Patents

Literature

66results about How to "Operation is disabled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power supply methods and configurations

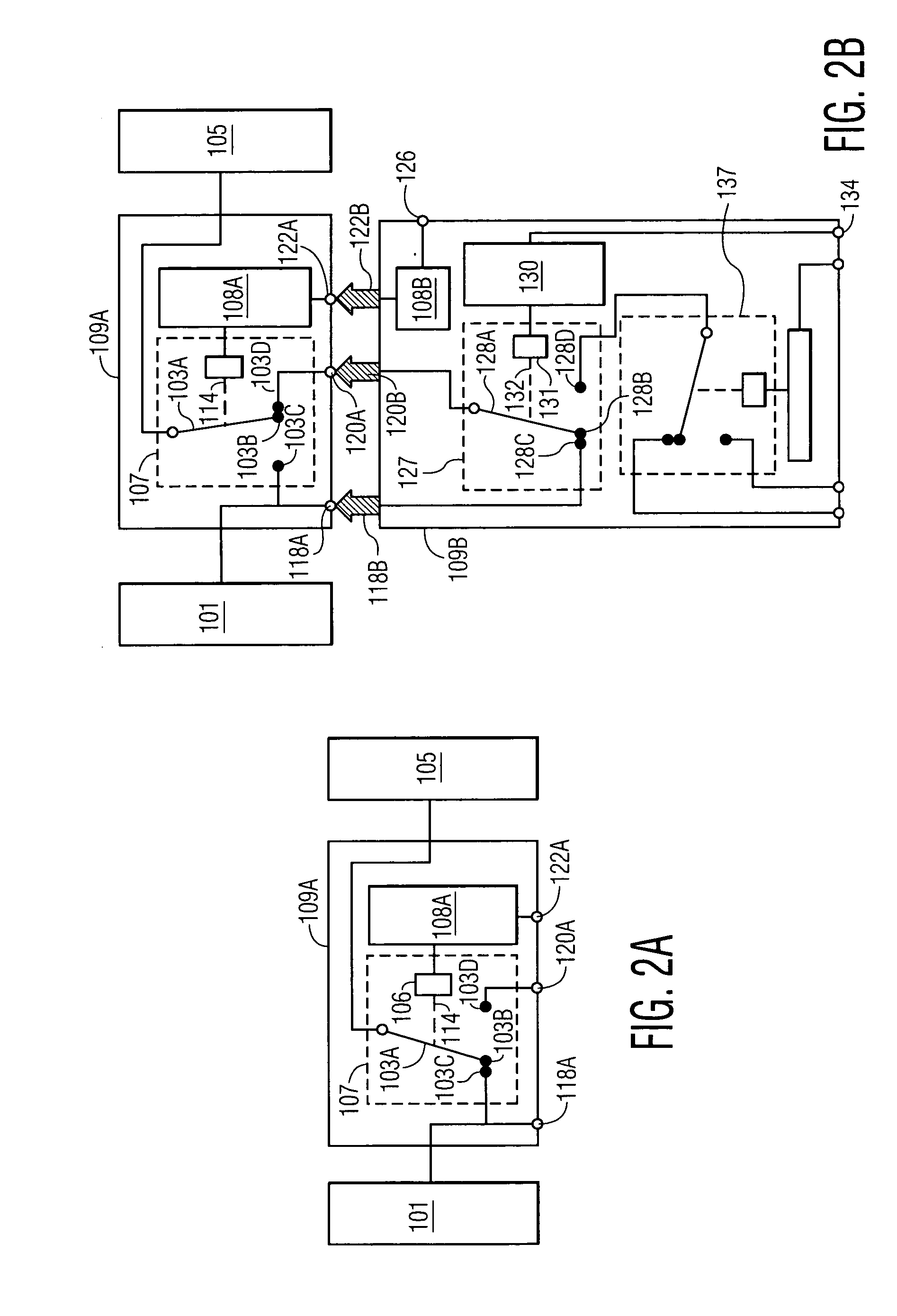

InactiveUS7002265B2Charging operation can be disabledFunction increaseVolume/mass flow measurementRailway vehiclesData acquisitionEngineering

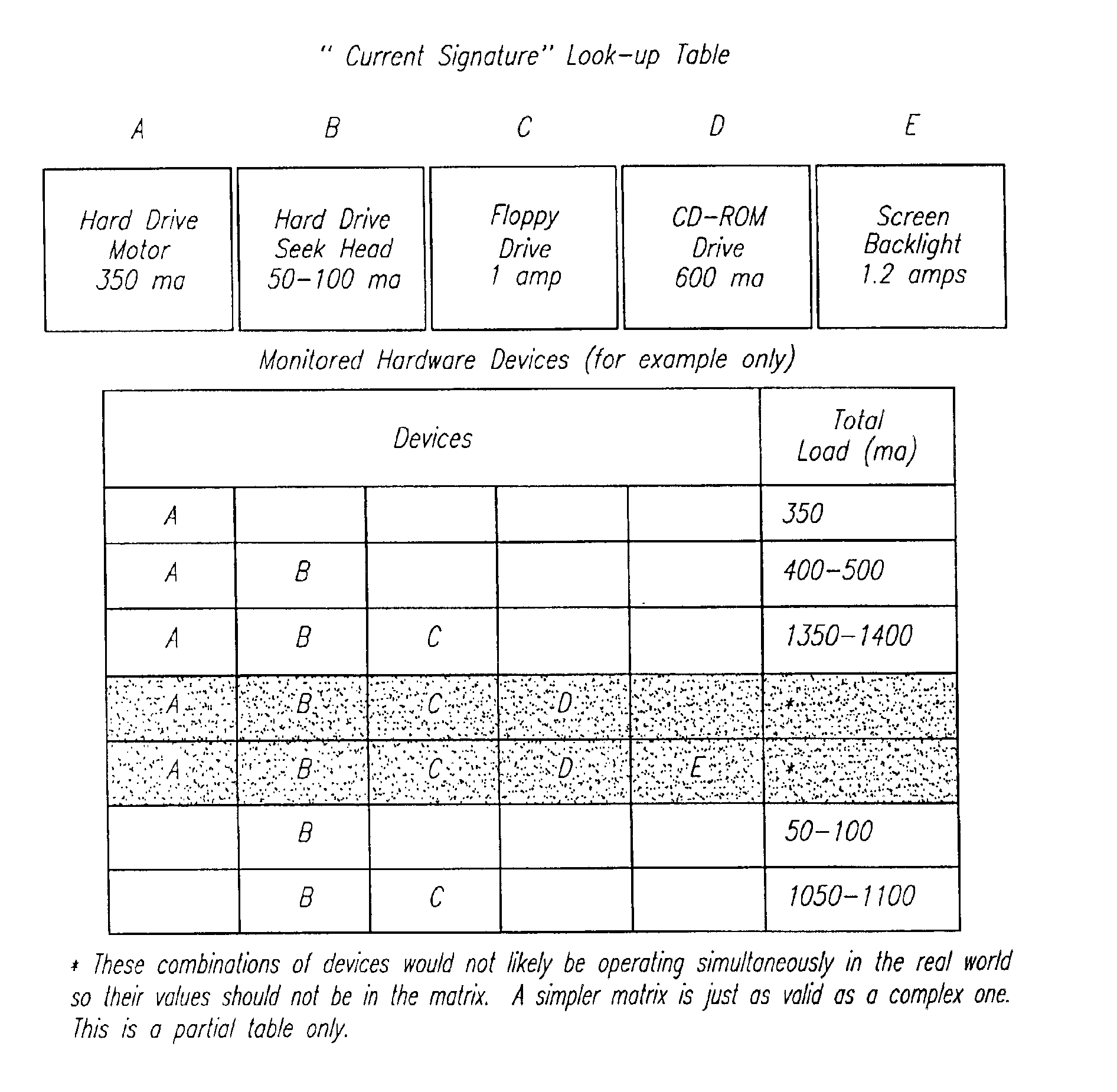

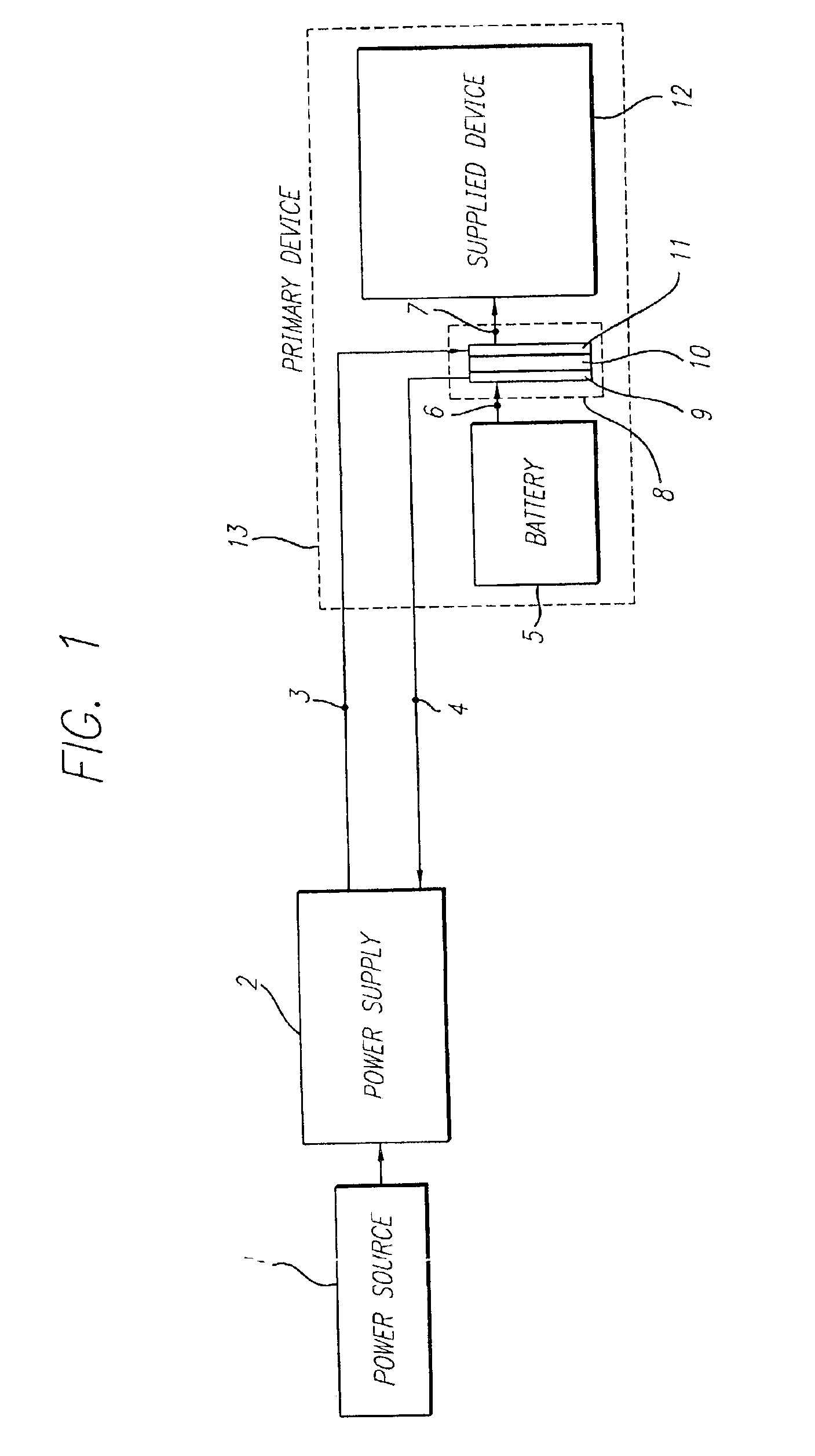

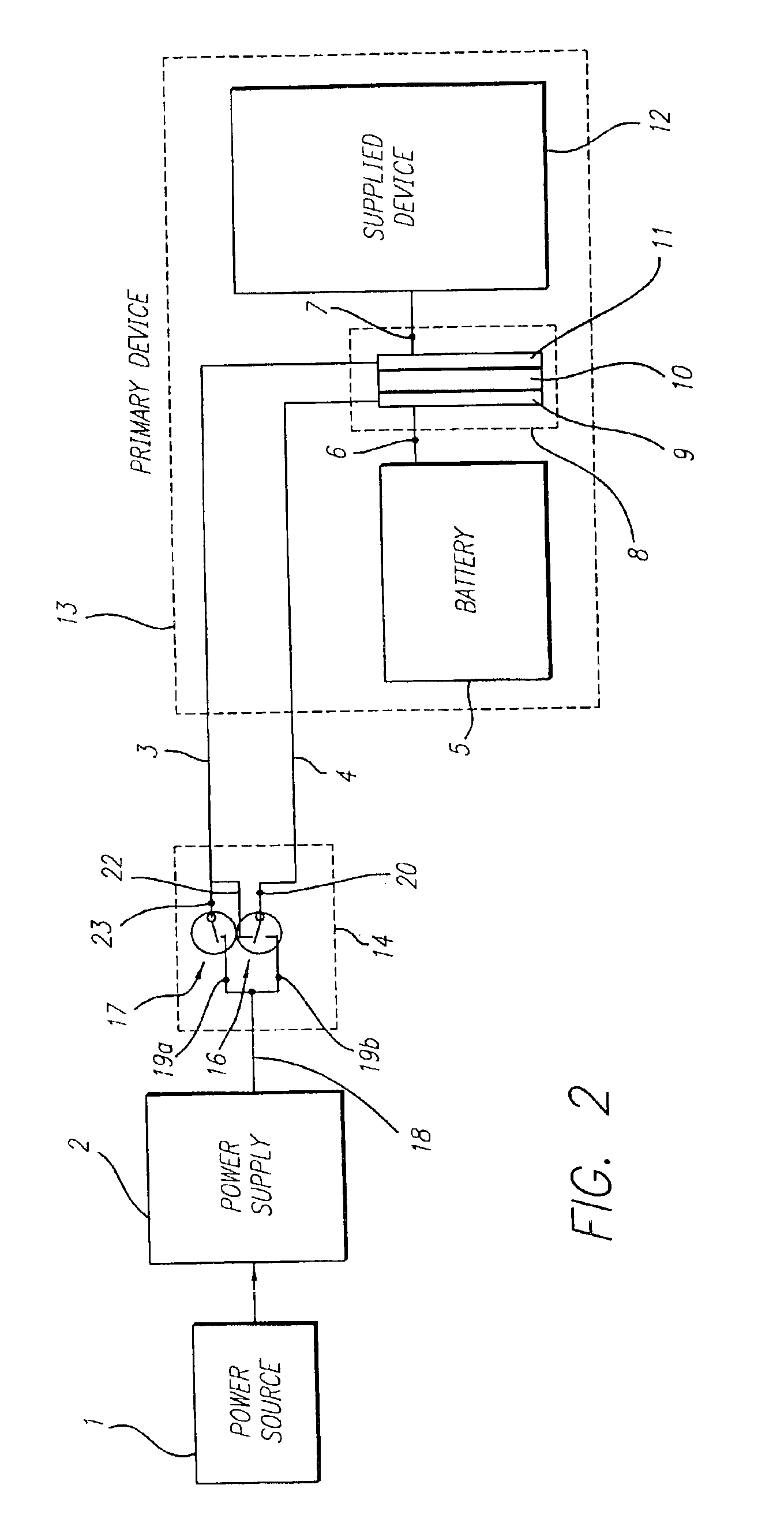

A look-up table assists a source of logic of an apparatus in determining the power requirements of an unknown battery-powered device, so that a configurable power supply adjusts its output to provide the correct power to the device. The functions of the look-up table, in conjunction with generic templates and update-able historical information, if available, are substantially based on determining a “power signature” of the device. As a secondary function, the look-up table enables detection of battery charging activity and, when necessary, provides various means of disabling charging operations. More than one look-up table is available, and a look-up table can be located at any inter-connected device, apparatus, or power source. Inter-device communications further enhance the functionality of the look-up table, especially for collaborative data-acquisition.

Owner:POTEGA PATRICK HENRY

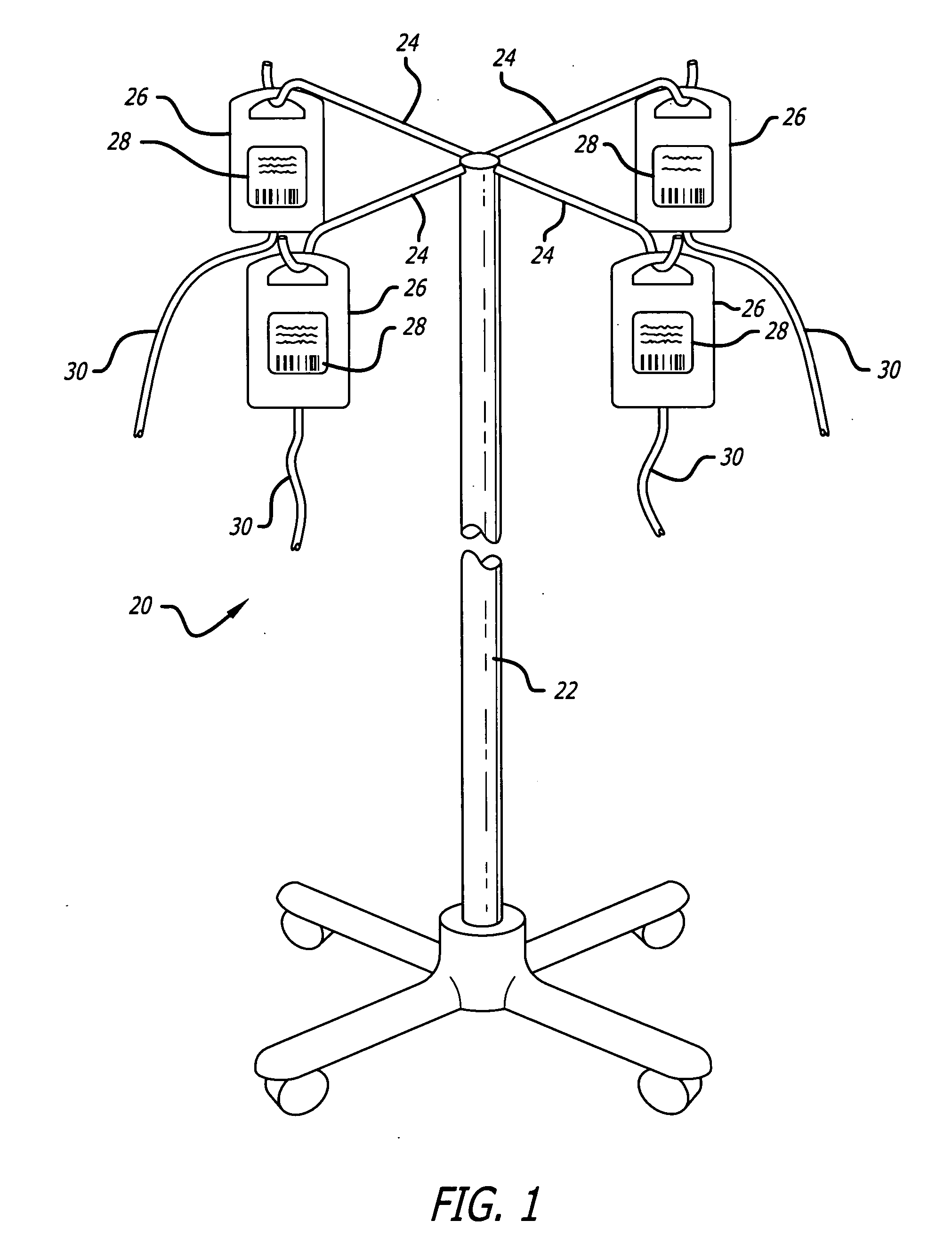

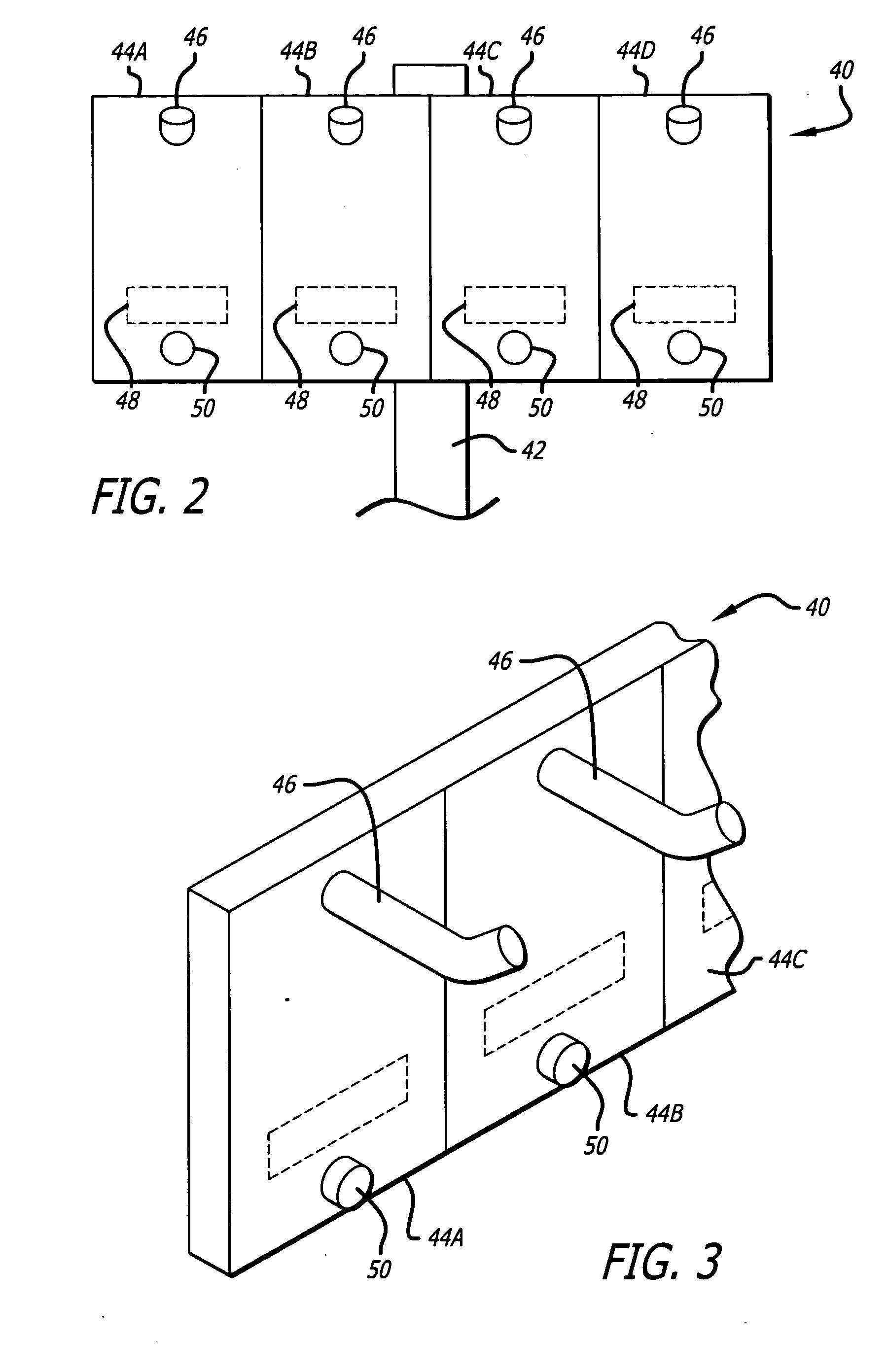

Medication safety system featuring a multiplexed RFID interrogator panel

ActiveUS20060265246A1Operation is disabledNot disabling operationData processing applicationsDiagnosticsEngineeringFace sheet

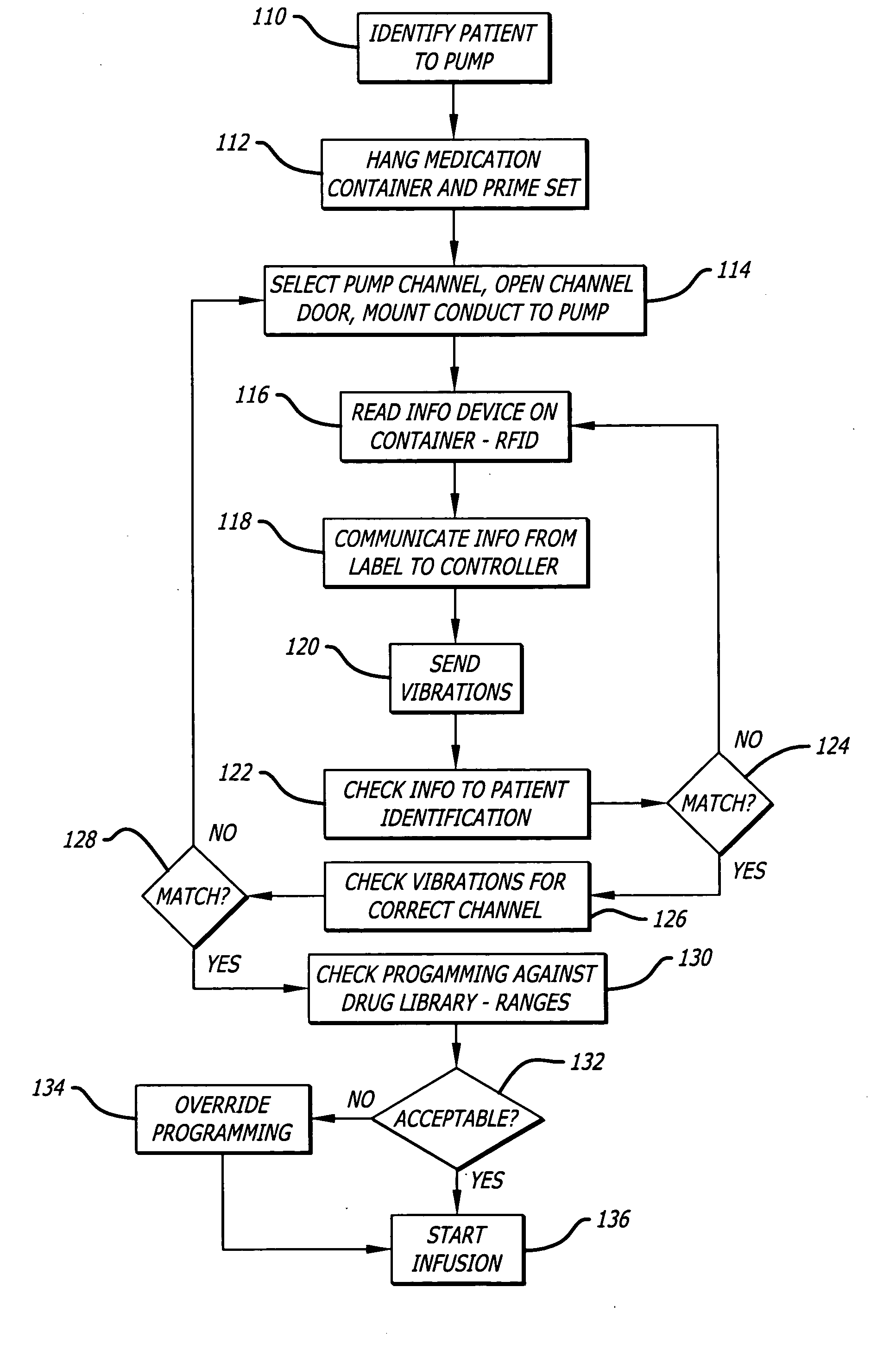

A medication safety system includes a panel mounted to an IV pole above a multi-channel infusion pump also mounted to the IV pole. The panel includes multiple RFID readers for reading the RFID tags placed on each of the medication containers mounted to the panel. The pump includes a controller that communicates with the RFID readers at the panel to receive the information read by the RFID readers and automatically program the respective pump channel. A verification program verifies that the medication delivery information from the containers matches the patient identified for the pump and the programming parameters of the pump fall within acceptable ranges. In another aspect, the panel contains multiple vibration devices to impart vibrations to the medication of each of the containers mounted to the panel. Those vibrations are sensed by the particular pumping channel to confirm that the correct channel has been programmed for that medication. When the clinician opens the door of the pumping channel, the pump may request information from the RFID reader at the panel for that medication and may wait for receipt of the vibrations in the medication of the tubing mounted into the channel.

Owner:CAREFUSION 303 INC

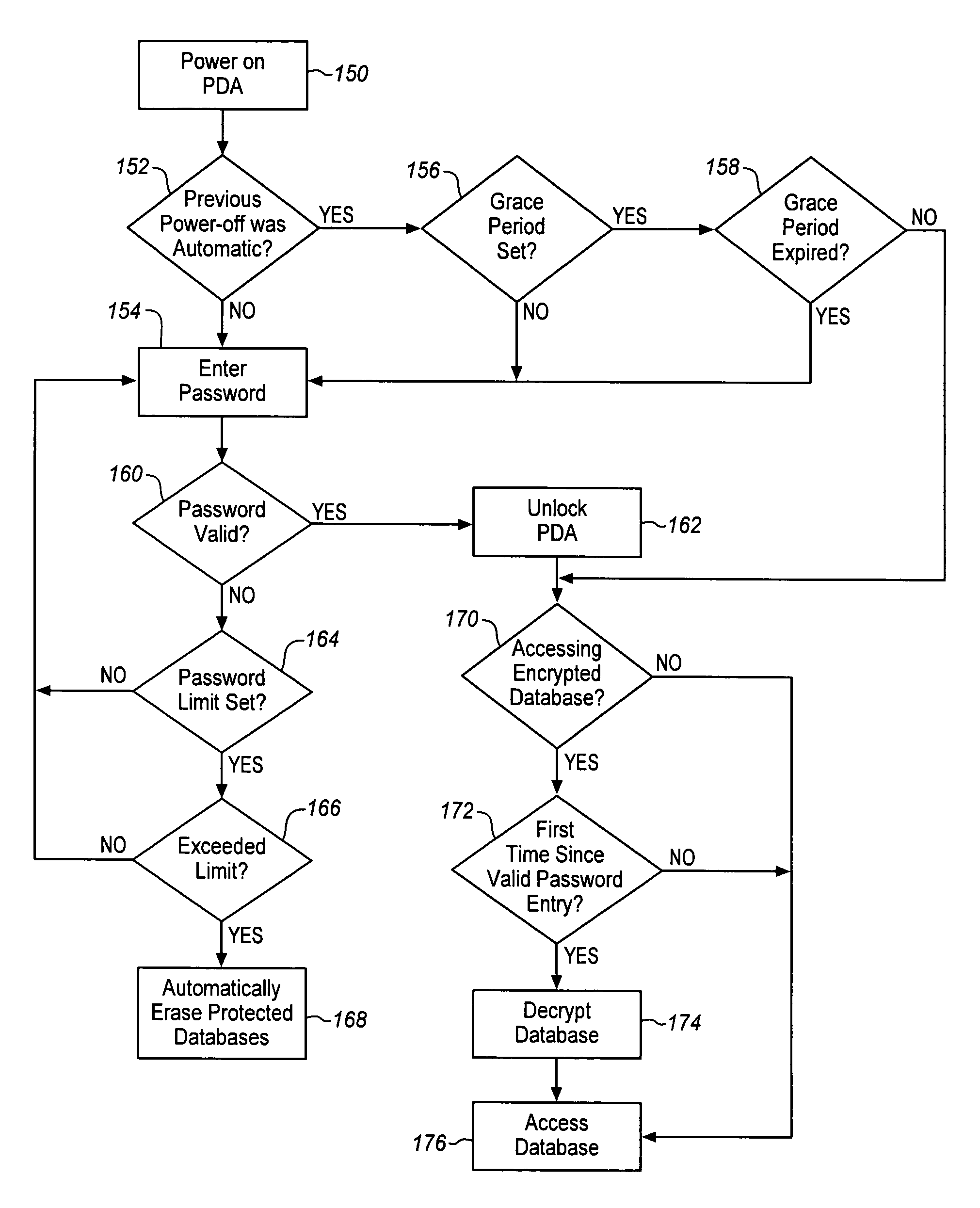

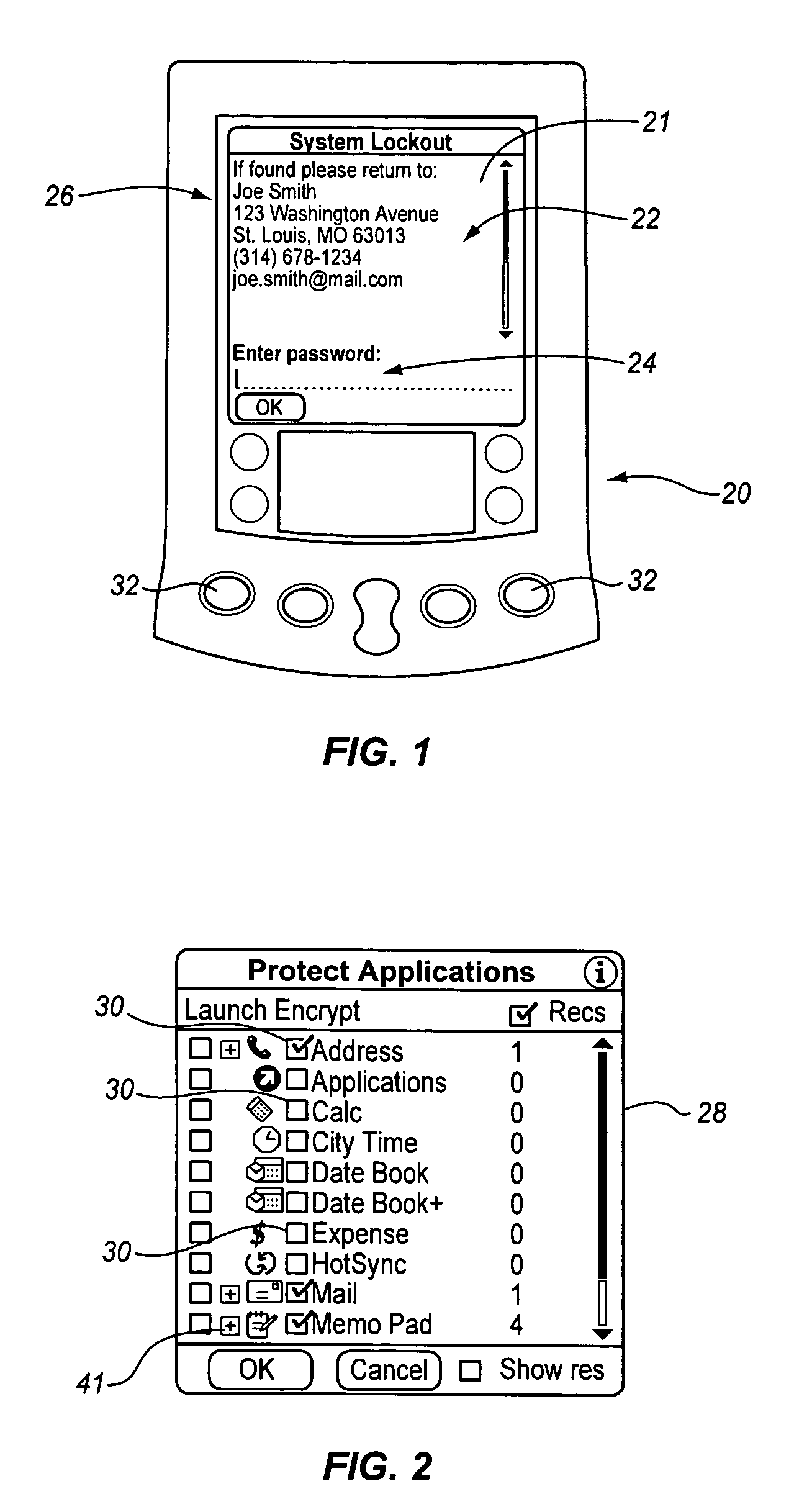

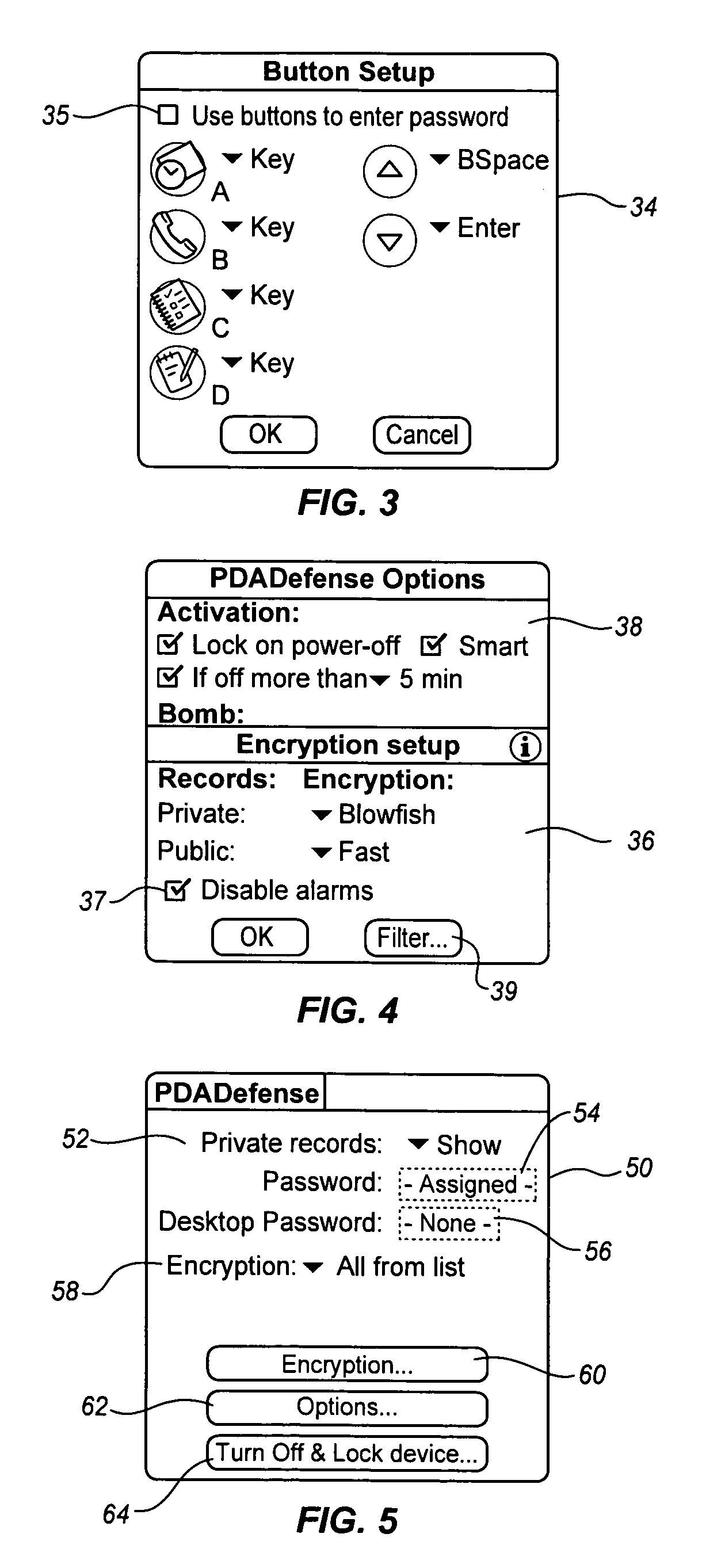

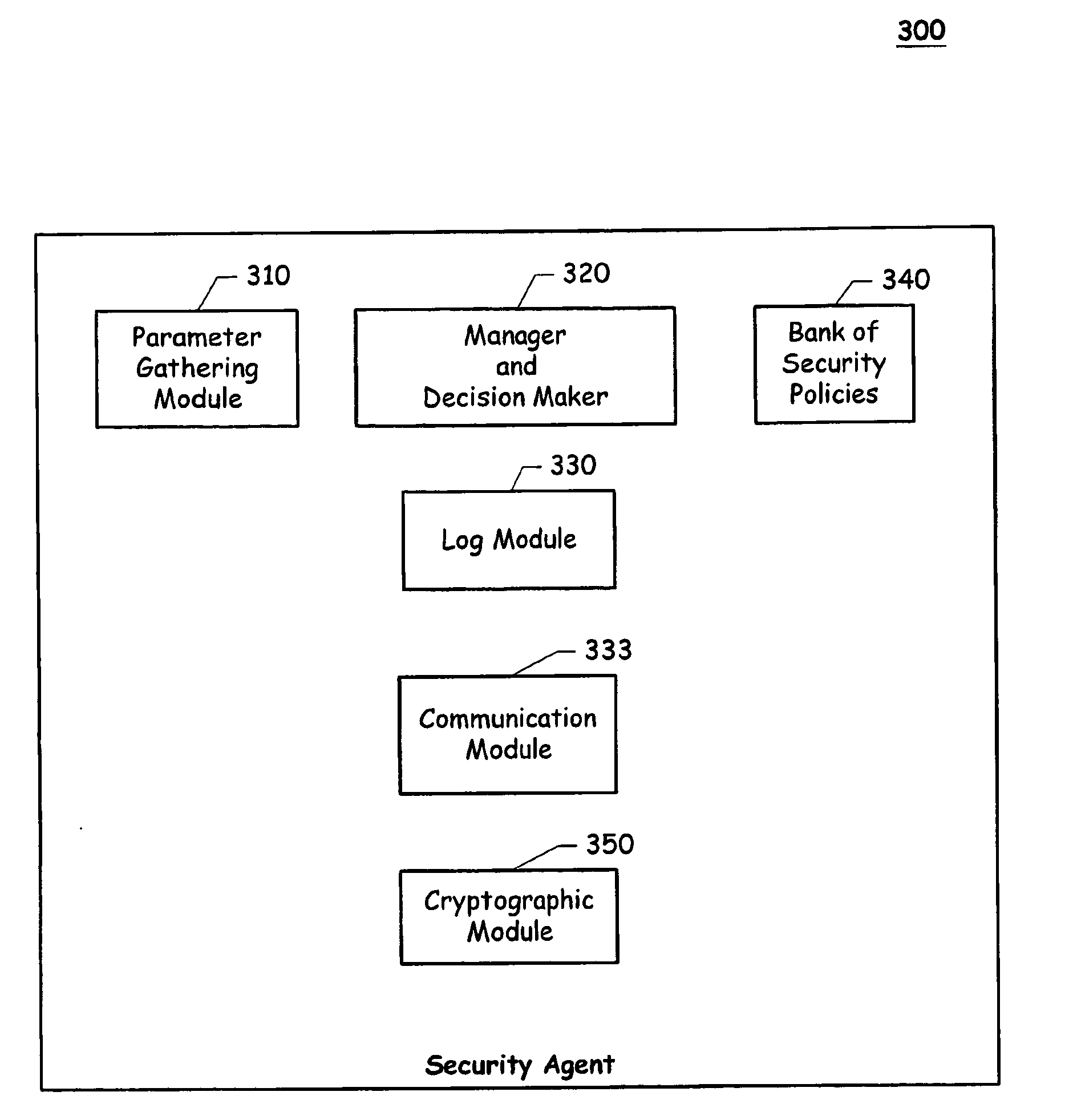

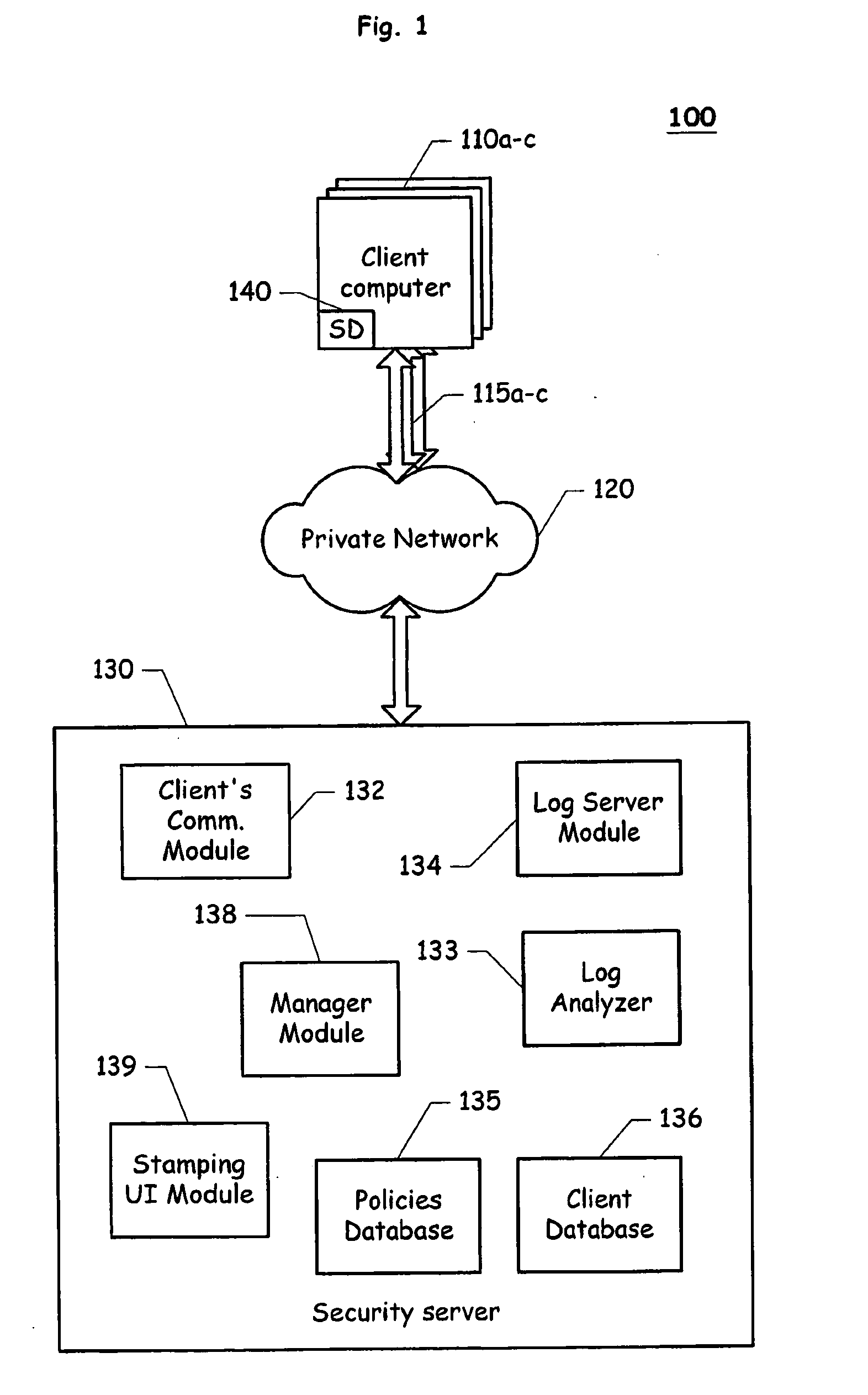

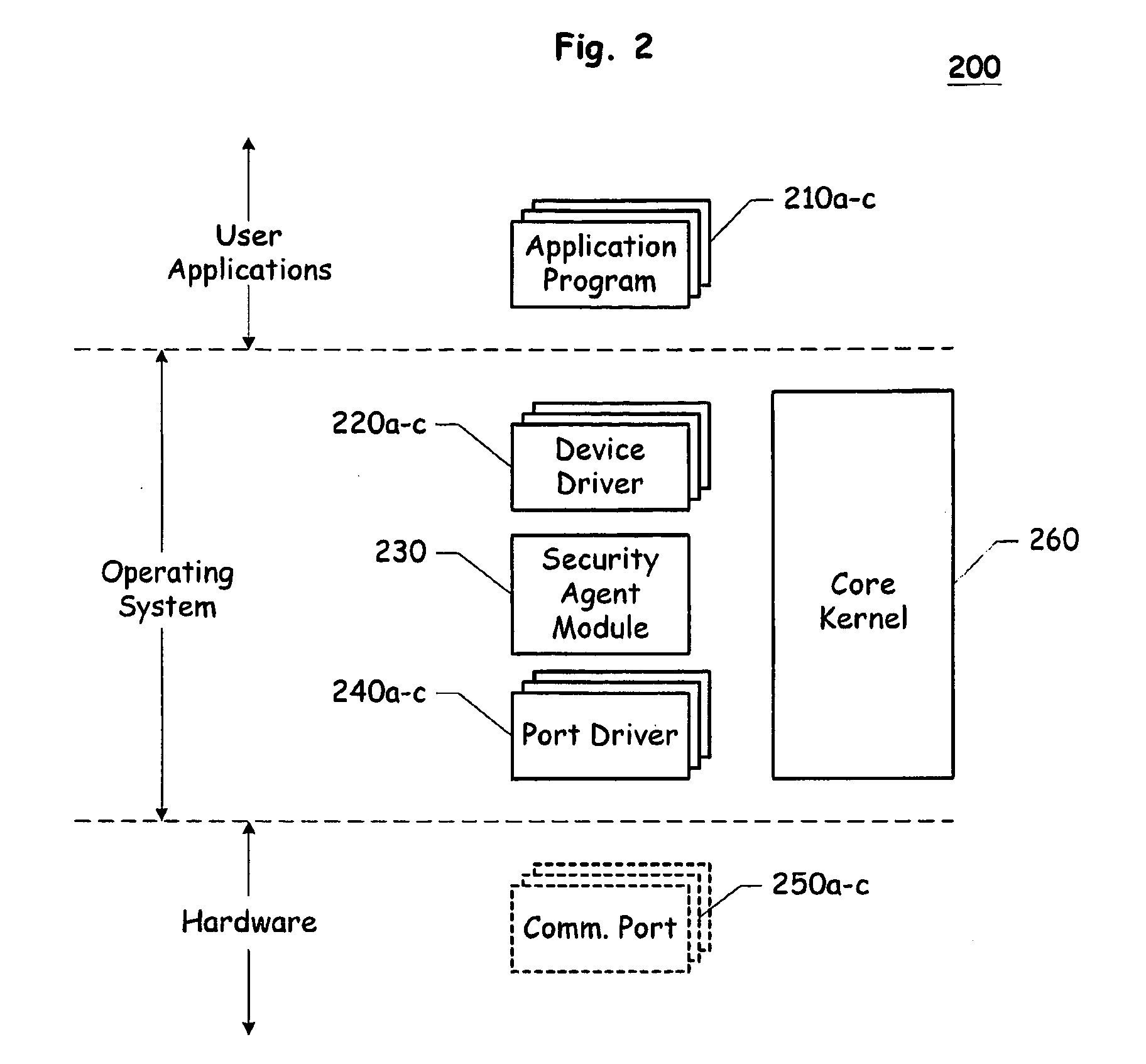

Method and system for protecting data within portable electronic devices

ActiveUS7159120B2Operation is disabledKey distribution for secure communicationDigital data processing detailsComputer hardwareData transmission

A system and method for protecting data within a portable electronic device to prevent unauthorized access to that data. Encryption of data within the portable electronic device and automatic erasure of data upon unauthorized attempted access is provided. A limited number of attempts to access the portable electronic device are allowed, and if exceeded, the data is automatically erased without notification. Data transfer functions of the portable electronic device are also disabled when the device is locked. Erasing of data is also provided if the portable electronic device is not synced with another device during a predetermined time period.

Owner:GOOGLE TECH HLDG LLC +1

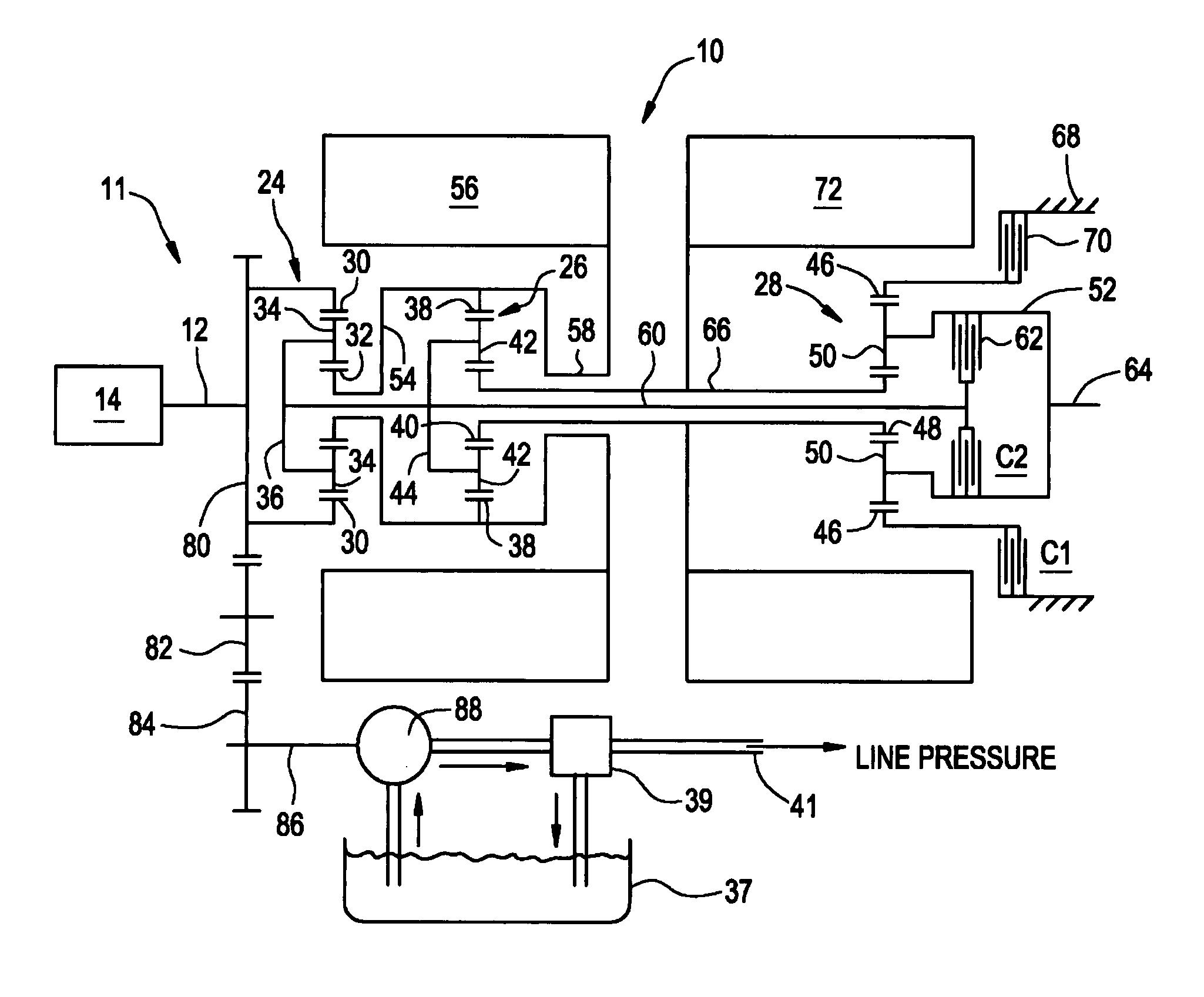

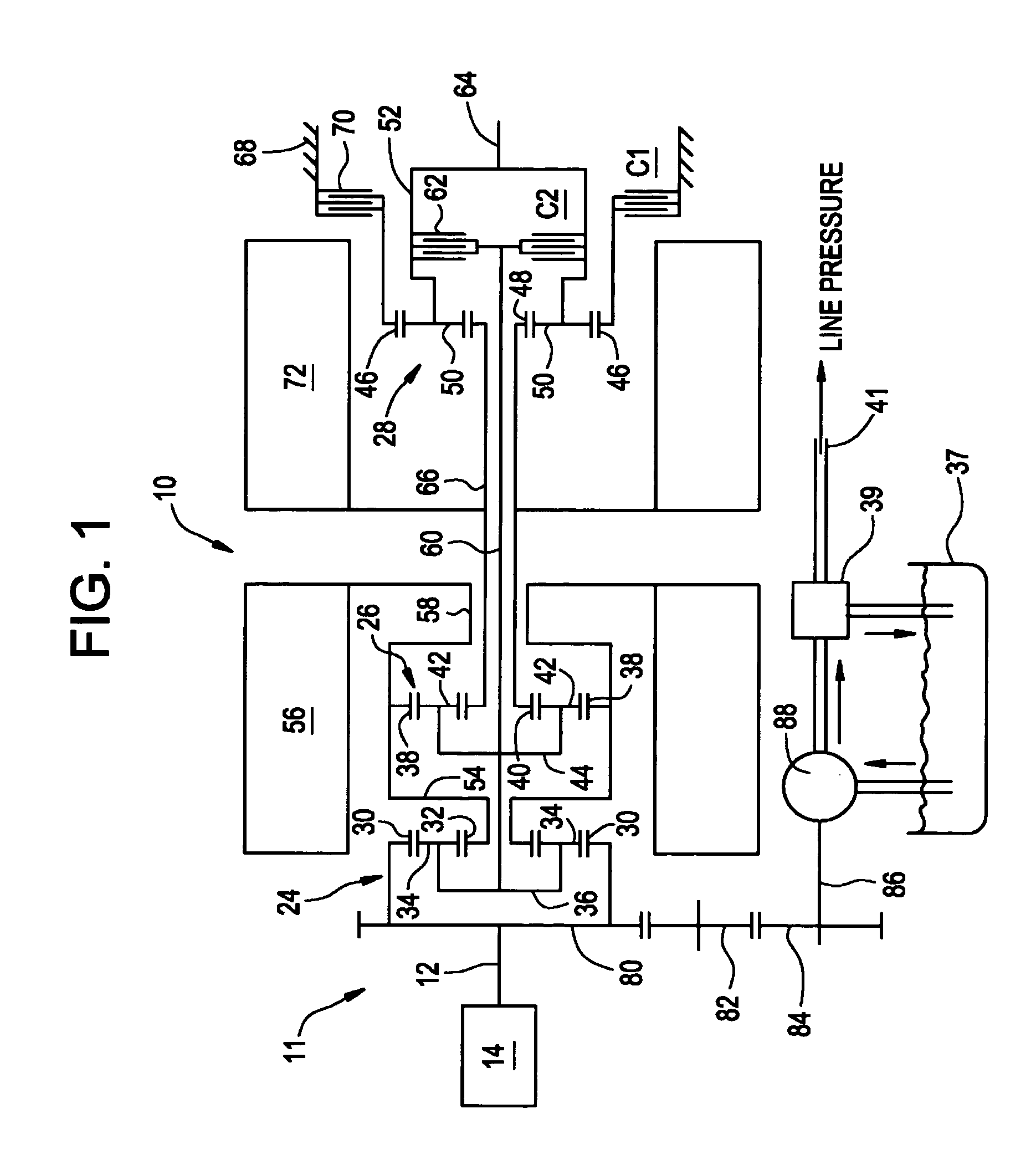

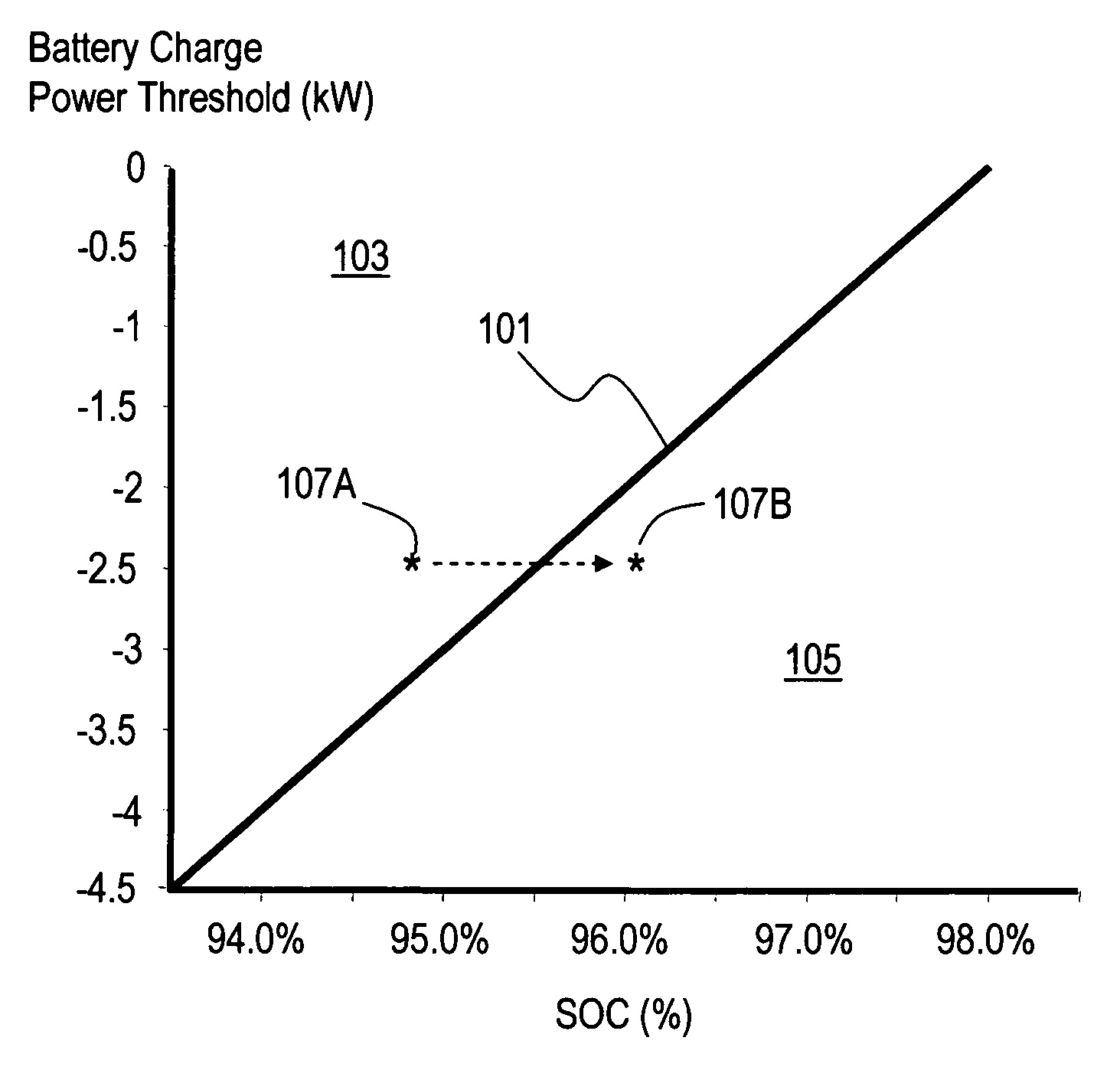

Energy storage system state of charge diagnostic

ActiveUS20050189918A1Avoid damageVehicle operation can be disabled and may become disabledBatteries circuit arrangementsPropulsion using engine-driven generatorsStored energyOperating point

An energy storage system determined to be at an operating point indicative of incipient threat to its condition is permitted to continue power flow for a duration that is a function of the state of charge before a diagnosis of a critical state of charge condition is rendered. If the state of charge returns to an acceptable region before the duration expires, no diagnosis of a critical state of charge condition is rendered. Generally, the duration increases as the state of charge trends toward the region of acceptable state of charge and decreases as the state of charge trends away from the region of acceptable state of charge.

Owner:ALLISON TRANSMISSION INC

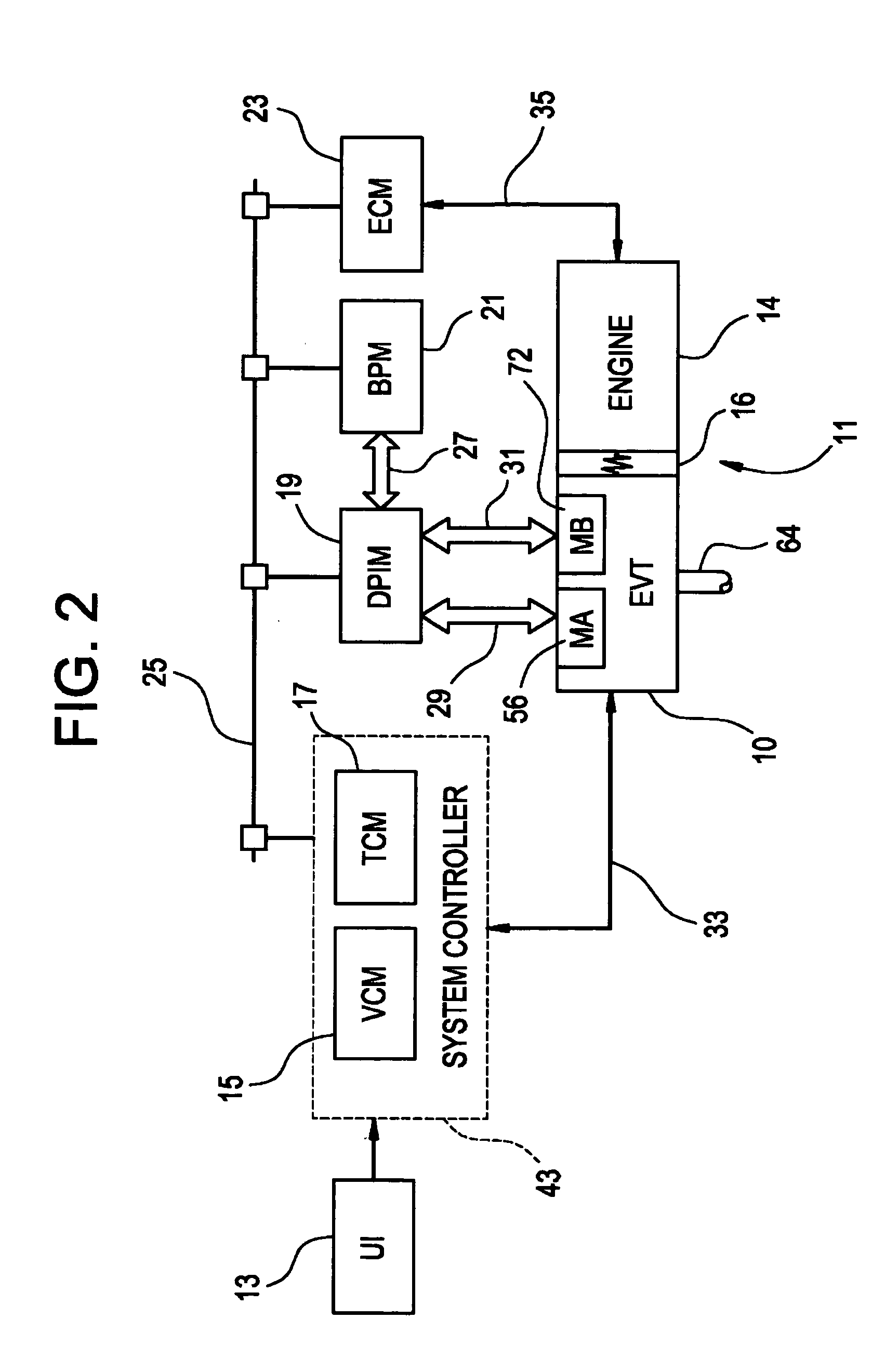

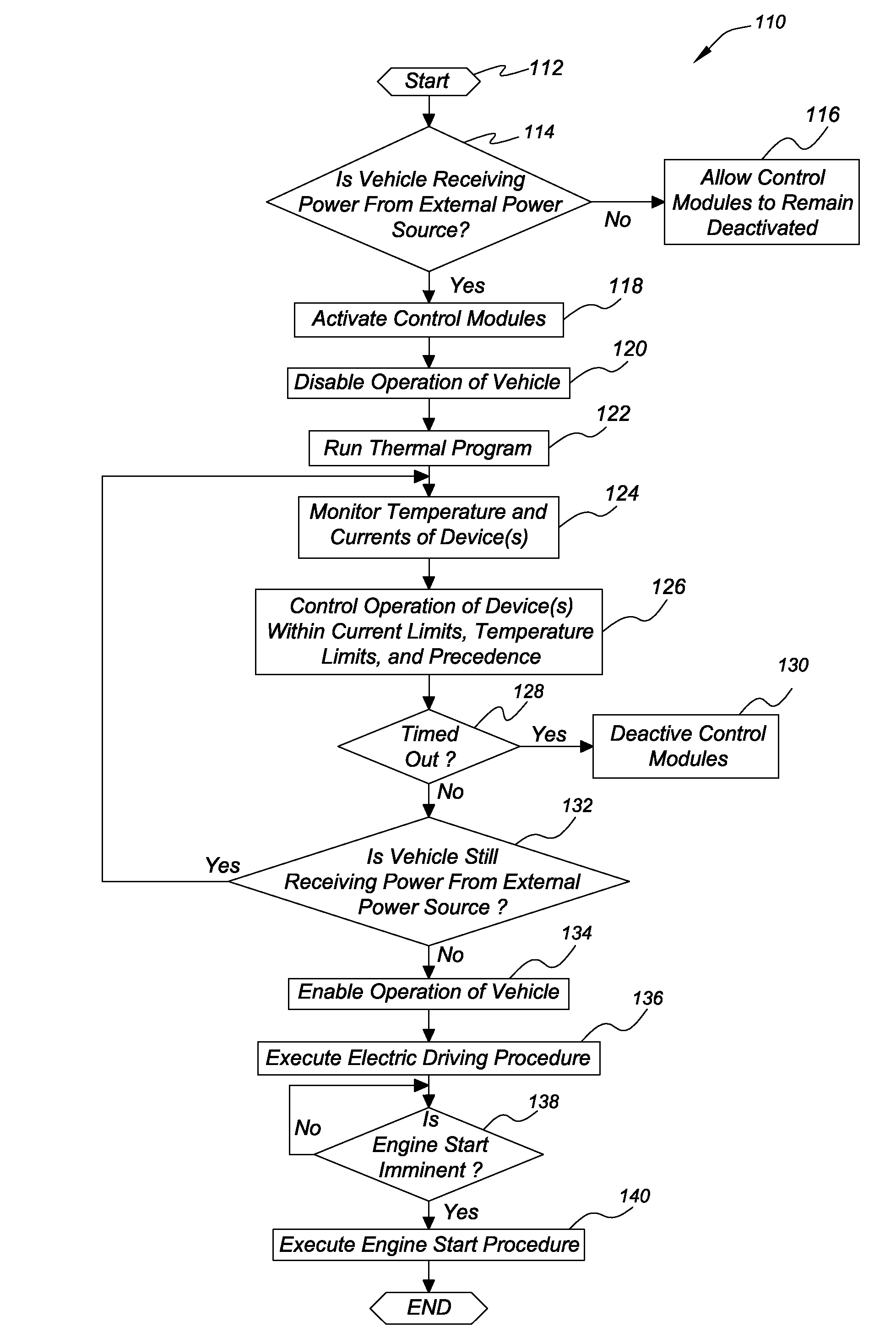

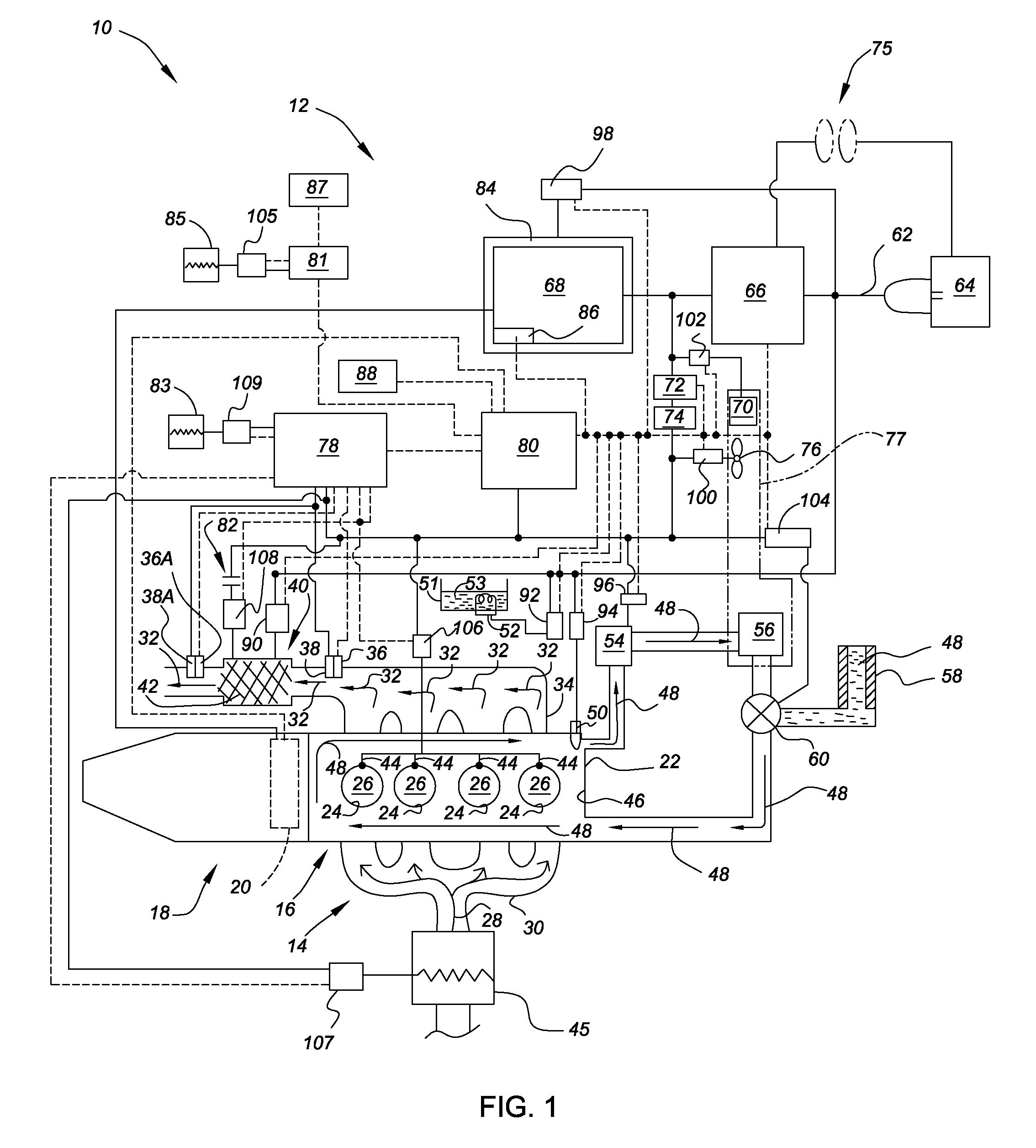

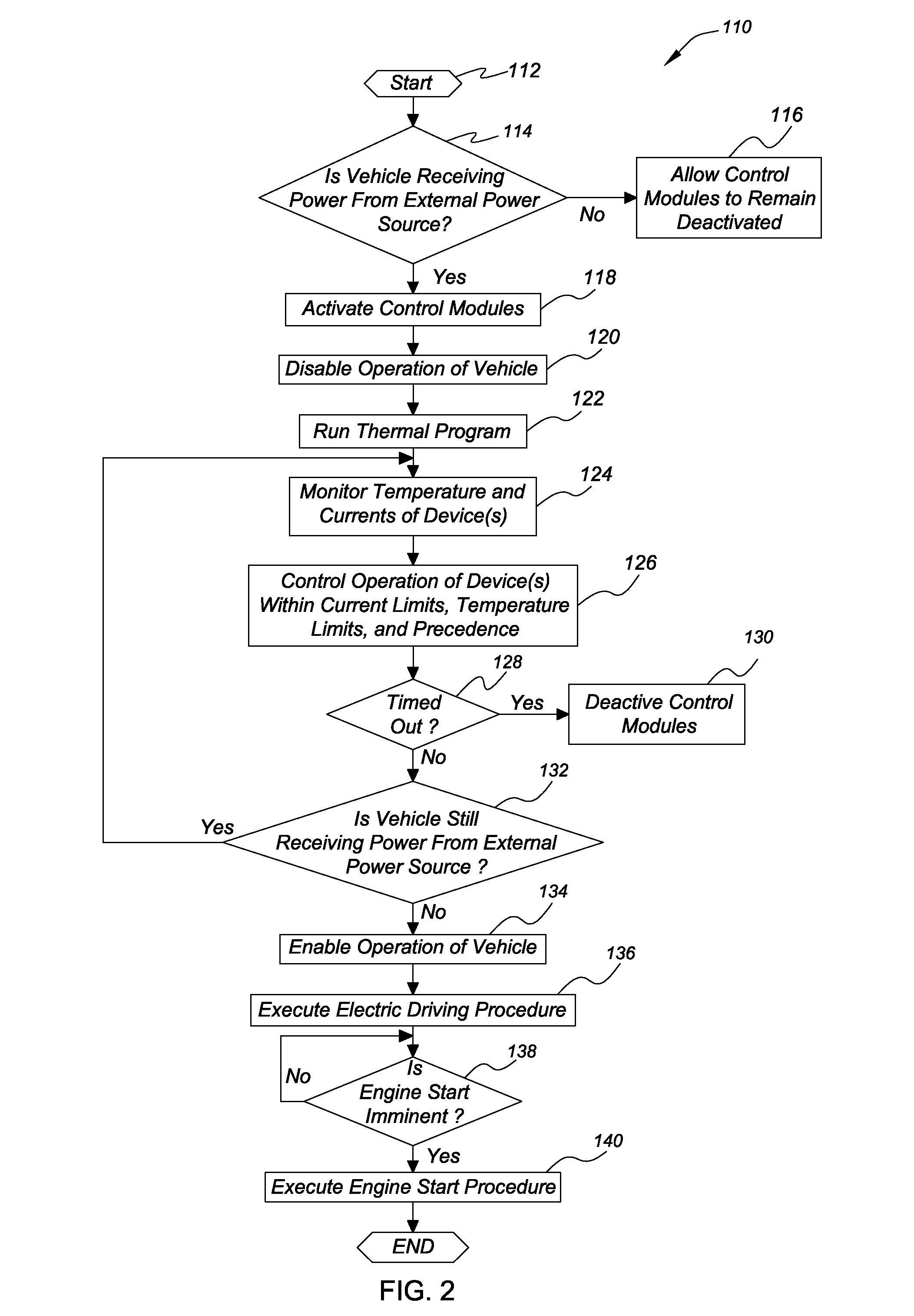

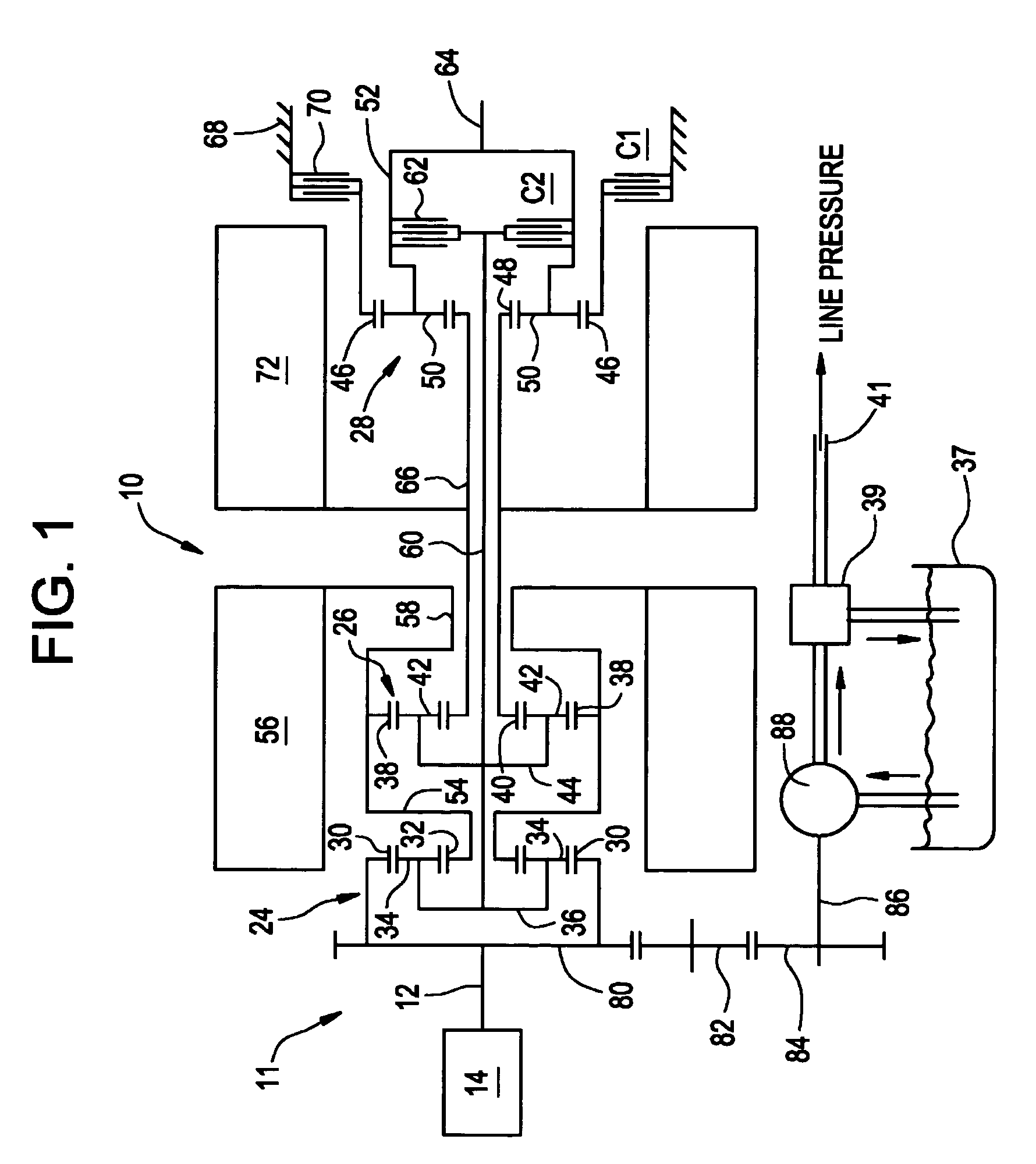

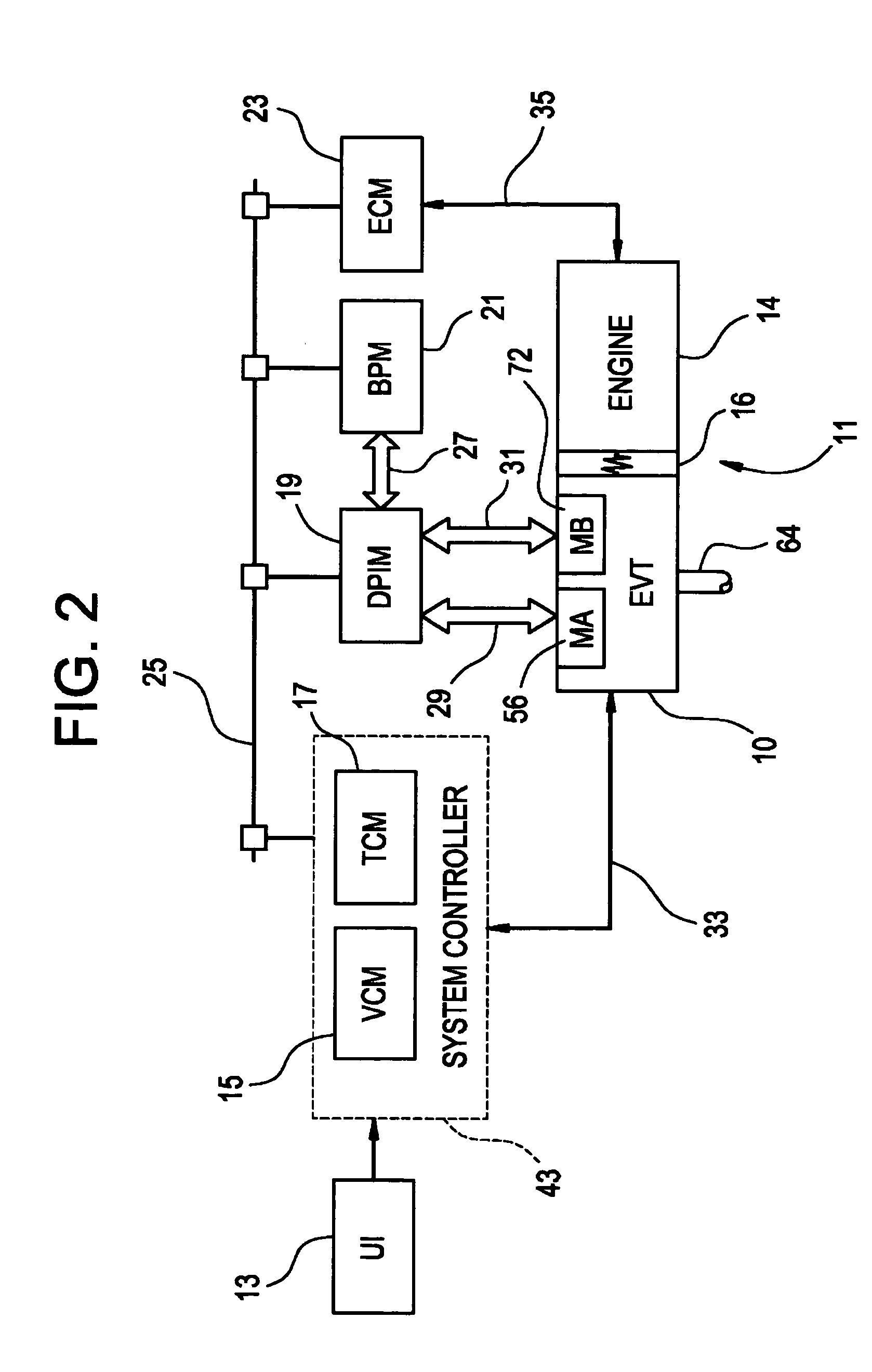

Method of operating a plug-in hybrid electric vehicle

InactiveUS20080275600A1Operation is disabledOptimizationVehicle testingAuxillary drivesElectrical batteryState of charge

A method of operating a plug-in hybrid electric vehicle is provided including the steps of: A) determining whether the plug-in hybrid electric vehicle is receiving power from an external power source; B) disabling the operation of the plug-in hybrid electric vehicle and executing a thermal program if the plug-in hybrid electric vehicle is receiving power from the external power source, wherein the thermal program includes charging a high voltage battery and monitoring the state of charge of the high voltage battery; C) determining if the plug-in hybrid electric vehicle continues to receive power from the external power source; and D) enabling operation of the plug-in hybrid electric vehicle if the plug-in hybrid electric vehicle is no longer receiving power from the external power source.

Owner:GM GLOBAL TECH OPERATIONS LLC

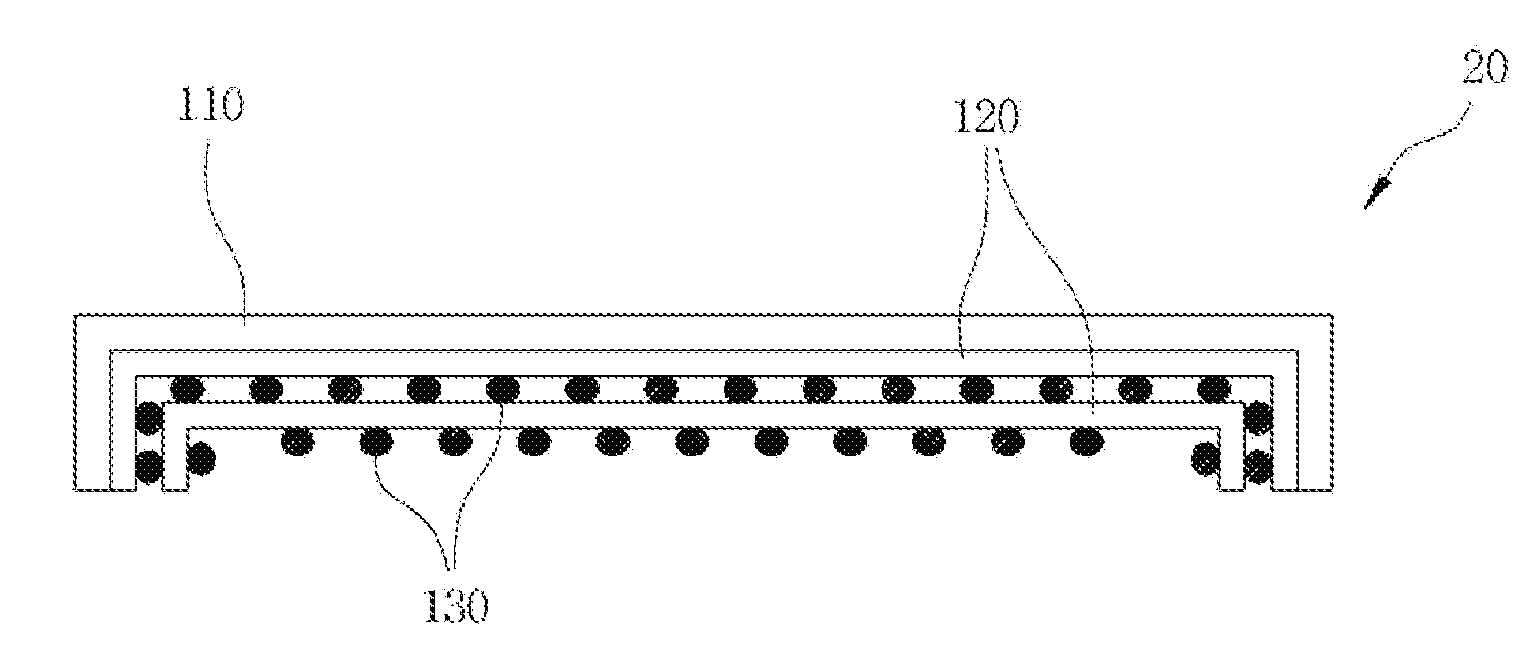

Tamper respondent covering

ActiveUS8589703B2Operation is disabledPrevent illegal useDigital data processing detailsCasings/cabinets/drawers detailsPrinted circuit board

Disclosed is a tamper respondent covering. The tamper respondent covering has a cover-shaped structure to cover an electronic part which is exposed. This covering protects electronic parts embedded inside or exposed outside a product, such as ICs that contains data concerning security and certification, communication connectors that transmit data, etc. from a tempering operation or an alternating operation. The tamper respondent covering protects data from a tampering operation or an altering operation by erasing the data or disabling operation of the electronic part containing the data in response to an act of attempting to remove the covering from a printed circuit board of the electronic part or to drill a hole in the covering.

Owner:LEE CHEOL JAE

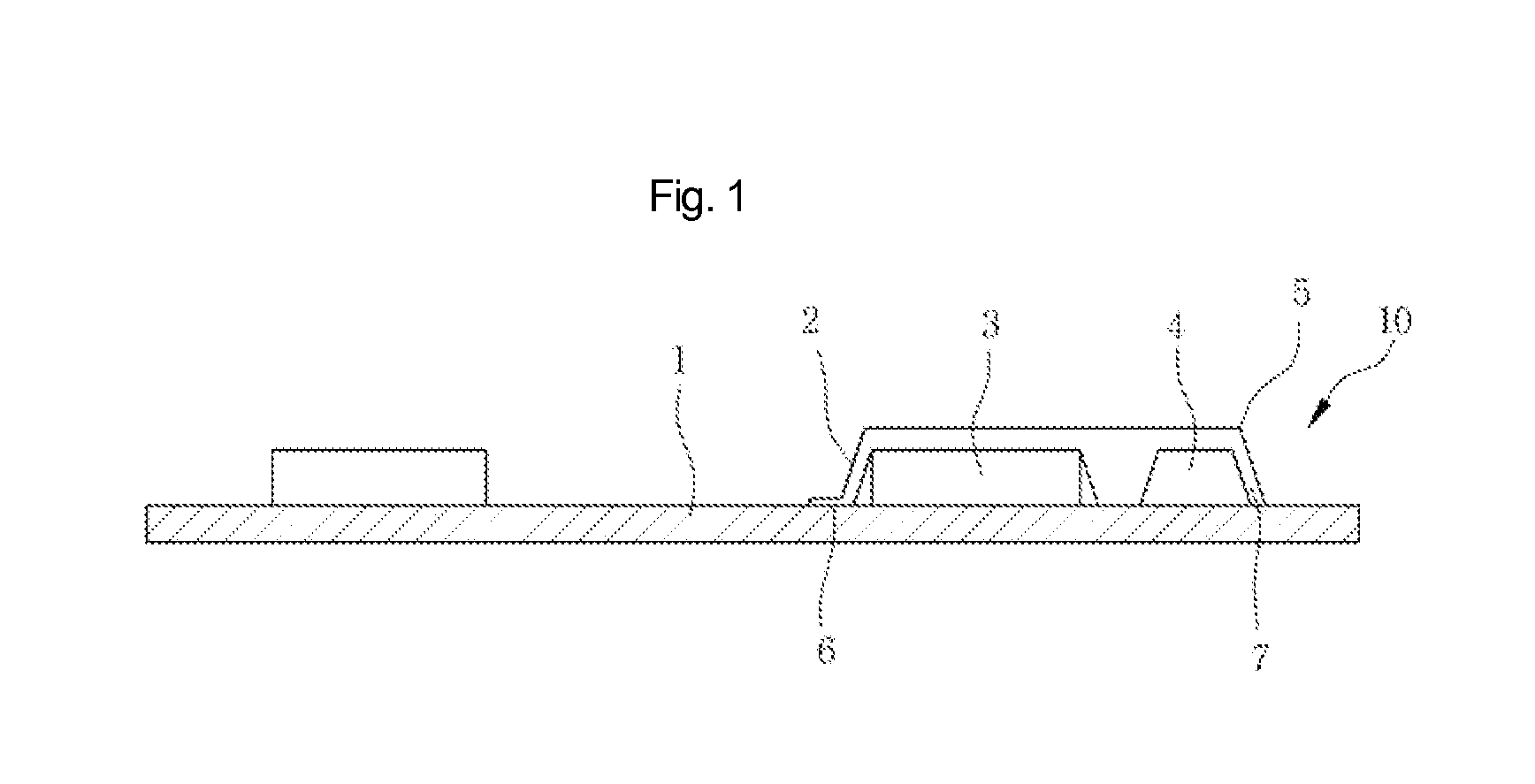

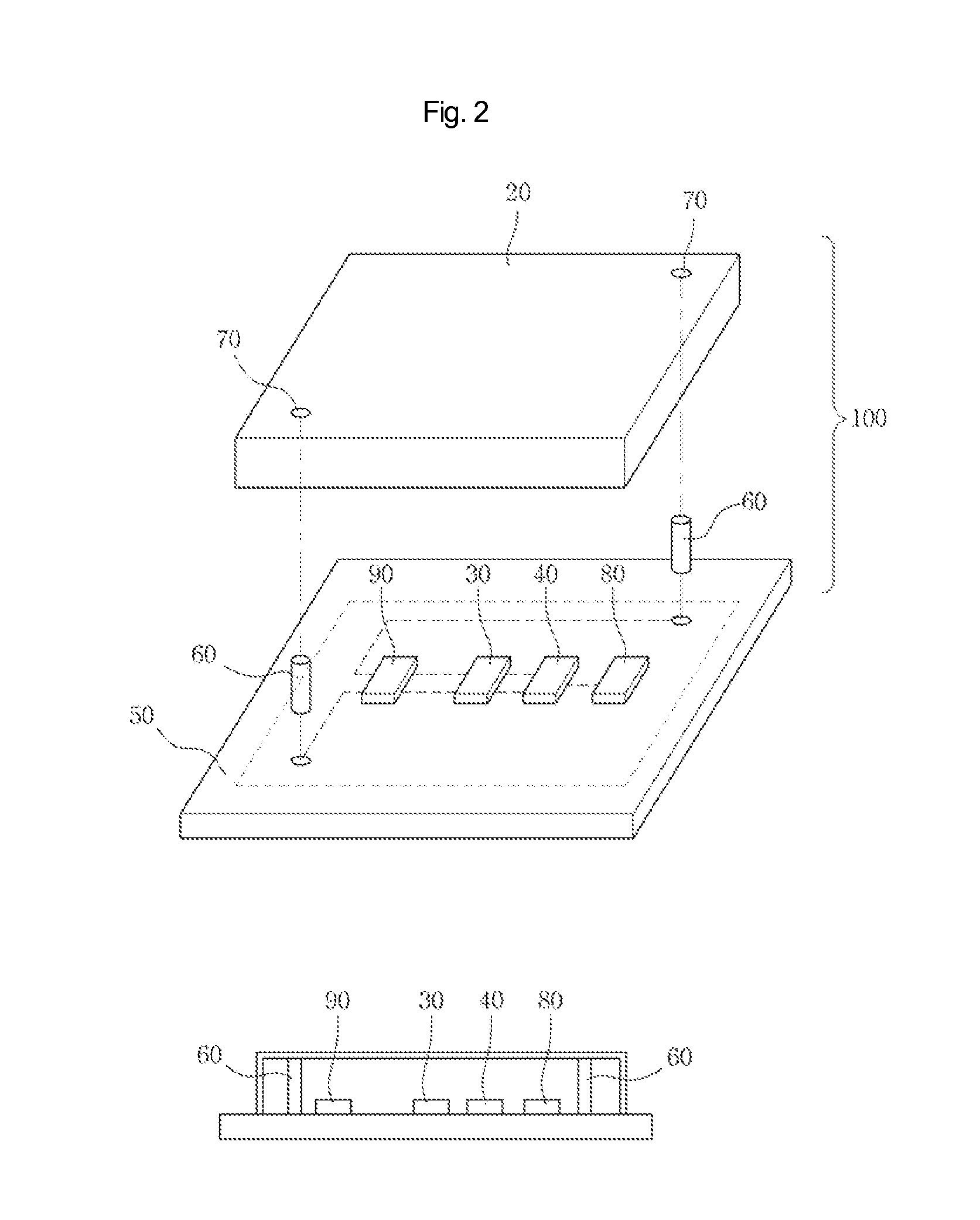

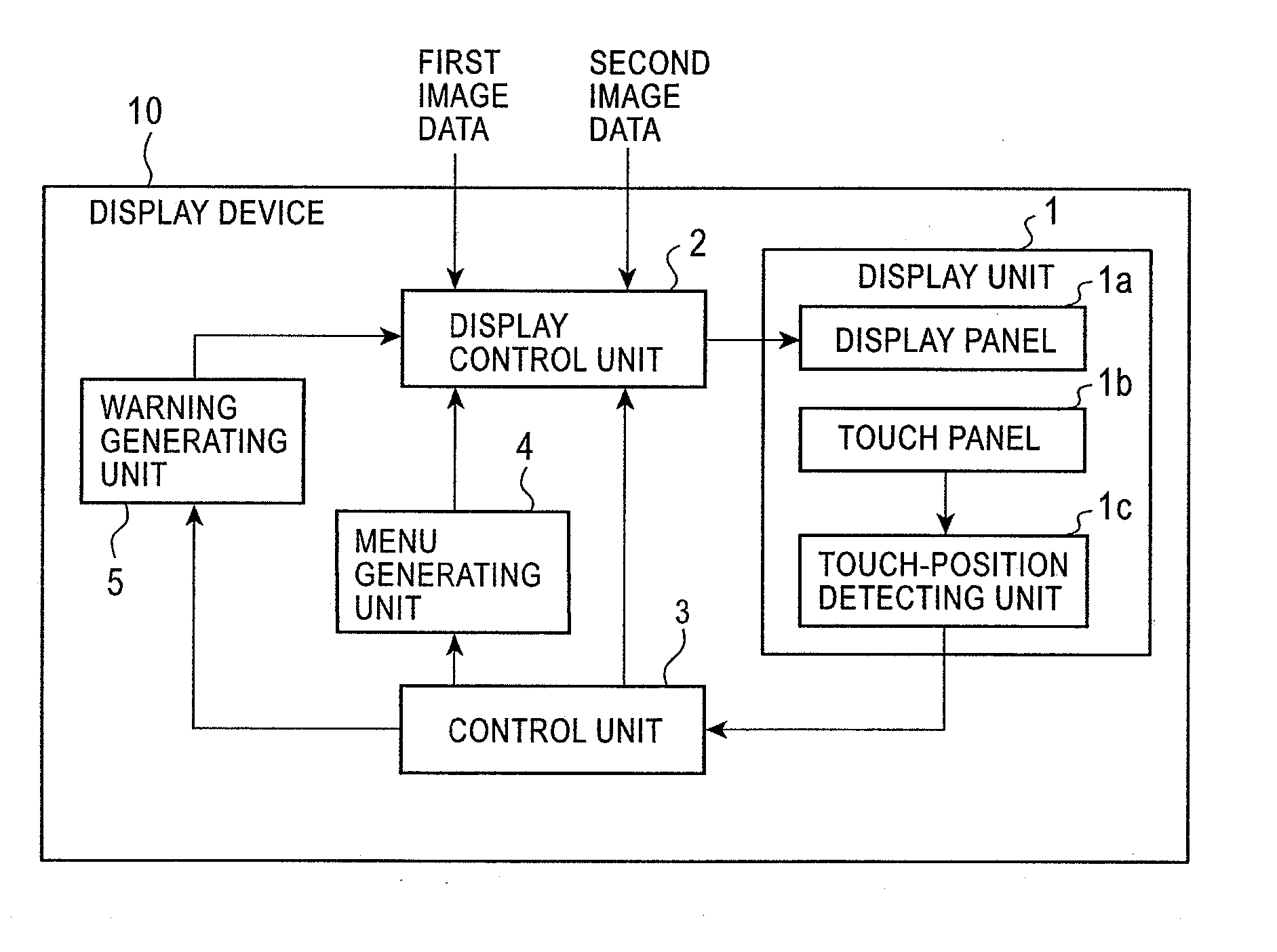

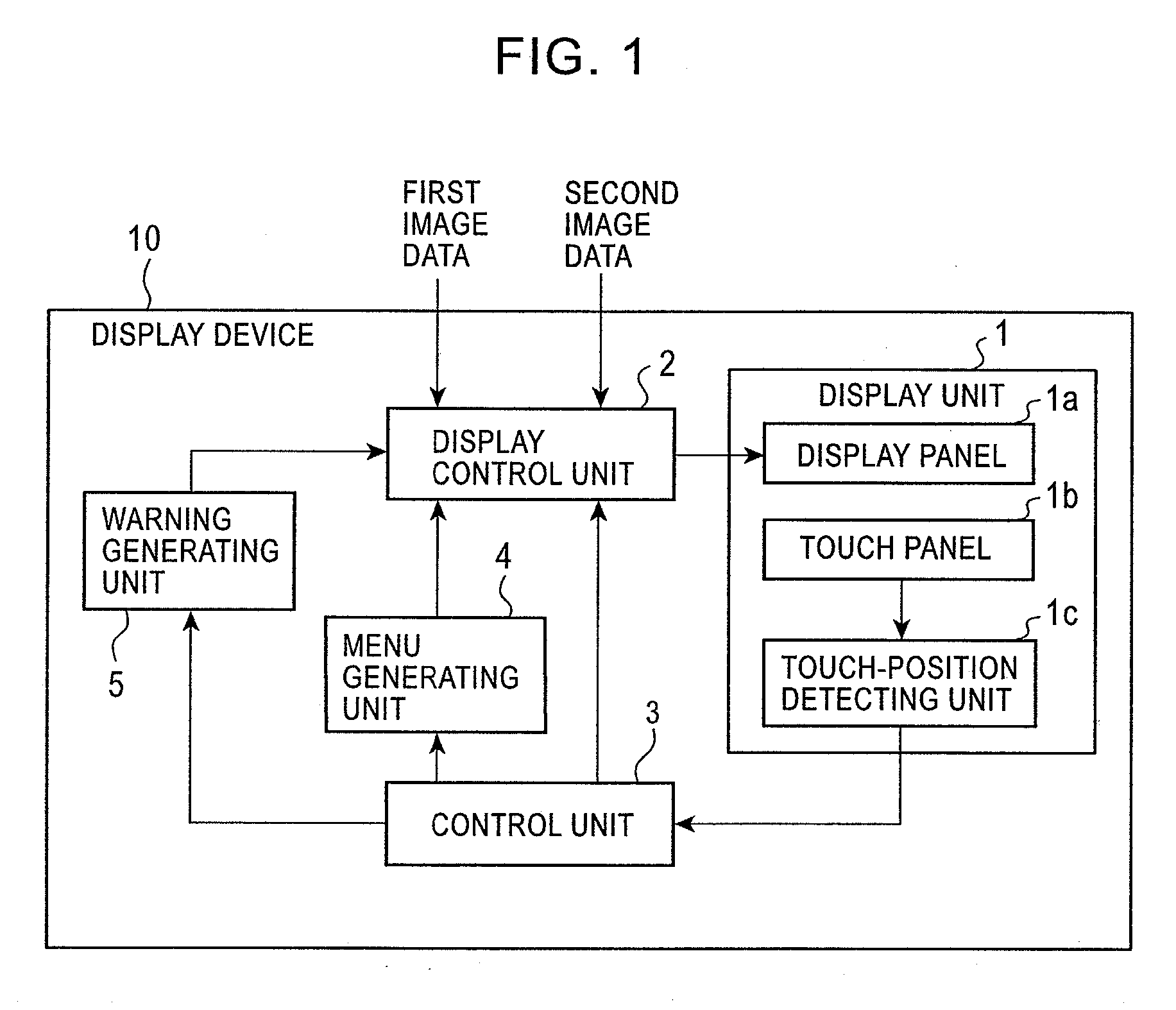

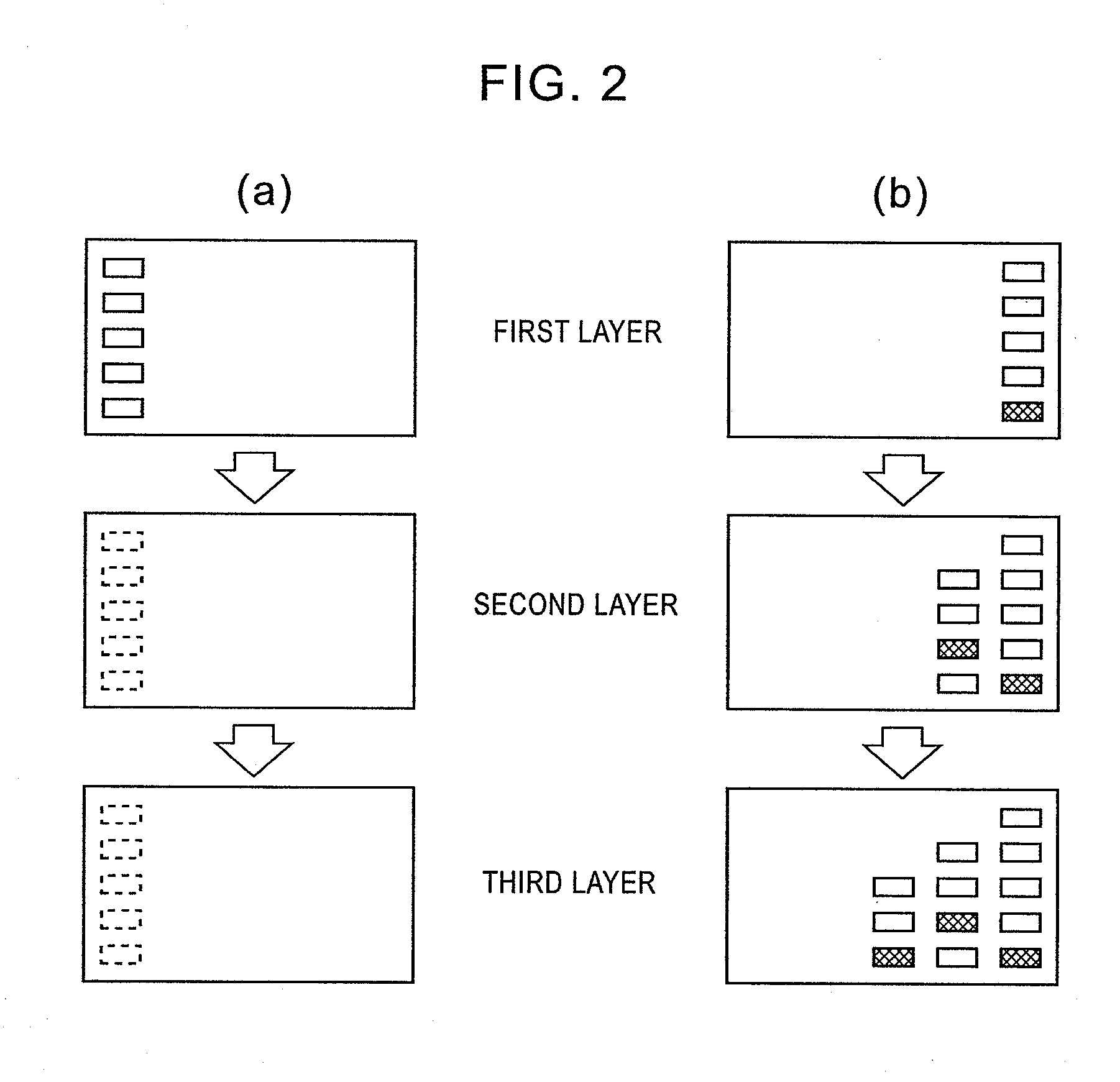

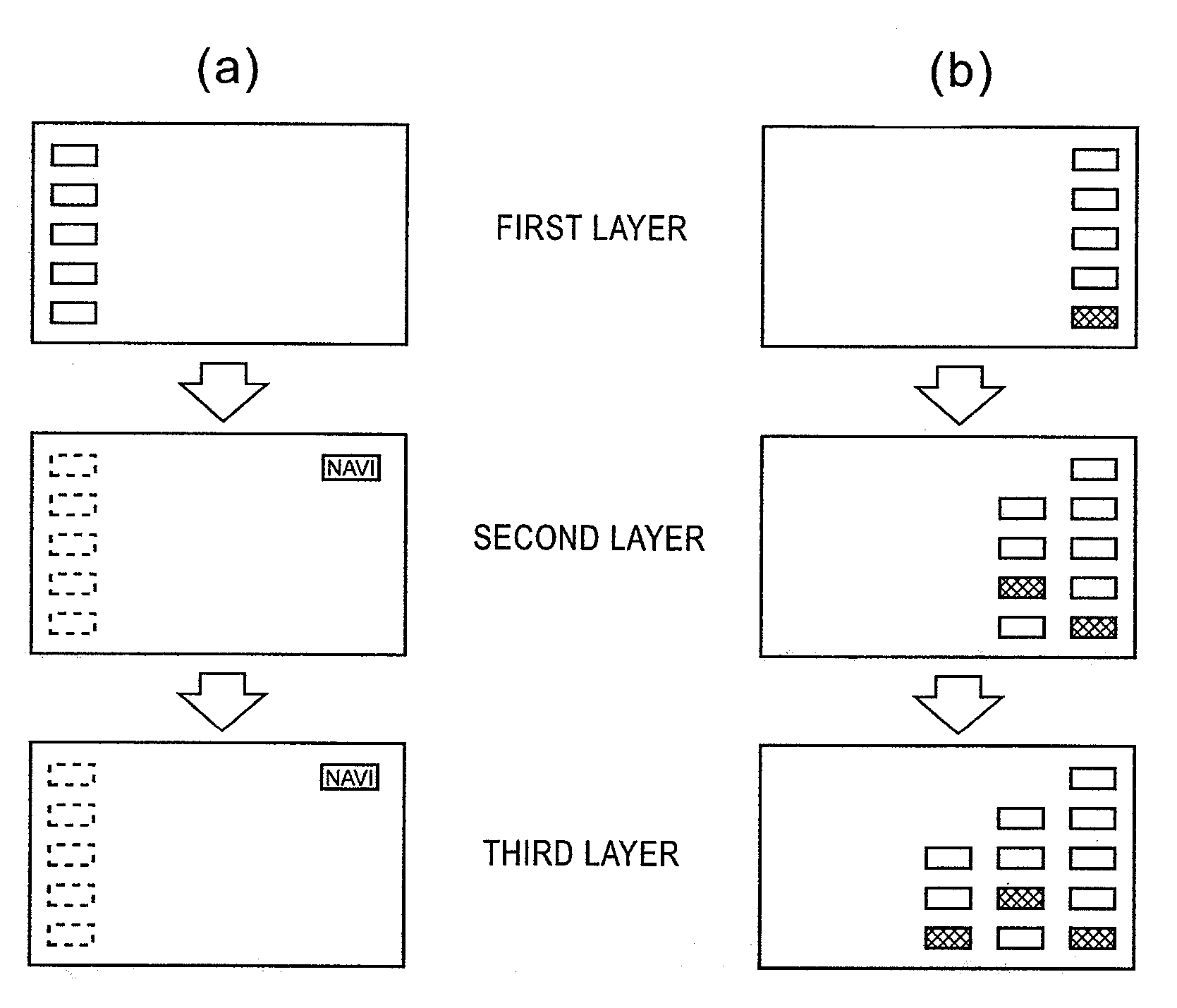

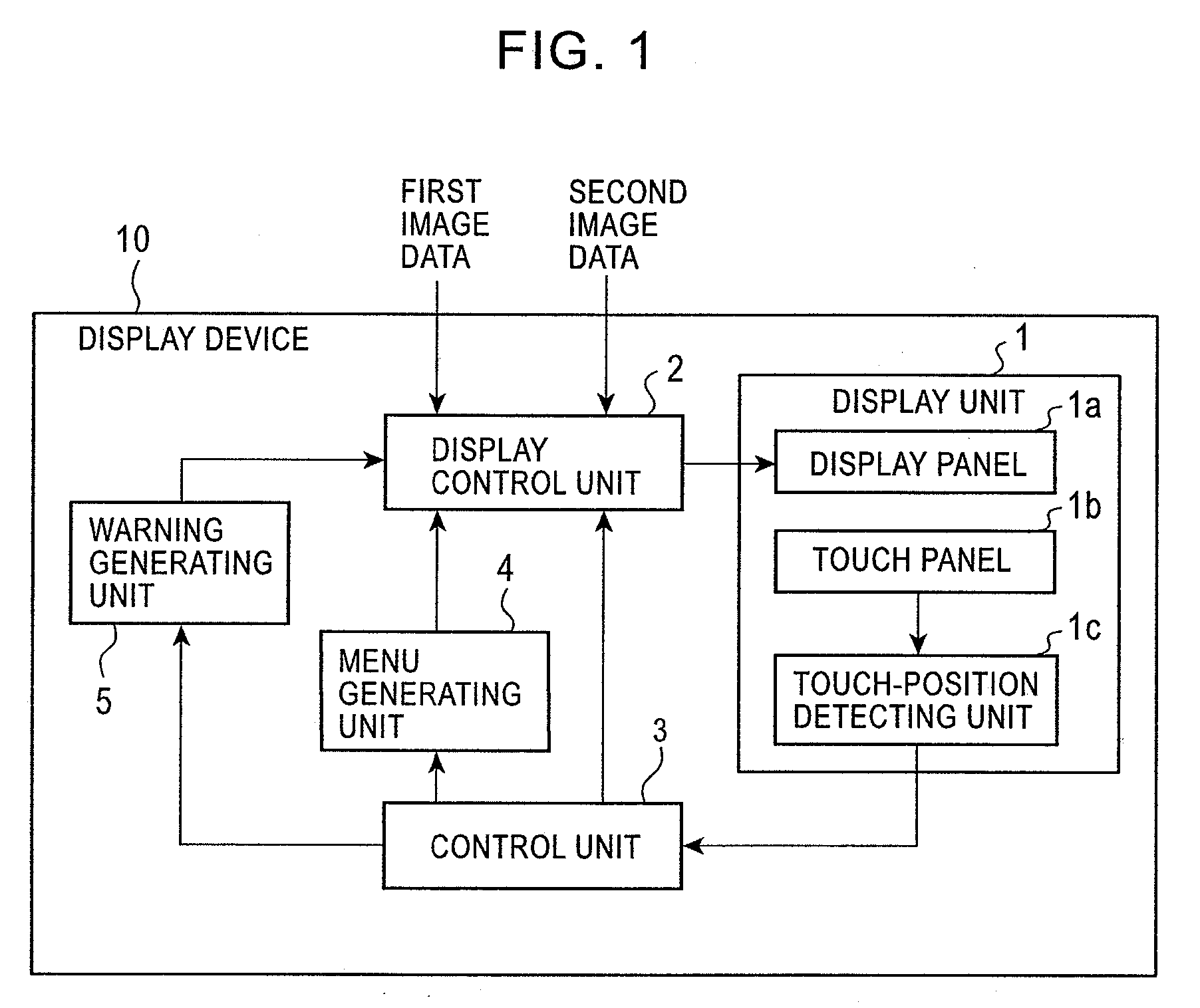

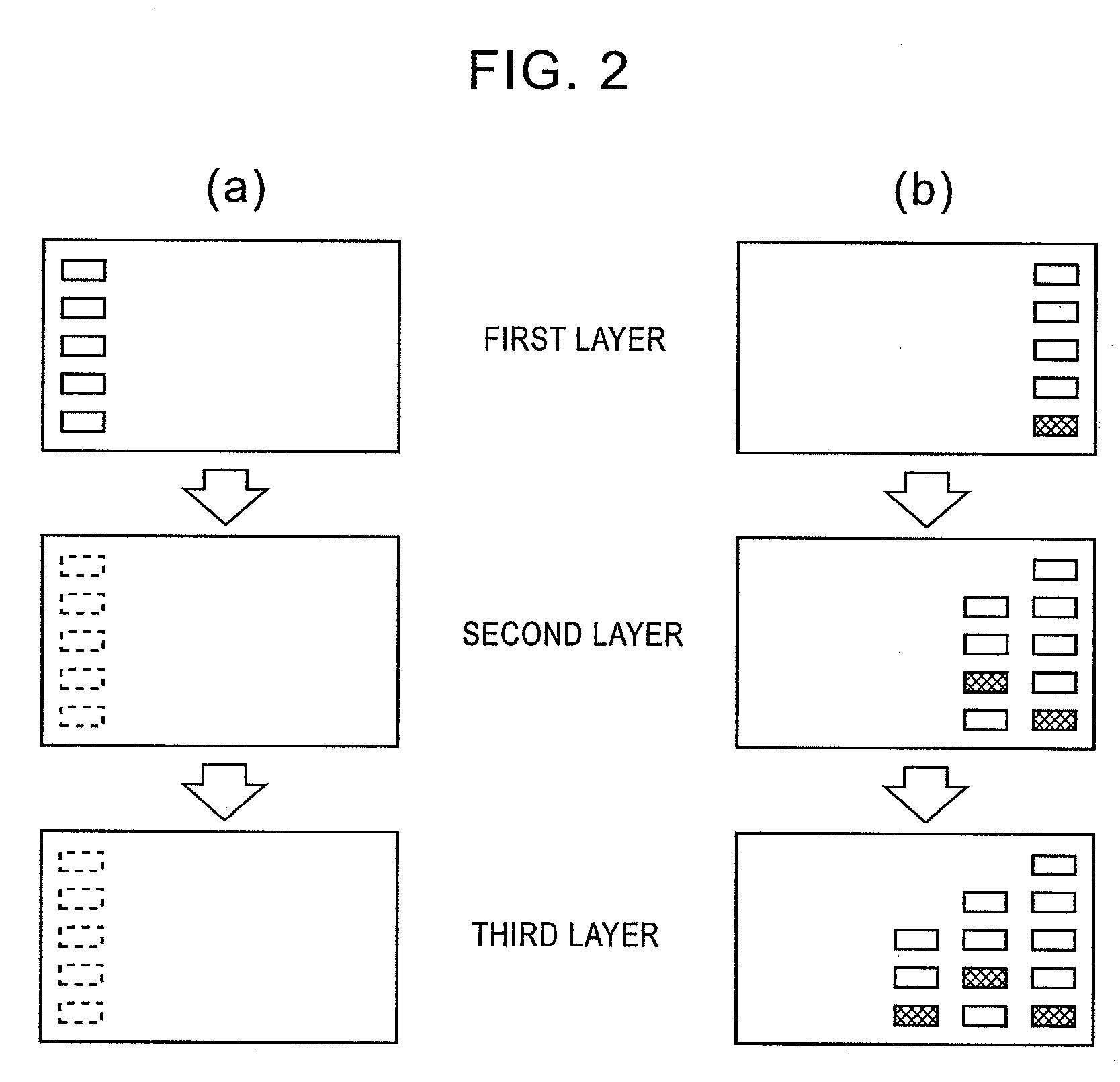

Display Device, User Interface, and Method for Providing Menus

ActiveUS20070182721A1Easy to operateLow costSteroscopic systemsInput/output processes for data processingLocation detectionDisplay device

A display device may include a display unit, a touch detecting unit that detects a touch on the display unit, a touch-position detecting unit that detects a touch position on the touch detecting unit and outputs coordinate data of the position, a display control unit that causes the display unit to provide dual view display of an image and display a menu image, a menu generating unit that generates first and second top menus, and a control unit that performs control to display the top menus in different positions on a screen of the display unit, to determine, on the basis of the coordinate data from the touch-position detecting unit, which of the top menus has been touched, to enable operations on one of the top menus that has been touched, and to disable operations on the other one of the top menus.

Owner:ALPINE ELECTRONICS INC

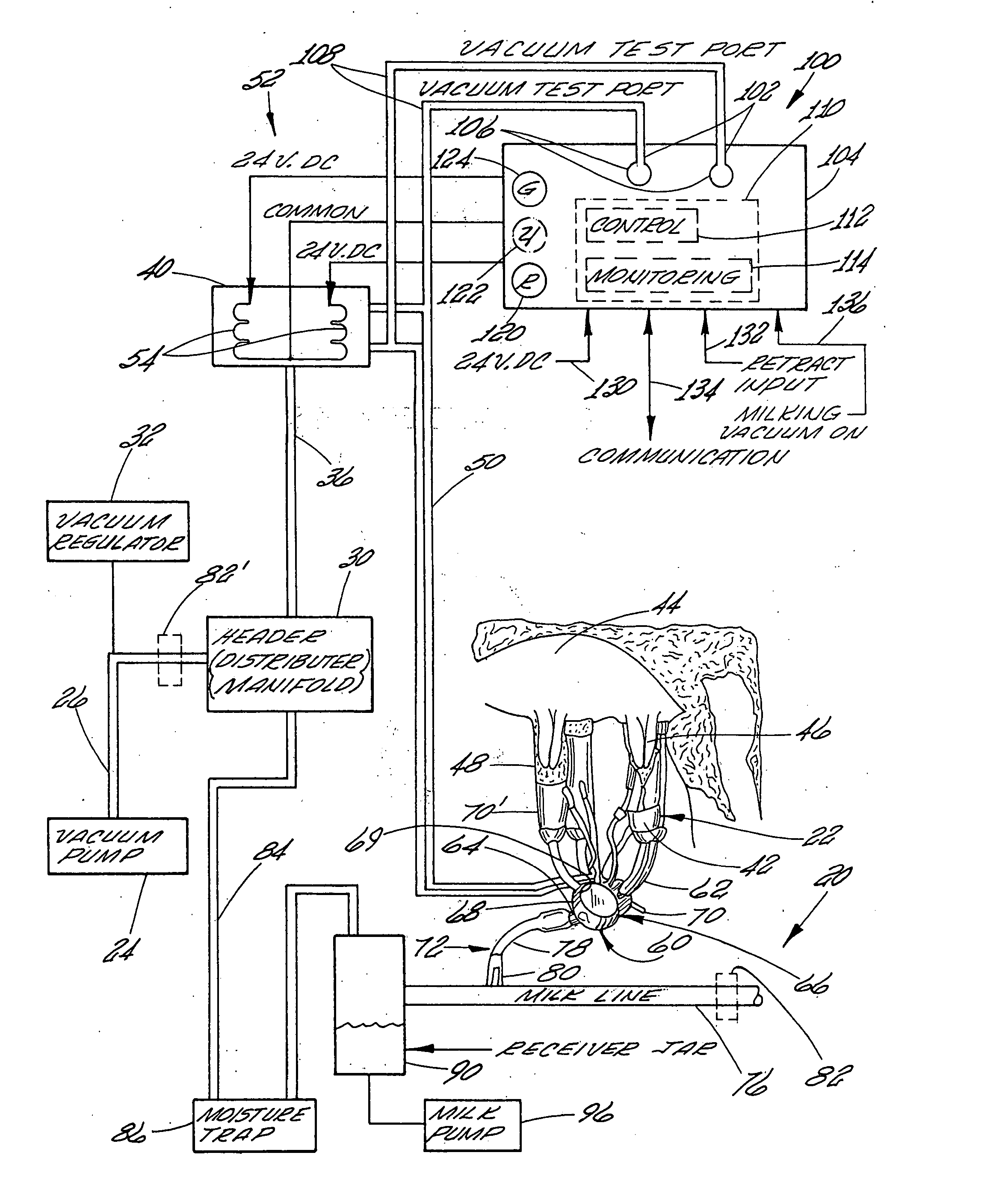

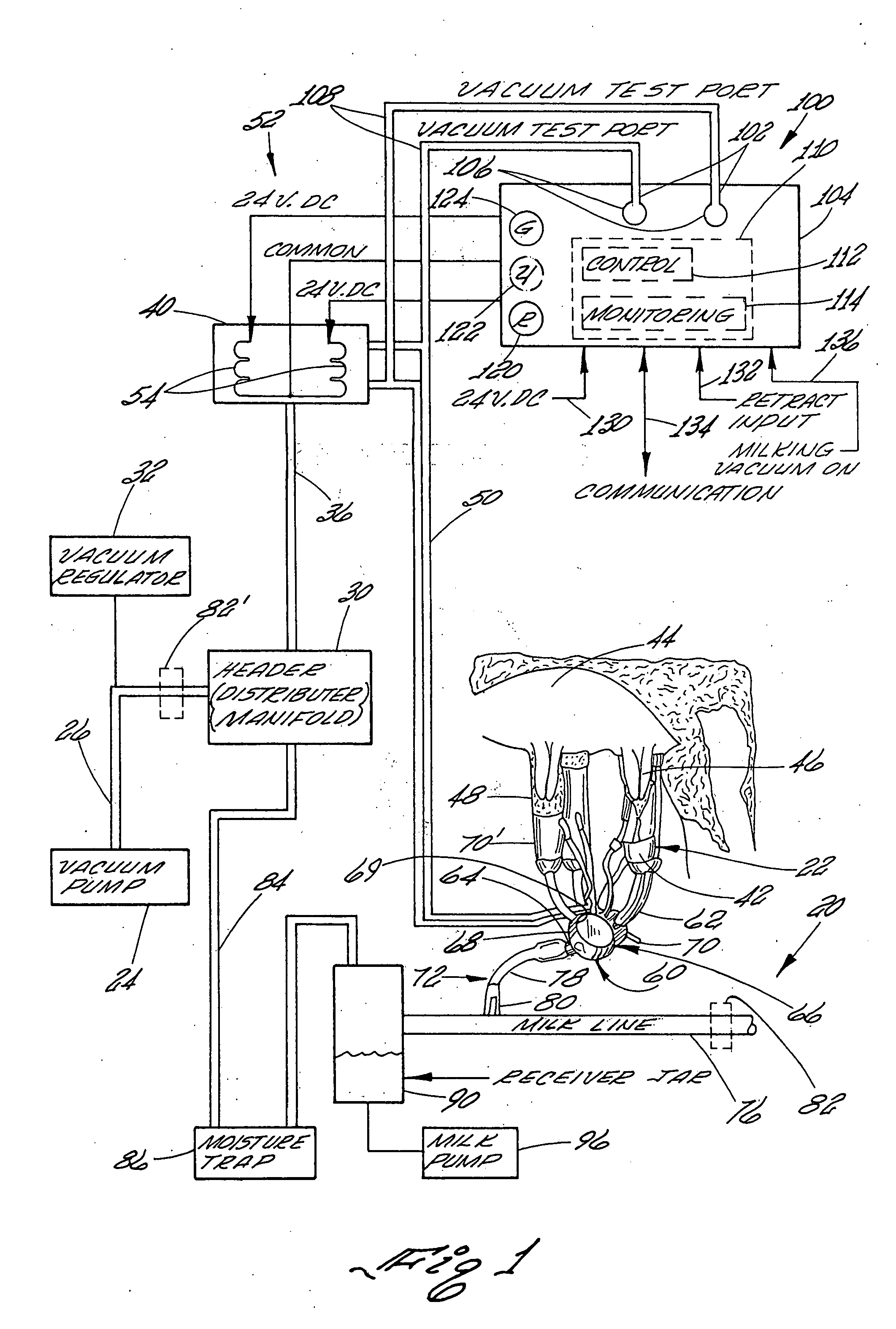

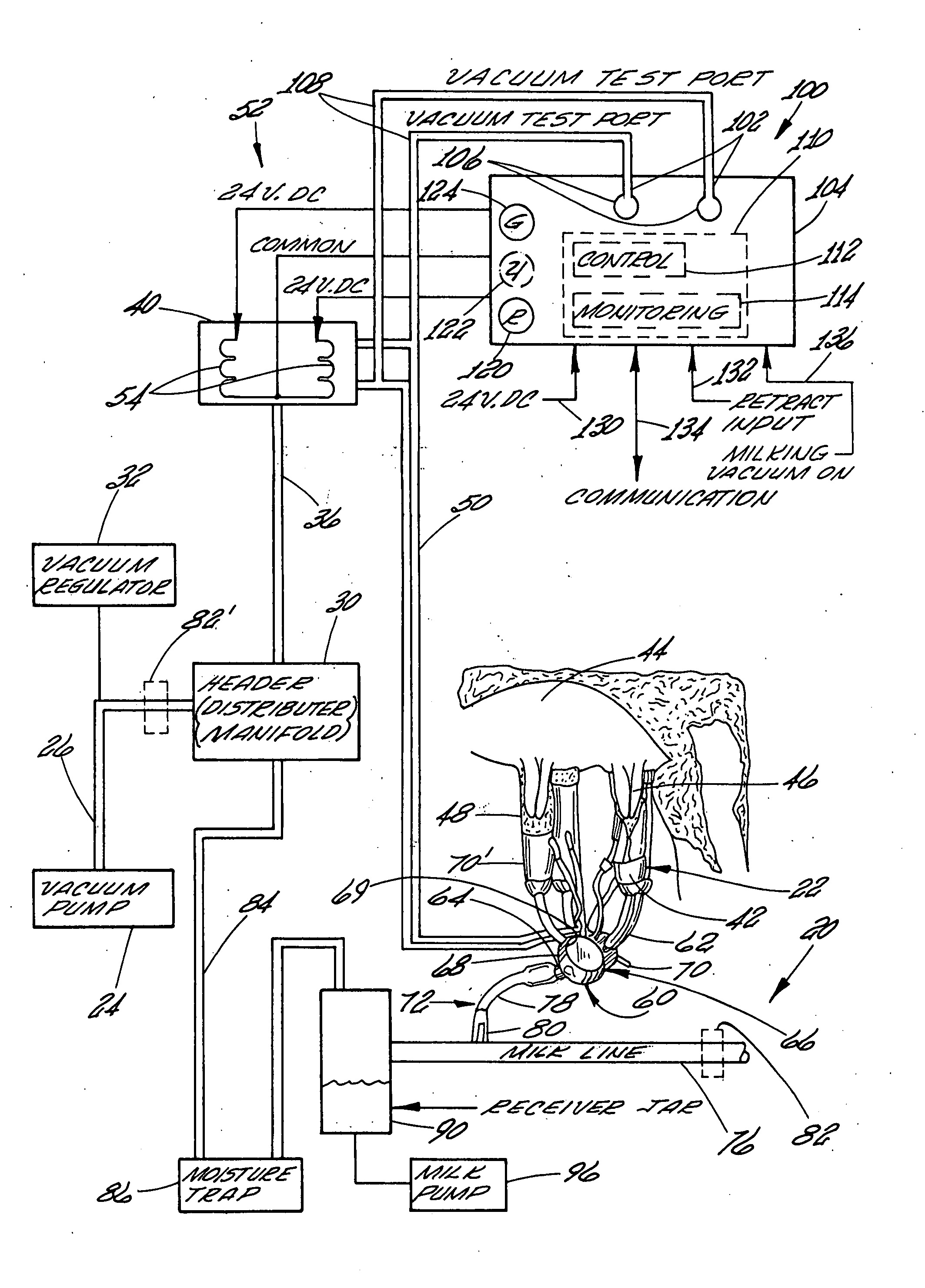

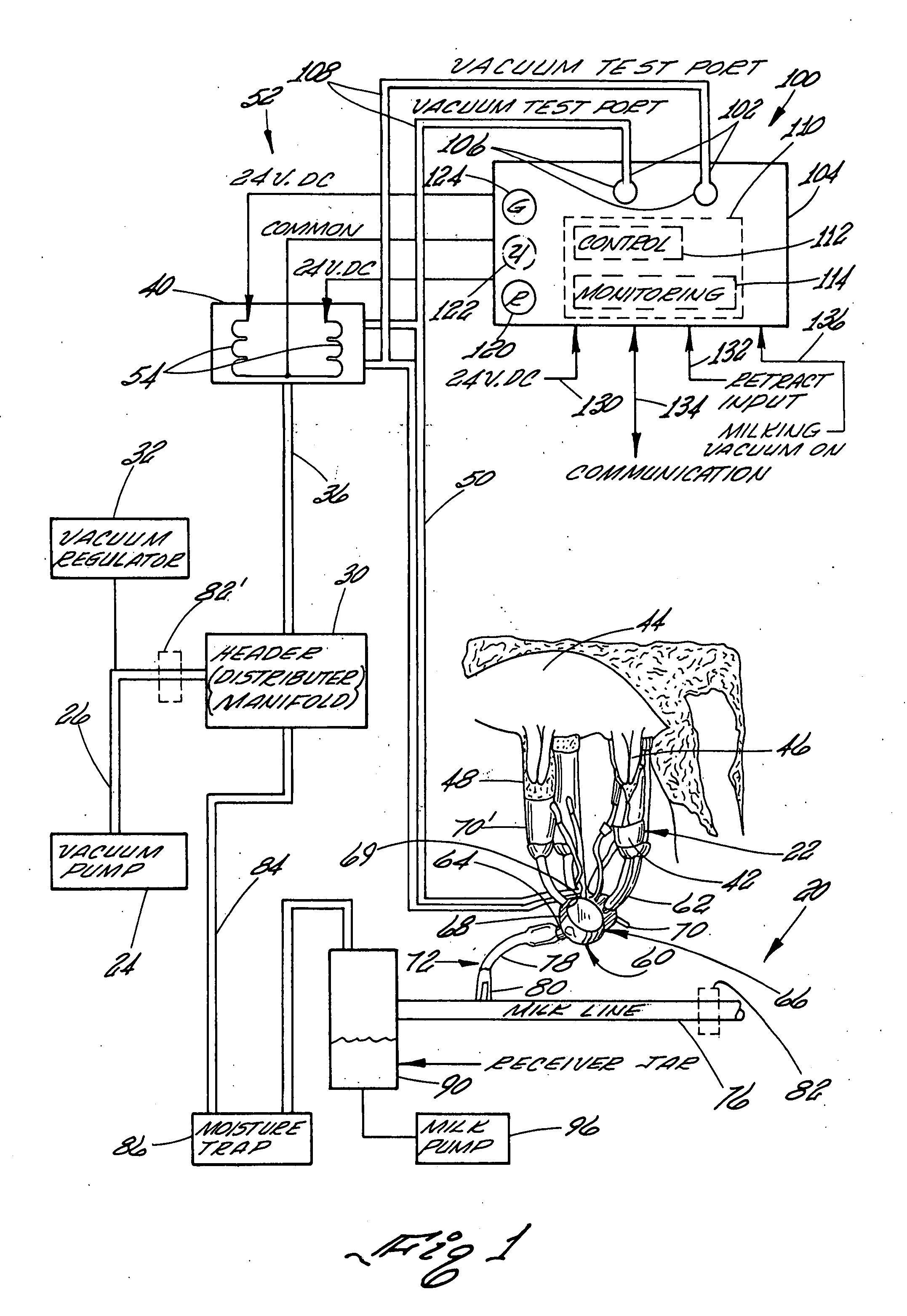

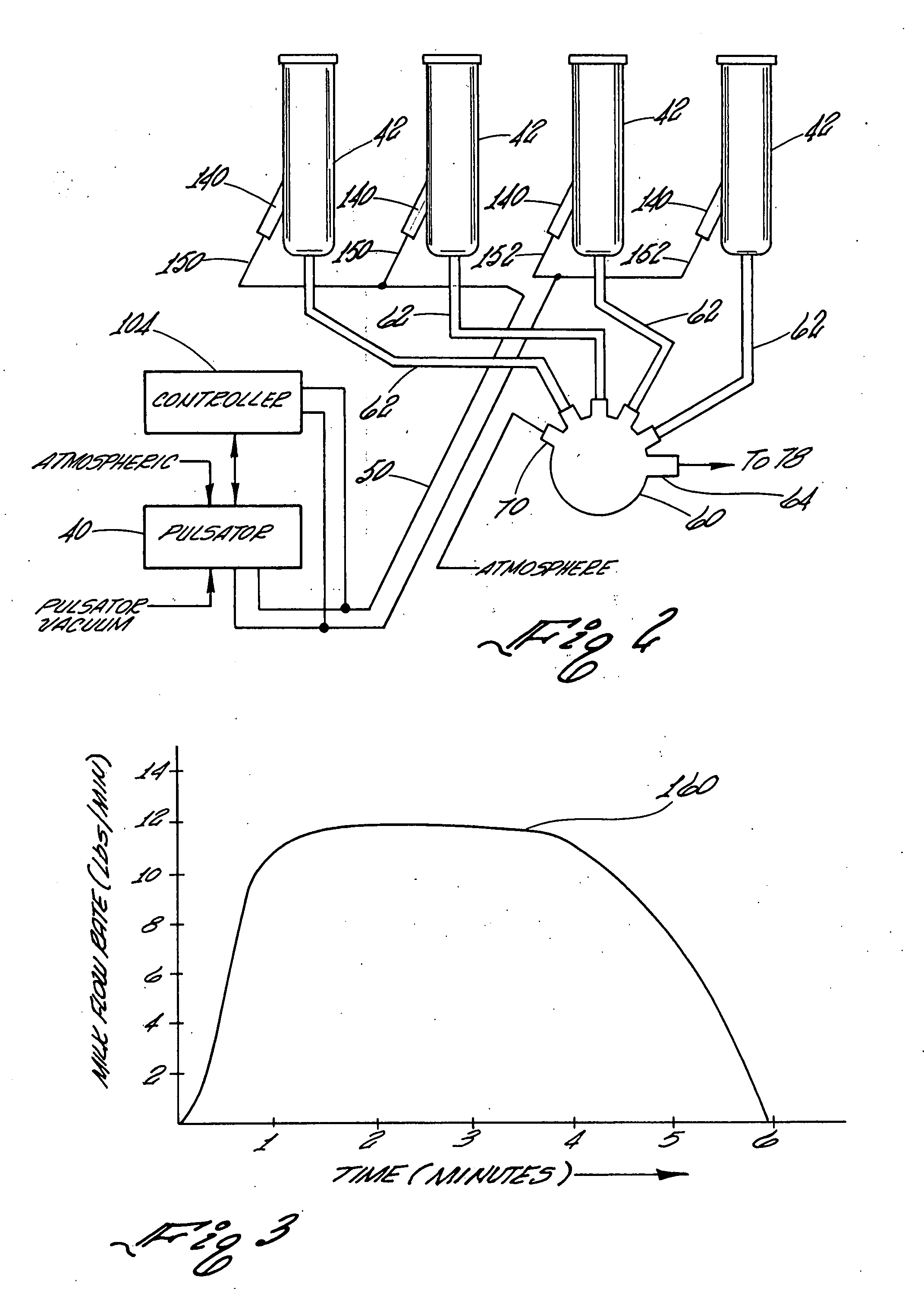

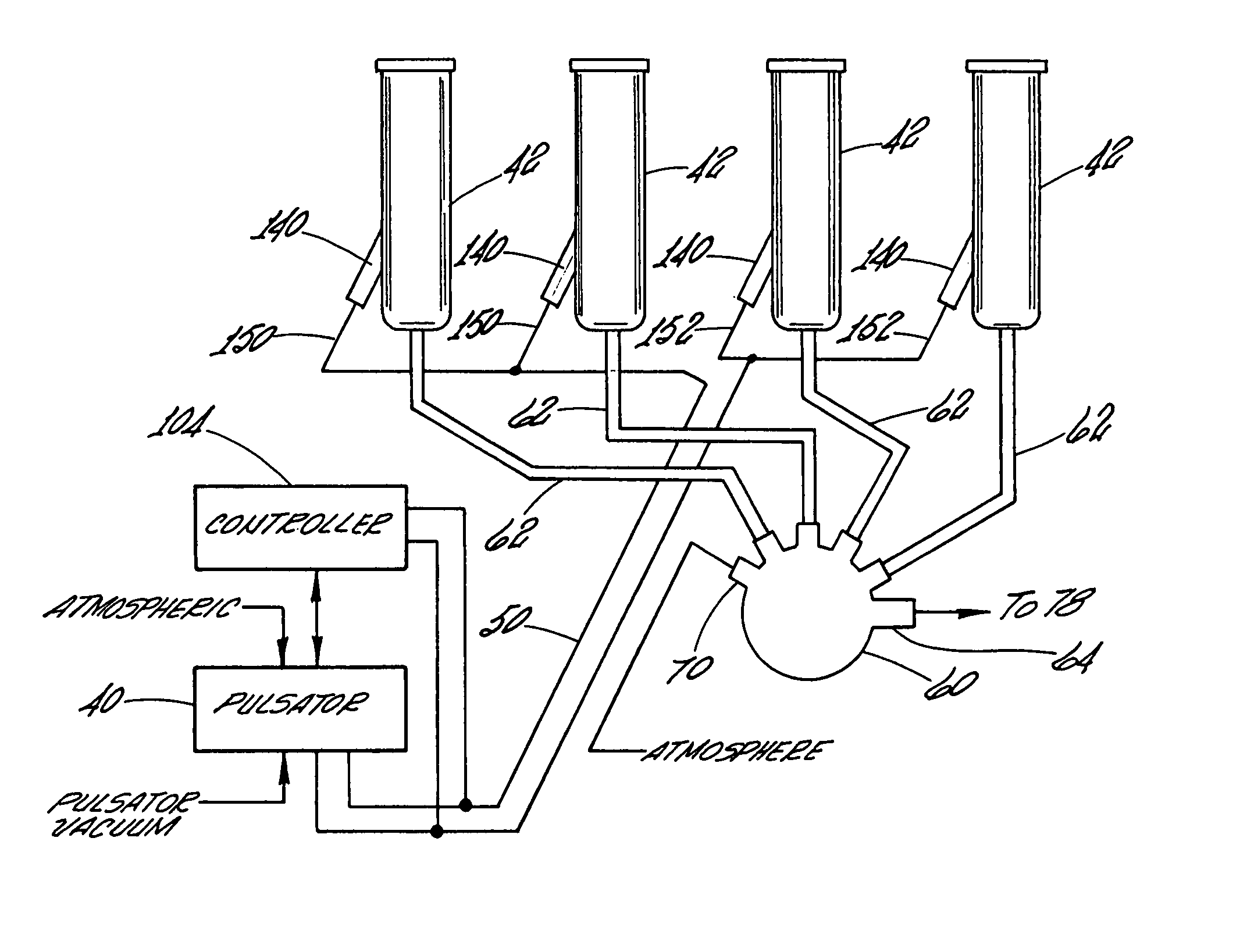

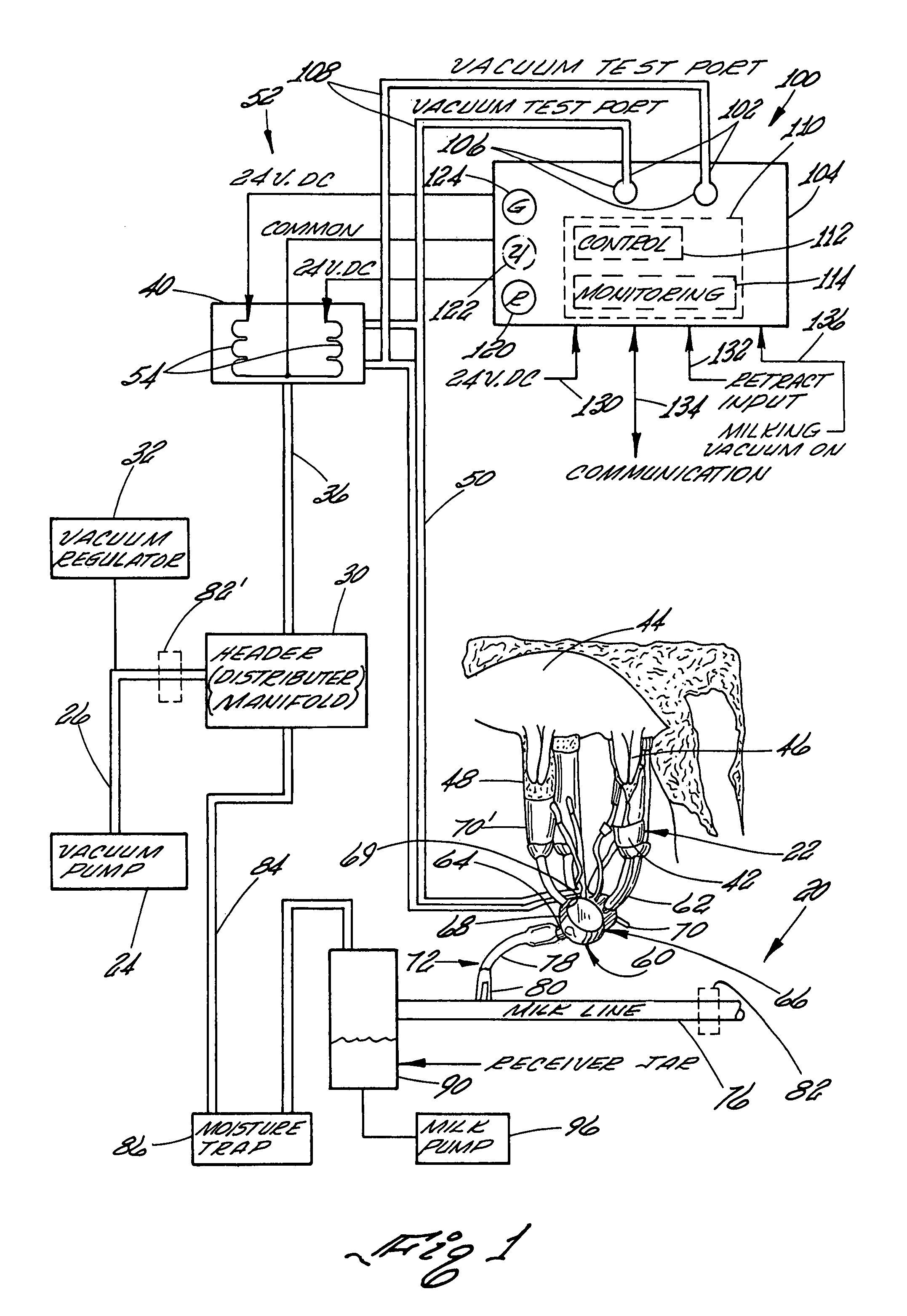

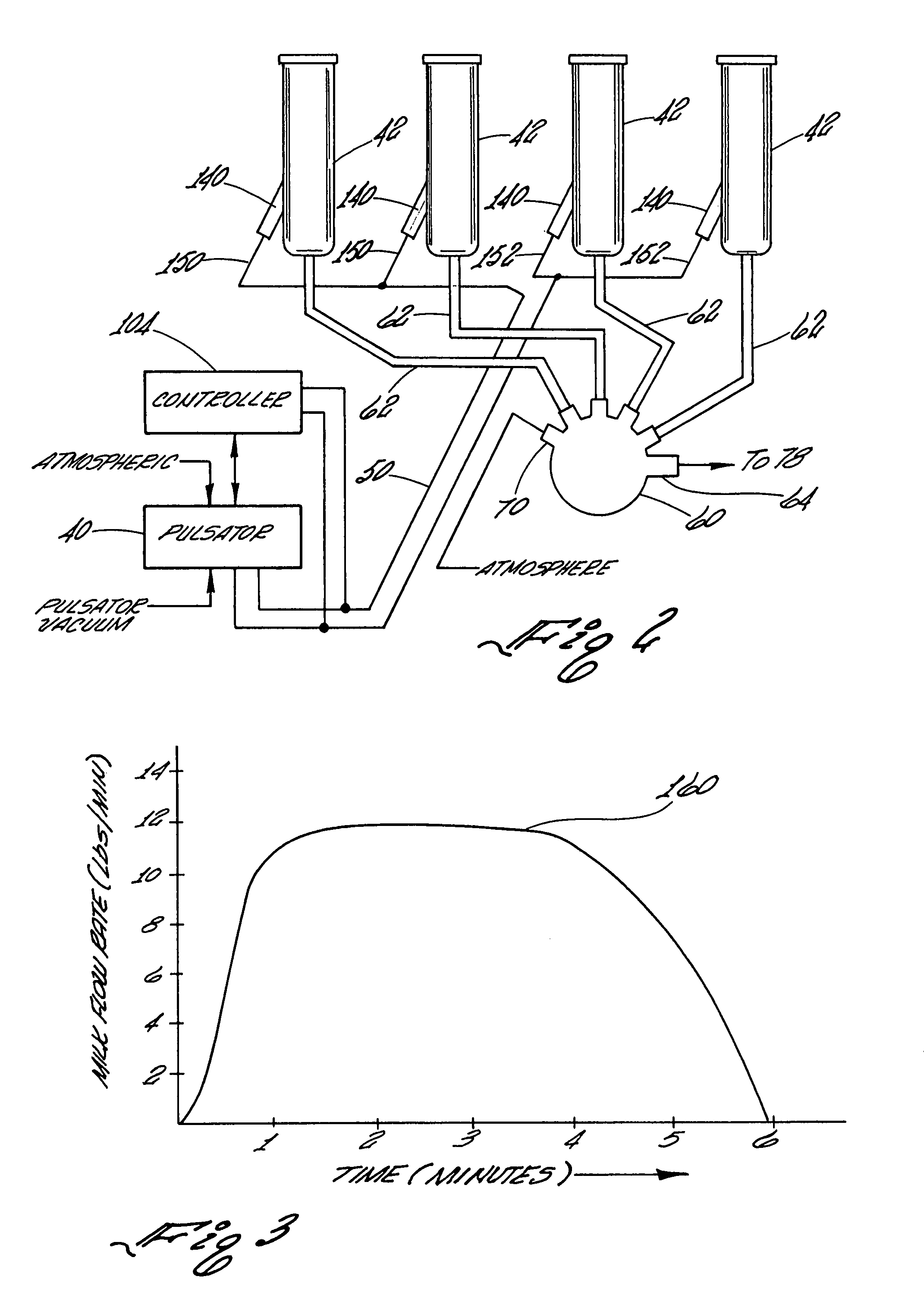

Controller for monitoring and controlling pulsators in a milking system

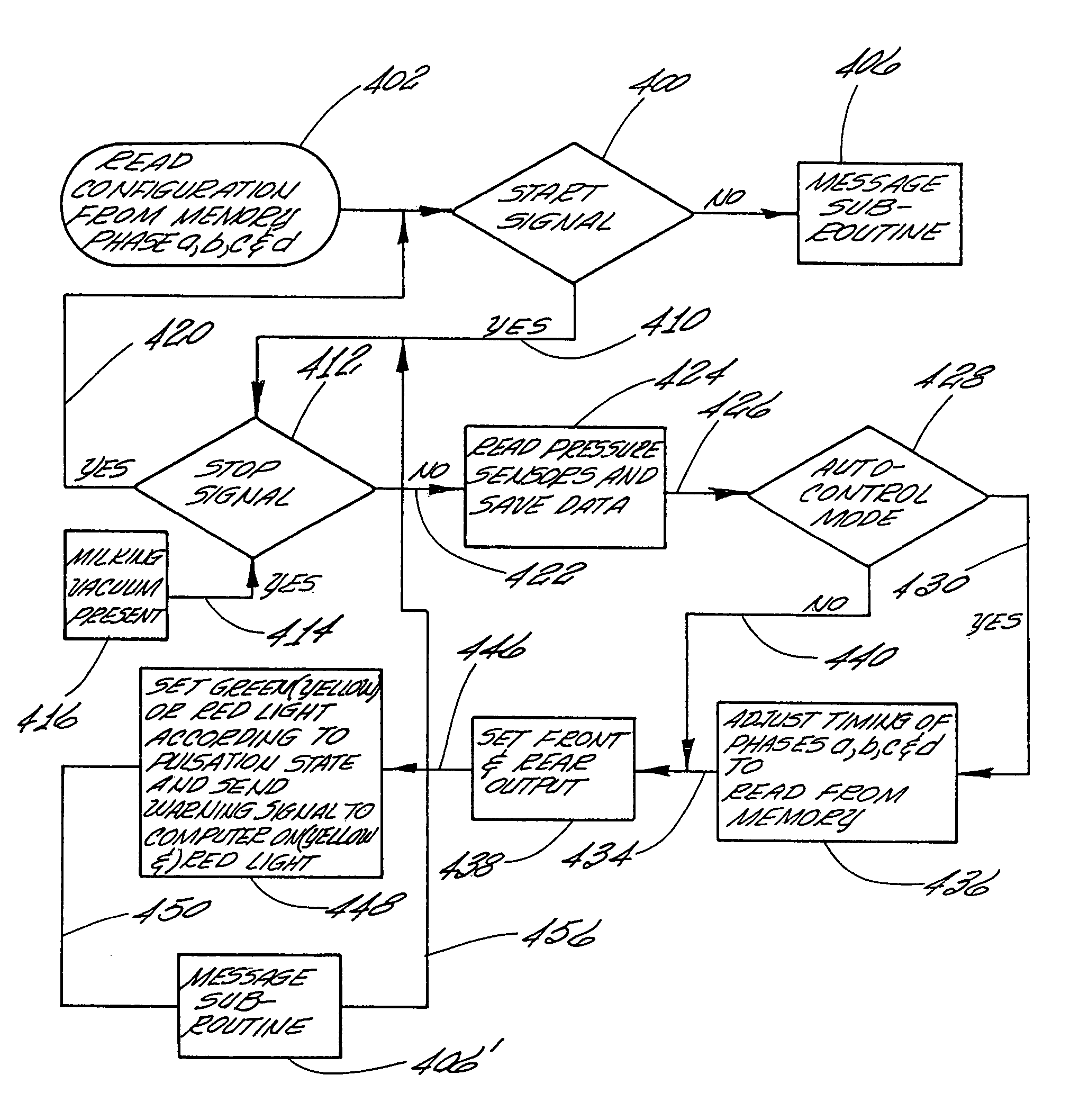

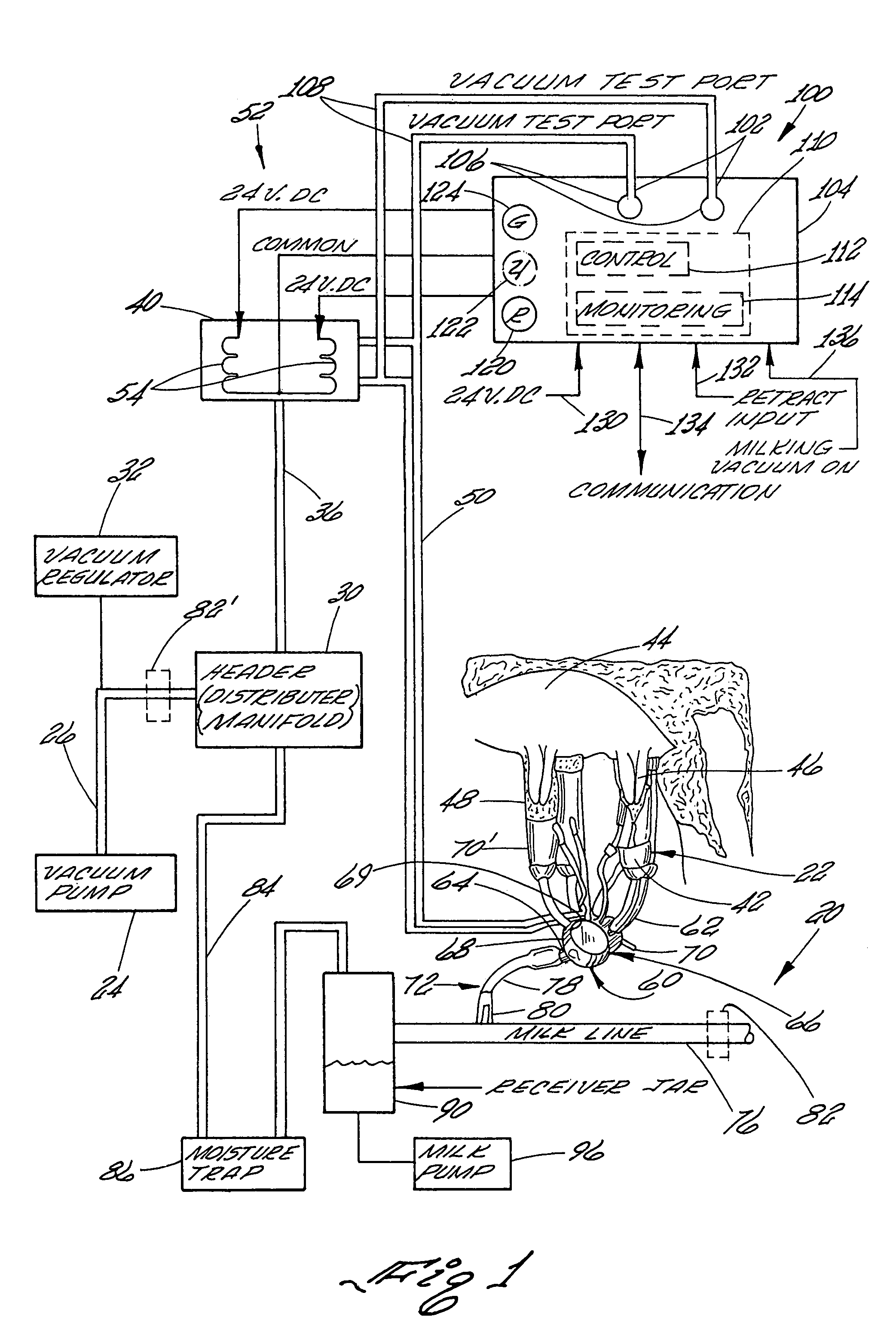

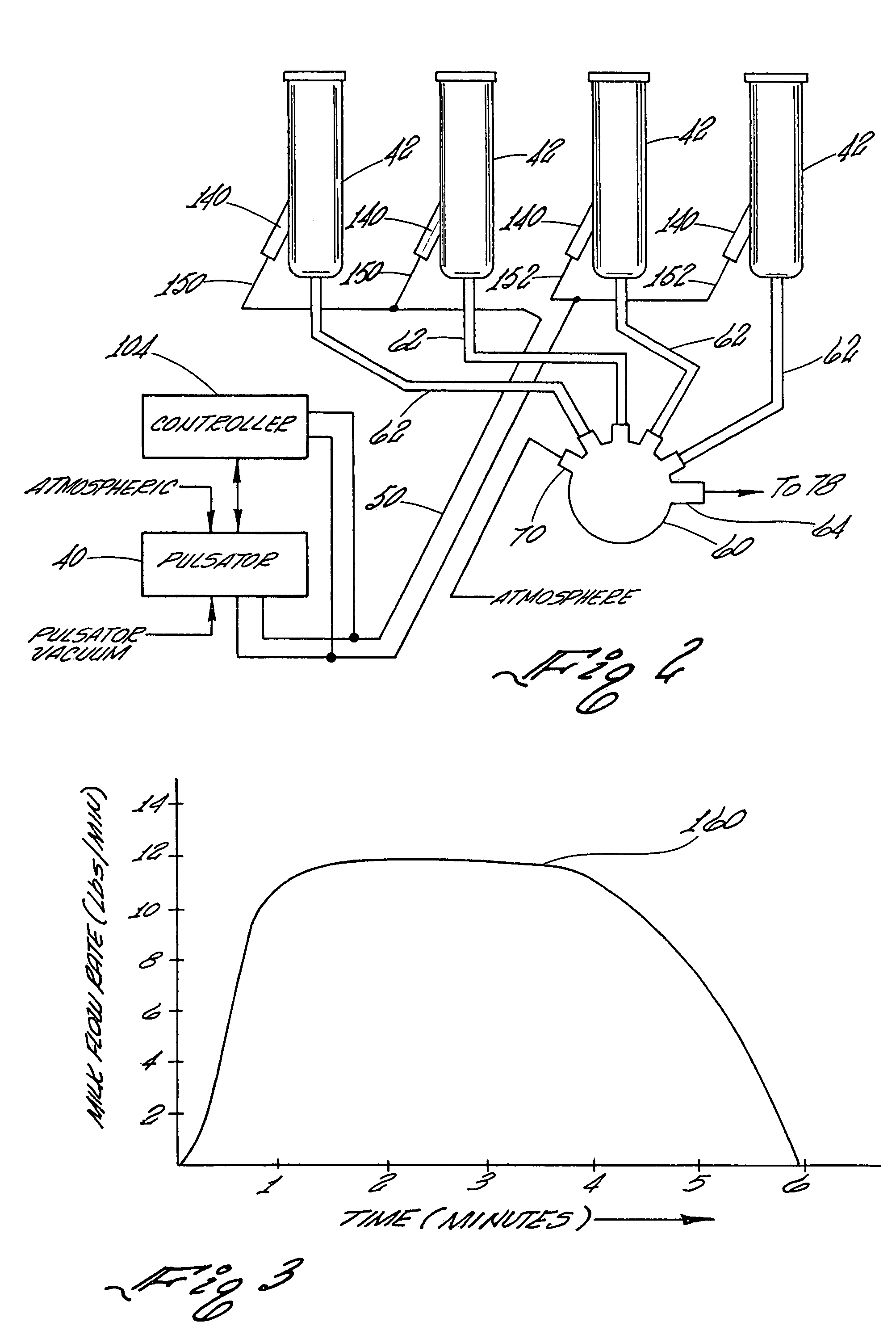

A controller for monitoring and controlling an operating pulsator in a milking system is shown. The controller comprises a first sensor operatively connected to a designated pulsator for receiving a pulsating vacuum therefrom. The controller produces a first signal representing the pulsating vacuum level. A processor is operatively connected to the first sensor for receiving the first signal. The processor includes a comparator for comparing the first signal to a stored reference signal representing a predetermined vacuum range of pulsating vacuum levels programmed as acceptable for milking systems pulsators. The processor generates at least one control signal when the designated pulsator pulsating vacuum level is at a vacuum level outside of the predetermined vacuum range. A control circuit signals that the designated pulsator pulsating vacuum level is outside the range of pulsating vacuum levels programmed as acceptable for the milking system pulsators.

Owner:TECH HLDG

Controller for monitoring and controlling pulsators in a milking system

A controller for monitoring and controlling an operating pulsator in a milking system is shown. The controller comprises a first sensor operatively connected to a designated pulsator for receiving a pulsating vacuum therefrom. The controller produces a first signal representing the pulsating vacuum level. A processor is operatively connected to the first sensor for receiving the first signal. The processor includes a comparator for comparing the first signal to a stored reference signal representing a predetermined vacuum range of pulsating vacuum levels programmed as acceptable for milking systems pulsators. The processor generates at least one control signal when the designated pulsator pulsating vacuum level is at a vacuum level outside of the predetermined vacuum range. A control circuit signals that the designated pulsator pulsating vacuum level is outside the range of pulsating vacuum levels programmed as acceptable for the milking system pulsators.

Owner:TECH HLDG

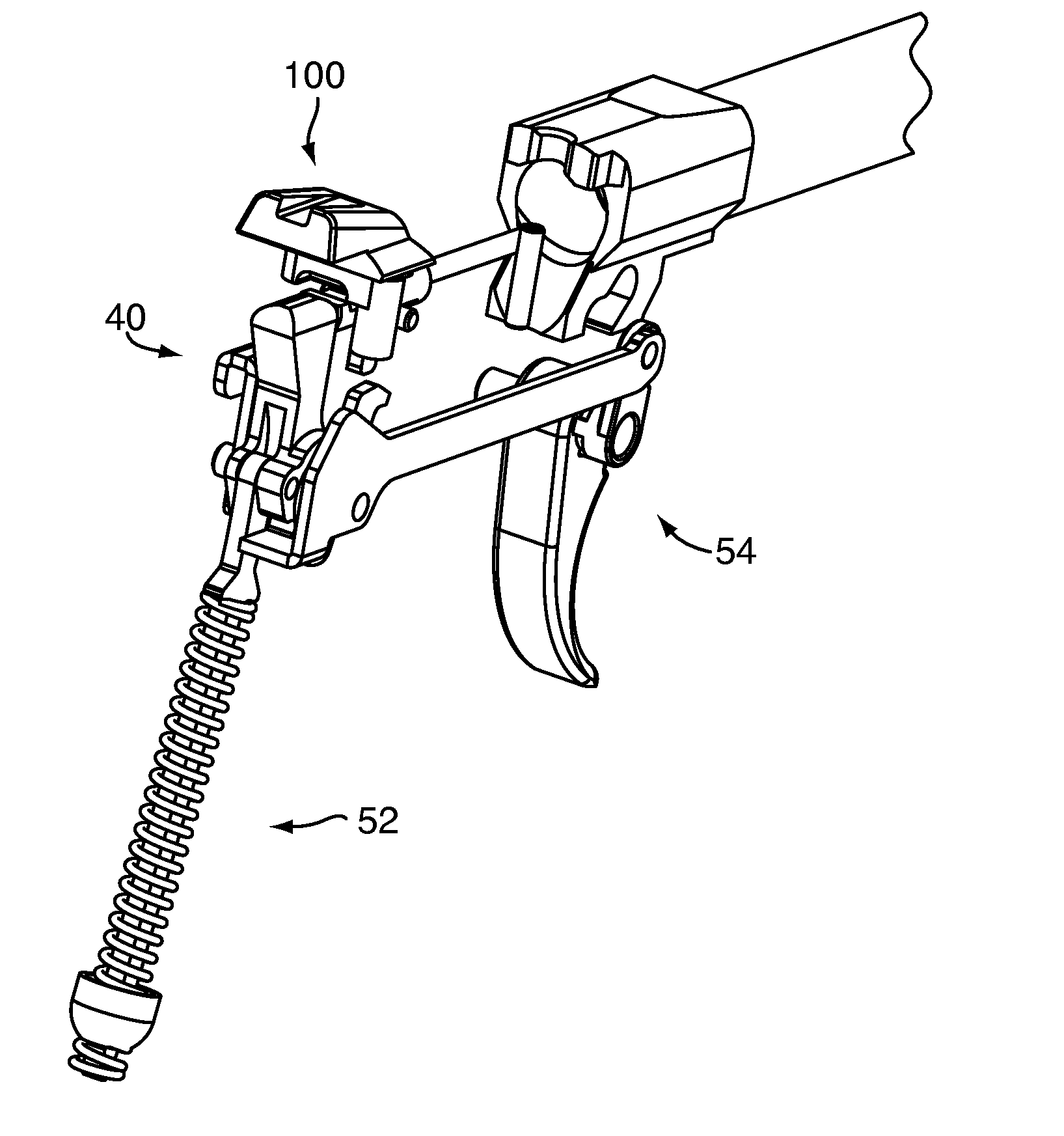

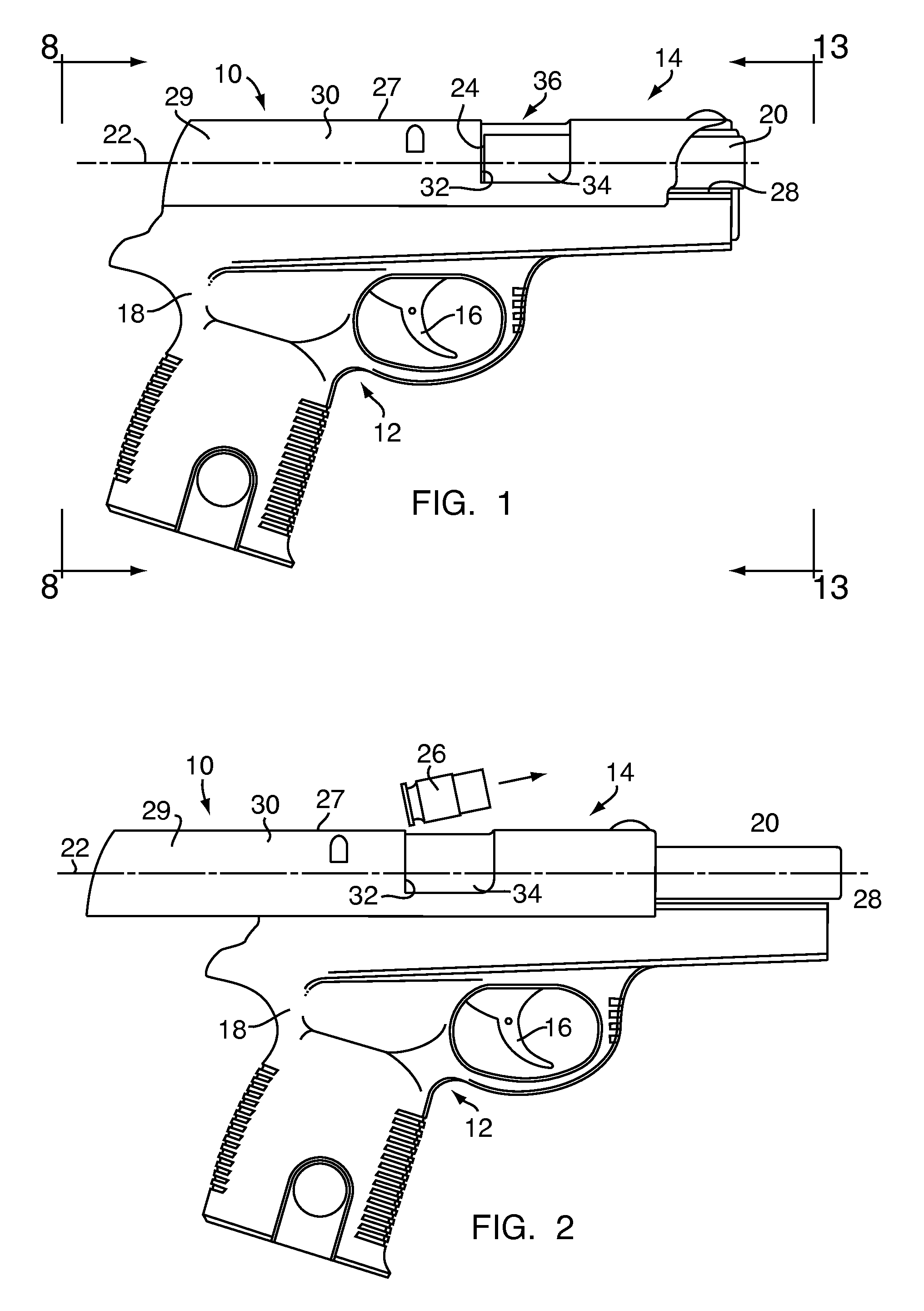

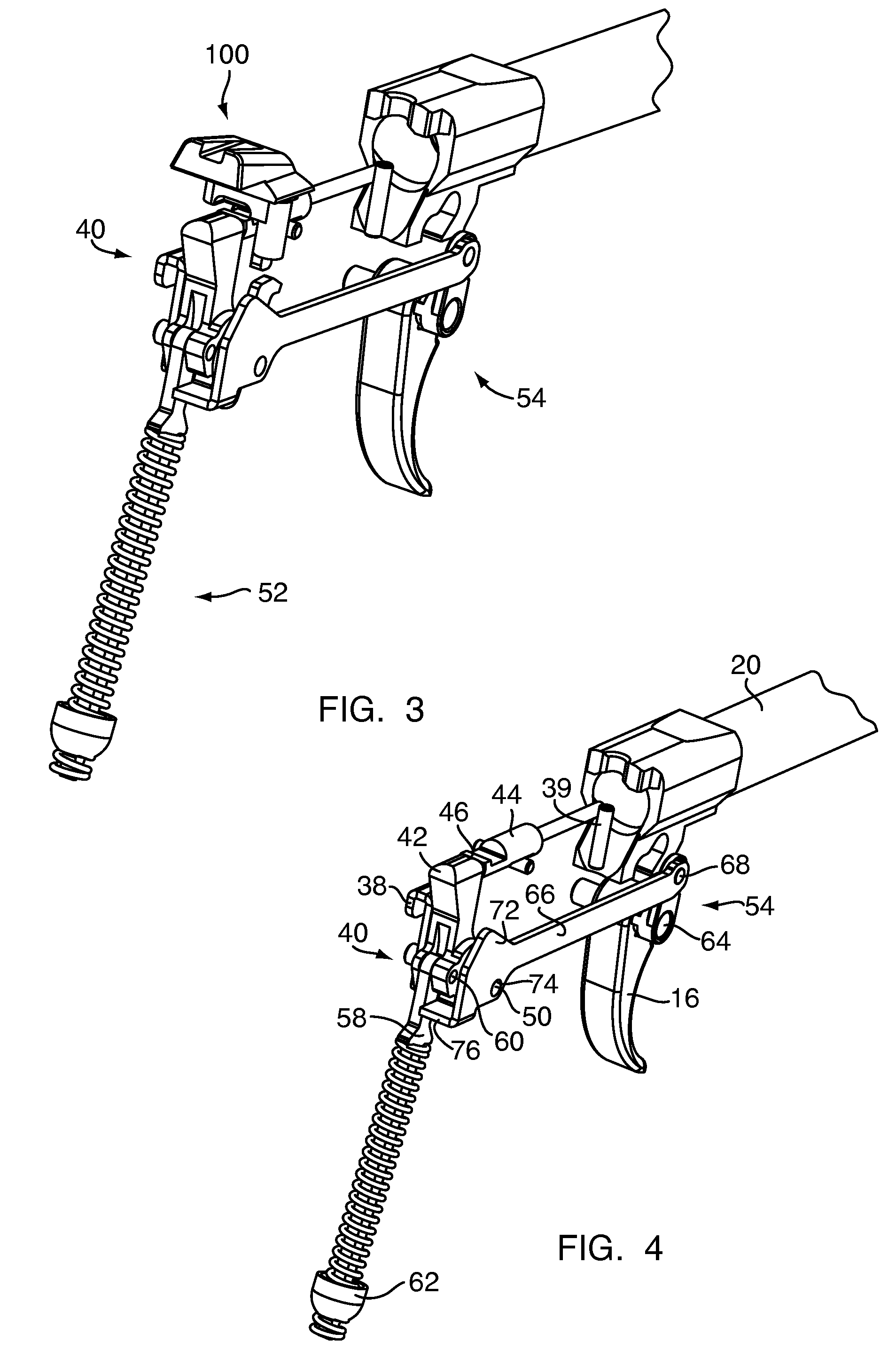

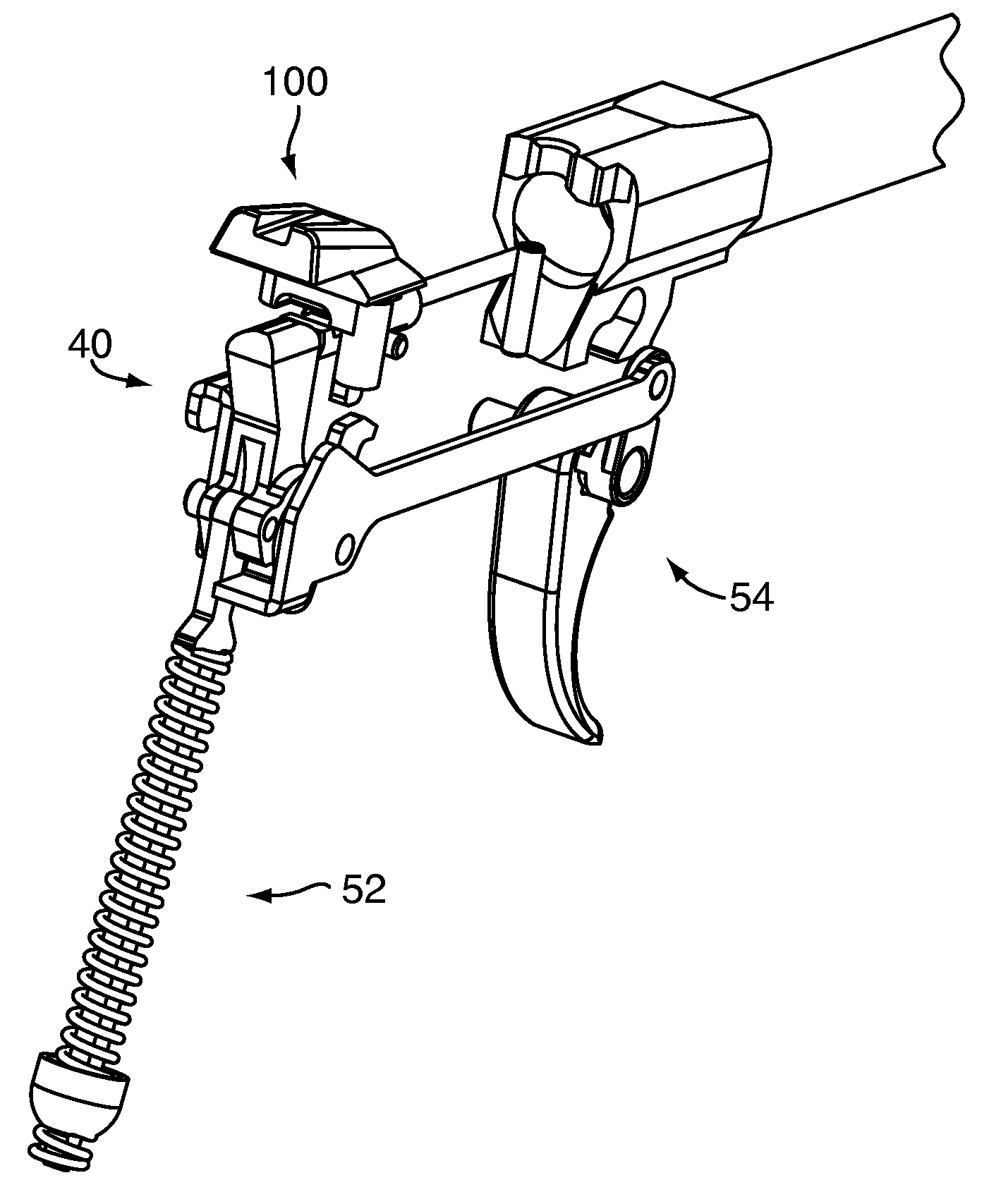

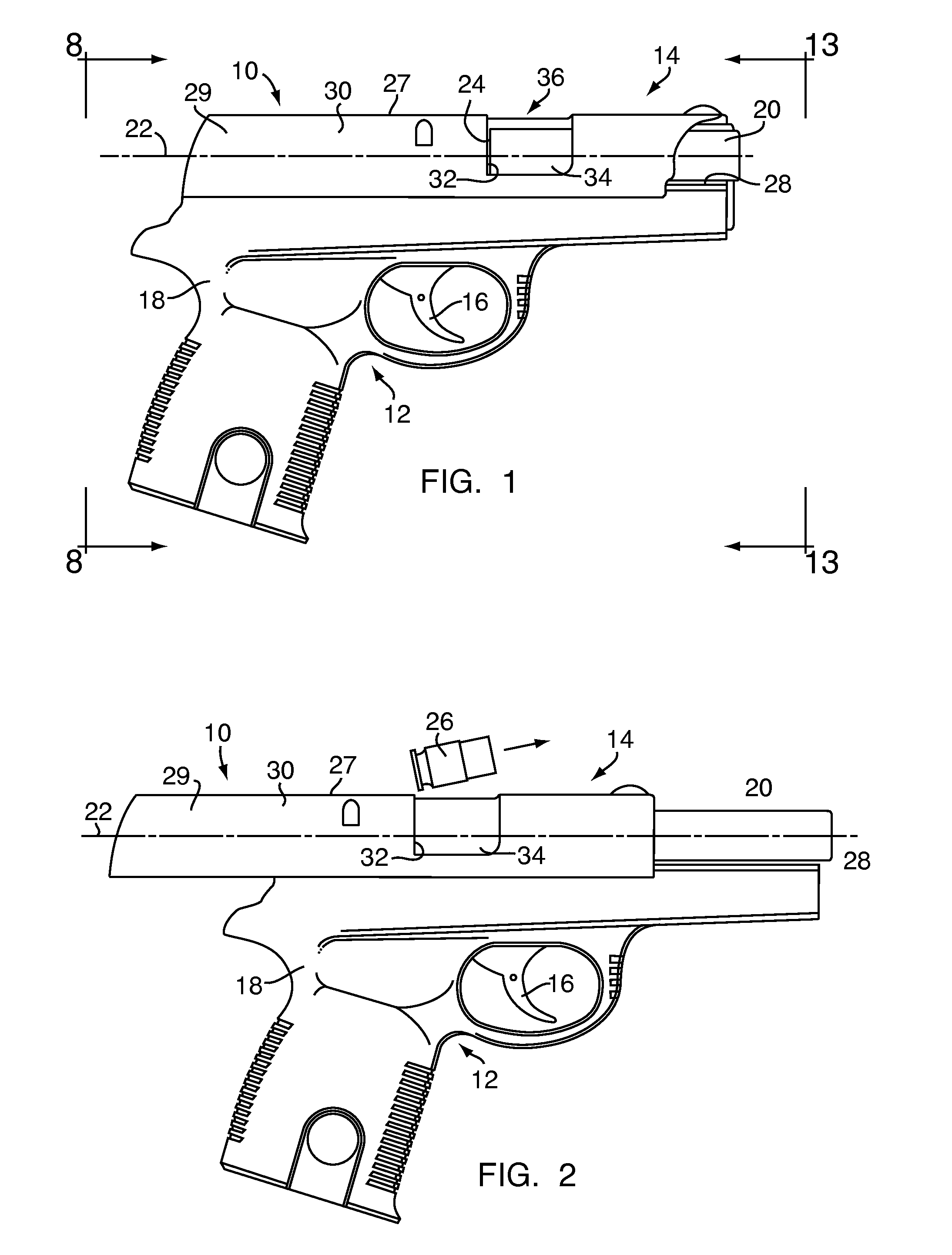

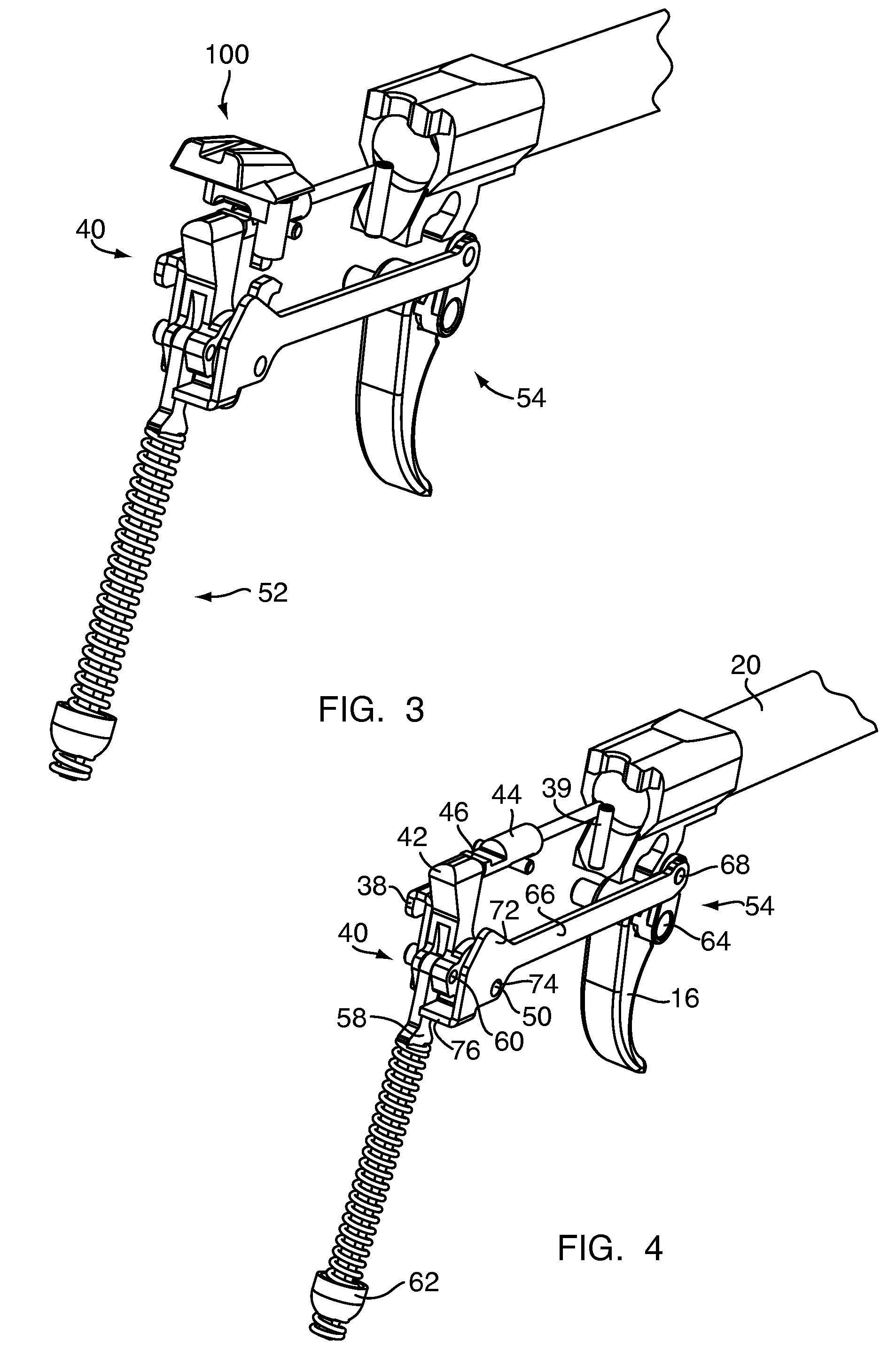

Automatic firing pin block safety for a firearm

Owner:SMITH & WESSON

Controlling for monitoring and controlling pulsators in a milking system

A controller for monitoring and controlling an operating pulsator in a milking system is shown. The controller receives a start signal generated when a milking apparatus is attached to a cow. A first sensor is operatively connected to a designated pulsator for receiving a pulsating vacuum and for producing a first signal representing the pulsating vacuum level. The controller includes a processor having a comparator for comparing the first signal to a stored reference of predetermined vacuum ranges and for generating a control signal when the designed pulsator pulsating vacuum level is outside of a predetermined vacuum range. A control circuit signals that the designated pulsator pulsating vacuum level is outside of the predetermined vacuum range.

Owner:TECH HLDG

Automatic firing pin block safety for a firearm

A firearm has a frame, a trigger, a trigger bar, a hammer-type firing mechanism including a hammer having a hammer pin connected to the trigger via the trigger bar and a firing pin, and an automatic firing pin block safety mechanism (“automatic safety”) including a flange that is spring biased into engagement with the firing pin and a pivot lock arm rotatably mounted to the hammer pin and releasable engageable with the flange. The flange blocks the firing pin from discharging a chambered round unless and until the trigger is positively actuated. The automatic safety reduces the risk of accidental discharge, thereby rendering the firearm safer.

Owner:SMITH & WESSON

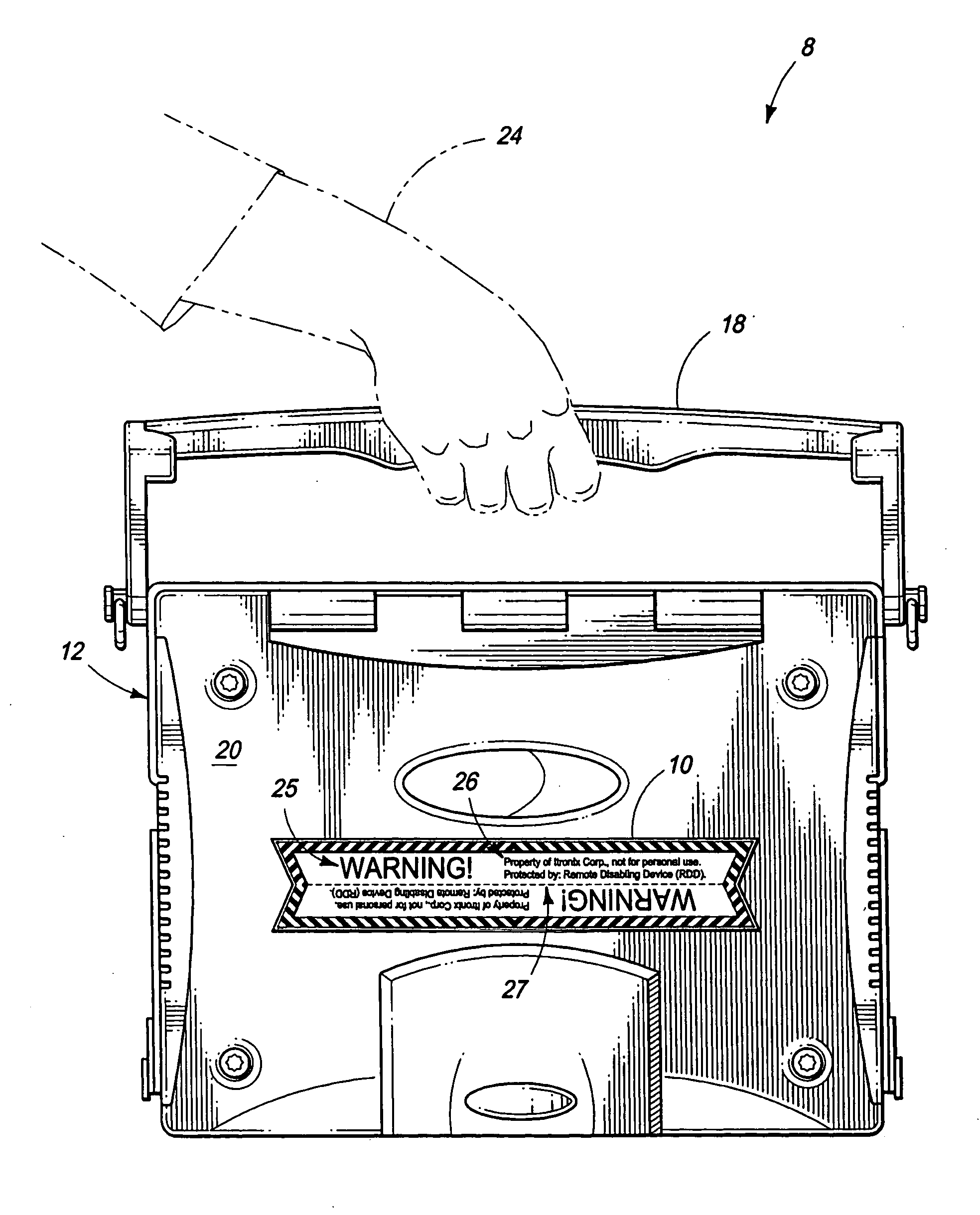

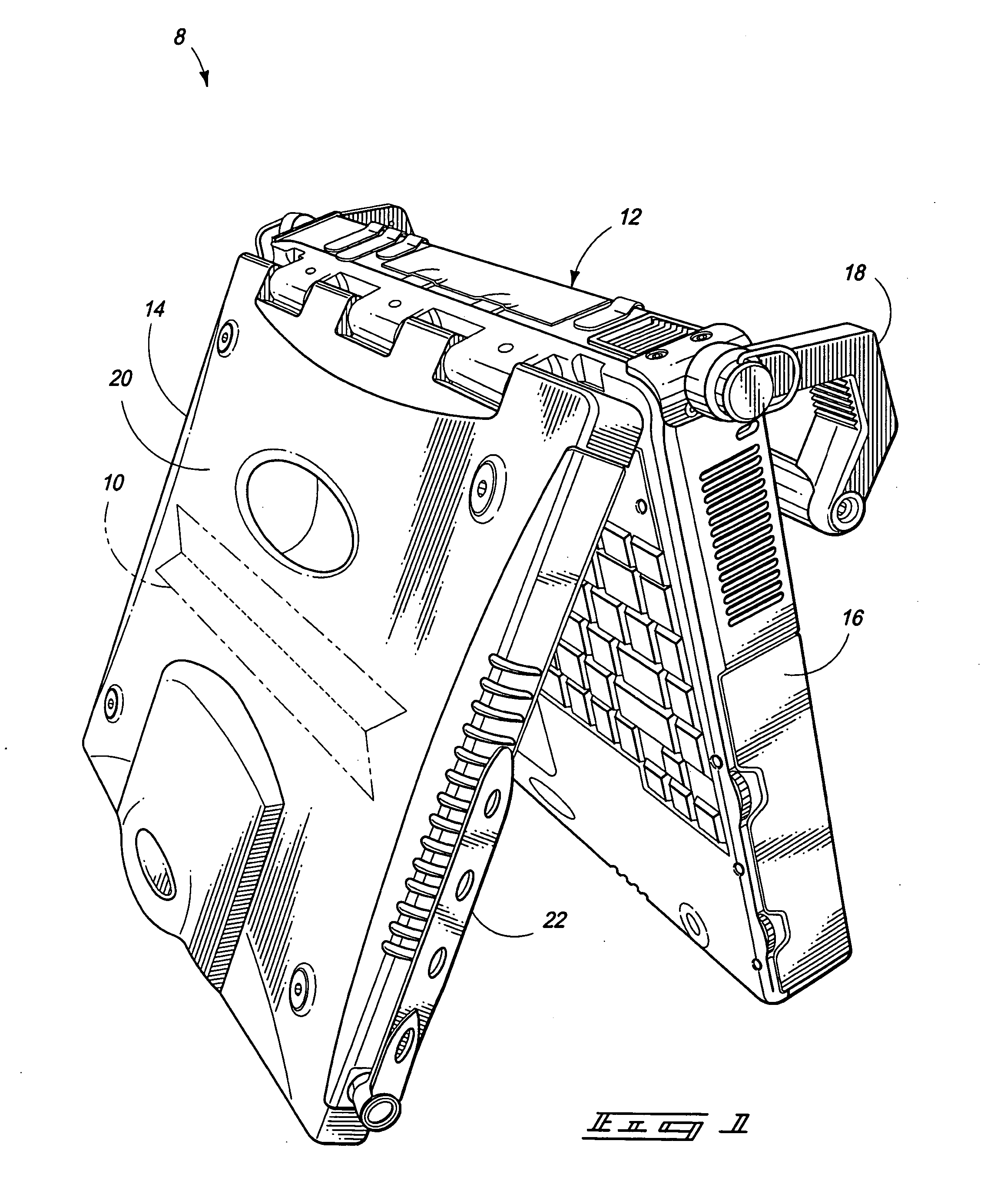

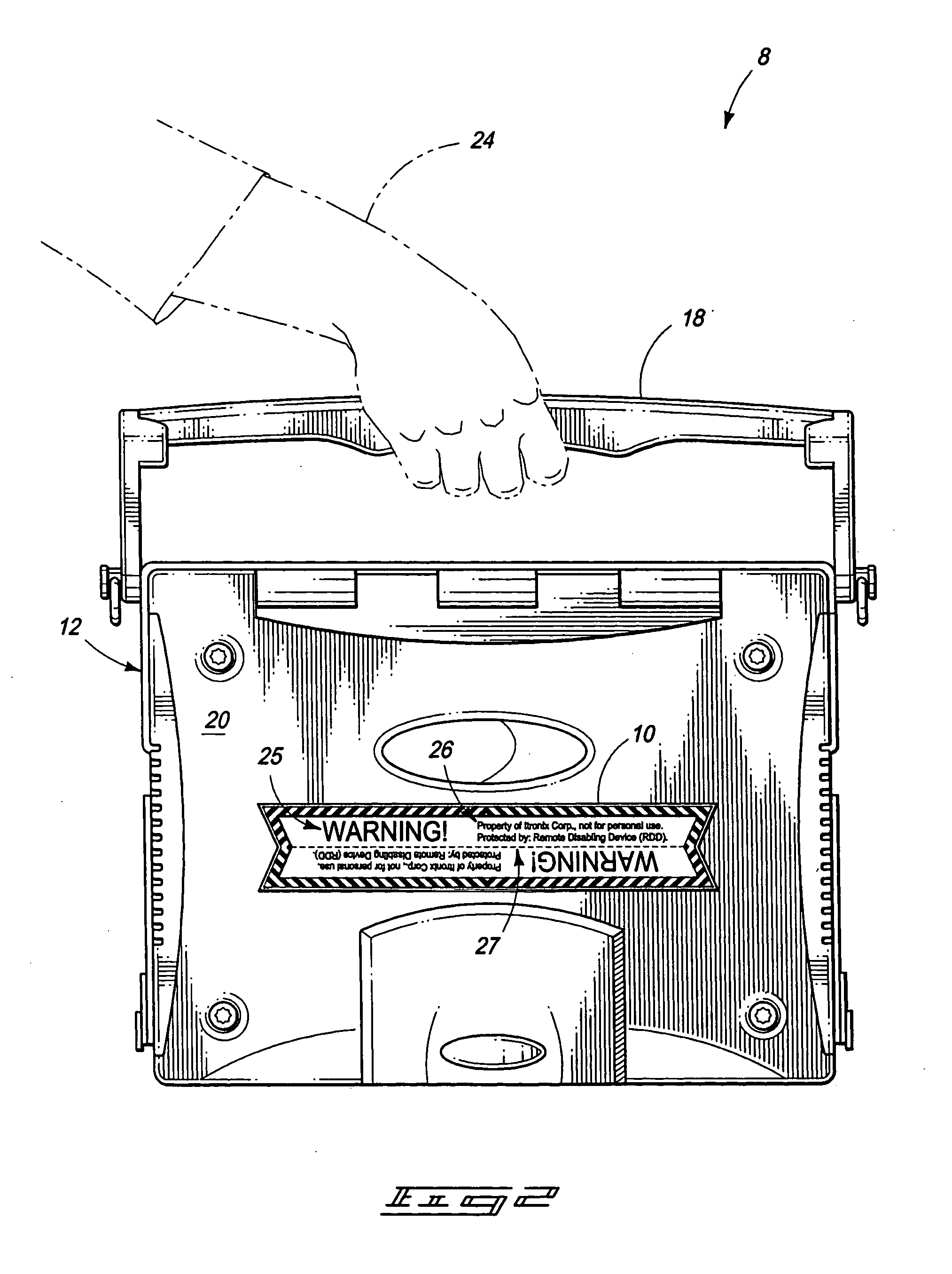

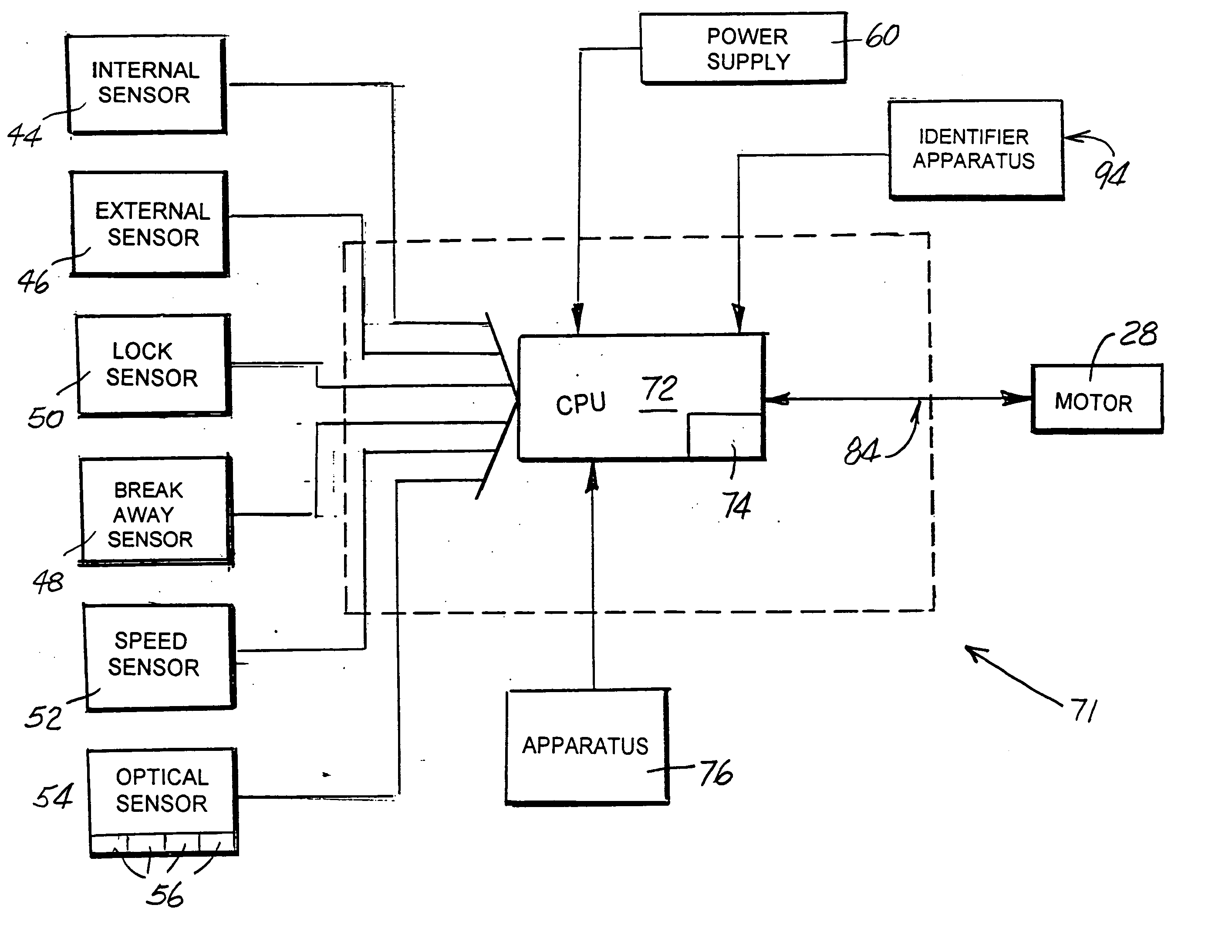

Theft deterrence system for a portable computer and method

InactiveUS20070030149A1Operation is disabledStop theftInternal/peripheral component protectionBurglar alarm by hand-portable articles removalEmbedded systemVisual perception

A theft deterrence system is provided for a portable computer. The system includes a portable computer, a theft. deterrence label, a sensor, and circuitry. The theft deterrence label is provided on the portable computer at a visually perceptible location and has indicia that visually alert a reader to deter theft of the computer. The sensor is carried by the portable computer and is configured to enable detection of removal of the label from the portable computer. The circuitry communicates with the sensor and is configured to receive an alert signal from the sensor responsive to removal of the label from the portable computer. The circuitry also disables a functionality component of the computer responsive to the alert signal. A method is also provided.

Owner:ITRONIX CORP

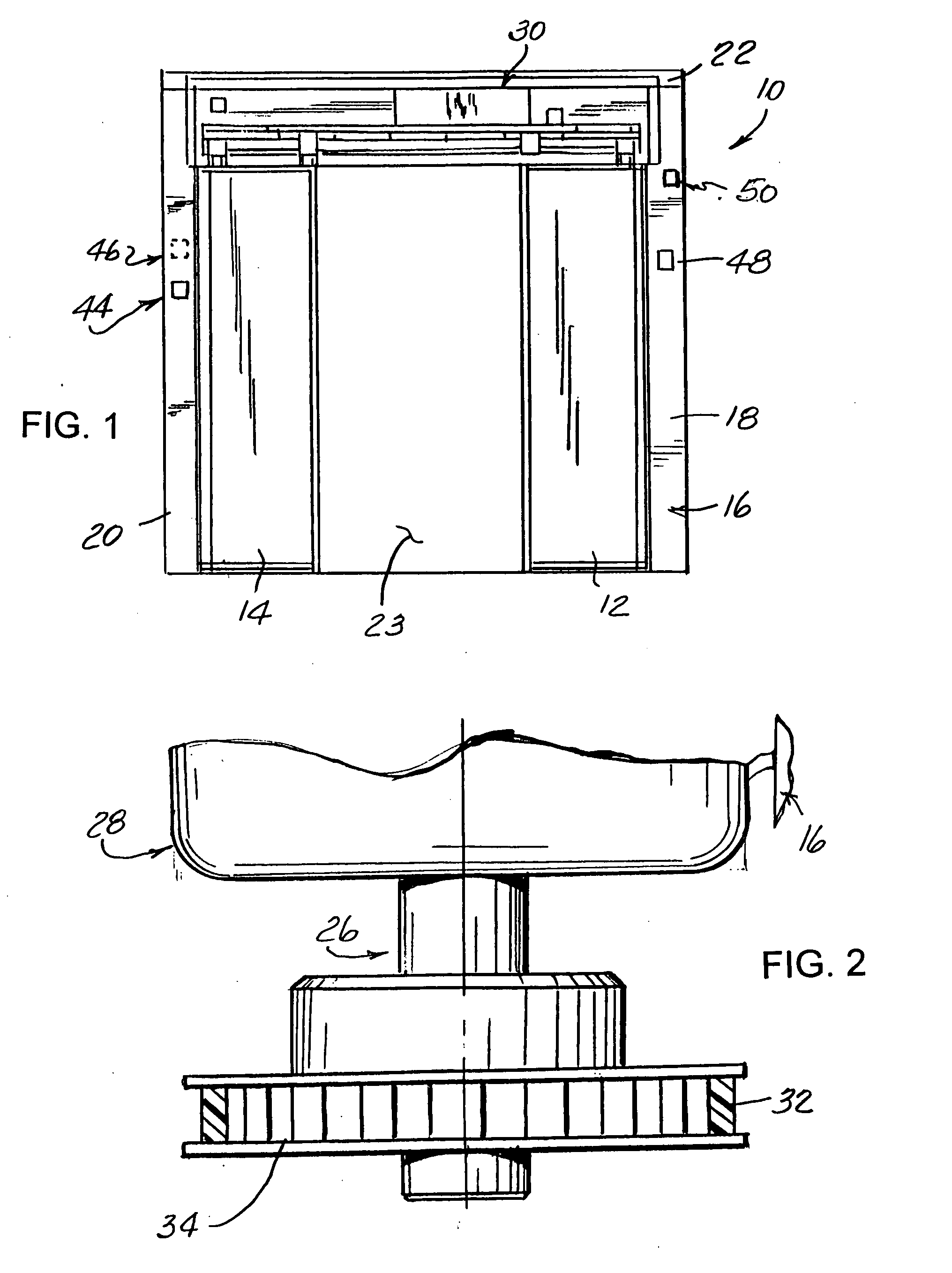

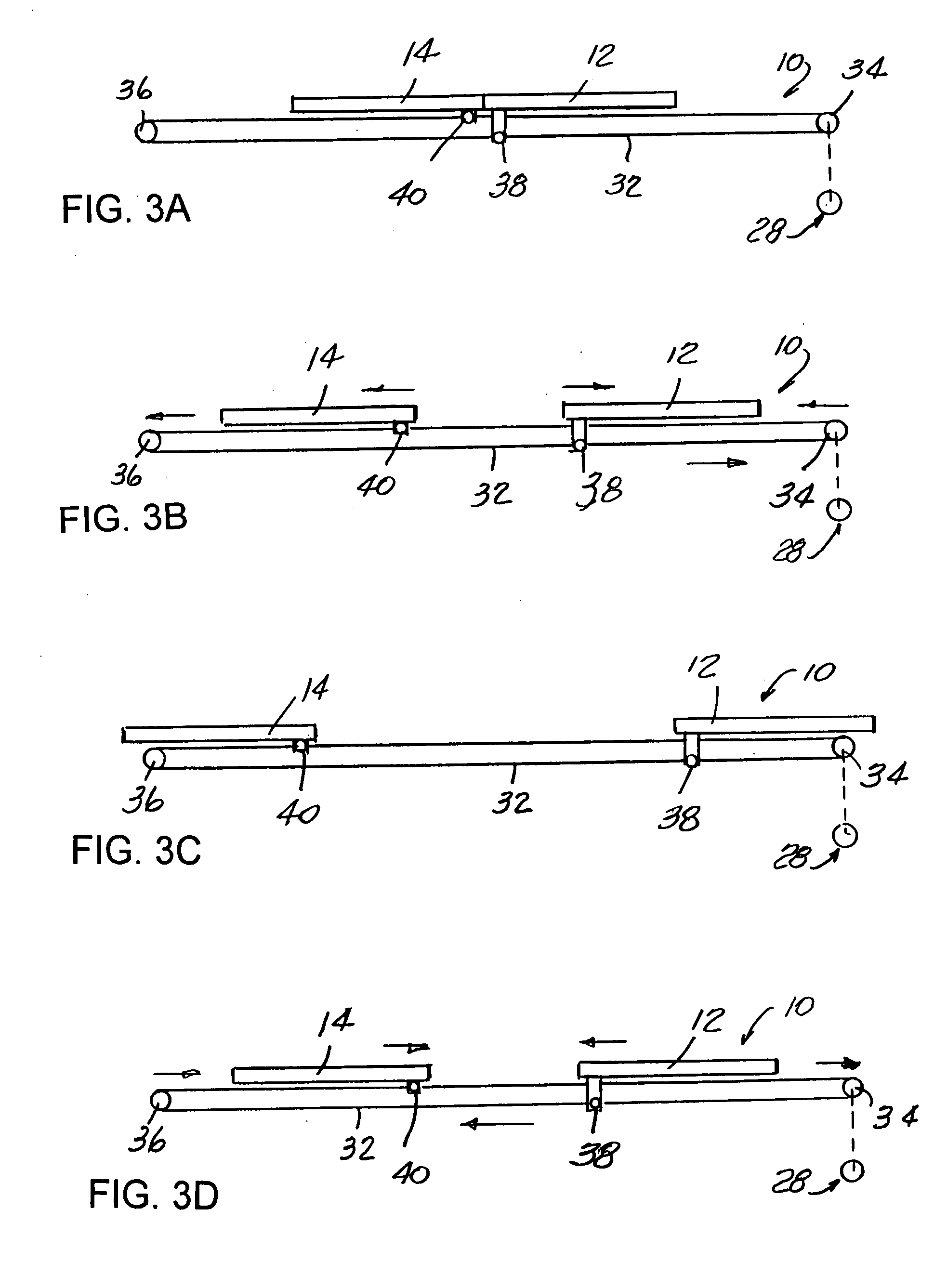

Universal controller for automatic door systems

ActiveUS20070108927A1Shorten the timeOperation is disabledVehicle testingDC motor speed/torque controlAutomatic controlModularity

A universal controller for an automatic door system including a door carried on a frame for movement along a predetermined path of movement between open and closed positions. The universal controller includes a housing for mounting the controller in a stationary position relative to the door frame and an assembly including a processor carried by the housing for processing data operatively received from a plurality of sensors and relating to the operation of the movable door. The processor is configured to generate operational values which are transmitted to and control a drive motor used to move the door between the open and closed positions. The assembly further includes an arrangement for adjusting the operational values generated by the processor and transmitted to the drive motor. A modular harness connects the controller to the drive motor and to the sensors. An apparatus operably coupled to the modular harness identifies the particular drive motor and sensors used in combination with the automatic door system. A method for automatically controlling operation of an automatic door system having at least one door movable between open and closed positions in response to operation of an output drive of a bi-directional drive motor is also provided.

Owner:MOTIONACCESS

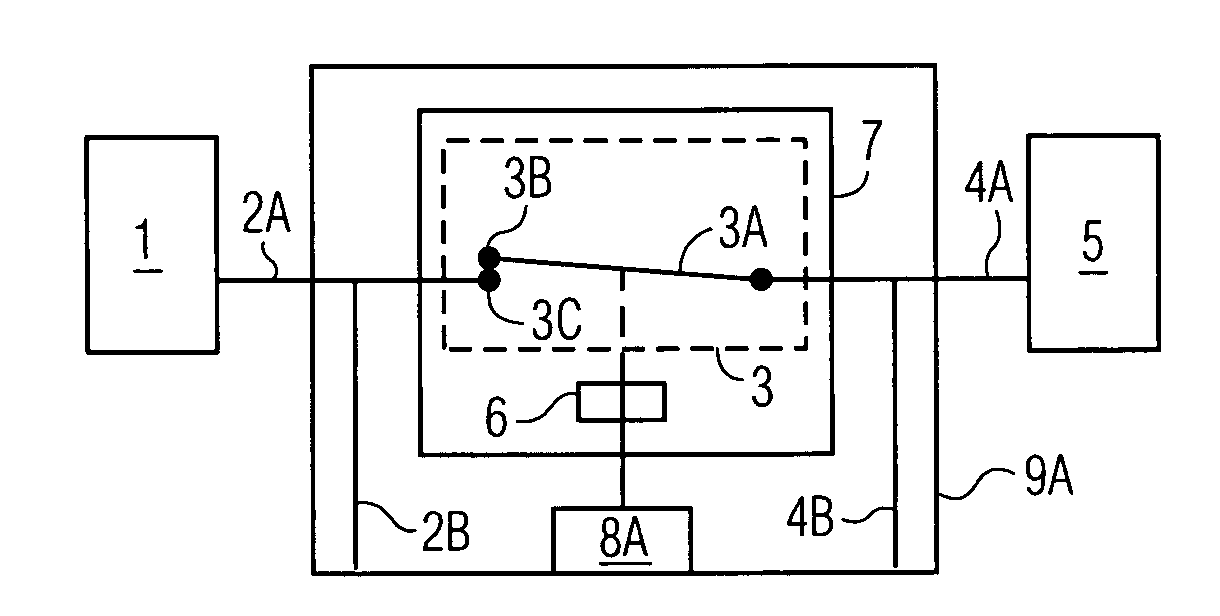

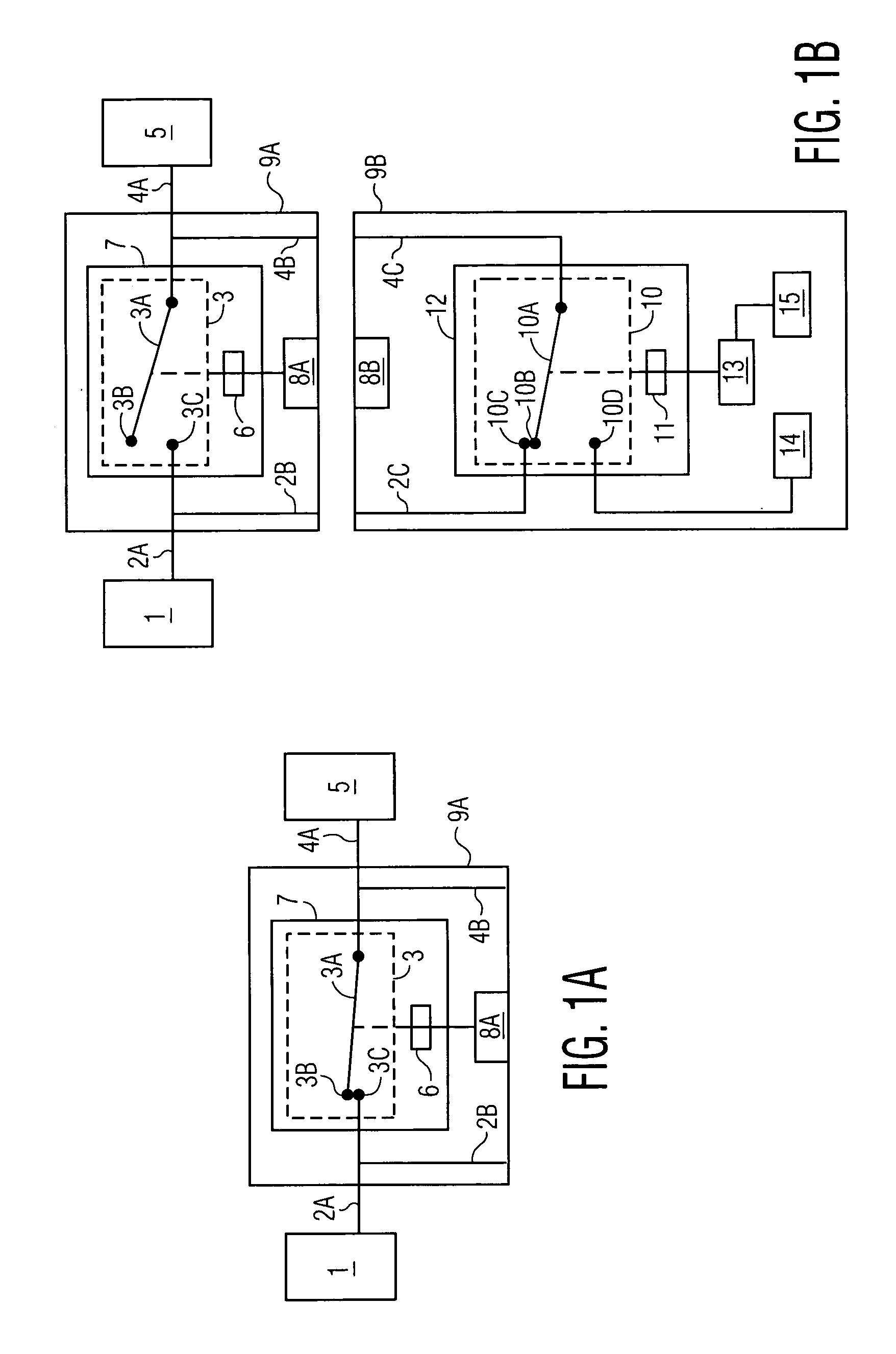

Modular construction of an aircraft control system

ActiveUS20070029449A1Easy to upgradeThe process is convenient and fastAnalogue computers for vehiclesAircraft stabilisationControl signalControl system

Apparatus is disclosed for disabling on-board pilot operation of an aircraft and transferring aircraft operation to an alternate source of control. The aircraft has an aircraft control system for controlling at least one controlled component, such as an aircraft attitude control surface or an aircraft engine throttle. The apparatus is of modular construction, and includes two control modules. A first control module has an interruptible link that passes the first control signals from the control device to the aircraft control system. This first control module has a first connecting device for (i) interrupting the link and (ii) directing said first control signals to a second control module. The second control module is adapted to be connected to (e.g. plugged into) the first control module, and has a second connecting device. This connecting device is responsive to third control signals, for connecting one of (i) the first control signals received from the first control module and (ii) second control signals received from an alternate source of control, to the aircraft control system for control of the aforementioned controlled component.

Owner:KARL F MILDE JR

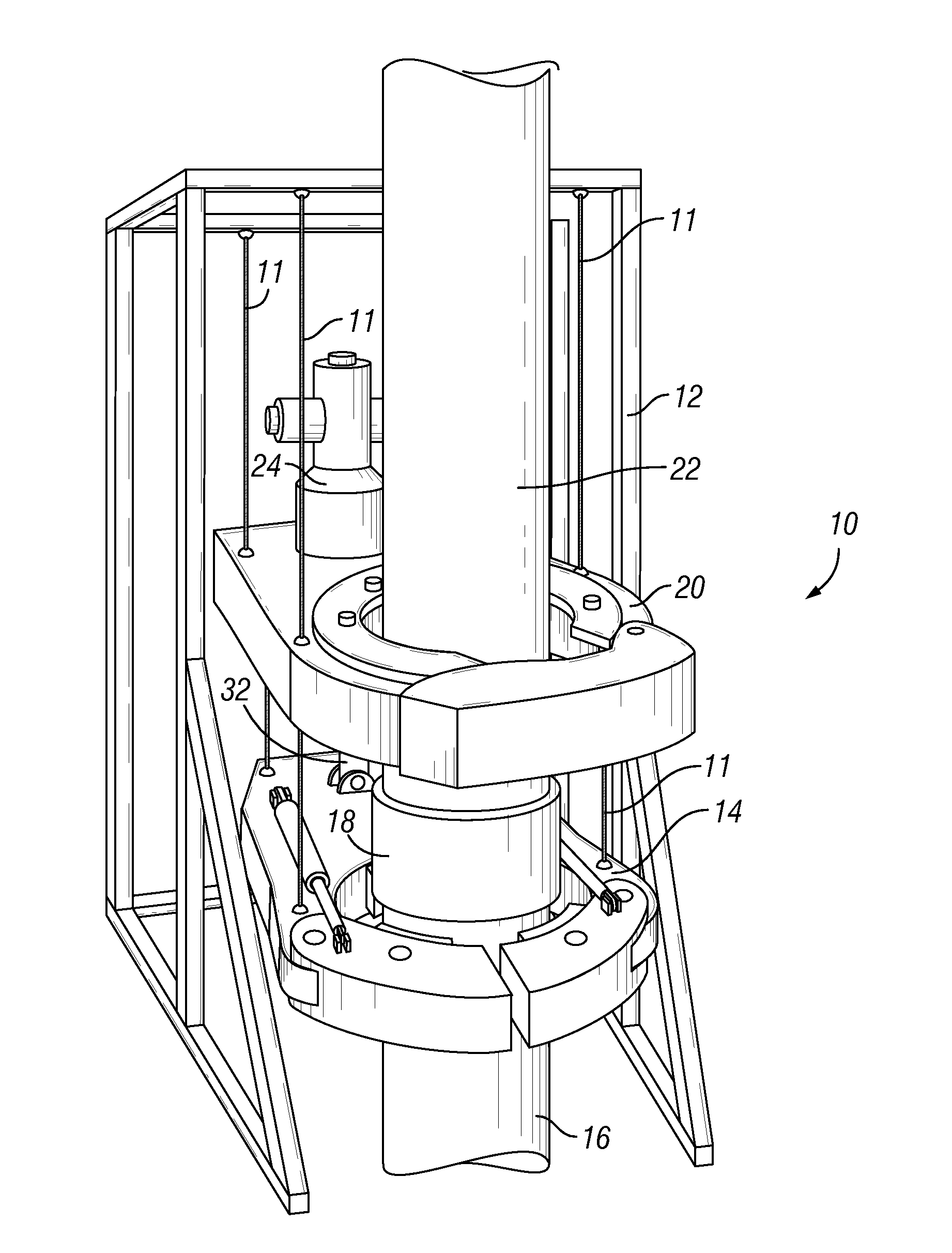

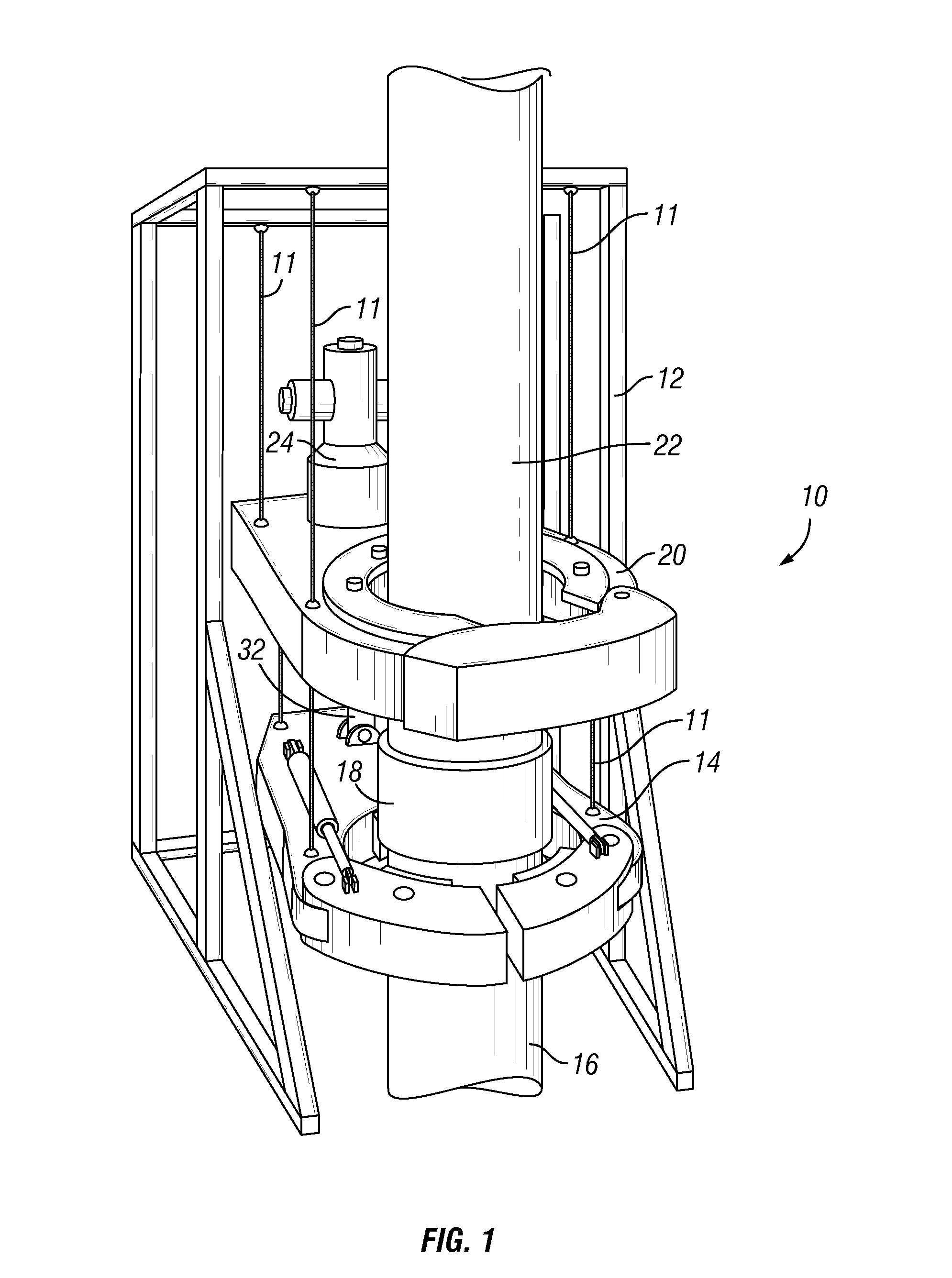

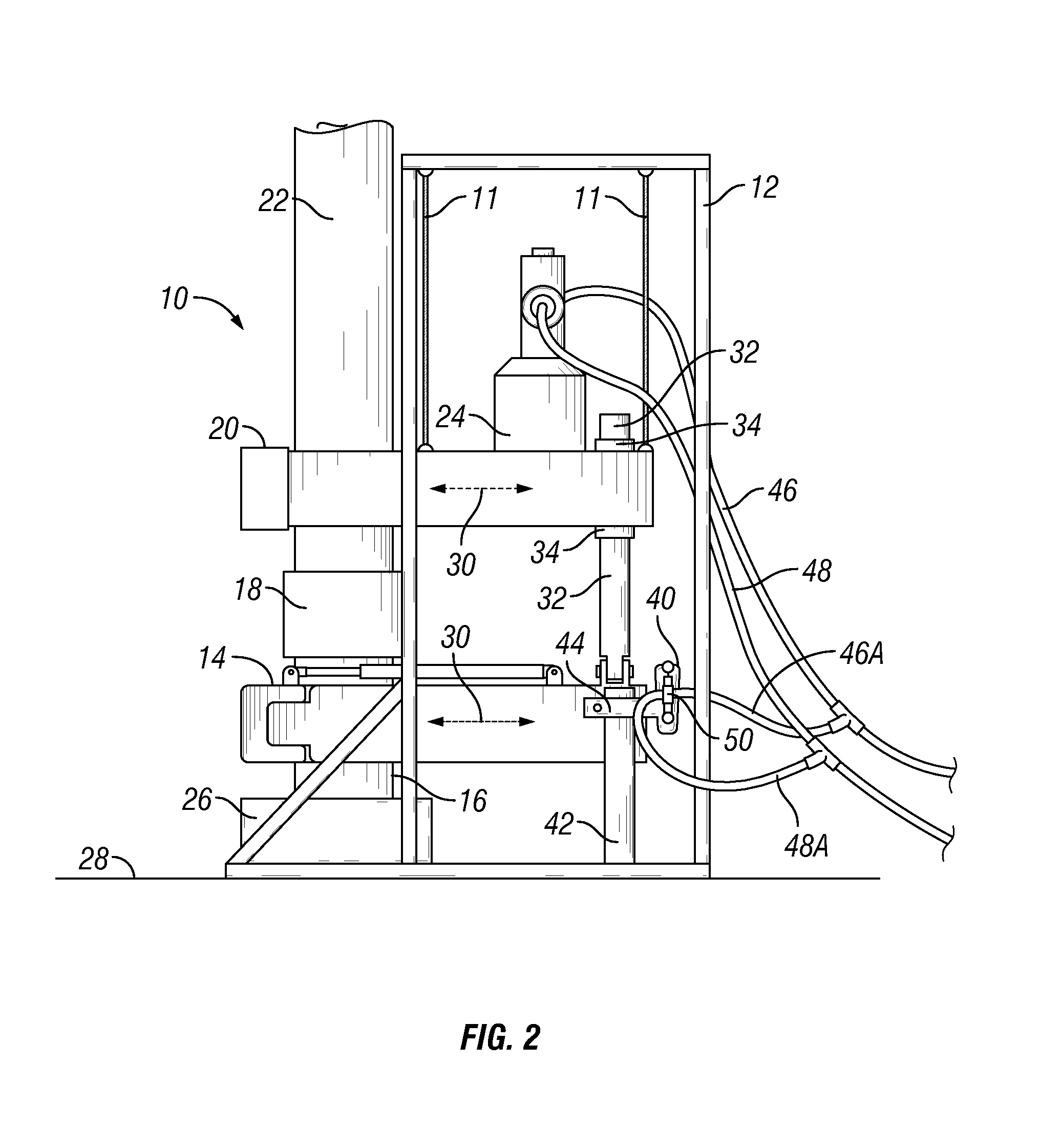

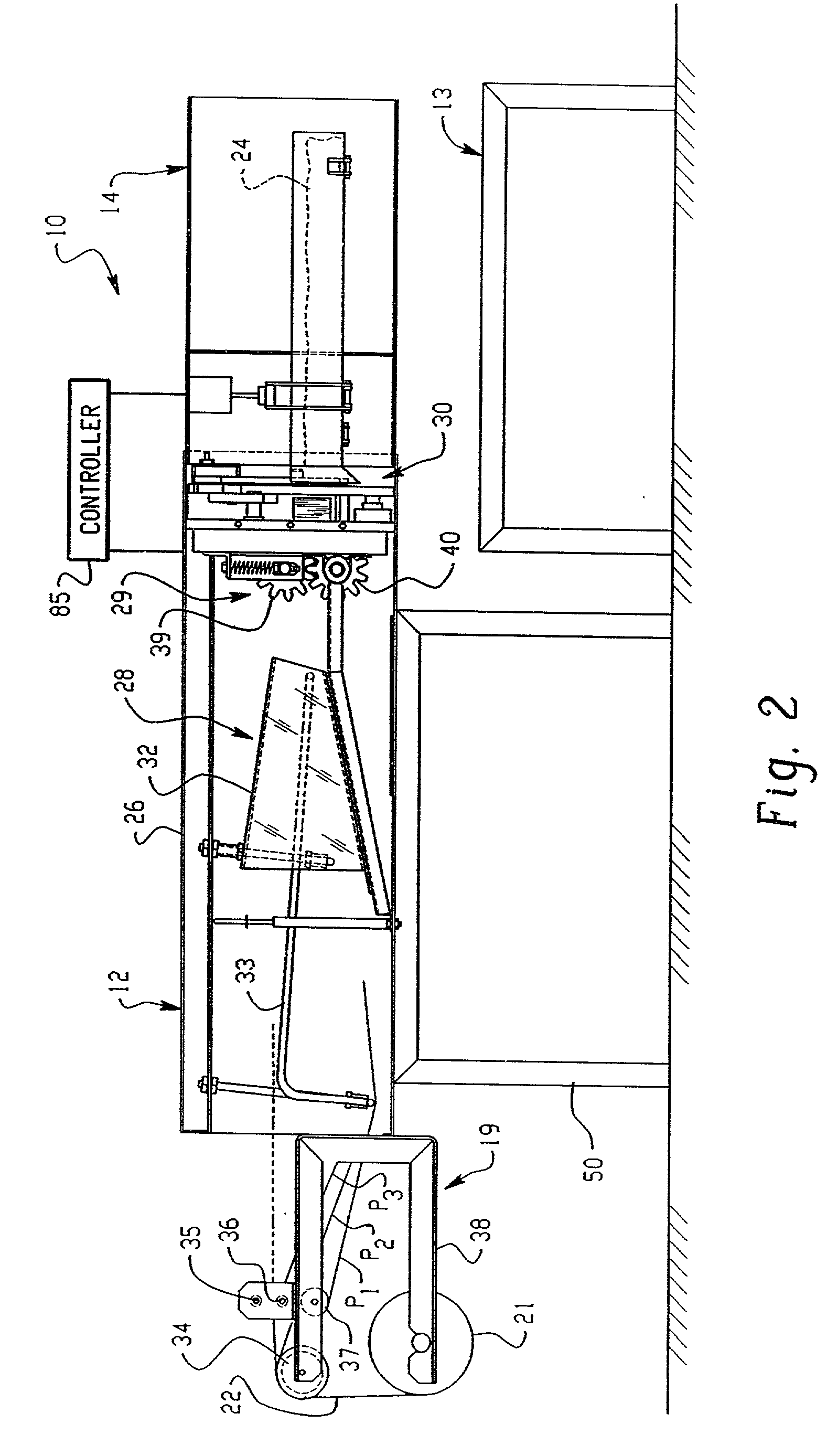

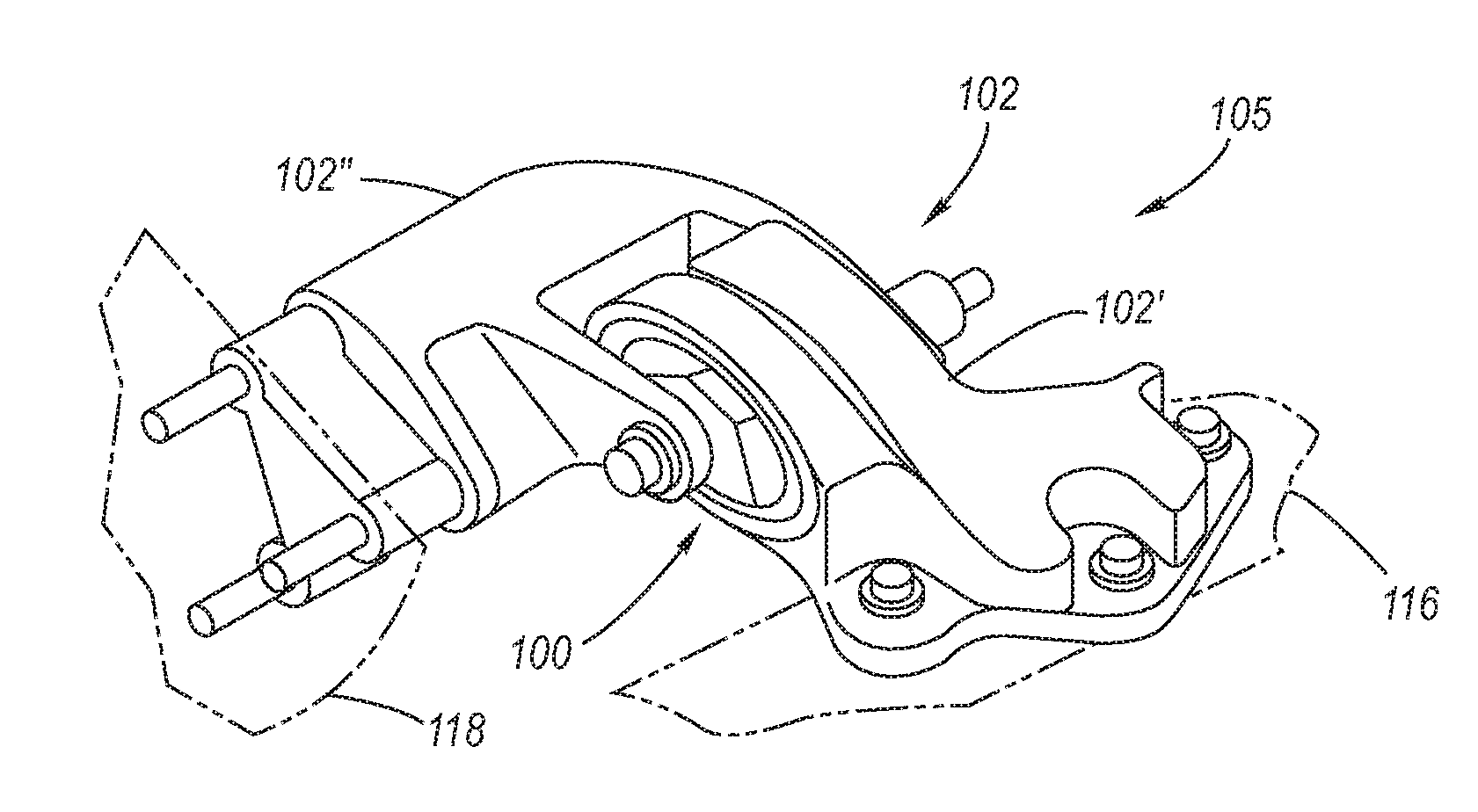

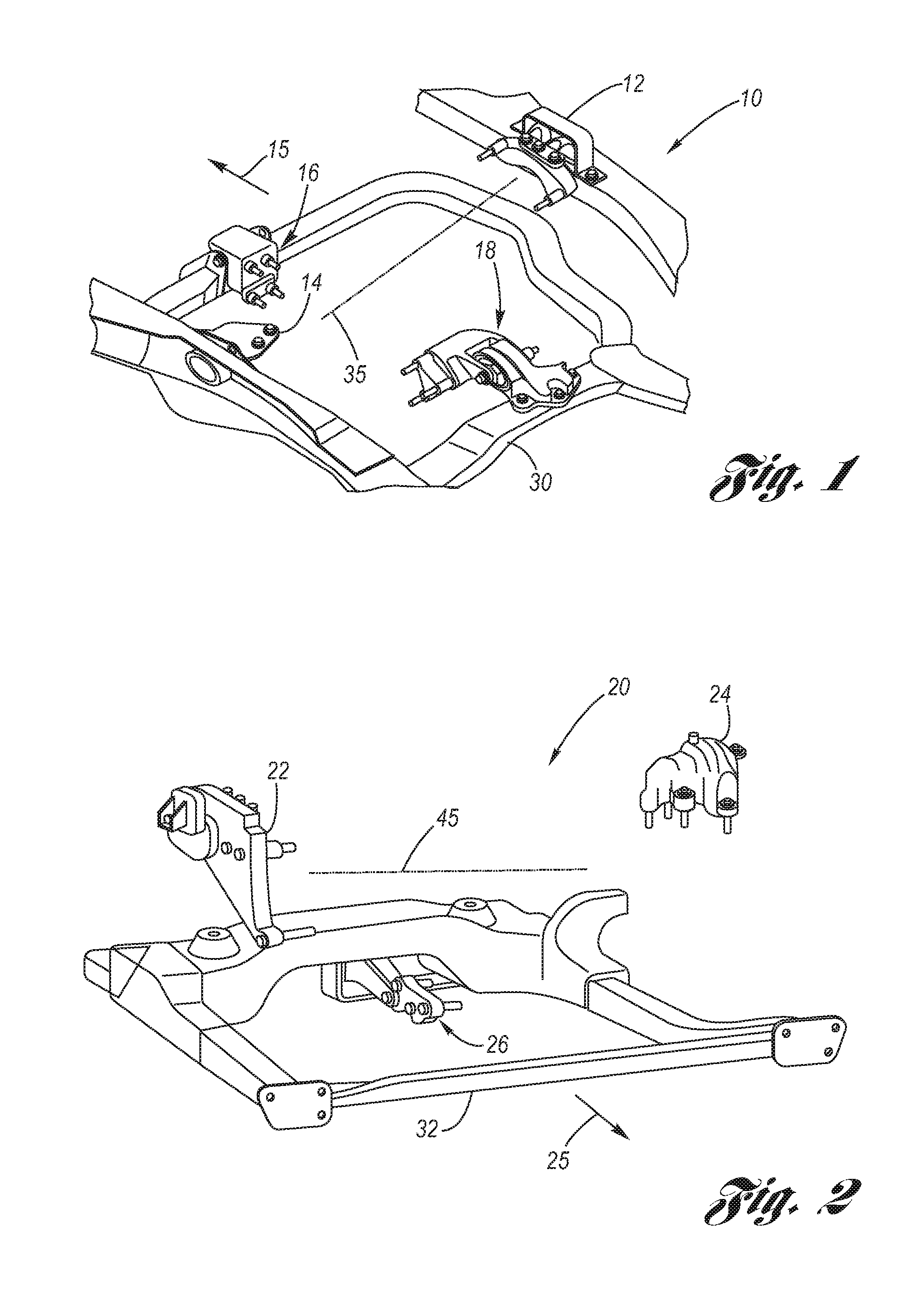

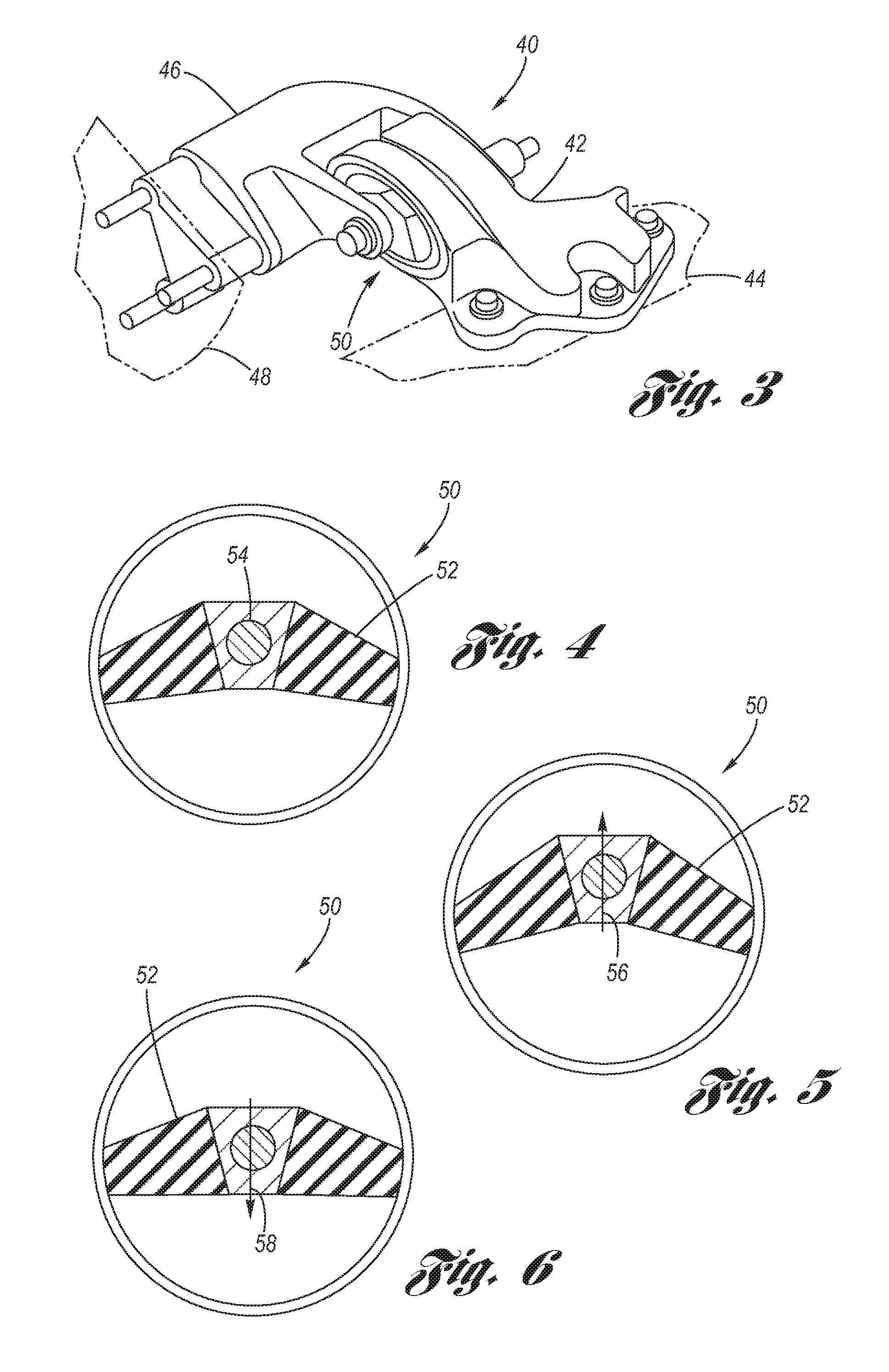

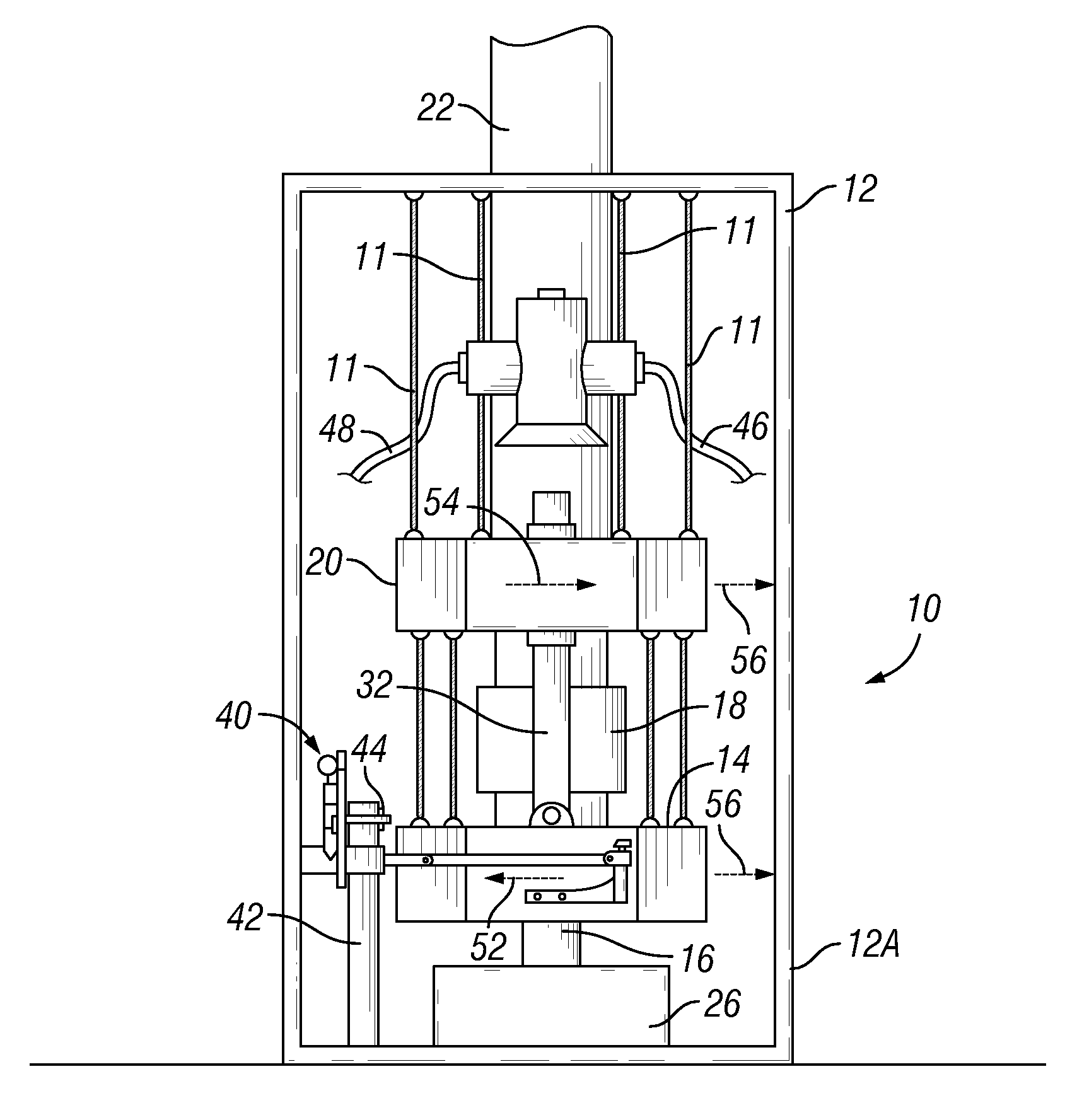

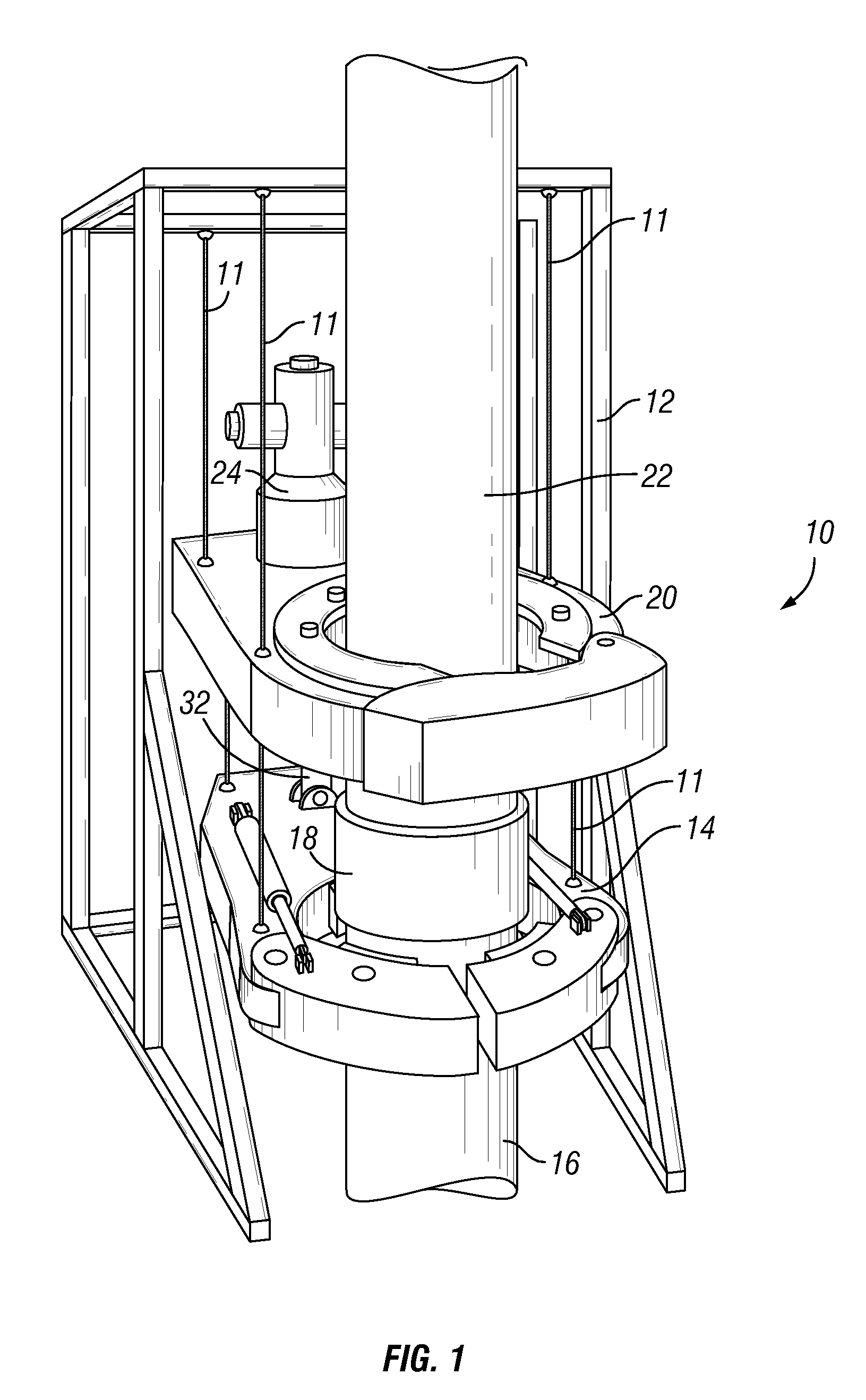

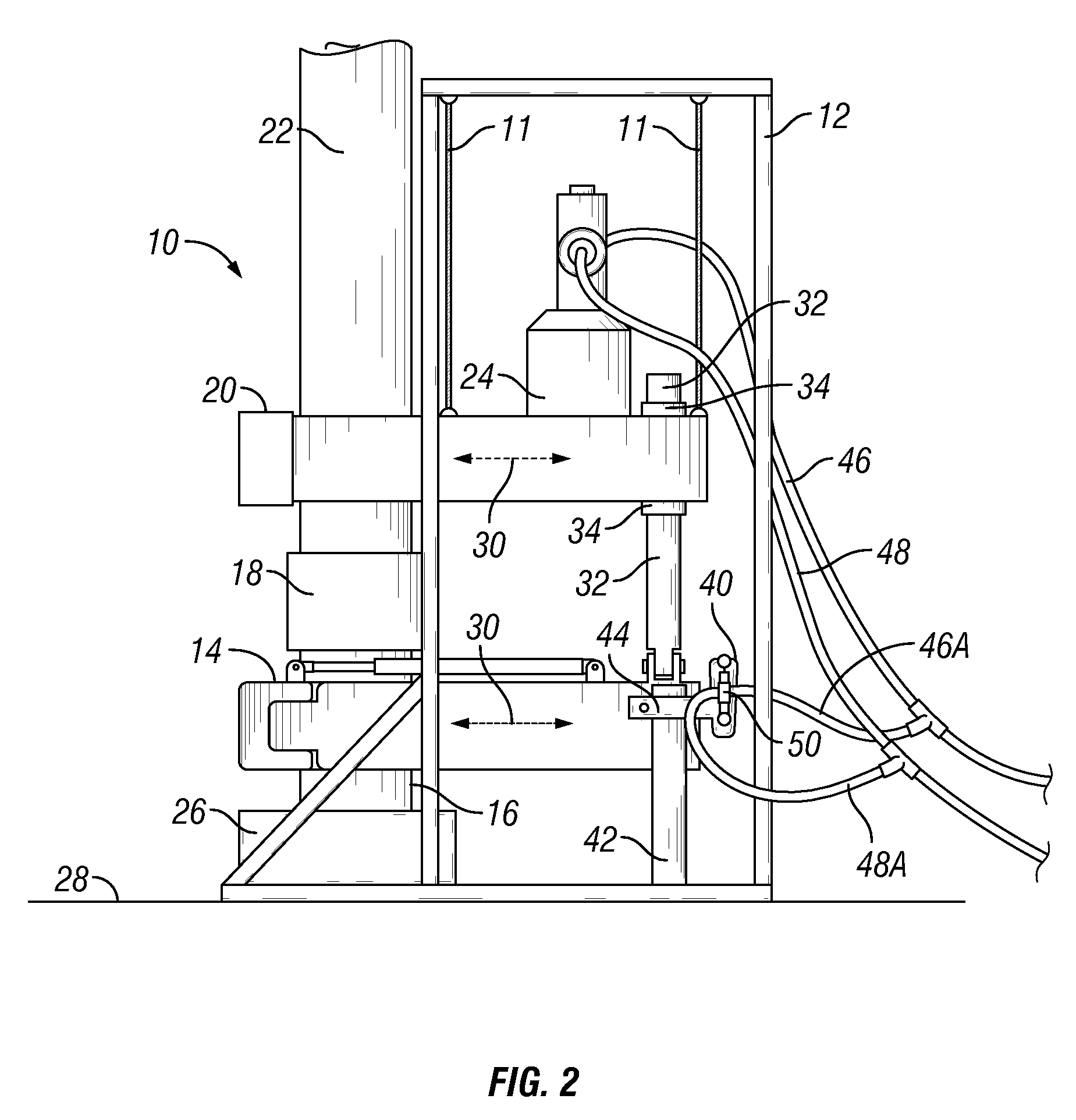

Slippage Sensor and Method of Operating an Integrated Power Tong and Back-Up Tong

ActiveUS20090126536A1Improve resolutionHigh sensitivityDrilling rodsFluid removalEngineeringMotive power

Method and apparatus to make-up or break-out a threaded tubular connection using an integrated power tong and back-up tong (10). The power tong (20) may be disabled upon sensing a predetermined threshold amount of displacement of at least a portion of a back-up tong (14). The sensed displacement indicates that the back-up tong (14) is slipping, and power tong (20) rotation may be disabled to prevent damage to the pipe string (16) or surrounding equipment. A slippage sensor (40) may be disposed to sense displacement of at least a portion of the back-up tong (14) relative to a supporting frame (12). In one embodiment, the slippage sensor (40) may be operatively coupled to a valve (50) disposed in communication with a fluid line (46) supplying power fluid to the power tong (20). The power tong (20) may be disabled by impairing flow to the power tong (20) upon sensing a predetermined displacement of the back-up tong (14).

Owner:FRANKS INT

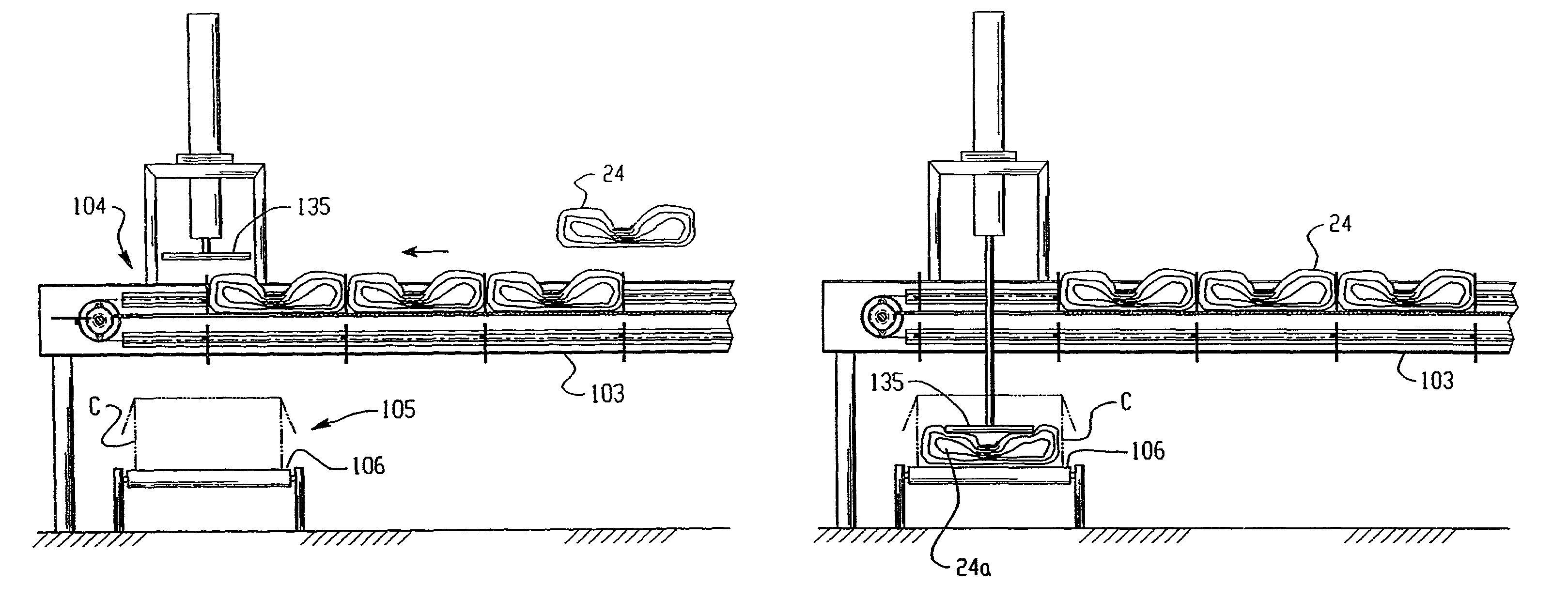

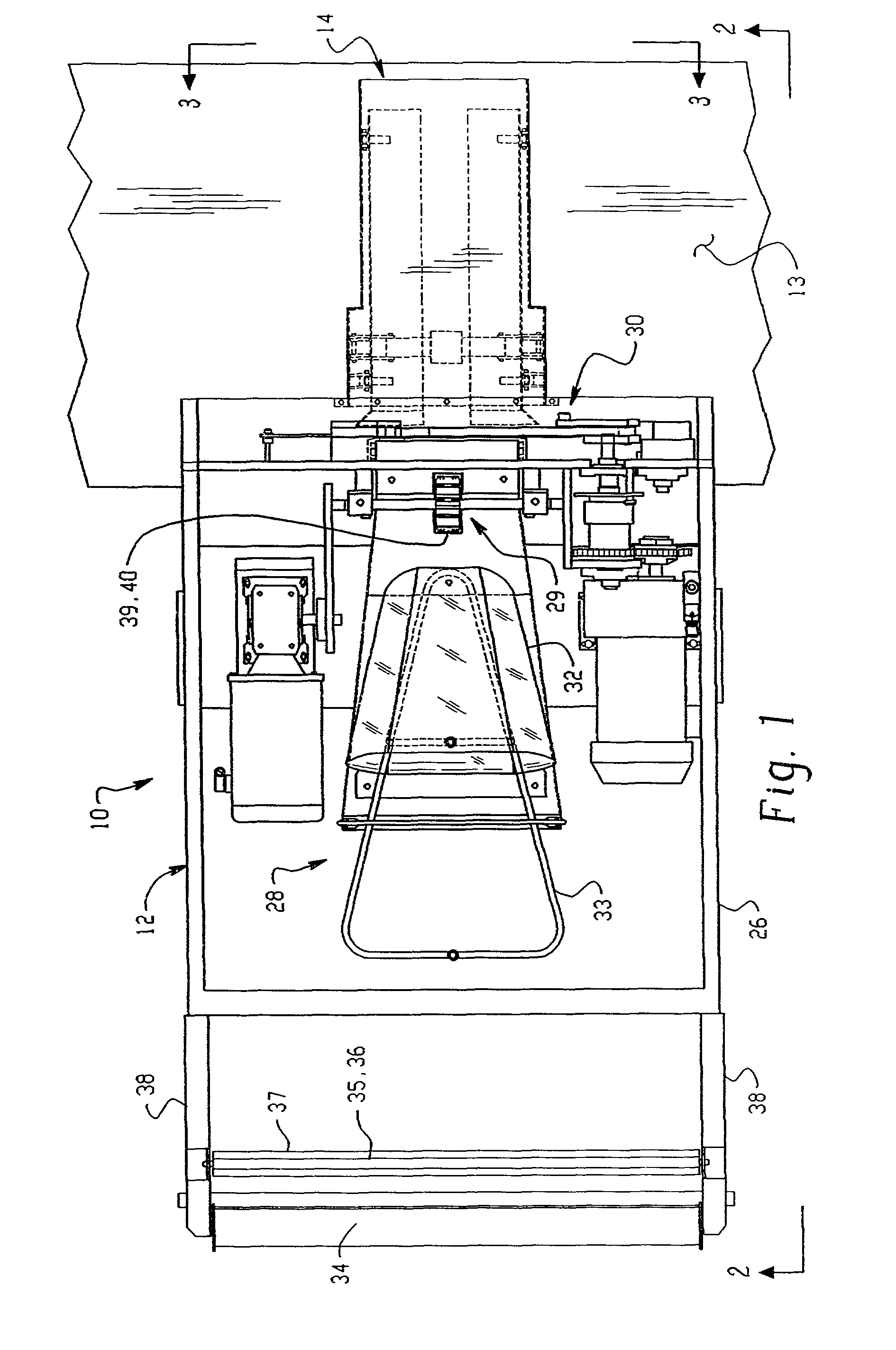

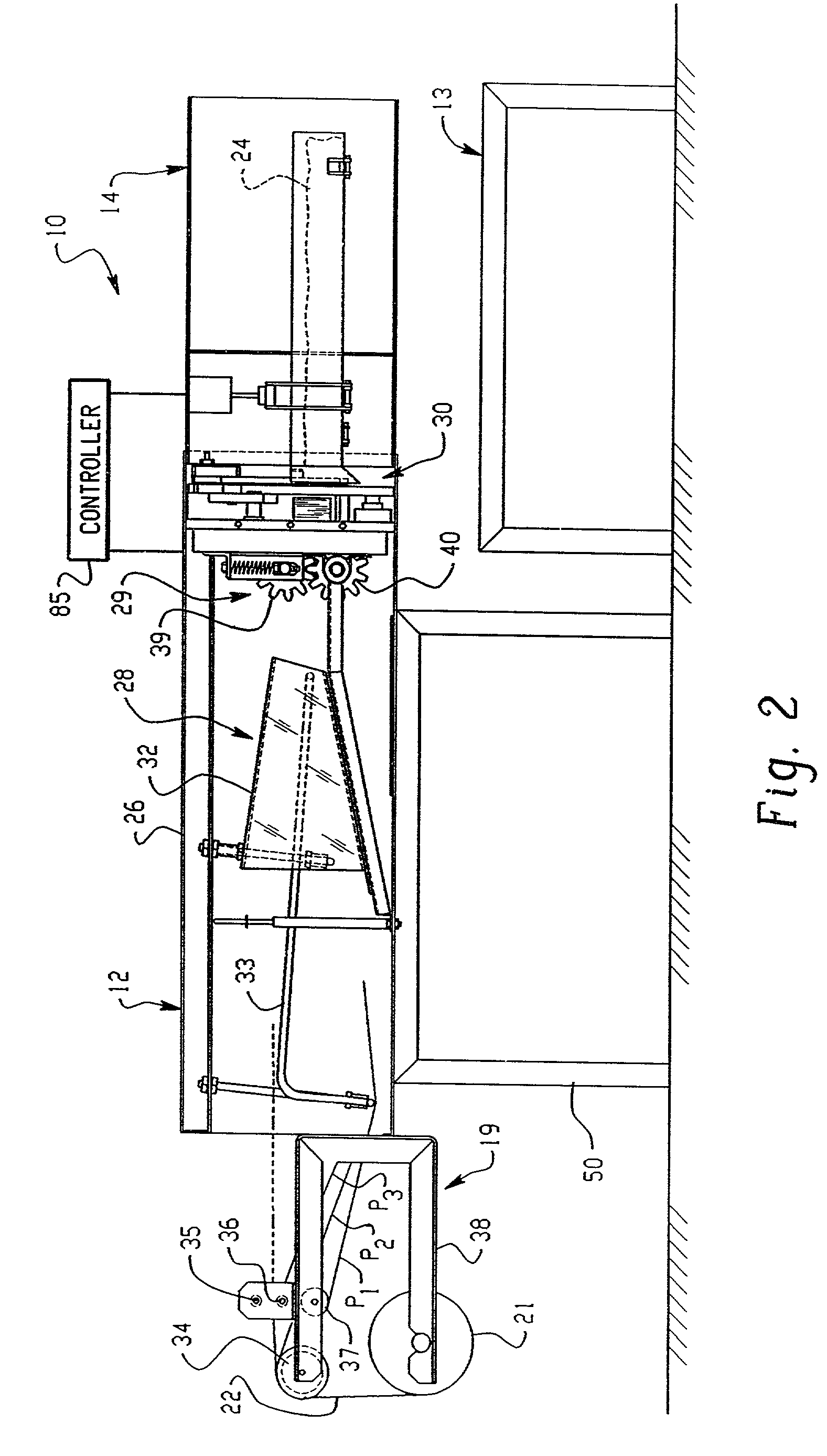

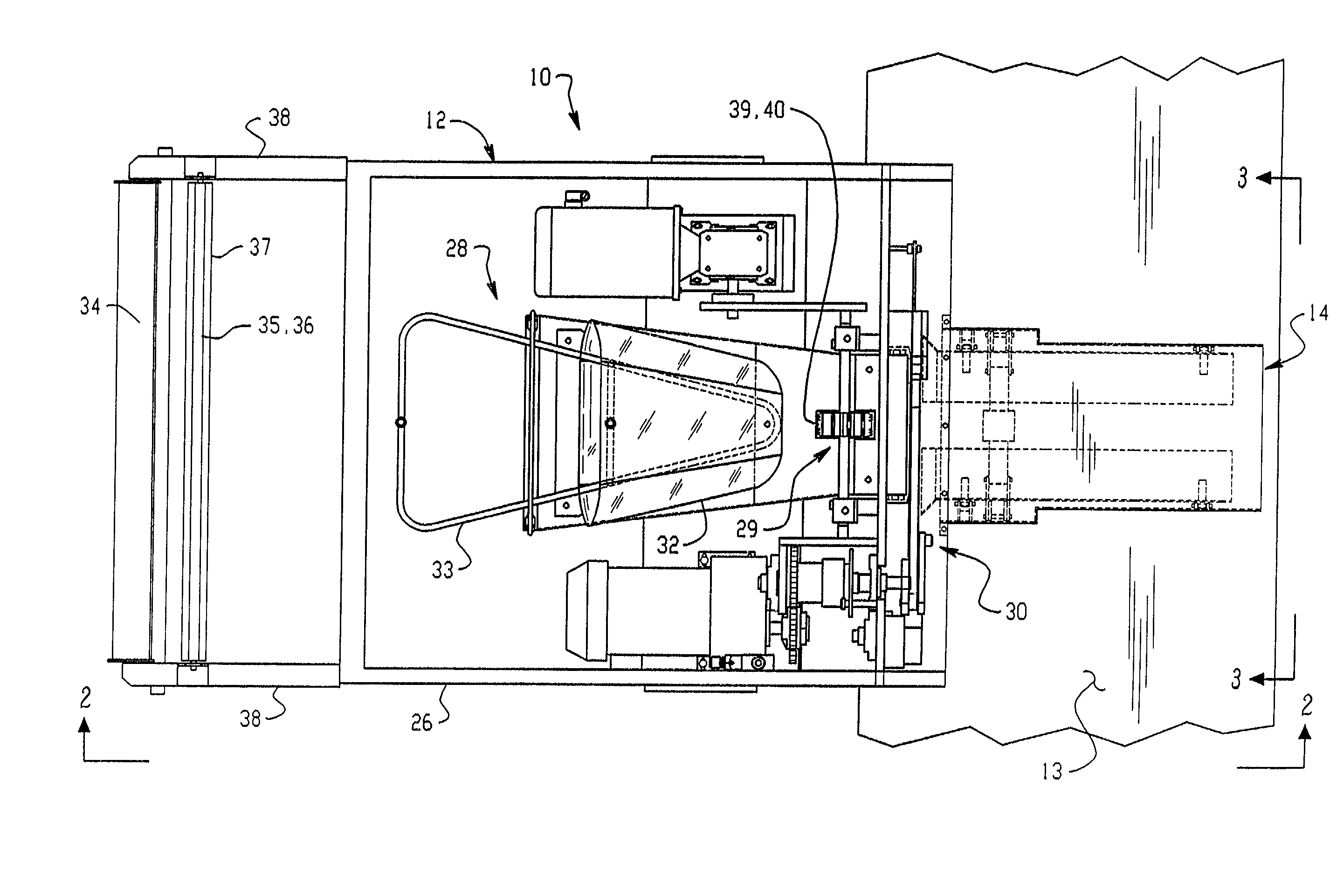

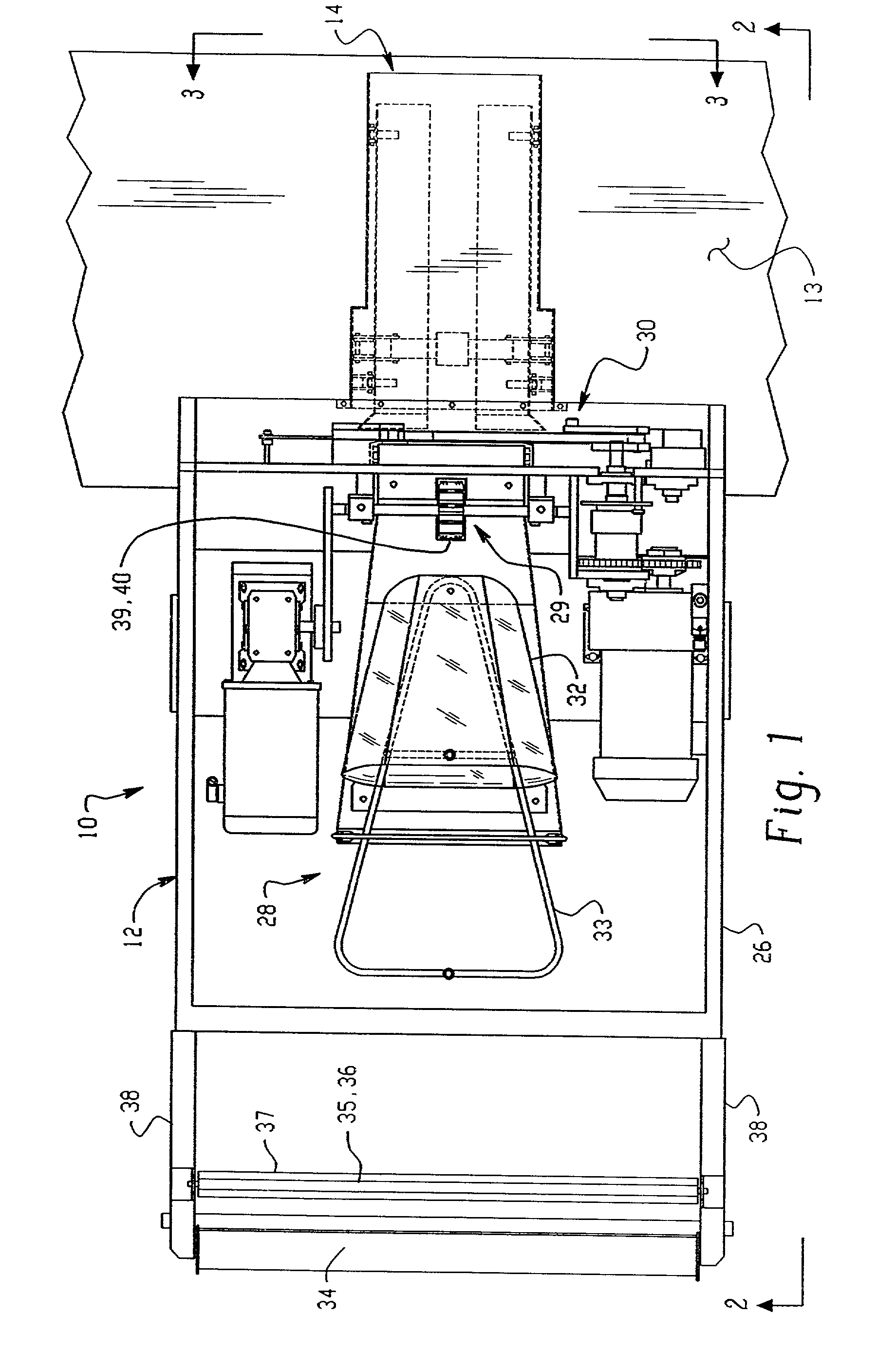

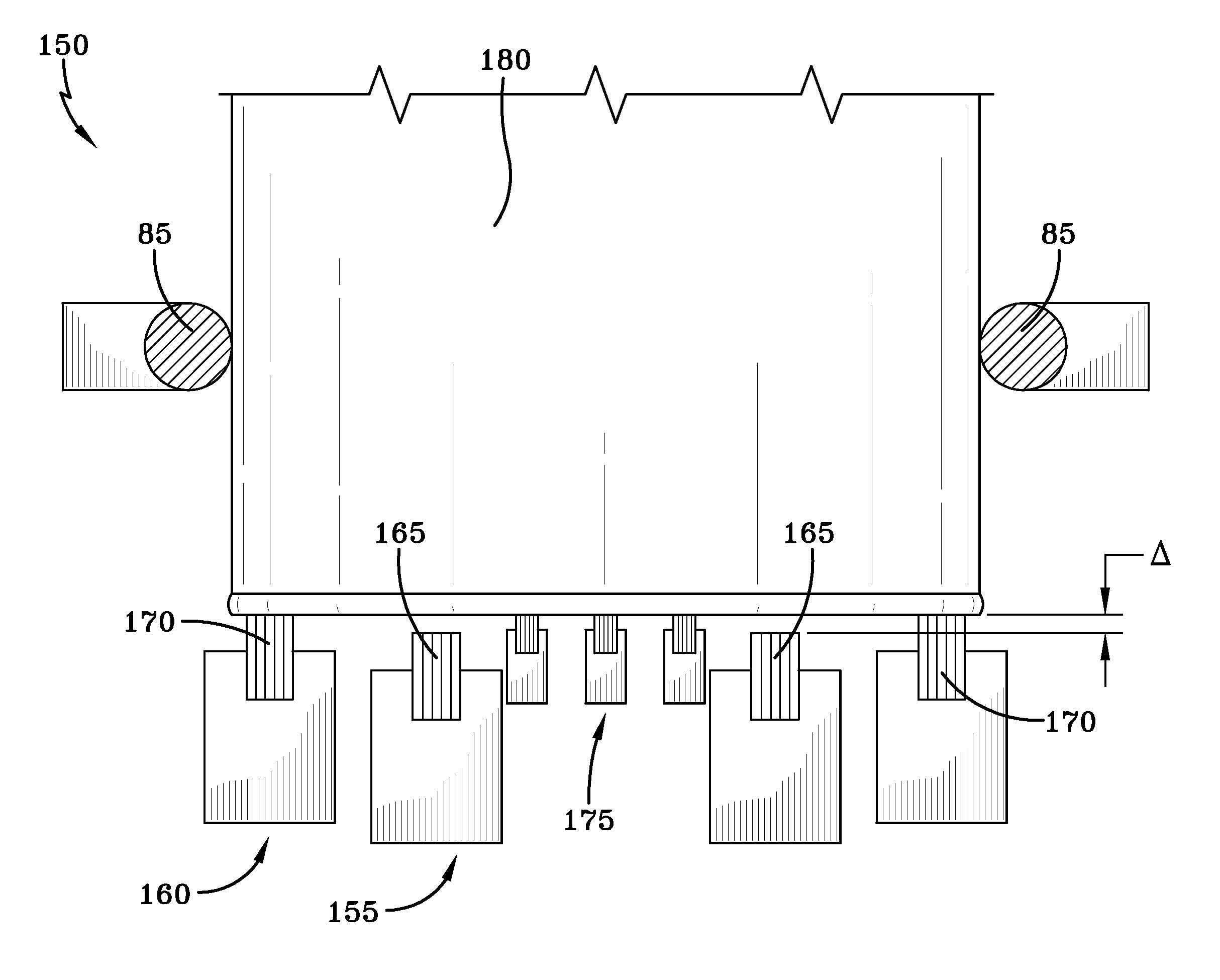

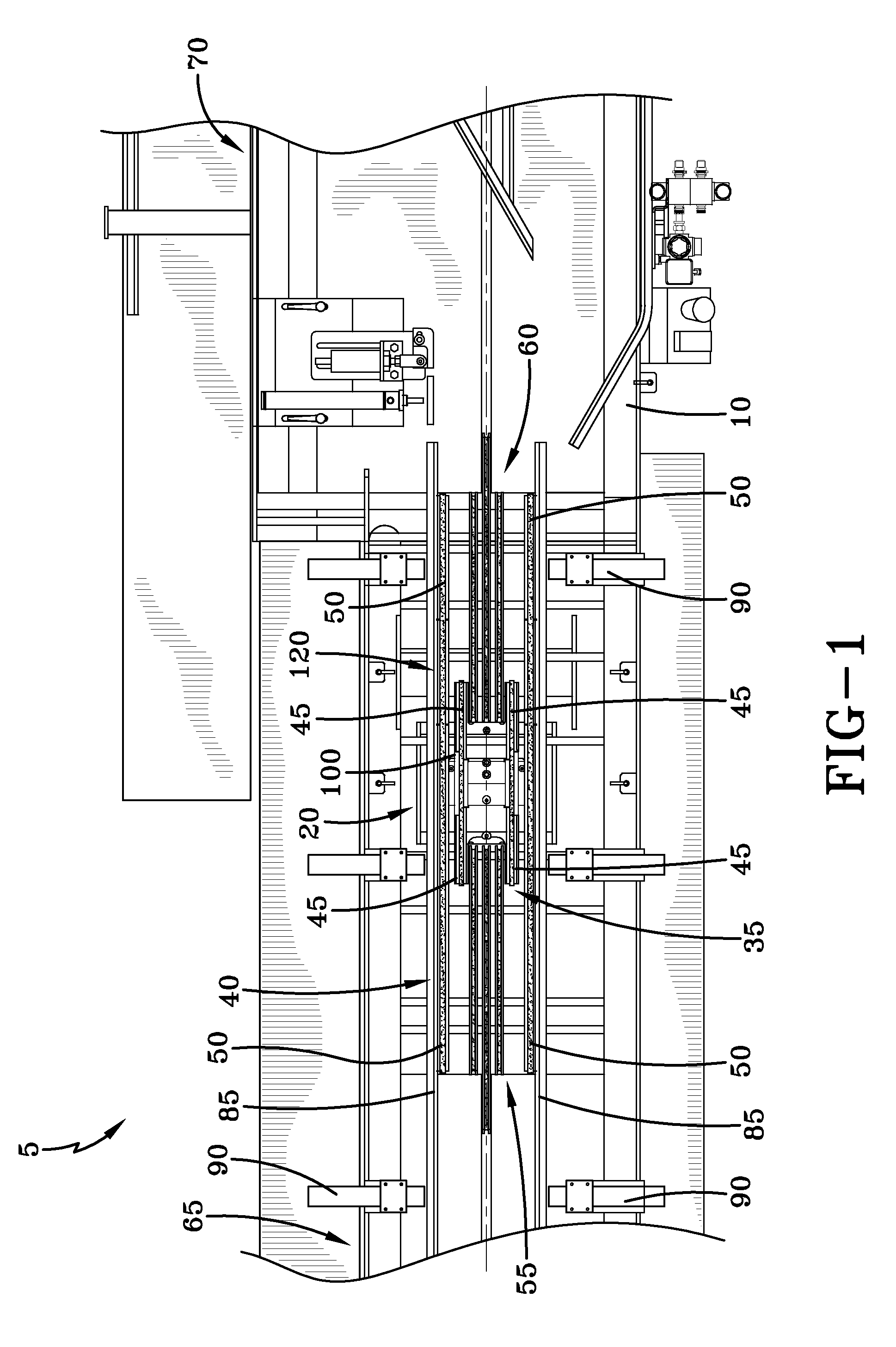

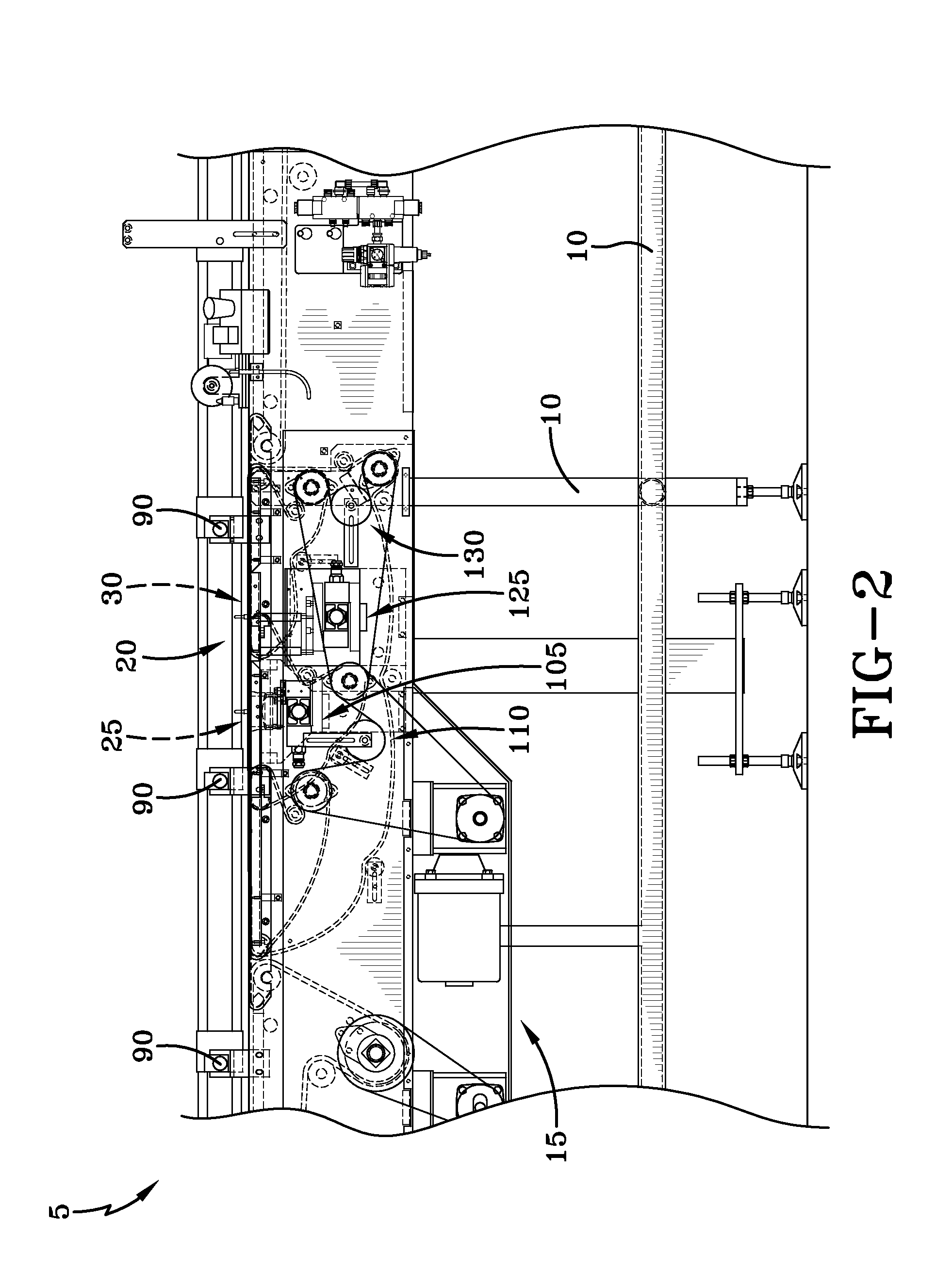

Dunnage production and packaging

InactiveUS7866125B2Operation is disabledAvoid assemblyPaper/cardboard articlesLayered productsDunnageEngineering

A packaging system for automatically producing dunnage pads and inserting one or more of the pads into a container for packaging an article in the container. The invention includes a pad discharge assembly and / or pad insertion assembly. The discharge assembly includes a gating device for effecting passage of the pad out of a holding zone in a direction transverse to the pad length and onto a working surface, preferably a conveyor. The conveyor conveys the pad into a pad insertion zone in a first direction, and a pusher assembly is operative to push the pad from the pad insertion zone in a direction transverse to the first direction. A plunger is provided for pushing a pad located at the pad insertion zone through an opening over which the pad is conveyed for insertion into a container.

Owner:RANPAK CORP

Dunnage pad production and packaging system

InactiveUS20020129583A1Operation is disabledAvoid assemblyPaper/cardboard articlesLayered productsForeign matterDunnage

A pad production (supply) and packaging system, and method, for automatically producing dunnage pads and inserting one or more of the produced dunnage pads into a container for packaging of an article in the container. The invention is characterized by a pad discharge assembly and / or pad insertion assembly to provide an automatic pad production and packaging system, and method, that afford advantages over existing pad production and packaging arrangements. The discharge assembly, which provides for controlled discharge of dunnage pads produced by a pad producing machine, includes a gating device for effecting passage of the pad out of the holding zone in a direction transverse to the pad length. A controller causes the discharge assembly to release a pad held in the holding zone for passage onto a working surface and preferably a conveyor in synchronous relation to movement of the conveyor for controlled deposition of pads onto the conveyor. The conveyor conveys the pad into a pad insertion zone in a first direction, and a pusher assembly is operative to push the pad from the pad insertion zone in a direction transverse to the first direction. The pusher assembly includes a plunger for engaging and pushing a pad located at the pad insertion zone; and the pad insertion zone includes an opening over which a pad is conveyed by the conveyor, and the plunger is operable to push the pad through the opening for insertion into a container. A sensor curtain is disposed near the holding zone and / or pad insertion zone to detect the insertion of a foreign object and provide an output for disabling a severing operation. One or more pad insertion assemblies can be swivelly mounted to a stand to permit relative rotatable movement therebetween from an operating position to a loading / servicing position and vice versa.

Owner:RANPAK CORP

Method and system for securely identifying computer storage devices

InactiveUS20100071030A1Avoid accessOperation is disabledRandom number generatorsUser identity/authority verificationInternet privacyPrivate network

In a private network setting in which various computers can be attached, the confidential or sensitive data within the various devices on the private network is vulnerable. The ability to copy such confidential or sensitive data to a storage device communicatively coupled to a client computer on the network is governed and controlled. Only devices that include an authentic stamp or digital certificate can be accessed by client computers. If a device does not have a valid stamp or the stamp has been black listed, then the access to the device can be prevented or greatly limited.

Owner:SUPERCOM IP LLC

Mounting Systems for Transverse Front Wheel Drive Powertrains with Decoupled Pitch Damping

InactiveUS20120090912A1Increase stiffnessOperation is disabledSpringsUnderstructuresVibration amplitudeDrivetrain

A powertrain mounting system with a decoupled hydraulic bushing device as a torque reacting element. An elastic element of the bushing mount vibrates in response to powertrain pitch torque. At high vibration amplitude of the elastic element, high hydraulic damping is provided via a main liquid reservoir, bounce inertia track and bellowed secondary liquid reservoir, with a decoupler fluid passage being passively disabled. At low vibration amplitude of the elastic element, minimal hydraulic damping is provided via a decoupler system.

Owner:GM GLOBAL TECH OPERATIONS LLC

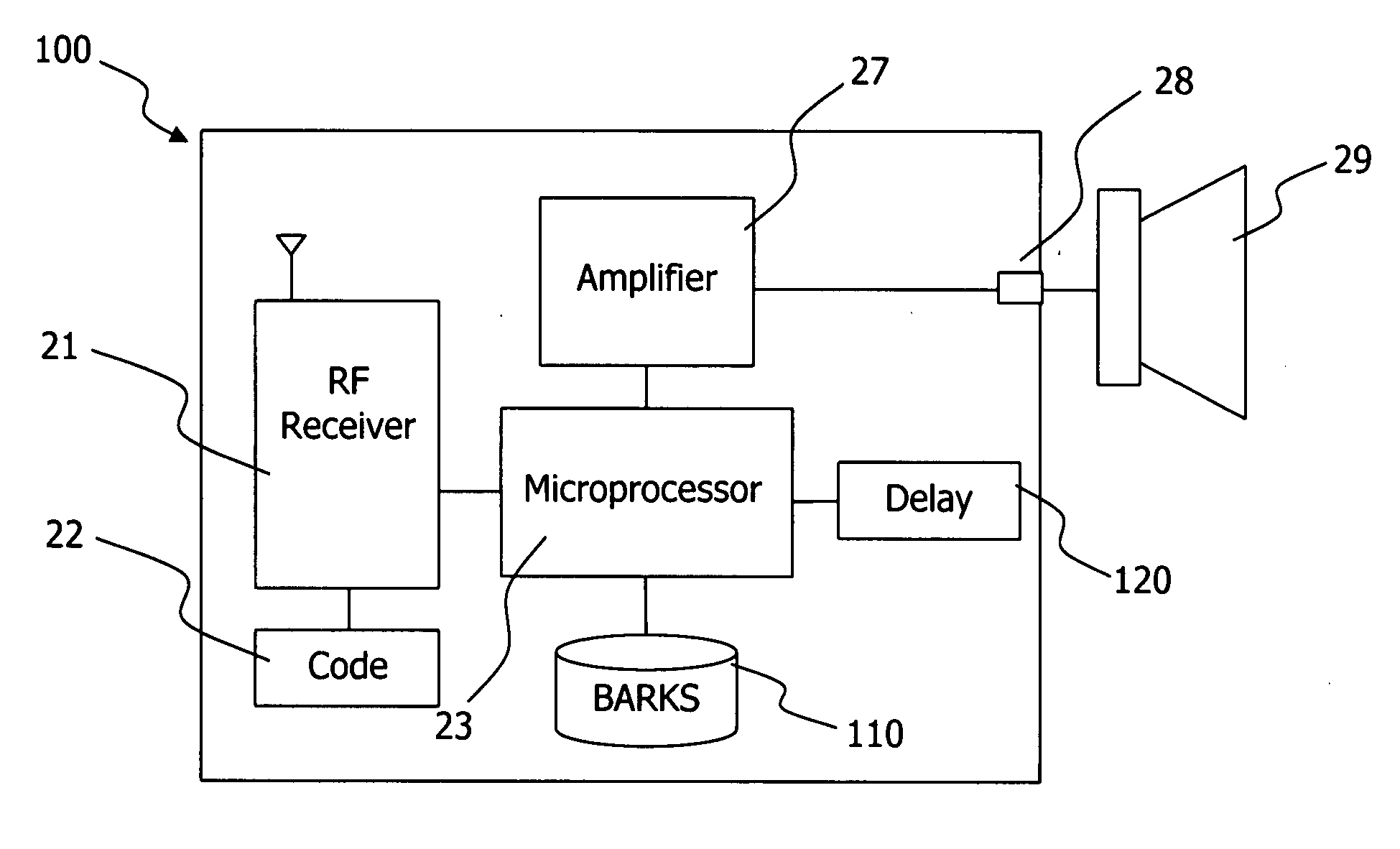

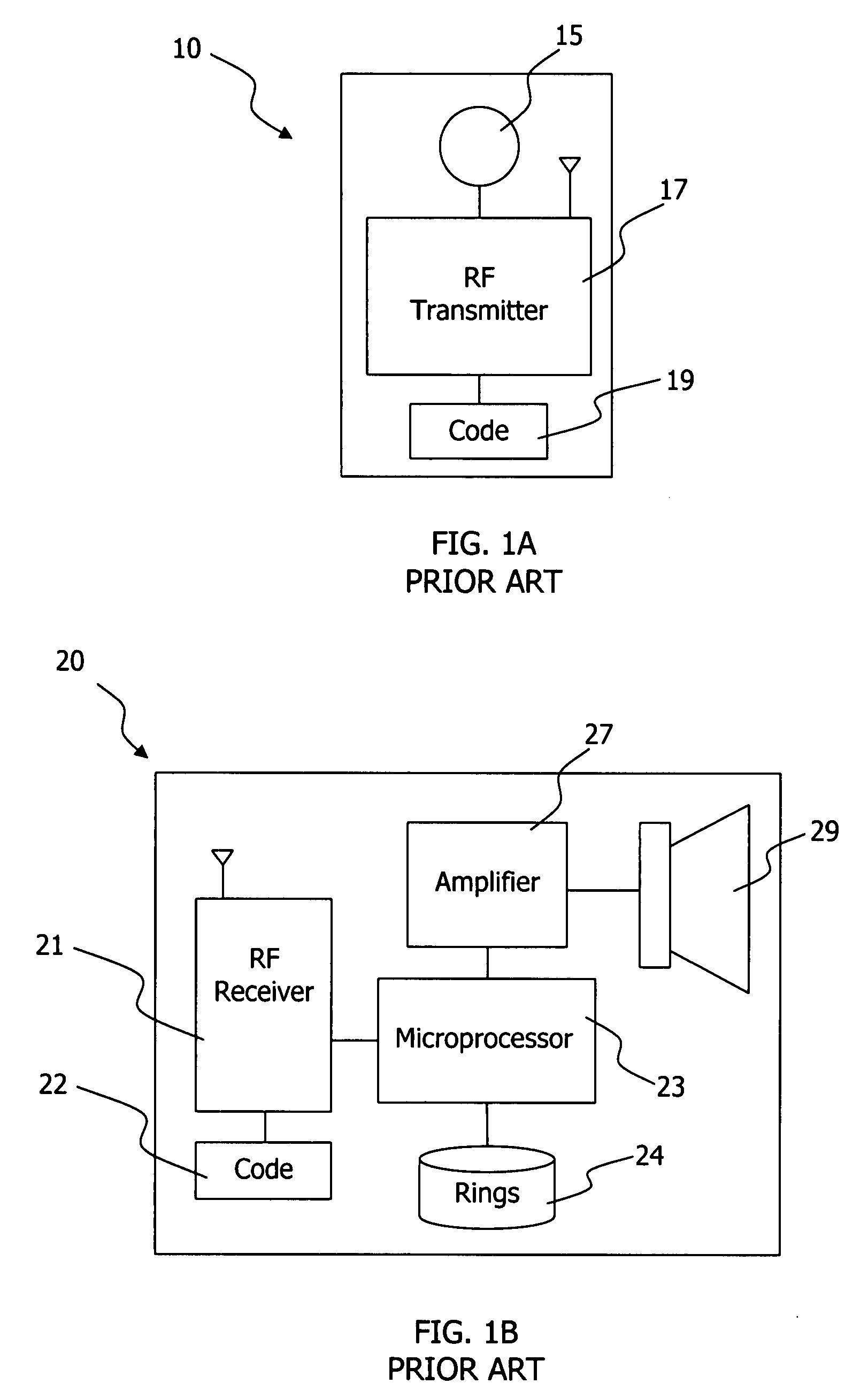

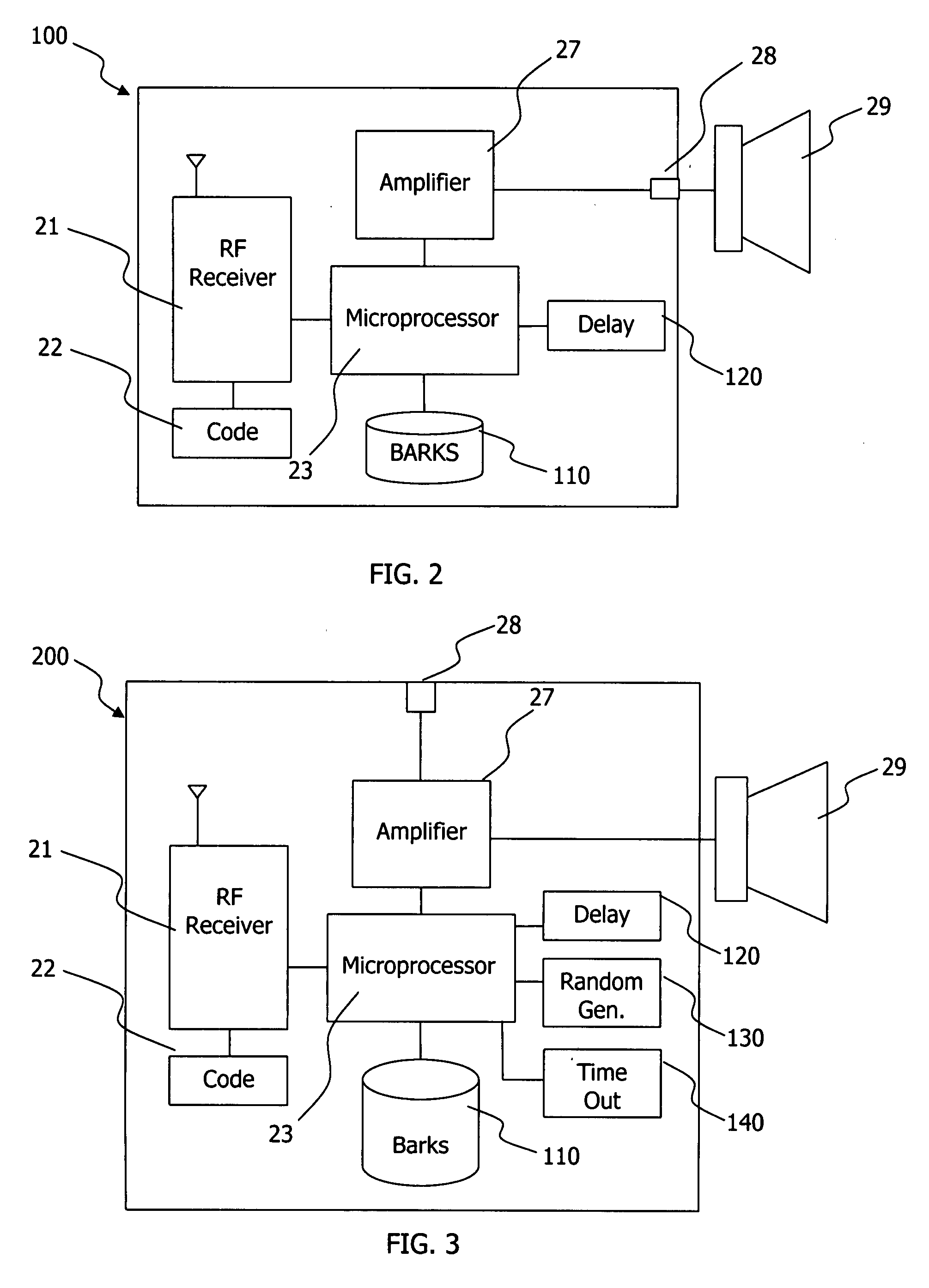

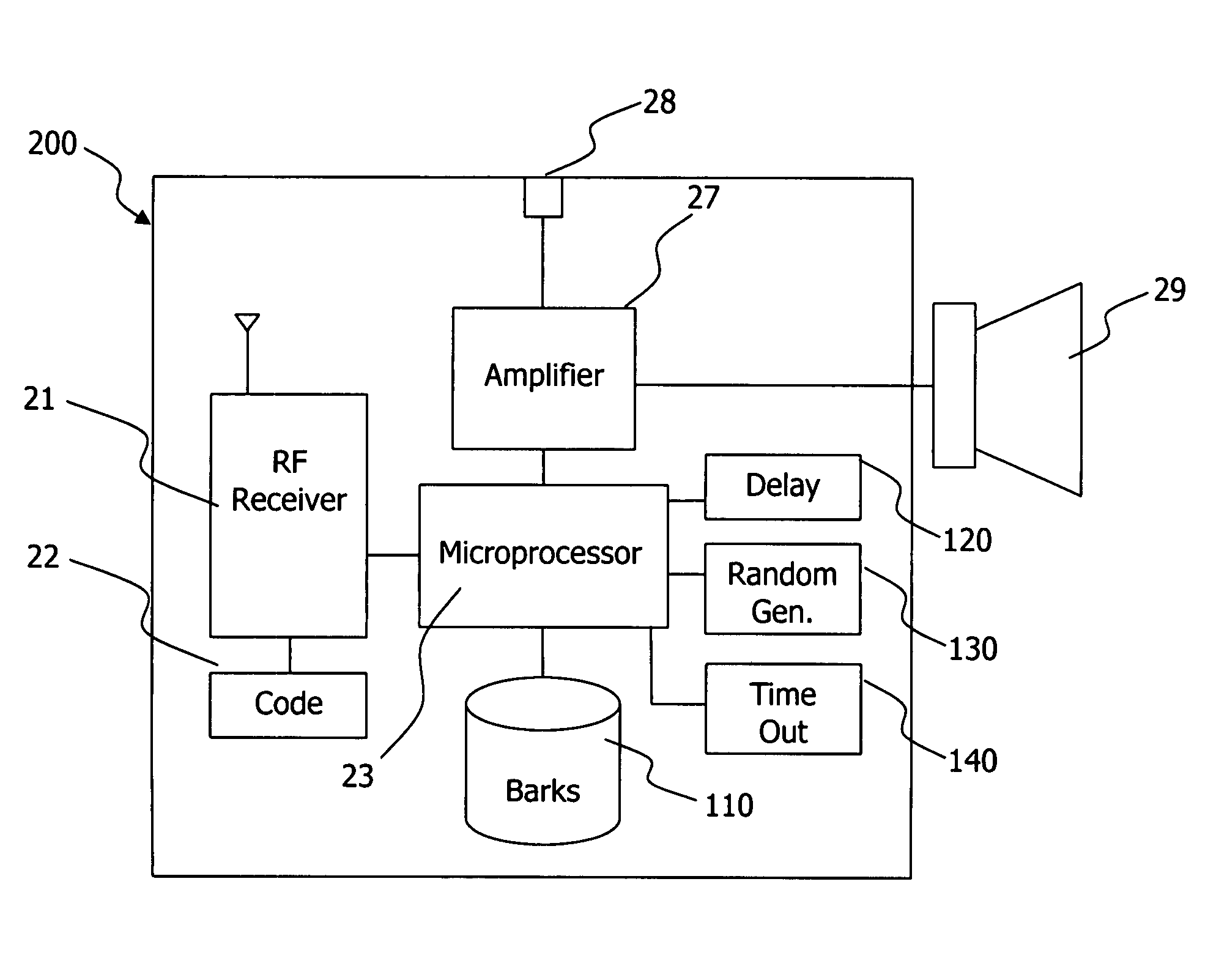

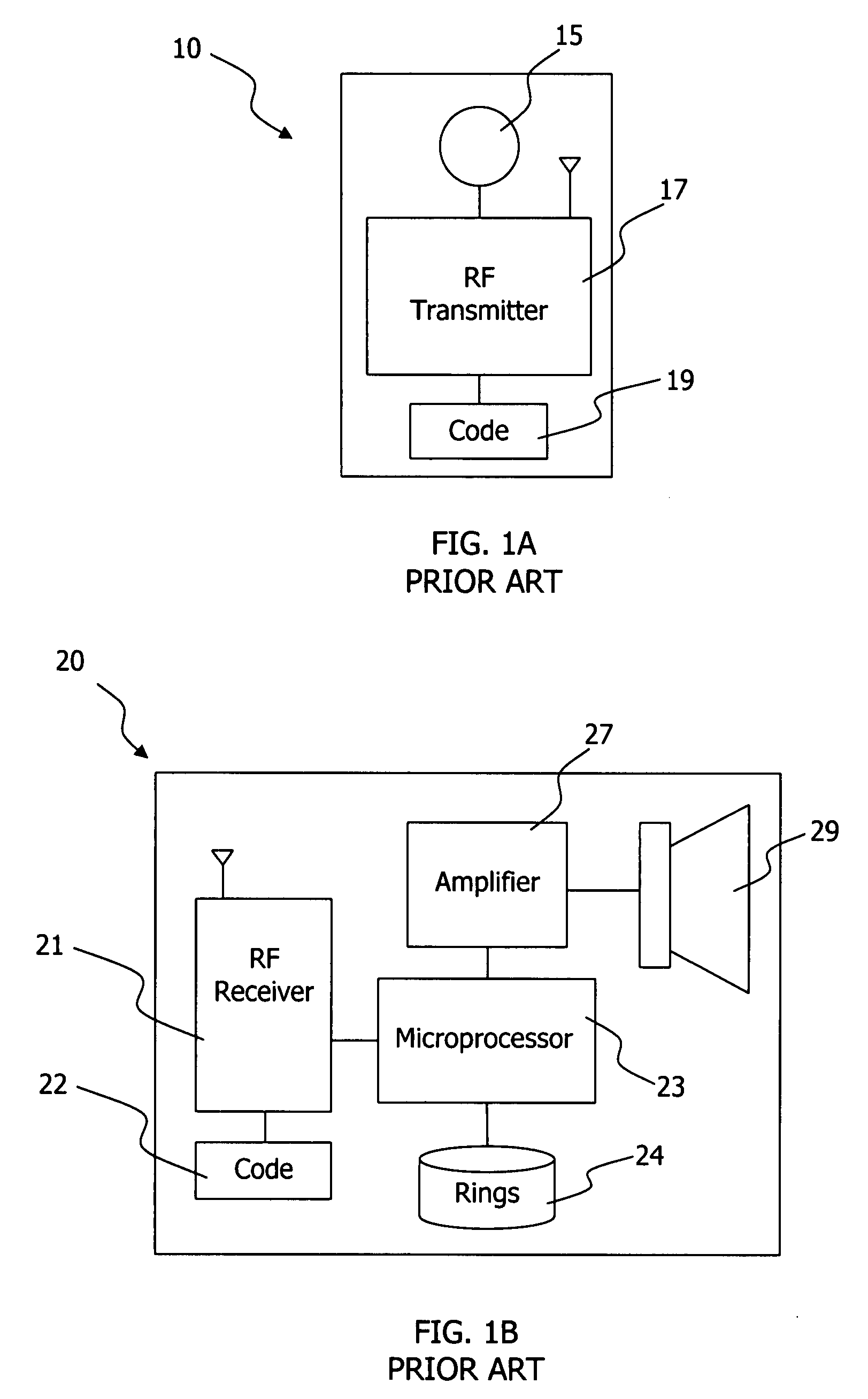

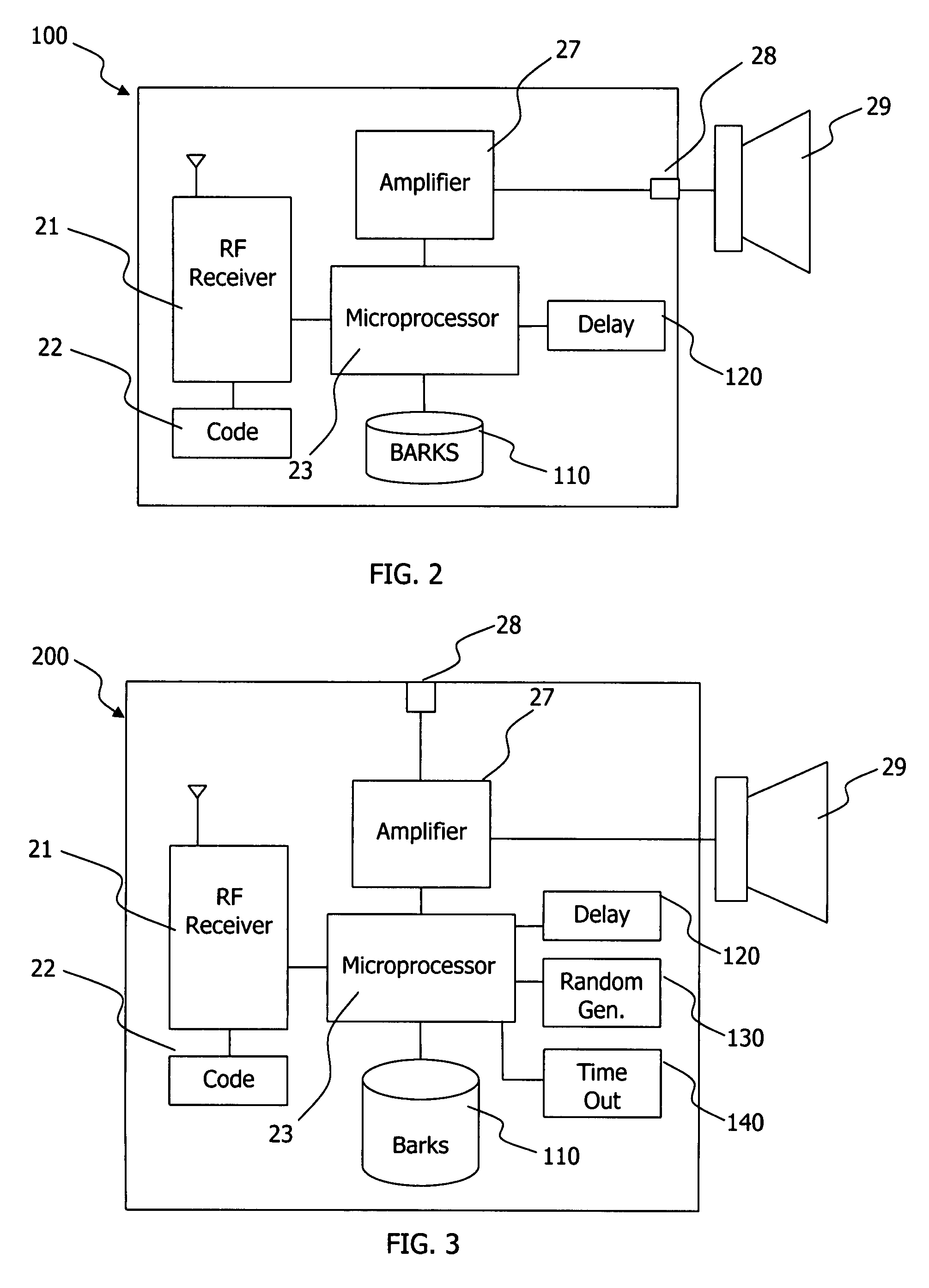

Dog bark door bell notification and personal protection system

InactiveUS20080309509A1Operation is disabledAlarms with occupancy stimulationSignalling system detailsDoorbellAudio power amplifier

A door bell notification and personal protection system includes a warning notification module adapted to recognize at least one of a door bell notification from a door bell ringer or emergency transmission signal from a wireless transmitter and thereafter provide a recognition signal to a microprocessor. The microprocessor is adapted to retrieve dog barking sounds stored in a memory and provide the dog barking sounds to at least one of an amplifier or radio frequency transmitter after the microprocessor receives the recognition signal from the warning notification module. Dog barking sounds can be broadcasted using the wireless transmitter. A delay module can enable processing with a delay time after first receipt of the recognition signal. A random module can enable random retrieval of various dog barking sounds from memory for processing. A time out module can disable operation of the microprocessor at a set time after recognition signal receipt.

Owner:ORTIZ MELISENDRO T +1

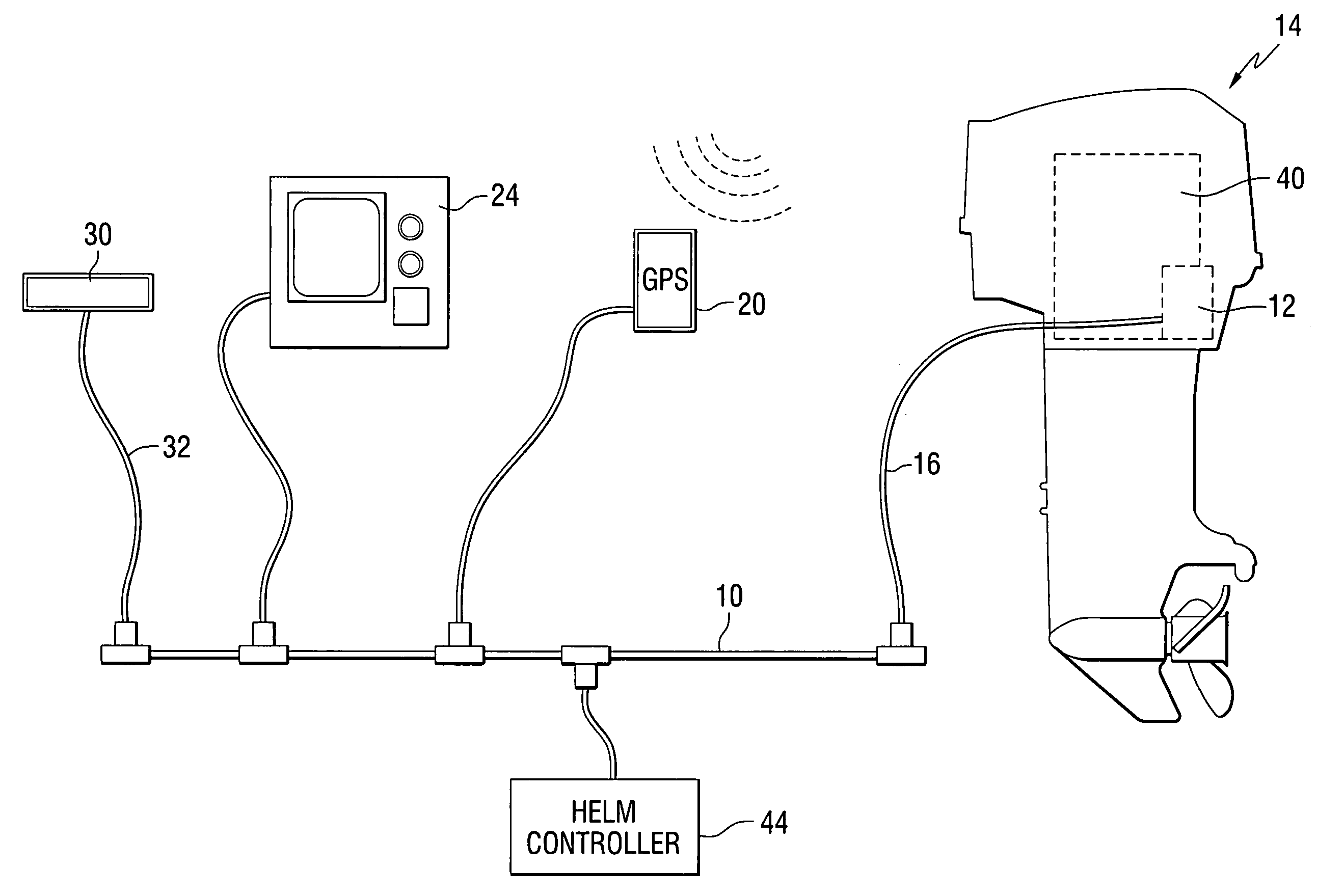

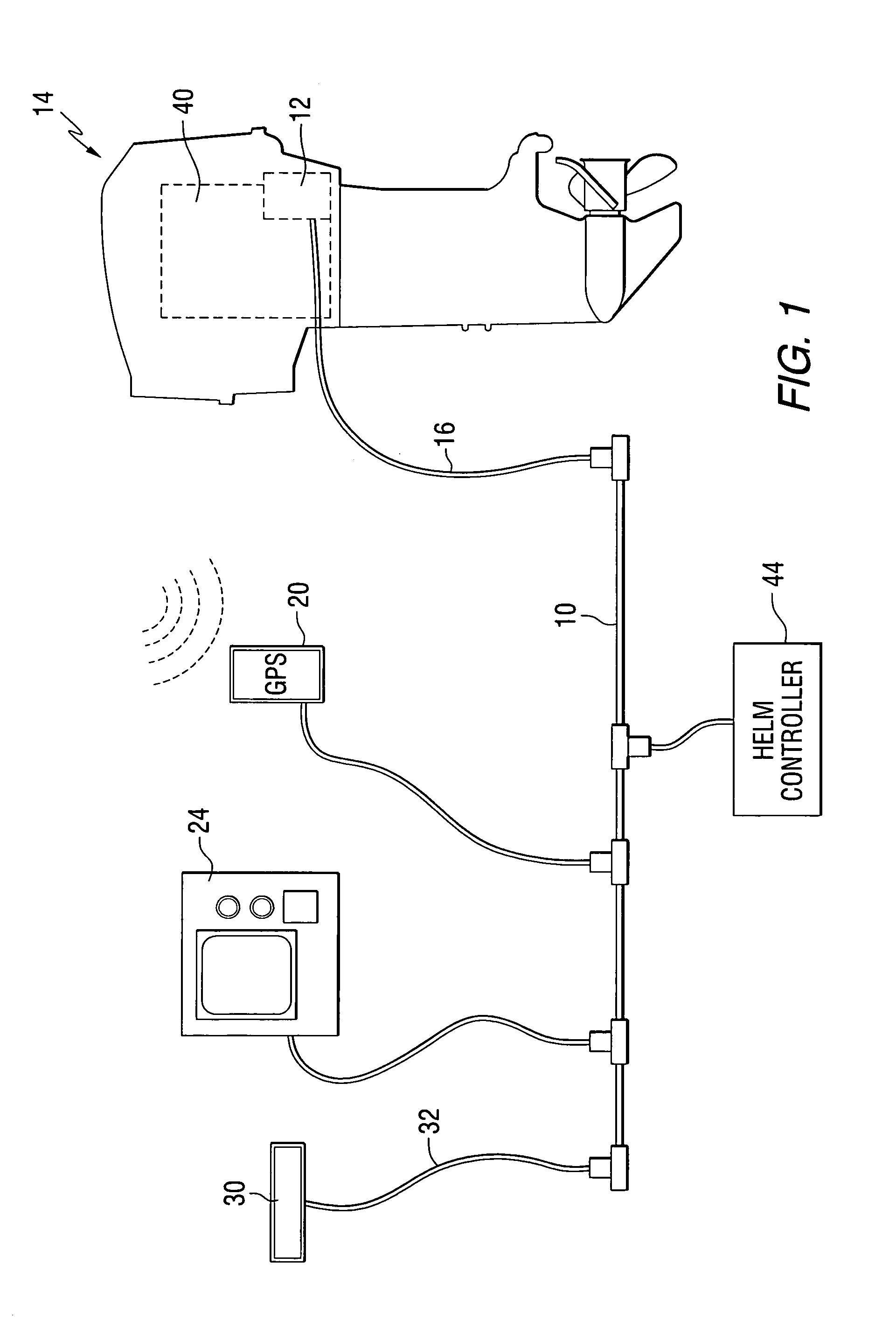

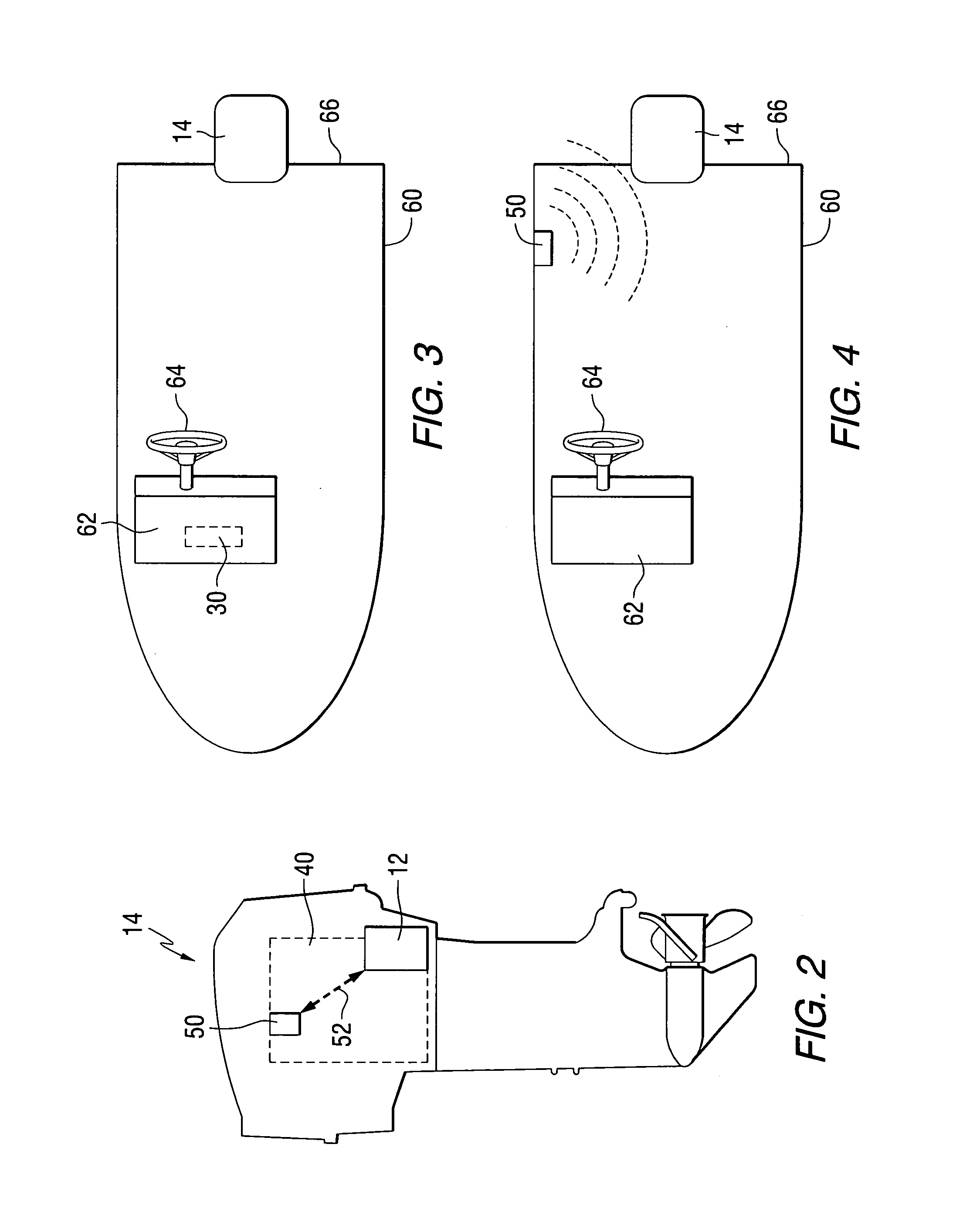

Security system for a marine vessel

InactiveUS7104851B1Operation is disabledDigital data processing detailsAnti-theft devicesMarine propulsionControl system

A security system for a marine vessel uses identification values to ascertain whether or not the devices used in a marine vessel control system are those which are expected. If an identification value is received by one device from another device, appropriate operation of the devices is permitted. However, if an incorrect identification value is received or no identification value is received, continued operation of the marine propulsion system is disabled.

Owner:BRUNSWICK CORPORATION

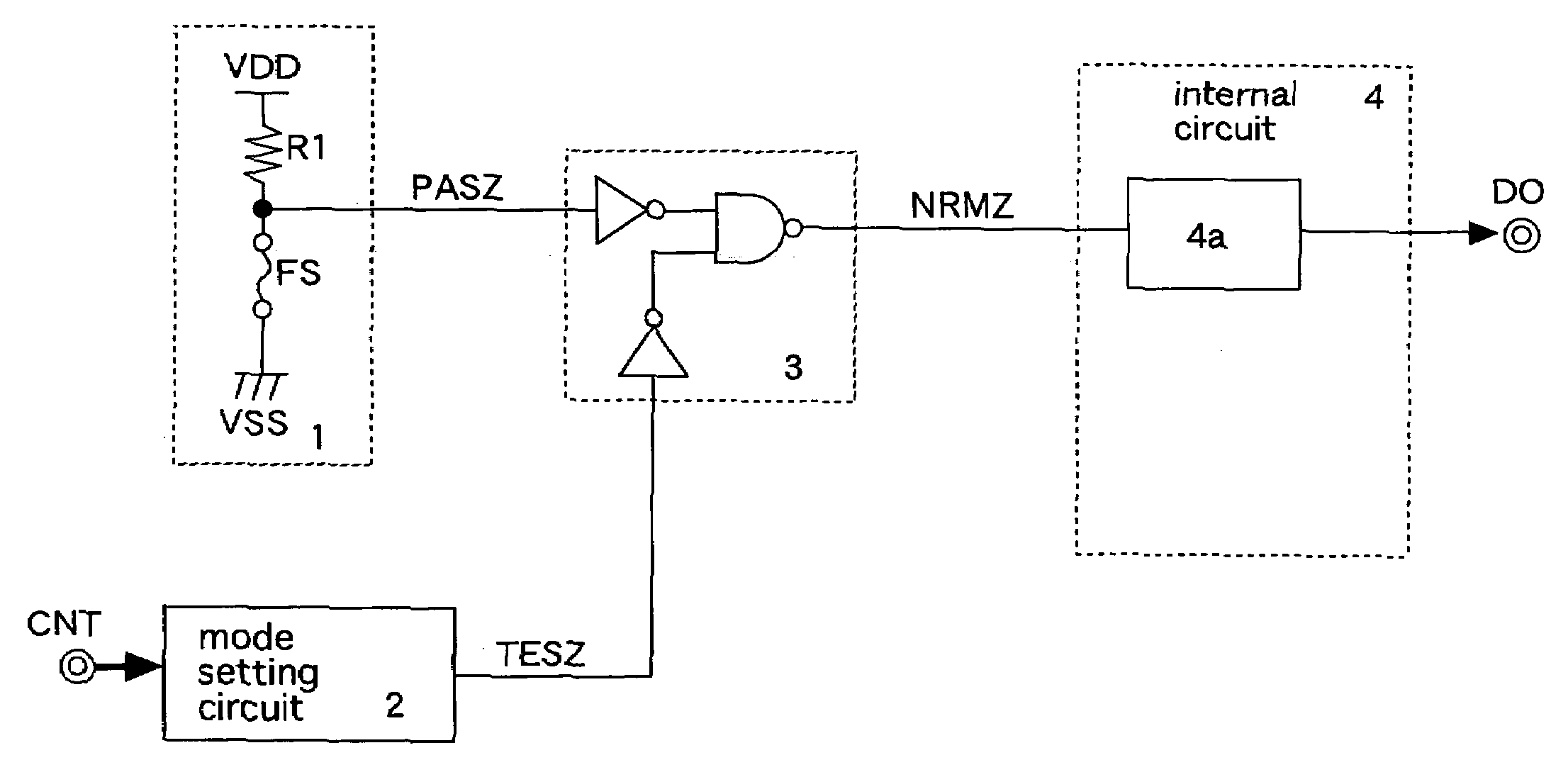

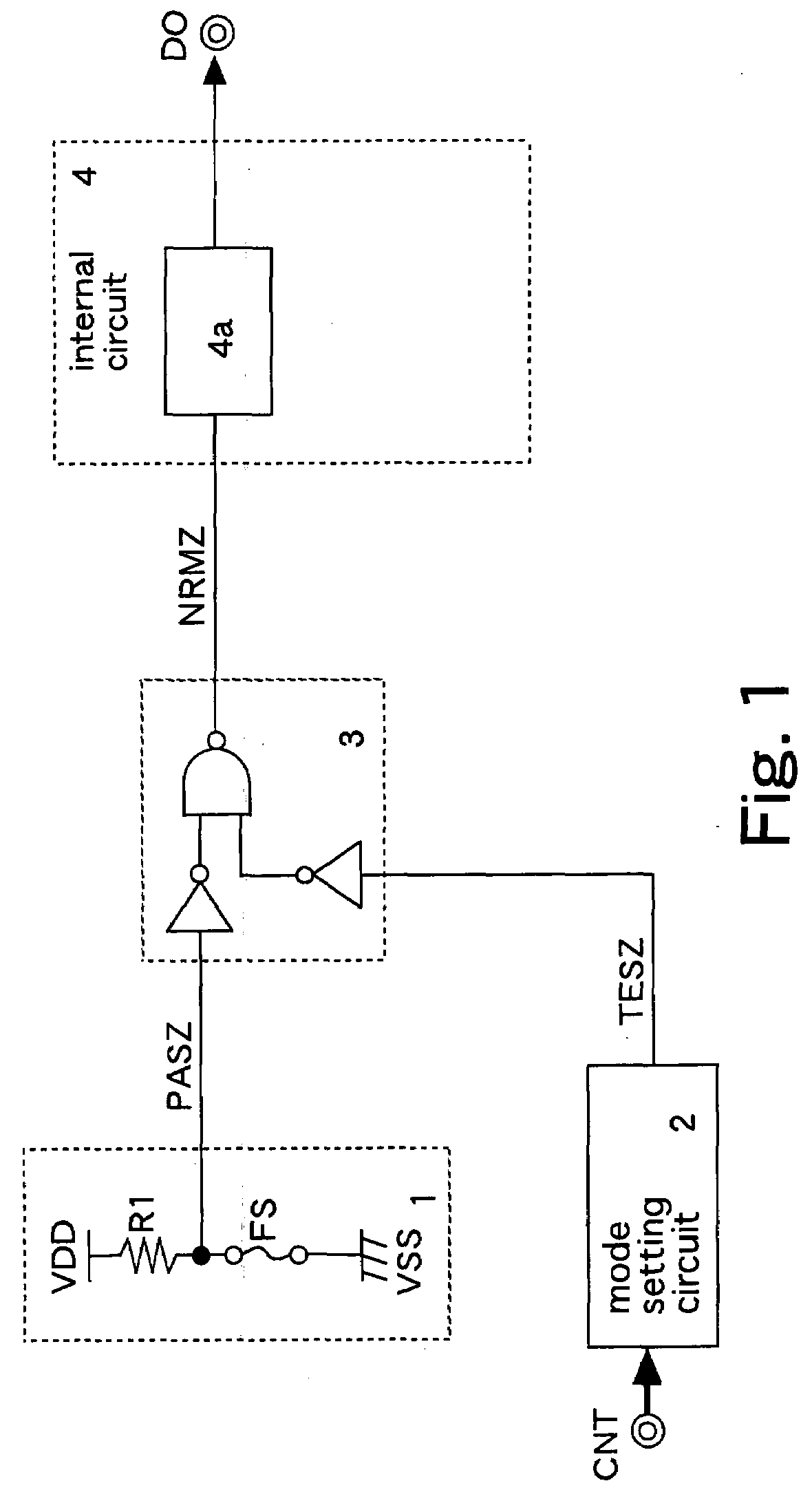

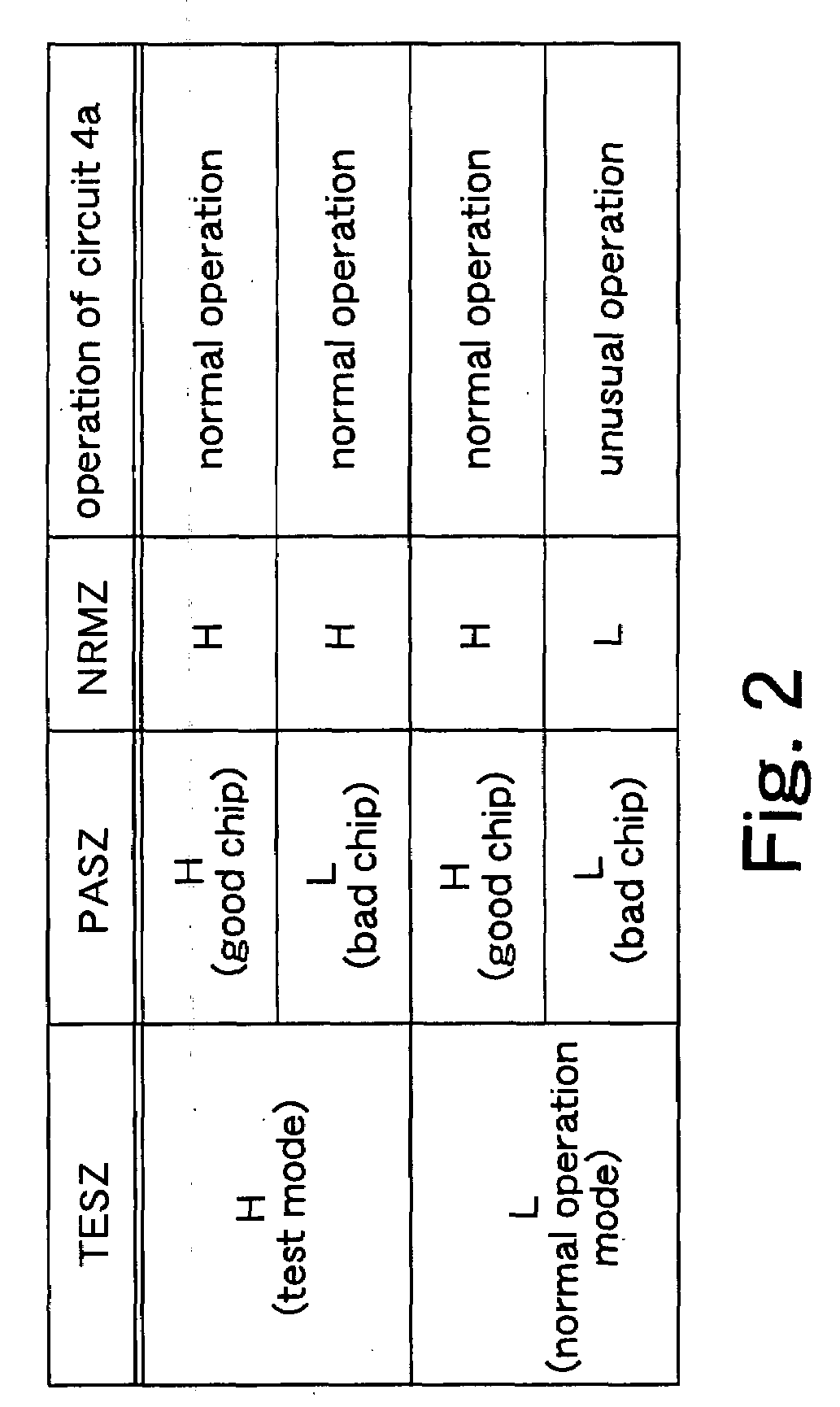

Semiconductor integrated circuit and testing method of same

InactiveUS20080048703A1Easy to identifyConvenient performance testingSemiconductor/solid-state device testing/measurementElectronic circuit testingOperation modeProgram unit

A program circuit activates a pass signal when a first program unit is programmed. The first program unit is programmed when a test of an internal circuit is passed. A mode setting circuit switches an operation mode to a normal operation mode or a test mode by external control. A state machine allows a partial circuit of the internal circuit to perform an unusual operation different from a normal operation when the pass signal is inactivated during the normal operation mode. By recognizing the unusual operation during the normal operation mode, it can be easily recognized that a semiconductor integrated circuit is bad. Since a failure can be recognized without shifting to the test mode, for example, a user who purchases the semiconductor integrated circuit can also easily recognize the failure.

Owner:SOCIONEXT INC

Controller for monitoring and controlling pulsators in a milking system

A controller for monitoring and controlling an operating pulsator in a milking system is shown. The controller receives a start signal generated when a milking apparatus is attached to a cow. A first sensor is operatively connected to a designated pulsator for receiving a pulsating vacuum and for producing a first signal representing the pulsating vacuum level. The controller includes a processor having a comparator for comparing the first signal to a stored reference of predetermined vacuum ranges and for generating a control signal when the designed pulsator pulsating vacuum level is outside of a predetermined vacuum range. A control circuit signals that the designated pulsator pulsating vacuum level is outside of the predetermined vacuum range.

Owner:TECH HLDG

Slippage sensor and method of operating an integrated power tong and back-up tong

ActiveUS7891418B2Improve resolutionHigh sensitivityDrilling rodsFluid removalEngineeringElectrical and Electronics engineering

Method and apparatus to make-up or break-out a threaded tubular connection using an integrated power tong and back-up tong (10). The power tong (20) may be disabled upon sensing a predetermined threshold amount of displacement of at least a portion of a back-up tong (14). The sensed displacement indicates that the back-up tong (14) is slipping, and power tong (20) rotation may be disabled to prevent damage to the pipe string (16) or surrounding equipment. A slippage sensor (40) may be disposed to sense displacement of at least a portion of the back-up tong (14) relative to a supporting frame (12). In one embodiment, the slippage sensor (40) may be operatively coupled to a valve (50) disposed in communication with a fluid line (46) supplying power fluid to the power tong (20). The power tong (20) may be disabled by impairing flow to the power tong (20) upon sensing a predetermined displacement of the back-up tong (14).

Owner:FRANKS INT

Checkweigher with independent scales

ActiveUS8237067B2Valuable line spaceLow costWeighing apparatus for continuous material flowWeighing apparatus with automatic feed/dischargeHeavy weightCheck weigher

Owner:METTLER TOLEDO INC

Dog bark door bell notification and personal protection system

InactiveUS7683800B2Operation is disabledAlarms with occupancy stimulationSignalling system detailsDoorbellAudio power amplifier

A door bell notification and personal protection system includes a warning notification module adapted to recognize at least one of a door bell notification from a door bell ringer or emergency transmission signal from a wireless transmitter and thereafter provide a recognition signal to a microprocessor. The microprocessor is adapted to retrieve dog barking sounds stored in a memory and provide the dog barking sounds to at least one of an amplifier or radio frequency transmitter after the microprocessor receives the recognition signal from the warning notification module. Dog barking sounds can be broadcasted using the wireless transmitter. A delay module can enable processing with a delay time after first receipt of the recognition signal. A random module can enable random retrieval of various dog barking sounds from memory for processing. A time out module can disable operation of the microprocessor at a set time after recognition signal receipt.

Owner:ORTIZ MELISENDRO T +1

Energy storage system state of charge diagnostic

ActiveUS7301304B2Avoid damageExtended service lifeBatteries circuit arrangementsPropulsion using engine-driven generatorsOperating pointState of charge

Owner:ALLISON TRANSMISSION INC

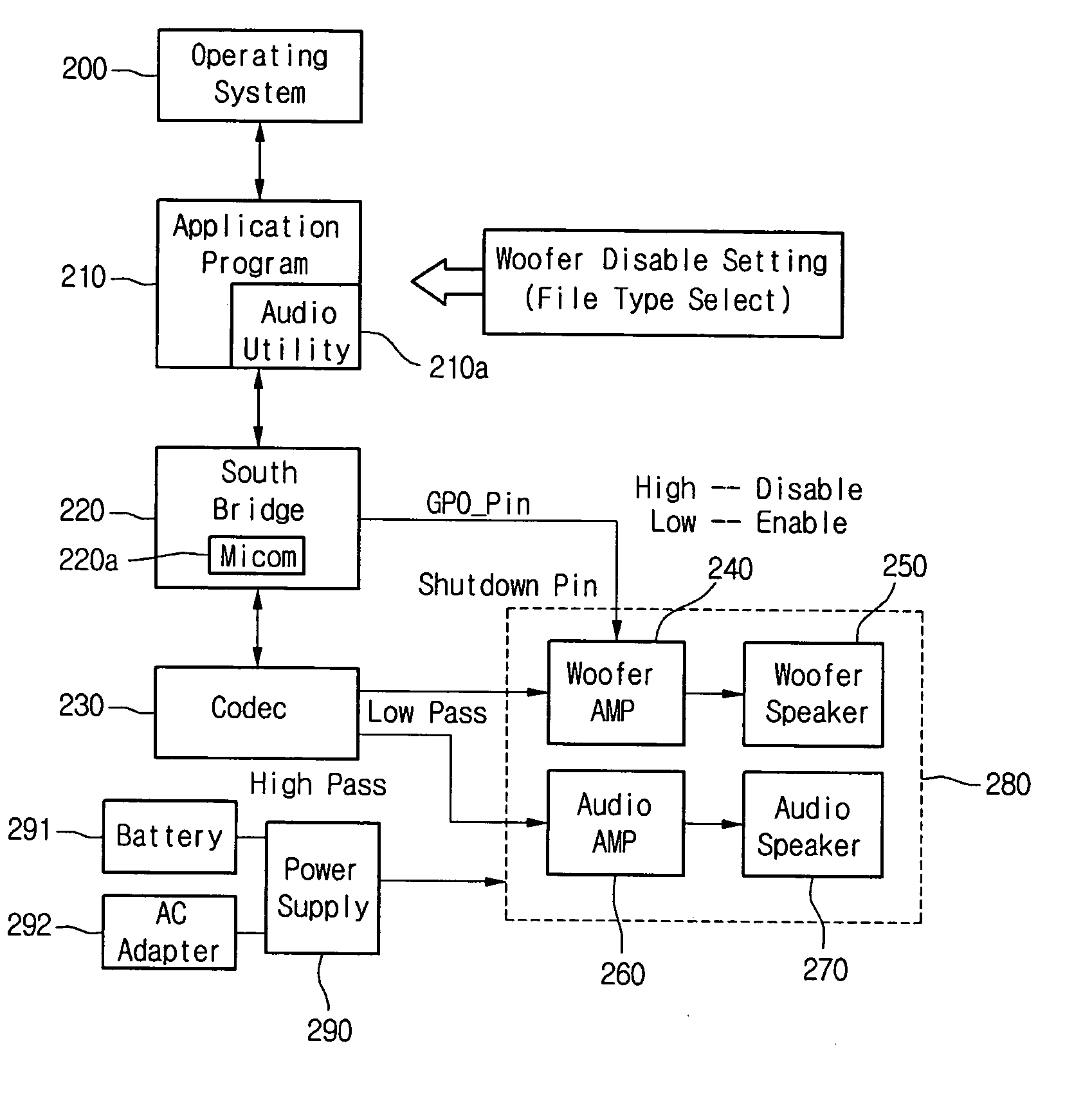

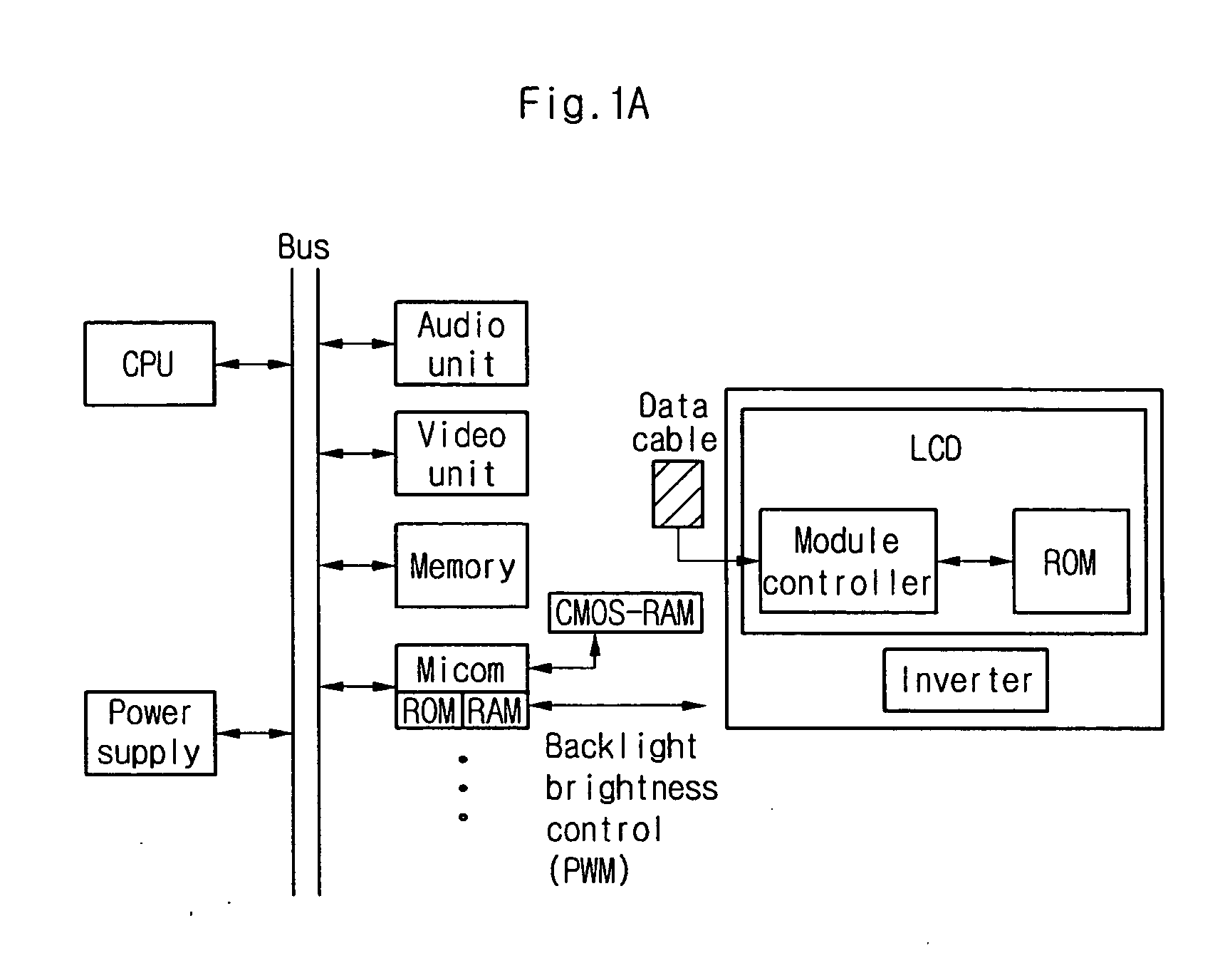

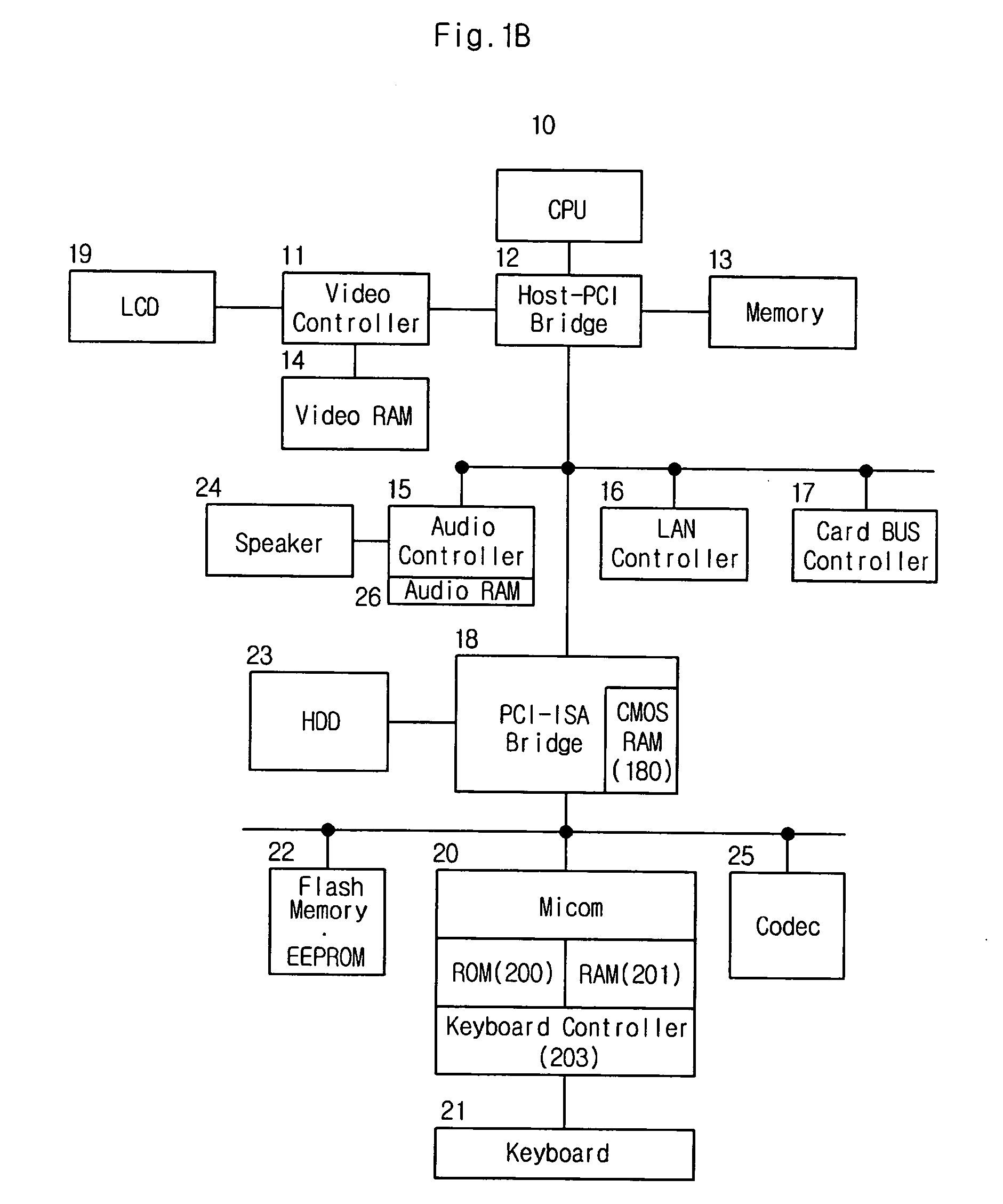

Apparatus and method for controlling operation of audio low sound output means

InactiveUS20050192687A1Low audio outputOperation is disabledNear-field transmissionDigital data processing detailsWooferData type

The present invention is related to an apparatus and a method for controlling operations of low sound output in an audio system. Embodiments of an apparatus and a method for controlling an operation of an audio woofer in a machine provided with an audio system such as a portable computer can operate using at least one or more information of an audio data type, an audio signal, an audio channel number and a power source. Therefore, it is possible to accurately select and listen to an audio of a high-pass component only by stopping operations of a low-pass component for an audio as reproduced. In addition, embodiments of the present invention can extend a time for using a battery by controlling operations of a woofer, when using the battery power.

Owner:LG ELECTRONICS INC

Display device, user interface, and method for providing menus

ActiveUS7747961B2Easy to operateLow costDigital computer detailsCathode-ray tube indicatorsLocation detectionDisplay device

A display device may include a display unit, a touch detecting unit that detects a touch on the display unit, a touch-position detecting unit that detects a touch position on the touch detecting unit and outputs coordinate data of the position, a display control unit that causes the display unit to provide dual view display of an image and display a menu image, a menu generating unit that generates first and second top menus, and a control unit that performs control to display the top menus in different positions on a screen of the display unit, to determine, on the basis of the coordinate data from the touch-position detecting unit, which of the top menus has been touched, to enable operations on one of the top menus that has been touched, and to disable operations on the other one of the top menus.

Owner:ALPINE ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com