Patents

Literature

40 results about "Ones' complement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ones' complement of a binary number is defined as the value obtained by inverting all the bits in the binary representation of the number (swapping 0s for 1s and vice versa). The ones' complement of the number then behaves like the negative of the original number in some arithmetic operations. To within a constant (of −1), the ones' complement behaves like the negative of the original number with binary addition. However, unlike two's complement, these numbers have not seen widespread use because of issues such as the offset of −1, that negating zero results in a distinct negative zero bit pattern, less simplicity with arithmetic borrowing, etc.

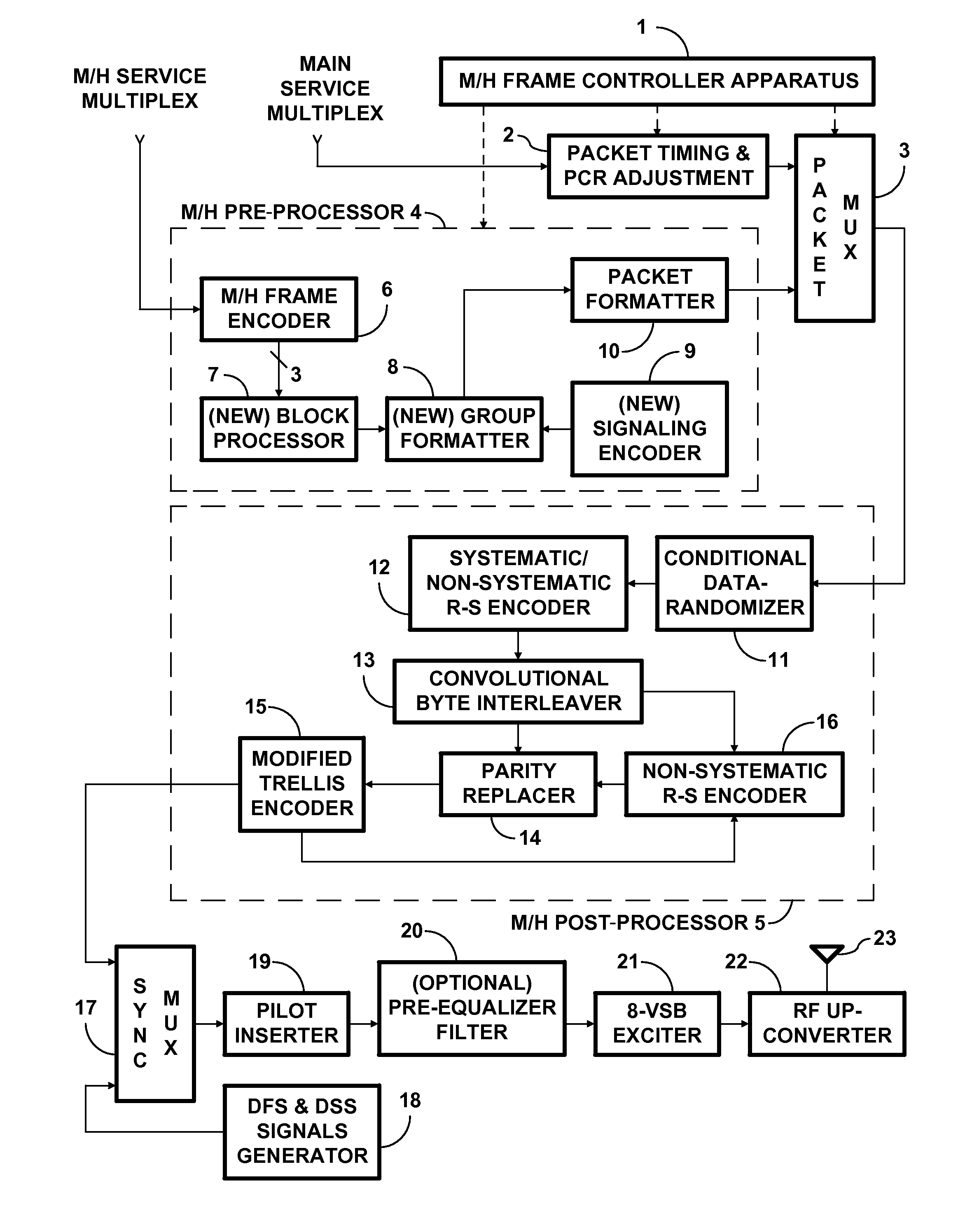

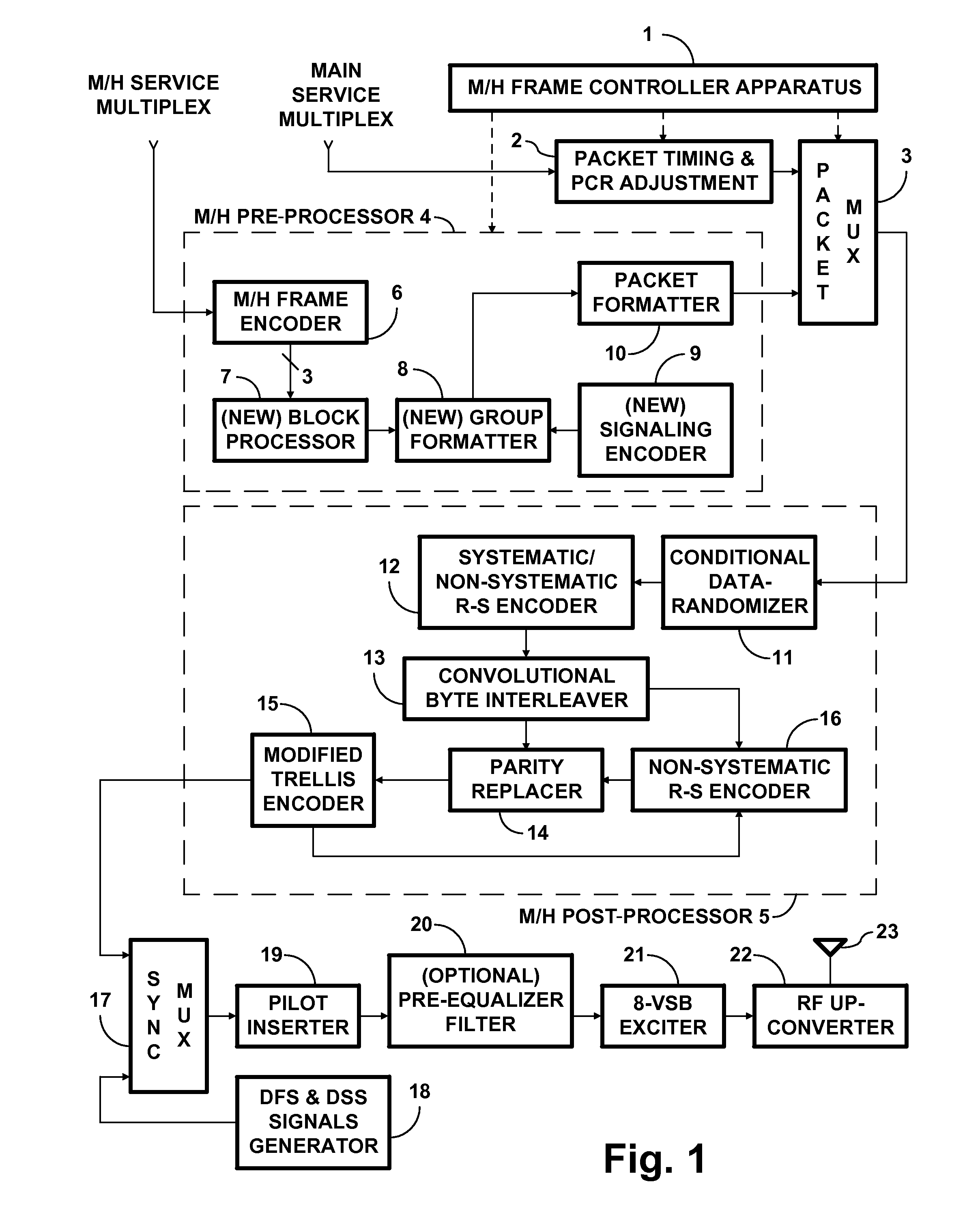

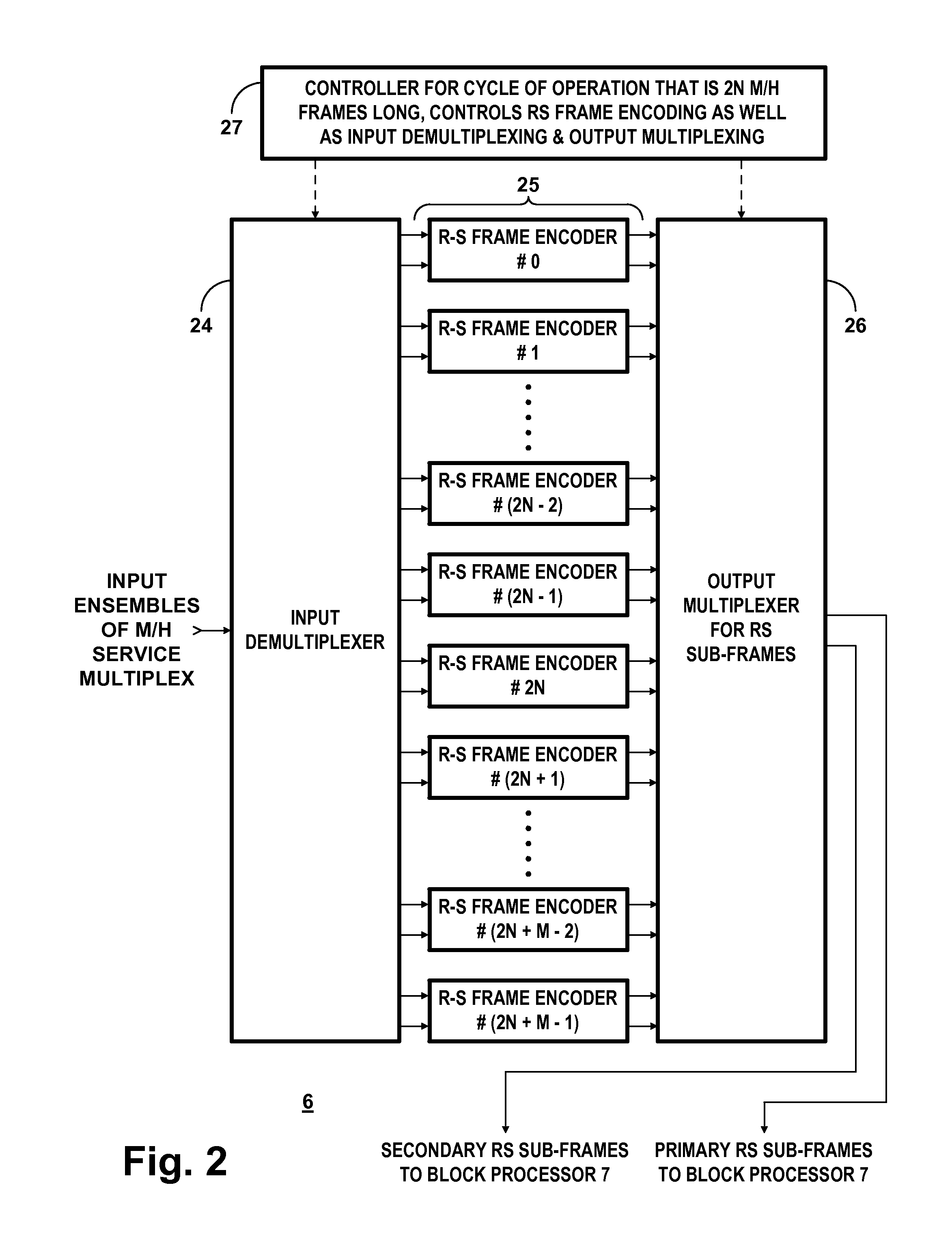

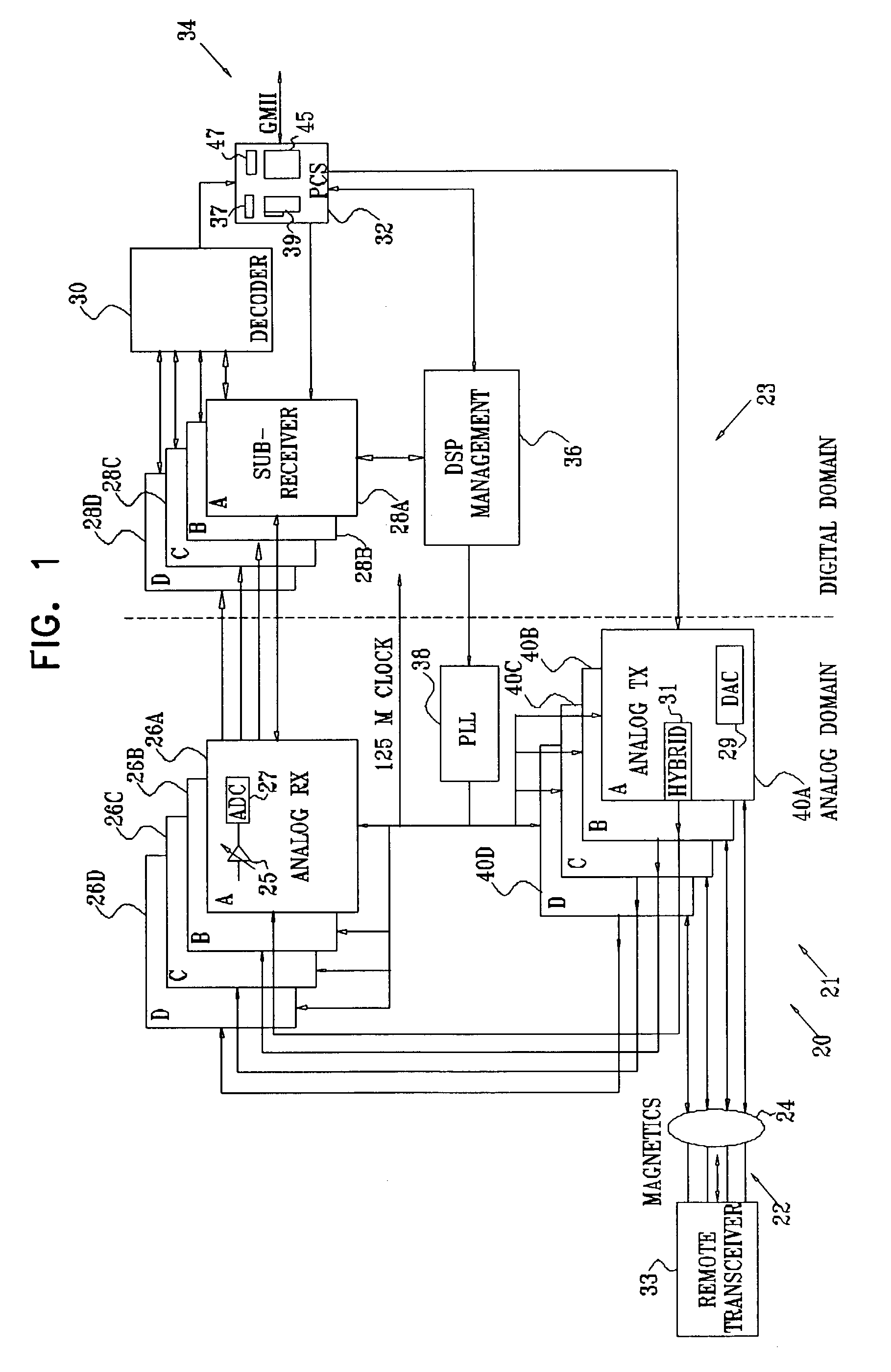

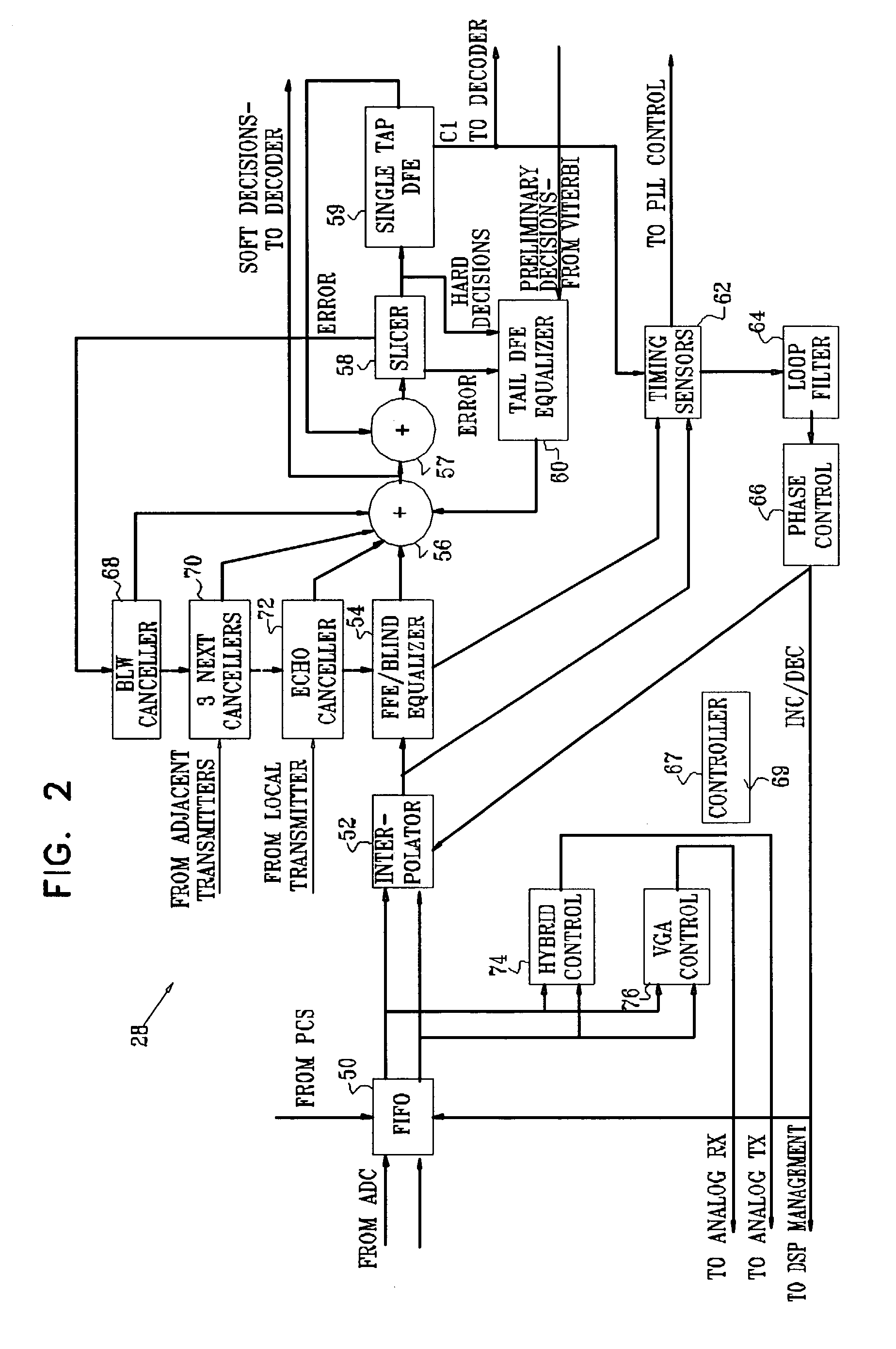

Digital television systems employing concatenated convolutional coded data

InactiveUS20100100793A1ConfidenceAvoid problemsCode conversionError correction/detection by combining multiple code structuresConvolutional codeDiversity scheme

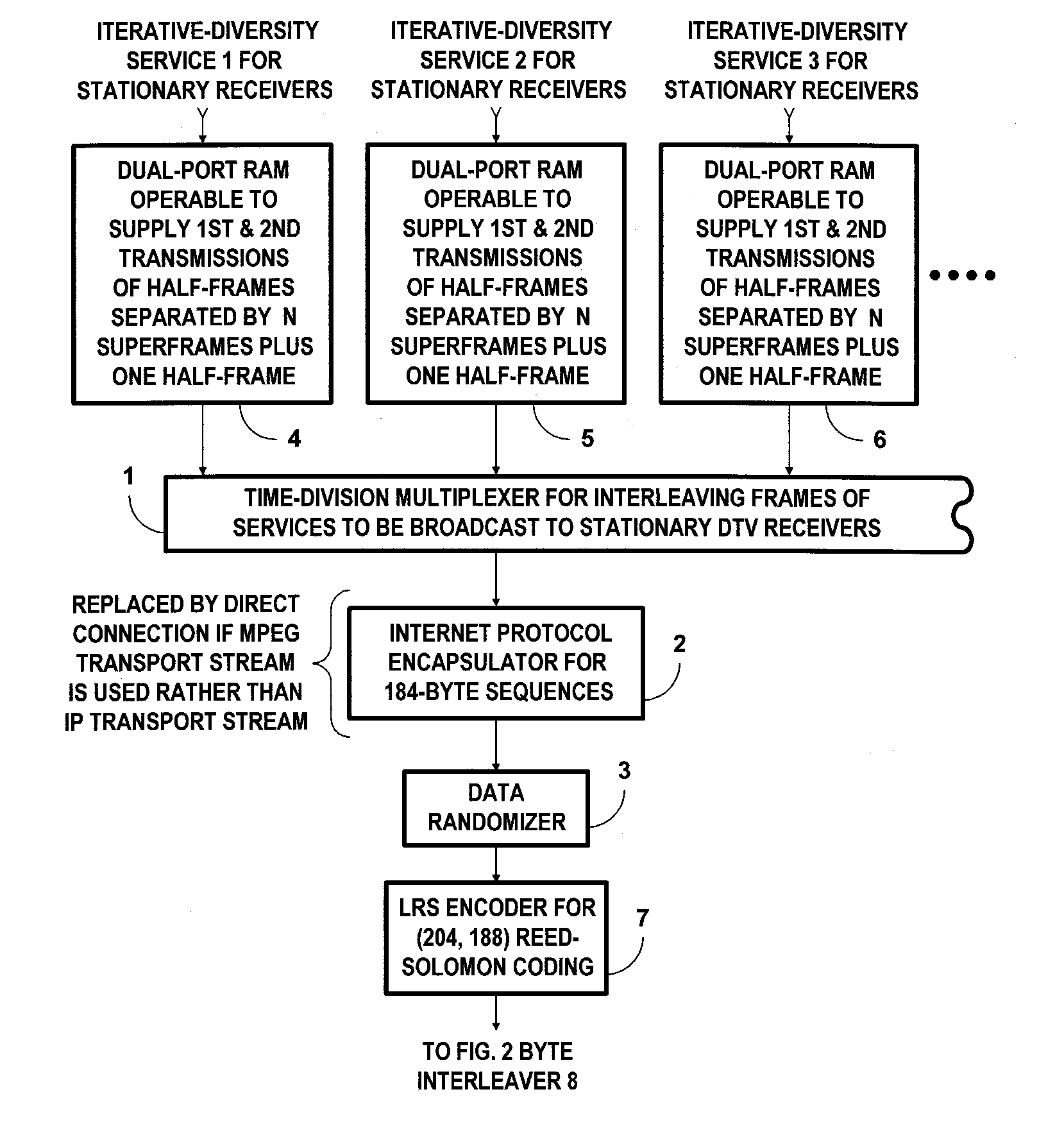

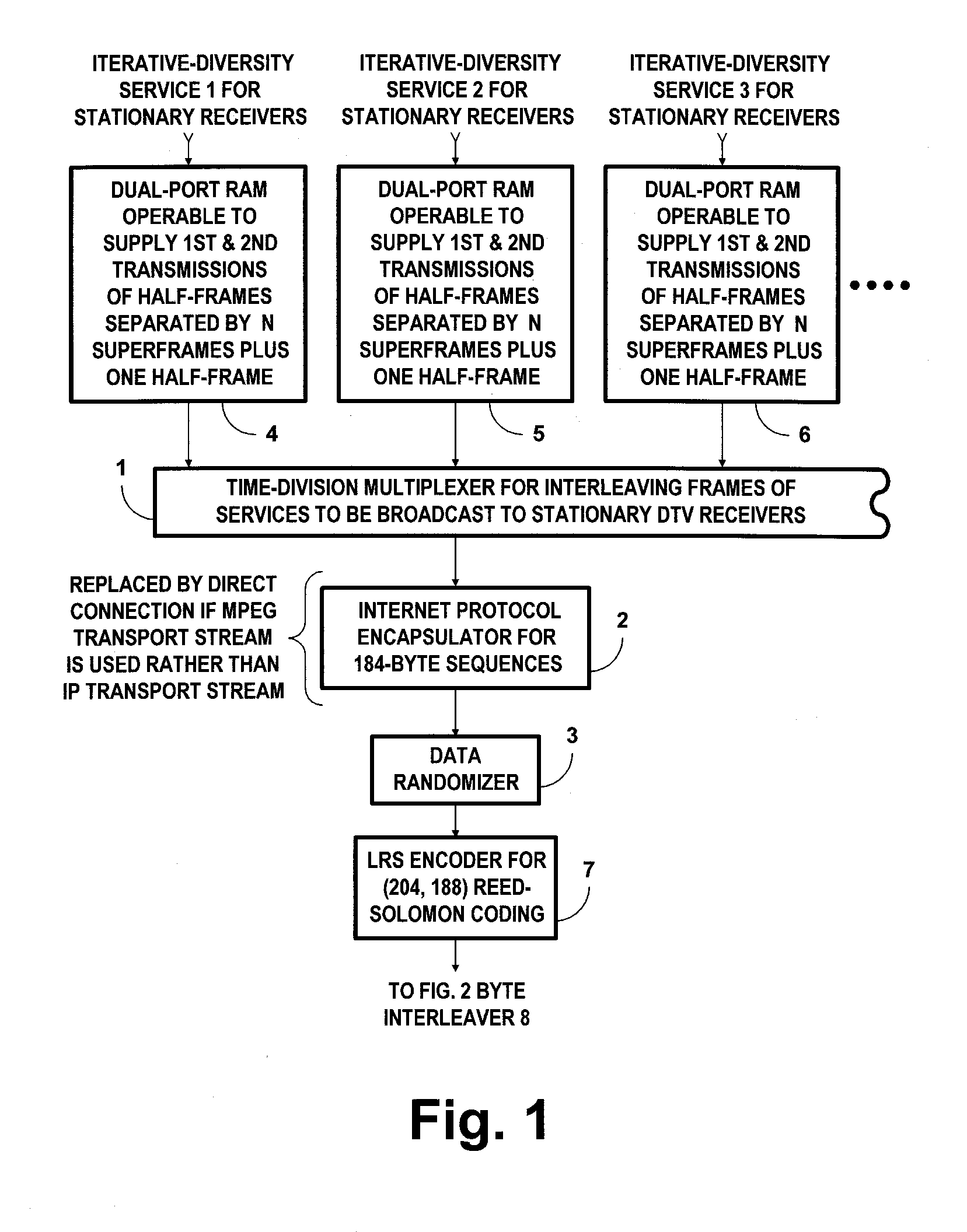

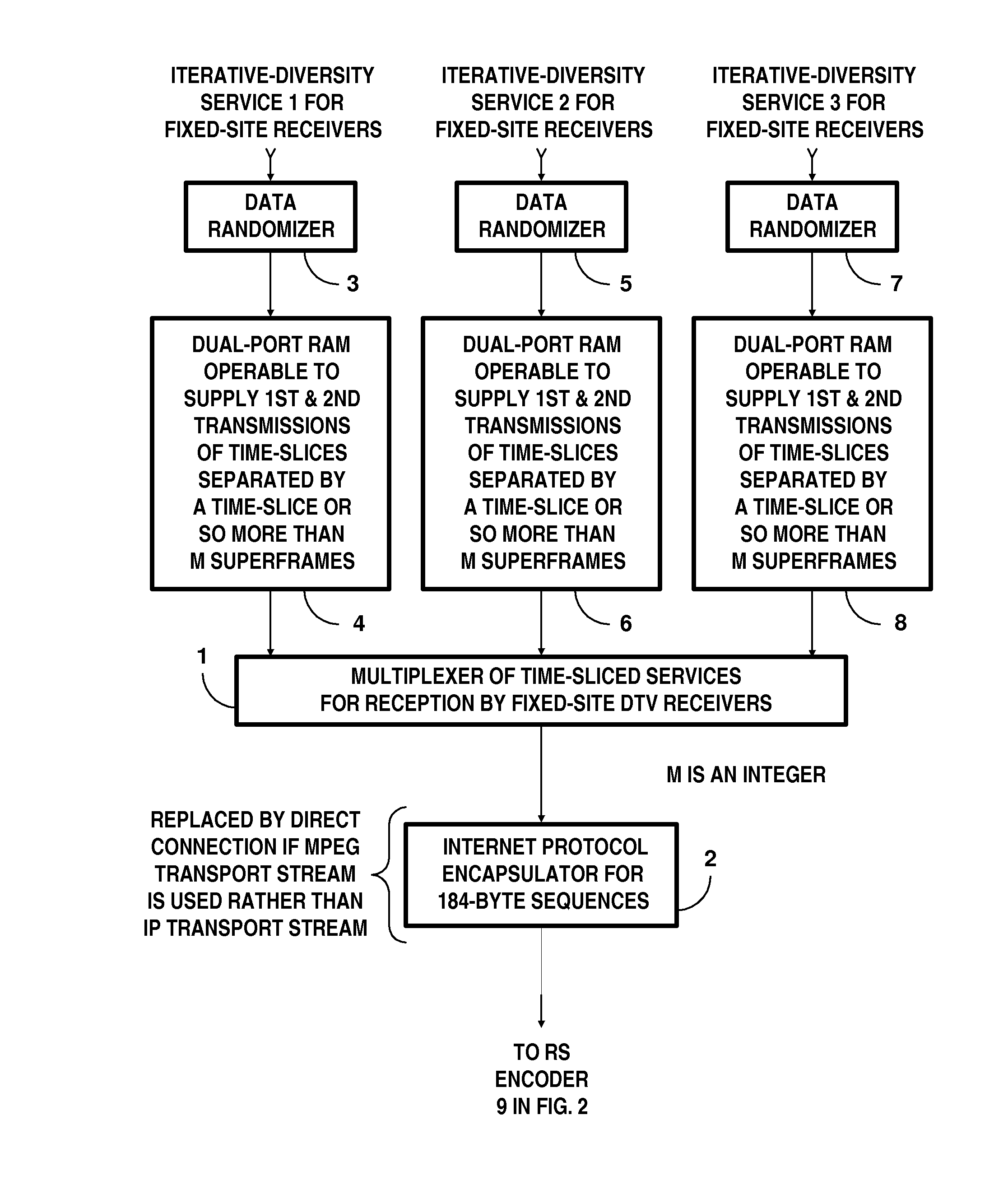

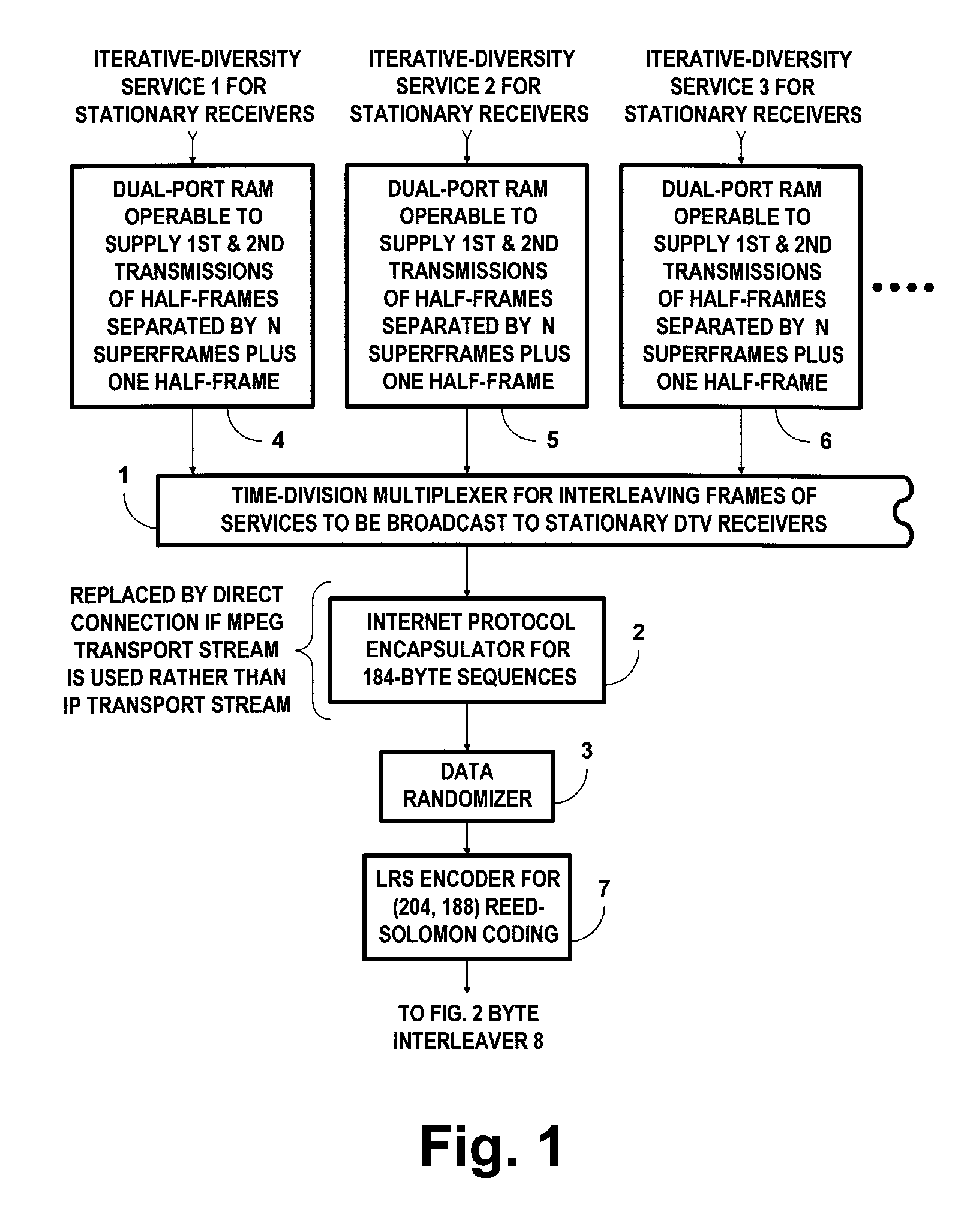

In iterative-diversity (ID) transmission systems for signals with concatenated convolutional coding (CCC), paired iterative diversity signals each have ½ the code rate of the 8VSB DTV signals prescribed by the 1995 ATSC Digital Television Broadcast Standard. Known serial concatenated convolutional coding (SCCC) or novel parallel concatenated convolutional coding (PCCC) is used in such system. Pairs of CCC signals code data bits and ones' complemented data bits respectively, using similar coding algorithms. Receivers for this transmission system use respective turbo decoders for turbo decoding the earlier-transmitted and later-transmitted CCC signals. Turbo decoding of the earlier-transmitted portions of iterative diversity signals is delayed to be contemporaneous with turbo decoding of the later-transmitted portions of iterative diversity signals. This facilitates the turbo decoders exchanging information concerning confidence levels of data bits during the turbo decoding procedures.

Owner:SAMSUNG ELECTRONICS CO LTD

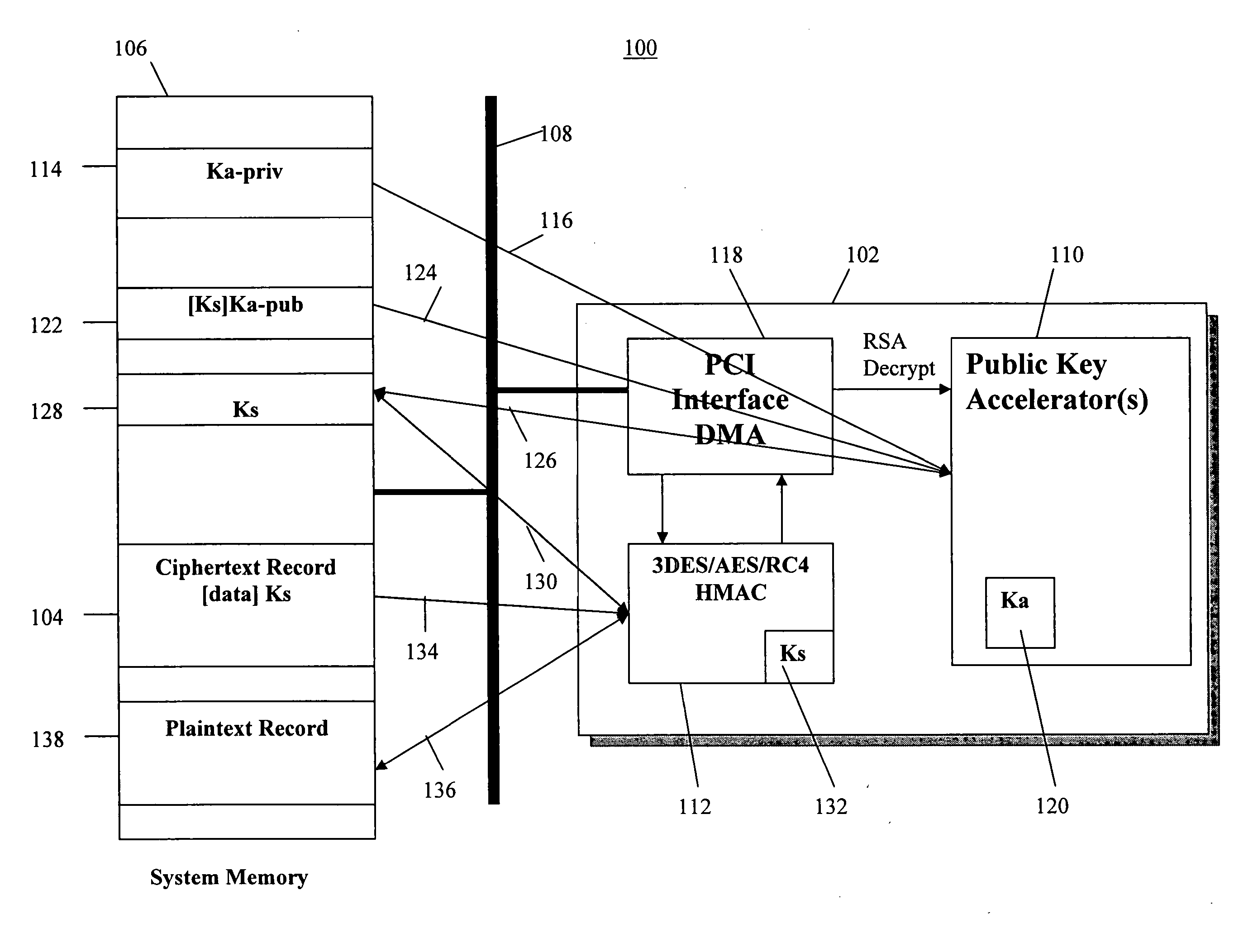

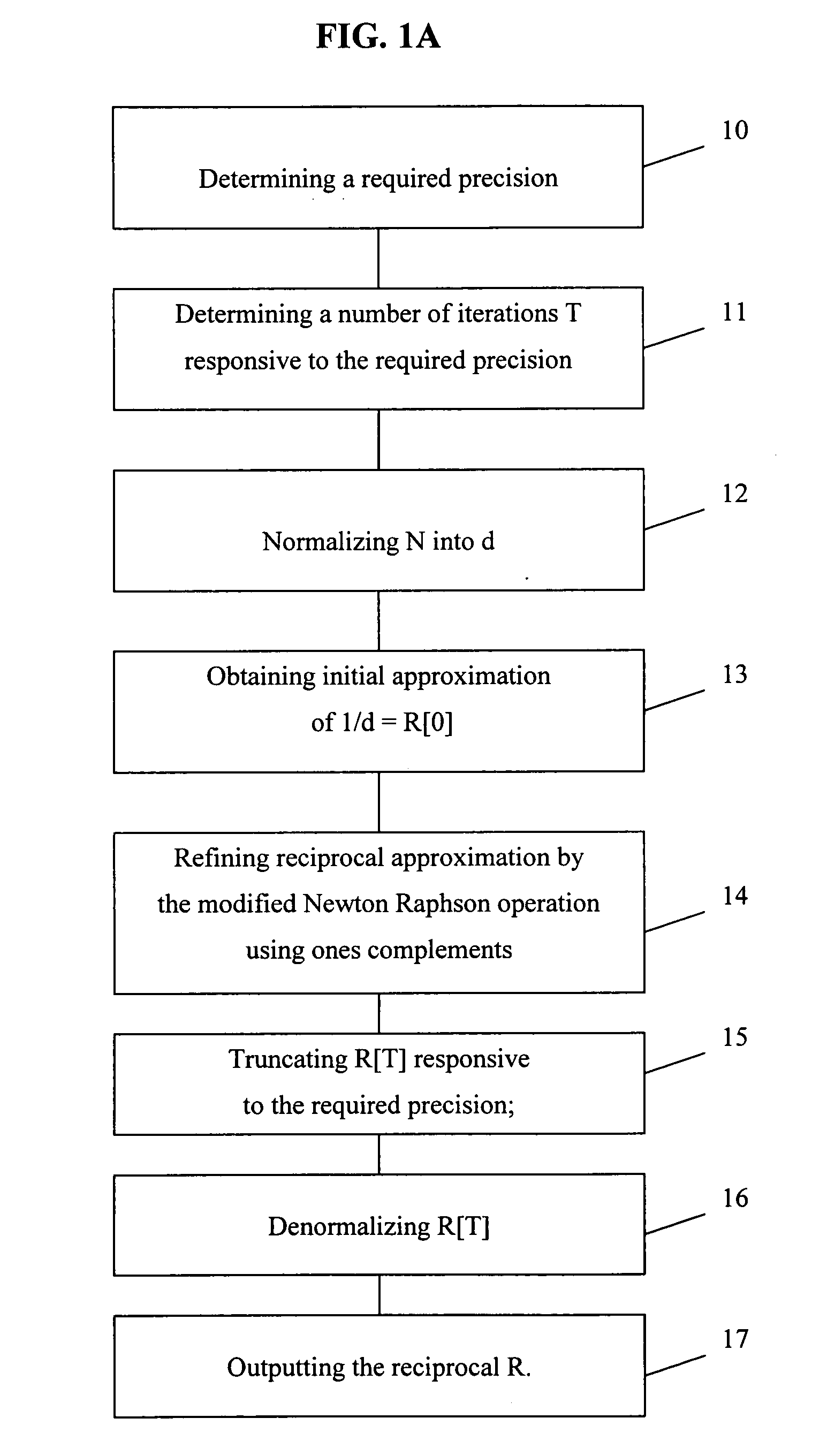

System and method for optimized reciprocal operations

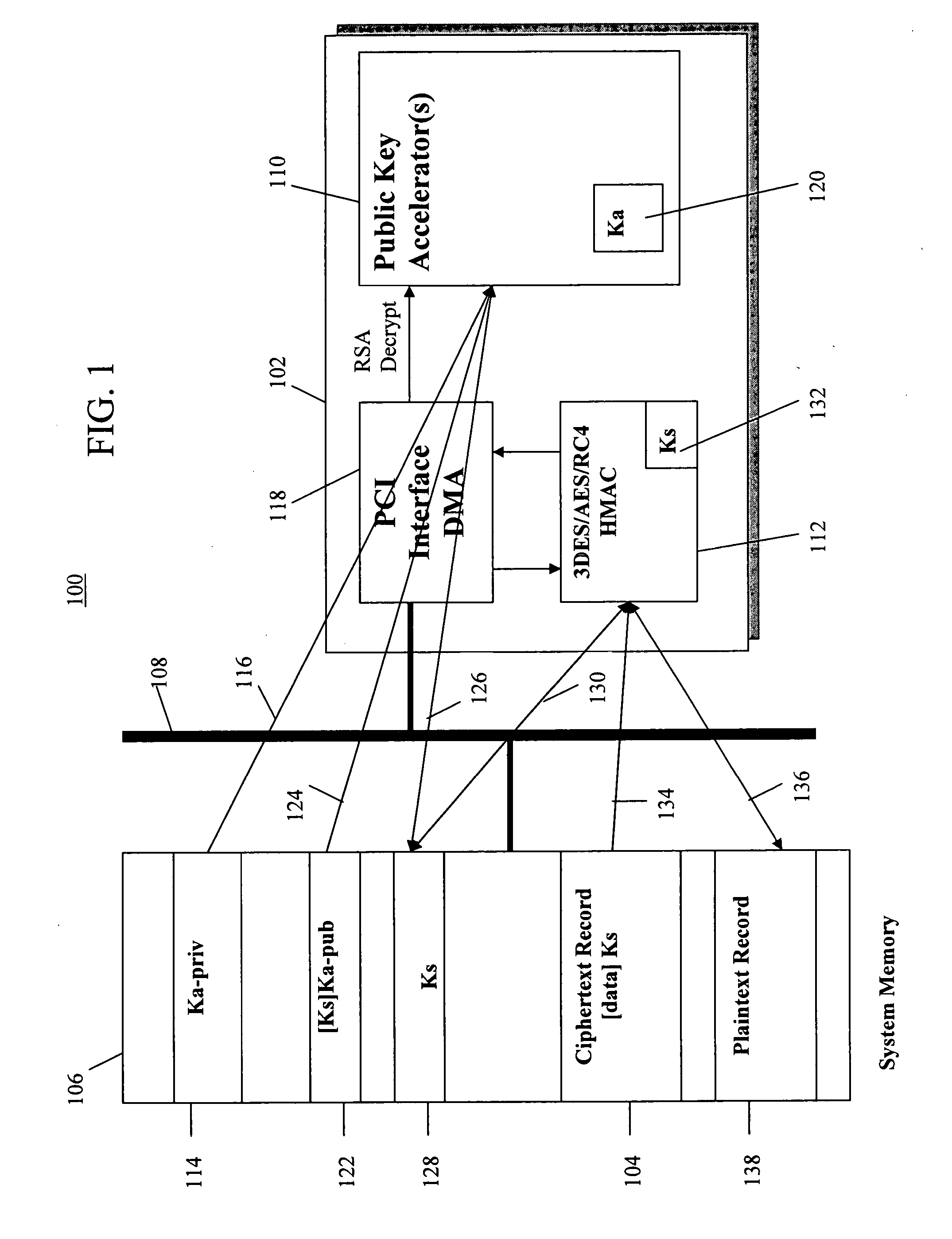

InactiveUS20070083586A1Public key for secure communicationSecret communicationAlgorithmOnes' complement

Owner:AVAGO TECH INT SALES PTE LTD

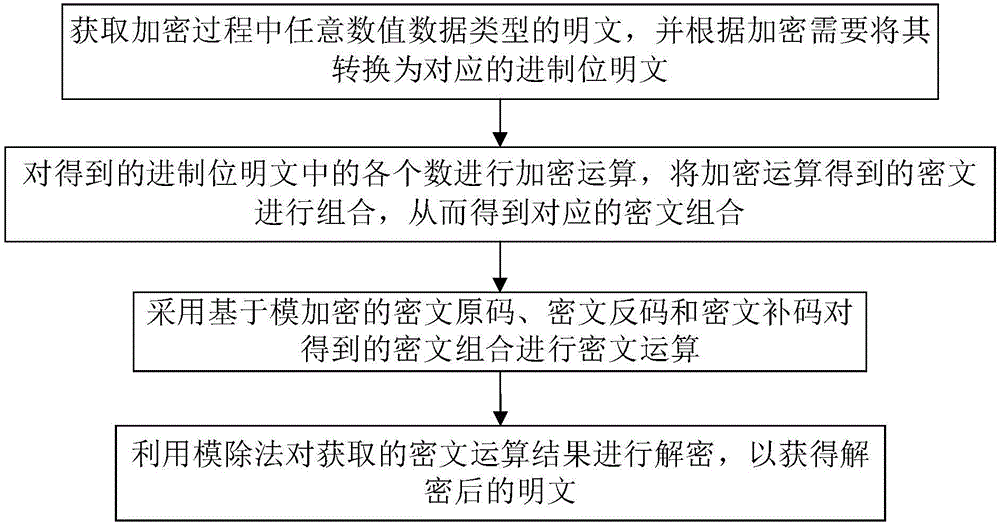

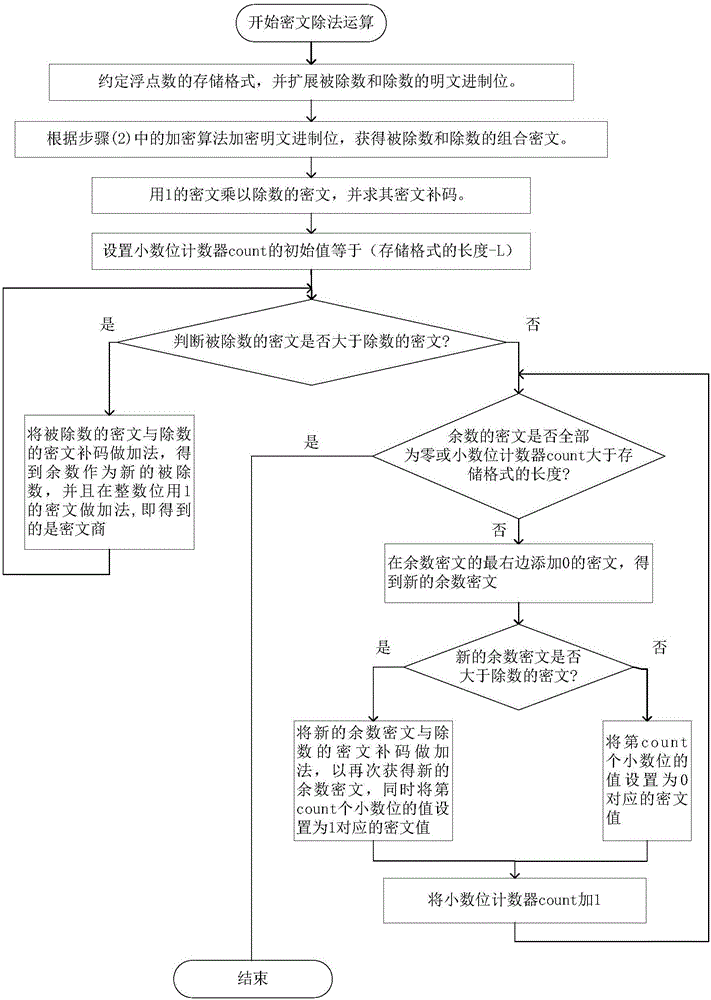

Fully homomorphic encryption processing method based on modular operation

ActiveCN106452723ASolve technical problems that cannot be decrypted correctlySolve the noiseCommunication with homomorphic encryptionPlaintextComputer hardware

The invention discloses a fully homomorphic encryption processing method based on modular operation. The method comprises the following steps: acquiring plaintext of any numerical data type in an encryption process, converting the plaintext into corresponding binary bit plaintext, performing encryption operation on each digits in the obtained binary bit plaintext, combining ciphertext obtained by the encryption operation to obtain a corresponding ciphertext combination, performing ciphertext operation of addition, subtraction, multiplication and division on the obtained ciphertext combination by using ciphertext true form, ciphertext radix-minus-one complement and ciphertext complement based on modular encryption, and decrypting the obtained ciphertext operation result by using a modular division method to obtain decrypted plaintext. By adoption of the fully homomorphic encryption processing method based on modular operation disclosed by the invention, the following technical problem in the existing fully homomorphic encryption processing method based on modular operation is solved: the ciphertext multiplication noise is hard to control and the result of the ciphertext addition is equal to the binary ciphertext summarizing result, resulting in errors in the decryption process, such that the encryption result cannot be correctly decrypted.

Owner:SHENZHEN FULLY HOMOMORPHIC ENCRYPTION SCI & TECH CO LTD

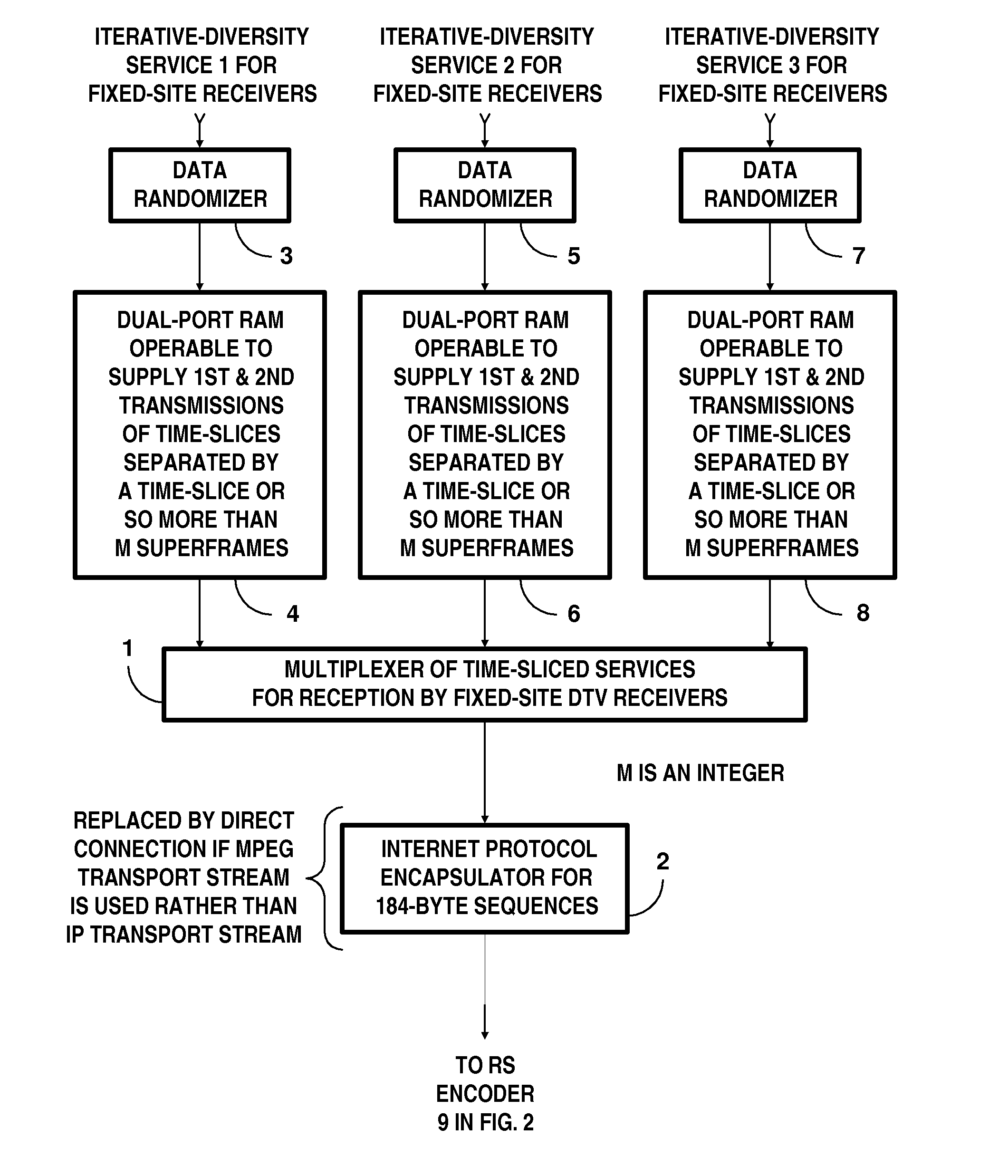

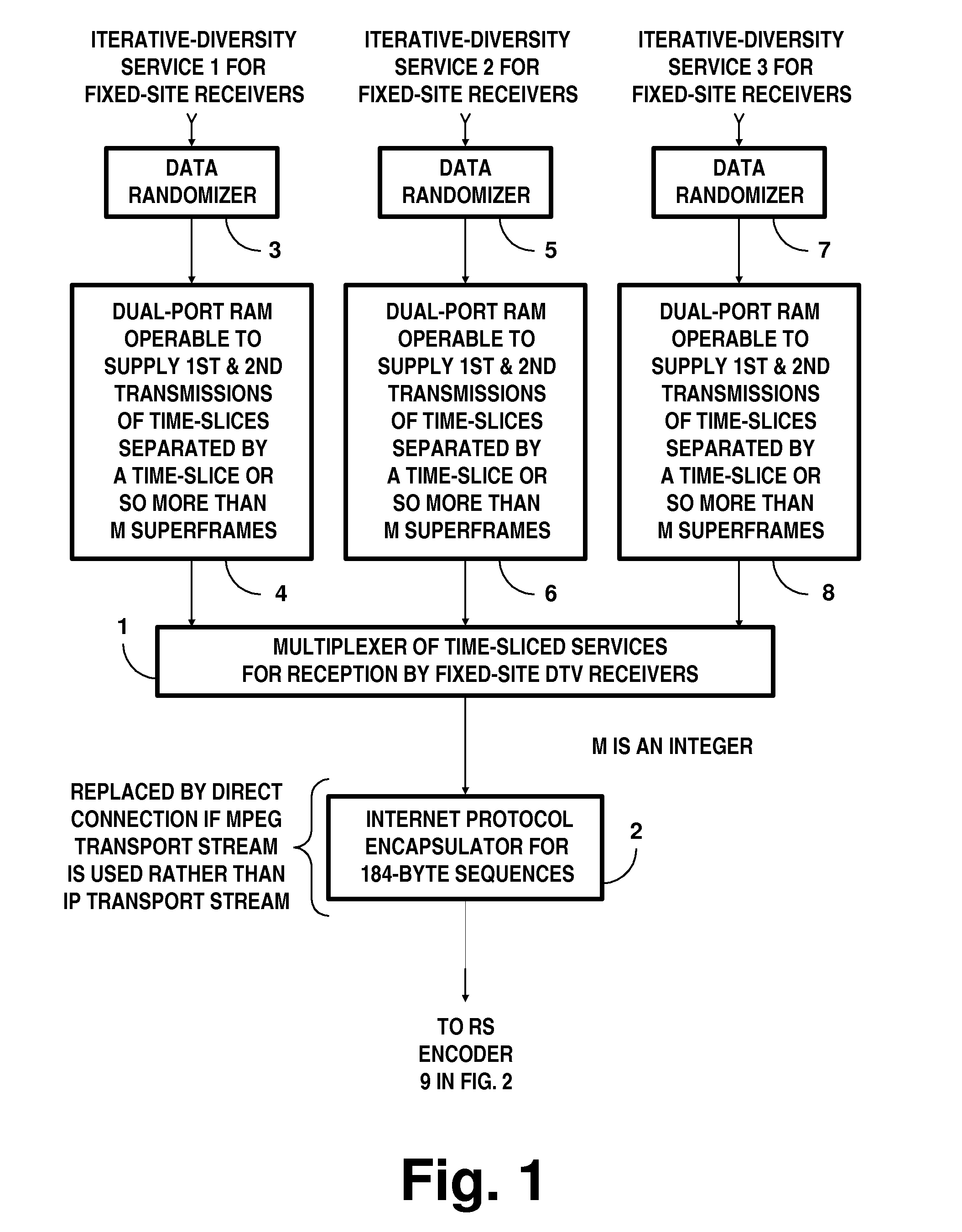

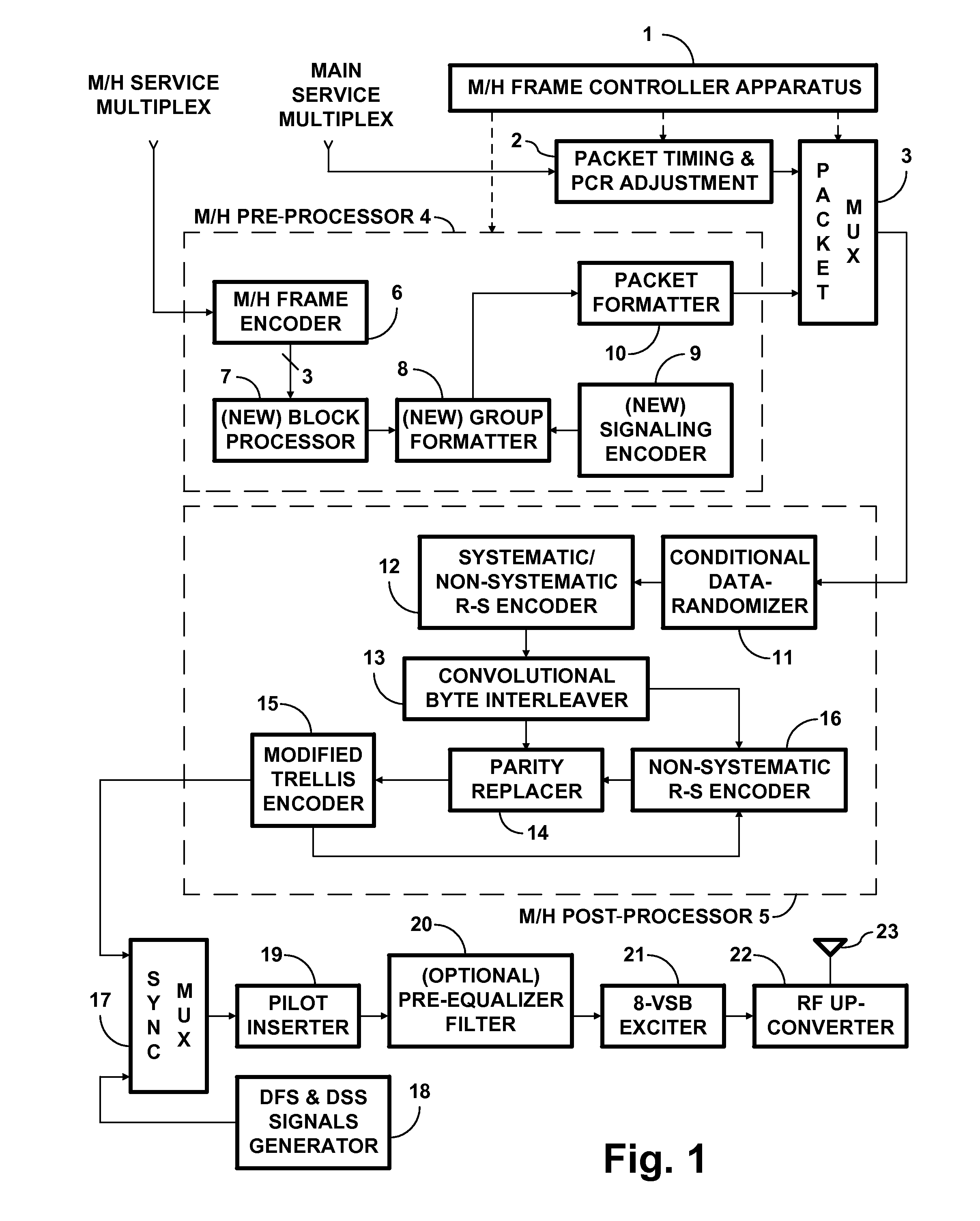

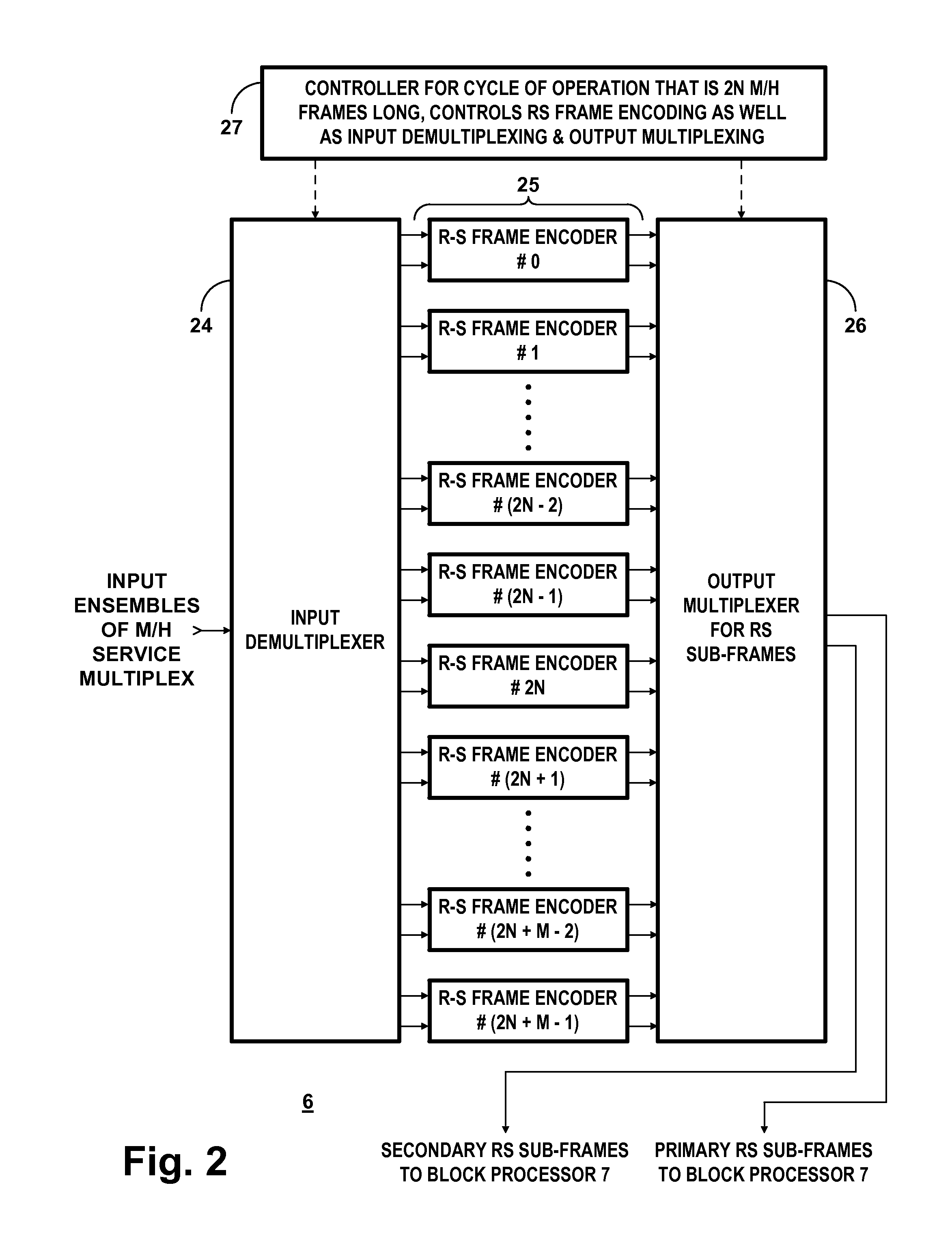

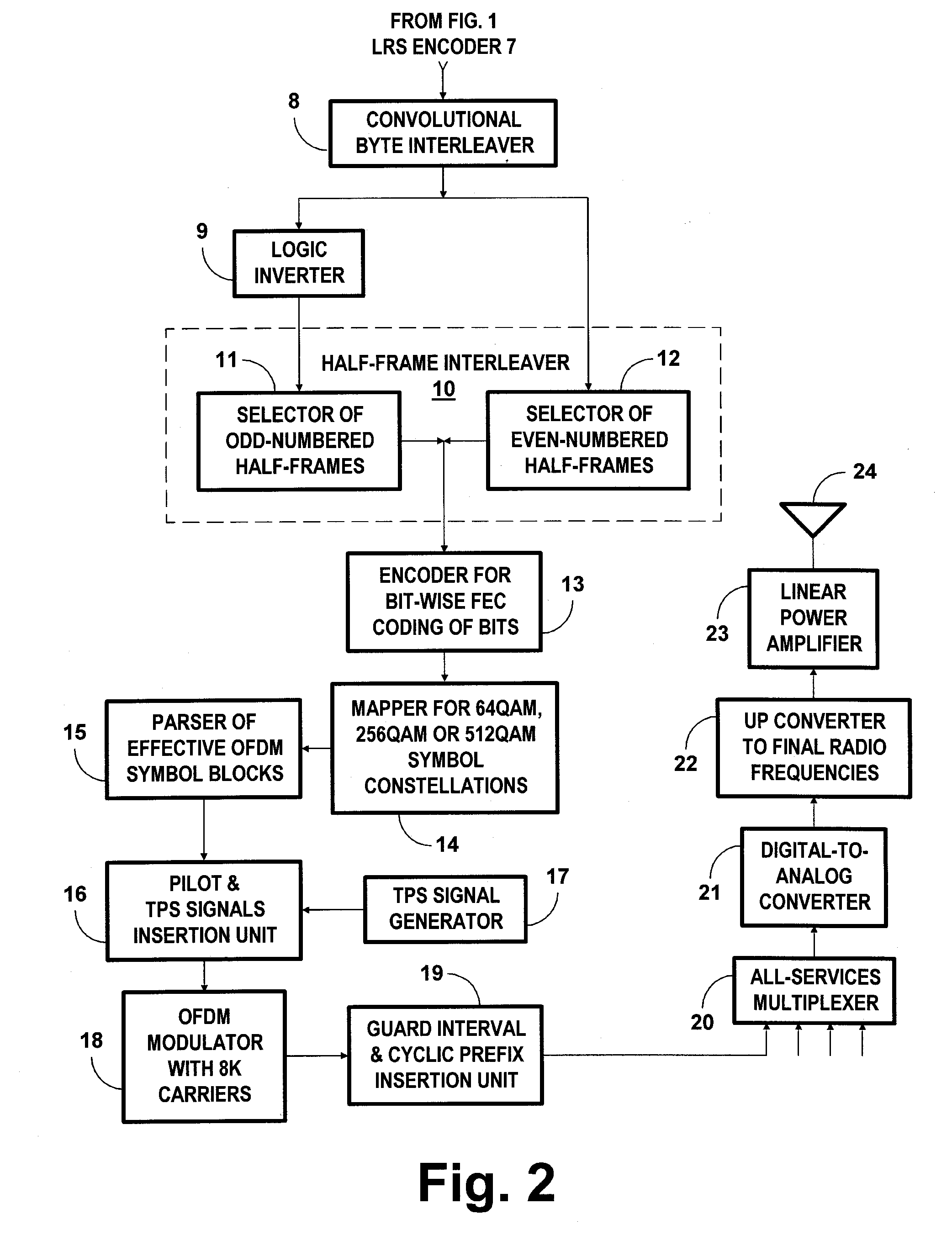

Digital broadcasting systems using parallel concatenated coding of bit-complementary bitstreams

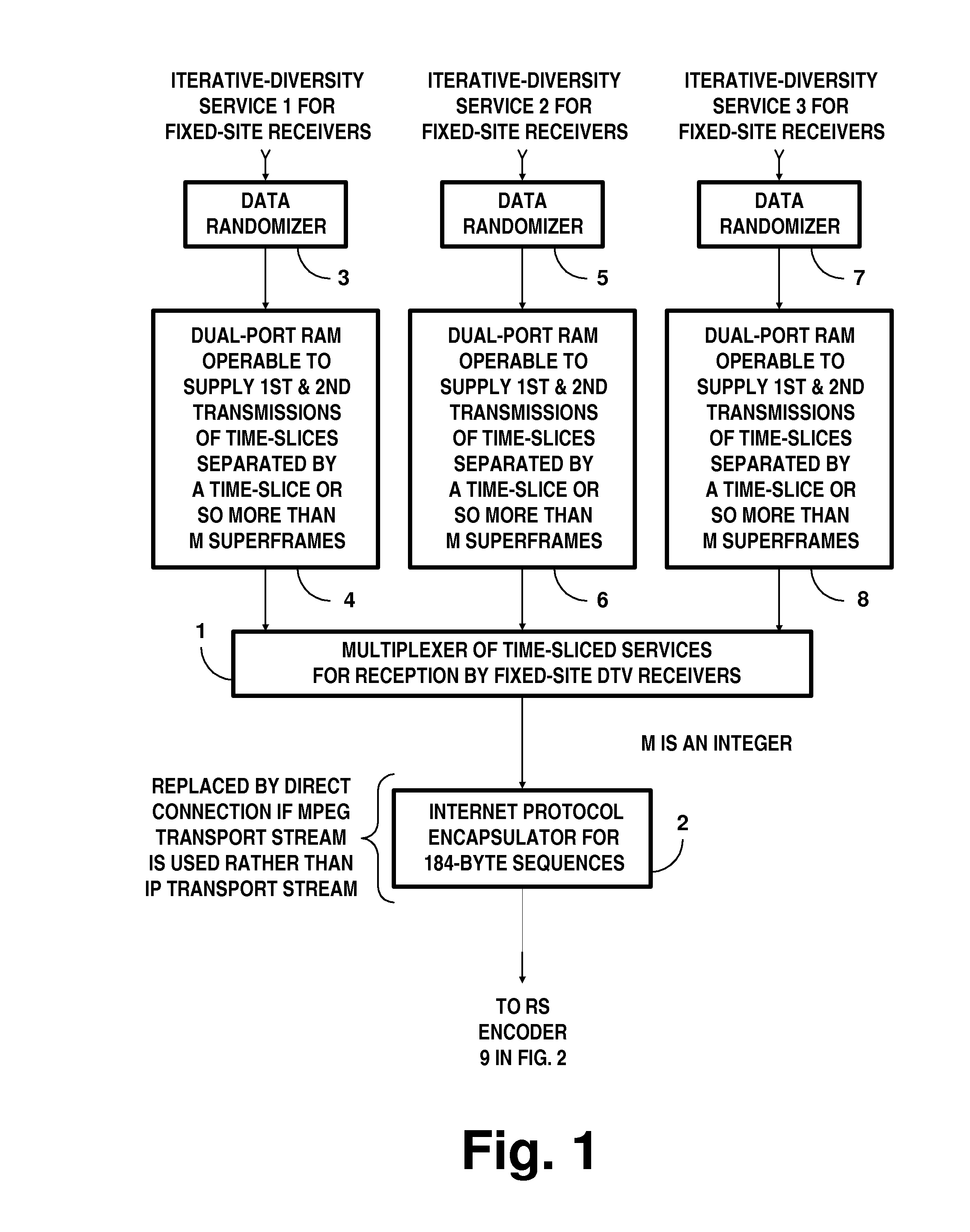

InactiveUS20130028335A1Color television with pulse code modulationColor television with bandwidth reductionRandomizationDigital broadcasting

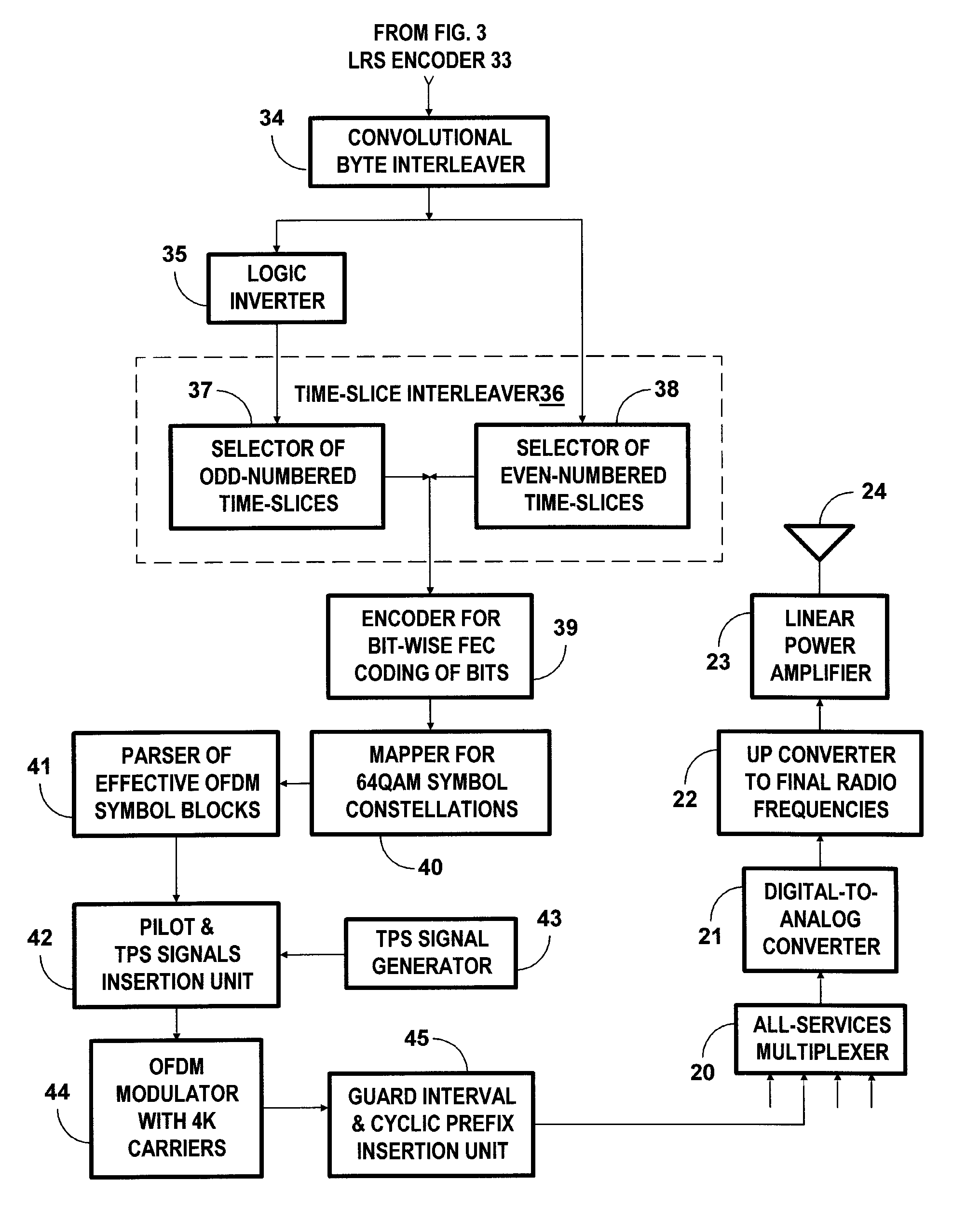

A digital television (DTV) system uses parallel concatenated coding (PCC), together with QAM constellations for modulating OFDM carriers. A first encoder responds to ONEs' complemented bits of randomized data to generate a first component of PCC. A second encoder responds to delayed bits of the randomized data to generate a second component of PCC. A constellation mapper generates QAM symbols responsive to successive time-slices of the first component of the PCC interleaved with successive time-slices of the second component of the PCC. An OFDM modulator generates a COFDM modulating signal responsive to the QAM symbols. In a receiver for the DTV system, the second component of the PCC and delayed first component of the PCC are iteratively decoded. Soft bits from the second component and delayed first component of the parallel concatenated coding are code-combined to supply soft randomized data used in that iterative decoding.

Owner:LIMBERG ALLEN LEROY

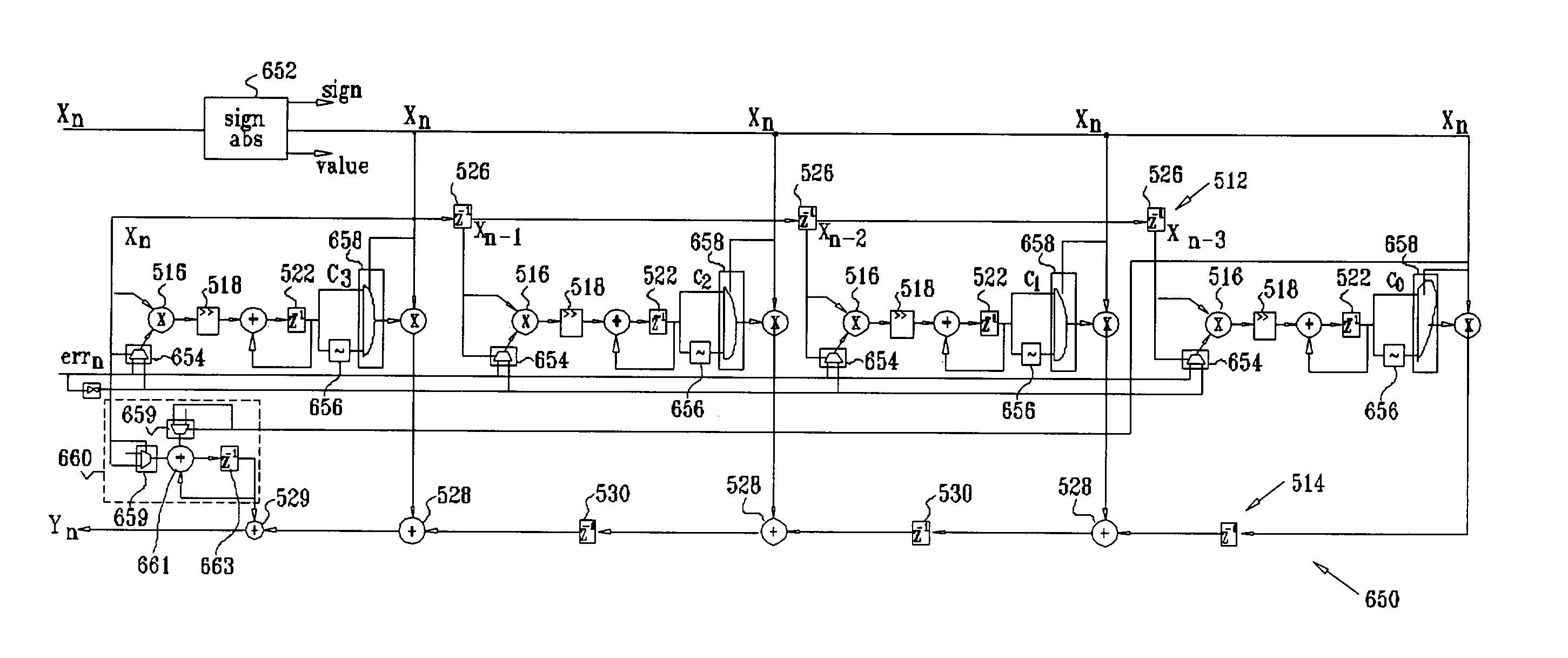

Filter with multipliers operating in ones complement arithmetic

InactiveUS7167883B2Reduce areaReduce dataMultiple-port networksReceiver initialisationFinite impulse responseBinary multiplier

A finite impulse response filter, including a plurality of taps arranged to receive and process a sequence of input data samples so as to generate a filter output. Each tap consists of a multiplier operating in one's complement arithmetic, the multiplier being coupled to multiply a respective input sample from the sequence by a respective equalization coefficient, and an adder, which sums an output from the multiplier. The taps are arranged in sequence so that the input sample to each of the taps, except to a first tap in the sequence, is delayed relative to a preceding tap in the sequence. The filter also includes an adjustment-accumulator coupled to receive the filter output and responsive thereto to generate an adjustment that is adapted to correct the filter output to a twos complement result, and an adjustment-adder which sums the adjustment and the filter output to generate a final output.

Owner:CADENCE DESIGN SYST INC

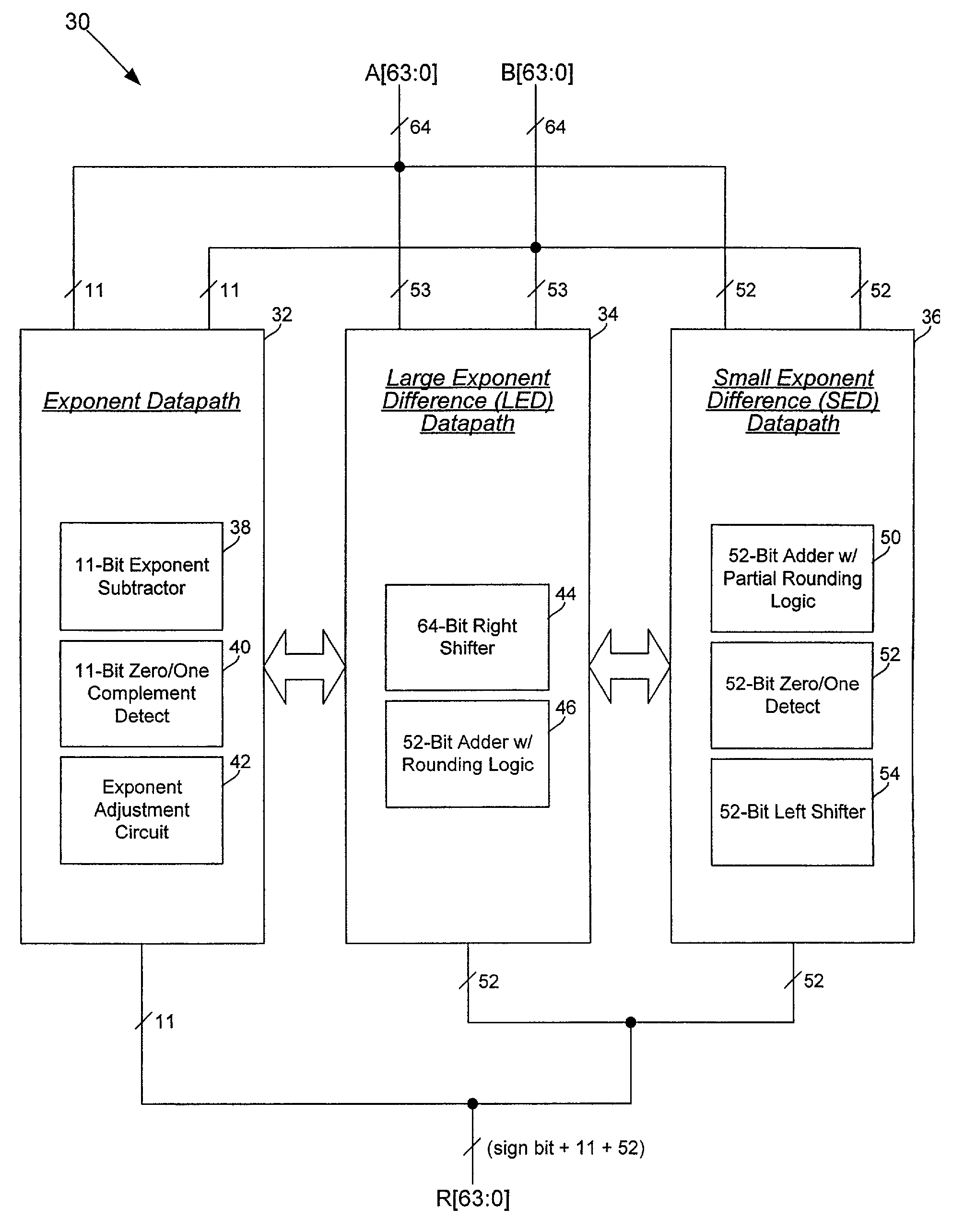

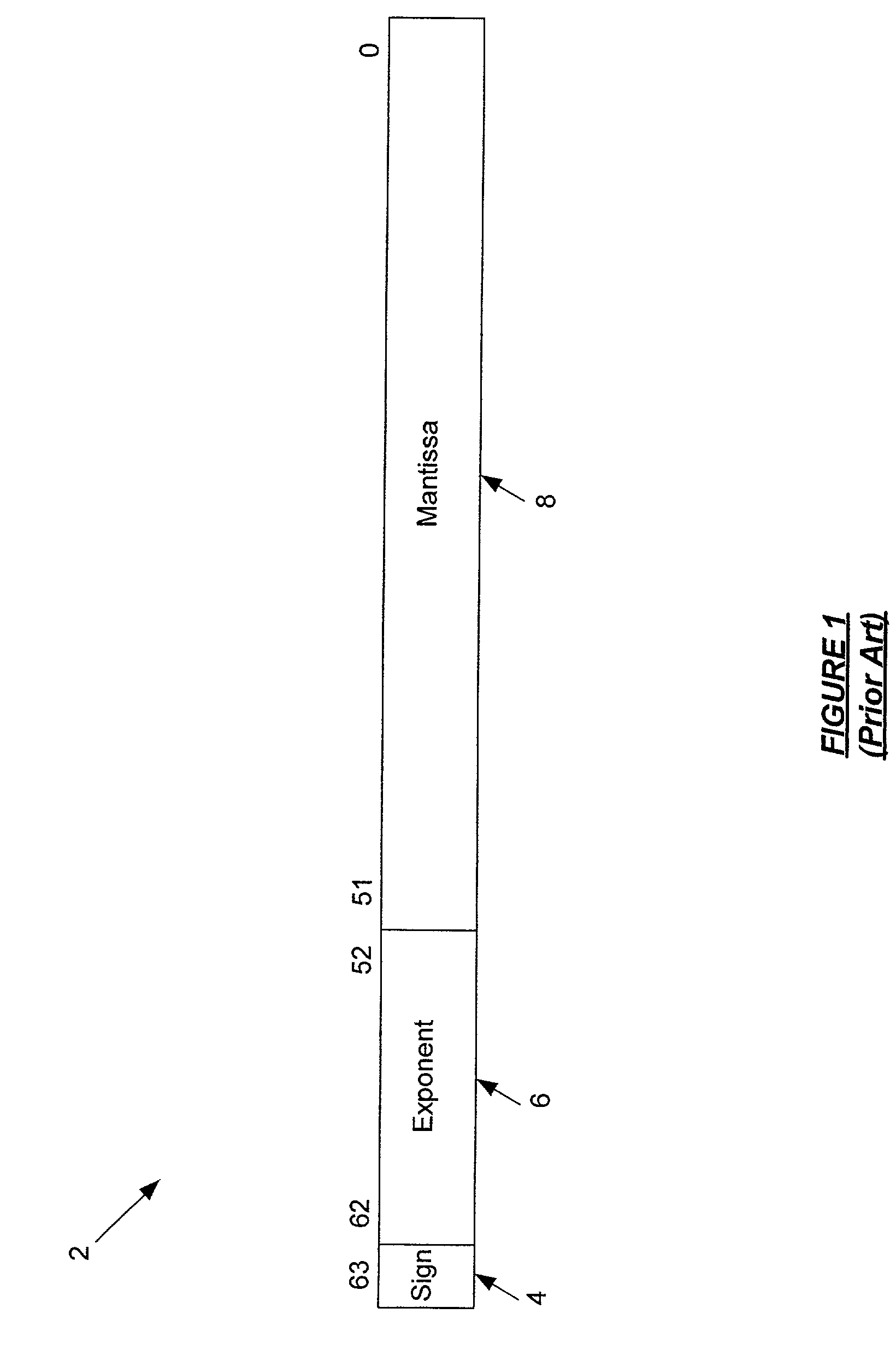

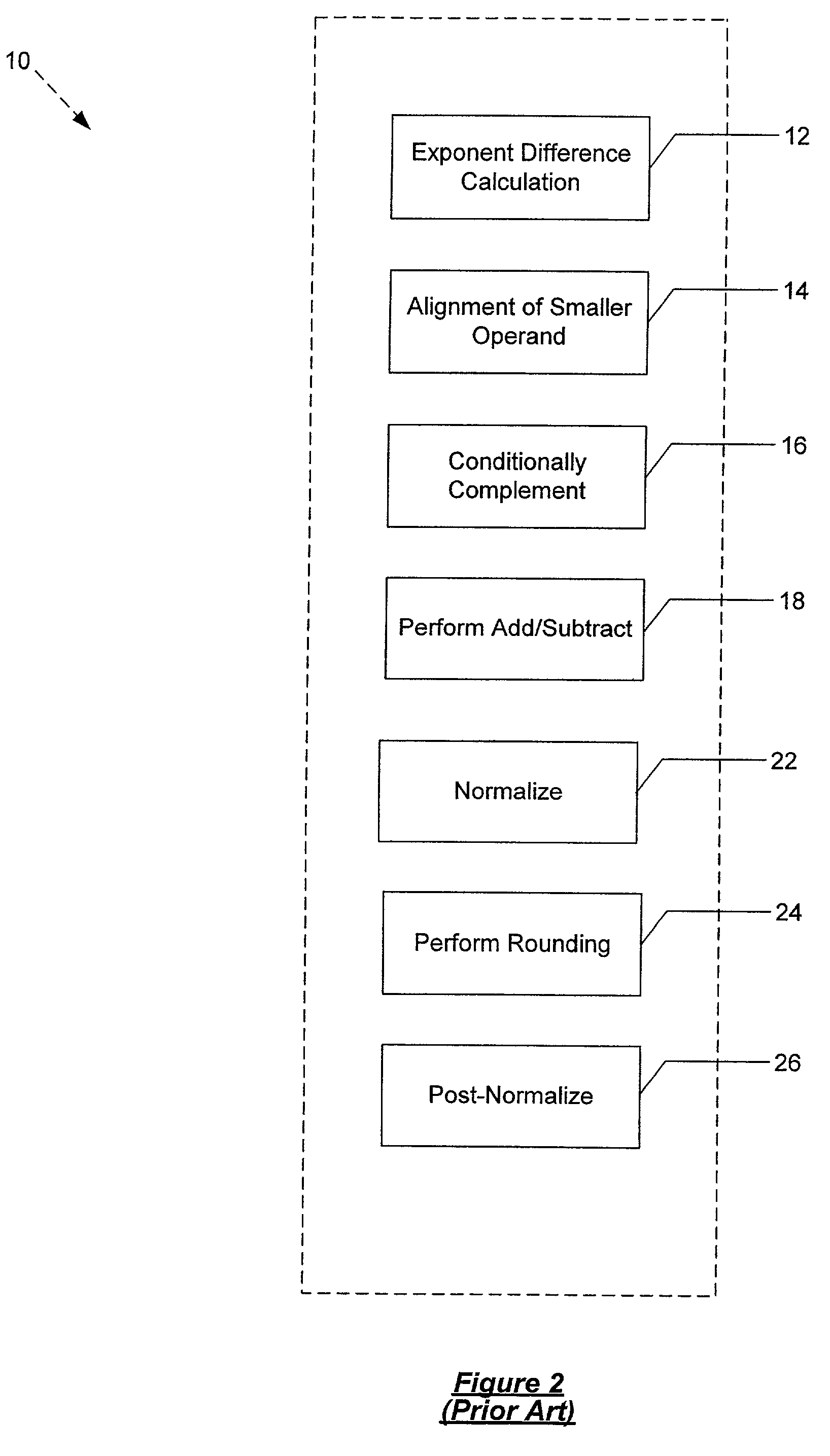

Method/apparatus for conversion of higher order bits of 64-bit integer to floating point using 53-bit adder hardware

ActiveUS6990505B2Computation using non-contact making devicesCode conversionFloating-point unitOperand

A floating point unit capable of converting a 64-bit integer number to a floating point format is provided. The floating point unit includes an 11-bit zero / one complement detect circuitry in an exponent datapath of the floating point unit, where the 11-bit zero / one complement detect circuitry is used to determine a shift count for a right shifter in a large exponent difference mantissa datapath of the floating point unit. The 11-bit zero / one complement detect circuitry determines shift counts based on particular bit groupings of the 64-bit operand.

Owner:ORACLE INT CORP

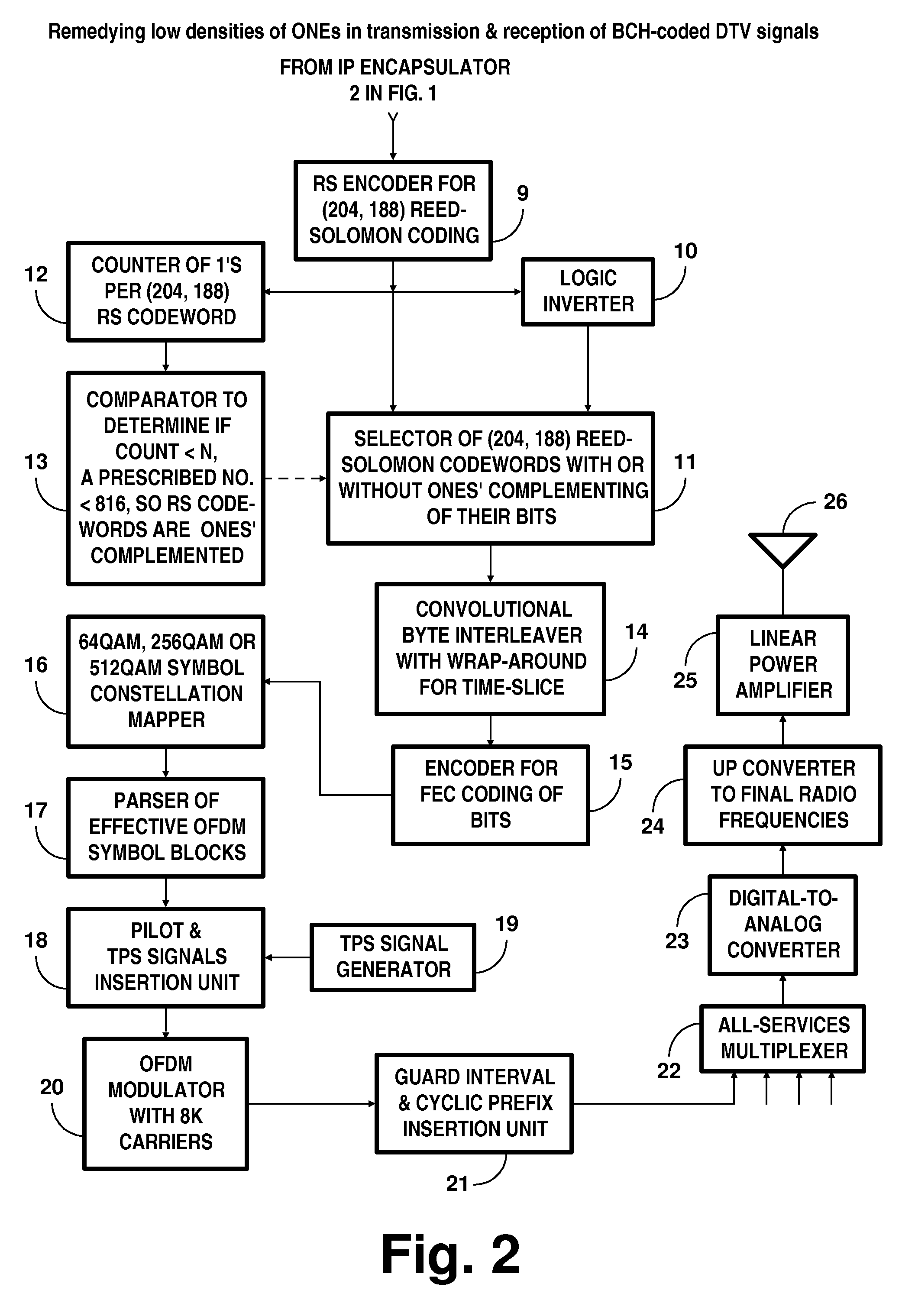

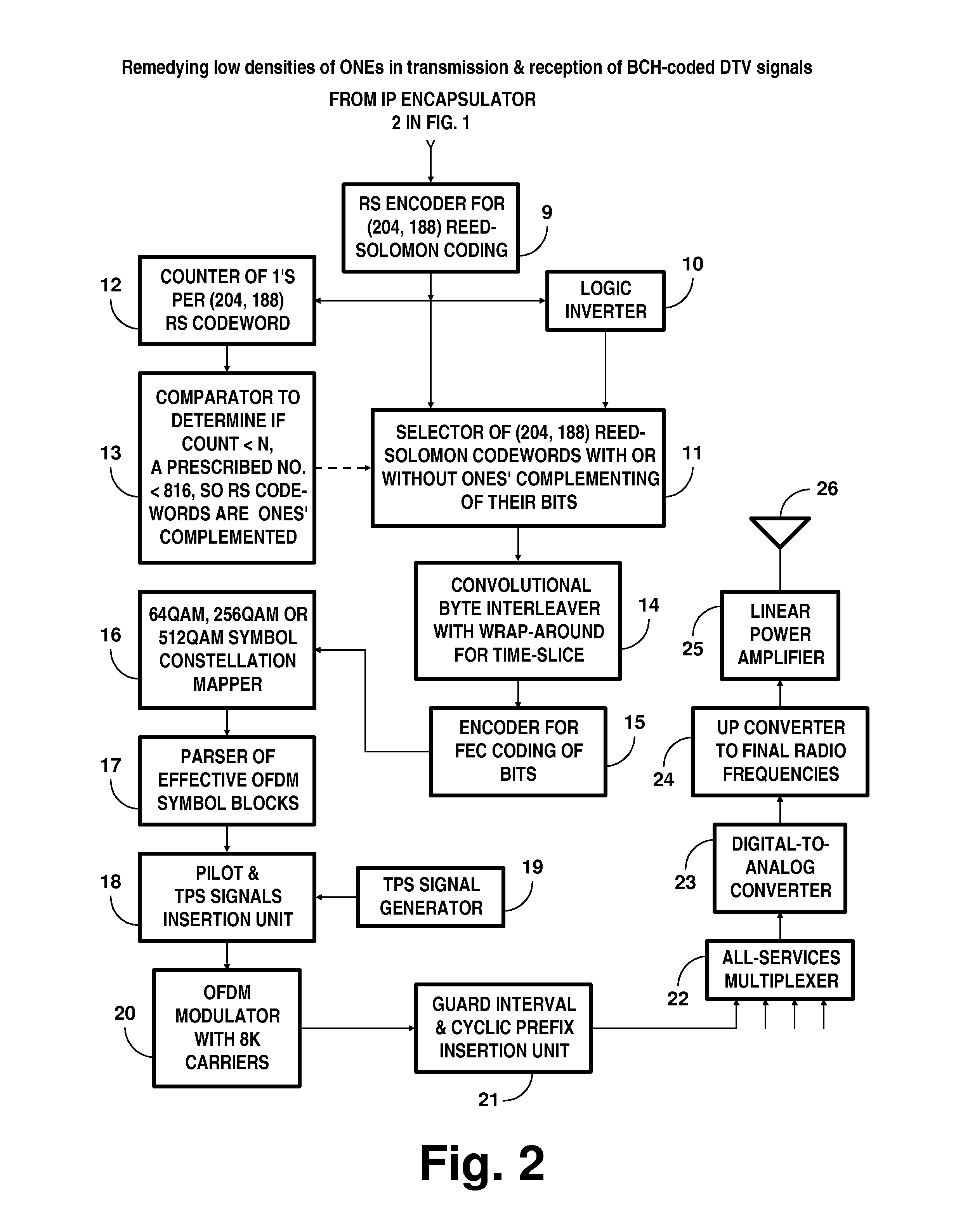

Remedying low densities of ONEs in transmission and reception of digital television signals

InactiveUS20140177731A1Reduce payloadHigh densityPicture reproducers using cathode ray tubesCode conversionCarrier signalDTV receiver

In a DTV transmitter the bits of shortened BCH codewords that exhibit undesirably low densities of ONEs are ONEs' complemented before being further coded, and used to modulate carrier waves. In a DTV receiver the further coding is decoded after demodulation. The results of such decoding are processed to recover successive shortened BCH codewords, some of which are in TRUE form and others of which have had their bits ONEs' complemented. Each shortened BCH codeword is extended to full length with ZEROs, and decoding is attempted. Successful decoding confirms that the shortened BCH codeword was received in TRUE form. If decoding is unsuccessful, the bits of the shortened BCH codeword as received are ONEs' complemented, extended to full length with ZEROs, and decoding is attempted. Successful decoding confirms that the shortened BCH codeword was received in ONEs' complemented form and has subsequently been converted to TRUE form.

Owner:LIMBERG ALLEN LEROY

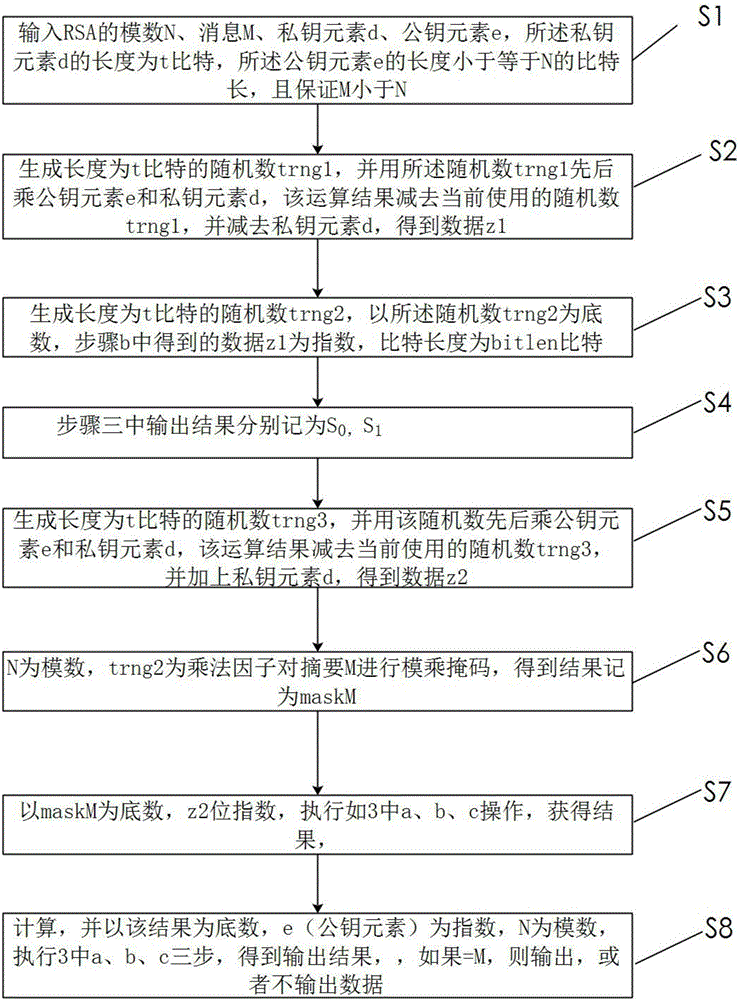

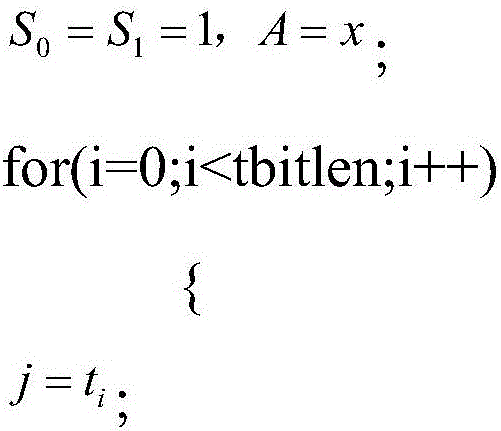

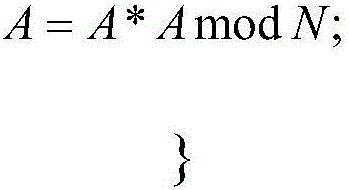

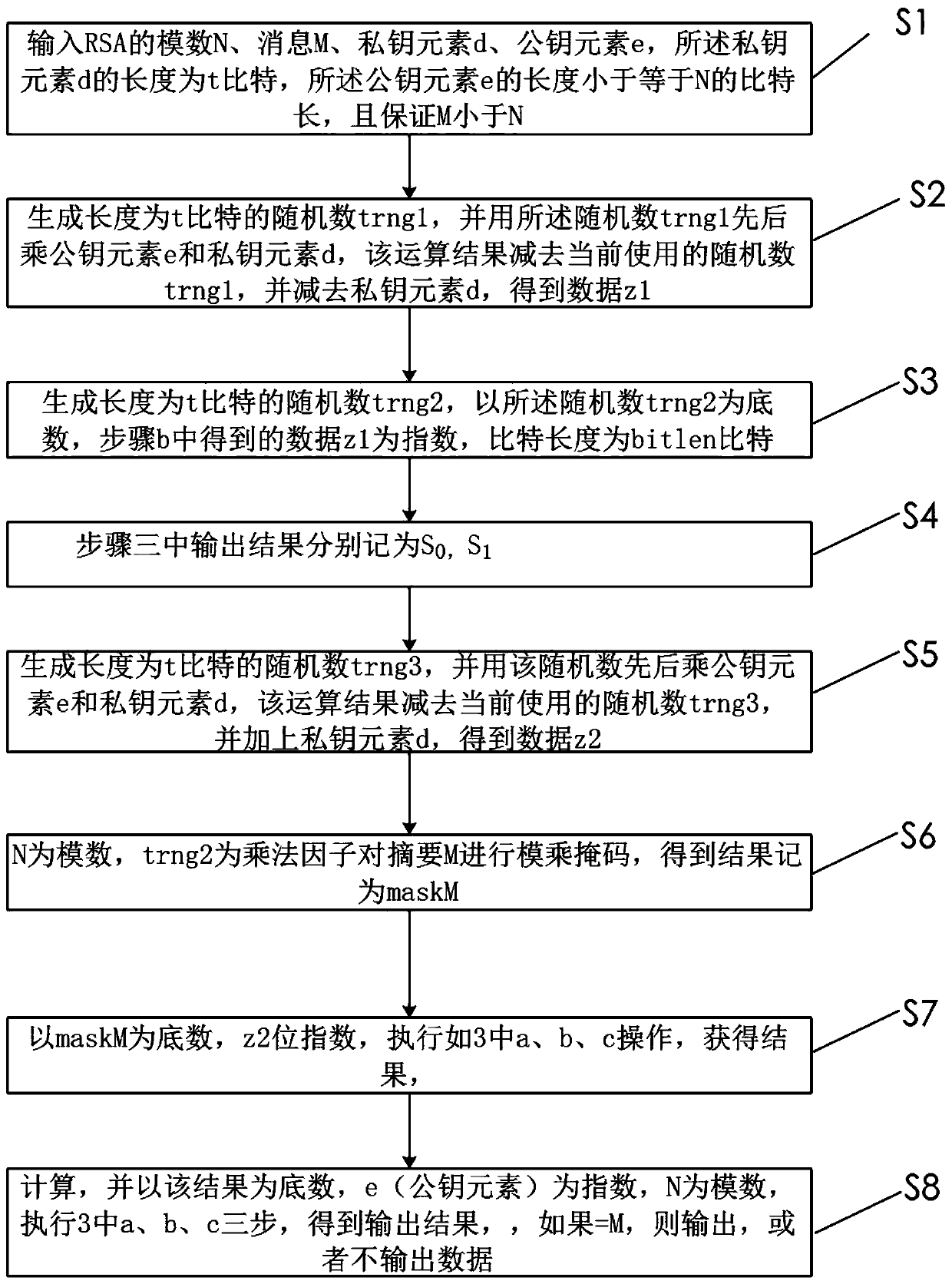

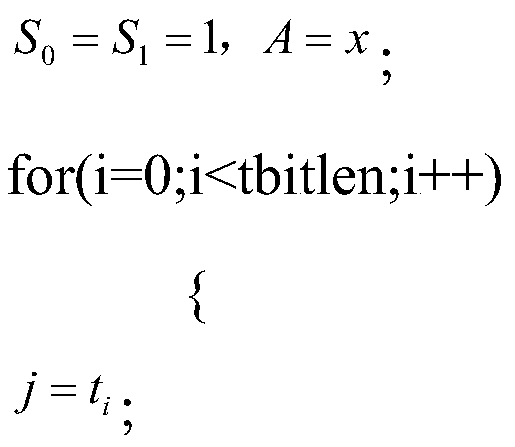

Signature method of preventing side-channel attack from multi-azimuth

ActiveCN106452789APrevent inversionAvoid time consuming inversionUser identity/authority verificationCryptographic attack countermeasuresModular exponentiationOnes' complement

The invention discloses a signature method of preventing side-channel attack from multi-azimuth. The signature method of preventing side-channel attack from multi-azimuth is characterized in that the technology or similar technology contained in the signature method masks the base, and an RSA signature or other public key system signatures are obtained; in the signature method of preventing side-channel attack from multi-azimuth, two module exponentiation results are obtained at the same time, and the power exponents are radix minus one complement for each other; when modular exponentiation is realized, the verification technology of preventing outputting error data is used; and for the modular exponentiation algorithm which does not use the jump statement, the signature method of preventing side-channel attack from multi-azimuth is the technology that during the operation process, the data or the operation result data is equal to the Hamming weight. The signature method of preventing side-channel attack from multi-azimuth effectively protects the step which is known and is easy to be attacked during the RSA STD operation process. The modular exponentiation provided by the signature method of preventing side-channel attack from multi-azimuth can be fully applied to the RSA CRT operation, and can realize that the algorithm of the modular exponentiation algorithm and the complementary power can be transplanted to the point multiplication operation of SM2 at the same time. The test that whether the module exponentiation is attacked can be similarly transplanted in the point multiplication operation of SM2.

Owner:BEIJING HONGSI ELECTRONICS TECH

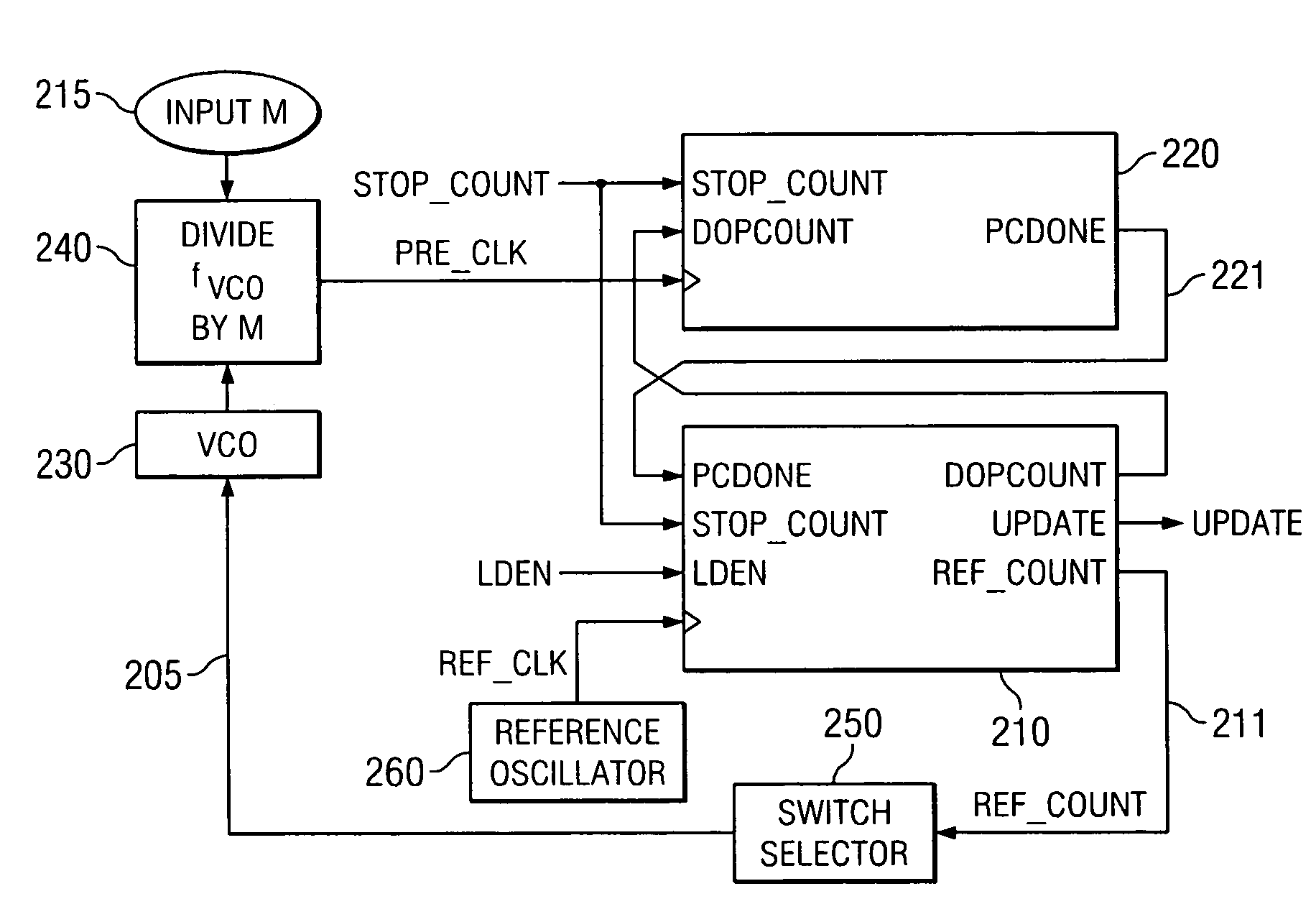

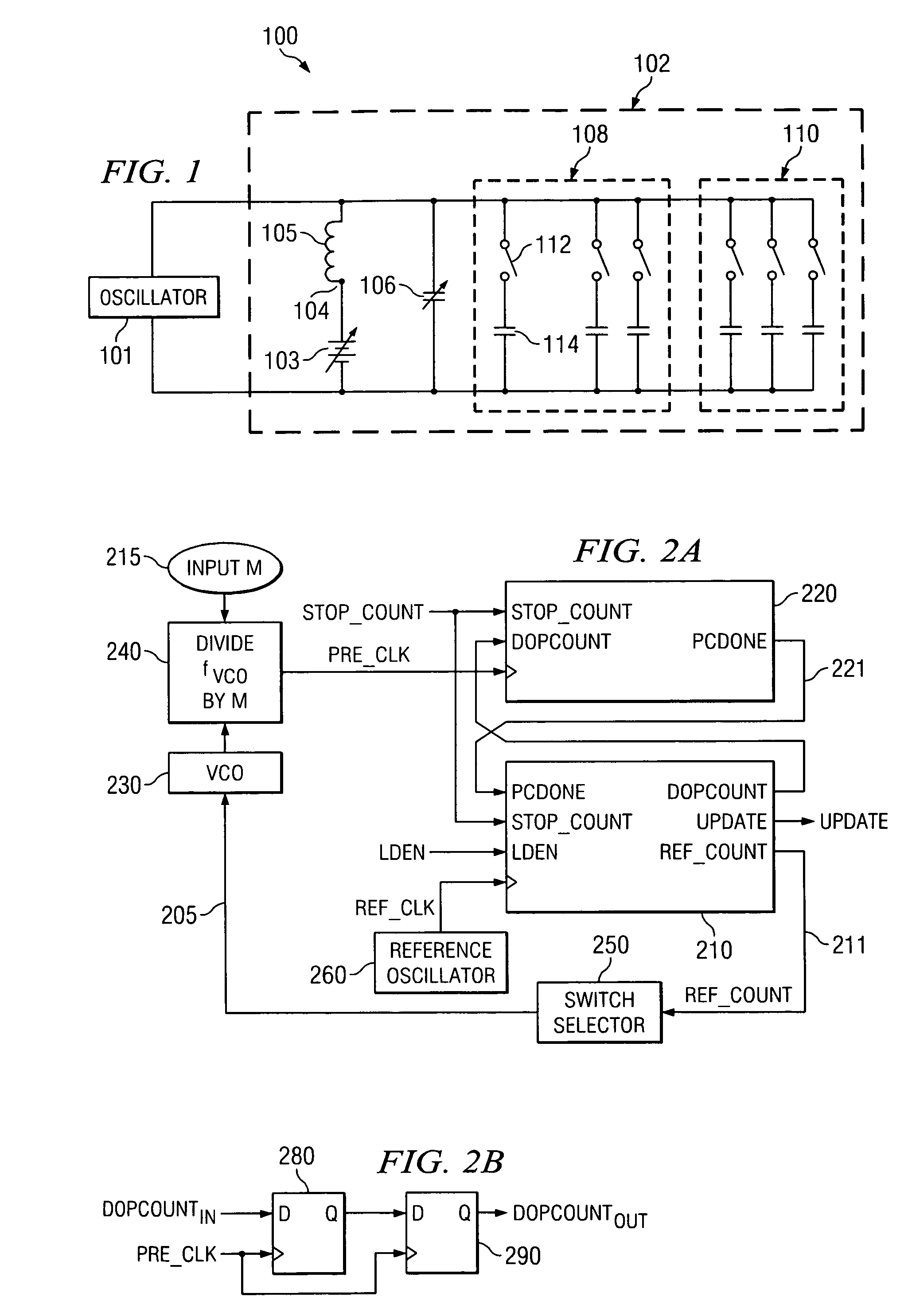

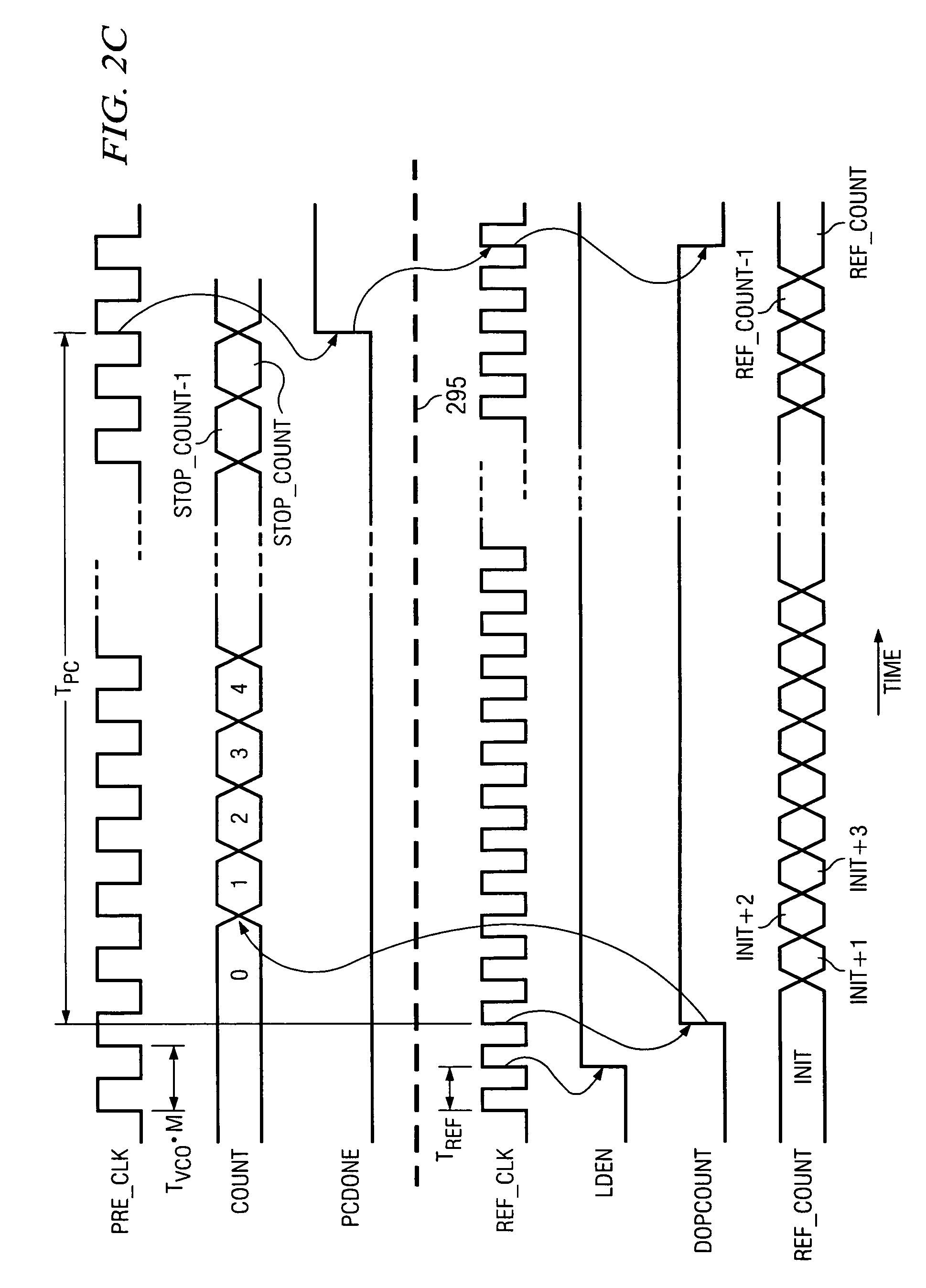

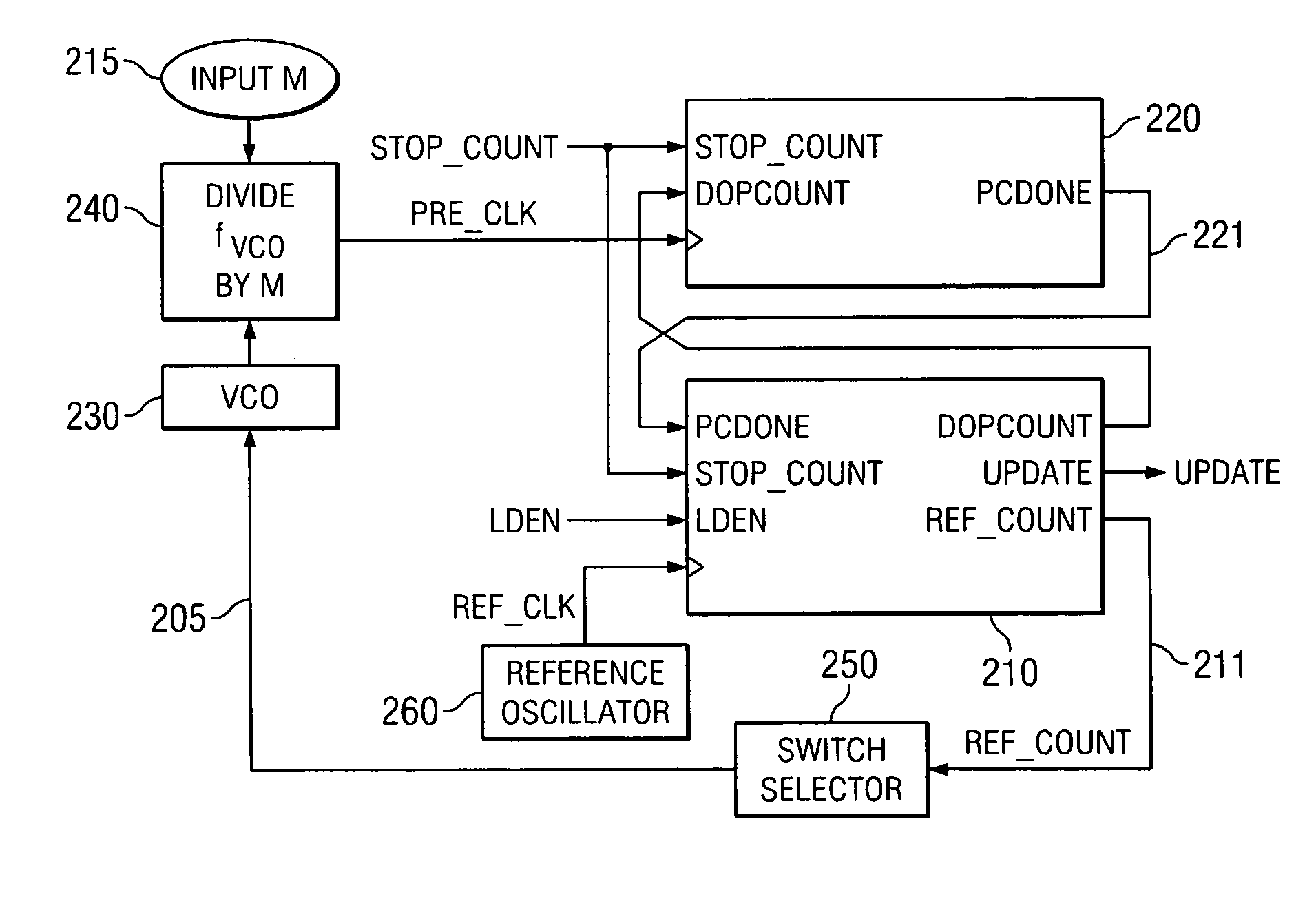

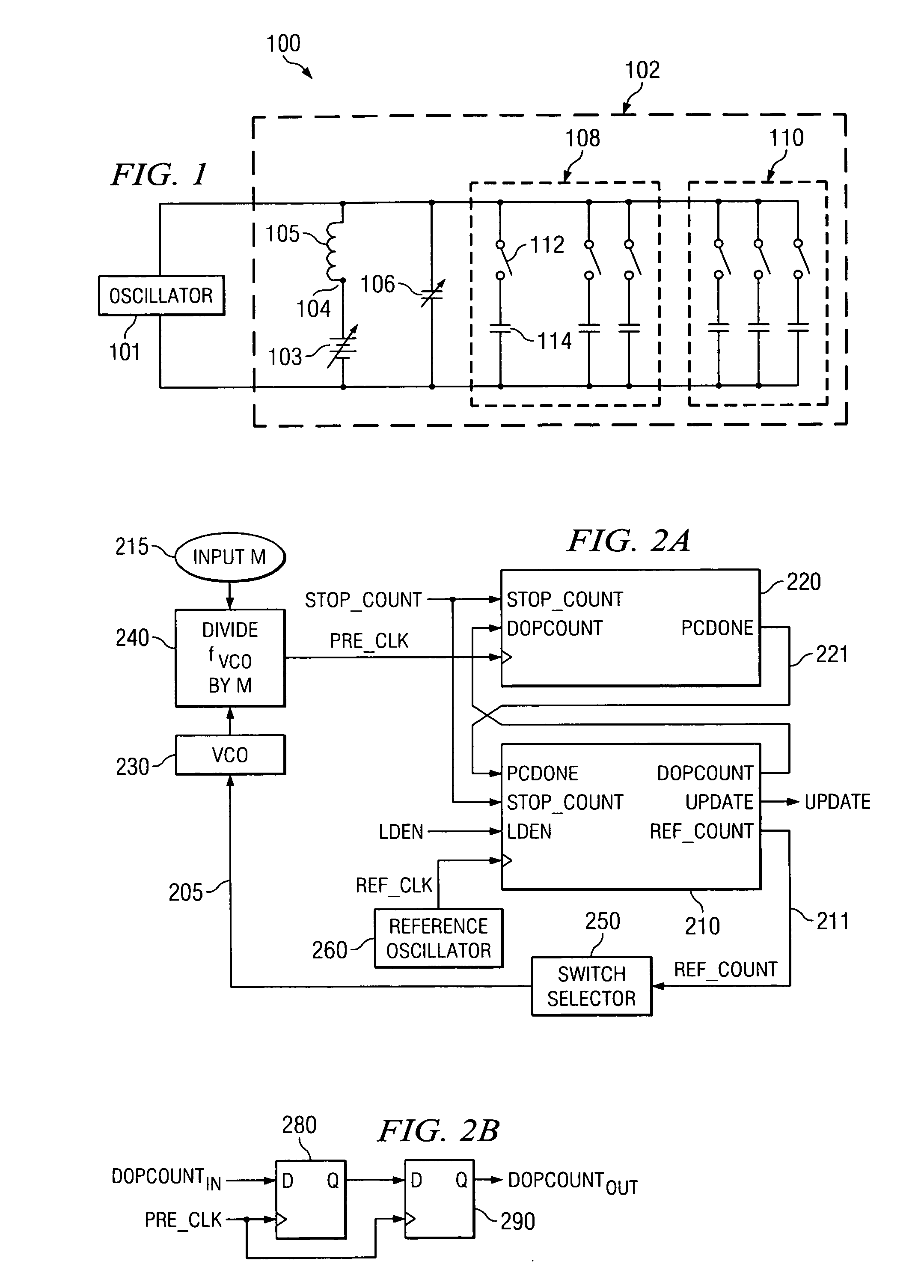

Method and apparatus for rapid local oscillator frequency calibration

ActiveUS7330079B2Quickly and efficiently selectingResonant circuit tuningPulse automatic controlCounting NumberLocal oscillator

Owner:TEXAS INSTR INC

Method and apparatus for rapid local oscillator frequency calibration

ActiveUS20070096840A1Quickly and efficiently selectingResonant circuit tuningPulse automatic controlCounting NumberLocal oscillator

A controller for an adjustable-frequency oscillator includes a first counter supplied with a stop-count value to count adjustable-frequency oscillator cycles divided by the ratio of desired frequency to reference oscillator frequency, to produce a stop signal when the first counter reaches the stop-count value. A second counter counts cycles of a reference oscillator starting from an initial number related to the stop-count value. The second counter stops counting and produces an end-count when the second counter receives the stop signal from the first counter. A resonant tank circuit includes a bank of capacitors with switches to select resonant tank circuit capacitors. The switches are selectively controlled using the end-count in the second counter. The stop-count value is set for the first counter so that the end count number in the second counter using a ones-complement binary format can be used to iteratively set the switches with minimal digital computation.

Owner:TEXAS INSTR INC

X-ray CT apparatus

A method, system and computer program product for compensating for unavailability of projection data of a scanned object at selected points that are outside the detection range of a detector. The method includes the step of obtaining projection data of the scanned object, and based on the obtained projection data and the coordinates of the selected point relative to the detector, compensating for the unavailability of the projection data at the selected point. The step of compensating includes determining at least one complementary projection angle and the coordinates of at least one complementary point based on the source projection angle and the coordinates of the selected point relative to the detector, and based on the acquired projection data, the at least one complementary projection angle, and the at least one complementary point coordinates to estimate the projected data values at the selected point.

Owner:TOSHIBA MEDICAL SYST CORP

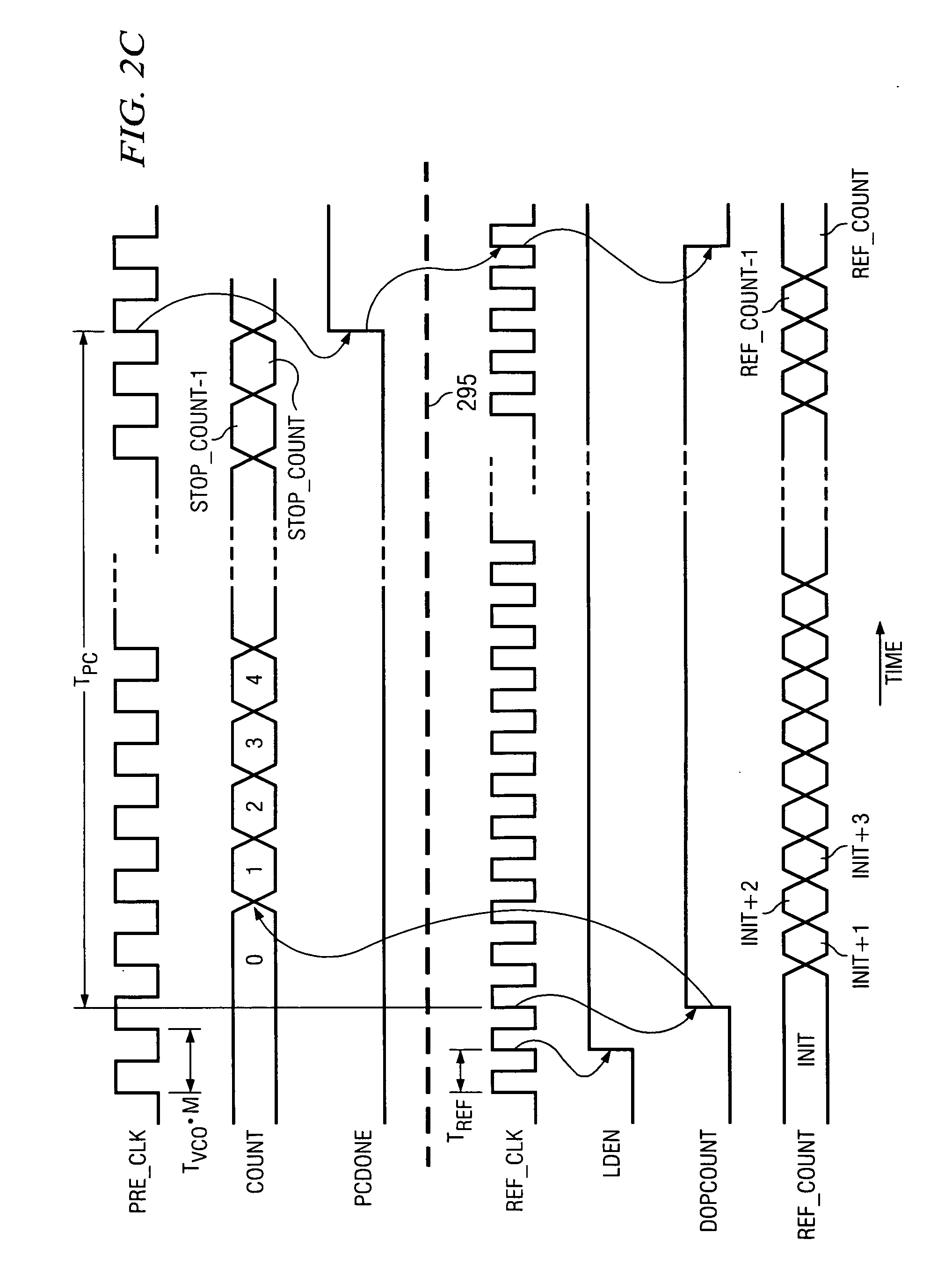

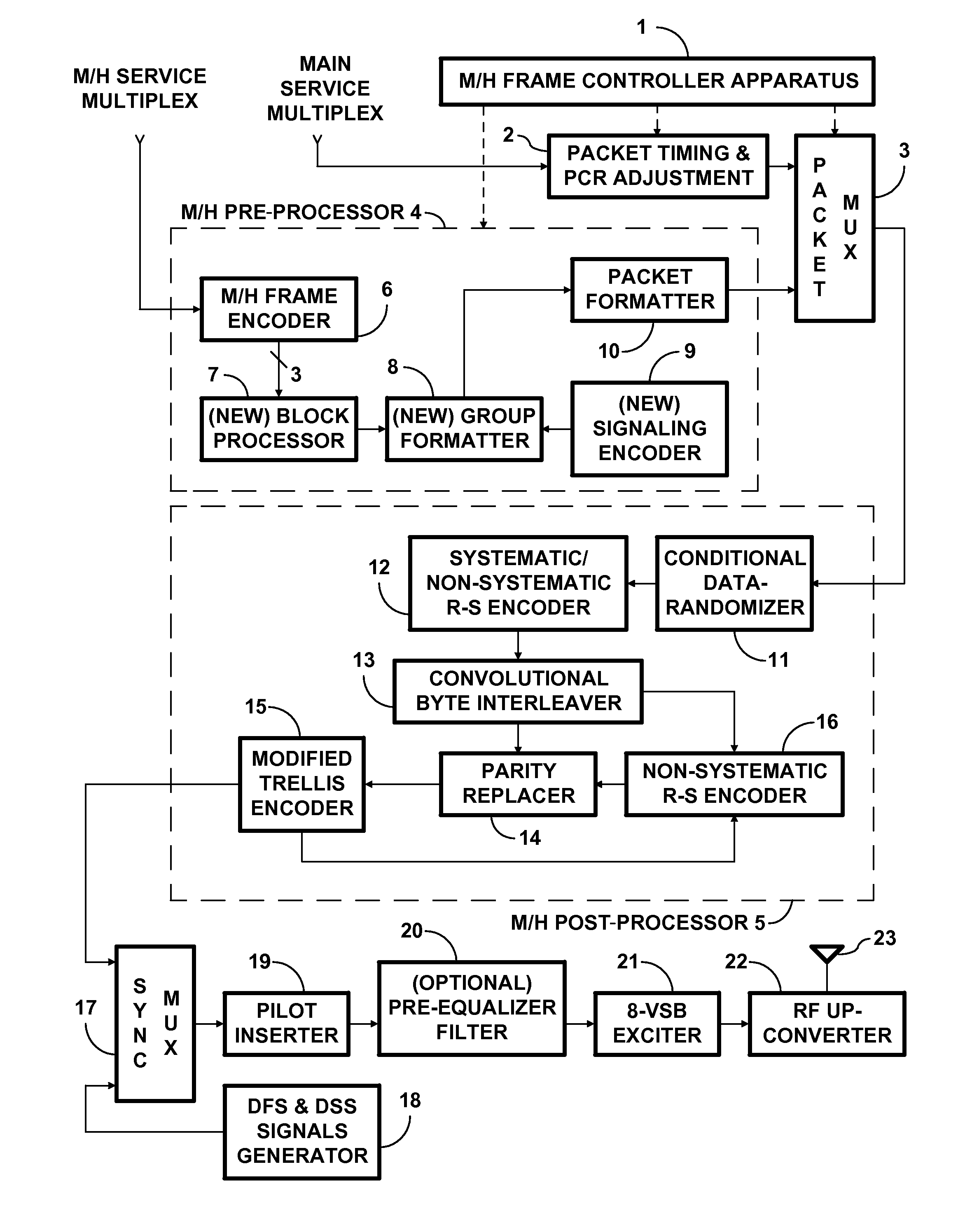

Digital television systems employing concatenated convolutional coded data

InactiveUS8301973B2Error fasterImprove performanceData representation error detection/correctionError detection/correctionConvolutional codeDiversity scheme

In iterative-diversity (ID) transmission systems for signals with concatenated convolutional coding (CCC), paired iterative diversity signals each have ½ the code rate of the 8VSB DTV signals prescribed by the 1995 ATSC Digital Television Broadcast Standard. Known serial concatenated convolutional coding (SCCC) or novel parallel concatenated convolutional coding (PCCC) is used in such system. Pairs of CCC signals code data bits and ones' complemented data bits respectively, using similar coding algorithms. Receivers for this transmission system use respective turbo decoders for turbo decoding the earlier-transmitted and later-transmitted CCC signals. Turbo decoding of the earlier-transmitted portions of iterative diversity signals is delayed to be contemporaneous with turbo decoding of the later-transmitted portions of iterative diversity signals. This facilitates the turbo decoders exchanging information concerning confidence levels of data bits during the turbo decoding procedures.

Owner:SAMSUNG ELECTRONICS CO LTD

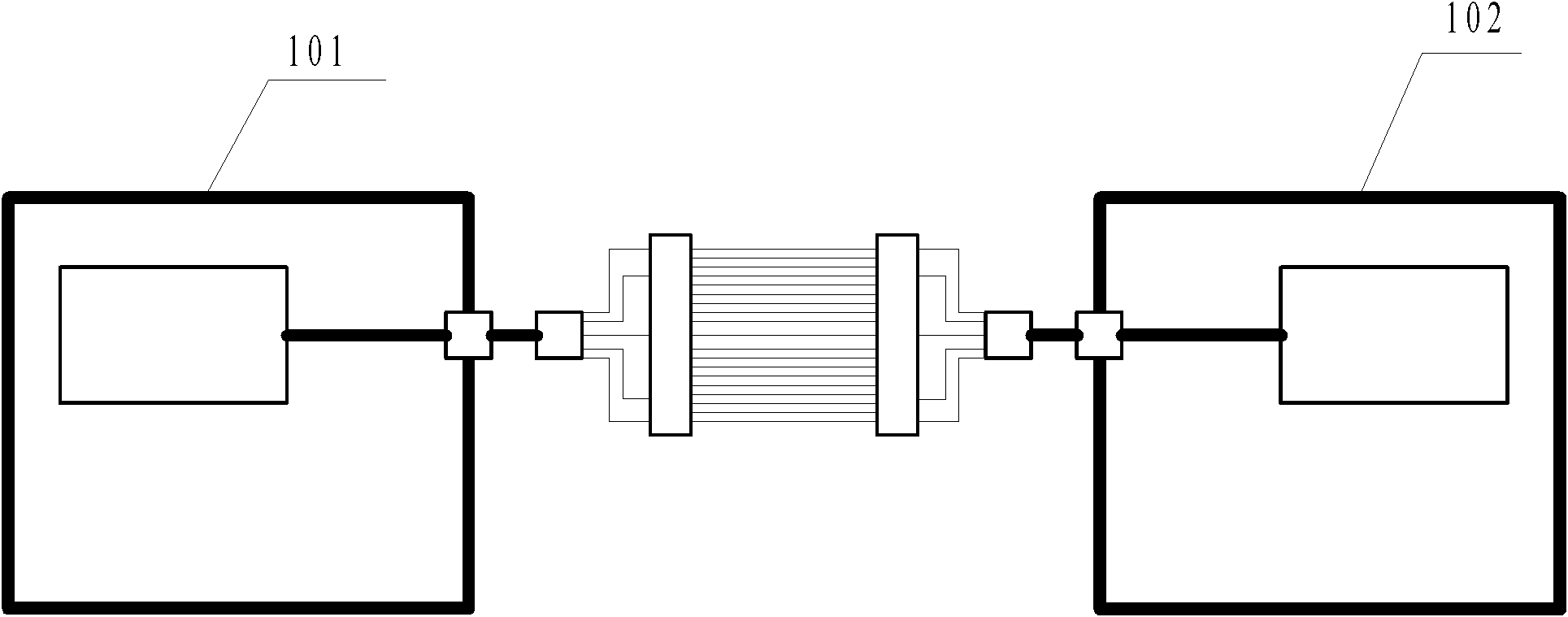

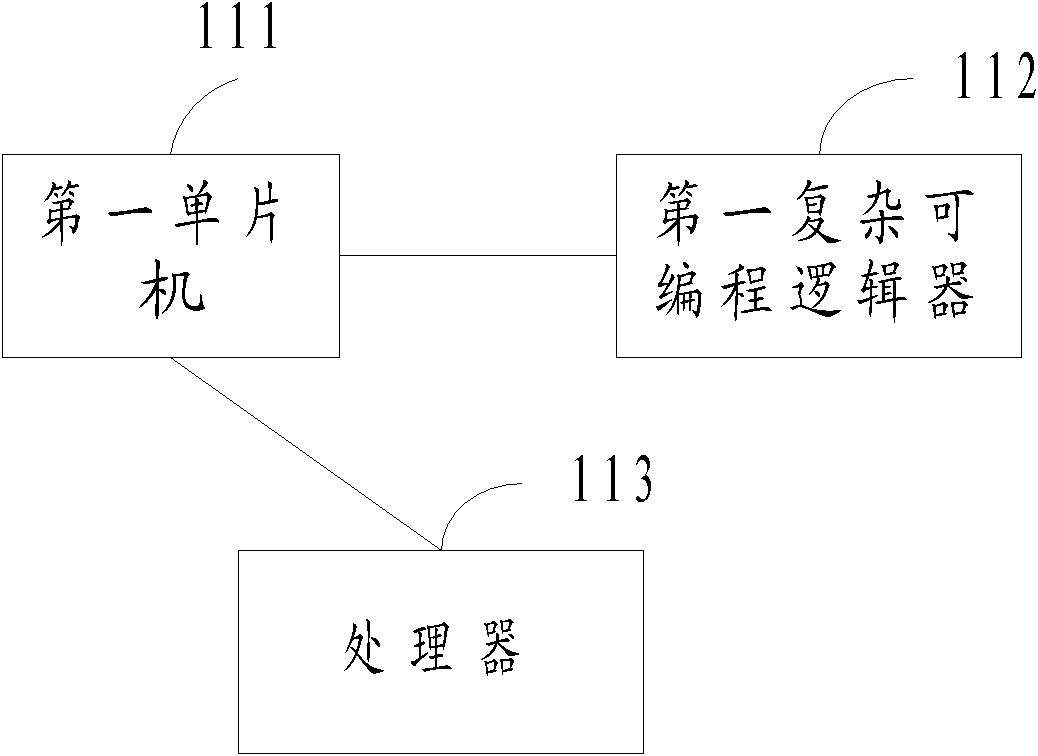

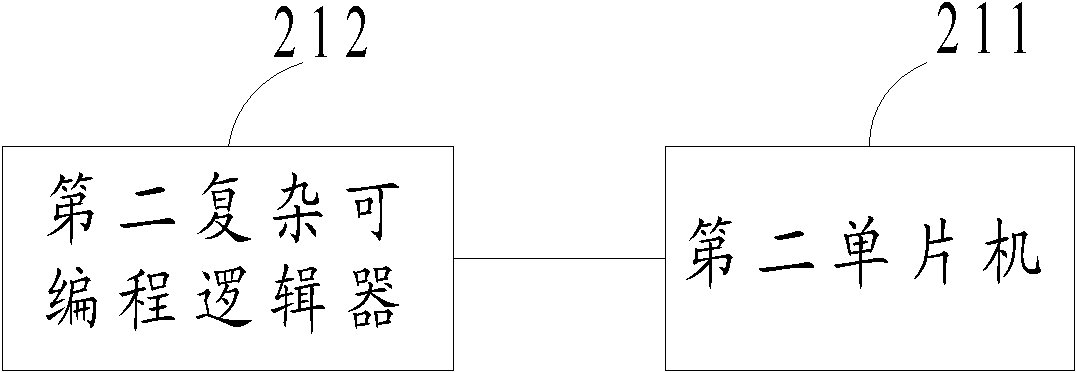

Cable detection method and system

The invention discloses a cable detecting system which comprises a transmitting terminal and a receiving terminal, wherein a port of the transmitting terminal can be connected with a port at one side of each core wire of a to-be-tested cable, and a port of the receiving terminal can be connected with a port at the other side of each core wire of the to-be-tested cable, the transmitting terminal is used for transmitting test codes to the receiving terminal by the to-be-tested cable, and generating a cable test report on the basis of radix-minus-one complements of port codes fed back by the receiving terminal and the test codes. When the transmission fluency of the to-be-tested cable needs to be tested in the cable detecting system disclosed by the invention, the transmitting terminal can transmit the test codes which are transmitted to the receiving terminal by the to-be-tested cable, when the receiving terminal receives the test codes, the receiving terminal can transmit the radix-minus-one complements of the port codes to the transmitting terminal, the transmitting terminal can generate the cable test report on the basis of the generated radix-minus-one complements of the port codes and the test codes through the to-be-tested cable. Therefore, the on-off state of each core wire of the to-be-tested cable can be known by directly reading the cable test cable, without the help of manpower, and the operation is simple and convenient.

Owner:BEIJING RAILWAY SIGNAL

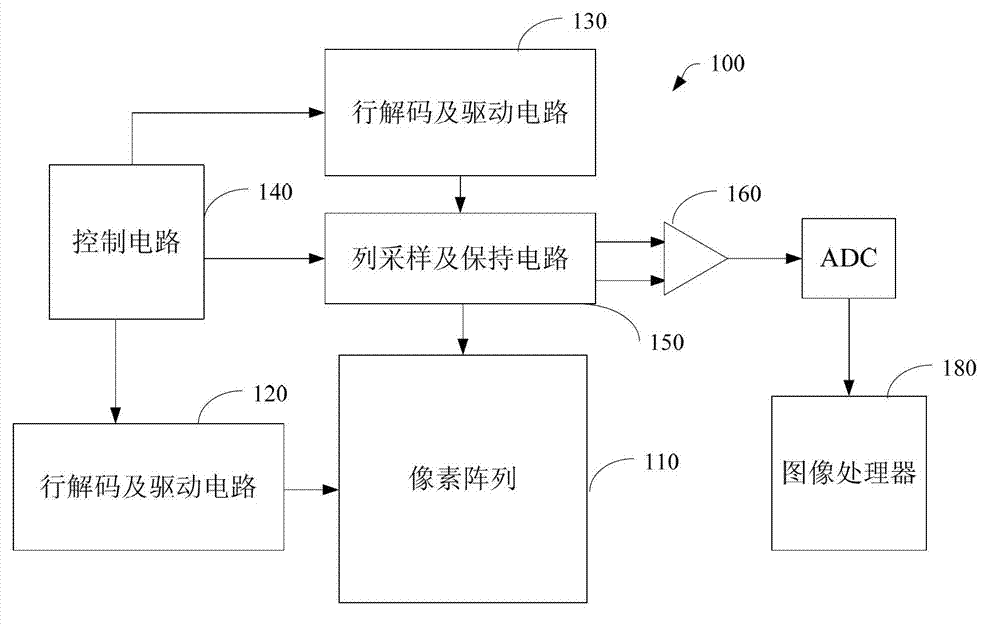

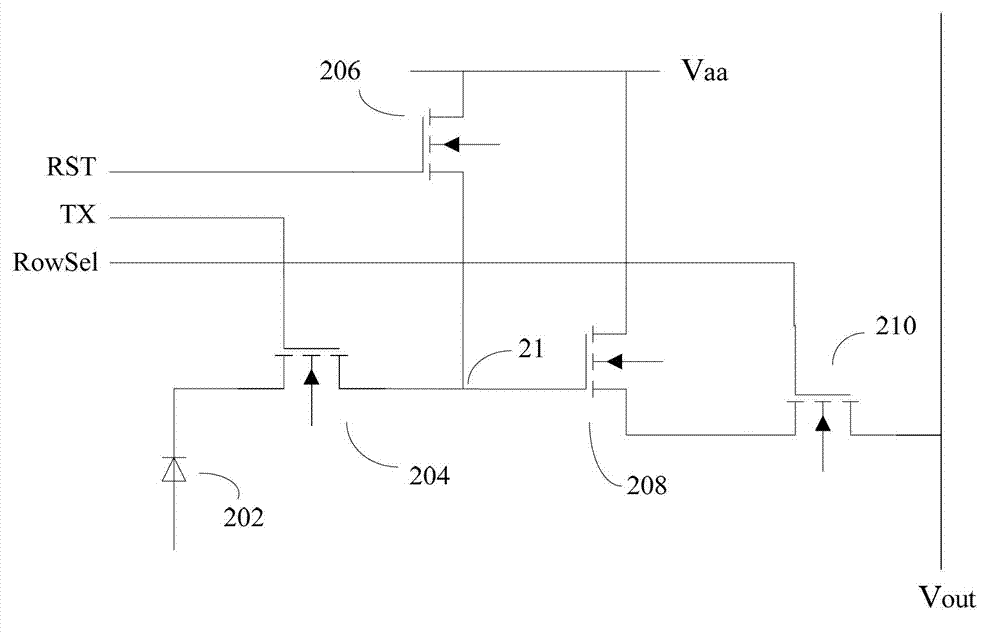

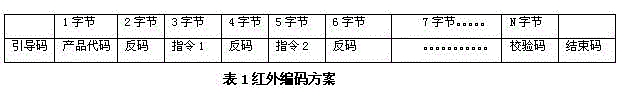

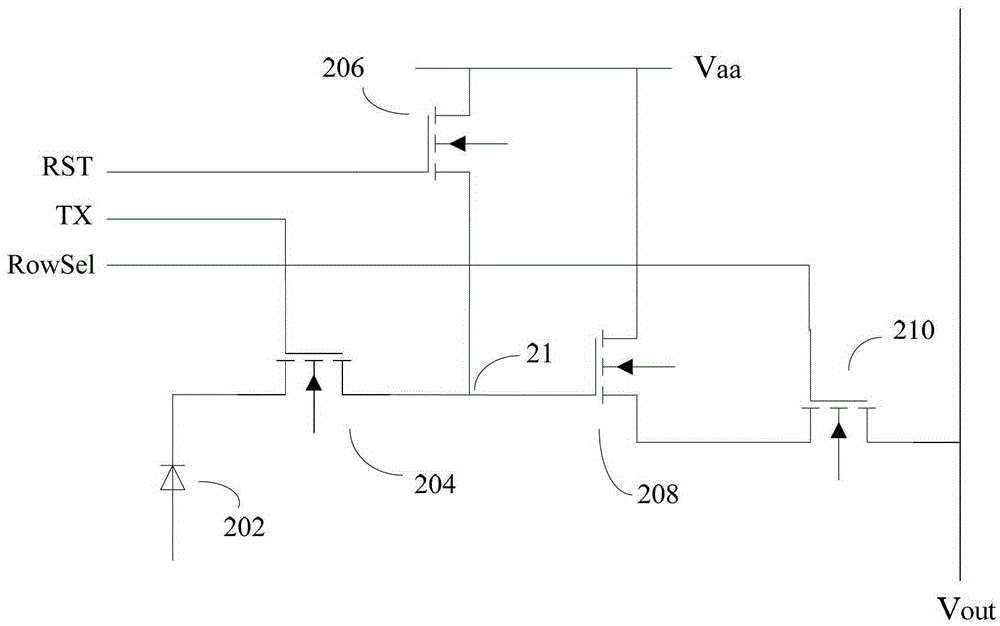

Imaging device and imaging method thereof

The invention relates to an imaging device which comprises a pixel array. The pixel array includes a plurality of pixels which are arrayed into lines and rows, and a plurality of column circuits, wherein each column circuit corresponds to one row of pixels in the pixel array. Each column circuit comprises a comparator and a radix-minus-one complement counter, wherein the comparator compares signals from pixels of a corresponding row with ramp signals, and the radix-minus-one complement counter counts and conducts radix-minus-one complement calculation on output signals of the comparator.

Owner:思特威(上海)电子科技股份有限公司

Remedying low densities of ONEs in transmission and reception of digital television signals

InactiveUS9118352B2Reduce payloadHigh densityOther decoding techniquesCode conversionDTV receiverCarrier signal

Owner:LIMBERG ALLEN LEROY

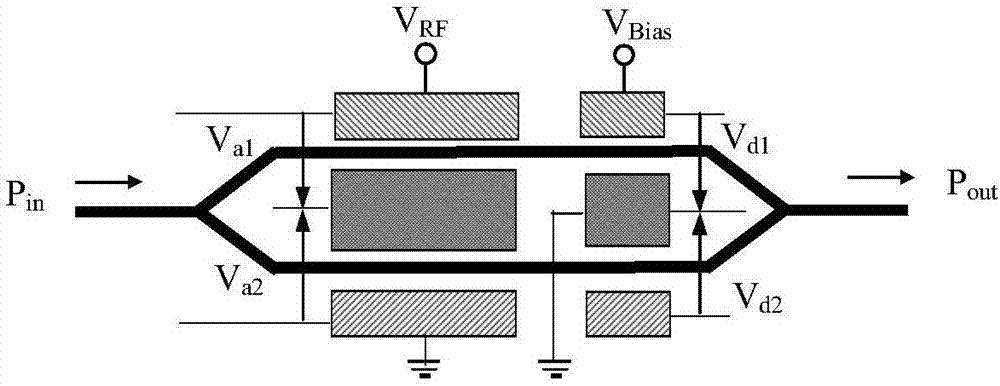

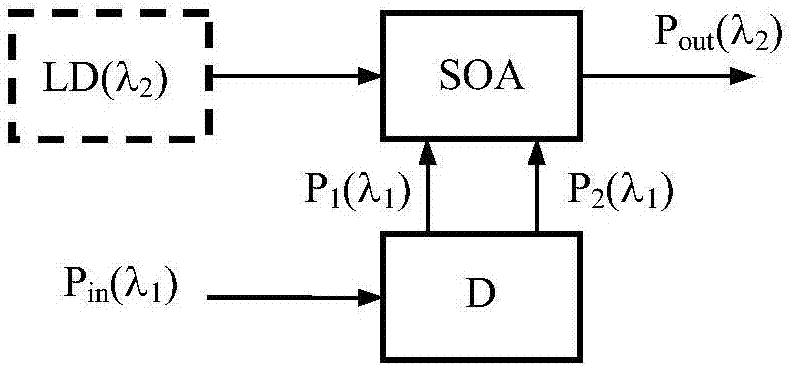

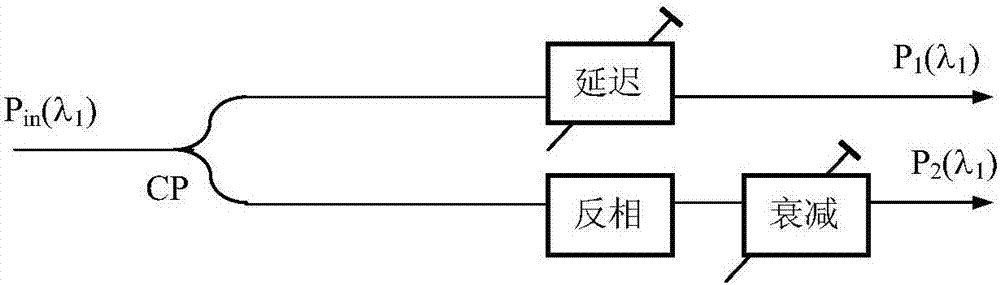

All-optical phase modulator

ActiveCN107070559AAchieve modulationNo need to worry about synchronizationElectromagnetic transmittersLight demodulationAudio power amplifierCross gain modulation

The invention discloses an all-optical phase modulator which comprises a differential balance signal forming unit and an optical phase modulation unit. The optical phase modulation unit comprises a semiconductor optical amplifier; the differential balance signal forming unit is used for changing an intensity-modulated optical signal with a wavelength of lambda 1 into two paths of differential balance signals, and the two paths of differential balance signals are injected into the semiconductor optical amplifier respectively in the same direction with probe light and in a different direction with the probe light; the two paths of differential balance signals respectively are a first path of optical signal with the wavelength of lambda 1 and a second path of optical signal with a wavelength of lambda' 1 after radix-minus-one complement; the first path of optical signal and the second path of optical signal after radix-minus-one complement are reverse codes mutually; and the semiconductor optical amplifier is used for generating cross phase modulation according to interaction of two paths of differential balance signals and the probe light which needs to be modulated. The all-optical phase modulator disclosed by the invention can implement rapid tuning, and is simple in structure and convenient to use.

Owner:NANJING HENGGAO OPTO ELECTRONICS RES INST CORP

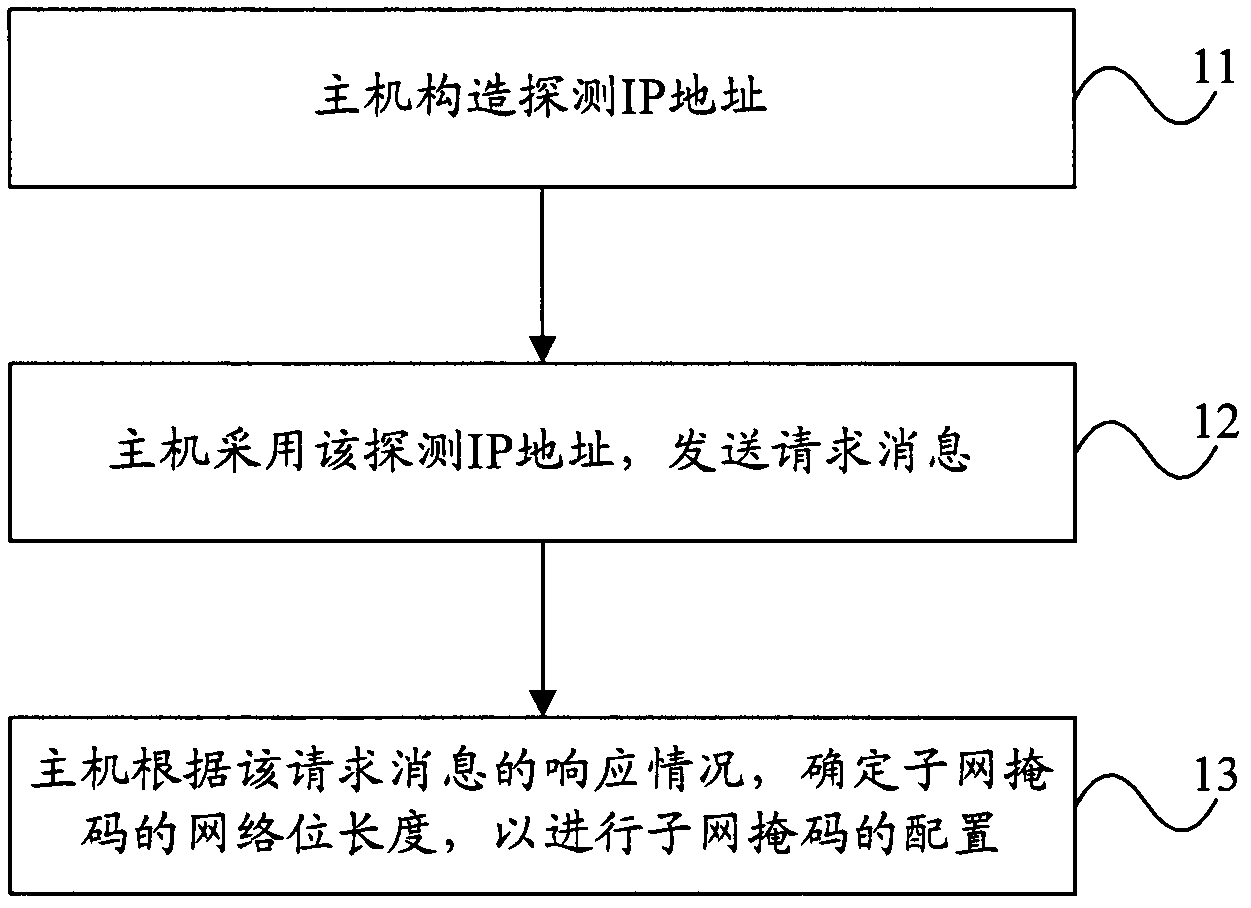

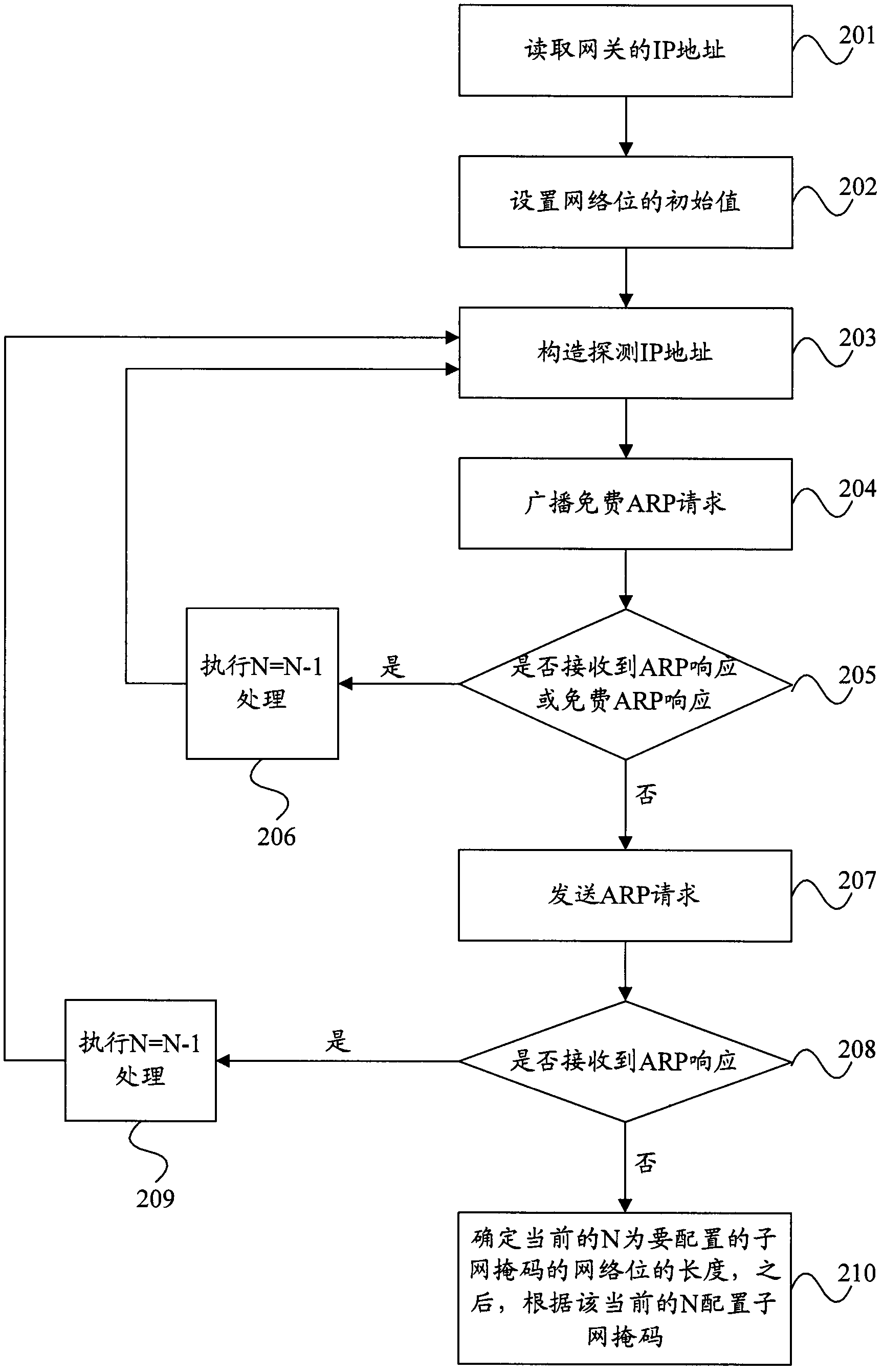

Method and device for configuring subnet mask

ActiveCN102143244AImplement automatic configurationAvoid problems caused by manual configurationData switching networksIp addressOnes' complement

The invention provides a method and a device for configuring a subnet mask. The method comprises the following steps of: constructing a detection internet protocol (IP) address; sending a request message by adopting the detection IP address; and according to the response of the request message, determining the network bit length of the subnet mask so as to configure the subnet mask, wherein the network bit length of the subnet mask is the number of continuous same high bits in the detection IP address and an IP address of a gateway in the same network segment when a response message corresponding to the request message can be critically received, and the detection IP address and the IP address of the gateway meet the following condition: low bits of adjacent same high bits in the detection IP address and the IP address of the gateway are ones-complement codes of each other. The embodiment of the invention can realize automatic configuration of the subnet mask.

Owner:HUAWEI TECH CO LTD

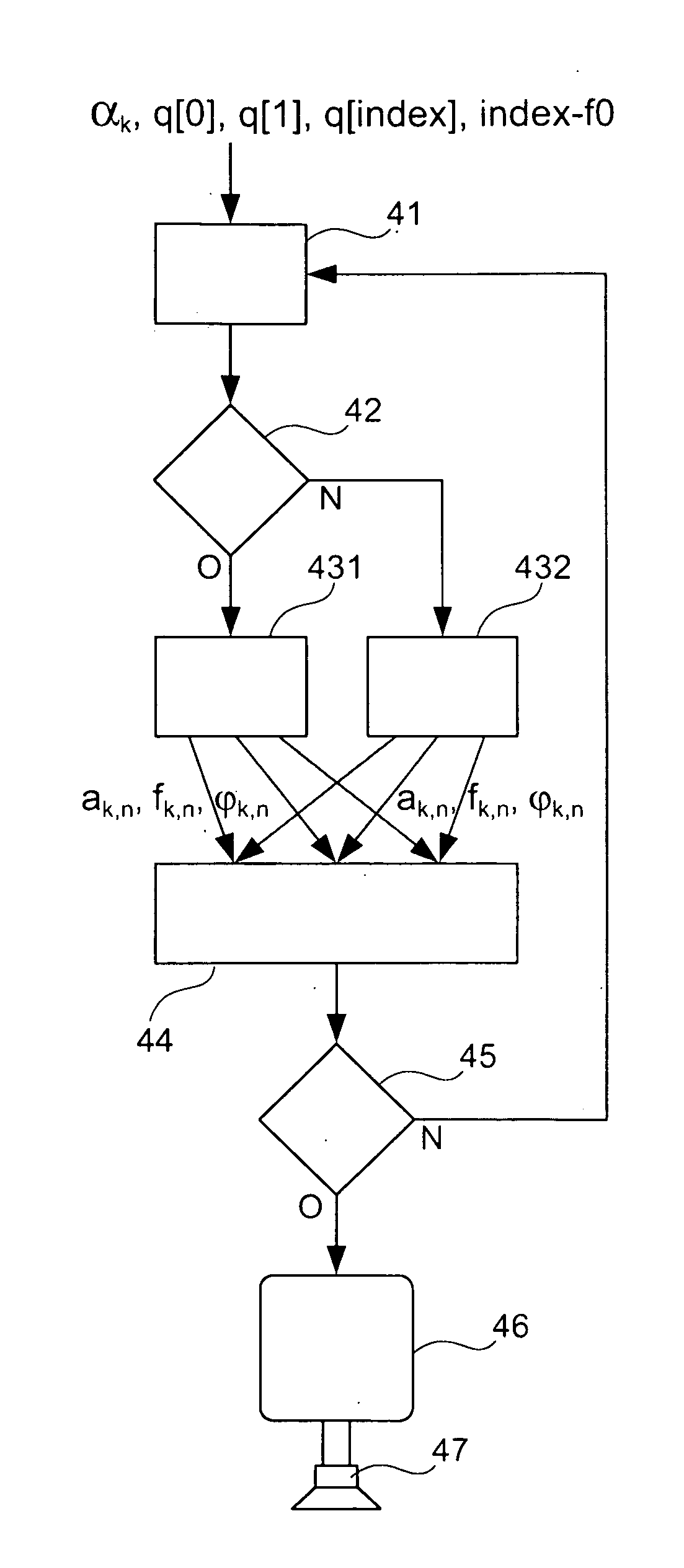

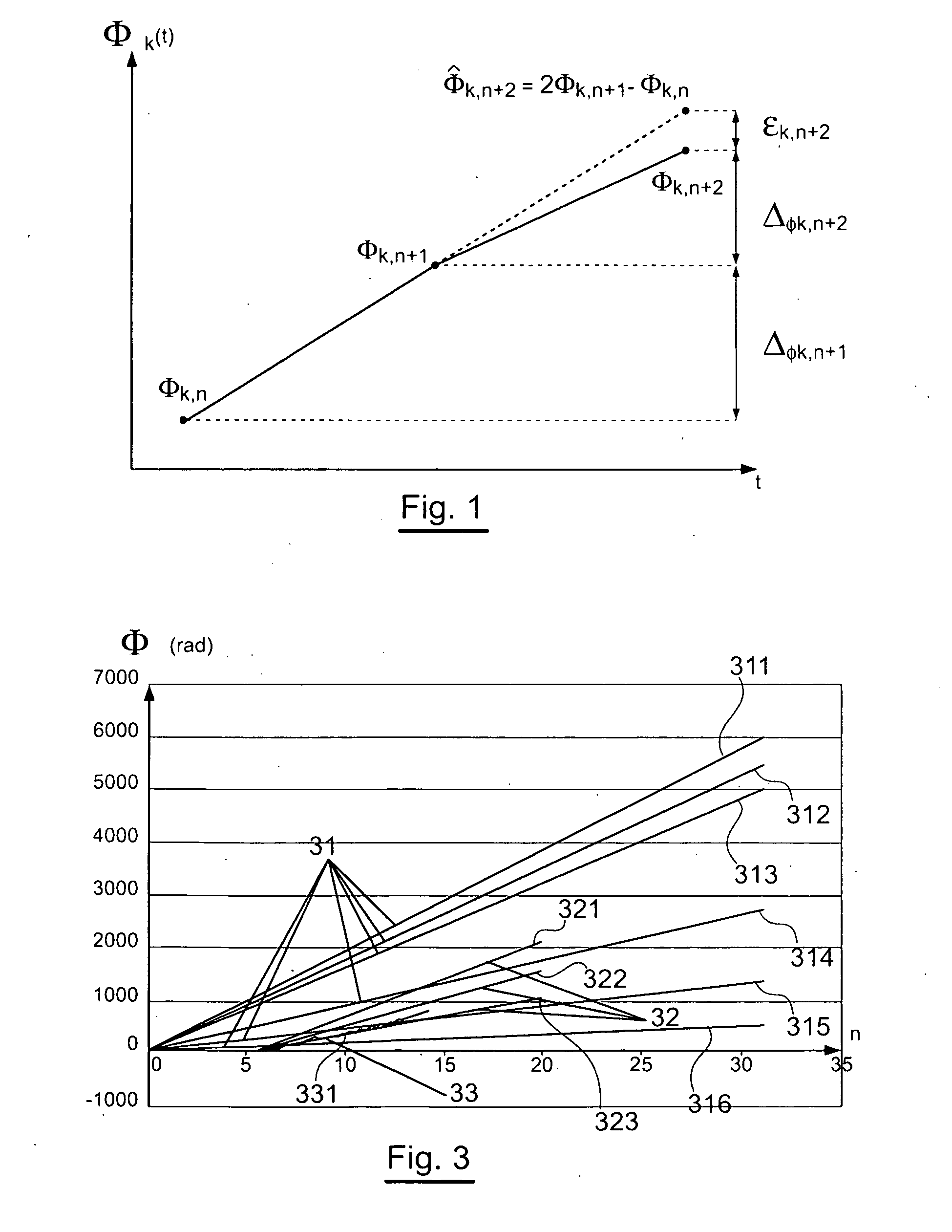

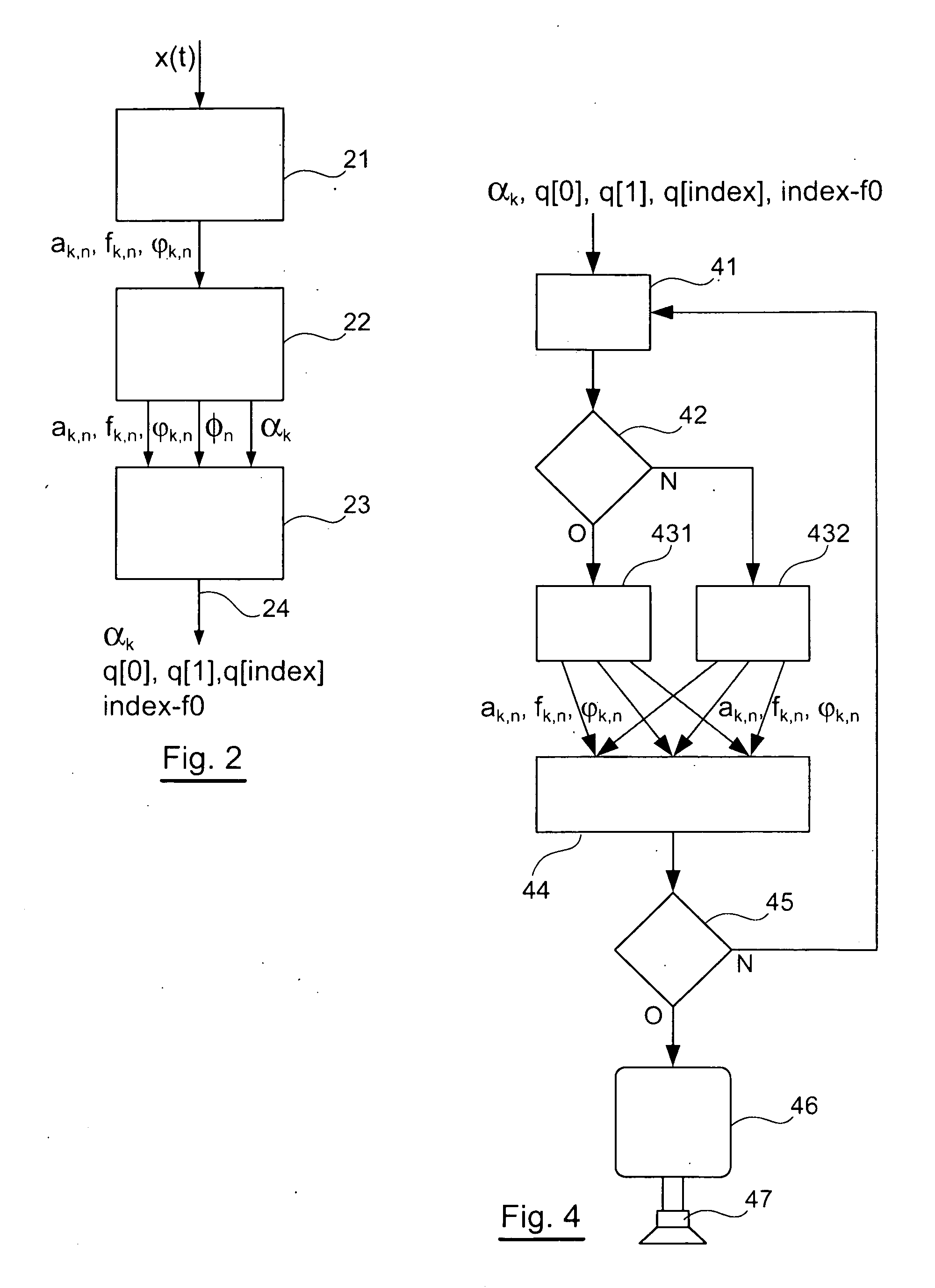

Method for encoding a source audio signal, corresponding encoding device, decoding method, signal, data carrier and computer program product

A method is provided for coding a source audio signal, involving the transformation of an amplitude / time space into a multi-component amplitude / phase / time space, including the sinusoidal modeling of the audio signal and the delivery of the sinusoidal components that change over time. The method includes the following steps in which: the components are compared to one another in order to define at least one group with at least two components using at least one similarity criterion; and, for at least one group, at least one reference datum is coded, the reference datum being represented by an evolved phase originating from a first component of the group, known as the reference component, and at least one complement datum is coded, the complement datum being associated with at least a second component from the group and, together with the reference datum, enabling the reconstruction of at least one piece of information that is representative of at least one component.

Owner:FRANCE TELECOM SA

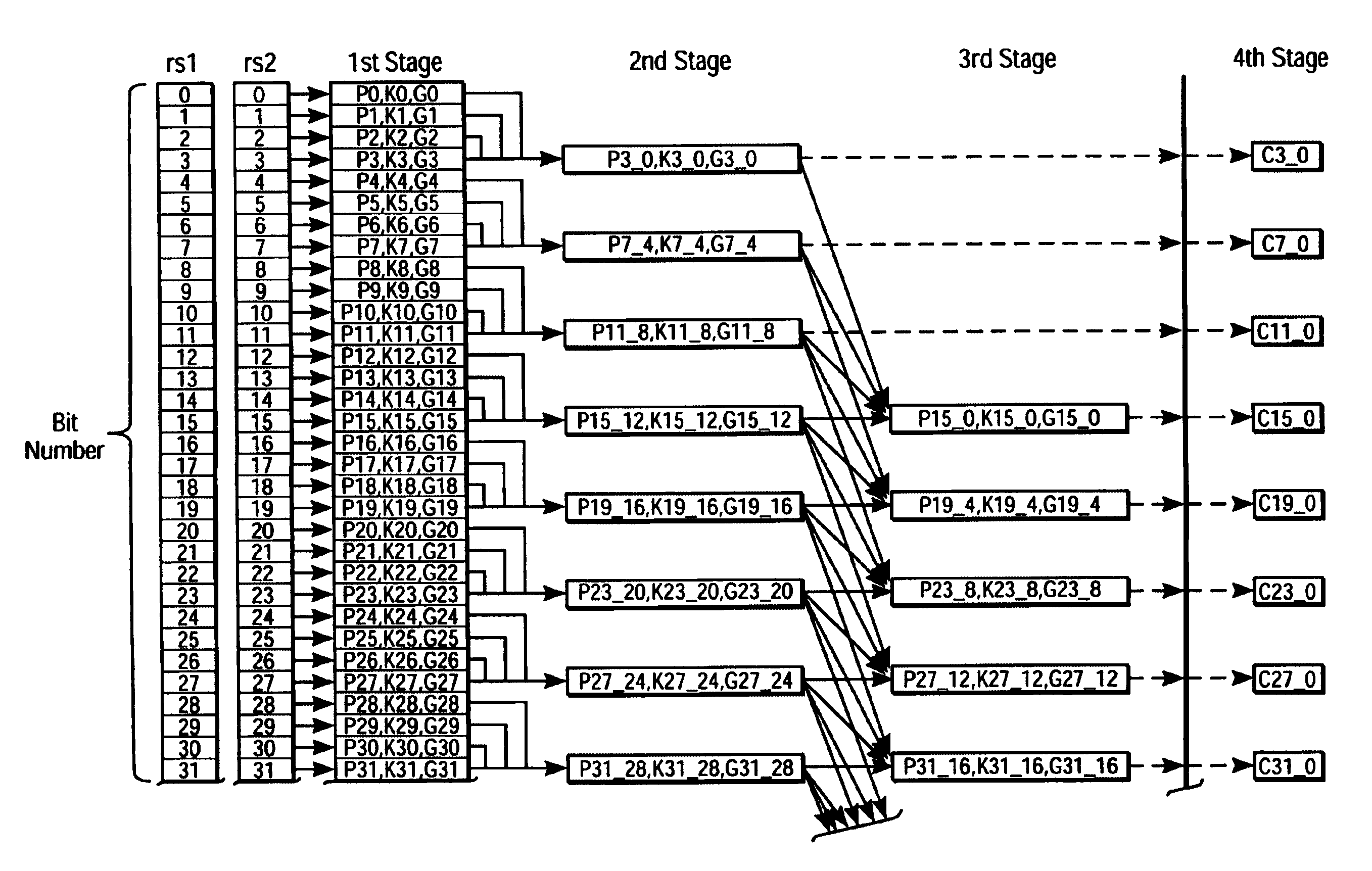

Complementary pass gate logic implementation of 64-bit arithmetic logic unit using propagate, generate, and kill

ActiveUS7194501B2Efficient outputImprove performanceComputation using non-contact making devicesArithmetic logic unitComputer architecture

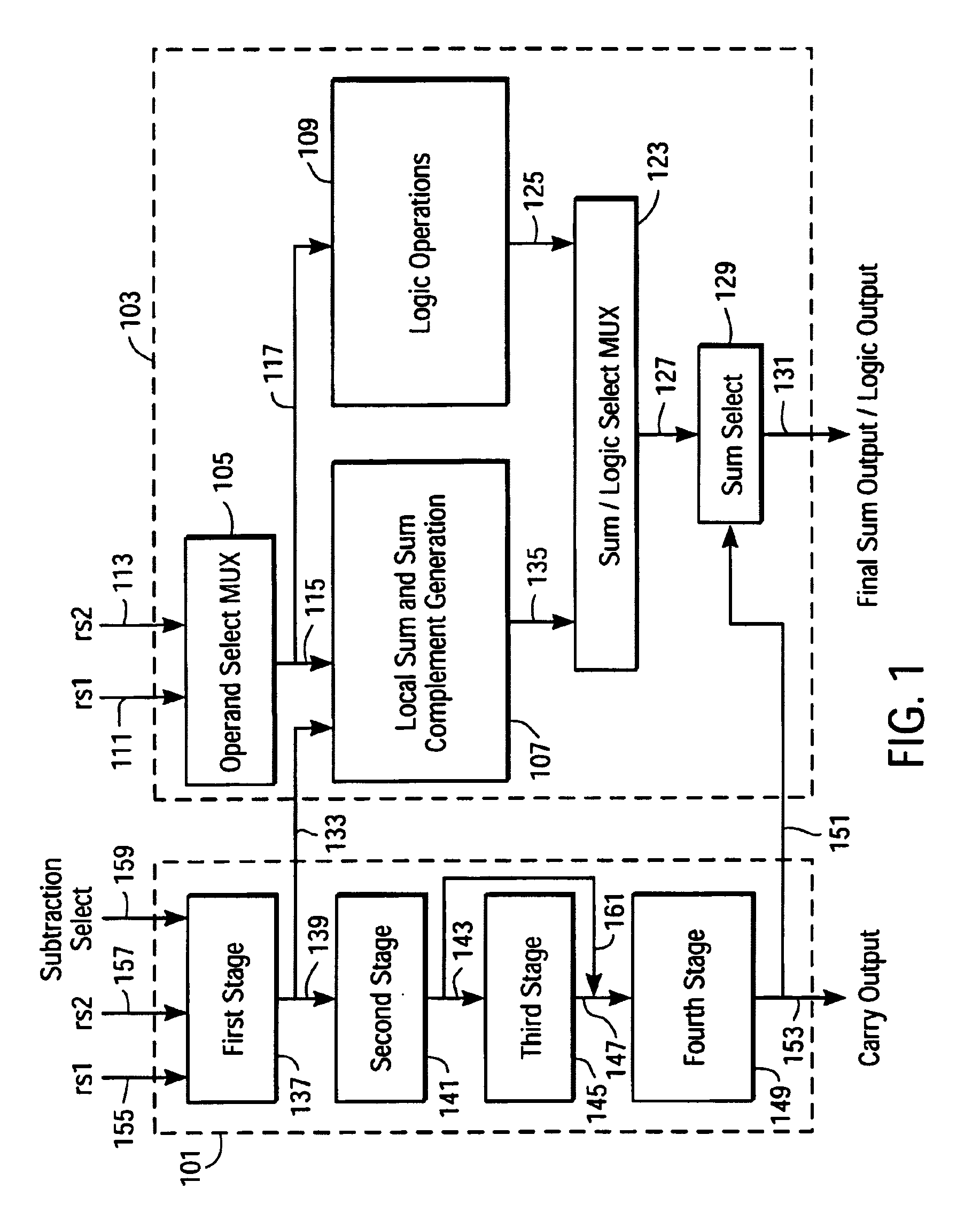

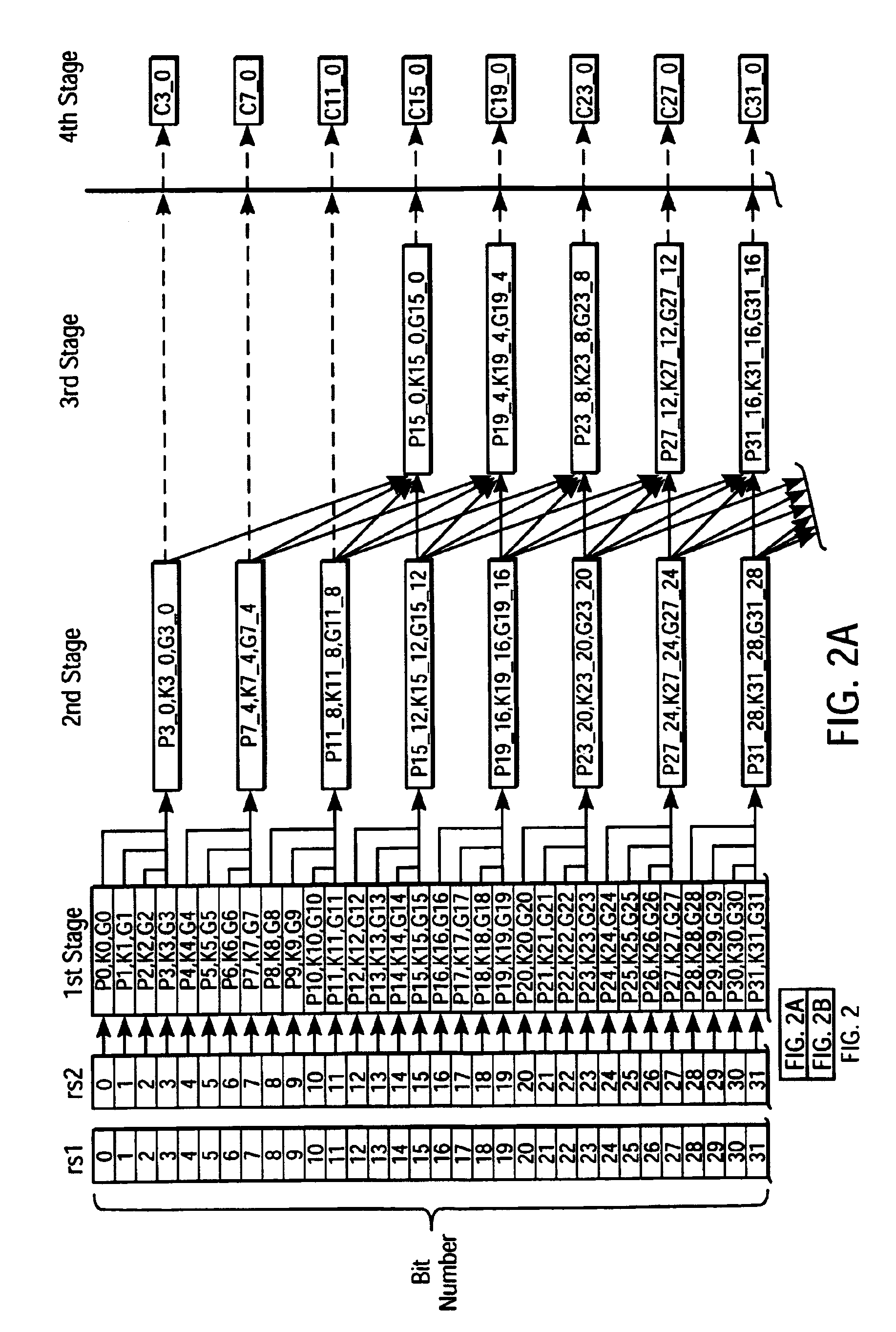

An arithmetic logic unit (ALU) implemented with complementary pass gate logic using propagate, generate, and kill is provided. Broadly speaking, the ALU is a 64-bit ALU using a multi-stage global carry chain to generate intermediate fourth-bit carries that are folded with local four-bit sums to efficiently generate a final sum output. The ALU implements ones complement subtraction by incorporating a subtraction select signal to invert each bit of a second operand. The ALU circuitry implements a push-pull methodology to improve performance.

Owner:ORACLE INT CORP

Digital broadcasting systems using parallel concatenated coding of bit-complementary bitstreams

InactiveUS8718189B2Picture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningDigital broadcastingOnes' complement

A digital television (DTV) system uses parallel concatenated coding (PCC), together with QAM constellations for modulating OFDM carriers. A first encoder responds to ONEs' complemented bits of randomized data to generate a first component of PCC. A second encoder responds to delayed bits of the randomized data to generate a second component of PCC. A constellation mapper generates QAM symbols responsive to successive time-slices of the first component of the PCC interleaved with successive time-slices of the second component of the PCC. An OFDM modulator generates a COFDM modulating signal responsive to the QAM symbols. In a receiver for the DTV system, the second component of the PCC and delayed first component of the PCC are iteratively decoded. Soft bits from the second component and delayed first component of the parallel concatenated coding are code-combined to supply soft randomized data used in that iterative decoding.

Owner:LIMBERG ALLEN LEROY

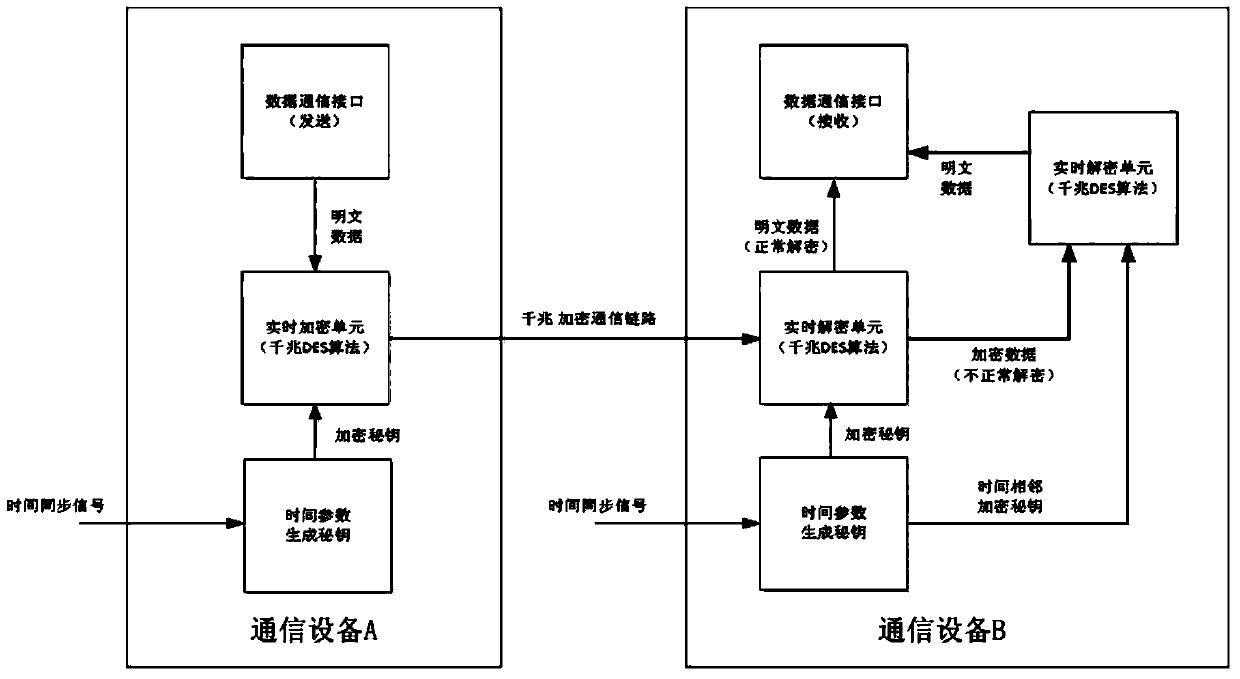

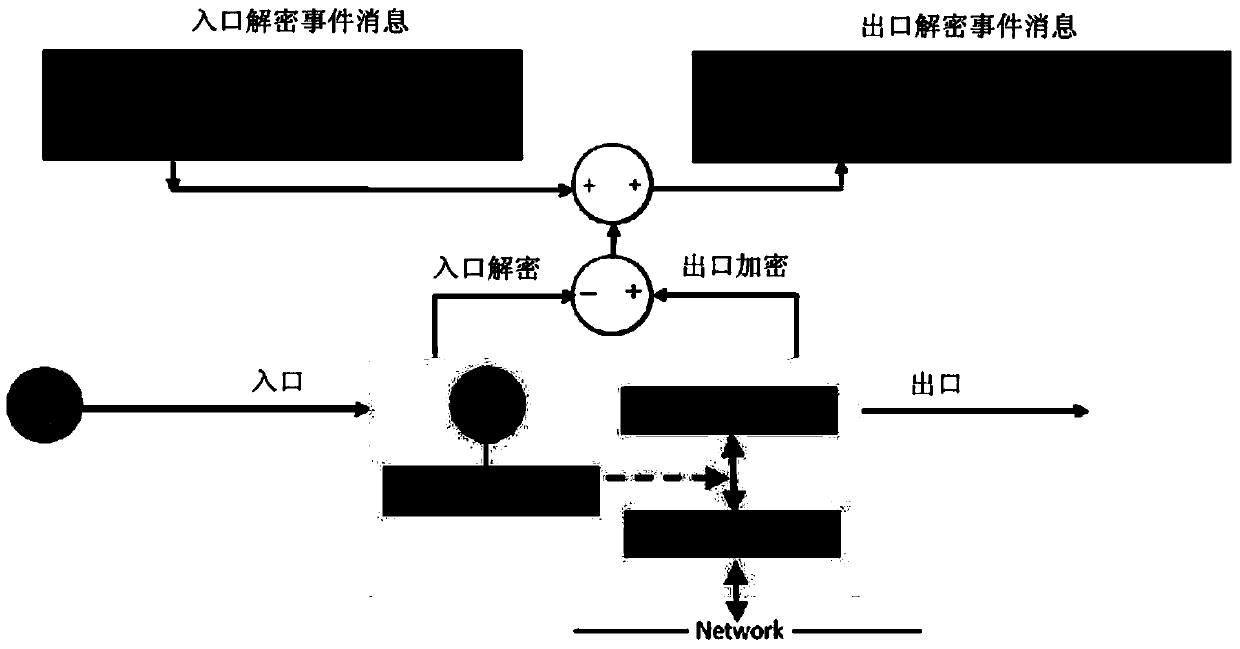

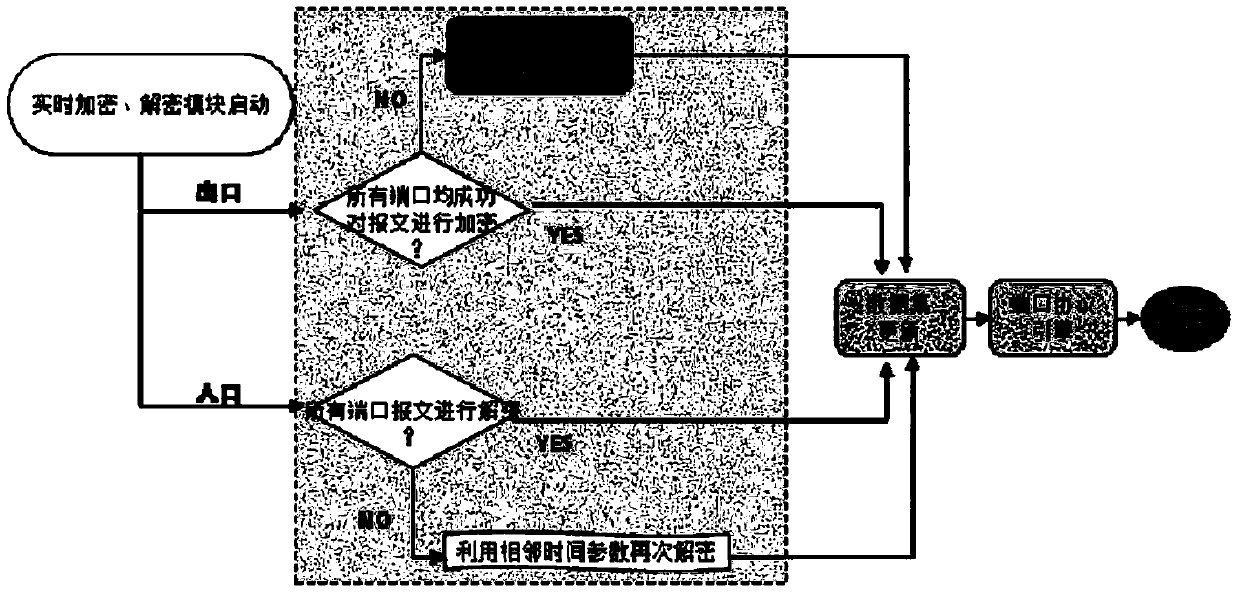

Method and device of real-time encryption for data communication network of wide area protection system

InactiveCN104219057APlay an encryption roleImplement encryptionUser identity/authority verificationComputer hardwareWide area

The invention relates to a method and a device of real-time encryption for a data communication network of a wide area protection system. The device is characterized by comprising a transmitting communication device A and a receiving communication device B, wherein the transmitting communication device A has a real-time encryption function and a real-time encryption structure, while the receiving communication device B has a real-time decryption function and a real-time decryption structure; the transmitting communication device A is used for encrypting data transmitted by the physical link of a data network device, hiding the communication data messages of the wide area protection system and the information of a logic information and encrypting the transmitted data; a DES encryption algorithm is adopted for a gigabit communication port, and the length of the private key of the DES encryption algorithm is 64 bits, including 56 significant bits; the transmitting communication device A is used for converting an input time synchronization signal into a 56-bit private key in real time and then encrypting the communication link data; or radix-minus-one complement encryption is adopted for a ten-gigabit communication port by considering a large encryption calculation amount, in other words, 0 in raw data is altered into 1, while 1 in raw data is altered into 0. The method and the device of real-time encryption for the data communication network of the wide area protection system have the beneficial effect that the encryption is difficult for the outside to break through by virtue of traversal try, or messages cannot be read out by the outside.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD +1

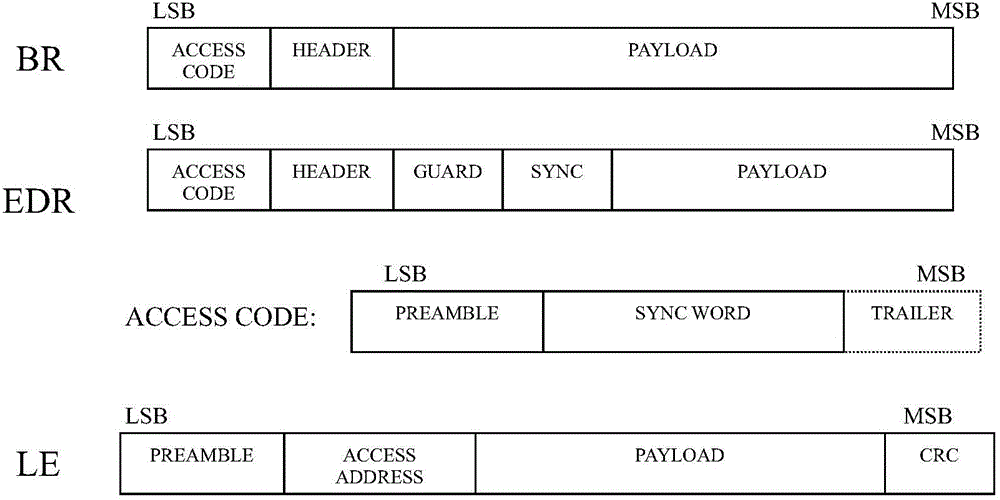

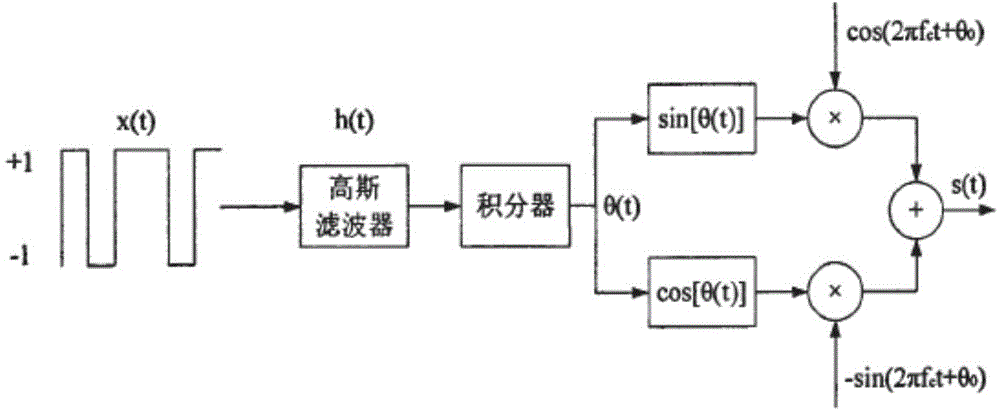

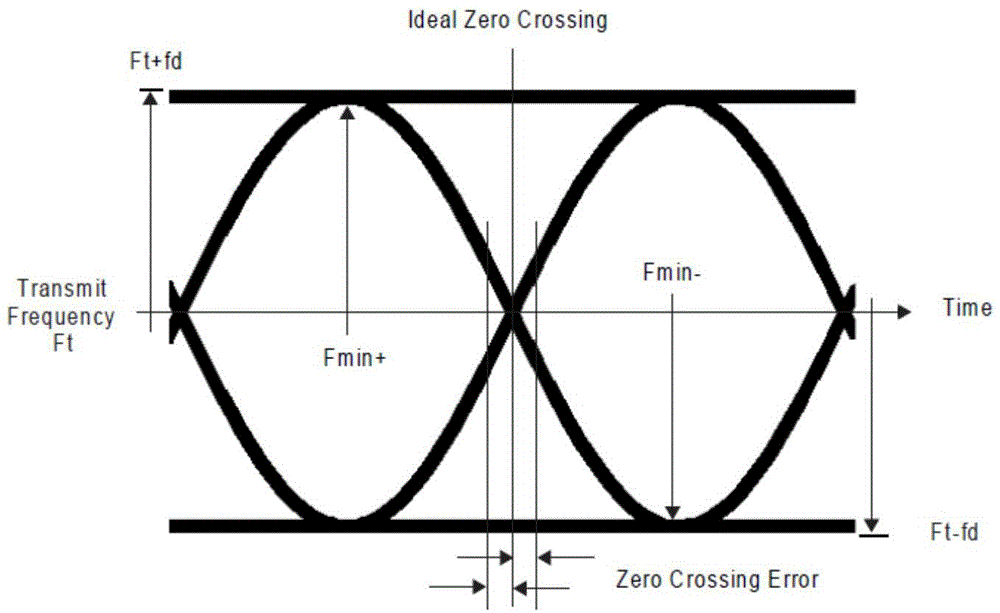

Digital signal frequency offset estimation method and device for Bluetooth system

ActiveCN104468431AReduced dynamic range requirementsGood frequency offset estimation performanceBaseband system detailsEstimation methodsNetwork packet

The invention discloses a digital signal frequency offset estimation method and device for a Bluetooth system. The method comprises the following steps that the odd number of binary sequence pairs are searched for in all fields of a Bluetooth standard data packet, the binary sequence pairs comprise a first binary sequence and a second binary sequence, the first binary sequence and the second binary sequence are radix-minus-one complements of each other, and the binary sequence pairs are prestored; frequency of each digital signal of the corresponding field in the received Bluetooth standard data packet is calculated to generate a binary digit, and the binary sequence pairs are searched for in the binary digits; if the binary sequence pairs exist, a frequency sum value of a half of the frequency corresponding to the middle digit in the first binary sequence and a half of the frequency corresponding to the middle digit in the second binary sequence is calculated. The method is simple and efficient, has better frequency offset estimation performance, can be applied to the Bluetooth system of dynamic AGC, and lowers the requirements for the gain range of a radio frequency module and the dynamic range of modulus conversion.

Owner:ALLWINNER TECH CO LTD

A multi-directional signature method for preventing side-channel attacks

ActiveCN106452789BPrevent inversionAvoid time consuming inversionUser identity/authority verificationCryptographic attack countermeasuresDirectional antennaModular exponentiation

The invention discloses a signature method of preventing side-channel attack from multi-azimuth. The signature method of preventing side-channel attack from multi-azimuth is characterized in that the technology or similar technology contained in the signature method masks the base, and an RSA signature or other public key system signatures are obtained; in the signature method of preventing side-channel attack from multi-azimuth, two module exponentiation results are obtained at the same time, and the power exponents are radix minus one complement for each other; when modular exponentiation is realized, the verification technology of preventing outputting error data is used; and for the modular exponentiation algorithm which does not use the jump statement, the signature method of preventing side-channel attack from multi-azimuth is the technology that during the operation process, the data or the operation result data is equal to the Hamming weight. The signature method of preventing side-channel attack from multi-azimuth effectively protects the step which is known and is easy to be attacked during the RSA STD operation process. The modular exponentiation provided by the signature method of preventing side-channel attack from multi-azimuth can be fully applied to the RSA CRT operation, and can realize that the algorithm of the modular exponentiation algorithm and the complementary power can be transplanted to the point multiplication operation of SM2 at the same time. The test that whether the module exponentiation is attacked can be similarly transplanted in the point multiplication operation of SM2.

Owner:BEIJING HONGSI ELECTRONICS TECH

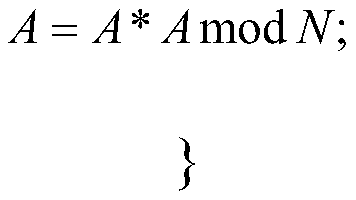

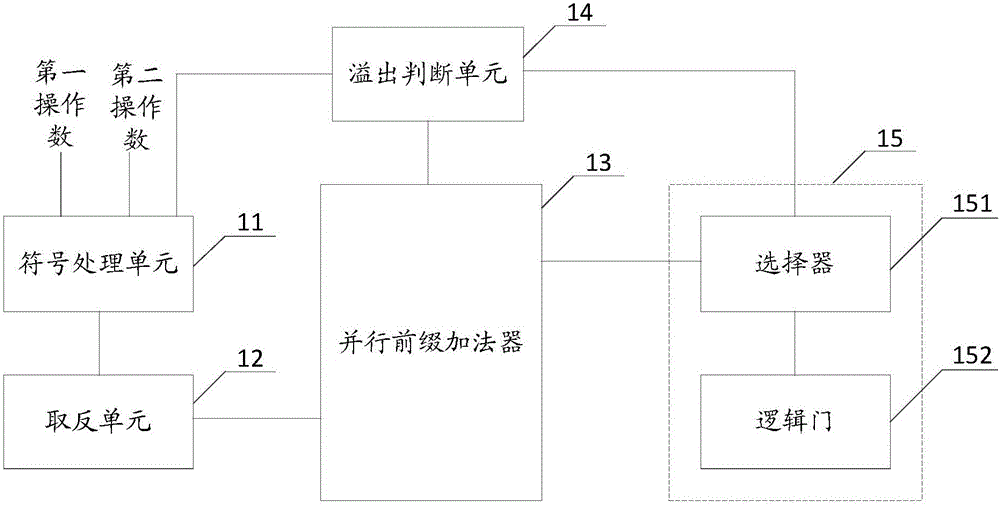

Radix-minus-one complement adder

InactiveCN105045558AReduce latencyReduce areaComputation using non-contact making devicesNegationOperand

The invention discloses a radix-minus-one complement adder. The radix-minus-one complement adder comprises a sign processing unit, a negation unit, a parallel prefix adder body, an overflow judging unit and an operation result selecting and processing unit, wherein the sign processing unit is used for receiving a first operand and a second operand and judging the sign bit of the first operand and the sign bit of the second operand to obtain a first judgment result; the negation unit is used for carrying out negation on the first operand and the second operand according to the first judgment result; the parallel prefix adder body is used for carrying out operation on the first operand and the second operand after negation to obtain sum and sum+1; the overflow judging unit is used for carrying out overflow judgment on the sign bit of sum, the sign bit of sum+1, the sign bit of the first operand and the sign bit of the second operand to obtain a second judgment result; the operation result selecting and processing unit is used for selecting sum or sum+1 according to the second judgment result to be subjected to negation so as to obtain a final operation result. The structural area of the adix-minus-one complement adder is reduced, the delay time of critical paths is shortened, and operation efficiency is improved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

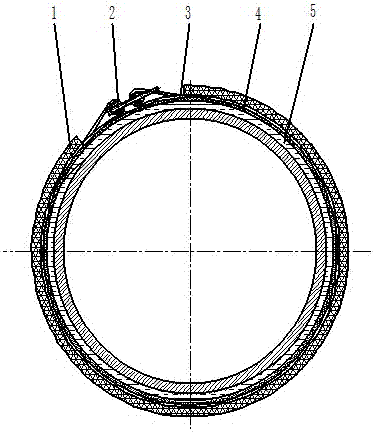

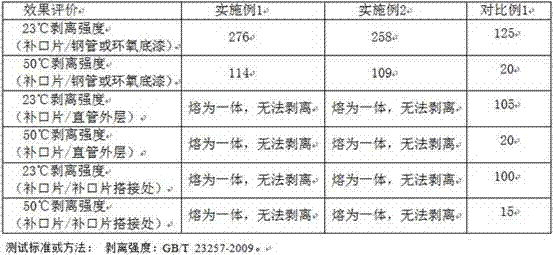

a mouth filling method

ActiveCN104633392BStrong rust resistanceImprove barrier propertiesCoatingsWater vaporBonding process

The invention discloses a joint coating method. The method comprises the steps that: firstly, surface treatment is carried out; secondly, preheating is carried out on a steel pipe; thirdly, the surface is coated with a joint coating piece; fourthly, the joint coating piece is coated with a metal interior lining panel; fifthly, coating and tightly locking are carried out on a steel hoop and an electric heating device; sixthly, warming is carried out by a program; seventhly, equipment is disassembled. The metal interior lining panel is high in rust-proof capacity, and is tightly connected with the joint coating piece as a whole in an adhesive mode, so that the barrier property to visible light, ultraviolet light, water, oxygen, and vapour of a joint coating layer is greatly improved, the mechanical damage resistance to a pointed object is enhanced, and the service life of the joint coating layer is greatly prolonged. By means of the steel hoop to carry out tightly locking and pressuring, enormous pressure is exerted on the joint coating piece during the softening and bonding process, the bonding strength on the steel pipe is greatly improved, the peeling strength under 23 DEG C can reach above 250 N / cm, the peeling strength under 50 DEG C can reach above 100 N / cm, and the peeling strength under 23 DEG C and the peeling strength under 50 DEG C are twice and five times stronger than the heat shrinking sleeve (belt) joint coating respectively.

Owner:SICHUAN KINGFA TECH DEV

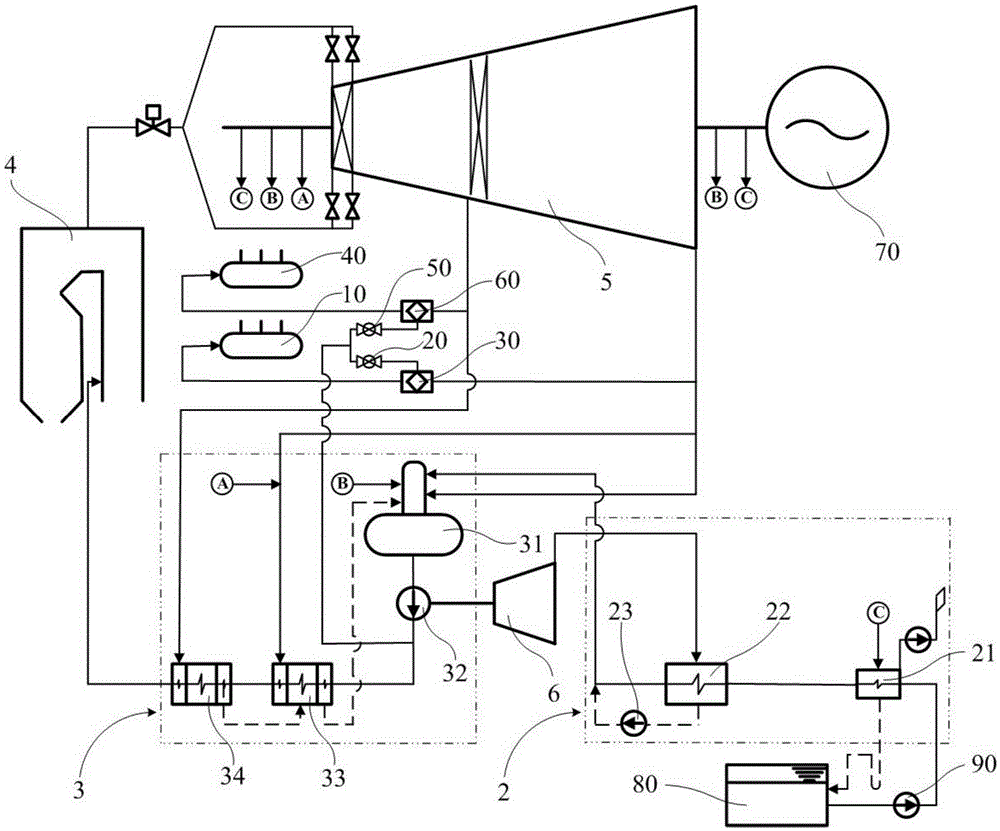

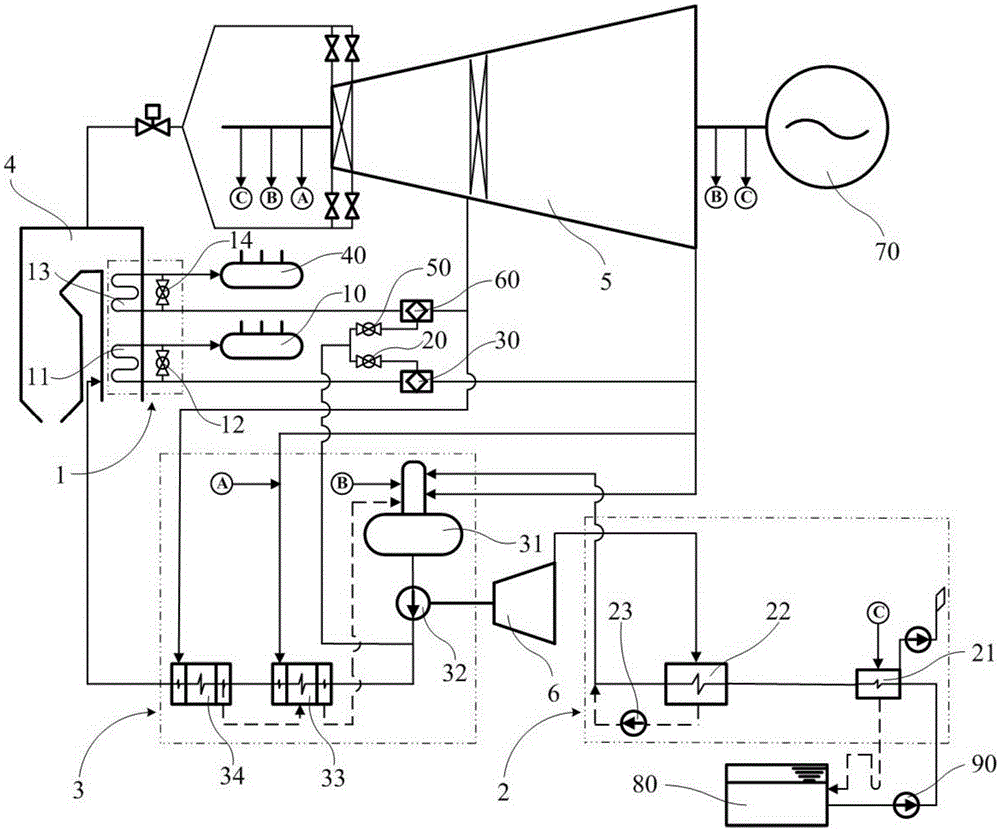

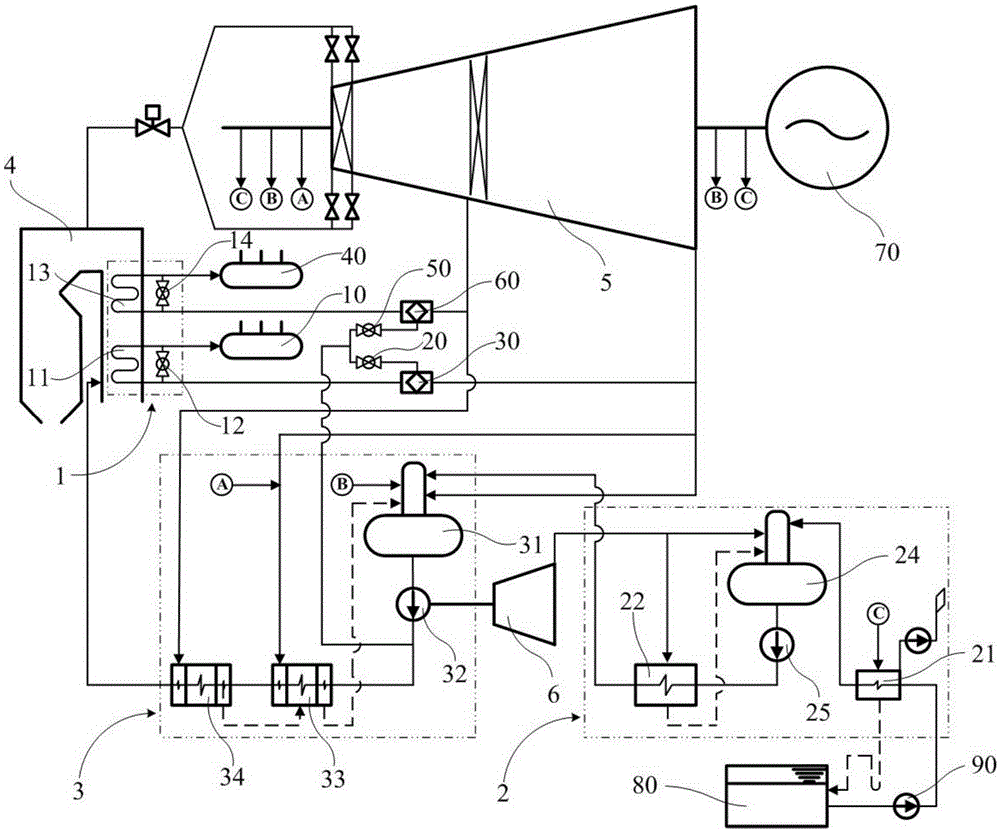

A heat-supplementing ultra-high pressure/subcritical back pressure heating unit thermal system

ActiveCN104763485BIncrease main steam pressureImprove working abilitySteam engine plantsUltra high pressureSteam pressure

Owner:南京博沃科技发展有限公司

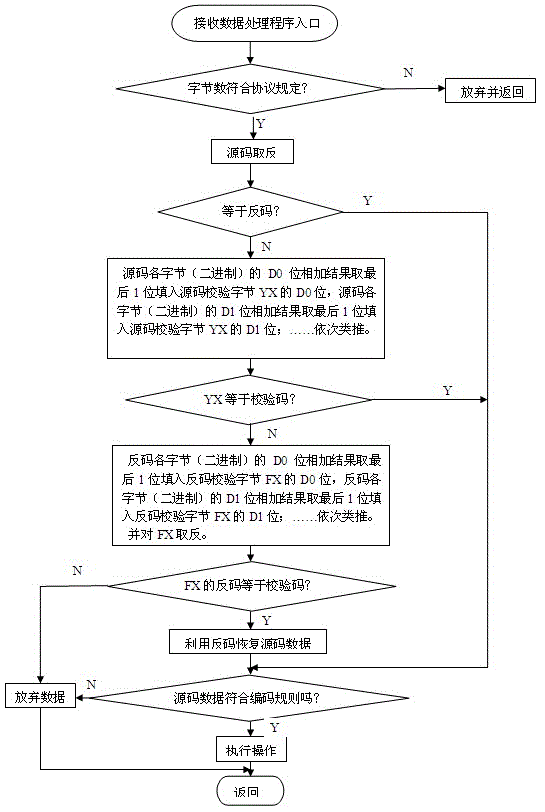

A Fixed Code Length Complementary Encoding Method for Infrared Remote Control and Its Decoding Method

ActiveCN103051417BConducive to technical standardizationFacilitate judging technical standardizationNon-electrical signal transmission systemsError preventionDecoding methodsRemote control

The invention relates to a fixed code length complementary type coding method for an infrared remote controller. According to the method, the infrared remote controller adopts the complementary type coding mode, i.e. each byte is coded, the ones-complement code of the byte tightly follows behind the byte, and in addition, a check code is set in the fixed code length; and corresponding decoding rules are correspondingly compiled on a receiving controller matched with the infrared remote controller and are used for receiving infrared codes sent by the infrared remote controller, in addition, the data can be confirmed and judged according to the original code, the ones-complement code and the check code, when the original code of the data has error codes, the correct data can also be recovered according to the ones-complement code and the check code, and the anti-interference capability is improved.

Owner:浙江西盈科技股份有限公司

Imaging device and imaging method thereof

The invention relates to an imaging device which comprises a pixel array. The pixel array includes a plurality of pixels which are arrayed into lines and rows, and a plurality of column circuits, wherein each column circuit corresponds to one row of pixels in the pixel array. Each column circuit comprises a comparator and a radix-minus-one complement counter, wherein the comparator compares signals from pixels of a corresponding row with ramp signals, and the radix-minus-one complement counter counts and conducts radix-minus-one complement calculation on output signals of the comparator.

Owner:思特威(上海)电子科技股份有限公司

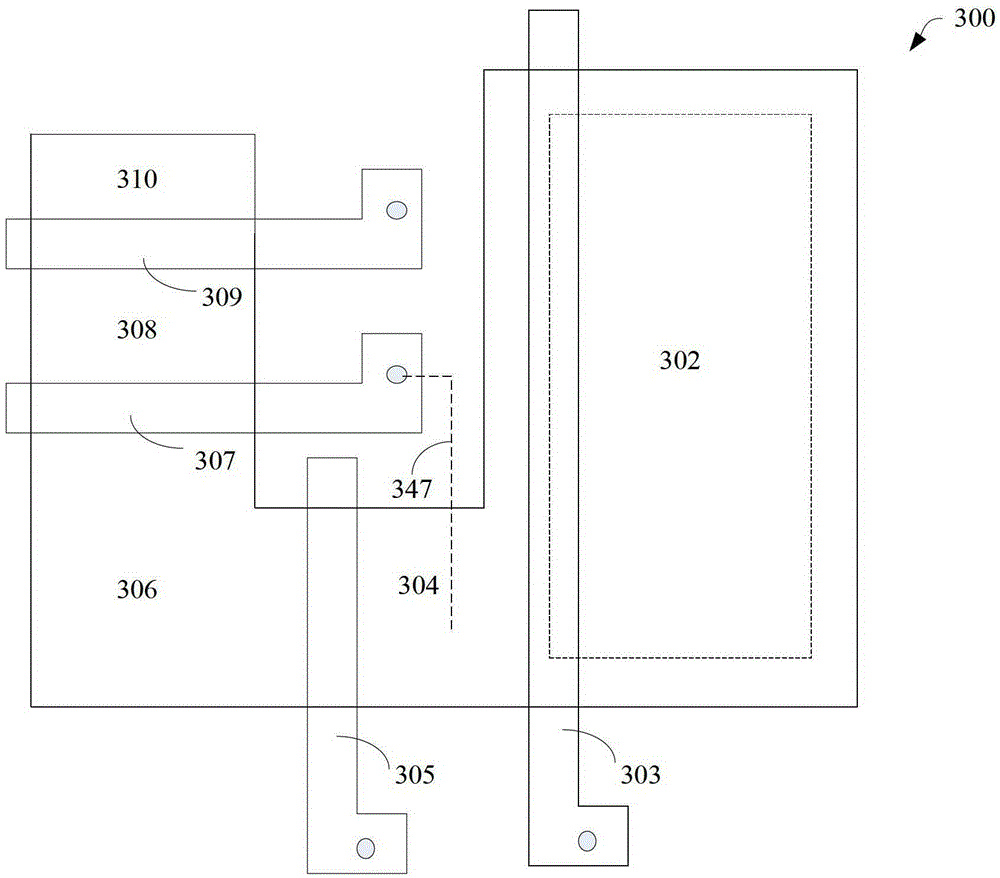

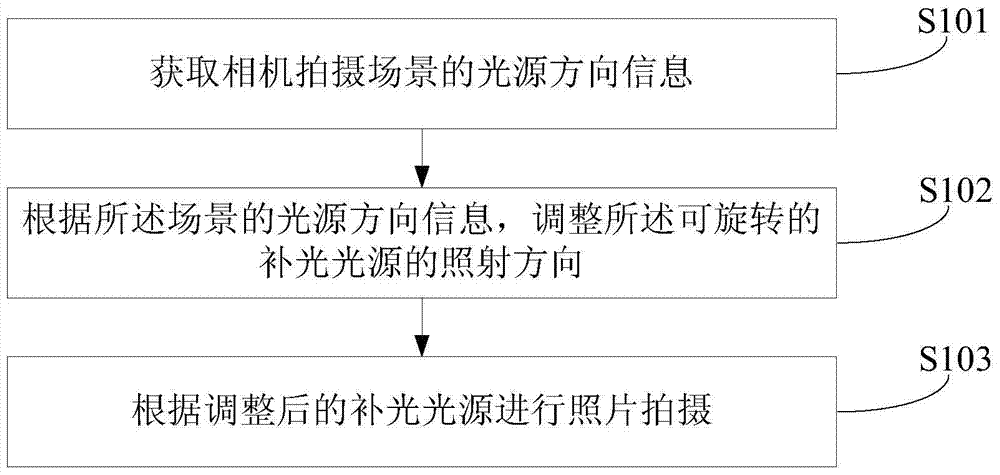

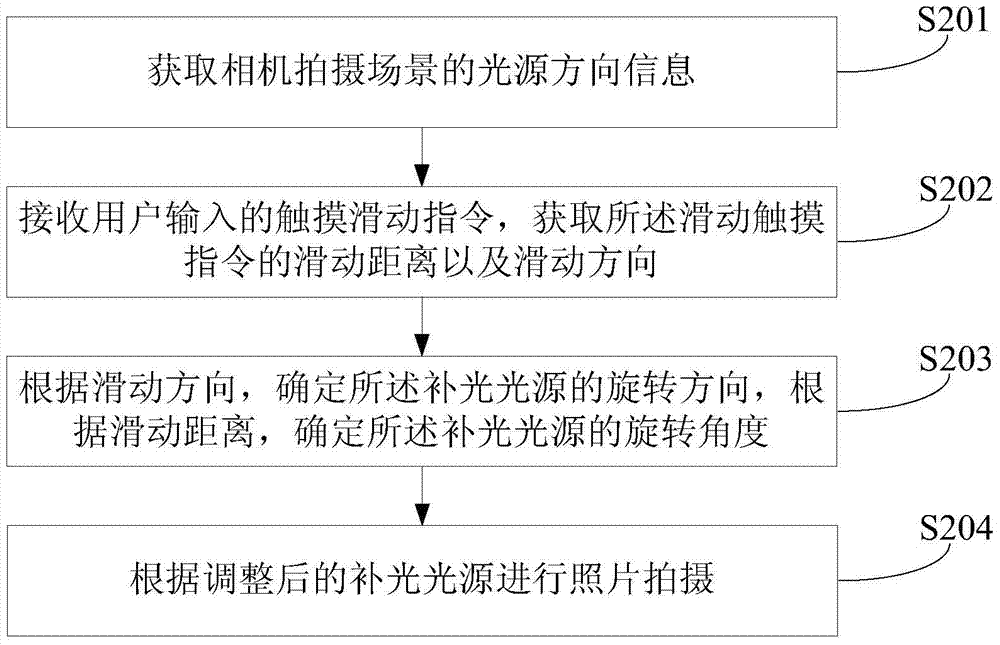

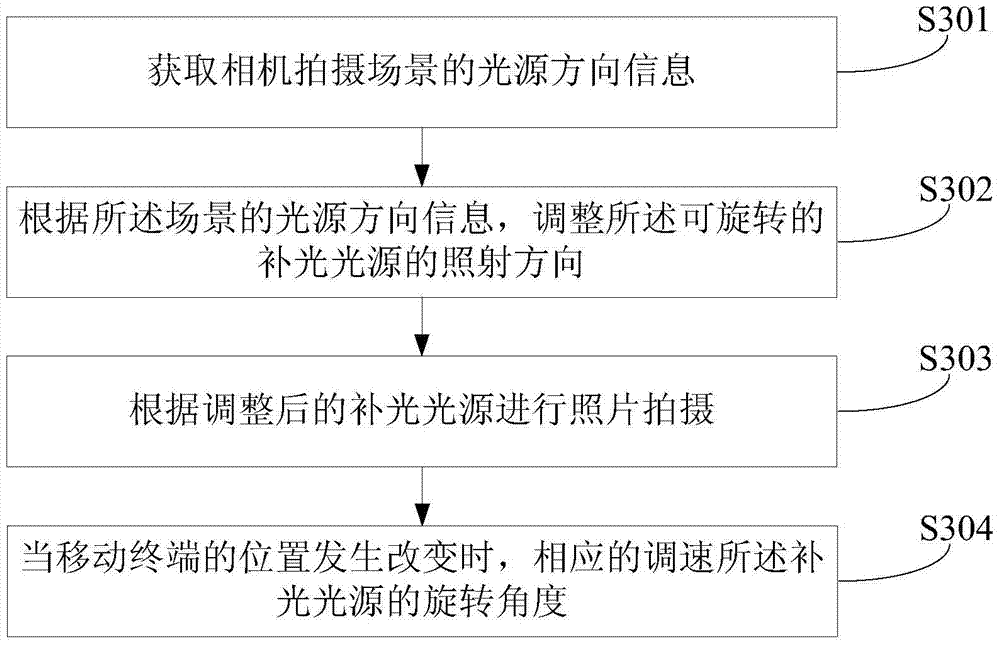

Method and device for supplementary light for camera shooting

ActiveCN104580928BPure light sourceTelevision system detailsColor television detailsDirection informationIrradiation

The present invention is applicable to the field of photography, and provides a method and device for supplementary light for camera photography, the method comprising: acquiring light source direction information of a scene photographed by a camera; adjusting the rotatable supplementary light according to the light source direction information of the scene The irradiation direction of the light source is to make the direction of the light source of the scene consistent with the irradiation direction of the supplementary light source; take pictures according to the adjusted supplementary light source. The present invention can obtain the light irradiated by the light source in the same direction in the shooting scene, so that the irradiated light source of the photographed object can be made purer, and clearer photos can be taken.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

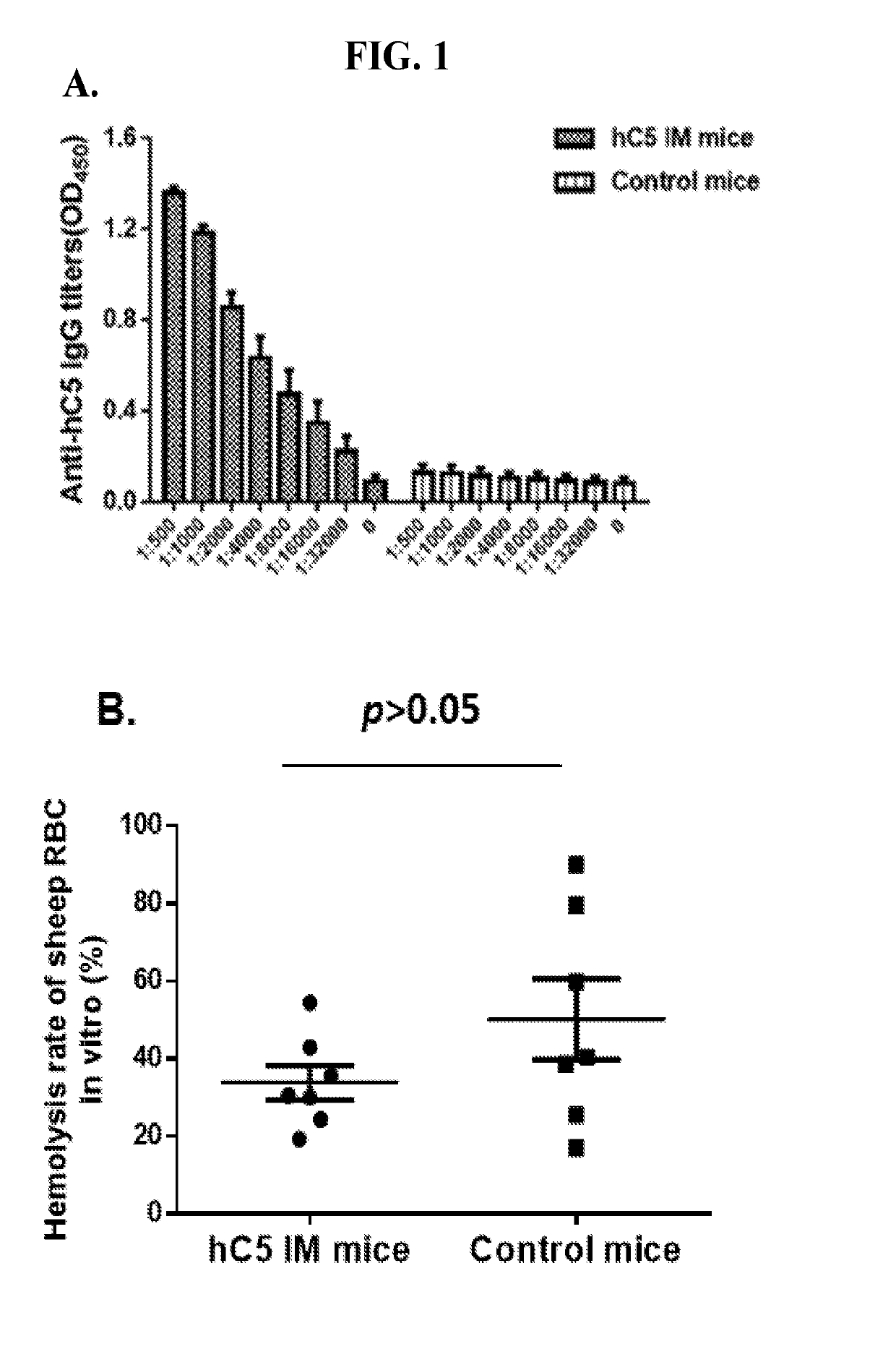

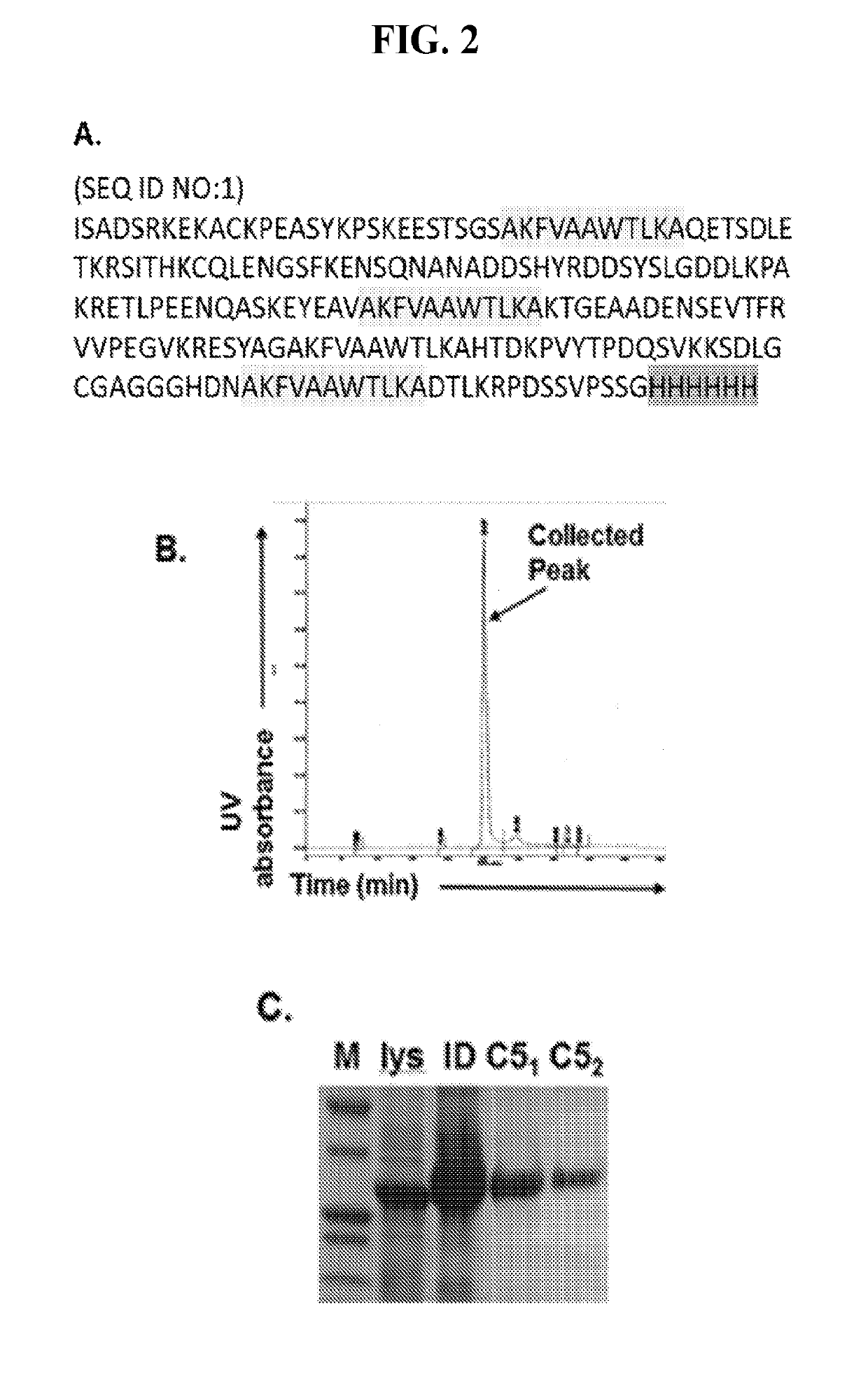

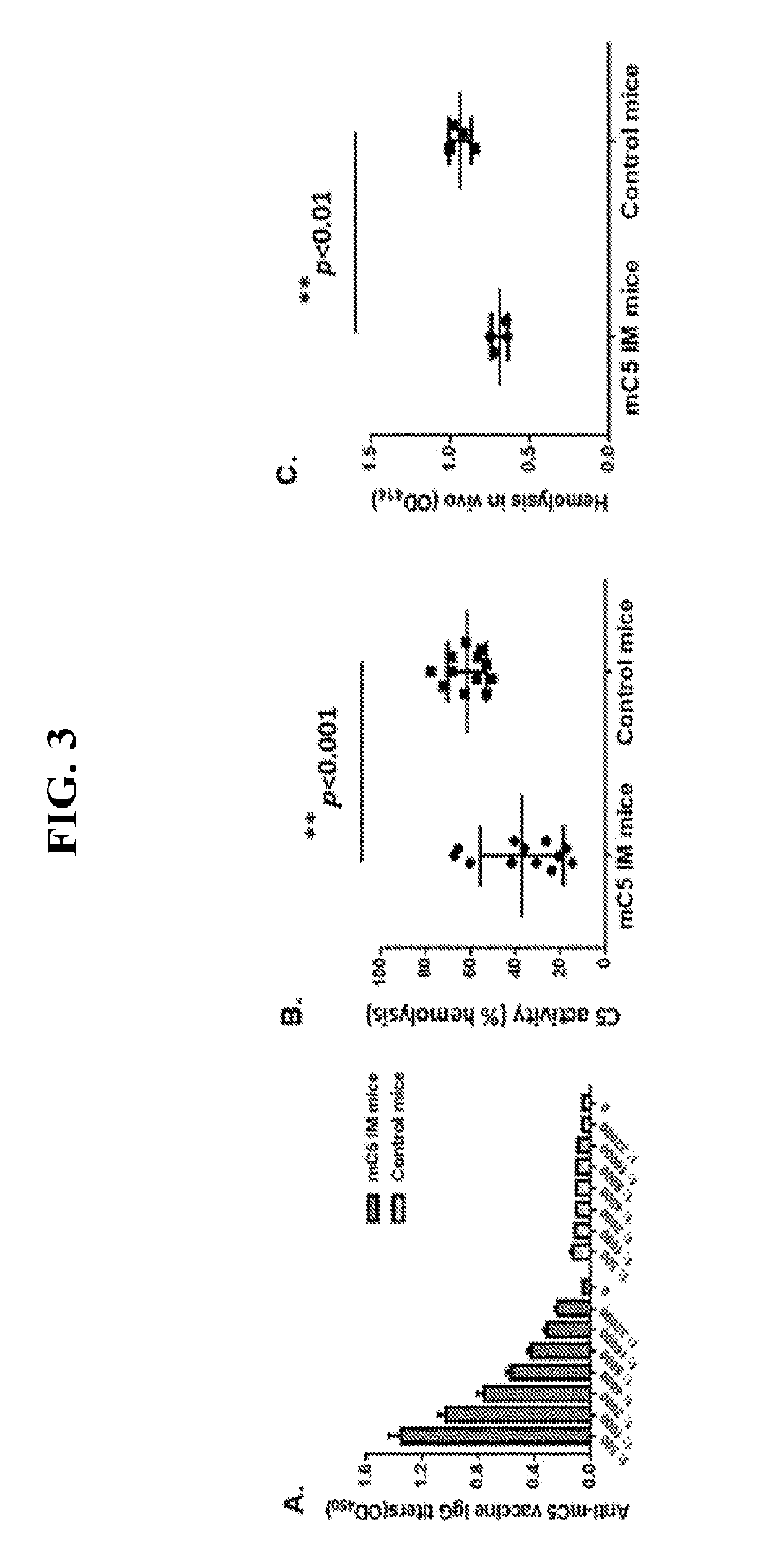

C5 immunization for autologous Anti-c5 antibody production

Provided herein are immunogenic compositions comprising an immunogen with at least one complement component 5 (C5) epitope, wherein the immunogen is capable of generating autologous anti-C5 antibodies in a subject. In certain embodiments, such compositions are employed for treating and preventing complement component 5 (C5) related diseases. In certain embodiments, the immunogenic compositions comprise virus like particles and / or PADRE sequences, in addition to the C5 epitope(s).

Owner:THE CLEVELAND CLINIC FOUND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com