Patents

Literature

43results about How to "Different diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

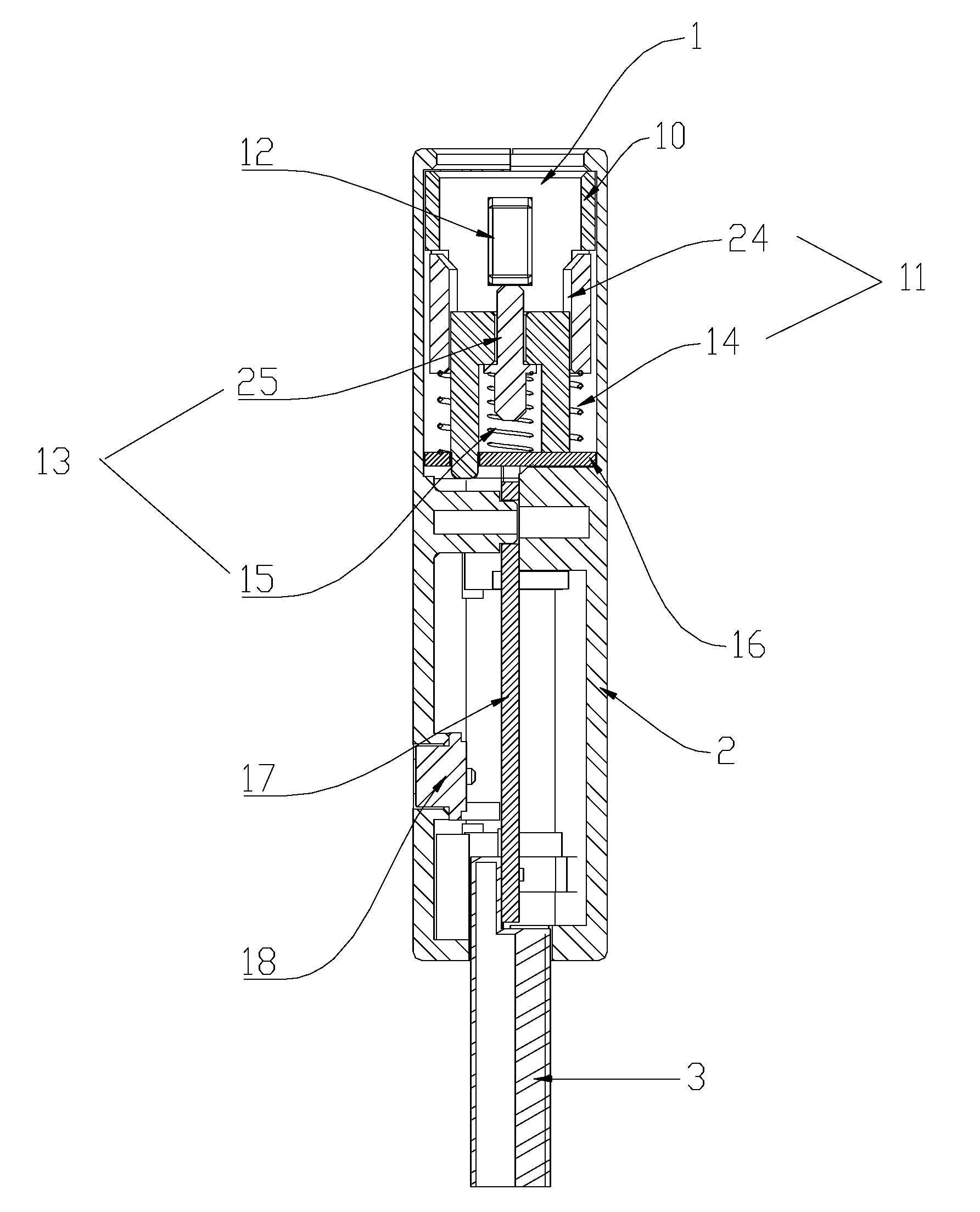

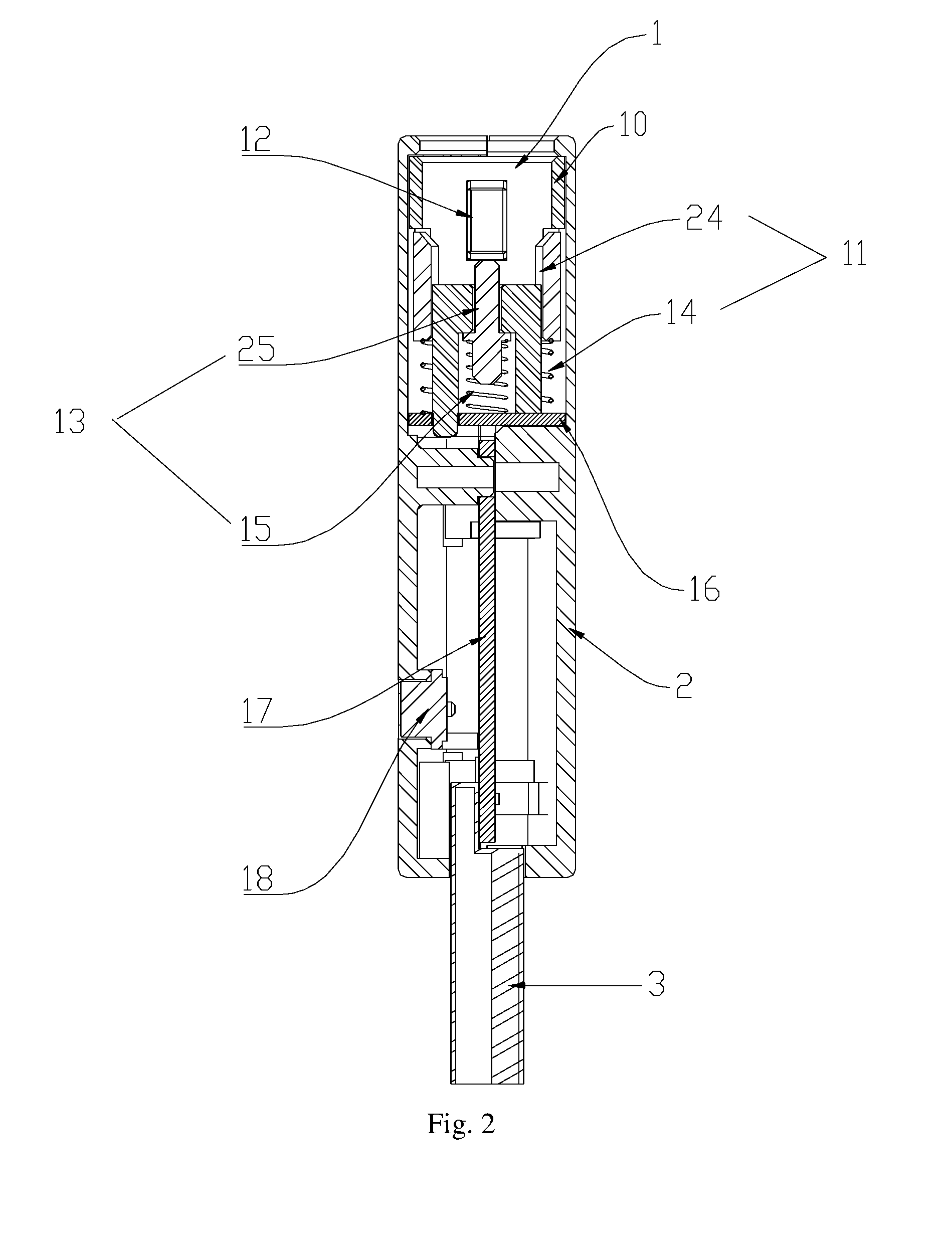

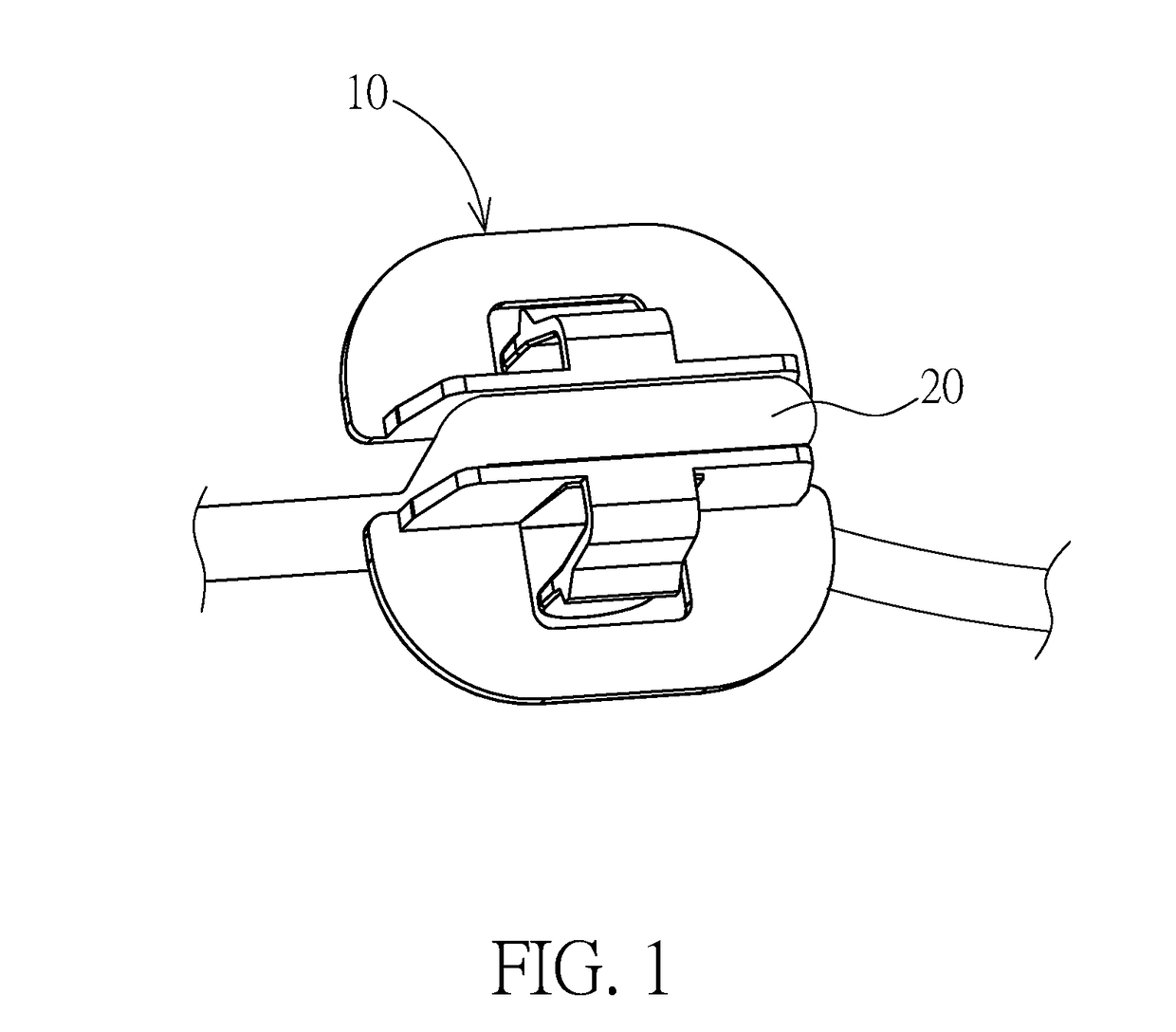

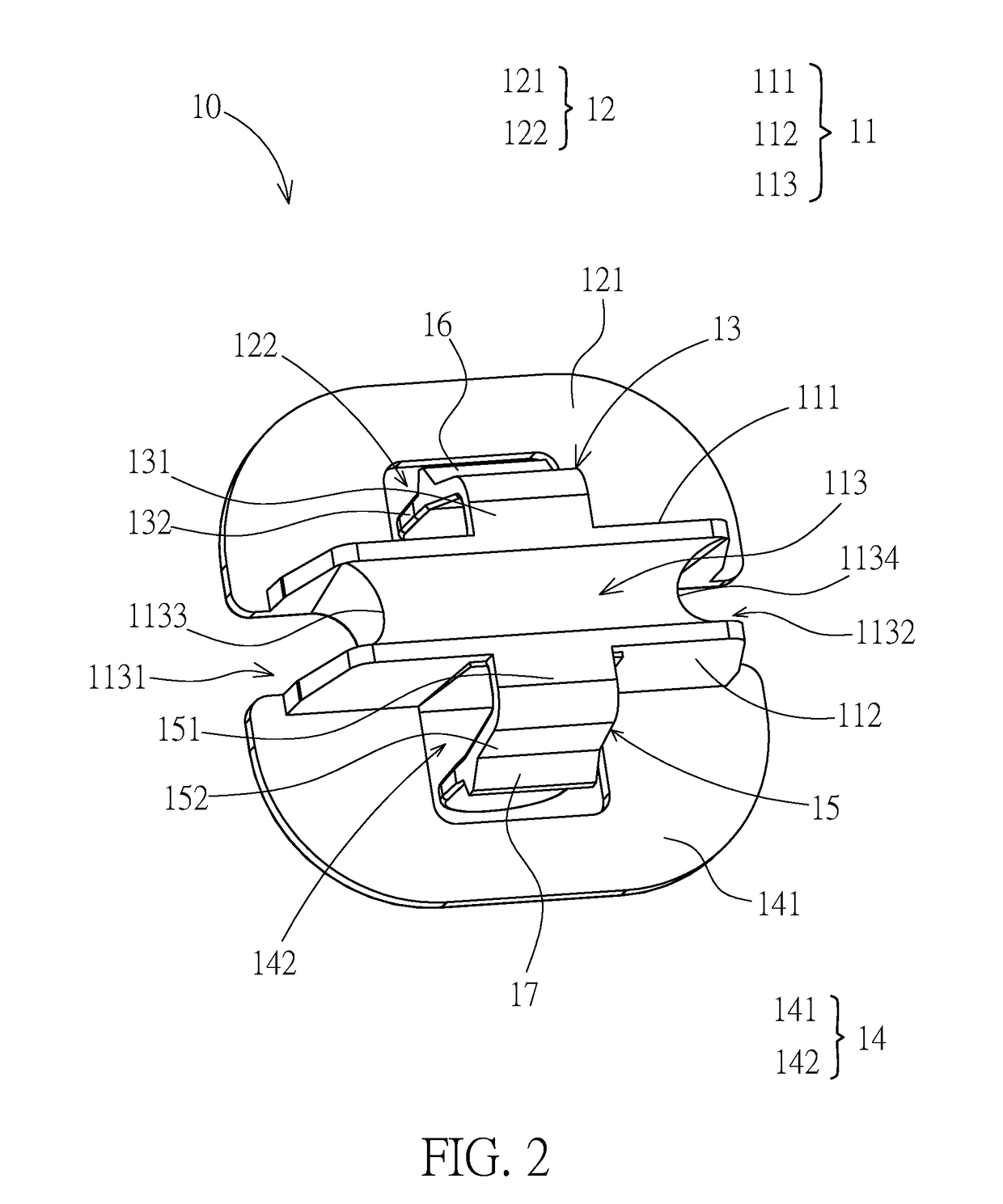

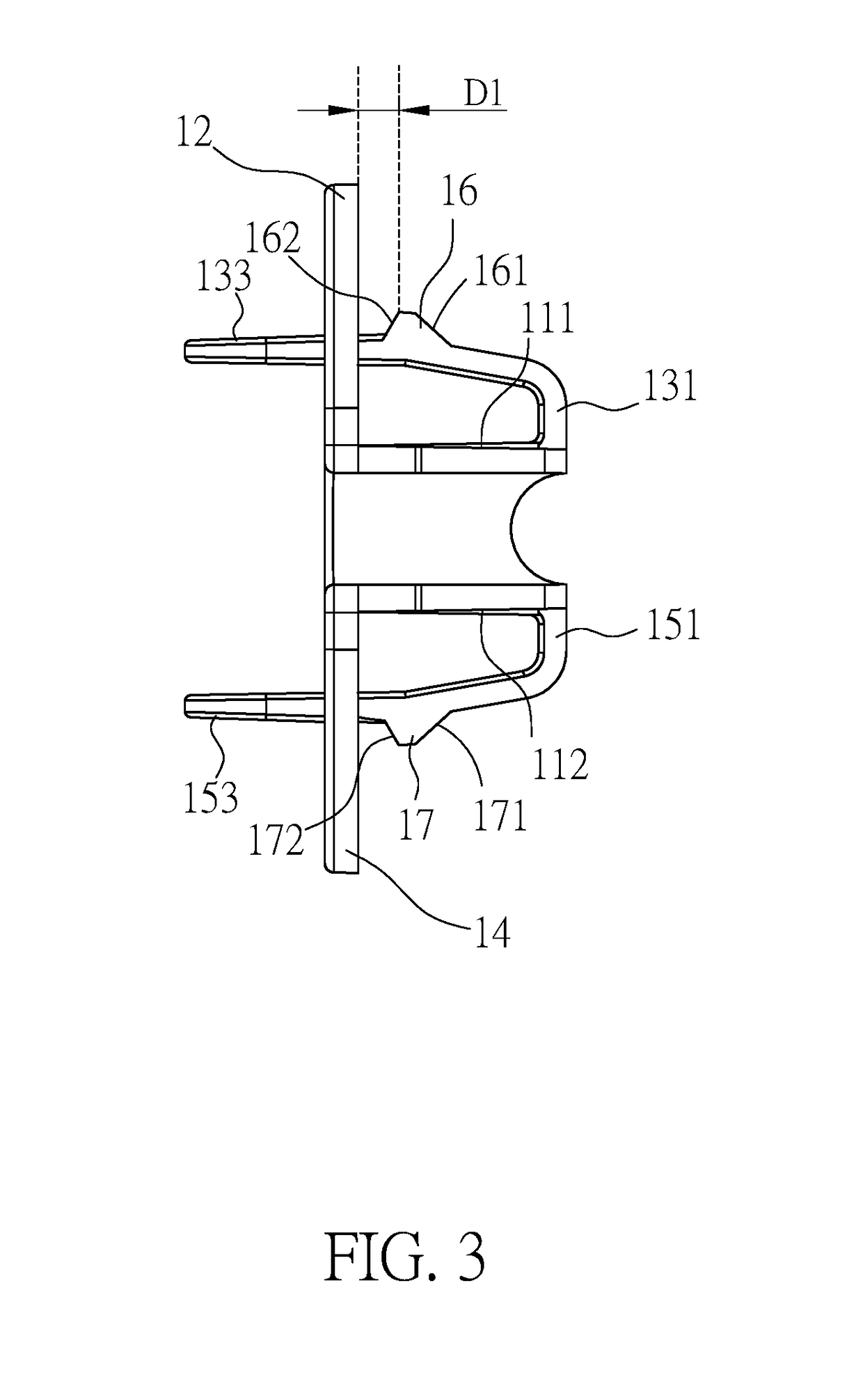

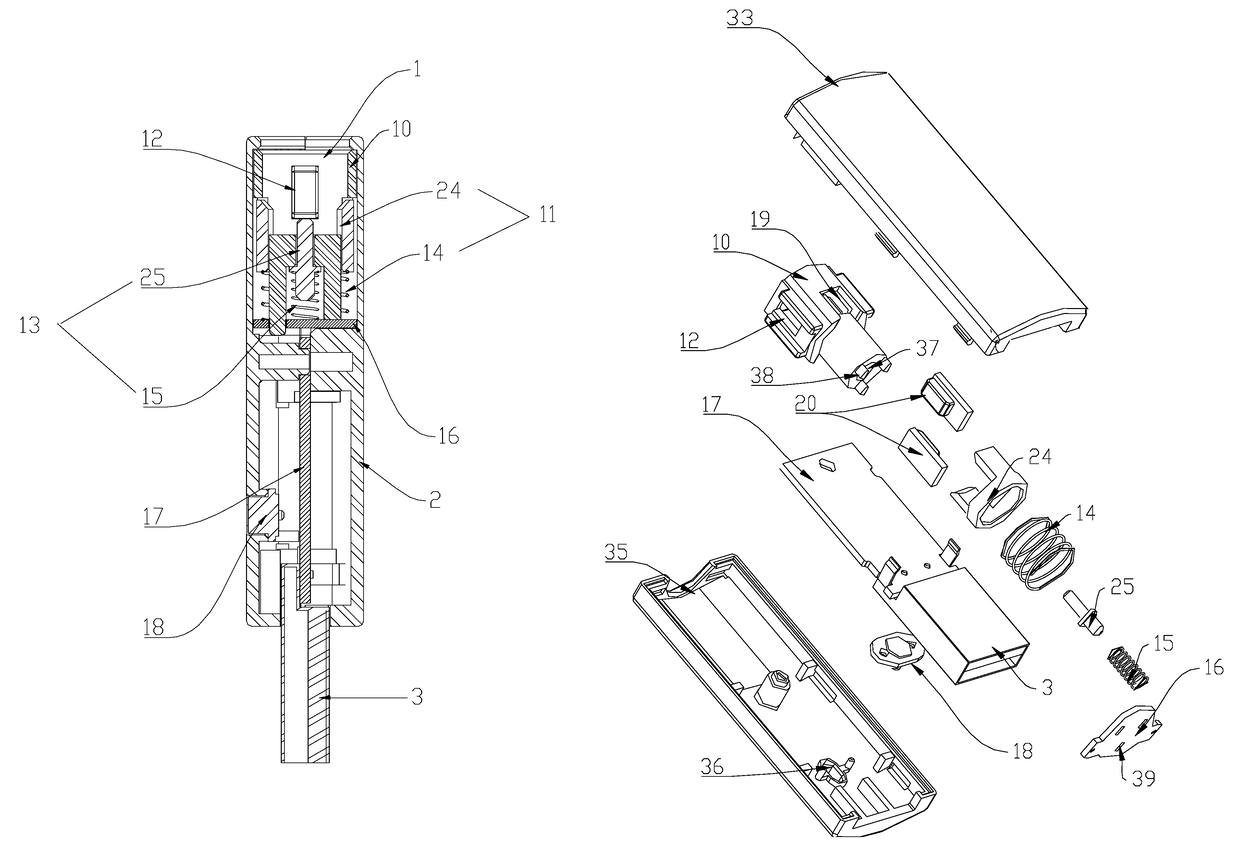

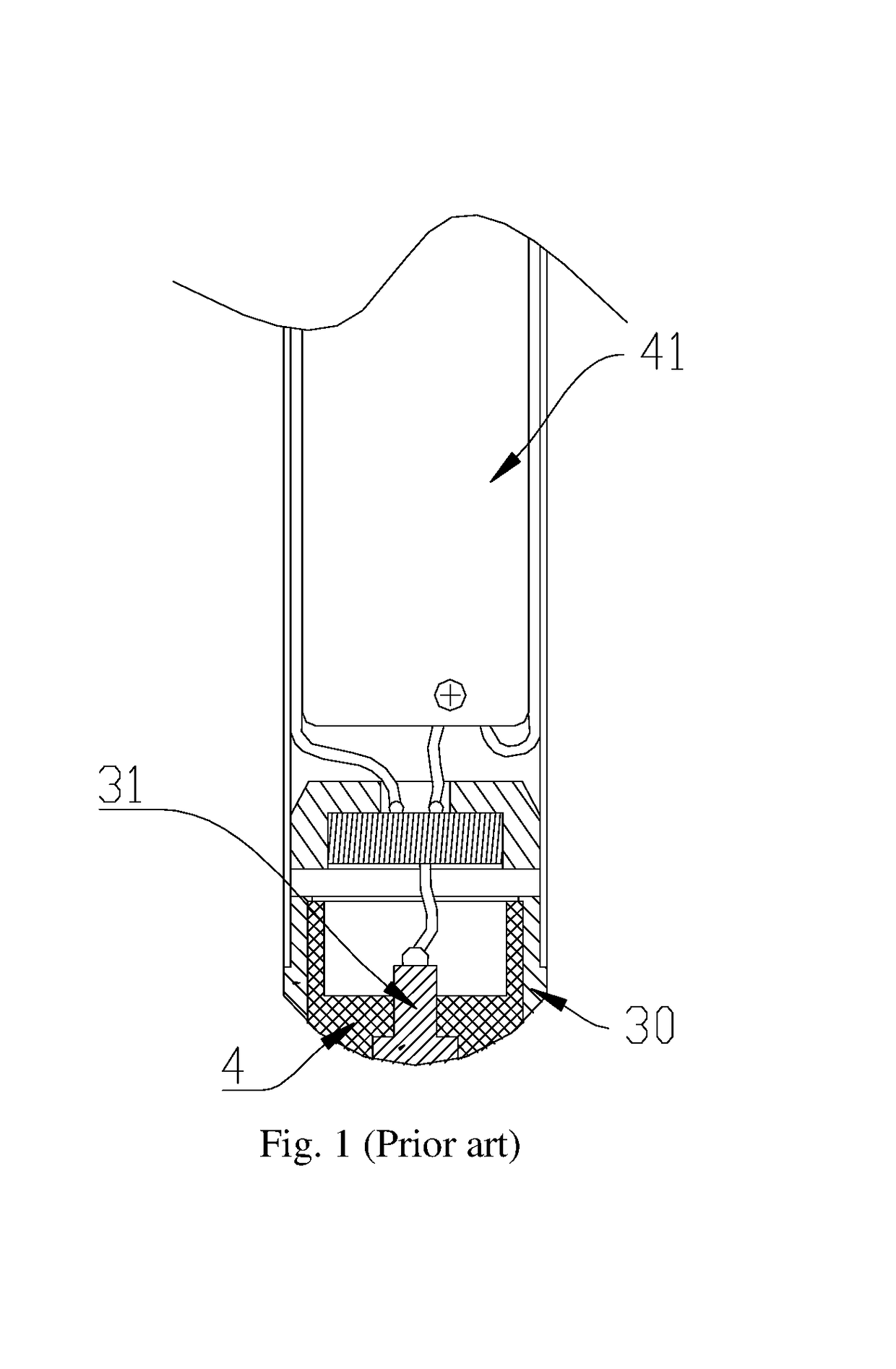

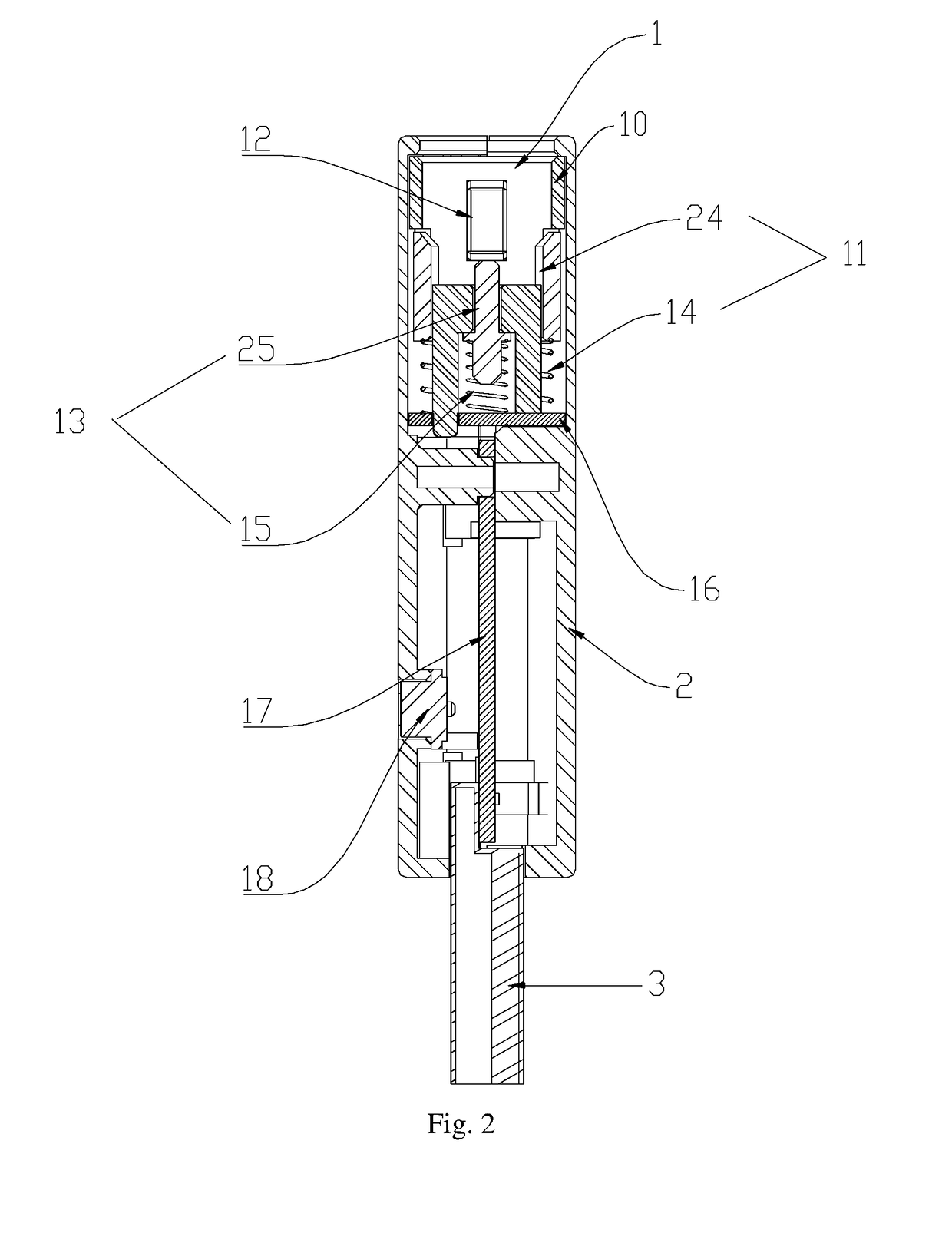

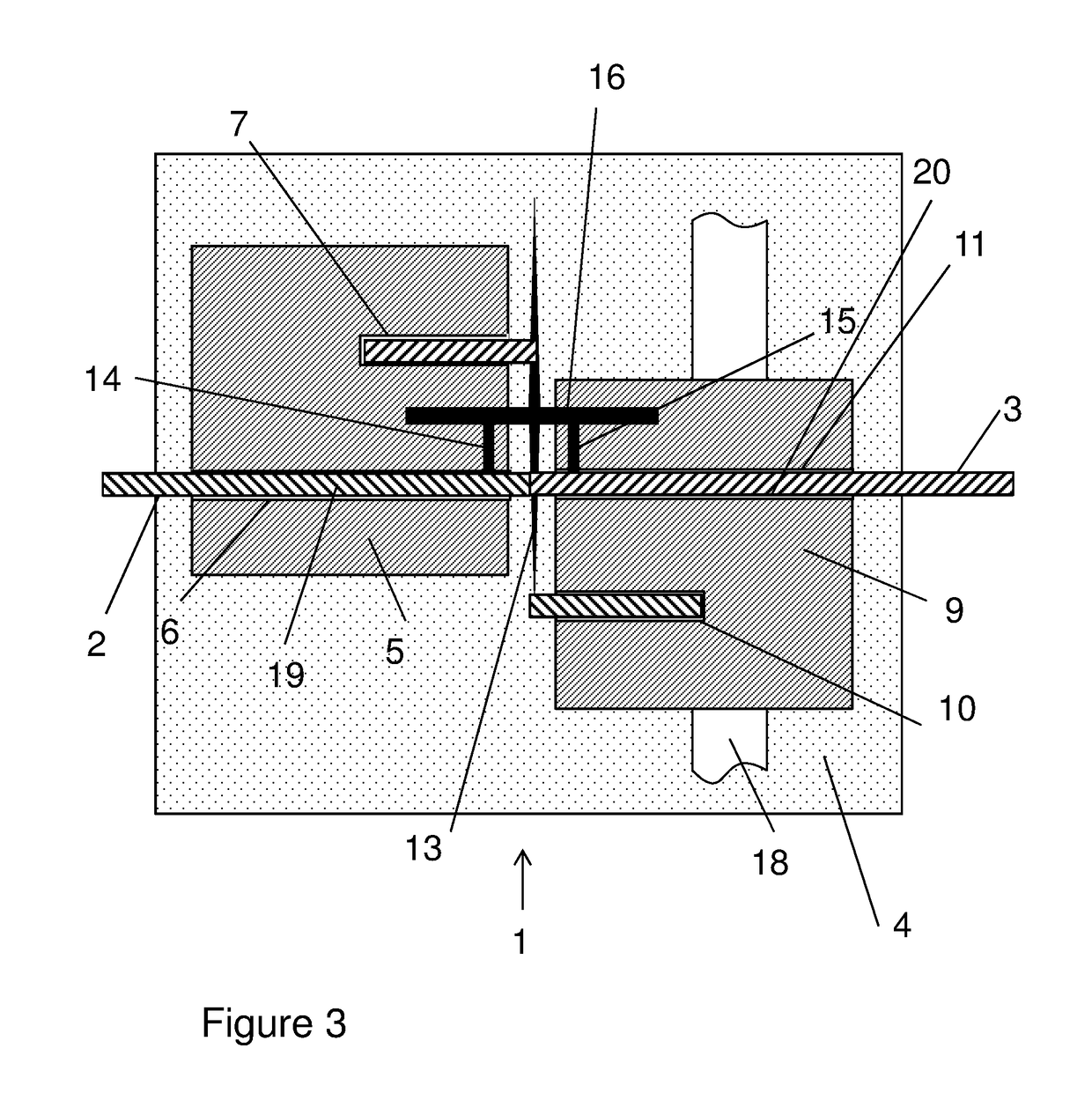

Charging device of electronic cigarette and charging method thereof

InactiveUS20160268824A1Avoid defectsSimple and compact structureIndicating/monitoring circuitsTobacco devicesElectronic cigaretteMechanical engineering

This present application relates to a charging device of an electronic cigarette and a charging method thereof. The charging device including a charging base, in which a first charging electrode assembly and a second charging electrode assembly are arranged separately for connecting with a first and a second electrode of the electronic cigarette, wherein in the charging base, a charging slot is defined in the charging base. The first charging electrode assembly, the second charging electrode assembly and the charging base are coaxially sheathed, and both the first charging electrode assembly and the second charging electrode assembly extend into the charging slot. By implementing this structure, the electronic cigarette has a simplified and compact structure and an easy assembly, also facilitates a steady electrical connection with the electronic cigarette. When charging, it is only needed to insert the electronic cigarette into the charging slot.

Owner:HUIZHOU KIMREE TECH

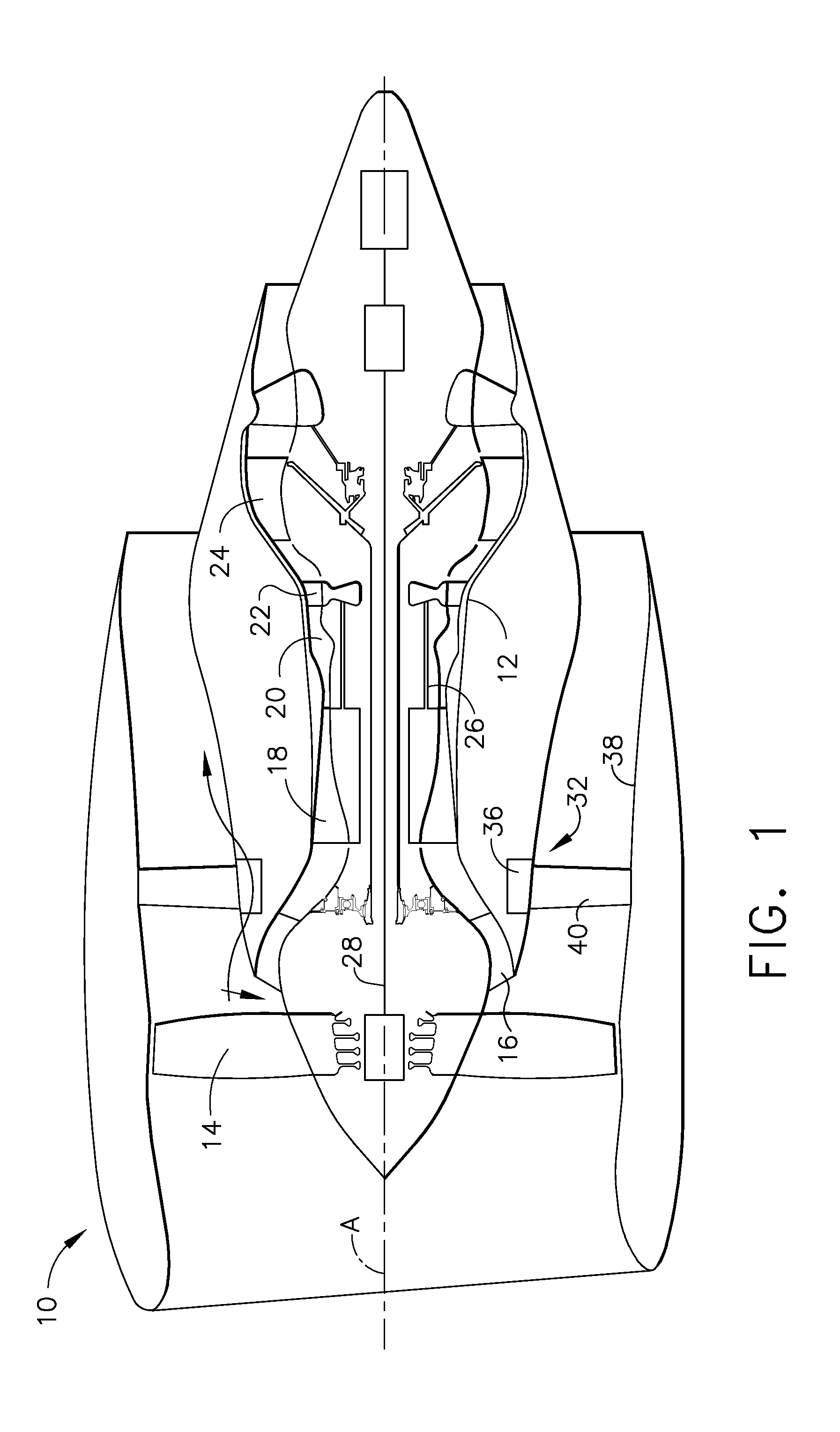

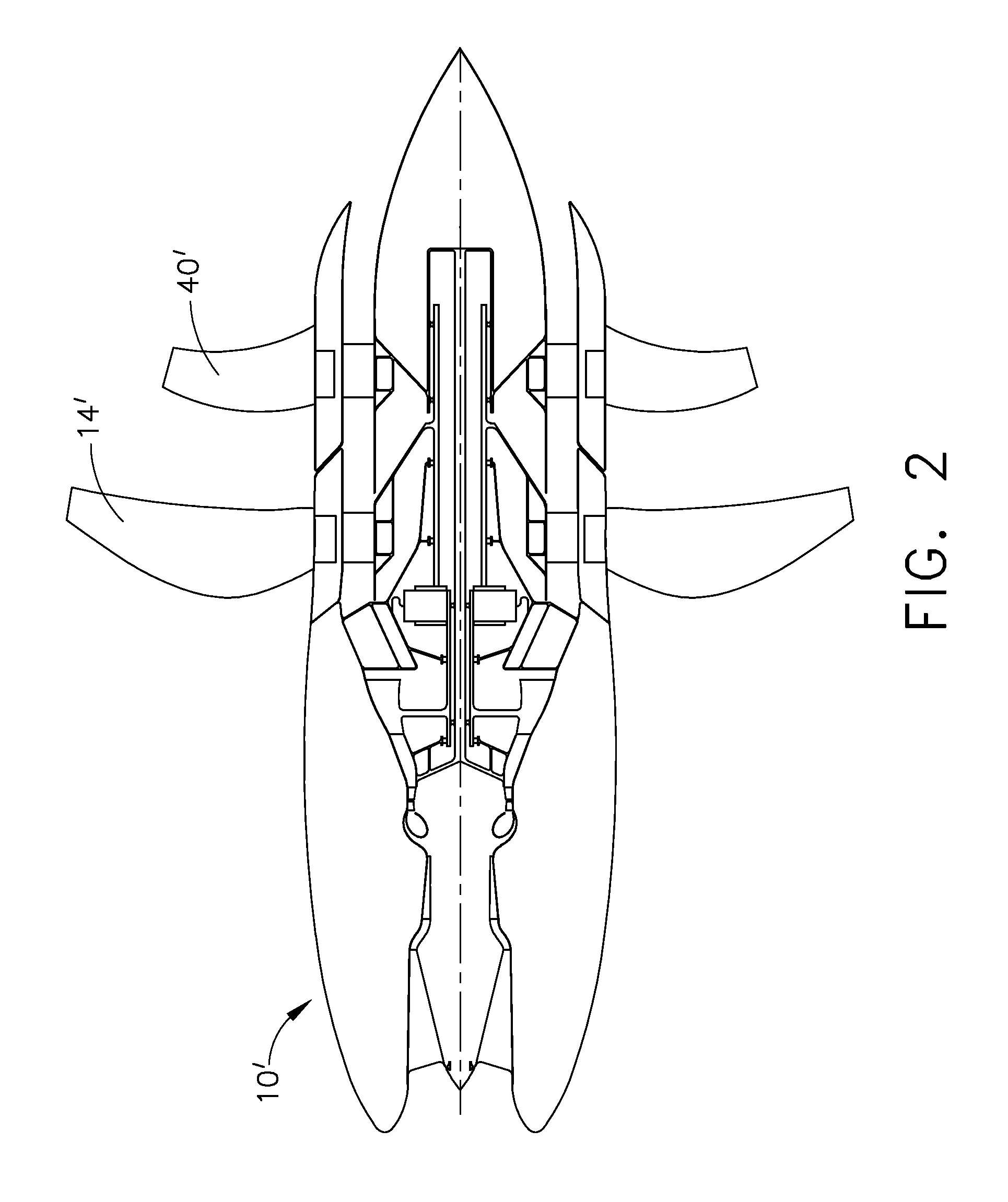

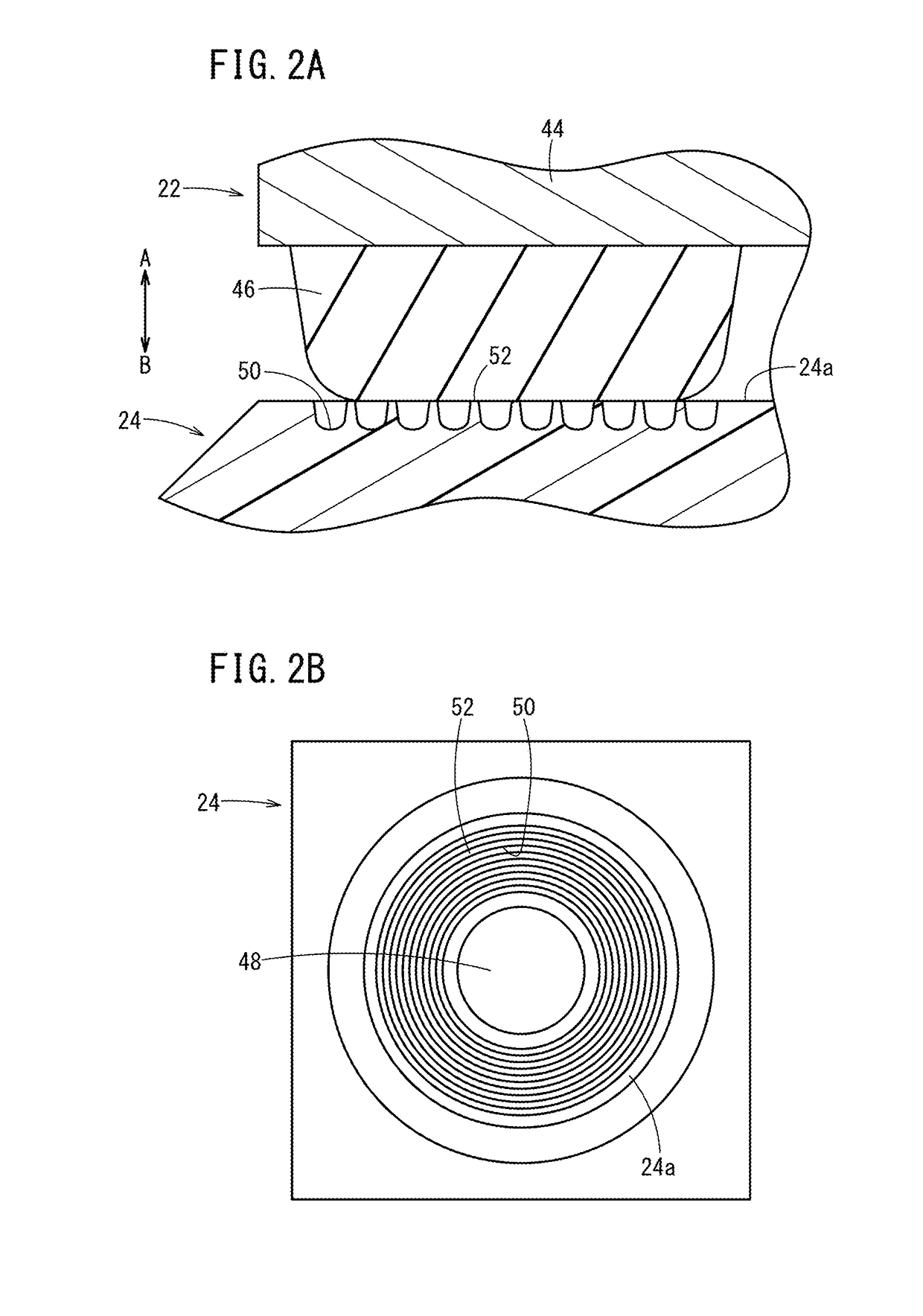

Gas turbine engine component with integrated heat pipe

ActiveUS20160305279A1Different diameterTurbine/propulsion engine coolingEngine fuctionsAerospace engineeringGas turbines

A heat transfer apparatus for a gas turbine engine includes: a component having a wall structure defining a flow bounding surface; a chamber formed in the component, the chamber including a wicking structure, a vapor channel, and a working fluid.

Owner:GENERAL ELECTRIC CO

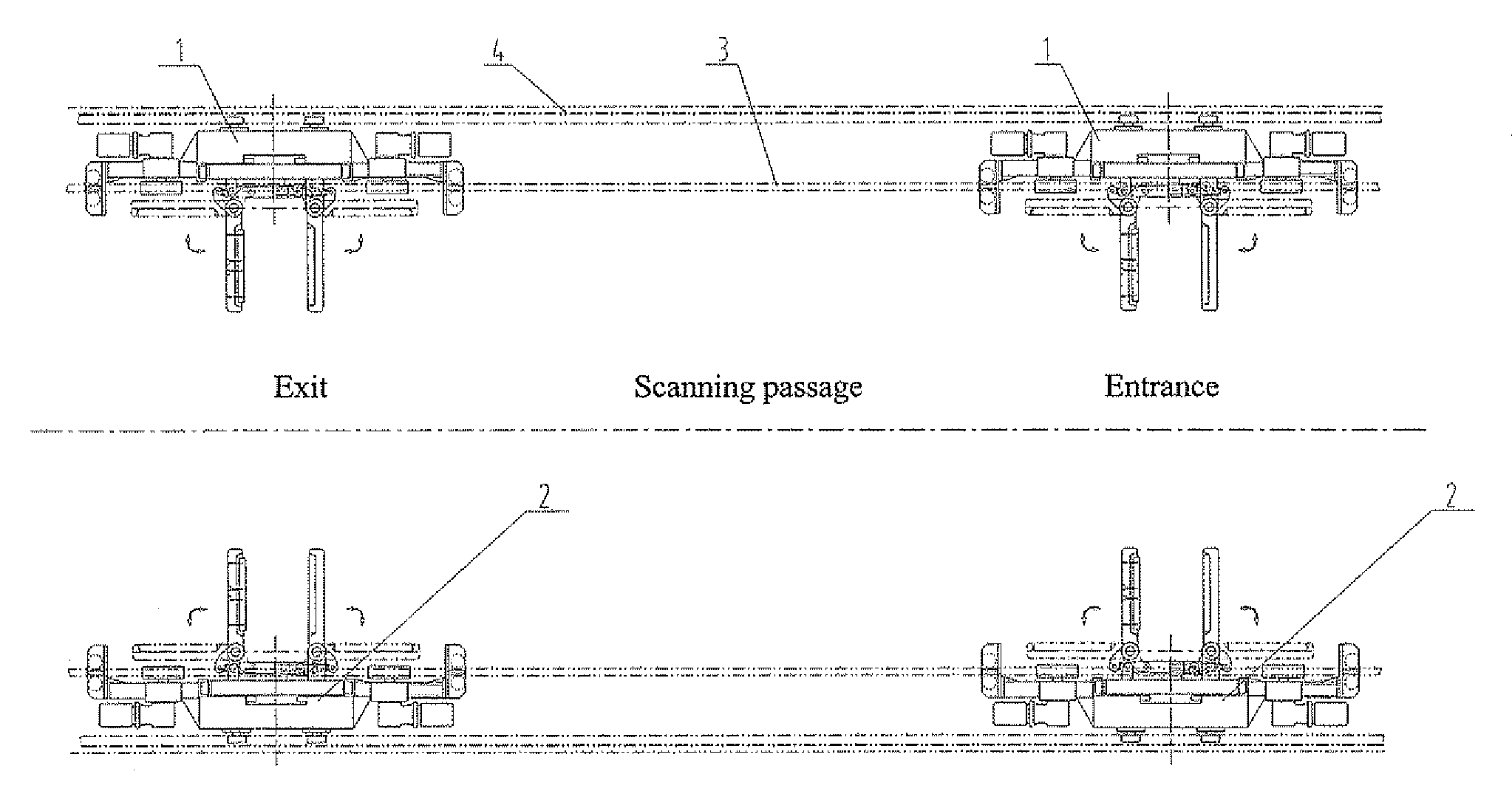

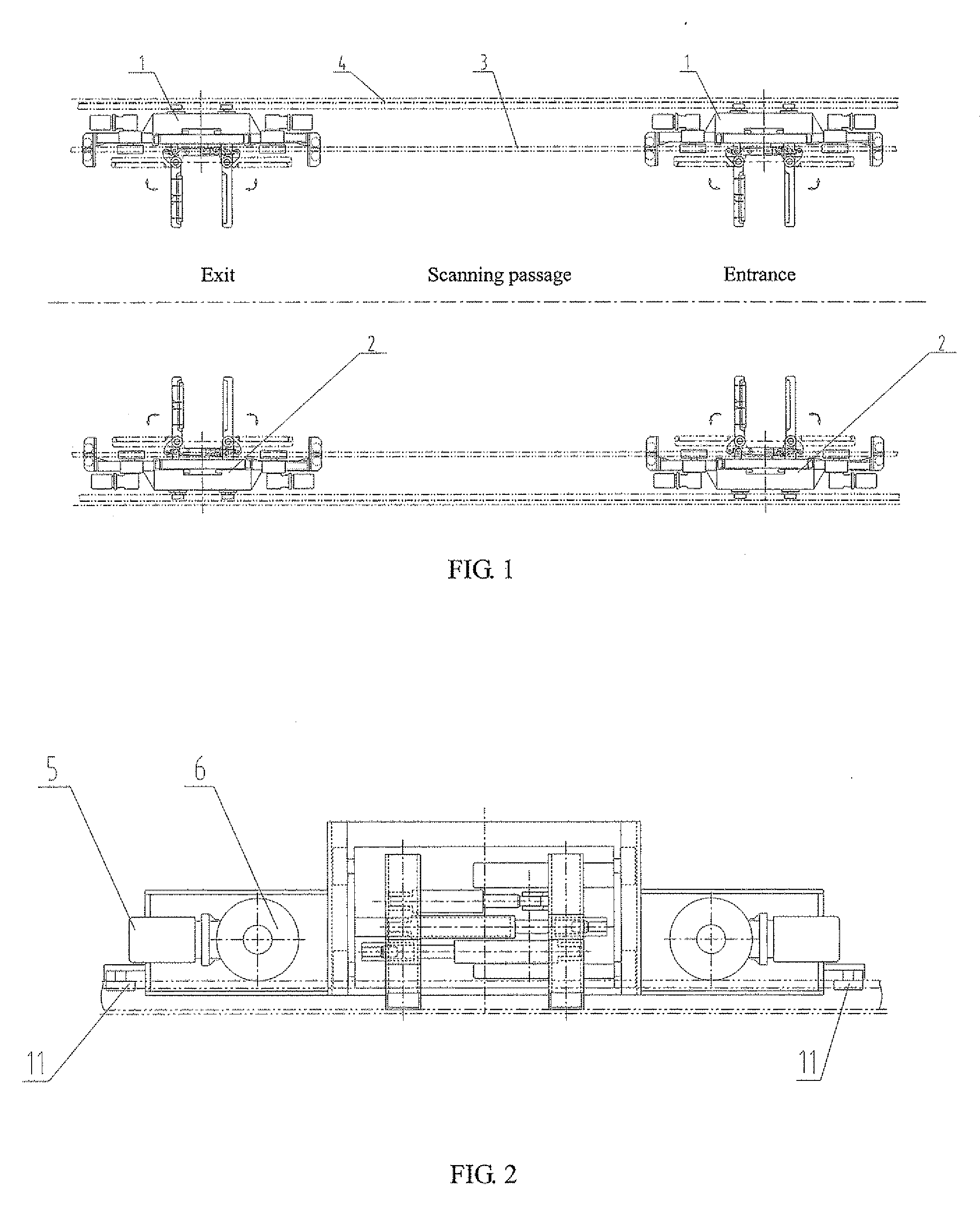

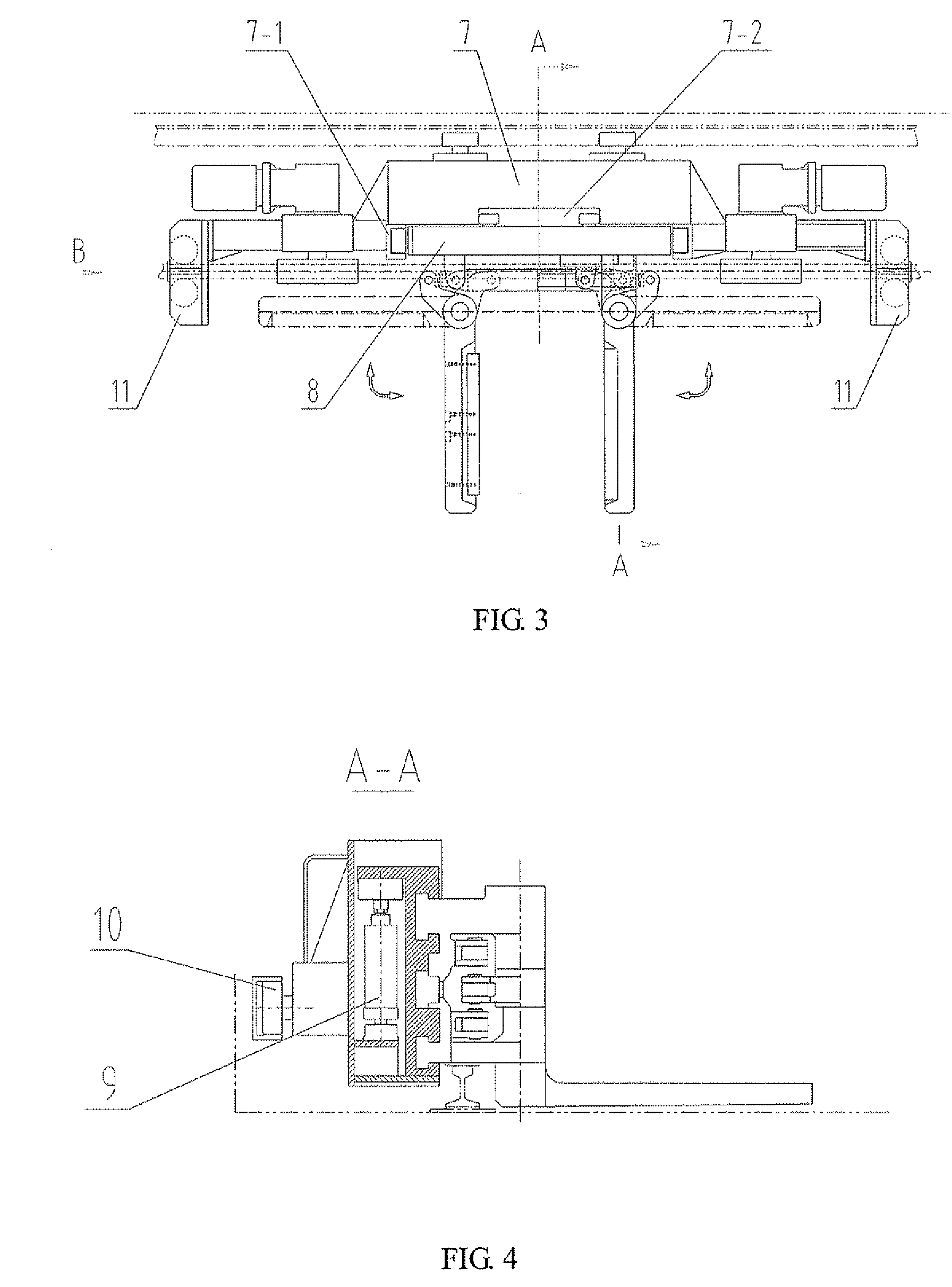

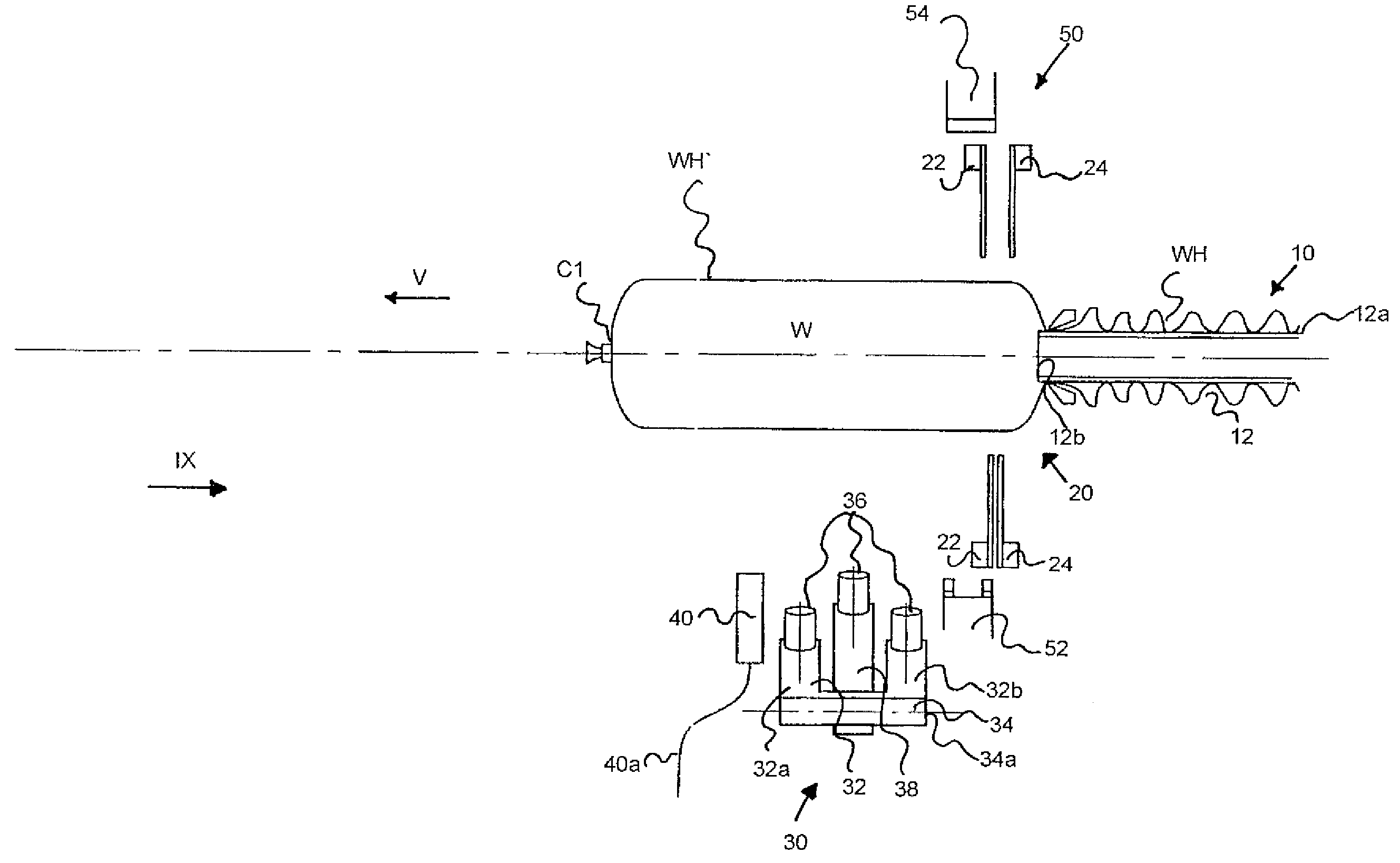

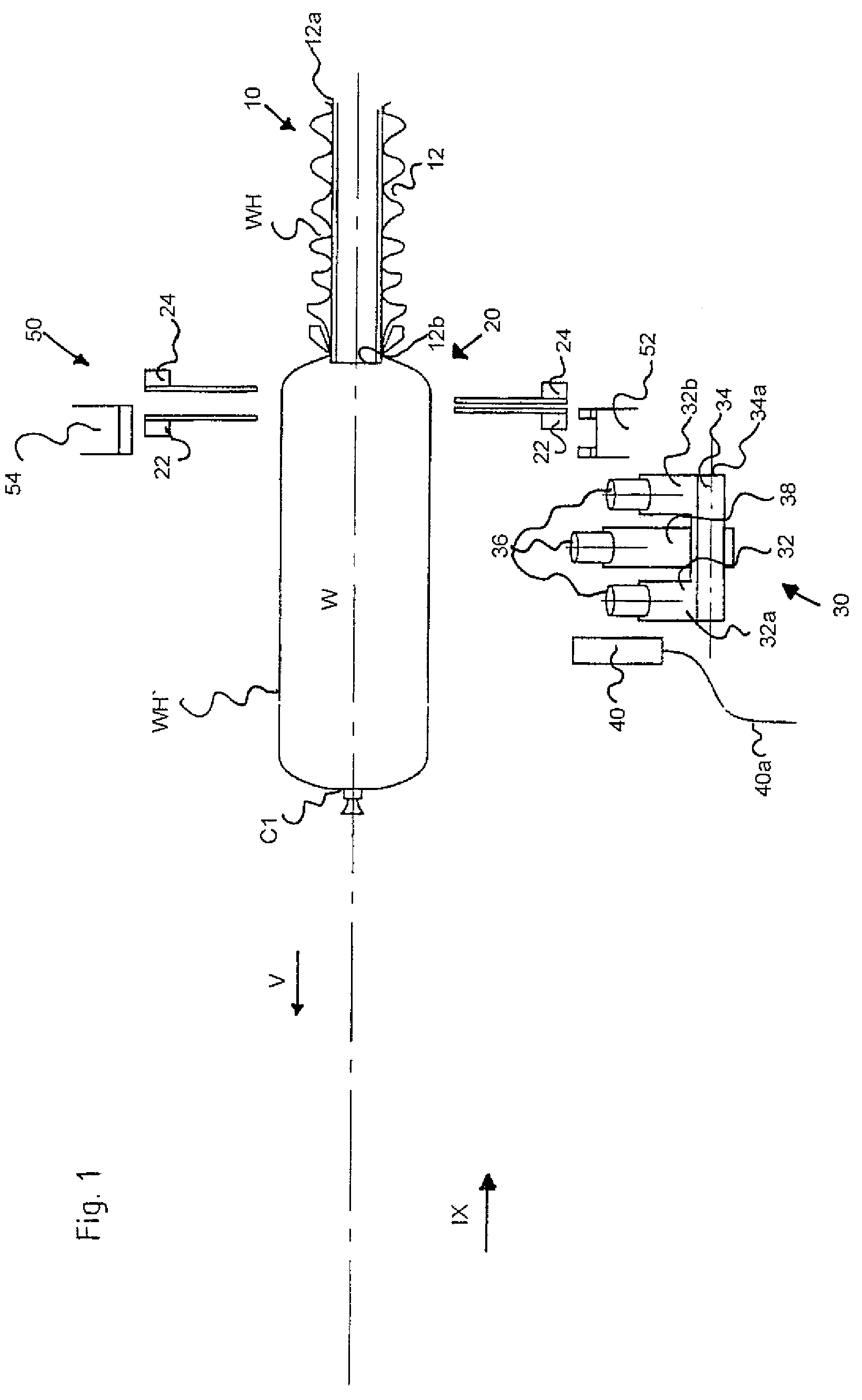

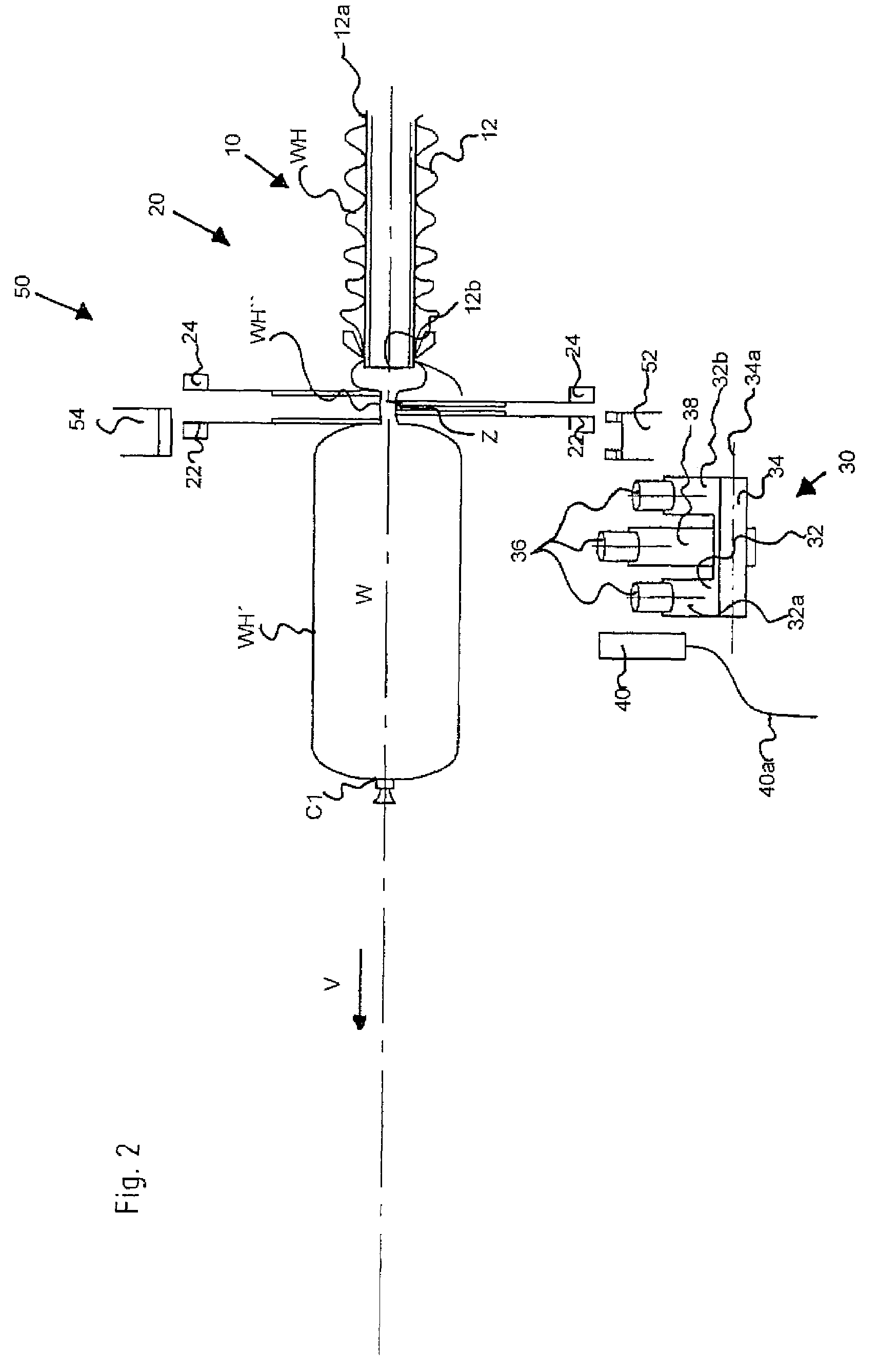

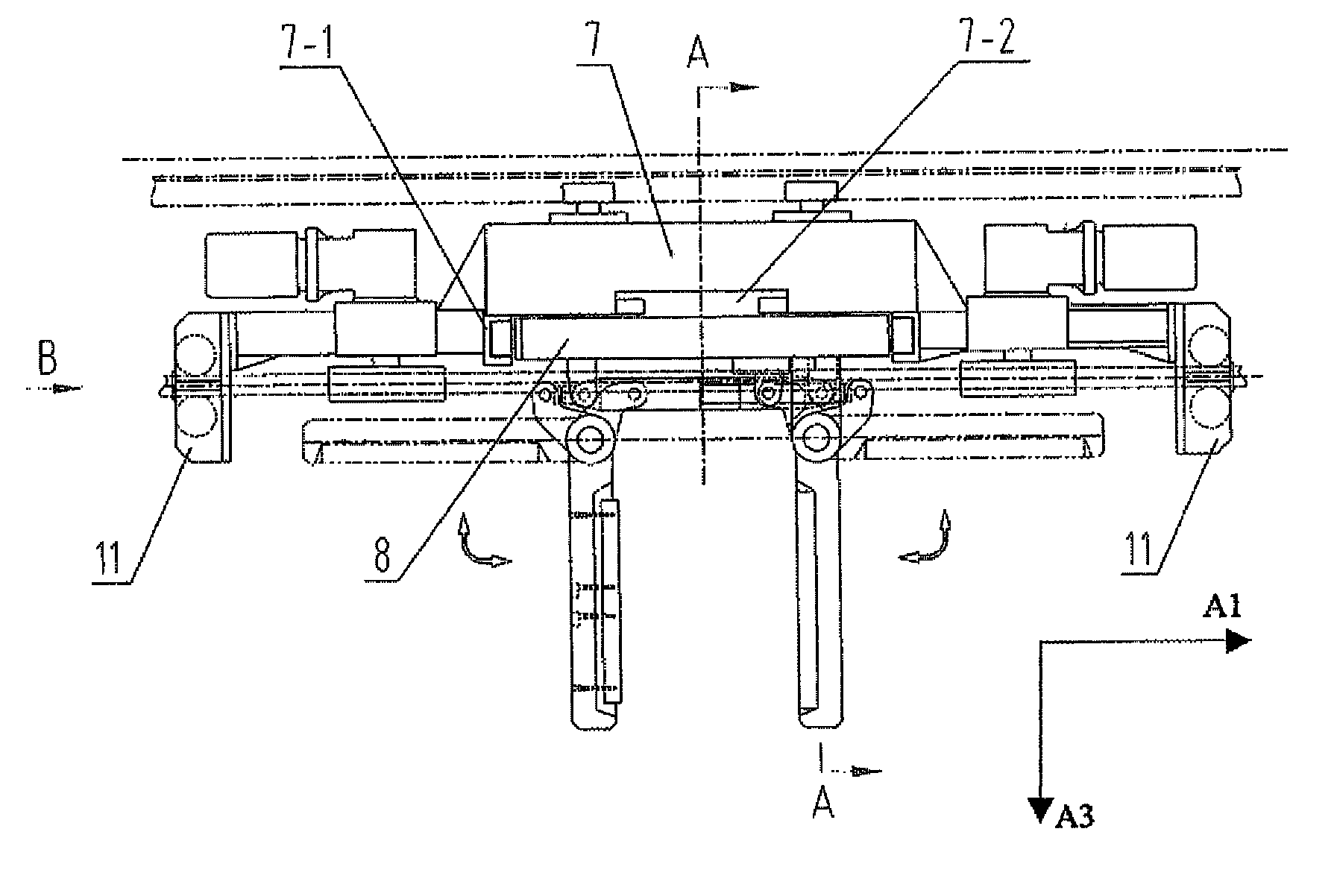

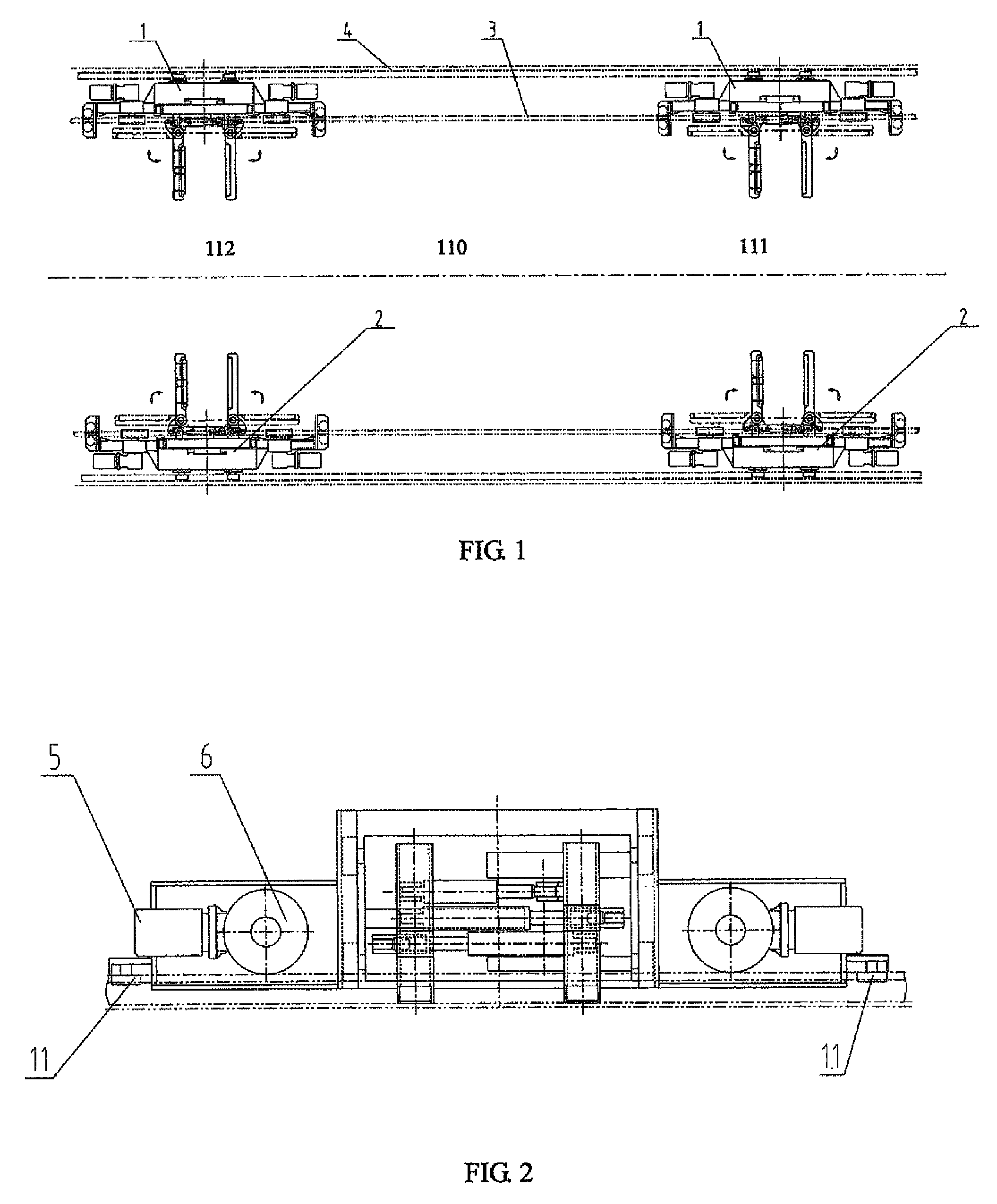

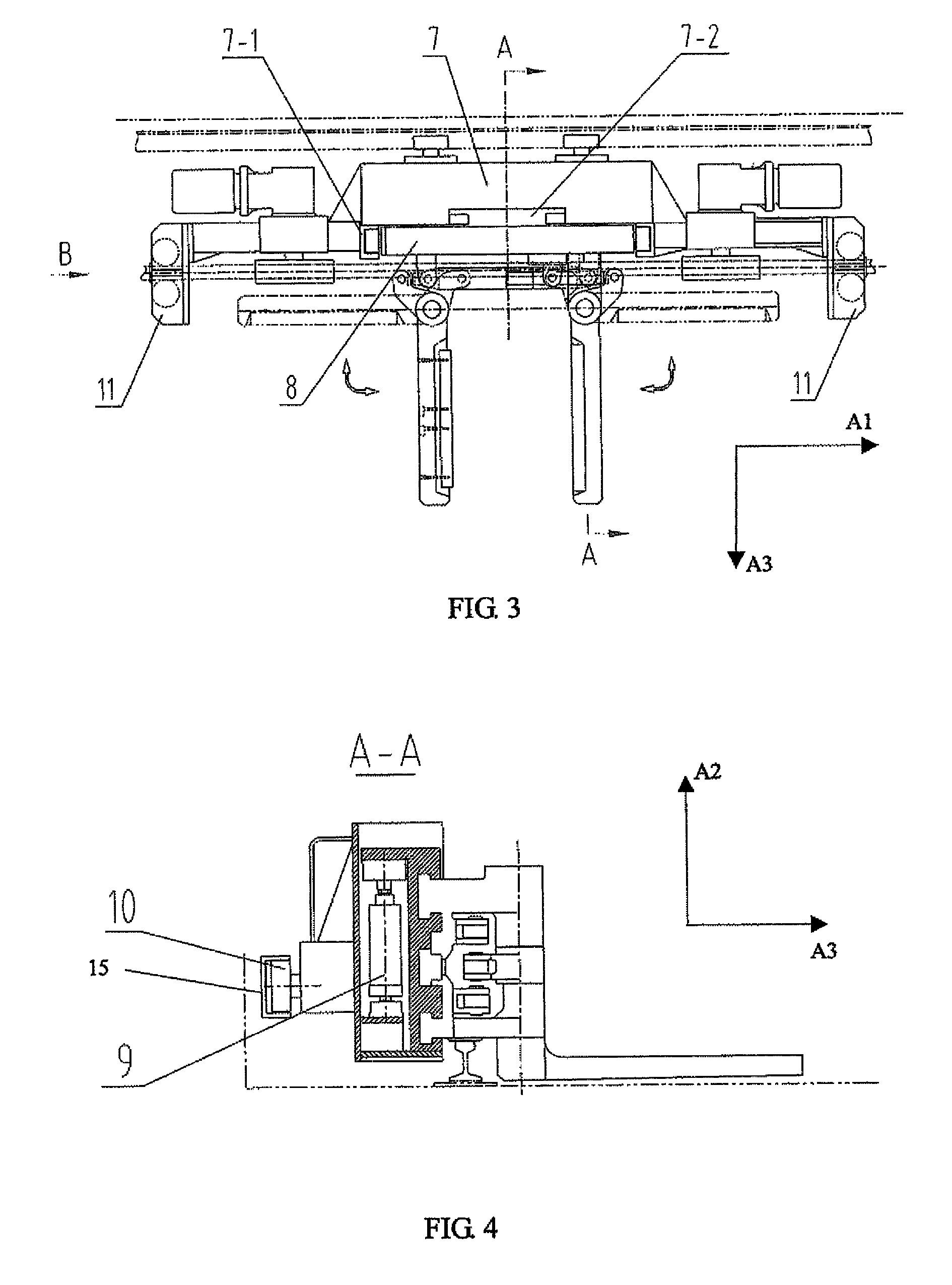

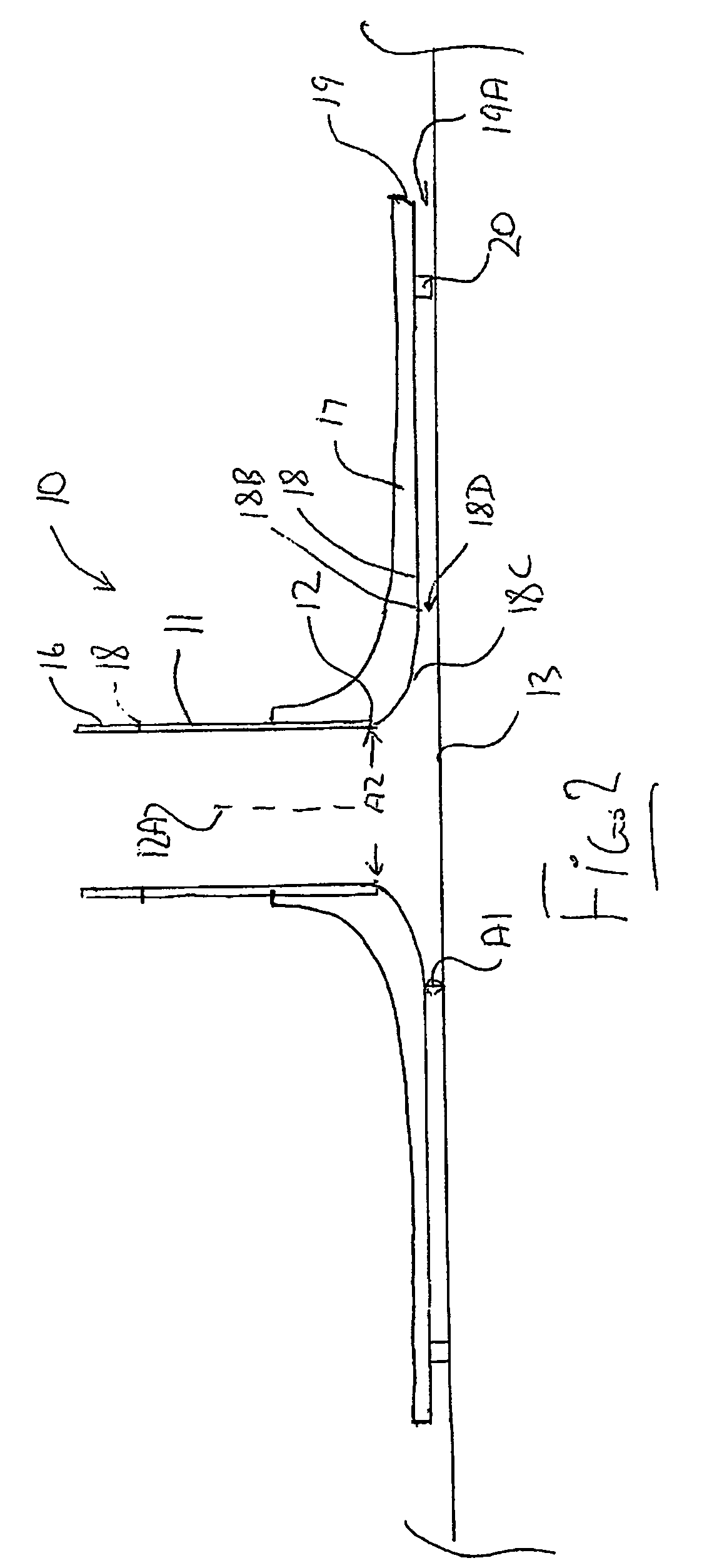

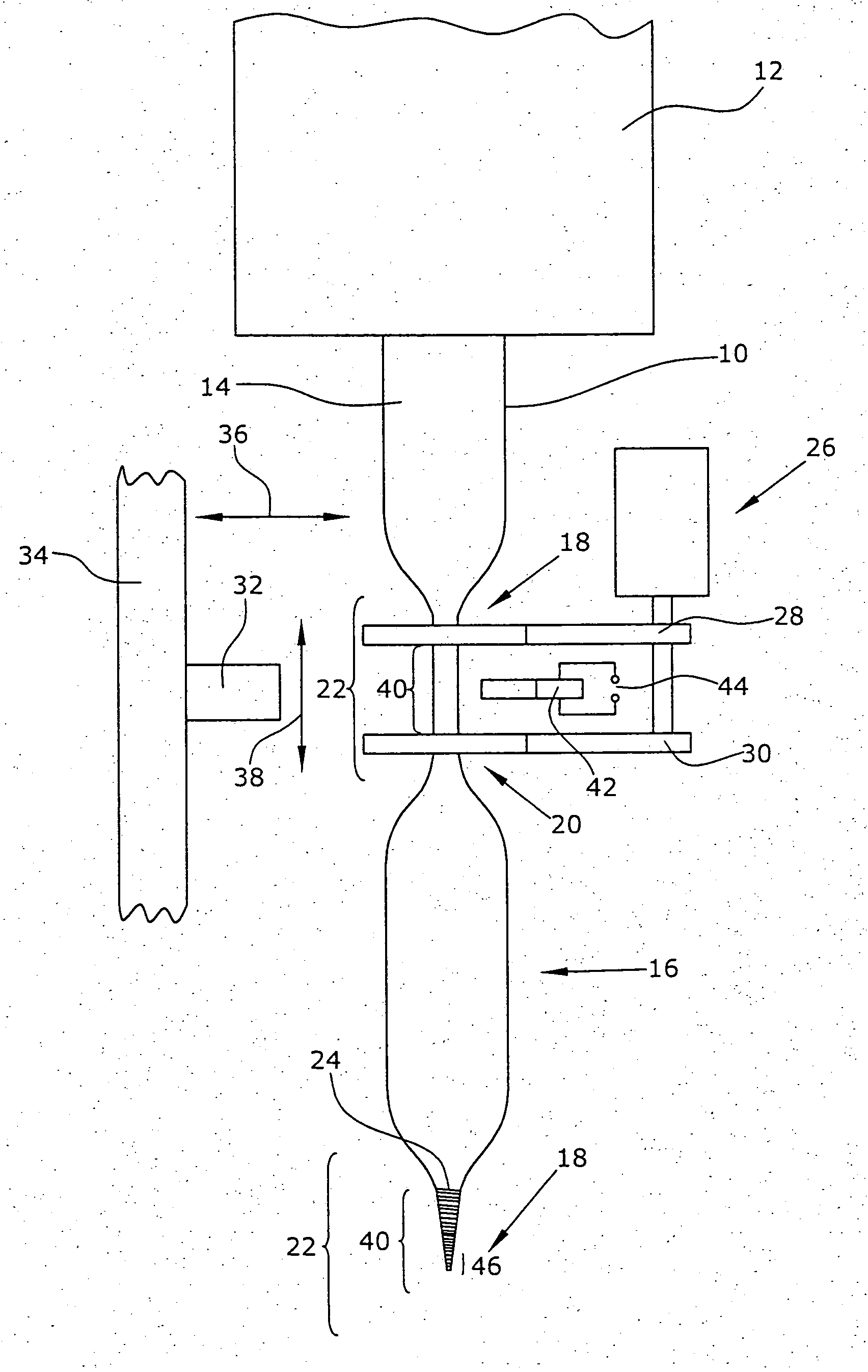

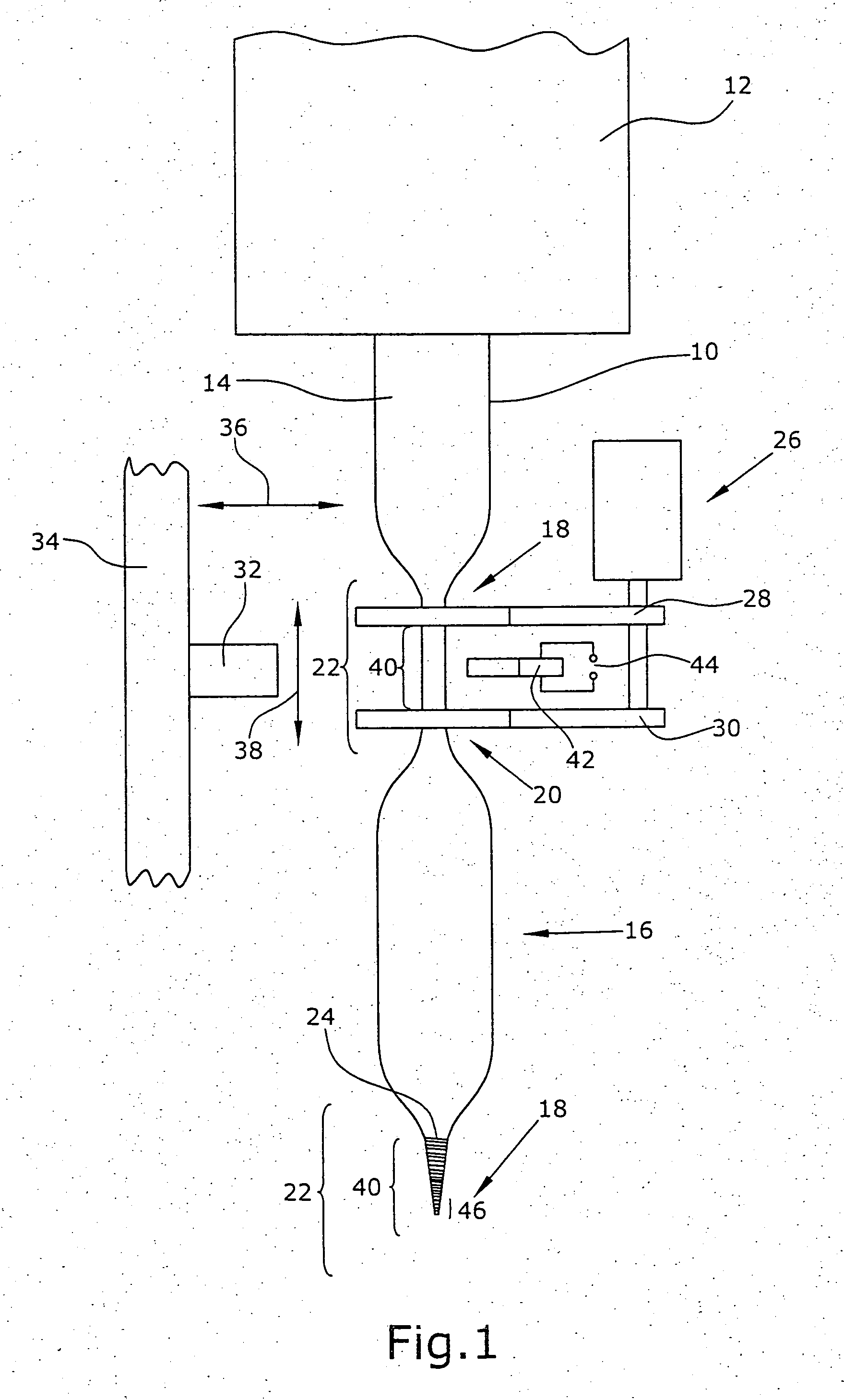

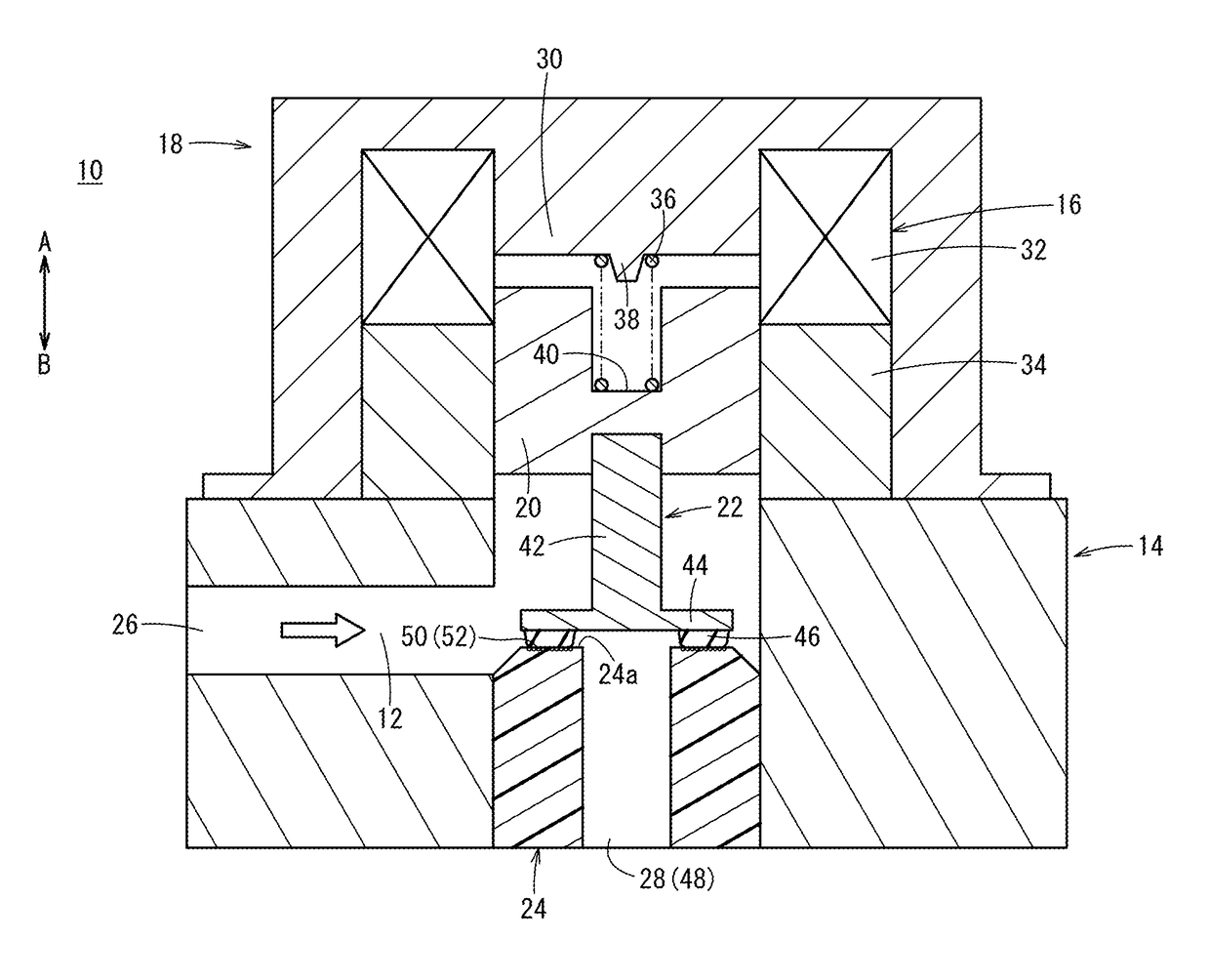

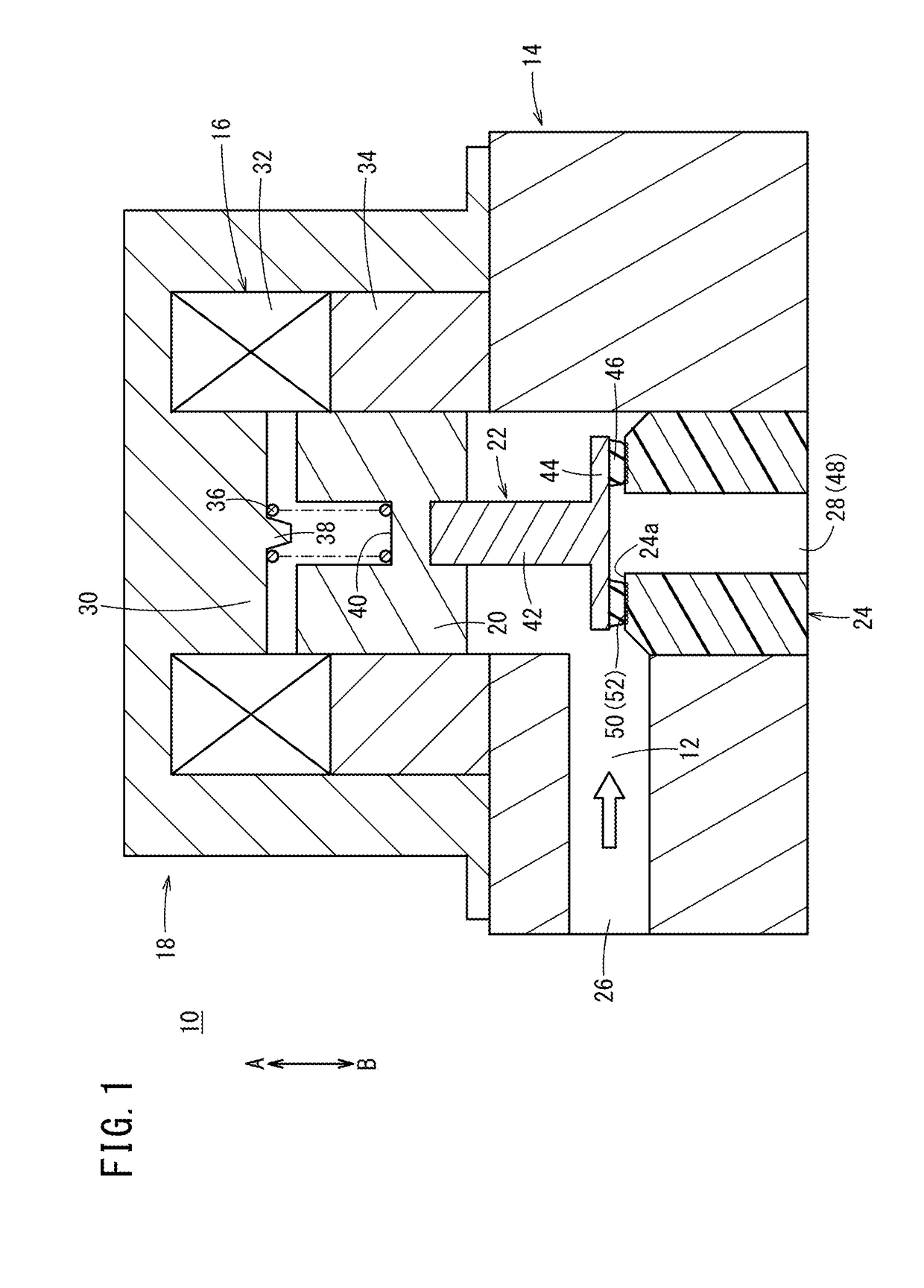

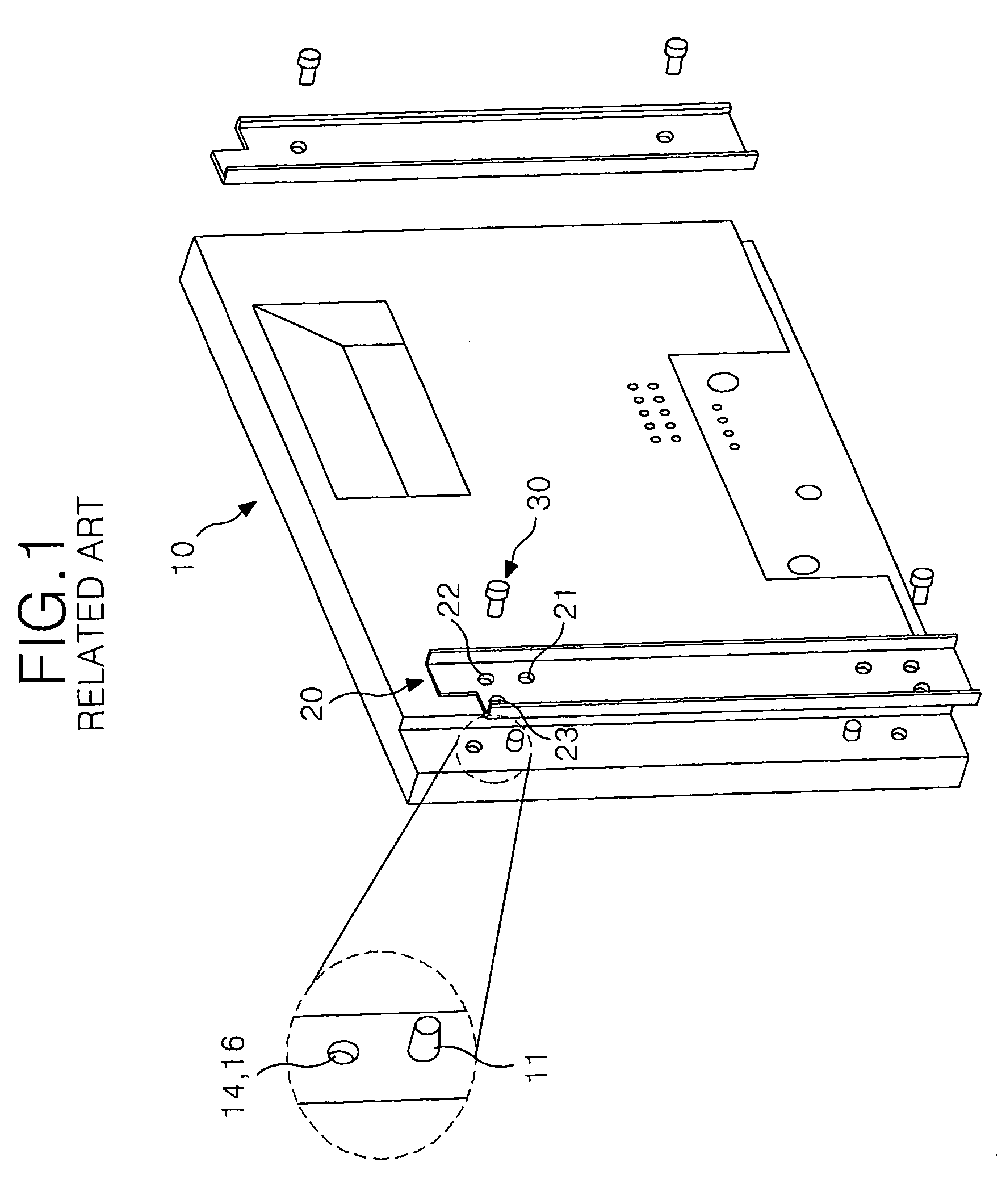

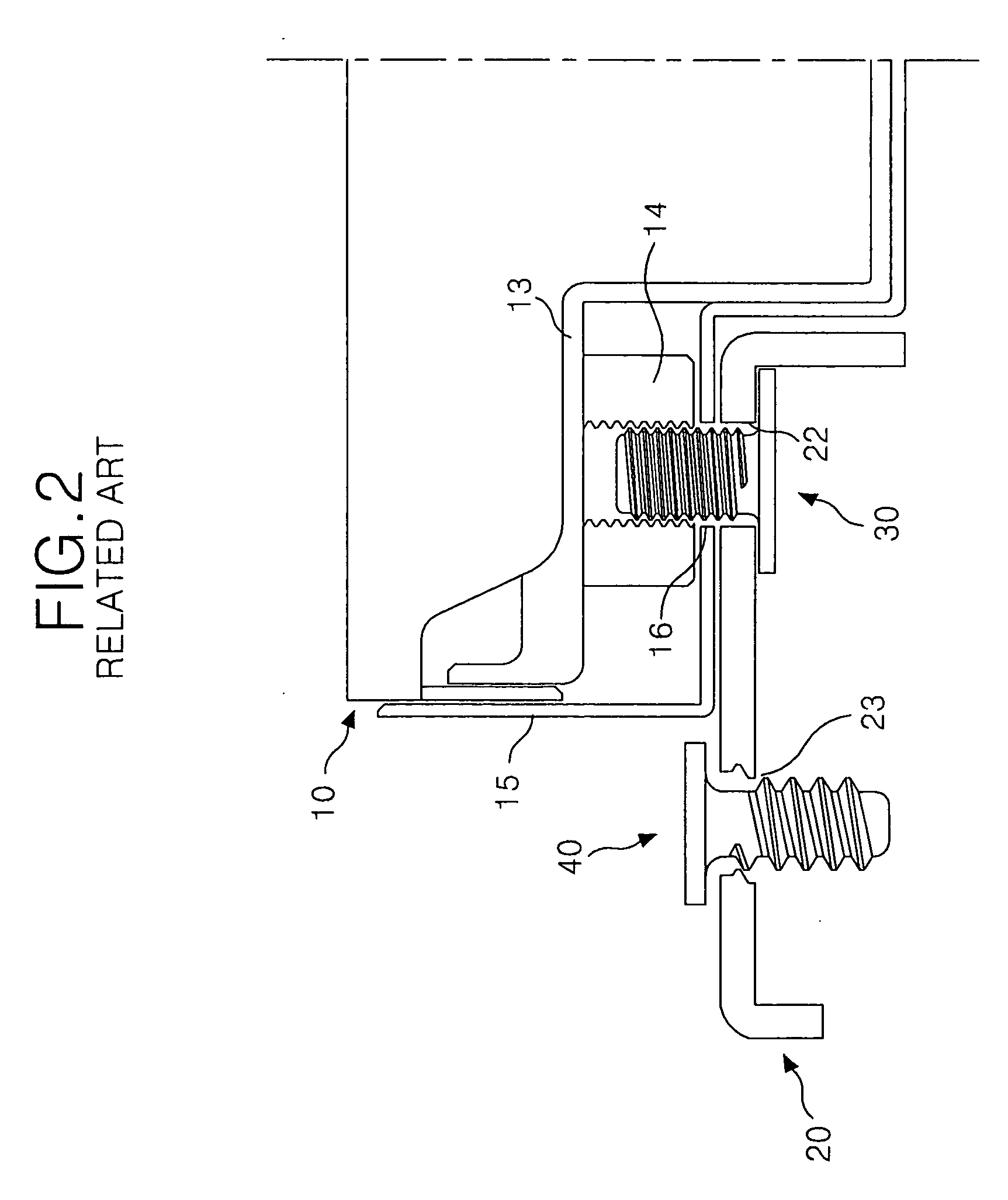

Trailer system and method for inspecting vehicle by radiation imaging of vehicle through trailer system

ActiveUS20080159840A1Guaranteed stable operationSimple structureSlipwaysTramway railsRadiation imagingSelf driving

The present invention relates to a trailer system, and particularly to a self-driving trailer system for a radiation imaging inspection system and a method for inspecting a vehicle by radiation imaging of a vehicle through the trailer system. The self-driving trailer system comprises two trailers symmetrical in structure. Each of the trailers comprises a driving device, running wheels, a trailer body, a carrying device, a lift cylinder, a balance wheel, and two pairs of guide wheels. The driving device, the running wheels, and the balance wheel are coupled with the trailer body. The carrying device is coupled with the trailer body through the lift cylinder. A front carrying arm and a rear carrying arm can clamp front wheels of a vehicle under inspection, and move upwards and downwards by the lift cylinder. The trailer system according to the present invention is smooth and reliable in operation and simple in structure, and is applicable to different diameters of wheels of container lorries under inspection and is convenient in operation.

Owner:NUCTECH CO LTD +1

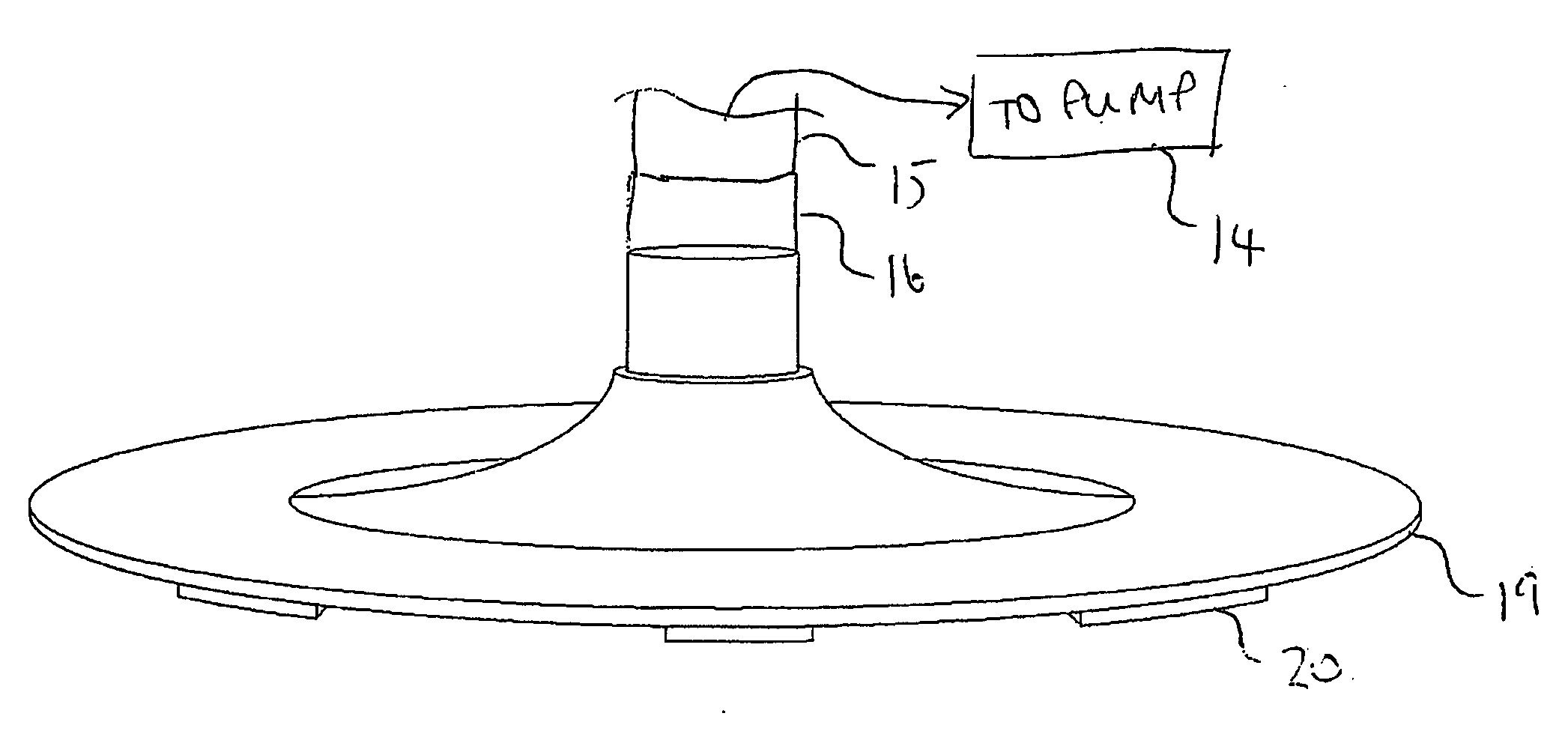

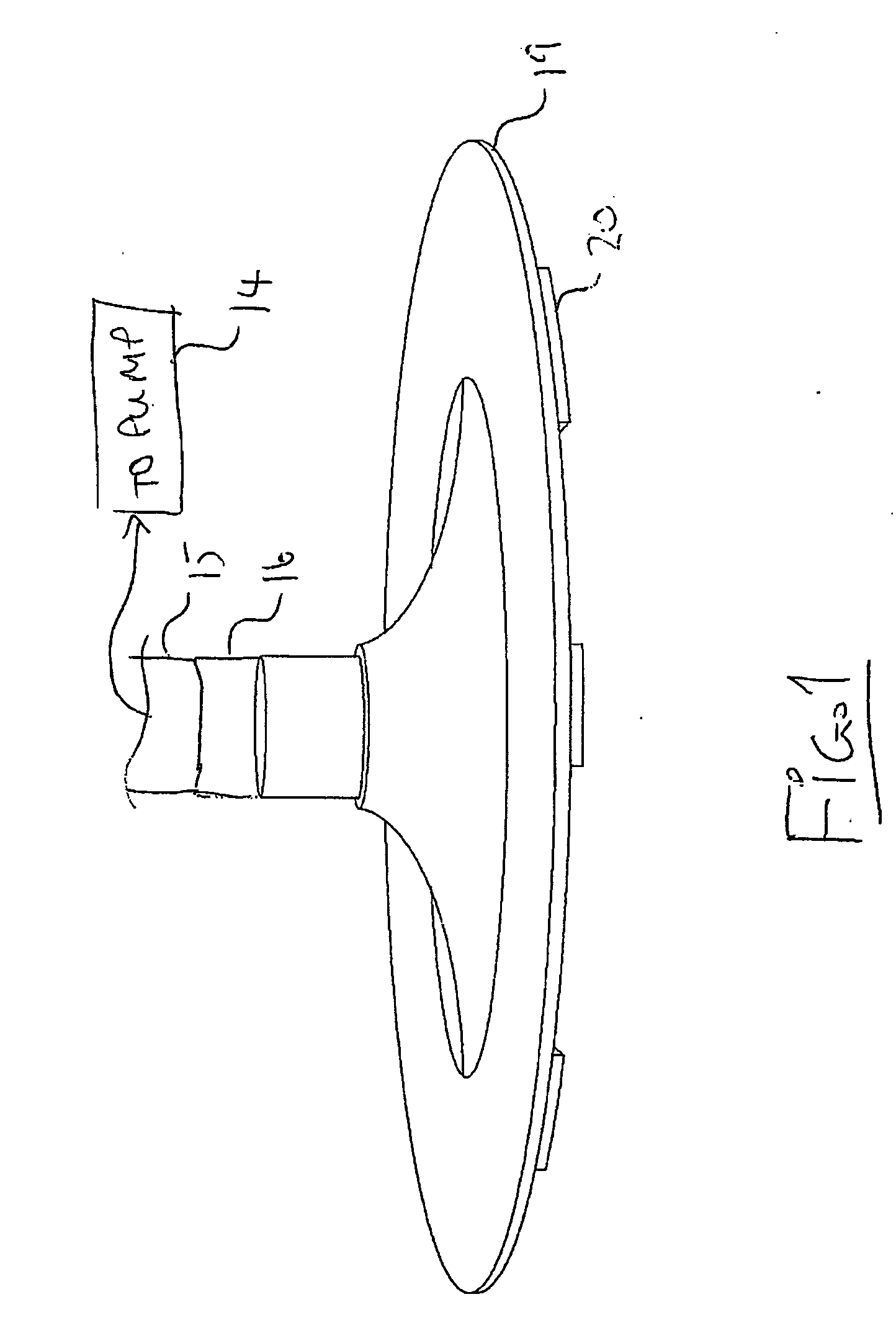

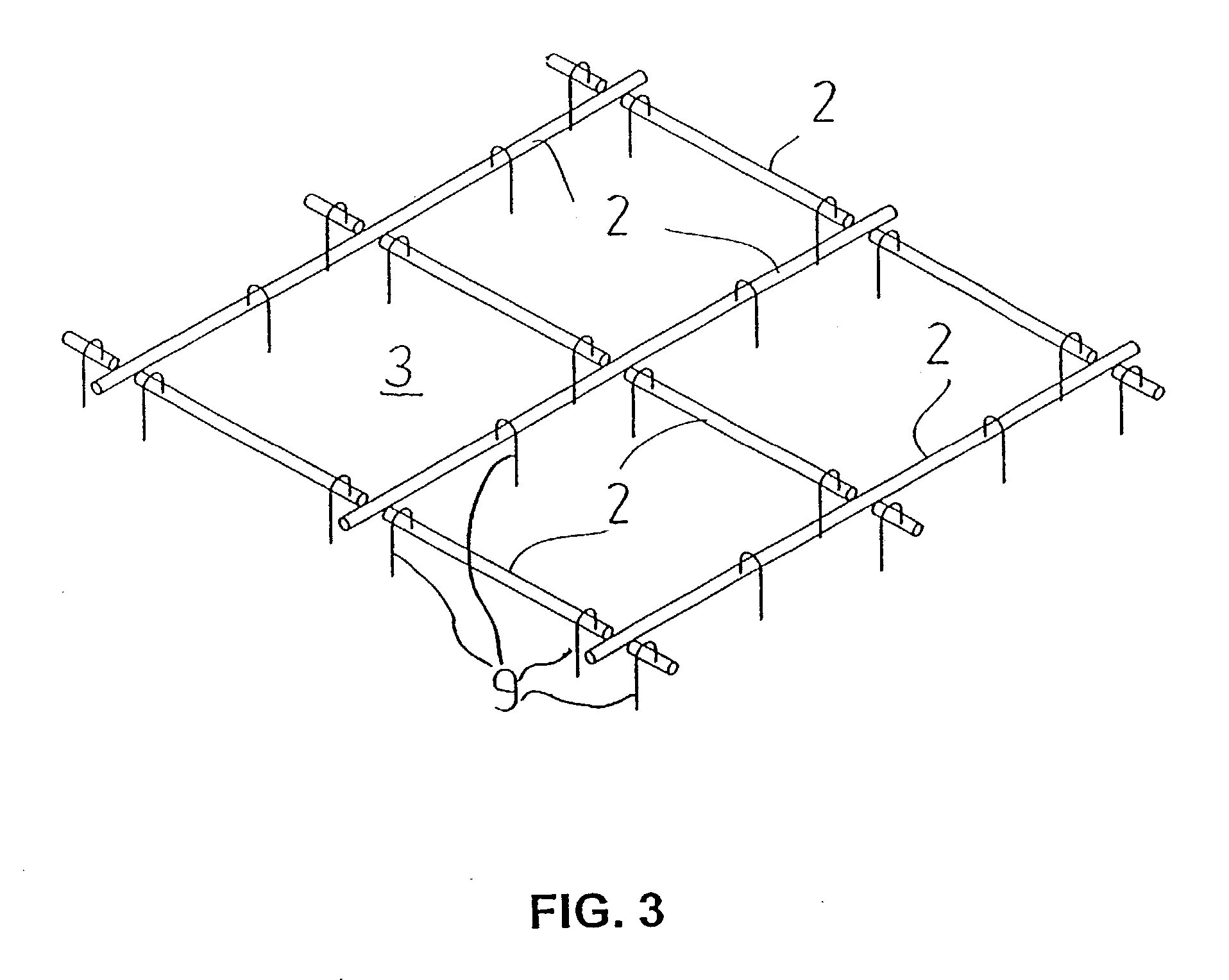

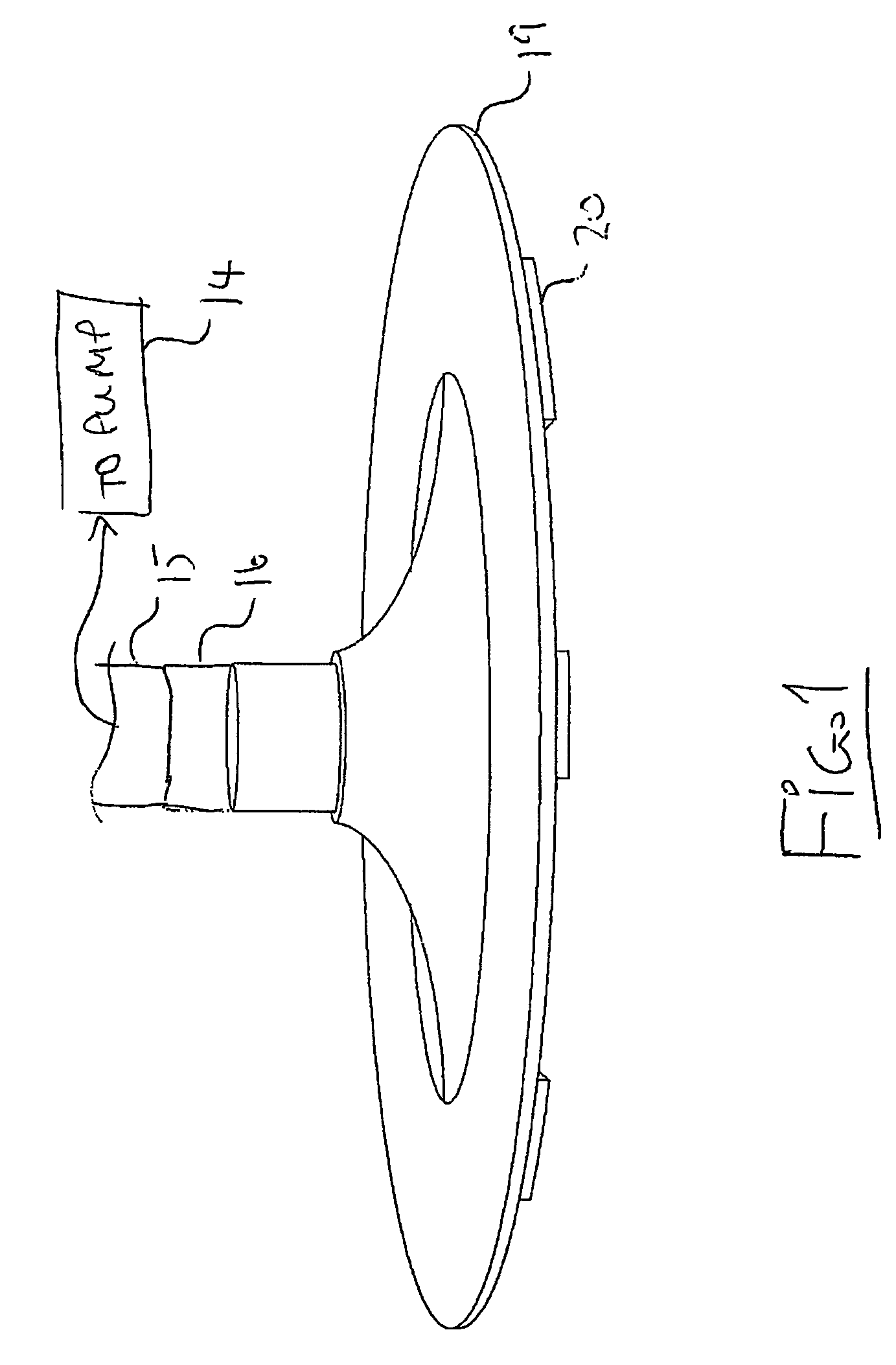

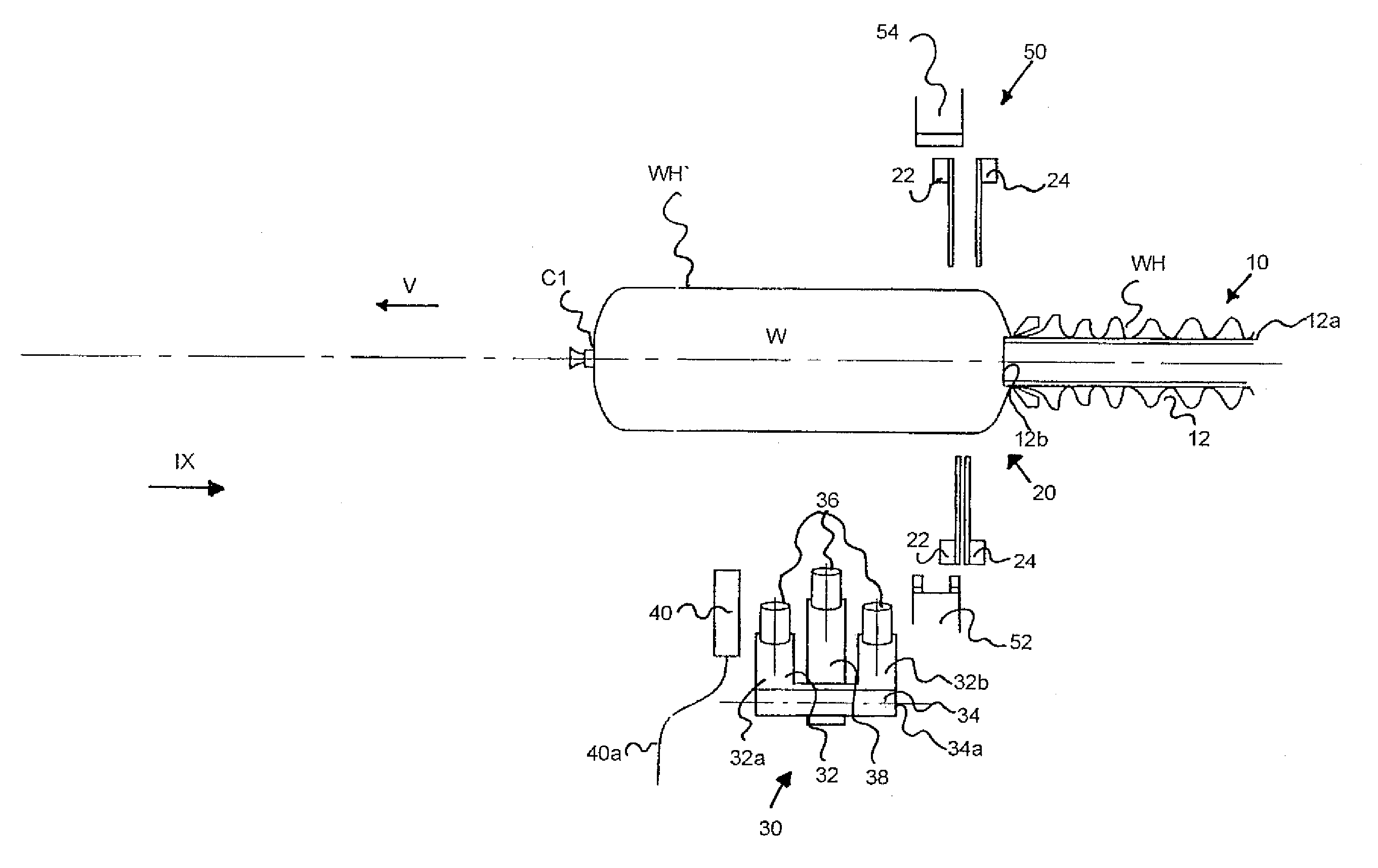

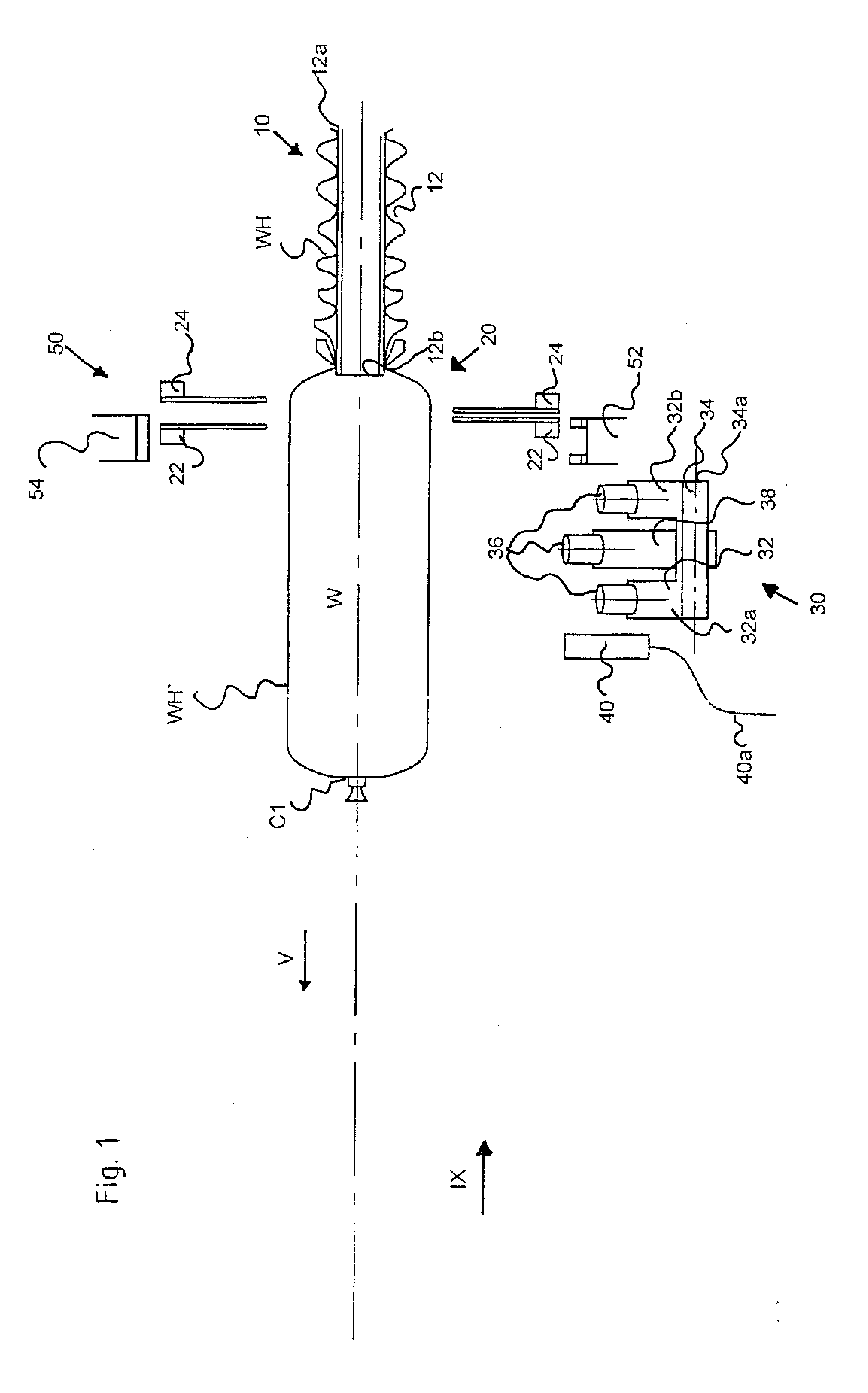

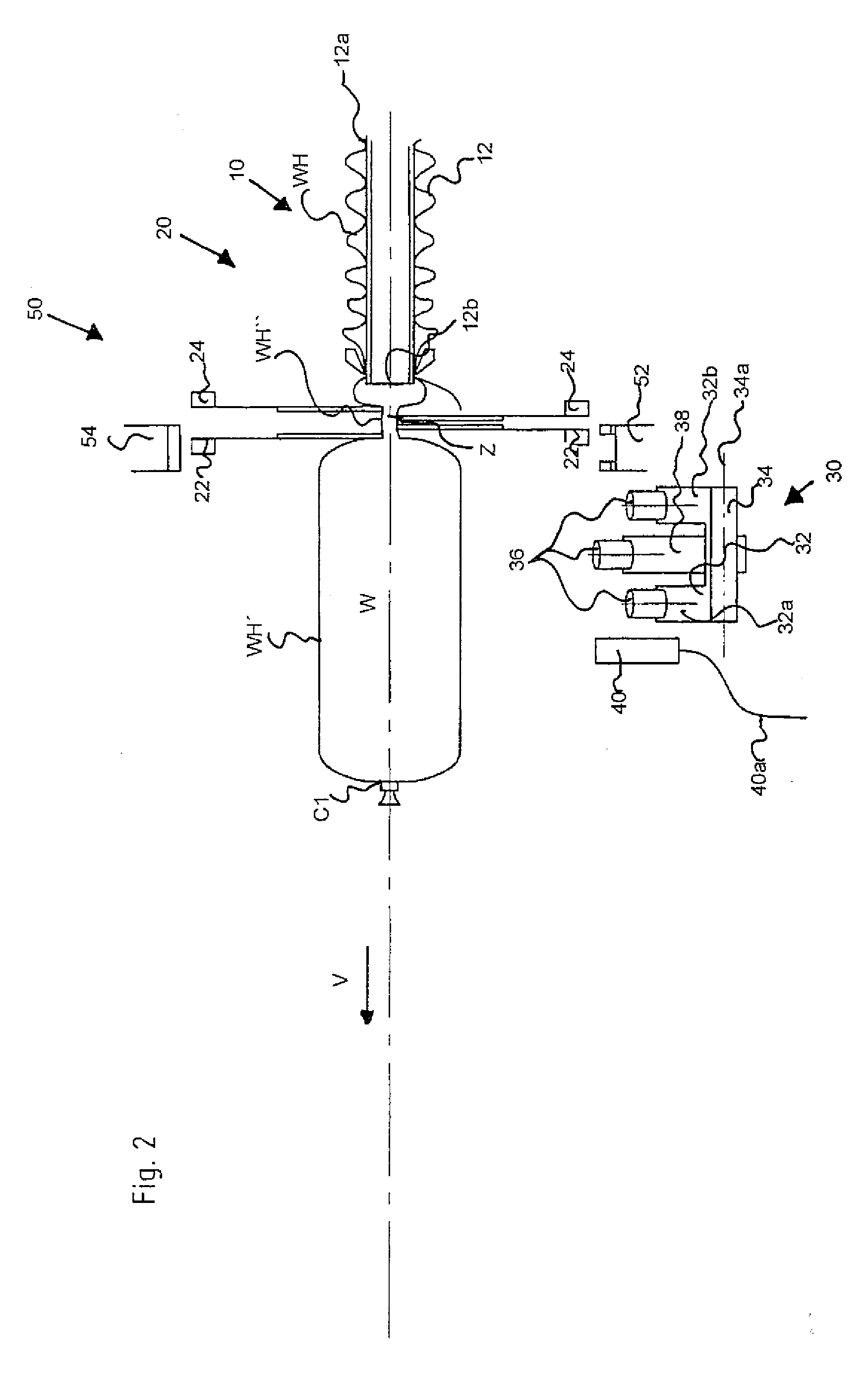

Intake nozzle for a pump

InactiveUS20100252136A1Larger the radius of the deviceReduce gapPipe supportsPositive displacement pump componentsEngineeringConstant velocity

An intake nozzle for the inlet pipe of a pump has a vertical duct with a downwardly facing mouth and a surrounding disk shaped intake portion with a bottom surface which faces a flat surface such as a floor or tank bottom to take liquid from the floor down to a shallow depth. The bottom surface is shaped with a flat outer part and an upwardly and inwardly curved inner part converging to the mouth. The surface is shaped and spaced from the flat surface with annular areas defined therebetween so that the liquid enters the peripheral edge slowly and accelerates up to an inner edge of the flat portion and then remains at constant velocity from the inner edge of the flat portion through the mouth and the pipe to the intake of the pump.

Owner:KOCH EDWARD JOHN

Device for providing a second tail length

Owner:POLY CLIP SYST

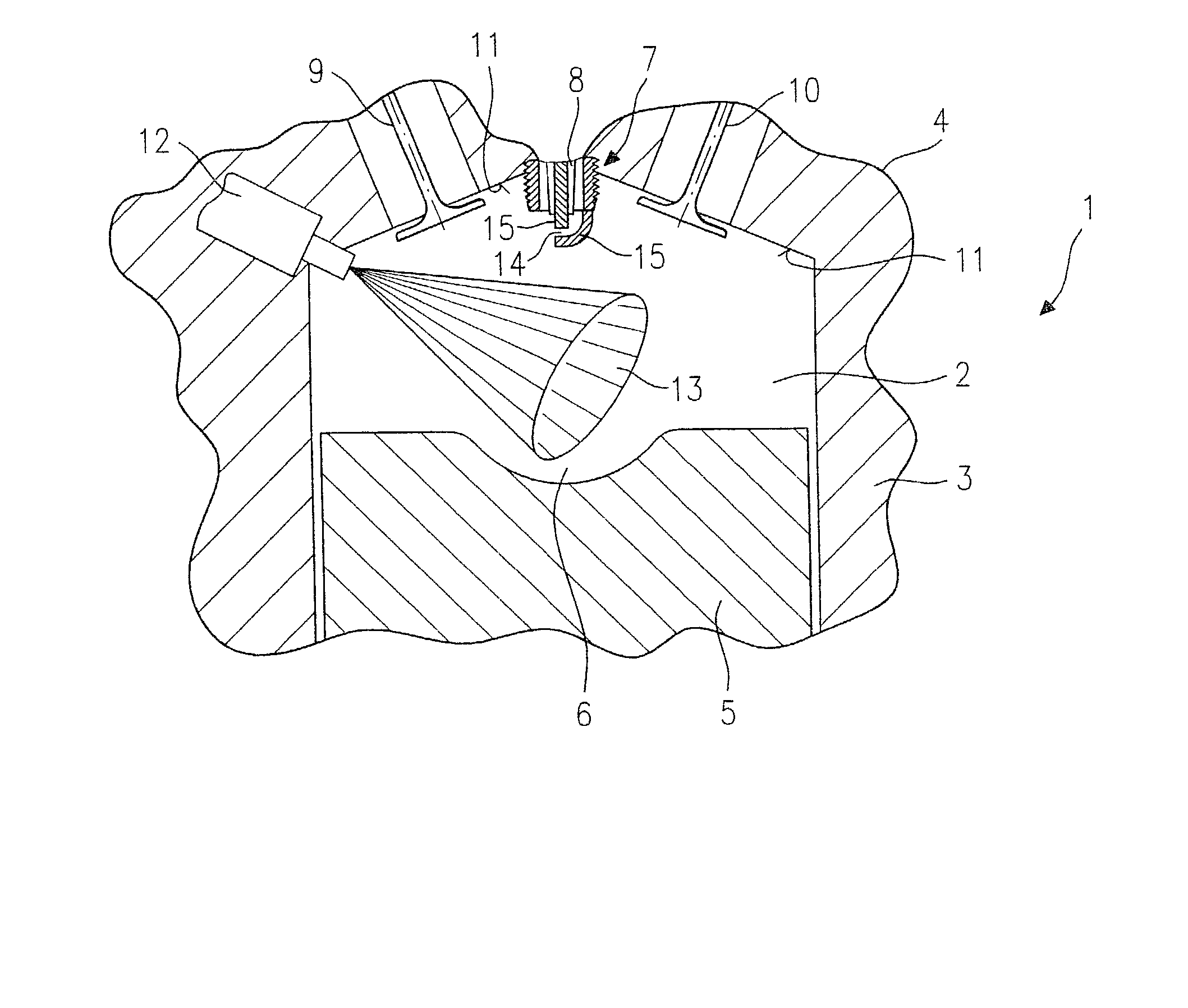

Fuel injection system

InactiveUS20020185104A1Emission reductionNegligible nitrogen oxide emissionInternal combustion piston enginesCylinder headsCombustion chamberInternal combustion engine

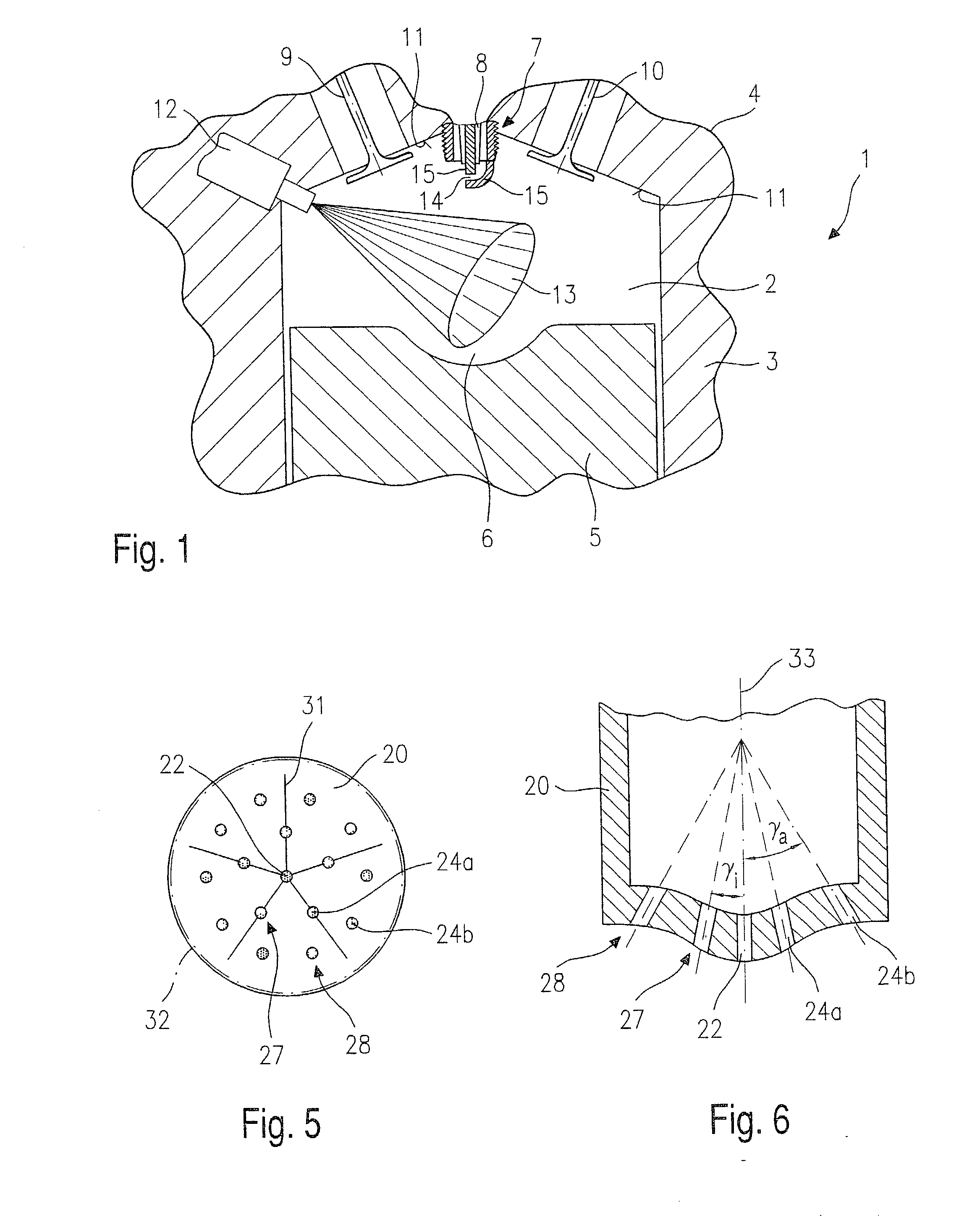

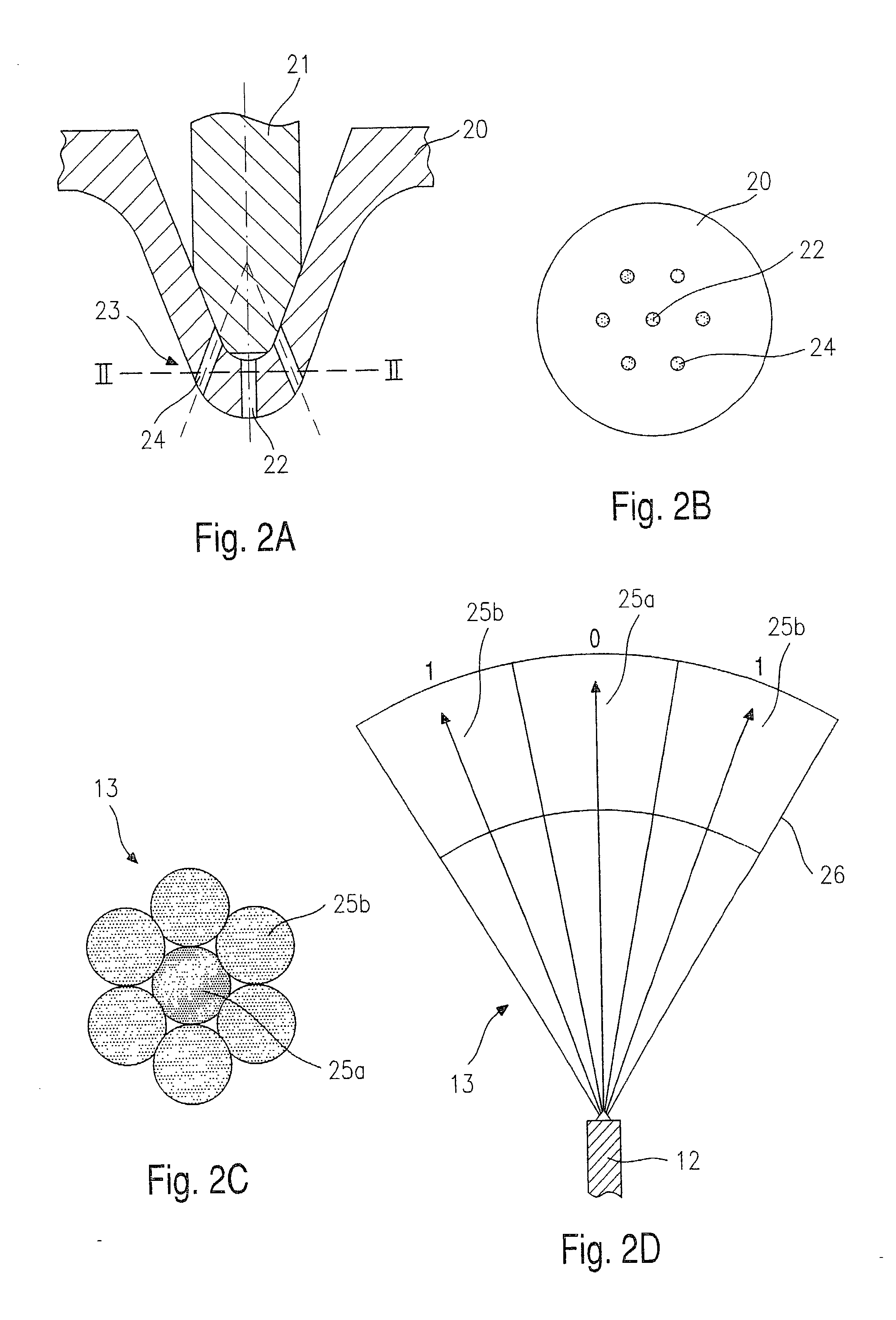

A fuel injection system for internal combustion engines comprises a fuel injector that injects fuel into a combustion chamber, the combustion chamber being delimited by a cylinder wall in which a piston is guided, and a spark plug that protrudes into combustion chamber. The fuel injector produces a conical mixture cloud in the combustion chamber through at least one row of injection orifices arranged circumferentially on a valve body of the fuel injector. The valve body also provides a centrally arranged injection orifice that produces a central area of the mixture cloud directed towards the spark plug.

Owner:ROBERT BOSCH GMBH

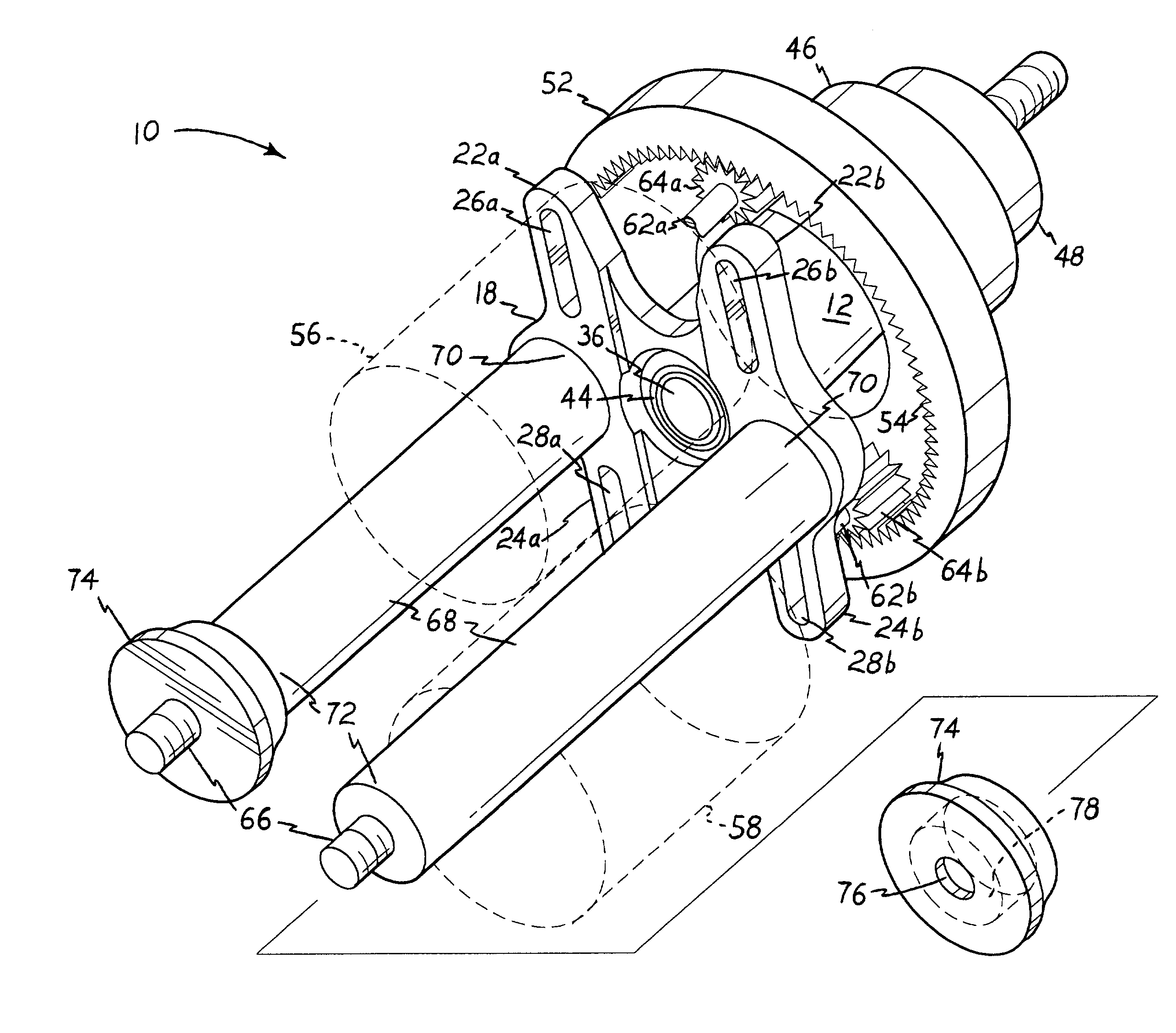

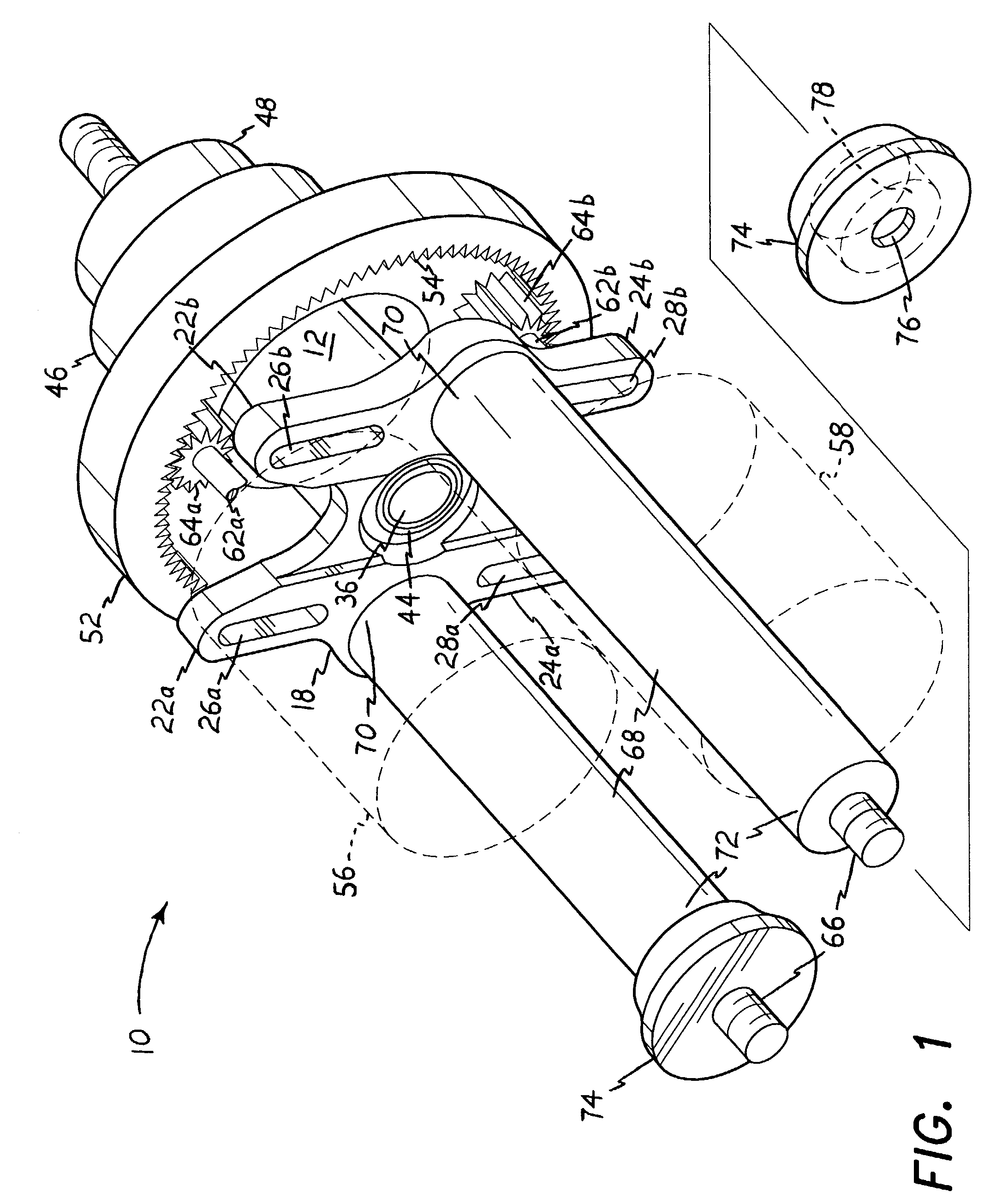

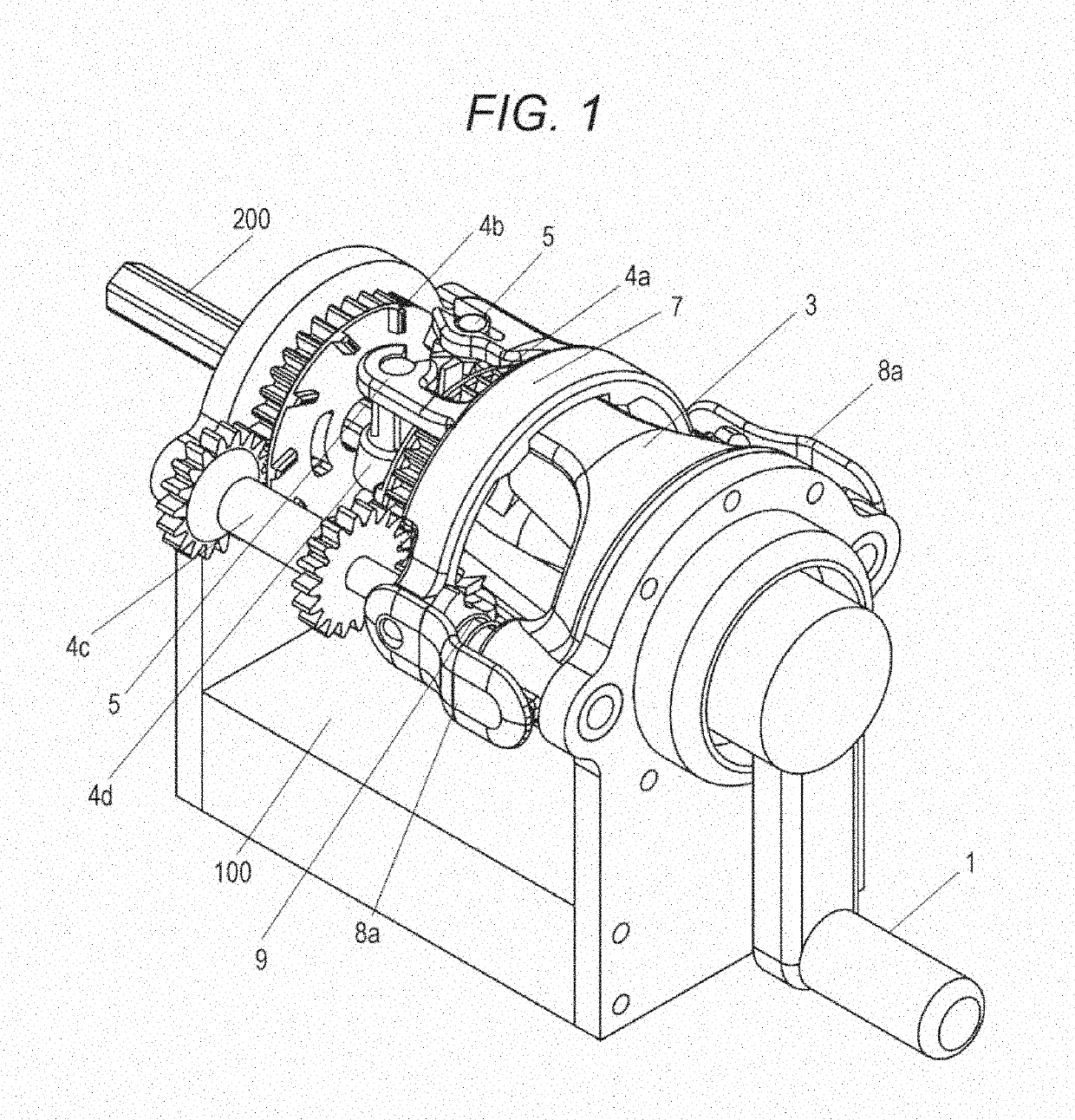

Internal spur gear drive

InactiveUS7011275B2Change gear ratioDifferent diameterPower plant arrangements/mountingToothed gearingsMotor driveGear wheel

An internal spur gear drive has a mounting base including one or more sets of motor mounting lugs extending therefrom, for attaching a corresponding number of drive motors thereto. A drive shaft housing containing a rotary drive shaft extends from the mounting base. A drive bell is affixed to the drive shaft distal end, and rotates therewith. The opposite end of the drive bell has an internally toothed ring gear extending therefrom. Each motor drives a pinion gear which engages the internal teeth of the drive bell ring gear to rotate the drive bell and thus rotate the drive shaft as well. The motor mounting lugs are slotted, allowing the motors to be adjusted radially relative to the drive shaft and drive bell ring gear. This provides adjustment for gear lash, as well as permitting different sizes of pinion gears to be installed on the motors for different gear ratios.

Owner:REDFERN DANIEL J

Trailer system and method for inspecting vehicle by radiation imaging of vehicle through trailer system

ActiveUS7845286B2Guaranteed stable operationSimple structureSlipwaysTramway railsRadiation imagingSelf driving

The present invention relates to a trailer system, and particularly to a self-driving trailer system for a radiation imaging inspection system and a method for inspecting a vehicle by radiation imaging of a vehicle through the trailer system. The self-driving trailer system comprises two trailers symmetrical in structure. Each of the trailers comprises a driving device, running wheels, a trailer body, a carrying device, a lift cylinder, a balance wheel, and two pairs of guide wheels. The driving device, the running wheels, and the balance wheel are coupled with the trailer body. The carrying device is coupled with the trailer body through the lift cylinder. A front carrying arm and a rear carrying arm can clamp front wheels of a vehicle under inspection, and move upwards and downwards by the lift cylinder. The trailer system according to the present invention is smooth and reliable in operation and simple in structure, and is applicable to different diameters of wheels of container lorries under inspection and is convenient in operation.

Owner:NUCTECH CO LTD +1

Apparatus for a junction point between two electrical high-voltage cables

InactiveUS8097807B2Simple and advantageous connectionDifferent diameterSoldered/welded conductive connectionsConnections effected by permanent deformationElectricityElectrical conductor

Apparatus for a connecting point between high-voltage cables, each cable having a conductor, inner conductive layer, insulation, outer conductive layer, and a sheath over the outer conductive layer and in which the conductors, from which the surrounding layers have been removed, are conductively connected to one another. The arrangement has electrical screening elements and an integral elongated sleeve body, composed of elastic insulating material and a through-hole. The sleeve body has at its axial ends, which are intended for the cable to pass through, electrical control funnels which abut the outer conductive layers, from which the sheaths have been removed. The internal diameters of the through-hole in the sleeve body, at its axial ends, are for its use in a connecting point of cables, having an external diameter of their insulation which differs by at least 10 mm, different in a defined manner and adapted to the different external diameters.

Owner:NEXANS

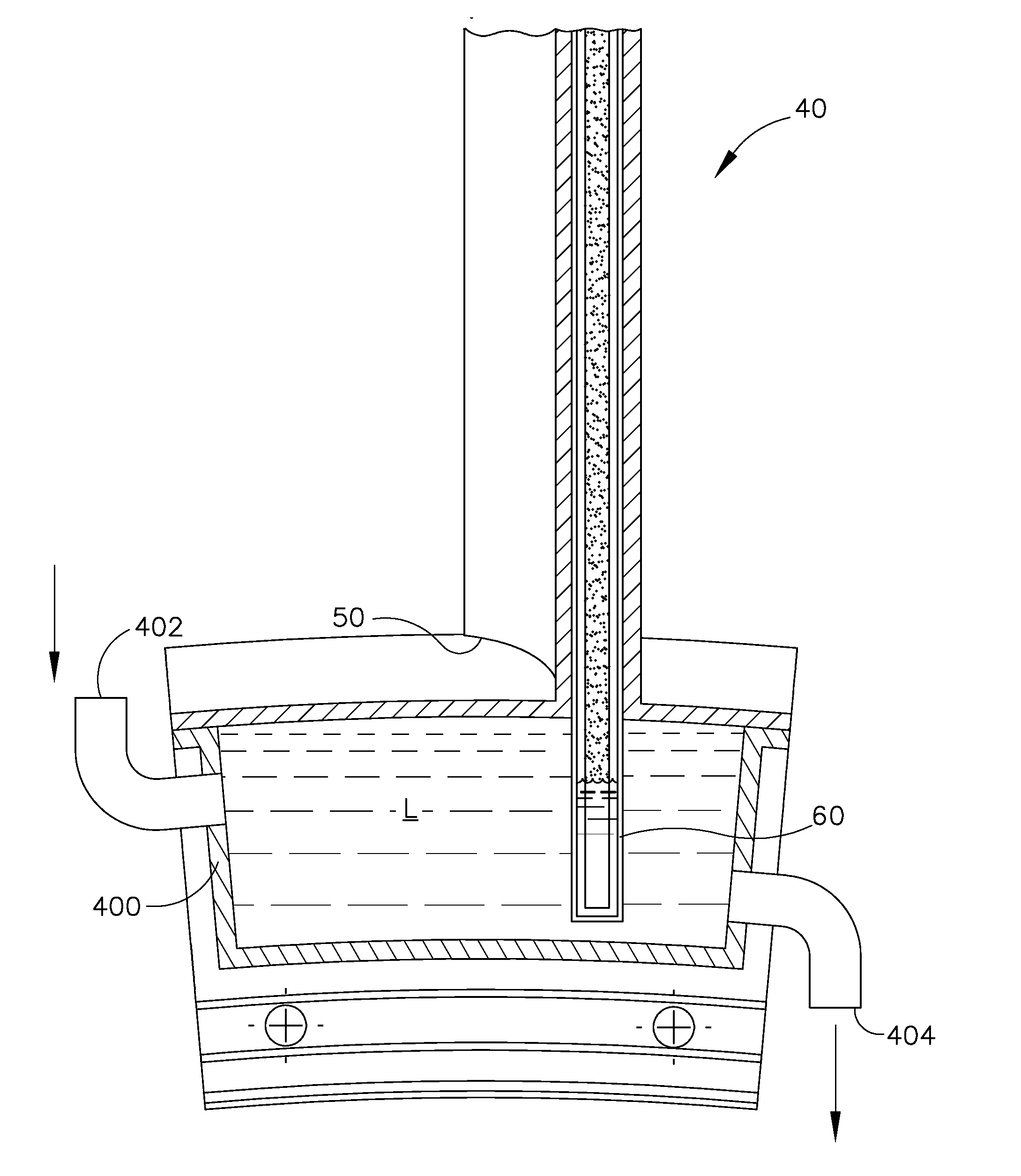

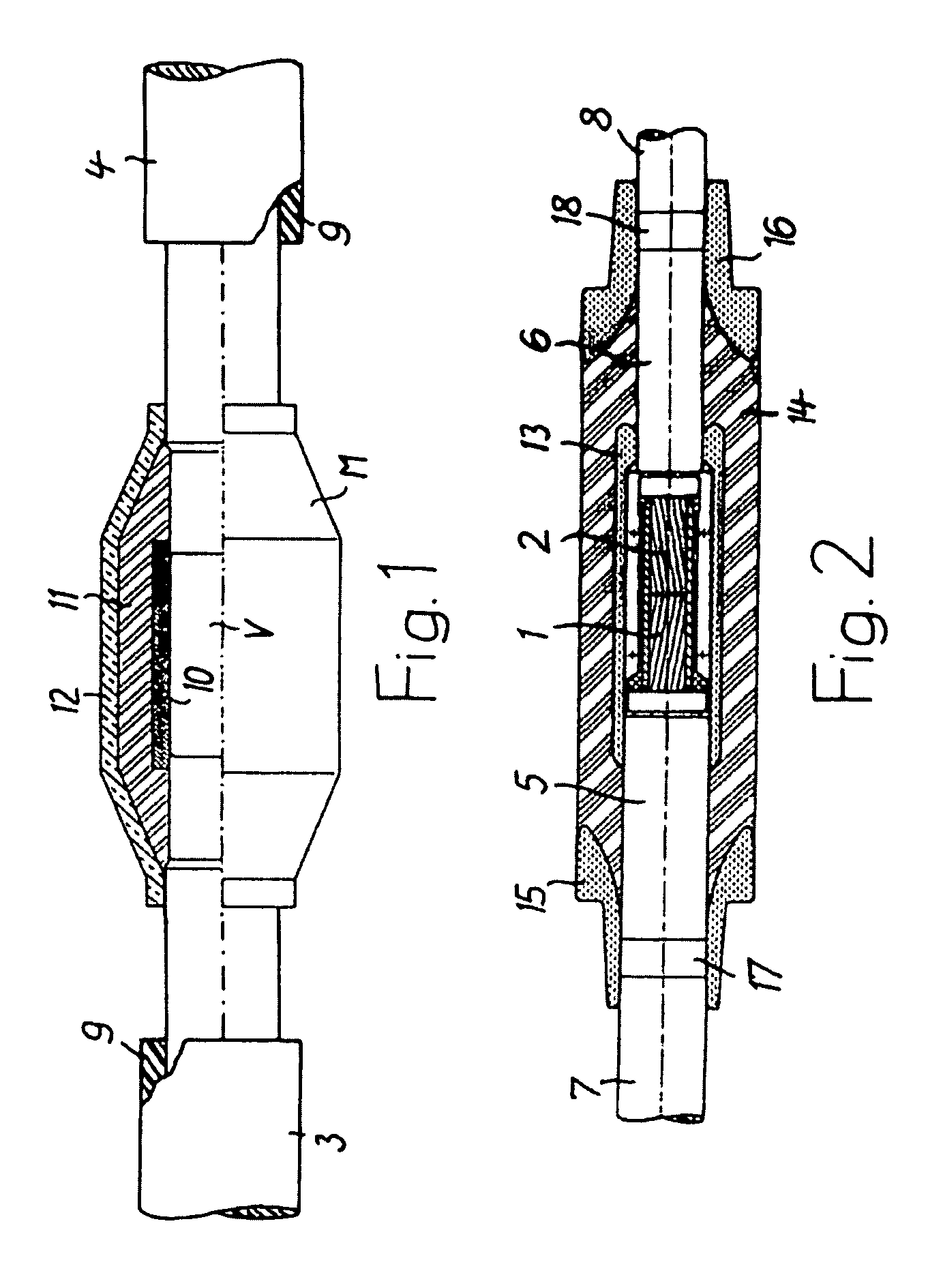

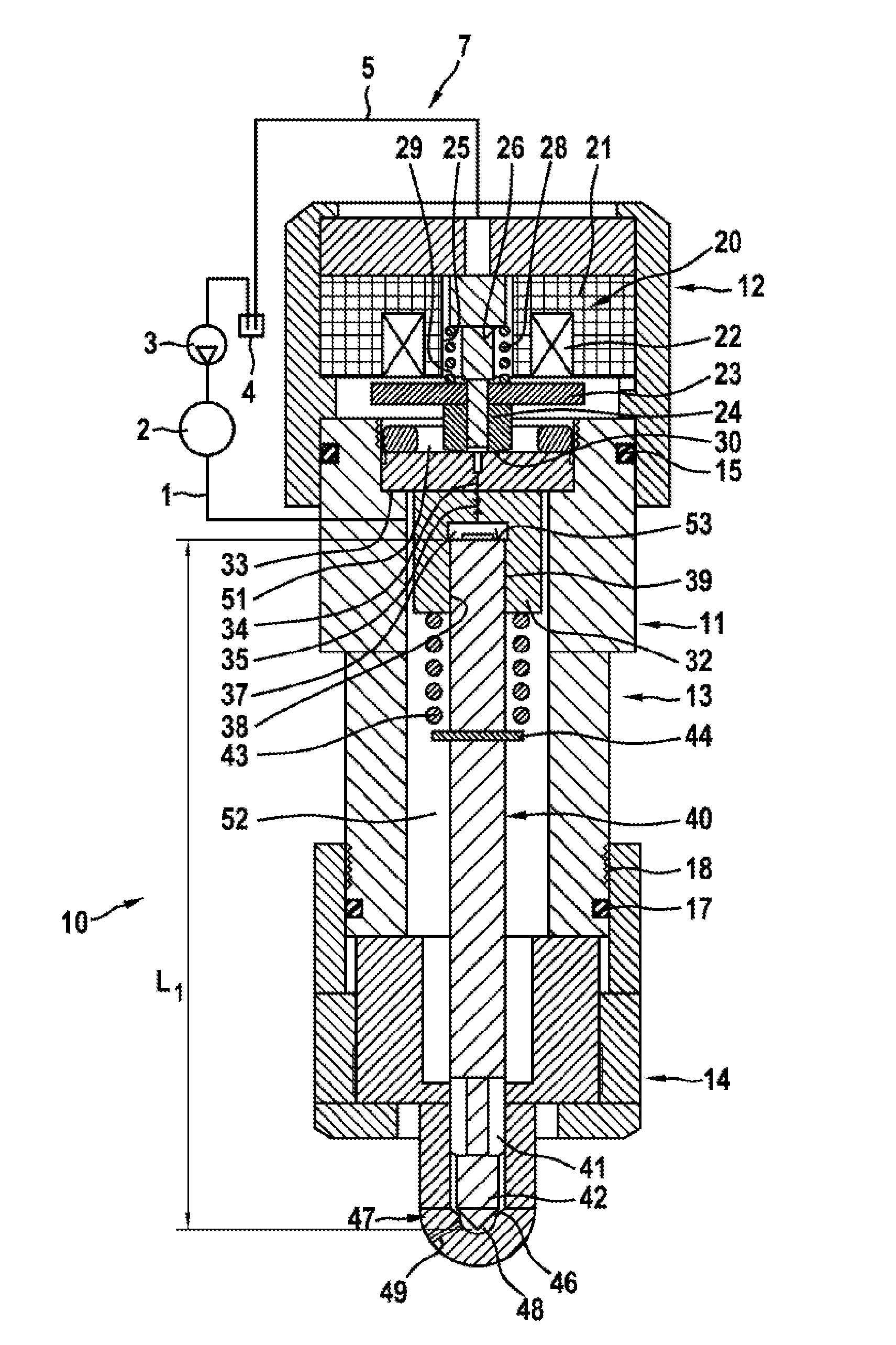

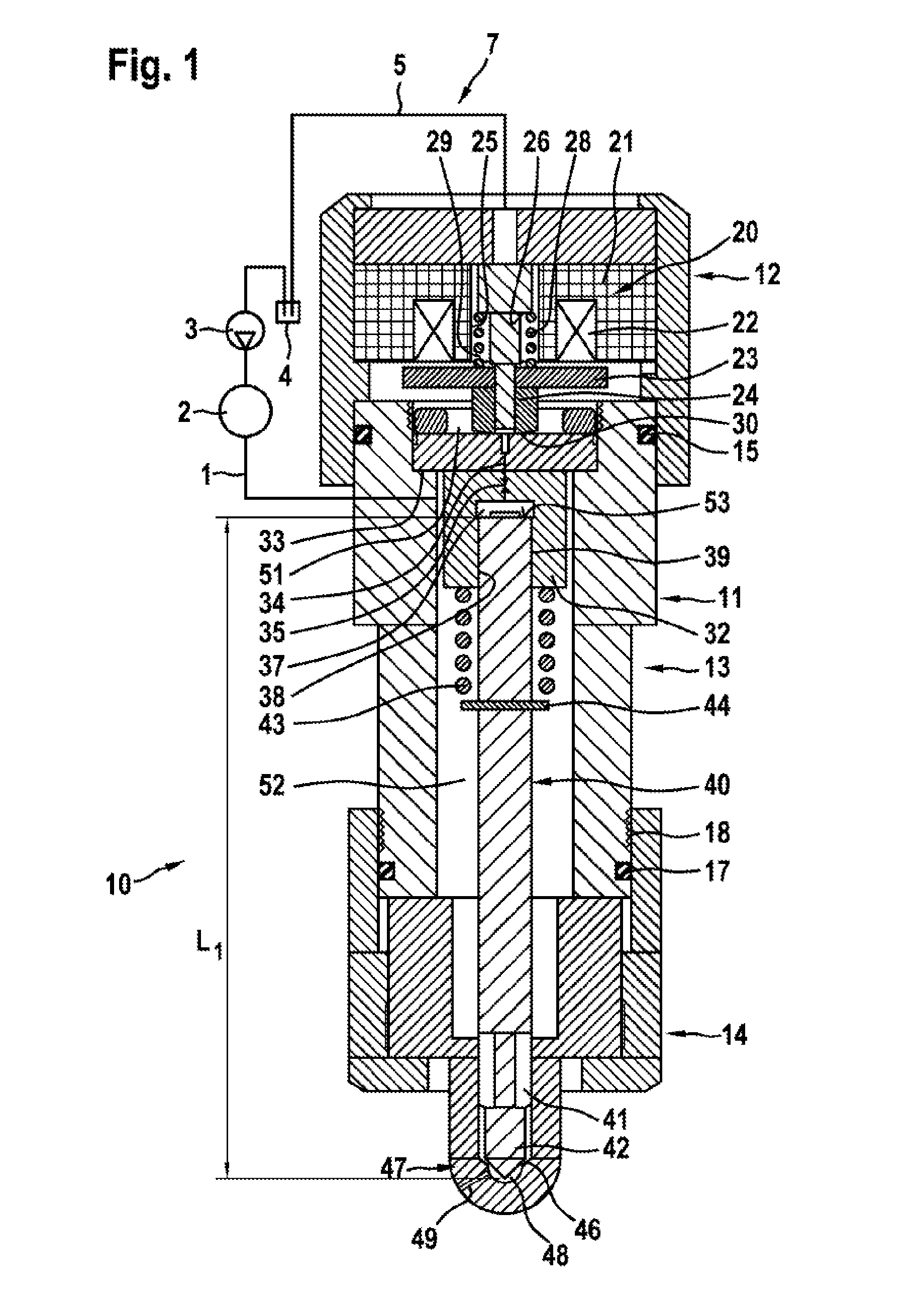

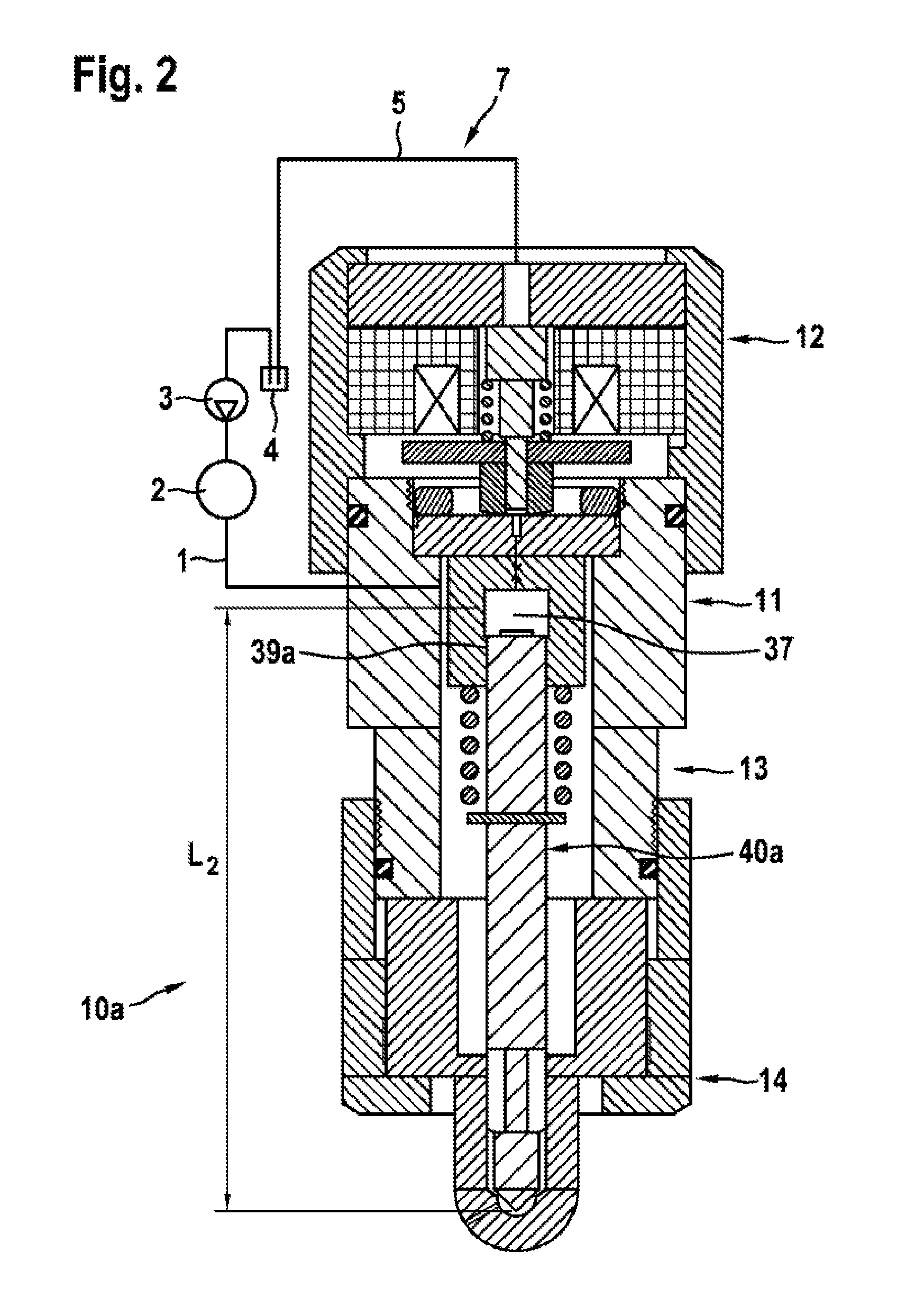

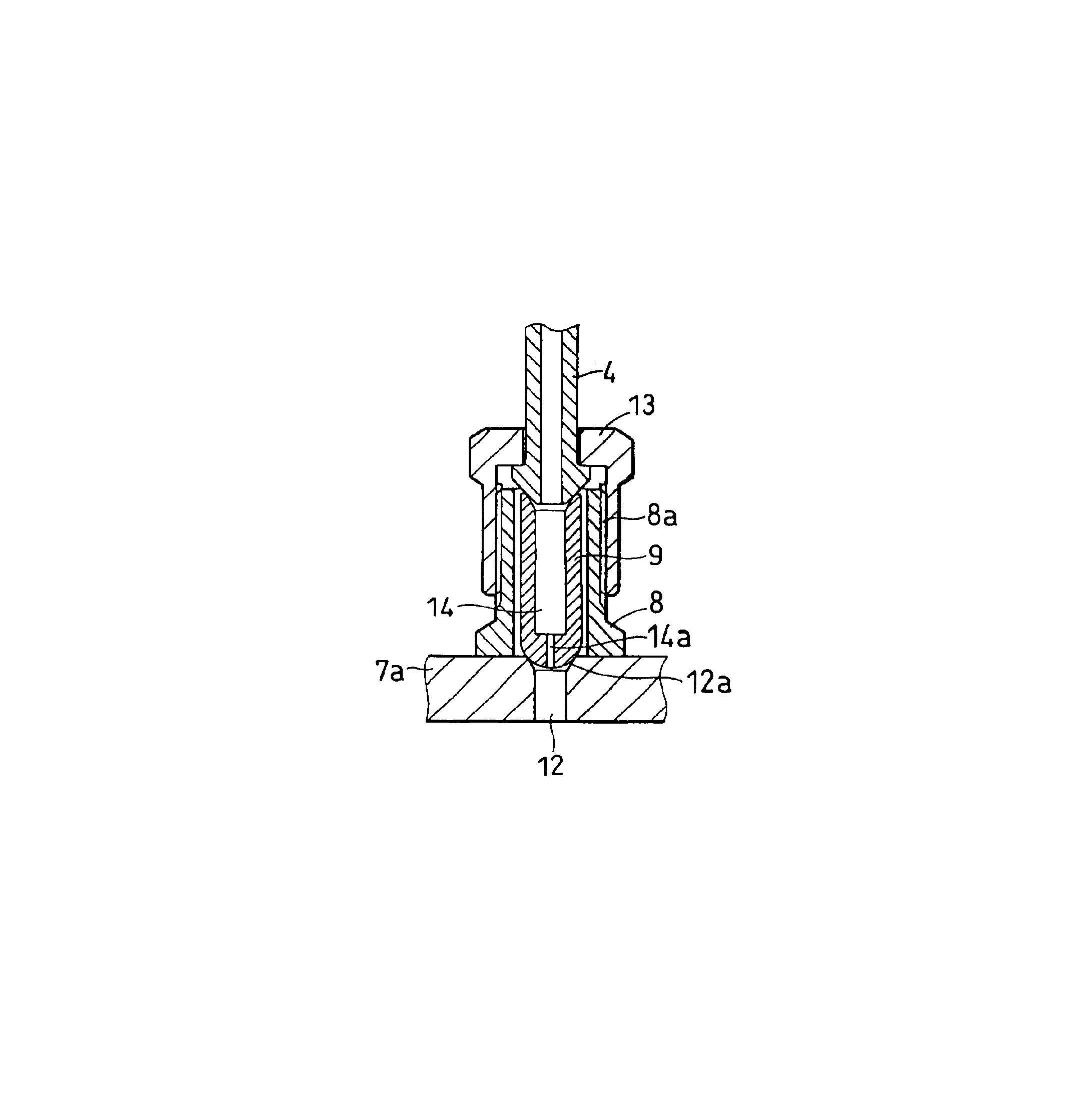

Method for producing a fuel injection valve, and fuel injection valve

InactiveUS20120205470A1Increase in sizeLong delay timeValve arrangementsSpray nozzlesEngineeringControl room

The invention relates to a method for producing a fuel injection valve (10; 10a; 60; 60a), in which a valve needle (40; 40a; 62; 62a) which closes at least one fuel outlet opening (49) is inserted into an injector housing (11), wherein that end of the valve needle (40; 40a; 62; 62a) which lies opposite the at least one fuel outlet opening (49) is guided in a valve element (32) which has a pressurized control chamber (37) which is filled with fuel, wherein the control chamber (37) can be closed on the side which faces away from the valve needle (40; 40a; 62; 62a) by a closing element (23) which forms a passage during opening and is connected at least indirectly to a fuel return line (5) which is under low pressure, wherein fuel volume which is present in the control chamber (37) flows away through the passage after opening of the control chamber (37) by means of the closing element (23), wherein the valve needle (40; 40a; 62; 62a) moves in the direction of the closing element (23), wherein the at least one fuel outlet opening (49) is opened, and wherein a delay time (t) occurs between the opening of the control chamber (37) and the opening of the at least one fuel outlet opening (49) on account of the magnitude of the volume of the control chamber (37) and on account of the rigidity of the valve needle (40; 40a; 62; 62a), which rigidity is caused by the modulus of elasticity, the diameter (D) and the length (L) of the valve needle (40; 40a; 62; 62a). There is provision according to the invention for at least the volume of the control chamber (37) to be adapted in order to achieve identical delay times (t) in fuel injection valves (10; 10a; 60; 60a) having injector housings (11) of different length and valve needles (40; 40a; 62; 62a) of different length, in such a way that the volume of the control chamber (37) is reduced in order to shorten the delay time (t) and the volume of the control chamber (37) is increased in order to lengthen the delay time (t).

Owner:ROBERT BOSCH GMBH

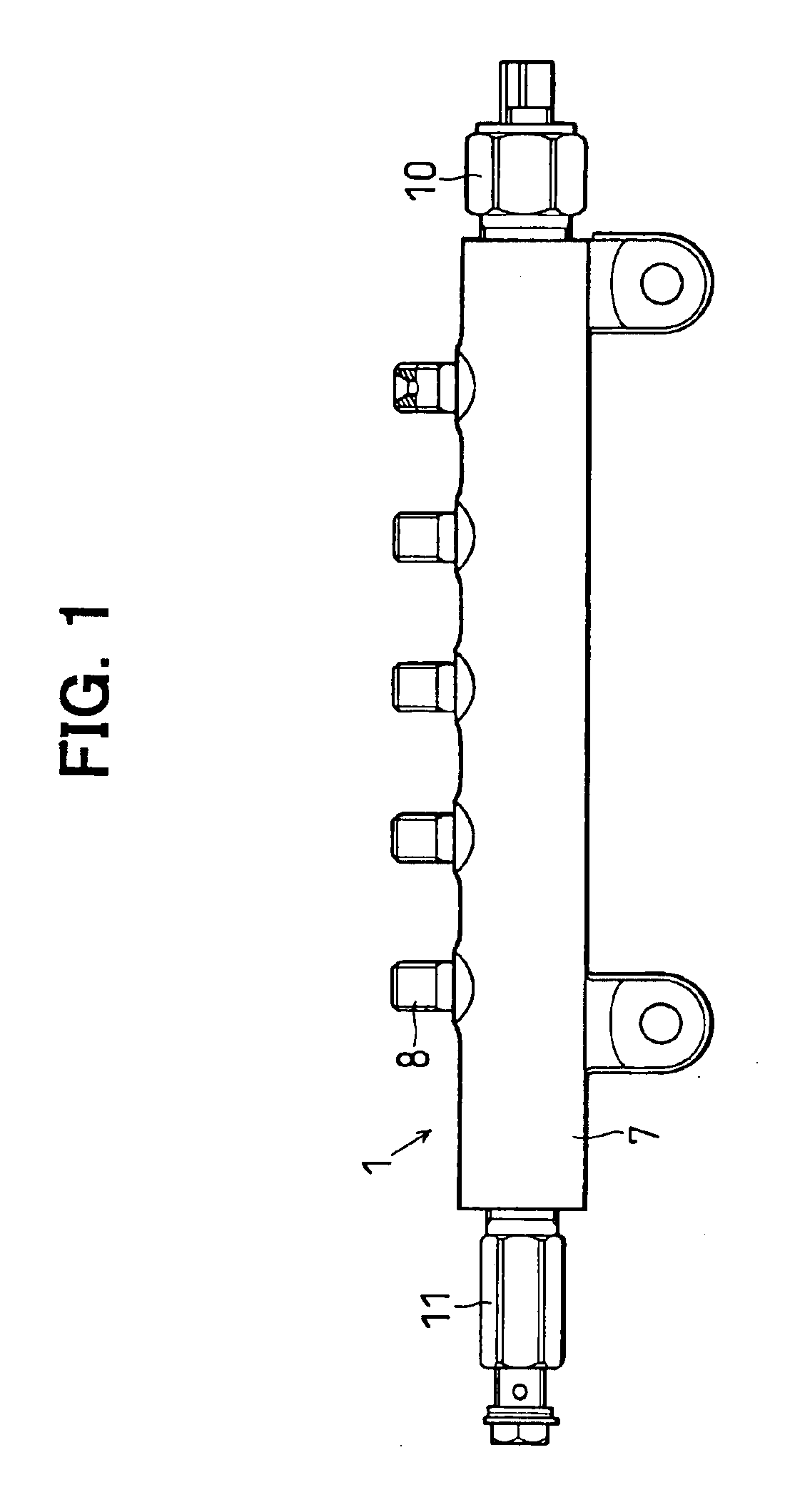

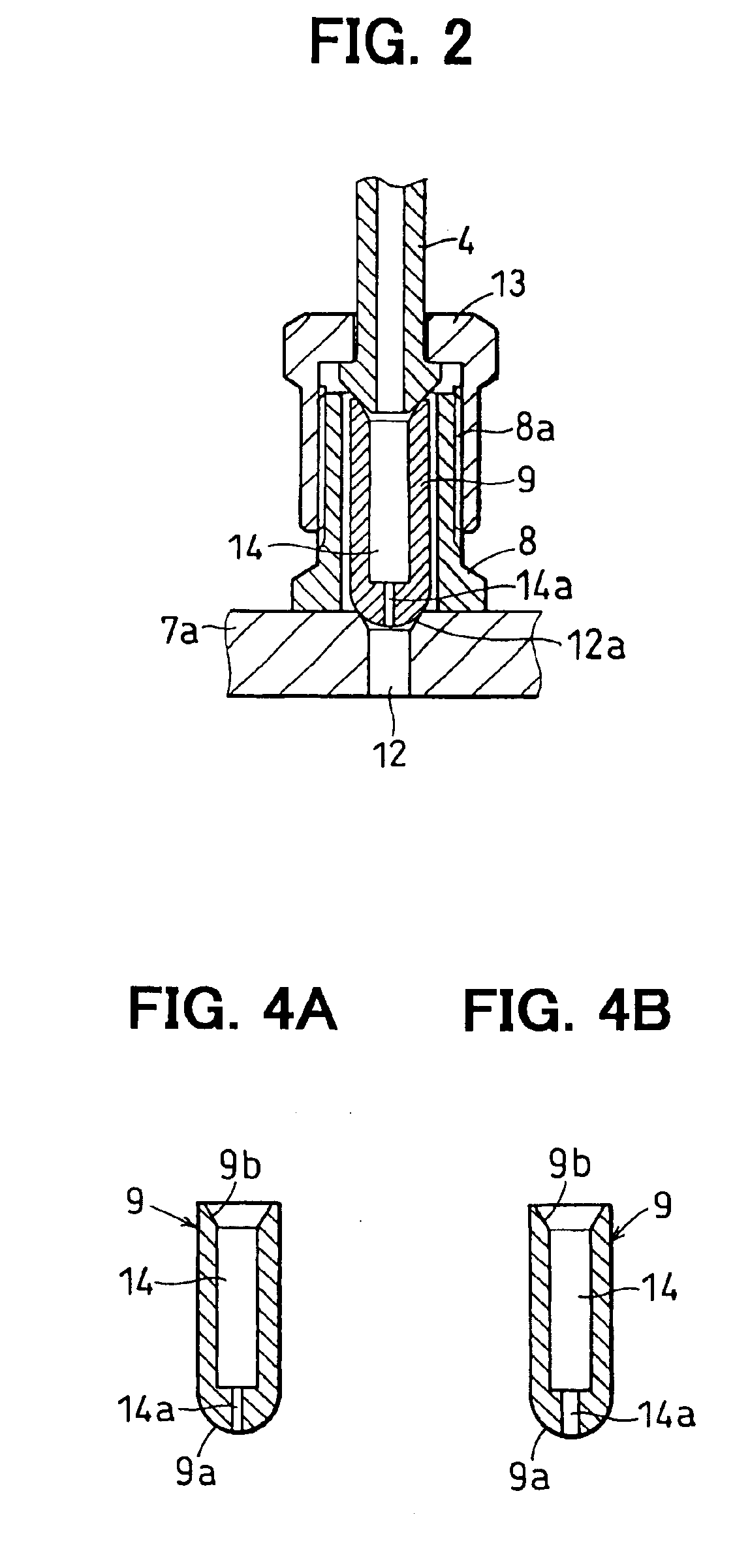

High pressure fuel accumulation device

InactiveUS6871638B2Well formedReduce manufacturing costLow pressure fuel injectionMachines/enginesCommon railGuide tube

A common rail has an accumulation pipe in which high pressure fuel is accumulated, a pipe joint to which a high pressure pipe is connected and an orifice member housed inside the pipe joint. The orifice member is provided with a conduit through which a fuel port formed in the accumulation pipe communicates with the high pressure pipe. The conduit is provided at an end thereof with an orifice. The orifice serves to reduce pressure pulsation generated by fuel injection of an injector so that fuel pressure in the common rail is stable. Since the orifice is formed in the orifice member housed in the pipe joint, the orifice is easily and accurately manufactured at a lower cost, compared to an orifice formed in the accumulation pipe. It is easy to standardize the manufacture of plural models of common rails whose orifice diameters are different.

Owner:DENSO CORP

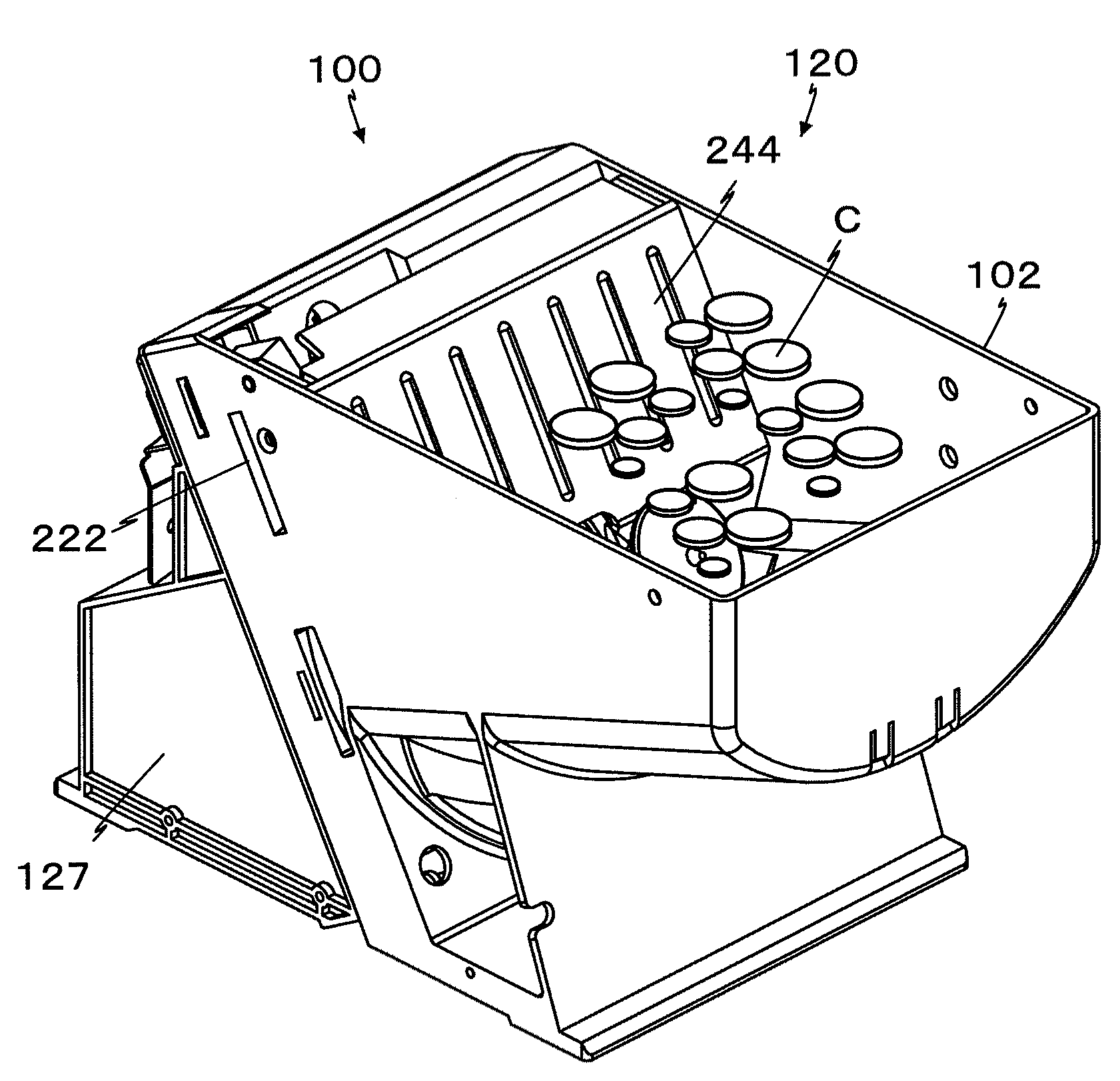

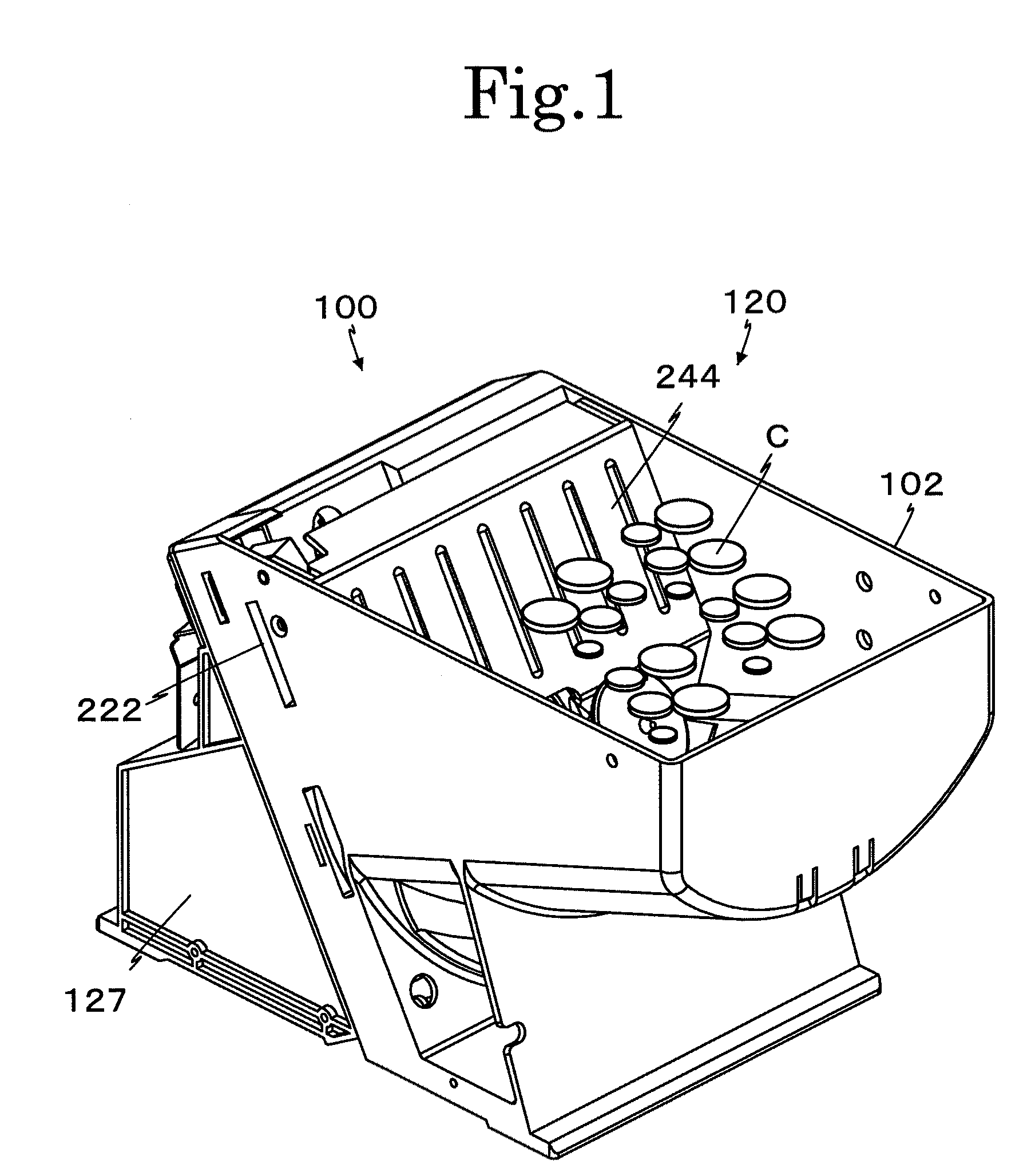

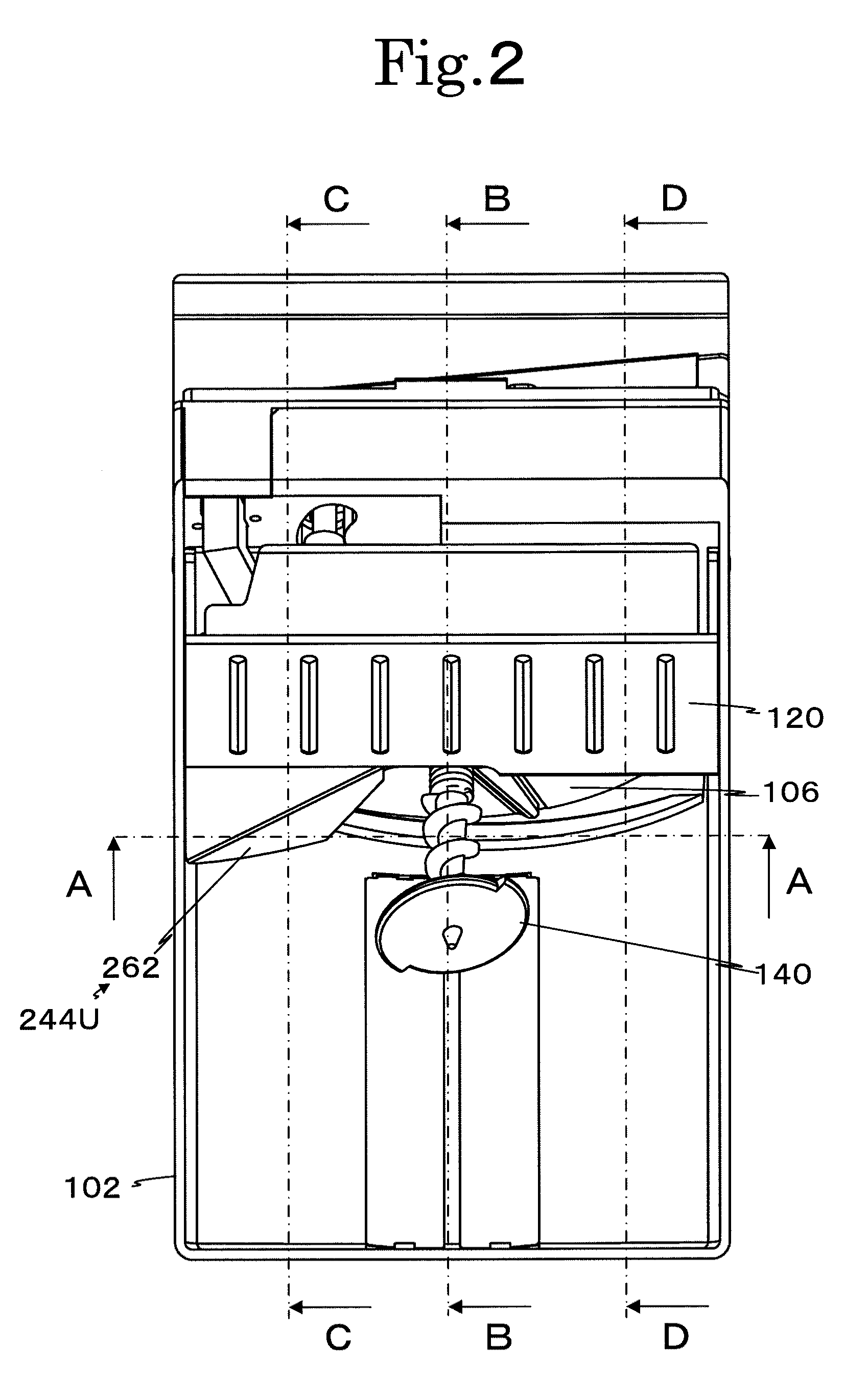

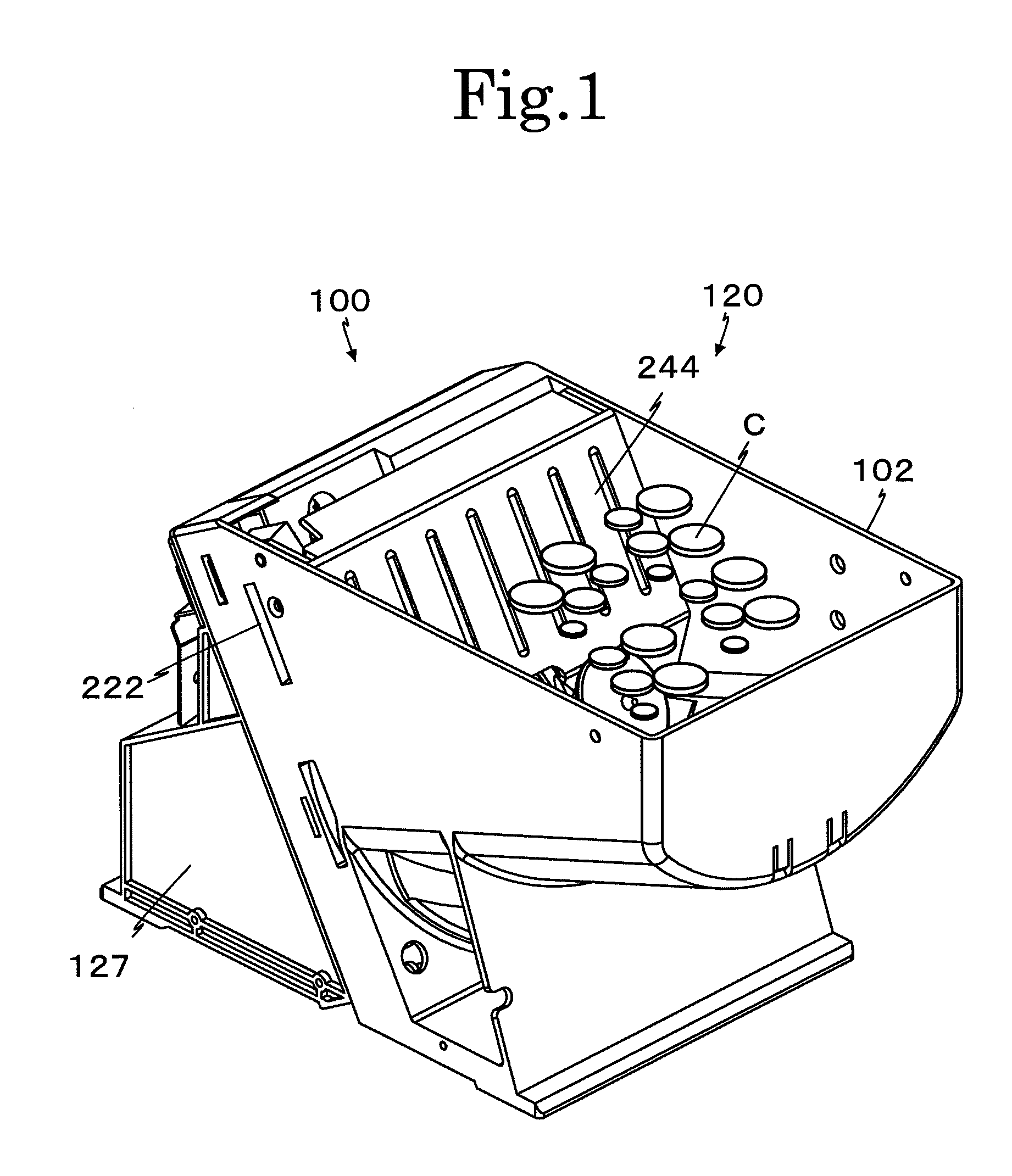

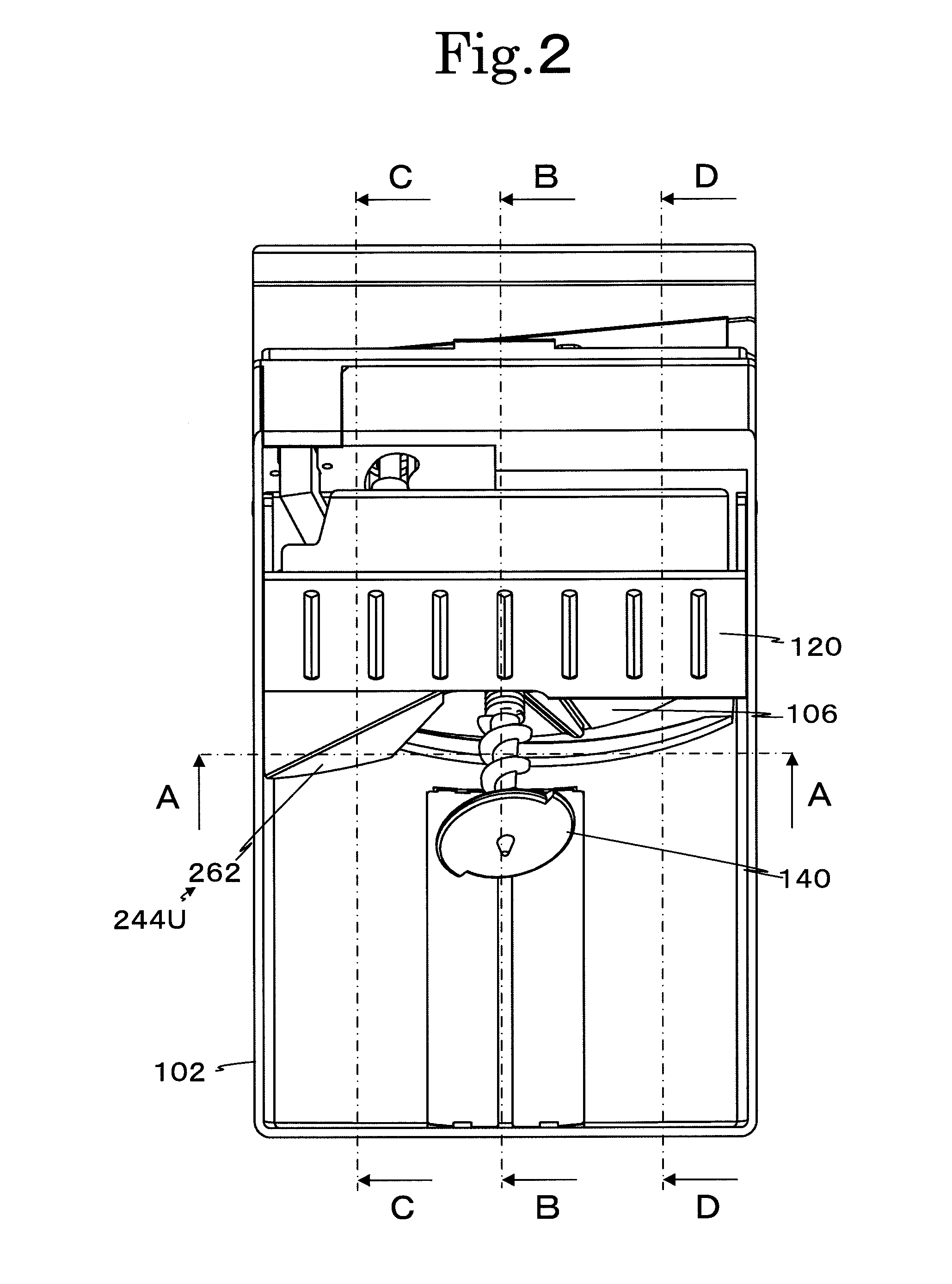

Coin hopper

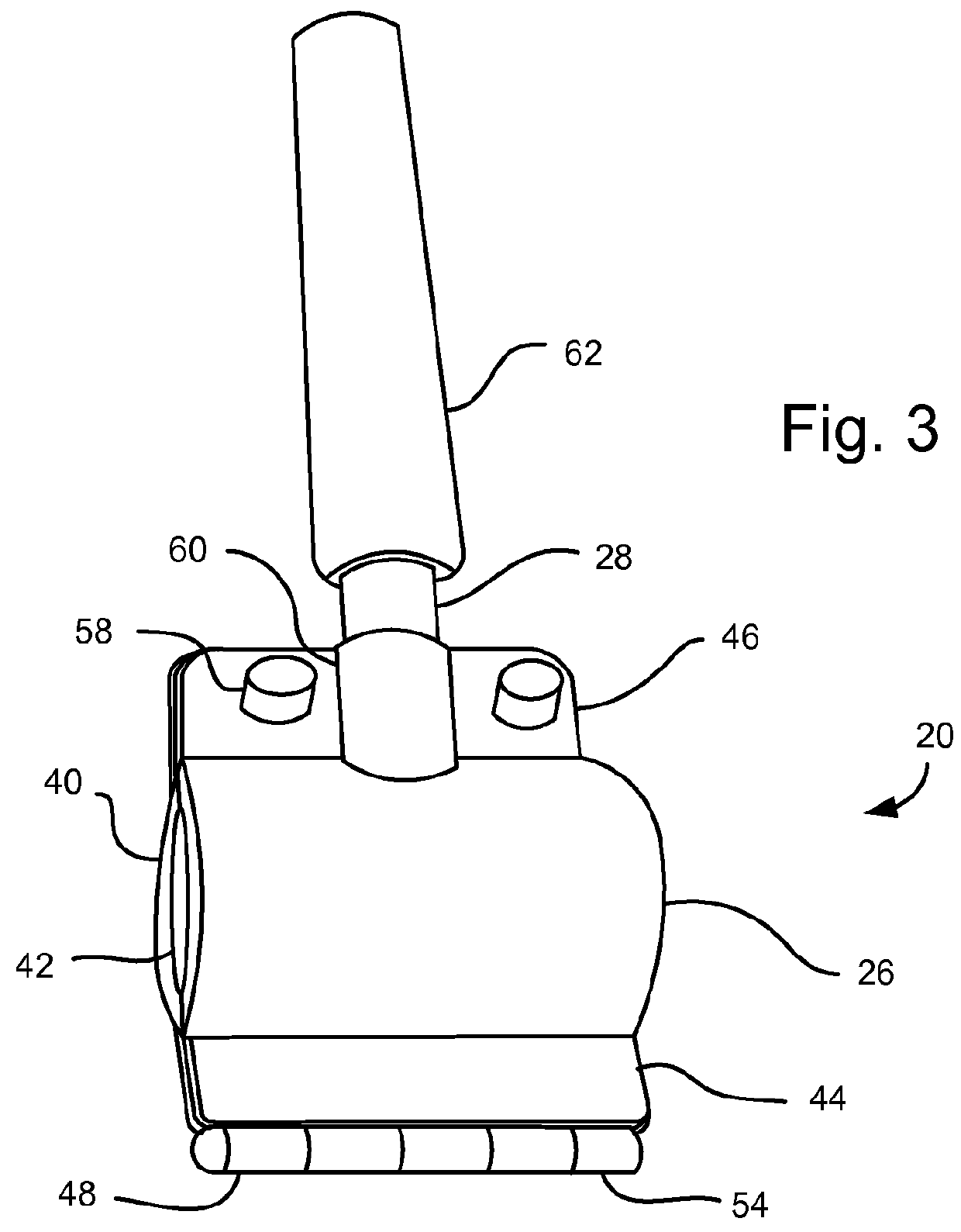

ActiveUS20080299886A1Increase the discharge speedReverse rotationCoin countersCoin dispensersRotating discCentral region

A coin hopper includes a rotating disk provided obliquely upward at a predetermined angle; an outer covering unit covering at least a lower outer circumference of the rotating disk; a holding bowl continuing from the outer covering unit and holding coins; a circular supporting rack provided in a central region of an upper surface of the rotating disk; and coin stoppers being provided on the upper surface of the rotating disk and extending radially from the supporting rack in a circumferential direction to a periphery of the rotating disk at an equal interval. Coins are accepted one by one while a surface thereof is contacted with a holding surface of the upper surface of the rotating disk between the coin stoppers, are moved in one direction while a periphery thereof is held by the supporting rack, and are received from the coin stoppers during transportation by a coin receiver.

Owner:ASAHI SEIKO CO LTD

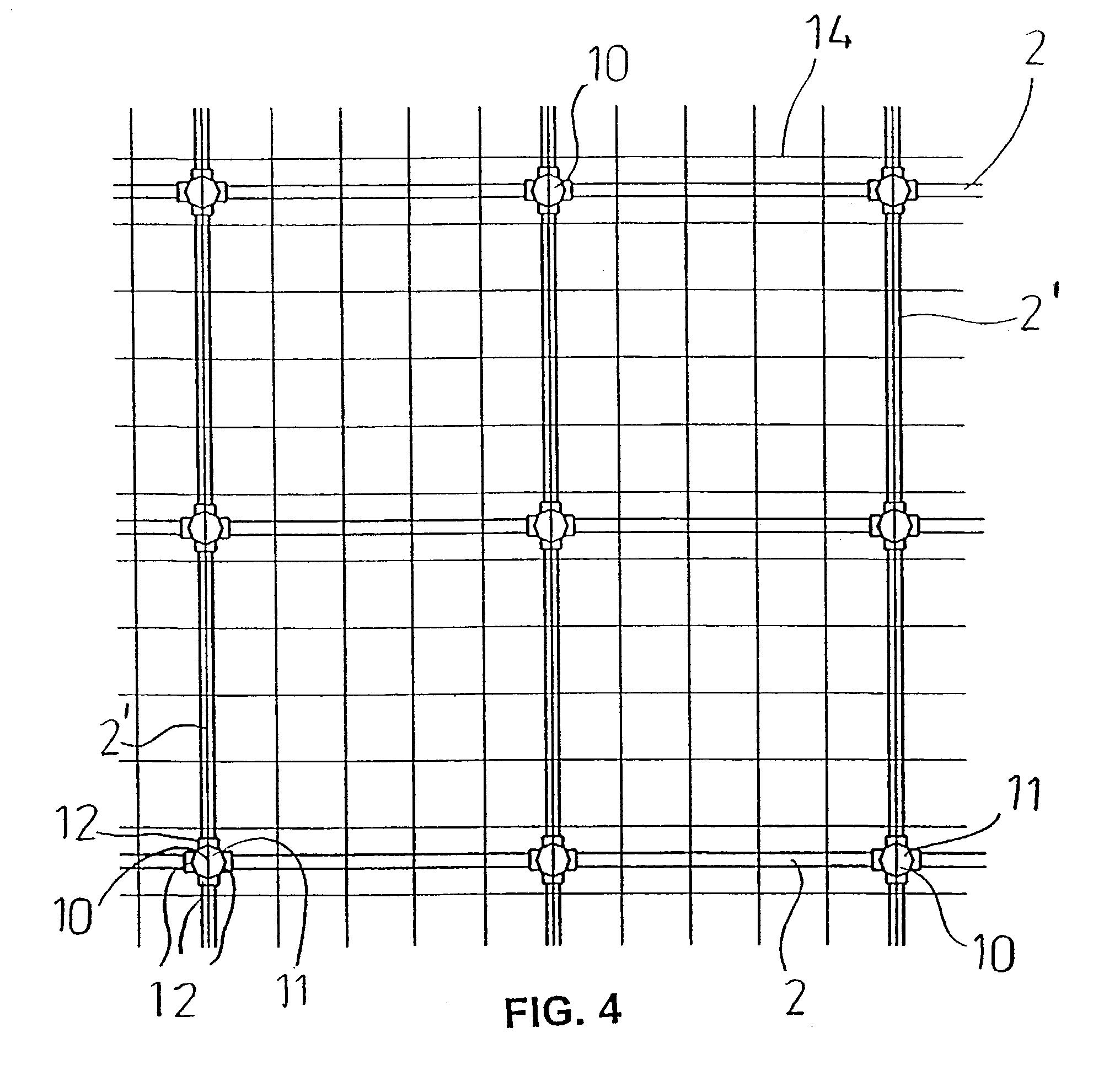

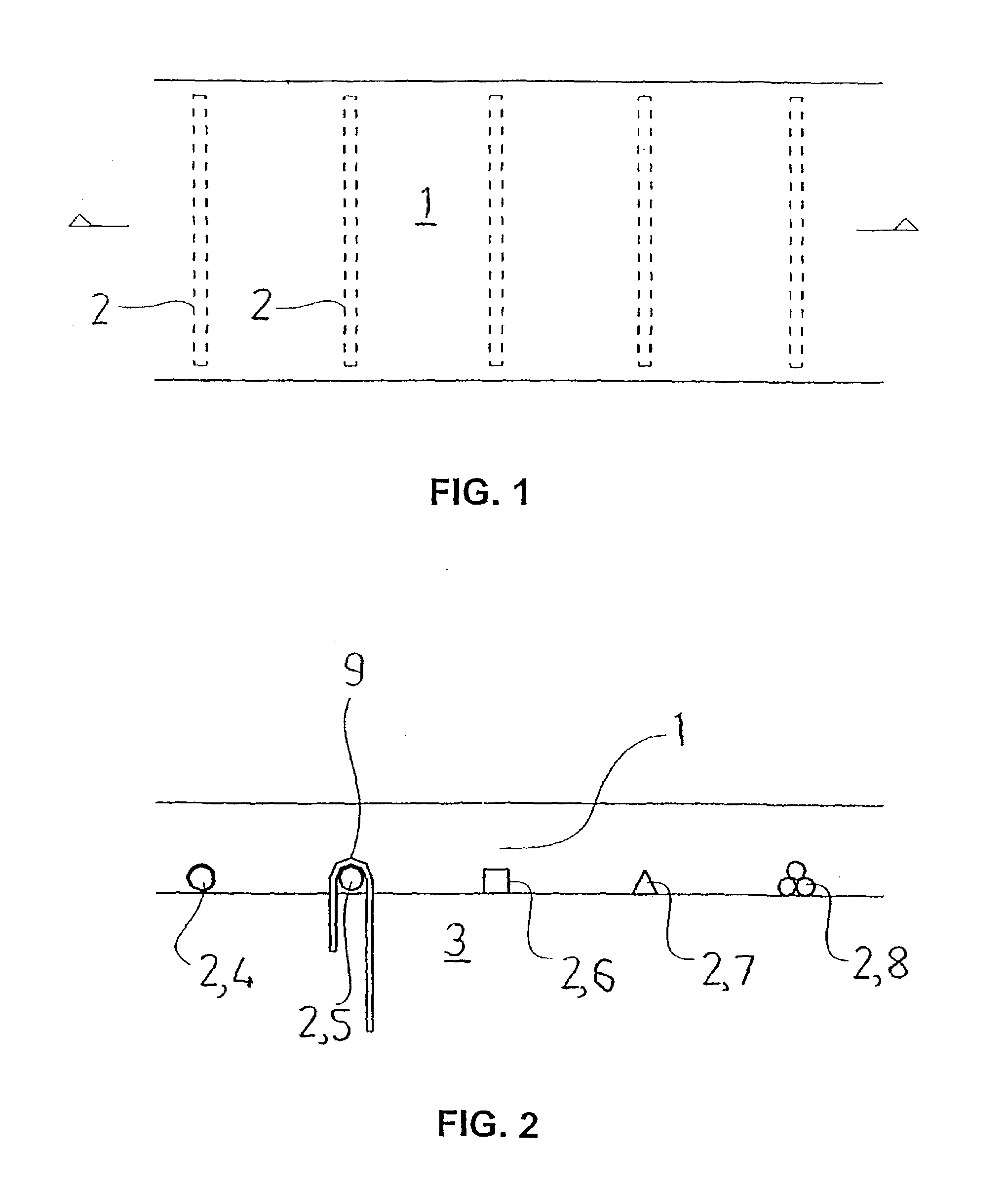

Method and system for constructing large, continuous, concrete slabs

InactiveUS7069703B2Easy to crackAvoid crackingPaving reinforcementsIn situ pavingsStructural engineeringMesh grid

A method and system are provided for constructing large, continuous, concrete slabs without using conventional shrinkage joints. The system comprises a grid of closely-spaced crack inducers (2) arranged relative to a concrete-pouring surface and adapted to be covered by concrete. The crack inducers (2) may be connected to one another with connectors (10). The crack inducers (2) are of a size, shape and spacing to promote formation of fine cracks in the vicinity of the inducers (2) throughout the slab when the concrete sets.

Owner:BUILDING INNOVATIONS PTY LTD

Intake nozzle for a pump

InactiveUS8245890B2Larger the radius of the deviceReduce gapPipe supportsPositive displacement pump componentsEngineeringConstant velocity

An intake nozzle for the inlet pipe of a pump has a vertical duct with a downwardly facing mouth and a surrounding disk shaped intake portion with a bottom surface which faces a flat surface such as a floor or tank bottom to take liquid from the floor down to a shallow depth. The bottom surface is shaped with a flat outer part and an upwardly and inwardly curved inner part converging to the mouth. The surface is shaped and spaced from the flat surface with annular areas defined therebetween so that the liquid enters the peripheral edge slowly and accelerates up to an inner edge of the flat portion and then remains at constant velocity from the inner edge of the flat portion through the mouth and the pipe to the intake of the pump.

Owner:KOCH EDWARD JOHN

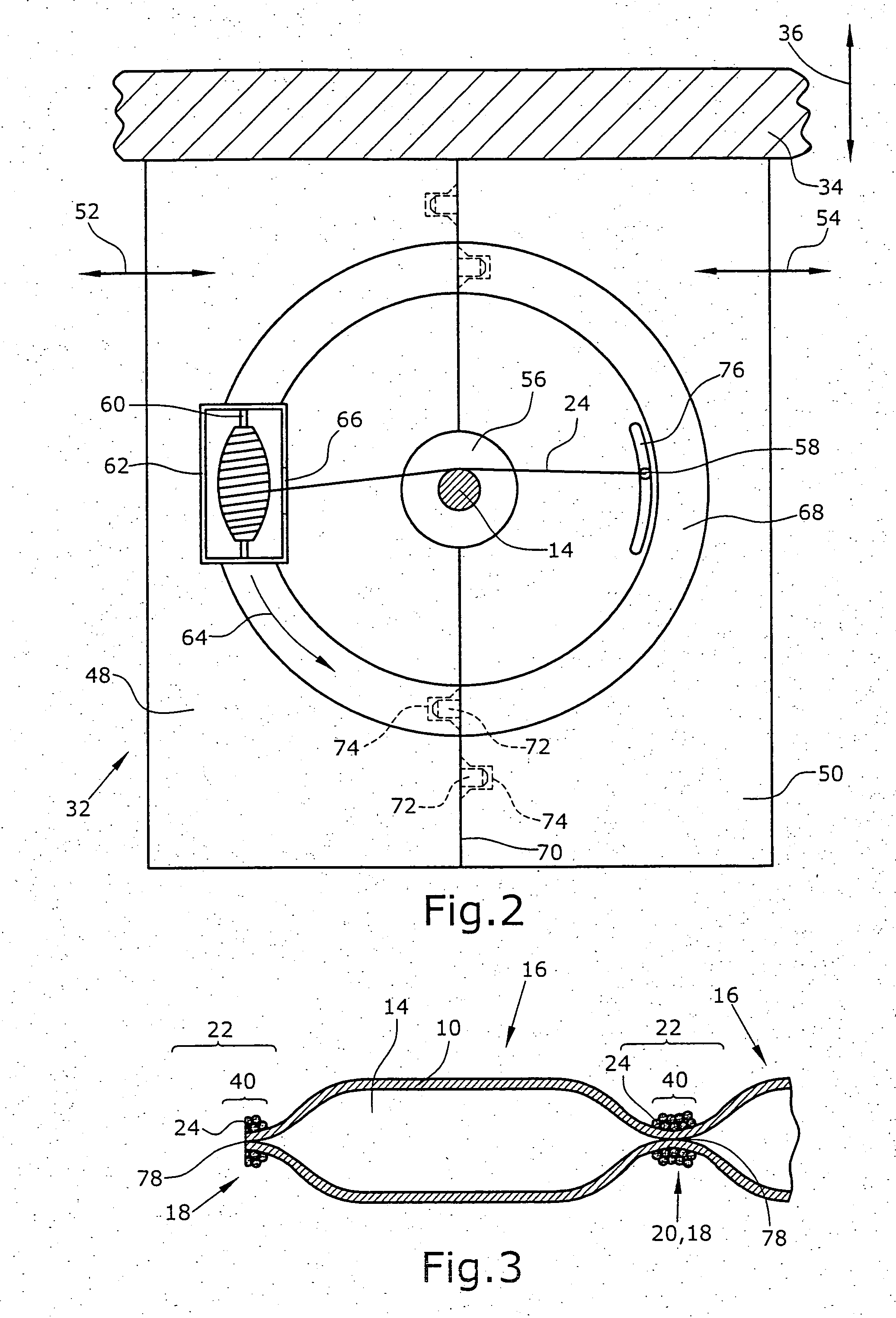

Device for providing a second tail length

A device as well as a method for forming a sausage tail on a casing material, that receives a filling product, in particular sausage meat, wherein the sausage tail at least approximately does not contain filling product at least while it is being formed. The device contains a feeding path for the casing material, which extends in an at least approximately linear direction and along which the sausage tail is formed, a supply unit for receiving a supply of empty casing material and a first unit for forming sausage tails that is capable of acting on the casing material in direction of the feeding path for forming a first sausage tail length by pulling casing material from the supply. Furthermore, a second unit for forming sausage tails is provided that is capable of forming a second sausage tail length by pulling further casing material from the supply.

Owner:POLY CLIP SYST

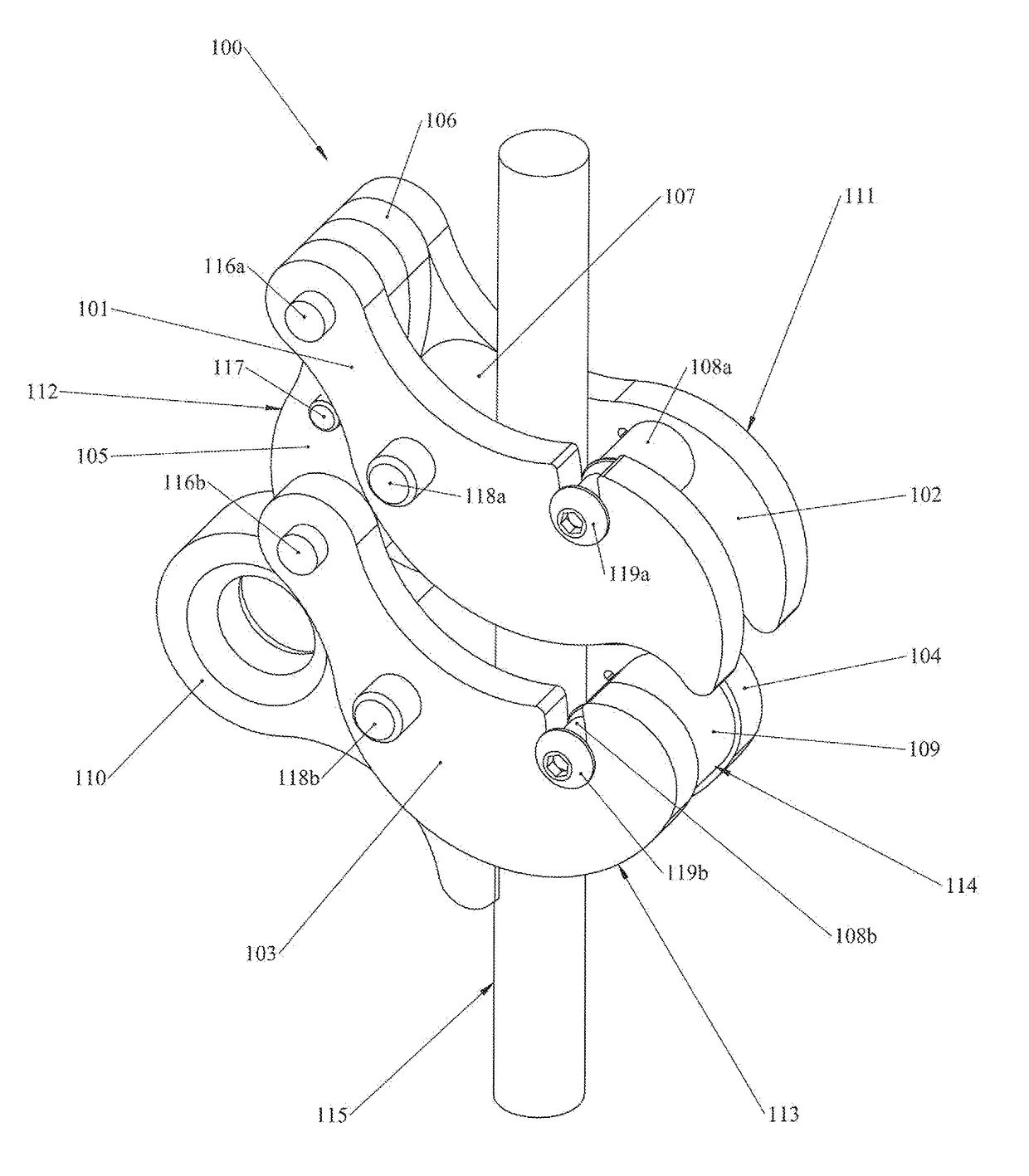

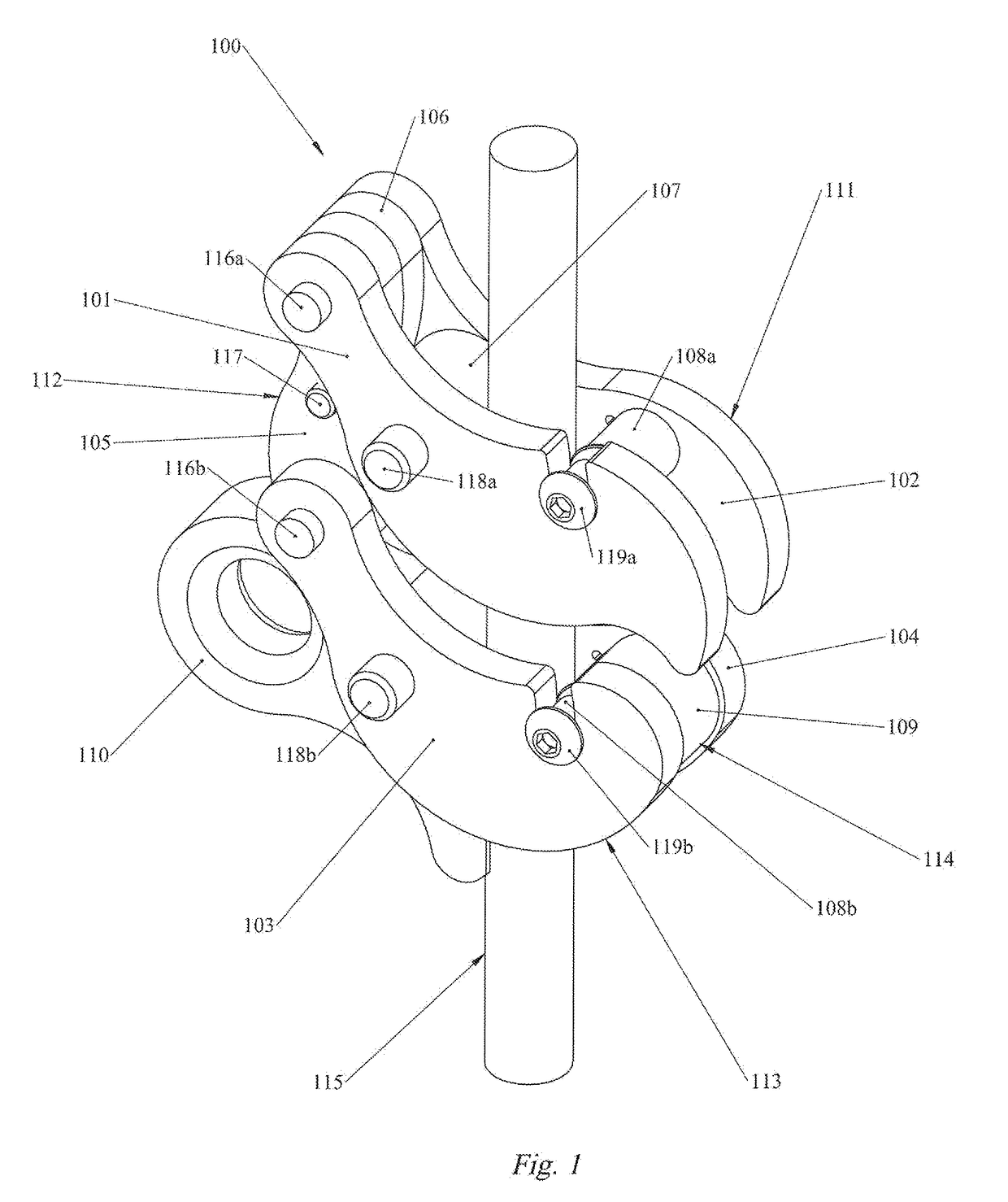

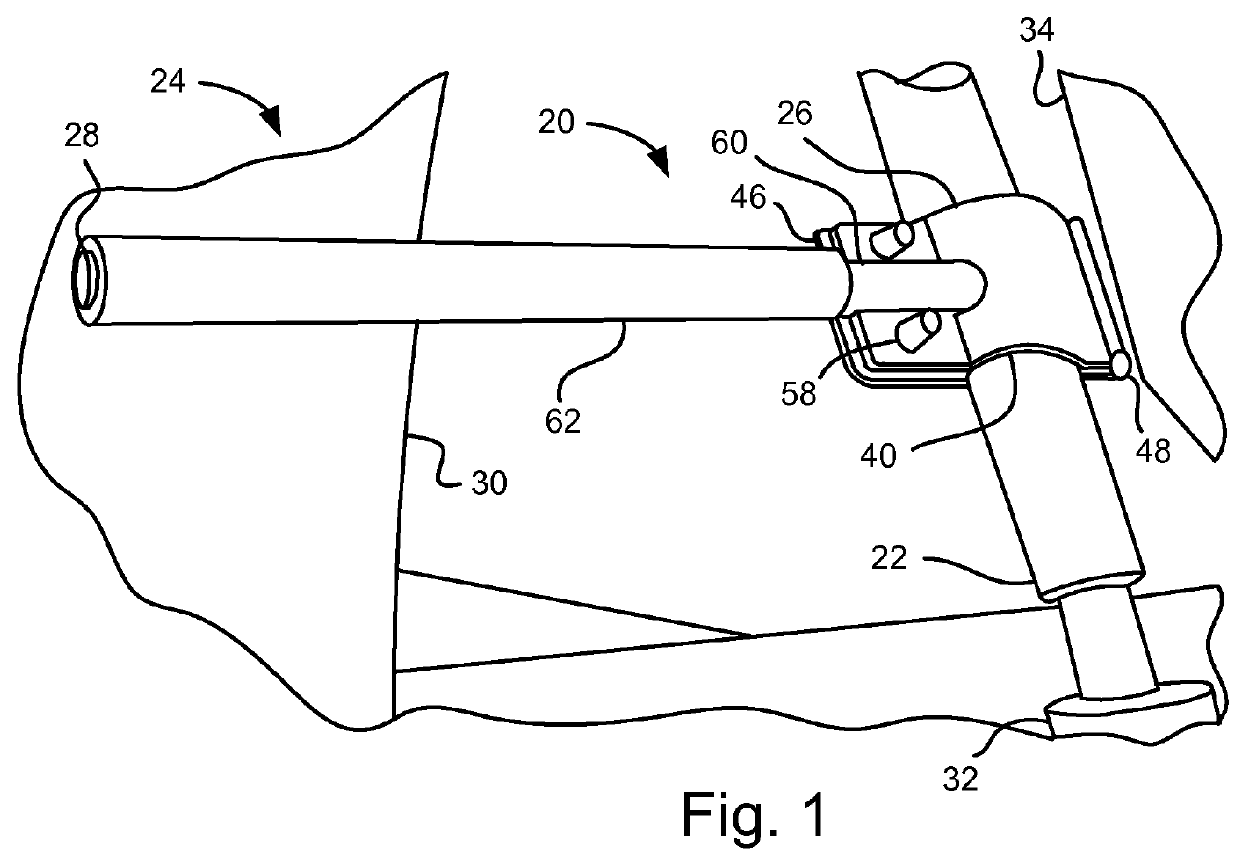

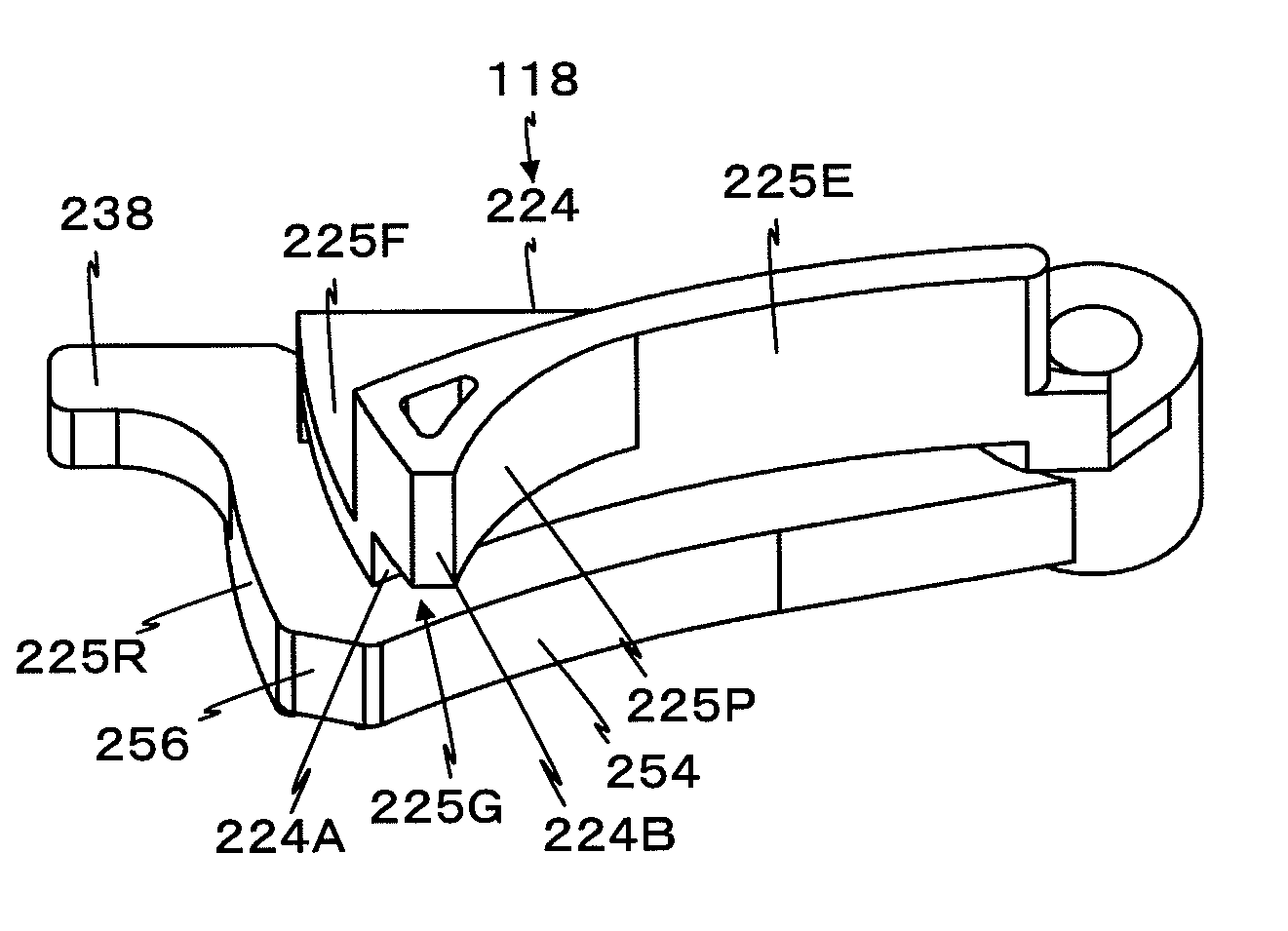

On-rope work positioning device

A rope-climbing device has an upper assembly with planar side plates spaced apart by a roller, such that the side plates rotate relative to one another about a roller axis, a spine unit comprising planar links of common width each of half the plate spacing, the links pivoted at a central point, and a lower assembly comprising third and fourth side plates spaced apart by a clamp element such that the third and fourth side plates are enabled to rotate relative to one another about the clamp axis, and the clamp element is enabled to clamp a rope between the plates. The device may be opened by aligning pivot points, a rope inserted, and closed on the rope. Engaged on the rope, the device may be set to slide on the rope, or clamp to the rope by action of a user.

Owner:MERRITT ARBOREAL DESIGN INC

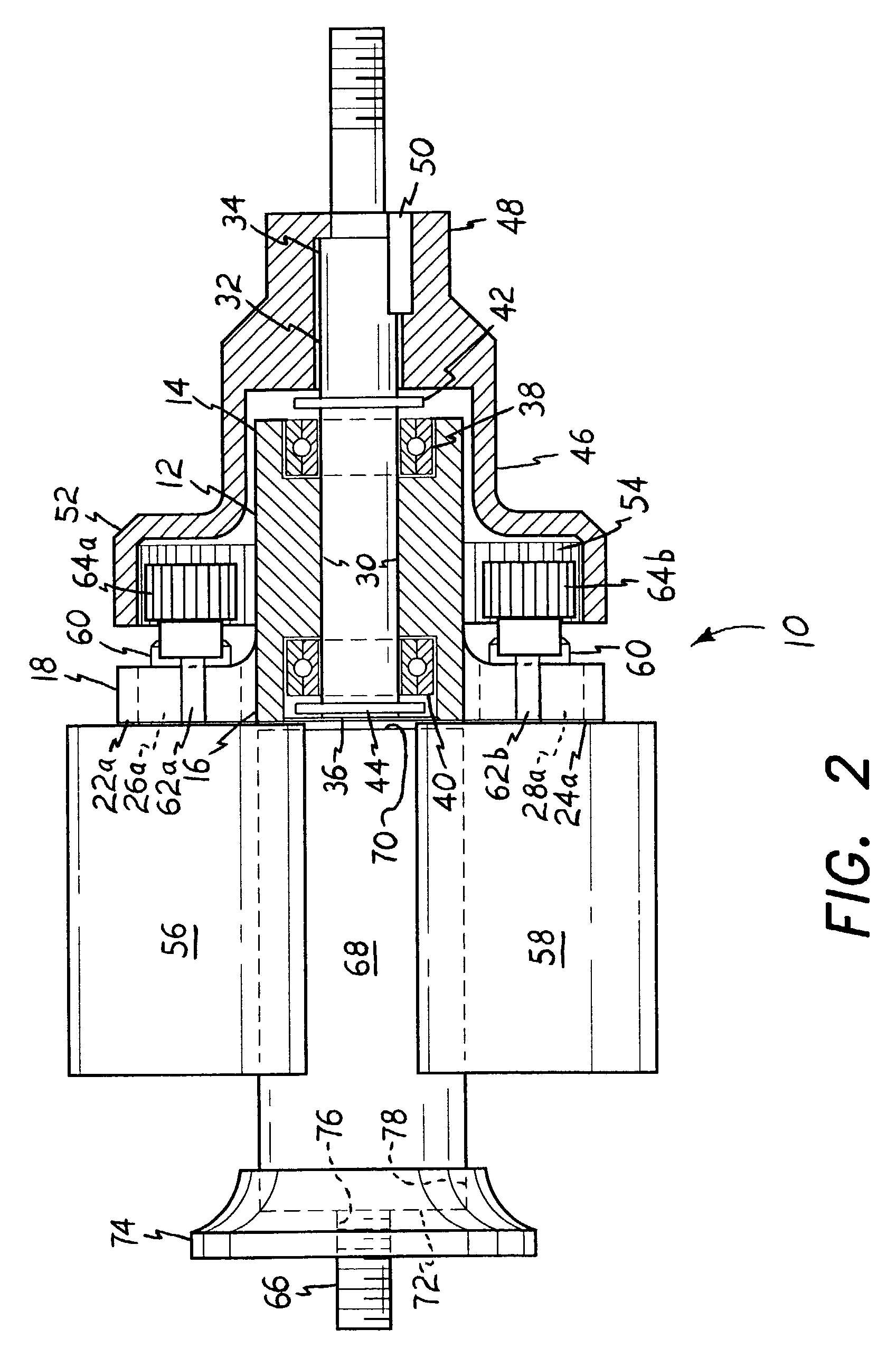

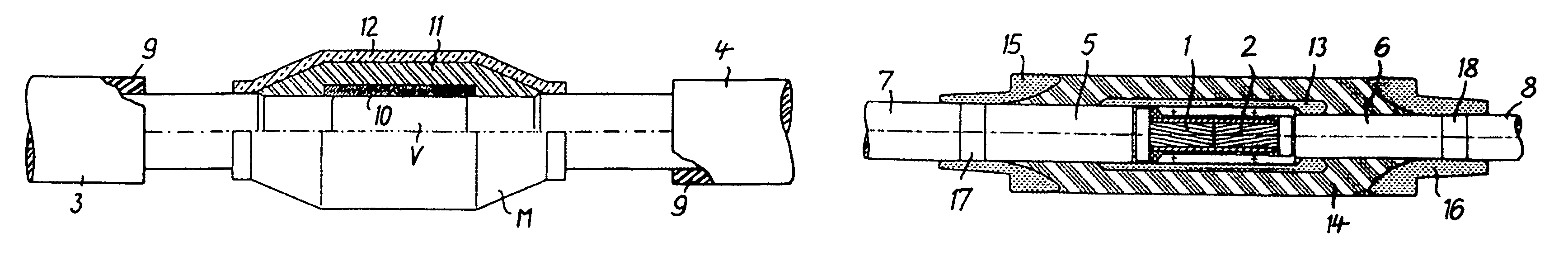

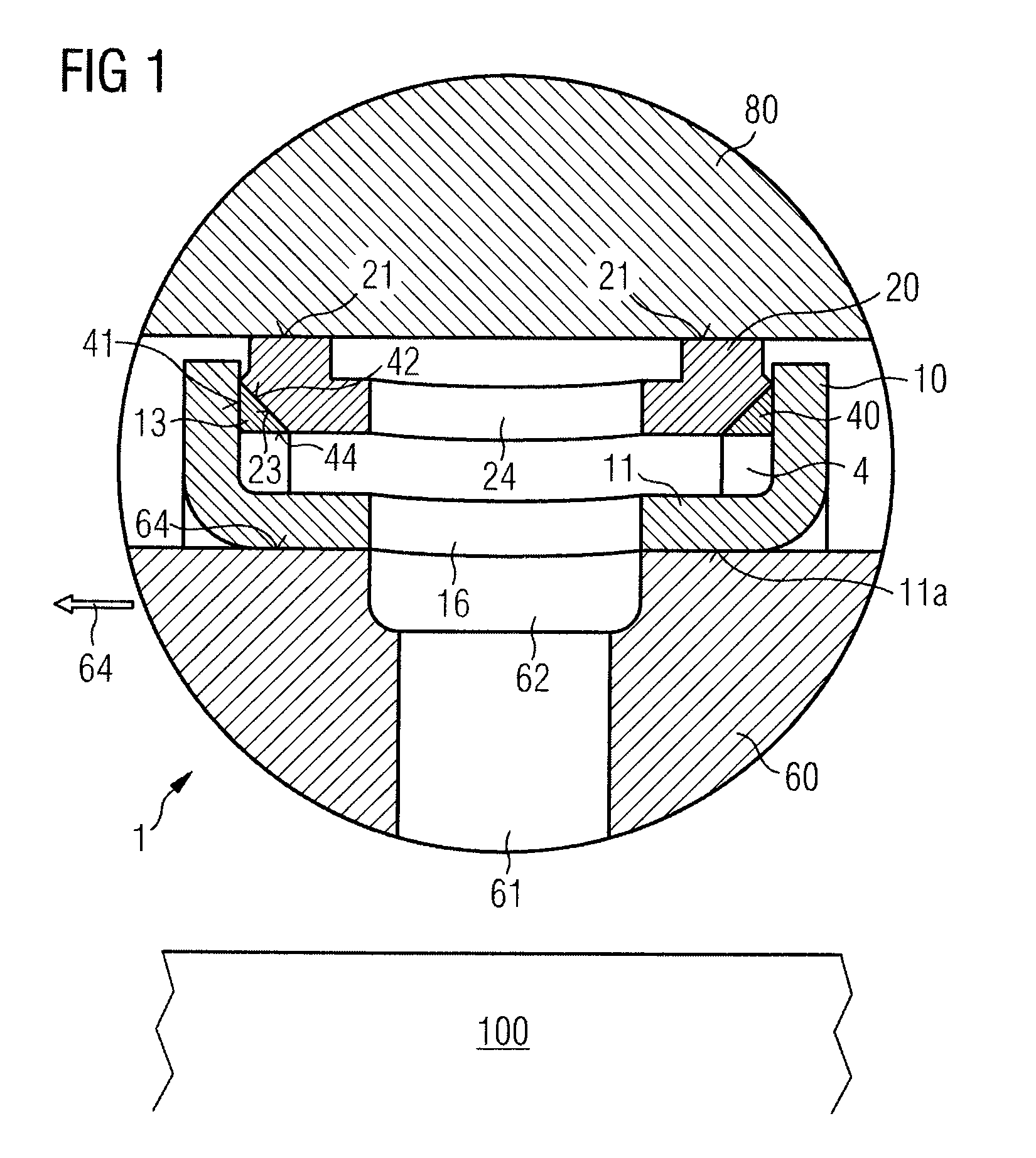

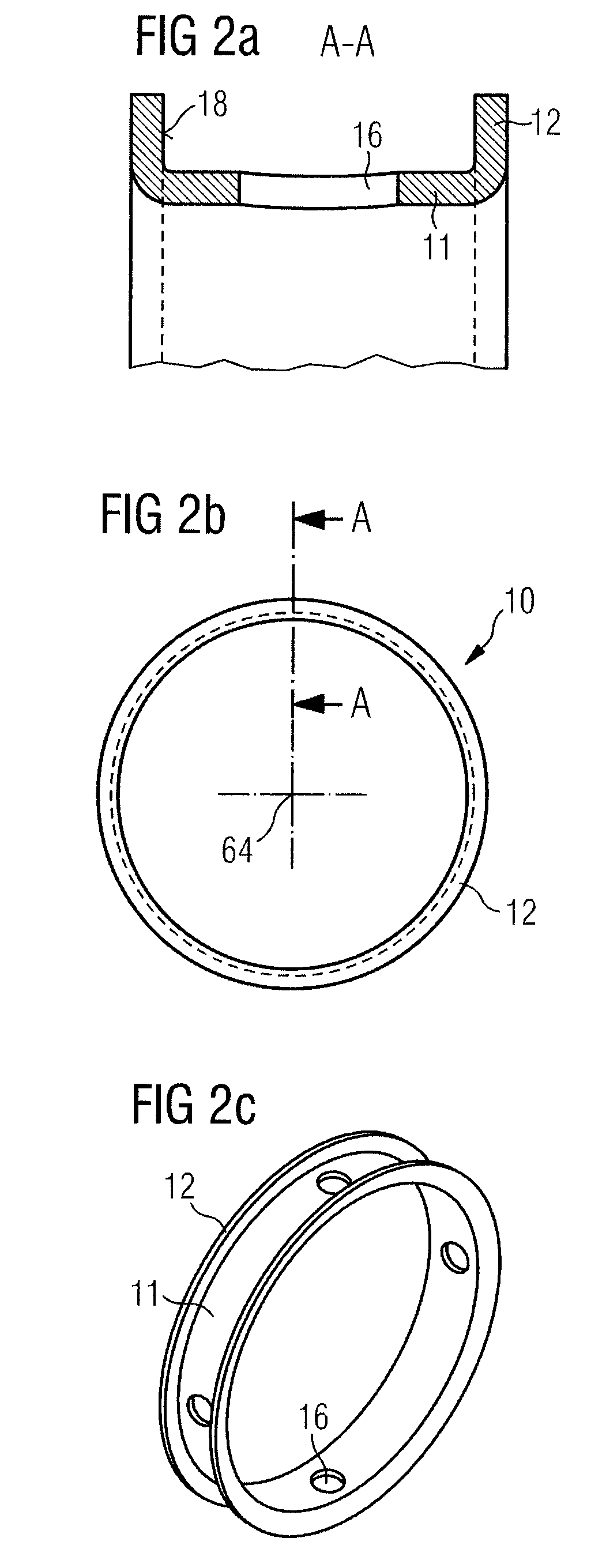

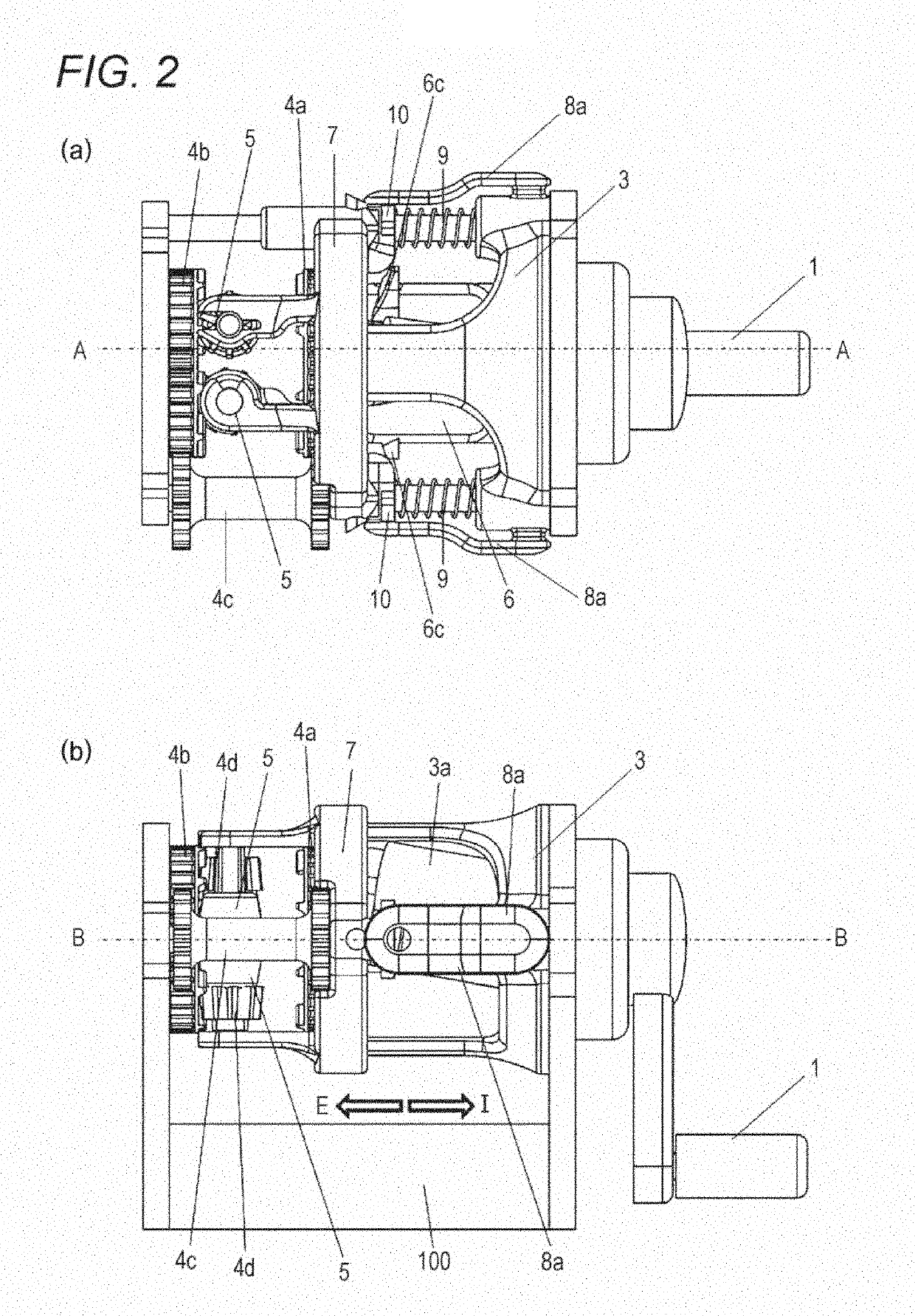

Rotary oil feedthrough

ActiveUS20110018208A1Minimum possible leakageImprove response characteristicsEngine sealsAdjustable jointsEngineeringMechanical engineering

A rotary oil feedthrough is provided for sealing off a pressurized oil compartment between a rotatable shaft and a shaft mount, where the rotary oil feedthrough displays a radial oil passage for connecting an oil duct of the shaft and / or the mount to the pressurized oil compartment in fluid-permeable fashion, and has a seal arrangement that seals off the pressurized oil compartment on both sides in the axial direction of the shaft. The rotary oil feedthrough displays a sealing ring carrier that can be fastened to the shaft or the mount in non-rotating and fluid-tight fashion, the sealing ring carrier being arranged coaxially to the shaft or the mount, and an adapter that can be positioned on the other component of shaft and mount in fluid-tight fashion, and is surrounded laterally by the sealing ring carrier in the axial direction of the shaft. Located between sealing ring carrier and adapter are two axially separated sealing rings that each lie on the sealing ring carrier and the adapter in sealing fashion in order to seal off the pressurized oil compartment in the axial direction of the shaft, and that can be rotated relative to the sealing ring carrier and / or the adapter. The rotary oil feedthrough displays the longest possible service life, the minimum possible leakage, and good response characteristics, and is of simple structural design.

Owner:GAPI TECHN PROD

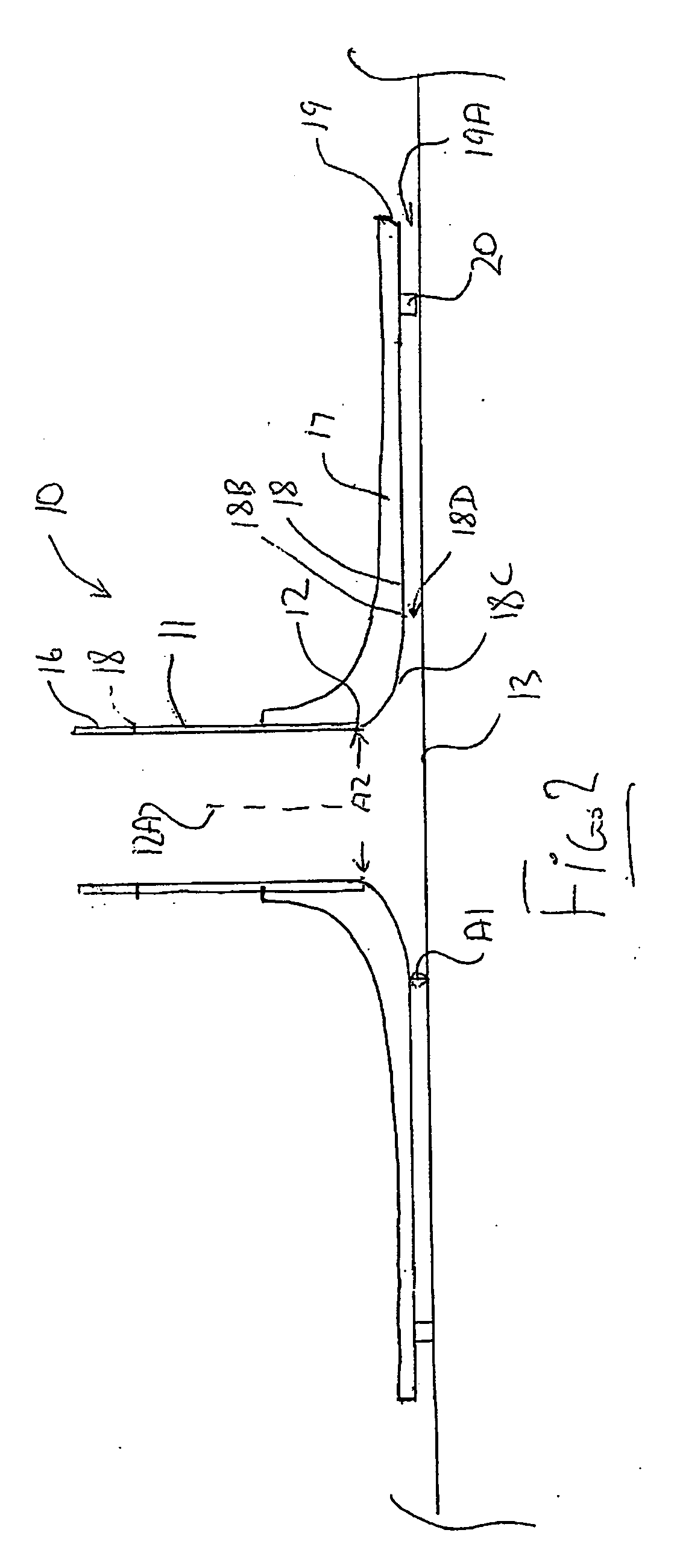

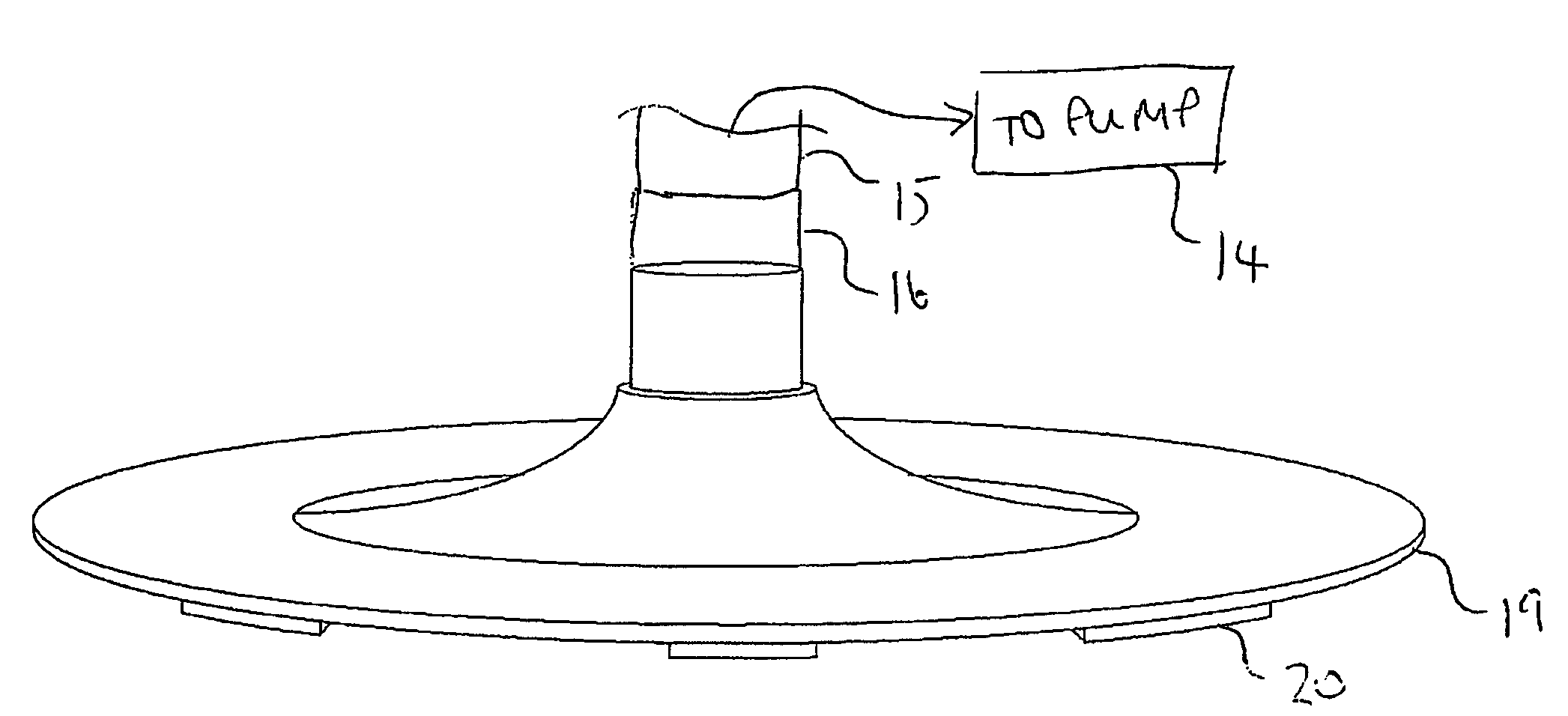

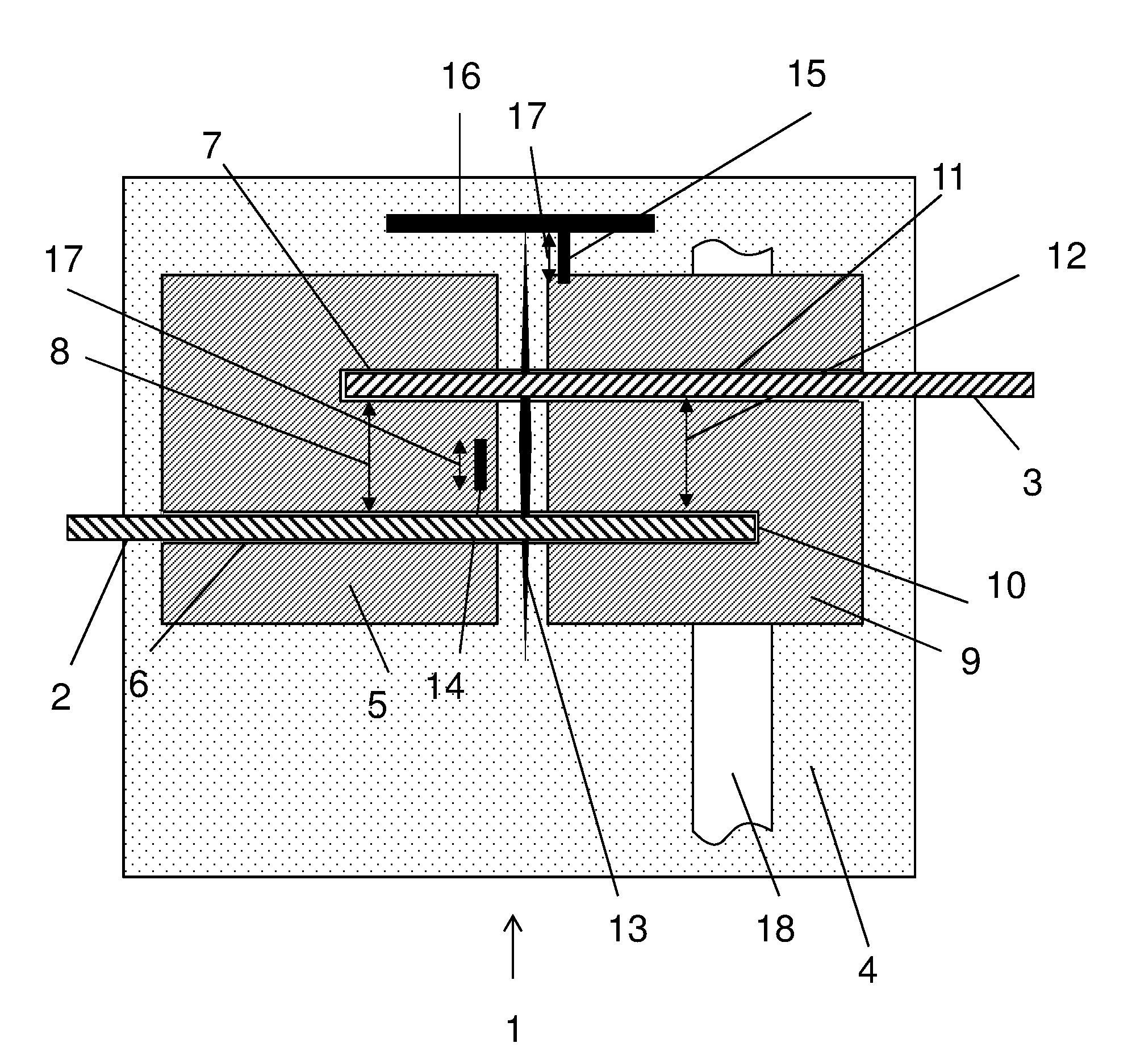

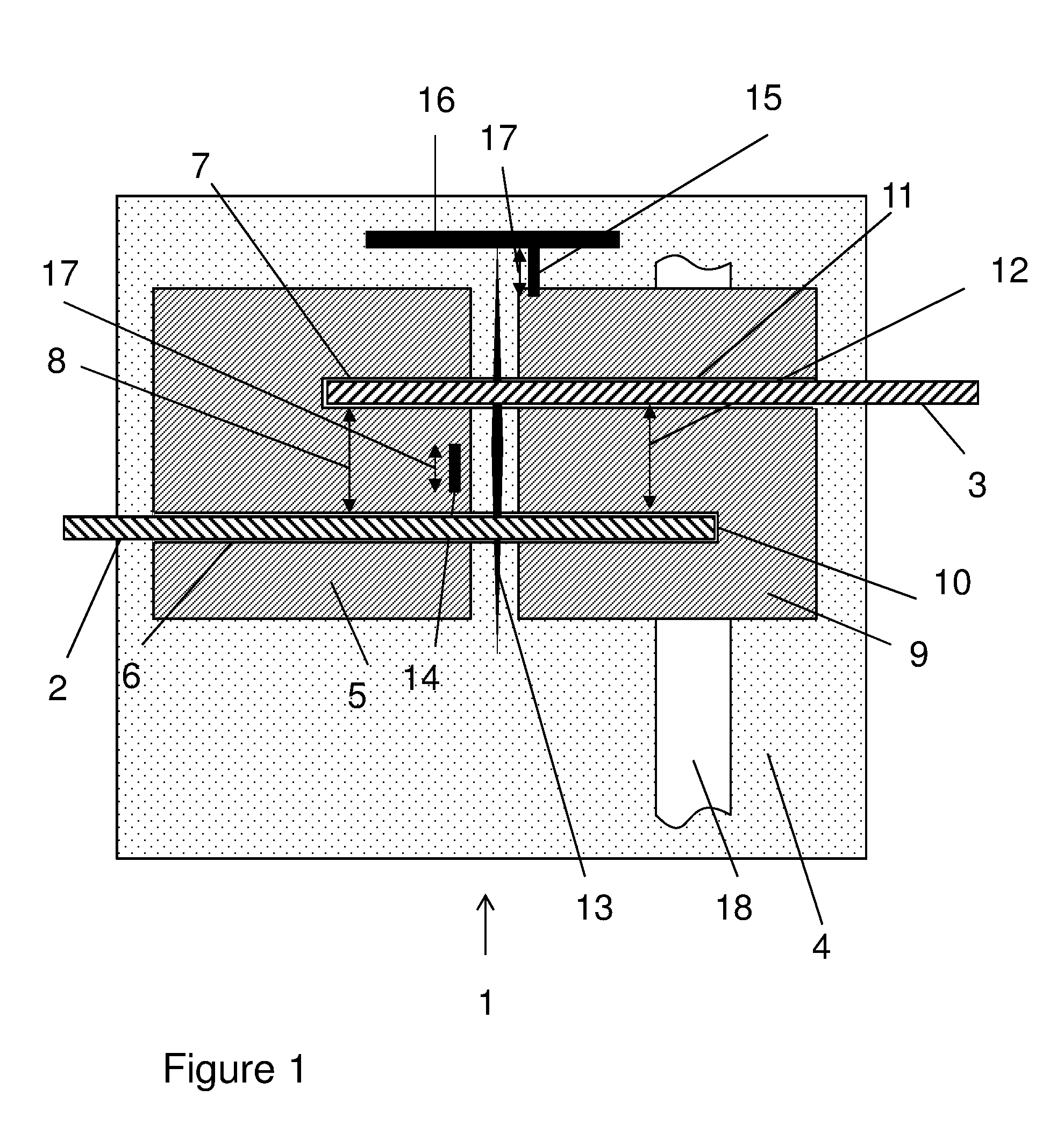

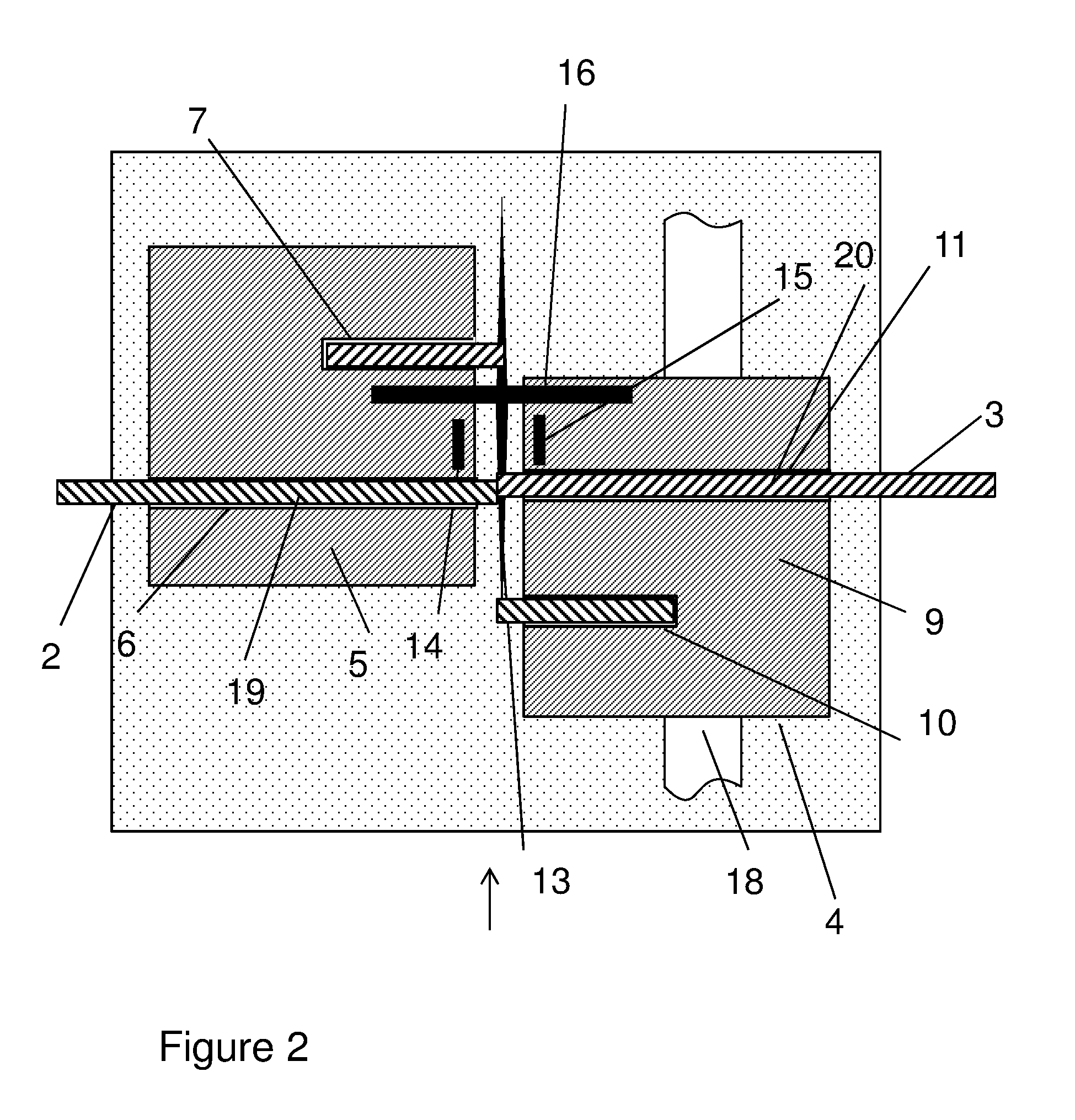

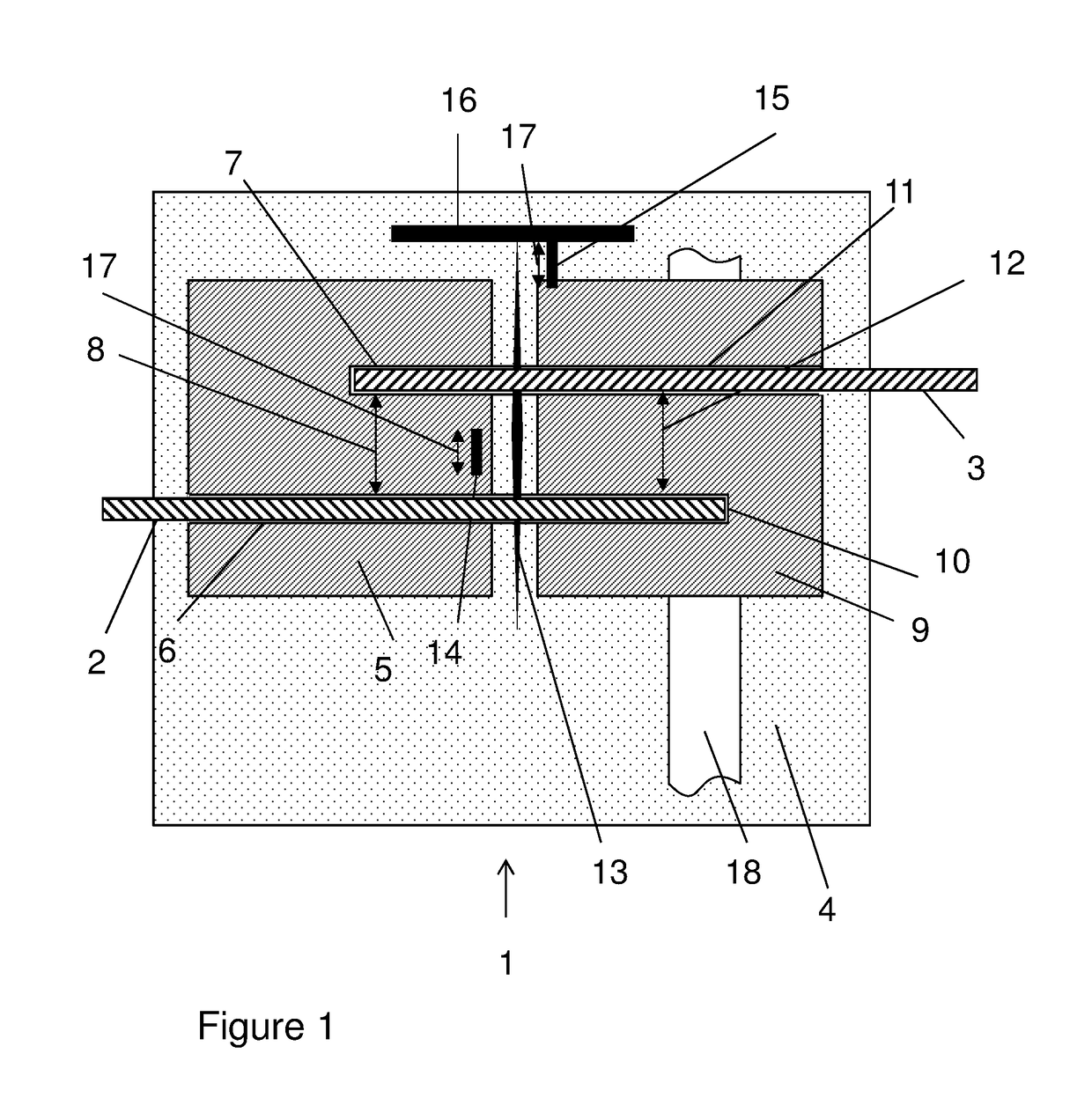

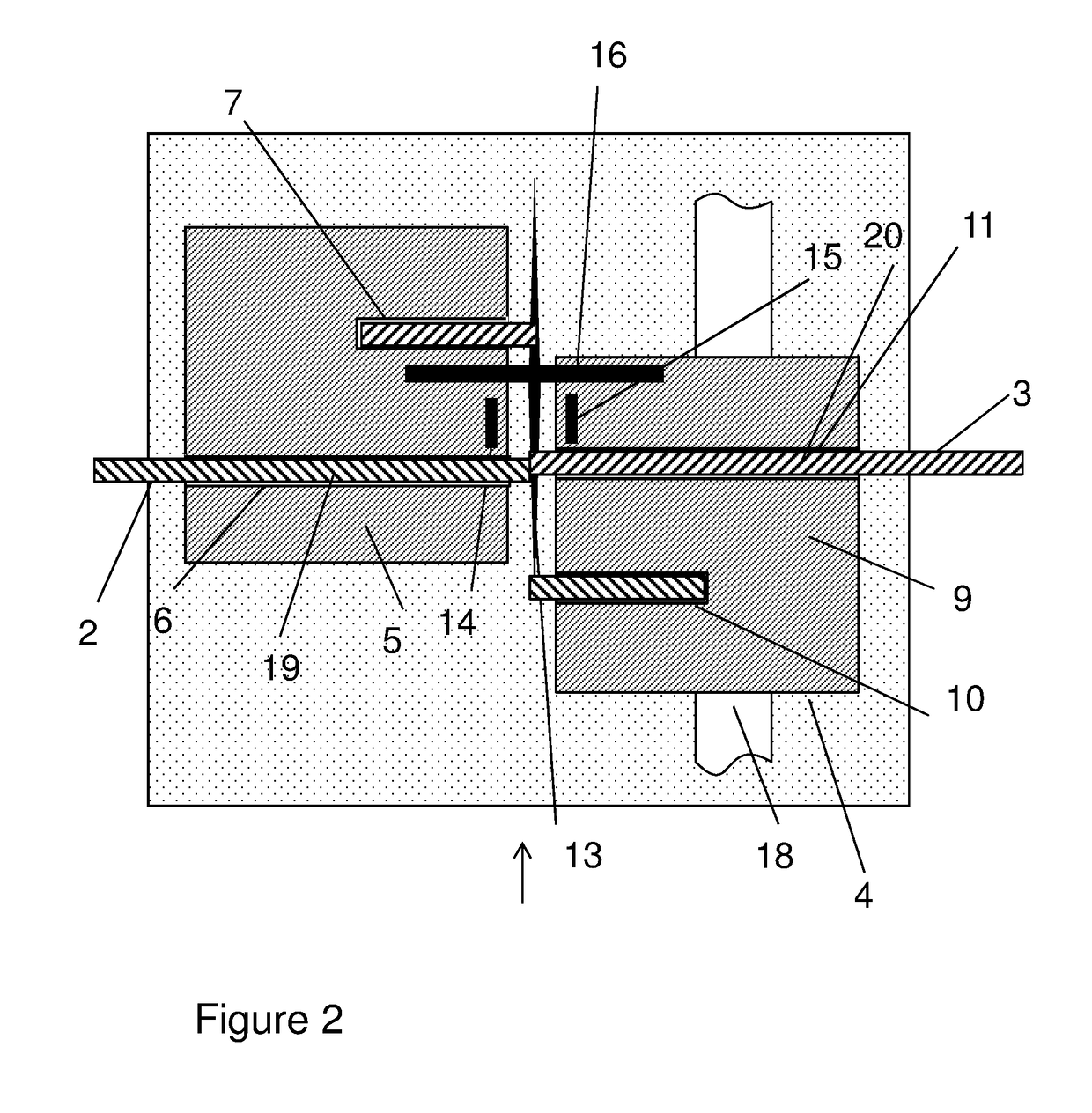

Apparatus for connection of thermoplastic tubing

ActiveUS20160250806A1High strengthPrecise alignmentTube connectorsDomestic articlesEngineeringWelding

The invention discloses an apparatus (1) for aligning and supporting a first (2) and a second (3) length of thermoplastic tubing, preparatory to and during cutting and welding of said lengths of tubing, where the apparatus comprises the following components arranged on a base support (4):a) a first holder (5) arranged to accommodate portions of the first and second lengths of tubing in a first (6) and a second (7) elongated holding space respectively, wherein the holding spaces are essentially parallel to each other and separated from each other by a first distance (8);b) a second holder (9) arranged to accommodate portions of the first and second lengths of tubing in a third (10) and a fourth (11) elongated holding space respectively, wherein the holding spaces are essentially parallel to each other and to the holding spaces in the first holder and separated from each other by a second distance (12) substantially the same as the first distance (8), and wherein said second holder is movable in a direction essentially perpendicular to the holding spaces of the first and second holders from a cutting position where said first holding space (6) is aligned with said third holding space (10) and said second holding space (7) is aligned with said fourth holding space (11) to a welding position where said first holding space (6) is aligned with said fourth holding space (11);c) cutting means (13) arranged between said first and second holders for cutting said lengths of tubing when the second holder is in the cutting position;d) aligning means arranged to abut the outside of a cut length of tubing accommodated in the first holding space (6) and the outside of a cut length of tubing accommodated in the fourth holding space (11) and to align these lengths of tubing with each other.

Owner:CYTIVA SWEDEN AB

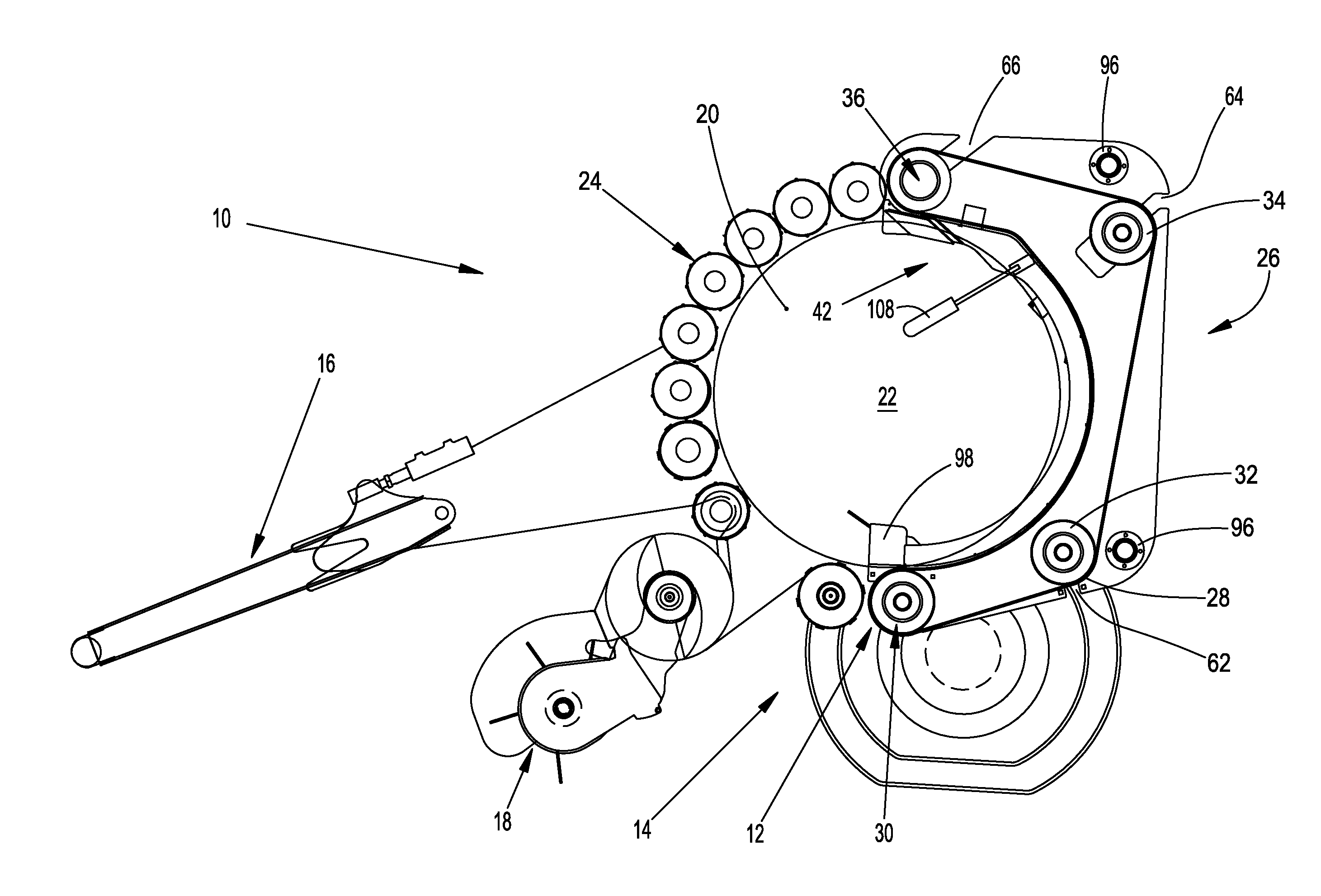

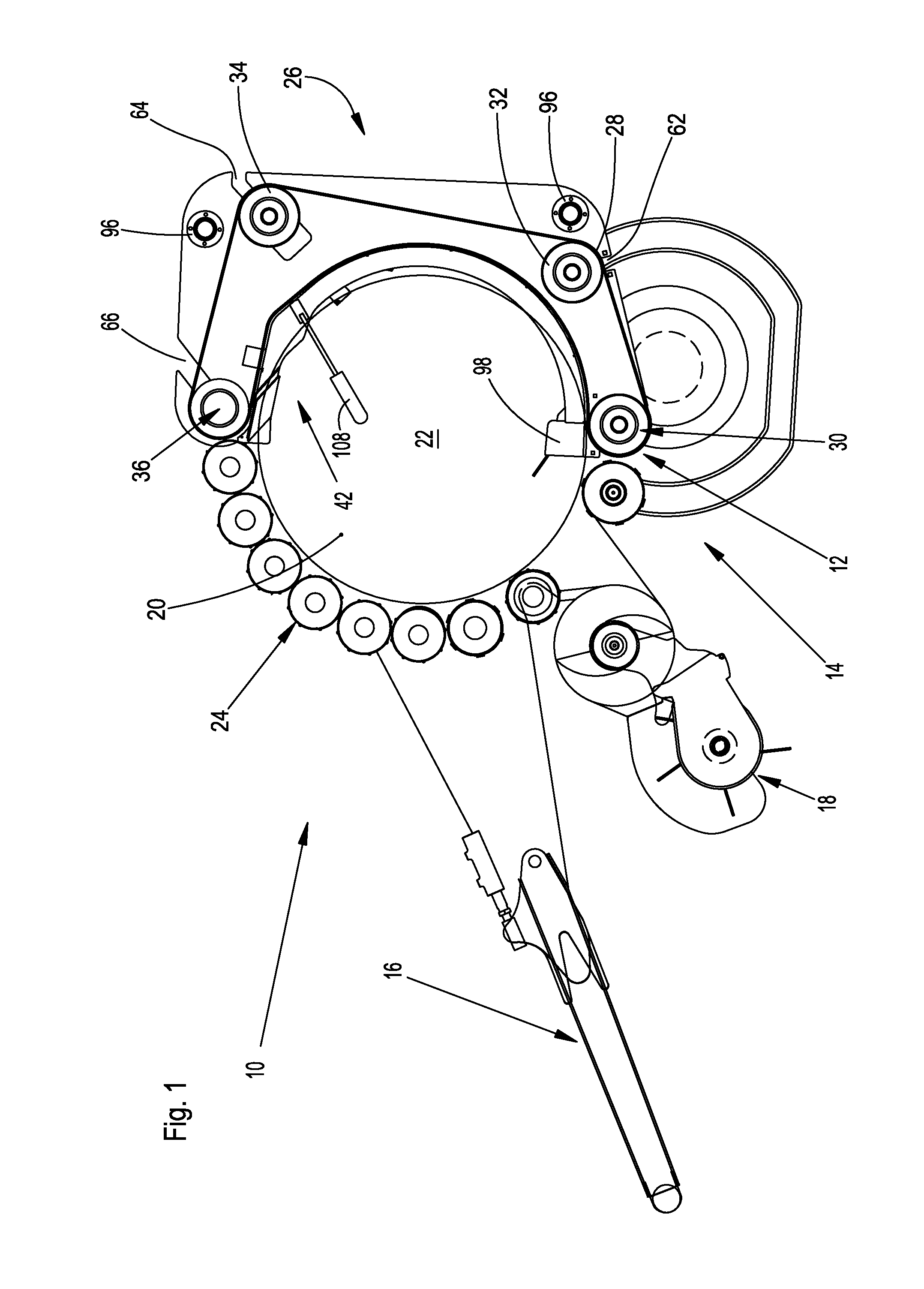

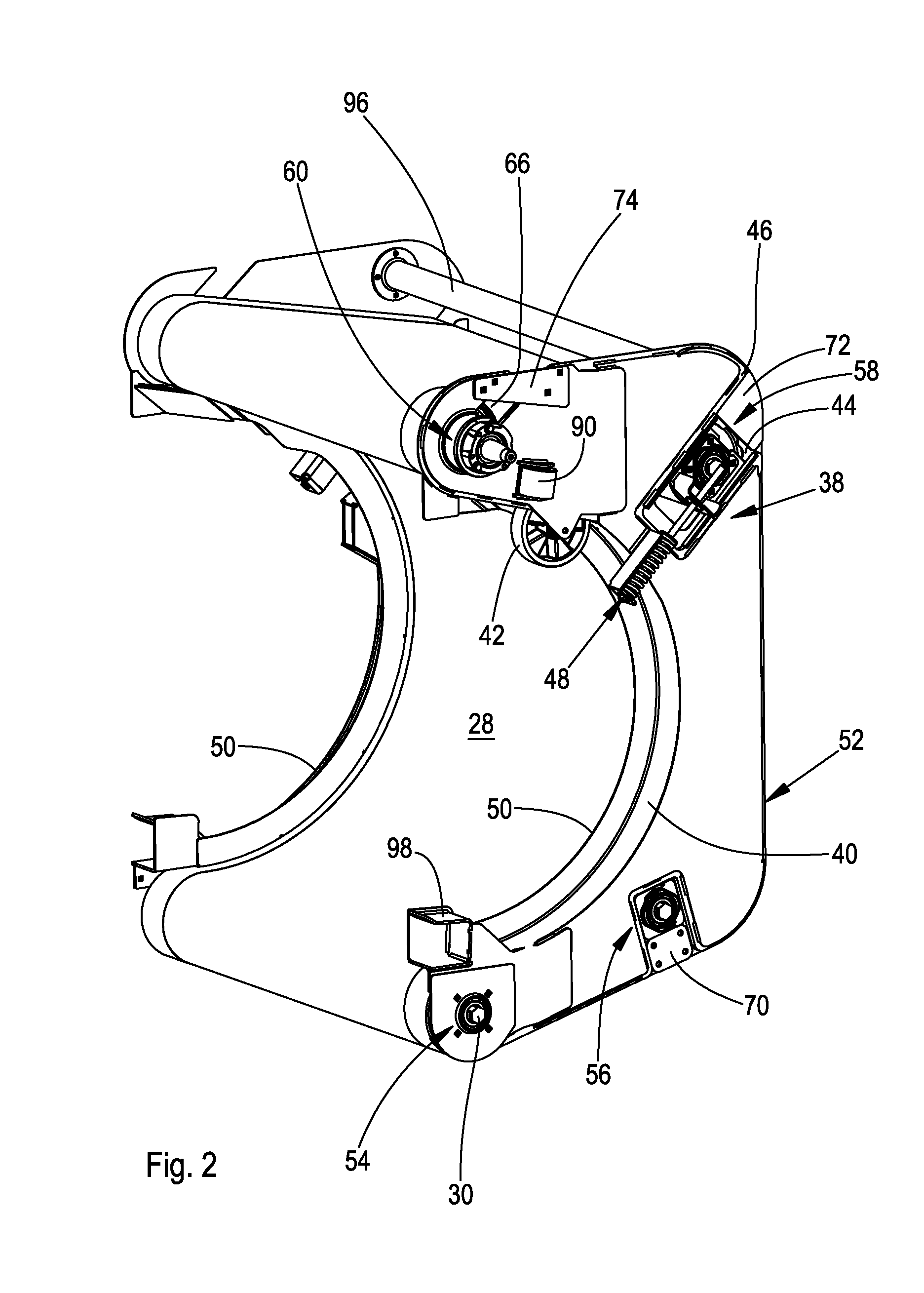

Round Baler

InactiveUS20120132090A1Reduce rolling resistanceDifferent diameterBalingPressesEngineeringMechanical engineering

Owner:DEERE & CO

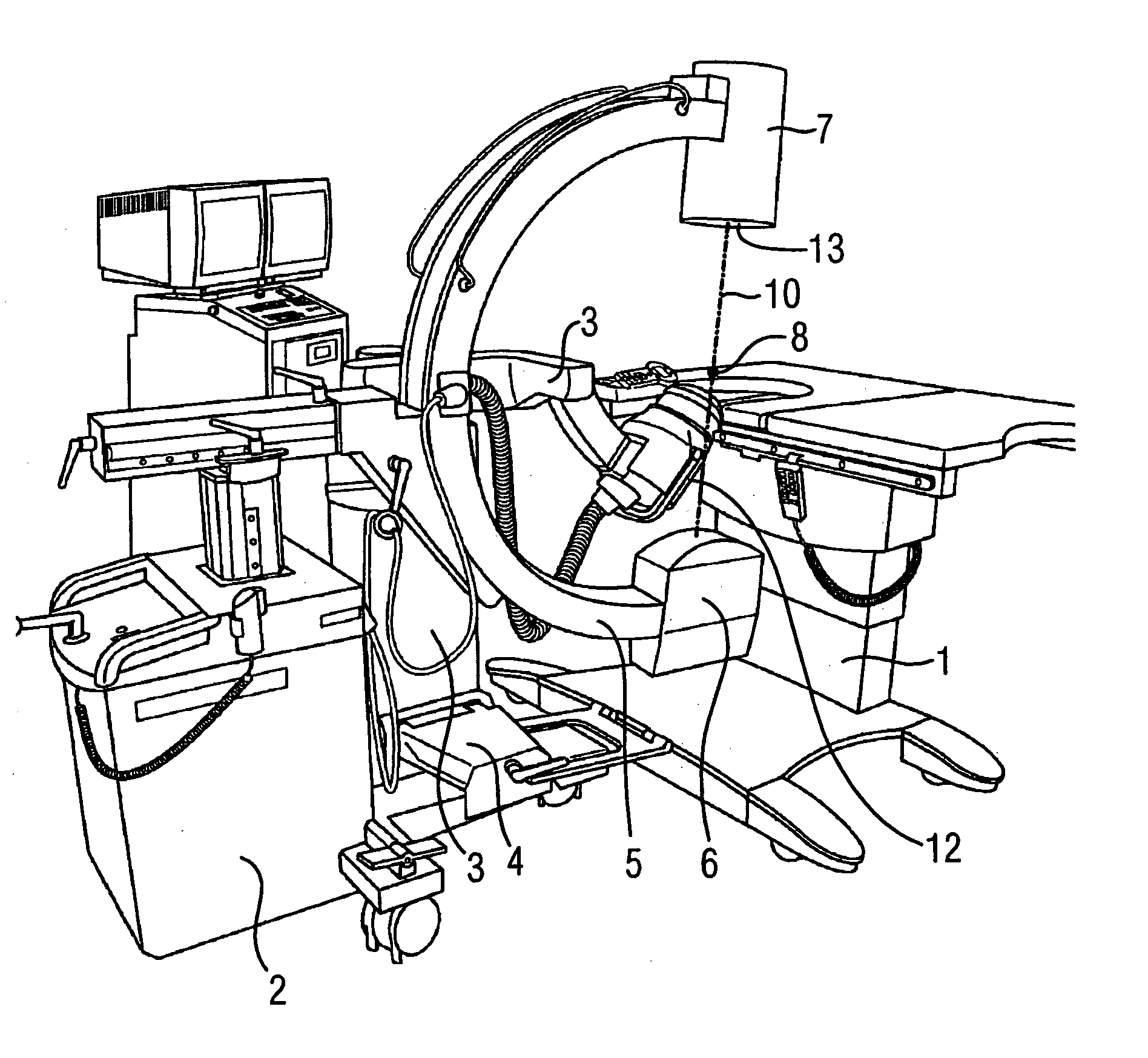

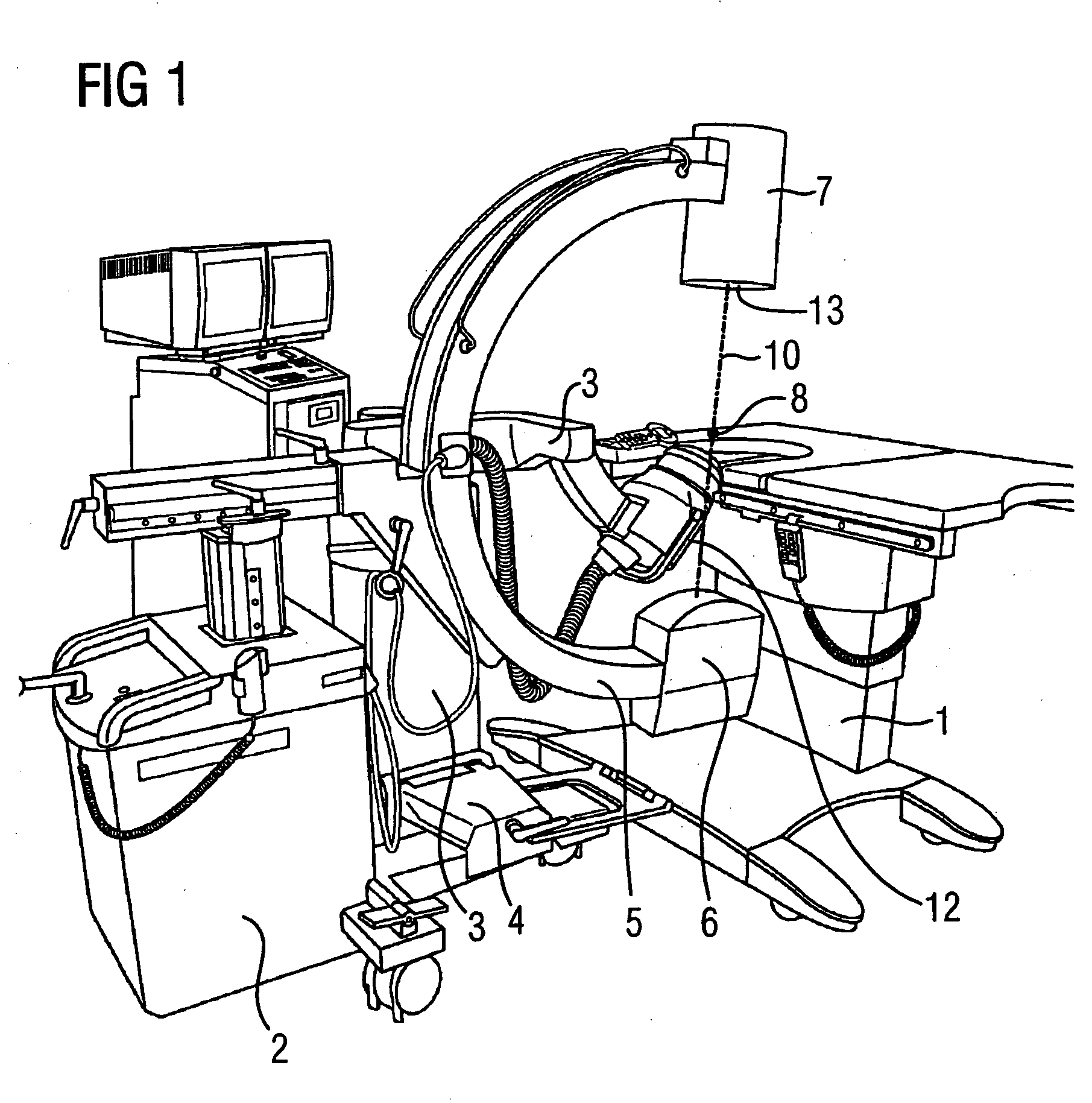

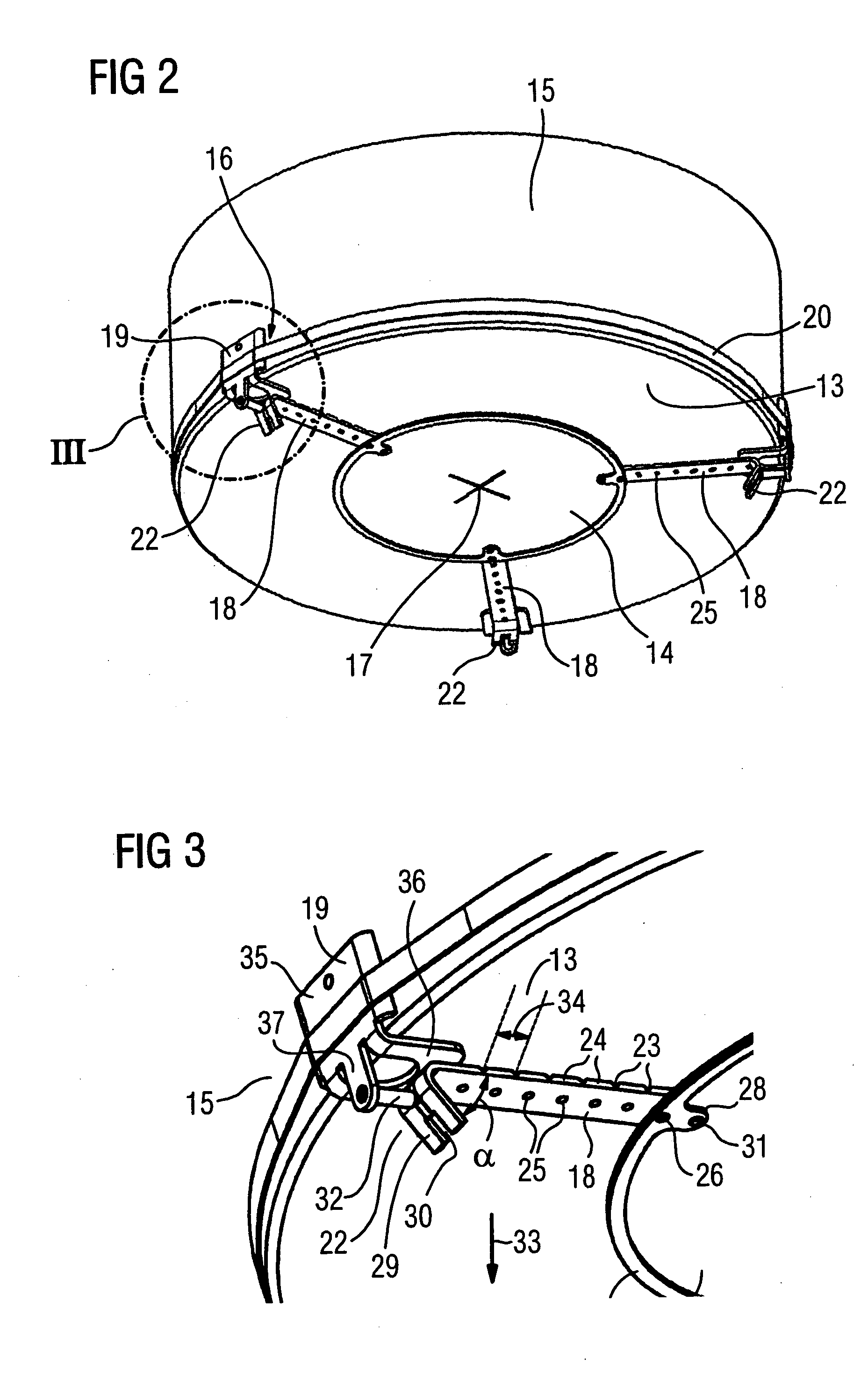

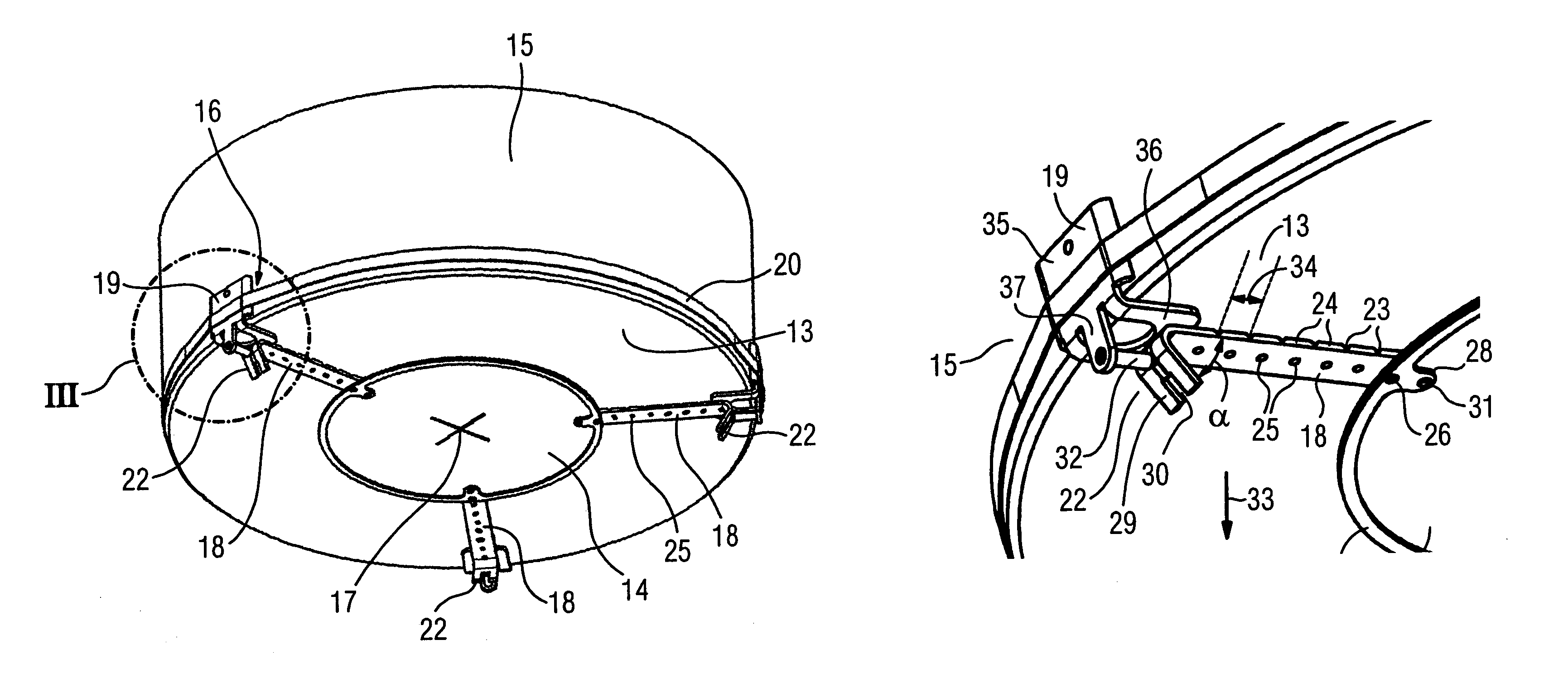

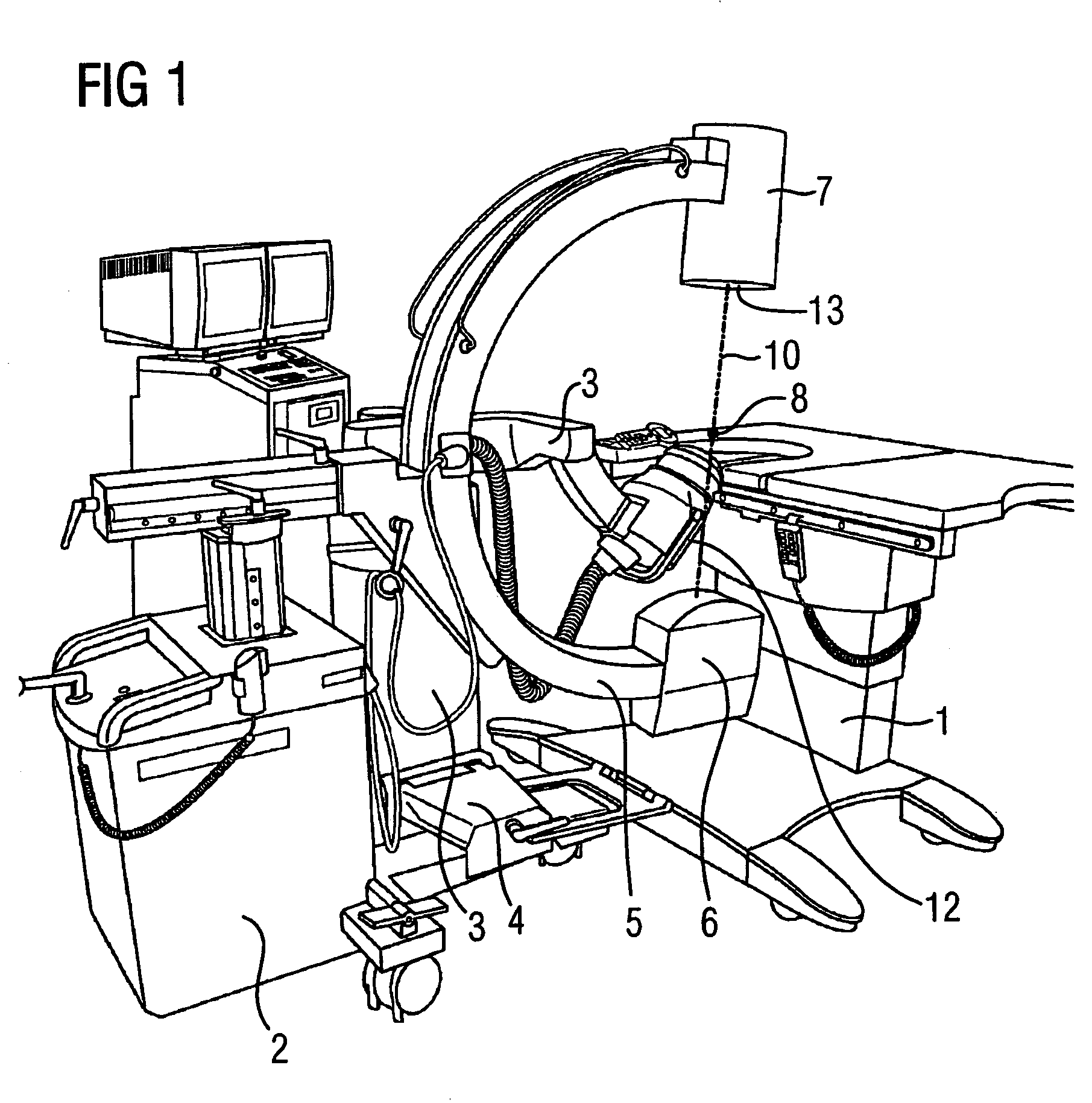

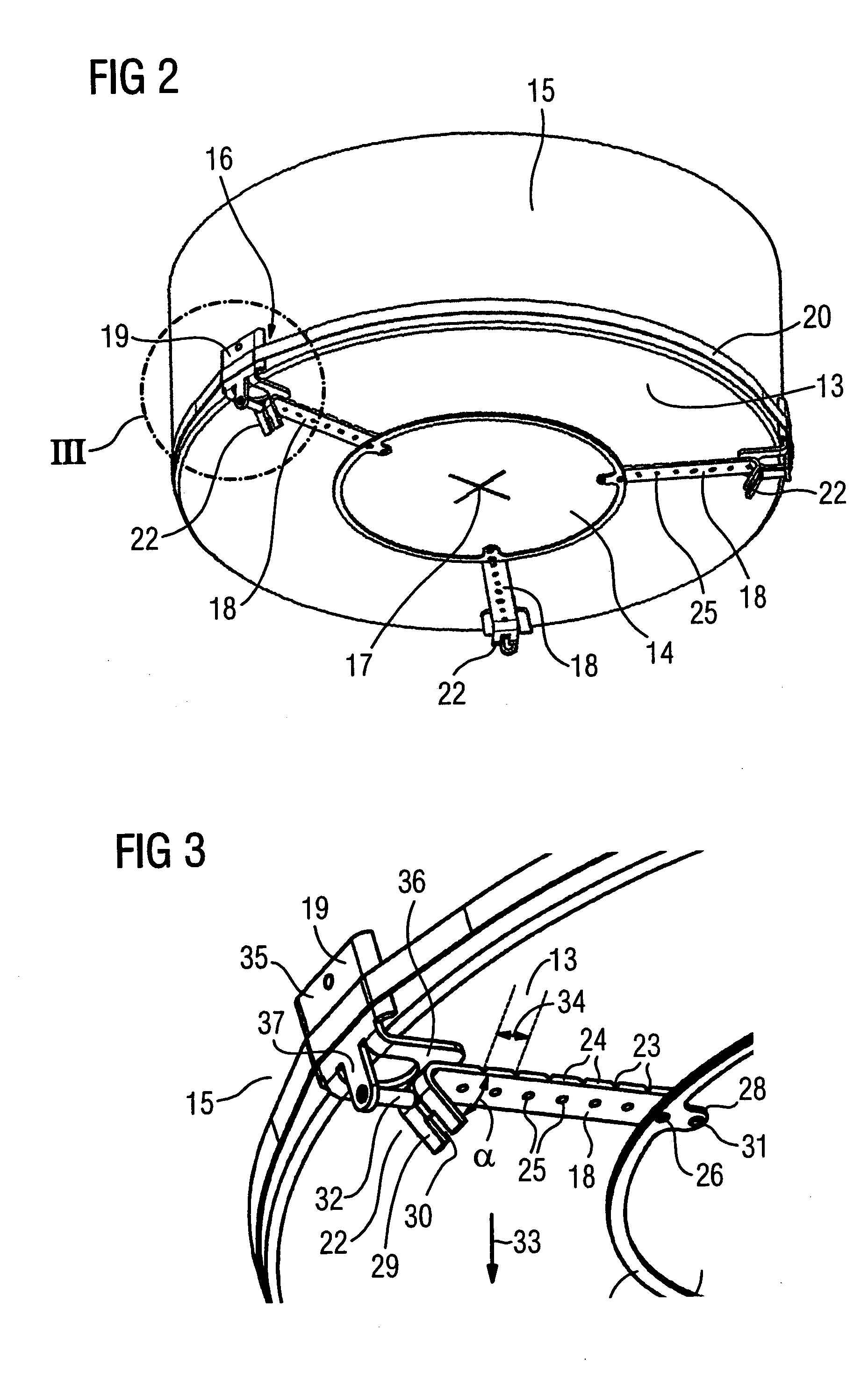

Device fittable to the therapy head of an x-ray guided lithotripsy system to allow adjustment of the focus thereof

ActiveUS20050232398A1Different diameterSurgeryImage-conversion/image-amplification tubesX-rayFocal position

A device to adjust the focus position of the therapy head of a lithotripsy system having an x-ray system, has a cross-hair disc that can be attached to an image intensifier of the x-ray system, such that extending away from the edge of the cross-hair disc are variable-length connection elements whose outer end facing away from the cross-hair disc can be indirectly or directly affixed to the image intensifier.

Owner:SIEMENS HEALTHCARE GMBH

Device fittable to the therapy head of an x-ray guided lithotripsy system to allow adjustment of the focus thereof

ActiveUS7104688B2Different diameterSurgeryImage-conversion/image-amplification tubesX-rayEngineering

Owner:SIEMENS HEALTHCARE GMBH

Method and device for manufacturing tubular packs filled with a material as well as tubular pack filled with a material

InactiveUS20040211156A1Increase the areaHigh strengthOther accessoriesWrapper twisting/gatheringEngineeringConductor Coil

Owner:FRANS VERMEE

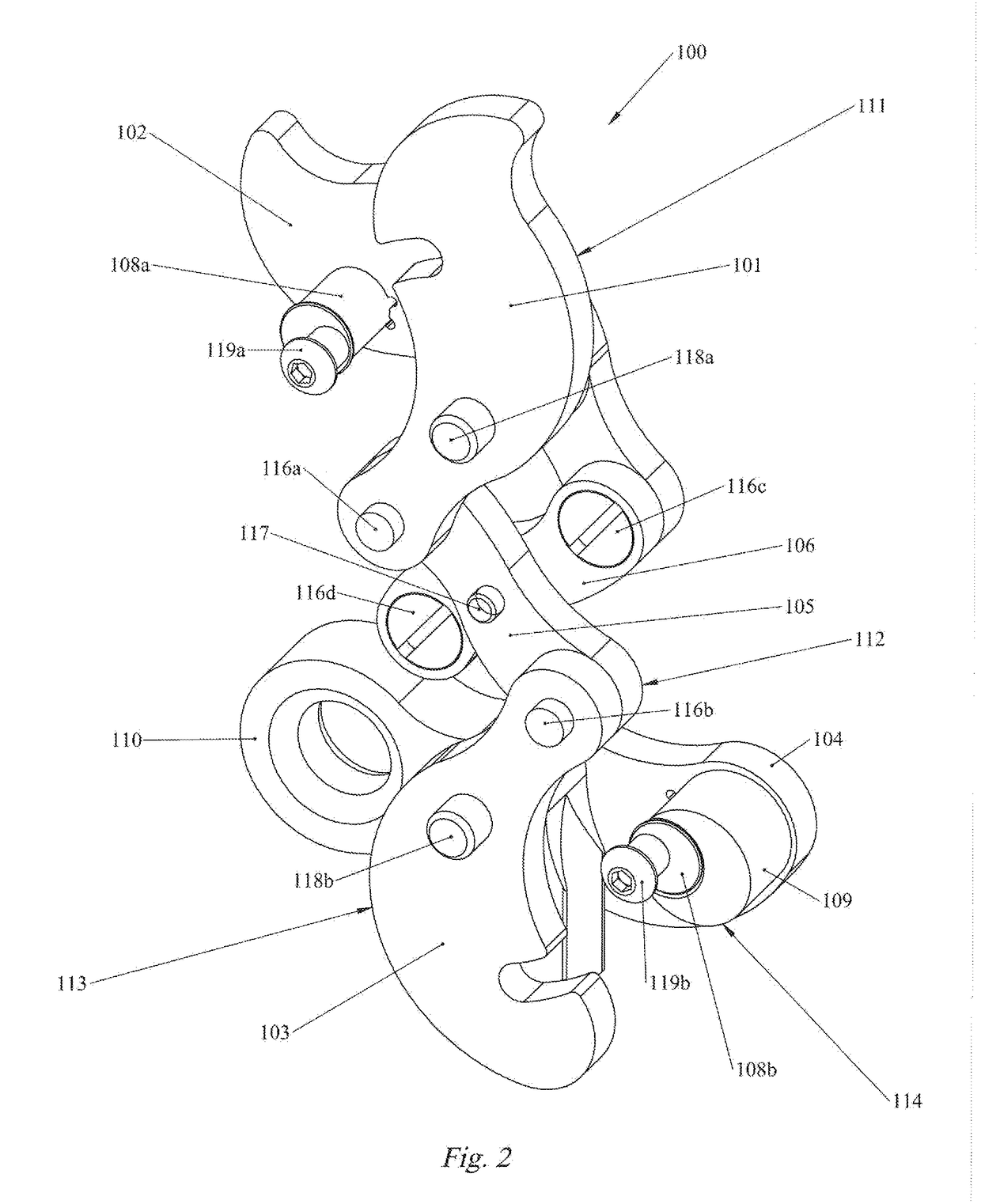

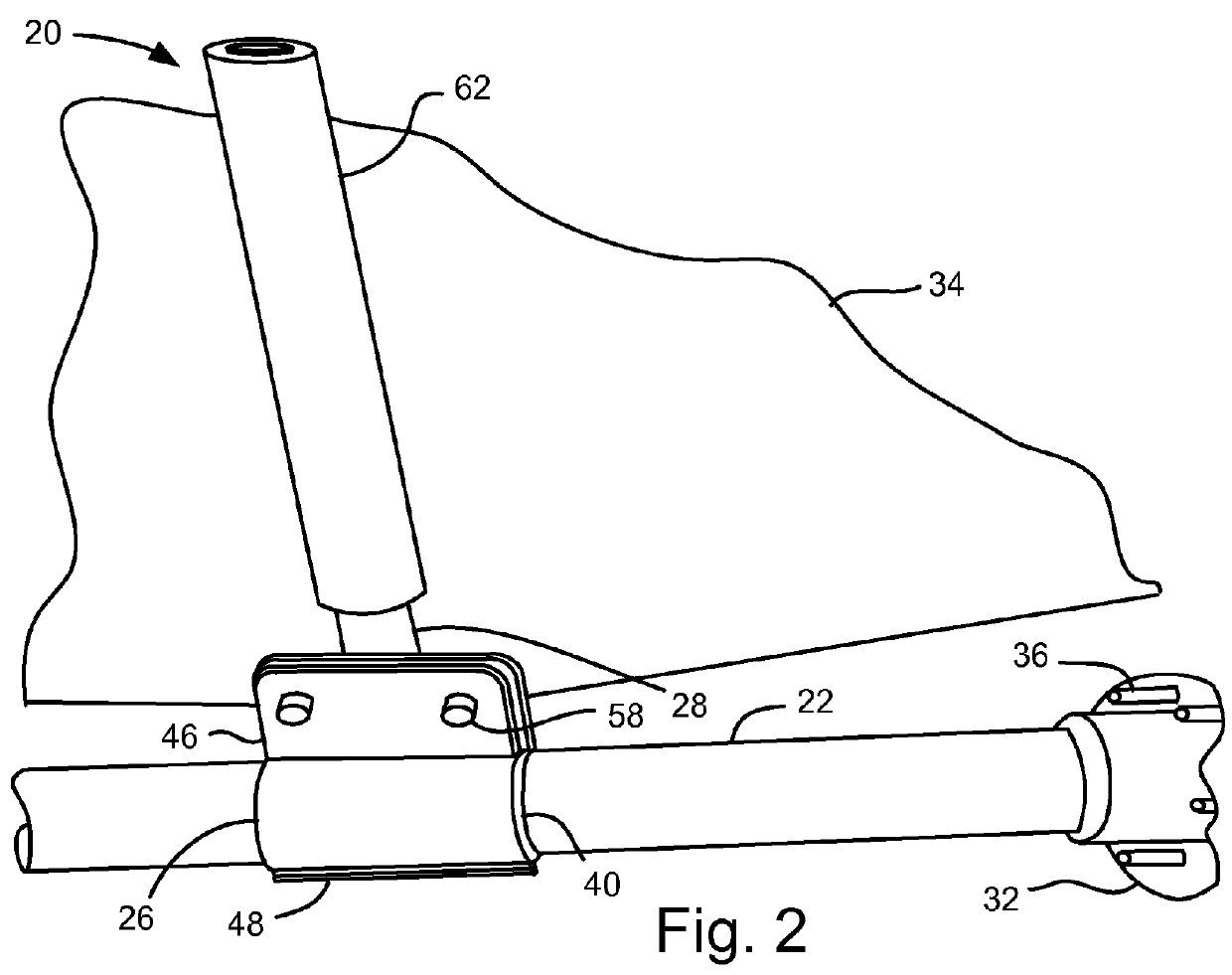

Propshaft holding tool

A holding tool for releasably securing a shaft from rotation relative to the holding tool. The holding tool may have a head including a pair of semi-cylindrical main bodies, each head having a hinge flange extending from a respective first end of the main body and a bolt flange extending from a respective, opposed second end of the main body, with each bolt flange including a fastener hole; a hinge pivotally securing the hinge flanges together; a fastener received through the fastener hole and selectively biasing the bolt flanges toward one another; a pair of semi-cylindrical shaped resilient inserts, each secured to an inner surface of the main bodies, defining a cylindrical channel to receive the shaft; and a handle extending generally radially outward from the head. The holding tool may be used to secure a propshaft to a vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cable management device

ActiveUS20190069435A1Easy to removeEasy to replaceServersData center roomsEngineeringCable management

A cable management device includes a wiring body, having a first sidewall, a second sidewall and a groove rail, wherein the groove rail is formed between the first and second sidewalls and has a input end, a output end, and a corner between the input end and the output end. A first resisting element extends from one side of the first sidewall of the wiring body. A first elastic connecting element includes a first connecting part and a first elastic arm, wherein the first connecting part is connected between the wiring body and the first elastic arm. A second resisting element extends from one side of the second sidewall of the wiring body. A second elastic connecting element has a second connecting part and a second elastic arm, wherein the second connecting part is connected between the wiring body and the second elastic arm.

Owner:AVER INFORMATION INC

Coin hopper

ActiveUS7682230B2Different diameterReverse rotationCoin countersCoin dispensersEngineeringMechanical engineering

Owner:ASAHI SEIKO CO LTD

Valve apparatus

ActiveUS20170248238A1Avoid stickingDesired performanceOperating means/releasing devices for valvesLift valveEngineeringVALVE PORT

In a valve apparatus, an annular contact portion made of elastic material is provided on a valve portion of a valve plug. A plurality of annular grooves are formed on a proximal end surface of a valve seat member which abuts against the contact portion. The annular grooves are formed around a communication hole through which fluid flows. The annular grooves have different diameters, and are concentric with one another.

Owner:HONDA MOTOR CO LTD

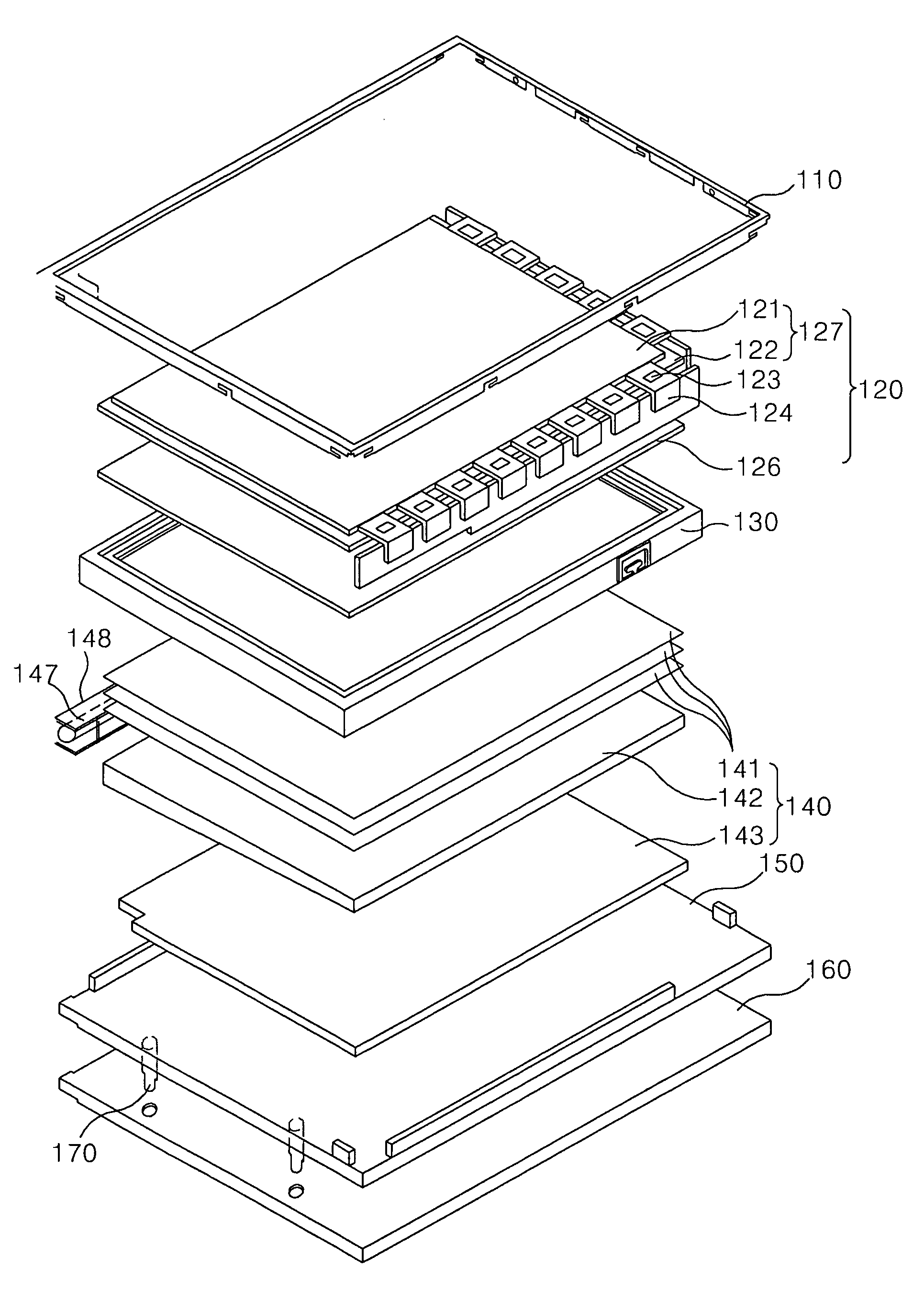

Liquid crystal display

A liquid crystal display includes a cover bottom and a cover shield. The liquid crystal display includes a nut coupled to a bracket through a fastening bolt. An upper portion and a lower portion of the nut have different diameters.

Owner:LG DISPLAY CO LTD

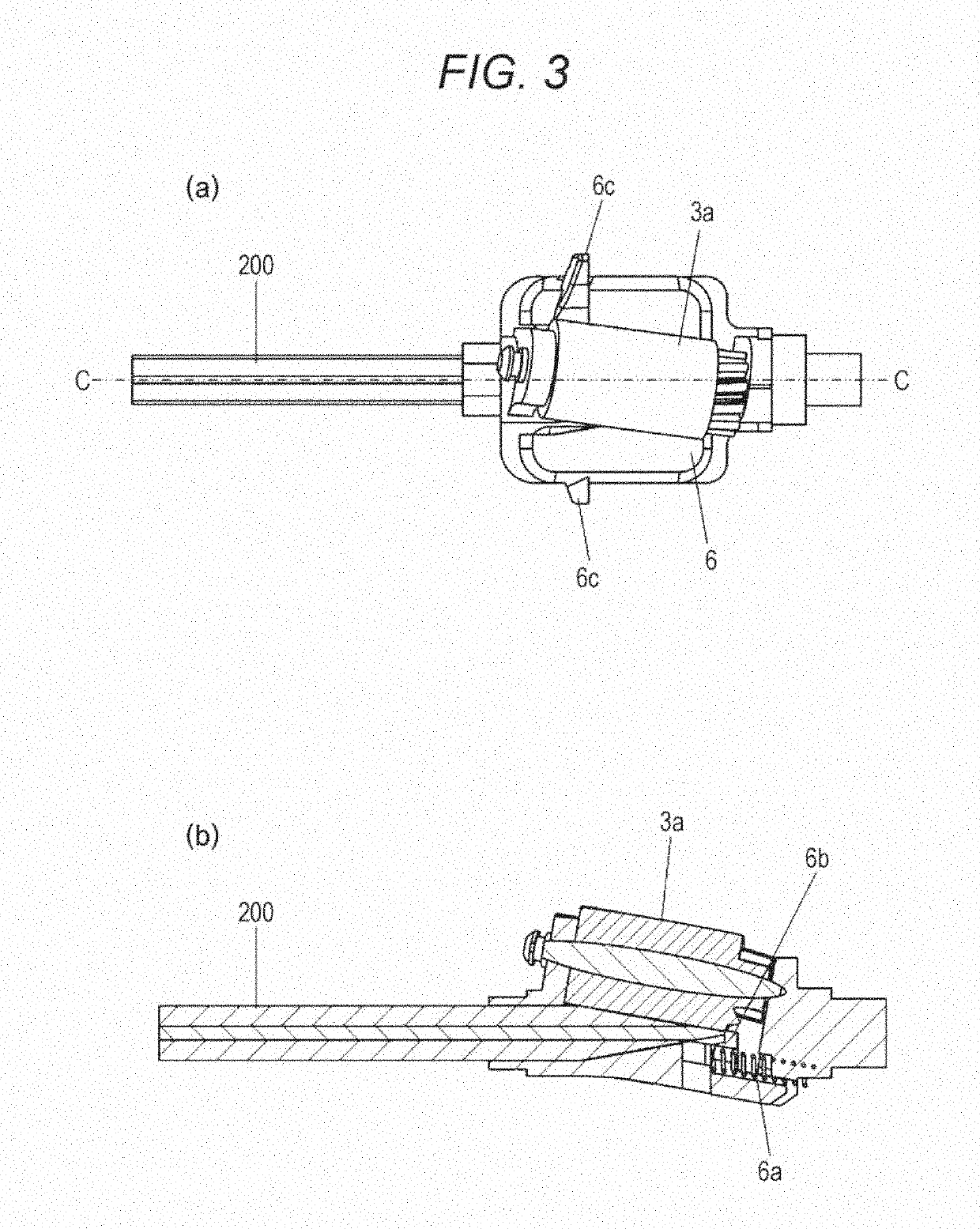

Pencil sharpener

ActiveUS20190126664A1Prevention of unnecessary sharpeningReliable stopSharpenersHeavy loadMechanical engineering

The present invention provides a sharpening completion detection mechanism that does not apply a heavy load to a core tip, and especially proposes a mechanism that moves a pencil in an ejection direction immediately when the sharpening completion detection mechanism detects completion of sharpening to mitigate damage to the core. Specifically, a pencil sharpener according to the present invention includes: a slide unit that translates in pencil insertion and pencil ejection directions; a pencil biasing means supported by the slide unit; a slide locking means that locks a translation position of the slide unit upon the slide unit translating in the insertion direction; and a slide unit unlocking means that releases the lock for the translation position of the slide unit upon the sharpening completion detection means detecting a fully sharpened state of the pencil, and includes slide unit ejecting means that biases the slide unit in the ejection direction with energy stored by movement of the slide unit to a lock position.

Owner:OSAKA CLIP CO LTD

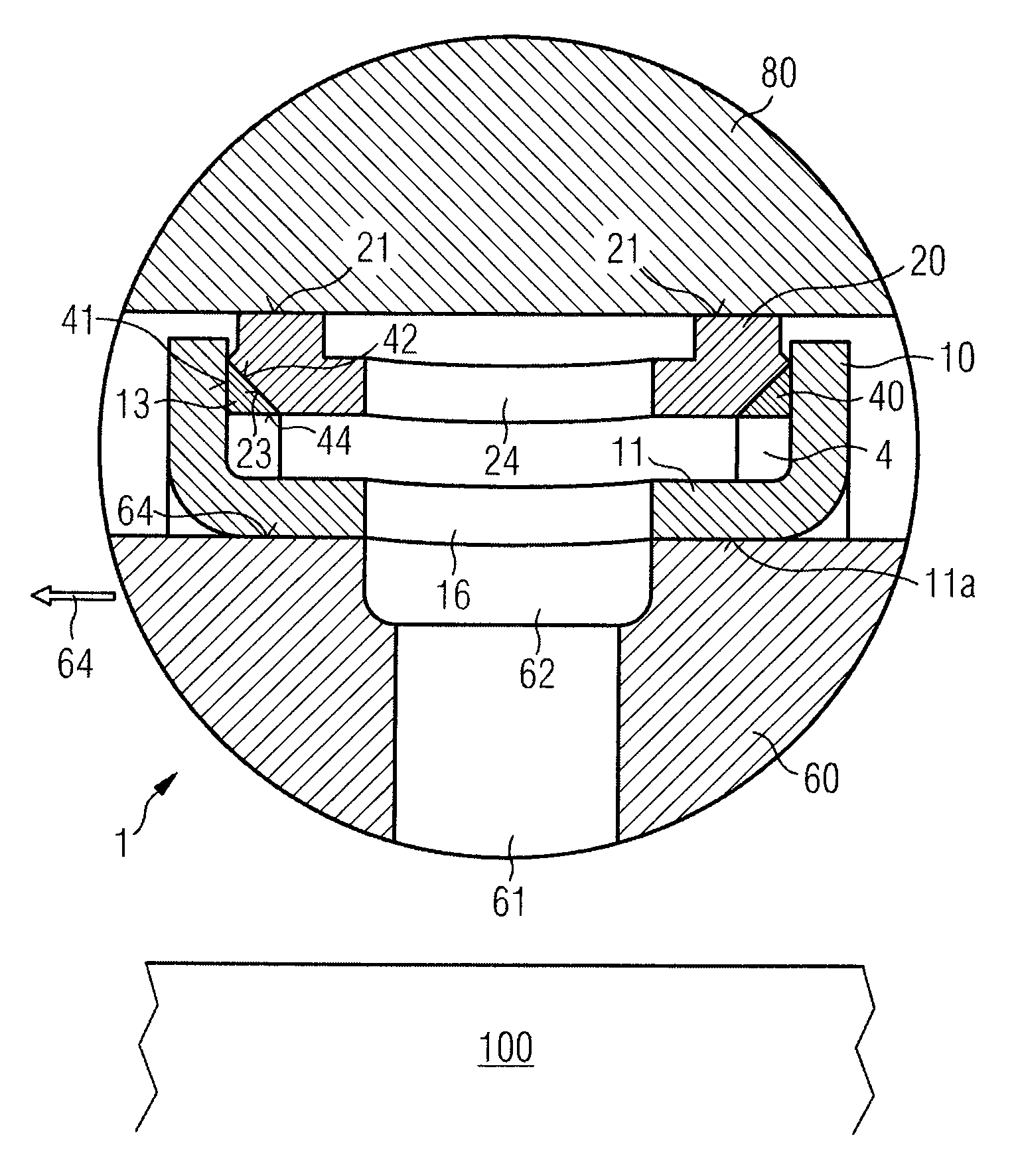

Charging device of electronic cigarette and charging method thereof

InactiveUS9906056B2Avoid defectsSimple and compact structureIndicating/monitoring circuitsTobacco devicesElectricityElectrical connection

This present application relates to a charging device of an electronic cigarette and a charging method thereof. The charging device including a charging base, in which a first charging electrode assembly and a second charging electrode assembly are arranged separately for connecting with a first and a second electrode of the electronic cigarette, wherein in the charging base, a charging slot is defined in the charging base. The first charging electrode assembly, the second charging electrode assembly and the charging base are coaxially sheathed, and both the first charging electrode assembly and the second charging electrode assembly extend into the charging slot. By implementing this structure, the electronic cigarette has a simplified and compact structure and an easy assembly, also facilitates a steady electrical connection with the electronic cigarette. When charging, it is only needed to insert the electronic cigarette into the charging slot.

Owner:HUIZHOU KIMREE TECH

Apparatus for connection of thermoplastic tubing

The invention discloses an apparatus for aligning and supporting a first and a second length of thermoplastic tubing, preparatory to and during cutting and welding of said lengths of tubing, that includes a first holder arranged to accommodate portions of the first and second lengths of tubing in a first and a second elongated holding space respectively, a second holder arranged to accommodate portions of the first and second lengths of tubing in a third and a fourth elongated holding space respectively, and movable in a direction essentially perpendicular to the holding spaces of the first and second holders from a cutting position, a cutting means arranged between said first and second holders for cutting said lengths of tubing when the second holder is in the cutting position and an aligning means to align these lengths of tubing with each other.

Owner:CYTIVA SWEDEN AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com