Patents

Literature

85 results about "Re optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

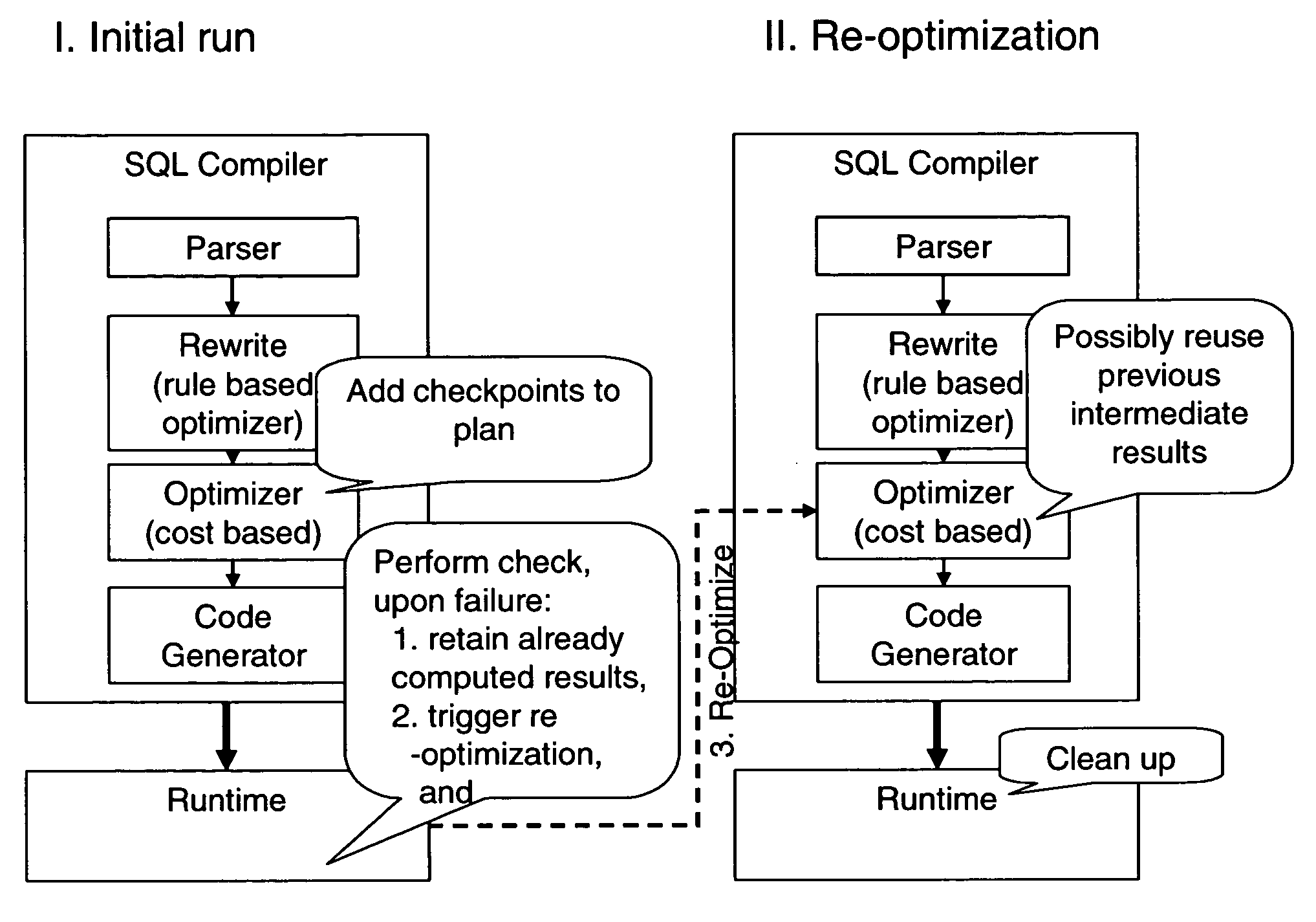

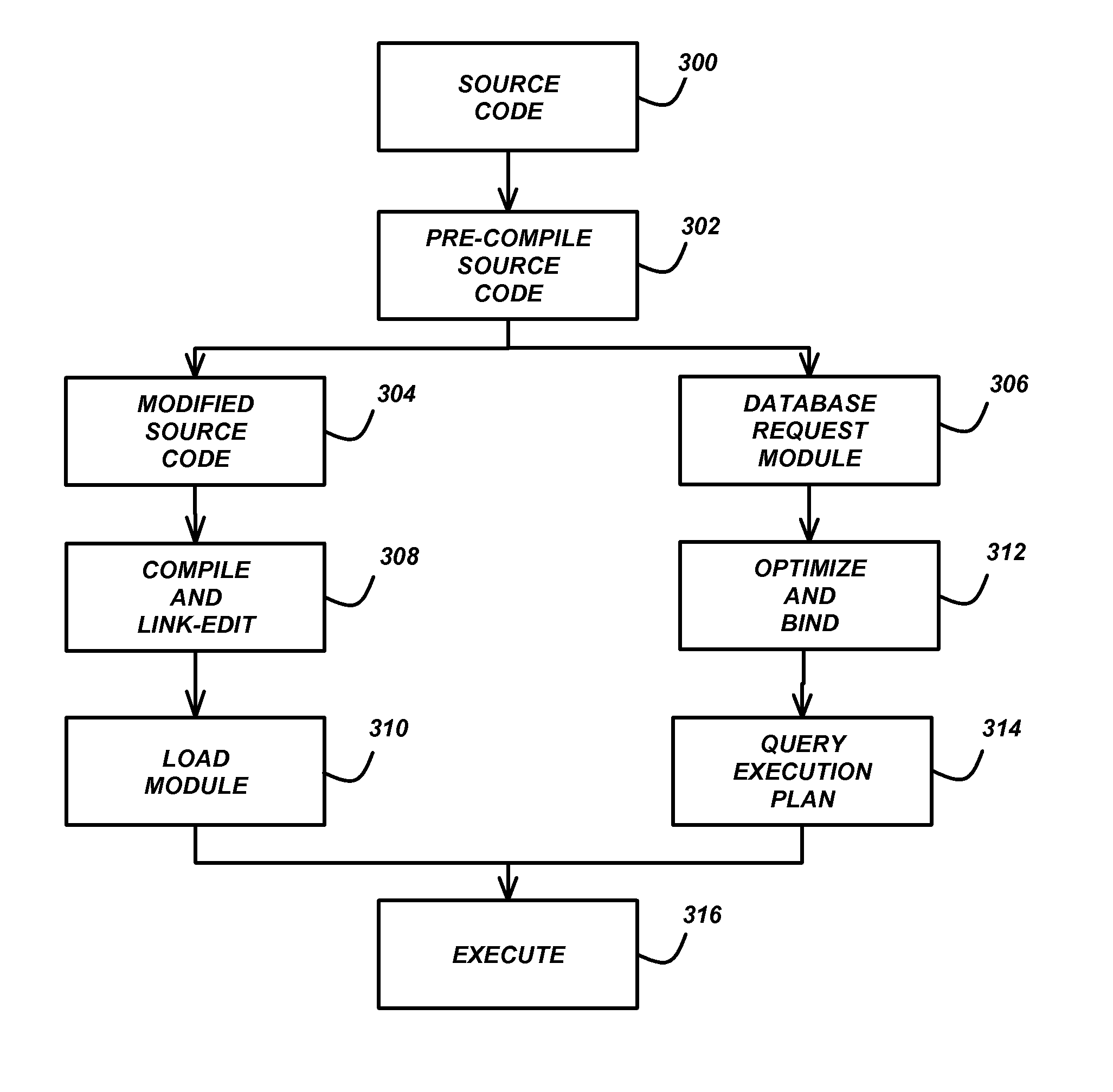

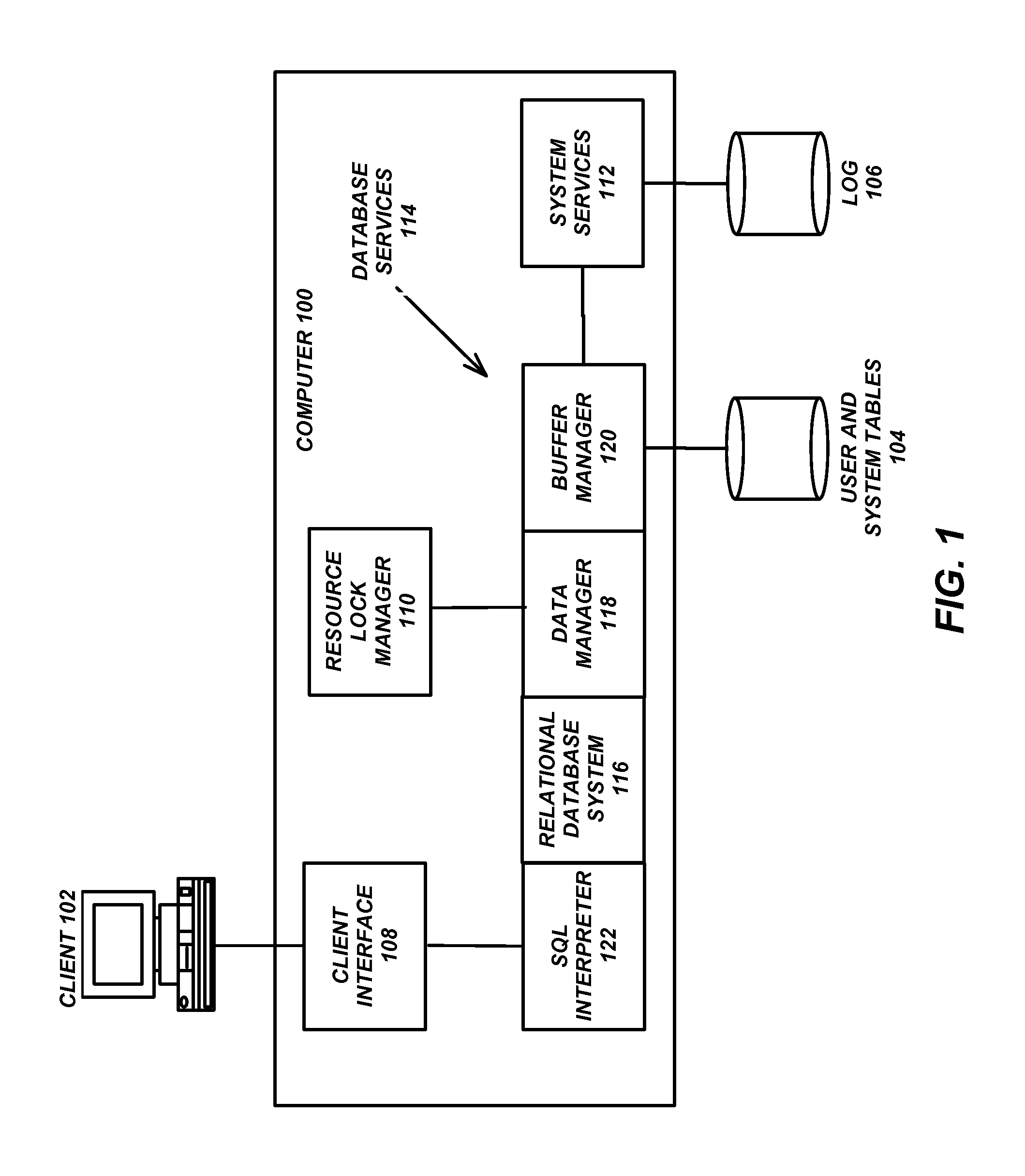

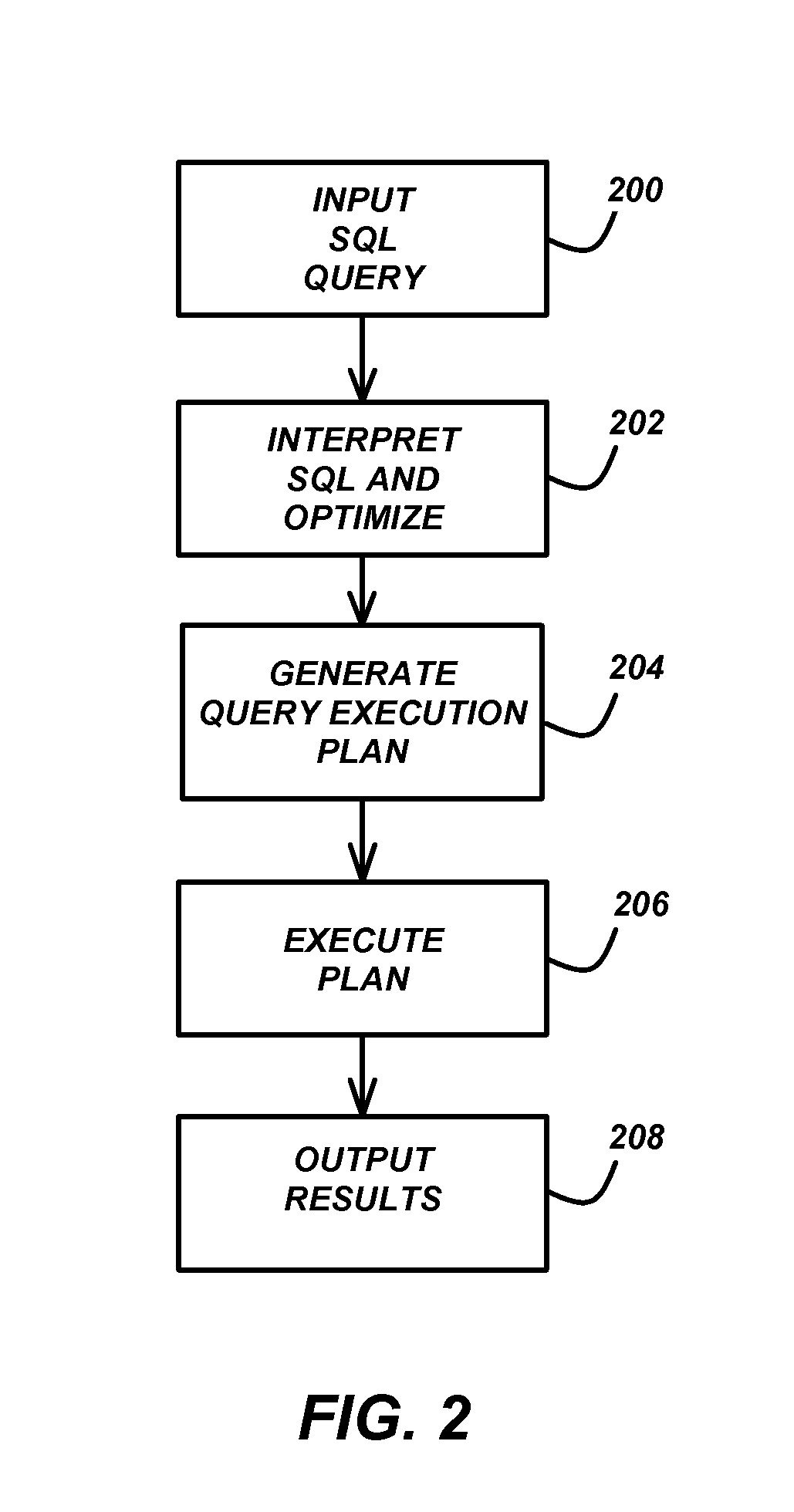

System, method, and computer program product for progressive query processing

ActiveUS20050097078A1Reduce computing costEliminate duplicationData processing applicationsDigital data information retrievalExecution planView maintenance

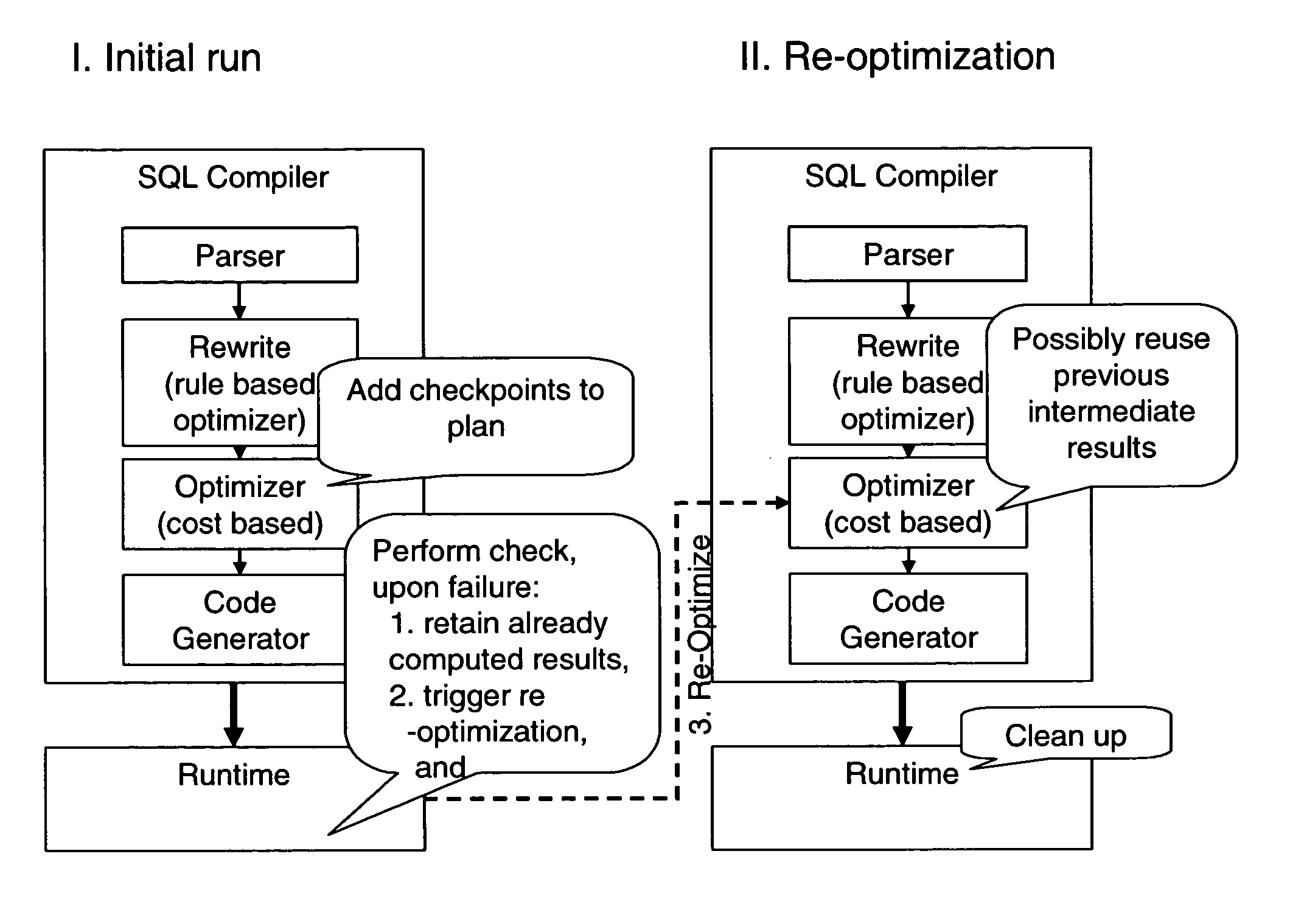

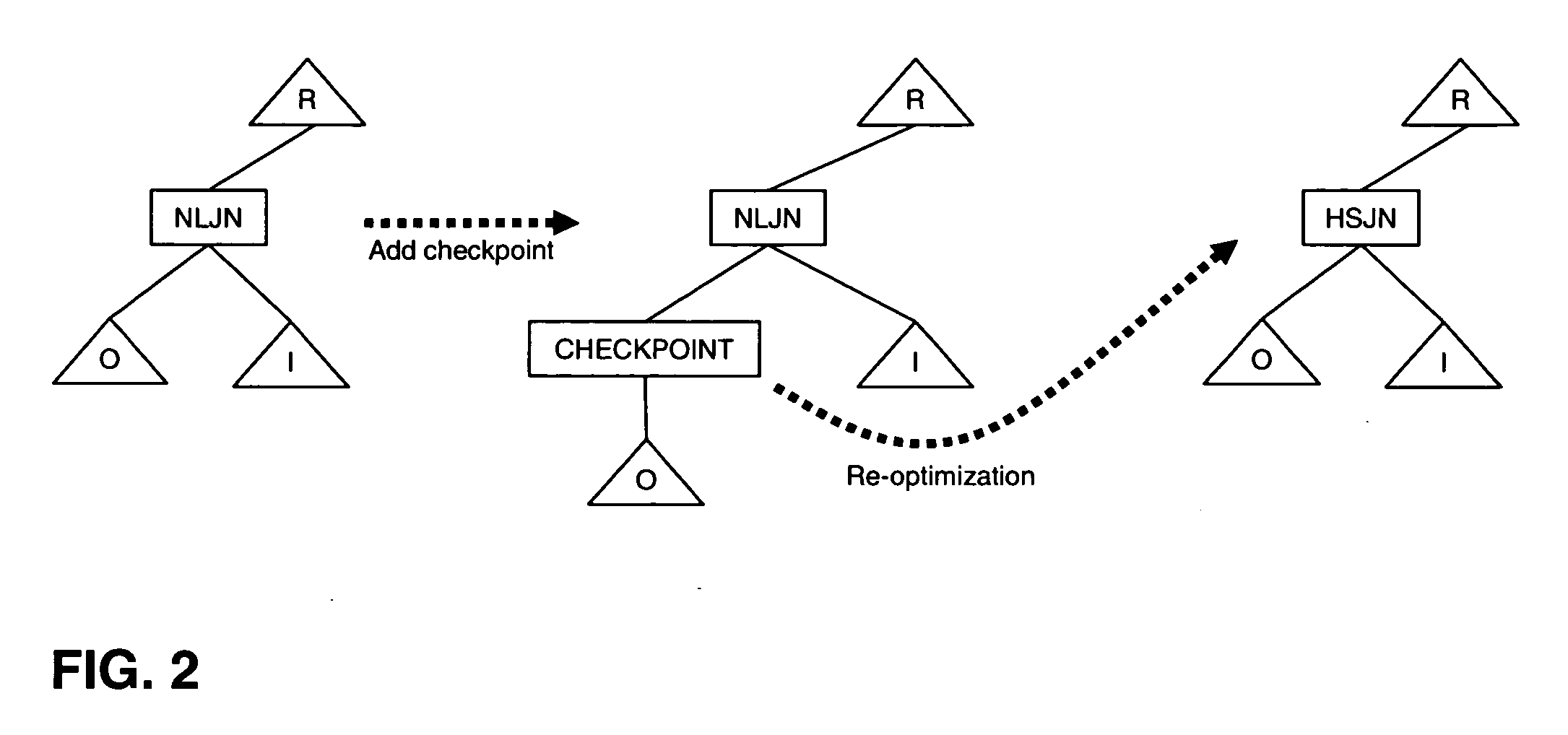

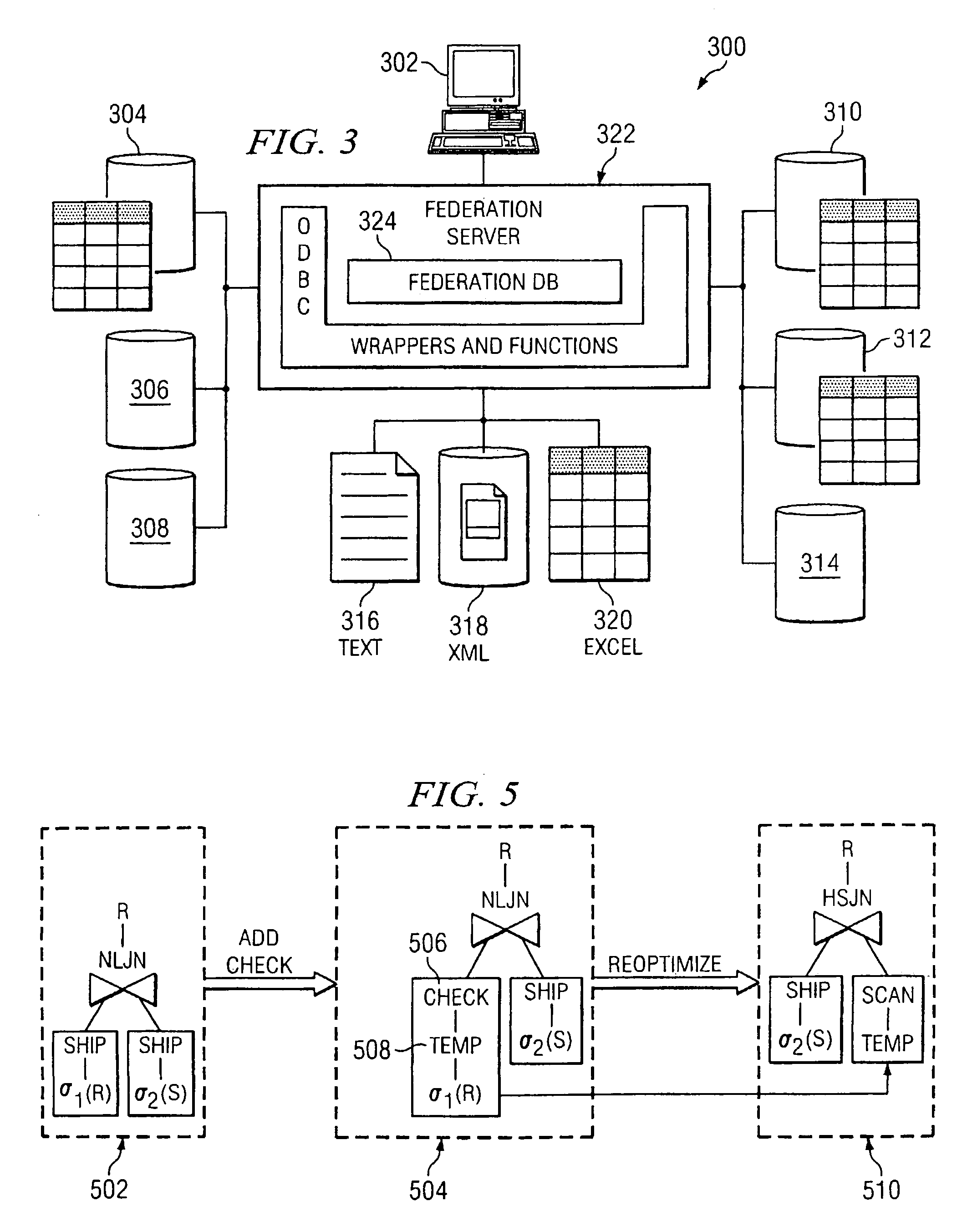

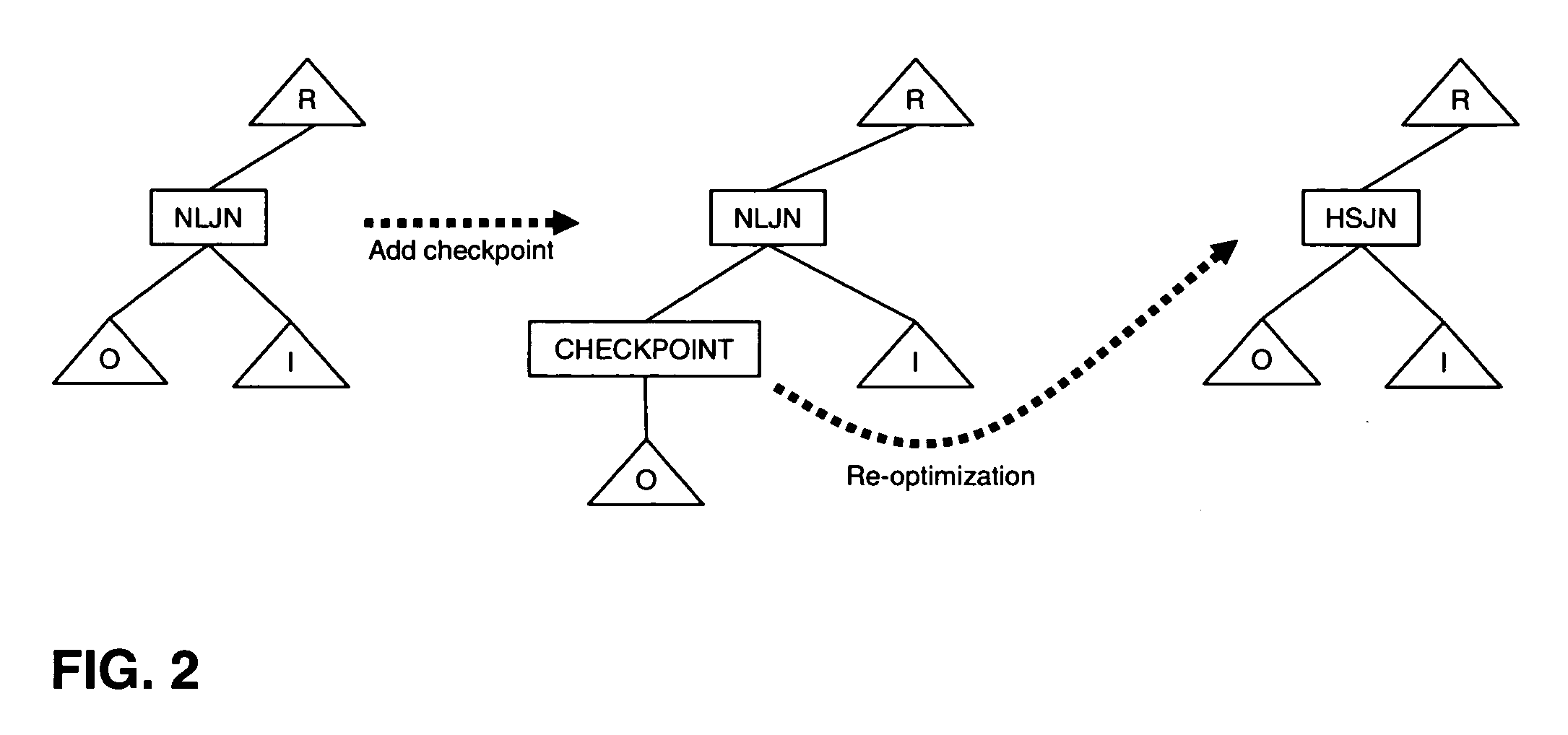

A method, system, and computer program product to make query processing more robust in the face of optimization errors. The invention validates the statistics and assumptions used for compiling a query as the query is executed and, when necessary, progressively re-optimizes the query in mid-execution based on the knowledge learned during its partial execution. The invention selectively places a number of CHECK operators in a query execution plan to validate the optimizer's cardinality estimates against actual cardinalities. Errors beyond a threshold trigger re-optimization, and the optimizer decides whether the old plan is still optimal and whether to re-use previously computed results. The invention addresses arbitrary SQL queries whose plans can contain sub-queries, updates, trigger checking, and view maintenance operations. The invention can handle concurrent update transactions or updates of common sub-expressions in a query execution plan without compromising consistency and isolation as locking information is tied to the record ID.

Owner:HULU

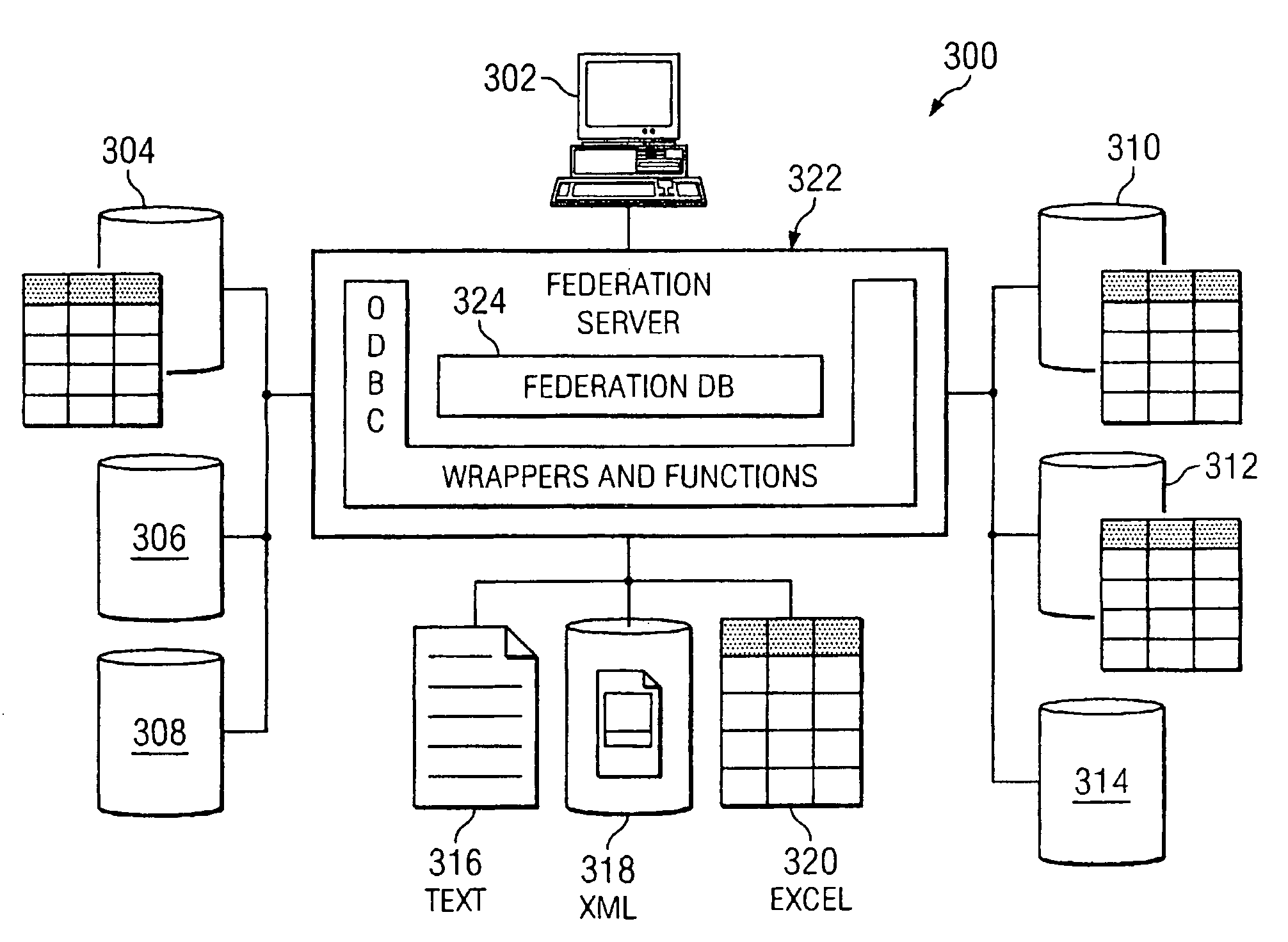

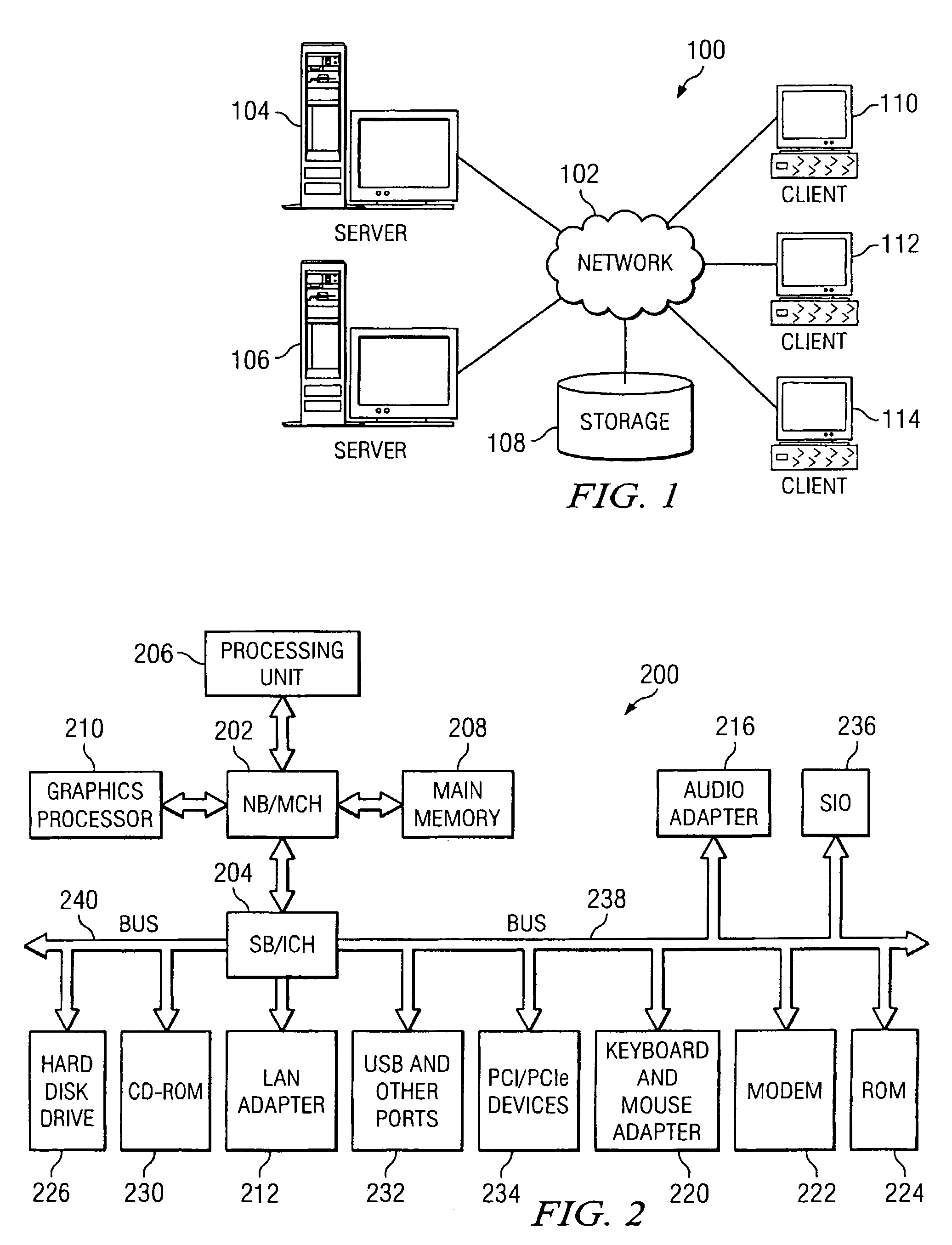

Progressive refinement of a federated query plan during query execution

InactiveUS7877381B2Digital data information retrievalDigital data processing detailsProgramming languageQuery plan

A way for progressively refining a query execution plan during query execution in a federated data system is provided. Re-optimization constraints are placed in the query execution plan during query compilation. When a re-optimization constraint is violated during query execution, a model of the query execution plan is refined using a partially executed query to form a new query execution plan. The new query execution plan is compiled. The compiled new query execution plan is executed.

Owner:INT BUSINESS MASCH CORP

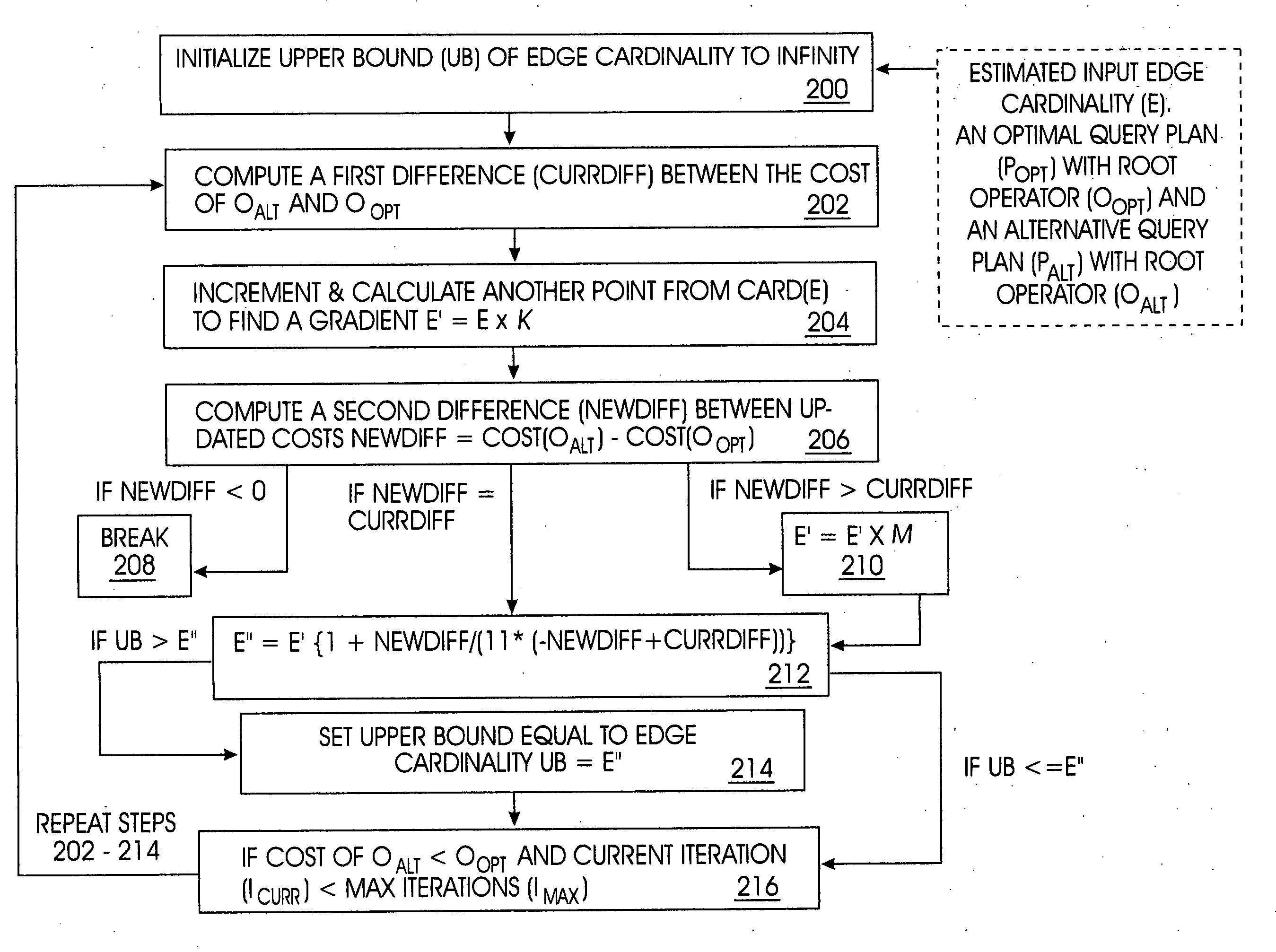

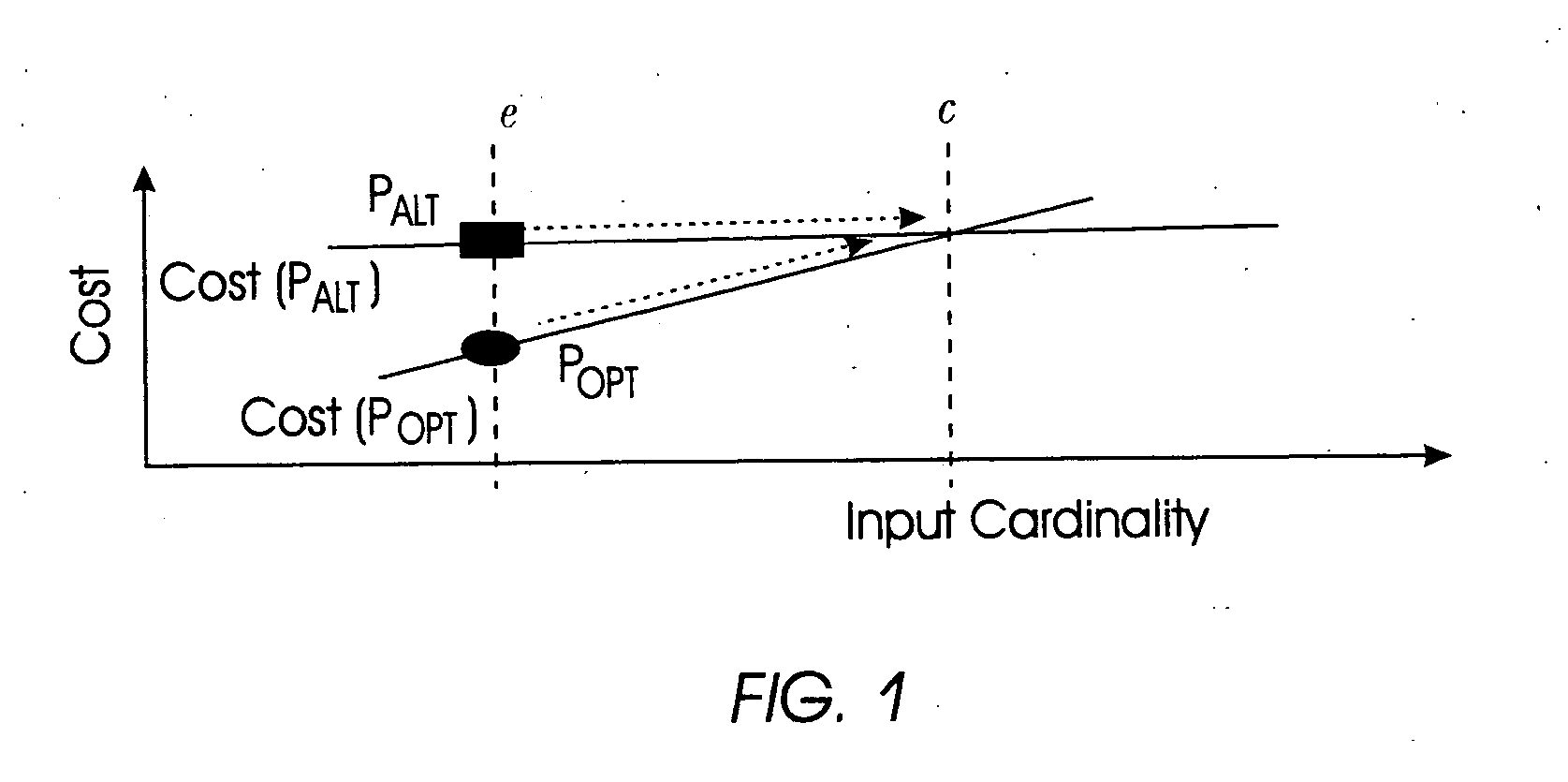

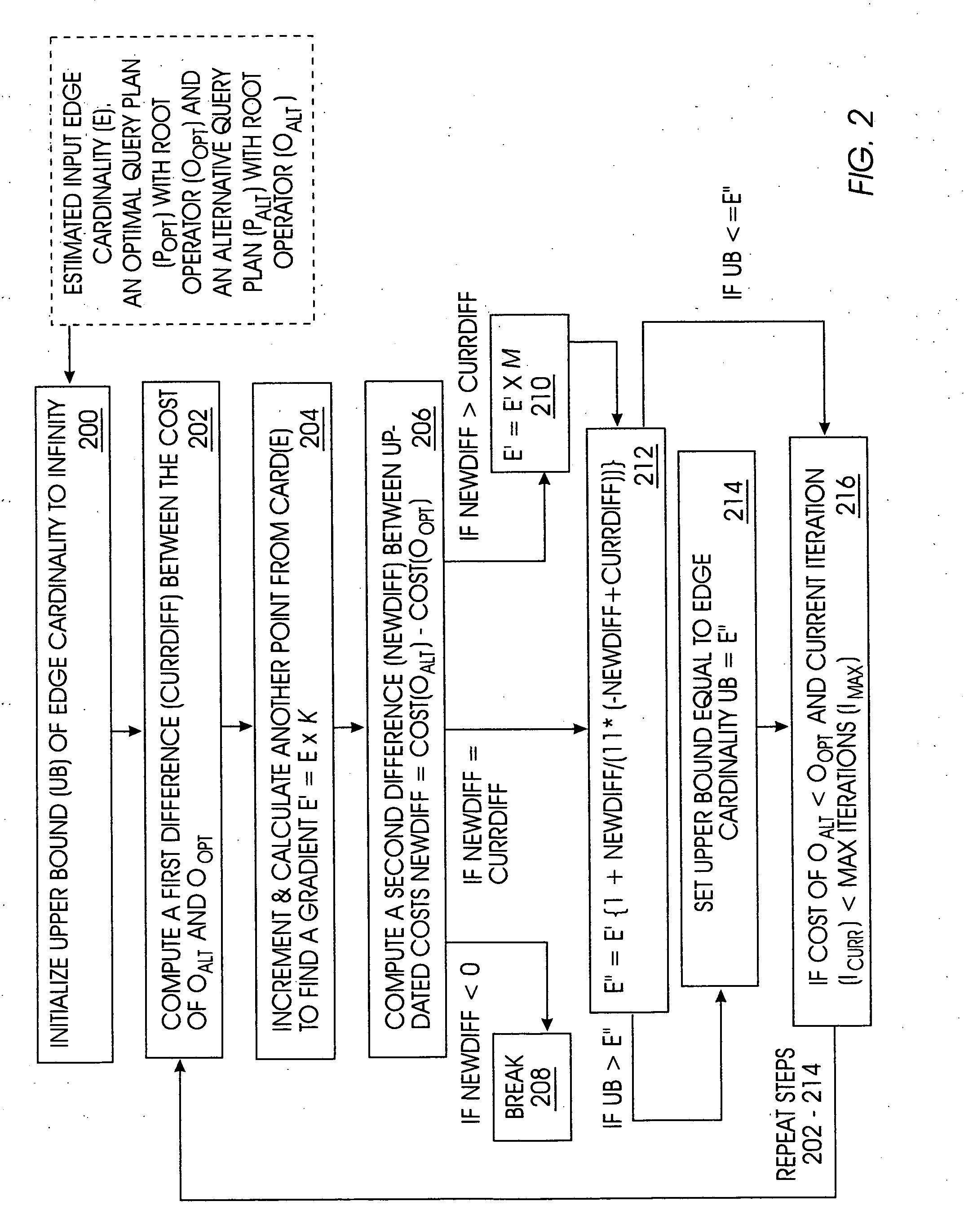

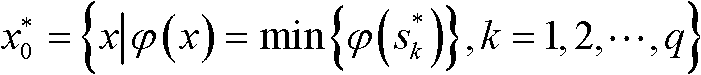

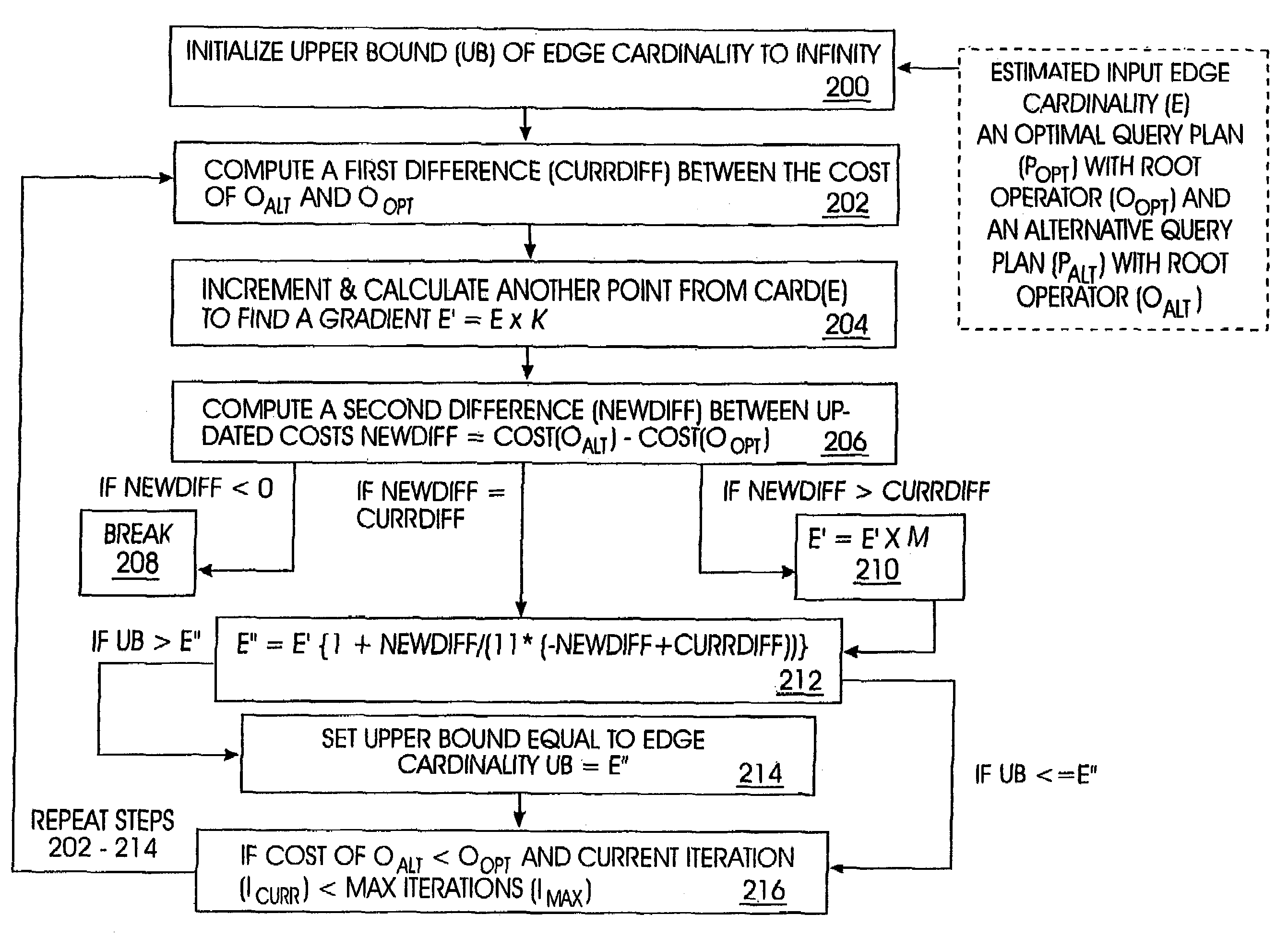

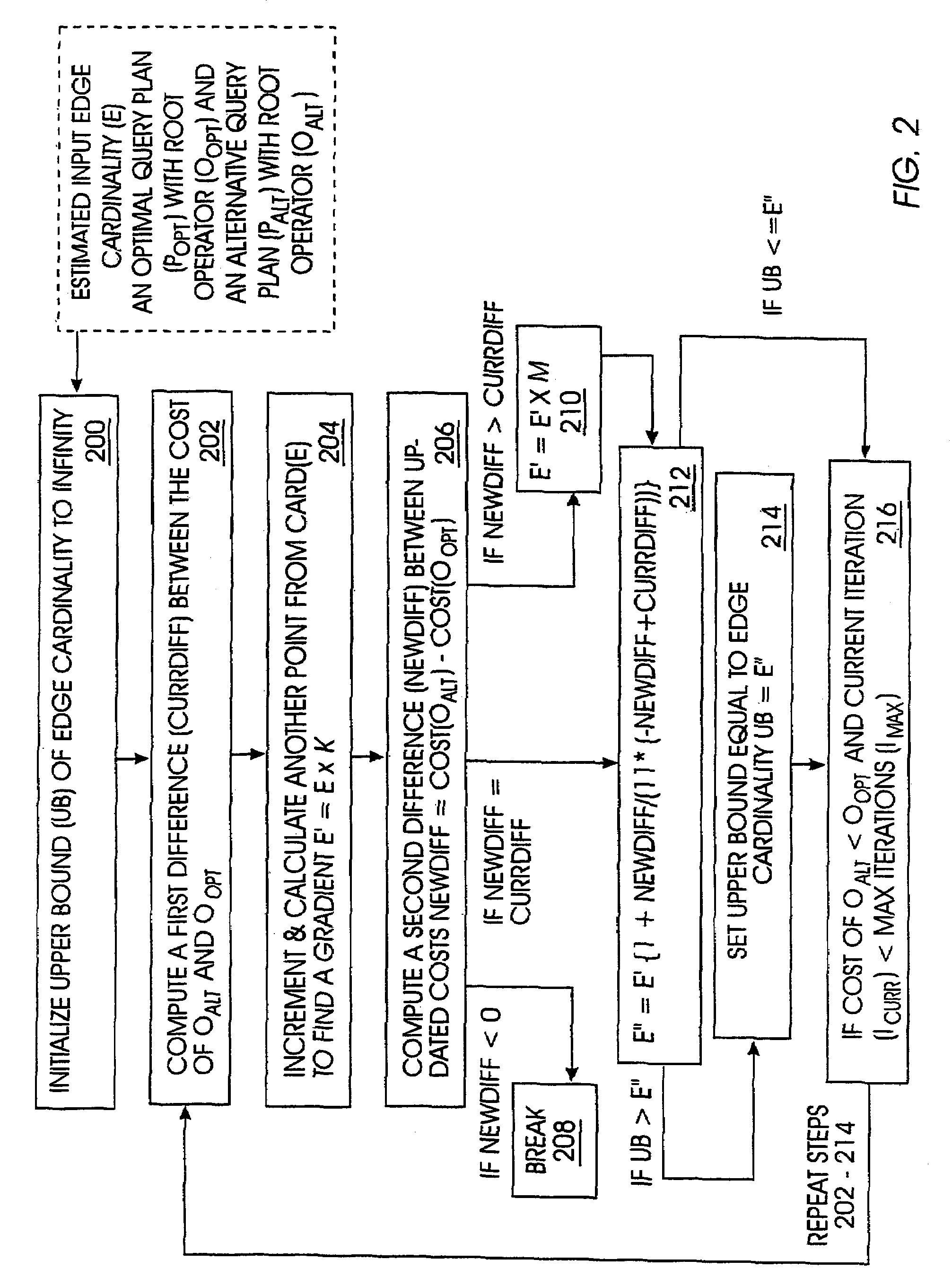

Determining validity ranges of query plans based on suboptimality

InactiveUS20050267866A1Improve robustnessAccurate thresholdData processing applicationsDigital data information retrievalQuery planAlgorithm

“Determining Validity Ranges of Query Plans Based on Suboptimality” A method for approximating a validity range for a domain of cardinalities of input to an optimal query plan is provided. Such a validity range is iteratively approximated using a modified Newton-Raphson method to find roots of cost functions for optimal and alternative query plans, respectively. The Newton-Raphson method is combined with a method of incrementing roots of cost functions, known as input cardinalities, such that discontinuous and non-differentiable points in cost functions are avoided. In this manner, input cardinalities remain within a domain for which a valid range can be specified. Additionally, a robustness measure is determined by a sensitivity analysis performed on an approximated validity range. Using a robustness measure provided by a sensitivity analysis and resultant validity range and, query plan sub-optimality detection is simplified, re-optimization is selectively triggered, and robustness information is provided to a system or user performing corrective actions.

Owner:IBM CORP

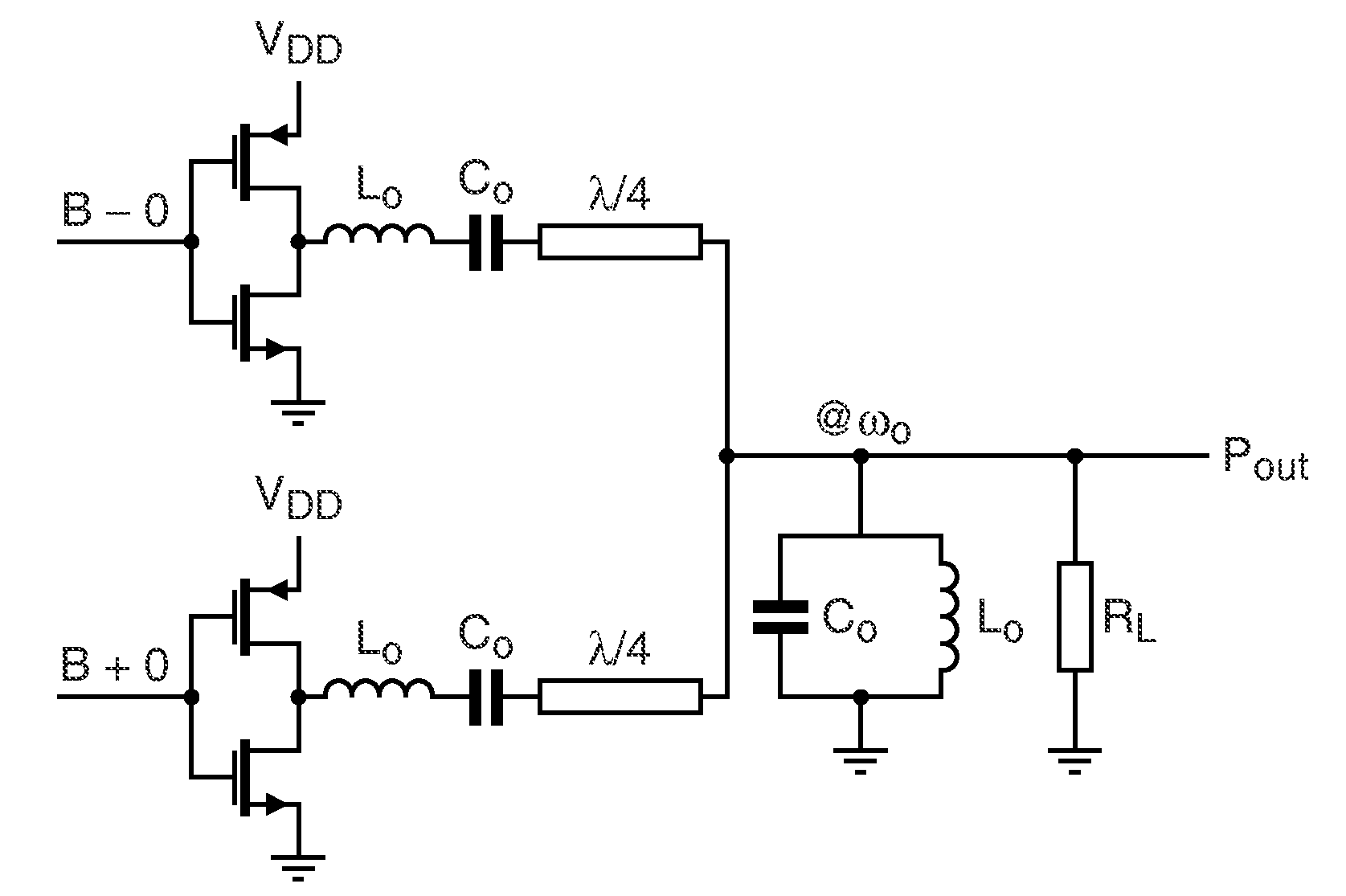

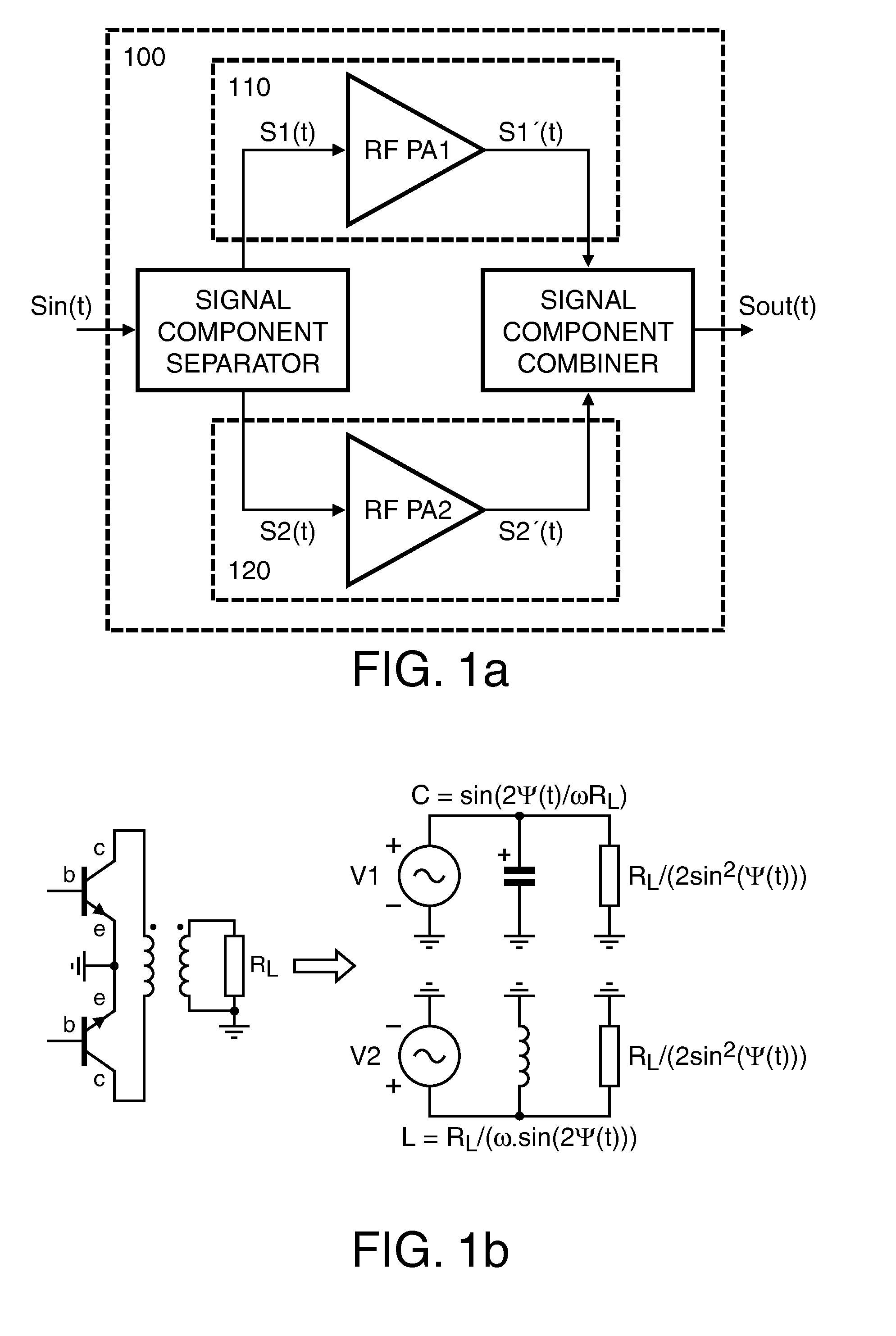

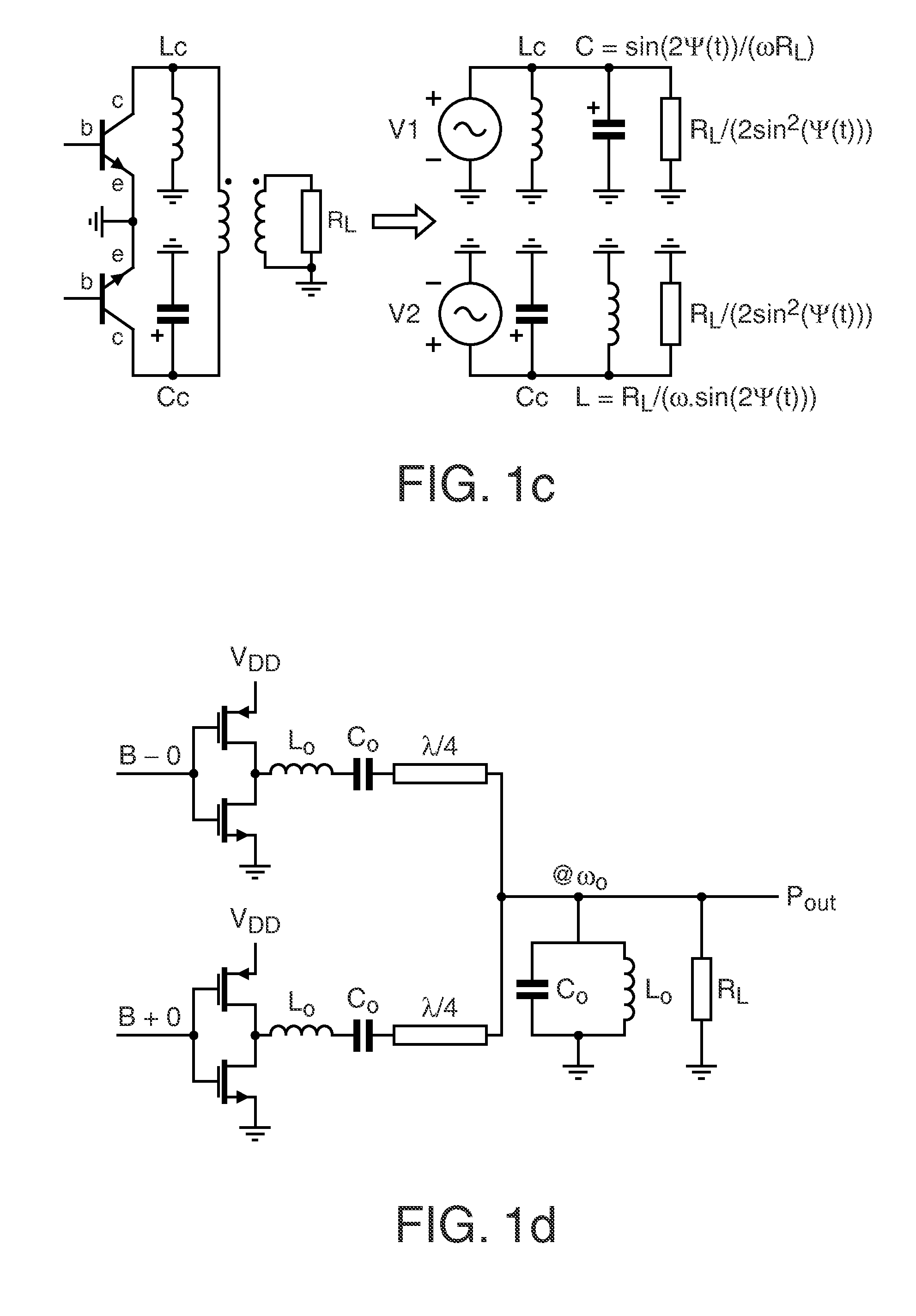

Efficient linear linc power amplifier

InactiveUS20110051842A1Improve efficiencyImproved power amplificationModulated-carrier systemsAmplifier combinationsCapacitanceDead time

Method for setup of parameter values in a RF power amplifier circuit arrangement (200), wherein the amplifier circuit arrangement (200) comprises a first (210) and a second (220) amplification branch and is operated in an out-phasing configuration for amplification of RF input signals with modulated amplitude and modulated phase and respective circuit arrangements are disclosed. According to a first aspect a re-optimization of the dead-time or conversely the duty-cycle, respectively, the phase of the output signal after the combiner can be kept linear with respect to the out-phasing angle. Further, according to a second aspect, additionally to introduction of an optimally chosen dead-time, a non-coherent combiner (Lx, Lx*) can reduce crowbar current and switching losses due the output capacitance (Cds). Furthermore, according to a third aspect the reactive compensation can, additionally or alternatively, be controlled by operating both amplification branches at different duty-cycles.

Owner:AMPLEON NETHERLANDS

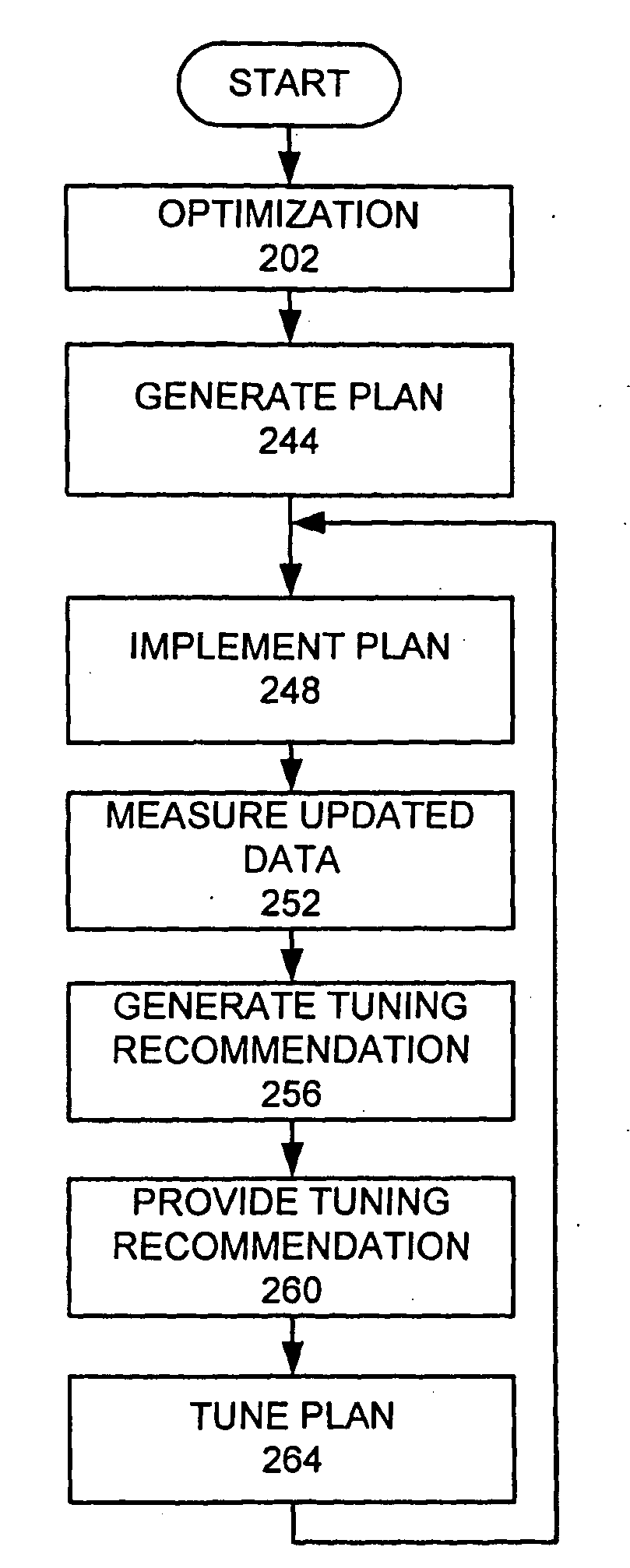

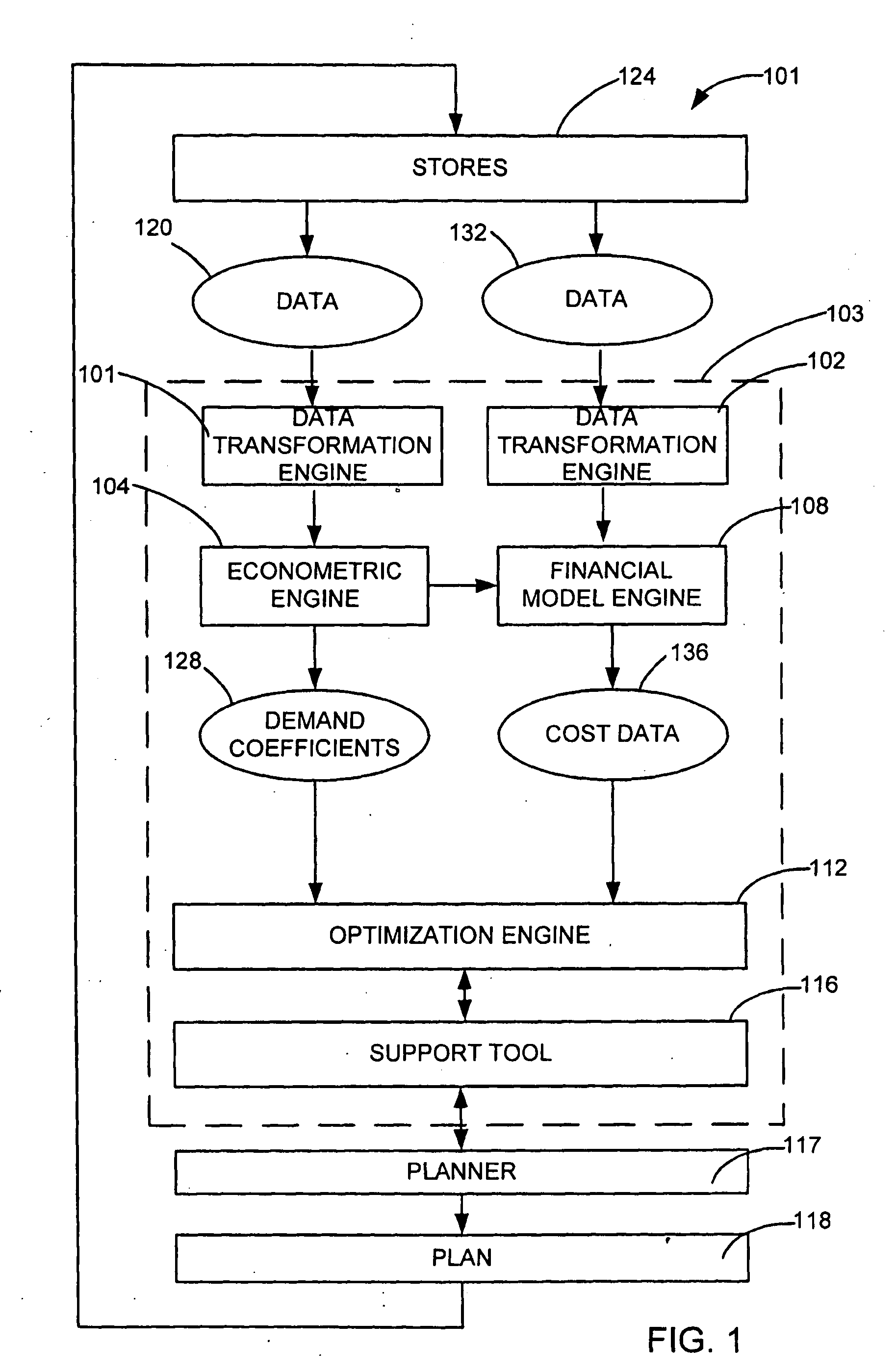

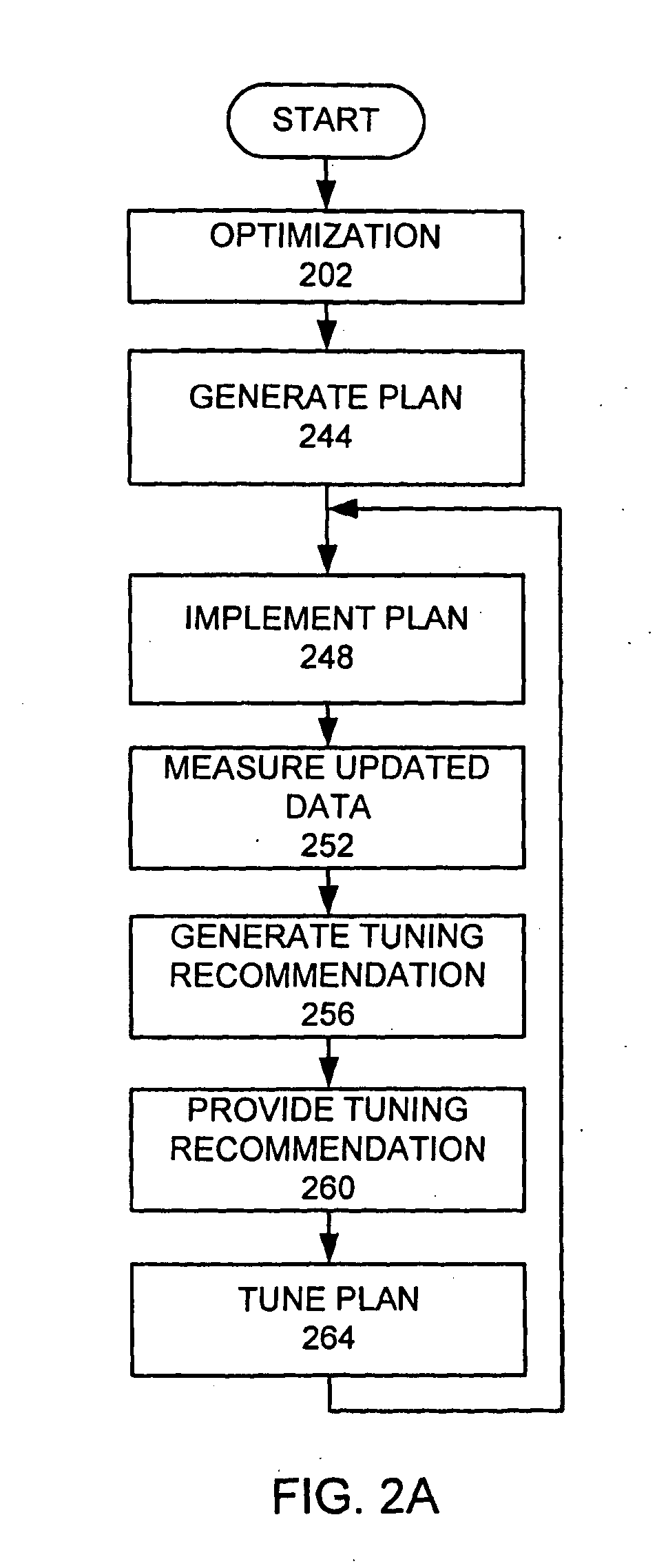

System and Methods for Pricing Markdown with Model Refresh and Reoptimization

A system and method for tuning markdown plans is provided. Such a system and method may include configuring initial rule set. Initial Demand models are generated. A first optimization for inventory pricing may be received from the price optimization system. The first optimization uses the initial demand models and cost data. A markdown plan is generated by applying the initial rule set to the first optimization. The plan is implemented. Updated data may be received which mandates a re-optimization of the plan. Demand models are refreshed using the updated data. Initial rule set is updated by cross referencing plan history with the initial rule set and subtracting rule events that have previously occurred. A second optimization is received which uses the refreshed demand models and cost data. Then, the markdown plan is re-optimized by applying the updated rule set to the second optimization. The re-optimized markdown plan is reported, approved and implemented.

Owner:IBM CORP

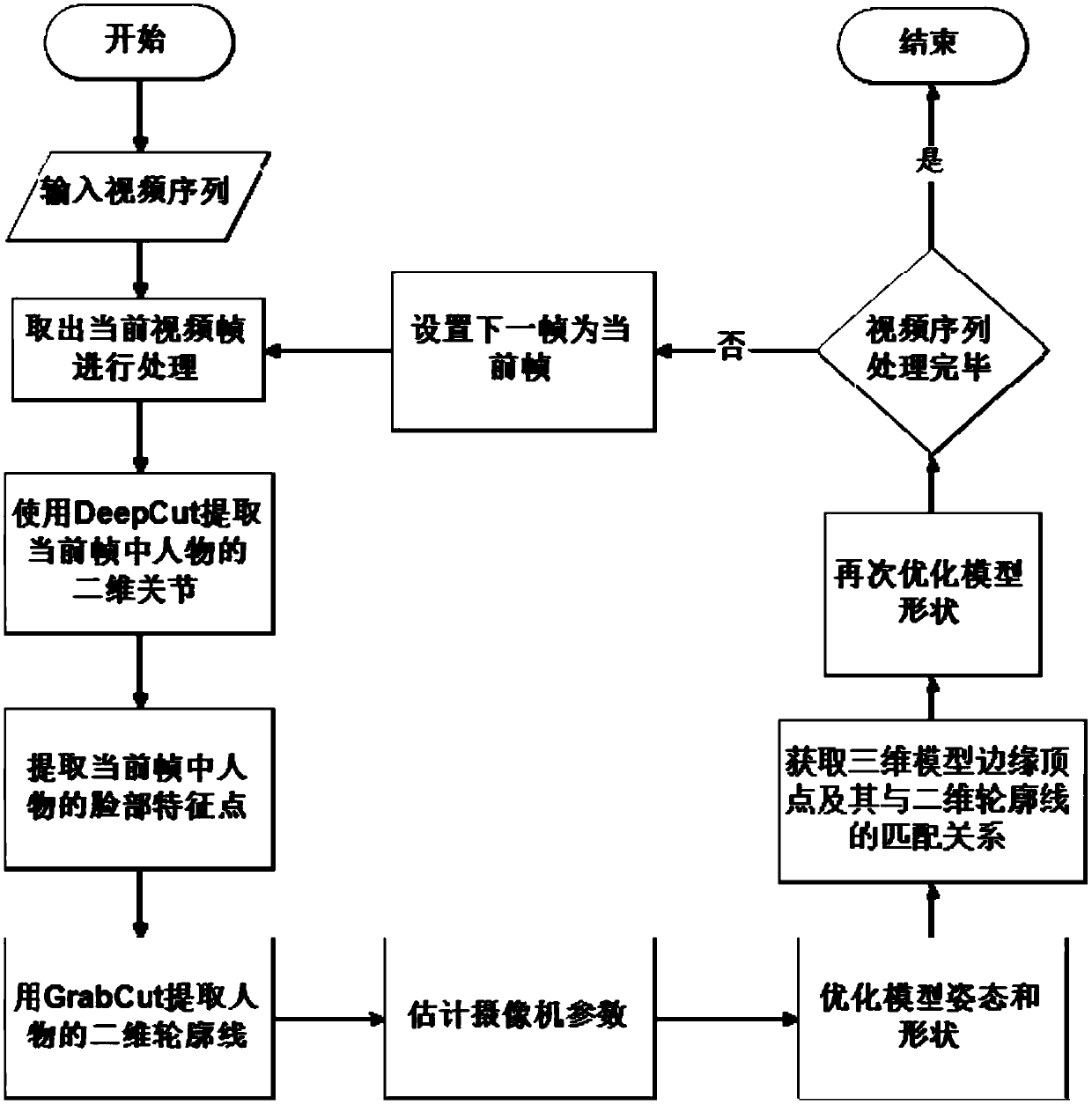

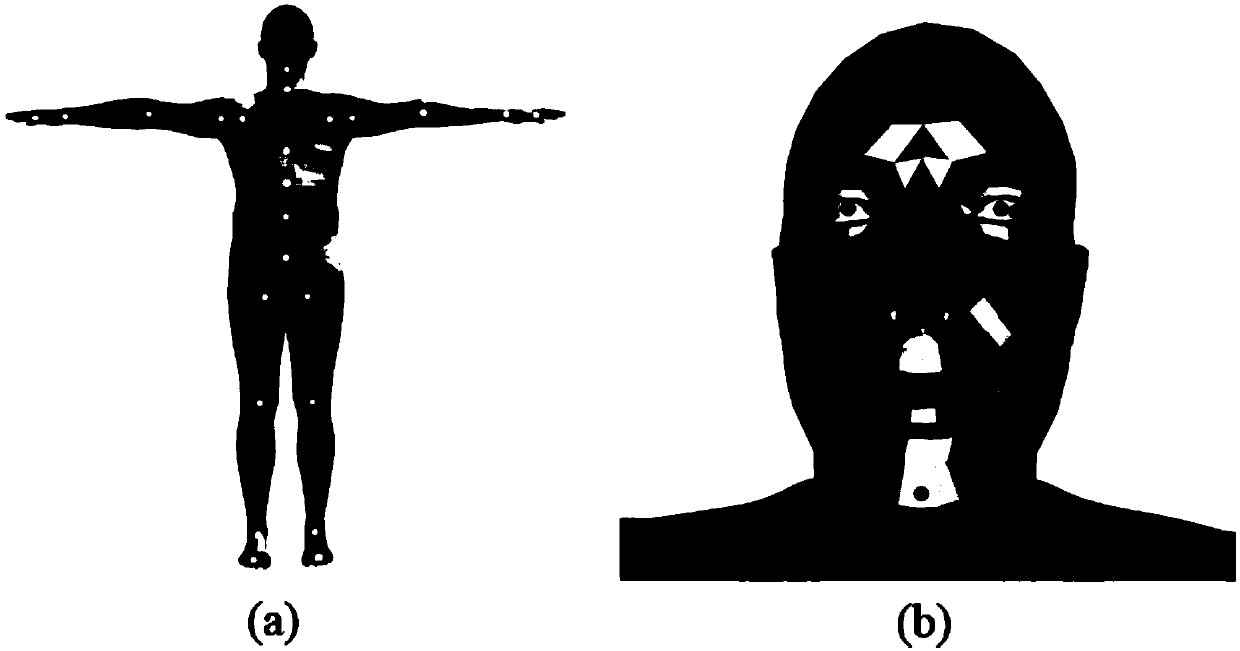

Three-dimensional human body model attitude and shape reconstruction method through video sequence

ActiveCN108629801AAvoid the problem of attitude flipImprove accuracyImage enhancementImage analysisPattern recognitionVideo sequence

The invention discloses a three-dimensional human body model attitude and shape reconstruction method through a video sequence, and the method comprises the steps: 1), extracting two-dimensional jointpoints of a person in a video frame; 2), extracting facial feature points of the person in the video frame; 3), extracting a two-dimensional contour line of the person in the video frame; 4), estimating camera parameters, and generating a perspective matrix according to the camera parameters; 5), carrying out the optimization of the model posture and shape through an optimization method; 6), obtaining the edge points of the 3D human body model at the camera angle and the matching relationship between the edge point and the 2D contour line; 7), carrying out the re-optimization of the shape ofthe model through the optimization method so that the sum of the differences between the distances from the positions of the edge points of the three-dimensional model at the camera angle after projection to the positions of the two-dimensional contour points in the video frame is minimized. The method can avoid the posture turnover in the reconstruction process, and also can accurately reconstruct the posture of a head under the condition that the overall similarity of the model is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

System, method, and computer program product for progressive query processing

ActiveUS7383246B2Reduce computing costEliminate duplicationDigital data information retrievalData processing applicationsExecution planView maintenance

A method, system, and computer program product to make query processing more robust in the face of optimization errors. The invention validates the statistics and assumptions used for compiling a query as the query is executed and, when necessary, progressively re-optimizes the query in mid-execution based on the knowledge learned during its partial execution. The invention selectively places a number of CHECK operators in a query execution plan to validate the optimizer's cardinality estimates against actual cardinalities. Errors beyond a threshold trigger re-optimization, and the optimizer decides whether the old plan is still optimal and whether to re-use previously computed results. The invention addresses arbitrary SQL queries whose plans can contain sub-queries, updates, trigger checking, and view maintenance operations. The invention can handle concurrent update transactions or updates of common sub-expressions in a query execution plan without compromising consistency and isolation as locking information is tied to the record ID.

Owner:HULU

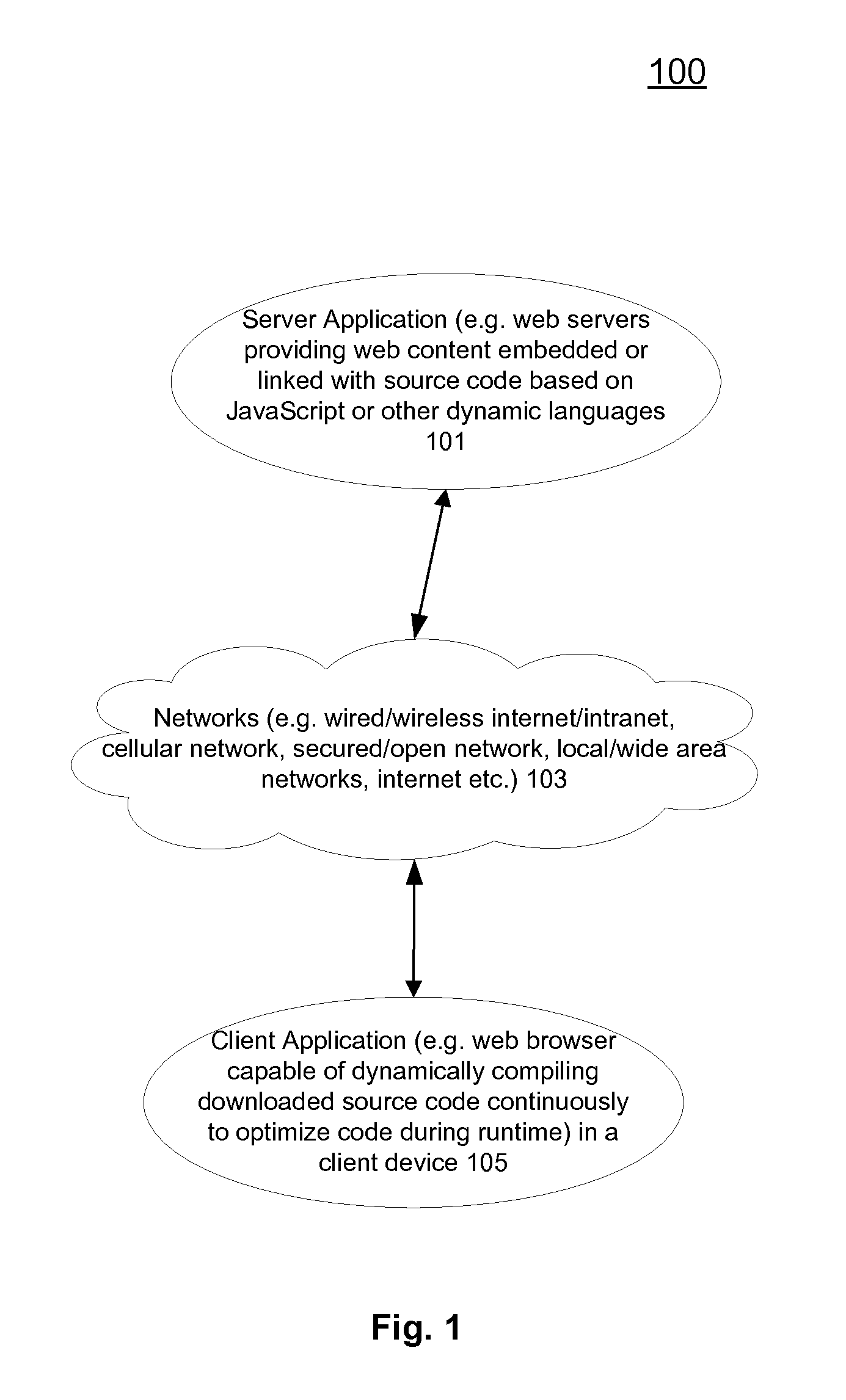

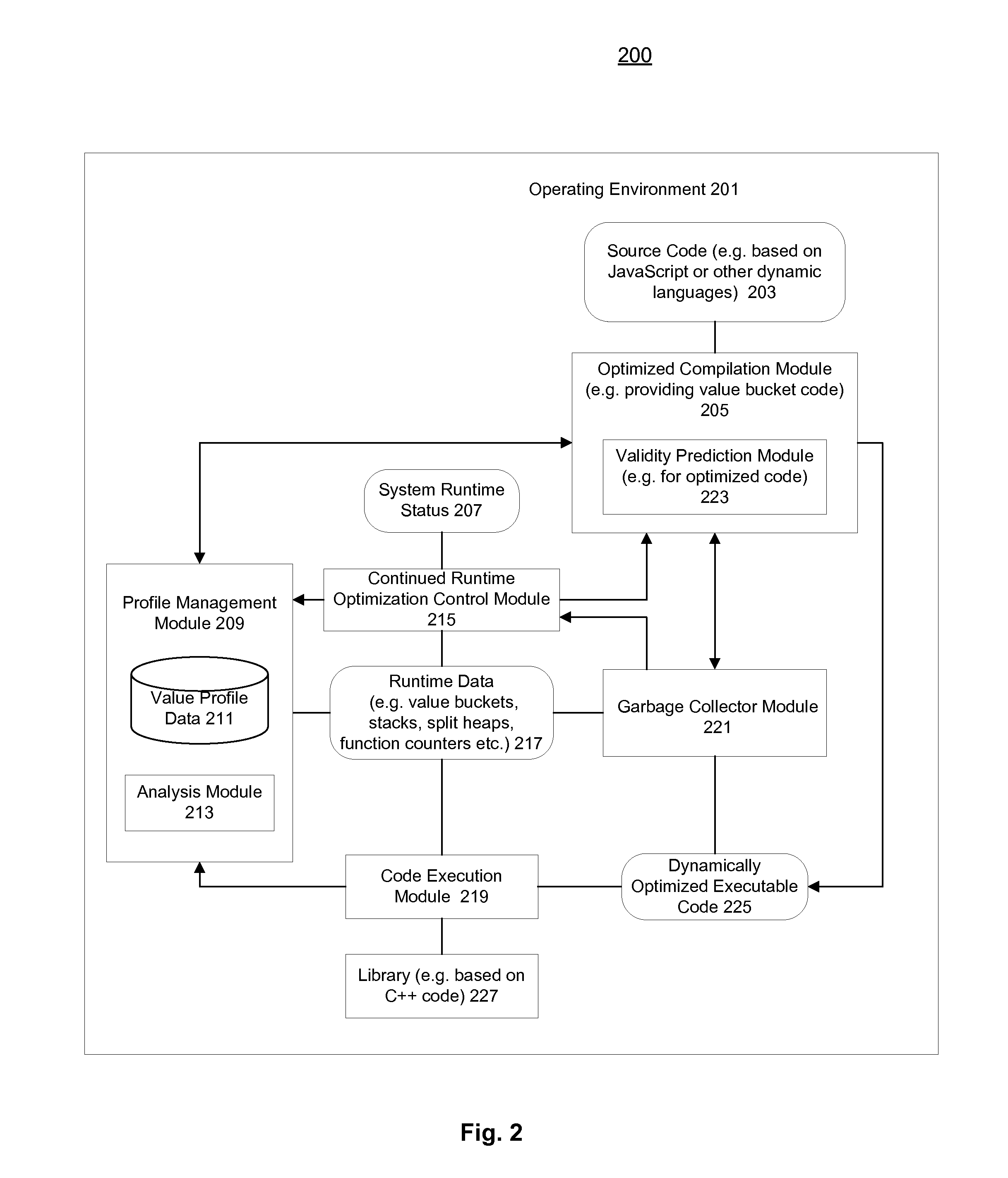

Performance of computer programs while they are running

ActiveUS7577951B2Improve performanceSoftware simulation/interpretation/emulationMemory systemsHuman languageRe optimization

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

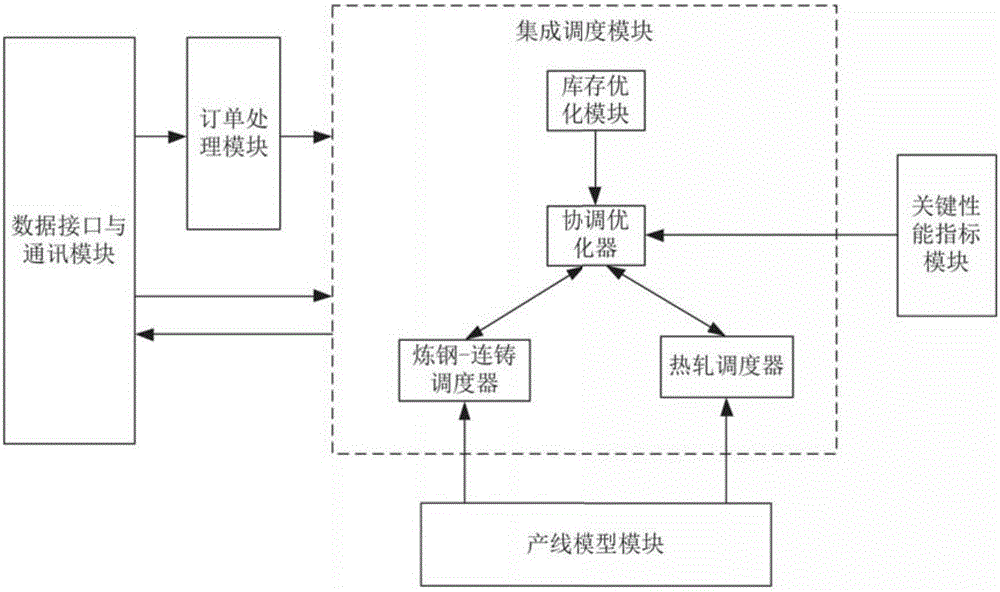

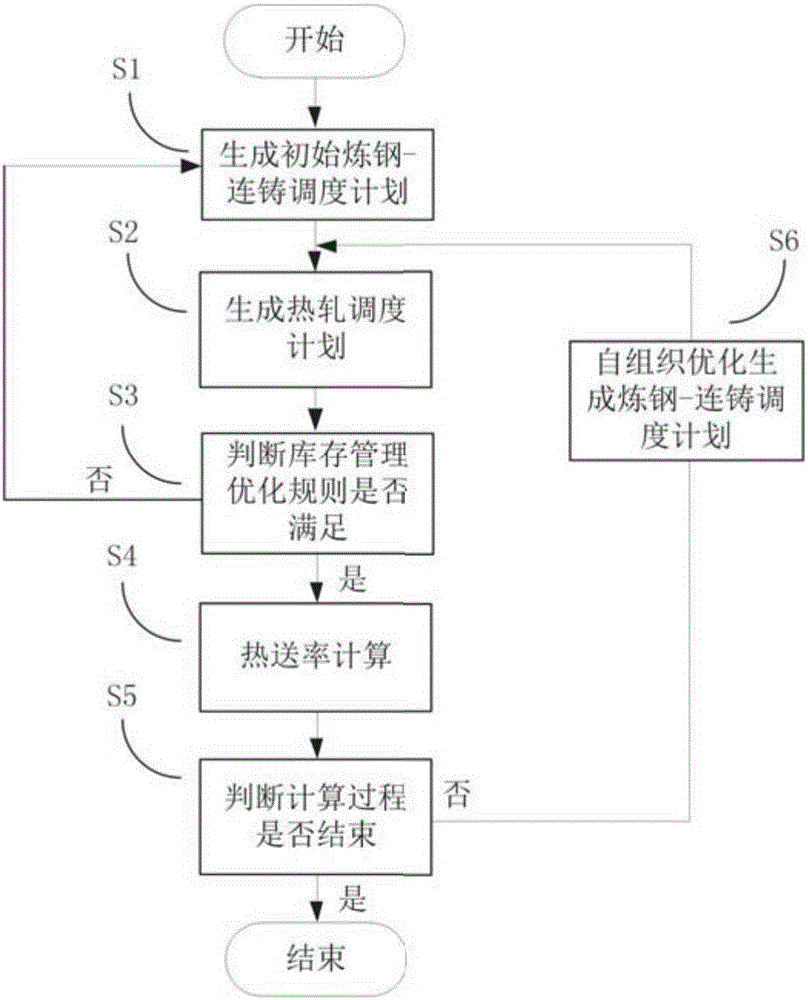

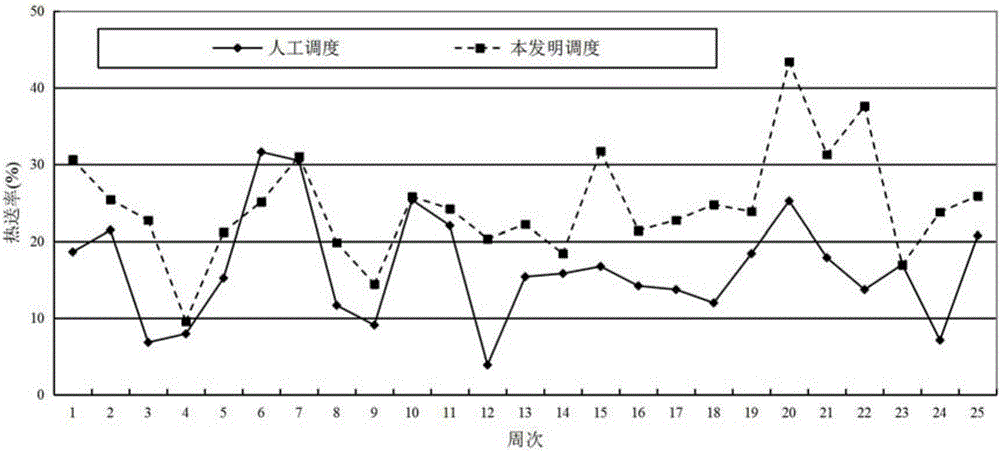

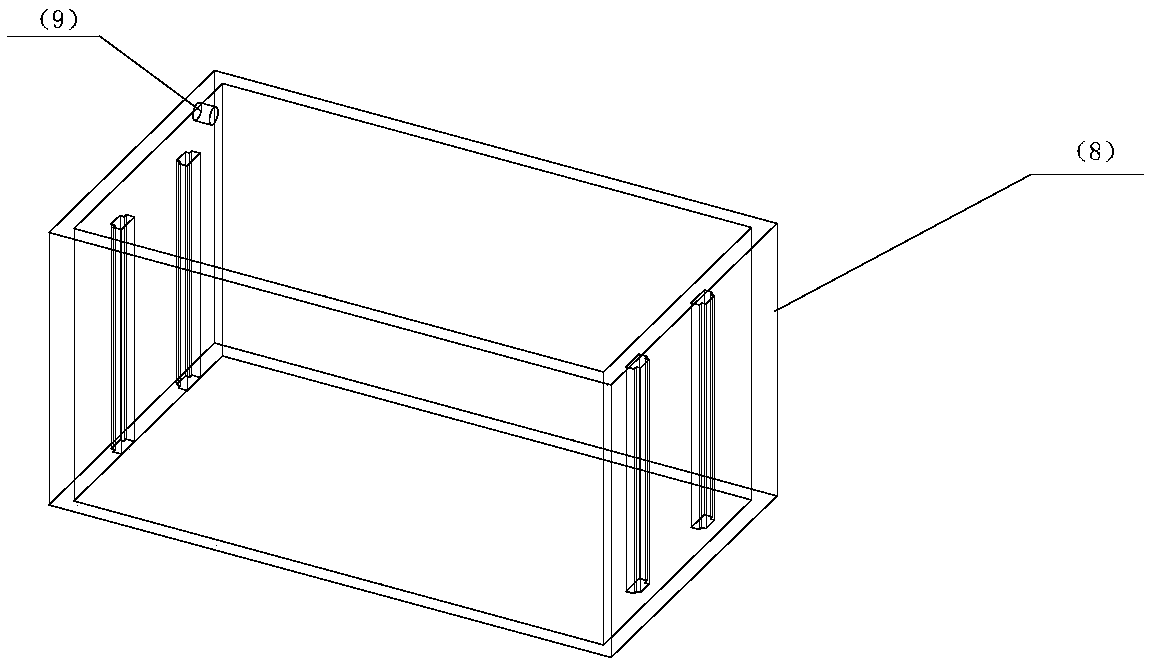

Steelmaking-continuous casting-hot rolling integrated scheduling method and system

ActiveCN106779220AAvoid confictImprove heat transfer rateForecastingResourcesProduction lineHardness

The invention provides a steelmaking-continuous casting-hot rolling integrated scheduling method and system. The method comprises the steps of S1, performing initialization to obtain a steelmaking-continuous casting scheduling plan; S2, obtaining a hot rolling scheduling plan according to the current steelmaking-continuous casting scheduling plan as well as a working order demand, a production line model, a current production rhythm, a rolling unit length constraint, and a rolling unit internal adjacent plate blank width, thickness and hardness jump constraint; S3, determining whether an inventory change situation meets a preset inventory optimization plan or not according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan, and if the preset rule is met, entering the next step, otherwise, adjusting current parameters related to inventory optimization and returning to the step S1; S4, obtaining overall heat supply rate data according to the current steelmaking-continuous casting scheduling plan and the hot rolling scheduling plan; S5, judging whether an integrated scheduling stop condition is met or not, and if the stop condition is met, performing the scheduling plan, otherwise, performing the next step; and S6, performing re-optimization to generate the steelmaking-continuous casting scheduling plan, and returning to the step S2.

Owner:ZHEJIANG SUPCON RES

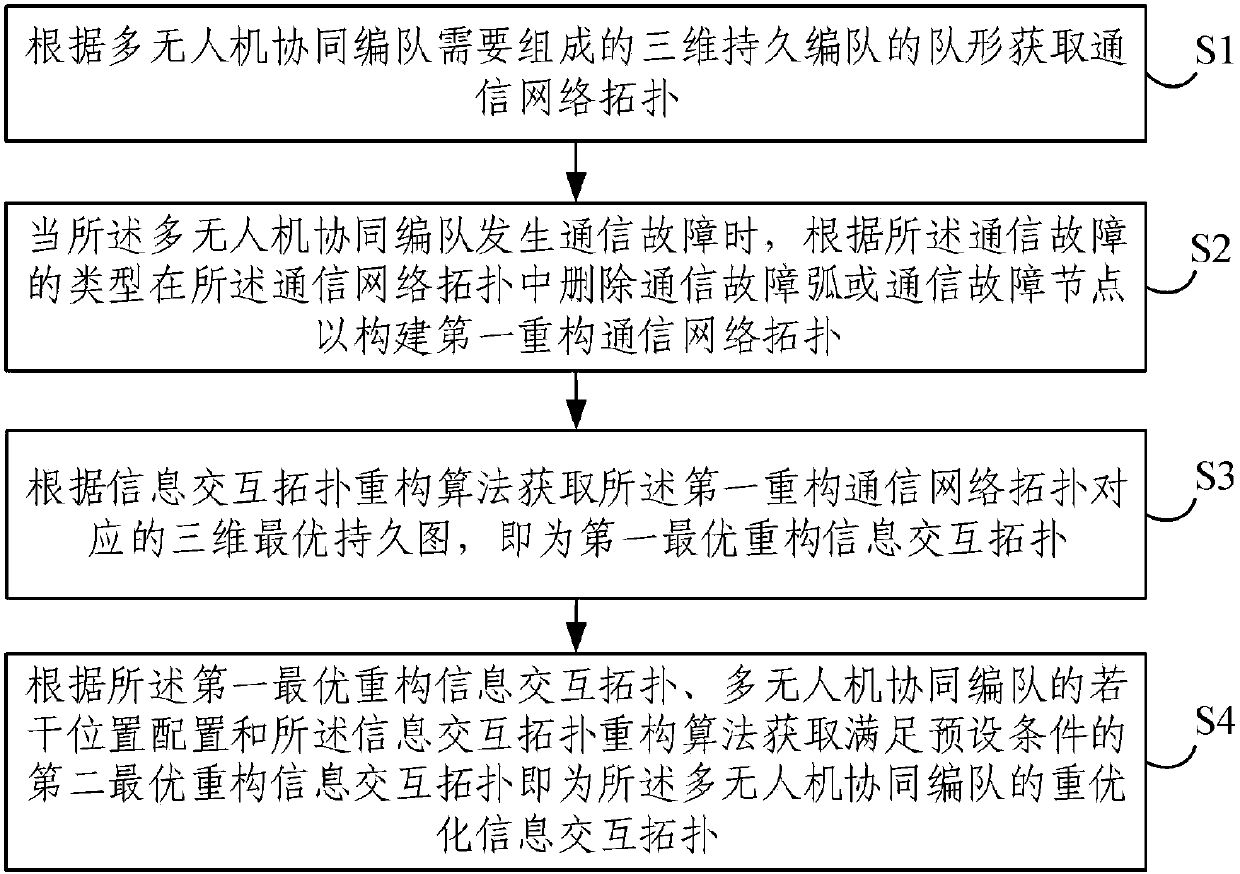

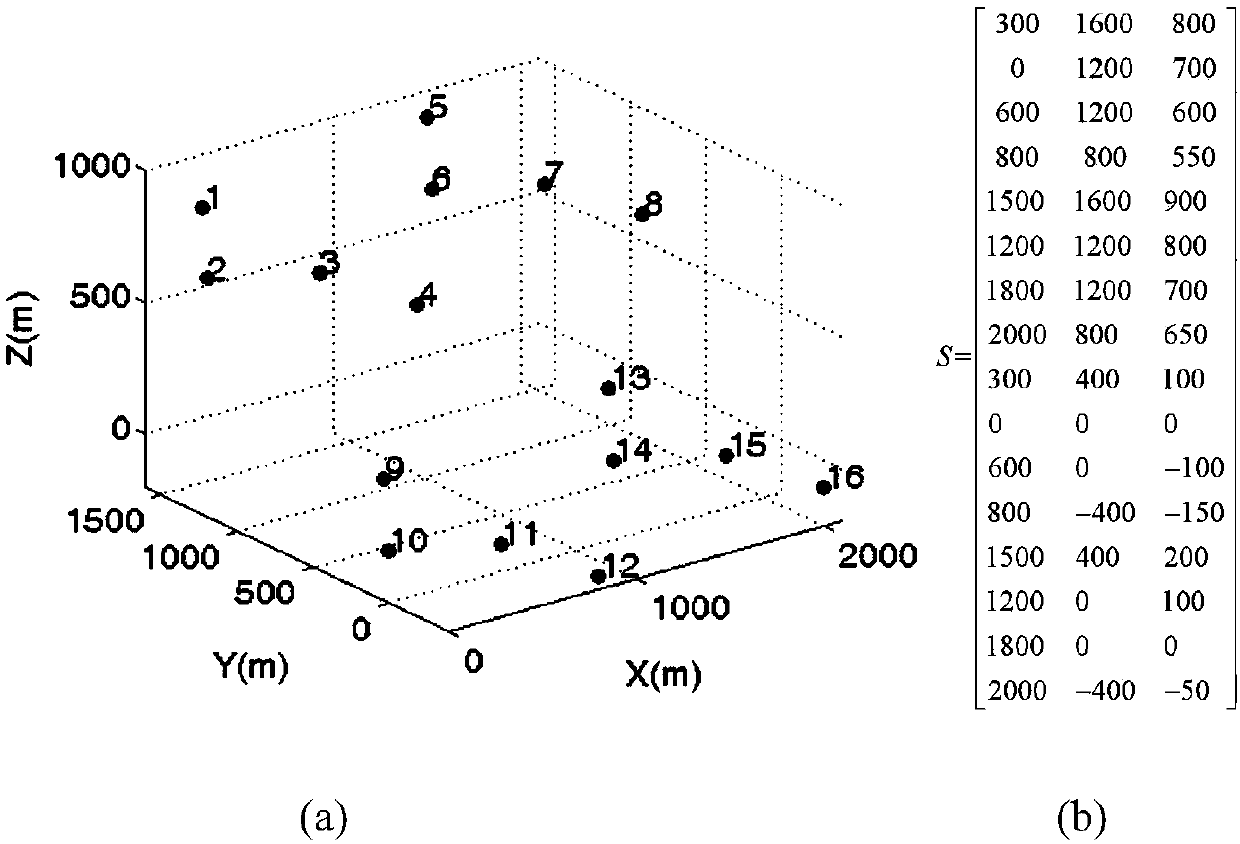

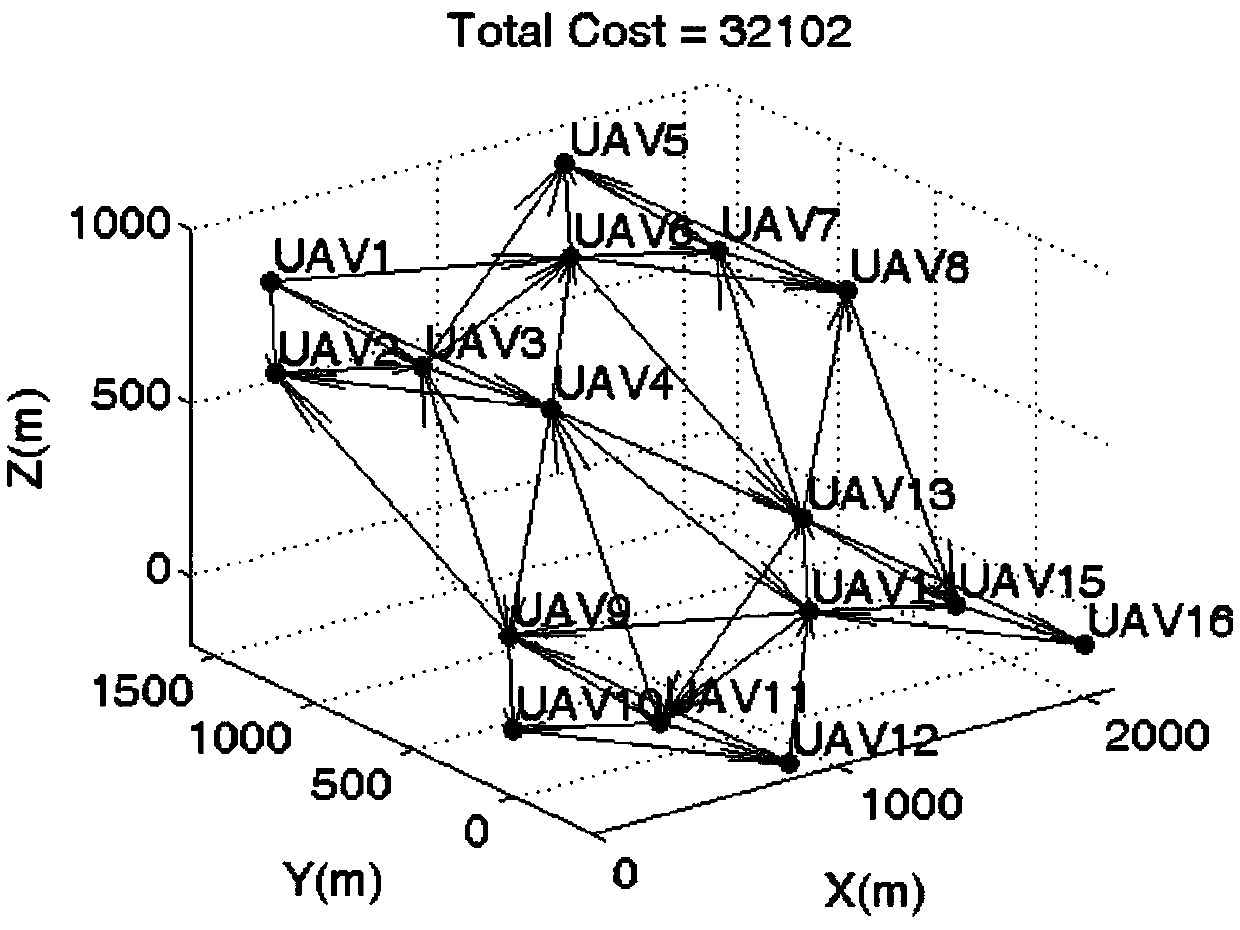

Heuristic optimization method and device for information exchange topology in multi-unmanned-aerial-vehicle coordinated formation

InactiveCN107797564AReduce communication costPosition/course control in three dimensionsReconstruction algorithmNetwork topology

The invention provides a heuristic optimization method and device for information exchange topology in a multi-unmanned-aerial-vehicle coordinated formation. The method comprises: S1, a communicationnetwork topology is obtained according to a three-dimensional persistent formation formed by the multi-unmanned-aerial-vehicle coordinated formation; S2, when a communication failure occurs in the multi-unmanned-aerial-vehicle coordinated formation, a communication failure arc or communication failure node is deleted in the communication network topology based on the type of the communication failure to construct a first reconfigured communication network topology; S3, according to an information exchange topology reconstruction algorithm, a three-dimensional optimal enduring map correspondingto the first reconfigured communication network topology being a first optimal reconstruction information exchange topology is obtained; and S4, according to the first optimal reconstruction information exchange topology, configuration of a plurality of position in the multi-unmanned-aerial-vehicle coordinated formation, and the information exchange topology reconstruction algorithm, a second optimal reconstruction information exchange topology meeting a preset condition is obtained, wherein the second optimal reconstruction information exchange topology is the re-optimization information exchange topology of the multi-unmanned-aerial-vehicle coordinated formation and the preset condition is as follows: n is larger than |V|*(|V|-1) / 2. According to the invention, an unmanned-aerial-vehiclecollision accident in the large-scale multi-unmanned-aerial-vehicle coordinated formation in a communication failure occurrence state is avoided and the formation is recovered; and the communicationcost of the formation is kept to be low.

Owner:HEFEI UNIV OF TECH

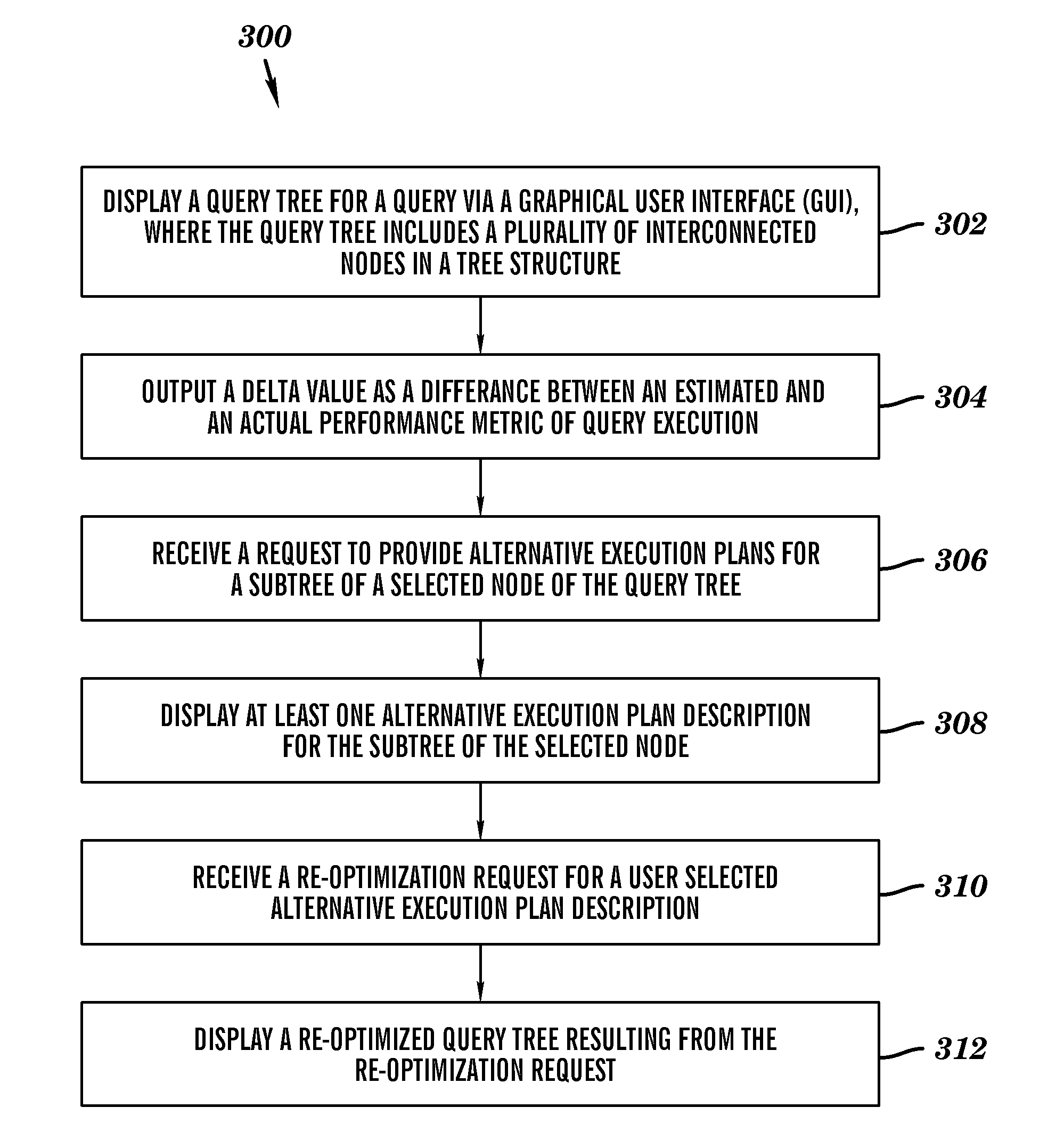

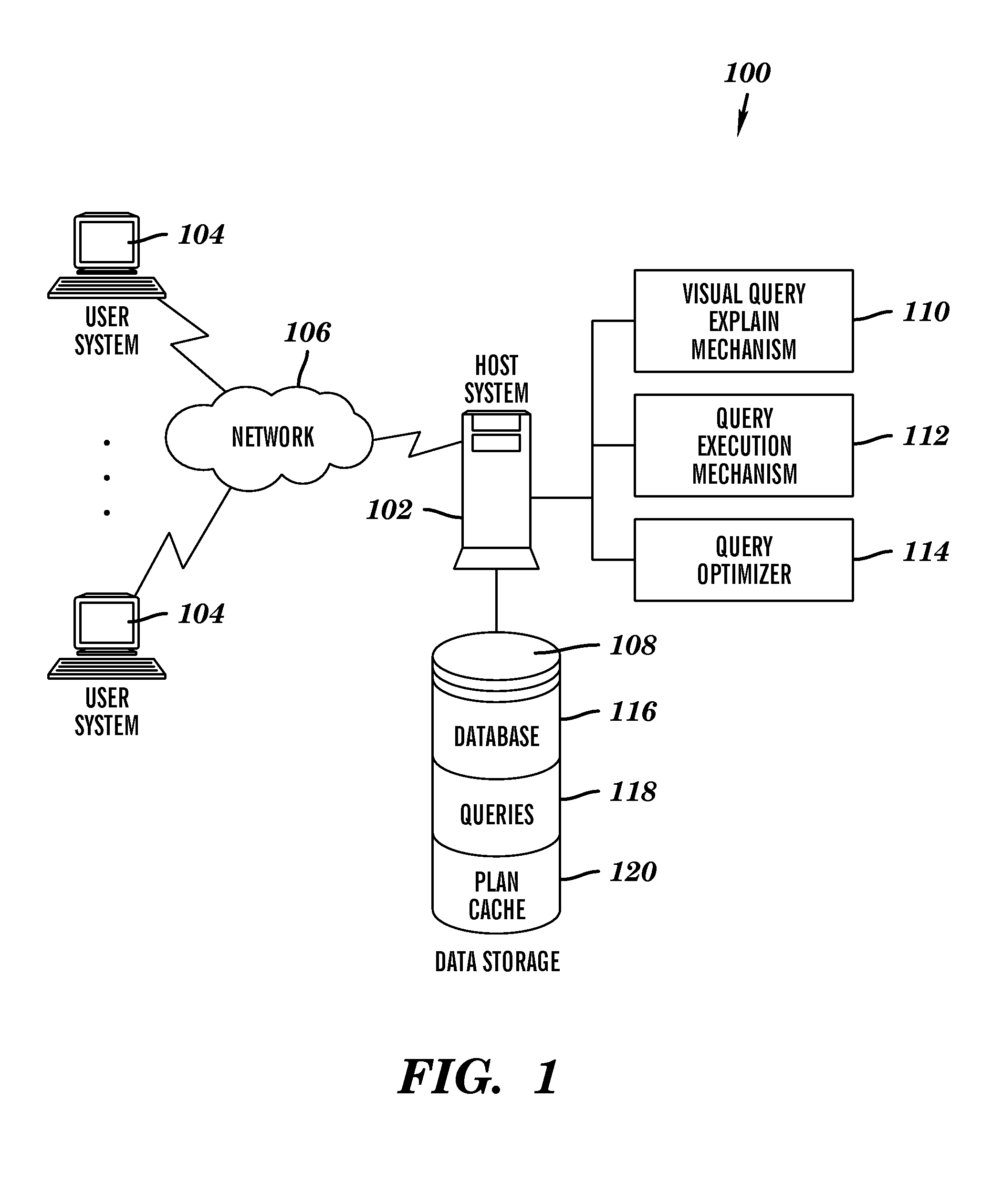

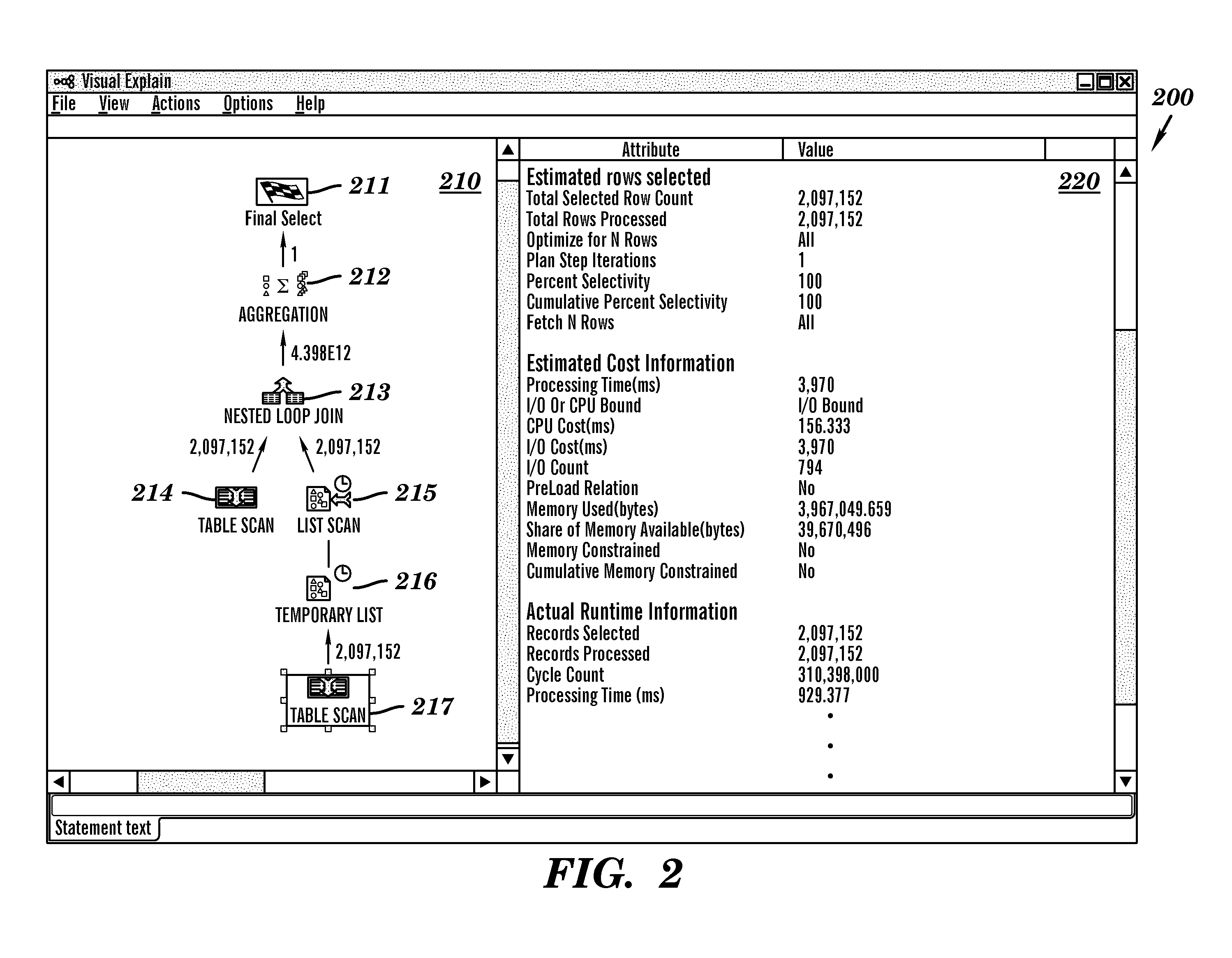

Methods, systems, and computer program products for user-driven targeted query re-optimizations using delta values

InactiveUS20090077013A1Digital data information retrievalDigital data processing detailsExecution planGraphics

A method, system, and computer program product for user-driven targeted query re-optimizations using delta values are provided. The method includes displaying a query tree for a query via a graphical user interface (GUI), where the query tree includes a plurality of interconnected nodes in a tree structure, and outputting a delta value as a difference between an estimated and an actual performance metric of query execution. The method also includes receiving a request to provide alternative execution plans for a subtree of a selected node of the query tree, and displaying at least one alternative execution plan description for the subtree of the selected node. The method further includes receiving a re-optimization request for a user selected alternative execution plan description, and displaying a re-optimized query tree resulting from the re-optimization request.

Owner:IBM CORP

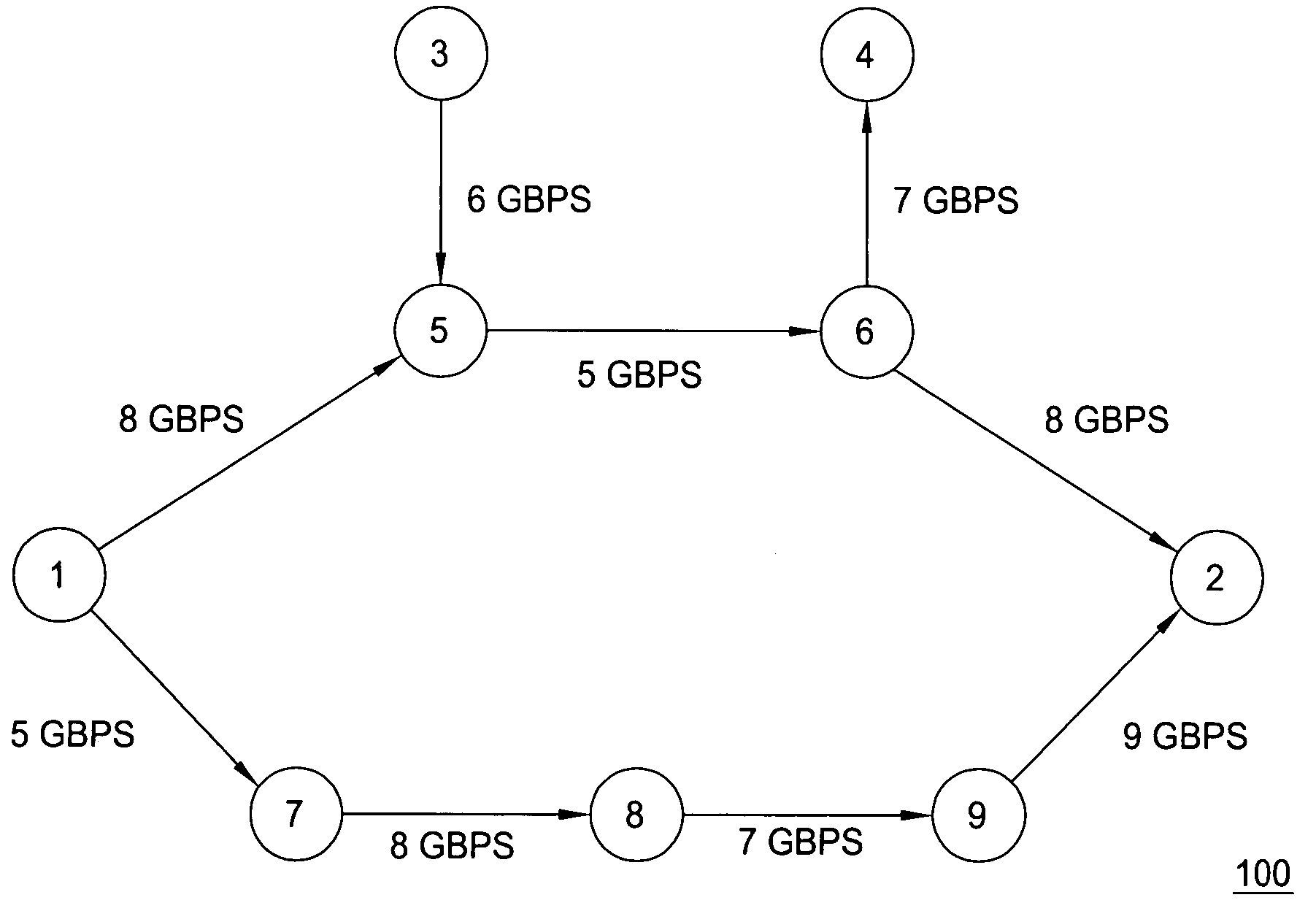

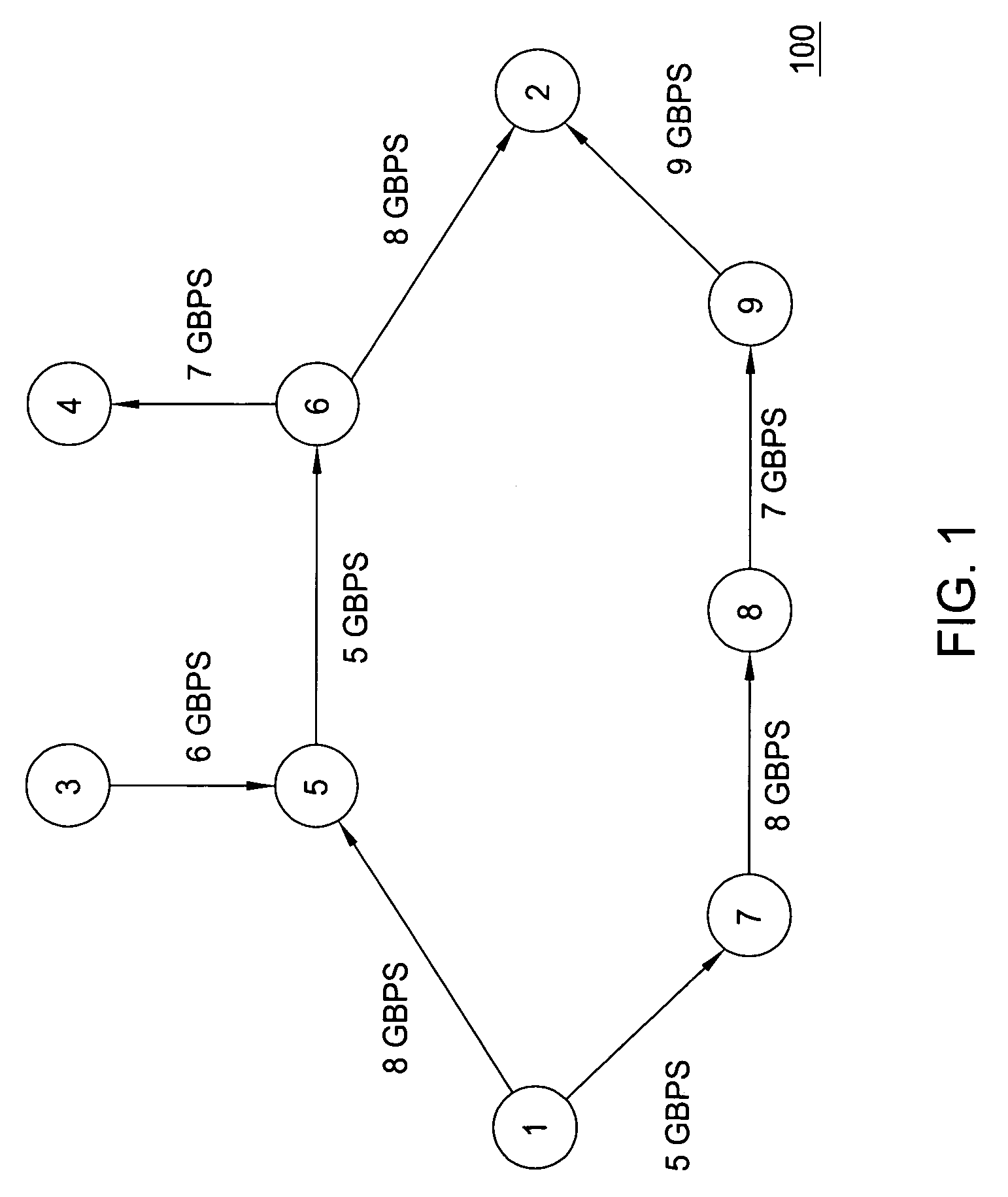

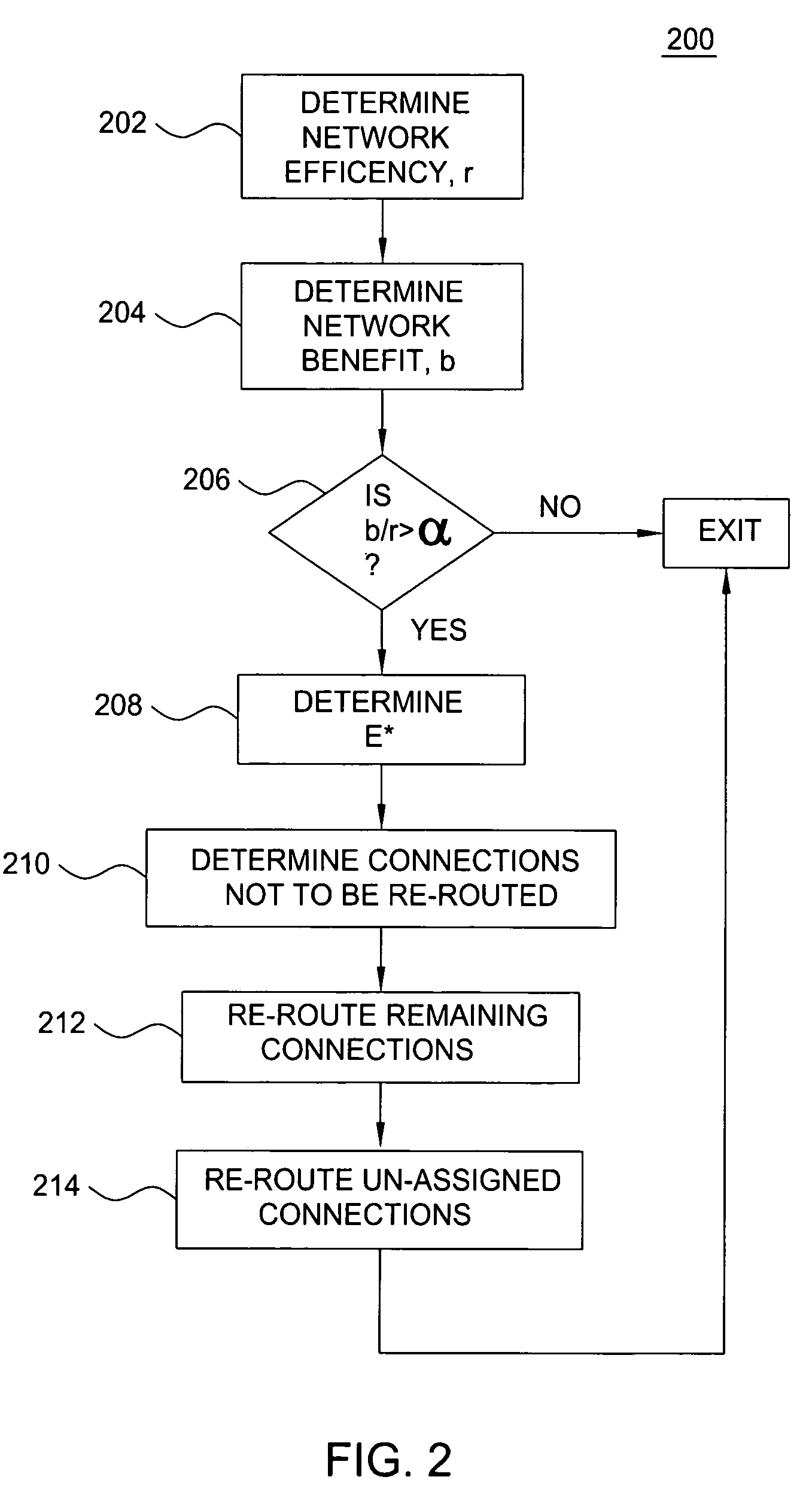

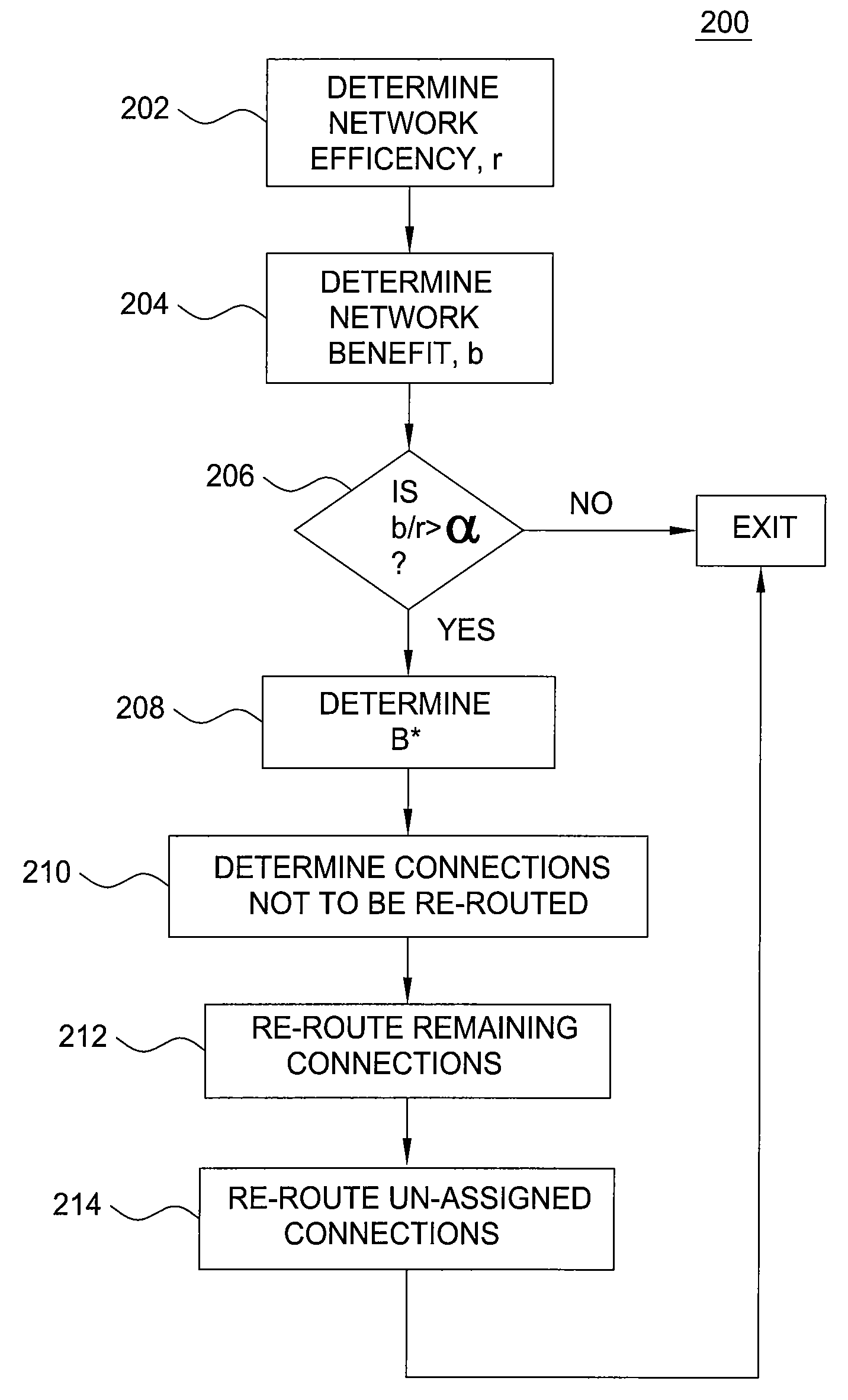

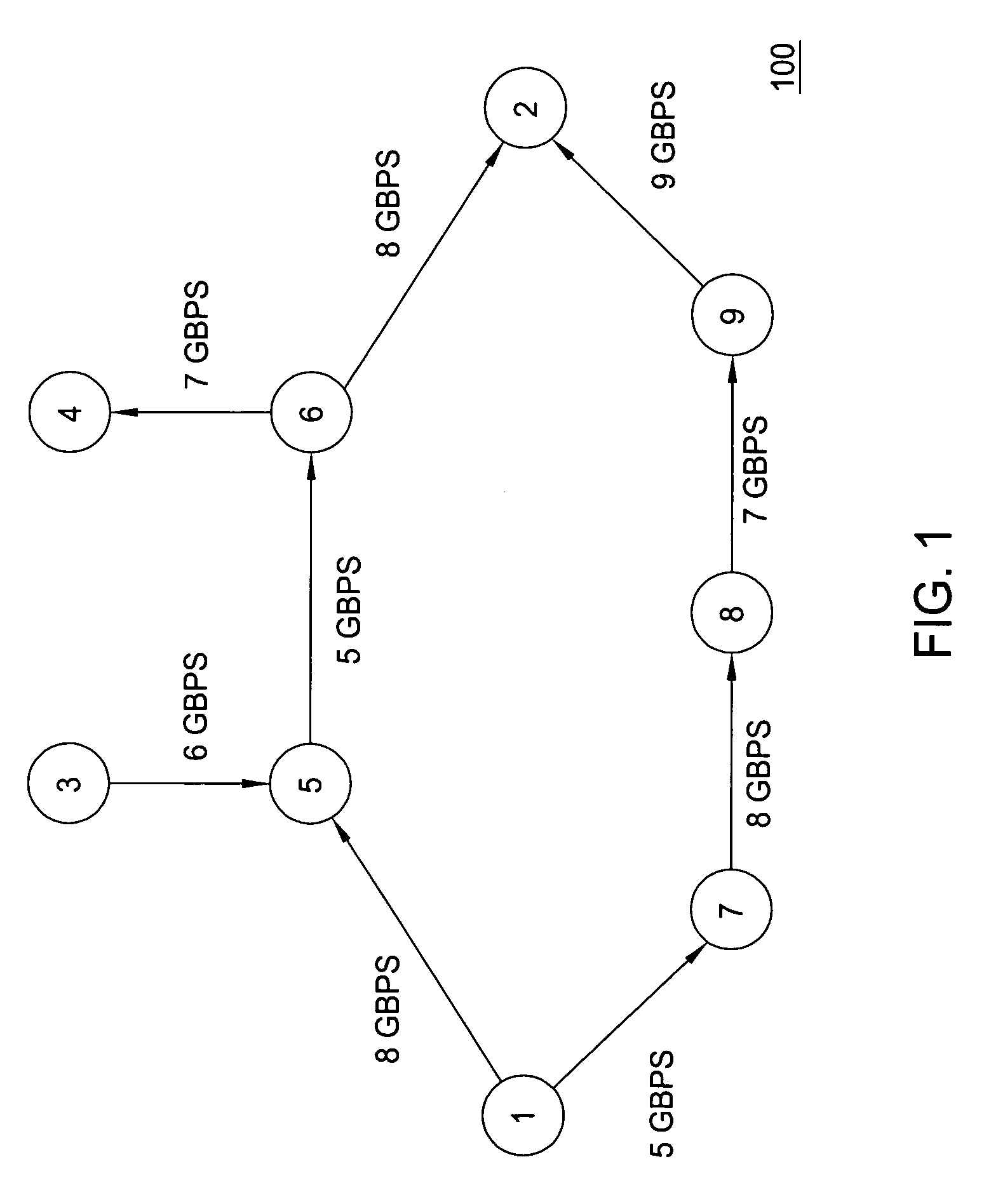

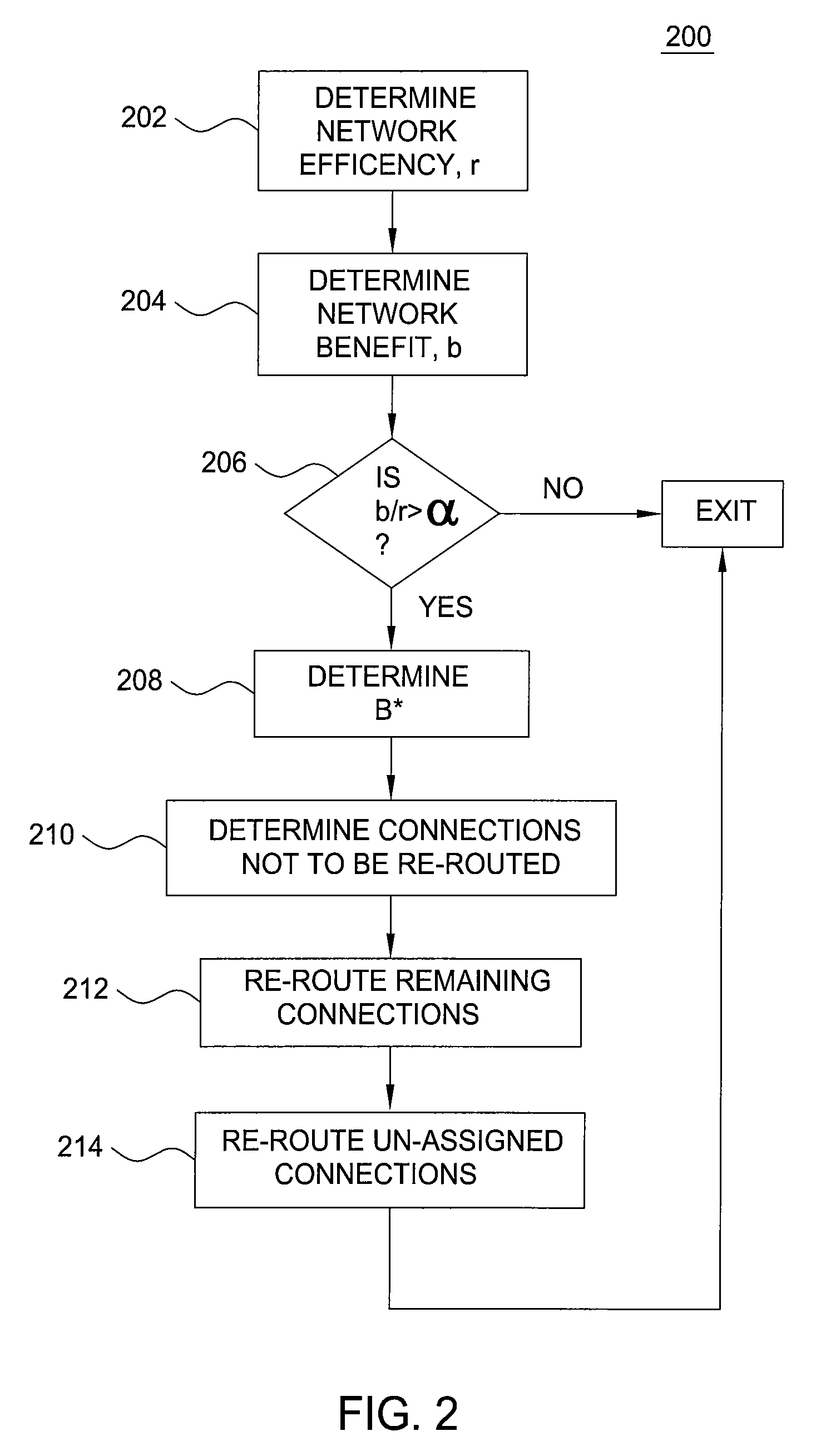

Method for fast network re-optimization

InactiveUS20050147031A1Convenient amountMinimal numberTransmission systemsFrequency-division multiplex detailsLeast costDistributed computing

A fast and efficient method for network re-optimization is described. In one embodiment, the technique uses an algorithm that requires limited aggregate information to continually monitor the network for re-optimization opportunities. The re-optimization of the present invention enables a network to accommodate more traffic without adding capacity. The re-optimization of the present invention is performed only when network efficiency benefits above a predetermined threshold may be obtained. In addition, a least-cost set of sessions is determined to perform the re-routing of the present invention to attain the desired network efficiency.

Owner:LUCENT TECH INC

Method for fast network re-optimization

InactiveUS7433315B2Convenient amountMinimal numberFrequency-division multiplex detailsTransmission systemsLeast costDistributed computing

A fast and efficient method for network re-optimization is described. In one embodiment, the technique uses an algorithm that requires limited aggregate information to continually monitor the network for re-optimization opportunities. The re-optimization of the present invention enables a network to accommodate more traffic without adding capacity. The re-optimization of the present invention is performed only when network efficiency benefits above a predetermined threshold may be obtained. In addition, a least-cost set of sessions is determined to perform the re-routing of the present invention to attain the desired network efficiency.

Owner:LUCENT TECH INC

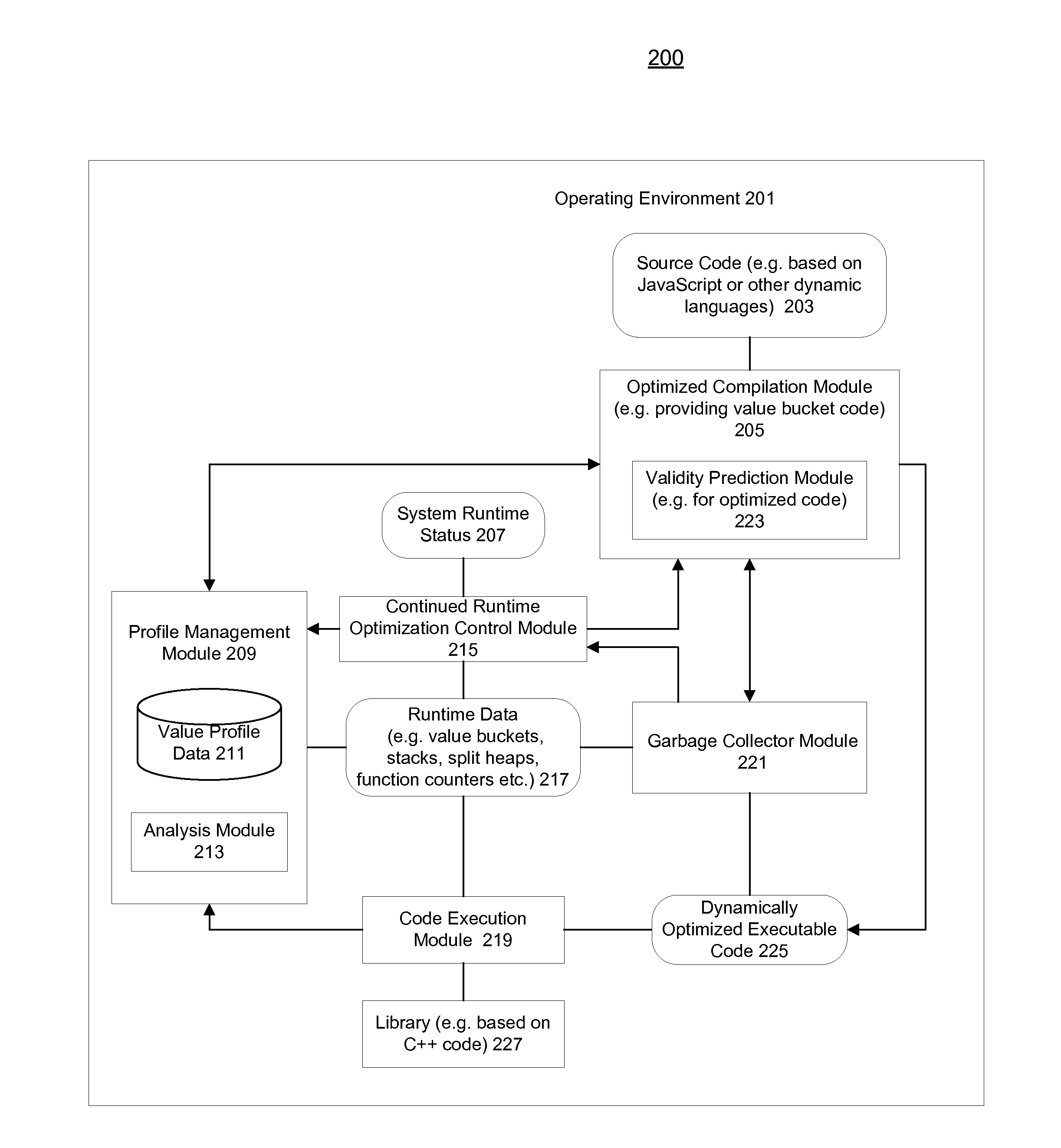

Runtime State Based Code Re-Optimization

InactiveUS20140047423A1Error detection/correctionProgramming languages/paradigmsSpeculative optimizationParallel computing

A method and an apparatus to execute a code compiled from a source code to access an untyped variable are described. An optimized access code may be compiled in the code with speculative optimization via a type prediction of runtime value of the untyped variable. Invalidity of the type prediction may be dynamically detected for future runtime values of the untyped variable. The code may be updated with an access code compiled for the access without the speculative optimization based on the invalidity detection. The updated code can be executed for the access to the untyped variable without executing the optimized access code.

Owner:APPLE INC

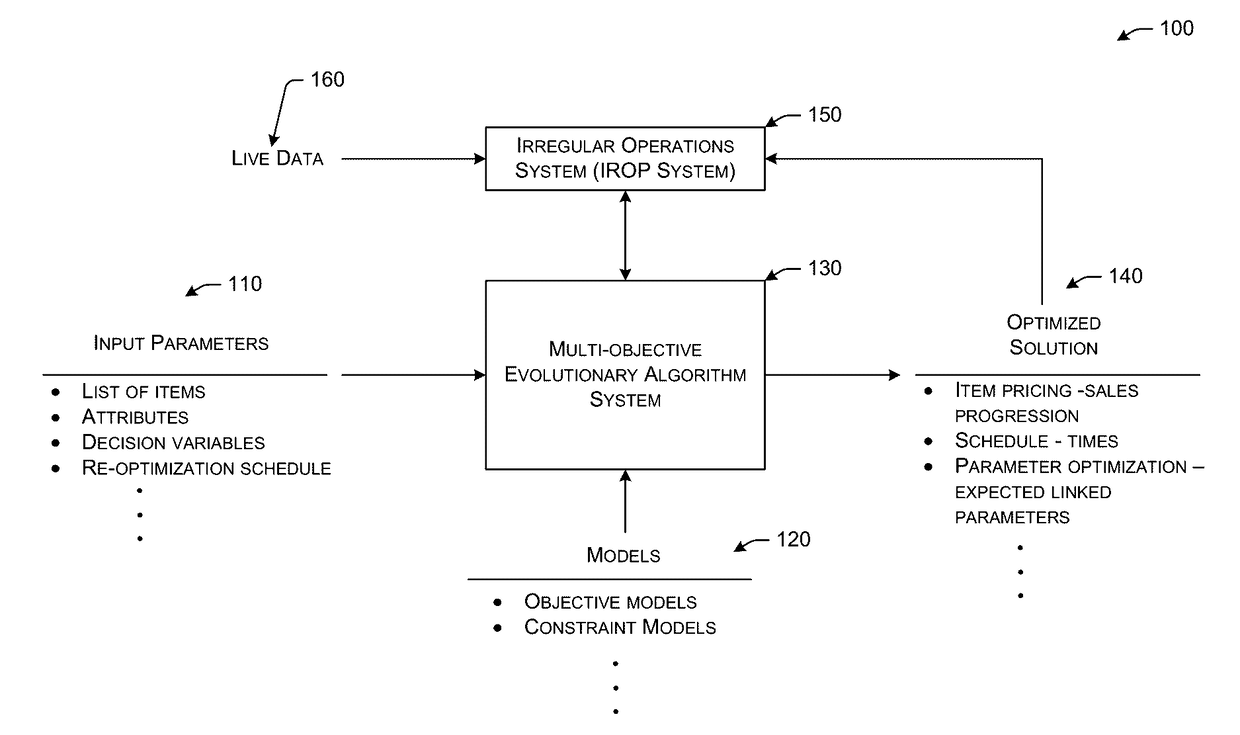

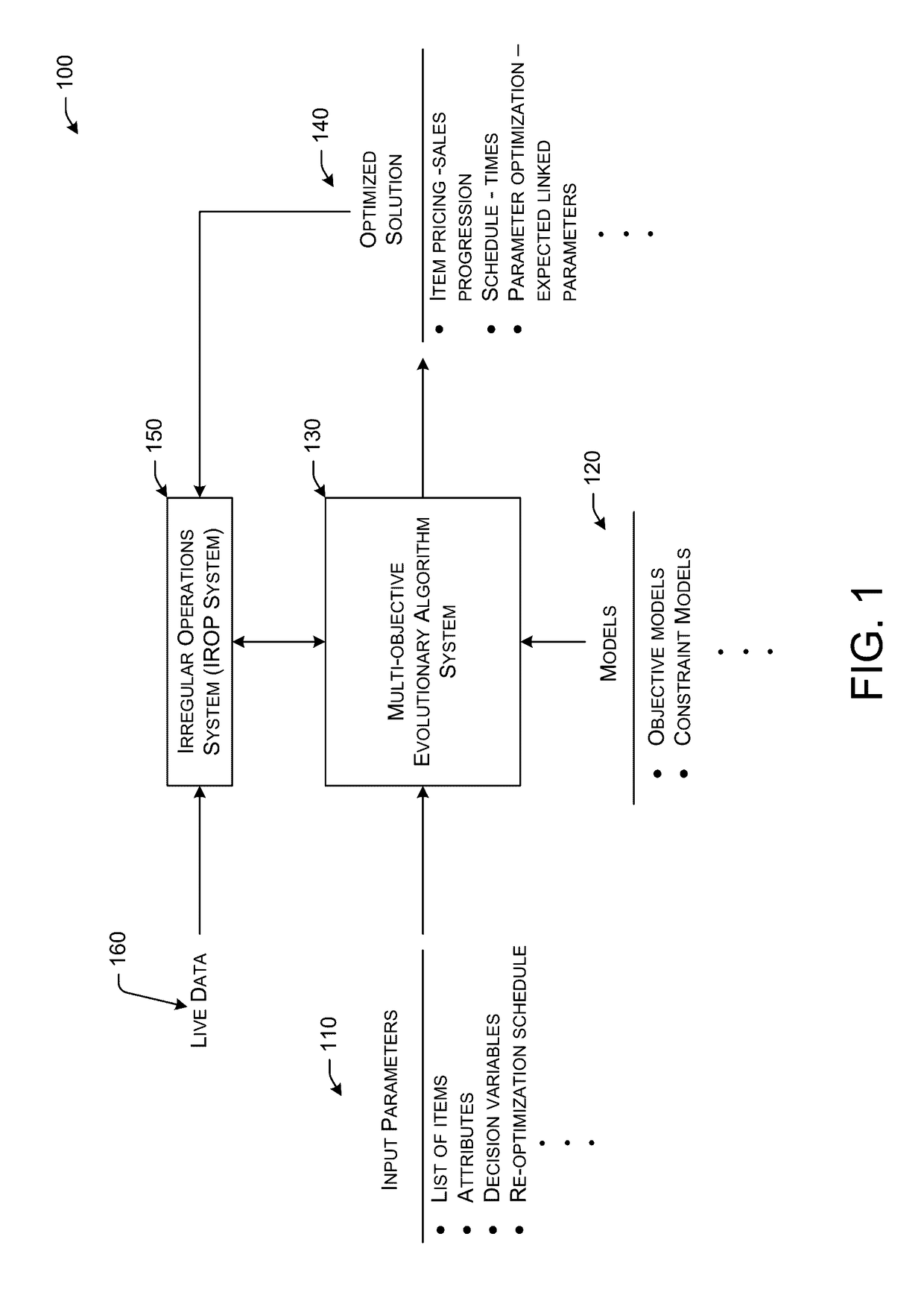

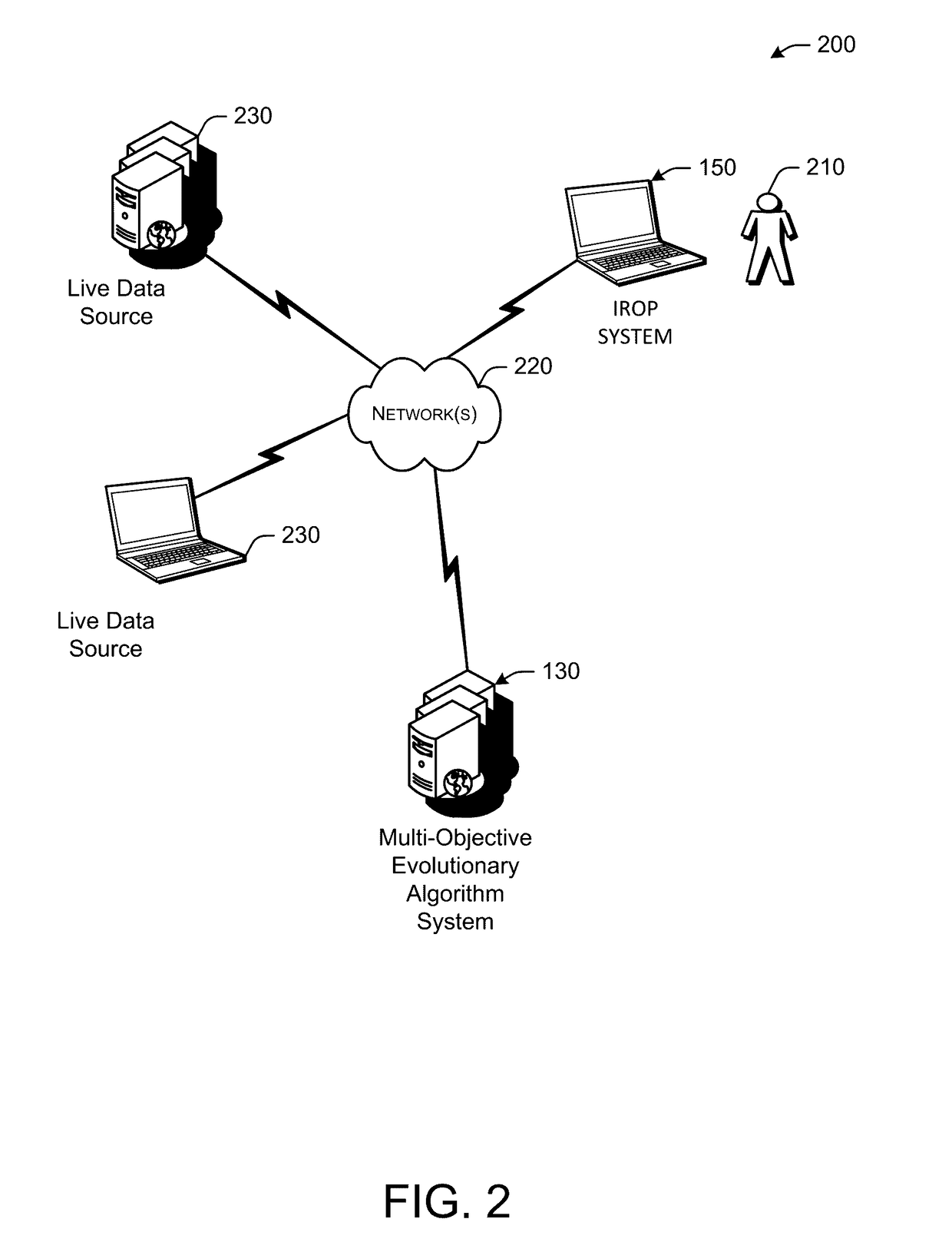

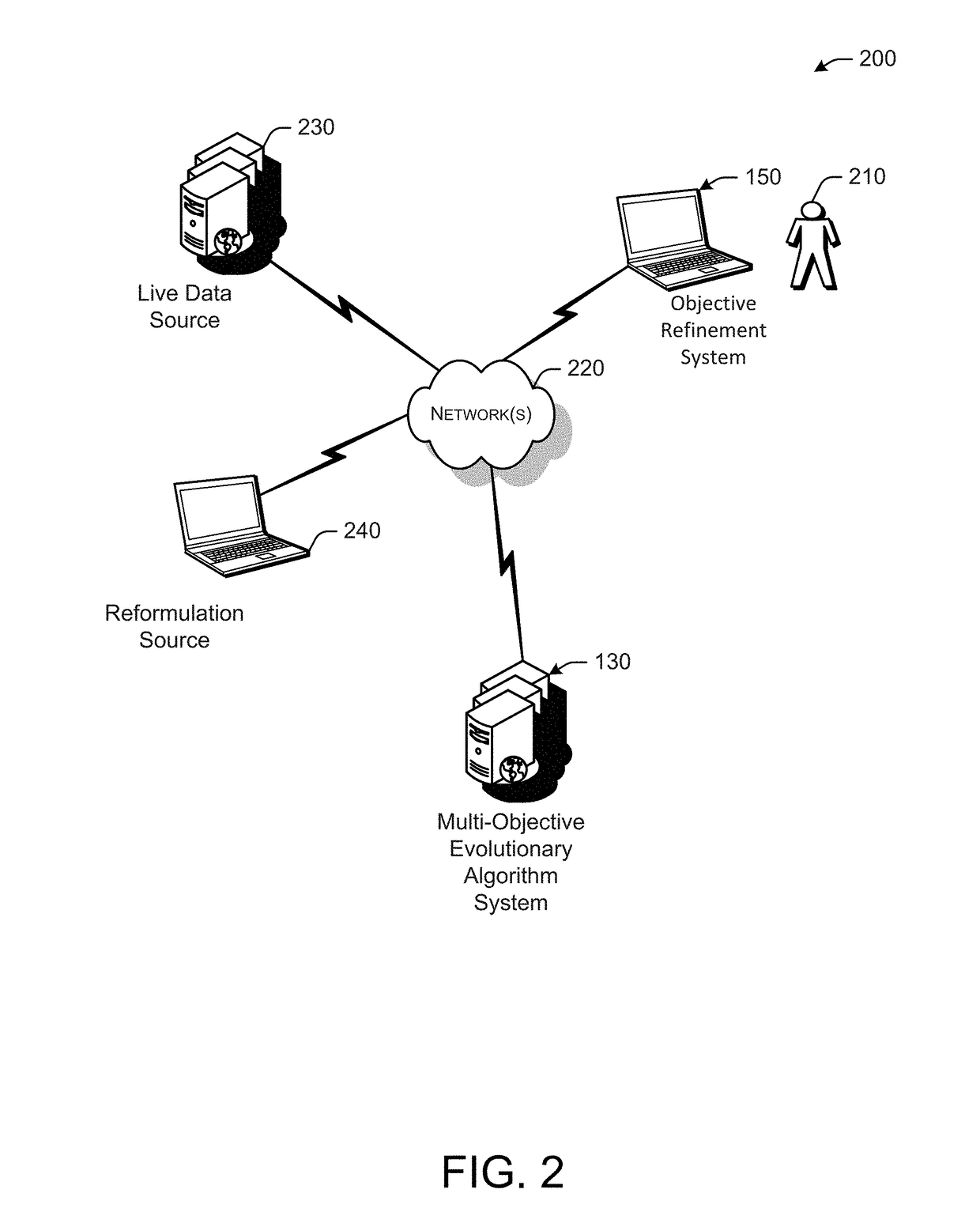

Systems and Methods for Multi-Objective Optimizations with Live Updates

Owner:THE AEROSPACE CORPORATION

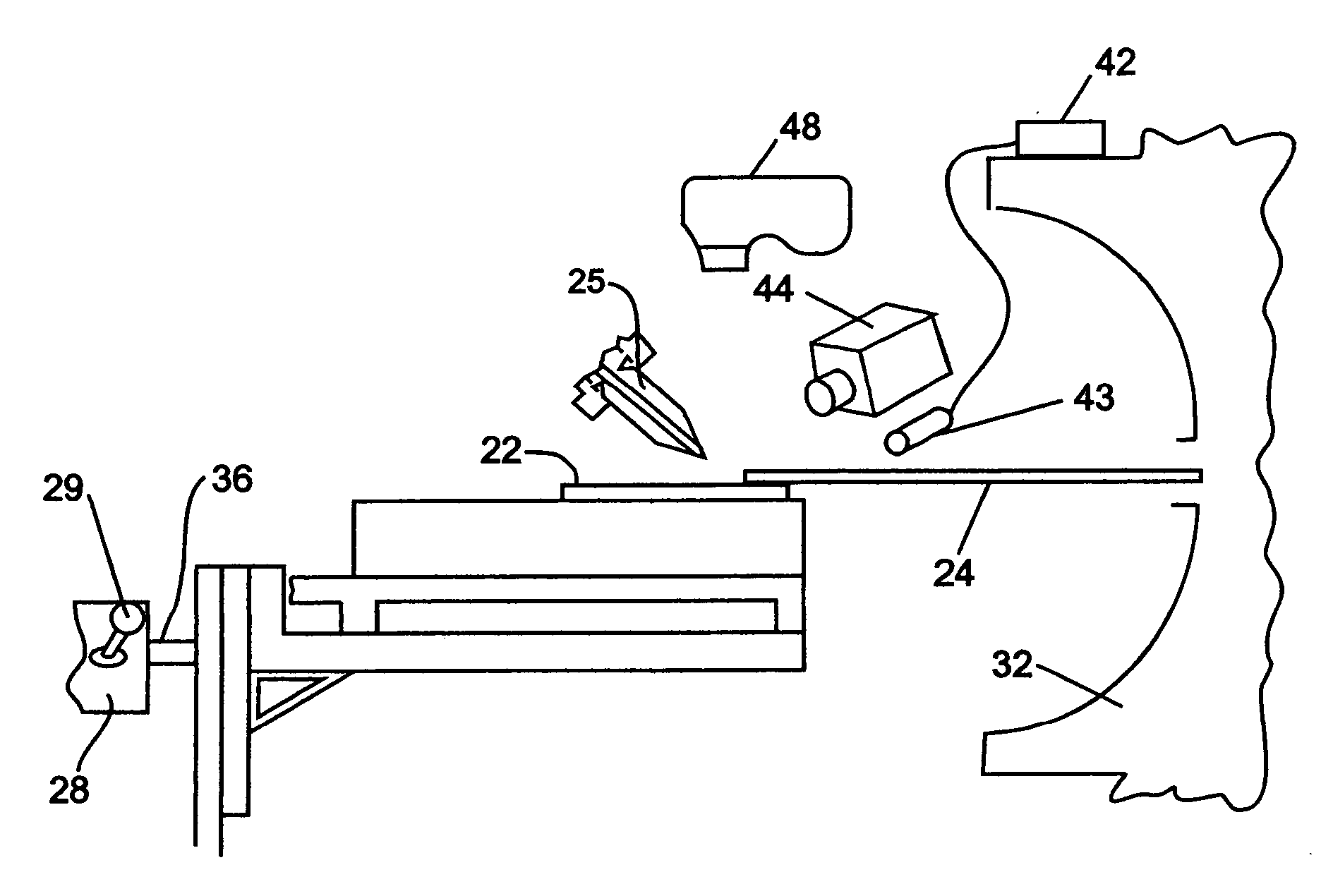

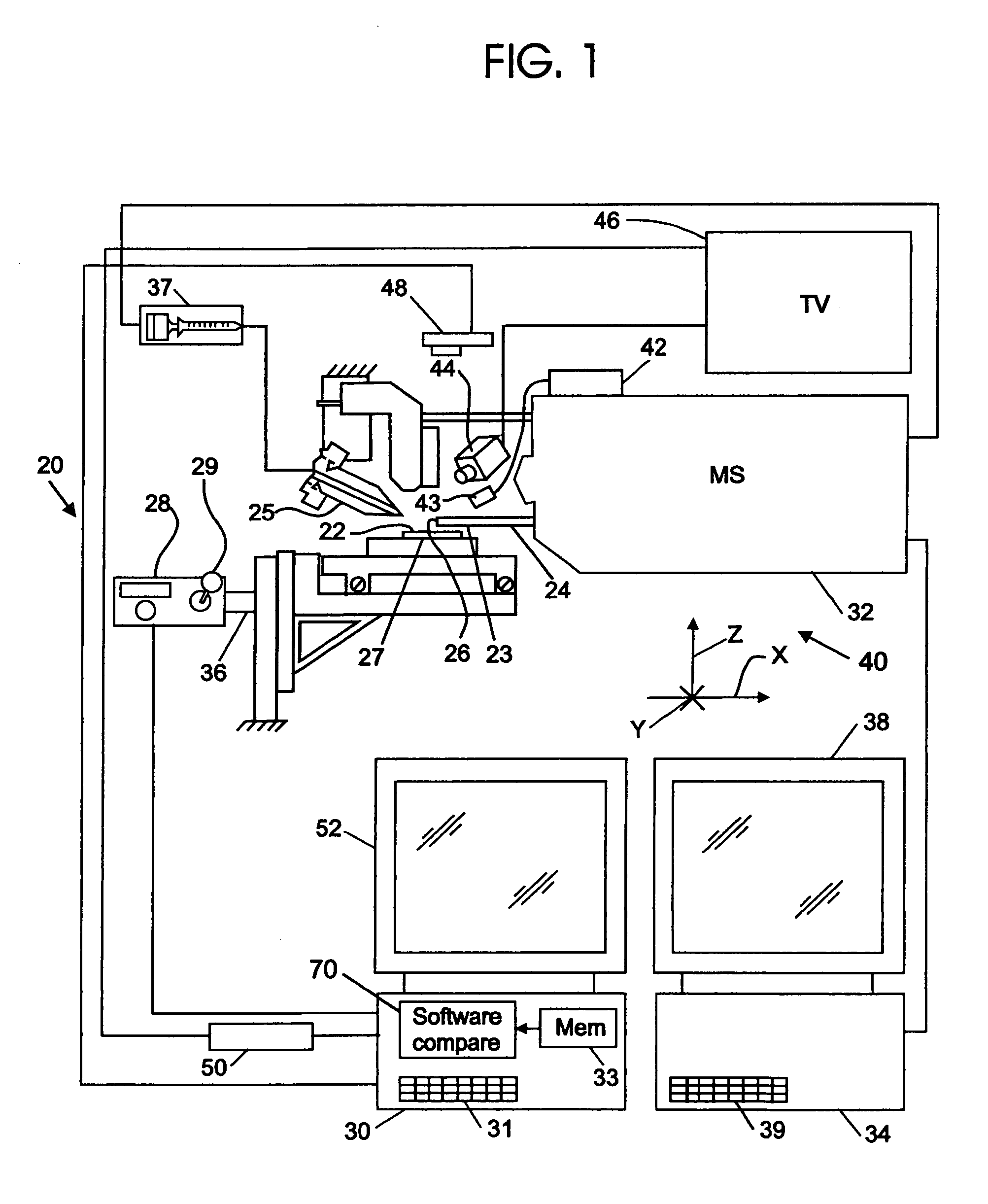

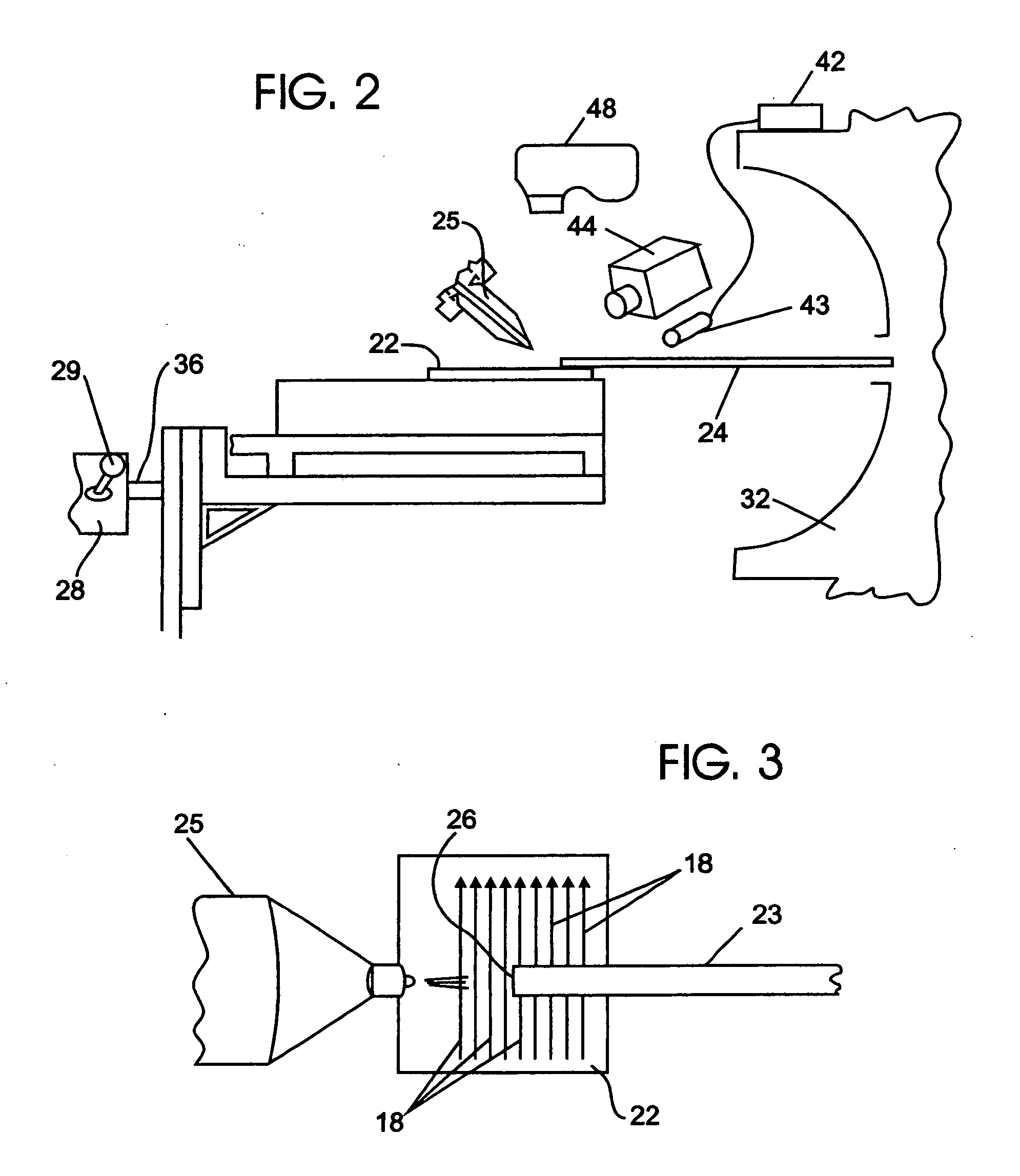

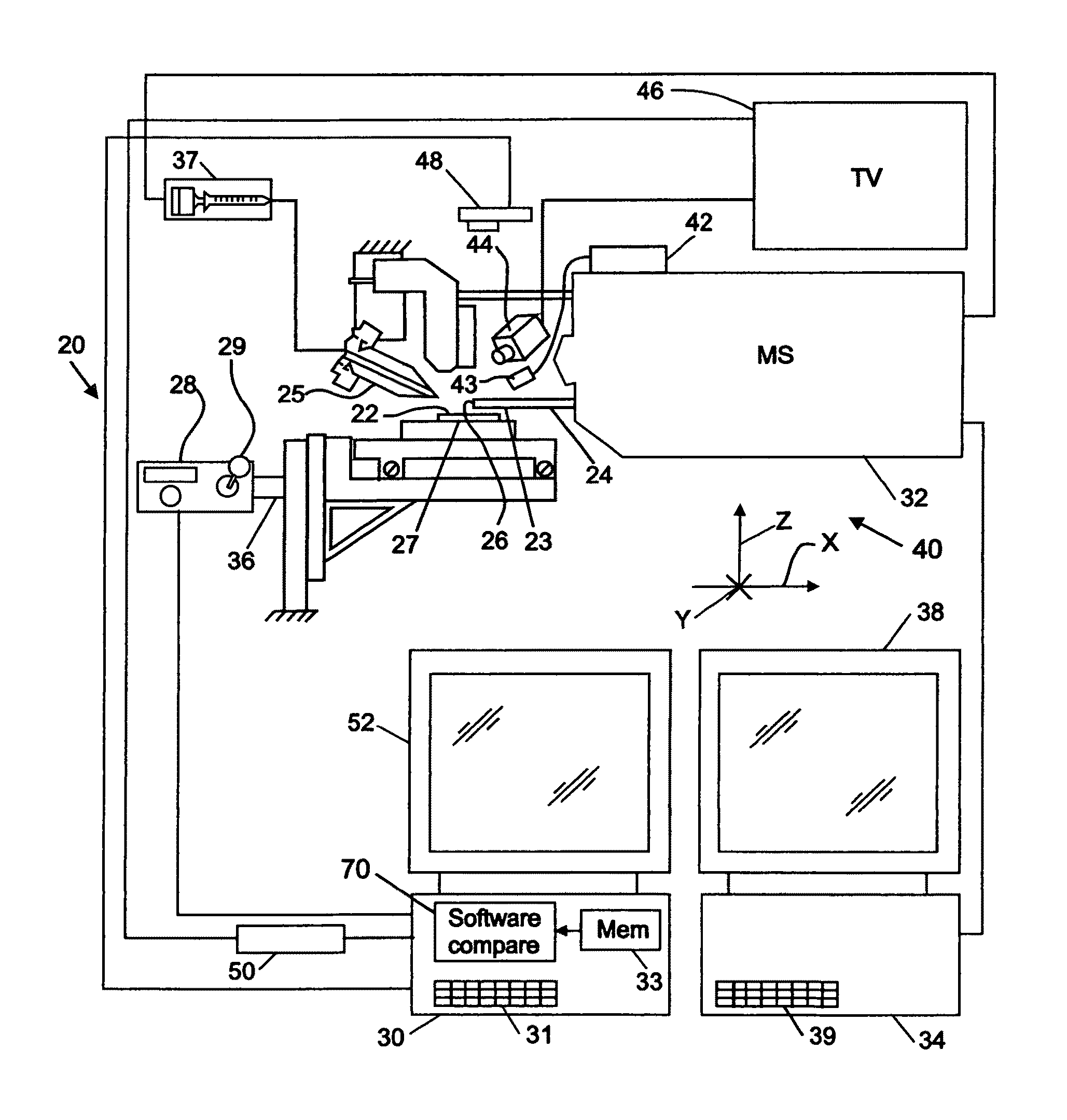

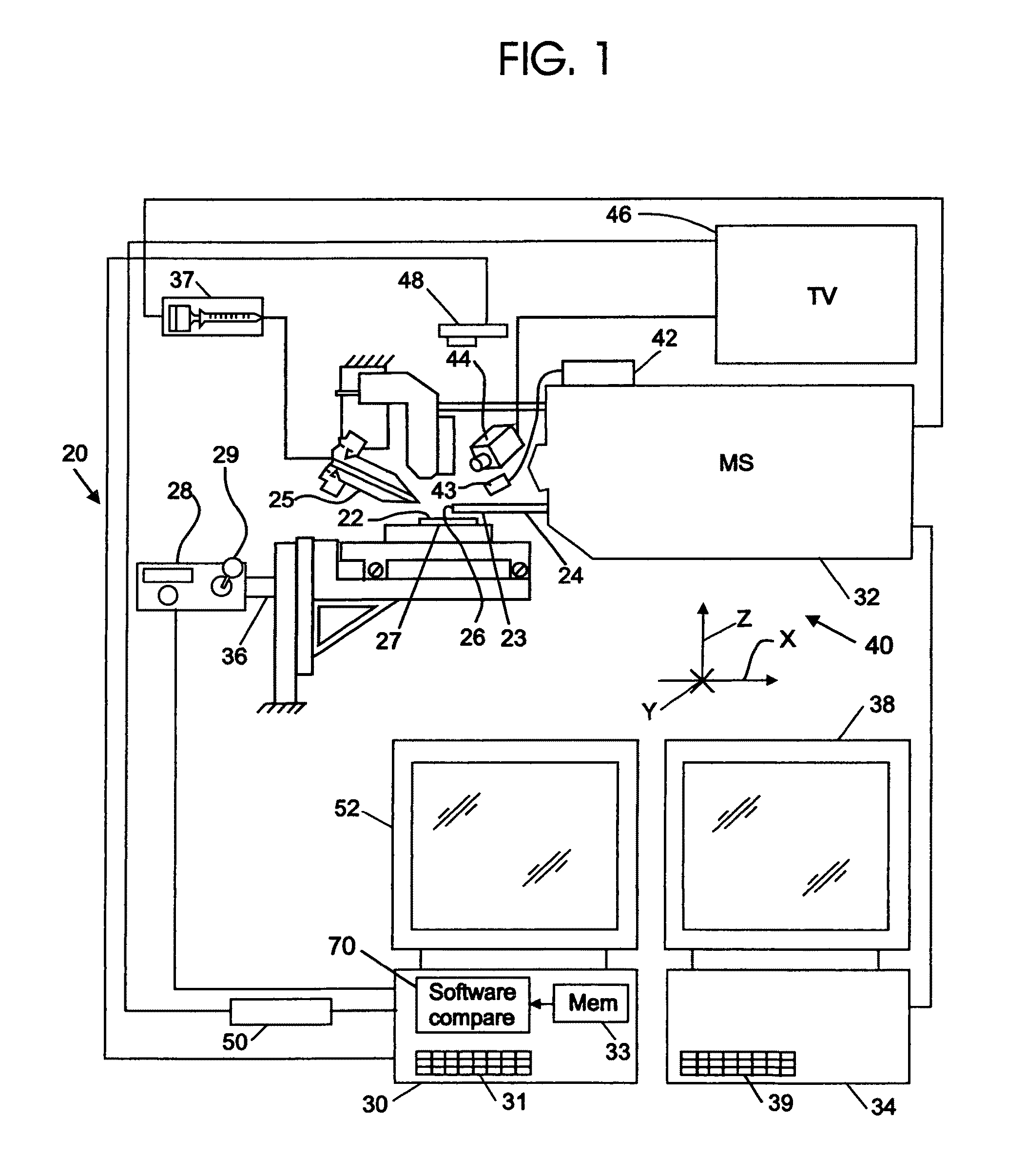

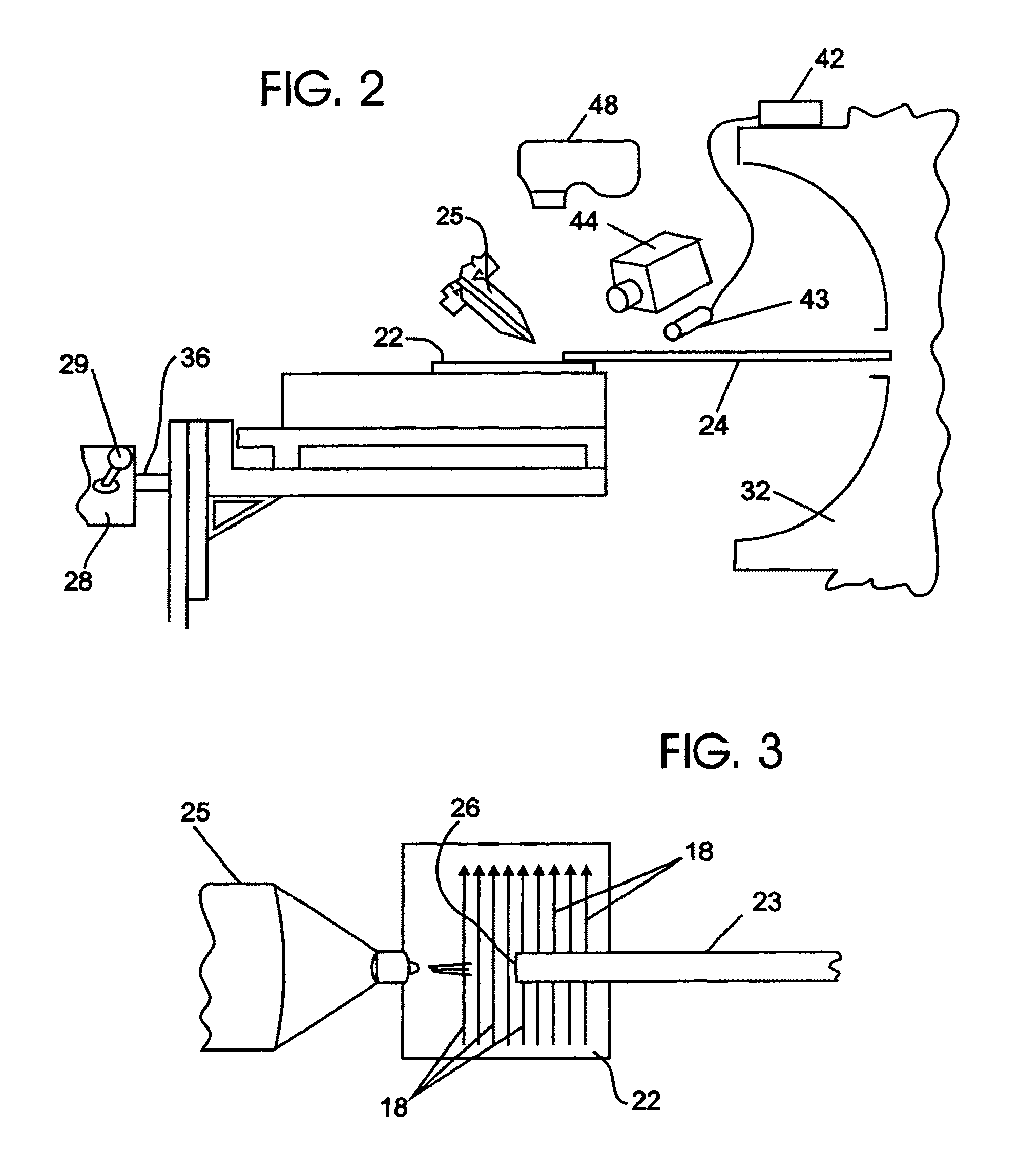

Control of the positional relationship between a sample collection instrument and a surface to be analyzed during a sampling procedure with image analysis

ActiveUS20100002905A1Material analysis using wave/particle radiationParticle separator tubesImaging analysisMass spectrometric

A system and method utilizes an image analysis approach for controlling the collection instrument-to-surface distance in a sampling system for use, for example, with mass spectrometric detection. Such an approach involves the capturing of an image of the collection instrument or the shadow thereof cast across the surface and the utilization of line average brightness (LAB) techniques to determine the actual distance between the collection instrument and the surface. The actual distance is subsequently compared to a target distance for re-optimization, as necessary, of the collection instrument-to-surface during an automated surface sampling operation.

Owner:UT BATTELLE LLC

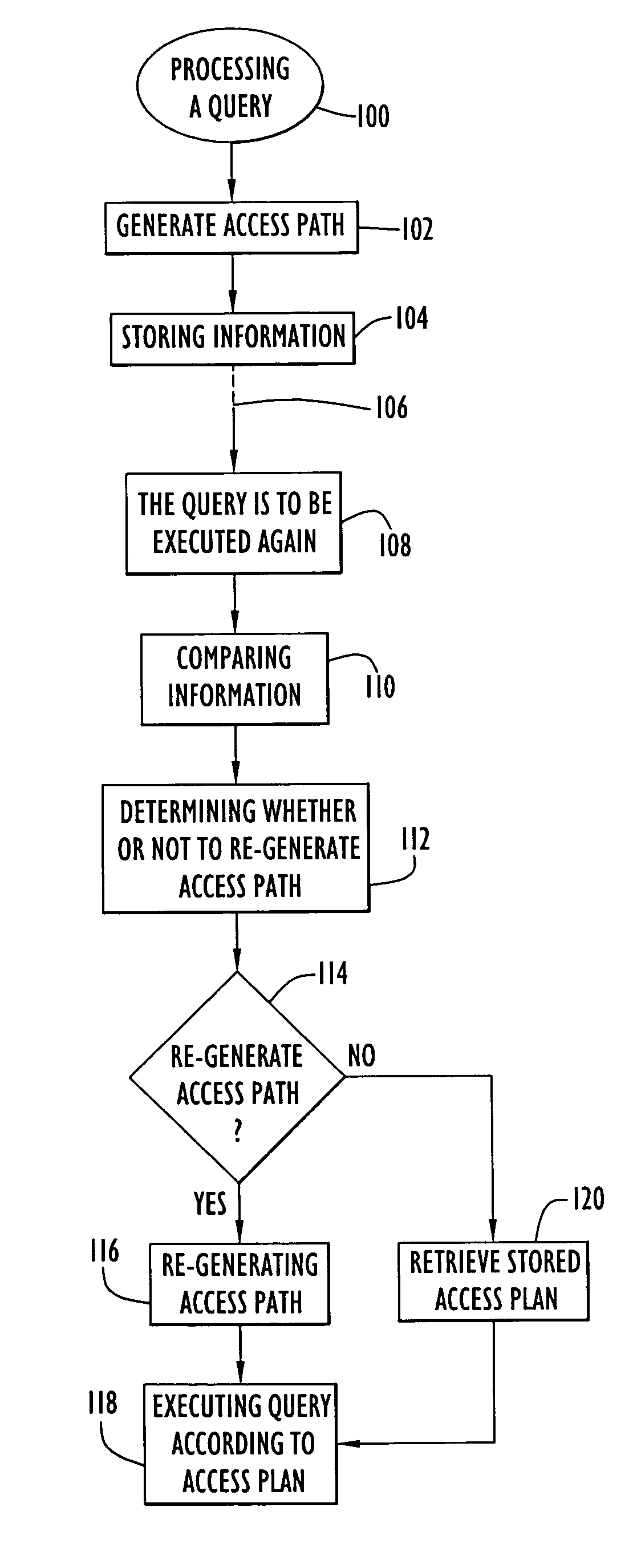

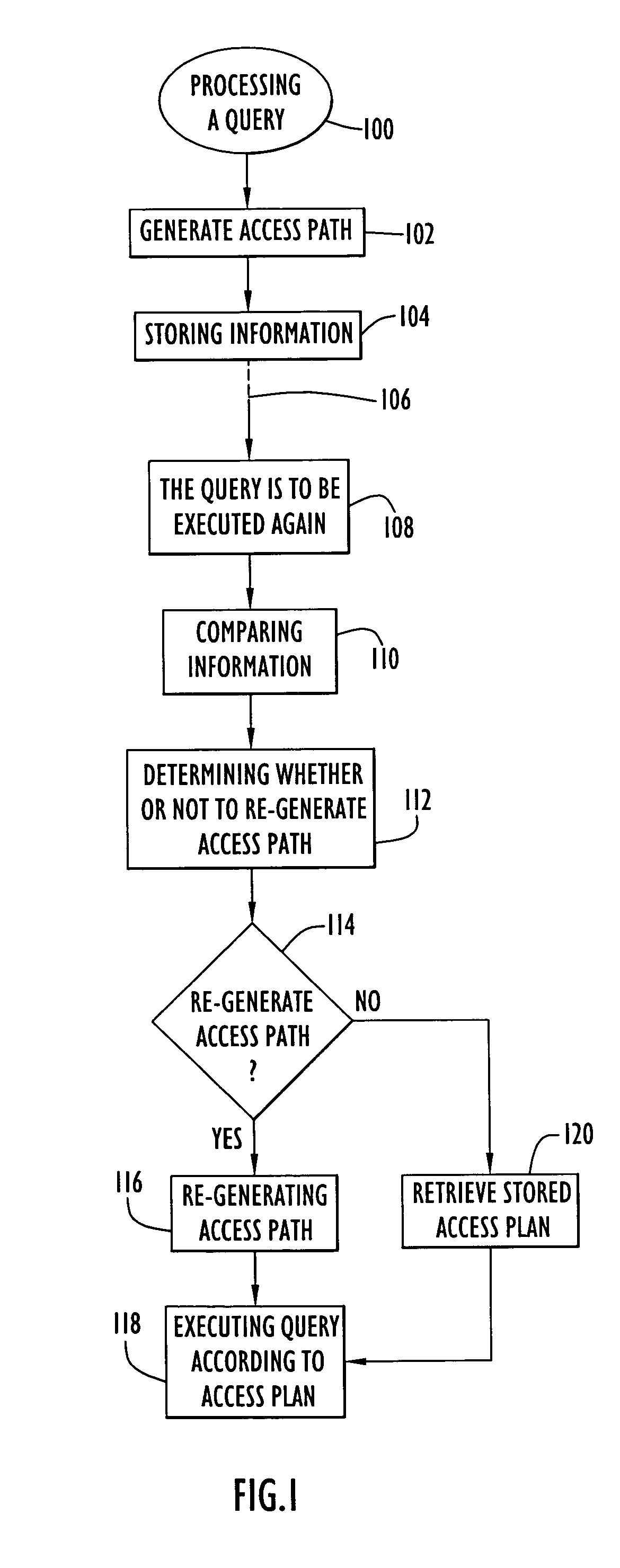

Method and system for reducing host variable impact on access path selection

InactiveUS7275051B2Efficient executionInexpensively assessedData processing applicationsDigital data information retrievalComputer scienceRe optimization

The present invention proposes enhancing the access path selection process by storing the relevant frequency distribution and the host variables values used for selecting the access path together with the corresponding access path executable. This way, the host variables impact to the access path can be inexpensively assessed and the re-optimization triggered only if necessary.

Owner:SNOWFLAKE INC

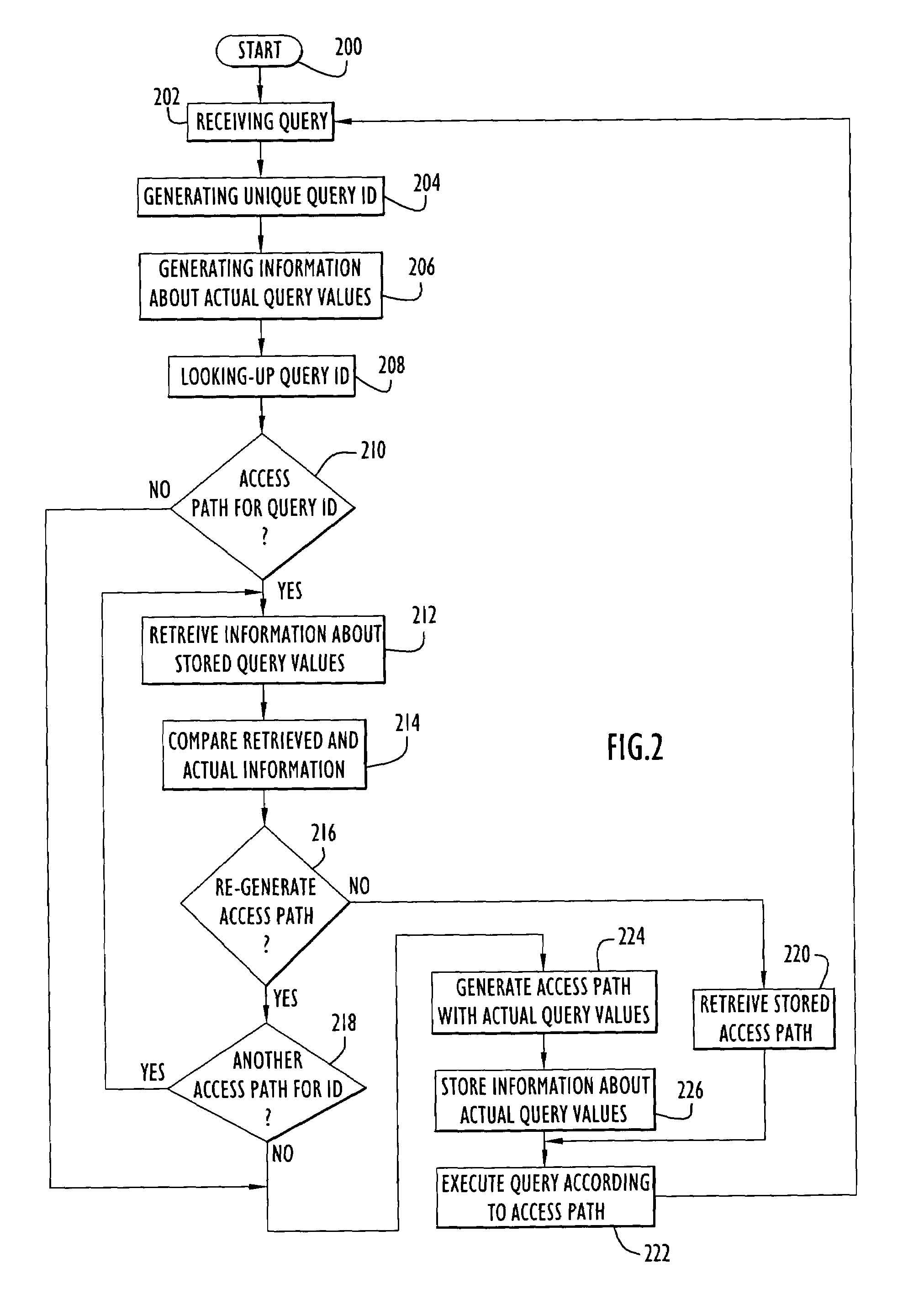

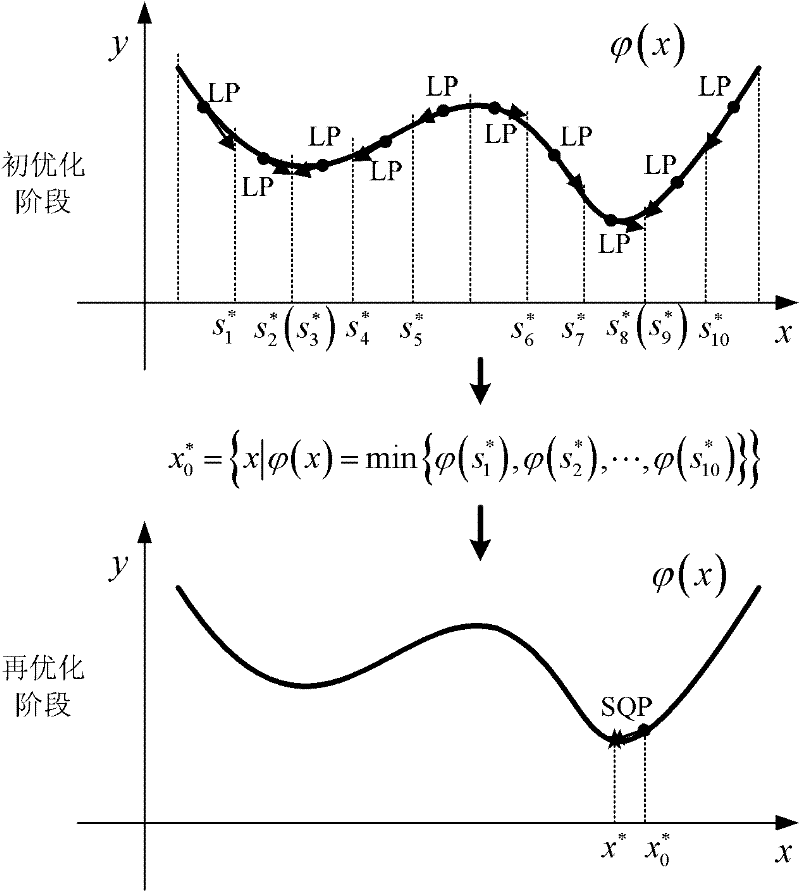

A Novel Hybrid Optimization Method for Optimal Control of Aeroengine Performance

InactiveCN102289203ASolve online performance optimization problemsImprove real-time performanceAdaptive controlAviationGlobal optimization

The invention relates to a novel hybrid optimization method for performance optimization control of aero-engines. The method is a hybrid optimization method based on subregional parallel linear programming and sequential quadratic programming. Its characteristic is that the optimization calculation process is divided into initial optimization and re-optimization There are two stages of optimization: (a) In the initial optimization stage, the global initial feasible solution is solved by using the subregional parallel linear programming method. In the initial optimization stage, no iterative convergence process is required, and the initial feasible solution is allocated to the global optimal solution through the subregional parallel mechanism. In the small area near the optimal solution; (b) In the re-optimization stage, the initial feasible solution is taken as the initial iteration point, and the sequential quadratic programming method is used to iteratively optimize to ensure good global convergence, optimization accuracy and search ability along the constraint boundary. The method of the invention coordinates the relationship between optimization accuracy and convergence speed through combined optimization logic, has the advantages of high optimization accuracy, good real-time performance, and moderate method complexity, and is suitable for solving the problem of aeroengine performance optimization control.

Owner:BEIHANG UNIV

Determining validity ranges of query plans based on suboptimality

InactiveUS7353219B2Overcome limitationsImprove robustnessData processing applicationsDigital data information retrievalQuery planAlgorithm

“Determining Validity Ranges of Query Plans Based on Suboptimality” A method for approximating a validity range for a domain of cardinalities of input to an optimal query plan is provided. Such a validity range is iteratively approximated using a modified Newton-Raphson method to find roots of cost functions for optimal and alternative query plans, respectively. The Newton-Raphson method is combined with a method of incrementing roots of cost functions, known as input cardinalities, such that discontinuous and non-differentiable points in cost functions are avoided. In this manner, input cardinalities remain within a domain for which a valid range can be specified. Additionally, a robustness measure is determined by a sensitivity analysis performed on an approximated validity range. Using a robustness measure provided by a sensitivity analysis and resultant validity range and, query plan sub-optimality detection is simplified, re-optimization is selectively triggered, and robustness information is provided to a system or user performing corrective actions.

Owner:IBM CORP

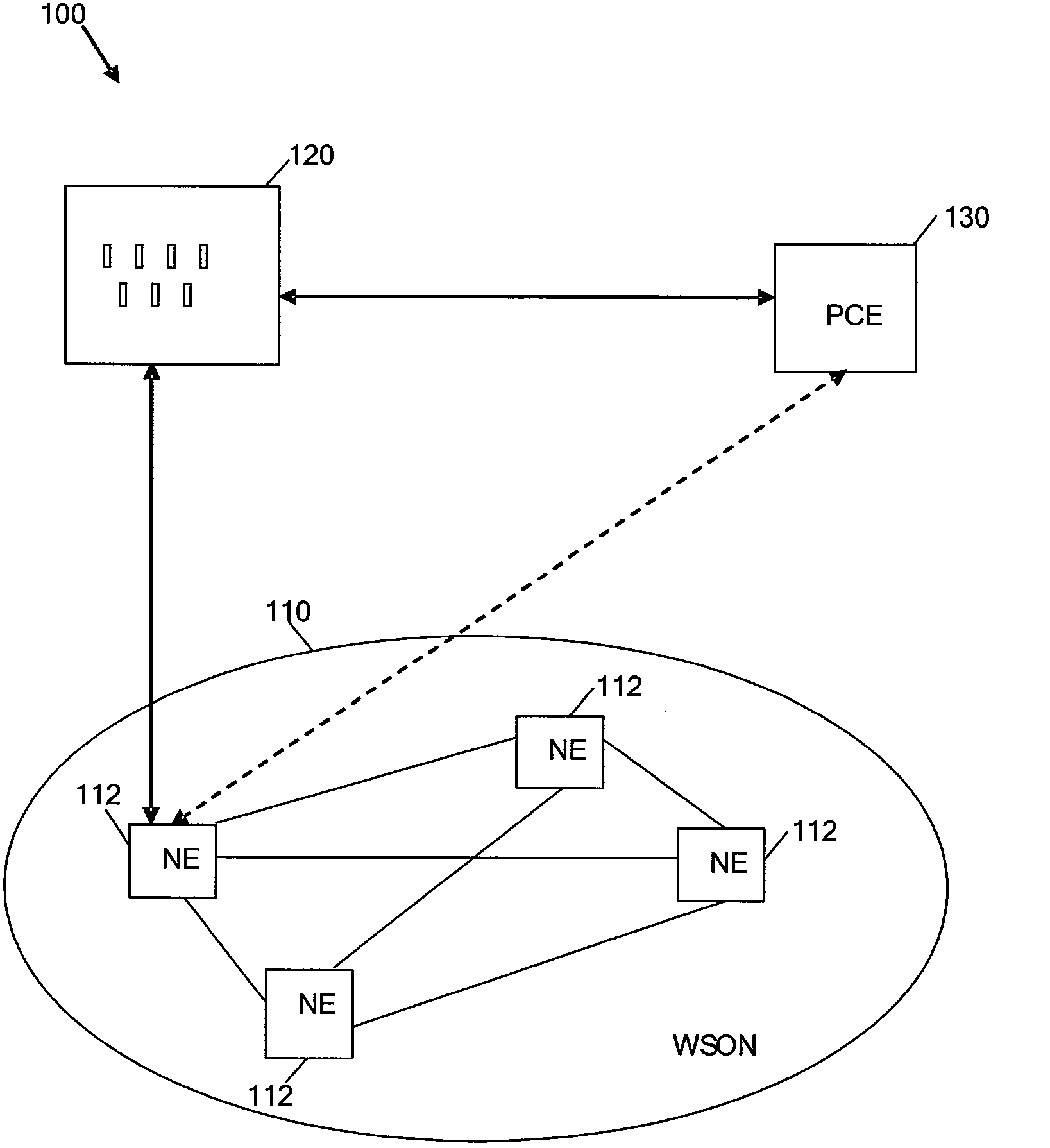

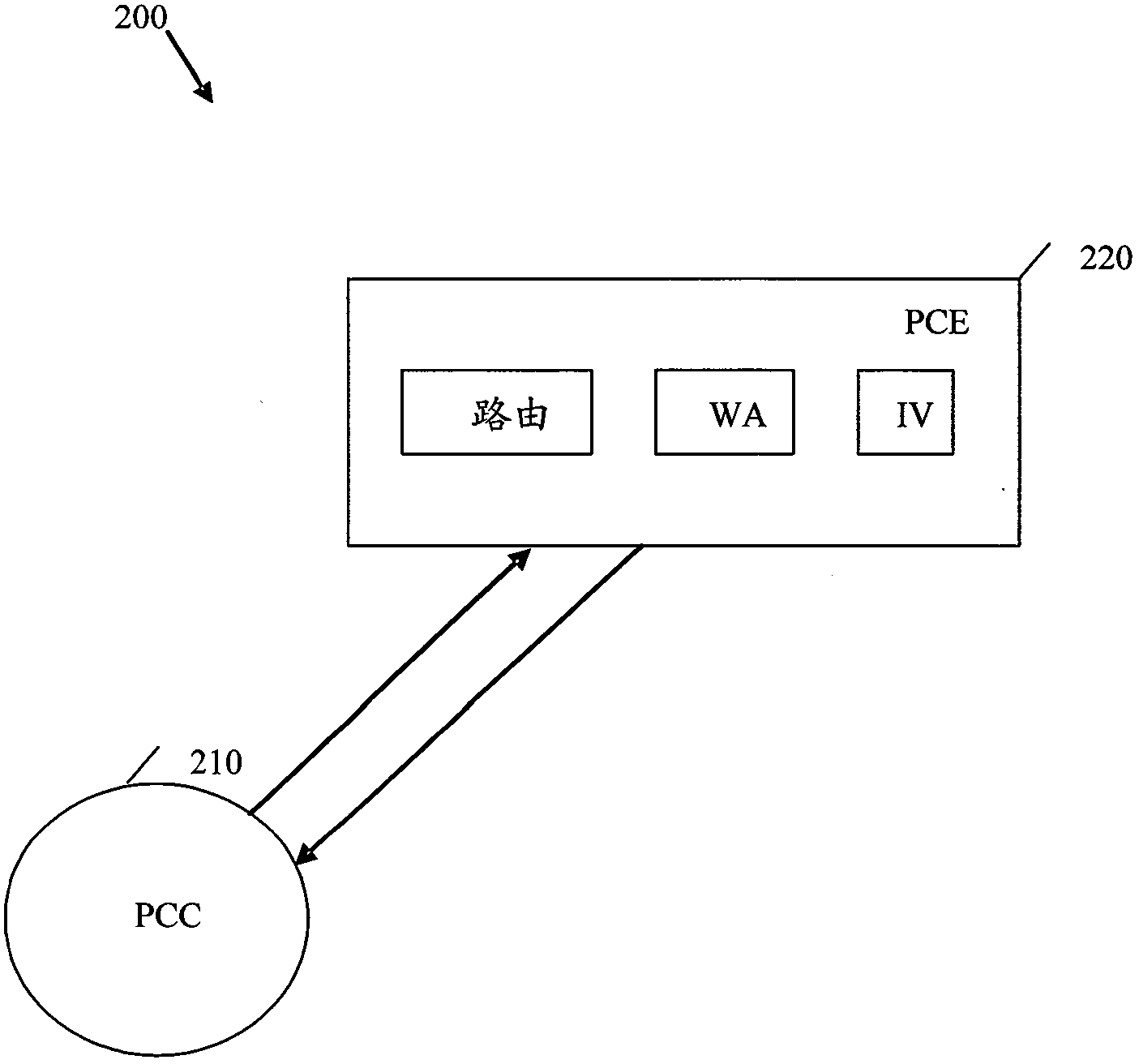

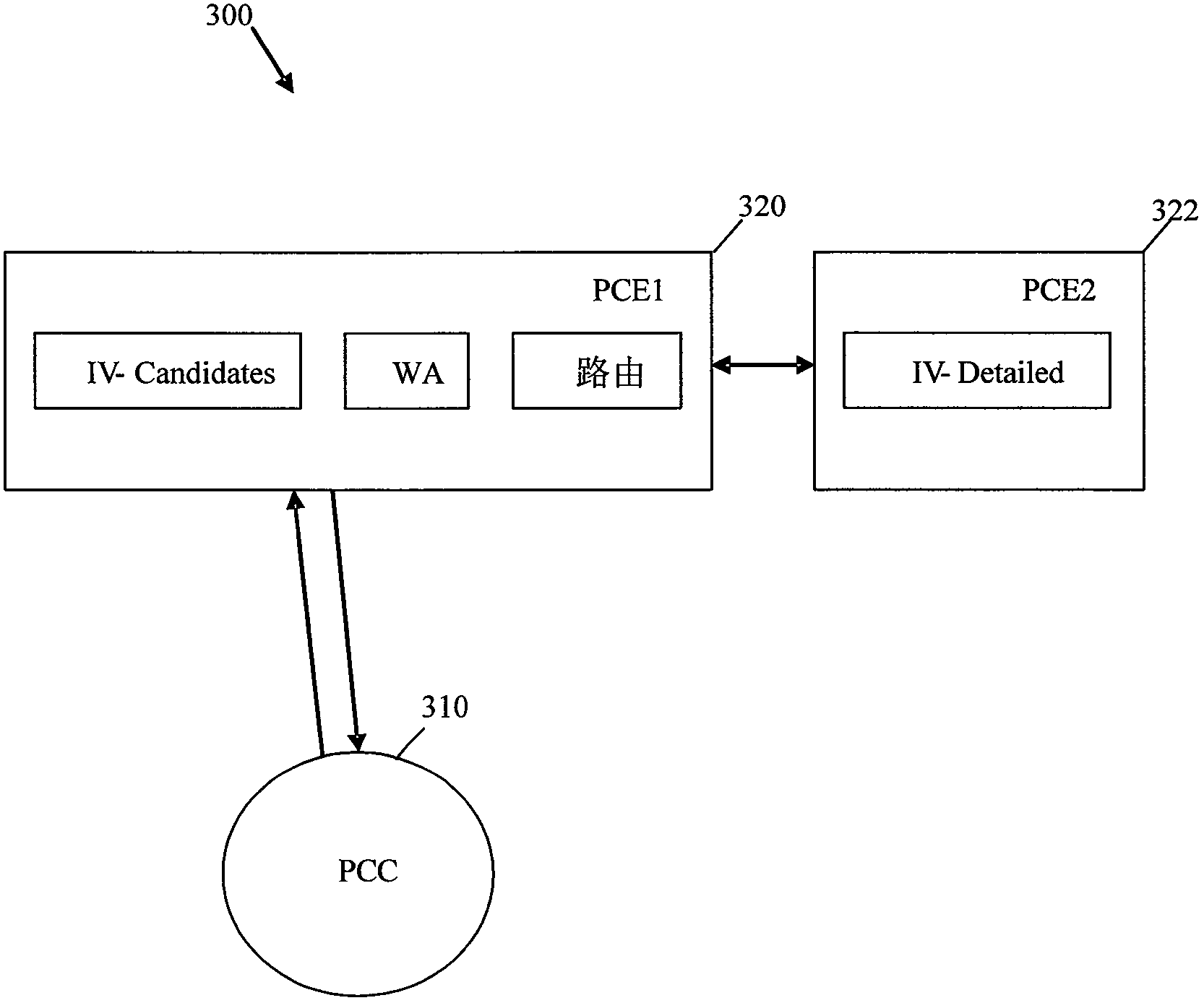

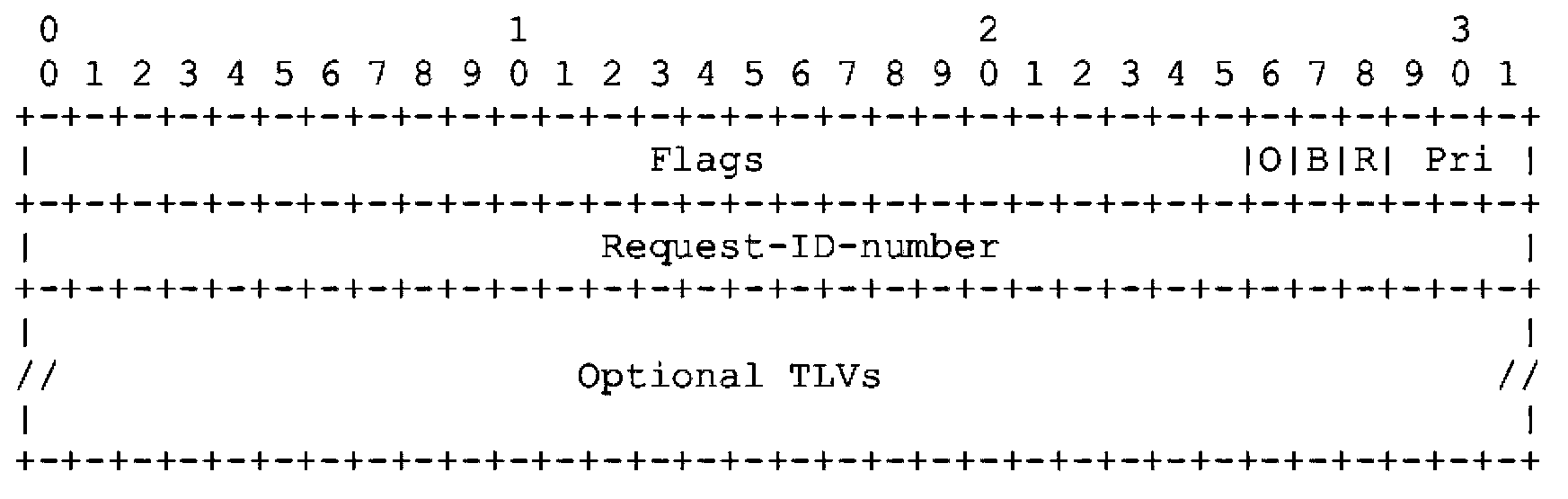

Path computation element protocol (PCEP) operations to support wavelength switched optical network routing, wavelength assignment, and impairment validation

ActiveCN102783066AMultiplex system selection arrangementsWavelength-division multiplex systemsWavelength switched optical networkLength wave

An apparatus comprising a path computation element (PCE) configured for at least partial impairment aware routing and wavelength assignment (RWA) and to communicate with a path computation client (PCC) based on a PCE protocol (PCEP) that supports path routing, wavelength assignment (WA), and impairment validation (IV). The PCEP comprises at least one operation selected from the group consisting of a new RWA path request operation and a path re-optimization request operation. Also disclosed is a network component comprising at least one processor configured to implement a method comprising establishing a PCEP session with a PCC, receiving path computation information comprising RWA information and constraints from the PCC, and establishing impairment aware RWA (IA-RWA) based on the path computation information and a private impairment information for a vendor's equipment.

Owner:HUAWEI TECH CO LTD

Control of the positional relationship between a sample collection instrument and a surface to be analyzed during a sampling procedure with image analysis

ActiveUS7995216B2Material analysis using wave/particle radiationParticle separator tubesImaging analysisMass spectrometric

A system and method utilizes an image analysis approach for controlling the collection instrument-to-surface distance in a sampling system for use, for example, with mass spectrometric detection. Such an approach involves the capturing of an image of the collection instrument or the shadow thereof cast across the surface and the utilization of line average brightness (LAB) techniques to determine the actual distance between the collection instrument and the surface. The actual distance is subsequently compared to a target distance for re-optimization, as necessary, of the collection instrument-to-surface during an automated surface sampling operation.

Owner:UT BATTELLE LLC

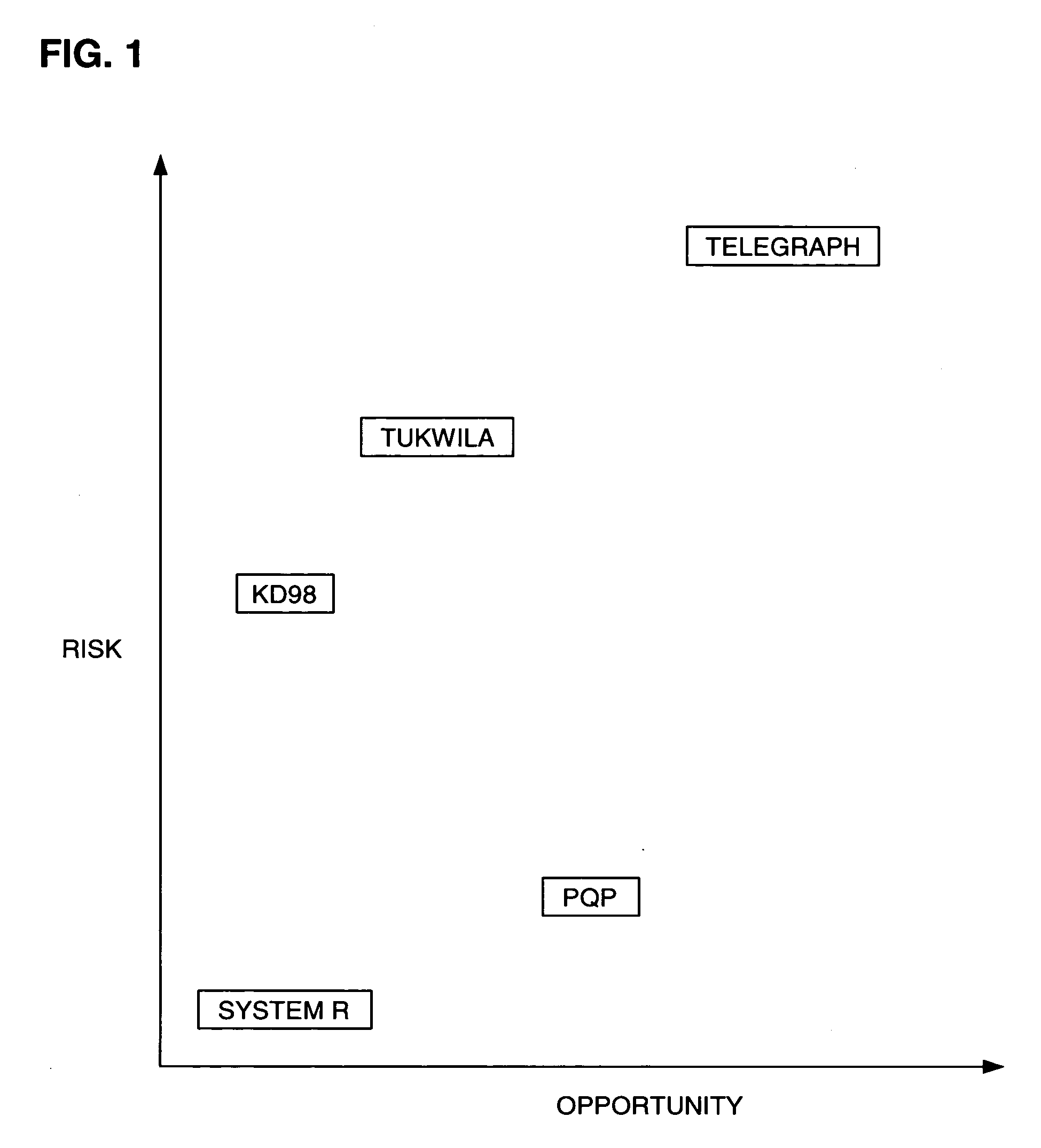

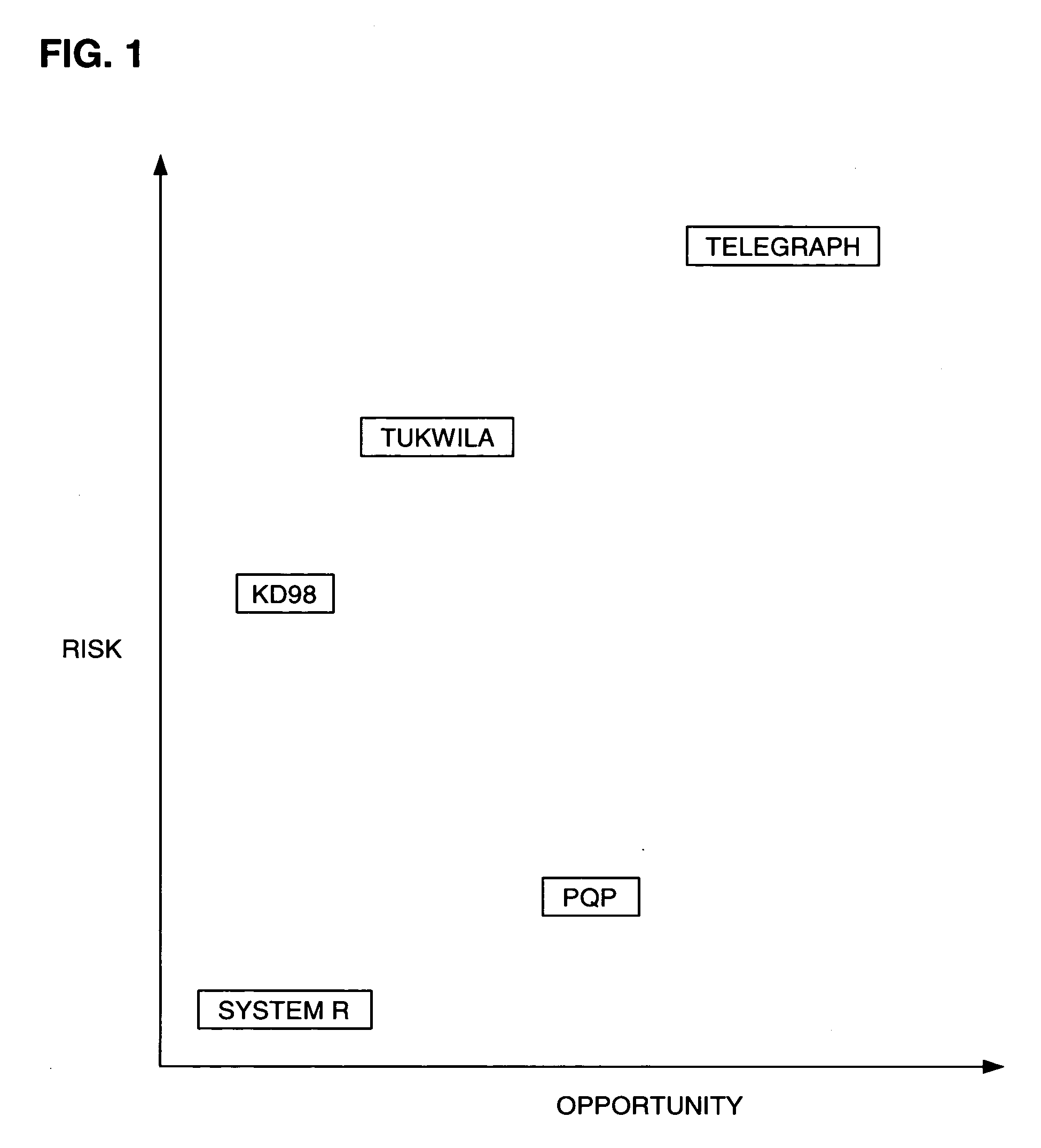

Technique for factoring uncertainty into cost-based query optimization

ActiveUS20140108378A1Reduce riskFactoring uncertainty into cost-based query optimizationDigital data processing detailsSpecial data processing applicationsQuery optimizationCost estimate

A technique for factoring uncertainty into cost-based query optimization includes: determining the degree of uncertainty involved in the cost estimates for the query, determining the degree of sensitivity the query has to that uncertainty, and determining if there is an access path that performs well across the range of possible conditions that could occur at execution time, reducing the risk of performance spikes and performance volatility. If such an access path exists, select that access path; if not, perform parametric query optimization or query re-optimization.

Owner:IBM CORP

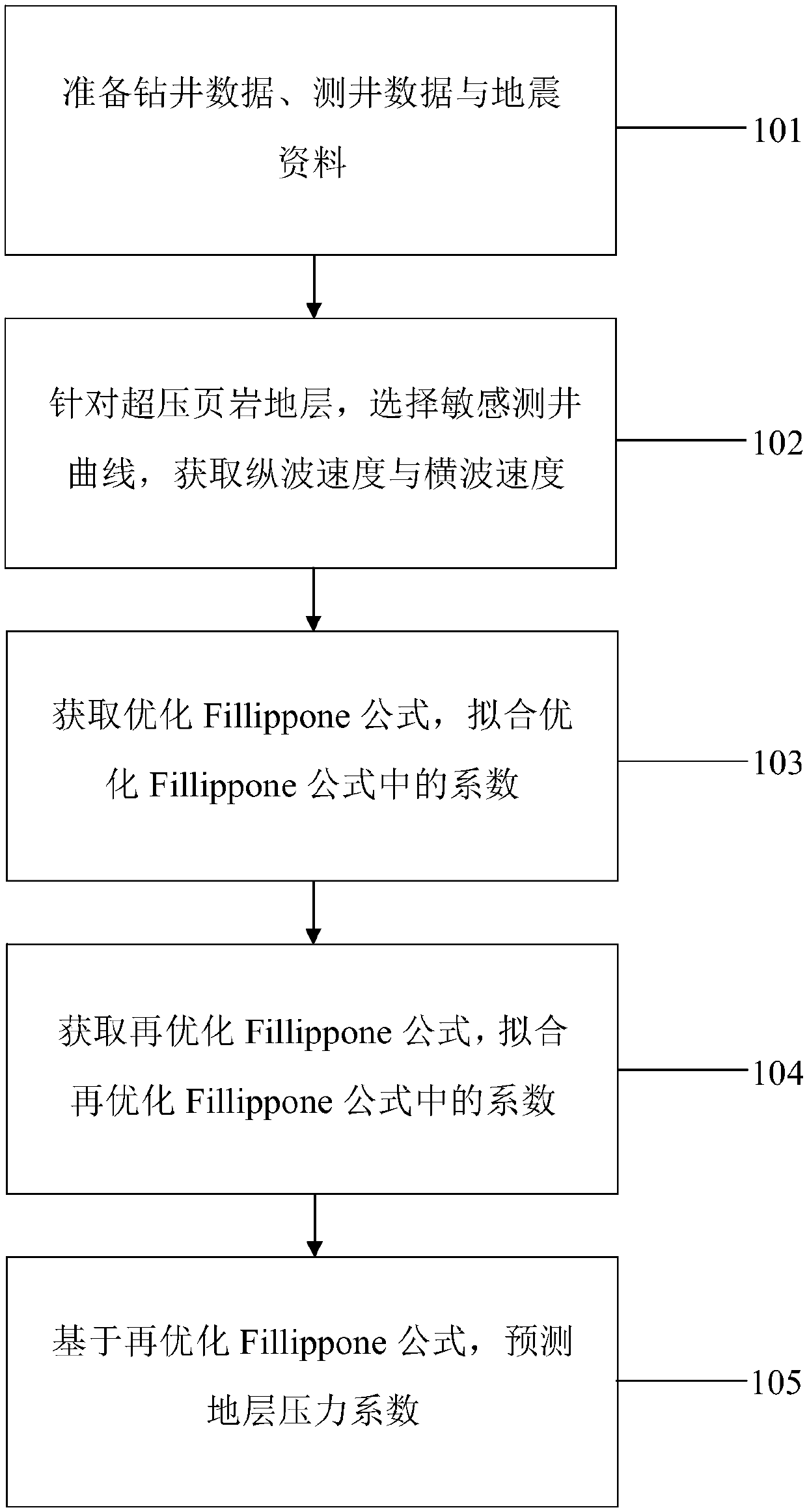

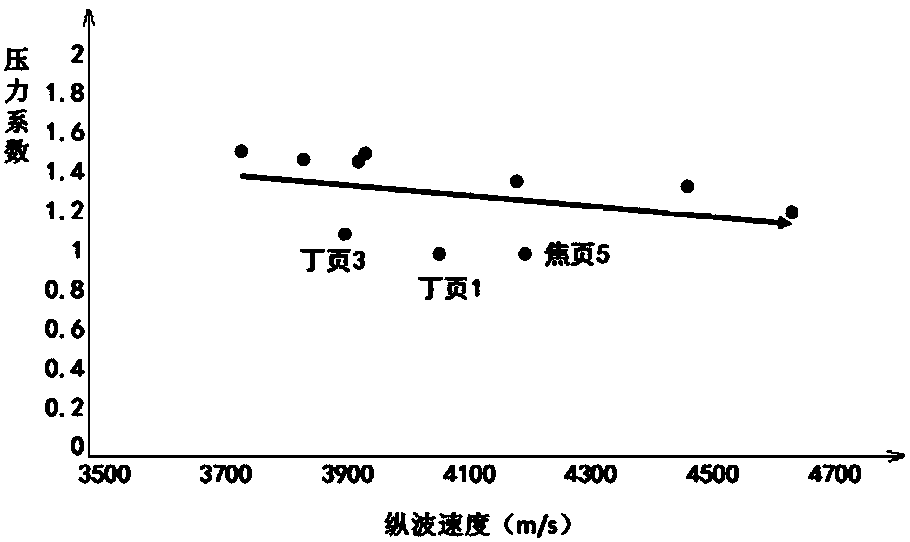

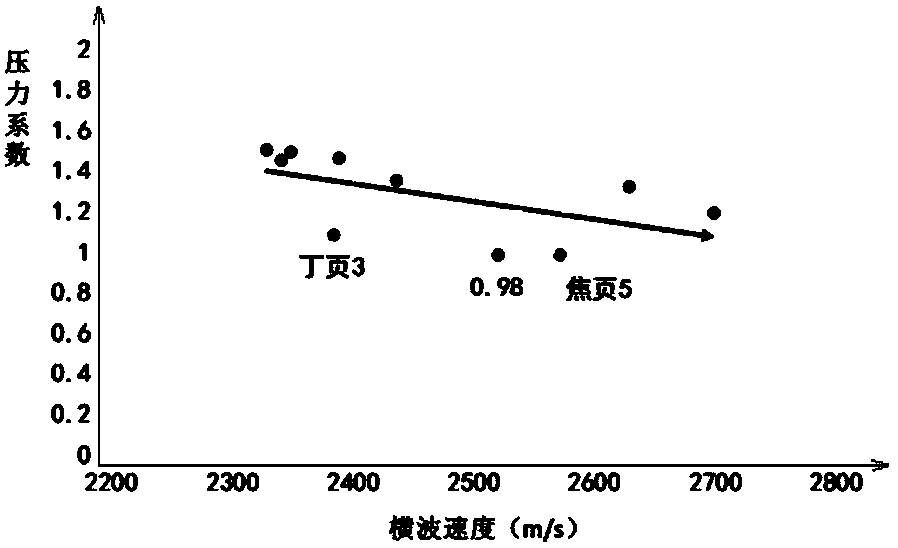

Pressure coefficient prediction method and system of marine mud shale formation

ActiveCN107817520AImprove and deepen the sweet spot prediction technology sequenceImprove the success rate of explorationSeismic signal processingWell drillingLongitudinal wave

The invention discloses a pressure coefficient prediction method and system of a marine mud shale formation. The pressure coefficient prediction method of a marine mud shale formation includes the steps: preparing the drilling data, the logging data and the seismic data; for an overpressure shale formation, selecting a sensitive logging curve, and acquiring the longitudinal wave speed and the transverse wave speed; based on the drilling data, analyzing the relation between drilling density and the longitudinal wave speed, acquiring a Gardner formula, optimizing a Fillippone formula, obtainingan optimized Fillippone formula, and performing fitting on the coefficients in the optimized Fillippone formula; based on the transverse wave speed, performing re-optimization on the optimized Fillippone formula, obtaining a re-optimized Fillippone formula, and performing fitting on the coefficients in the re-optimized Fillippone formula; and based on the re-optimized Fillippone formula, predicting the formation pressure coefficient. The pressure coefficient prediction method of a marine mud shale formation performs quantitative evaluation research on the shale gas preservation conditions, cancomplete and deepen the shale gas dessert prediction technique sequence, and can realize optimization of the shale gas high-yield enrichment region.

Owner:CHINA PETROLEUM & CHEM CORP +1

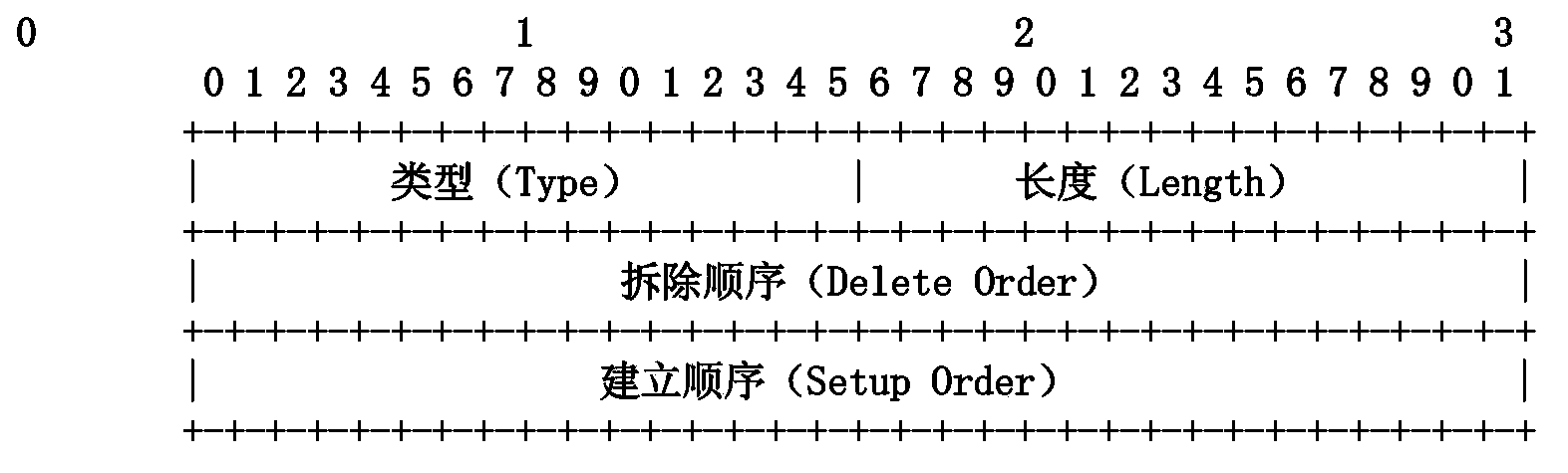

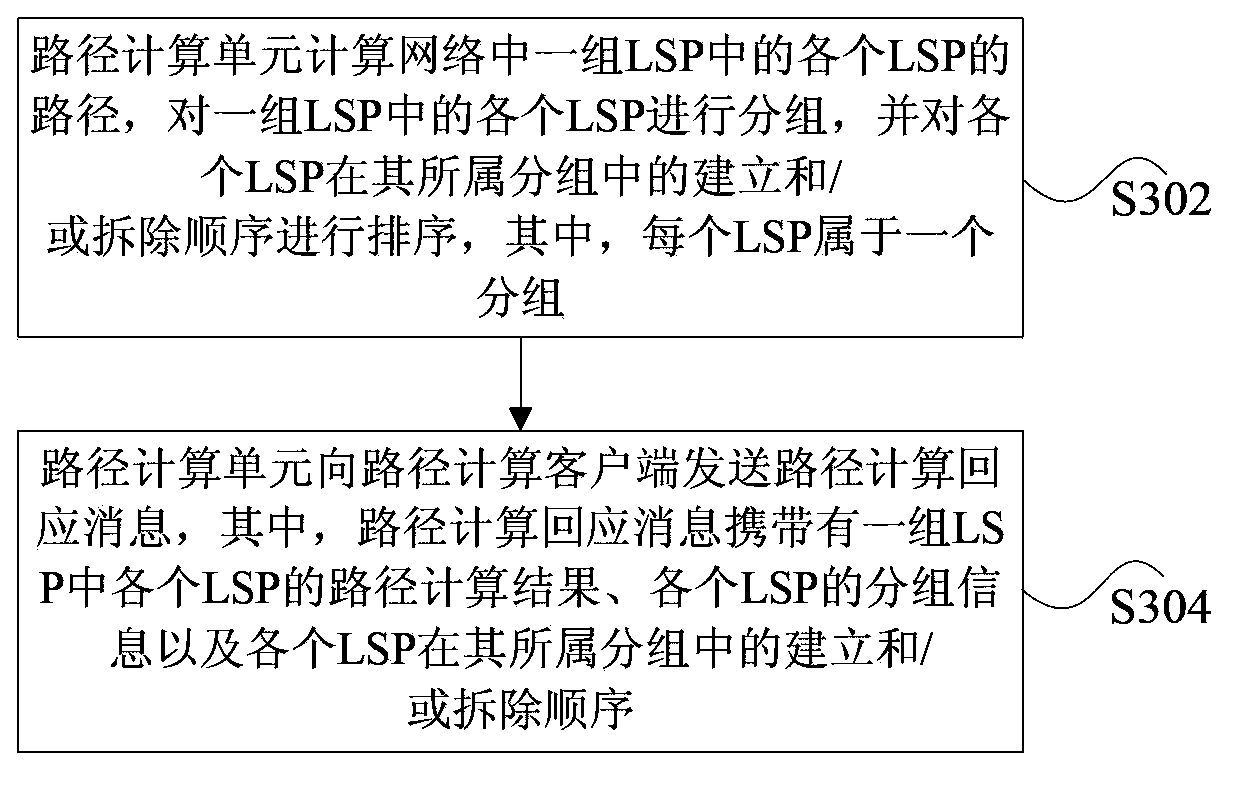

Method, device and system for global concurrent optimization of label switching paths

InactiveCN103795629AShorten the timeImprove efficiency of optimization/reoptimization operationsData switching networksWireless communicationSimulationLabel switching

The invention discloses a method, a device and a system for global concurrent optimization of label switching paths. The method comprises the following steps: a path calculate element calculates all LSPs of a group of LSPs in a network, groups the LSPs, and sorts the LSPs according to the establishment and / or removal order in the group thereof, wherein each LSP belongs to one group; and the path calculate element sends a path calculate response message to a path calculate client, wherein the path calculate response message carries path calculate results of all the LSPs in one group of LSPs, grouping information of all the LSPs, and the establishment and / or removal order of all the LSPs in the group thereof. According to the method, a large number of LSPs are divided into a plurality of optimization / re-optimization groups, the establishment and / or removal order of all the LSPs in each group is established, optimization / re-optimization of the LSPs through a GCO method is carried out concurrently among all groups, and the optimization / re-optimization efficiency is improved.

Owner:ZTE CORP

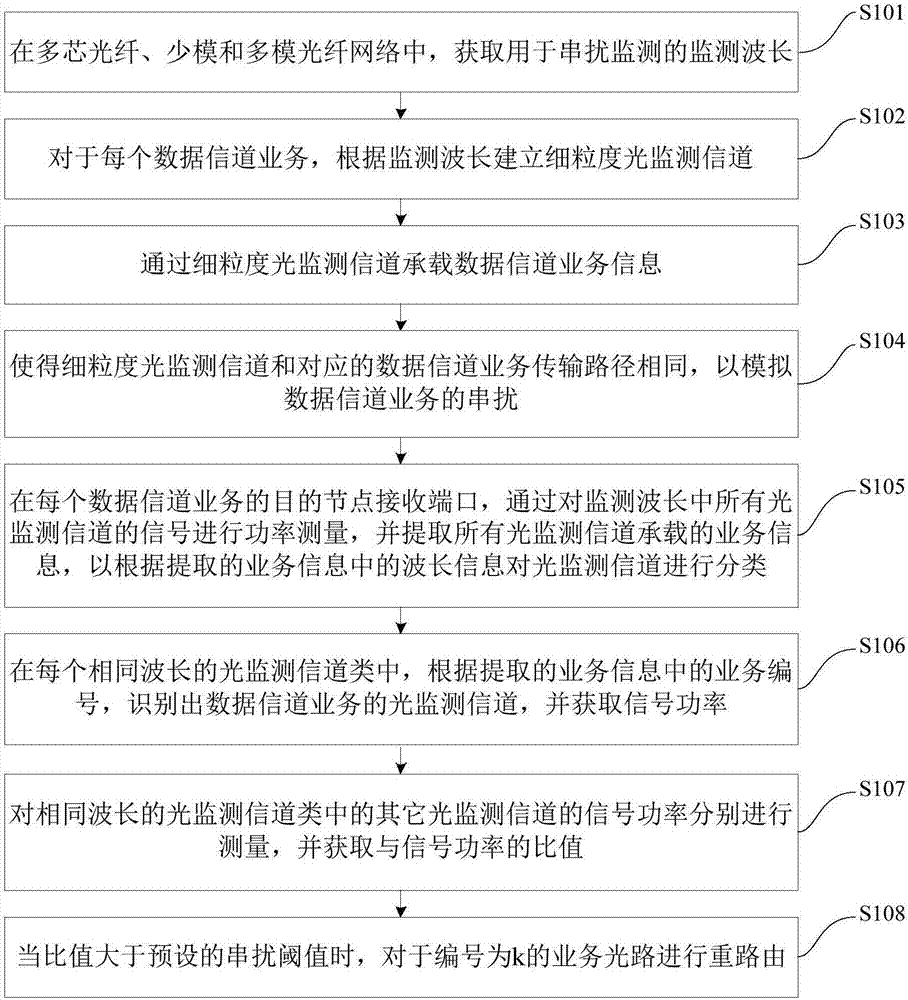

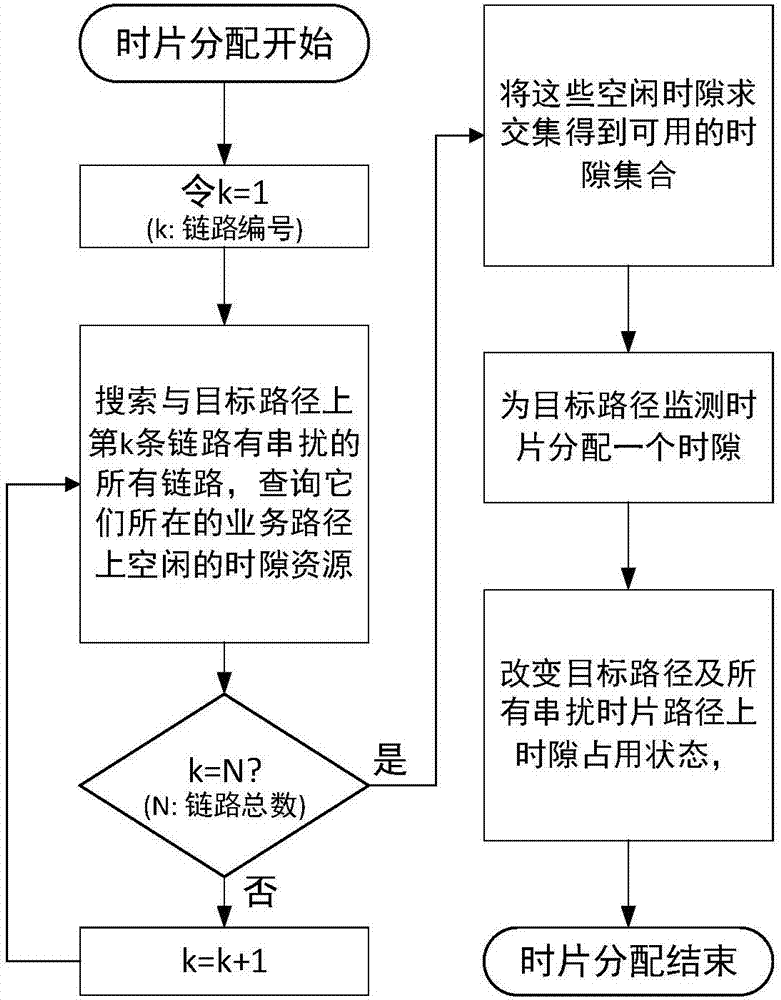

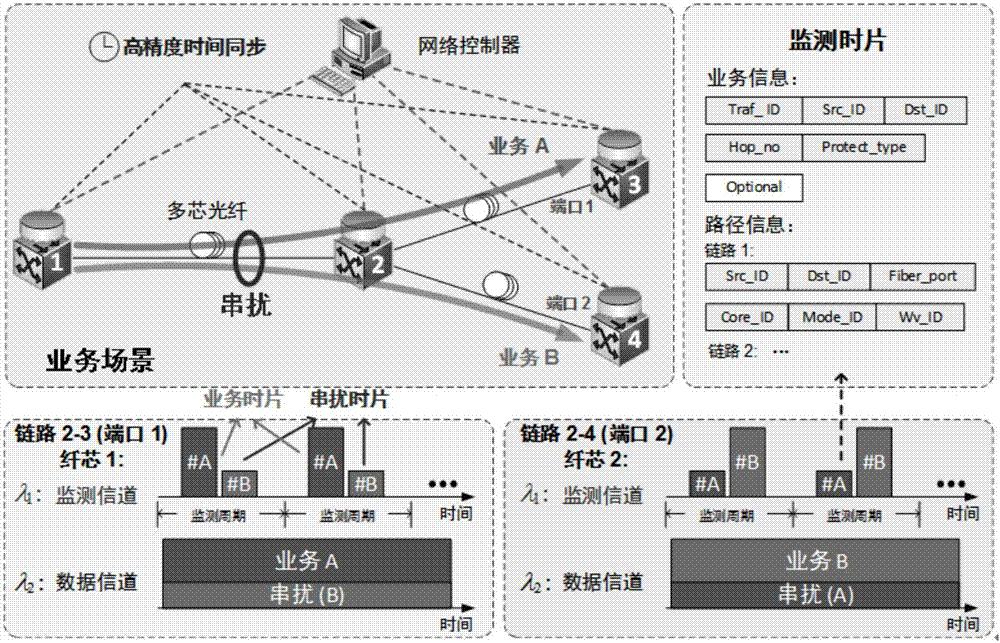

Space-division multiplexing optical network crosstalk monitoring, source tracing and optical path re-optimization method

ActiveCN107994941AImprove reliabilityImprove real-time performanceMultiplex system selection arrangementsElectromagnetic transmissionSource tracingPower measure

The invention discloses a space-division multiplexing optical network crosstalk monitoring, source tracing and optical path re-optimization method, comprising the following steps: acquiring a monitoring wavelength for crosstalk monitoring; building a fine grit optical monitoring channel; bearing a data channel service information; simulating crosstalk of the data channel service; classifying the optical monitoring channels according to a wavelength information in the extracted service information; identifying the optical monitoring channel of the data channel service, and acquiring a signal power P<0>; respectively measuring the signal power P<k> of the other optical monitoring channels in the type of the optical monitoring channels of same wavelength, and acquiring a ratio XT<k> to the signal power P<0>; and when the ratio XT<k> is greater than a preset crosstalk threshold value XT, performing rerouting for a service optical path of which a serial number is k. The method providedby the invention can perform power measurement and information extraction for the signals of all the optical monitoring channels in the monitoring wavelength to realize crosstalk monitoring and sourcetracing, can perform rerouting for the optical path with serious crosstalk, thereby, effectively improves reliability and real-time performance of crosstalk monitoring and optical path re-optimization.

Owner:TSINGHUA UNIV

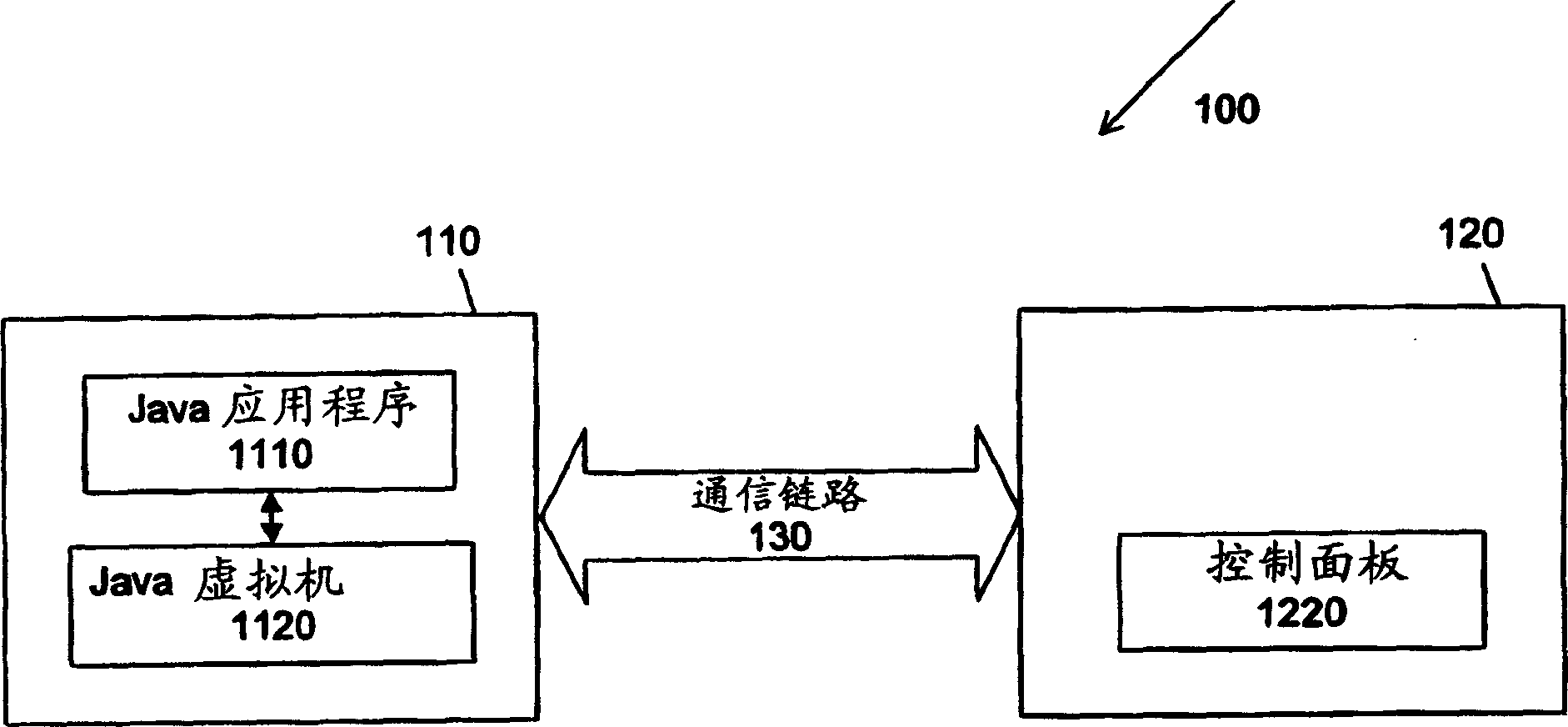

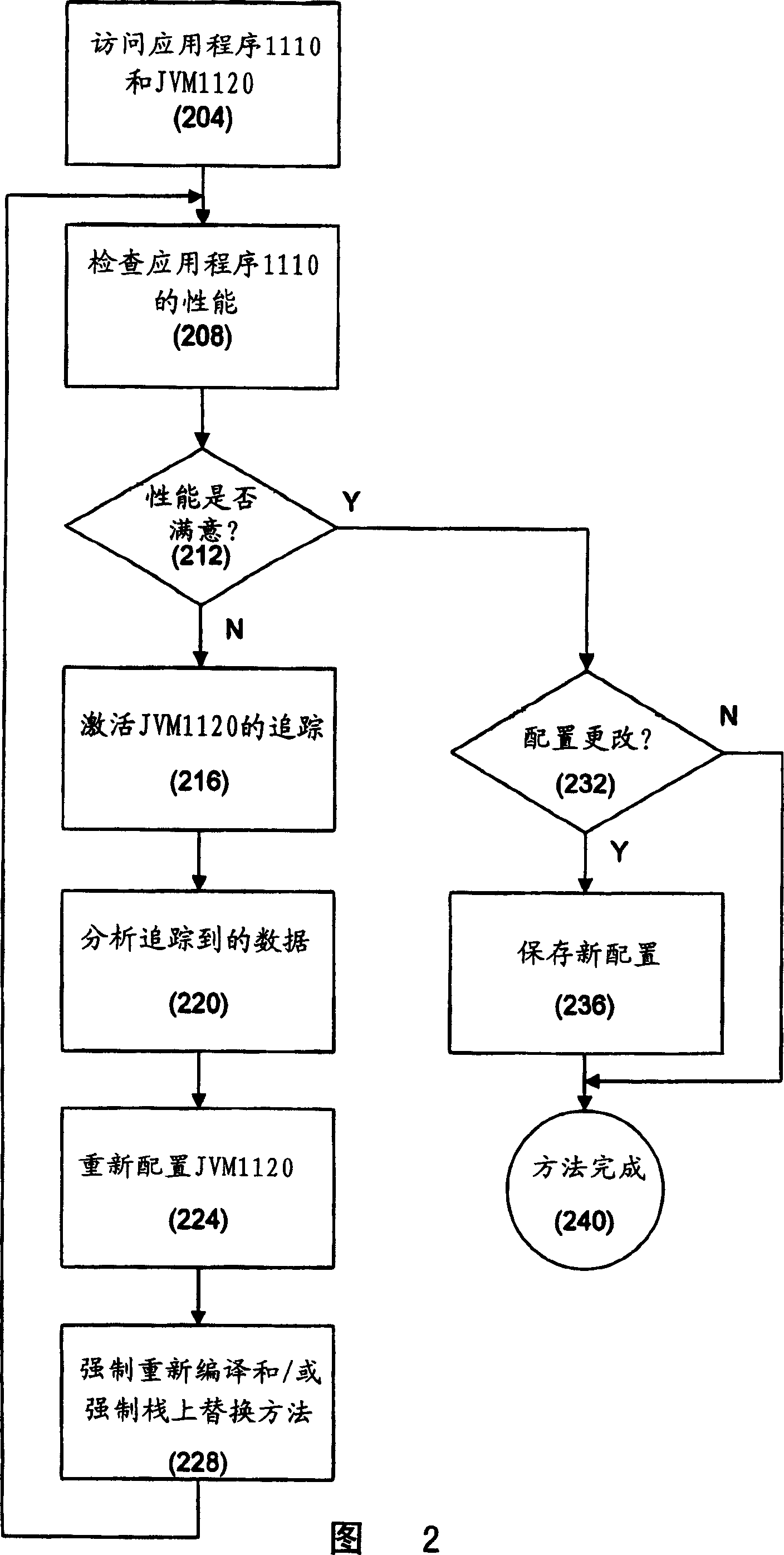

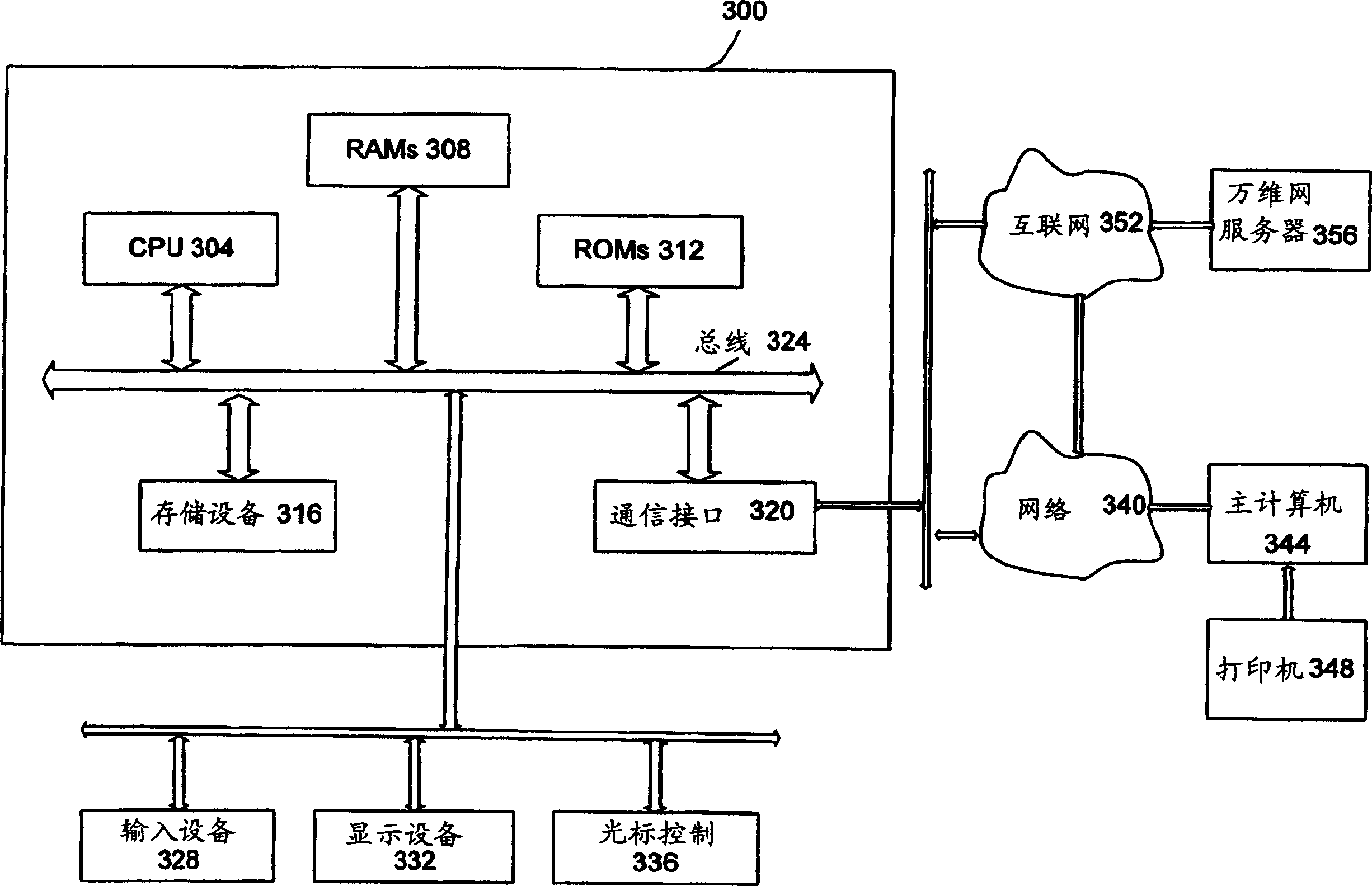

Improving performance of computer program when they operating

InactiveCN1461991AImprove performanceEasy parameter adjustmentProgram control using stored programsSoftware simulation/interpretation/emulationJava virtual machineRe optimization

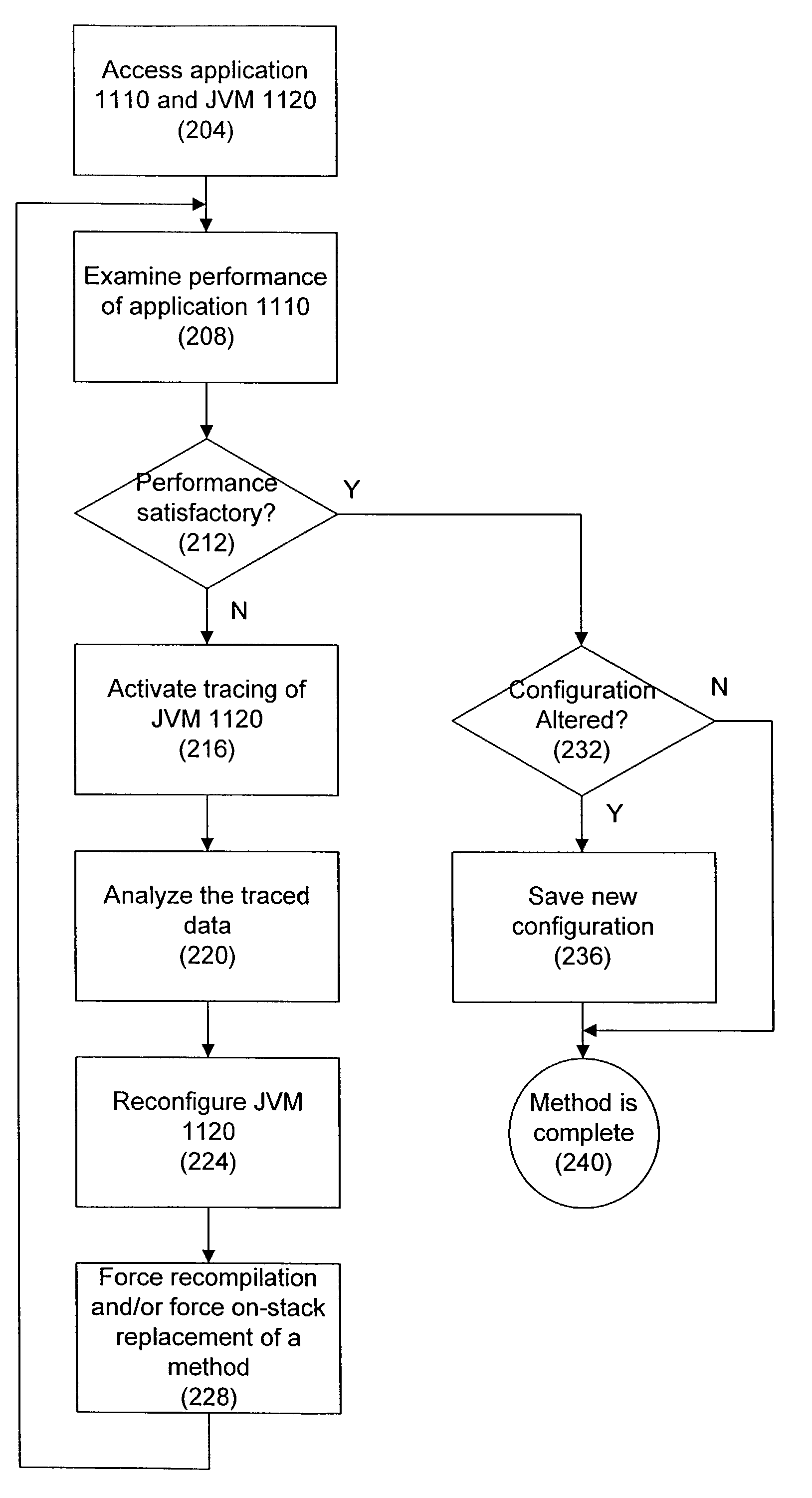

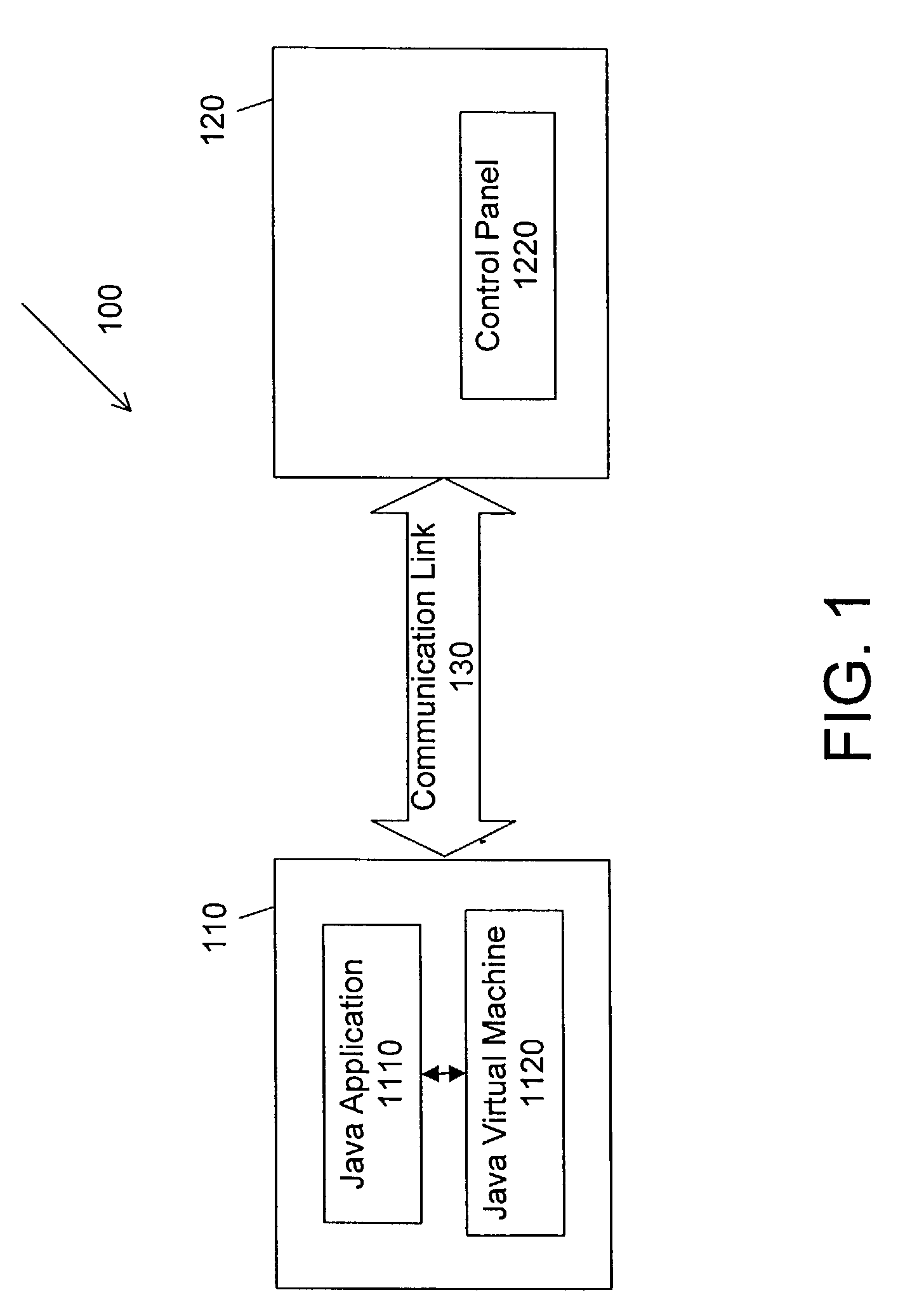

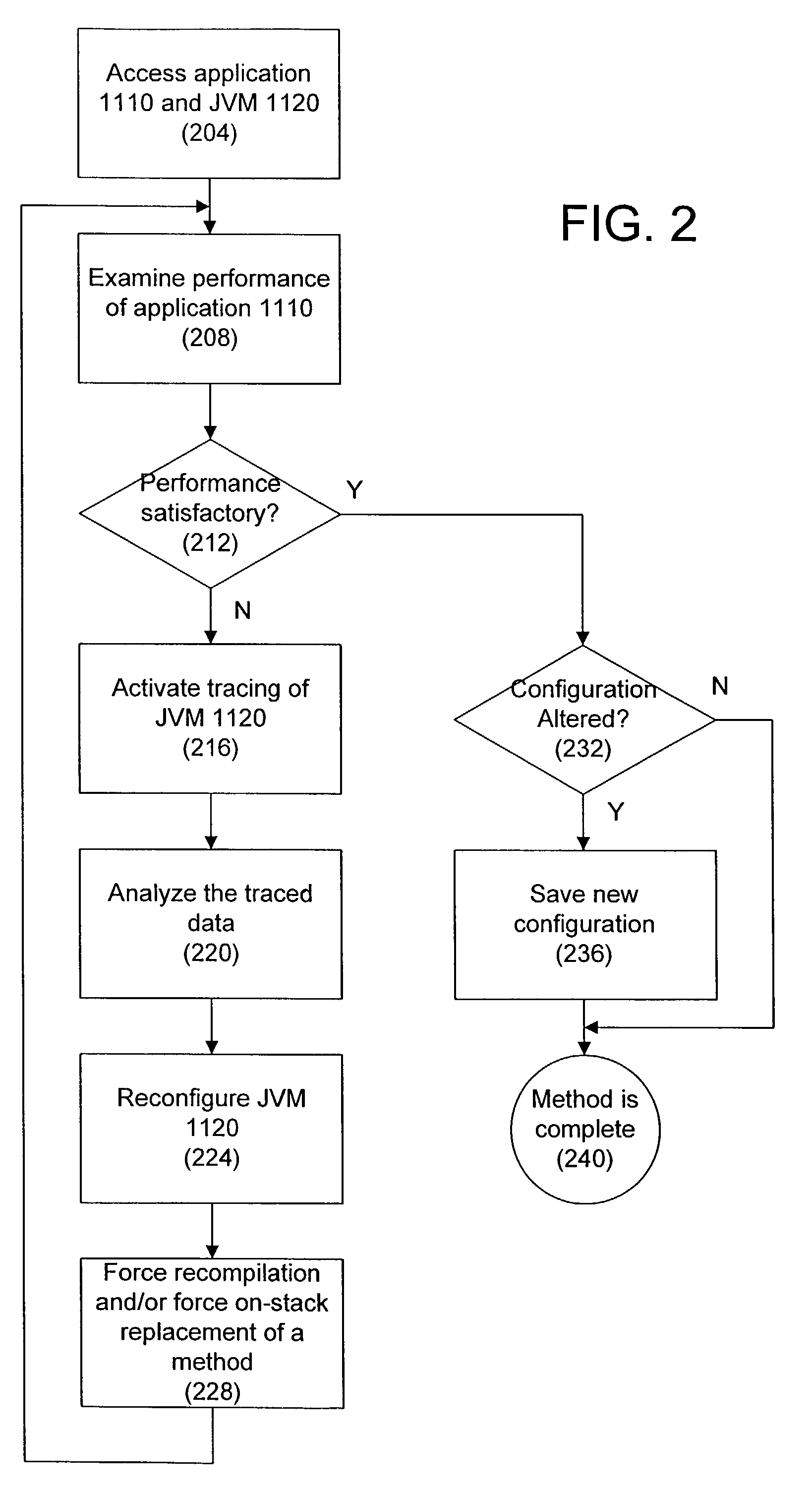

The present invention, in various embodiments, provides techniques for improving performance of programs. In one embodiment, the program is written in the Java language and runs in the Java Runtime Environment (JRE) that includes a Java Virtual Machine (JVM) having a configuration. A control panel having access to the JVM is invoked. Via the control panel, a user observes the execution of the Java program, analyzes the results of the execution, changes the configuration of the JVM, and forces re-optimization of the critical portions of the running program. By repeating the above steps of observing the program execution, analyzing the results, changing the configuration of the Java machine, and forcing re-optimization of the critical portions of the program, the user improves the program's overall performance.

Owner:HEWLETT PACKARD CO

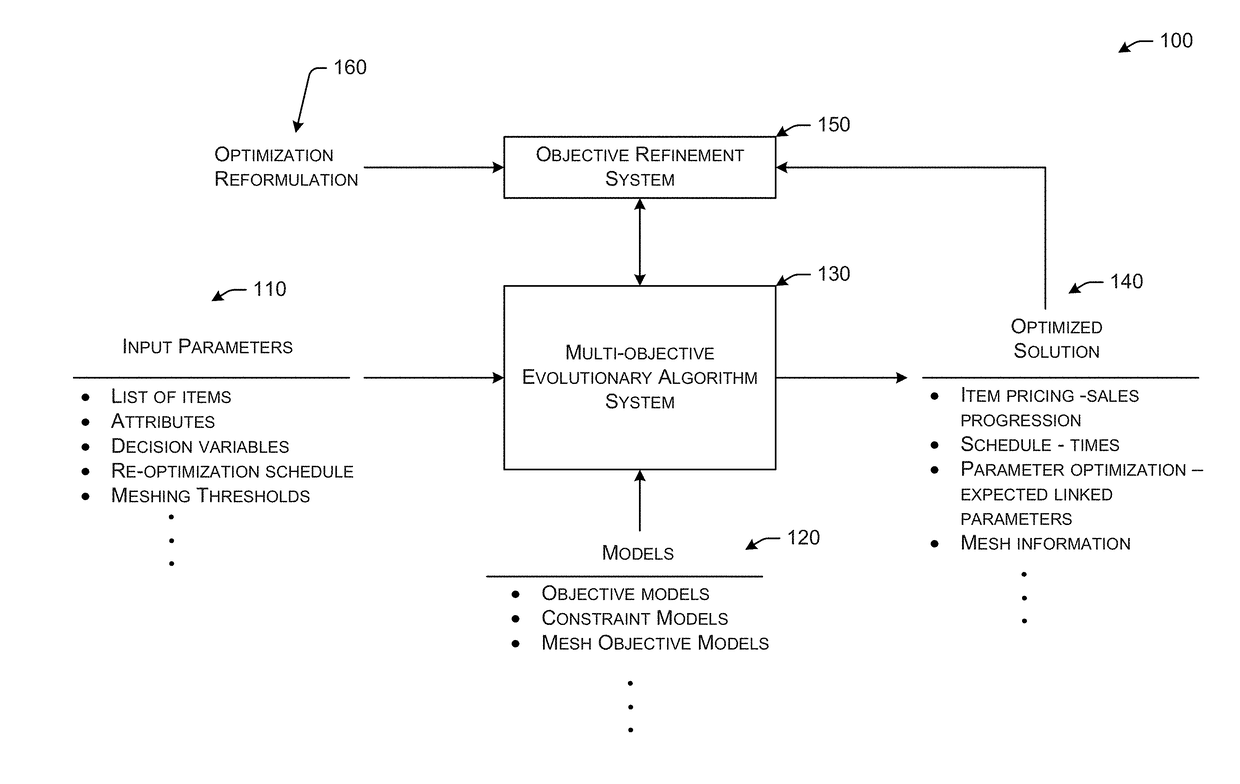

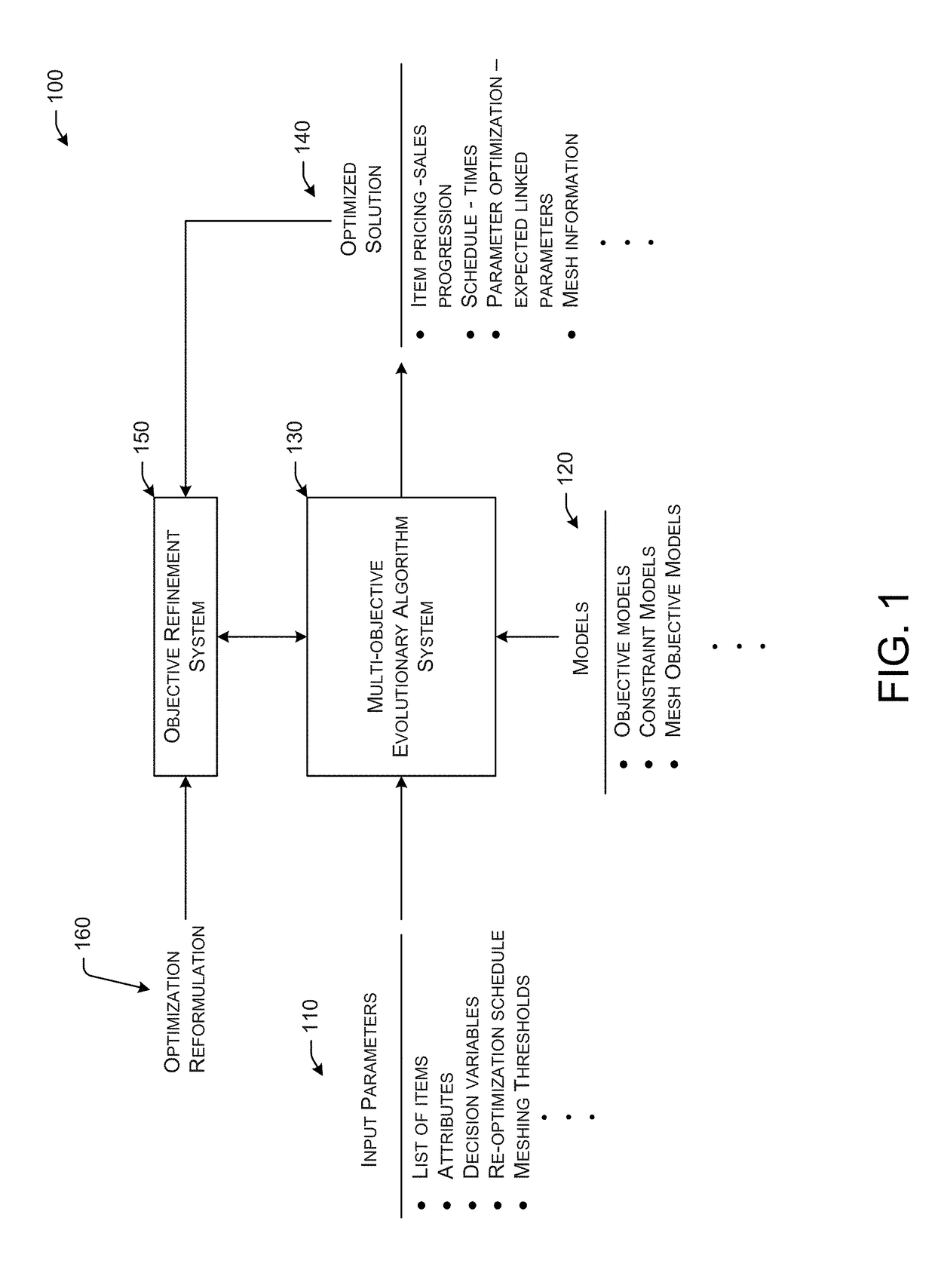

Systems and Methods for Multi-Objective Optimizations with Objective Space Mapping

Systems and methods are provided for operating to an initial optimized baseline solution to a multi-objective problem. As the initial optimized baseline solution is determined, some regions, such as local or global maxima, minima, and / or saddle points in the objective space may be mapped. The mapping may be performed by storing mesh chromosomes corresponding to some of the features (e.g., extrema, saddle points, etc.) in the objective space along with the location of those chromosomes within the objective space (e.g., objective values corresponding to each of the objectives). The mesh chromosome may be used in subsequent re-optimization problems, such as with reformulation. Although in a re-optimization the objectives, decision variables, and or objective / constraint models may change, the mesh chromosomes may still provide information and direction for more quickly and / or with reduced resources converge on a re-optimized solution.

Owner:THE AEROSPACE CORPORATION

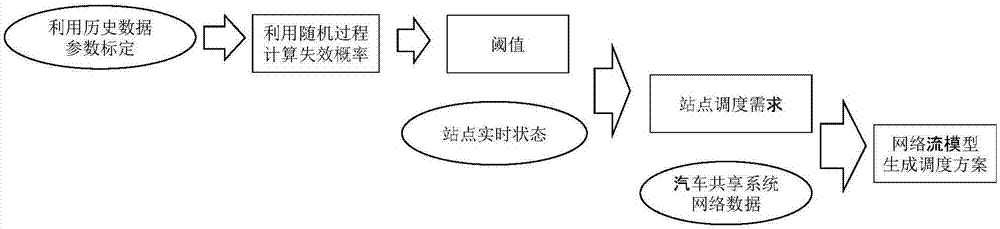

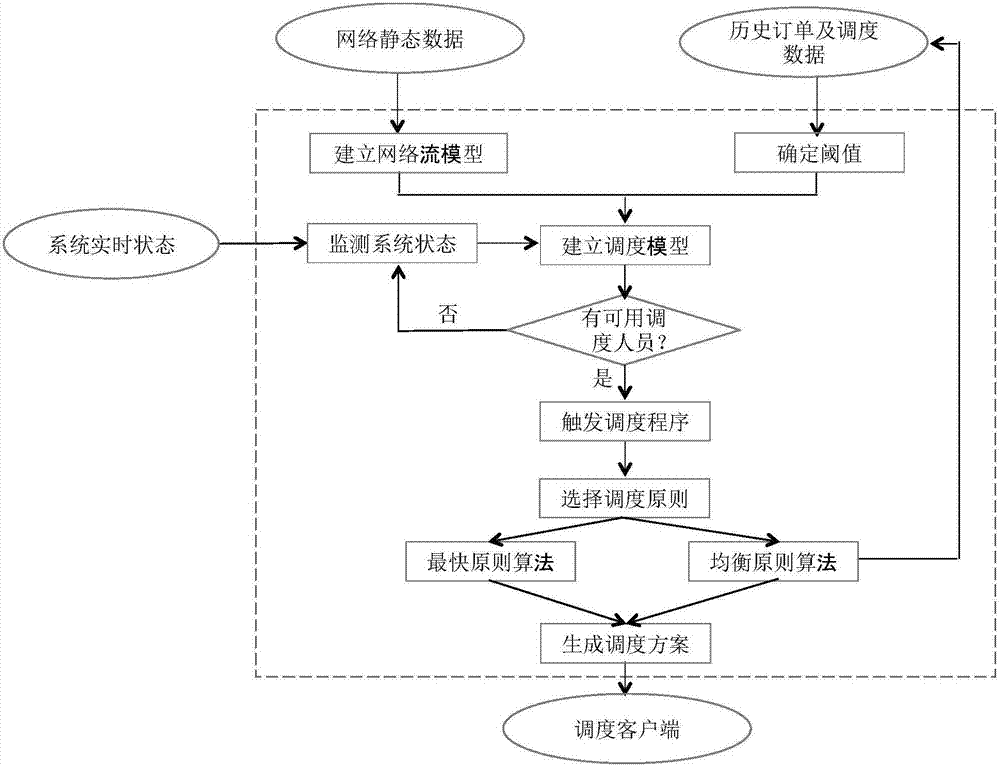

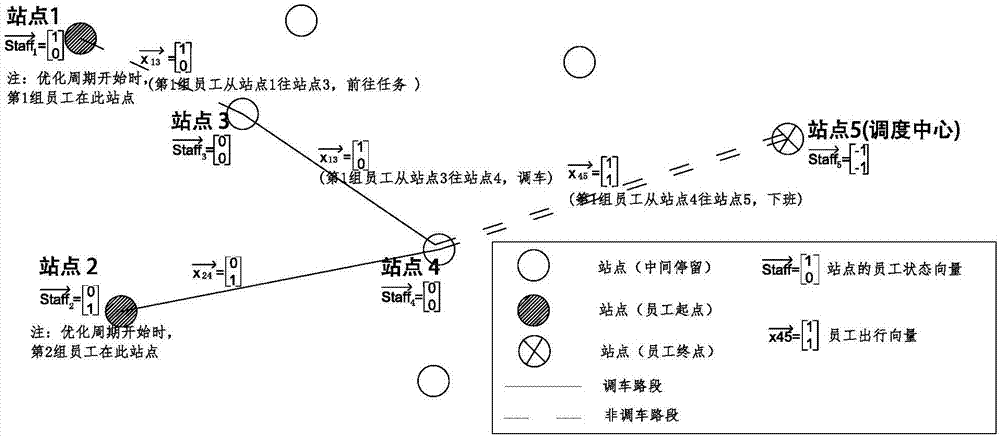

Vehicle sharing system's vehicle scheduling method

ActiveCN107239883AFew parametersEasy CalibrationInternal combustion piston enginesBuying/selling/leasing transactionsPriority settingCar sharing

Owner:TONGJI UNIV

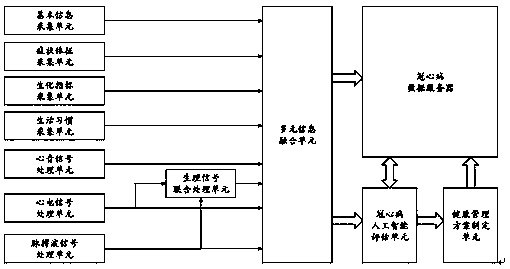

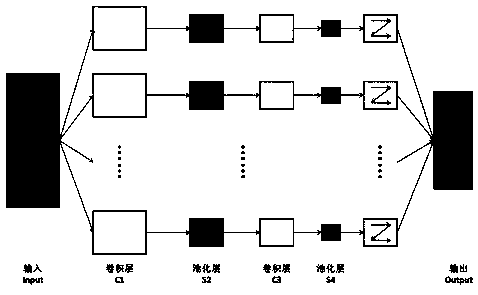

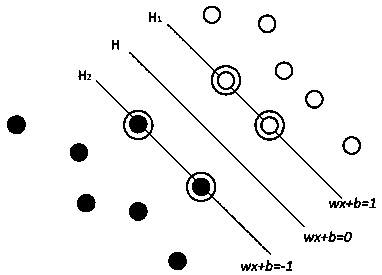

Coronary heart disease intelligent screening device on basis of machine learning methods

InactiveCN109497992AImprove the specificity indexIncreased sensitivityTherapiesHealth-index calculationEcg signalHeart sounds

The invention discloses a coronary heart disease intelligent screening device on the basis of machine learning methods. The coronary heart disease intelligent screening device comprises a basic information acquisition unit, a symptom and sign acquisition unit, a biochemical index acquisition unit, a living habit acquisition unit, an electrocardiography signal processing unit, a heart sound signalprocessing unit, a pulse wave signal processing unit, a physiological signal joint processing unit, a multi-information fusion unit, a coronary heart disease manual intelligent assessment unit, a health management scheme formulation unit and a coronary heart disease data server. The coronary heart disease intelligent screening device has the advantages that electrocardiography signals, heart soundsignals and pulse wave signals are deeply mined, specific indexes capable of improving the coronary heart disease screening accuracy are extracted, the electrocardiography signals and the pulse wavesignals are jointly synchronously analyzed, indexes capable of reflecting the coronary arteriosclerosis degrees are extracted, accordingly, coronary heart disease incidence risks can be assessed at multiple levels and multiple angles, and the coronary heart disease screening sensitivity can be improved; the coronary heart disease intelligent screening device has additional self-learning and re-optimization functions, and accordingly the coronary heart disease screening accuracy can be constantly improved.

Owner:济南汇医融工科技有限公司

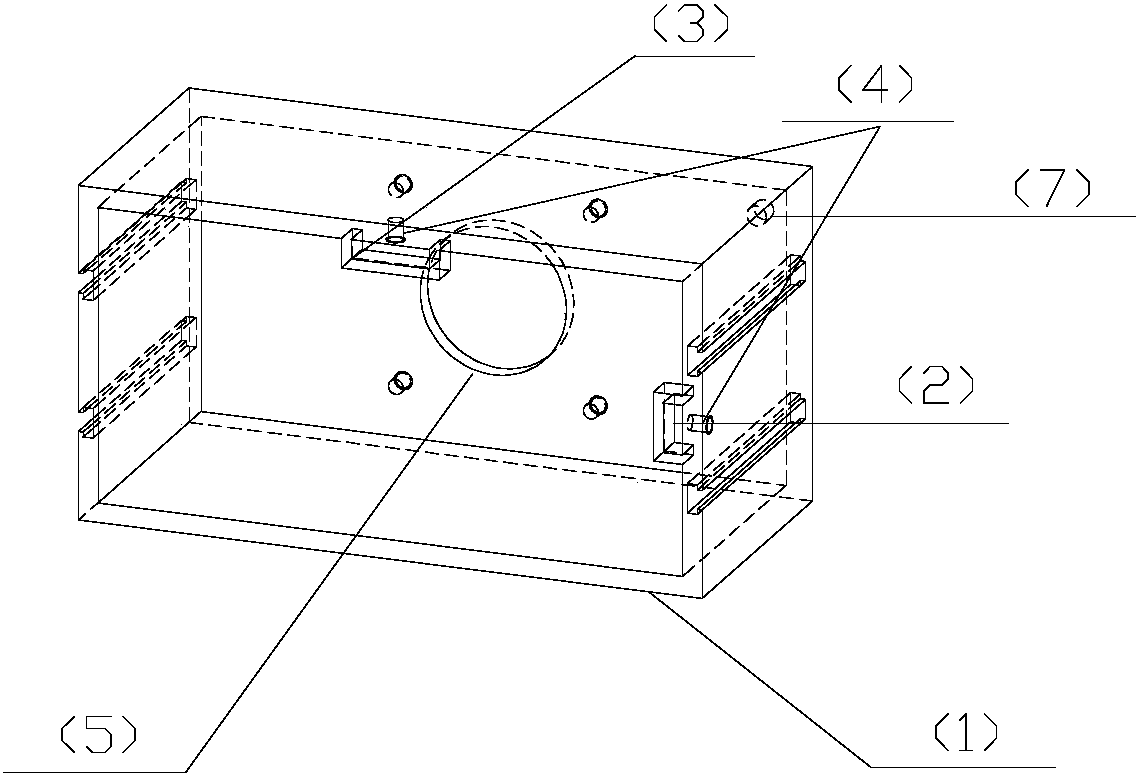

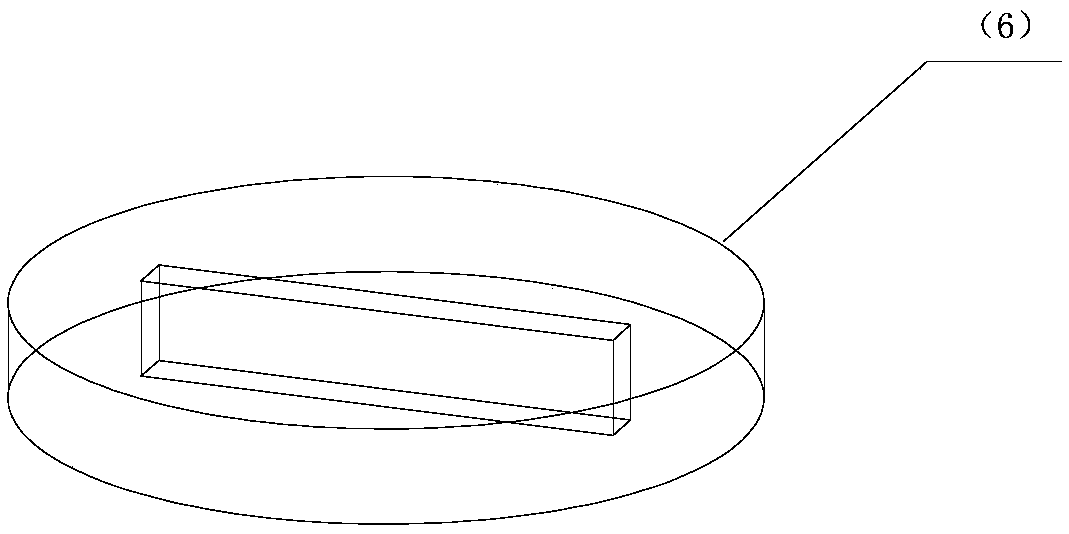

Portable metal material tensile stress electrochemical corrosion device

ActiveCN108593537AReal-time observation of fractureEasy to use and loadWeather/light/corrosion resistanceMetallic materialsLiquid tank

The invention discloses a metal material tensile stress electrochemical corrosion liquid tank device and a method thereof. A corrosion test tank is a coverless transparent cuboid-shaped acrylic expandable box body, and a corrosion test tank is a coverless transparent cuboid-shaped acrylic expandable box body, and is connected with the top of a clamp by screws. Samples with different gauge lengthscan be immersed by adjusting the height of a liquid tank through the sliding between a sleeve shell and the liquid tank, the bottom end of the liquid tank is provided with a hole groove, and a fittingis cooperated to carry out stress corrosion experiments on samples with different shapes. In addition, every box body is provided with a corrosion liquid injection hole and an output hole to achievedynamic change of the corrosive environment. The novel corrosion liquid tank device and the method thereof have the advantages of realization of the in-situ electrochemical and tensile property detection of tensile samples with different shapes and different sizes under stress, erosion and corrosion coupled action, convenience in disassembling and assembling, easiness in cleaning, quickness and accurateness in providing a test result, elimination of the limitation of the sizes of the samples, reduction of the process re-optimization cost, and increase of the production efficiency.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com