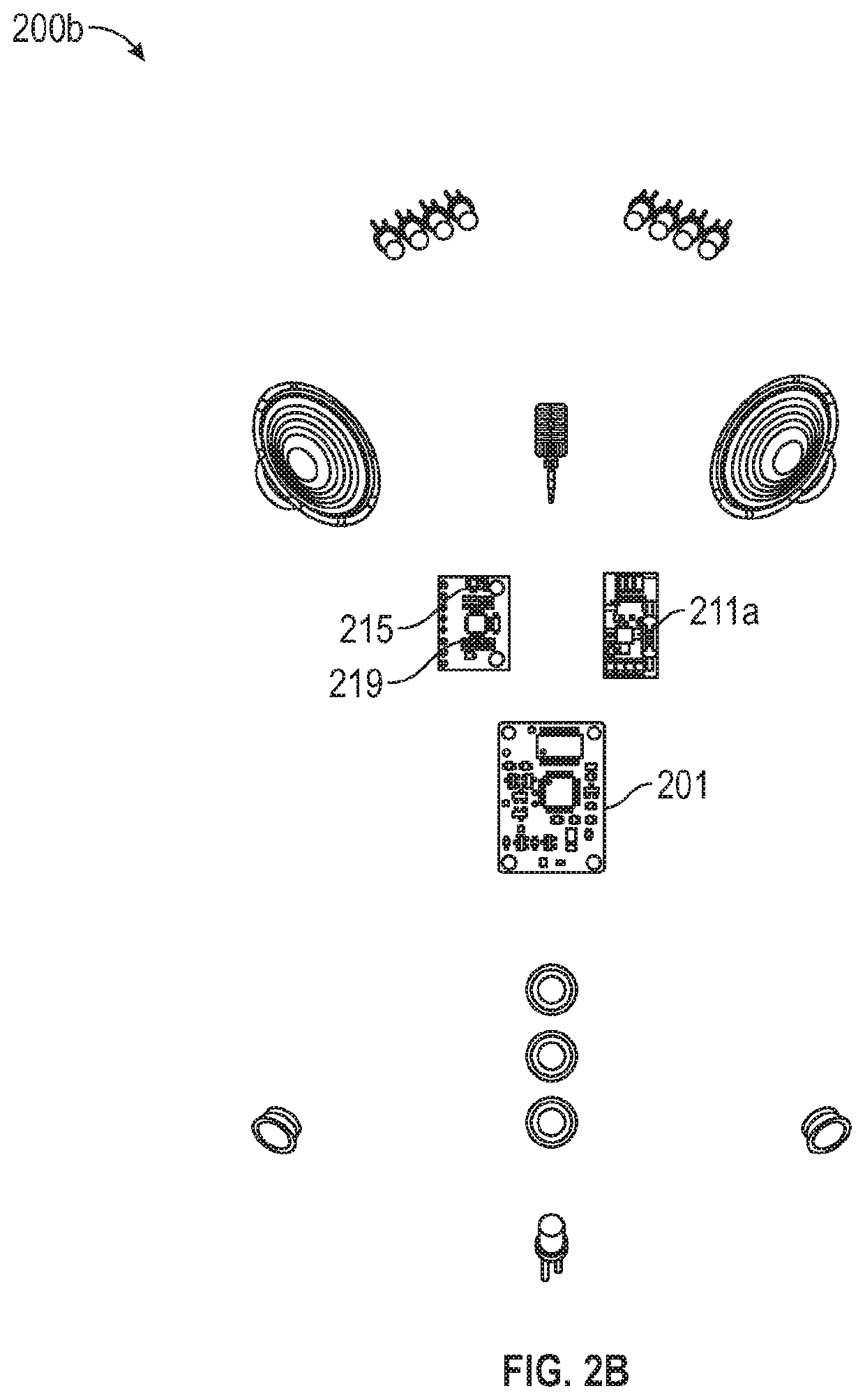

Integrated smart helmet and methods and systems of controlling smart helmet

ActiveUS20220047028A1Easy to prepareReduce needCycle control systemsConnection managementComputer hardwareControl cell

Exemplary embodiments of the present disclosure are directed towards an integrated smart helmet system, comprising: a control unit-PCB 201 is wirelessly connected to a computing device 303 over network 305, computing device 303 is configured to enable a user to use different functionalities without having to remove helmet 102 and access the computing device 303 and the control unit-PCB 201 is configured to detect crashes while wearing the helmet 102 by the user and notify crash detected information to computing device 303 over network 305, buttons 213a-213d are positioned at the rear or side of helmet 102 and control unit-PCB 201 is electrically coupled to buttons 213a-213d, buttons 213a-213d are configured to initiate prompts to direct the user to put away the computing device 303 while driving and disable certain dangerous functions.

Owner:QUINTESSENTIAL DESIGN INC

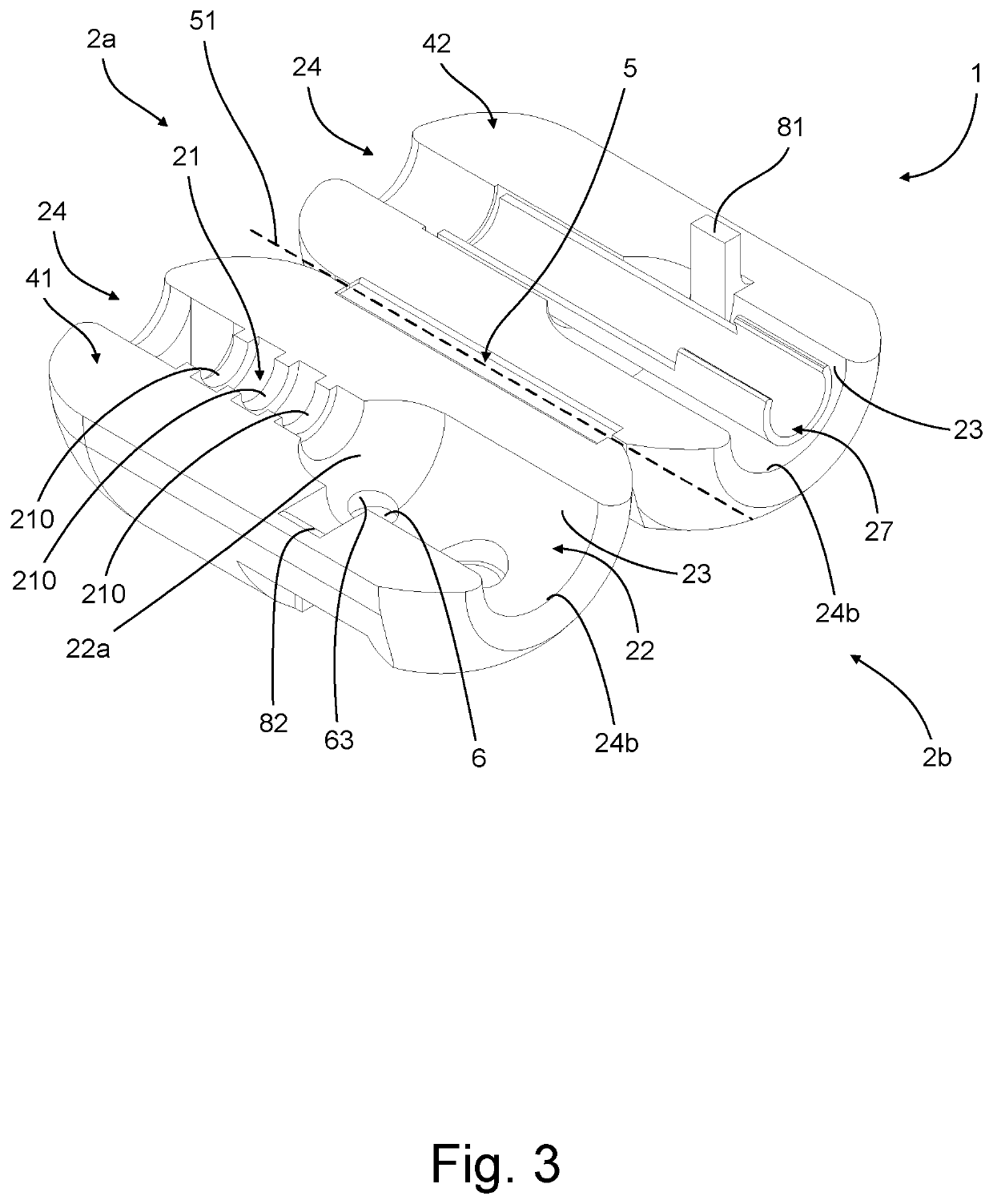

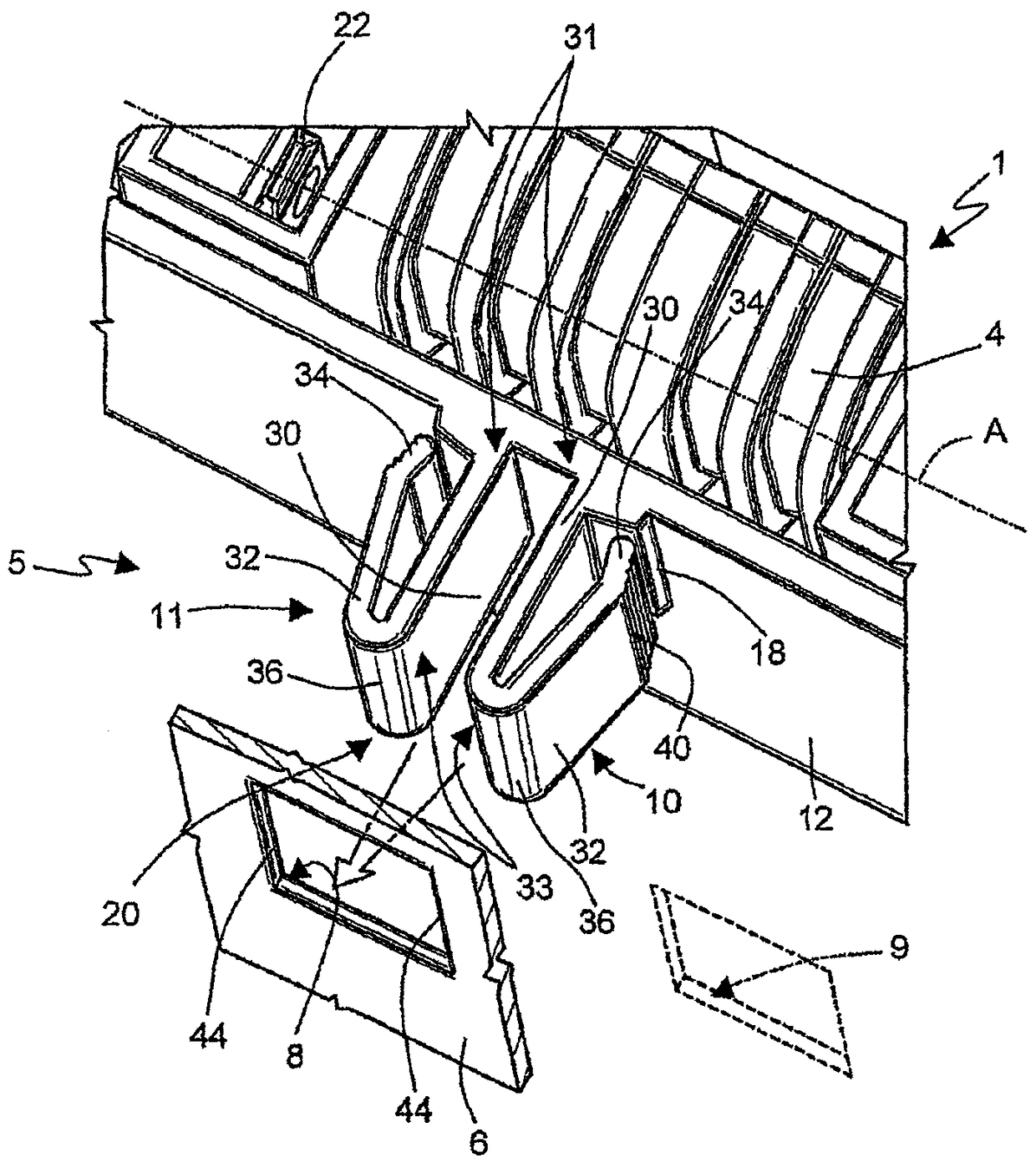

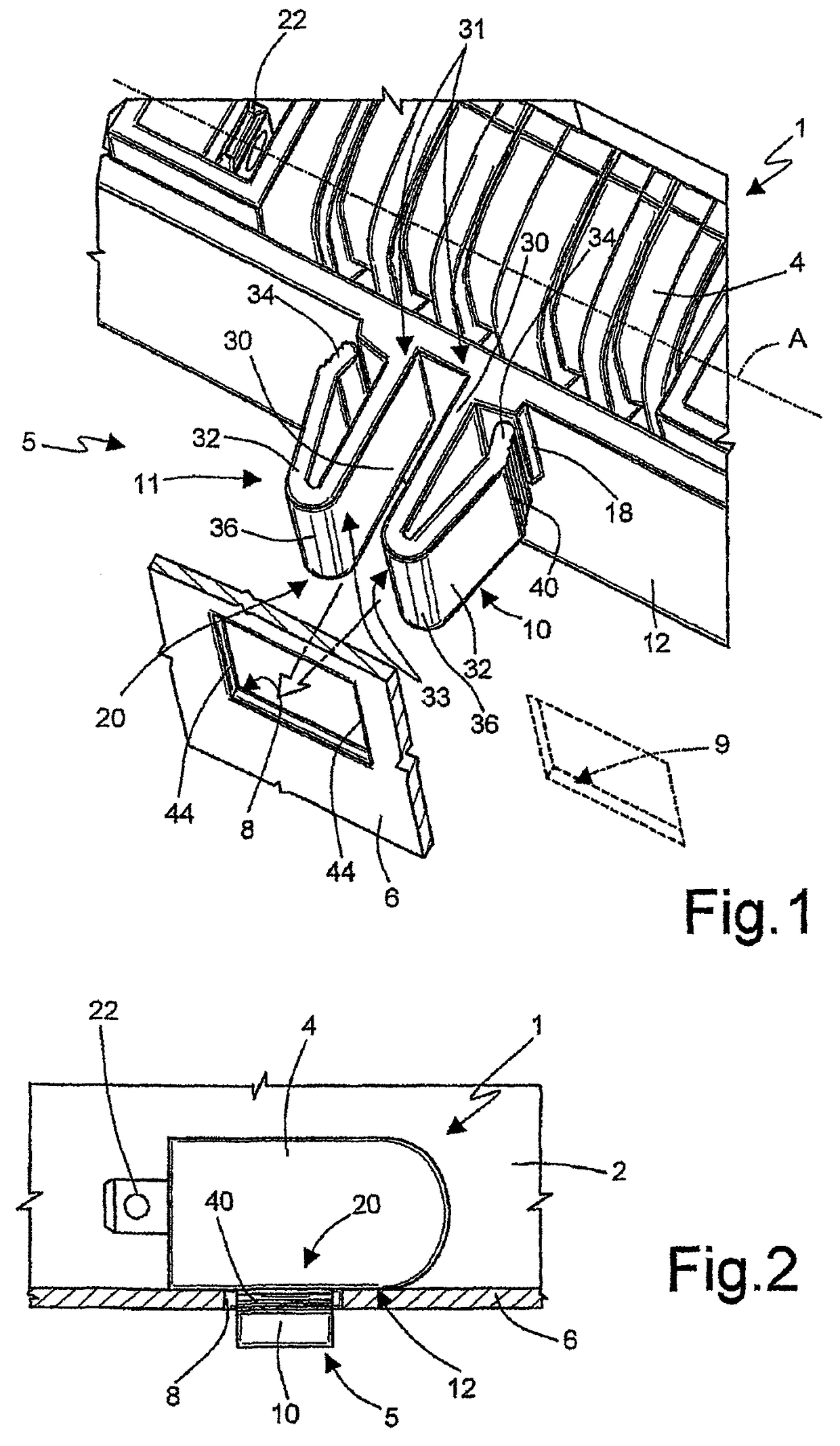

Gas lighting device having simplified fastening means to an electric household appliance, in particular a cooking range

ActiveUS9915430B2Improve reliabilitySimplified fastening meansDomestic stoves or rangesIncandescent ignitionGas lightingEngineering

Owner:ITW IND COMPONENTS SRL

Device, method and use for transfer of equipment for a wireline operation in a well

ActiveUS8622143B2Reduce disadvantagesSimple and flexible and compact and cheapDrilling rodsFluid removalTop driveRemote control

Device for transfer of equipment for a wireline operation in a well connected to a drilling derrick via a top drive. The device comprises a beam structured for releasable connection to said top drive; wherein the beam is structured in a manner allowing it to extend, when in its position of use, transversely relative to a center line between the top drive and the well; wherein the beam is provided with at least one hoisting device with a lifting line for vertical movement of said equipment; wherein a support point for the lifting line is connected to the beam and is structured so as to be movable in the longitudinal direction of the beam, whereby said equipment may be moved horizontally relative to said center line; and wherein said hoisting device and support point are structured for remote-controlled operation.

Owner:QUALITY INTERVENTION

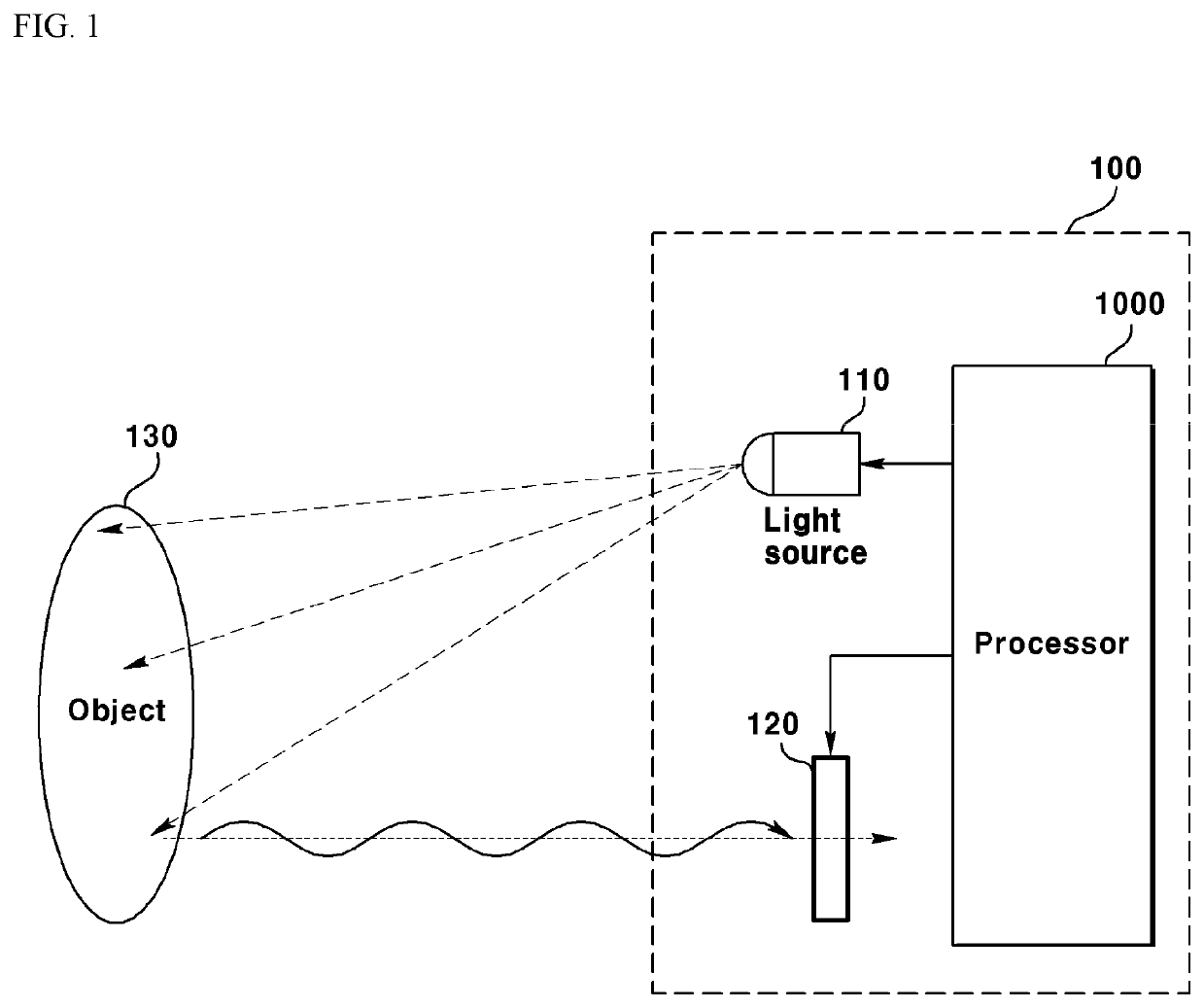

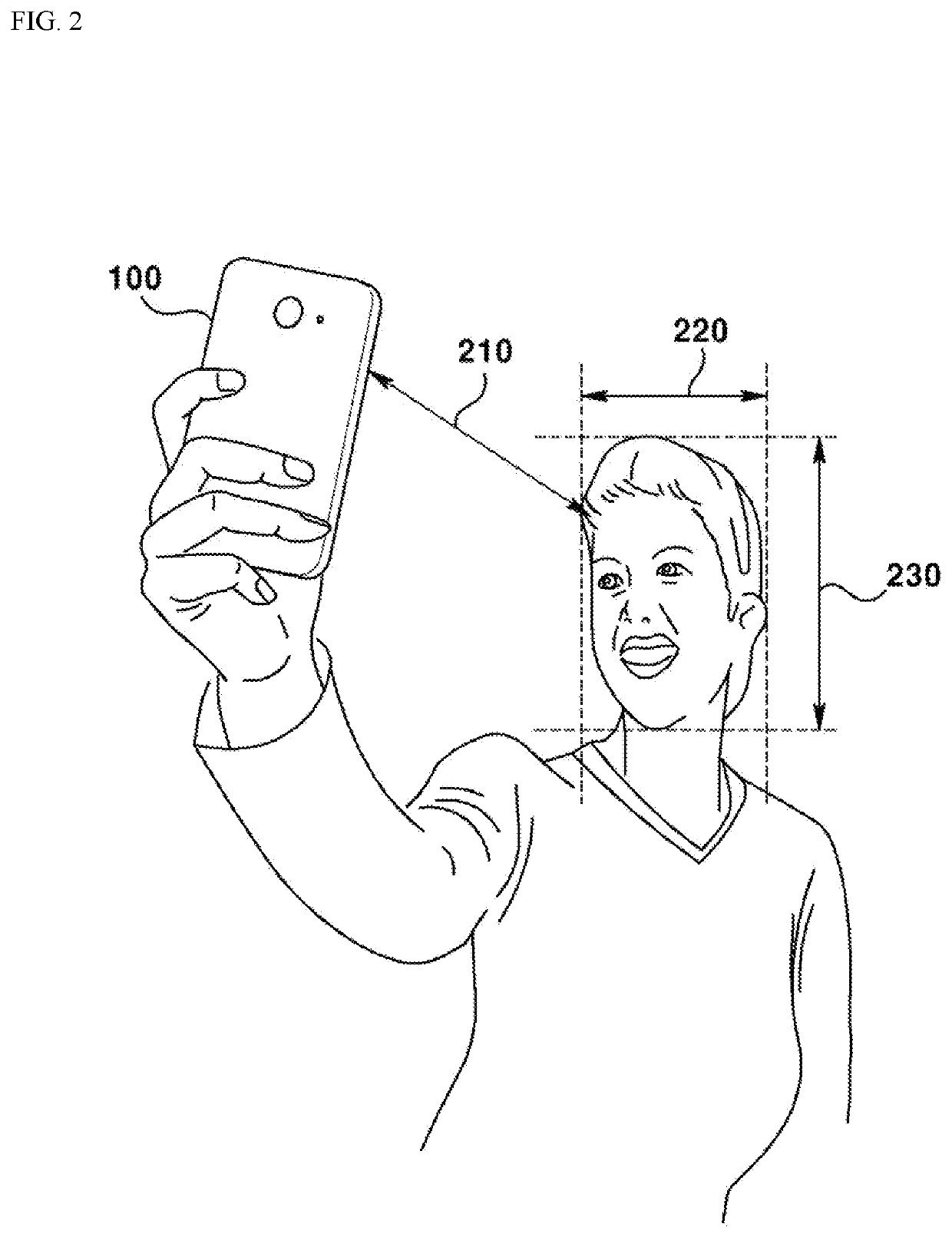

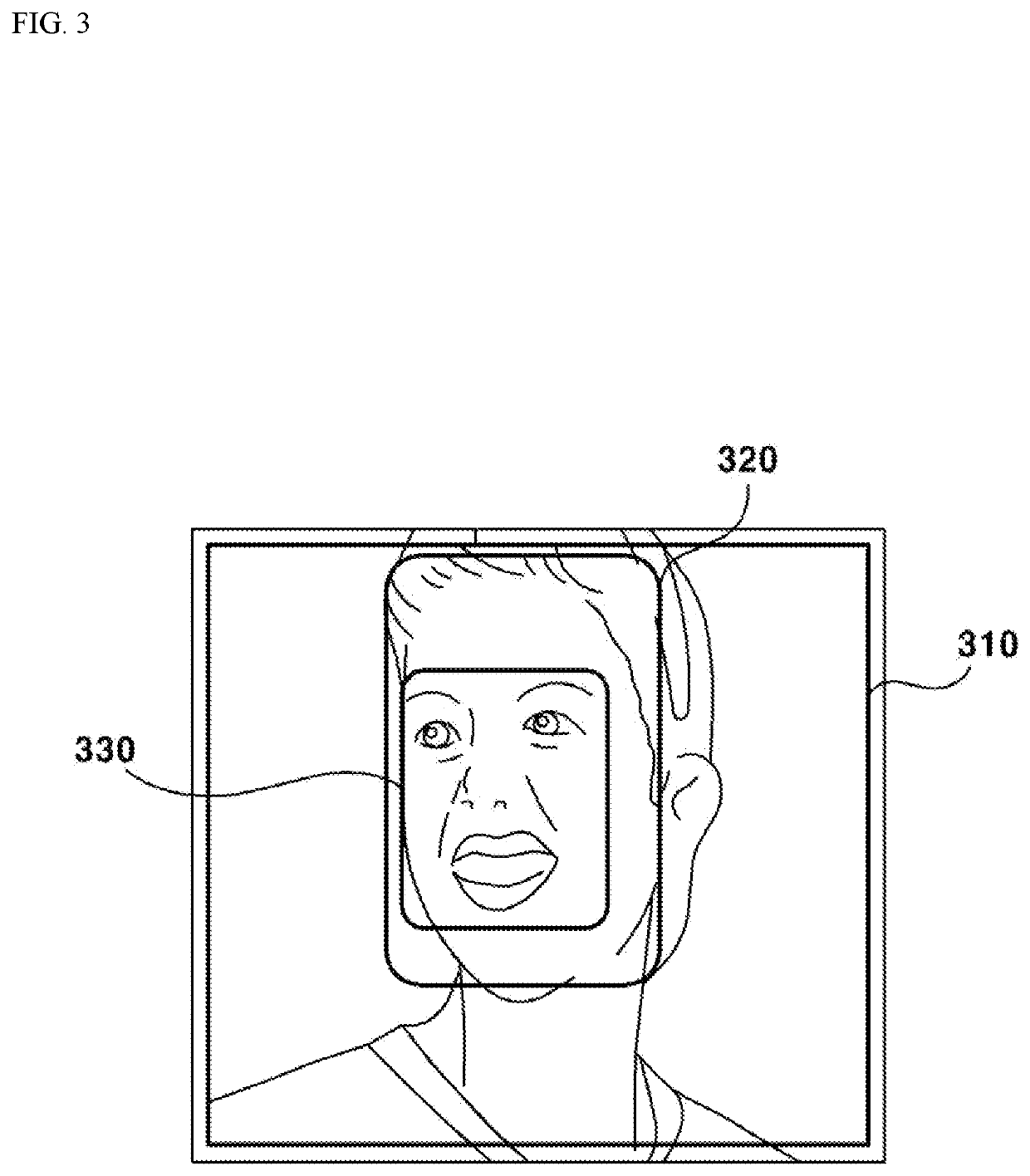

Method and device for outputting light

PendingUS20210263136A1Safely outputting lightEnsure Lighting SafetyLaser output parameters controlCharacter and pattern recognitionEngineeringMaterials science

Owner:LG INNOTEK CO LTD

Photosensitive lithographic printing plate

ActiveUS7695888B2High definitionEnsure Lighting SafetyPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundDouble bond

A photosensitive lithographic printing plate comprising a hydrophilic support and a photopolymerizable photosensitive layer containing: (i) a sensitizing dye having an absorption maximum in a wavelength range of from 360 to 450 nm; (ii) a hexaarylbisimidazole compound; (iii) an addition polymerizable compound having an ethylenically unsaturated double bond; (iv) a binder polymer; and (v) a mercapto compound represented by the following formula (1) as defined herein.

Owner:FUJIFILM HLDG CORP +1

LED module sealing technology

ActiveUS10243341B2No damage to products itselfImprove sealingRelieving strain on wire connectionCouplings bases/casesWater vaporEngineering

Owner:HANGZHOU HPWINNER OPTO CORP

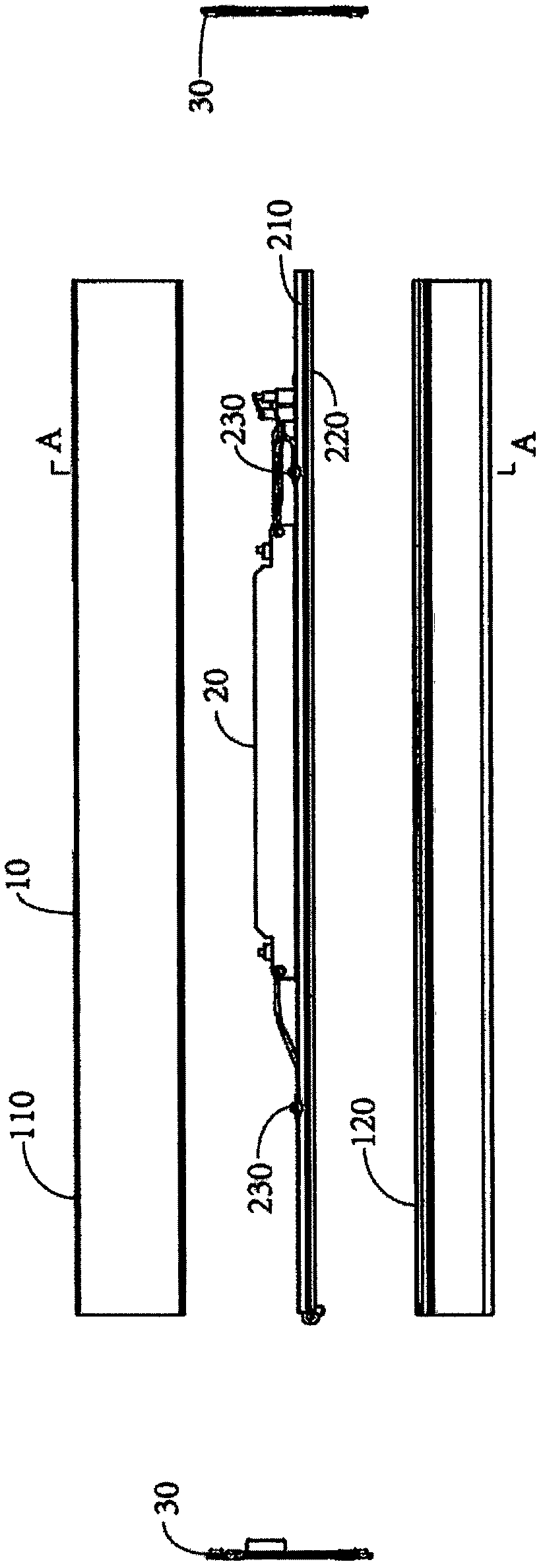

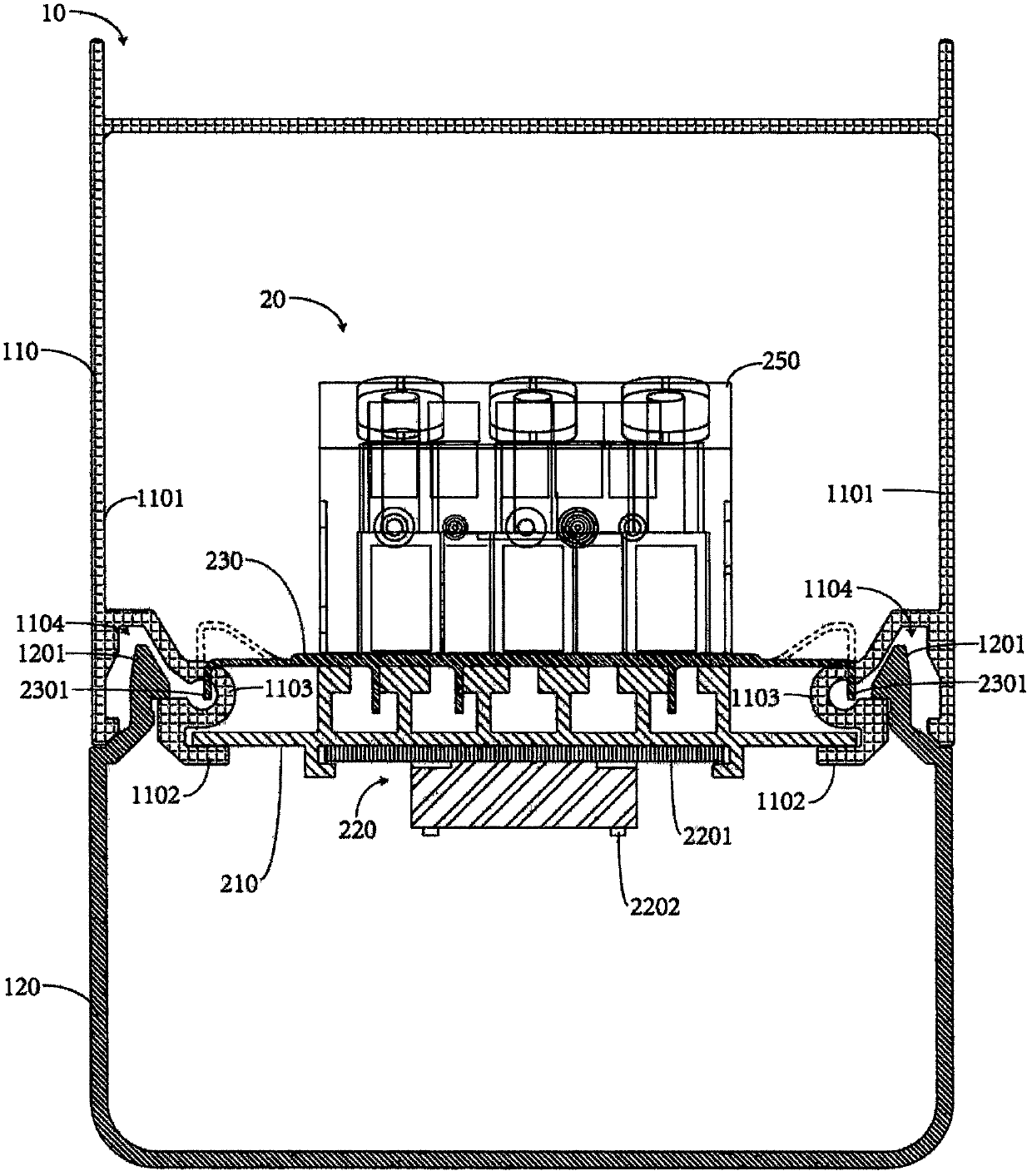

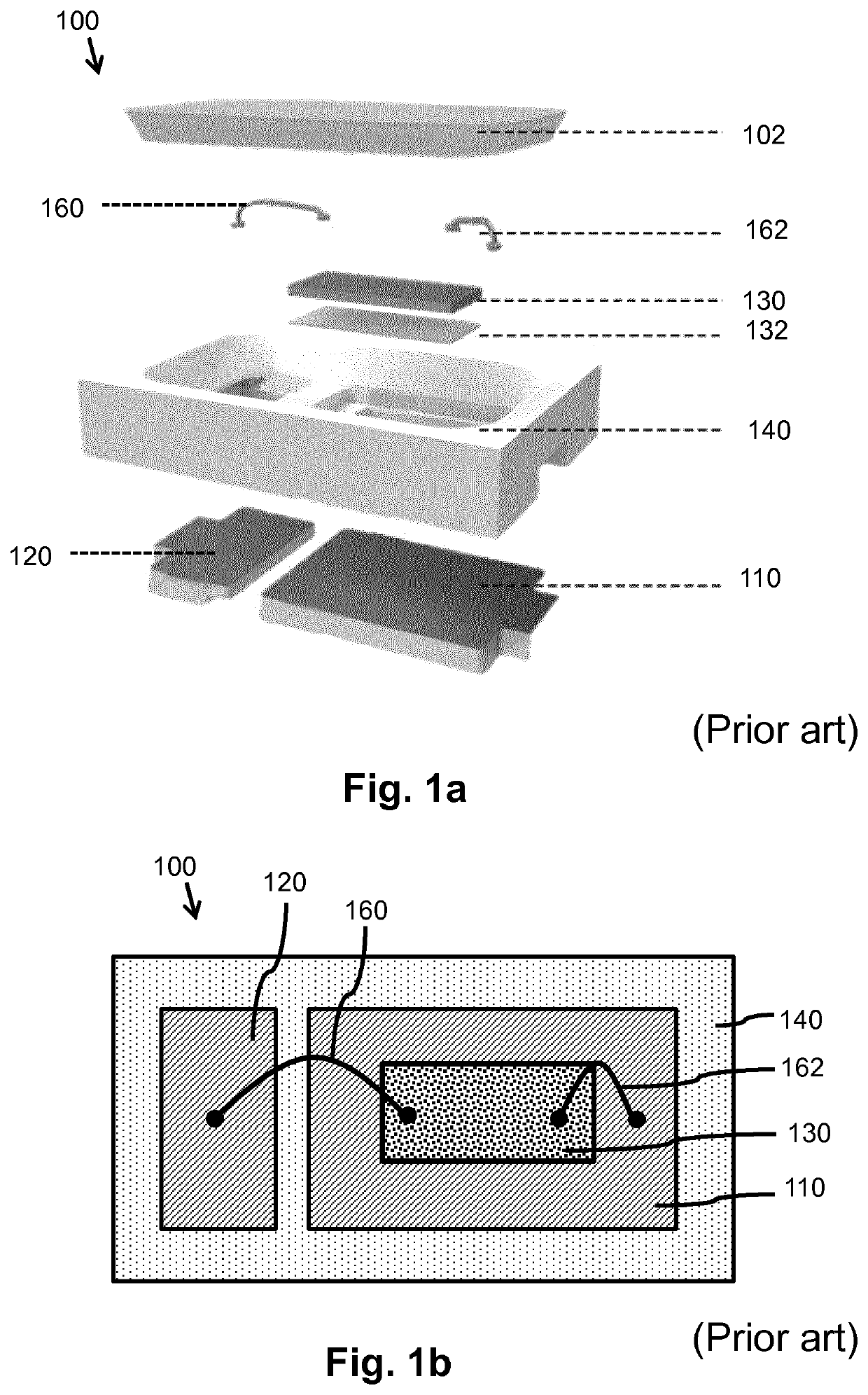

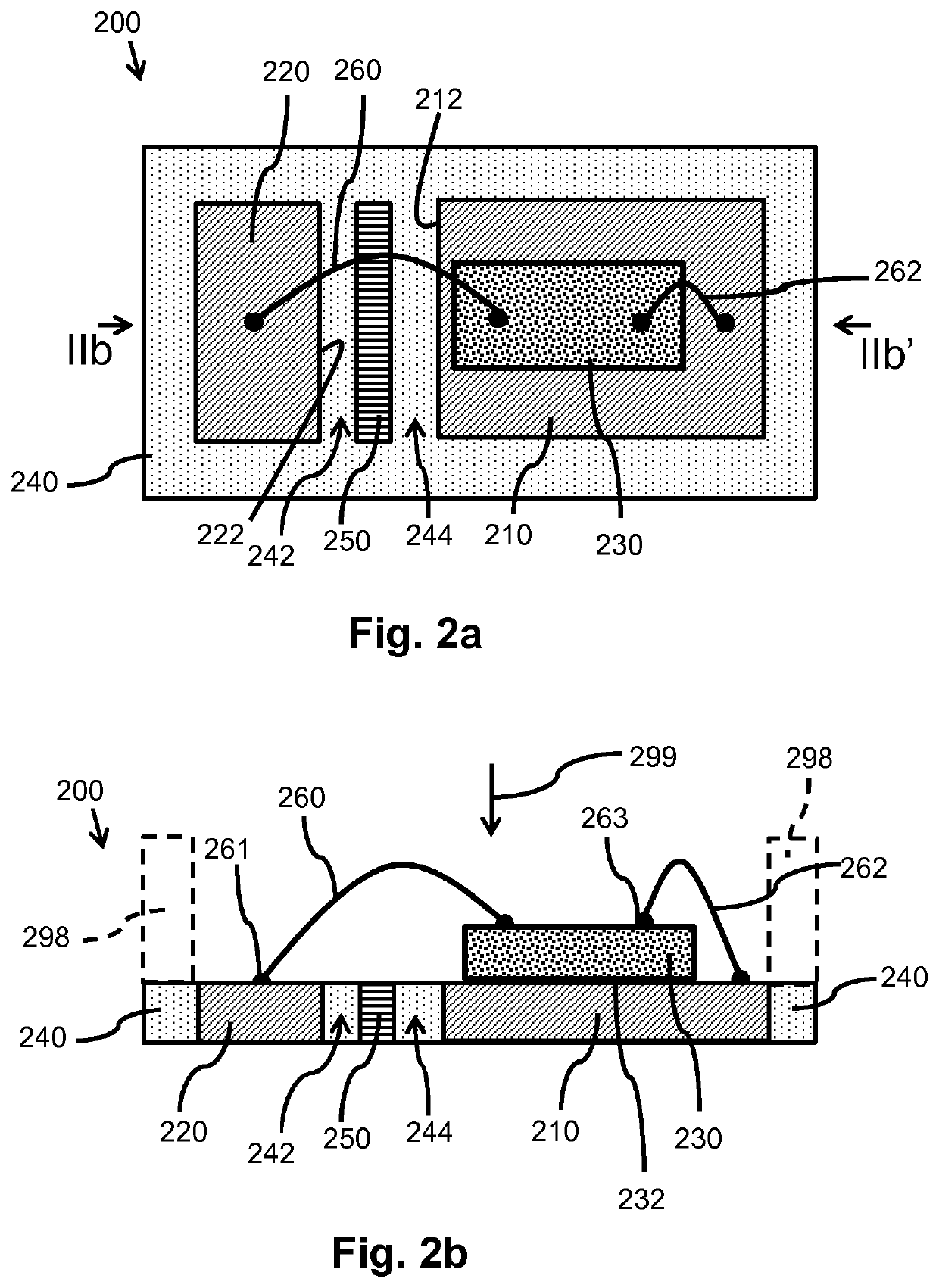

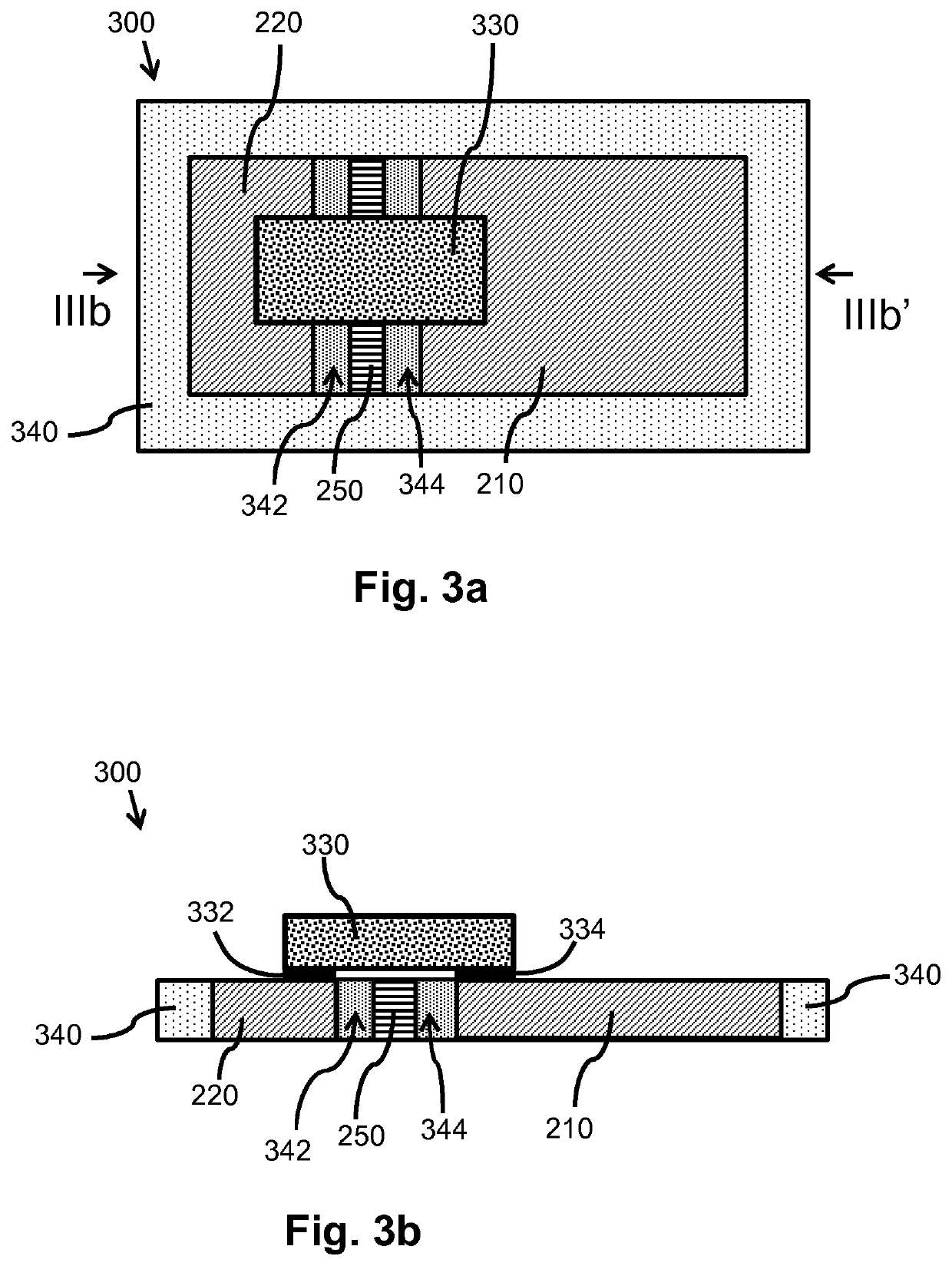

Solid state light emitter package, a lamp, a luminaire and a method of manufacturing a solid state light emitter package

ActiveUS20200035893A1Increase the differential pressureIncrease distanceSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

A solid state light emitter package (200), a lamp, a luminaire and a method of manufacturing the solid state light emitter package are provided. The solid state light emitter package comprising a solid state light emitter die (230), a first and second lead frame (210, 220), an electrical insulating material (242, 244), a thermal element (250) and a bridging element (260). The first and second lead frame are electrically isolated from each other and provide power to said die. Said die is at least partially provided on the first lead frame. The thermal element is in between the first and second lead frame and is electrically isolated by the electrical insulating material from said lead frames. The thermal element is at least one of a heat absorber or a heat spreader. The bridging element bridges the electrical insulating material and the thermal element and provides an electrical connection between said die and the second lead frame.

Owner:SIGNIFY HLDG BV

Lighting apparatus with lens having safety light-dispersing structures

ActiveUS10151431B2Improve securityLarge structureLighting applicationsMechanical apparatusDistribution controlLight equipment

A lighting apparatus having laser light as a light source is provided. The lighting apparatus includes: a light-emitter which radiates light of a wavelength different from a wavelength of the laser light; and a lens including a light distribution controlling structure that controls distribution of the light radiated from the light-emitter. The lens is disposed opposite a laser light entry side of the lighting apparatus. The light-emitter is disposed between the lens and the laser light entry side. The lens integrally includes, along an optical axis of the laser light, a light-dispersing structure configured to disperse the laser light.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Integrated smart helmet and methods and systems of controlling smart helmet

ActiveUS11406152B2Reduce needEnsure Lighting SafetyCycle control systemsConnection managementComputer hardwareControl cell

Owner:QUINTESSENTIAL DESIGN INC

Displacement measuring instrument and displacement measuring method

ActiveUS8081315B2Accurate displacementEasy to calculateInterferometersUsing optical meansBeam splitterMeasuring instrument

A laser interferometric measuring instrument includes: a light source that emits a laser beam of 1064 nm and another laser beam of 532 nm; a polarizing beam splitter; a dichroic mirror that splits a long-wavelength laser beam provided in a measurement optical path; a long-wavelength corner cube that reflects the split laser beam; a measurement corner cube that is displaceable along the measurement optical path; a reference corner cube that is displaceable along a reference optical path; a optical path changing unit that changes an optical path length of the long-wavelength laser beam; a phase detector that outputs interference signals; a sum signal computer that calculates a sum signal; a displacement controller that displaces the reference corner cube so as not to change a phase of the sum signal; a reference displacement detector that detects a displacement of the reference corner cube; and a measurement displacement computer that calculates a displacement of the measurement corner cube.

Owner:MITUTOYO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com