Patents

Literature

41results about How to "Practical implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

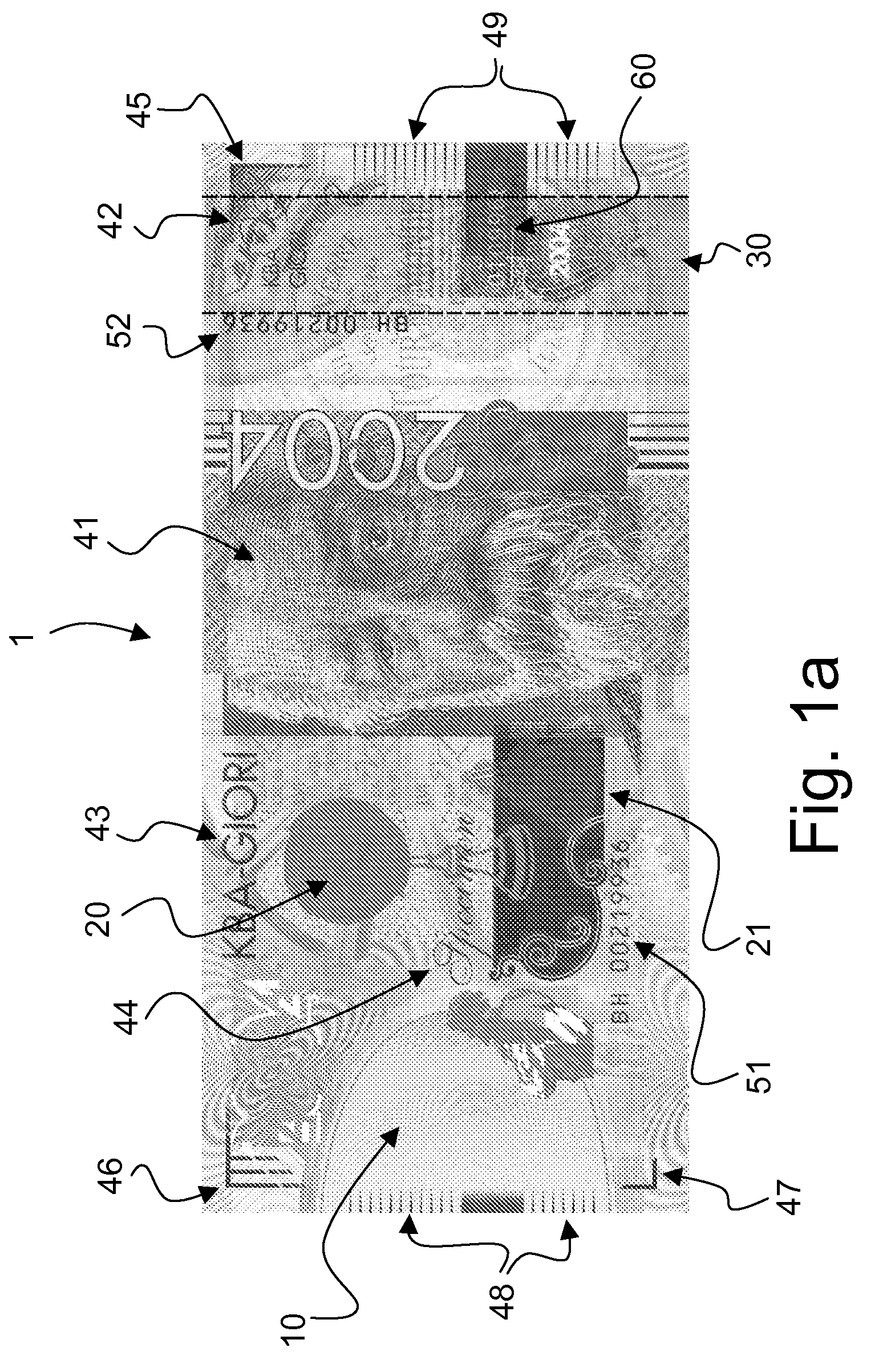

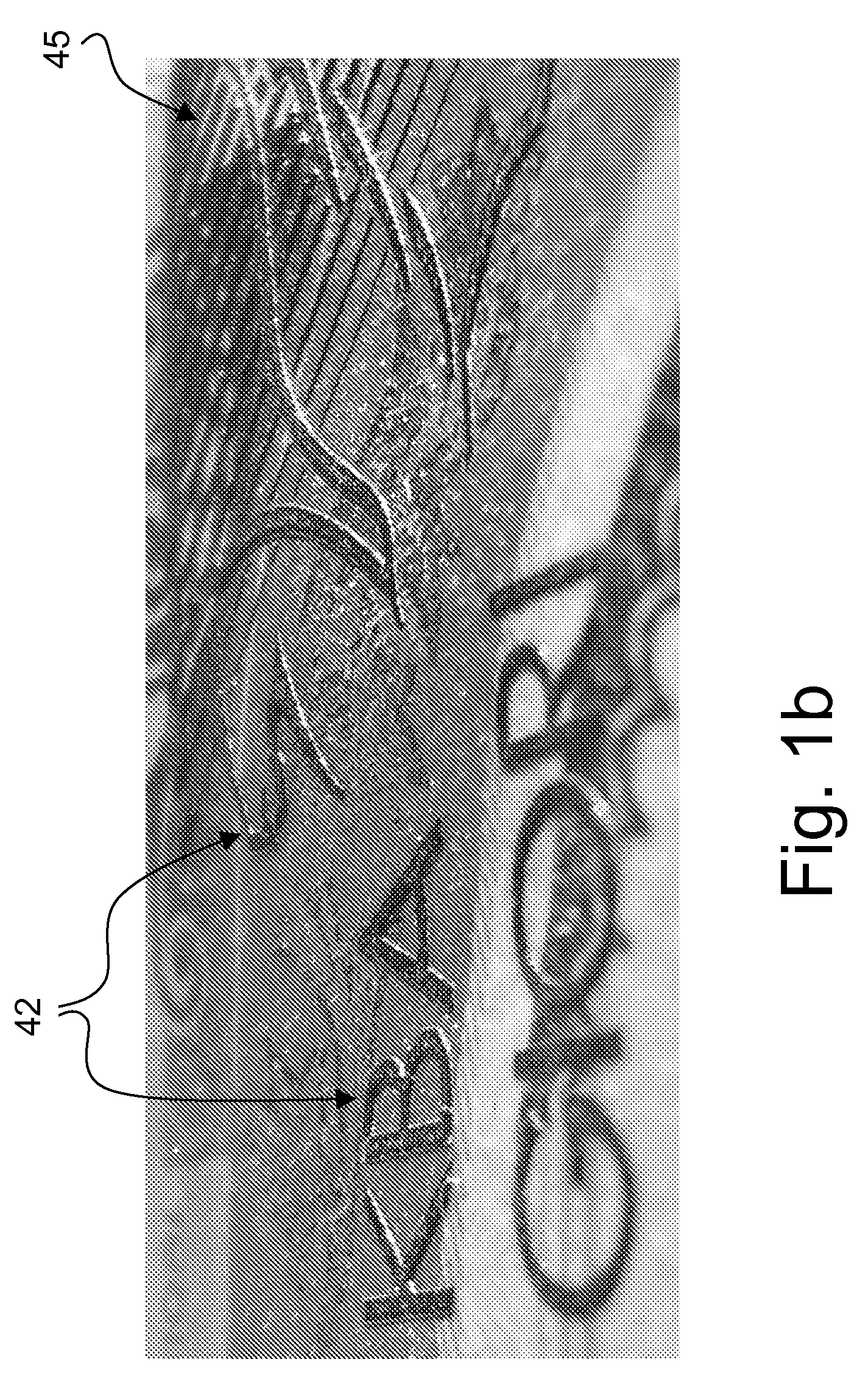

Authentication of Security Documents, in Particular of Banknotes

ActiveUS20100195894A1Robust and efficient differentiationSimple wayImage analysisPaper-money testing devicesSample imageDocumentation

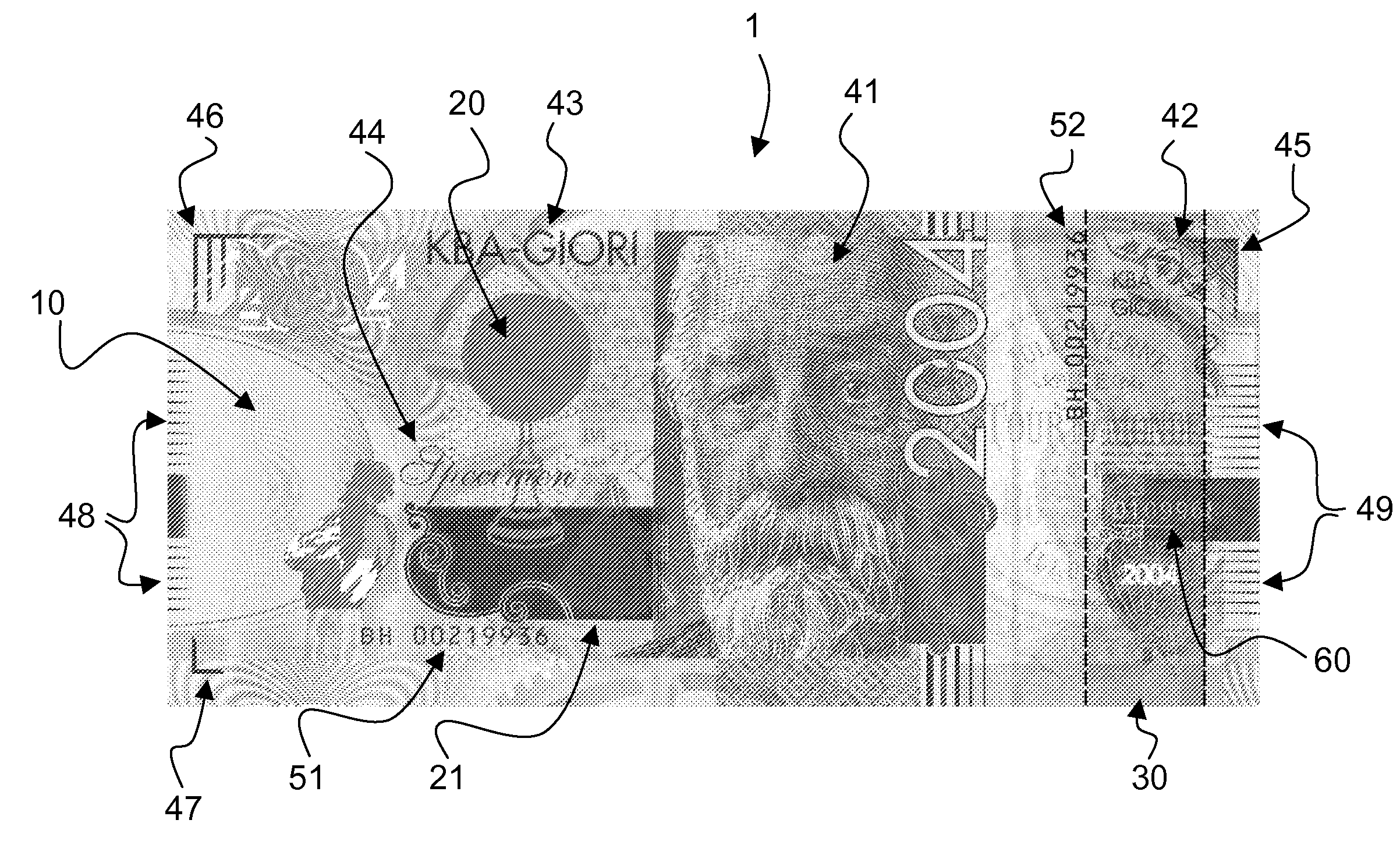

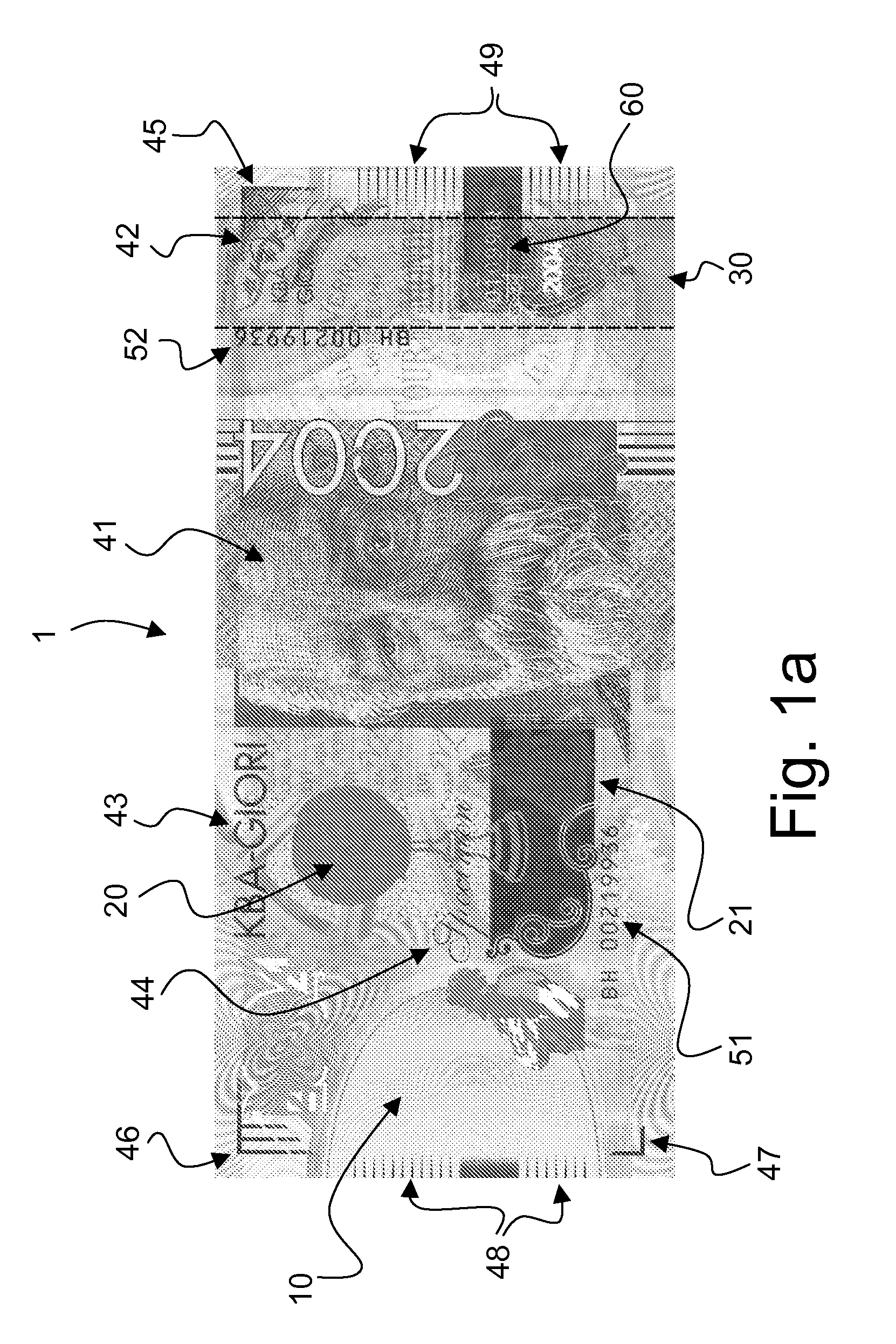

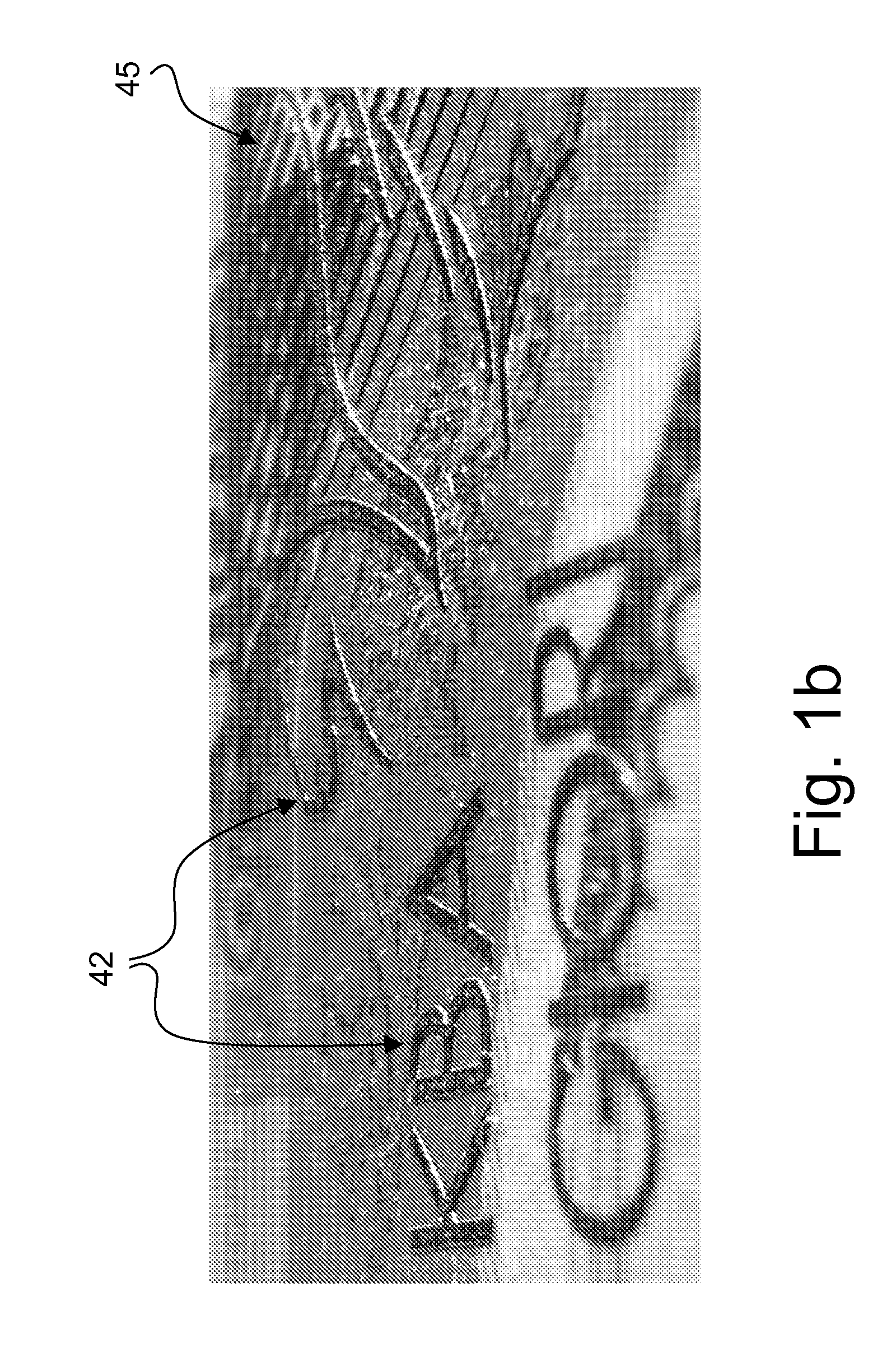

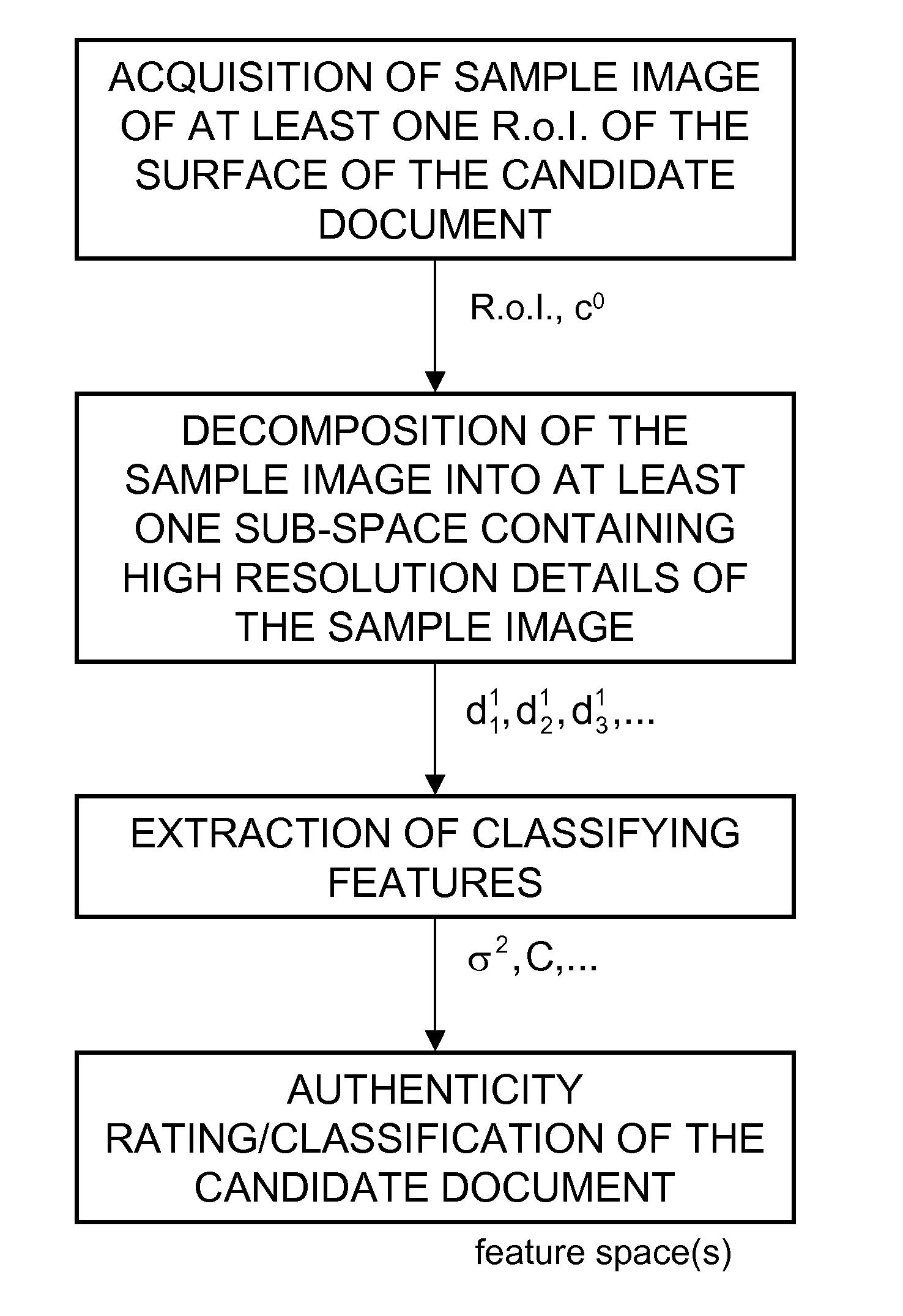

There is described a method for checking the authenticity of security documents, in particular banknotes, wherein authentic security documents comprise security features printed, applied or otherwise provided on the security documents, which security features comprise characteristic visual features intrinsic to the processes used for producing the security documents. The method comprises the steps of (i) acquiring a sample image of at least one region of interest of the surface of a candidate document to be authenticated, which region of interest encompasses at least part of the security features, (ii) digitally processing the sample image by performing a decomposition of the sample image into at least one scale sub-space containing high resolution details of the sample image and extracting classifying features from the scale sub-space, and (iii) deriving an authenticity rating of the candidate document based on the extracted classifying features.

Owner:KBA NOTASYS SA

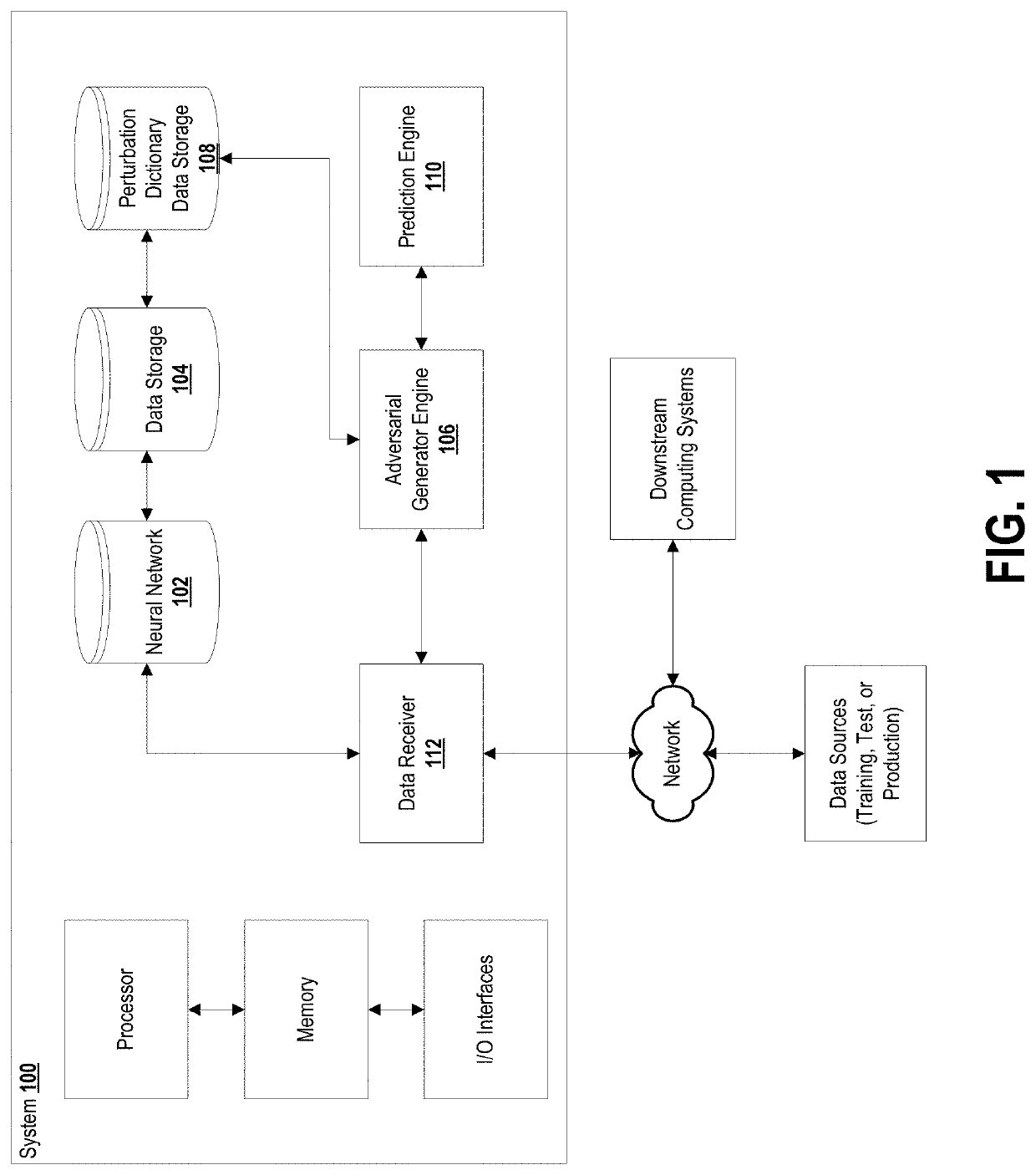

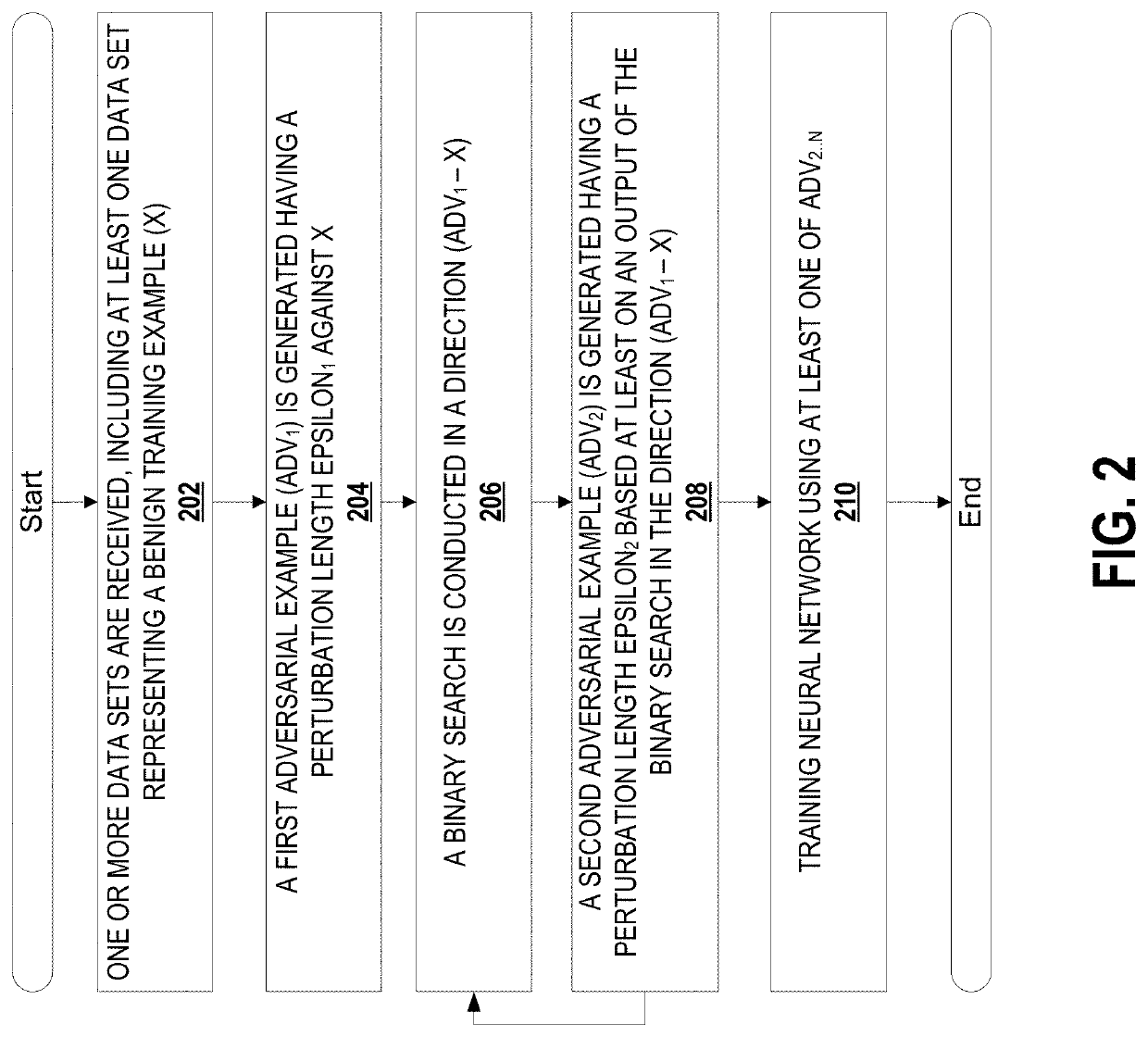

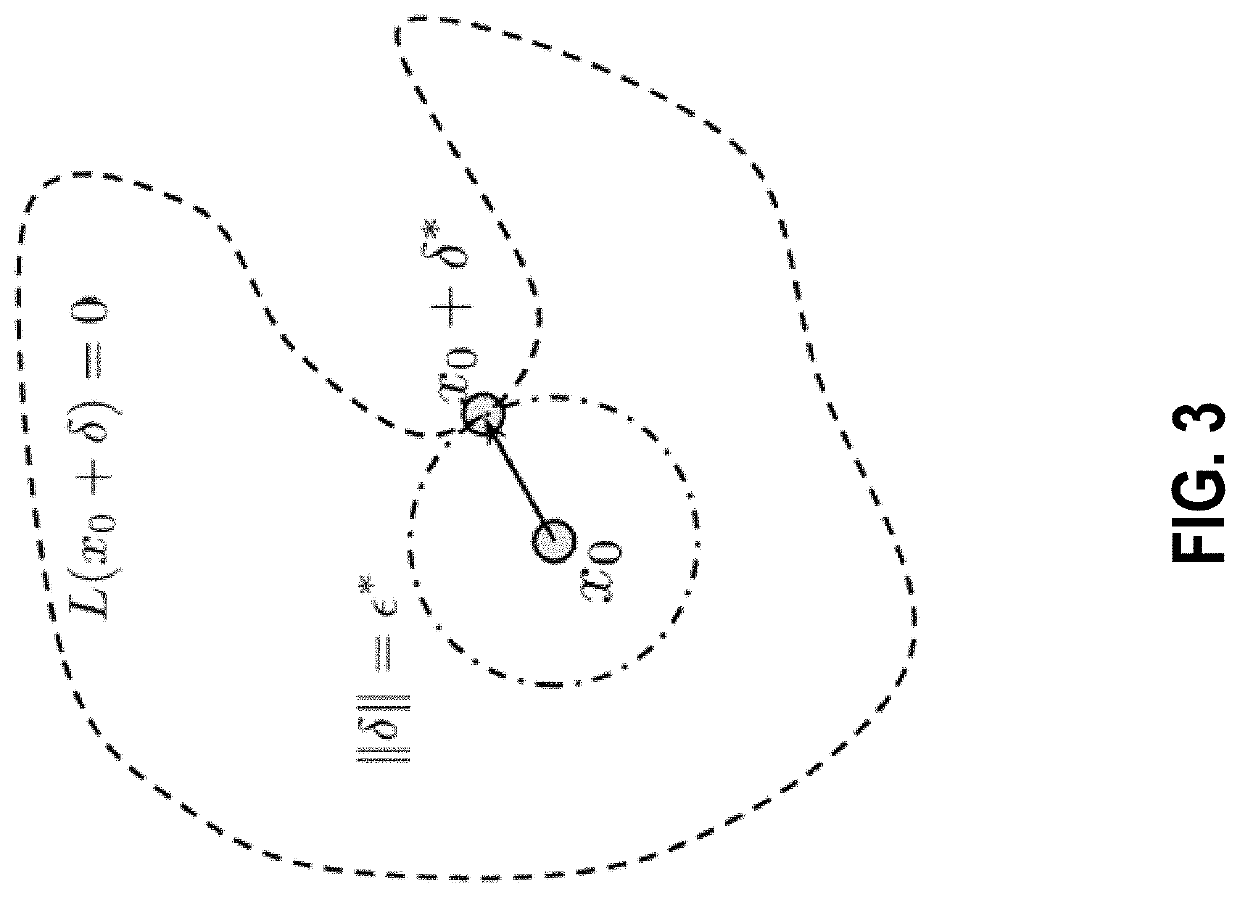

System and method for max-margin adversarial training

ActiveUS20200134468A1High strengthDegrades accuracy of predictionEnsemble learningKernel methodsData setDecision boundary

A system for generating an adversarial example in respect of a neural network, the adversarial example generated to improve a margin defined as a distance from a data example to a neural network decision boundary. The system includes a data receiver configured to receive one or more data sets including at least one data set representing a benign training example (x); an adversarial generator engine configured to: generate, using the neural network, a first adversarial example (Adv1) having a perturbation length epsilon1 against x; conduct a search in a direction (Adv1-x) using the neural network; and to generate, using the neural network, a second adversarial example (Adv2) having a perturbation length epsilon2 based at least on an output of a search in the direction (Adv1-x).

Owner:ROYAL BANK OF CANADA

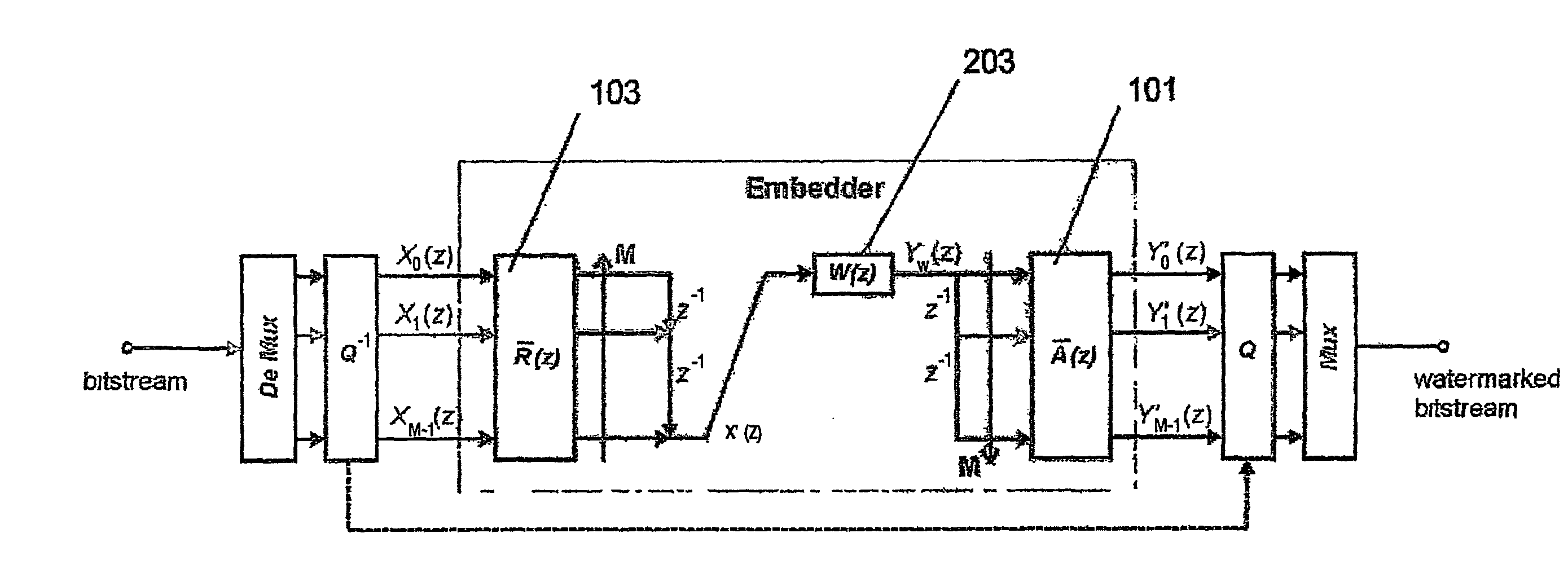

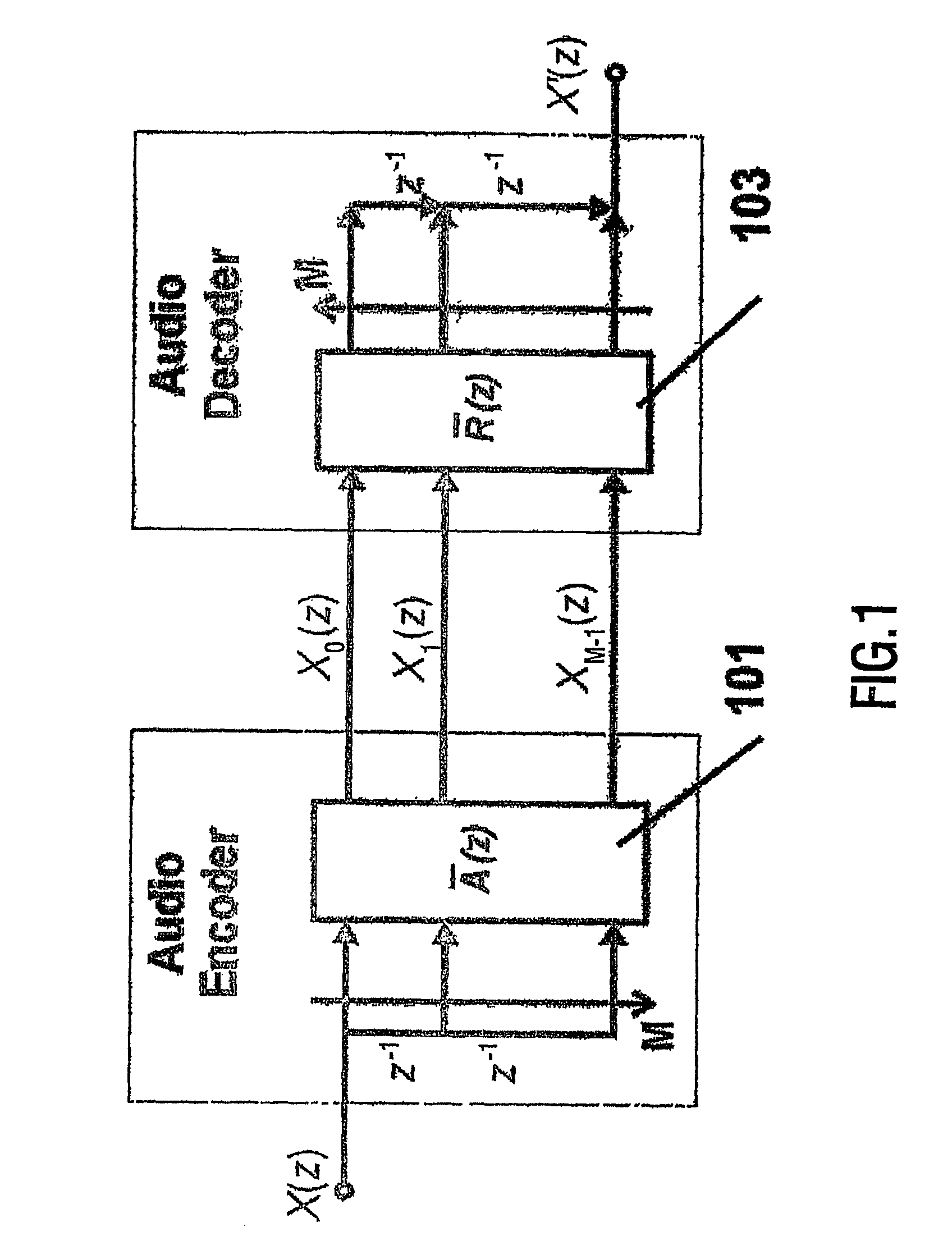

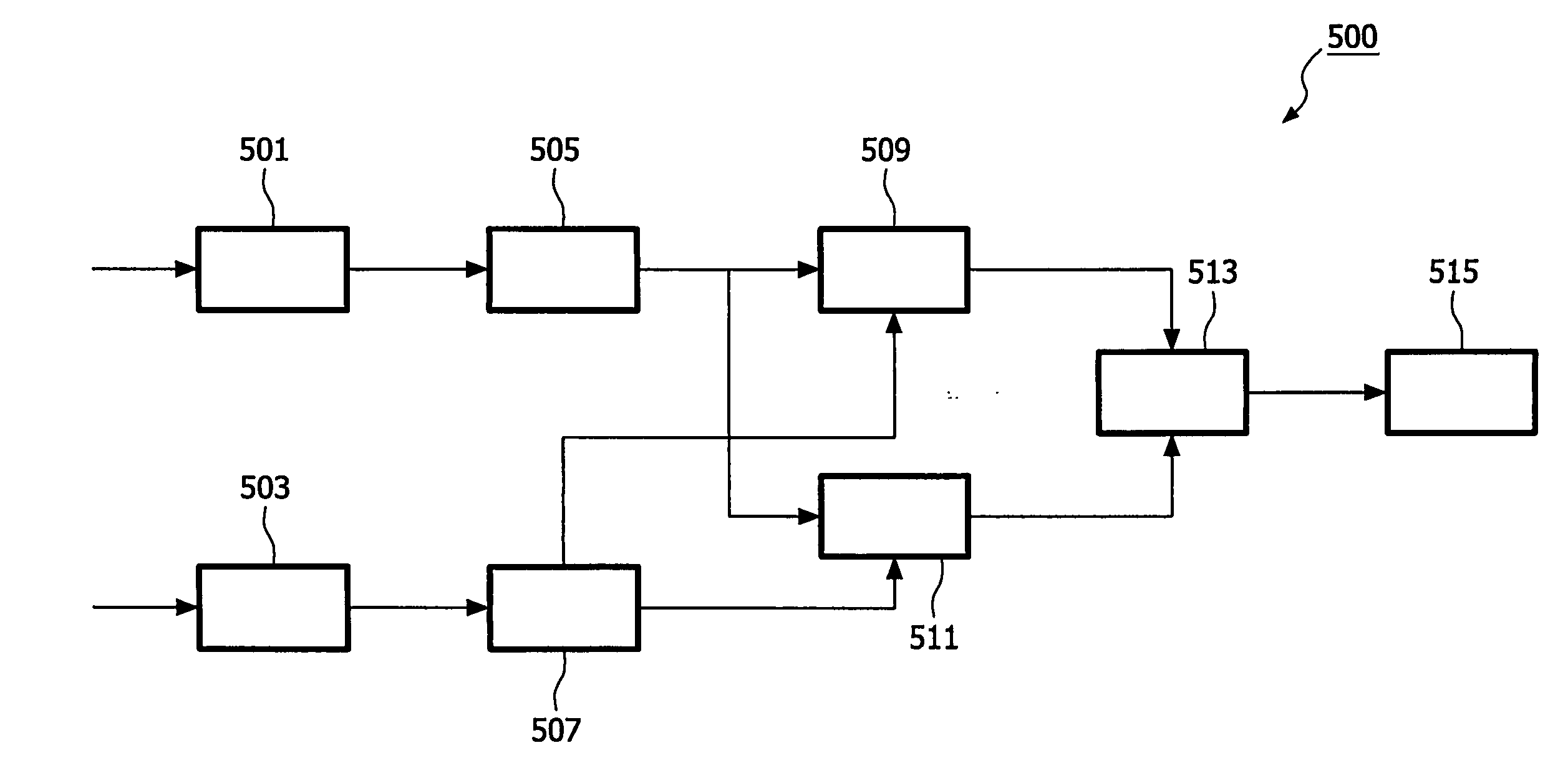

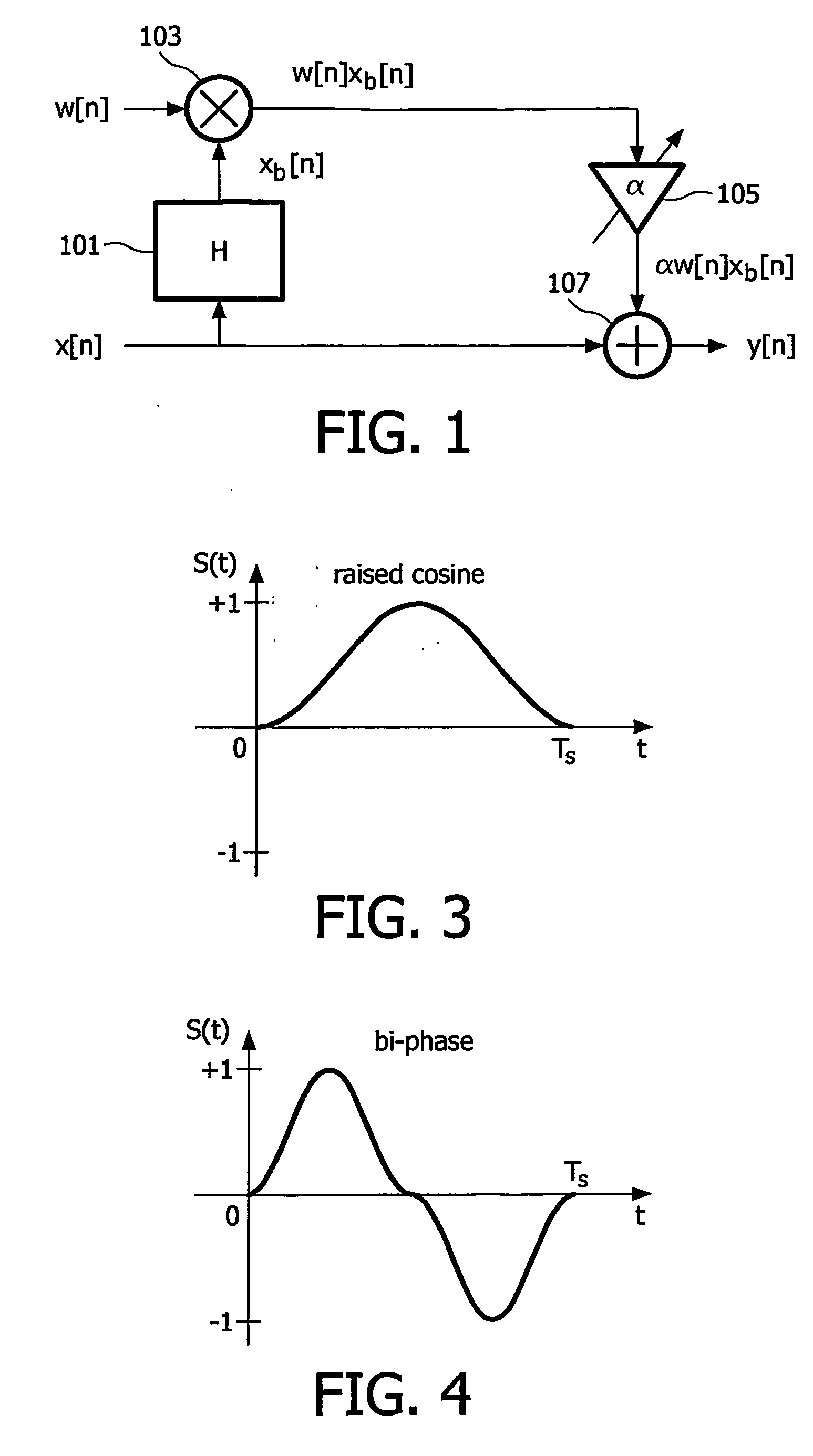

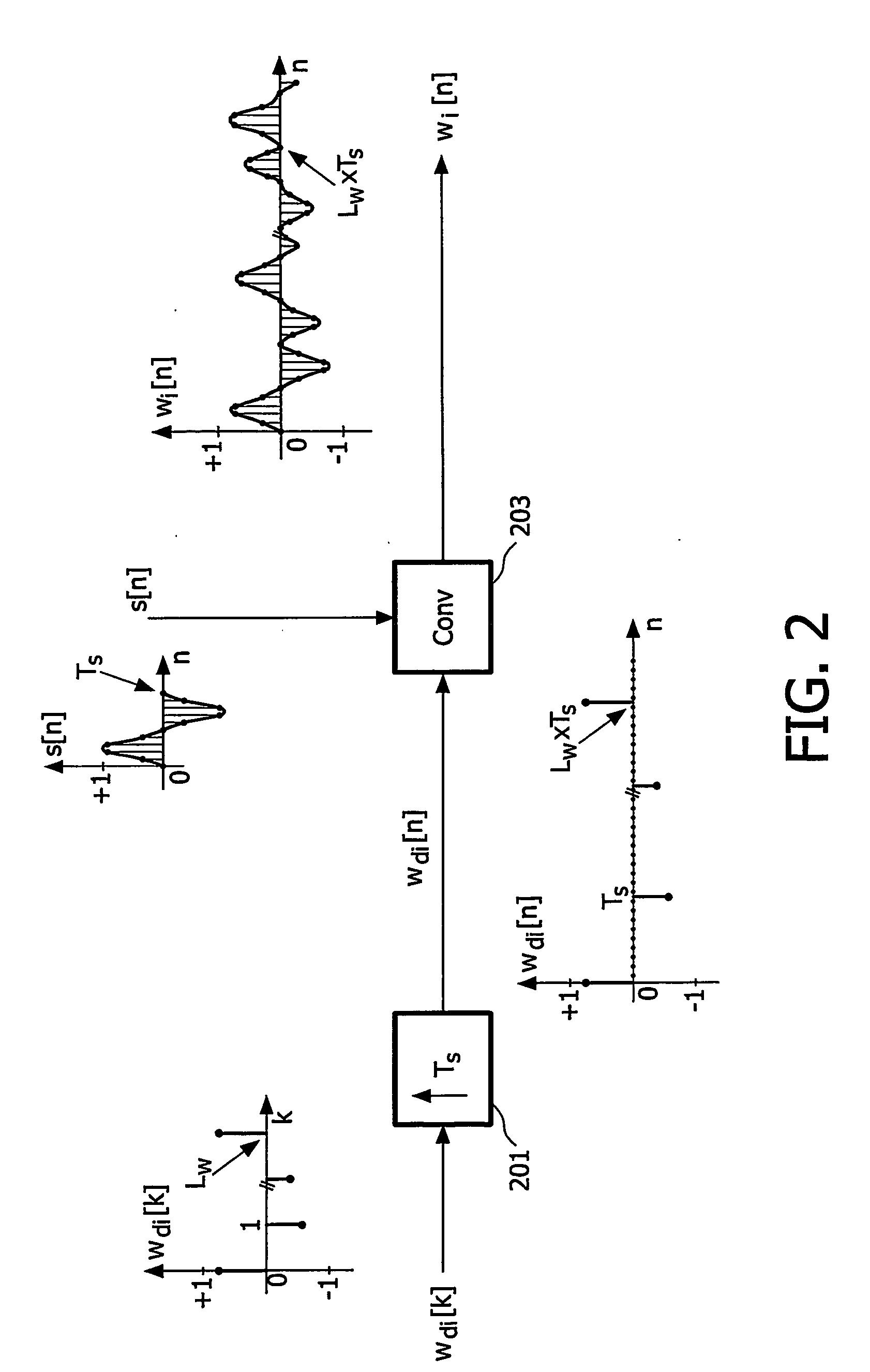

Apparatus and method for embedding a watermark using sub-band filtering

InactiveUS20070071277A1Reduced delay and complexity and delaySimple methodTelevision system detailsSpeech analysisComputer scienceLow complexity

The invention relates to a system for embedding a watermark into an input media signal. A plurality of sub-band signals of a sub-band encoded input signal is obtained; preferably by de-multiplexing of the corresponding bitstream. A set of sub-band signals is filtered by a sub-band filter (507) which has a response associated with the watermark. The sub-band filter (507) thereby generates a set of filtered sub-band signals which are combined into an output signal having the desired watermark. The output signal is preferably a compressed sub-band bitstream signal. A low complexity approach for embedding a watermark into a media signal by filtering in the sub-band domain is thus achieved obviating the requirement for decoding and re-encoding of the media signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

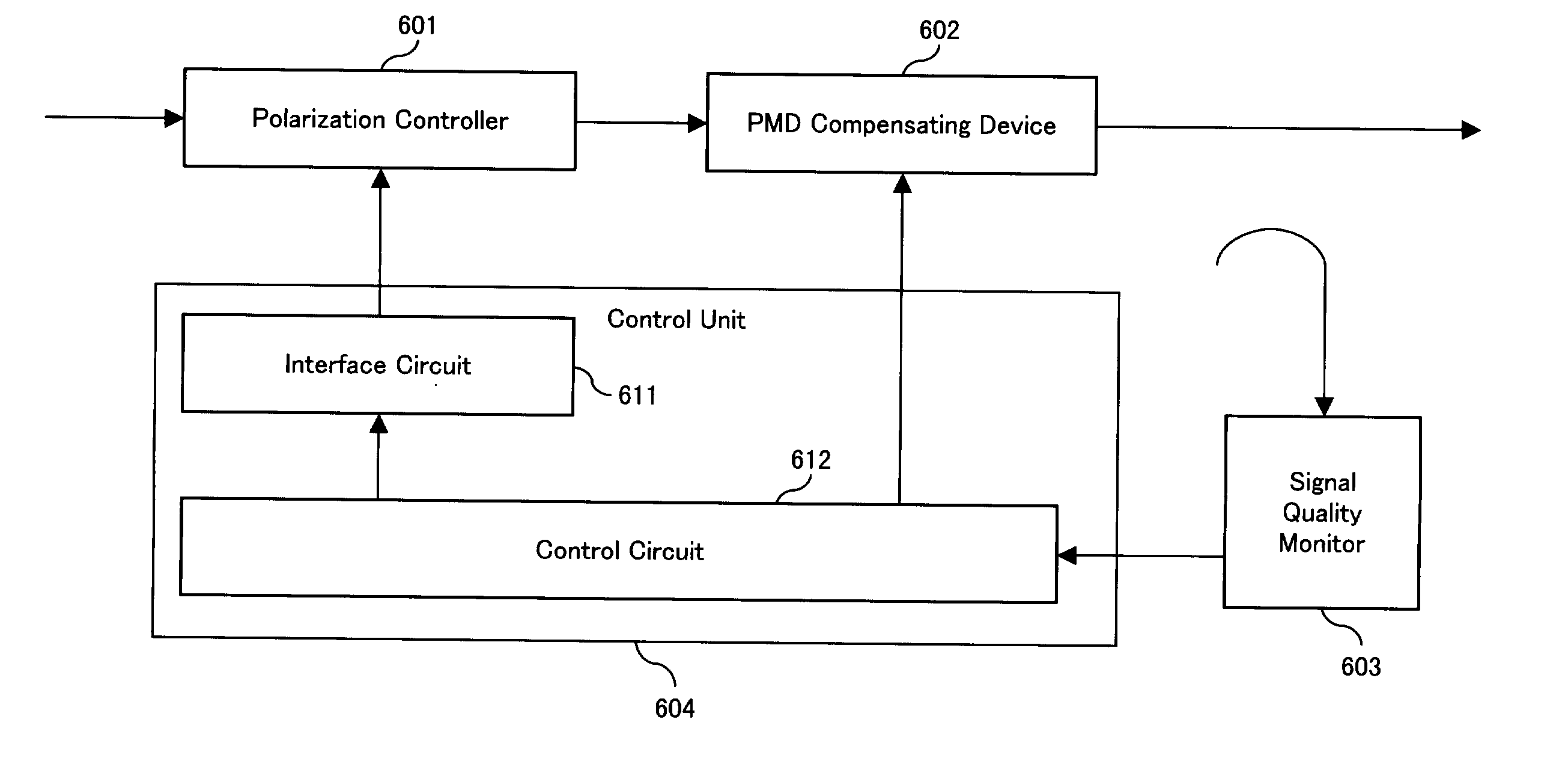

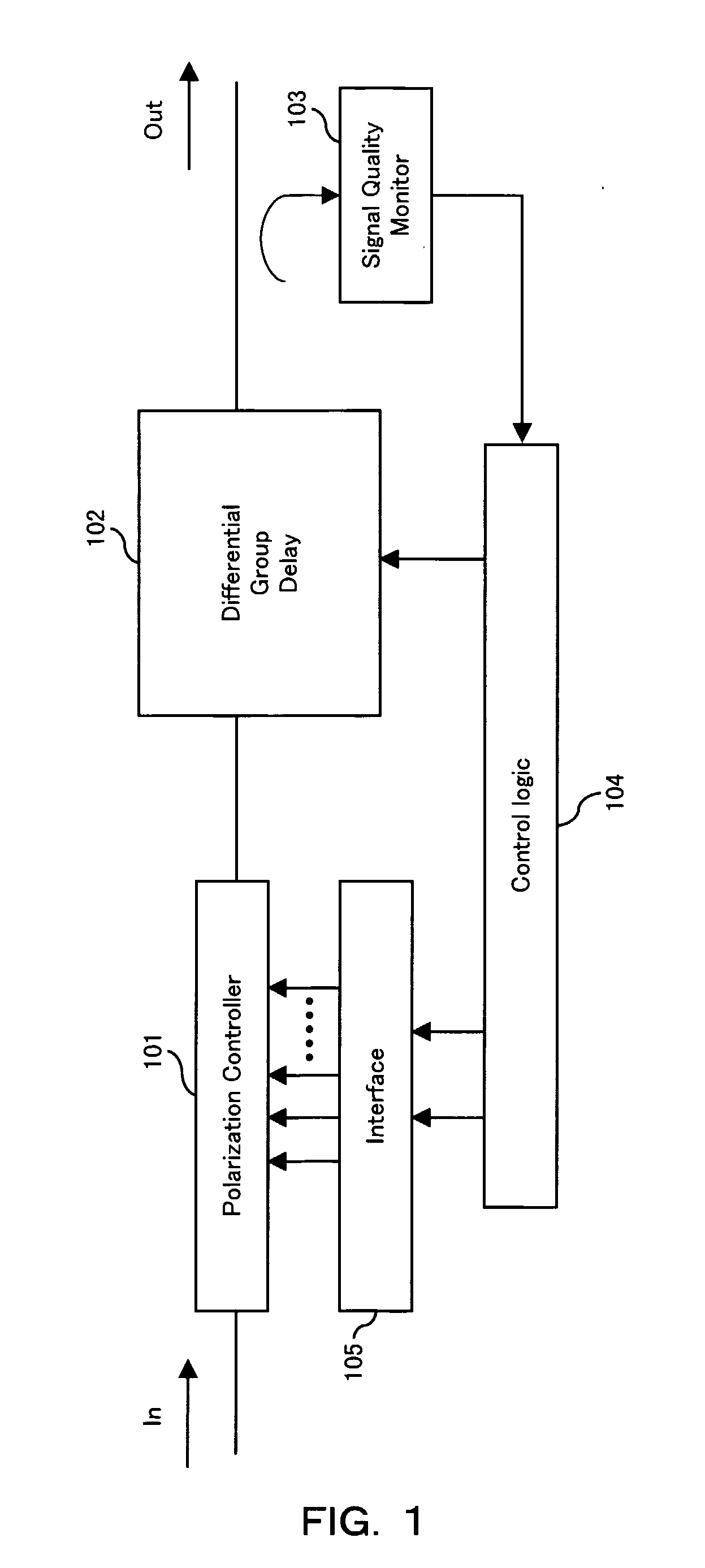

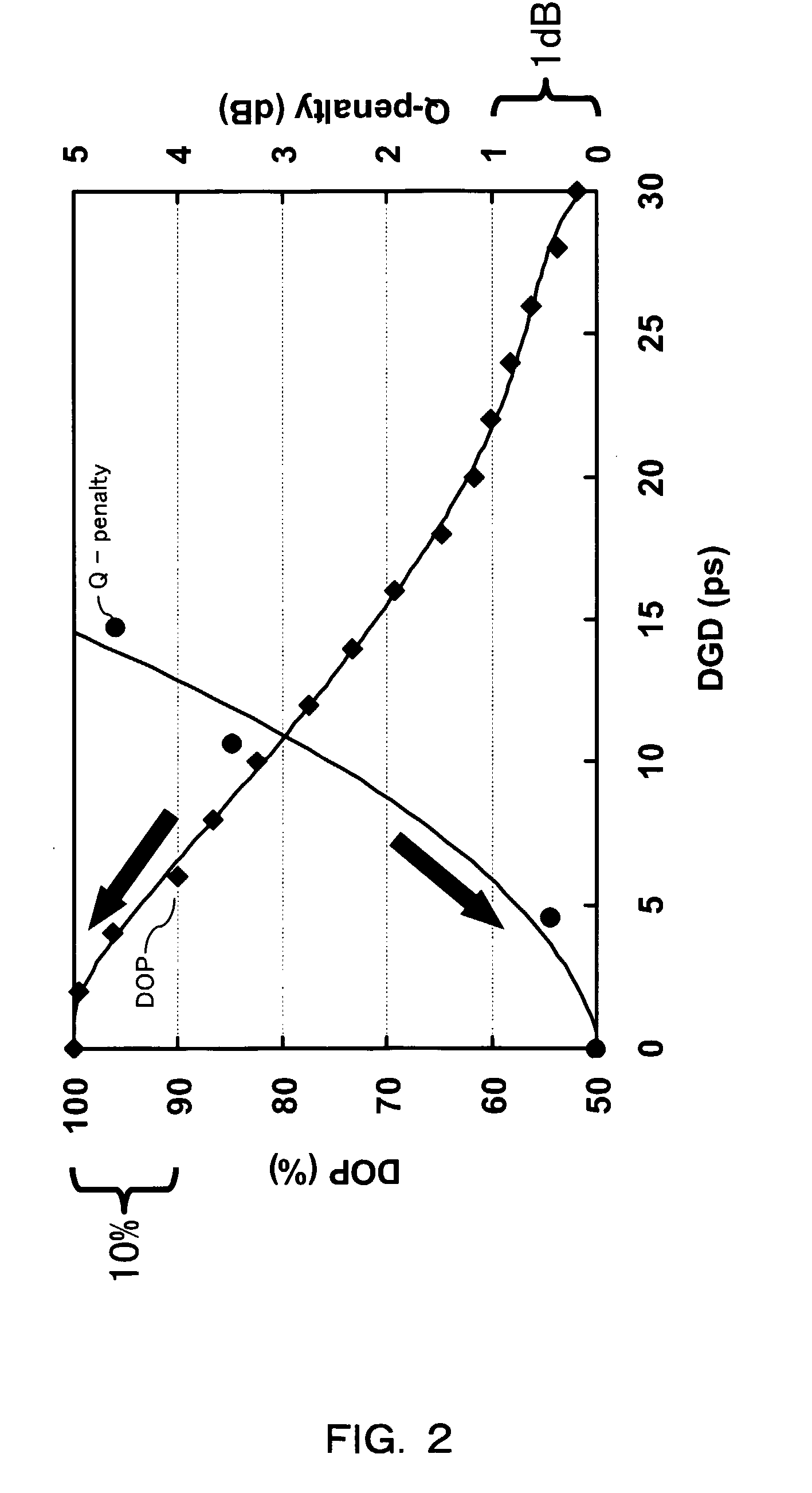

Polarization mode dispersion compensator and polarization mode dispersion compensating method

InactiveUS20070110451A1Practical implementationDistortion/dispersion eliminationTransmission monitoring/testing/fault-measurement systemsPhysicsPolarization mode dispersion

An amount of change of a control signal applied to a polarization controller in a polarization mode dispersion compensator is determined for each feedback loop by evaluating degree of polarization response in past feedback loops.

Owner:FUJITSU LTD

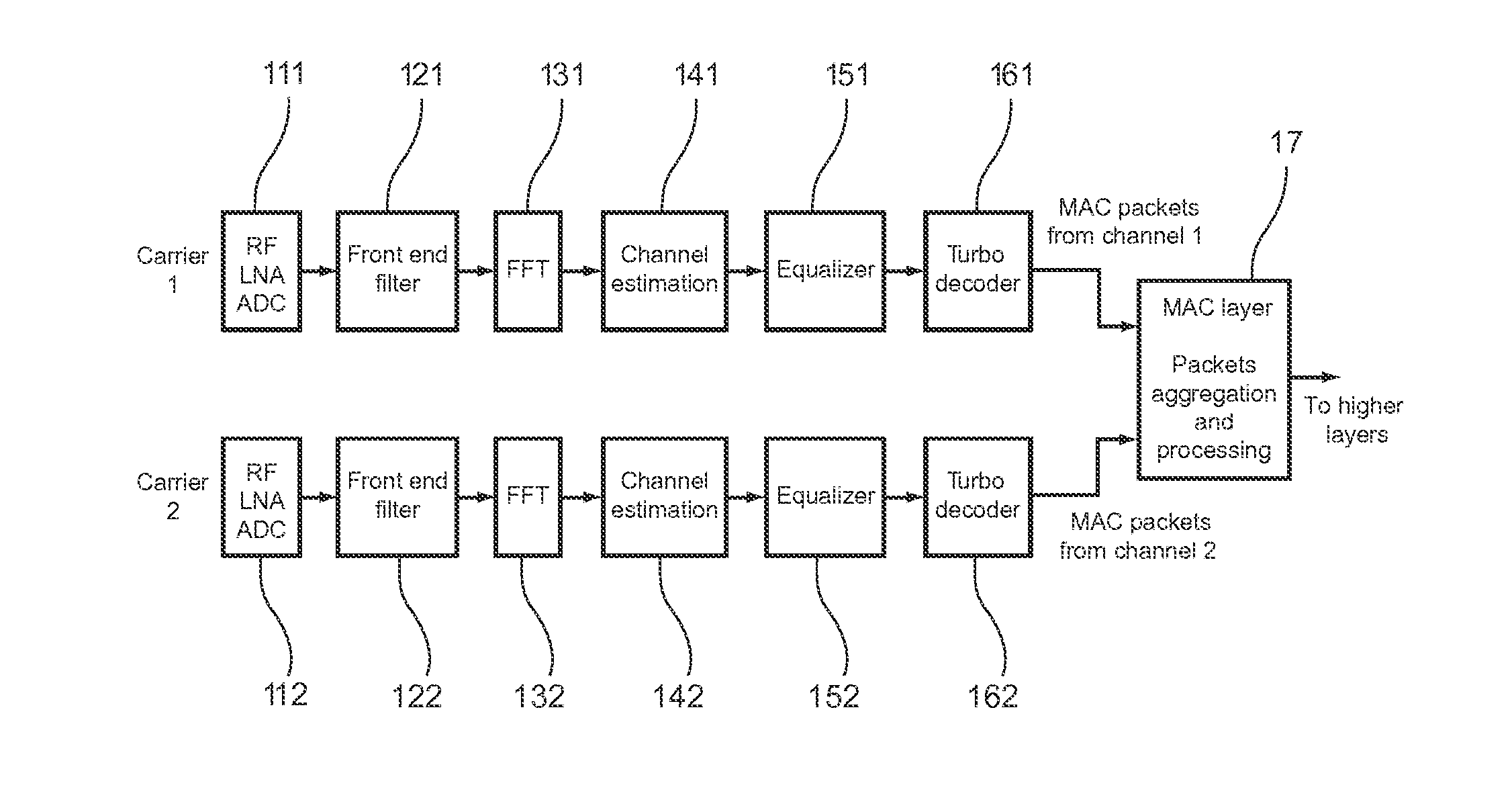

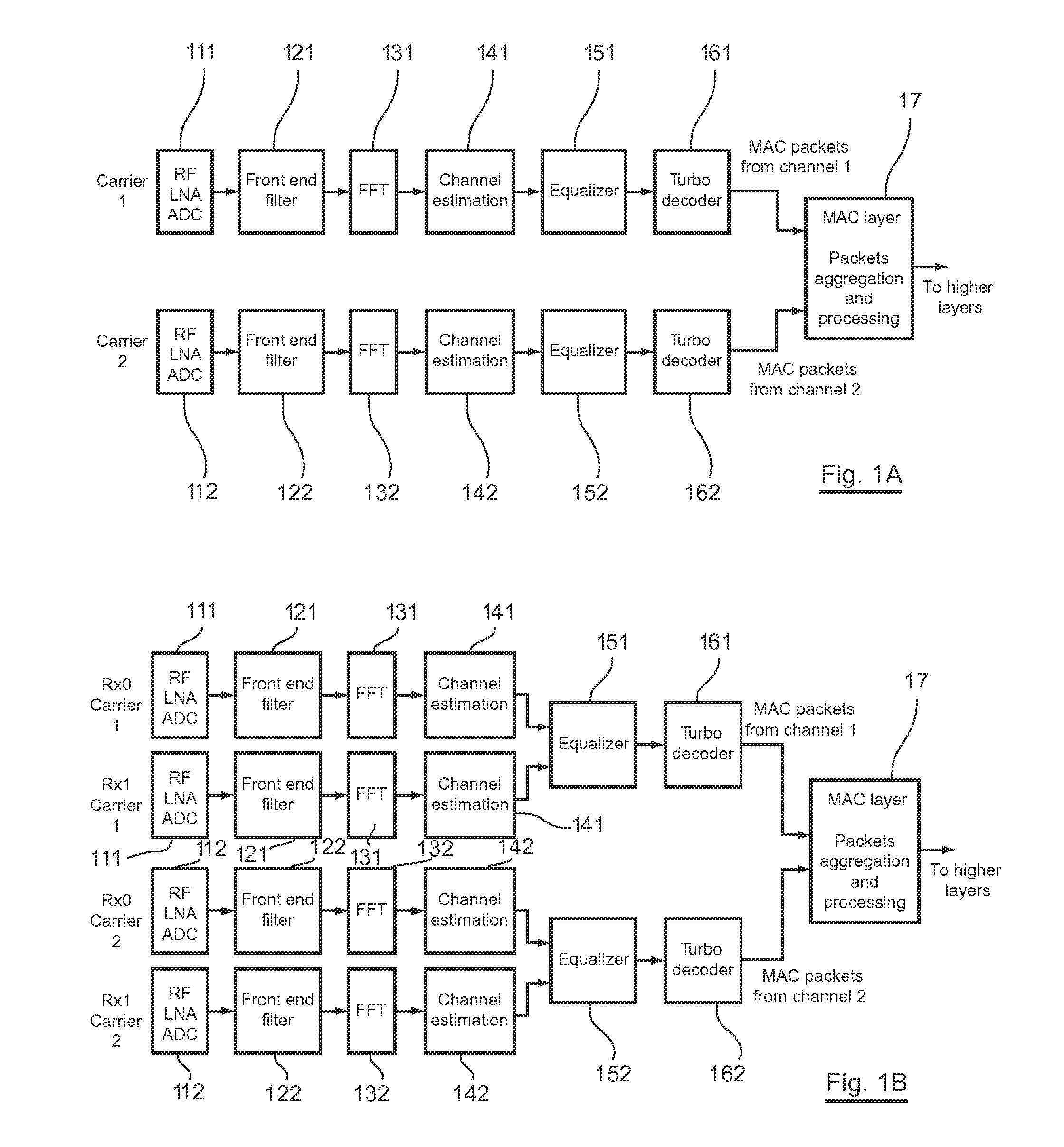

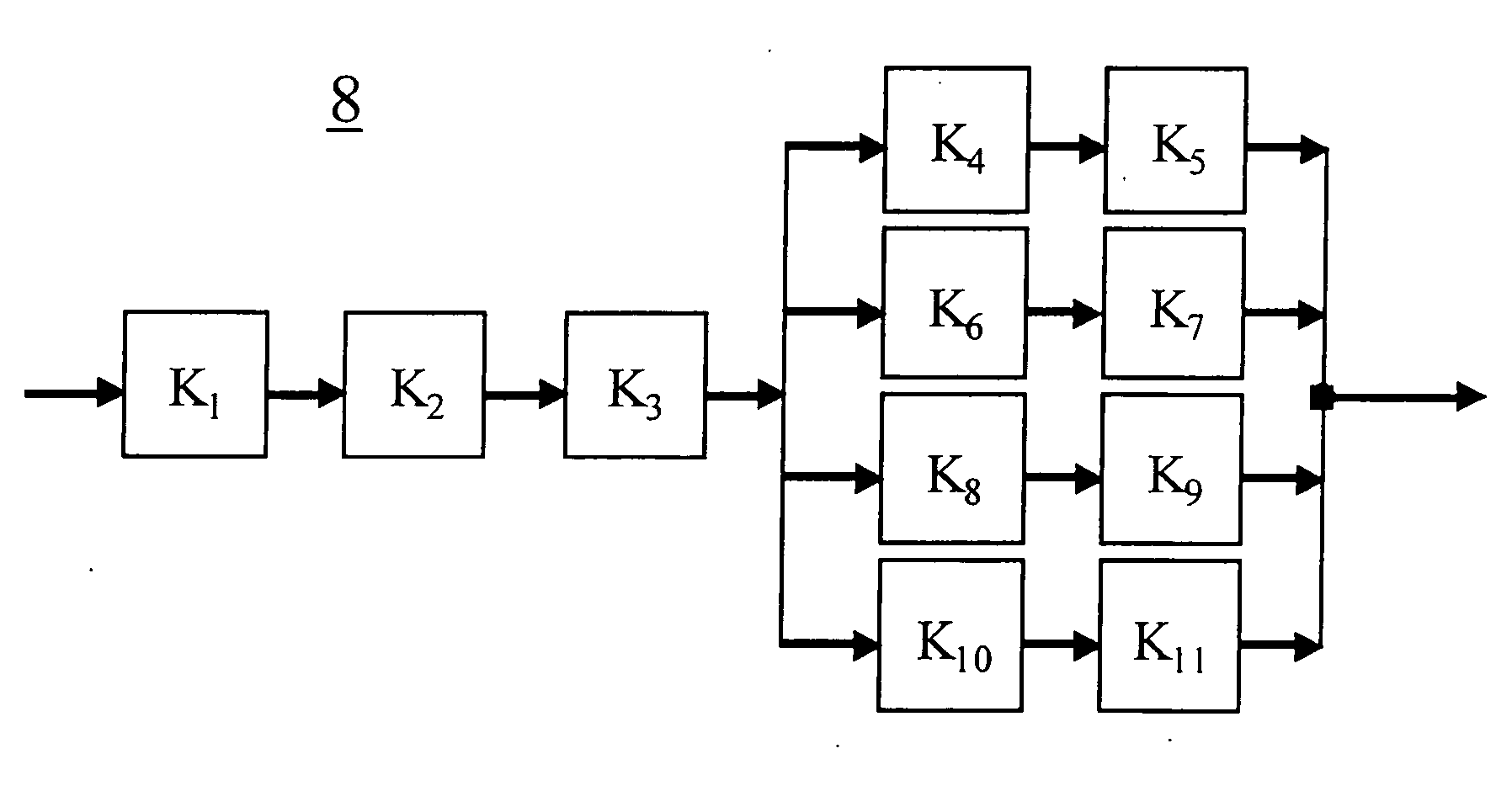

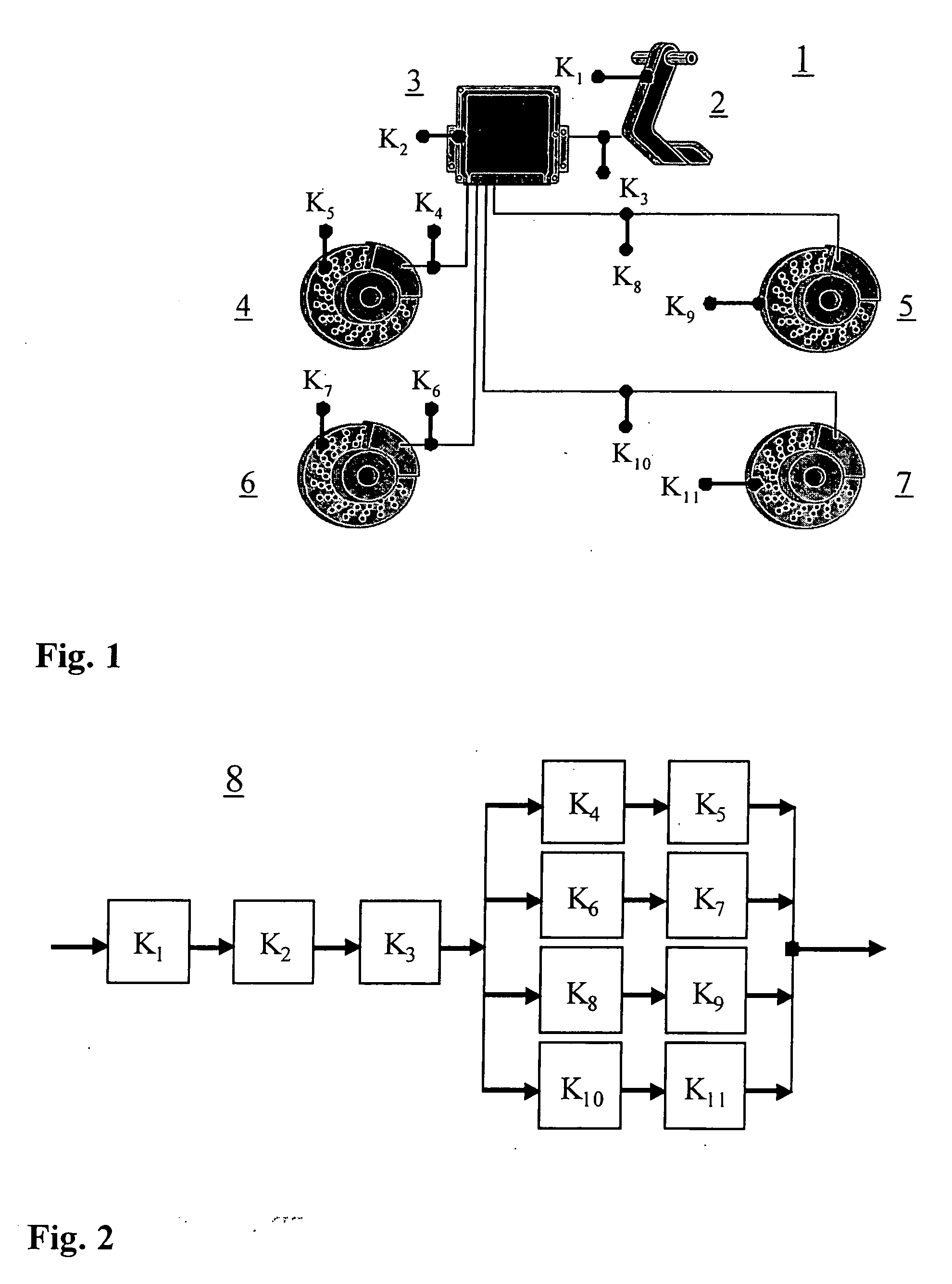

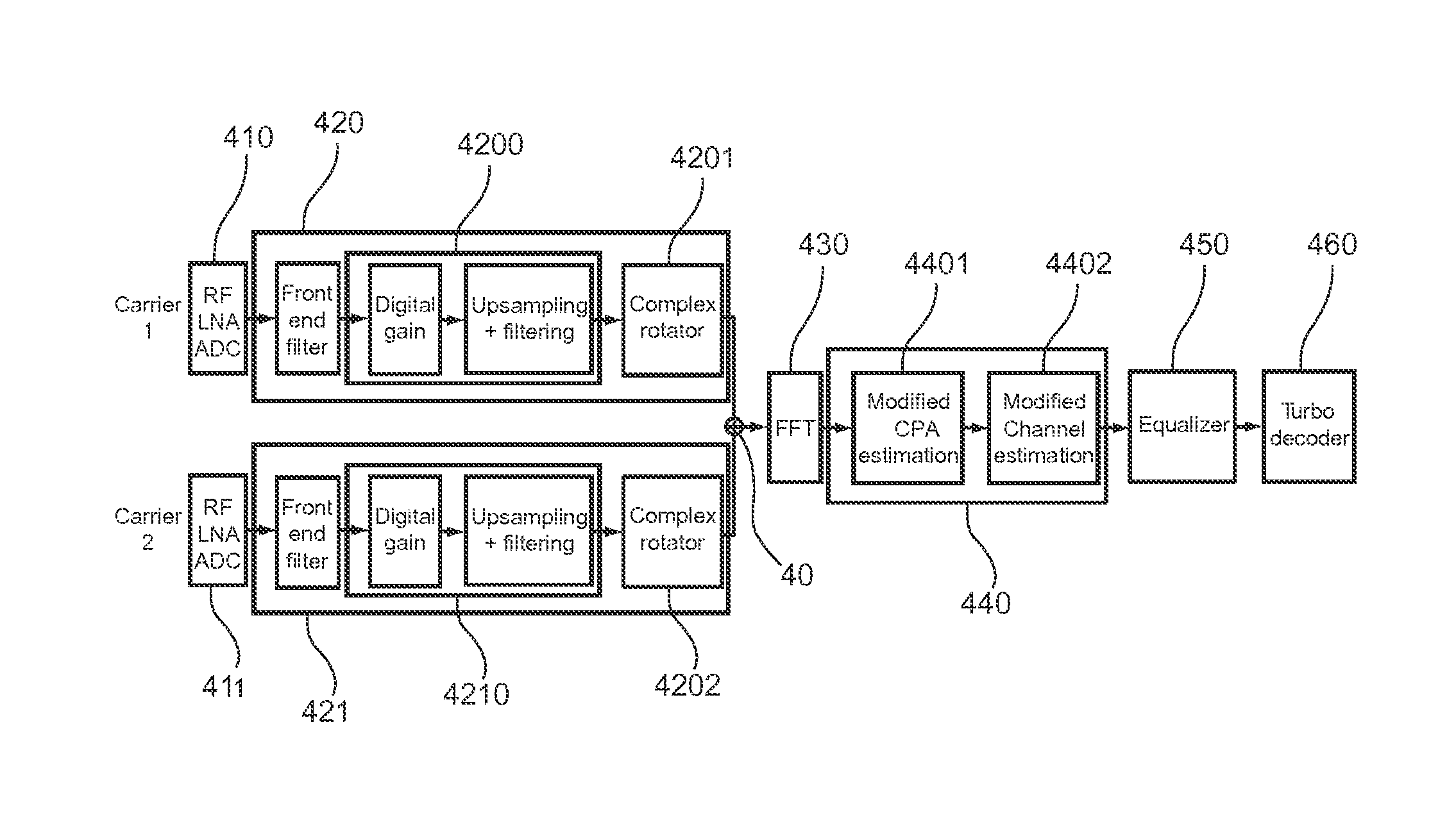

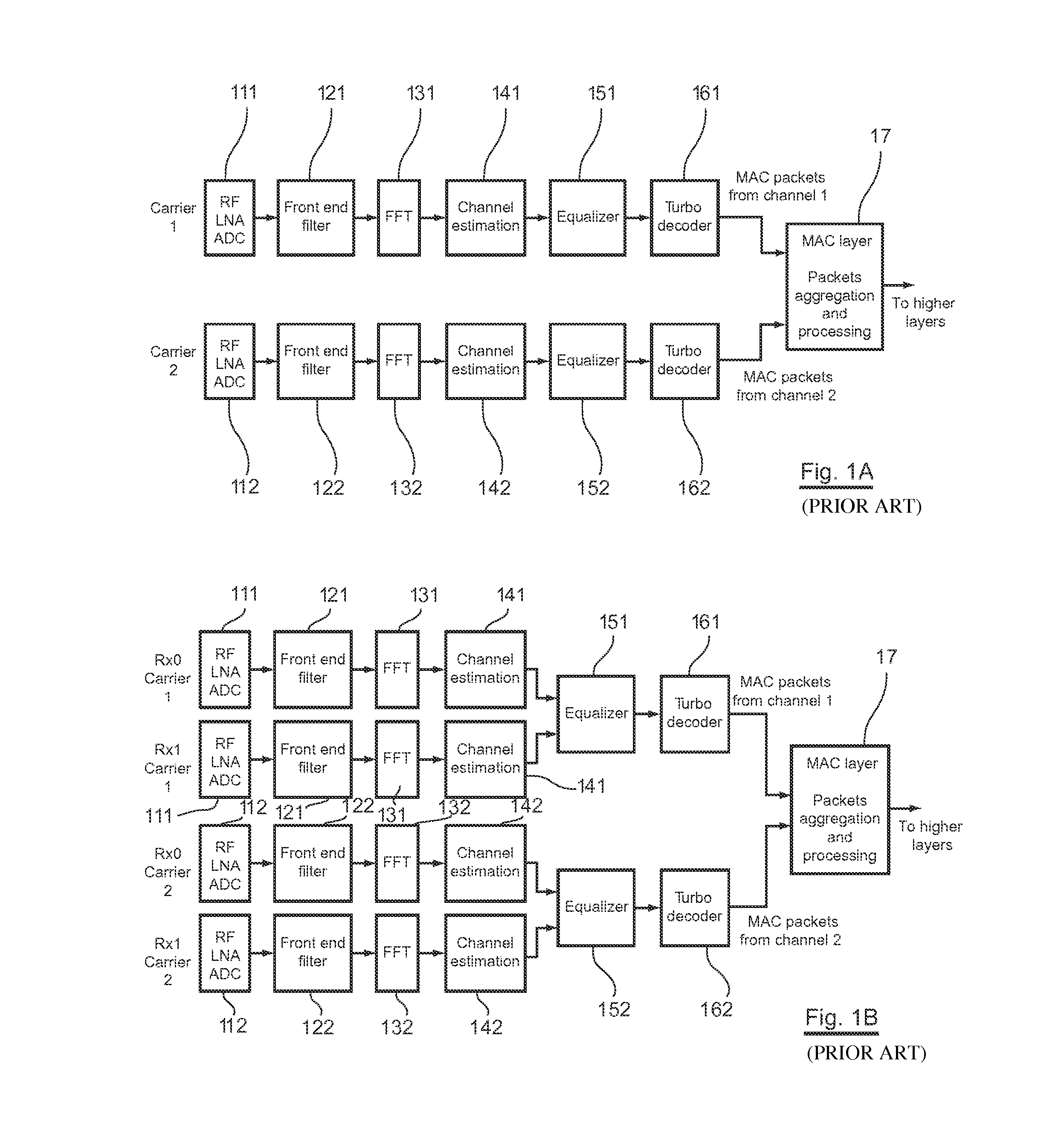

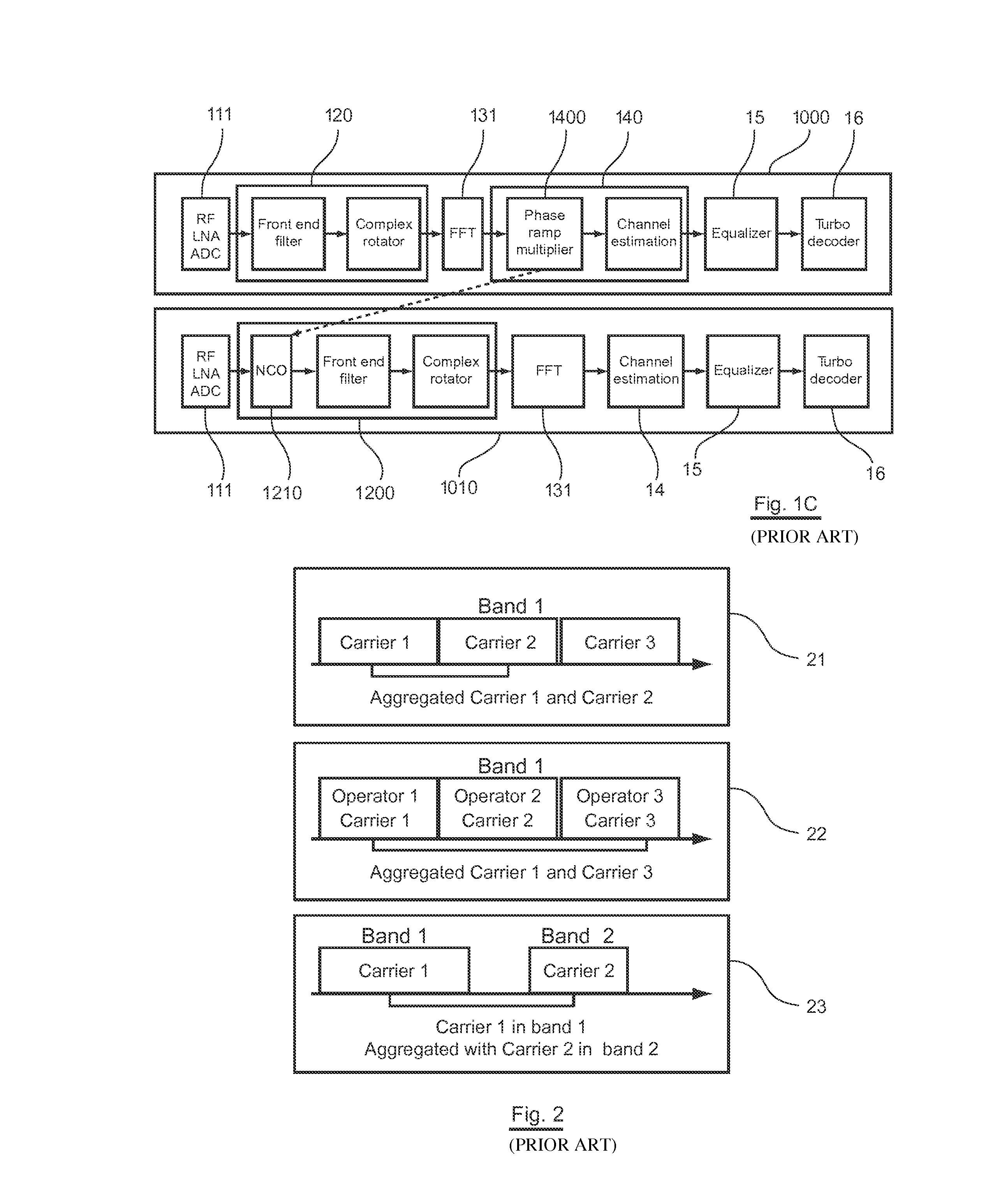

Method and User Equipment for Carrier Aggregation

ActiveUS20130322575A1Easy to implementSave consumptionTransmission path divisionAmplitude-modulated carrier systemsCarrier signalComputer science

User equipment is provided for receiving an OFDM signal. The user equipment includes a plurality of carrier processing chains and a carrier aggregation module, aggregating the signals received on each carrier processed by the plurality of carrier processing chains. The aggregation module delivers a set of aggregated signals of the plurality of carrier processing chains at the input of a Fast Fourier Transform module of a PHY layer processing subsystem of the user equipment. The Fast Fourier transform module is able to process a size of data according to a predetermined rate depending on the aggregated bandwidth of the set of aggregated signals of the plurality of carrier processing chains, and the carrier aggregation module includes at least one frequency shifter for frequency shifting carriers.

Owner:SEQUANS COMMUNICATIONS

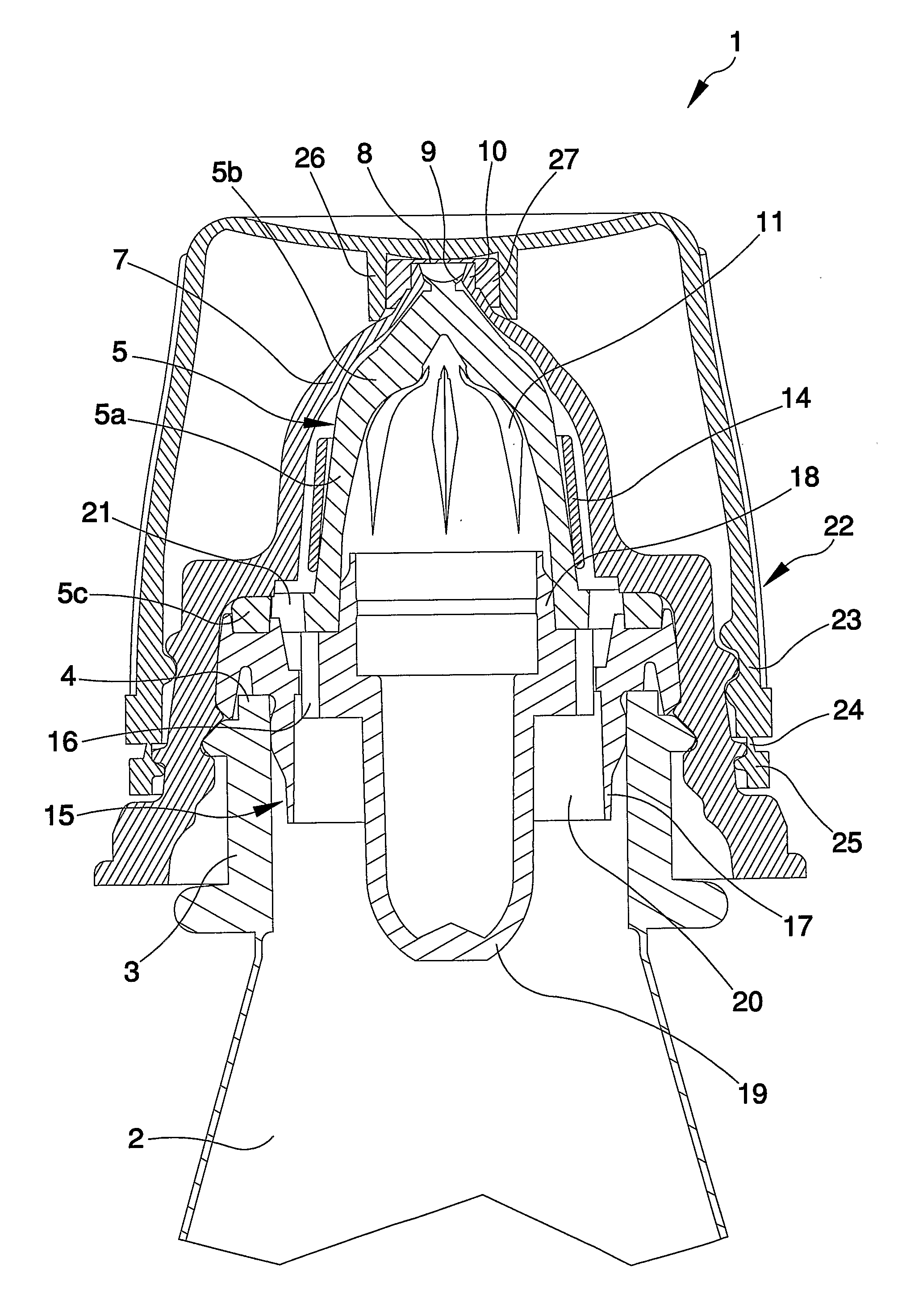

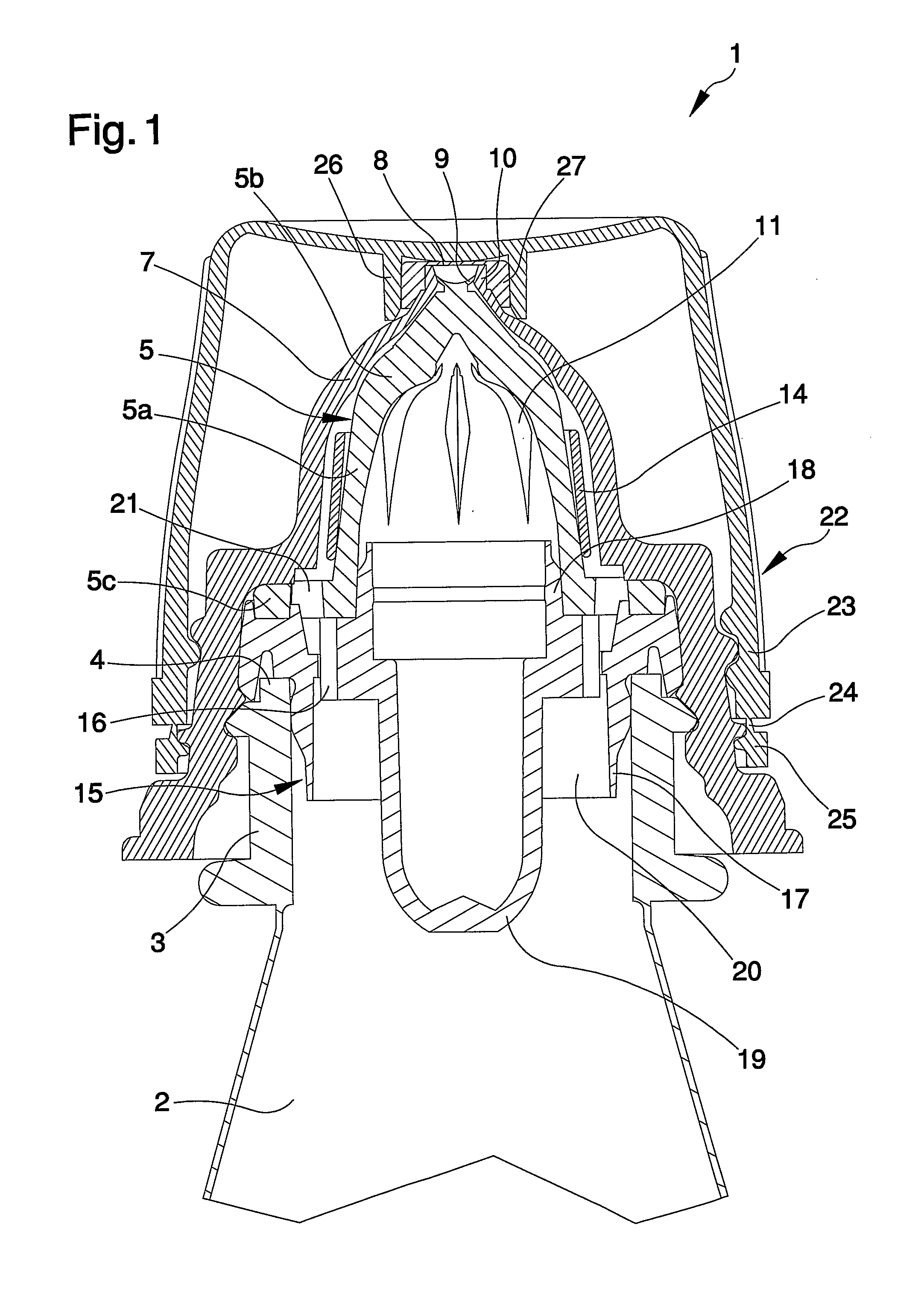

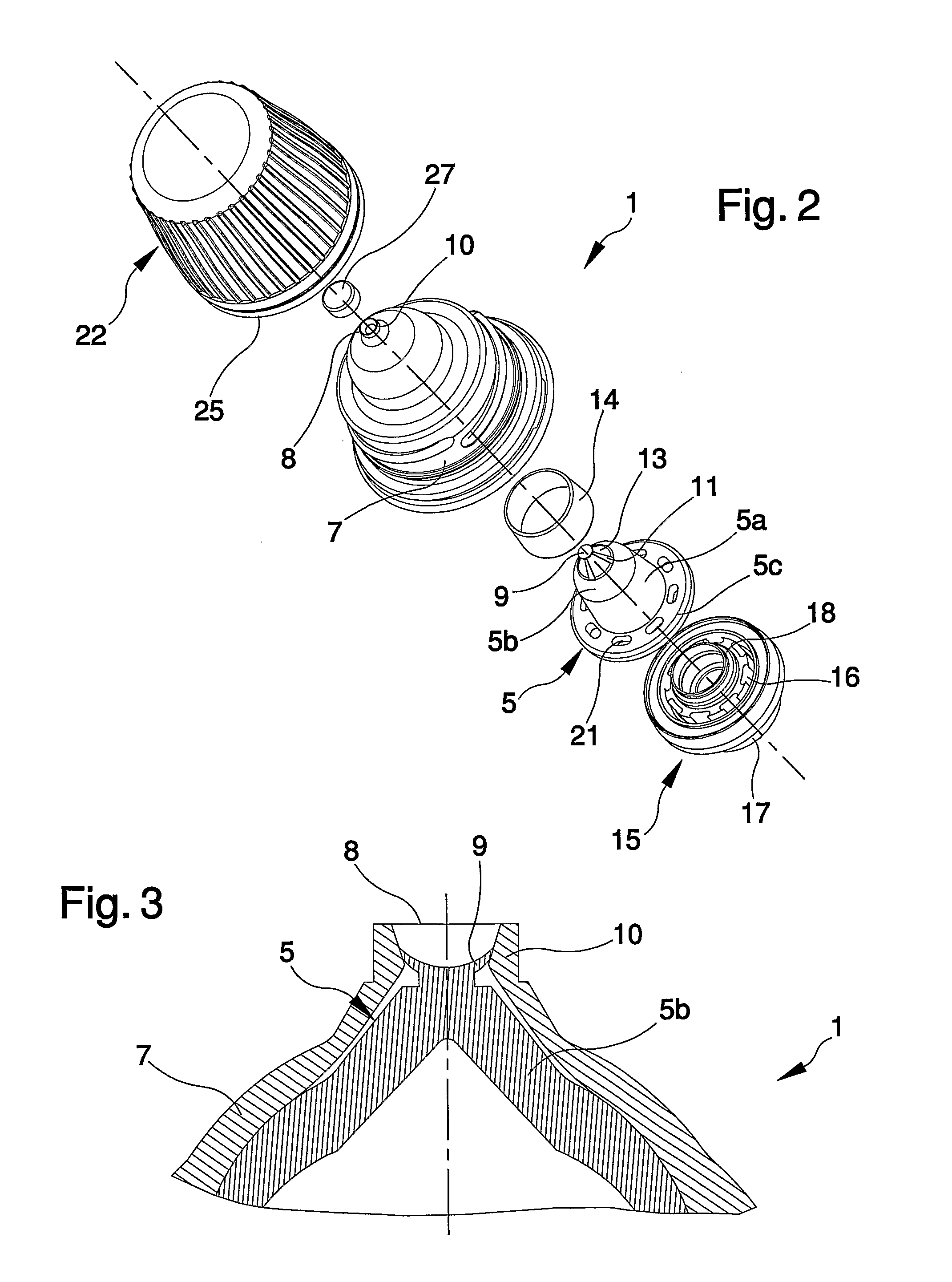

Bottle for containing fluids, particularly for pharmaceutical products or the like

InactiveUS20090321479A1Shorten the timeReduce formationClosure capsLiquid flow controllersComing outBottle

The invention refers to a bottle for containing fluids, particularly for pharmaceutical products or the like, which comprises a fluid container (2) made in a deformable material and which features a mouth for the passage of fluid, a valve (5) in an elastically deformable material that defines a flexible inner chamber arranged in proximity of the mouth, a cap (7) that substantially fits on and seals the valve and which features a dispensing opening for the fluid, and a containment ring (14) placed between said cap and said valve, arranged so that it externally embraces a portion of the valve and able to limit its deformation. A squeezing of the container causes the fluid to push up towards the mouth, the valve to compress, the fluid to flow between the valve and the cap and then to come out through the dispensing opening.

Owner:MRP MEDICAL RES & PROMOTION ESTAB

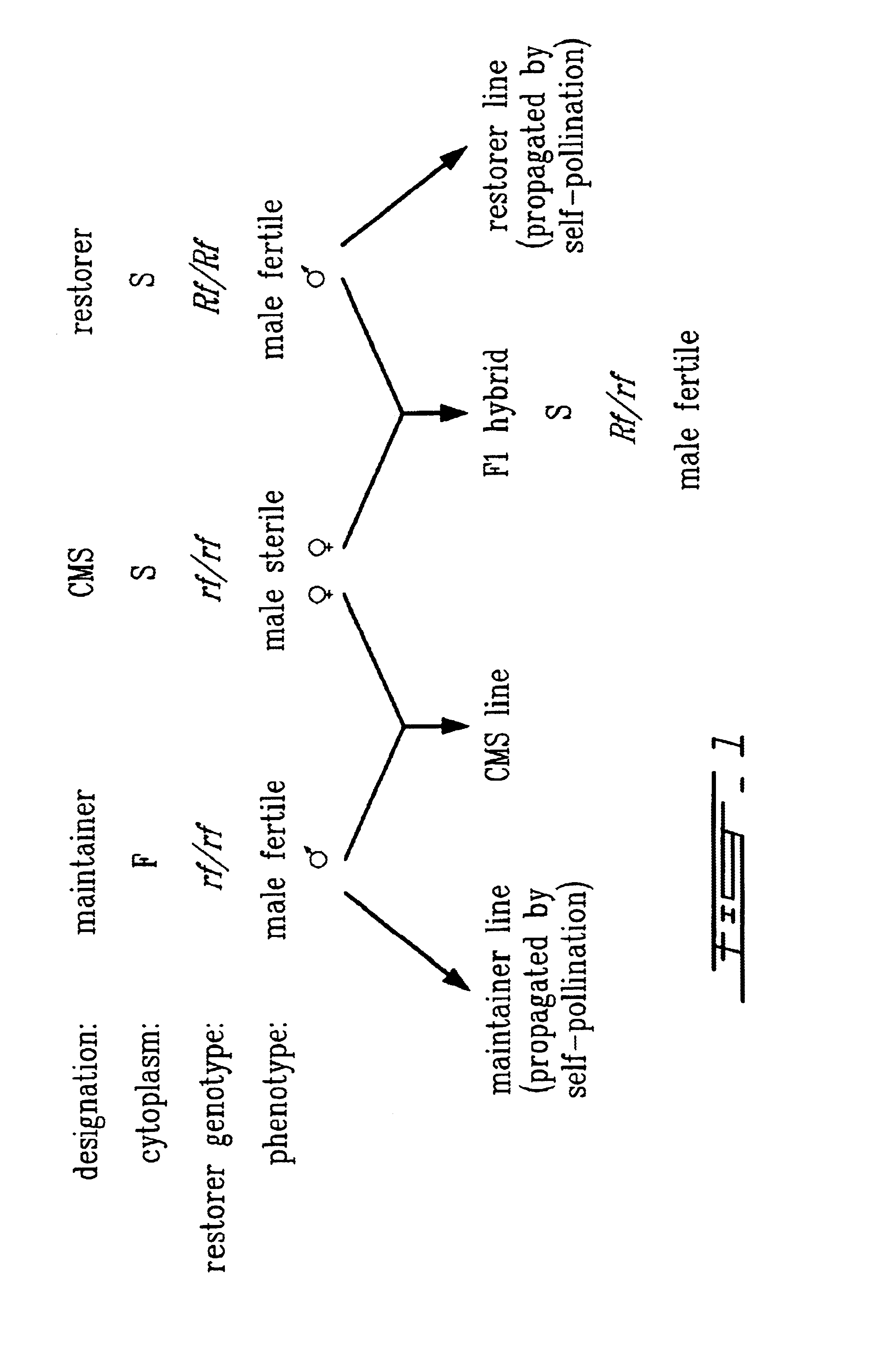

Method for enhancement of naturally occurring cytoplasmic male sterility and for restoration of male sterility and for restoration of male fertility and uses thereof in hybrid crop production

InactiveUS6951970B2Easy maintenanceShorten the timeOther foreign material introduction processesPlant peptidesPlant cellTransit Peptide

The present invention relates to methods for enhancement of naturally occurring cytoplastic male sterility and for restoration of male fertility and uses thereof in hybrid crop production. There is also disclosed a method for restoration of male fertility to cytoplasmic male sterile plants; which comprises the steps of: a) introducing into the nucleus of a plant cell a gene construct essentially consisting of a sequence encoding a mitochondrial transit peptide fused upstream of and in frame with an edited form of a normal mitochondrial gene that is co-transcribed with an usual CMS-associated mitochondrial gene; b) selecting for plant cells that have acquired the gene construct in step a); and c) inducing regeneration of selected plant cells to produce a mature plant.

Owner:MCGILL UNIV

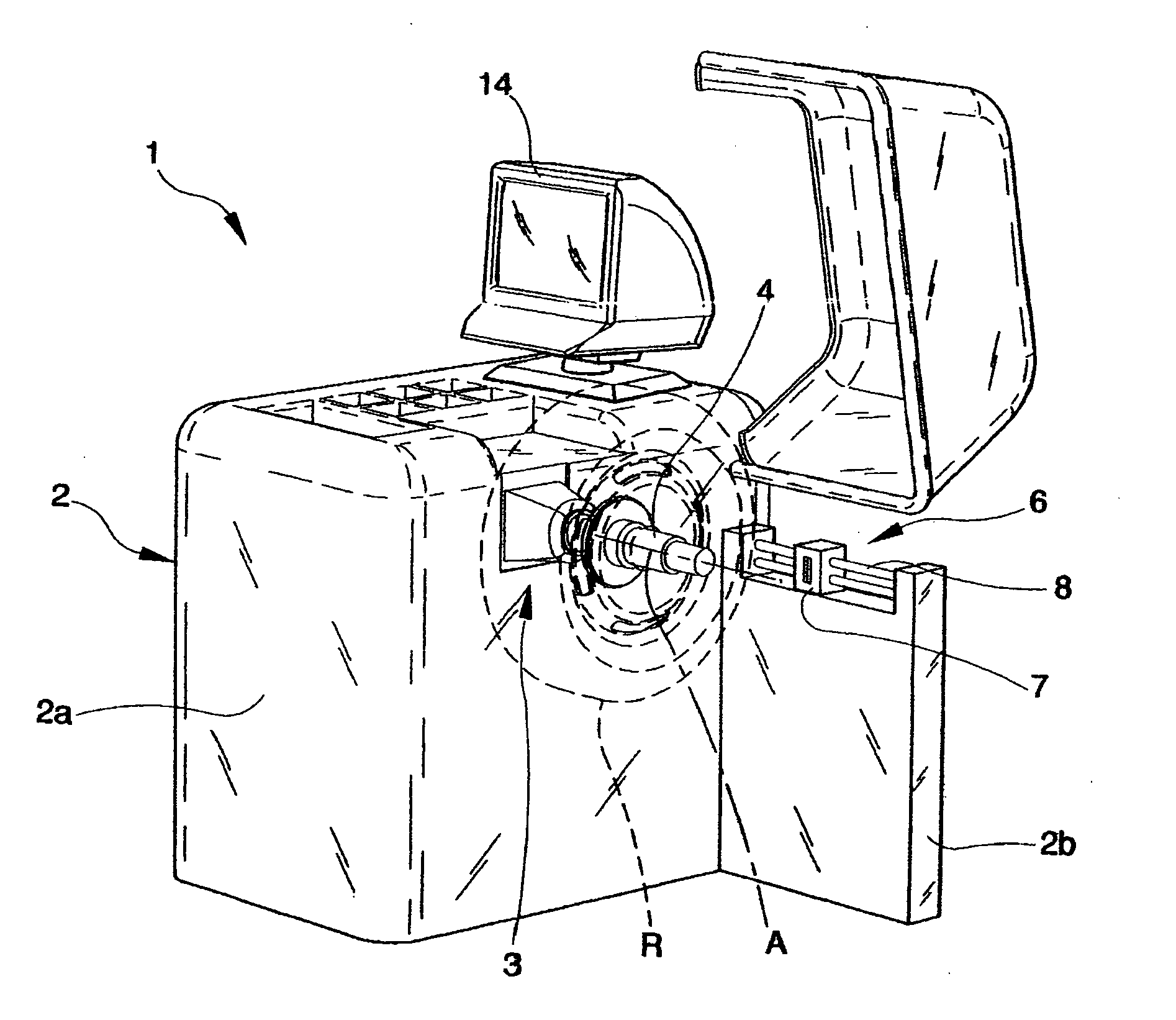

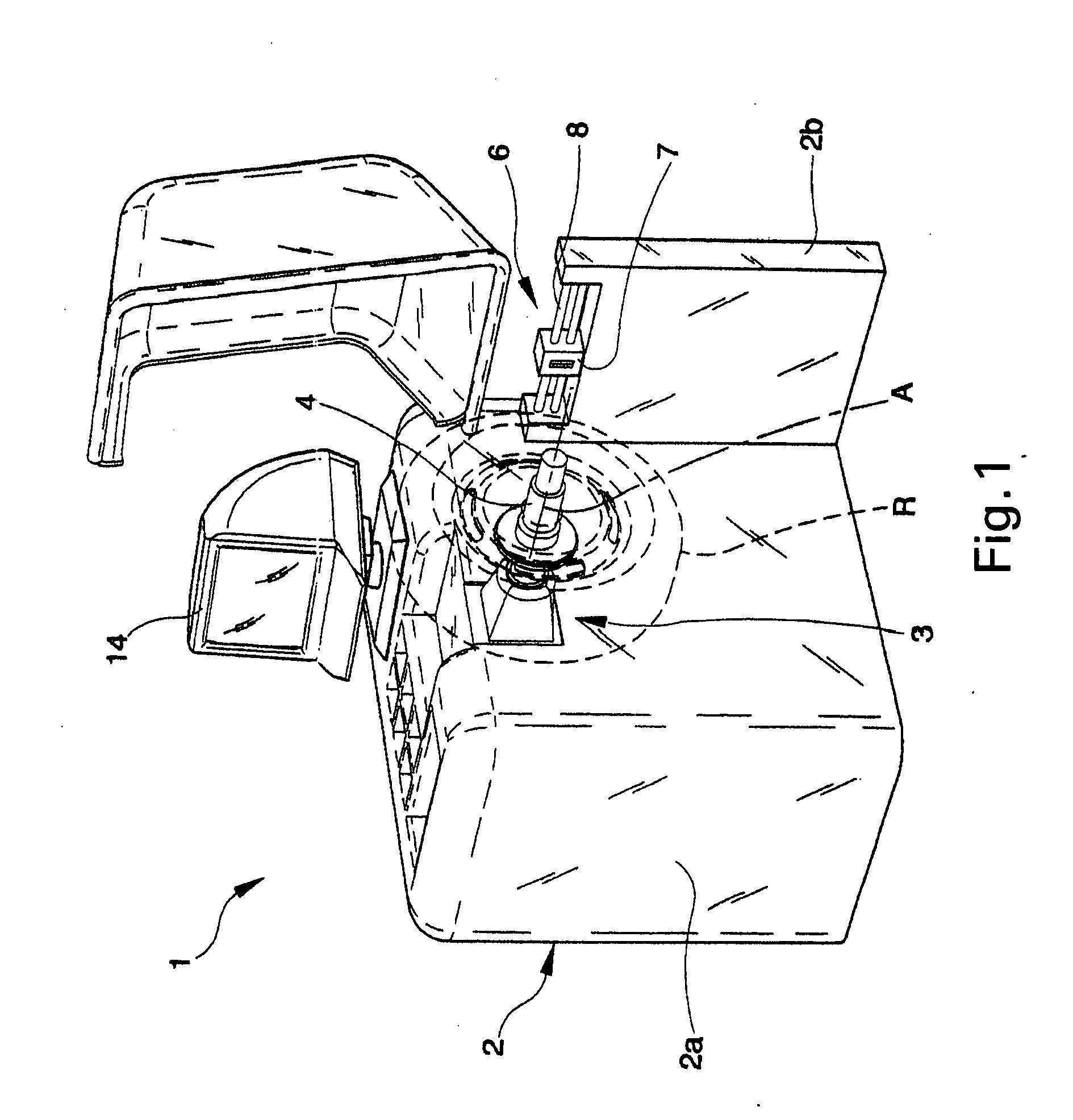

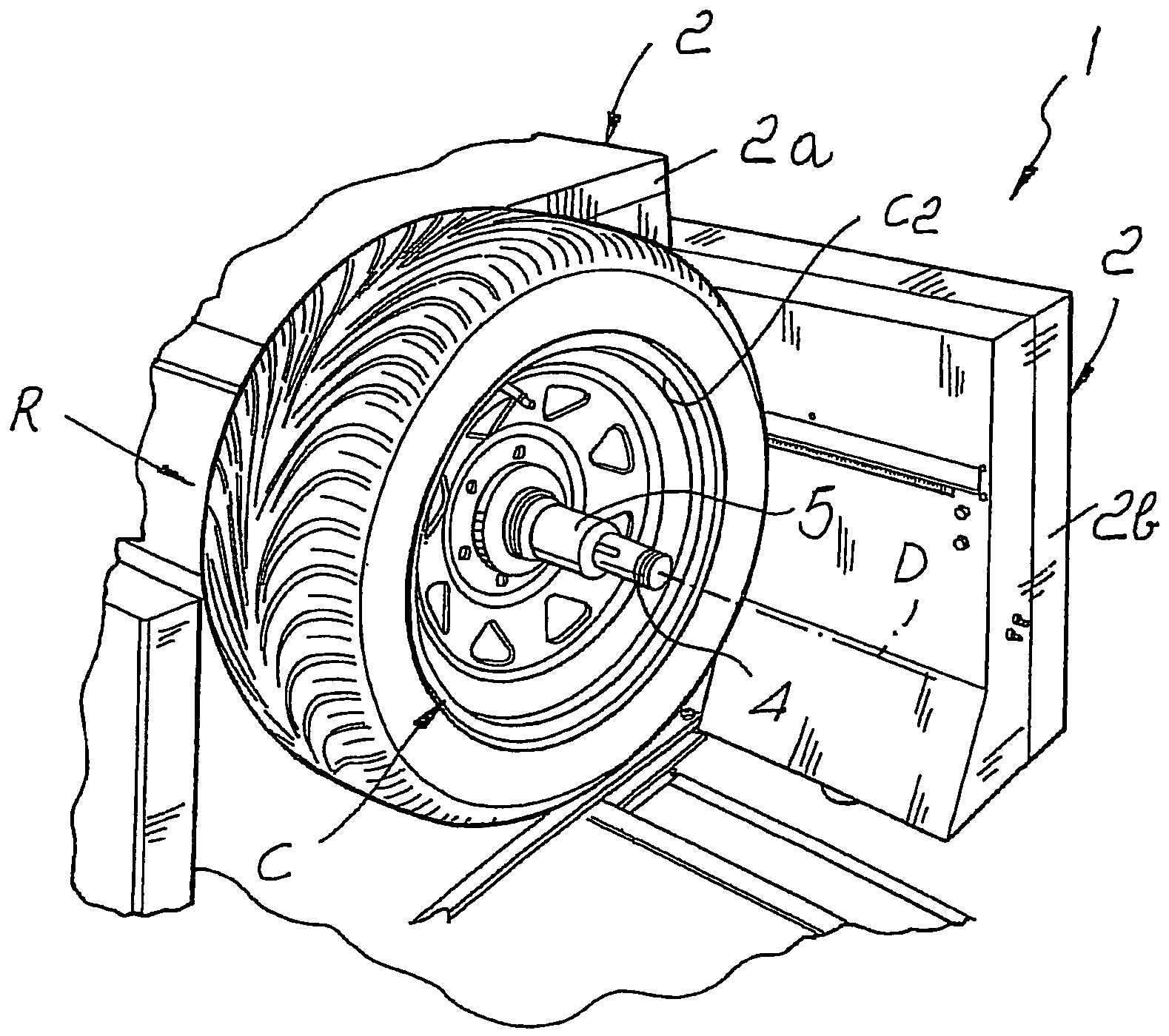

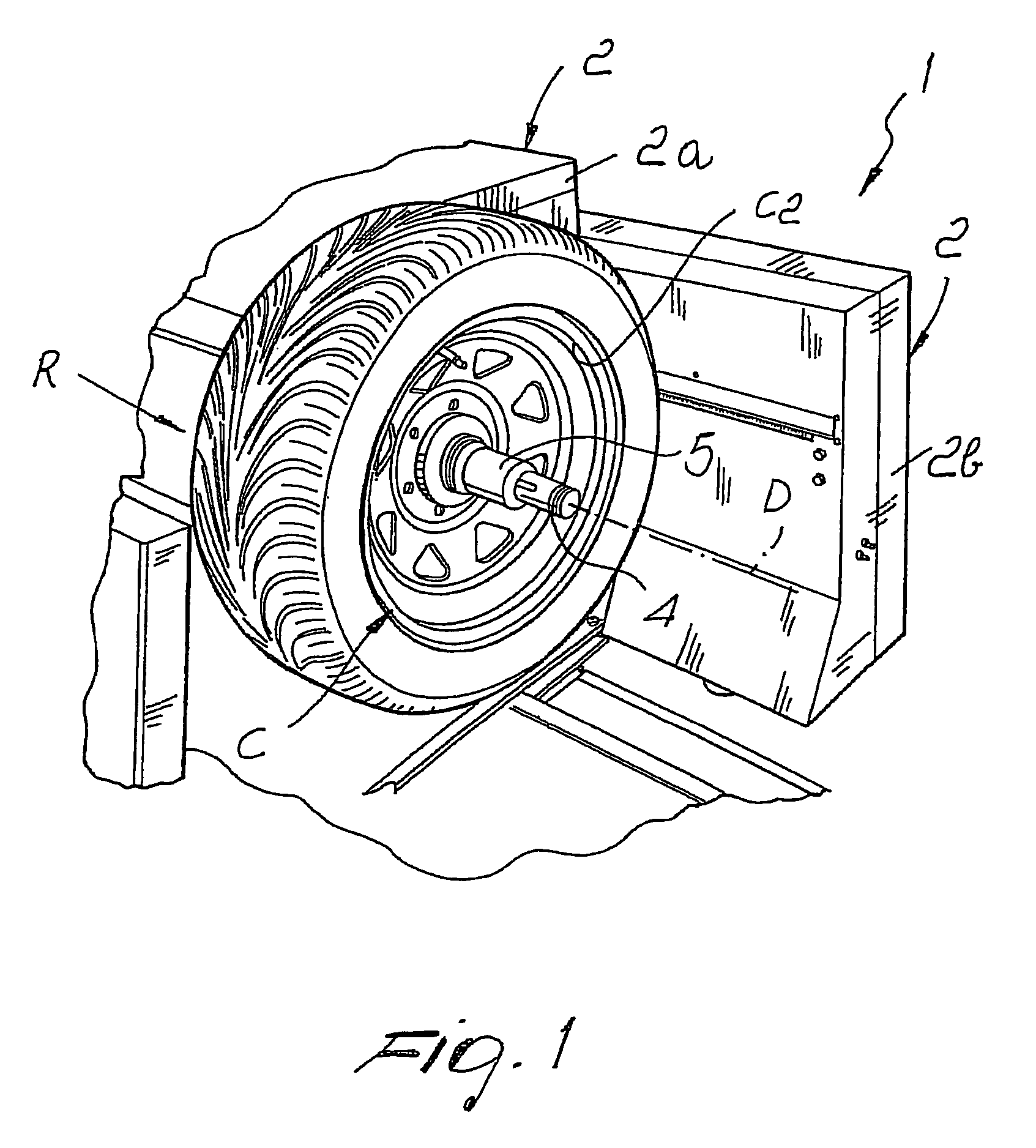

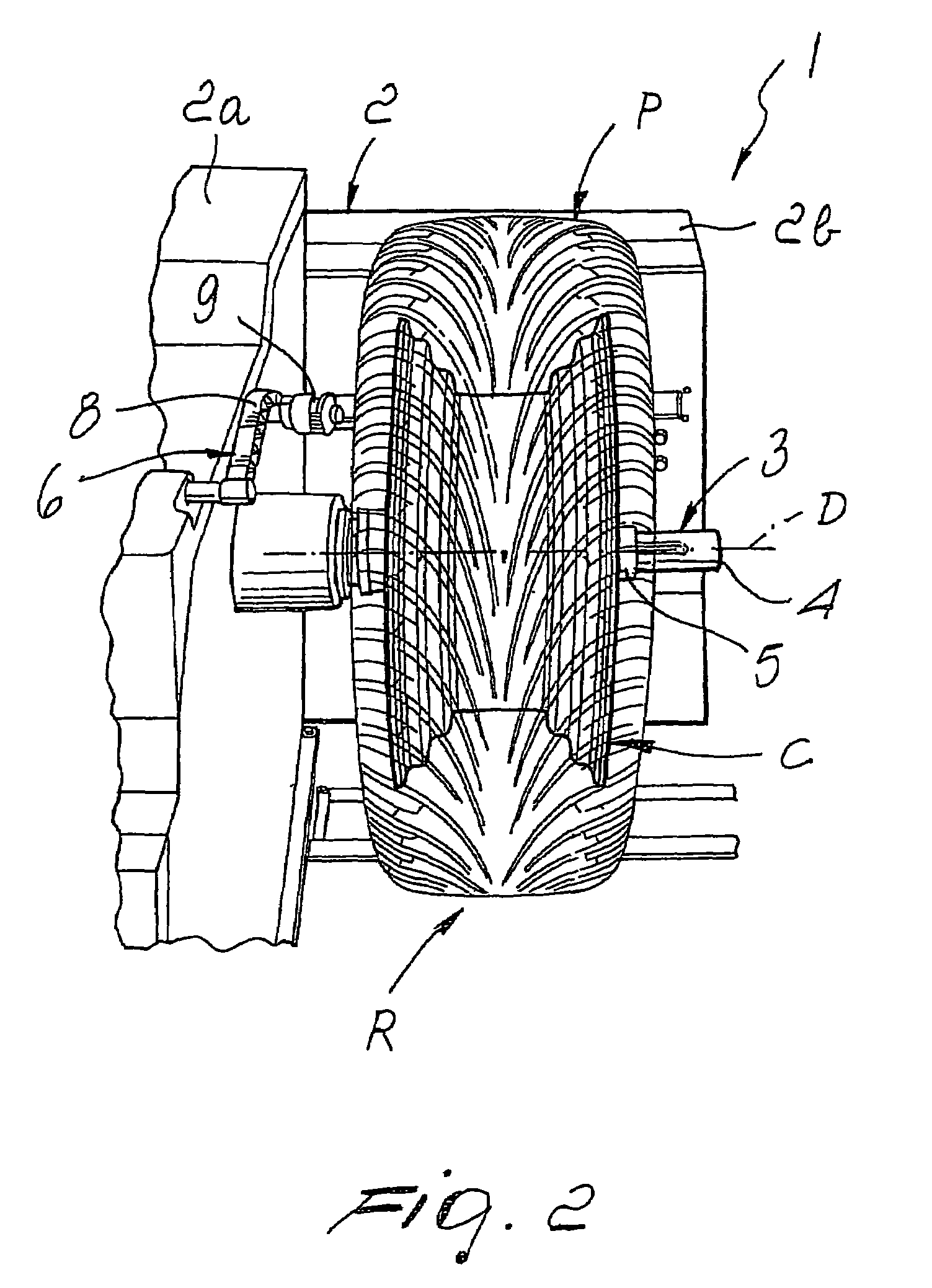

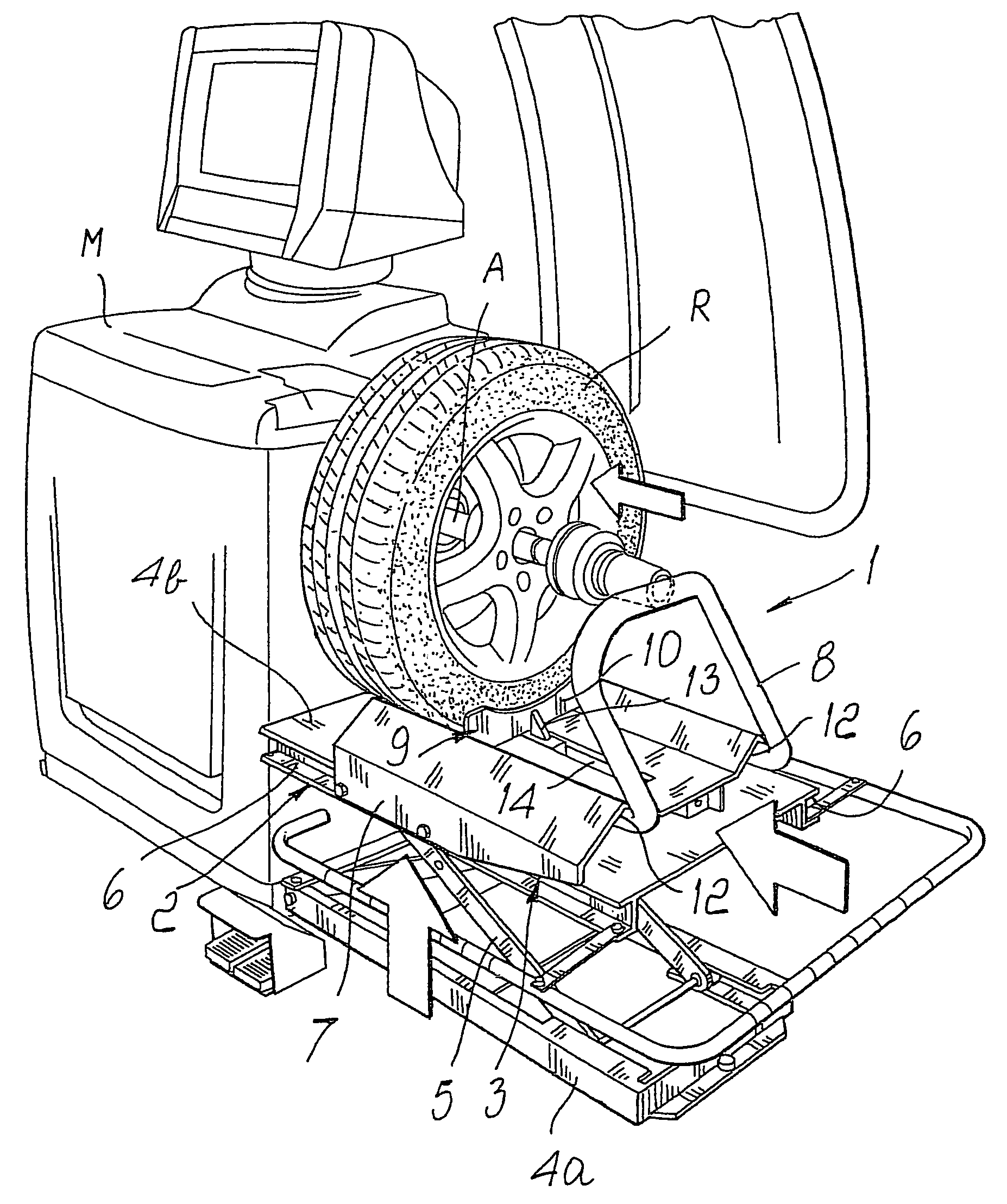

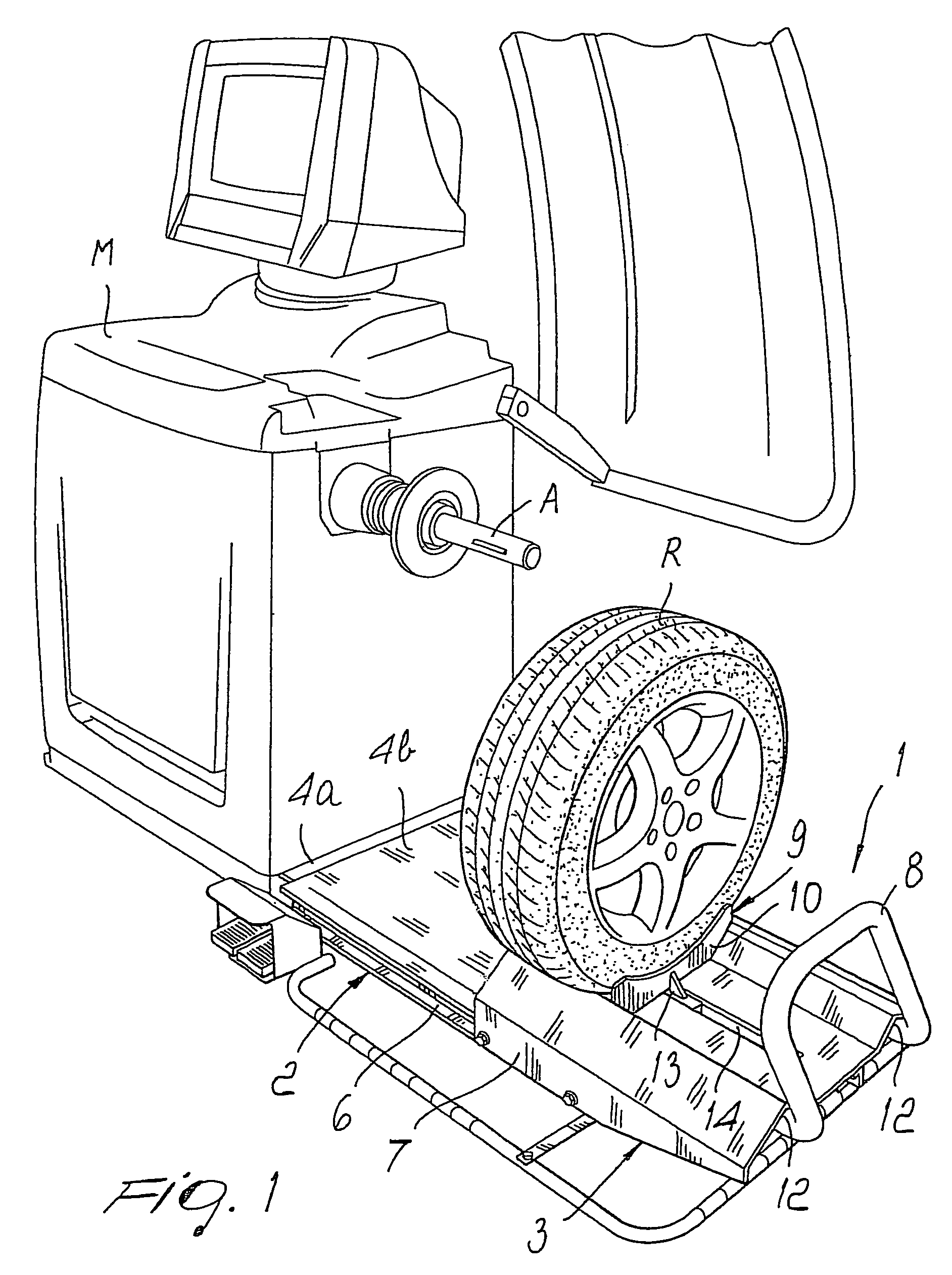

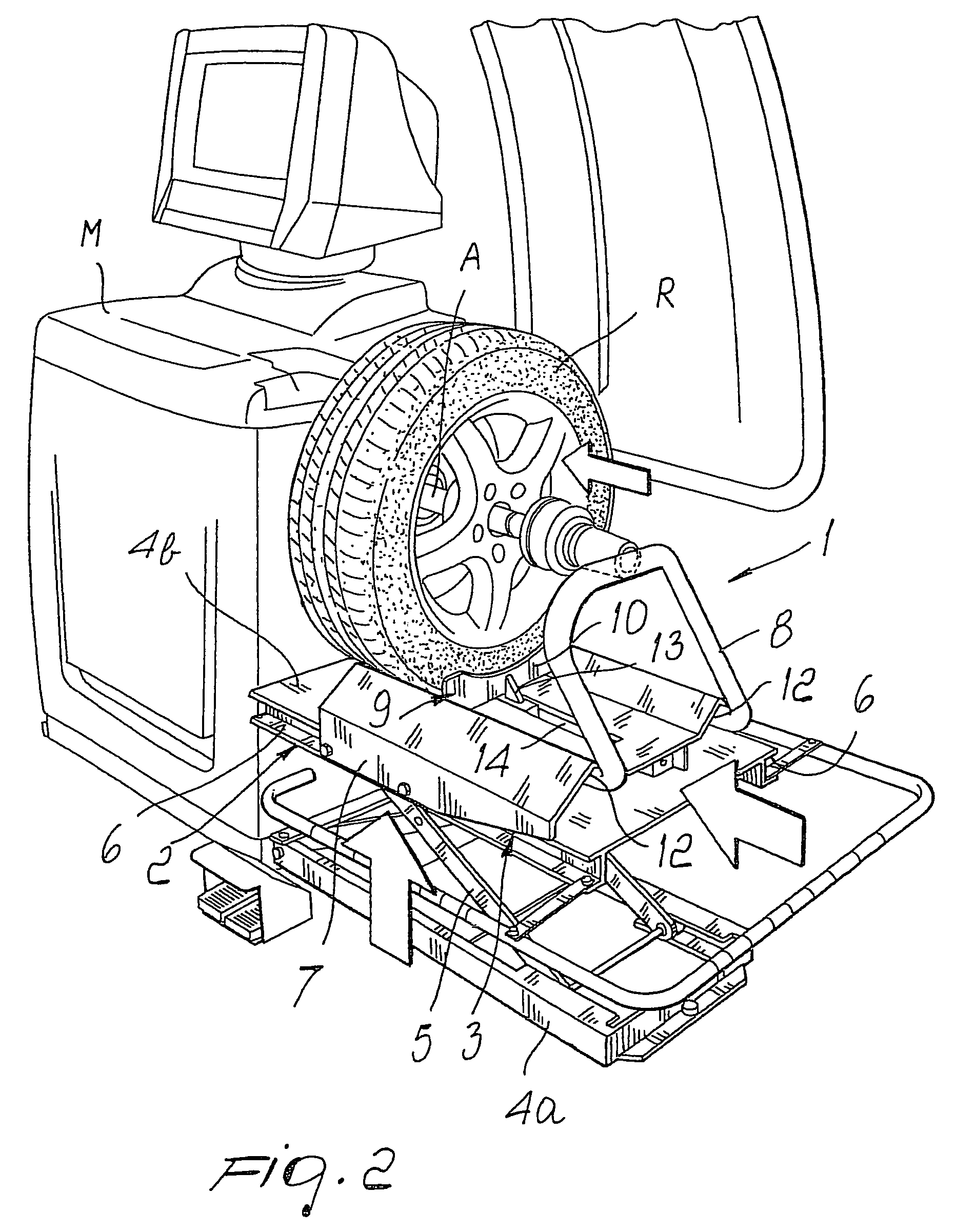

Balancing machine for vehicle wheels with analog to digital conversion and adjustable sampling frequency

InactiveUS20080053223A1Quality and precision of takenIncrease angular resolutionStatic/dynamic balance measurementBalancing machineA d converter

The upgraded balancing machine for vehicle wheels comprise a supporting frame for gripping and rotation means for gripping and rotating a wheel to be balanced around a rotation axis, a first sensor for detecting the unbalance of the wheel with respect to the rotation axis suitable for generating a first analog signal, a second sensor for detecting at least one portion of the profile of the wheel suitable for generating a second analog signal, at least one analog to digital converter associated with at least one of the first and the second detection sensors and suitable for converting at least one of the first and the second analog signal into a corresponding digital signal, a processing and control unit associated with the conversion device and suitable for processing the digital signal, and an adjustment unit for adjusting the sampling frequency of at least one of the first and the second analog signals associated with the conversion device. The adjustment unit responds to a first signal generated by a shaft encoder, and responds to a programmable timer, so that the frequency of the sampling operation can be altered.

Owner:SICAM SRL

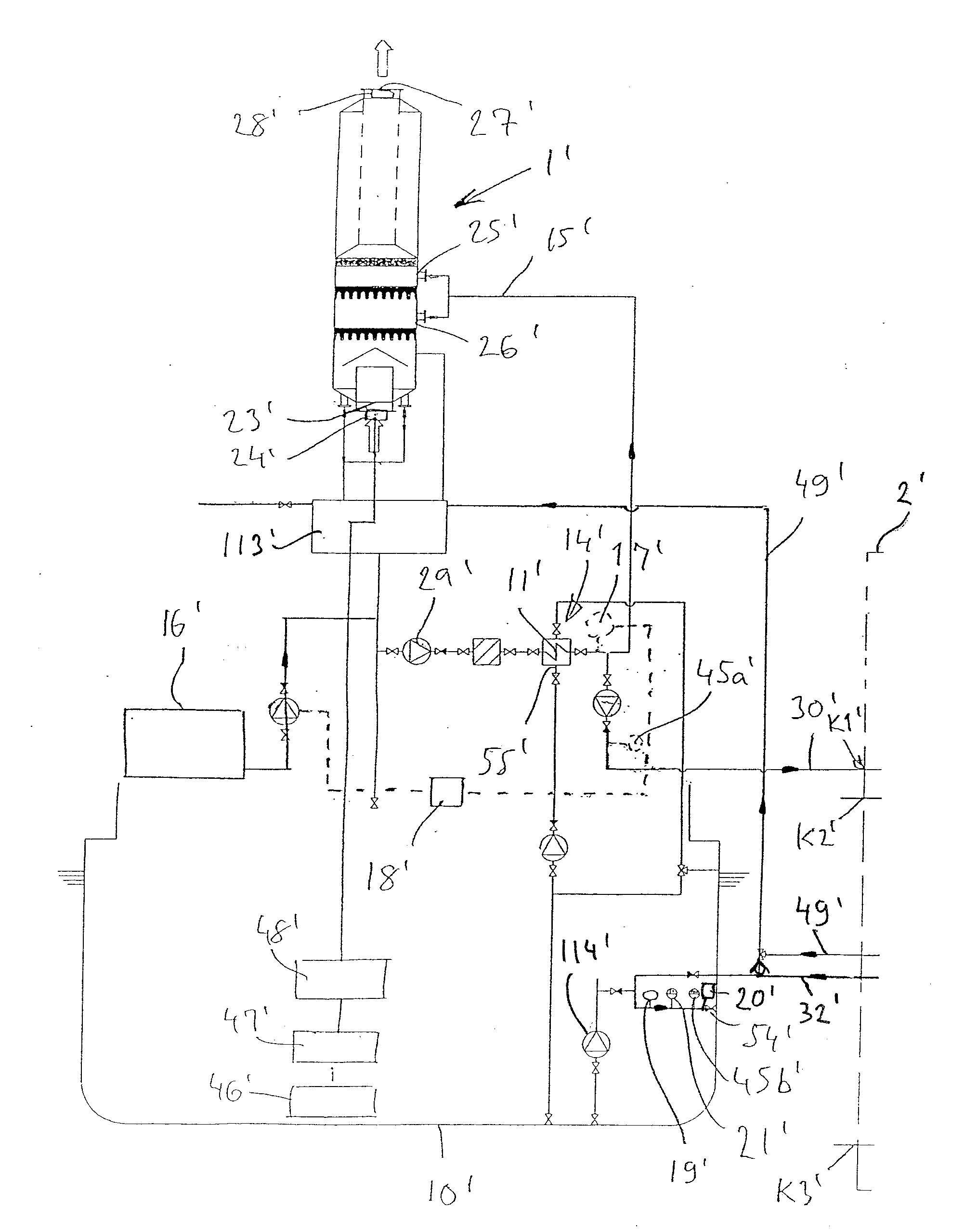

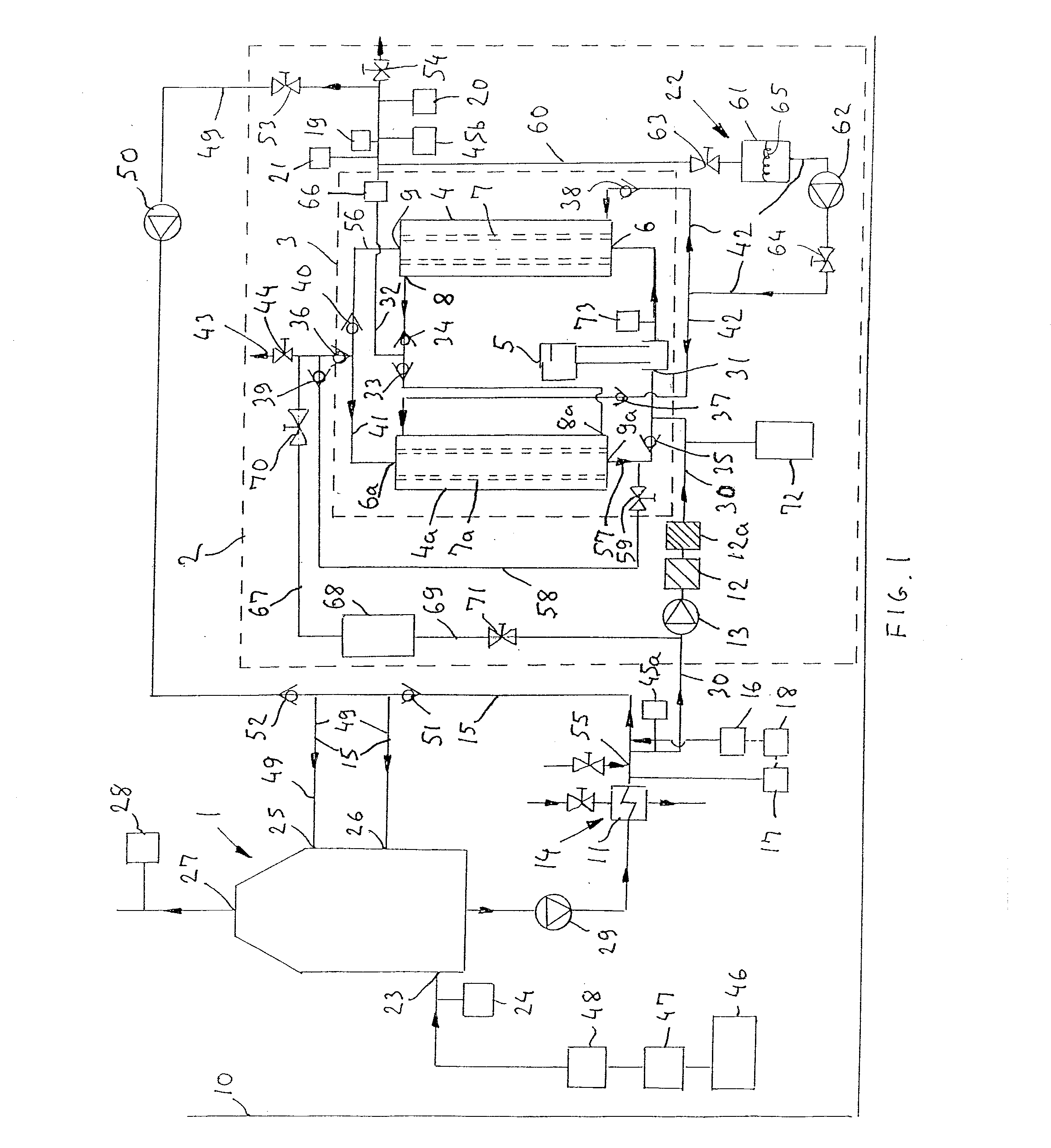

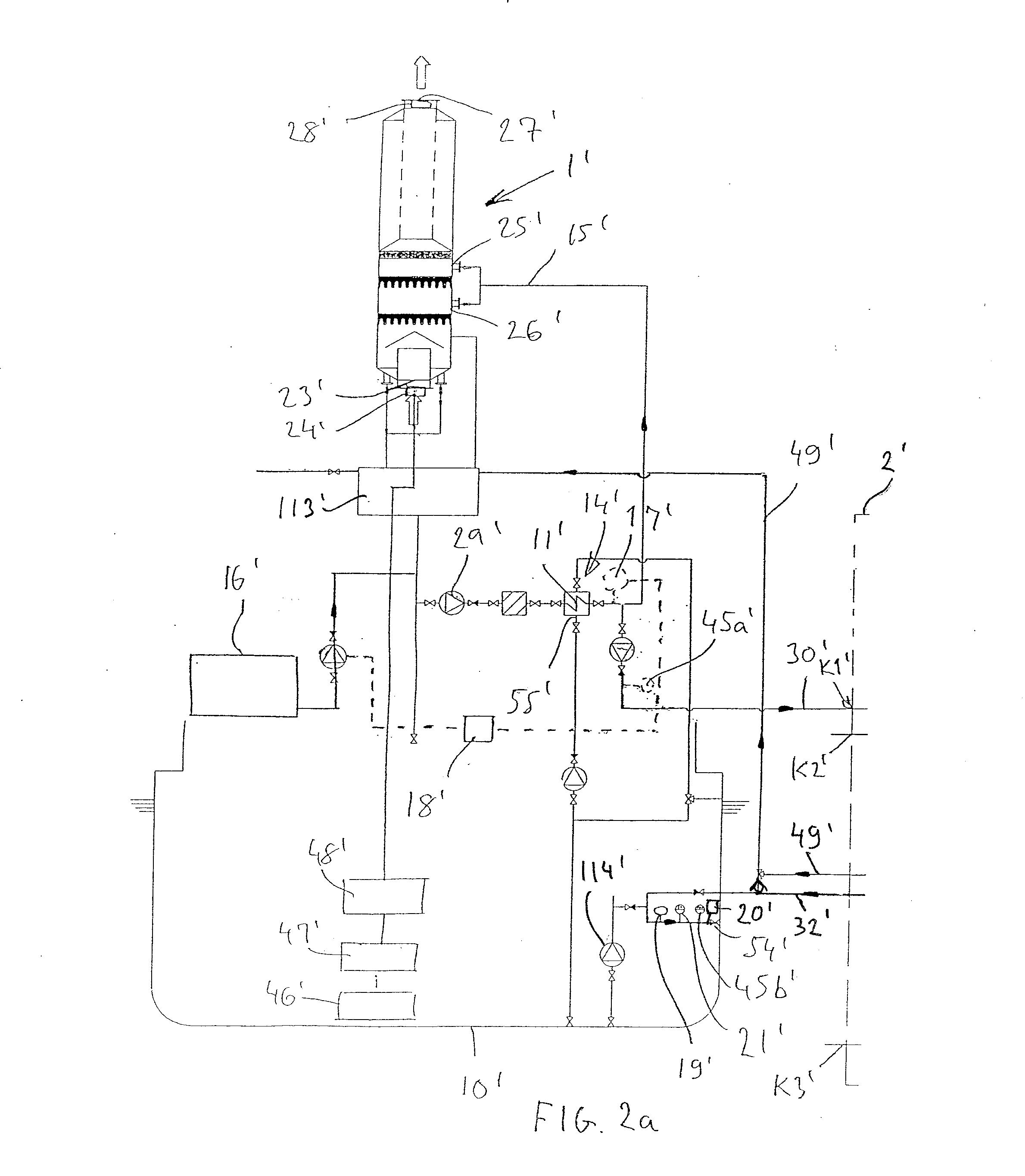

Method for treating impurities contained in exhaust gases of ships, ship with exhaust gas scrubber, and purification unit

ActiveUS20150007719A1Easy to placeEasy to implementDispersed particle filtrationExhaust apparatusWash waterExhaust fumes

Method for treating impurities contained in exhaust gases of ships to reduce sulphur oxide and other emissions. In order for the method to purify wash water exiting from an exhaust gas scrubber sufficiently enough to be directly dischargeable to sea, and in order for a purification unit used to be small enough to be easily placed onboard a ship, exhaust gases are scrubbed in the exhaust gas scrubber and wash water containing impurities and exiting from the scrubber is supplied to the purification unit, circulated in an effluent circuit, and filtered through a semipermeable membrane of a filter to obtain purified effluent and a residue containing impurities, when necessary, the pH value of the purified effluent is adjusted to be at least 6.5, after which it is discharged into the sea or recycled to the scrubber while the residue containing impurities is led back to the effluent circuit.

Owner:OY LANGH SHIP AB

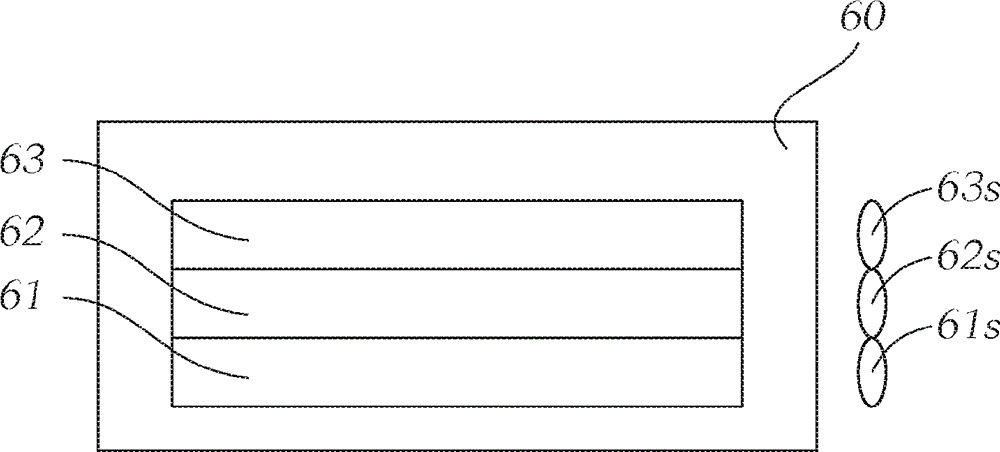

Headlight for a motor vehicle and method for distributing light

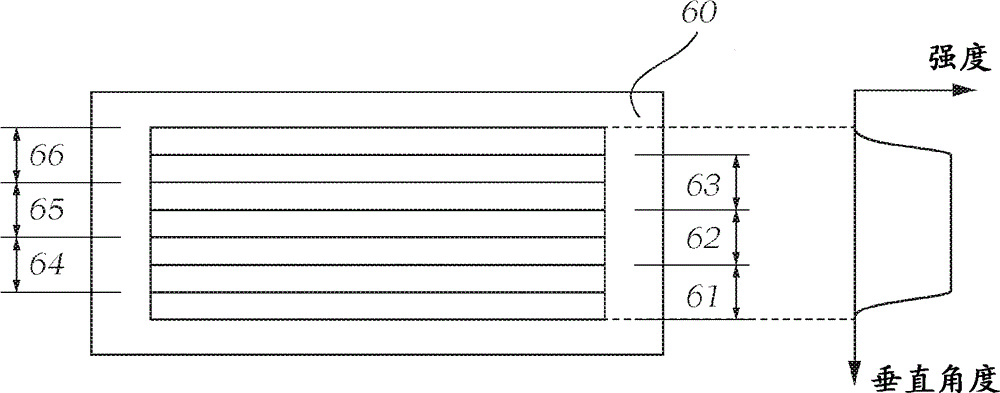

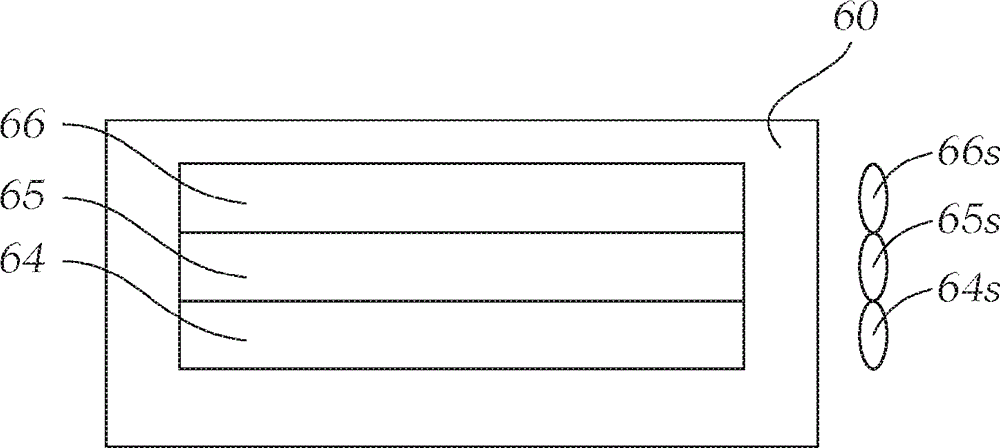

ActiveCN104968996ABeneficial generationPractical implementationVehicle headlampsPoint-like light sourcePhysicsLaser light

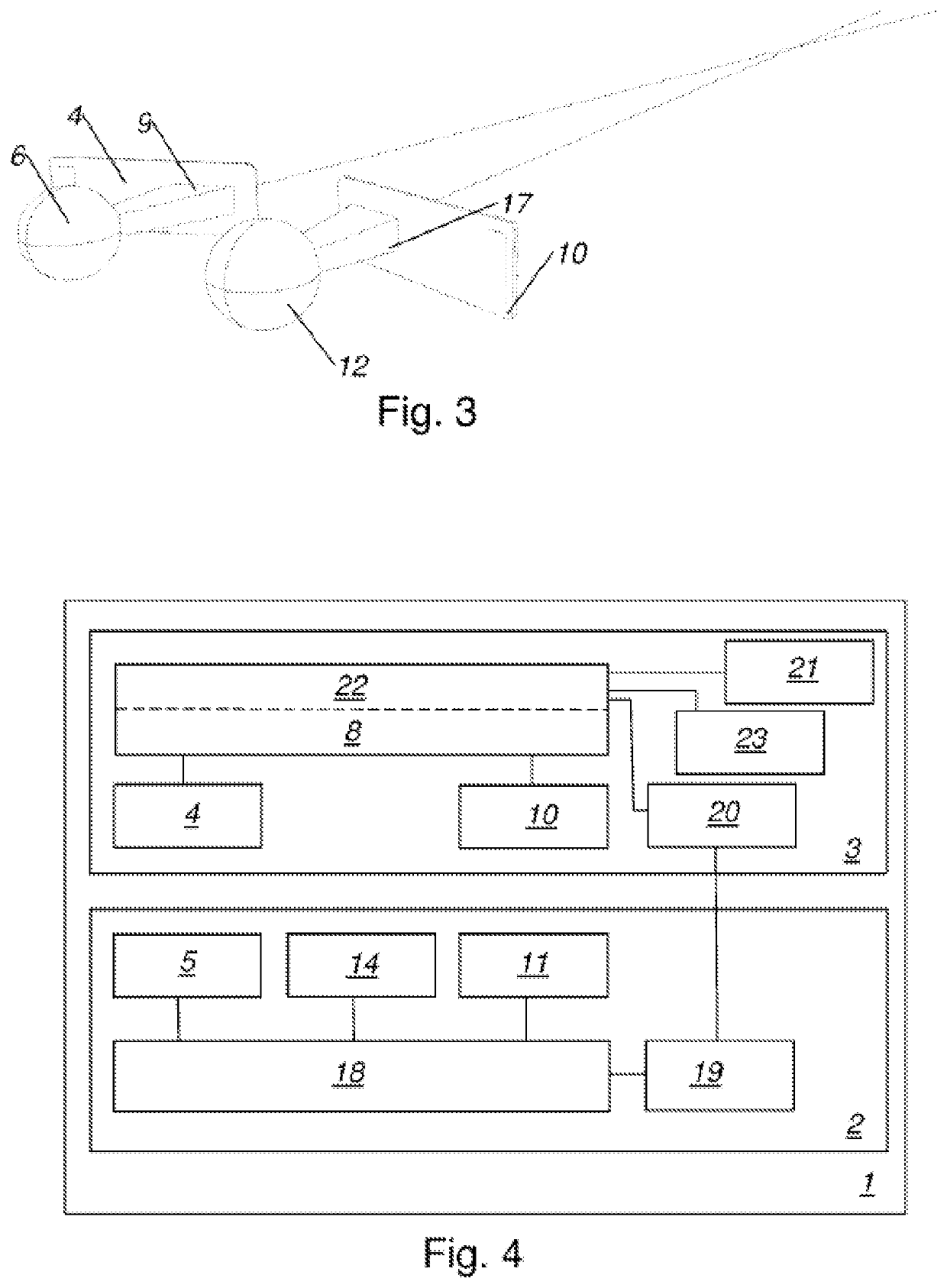

The invention relates to a headlight for motor vehicles comprising at least one modular laser light source (11 - 16), the laser beam thereof being directed, via beam deflection means (51, 52) which are controlled by a deflection control (9), to light conversion means (60), also comprising a projection system (70) for projecting the light image generated on the light conversion means to the road. A first group (1) of at least two laser light sources (11, 12, 13) for generating a first group of at least two superimposed, essentially horizontal light bands (61, 62, 63) on the light conversion means (60) and a second group (2) of at least two laser light sources (14, 15, 16) for generating a second group of at least two superimposed, essentially horizontal light bands (64, 65, 66) on the light conversion means (60) are provided. A laser control (3) is associated with the laser light sources (11 - 16), and the laser beams (11s - 16s) are directed by the laser deflection means (51, 52) to the light conversion means (60) such that light bands (61, 62, 63) of the first group (1) and light bands (64, 65, 66) of the second group overlap each other.

Owner:ZKW GRP GMBH

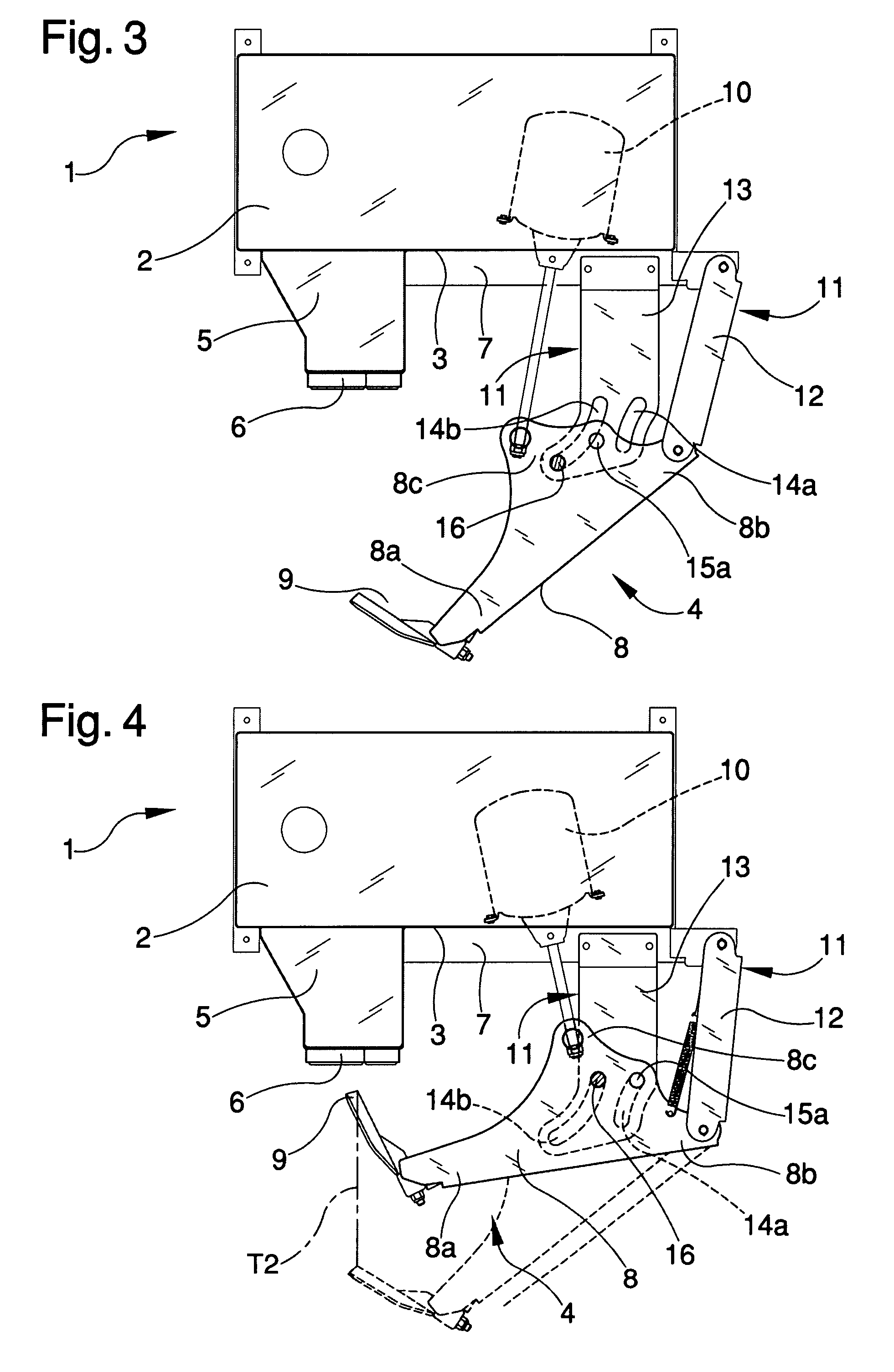

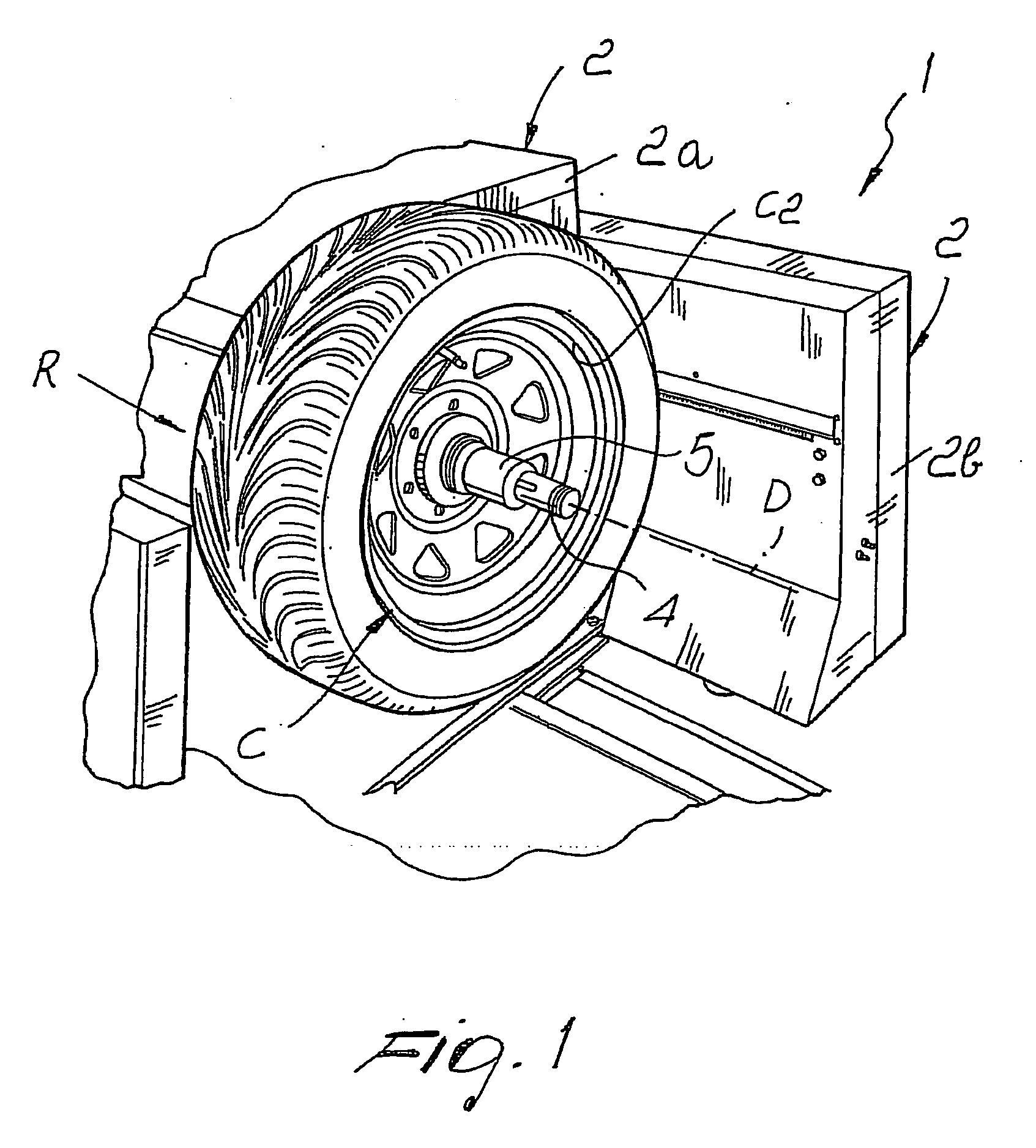

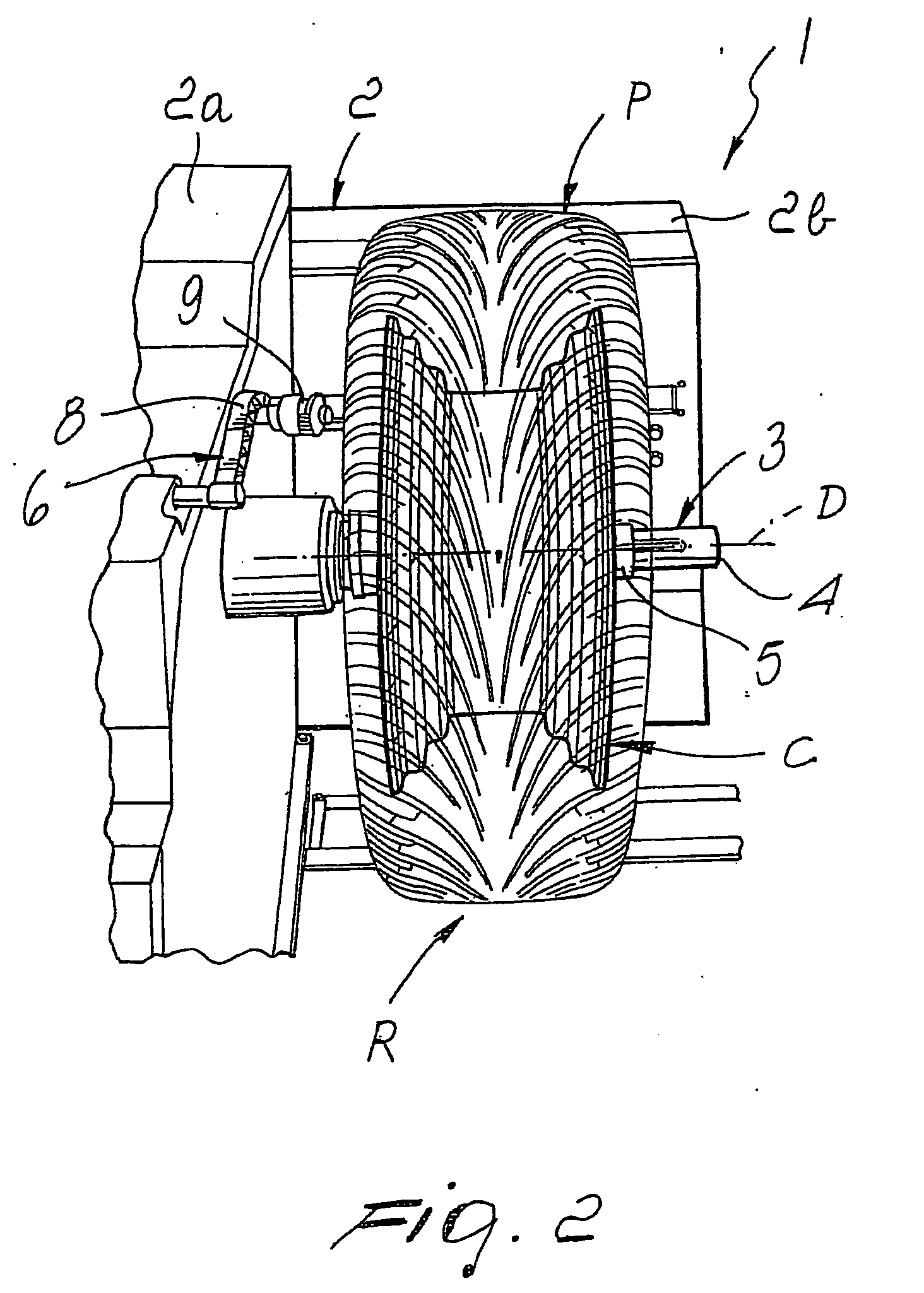

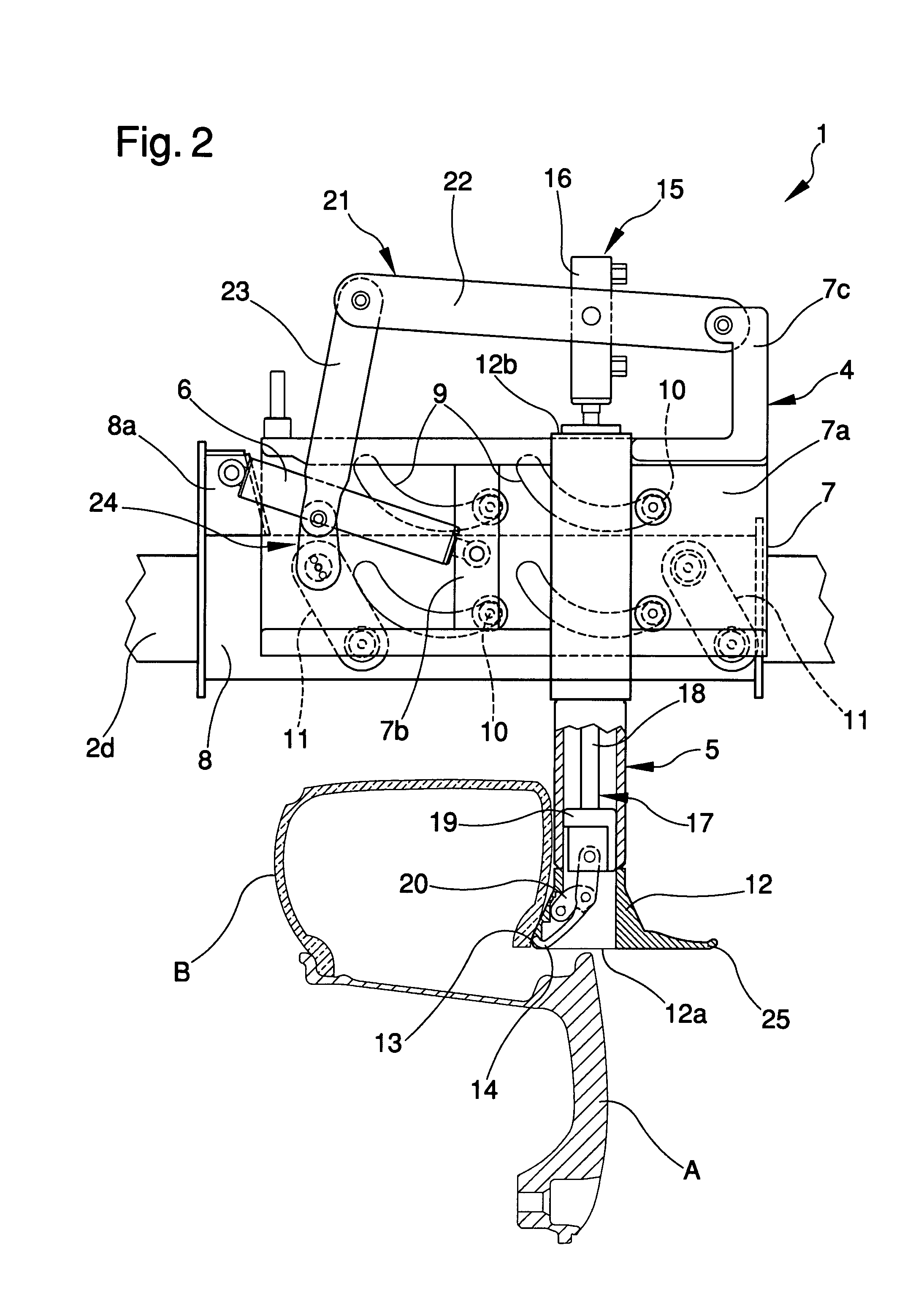

Bead breaking unit for tire changing machines

A bead breaking unit includes an arm which is attachable to the base of a tire changing machine and has a first end for attachment of a bead breaking tool and a second end opposite the first. The first end is mobile between an idle position, in which the bead breaking tool is placed away from the base, and a working position, in which the bead breaking tool is placed in contact with a wheel to bead break, positioned in proximity to the base. The bead breaking unit also includes an adjustment device for adjusting the trajectory of the bead breaking tool when moving between the idle position and the working position, which are interposed between the base and the arm and suitable for defining a first operating configuration in which the trajectory is curvilinear and a second operating configuration in which the trajectory is rectilinear.

Owner:GIULIANO GROUP

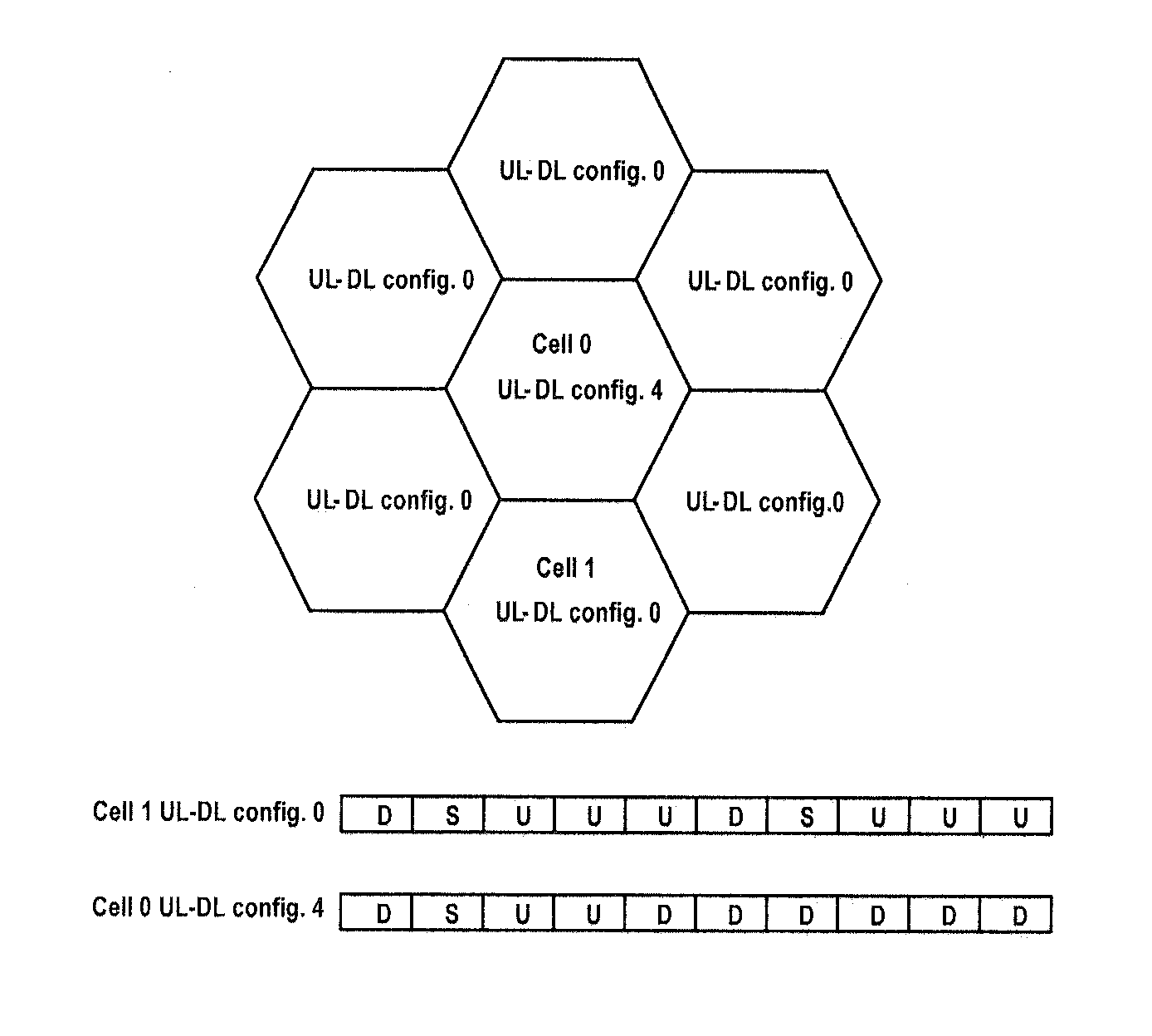

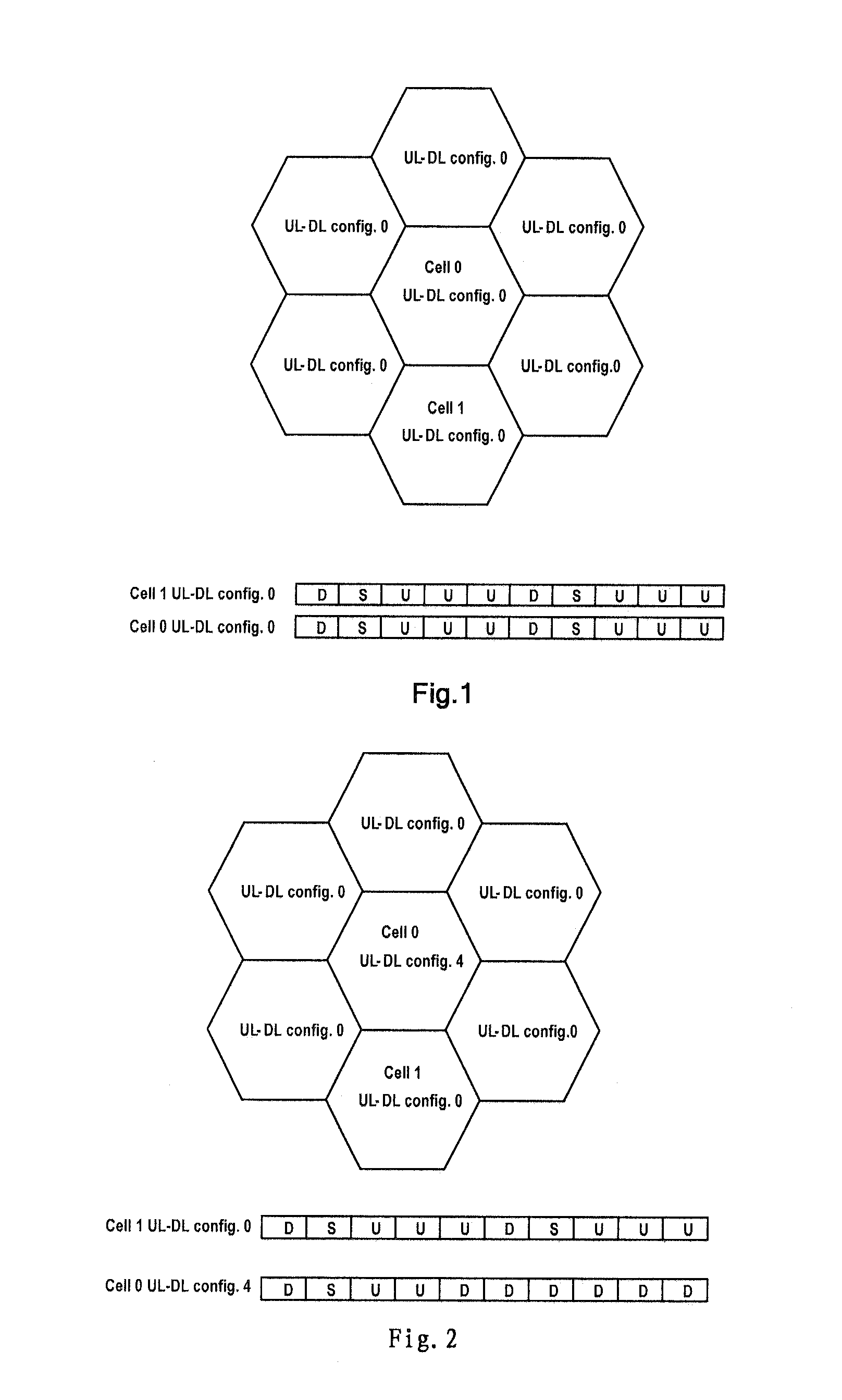

Method and apparatus for reporting and cancelling cross-subframe co-channel interference

InactiveUS20140369281A1Improve resource utilizationPractical implementationError detection/prevention using signal quality detectorCriteria allocationTelecommunicationsEngineering

Embodiments of the disclosure provide methods and apparatuses for cancelling cross-subframe co-channel interference (CCI), the method comprising receiving a channel quality indicator (CQI) of a cross-subframe from a user equipment (UE), the cross-subframe is a downlink subframe that is interfered by an uplink subframe in a neighboring cell; determining if the UE should be scheduled during cross-subframes by comparing the CQI with an adaptive threshold; and scheduling the UE during the cross-subframes if the UE is determined to be scheduled. By means of determining the resources scheduling based on an adaptive threshold, CCI may be cancelled and the overall resource usage will be increased according to the present invention. Furthermore, the adaptive threshold scheme can be easily implemented in practice.

Owner:NEC (CHINA) CO LTD

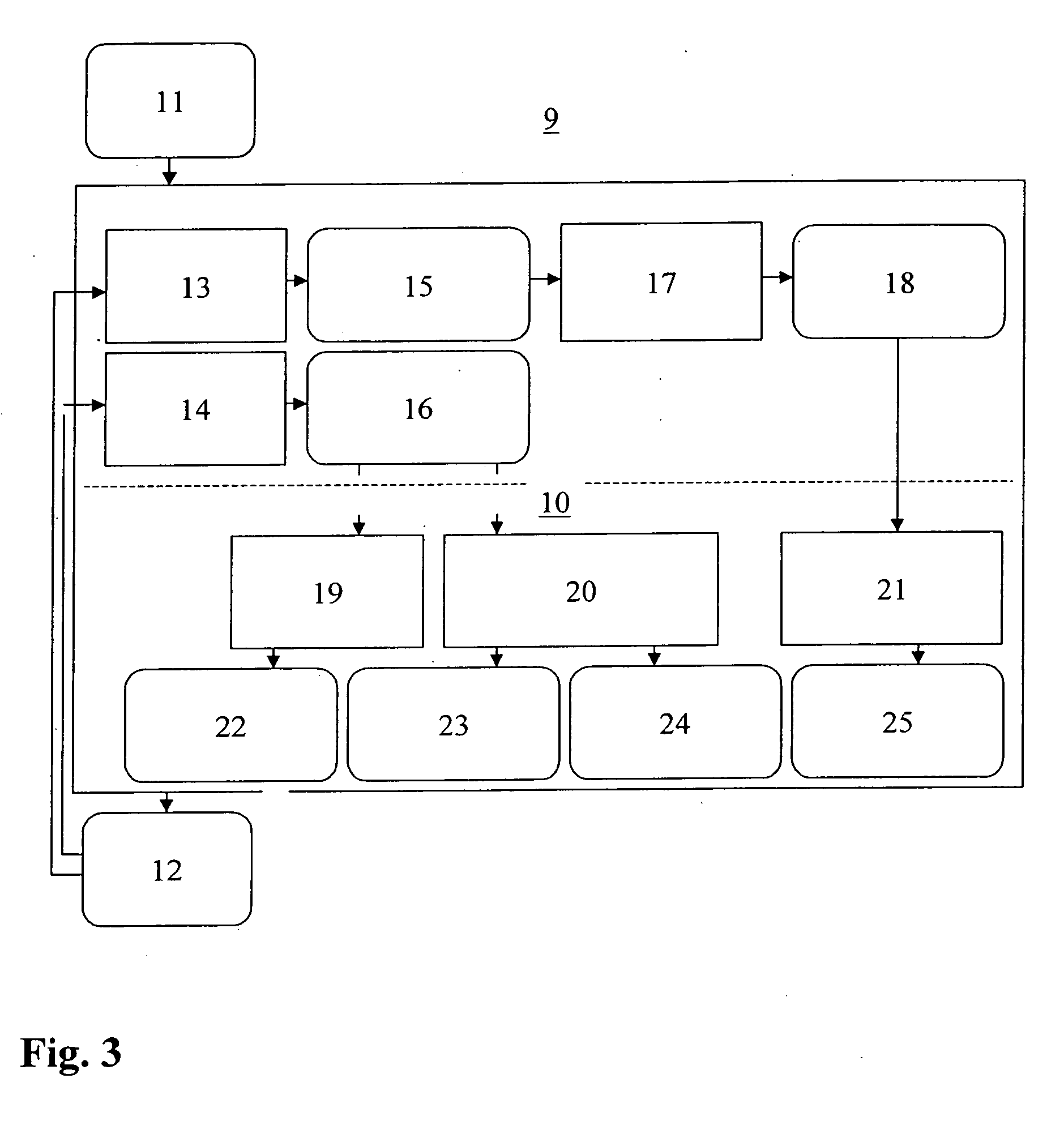

Method for checking the safety and reliability of software-based electronic system

InactiveUS20070016840A1Simplify System DesignLimit and reduce stressCode conversionReliability/availability analysisElectronic systemsDependability

A method for checking the safety and reliability of software-based electronic systems, using a reliability function for checking the functions of the system that are called for, based on the hardware components of the system required for this. In this connection it is provided that a reliability function is determined for calculating the reliability of at least one of the required functions of the system, and an additional reliability function is determined for calculating the reliability of at least one of the safety functions of the system, in the determination of these reliability functions, software components of the system being taken into consideration with the aid of hardware components onto which these software components are distributed. This makes possible the early valuation of different monitoring concepts for such systems, and of functions of these systems which are implemented by software and hardware.

Owner:ROBERT BOSCH GMBH

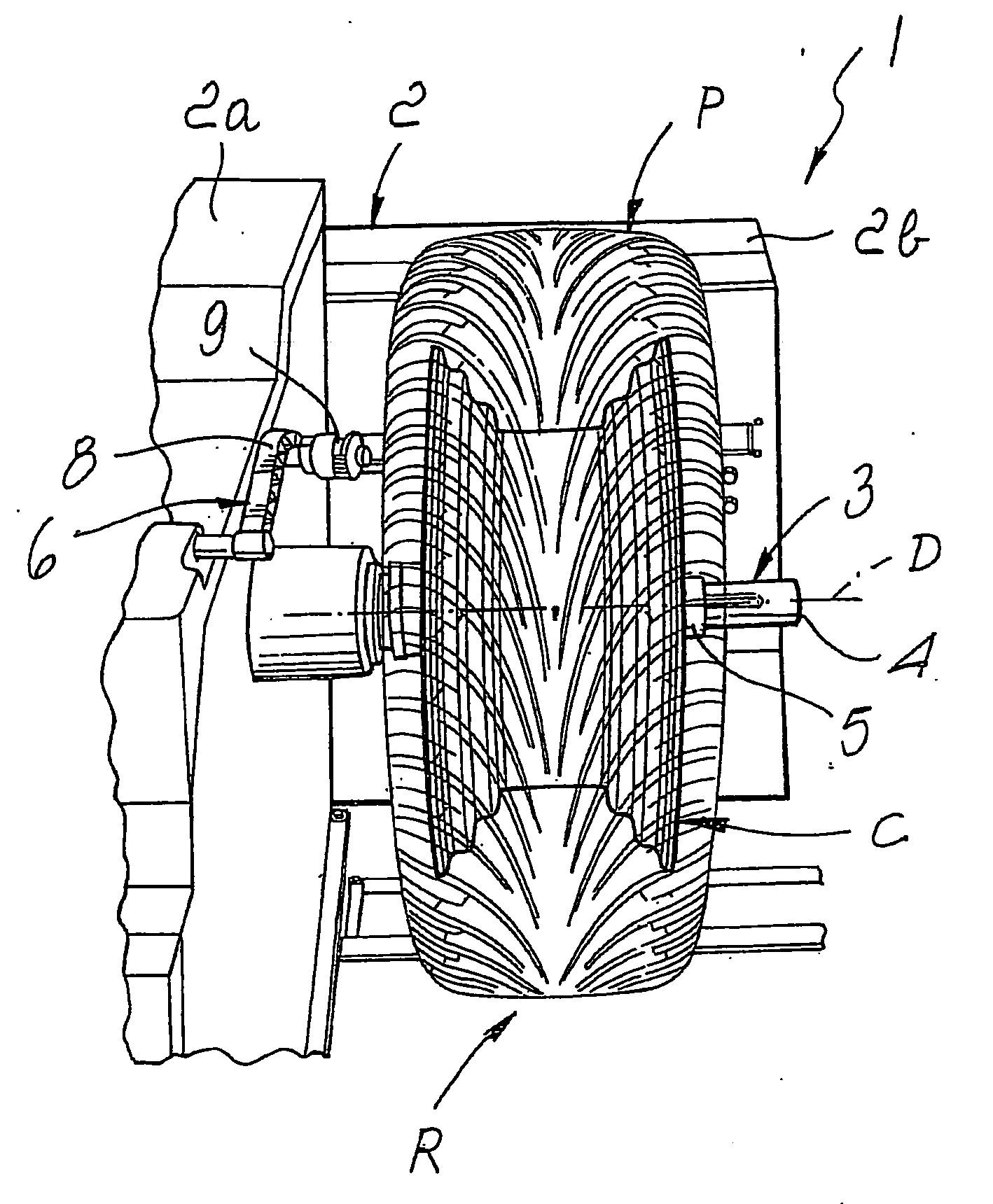

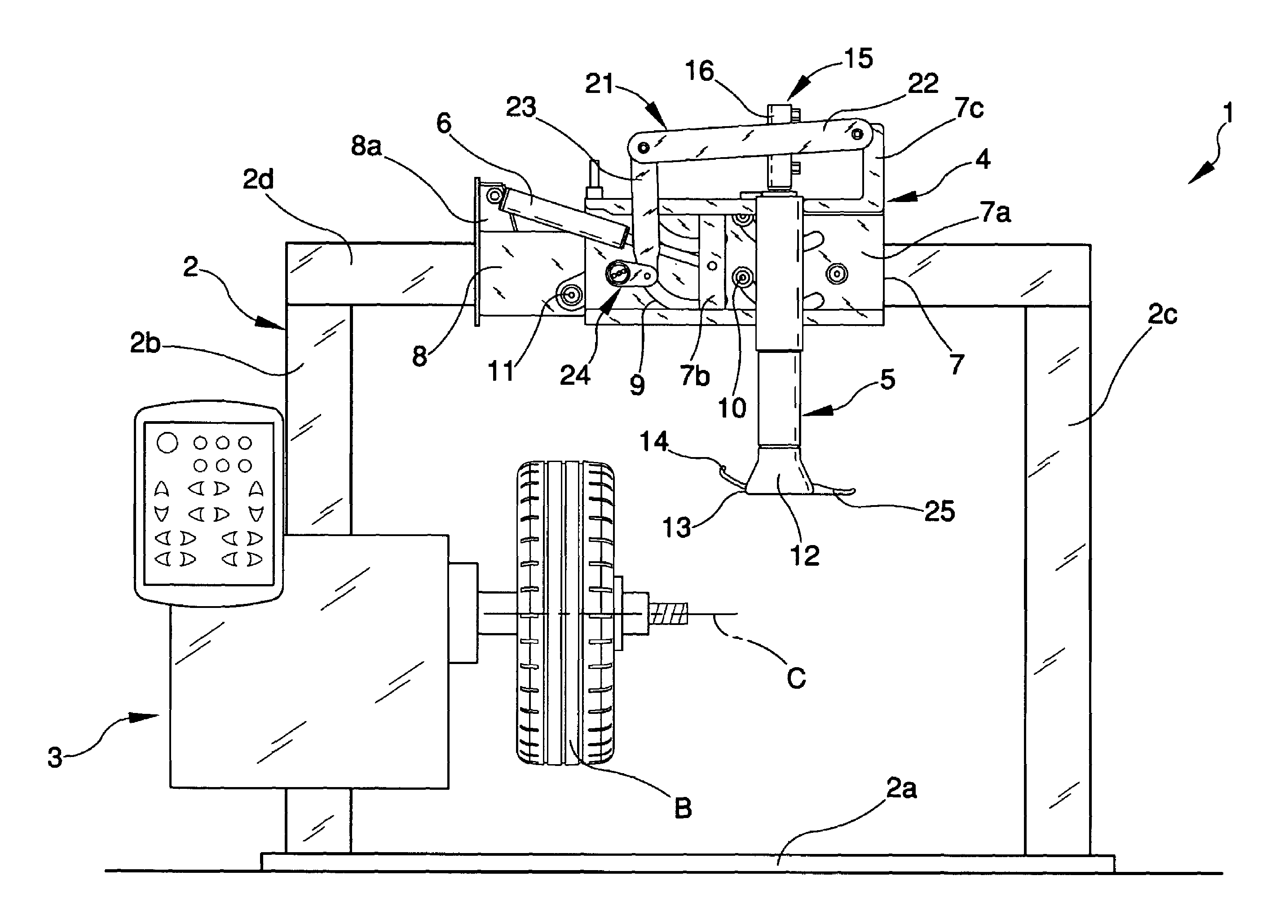

Machine for balancing vehicle wheels

InactiveUS20070069571A1Simple structurePractical implementationHubsStatic/dynamic balance measurementMotor driveHorizontal axis

A machine for balancing vehicle wheels, such wheels including a rim with a pair of axially spaced, ring-shaped or annular, flanges, and a tire seated up on the rim. The machine includes a frame with motor driven devices for gripping the vehicle wheel to be balanced and rotating same about a horizontal axis. A mechanical feeler, or probe, determines the position of the first of the pair of flanges on the rim. A contact-less, or remotely spaced, sensor, such as a laser, ascertains the profile of the tire by taking a series of discrete measurements without touching the tire. The mechanical feeler, or probe, and the contact-less sensor, are connected to a control unit in the machine. The control unit interpolates the values provided by the mechanical feeler and the contact-less sensor, and determines the location of the second flange on the wheel rim. The control unit may include an archive, or database, of the dimensions of known rims, to facilitate the accurate determination of the location of the second flange, on the wheel rim.

Owner:SICAM SRL

Machine for fitting and removing tires and wheel rims for vehicles

A machine for removing and fitting tires and wheel rims for vehicles includes a supporting structure of clamping and rotating device for clamping and rotating the rim of a vehicle wheel around a rotation axis, at least one operating unit which is movably associated with the supporting structure and which includes at least one operating head for fitting and removing a tire onto / from the rim provided with a pushing body for pushing at least one portion of the side surface of the tire and with a grip tool for gripping at least one section of the tire bead, an actuator element for operating the sideways movement of the operating head with respect to the structure and guide means of such sideways movement along a substantially curvilinear direction between a first position, in which the operating head is substantially close to the clamping and rotating device and a second position, in which the operating head is substantially moved away from the clamping and rotating device.

Owner:GIULIANO GROUP

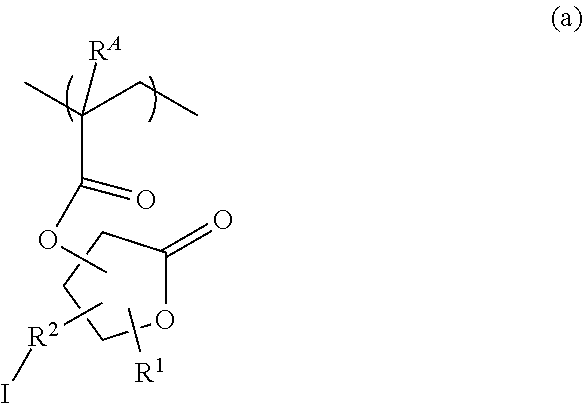

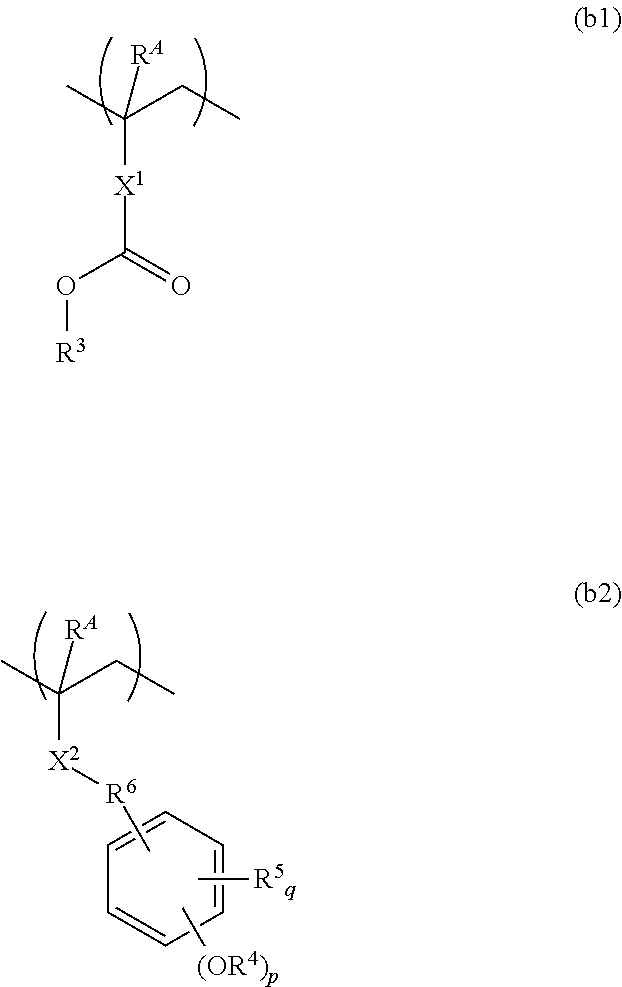

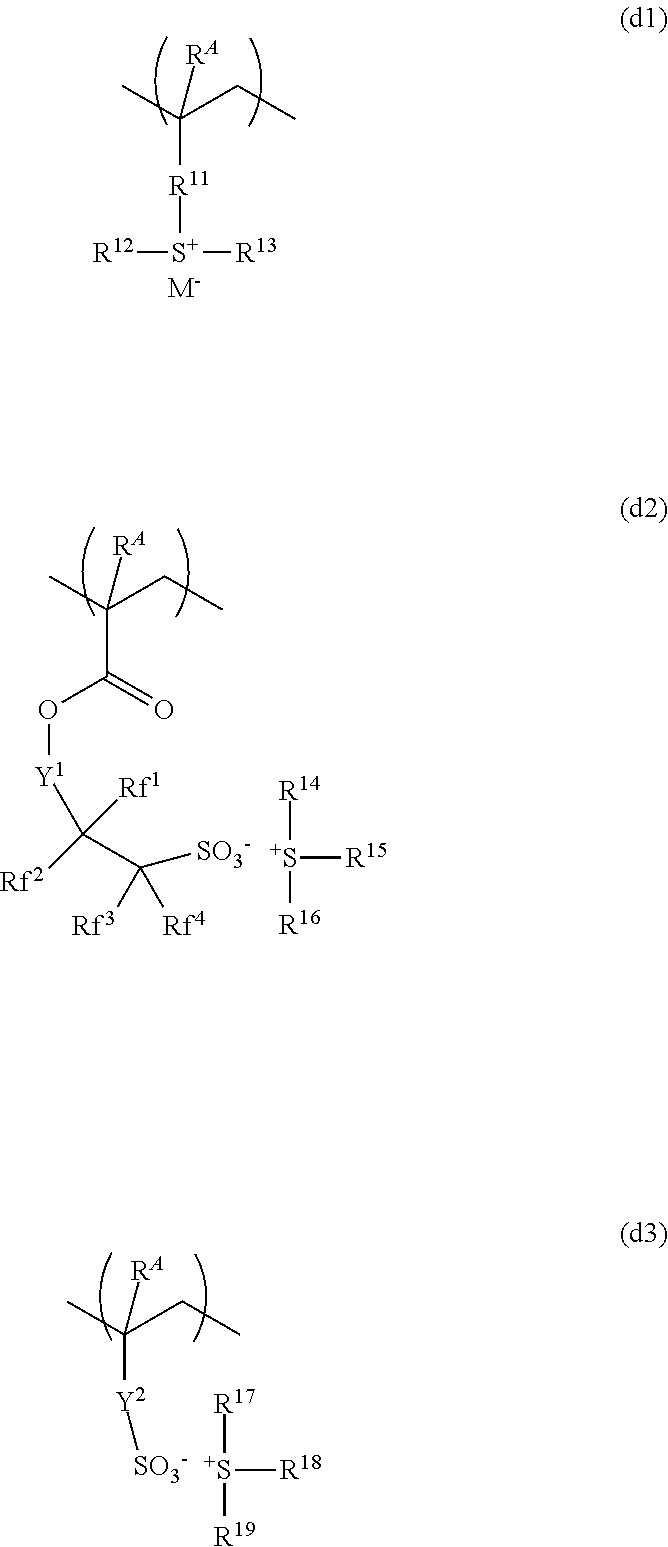

Resist composition and patterning process

ActiveUS10303056B2High sensitivitySatisfied with the effectOrganic chemistryPhotomechanical coating apparatusResistPolymer chemistry

Owner:SHIN ETSU CHEM IND CO LTD

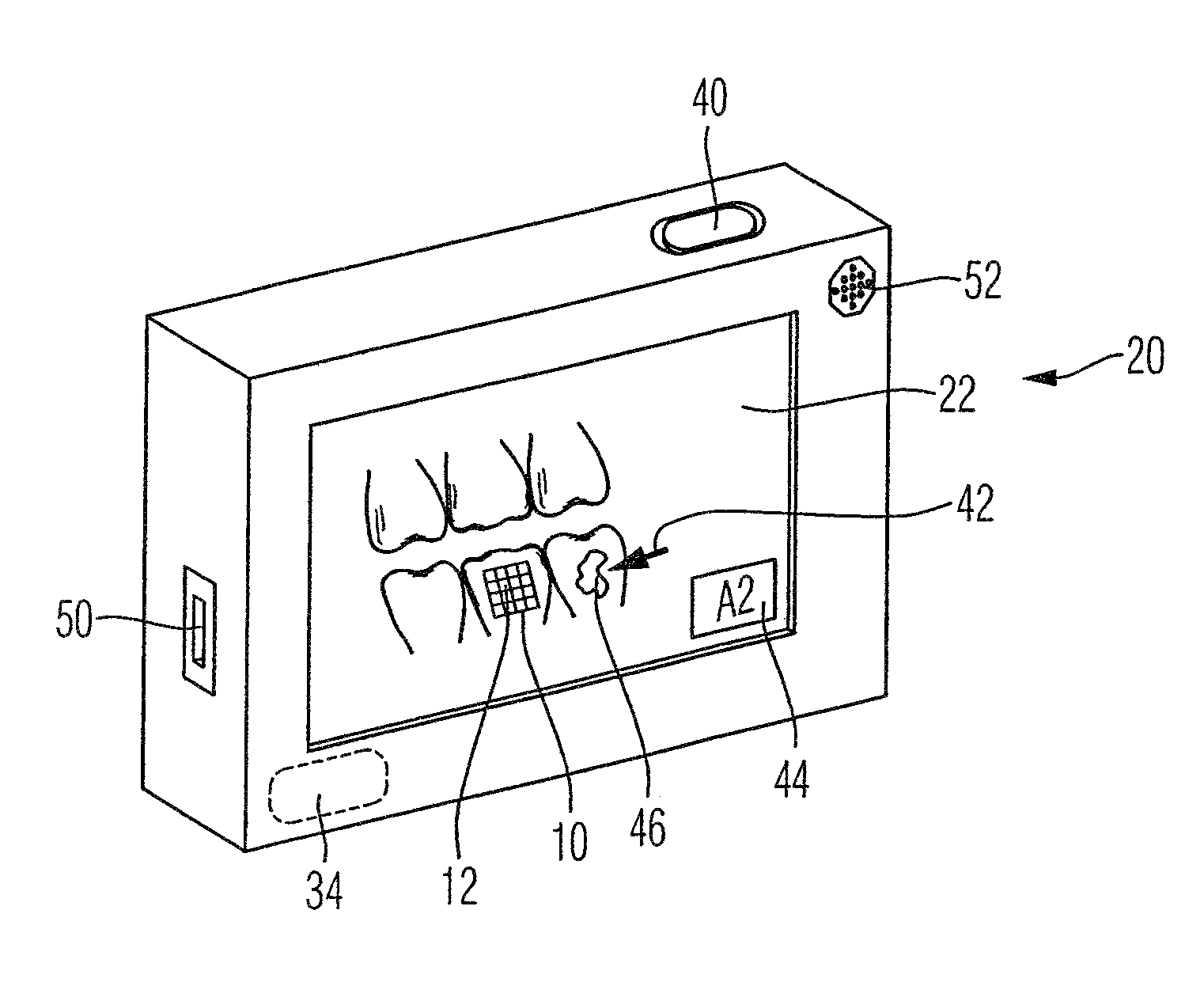

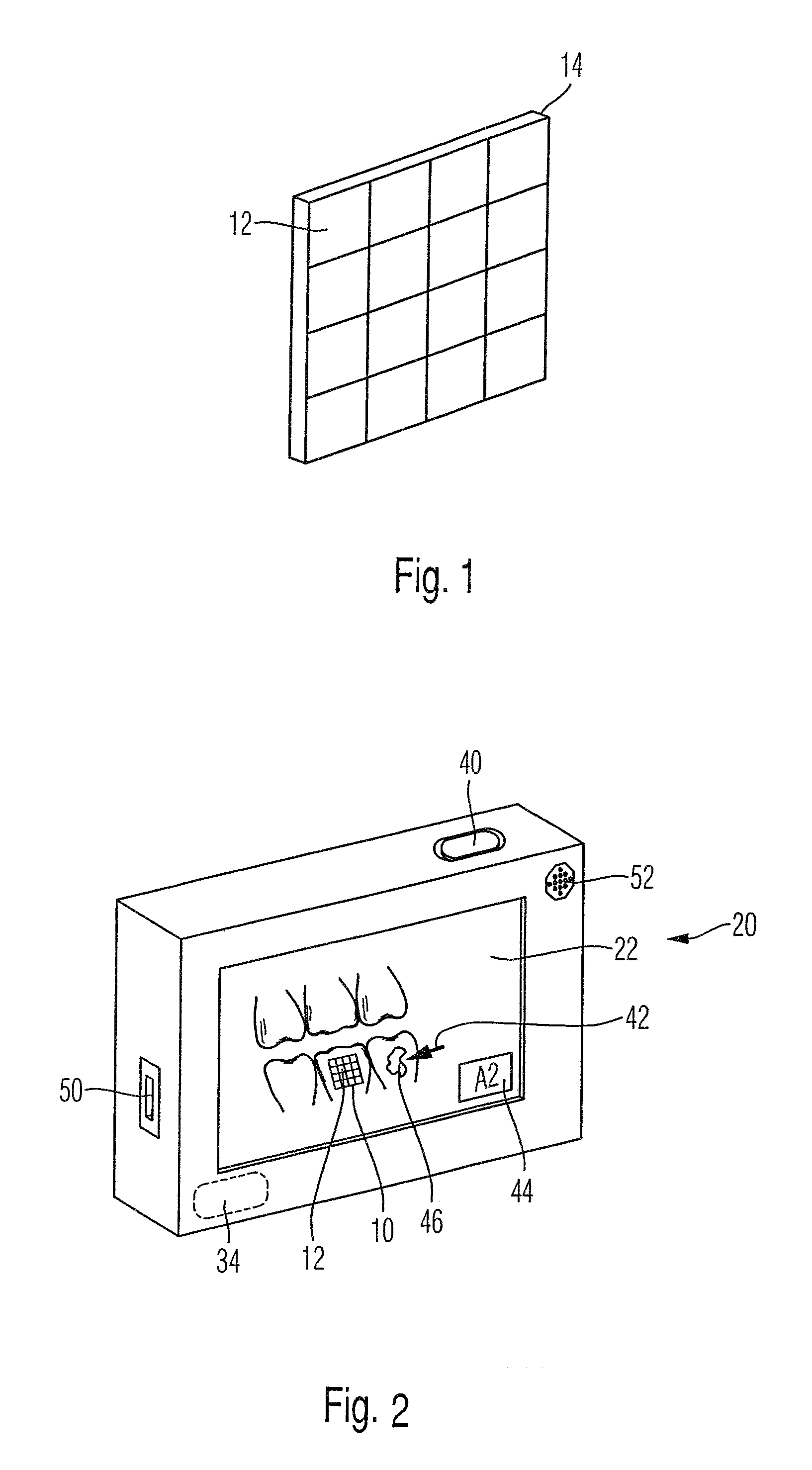

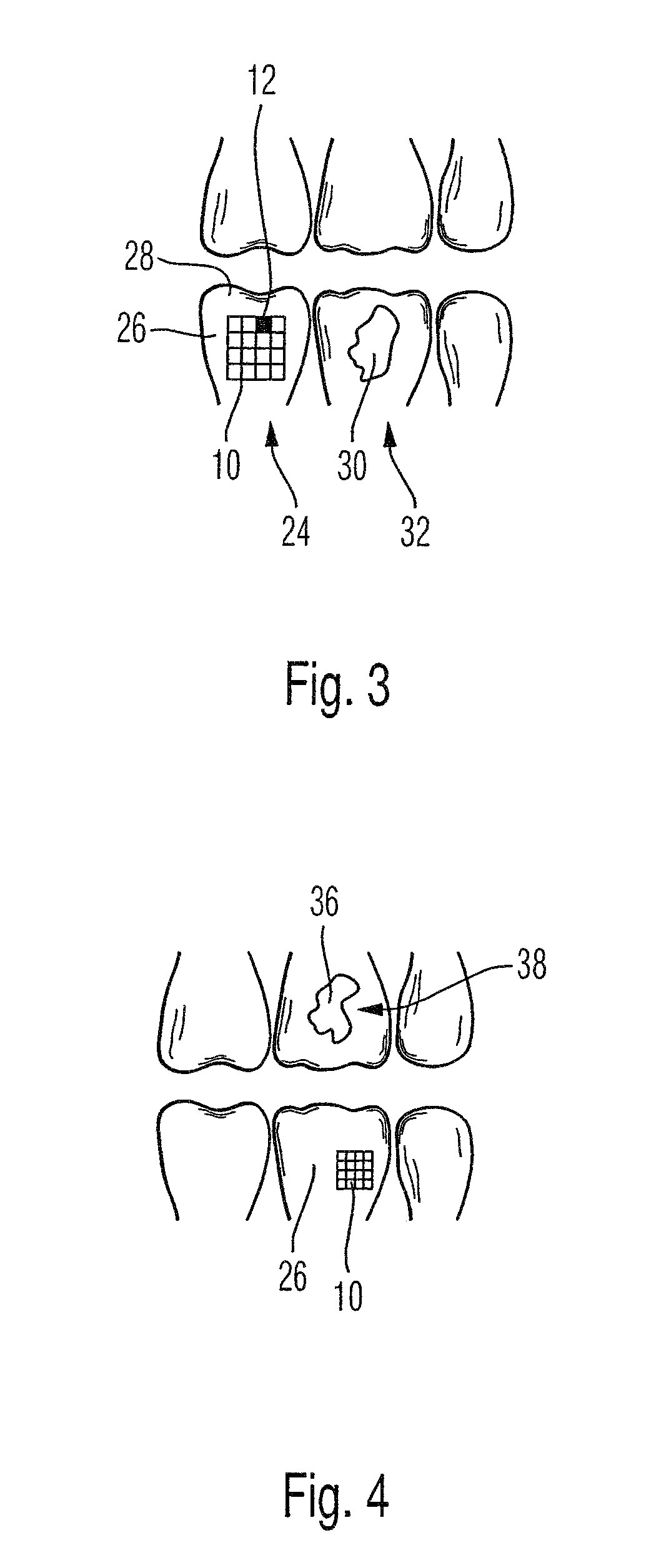

Dental color analyzing device and methof of use

ActiveUS9008417B2Easy to handleCost efficient to manufactureRadiation pyrometryDentistryDisplay deviceComputer science

The invention relates to a dental color analyzing device comprising a housing, a computer device having a storage unit, and a display on which a reference object together with at least one tooth and / or a gingival area is represented, wherein at least one first image section that shows the reference object as well as at least one second image section that displays the tooth, a tooth region or a gingival area, may be detected with the aid of the computer device, characterized in that the reference object is mounted on a tooth and in particular is attached thereto and comprises a smaller size than the represented tooth, wherein the reference object is a dental color key comprising color samples that are arranged next to one another and that each represent a dental color, and in that the color of the second, in particular selectable image section, is comparable to the represented color samples with the aid of the computer device such that the color sample that matches the color of the second image section best, may be displayed on the display.

Owner:IVOCLAR VIVADENT AG

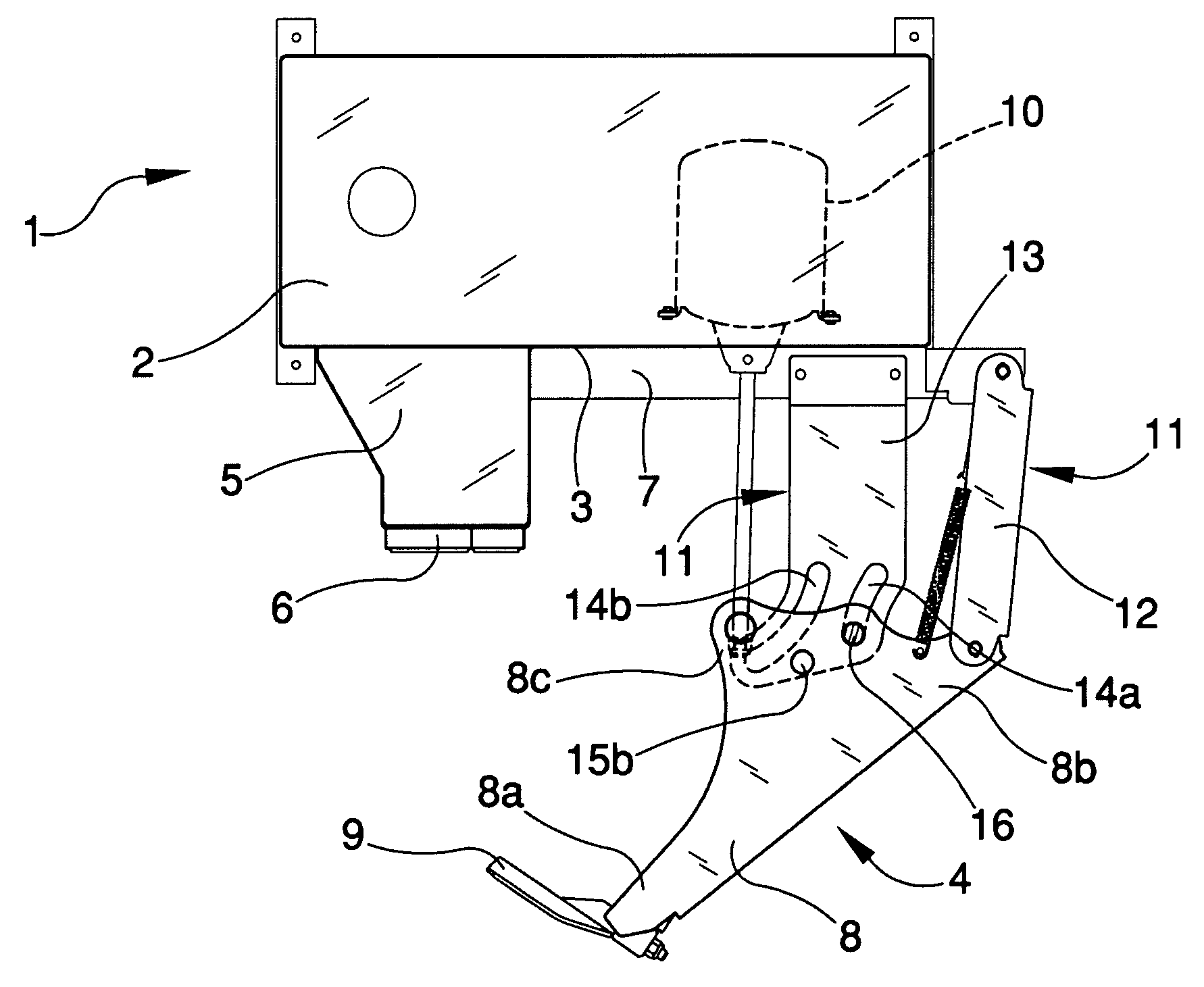

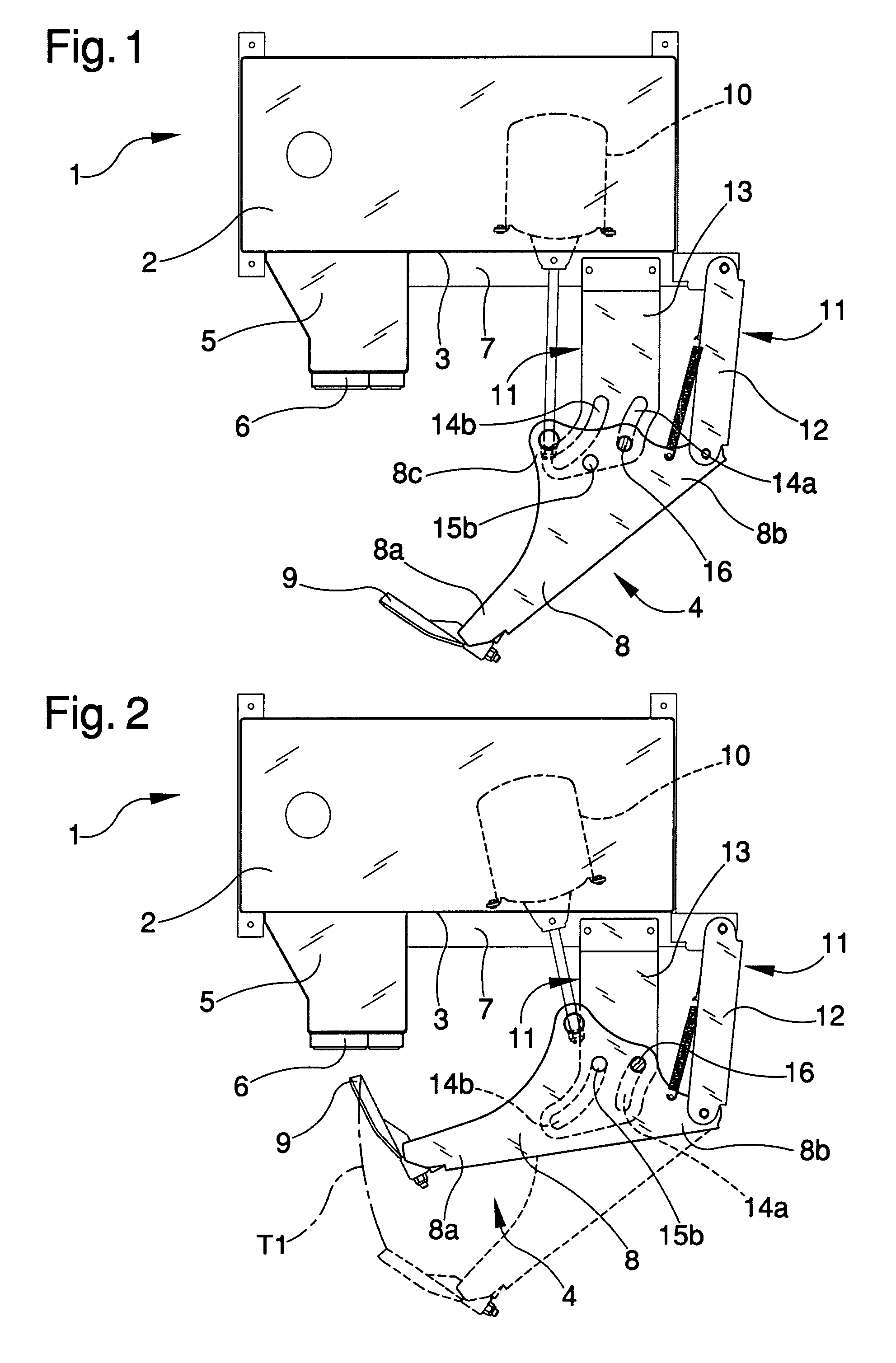

Machine for balancing vehicle wheels

InactiveUS7594437B2Simple structurePractical implementationStatic/dynamic balance measurementMotor driveHorizontal axis

A machine for balancing vehicle wheels, such wheels including a rim with a pair of axially spaced, ring-shaped or annular, flanges, and a tire seated up on the rim. The machine includes a frame with motor driven devices for gripping the vehicle wheel to be balanced and rotating same about a horizontal axis. A mechanical feeler, or probe, determines the position of the first of the pair of , flanges on the rim. A contact-less, or remotely spaced, sensor, such as a laser, ascertains the profile of the tire by taking a series of discrete measurements without touching the tire. The mechanical feeler, or probe, and the contact-less sensor, are connected to a control unit in the machine. The control unit interpolates the values provided by the mechanical feeler and the contact-less sensor, and determines the location of the second flange on the wheel rim. The control unit may include an archive, or database, of the dimensions of known rims, to facilitate the accurate determination of the location of the second flange, on the wheel rim.

Owner:SICAM SRL

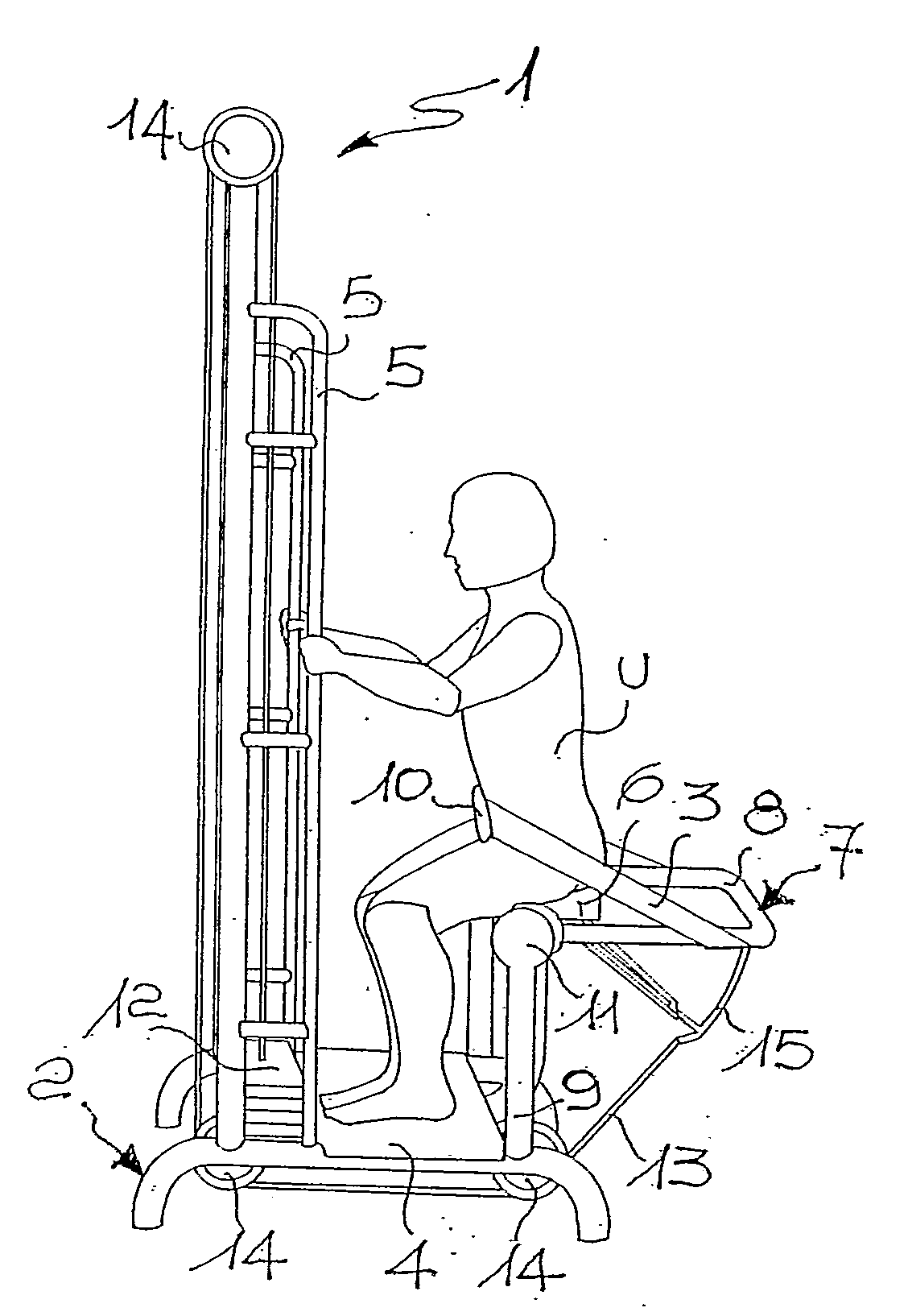

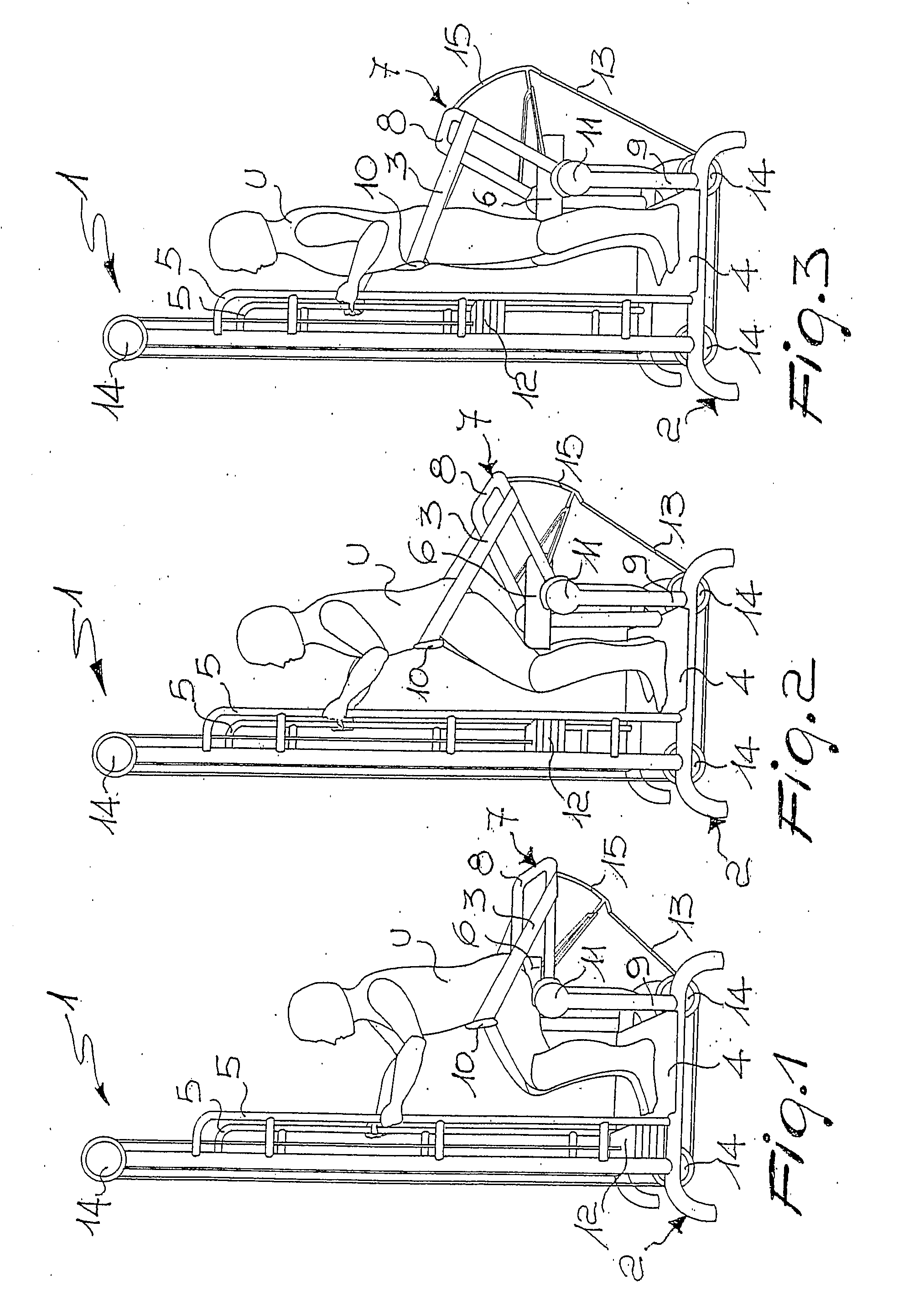

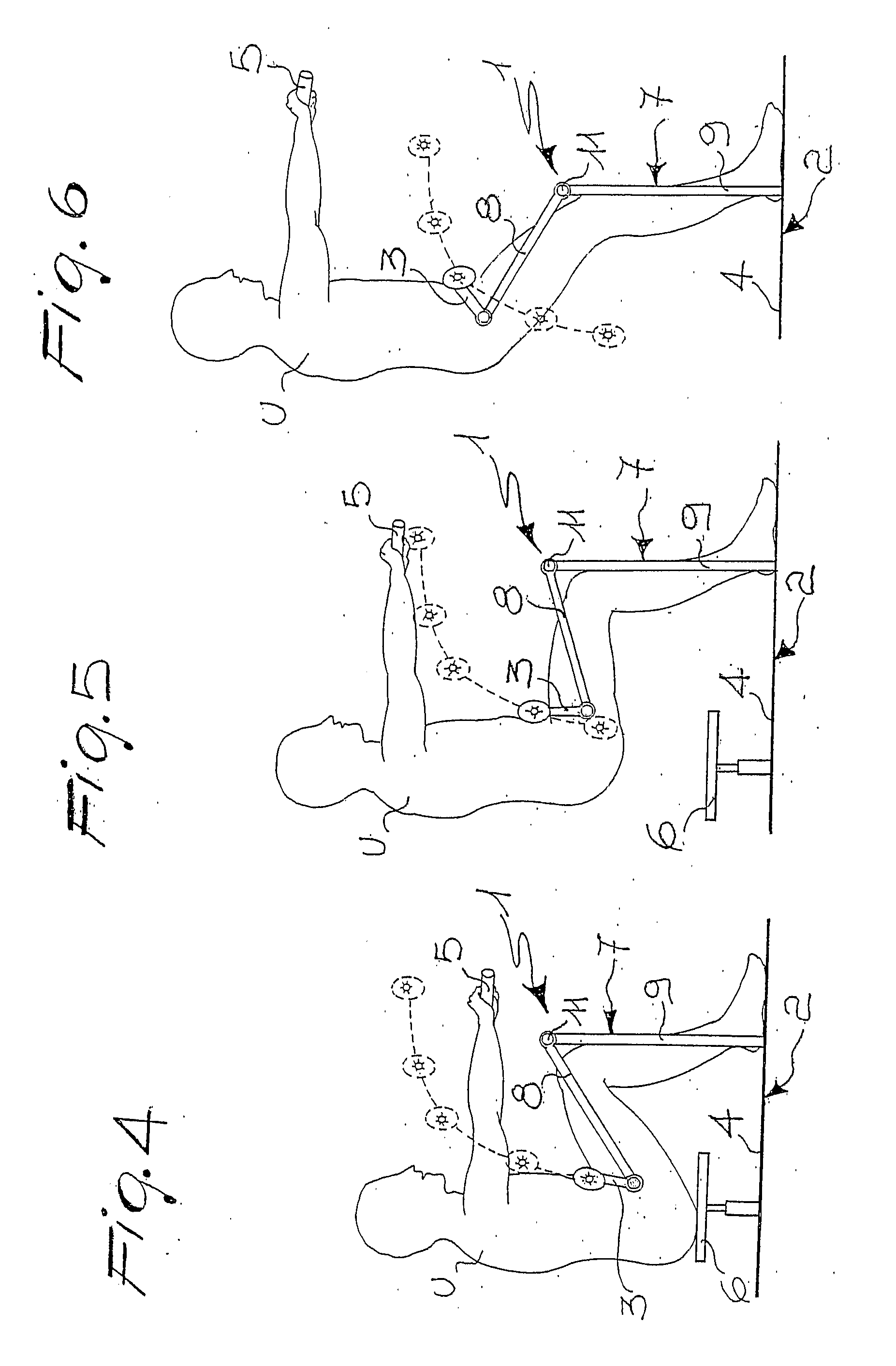

Gymnastic apparatus, particularly for exercising extensor muscles of inferior limbs thighs muscles and gluteus muscles

InactiveUS20090082181A1Drawback can be obviatedSimple structureFrictional force resistorsExtensors musclesPelvis

The gymnastics apparatus, particularly for exercising the extensor muscles of the inferior limbs, thigh muscles and gluteus muscles, comprises a support frame for a gradually-yielding resistant element suitable for contact with a pelvic-abdominal region of the torso of a user moving from an initial position, in which the lower limbs of the user are bent, to a final orthostatic position, the resistant action of the resistant element being directed along a direction transversal to the longitudinal axis of the thigh bones of the user in movement.

Owner:NOBILTEC COMFORT

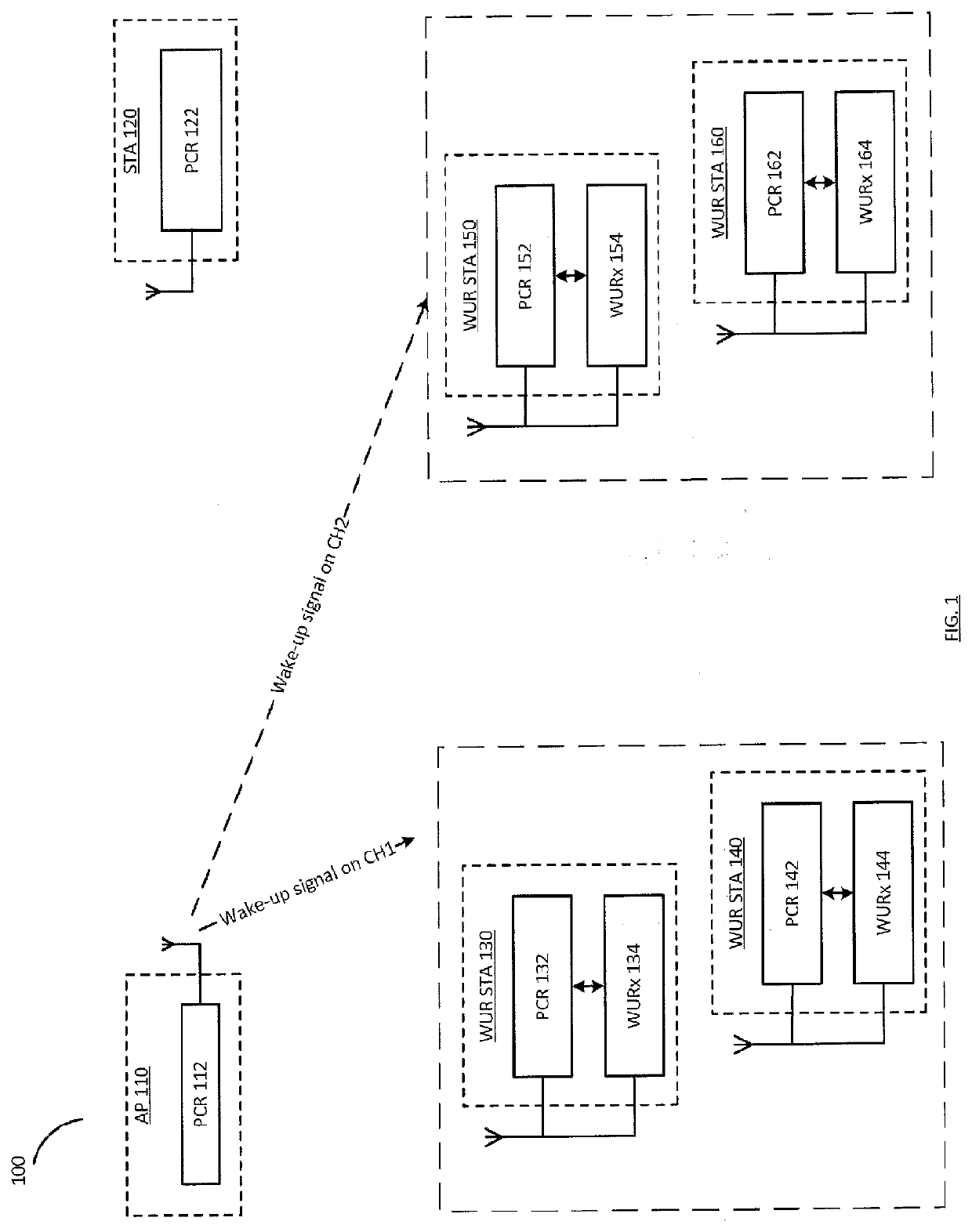

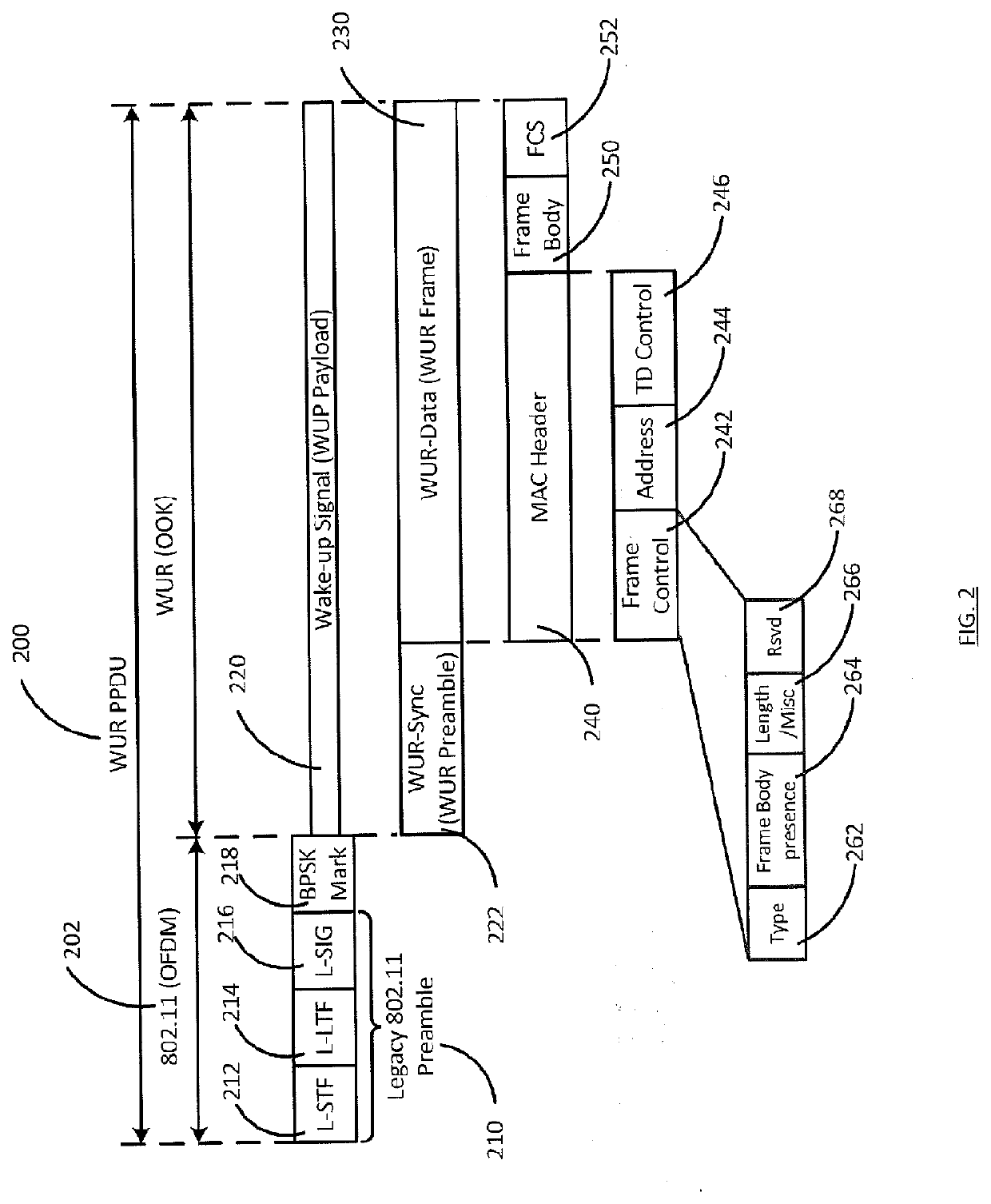

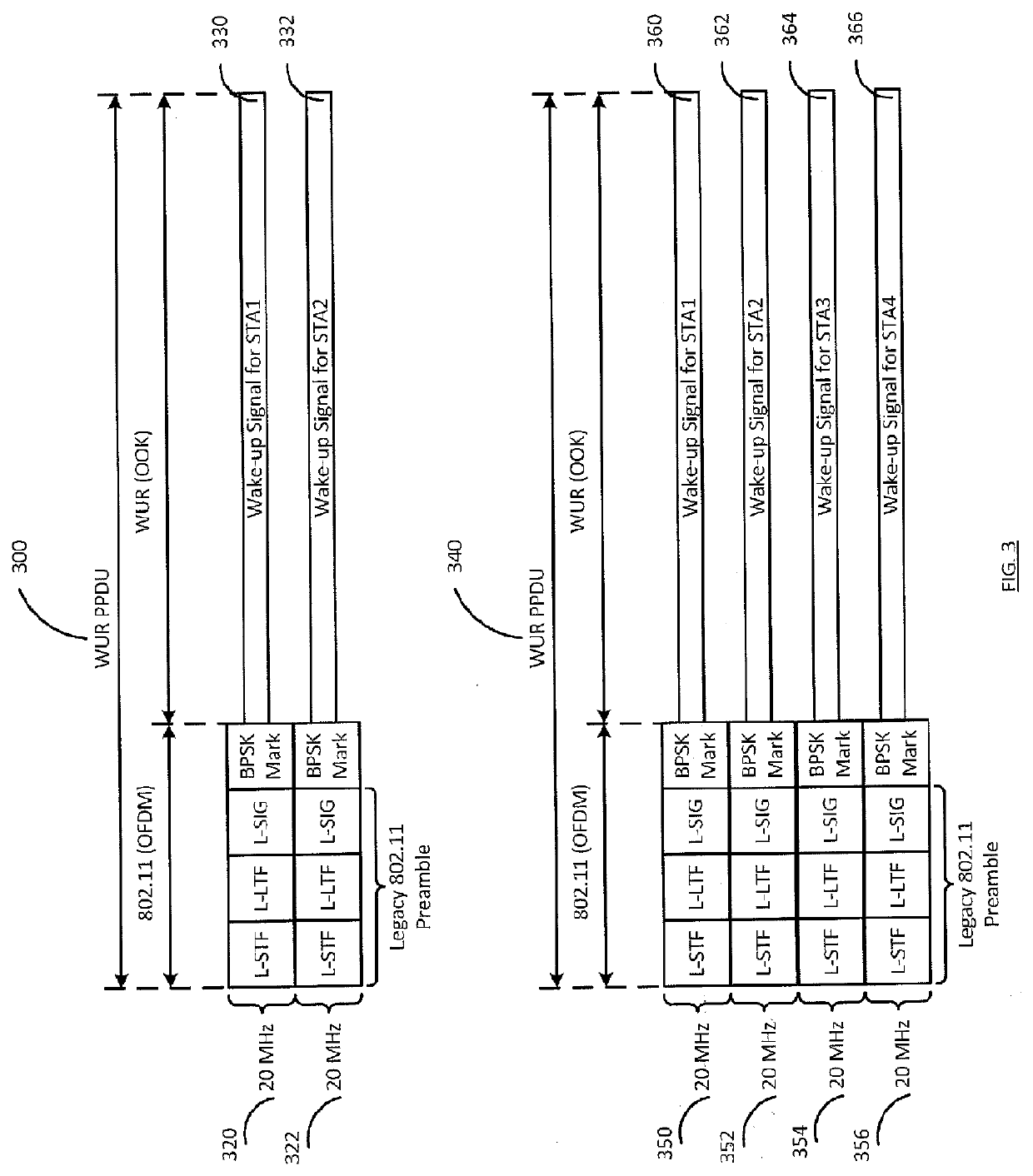

Communication apparatus and communication method for duty cycled low power multi-user transmission

ActiveUS20210227471A1Improve transmission efficiencySave battery powerPower managementNetwork topologiesBeacon frameCommunication device

The present disclosure provides a communication apparatus that comprises a receiver which, in operation, receives a wake-up radio (WUR) frame, during an on duration in a duty cycle, in a first channel assigned to the communication apparatus by an Access Point (AP), and receives a WUR Beacon frame in a second channel, a transmission of the WUR Beacon frame being scheduled at a target WUR beacon transmission time (TWBTT); and a processor which, in operation, operates the duty cycle, wherein, during a determined time from the TWBTT, any WUR frame is not transmitted in the first channel from the AP.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

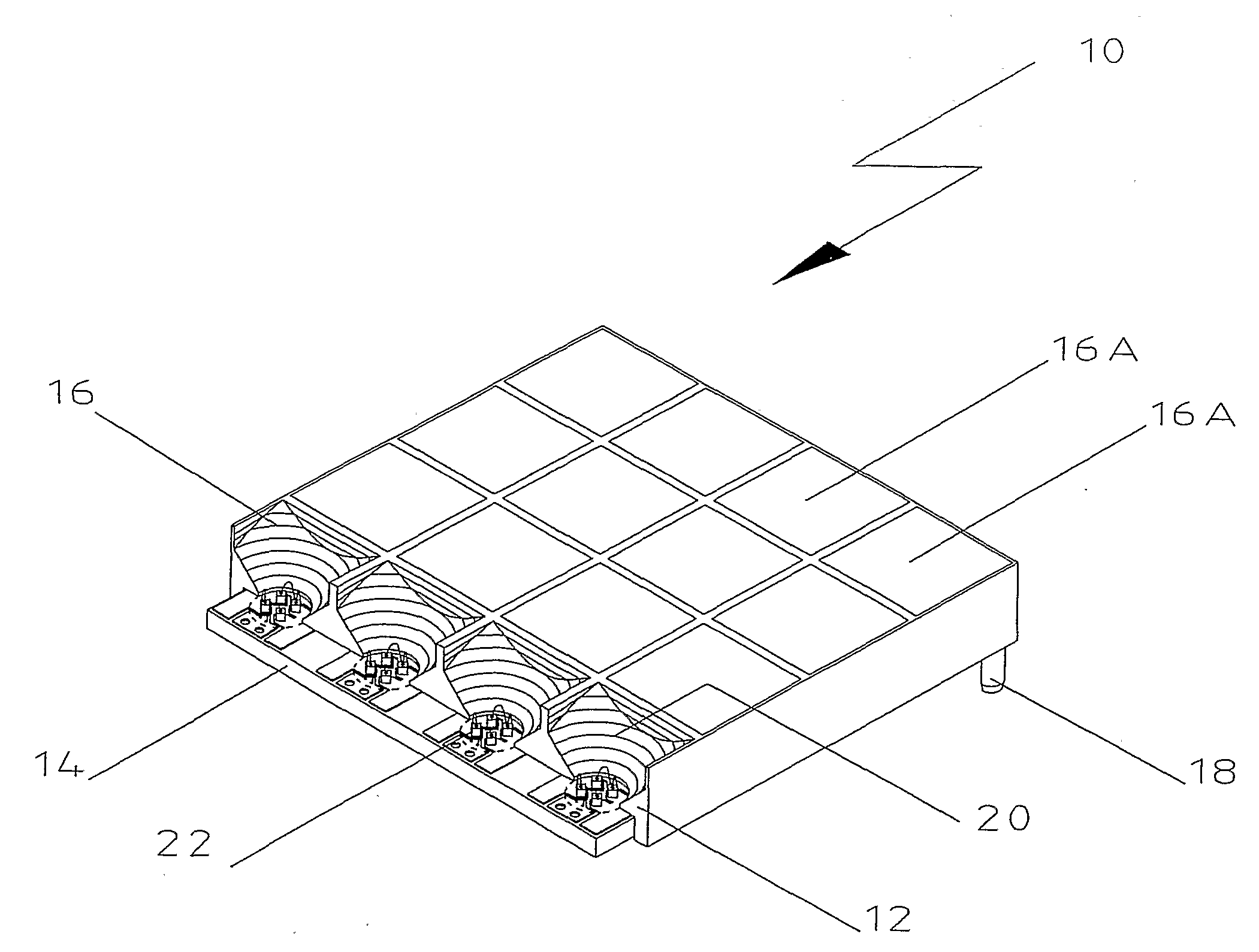

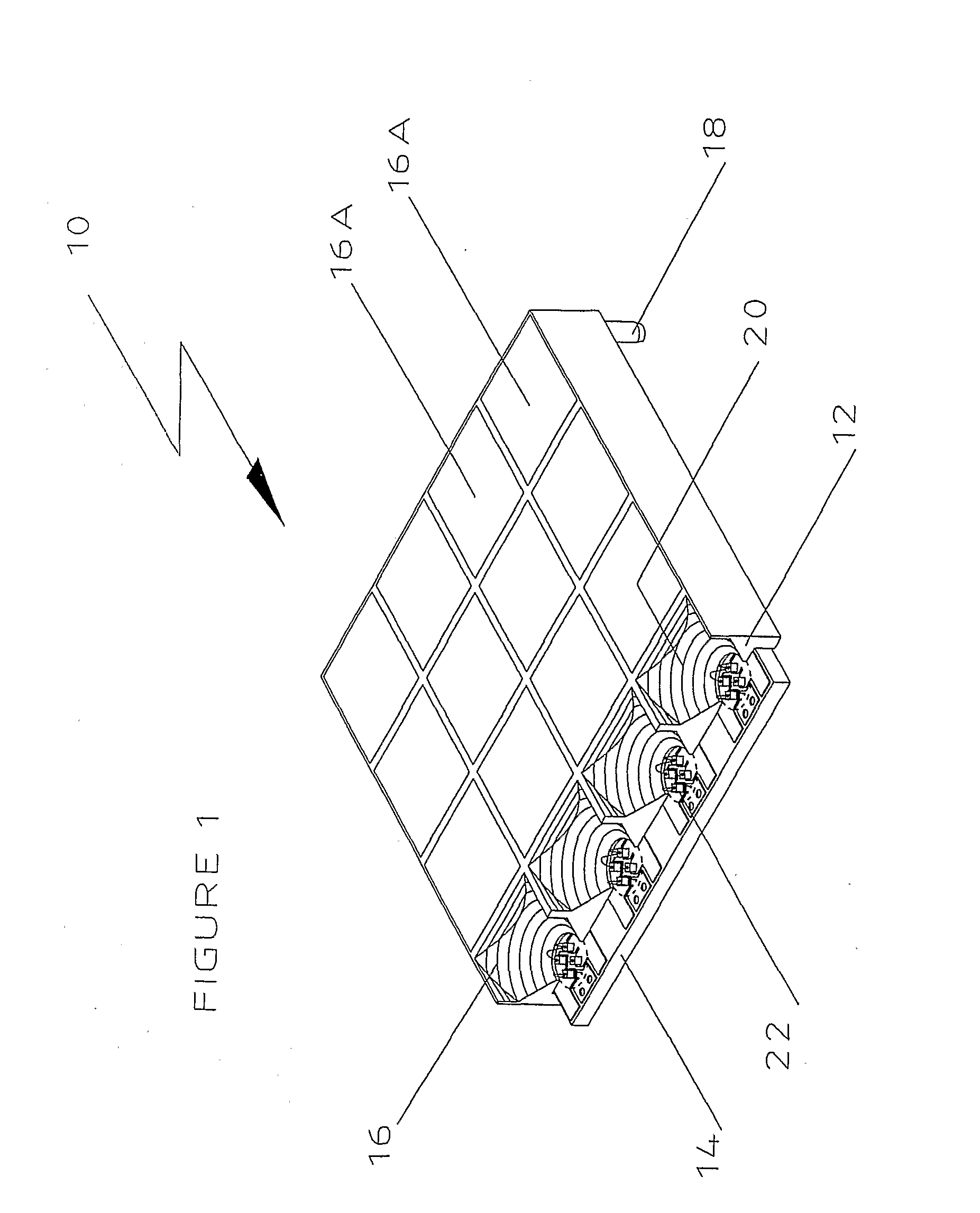

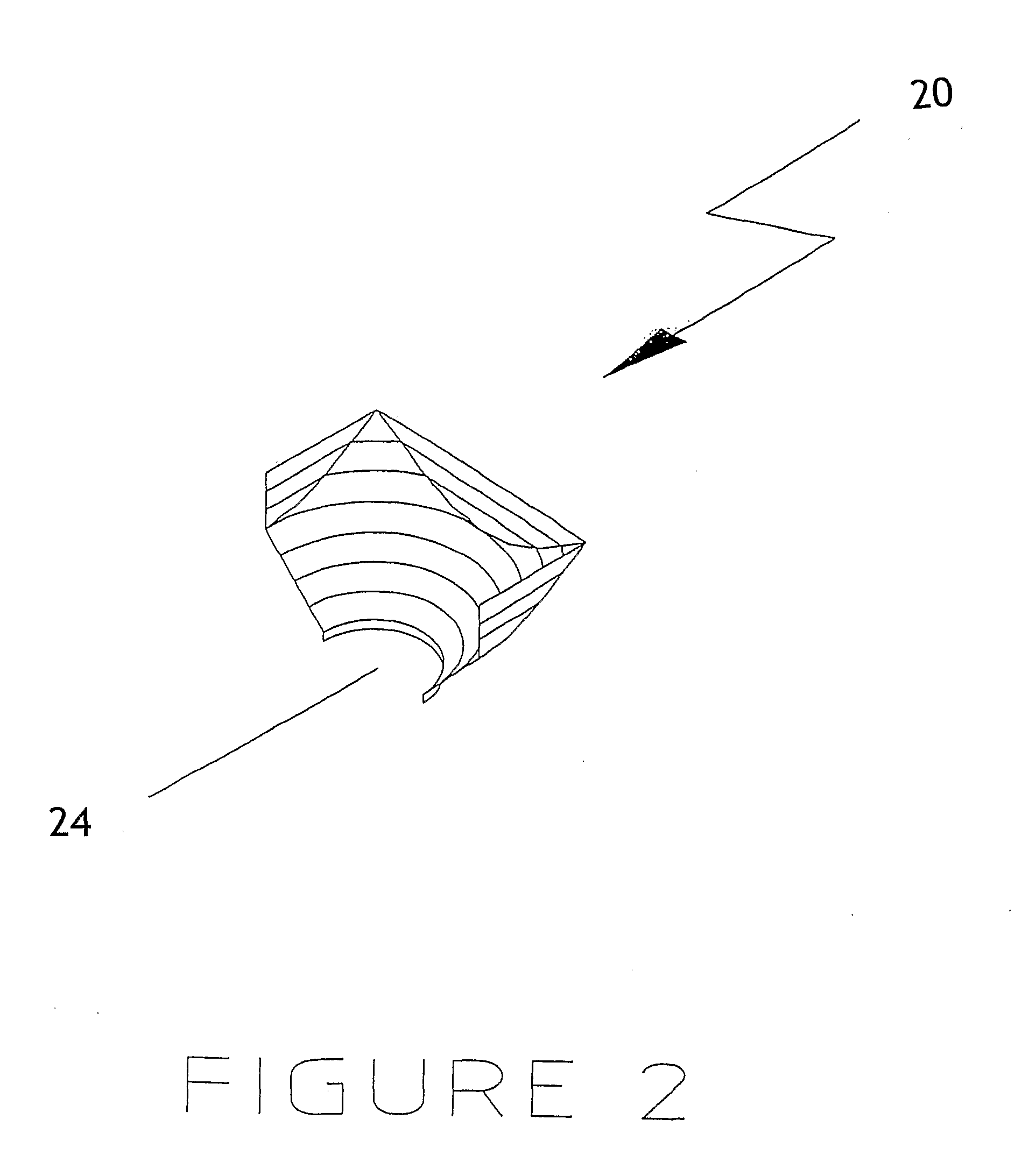

Pixel Array and Tile for a Video Display

InactiveUS20090002980A1Connection is neededPractical implementationSemiconductor/solid-state device manufacturingSpectral modifiersComputer graphics (images)Display device

The invention provides a rectangular pixel array, a tile for a large display such as a video and a method for forming a rectangular array of pixels. The pixel array includes a reflector array having a reflector well for each pixel and a dice carrier including a plurality of dice for each pixel.

Owner:MICHAEL ROBERT

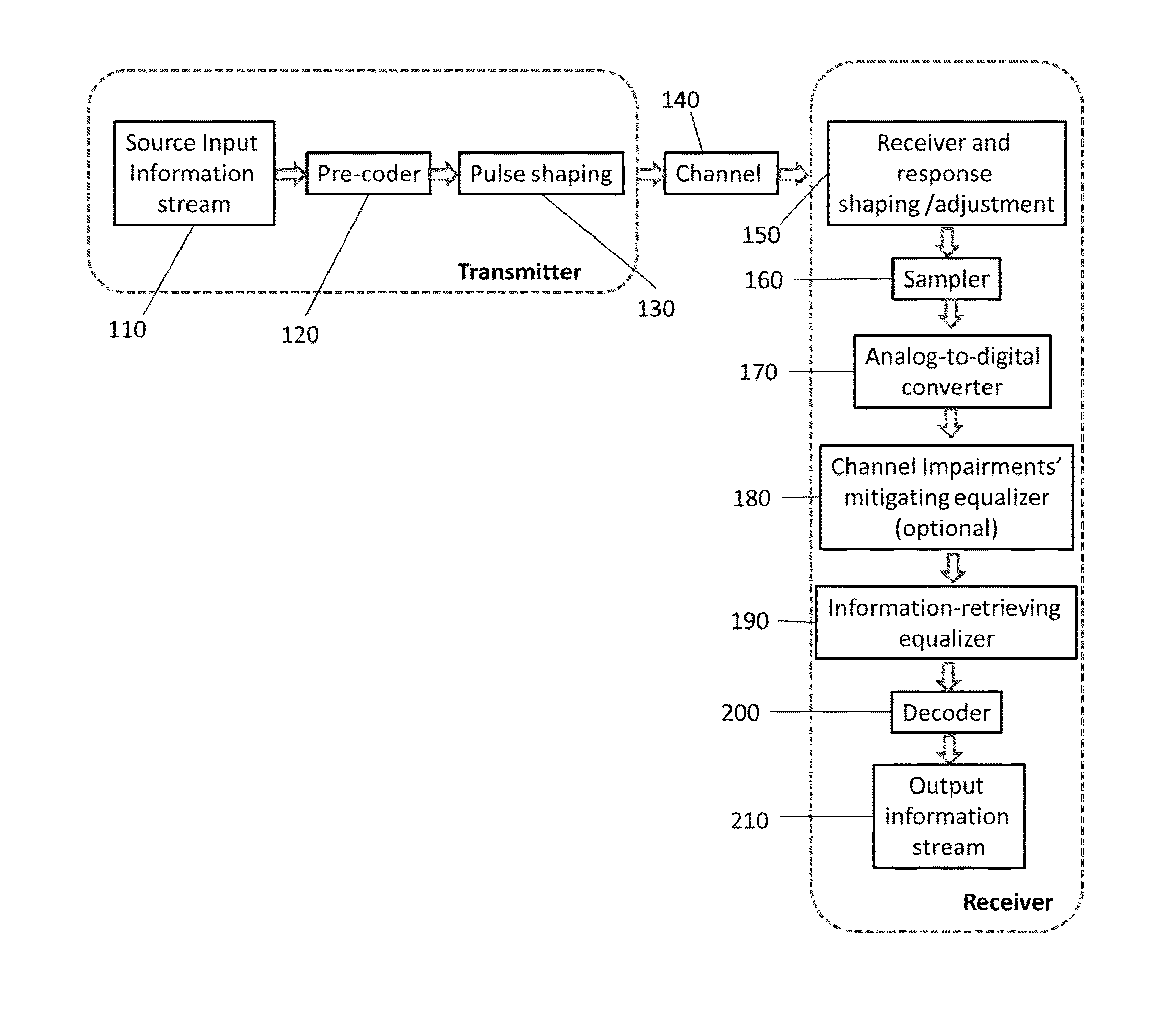

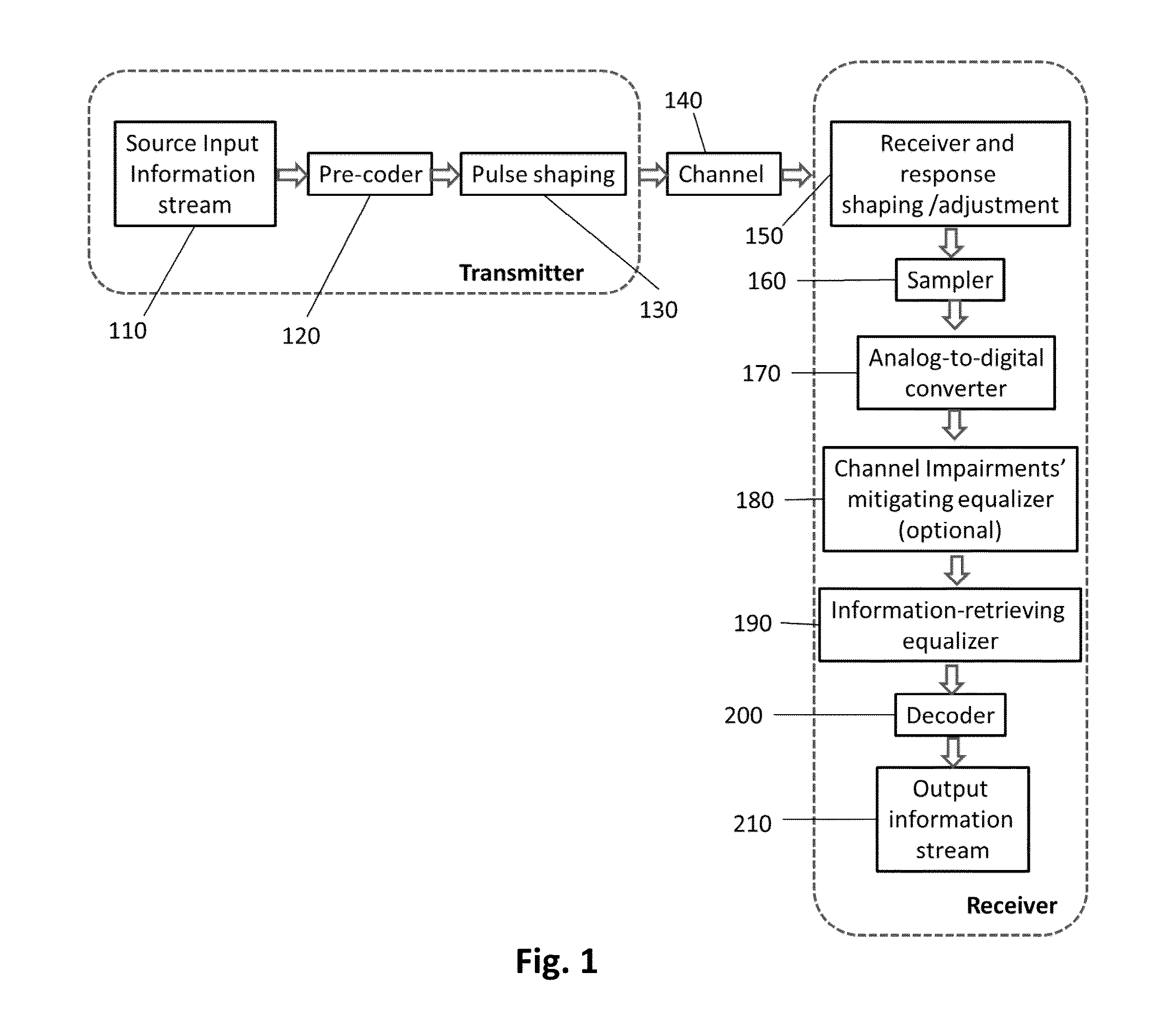

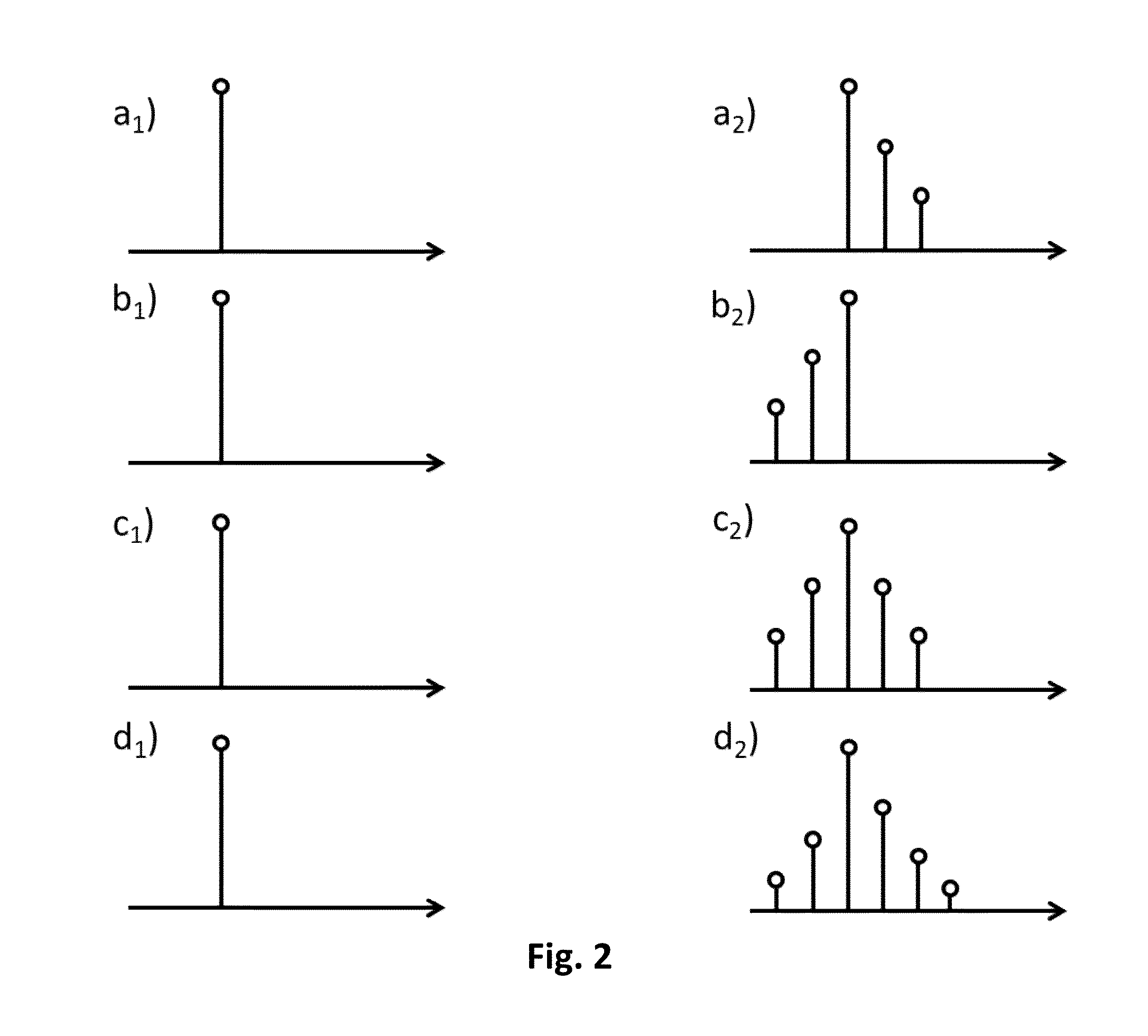

Method for reducing equalizer complexity in communication links

ActiveUS20140269885A1Complexity equalization structureReduce complexityMultiple-port networksDelay line applicationsTelecommunications linkCommunications system

The present invention relates to a method of reducing equalizer complexity in communication systems, which also provides for reduced power dissipation. The method consists of reducing the number of channel responses expected by the equalizer by averaging sub-groups of all of the possible the channel responses chosen in a particular way.

Owner:NTWINE LLC

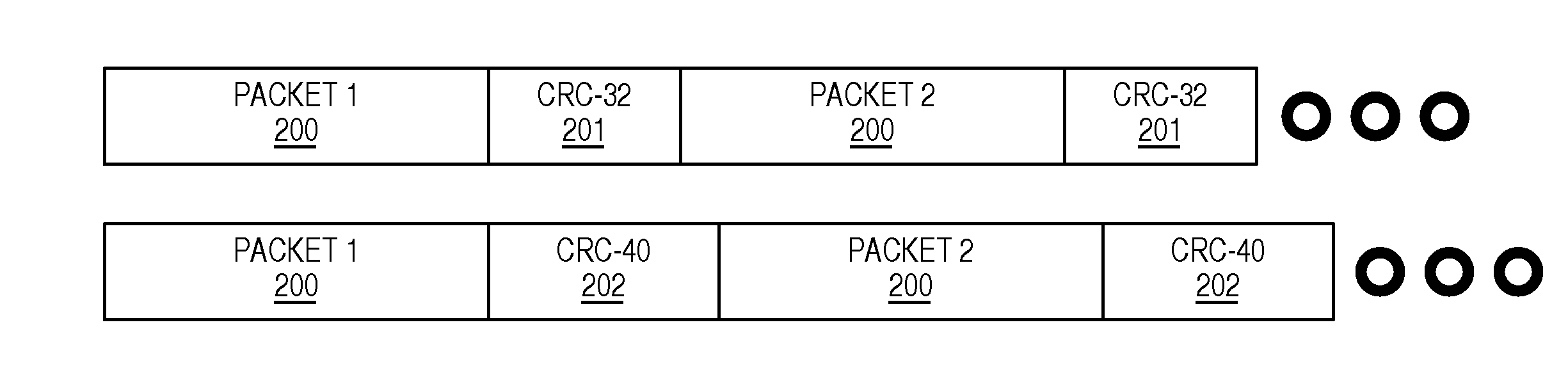

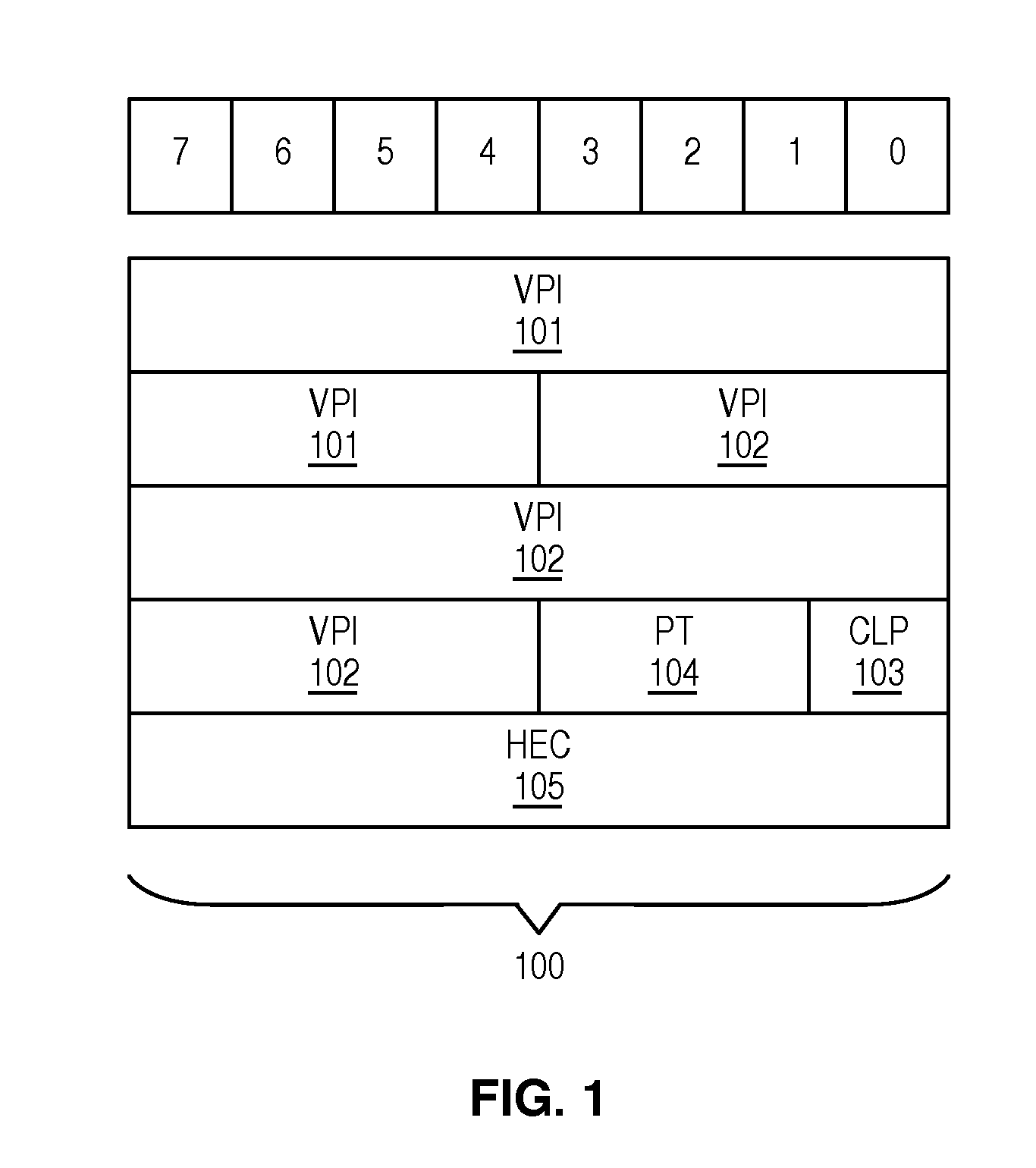

Making a secure connection over insecure lines more secure

ActiveUS20170034135A1Practical implementationError preventionData stream serial/continuous modificationCommunications systemSecure communication system

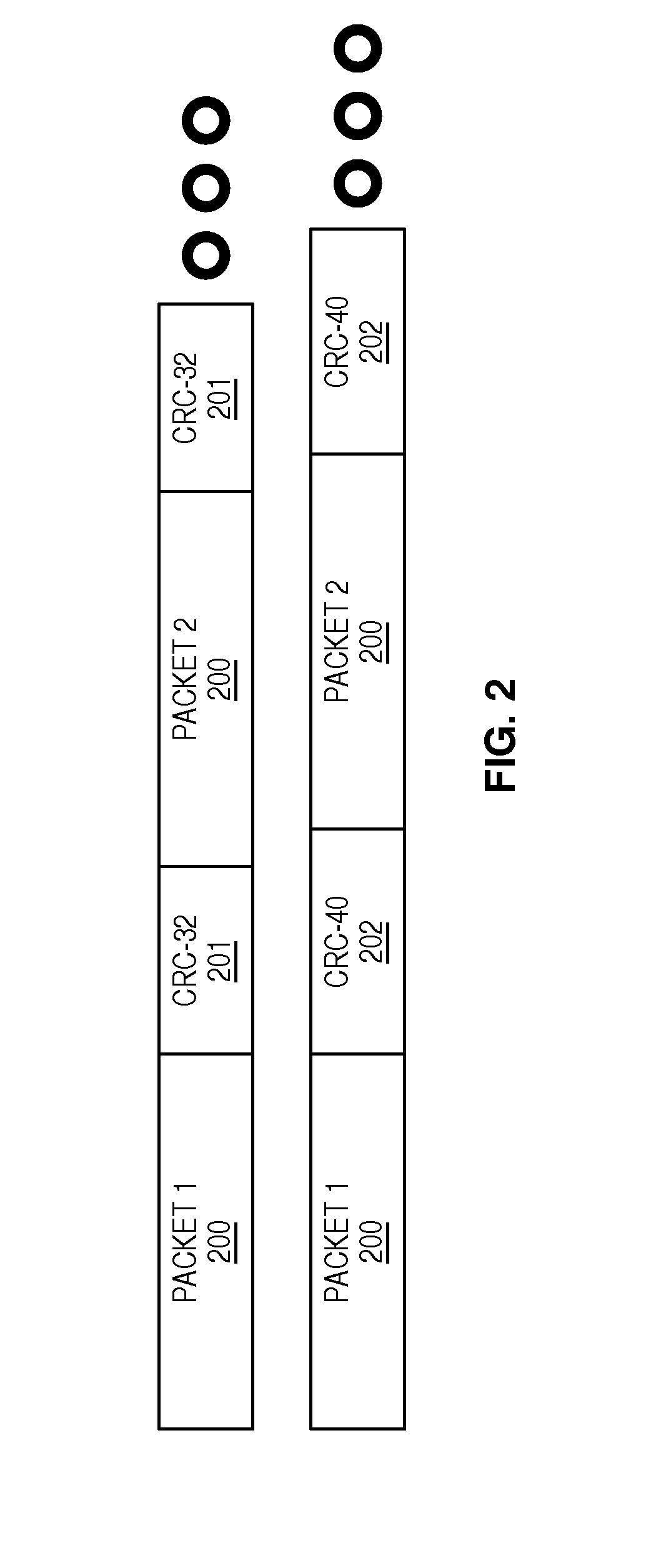

A secure or insecure communications channel for a secure communications system that carries sensitive user datagrams inside a proprietary or other undisclosed protocol so as to be able to encrypt the entire user datagram, including all header information so that if a malevolent entity were covertly or otherwise receiving said transmission they would be unable to determine the destination addresses of the user datagrams. Further the proprietary or undisclosed protocol is broken up into packets whose packet-to-packet boundaries are hidden so that malevolent entities will not be able to glean any information from the changes in traffic that occur during stimuli designed to provoke an expected response, thereby rendering said malevolent entities unable to determine what actual responses are occurring during real world events.

Owner:PIERSON FORREST L +1

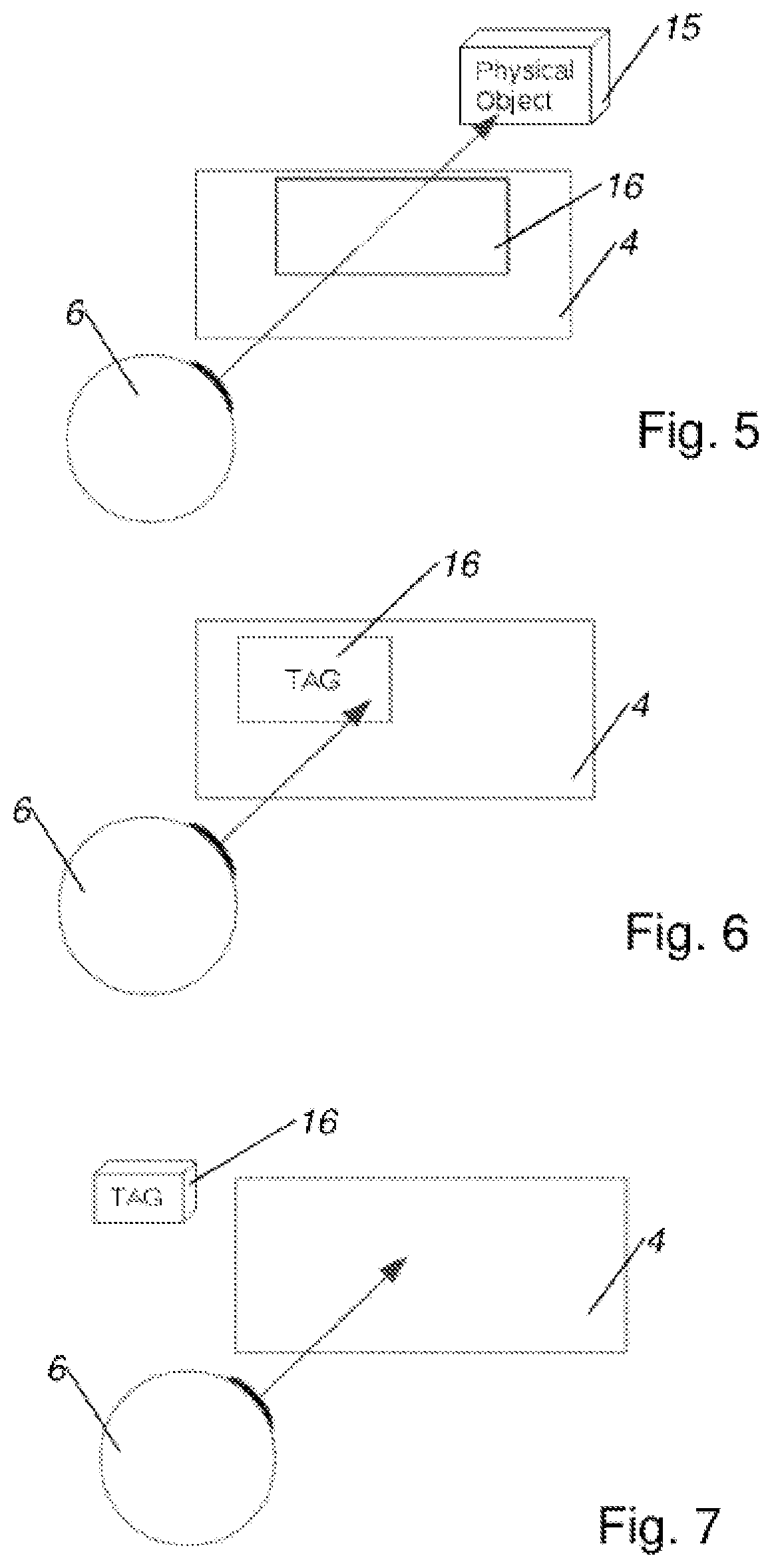

Authentication of security documents, in particular of banknotes

ActiveUS8781204B2Robust and efficient differentiationSimple wayImage analysisPaper-money testing devicesSample imageMinutiae

There is described a method for checking the authenticity of security documents, in particular banknotes, wherein authentic security documents comprise security features printed, applied or otherwise provided on the security documents, which security features comprise characteristic visual features intrinsic to the processes used for producing the security documents. The method comprises the steps of (i) acquiring a sample image of at least one region of interest of the surface of a candidate document to be authenticated, which region of interest encompasses at least part of the security features, (ii) digitally processing the sample image by performing a decomposition of the sample image into at least one scale sub-space containing high resolution details of the sample image and extracting classifying features from the scale sub-space, and (iii) deriving an authenticity rating of the candidate document based on the extracted classifying features.

Owner:KBA NOTASYS SA

Method and user equipment for carrier aggregation

ActiveUS9077601B2Save consumptionSaving of sizeTransmission path divisionAmplitude-modulated carrier systemsCarrier signalFourier transform on finite groups

User equipment is provided for receiving an OFDM signal. The user equipment includes a plurality of carrier processing chains and a carrier aggregation module, aggregating the signals received on each carrier processed by the plurality of carrier processing chains. The aggregation module delivers a set of aggregated signals of the plurality of carrier processing chains at the input of a Fast Fourier Transform module of a PHY layer processing subsystem of the user equipment. The Fast Fourier transform module is able to process a size of data according to a predetermined rate depending on the aggregated bandwidth of the set of aggregated signals of the plurality of carrier processing chains, and the carrier aggregation module includes at least one frequency shifter for frequency shifting carriers.

Owner:SEQUANS COMMUNICATIONS

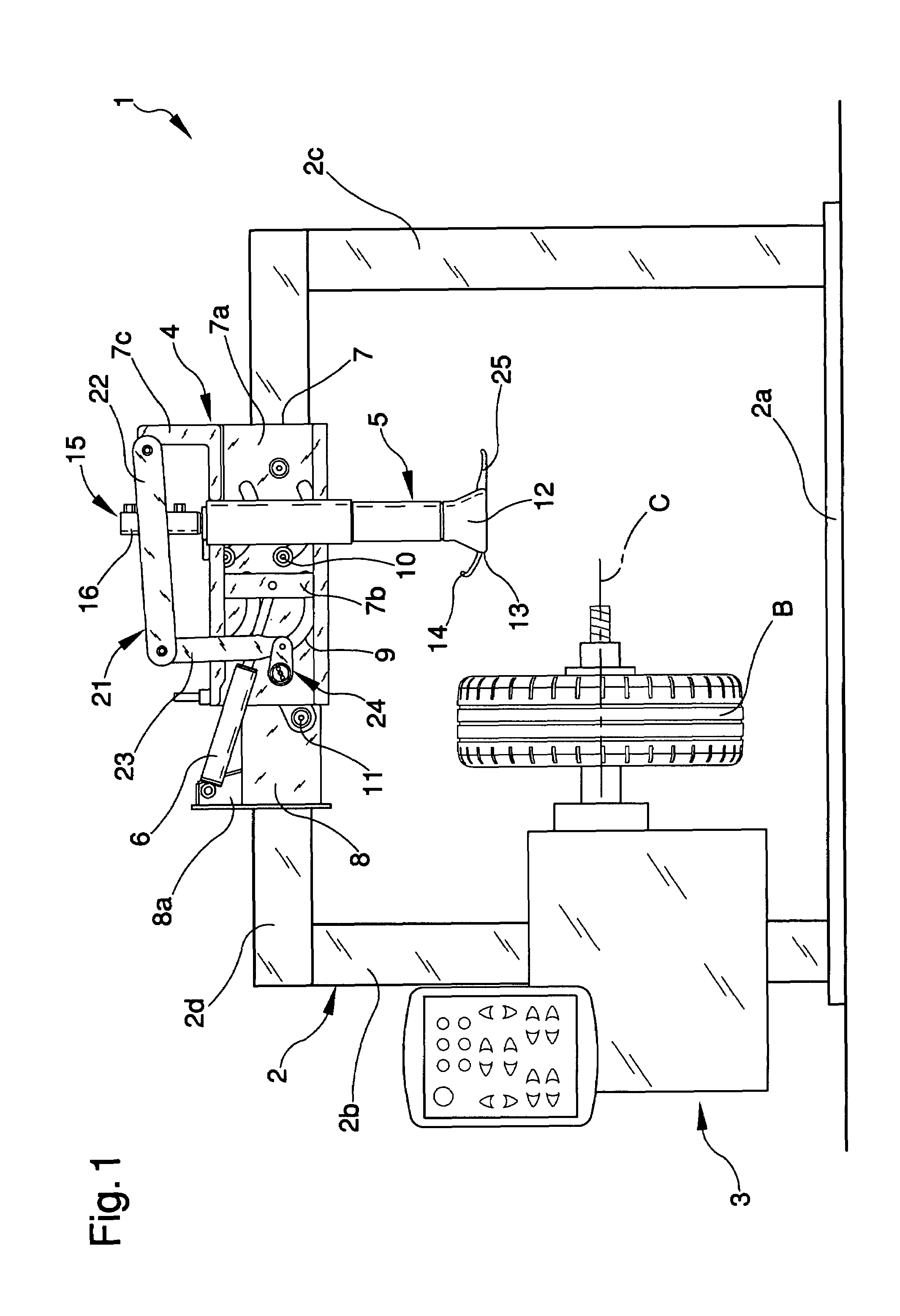

Lifting device for fitting vehicle wheels on wheel balancers

ActiveUS7337664B2Easy and functionalSimple methodStatic/dynamic balance measurementMobile jacksBalance shaftEngineering

Lifting device for fitting vehicle wheels on wheel balancers, comprising a support platform for at least one vehicle wheel to be fitted on / removed from the substantially horizontal balancing shaft of a wheel balancer, a jack for lifting or elevating said platform, and grooves and side appendices on said platform that enable the platform to slide relative to a base in a substantially parallel direction to said balancing shaft, a first and second jaw on said platform, and an actuator for translating one jaw relative to the other jaw, so that the jaws engage opposite sides of the vehicle wheel and retain same in a vertical orientation on the support platform. The actuator is located below the support platform, and is connected to one of the jaws by a bracket which passes through a slot in the support platform.

Owner:SICAM SRL

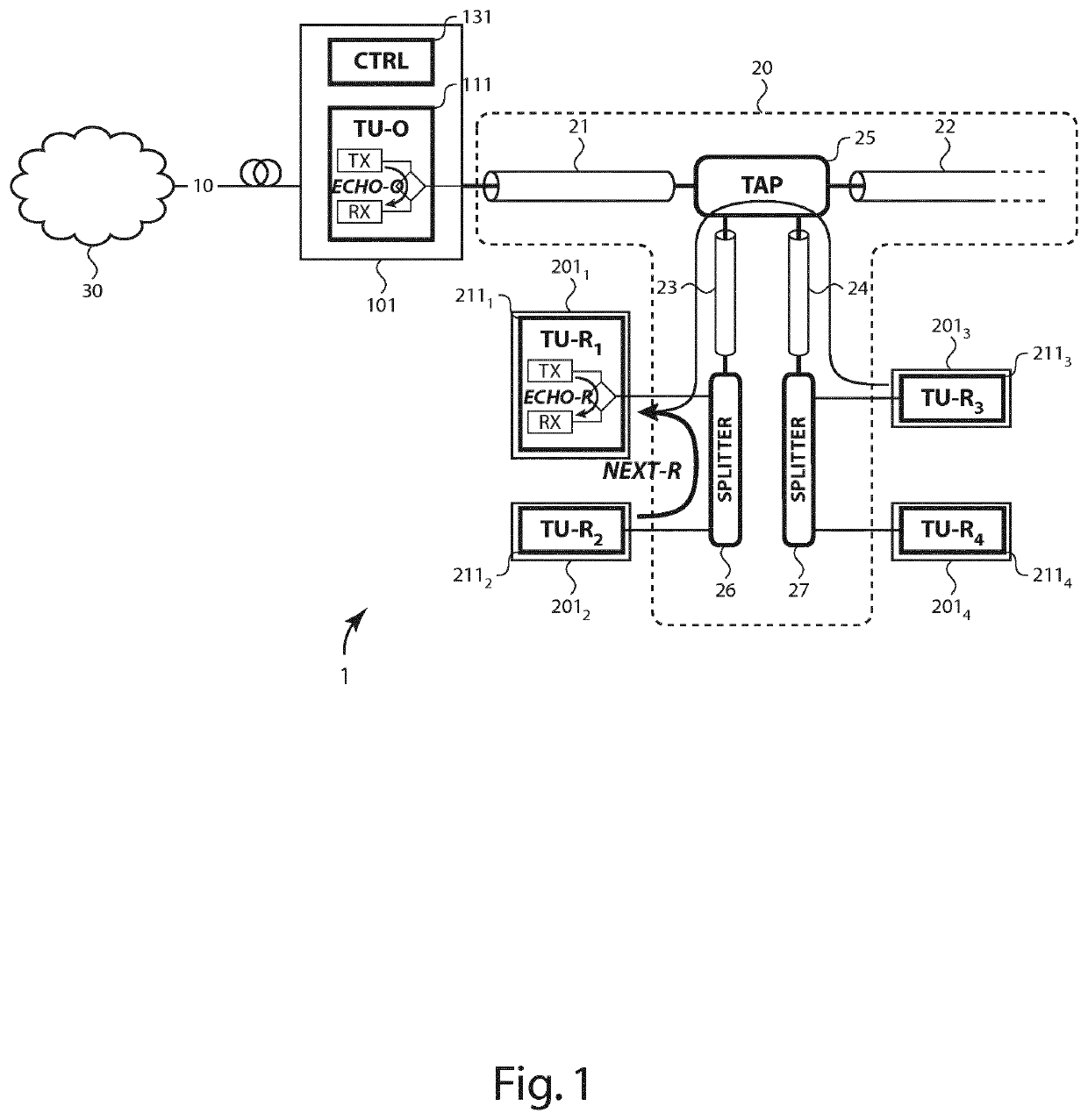

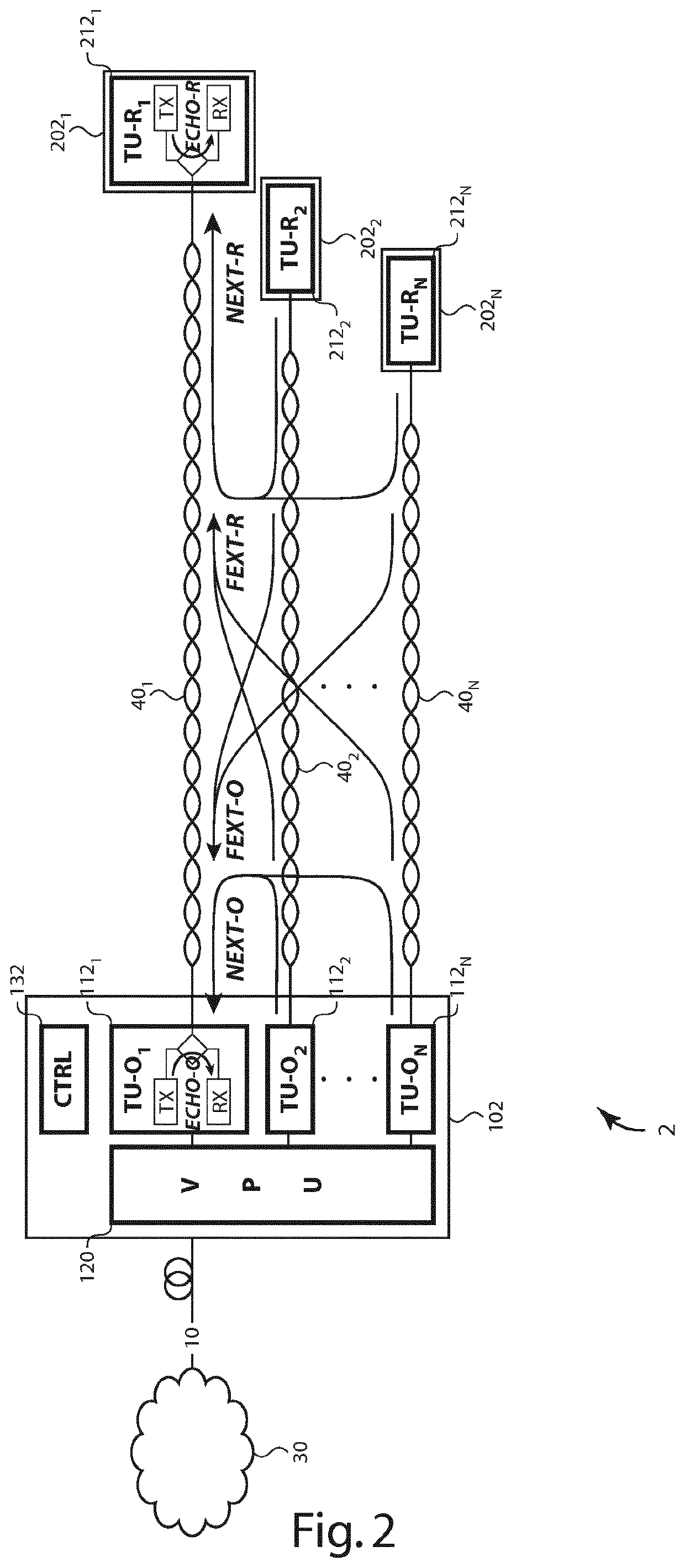

Method and Apparatus for Full-Duplex Communication over Wired Transmission Media

ActiveUS20210135707A1Improve performancePractical implementationCross-talk reductionTransmitter/receiver shaping networksComputer networkTelecommunications

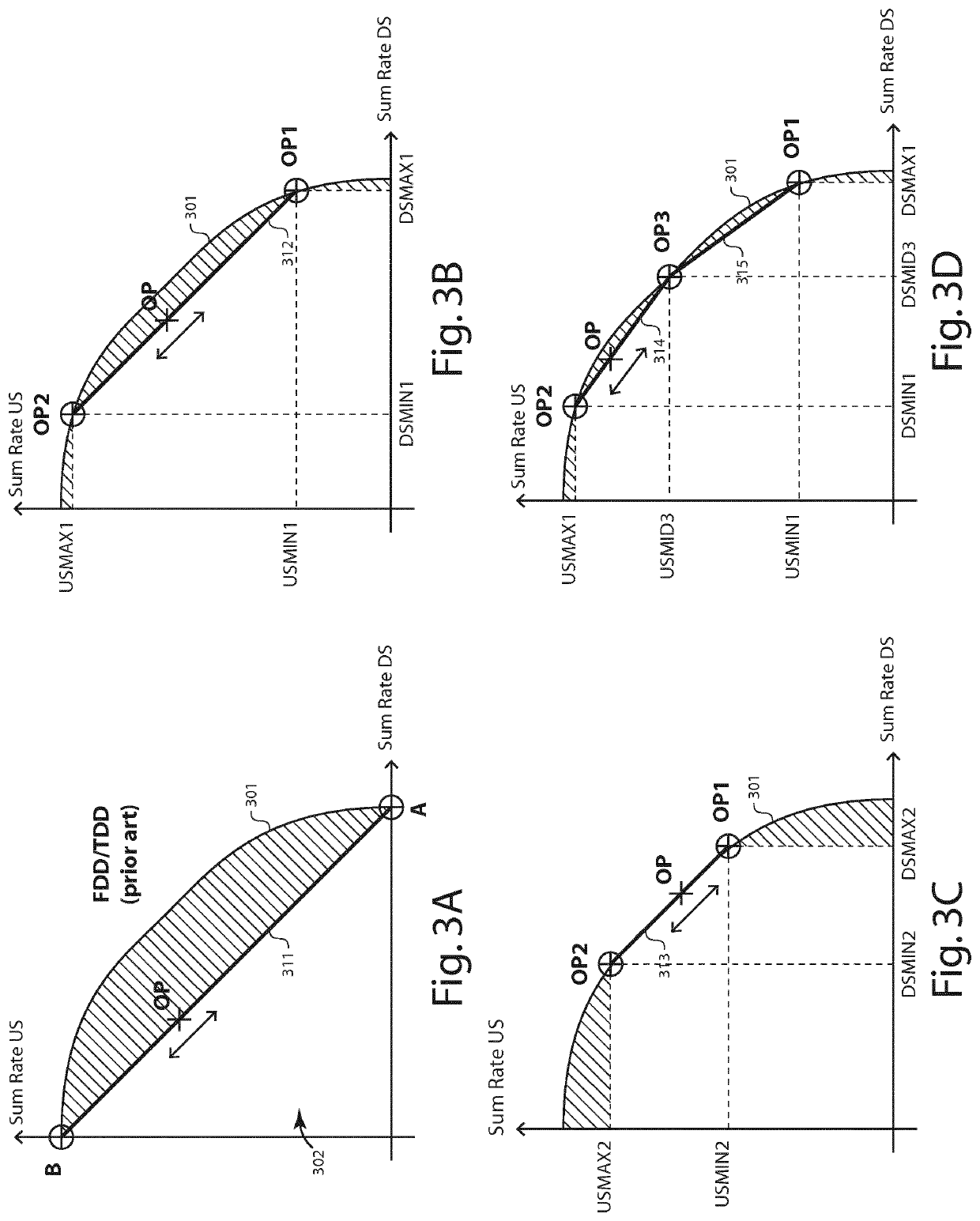

The present invention relates to a communication controller (131; 132) and method for controlling communications between an access node (101; 102) and a plurality of remote communication units (211; 212) coupled to the access node via at least one wired transmission medium (20; 40). At least one communication unit (111, 211; 112, 212) of the access node and of the plurality of remote communication units is configured to operate in full-duplex mode according to a first full-duplex communication profile (OP1) when using a first subset of transmission resources (TSSET1; TONESET1) selected from a whole set of transmission resources available for communication over the at least one transmission medium, and according to a second full-duplex communication profile (OP2) when using a second non-overlapping subset of transmission resources (TSSET2; TONESET2) selected from the whole set of transmission resources. The first full-duplex communication profile includes first downstream and upstream transmit power profiles (PSDDS1, PSDUS1) to achieve first aggregate downstream and upstream data rates (DSMAX1, USMIN1; DSMAX2, USMIN2) over the at least one transmission medium, and the second full-duplex communication profile includes second downstream and upstream transmit power profiles (PSDDS2, PSDUS2) to achieve second aggregate downstream and upstream data rates (USMAX1, DSMIN1; USMAX2, DSMIN2) over the at least one transmission medium distinct from the respective first aggregate downstream and upstream data rates. The present invention also relates to a so-configured full-duplex communication unit

Owner:ALCATEL LUCENT SAS

Resist composition, patterning process, monomer, and copolymer

ActiveUS20130309606A1Satisfactory effect of suppressing acid diffusionHigh resolutionOrganic chemistryPhotosensitive materialsPolymer scienceMeth-

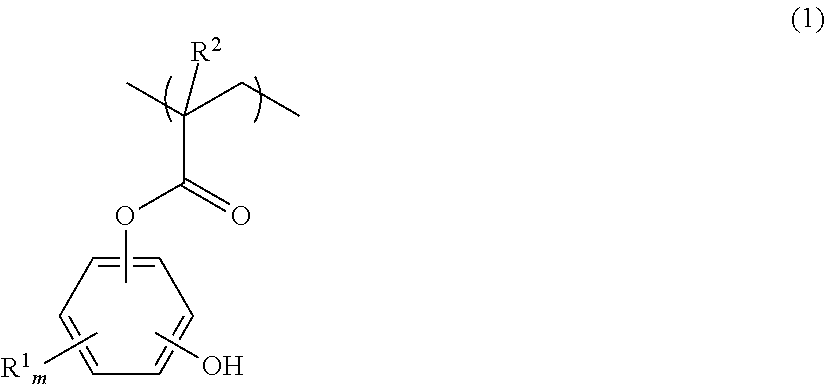

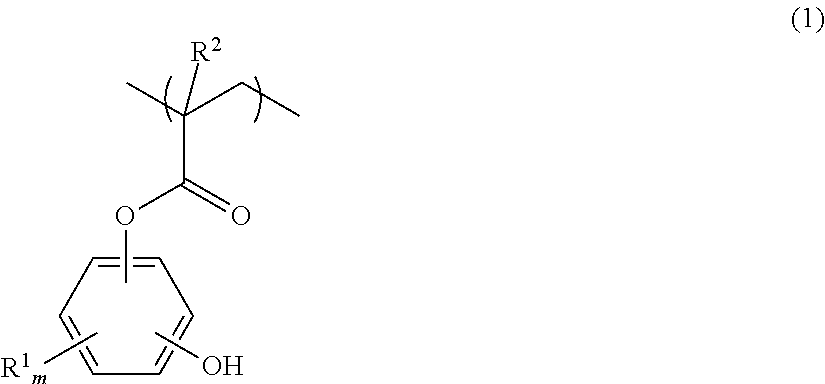

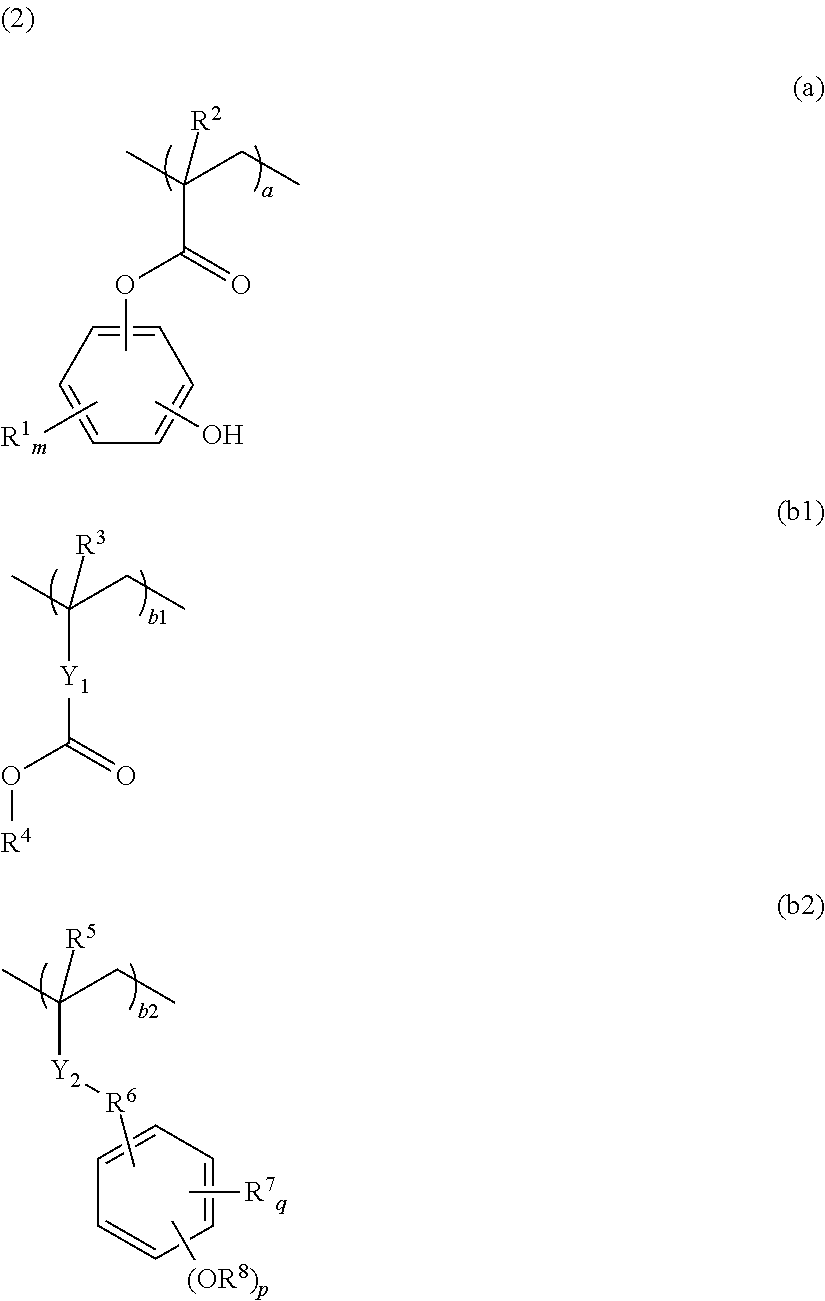

A polymer is obtained from copolymerization of a recurring unit having a carboxyl and / or phenolic hydroxyl group substituted with an acid labile group and a recurring unit having formula (1) wherein R1 is methyl, ethyl, propyl, methoxy, ethoxy or propoxy, R2 is H or CH3, and m is 1 to 4. The polymer is used as a base resin to formulate a resist composition, which is improved in contrast of alkali dissolution rate before and after exposure, acid diffusion control, resolution, and profile and edge roughness of a pattern after exposure.

Owner:SHIN ETSU CHEM IND CO LTD

Method and apparatus for detecting a watermark in a signal

InactiveUS20070286450A1Improve performanceImprove reliabilityTelevision system detailsPicture reproducers using cathode ray tubesComputer science

The invention relates to a system for detecting a watermark using informed detection. A first signal potentially having a watermark embedded is received (601) as is a second signal corresponding to the original signal. The signals are segmented (605) into symbol segments. For each symbol segment a first characteristic is determined (607) for a first section and a second characteristic is determined (609) for a second section in response to the first and second signals in those sections. Specifically, ratios between average envelopes are determined. Thus, the first and second characteristic is indicative of the variations of the envelope during a watermark symbol. A watermark symbol estimate is determined (611) from the first and second characteristic. A sequence of estimated watermark symbols is compared to reference watermark symbols and the presence of a watermark symbol is determined (615) depending on the comparison. The invention is particularly suitable for improved detection of a multiplicative watermark.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

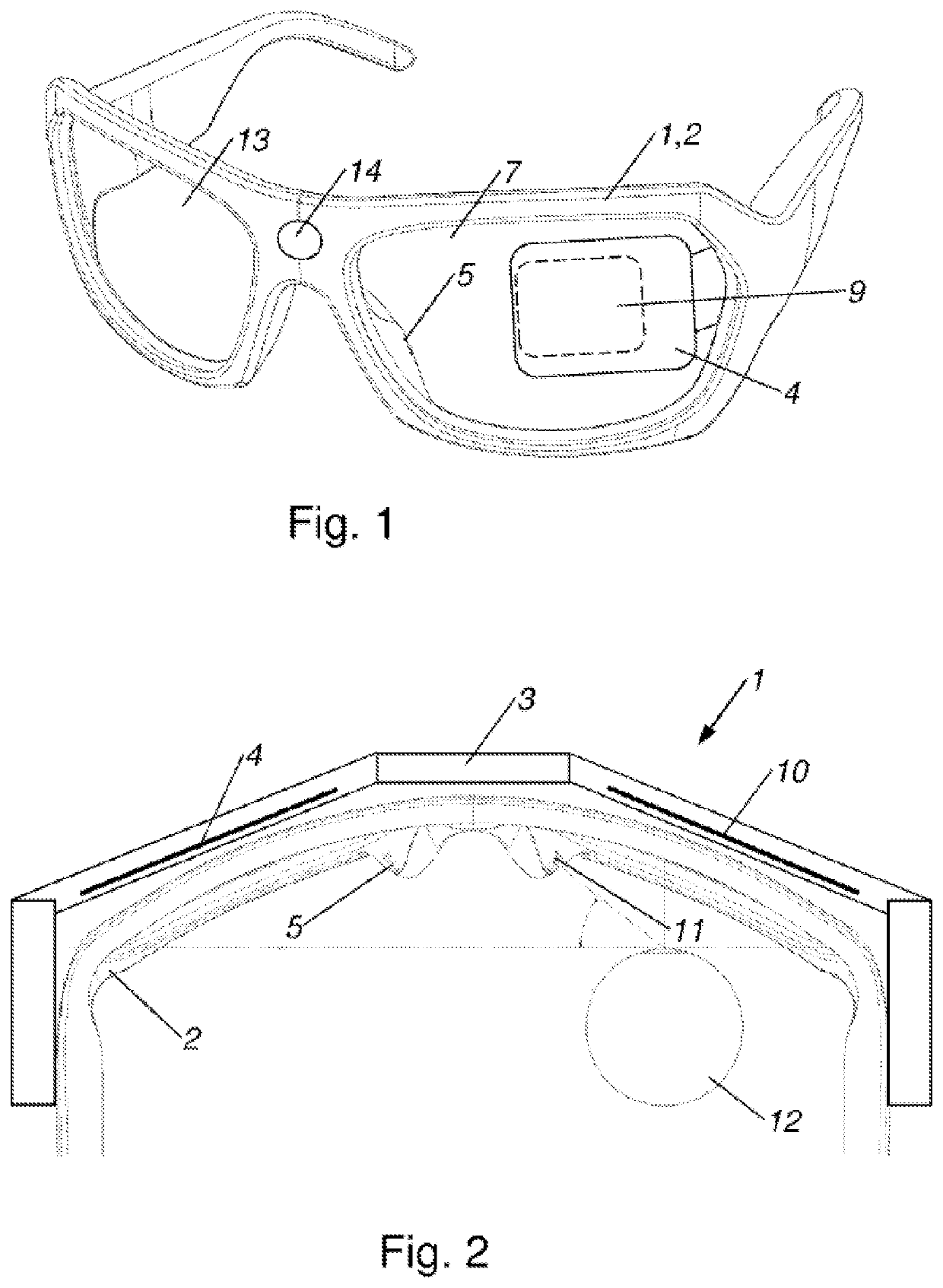

Method for generating and displaying a virtual object by an optical system

ActiveUS20220075187A1Accurate displayAdapted to an individual user quickly and easilyInput/output for user-computer interactionEye diagnosticsComputer graphics (images)Display device

The invention relates to a method for generating and displaying a virtual object to an individual user by an optical system consisting of gaze-tracking glasses and at least one display unit connected to the gaze-tracking glasses, the display unit having a first display, the gaze-tracking glasses having a first eye-tracking camera, the first display being arranged in a first viewing region of the gaze-tracking glasses. According to the invention, the optical system is adapted to an individual user, a first target value for adaptation of a display control unit of the display unit for controlling the first display being determined, a current viewing direction of the first eye being determined by the gaze-tracking glasses, a virtual object being generated and, taking account of the first target value, the virtual object being displayed in the first display at a position in the determined viewing direction of the first eye.

Owner:VIEWPOINTSYST GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com