Patents

Literature

42 results about "Nonlinear feature extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

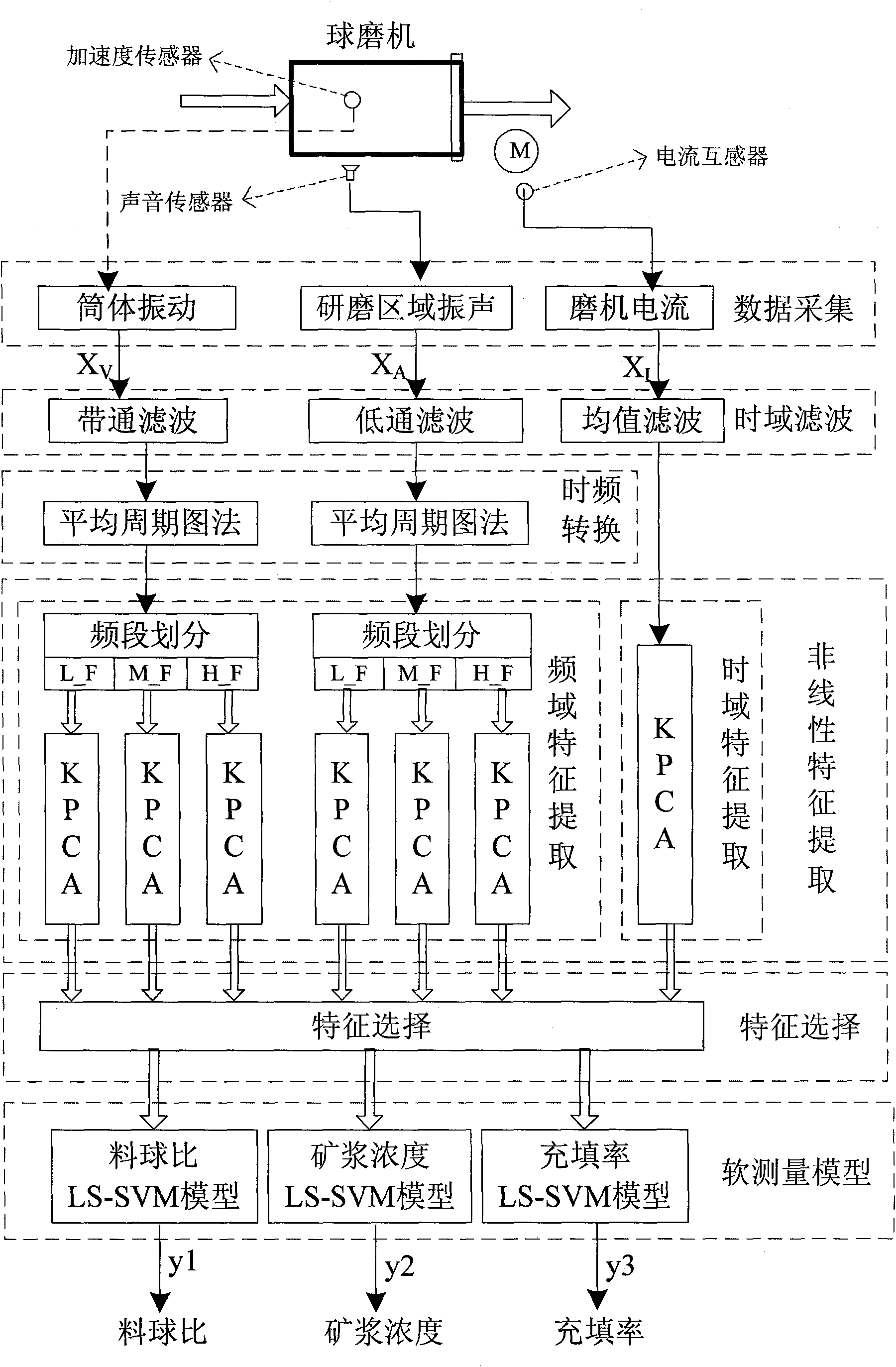

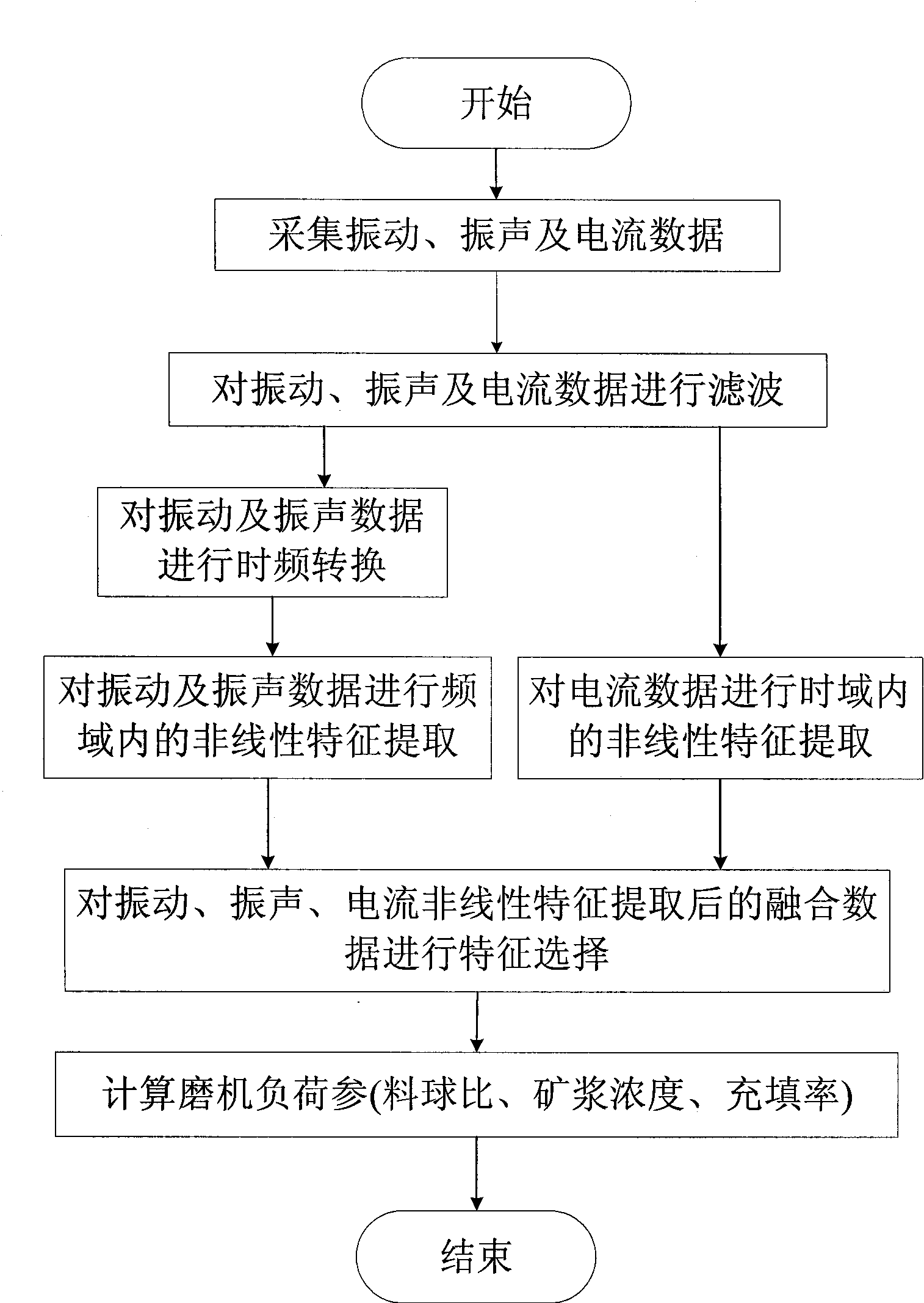

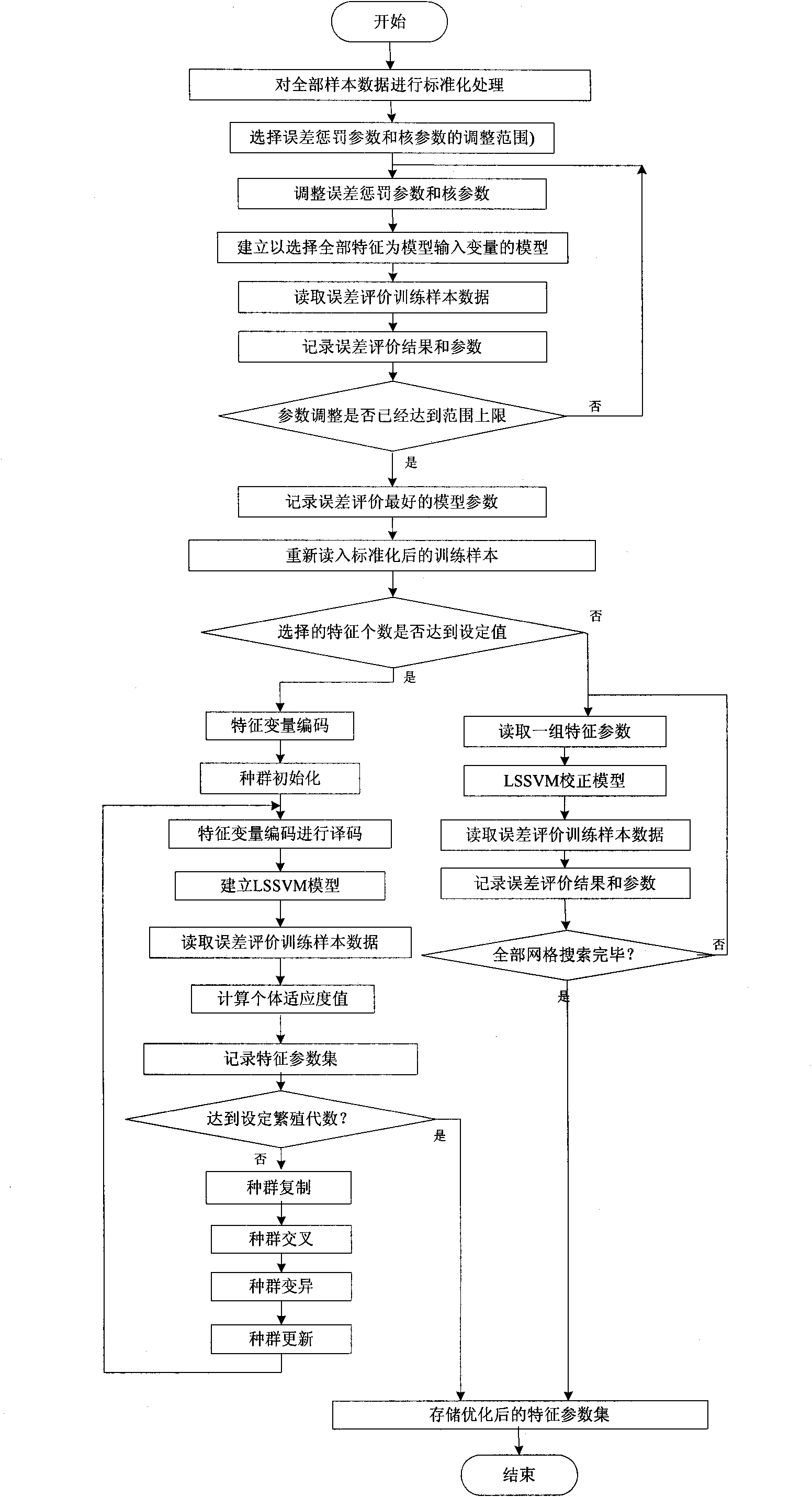

Soft sensing method for load parameter of ball mill

ActiveCN101776531AThe frequency band features are obviousObvious high frequency featuresSubsonic/sonic/ultrasonic wave measurementCurrent/voltage measurementLeast squares support vector machineEngineering

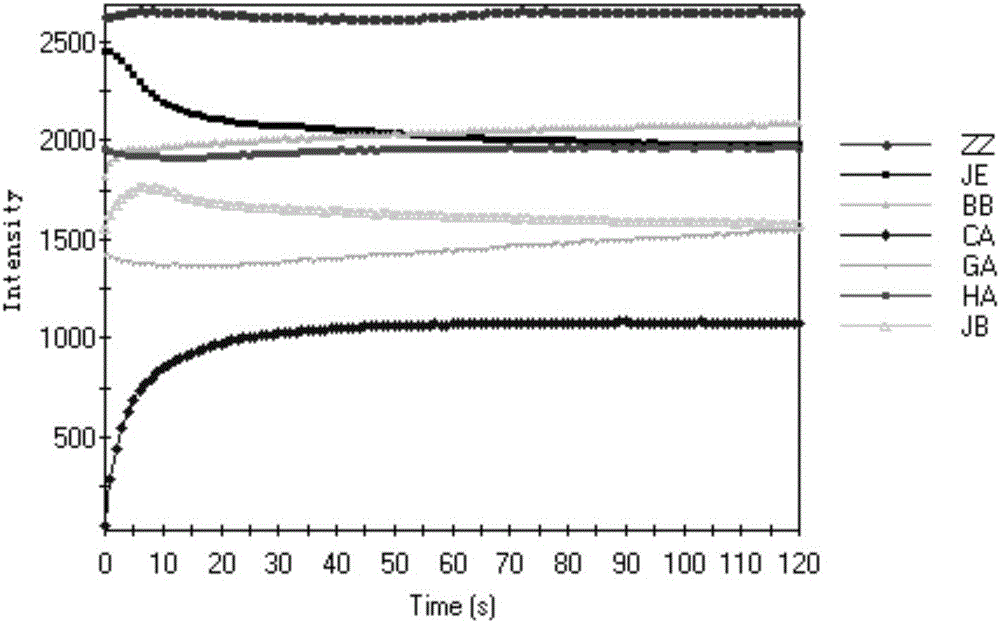

The invention relates to a soft sensing method for load parameters of a ball mill. The method is that a hardware supporting platform is used to obtain vibration signals, vibration sound signals and current signals of a ball mill cylinder to soft sense ball mill internal parameters (ratio of material to ball, pulp density and filling ratio) characterizing ball mill load. The method comprises the following steps that: the vibration, the vibration sound, the current data and the time-domain filtering of the ball mill cylinder are acquired, time frequency conversion is conducted to the vibration and the vibration sound data, kernel principal component analysis based nonlinear features of the sub band of the vibration and the vibration sound data in frequency domain are extracted, nonlinear features of the time domain current data are extracted, feature selection is conducted to the fused nonlinear feature data and a soft sensing model based on a least squares support vector machine is established. The soft sensing method of the invention has the advantages that the sensitivity is high, the sensed results are accurate, the practical value and the popularization prospect are very good, and the realization of the stability control, the optimization control, the energy saving and the consumption reduction of the grinding production process is facilitated.

Owner:NORTHEASTERN UNIV

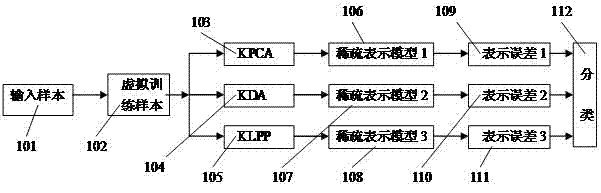

Multiple-sparse-representation face recognition method for solving small sample size problem

InactiveCN104268593AImprove robustnessImprove classification effectCharacter and pattern recognitionKernel principal component analysisSmall sample

Provided is a multiple-sparse-representation face recognition method for solving the small sample size problem. In the method, two modes are adopted to solve the small sample size problem during face recognition, one mode is that given original training samples produce 'virtual samples' so as to increase the number of the training samples, and the other mode is that three nonlinear feature extraction methods, namely a kernel principle component analysis method, a kernel discriminant analysis method and a kernel locality preserving projection algorithm method are adopted to extract features of the samples on the basis that the virtual samples are produced. Therefore, three feature modes are obtained, sparse-representation models are established for each feature mode. Three sparse-representation models are established for each sample, and finally classification is performed according to representation results. By means of the multiple-sparse-representation face recognition method, virtual faces are produced through mirror symmetry, and then norm L1 based multiple-sparse-representation models are established and classified. Compared with other classification methods, the multiple-sparse-representation face recognition method is good in robustness and classification effect and is especially suitable for a lot of classification occasions with high data dimensionality and few training samples.

Owner:EAST CHINA JIAOTONG UNIVERSITY

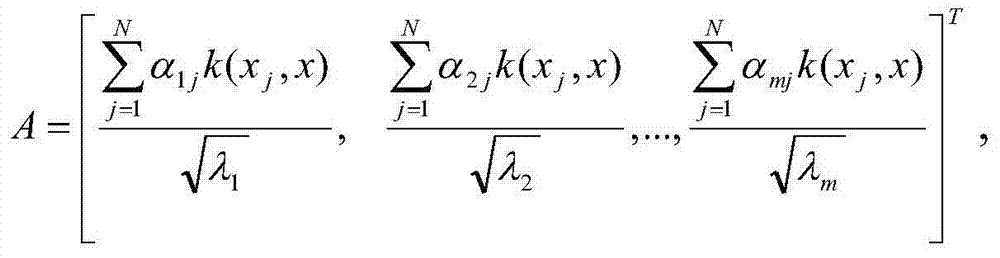

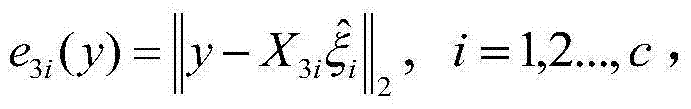

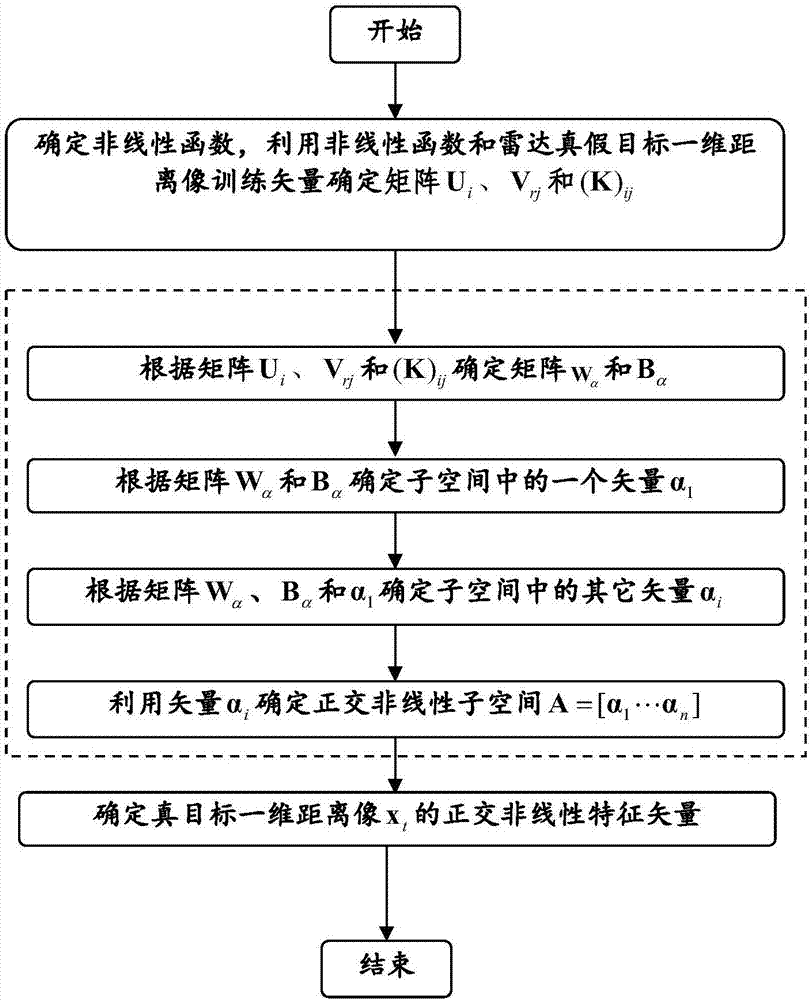

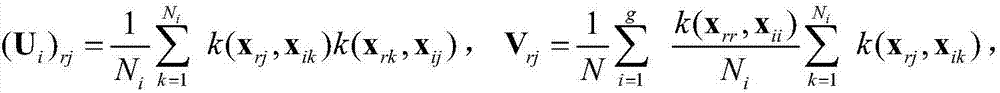

True and false target one dimensional range image quadrature non-linear subspace feature extraction method

ActiveCN107238822ASettle the lossEasy to identifyRadio wave reradiation/reflectionRadarCharacteristic space

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Network invasion abnormity detection method

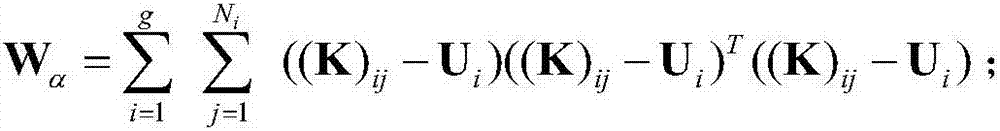

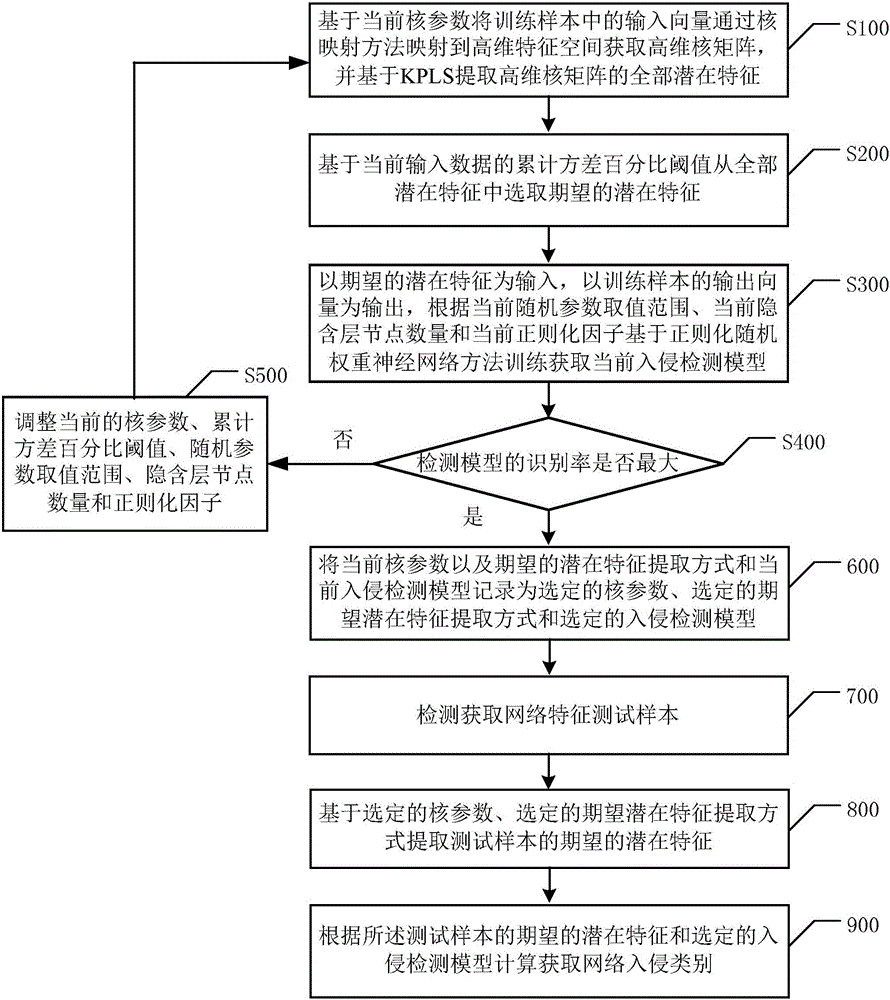

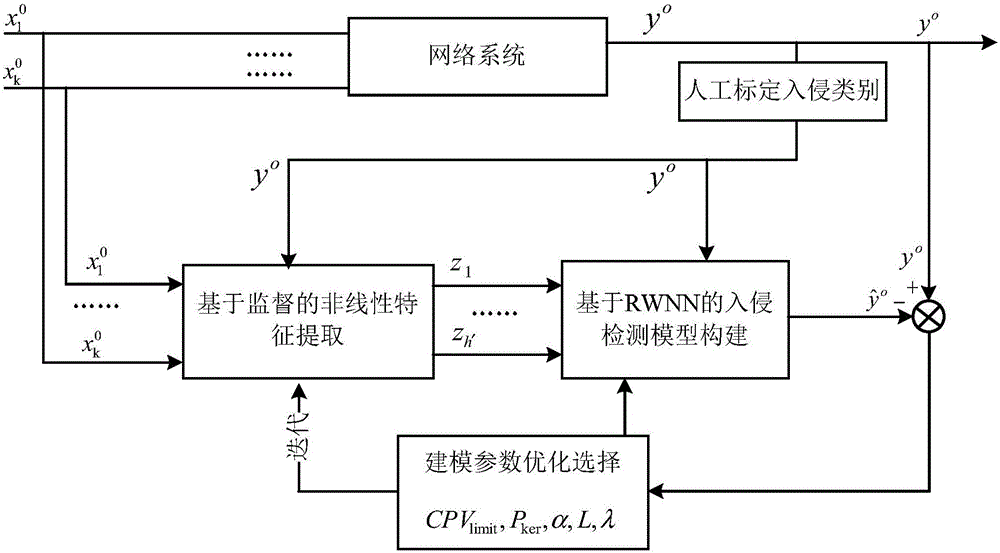

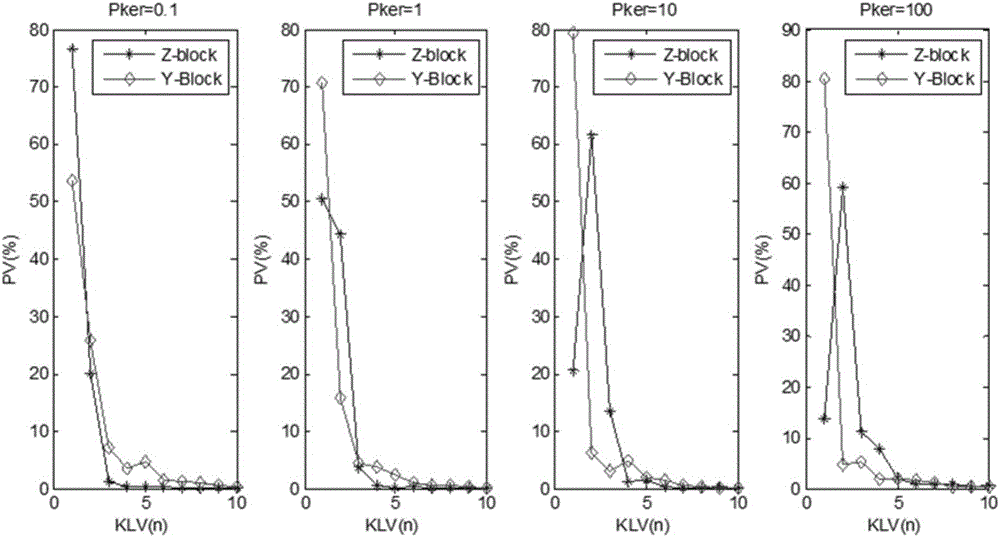

For an invasion detection model construction problem, the present invention provides a new network invasion abnormity detection method of supervising the non-linear feature extraction and a regularization random weight neural network (RRWNN). A kernel partial least square (KPLS) algorithm is used to process the colinearity of the input features and the complicated nonlinear mapping. The extracted potential features are inputted to an RRWNN algorithm to construct an invasion detection model possessing a higher learning speed and a better generalization performance. A global optimization strategy is adopted to select the modeling parameters of a KPLS-RRWNN-based invasion detection model, and the simulation based on the KDD99 data indicates the validity of the method.

Owner:中国人民解放军61599部队计算所 +1

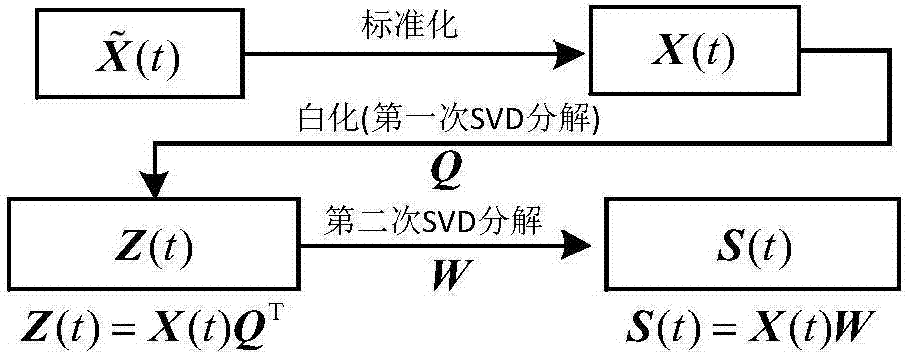

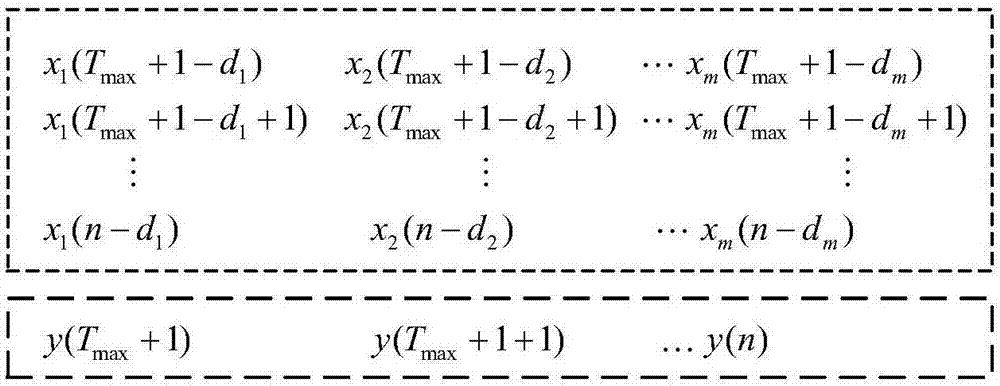

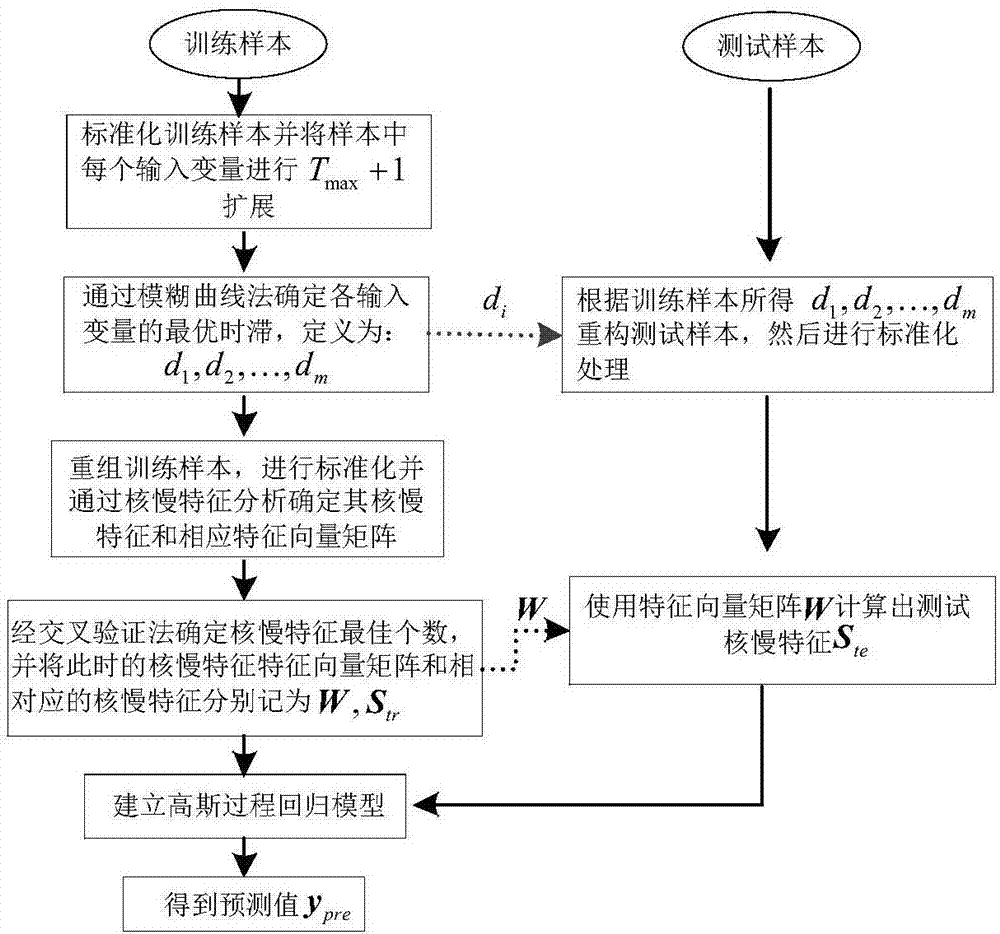

GPR modeling based on kernel slow feature analysis and time delay estimation

ActiveCN107423503ARealize online estimationIncrease productionDesign optimisation/simulationSpecial data processing applicationsAlgorithmAnalysis method

The present invention discloses a GPR modeling method based on kernel slow feature analysis and time delay estimation, which is applied to chemical processes with time delay and non-linearity. The method is characterized in that: by using fuzzy curve analysis, the delay information in industrial data is fully tapped to obtain the optimal delay in the data, and the reconstruction of the modeling data is carried out; the kernel slow feature analysis method is further used to carry out nonlinear feature extraction on the reconstructed data; and finally, based on the extracted features, a Gaussian process regression model is established to realize accurate prediction of the key variables, so as to improve product quality and reduce production costs.

Owner:JIANGNAN UNIV

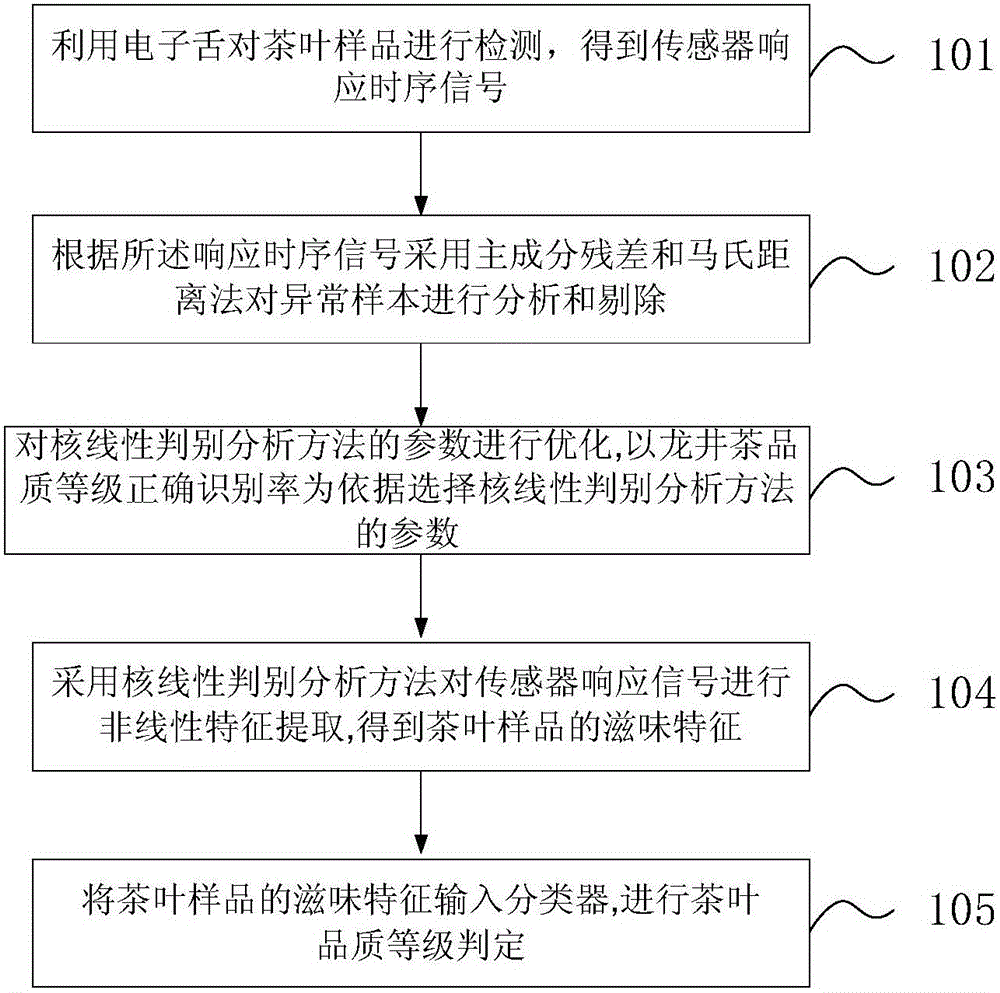

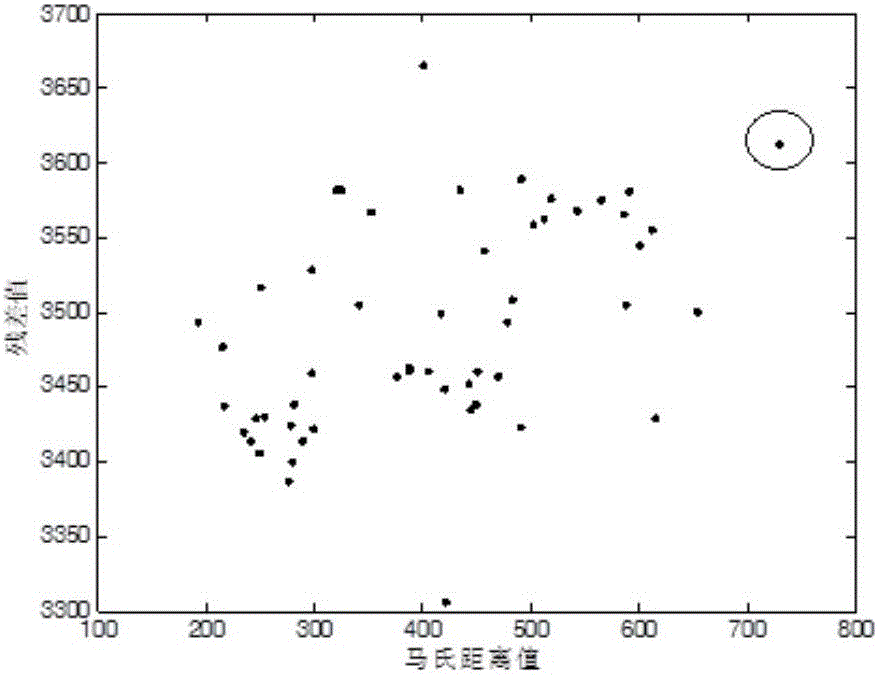

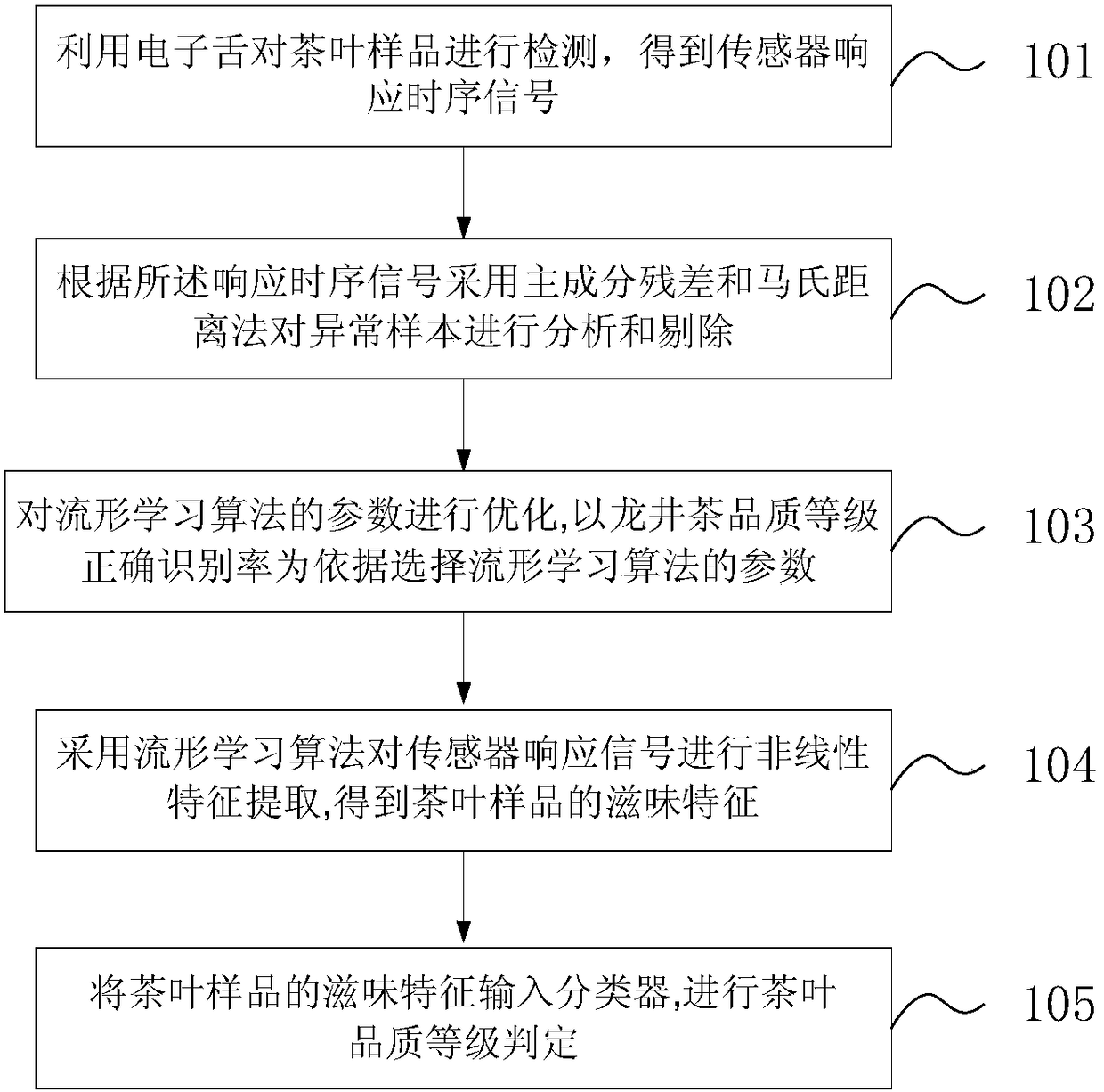

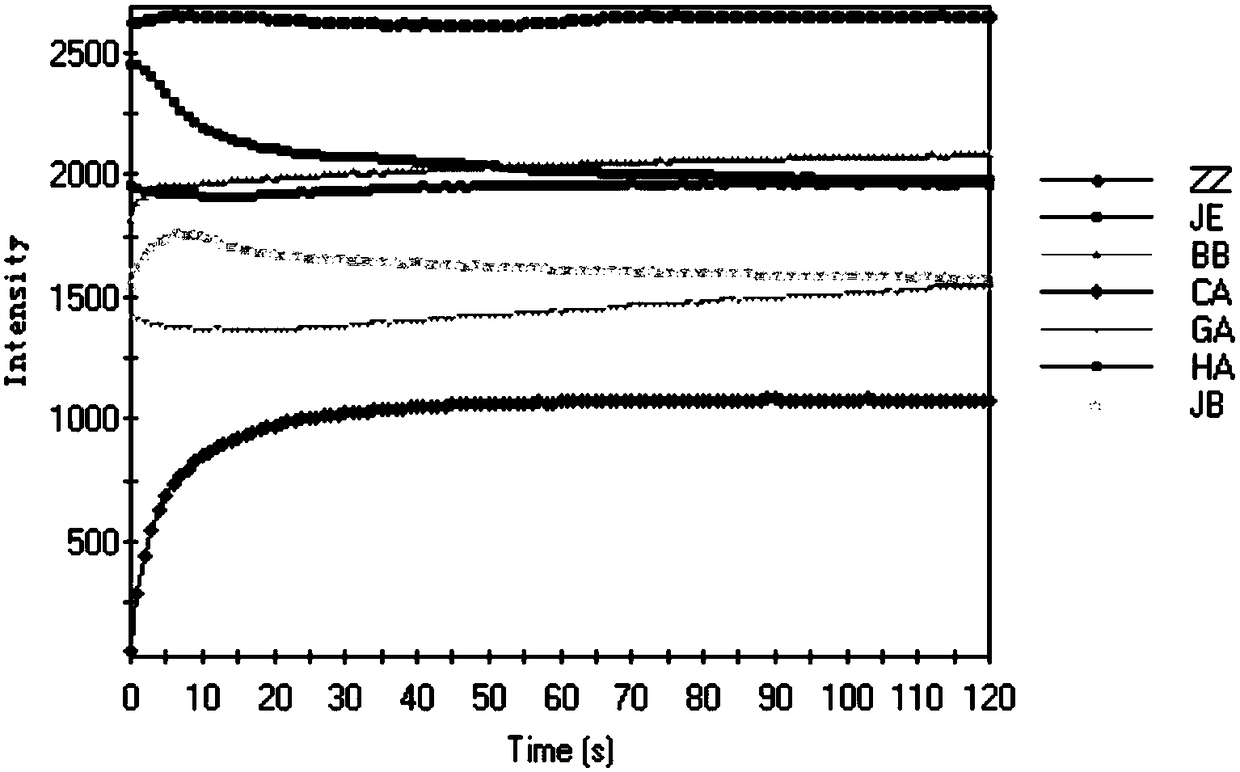

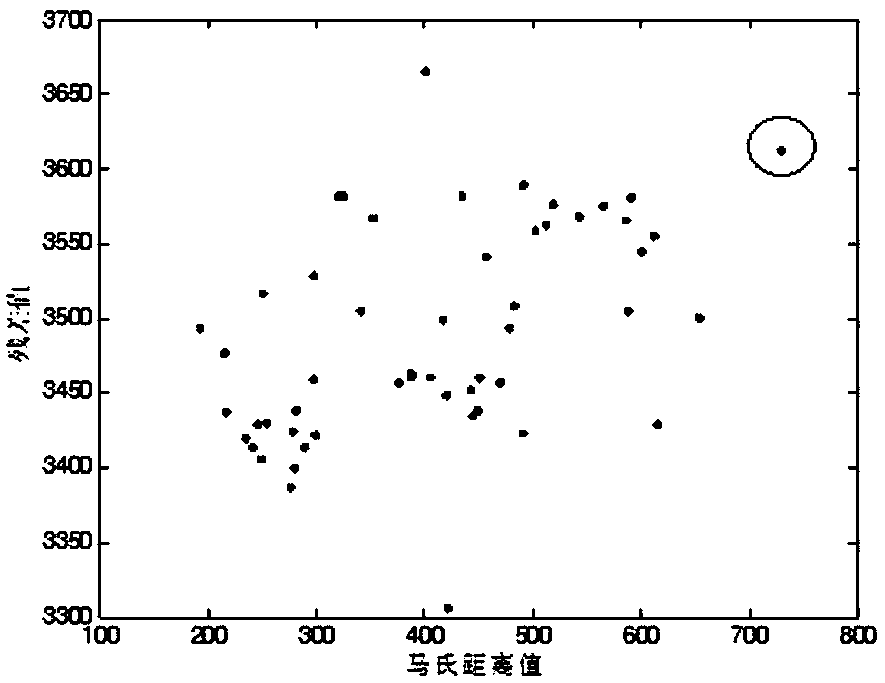

Gustatory induction signal variation feature extraction method based on kernel linear discriminant analysis

ActiveCN106096649ACharacterize nonlinear featuresImprove signal diversityCharacter and pattern recognitionMahalanobis distanceHigh dimensional

The invention provides a gustatory induction signal variation feature extraction method based on kernel linear discriminant analysis. The method comprises the following steps: obtaining sensor response sequential signals by detecting tea samples by use of an electronic tongue; according to the response sequential signals, analyzing and rejecting abnormal samples by use of a main component residual error and Mahalanobis distance method; optimizing parameters of a kernel linear discriminant analysis method, and taking a Longjing tea quality grade correct recognition rate as a basis, selecting parameters of the kernel linear discriminant analysis; obtaining taste features of tea samples by performing nonlinear feature extraction on the sensor response signals by use of the kernel linear discriminant analysis method; and inputting the taste features of the tea samples into a classifier, and carrying out teat quality grade determination. According to the invention, abnormal value rejection is performed on the tea samples, nonlinear features of the tea samples with different grades can be represented better by use of the kernel linear discriminant analysis method after parameter optimization, and signal variation of the samples after nonlinear mapping in a high-dimensional feature space is improved.

Owner:UNIV OF SCI & TECH BEIJING

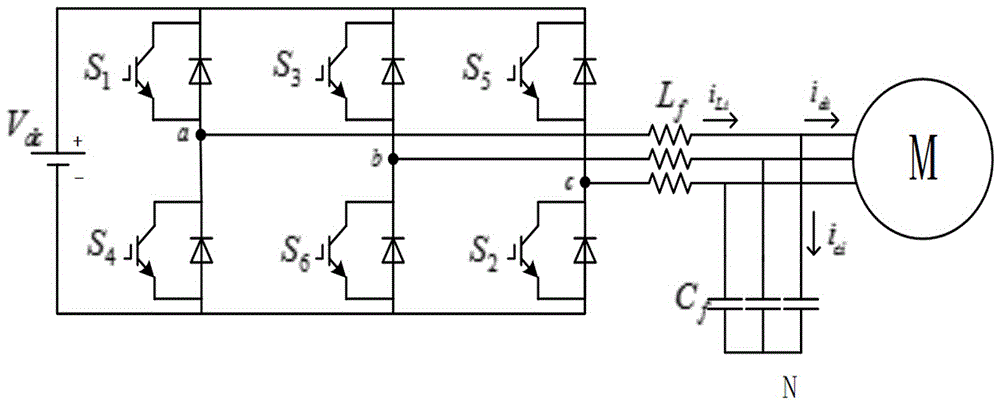

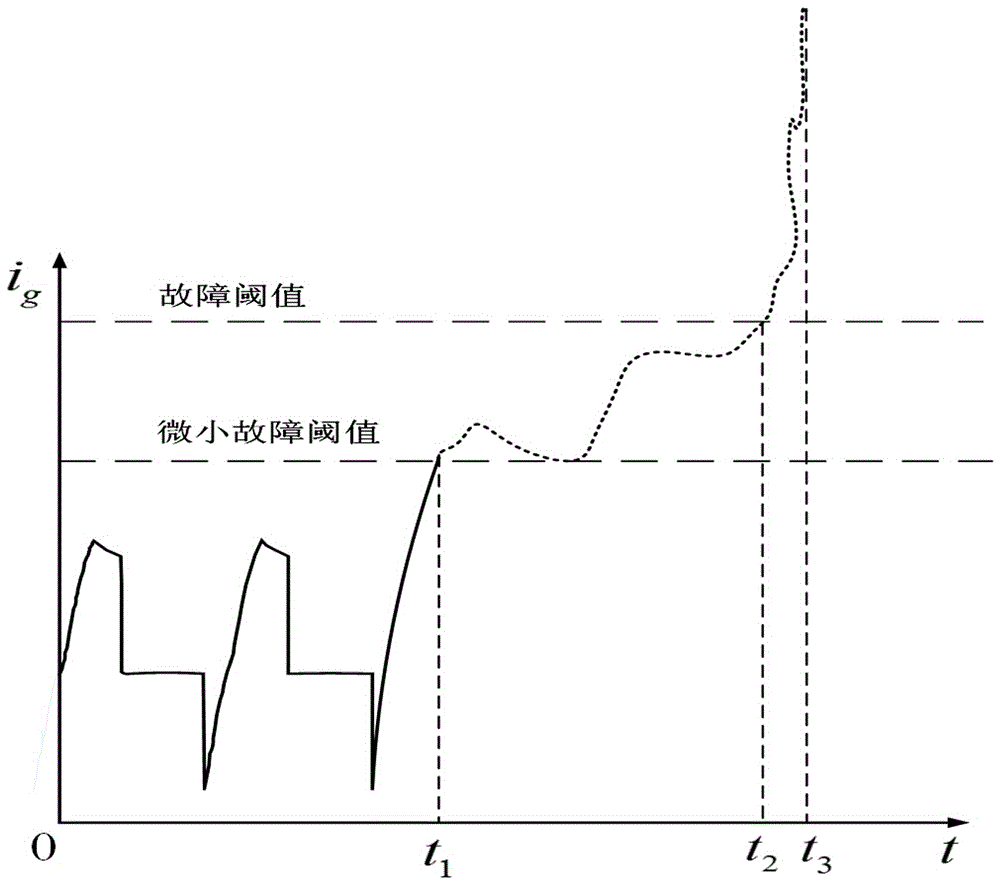

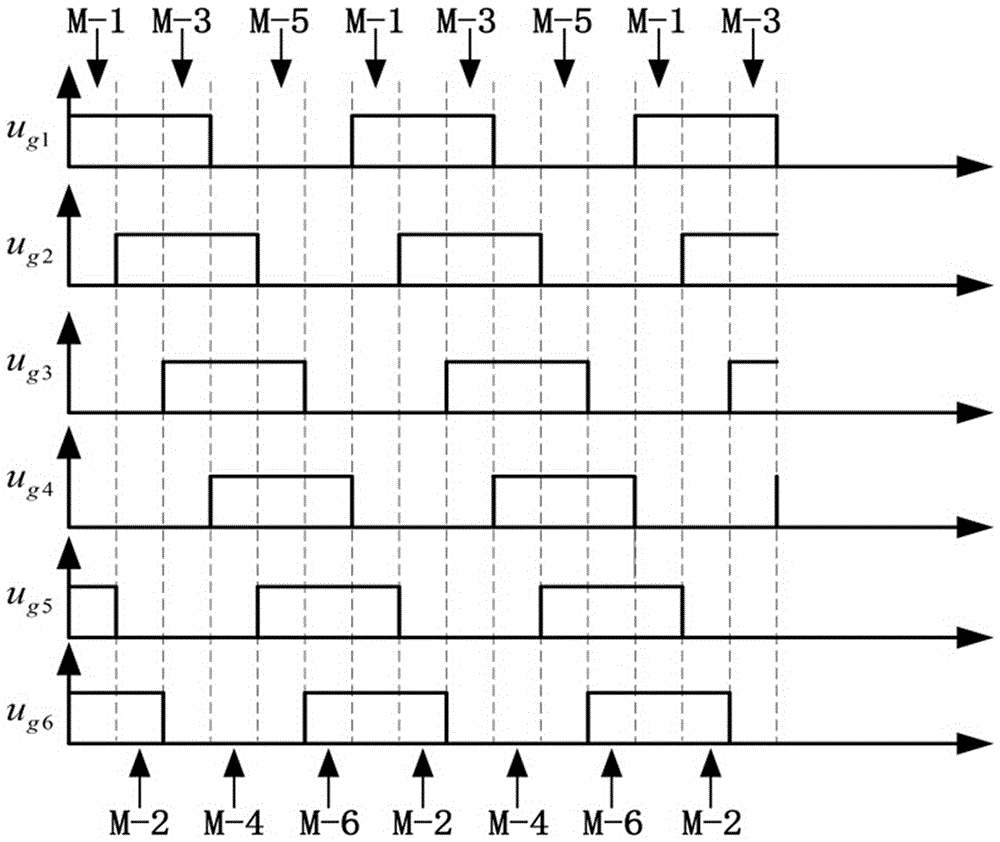

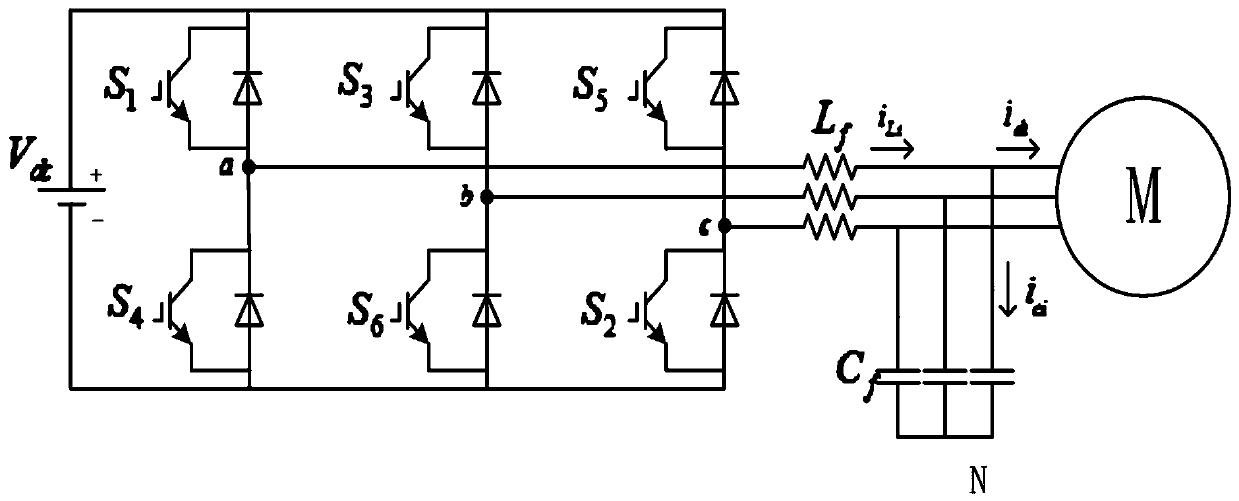

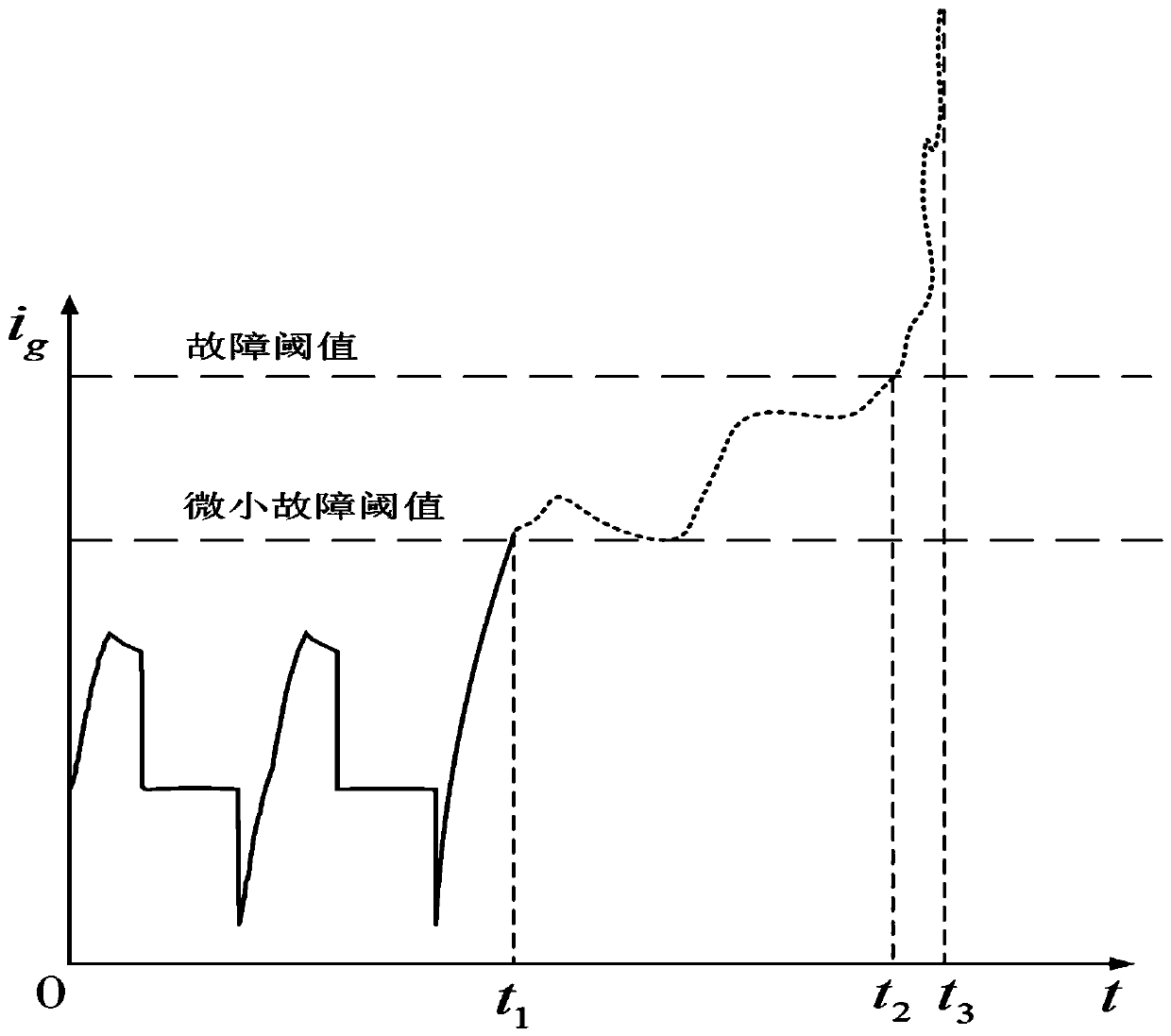

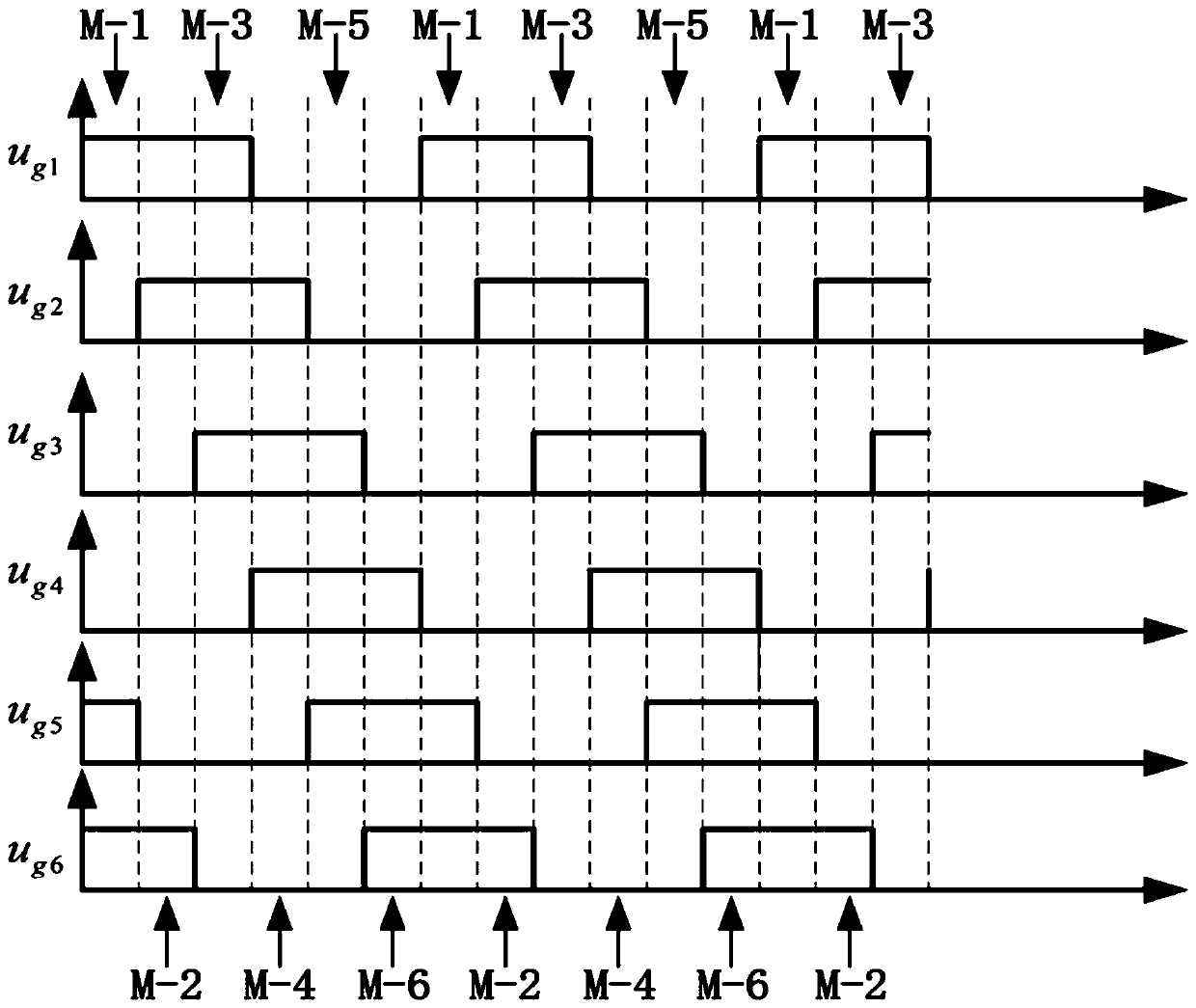

Method for diagnosing minor faults of CRH5 high-speed railway inverter

ActiveCN106093626AAccurate distributionCharacterize nonlinear propertiesTesting electric installations on transportKernel principal component analysisOriginal data

The invention discloses a method for diagnosing the minor faults of a CRH5 high-speed railway inverter. A multi-modal kernel principal component analysis method is provided. Data acquired by a sensor is preprocessed. A system model on a normal condition is obtained. Whether an electrical system has a fault is detected by processing online data according to the characteristic of the electrical system. Specific data is processed and analyzed. Acquired data has two dimensionalities. Two dimensionalities including period and modal are added to original data so that the original data is projected onto a four-dimensional space. Thus, the original nonlinear data is more accurately distributed in a high-dimensional space. The characteristic of each mode is extracted according to a nonlinear characteristic extraction method. Compared with a linear PCA algorithm and a nonlinear KPCA algorithm, the method is more precise in detection of the minor faults of a CRH5 high-speed railway inverter, more accurate in diagnosed results, lower in missing report rate, and more advantageous.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

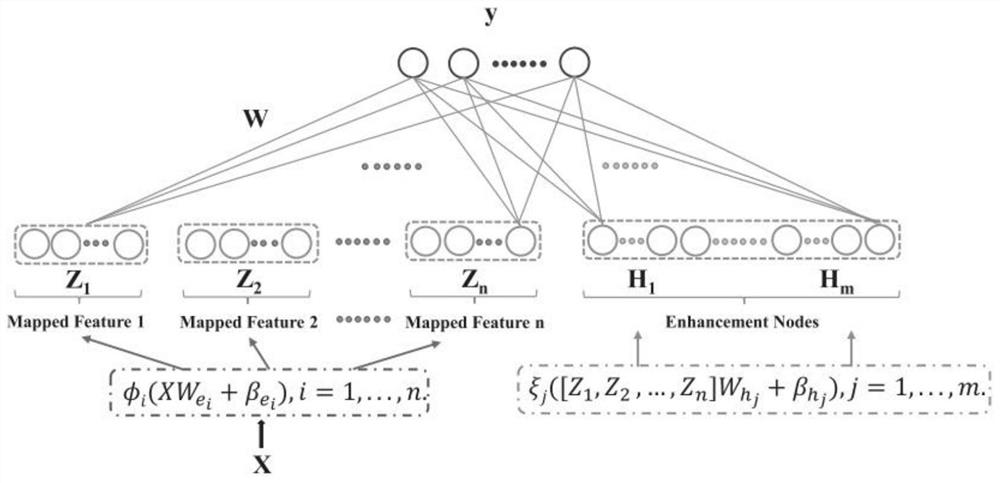

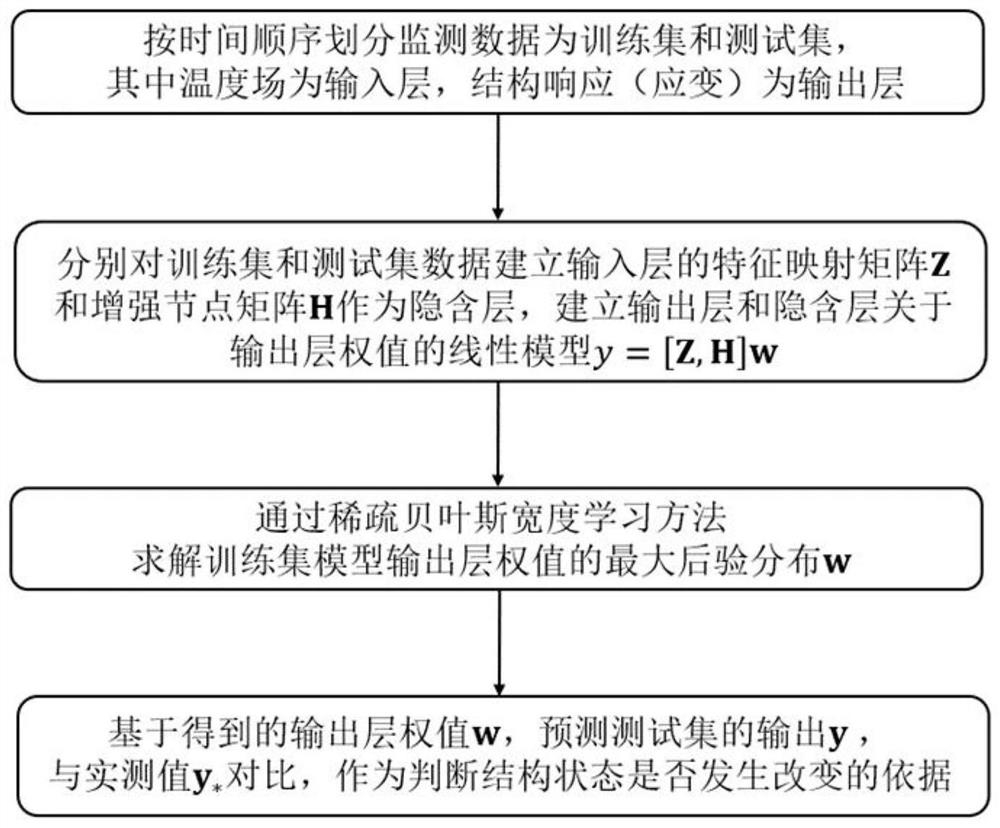

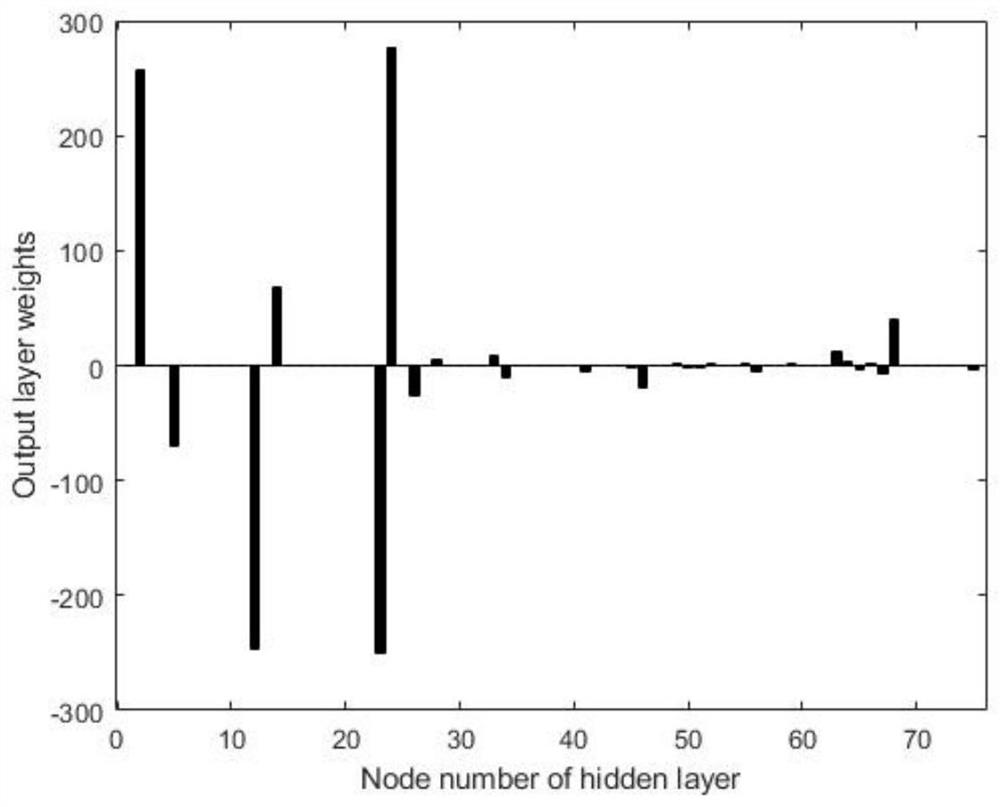

High-speed rail track response prediction method based on sparse Bayesian width learning

ActiveCN113297790AReduce workloadReduce overfittingMathematical modelsDesign optimisation/simulationEngineeringOverfitting

The invention provides a high-speed rail track response prediction method based on sparse Bayesian width learning. The method comprises the steps: carrying out the linear and nonlinear feature extraction of an input temperature field variable, carrying out the maximum posteriori estimation of a hidden layer neuron node output layer weight, predicting a structure response output result, and evaluating the structure state of the track preliminarily. According to the method, the sparse Bayesian width learning method is adopted to carry out correlation mining on the data of the high-speed rail monitoring system, and the over-fitting problem of regression prediction can be effectively avoided through sparse solution of the weight w reflecting the relation between data variables. The method has the advantages of high prediction precision, high calculation speed and loose equipment hardware requirements, so that the mining of the correlation between the temperature load and the structural strain implied in a large amount of monitoring data can be realized, and meanwhile, the evolution of a monitoring data model is found in time to serve as a basis for judging the abnormal service state of the track structure.

Owner:HARBIN INST OF TECH

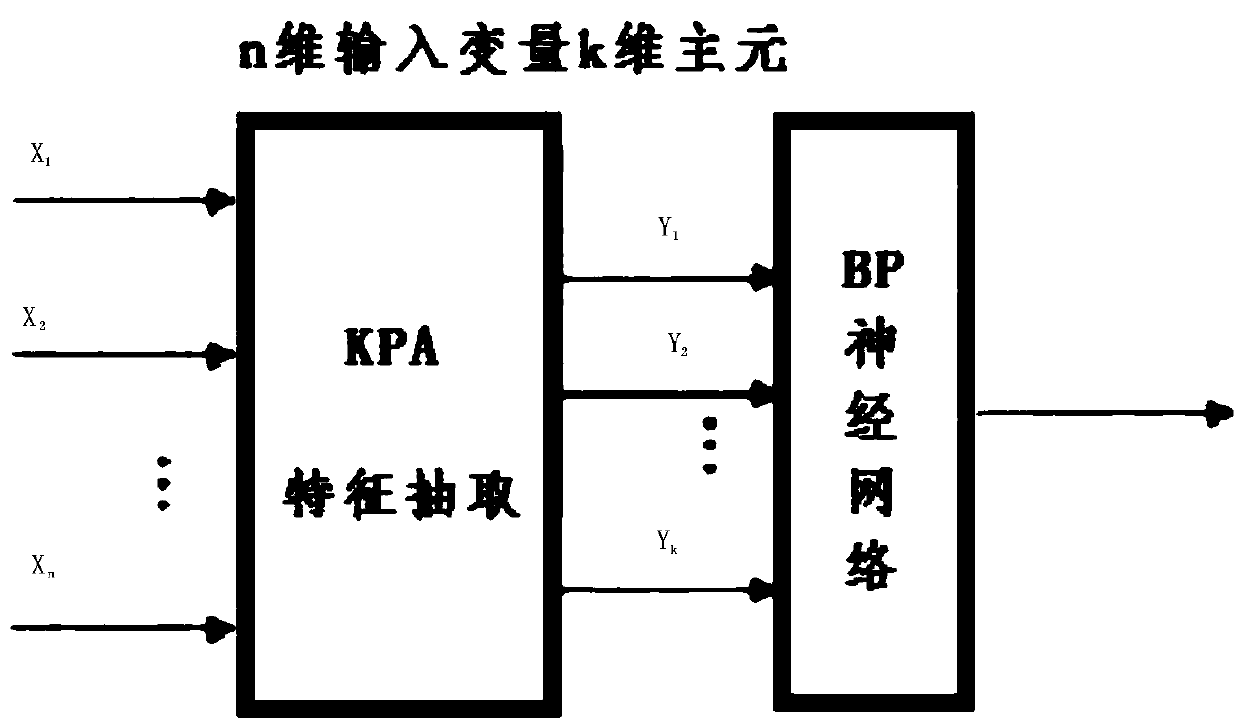

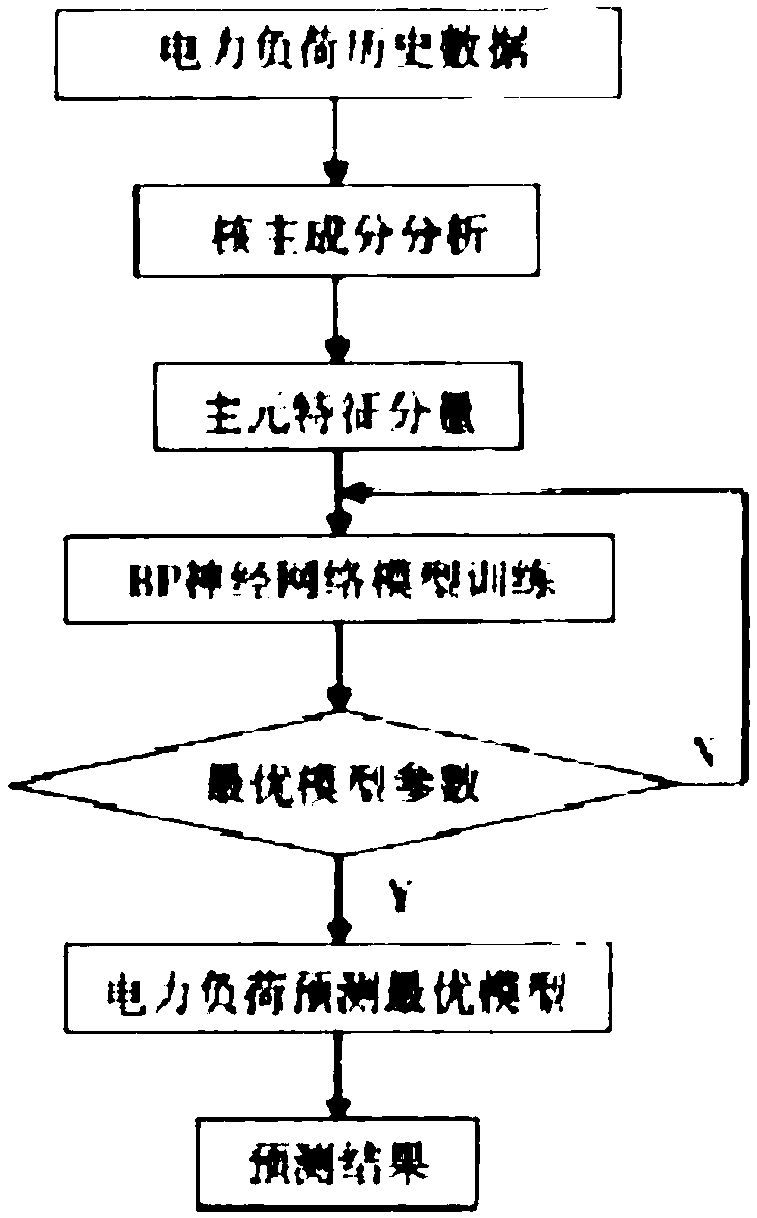

Short-term electric power load prediction modeling method

The invention discloses a short-term electric power load prediction modeling method, comprising the steps that based on the feature of electric load and by means of core major constituent analysis, non-linear feature extraction is conducted on the affecting factors influencing the electric load; redundancy and co-linear information among variables can be eliminated, and the principal component feature components affecting the electric load can be obtained; the electric load can be predicted by means of BP nerve network having strong non-linear analysis capability. The invention is advantageousin that under the precondition that more information of the original data is fully reserved, the core major constituent analysis effectively conducts feature dimension reduction on the electric loaddata, and thereby the structure of the BP nerve network is optimized, and prediction speed and precision can be greatly improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

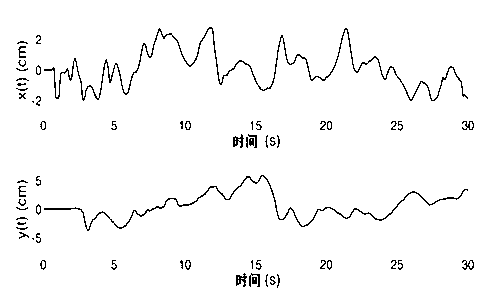

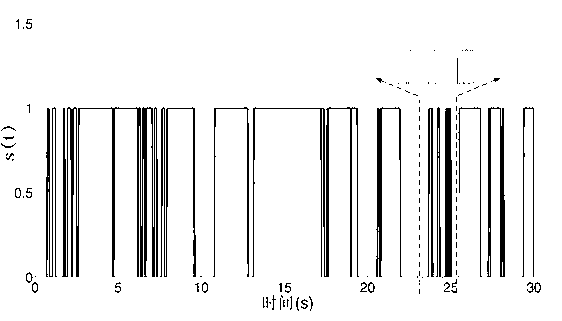

Complexity based pressure center nonlinear feature extraction method

The invention discloses a complexity based pressure center nonlinear feature extraction method. Conventional COP (center of pressure) feature parameters cannot effectively describe nonlinear features of shaking of human bodies. The method is used for extracting COP nonlinear dynamical features by utilizing an established model based on neighborhood coarse graining two-dimensional Lempel-Ziv complexity and specifically includes step1, acquiring COP signals; step 2, performing sequence reconstructing based on neighborhood coarse graining; and step 3, calculating normalized Lempel-Ziv complexity of the COP signals based on a reconstructed sequence. The complexity based pressure center nonlinear feature extraction method effectively solves the problem about how to apply the Lempel-Ziv complexity to process the two-dimensional COP signals to extract nonlinear features of the COP signals, so that quantitative description can be performed to irregular degree of posture shaking of the human bodies.

Owner:HANGZHOU DIANZI UNIV

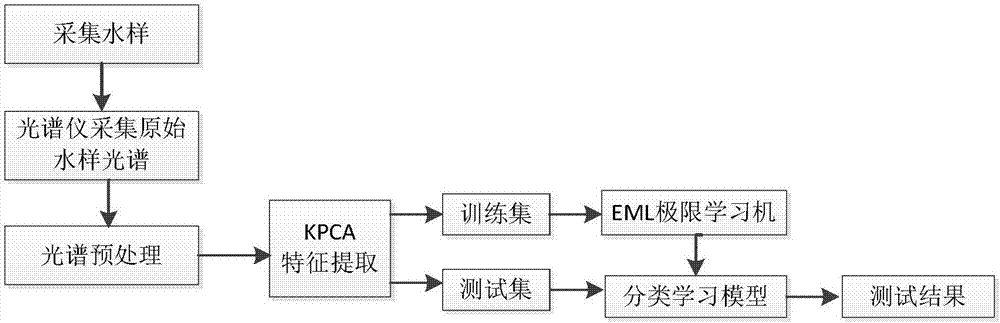

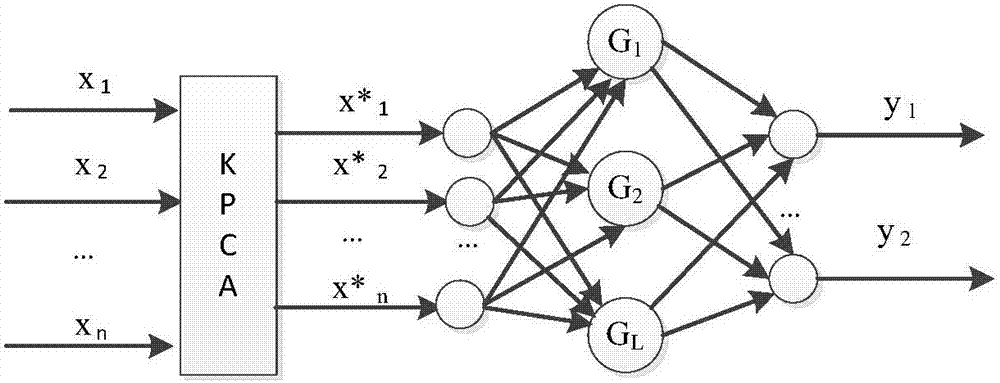

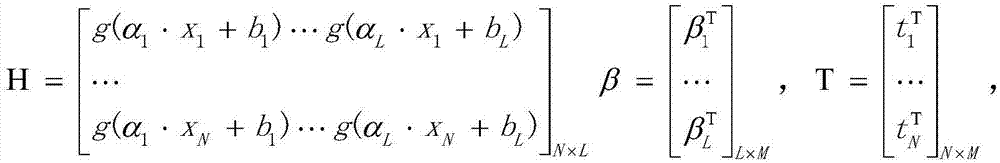

Nonlinear identification method for mine water inrush source

InactiveCN106971073AOptimize learning parametersReduce training parametersCharacter and pattern recognitionInformaticsKernel principal component analysisWater source

The invention relates to a nonlinear identification method for a mine water inrush source. The method comprises the following steps of (1) collecting spectrum data; (2) preprocessing the collected original spectrum data by utilizing a Savitzky-Golay (SG) smoothing technology; (3) performing data dimension reduction by utilizing a nonlinear kernel principal component analysis method, and performing nonlinear feature extraction; (4) establishing independent test set and training set by collected water samples; and (5) establishing an ELM by utilizing the training set, and then performing classification result testing through the test set. According to the method, the feature extraction is performed in a nonlinear way, so that the time and space complexity is lowered and the sample identification performance is provided; the kernel principal component analysis optimizes learning parameters of the ELM; an ELM classification model has the characteristics of few training parameters, high learning speed and the like; the KPCA and the ELM are combined for nonlinear identification of the mine water inrush source; and the method is very suitable for online water inrush source monitoring.

Owner:ANHUI UNIV OF SCI & TECH

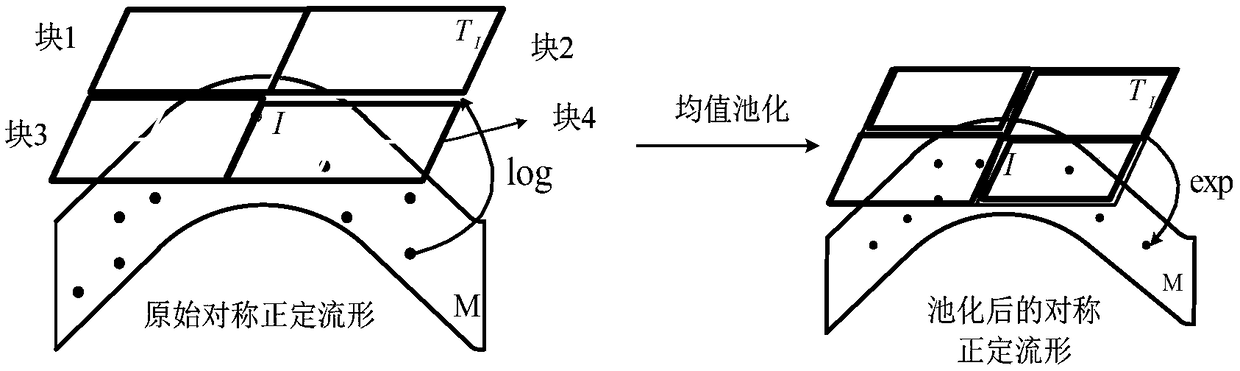

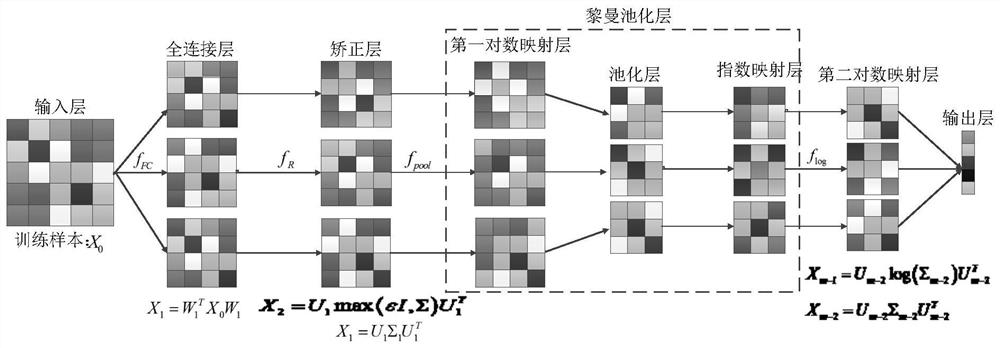

Manifold learning network and computer vision image set classification method based on the same

ActiveCN109376787AThe process is easy to realizeEasy to applyCharacter and pattern recognitionClassification methodsVideo sequence

Owner:聚时科技(上海)有限公司

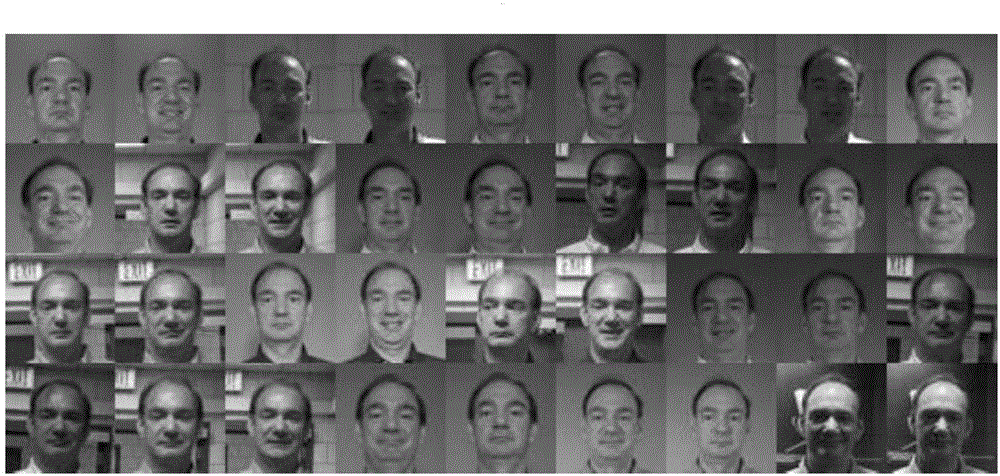

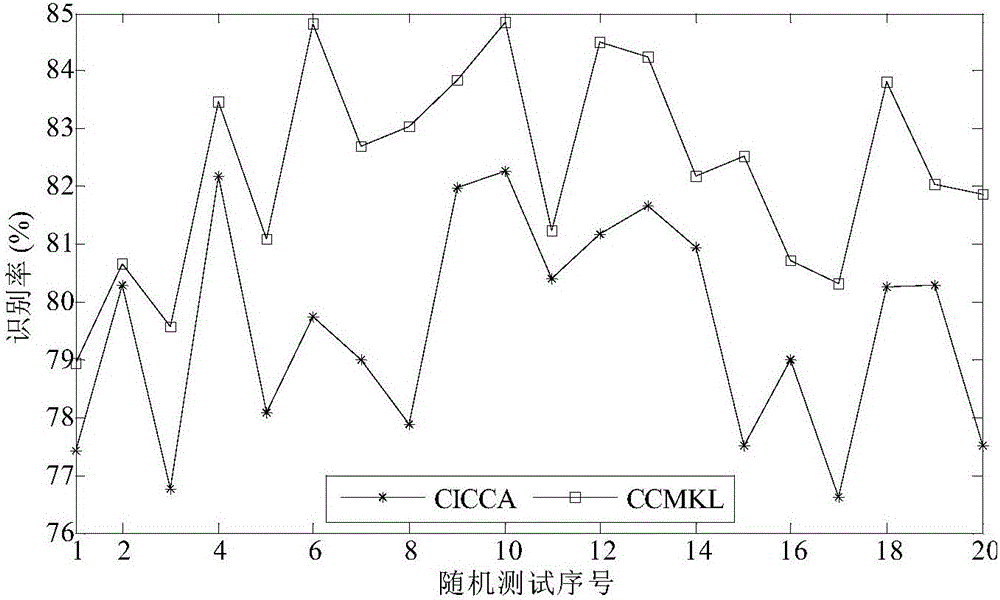

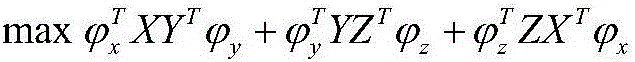

Color face recognition method based on typical correlation multi-kernel learning

ActiveCN106446840AEasy to identifyImprove classification performanceCharacter and pattern recognitionColor imageCorrelation analysis

The invention discloses a color face recognition method based on typical correlation multi-kernel learning, and the method comprises the steps: enabling the multi-kernel learning technology to be used in typical correlation analysis of a color face image, respectively employing three different kernel mapping modes for three color components, and then respectively carrying out the nonlinear feature extraction of the three color components through the typical correlation multi-kernel learning; and carrying out the classification and recognition of the extracted features through employing a nearest neighbor classifier based on the cosine distance. The method is higher in recognition effect, and remarkably improves the classification capability of color face features through the typical correlation multi-kernel learning.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Pressure center nonlinear feature extraction method based on complexity

The invention discloses a complexity based pressure center nonlinear feature extraction method. Conventional COP (center of pressure) feature parameters cannot effectively describe nonlinear features of shaking of human bodies. The method is used for extracting COP nonlinear dynamical features by utilizing an established model based on neighborhood coarse graining two-dimensional Lempel-Ziv complexity and specifically includes step1, acquiring COP signals; step 2, performing sequence reconstructing based on neighborhood coarse graining; and step 3, calculating normalized Lempel-Ziv complexity of the COP signals based on a reconstructed sequence. The complexity based pressure center nonlinear feature extraction method effectively solves the problem about how to apply the Lempel-Ziv complexity to process the two-dimensional COP signals to extract nonlinear features of the COP signals, so that quantitative description can be performed to irregular degree of posture shaking of the human bodies.

Owner:HANGZHOU DIANZI UNIV

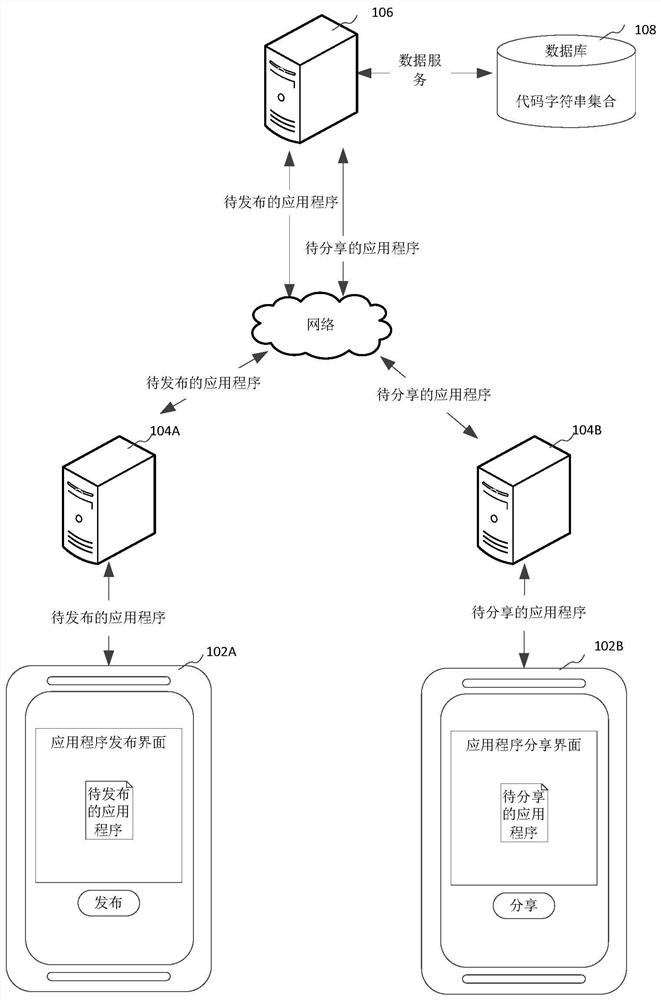

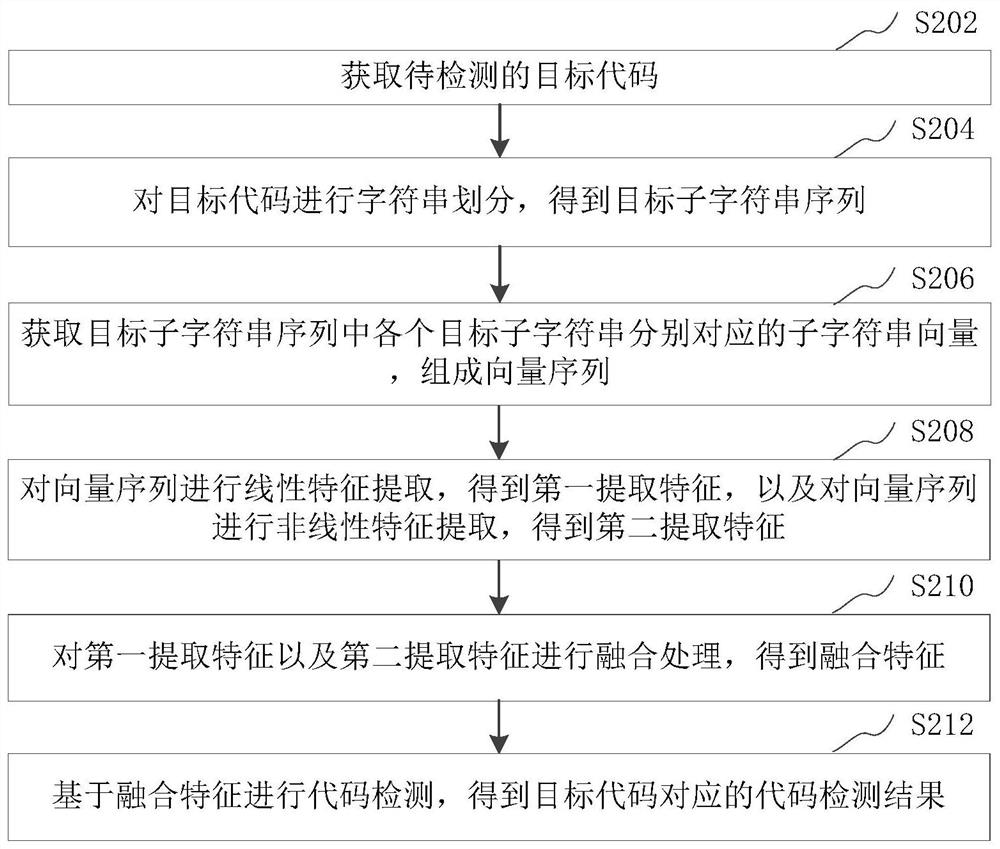

Code detection method and device, computer equipment and storage medium

PendingCN114817913AImprove accuracyNatural language data processingPlatform integrity maintainanceAlgorithmTheoretical computer science

The invention relates to a code detection method and device, computer equipment and a storage medium. The method comprises the steps of obtaining a to-be-detected target code; performing character string division on the target code to obtain a target sub-character string sequence; obtaining sub-character string vectors respectively corresponding to each target sub-character string in the target sub-character string sequence to form a vector sequence; performing linear feature extraction on the vector sequence to obtain a first extraction feature, and performing nonlinear feature extraction on the vector sequence to obtain a second extraction feature; performing fusion processing on the first extraction feature and the second extraction feature to obtain a fusion feature; and performing code detection based on the fusion feature to obtain a code detection result corresponding to the target code. The cloud server can utilize a malicious code detection model based on artificial intelligence to realize the code detection method, and the purpose of reducing network attacks is realized. By adopting the method, the malicious code detection accuracy can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

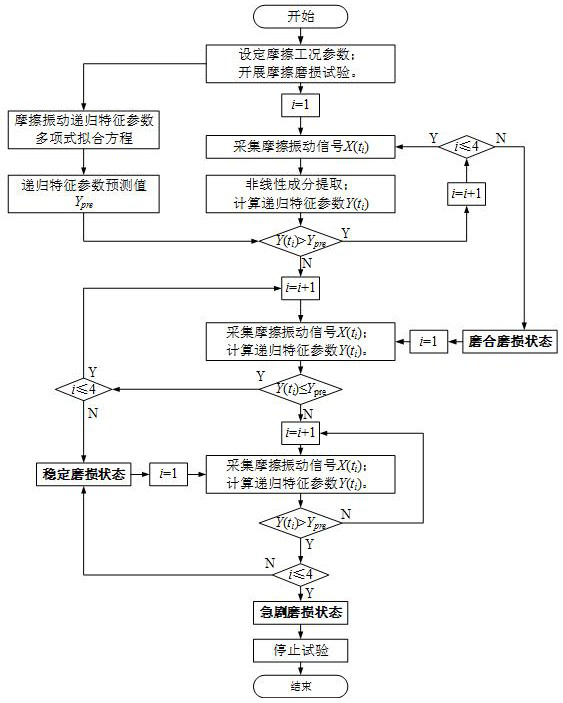

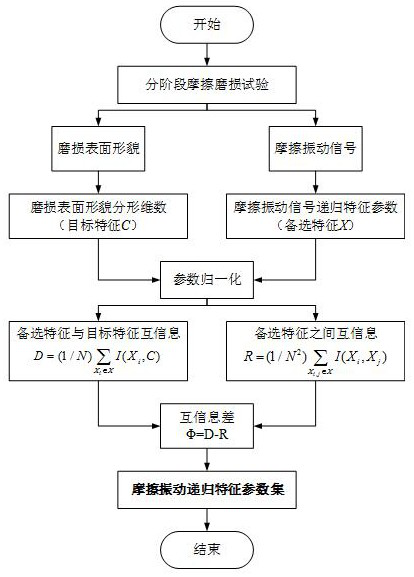

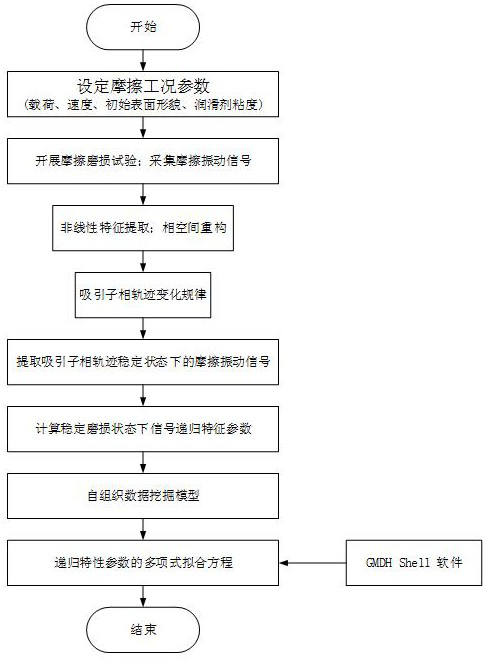

Tribological state online identification method based on friction signal recursive characteristics

ActiveCN112525749AOptimizing Recursive Characterization ParametersImprove accuracySubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionWear testingDimensionality reduction

The invention discloses a tribological state online identification method based on friction signal recursive characteristics. The method comprises the following steps that: friction vibration signalsin a friction and wear process are collected through an acceleration sensor installed on the side edge of a clamp on a sliding friction and wear testing machine and are expressed as X=[x (1), x (2),..., x (t),..., x (n)]; nonlinear feature extraction is carried out ton the obtained friction vibration signals and a quantitative recursion parameters of the signals are extracted; feature extraction is carried out on the extracted quantitative recursive parameters, and a feature parameter set which has been subjected to dimension reduction and obtained by processing is adopted as a characterization quantity of the recursive characteristic of the friction signals; a system-dependent polynomial fitting equation of the characteristic parameter set relative to friction control parameters is established, and the polynomial fitting equation is made to predict the recursive characteristic parameters of the friction vibration signals under different control parameter conditions and by means of nonlinear mapping and mathematical modeling capability of self-organized data mining; and the frictional wear state of the actually measured friction signals is accurately identified. According to the method of the invention, the tribological state of a sliding friction pair can be effectively monitored and identified.

Owner:YANGZHOU UNIV

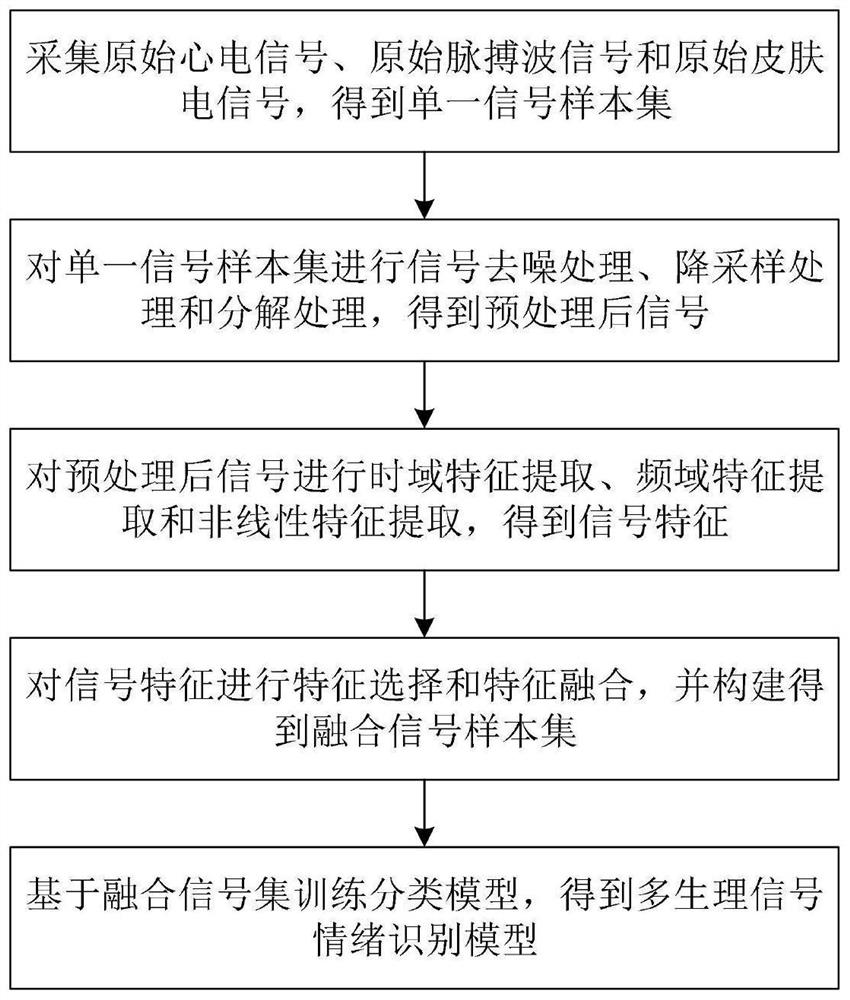

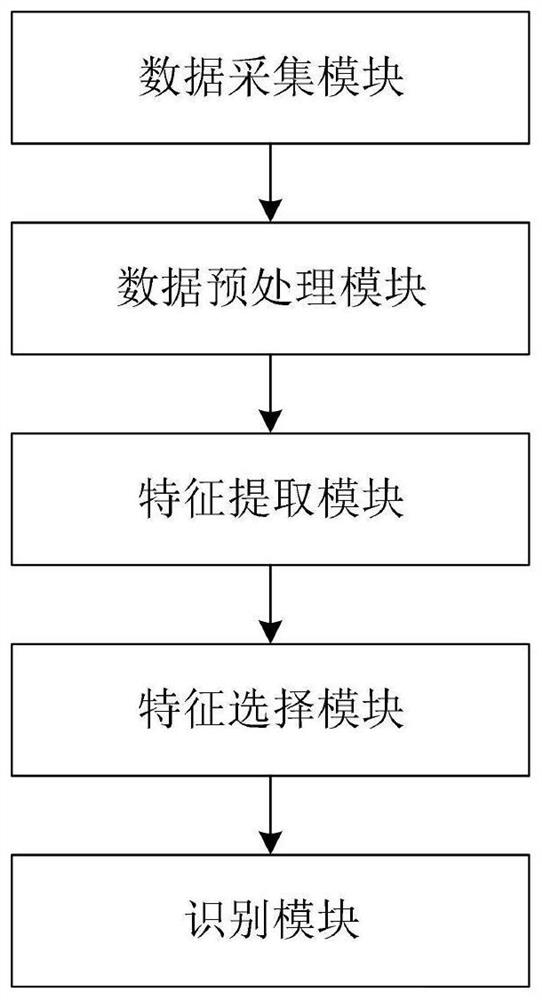

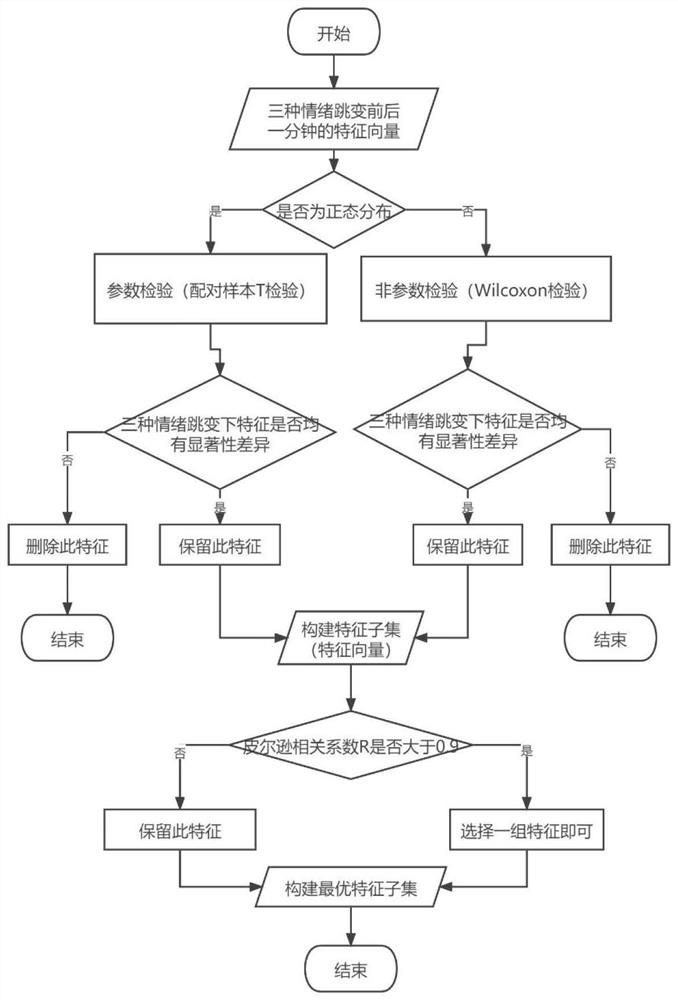

Emotion recognition method and system based on filtering type feature selection

PendingCN114391846AHigh precisionGood feature selectionSensorsPsychotechnic devicesEcg signalData acquisition

The invention discloses an emotion recognition method and system based on filtering type feature selection, and the method comprises the steps: collecting an original electrocardiosignal, an original pulse wave signal and an original skin electric signal, and obtaining a single signal sample set; performing signal de-noising processing, down-sampling processing and decomposition processing on the single signal sample set to obtain a pre-processed signal; performing time domain feature extraction, frequency domain feature extraction and nonlinear feature extraction on the preprocessed signals to obtain signal features; feature selection and feature fusion are carried out on the signal features, and a fusion signal sample set is constructed; and training a classification model based on the fusion signal set to obtain a multi-physiological signal emotion recognition model. The system comprises a data acquisition module, a data preprocessing module, a feature extraction module, a feature selection module and an identification module. According to the invention, the emotion features can be completely expressed, so that the effect of the emotion recognition model is improved. The method can be widely applied to the field of emotion recognition.

Owner:SUN YAT SEN UNIV

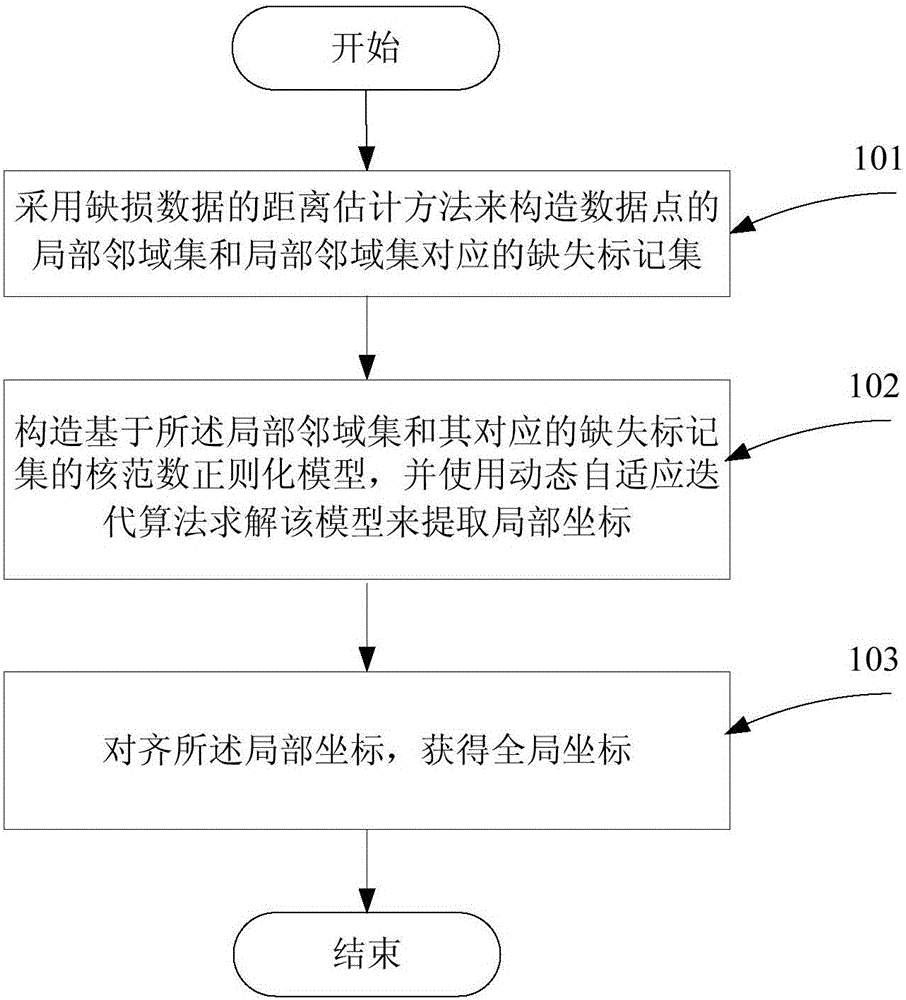

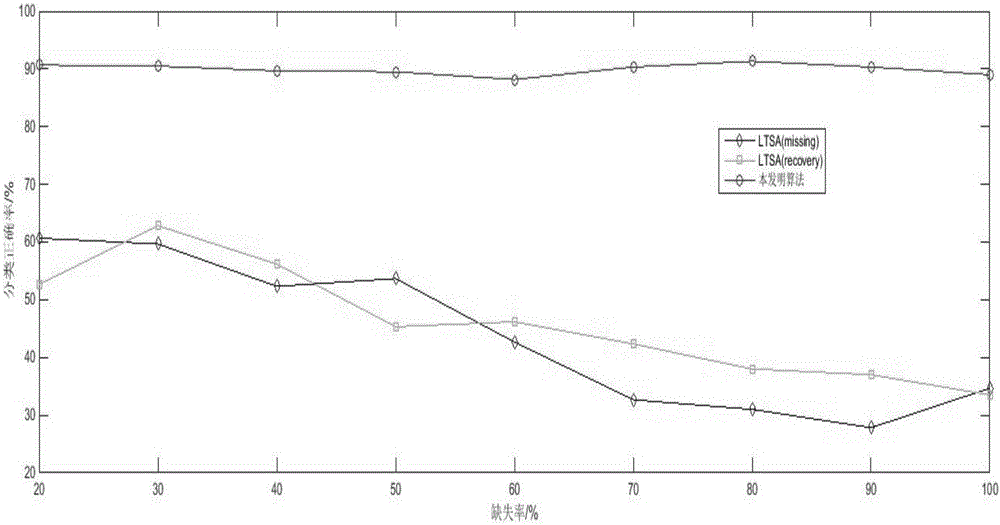

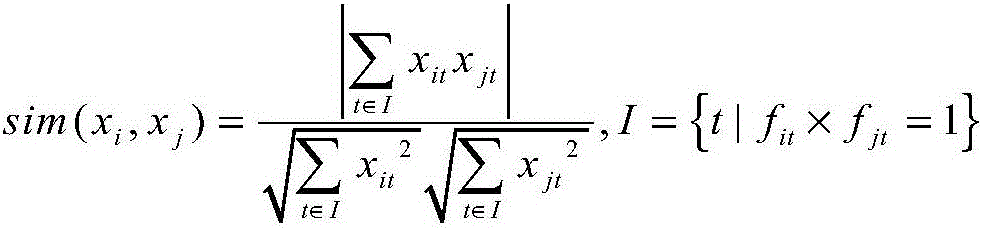

Nonlinear characteristic extraction and classification based on defect data

ActiveCN106203480APrecise constructionAccurate extractionCharacter and pattern recognitionNuclear norm regularizationEstimation methods

The present invention discloses a nonlinear characteristic extraction and classification based on defect data. The method comprises a step of using the distance estimation method of defect data to construct the local neighborhood set of a data point and a missing marker set corresponding to the local neighborhood set, a step of constructing a nuclear norm regularization model based on the local neighborhood set and the corresponding missing marker set, and using an adaptive fixed point iteration algorithm to solve the model to extract a local coordinate, and a step of aligning the local coordinate to obtain a global coordinate. According to the method, in facing the defect data, the local neighborhood set can be constructed, the local coordinate can be extracted, the global coordinate can be covered, and the nonlinear characteristic extraction and classification of the defect data are finally realized.

Owner:HUAQIAO UNIVERSITY

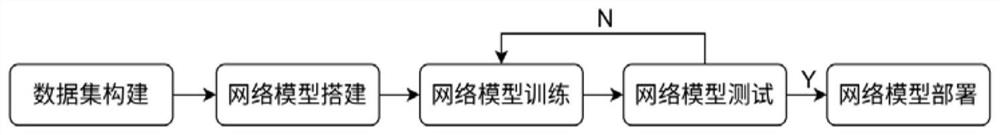

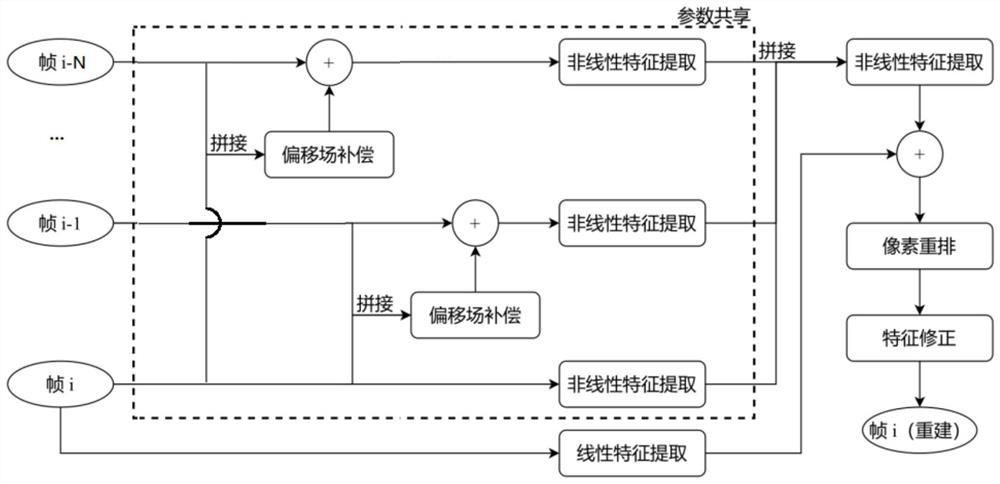

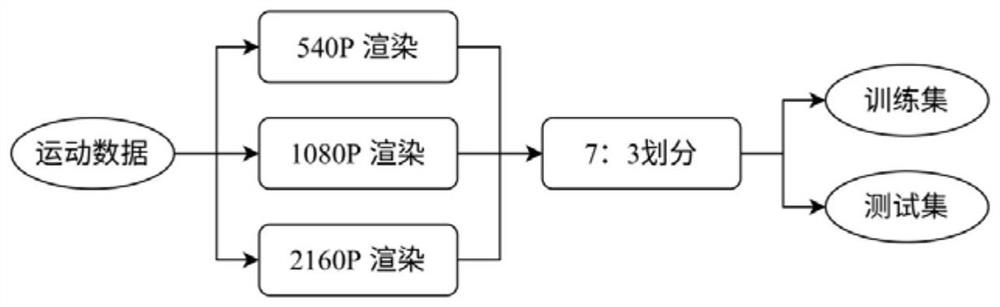

Real-time super-resolution reconstruction method and system based on historical feature fusion

PendingCN114155152AReduce computing power requirementsAvoid callingImage enhancementImage analysisImaging qualityImage resolution

The invention discloses a real-time super-resolution reconstruction method and system based on historical feature fusion. The method comprises the following steps: constructing a network model; the construction of the network model comprises the following steps: carrying out linear feature extraction on a current frame to obtain a linear feature graph of the current frame; performing nonlinear feature extraction and feature fusion on the current frame and the historical frame to obtain a nonlinear feature map after feature fusion; wherein the historical frame is the previous N frames of the current frame, and N is a natural number; the nonlinear feature extraction of the historical frame is carried out based on the image after the motion compensation of the historical frame; and obtaining a super-resolution reconstruction image of the current frame based on the nonlinear feature map after feature fusion and the linear feature map of the current frame. According to the method, a series of problems of poor real-time performance, detail time sequence breakage, false color, poor universality and the like existing in the current super-resolution technology are solved, and the real-time performance and the image quality are both considered.

Owner:芯动微电子科技(珠海)有限公司 +1

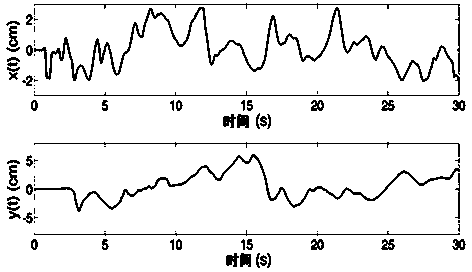

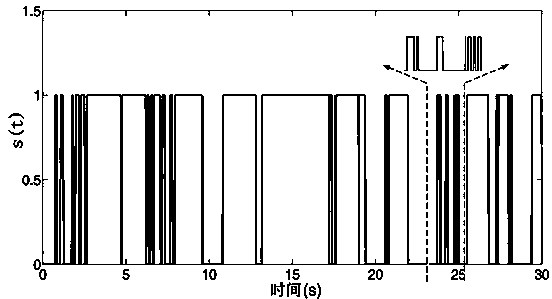

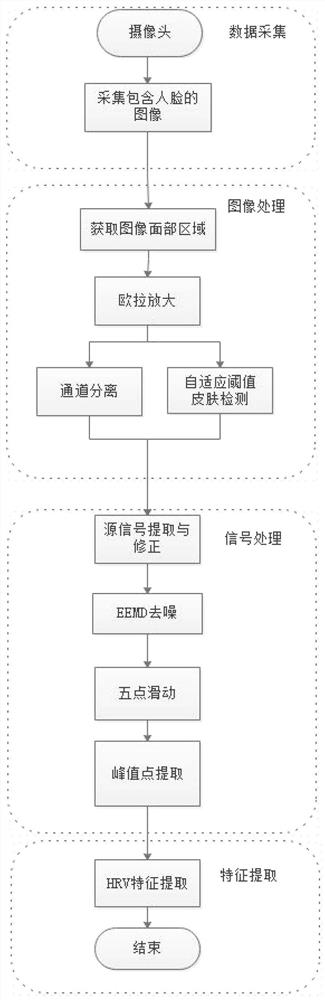

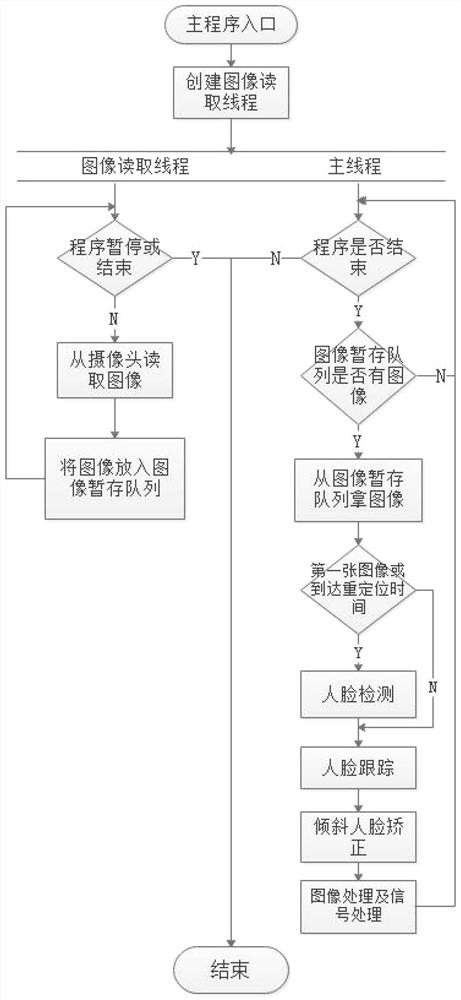

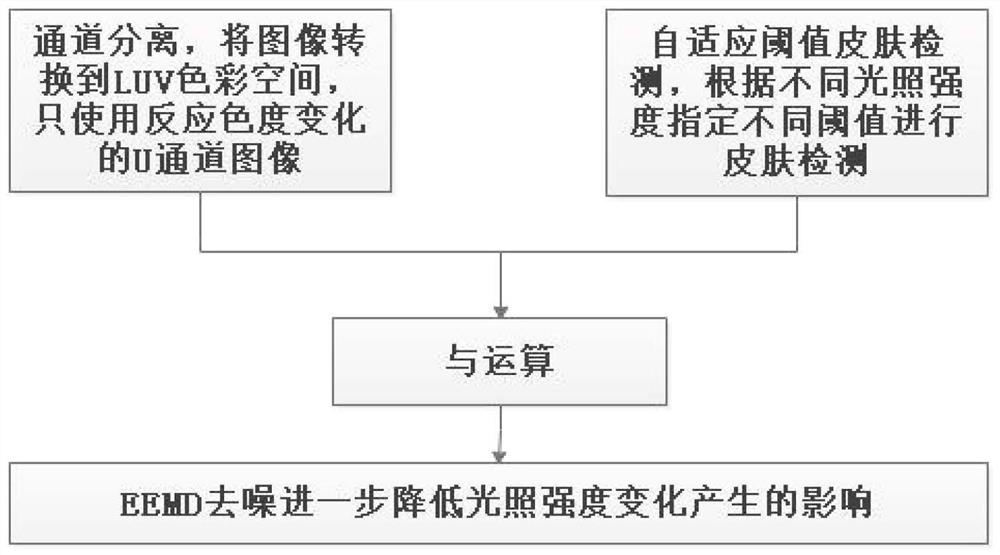

Non-contact heart rate variability feature extraction method based on real application scene

PendingCN113657345ARealize automatic switchingFast extractionCharacter and pattern recognitionFace detectionFacial region

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

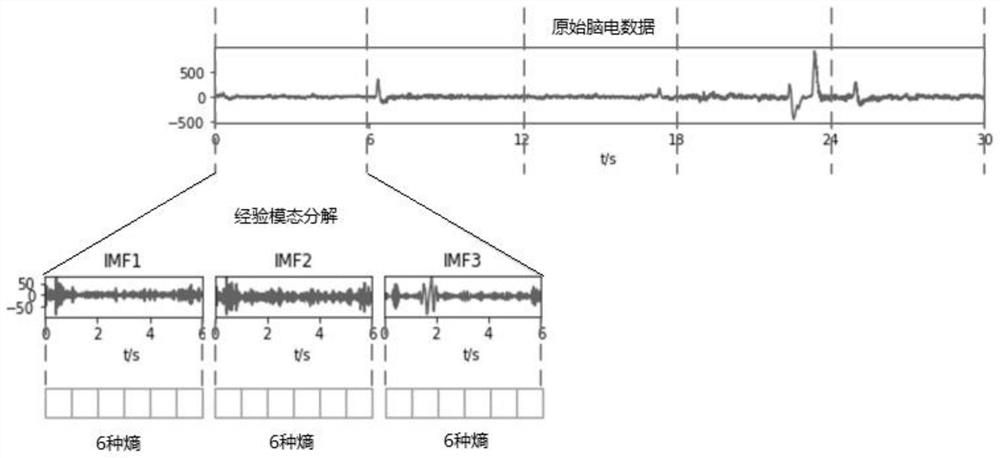

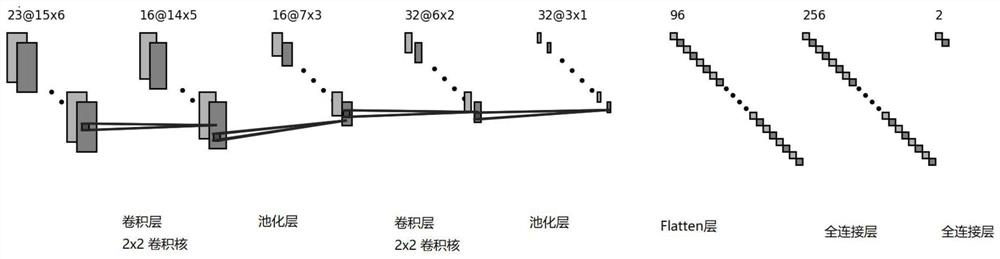

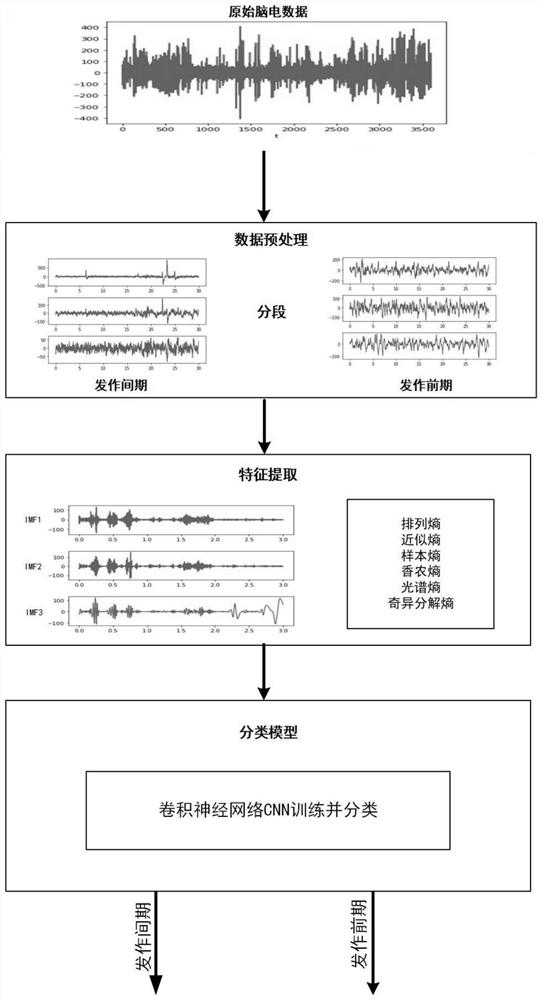

Epileptic seizure prediction method based on electroencephalogram signals

The invention discloses an epileptic seizure prediction method based on electroencephalogram signals, which is used for predicting epileptic seizure by combining empirical mode decomposition and a convolutional neural network and helping doctors to diagnose. The method mainly comprises the following steps that electroencephalogram signals monitored for a long time are marked and segmented, empirical mode decomposition is conducted on segmented electroencephalogram data, entropy features are extracted, finally, the extracted features are learned through a convolutional neural network, and the electroencephalogram signals in the early stage of attack and in the interval of attack are classified. According to the method, a time-frequency domain and nonlinear feature extraction method is combined with a deep neural network classification method, so that the accuracy of epilepsy electroencephalogram signal prediction is effectively improved, a doctor patient can make full preparation before epileptic seizure comes, and epilepsy can be treated more effectively.

Owner:BEIJING UNIV OF TECH

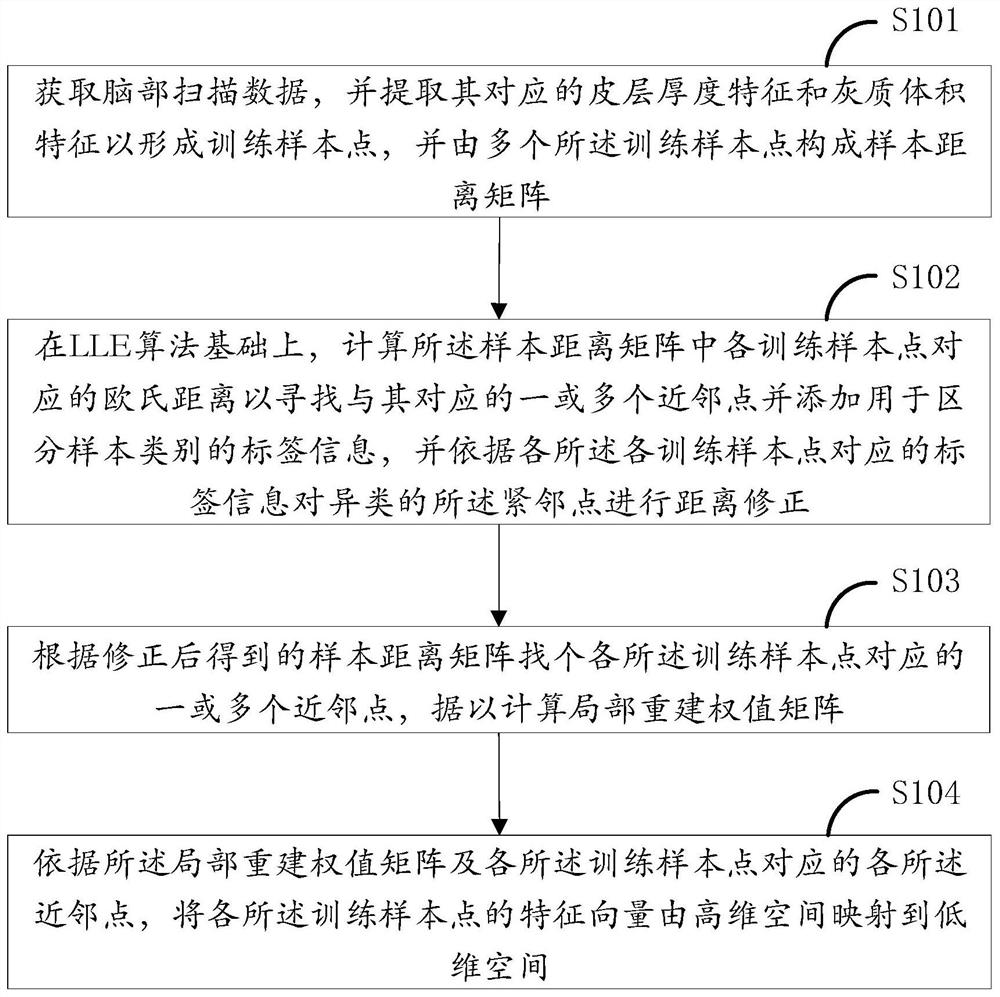

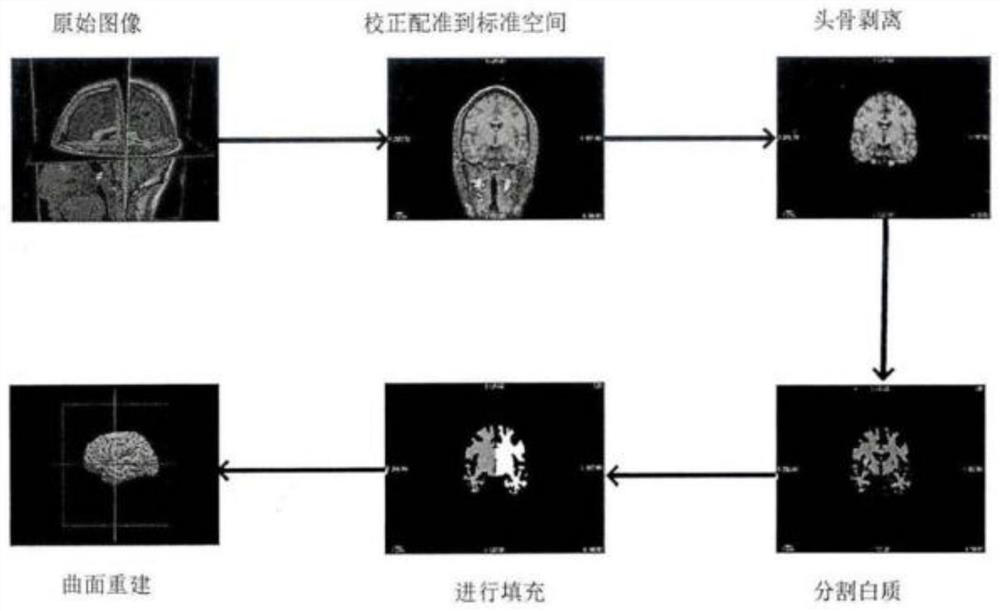

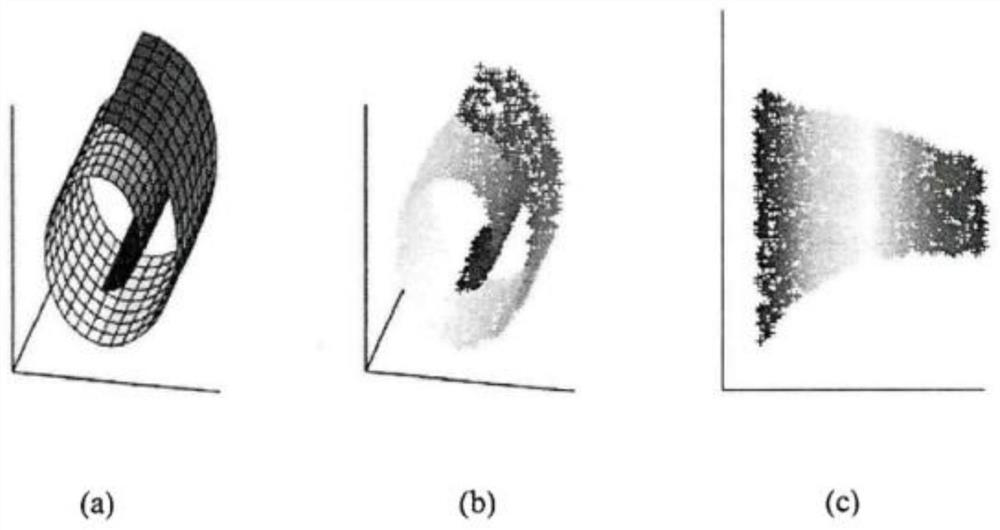

Locally linear embedding-based (LLE-based) early diagnosis method for Alzheimer disease, device and system

PendingCN111938644AAchieve the effect of discrete dimensionality reduction between classesAchieve dimensionality reductionDiagnostic recording/measuringSensorsAlgorithmDiagnosis methods

The application provides a locally linear embedding-based (LLE-based) early diagnosis method for the Alzheimer disease, a device and a system. Aiming at the defects that a traditional linear feature extraction method ignores nonlinear distribution of early stage data of the Alzheimer disease (AD), and local linear embedding method (LLE) in nonlinear feature extraction does not fully utilize labelinformation, the application proposes that a supervised locally linear embedding (SLLE) method is employed to carry out early diagnosis on the AD. A modified local linear embedding (MLLE) algorithm for modified distance is proposed; neighbor points are calculated by the geodesic distance between sample points, and the sample distance is adjusted by utilizing a reciprocal of an average value of thedistance between the sample points and the neighbor points, so that overall distribution tends to be uniform. In combination with the idea of supervised learning, an SMLLE method for supervised homogenized distance is applied to early diagnosis of the AD, and the algorithms of the invention better improve the effect of early classification of the AD.

Owner:SHANGHAI ENG RES CENT FOR BROADBAND TECH & APPL

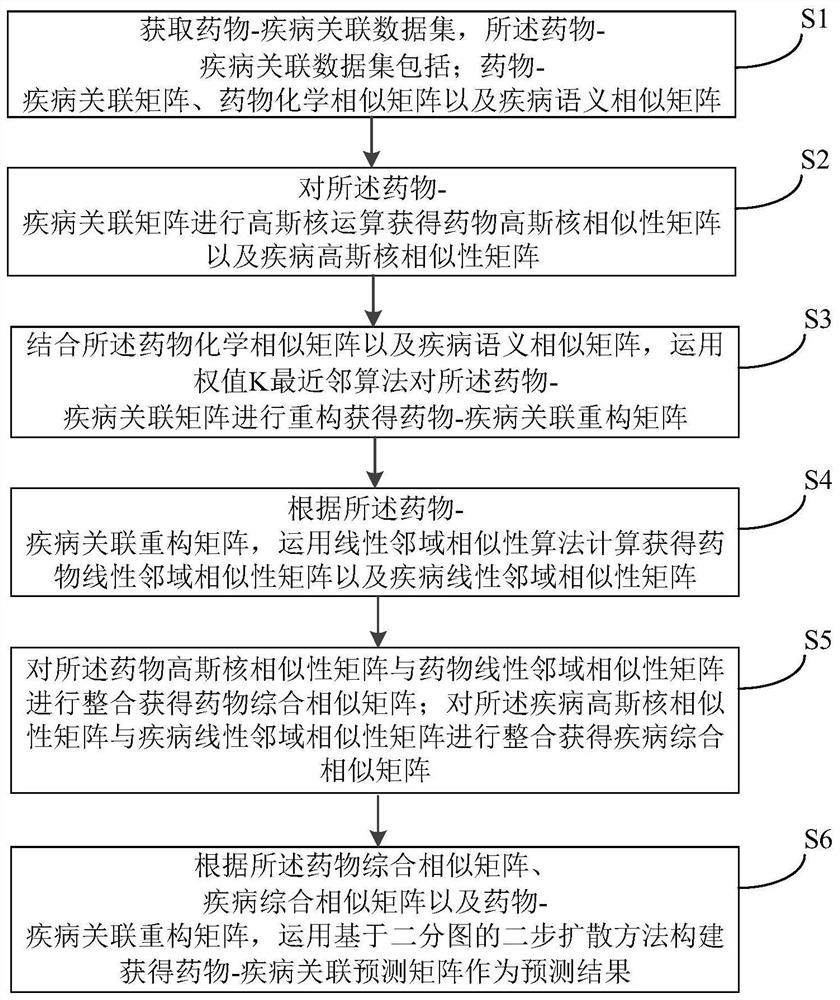

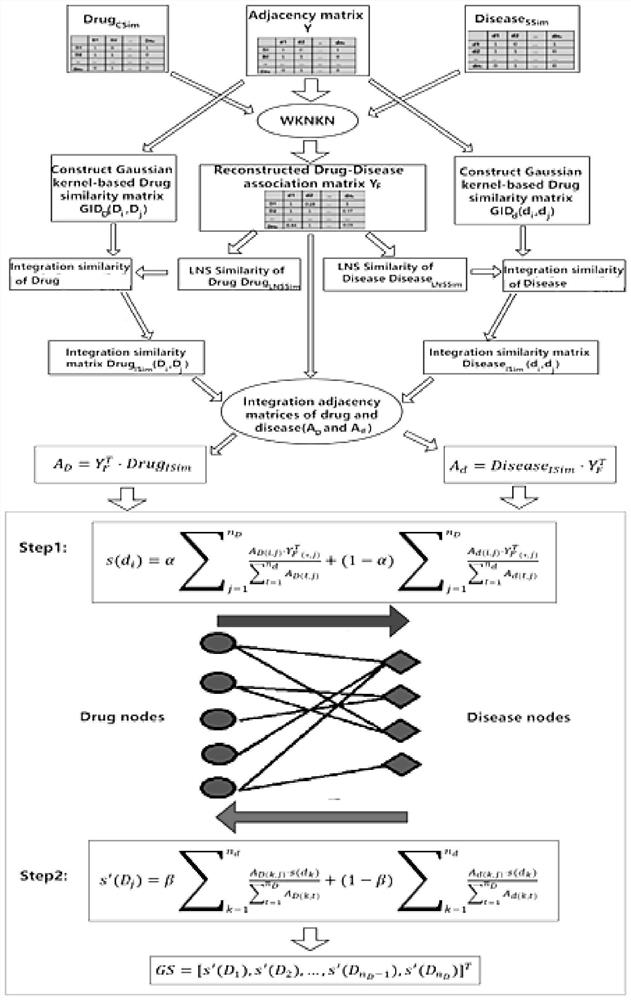

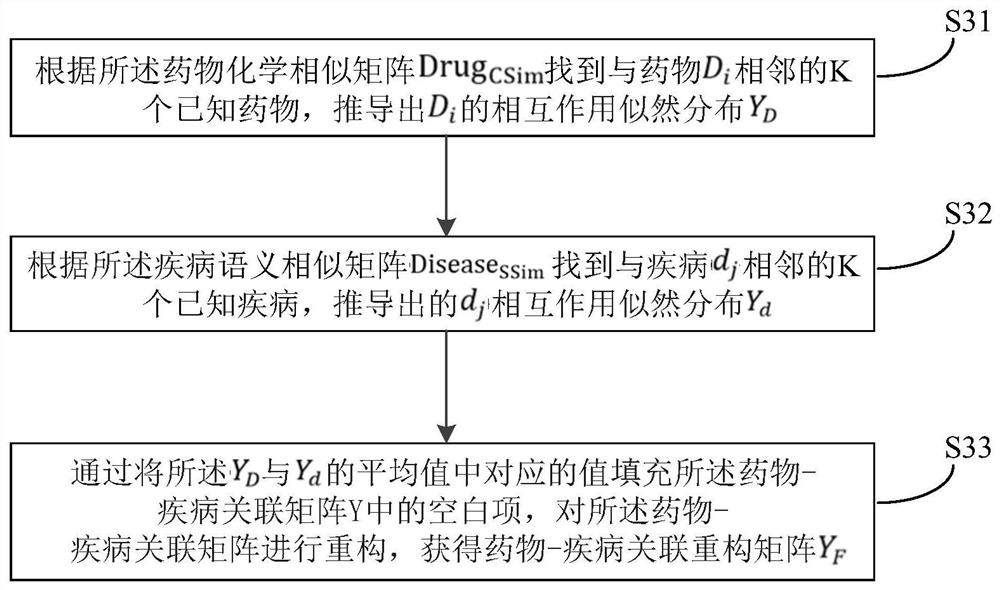

Drug-disease association prediction method and system

Aiming at the limitation of the existing drug relocation technology, the invention provides a drug-disease association prediction method and system, and the method partially reduces the sparsity of an existing drug-disease original association matrix by applying a weight K nearest neighbor algorithm; meanwhile, a linear feature extraction mode and a nonlinear feature extraction mode are integrated when the similarity feature information of the medicine and the disease is extracted, so that more comprehensive similar feature information is obtained, and the relationship between the medicine and the disease can be fully reflected; and a bipartite graph diffusion method is adopted to calculate a drug-disease associated prediction score, so that excellent prediction performance is obtained.

Owner:GUANGDONG UNIV OF TECH

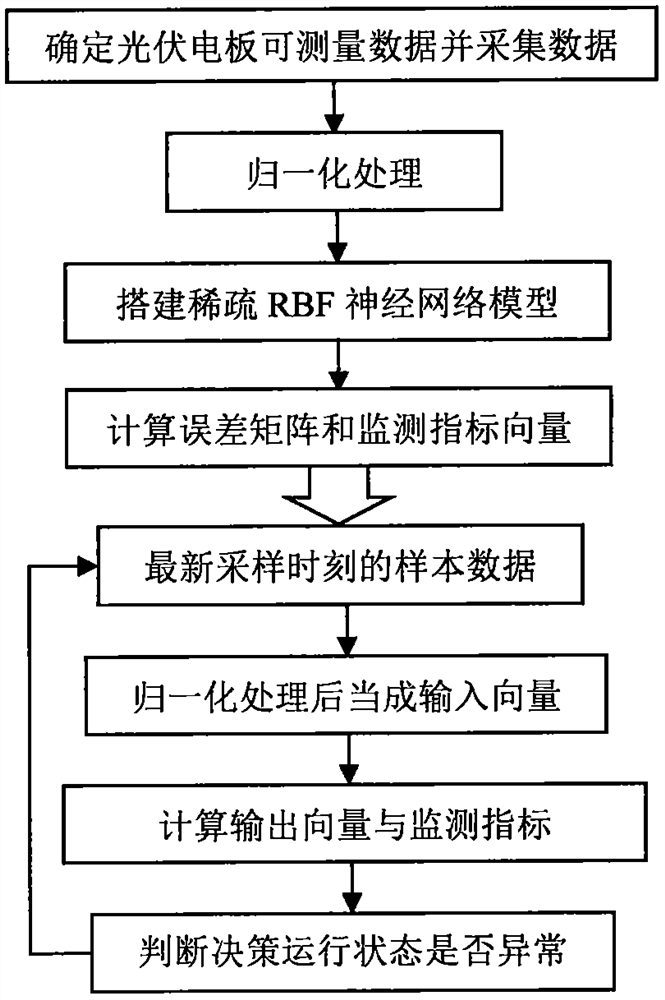

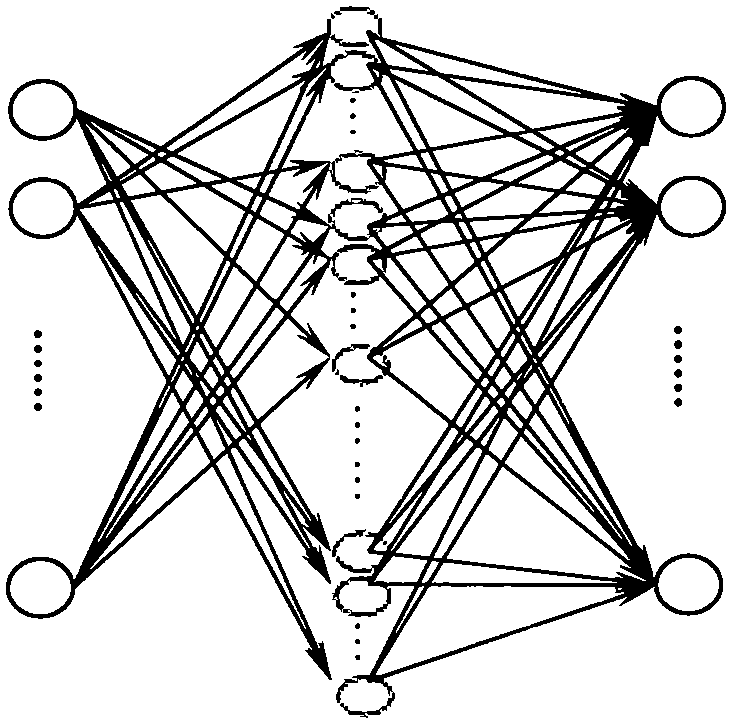

Photovoltaic panel operation state monitoring method based on sparse RBF neural network

The invention discloses a photovoltaic panel operation state monitoring method based on a sparse RBF neural network, and aims to effectively mine nonlinear relation characteristics among measurement data of a photovoltaic panel and monitor the operation state of the photovoltaic panel on the basis of the nonlinear relation characteristics. Specifically, according to the method, a sparse RBF neural network structure is designed, real-time sampling data of the photovoltaic panel serve as input and output at the same time, and whether the running state of the photovoltaic panel is abnormal or not is reflected through generated errors. The method disclosed by the invention has the advantages that firstly, the nonlinear fitting capability of the RBF neural network is utilized, and the nonlinear feature extraction of the sample data of the photovoltaic panel in the normal operation state is realized through the established sparse RBF neural network; and secondly, according to the method, errors are generated through the sparse RBF neural network and are used for judging whether the photovoltaic panel is abnormal or not in real time, and the method is different from non-linear feature components monitored and extracted through a traditional method.

Owner:COLLEGE OF SCI & TECH NINGBO UNIV

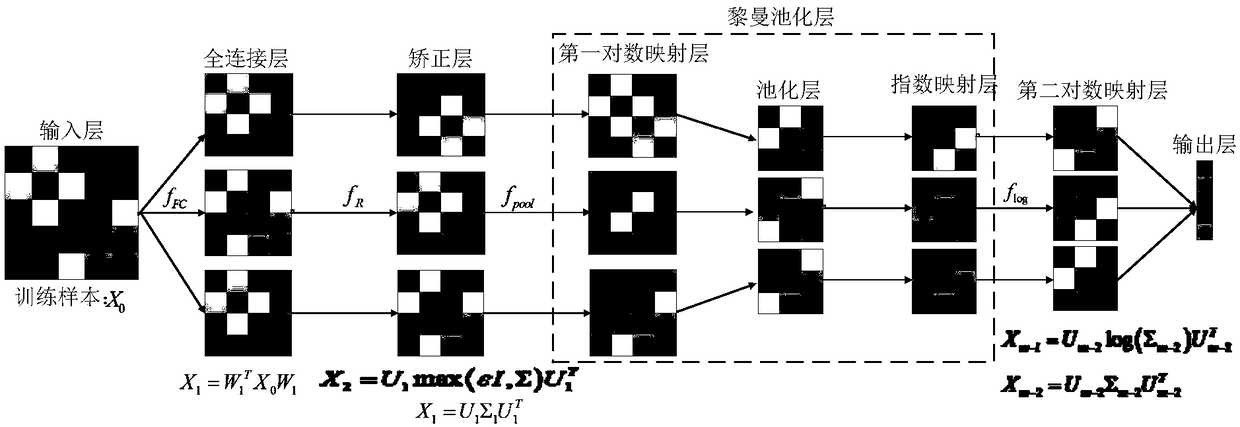

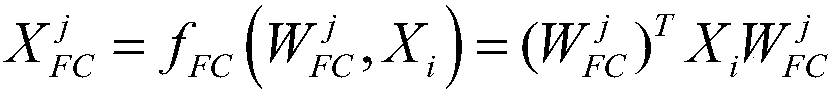

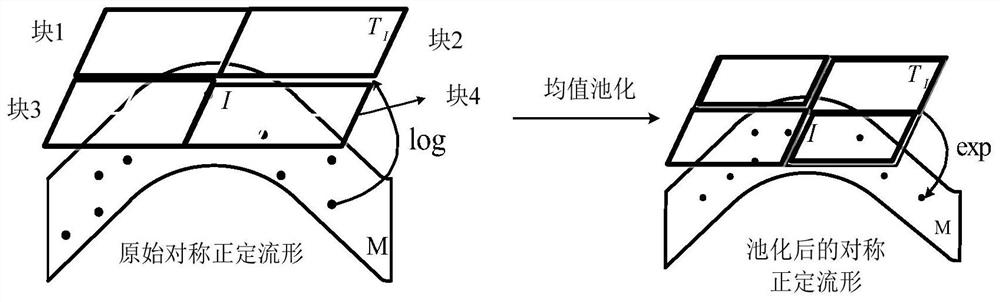

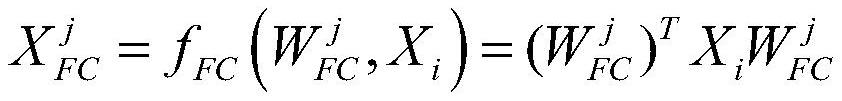

Manifold learning network and its computer vision image set classification method

ActiveCN109376787BThe process is easy to realizeEasy to trainCharacter and pattern recognitionClassification methodsVideo sequence

The present invention relates to a manifold learning network and a method for classifying computer vision image sets based on it. The manifold learning network includes an input layer, a fully connected layer, a correction layer, a Riemann pooling layer, a second logarithmic mapping layer and an output layer , which is mainly used to classify the collected video sequences, by building a simple learning network on the Riemannian manifold, and using bidirectional two-dimensional principal component analysis technology to optimize the weight parameters to complete the nonlinear feature extraction and Classification. Compared with the prior art, the present invention can effectively improve the object classification accuracy in complex scenes, and at the same time, the training time is shorter.

Owner:聚时科技(上海)有限公司

A method for diagnosing minor faults of crh5 type high-speed rail inverters

ActiveCN106093626BTesting electric installations on transportKernel principal component analysisOriginal data

The invention discloses a method for diagnosing the minor faults of a CRH5 high-speed railway inverter. A multi-modal kernel principal component analysis method is provided. Data acquired by a sensor is preprocessed. A system model on a normal condition is obtained. Whether an electrical system has a fault is detected by processing online data according to the characteristic of the electrical system. Specific data is processed and analyzed. Acquired data has two dimensionalities. Two dimensionalities including period and modal are added to original data so that the original data is projected onto a four-dimensional space. Thus, the original nonlinear data is more accurately distributed in a high-dimensional space. The characteristic of each mode is extracted according to a nonlinear characteristic extraction method. Compared with a linear PCA algorithm and a nonlinear KPCA algorithm, the method is more precise in detection of the minor faults of a CRH5 high-speed railway inverter, more accurate in diagnosed results, lower in missing report rate, and more advantageous.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

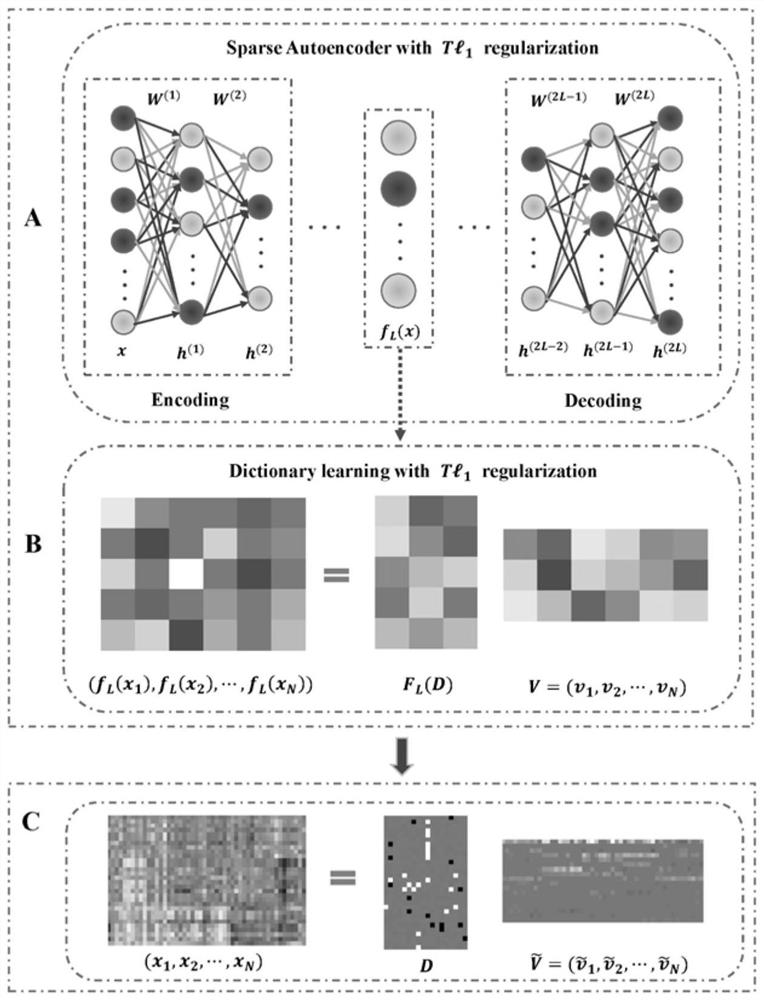

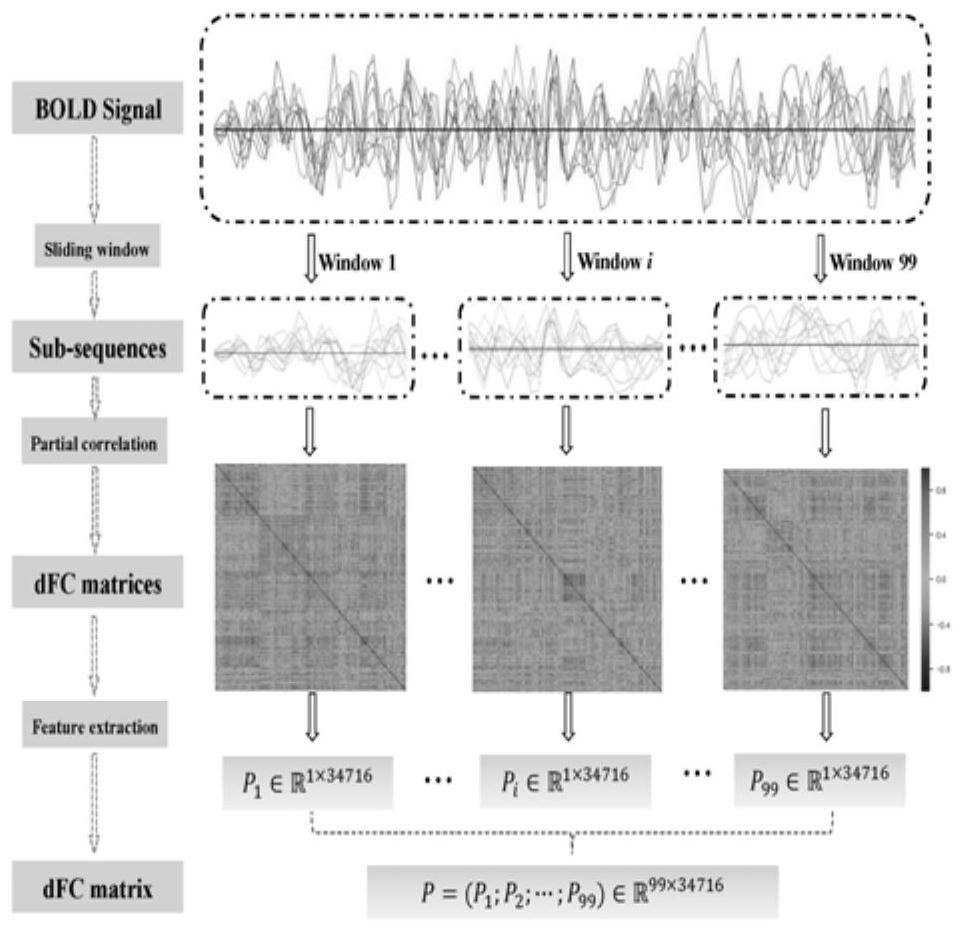

Method, system and device for identifying brain nerve development time-varying function connection difference and storage medium

PendingCN113505528AImprove adaptive learningPrevent overfittingCharacter and pattern recognitionDesign optimisation/simulationFunctional connectivityAlgorithm

The invention discloses a method, a system and equipment for identifying brain nerve development time-varying function connection differences, and a storage medium. The method comprises the following steps: constructing a sparse deep dictionary learning model; a sparse depth dictionary learning model is trained, in the training process, a sparse depth automatic encoder learns a dictionary from original data of a potential space, and meanwhile, a Tl1 norm and a KL divergence are used for executing a sparse regularization item; the trained sparse deep dictionary learning model is utilized to analyze the brain neural development time-varying function connection difference, the method, system and device and the storage medium can identify the brain neural development time-varying function connection difference, and meanwhile, the advantage of deep learning in advanced nonlinear feature extraction and the interpretability of dictionary learning are combined.

Owner:XI AN JIAOTONG UNIV

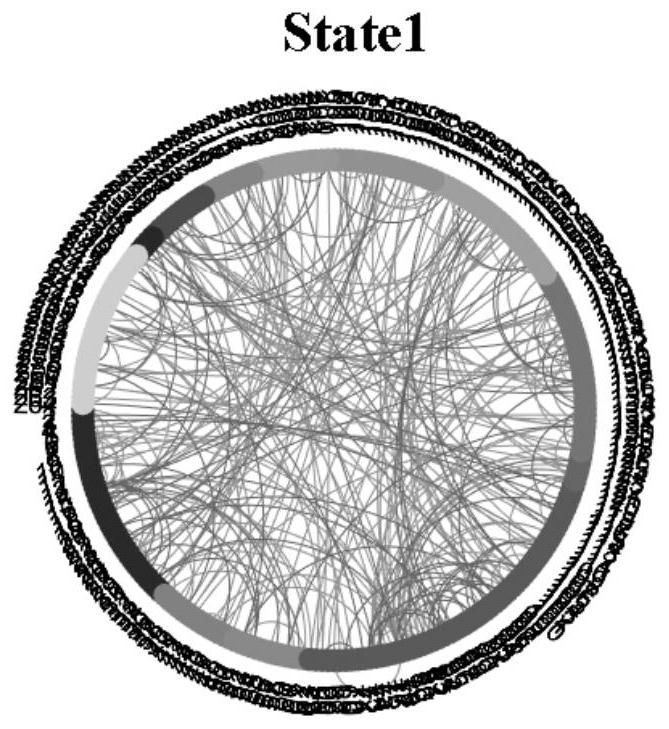

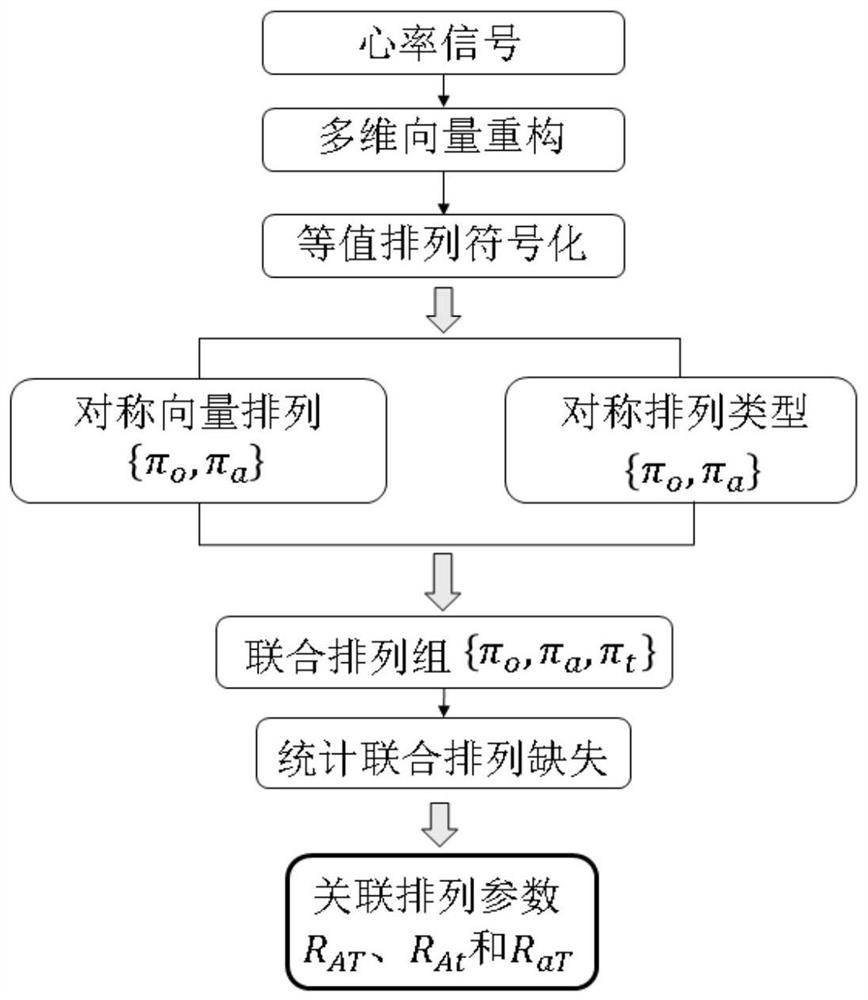

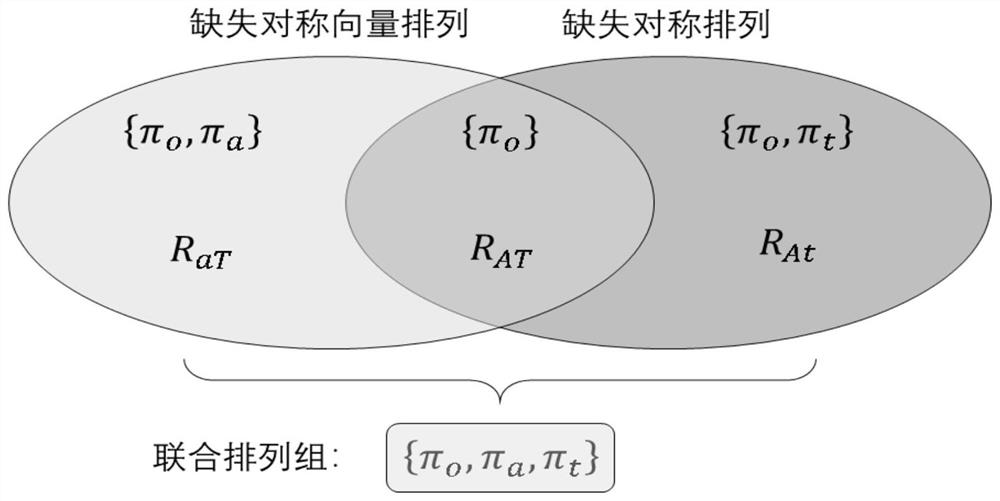

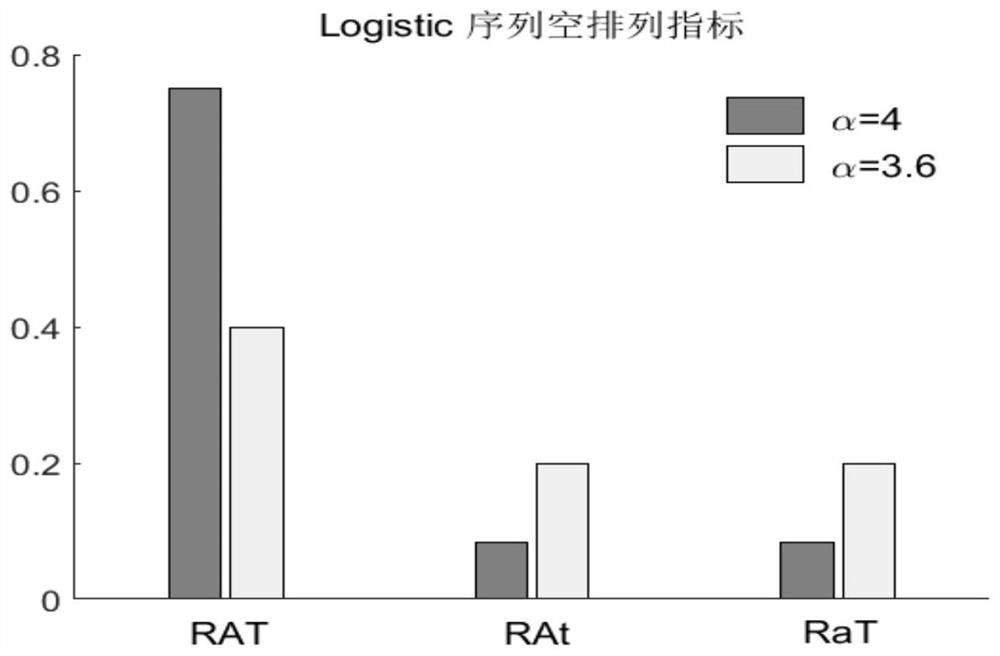

A Non-Linear Feature Extraction Method of Physiological Signals Based on Empty Arrangement

ActiveCN110807438BEfficient extractionCharacter and pattern recognitionBiomedical engineeringSignal processing

The invention discloses a method for extracting nonlinear features of physiological signals based on empty arrays, which is applied in the field of physiological signal processing. Aiming at the lack of parameter extraction and analysis of nonlinear features of physiological signals based on empty arrays in the prior art, the present invention uses The acquired physiological signal is symbolized by equivalent arrangement to obtain a first vector and its first arrangement type; then find a symmetrical arrangement type of the first arrangement type, and classify the first arrangement type and its symmetrical arrangement type into a first combination; Then find the symmetric vector of the first vector, and obtain the permutation type of the symmetric vector, record it as the second permutation type, classify the first permutation type and the second permutation type into the second combination; then according to the first combination and the second Combining to build a joint permutation group, and counting the feature quantities in the joint permutation group; finally extracting the nonlinear characteristic parameters of the physiological signal according to the feature quantity; the method of the present invention can correctly and effectively characterize the physiological signals under different physiological states based on the empty permutation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Soft sensing method for load parameter of ball mill

ActiveCN101776531BHigh sensitivityImprove forecast accuracySubsonic/sonic/ultrasonic wave measurementCurrent/voltage measurementLeast squares support vector machineEngineering

The invention relates to a soft sensing method for load parameters of a ball mill. The method is that a hardware supporting platform is used to obtain vibration signals, vibration sound signals and current signals of a ball mill cylinder to soft sense ball mill internal parameters (ratio of material to ball, pulp density and filling ratio) characterizing ball mill load. The method comprises the following steps that: the vibration, the vibration sound, the current data and the time-domain filtering of the ball mill cylinder are acquired, time frequency conversion is conducted to the vibration and the vibration sound data, kernel principal component analysis based nonlinear features of the sub band of the vibration and the vibration sound data in frequency domain are extracted, nonlinear features of the time domain current data are extracted, feature selection is conducted to the fused nonlinear feature data and a soft sensing model based on a least squares support vector machine is established. The soft sensing method of the invention has the advantages that the sensitivity is high, the sensed results are accurate, the practical value and the popularization prospect are very good, and the realization of the stability control, the optimization control, the energy saving and the consumption reduction of the grinding production process is facilitated.

Owner:NORTHEASTERN UNIV LIAONING

A Method of Electronic Tongue Signal Feature Extraction Based on Manifold Learning

ActiveCN106018515BCharacterize nonlinear featuresImprove signal diversityMaterial electrochemical variablesSequence signalMahalanobis distance

The invention provides a feature extraction method for signals of an electronic tongue based on manifold learning. The method comprises the following steps: detecting tea samples with the electronic tongue so as to obtain sensor-responsive sequence signals; analyzing and rejecting abnormal samples by using a principal component residual method and a Mahalanobis distance method; optimizing the parameters of a manifold learning algorithm and selecting the parameters of the manifold learning algorithm on the basis of the correct recognition rata of the quality grade of Longjing tea; carrying out non-linear feature extraction on sensor-responsive signals by using the manifold learning algorithm so as to obtain characteristics characterizing the taste information of the tea samples; and inputting the taste characteristics of the tea samples into a classifier and determining the quality grade of the Longjing tea. The feature extraction method can reject the abnormal values of the tea samples; and the parameter-optimized manifold learning algorithm can better characterize the non-linear characteristics of tea samples of different grades and improve signal difference of samples having undergone nonlinear mapping in high-dimensional feature space.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com