Patents

Literature

36 results about "Bidirectional map" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer science, a bidirectional map, or hash bag, is an associative data structure in which the (key,value) pairs form a one-to-one correspondence. Thus the binary relation is functional in each direction: each value can also be mapped to a unique key. A pair (a,b) thus provides a unique coupling between a and b so that b can be found when a is used as a key and a can be found when b is used as a key.

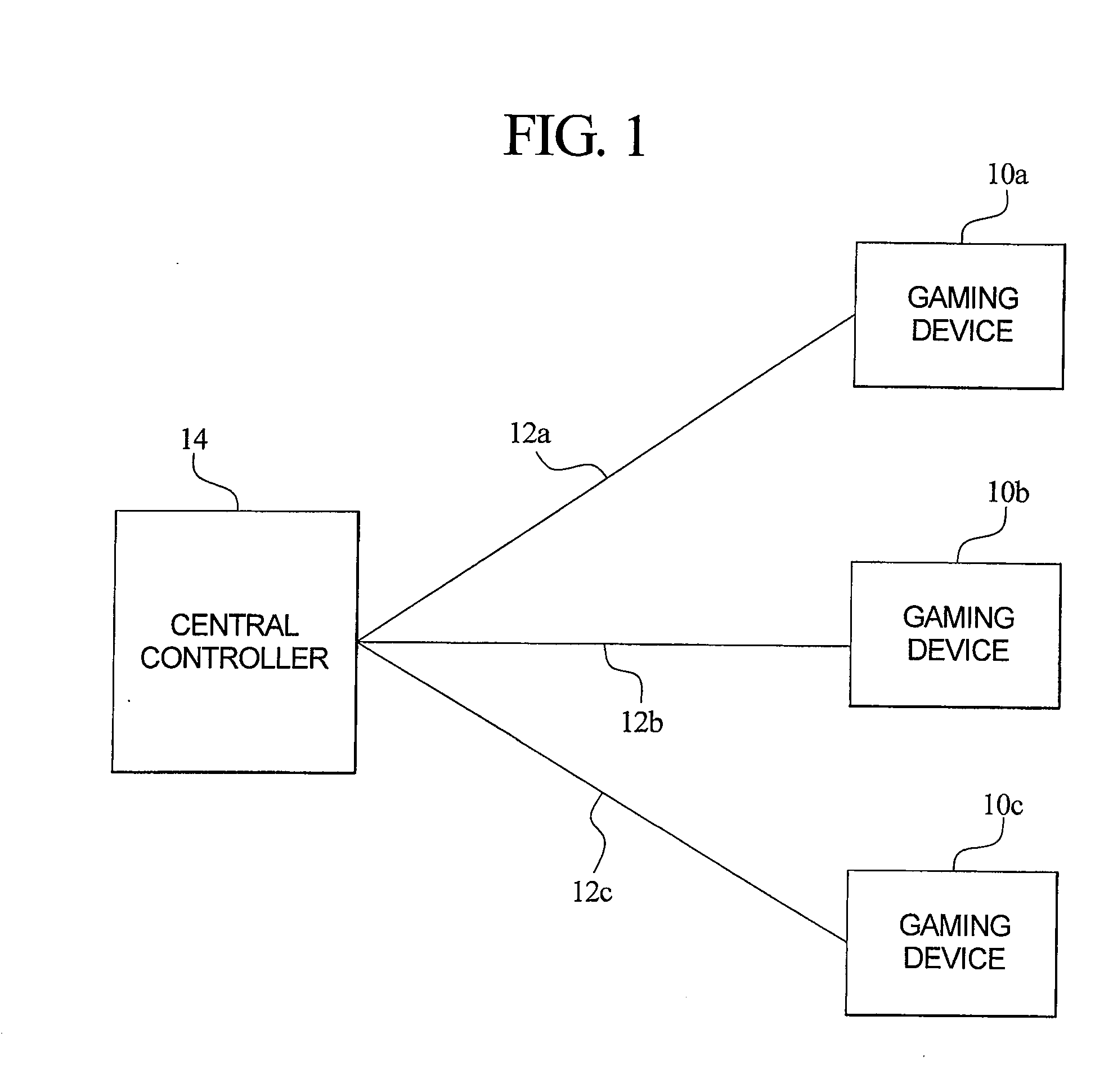

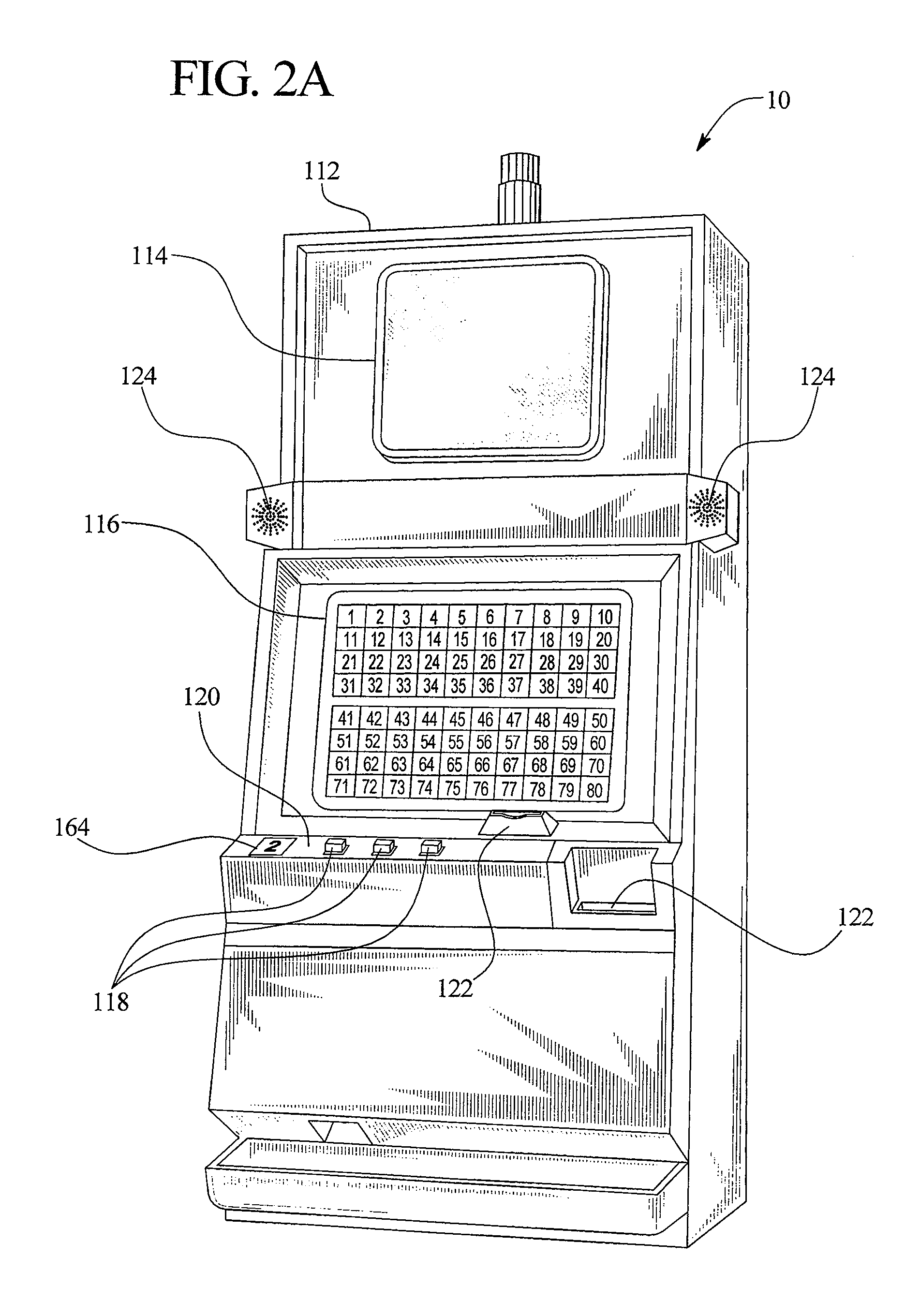

Central determination gaming system with a keno game

InactiveUS7399227B2Improve the level ofIncreases level of enjoymentLottery apparatusBoard gamesEngineeringComputer terminal

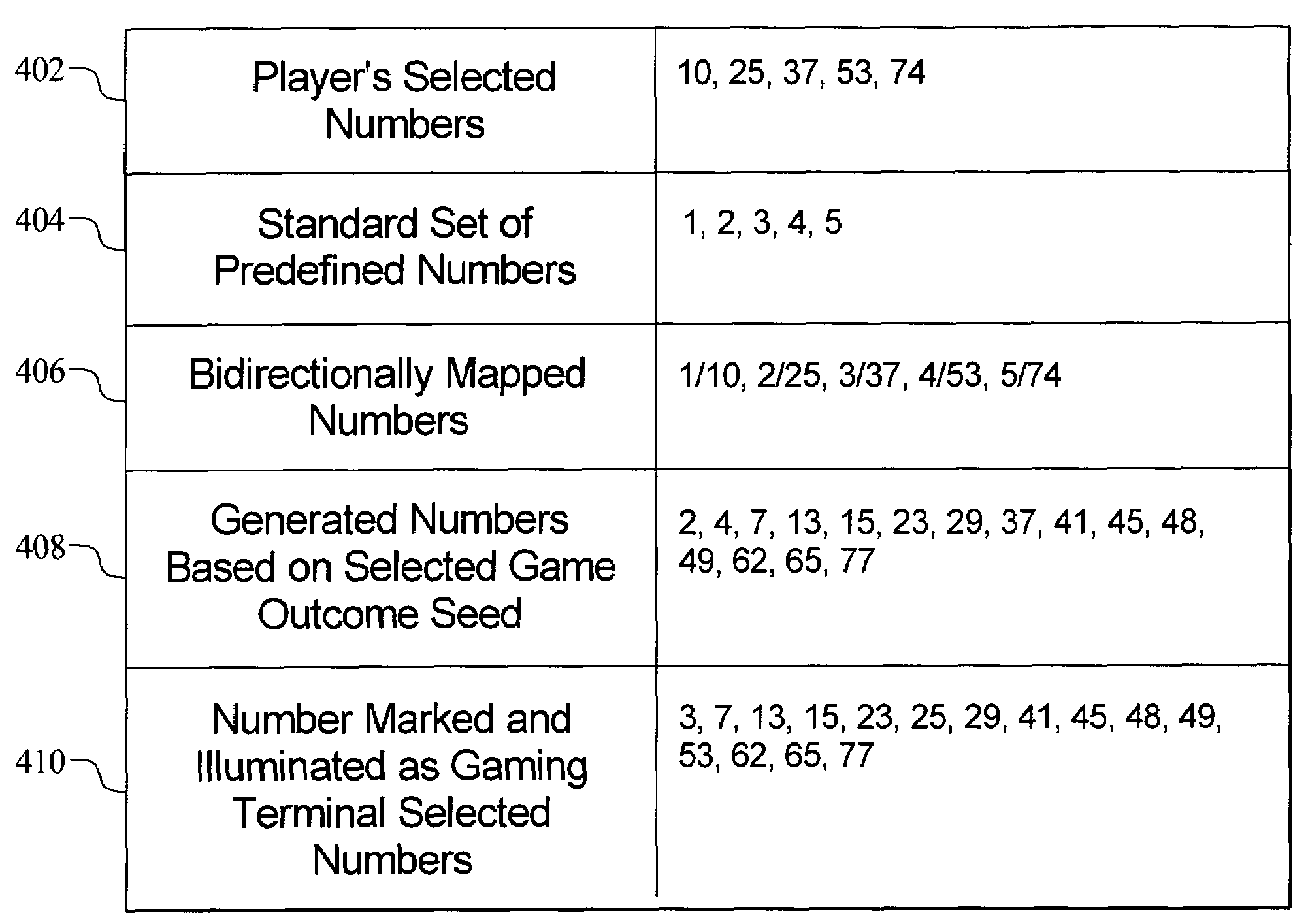

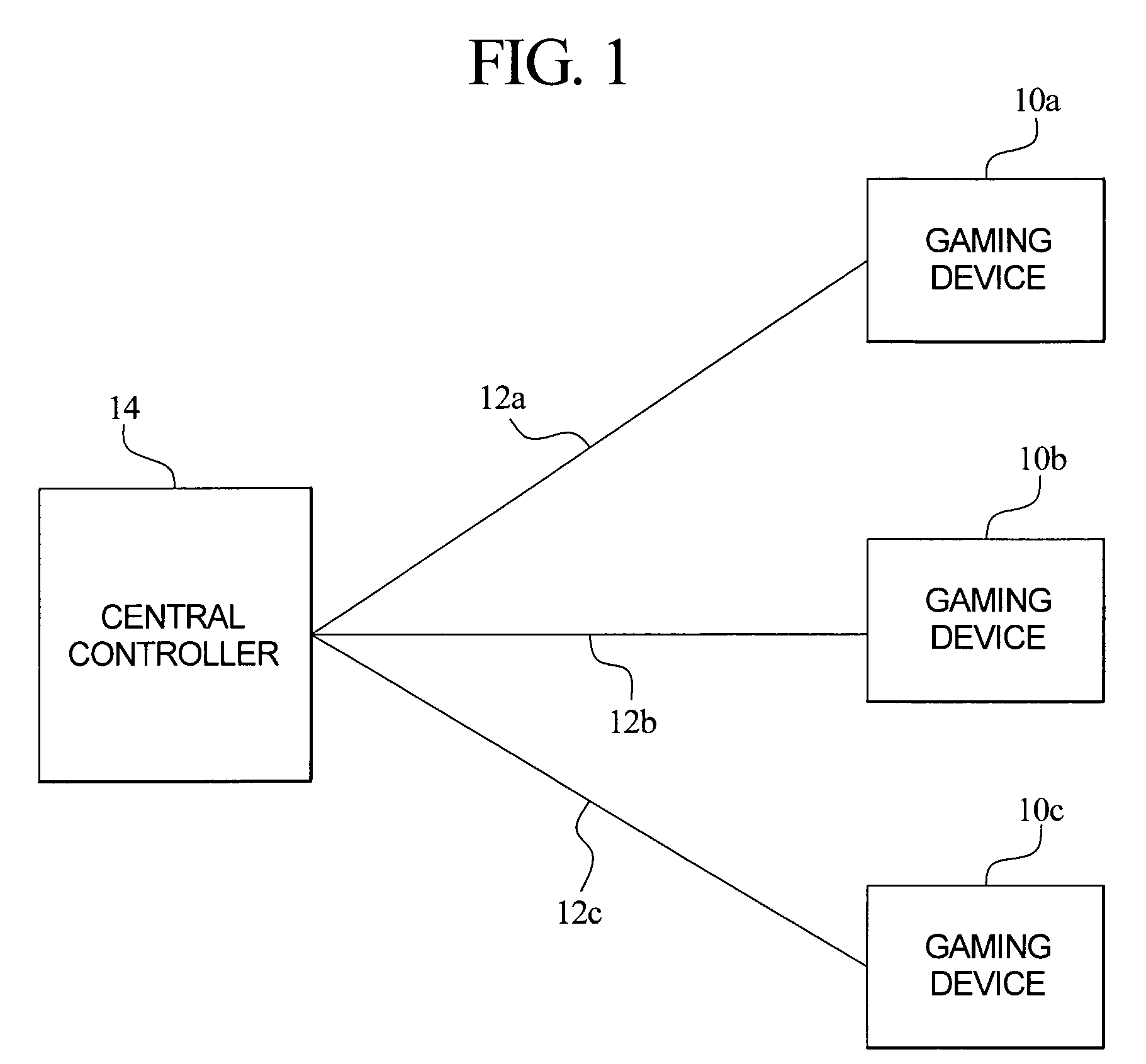

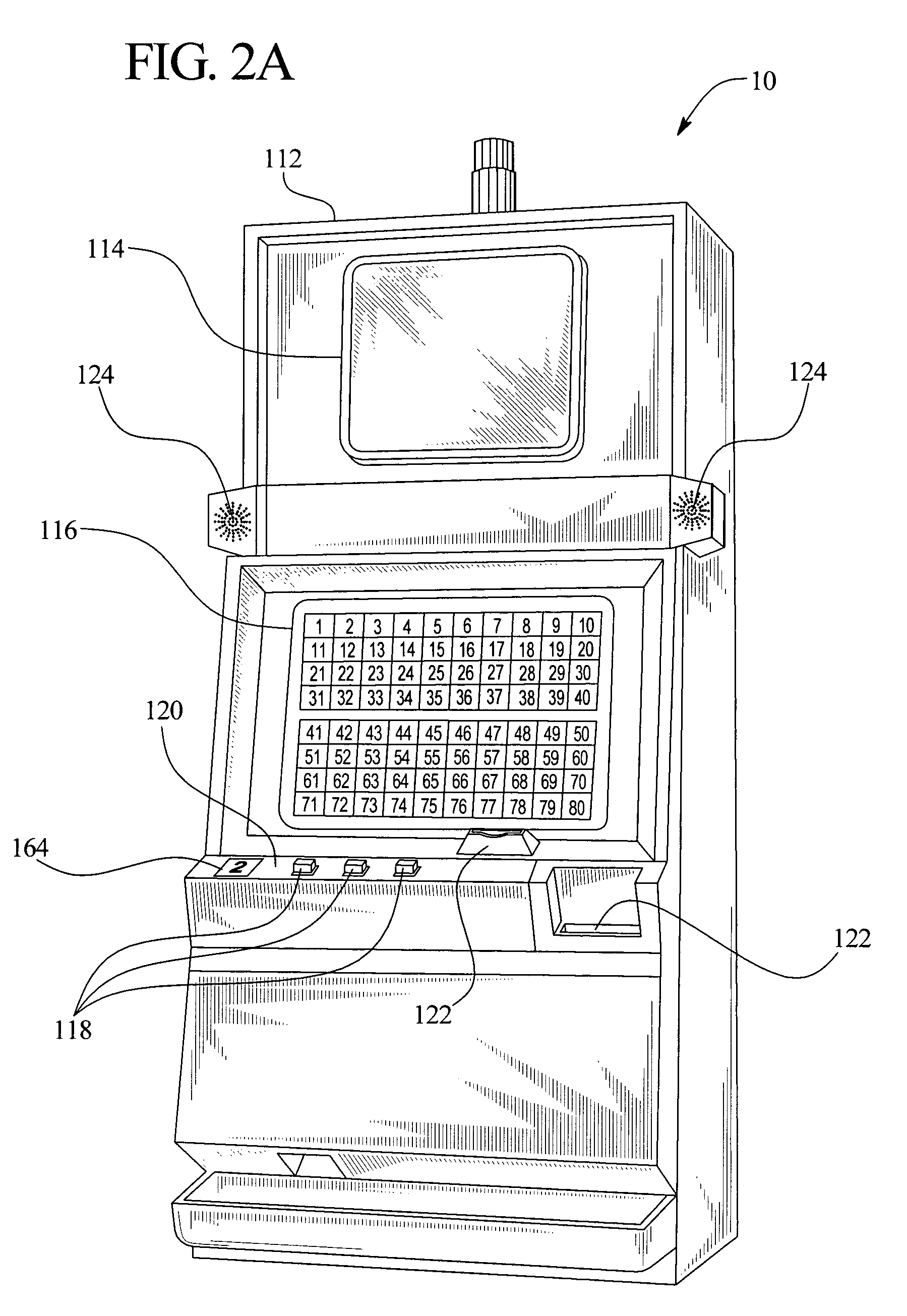

A central determination gaming system with a keno game. Upon a player initiating a game play at gaming terminal, the gaming terminal enables the player to select a plurality of symbols. The gaming terminal accesses a standard set of predefined symbols for the specific game played. The gaming terminal bidirectionally maps the player's selected symbols with the standard set of predefined symbols. The gaming terminal receives a predetermined game outcome seed from a central controller. The gaming terminal utilizes the selected game outcome seed to generate a plurality of game symbols. The gaming terminal determines if each of the generated game symbols needs to be modified. If so, the gaming terminal modifies these generated game symbols based on the bidirectionally mapping, presents the modified game symbols to the player and provides the player a game outcome that is determined based on the selected game outcome seed.

Owner:IGT

Central determination gaming system with a keno game

ActiveUS20080254894A1Generate numberImprove the level ofLottery apparatusBoard gamesEngineeringComputer terminal

A central determination gaming system with a keno game. Upon a player initiating a game play at a gaming terminal, the gaming terminal enables the player to select a plurality of symbols. The gaming terminal accesses a standard set of predefined symbols for the specific game played. The gaming terminal bidirectionally maps the player's selected symbols with the standard set of predefined symbols. The gaming terminal receives a predetermined game outcome seed from a central controller. The gaming terminal utilizes the selected game outcome seed to generate a plurality of game symbols. The gaming terminal determines if each of the generated game symbols needs to be modified. If so, the gaming terminal modifies these generated game symbols based on the bidirectionally mapping, presents the modified game symbols to the player and provides the player a game outcome that is determined based on the selected game outcome seed.

Owner:IGT

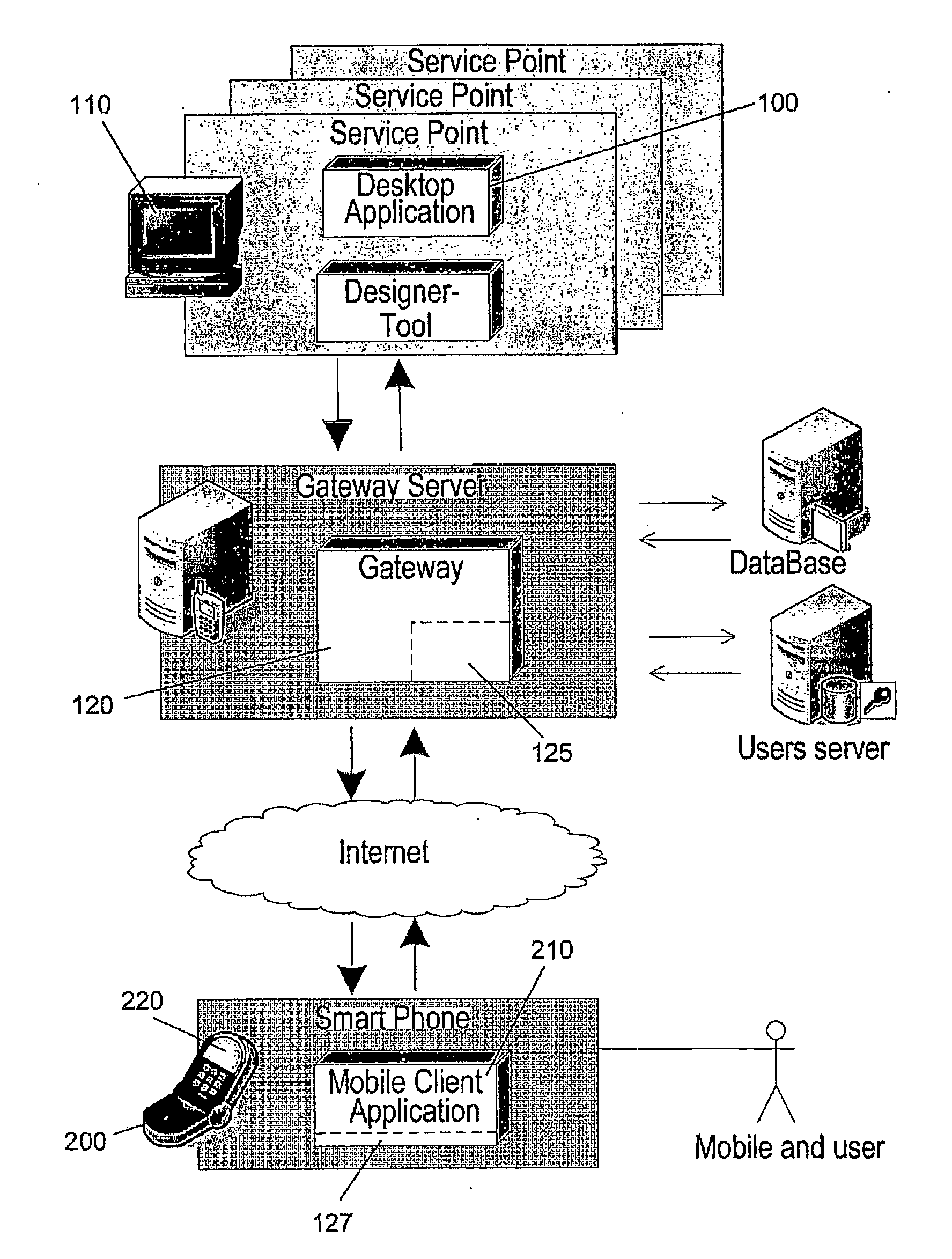

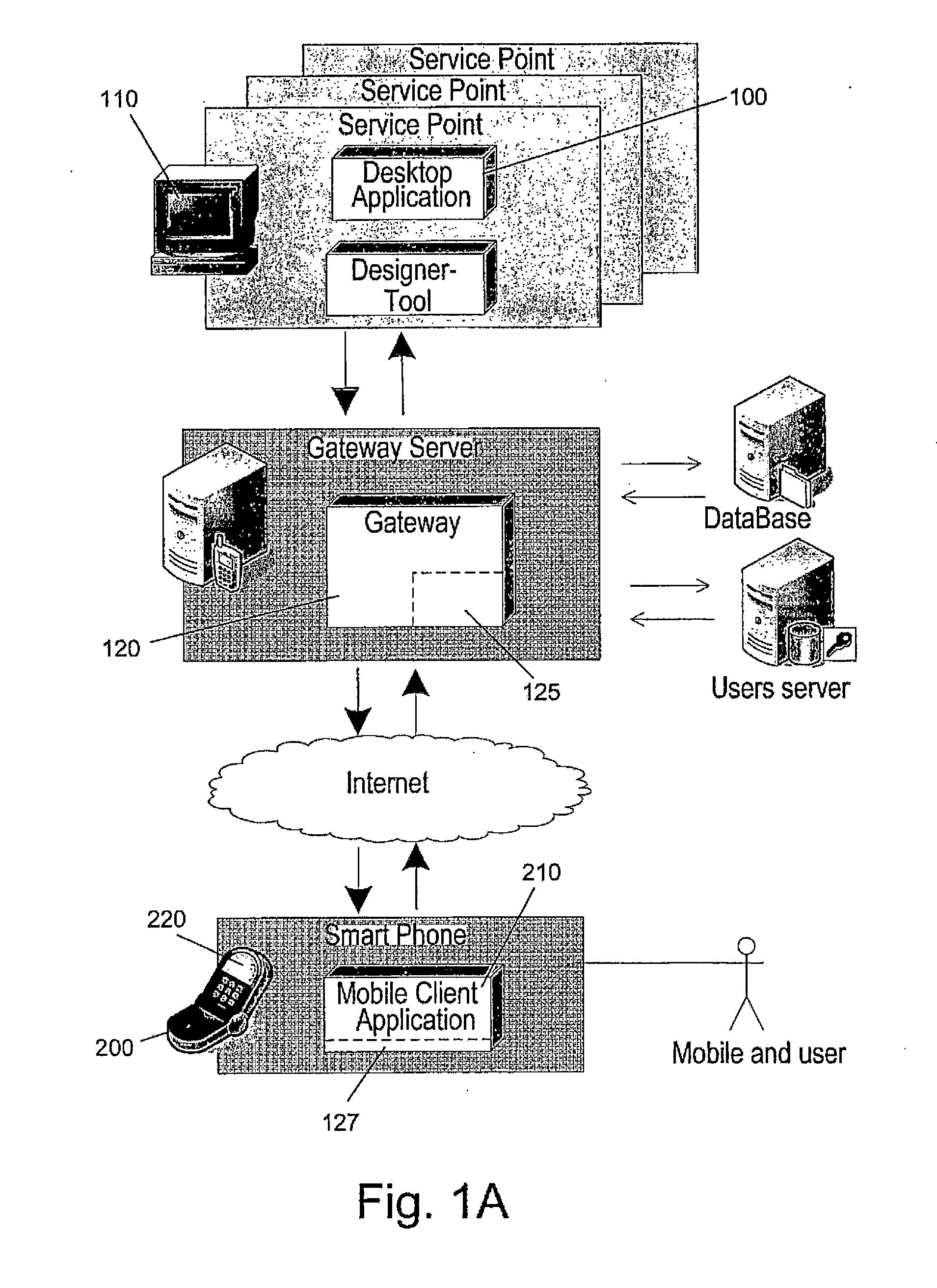

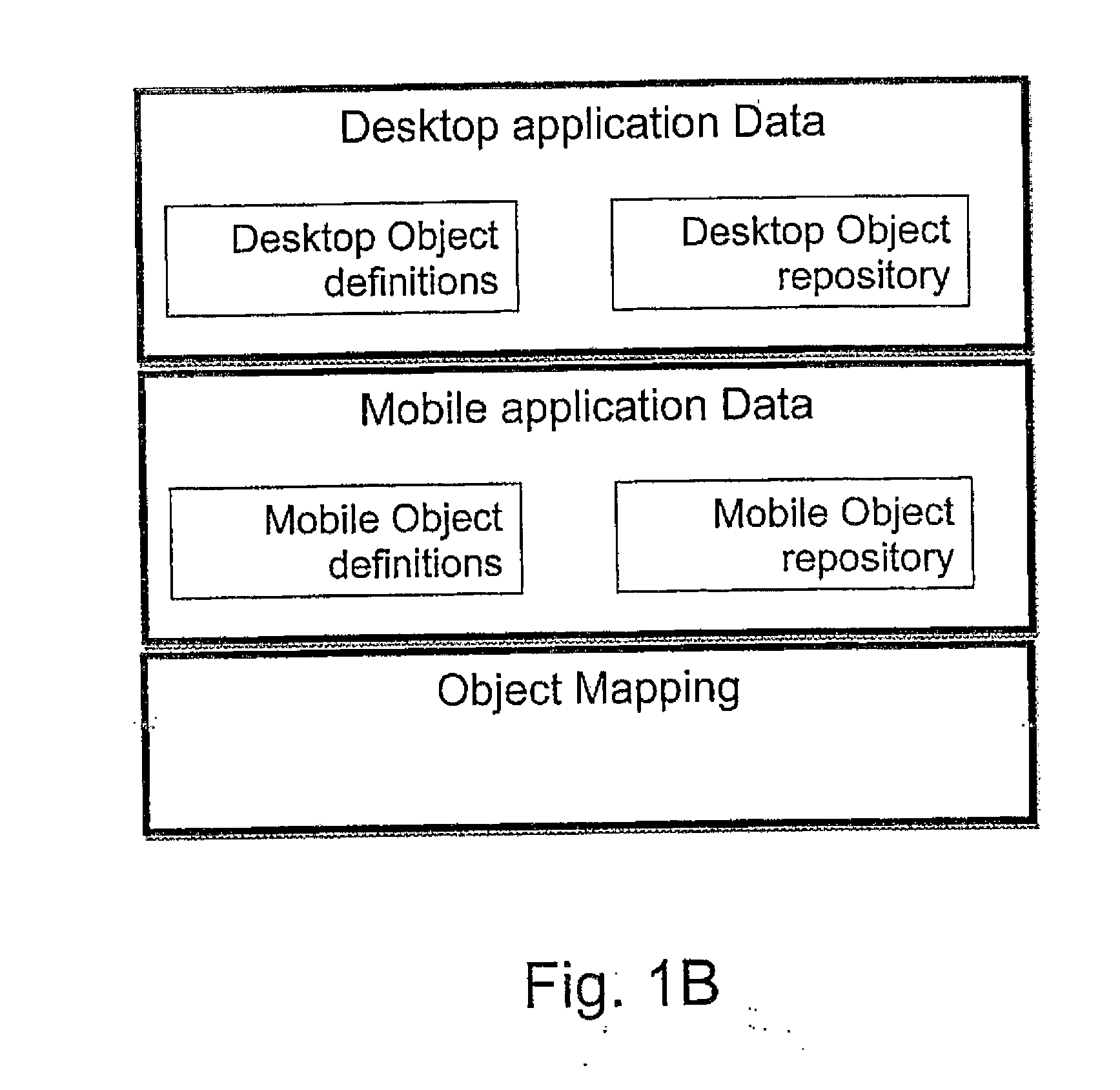

Method and system for emulating desktop software applications in a mobile communication network

A data processing system for emulating a desktop application desktop software applications in a mobile communication network that comprises (a) an agent for identifying and activating UI objects of a desktop application, and changes in the UI objects (b) a Designer-Tool that is associated with the agent, to generate offline (b.1) a plurality of data sets including representations for objects and states of the desktop application to be converted to corresponding mobile objects and states; (b.2) a plurality of representations of required changes in objects in response to user actions; (b.3) a plurality of data sets for bidirectional mapping between the objects and states of the desktop application and the corresponding mobile objects and states; (c) a user client to control the GUI and represent objects and states of the desktop application and to receive user actions from the GUI; change the represented objects responsive to user actions; and send the user actions to a gateway that is in communication with the user client and with the desktop application via the agent, and during runtime, to (d.1) map the user actions from the user client to corresponding actions in the desktop application to be used by the agent using the datasets; (d.2) receive updated outputs from the desktop application via the agent; (d.3) map the updated output and UI objects to a mobile format, using the datasets; (d.4) send the mapped updated output to the user client; (d.5) manage sessions of users with the desktop applications in the form of service points running on the server or desktop computer.

Owner:YUBITECH TECH

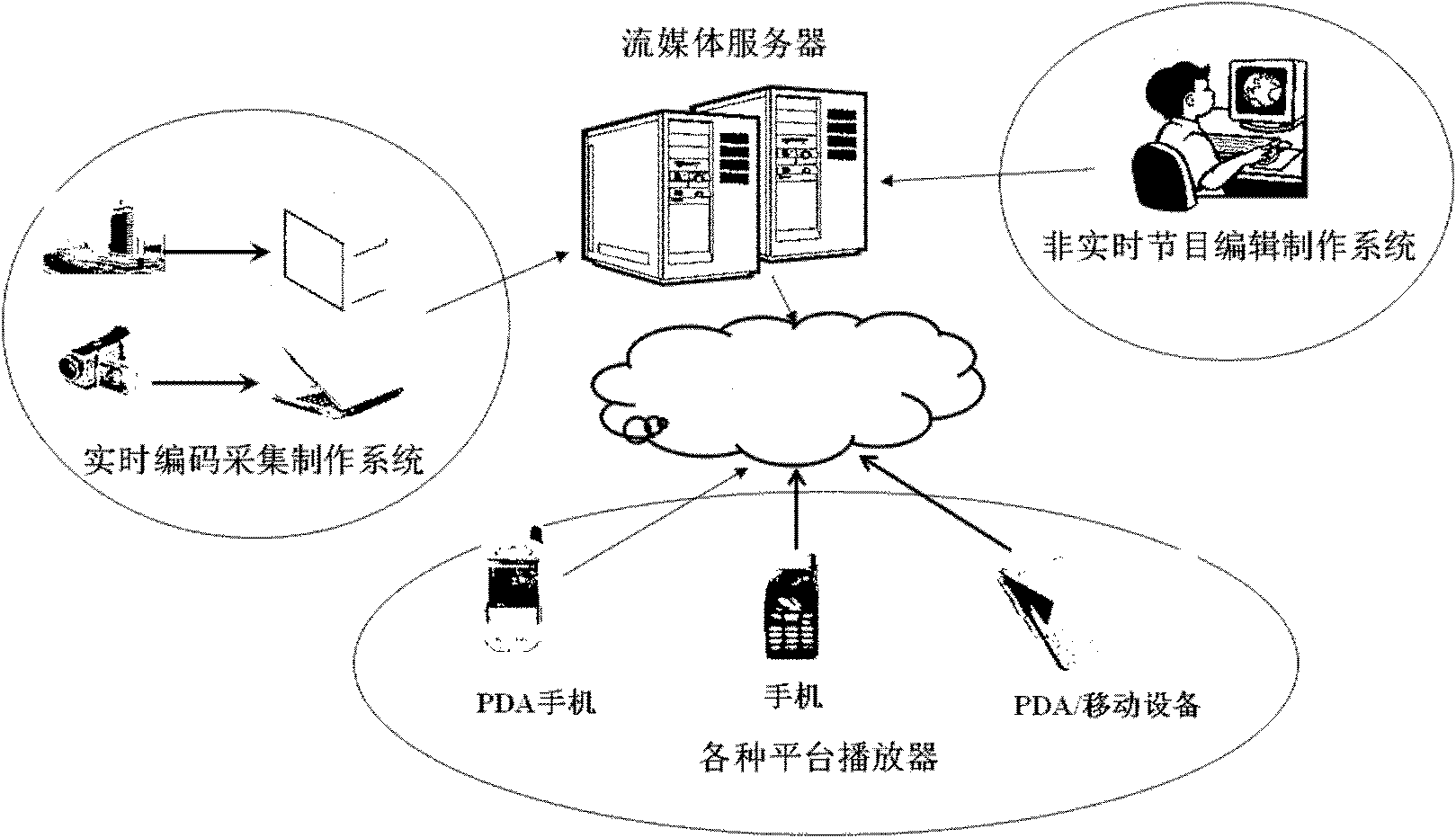

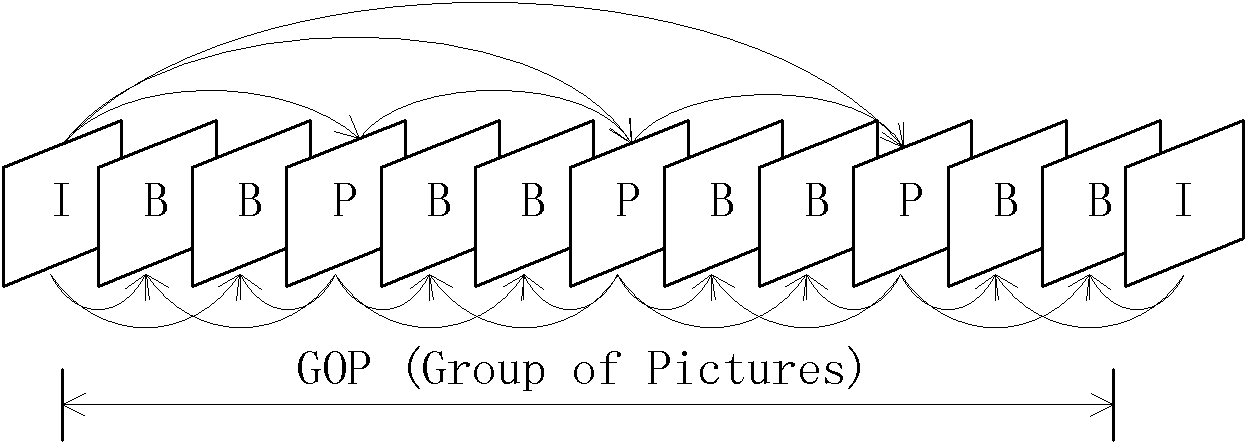

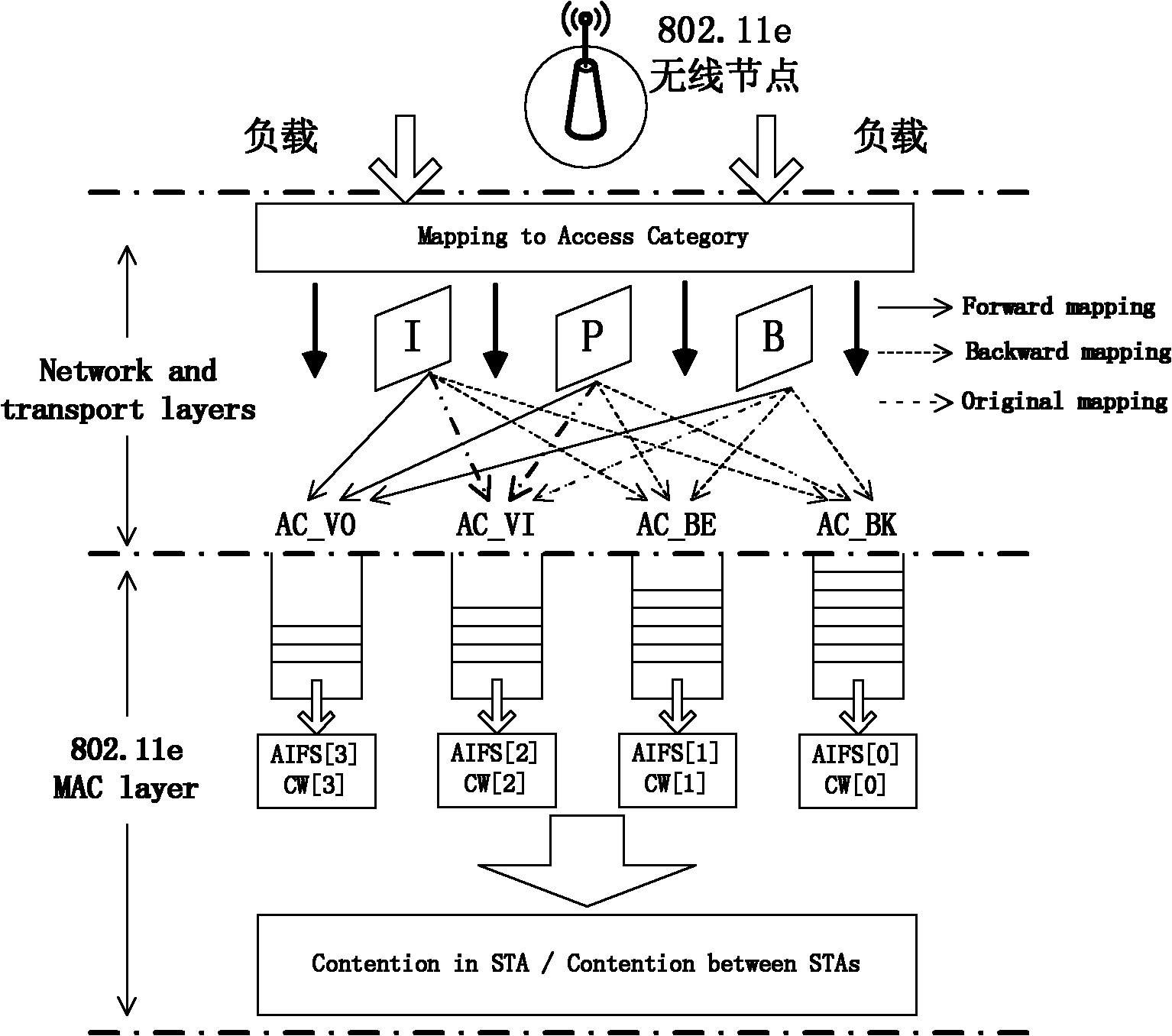

Mapping parameter dynamic adaptive wireless streaming media transmission control method

ActiveCN102104538AImprove throughputImprove transmission qualityTelevision systemsDigital video signal modificationVideo transmissionNetwork conditions

The invention discloses a mapping parameter dynamic adaptive wireless streaming media transmission control method, which comprises the following steps of: 1) adding initial priority identifiers in a network transmission layer according to the importance of video frames by using the video stream coding of an application layer, and mapping nodes to corresponding priorities according to final priority identifiers of each data frame in a medium access control (MAC) layer respectively; 2) according to real-time network load distribution and the congestion conditions of each priority queue, dynamically calculating the mapping possibilities of each video frame to the corresponding priorities based on the characteristics of each video frame; 3) adopting a bidirectional mapping mechanism for key frames and adopting a double downward mapping mechanism for other enhancement layer data frames according to real-time network conditions; and 4) feeding information back to the application layer and the transmission layer according to current network conditions and video frame mapping results by using the MAC layer. By the method, the network throughput is effectively increased, relatively shorter real-time video transmission delay is achieved and video stream transmission quality is improved.

Owner:杭州远传新业科技股份有限公司

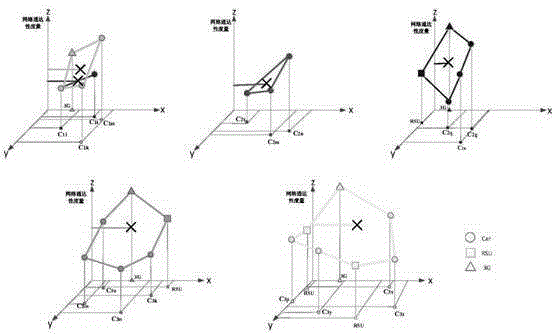

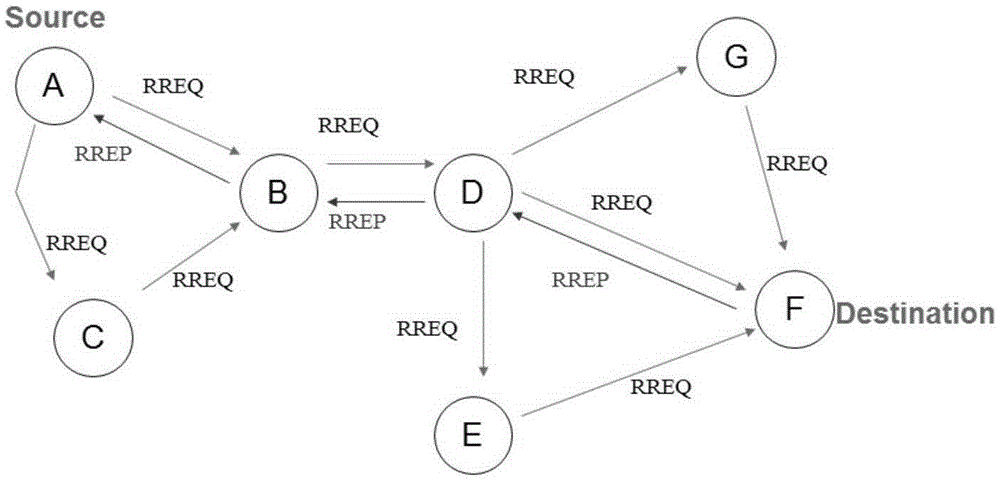

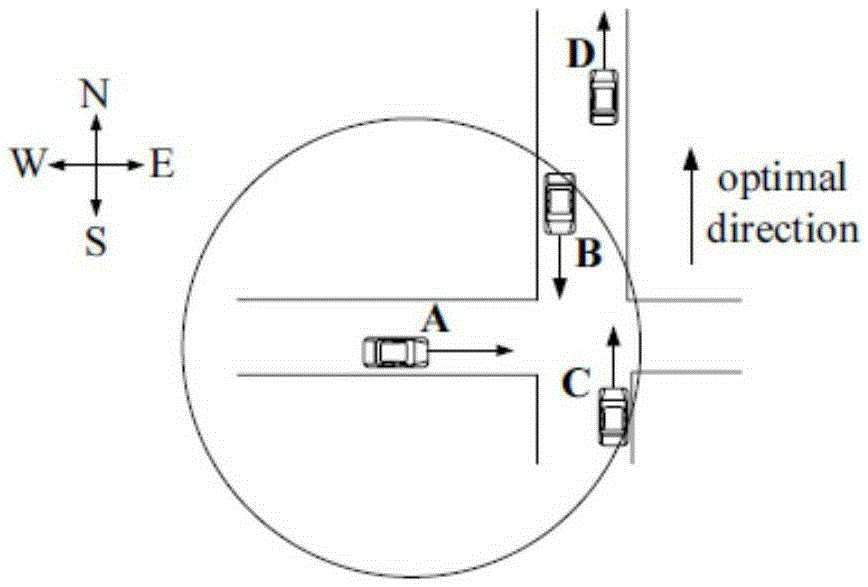

Telematics network node screening and accessibility routing construction method based on self-encoding network

ActiveCN105245608AImprove performanceIncrease average latencyTransmissionScreening methodScreening algorithm

The invention relates to the technical field of telematics, and provides a telematics network node screening and accessibility routing construction method based on a self-encoding network. The entire routing mechanism comprises data preprocessing, self-encoding network training and node screening algorithm realization. The self-encoding network can provide a high-dimensional continuous data space and bidirectional mapping of a low-dimensional nested structure. The self-encoding network can be used to excavate and extract the related characteristics of node information in a large-scale road transport network. Dimension lowering is carried out on original information. The amount of data in a data transmission process is reduced. An effective way is provided for screening key nodes in the network. According to the invention, a great node screening method is provided for a highway scene, and the network performance is effectively improved.

Owner:TONGJI UNIV

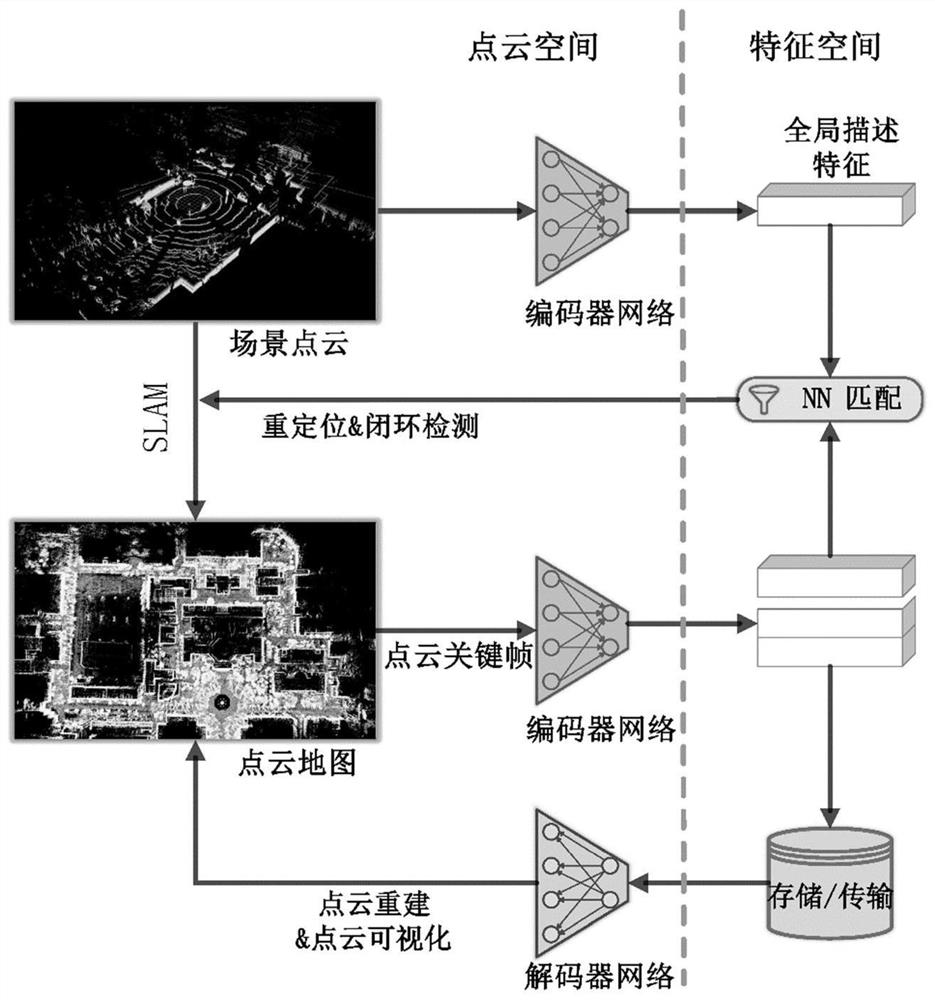

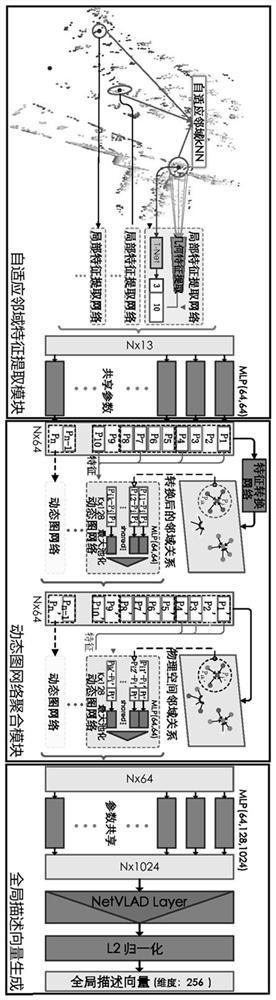

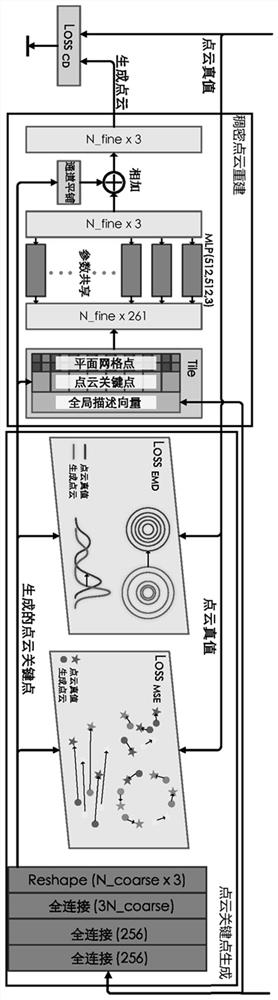

Point cloud feature space representation method for laser SLAM

InactiveCN111783838AEasy to detectAchieve positioningCharacter and pattern recognitionPoint cloudFeature extraction

The invention discloses a point cloud feature space representation method for laser SLAM, and the method builds the bidirectional mapping of a point cloud space and a point cloud feature space based on a deep learning network, and achieves the closed-loop detection and repositioning in the laser SLAM and the map compression storage and transmission in the feature space. Global description featureextraction and compression reconstruction of the large-scale scene point cloud are realized through a neural network of an auto-encoder structure; an encoder network is designed to extract global description features to form a feature space of the point cloud, and similarity measurement of scenes is given according to the distance in the feature space and used for judging whether two or more scenestructures are similar or not, so that closed-loop detection and repositioning of laser SLAM are realized; the method includes reconstructing the point cloud through the designed decoder network, reconstructing the original point cloud from the global description features extracted from the encoder network, and realizing compressed storage and low-bandwidth transmission of the point cloud map; the constructed encoder network does not need to be trained in advance according to a point cloud map, and has strong generalization ability.

Owner:SOUTHEAST UNIV

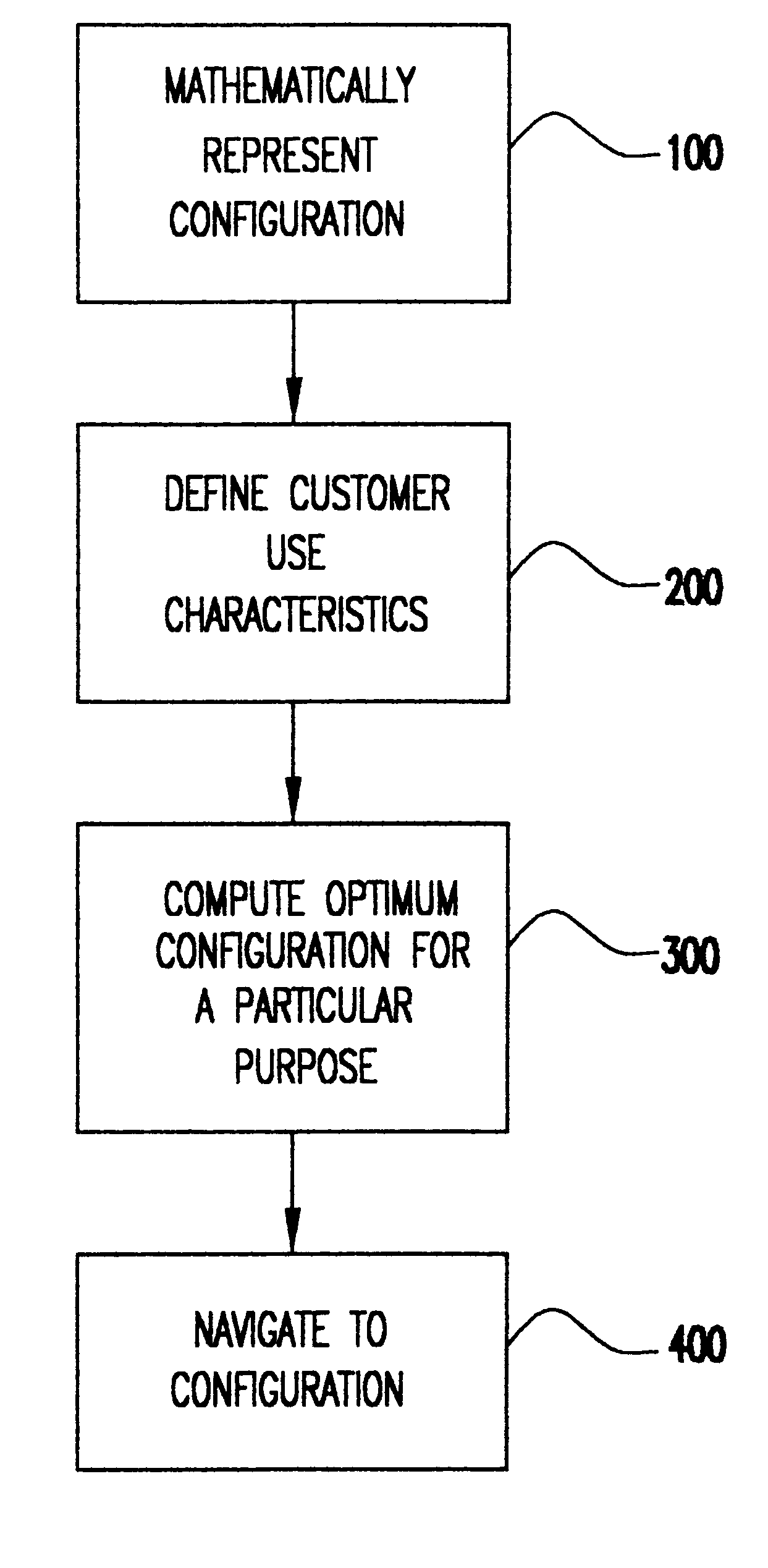

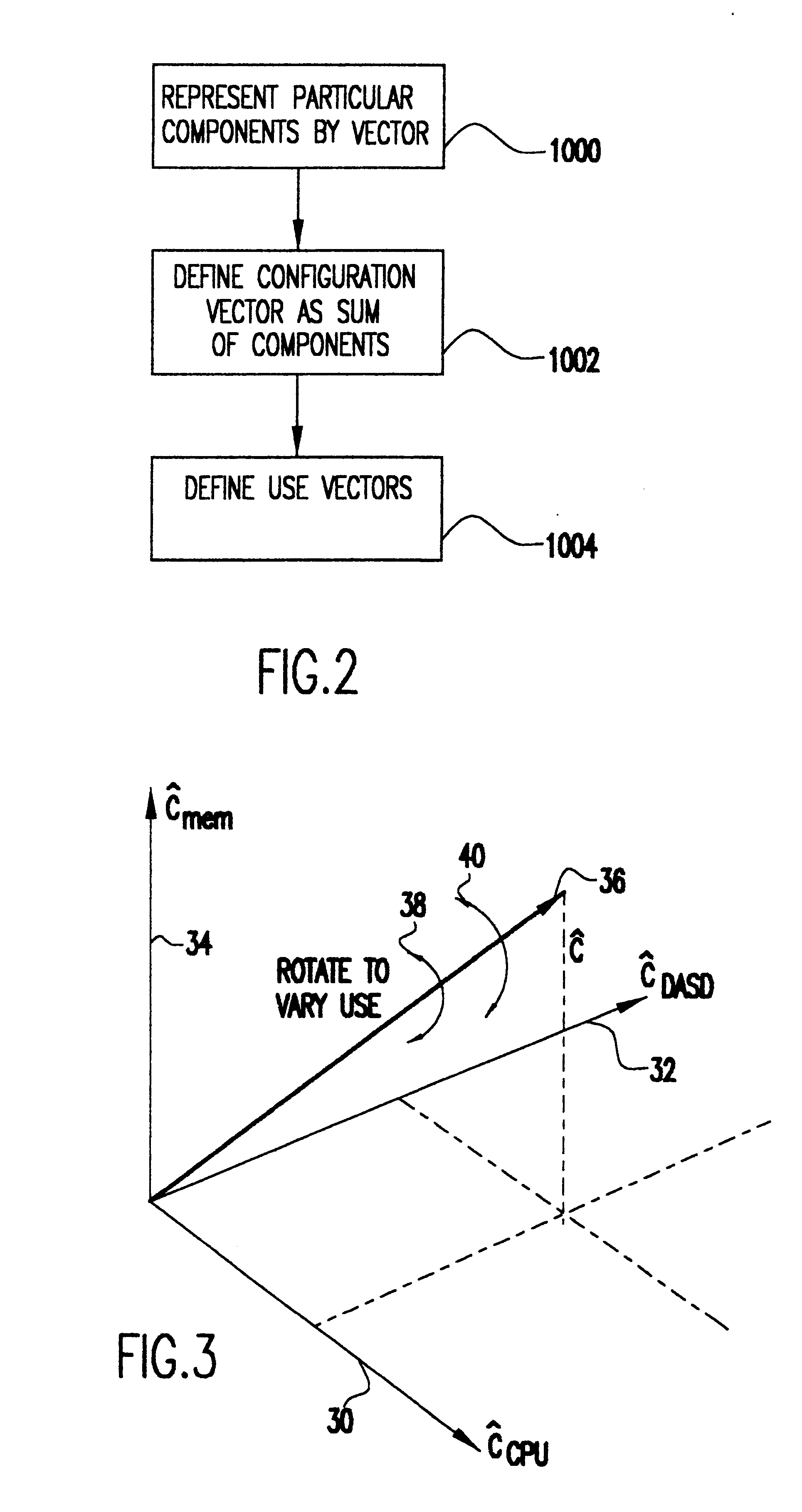

Specifying complex device configeration through use characteristics

InactiveUS6178502B1Digital computer detailsData resettingTechnical communicationUltimate tensile strength

A method for relating a specific configuration of complex units constructed from components with standardized interfaces to the user characteristics of the complete unit. The invention provides a bidirectional mapping between a statement of value to the user through the computation of fitness for a particular purpose (or "use") and a technical configuration. The customer can be presented with a system optimized for a particular use at a particular price point. Through presenting a range of systems around the optimum point and presenting the strength of the system for a variety of uses as the customer varies components, a wide range of customer choice is presented within an understandable range of choices. Each component is characterized by a strength parameter, and the set of components is arranged as a vector. This configuration vector can then be projected on a vector representing a standard use. Particular configuration vectors are characterized by a direction and a magnitude. The magnitude represents an overall strength of a configuration related to the performance or capacity of its individual components. The direction of a general configuration vector can be compared to the direction of a configuration tuned for a particular purpose or use. Similarly, a configuration can be constructed by scaling its magnitude along the direction defined by a tuned configuration and varying the direction to optimize among various uses.

Owner:IBM CORP

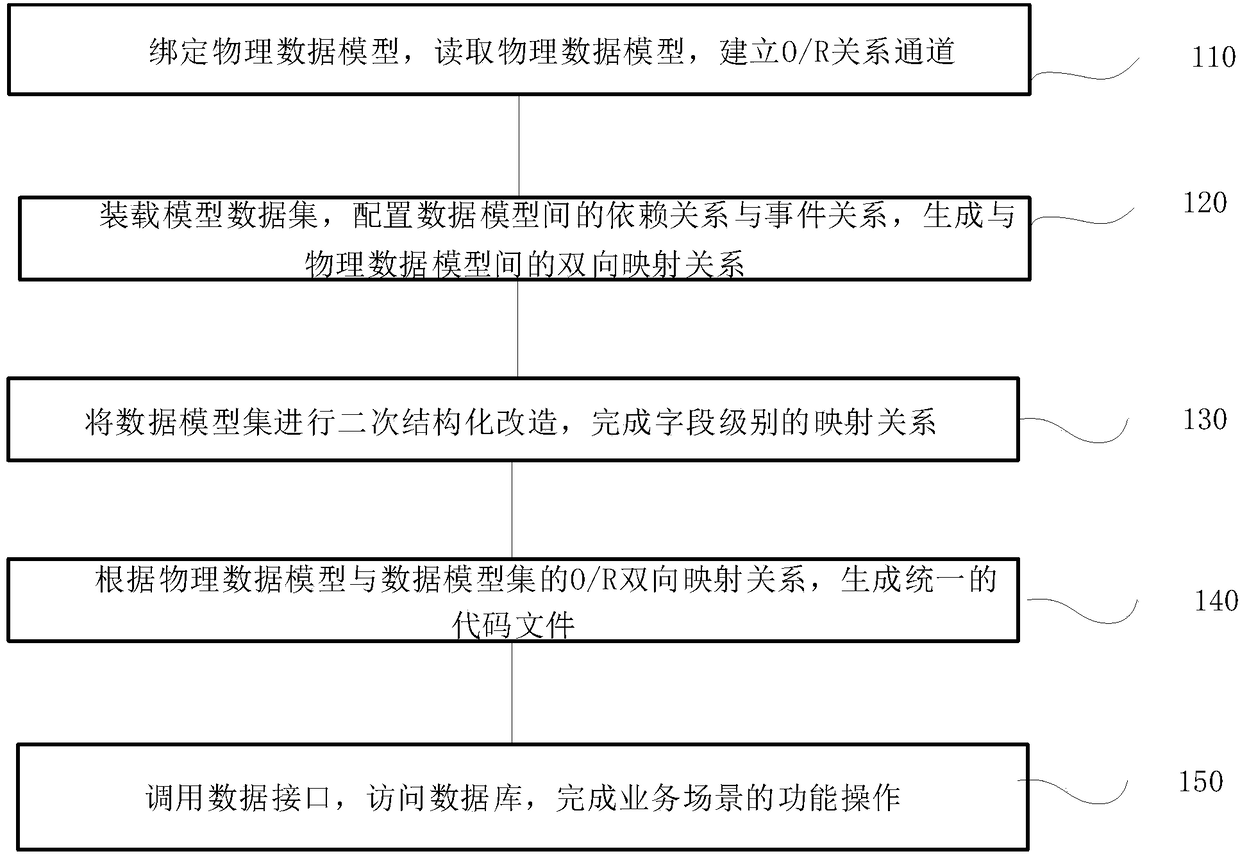

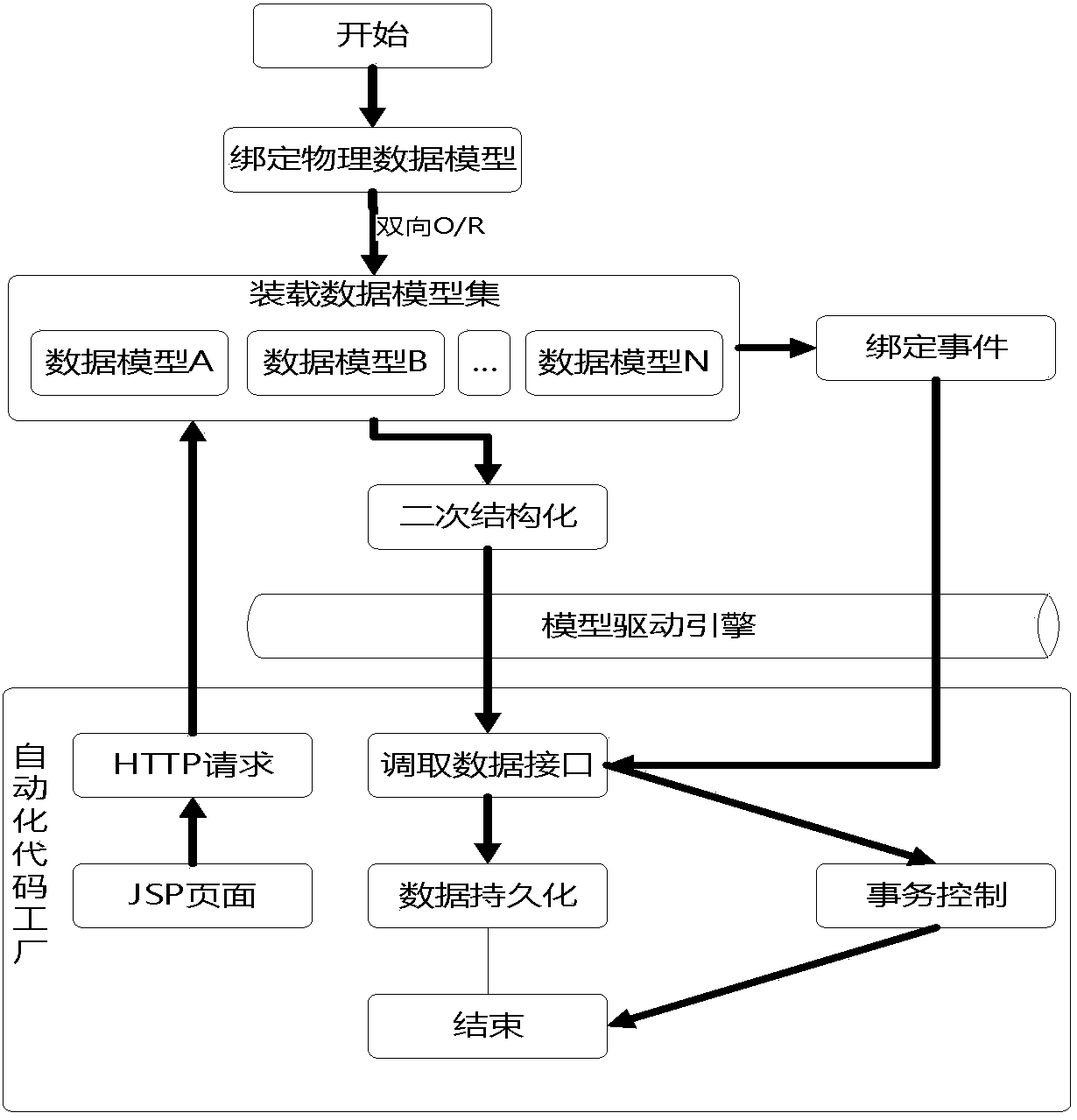

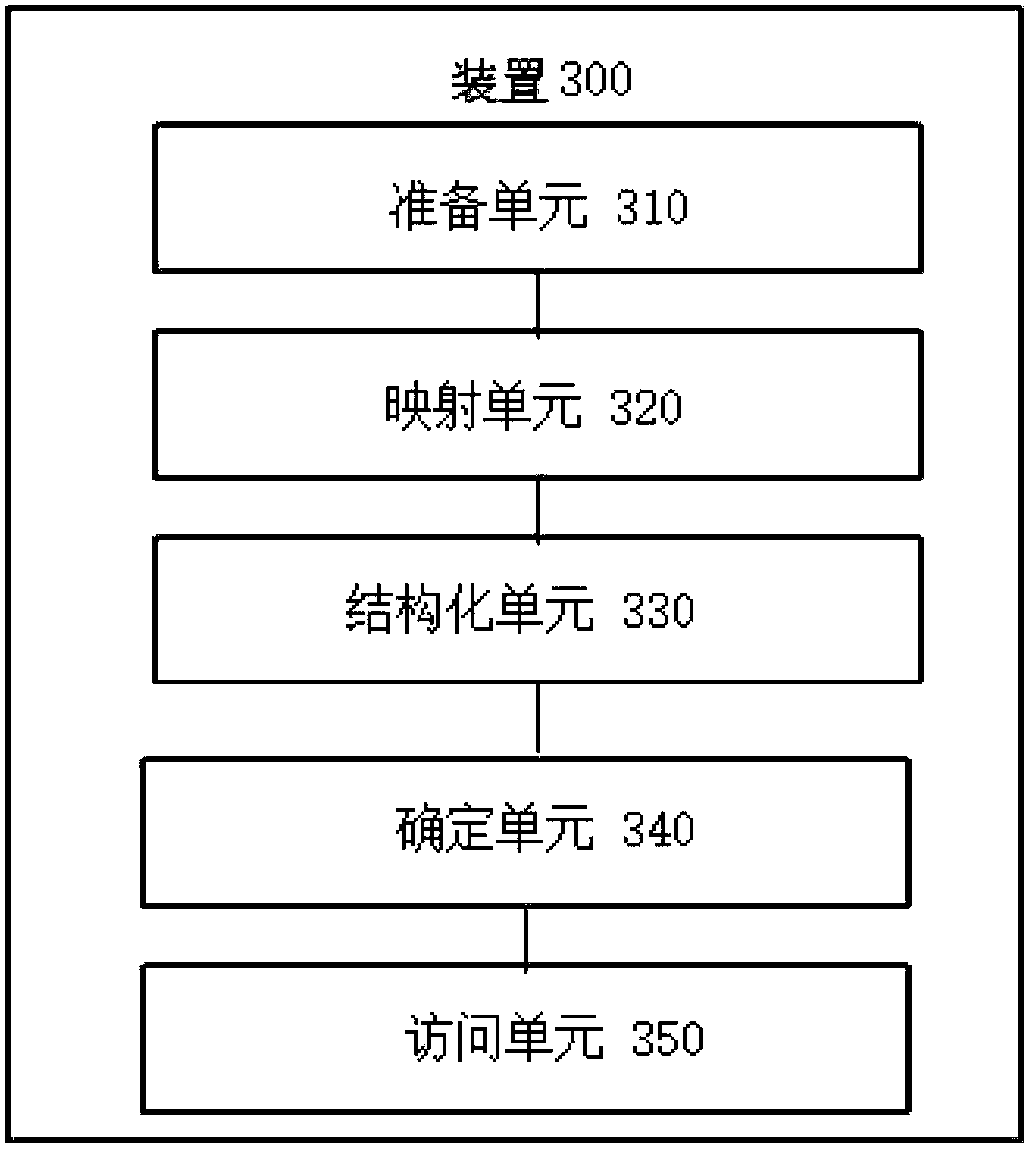

Configuration method, device, terminal and storage medium of visual development environment

ActiveCN109032590AAchieve real-time synchronization mechanismReduce configurationVisual/graphical programmingData setSoftware engineering

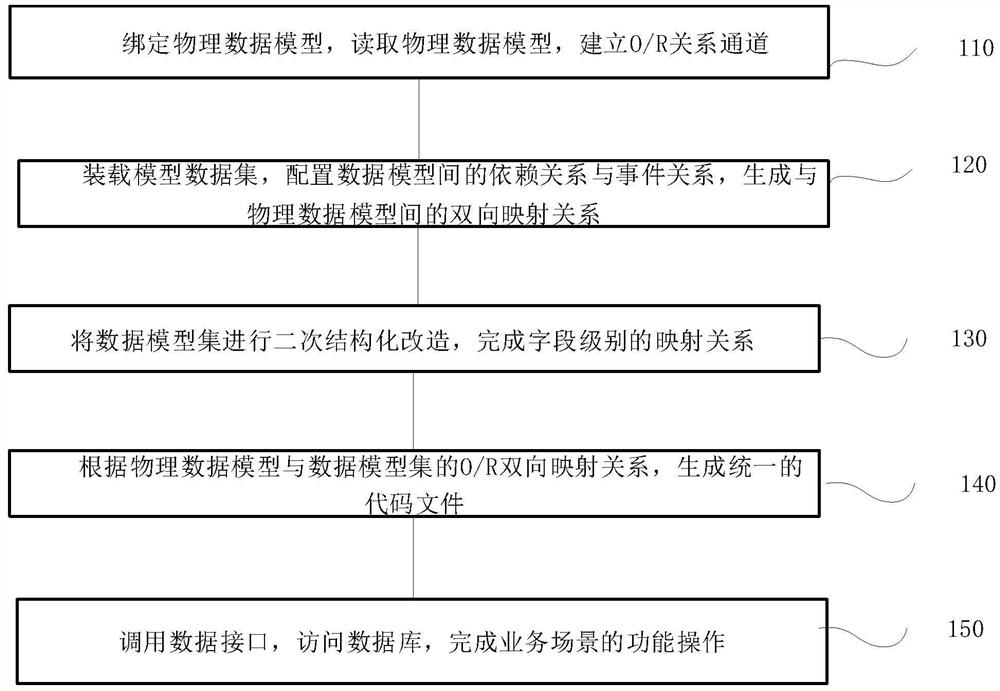

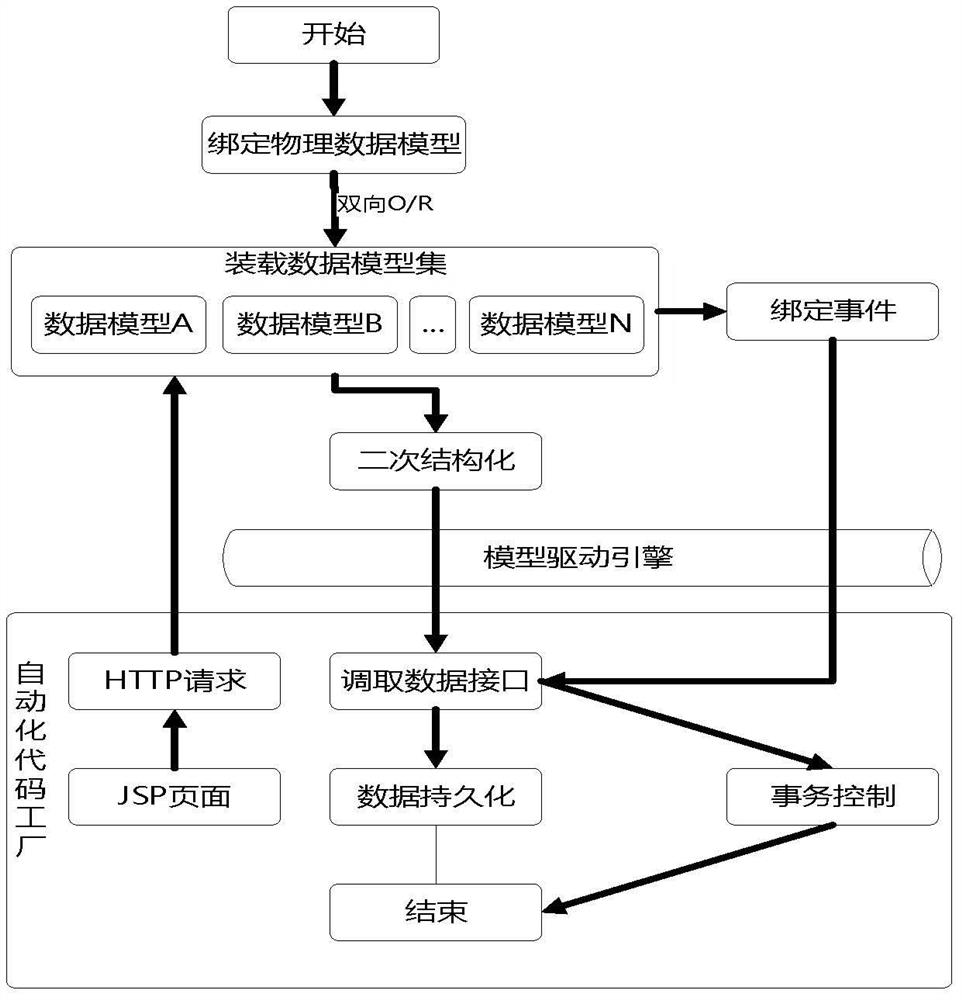

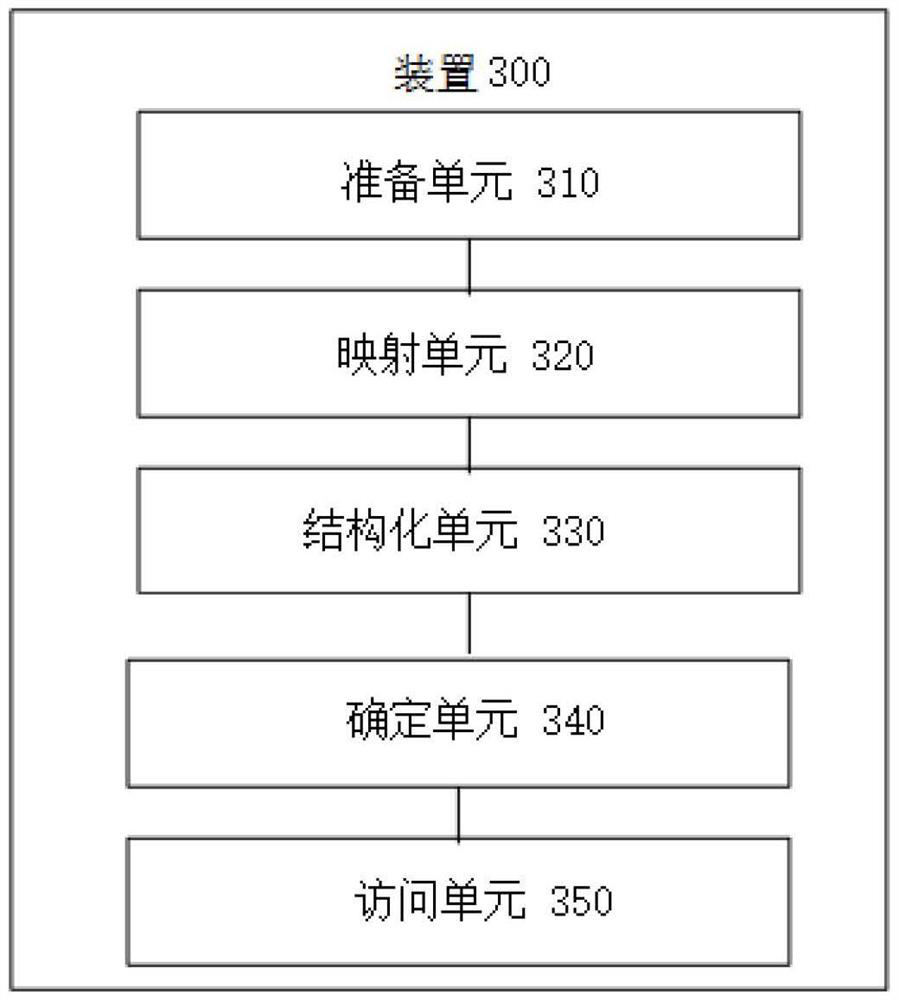

The embodiment of the application provides a configuration method, a device, a terminal and a storage medium of a visual development environment. The method comprises the following steps: binding a physical data model, reading the physical data model, and establishing an O / R relationship channel; loading model data sets, configuring dependencies and event relationships between data models, and generating bi-directional mapping relationships with physical data models; the data model set being restructured to complete the mapping relationship at the field level; a unified code file being generated according to the O / R bi-directional mapping relationship between the physical data model and the data model set; calling data interface, accessing database, completing the function operation of business scenario. The method provided by the present application unifies the technical framework, at the same time, the technical framework has the characteristics of high automation, high development efficiency, low professional requirements, few loopholes, code specifications, safety, simplicity and ease of use, and comprehensive functions, and saves time cost and labor cost.

Owner:SHANDONG LUNENG SOFTWARE TECH

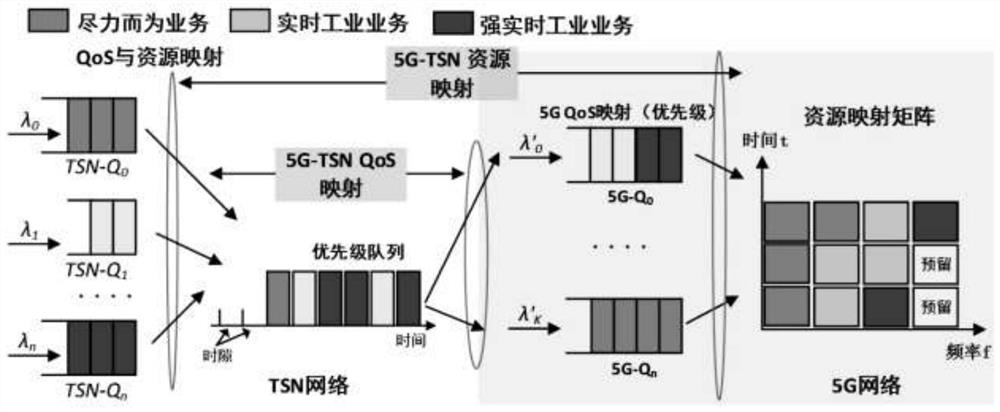

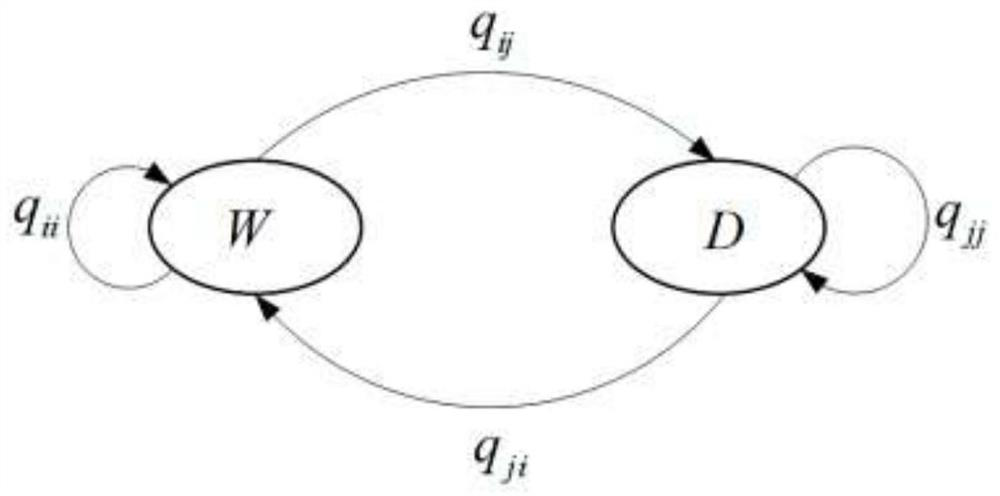

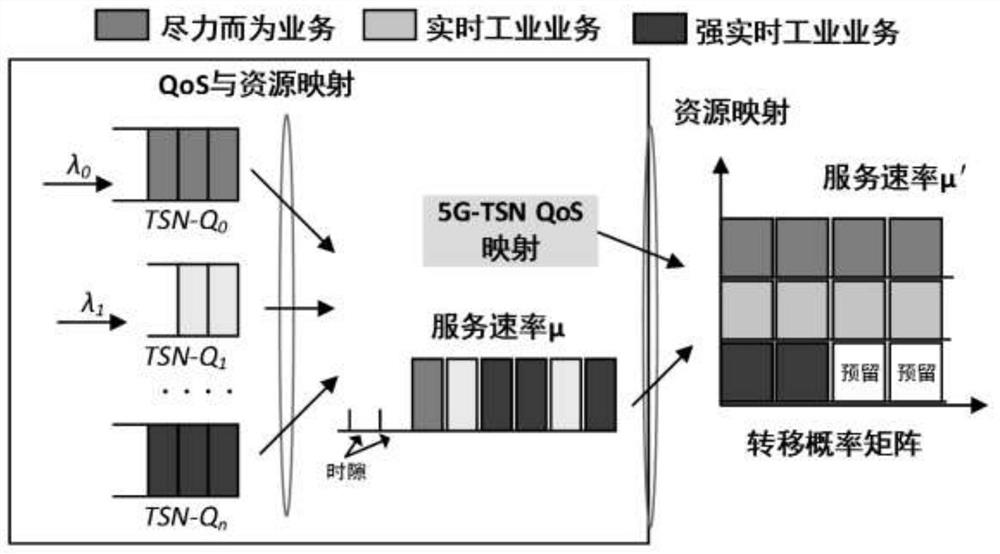

5G-TSN cross-domain QoS and resource mapping method and device, and computer readable storage medium

ActiveCN113543210ANetwork traffic/resource managementComplex mathematical operationsService flowData pack

The invention provides a 5G-TSN cross-domain QoS and resource mapping method and device and a computer readable storage medium. The method comprises the following steps: establishing a Markov-based 5G-TSN resource mapping conversion relation model according to arrival rates and service rates of service flows and data packets, and constructing a 5G-TSN system state conversion balance equation according to corresponding transition probability matrix constraint conditions; and completing a network operation state conversion process of service flow QoS resource mapping of the 5G-TSN system in a framework of the balance equation. According to the method, the association relationship between the TSN time slot and the 5G resource block required for bearing the service association data message is researched aiming at the resource characteristic difference of the 5G and the TSN in the physical layer, so that bidirectional mapping of different QoS service characteristics of the heterogeneous network is realized, and rapid data conversion and scheduling are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

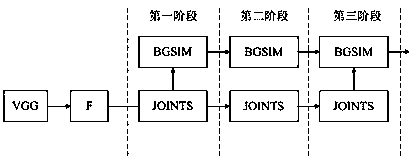

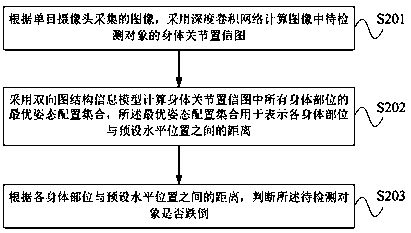

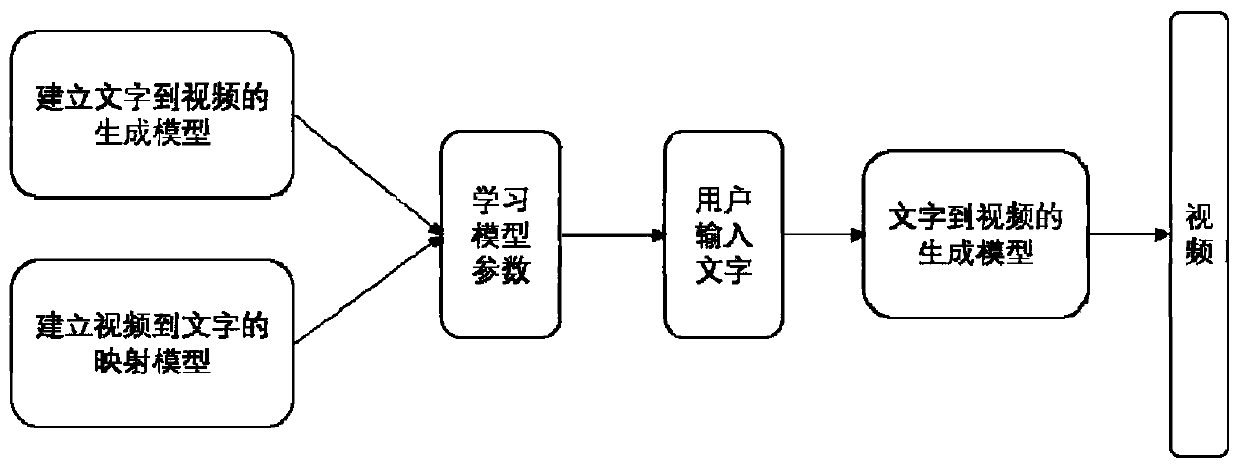

Falling detection method based on deep convolutional network

ActiveCN108805032AHigh precisionLow costCharacter and pattern recognitionAlarmsBody jointsConfidence map

The invention provides a falling detection method based on a deep convolutional network. The method comprises the following steps that: S1: according to an image collected by a monocular camera, adopting the deep convolutional network to calculate the body joint confidence map of an object to be detected in the image; S2: adopting a bidirectional map structure information model to calculate the optimal gesture configuration set of all body positions in the body joint confidence map, wherein the optimal gesture configuration set is used for showing distance between each body position and a preset horizontal position; and S3: according to the between each body position and the preset horizontal position, judging whether the object to be detected falls or not. By use of the method, a multi-stage deep convolutional network is adopted to analyze the image so as to better extract the characteristic information of the image, shorten operation time and improve detection accuracy.

Owner:ZHENGZHOU UNIV

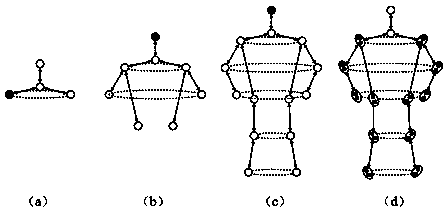

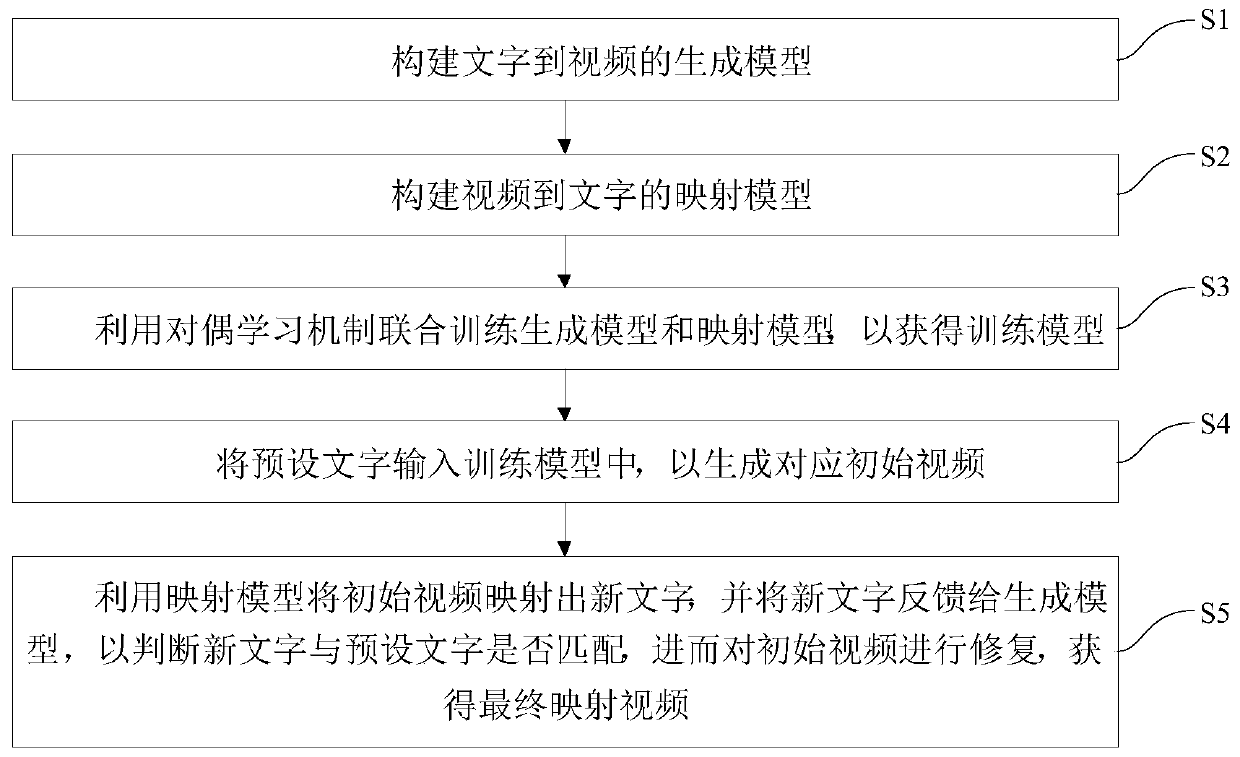

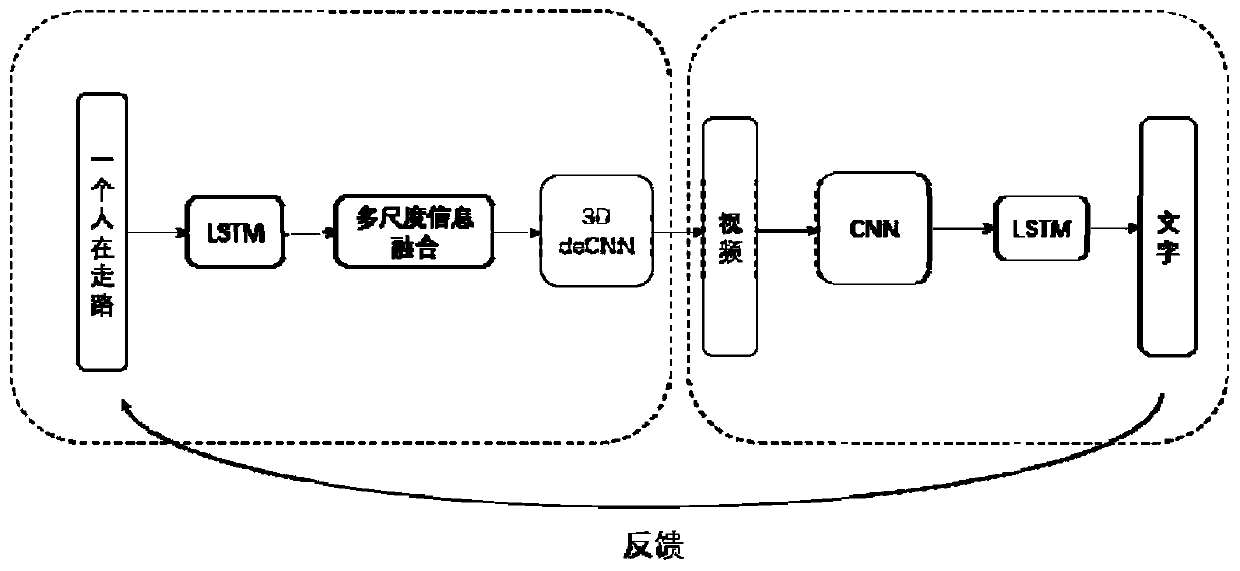

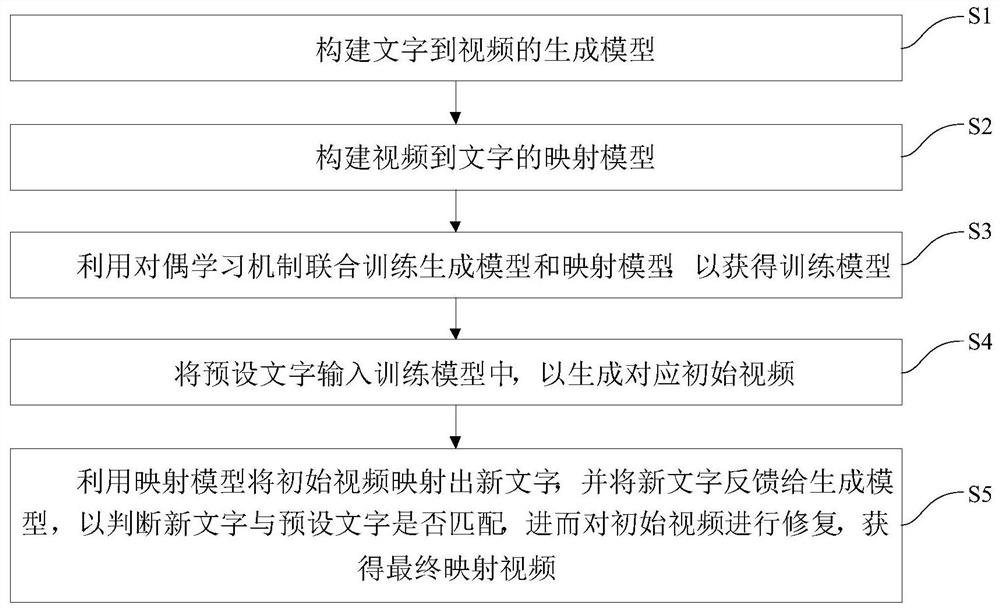

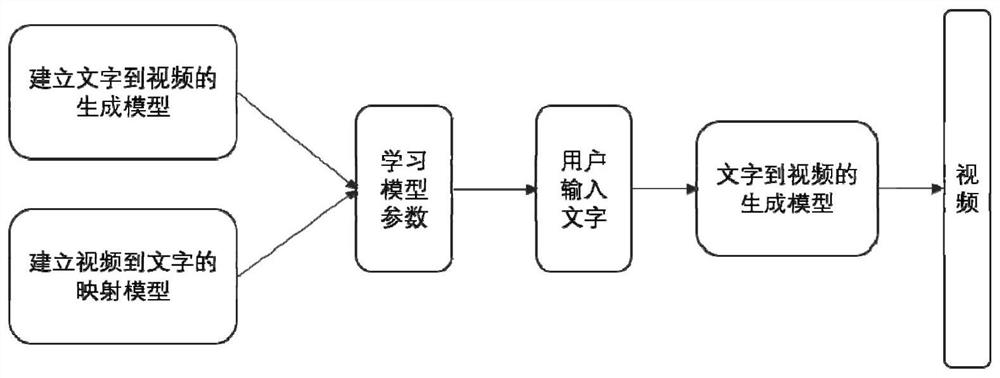

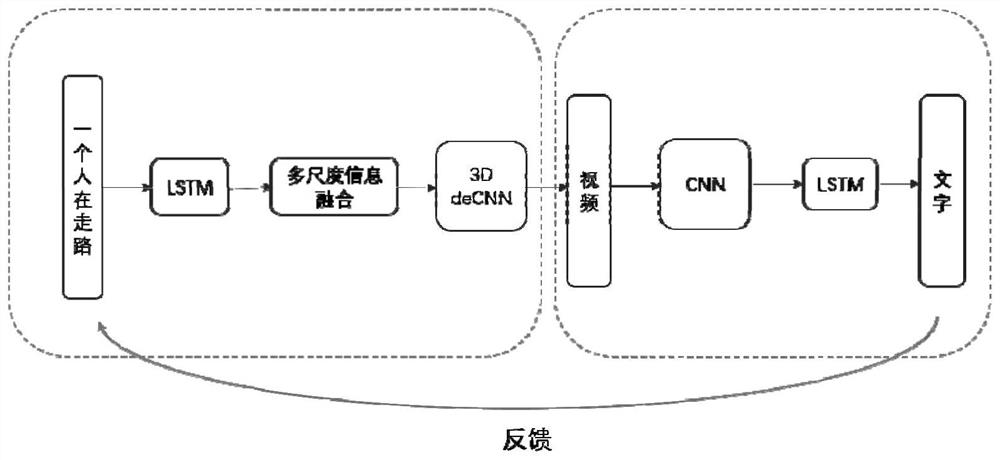

Method and system for generating video by using cross-modal characters based on dual learning

ActiveCN110717054ARealize generationImprove performanceDigital data information retrievalNatural language data processingLearning machineUser needs

The invention discloses a dual learning-based cross-modal text video generation method and system, and the method comprises the following steps: constructing a text-to-video generation model; constructing a video-to-text mapping model; utilizing a dual learning mechanism to jointly train the generation model and the mapping model to obtain a training model; inputting preset characters into the training model to generate a corresponding initial video; and mapping the initial video into new characters by utilizing the mapping model, and feeding back the new characters to the generation model tojudge whether the new characters are matched with preset characters or not, and then repairing the initial video to obtain a final mapped video. The bidirectional mapping between the text informationand the video information is considered, so that the text-to-video generation is better realized, and meanwhile, the generated video is higher in quality and higher in matching degree with user requirements.

Owner:TSINGHUA UNIV

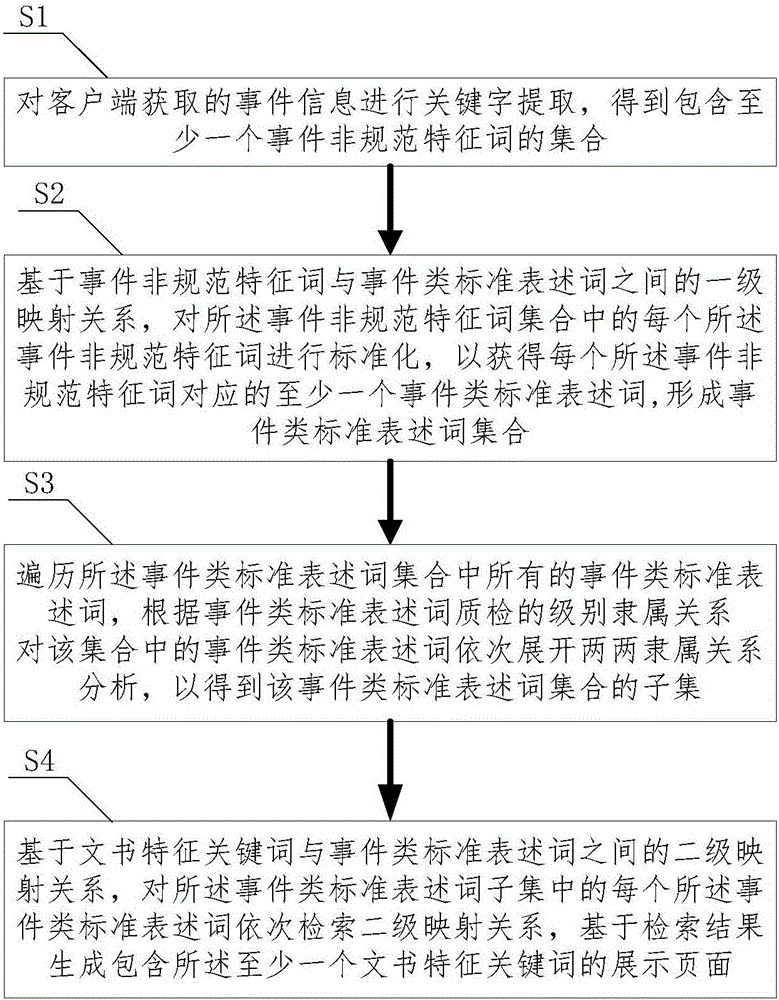

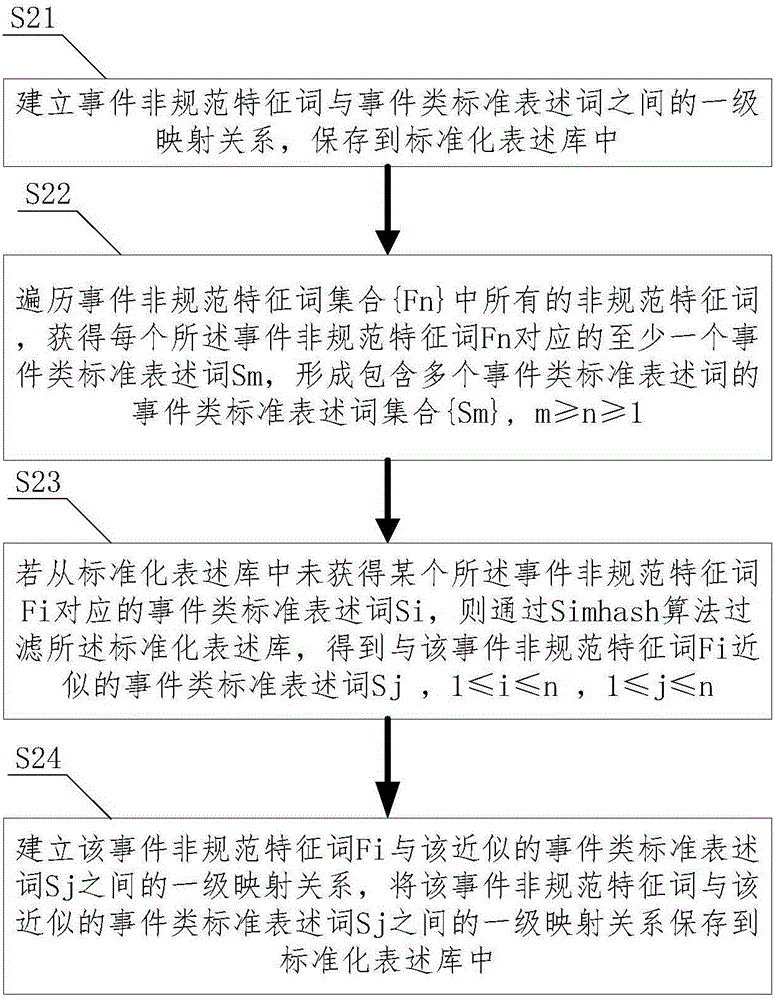

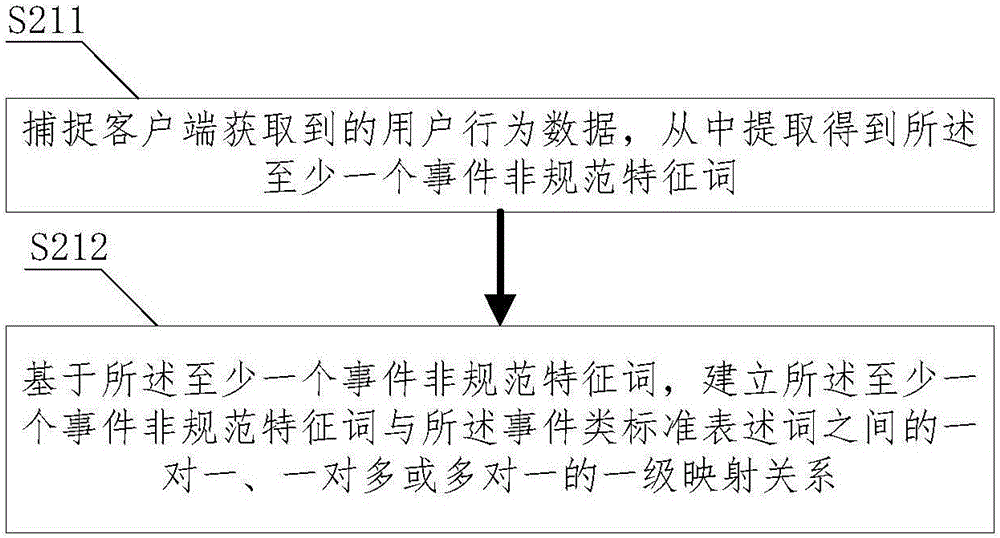

Search method and system based on bidirectional mapping

ActiveCN105824938ASolve the problem of incomplete evaluation of practicePrecise positioning of retrieval needsWeb data indexingSpecial data processing applicationsData retrievalButt joint

The invention relates to a search method and system based on bidirectional mapping. By adopting first-grade mapping and second-grade mapping, on one hand, the problem that a user is lack of legal knowledge and cannot position own actual retrieval demand requirements very well is solved; on the other hand, the problem that the evaluation of lawyers practice conditions is not comprehensive, caused by a fact that determination and expressions of causes of action for administration cases in local courts of justice are different, is solved; on the basis of mapping in the two aspects, the butt joint of a user retrieval demand and a retrieval object is further realized, so that the user retrieval demand is accurately positioned, the accuracy of a retrieval result and the data retrieval efficiency are improved.

Owner:点击律(上海)网络科技有限公司

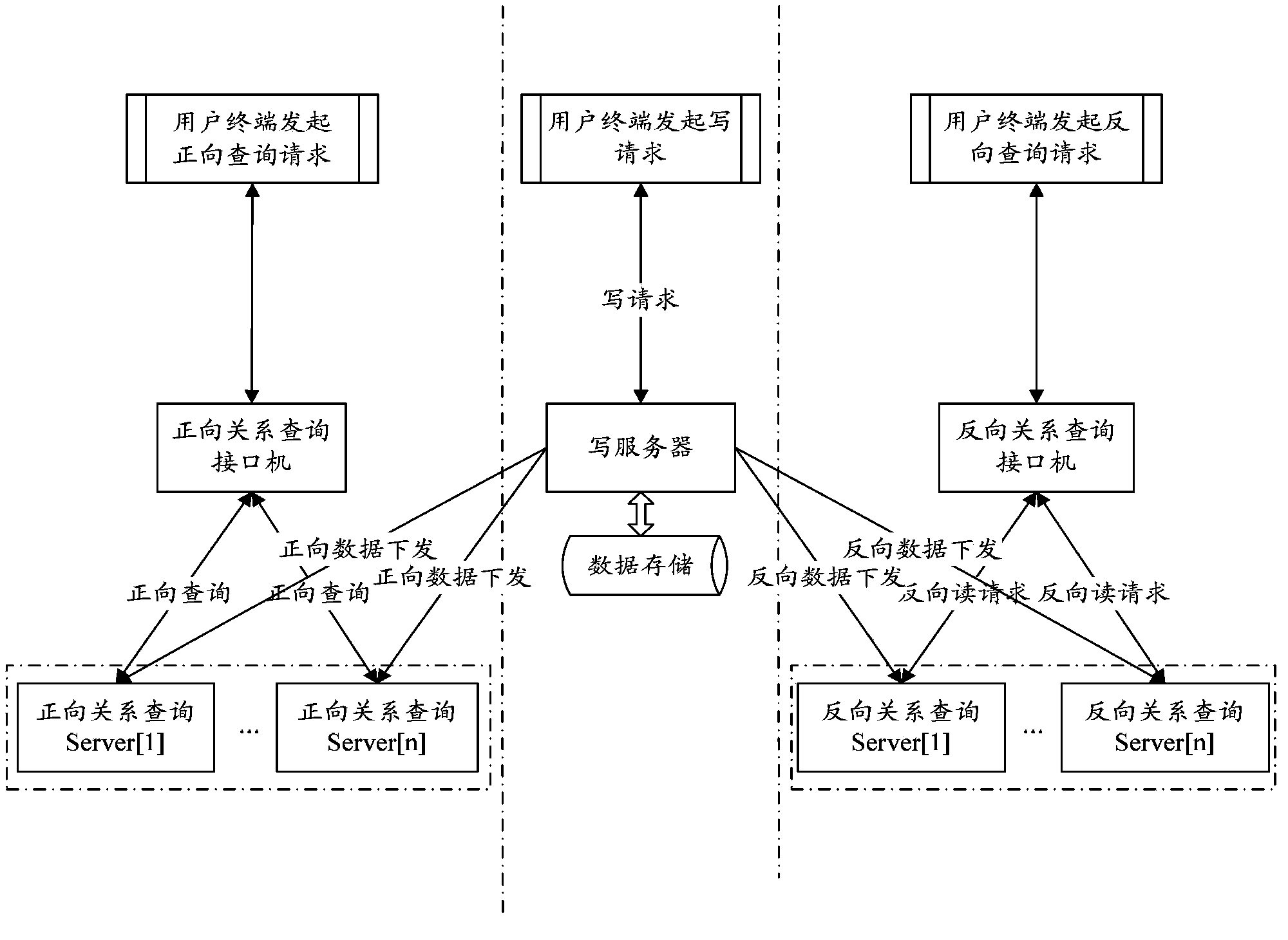

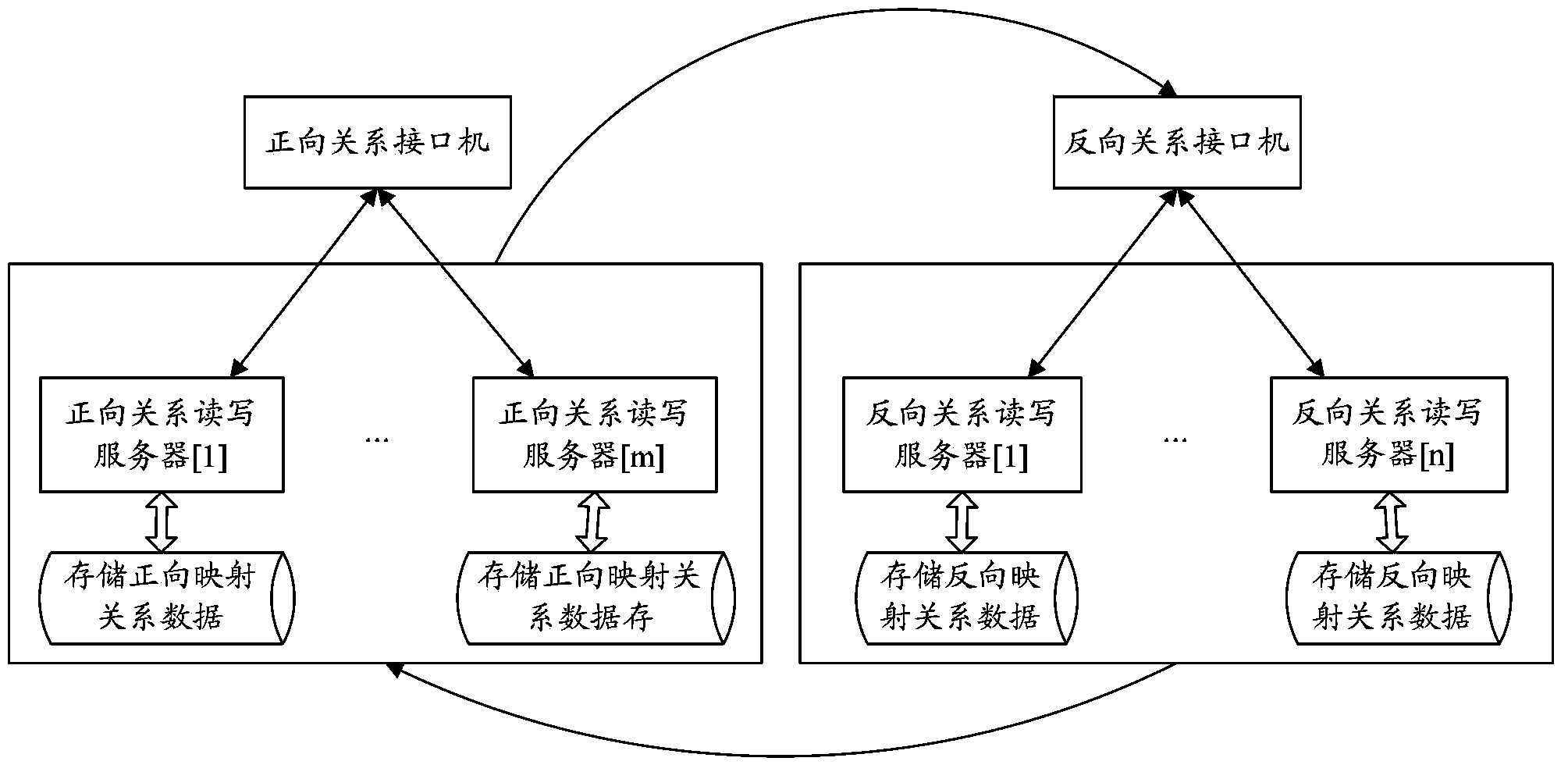

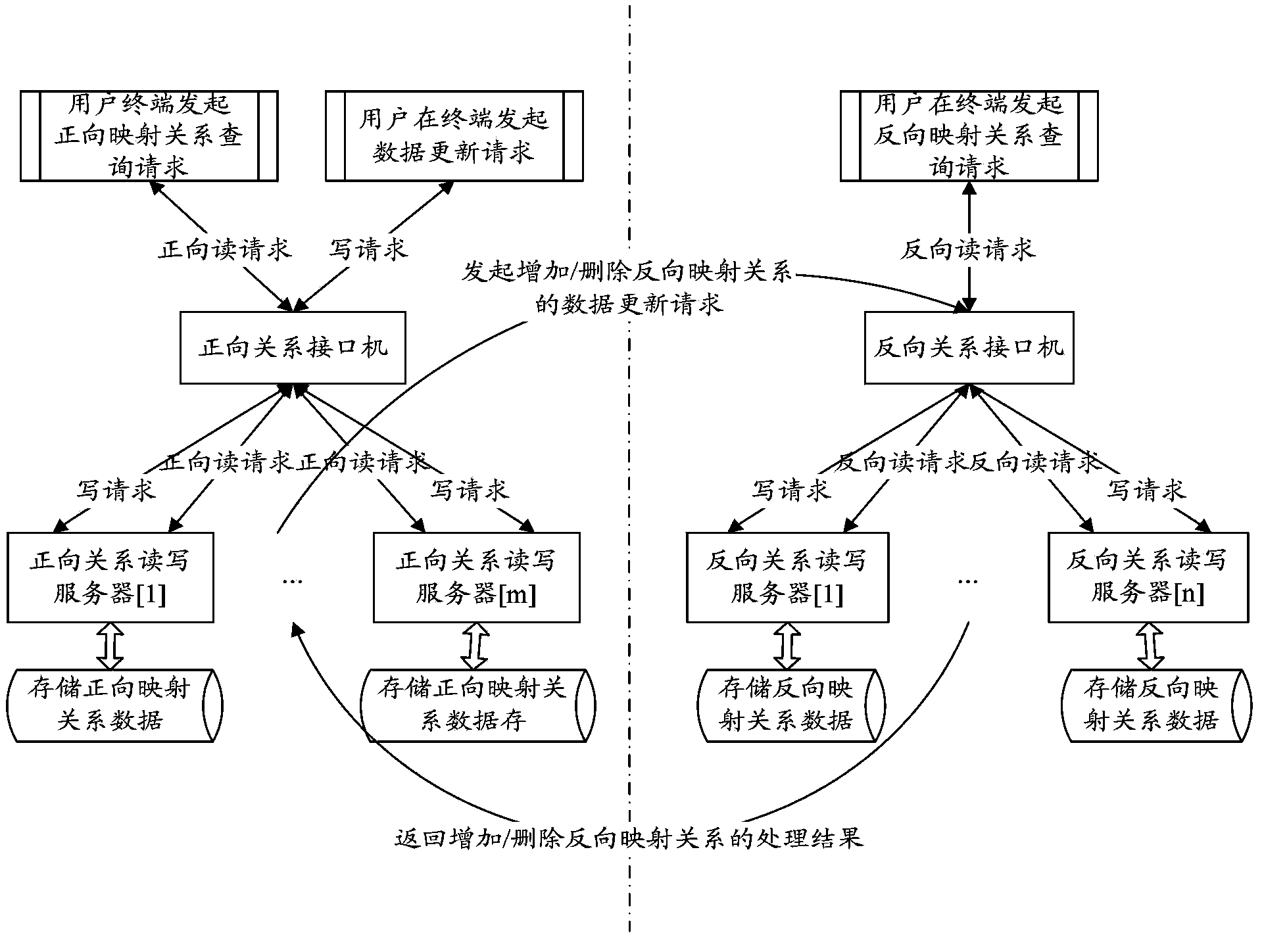

Bidirectional-mapping-relation data processing method and system

ActiveCN103577422AMeet service needsSolve single-point performance bottlenecksDatabase updatingSpecial data processing applicationsData processing systemSystem stability

The invention discloses a bidirectional-mapping-relation data processing method. The method comprises that a positive-relation interface receives a data update request made by a user terminal and routes the data update request to a corresponding positive-relation read-write server; the positive-relation read-write server receives the data update request and sends a data update request for updating a negative mapping relation to a negative-relation interface; the negative-relation interface receives the data update request for updating the negative mapping relation, updates a local negative mapping relation and feeds a response of successful updating of the negative mapping relation back to the positive-relation read-writer server; the positive-relation read-write server receives the response of successful updating of the negative mapping relation and updates a local positive mapping relation. Correspondingly, the invention also discloses a bidirectional-relation data processing system. The bidirectional-mapping-relation data processing method and system can be expanded horizontally as required, improve the system stability and facilitate system maintaining and repairing cost reduction and data processing efficiency improvement.

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

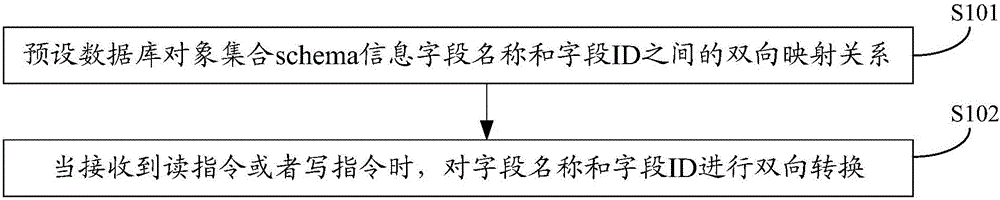

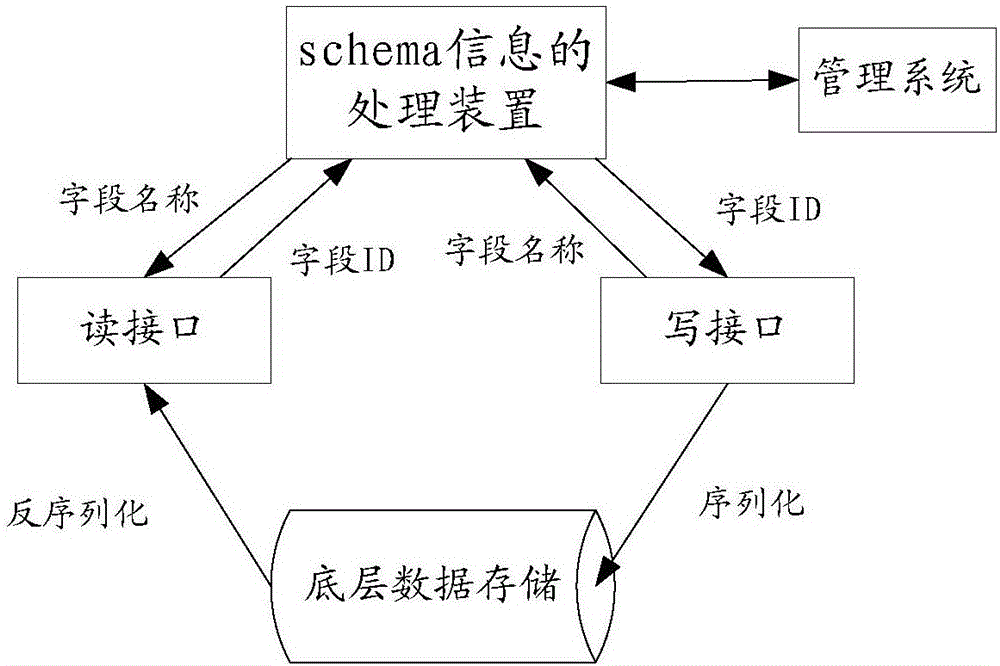

Method and device for processing database object set schema information and management system

ActiveCN106649641ASolve the problem of large storage spaceReduce memory spaceSpecial data processing applicationsComputer scienceData store

The invention discloses a method and device for processing database object set schema information and a management system. The method comprises following steps: presetting the bidirectional mapping relationship between the field names of database object set schema information and field ID; performing bidirectional conversion on the field names and the field ID when receiving a reading instruction or a writing instruction so as to reduce the occupied memory and disk space due to data storage and thus the storage cost is reduced; the disk I / O and network I / O are reduced and system performance is increased; the problem of large occupied space due to database object set schema information storage in the prior art is solved.

Owner:BEIJING 58 INFORMATION TTECH CO LTD

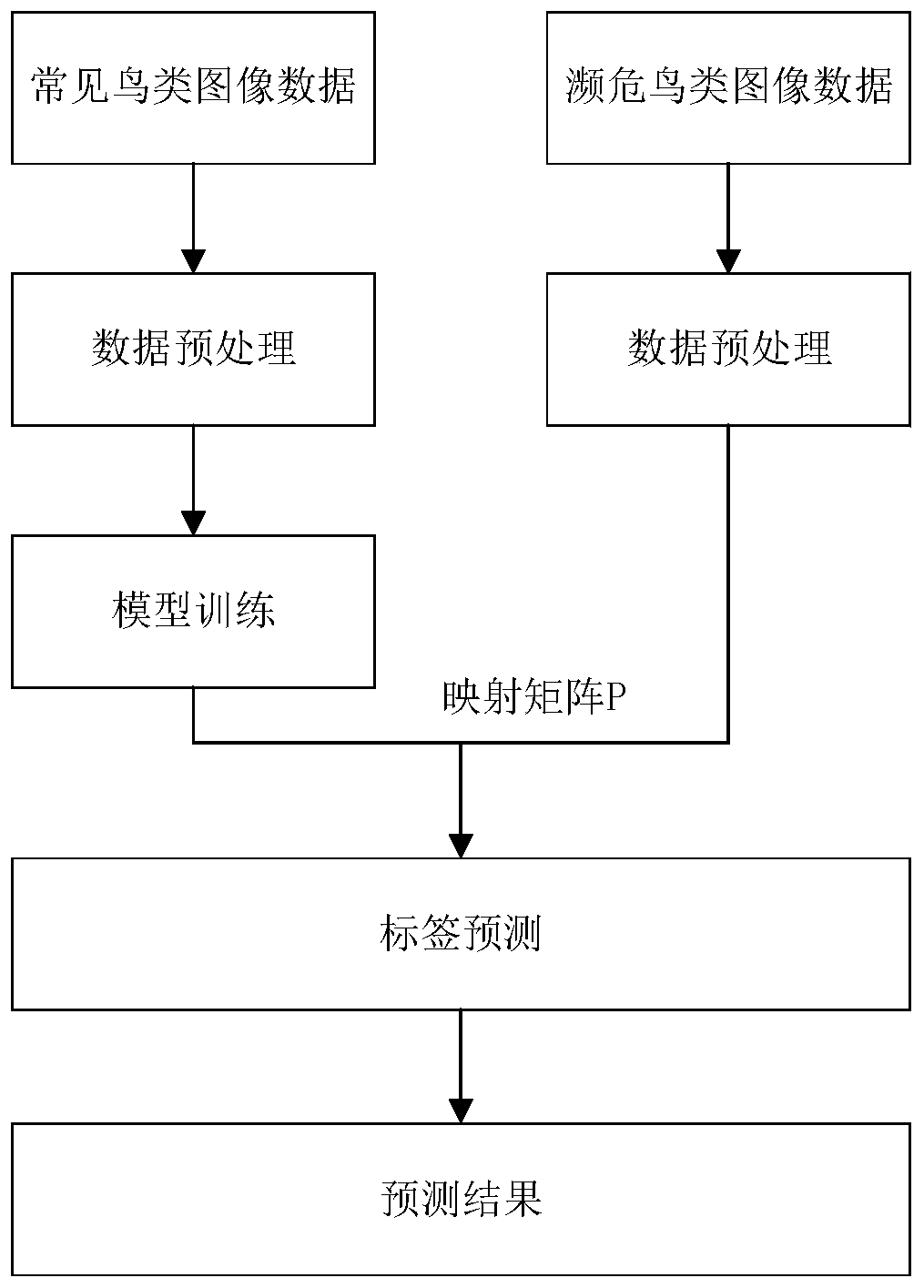

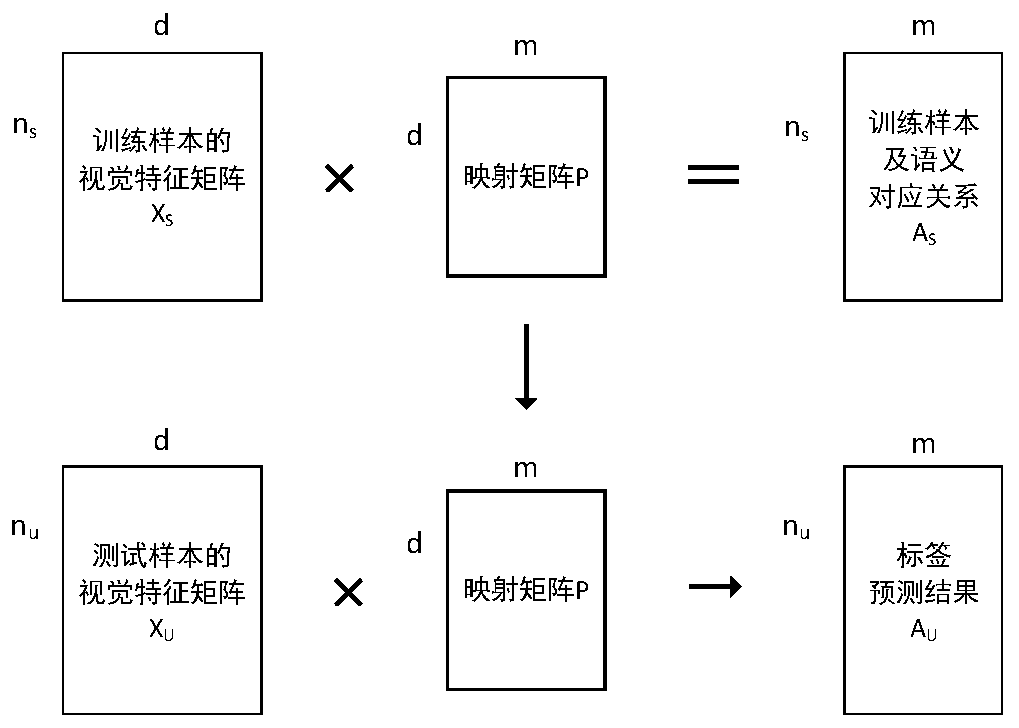

Bird endangered species identification method based on structure-preserving zero-sample learning

ActiveCN110717512ASolving recognition problemsRealize identificationCharacter and pattern recognitionData setAlgorithm

The invention discloses a bird endangered species identification method based on structure-preserving zero sample learning, and the method comprises the following steps: a data input step: inputting adata set which comprises the visual features, semantic information and label information of a common bird image, and the semantic information of bird endangered species; and a training step: learningbidirectional mapping from a visual feature space to a semantic space, and meanwhile, and further constraining the mapping by using manifold consistency, wherein the optimization problem is summarized into a Sylvester equation solving problem, the solving process is simple and easy to implement, and the solving result is a mapping matrix P; and a prediction step of identifying the bird endangeredspecies image with the given semantic information by using the mapping matrix P obtained in the training step. According to the method, structural information between data is reserved, the problem ofdomain drift is solved, the image classification accuracy is improved, the method can be applied to complex bird image recognition, and endangered species without known label information can be recognized.

Owner:SOUTH CHINA UNIV OF TECH

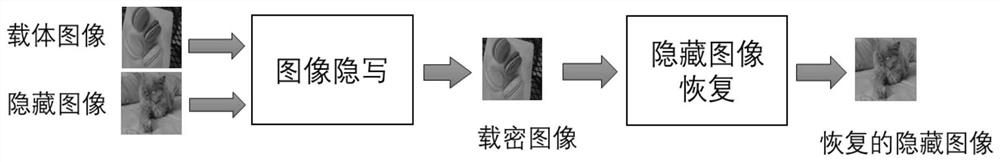

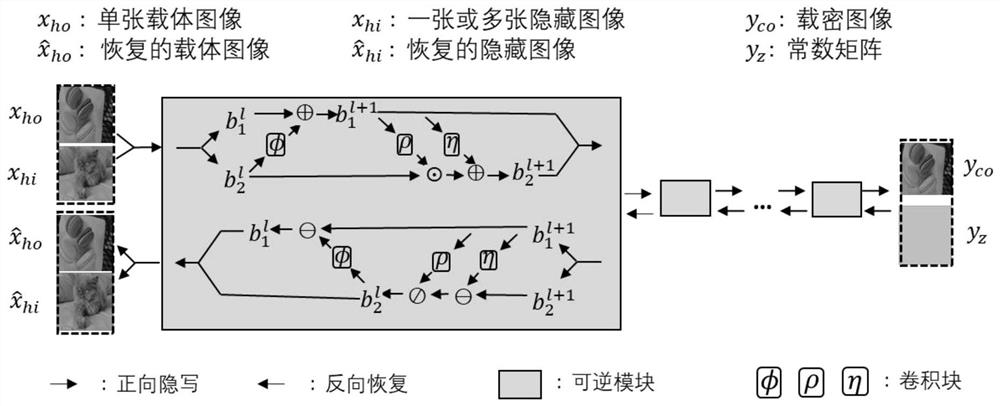

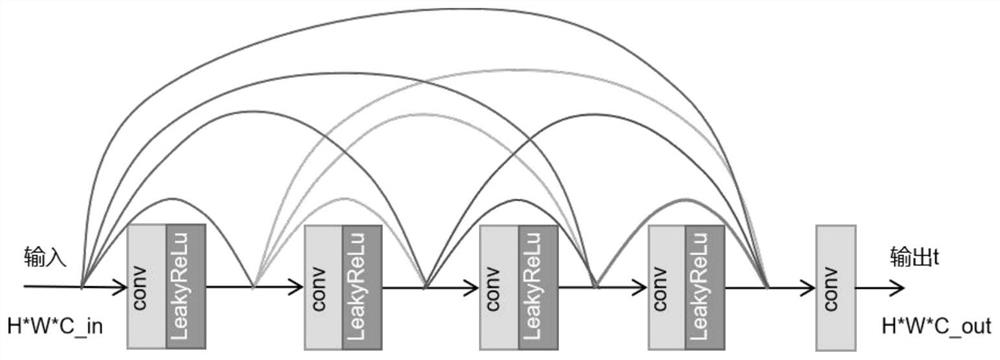

High-capacity image steganography and recovery method based on reversible neural network

ActiveCN112884630ASteganographic Capacity ImprovementGood effectImage data processing detailsNeural architecturesPattern recognitionEngineering

The invention discloses a high-capacity image steganography and recovery method based on a reversible neural network. The purpose of the method is to embed one or more hidden images into a single carrier image and recover all hidden images from a secret-carrying image. According to the method, an image steganography model capable of realizing bidirectional mapping is designed. The model is formed by cascading reversible modules comprising a carrier branch and a hidden branch, forward mapping embeds a hidden image into a carrier image to synthesize a secret-carrying image, and reverse mapping separates and recovers the carrier image and the hidden image from a single secret-carrying image. According to the method, the reversibility of the model is fully utilized, all parameters are shared in the forward steganography process and the reverse recovery process, the high-quality secret-carrying image and the high-quality recovered image can be obtained at the same time, and the steganography capacity is effectively improved.

Owner:NANKAI UNIV

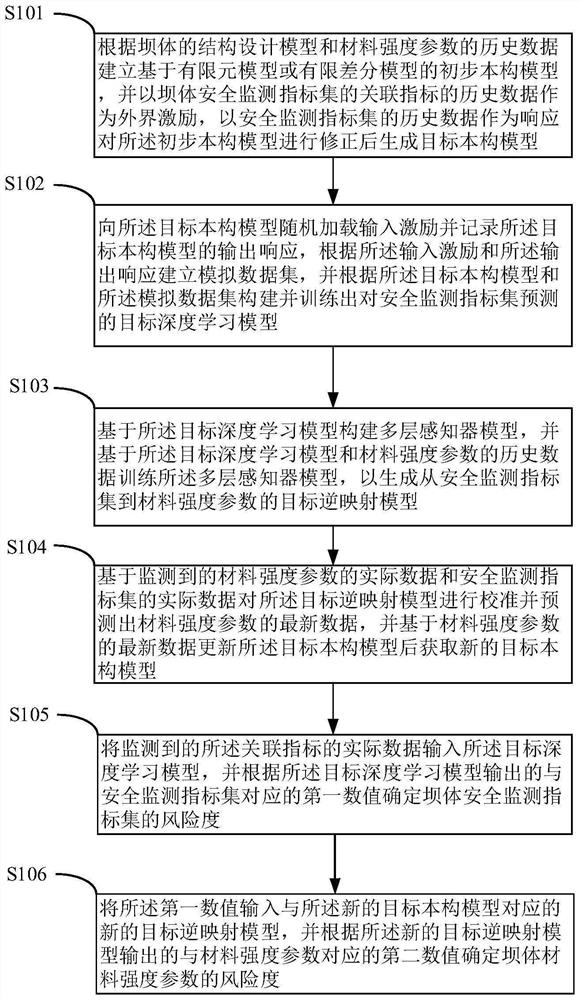

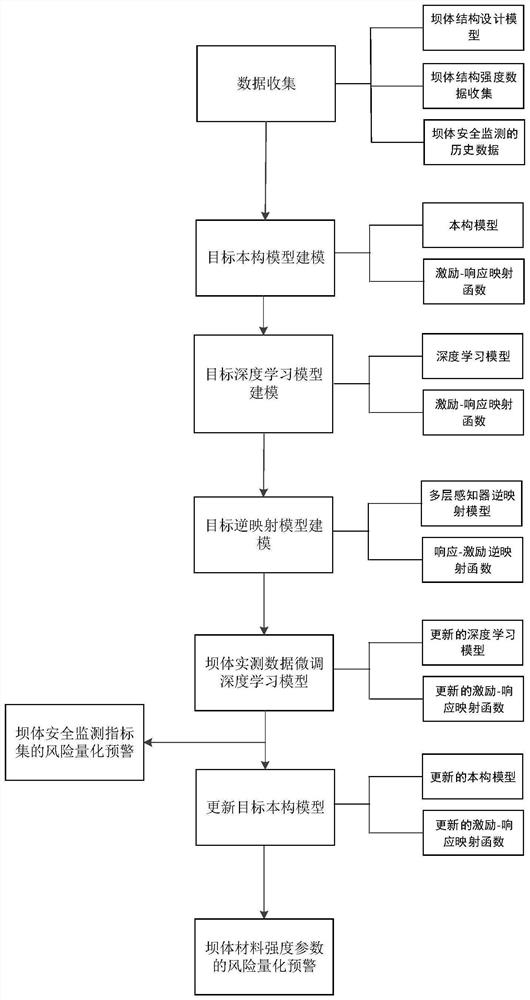

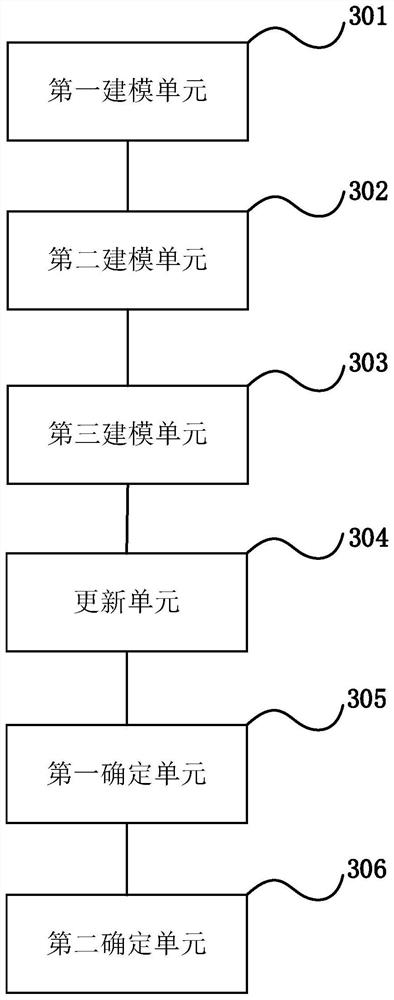

Dam body safety monitoring method and system

ActiveCN114417650AAccurate safety monitoringImprove securityDesign optimisation/simulationNeural architecturesStructural engineeringData-driven

The invention discloses a dam body safety monitoring method and system, and the method comprises the steps: building a bidirectional mapping model from a dam body material strength parameter to a dam body safety monitoring index set based on a deep learning mode of knowledge driving and data driving fusion, and achieving the prediction of safety monitoring index data and the calibration and prediction of the dam body material strength parameter. Therefore, dam body safety risk quantitative early warning can be carried out according to the dam body safety monitoring index set and the material strength parameters, safety monitoring can be carried out on the dam body more accurately, and the safety of the dam body is improved.

Owner:中国华能集团有限公司江西分公司

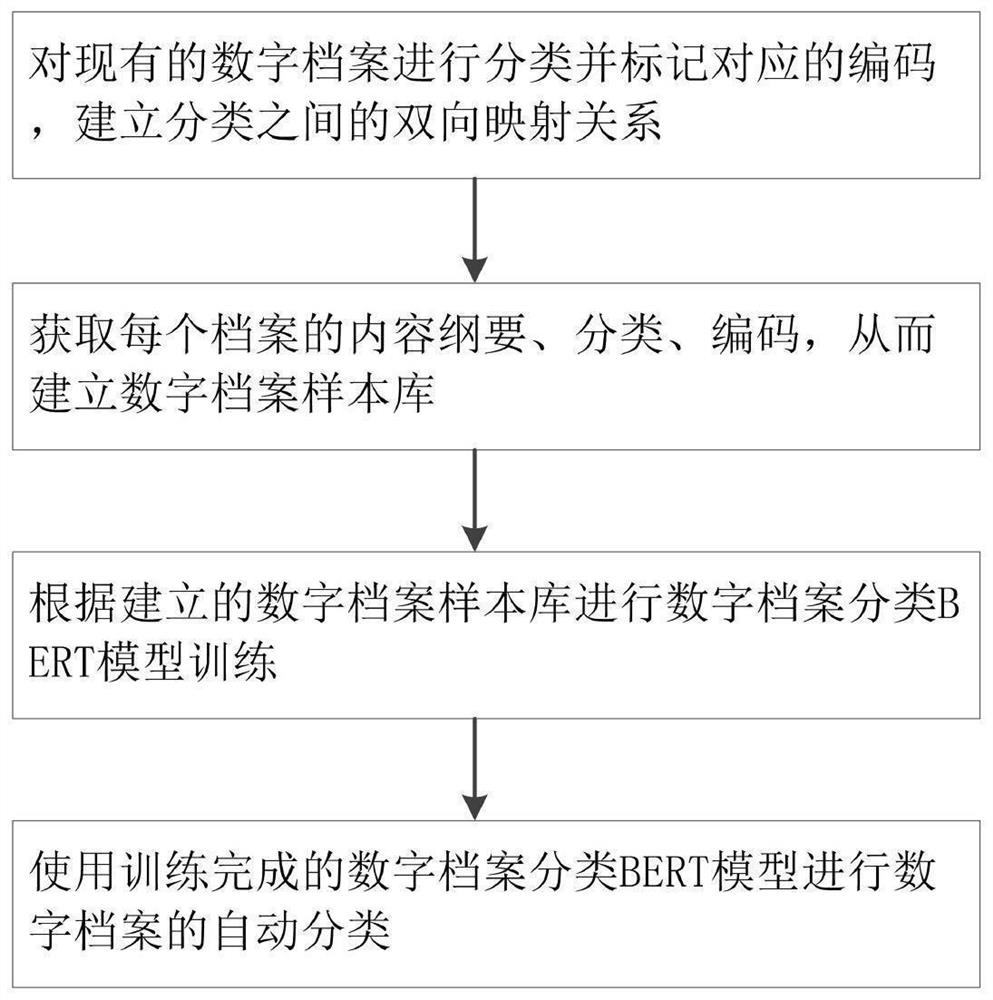

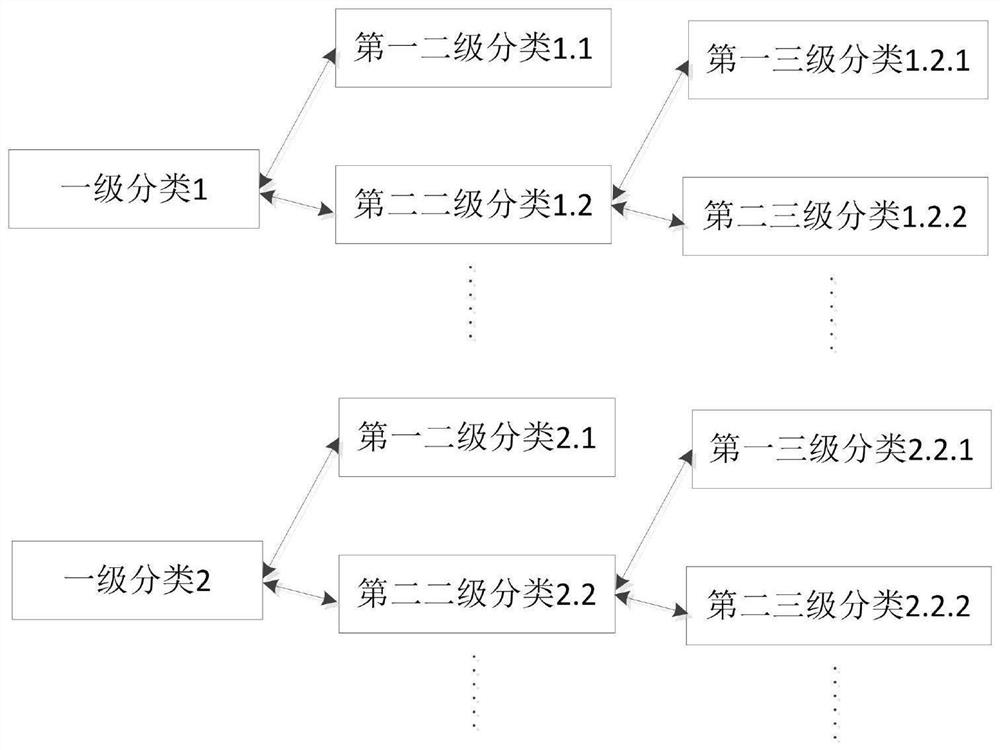

Automatic classification method for digital archives

ActiveCN113610194AImprove standardizationImprove efficiencyCharacter and pattern recognitionInference methodsClassification methodsDigital Archives

The invention discloses an automatic classification method for digital archives, and the method specifically comprises the following steps: S1, determining all levels of classifications of existing digital archives, marking corresponding codes, and building a bidirectional mapping relation between all levels of classifications; S2, obtaining the content outline of each existing digital archive, classifying and coding so as to establish a digital archive sample library; S3, performing digital archive classification BERT model training according to the digital archive sample library established in the S2; and S4, automatically classifying the digital archives by using the digital archive classification BERT model trained in the S3. The existing digital archives are classified and coded and pre-trained by using the BERT model, so that the digital archives to be classified are automatically classified, and the classification efficiency of the digital archives is improved.

Owner:CHONGQING CYBERCITY SCI TECH

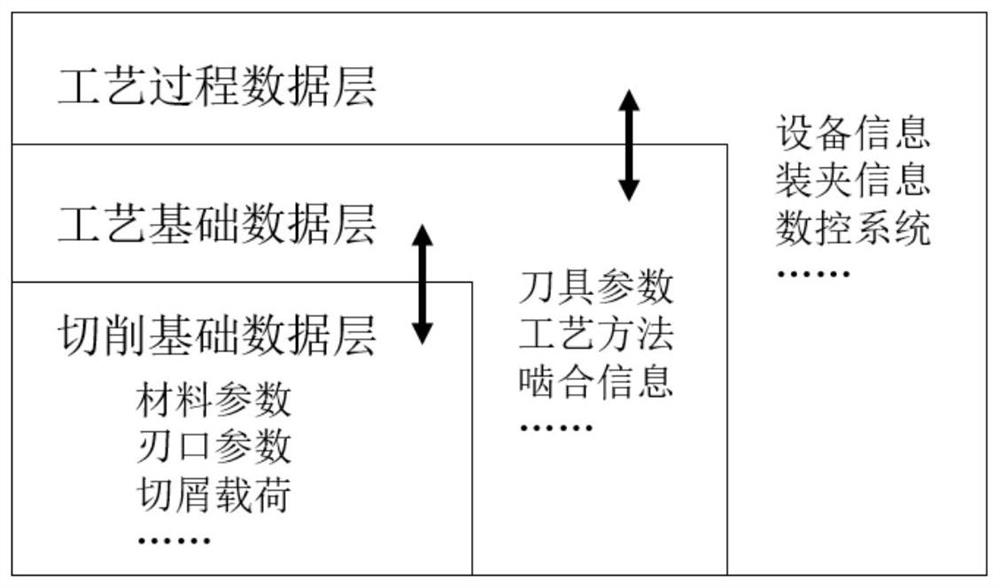

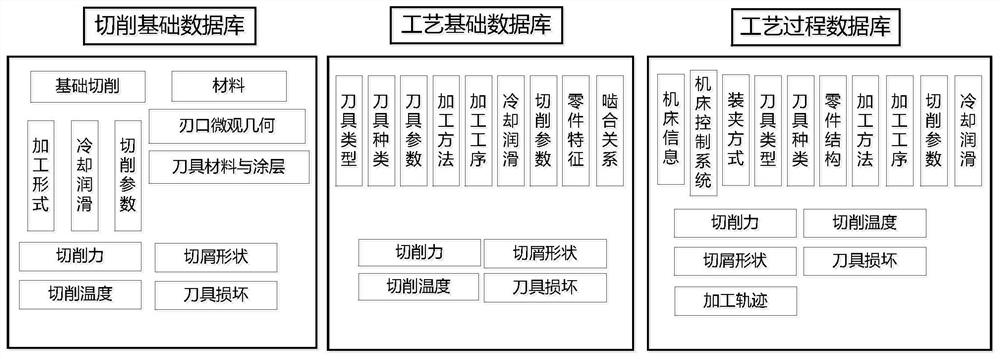

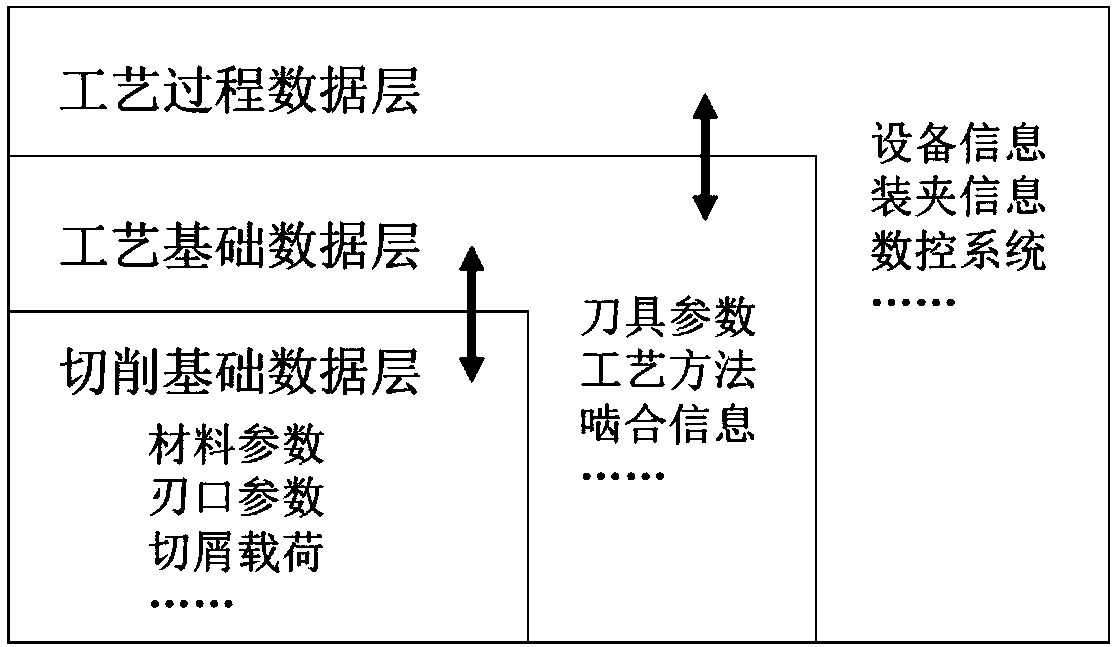

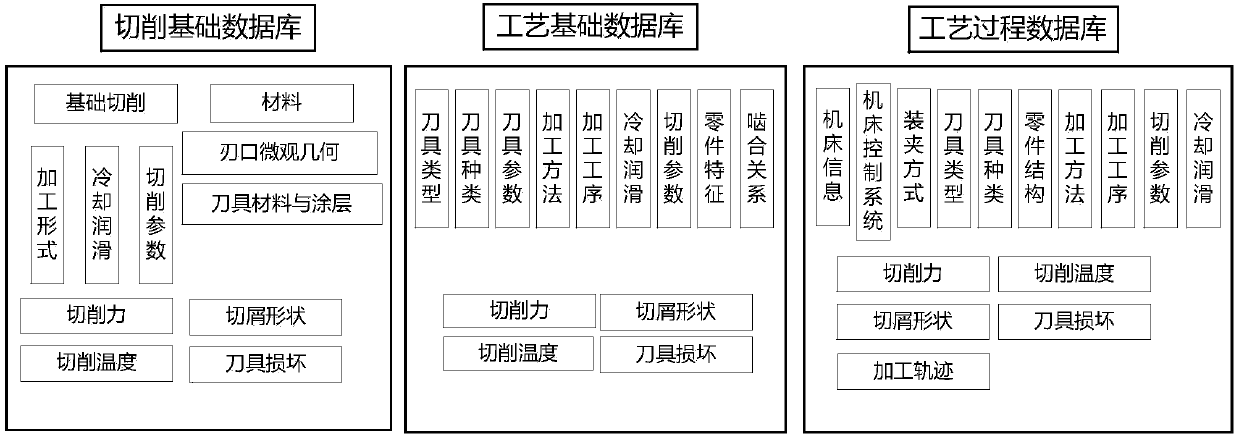

Hierarchical Database Model Based on Material-Structure-Technology-Process Correlation

ActiveCN107798081BImplement bidirectional mappingReasonable useHierarchical databasesSpecial data processing applicationsHierarchical database modelData store

The invention discloses a layered database model based on material-structure-process-process correlation, which is used to solve the technical problem of poor practicability of the existing layered database model. The technical solution is to divide the working conditions along the machining trajectory according to the tool-workpiece contact state, part structure and position relationship, and correspond the part structural features with the processing technology and process parameters. In terms of data storage, it is divided into cutting basic data layer, process basic data layer and process data layer. The cutting basic data layer stores data such as tool coating, cutting edge geometry, and constitutive equations; the process basic data layer adds tool parameters, process methods, and tool-workpiece meshing relationships on the basis of the cutting basic data layer; the process data layer stores additional tools ‑Spindle subsystem information, workpiece‑fixture subsystem information, processing environment information and CNC system information. The invention realizes the two-way mapping between different levels of data, and has good practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

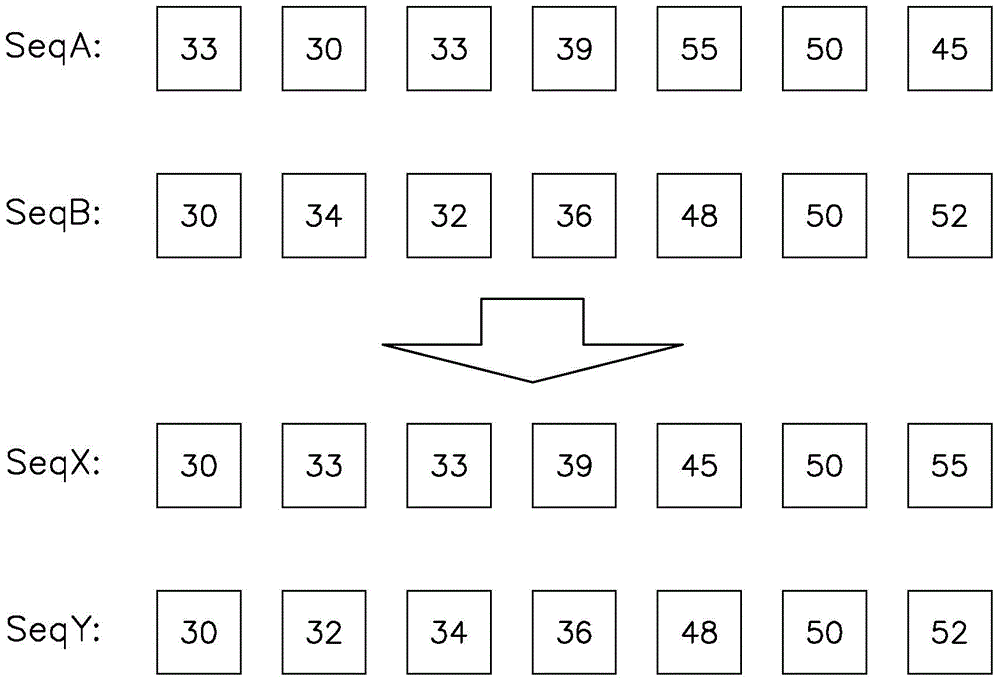

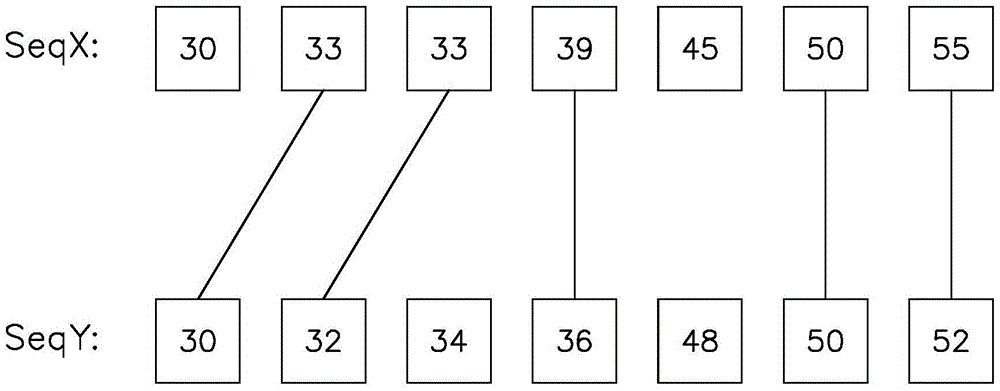

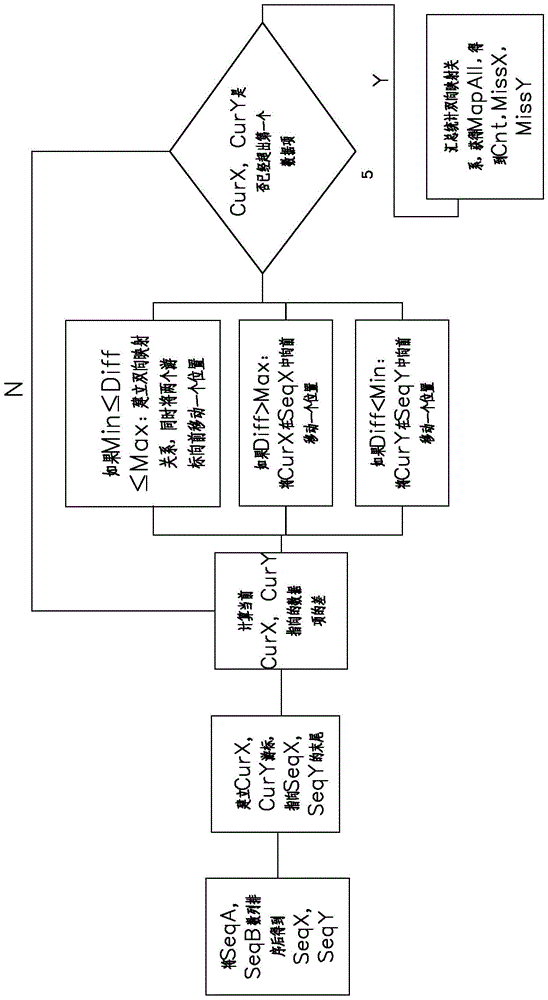

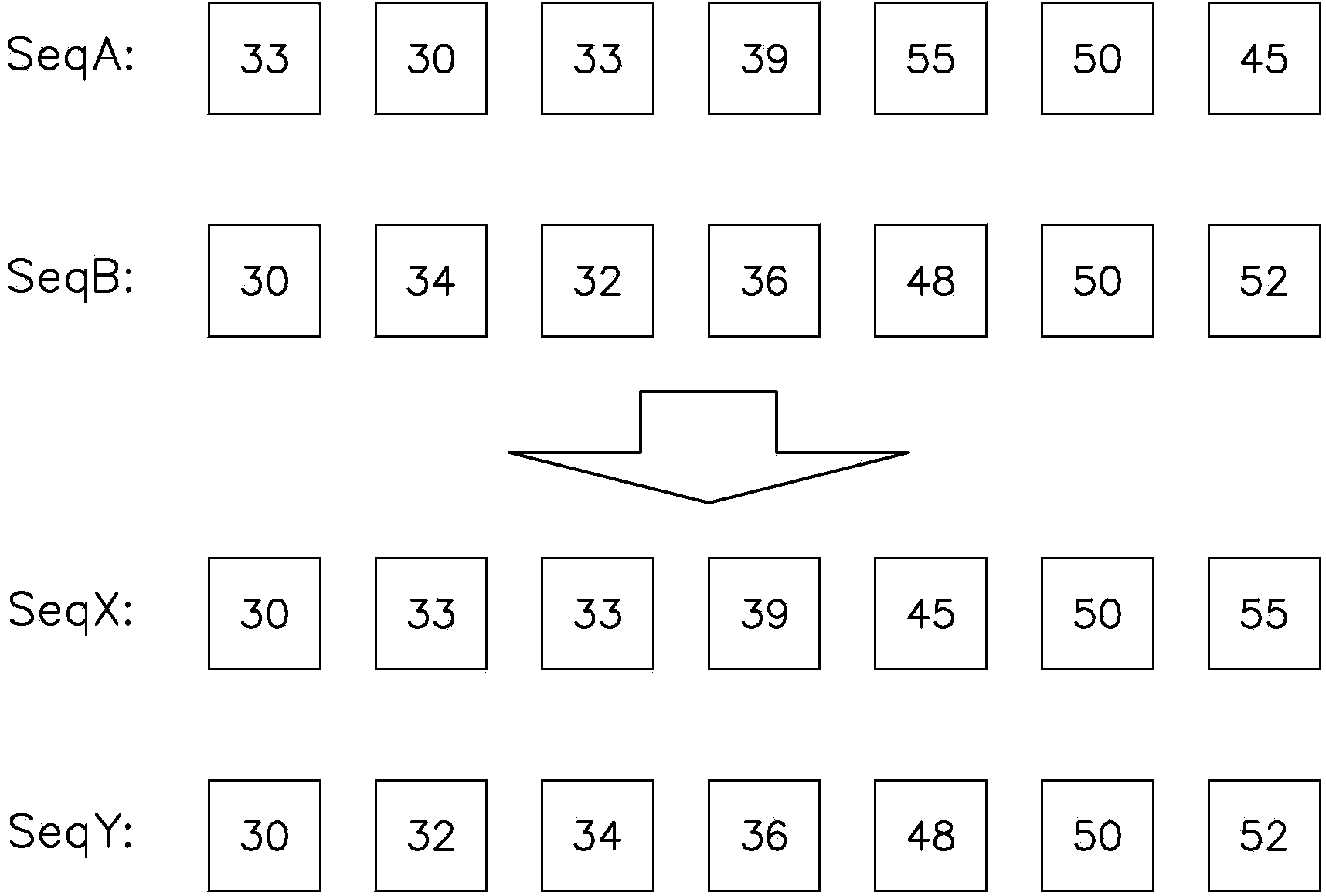

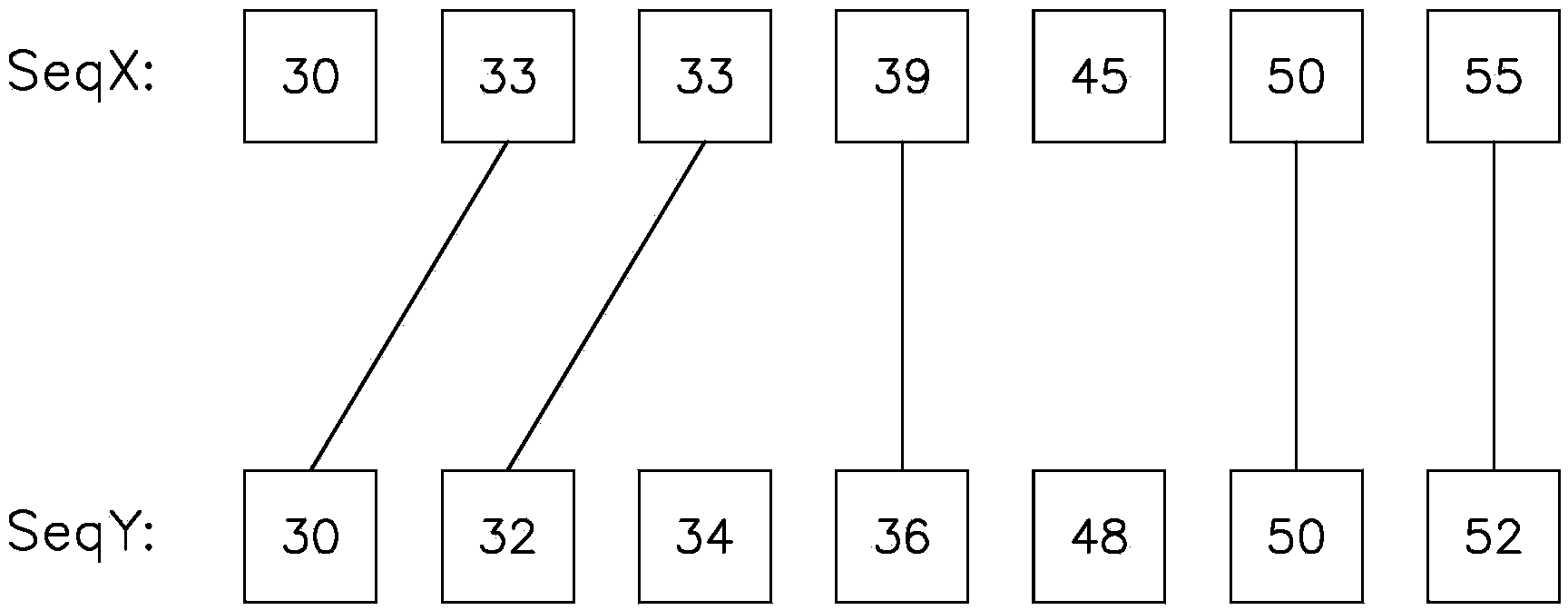

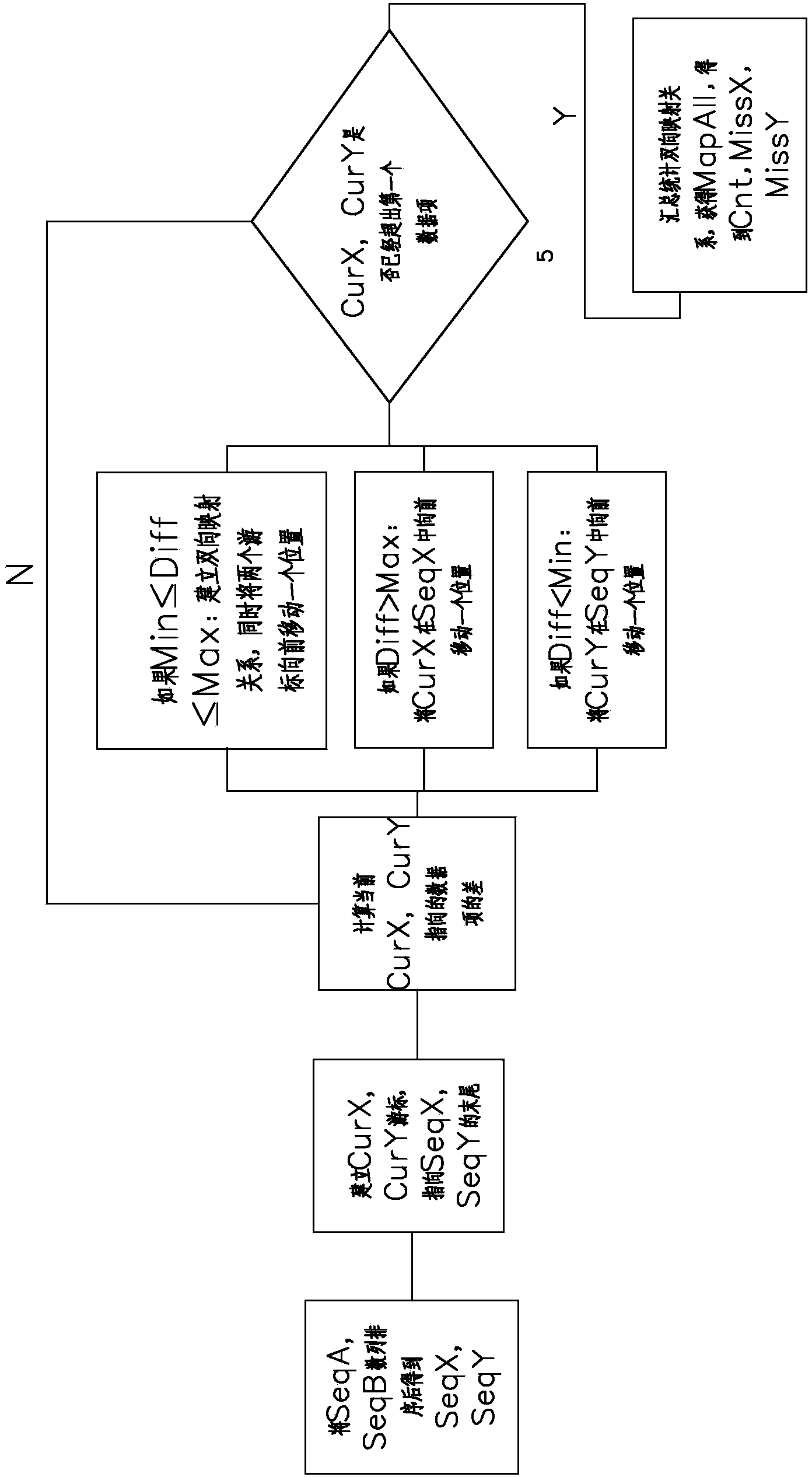

A Method of Establishing Bidirectional Mapping Between Sequences Under the Condition of Limiting Differences

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

Method and system for cross-modal text generation based on dual learning

ActiveCN110717054BRealize generationImprove performanceDigital data information retrievalNatural language data processingLearning machineUser needs

The invention discloses a method and system for generating video from cross-modal text based on dual learning, wherein the method includes the following steps: constructing a text-to-video generation model; constructing a video-to-text mapping model; using a dual learning mechanism to combine Train the generative model and the mapping model to obtain the training model; input the preset text into the training model to generate the corresponding initial video; use the mapping model to map the initial video to new text, and feed back the new text to the generative model to judge the new text. Whether the text matches the preset text, and then repair the initial video to obtain the final mapping video. This method considers the bidirectional mapping between text information and video information to better realize the generation of text to video, and at the same time, it also makes the generated video higher in quality and more closely matched with user needs.

Owner:TSINGHUA UNIV

Material-structure-technology-process correlation-based hierarchical database model

ActiveCN107798081AImplement bidirectional mappingReasonable useHierarchical databasesSpecial data processing applicationsBidirectional mapHierarchical database model

The invention discloses a material-structure-technology-process correlation-based hierarchical database model, which is used for solving the technical problem of poor practicality of an existing hierarchical database model. According to the technical scheme, working condition division is performed according to a tool-workpiece contact state and a part structure and position relationship along a processing track; and part structure features are enabled to correspond to a processing technology and process parameters. In the aspect of data storage, the data storage is divided into a cutting basicdata layer, a technology basic data layer and a technology process data layer. The cutting basic data layer stores data such as a tool coating, cutting edge geometry, a constitutive equation and thelike; the technology basic data layer adds tool parameters, a technology method and a tool-workpiece meshing relationship based on the cutting basic data layer; and the technology process data layer stores and adds information such as tool-spindle subsystem information, workpiece-clamp subsystem information, processing environment information, numerical control system information and the like. Thebidirectional mapping among different hierarchical data is realized; and the practicality is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

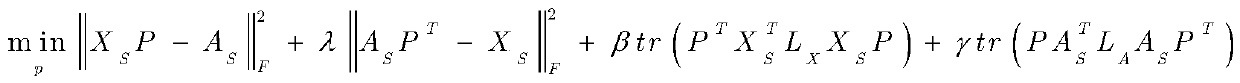

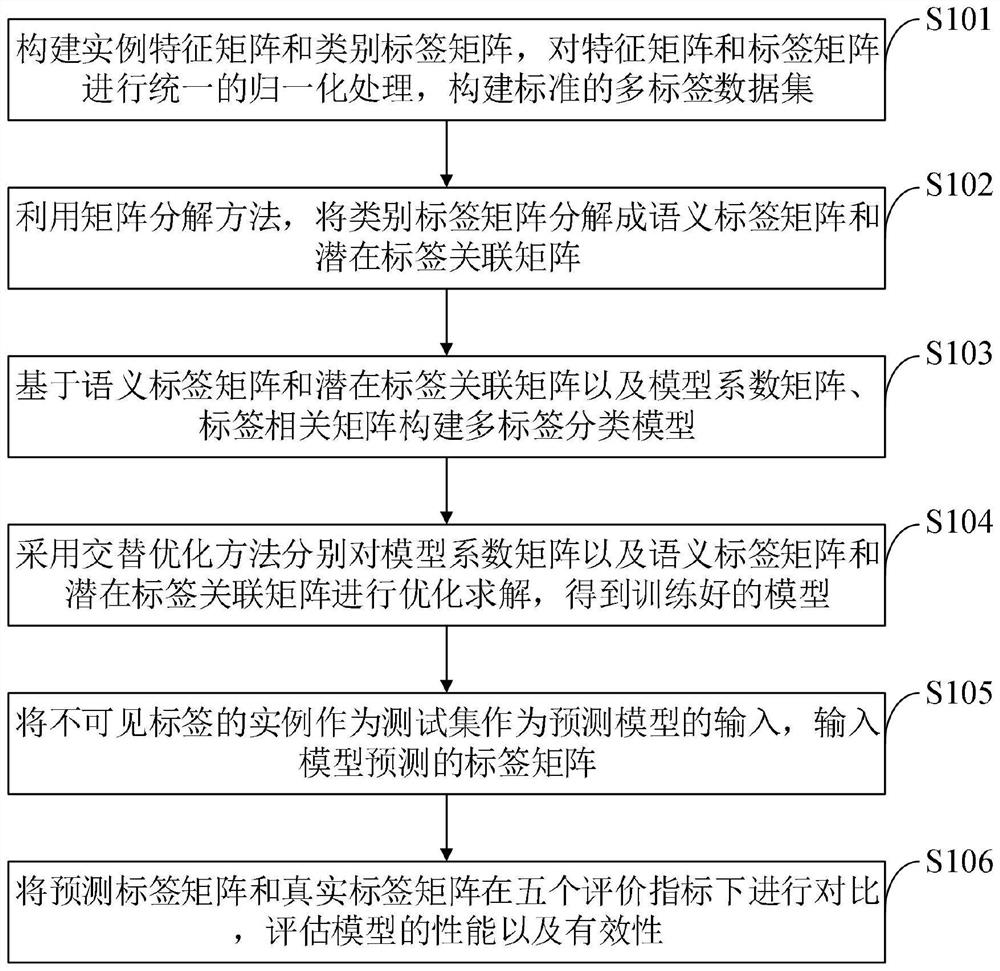

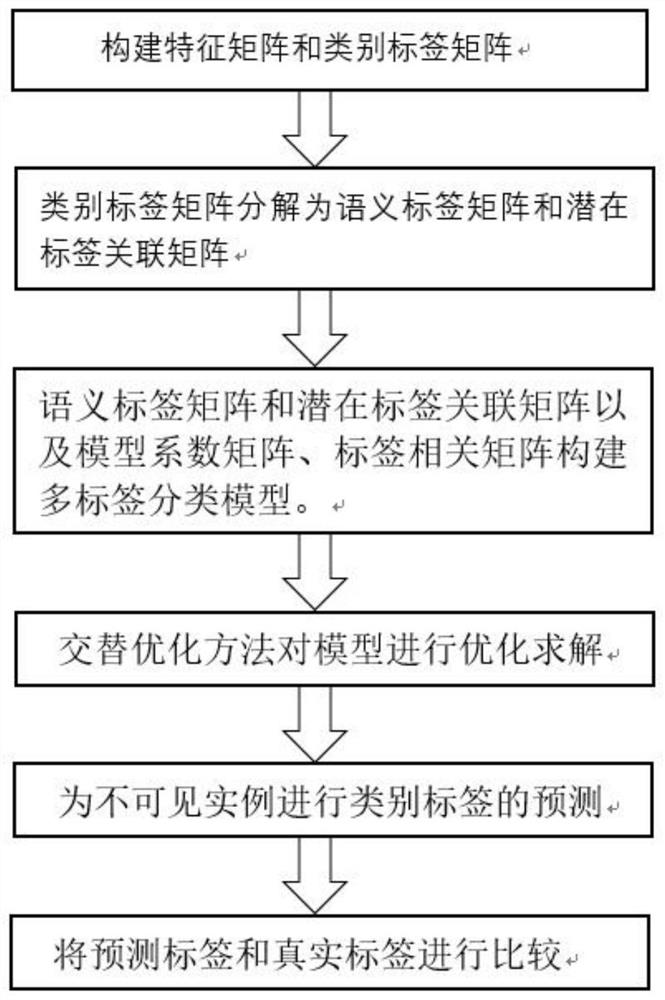

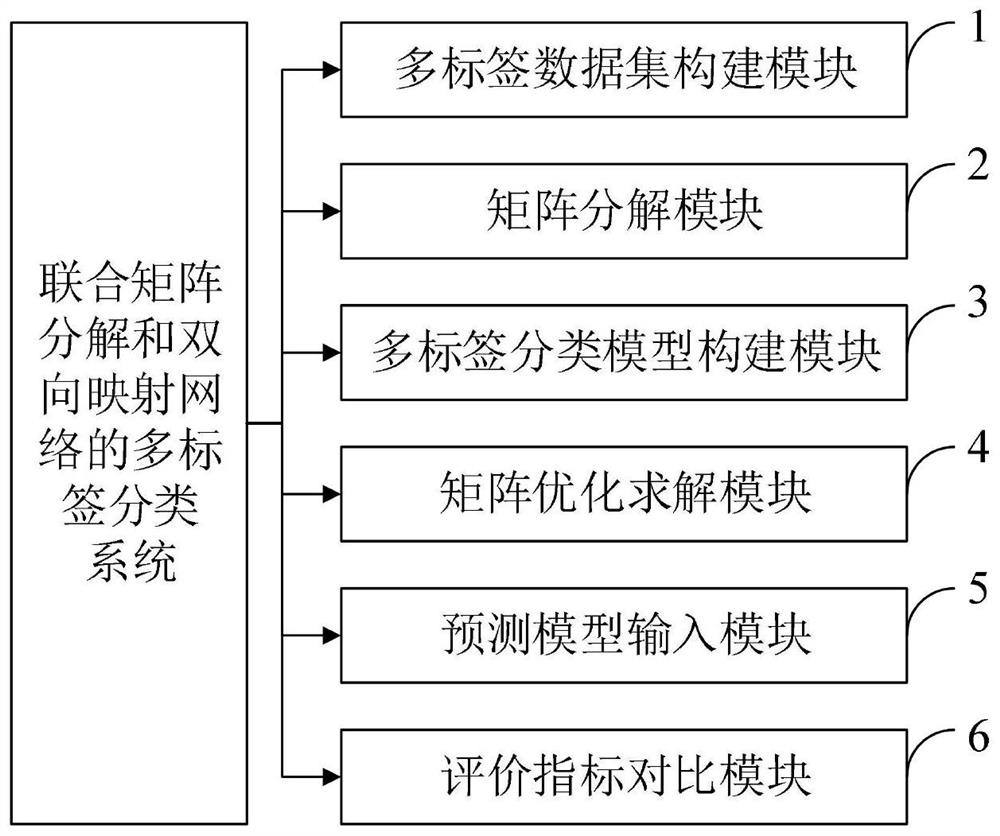

Multi-label classification method and system combining matrix decomposition and bidirectional mapping network

PendingCN114781535AImprove performanceImprove generalization abilityCharacter and pattern recognitionComplex mathematical operationsMatrix decompositionData set

The invention belongs to the technical field of computer application, and discloses a multi-label classification method and system combining matrix decomposition and a bidirectional mapping network, and the method comprises the steps: constructing an instance feature matrix and a category label matrix, carrying out the normalization processing, and constructing a standard multi-label data set; decomposing the category label matrix into a semantic label matrix and a potential label incidence matrix; constructing a multi-label classification model based on the semantic label matrix, the potential label incidence matrix, the model coefficient matrix and the label correlation matrix; respectively carrying out optimization solution on the model coefficient matrix, the semantic tag matrix and the potential tag incidence matrix to obtain a trained model; taking instances of invisible labels as a test set to be input into a label matrix predicted by the model; and comparing the predicted label matrix with the real label matrix under five evaluation indexes, and evaluating the performance and effectiveness of the model. Related experiments are carried out on multi-label data sets in multiple fields, and the experiments prove the effectiveness and competitiveness of the method.

Owner:ANHUI UNIVERSITY

Method for establishing bi-directional mapping among sequences under condition of difference limitation

ActiveCN103513991ASolve the inability to judge their similaritySolve the problem of relevanceSpecific program execution arrangementsComputer scienceBidirectional map

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

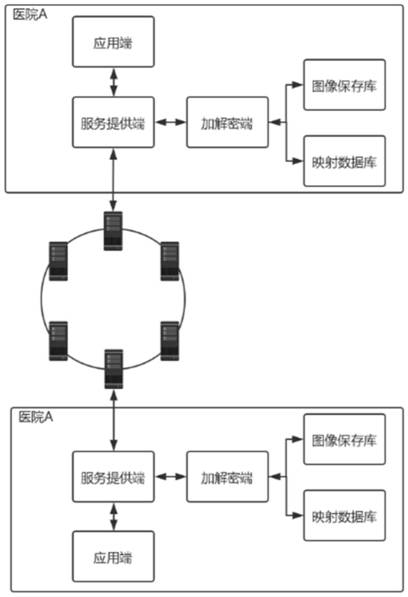

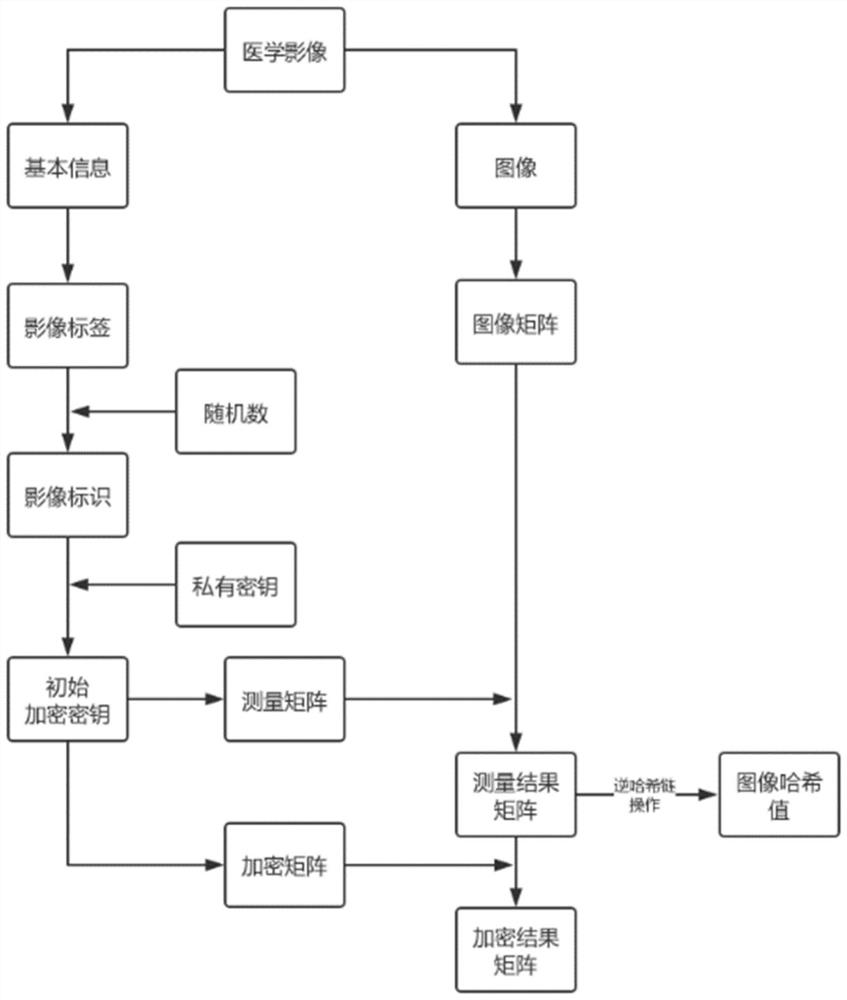

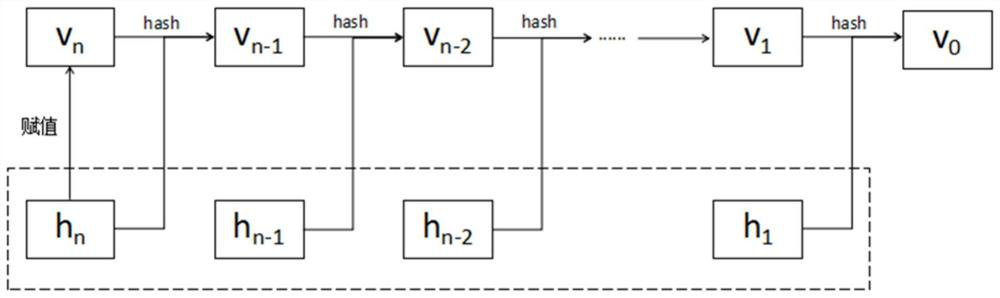

Double mapping method for on-chain representation and off-chain security edge storage of medical image

PendingCN114372294AKey distribution for secure communicationEncryption apparatus with shift registers/memoriesData informationTrusted Computing

The invention provides a medical image on-chain representation and under-chain secure edge storage method based on a block chain technology, a trusted computing technology and a compressed sensing encryption and decryption image technology. Generating a first hash chain and a second hash chain according to the initial key by using an image encryption method based on hash chain compressed sensing; and obtaining a measurement matrix and an encryption matrix according to the first hash chain and the second hash chain, obtaining a measurement result matrix through the original image and the measurement matrix, and obtaining an encryption image matrix through the measurement result matrix and the encryption matrix. And hashing the measurement matrix again to obtain a hash value of the measurement matrix, and storing the medical image related information, the hash value of the measurement matrix and the node signature into the block chain. And storing the encrypted image matrix in a node local space. In the whole process, existence proof, namely on-chain representation of the medical image, of the medical image is achieved, the image is safely stored in a node local space, namely under-chain safe edge storage is achieved, and bidirectional mapping of the medical image and the under-chain safe edge storage is achieved through uniquely-identified medical data information and the hash value of an image measurement matrix.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

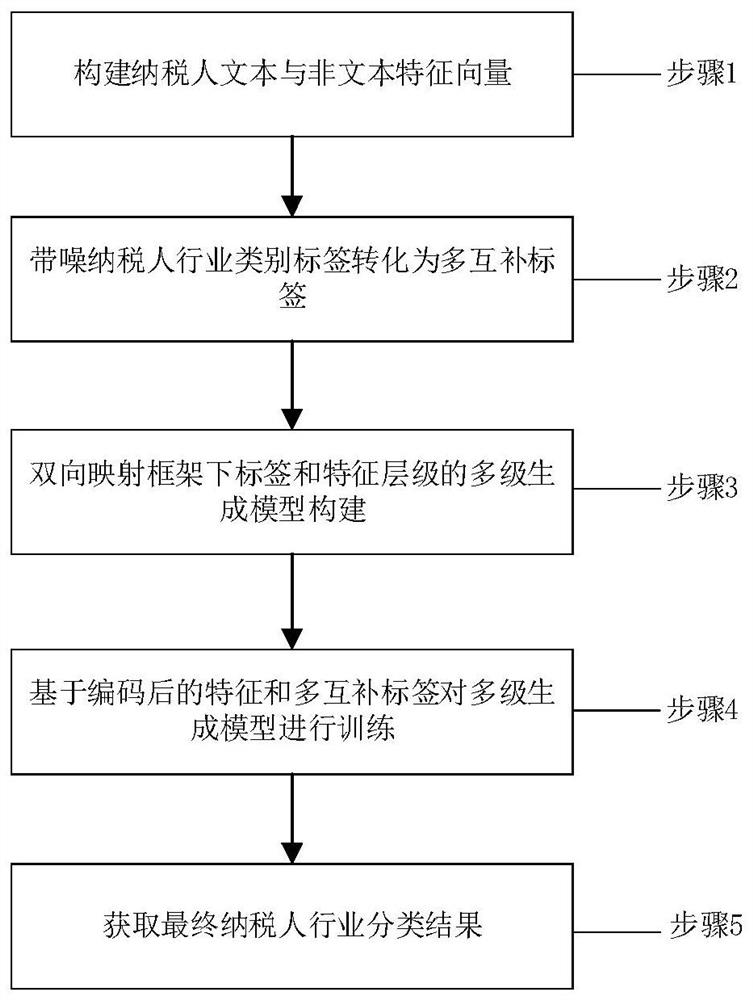

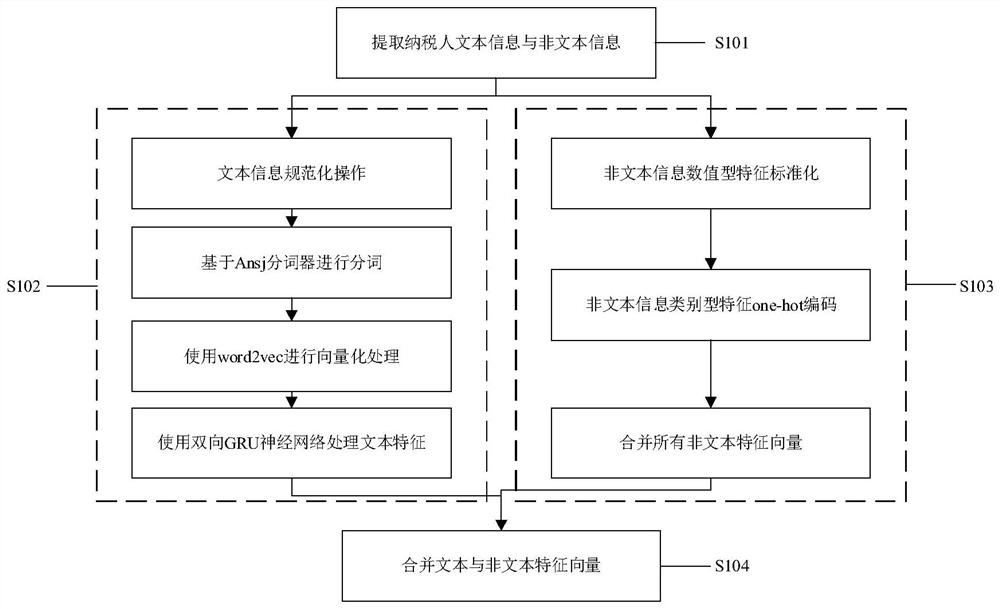

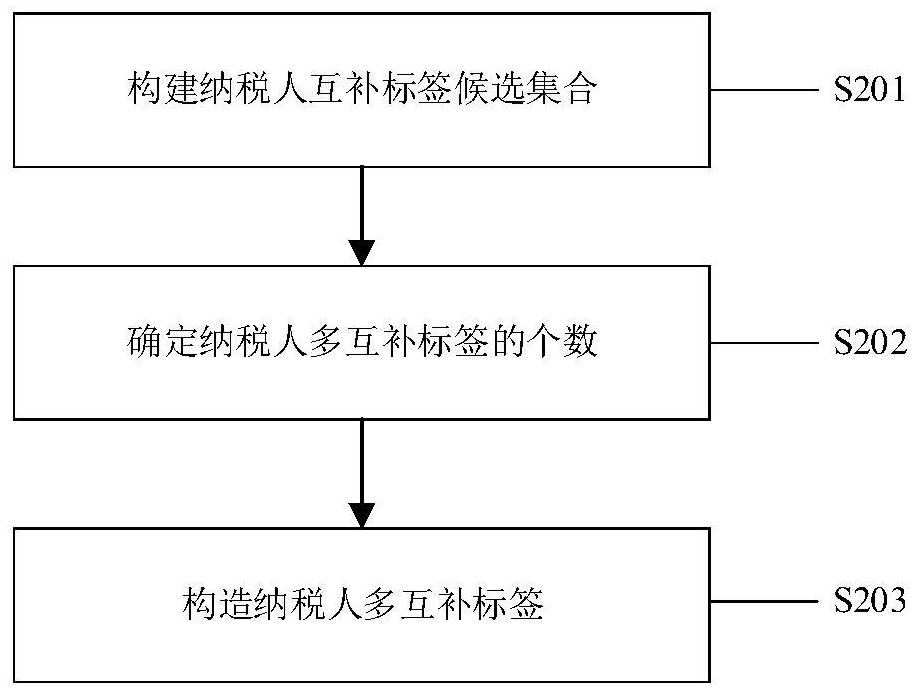

Taxpayer industry classification method based on multistage generative model

ActiveCN112860895AReduce noise ratePreventing the problem of classification accuracy degradationFinanceCharacter and pattern recognitionClassification methodsEngineering

The invention discloses a taxpayer industry classification method based on a multistage generative model, which comprises the following steps: firstly, extracting to-be-mined text and non-text information in taxpayer industry information to carry out text embedding and coding, and carrying out feature processing on the coded information; secondly, converting the taxpayer industry category label with noise into a multi-complementary label; thirdly, constructing a multi-level generation model of label and feature levels under the bidirectional mapping framework; then, training the device based on the encoded features and the generated multiple complementary tags; and finally, taking the prediction of the label level on the real label as the final taxpayer industry category of the test data. According to the method, the noise rate of the tag is reduced by converting the noisy tag into the multi-complementary tag, the feature and tag level bidirectional mapping is introduced to cope with feature-dependent noise existing in the taxpayer industry category tag, and the taxpayer industry classification accuracy can be effectively improved.

Owner:XI AN JIAOTONG UNIV

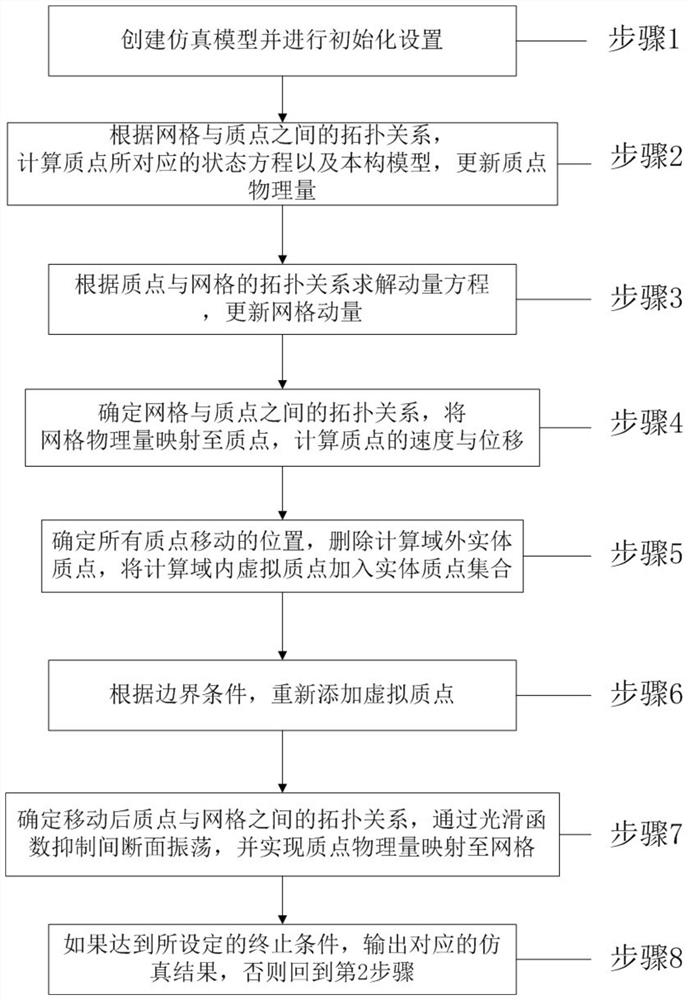

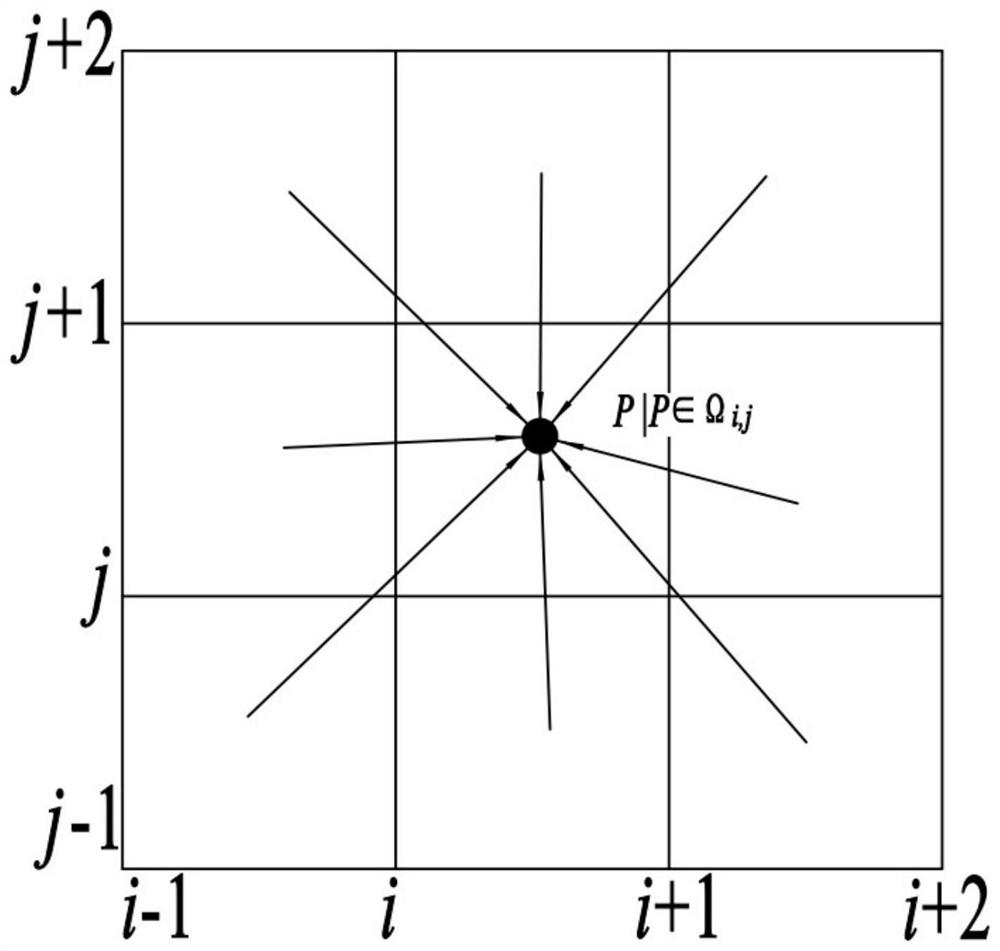

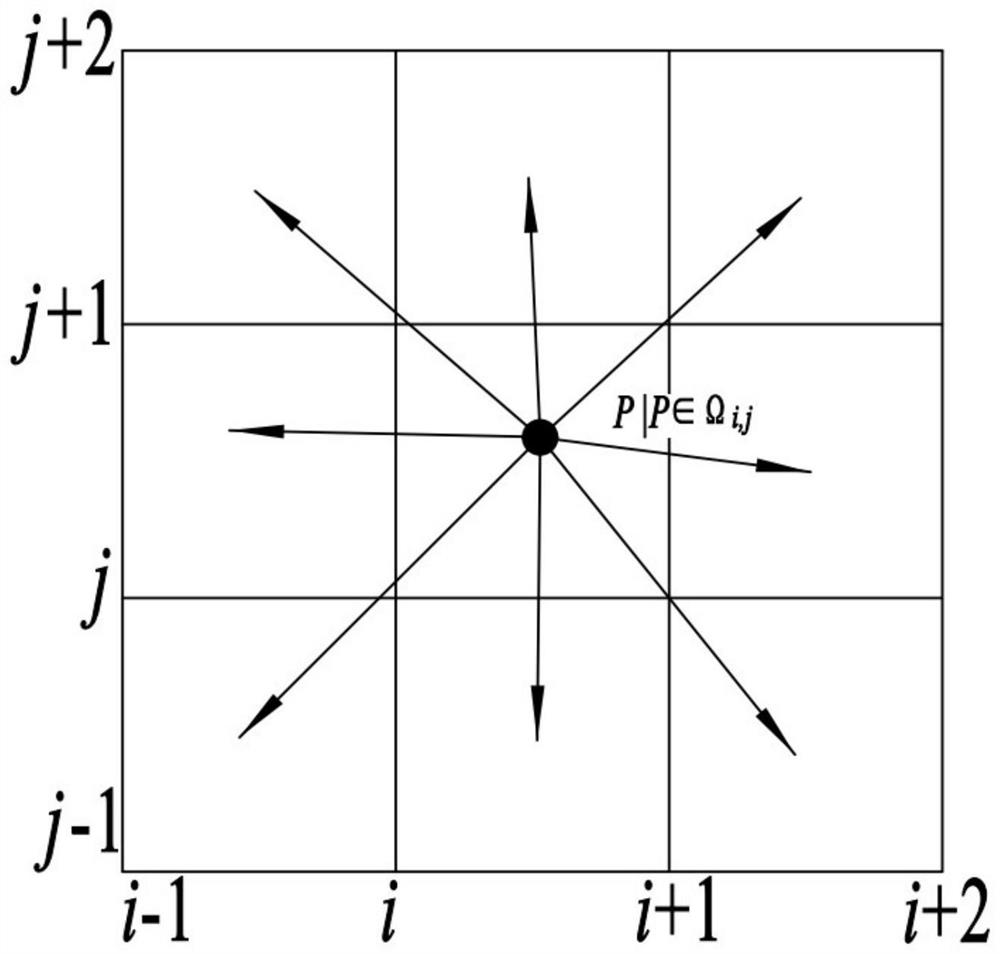

Method for accurately capturing shock wave discontinuity surface based on weighted bidirectional mapping

PendingCN113673185AAvoid numerical fluctuation defectsAccurate SnappingCAD network environmentDesign optimisation/simulationClassical mechanicsComputational physics

The invention discloses a method for accurately capturing a shock wave discontinuous surface based on weighted bidirectional mapping, and belongs to the field of computational explosion mechanics. The method comprises the following steps: tracking a medium in a grid by adopting a Lagrange mass point, performing weighted bidirectional mapping on the mass point and a grid physical quantity by using a three-order shape function, and overcoming numerical value fluctuation generated by a mass point type method due to a finite mass point number; employing a smooth mass point method with a limiter for processing the problem of significant numerical oscillation existing at a discontinuous surface, so the method has more excellent calculation performance; adding a fixed grid, wherein due to the topological mapping relation between an Euler grid and a Lagrangian mass point, inlay penetration does not occur between different substances; adding virtual Lagrangian particles at the boundary, simulating continuous fluid, and realizing the inflow, outflow and periodic boundary conditions by increasing and deleting the whole particles. The method is suitable for the field of explosion and impact, numerical simulation of accurate tracking is carried out on conditions of propagation of high-strength impact waves, interaction of impact waves with different strengths and the like, and pressure at any moment can be recorded to provide damage criteria for target damage assessment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

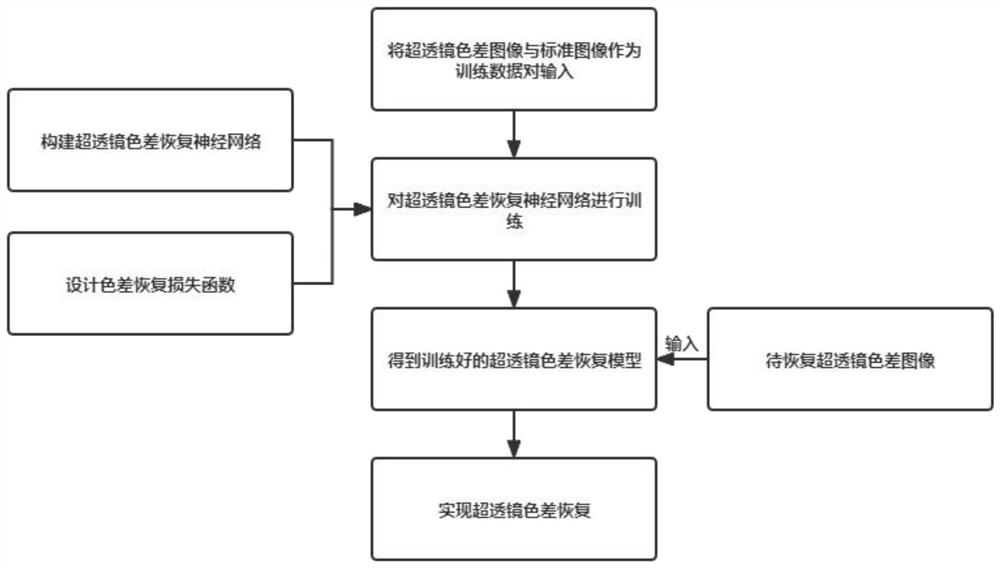

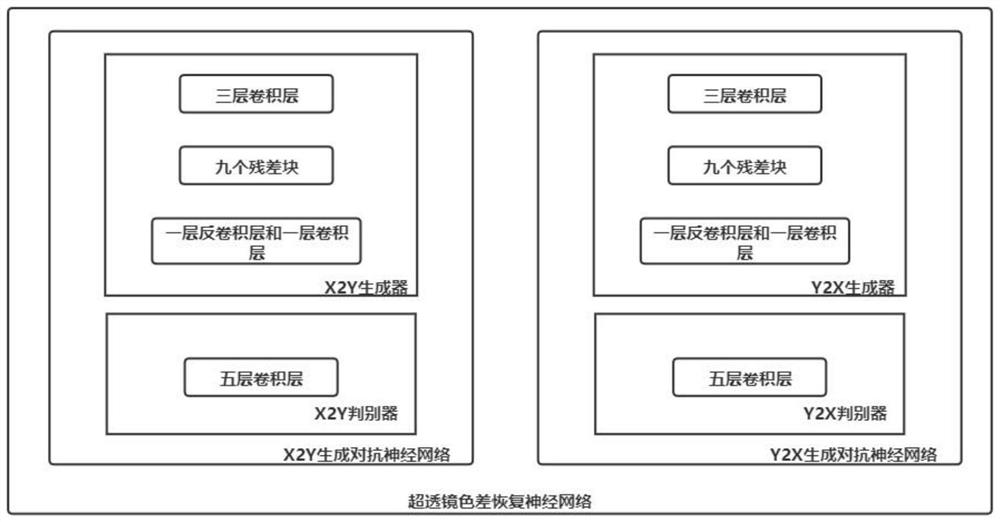

Super-lens chromatic aberration recovery method based on deep learning

InactiveCN114331891ALow costSimple structureImage enhancementNeural architecturesOphthalmologyComputer science

The invention discloses a super-lens chromatic aberration recovery method based on deep learning. The method comprises the following steps: 1) constructing a super-lens chromatic aberration recovery neural network and a chromatic aberration recovery loss function; 2) taking the super-lens chromatic aberration image x and a standard image y corresponding to the super-lens chromatic aberration image x as a training data pair, training the super-lens chromatic aberration recovery neural network to enable a chromatic aberration recovery loss function value to be less than 8, realizing bidirectional mapping from the super-lens chromatic aberration image to the standard image corresponding to the super-lens chromatic aberration image, and obtaining a trained super-lens chromatic aberration recovery model; and 3) inputting the to-be-recovered super-lens chromatic aberration image into the trained super-lens chromatic aberration recovery model by using the step 2) to realize super-lens chromatic aberration recovery.

Owner:CHINA JILIANG UNIV

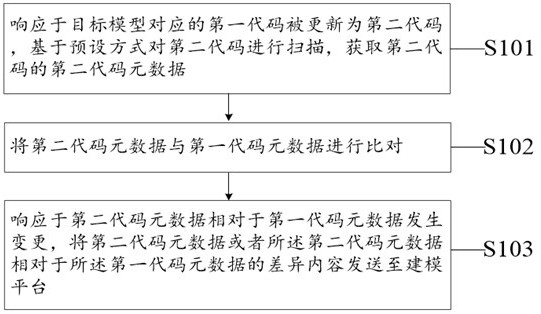

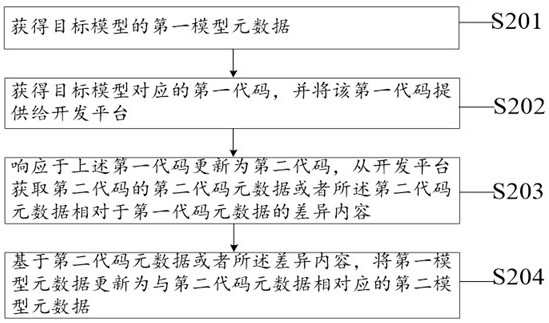

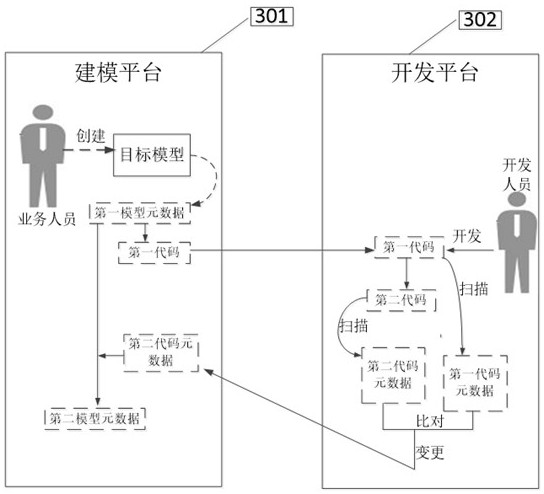

Model-code synchronization method

The invention discloses a model-code synchronization method. The method comprises the following steps of: in response to a situation that a first code corresponding to a target model is updated into a second code, scanning the second code based on a preset mode to obtain second code metadata of the second code; comparing the second code metadata with first code metadata; and in response to the change of the second code metadata relative to the first code metadata, sending the second code metadata to a modeling platform, so as to make the modeling platform update first model metadata into second model metadata corresponding to the second code metadata. According to the method, the code metadata is introduced, and the code metadata corresponds to the model metadata and can be used for establishing association between a model and a code, realizing linkage between code change and model change and realizing bidirectional mapping between the model and the code, namely, the code can be generated based on the model, and the model change is correspondingly realized based on the change of the code.

Owner:ALIBABA CLOUD COMPUTING LTD

Configuration method, device, terminal and storage medium of a visual development environment

ActiveCN109032590BAchieve real-time synchronization mechanismReduce configurationVisual/graphical programmingData setSoftware engineering

The embodiment of the present application provides a configuration method, device, terminal and storage medium of a visual development environment, the method includes: binding a physical data model, reading the physical data model, establishing an O / R relationship channel; loading the model data set, Configure the dependency relationship and event relationship between data models to generate a two-way mapping relationship with the physical data model; carry out secondary structural transformation of the data model set to complete the field-level mapping relationship; according to the physical data model and data model set O / R two-way mapping relationship to generate a unified code file; call the data interface, access the database, and complete the functional operation of the business scenario; the method provided by this application unifies the technical framework, and at the same time, the technical framework has high automation, high development efficiency, and low professional requirements. , Few loopholes, standardized code, safe, easy to use, and comprehensive functions, saving time and labor costs.

Owner:SHANDONG LUNENG SOFTWARE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com