Patents

Literature

30results about How to "Fast and easy to perform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for directing a user of a mobile device from a current location to a product

ActiveUS7734507B2Avoid disadvantagesFast and easy to performPosition fixationBuying/selling/leasing transactionsName serverGeolocation

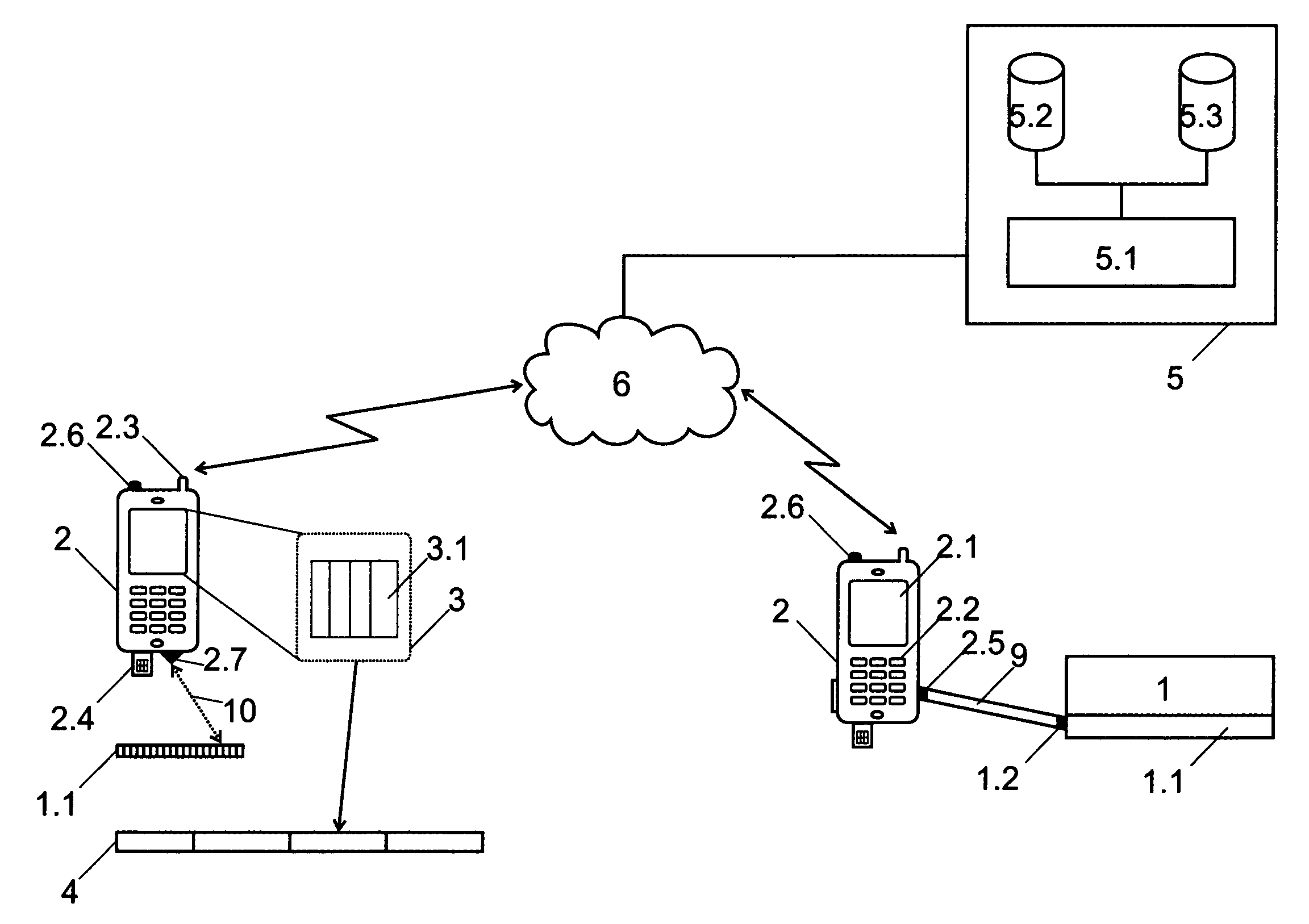

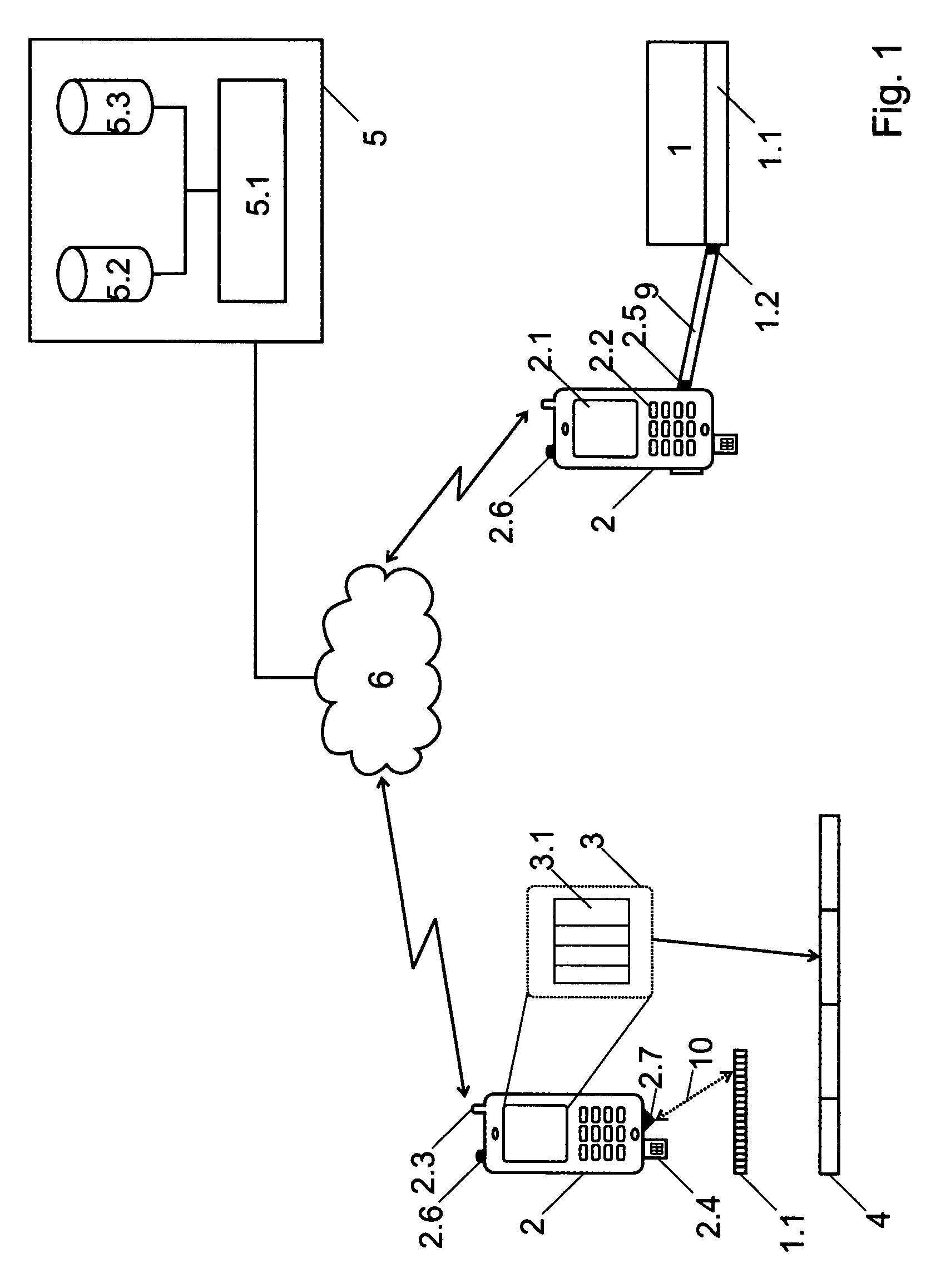

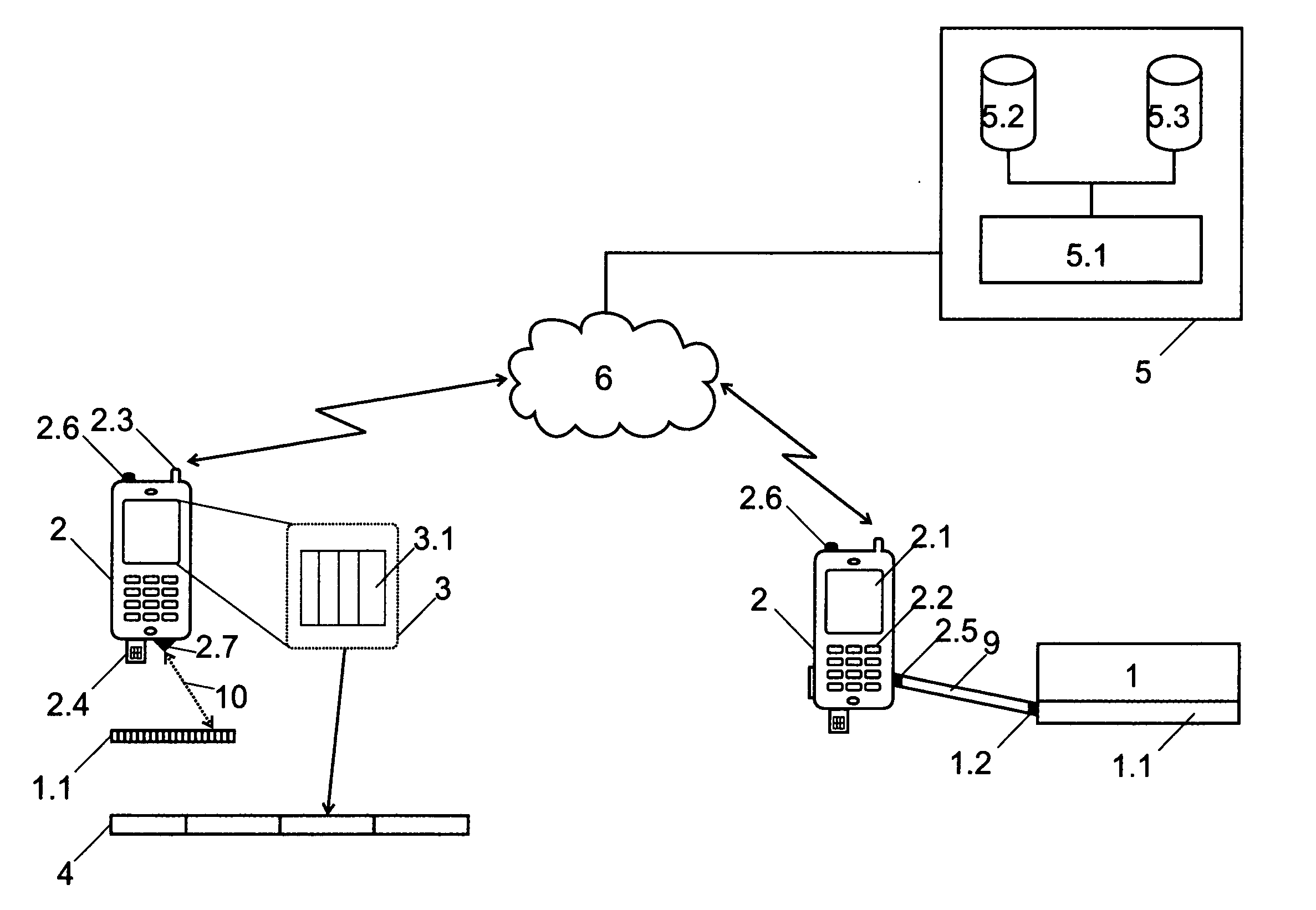

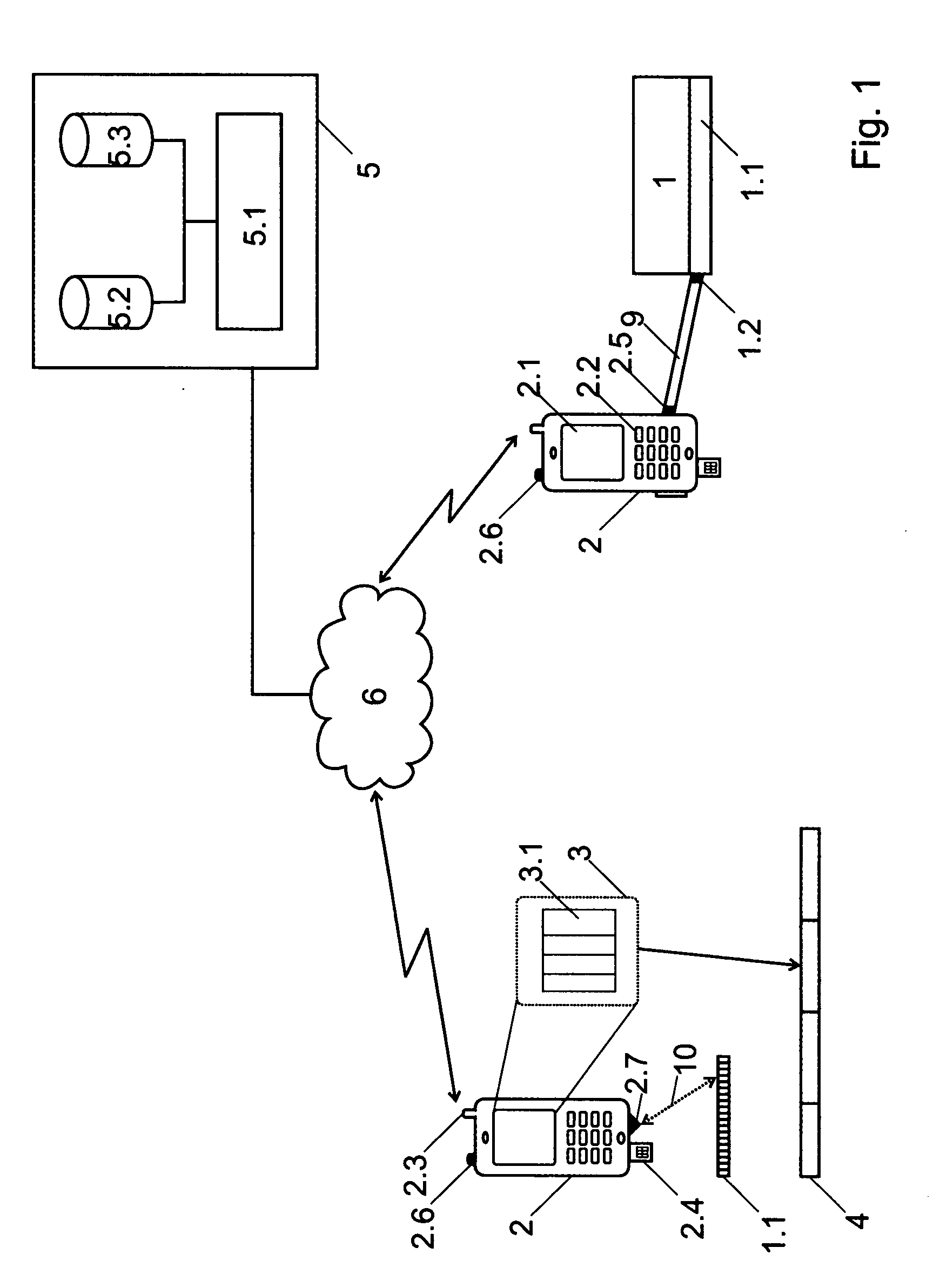

A method is described for directing a user of a mobile device from a current location to a product, wherein an identification code of the product is recorded in the mobile device and transmitted to a name server. The identification code is used in the name server among others for loading product-related data into the mobile device, e.g. a geographical location where the product can be bought. Following this, the user of the mobile device can go to said geographic location. For directing said user to the product, a direct contactless connection is established between said mobile device and a RFID element with which said product is marked, by using the same identification code or product-related data previously supplied by the name server.

Owner:INTERDIGITAL CE PATENT HLDG

Method for directing a user of a mobile device from a current location to a product

ActiveUS20060079247A1Avoid disadvantagesFast and easy to performPosition fixationRadio/inductive link selection arrangementsName serverGeolocation

A method is described for directing a user of a mobile device from a current location to a product, wherein an identification code of the product is recorded in the mobile device and transmitted to a name server. The identification code is used in the name server among others for loading product-related data into the mobile device, e.g. a geographical location where the product can be bought. Following this, the user of the mobile device can go to said geographic location. For directing said user to the product, a direct contactless connection is established between said mobile device and a RFID element with which said product is marked, by using the same identification code or product-related data previously supplied by the name server.

Owner:INTERDIGITAL CE PATENT HLDG

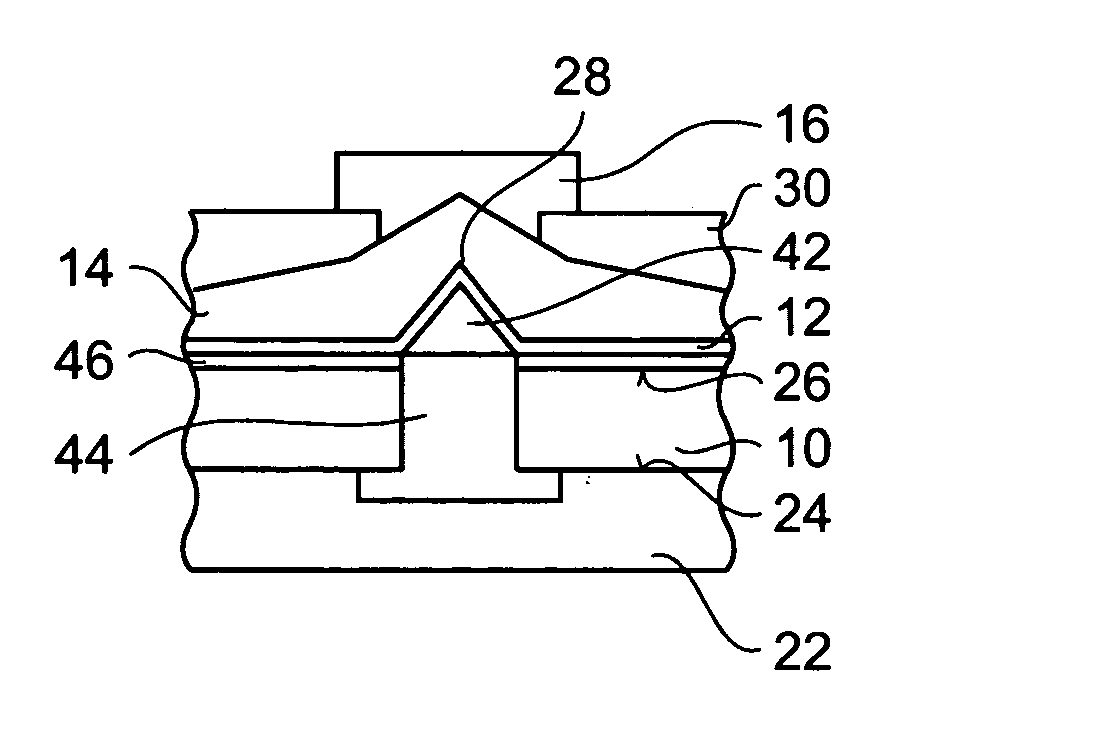

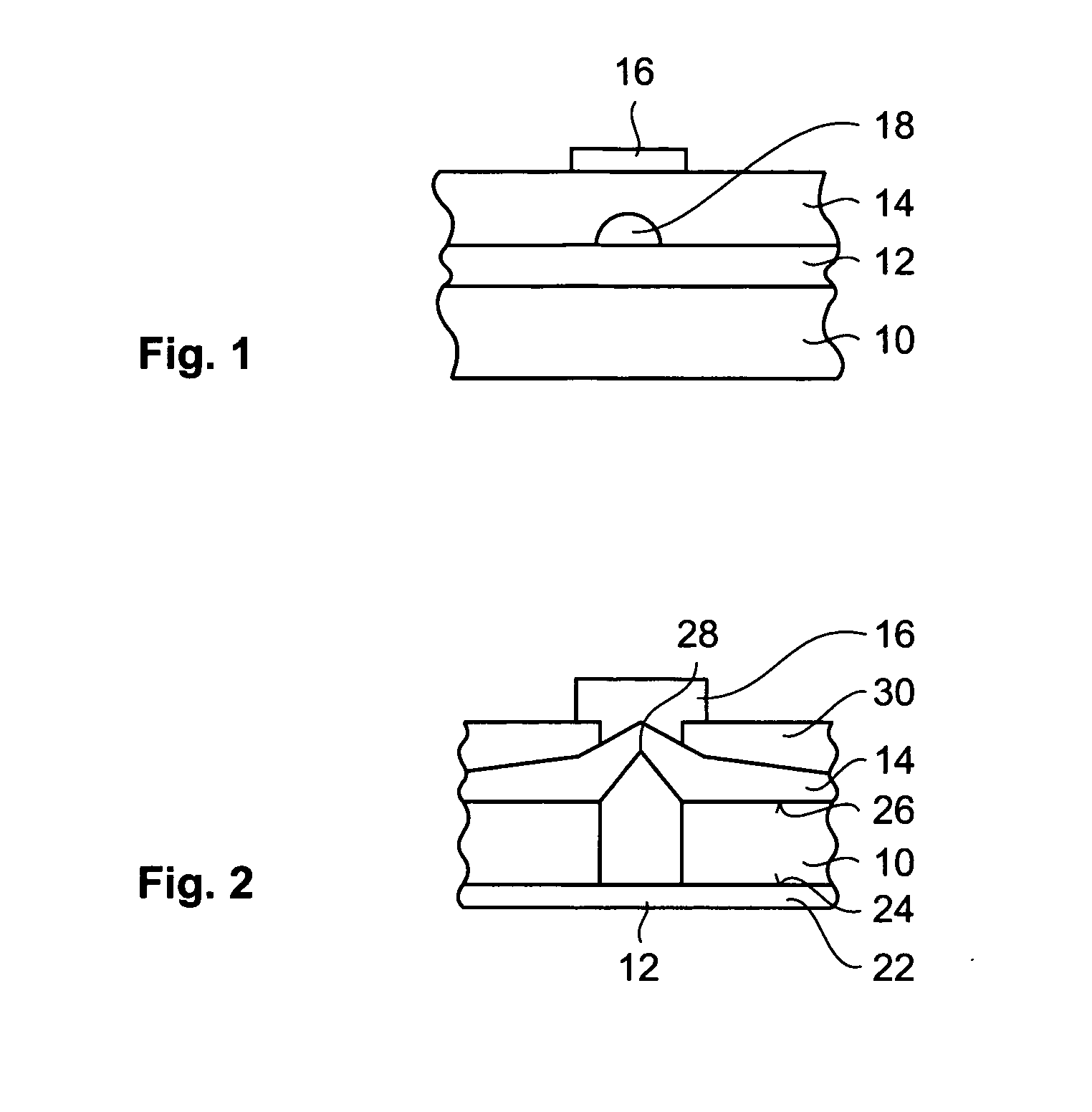

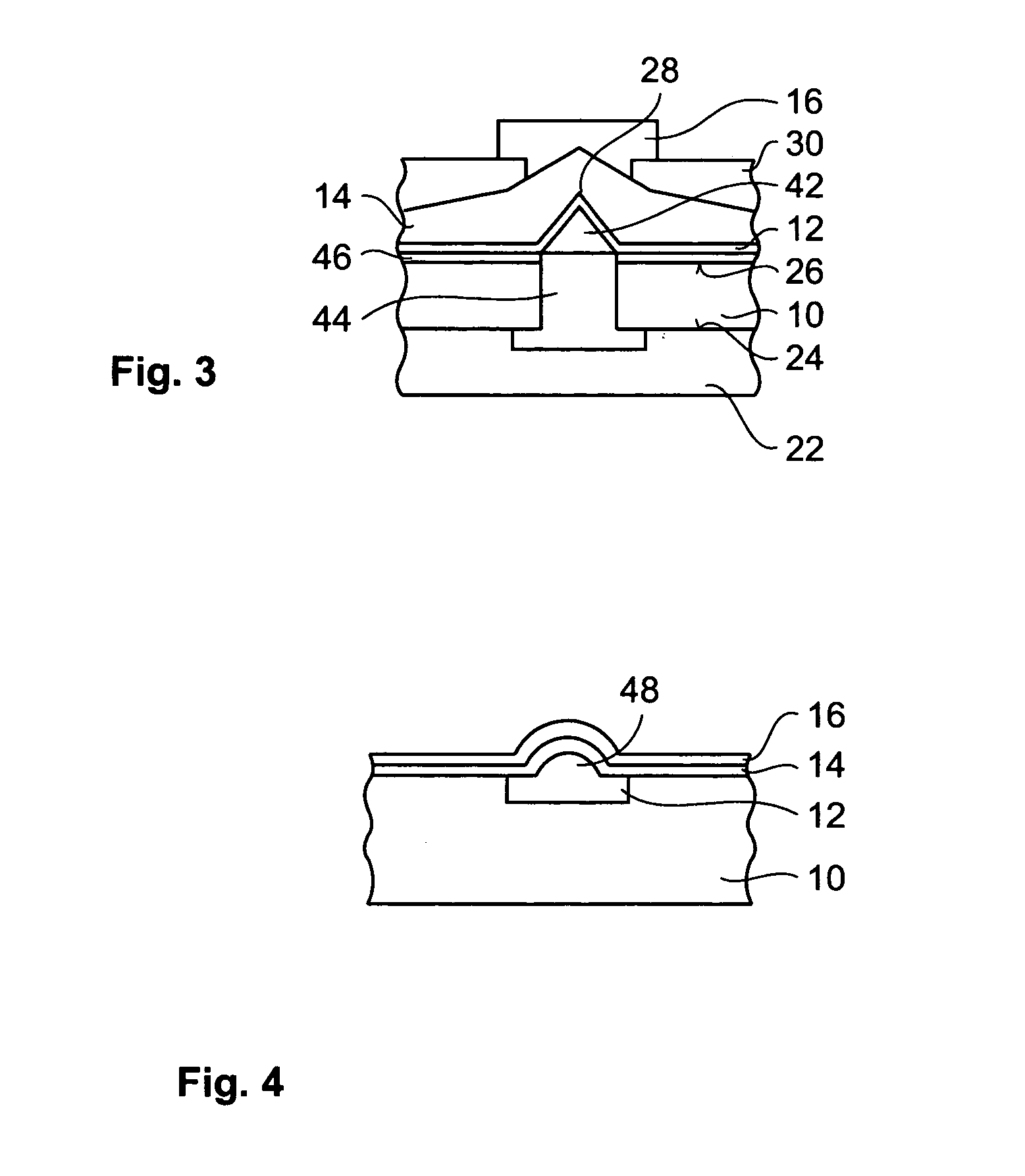

Resistor with improved switchable resistance and non-volatile memory device

InactiveUS20060006471A1Easy to shapeFast and easy to performSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceEngineering

Provides a resistor with improved switchable resistance and non-volatile memory device. An example resistor includes a first electrode, a second electrode facing the first electrode and a resistance structure between the first electrode and the second electrode. The resistance structure includes an insulating dielectric material in which a confined switchable conductive region is formed between the first and second electrode. The resistor further includes a perturbation element, locally exerting mechanical stress on the resistance structure in the vicinity of the perturbation element at least during a forming process in which the confined switchable conductive region is formed.

Owner:GLOBALFOUNDRIES INC

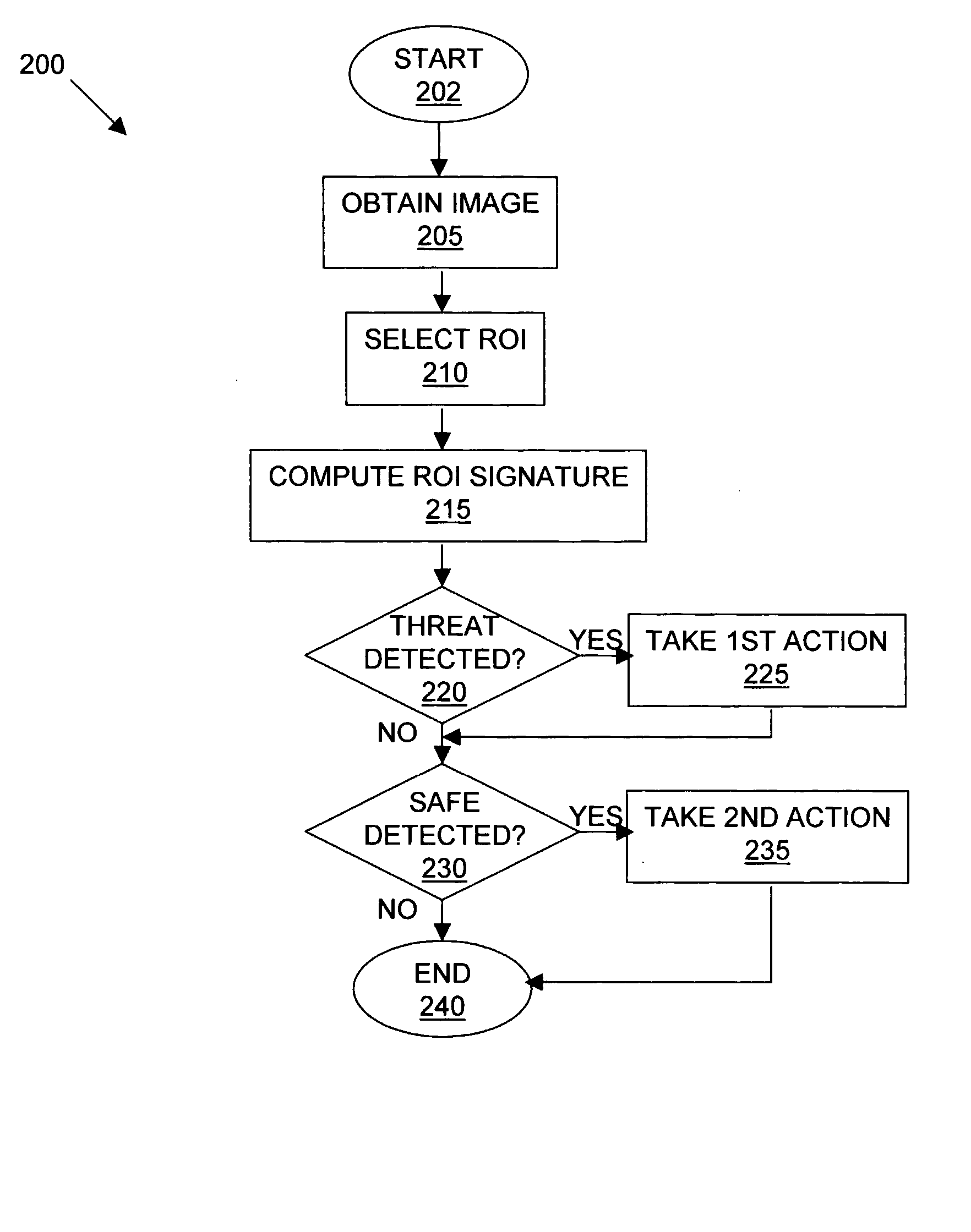

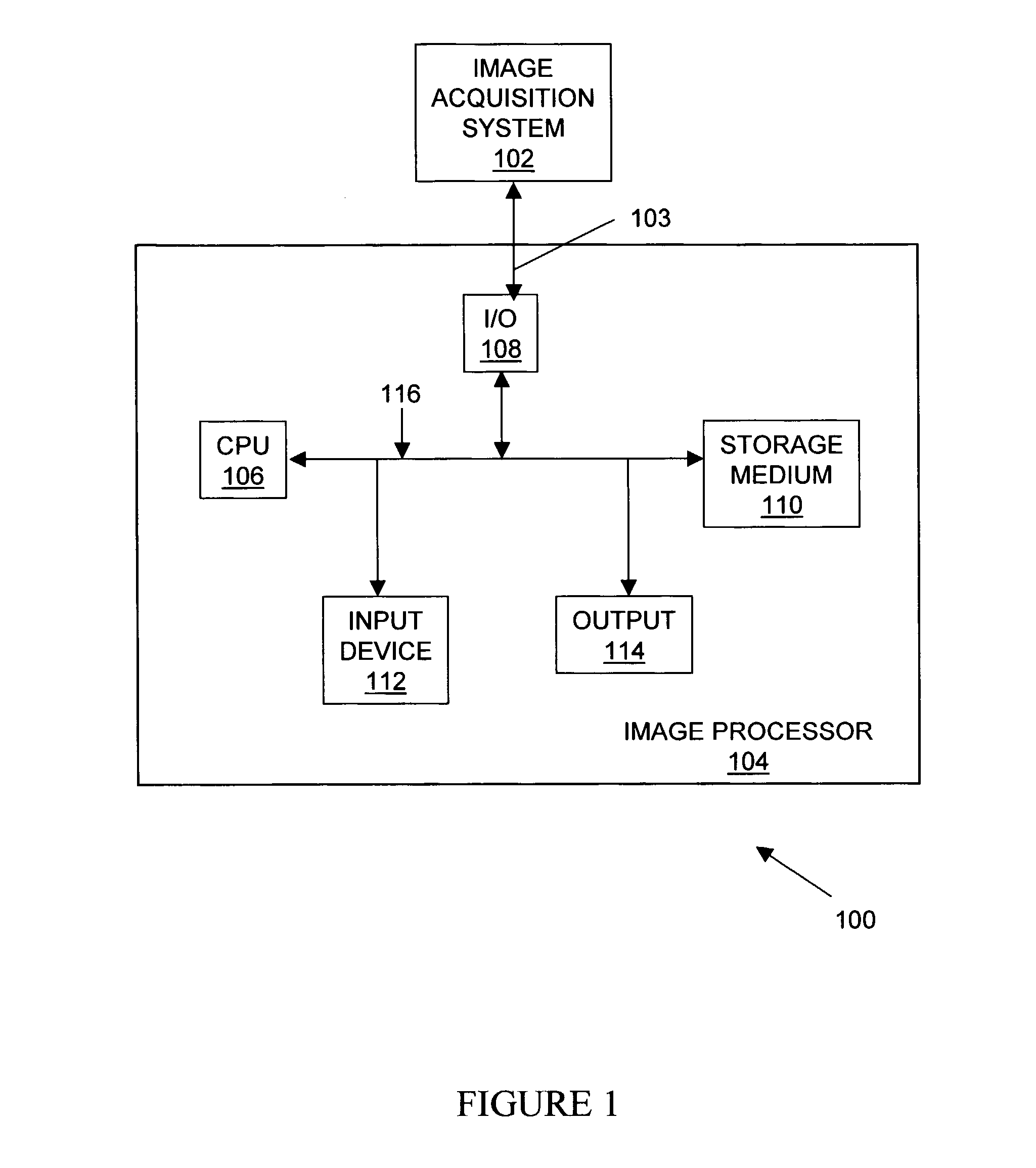

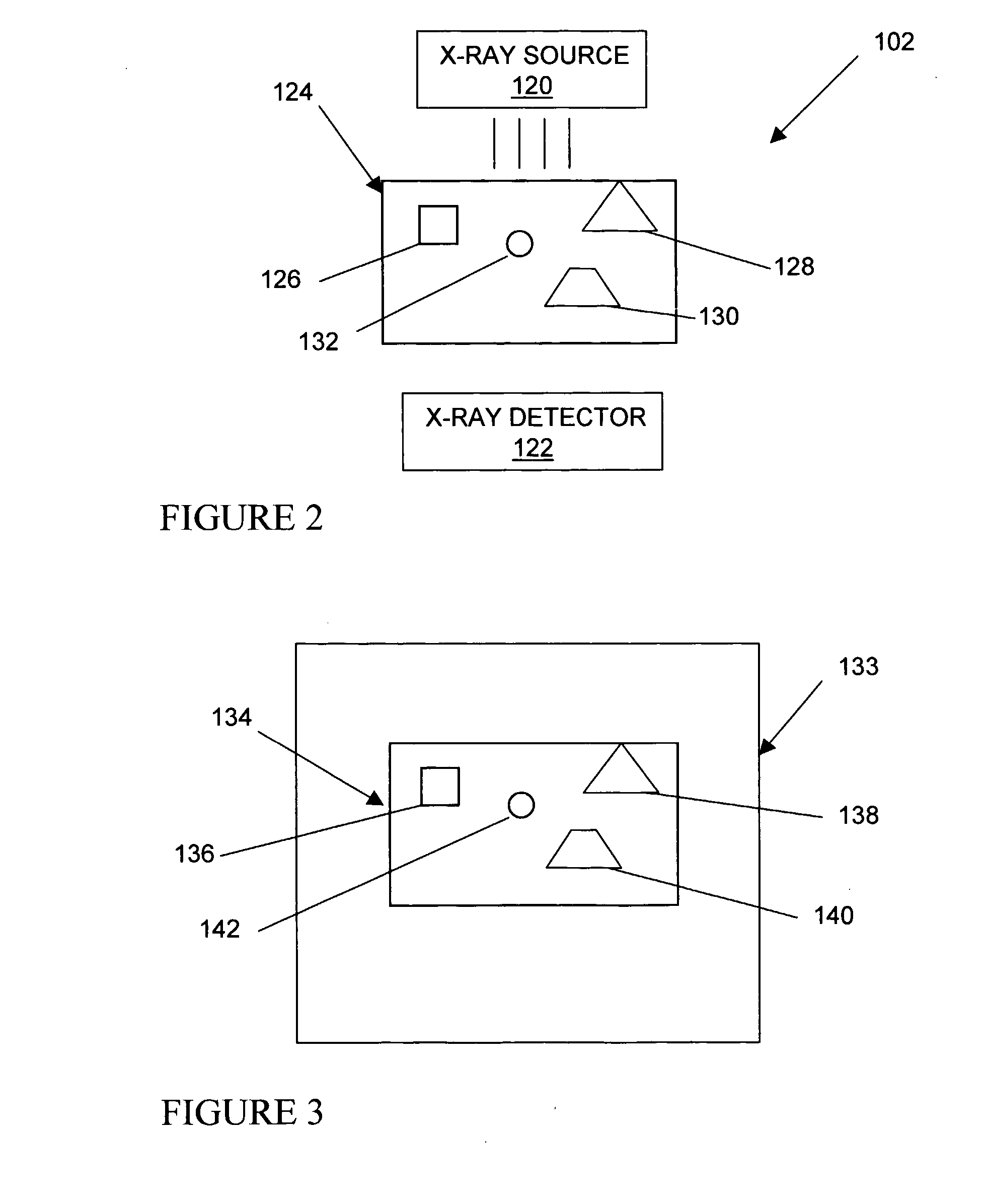

System and Method for Detecting the Presence of a Threat in a Package

InactiveUS20080063140A1Easy to detectFast and easy to performMaterial analysis by transmitting radiationX ray imageVoxel

A method for scanning an object for potential threats. The method includes steps obtaining a plurality of stereographic colored X-ray images of the object, combining the plurality of stereographic images to produce a tridimensional model of the object, classifying each voxel from the tridimensional model into a predetermined material class indicative of a type of material included at a physical location modeled by the voxel, segmenting the tridimensional model using the intensity values and material classes associated with the voxels, thereby producing a segmented model including a plurality of object sub-components classifying each of the object sub-components included in the segmented model into a threat class, and issuing an alert signal upon a detection of an object subcomponent classified into a threatening class.

Owner:VOTI INC

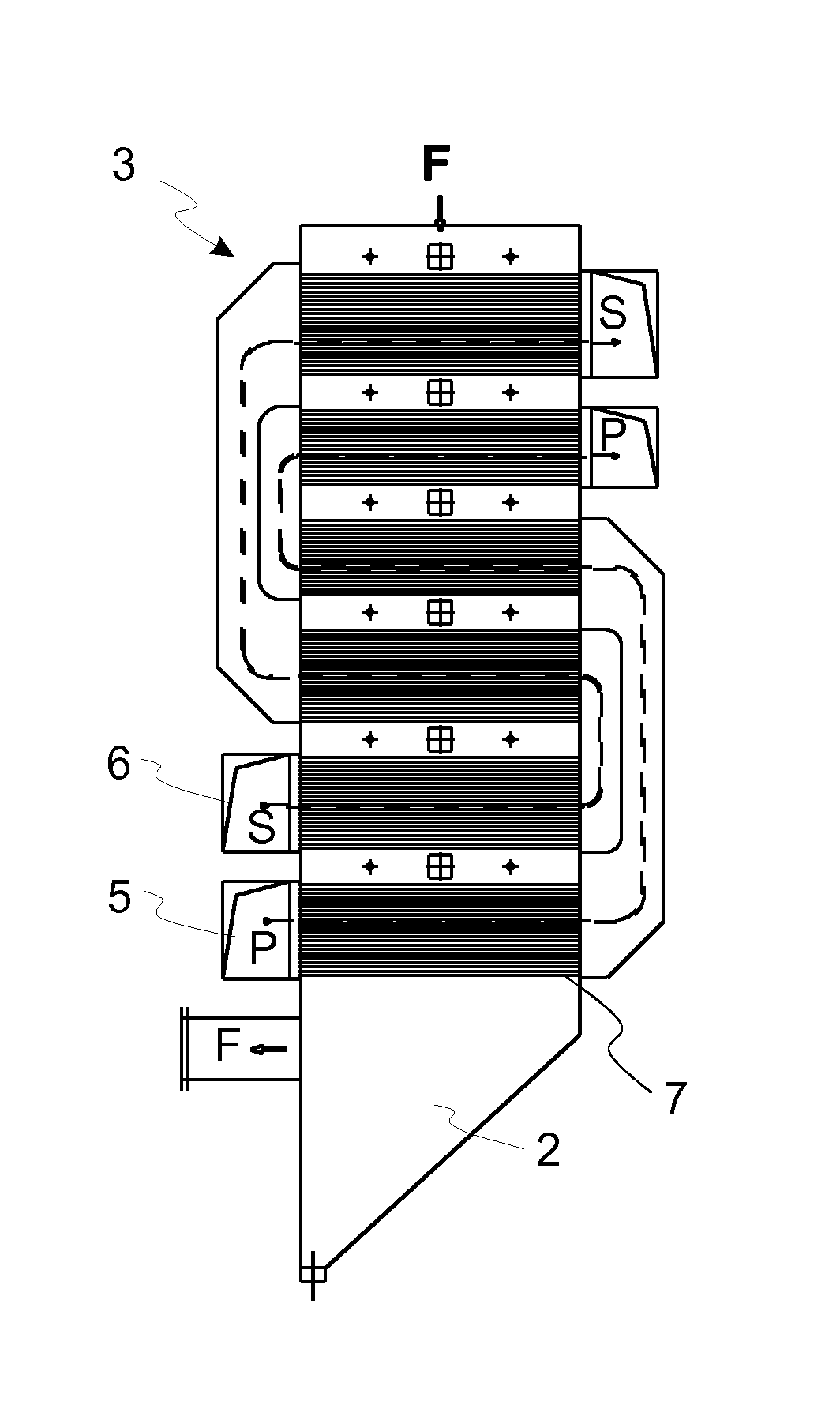

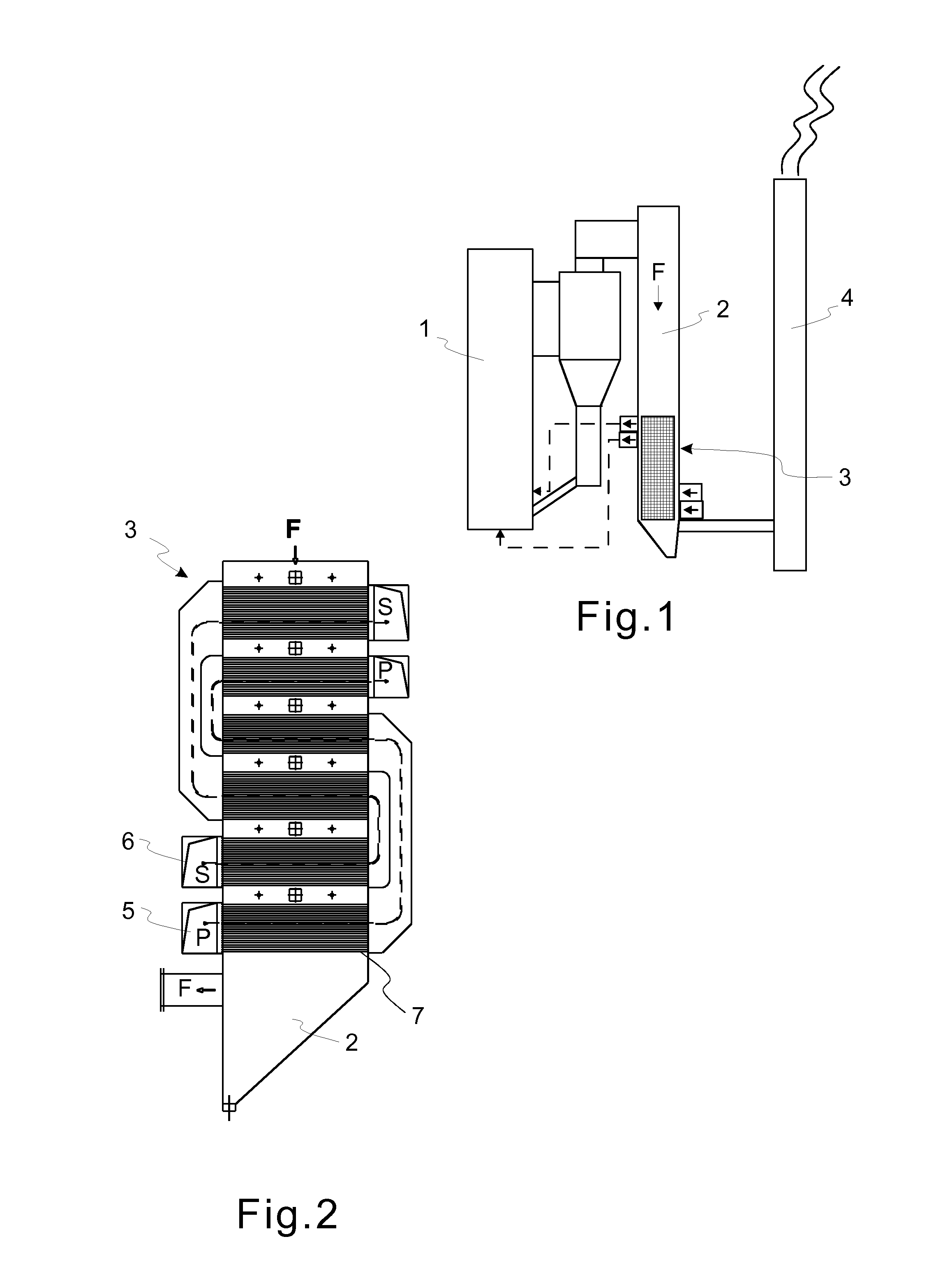

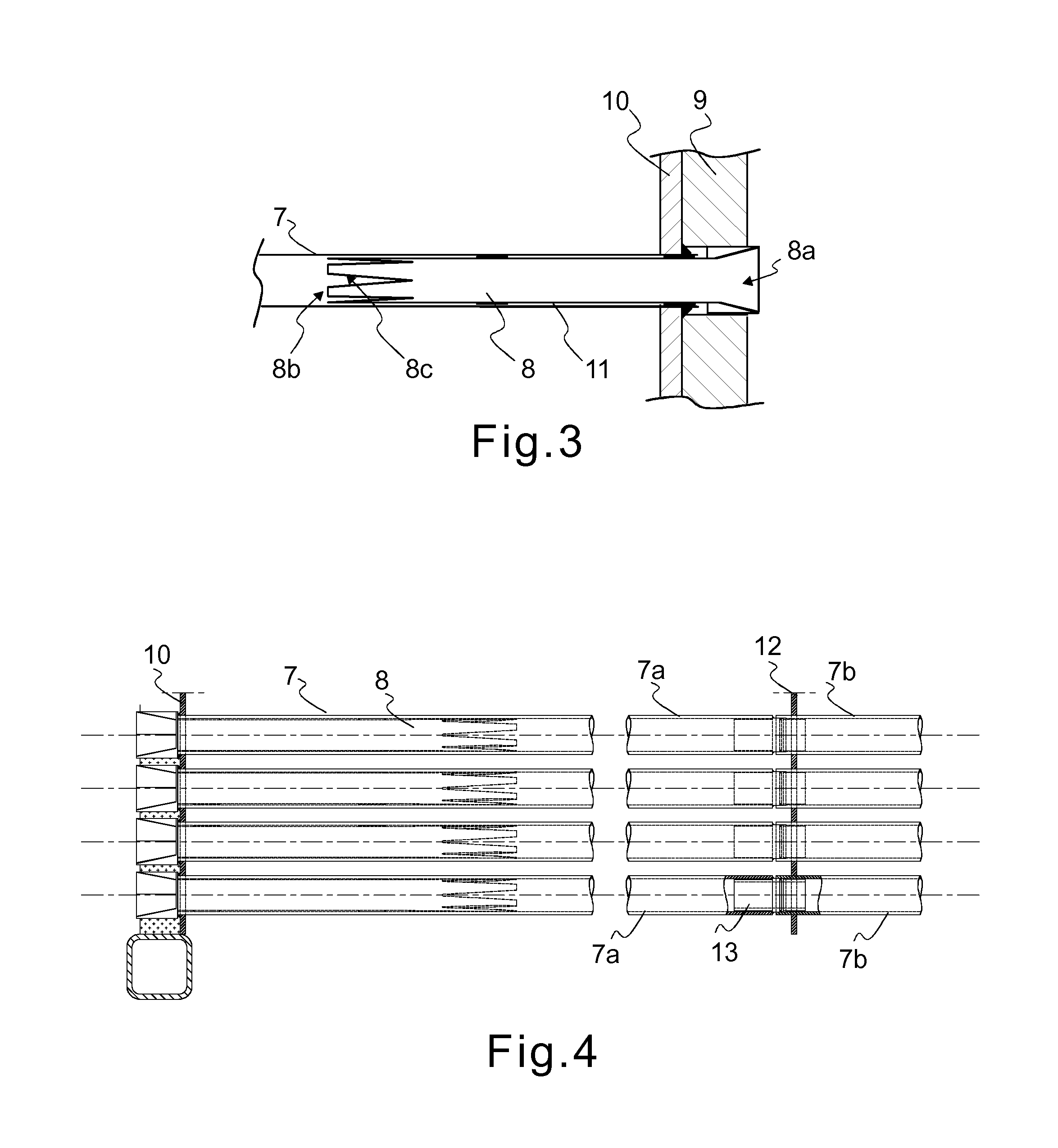

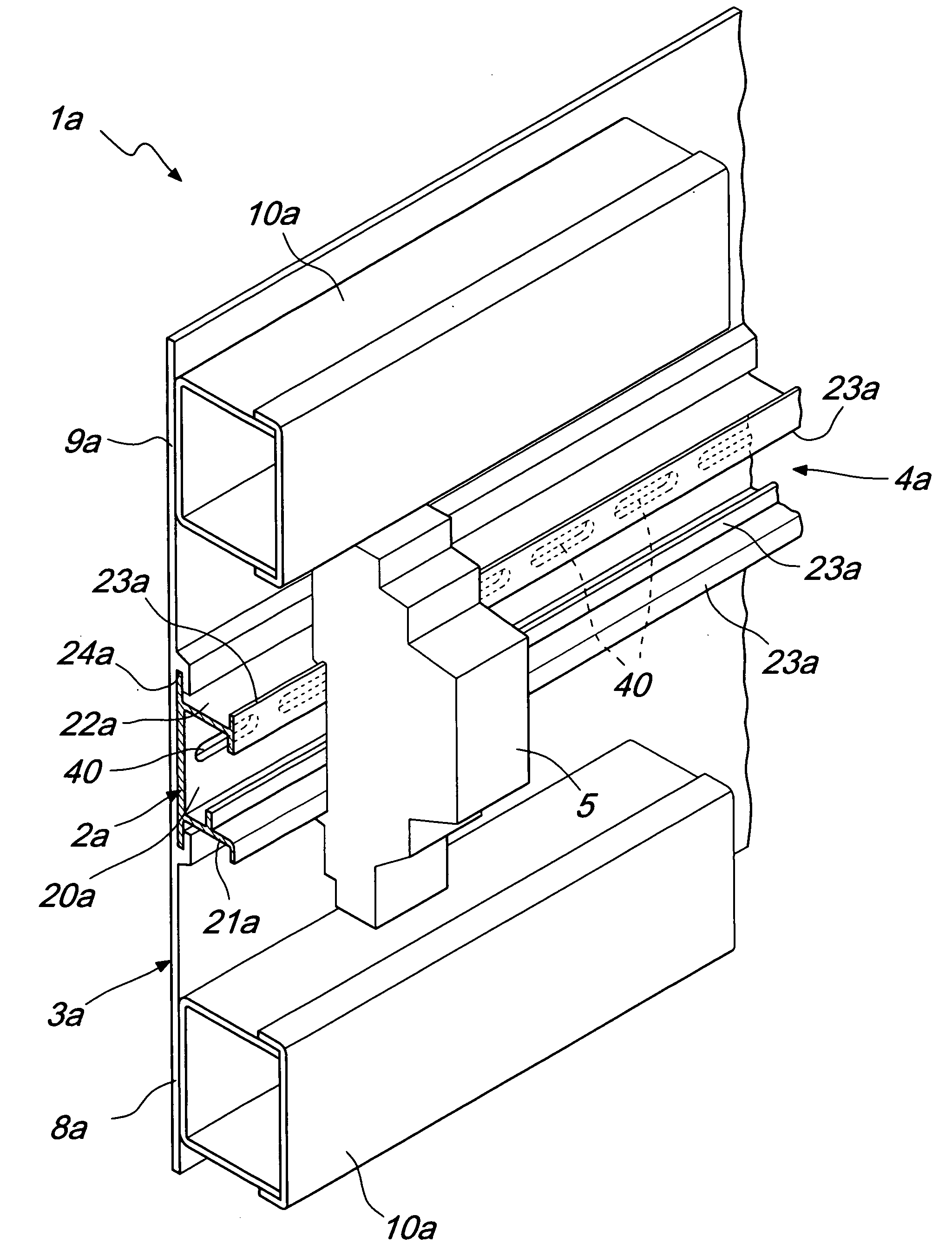

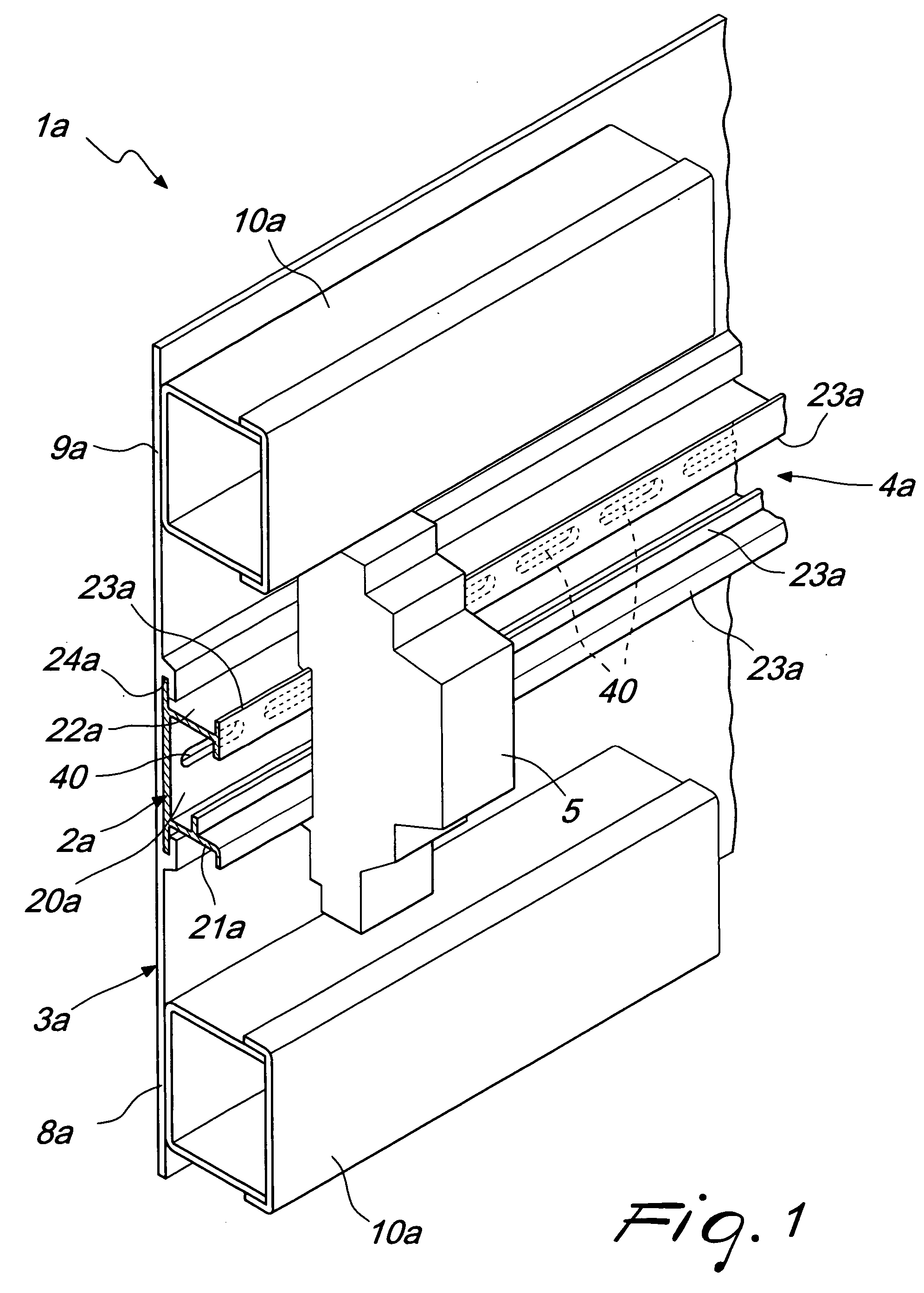

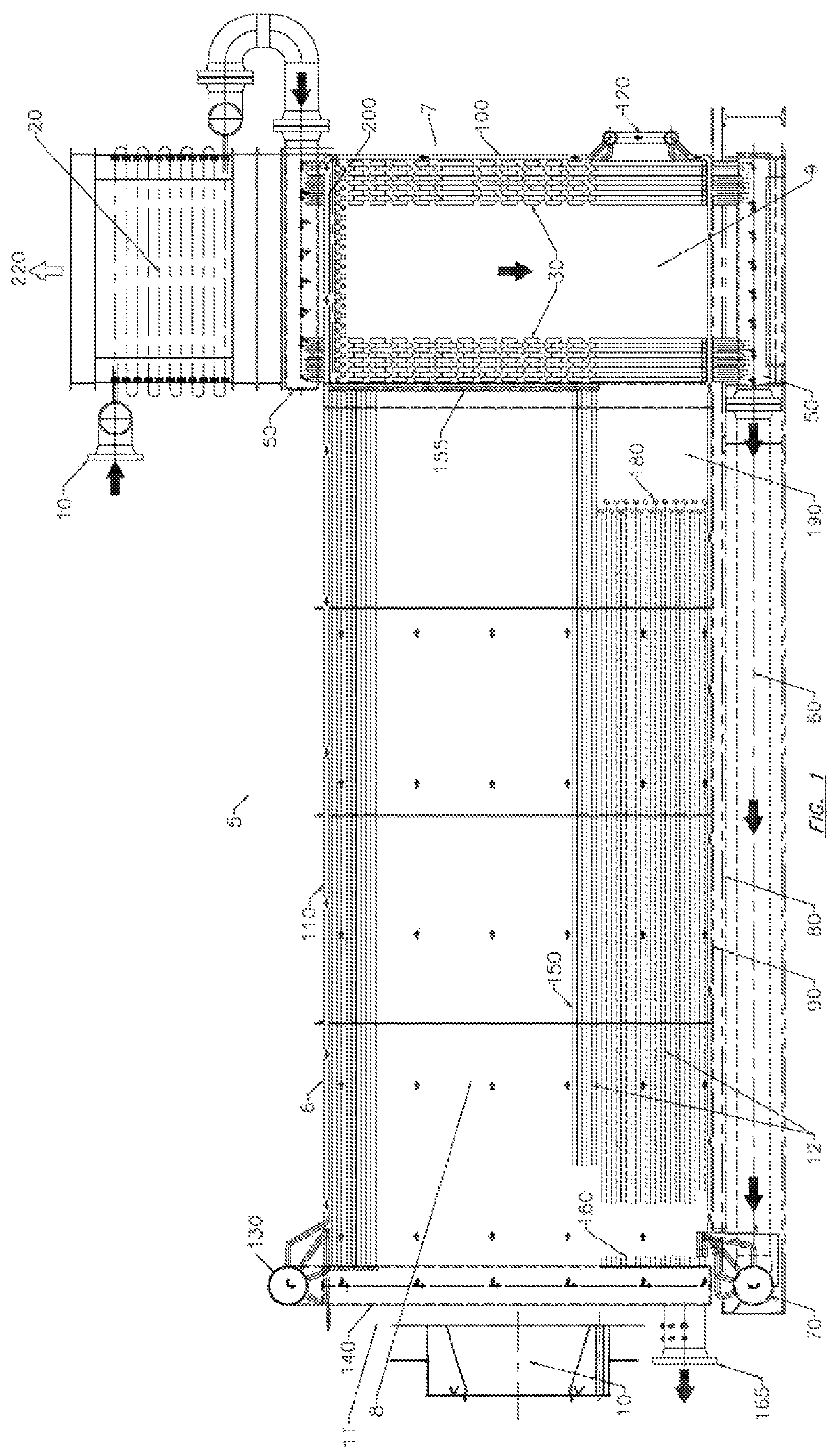

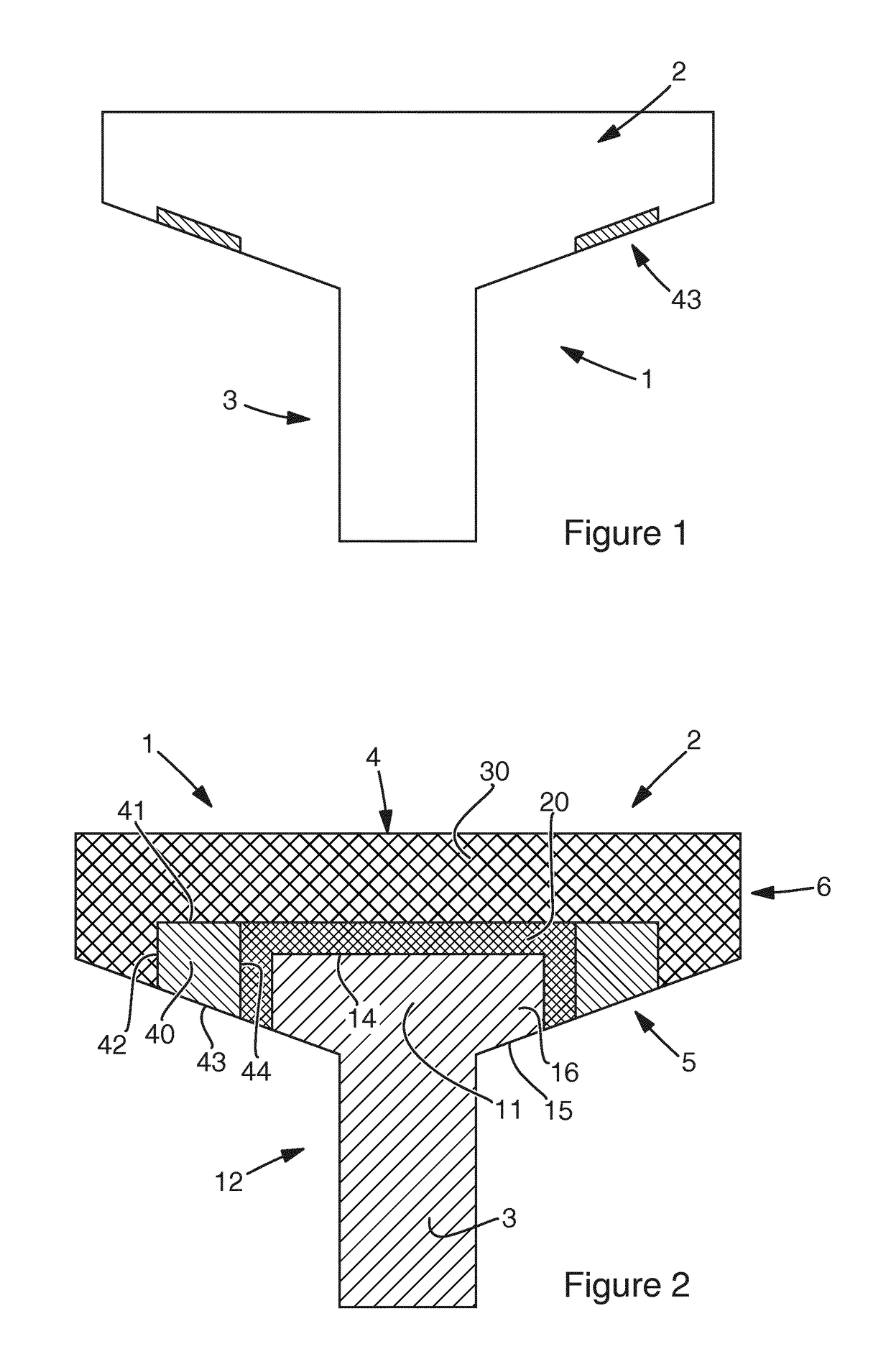

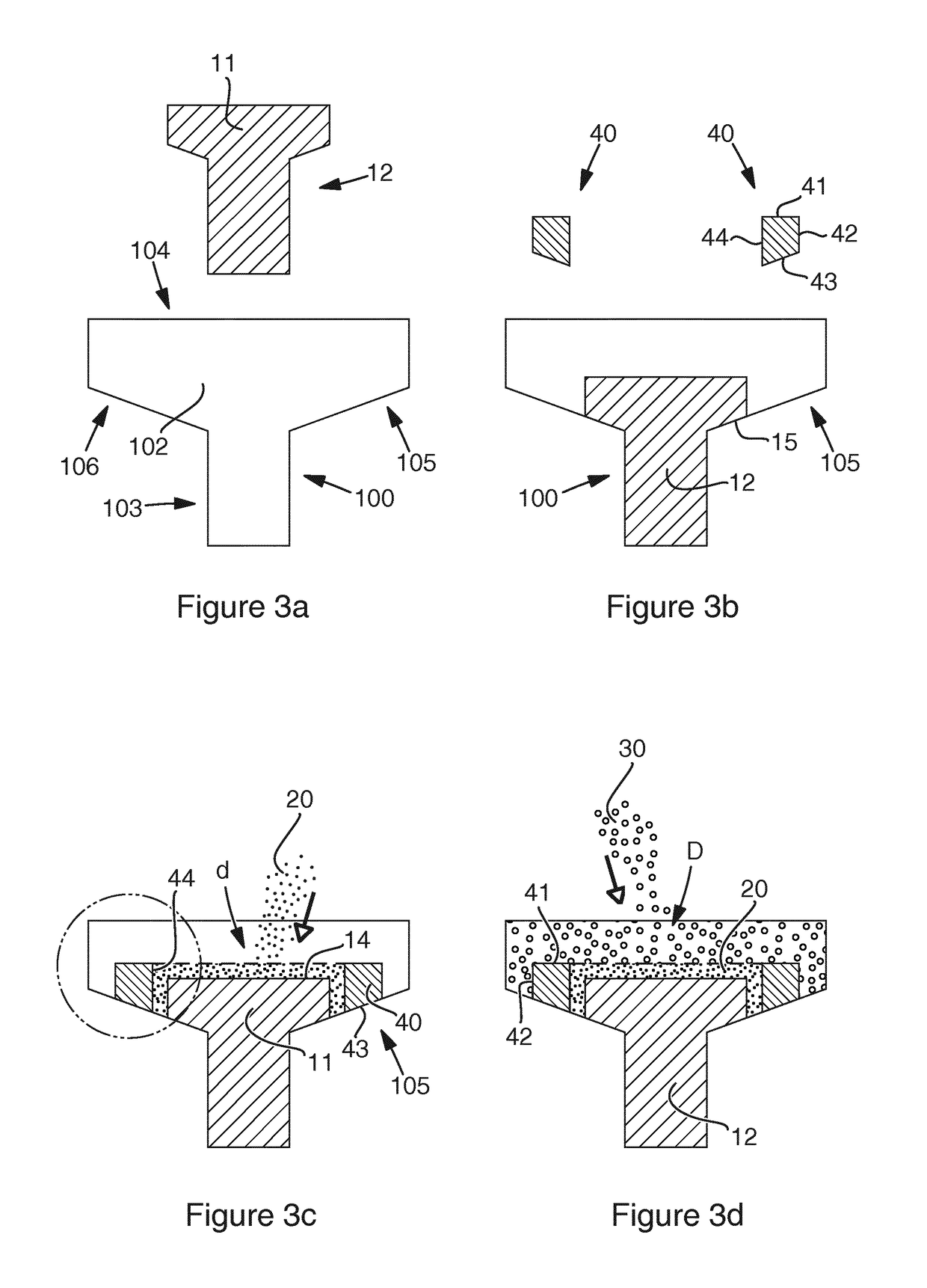

Flue gas air preheater, and a method for installation, as well as an air pipe component for a flue gas air preheater

InactiveUS20130062044A1Reduce turbulenceEasy to replaceCombustion processHeat exhanger sealing arrangementAir preheaterFlue gas

A flue gas air preheater and a method for the installation of air pipes for a flue gas air preheater. The method includes cutting an air pipe connected to the preheater and detaching the portion of the air pipe that is to be removed from the preheater for replacement; fitting a separate new air pipe in place of the air pipe portion to be removed; and connecting the new air pipe to the remaining portion of the air pipe in a sealed manner. The fixing may be performed utilizing a fastening sleeve fixed to the end of the new air pipe and inserting it in the remaining portion of the air pipe. The fixing may be performed by a mechanical sealing solution without welding. The air pipe component for the flue gas air preheater includes an air pipe, and a fastening sleeve.

Owner:VALMET TECH OY

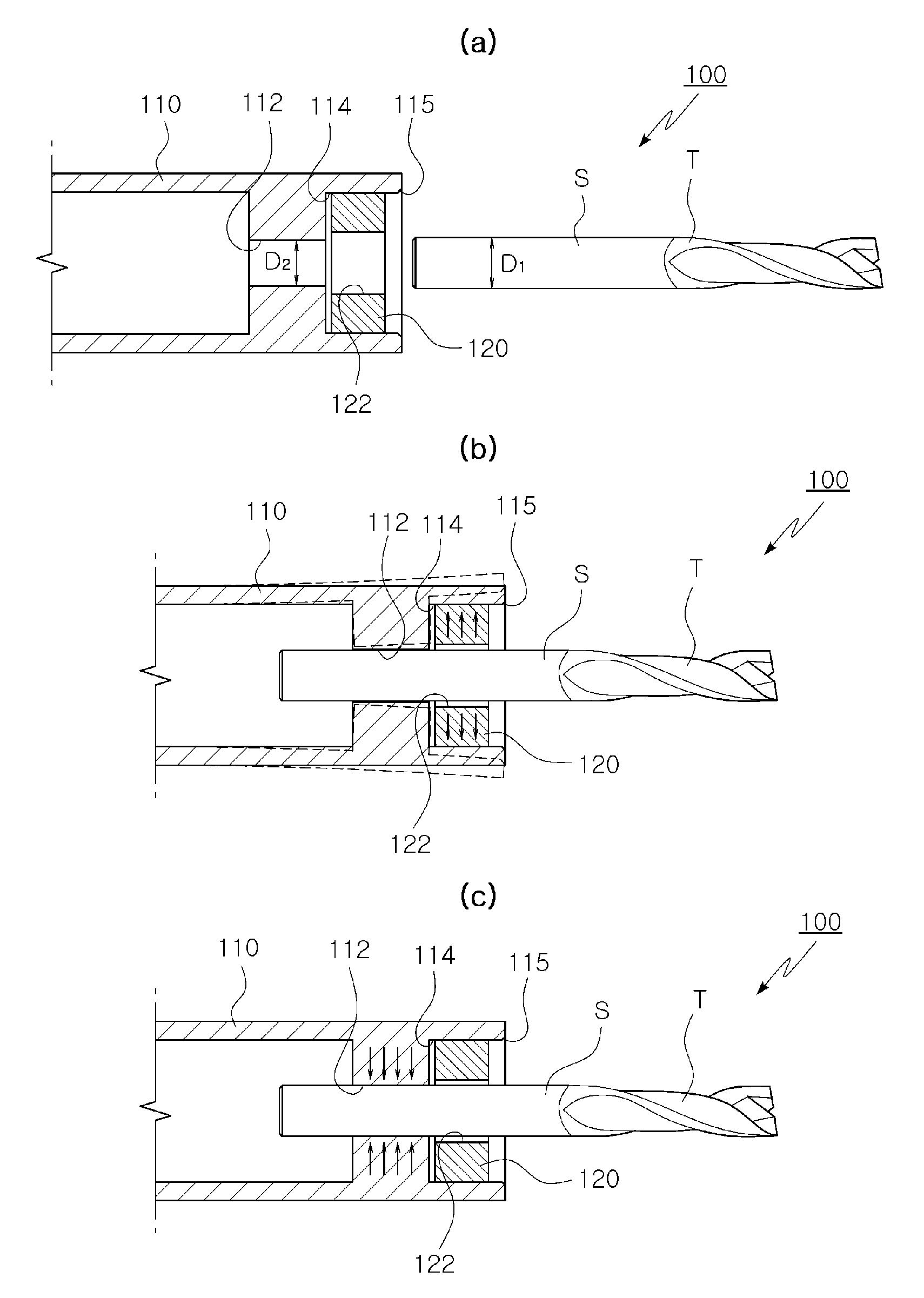

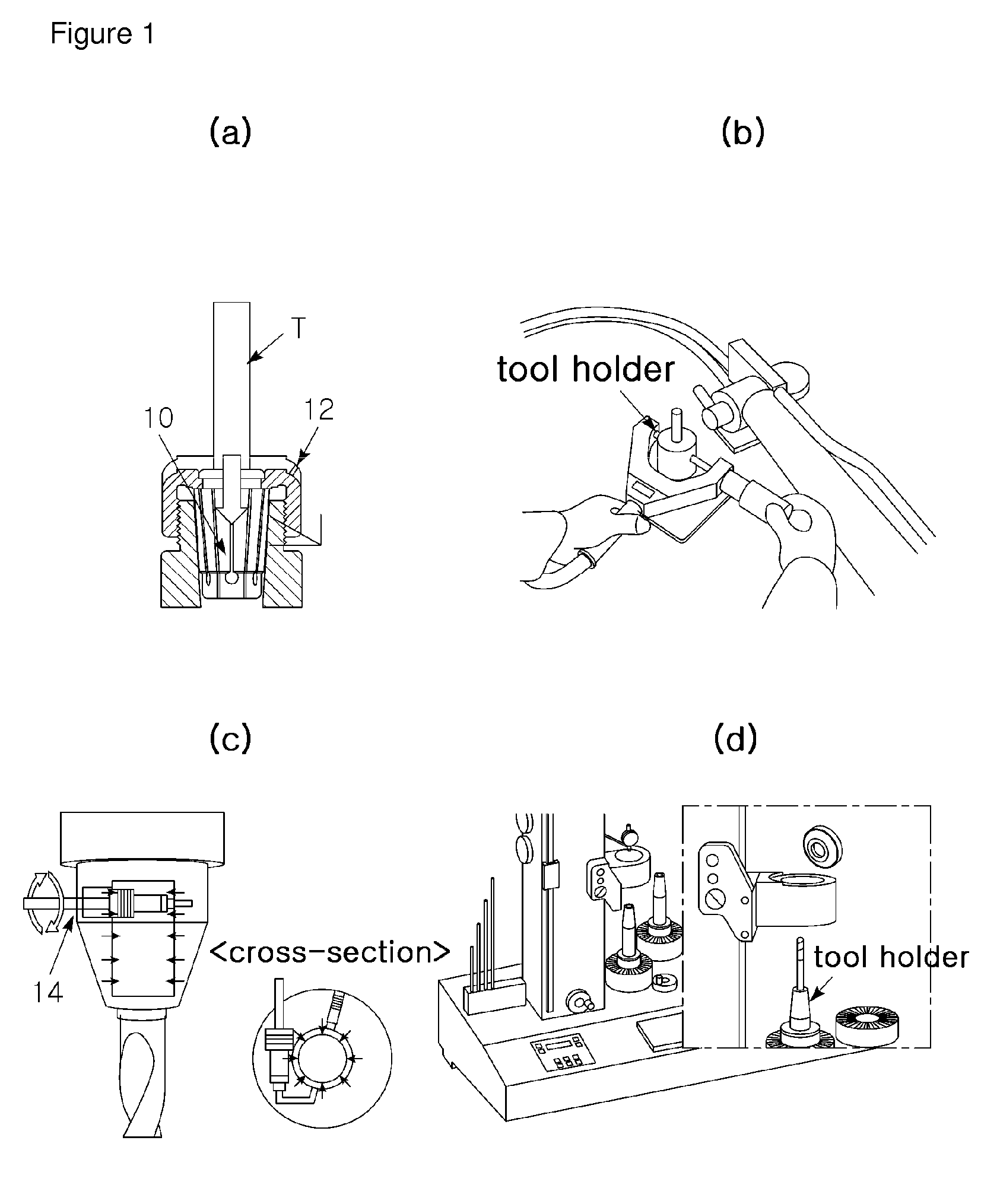

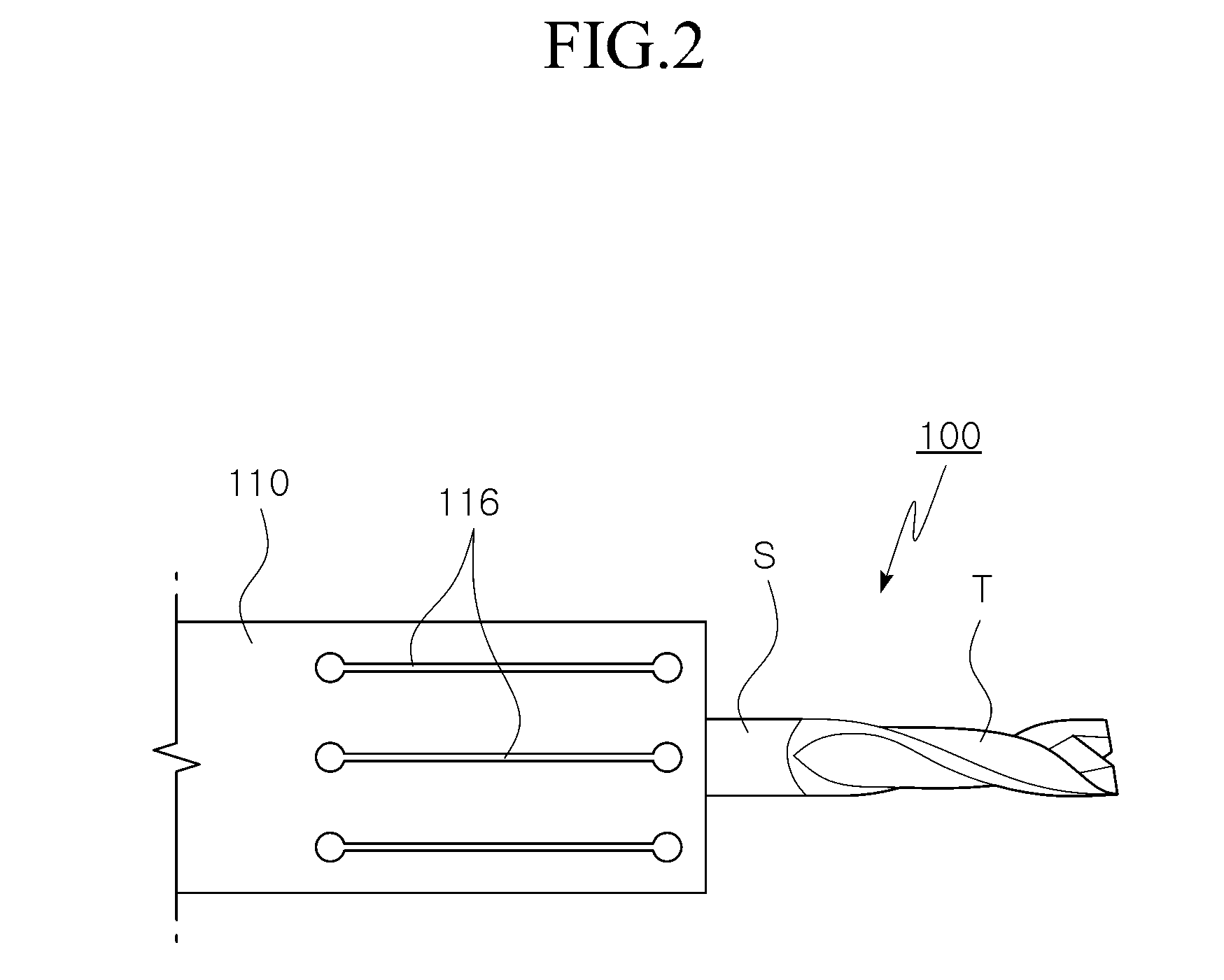

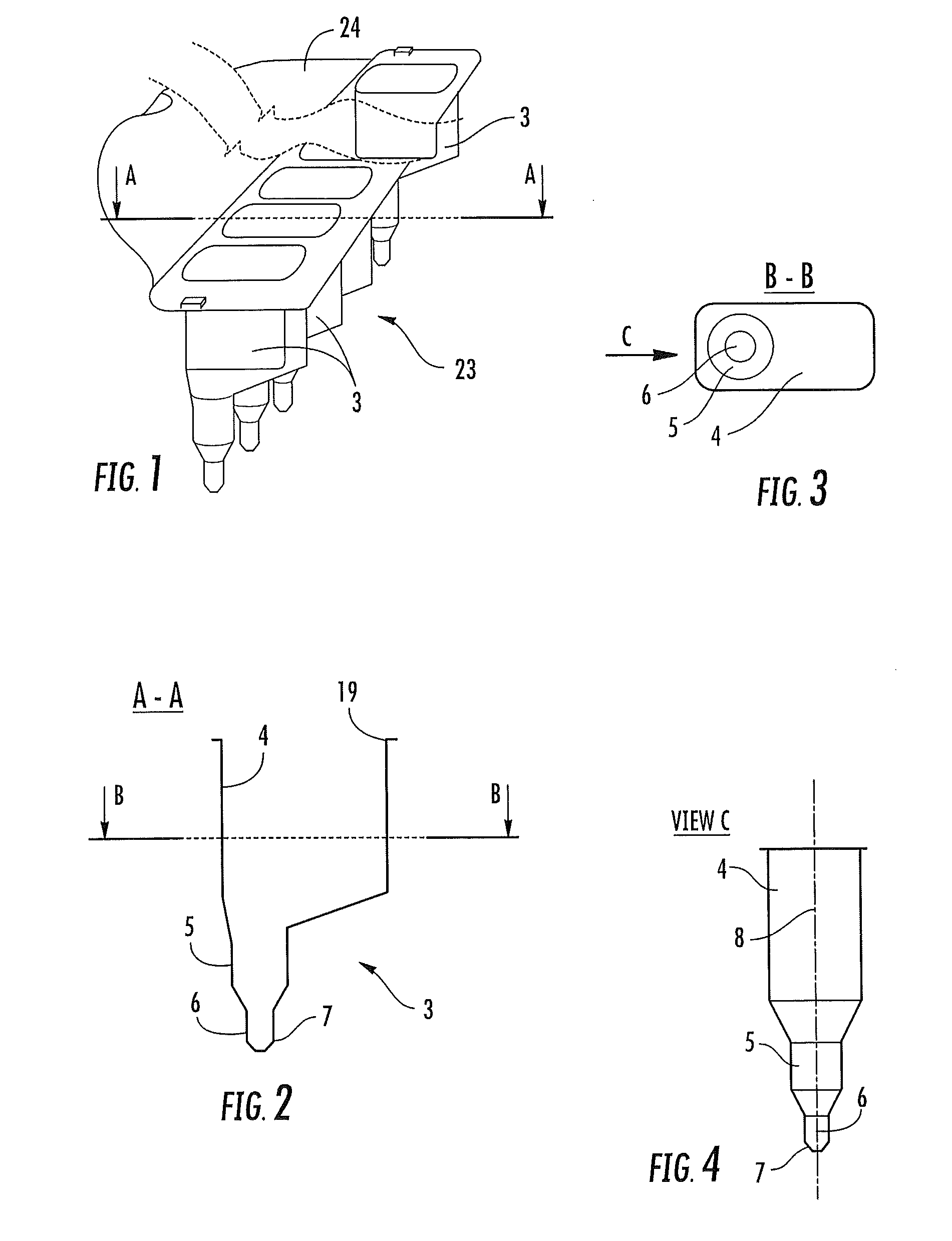

Tool holder using shape memory alloy and tool holding method

ActiveUS9180525B2Improve errorRotating imbalanceThread cutting machinesTransportation and packagingShape-memory alloyAlloy

A tool holder holding a tool according to the present invention includes: a tool mounting unit forming and penetrating a tool fixing hole having an interior diameter that is relatively smaller than an exterior diameter of a shank unit of the tool; and at least one shape memory alloy ring inserted and arranged to a ring fixing hole formed at the tool mounting unit to have an interior diameter that is relatively larger than the tool fixing hole, wherein an interior diameter size of the tool fixing hole is forcibly changed by deformation of a shape memory alloy ring by a heating source and a cooling source provided to the shape memory alloy ring for clamping or unclamping the tool.

Owner:KOREA INST OF MACHINERY & MATERIALS

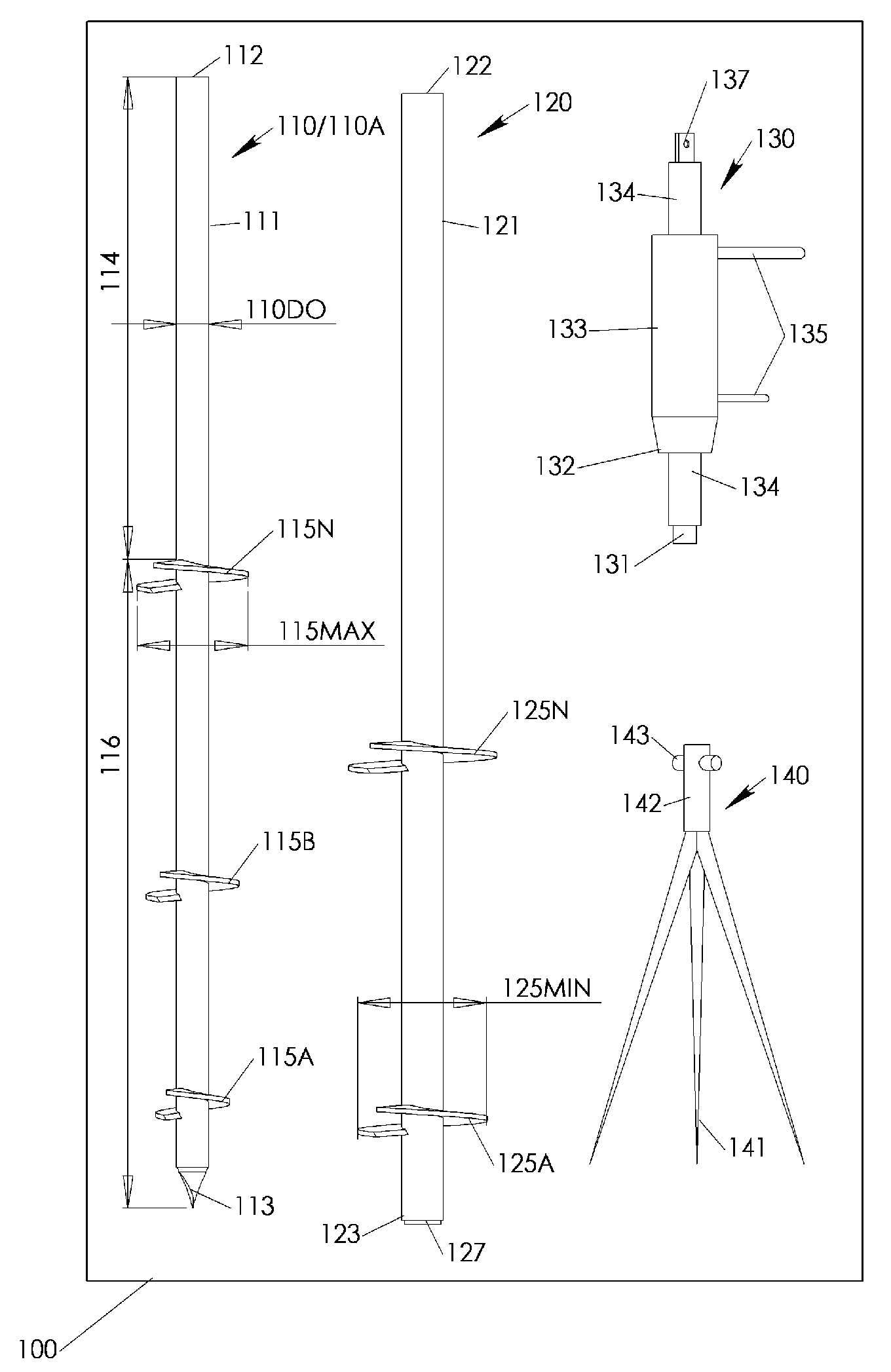

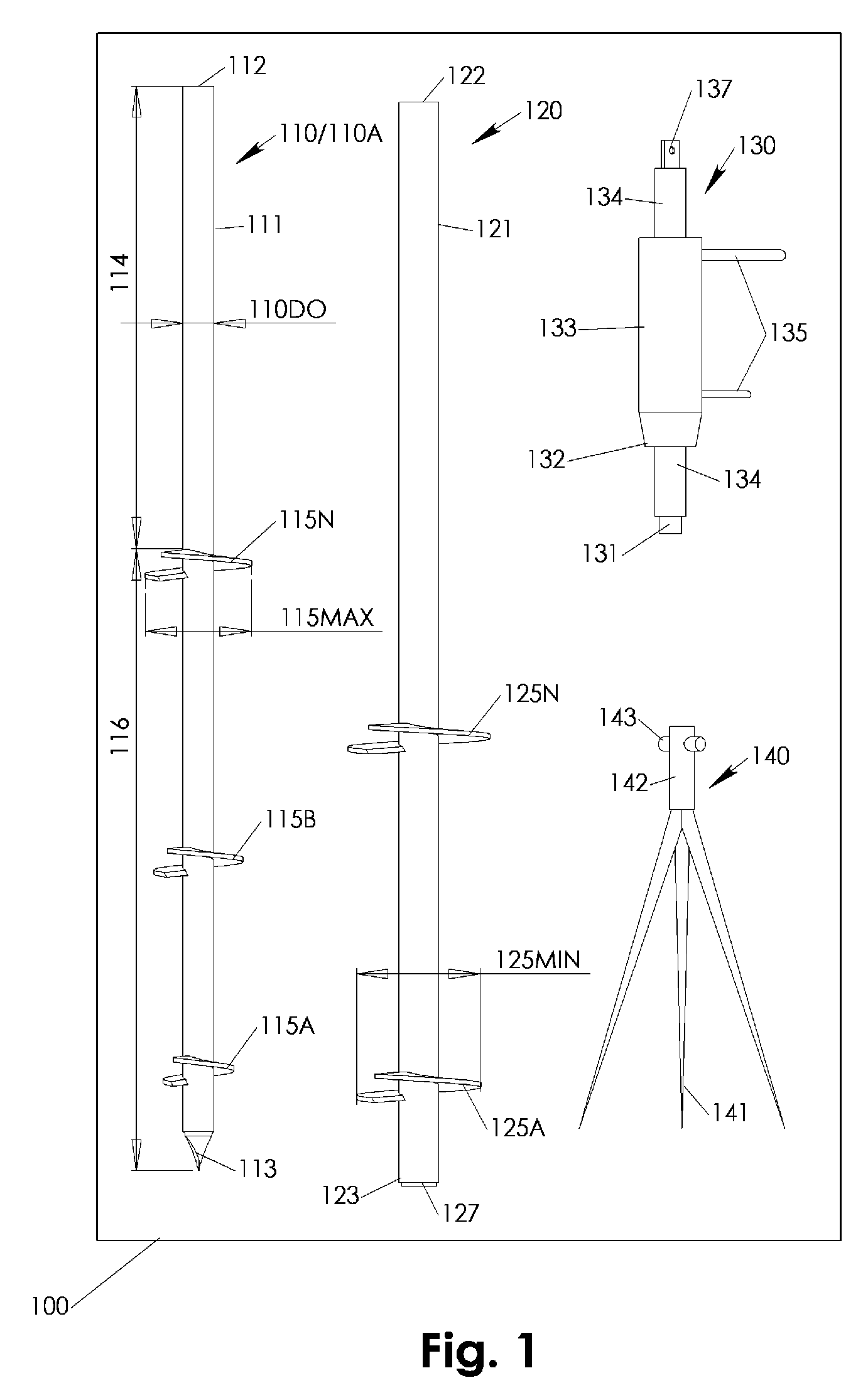

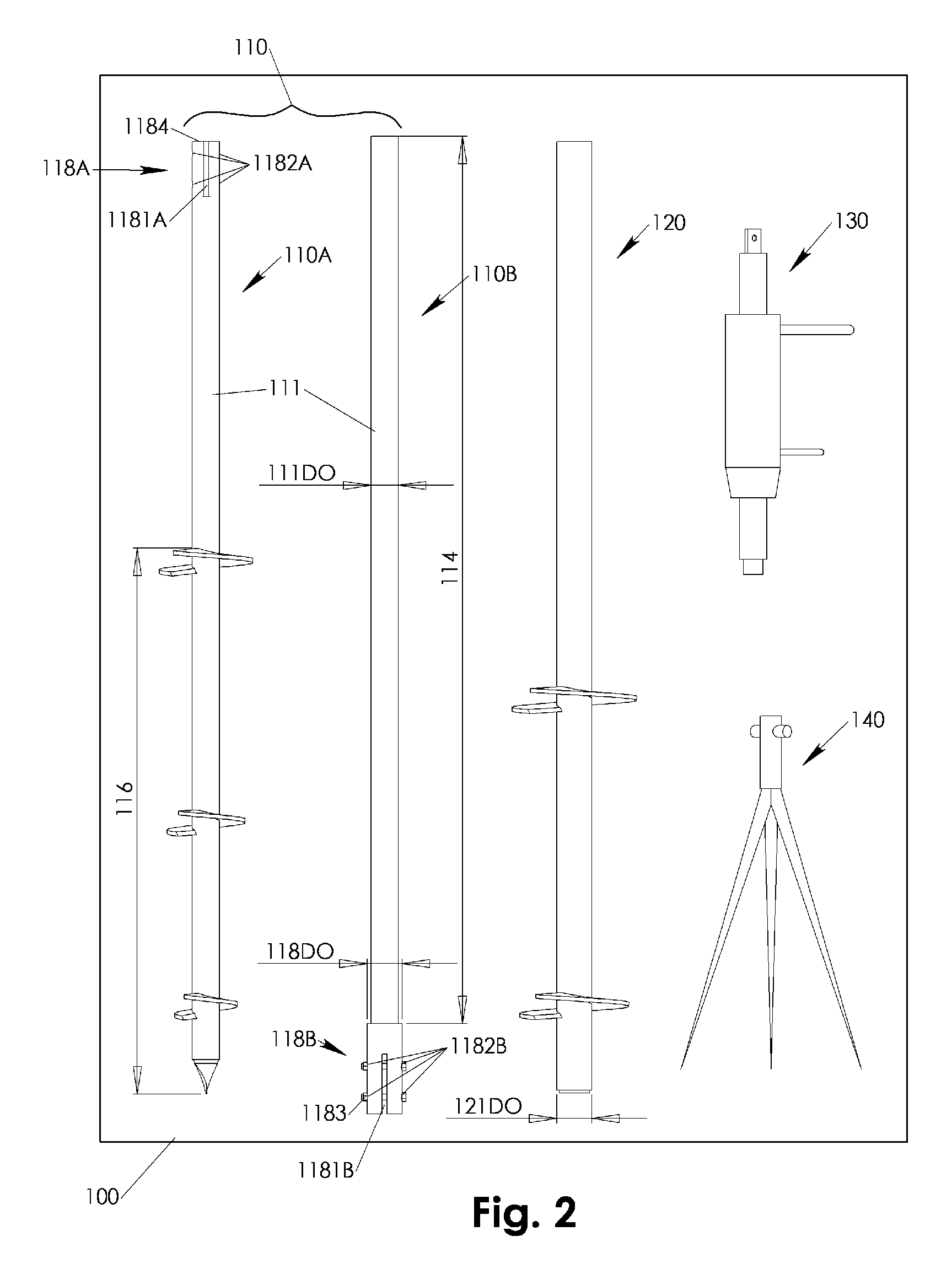

Ground anchor load testing system and method

InactiveUS7441471B1Fast and easy to performPrecise positioningDrilling with mechanical conveyingFoundation testingFlangingAutomotive engineering

A ground anchor load testing system includes a ground anchoring unit having a bare upper drill shaft portion along and around which a reaction anchor with its hollow shaft is temporary installed. During test loading of the installed ground anchoring unit, a test loading head is coupled with both concentric flanging ends of the ground anchoring unit and the temporarily installed reaction anchor. The test loading head exerts via a first coupling the push test load on the first flanging end of the ground anchoring unit while withholding itself via a second coupling on the second flanging end of the reaction anchor. A measurement device may be positioned on the ground adjacent the test load head. Eventual axial displacement of the ground anchoring unit under test load may be externally recognized by the measurement device via an axial displacement indicator in axial connection with the first coupling.

Owner:DAVIS JOHN D

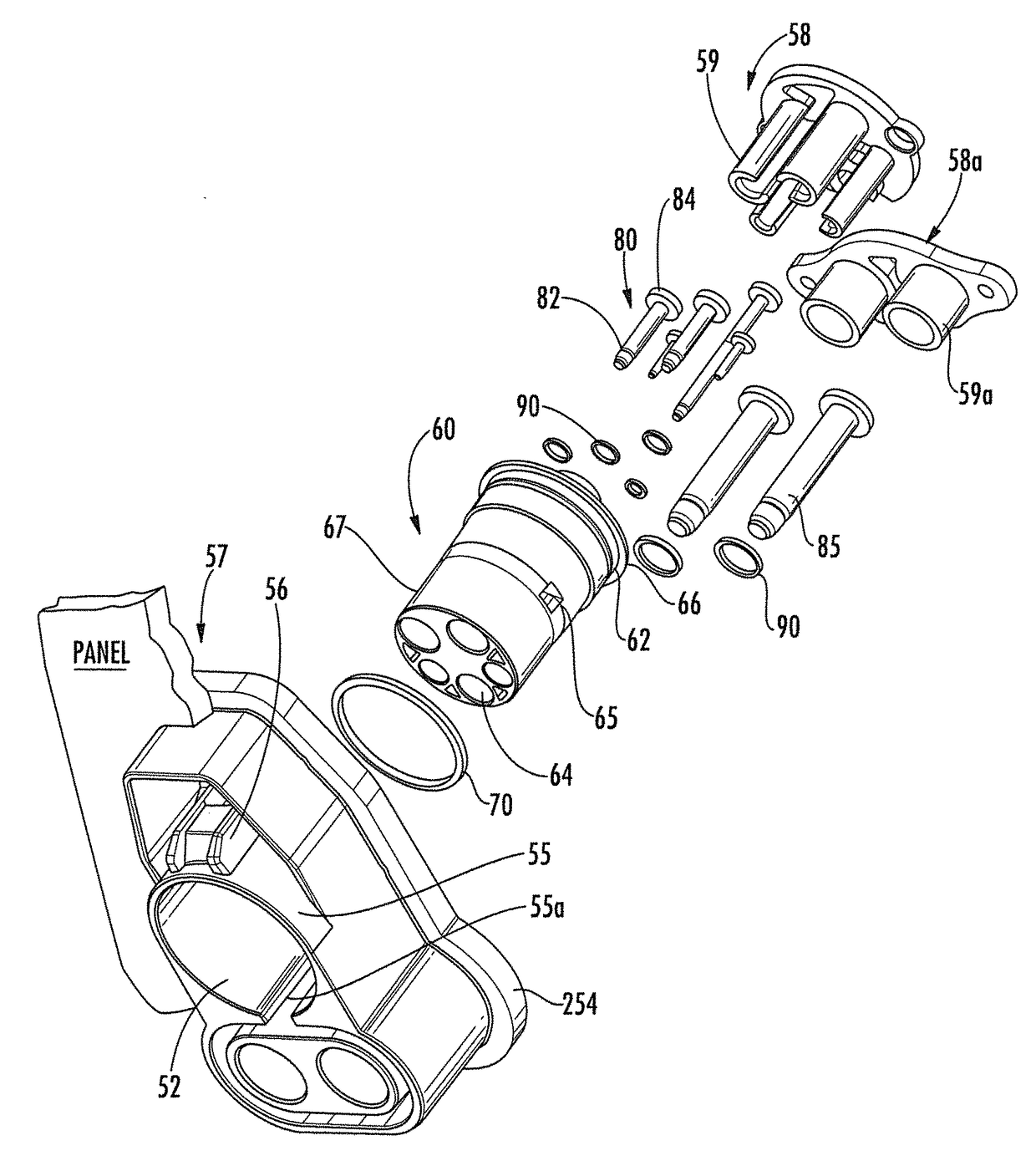

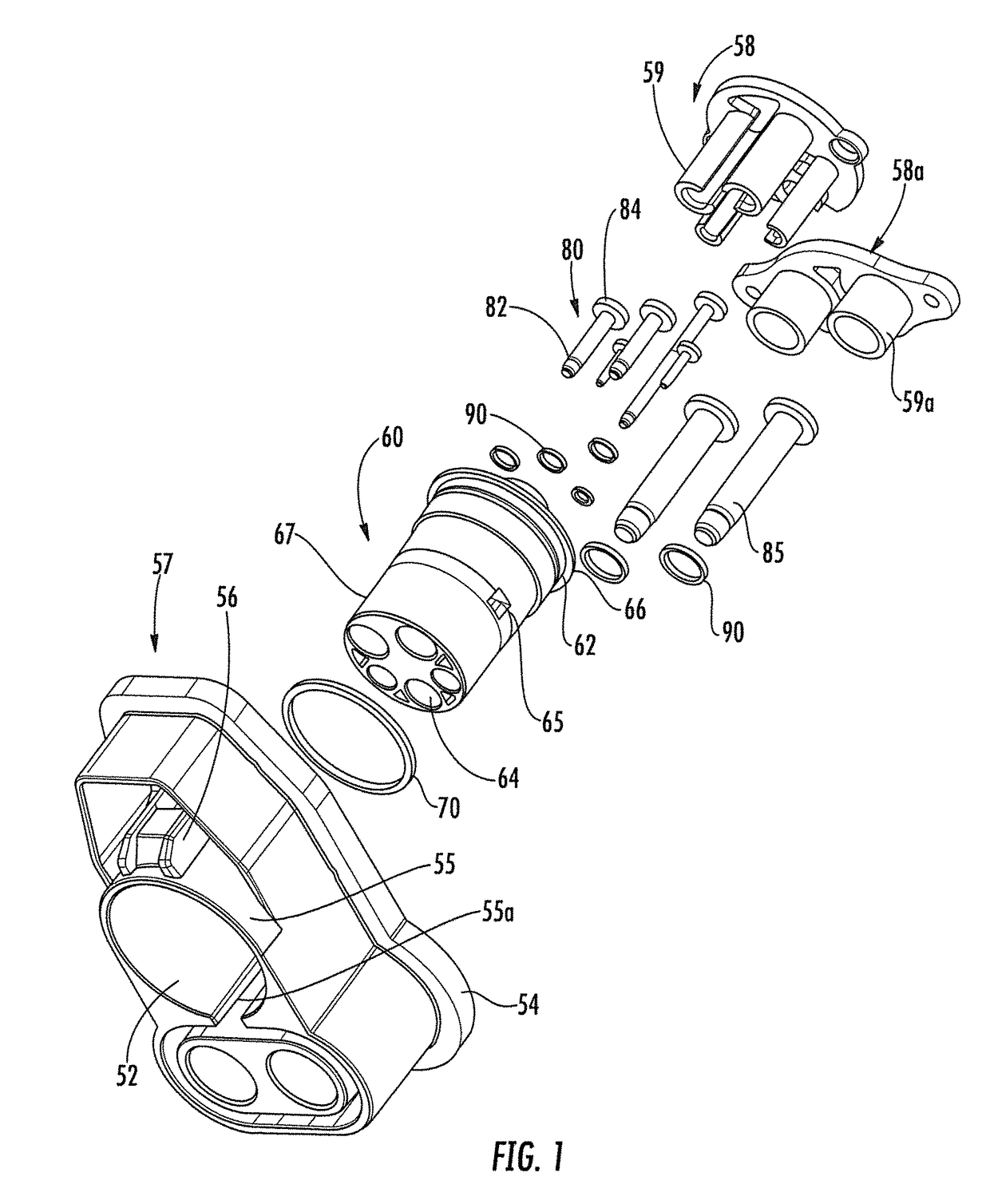

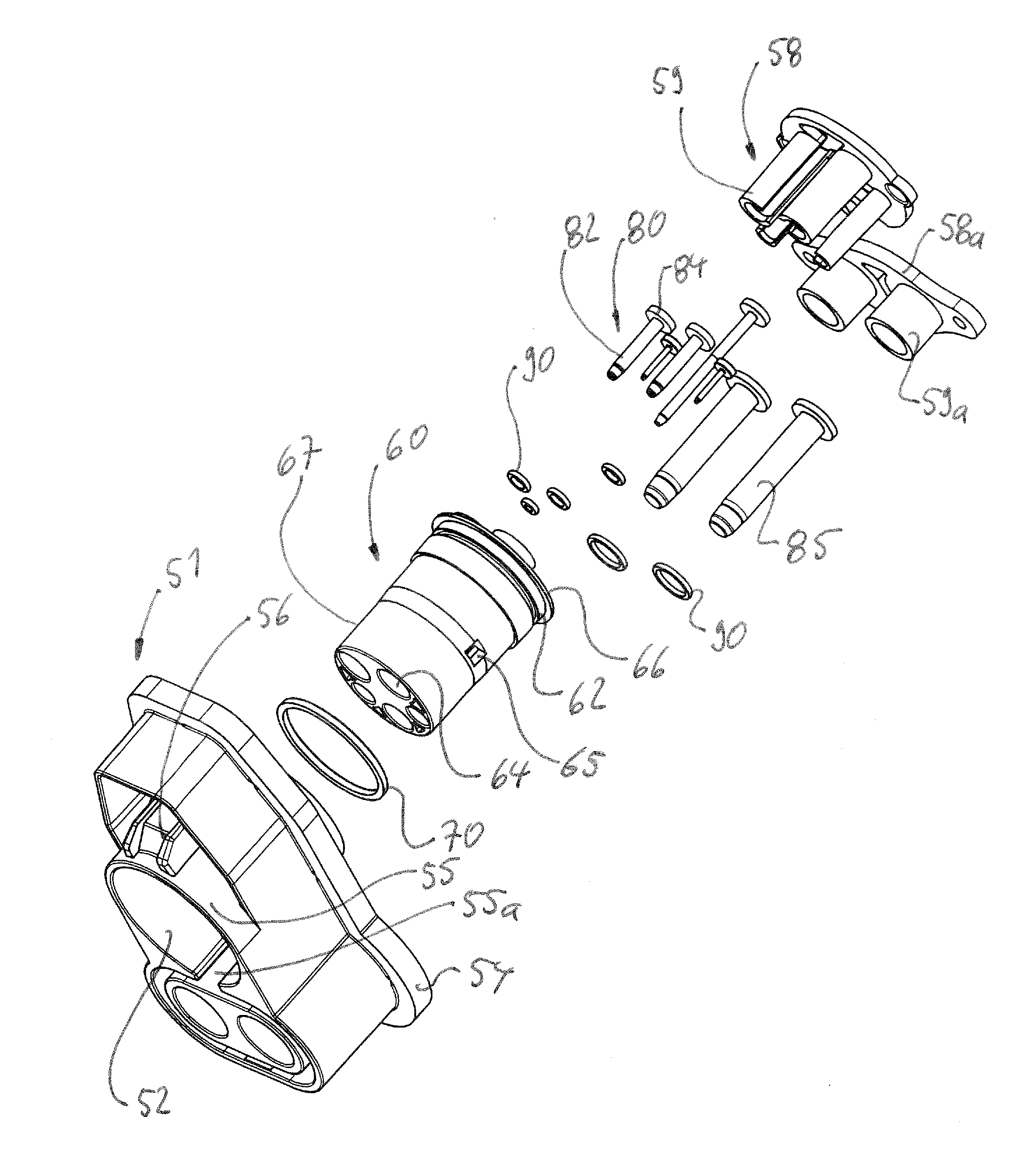

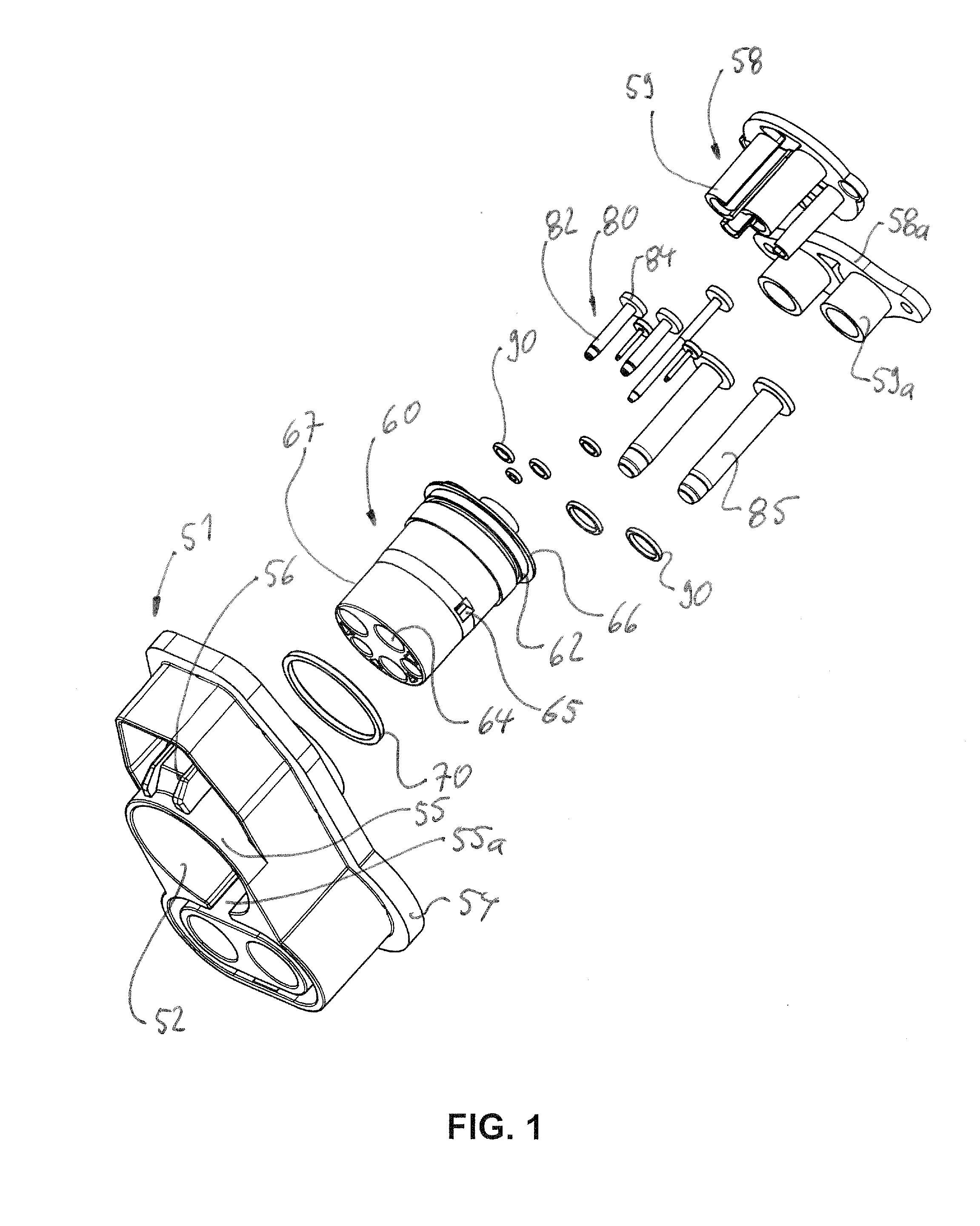

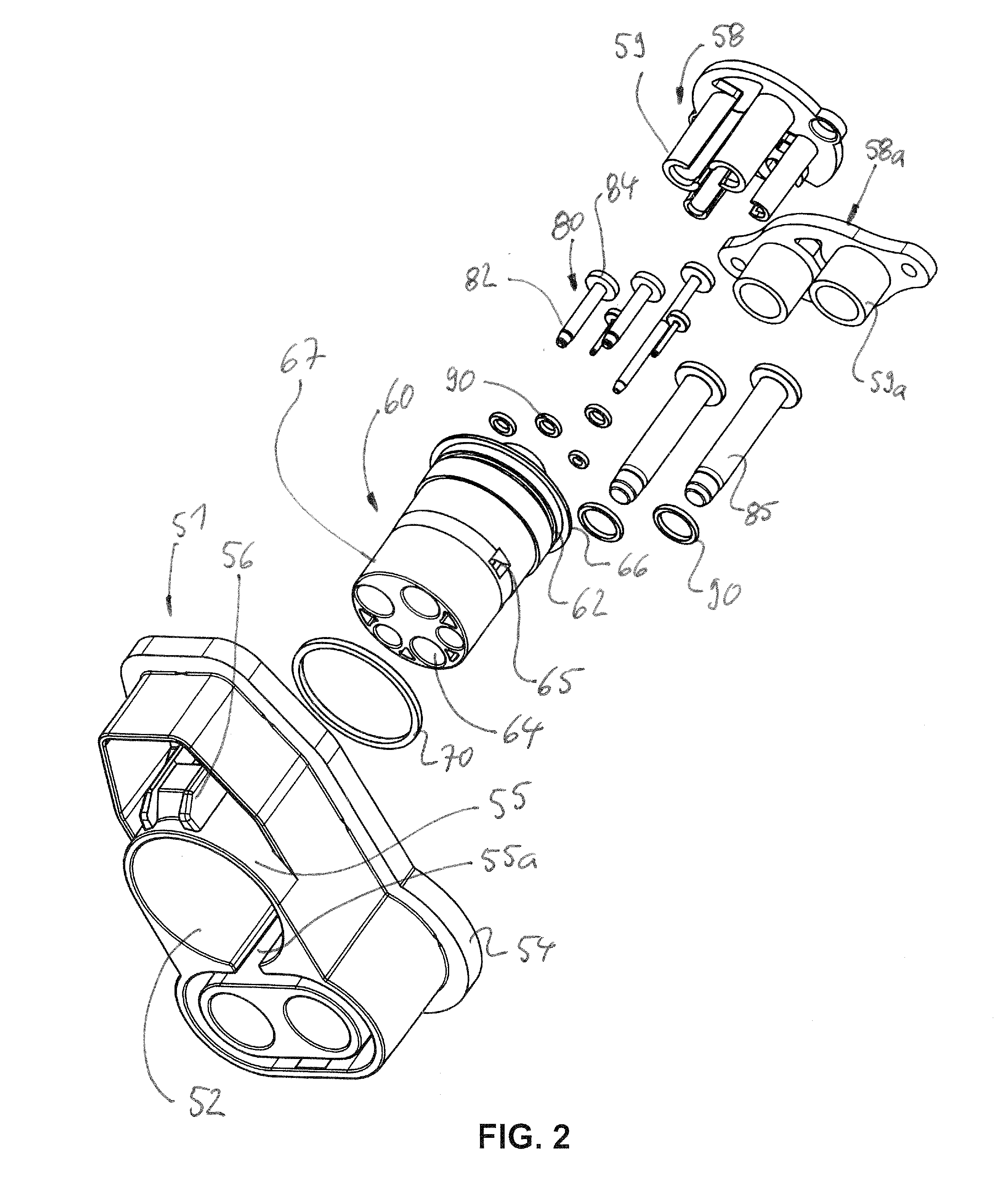

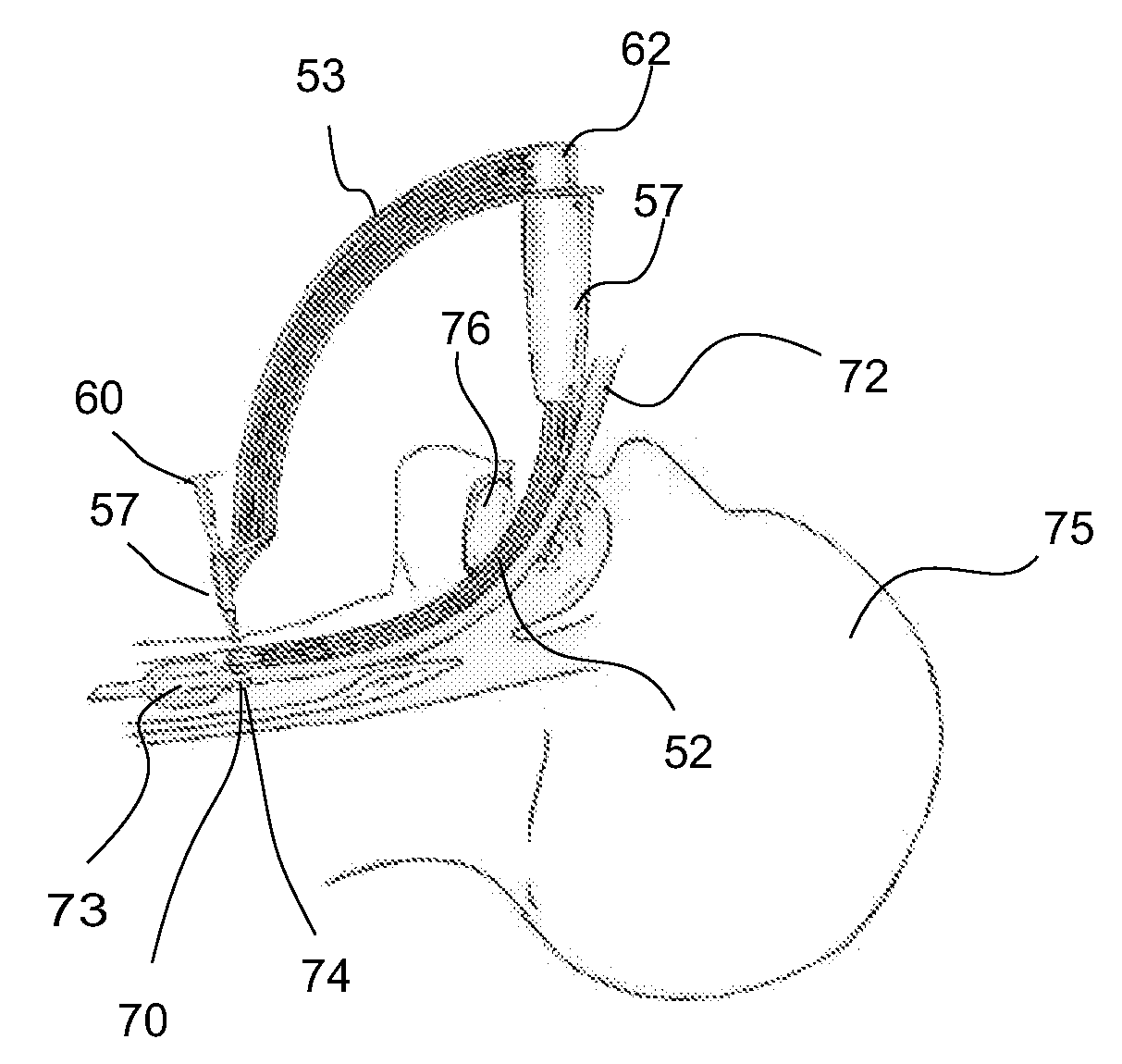

Charging connector and method of mounting the same

ActiveUS9601864B2Easy to disassembleFast and easy to performCouplings bases/casesTowerElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

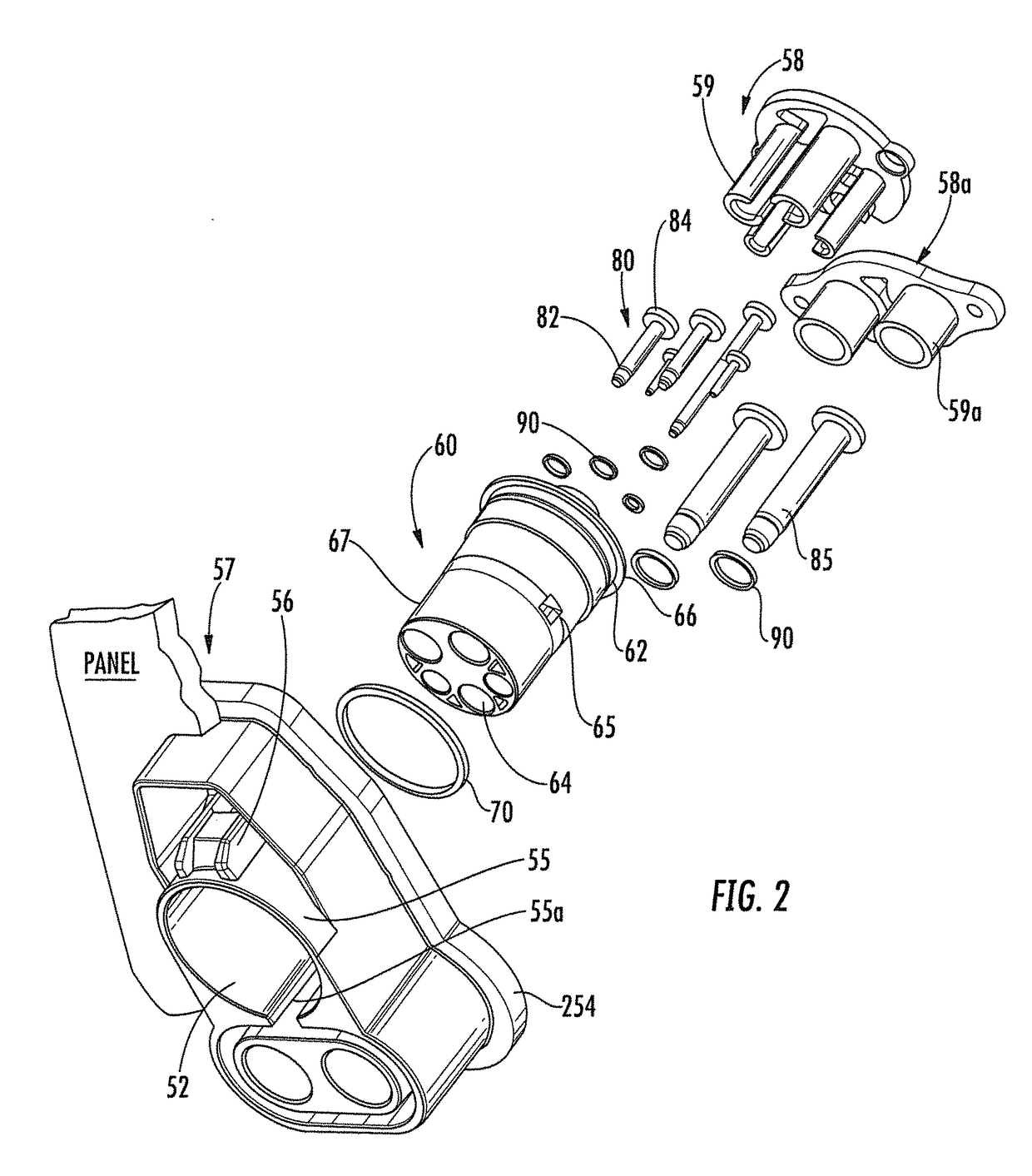

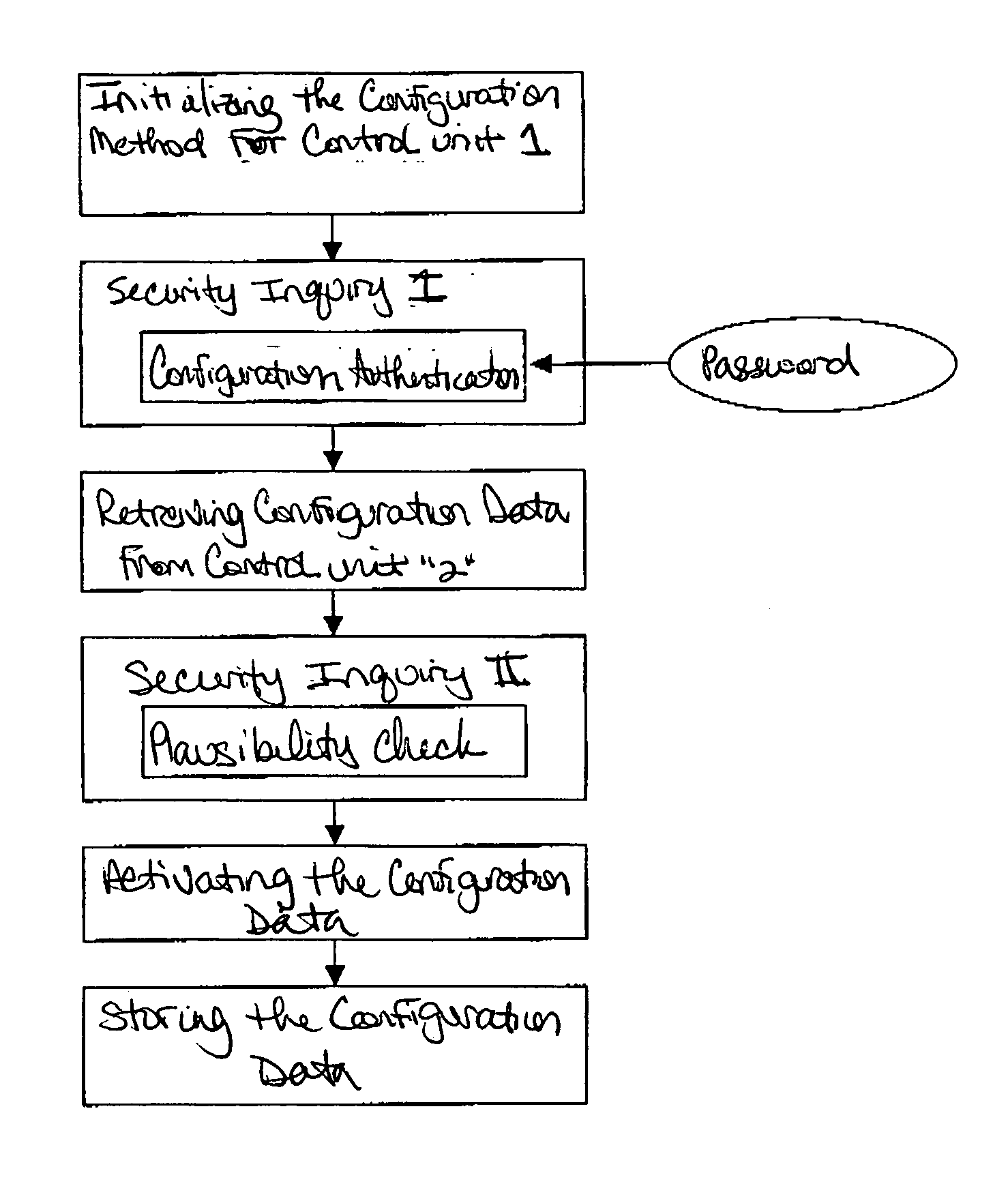

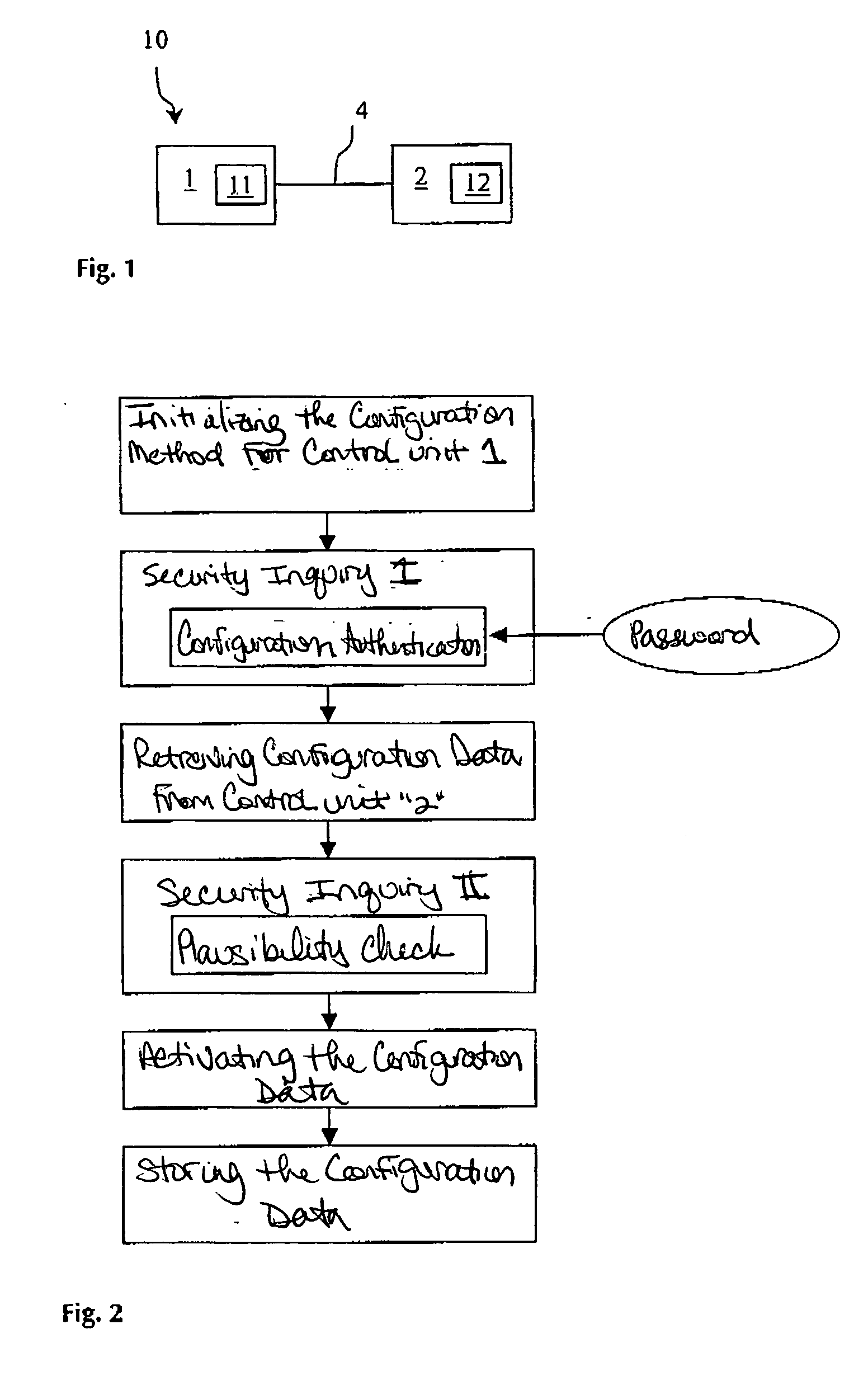

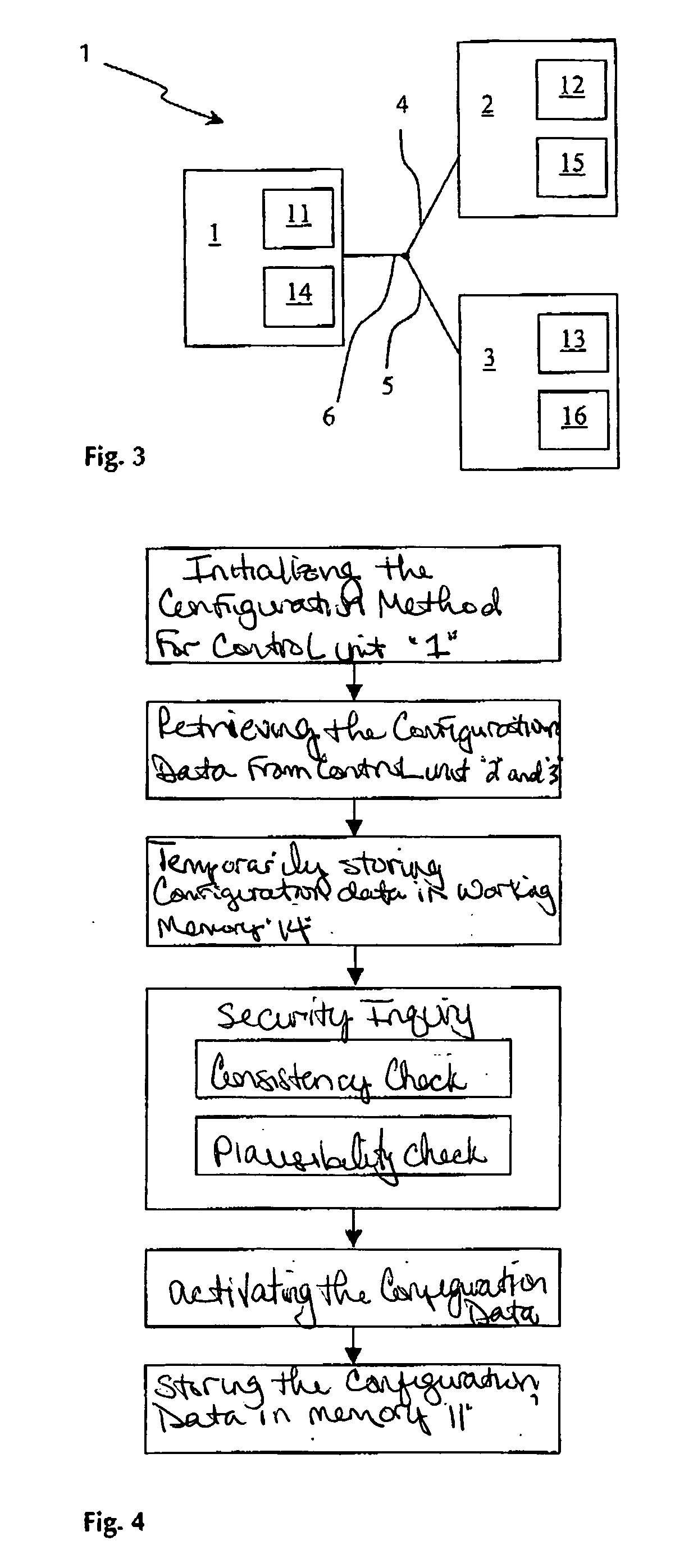

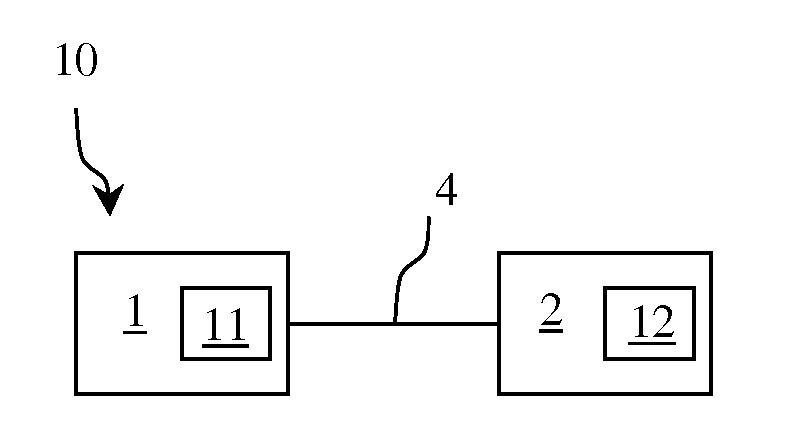

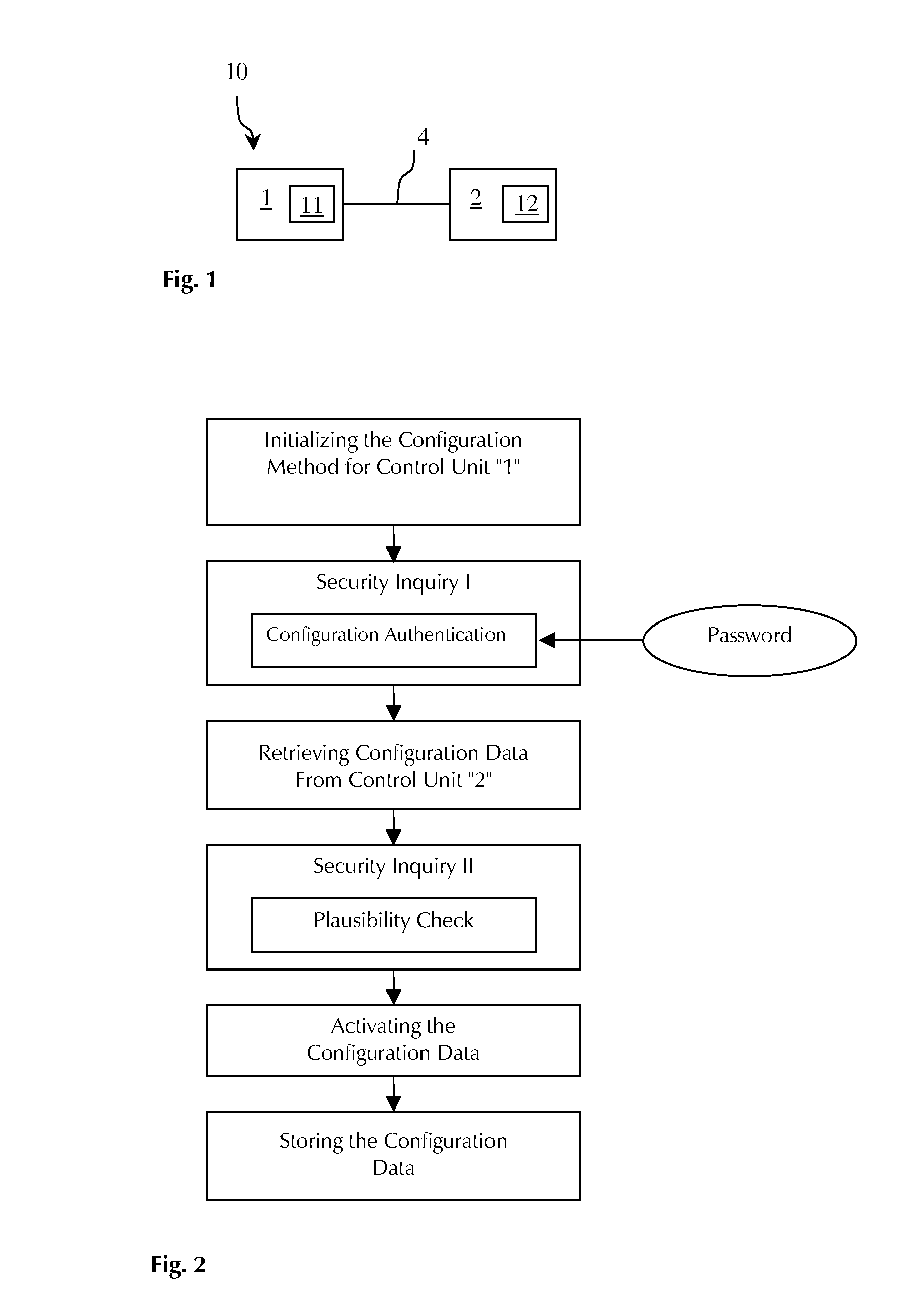

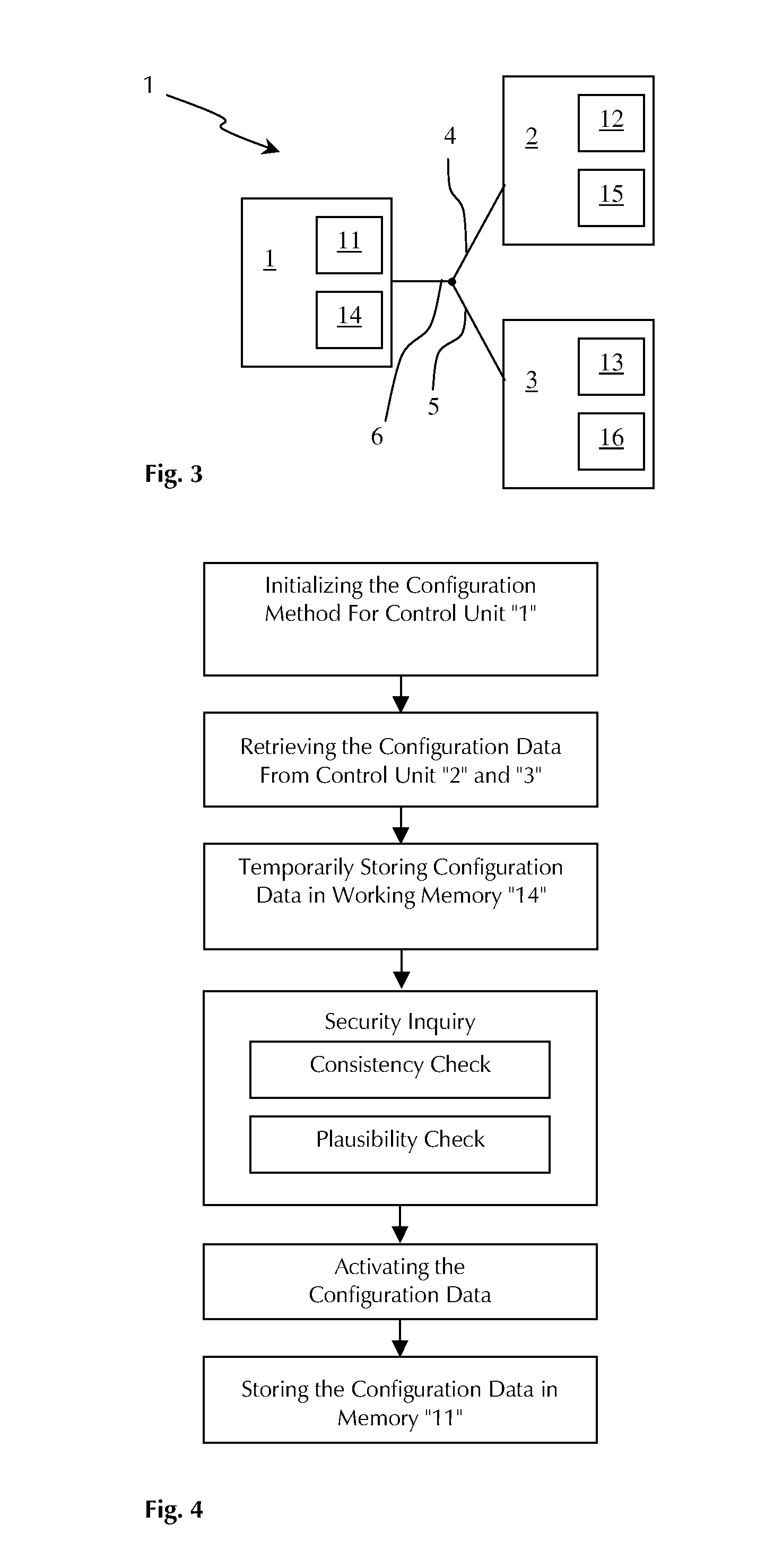

Configuration method for control units

ActiveUS20060282657A1Easy and fast to carry-outFast and easy to performProgramme controlDigital data processing detailsData connectionMachine control

The invention relates to a configuration method for a control unit of a machine, the control unit having a data memory and being mounted in a machine control system having at least one already configured control unit with a data memory, the to-be-configured control unit communicating via a data connection with the already configured control unit of the machine control system and retrieving therefrom configuration data for its own configuration.

Owner:BOMAG

Charging connector and method of mounting the same

ActiveUS20160104967A1Increase freedomWell formedContact member assembly/disassemblySecuring/insulating coupling contact membersElectrical and Electronics engineeringTower

A charging connector for charging a battery in a vehicle has a housing (51) mounted to a vehicle. A tower (60) is in the housing (51) and has at least one accommodating chamber (64) for accommodating at least one terminal fitting (80). The tower (60) is inserted into a mating hole (52) of the housing (51). A seal (70) is between the tower (60) and the housing (51). The accommodating chamber (64) has a fitting (64a) at a rear end for fitting the terminal fitting (80) and an exposed portion (64b) at a front end for exposing a leading contact (82) of the terminal fitting (80) to be contacted with a mating terminal fitting of a mating charging connector on a charging cable. The tower (60) can be assembled and disassembled from the housing (51) with the terminal fitting(s) (80) mounted within the accommodating chamber(s) (64) of the tower (60).

Owner:SUMITOMO WIRING SYST LTD

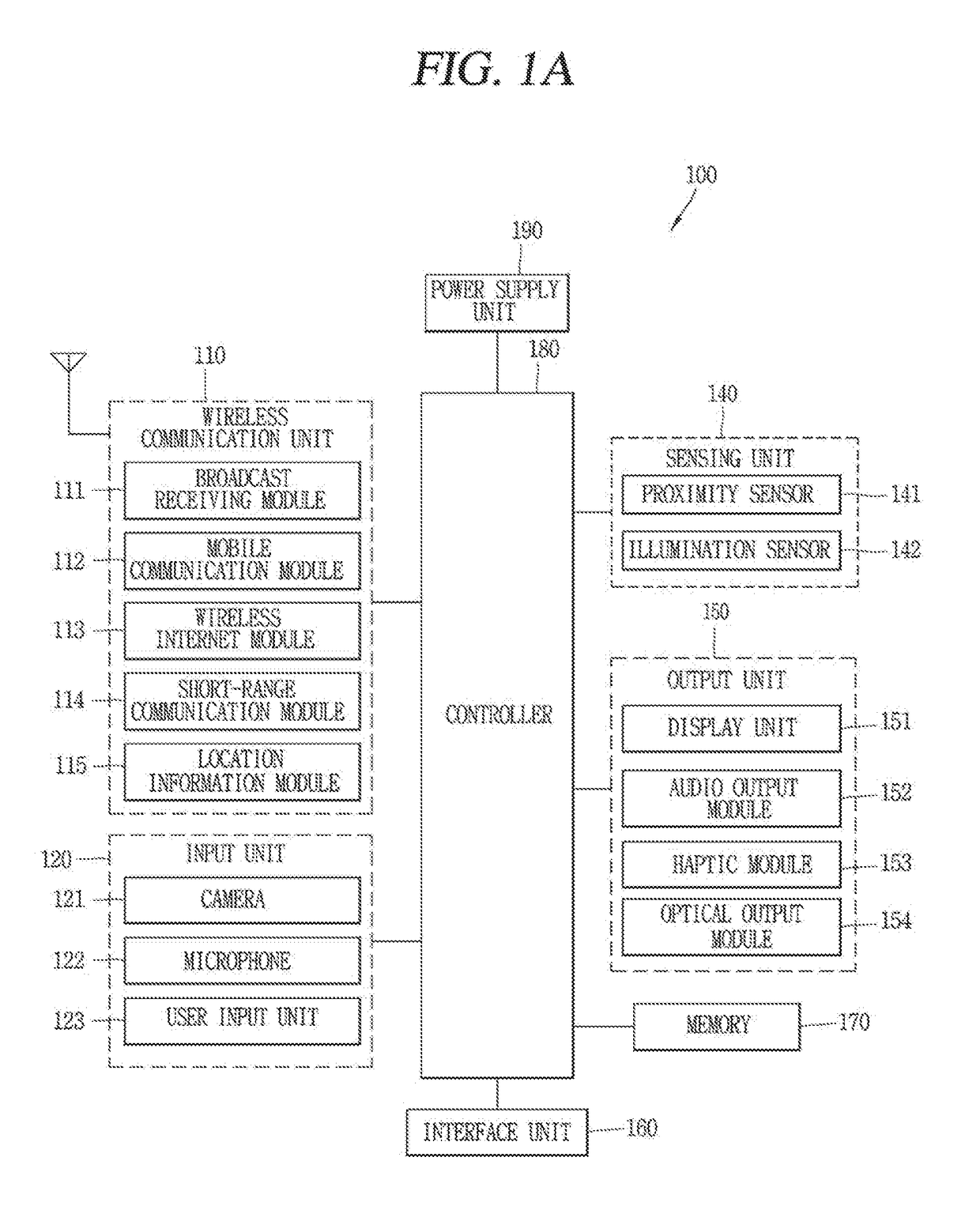

Device for supporting electrical components and wiring accessories

InactiveUS20060240707A1Convenient wiring operationFaster and easy to performSubstation/switching arrangement detailsCoupling device detailsCouplingLateral extension

A device for supporting electrical components and wiring accessories comprises a body, composed of at least one longitudinally elongated section, fixable to a supporting element and forming a coupling region for electrical components. The body is provided with at least one lateral extension, which protrudes laterally with respect to the coupling region and is adapted to support wiring accessories, such as for example straps for supporting the cables to be connected to the electrical components and / or conduits for containing the cables to be connected to the electrical components and / or marking tags and / or L-shaped supports for connectors to be connected to the electrical components.

Owner:COEPTE RAIL

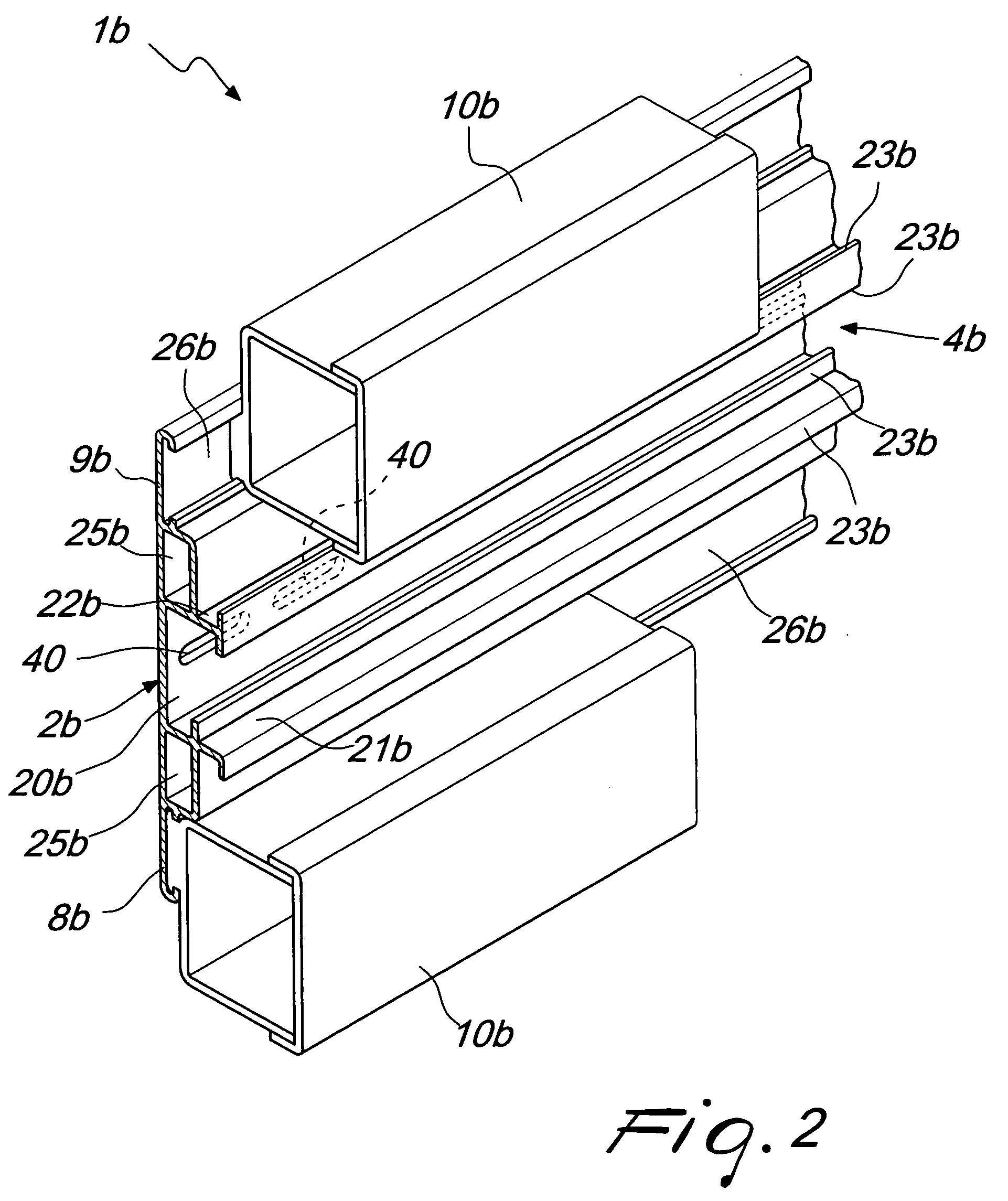

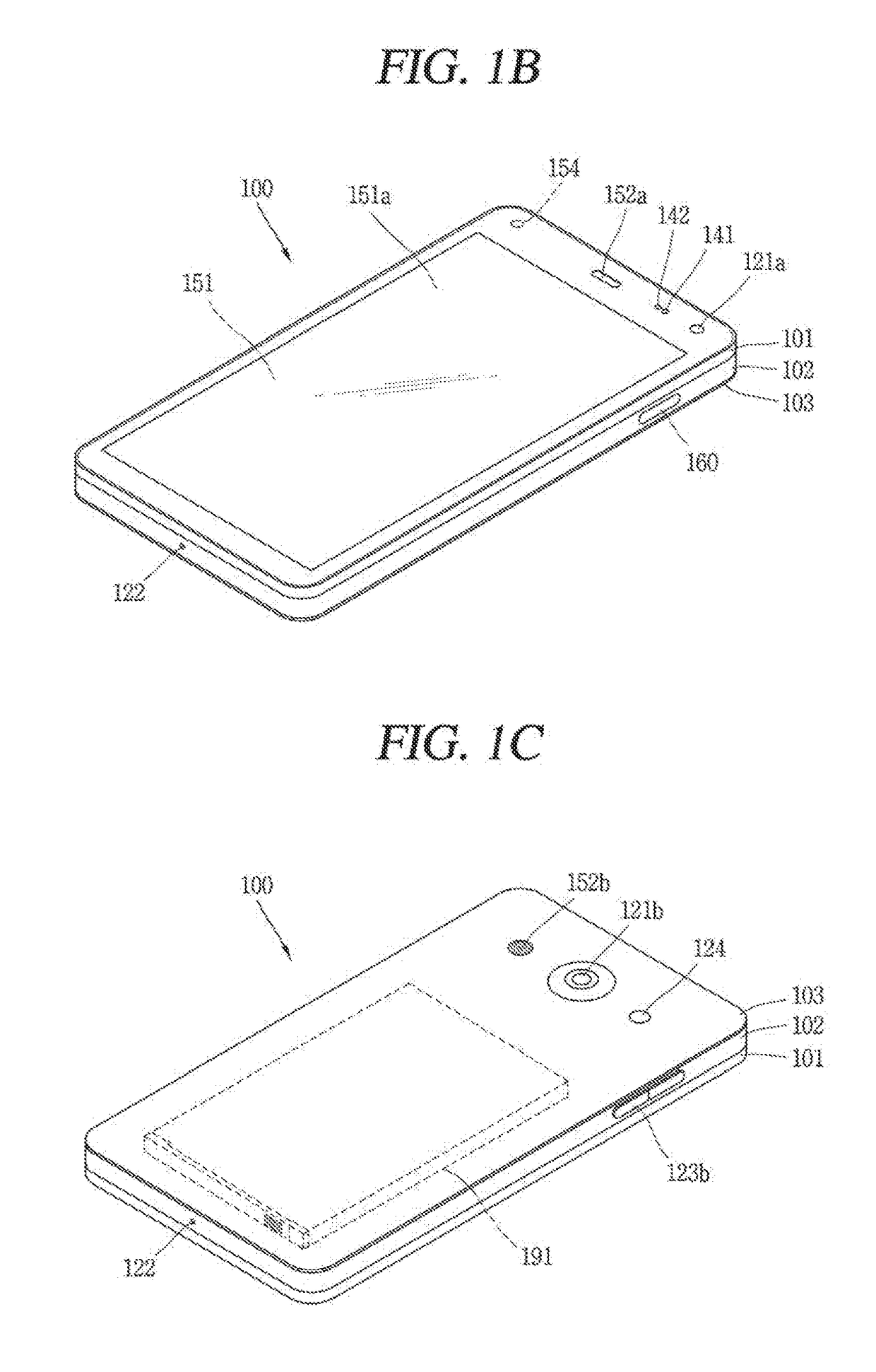

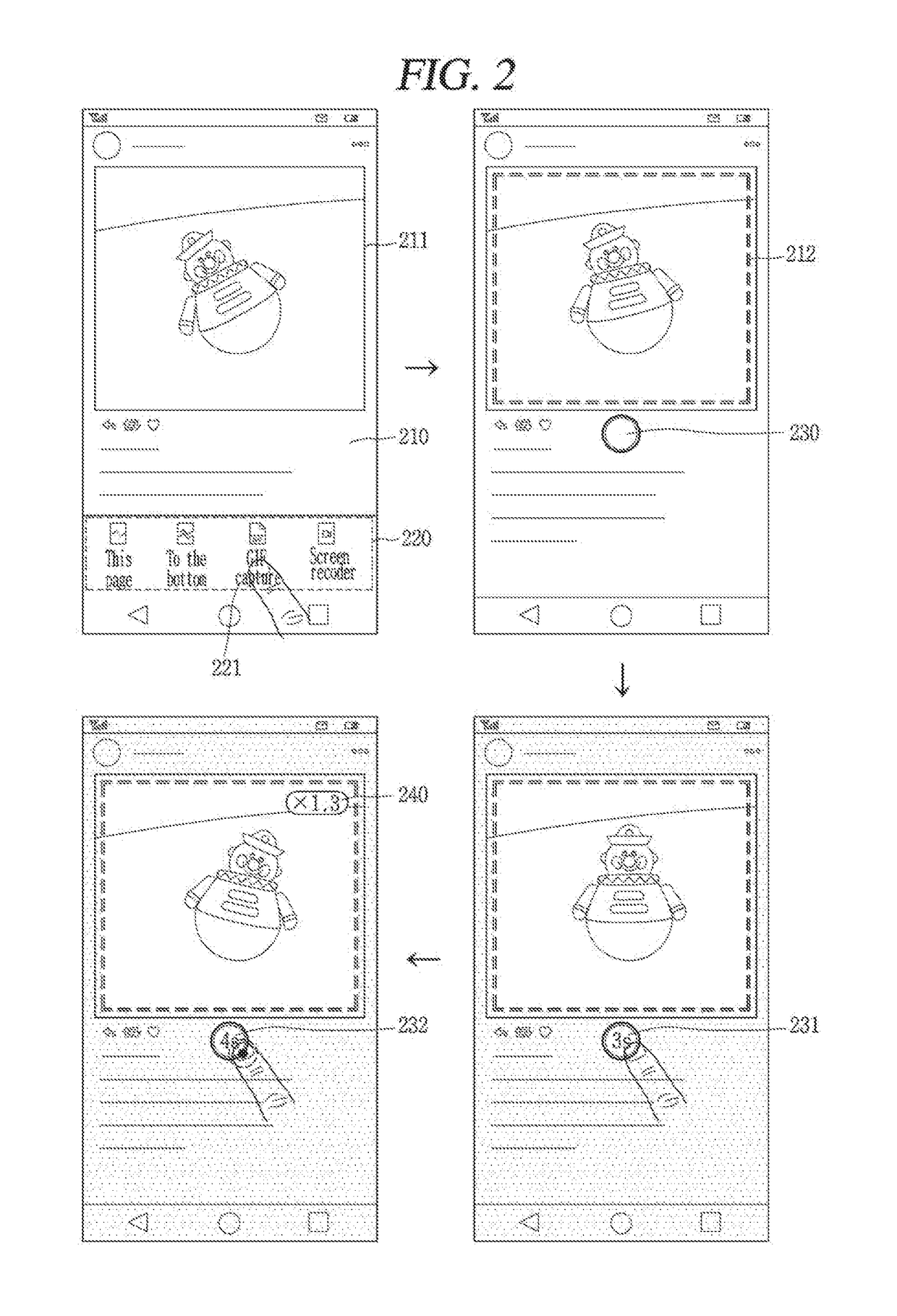

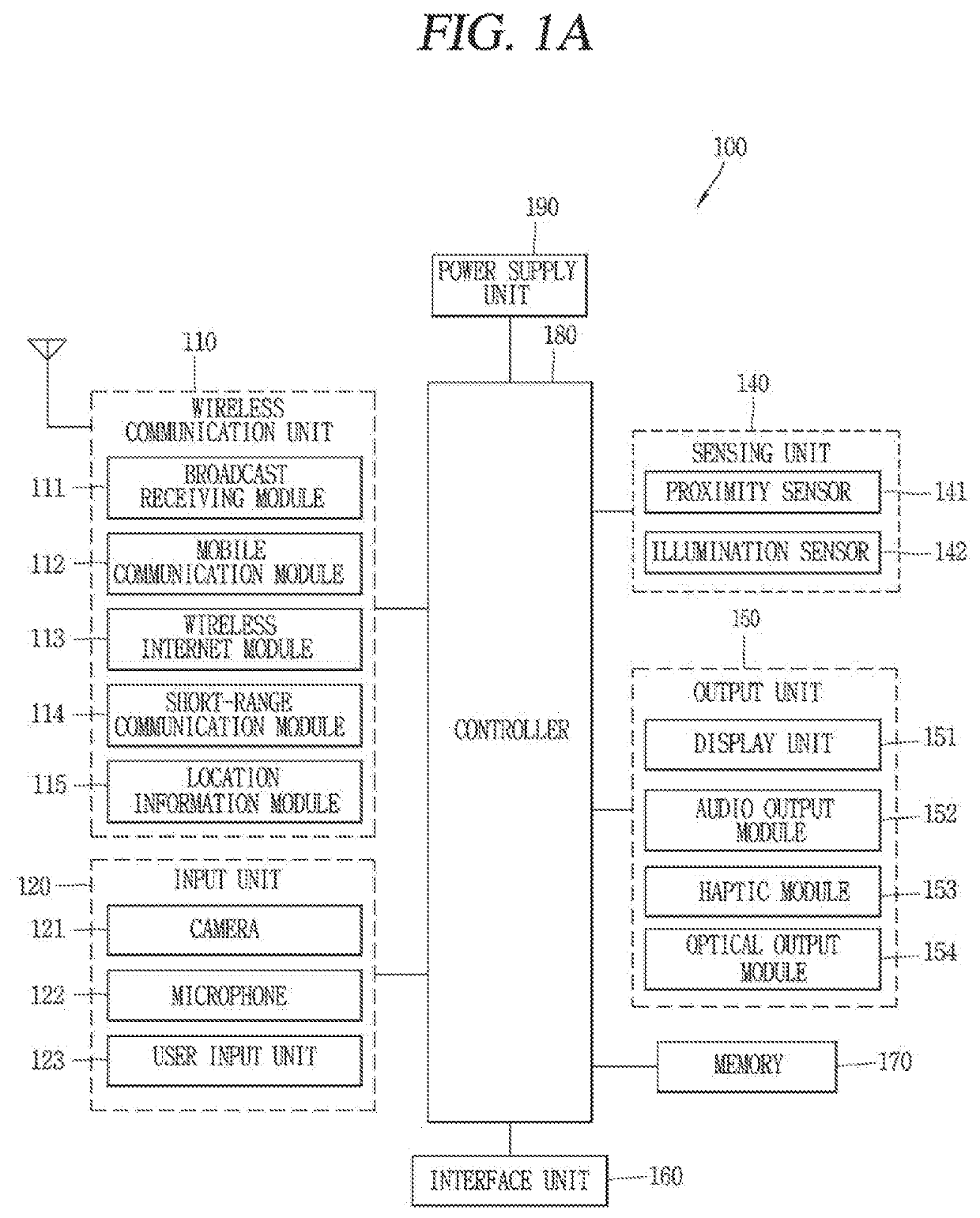

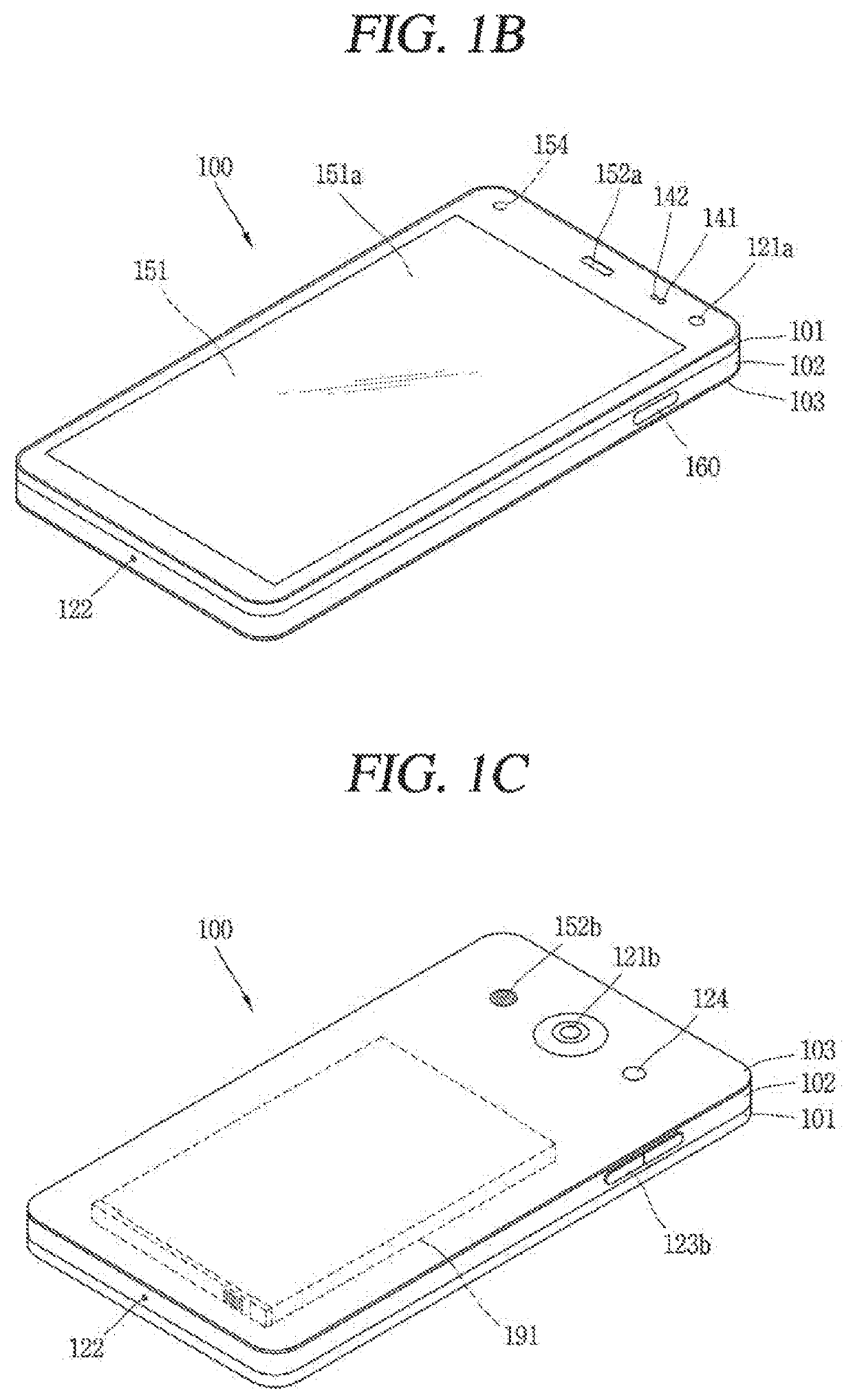

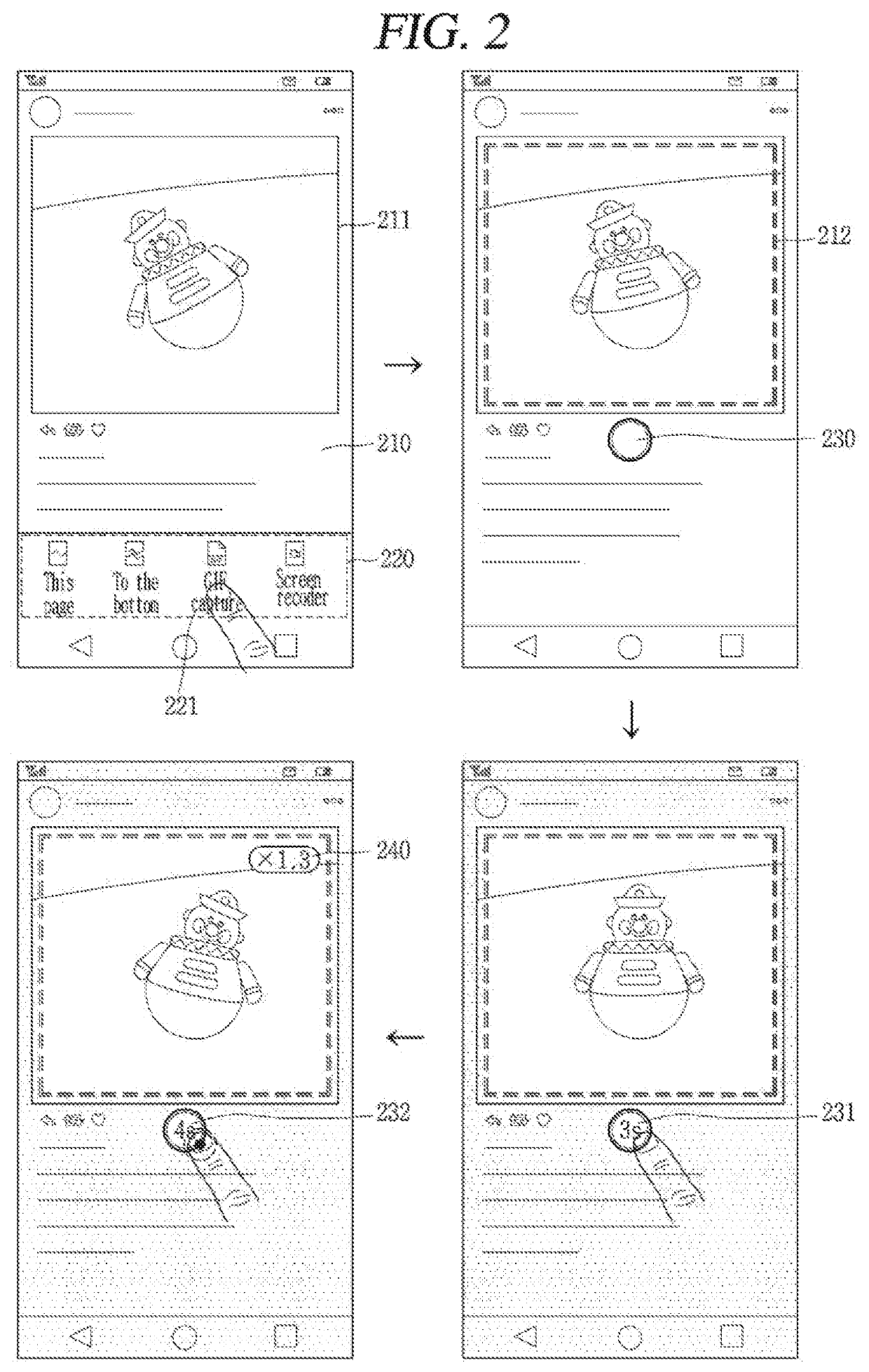

Mobile terminal and method for controlling the same

ActiveUS20180348992A1Fast and easy to performEasy to captureElectronic editing digitised analogue information signalsSubstation equipmentReal-time computingReproduction speed

The present invention relates to a terminal and a method of controlling the same. A terminal according to an embodiment of the present invention includes a touchscreen, and a controller configured to cause the touchscreen to display video at a reproduction speed, cause the touchscreen to display a first icon, capture the displayed video according to a touch received at the first icon, and adjust the reproduction speed of the video according to a degree of the touch.

Owner:LG ELECTRONICS INC

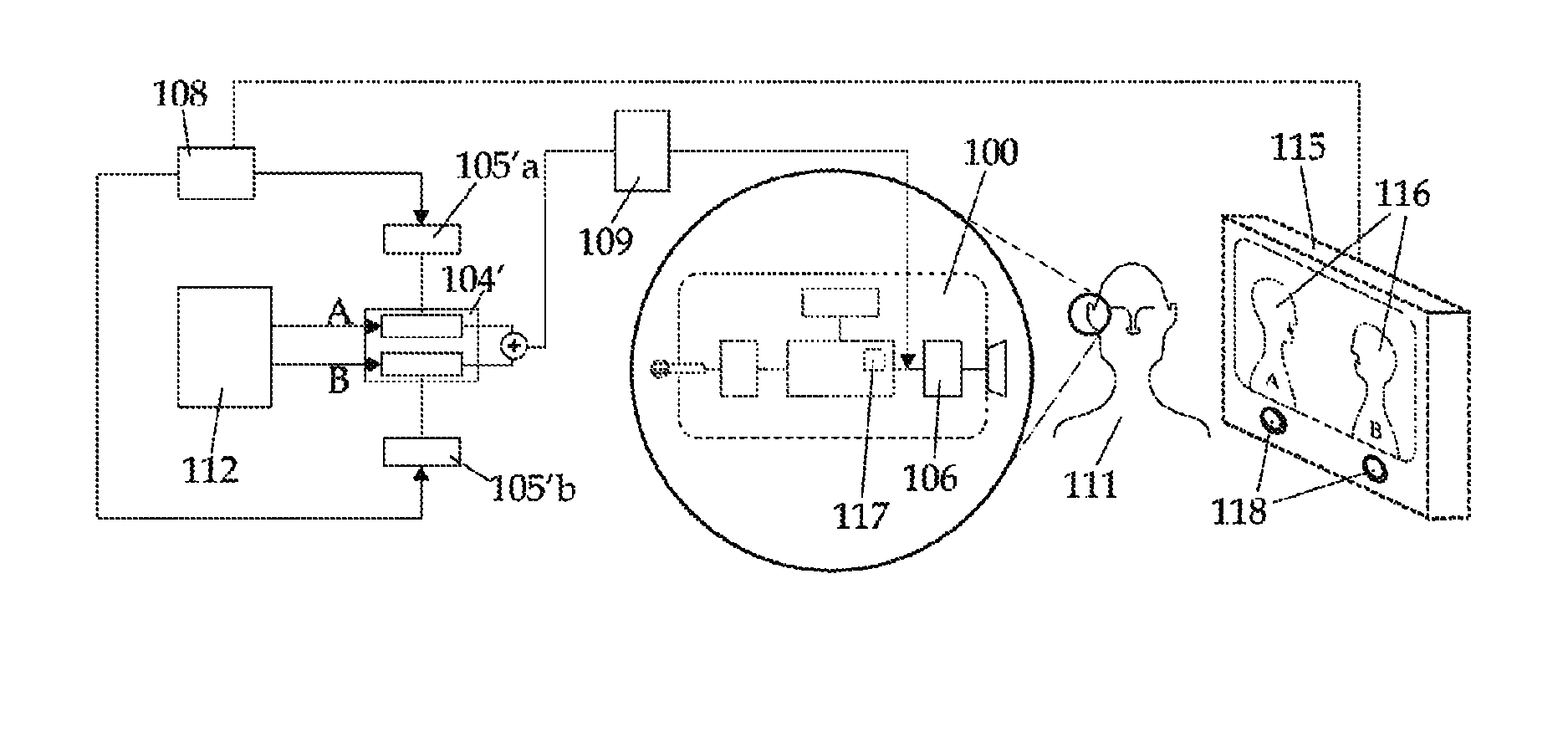

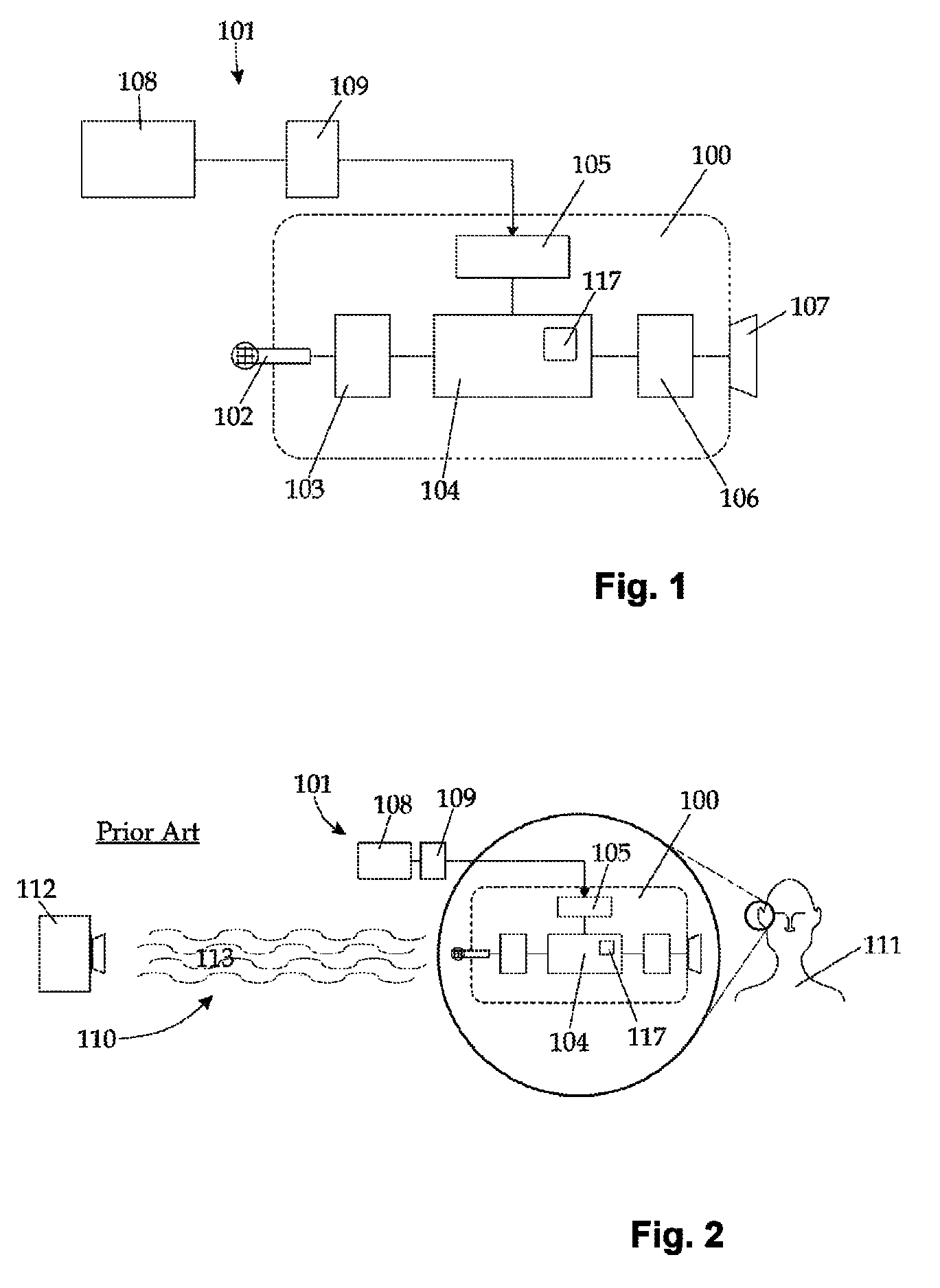

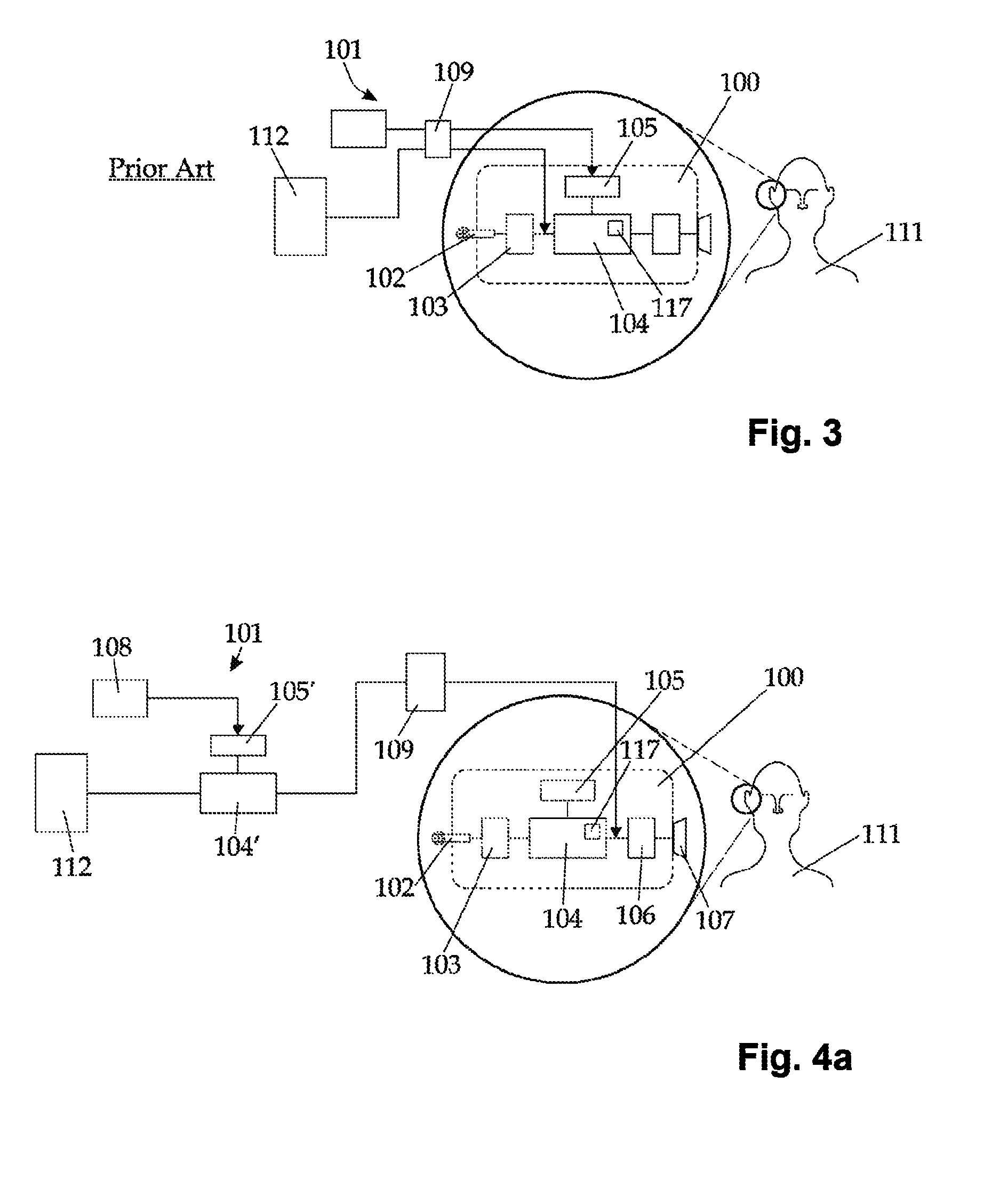

System and method for configuring a hearing device

ActiveUS8494196B2Easy to implementEasy to straightforwardDeaf aid adaptationSignal qualityHearing apparatus

The invention relates to a system and a method for configuring a hearing device by means of an external configuration unit, the hearing device comprising a microphone, an A / D-converter, a processing unit with a memory, a D / A-converter and a receiver, the external configuration unit comprising a programming host, an external processing unit, an interface and a playing device, the method including the steps of processing a sound recording from the playing device with a parameter setting externally, feeding the processed sound recording to the receiver of the hearing device via the interface and the D / A-converter, emitting the processed sound recording through the receiver, repeating steps a) to c) with varying parameter settings until a match between the quality of the signal and the requirements of the user is reached, and transmitting and storing the chosen parameter setting in the memory of the hearing device.

Owner:TWO PI SIGNAL PROCESSING APPL

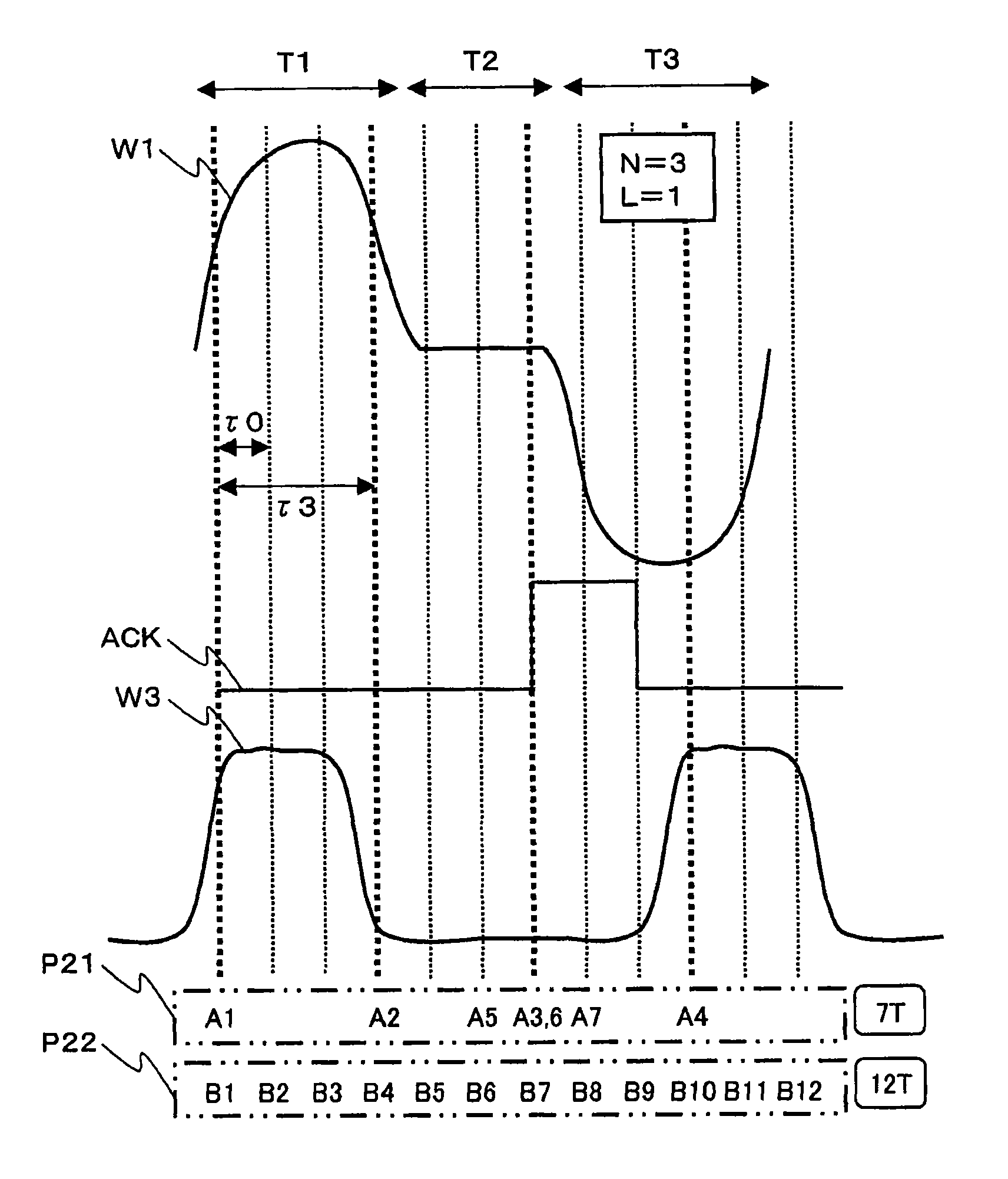

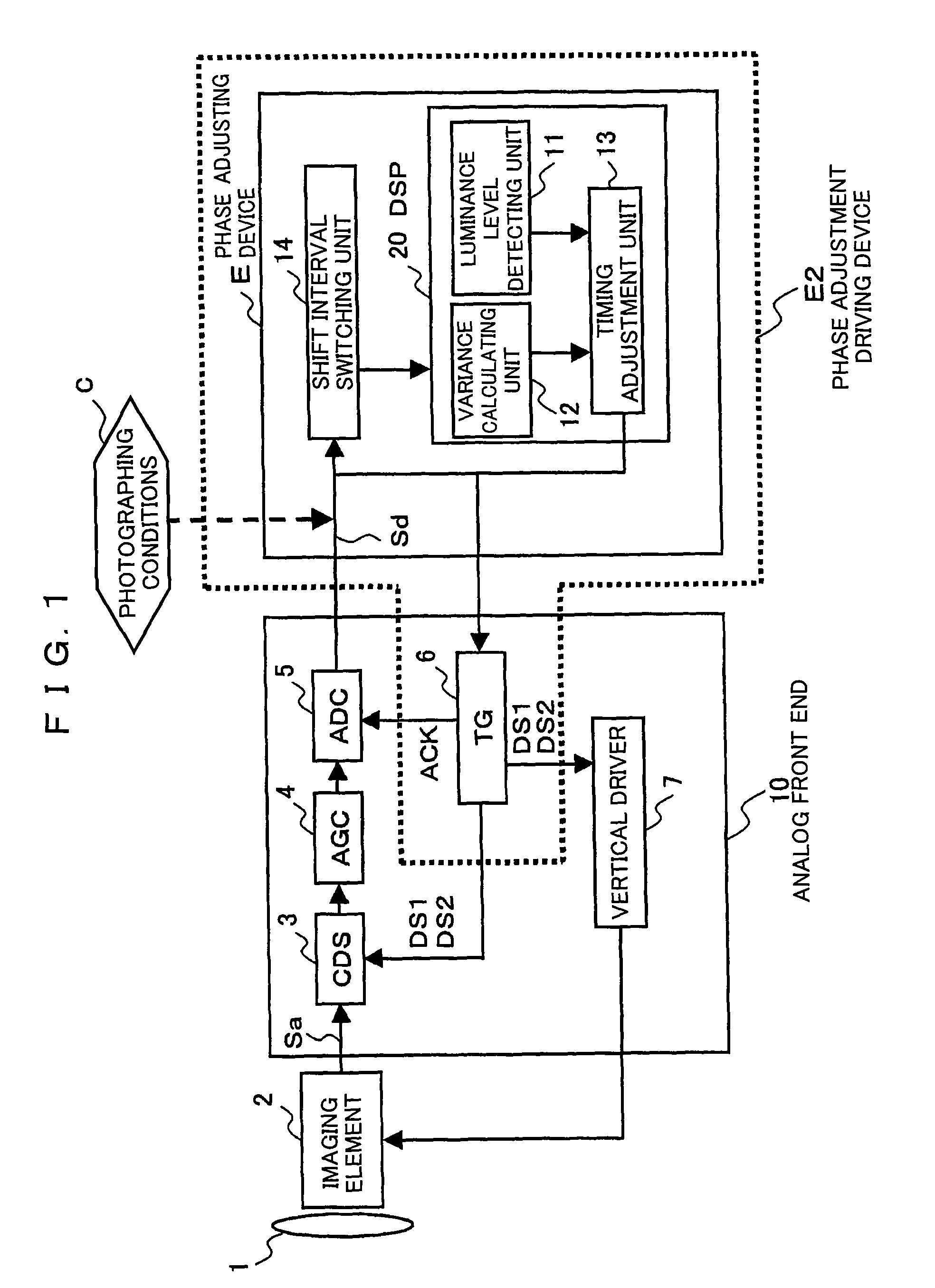

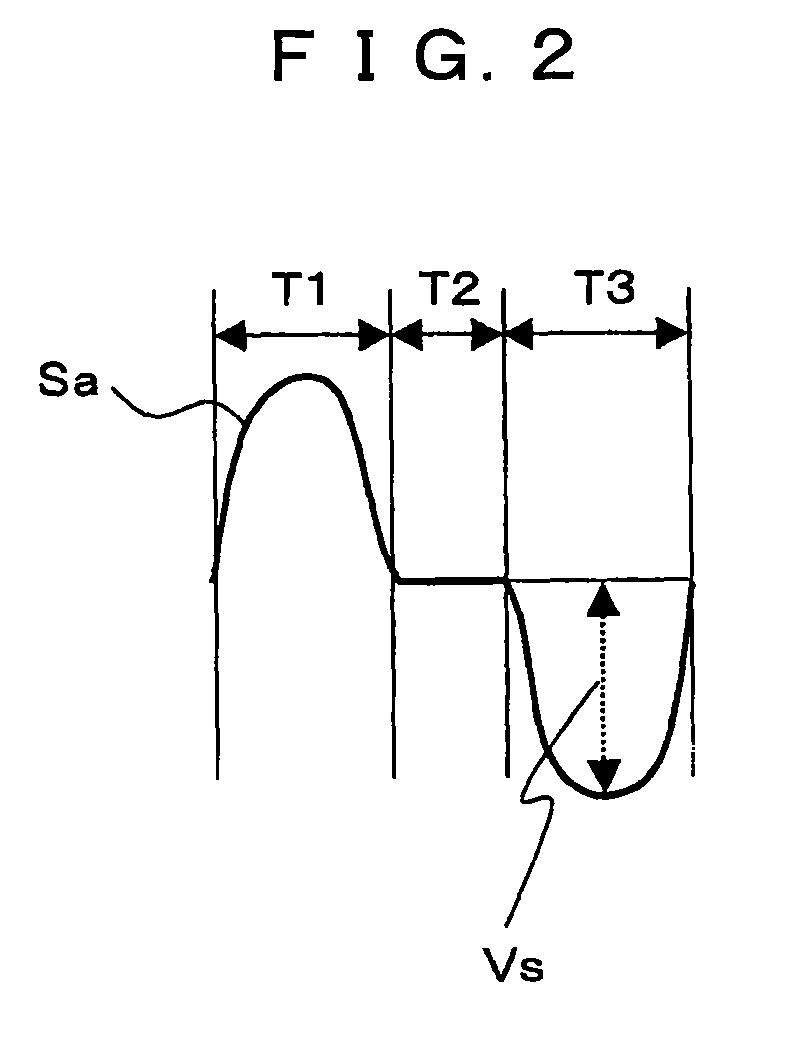

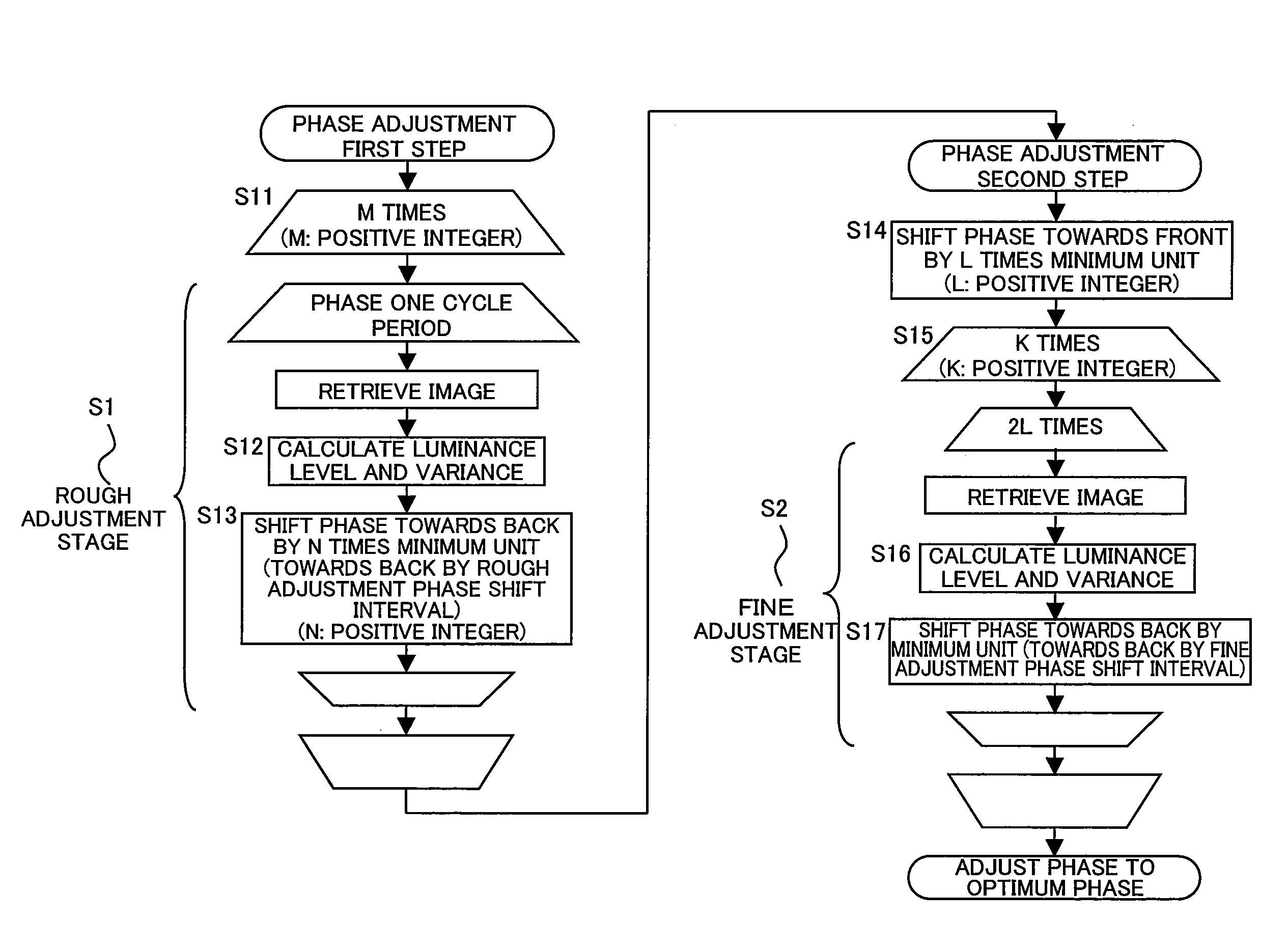

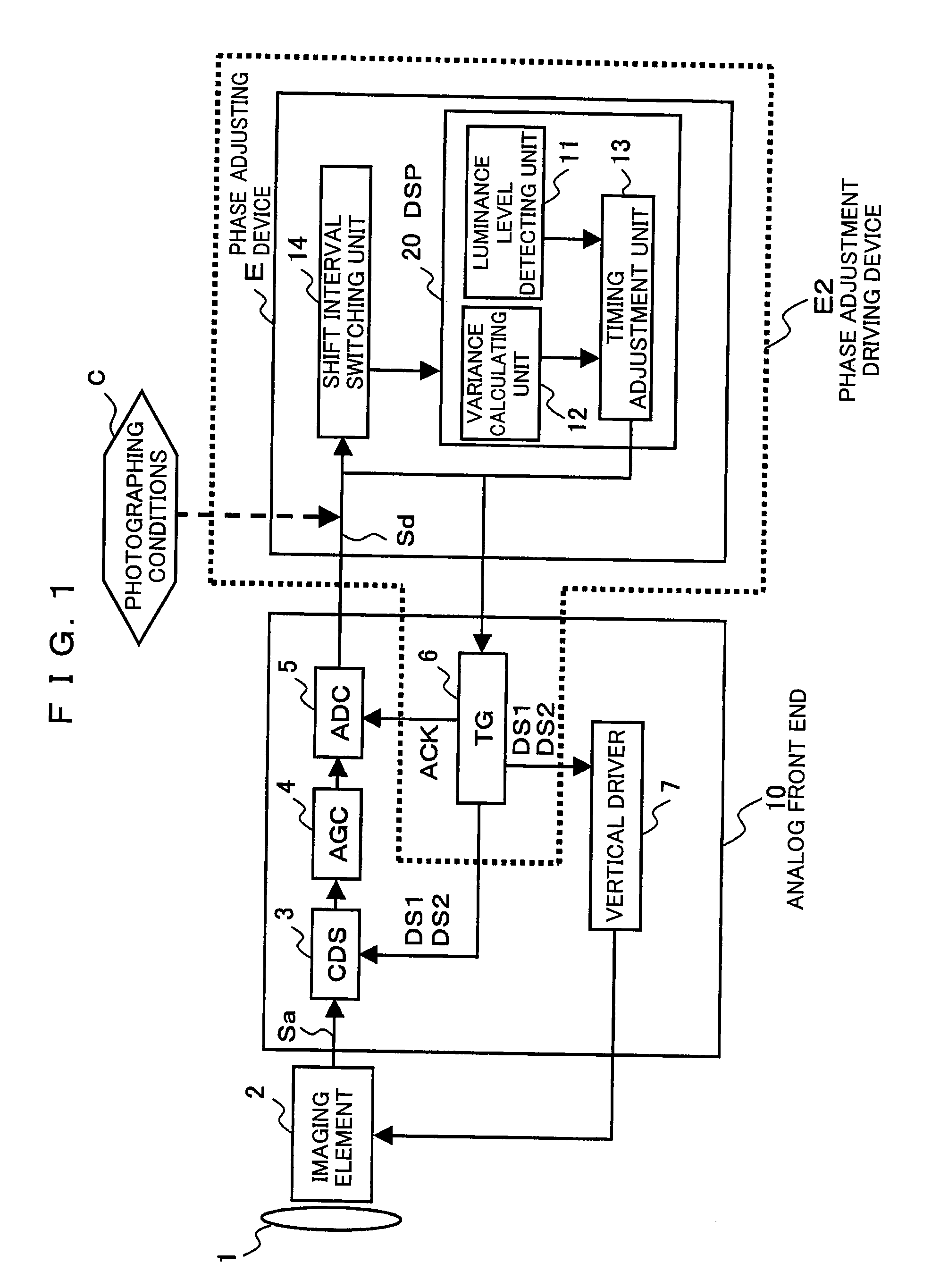

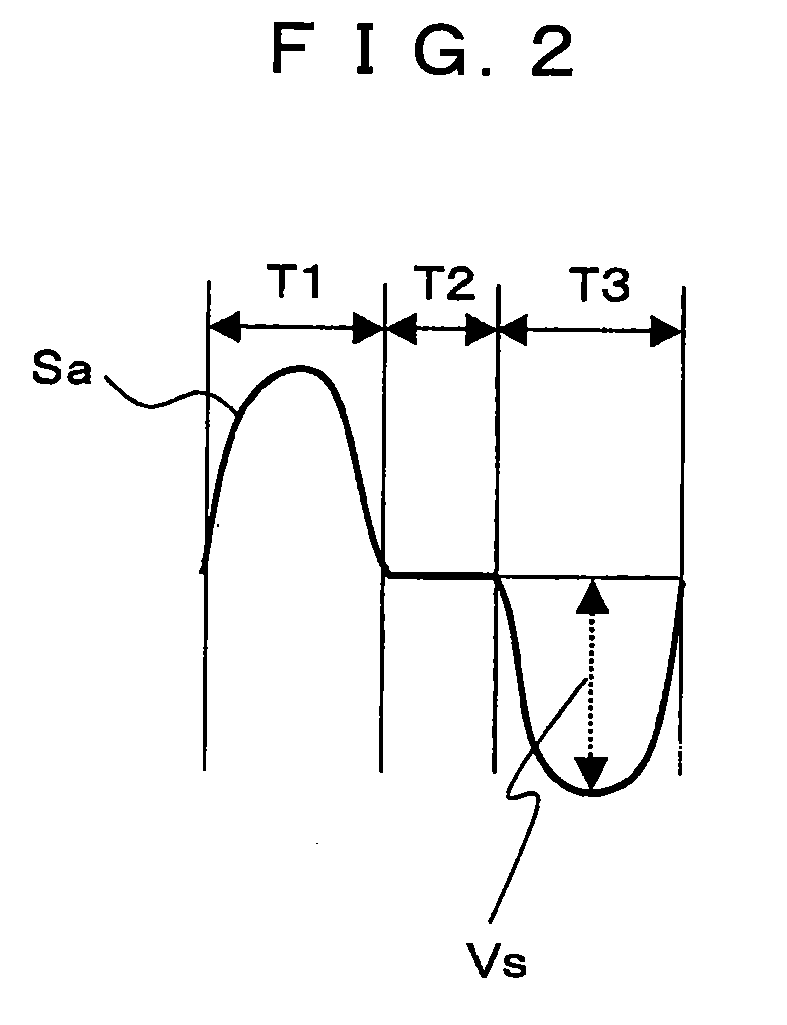

Phase adjusting device and related art thereof

ActiveUS8089539B2Fast and easy to performImprove accuracyTelevision system detailsTelevision system scanning detailsDigital imagingPhase shifted

A characteristic detecting unit detects characteristics of a digital imaged signal at every phase shift interval set in advance. A timing adjustment unit gives a phase adjustment instruction of a pulse so as to converge to an imaging phase in the digital imaged signal at which the characteristics are a predetermined value or within a predetermined range. A shift interval switching unit switches the phase shift interval according to photographing conditions of an imaging element.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Phase adjusting device and related art thereof

ActiveUS20080174352A1Fast and easy to performHigh precisionTelevision system detailsTelevision system scanning detailsPhase shiftedEngineering

A characteristic detecting unit detects characteristics of a digital imaged signal at every phase shift interval set in advance. A timing adjustment unit gives a phase adjustment instruction of a pulse so as to converge to an imaging phase in the digital imaged signal at which the characteristics are a predetermined value or within a predetermined range. A shift interval switching unit switches the phase shift interval according to photographing conditions of an imaging element.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

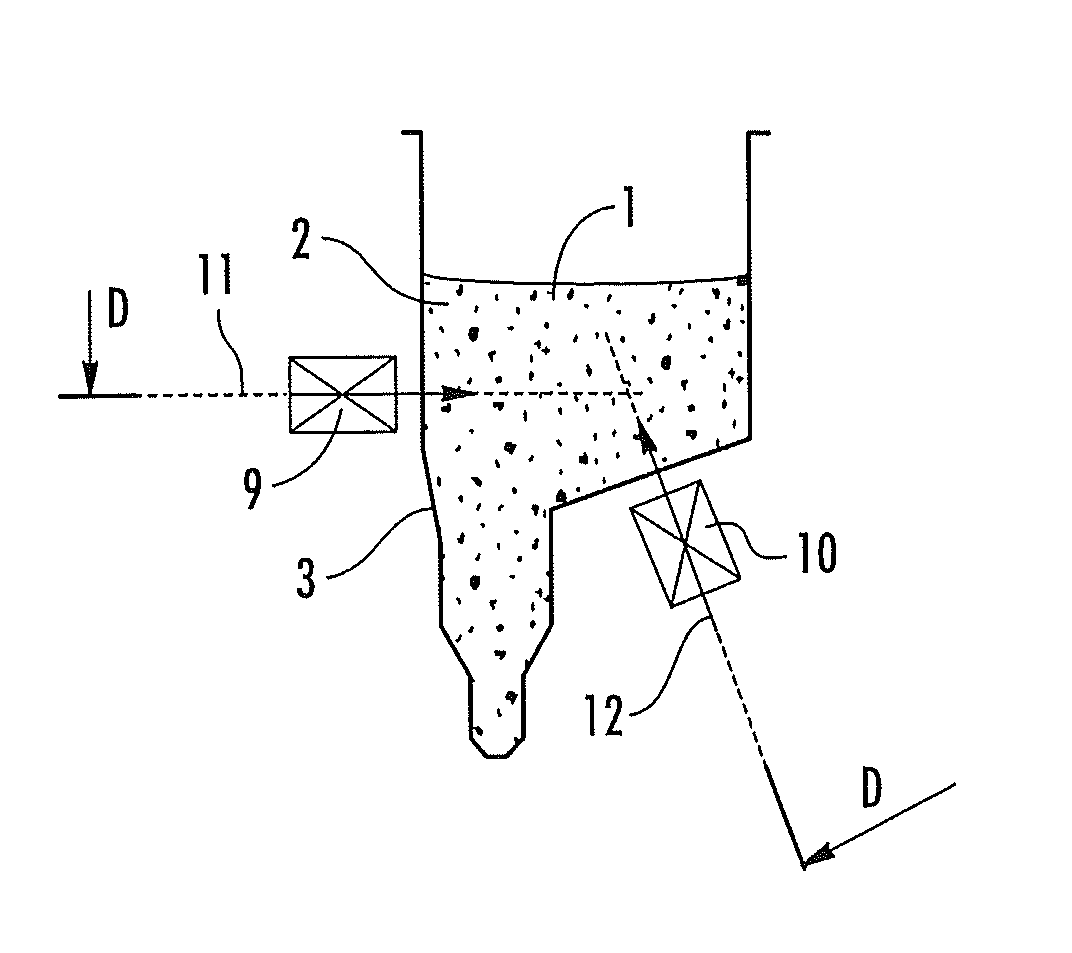

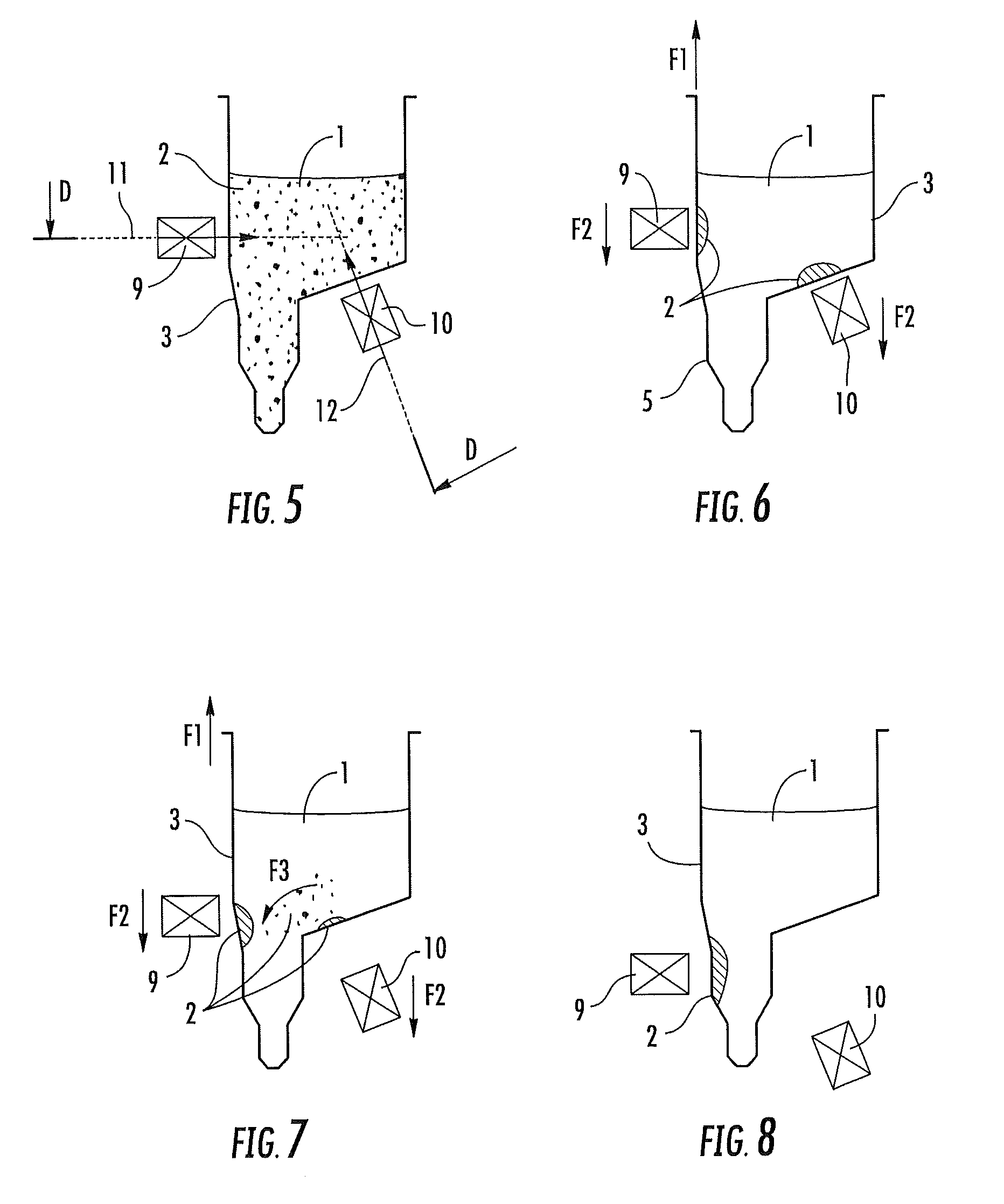

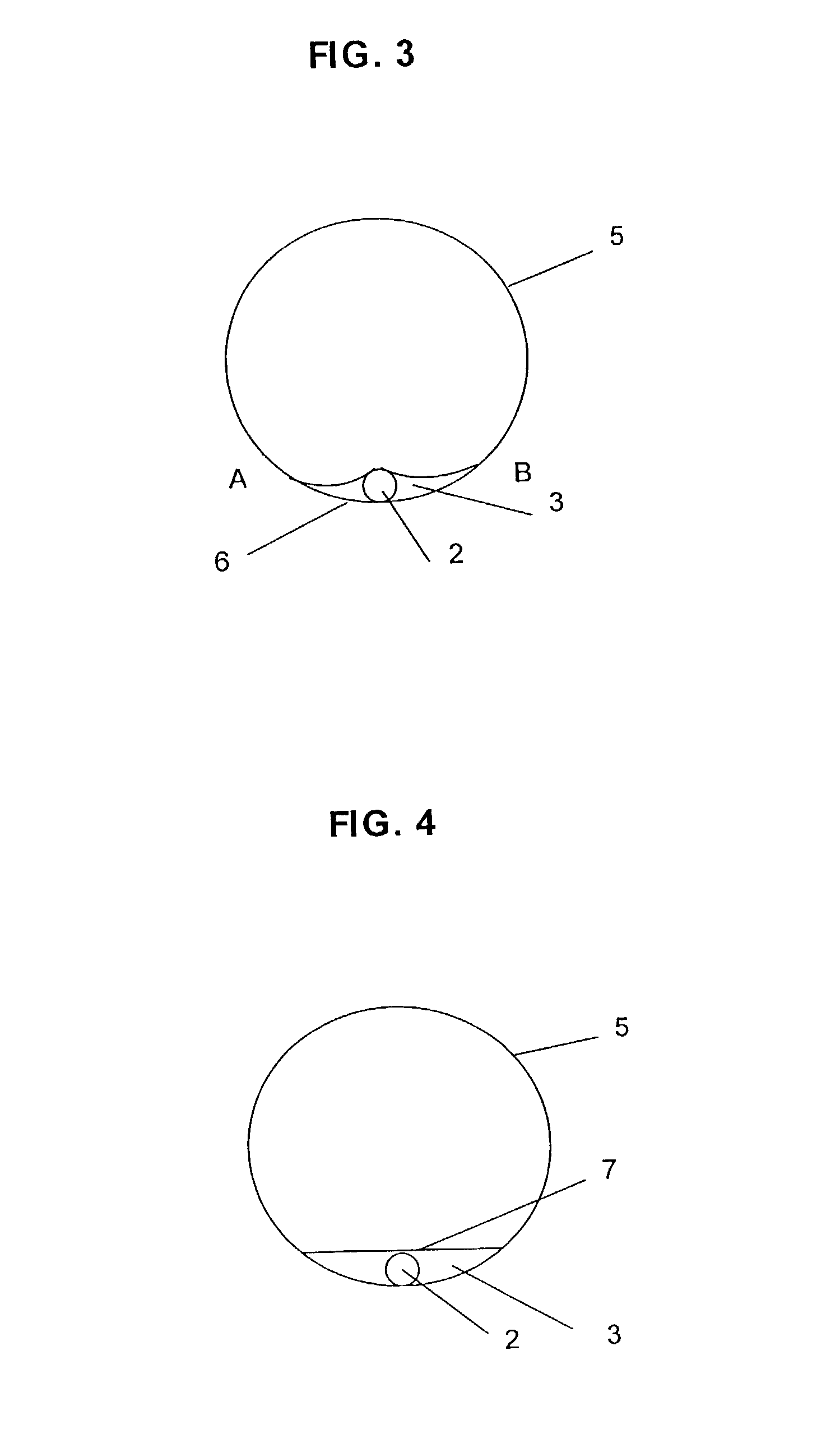

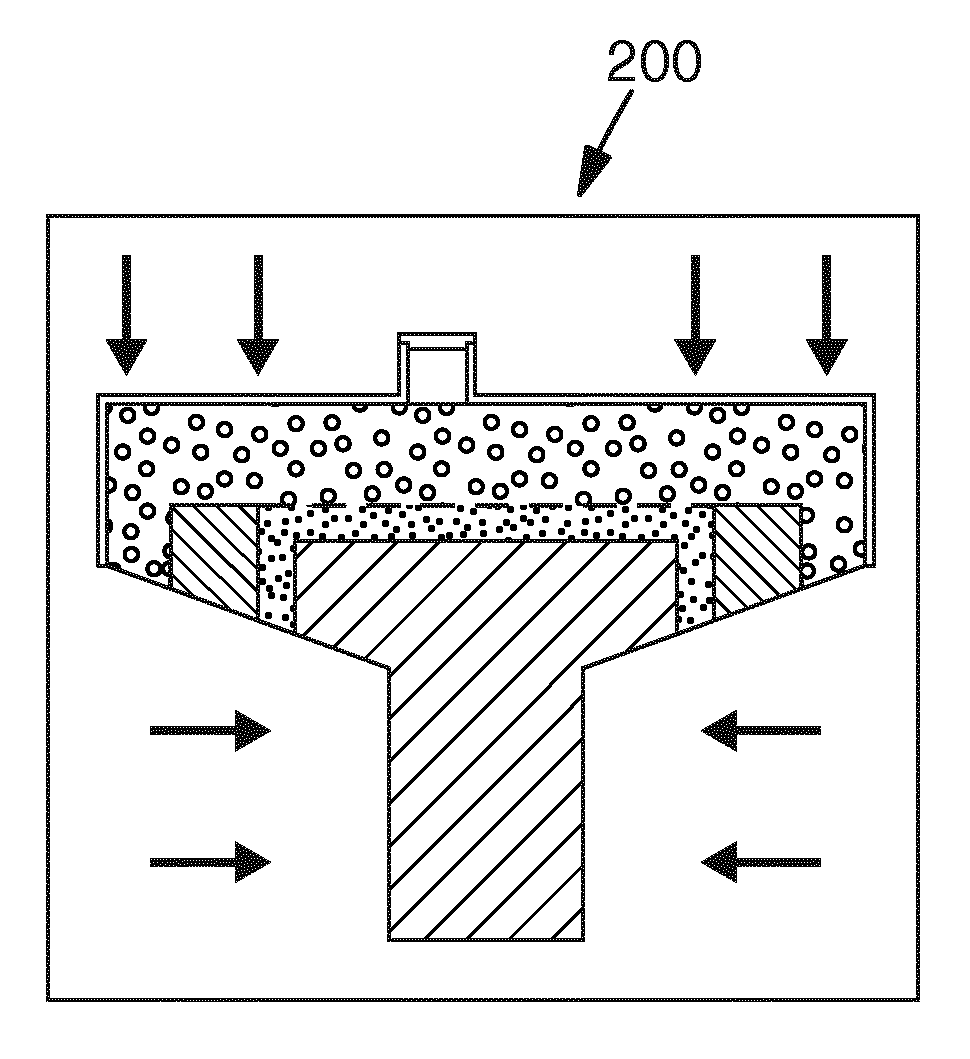

Devices for separating, mixing and concentrating magnetic particles with a fluid

ActiveUS8187460B2Effective contactReduce liquid volumeElectrostatic separationPreparing sample for investigationBiological entityChemistry

The present invention is related to devices for manipulating magnetic particles that are suspended in a fluid, possibly containing a biological entity of interest, the magnetic particles being able to bind the entity of interest, the fluid being contained in a reaction vessel constituted by a large upper compartment with a funnel shape, an elongate lower compartment with a substantially constant cross-section and a closed base. The devices are especially useful in methods for the extraction of nucleic acid to enable them for further processing.

Owner:BIOMERIEUX BV

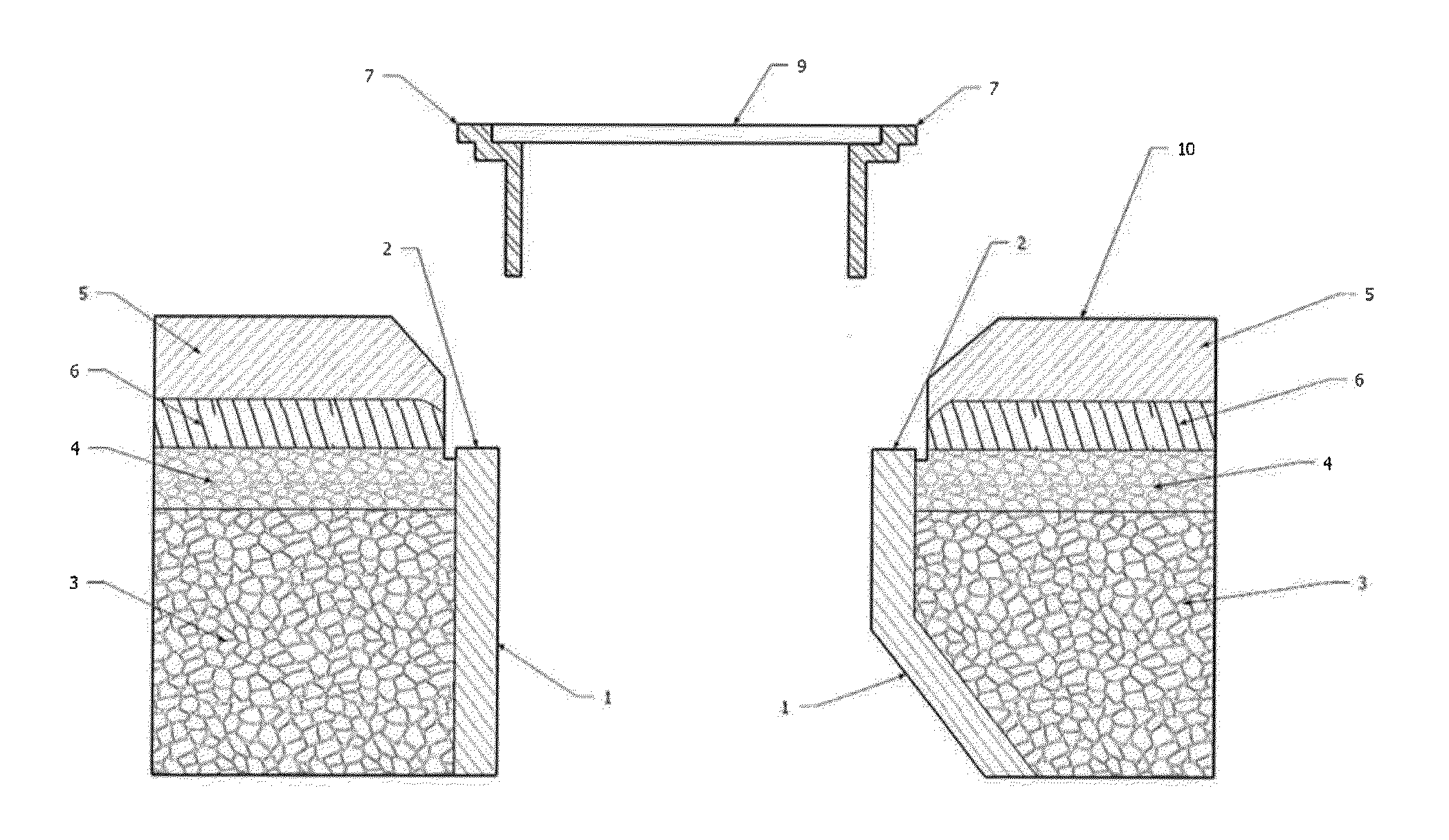

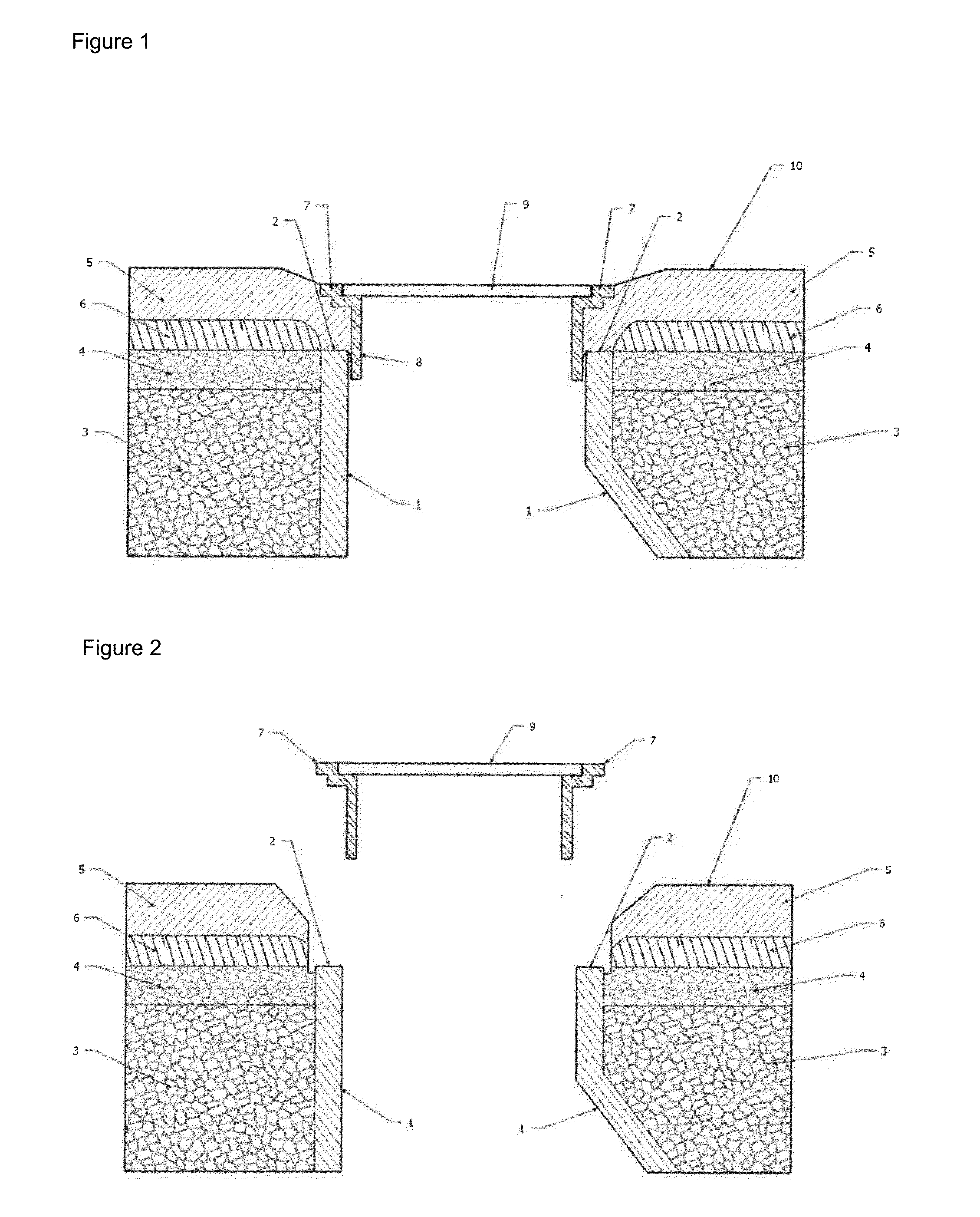

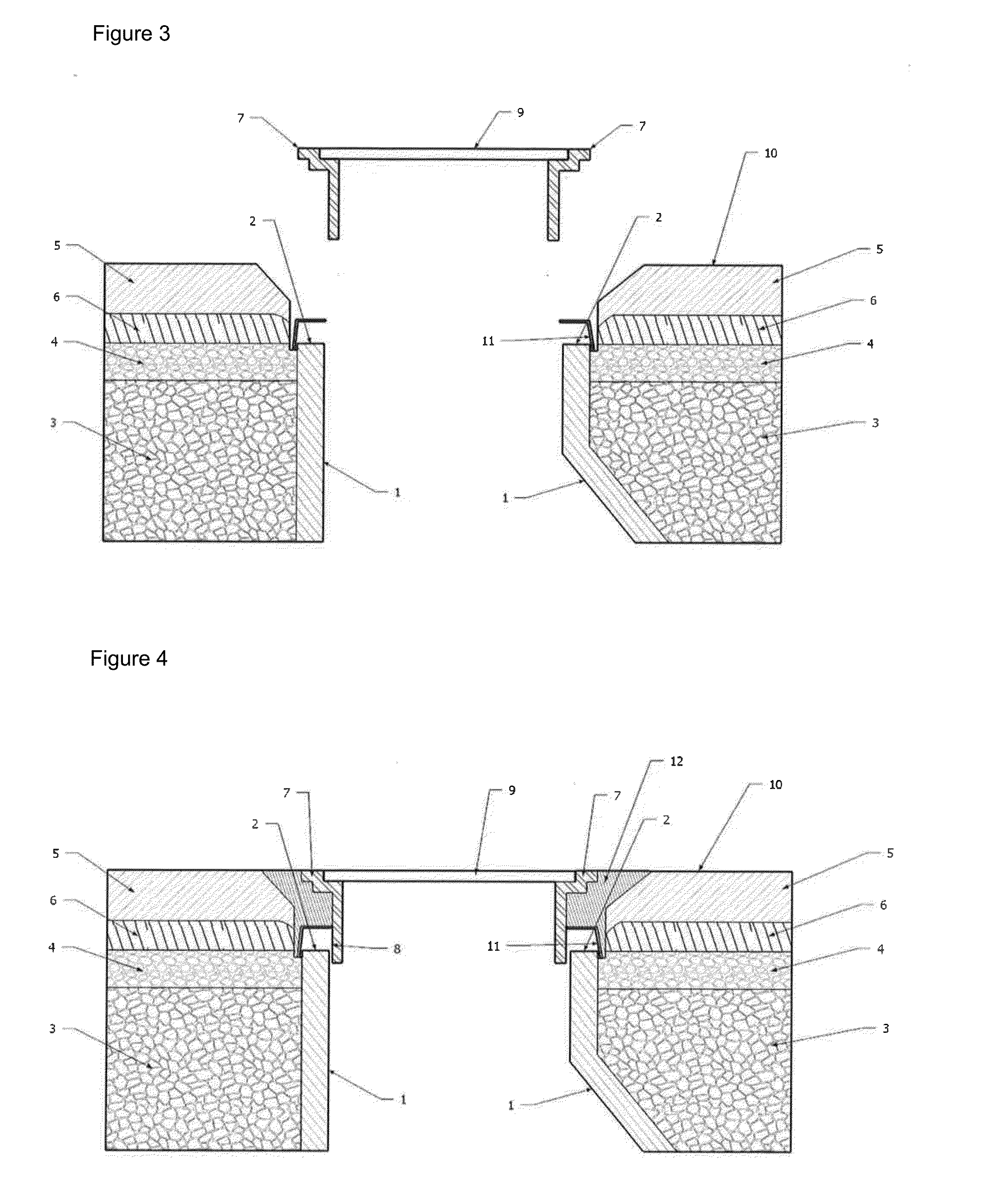

Method and device for installing or renovating a basin

InactiveUS20160108601A1Fast and easy to performPrevent penetrationPaving reinforcementsArtificial islandsEngineeringStructural engineering

A method is described for installing or renovating a basin in relation to a surface, wherein the basin includes at least a basin body (1) with top (2), frame (7) and cover (9), the method including lifting the basin frame from the basin body into a first position,then placing a formwork ring (11) around the basin top (2),lowering the basin frame into a second position wherein the frame is aligned on a level with said surface, the basin frame running through said formwork ring and into the basin body,injecting a casting mixture into a cavity formed between the surrounding ground and the basin frame.

Owner:STRAND EIRIK

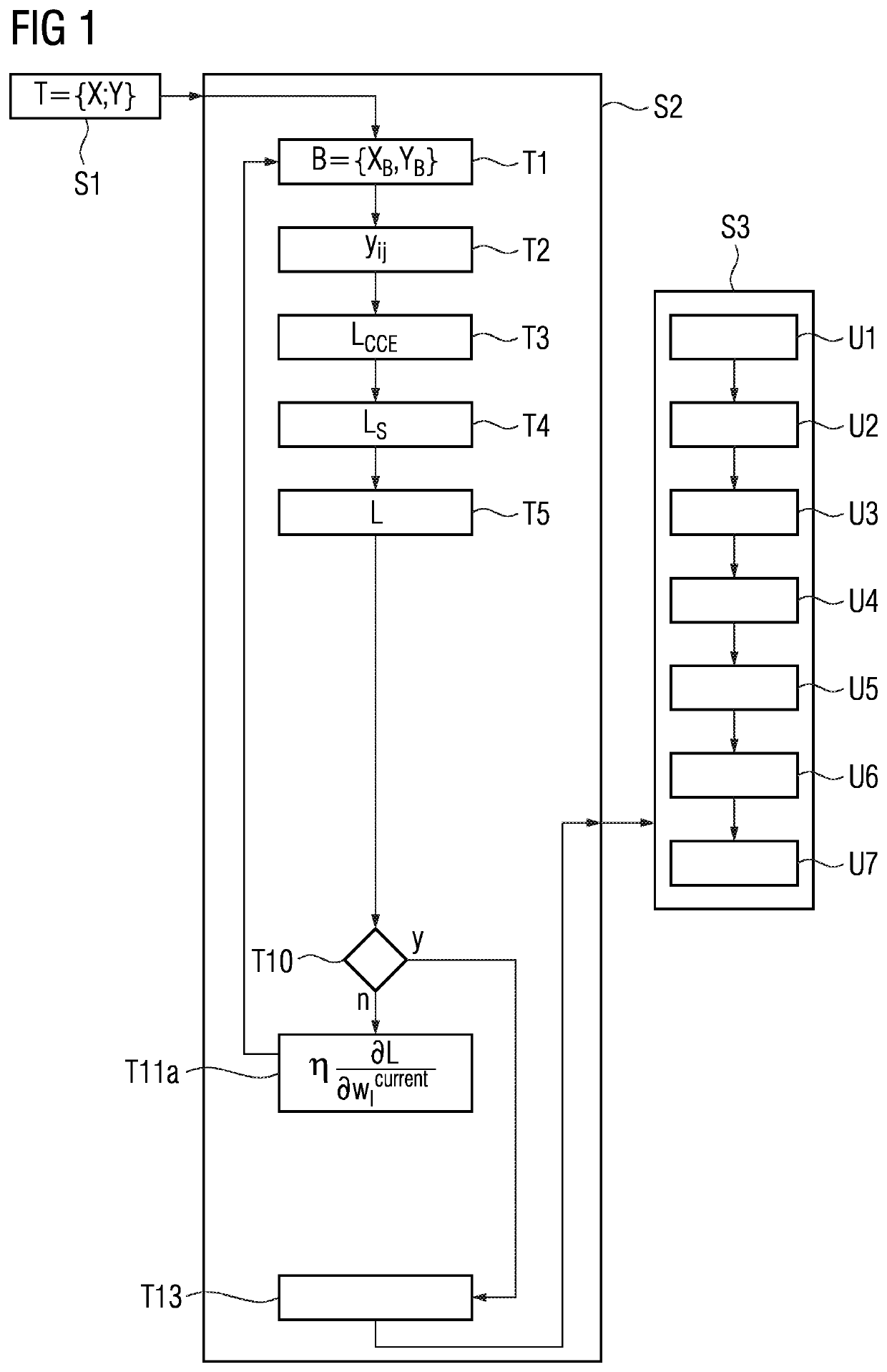

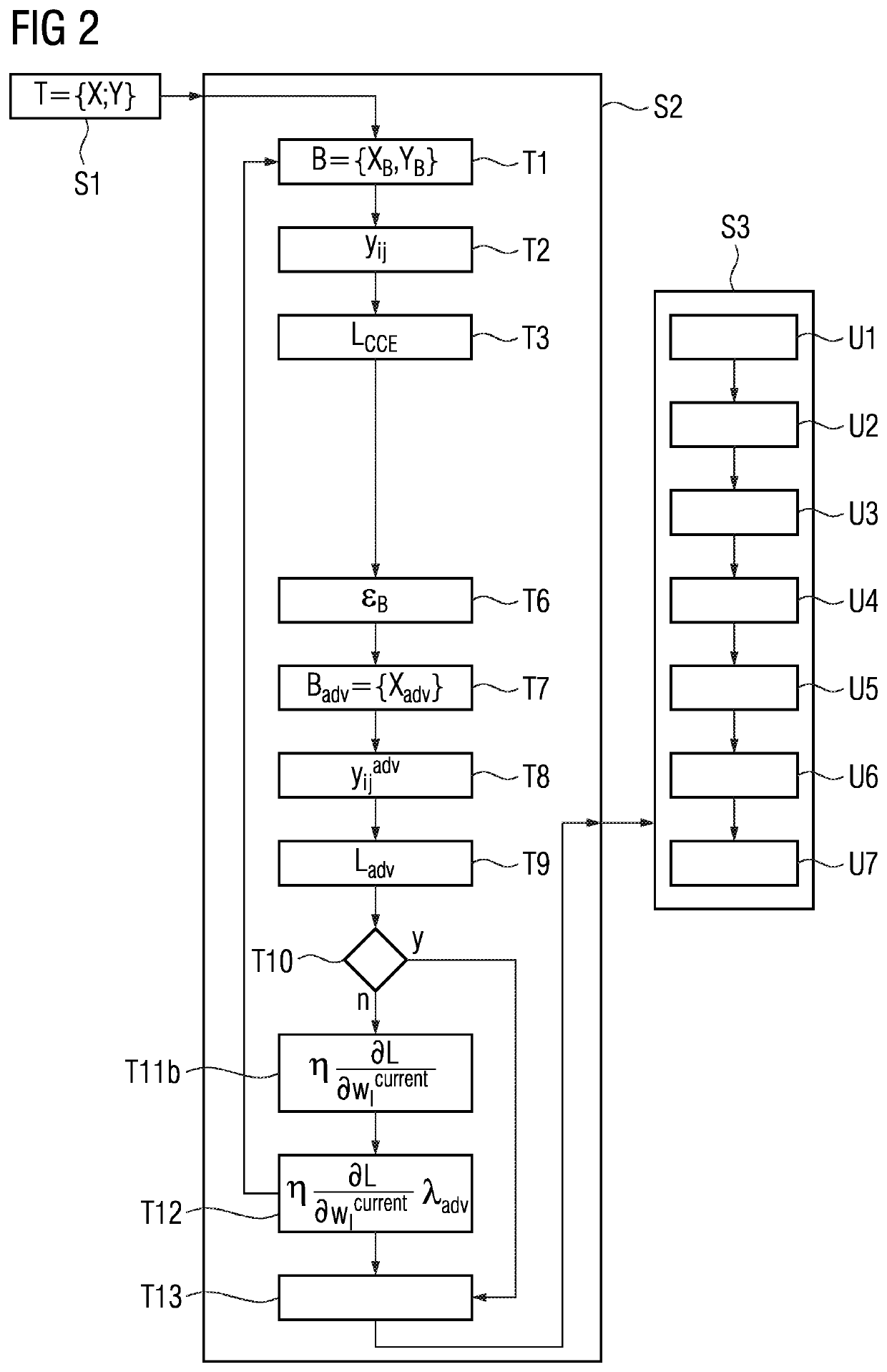

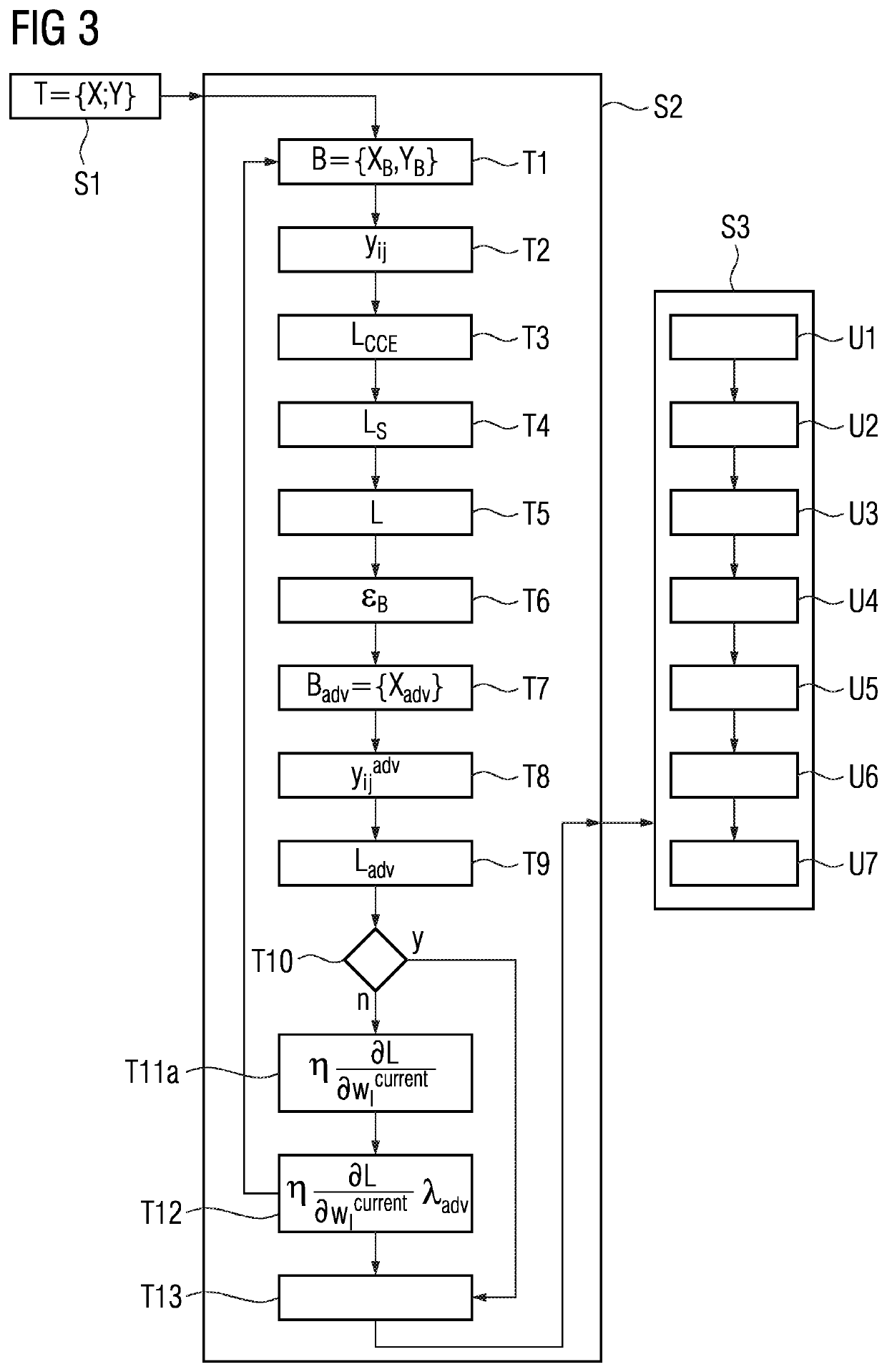

Transforming a trained artificial intelligence model into a trustworthy artificial intelligence model

PendingUS20220067588A1Fast and easy to performQuality improvementDigital data protectionDiagnostic recording/measuringData setWeb service

The following relates to a computer-implemented method and system for transforming a trained artificial intelligence model into a trustworthy artificial intelligence model, by providing the trained artificial intelligence model via a user interface of a webservice platform, providing a validation data set, which is based on training data of the trained artificial intelligence model, generating generic samples by a computing component of the webservice platform based on the validation data set, and transforming the trained artificial intelligence model by optimizing a calibration based on the generic samples. The transformation of the AI model is performed by a computing component of the web service platform. The input, i.e. the trained artificial intelligence model as well as a validation data set, is provided to the computing component via a user interface of the web service platform. Such a user interface is implemented by any applicable frontend.

Owner:SIEMENS AG

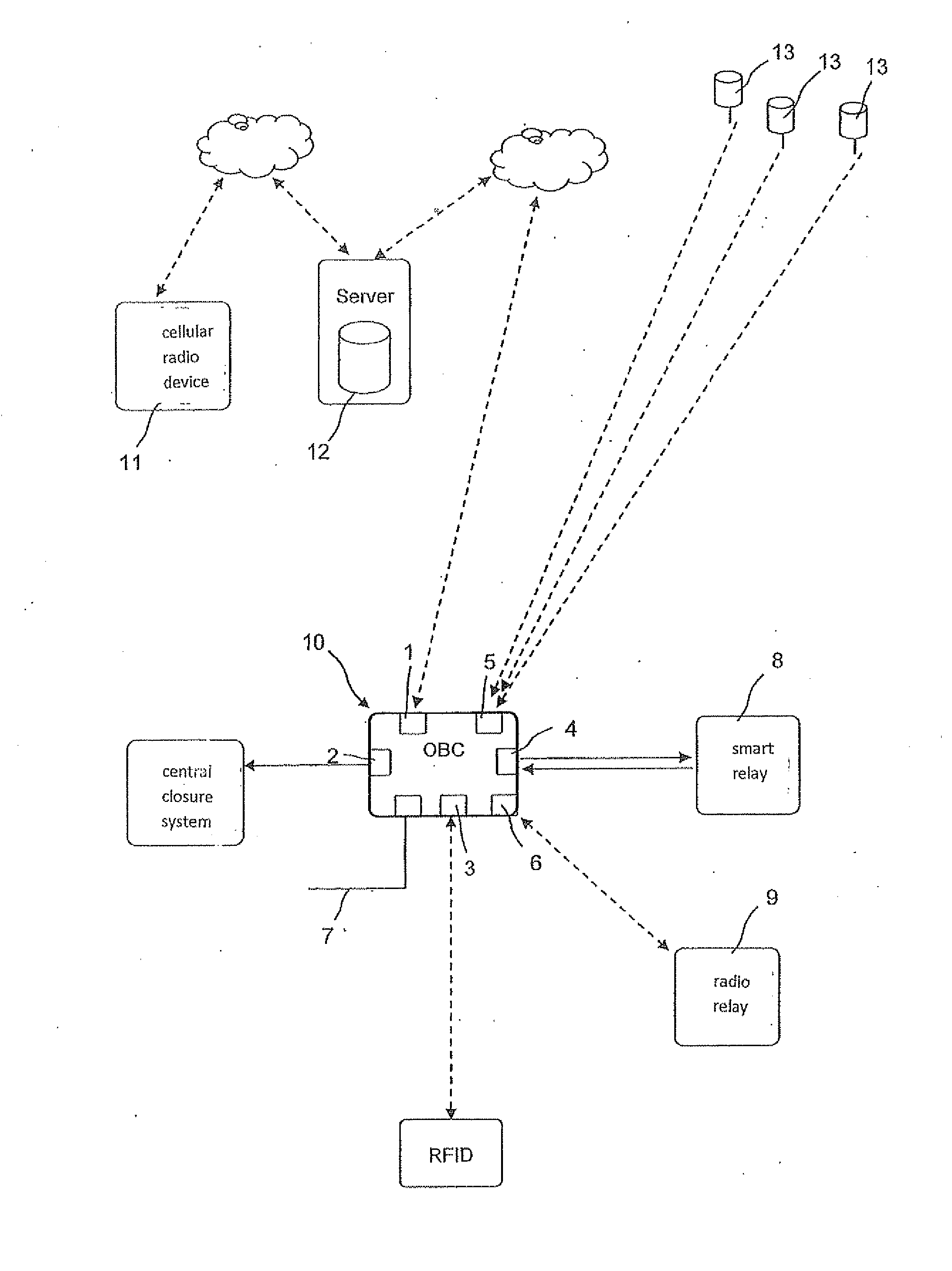

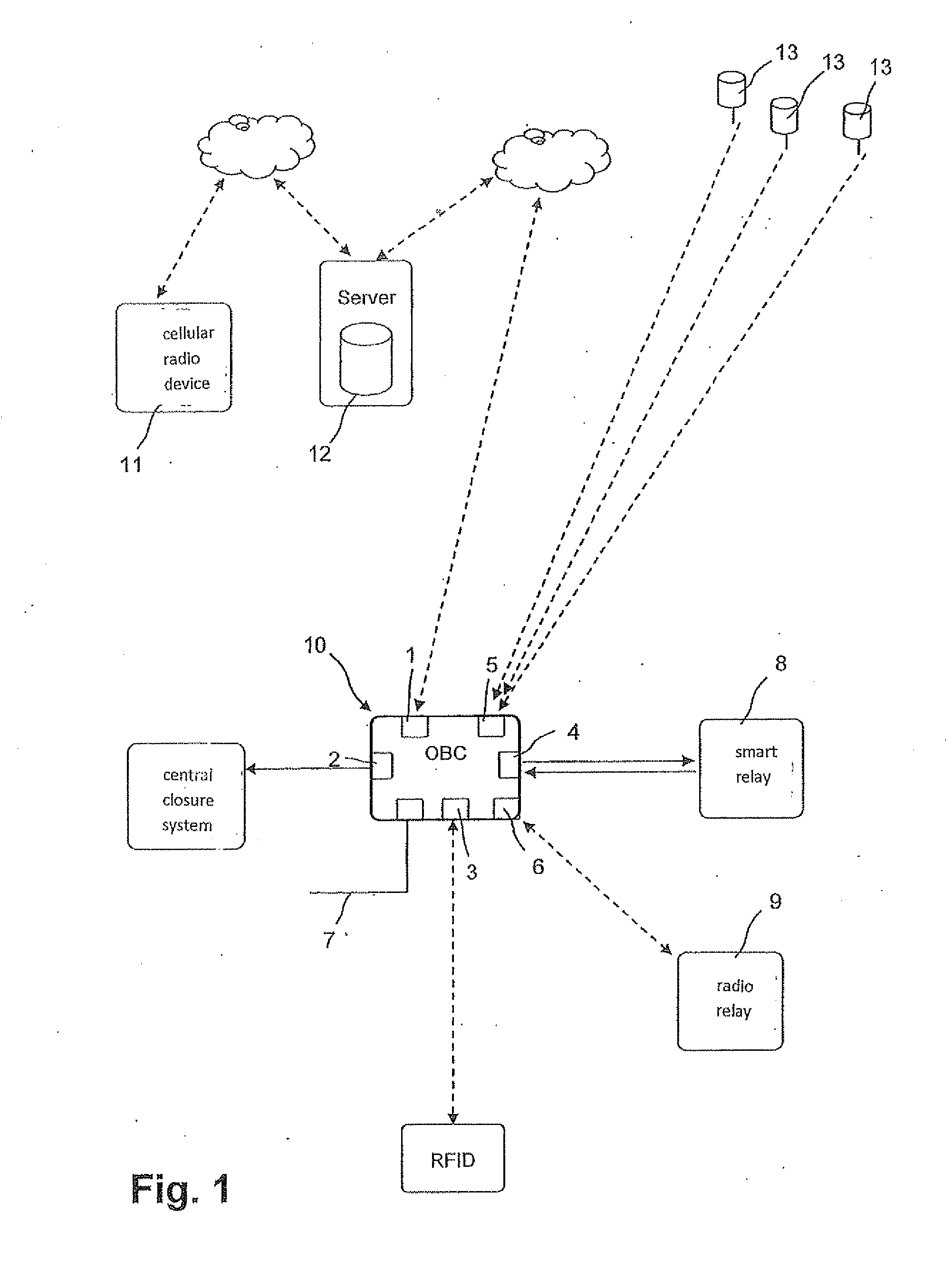

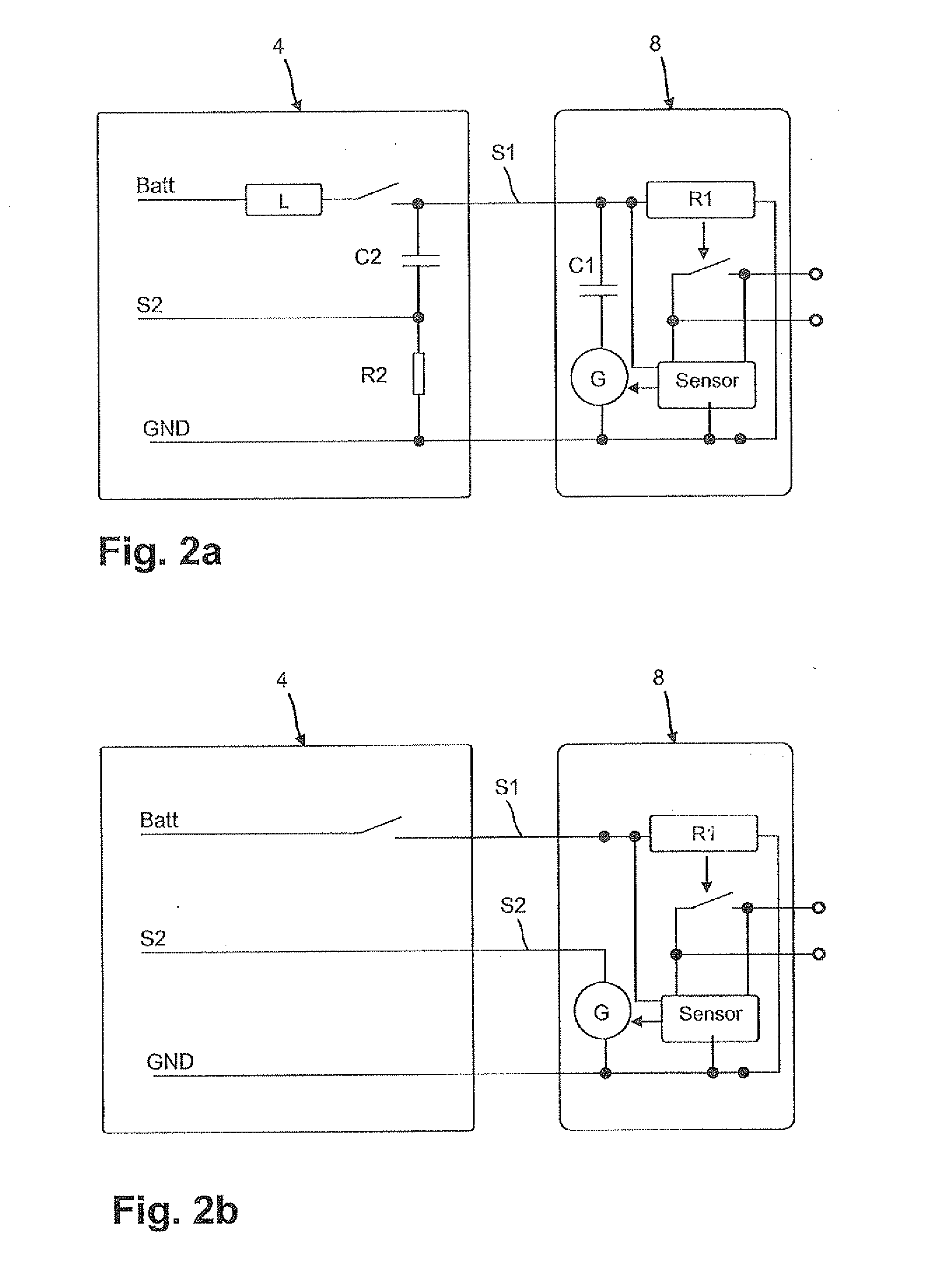

Mobile-radio-based additional electronic immobilizer having a door opener having a theft alarm

ActiveUS20150015396A1Reduce theft rateFast and easy to performNear-field transmissionBurglar alarm by openingControl signalEngineering

The present invention relates to a device and a method for an additional electronic immobilizer (10) having a door-opener and theft-alarm function for a vehicle, comprising: a) a micro-controller; b) a mobile radio interface (1); c) a second interface (2) to a central locking system for doors of the vehicle; d) a near-field radio interface (3) such as RFID or NFC; e) a smart relay interface (4) for transmitting a control signal (S1) for a smart relay (8) and for receiving a receiving signal (S2) of the smart relay (8).

Owner:LUNSTEDT OLIVER

Mobile terminal and method for controlling the same

ActiveUS10915223B2Easy to captureEasy to performTelevision system detailsElectronic editing digitised analogue information signalsComputer graphics (images)Reproduction speed

The present invention relates to a terminal and a method of controlling the same. A terminal according to an embodiment of the present invention includes a touchscreen, and a controller configured to cause the touchscreen to display video at a reproduction speed, cause the touchscreen to display a first icon, capture the displayed video according to a touch received at the first icon, and adjust the reproduction speed of the video according to a degree of the touch.

Owner:LG ELECTRONICS INC

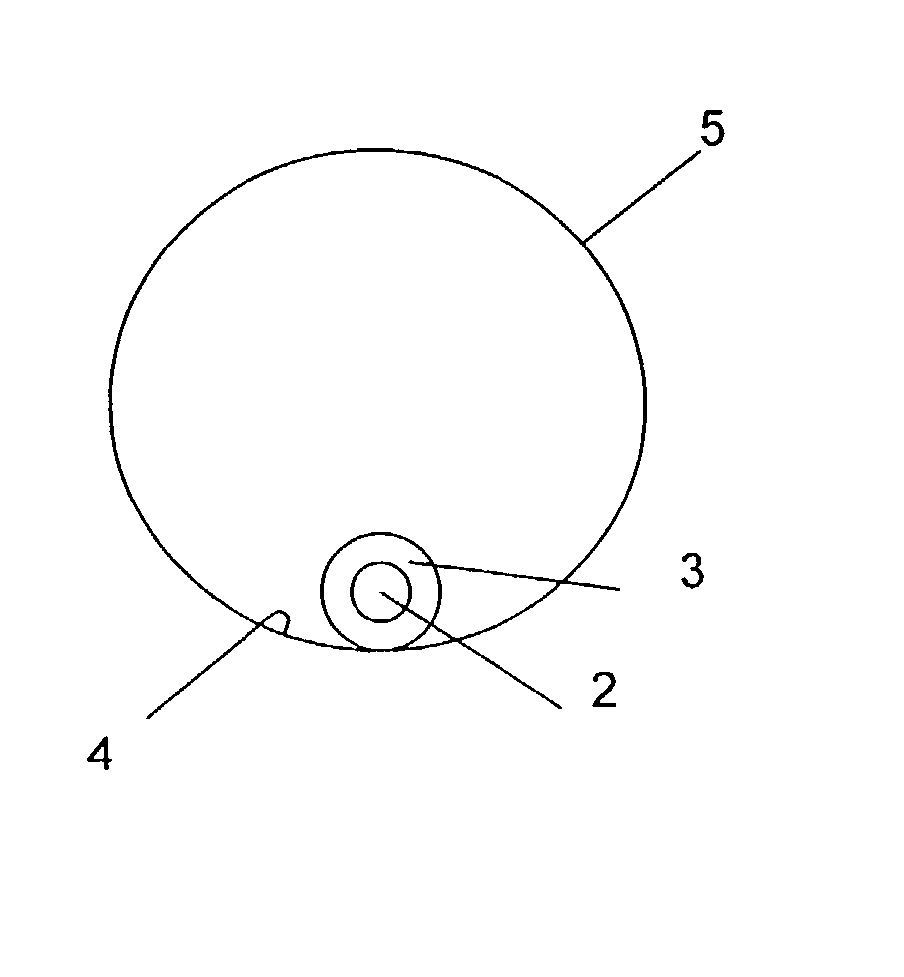

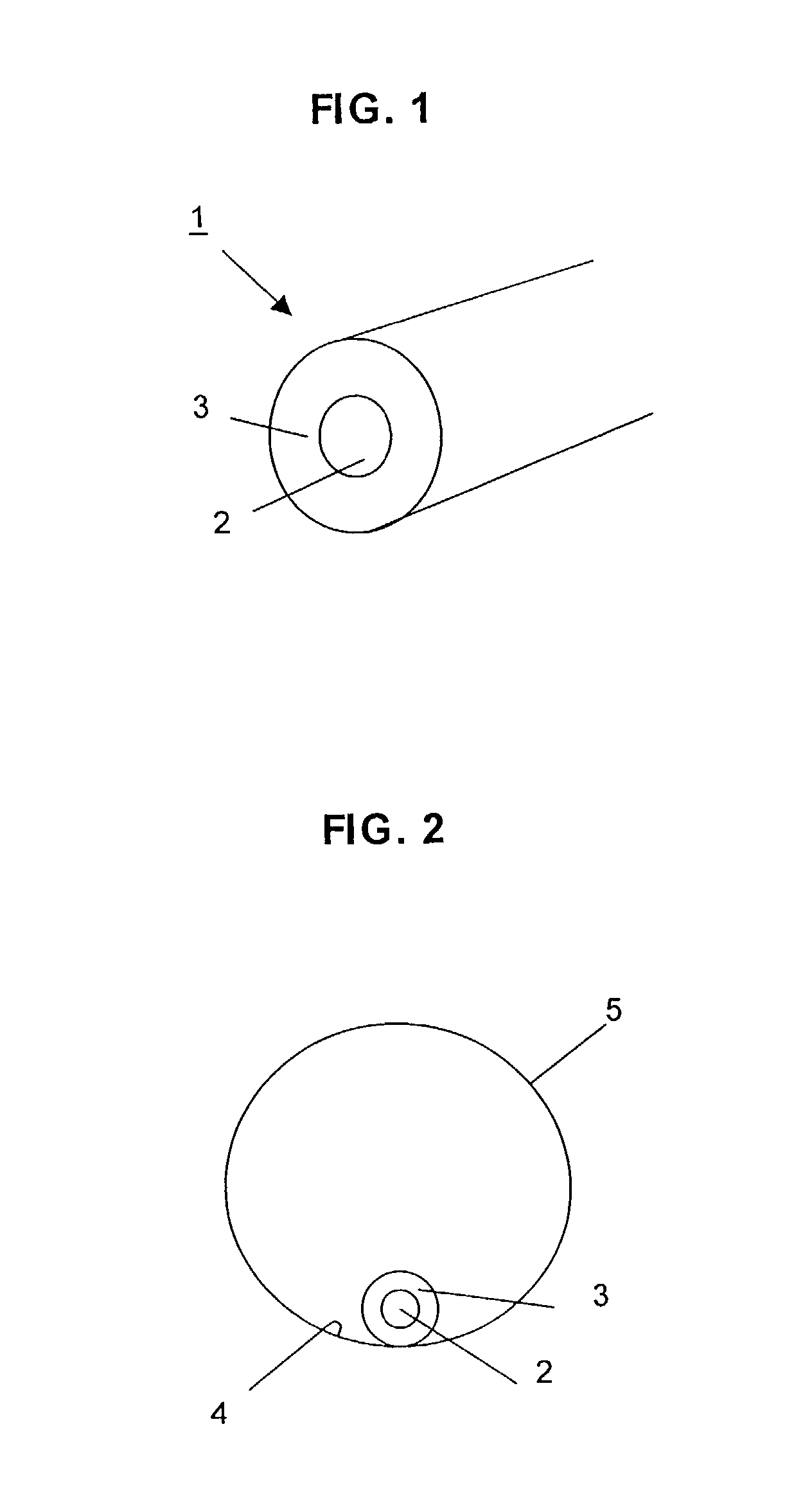

Method of installing a tubular element

InactiveUS20030051808A1Low costDrawback can be obviatedLamination ancillary operationsLaminationBiological activationBiomedical engineering

Owner:ALCATEL LUCENT SAS

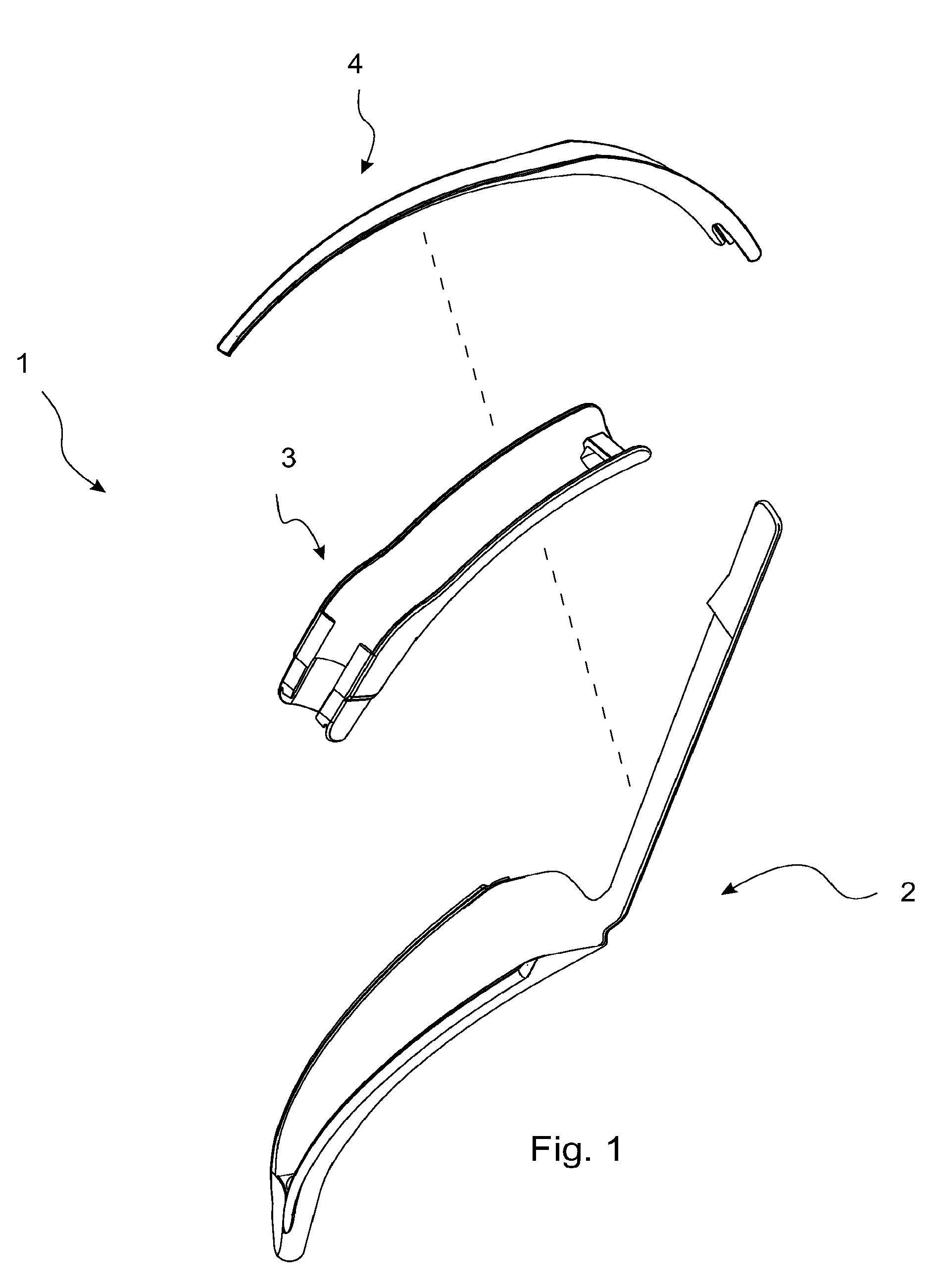

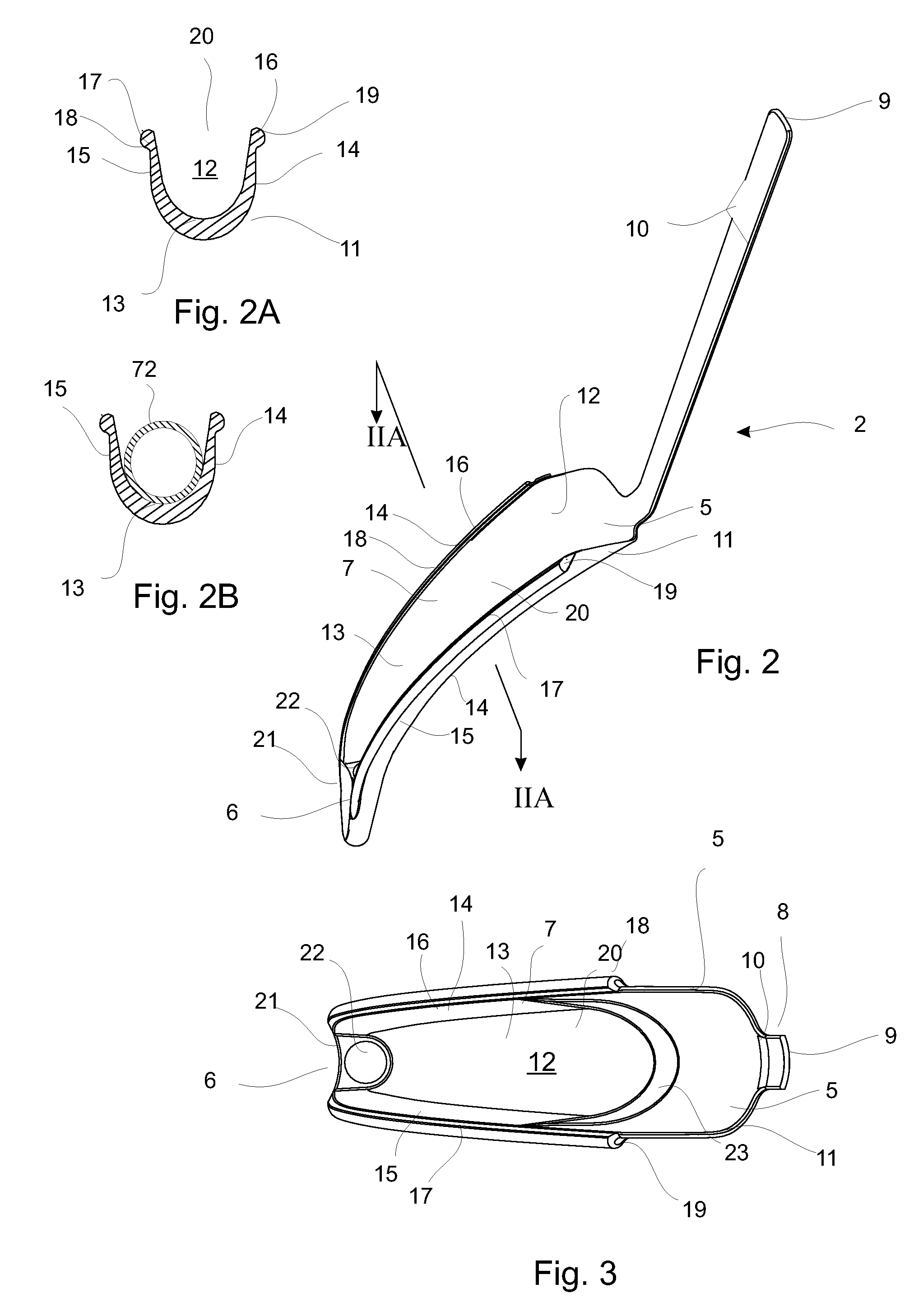

Dilator assembly, a device for facilitating tracheostomy and methods of making a percutaneous tracheostoma

A dilator assembly for percutaneous dilatational tracheostomy includes a dilator element having a wall and a proximal end part extending into a distal tip part via an intermediate part. The wall has a substantially U-shaped cross section defining a dilator opening. The assembly extends towards the distal tip part. The dilator assembly is part of a tracheostomy device. The device has a first branch for arranging inside the trachea, and a second branch co-operative with the first branch. The first branch has a first end and a receiving member while the opposing second end has a first coupling part. The second branch has a first end with a guide for a neck penetration member and an opposing second end with a second coupling part for coupling with the first coupling part of the first branch. The first and second branches are detachably coupled together at their respective second ends.

Owner:SAFETRACH

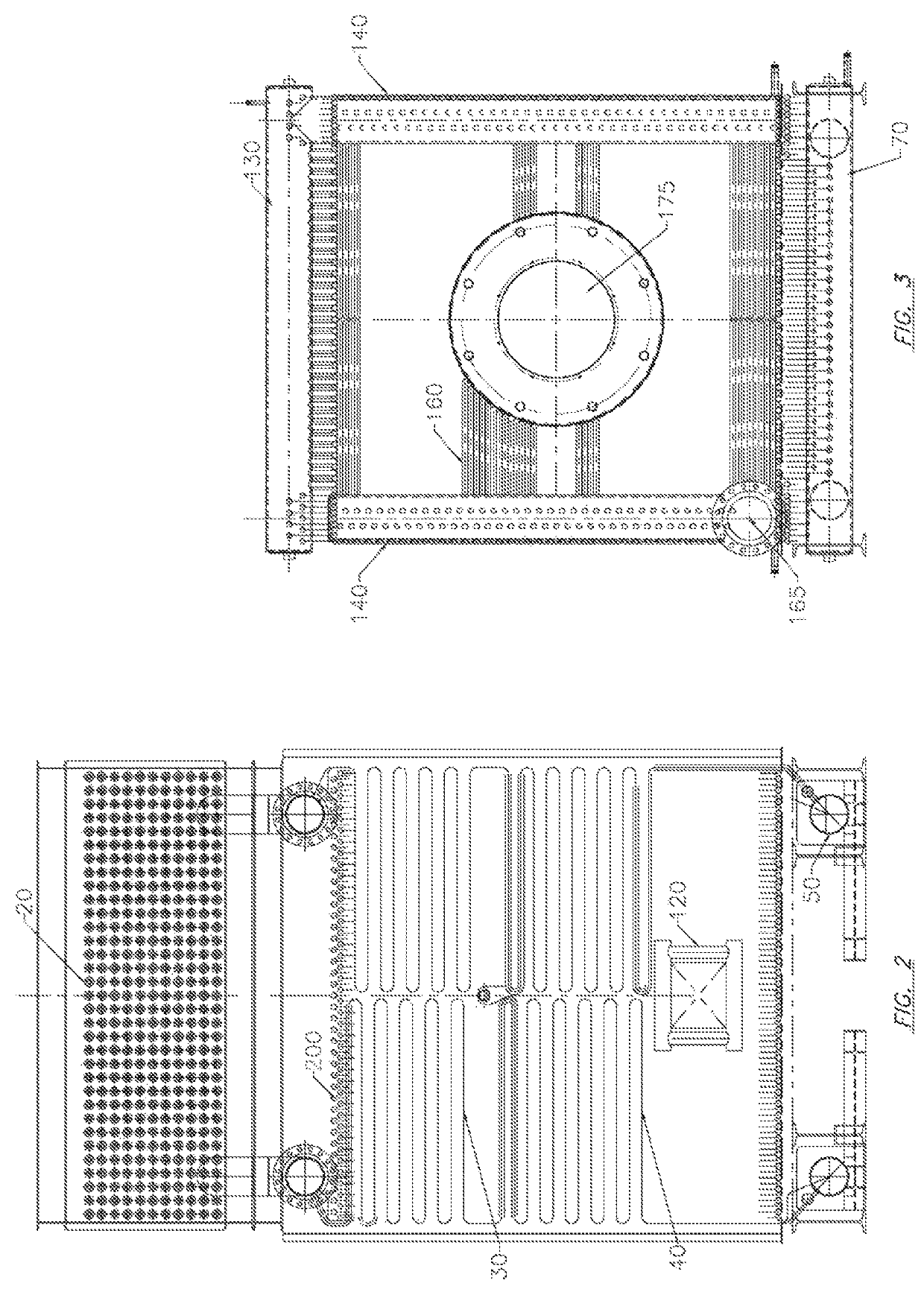

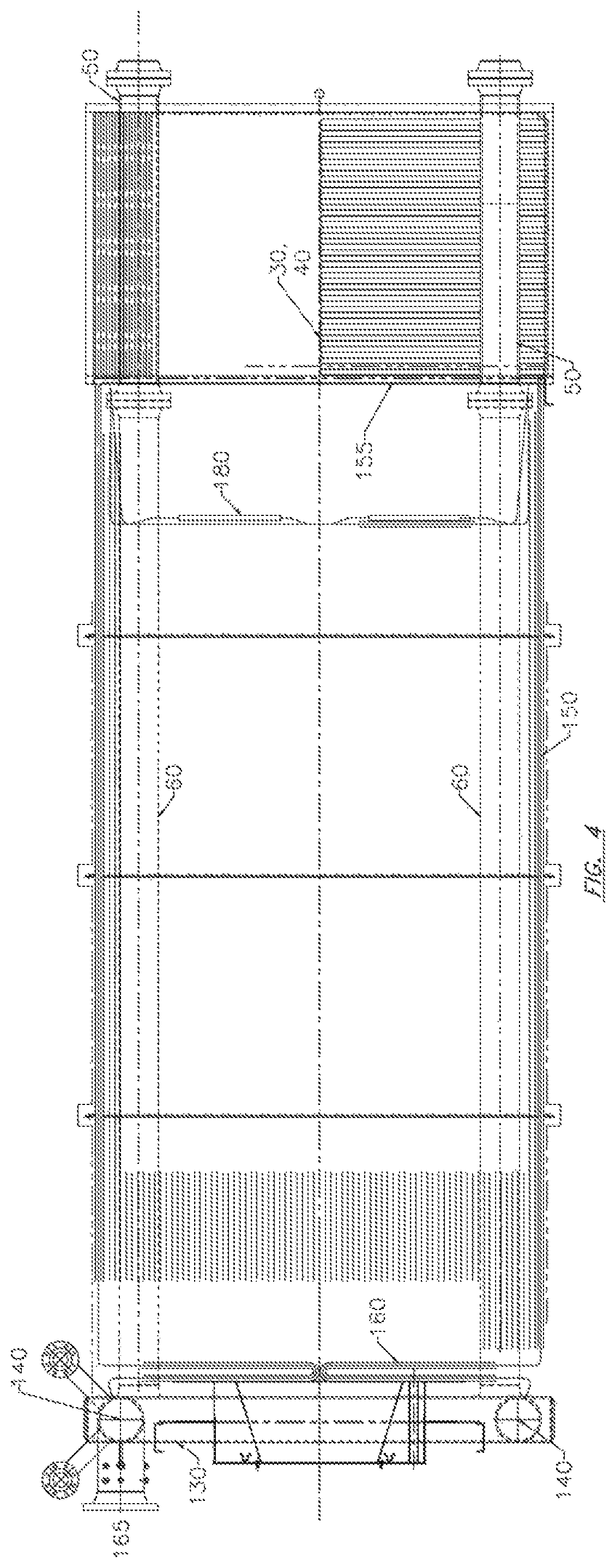

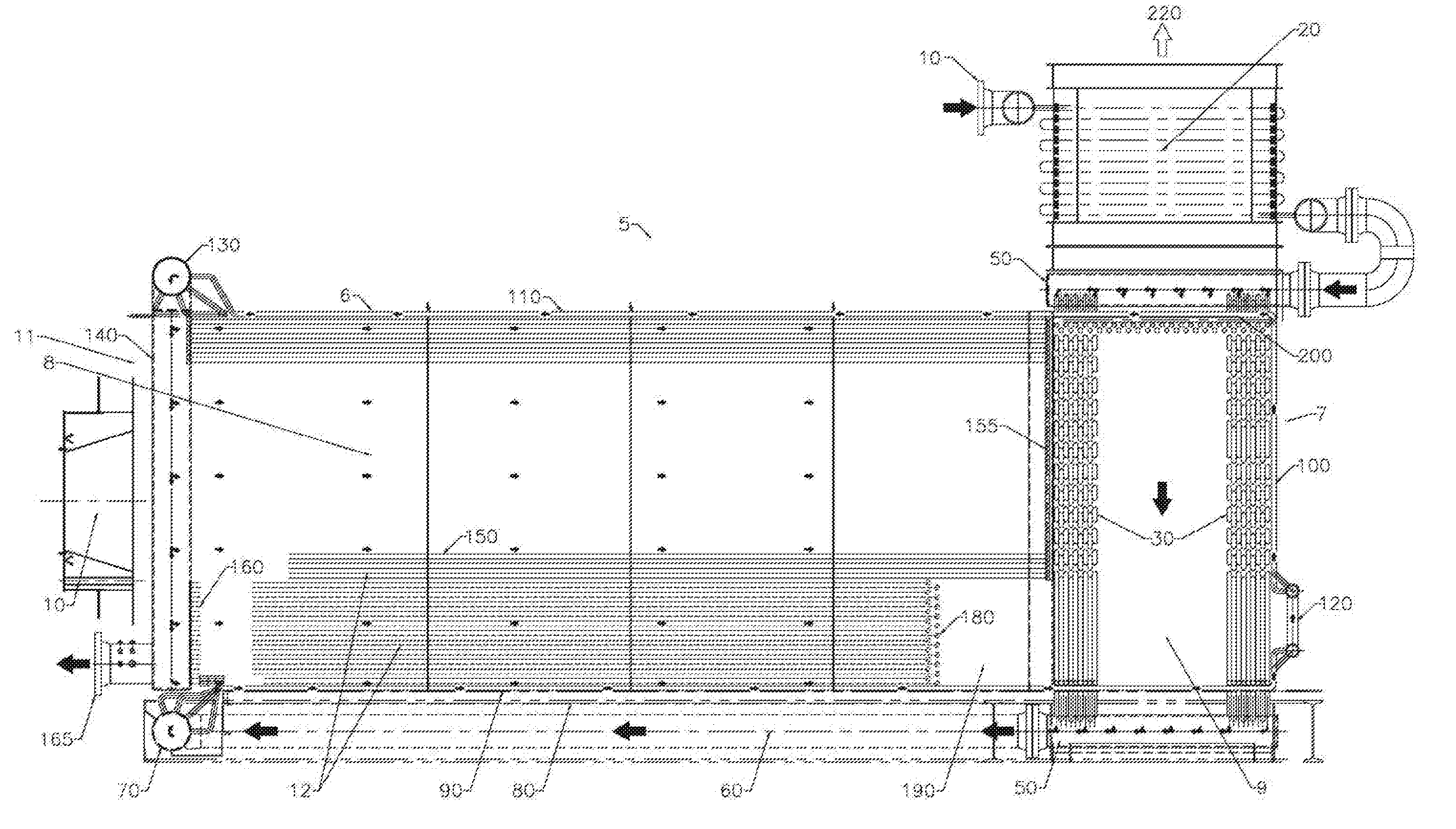

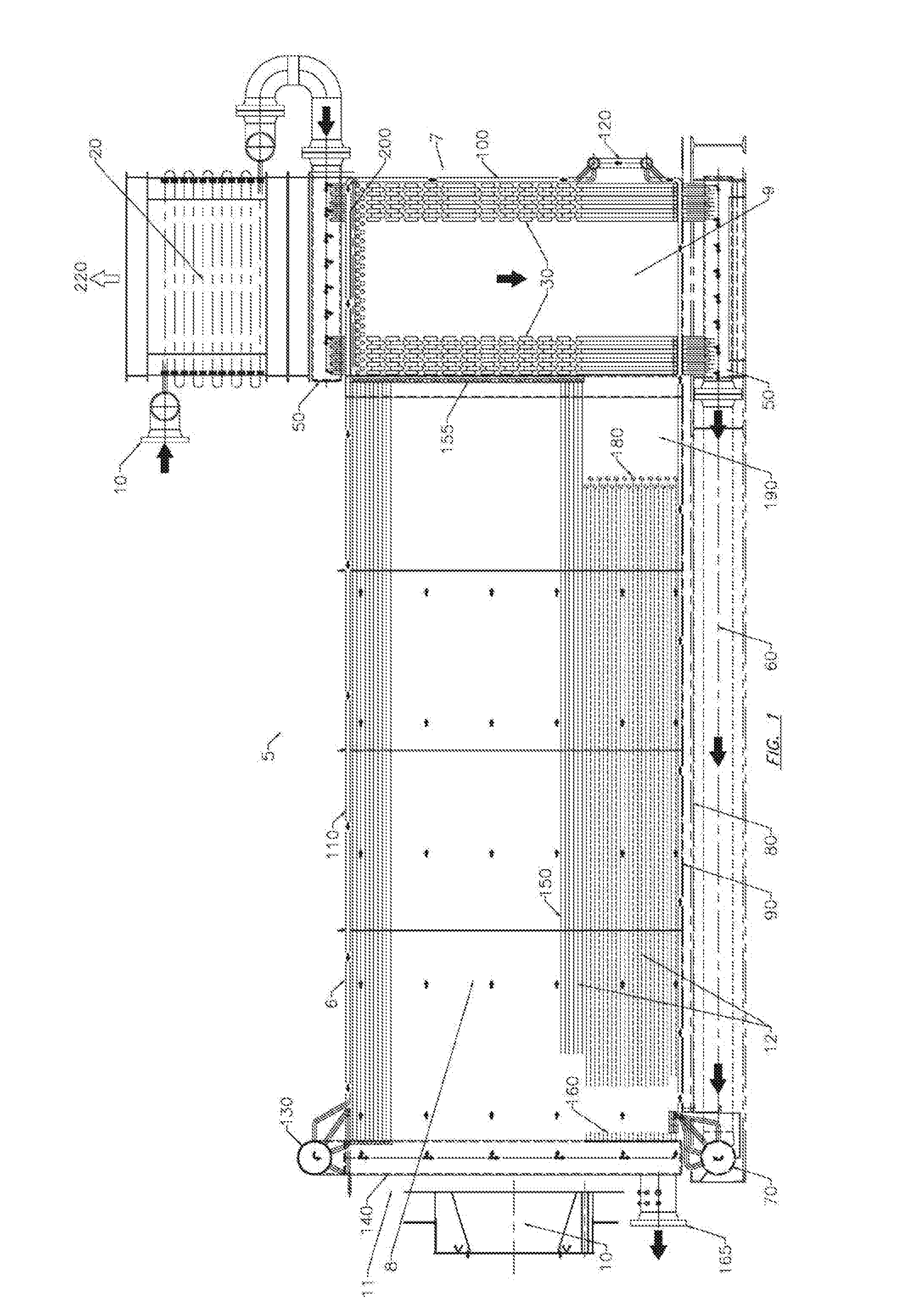

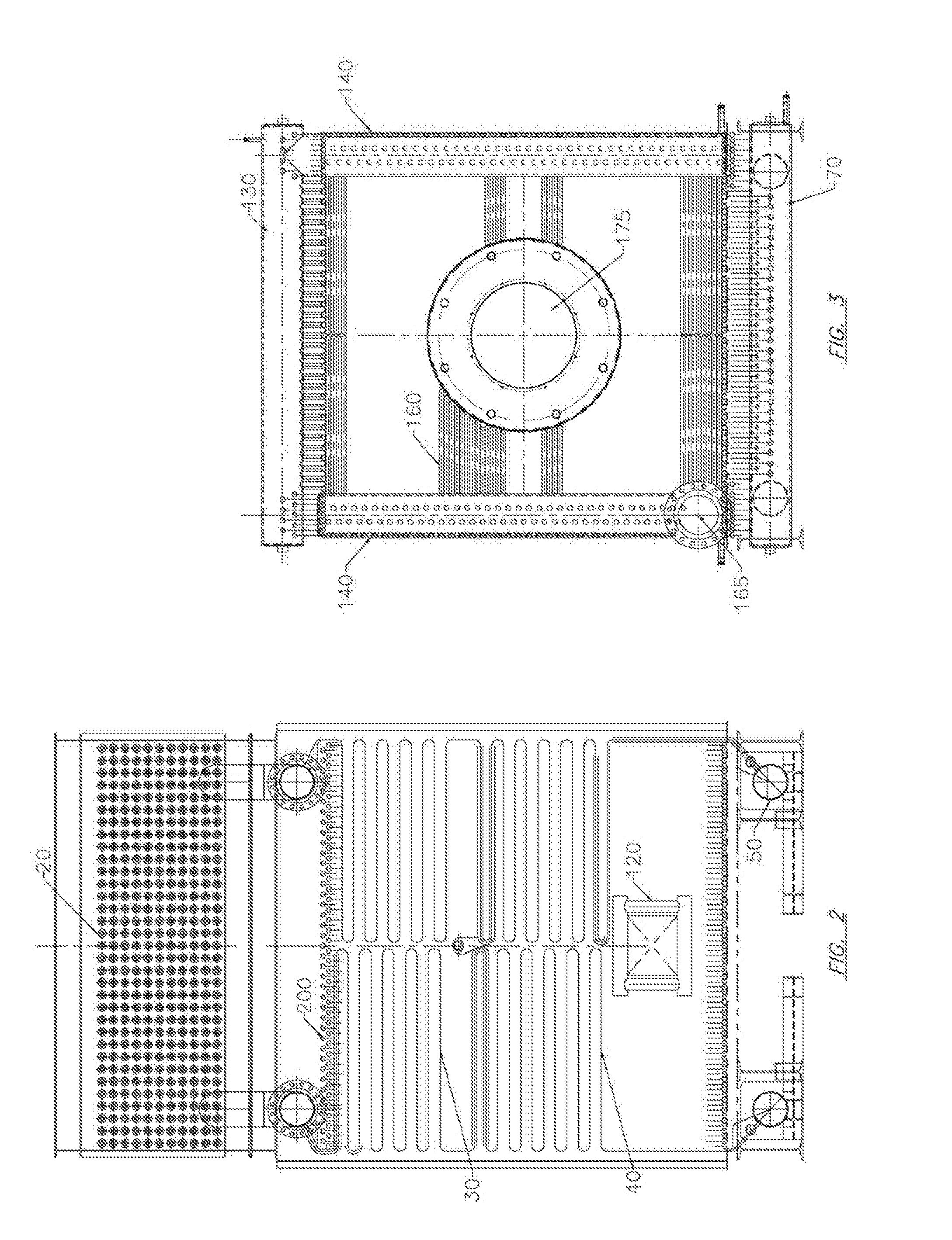

High temperature fluid generator

ActiveUS10704783B2Fast and easy to performImprove cooling effectCleaning heat-transfer devicesEnergy efficient heating/coolingThermodynamicsCombustion

A high temperature fluid generator is configured to heat a fluid (e.g. water; thermal oil or the like) to a high temperature (e.g. greater than 250 degrees Fahrenheit or 120 degrees Celsius) using a fuel-burning furnace. The generator generally comprises a furnace module, wherein fuel is burned, and a convection module where the combustion gases are put in contact with a series of fluid-bearing convection tubes. The furnace module comprises a series of fluidly interconnected headers, some of which are also fluidly connected to the convection tubes in the convection modules. The various headers contribute to the overall structure of the generator. The convection tubes are arranged into at least two bundles which are movably mounted in the convection module of the generator such to be movable in and out of the convection module for inspection, cleaning, maintenance and / or repair.

Owner:SIMONEAU P I INC

High temperature fluid generator

ActiveUS20170023240A1Improve cooling effectShorten the overall cycleCleaning heat-transfer devicesWater heatersCombustionDegree Celsius

A high temperature fluid generator is configured to heat a fluid (e.g. water; thermal oil or the like) to a high temperature (e.g. greater than 250 degrees Fahrenheit or 120 degrees Celsius) using a fuel-burning furnace. The generator generally comprises a furnace module, wherein fuel is burned, and a convection module where the combustion gases are put in contact with a el series of fluid-bearing convection tubes. The furnace module comprises a series of fluidly interconnected headers, some of which are en.) also fluidly connected to the convection tubes in the convection modules. The various headers contribute to the overall structure of the generator. The convection tubes are arranged into at least two bundles which are movably mounted in the convection module of the generator such to be movable in and out of the convection module for inspection, cleaning, maintenance and / or repair.

Owner:SIMONEAU P I INC

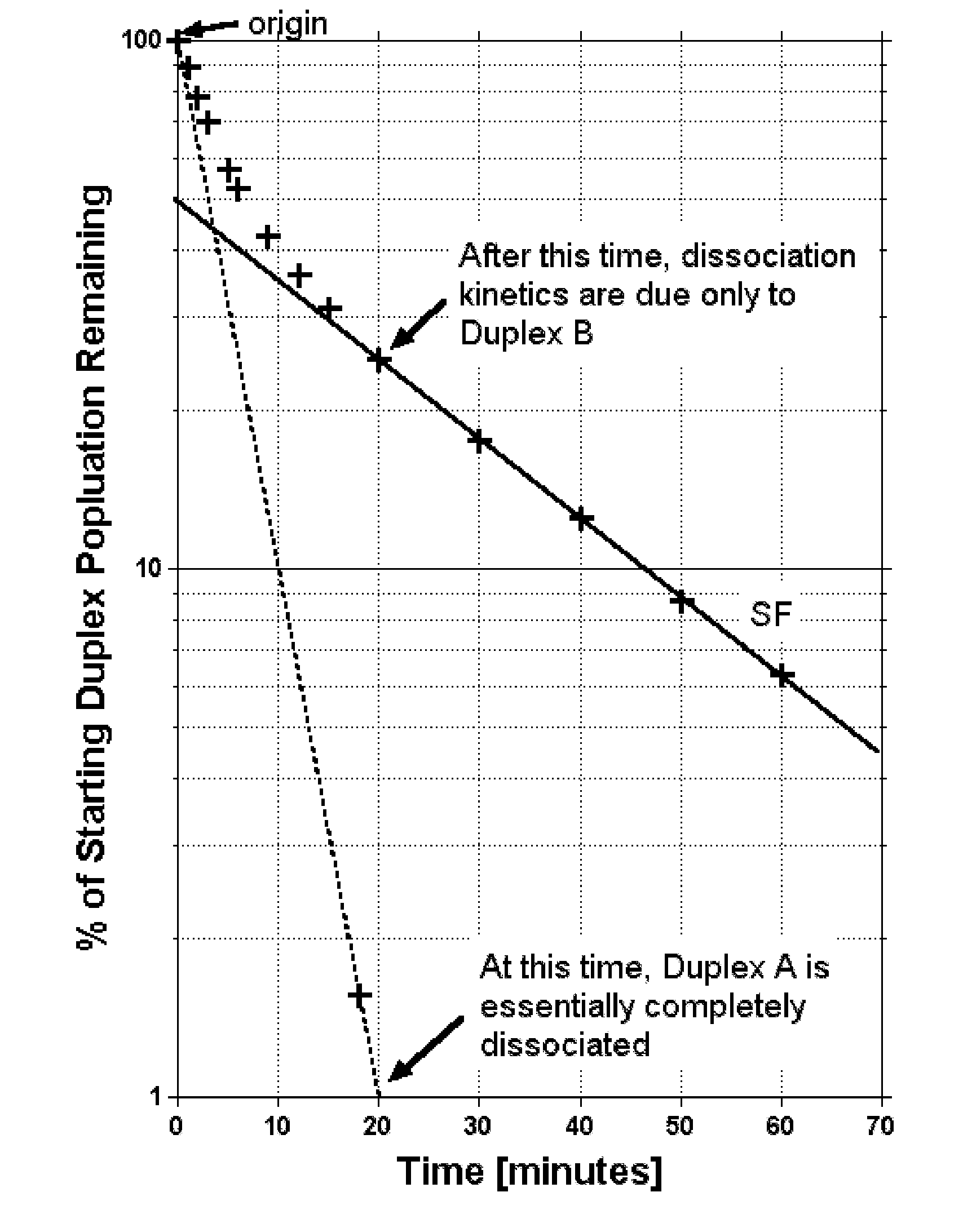

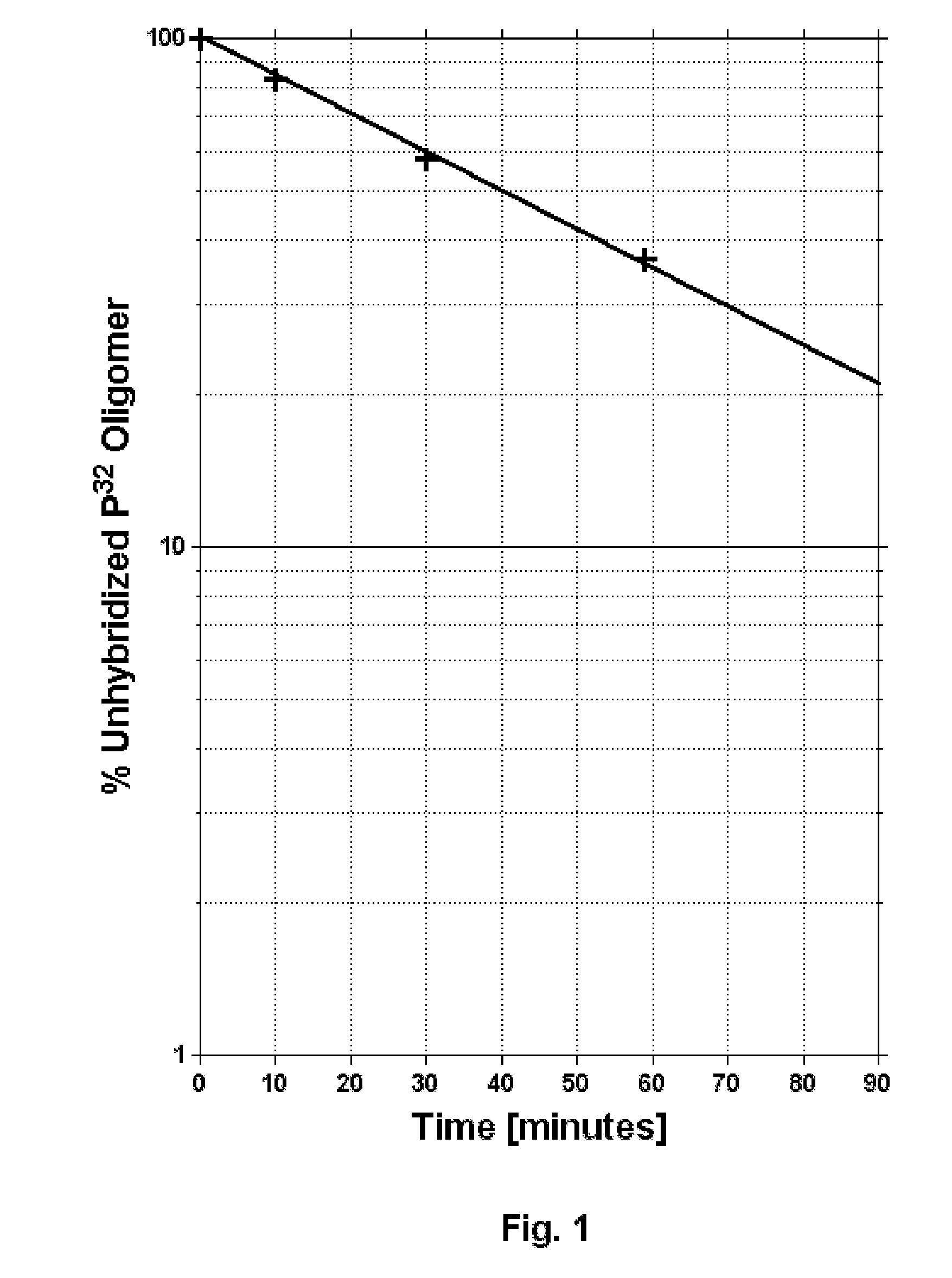

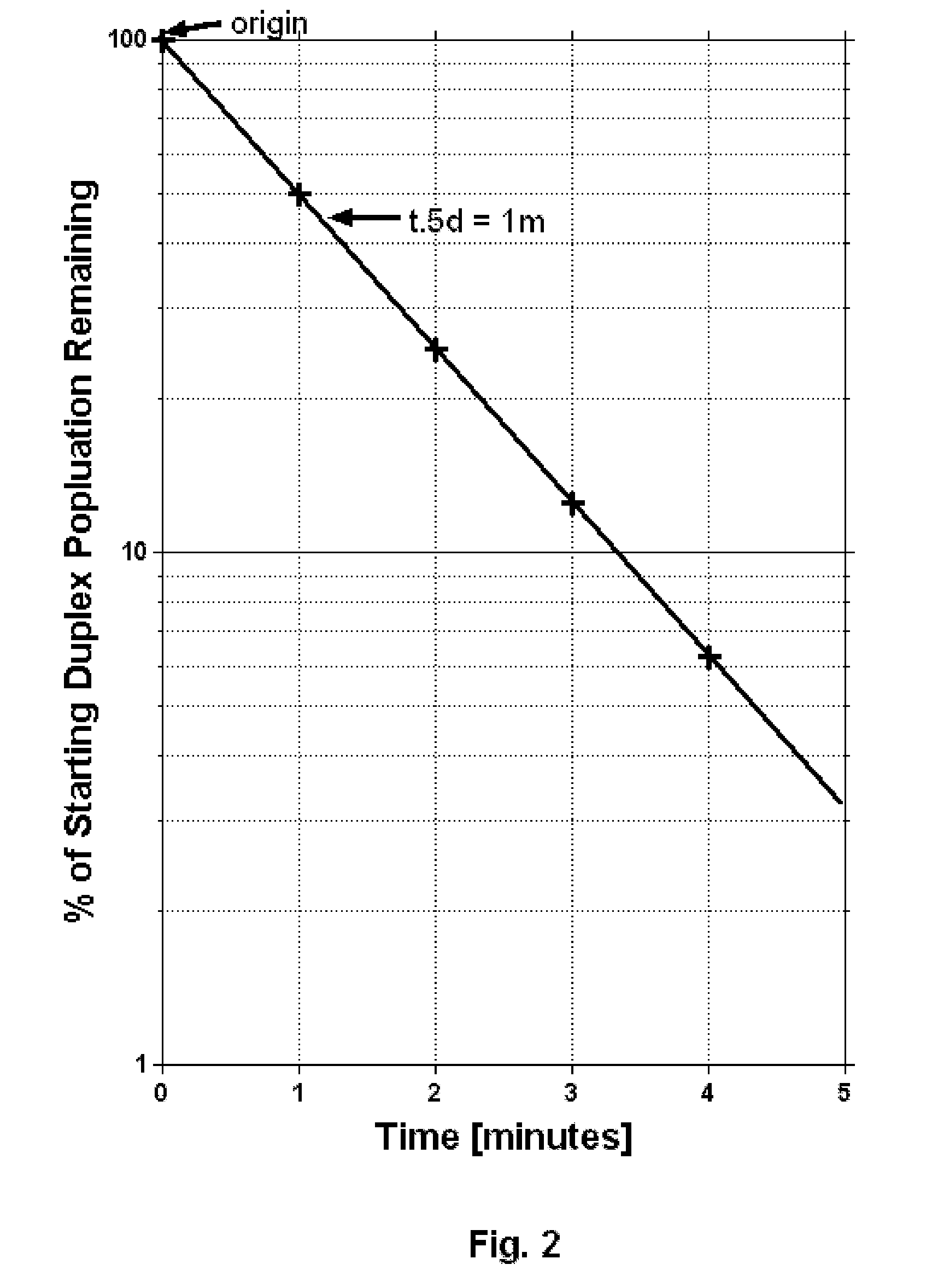

Method for producing improved nucleic acid oligomer functional homogeneity and functional characteristic information and results and oligomer application results

InactiveUS20070072201A1Improve accuracyGood precisionMicrobiological testing/measurementFermentationChemical synthesisOligomer

An approach and methods are provided for obtaining improved information and results concerning the functional homogeneity and functional characteristics of a chemically synthesized or biologically synthesized nucleic acid oligomer of any type, and for obtaining improved information and results concerning the functional homogeneity and functional characteristics of the oligomer under the conditions of the oligomer application, and for obtaining improved results for the oligomer application, and for obtaining improved results for any application which utilizes such improved oligomer application results.

Owner:KOHNE DAVID E

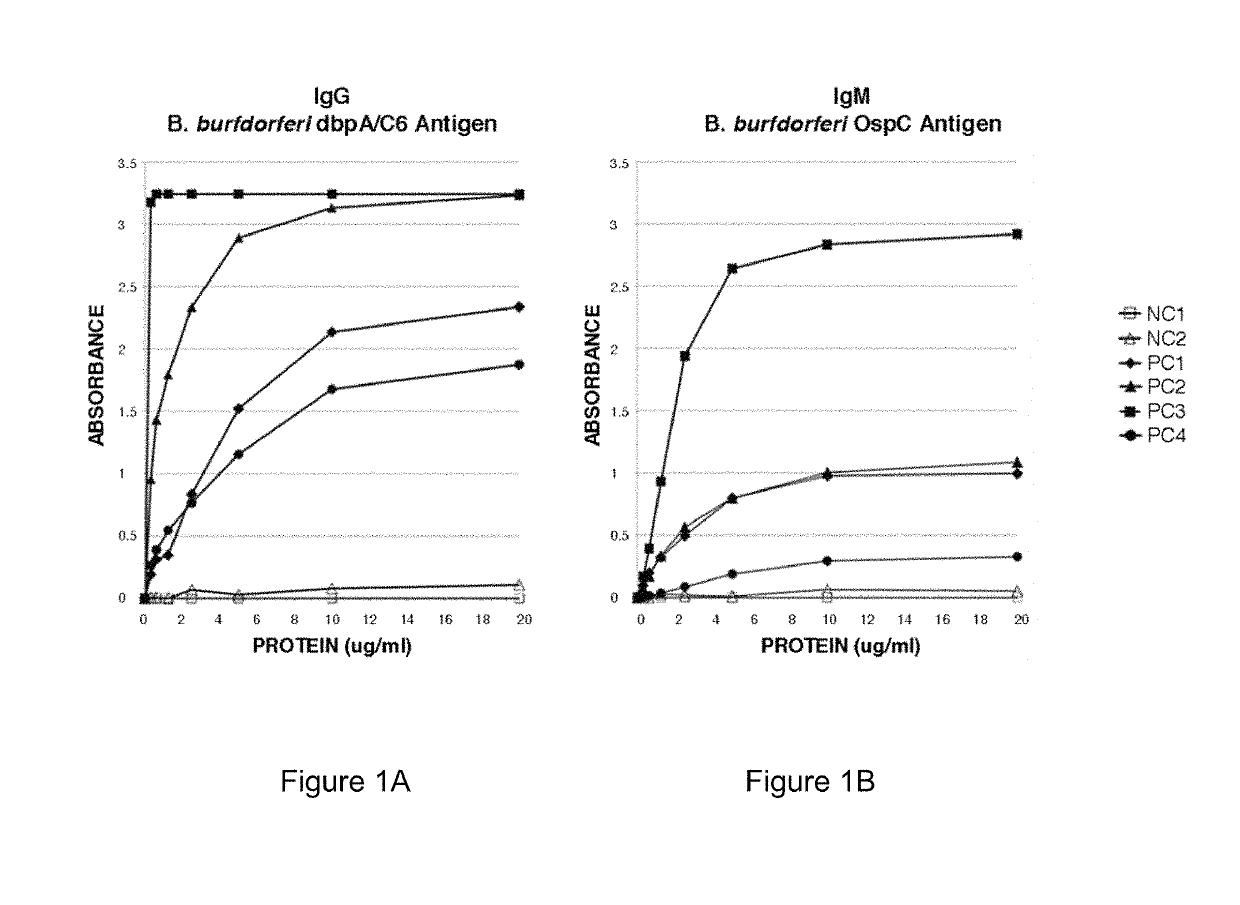

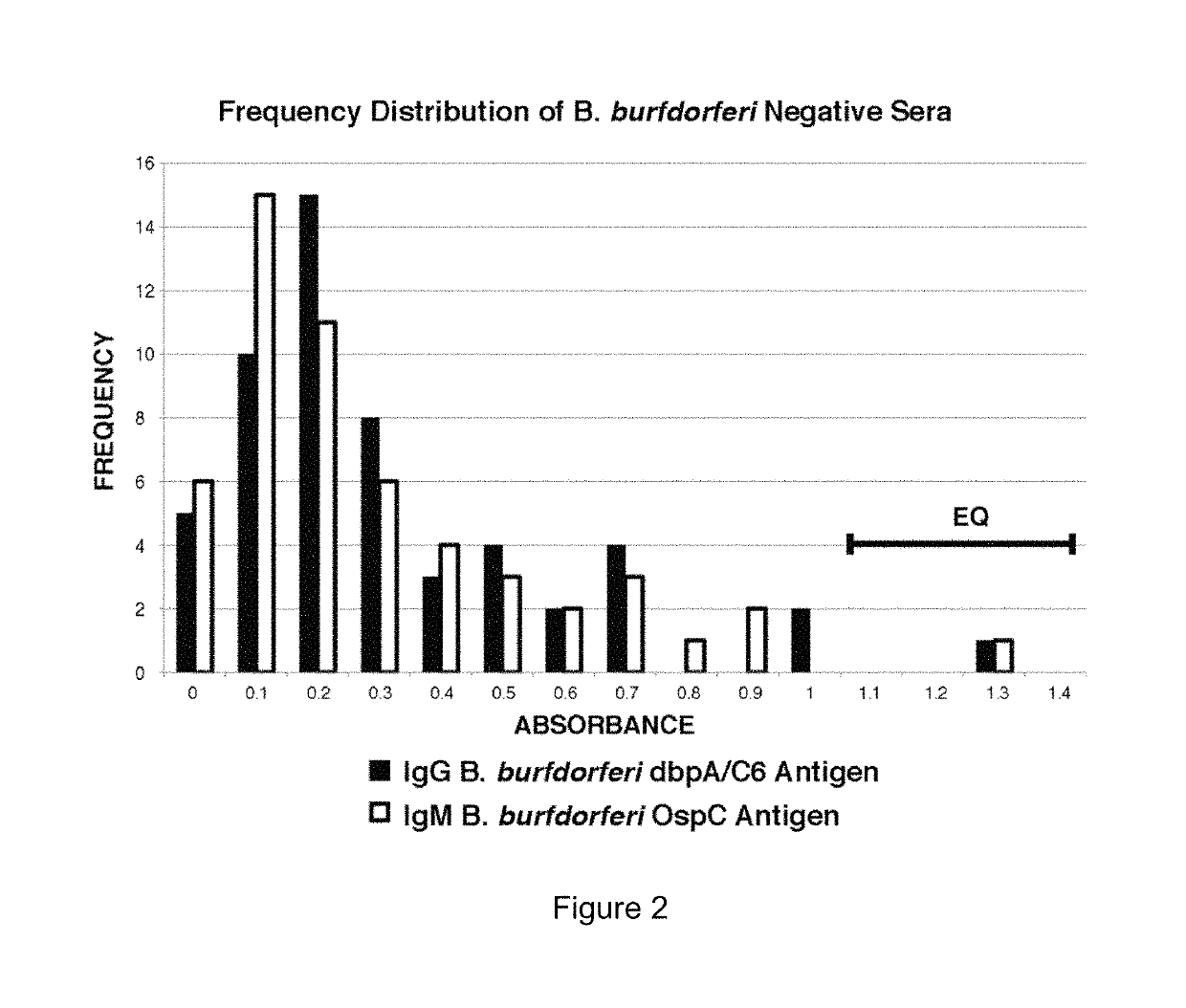

Serodiagnosis of lyme disease by use of two recombinant proteins in ELISA

ActiveUS10401358B1Great capacity to identifyFast and easy to performAntibody mimetics/scaffoldsDepsipeptidesSerodiagnosesEscherichia coli

Two Borrelia burgdorferi recombinant proteins were expressed in E. coli. These two proteins were generated from (a) the full length dbpA gene combined with the invariable region 6 of the VlsE gene (dbpA / C6), and (b) the full length OspC gene combined with the coding sequence for amino acids 1-121 of the E. coli maltose binding protein gene (OspC / MBP). Methods of using these recombinant proteins for detecting anti-Borrelia burgdorferi antibodies in patient sera and diagnosis of Lyme Disease are described.

Owner:ROSS SOUTHERN LAB

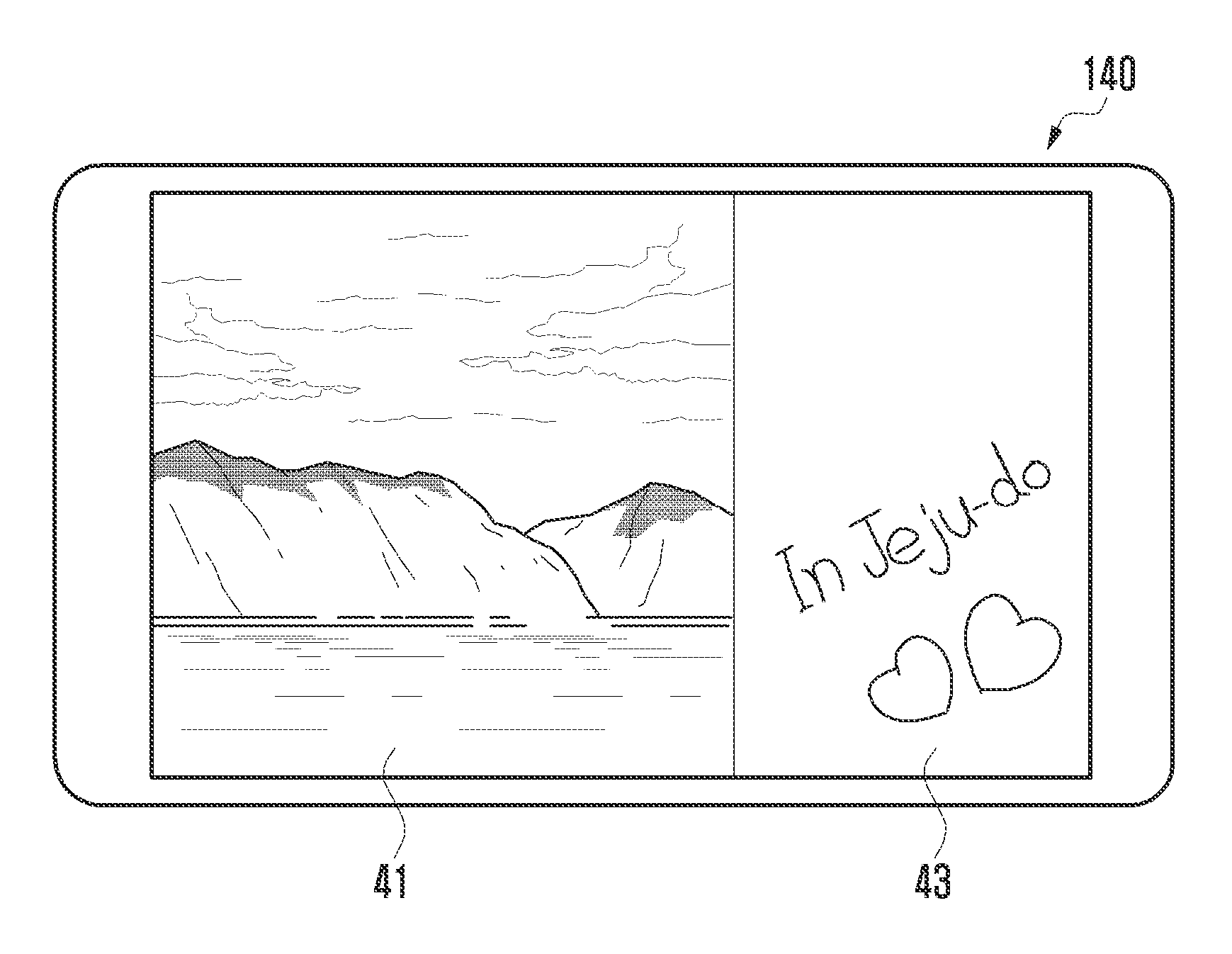

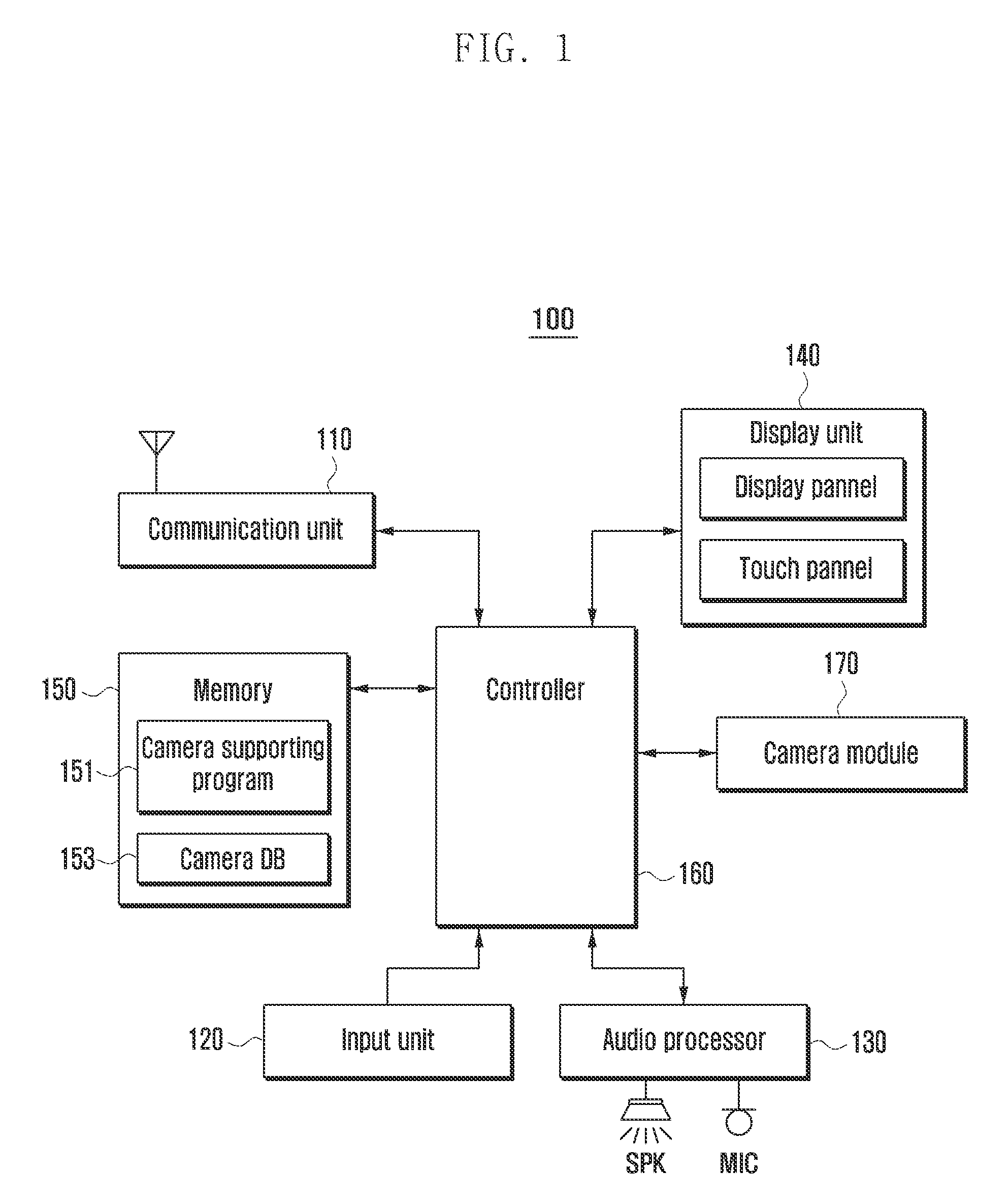

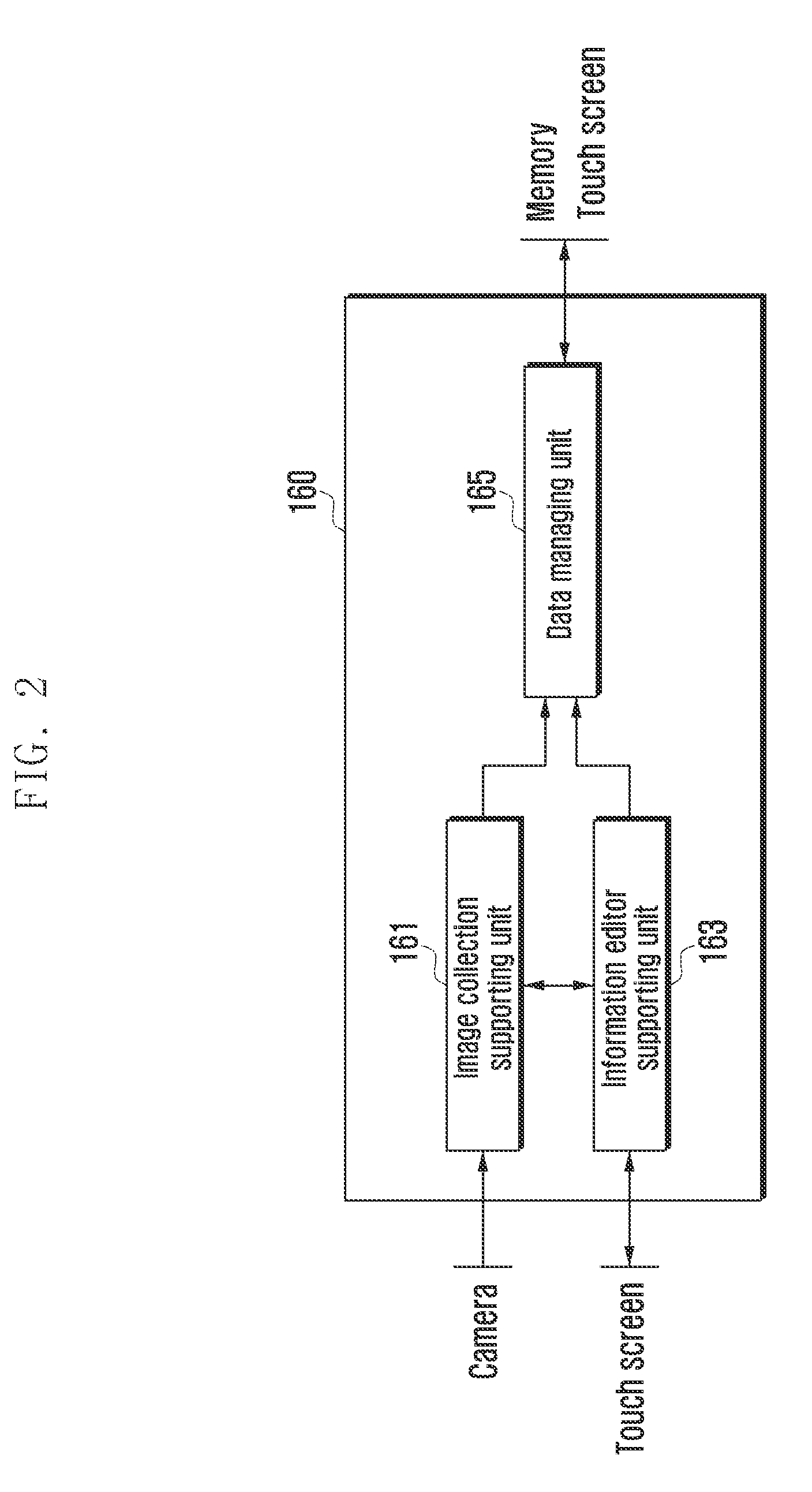

Method of operating camera including information supplement function and terminal supporting the same

ActiveUS9357049B2Fast and easy to performTelevision system detailsColor television detailsComputer graphics (images)Camera module

A method of operating a camera including an information supplement function which supports to write a specific type of information desired by a user during a camera operation, and a terminal for supporting the same are provided. The method includes activating the camera module, and outputting to a display unit, an information editing area having an information supplement function together with at least one of a preview area for outputting the preview image, a photographed image area according to completion of photographing, and an on-photographing area according to a state of on-photographing of at least one of time points when a preview image of an object for photographing at least one of a picture and a moving picture by the activated camera module is output, when a photographing for one of a picture and a moving picture is complete, and when a moving picture is being photographed.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for manufacturing a valve spindle

InactiveUS9616498B2Fast and easy to performLabor efficientMachines/enginesLift valveMetallic materialsValve stem

A method for manufacturing a valve spindle having a valve disc and a valve stem, the method comprising the steps of: providing a capsule, which defines at least a portion of the valve disc; arranging, in the capsule, a preformed core body that includes a core head, which constitutes an inner portion of the valve disc; arranging a preformed annular valve seat in the capsule, wherein the valve seat is arranged such that the inner circumferential side of the valve seat at least partially defines an inner space around the core head; filling the inner space with a first metallic material, forming the buffer layer, such that the core head is covered with the first material; filling the capsule with a second metallic material, forming the cladding layer; subjecting the capsule to Hot Isostatic Pressing (HIP) at a predetermined temperature, a predetermined isostatic pressure and for a predetermined time so that the preformed core body, the buffer layer, the cladding layer and the valve seat are bonded metallurgically.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Configuration method for control units

ActiveUS8555375B2Easy and fast to carry-outFast and easy to performProgramme controlDigital data processing detailsData connectionMachine control

The invention relates to a configuration method for a control unit of a machine, the control unit having a data memory and being mounted in a machine control system having at least one already configured control unit with a data memory, the to-be-configured control unit communicating via a data connection with the already configured control unit of the machine control system and retrieving therefrom configuration data for its own configuration.

Owner:BOMAG

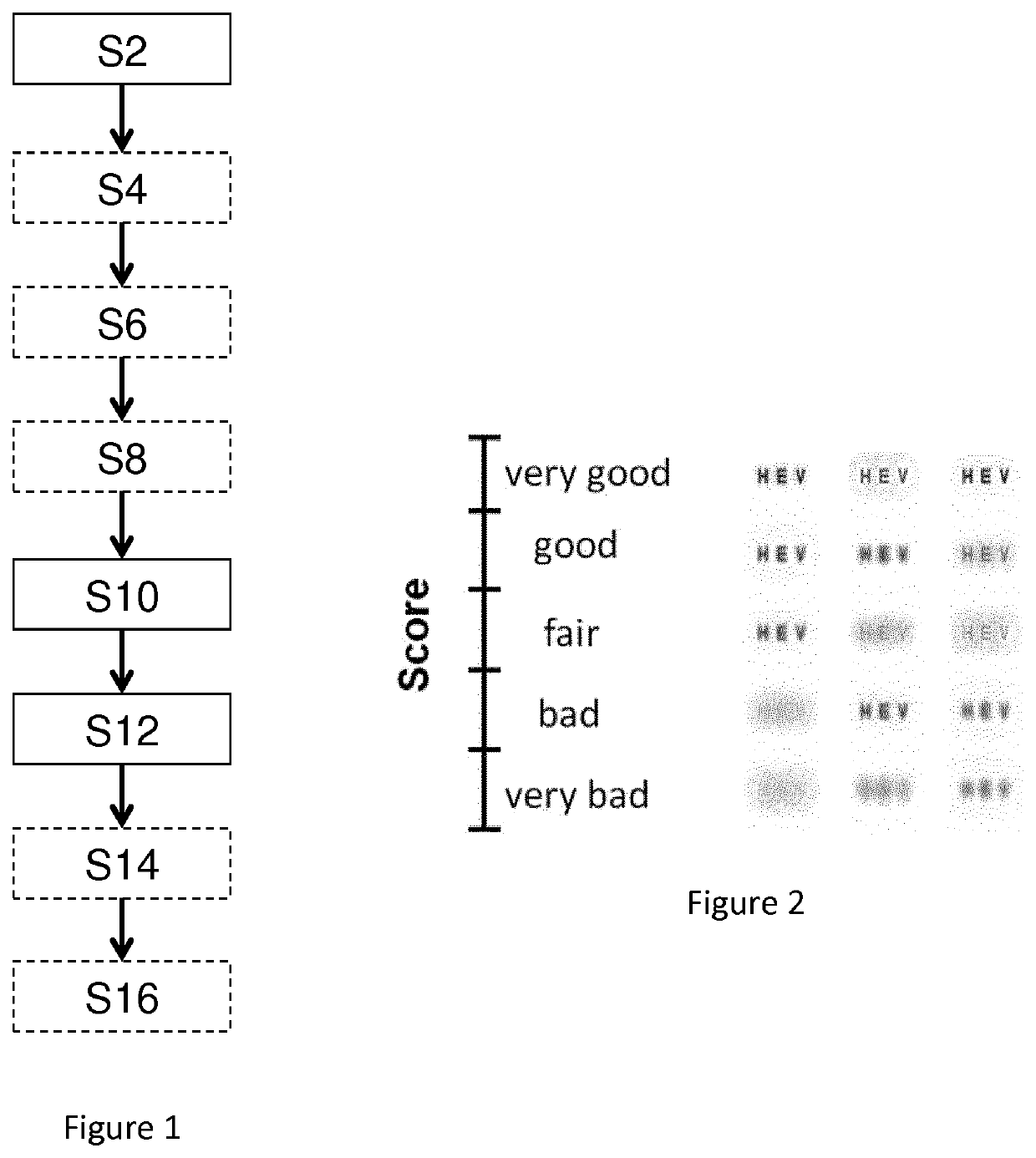

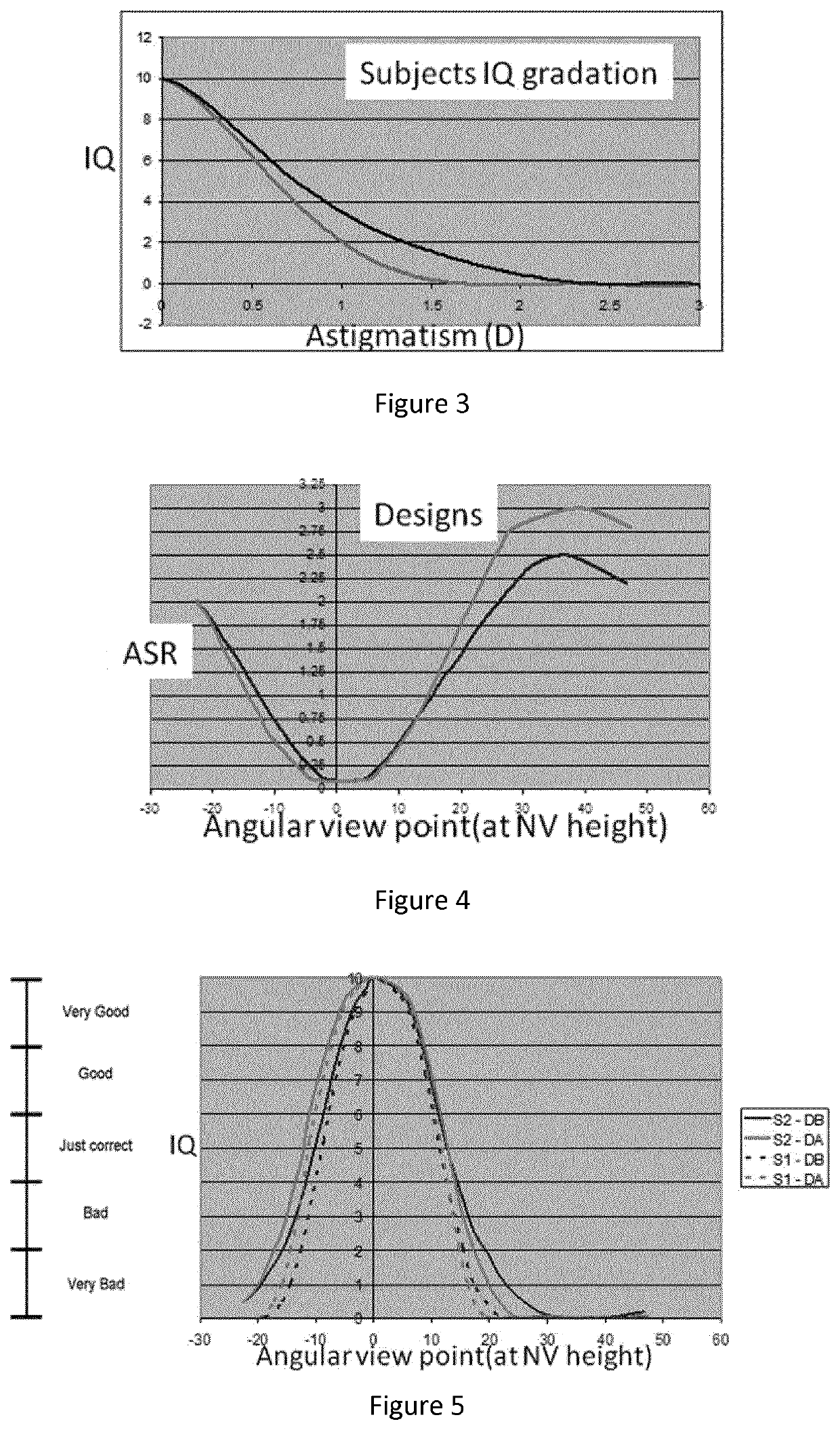

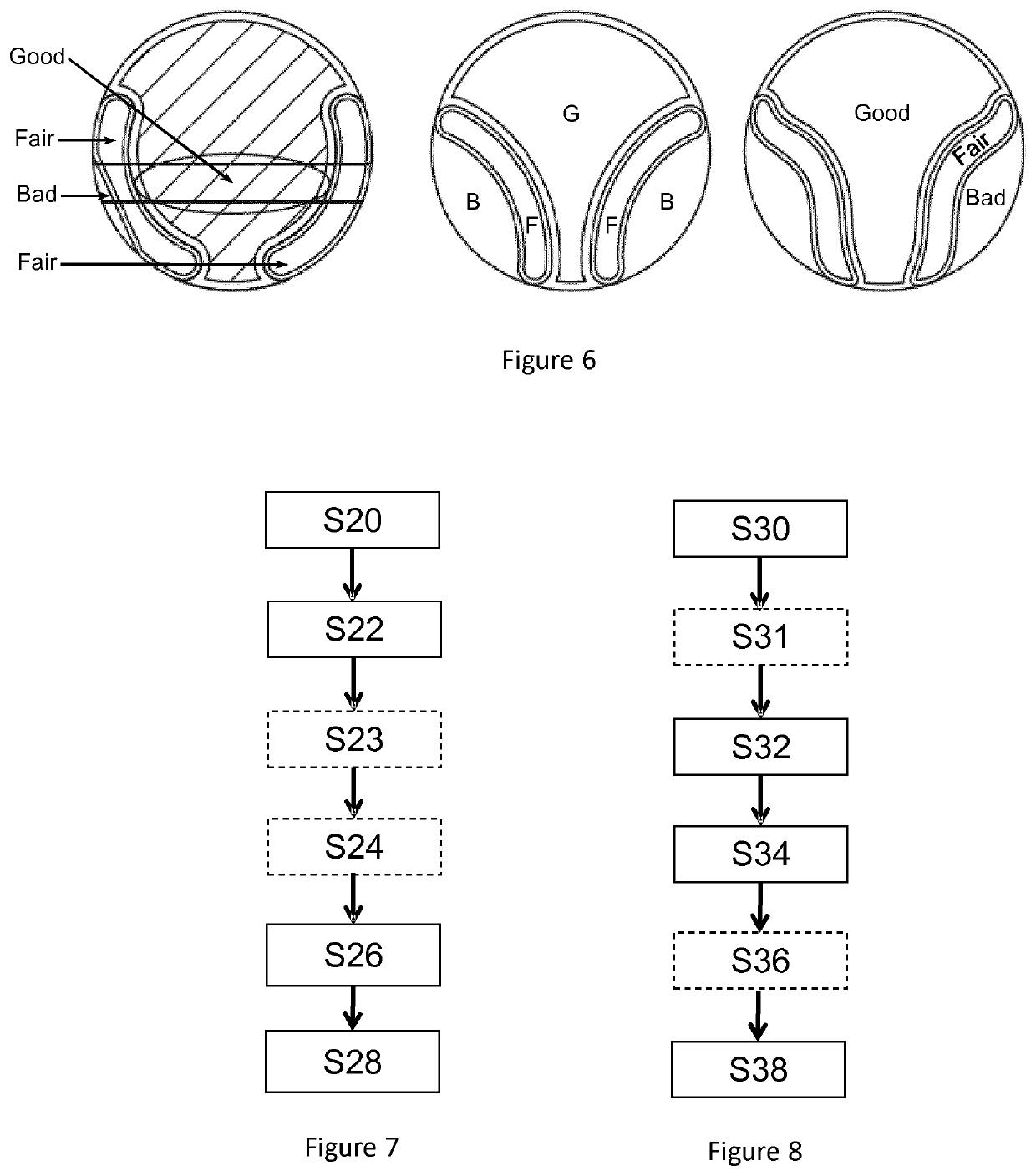

Method for determining to which extent a lens design is adapted to a user

PendingUS20210240008A1Fast and easy to performRendered more relevant and less fluctuatingOptical partsOphthalmologyOptical aberration

Owner:ESSILOR INT CIE GEN DOPTIQUE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com