Patents

Literature

66results about How to "Magnitude is large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

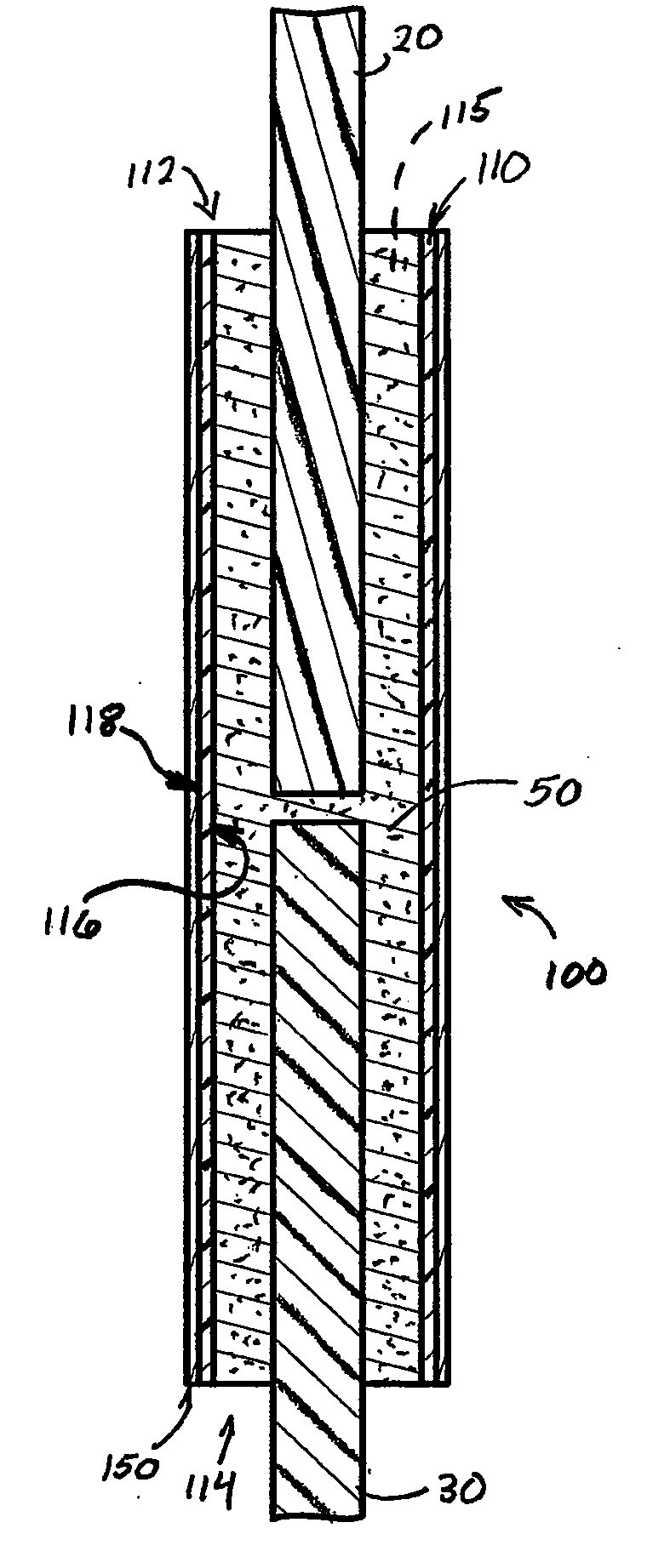

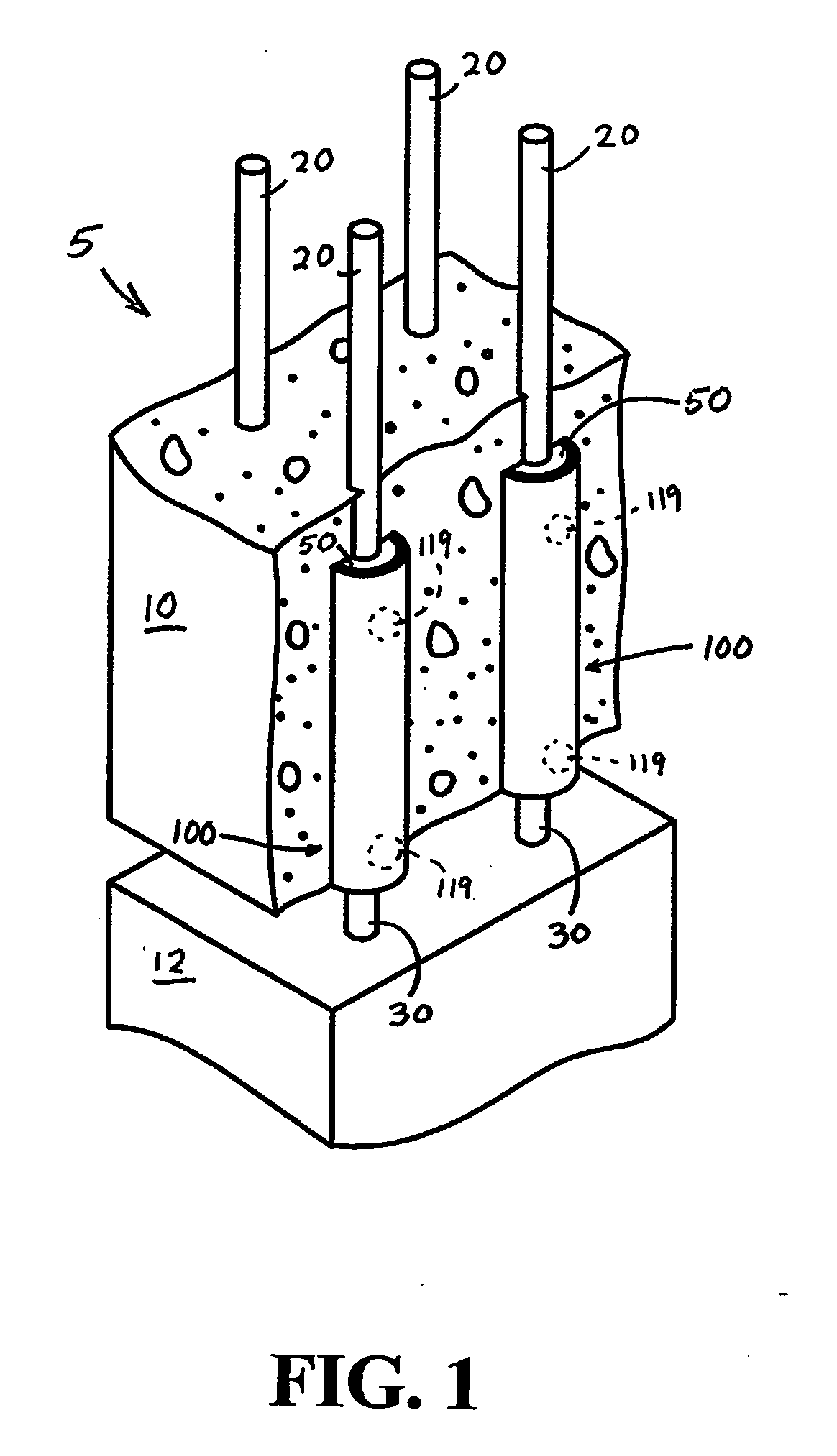

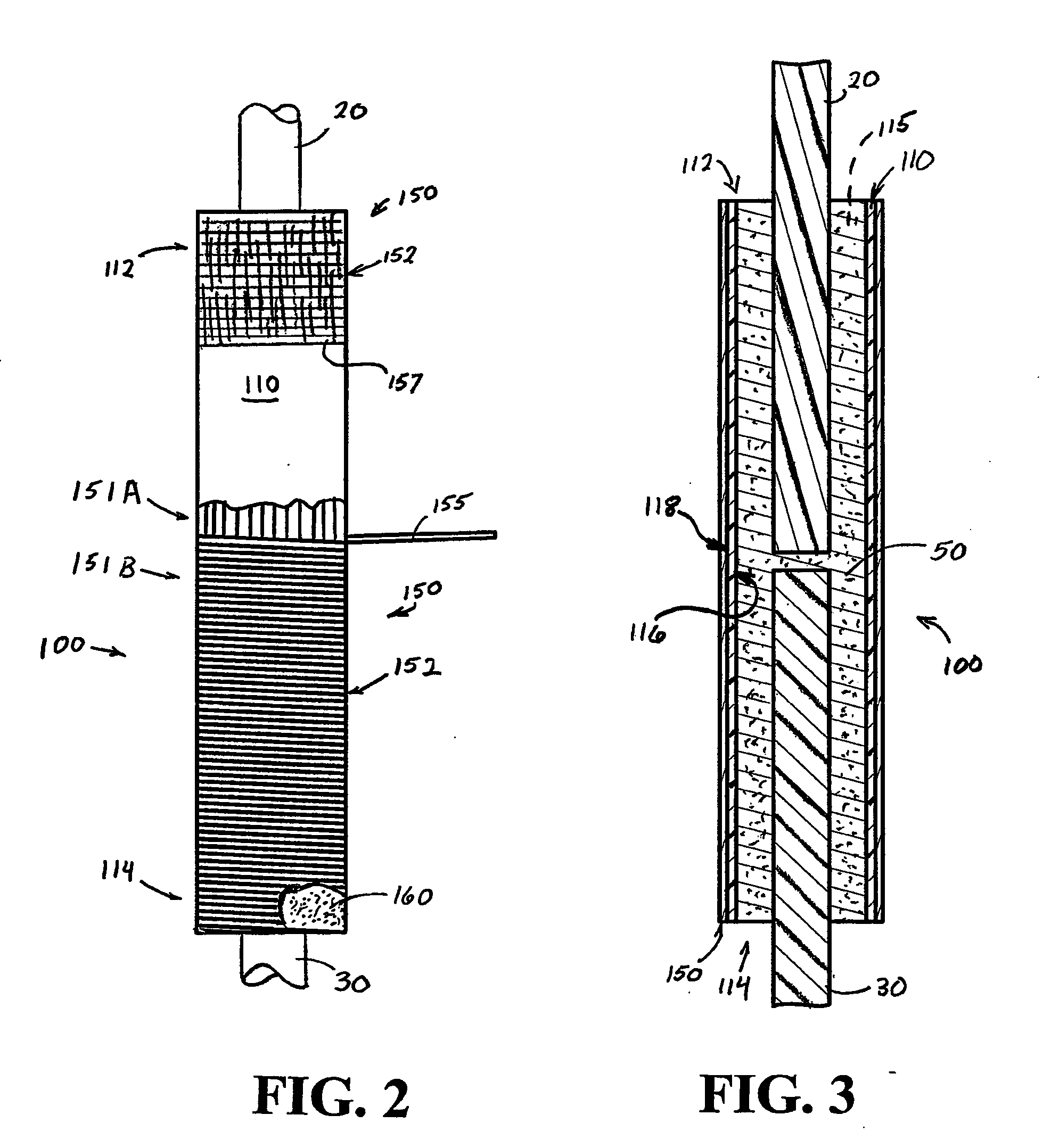

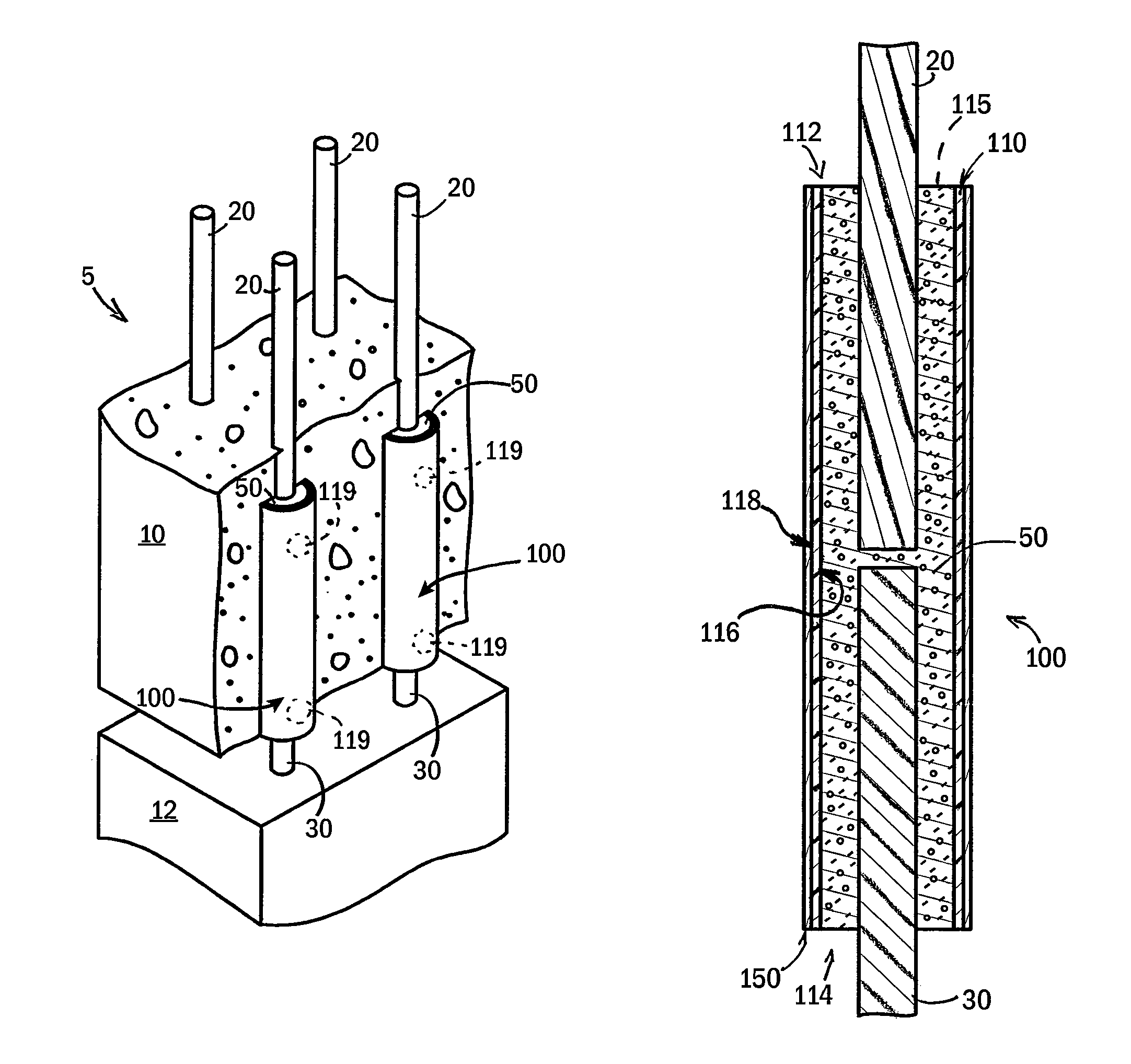

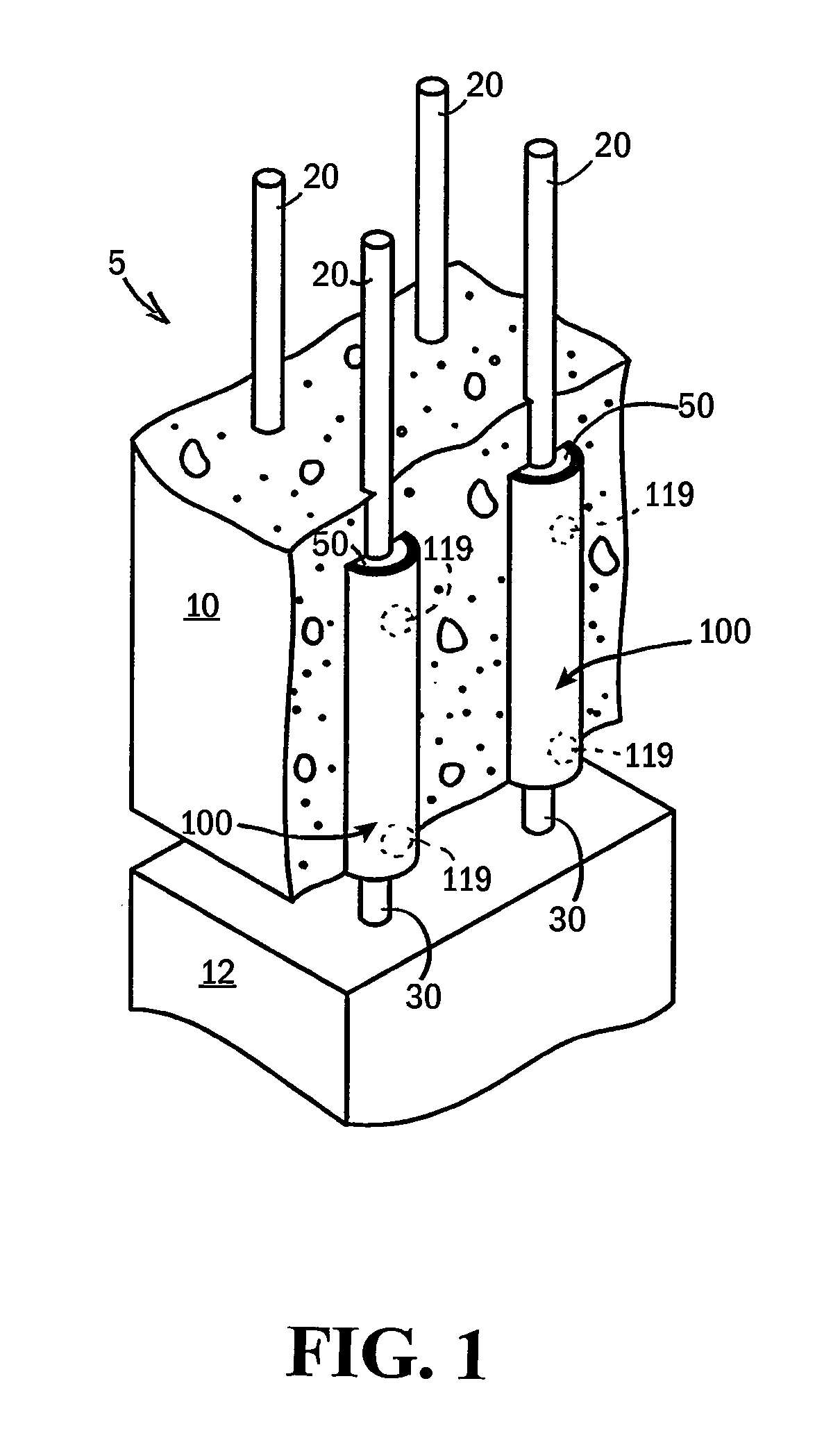

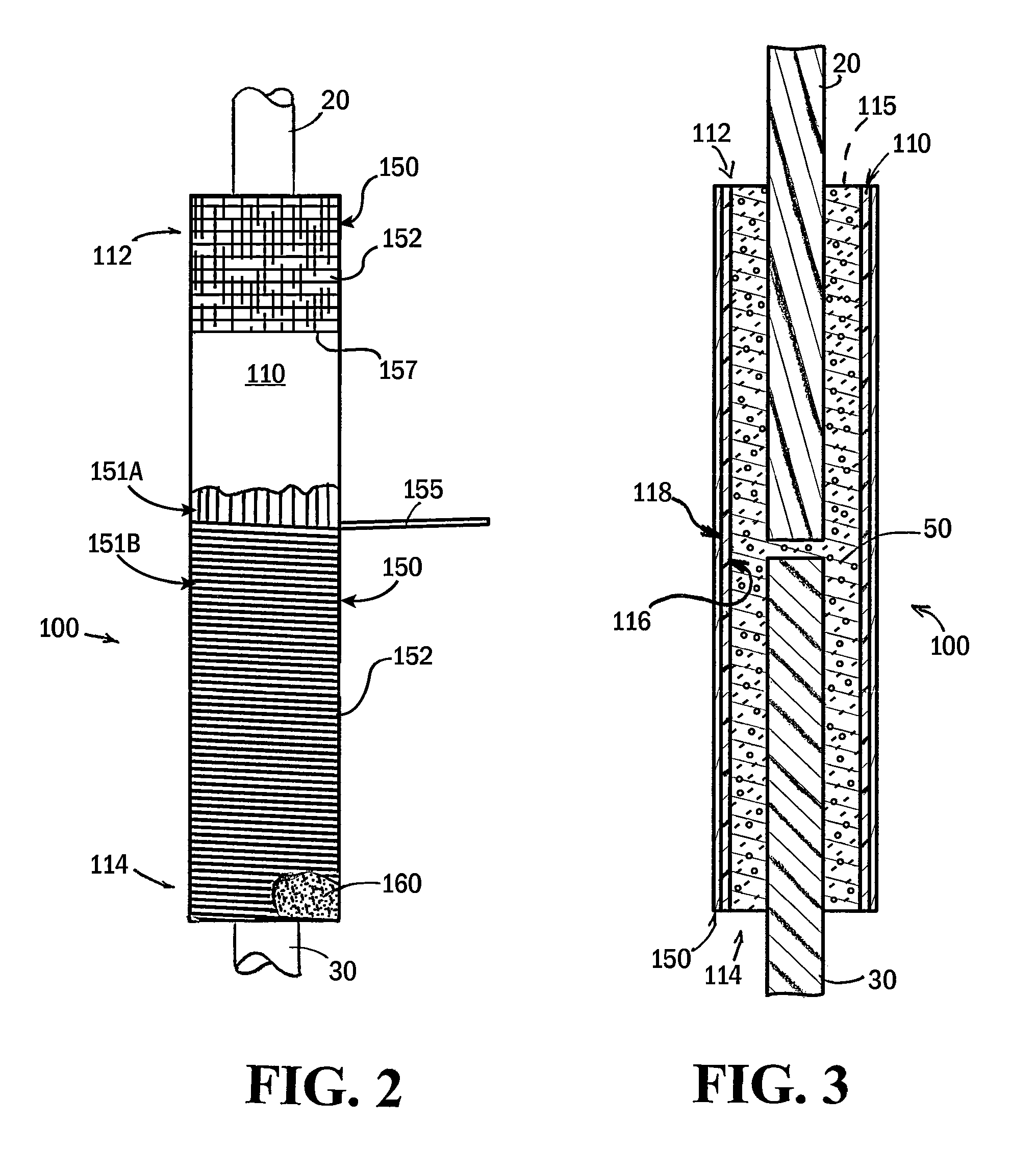

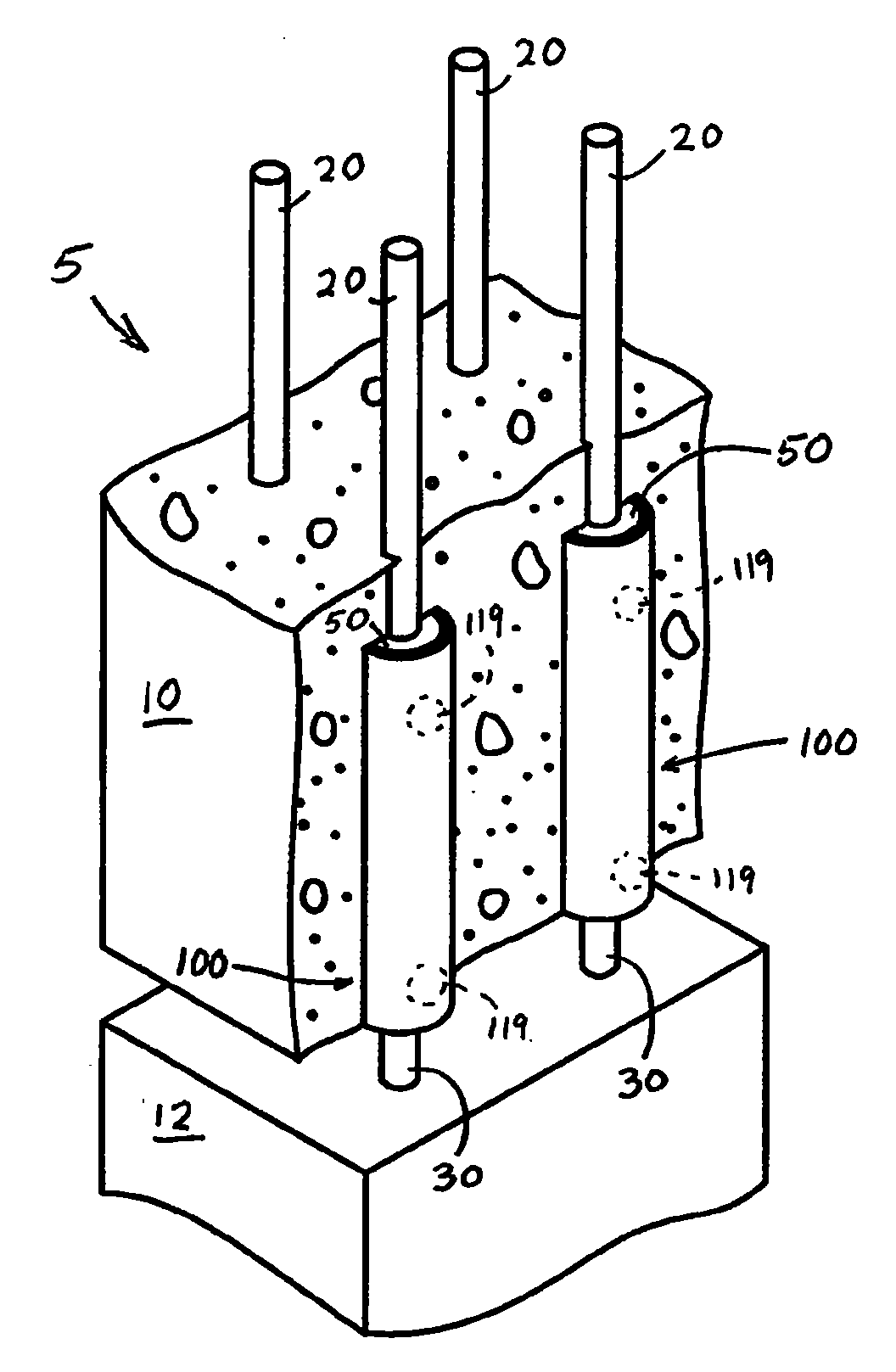

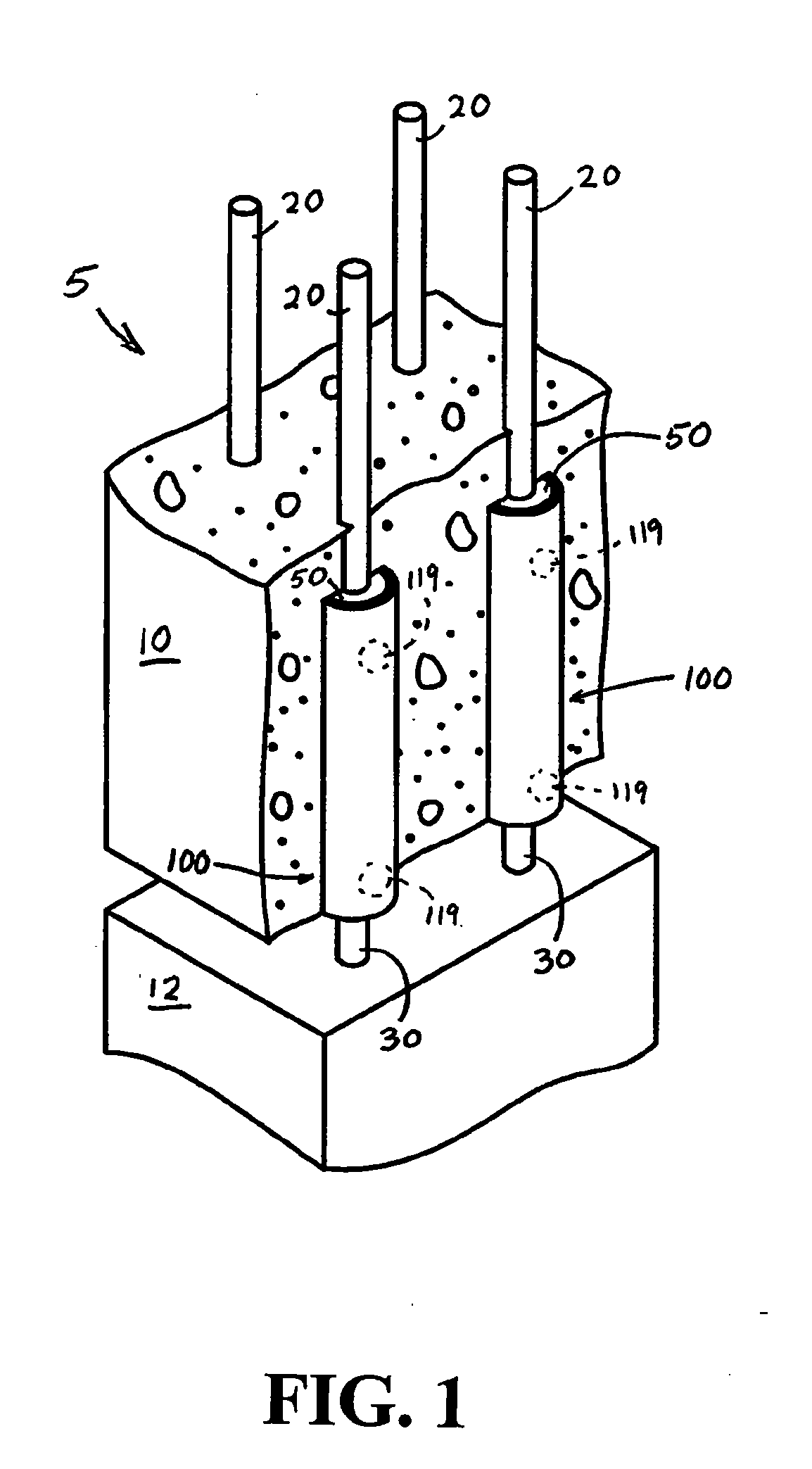

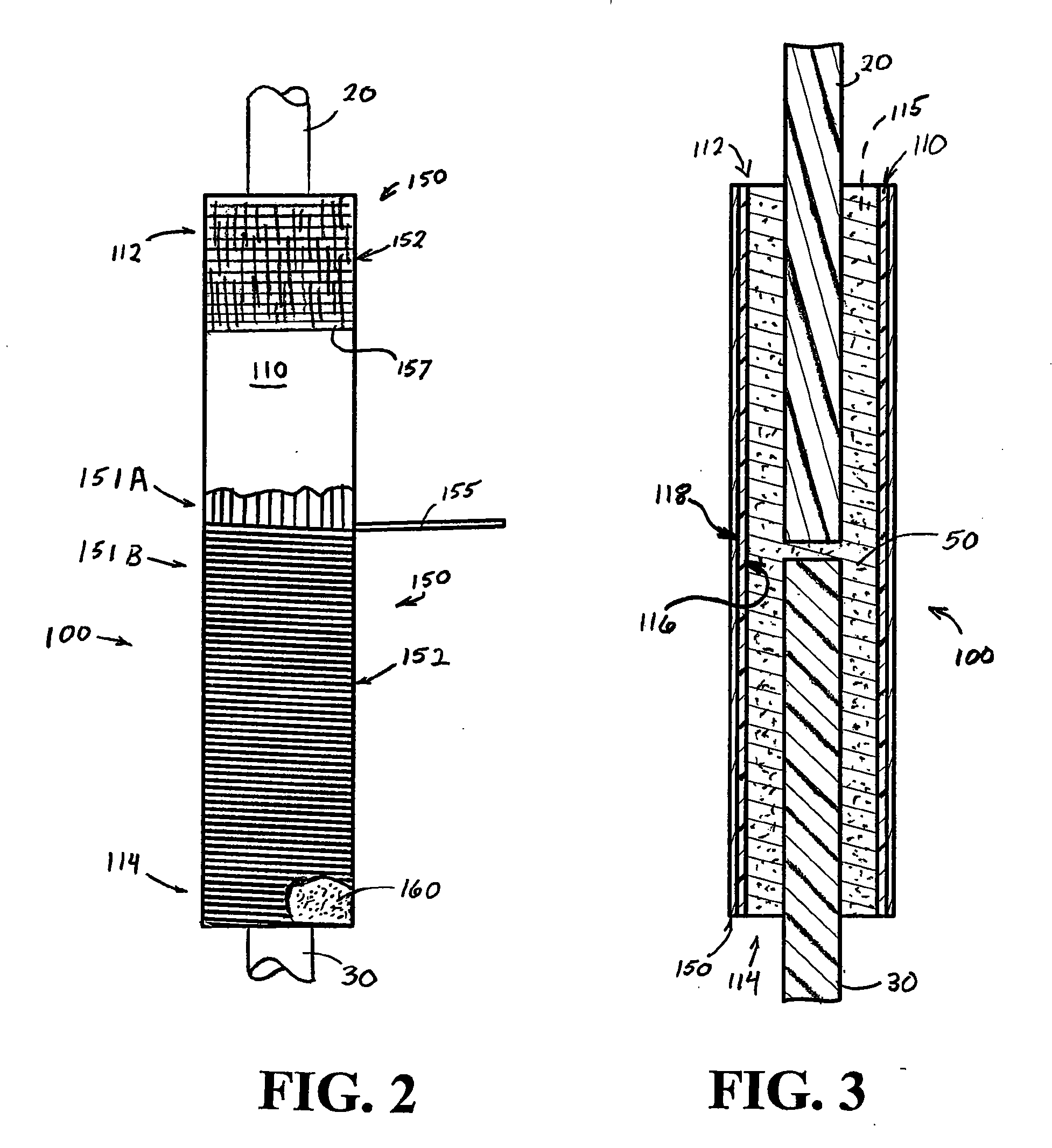

Splice System for Fiber-Reinforced Polymer Rebars

InactiveUS20100031607A1Highly corrosive environmentLong useful lifeRopes and cables for vehicles/pulleyBuilding repairsEngineeringRebar

A splice assembly and corresponding system for connecting multiple fiber-reinforced polymer rebars include a polymeric tube that is externally covered by a reinforcing layer to control radial expansion of grout within the polymeric tube and of the polymeric tube itself, and the polymeric tube may be internally provided with locking structures for mechanically interlocking with the grout, ensuring that the splice assembly functions as a unit for transferring loads from a first rebar, extending from a first end of the polymeric tube, to a second rebar, extending from a second end of the polymeric tube.

Owner:WISCONSIN ALUMNI RES FOUND

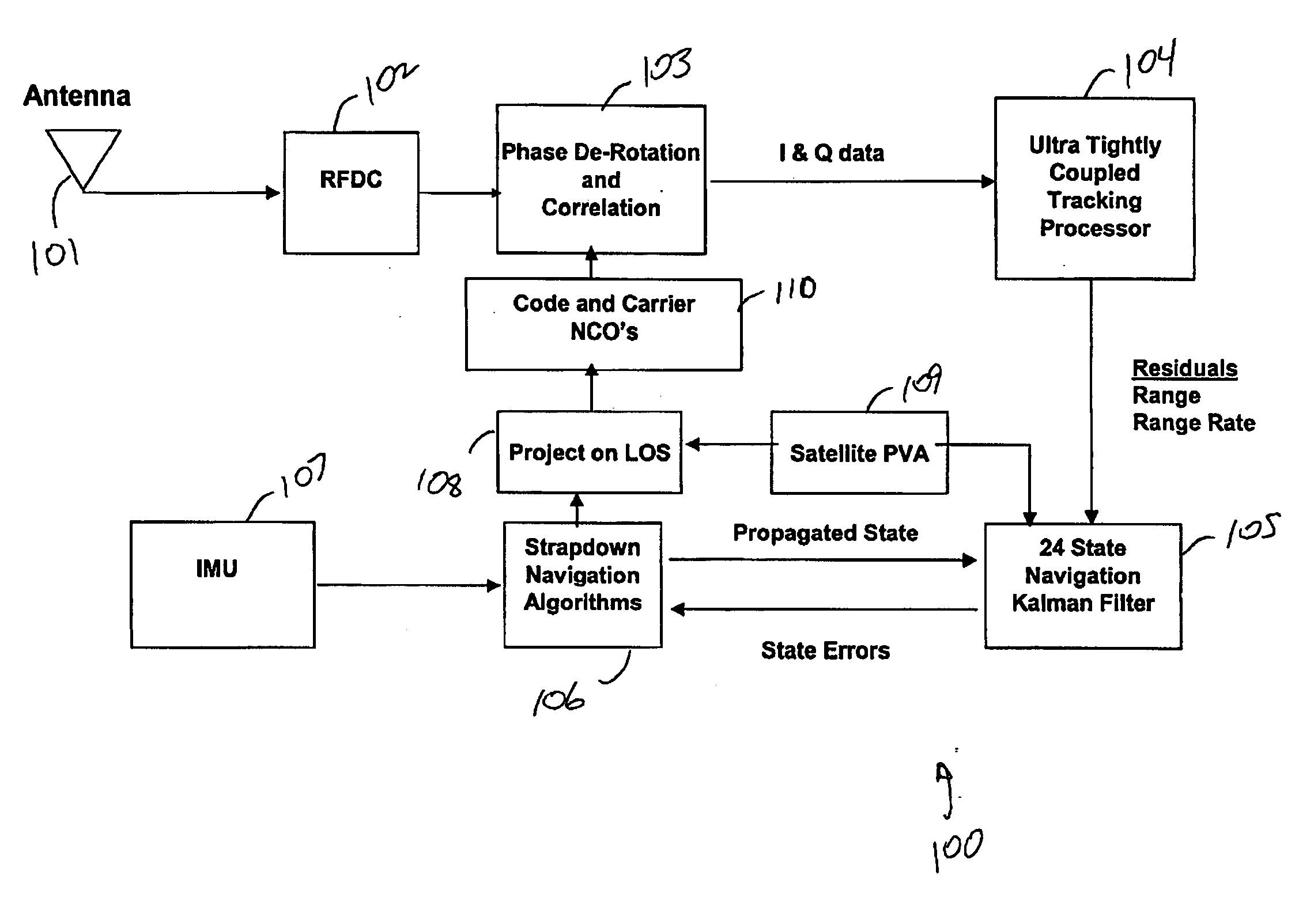

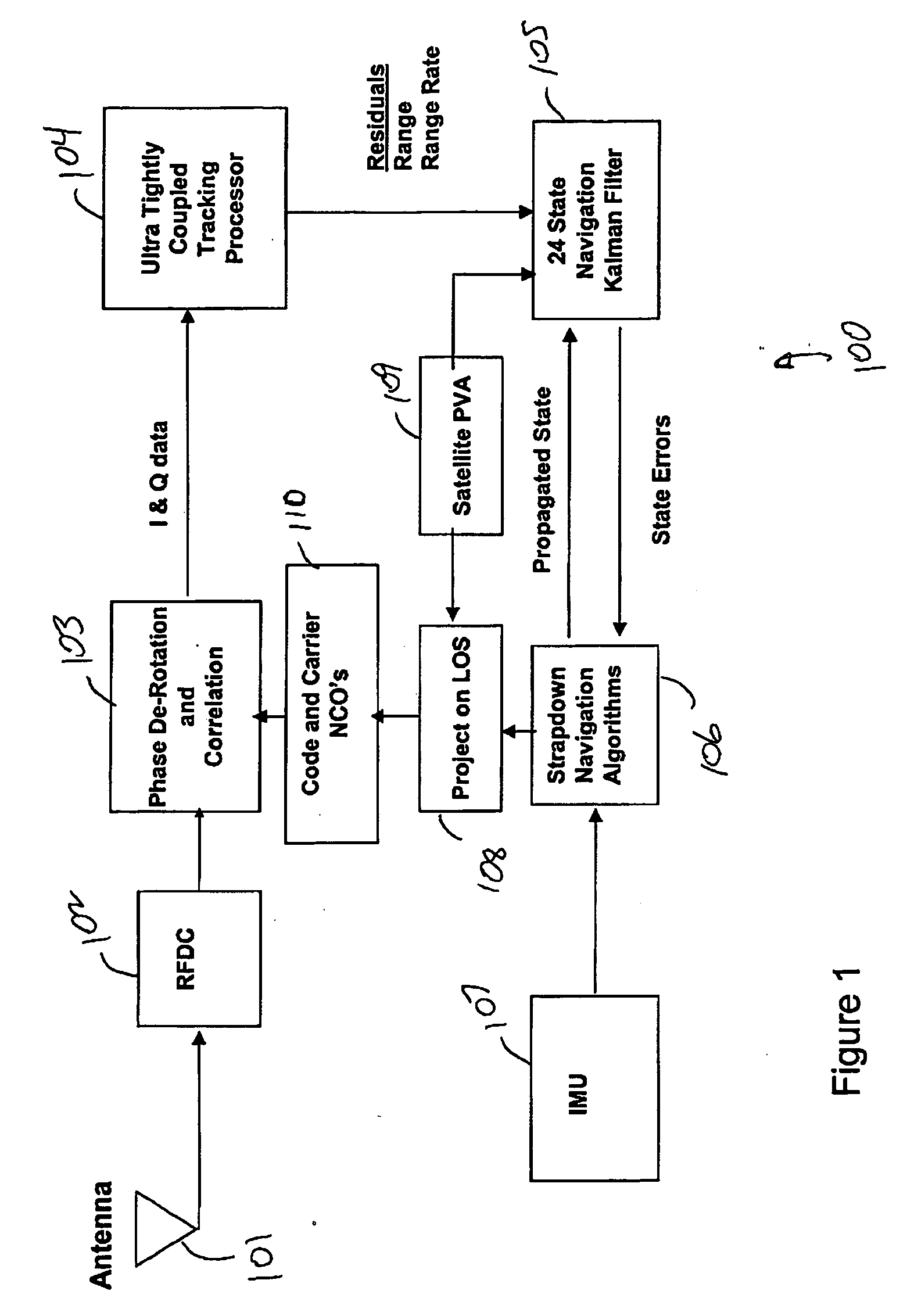

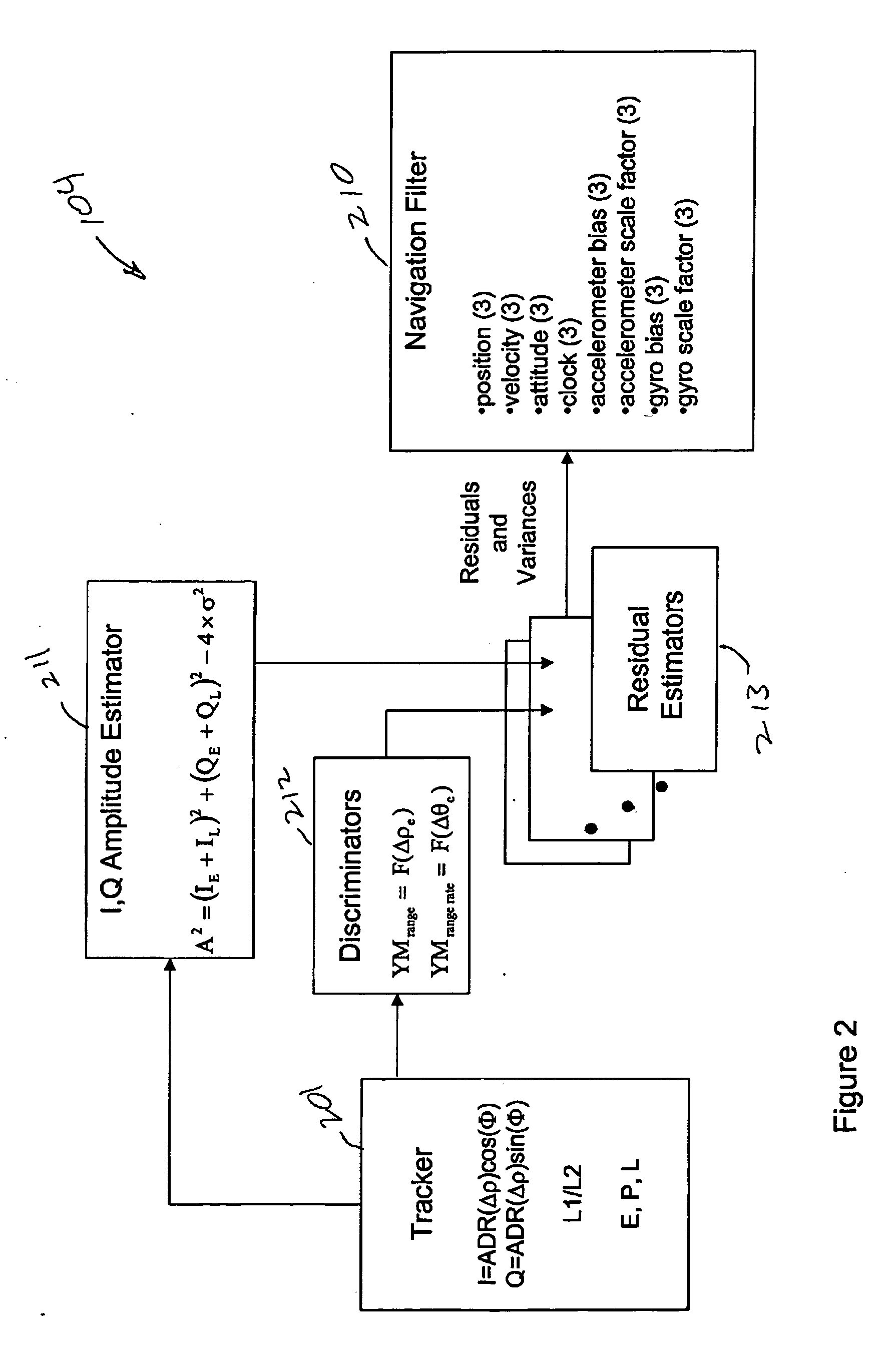

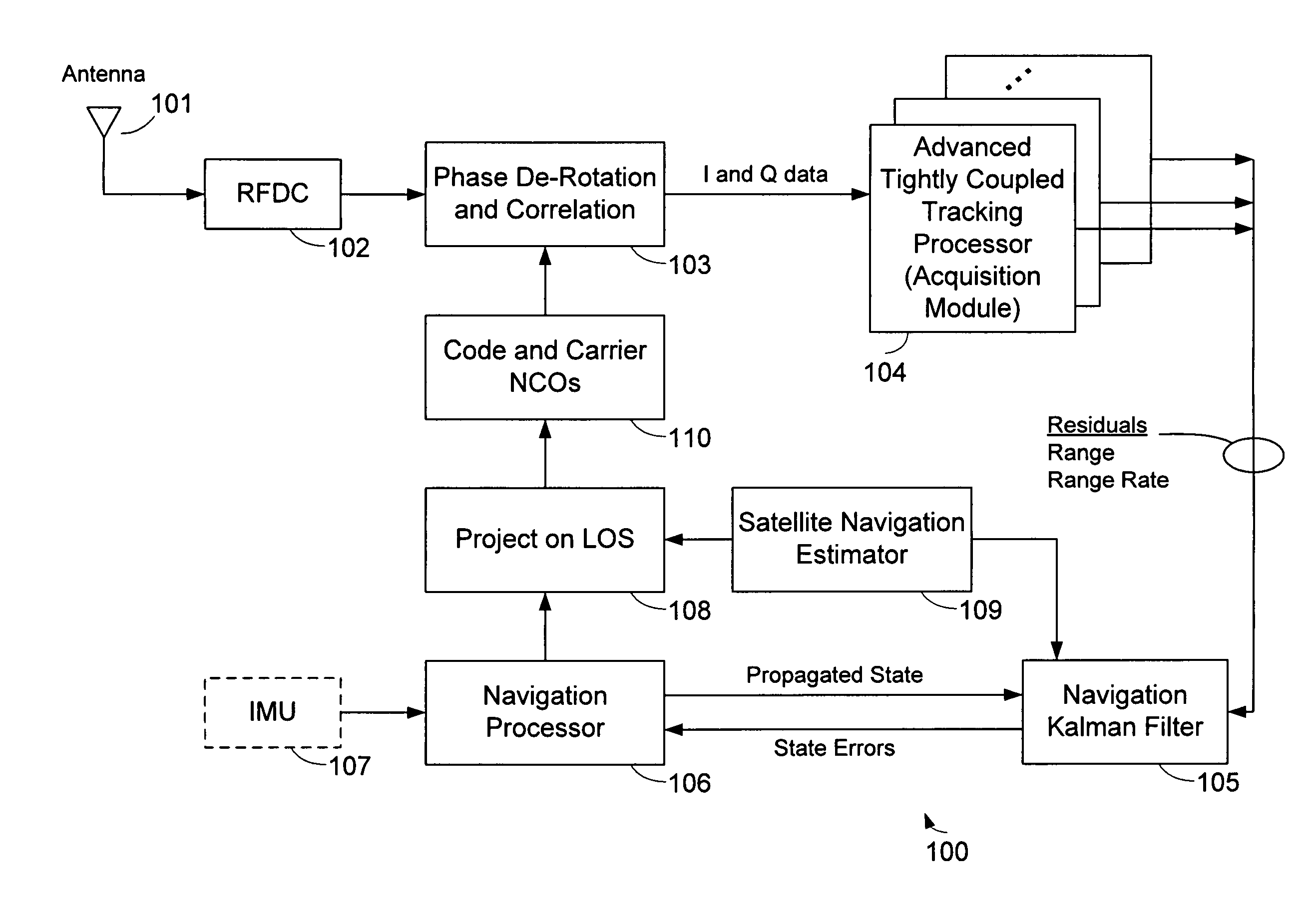

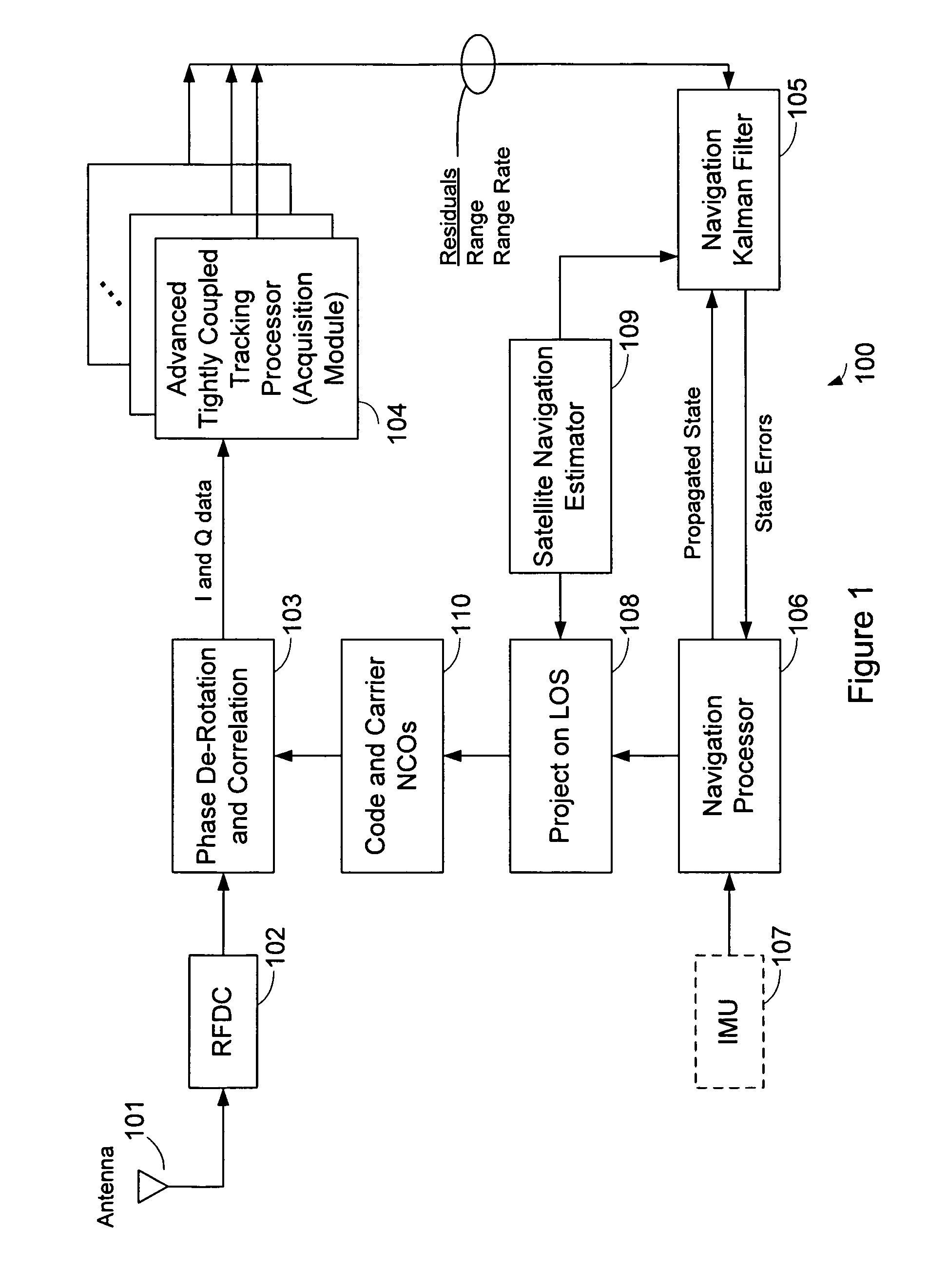

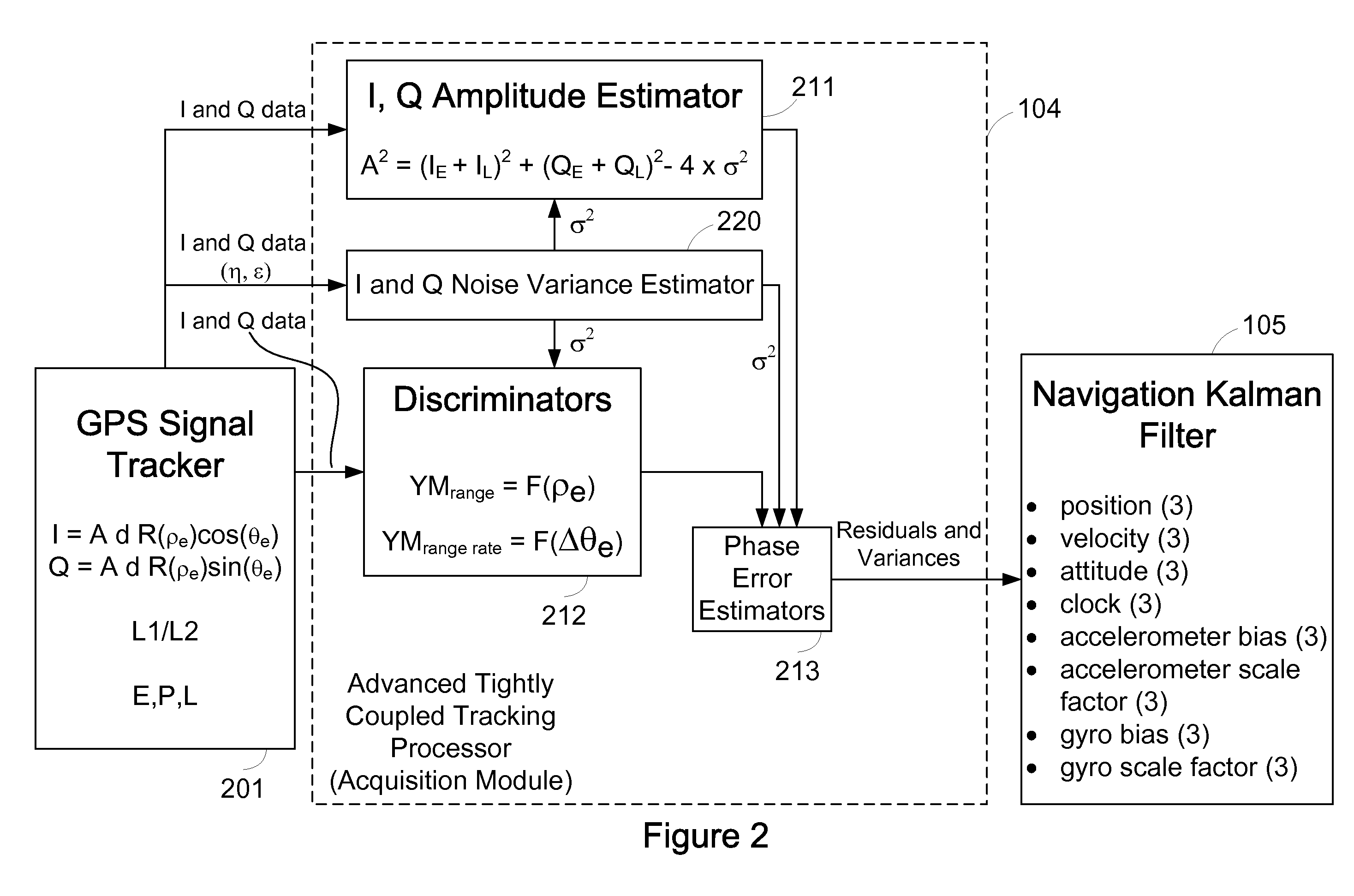

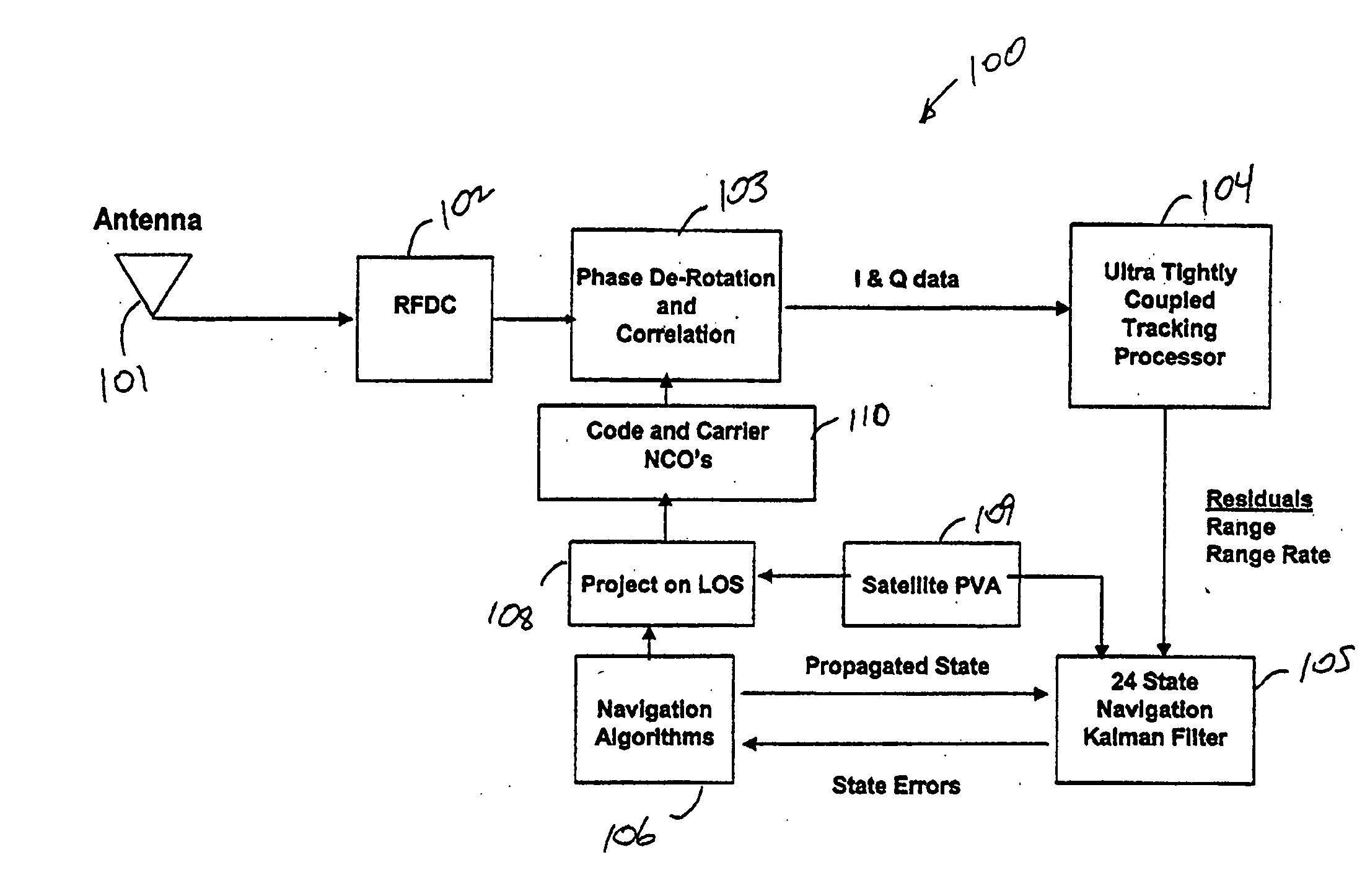

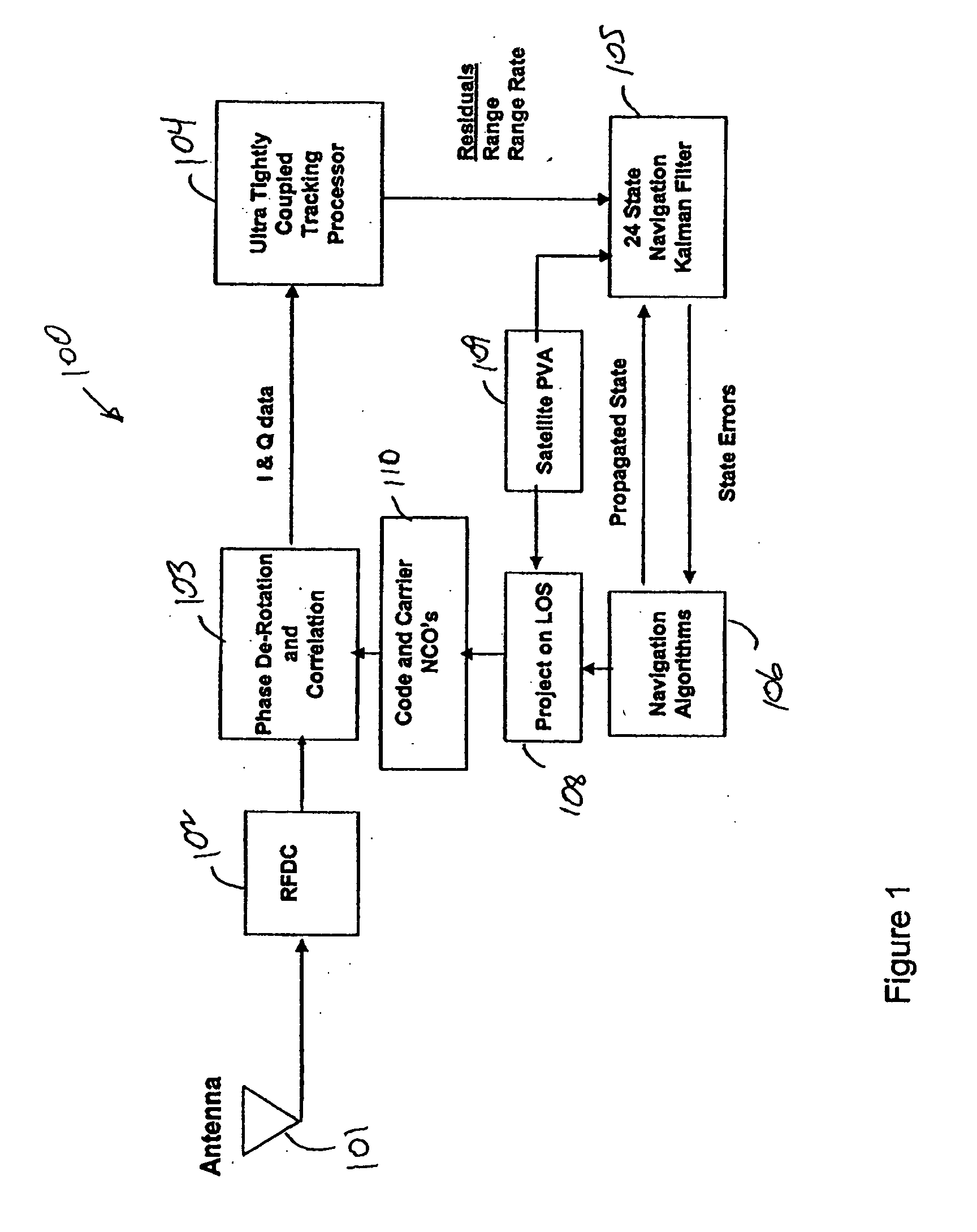

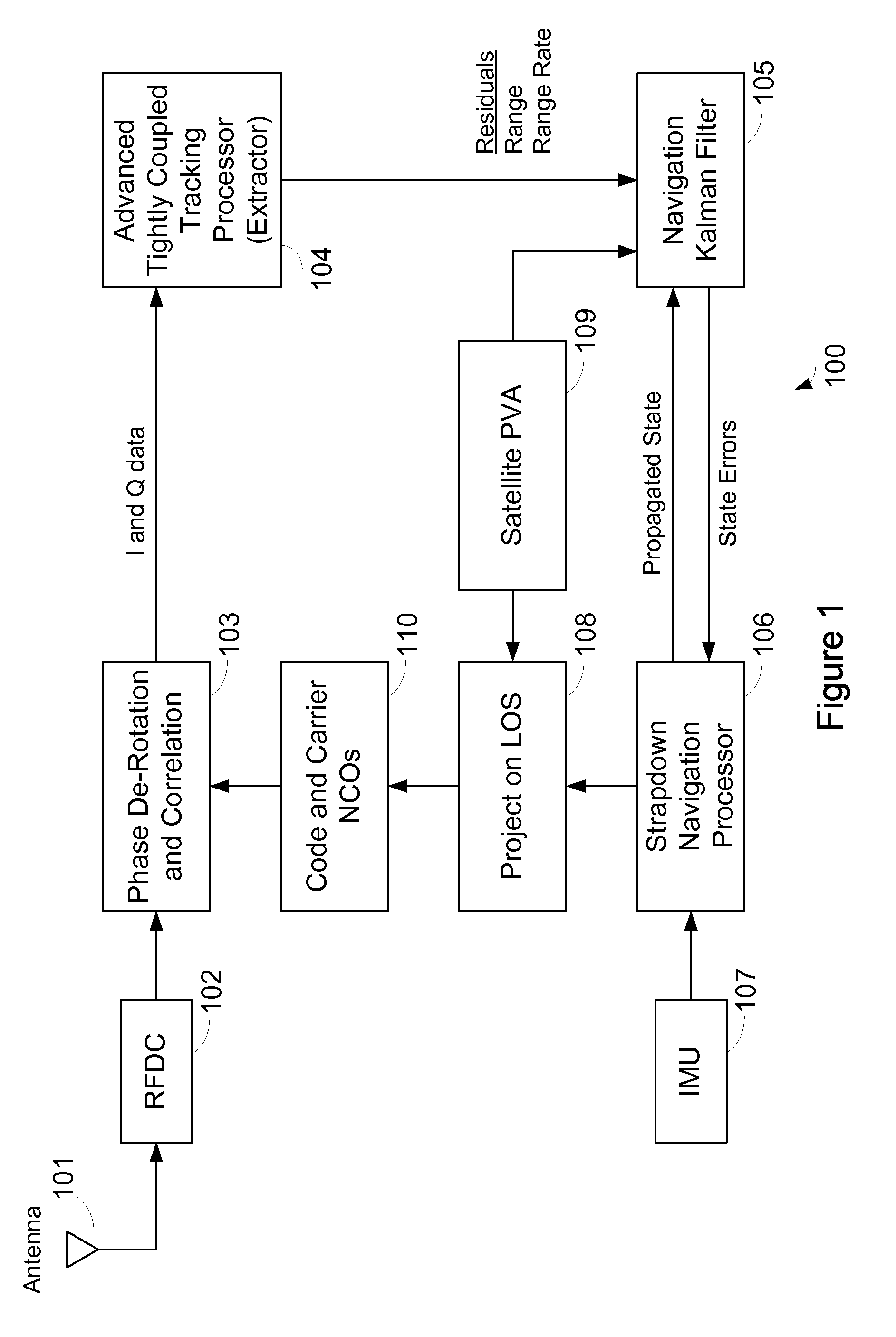

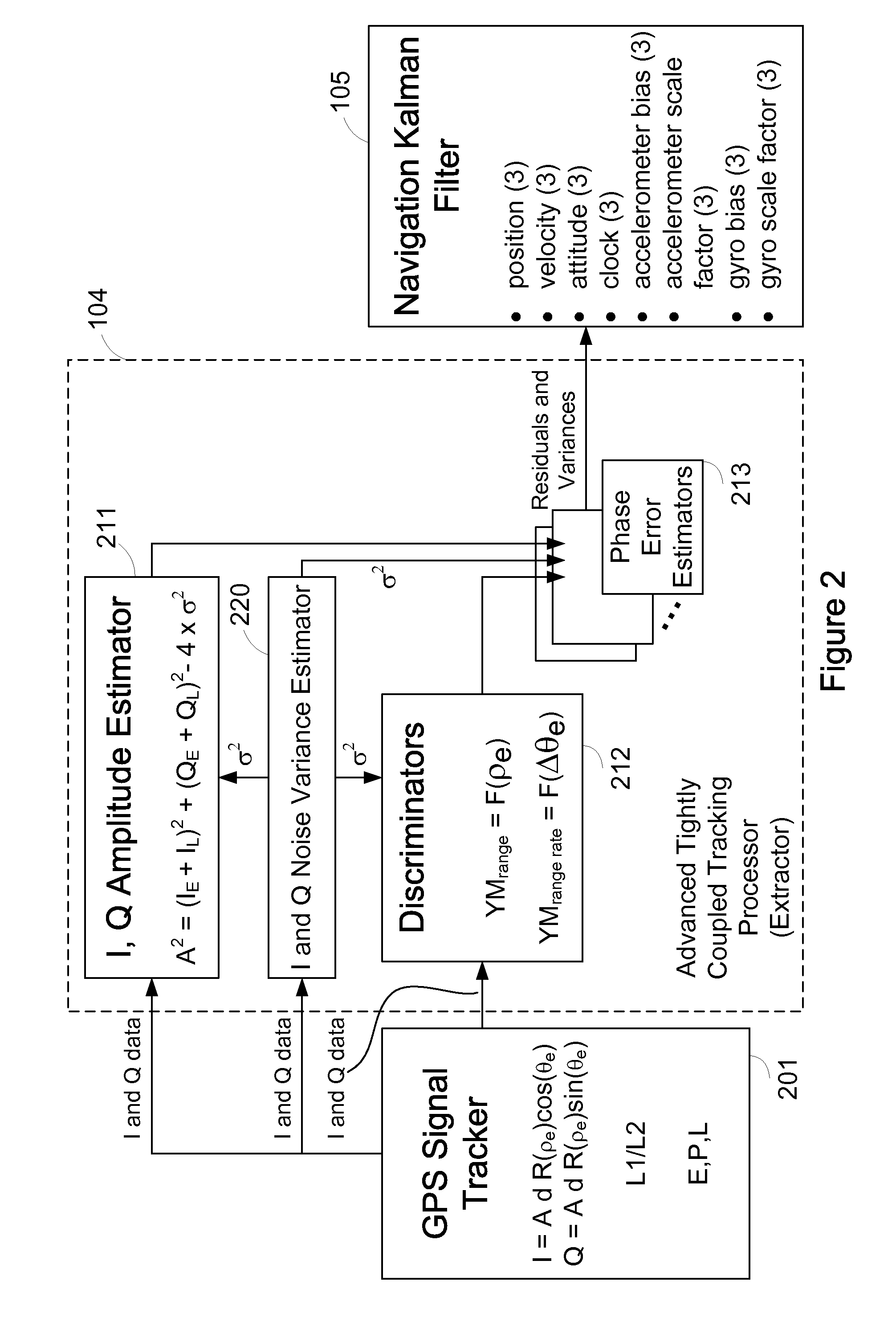

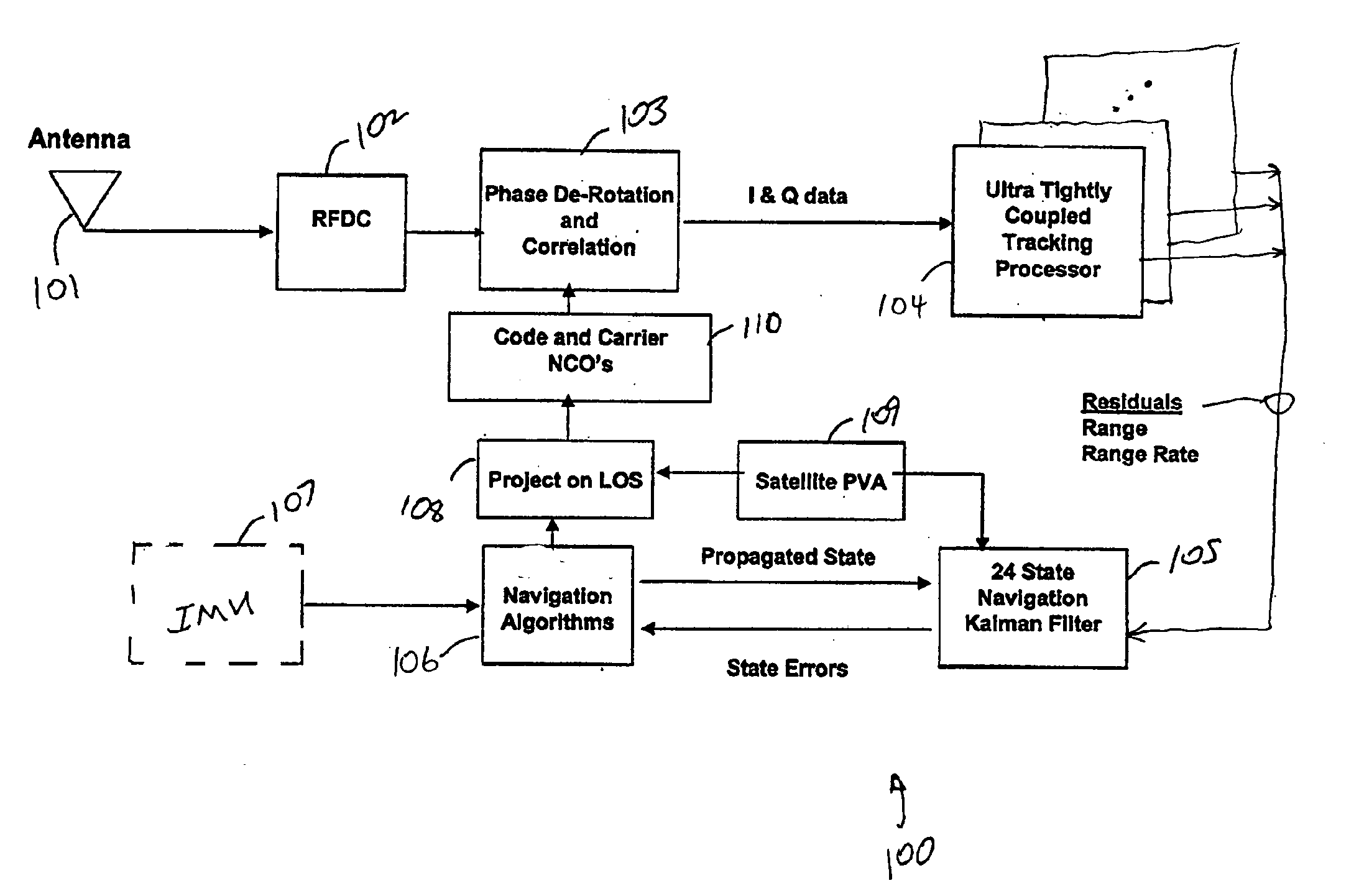

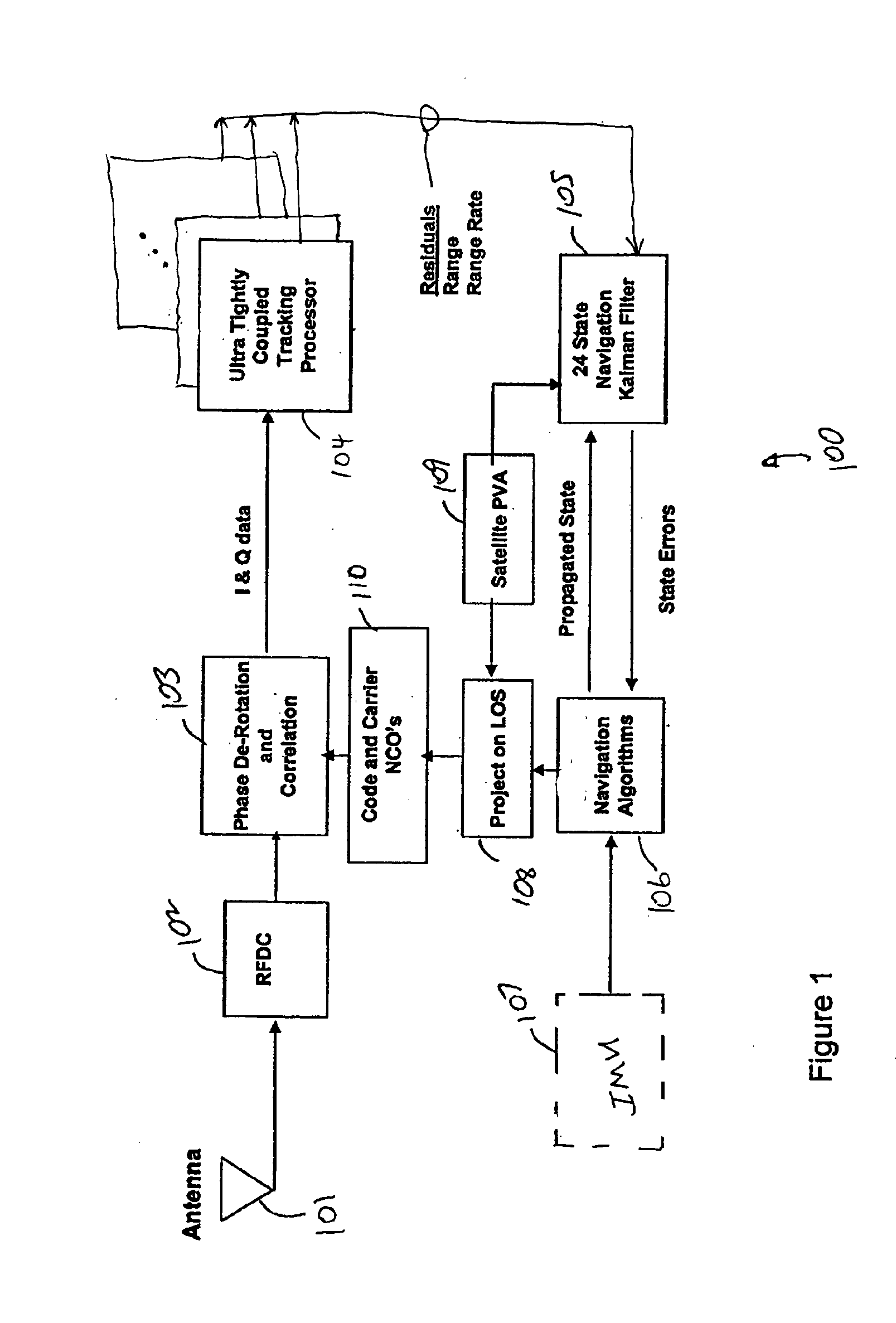

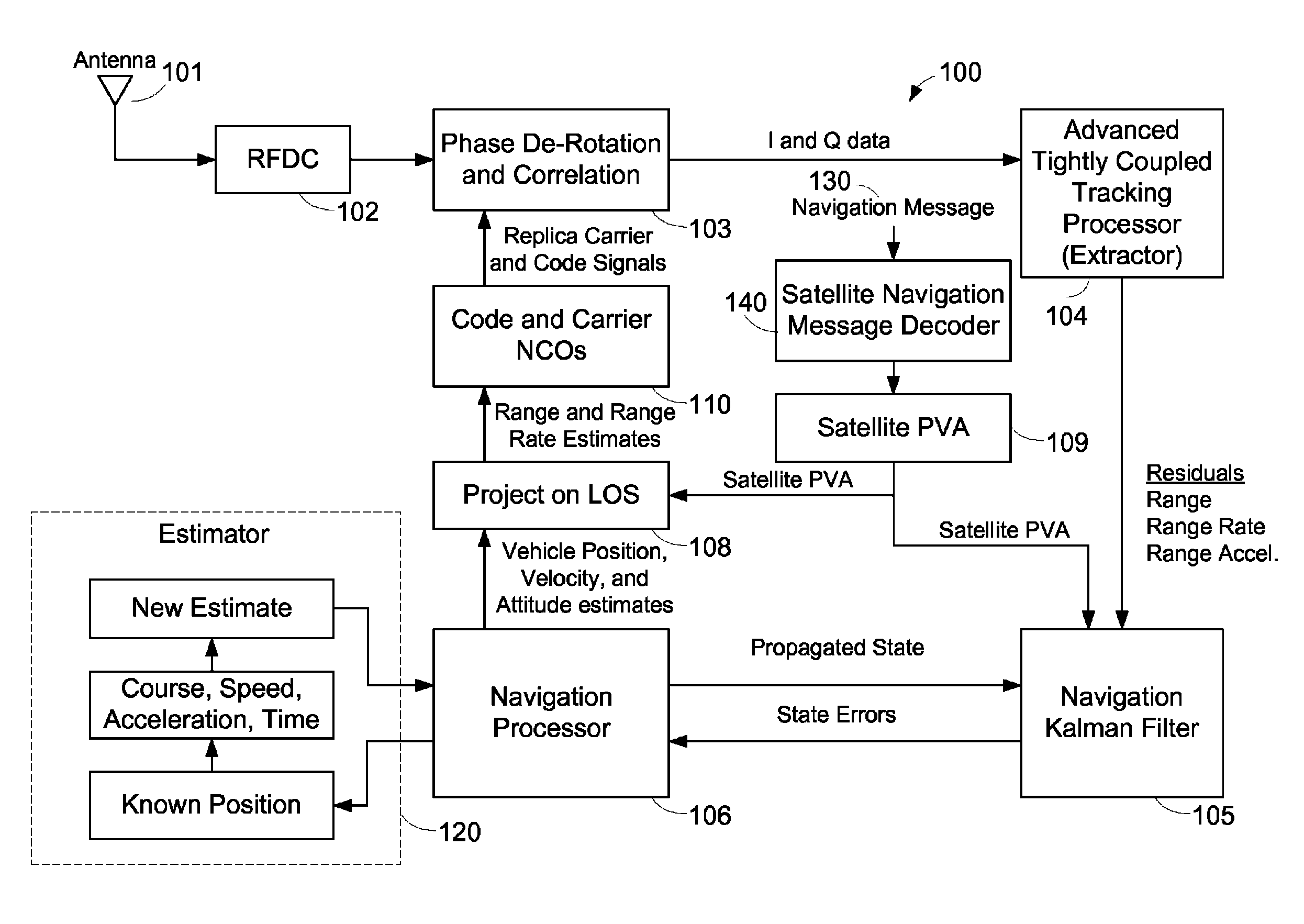

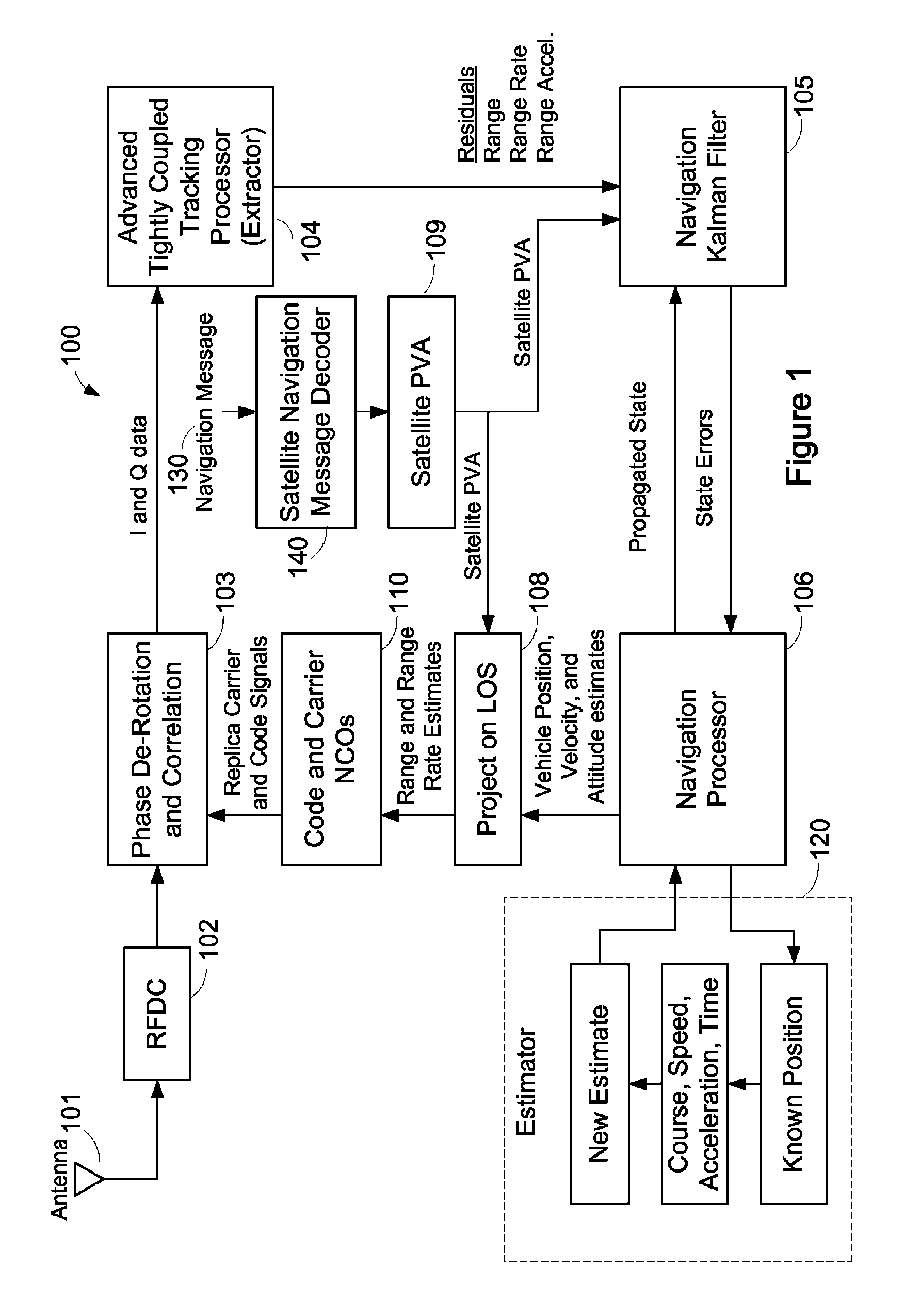

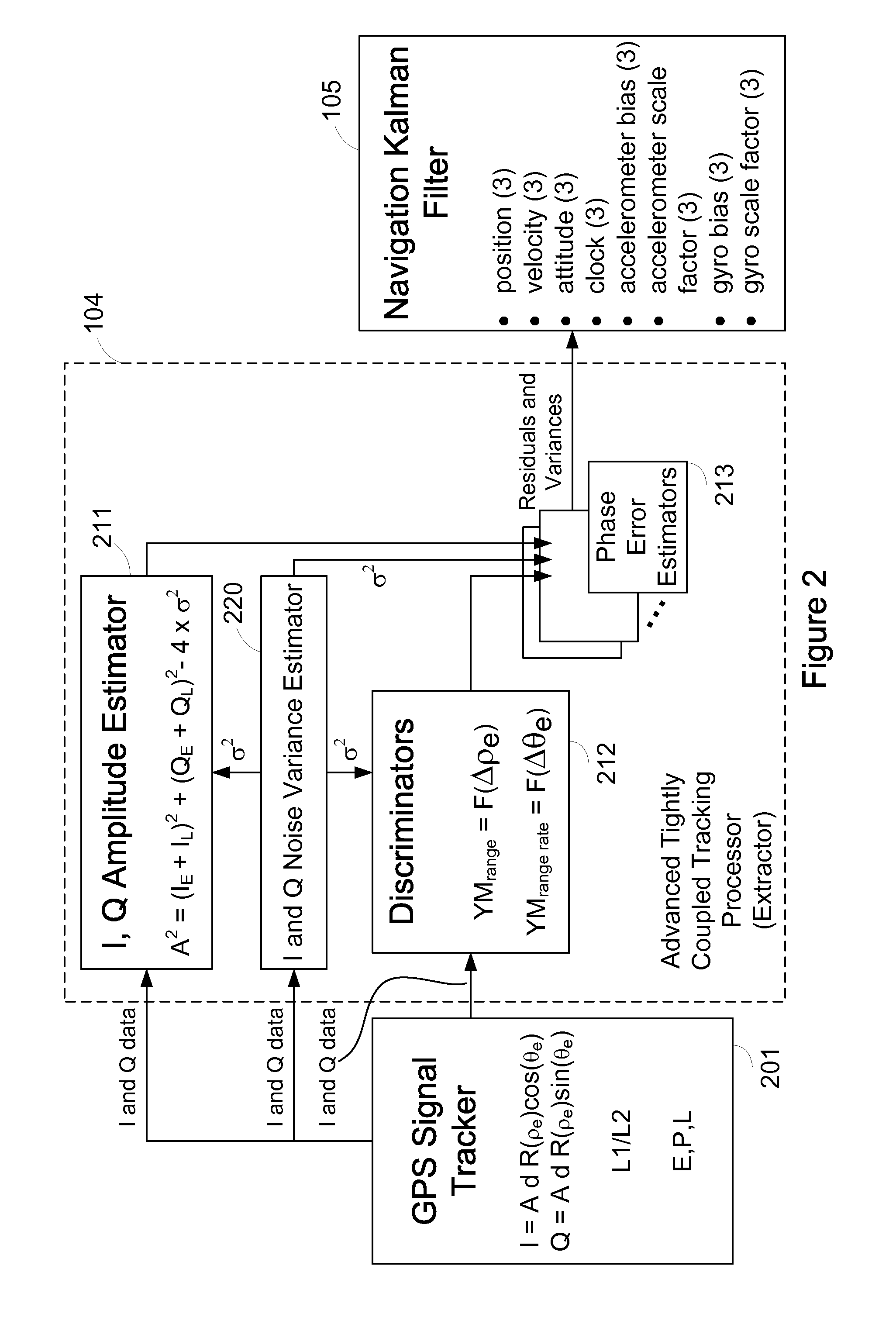

System and method for advanced tight coupling of GPS and inertial navigation sensors

ActiveUS20060161329A1Easily integrated into existing navigation filter designImprove the environmentDigital data processing detailsPosition fixationDiscriminatorSystem configuration

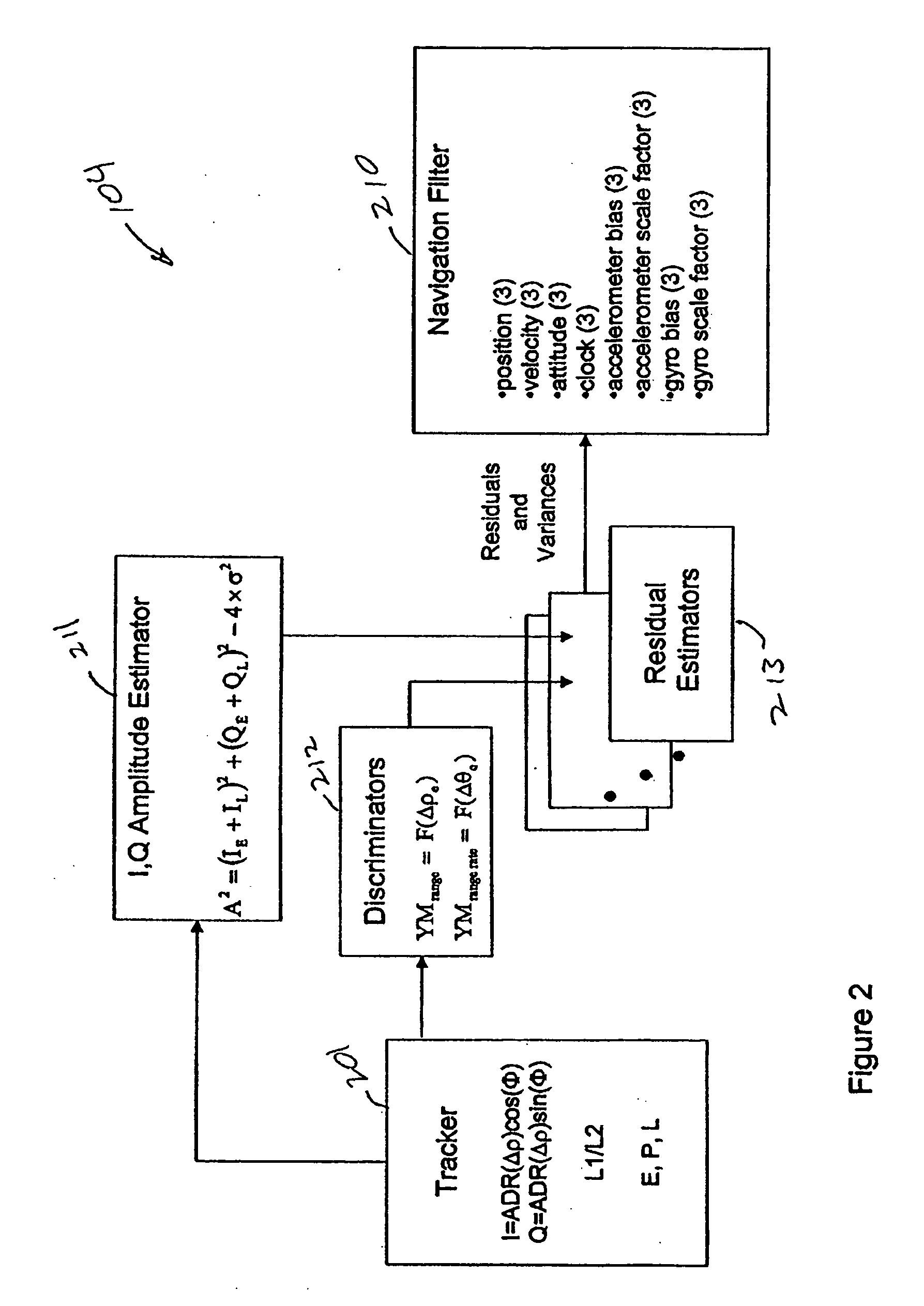

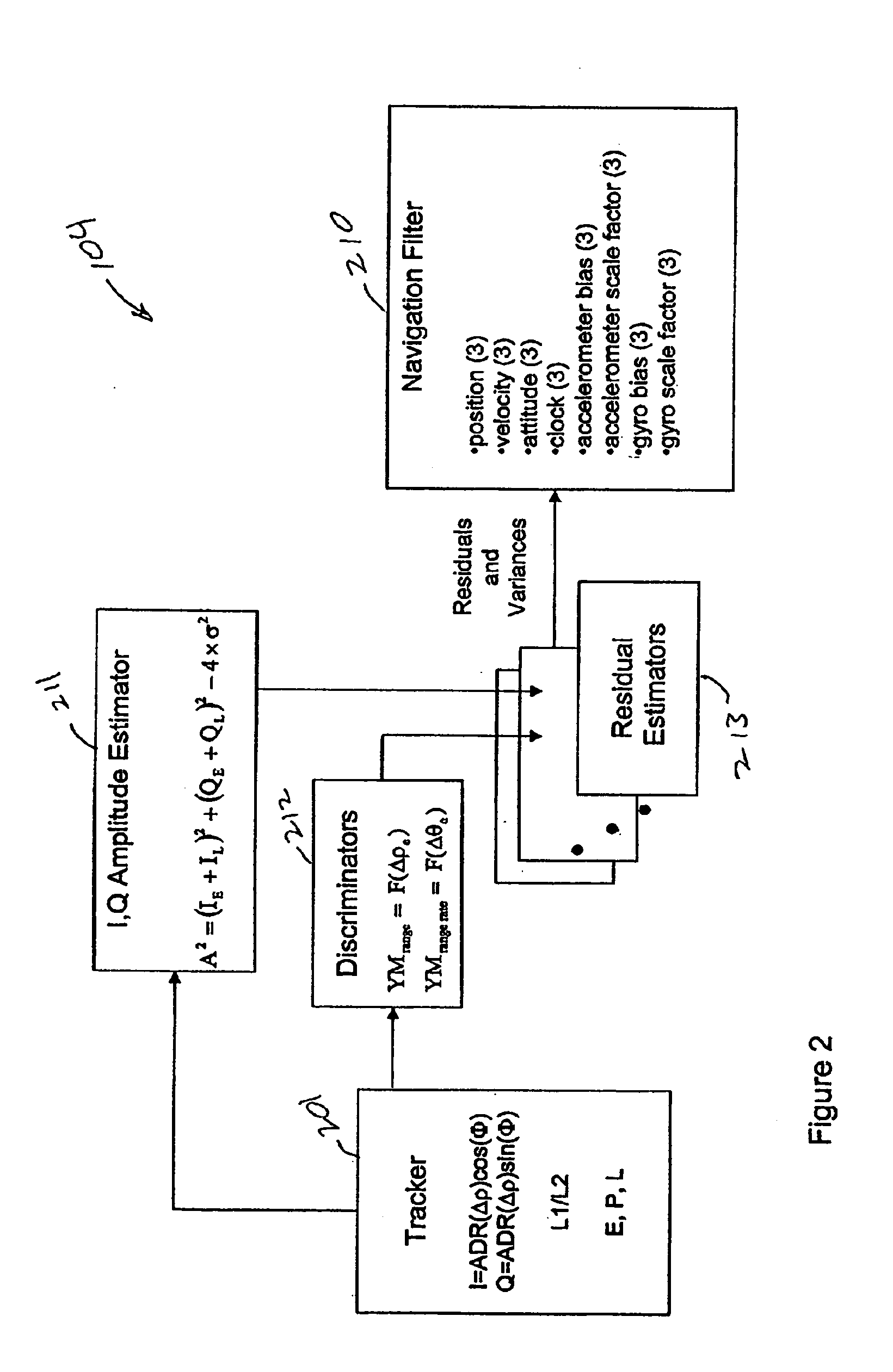

A system and method for generating a navigation solution in high interference and dynamic environments using Global Positioning System (GPS) and inertial measurement unit (IMU) data is described. The system configuration is a multi-satellite tracking loop structure obtained by closing each satellite's tracking loop through a single, multi-state navigation filter. This generates a robust navigation solution that can track GPS signals in a lower signal to noise ratio than can the standard GPS tightly coupled tracking loops. The system contains an Advanced Tightly Coupled (ATC) tracking processor which accepts early, late, and on-time I and Q data from the GPS signal tracker and outputs vehicle to satellite range, range rate and range acceleration residual measurements to a navigation Kalman filter. The ATC includes nonlinear discriminators which transform I and Q data into linear residual measurements corrupted by unbiased, additive, and white noise. It also includes an amplitude estimator configured to operate in rapidly changing, high power noise; a measurement noise variance estimator; and a linear residual smoothing filter for input to the navigation filter.

Owner:L3 TECH INC

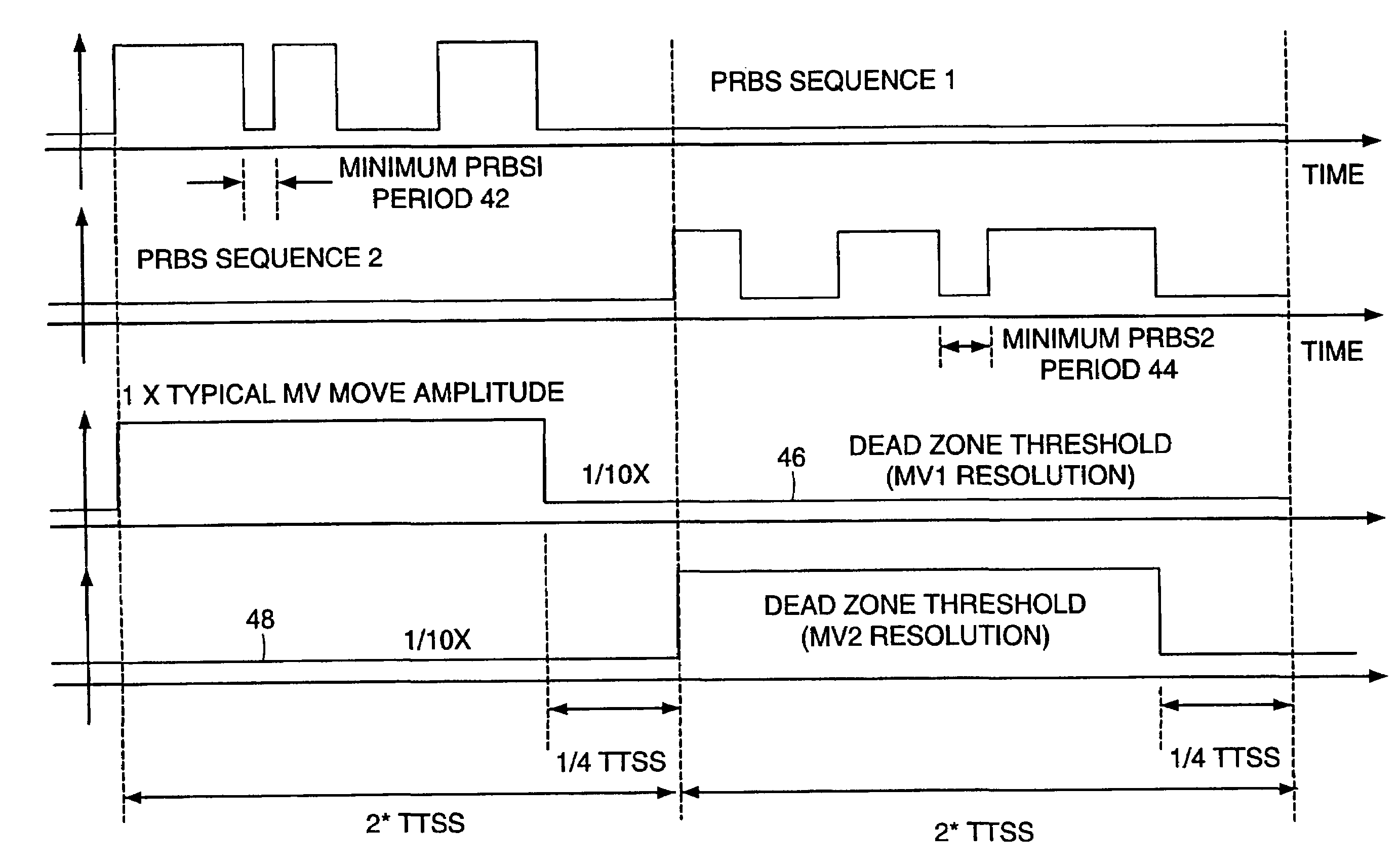

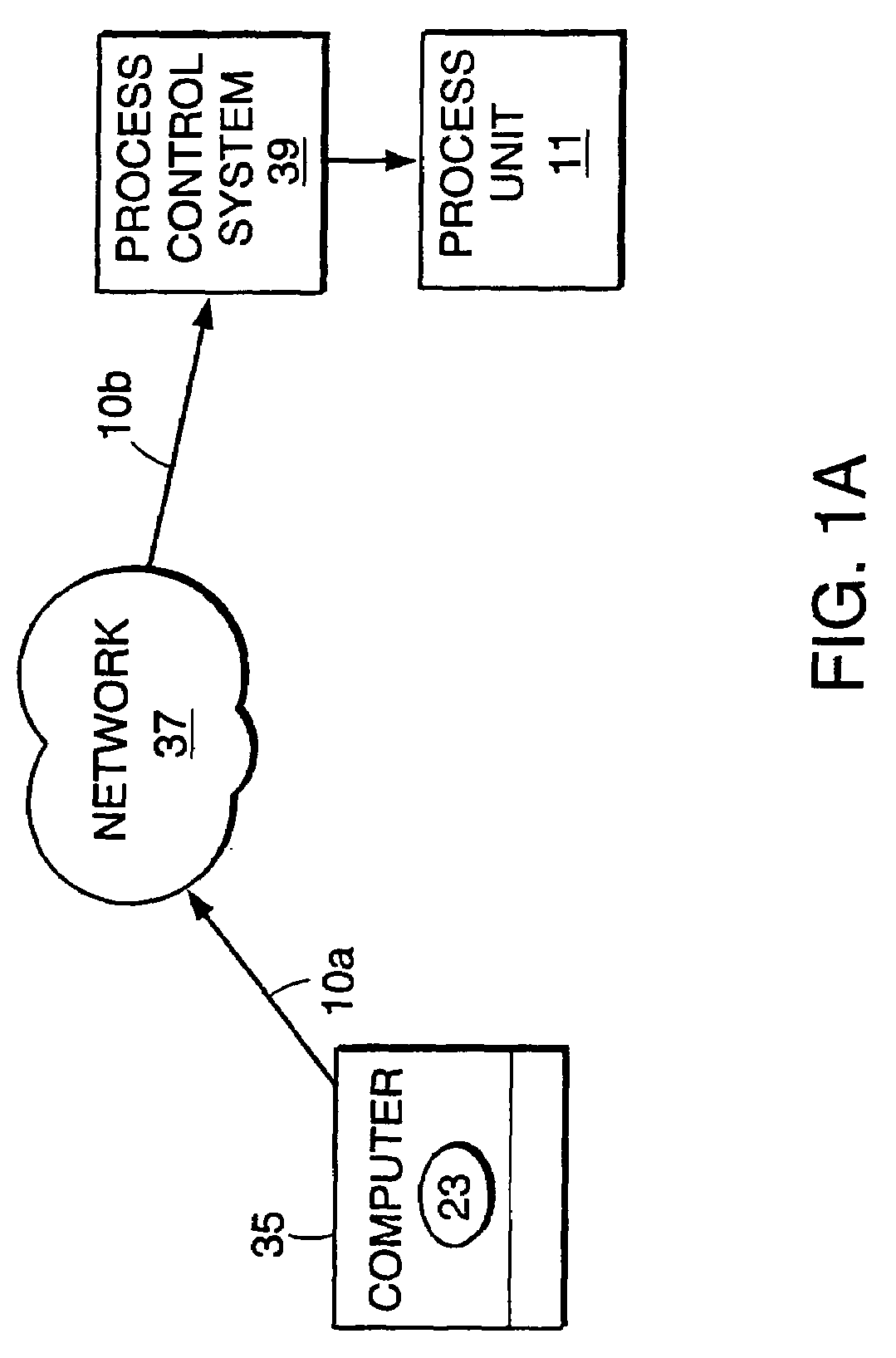

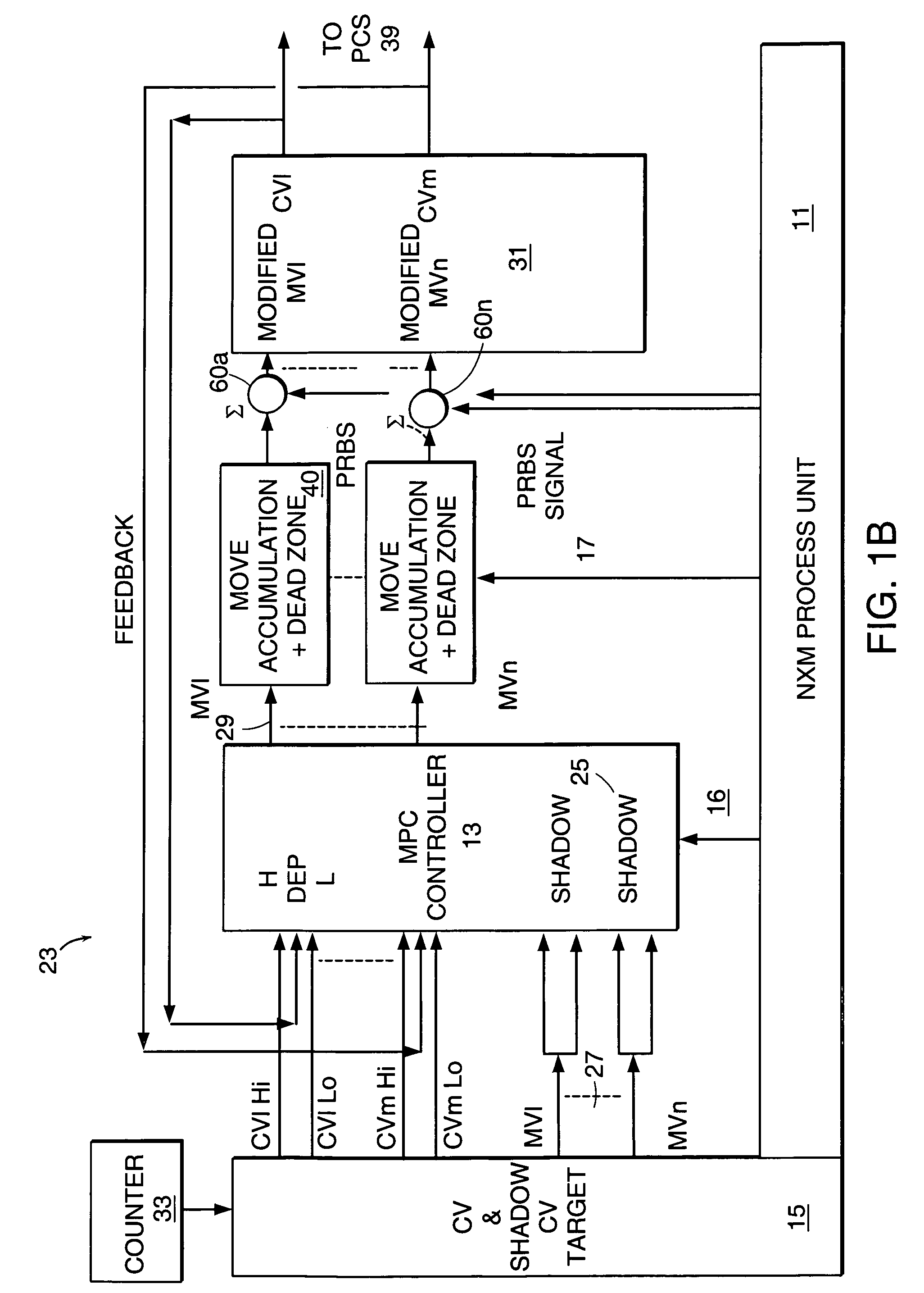

Automated closed loop step testing of process units

InactiveUS7209793B2Promote disturbanceMagnitude is largeSampled-variable control systemsSimulator controlNetwork connectionPredictive controller

A multivariable process controller controls a chemical, polymer or other physical process. Slow tuning and over-conservative controlled variable values are employed during step testing. While all controlled process variables are within safe limits, only one manipulated variable (MV) at a time is step changed. Several manipulated variables are moved when process variables exceed safe limits to ensure that the controlled process variables return to the safe range, such that suitable MV targets for step testing are able to be automatically discovered within a closed loop control environment. Thus, the step test is able to be conducted mostly unsupervised and / or remotely via a telephone or network connection. A new process perturbation approach simultaneously perturbs multiple or all of the process input variables in such a way that the process responses (process outputs) are maximized, while the process variables are maintained inside its predefined operating constraints. It uses magnitude modulated Generalized Binary Noise (MGBN) signals to excite multiple process variables, and uses a specially designed model predictive controller (MPC) to safeguard the process. The specially designed MPC controller uses minimal move and discrete control action to reduce interference with the GBN perturbations and prevents unwanted feedback from contaminating the data quality, while keeping the process operating in a desired range.

Owner:ASPENTECH CORP

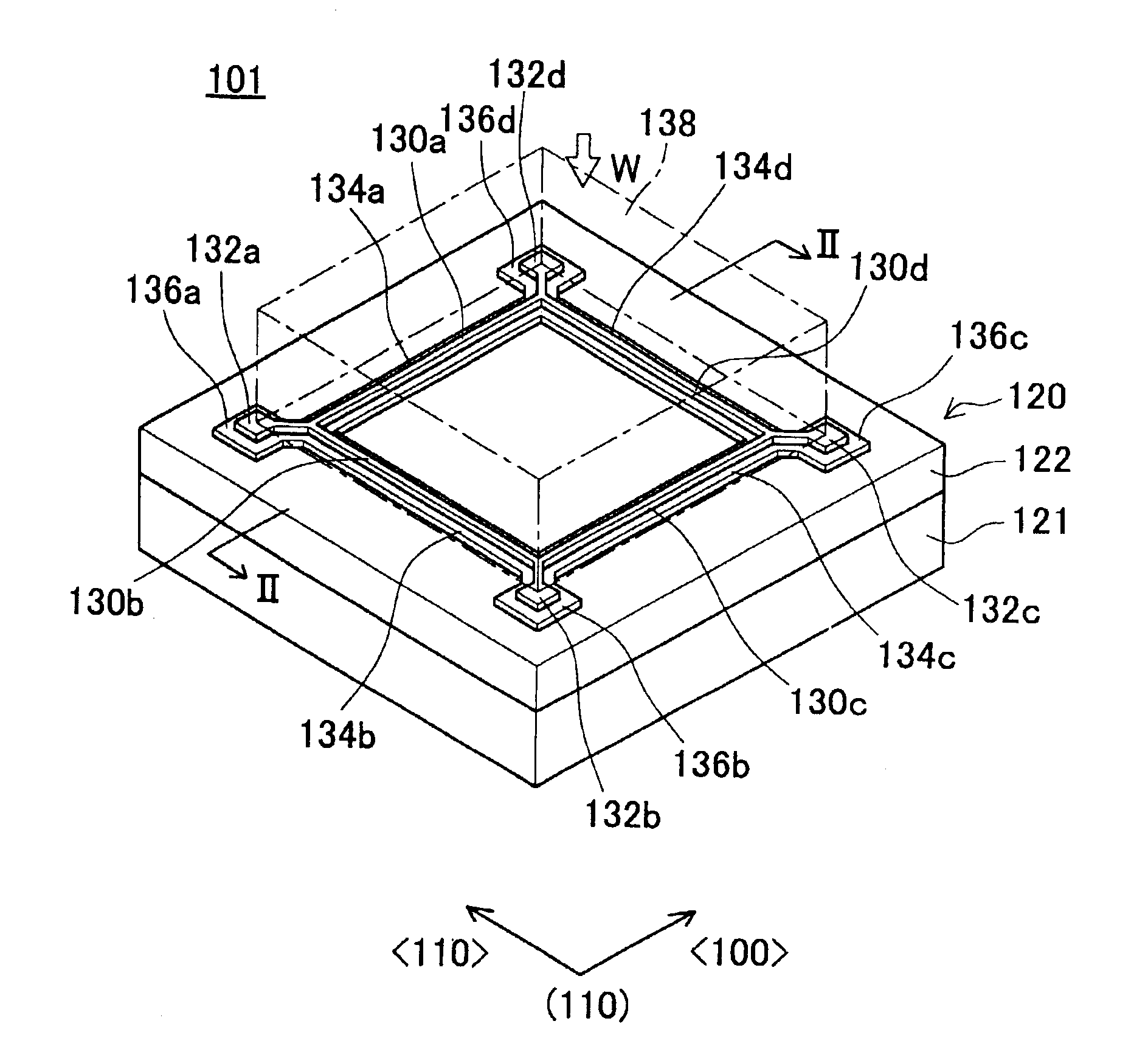

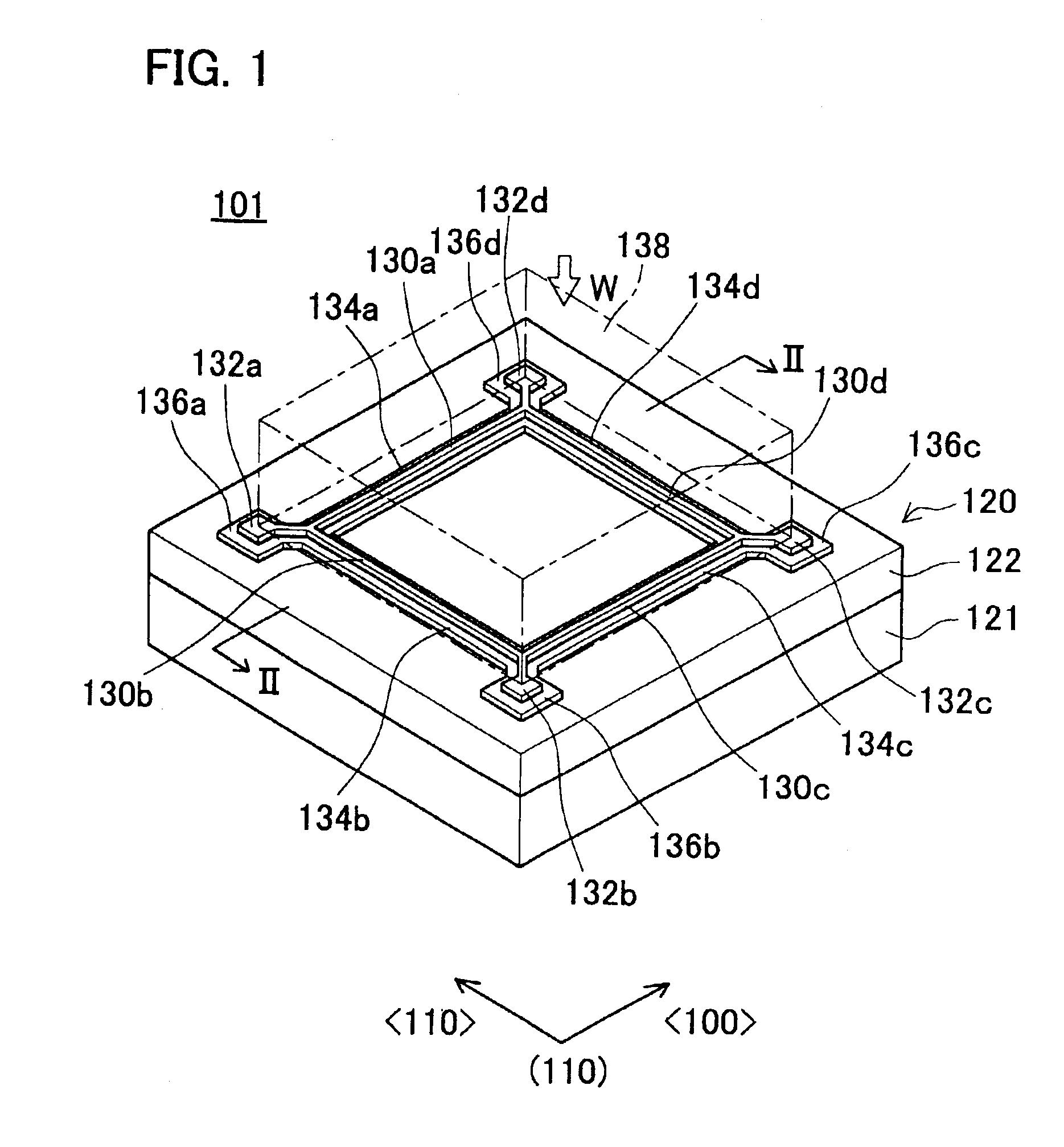

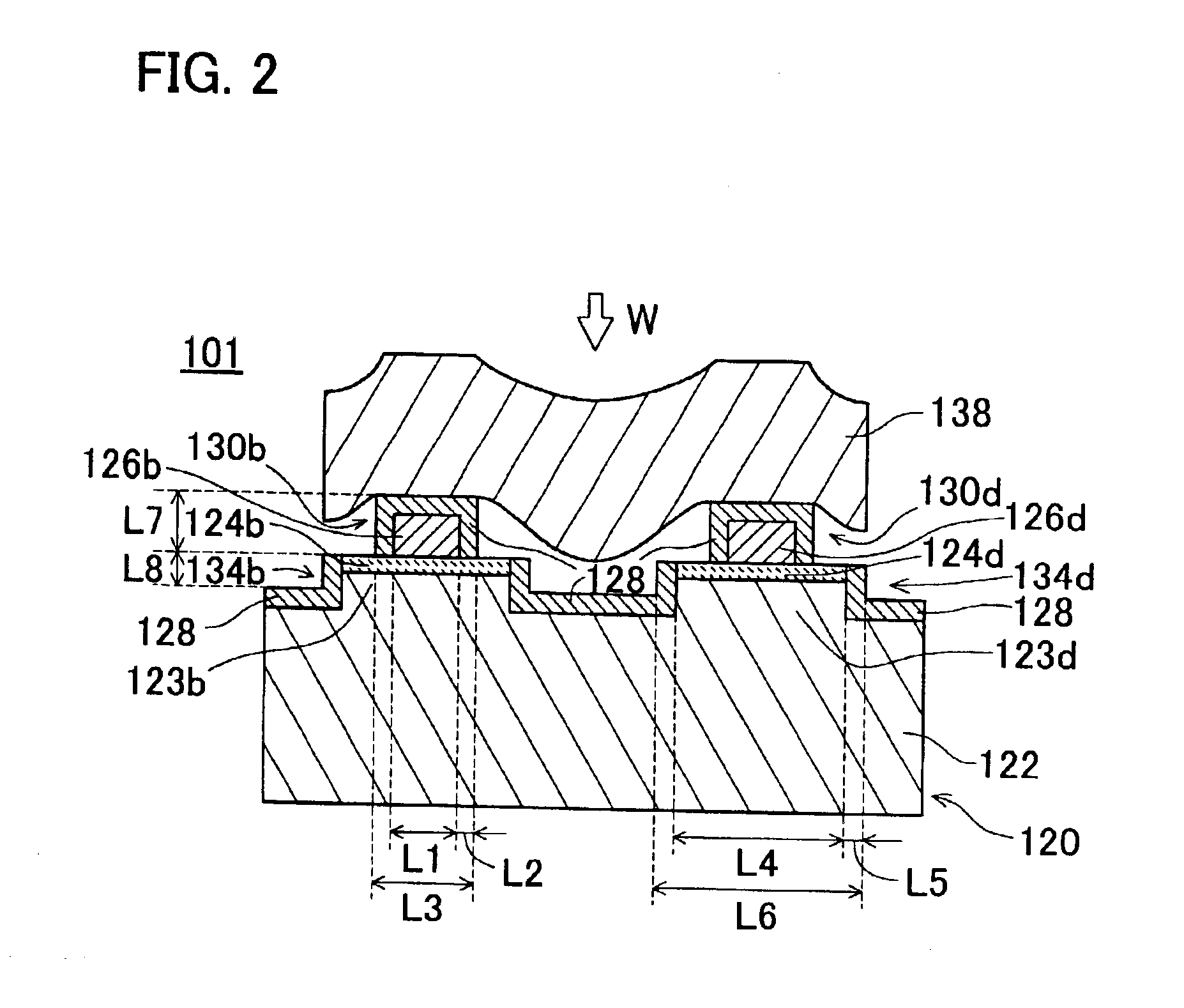

Piezoresistive transducers

InactiveUS6915702B2Detection precision can be improvedReduce volatilityUsing electrical meansForce measurement using piezo-resistive materialsTransducerEngineering

Owner:KK TOYOTA CHUO KENKYUSHO

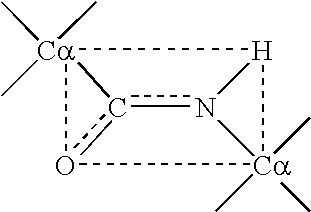

Modified factor ix

InactiveUS20040254106A1Modify characteristicMagnitude is largeFactor VIIPeptide/protein ingredientsEpitopeIn vivo

The invention in particular relates to the modification of human factor IX to result in factor IX proteins that are substantially non-immunogenic or less immunogenic than any non-modified counterpart when used in vivo. The invention relates, furthermore, to T-cell epitope sequences deriving from human factor IX, which are immunogenic.

Owner:MERCK PATENT GMBH

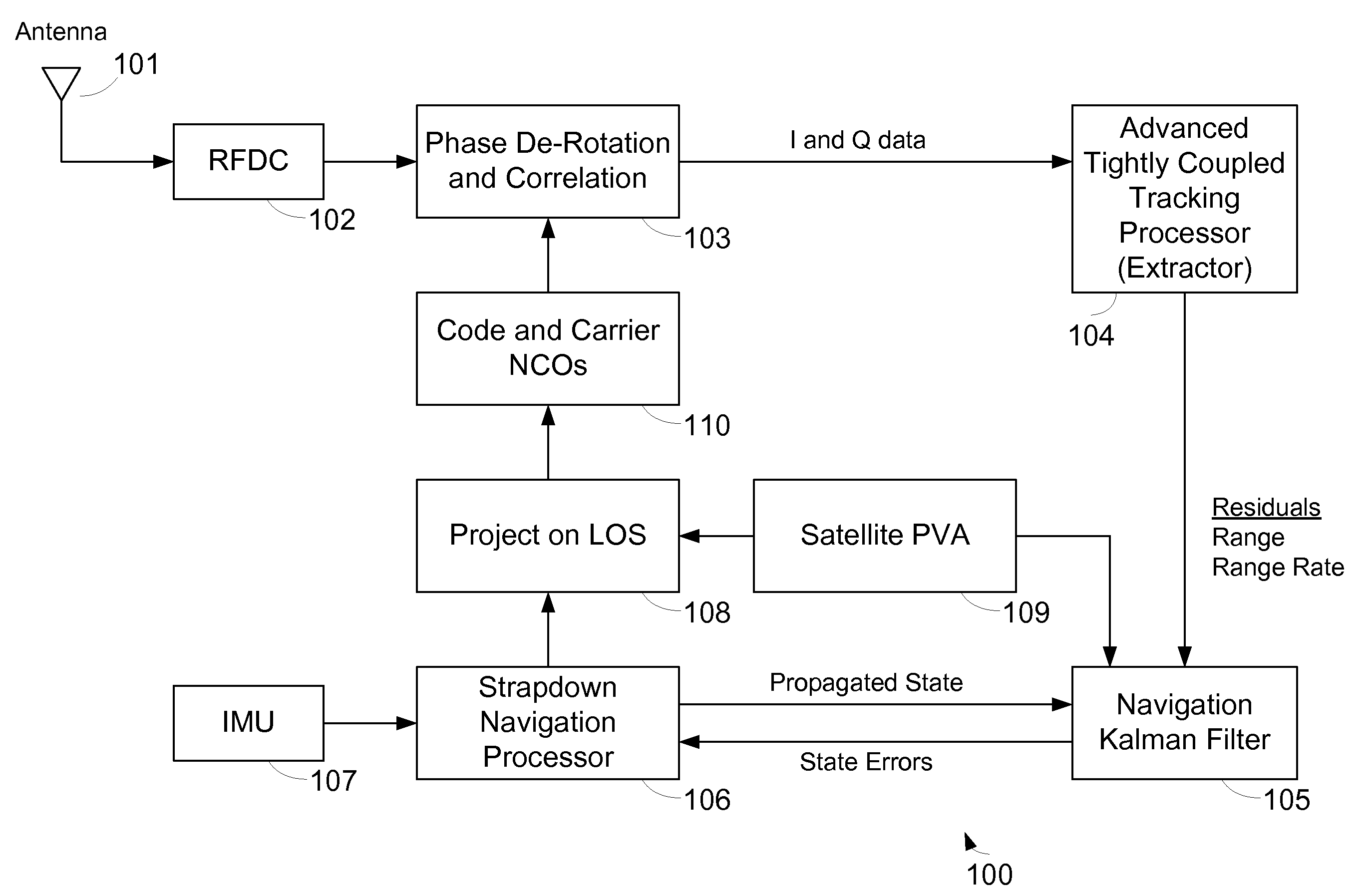

System and method for GPS acquisition using advanced tight coupling

ActiveUS7415354B2Easily integrated into existing navigation filter designImprove the environmentPosition fixationNavigation instrumentsCouplingSatellite

A system and method for GPS acquisition in relatively high interference is described. Acquisition is aided by an Advanced Tightly Coupled (ATC) tracking filters that compute a satellite range residuals and range rate residuals for satellites being acquired. Multiple channels are used in parallel to search for the desired satellites. Range residuals from the ATC filters are used to correct the computed receiver offset and thus allow acquisition in the presence of relatively high interference.

Owner:L3 TECH INC

Splice system for connecting rebars in concrete assemblies

ActiveUS8413396B2Highly corrosive environmentLong useful lifeRopes and cables for vehicles/pulleyLoad-supporting elementsFiberEngineering

A splice tube assembly and corresponding system for connecting multiple fiber-reinforced polymer rebars include a polymeric tube that is externally covered by a reinforcing layer to control radial expansion of grout within the polymeric tube and of the polymeric tube itself, and the polymeric tube may be internally provided with locking structures for mechanically interlocking with the grout, ensuring that the splice tube assembly functions as a unit for transferring loads from a first rebar, extending from a first end of the polymeric tube, to a second rebar, extending from a second end of the polymeric tube.

Owner:WISCONSIN ALUMNI RES FOUND

System and method for advanced tight coupling of GPS and navigation based on dead reckoning

ActiveUS20070252754A1Easily integrated into existing navigation filter designImprove the environmentPosition fixationSatellite radio beaconingDiscriminatorSystem configuration

A system and method for generating a navigation solution in high interference and dynamic environments using Global Positioning System (GPS) and navigation such as dead reckoning is described. The system configuration is a multi-satellite tracking loop structure obtained by closing each satellite's tracking loop through a multi-state navigation filter. This generates a robust navigation solution that can track GPS signals in a lower signal to noise ratio than can the standard GPS tightly coupled tracking loops. The system contains an Advanced Tightly Coupled (ATC) tracking processor which accepts early, late, and on-time I and Q data from the GPS signal tracker and outputs vehicle to satellite range, range rate and range acceleration residual measurements to a navigation Kalman filter. The ATC includes nonlinear discriminators which transform I and Q data into residual measurements corrupted by unbiased, additive, and white noise. It also includes an amplitude estimator configured to operate in rapidly changing, high power noise; a measurement noise variance estimator; and a linear residual smoothing filter for input to the navigation filter.

Owner:L3 TECH INC

System and method for advanced tight coupling of GPS and inertial navigation sensors

ActiveUS7274504B2Easily integrated into existing navigation filter designImprove the environmentDigital data processing detailsNavigation by speed/acceleration measurementsDiscriminatorGlobal Positioning System

A system and method for generating a navigation solution in high interference and dynamic environments using Global Positioning System (GPS) and inertial measurement unit (IMU) data is described. The system includes an Advanced Tightly Coupled (ATC) tracking processor for a multi-satellite tracking system. The ATC accepts early, late, and on-time I and Q data from the GPS signal tracker and outputs vehicle-to-satellite range and range rate residual measurements to a navigation Kalman filter. The ATC includes nonlinear discriminators which transform I and Q data into linear residual measurements corrupted by unbiased, additive, and white noise. It also includes an amplitude estimator configured to operate in rapidly changing, high power noise; a measurement noise variance estimator; and a linear residual smoothing filter for input to the navigation filter.

Owner:L3 TECH INC

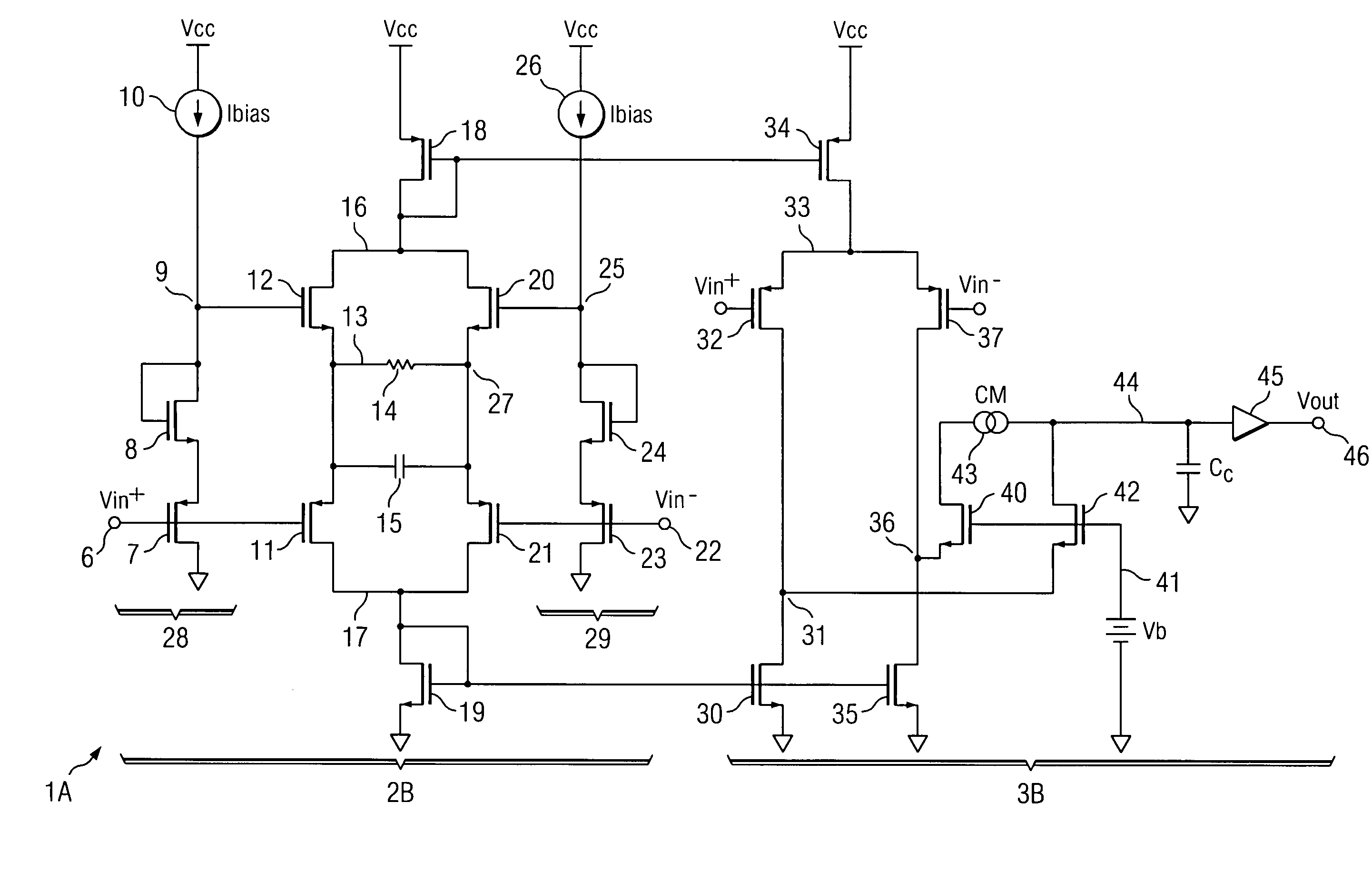

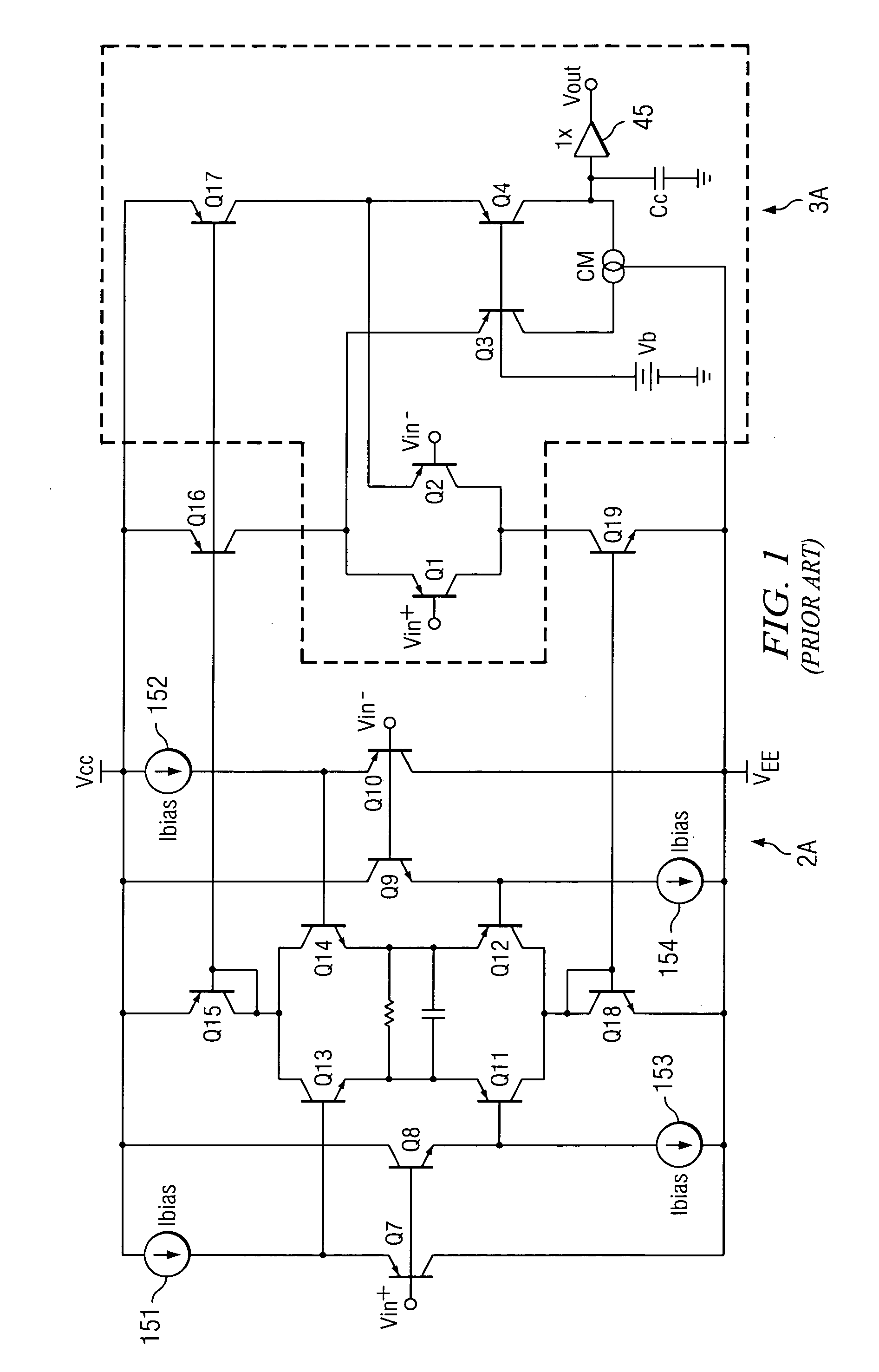

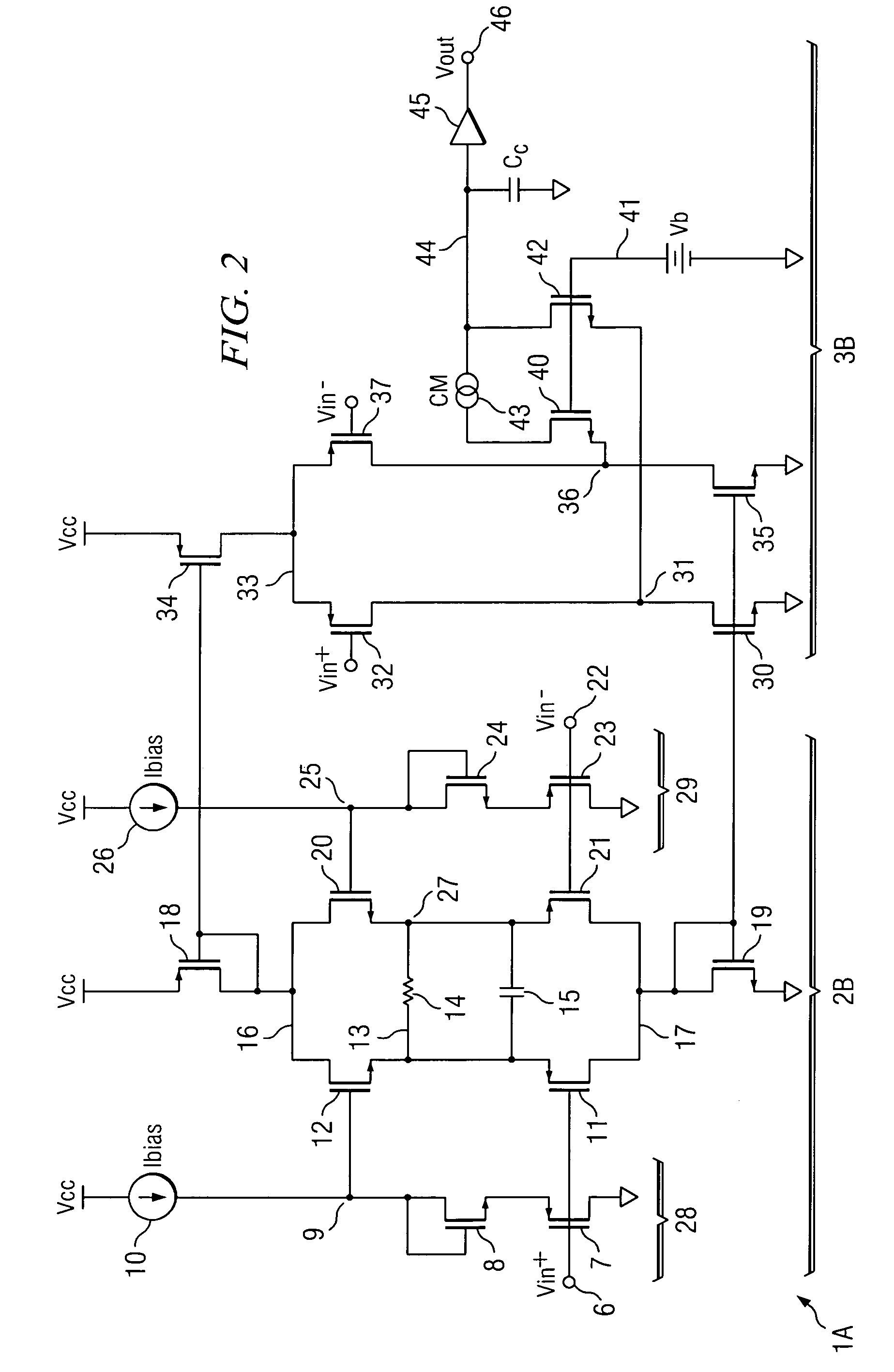

CMOS class AB folded cascode operational amplifier for high-speed applications

ActiveUS7176760B2Reduce noiseTurn fasterDifferential amplifiersDc-amplifiers with dc-coupled stagesCMOSAudio power amplifier

Owner:TEXAS INSTR INC

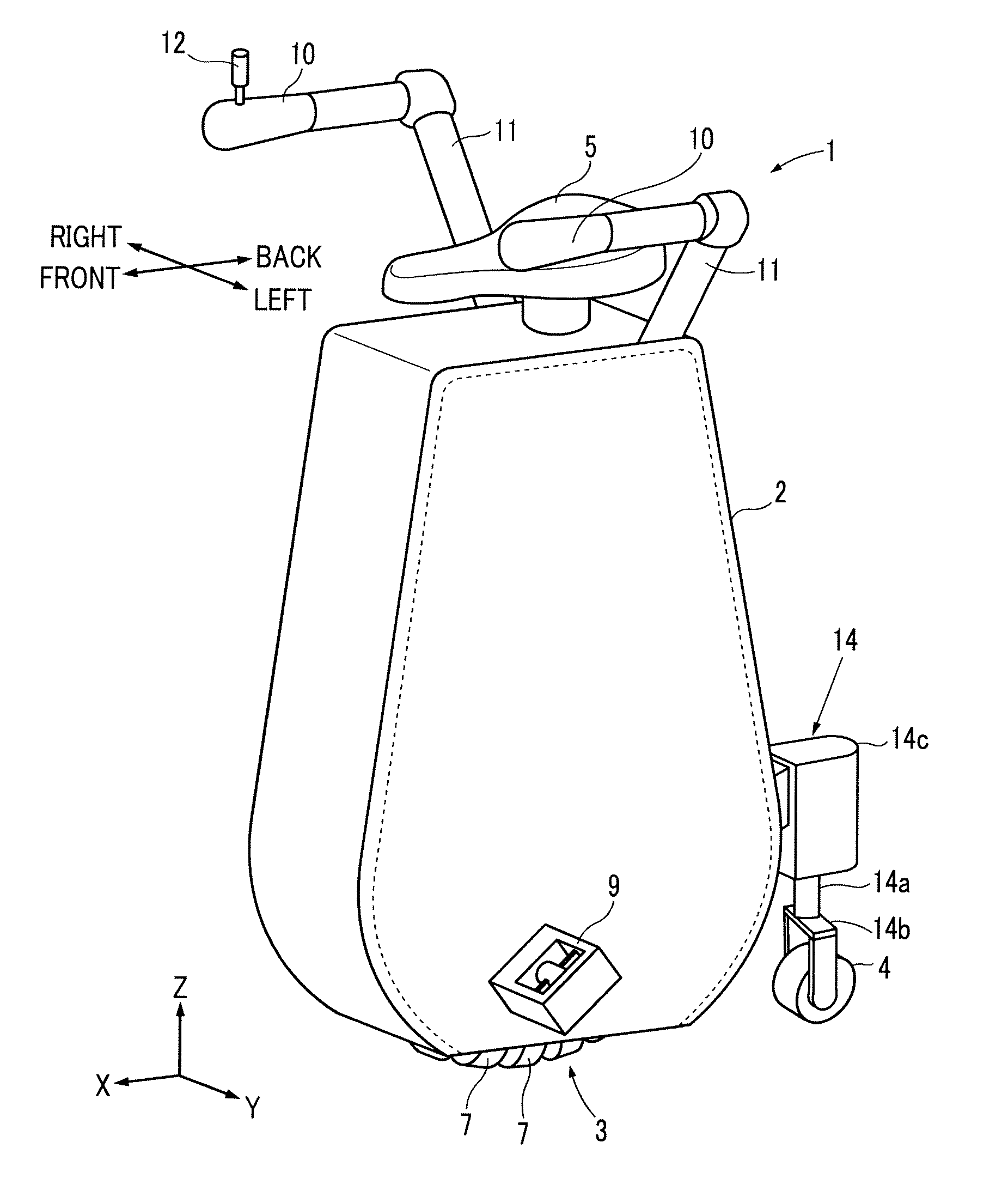

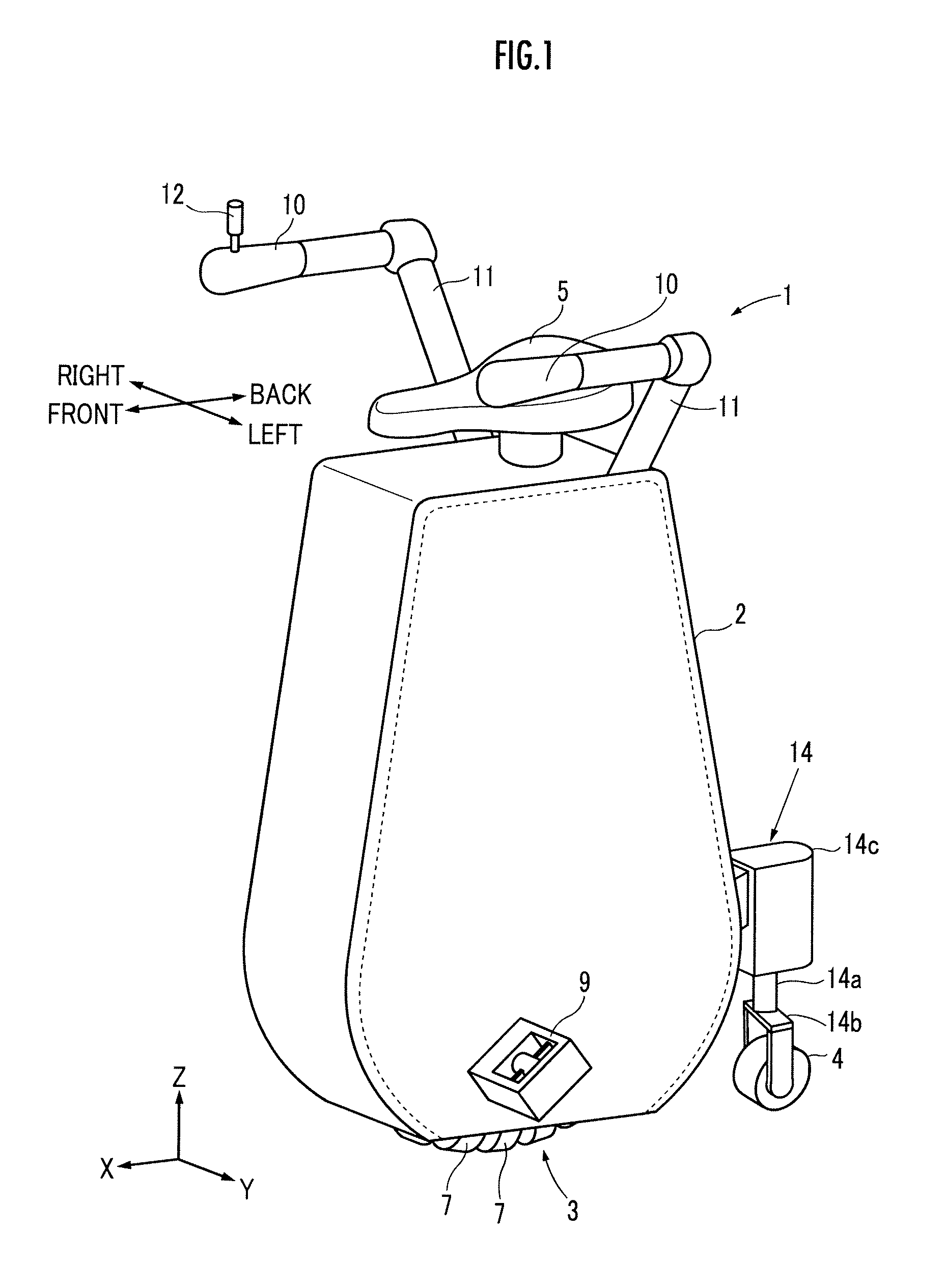

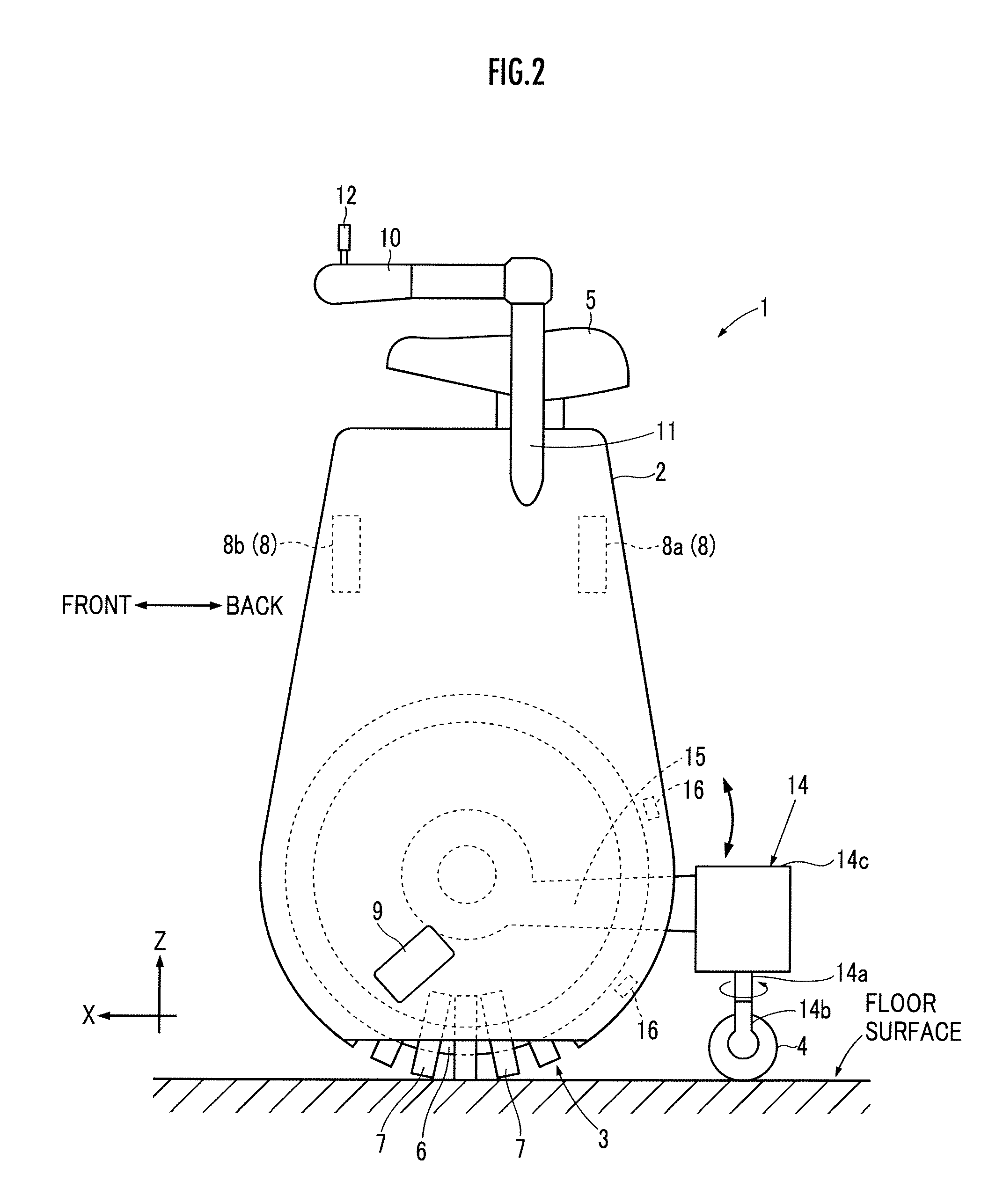

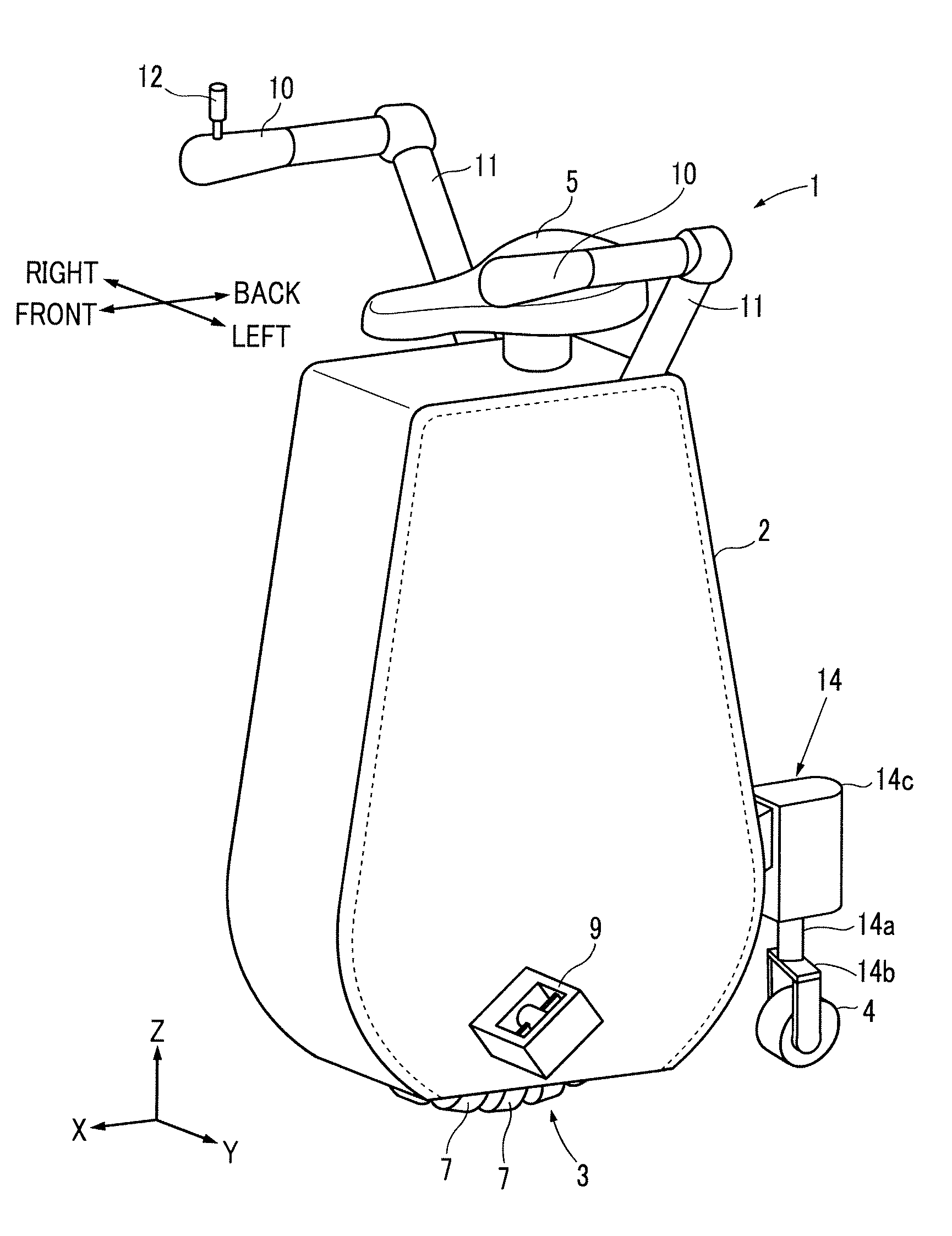

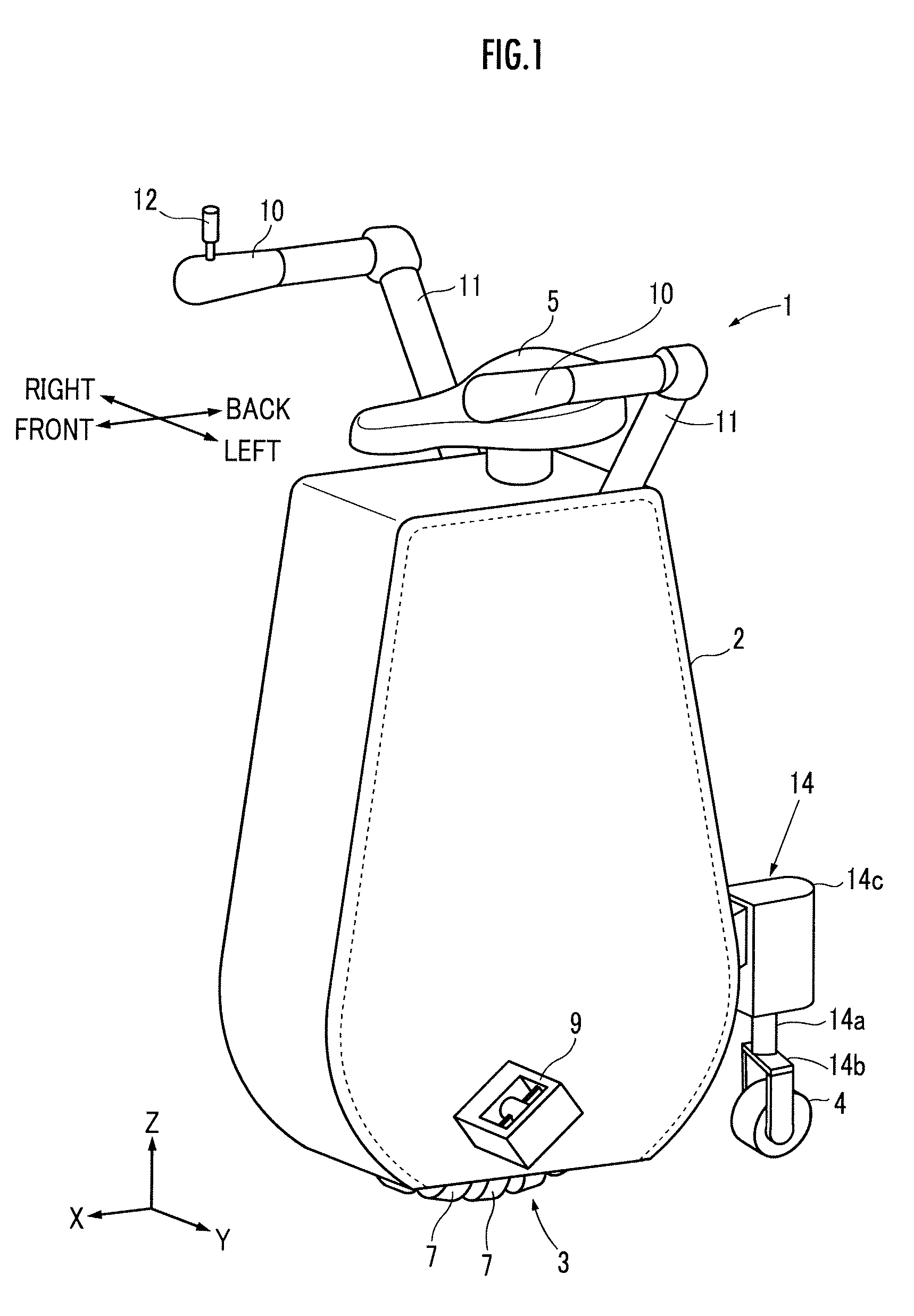

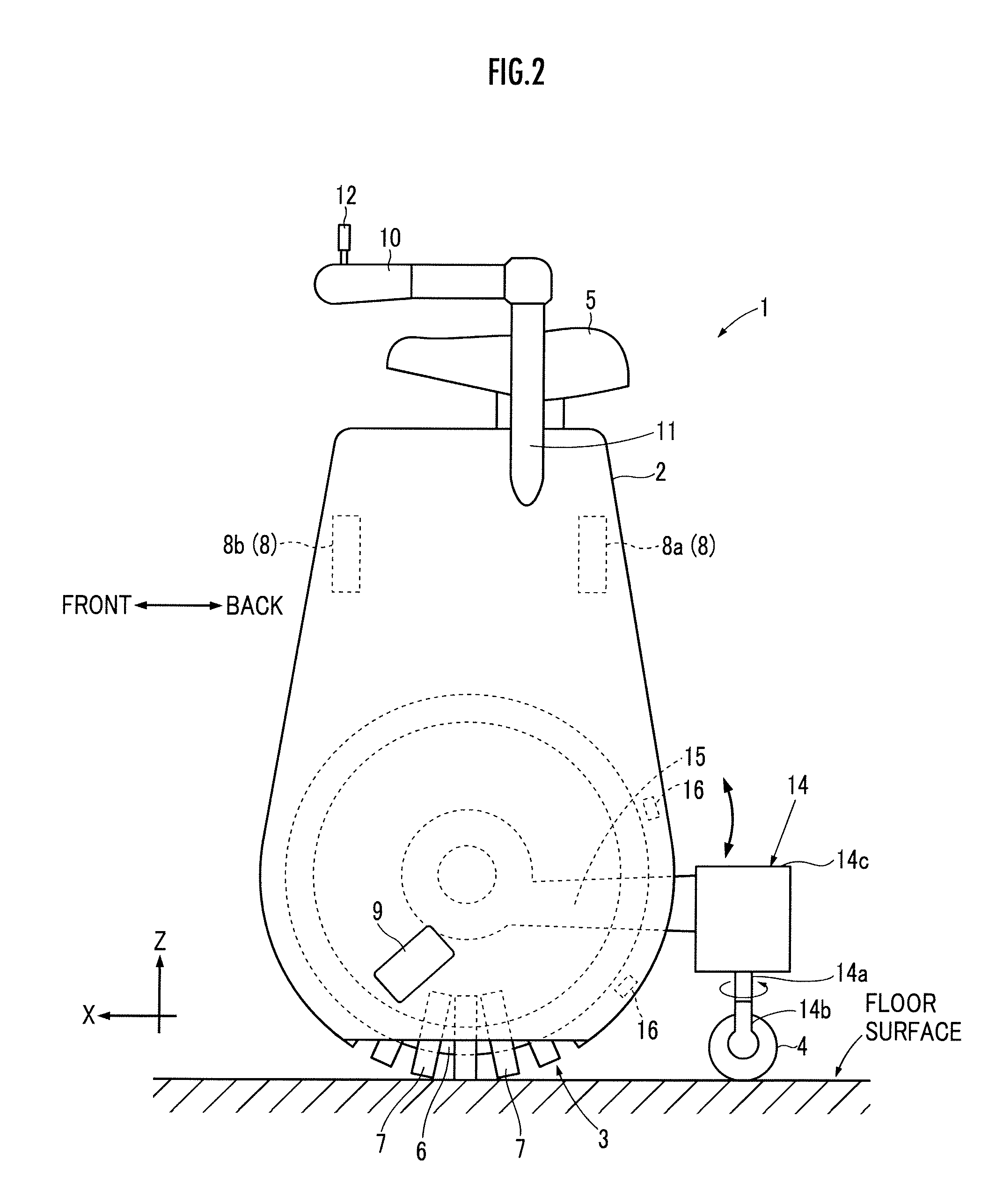

Inverted pendulum type vehicle, and control method of inverted pendulum type vehicle

A controller 21 of a vehicle 1 is equipped with a first control 24, which is configured to control a first actuator 8 so as to move a traveling motion unit 3 according to tilting of an occupant mounting section 5, and a second control unit 25, which is configured to control, in a case where a turning command is output from a joystick 12, an electric motor 14 such that a steering direction of a wheel 4 viewed from above the vehicle 1 becomes tilted with respect to a direction of a moving velocity vector V of the traveling motion unit 3.

Owner:HONDA MOTOR CO LTD

Splice System for Connecting Rebars in Concrete Assemblies

ActiveUS20110036049A1Highly corrosive environmentLong useful lifeRopes and cables for vehicles/pulleyLoad-supporting elementsFiberEngineering

A splice tube assembly and corresponding system for connecting multiple fiber-reinforced polymer rebars include a polymeric tube that is externally covered by a reinforcing layer to control radial expansion of grout within the polymeric tube and of the polymeric tube itself, and the polymeric tube may be internally provided with locking structures for mechanically interlocking with the grout, ensuring that the splice tube assembly functions as a unit for transferring loads from a first rebar, extending from a first end of the polymeric tube, to a second rebar, extending from a second end of the polymeric tube.

Owner:WISCONSIN ALUMNI RES FOUND

Modified human growth hormone

InactiveUS20050020494A1Modify characteristicMagnitude is largePeptide/protein ingredientsImmunoglobulinsHuman growth hormoneIn vivo

The invention relates to the modification of human growth hormone (high) to result in human growth hormone proteins that are substantially non-immunogenic or less immunogenic than any non-modified counterpart when used in-vivo. The invention relates, furthermore, to T-cell epitome sequences deriving from high, which are immunogenic.

Owner:MERCK PATENT GMBH

System and method for GPS acquisition using advanced tight coupling

ActiveUS20080309552A1Easily integrated into existing navigation filter designImprove the environmentPolarisation/directional diversityPosition fixationCouplingSatellite

A system and method for GPS acquisition in relatively high interference is described. Acquisition is aided by an Advanced Tightly Coupled (ATC) tracking filters that compute a satellite range residuals and range rate residuals for satellites being acquired. Multiple channels are used in parallel to search for the desired satellites. Range residuals from the ATC filters are used to correct the computed receiver offset and thus allow acquisition in the presence of relatively high interference.

Owner:L3 TECH INC

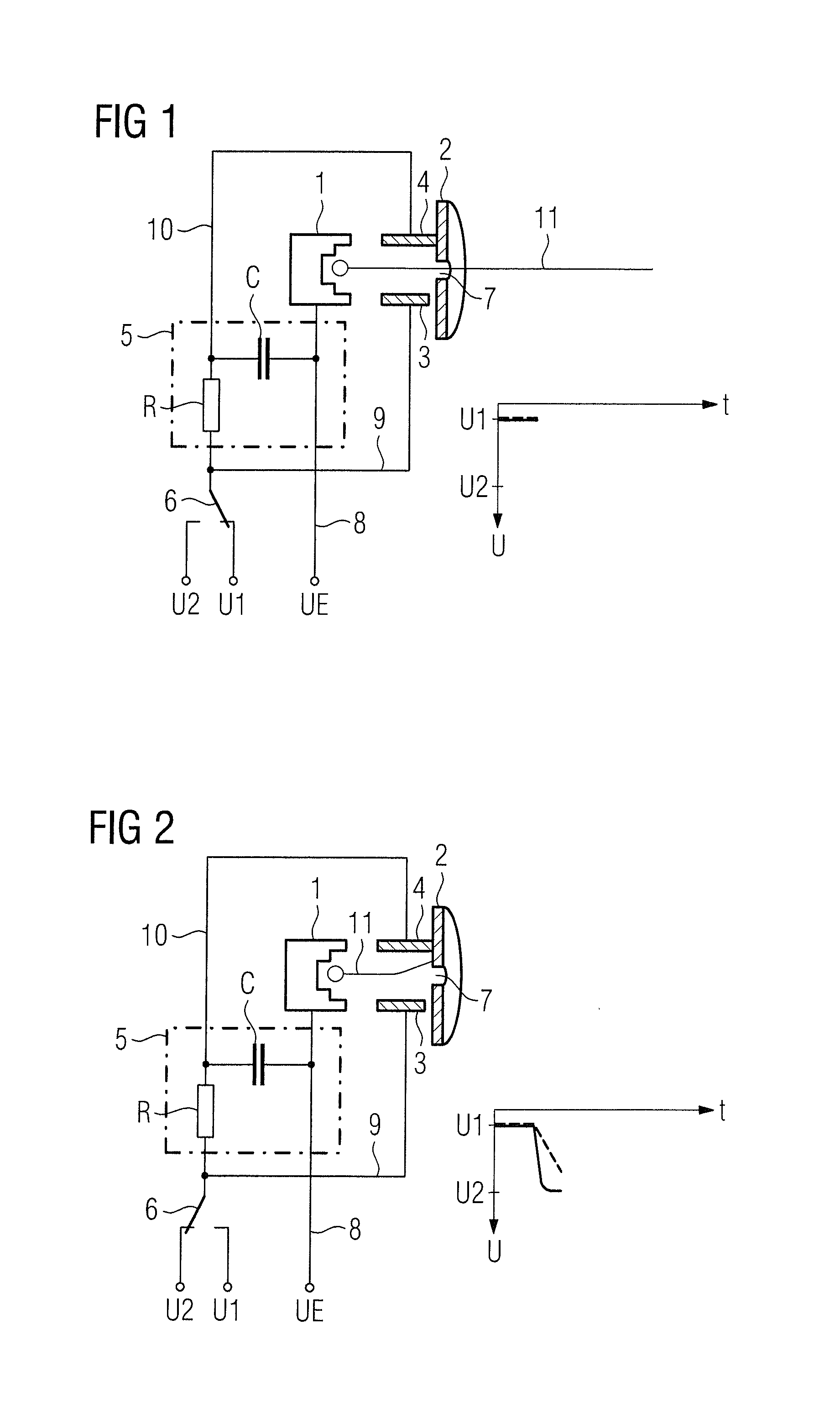

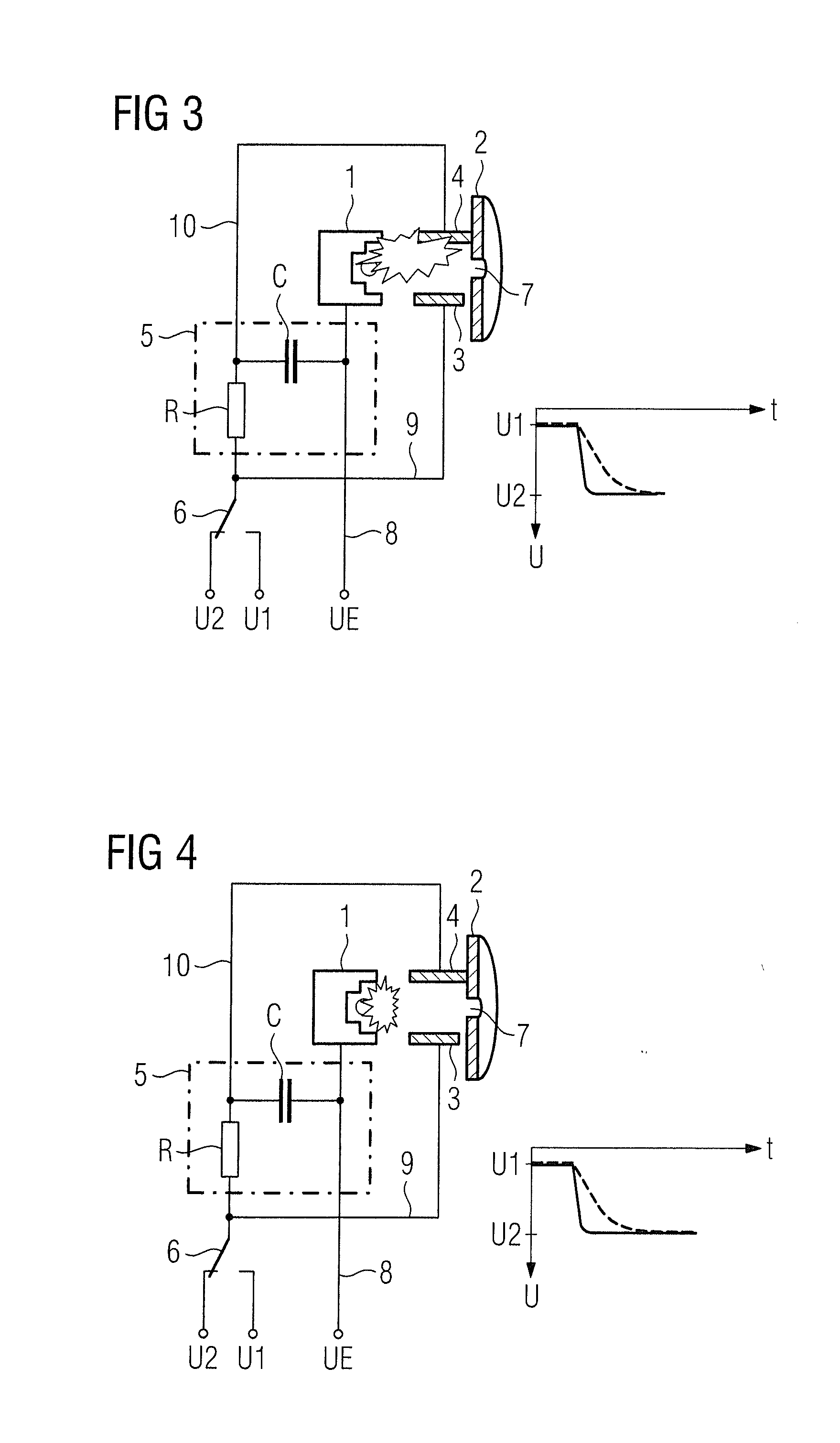

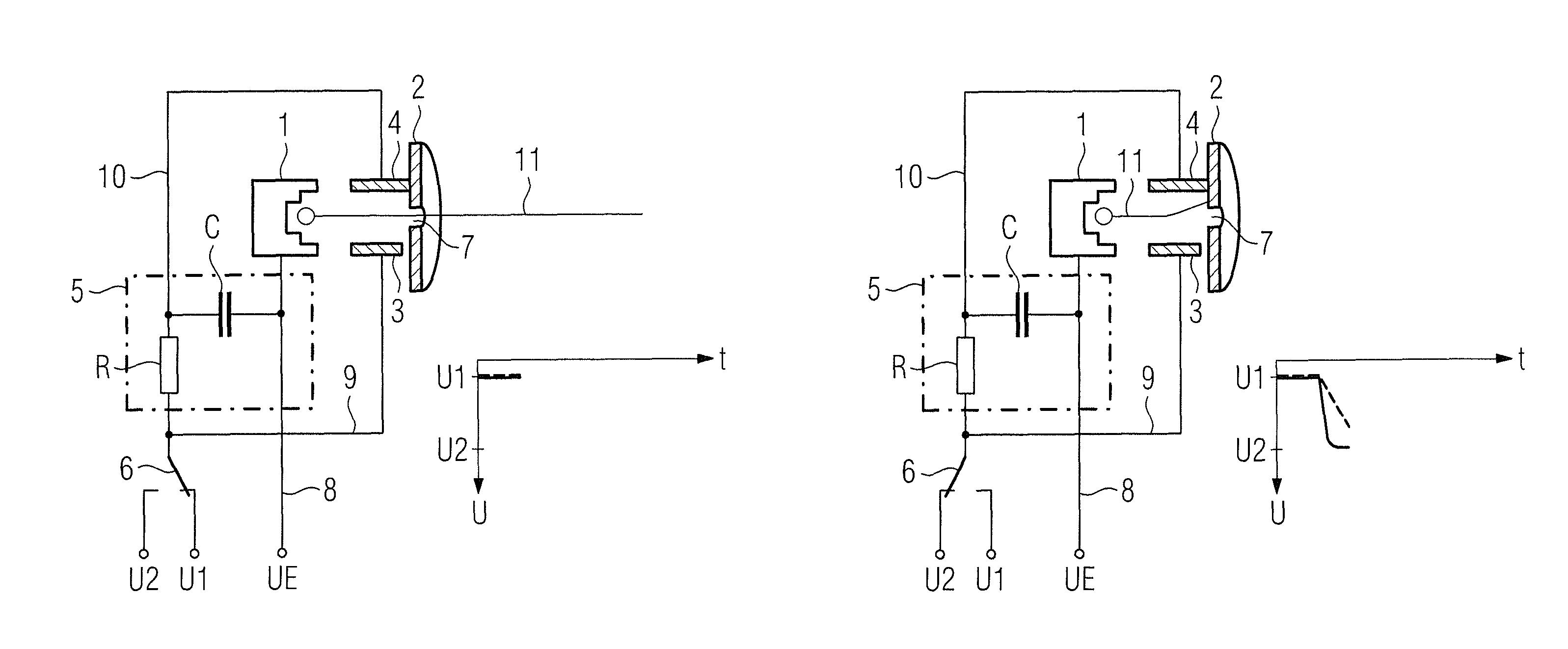

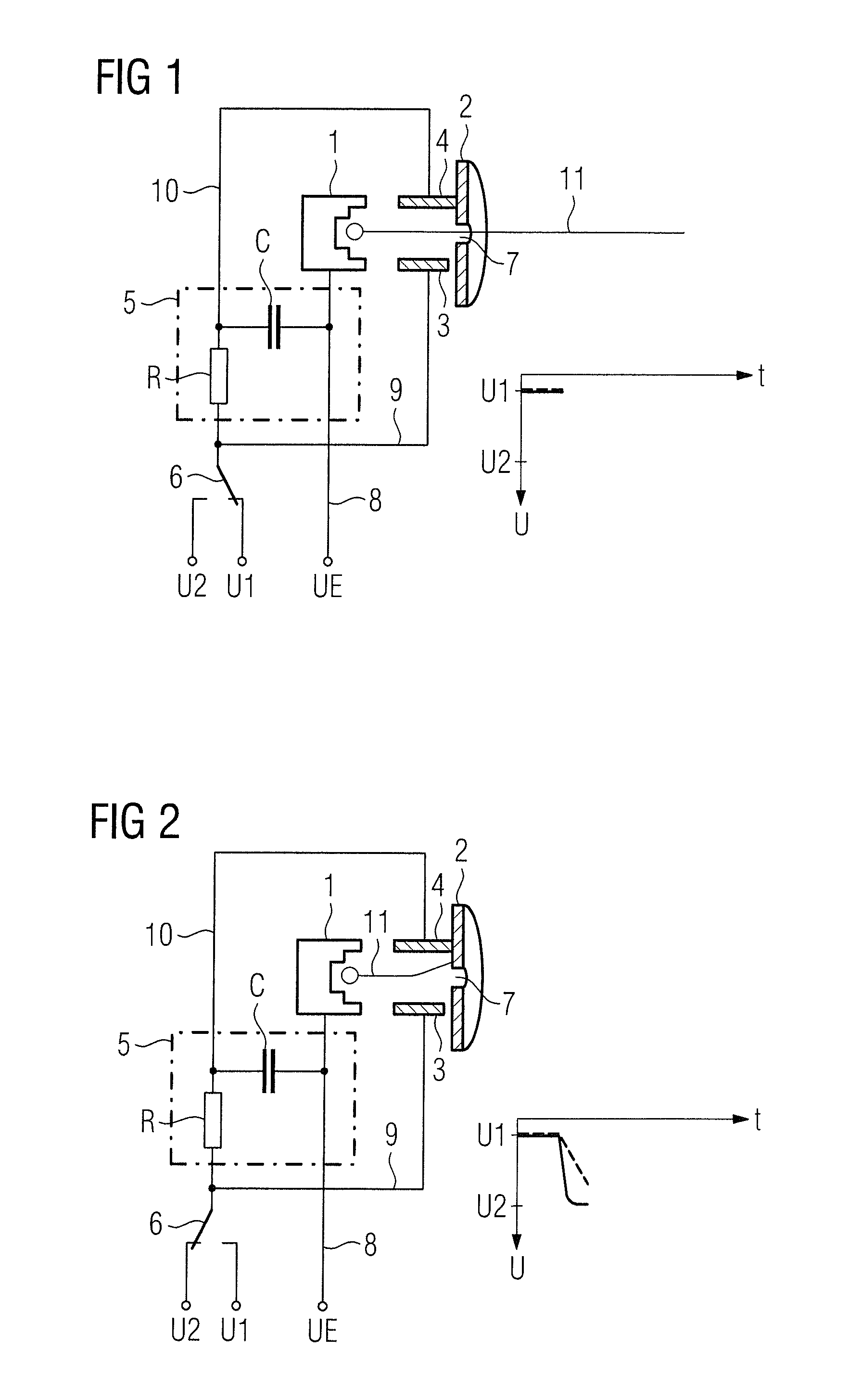

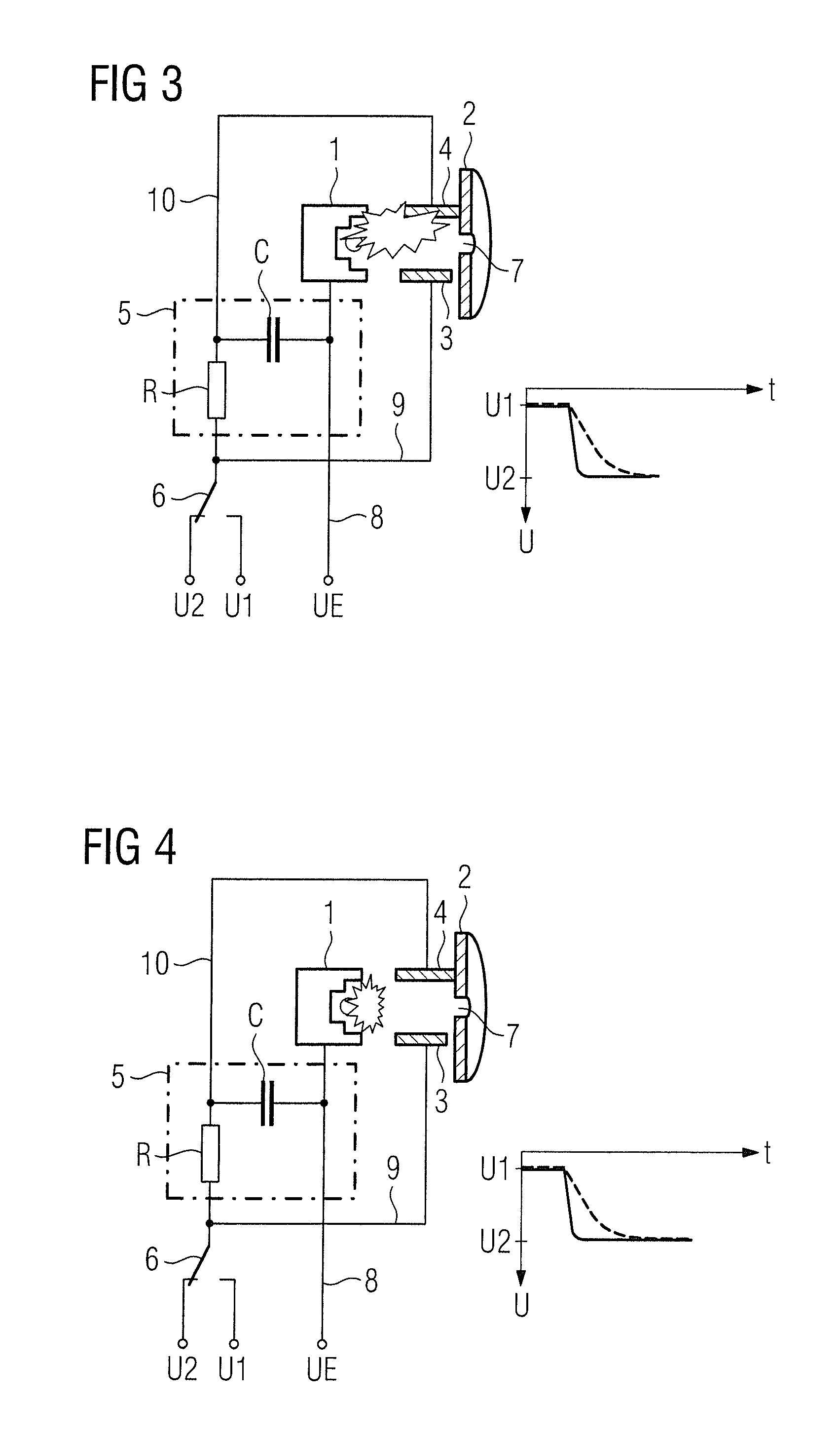

Device and method to control an electron beam for the generation of x-ray radiation, in an x-ray tube

ActiveUS20110038460A1Fast blockingSuppress generationX-ray tube electrodesCathode ray concentrating/focusing/directingSoft x rayVoltage

A device to control an electron beam for the generation of x-ray radiation, has an electron emitter to generate an electron beam, to which emitter an emitter voltage can be applied, a diaphragm, at least two control elements associated with the diaphragm to affect the electron beam, and switching arrangement with which at least two different electrical voltages can be applied to the at least two control elements. The same electrical voltage is applied to each of the at least two control elements. Upon switching the voltage, an electrical circuit that delays the setting of the respective voltage at the one control element is associated with the connection line of the one control element with the switching arrangement to switch over the voltage. The invention moreover concerns an operating method for the device and an x-ray tube provided with the device.

Owner:SIEMENS HEALTHCARE GMBH

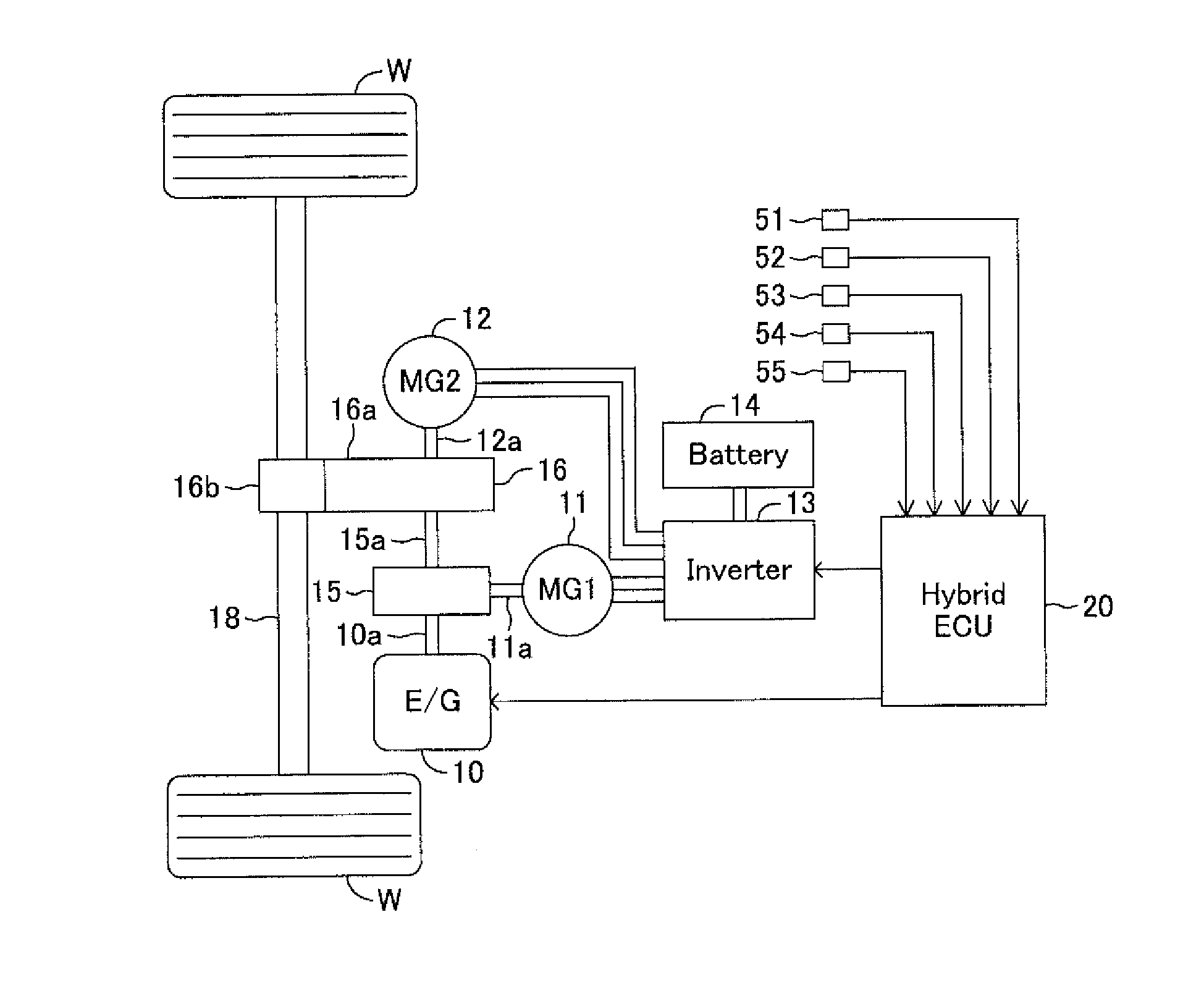

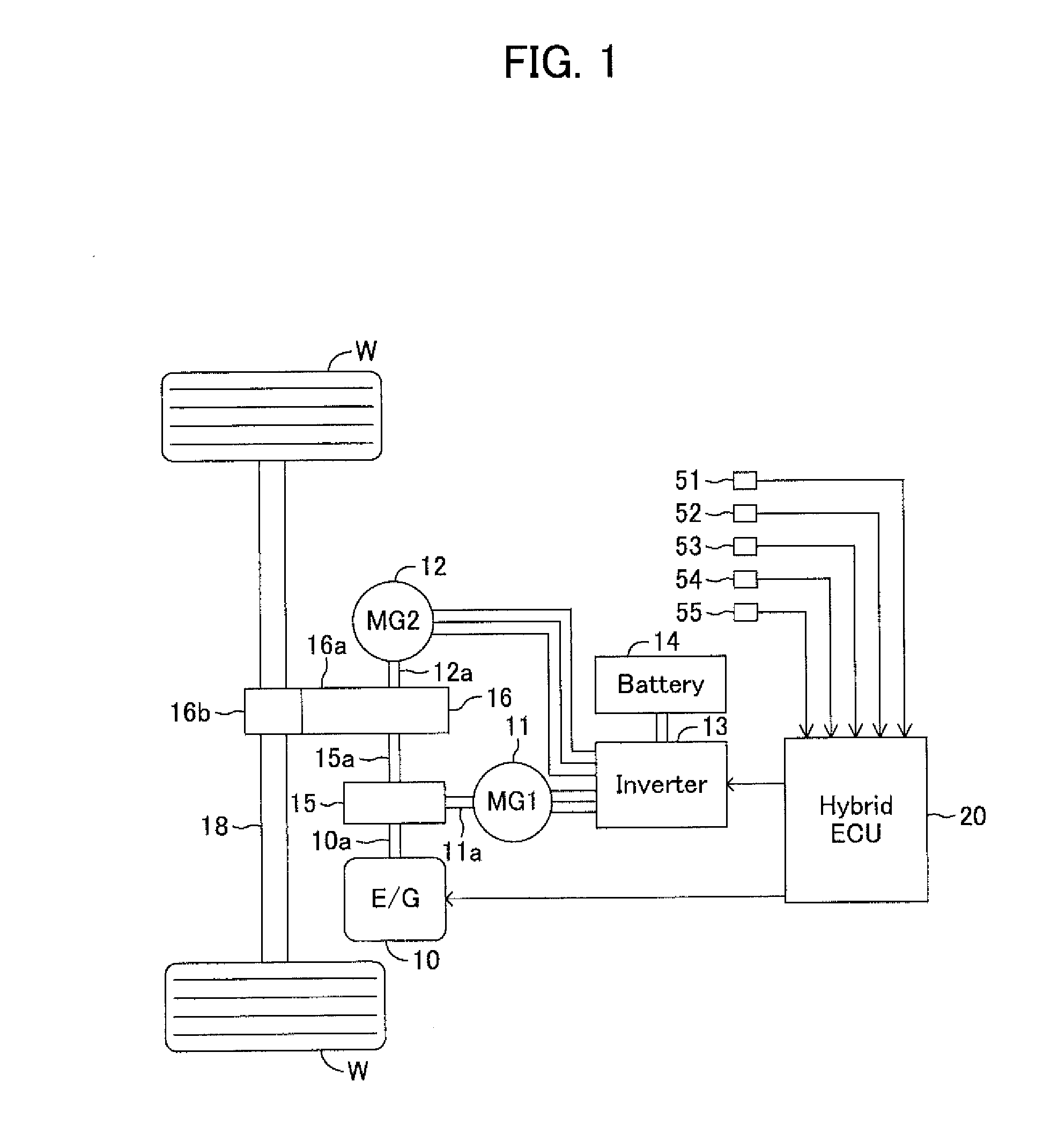

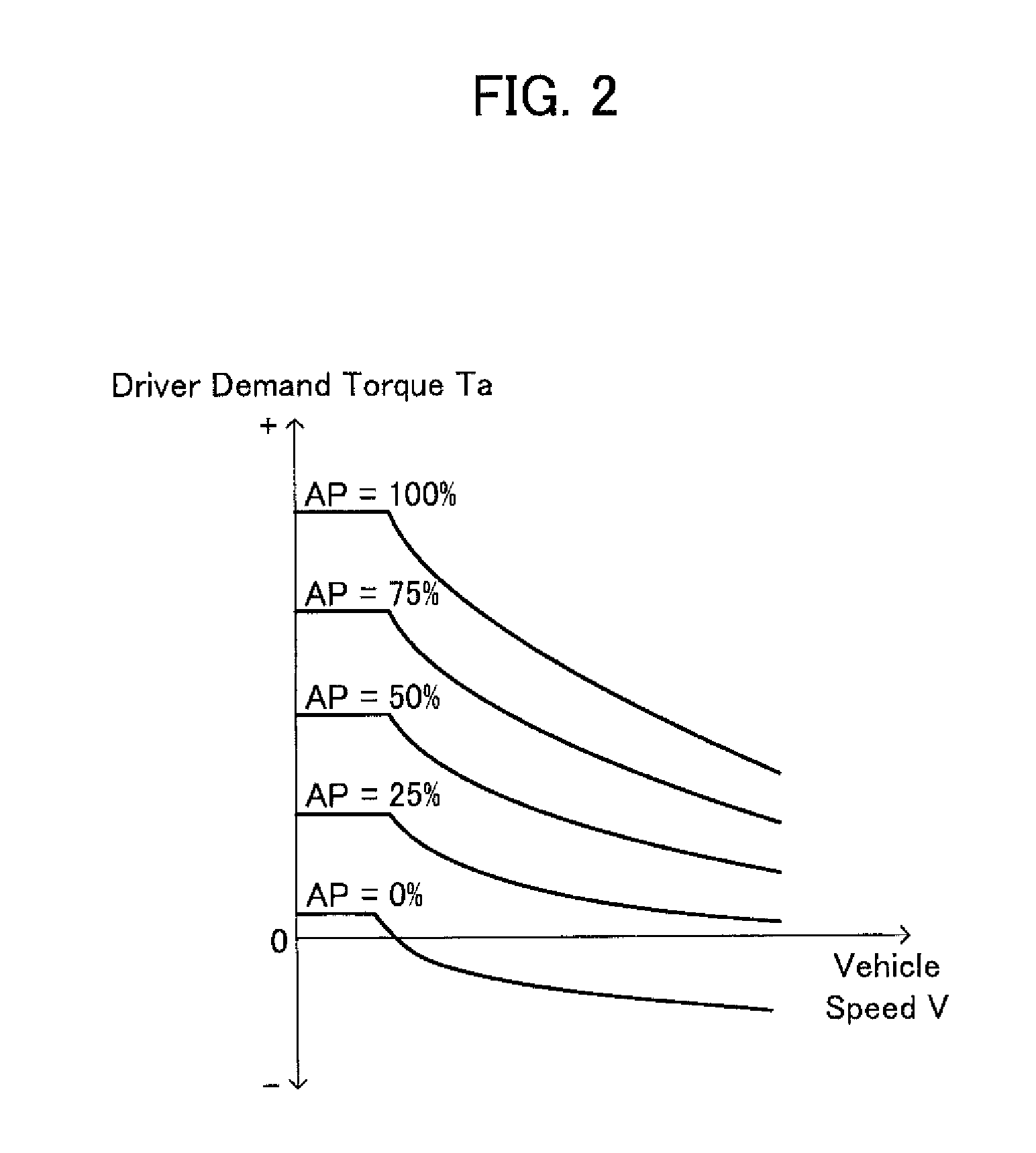

Driving-force control device for vehicle

ActiveUS20170036669A1Free runReduce necessityHybrid vehiclesPropulsion using engine-driven generatorsVertical vibrationControl theory

In a situation where it is predicted that a symbol of target torque reverses by turns to be positive and negative alternately, the hybrid ECU carries out an increasing correction of the target torque, in which the target torque is corrected by increasing the target torque by a set amount ΔT in a negative direction when a specific condition, in which it is judged that the degree of the vertical vibration of a vehicle body is larger than a standard value and it is judged there is no acceleration demand, is satisfied, and makes the vibration suppression control torque not to be contained in the target torque when the specific condition is not satisfied. Thereby, even when carrying out free run, the sprung vibration suppression control can be carried out during bad road running, and braking force can be suppressed and fuel consumption can be improved during good road running.

Owner:TOYOTA JIDOSHA KK

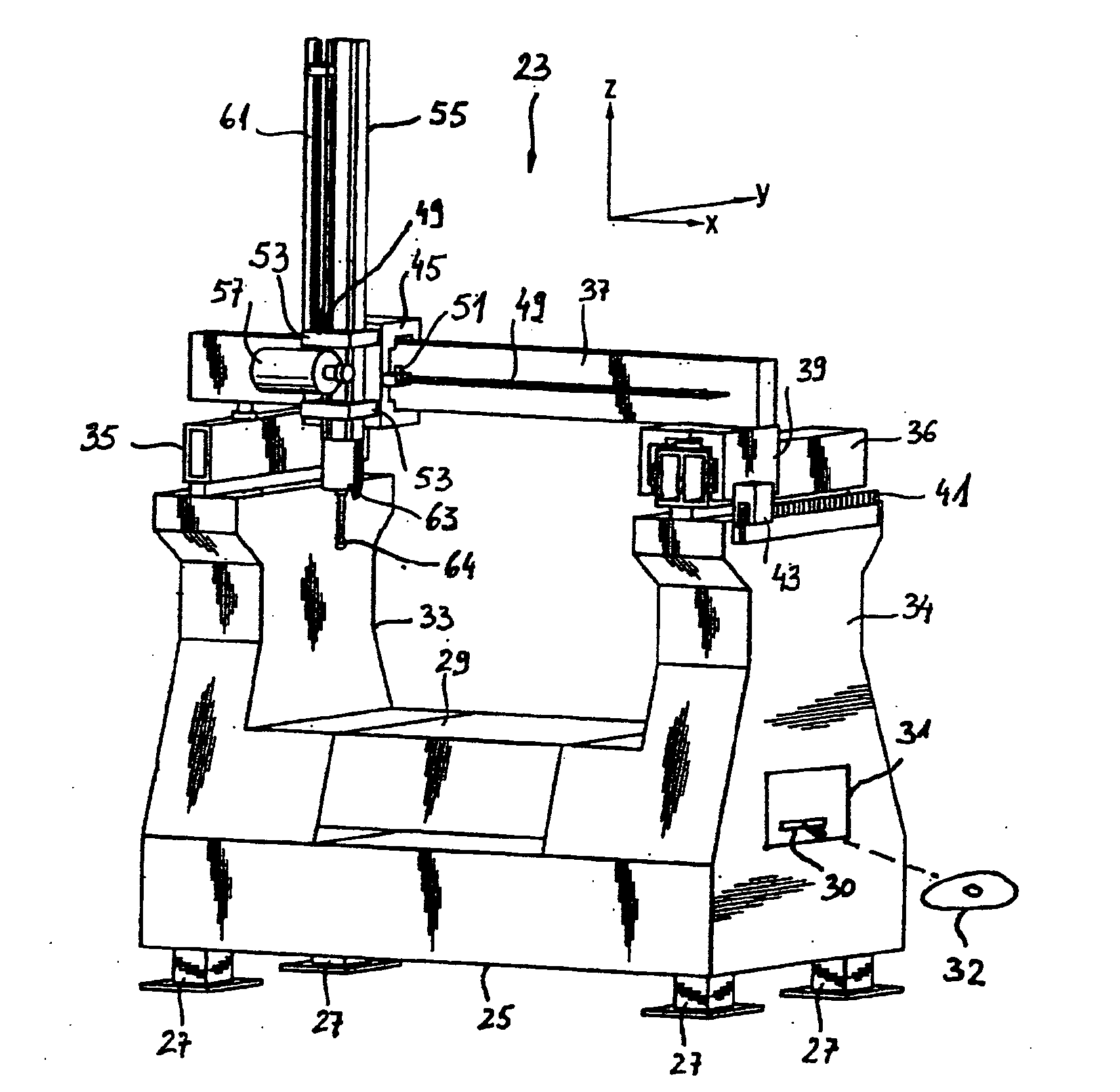

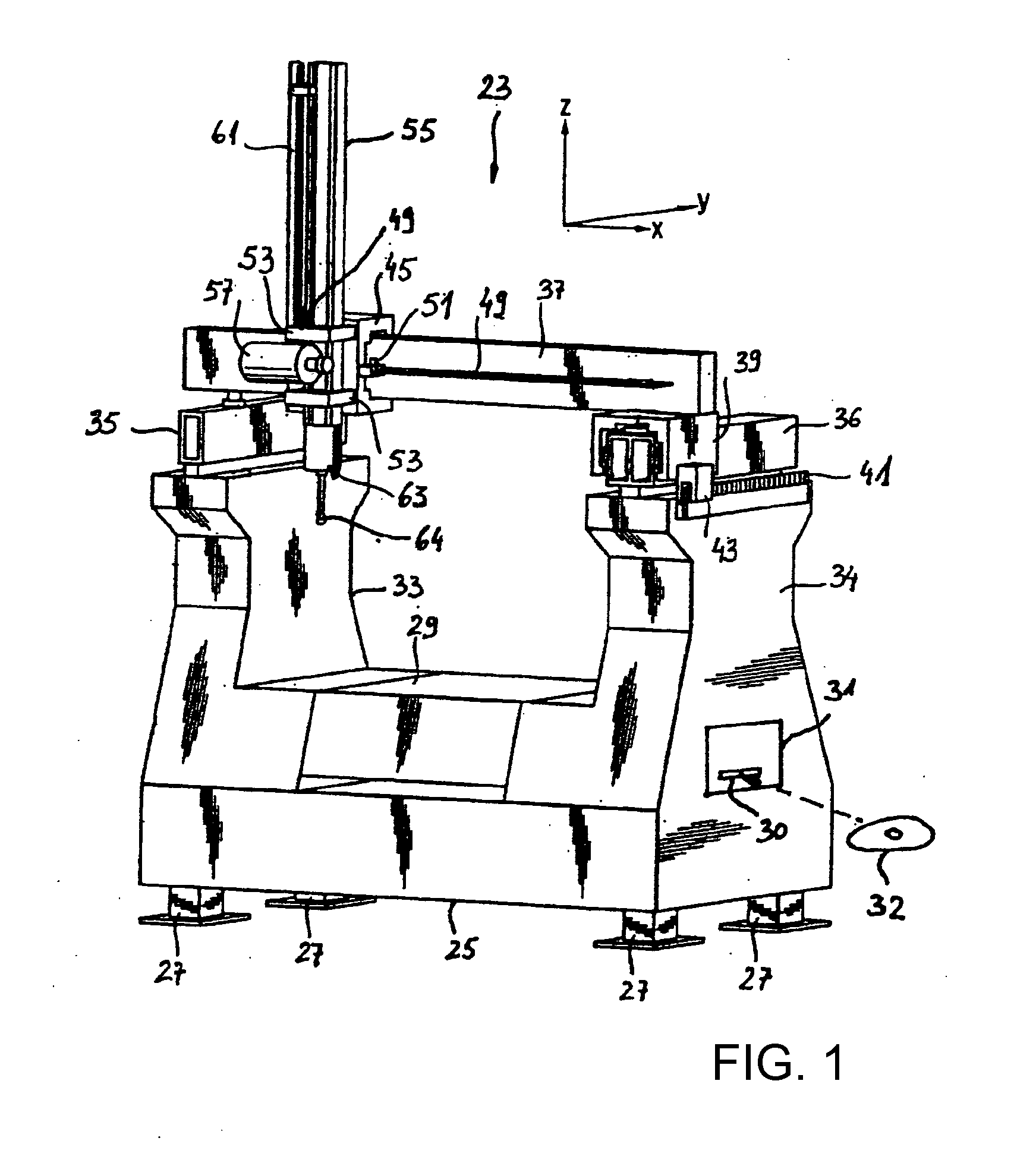

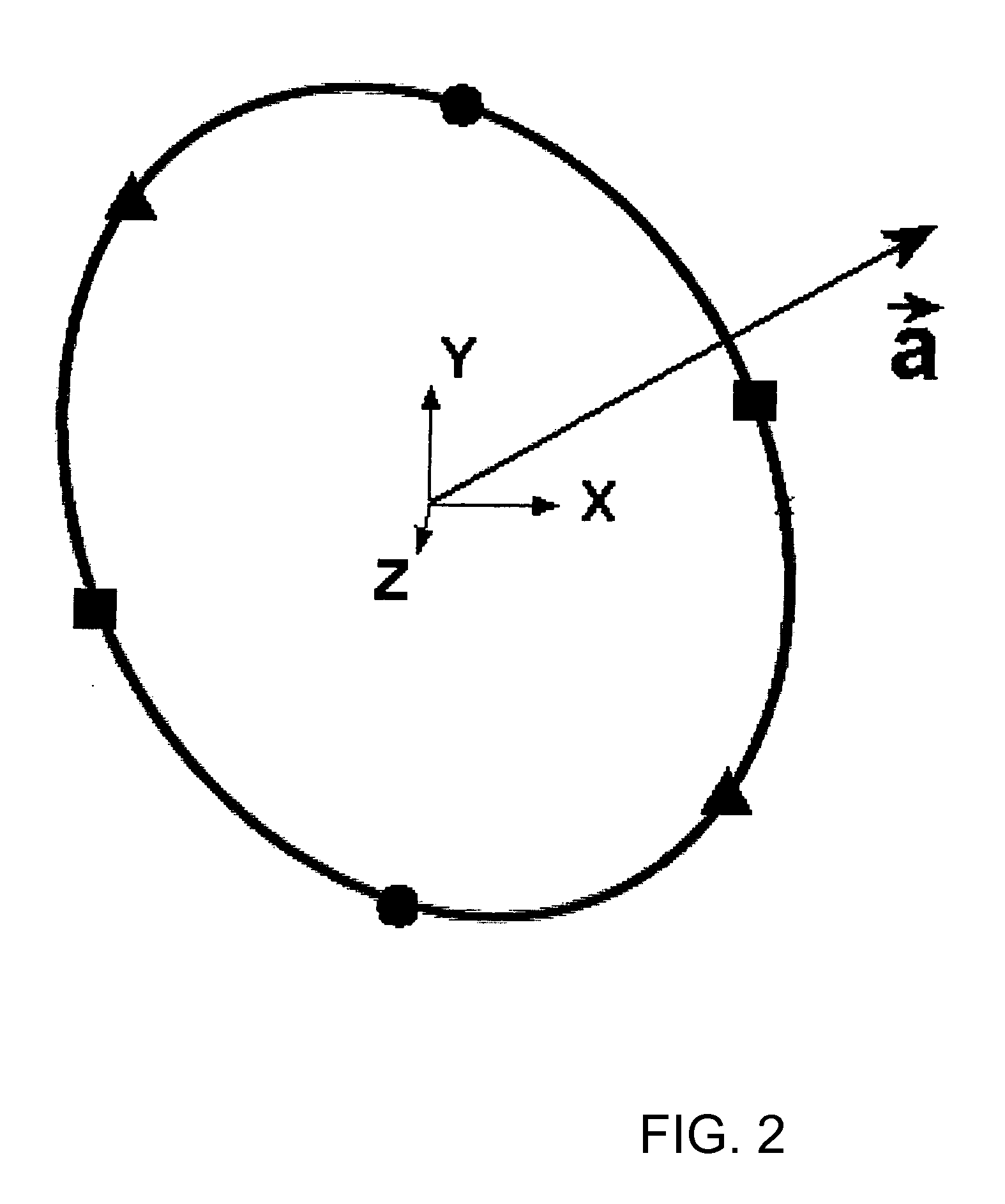

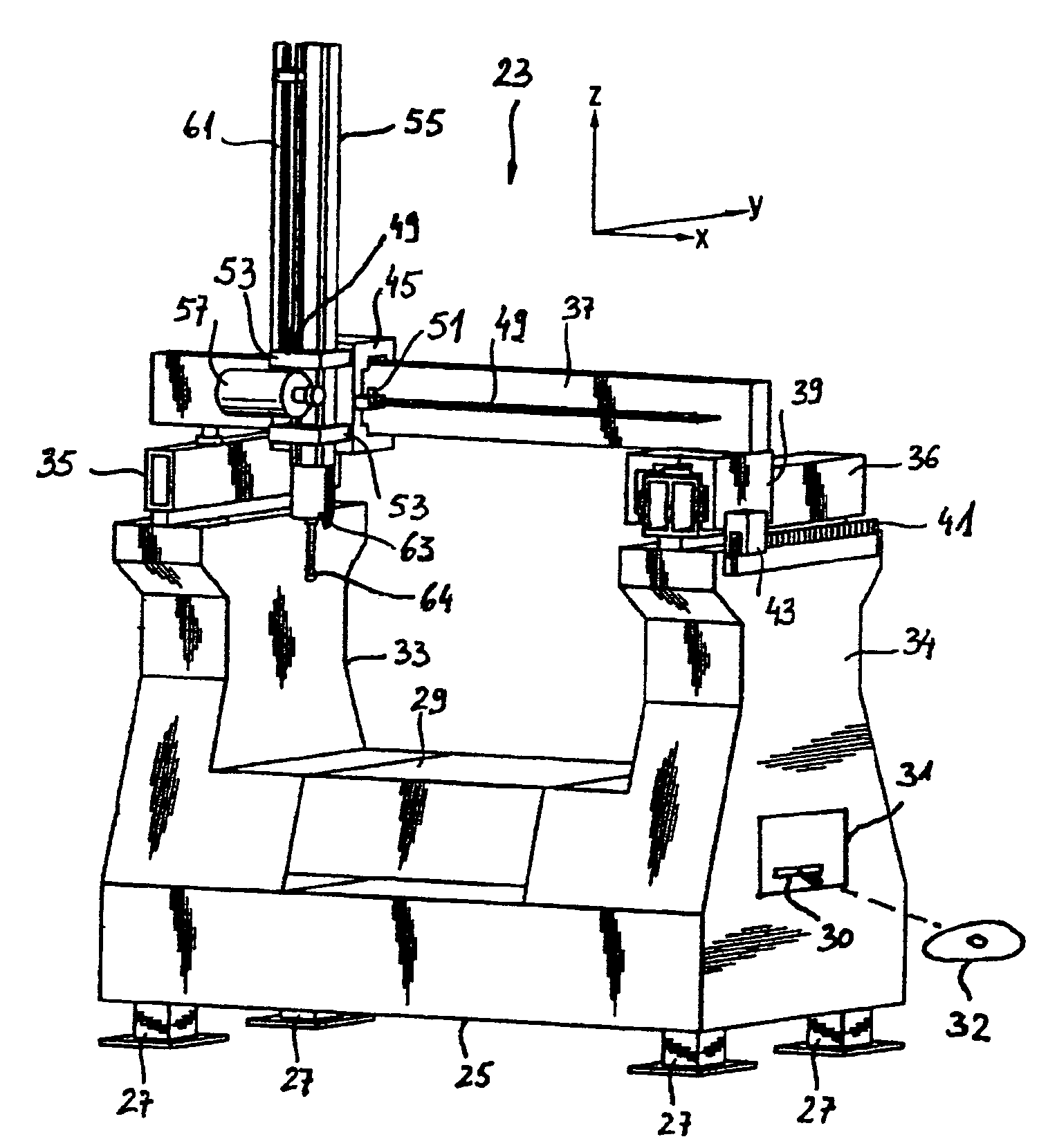

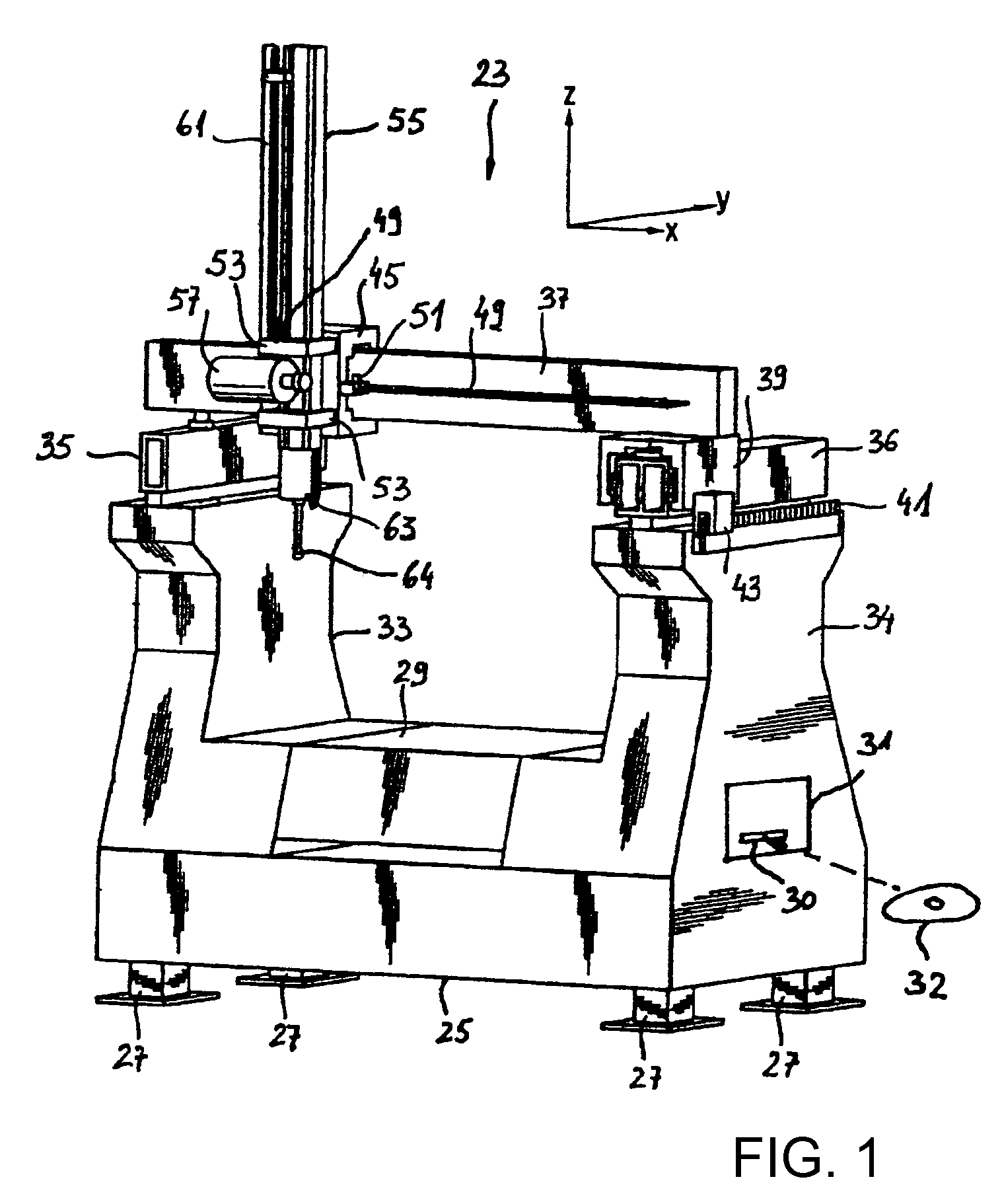

Method for Scanning a Surface with the Aid of a Coordinate Measuring Machine and Coordinate Measuring Machine

ActiveUS20080307662A1Huge savingsMeasuring period during scanning to be kept as shortMechanical measuring arrangementsMeasurement deviceDegrees of freedom

A method for scanning a work piece surface uses a coordinate measurement device. A probe element is brought into contact with the surface and the probe element is moved along the surface. The coordinate measurement device has a plurality of degrees of freedom, which are independent of one another, in the possible movements of the probe element with respect to the work piece. Maximum speeds which describe the maximum of a movement speed component of the probe element based on the respective degree of freedom are defined for the degrees of freedom. An estimated path on which the probe element is intended to move during scanning is predefined. The actual scanning path can differ from the estimated scanning path. A maximum scanning speed at which the estimated scanning path can be traveled with a constant speed of the probe element is determined.

Owner:CARL ZEISS IND MESSTECHN GMBH

Inverted pendulum type vehicle, and control method of inverted pendulum type vehicle

Owner:HONDA MOTOR CO LTD

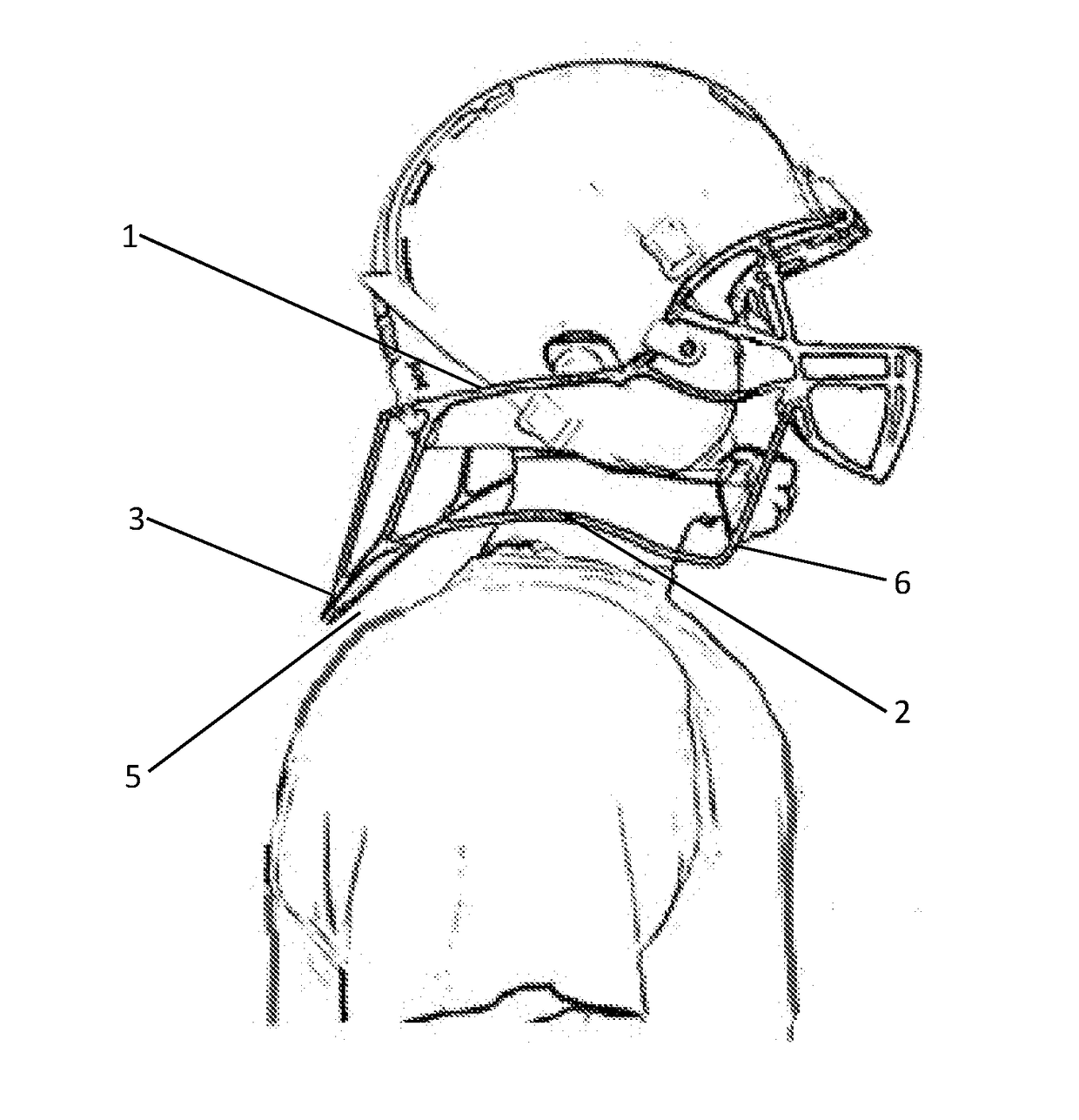

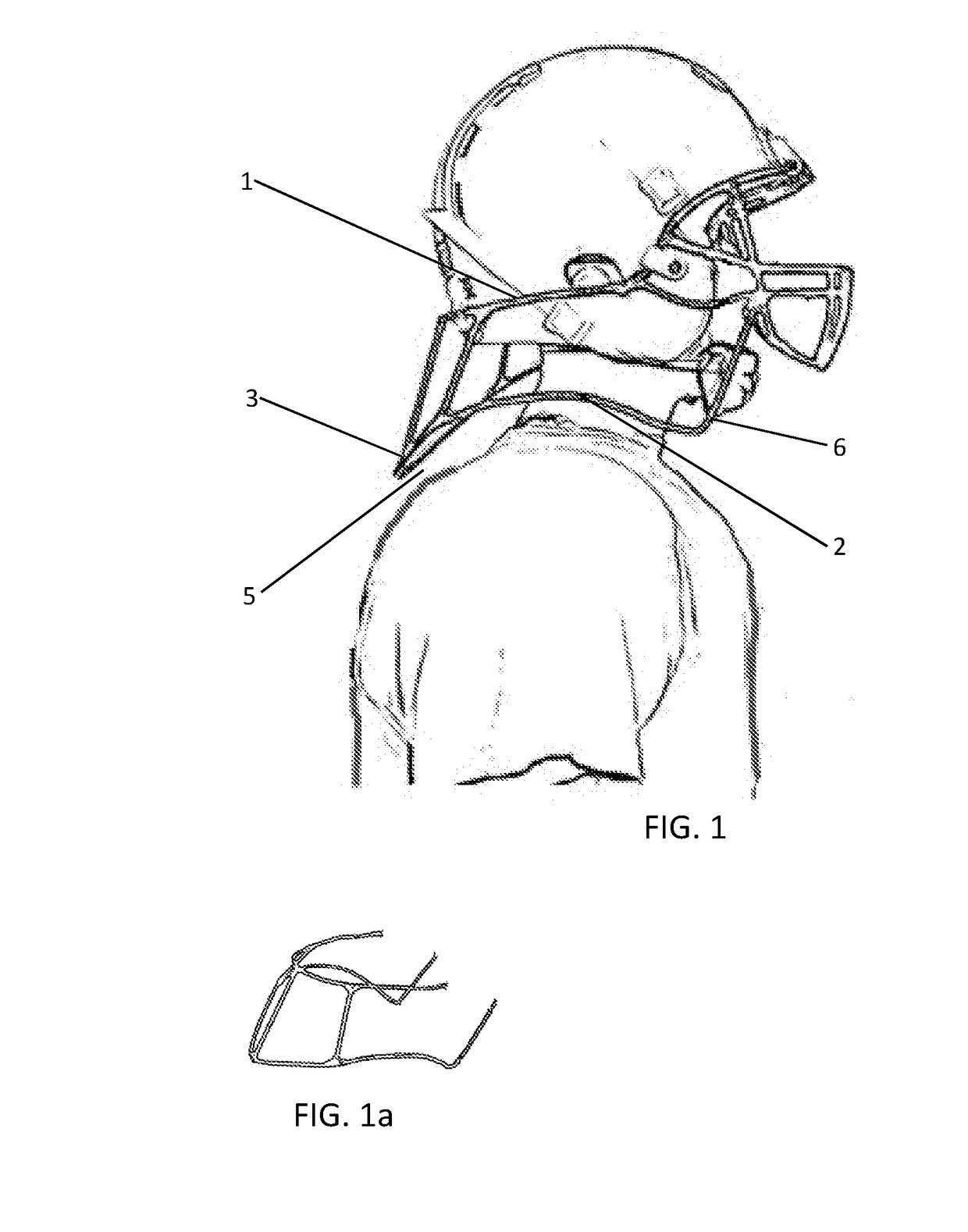

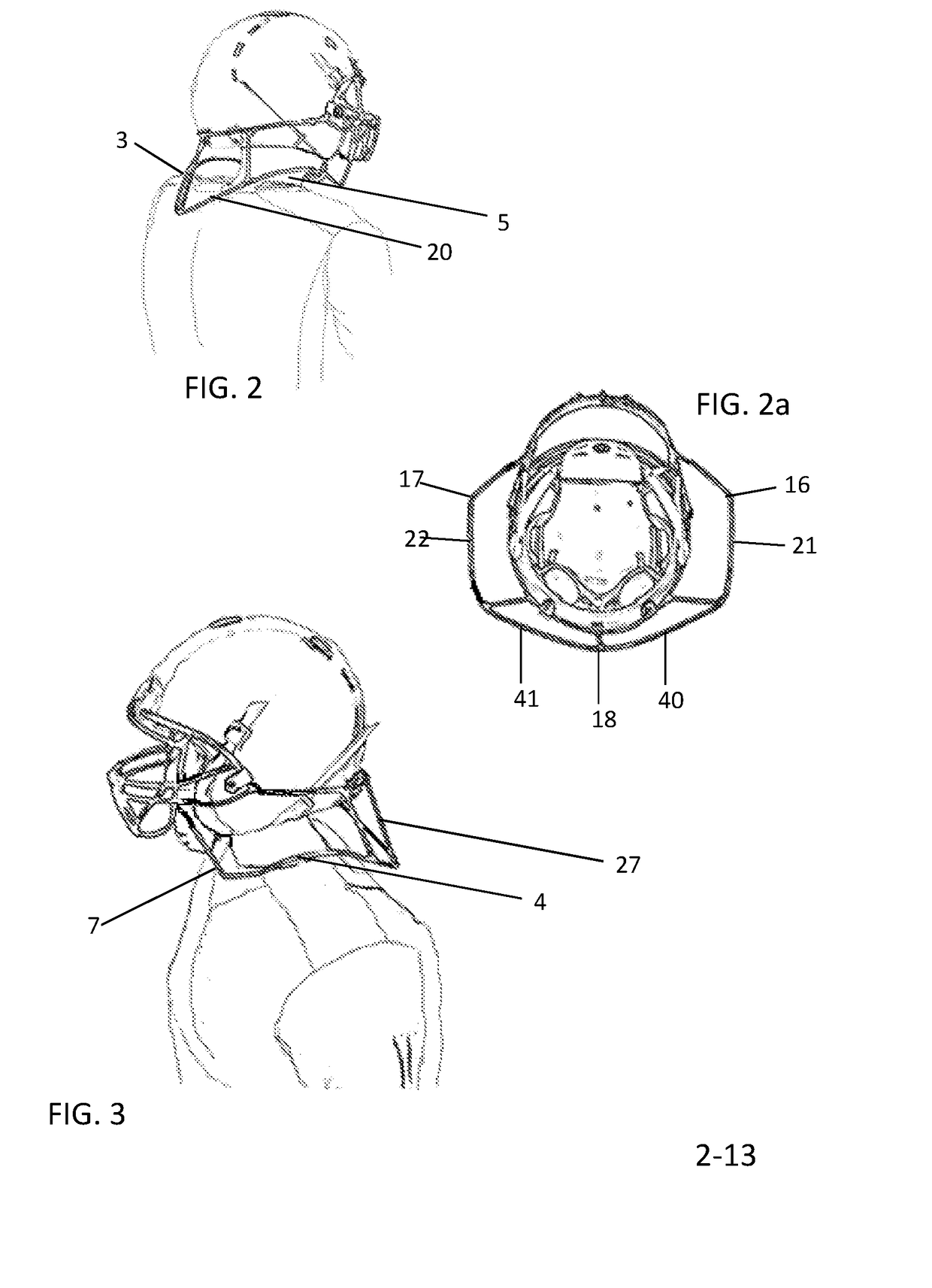

Concussive Reduction Helmet Attachment(s) Translational Axial Rotation Control and Bracing System (TARCBS).

InactiveUS20170251742A1Reduce brain damageAvailable spacePersonal protection gearSport apparatusTrauma injuryBody contact

A concussive reduction helmet attachment system which reduces the total area available for acceleration of the head in all axis, specifically designed to provide a measured reduction in accelerative force at the critical moment within the blow. A helmet attachment that reduces the factors that contribute to mechanical transfer of energy to the brain thereby reducing potential traumatic brain injury, concussions and neck compression. A helmet augmentation for body-contact sport helmets, also having utility for military ground based personnel helmets where blunt force trauma injury to the head and neck are apt to occur. A concussive helmet attachment having a Translational Axial Rotation Control Bracing System (TARCBS) that transfers mechanical energy to the torso, reduces available area for linear and rotational acceleration while reducing potential for neck and spinal injury. A concussive helmet attachment having two construction types, single and multiple component and three embodiments: hard, soft and mechanical.

Owner:PARTLO LOREN GEORGE

Tight coupling of GPS and navigation estimates with reduced or eliminated inertial measurement unit data

ActiveUS7916070B2Easily integrated into existing navigation filter designImprove the environmentPosition fixationSatellite radio beaconingData translationSystem configuration

A system and method for generating a navigation solution in high interference and dynamic environments using Global Positioning System (GPS) and navigation such as dead reckoning is described. The system configuration is a multi-satellite tracking loop structure obtained by closing each satellite's tracking loop through a multi-state navigation filter. This generates a robust navigation solution that can track GPS signals in a lower signal to noise ratio than can the standard GPS tightly coupled tracking loops. The system contains an Advanced Tightly Coupled (ATC) tracking processor which accepts early, late, and on-time I and Q data from the GPS signal tracker and outputs vehicle to satellite range, range rate and range acceleration residual measurements to a navigation Kalman filter. The ATC includes nonlinear discriminators which transform I and Q data into residual measurements corrupted by unbiased, additive, and white noise. It also includes an amplitude estimator configured to operate in rapidly changing, high power noise; a measurement noise variance estimator; and a linear residual smoothing filter for input to the navigation filter.

Owner:L3 TECH INC

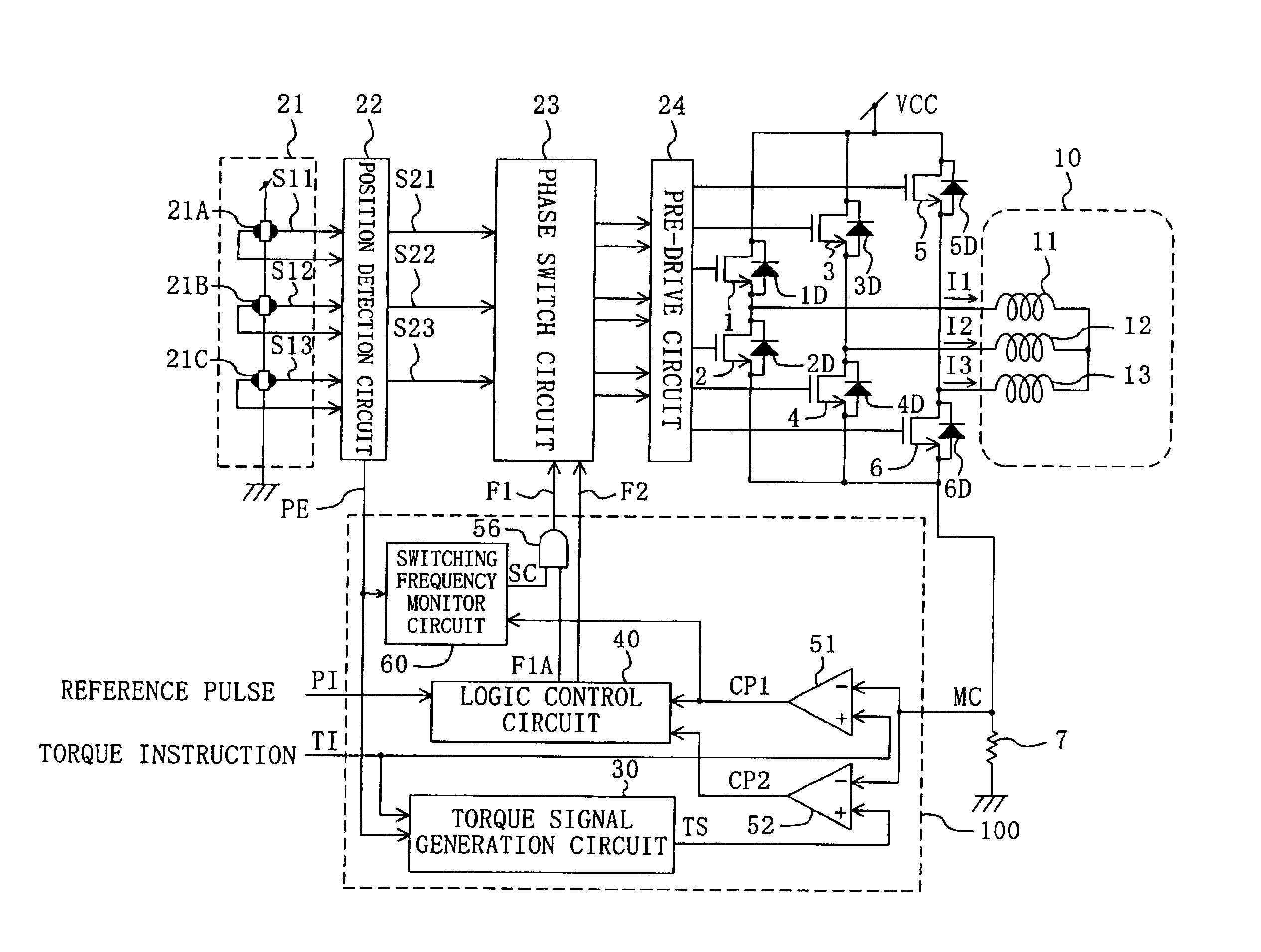

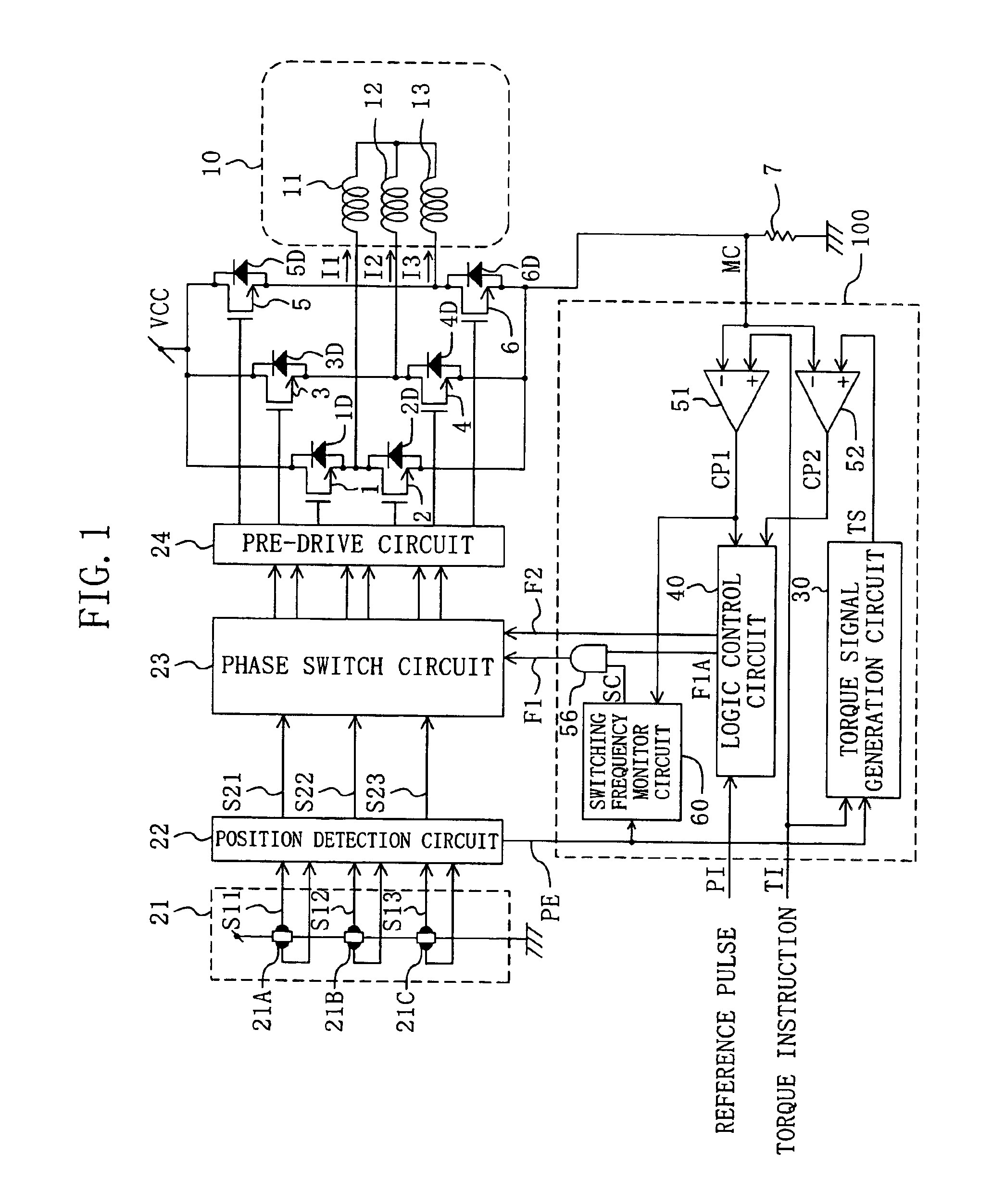

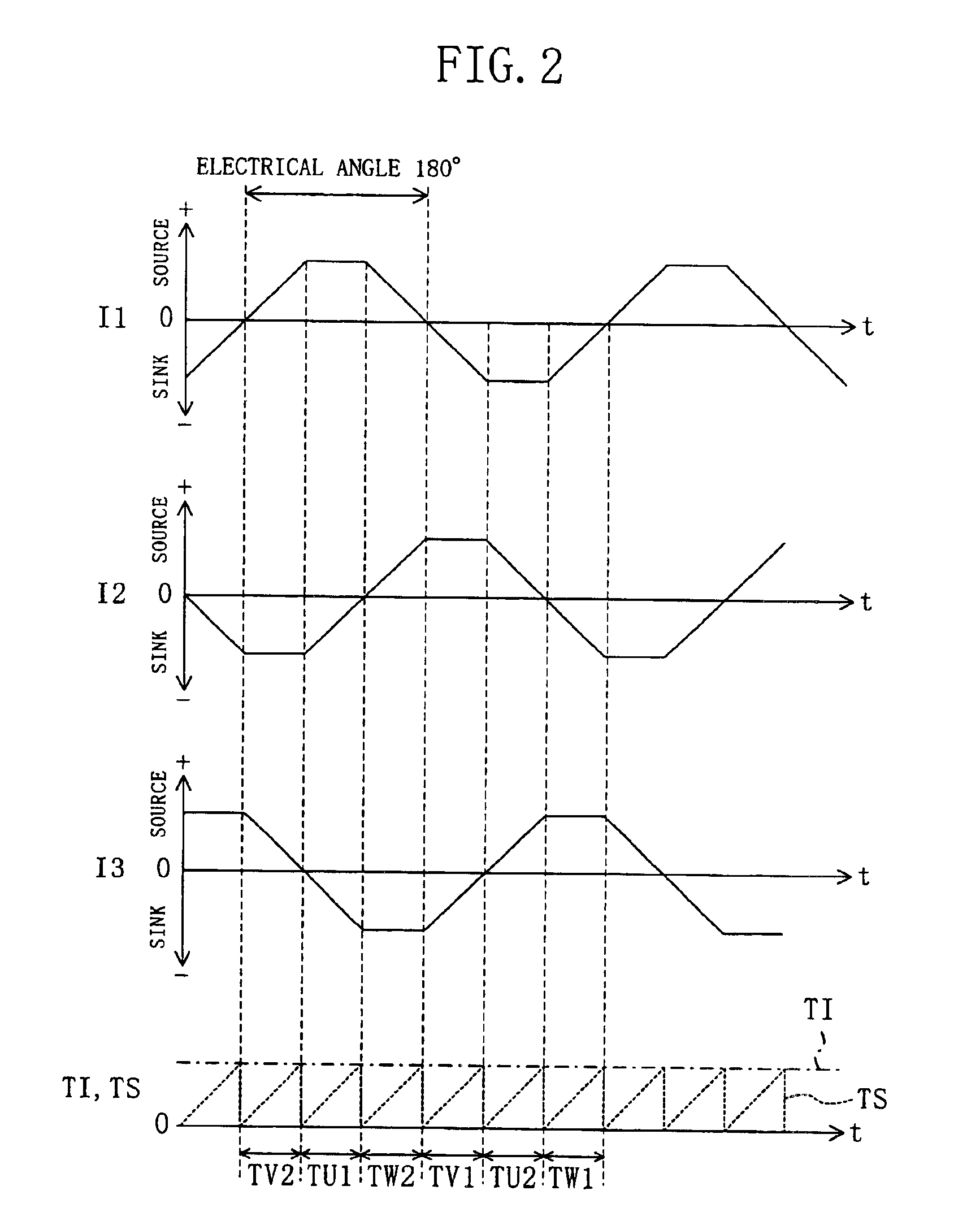

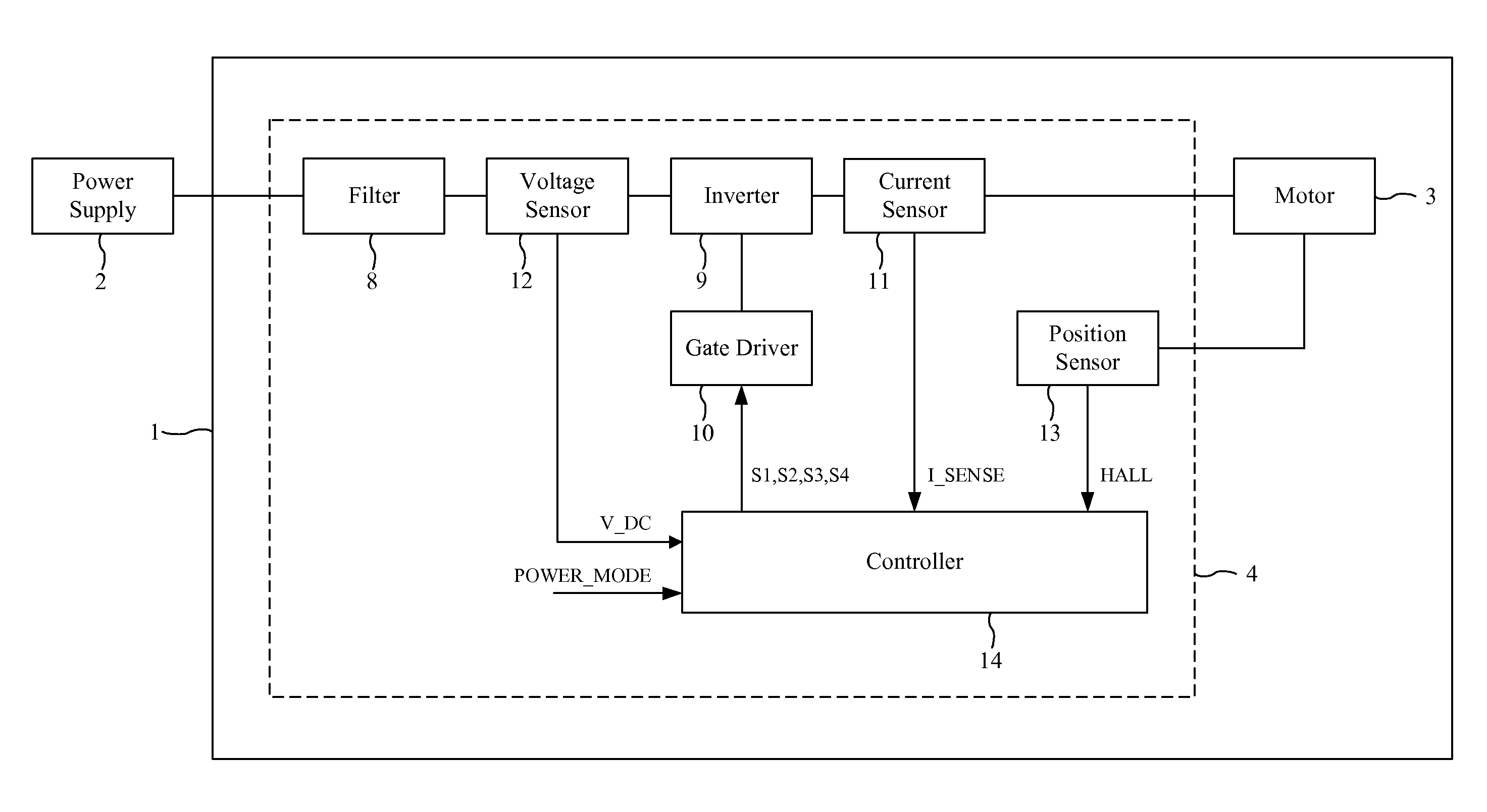

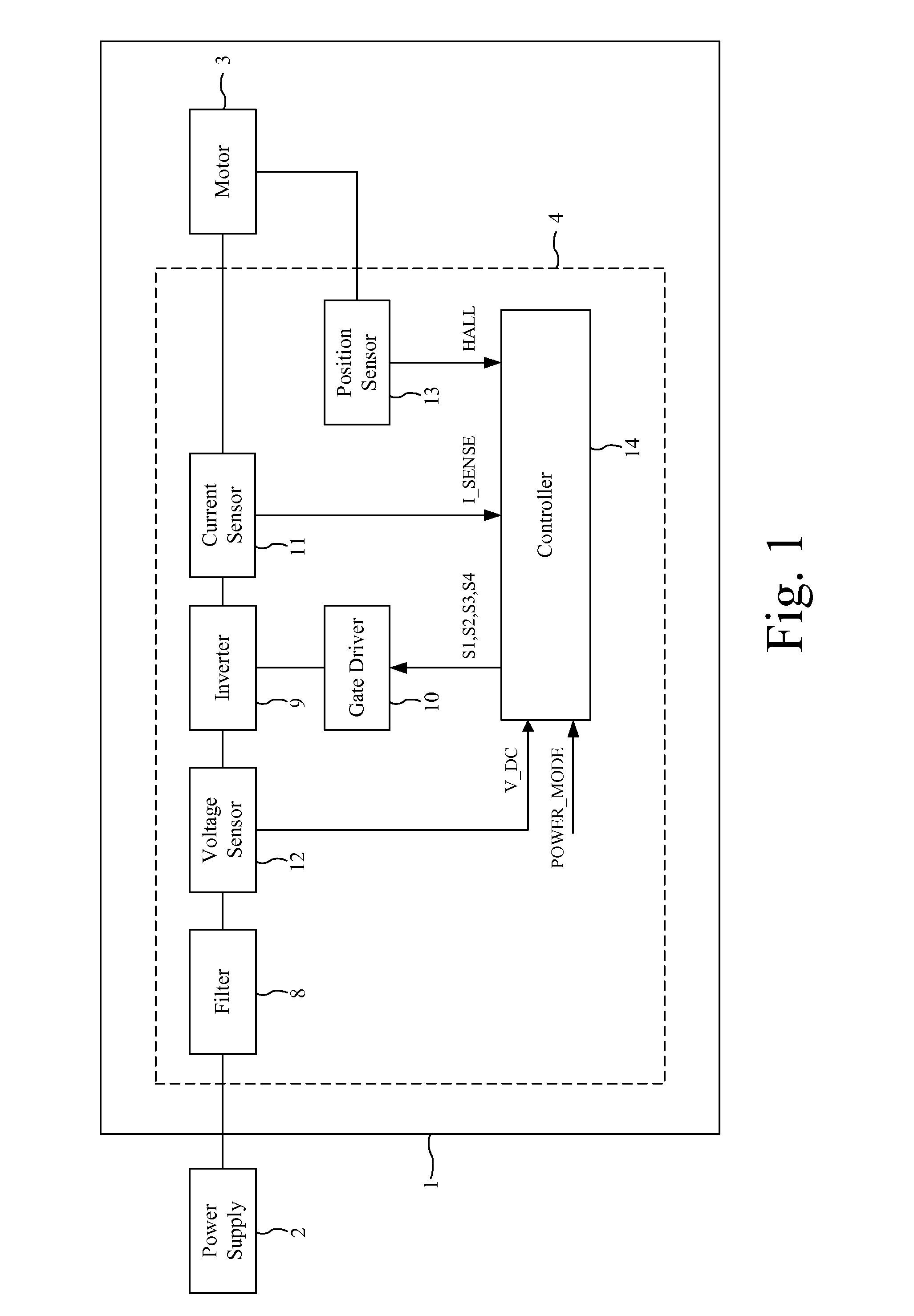

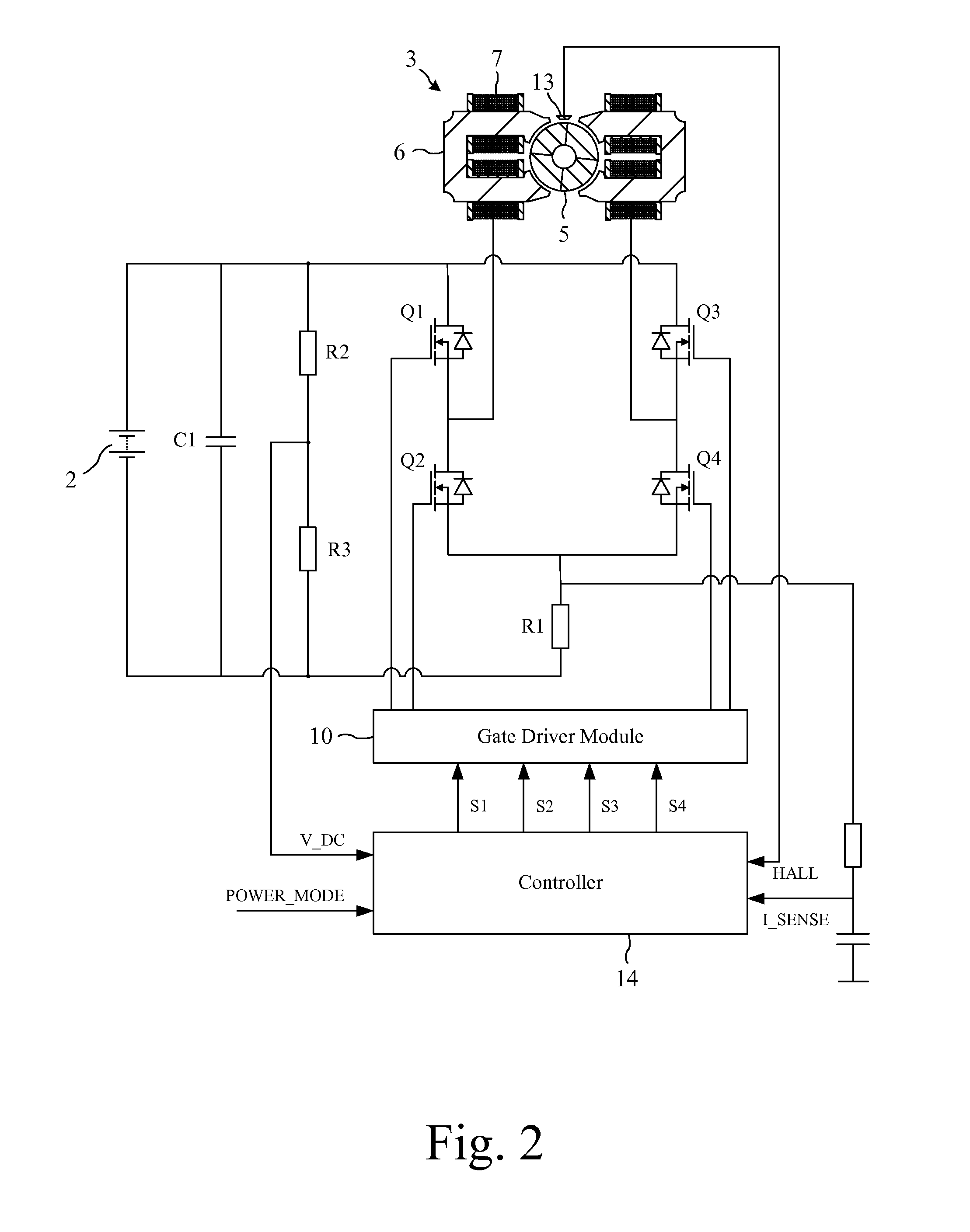

PWM controlled motor drive

InactiveUS6969963B2Low efficiencyOperation can be performedCommutation monitoringSynchronous motors startersMotor driveElectric machine

The motor driver having a plurality of output circuits each having two switching elements connected in series includes: a phase switch circuit for putting a switching element on one side of one output circuit among the plurality of output circuits in the ON state during a time period corresponding to a predetermined electrical angle, and performing switching operation for switching elements on the other side of plural output circuits among the remaining output circuits; and a conduction period control section. The conduction period control section generates a signal for controlling the switching operation. Specifically, when the number of times of switching operation performed during the time period corresponding to the predetermined electrical angle is equal to or less than a predetermined value, a switching element corresponding to a phase, for which the magnitude of the current should be decreased, is turned OFF in the time period corresponding to the next predetermined electrical angle.

Owner:PANASONIC CORP

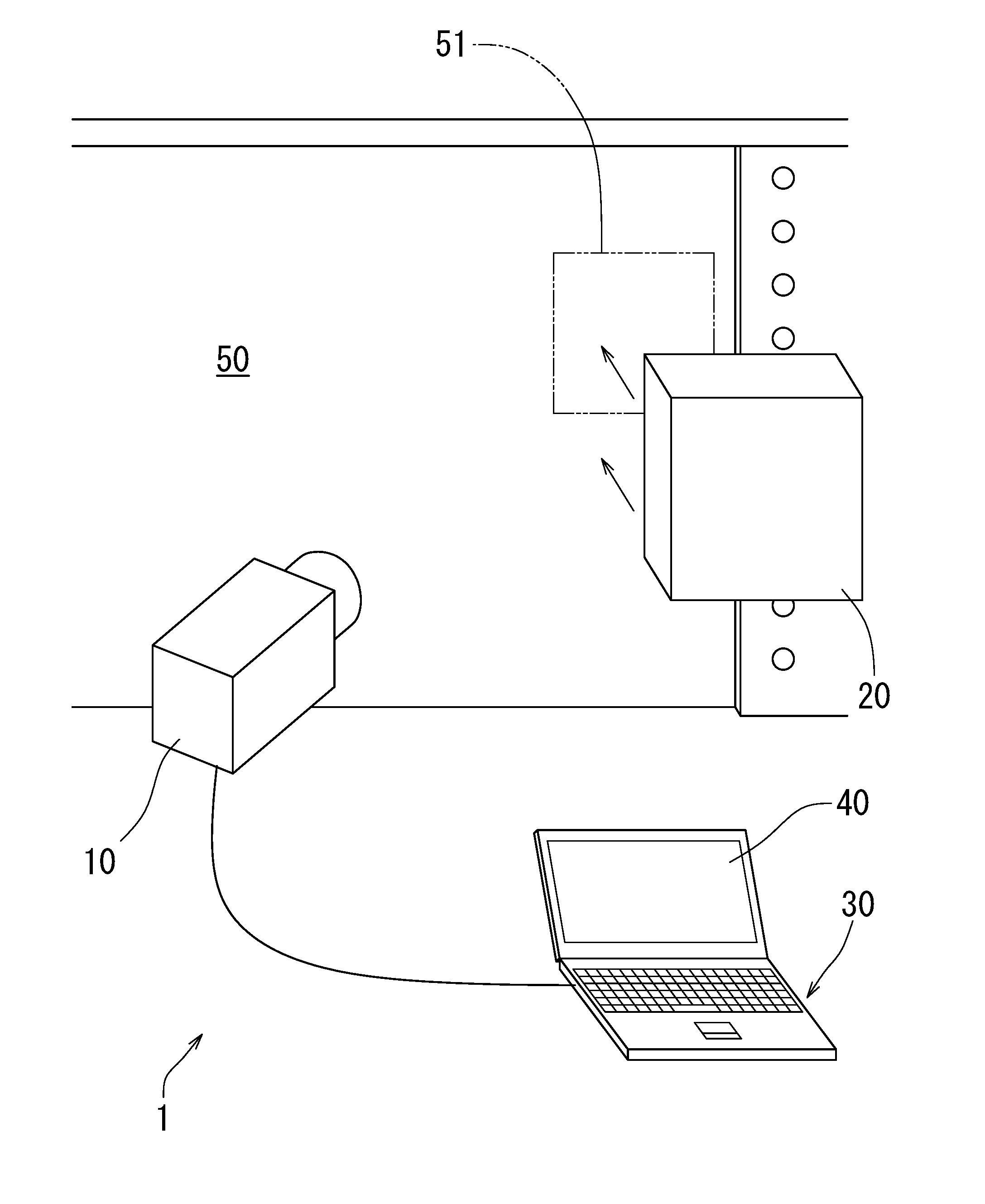

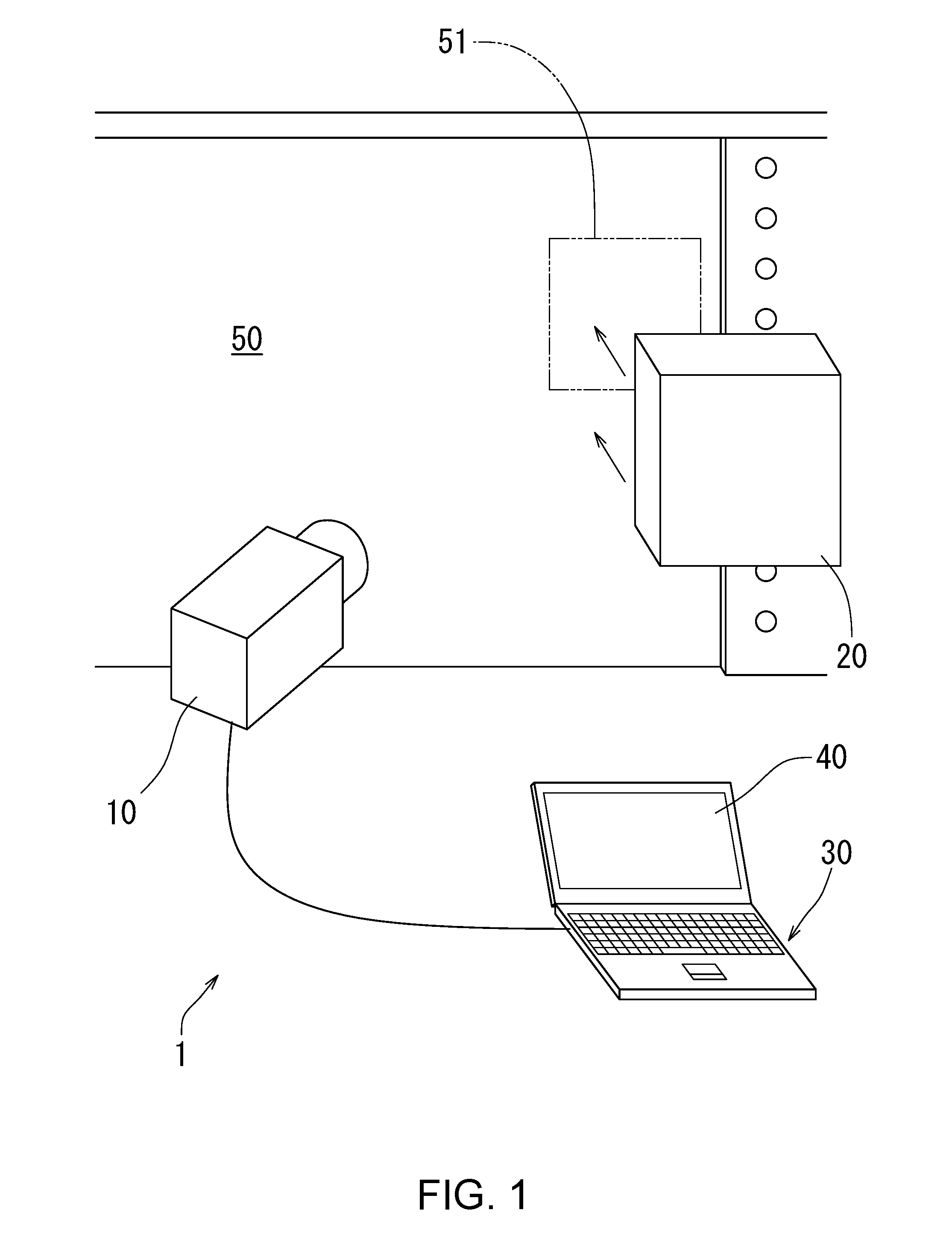

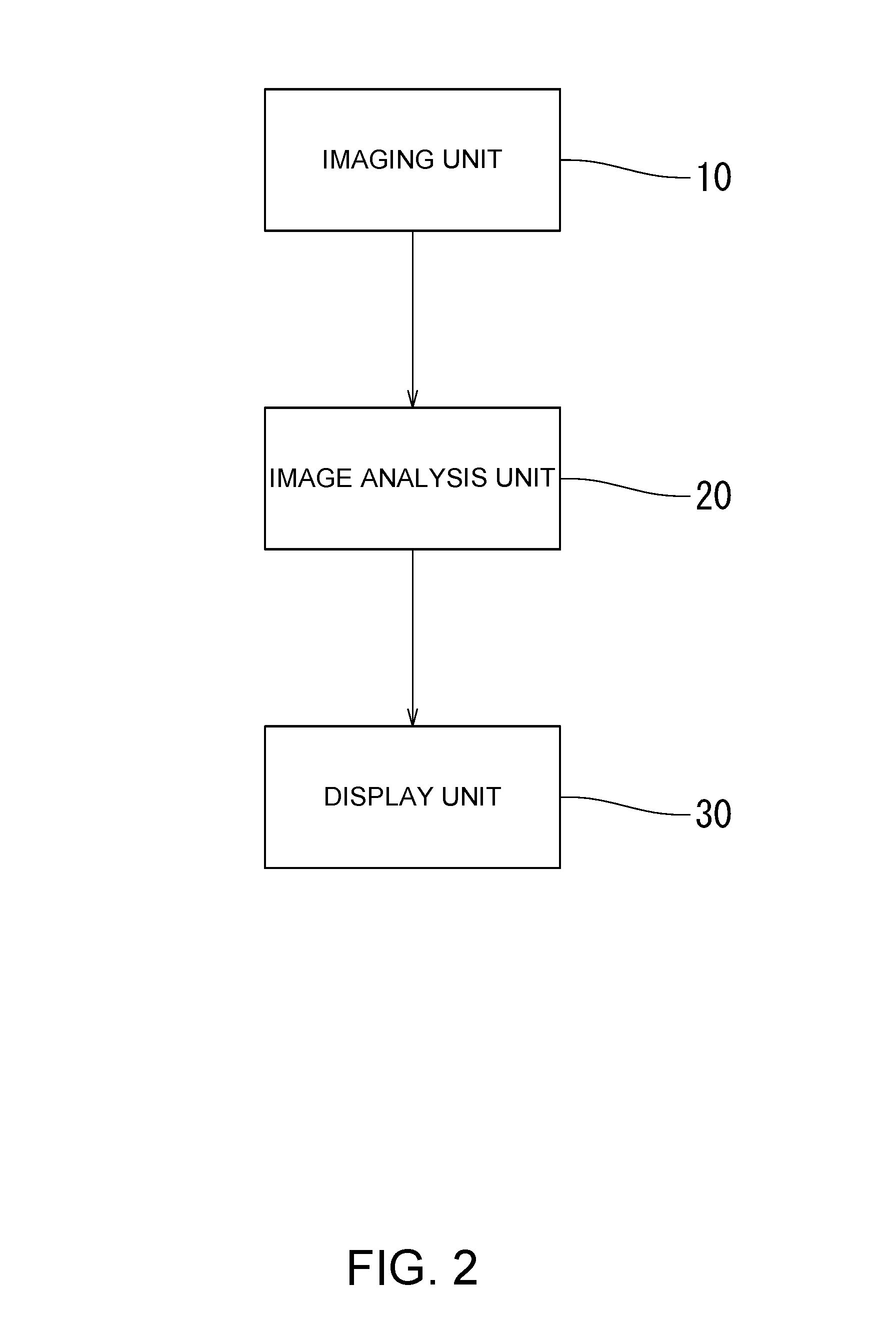

Cracking detection system and cracking detection method

InactiveUS20160252464A1Magnitude is largeMany stepsCoil arrangementsMaterial flaws investigationImaging analysisEngineering

There is provided a crack detection system in which a crack can be detected from a strain distribution of a part to be detected of an object. After taking the image of the part to be detected of the detection object by the imaging unit, the heat is applied by the heating unit. Furthermore, image of the part to be detected are taken again and an image analysis unit analyzes the images before and after applying the heat to acquire a strain distribution of the part to be detected, so that the crack can be detected based on difference in a state of strain between a place where the crack exist and the other place. Therefore, taking the images of the part to be detected including its coating layer enables the analysis to progress without removing the coating layer to detect the crack.

Owner:SAGA UNIVERSITY +1

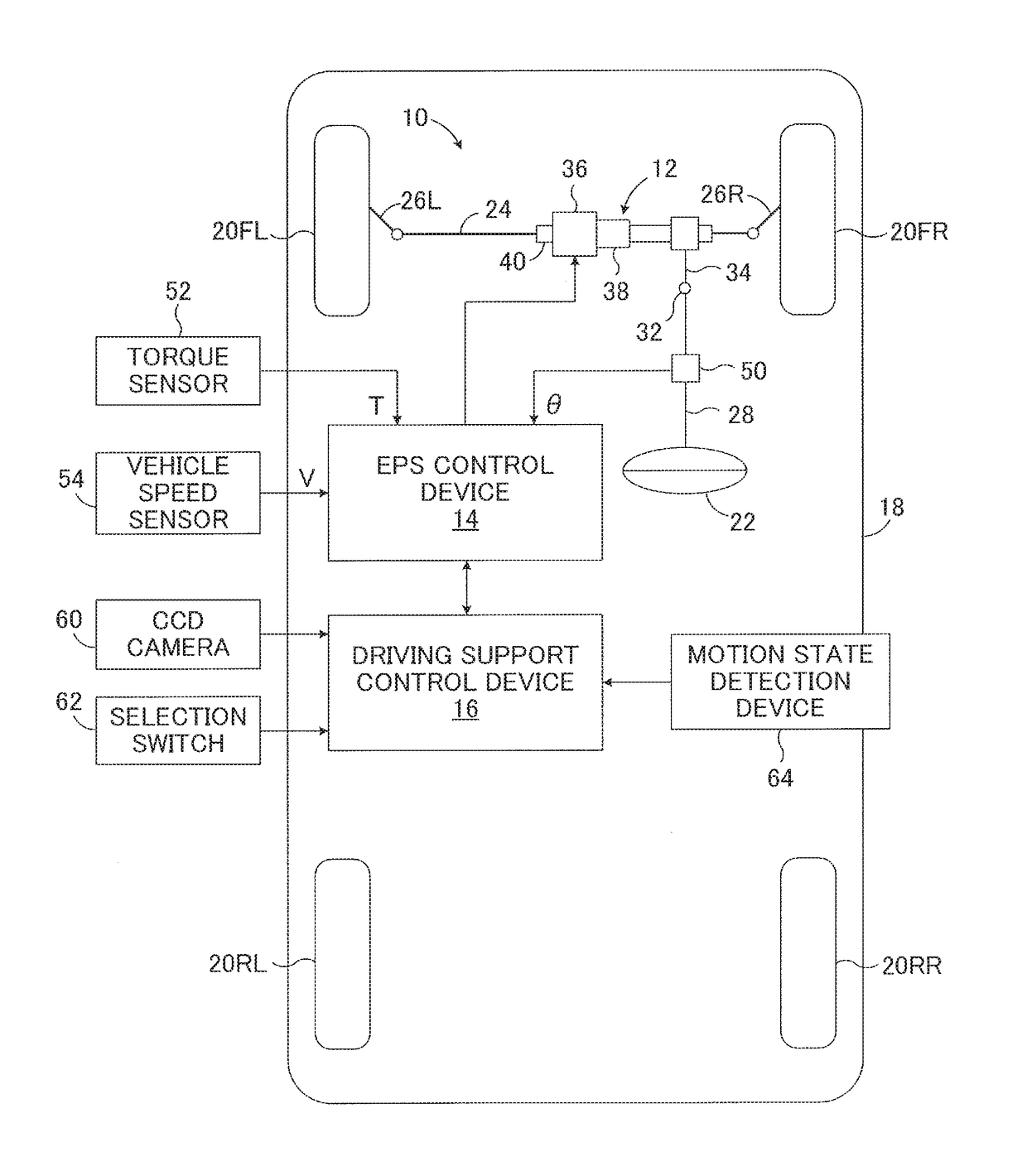

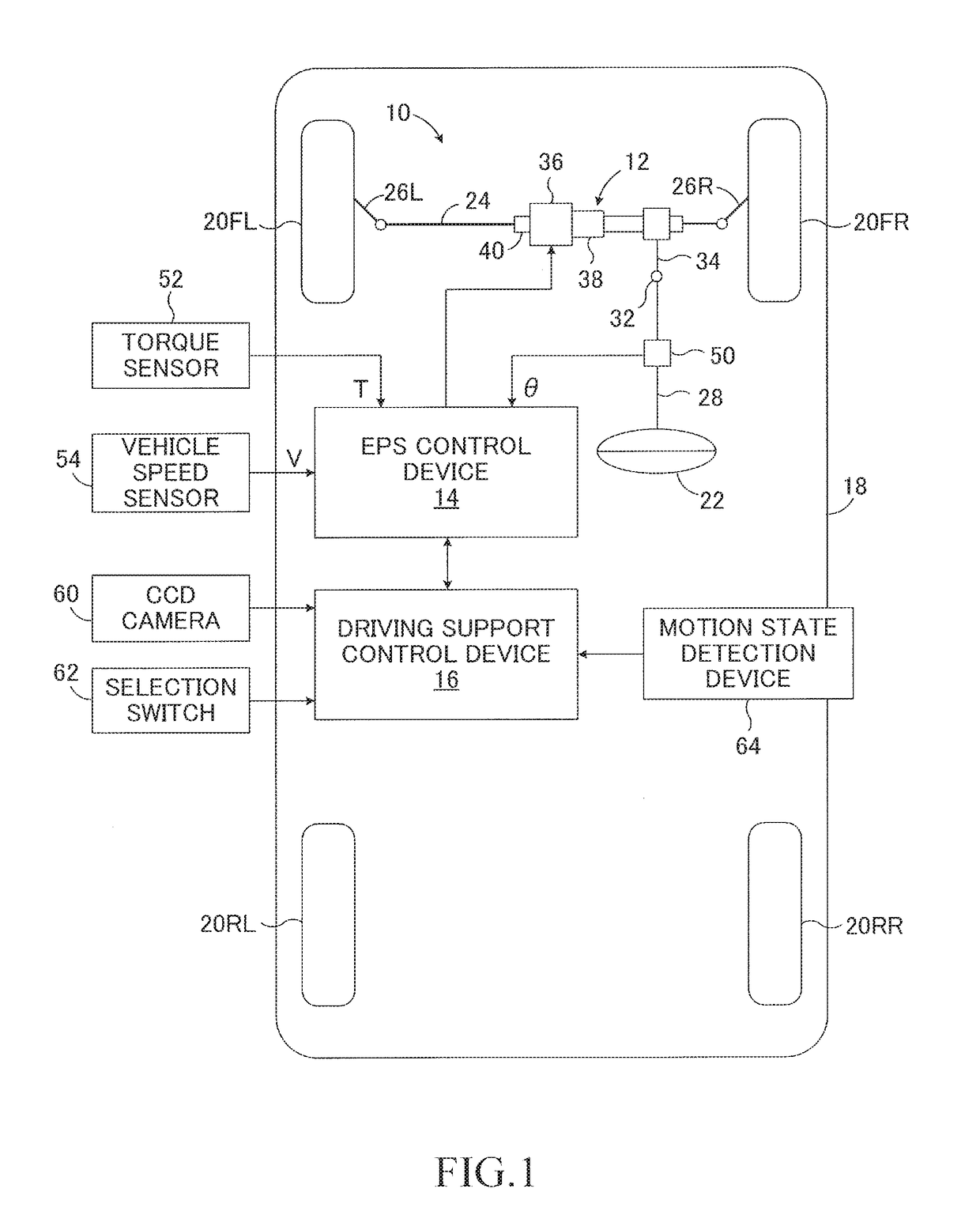

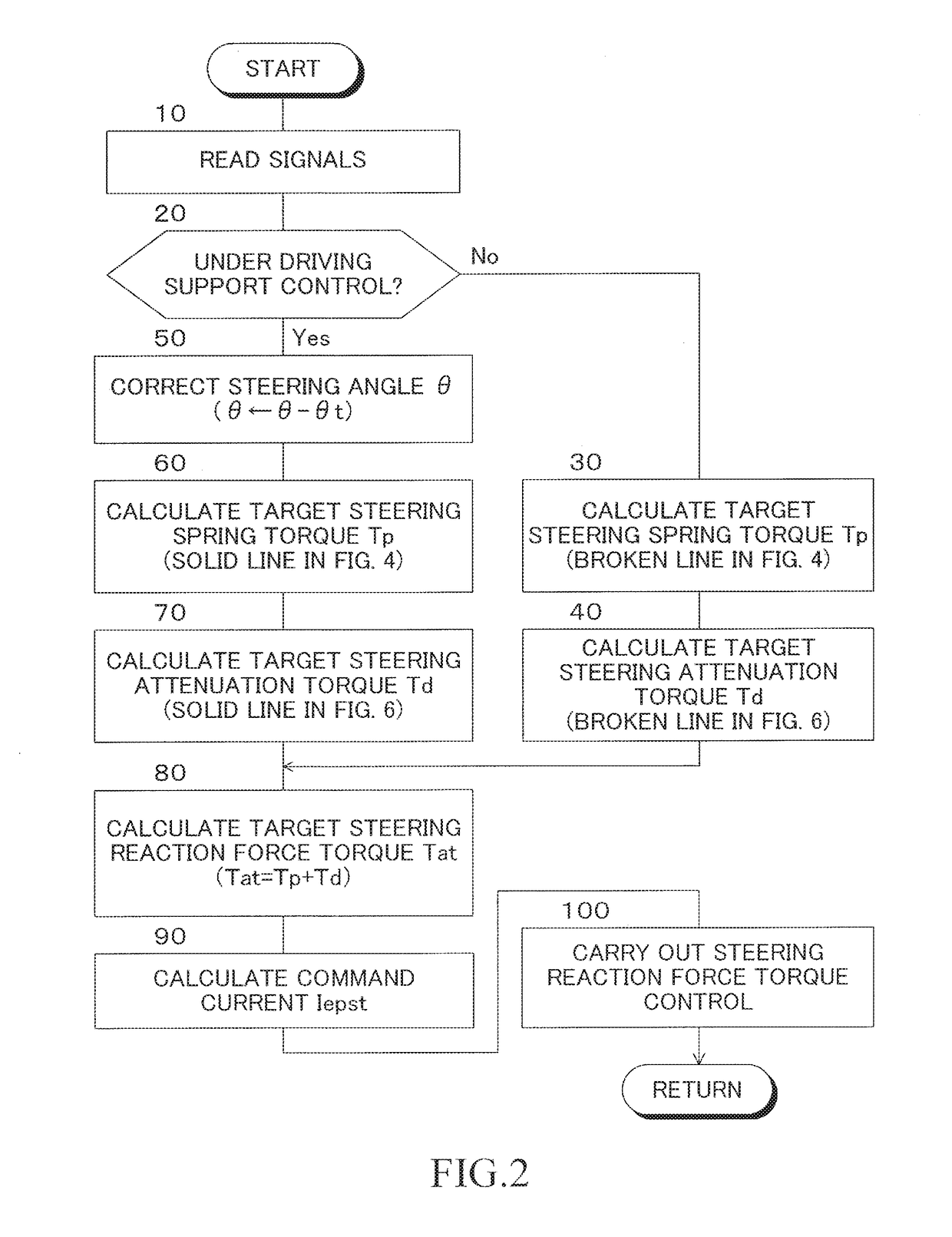

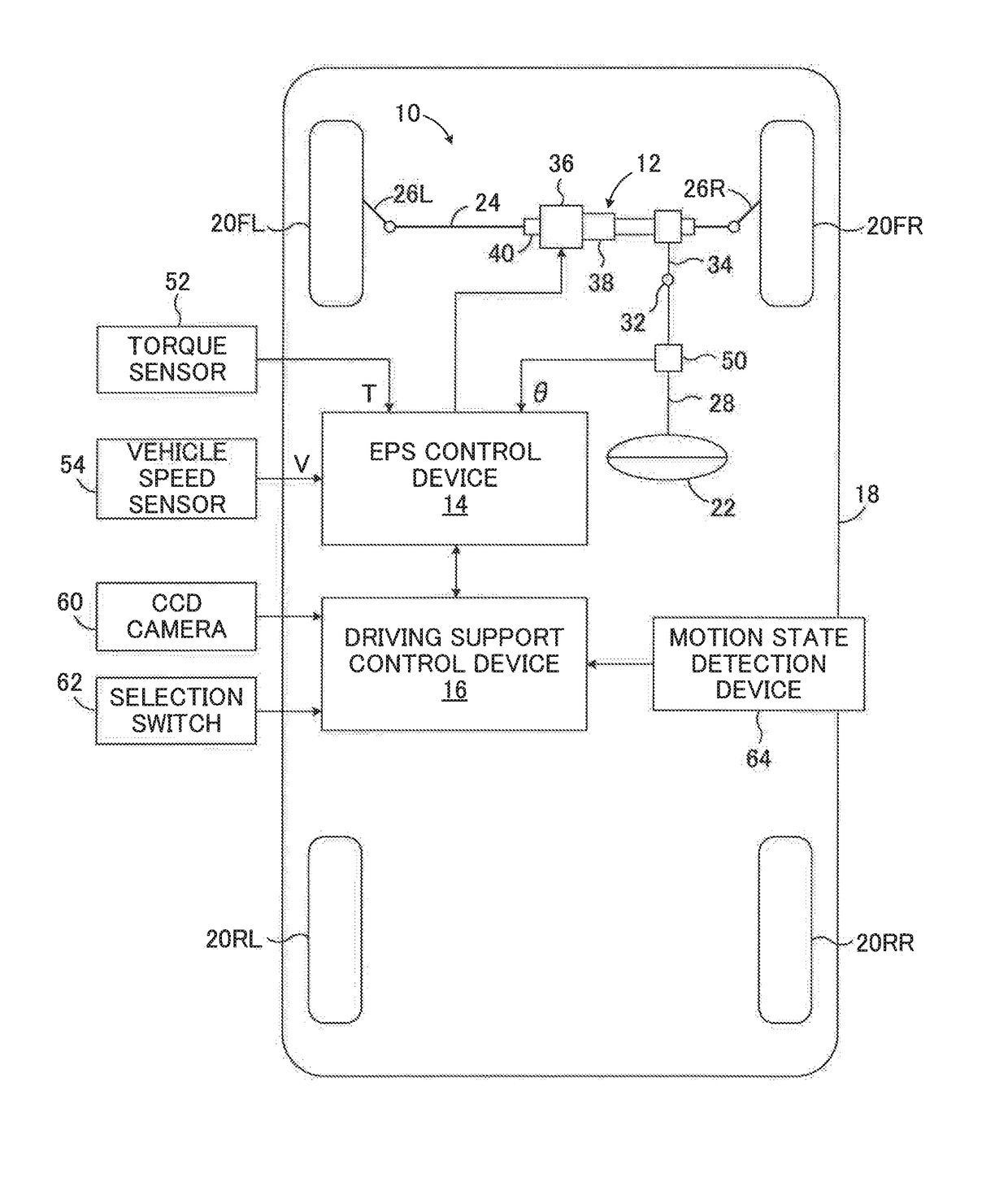

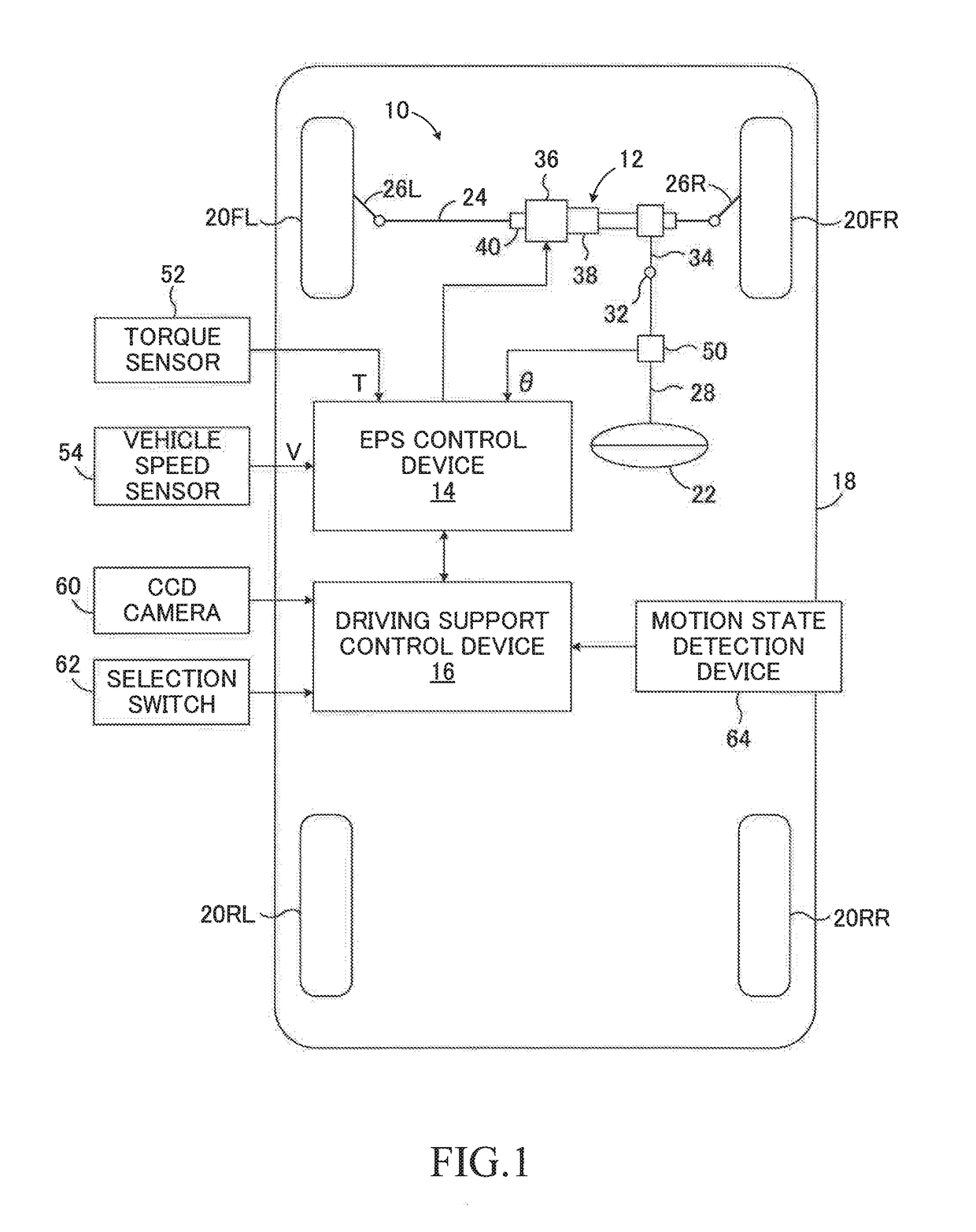

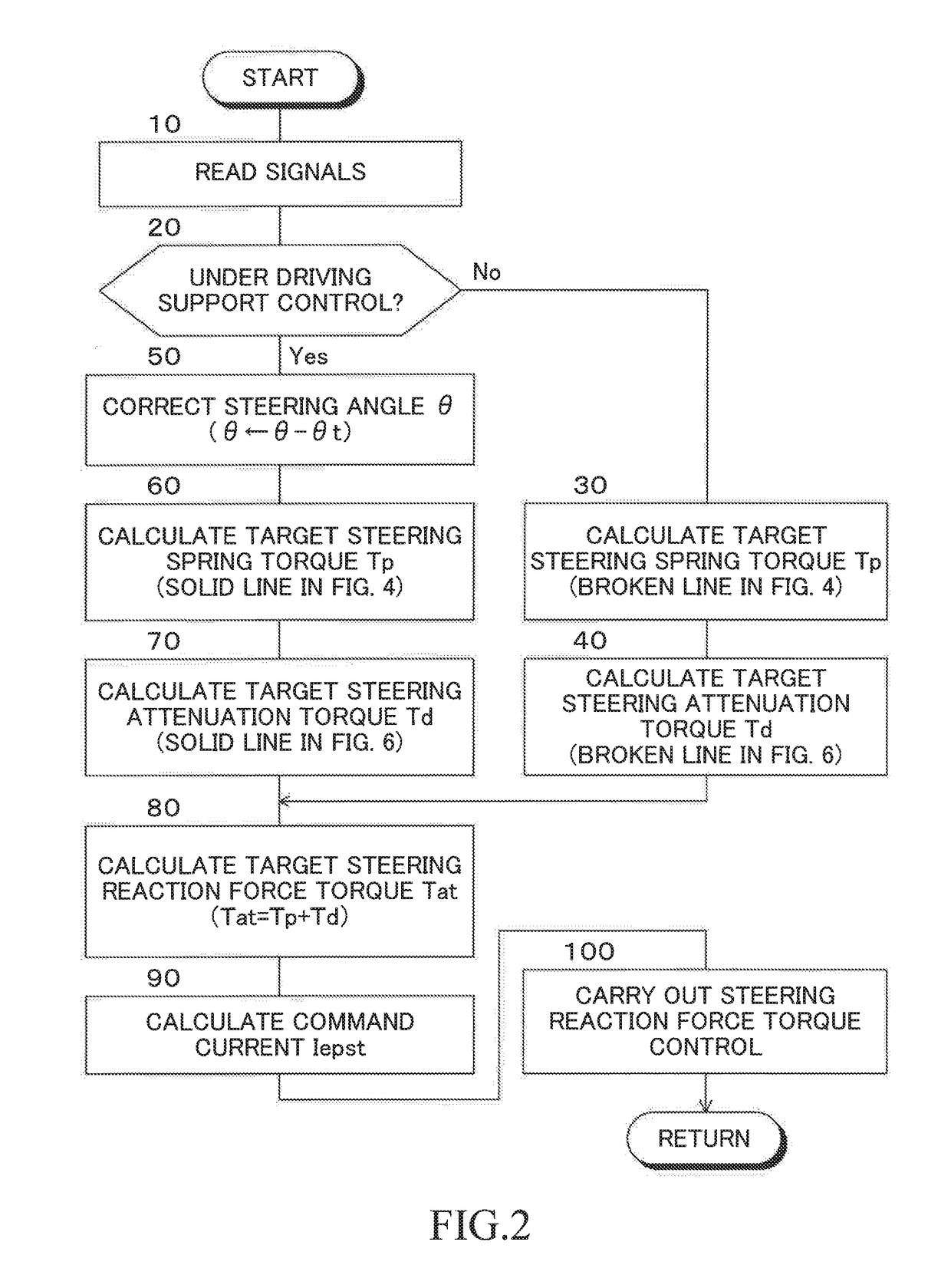

Steering reaction force control apparatus for vehicle

ActiveUS20170066476A1Low maneuverabilityImprove propertiesSteering linkagesAutomatic steering controlElectric power steeringSteering angle

Provided is a steering reaction force control apparatus for a vehicle including a driving support device configured to control an electric power steering device via a controller so that a steered angle of steered wheels reaches a target steered angle. When the driving support device is operating, the controller calculates a target steering spring torque based on a corrected steering angle corrected by a target steering angle for driving support control. When the magnitude of the corrected steering angle is less than a reference value, the target steering spring torque is calculated so that the magnitude of the target steering spring torque becomes larger in a case where the driving support device is operating compared with a case where the driving support device is not operating.

Owner:TOYOTA JIDOSHA KK

Steering reaction force control apparatus for vehicle

ActiveUS20170066475A1Reduced stabilityImprove propertiesSteering linkagesAutomatic steering controlUltrasound attenuationElectric power steering

Provided is a steering reaction force control apparatus for a vehicle including a driving support device configured to control an electric power steering device via a controller so that a steered angle of steered wheels reaches a target steered angle. When the driving support device is operating, the controller calculates a target steering attenuation torque based on a steering angular velocity that is a time derivative of the steering angle or a time derivative of a corrected steering angle acquired by correcting the steered angle with a target steered angle of the driving support device. When the magnitude of the steering angular velocity is less than a reference value, the target steering attenuation torque is calculated so that the magnitude of the target steering attenuation torque becomes smaller when the driving support device is operating compared with when the driving support device is not operating.

Owner:TOYOTA JIDOSHA KK

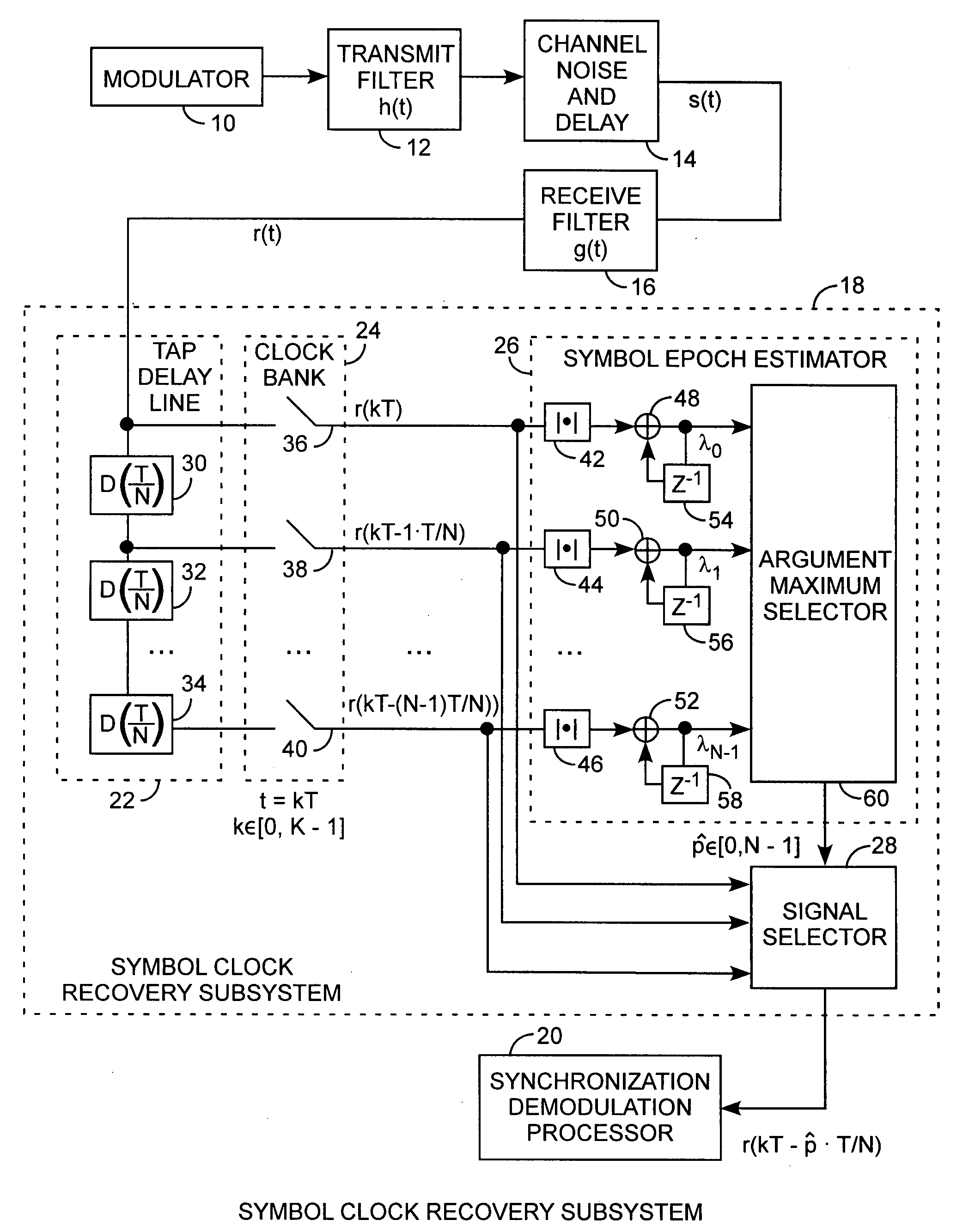

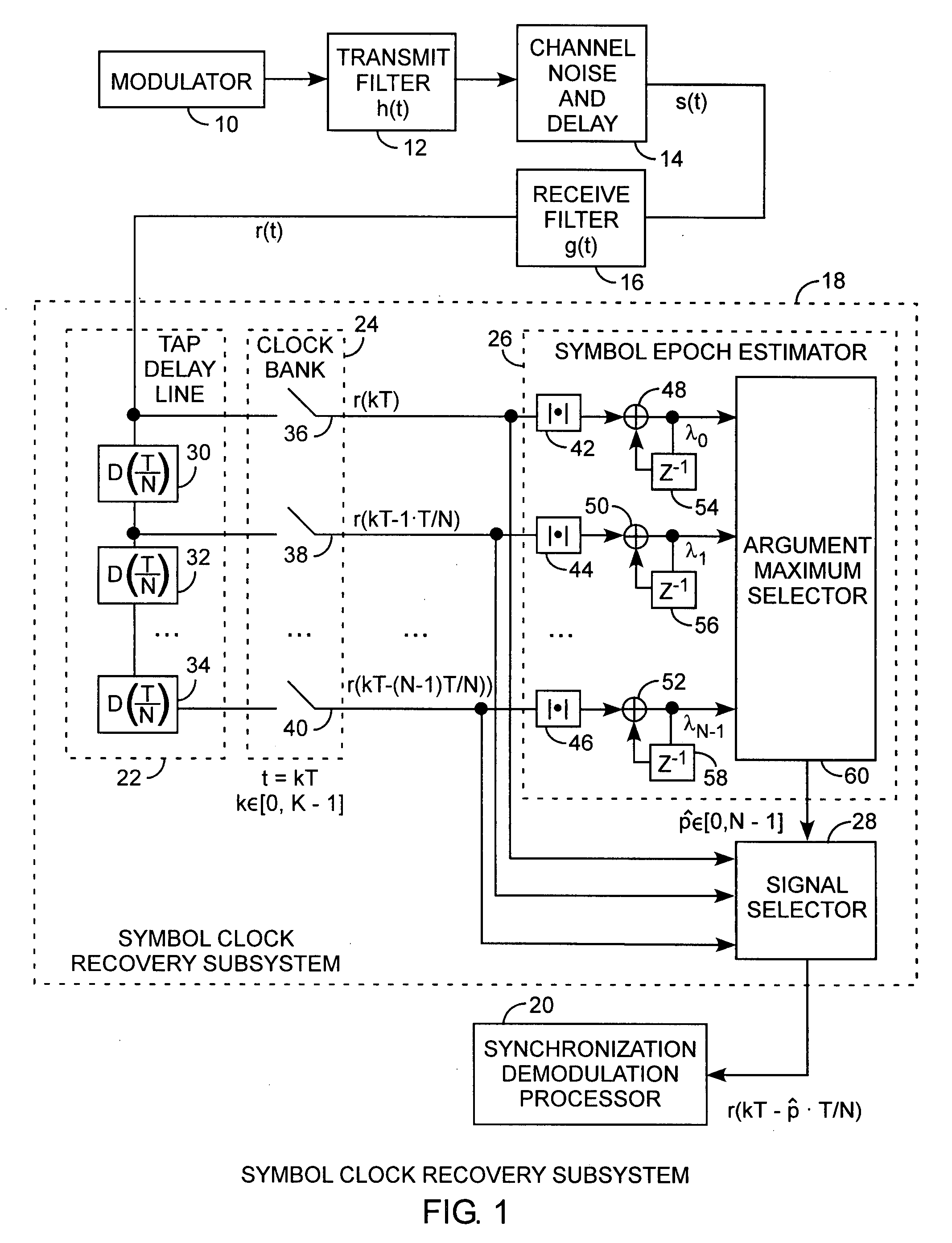

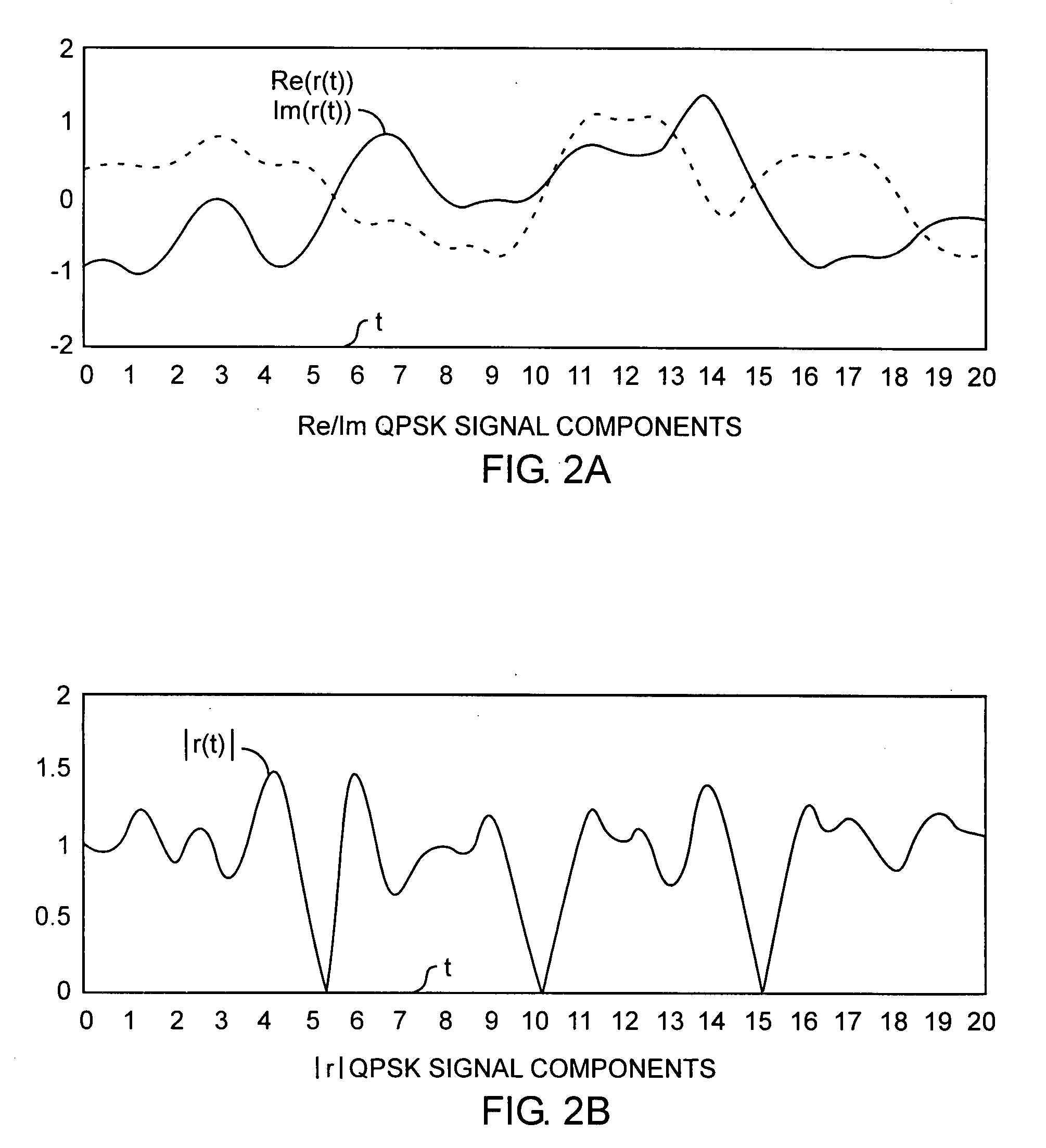

Noncoherent symbol clock recovery subsystem

InactiveUS20090016467A1Easy to implementIncrease probabilitySynchronisation error detectionFrequency/rate-modulated pulse demodulationCommunications systemSignal-to-noise ratio (imaging)

A symbol clock recovery subsystem uses a tap delay line having a set of delays, uses a clock bank of samplers providing time-staggered sampled noncoherently received signals, and uses a set of mean magnitude generators, in channelized form, for providing a set of mean magnitudes to a maximum selector for selecting a maximum one of the time-staggered sampled received signals having the greatest signal to noise ratio so as to provide a signal effectively occurring at symbol epoch time for demodulating a symbol stream in a digital communication system receiver.

Owner:THE AEROSPACE CORPORATION

Device and method to control an electron beam for the generation of x-ray radiation, in an x-ray tube

ActiveUS8358741B2Fast blockingSuppress generationX-ray tube electrodesCathode ray concentrating/focusing/directingX-rayElectron

A device to control an electron beam for the generation of x-ray radiation, has an electron emitter to generate an electron beam, to which emitter an emitter voltage can be applied, a diaphragm, at least two control elements associated with the diaphragm to affect the electron beam, and switching arrangement with which at least two different electrical voltages can be applied to the at least two control elements. The same electrical voltage is applied to each of the at least two control elements. Upon switching the voltage, an electrical circuit that delays the setting of the respective voltage at the one control element is associated with the connection line of the one control element with the switching arrangement to switch over the voltage. The invention moreover concerns an operating method for the device and an x-ray tube provided with the device.

Owner:SIEMENS HEALTHCARE GMBH

Method of controlling a brushless permanent-magnet motor

ActiveUS20140368140A1Improve efficiencyShorten the lengthMotor/generator/converter stoppersSynchronous motors startersPermanent magnet motorZero crossing

A method of controlling a brushless permanent-magnet motor. The method includes commutating a winding of the motor at times that are retarded relative to zero-crossings of back EMF in the winding.

Owner:DYSON TECH LTD

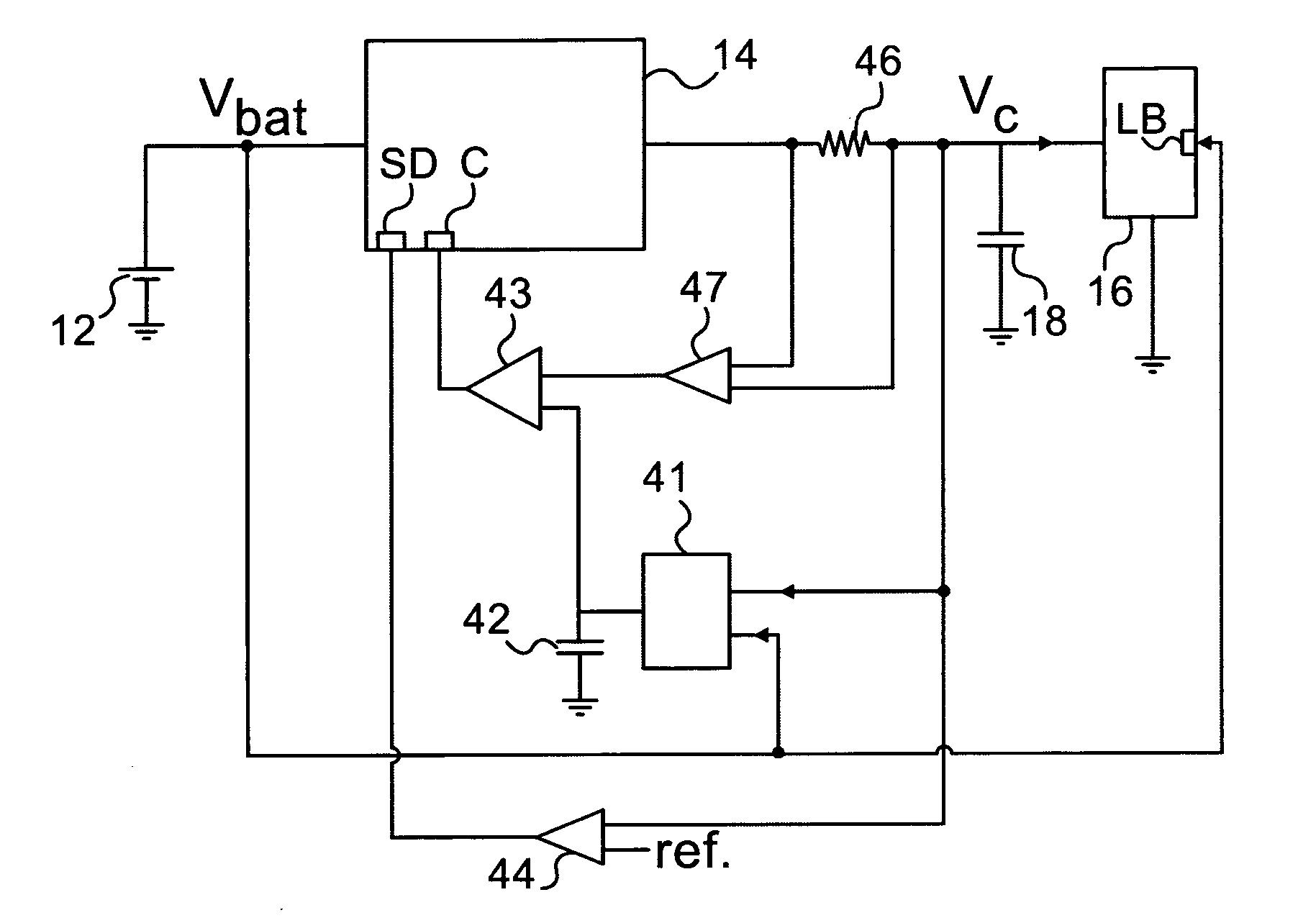

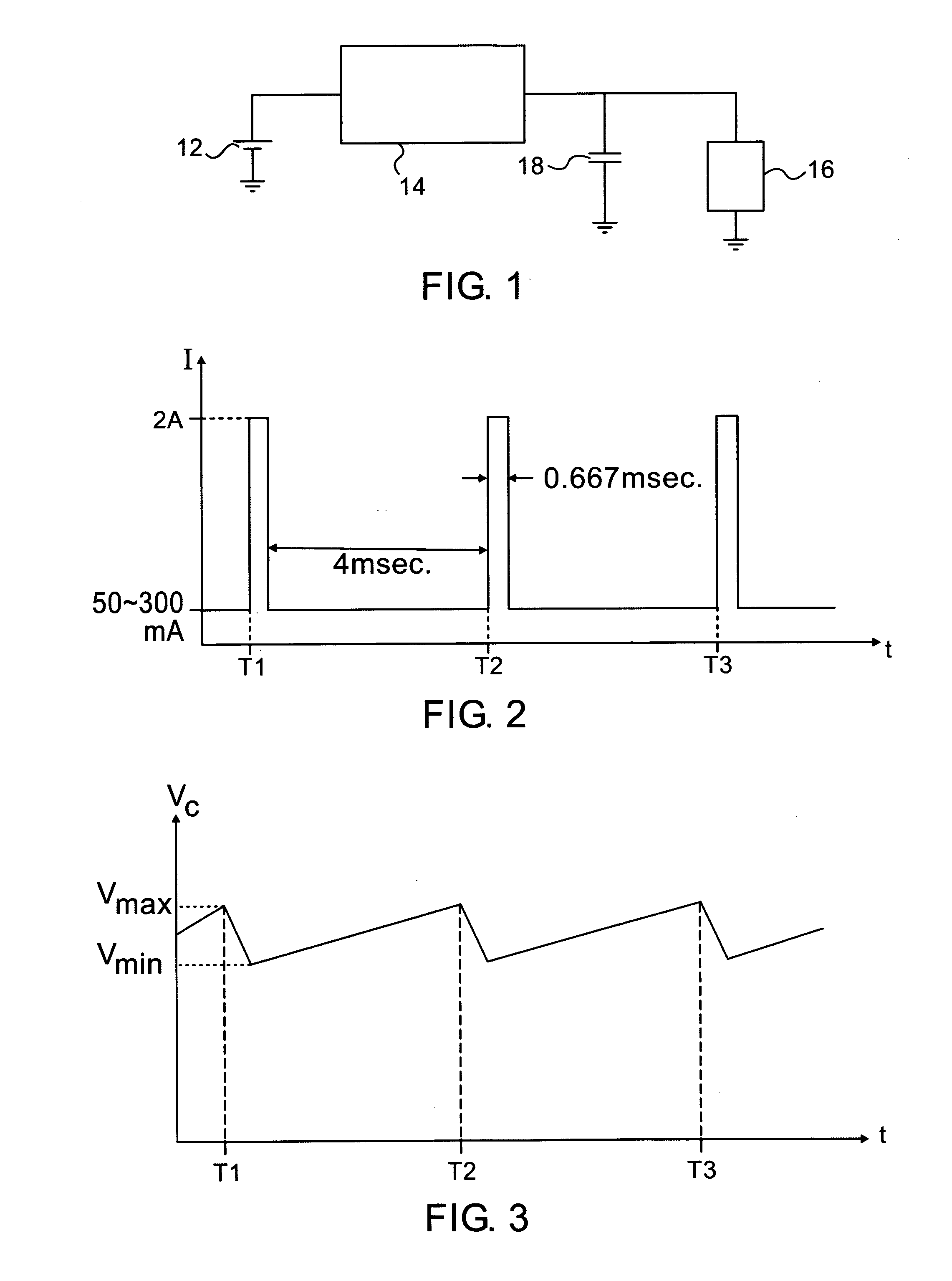

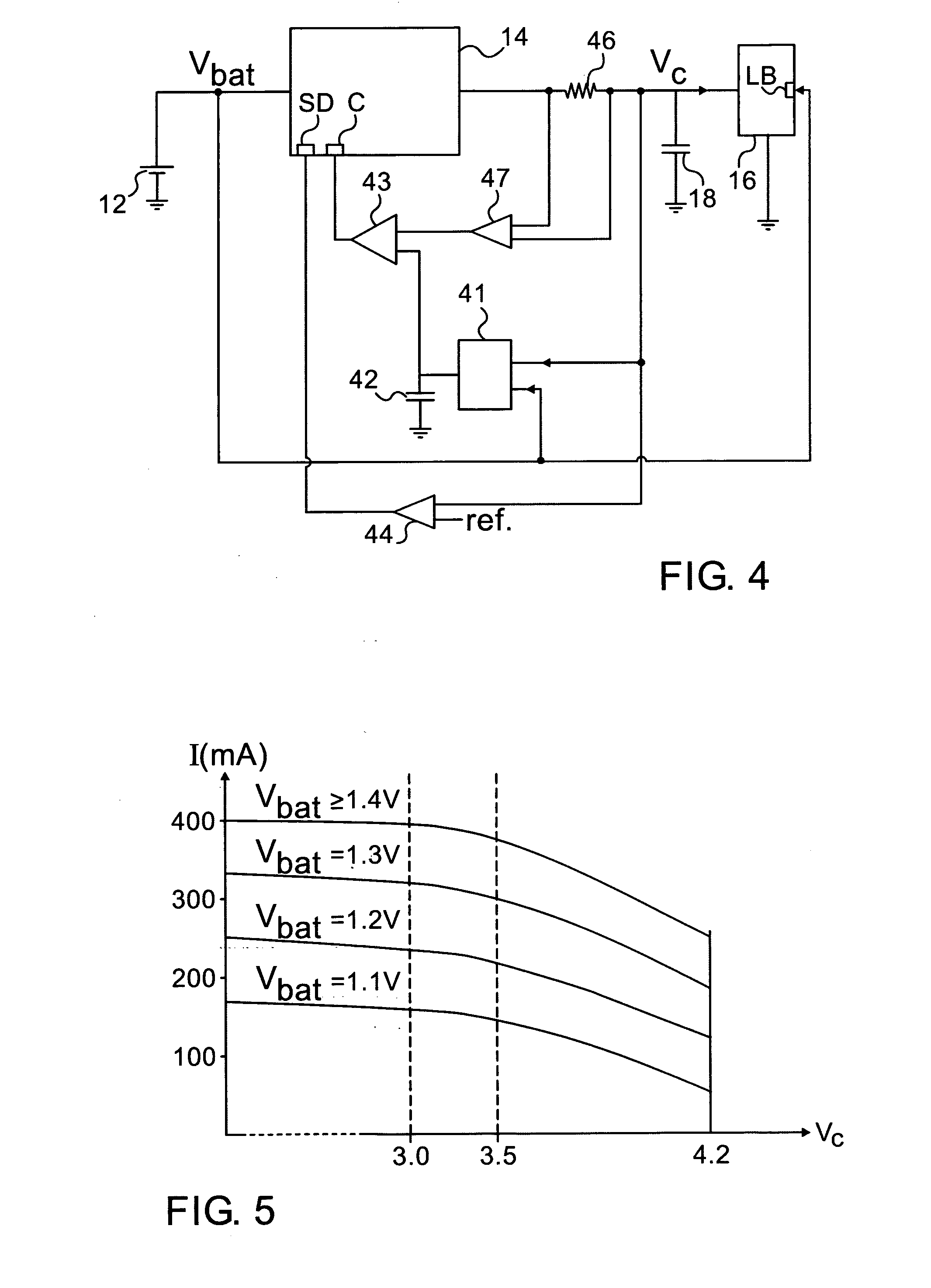

Capacitor powered mobile electronic device

InactiveUS20110244929A1Total current dropGuaranteed current efficiencyPower managementSubstation equipmentCapacitanceAverage current

A battery driven mobile communication device drawing a base current with periodic high current pulses during transmission. The current pulses may be larger than the current level which the device's battery can supply. The device uses a switched mode power supply with an output capacitor sufficiently large to provide the high current pulses when demanded by the load, without its voltage falling below that necessary to operate the device. This power supply provides the average current drawn by the load, and maintains the capacitor's charge. When the load demands a current pulse, that excess current is drawn from the capacitor, which begins to discharge. Once each pulse is completed, the battery continues to provide the lower baseline current of the device, and at the same time tops up the capacitor to replace the charge used during the pulse. The battery may be a low cost primary battery.

Owner:XPAL POWER INC +1

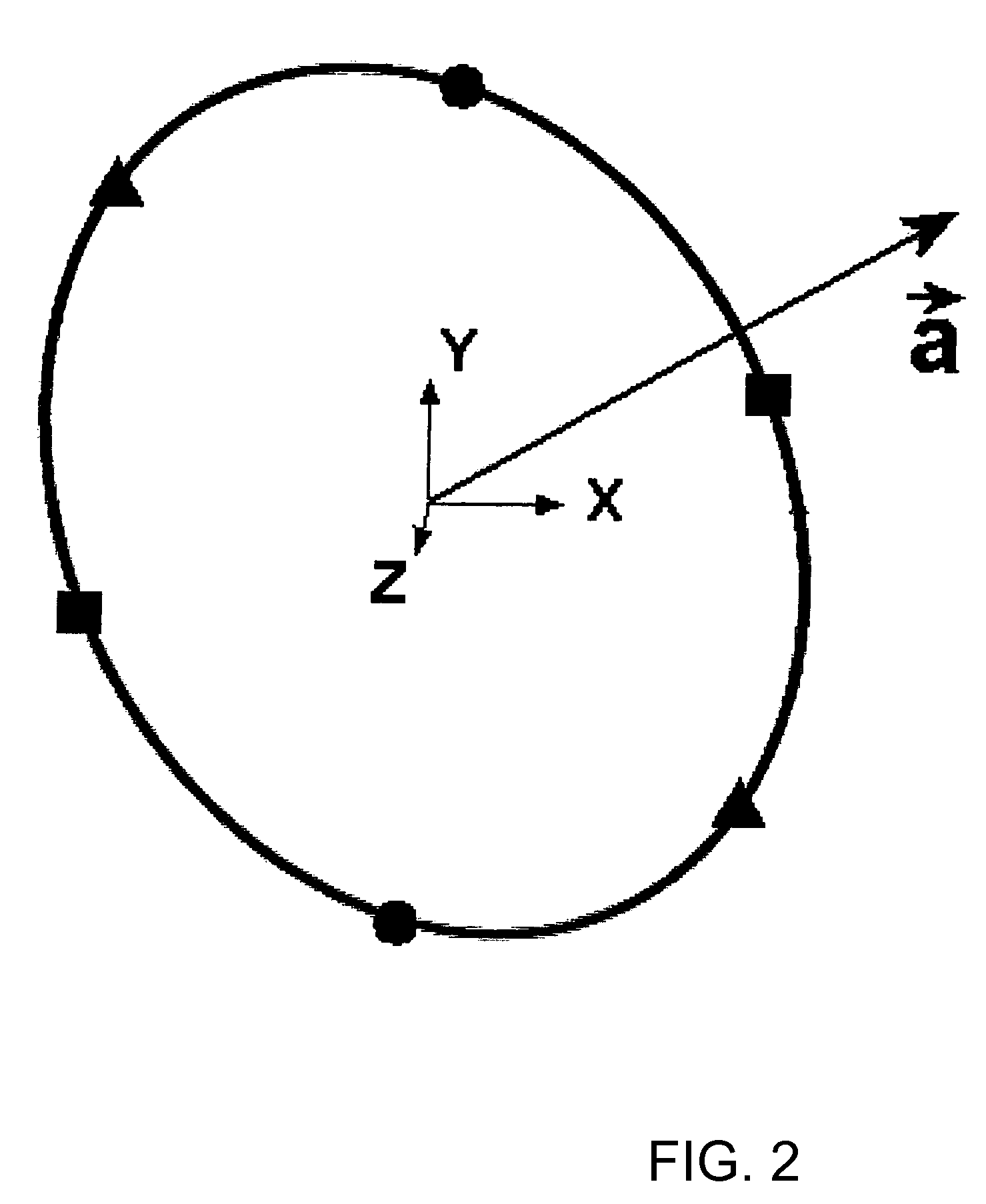

Method for scanning a surface with the aid of a coordinate measuring machine and coordinate measuring machine

ActiveUS7644507B2Measuring period during scanning to be kept as shortAvoid measurement errorsMechanical measuring arrangementsMeasurement deviceEngineering

A method for scanning a work piece surface uses a coordinate measurement device. A probe element is brought into contact with the surface and the probe element is moved along the surface. The coordinate measurement device has a plurality of degrees of freedom, which are independent of one another, in the possible movements of the probe element with respect to the work piece. Maximum speeds which describe the maximum of a movement speed component of the probe element based on the respective degree of freedom are defined for the degrees of freedom. An estimated path on which the probe element is intended to move during scanning is predefined. The actual scanning path can differ from the estimated scanning path. A maximum scanning speed at which the estimated scanning path can be traveled with a constant speed of the probe element is determined.

Owner:CARL ZEISS IND MESSTECHN GMBH

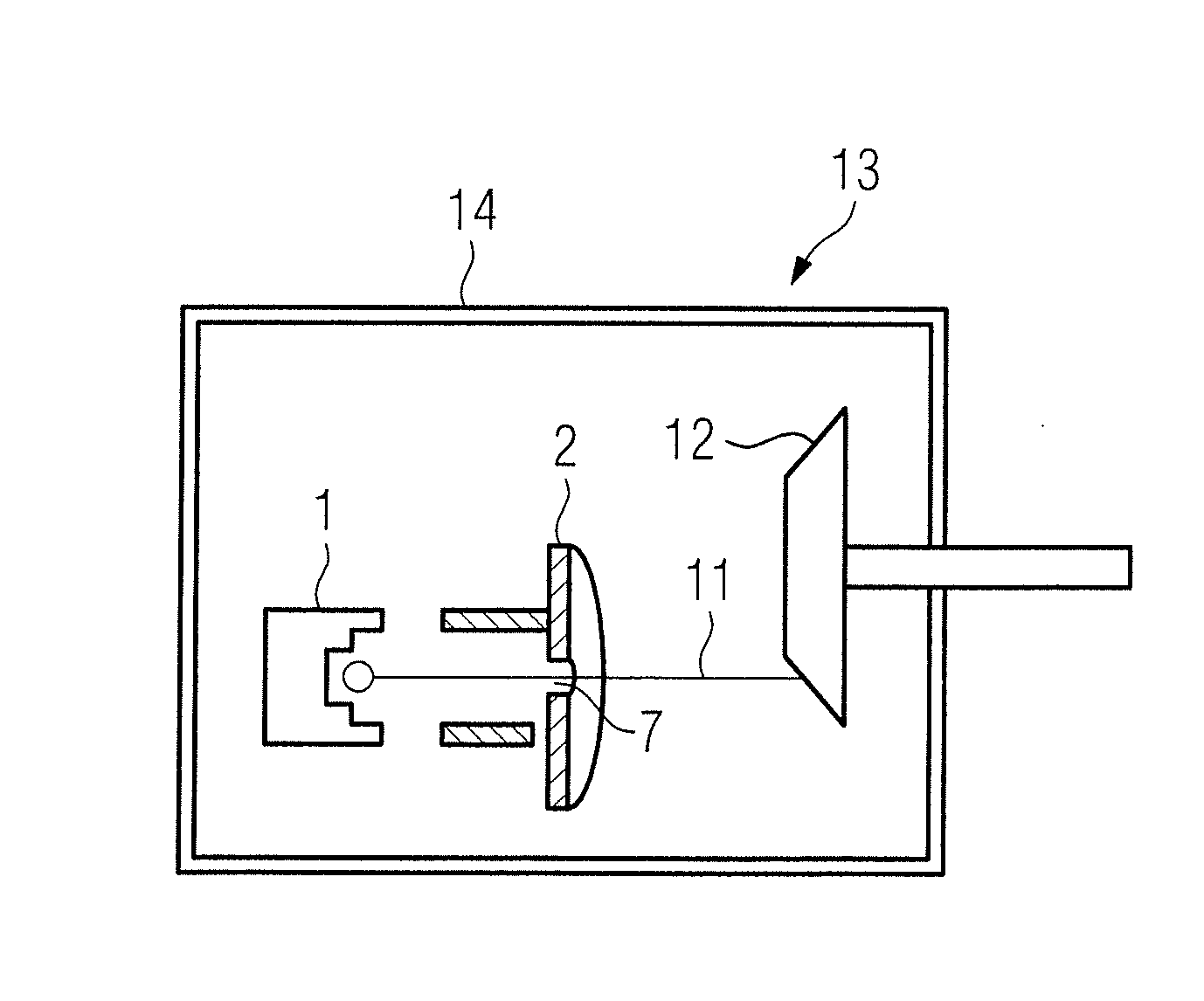

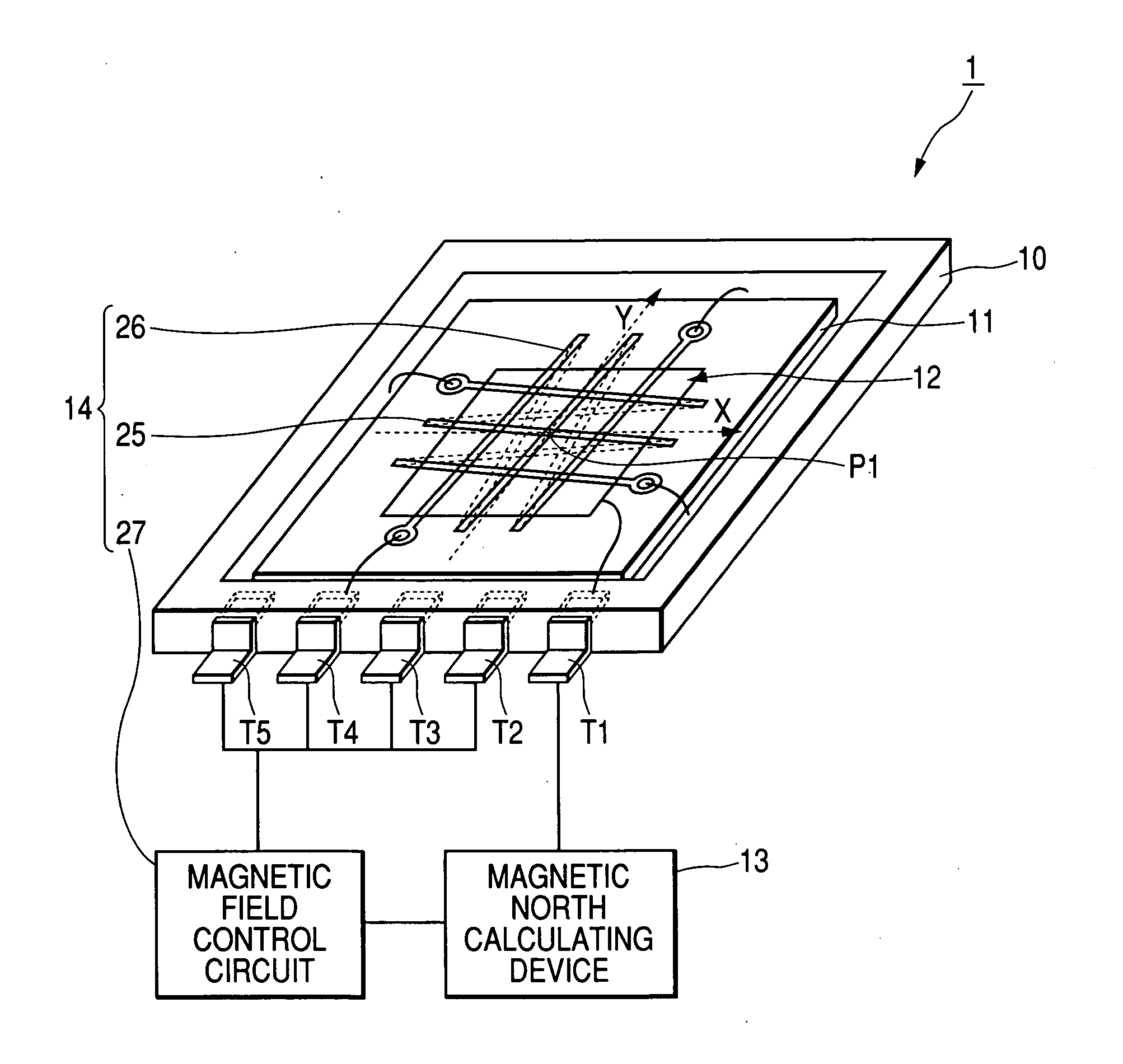

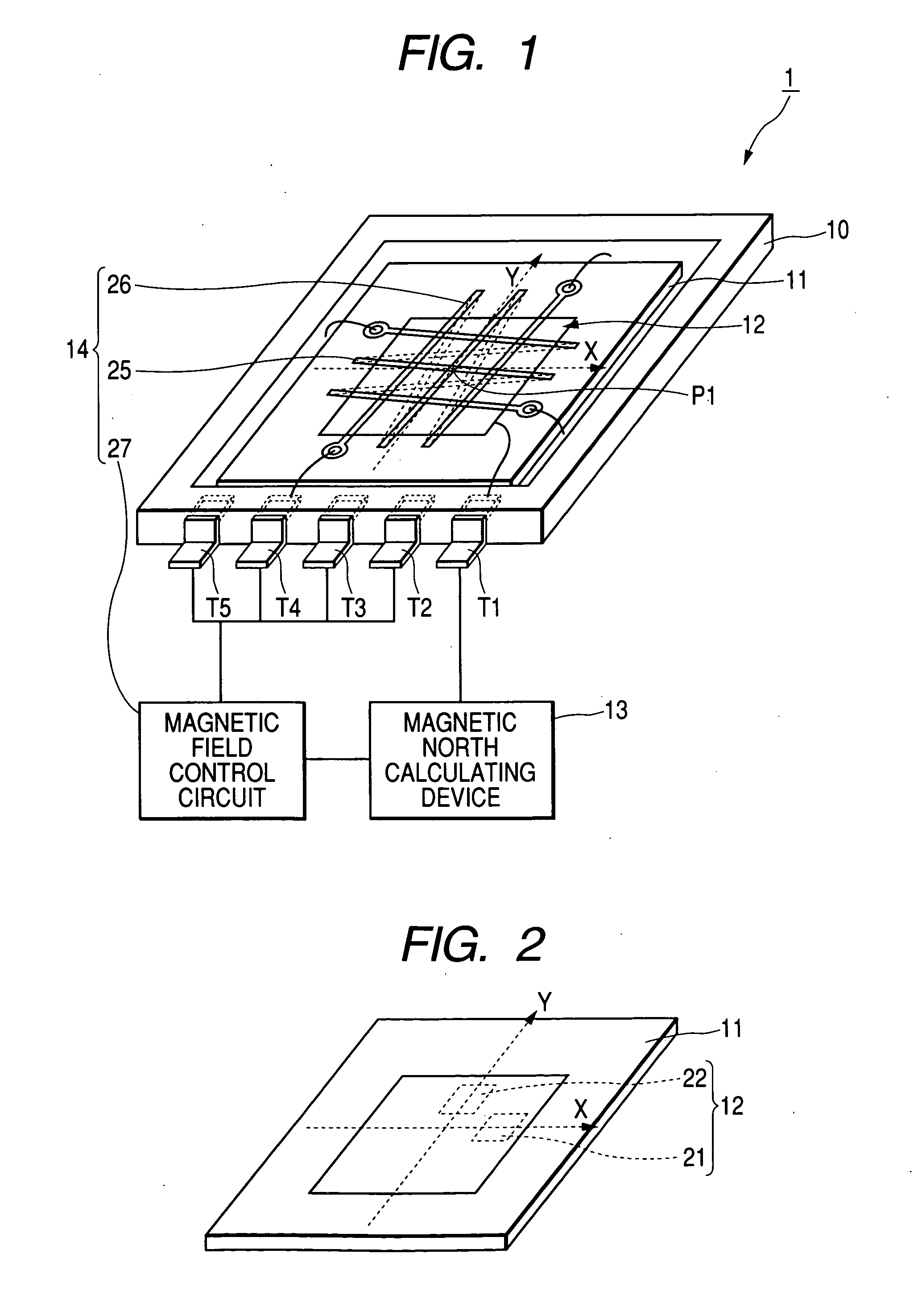

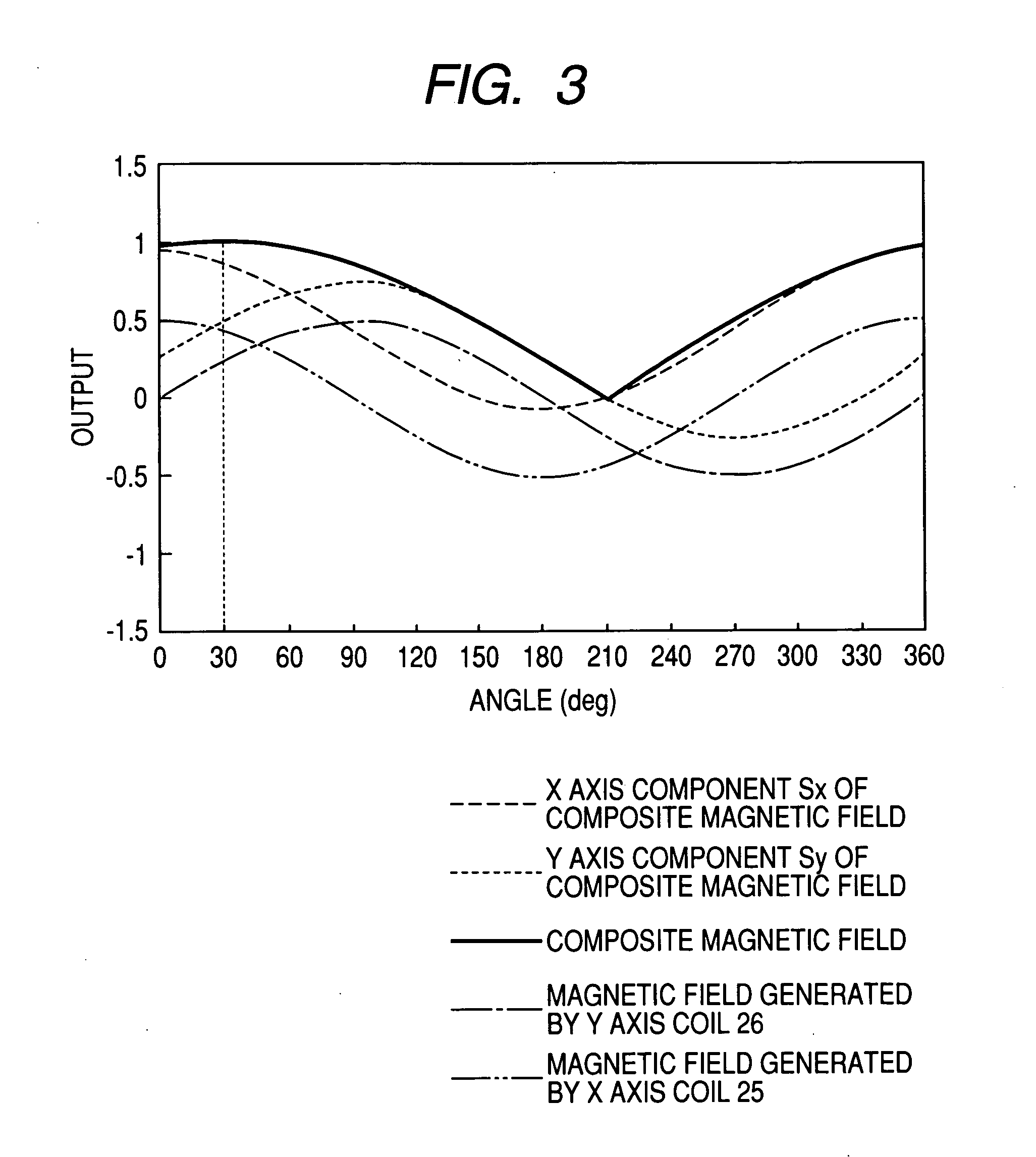

Magnetic compass

A small magnetic compass capable of suppressing the effects from the magnetic dip is provided. The magnetic compass includes a substrate 11, a two-axis sensor 12 arranged on the substrate 11, for detecting external magnetic fields, a magnetic north calculating device 13 for detecting an azimuth from outputs of the respective magnetic sensors, a rotating magnetic field generating device 14 for generating a rotating magnetic field on the plane of the substrate using a reference point P1 as a center of rotation.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com