Patents

Literature

112results about "Measurement devices for engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

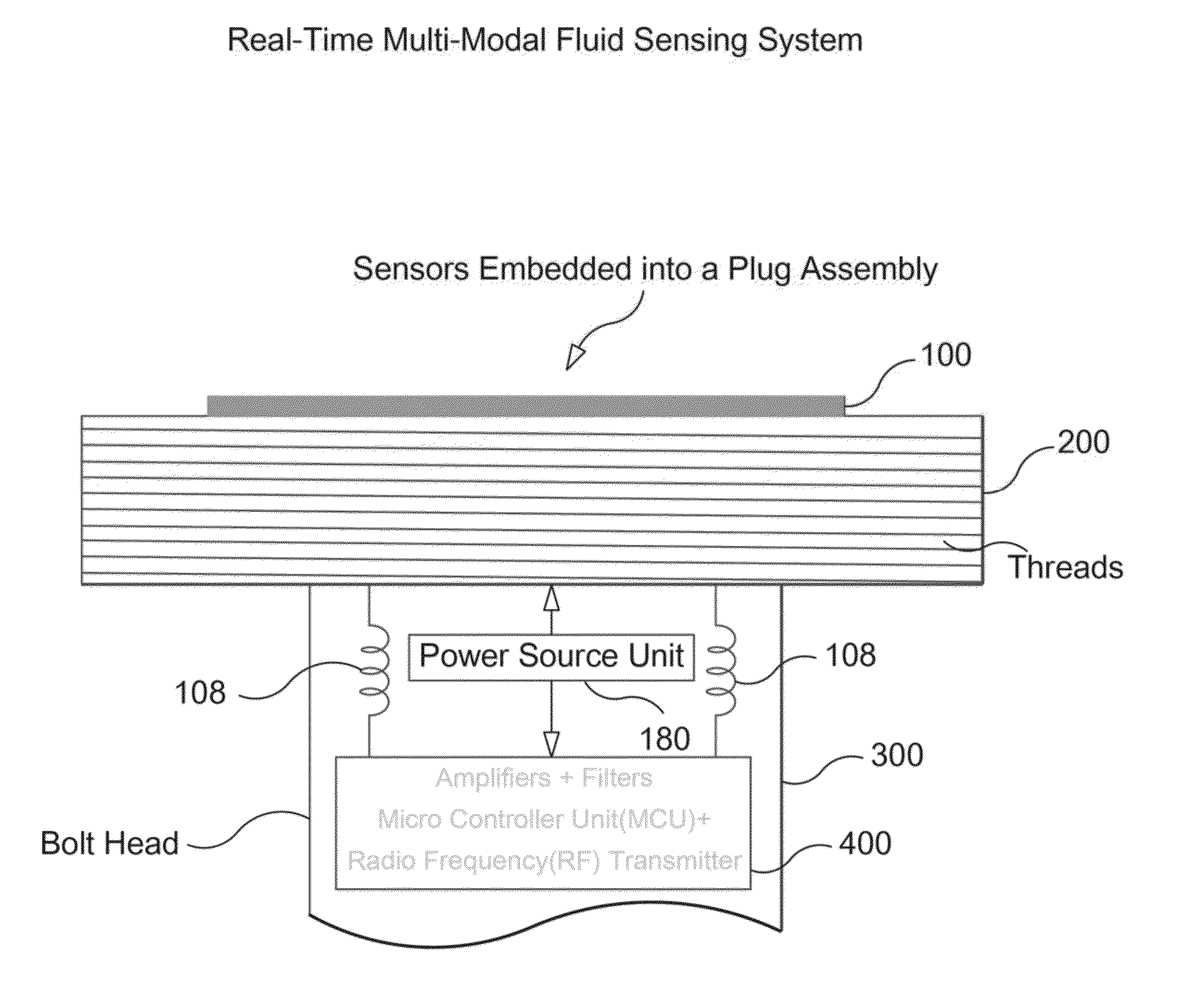

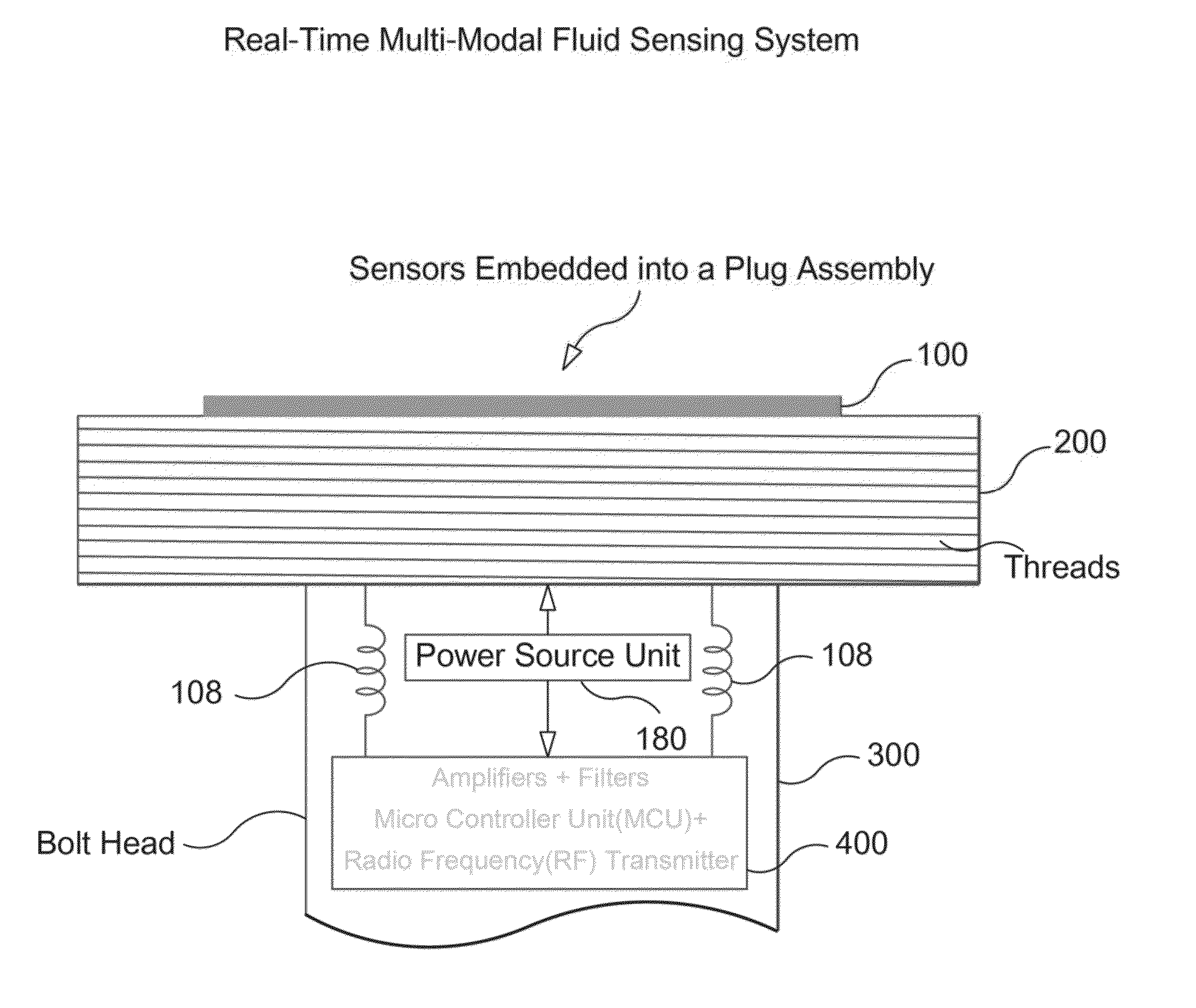

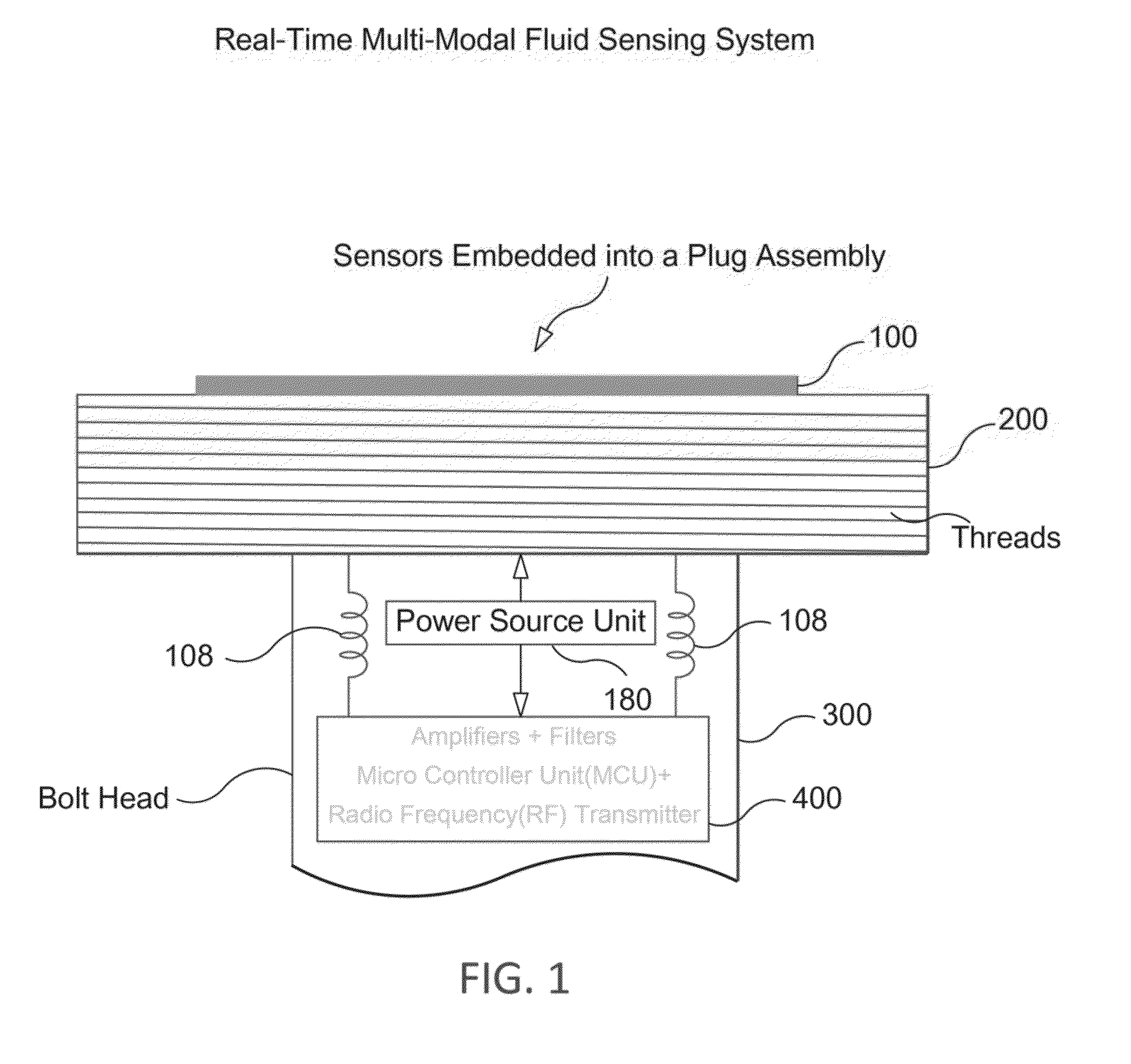

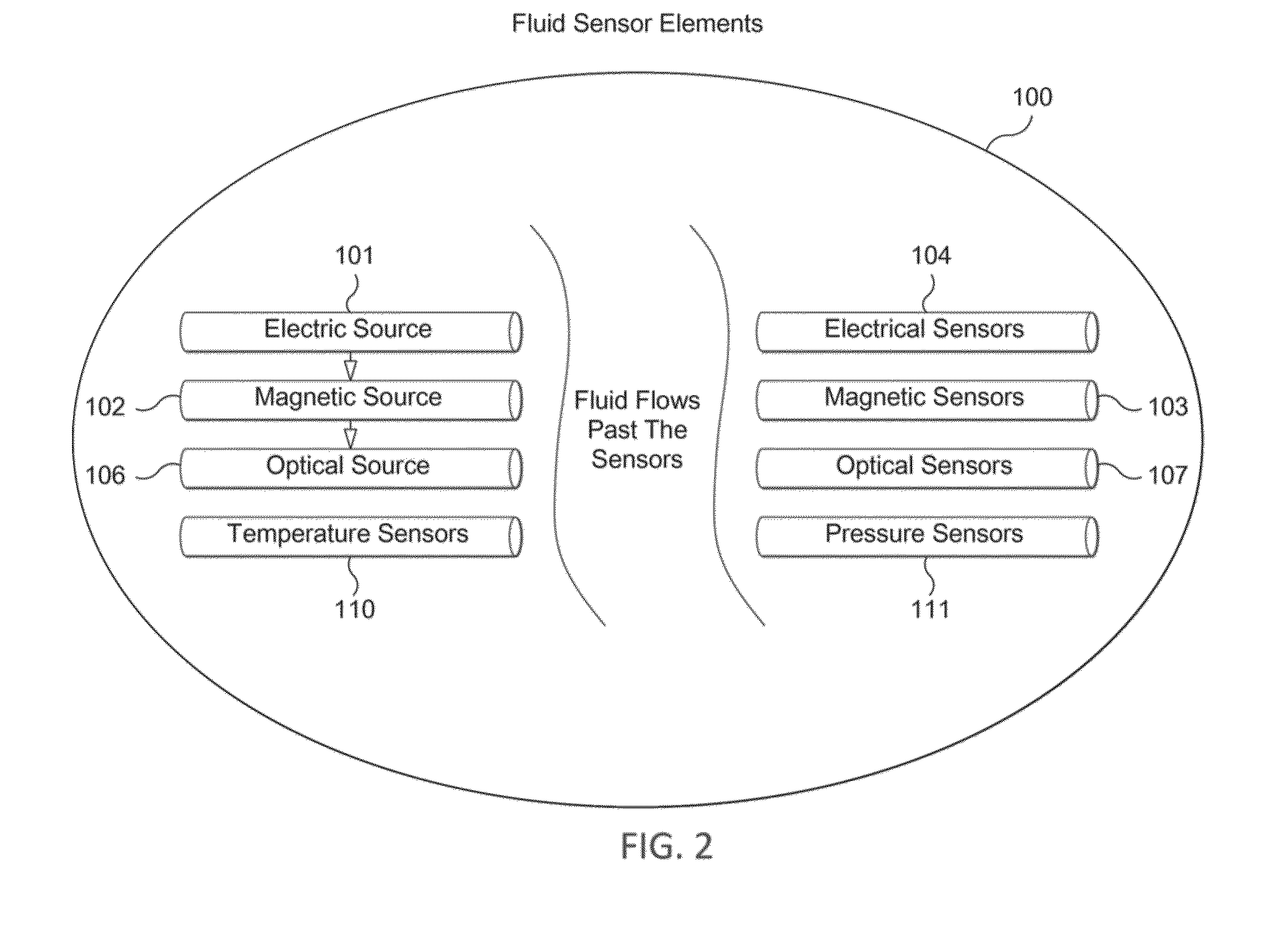

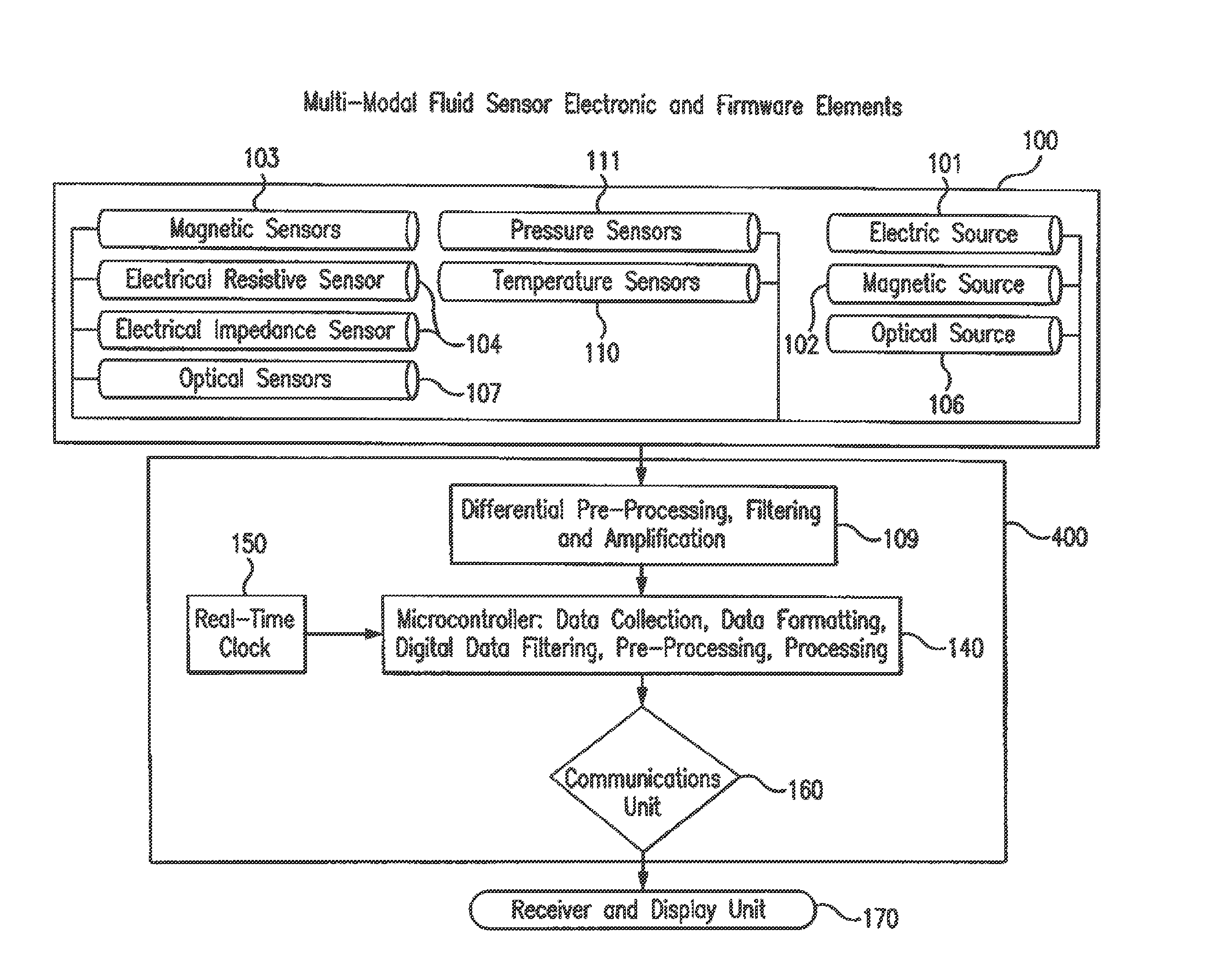

Multi-modal fluid condition sensor platform and system thereof

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. The mass and level of the fluid may also be monitored on an on-going basis. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

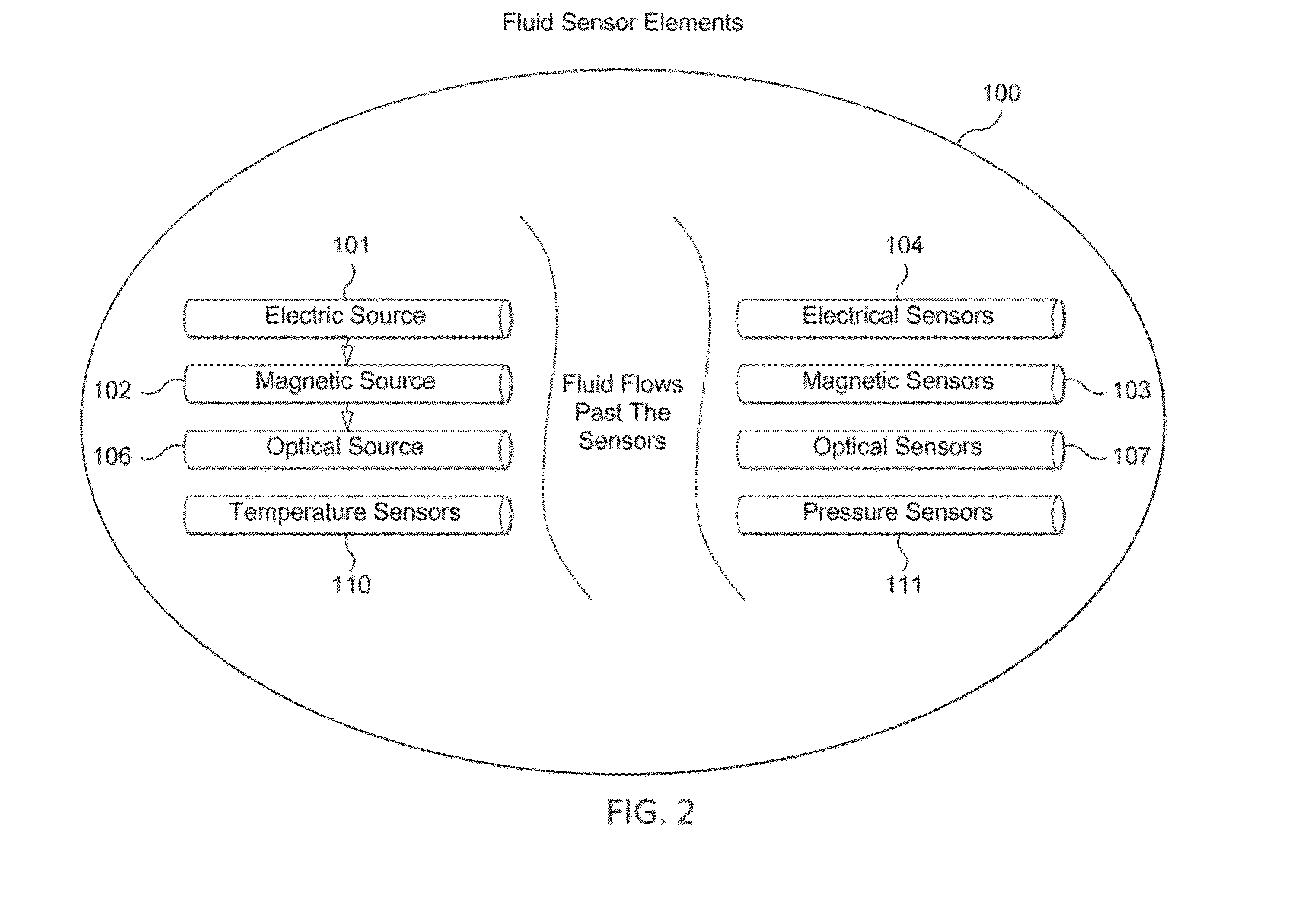

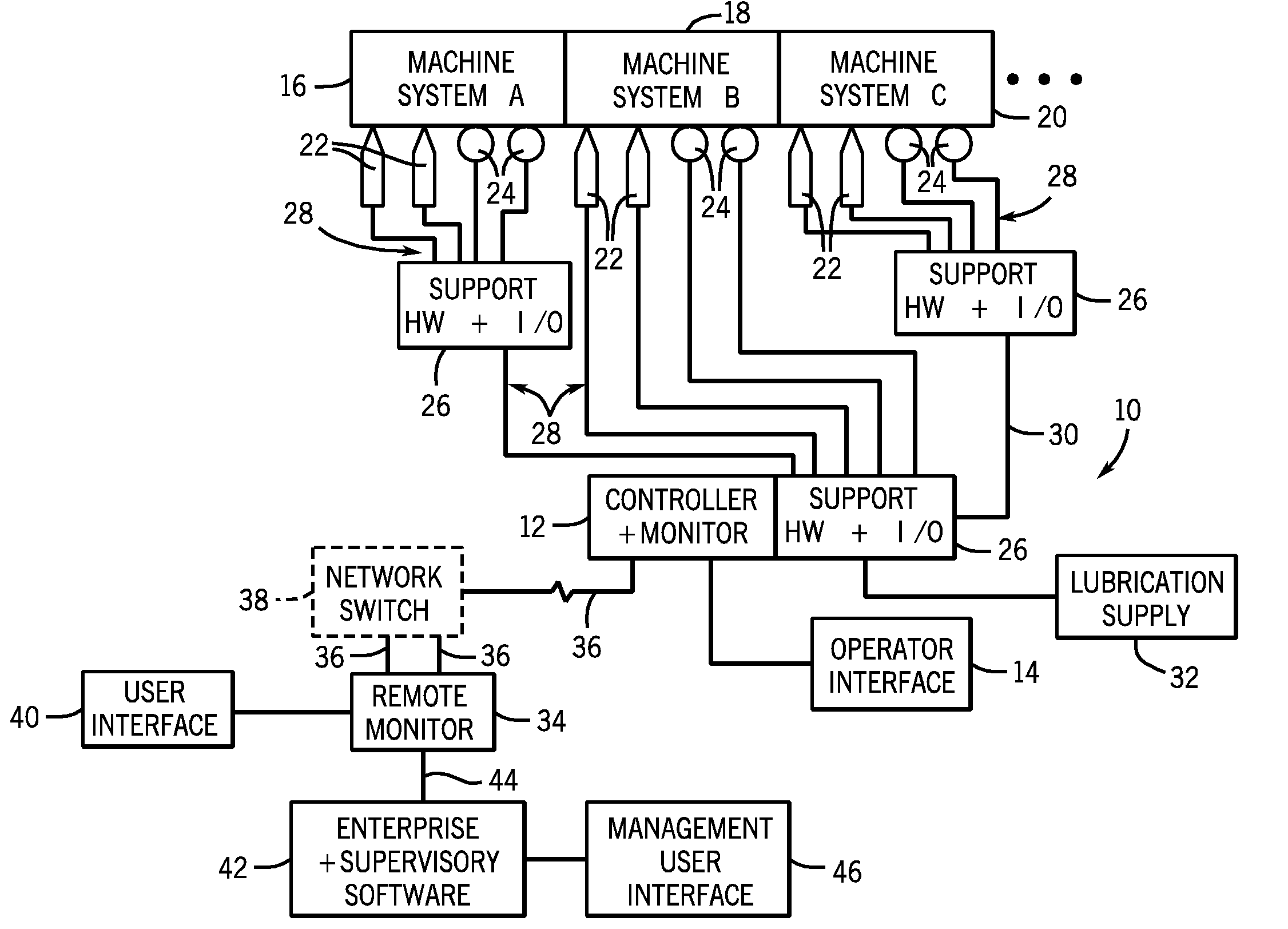

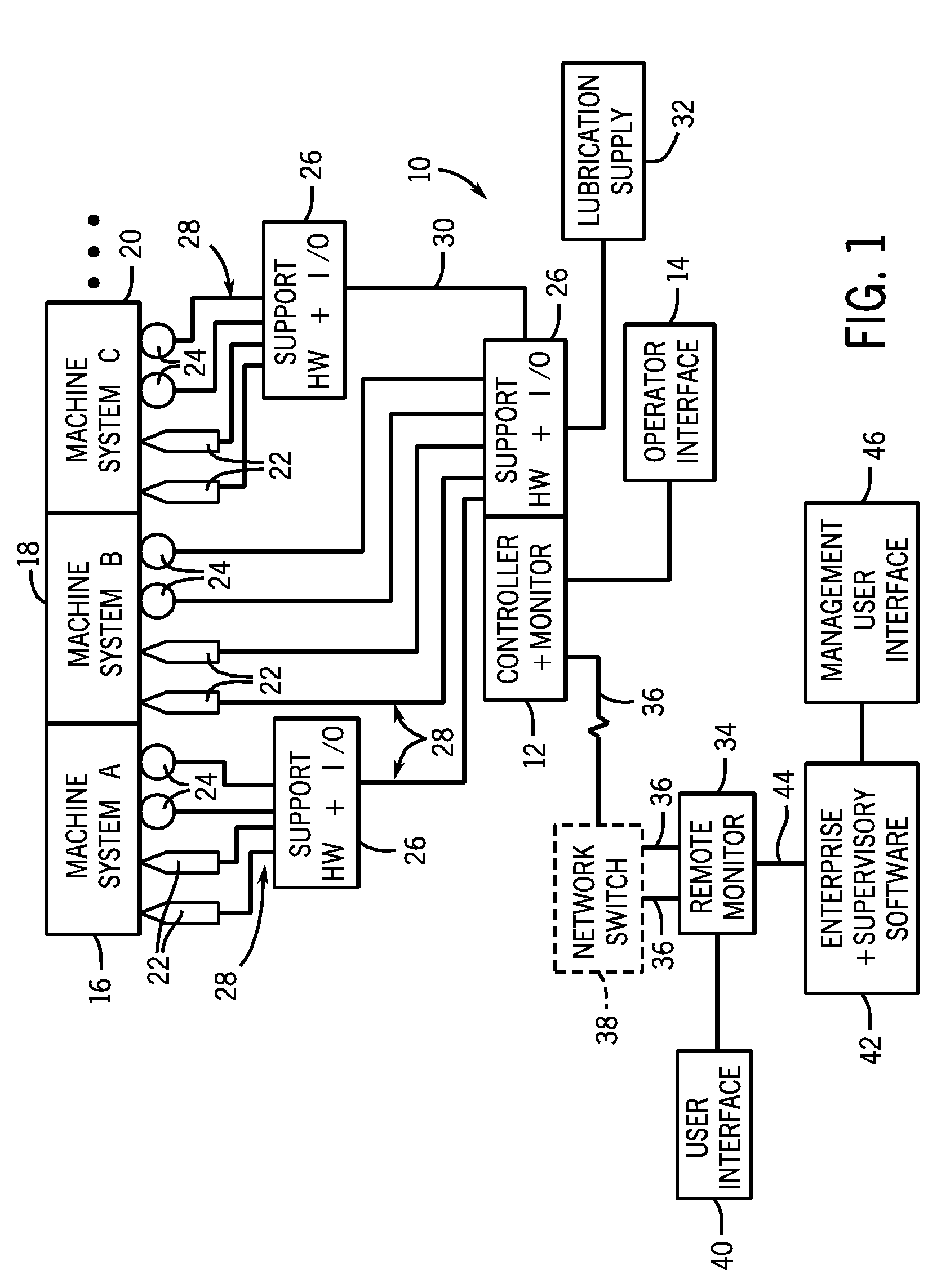

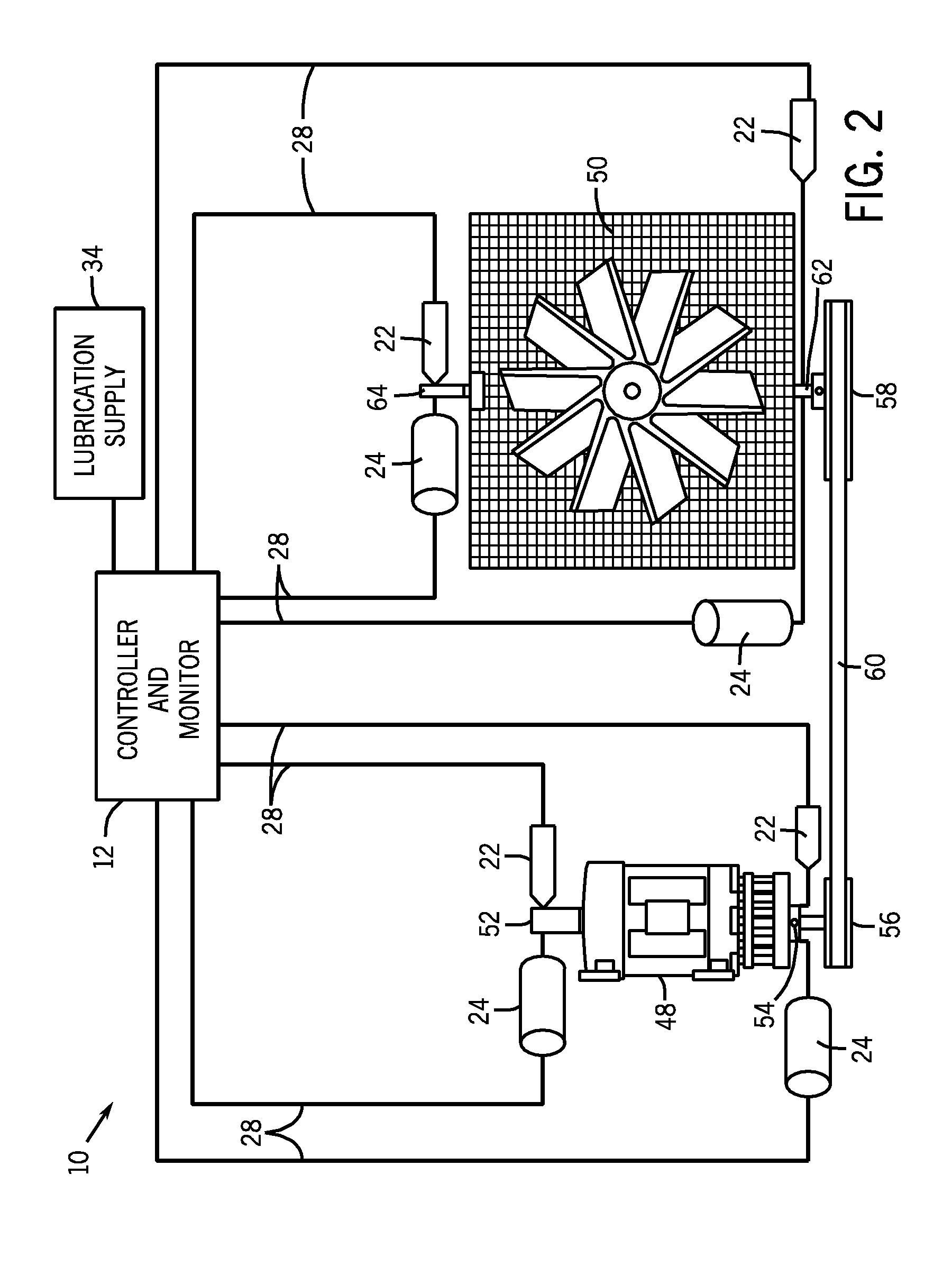

Machine conditioning monitoring closed loop lubrication system and method

ActiveUS20100147627A1Improve machine lifeReduce maintenanceVibration measurement in solidsProportioning devicesAccelerometerClosed loop

In one embodiment, the disclosed method for lubricating a machine bearing system includes monitoring a bearing system using a vibration sensor, such as an accelerometer, receiving a signal from the vibration sensor, calculating a parameter based on the signal; and adding a lubricant to the bearing system based upon the parameter. In another embodiment, a system may include a vibration sensor, a monitor configured to receive a signal from the vibration sensor and calculate a spike energy value, and a lubrication device configured to add a lubricant to a bearing system based on the spike energy value. The system and method help reduce maintenance and repair costs, while prolonging the life of the machine system components being monitored.

Owner:ROCKWELL AUTOMATION TECH

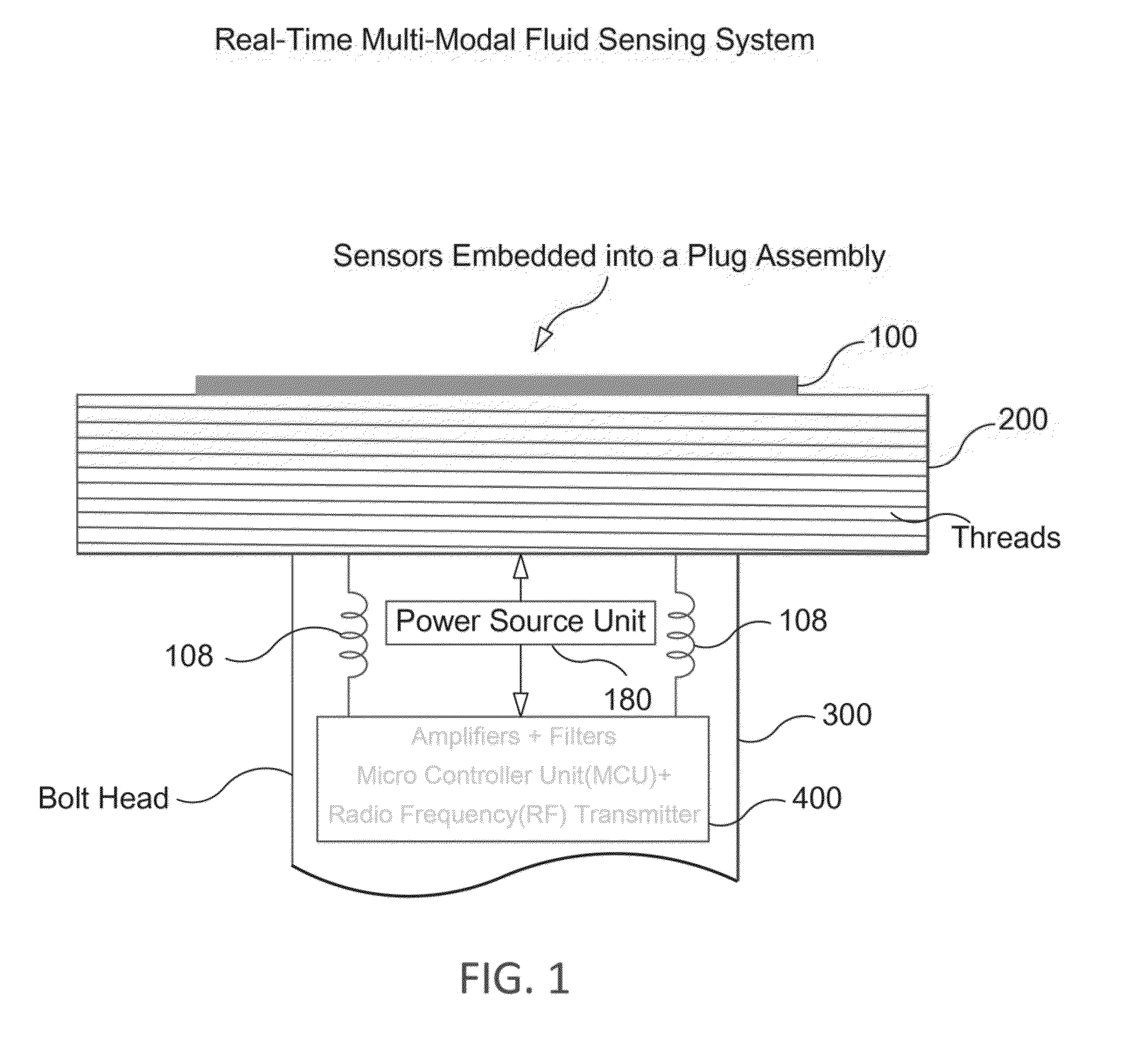

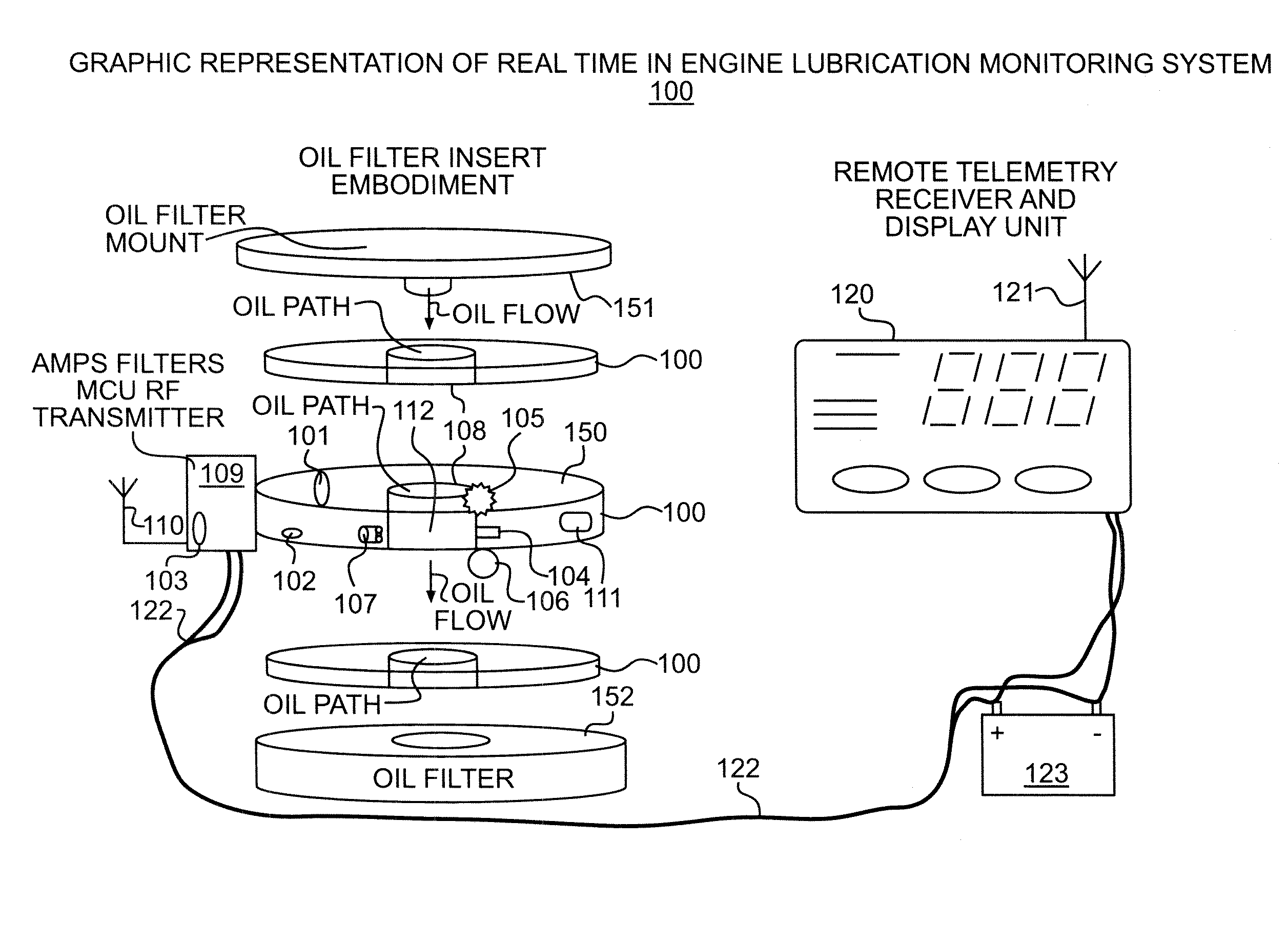

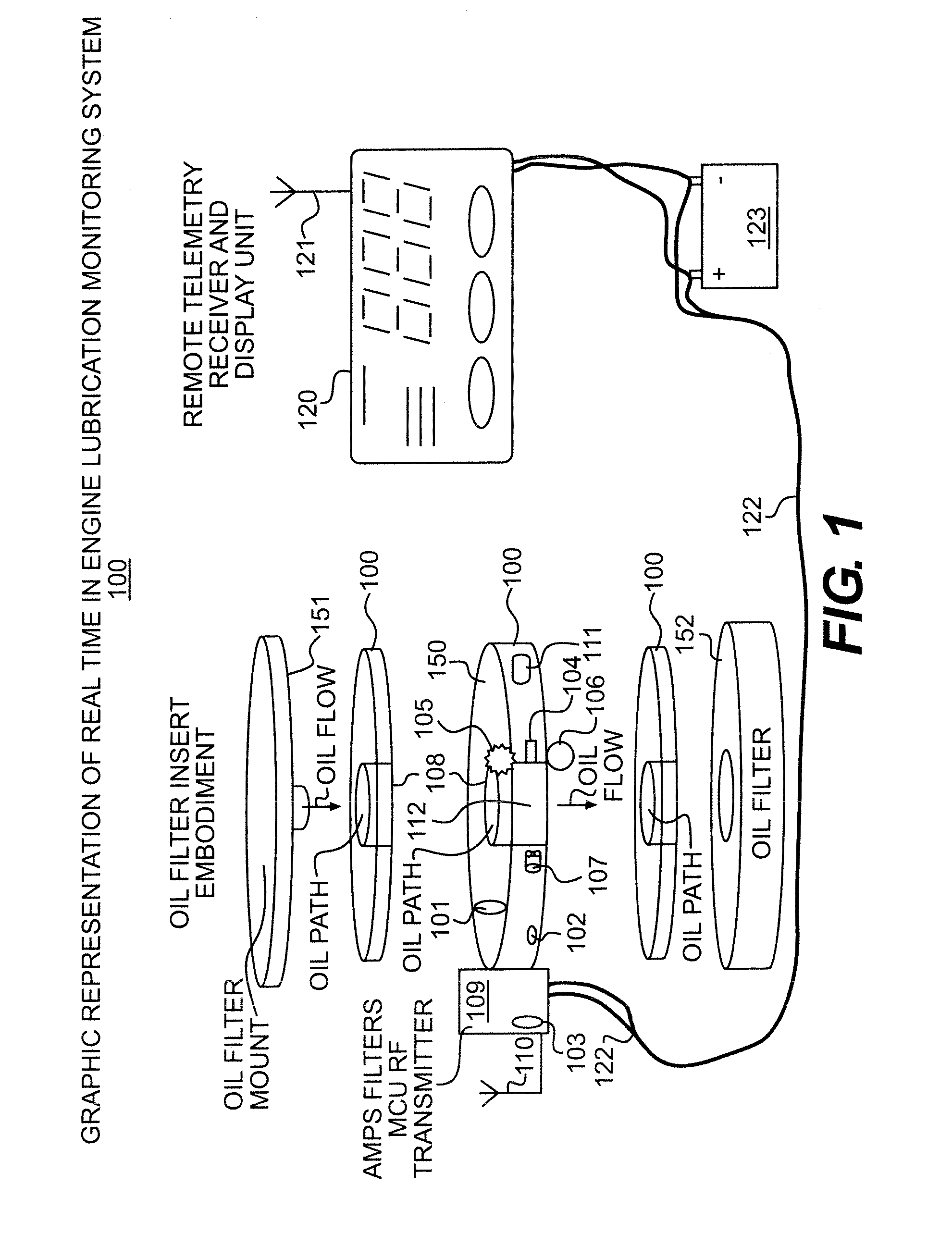

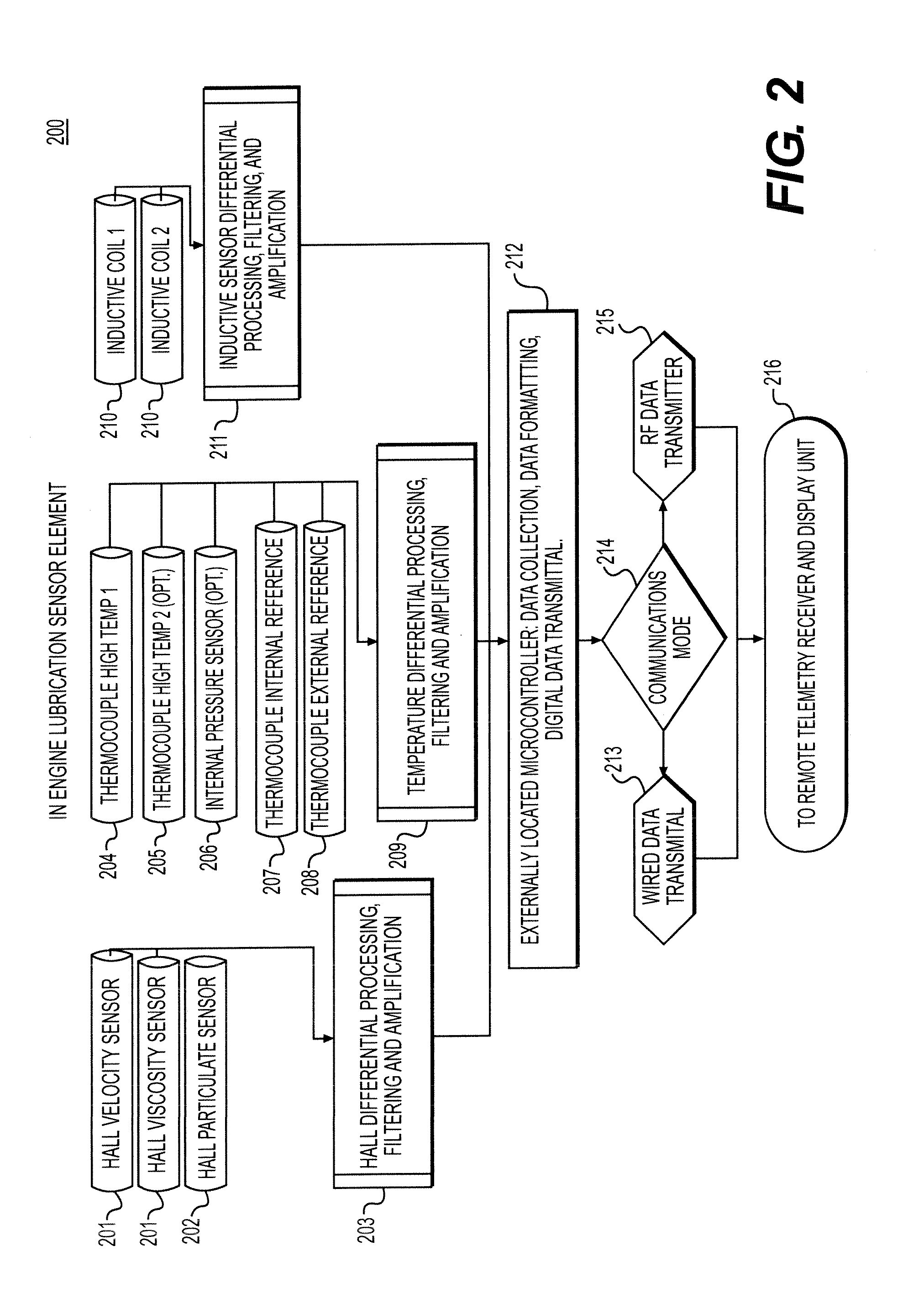

Hall Effect-Based Real-Time Lubrication Monitoring System Modes of Operation and Use Thereof

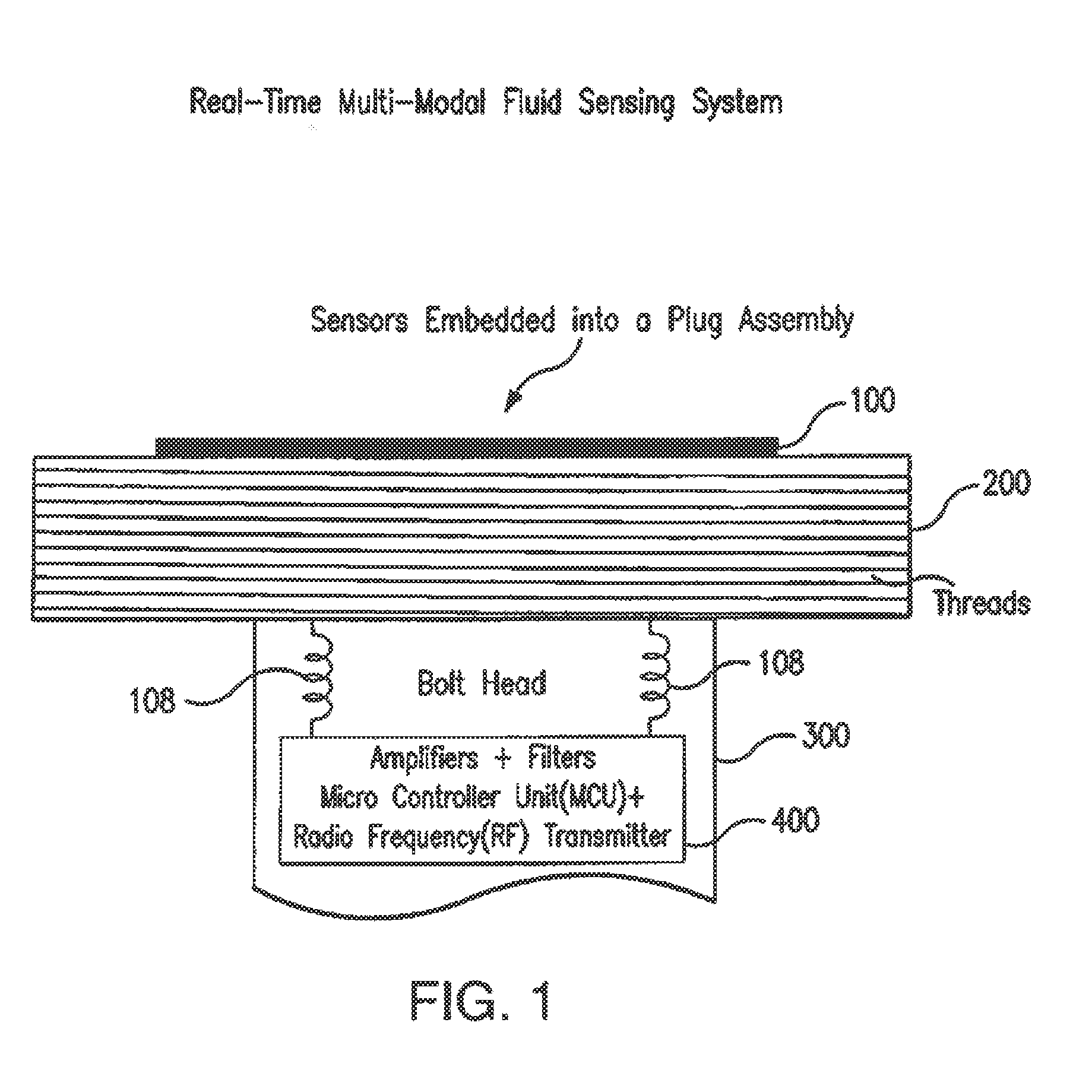

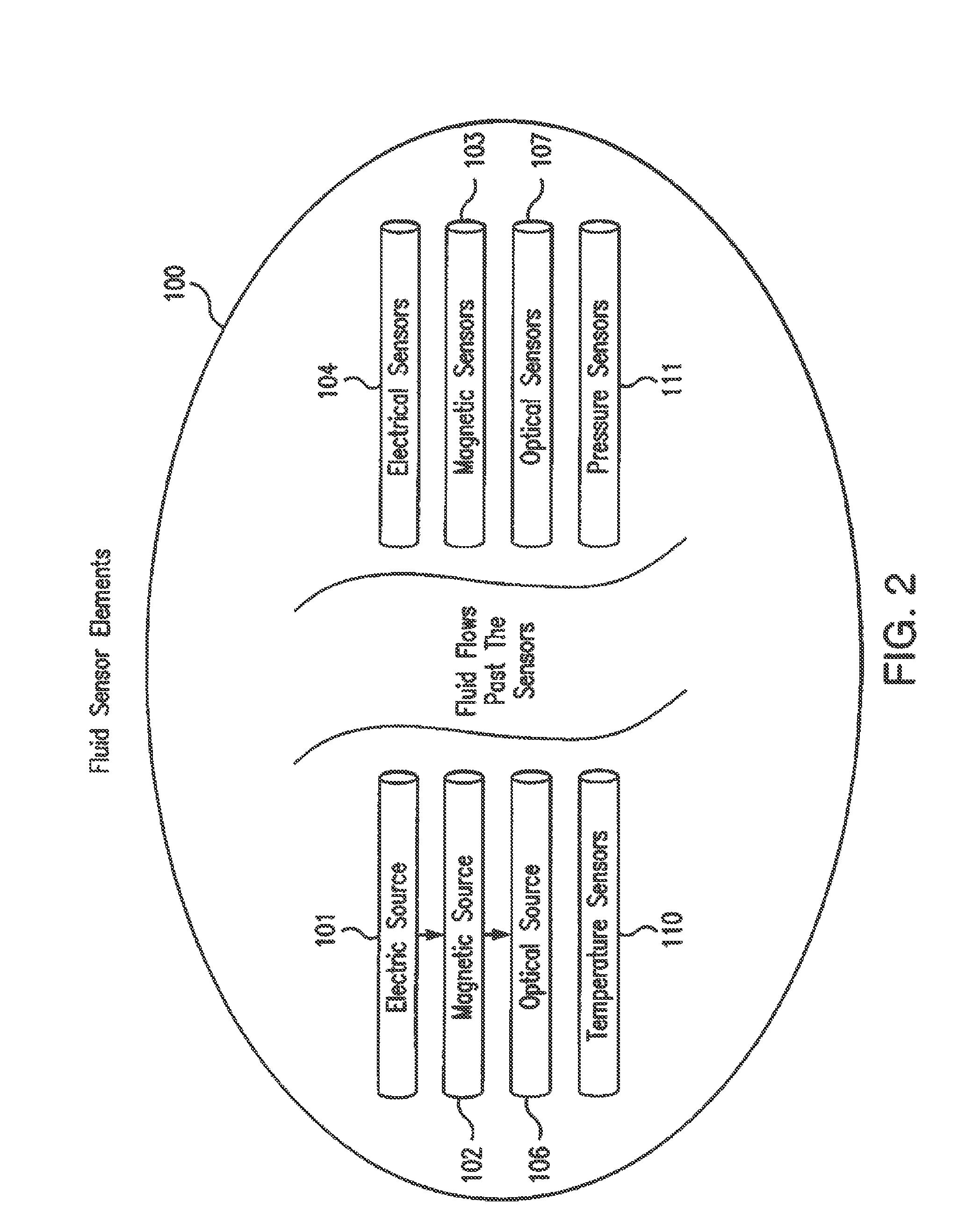

InactiveUS20100126251A1Flow propertiesVolume/mass flow measurementDigital signal processingMicrocontroller

The invention relates to a system for real-time monitoring of motile lubricants within the presently common reciprocating engine. A sensor array is fully submerged (or partially submerged) within the lubricant system fluid, for example, oil. The fluid property monitoring is accomplished by multiple sensors acting in unison to provide data to a remote processing and display portion of the system. The system allows for the unified data acquisition and real-time comparison by providing both a physical sensor unit with embedded multiple sensors of multiple types as well as multiple DSP (Digital Signal Processing) or microcontroller modules acting in parallel to provide best-fit results for purposes of real-time monitoring high-temperature motile lubricants for property degradation (namely viscosity and foreign particulate detection) and particulate accumulation.

Owner:MICROMEM TECH

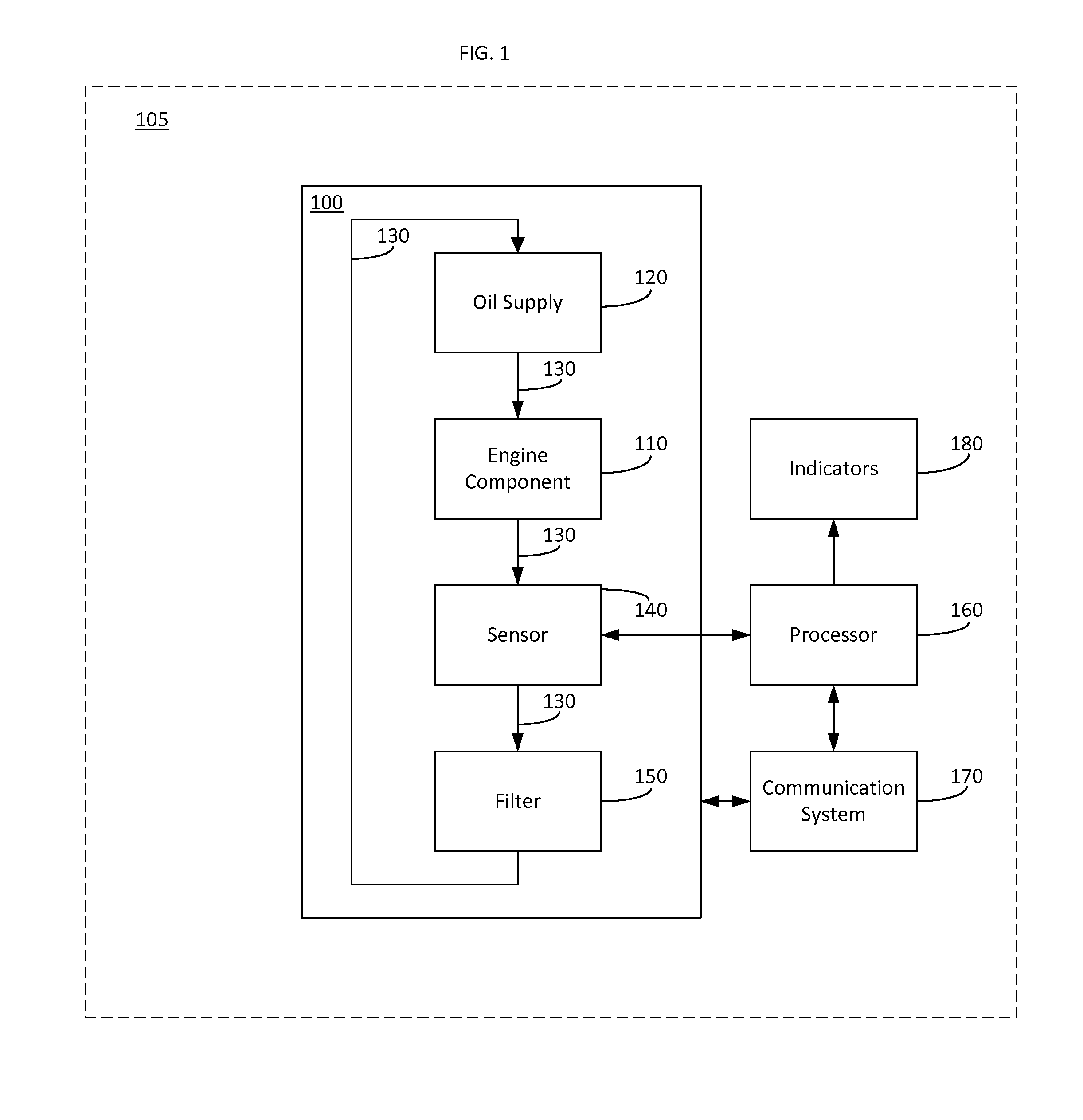

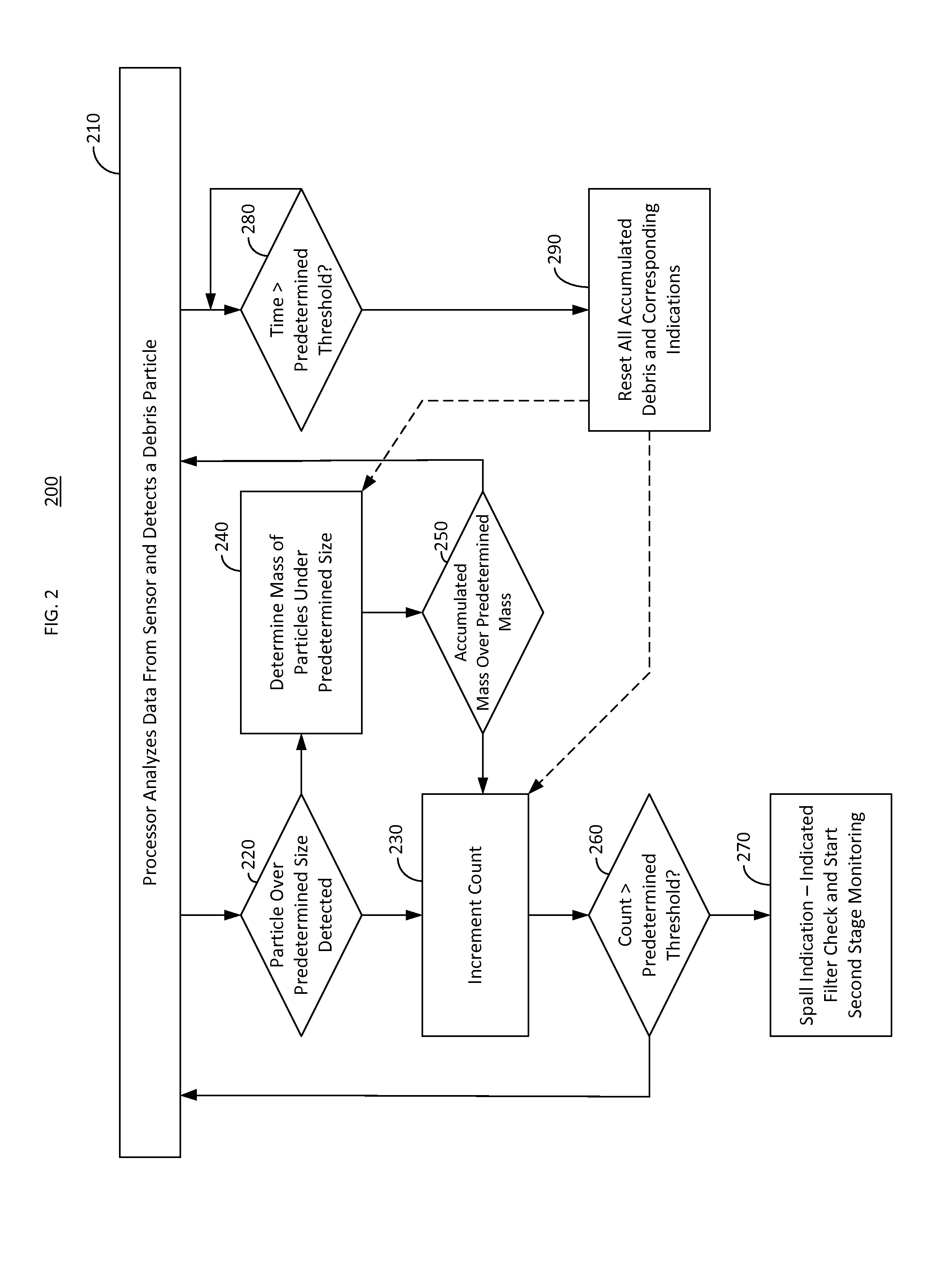

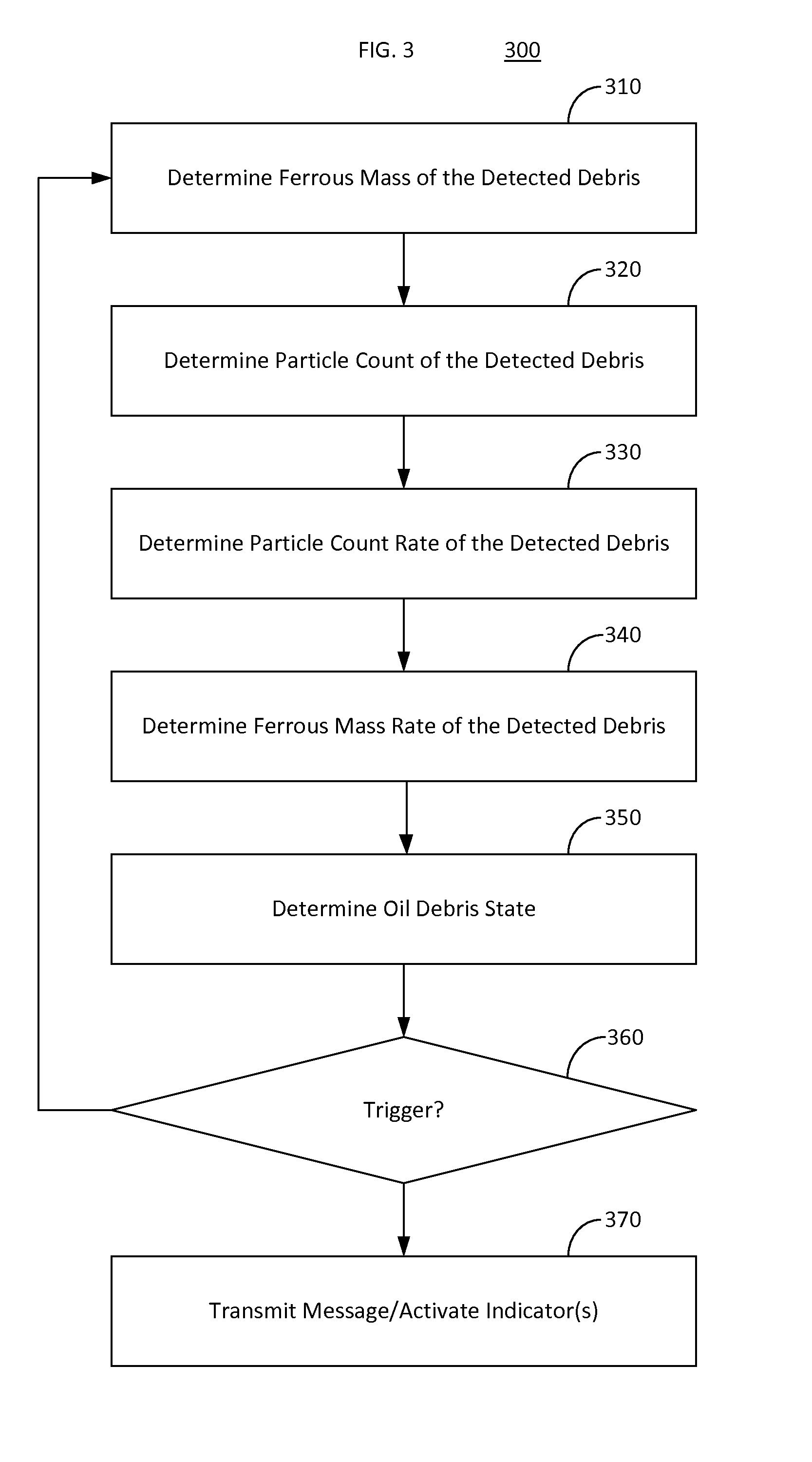

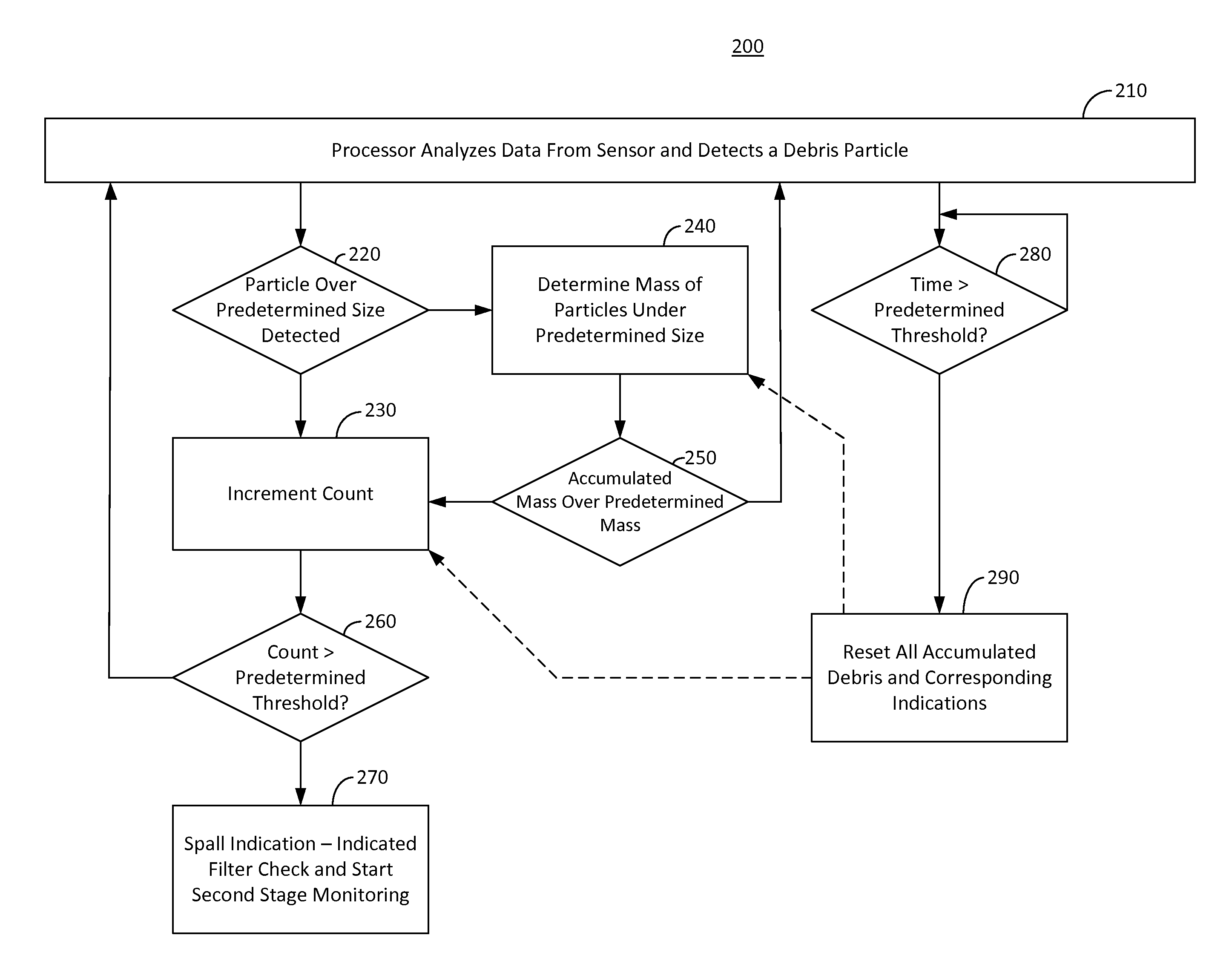

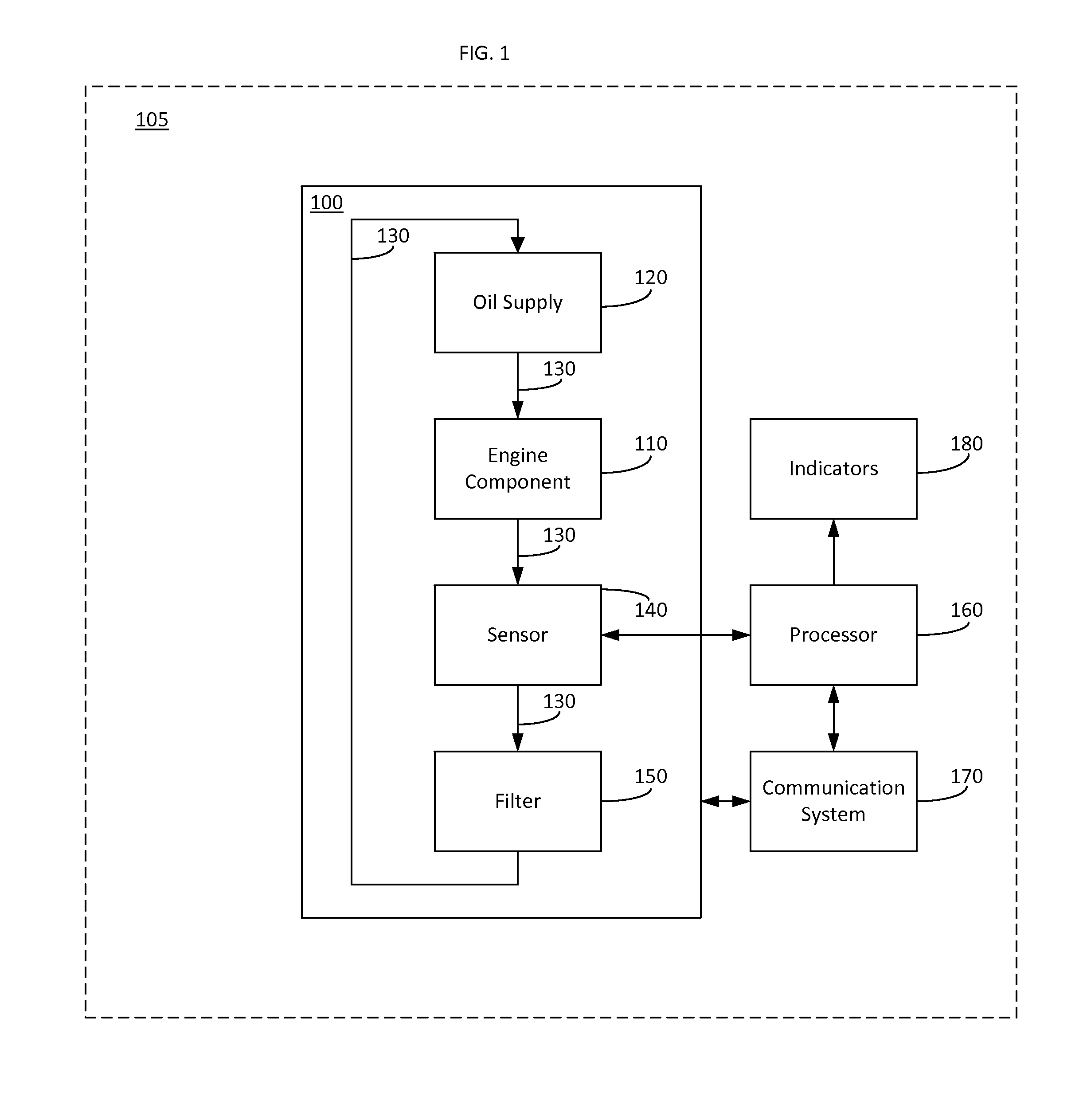

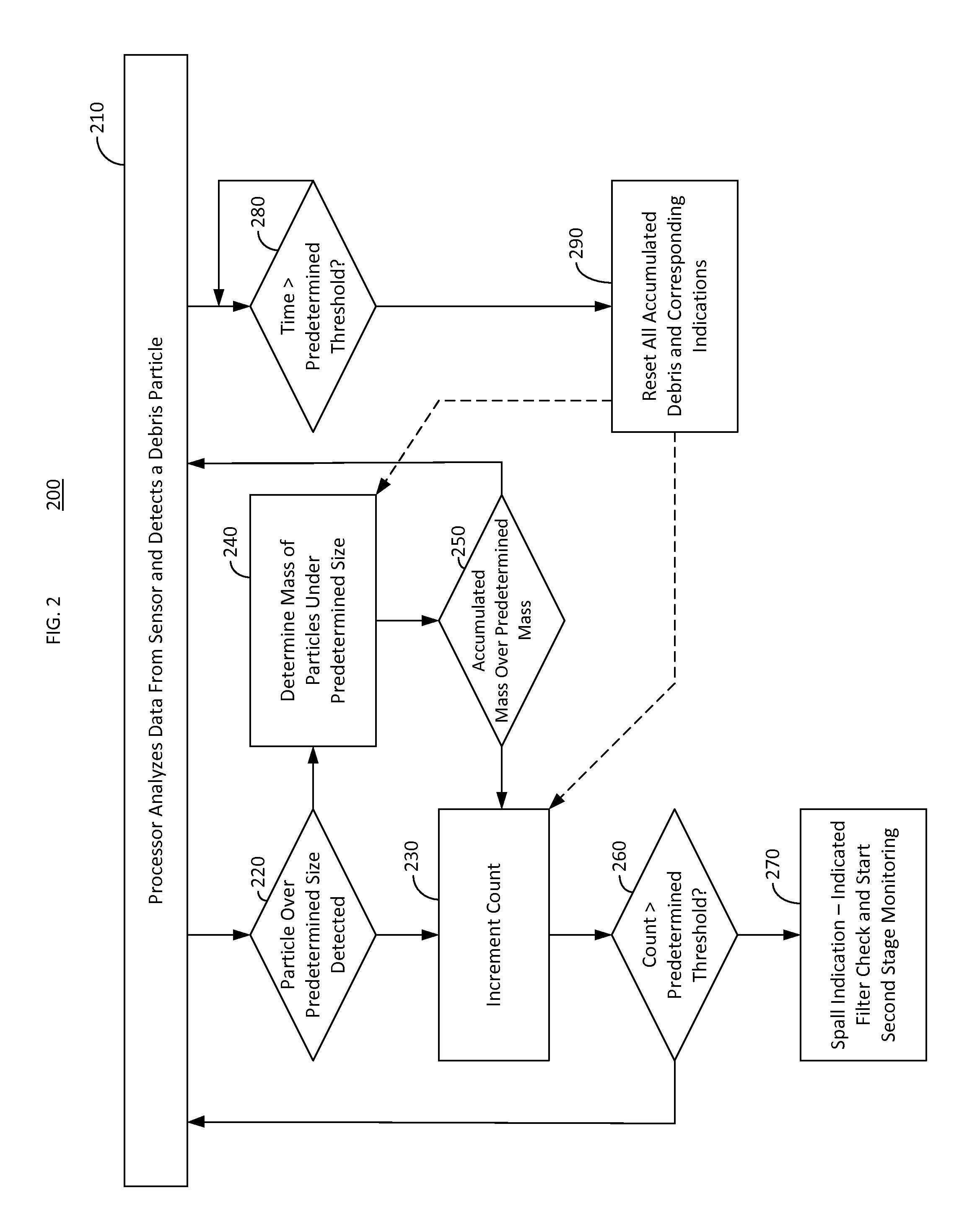

System and method for detecting spall initiation and defining end of life in engine components

ActiveUS20130332045A1Reduce downtimeImprove trustAnalogue computers for vehiclesLubrication elementsCommunications systemEngineering

A system and method are provided for detecting a spall in an engine. The vehicle, for example, may include, but is not limited to an engine, an oil debris sensor coupled to the engine, a communications system, and a processor communicatively coupled to the oil debris sensor and the communications system. The processor may be configured to increment a counter when the oil debris sensor detects a particle over a predetermined size, increment the counter when a mass of a plurality of particles under the predetermined size exceeds a predetermined mass threshold, transmit, via the communications system, a first message when the counter exceeds a predetermined counter threshold, and reset the counter after predetermined amount of time.

Owner:HONEYWELL INT INC

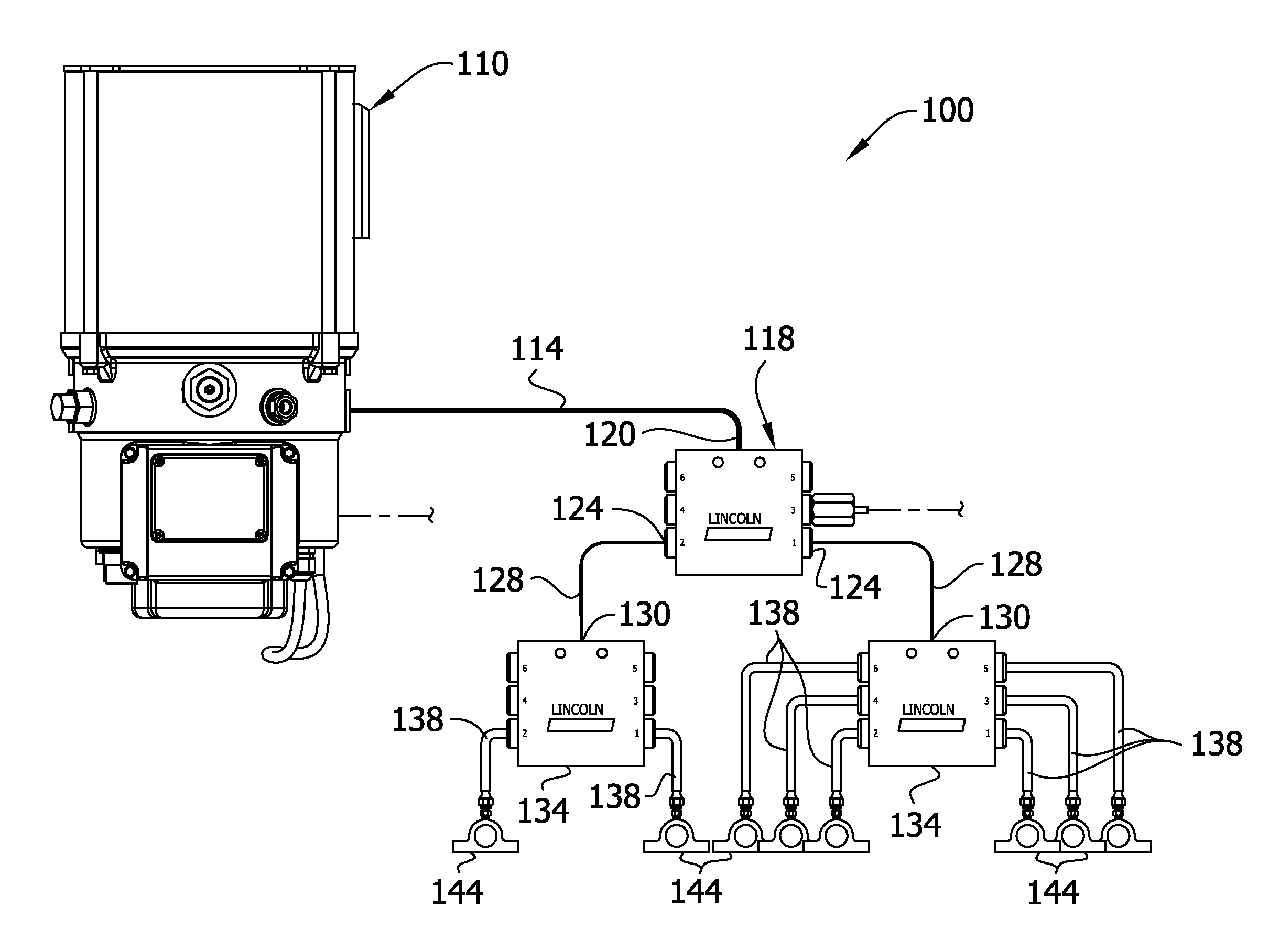

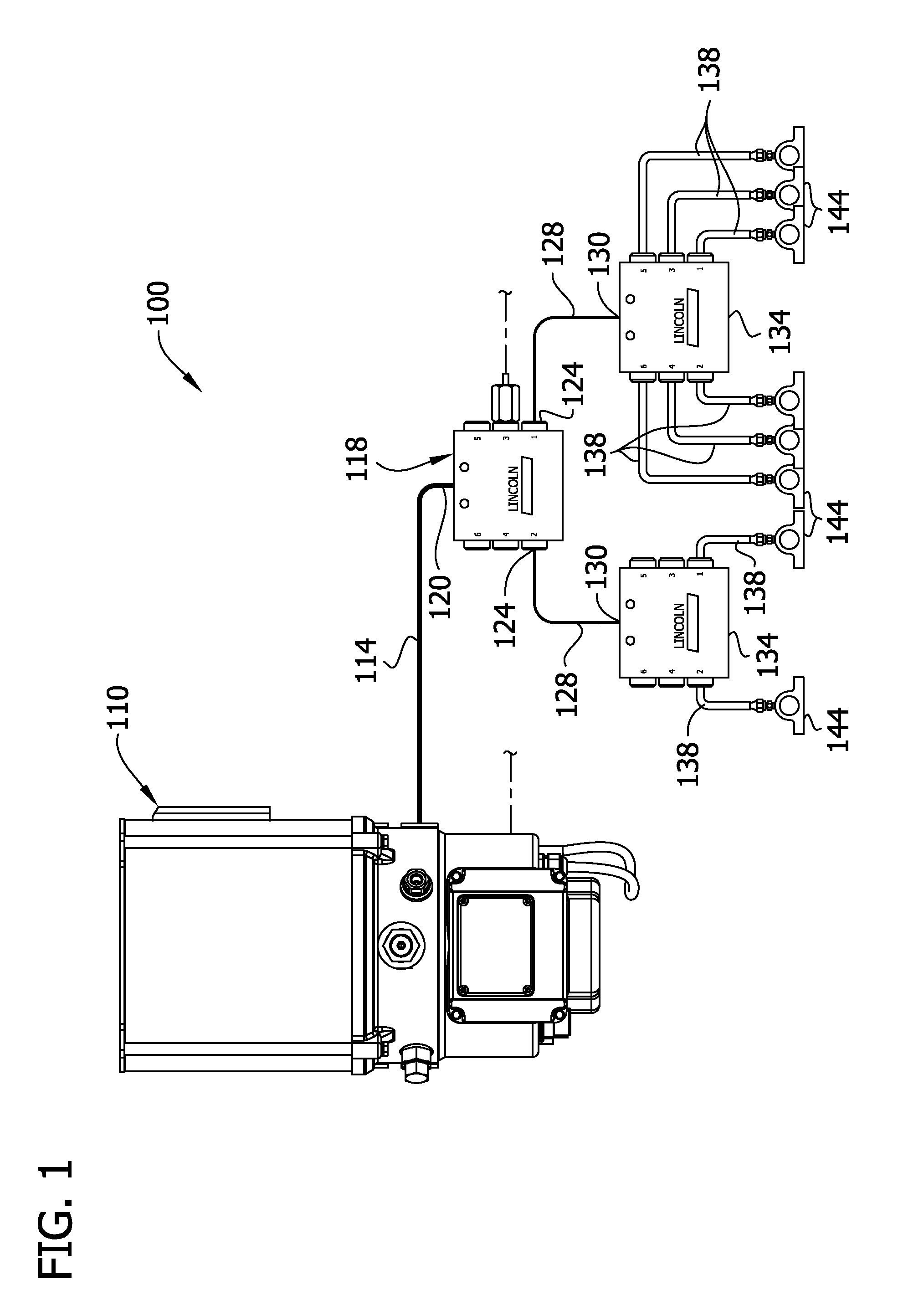

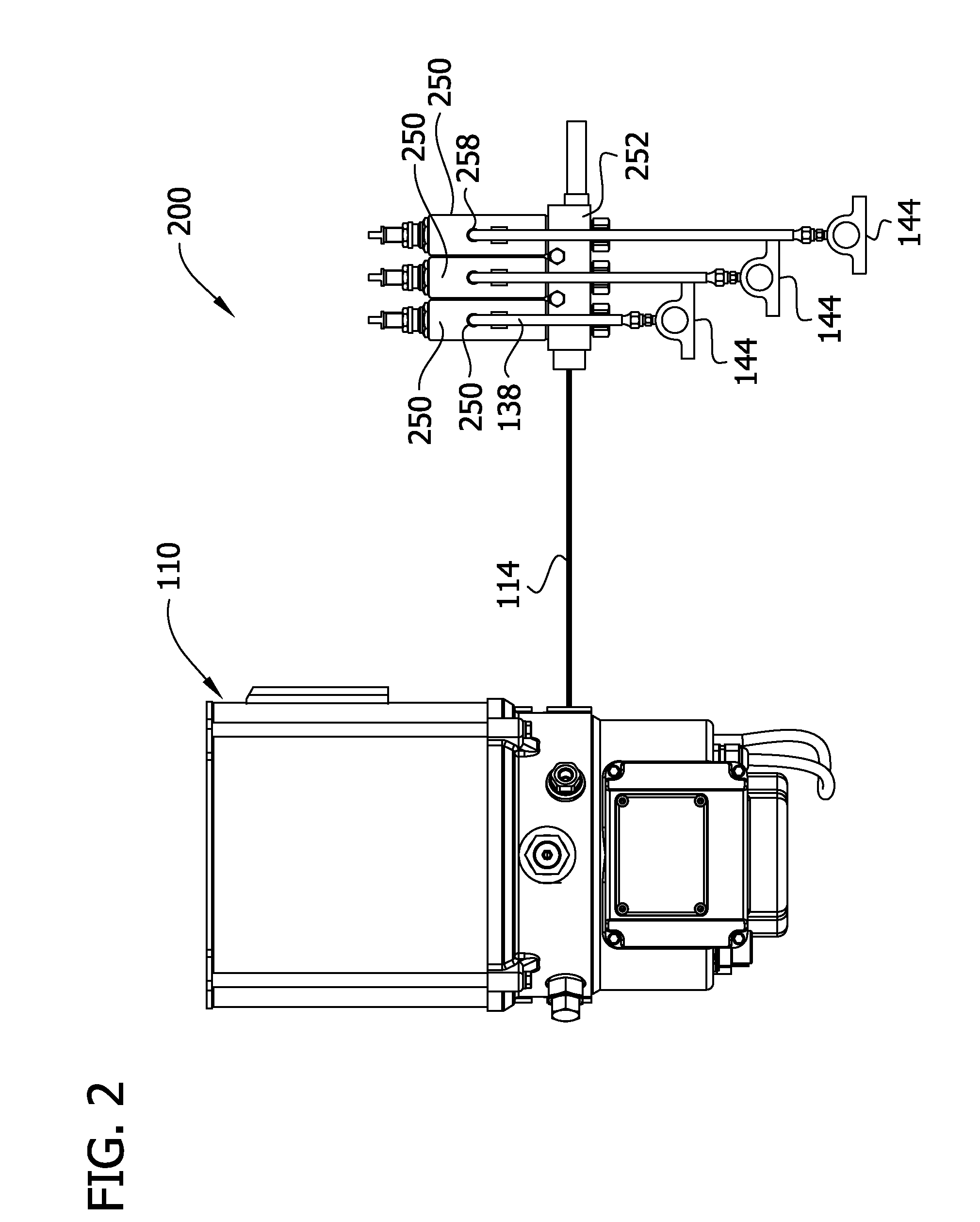

Apparatus and method for controlling a lubriation unit using flow rate feedback

A lubrication unit for delivering lubricant in a system and a method for controlling the unit. The lubrication unit includes a reservoir, a motor, and a pump. The lubrication unit has a flow rate sensor mounted downstream from the pump for measuring a flow rate of lubricant. The lubrication unit includes a control unit operatively connected to the flow rate sensor and the motor for controlling operation of the motor. The control unit includes an input selector for selecting at least one characteristic selected from a group consisting of a volume and a flow rate of lubricant pumped by the pump. The control unit adjusts motor speed to obtain the selected characteristic.

Owner:LINCOLN INDUSTRIES CORP

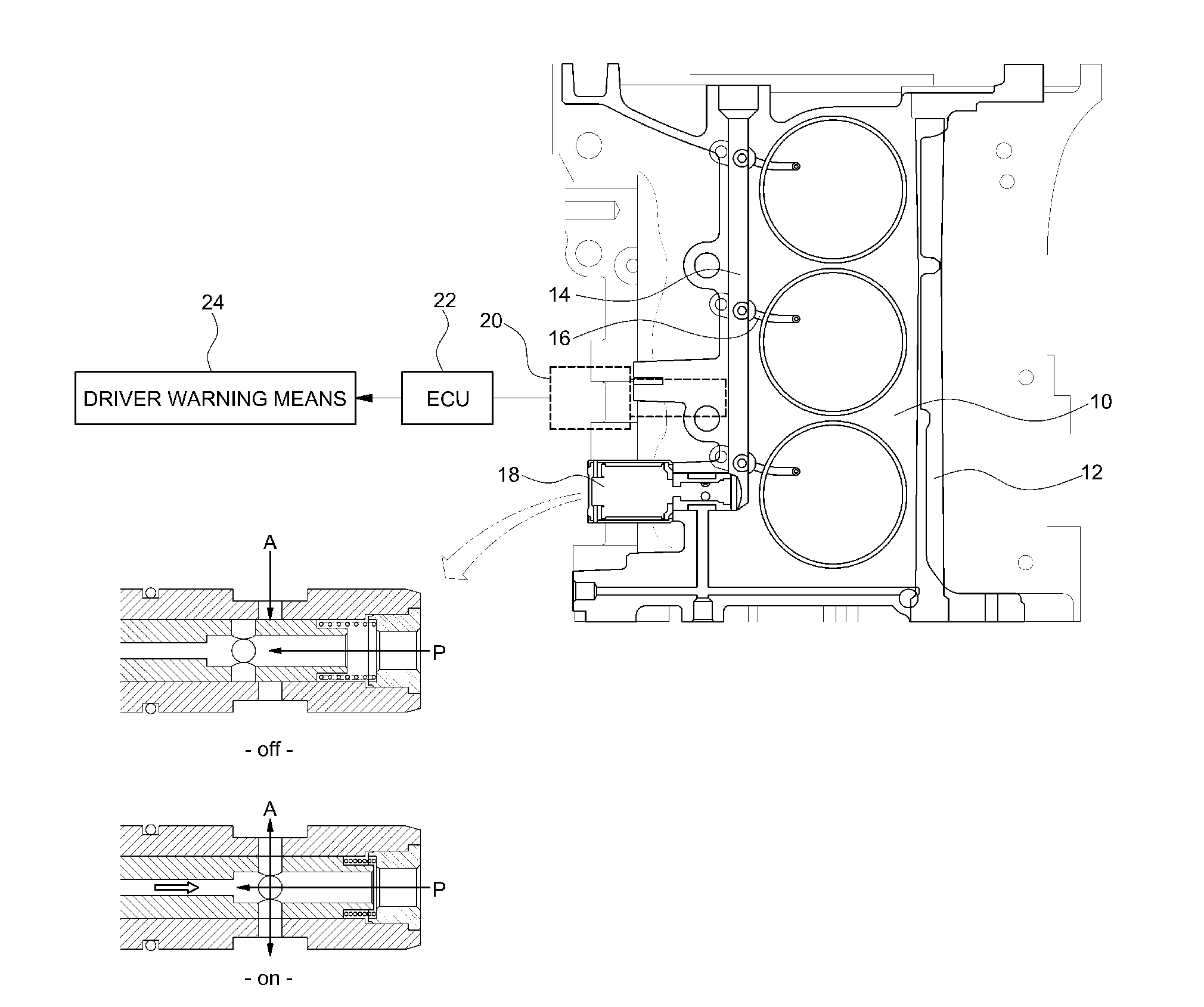

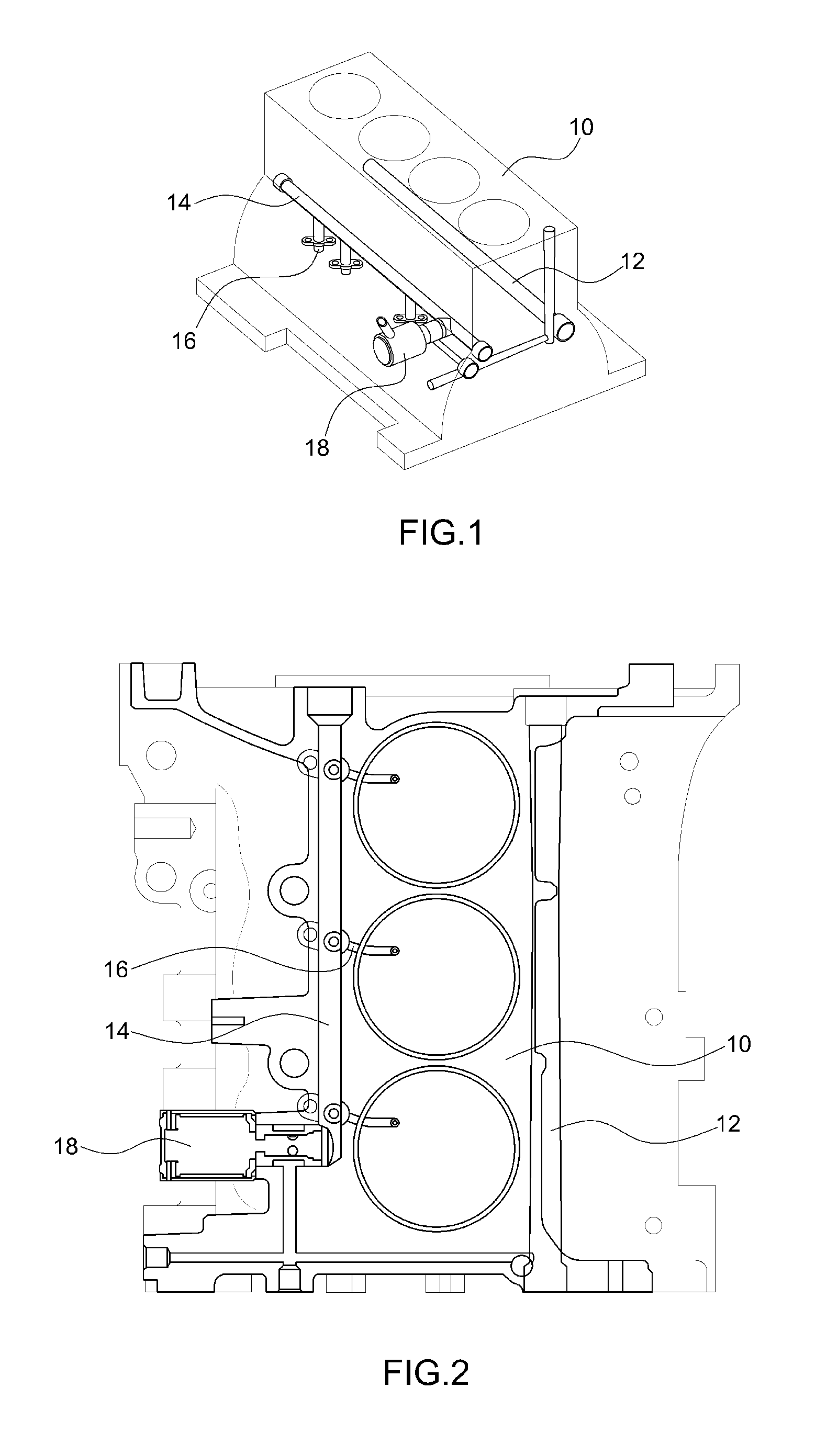

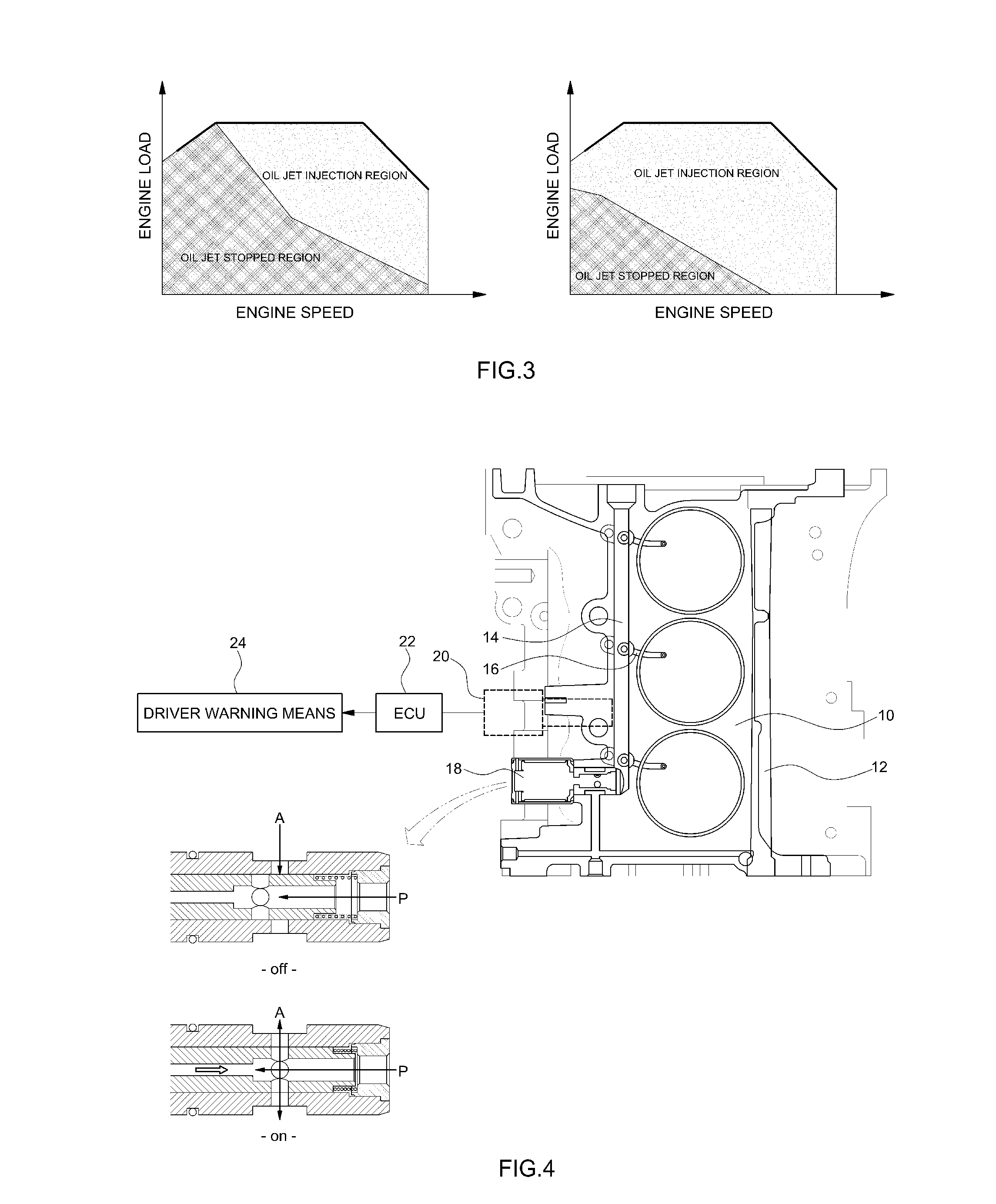

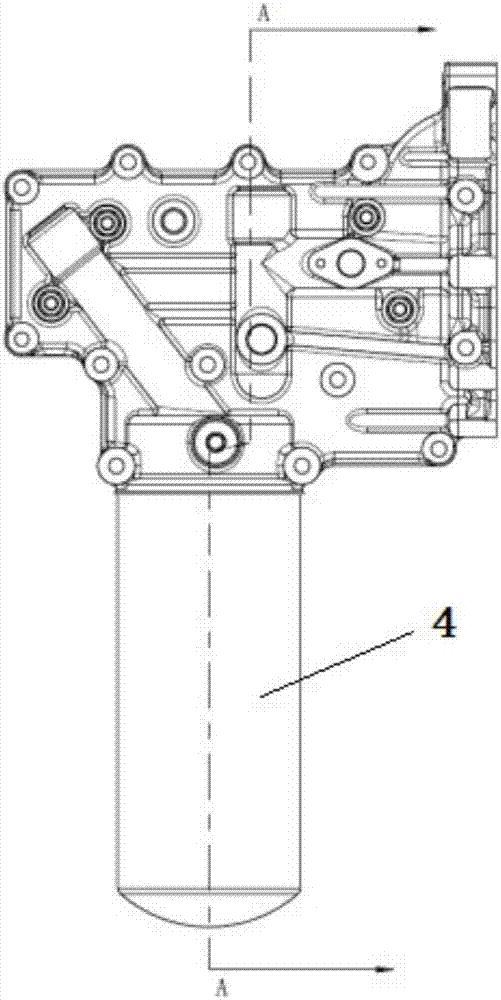

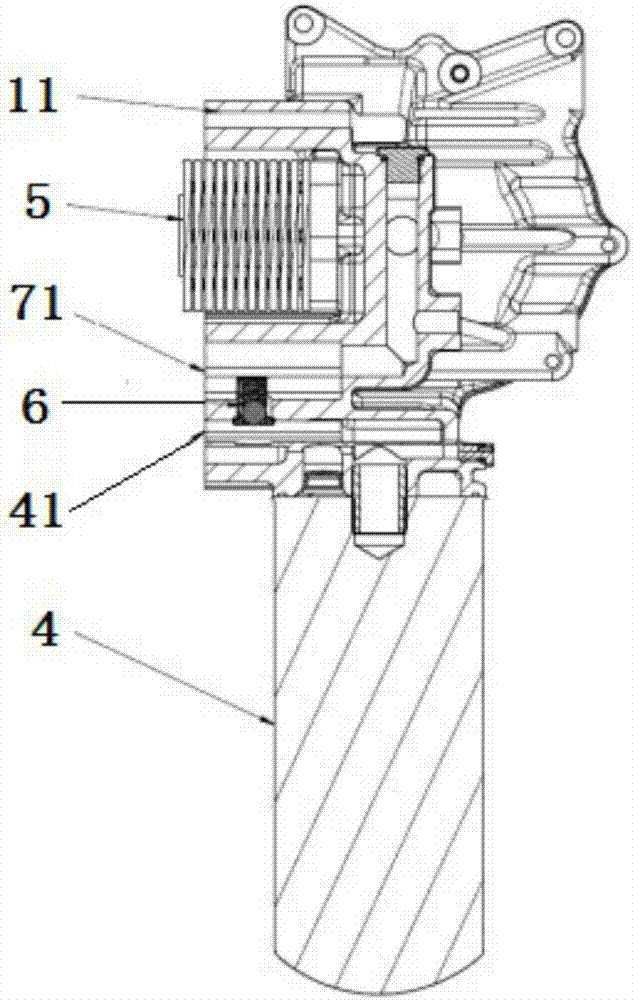

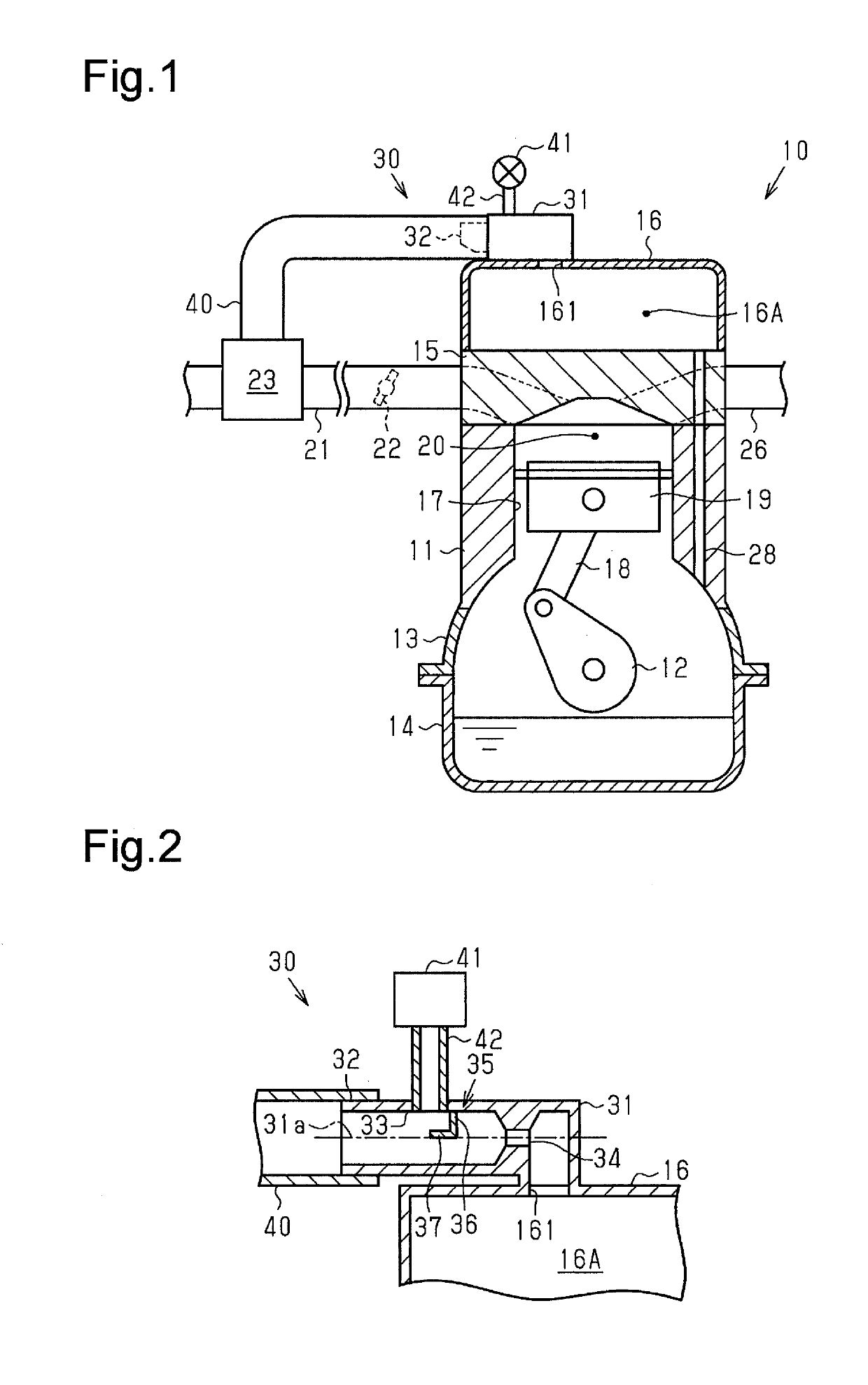

Apparatus and method for diagnosing failure of piston cooling jet of engine

InactiveUS20160363040A1Easy diagnosisLow costLiquid coolingMeasurement deviceSolenoid valveCylinder block

An apparatus for diagnosing failure of a piston cooling jet of an engine includes an oil line for a piston cooling jet arranged in a cylinder block in a longitudinal direction, a piston cooling jet mounted at the oil line for the piston cooling jet to inject oil to a piston, a solenoid valve mounted at an inlet of the oil line for the piston cooling jet to selectively allow an injection operation of the piston cooling jet, an oil pressure detecting means mounted at the oil line for the piston cooling jet after the solenoid valve to detect oil pressure, and a control unit configured to receive a detection signal of the oil pressure detecting means and determine whether the solenoid valve is in a failure state.

Owner:HYUNDAI MOTOR CO LTD +1

Method and apparatus for determining lubricant contamination or deterioration in an engine

An apparatus and method for determining lubrication contamination or deterioration in an engine or a lubricant system of an engine can include at least one sensor provided in the lubricant system. The sensor can sense an aroma of a lubricant or the air around the lubricant to measure a chemical composition or an aromatic. The sensed chemical composition or aromatic can be compared to a baseline or threshold to determine a particular contamination type or deterioration level of the lubricant.

Owner:GENERAL ELECTRIC CO

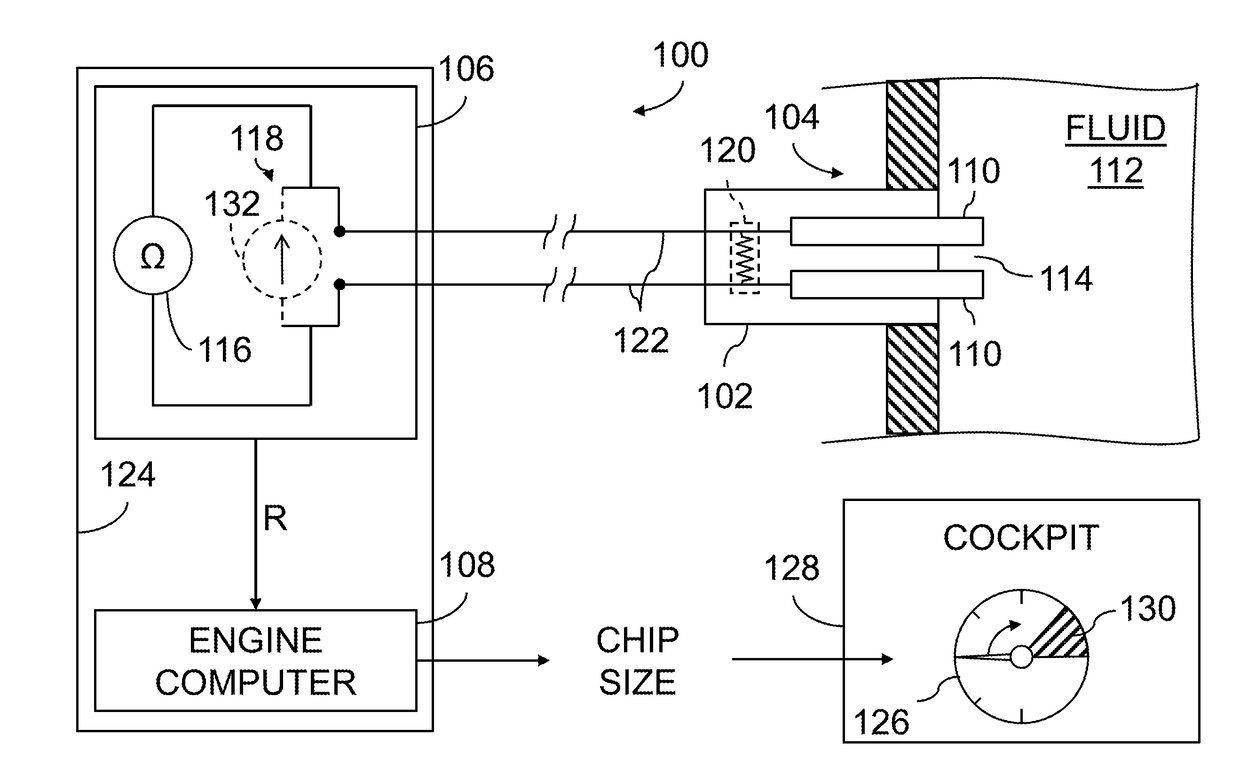

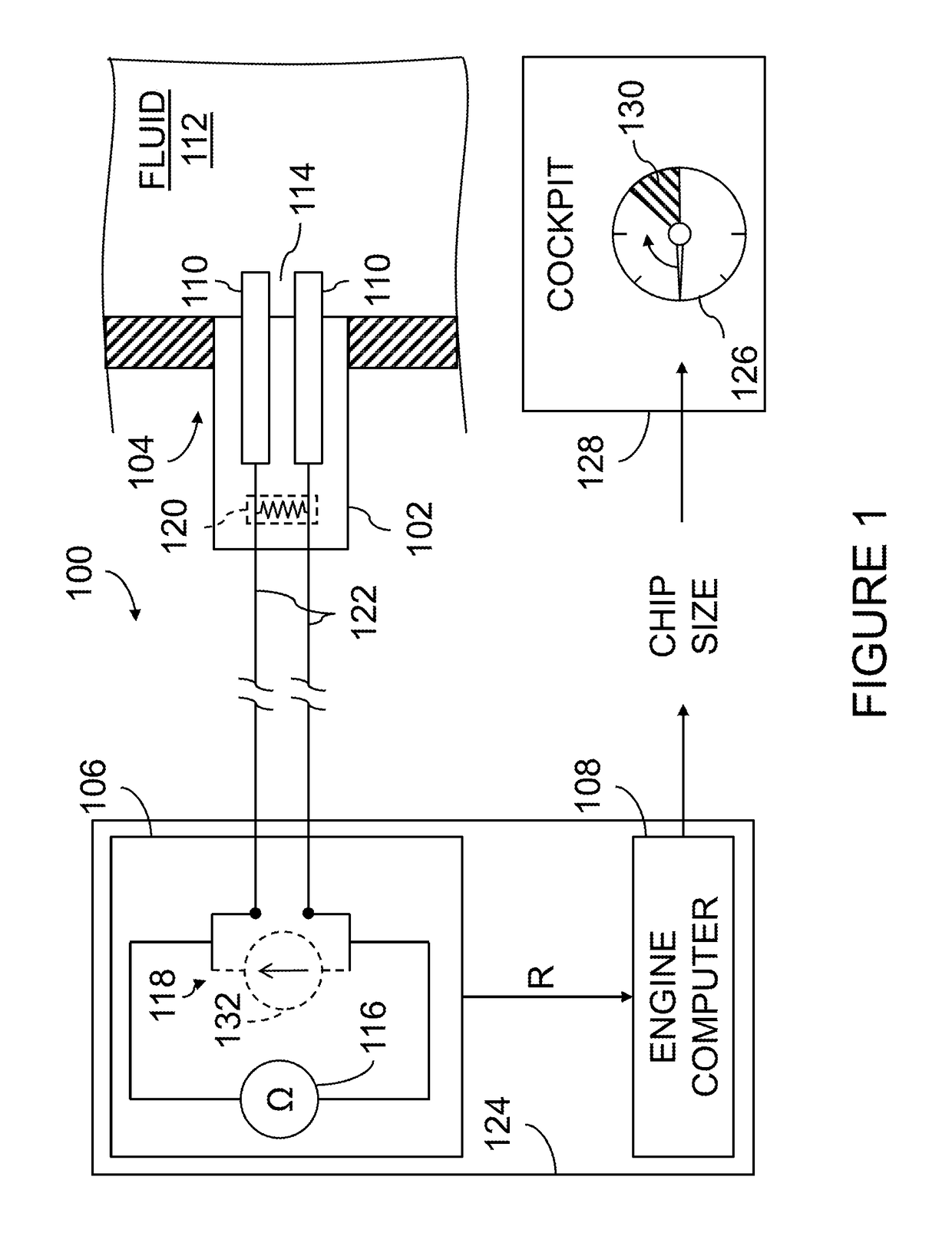

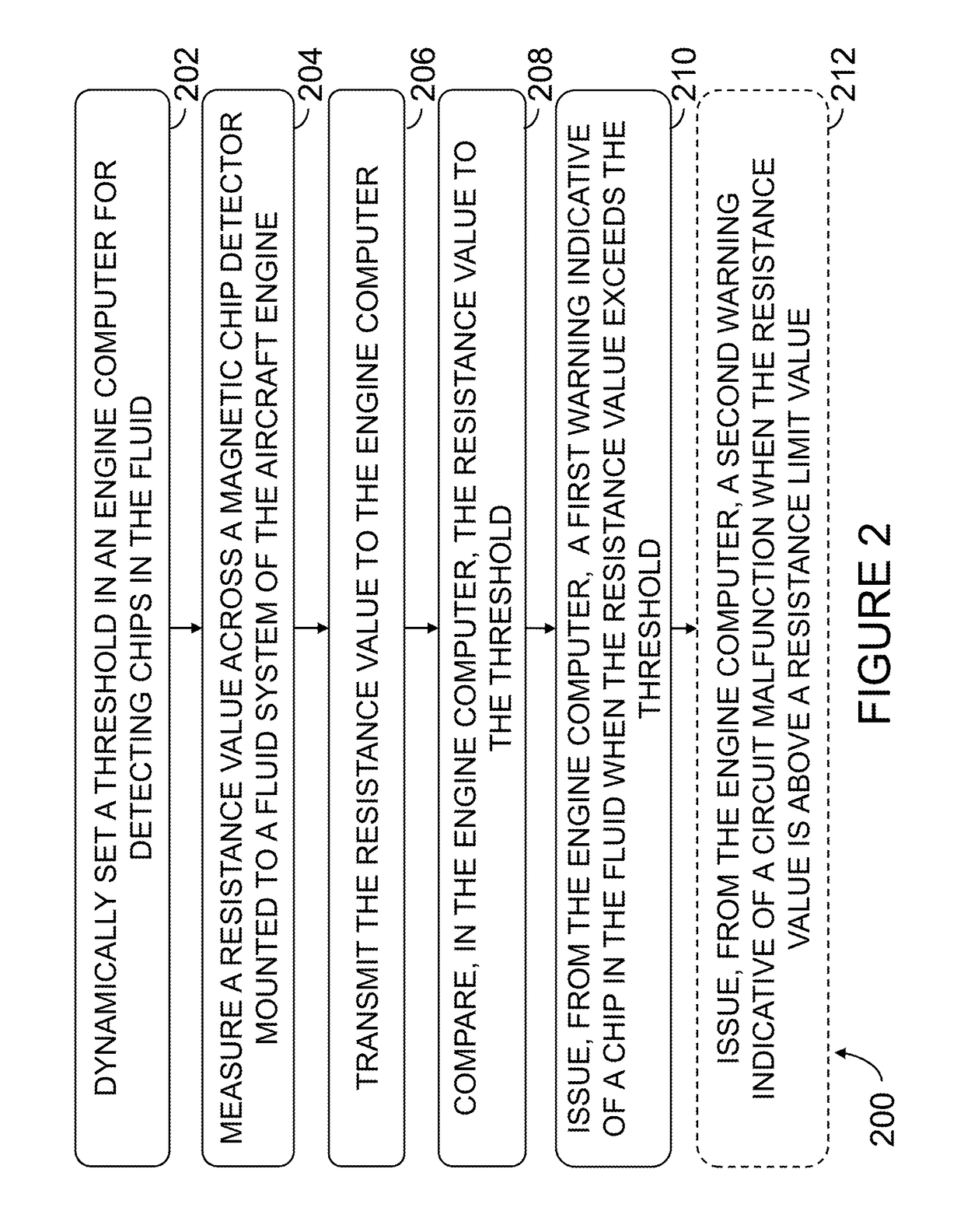

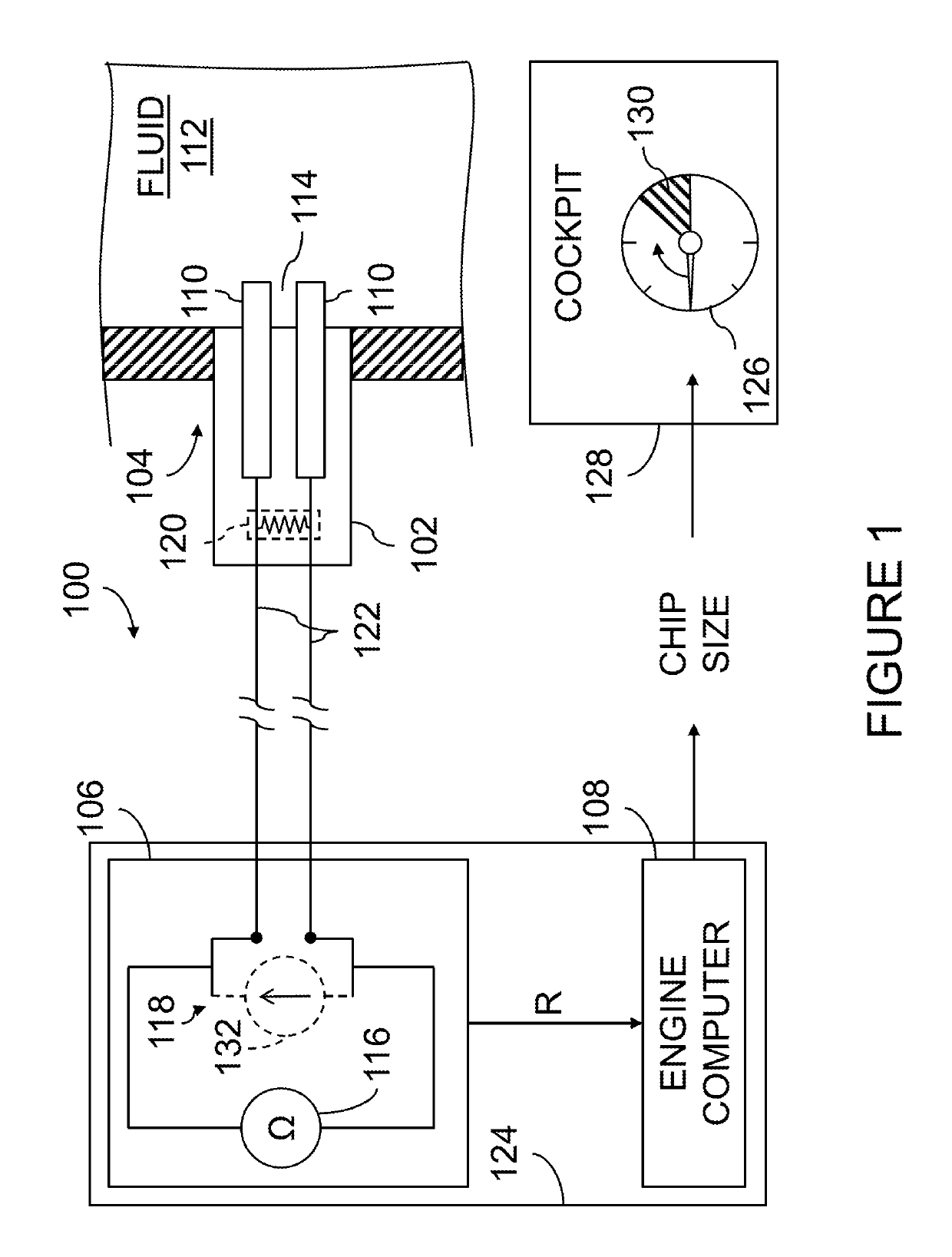

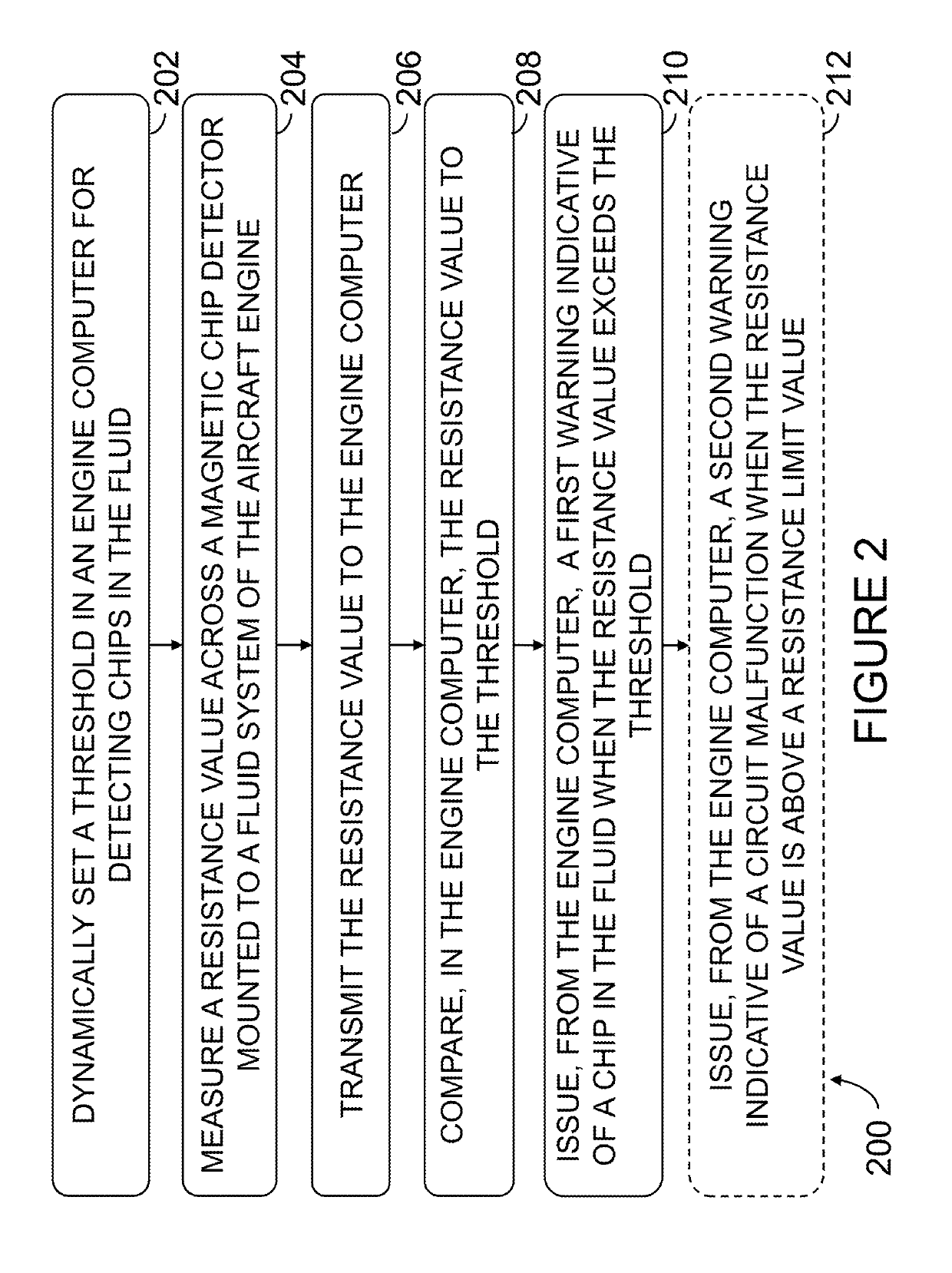

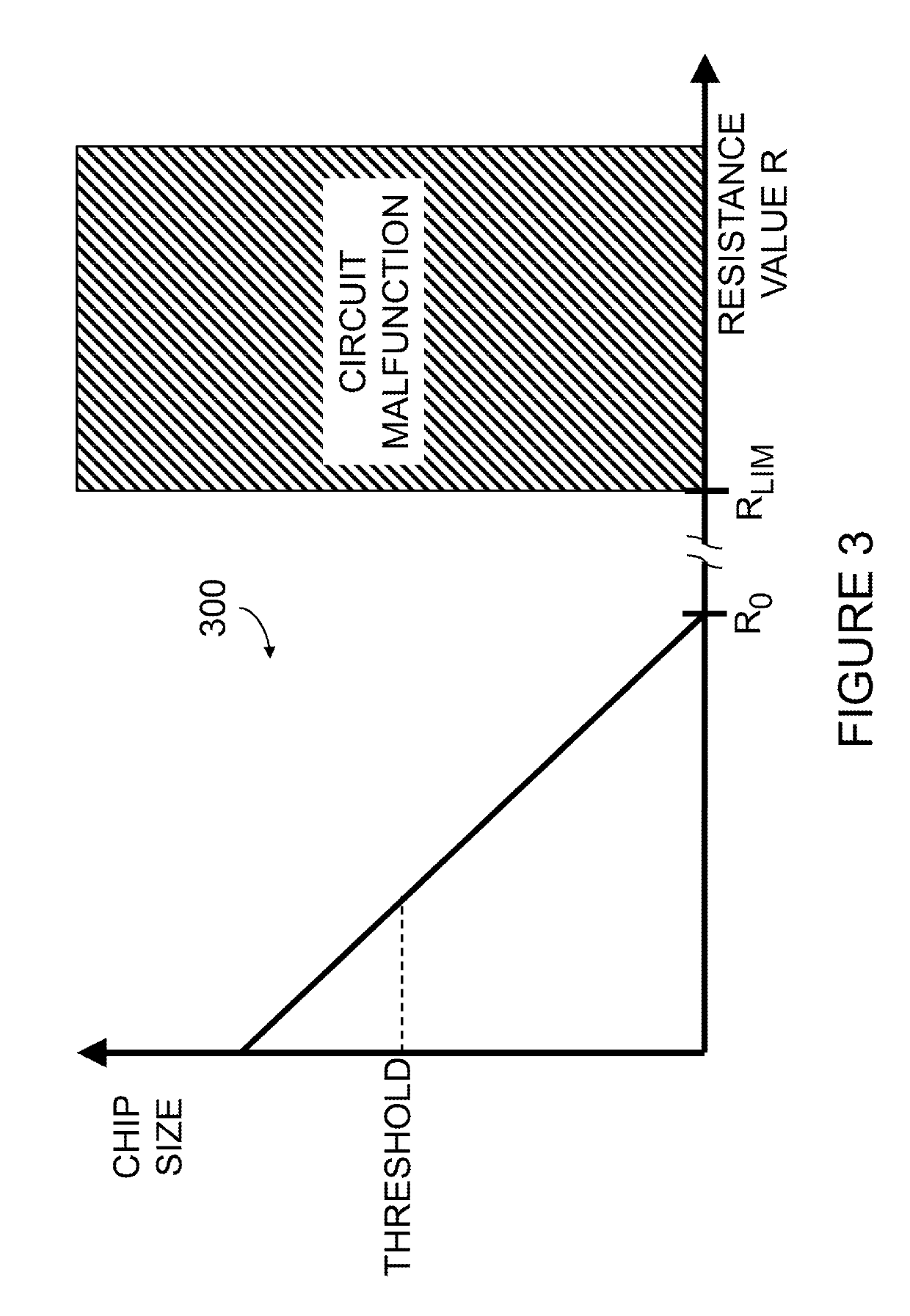

Systems and methods for detecting chips in fluid of aircraft engine

ActiveUS20180031504A1Easy to detectAircraft componentsTurbinesElectrical resistance and conductanceFluid system

There is described herein methods and systems for detecting of metallic chips in a fluid system of an aircraft engine. The method comprises measuring a resistance value across a magnetic chip detector mounted to a fluid system of the aircraft engine and transmitting the resistance value to an engine computer of the aircraft engine. The method further comprises, in the engine computer, comparing the resistance value to a first threshold and issuing a first warning indicative of a chip in the fluid when the resistance value exceeds the first threshold.

Owner:PRATT & WHITNEY CANADA CORP

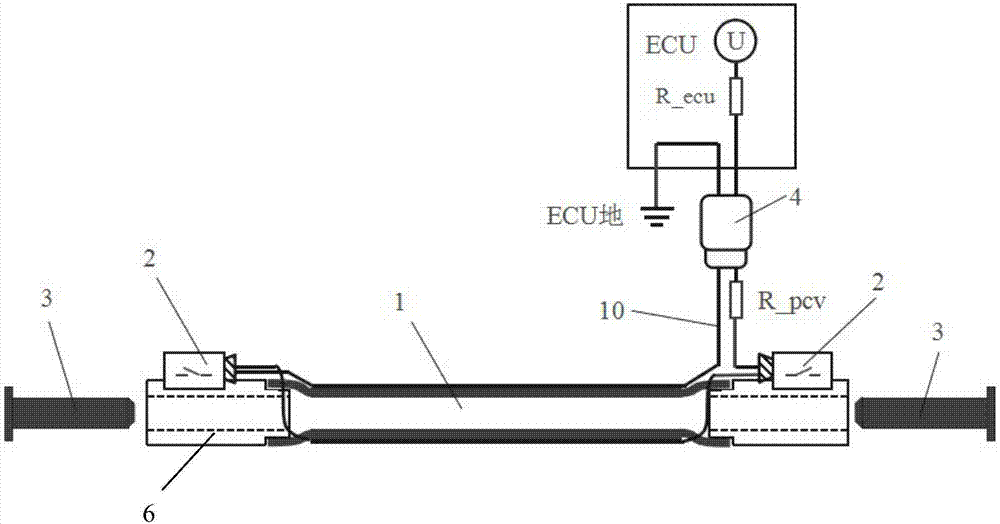

Pipeline disconnection detection system based on conducting loop mechanism

PendingCN107476848ASimple structureDetect open circuitElectrical controlInternal combustion piston enginesElectrical resistance and conductanceEngineering

The invention provides a pipeline disconnection detection system based on a conducting loop mechanism. A crankcase ventilation pipeline system comprises a main pipeline, male connectors connected with an engine crankcase or air inlet system are connected to the main pipeline, and the main pipeline is provided with connecting terminals; the pipeline disconnection detection system comprises a disconnection detection circuit fixed to the main pipeline and at least one connecting terminal, conducting switches are arranged on the portions, located in the connecting terminals or the joints of the male connectors and the connecting terminals, of the disconnection detection circuit, the conducting switches are switched on by inserting the male connectors into the connecting terminals or inserting male connector lock rings of the male connectors into the connecting terminals, the two ends of the disconnection detection circuit are connected with the power supply end and the ground end of an ECU unit respectively, and the disconnection detection circuit is provided with a resistor unit which is connected with the power supply end of the ECU unit and used for diagnosing the condition that the disconnection detection circuit has a short circuit to a power supply and the ground. According to the pipeline disconnection detection system based on the conducting loop mechanism, the completeness of a ventilation pipeline can be effectively detected.

Owner:TIANJIN DATRO TECH CO LTD

Systems and methods for detecting chips in fluid of aircraft engine

There is described herein methods and systems for detecting of metallic chips in a fluid system of an aircraft engine. A resistance value is measured across a magnetic chip detector mounted to a fluid system of the aircraft engine. The resistance value is transmitted to an engine computer of the aircraft engine. In the engine computer, The resistance value is compared to a first threshold and a first warning indicative of a chip in the fluid is issued when the resistance value exceeds the first threshold.

Owner:PRATT & WHITNEY CANADA CORP

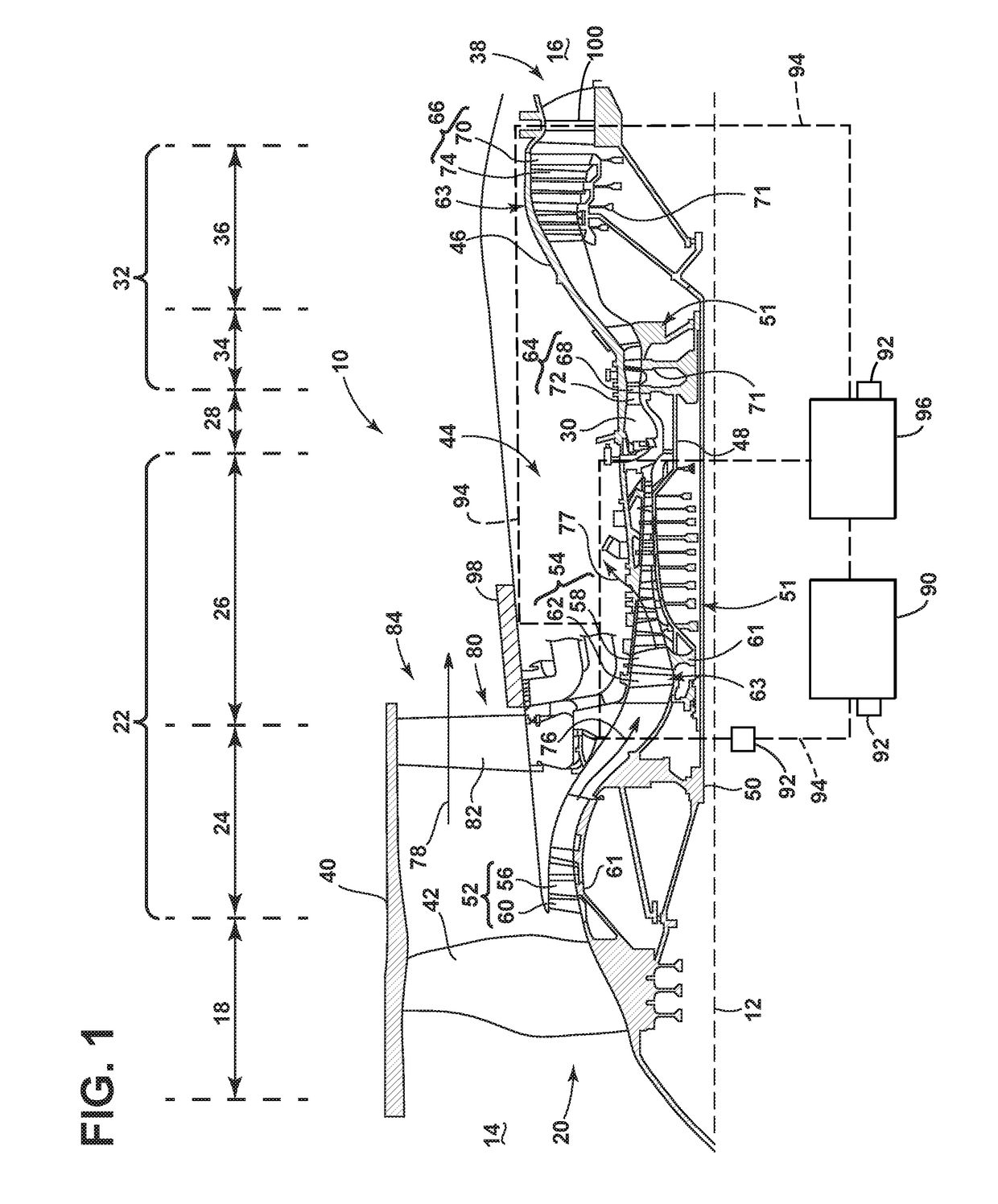

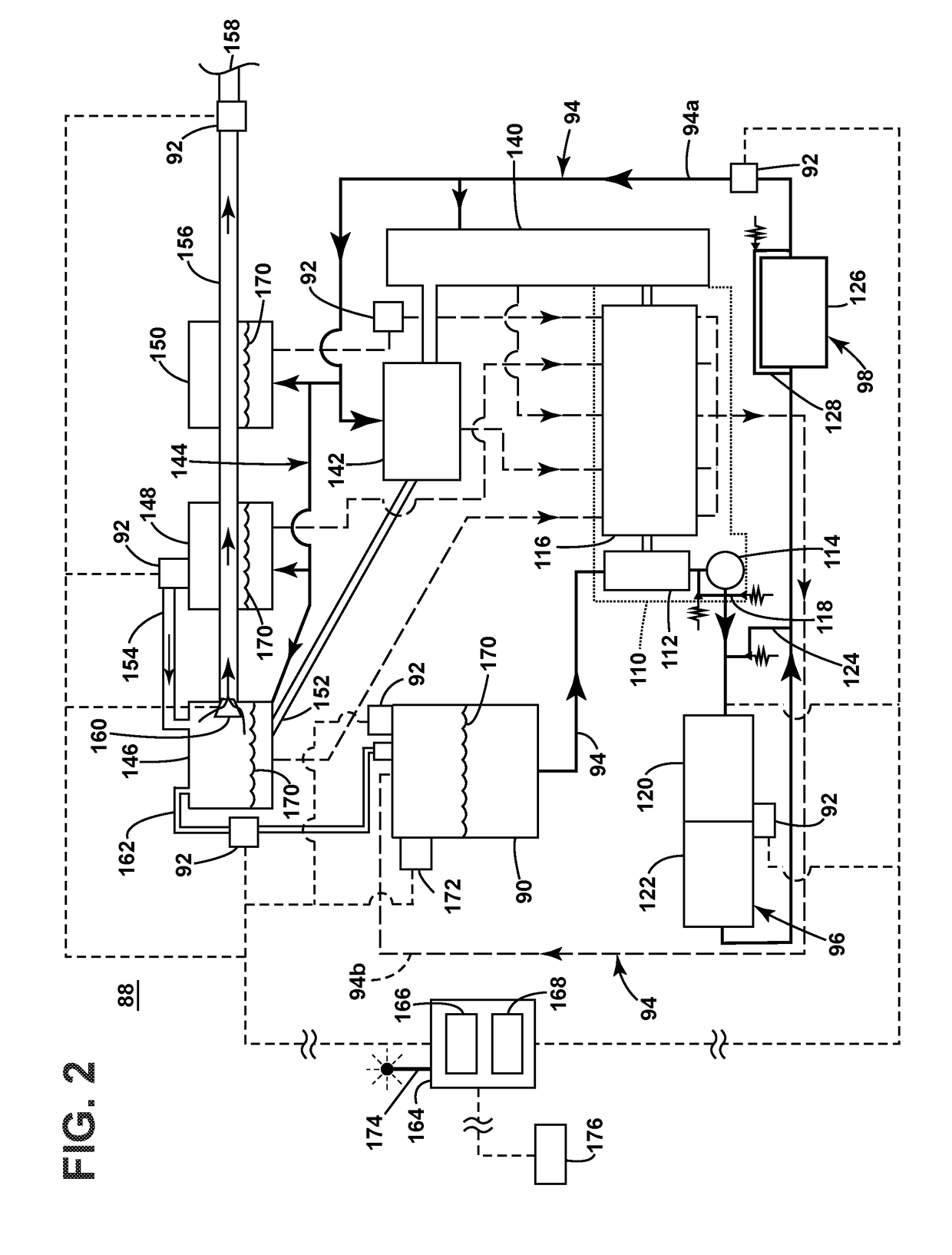

Multi-modal fluid condition sensor platform and system thereof

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. The mass and level of the fluid may also be monitored on an on-going basis. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

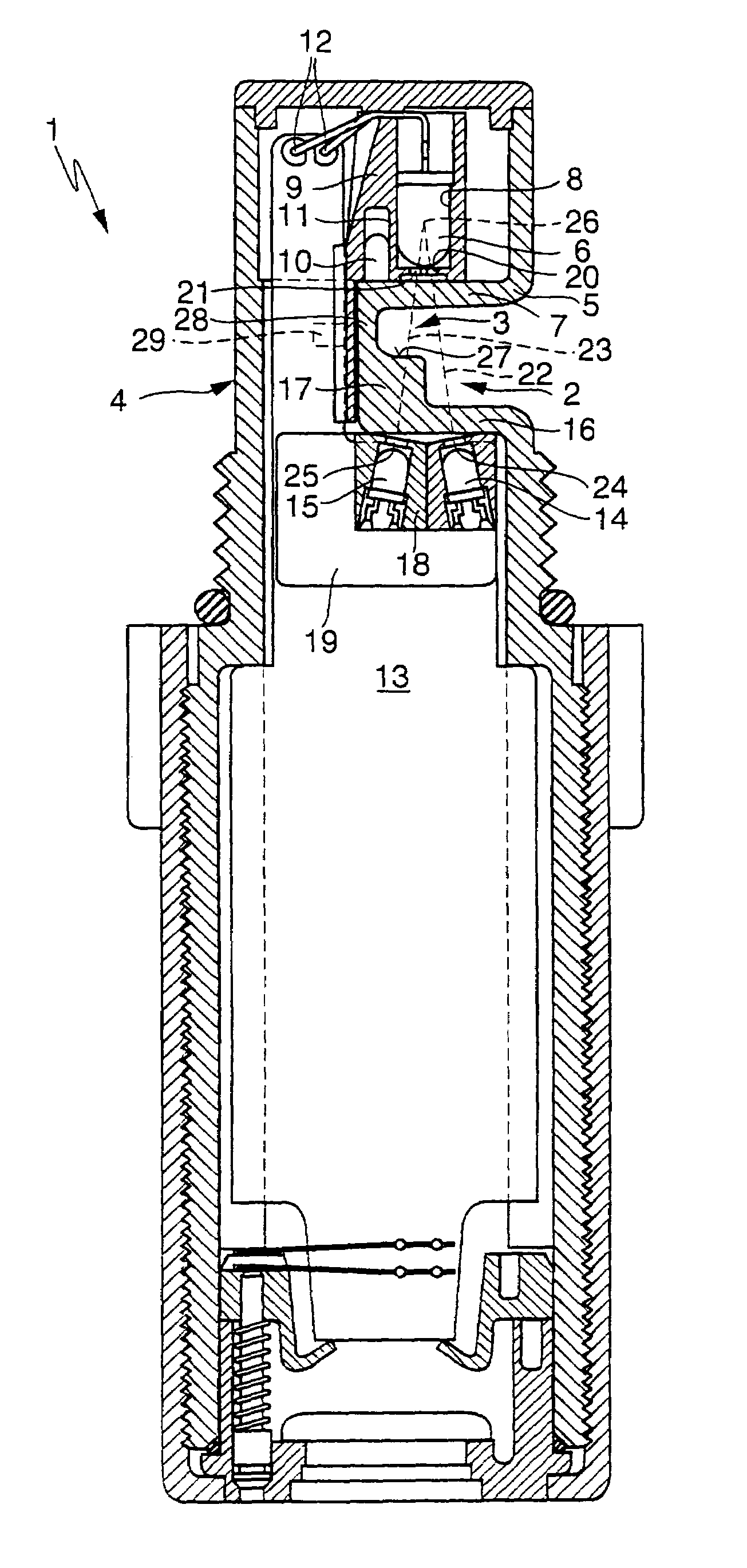

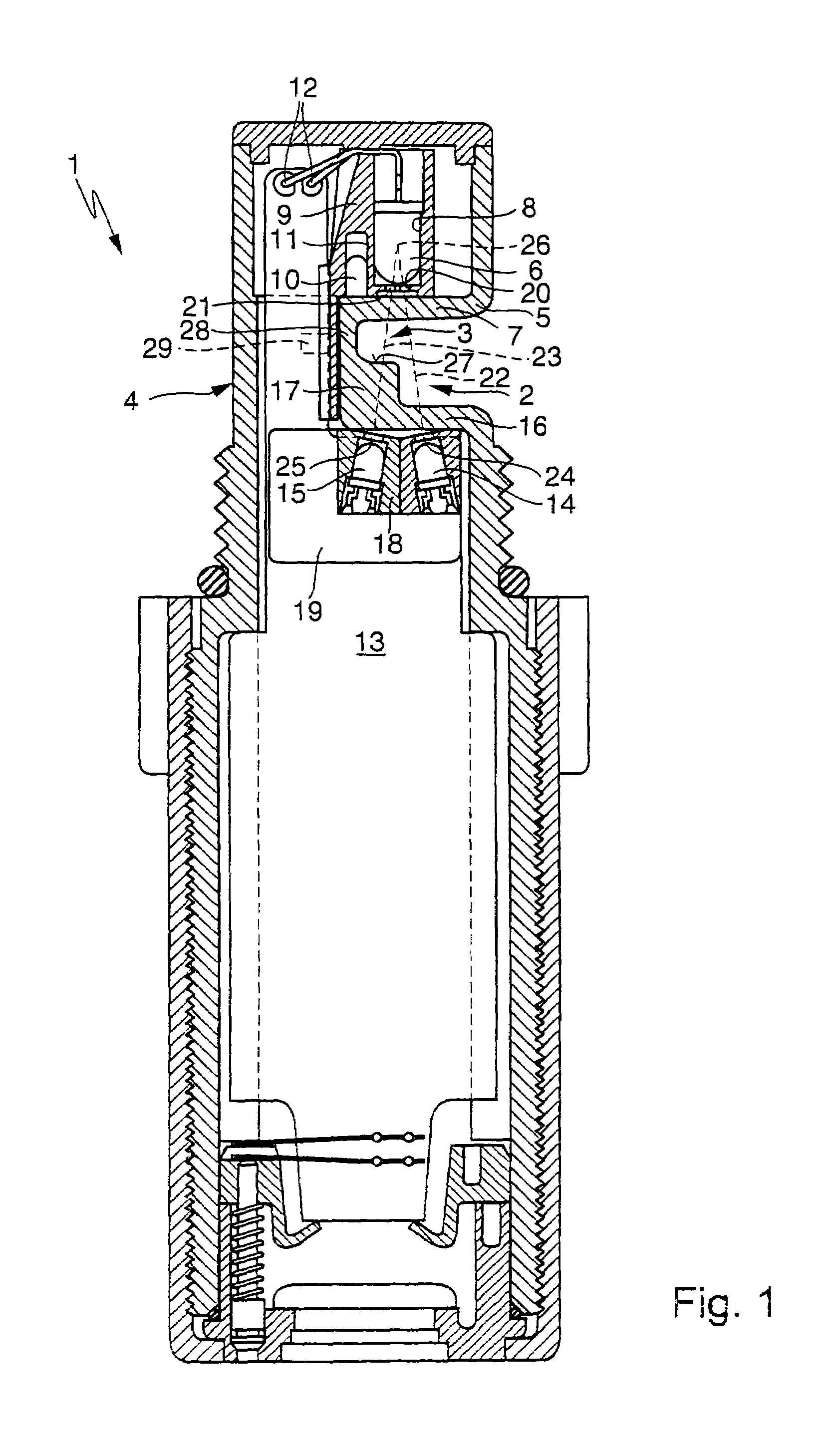

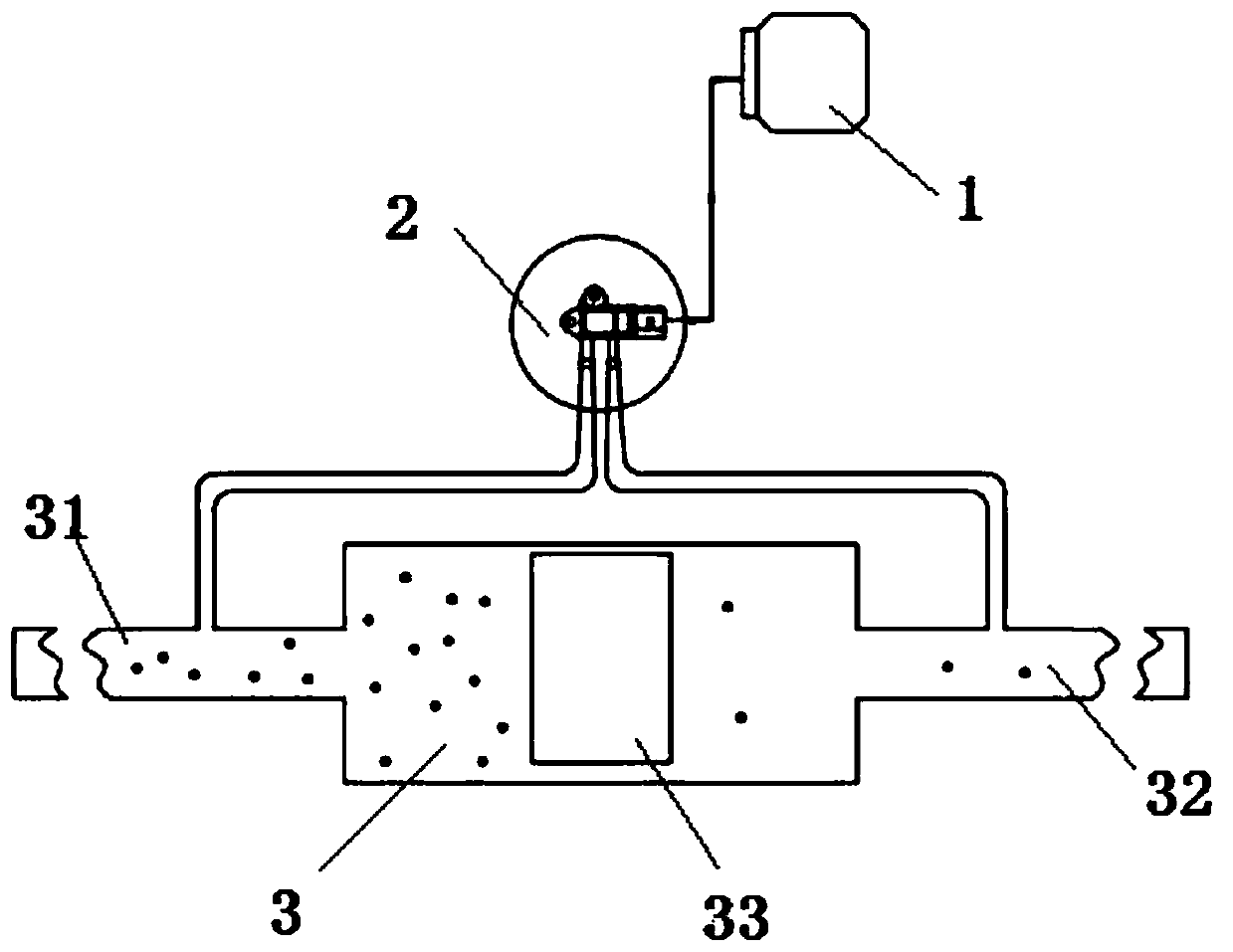

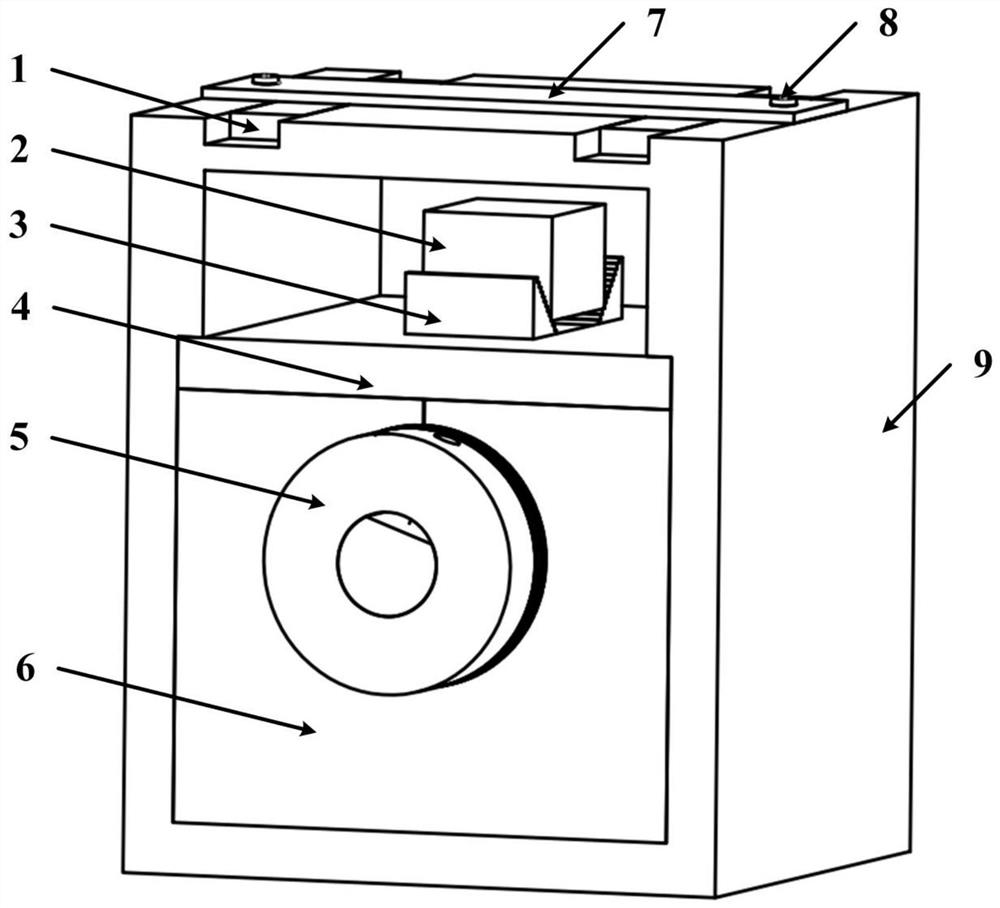

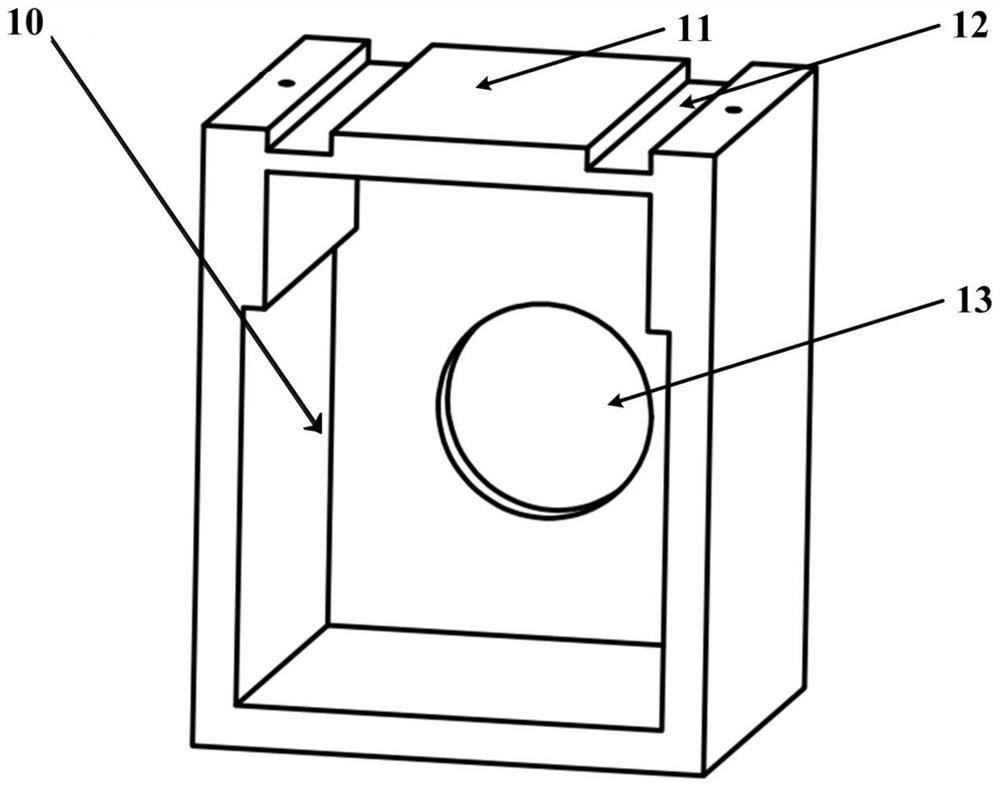

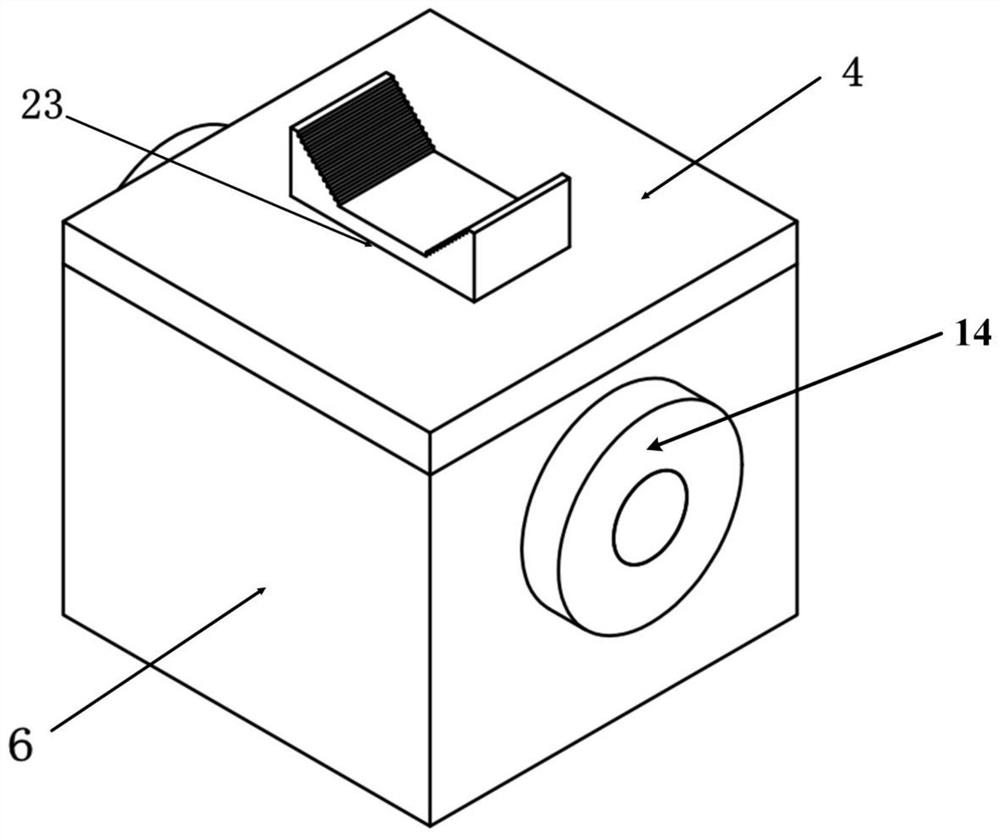

Transmission sensor

InactiveUS7060979B2Easy and inexpensive to manufactureImprove automationRadiation pyrometryInvestigating moving fluids/granular solidsElectromagnetic radiationTransmitter

The invention relates to a transmission sensor (1) for measuring the turbidity of a fluid, comprising a first and a second measuring section (2, 3). A transmitter (6) emits electromagnetic radiation into the two measuring sections (2, 3). A first receiver (14) is allocated to the first measuring section (2) and a second receiver (15) is allocated to the second measuring section (3). The transmitter (6) is inserted into a transmitter carrier (8) in such a way that the transmitter (6) is forced to adopt a predetermined oriented position. The receivers (14, 15) are inserted into a receiver carrier (18) in such a way that each of said receivers (14, 15) is forced to adopt a predetermined oriented position. A transmitter carrier holder (9) forcibly positions the transmitter carrier (8) in a predetermined location and a receiver carrier holder (19) forcibly positions the receiver carrier (18) in a predetermined location.

Owner:FILTRATION GRP GMBH +1

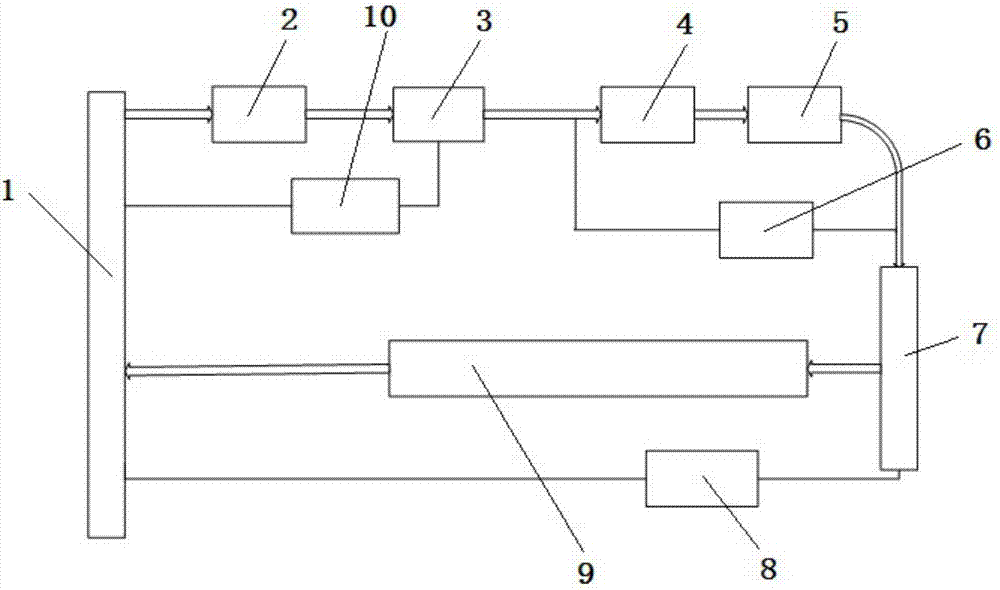

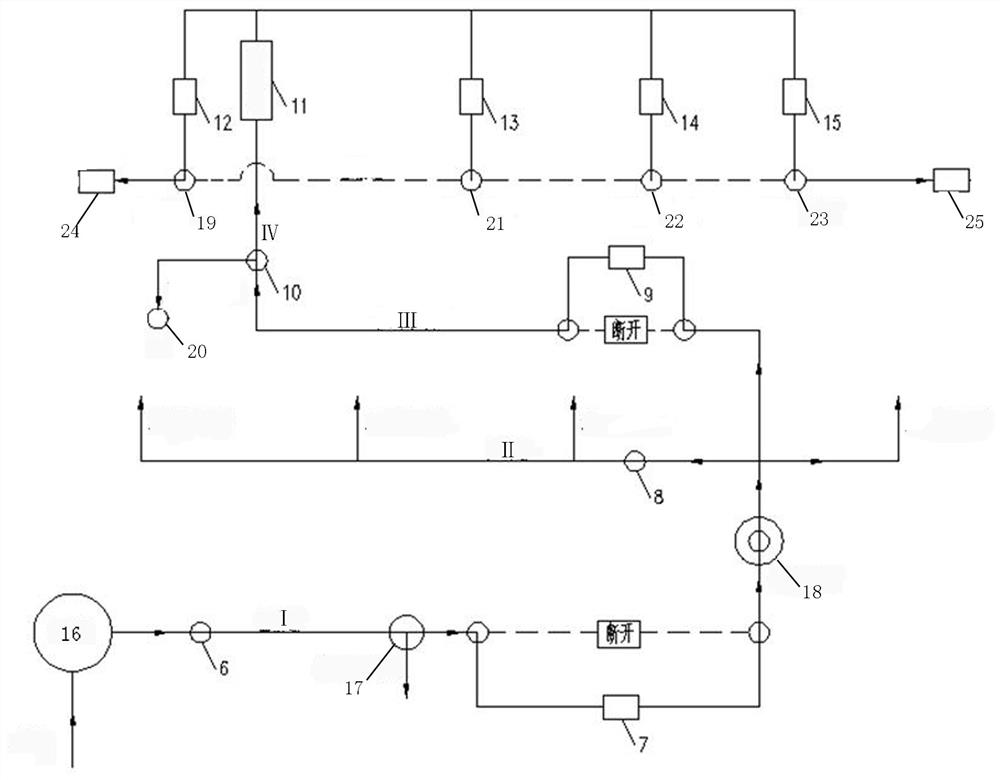

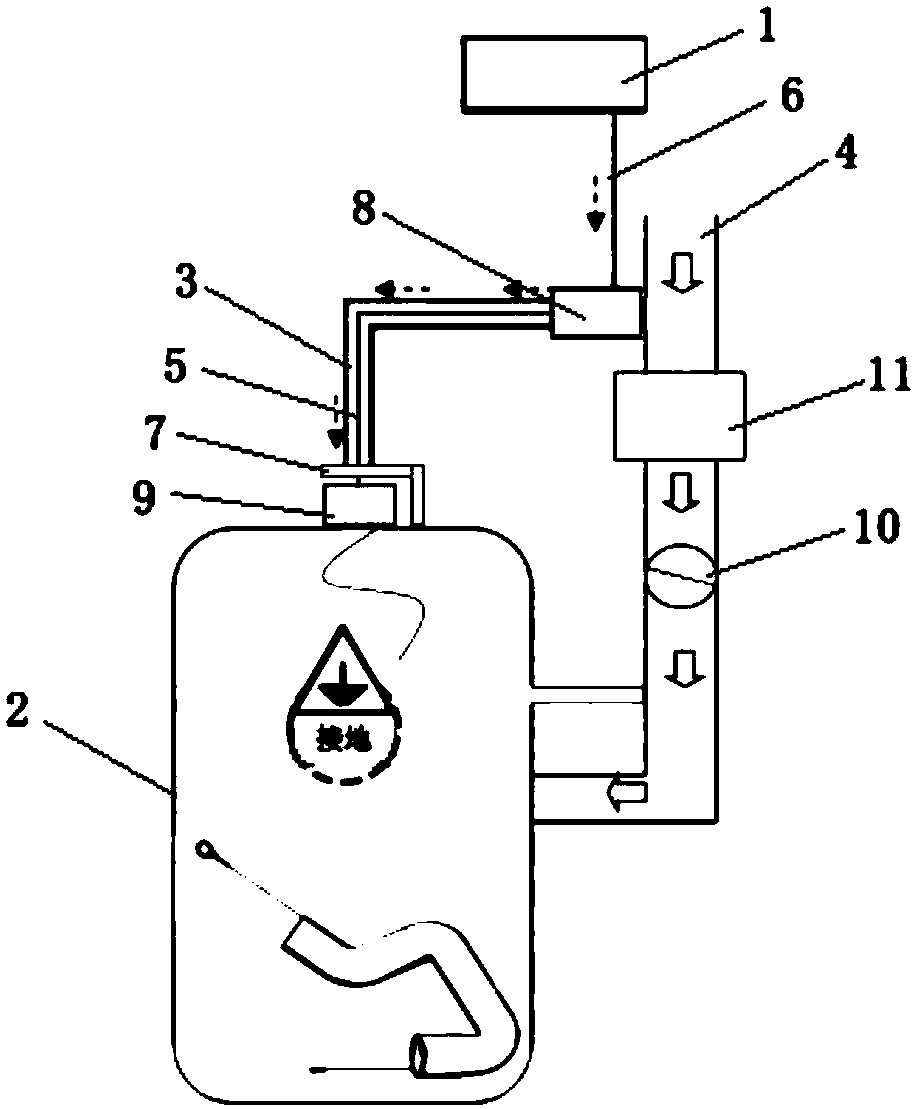

Lubricating system, engine and fault diagnosis method of lubricating system

InactiveCN107476844AGuaranteed lubrication effectImprove reliabilityMachines/enginesSafety devices for pressure lubricationDiagnosis methodsEngineering

The invention relates to the technical field of engines, and discloses a lubricating system and an engine with the lubricating system. The lubricating system comprises an oil pan, a suction filter, an oil pump, an oil filter, an oil cooler, a main oil gallery and a bypass oil gallery, wherein the oil pan, the suction filter, the oil pump, the oil filter, the oil cooler and the main oil gallery are connected in sequence through a pipeline, the bypass oil gallery communicates with an oil inlet of the oil filter and the main oil gallery, and a bypass valve is arranged on the bypass oil gallery. According to the lubricating system of the engine, when the oil filter and / or the oil cooler is plugged, oil getting out of the oil pump passes through the bypass oil gallery and directly enters the main oil gallery, therefore establishment of oil pressure of the main oil gallery are not affected, and lubrication of the engine still can be ensured; and in addition, one bypass oil gallery is only arranged, so that the system cost is reduced. The invention further discloses a fault diagnosis method of the lubricating system.

Owner:WEICHAI POWER CO LTD

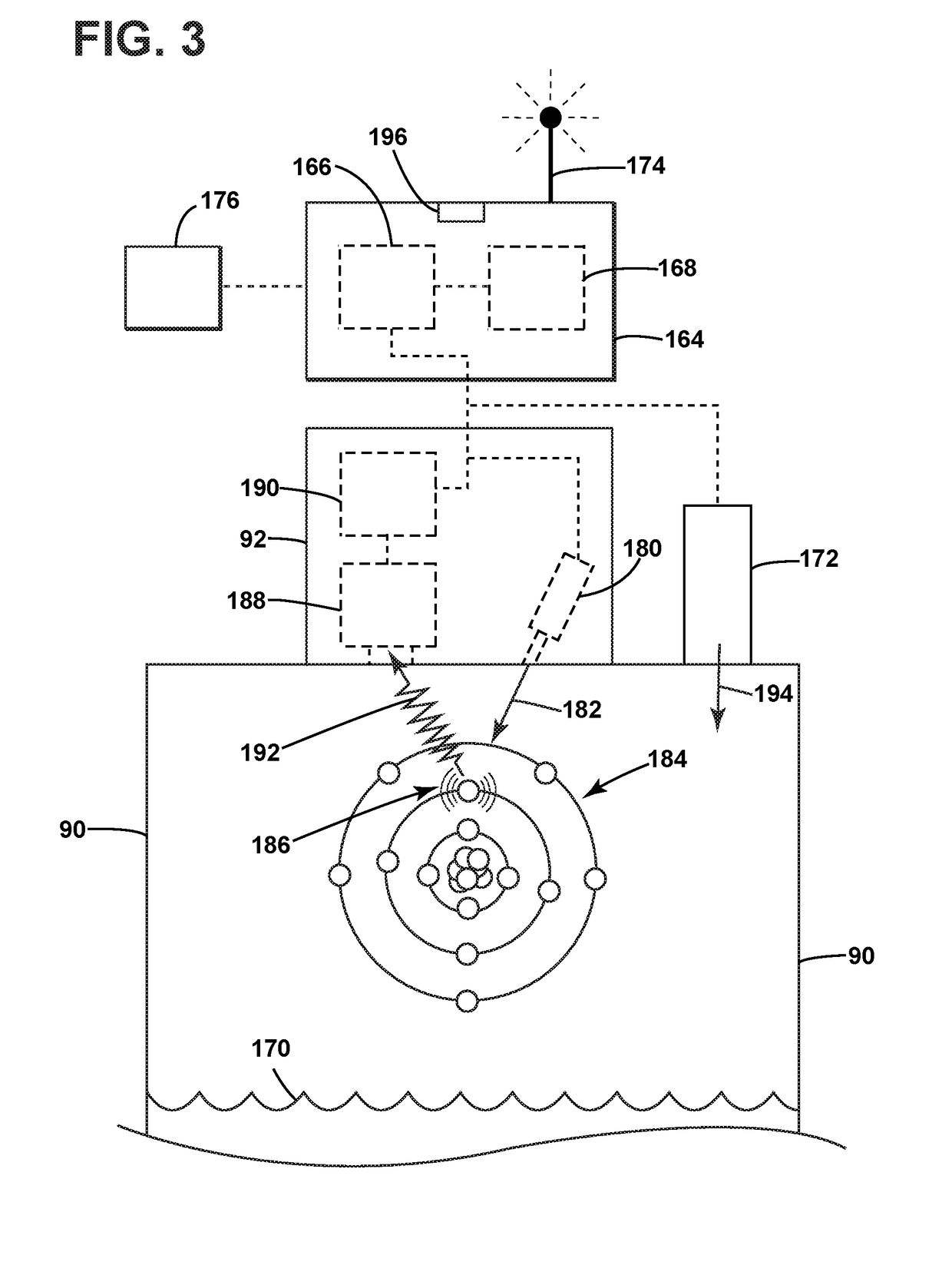

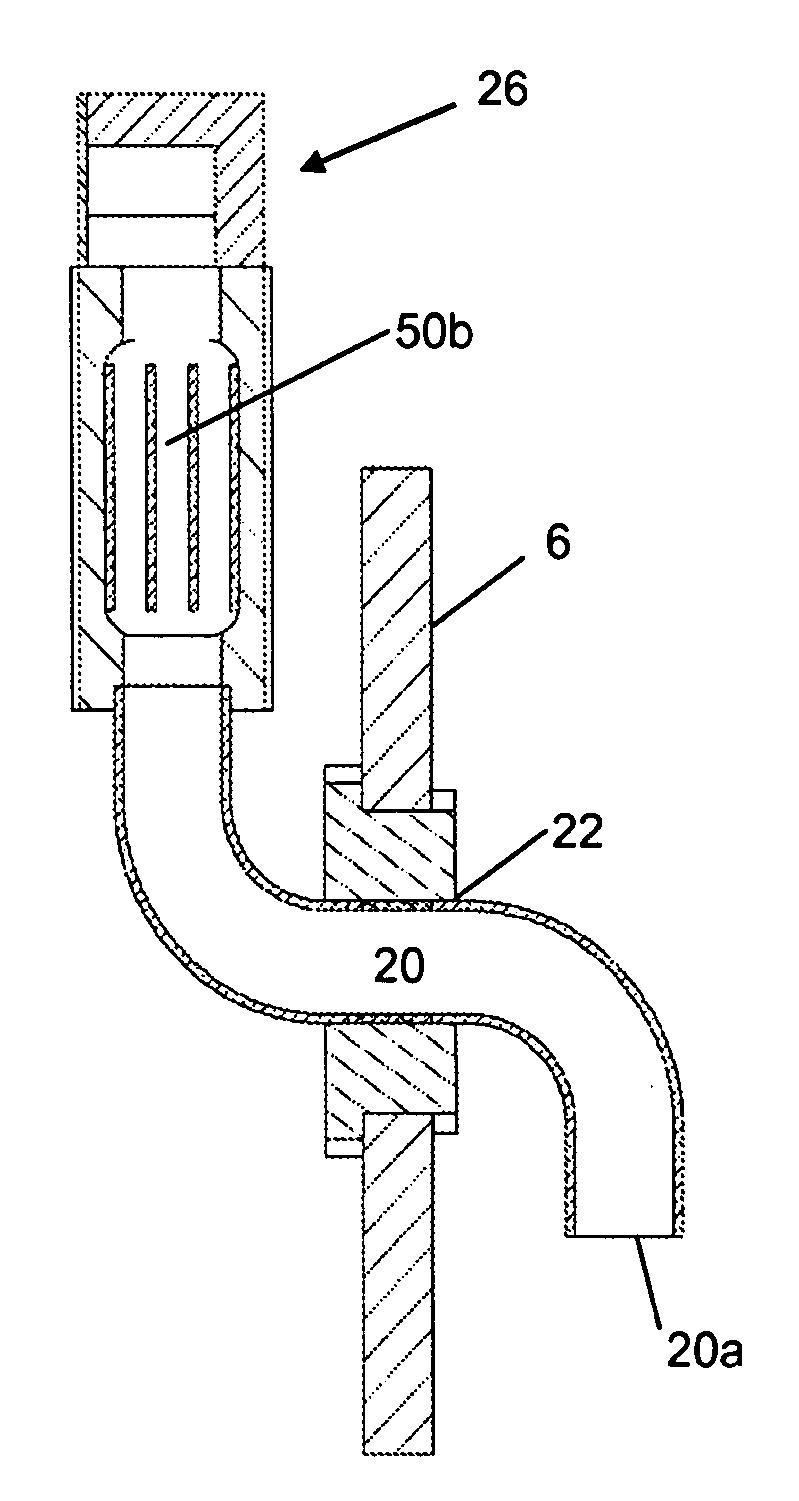

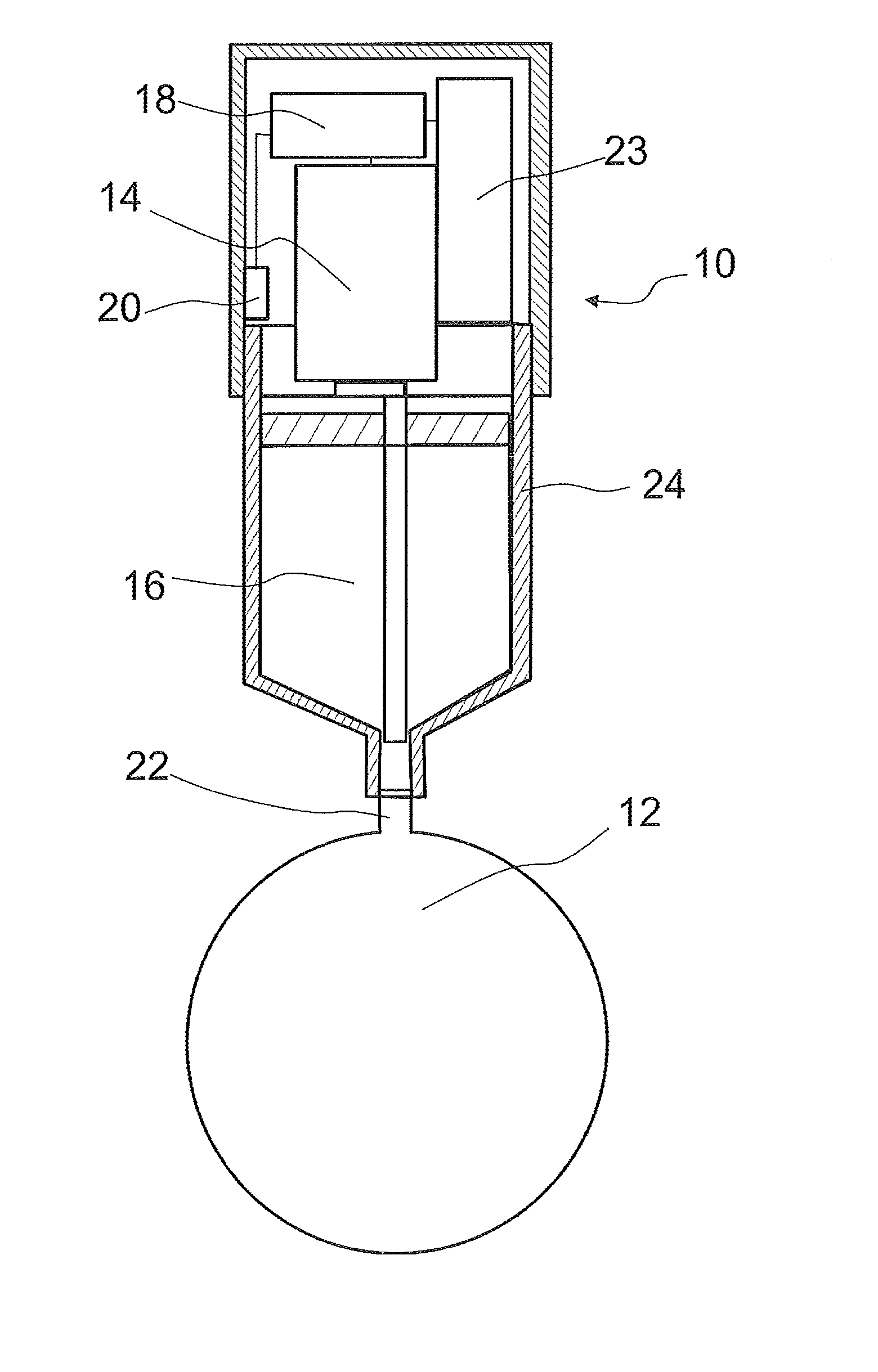

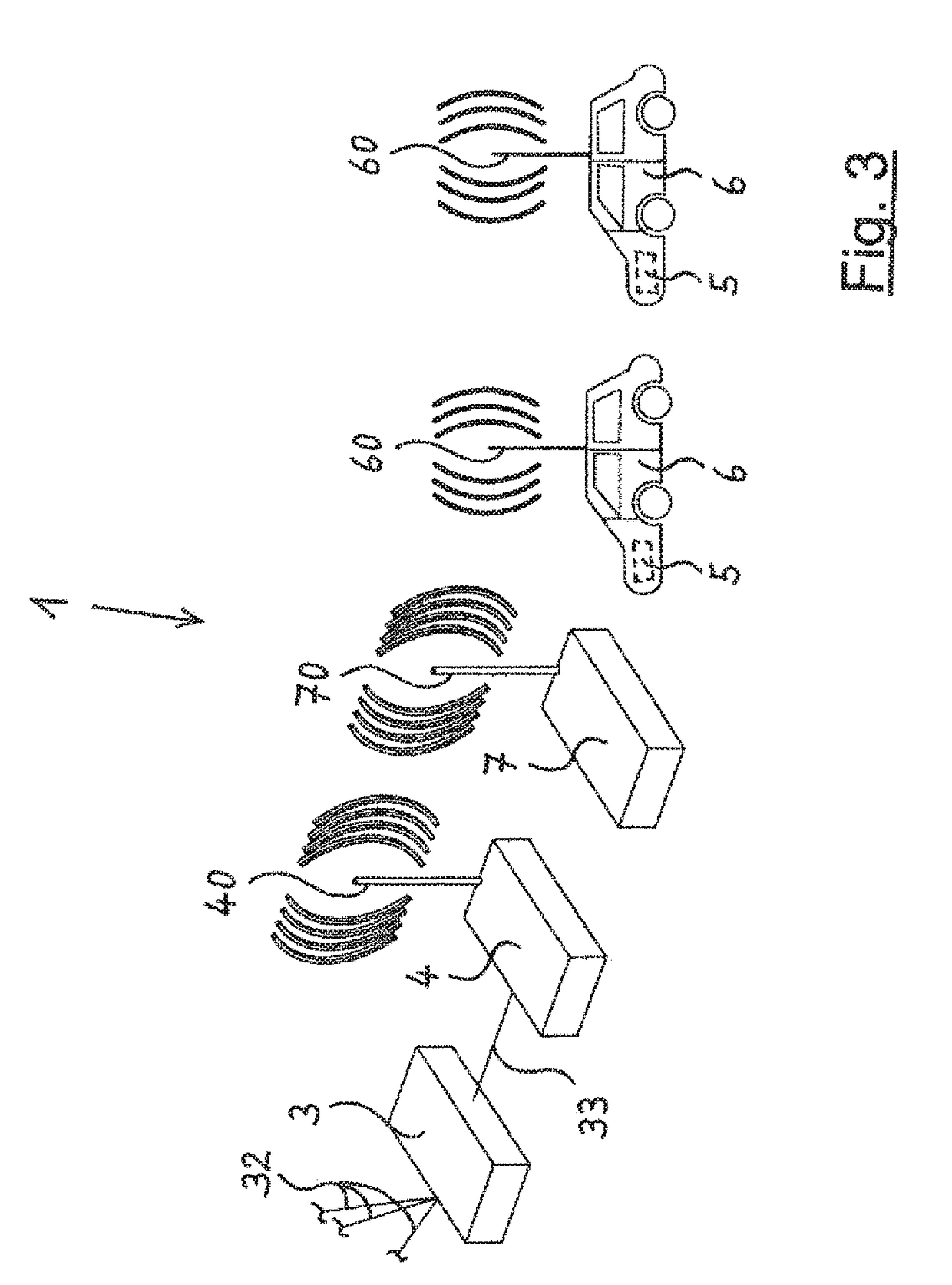

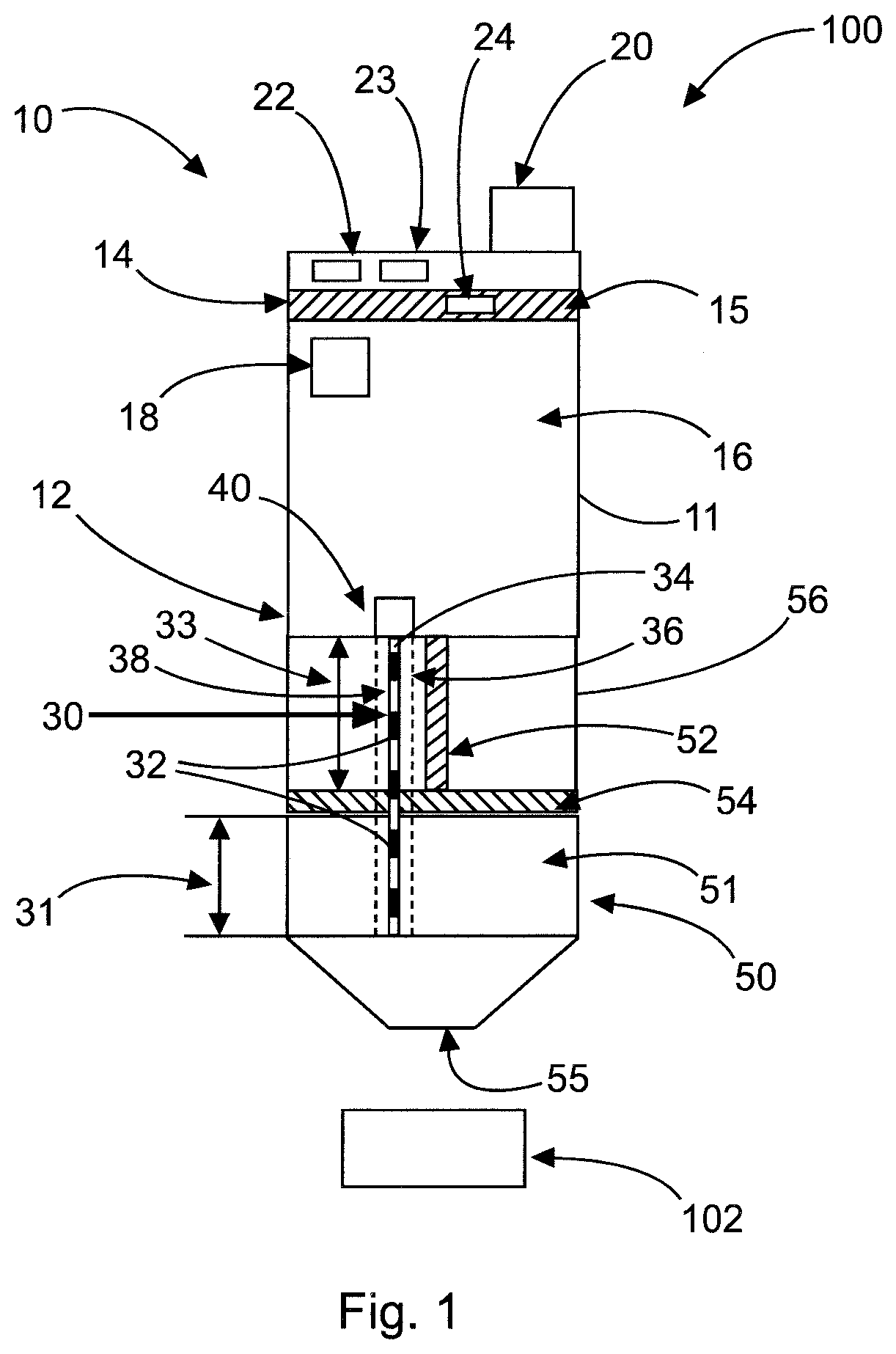

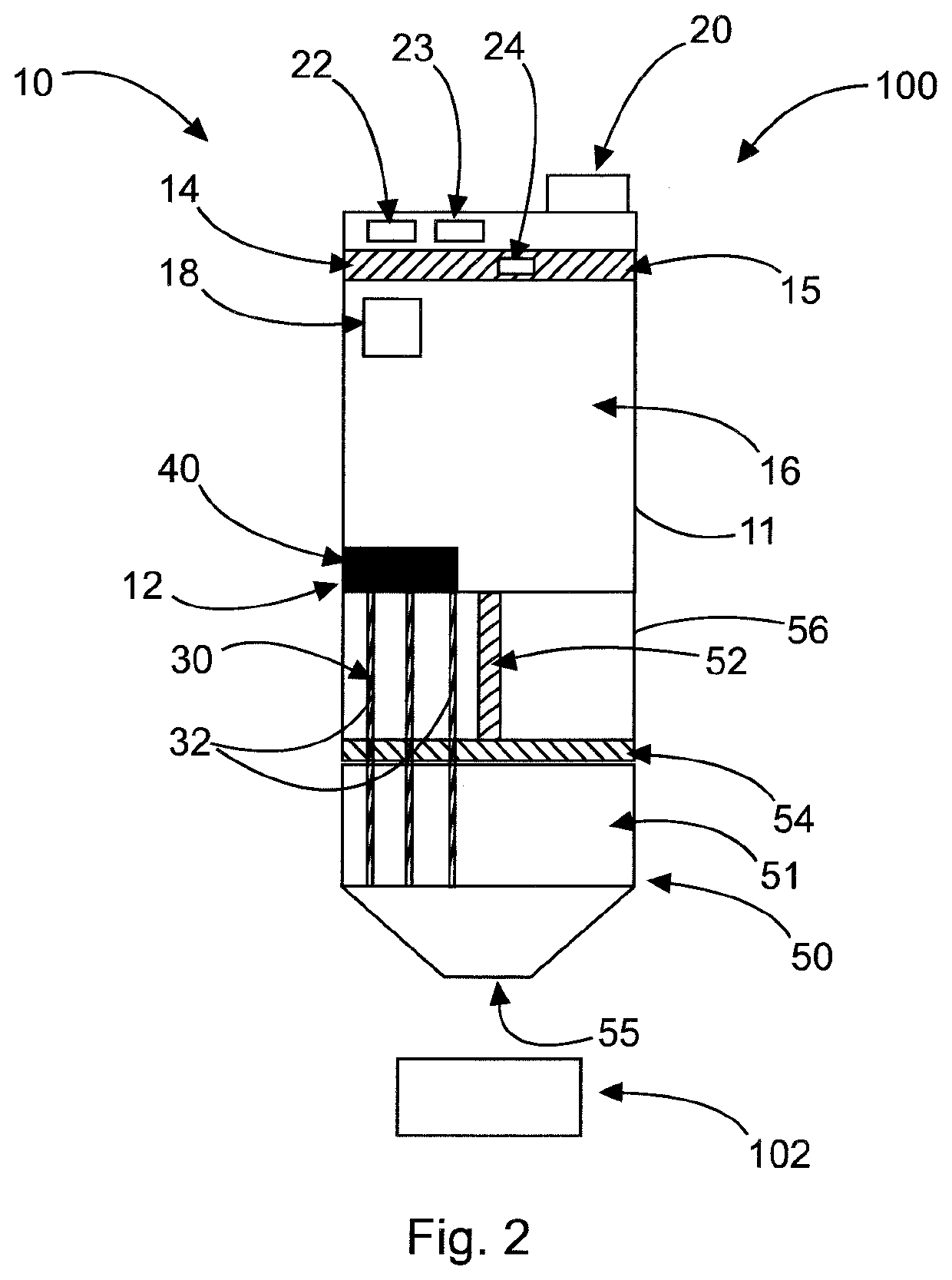

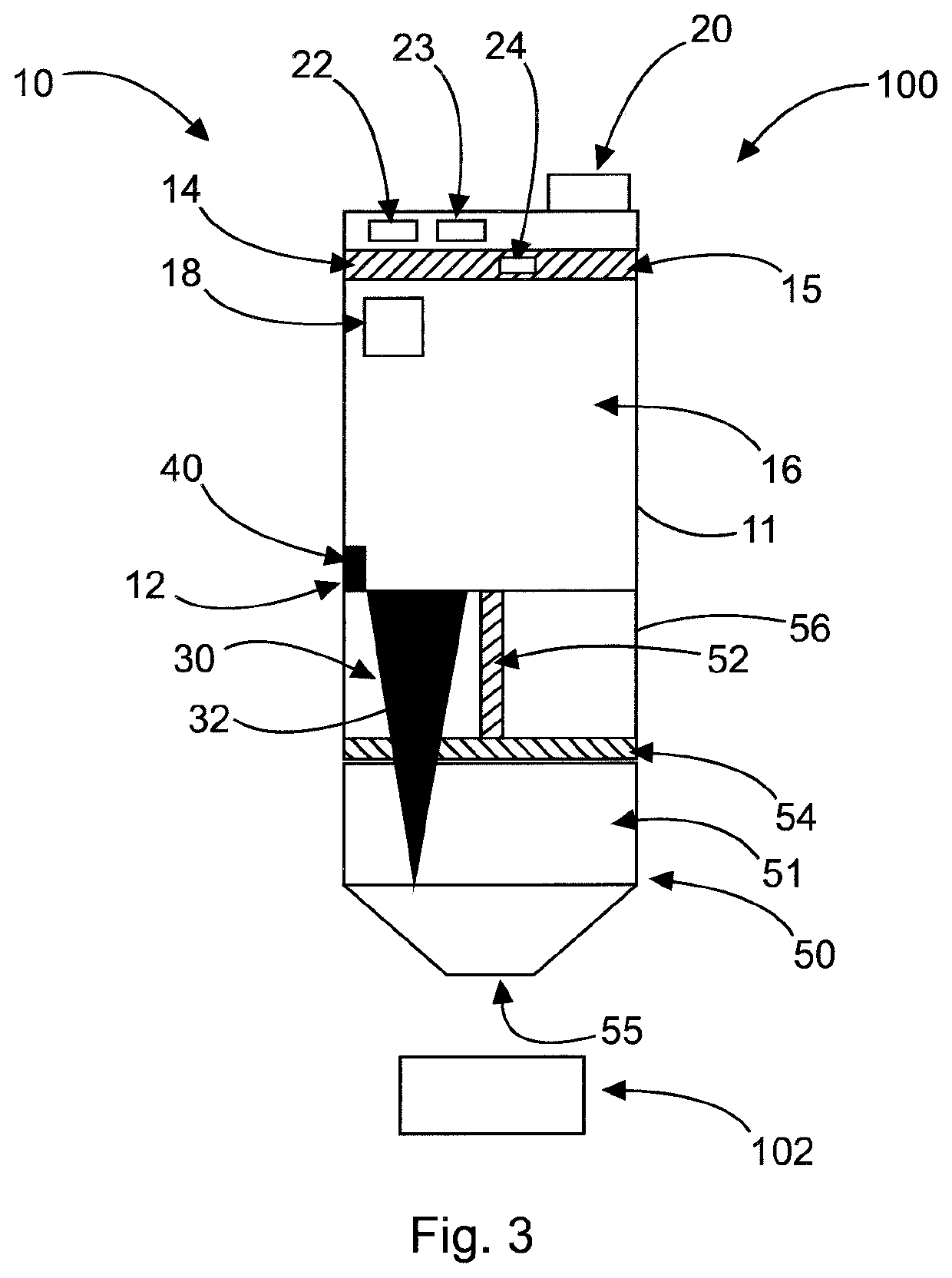

Multi-modal fluid condition sensor platform and system therefor

InactiveUS20130204488A1Vehicle testingAnalysing fluids using sonic/ultrasonic/infrasonic wavesState variationEngineering

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification that can be further enhanced using specifically designed nanoparticles that can be introduced into the system, engineered to specifically bind with the contaminants and / or undergo an irreversible state change upon certain experienced conditions to both increase the detectability as well as provide for a framework to improve filter performance.

Owner:MAST INC

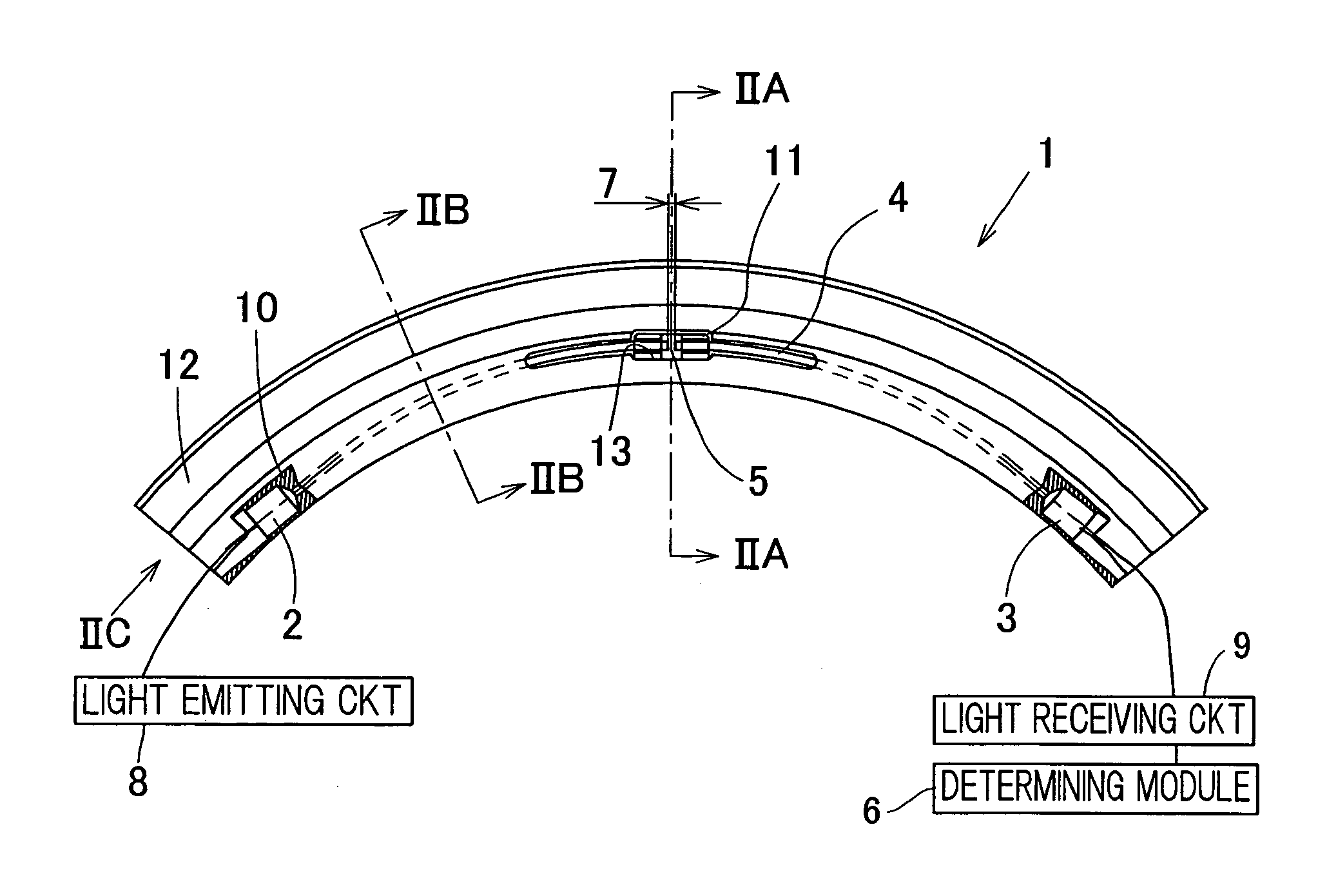

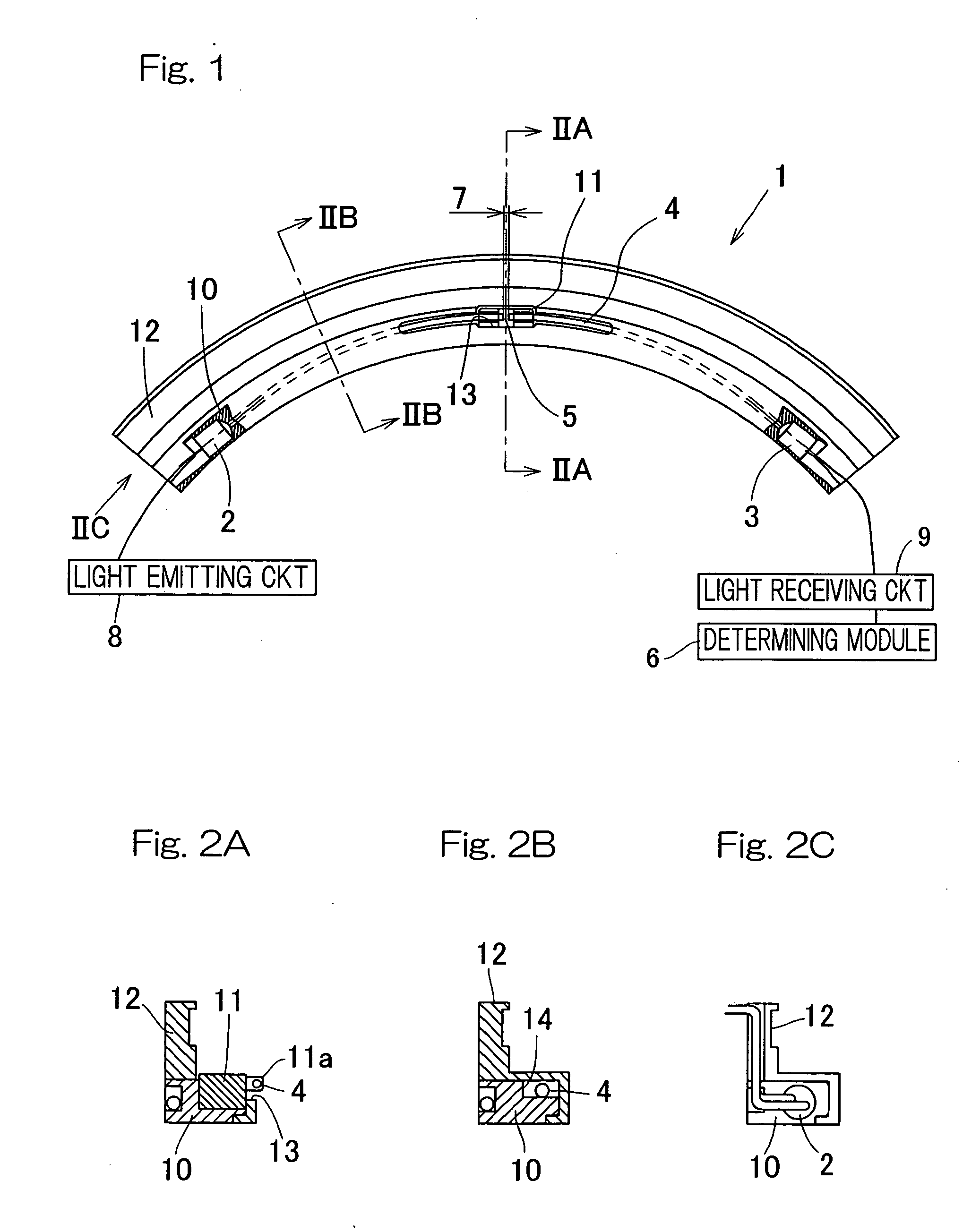

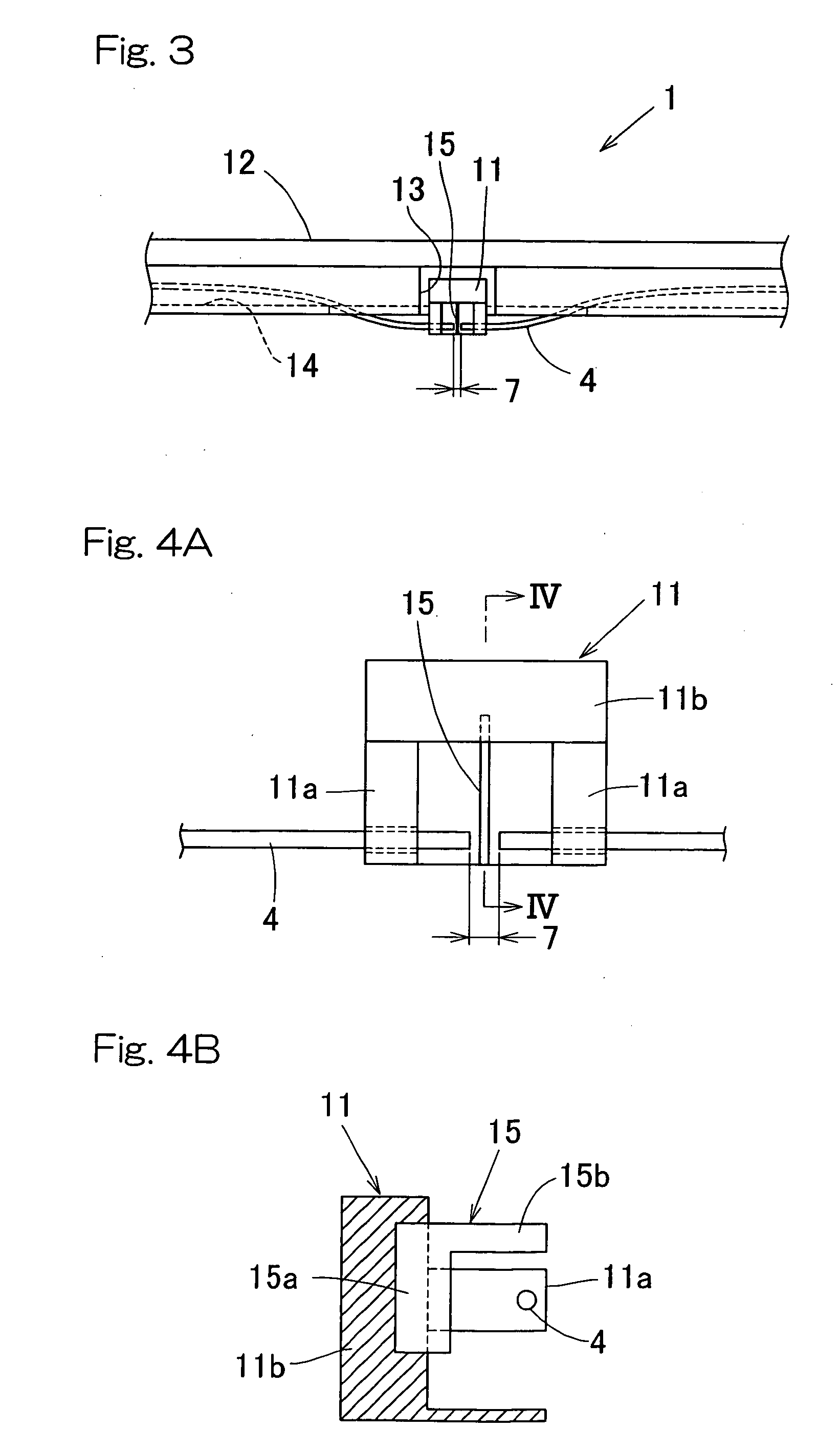

Lubricant deterioration detector and bearing assembly equipped with such detector

ActiveUS20100014087A1Accurate detectionAvoid damageBearing assemblyTransmissivity measurementsEngineeringLubrication

A lubricant deterioration detecting device includes an arcuate optical fiber (4) having one end positioned in face-to-face relation with a light emitting element and also having the opposite end positioned in face-to-face relation with a light receiving element, and a measuring gap (7) for intervening a lubricating agent (5) is provided in a portion of the arcuate optical fiber (4). In the vicinity of the measuring gap (7), a resistance element (15), the amount of deformation of which varies with change in state of lubrication performed with the lubricating agent, is provided for flowing of the lubricating agent (5) within the measuring gap (7).

Owner:NTN CORP

System and method for detecting spall initiation and defining end of life in engine components

ActiveUS9205845B2Analogue computers for vehiclesMaterial testing goodsCommunications systemEngineering

A system and method are provided for detecting a spall in an engine. The vehicle, for example, may include, but is not limited to an engine, an oil debris sensor coupled to the engine, a communications system, and a processor communicatively coupled to the oil debris sensor and the communications system. The processor may be configured to increment a counter when the oil debris sensor detects a particle over a predetermined size, increment the counter when a mass of a plurality of particles under the predetermined size exceeds a predetermined mass threshold, transmit, via the communications system, a first message when the counter exceeds a predetermined counter threshold, and reset the counter after predetermined amount of time.

Owner:HONEYWELL INT INC

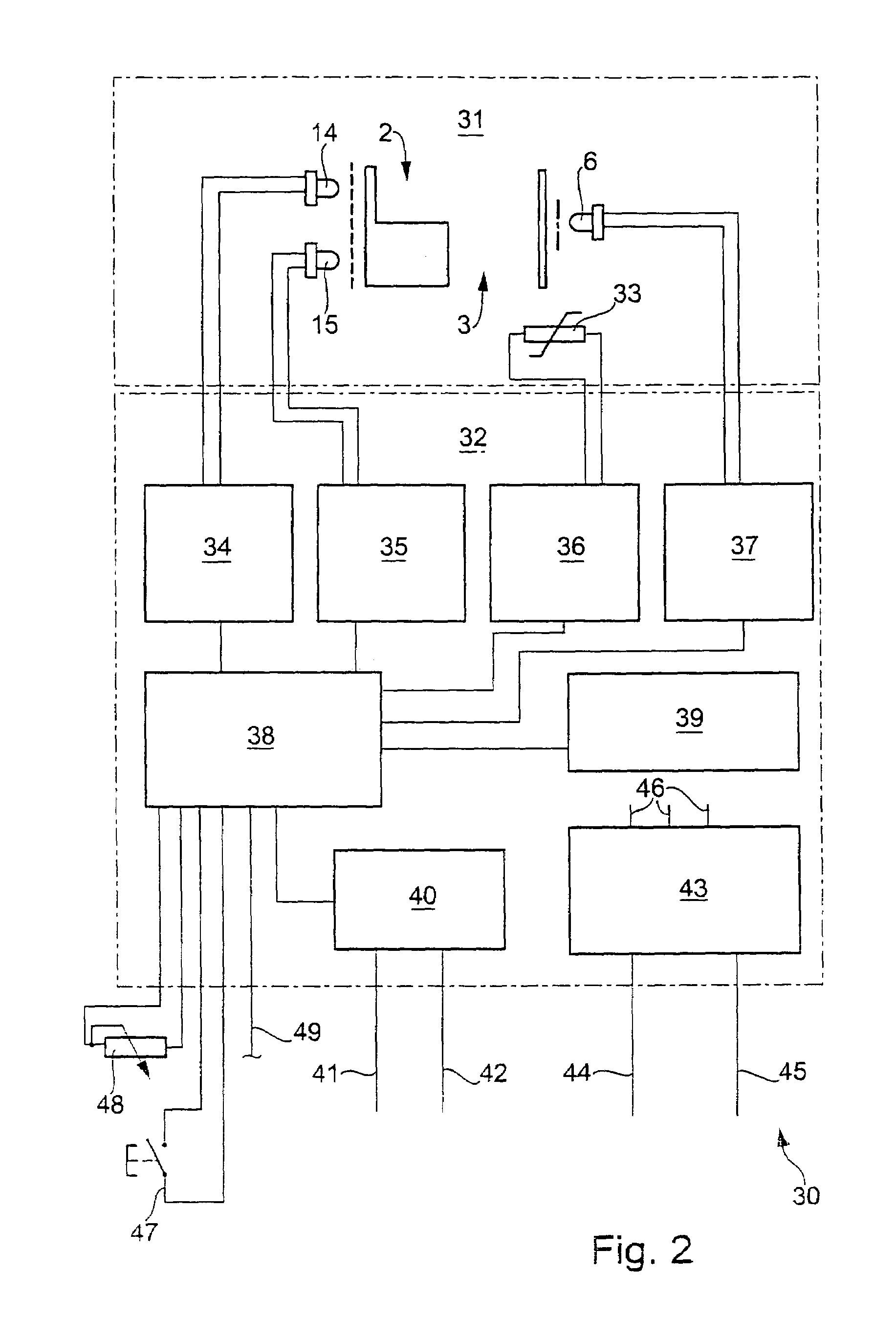

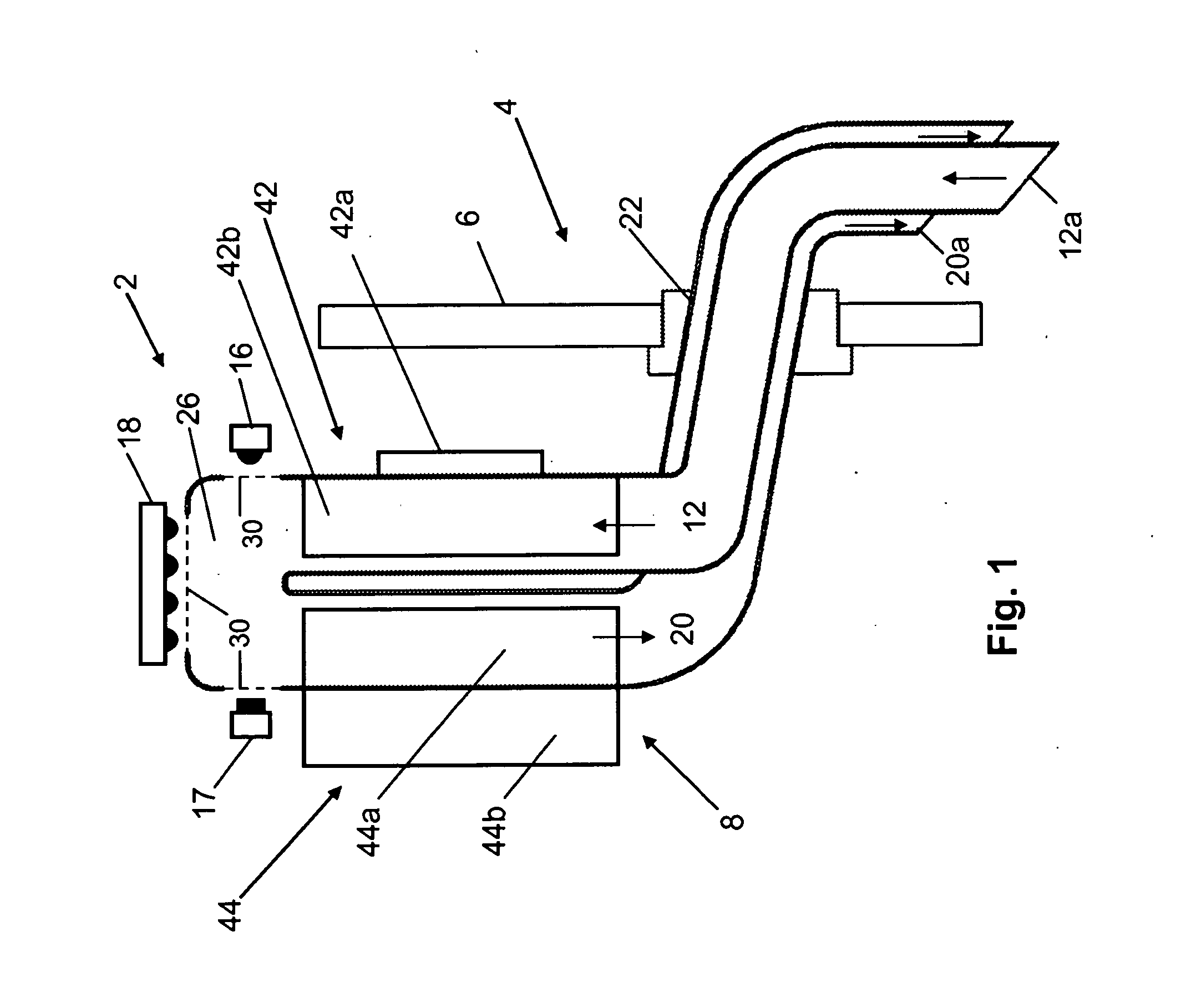

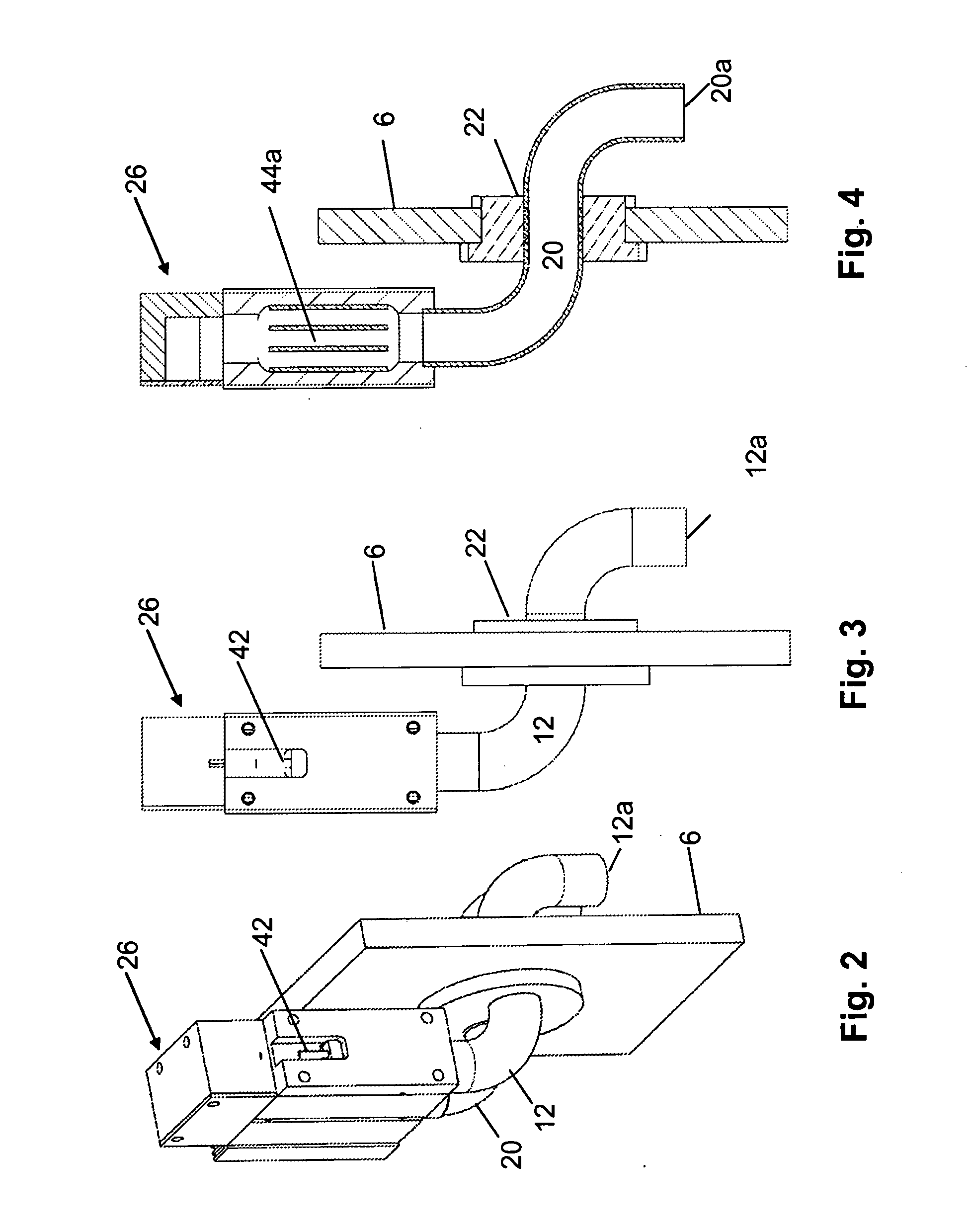

System and method for determining readings of gases and/or an aerosol for a machine

ActiveUS20130125624A1Not gained acceptanceWithdrawing sample devicesUsing mechanical meansMeasurement deviceEngineering

In order to improve a system for monitoring the working area atmosphere of an operating engine, measuring devices (2) for determining readings for a gas and / or an aerosol in the working area (4) of an operating engine are used as a starting point. Each measuring device comprises a suction means (8) which extracts a gas and / or a mixture of an aerosol from the working area (4) of the operating engine and feeds it to a sensor unit (16, 17, 18). An electronics module for operating the sensor unit (16, 17, 18) is also present. The suction means is designed as a convection pump (8) preferably with a heating device (42) and a cooling device (44).

Owner:SCHALLER AUTOMATION IND AUTOMATIONSTECHN

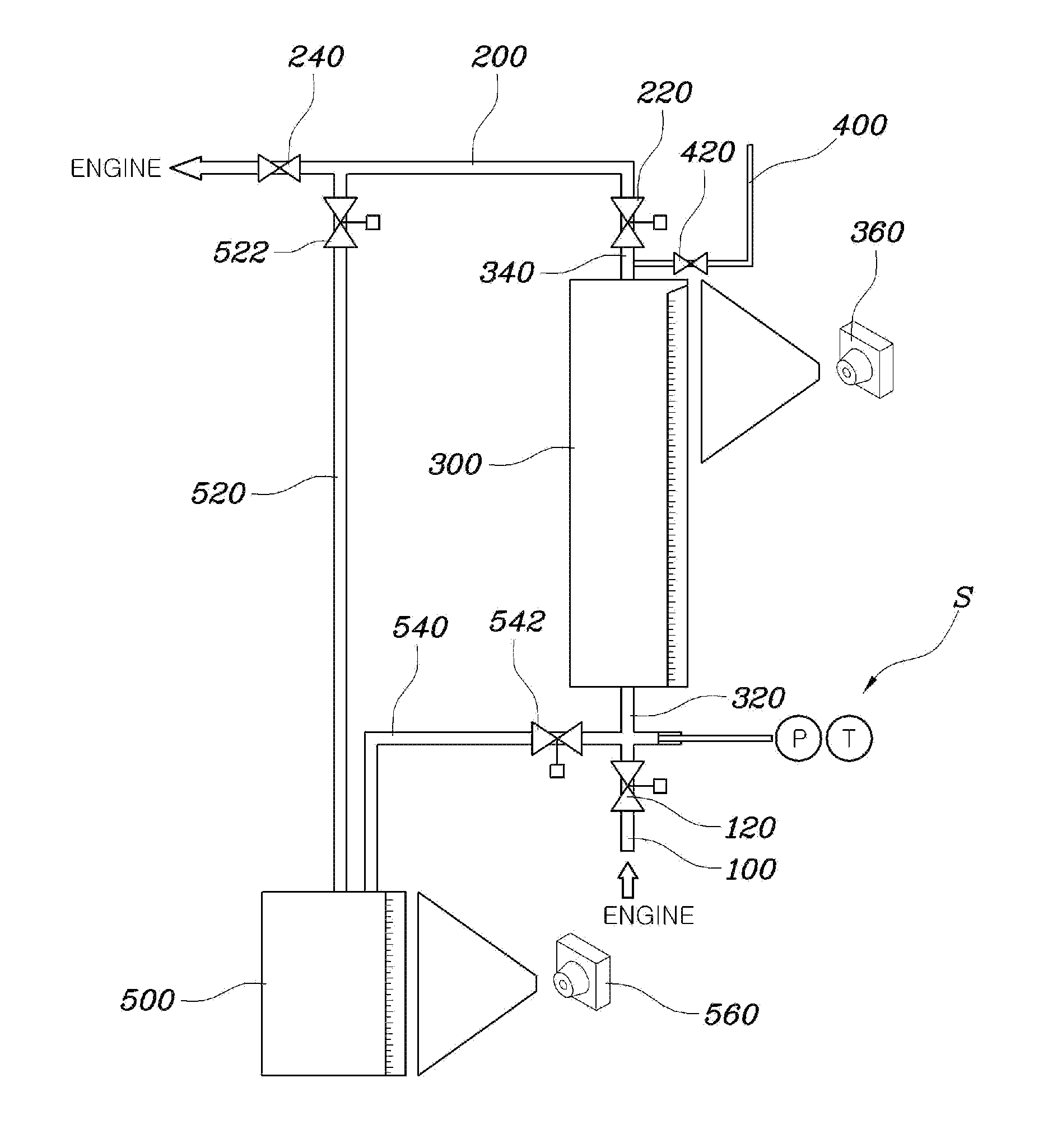

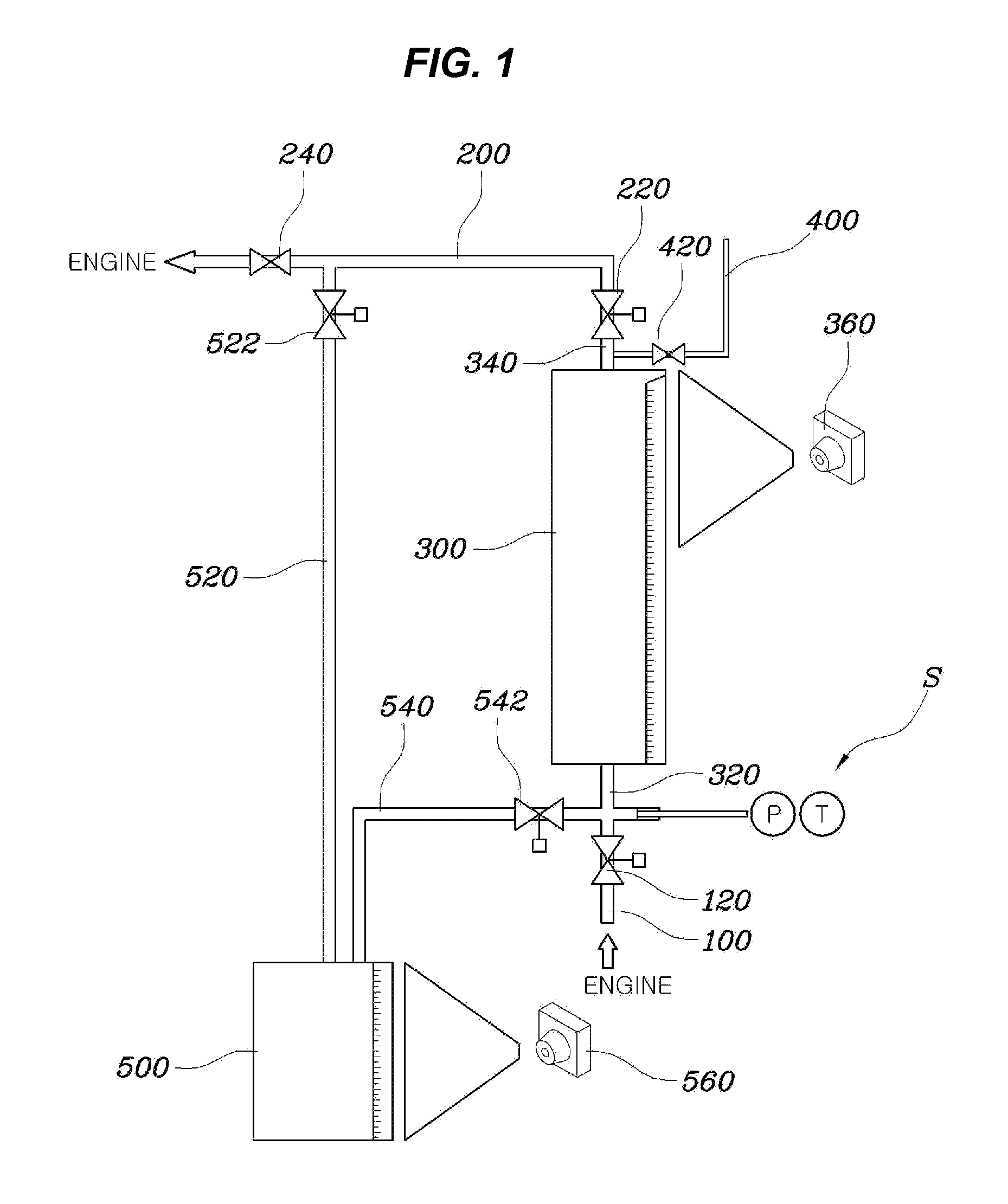

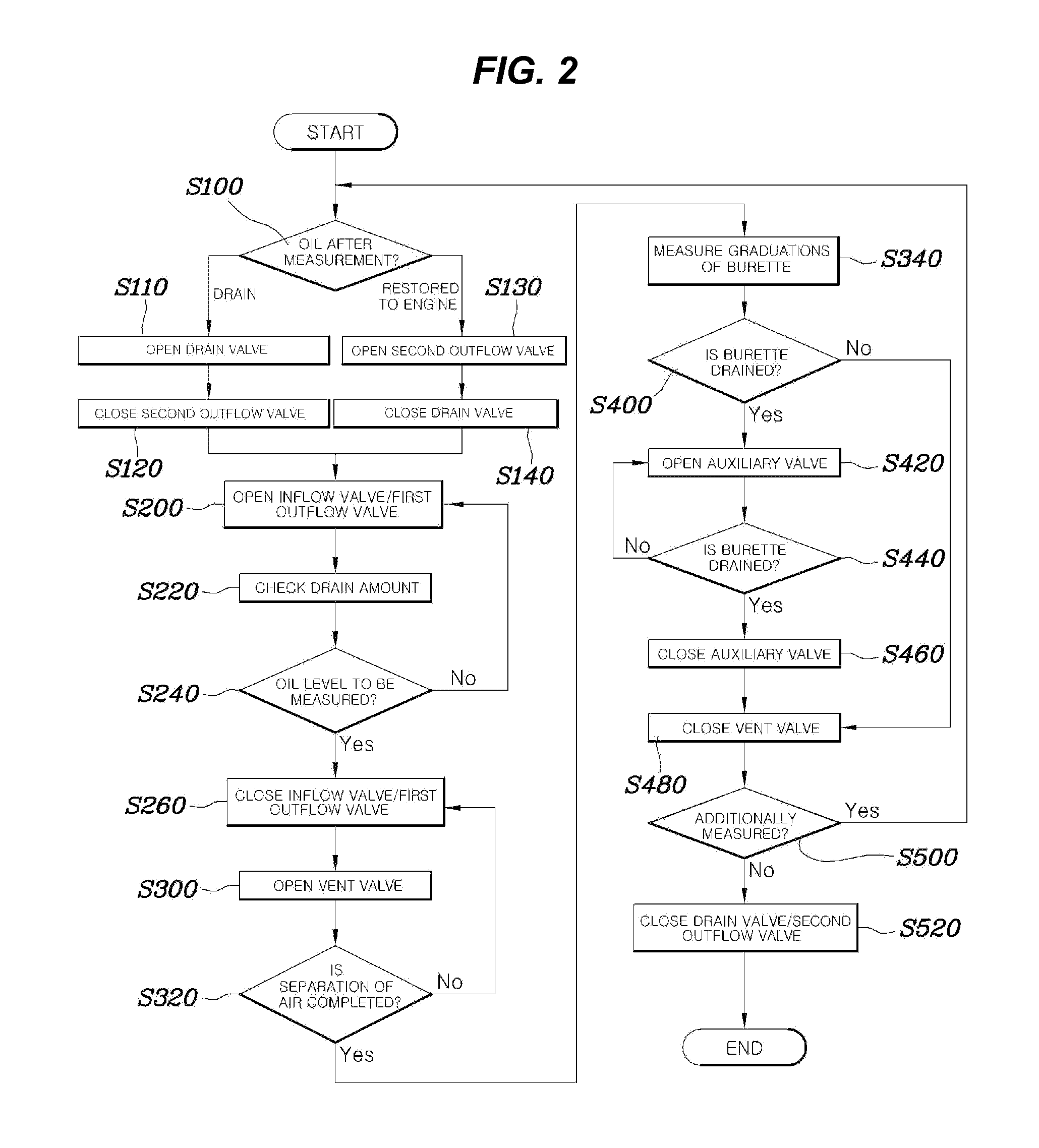

Apparatus for measuring air amount of engine oil and method using the same

InactiveUS20130118234A1Improve reliabilityImprove test efficiencyVehicle testingVolume measurement apparatus/methodsBuretteDraining tube

An apparatus for measuring air amount of engine oil includes an inflow pipe in which the engine oil flows in connection with an engine and an inflow valve, a measuring burette having an inflow hole connected with the inflow pipe and an outflow hole formed at the other side and a measurement camera provided at the side of the measuring burette to photograph graduations, a vent pipe branched from the outflow hole of the measuring burette and a bent valve provided on the vent pipe, a drain burette having a drain pipe connected with the outflow hole provided at one side thereof and having a drain valve provided on the drain pipe, an auxiliary drain pipe having one side branched from the inflow hole and the other side connected to the drain burette and an auxiliary valve provided on the auxiliary drain pipe, and a control unit.

Owner:HYUNDAI MOTOR CO LTD +1

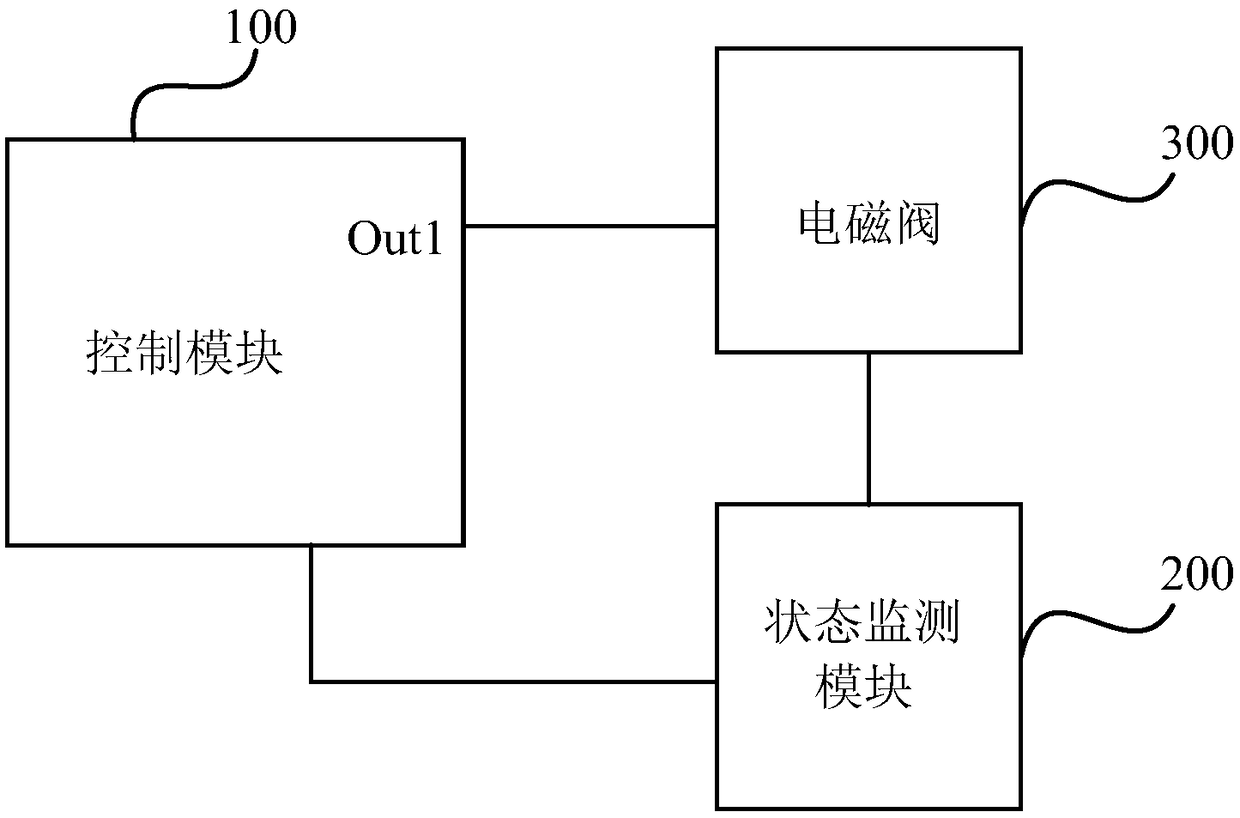

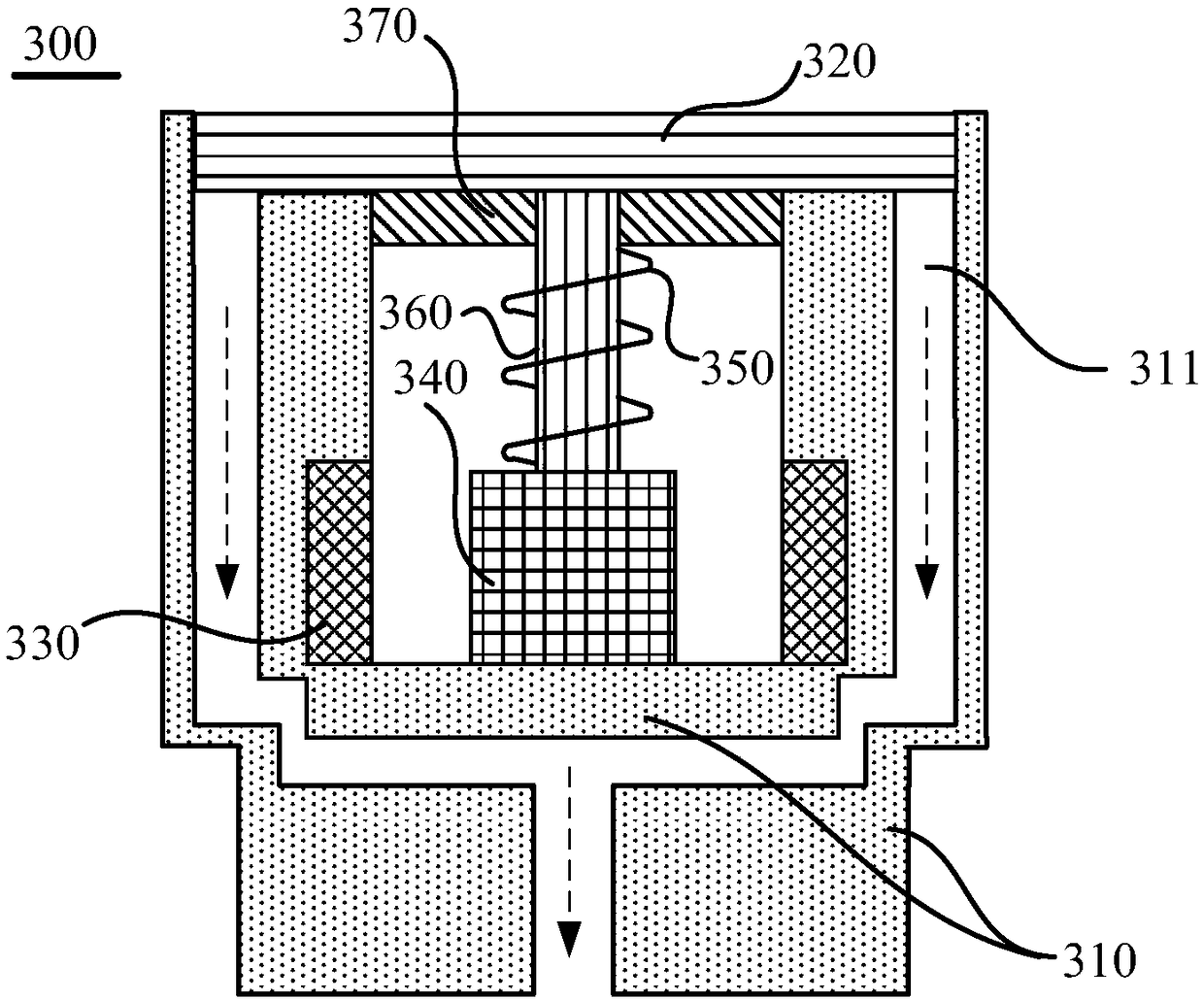

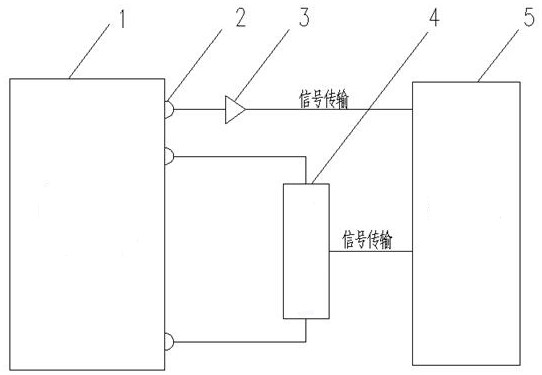

Fault detecting device for solenoid valve and oil sump for engine

ActiveCN108868959AAvoid getting out of controlReduce maintenance costsOilsumpsMachines/enginesElectricitySolenoid valve

The embodiment of the invention discloses a fault detecting device for a solenoid valve and an oil sump for an engine. The fault detecting device for the solenoid valve comprises a control module anda state monitoring module, wherein the first output end of the control module is electrically connected to the first end of the solenoid valve, and the control module is used for outputting a drivingsignal to the solenoid valve. The input end of the state monitoring module is electrically connected to the second end of the solenoid valve, and the output end of the state monitoring module is electrically connected to the input end of the control module. The state monitoring module is used for detecting the opening and closing states of the solenoid valve and outputting a detection signal to the control module according to the opening and closing states of the solenoid valve. The control module is further used for receiving the detection signal and determining a solenoid valve fault when itis determined that the relationship between the detection signal and the driving signal does not satisfy a preset relationship. The fault detecting device for the solenoid valve can detect the solenoid valve fault in time, avoids an engine failure caused by excessive topping up of oil or unable to replenish the oil, and thus the recondition expense is saved.

Owner:WEICHAI POWER CO LTD

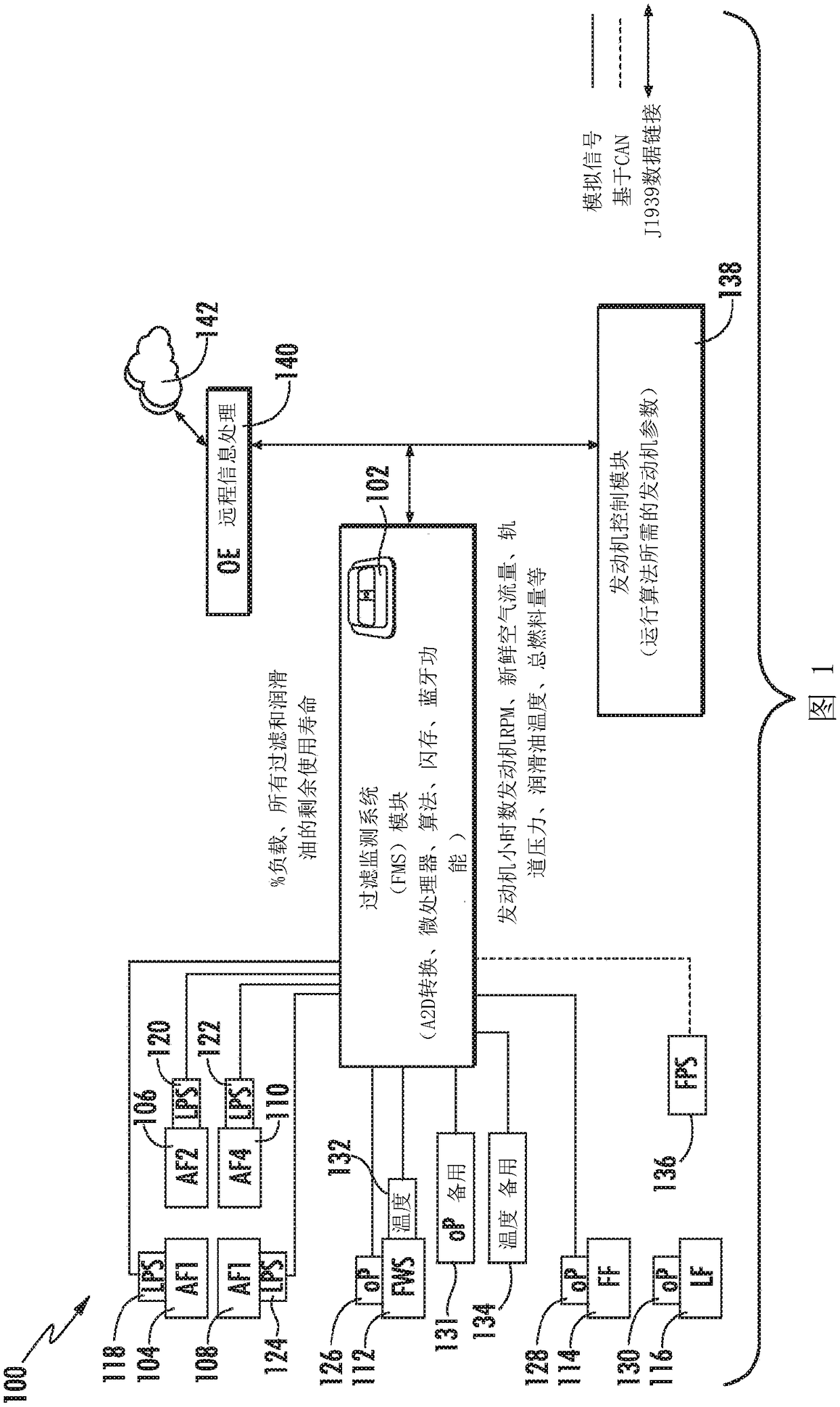

Filtration monitoring systems

ActiveCN108368788AInternal-combustion engine testingElectrical controlElectronic systemsFilter system

A filtration monitoring system is an electronic system control module installed on an internal combustion engine or within a vehicle powered by the internal combustion engine. The filtration monitoring system monitors the health and status of the filtration systems present on the engine. The filtration monitoring system tracks filter loading patterns and predicts remaining service life of the filters by running smart algorithms based on sensor feedback (e.g., pressure sensor feedback, fluid quality characteristic sensor feedback, etc.). In some arrangements, the described filtration monitoringsystems provide feedback as to whether a genuine (i.e., authorized, OEM approved, etc.) or unauthorized filter cartridge is installed in a given filtration system. The filtration monitoring system may be retrofit into an existing internal combustion engine or vehicle that does not already have a filtration monitoring system.

Owner:CUMMINS FILTRATION IP INC

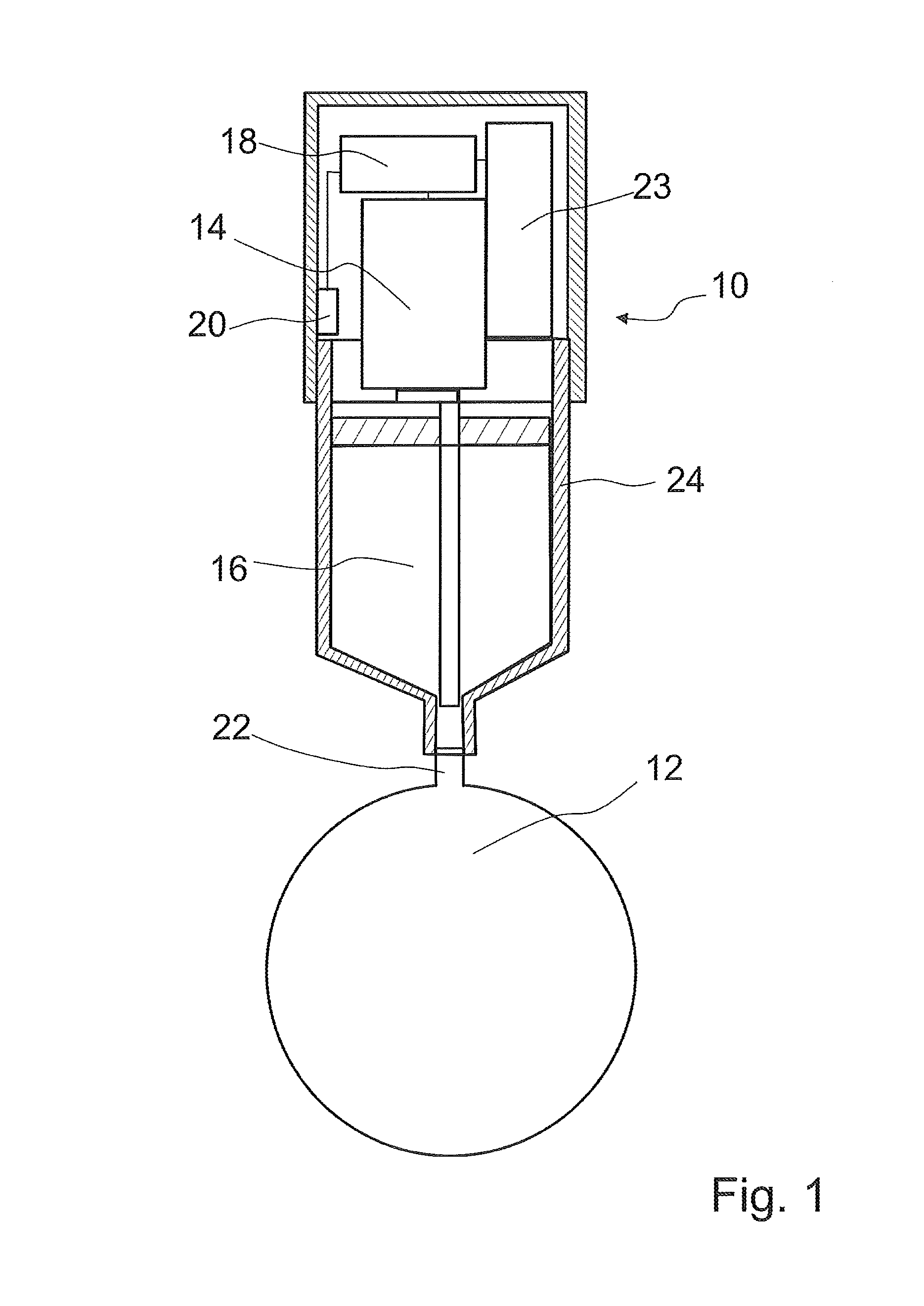

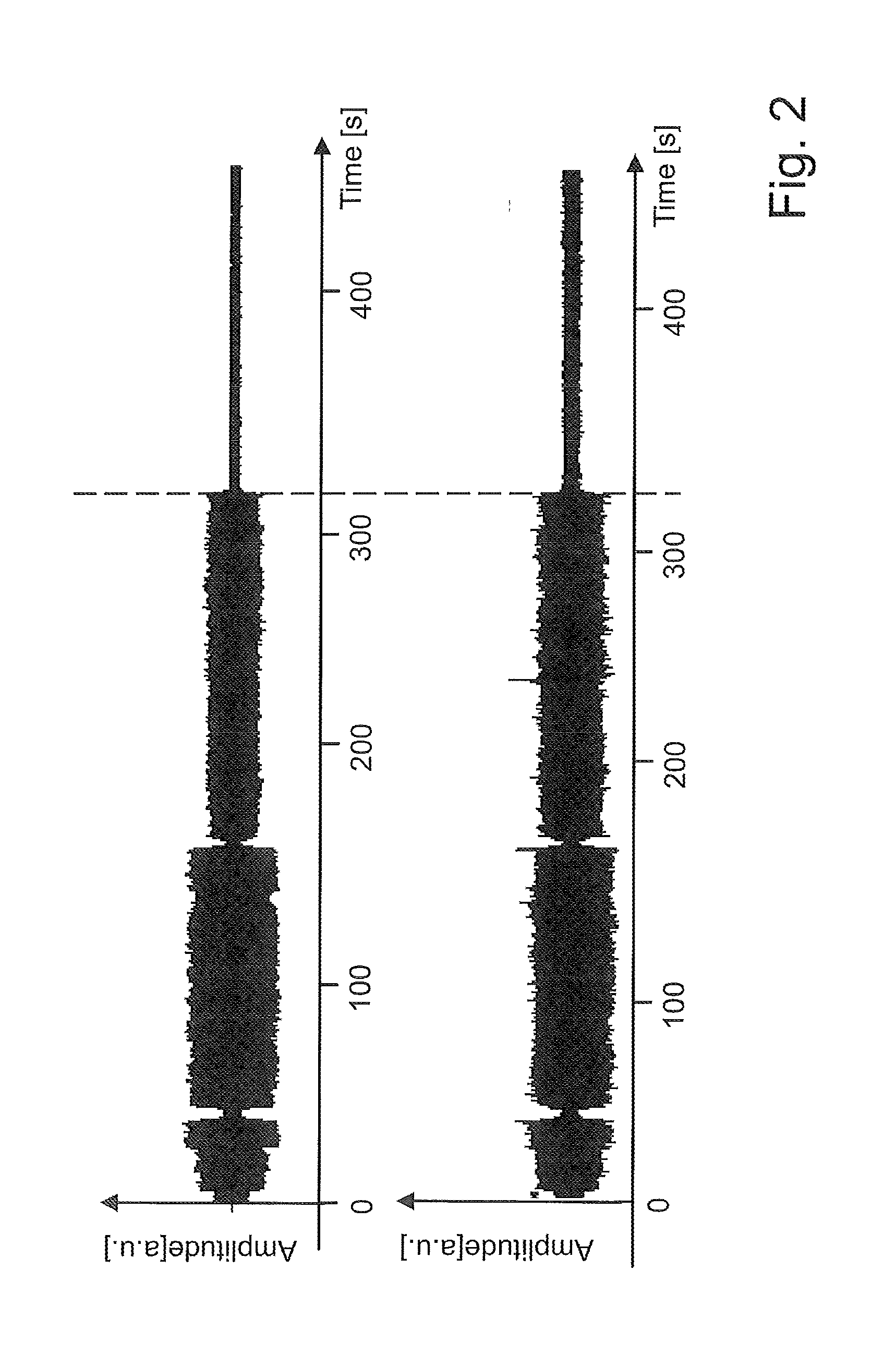

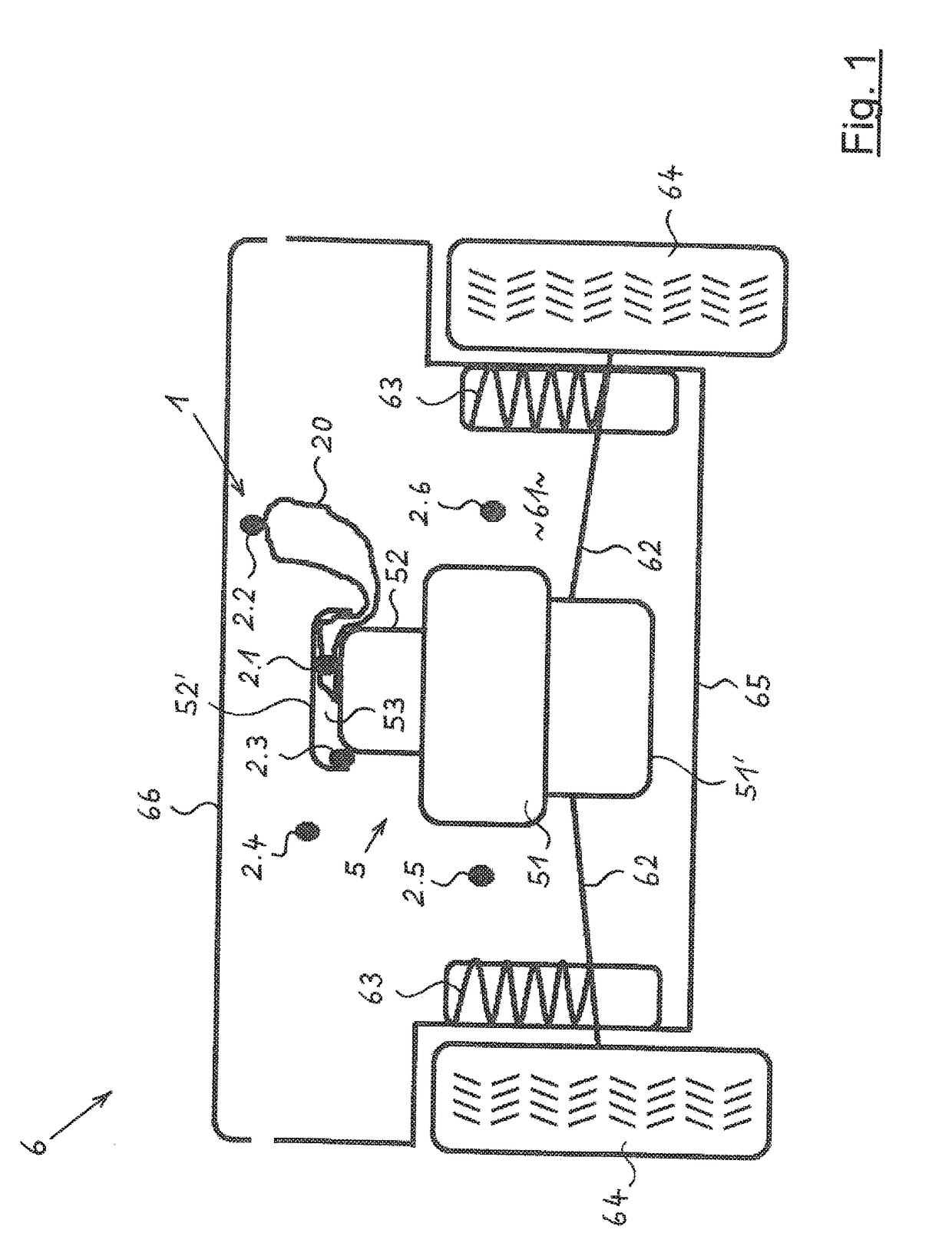

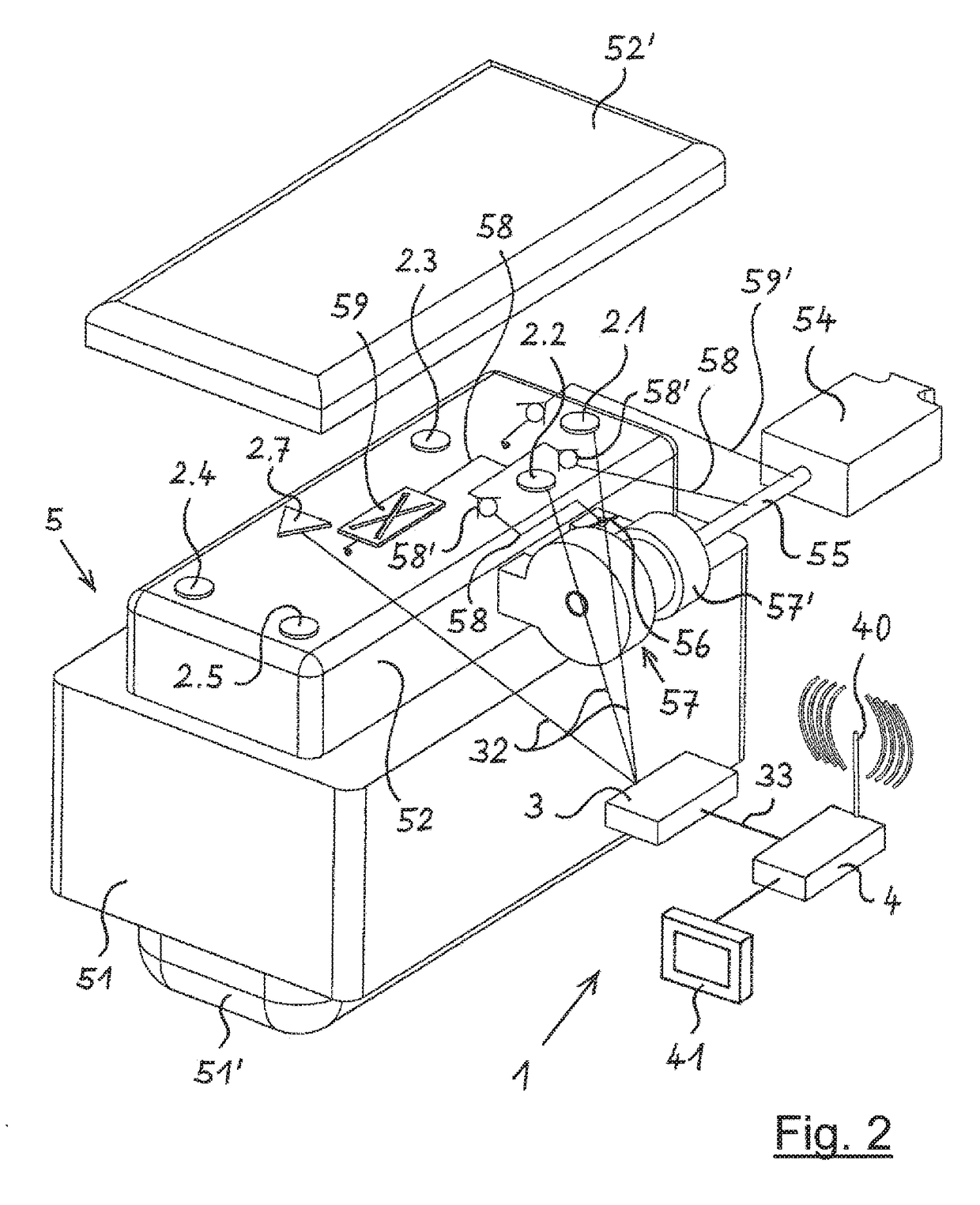

Lubricating device with a control unit for operating the lubricating pump

ActiveUS20160290558A1Reliably detecting long downtimeMinimize energy consumptionSignal processingLubricating pumpsEngineeringTime windows

The invention relates to a lubricating device that includes a lubricant pump, a lubricant reservoir for supplying lubricant to a machine to be lubricated, a control unit for determining an operating state of a machine and for operating the lubricant pump based on the signals of at least one sensor configured to detect emissions emanating from the machine to be lubricated, and a housing configured to be attached to a lubrication nozzle of the machine to be monitored. It is proposed that a reading of the signals of the sensor by the control unit is limited to a predetermined set of time windows with a predetermined width, wherein the time windows are separated by an interval where the signals of the sensor are not read.

Owner:AB SKF

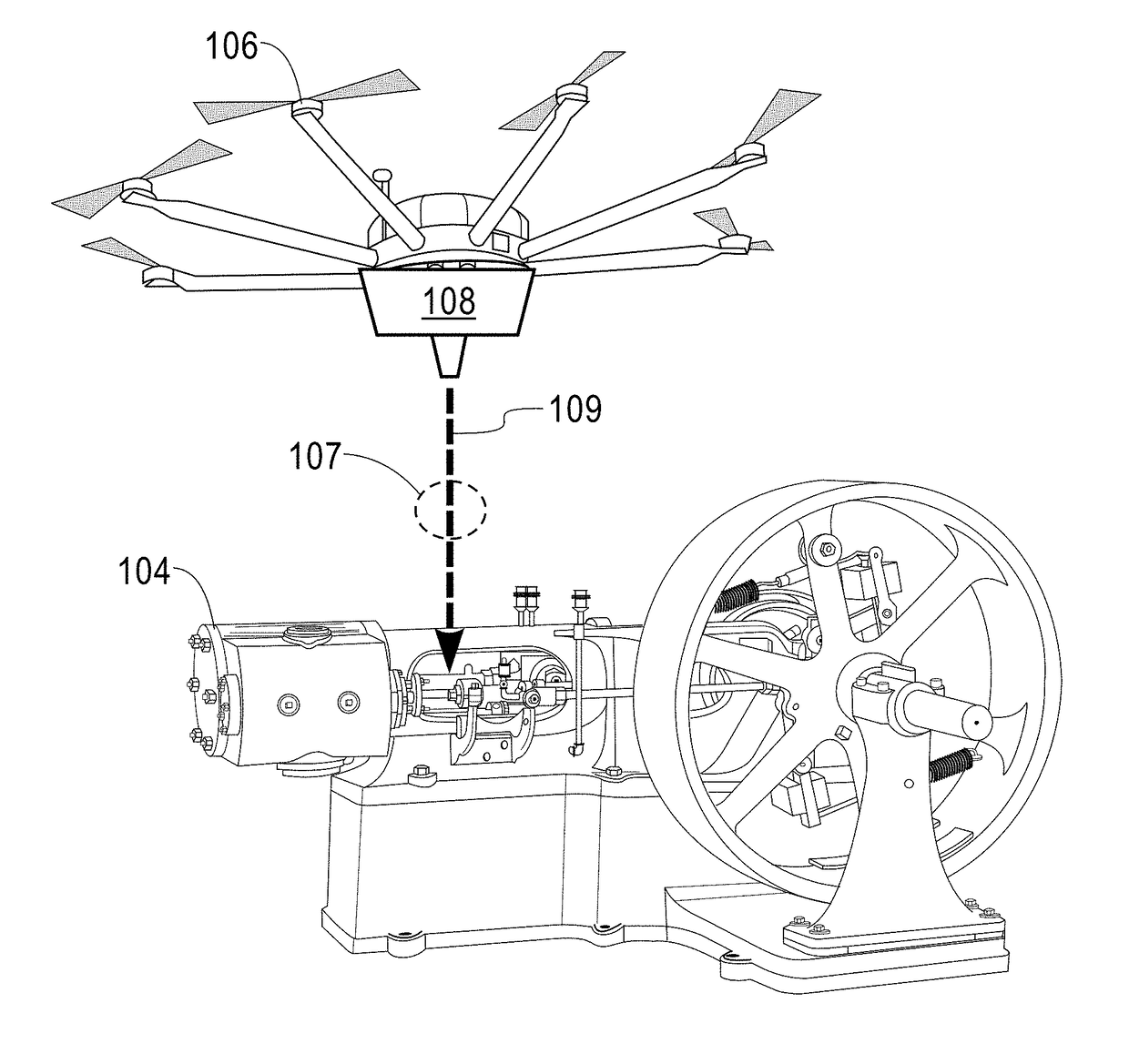

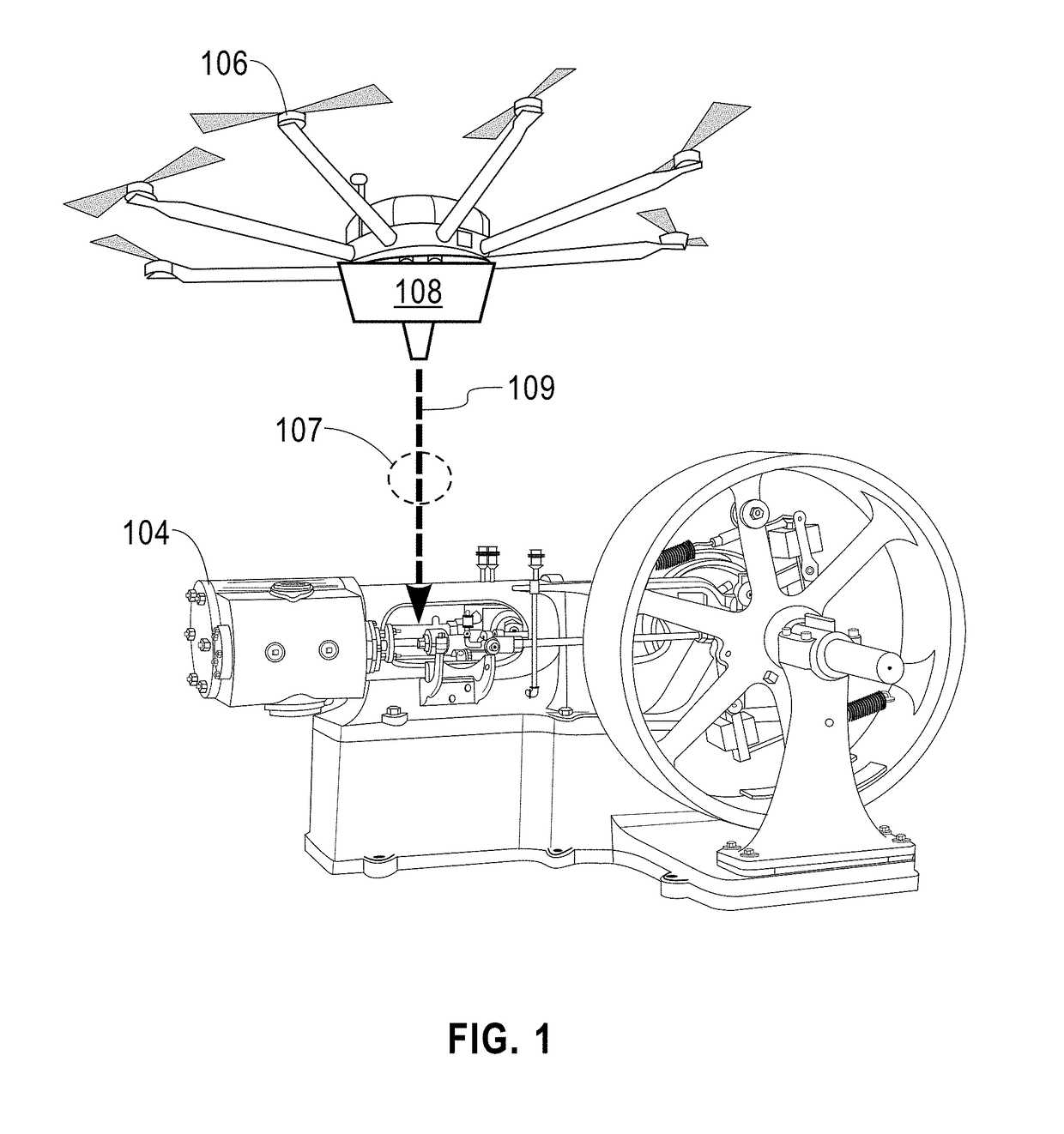

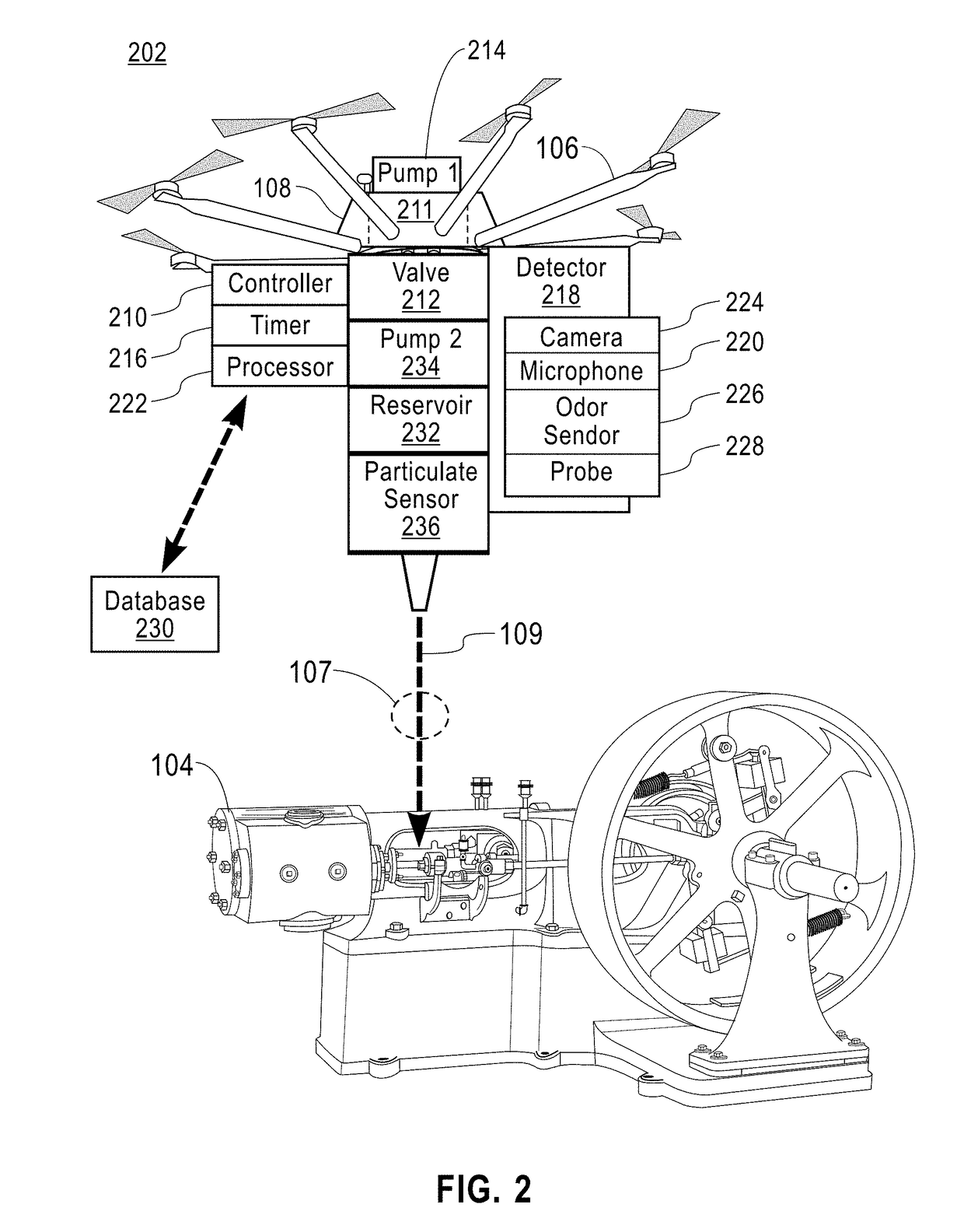

Deployment of lubricant with an unmanned aerial vehicle

A system for lubricating a machine. The system includes an unmanned aerial vehicle configured to fly to a lubrication location proximate the machine. A supply of lubricant is carried by the unmanned aerial vehicle. A controller is configured to deliver at least part of the supply of lubricant to the machine when the unmanned aerial vehicle is at the lubrication location.

Owner:IBM CORP

Method and device for monitoring the functioning of a crankcase ventilation system of an internal combustion engine

InactiveUS20180350169A1Low costAvoid disadvantagesRegistering/indicating working of vehiclesMachines/enginesExternal combustion engineEngineering

A method and a device for monitoring the functioning of a crankcase ventilation system of an internal combustion engine, crankcase ventilation gas being supplied to an intake line of the internal combustion engine via at least one crankcase ventilation line from the crankcase via an oil separator and a crankcase pressure regulating valve. An immediate surrounding environment of the internal combustion engine is monitored by at least one sensor that is sensitive to crankcase ventilation gas or to at least one crankcase ventilation gas component for the occurrence of crankcase ventilation gas, and that, if a presence of crankcase ventilation gas is determined, an informative or warning message is produced.

Owner:HENGST WALTER +1

Blow-by gas treatment device for internal combustion engine

A blow-by gas treatment device causes blow-by gas in a space defined by a cylinder head and a head cover in an internal combustion engine to flow back into an intake pipe. The blow-by gas treatment device includes a pipe joint and a blow-by gas pipe connected to the intake pipe. The pipe joint includes a basal end connected to the head cover, a distal end, a sensor-connected part connected to the pressure sensor, and a constriction located closer to the basal end than the sensor-connected part. The blow-by gas pipe is connected to a position of the pipe joint closer to the distal end than the sensor-connected part.

Owner:TOYOTA JIDOSHA KK

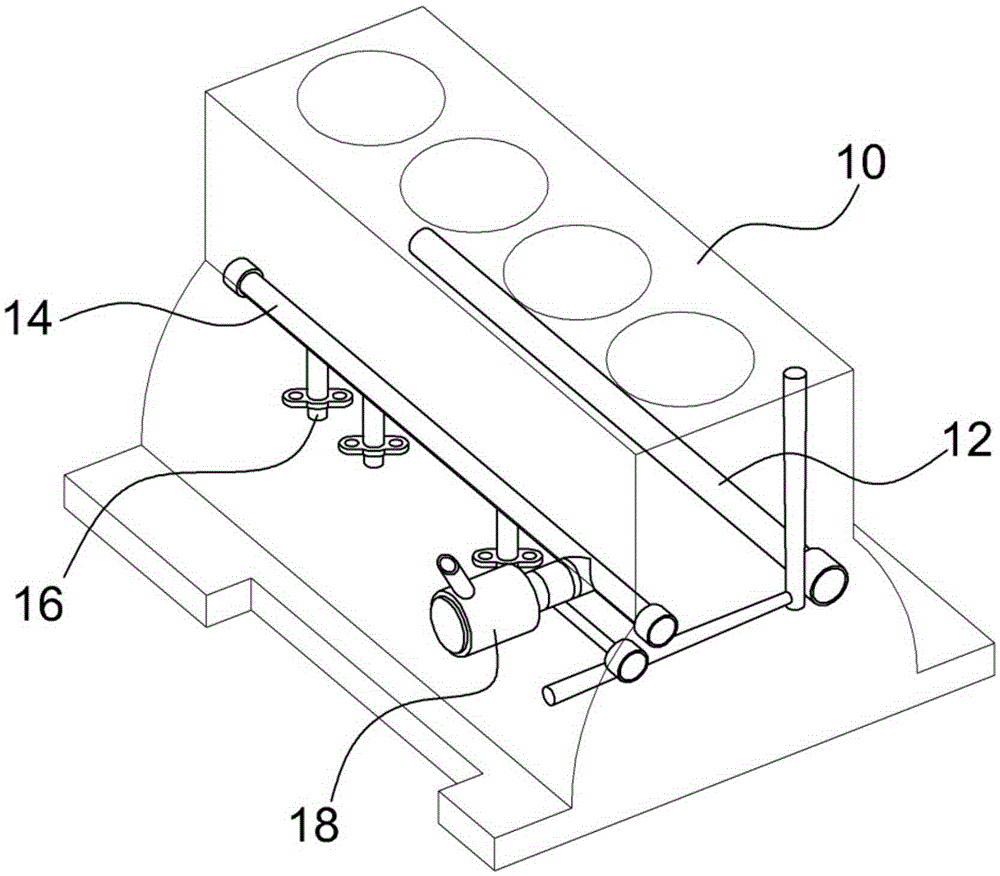

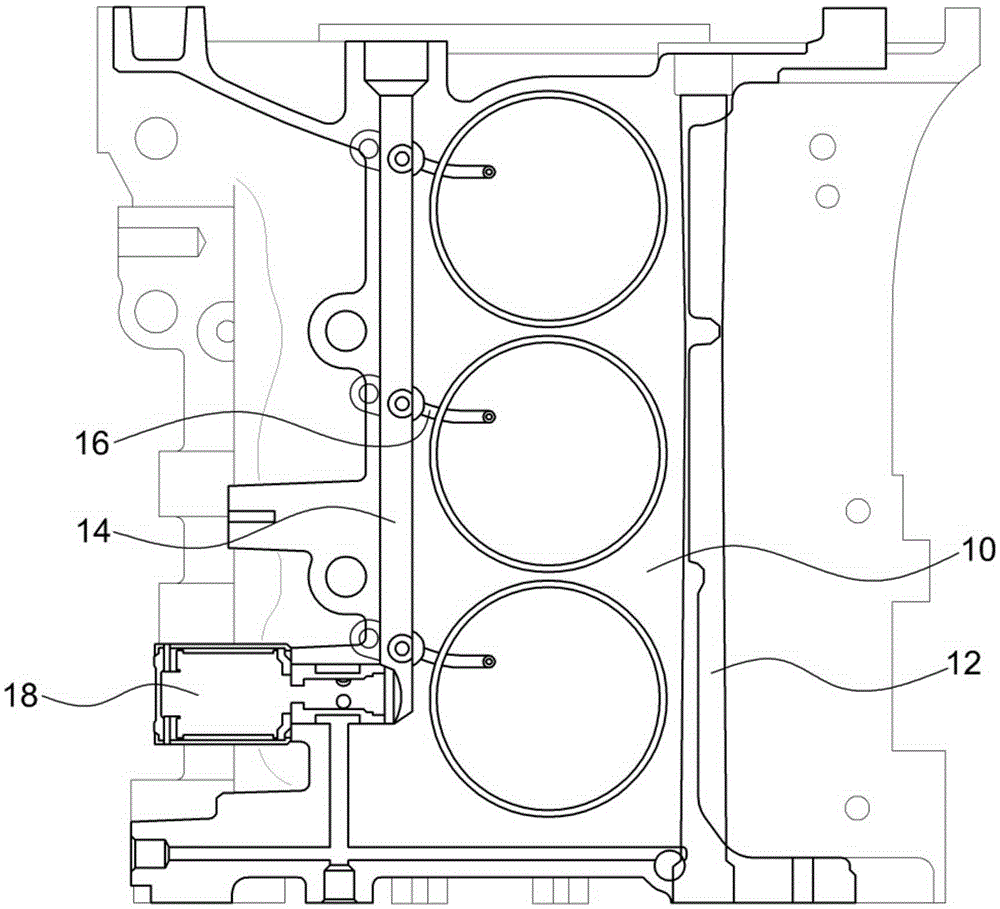

Apparatus and method for diagnosing failure of piston cooling jet of engine

An apparatus and a method for diagnosing failure of a piston cooling jet of an engine are disclosed. The apparatus for diagnosing failure of the piston cooling jet of the engine includes an oil line for a piston cooling jet arranged in a cylinder block in a longitudinal direction, a piston cooling jet mounted at the oil line for the piston cooling jet to inject oil to a piston, a solenoid valve mounted at an inlet of the oil line for the piston cooling jet to selectively allow an injection operation of the piston cooling jet, an oil pressure detecting means mounted at the oil line for the piston cooling jet after the solenoid valve to detect oil pressure, and a control unit configured to receive a detection signal of the oil pressure detecting means and determine whether the solenoid valve is in a failure state.

Owner:HYUNDAI MOTOR CO LTD +1

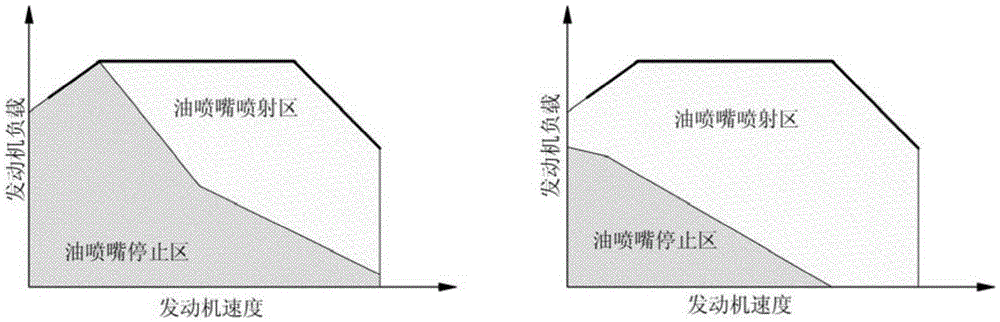

Diesel engine lubricating system testing device and testing method

The invention relates to a diesel engine lubricating system testing device and testing method. The testing device comprises a diesel engine for testing and a testing rack, wherein a plurality of to-be-tested oil ducts of a diesel engine body for testing are correspondingly provided with installation holes, temperature and pressure sensors used for measuring the temperature and the pressure of lubricating oil communicate with the diesel engine body for the testing through the installation holes, the temperature and pressure sensors are connected with the installation holes in a one-to-one correspondence mode, and the two ends of a flow meter used for measuring the flow of the lubricating oil are connected with two installation holes in the to-be-tested oil ducts, so that the lubricating oilin the to-be-tested oil ducts flows back into the diesel engine body for the testing after passing through the flow meter, the temperature and pressure sensors and the flow meter are in signal connection with the test bench correspondingly so as to transmit data, the lubricating oil flow and the temperature and pressure distribution of the diesel engine at different positions and at different rotating speeds can be accurately measured in real time according to the device, so that quantitative research on a diesel engine lubricating system is facilitated.

Owner:FIRST TRACTOR

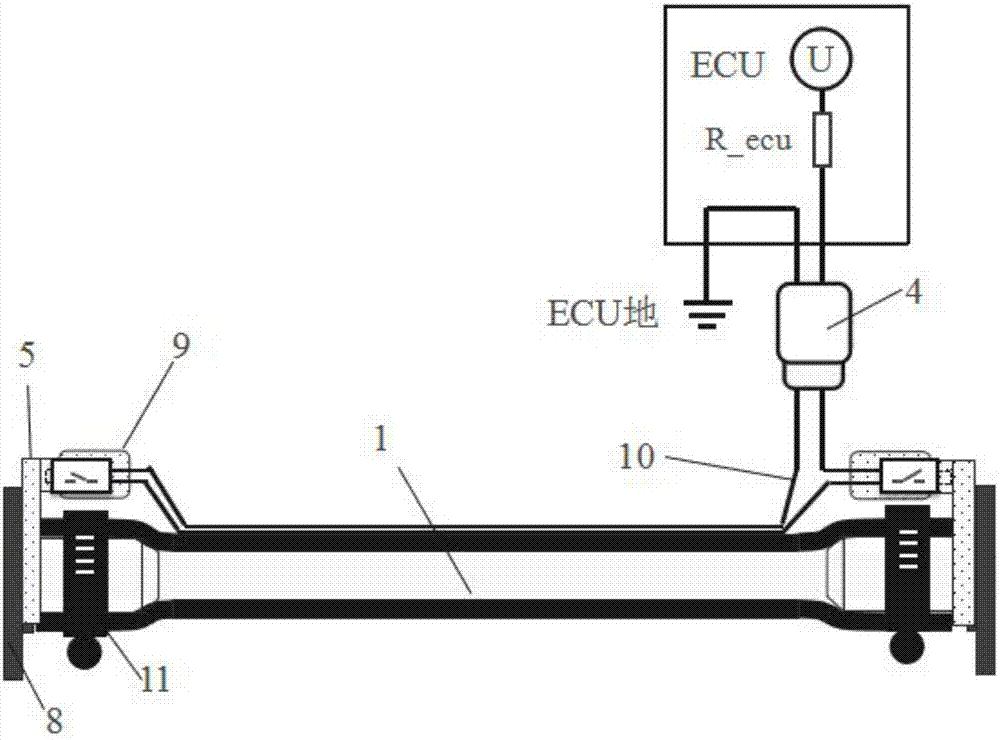

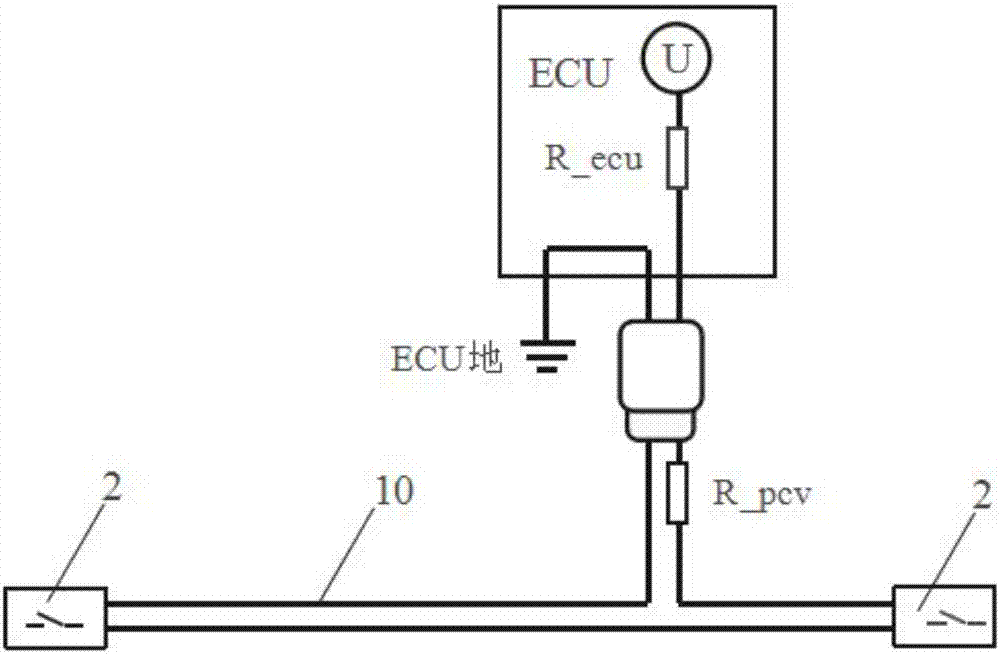

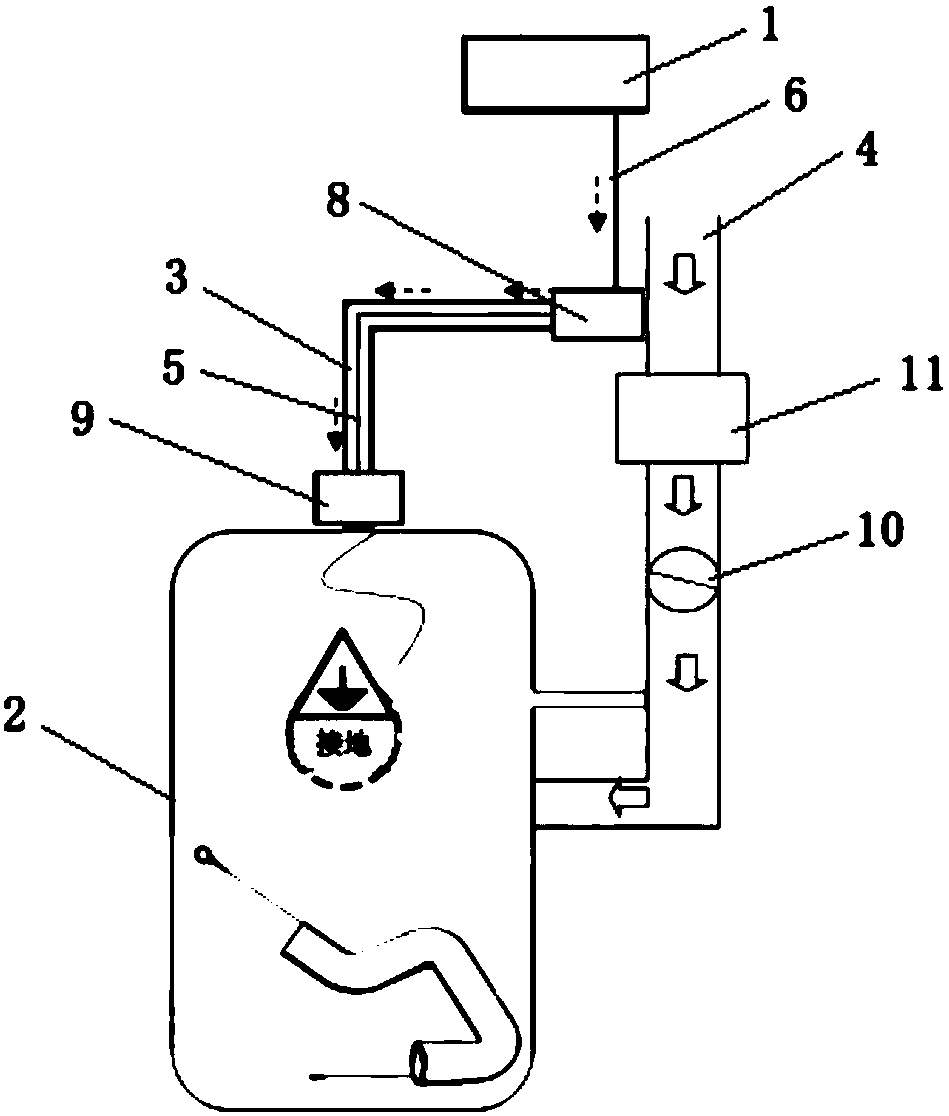

Detection device and method of ventilation pipe of crankcase

ActiveCN108087058ARemind in timeCheck connection statusMachines/enginesCrankcase ventillationCombustionElectrical conductor

The invention relates to the technical field of internal combustion engines, and particularly discloses a detection device and method of a ventilation pipe of a crankcase. A detection conductor is additionally arranged on the ventilation pipe of the crankcase and is connected into a vehicle-mounted computer of a vehicle to form a detection circuit. On-off of connection between the detection conductor and a communicating wire and / or a breakover support is utilized for indicating the connecting state of the ventilation pipe of the crankcase. Under the condition of normal connection of the ventilation pipe of the crankcase, the detection circuit is an access. Under the condition that any end of the ventilation pipe of the crankcase falls off, the detection circuit is switched off, and the detection circuit can be displayed through the vehicle-mounted computer so as to remind a user in time. By means of the detection device and method, the connecting state of joints of the ventilation pipeof the crankcase can be effectively detected, the advantages of low cost and convenient implementation are achieved, and the detection device and method are suitable for the improvement of an existing ventilation pipe of a crankcase.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS

Testing method for plugging of vehicle three-filtering system based on pressure sensor

InactiveCN110685839AExtended service lifeMachines/enginesAir cleaners for fuelDifferential pressureControl engineering

The invention discloses a testing method for plugging of a vehicle three-filtering system based on a pressure sensor. The testing method comprises the following steps that a, a differential pressure sensor is connected with an air inlet pipe and an air outlet pipe of a three-filter correspondingly, and meanwhile, a signal line of the differential pressure sensor is connected to an electronic control unit (ECU) module; b, a pressure difference value of the air inlet pipe and the air outlet pipe of the three-filter is measured by the differential pressure sensor, and a pressure difference signalis transmitted into the ECU module; c, the pressure difference value is compared with a pressure difference preset value by the ECU module; d, when the pressure difference value is greater than the pressure difference preset value, the three-filter is not needed to be replaced; and e, when the pressure difference value is less than the pressure difference preset value, the three-filter is neededto be replaced. According to the testing method for plugging of the vehicle three-filter system based on the pressure sensor, the pressure difference value of front and rear pipelines in the three-filtering system can be tested by using the differential pressure sensor, the three-filter is reasonably replaced according to a prompt signal, an automobile engine and related accessories are protected,and the service life is prolonged.

Owner:XIAN CHINASTAR M&C

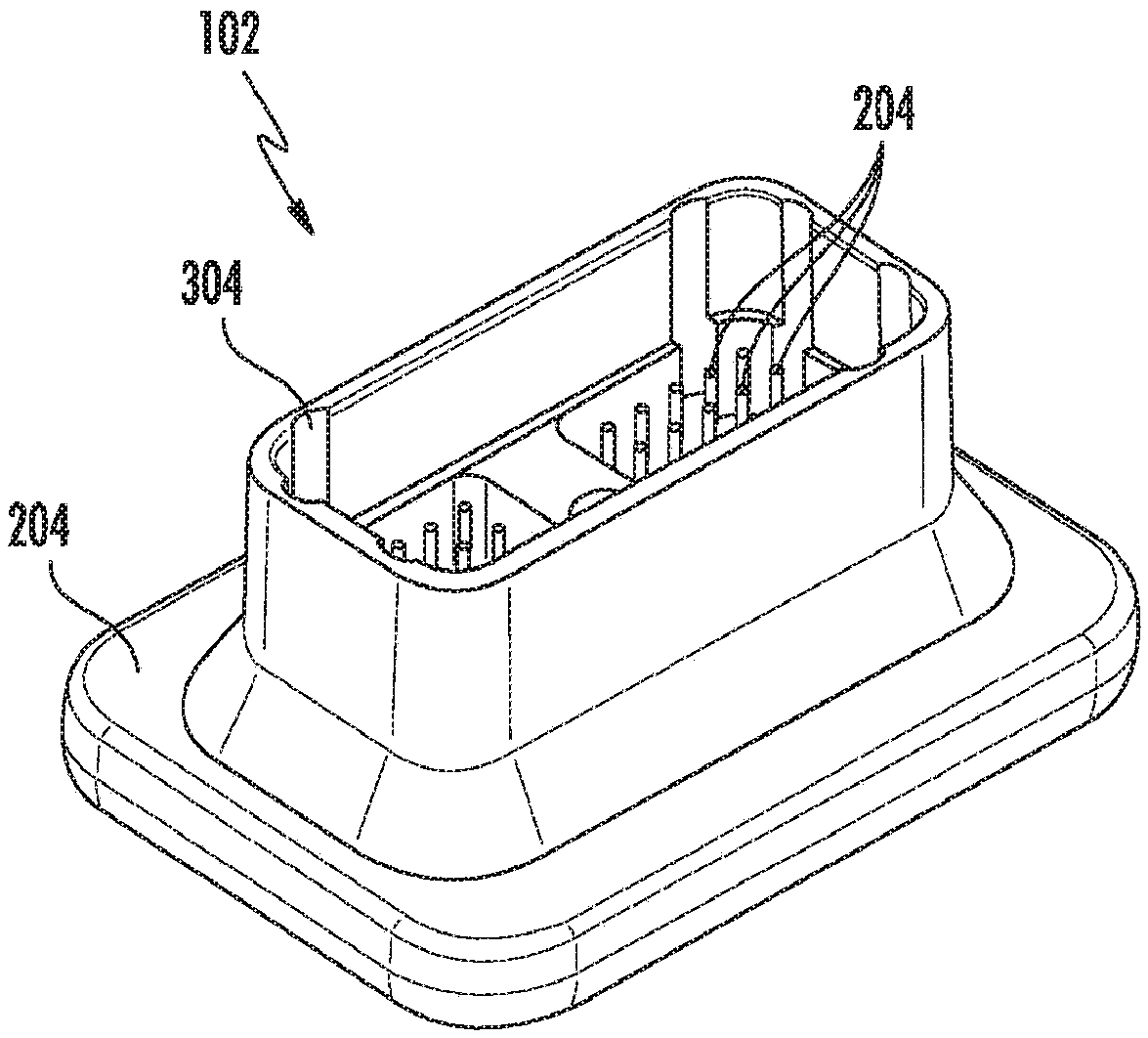

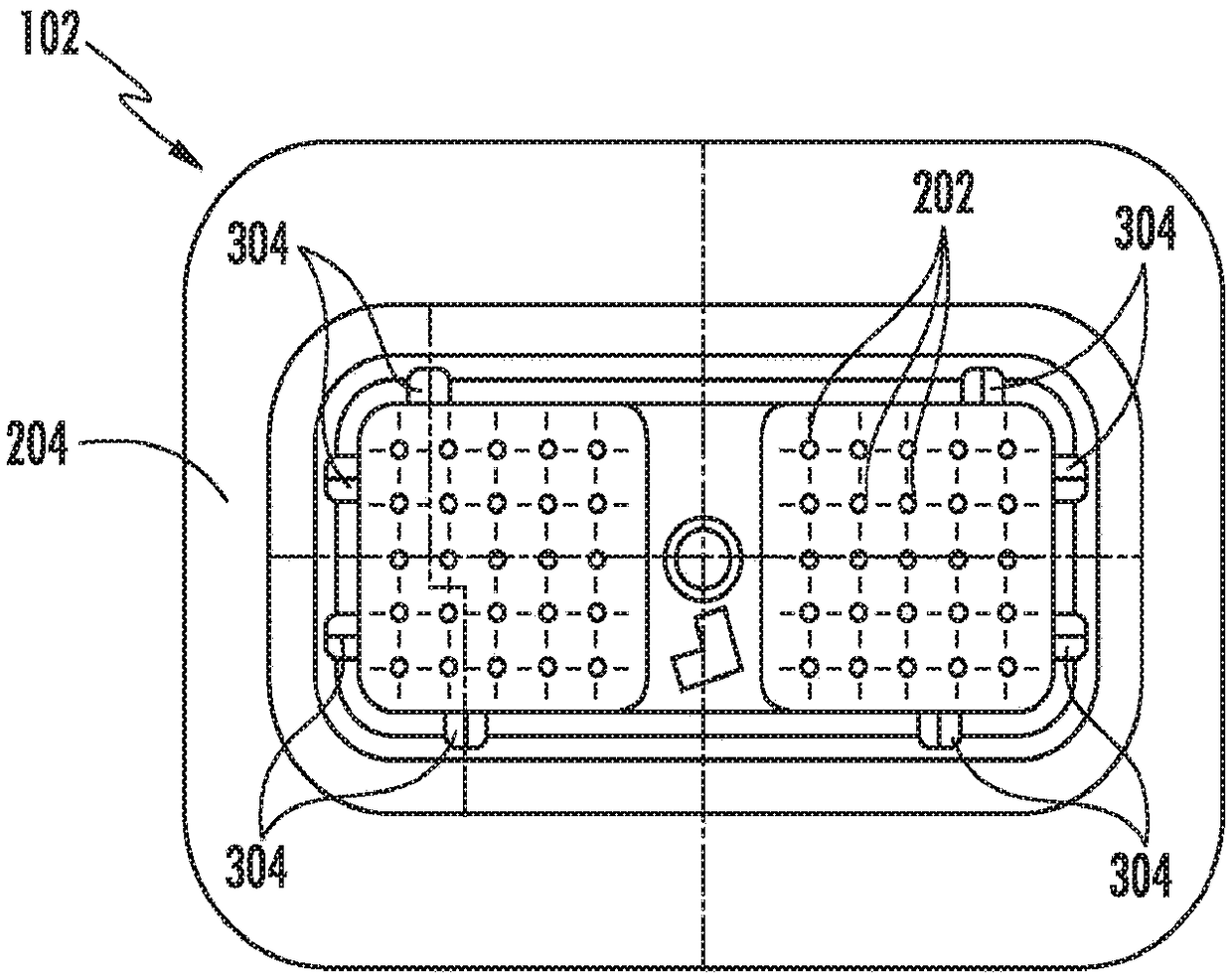

Automatic lubrication system for lubricating an object

ActiveUS20210199241A1Improved and enhanced functionalityExcessive lubricationLubrication elementsMeasurement devices for enginesRotational axisControl circuit

An automatic lubrication system for lubricating an object is provided, which includes a lubricant container configured to contain a lubricant and including a rotatable shaft with a piston to dispense the lubricant from an output of the lubricant container, a housing with a coupling section coupled with the lubricant container, an electric motor configured to drive the rotatable shaft of the lubricant container during at least one lubrication action, such that at least a part of the lubricant is dispensable from the lubricant container during the at least one lubrication action, at least one capacitive sensor including at least one electrode, wherein the at least one capacitive sensor is arranged at a wall of the lubricant container and configured to provide at least one sensor signal indicative of a capacitance in a vicinity of the at least one electrode, and a control circuitry configured to determine, based on the at least one sensor signal of the at least one capacitive sensor, at least one lubrication parameter indicative of the at least one lubrication action.

Owner:DODGE INDS +1

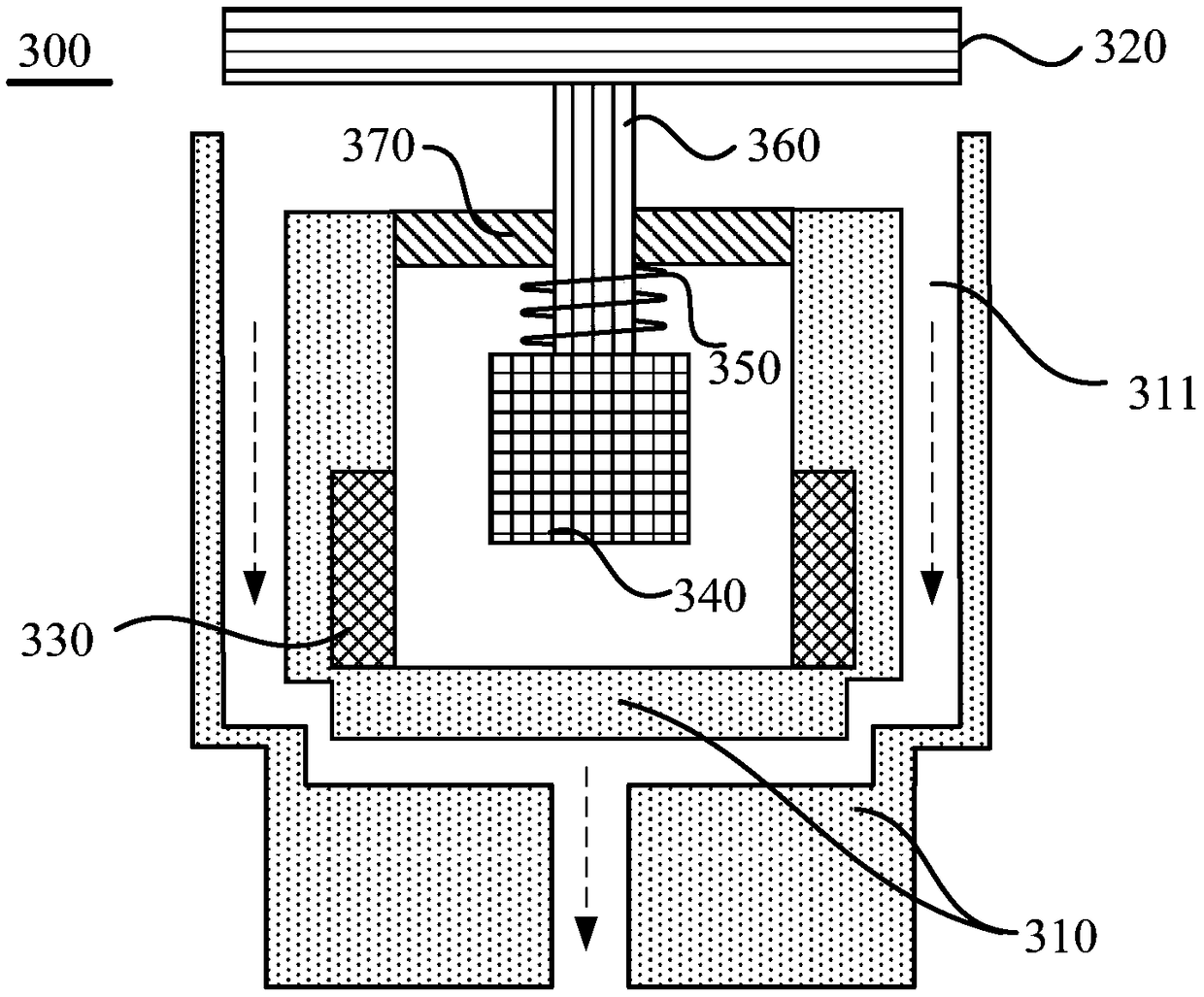

Friction pair magnetic field intensity fine adjustment device for magnetofluid lubrication and using method for friction pair magnetic field intensity fine adjustment device

ActiveCN112161185AWith self-locking functionHigh replaceabilityGearingMaterial strength using repeated/pulsating forcesTest sampleLubrication

The invention discloses a friction pair magnetic field intensity fine adjustment device for magnetofluid lubrication and a using method for the friction pair magnetic field intensity fine adjustment device. The friction pair magnetic field intensity fine adjustment device is used for adjusting a distance between a permanent magnet and the lower surface of a test sample and comprises an outer shellused for fixing the test sample, a containing cavity used for containing a lifting fine adjustment device is formed in the position, below the test sample, of the outer shell, and the lifting fine adjustment device comprises a box body, a box cover and a lead screw mechanism. By adopting the friction pair magnetic field intensity fine adjustment device, a lead screw transmission pair is driven byrotating a handle, epicyclic motion of a lead screw is converted to linear motion of a slider, the lead screw rotates to drive the slider, and then, two inclined wedged blocks are matched with each other to form low pair surface contact to bear the permanent magnet. The friction pair magnetic field intensity fine adjustment device has the characteristics of high stability, high transmission precision and easiness in implementation.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Popular searches

Lubrication indication devices Material impedance Bearing components Thermometers using electric/magnetic elements Using electrical means Fluid pressure measurement by mechanical elements Individual particle analysis Pressure lubrication Lubricant mounting/connection Special data processing applications

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com