Patents

Literature

38results about How to "Automate inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

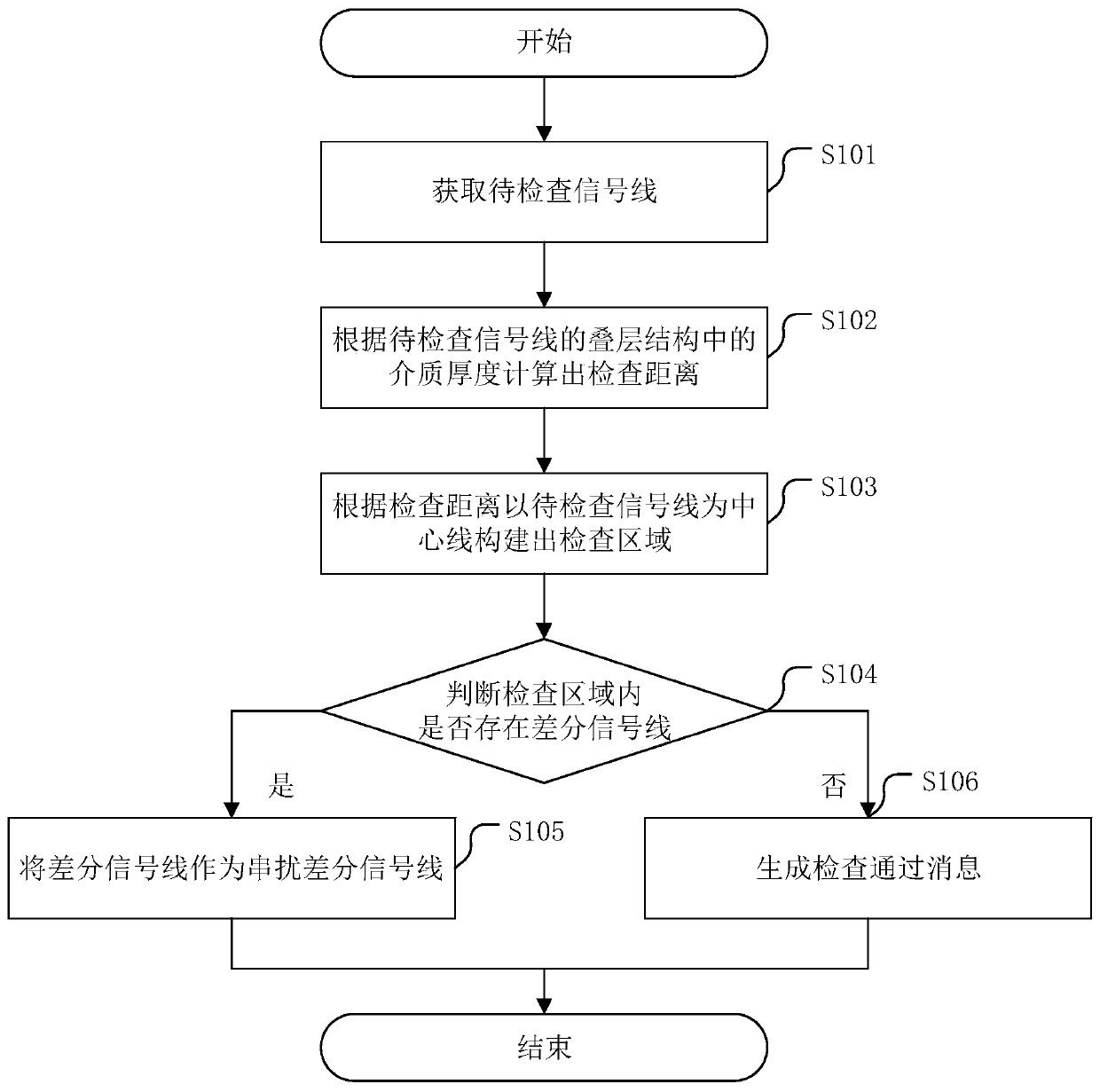

Pin routing inspection method of differential line and related device

InactiveCN110378062AAutomate inspectionImprove inspection efficiencySpecial data processing applicationsDifferential lineDifferential signaling

The invention discloses a pin routing inspection method of a differential line. The pin routing inspection method comprises the following steps: acquiring a to-be-inspected signal line; calculating aninspection distance according to the medium thickness in the laminated structure of the to-be-inspected signal line; constructing an inspection area by taking the to-be-inspected signal line as a center line according to the inspection distance; judging whether a differential signal line exists in the inspection area or not; and if so, taking the differential signal line as a crosstalk differential signal line. The inspection distance is calculated through the obtained medium thickness in the laminating mechanism corresponding to the to-be-inspected signal line. The detection distance and thesignal line are used as the center line to construct the detection area. Finally, the differential line in the detection area is detected, thereby achieving the automatic detection of the differential line, improving the detection efficiency, and maintaining the detection precision and accuracy. The invention further discloses a pin routing inspection device of the differential line, computer equipment and a computer readable storage medium, which have the above beneficial effects.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

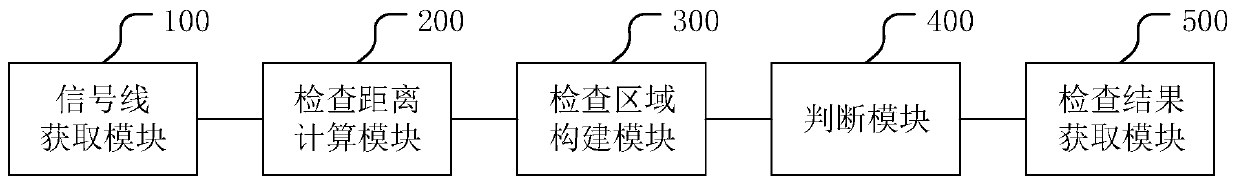

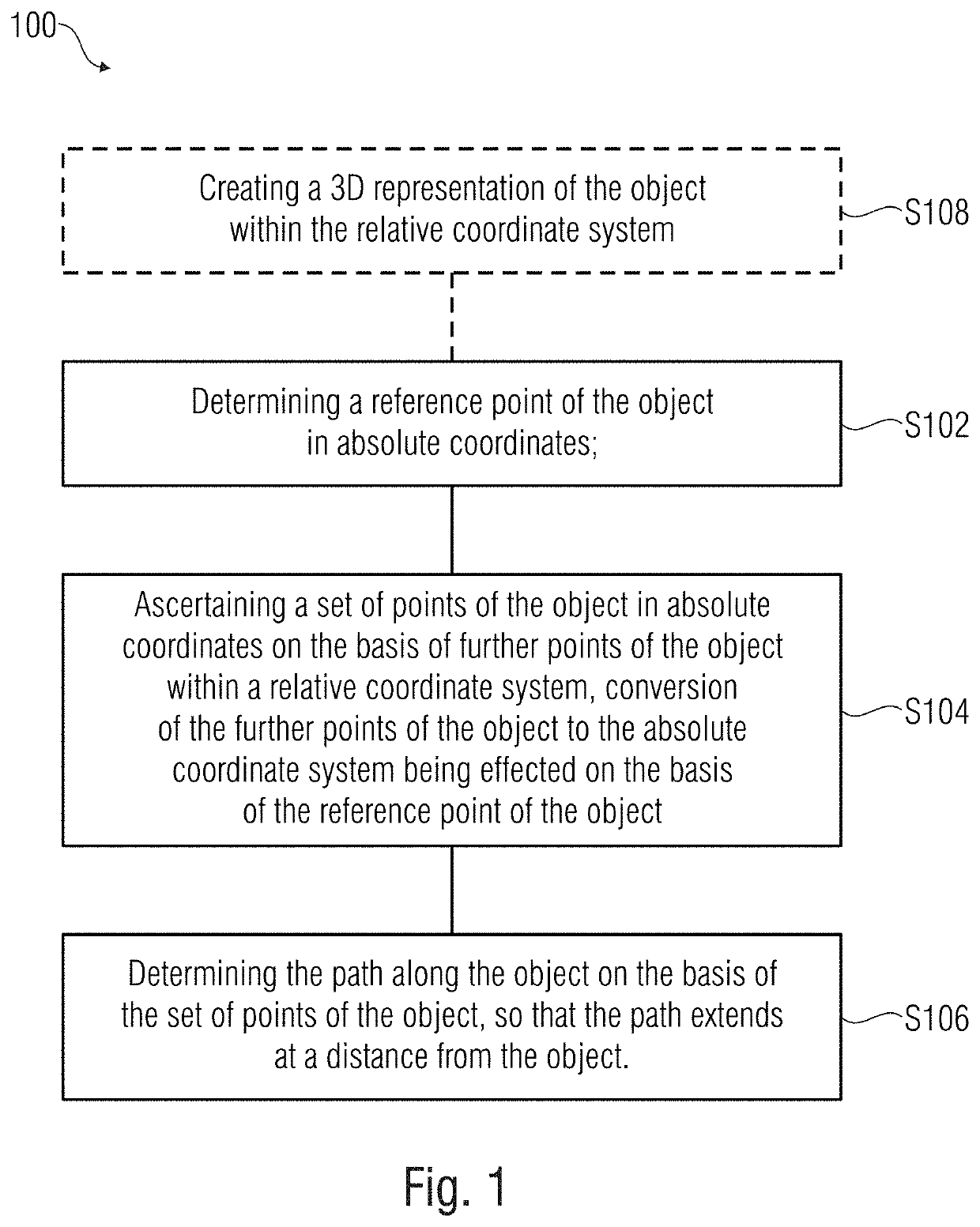

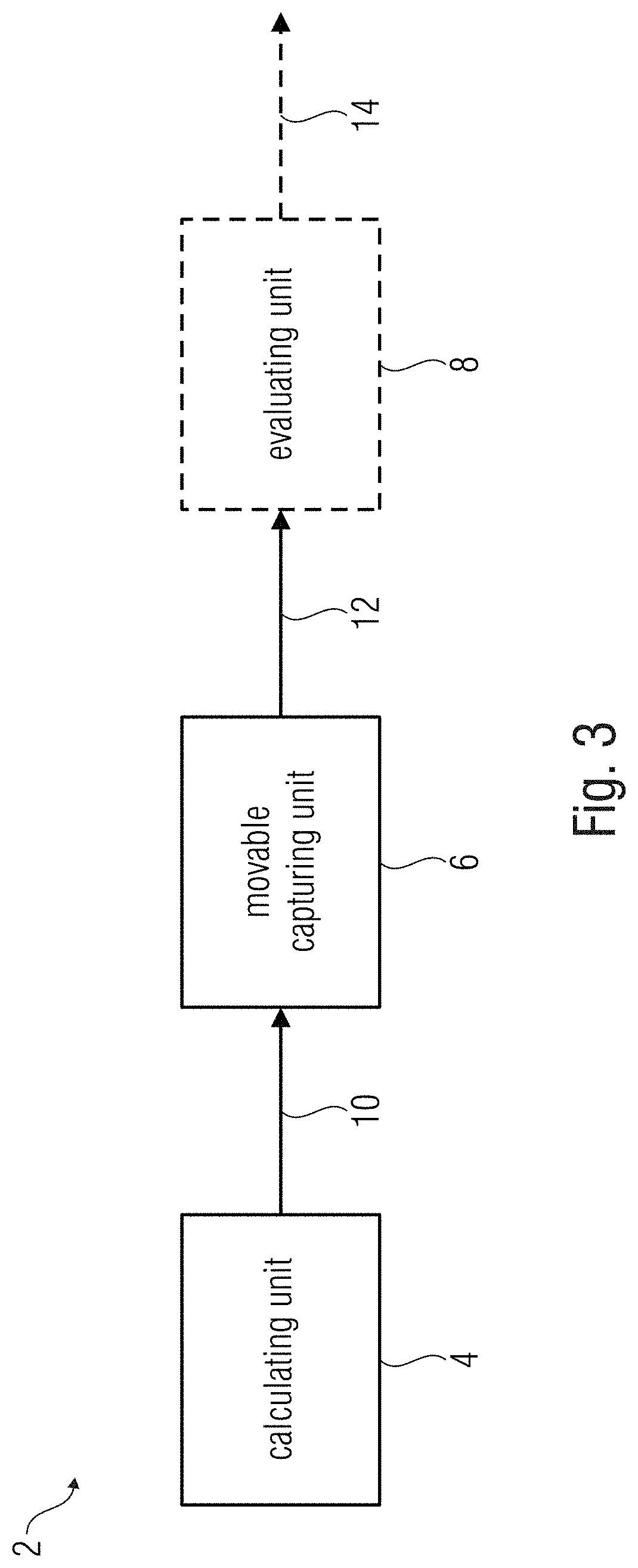

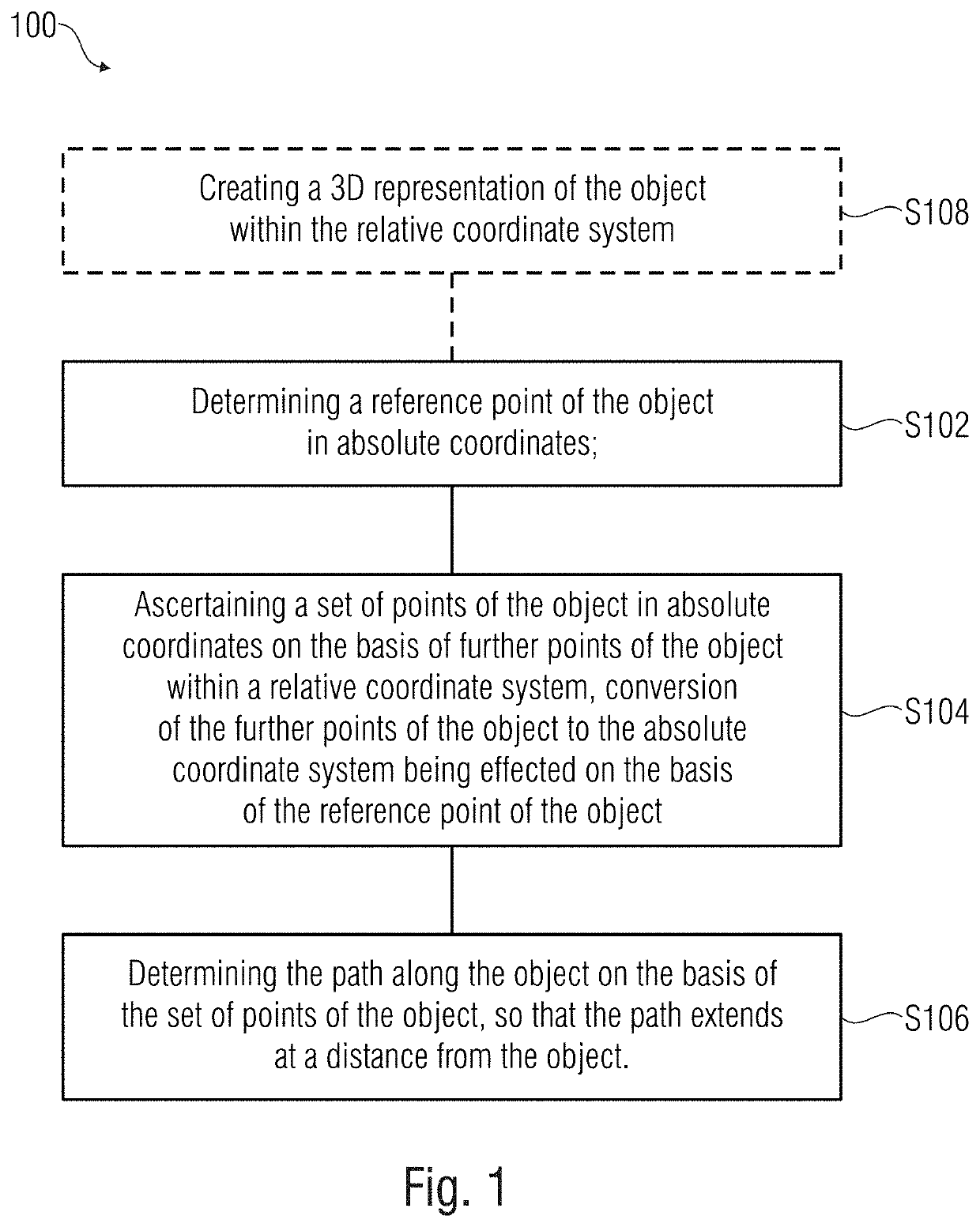

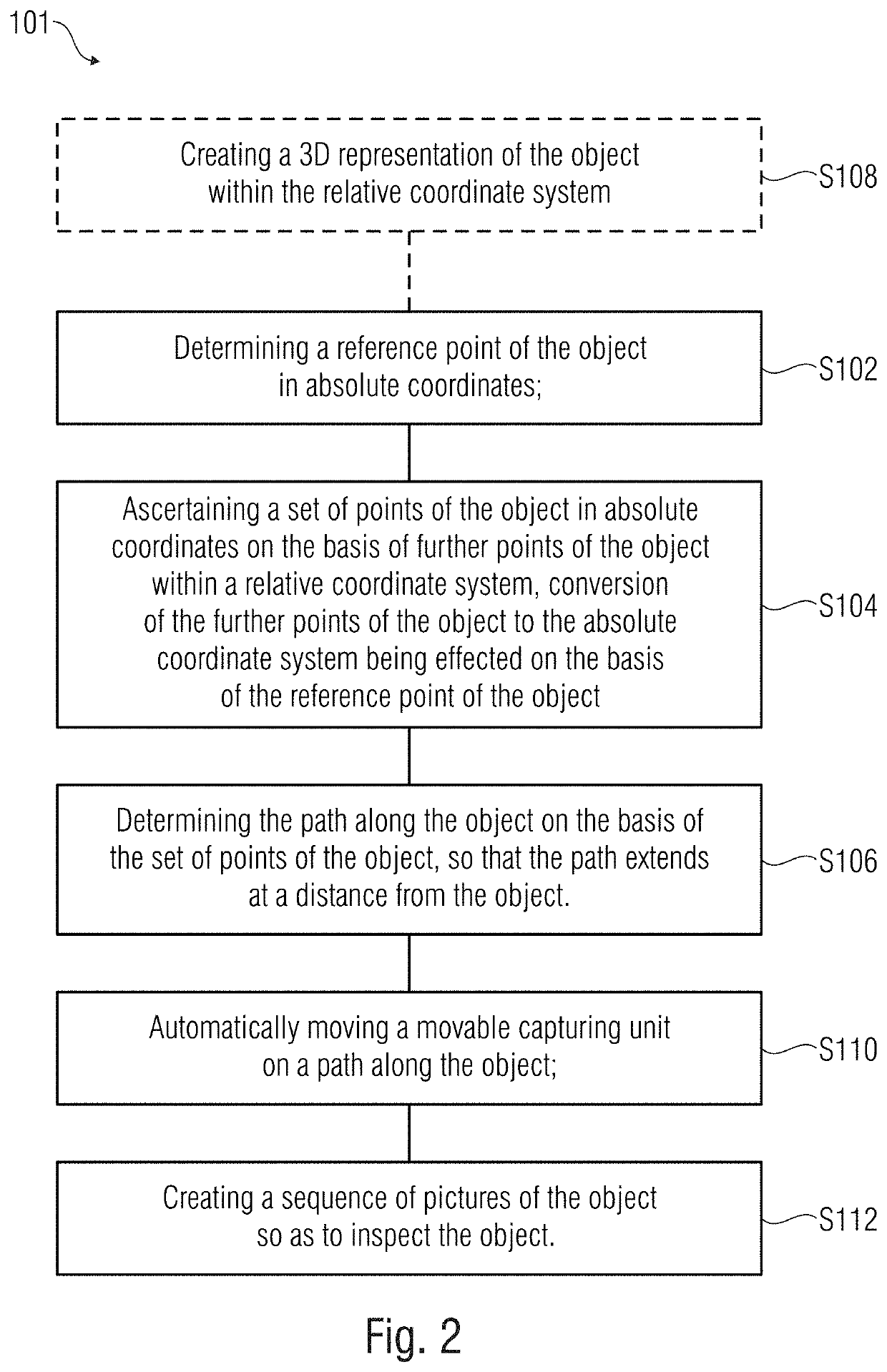

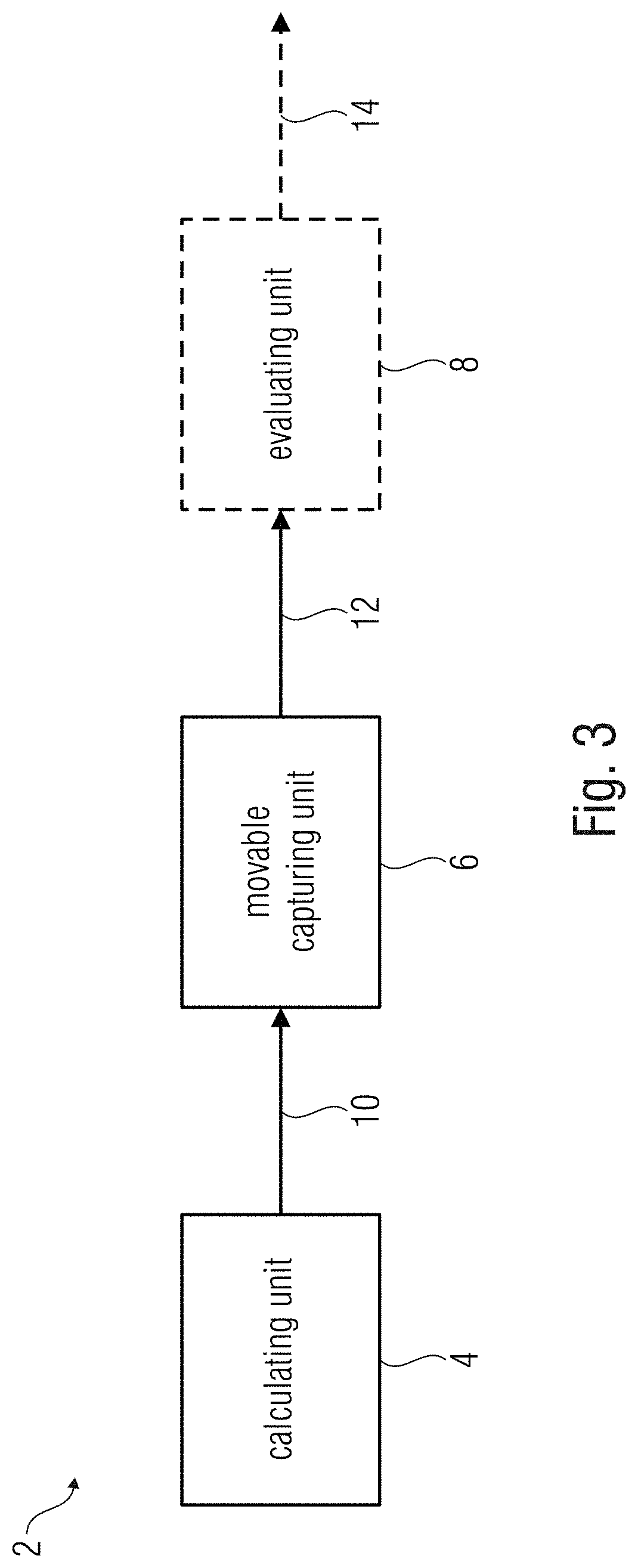

Method of determining a path along an object, system and method for automatically inspecting an object

ActiveUS20200005655A1Automate inspectionAvoid expensiveGeometric CADRegistering/indicating working of vehiclesPattern recognitionEngineering

A method of determining a path along an object includes a step of “determining a reference point of the object in absolute coordinates”, a step of “ascertaining a set of points of the object in absolute coordinates on the basis of further points of the object within a relative coordinate system, conversion of the further points of the object to the absolute coordinate system being effected on the basis of the reference point of the object”, and a step of “determining the path along the object on the basis of the set of points of the object, so that the path extends at a distance from the object”.

Owner:TOP SEVEN GMBH & CO KG

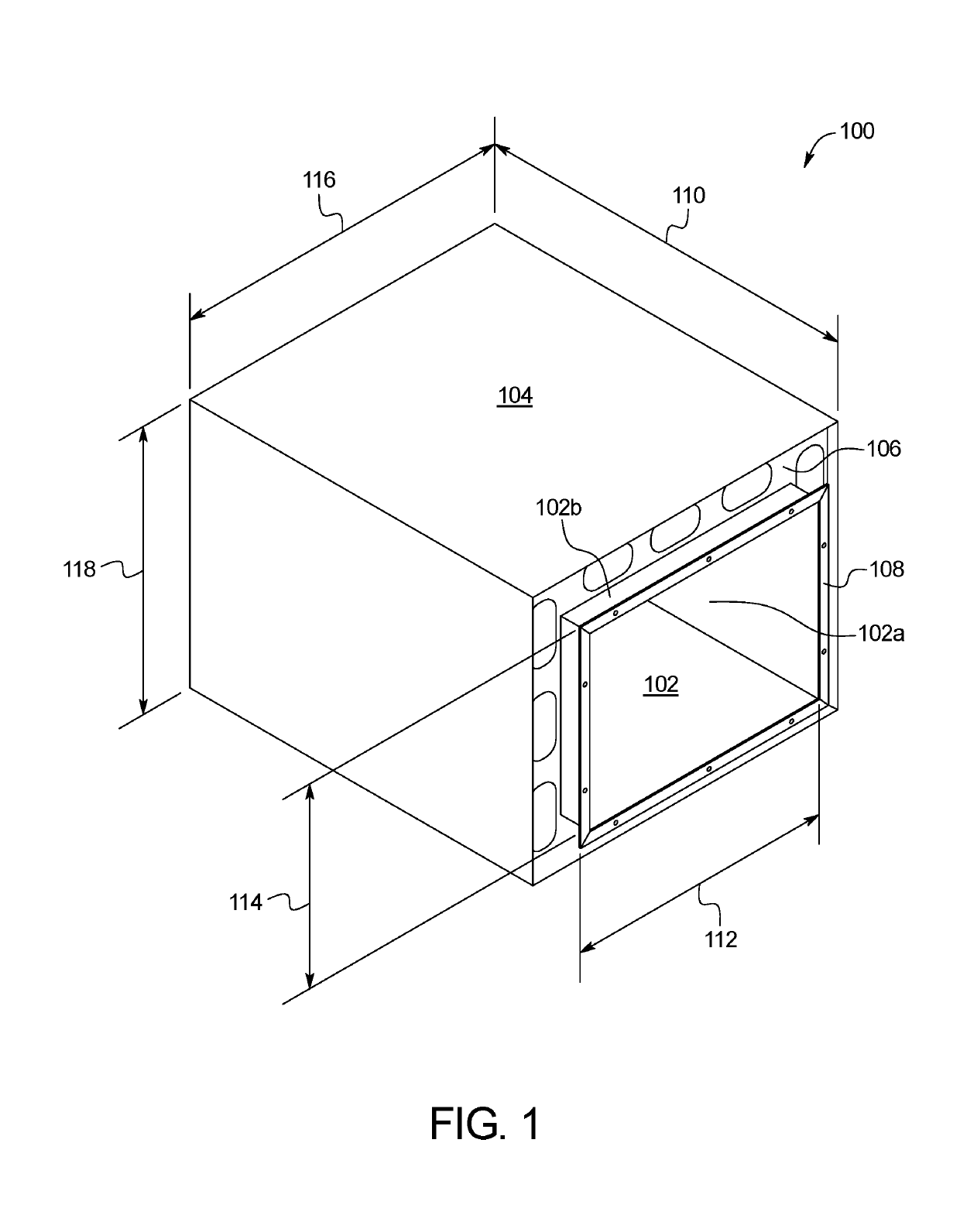

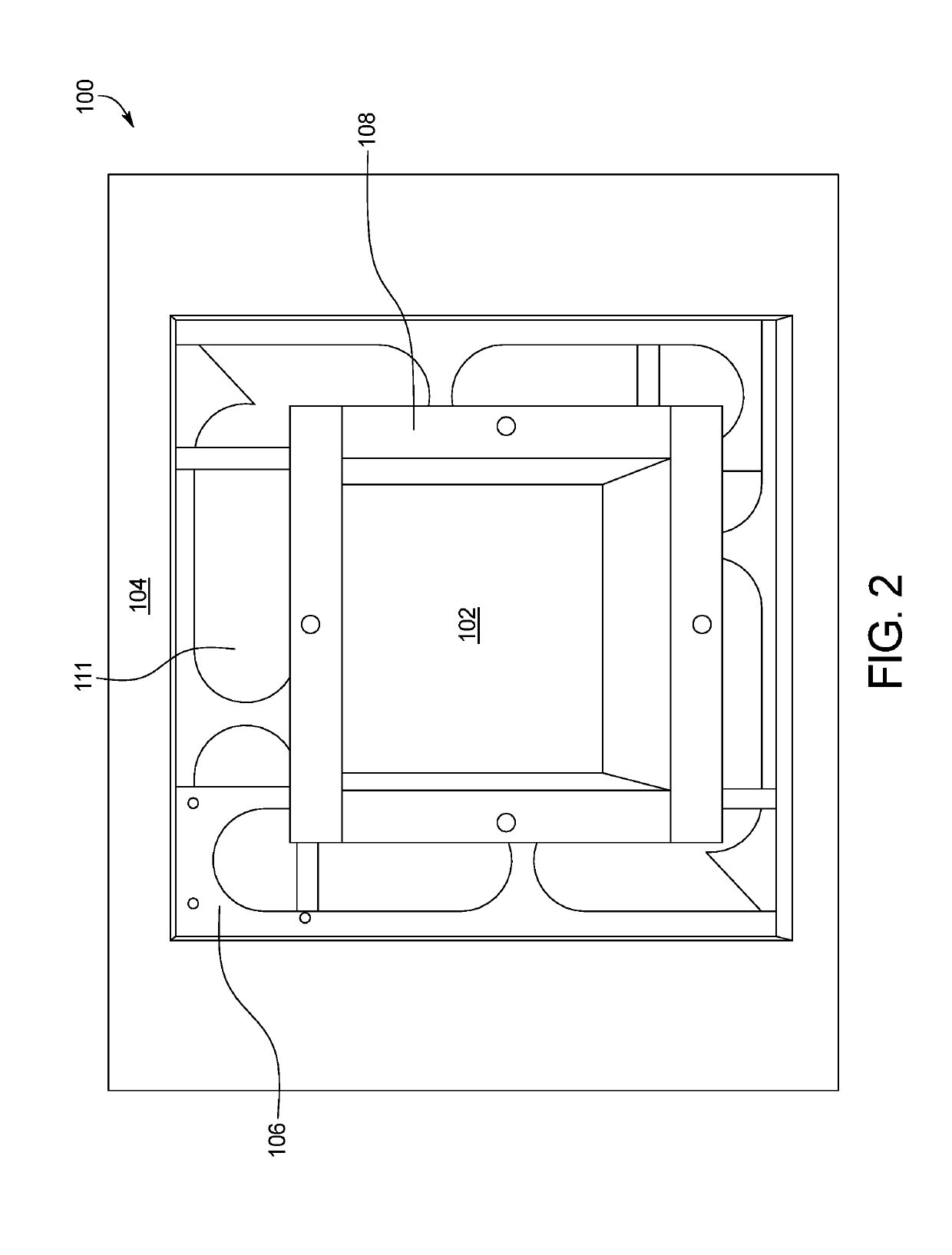

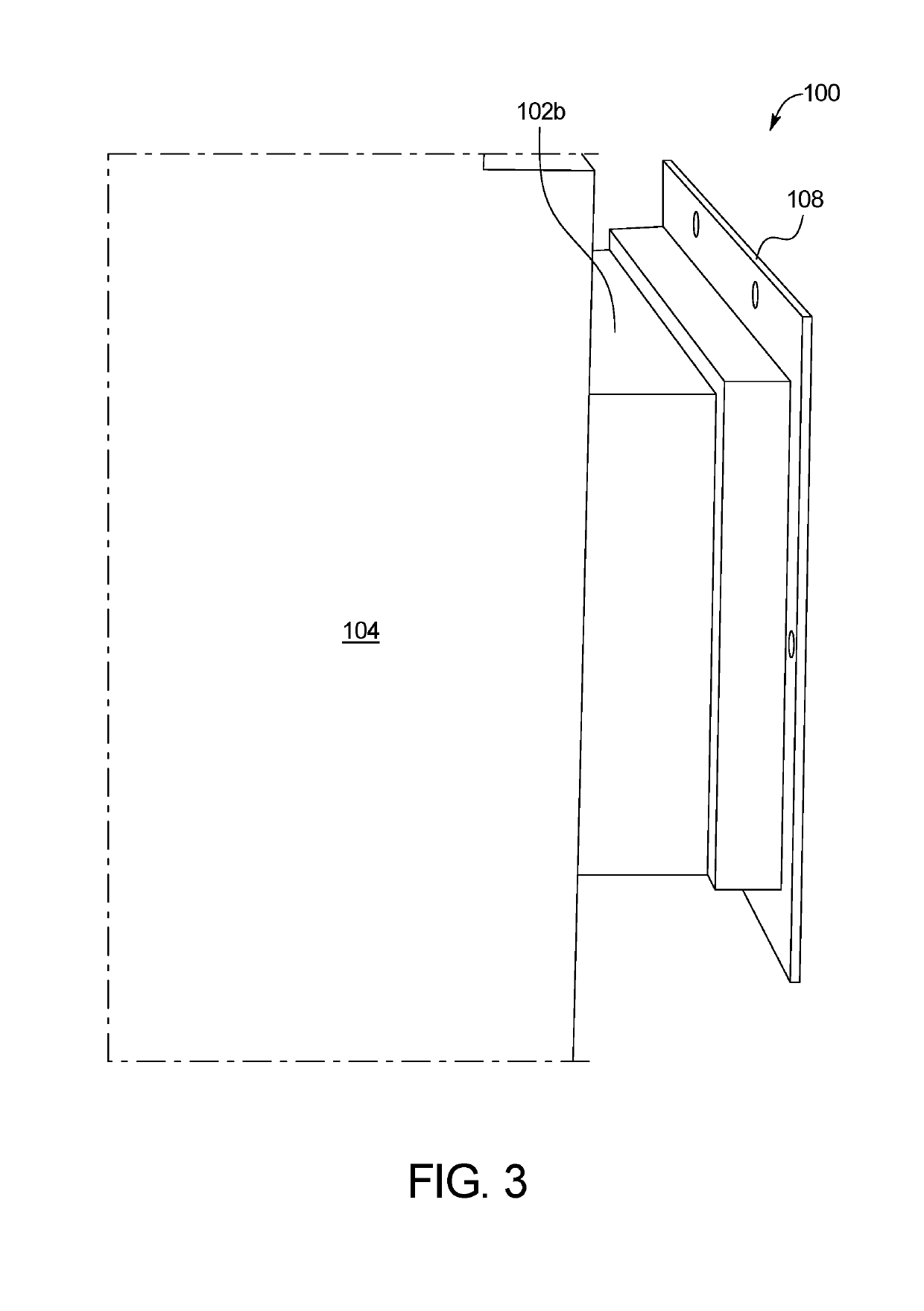

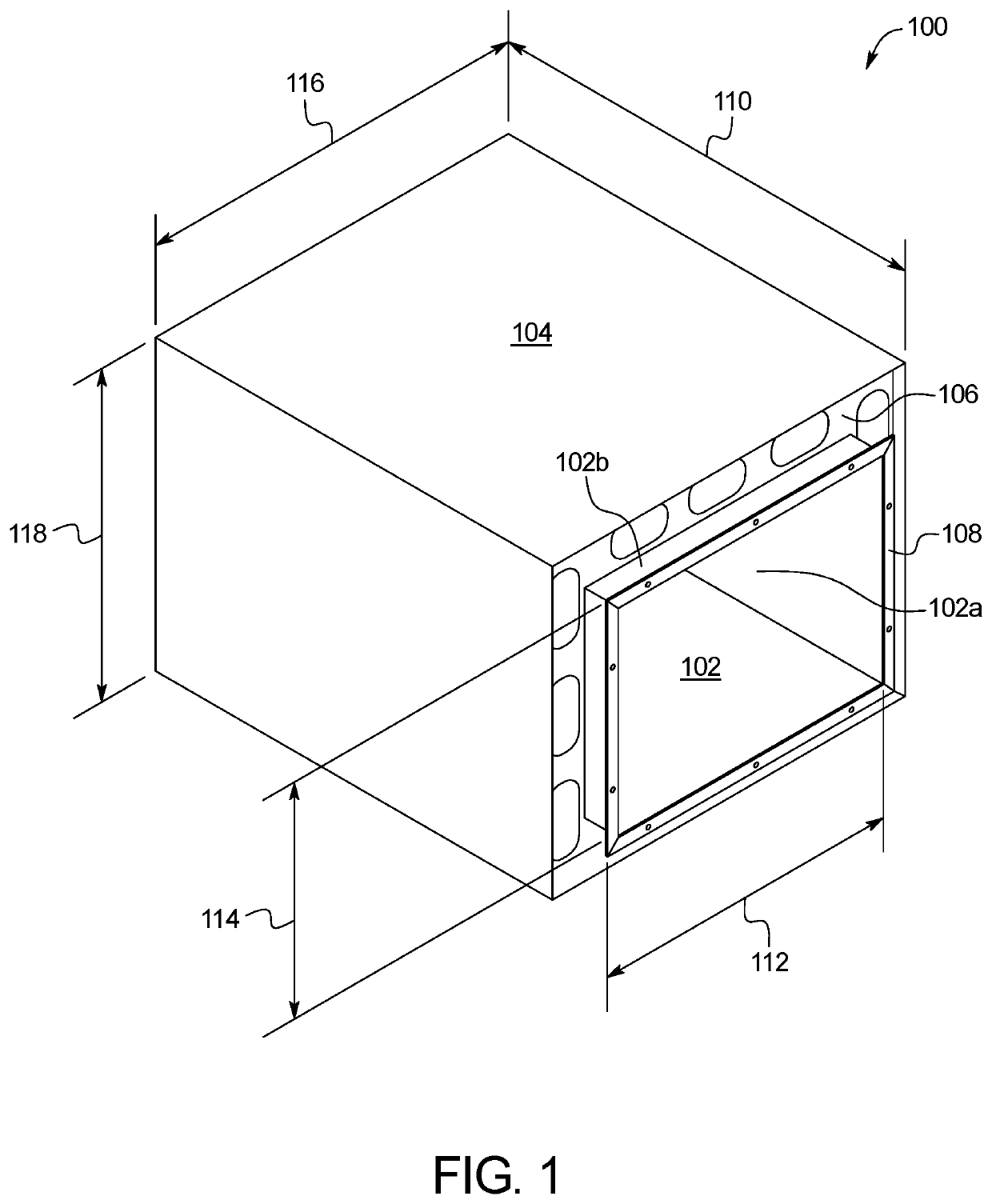

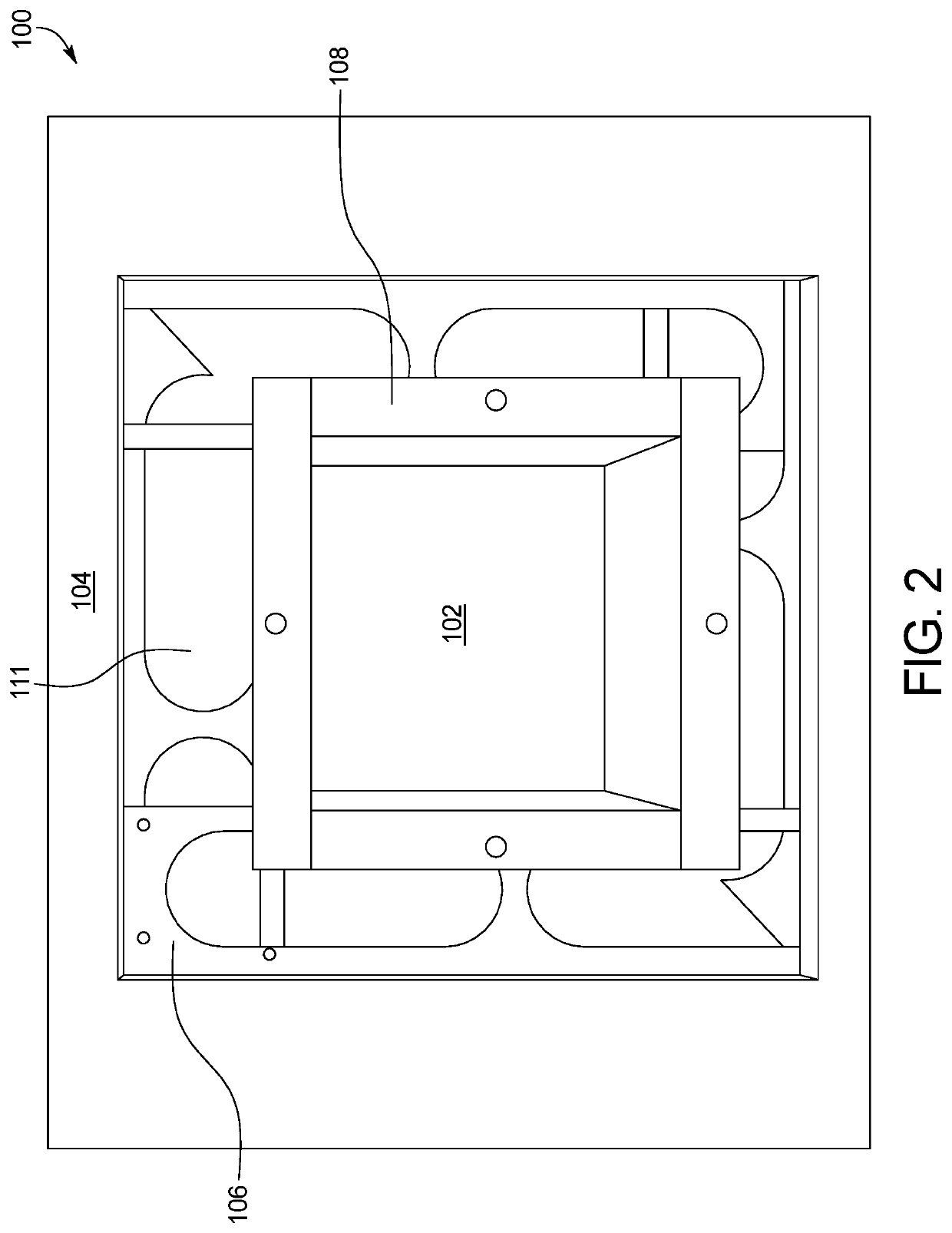

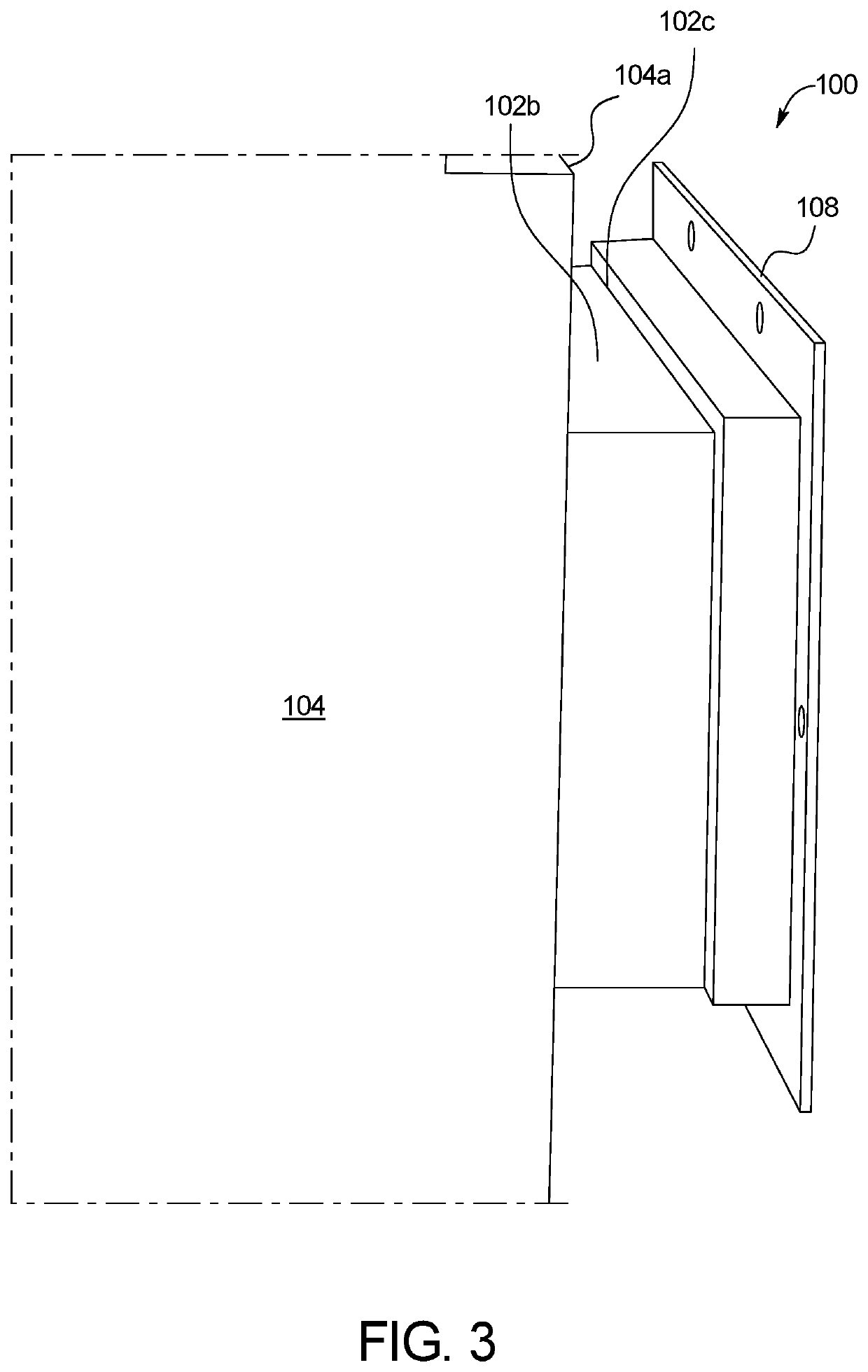

Pre-Fabricated Grease Duct System

ActiveUS20190293301A1Reduce riskAutomate inspectionDucting arrangementsDomestic stoves or rangesMetal stripsDouble wall

The present double walled grease duct includes a tubular outer shell surrounding a tubular inner liner, wherein a spacer is positioned perpendicular to the walls of the outer shell and the inner liner. The spacer can include a plurality of vertical metal strips extend from a top edge of the spacer to the bottom edge of the spacer, wherein the top edge of the spacer contacts the walls of the outer shell and wherein the bottom edge of the spacer contacts the walls of the inner liner. The metal strips resist the different rates of thermal expansion between the outer shell and inner liner ultimately preventing the collapse of the inner liner under pressure from thermal expansion.

Owner:VAN PACKER

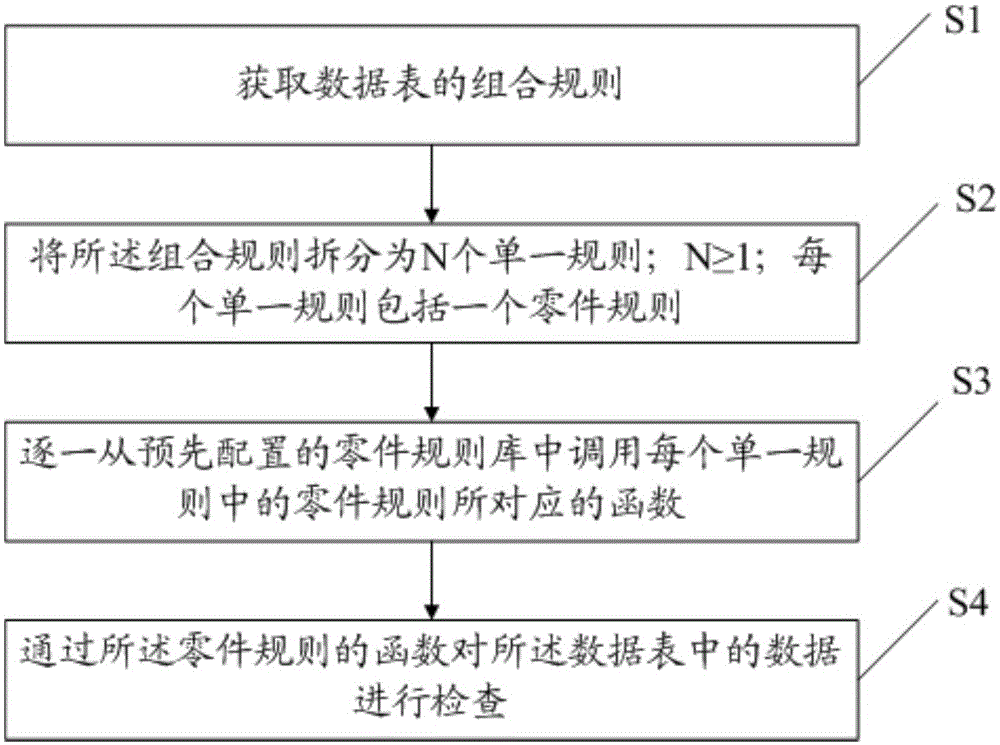

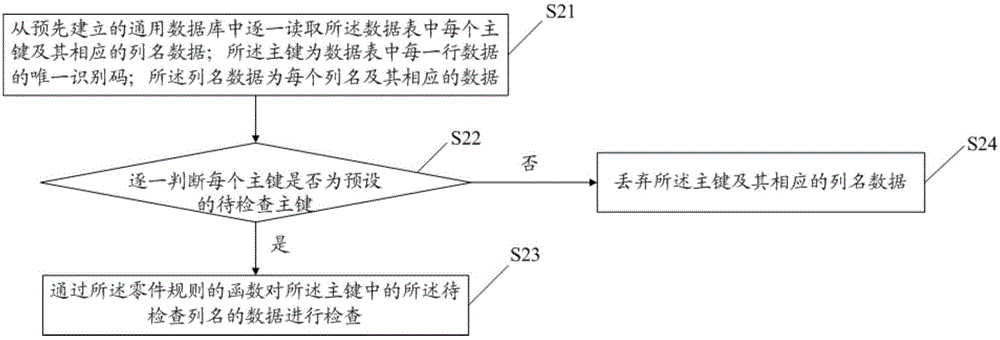

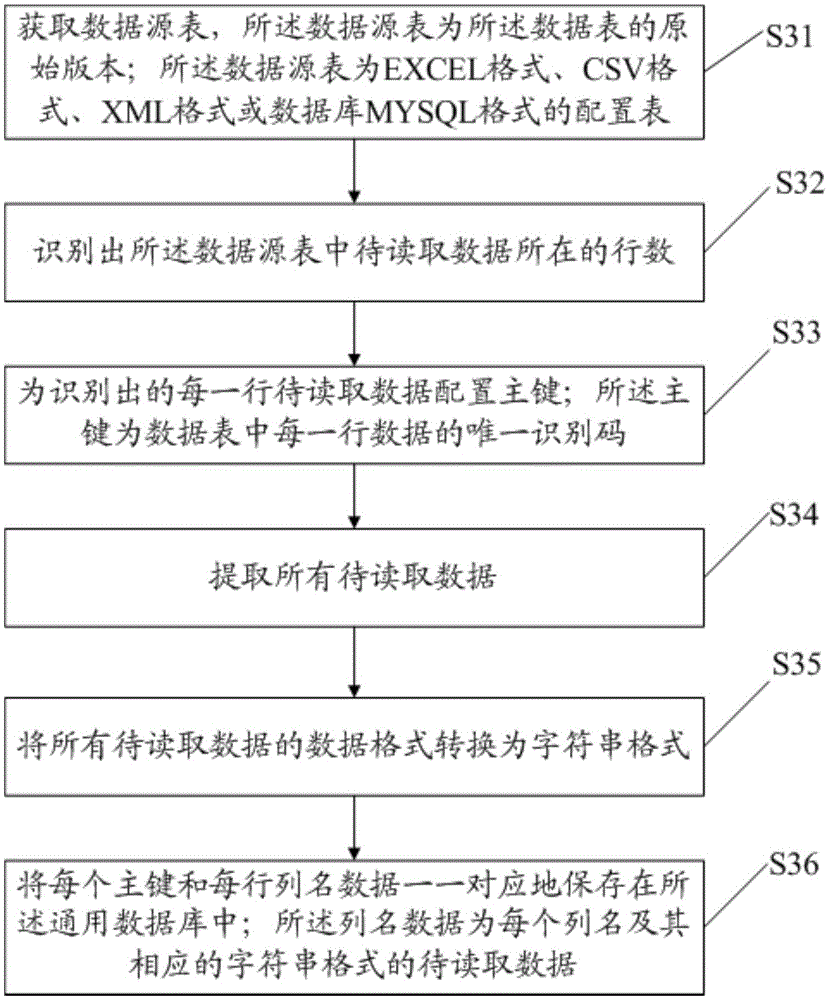

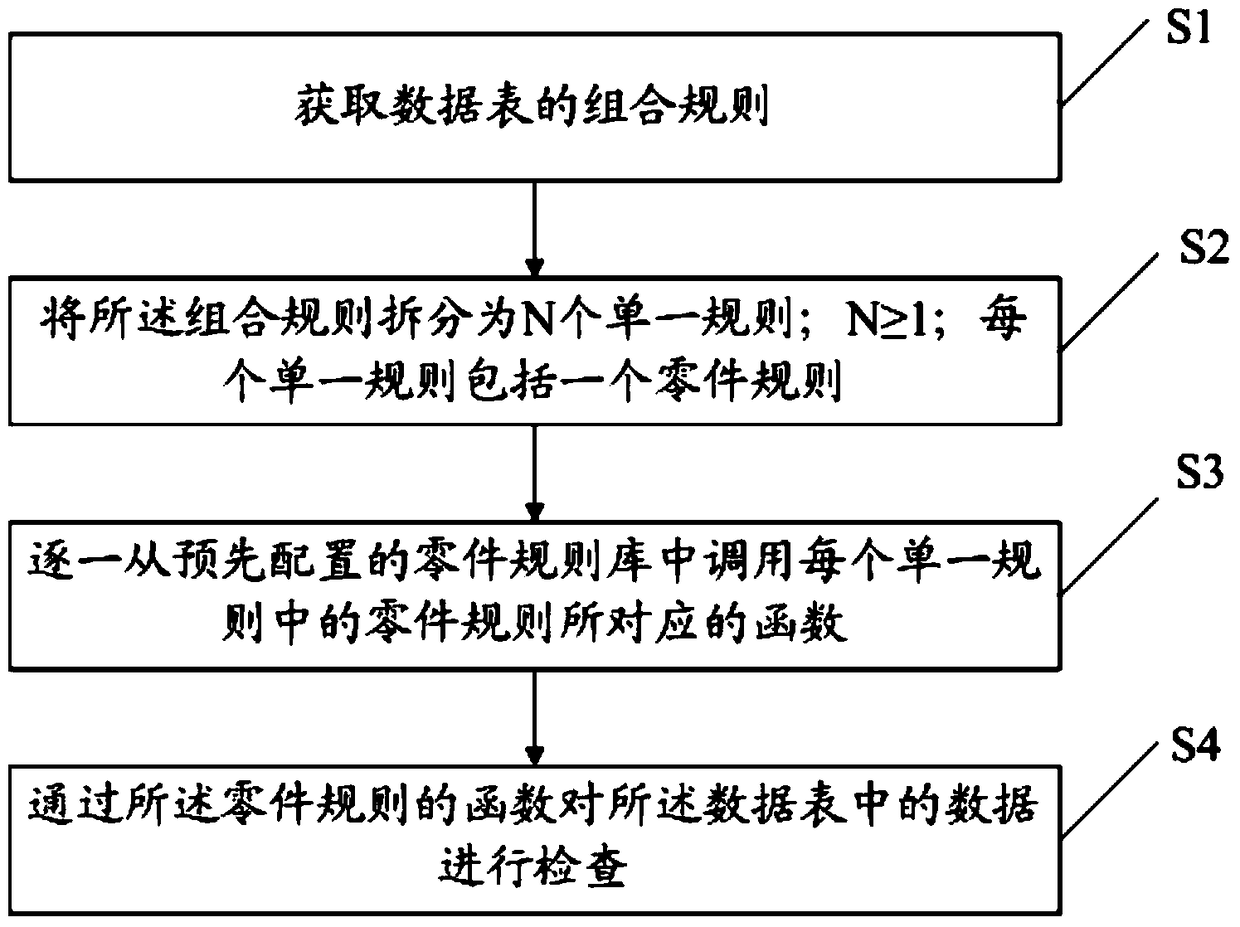

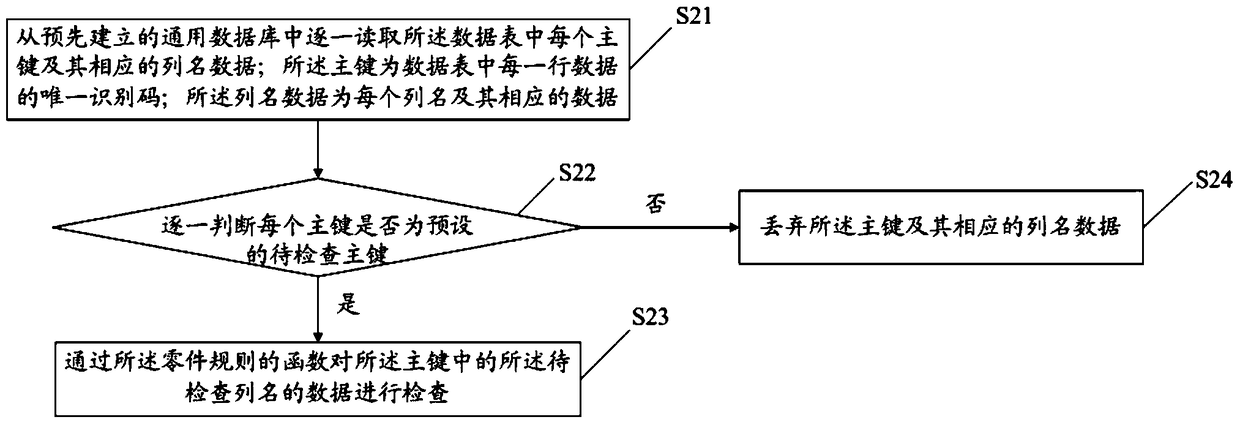

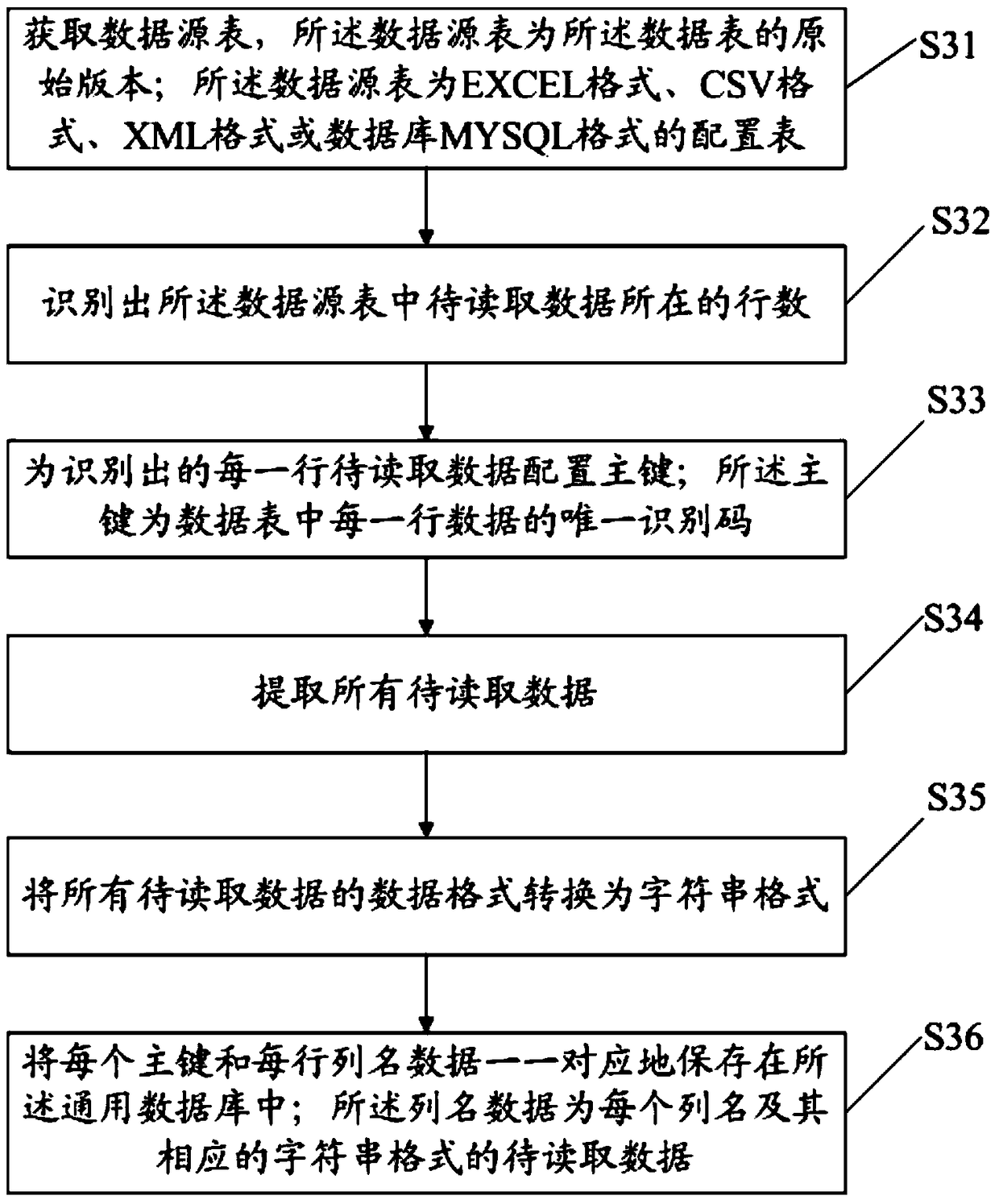

Data sheet inspection method and device

ActiveCN105094843AImprove inspection efficiencyImprove accuracySpecific program execution arrangementsCombining rulesData mining

The invention discloses a data sheet inspection method and device. The method comprises the steps of acquiring a combined rule of a data sheet; splitting the combined rule into N single rules, wherein N>=1, and each single rule comprises a part rule; calling a function corresponding to the part rule of each single rule one by one from a preconfigured part rule base; inspecting the data in the data sheet according to the functions of the part rules. By the adoption of the embodiment, data sheet inspection efficiency and accuracy can be improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

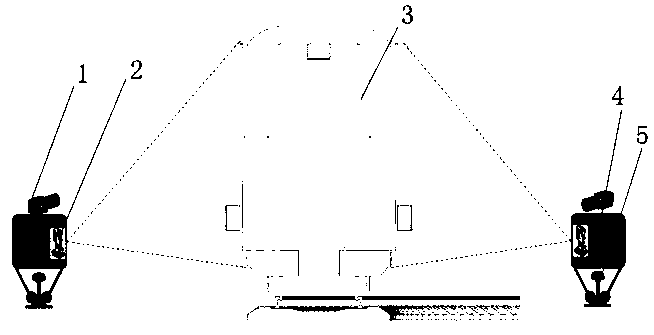

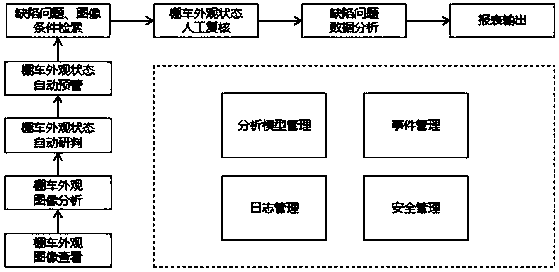

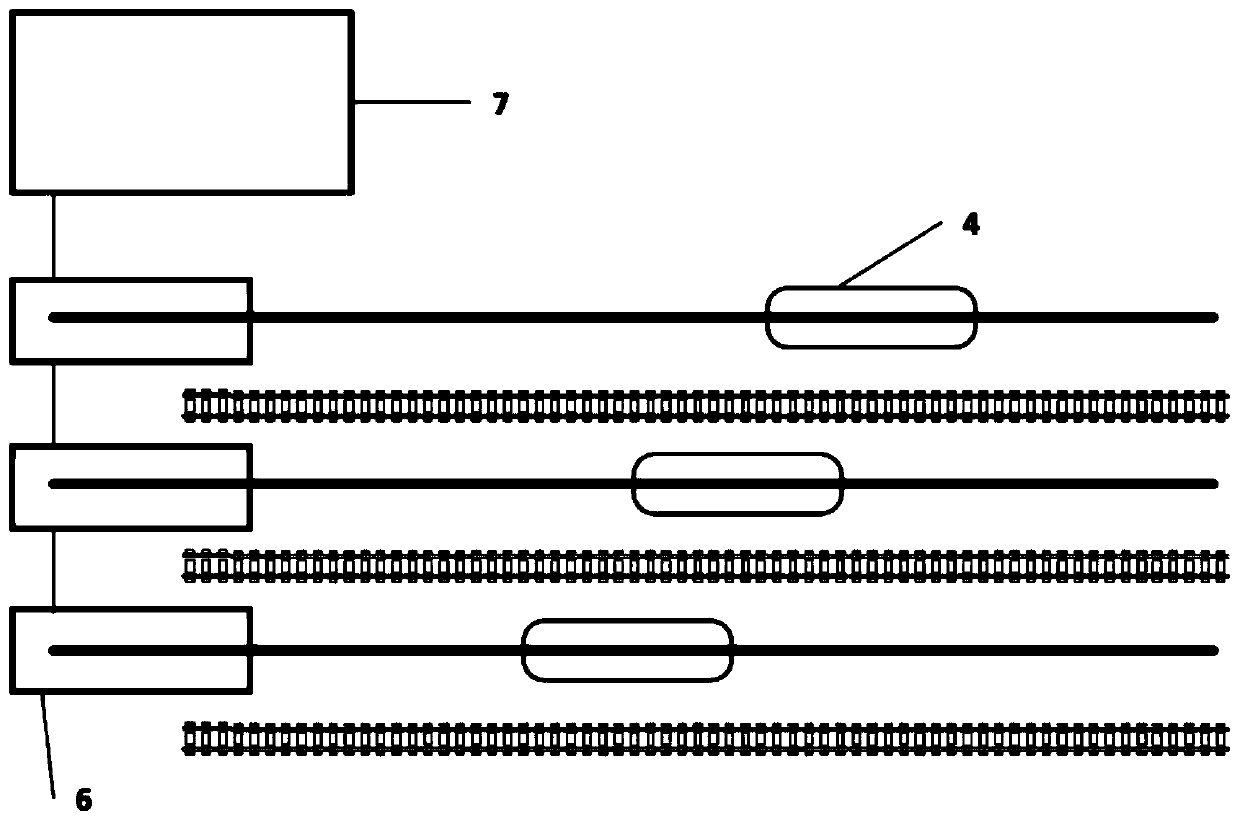

Intelligent image analysis system of railway cargo inspection robot

ActiveCN110524553AReal-time presentation of the inspection processPresent results in real timeProgramme-controlled manipulatorImaging analysisEngineering

The invention discloses an intelligent image analysis system of a railway goods inspection robot. A robot erected beside a railway rail slides on a customized rail for routing inspection, and the appearance state and the cargo loading state of a freight boxcar are collected in real time, wherein the appearance state and the cargo loading state include the appearance damage, the physical deformation, the sealing state and the like, and the data is transmitted to a station intelligent analysis terminal through a station WIFI, a 5G technology or a wired transmission mode, so that the inspection content and an inspection result during the cargo inspection process are presented in real time. By combining the information, such as the cargo inspection professional inspection standard, the normalappearance state of the cargo boxcar, etc., through a rear-end image analysis software, and by means of a machine learning algorithm and the model comparison, the functions of automatic inspection, fault warning, early warning and the like of the appearance state and the cargo loading state of the cargo boxcar, are achieved.

Owner:佳讯飞鸿(北京)智能科技研究院有限公司

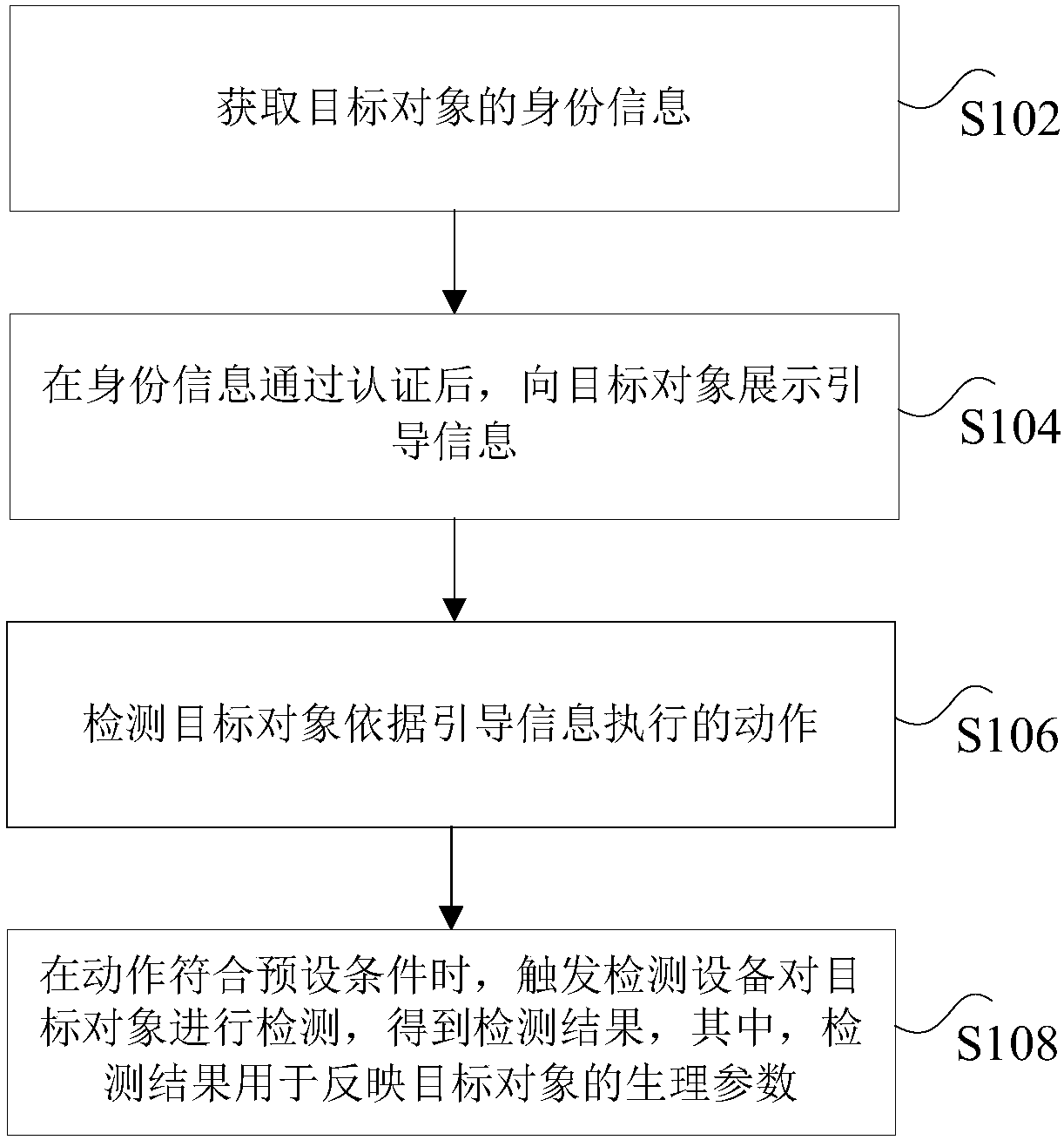

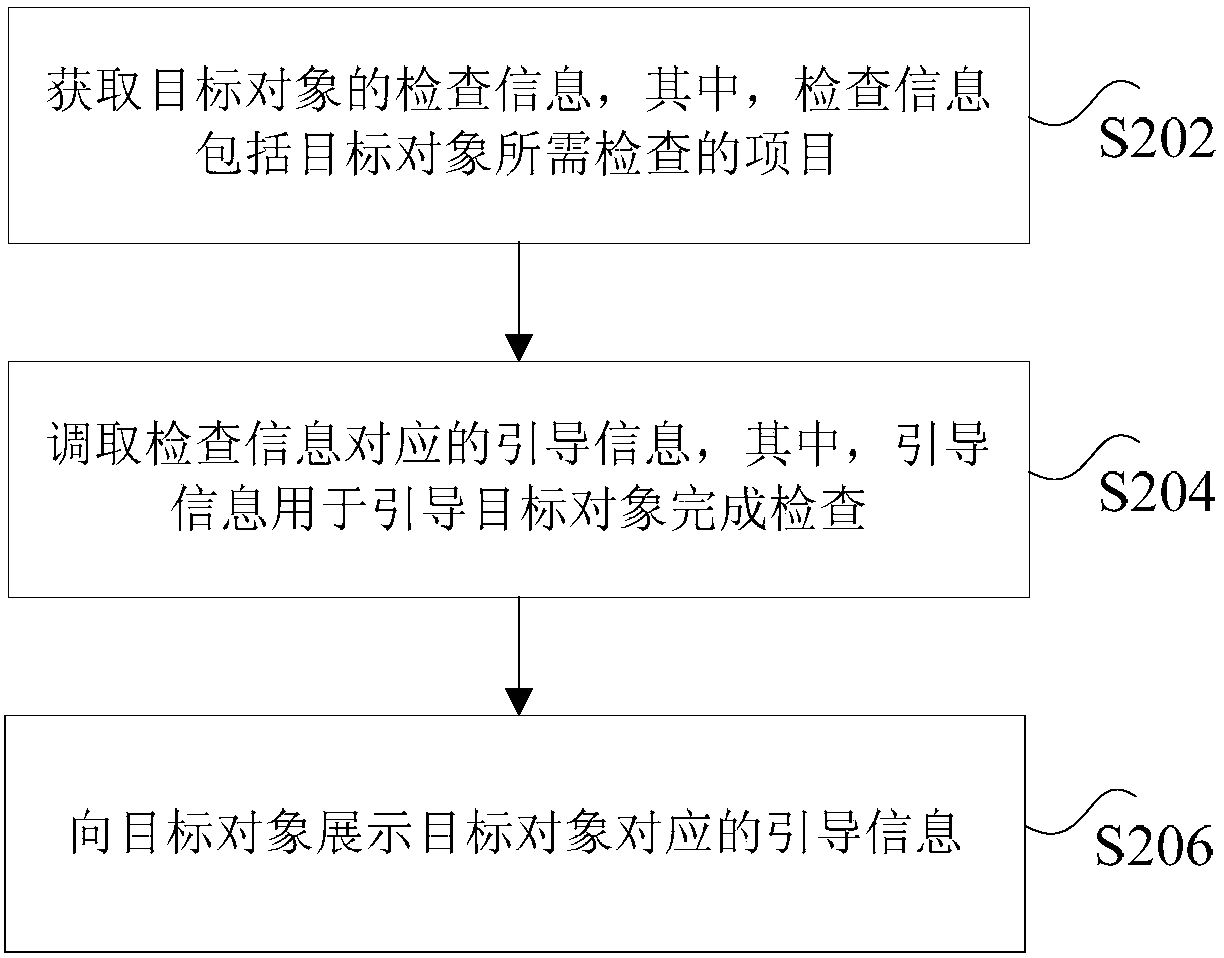

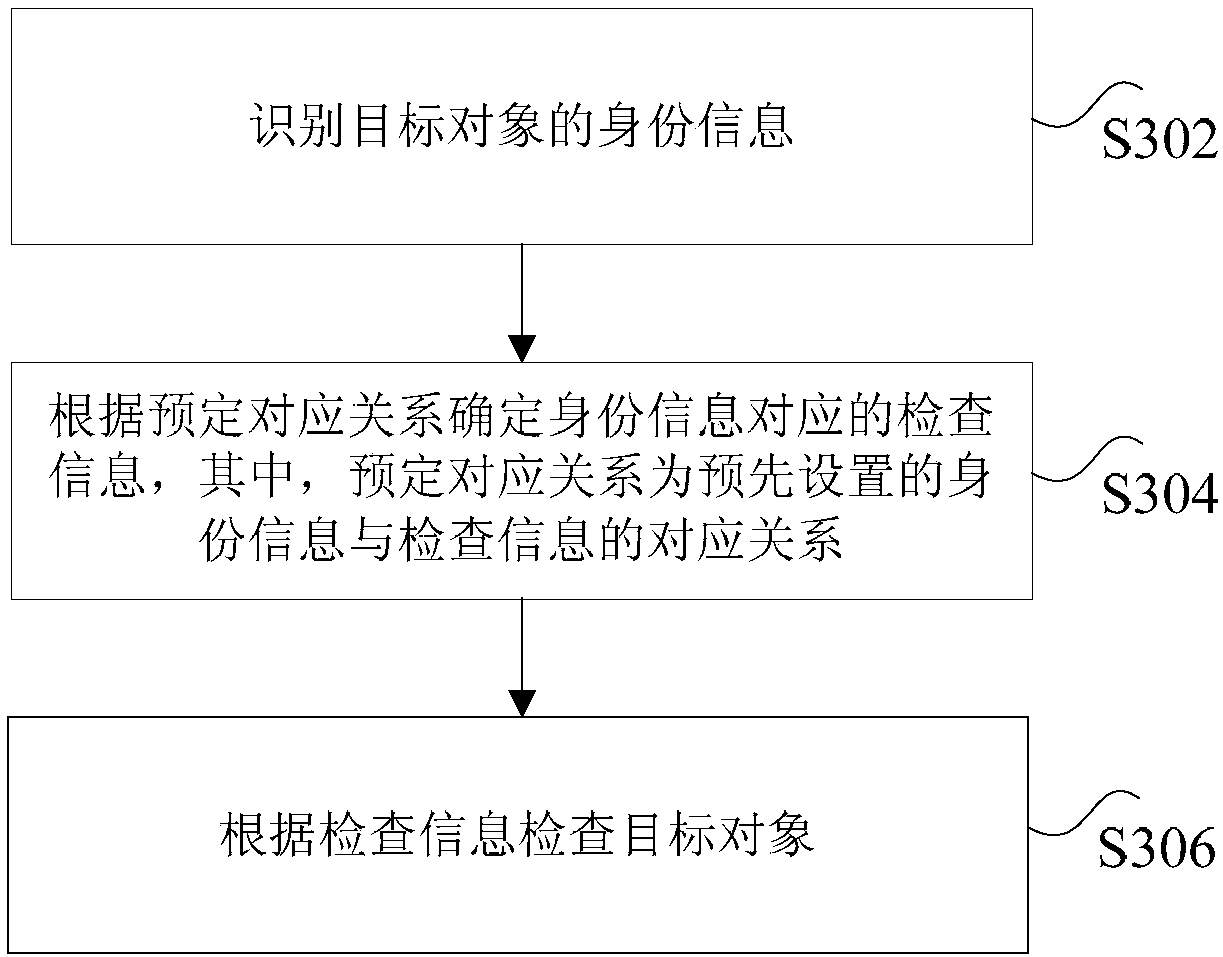

Guiding method, inspection method and inspection system

InactiveCN108324296AAutomate inspectionSolve technical problems that cannot automatically perform physical checks on usersComputerised tomographsTomographyComputer sciencePhysical examination

The invention discloses a guiding method, an inspection method and an inspection system. The method comprises the steps that identity information of a target object is obtained; after the identity information passes authentication, guiding information is displayed to the target object; the action executed by the target object according to the guiding information is inspected; when the action conforms to the preset condition, inspection equipment is triggered to inspect the target object, and an inspection result is obtained, wherein the inspection result is used for reflecting physiological parameters of the target object. Accordingly, the technical problem that in the prior art, physical examination cannot be automatically conducted on a user is solved.

Owner:朱光宇

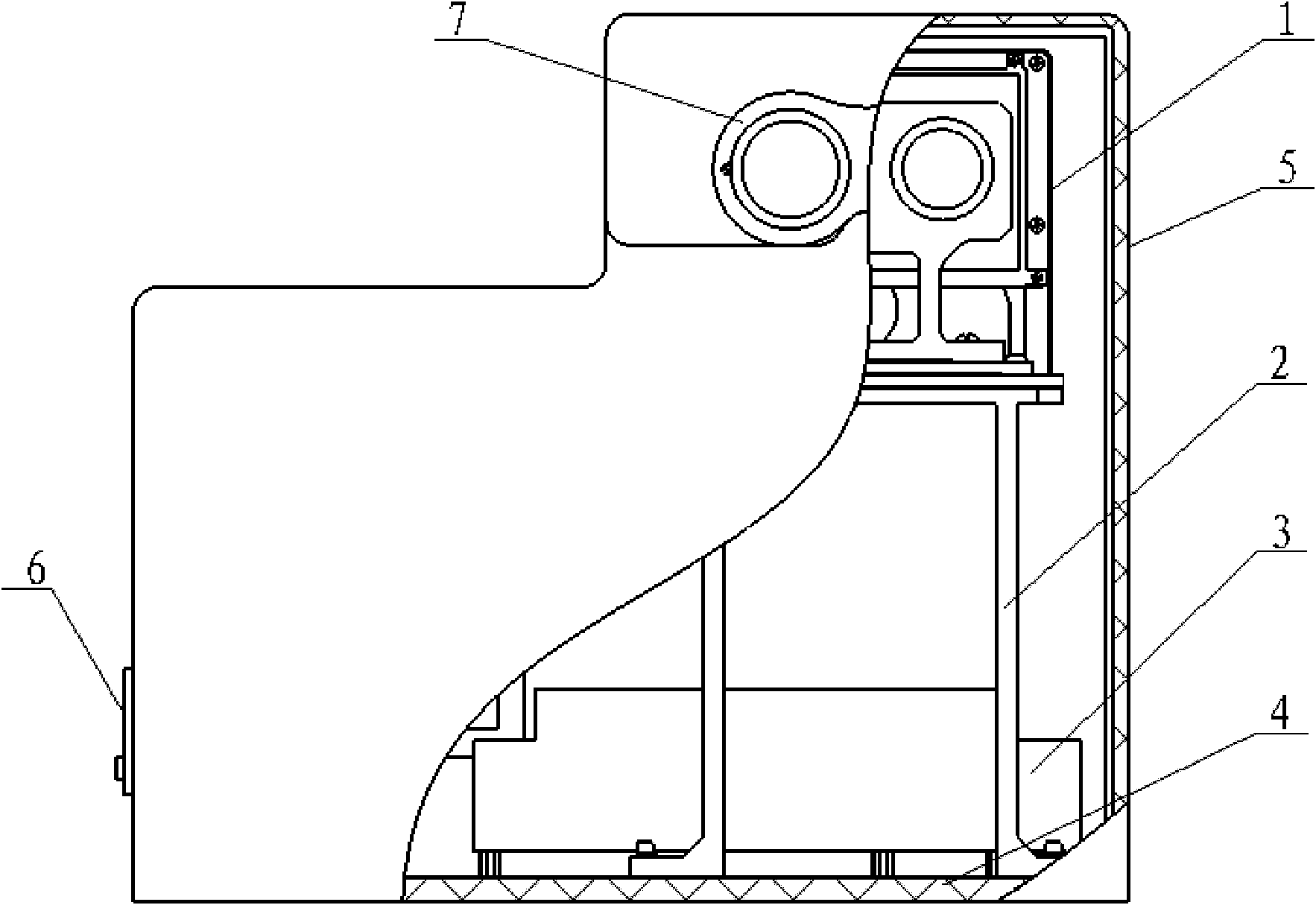

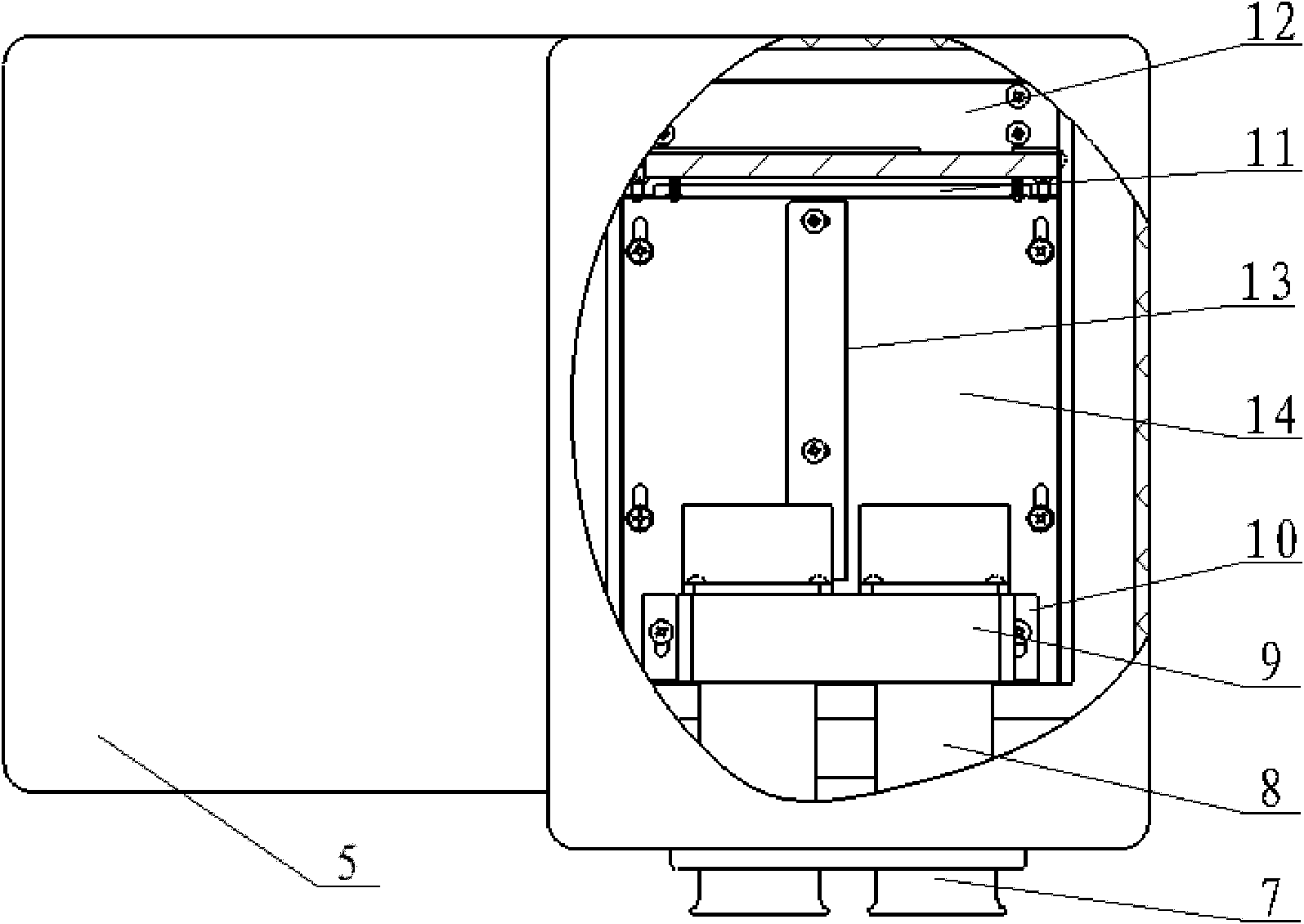

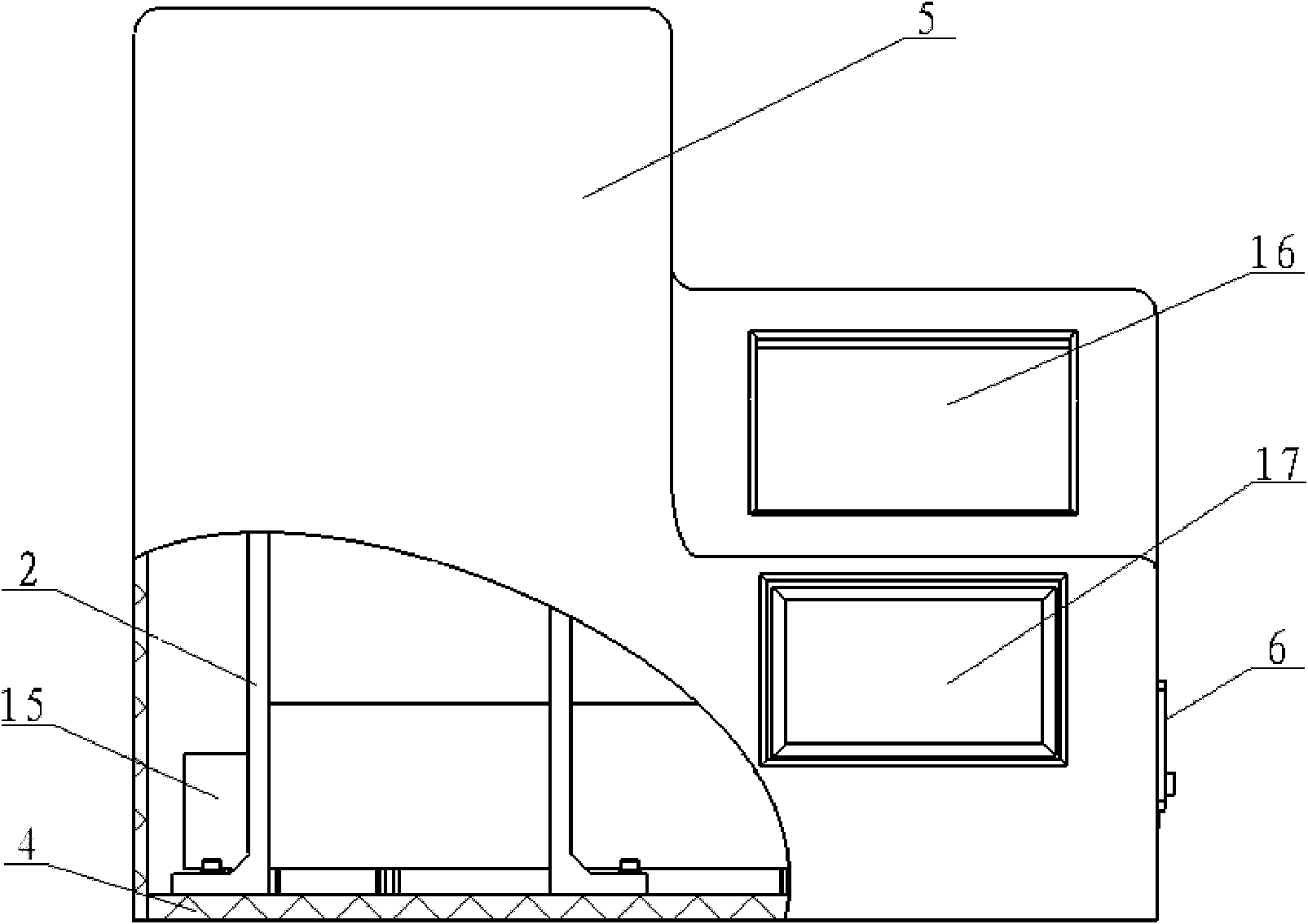

Automatic stereoscopic vision and colour vision examination instrument

InactiveCN102068238ASave human effortImprove efficiencyEye diagnosticsData processing systemVisual perception

The invention discloses an automatic stereoscopic vision and colour vision examination instrument, which belongs to the technical field of medical instruments and relates to an examination instrument. The technical problem to be solved is an automatic electronic stereoscopic vision and colour vision examination instrument. The technical scheme comprises an imaging system, an imaging system support, a data processing system, a bottom plate, a case, a power switch and other parts. The imaging system support is mounted on the right part of the bottom plate; the imaging system is mounted on the imaging system support; a computer in the data processing system is mounted on the bottom plate; a display screen is fixed on the case; a printer is mounted under the display screen; the power switch is inlaid on the right sidewall of the case; and the display screen, the printer and the power switch are respectively connected with the computer through wires. The examination instrument has the advantages that the automatization of examination can be realized, the precision is high, and the functions of displaying, storage and printing a result in real time can be realized.

Owner:CHANGCHUN UP OPTOTECH

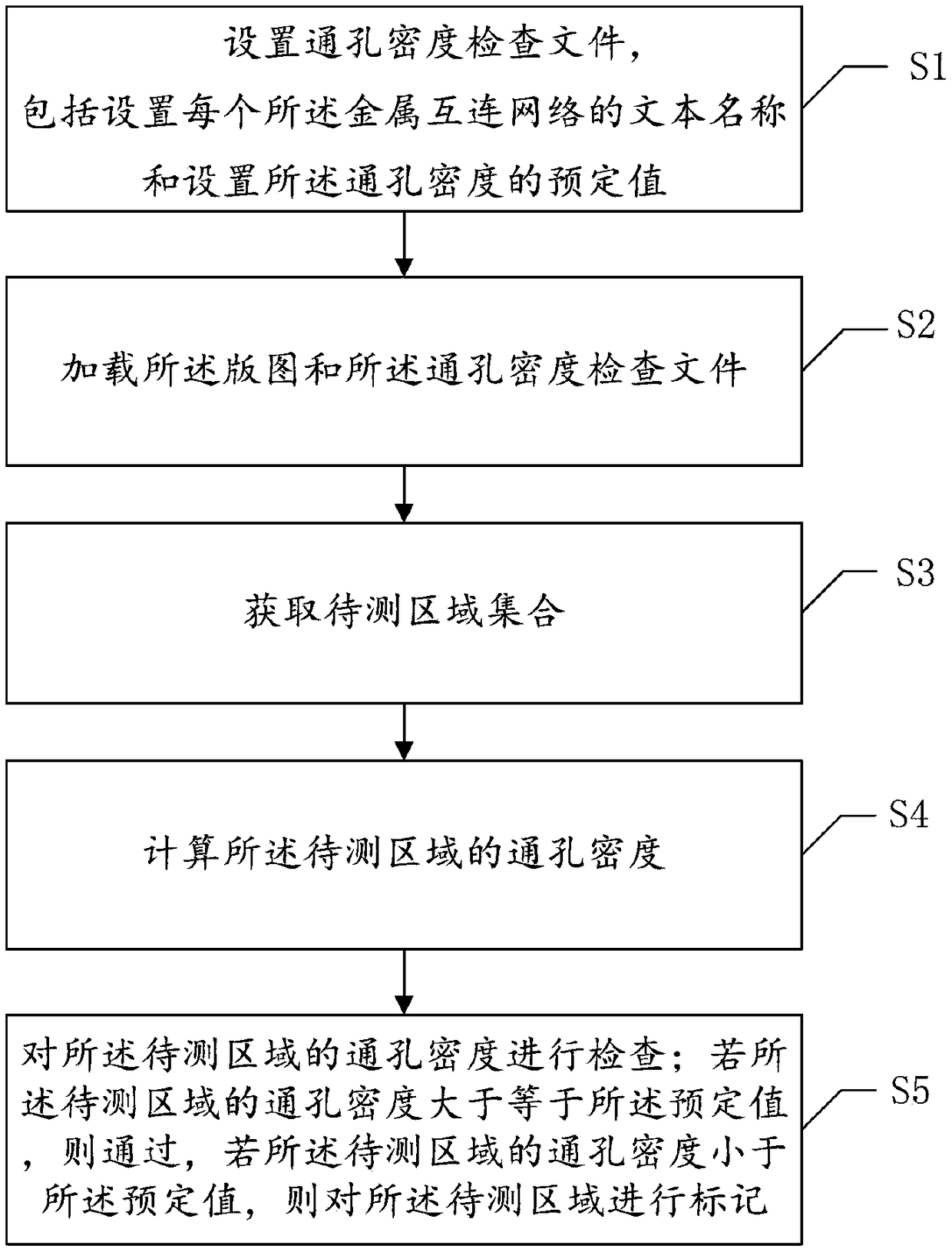

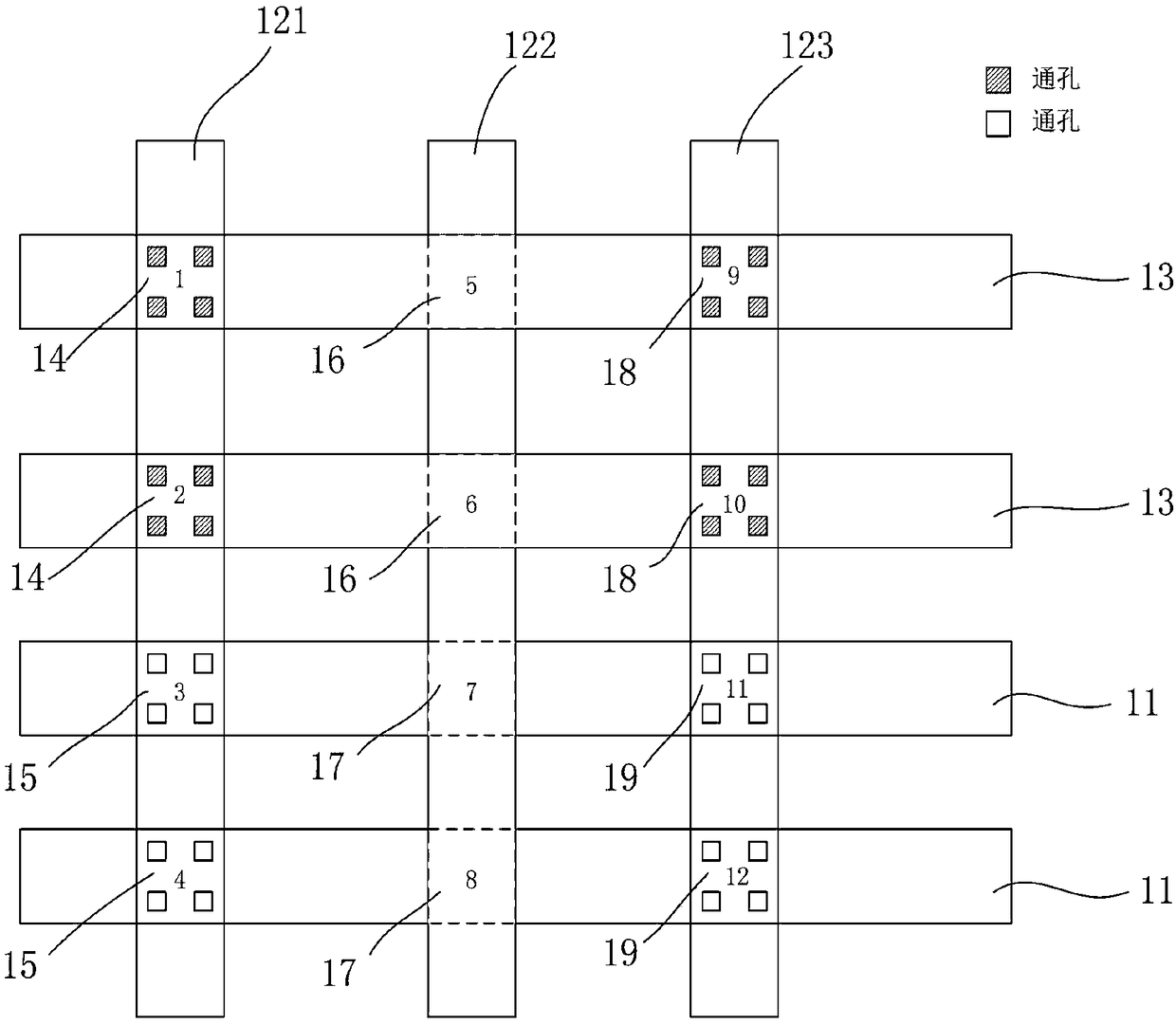

Integrated circuit layout checking method

PendingCN108830003ACheck for full coverageEasy to changeSpecial data processing applicationsDesign rule checkingIntegrated circuit layout

The invention provides an integrated circuit layout checking method. The integrated circuit layout checking method comprises the steps that a through hole density checking file is arranged; a to-be-detected area set is obtained; the through hole density of to-be-detected areas is calculated; the through hole density of to-be-detected areas is checked; if the through hole density of to-be-detectedareas is greater than or equal to a predetermined value, if yes, the through hole density of to-be-detected areas is smaller than the predetermined value, the to-be-detected areas are marked. According to the method, through hole density checking is converted into special layout design rule checking, automatic checking of the through hole density is achieved through design rule checking files, accurate positioning of missed through holes can be achieved, a checking coverage range is wide, prompt marking can be quickly and efficiently conducted on the areas which do not comfort to design rules,layout change of layout designers is facilitated, the checking efficiency is improved, and the cost is saved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

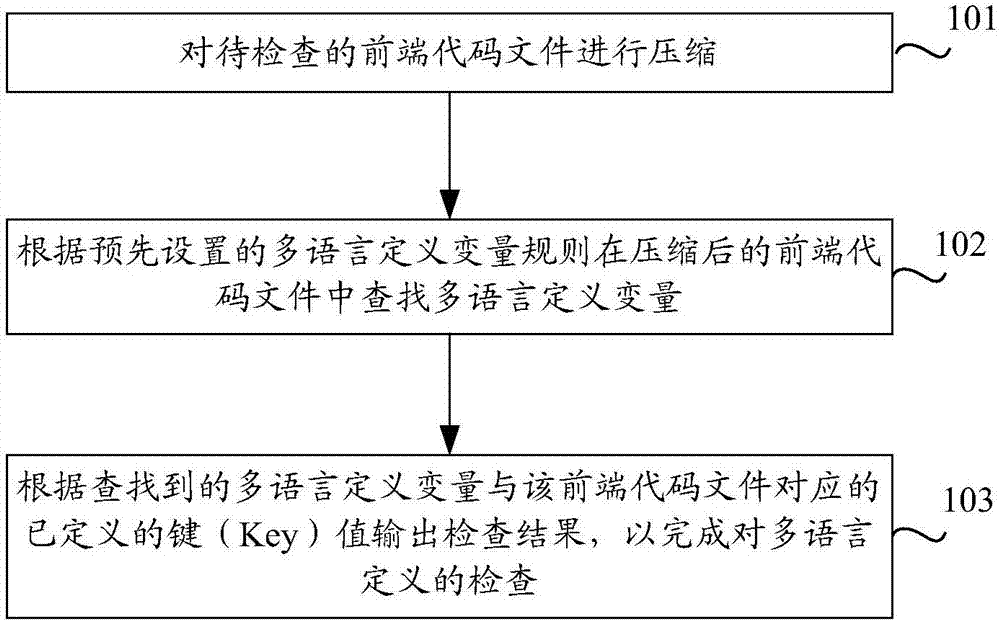

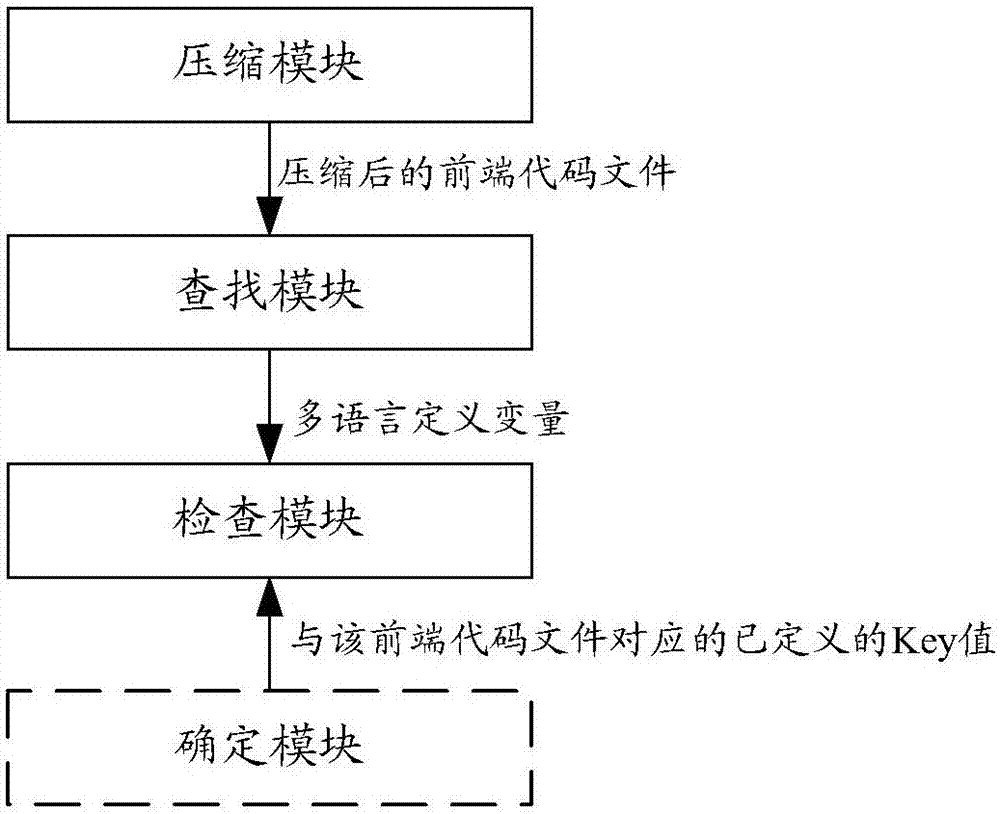

Multi-language definition checking method and device

InactiveCN107203405AImprove development efficiencyAutomate inspectionSoftware engineeringProgram controlMulti languageSoftware development

The invention discloses a multi-language definition checking method and device. The multi-language definition checking method comprises the steps that front-end code files to be checked are compressed; multi-language definition variables are looked up in the compressed front-end code files according to pre-set multi-language definition variable rules; according to the looked-up multi-language definition variables and defined key values corresponding to the front-end code files, checking results are output to complete multi-language definition checking. By adopting the embodiment, automatic multi-language definition checking is achieved, and the software development efficiency is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

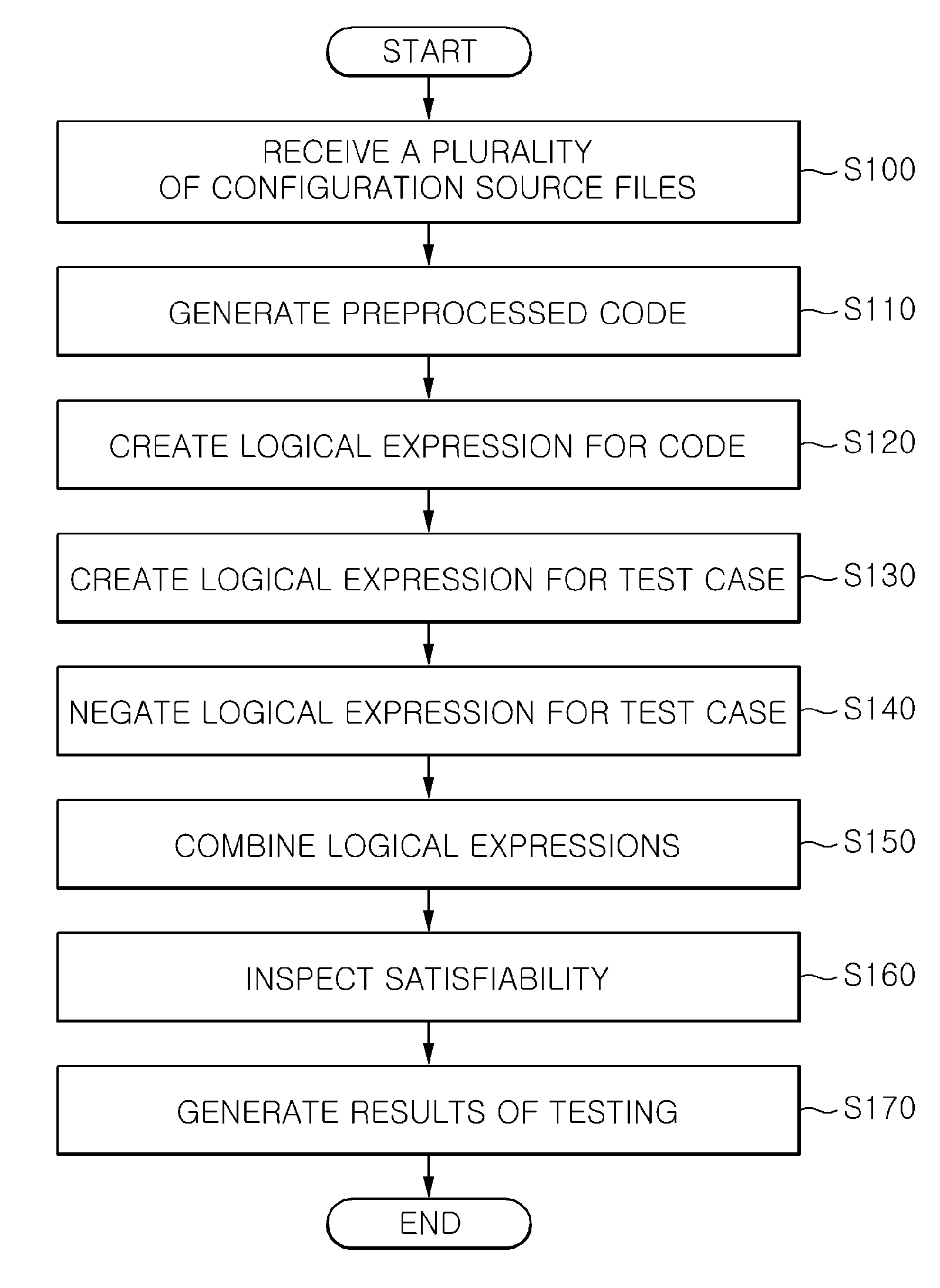

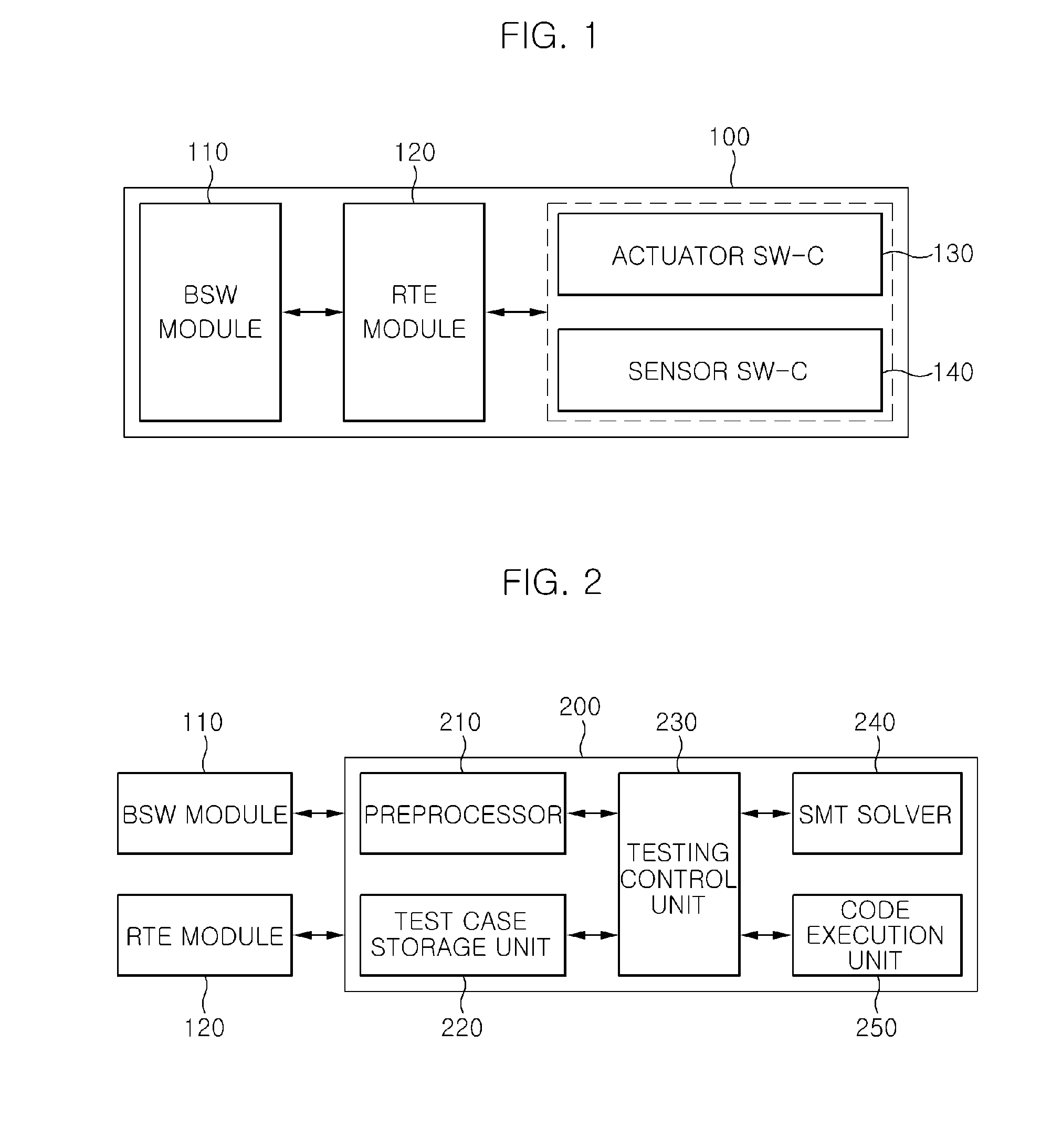

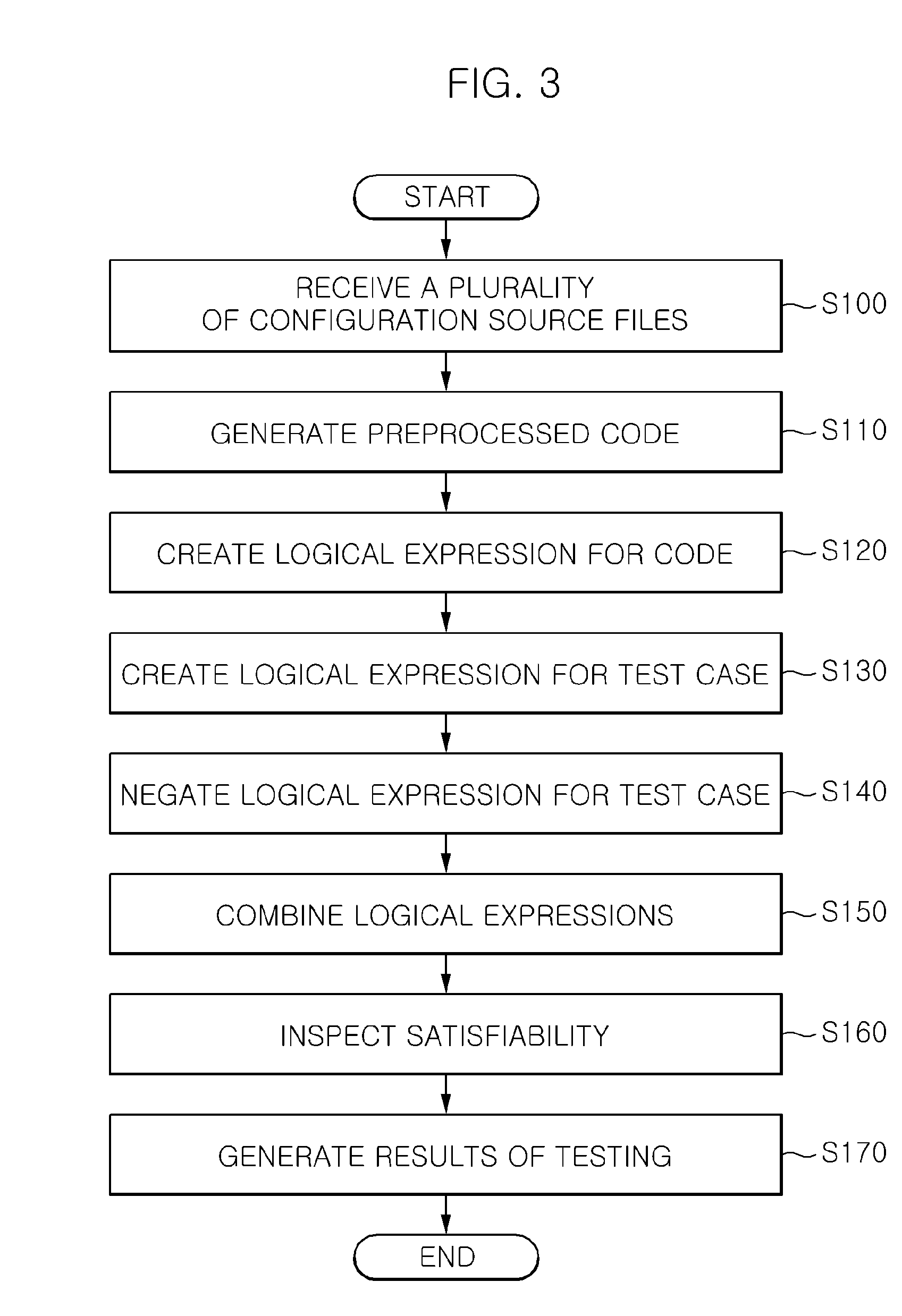

Software static testing apparatus and method

InactiveUS20120167037A1Automate inspectionSoftware maintainance/managementSoftware testing/debuggingAutomotive softwareStatic testing

A software static testing apparatus generates code by integrating a plurality of source files corresponding to automotive software, creates logical expressions for the code and a test case, and performs testing of the plurality of source files using a resulting logical expression obtained by using the logical expression for the code and the logical expression for the test case.

Owner:ELECTRONICS & TELECOMM RES INST

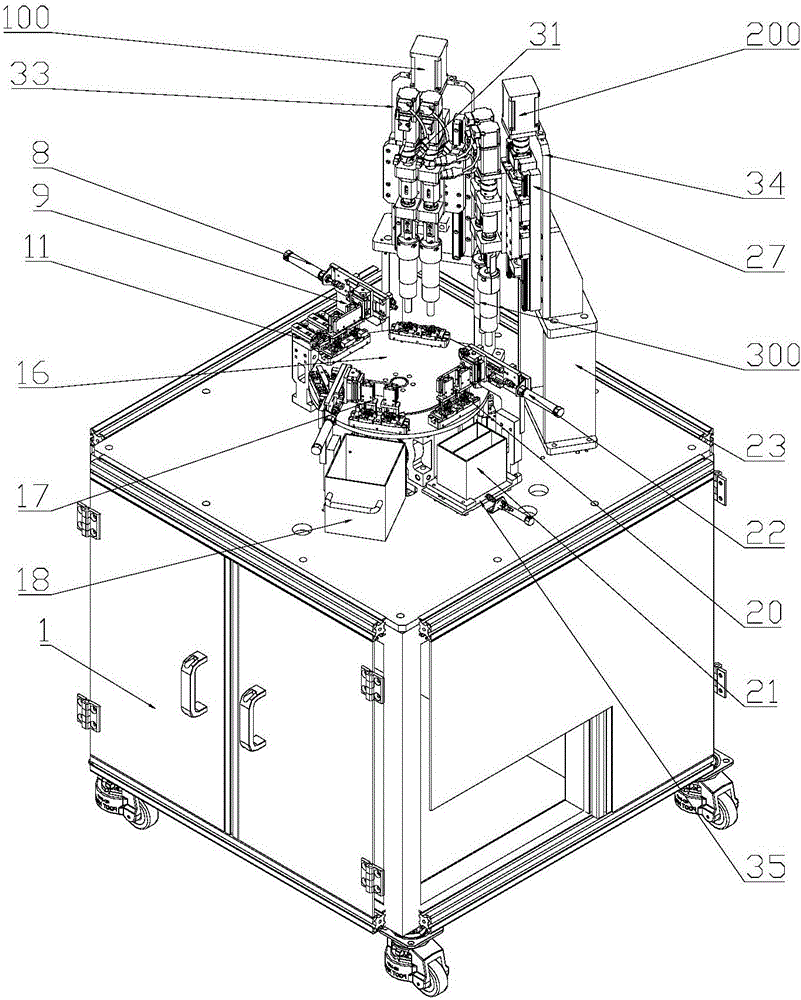

Automatic detecting equipment

InactiveCN106115194AReduce labor intensityAutomate inspectionMeasurement of torque/twisting force while tighteningConveyor partsAutomatic test equipmentCoupling

The invention discloses automatic detecting equipment. The automatic detecting equipment comprises a machine body; a turntable module is rotationally arranged on a working platform of the machine body; a staggered module, a finished product taking box, a testing NG box and a testing bracket are arranged on the working platform of the machine body around the turntable module in sequence; a taking module is arranged on the staggered module; a cylinder module is arranged on the taking module; the finished product taking box is provided with a finished product taking module corresponding to the turntable module; the testing NG box is provided with a finished product taking NG module and a NG taking module corresponding to the turntable module; the testing bracket is provided with a through testing main assembly and a stop testing main assembly; the stop testing main assembly is provided with a lead screw module; the through testing main assembly is provided with a through testing stepper motor; a stop testing stepper motor is arranged on the lead screw module; and the through testing stepper motor and the stop testing stepper motor are both axially connected with a torsion tester through couplings. The automatic detecting equipment realizes automatic testing, and reduces the labor intensity of workers.

Owner:昆山市张浦镇科伟自动化设备厂

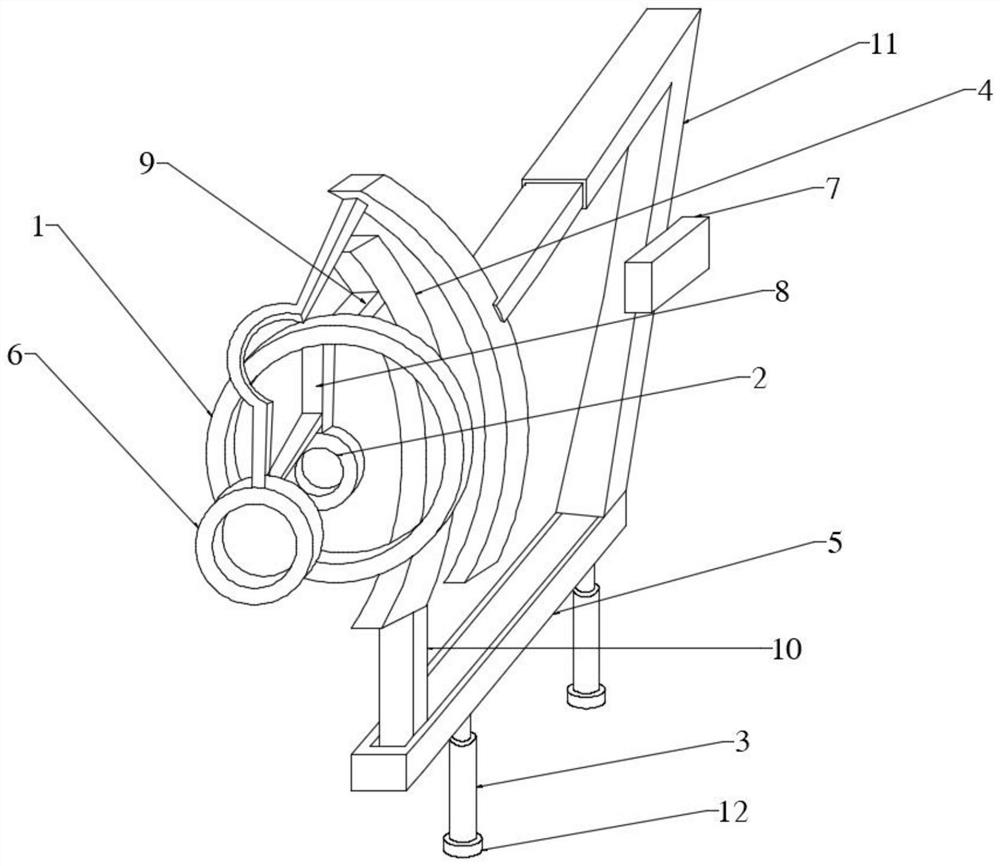

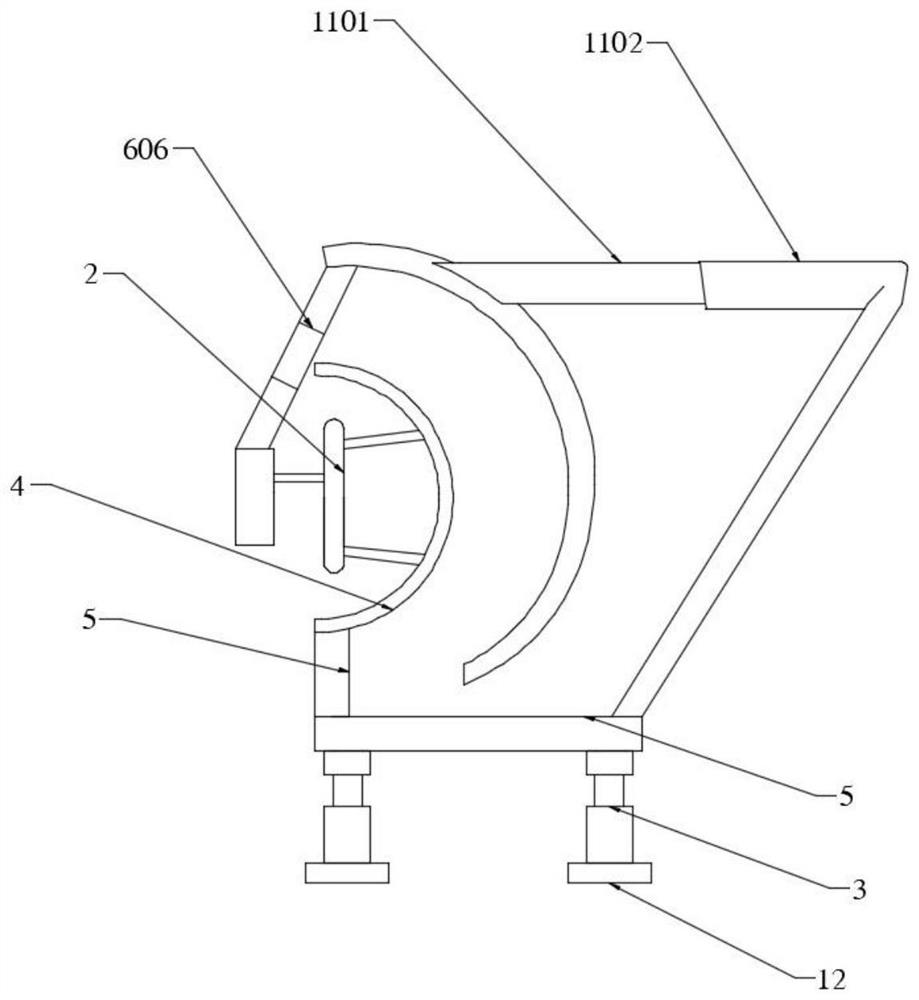

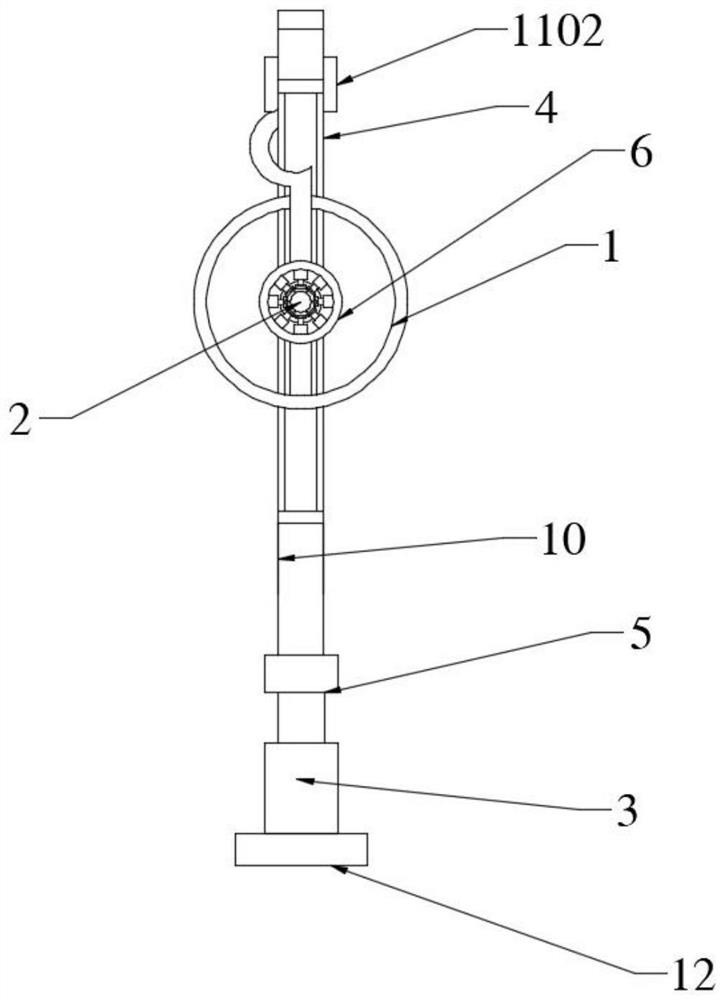

Detection device for adjusting eccentricity of piston rod

The invention discloses a detection device for adjusting eccentricity of a piston rod, and belongs to the technical field of detection equipment. The detection device comprises a detection ring, a detection inner ring, a follow-up rotating track, a moving track, an adjusting assembly and a monitoring box, the detection inner ring is arranged in the detection ring, the detection inner ring is rotationally connected with the detection ring through a detection arm, the detection ring is rotationally connected with the follow-up rotating track through a follow-up rotating arm, the follow-up rotating track is in sliding connection with the moving track through the moving arm, a cantilever arm is arranged at the end, away from the moving arm, of the moving track, an adjusting assembly is arranged at the end, away from the moving track, of the cantilever arm, a monitoring box is arranged on the cantilever arm, and the monitoring box is connected with the detecting arm, the follow-up rotating arm, the moving arm and the adjusting assembly through wires. The detection device has the eccentricity detection and adjustment functions of a conventional piston rod device.

Owner:江苏国安电器有限公司

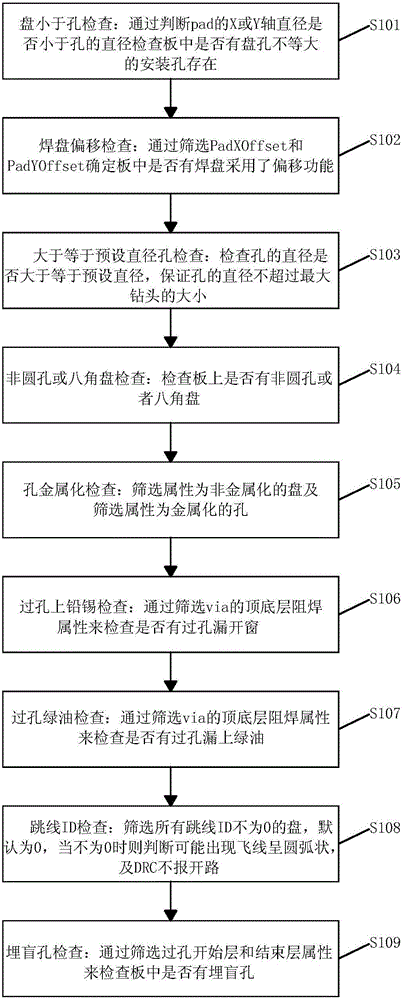

Method for checking hole problems of printed circuit board

InactiveCN106202775AAutomate inspectionEasy to operateSpecial data processing applicationsPrinted circuit boardComputer science

The invention discloses a method for checking hole problems of a printed circuit board. The method comprises the following steps of checking when a pad is smaller than a hole; checking the deflection of a bonding pad; checking the hole of which the diameter is greater than or equal to the preset diameter; checking a non-circular hole or an octagonal pad; checking the hole metalizing; checking lead tin on a via hole; checking green oil on the via hole; checking jumper ID (identification); checking an embedded blind via. The method has the advantages that the hole problems of the printed circuit board can be automatically checked; the operation is simple, convenience and rapidity in use are realized, the response speed is high, the check efficiency is high, and the check accuracy is high.

Owner:无锡军安电子科技有限公司

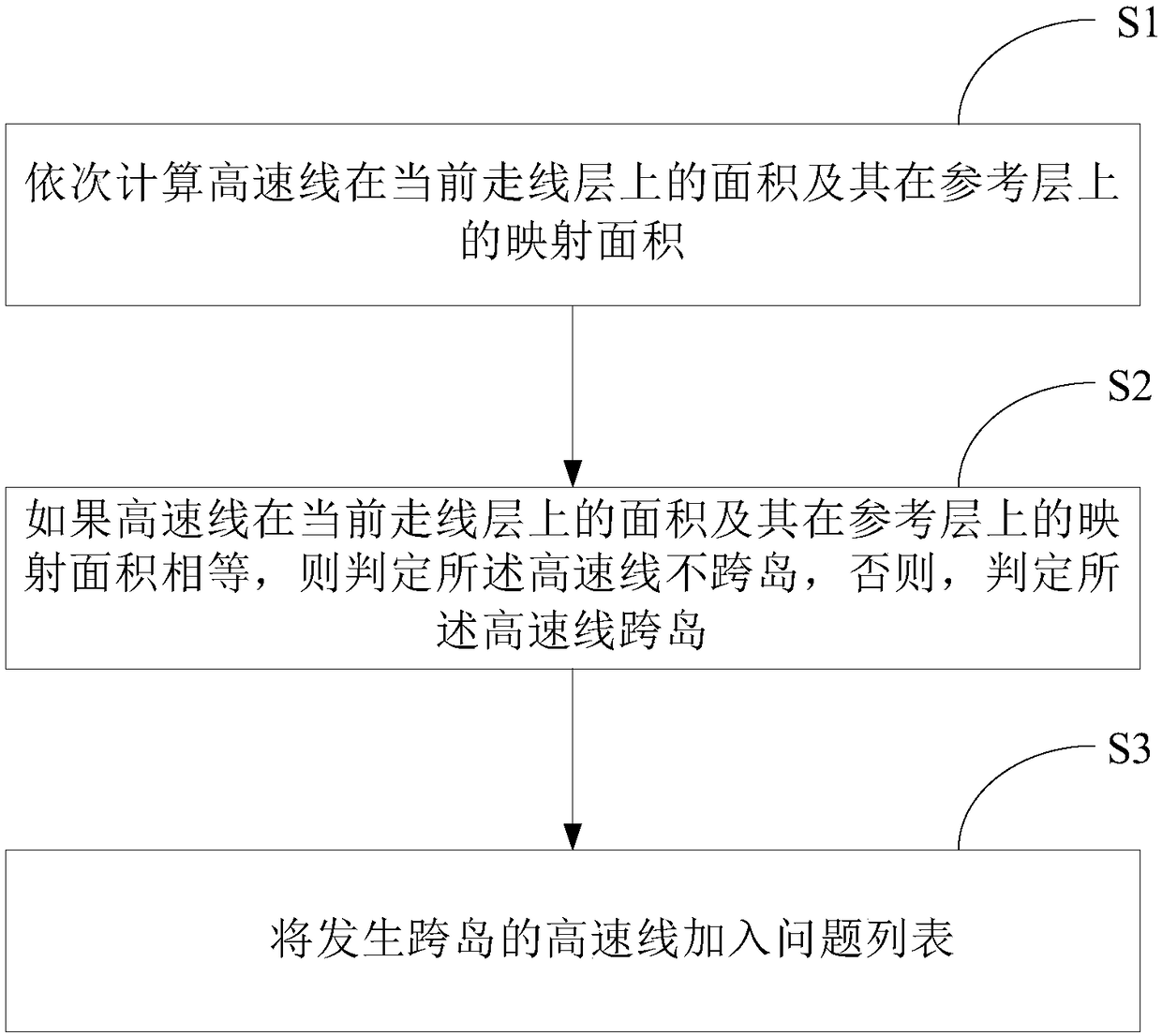

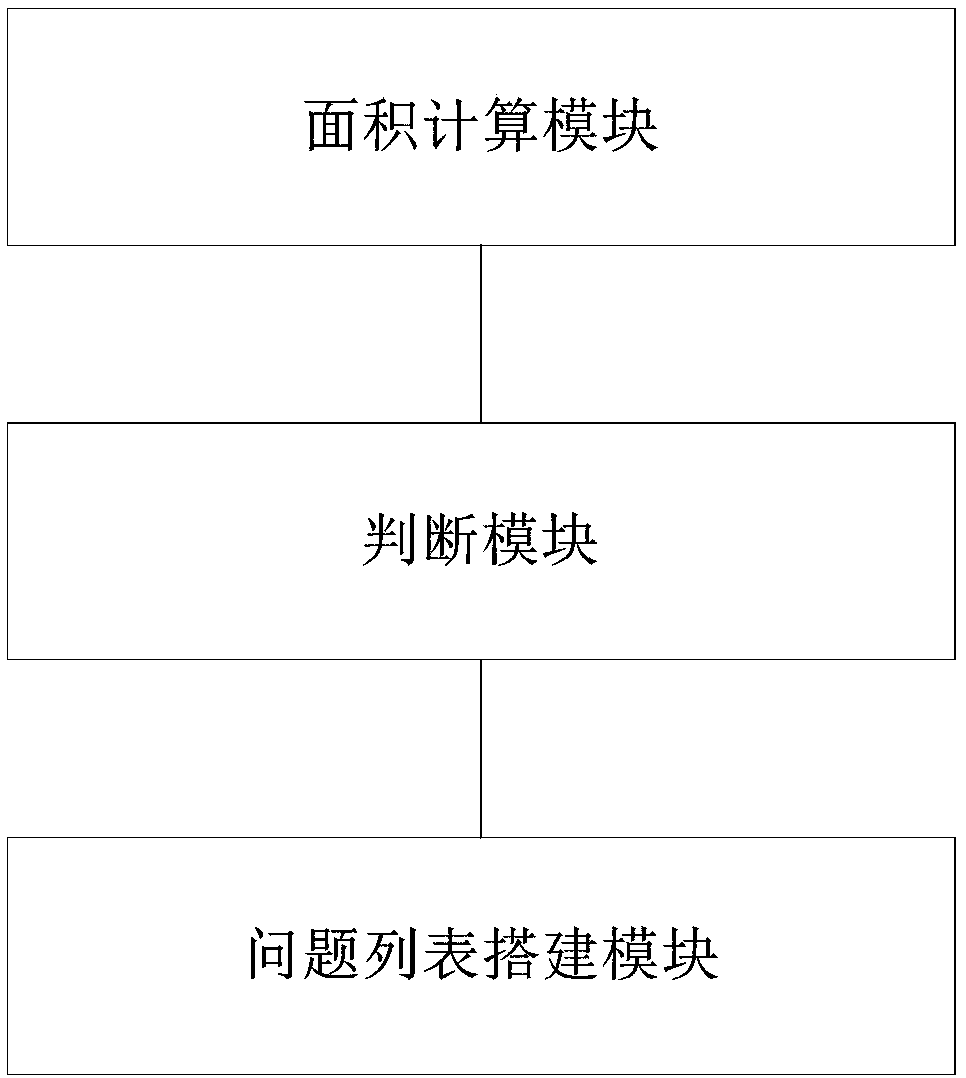

Method and system for checking island crossing of high-speed lines in locating and wiring

InactiveCN108549756AAvoid being missedImprove accuracySpecial data processing applicationsComputer moduleEngineering

The invention discloses a method and system for checking island crossing of high-speed lines in locating and wiring. The method comprises the following steps of: calculating an area, on the current wiring layer, of a high-speed line and a mapping area, on a reference layer, of the high-speed line in sequence; if the area, on the current wiring layer, of the high-speed line and the mapping area, onthe reference layer, of the high-speed line are equal, judging that the high-speed line does not cross an island, and otherwise, judging that the high-speed line crosses an island; and adding the island crossing high-speed line into a problem list, wherein the problem list comprises coordinates, layers and names of high-speed lines. The system comprises an area calculation module, a judging module and a problem list establishing module. Through the method and the system, the condition that certain high-speed lines are unchecked can be effectively avoided, and benefit is brought to improve thehigh-speed line island crossing checking correctness and efficiency.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

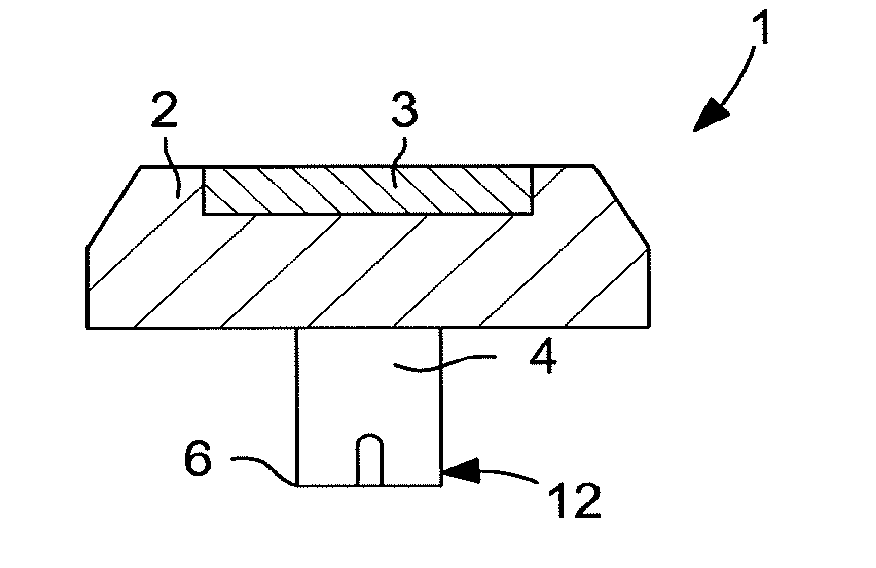

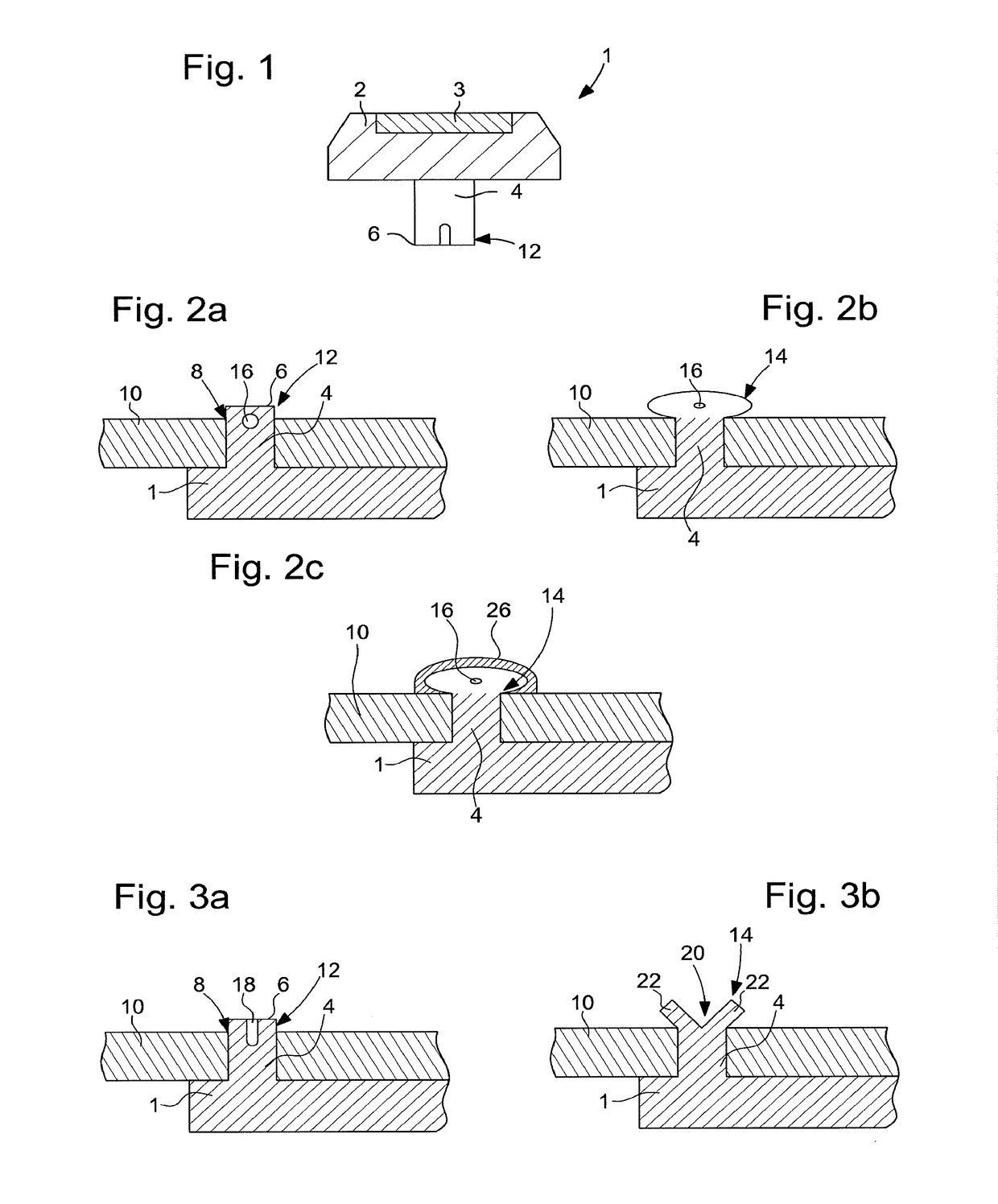

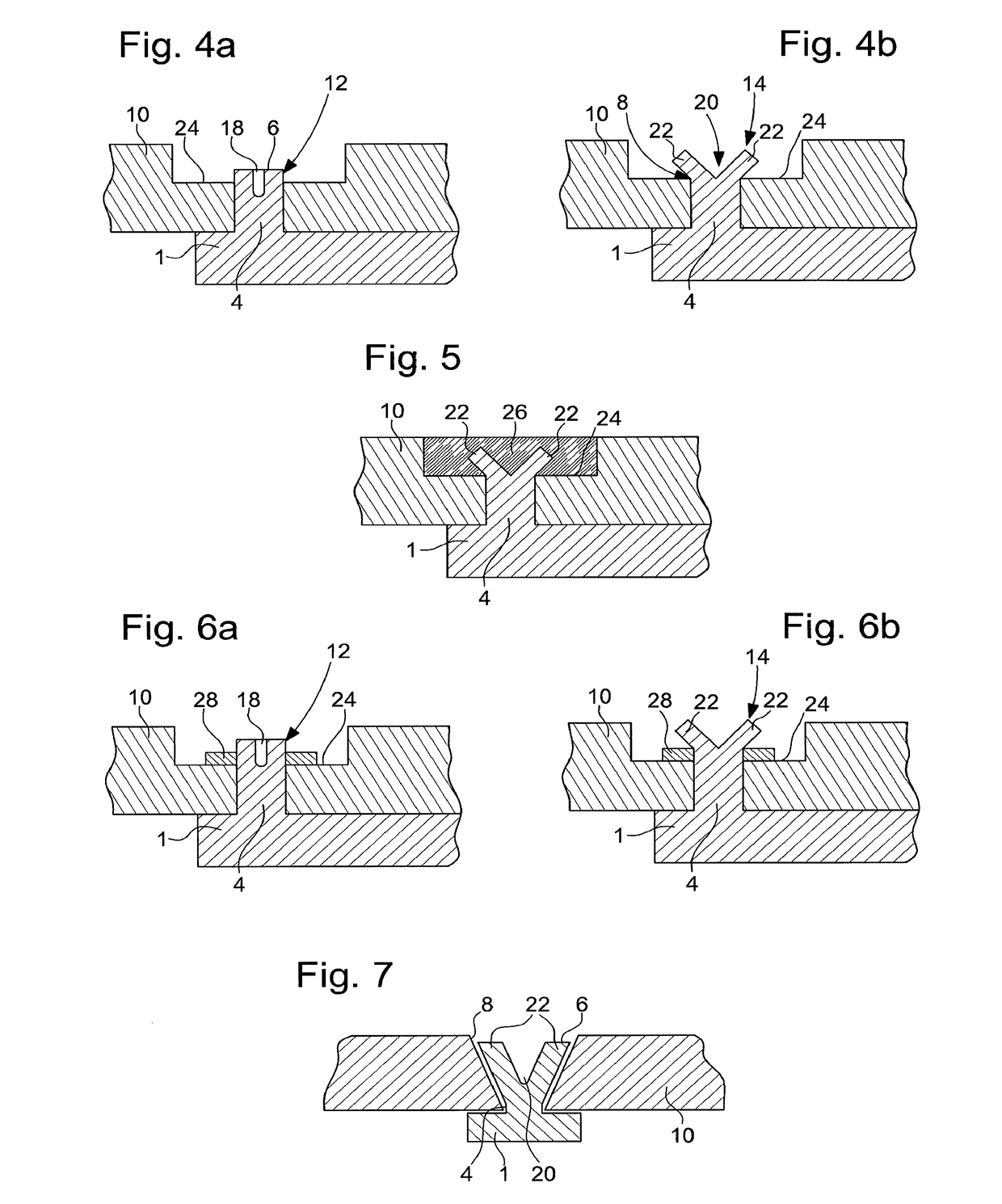

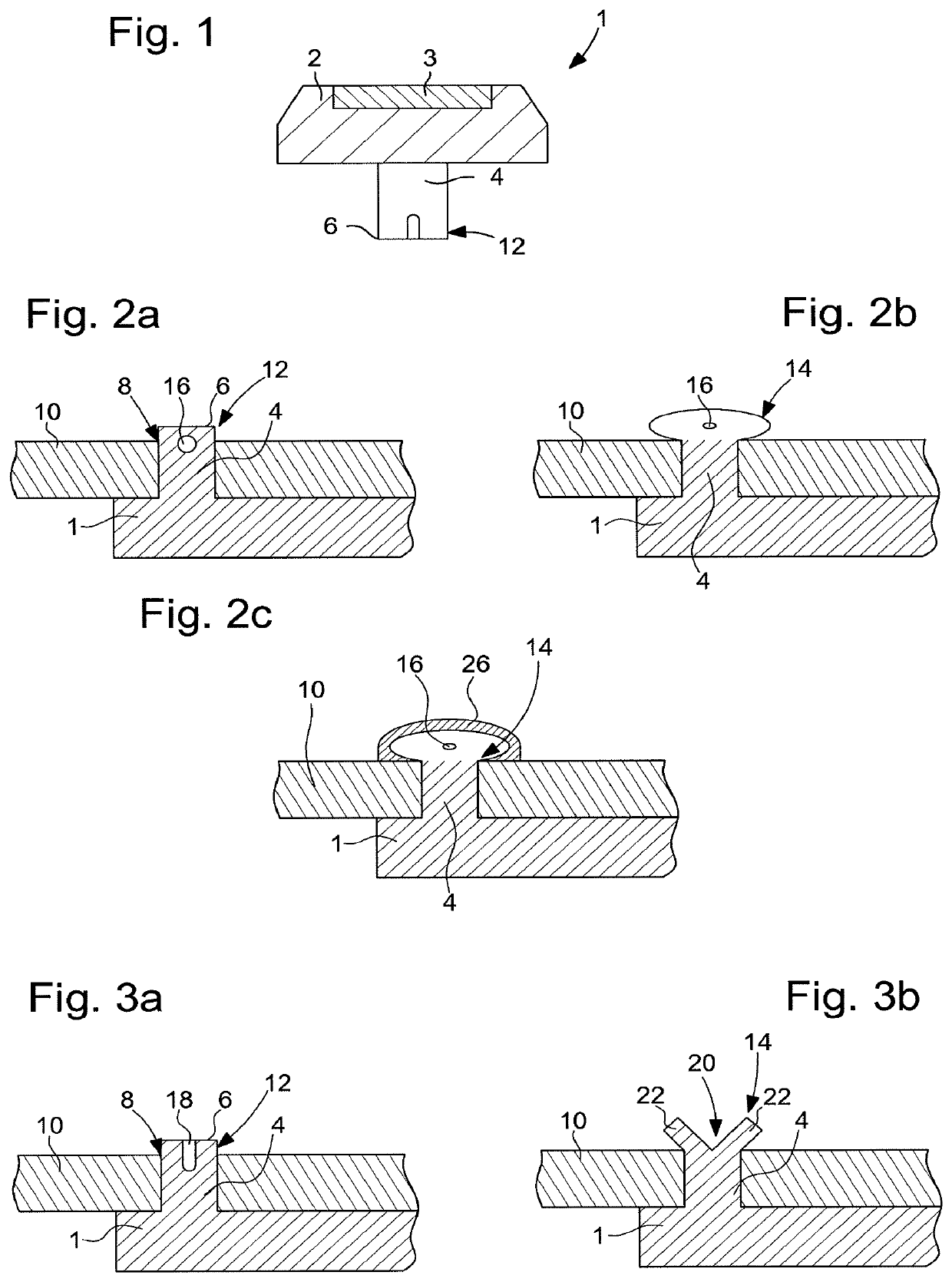

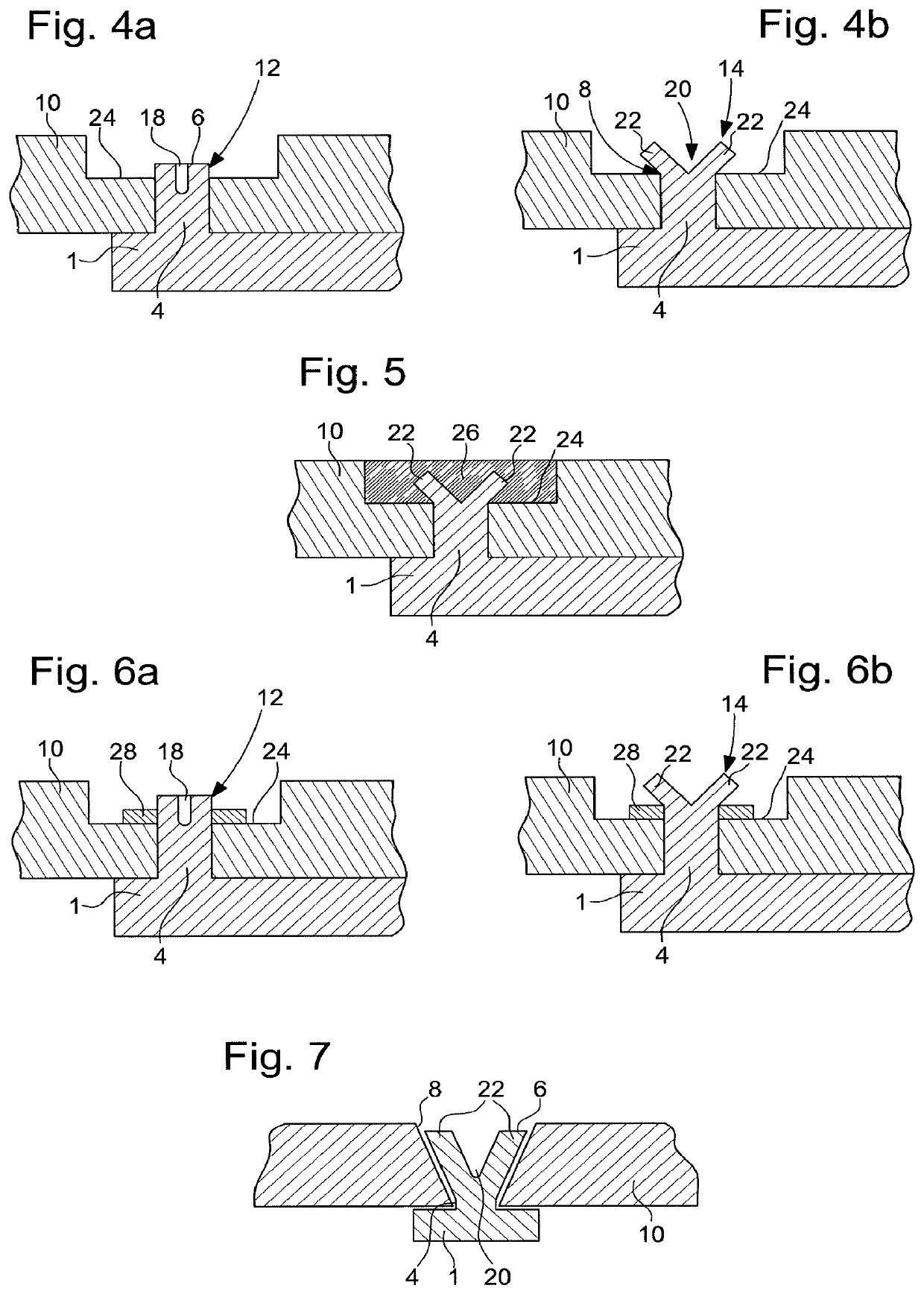

Dial applique for a timepiece

The invention relates to an applique intended to be affixed to a timepiece dial, comprising at least one foot portion having a first end attached to the applique and a second, free end, the foot portion being arranged to be capable of insertion into a hole provided in the dial. According to the invention, said foot portion comprises, on the side of the free end thereof, a plastically deformable area arranged to form, after deformation, once the foot portion is inserted into the hole in the dial, at least one locking area of the foot portion on the dial.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Dial applique for a timepiece

An applique is intended to be affixed to a timepiece dial, and includes at least one foot portion having a first end attached to the applique and a second, free end, the foot portion being arranged to be capable of insertion into a hole provided in the dial. The foot portion includes, on the side of the free end thereof, a plastically deformable area arranged to form, after deformation, once the foot portion is inserted into the hole in the dial, at least one locking area of the foot portion on the dial.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

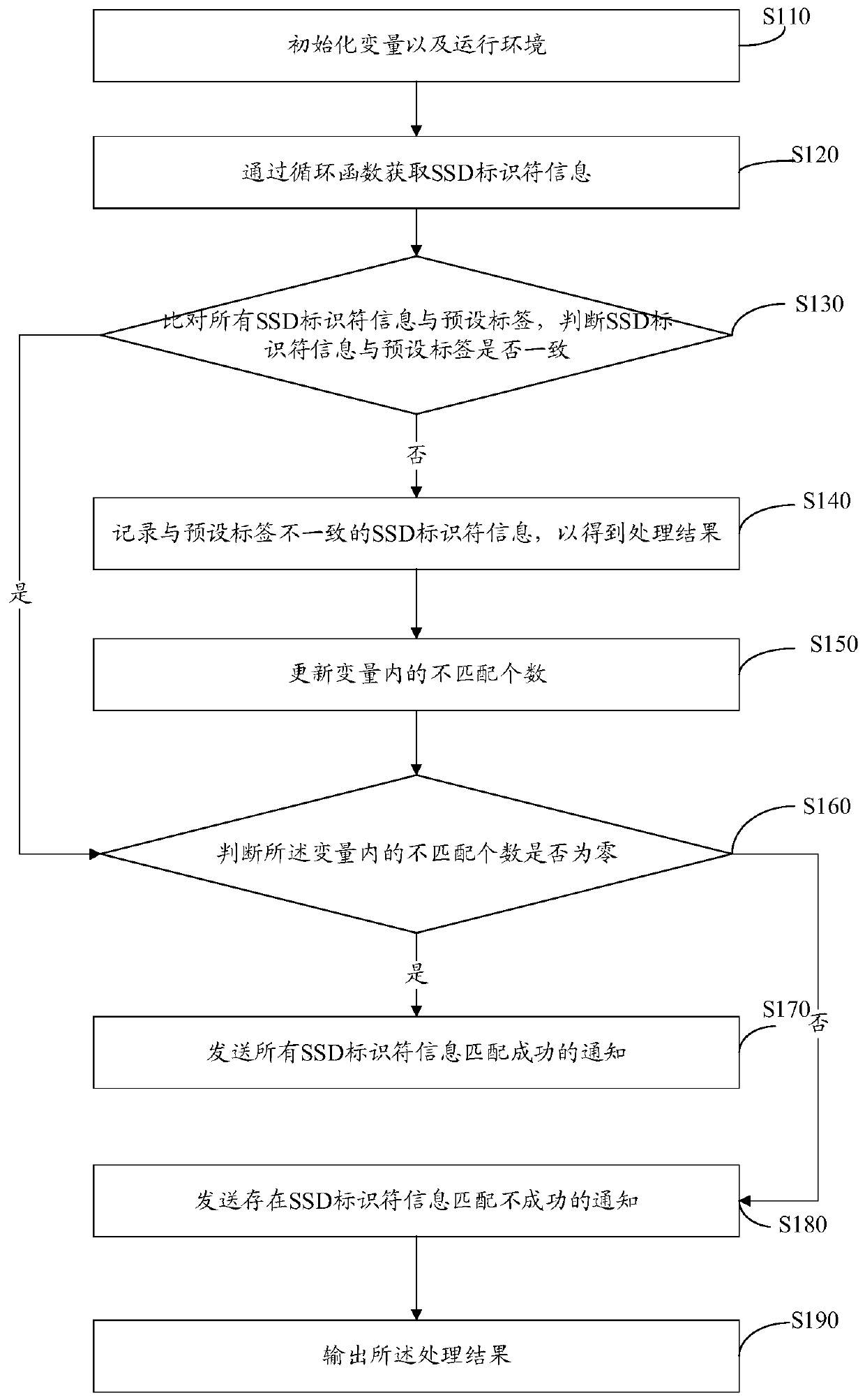

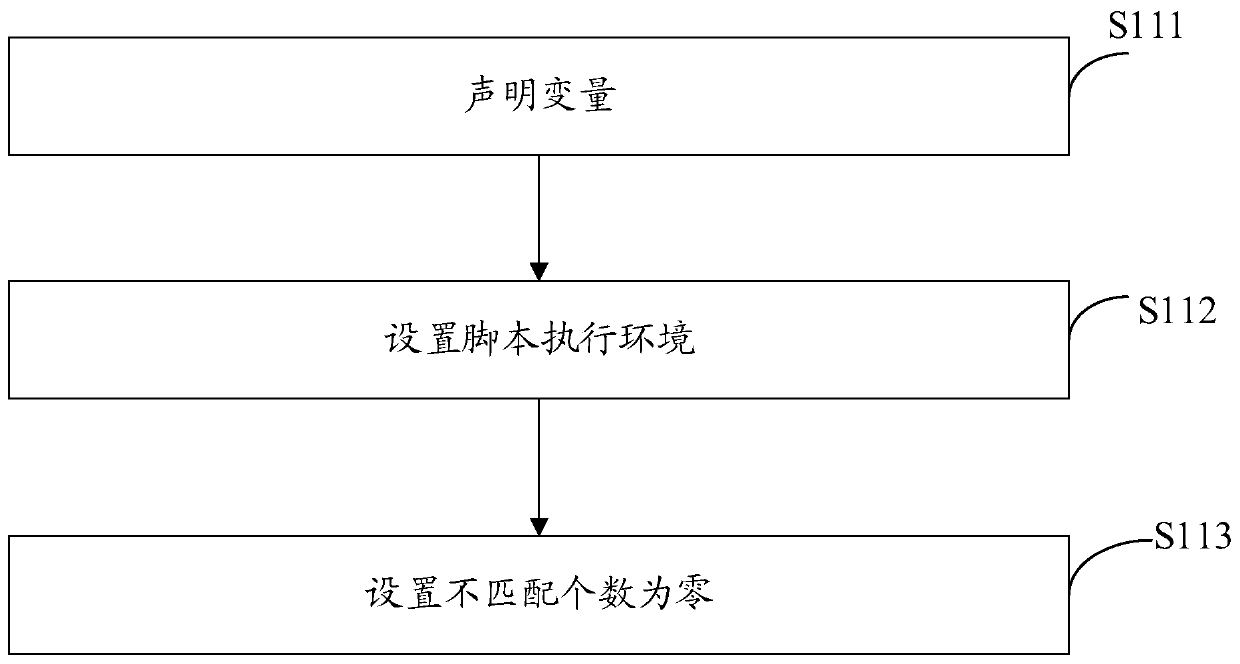

SSD identifier test method and device, computer equipment and storage medium

InactiveCN110427528AAutomate inspectionShorten test timeOther databases queryingSpecial data processing applicationsTest efficiencyTested time

The invention relates to an SSD identifier test method and device, computer equipment and a storage medium. The SSD identifier test method comprises the steps: initializing variables and a running environment; obtaining SSD identifier information through a cyclic function; comparing all SSD identifier information with a preset label, and judging whether the SSD identifier information is consistentwith the preset label; if not, recording SSD identifier information inconsistent with the preset label to obtain a processing result; updating the number of mismatches in the variable; if so, judgingwhether the number of mismatches in the variable is zero or not; if so, sending a notification that all SSD identifier information is successfully matched; if not, sending a notification that the SSDidentifier information is not successfully matched; and outputting processing results. According to the invention, the SSD identifier information is automatically checked, and the test time is greatly saved, and the test efficiency is improved.

Owner:DONGGUAN RAMAXEL MEMORY TECH LTD

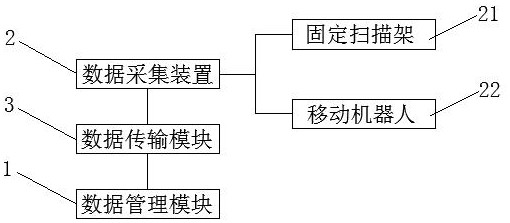

Railway vehicle intelligent maintenance auxiliary system

PendingCN113392992AAutomate inspectionReduce labor intensityTelevision system detailsData processing applicationsFeature extractionData transport

The invention discloses a railway vehicle intelligent maintenance auxiliary system, which comprises a data management module, a data acquisition device and a data transmission module, and the data acquisition device comprises a fixed scanning frame used for scanning the top and the side surface of a vehicle returning to a garage, a mobile robot carrying a detection terminal, and a mobile robot used for scanning the bottom of a static vehicle; after the data acquisition device acquires an image of a to-be-detected vehicle, the image is transmitted to the data management module through the data transmission module, after the data management module performs detection, preprocessing and feature extraction on the image, vehicle modeling is performed, and the vehicle is compared and matched with initialization information of the vehicle, so that whether the to-be-detected vehicle is damaged or not is judged. The system has the advantages that the automatic inspection of the vehicle is realized through all-directional scanning, modeling data providing, vehicle modeling and comparison, the inspection efficiency can be greatly improved, and the labor intensity of workers is reduced.

Owner:兰普电器股份有限公司

Pre-fabricated grease duct system

ActiveUS11397008B2Reduce riskAutomate inspectionDucting arrangementsDomestic stoves or rangesThermal dilatationMetal strips

The present double walled grease duct includes a tubular outer shell surrounding a tubular inner liner, wherein a spacer is positioned perpendicular to the walls of the outer shell and the inner liner. The spacer can include a plurality of vertical metal strips extend from a top edge of the spacer to the bottom edge of the spacer, wherein the top edge of the spacer contacts the walls of the outer shell and wherein the bottom edge of the spacer contacts the walls of the inner liner. The metal strips resist the different rates of thermal expansion between the outer shell and inner liner ultimately preventing the collapse of the inner liner under pressure from thermal expansion.

Owner:VAN PACKER

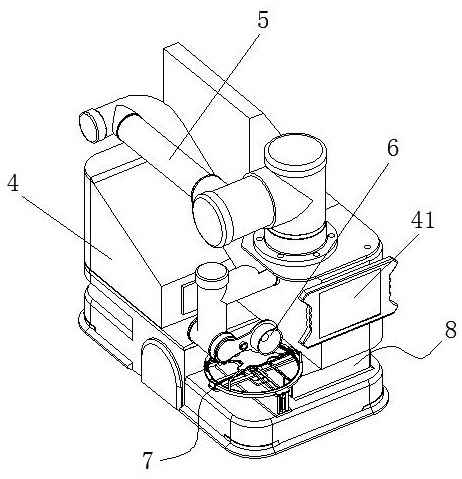

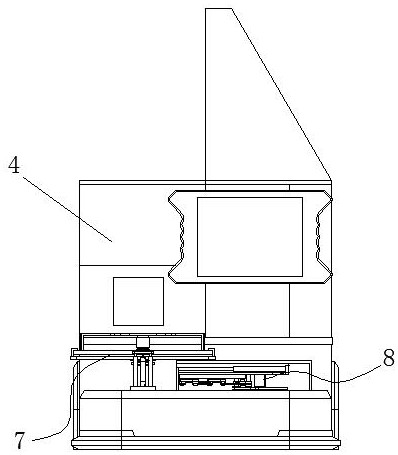

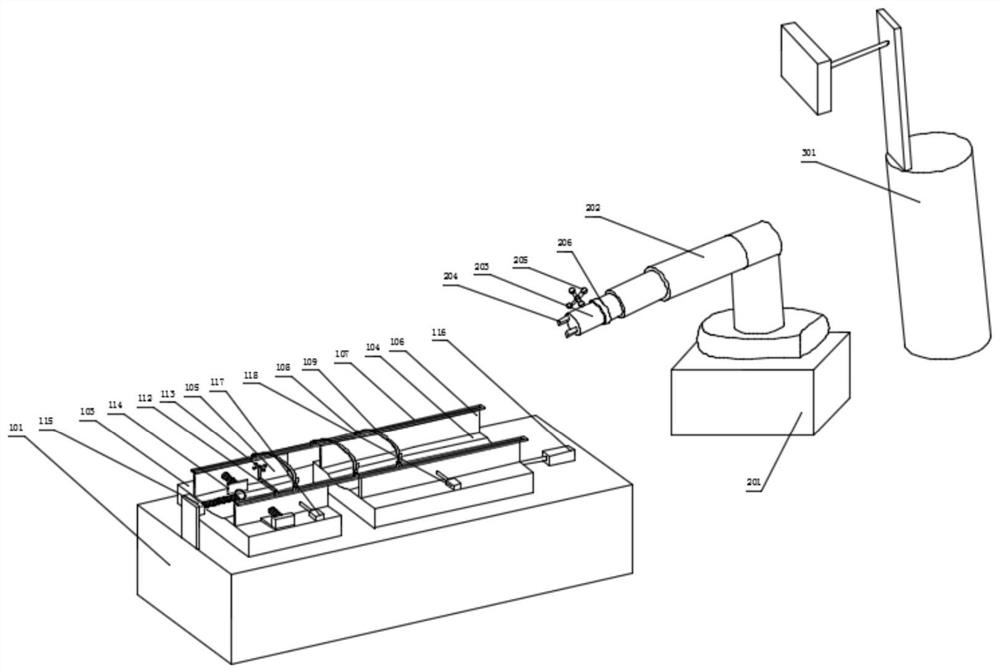

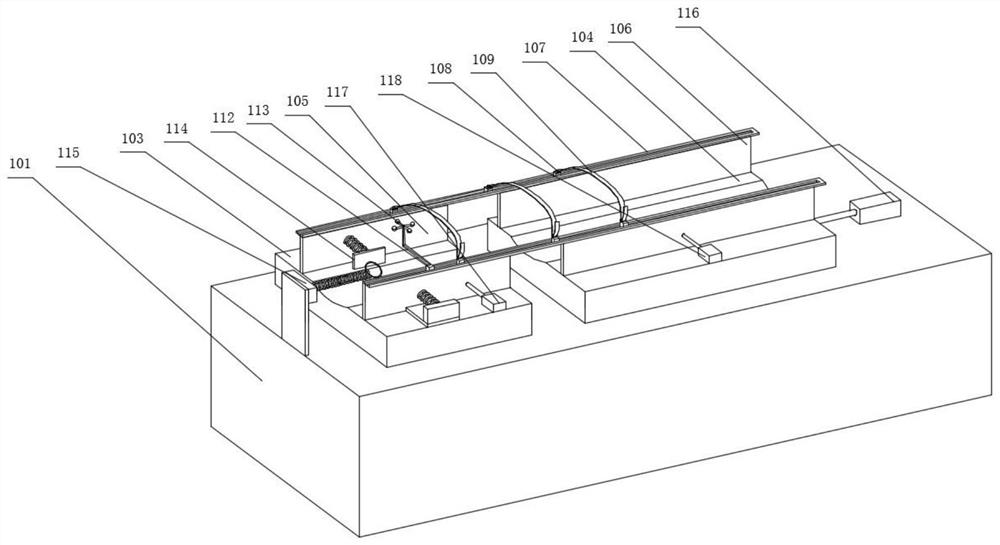

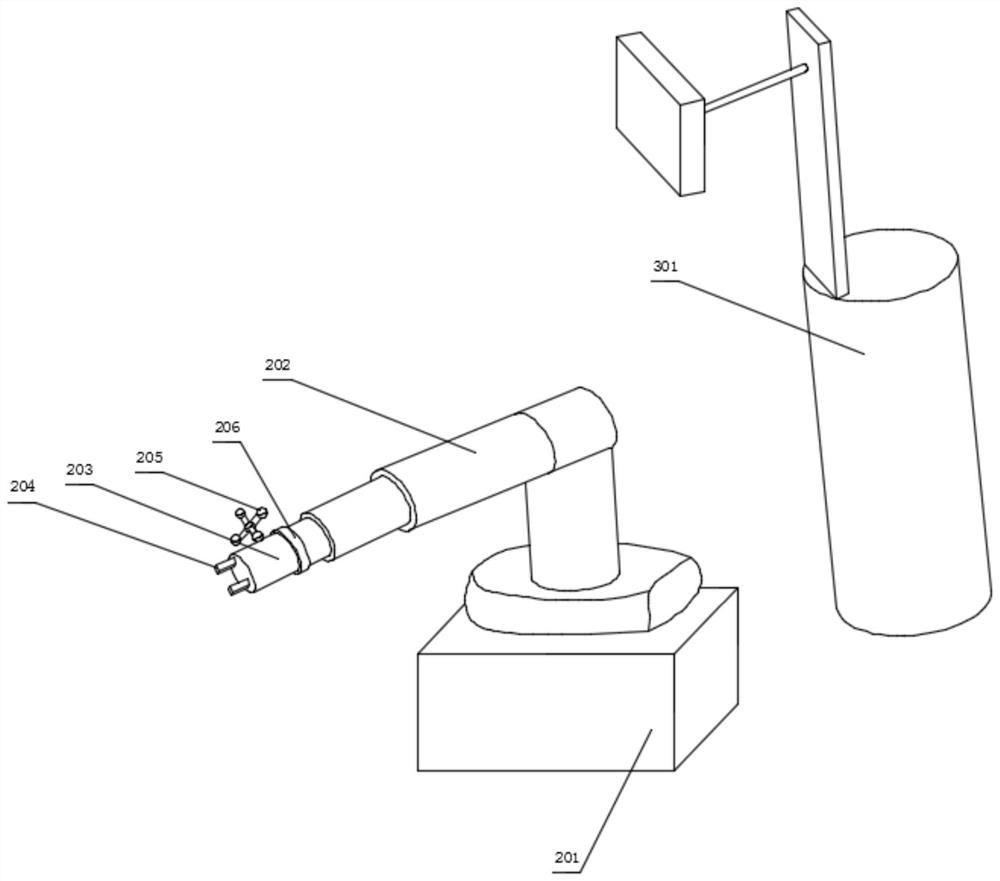

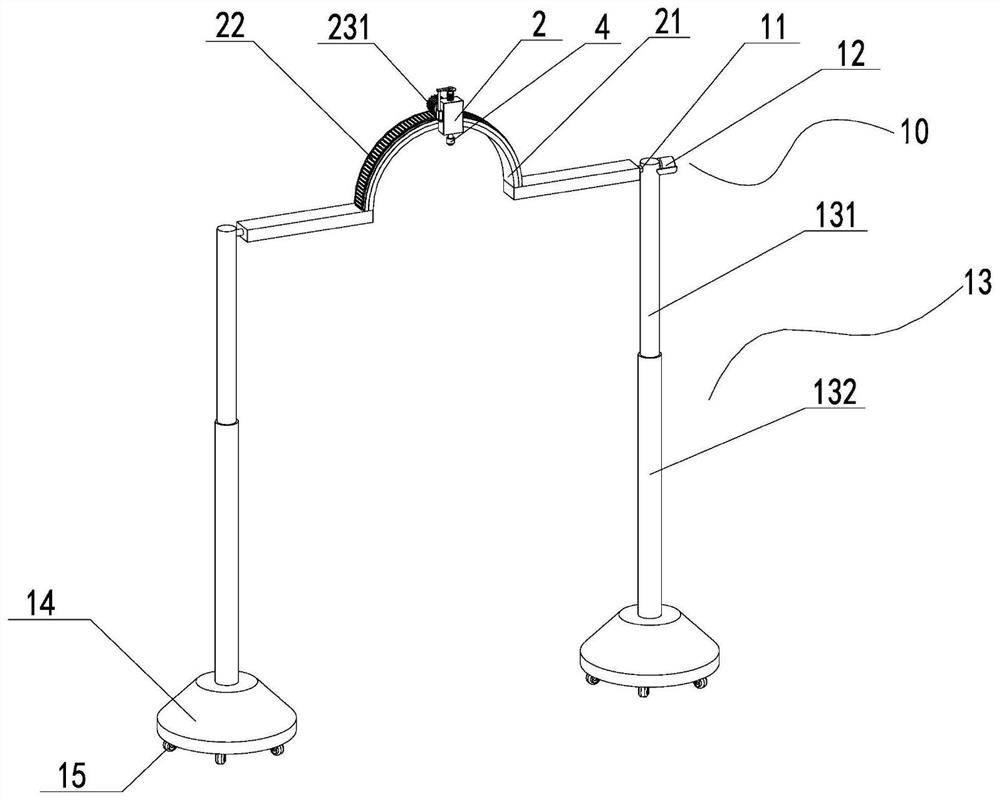

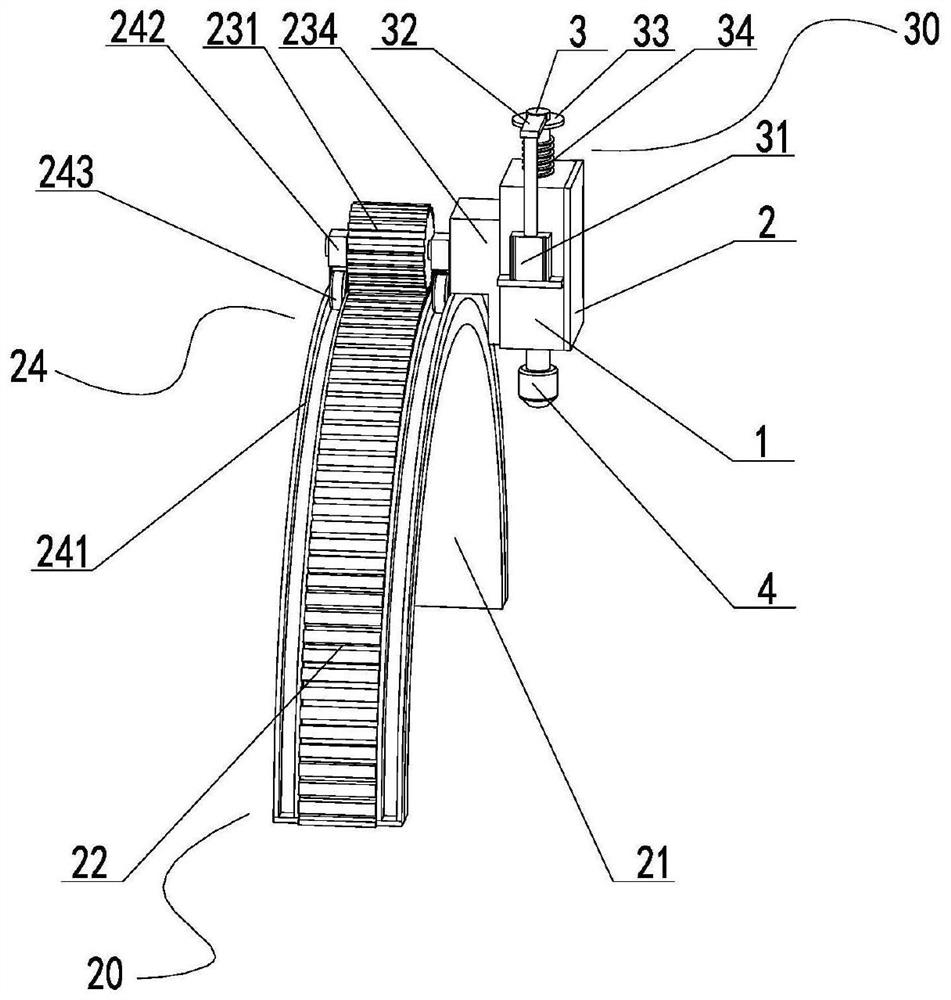

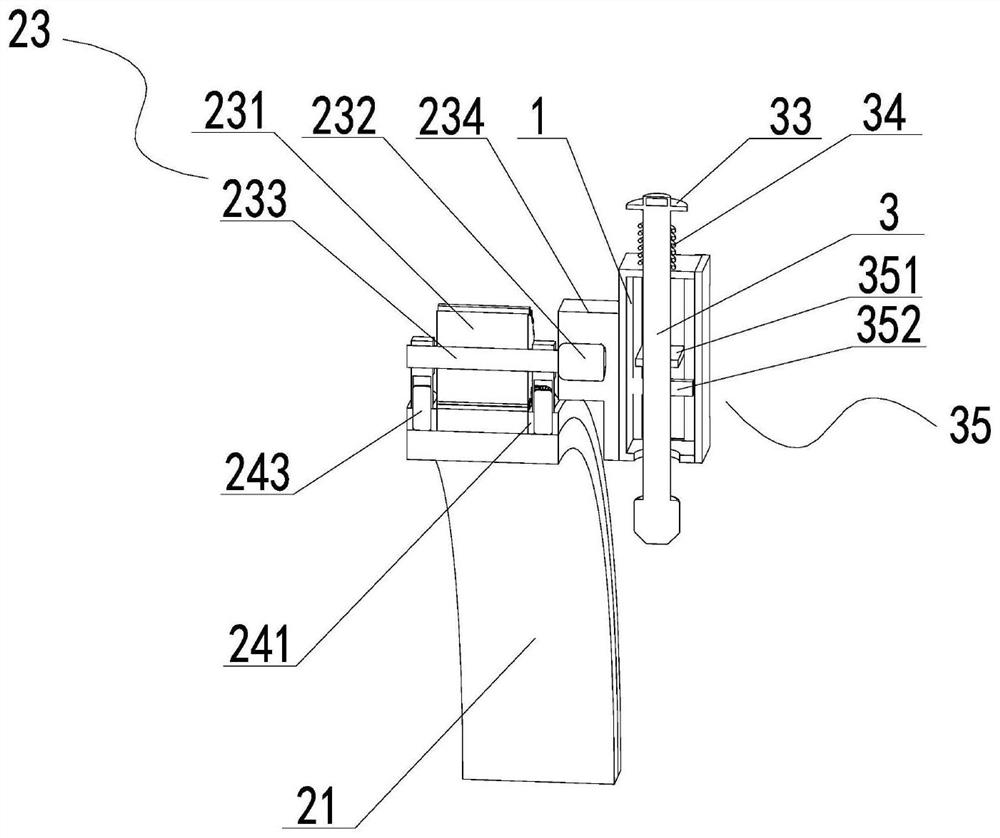

Neuromuscular electrophysiological examination robot

PendingCN113576500AFree handsHigh precisionDiagnostic recording/measuringSensorsControl systemPhysical therapy

The invention discloses a neuromuscular electrophysiological examination robot which comprises a recording robot, an execution robot, a navigation robot and a control system. The recording robot comprises a supporting table, a base, an elastic recording belt and a first positioning device, and the first positioning device can position a to-be-stimulated nerve part and a to-be-punctured muscle part; the execution robot is provided with a multi-axis mechanical arm, the multi-axis mechanical arm is connected with a clamping device and a second positioning device, and the clamping device can clamp a stimulator or a needle electrode; the navigation robot can recognize the positions of the first positioning device and the second positioning device and send information to the control system, and the control system can control the multi-axis mechanical arm to move so as to drive the clamping device to move to the to-be-stimulated nerve part and the to-be-punctured muscle part which are positioned by the first positioning device, thus the stimulator or the needle electrode can stimulate or puncture the to-be-stimulated part; the device can improve the detection efficiency in the process of nerve electrophysiological examination and muscle electrophysiological examination.

Owner:杜超

Percussion device for brain injury examination

PendingCN114224390AReduce laborAutomate inspectionLavatory sanitoryDiagnostic recording/measuringHuman bodyMedical equipment

The invention relates to the technical field of medical equipment, in particular to a percussion device for brain injury examination. Comprising a supporting assembly, an adjusting assembly, a mounting box, a switch door, a connecting rod, a hammer head and a power assembly. The adjusting assembly is connected with the supporting assembly, the mounting box is arranged on the adjusting assembly, the opening and closing door is rotationally connected with the mounting box, the connecting rod is slidably connected with the mounting box, and the hammer head is detachably connected with the connecting rod. The power assembly comprises a power piece, a connecting plate, an auxiliary plate, an auxiliary spring and an auxiliary component, the power piece is fixedly connected with the mounting box, the connecting plate is fixedly connected with the output end of the power piece and connected with the connecting rod, the auxiliary plate is fixedly connected with the connecting rod, and the auxiliary spring is detachably connected with the mounting box; the power piece is used for driving the connecting rod to move up and down to drive the hammer head to knock and carry out percussion examination on the brain of the human body, automatic examination is achieved, the labor amount of medical staff is reduced, and operation is more convenient.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Test data preparation method and device, equipment, medium and program product

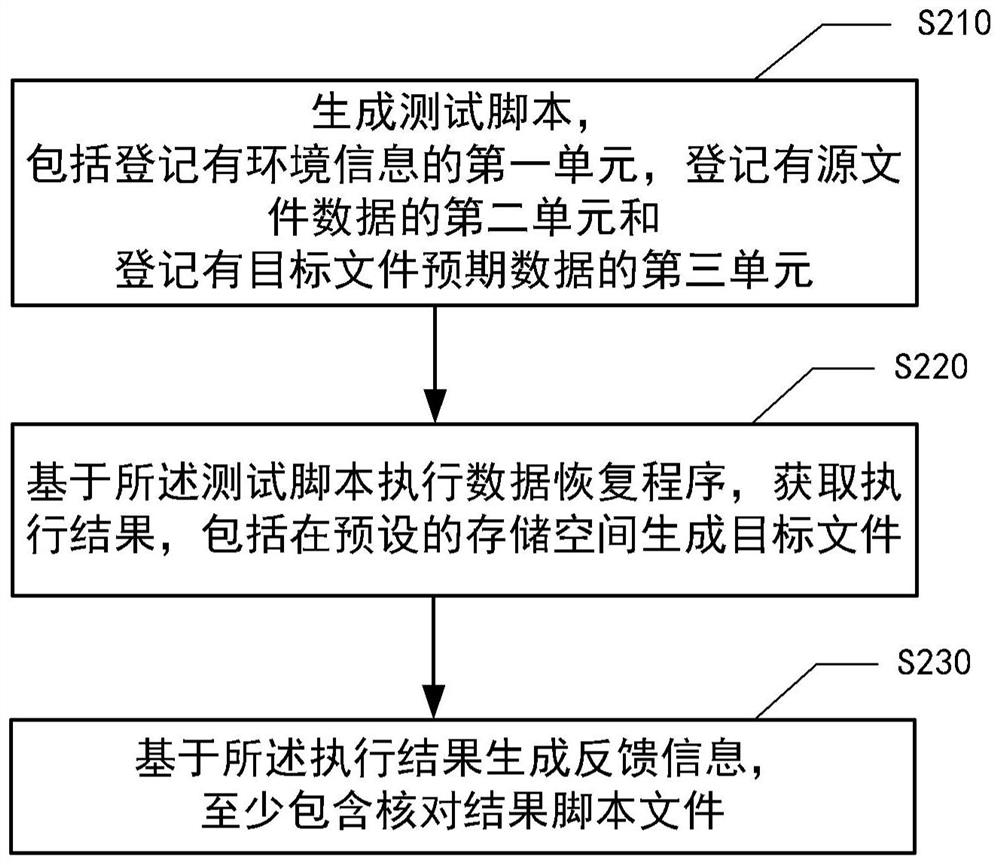

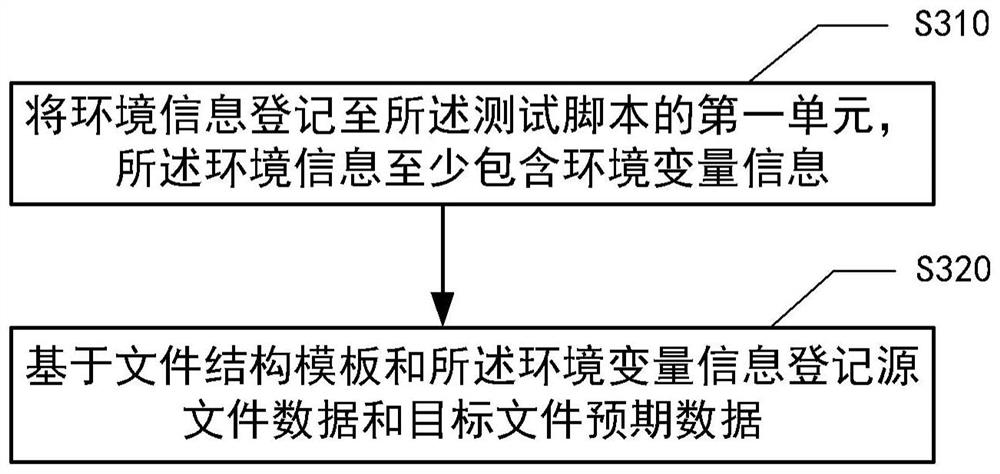

PendingCN114860610AImprove preparation efficiencyAutomate inspectionSoftware testing/debuggingTest scriptData preparation

The invention provides a test data preparation method which can be applied to the technical field of software testing or the financial field. The method comprises the steps that a test script is generated, a mapping relation exists between the test script and a to-be-tested application, the to-be-tested application is associated with at least one test program, and the test script comprises a first unit registered with environment information, a second unit registered with source file data and a third unit registered with target file expected data; a data recovery program is executed based on the test script, an execution result is obtained, and the step of obtaining the execution result comprises the step of generating a target file in a preset storage space; feedback information is generated based on the execution result, and the feedback information at least comprises a check result script file. The invention further provides a test data preparation device and equipment, a storage medium and a program product.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

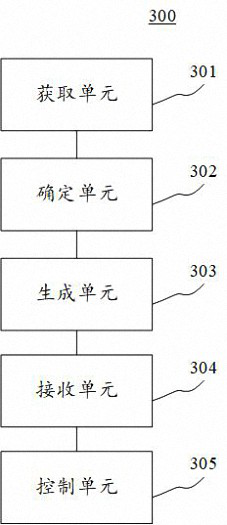

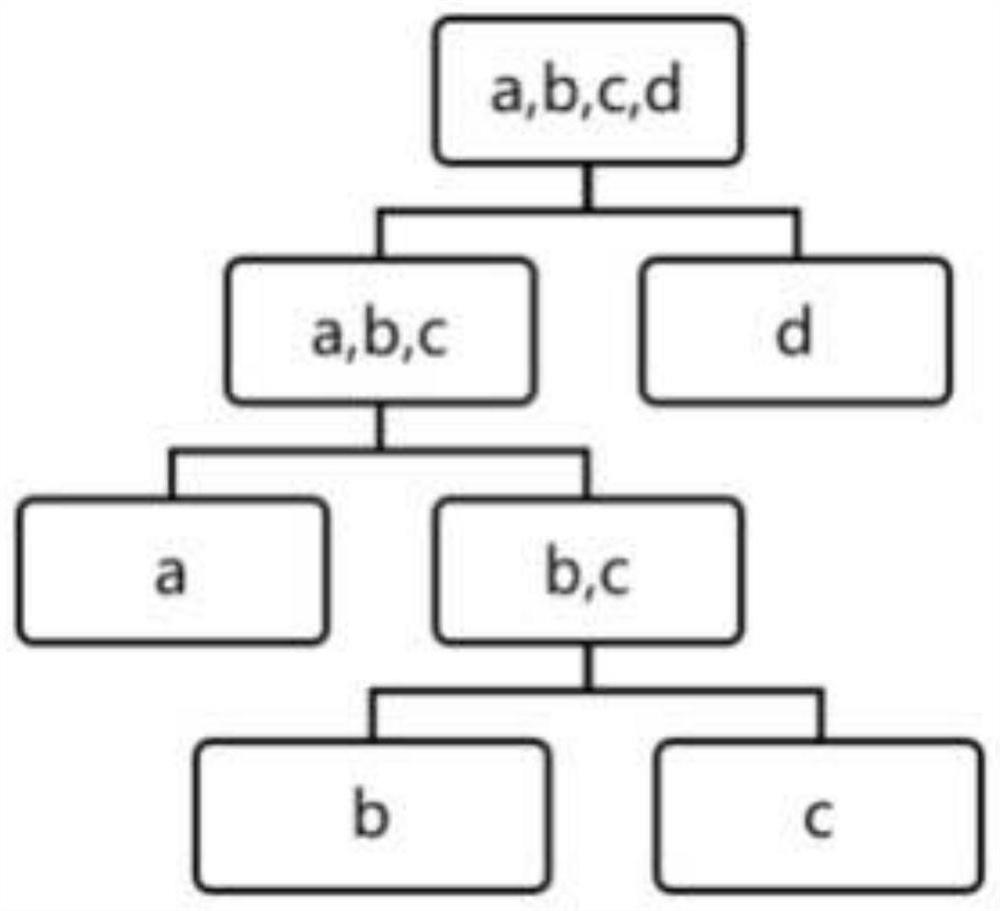

Alarm signal processing method, apparatus, electronic device and computer readable medium

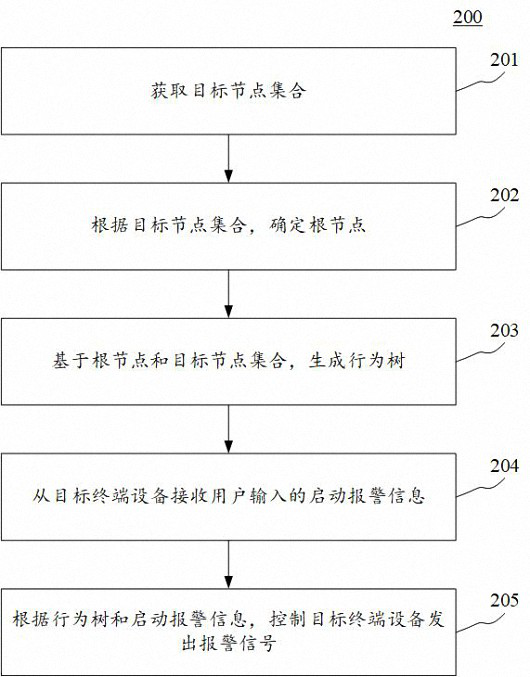

ActiveCN113110270BImprove inspection efficiencyAchieving control modularityProgramme controlComputer controlInformation controlTerminal equipment

The embodiment of the present disclosure discloses an alarm signal processing method, device, electronic equipment and computer readable medium. A specific implementation of the method includes: obtaining a target node set; determining the root node according to the target node set; generating a behavior tree based on the root node and the target node set; receiving the start-up alarm information input by the user from the target terminal device; and start the alarm information, and control the target terminal equipment to send out the alarm signal. This embodiment improves the inspection efficiency of devices in the robot.

Owner:北京德风新征程科技股份有限公司

Method and device for checking a data sheet

ActiveCN105094843BImprove reading speedImprove processing efficiencySpecial data processing applicationsCombining rulesData mining

The invention discloses a data sheet inspection method and device. The method comprises the steps of acquiring a combined rule of a data sheet; splitting the combined rule into N single rules, wherein N>=1, and each single rule comprises a part rule; calling a function corresponding to the part rule of each single rule one by one from a preconfigured part rule base; inspecting the data in the data sheet according to the functions of the part rules. By the adoption of the embodiment, data sheet inspection efficiency and accuracy can be improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Method of determining a path along an object, system and method for automatically inspecting an object

ActiveUS11397371B2Automate inspectionAvoid expensiveGeometric CADRegistering/indicating working of vehiclesPattern recognitionEngineering

Owner:TOP SEVEN GMBH & CO KG

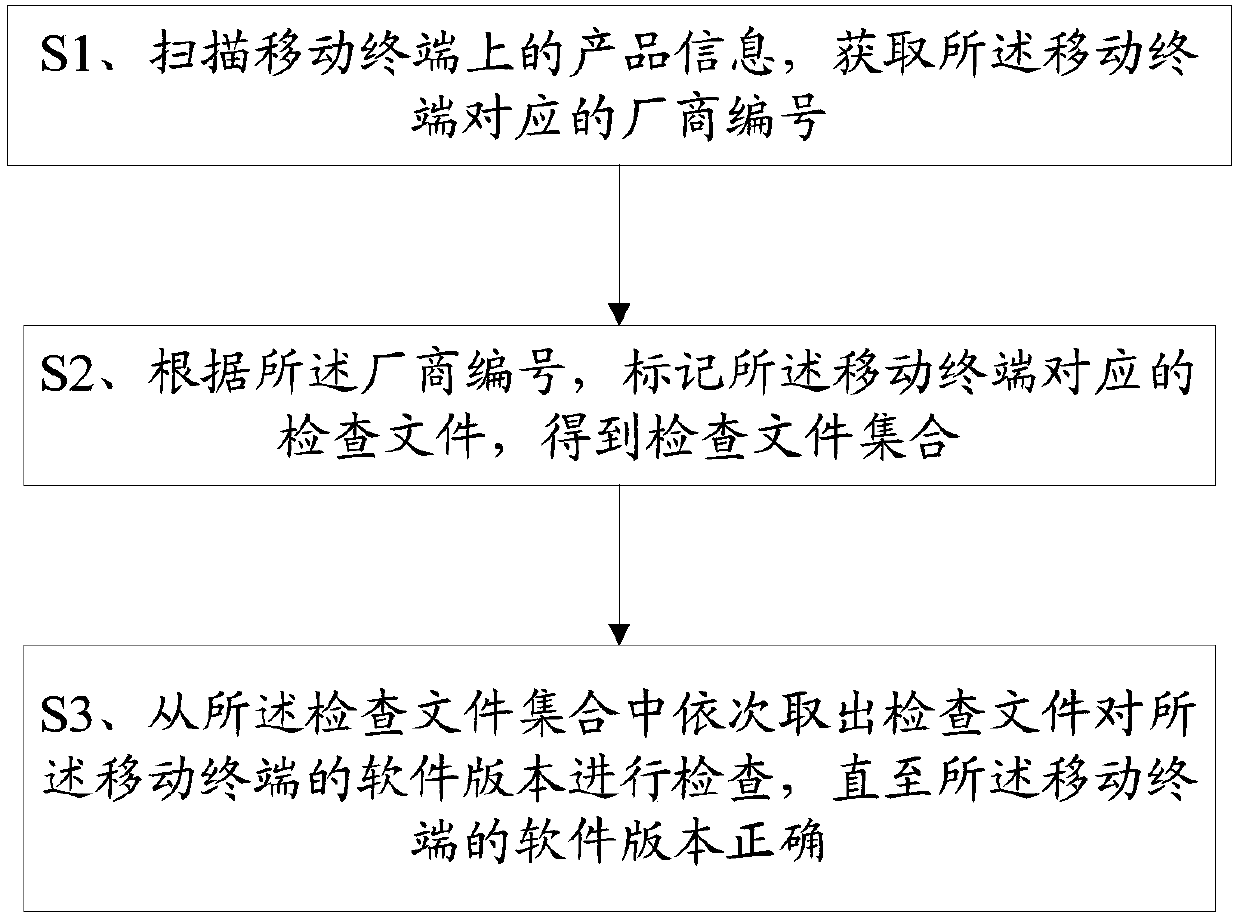

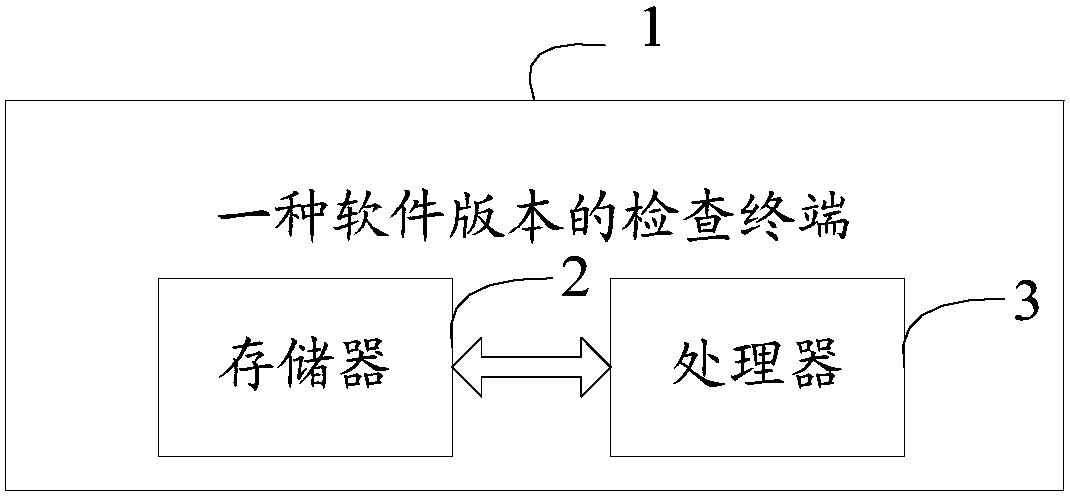

Software version checking method and terminal

InactiveCN108021387AAutomate inspectionImprove efficiencyVersion controlSoftware engineeringComputer terminal

The invention provides a software version checking method and a terminal. According to the method, product information on the mobile terminal is scanned, and a manufacturer number corresponding to themobile terminal is acquired; according to the manufacturer number, checking files corresponding to the mobile terminal are marked to obtain a checking file set; and the checking files are sequentially extracted from the checking file set to check the software version of the mobile terminal till the software version of the mobile terminal is correct. In this way, automatic checking of the softwareversion of the mobile terminal is realized, one-by-one manual checking is not needed, efficiency is high, and errors can be prevented.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Manufacturing method of hang tag with RFID tag

InactiveCN107154212ADesign does not affectImprove reliabilityStampsRecord carriers used with machinesComputer science

Owner:上海西文服饰有限公司

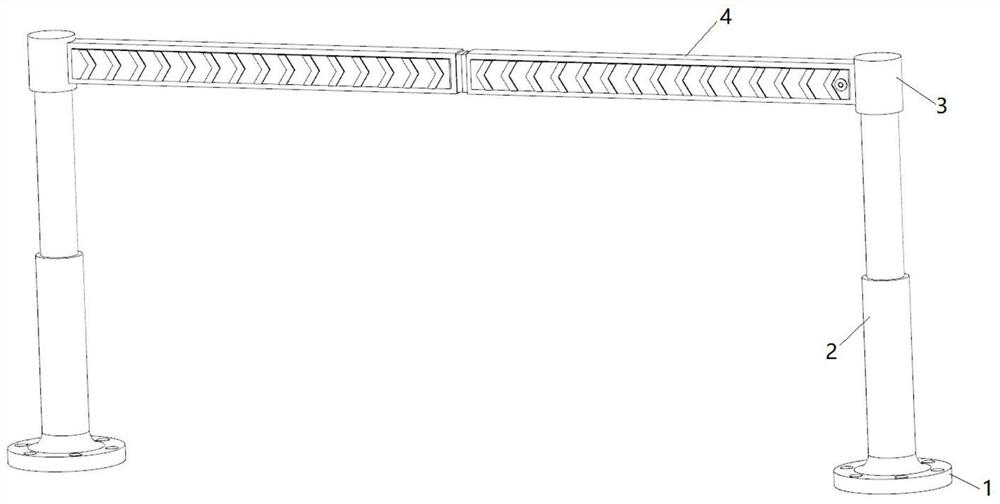

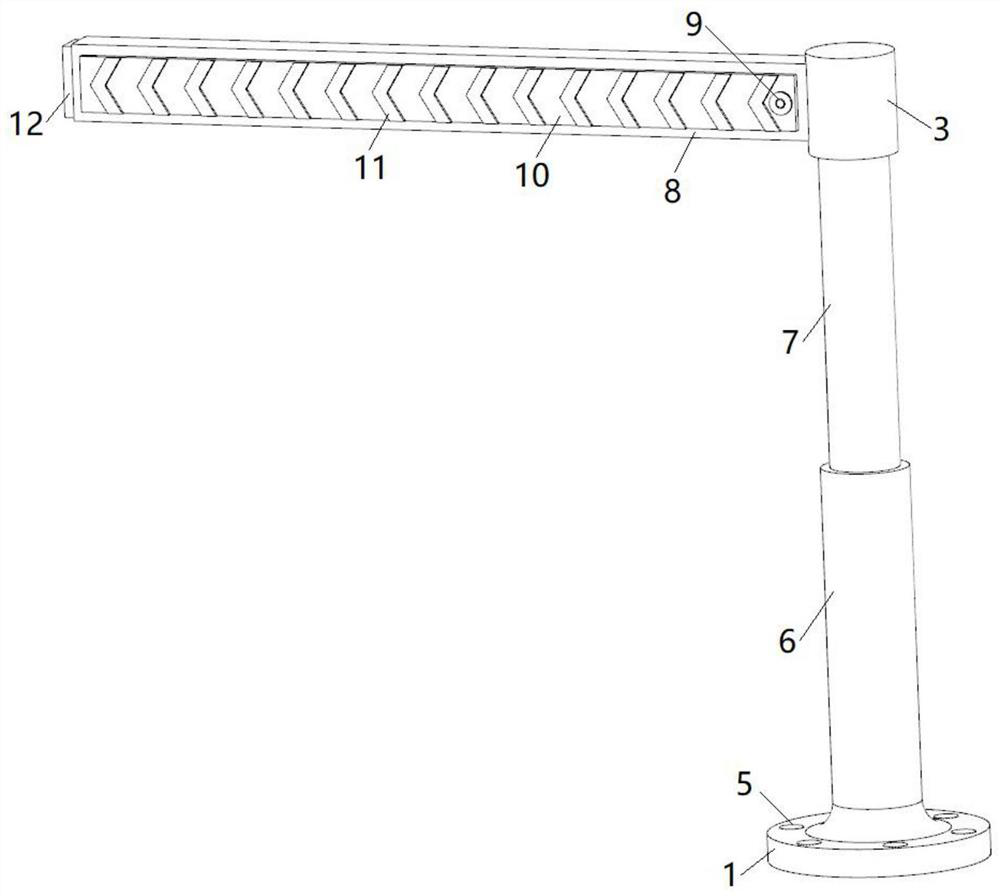

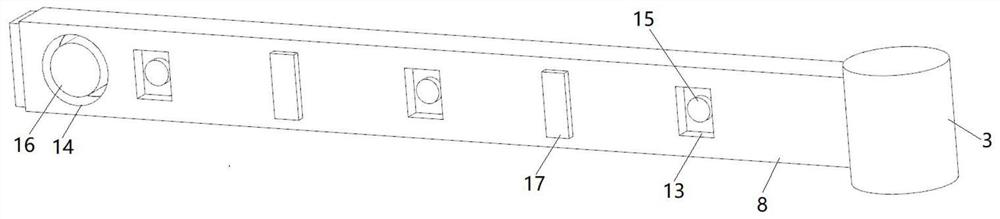

Cross bar anti-collision detection system, method and terminal based on RFID technology

InactiveCN113222089AImprove accuracyAvoid the risk of hitting the poleRecord carriers used with machinesSensing by electromagnetic radiationEmbedded systemElectrical and Electronics engineering

The invention discloses a cross bar anti-collision detection system, method and terminal based on RFID technology, and relates to the technical field of machinery. The system is provided with a base, a supporting column is fixedly mounted at the upper end of the base, a mounting shell is movably mounted at the upper end of the supporting column, a horizontally-arranged cross rod is welded to the mounting shell, a supporting rod is arranged in the cross rod, a camera is embedded in the tail end of the supporting rod, and an electromagnetic device is embedded in the head end of the supporting rod; a first containing cavity and a second containing cavity are formed in the front portion, the rear portion, the head portion and the tail portion of the supporting rod respectively, an RFID sensor is installed in the first containing cavity, and a vibration sensor is installed in the second containing cavity. According to the cross bar anti-collision detection system based on the RFID technology, unique matching of the tooling and the mold can be effectively achieved, manual inspection can be completely replaced, the accuracy is extremely high, and the risk of bar collision caused by the error of the tooling on a press line is thoroughly avoided through the technical means.

Owner:高解放

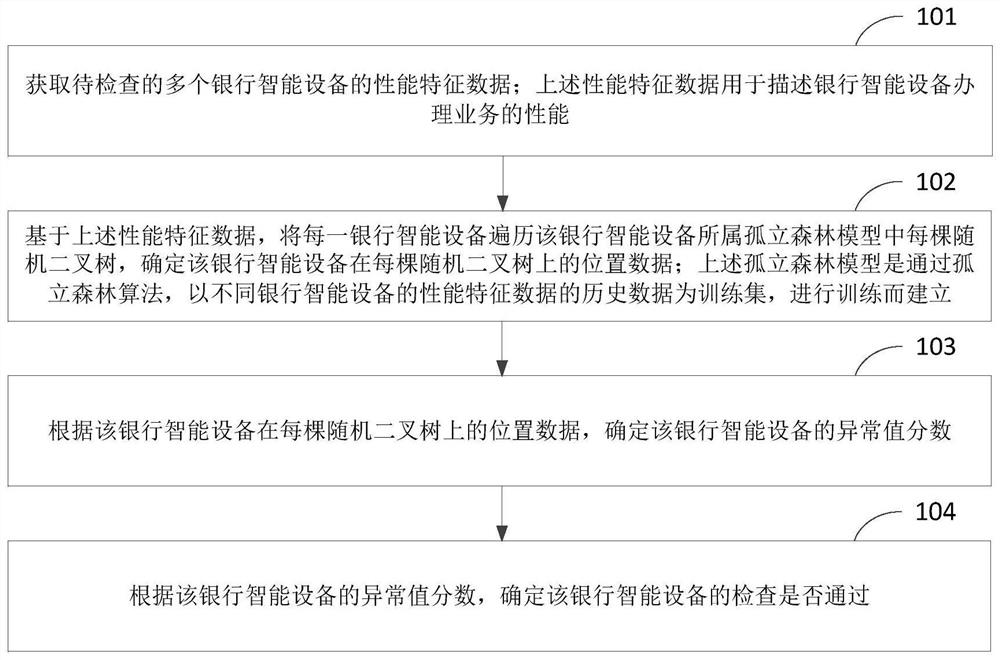

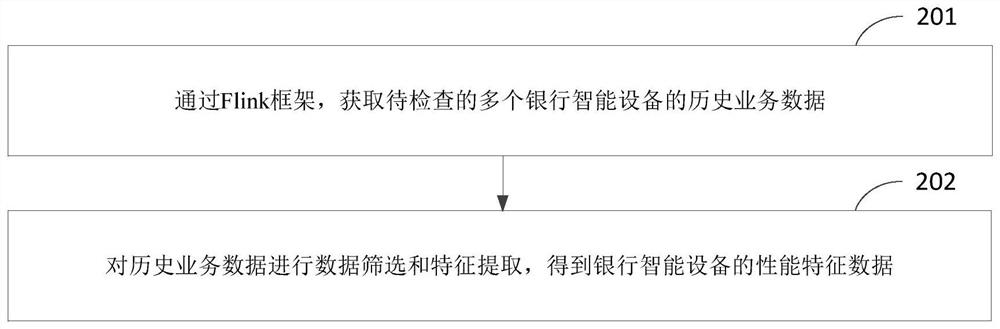

Bank intelligent equipment checking method and device

PendingCN113673724AAutomate inspectionImprove inspection efficiencyFinanceCharacter and pattern recognitionFeature dataData mining

The invention discloses a bank intelligent equipment checking method and device, and relates to the technical field of artificial intelligence. The method comprises the following steps: obtaining performance feature data of a plurality of pieces of to-be-checked bank intelligent equipment, wherein the performance feature data is used for describing business handling performance of the bank intelligent equipment; on the basis of the performance feature data, traversing each random binary tree in an isolated forest model to which the bank intelligent equipment belongs by each piece of intelligent equipment, and determining position data of the bank intelligent equipment on each random binary tree; determining an abnormal value score of the bank intelligent equipment according to the position data of the bank intelligent equipment on each random binary tree; and according to the abnormal value score of the bank intelligent equipment, determining whether a check of the bank intelligent equipment is passed or not. According to the invention, the efficiency and accuracy of bank intelligent equipment checking can be improved.

Owner:BANK OF CHINA

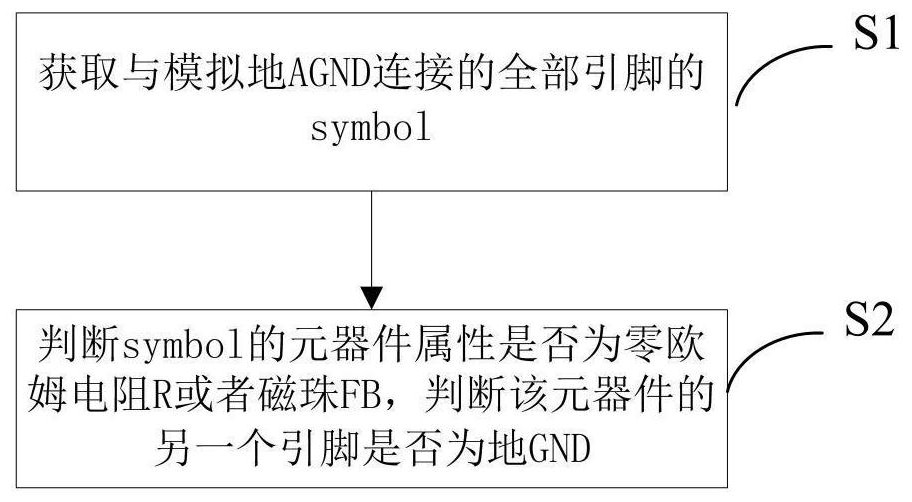

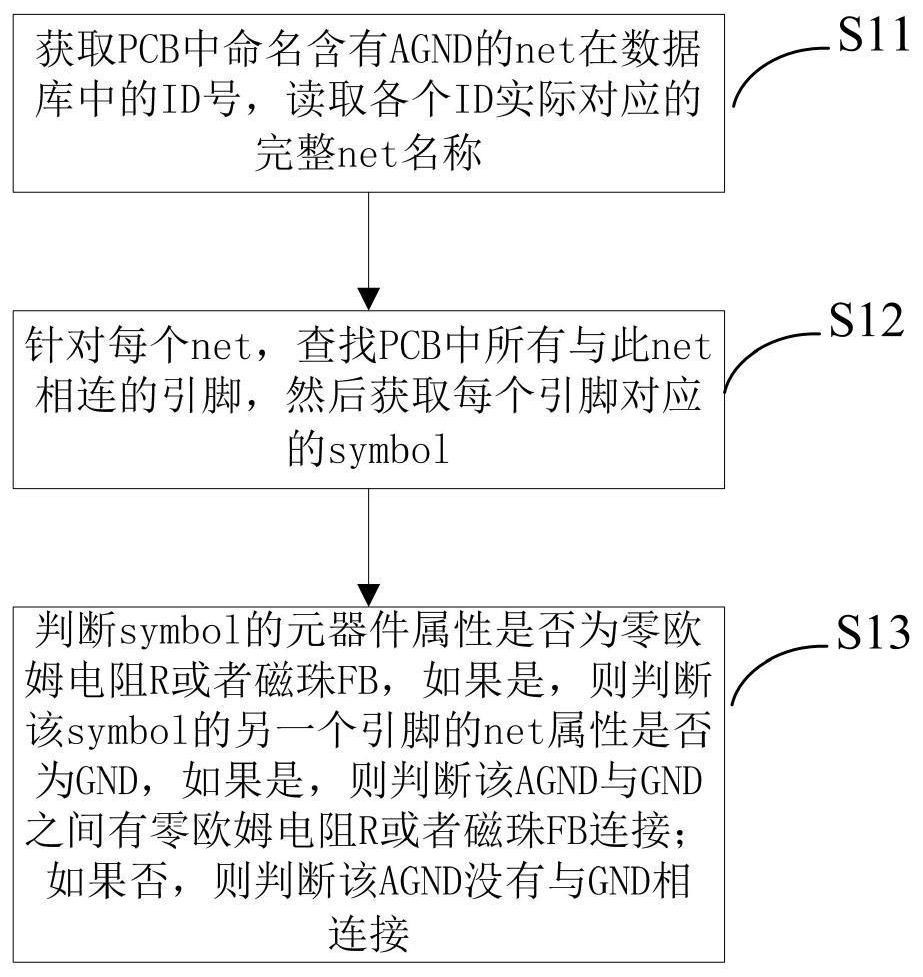

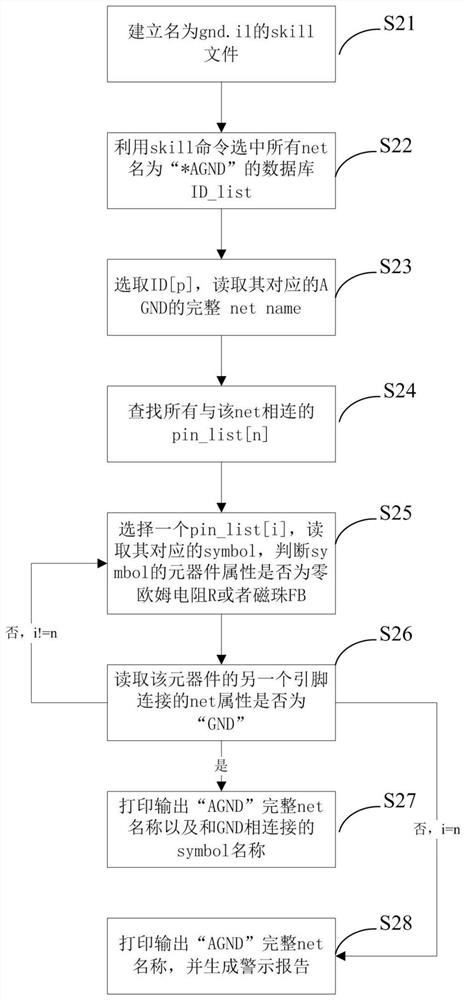

A method and device for checking electrical connection between analog ground and digital ground

ActiveCN108846202BImprove work efficiencyAutomate inspectionCAD circuit designSpecial data processing applicationsMagnetic beadElectrical connection

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com