Patents

Literature

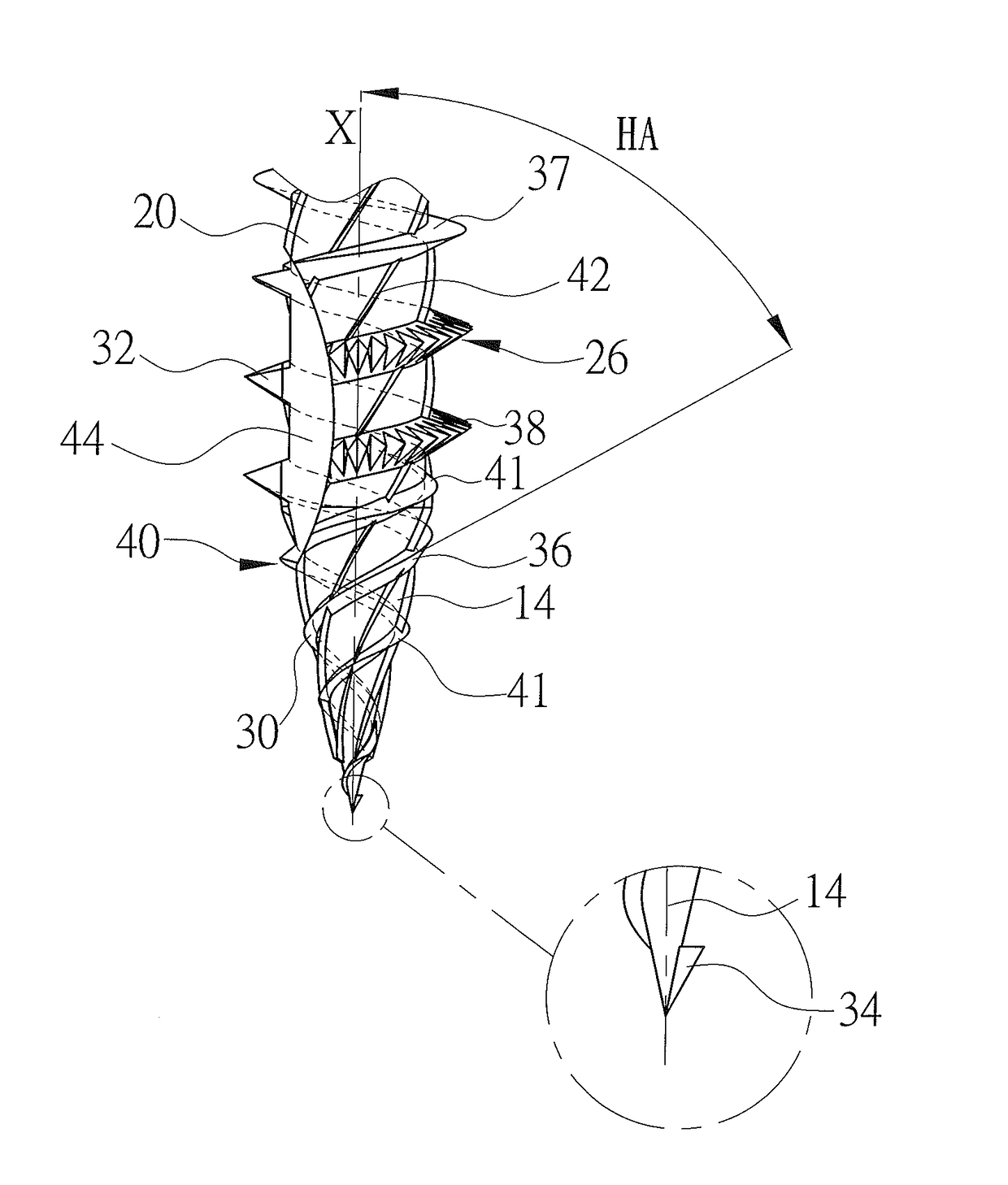

36results about How to "Smoothly and quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

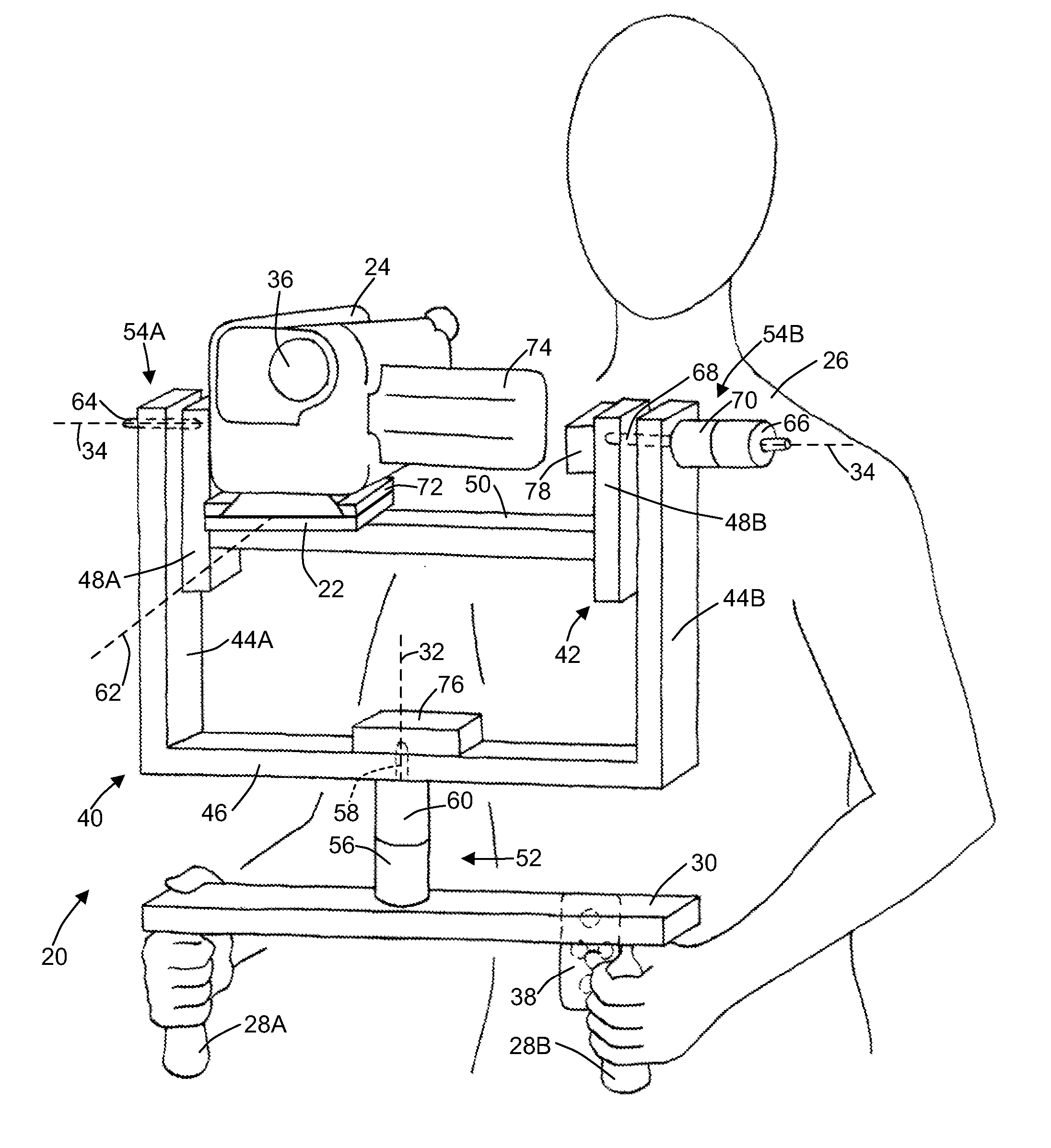

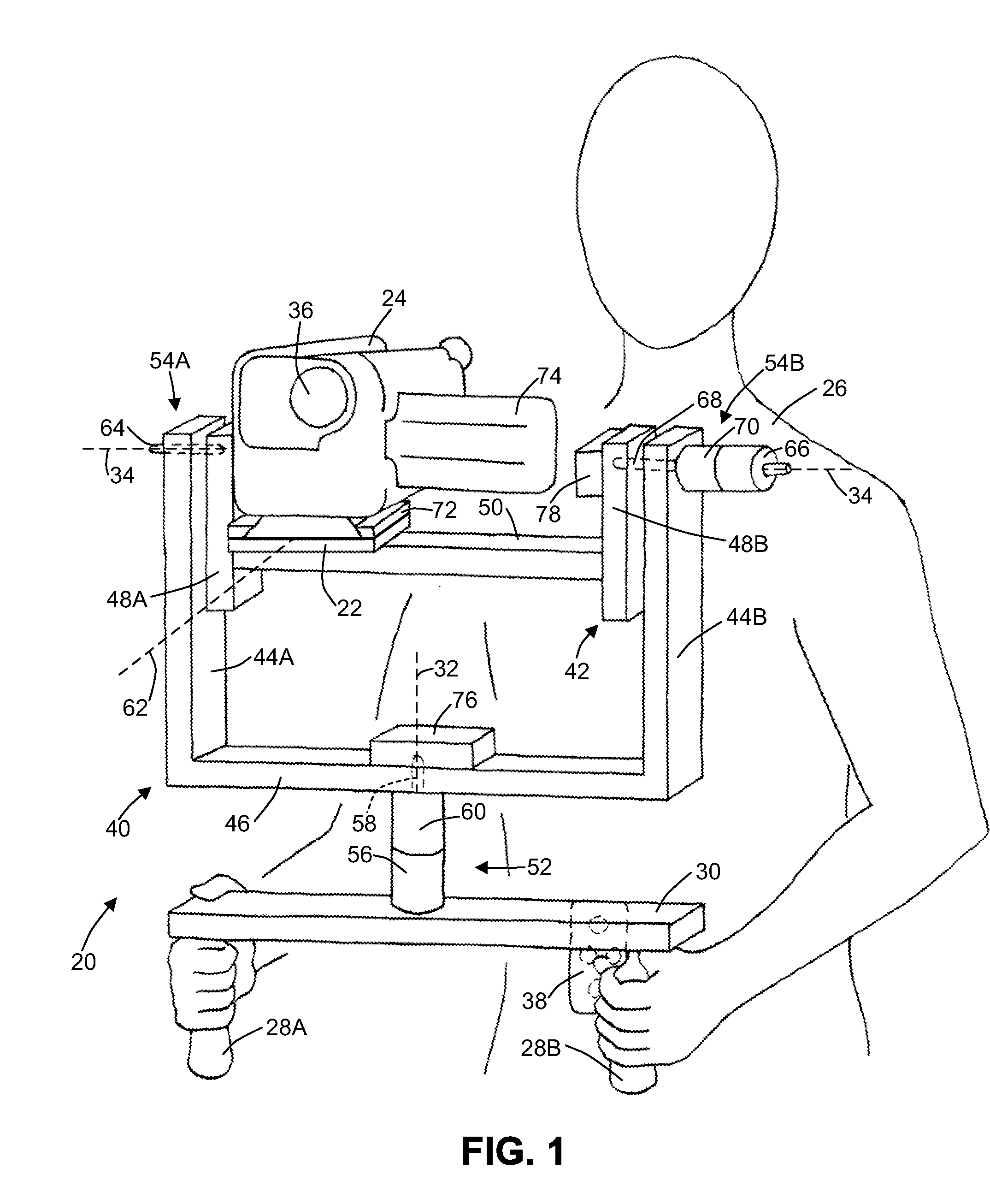

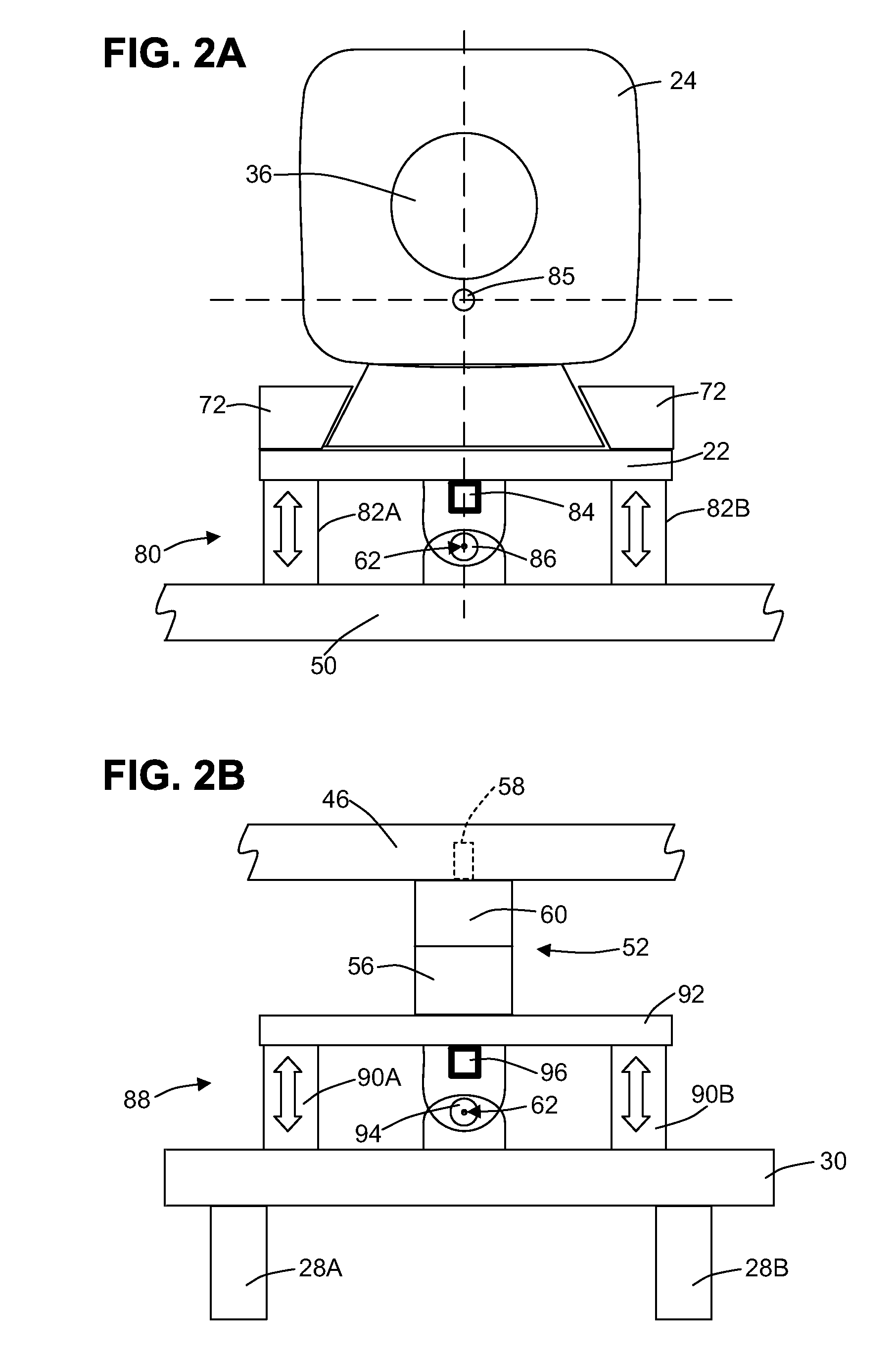

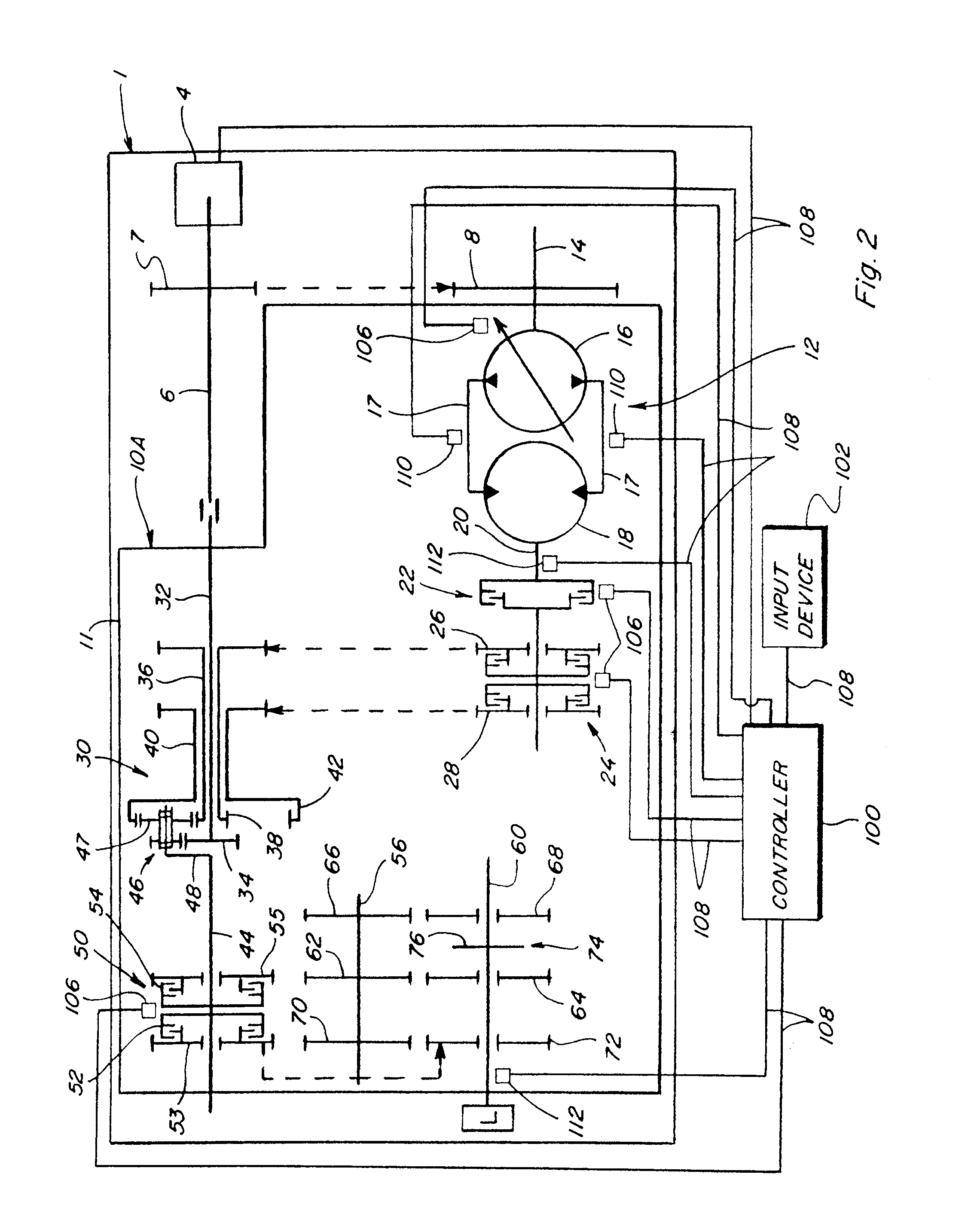

Handheld platform stabilization system employing distributed rotation sensors

ActiveUS20070050139A1Easy to liftLimit range of motionNavigation by speed/acceleration measurementsElement comparisonActuatorMotion simulator

A stabilization system including a platform supported by two or more rotatably-coupled gimbal frames each having a pivot assembly disposed at its rotation axis to couple an actuator to a rotation sensor having a rotation-sensitive sensor axis that is fixedly disposed with respect to the rotation axis, and a controller including means for accepting the sensor signals and for producing each motor signal needed to dispose the platform in a predetermined angular position with respect to each rotation axis independent of changes in the base orientation. A motion simulator embodiment includes controller means for accepting an external slew signal sequence and means for producing the motor signals needed to move the platform along a predetermined sequence of positions represented by the slew signal sequence.

Owner:SIDMAN ADAM D

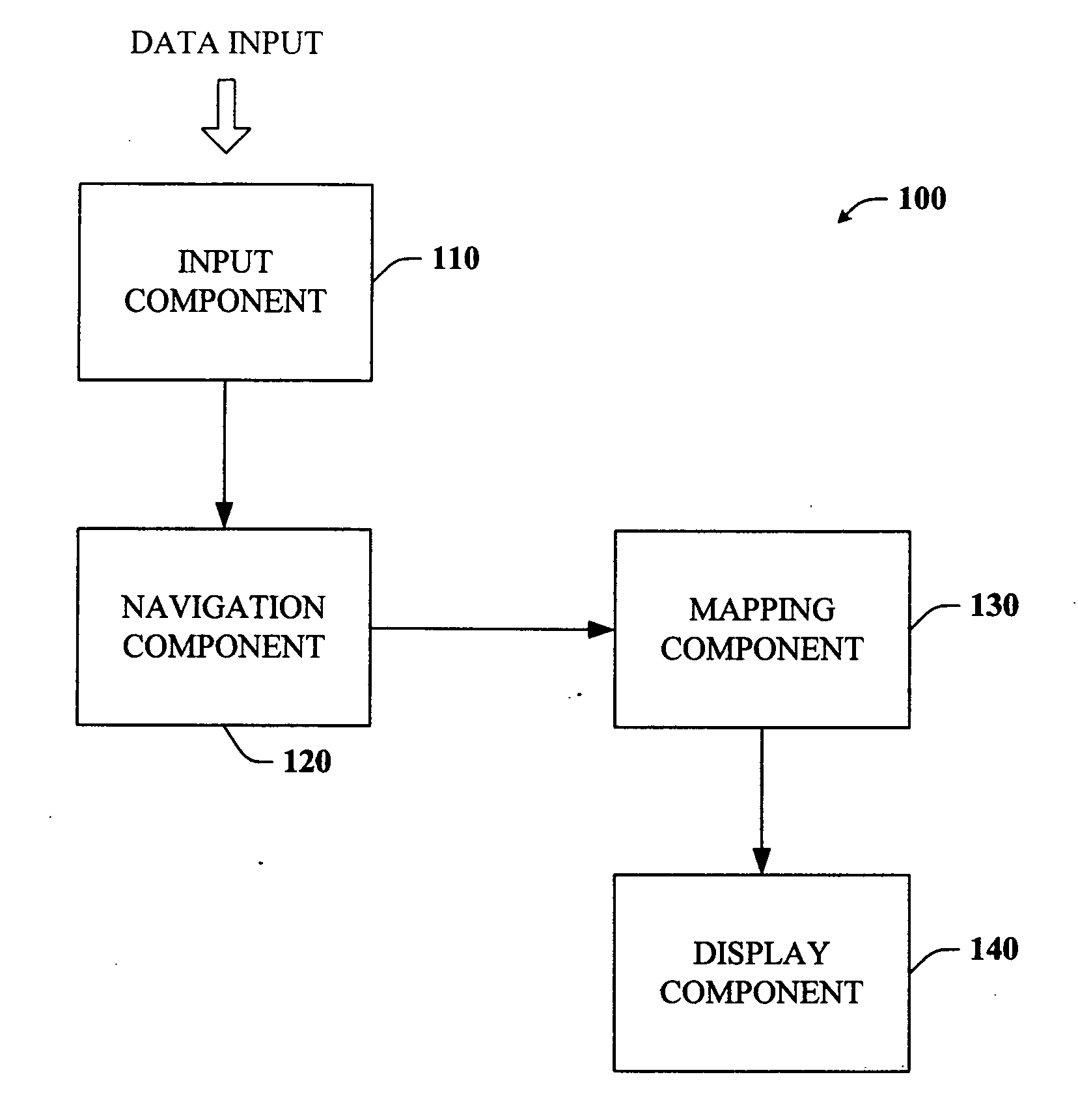

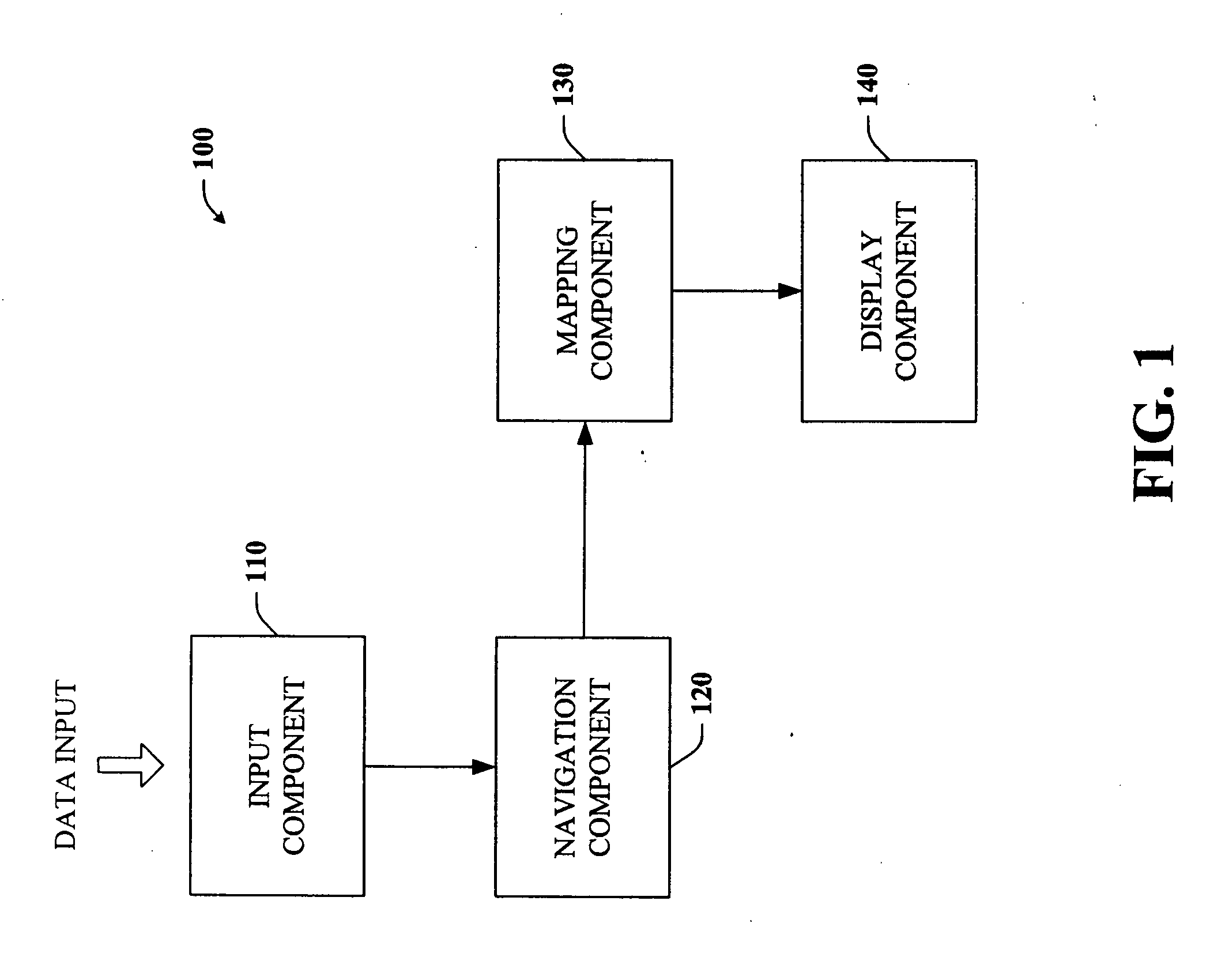

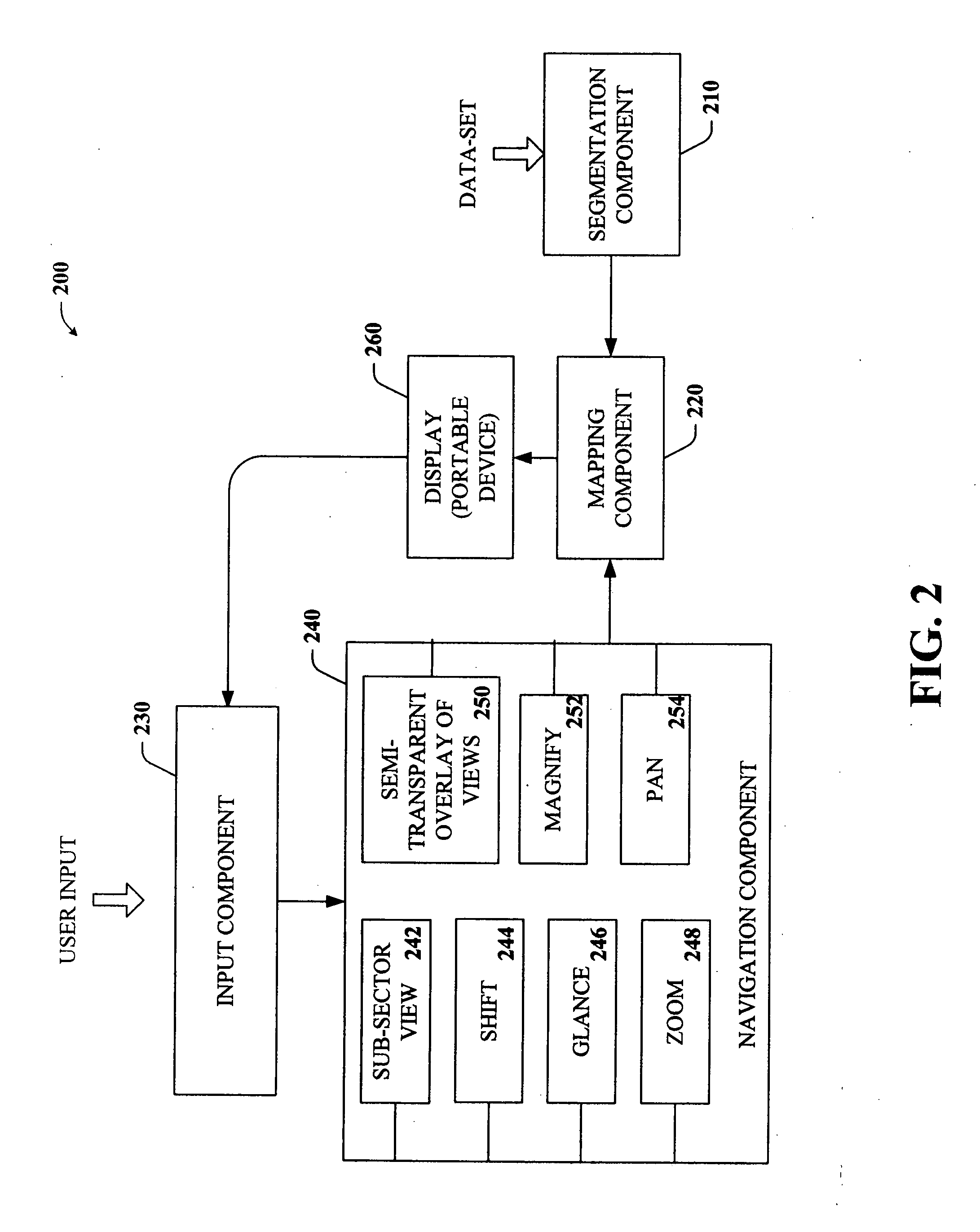

Advanced navigation techniques for portable devices

ActiveUS20050195154A1Smooth navigationLess detailControl with pedestrian guidance indicatorCathode-ray tube indicatorsComputer graphics (images)Pointing device

The present invention provides a unique system and method that facilitates navigating smoothly and gracefully through any type of content viewable on portable devices such as cell-phones, PDAs, and / or any other hybrids thereof. In addition, such navigation can be performed while preserving perspective and context with respect to a larger amount of content. Pointing devices can also be used to navigate through content—the amount or detail of the content being dependant on the speed of the pointing device. Additionally, a semi-transparent overview of content can be overlaid a zoomed-in portion of content to provide perspective to the zoomed in portion. Content shown in the semi-transparent overview can depend on the location of the pointing device with respect to the content.

Owner:SZ DJI TECH CO LTD

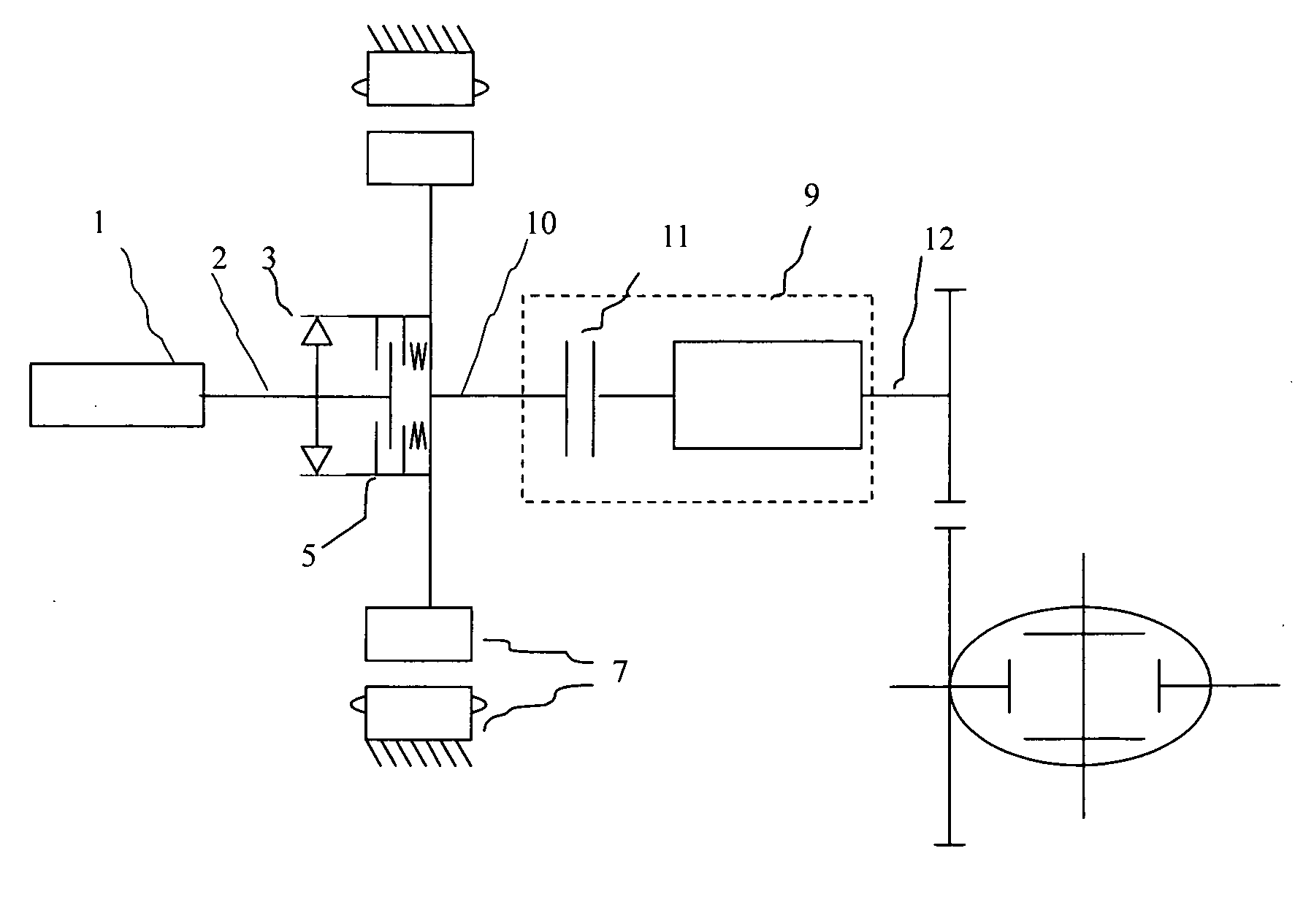

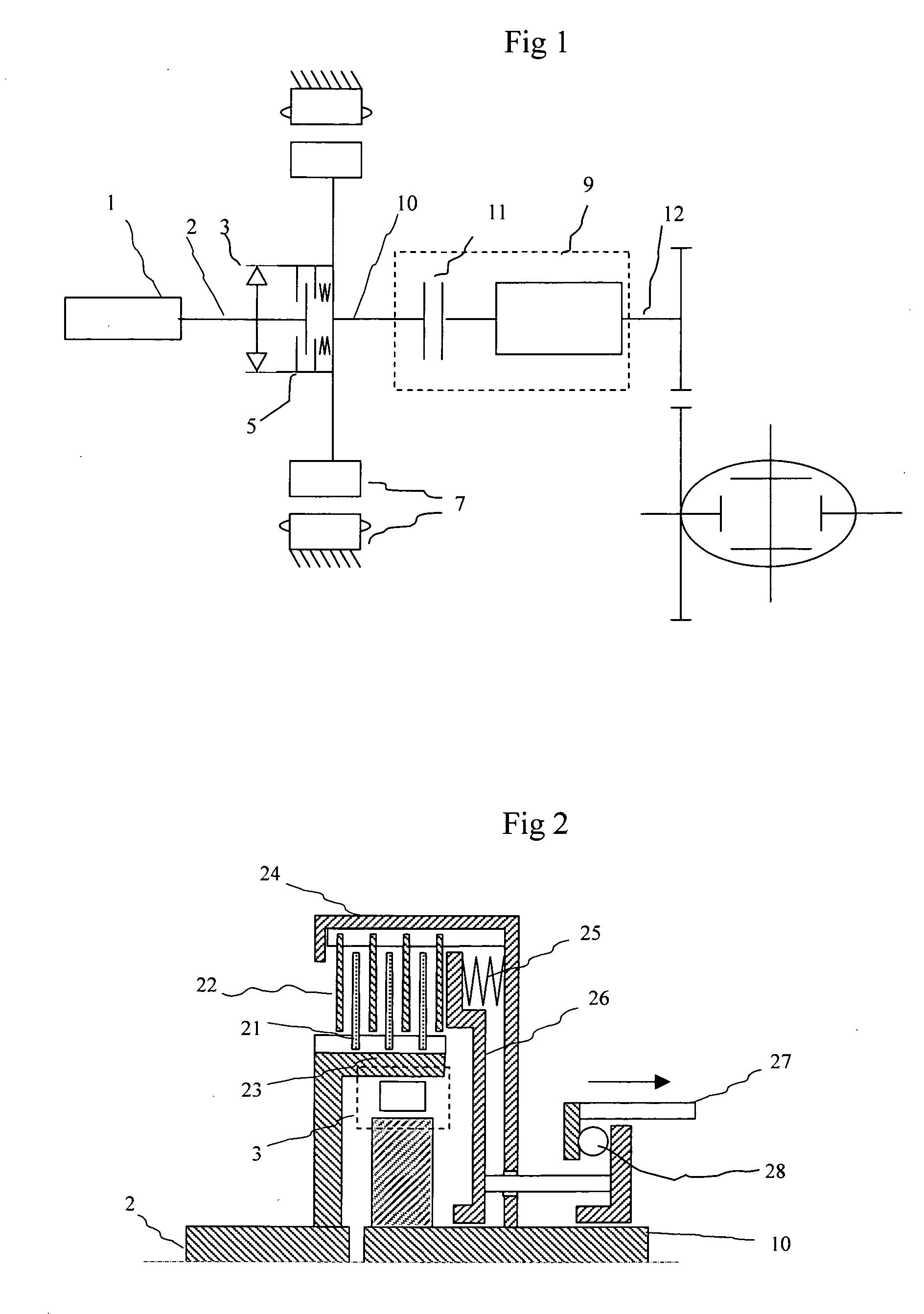

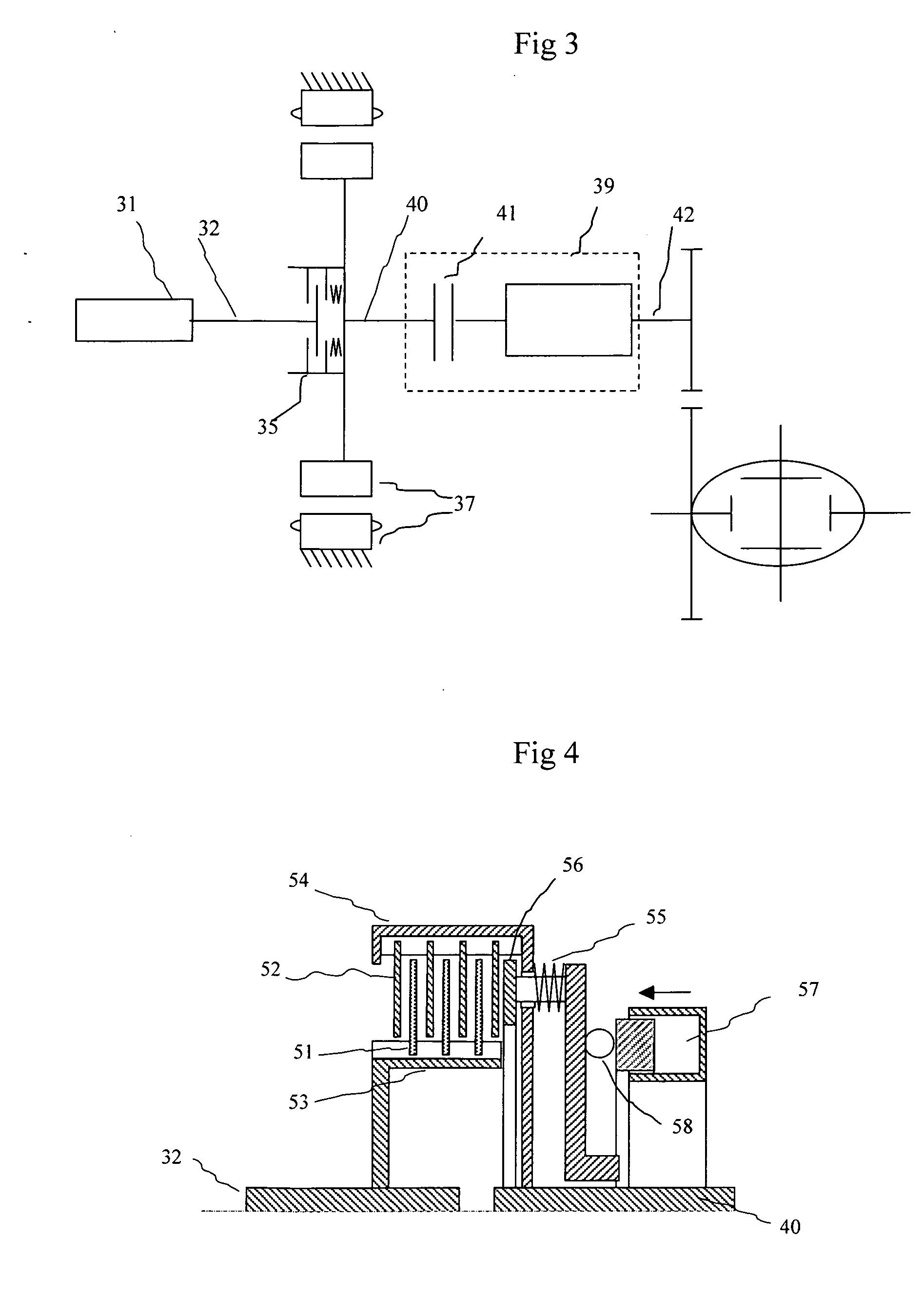

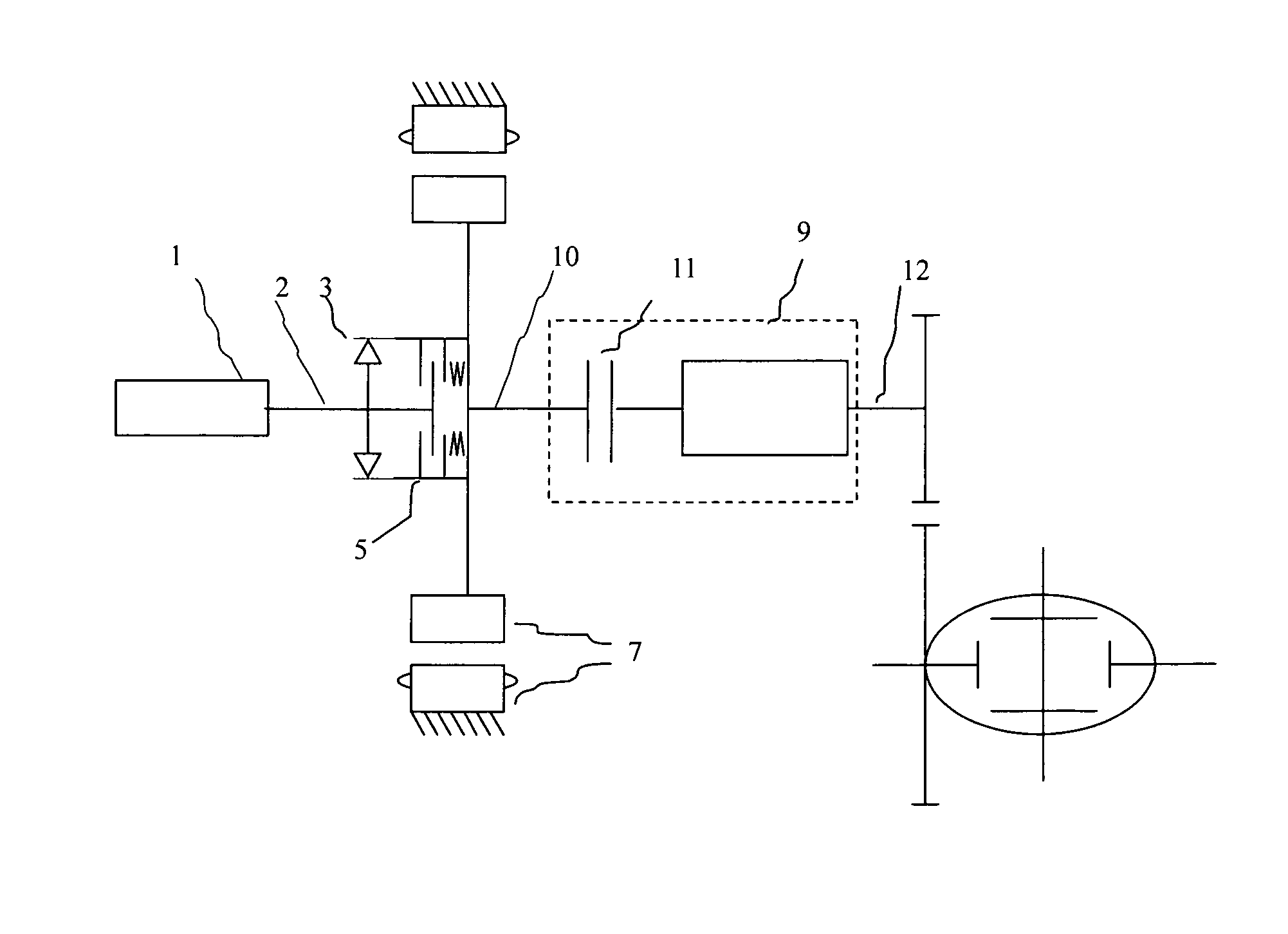

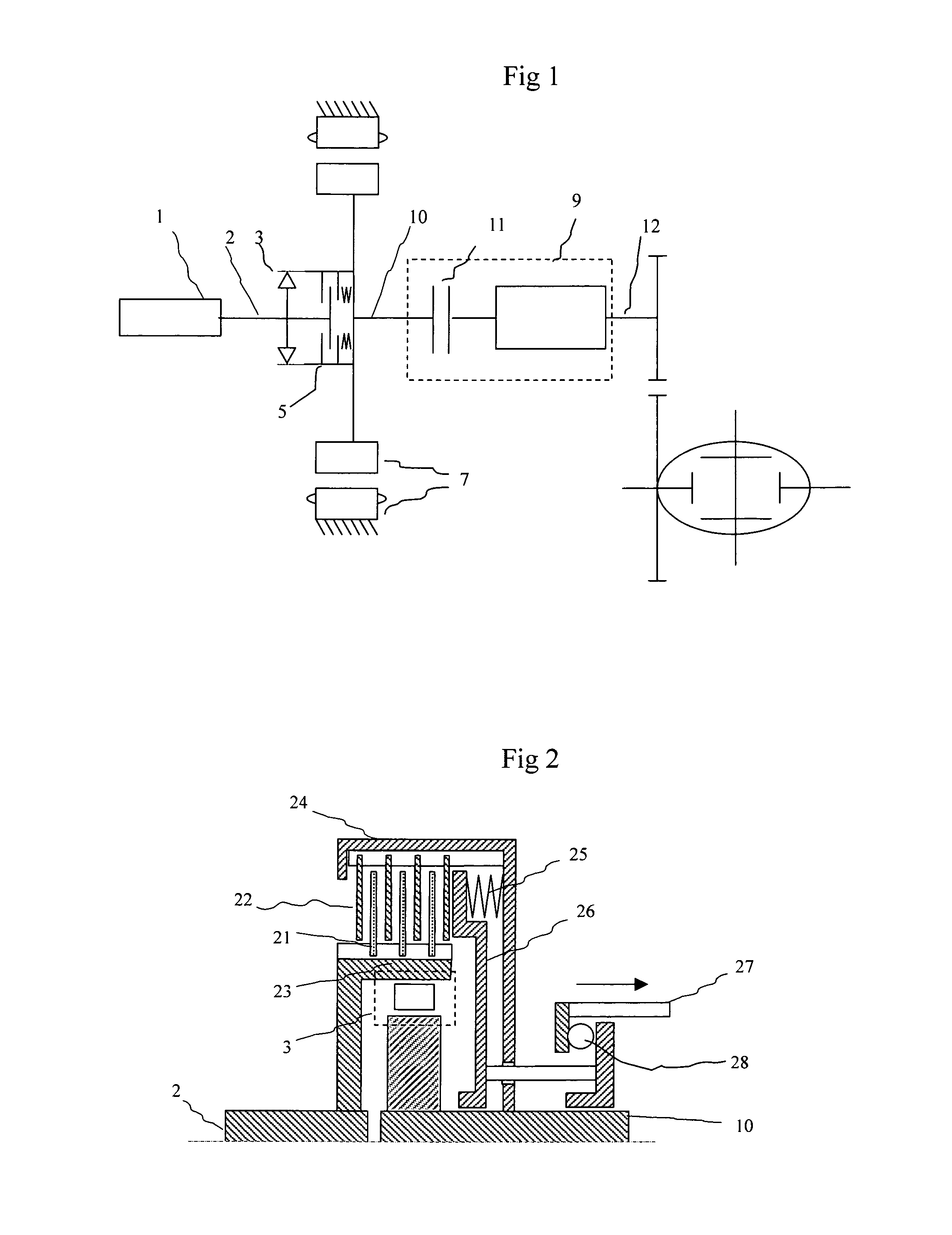

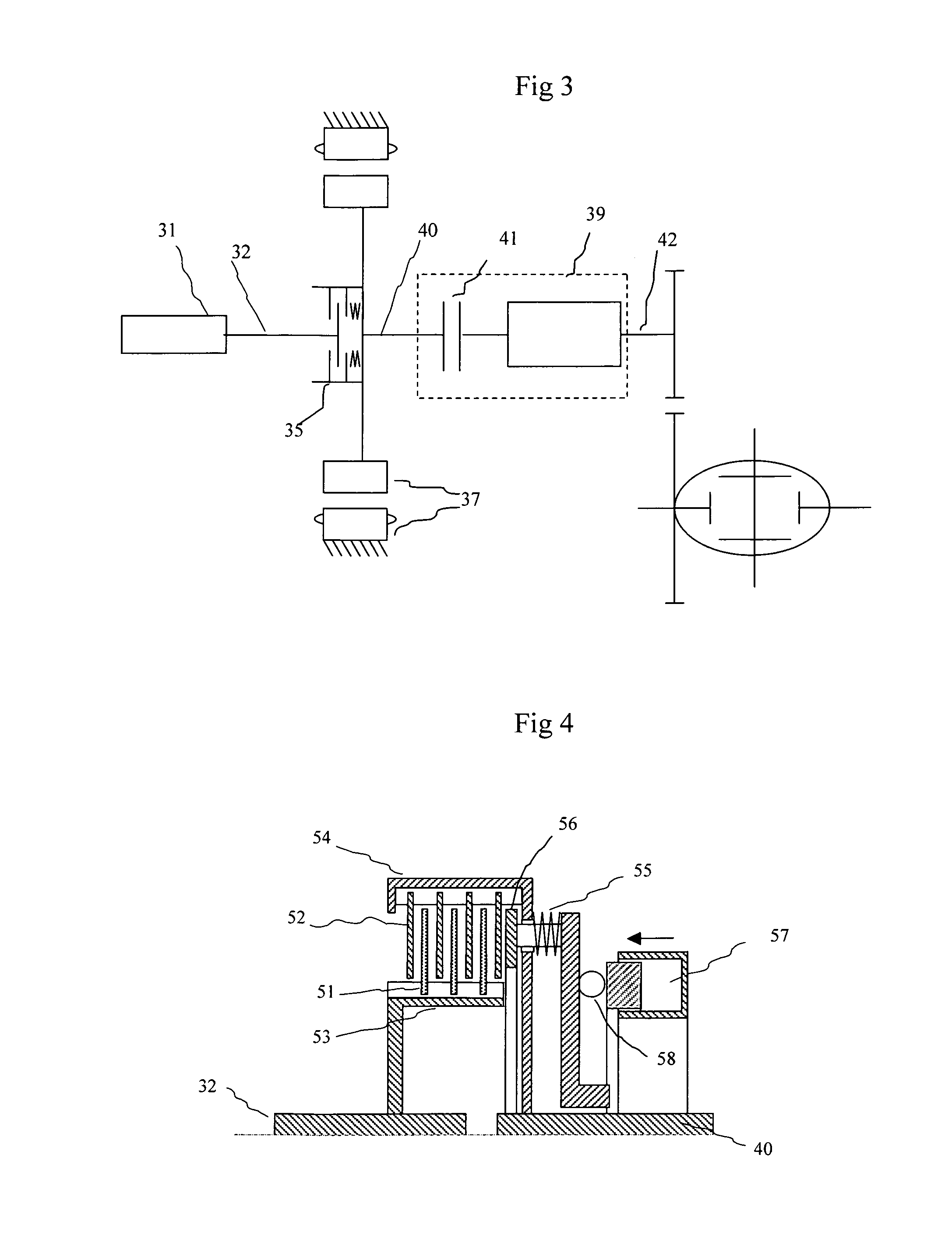

Hybrid electric vehicle

InactiveUS20090166109A1No energy lossSmoothly and quicklyElectric propulsion mountingPlural diverse prime-mover propulsion mountingElectricityMobile vehicle

A hybrid electric drive system for an automotive vehicle comprises a heat engine, an electric motor, a one-way-clutch, a torque-limiting clutch, and a transmission. The one-way-clutch disposed between the engine shaft and the motor shaft, and it can transmit torque from the engine shaft to the motor shaft. The transmission has an input shaft being connected to the motor shaft and an output shaft to drive the wheels. The torque-limiting clutch is also disposed between the engine shaft and the motor shaft. When it is disengaged, the torque-limiting clutch disconnects the motor shaft from the engine shaft, so the motor can solely drive the vehicle. When it is engaged, the clutch transmits a pre-determined level of torque from the motor shaft to the engine shaft in order to start the engine. The torque limiting clutch will smooth out the torque peak when the system starts the engine while the vehicle is running.

Owner:DUAN ZHIHUI +1

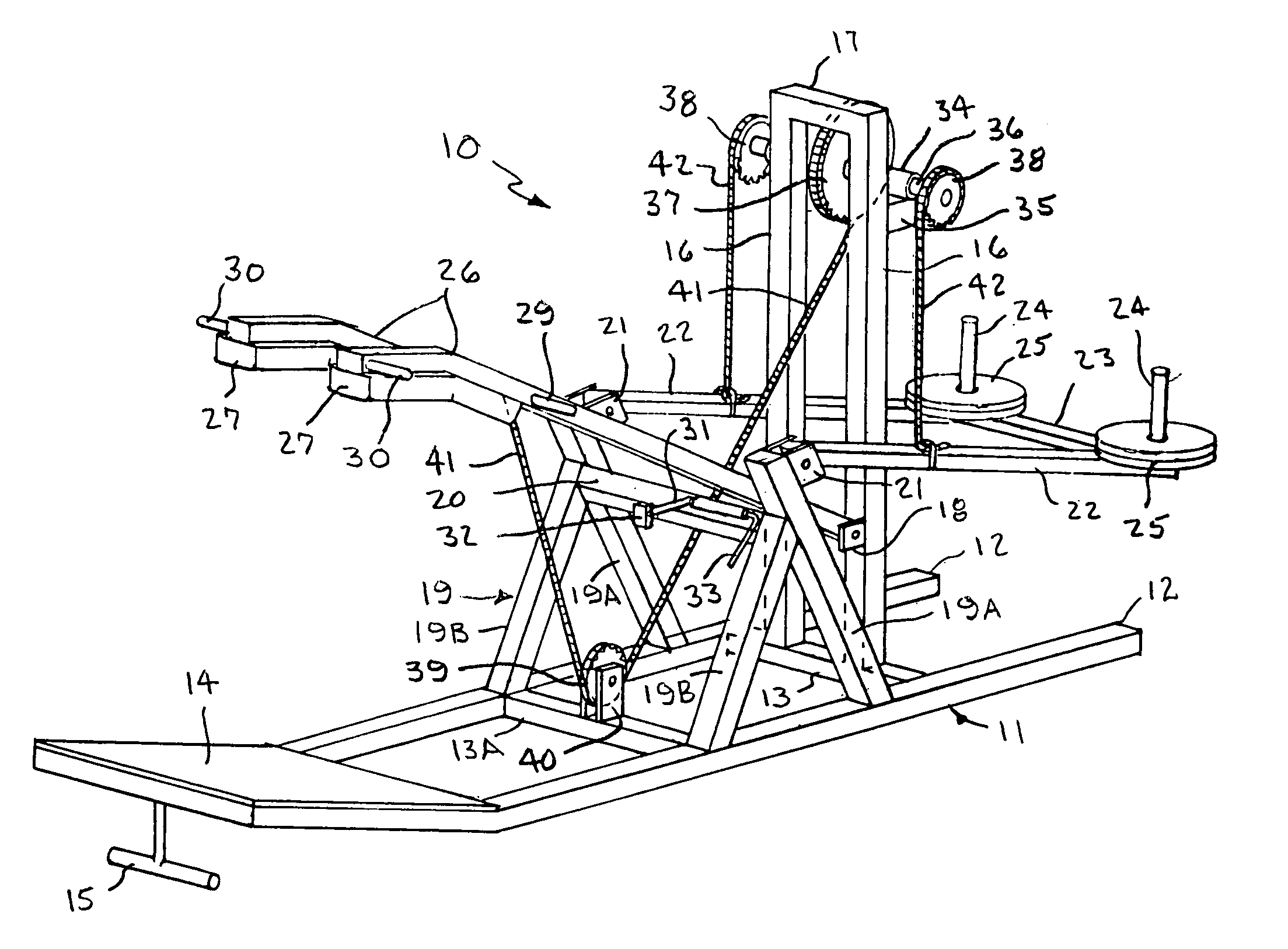

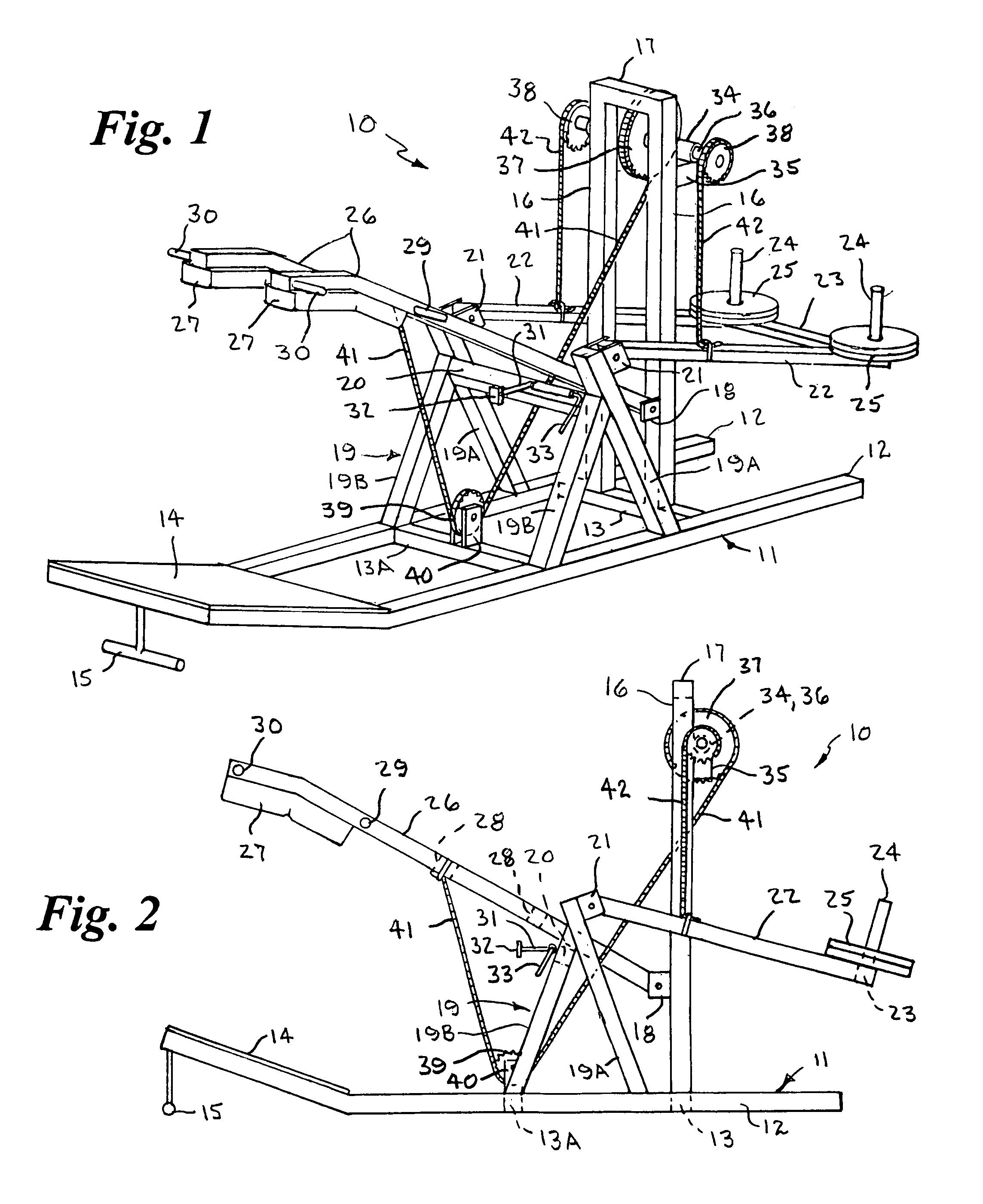

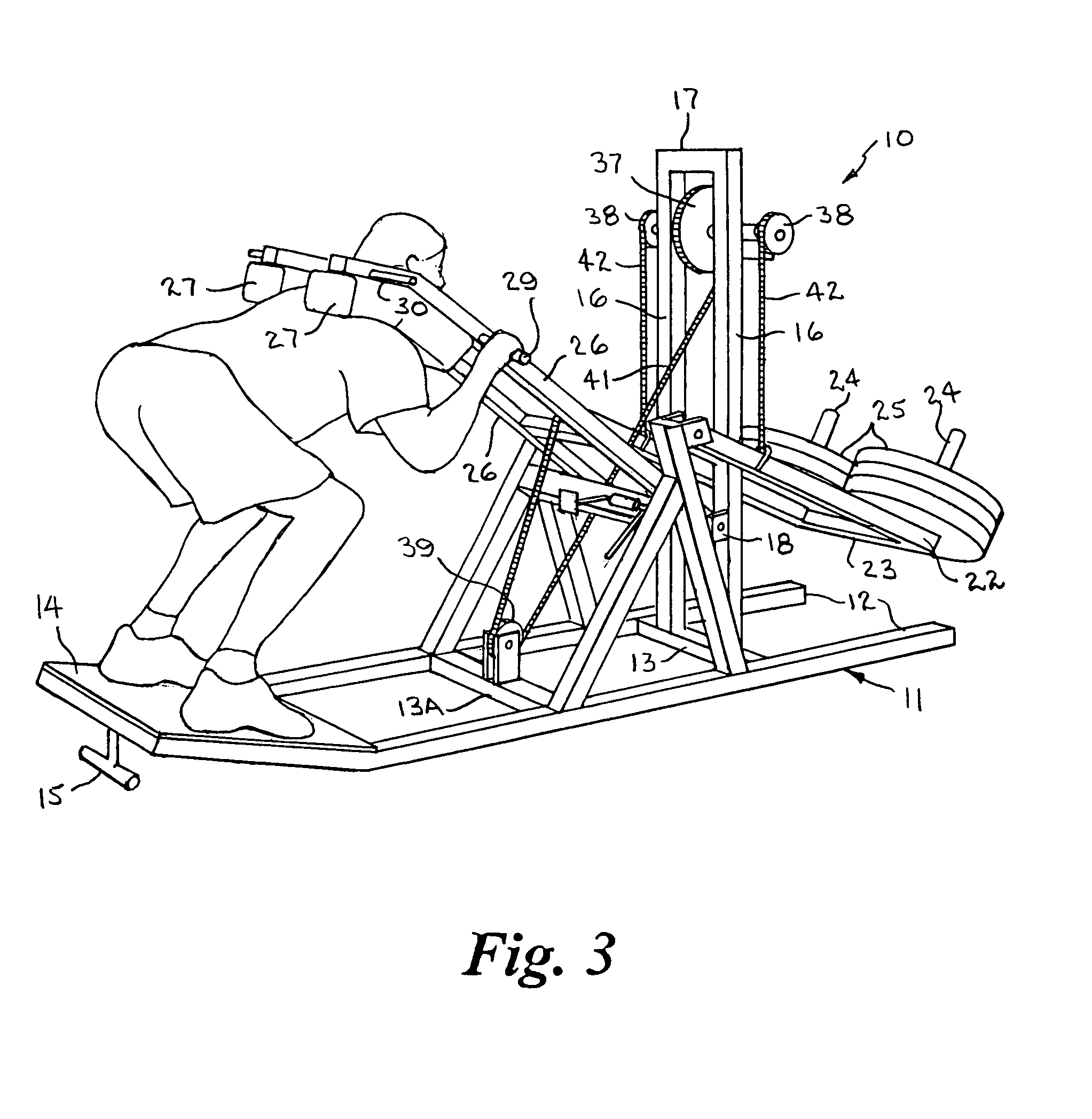

Exercise machine for conditioning athletes

InactiveUS7029426B1Strengthens and conditions the specific muscle groups usedMotion can be efficientMuscle exercising devicesSprocketEngineering

An exercise machine has a frame with a generally rectangular base and a platform disposed at an angle at one end upon which the user stands. A horizontal shaft rotatably mounted on a pair of vertical frame members near the forward end of the base has an upper central sprocket at its center and smaller sprockets at its outer ends. A lower central sprocket is rotatably mounted on the base. A weight support arm pivotally connected to a pair of upright frame members extends forwardly therefrom and a selected number of weights are received on the outer end thereof. An elongate lift arm pivotally connected to the vertical frame members extends angularly upward and rearward therefrom toward the platform and has a pair of shoulder pads at its outer end positioned a distance above the platform, with a first and second pair of lateral hand grips near each end of the pads for griping the bar in two positions. A first chain wrapped around the upper central sprocket extends under the lower central sprocket and has its free end connected to the lift arm and a pair of second chains each wrapped around an outer sprocket in the opposite direction have their free ends connected to the weight supporting member. When the lift arm is raised by an upward force on the shoulder pads and / or hand grips, the lift arm pivots upward pulling the first chain down causing rotation of the upper central sprocket and outer sprockets which causes the second chains to pivot the weight supporting member upward with the weights at the outer ends thereof resisting the upward force applied to the lift arm.

Owner:FULLER SR BARNEY R

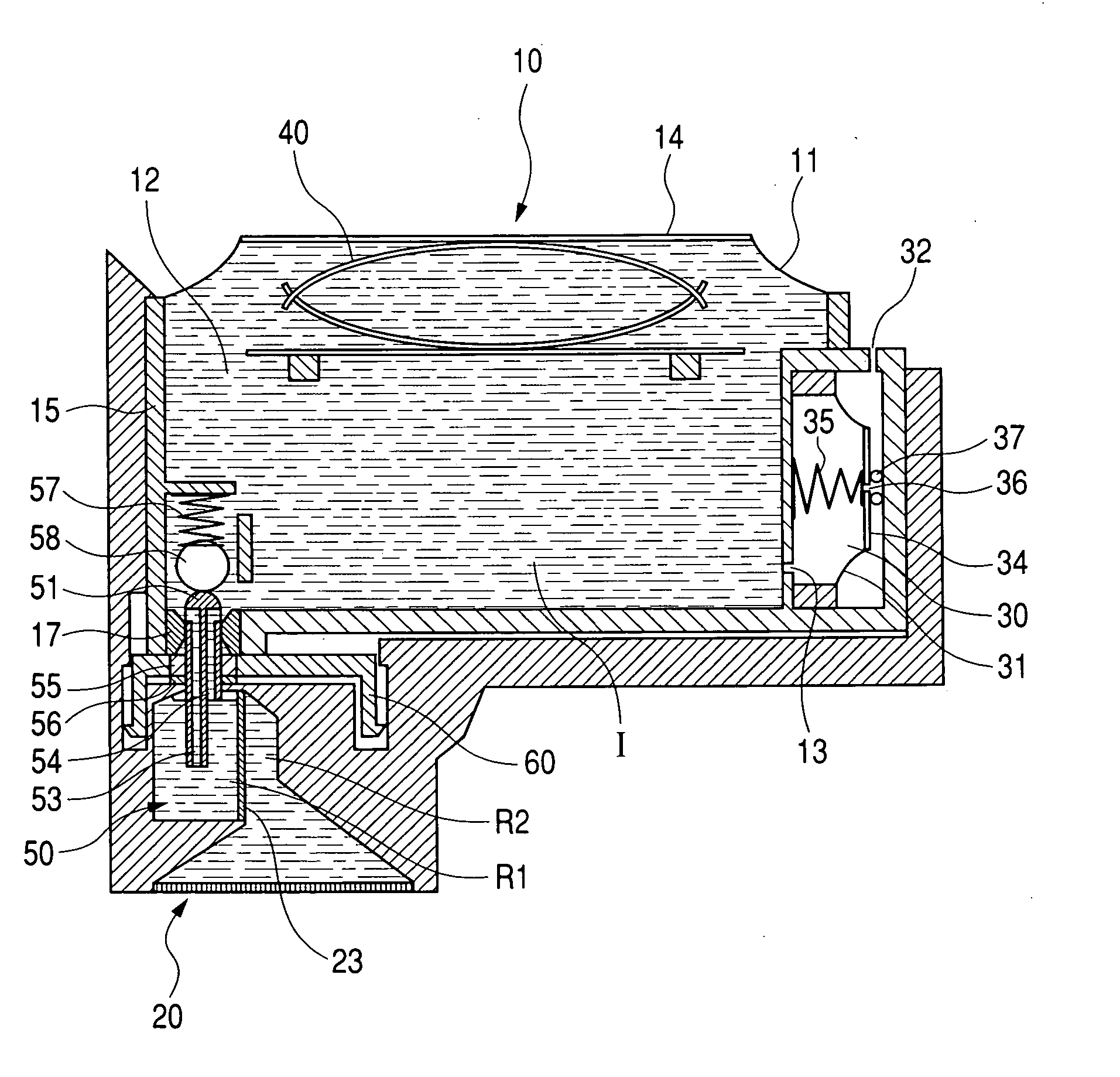

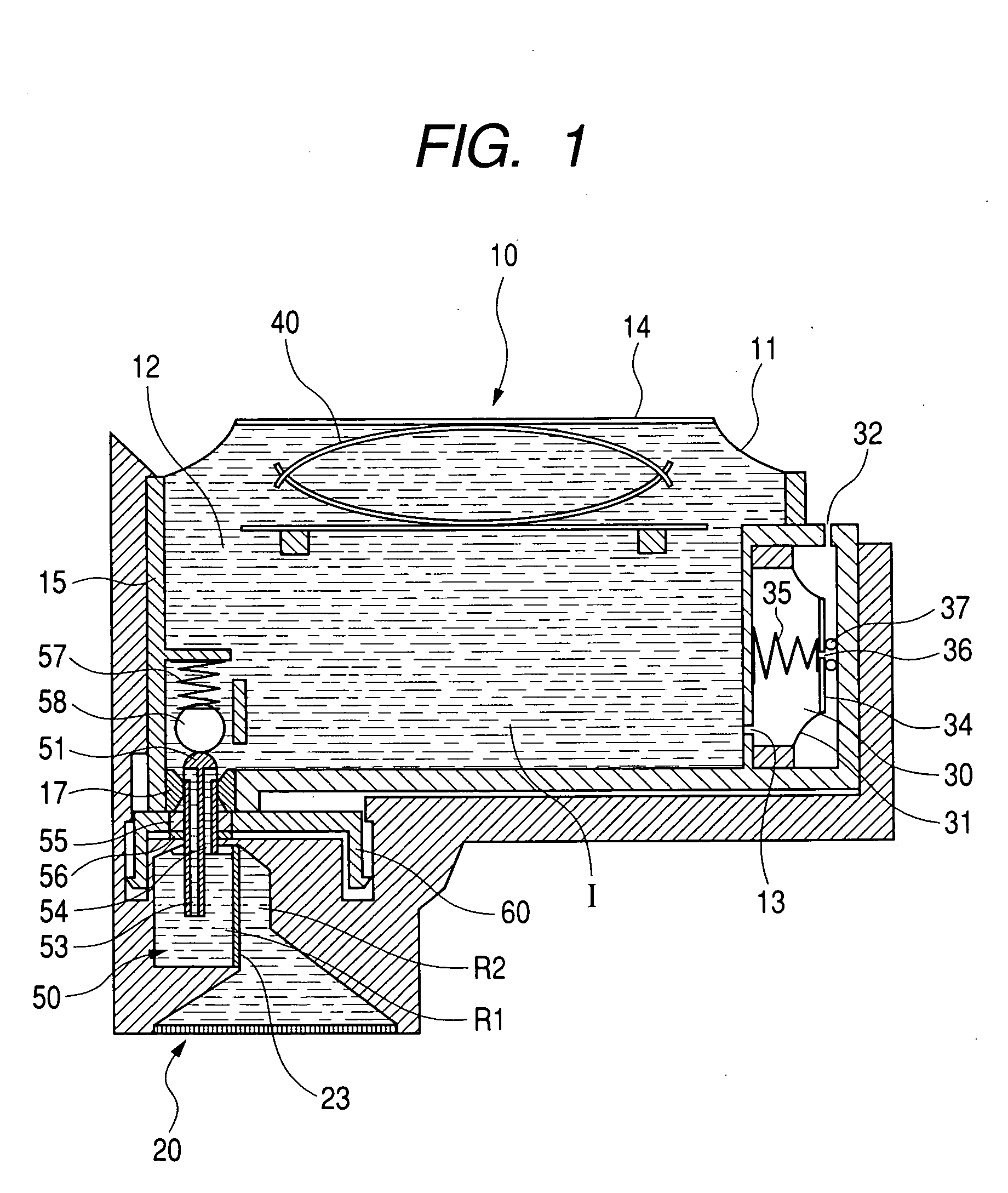

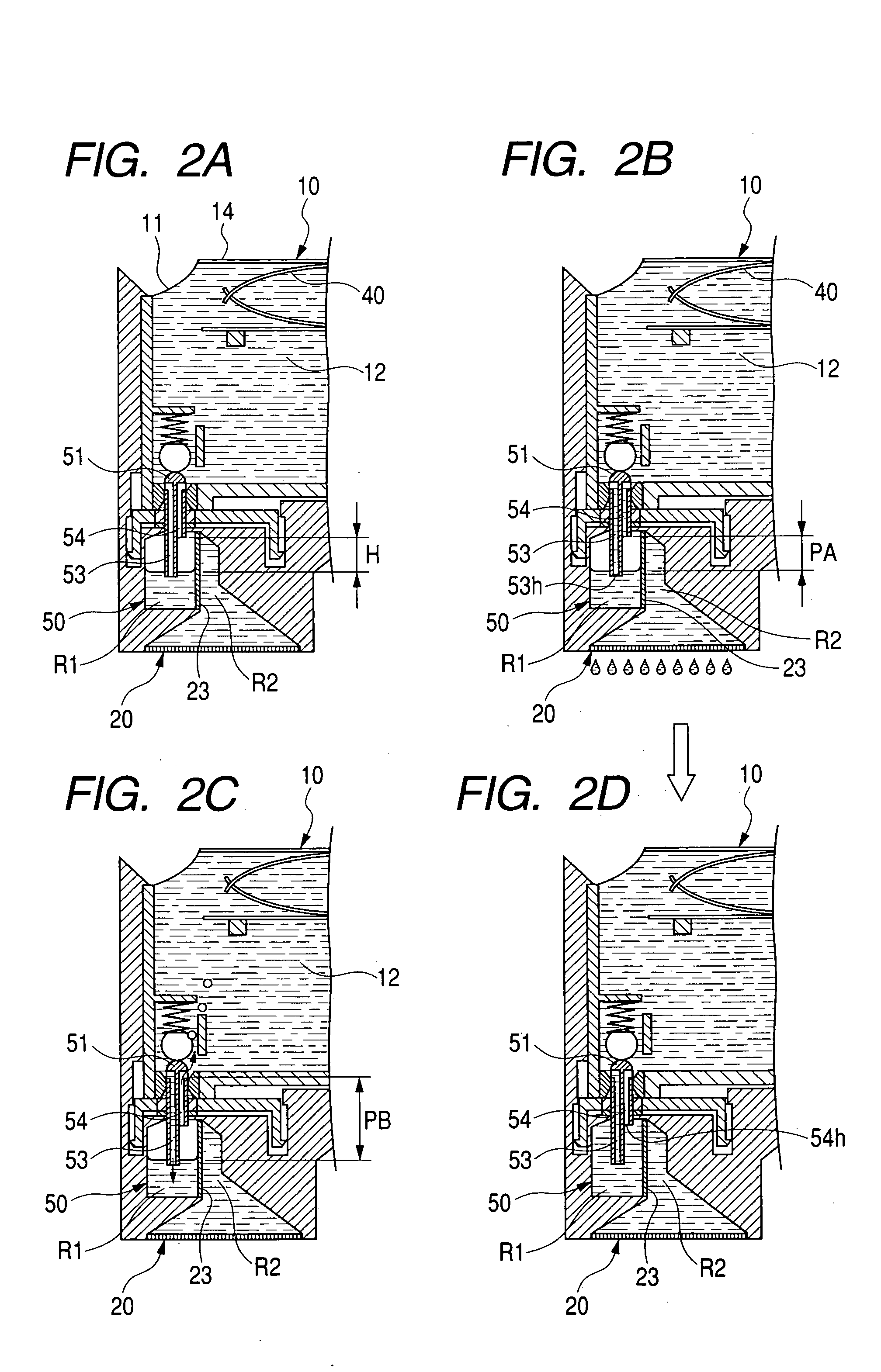

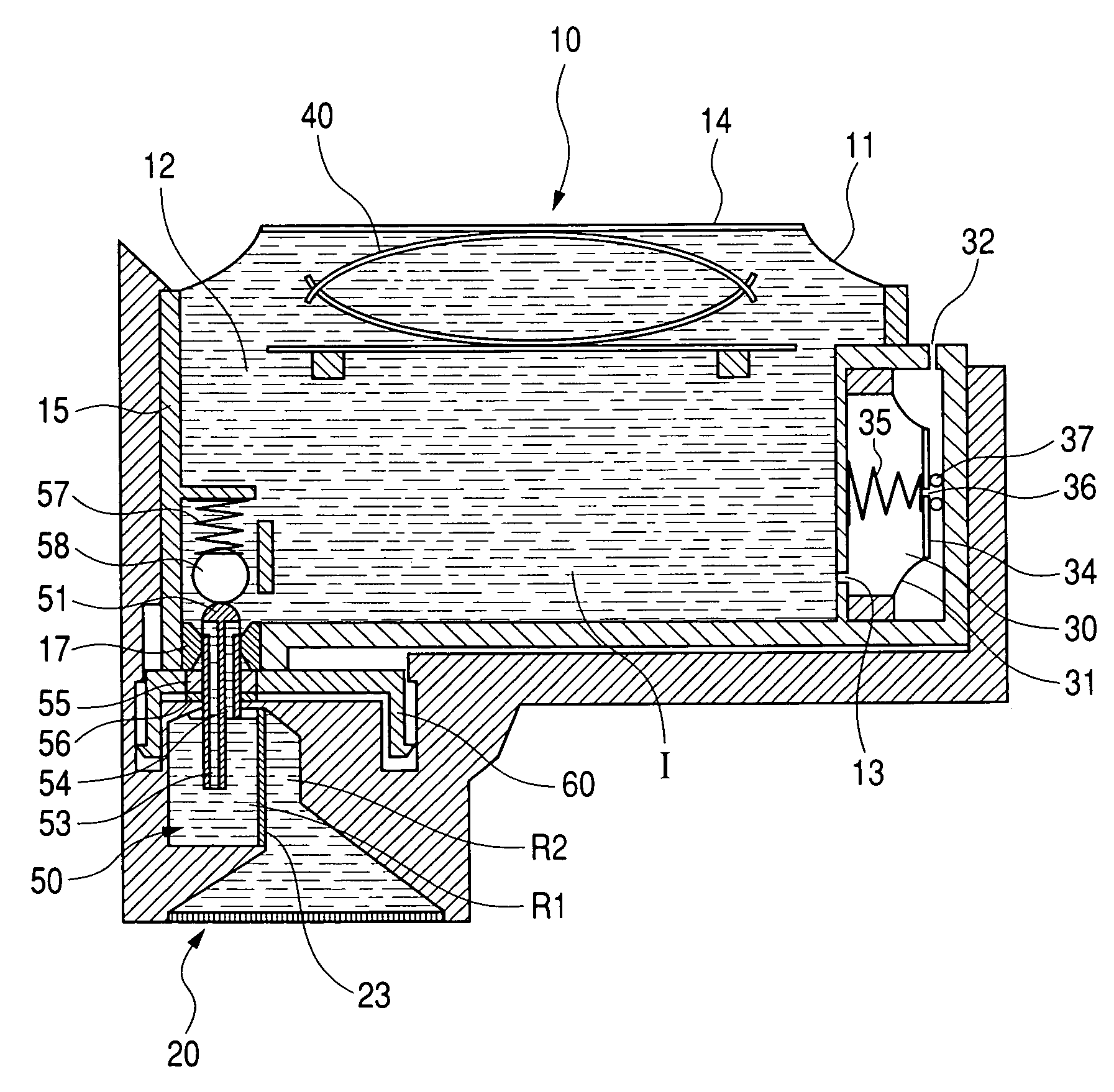

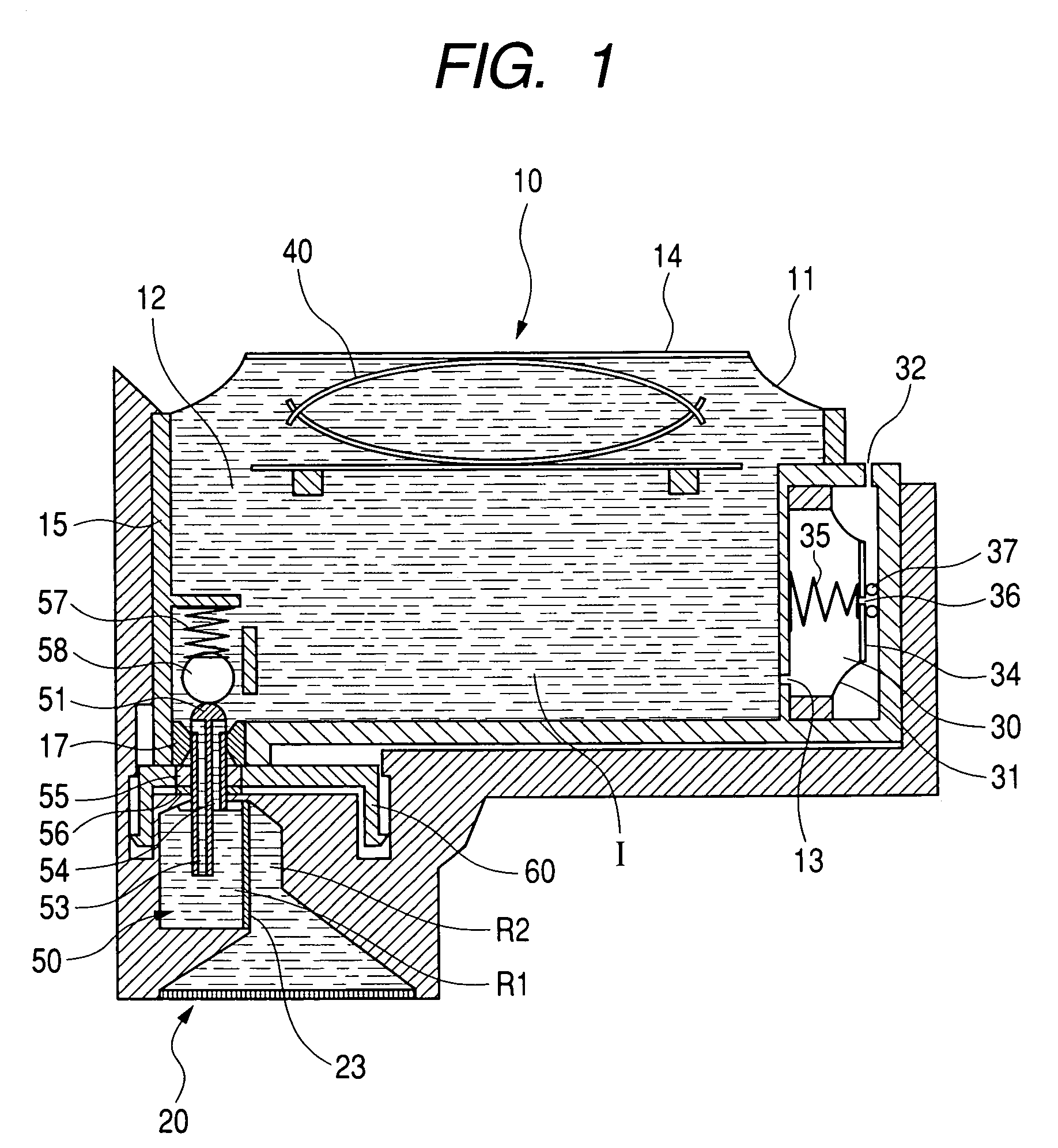

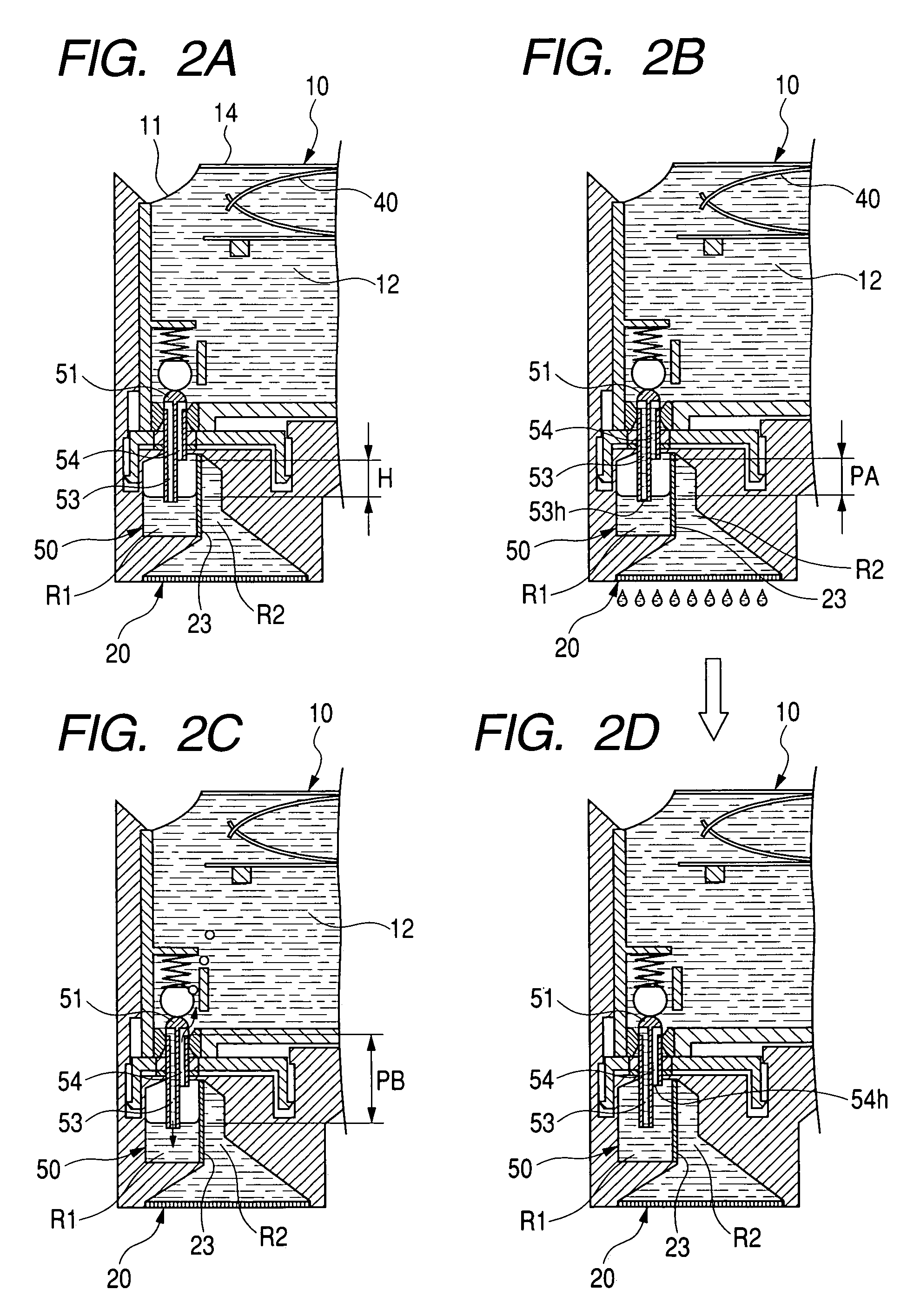

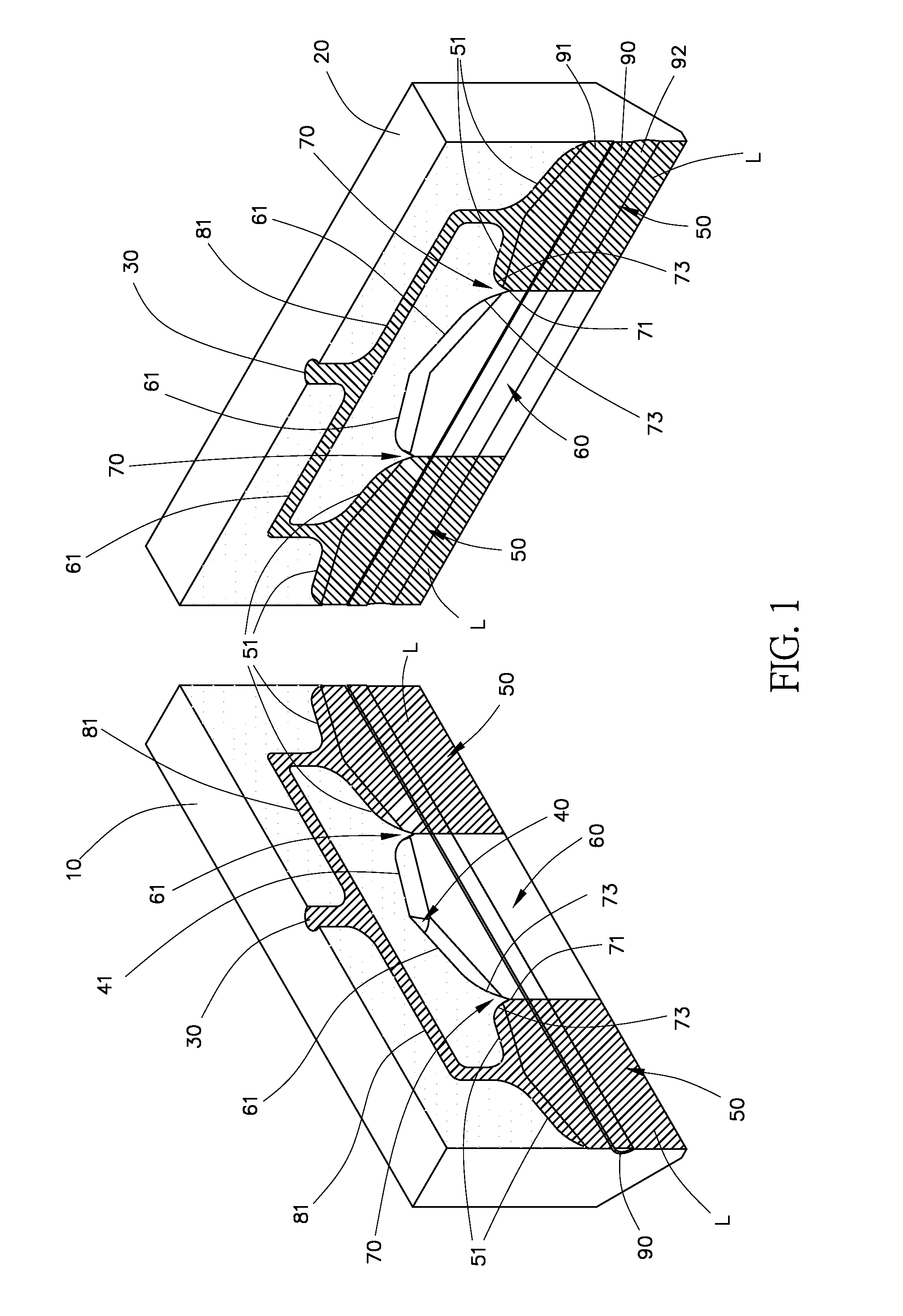

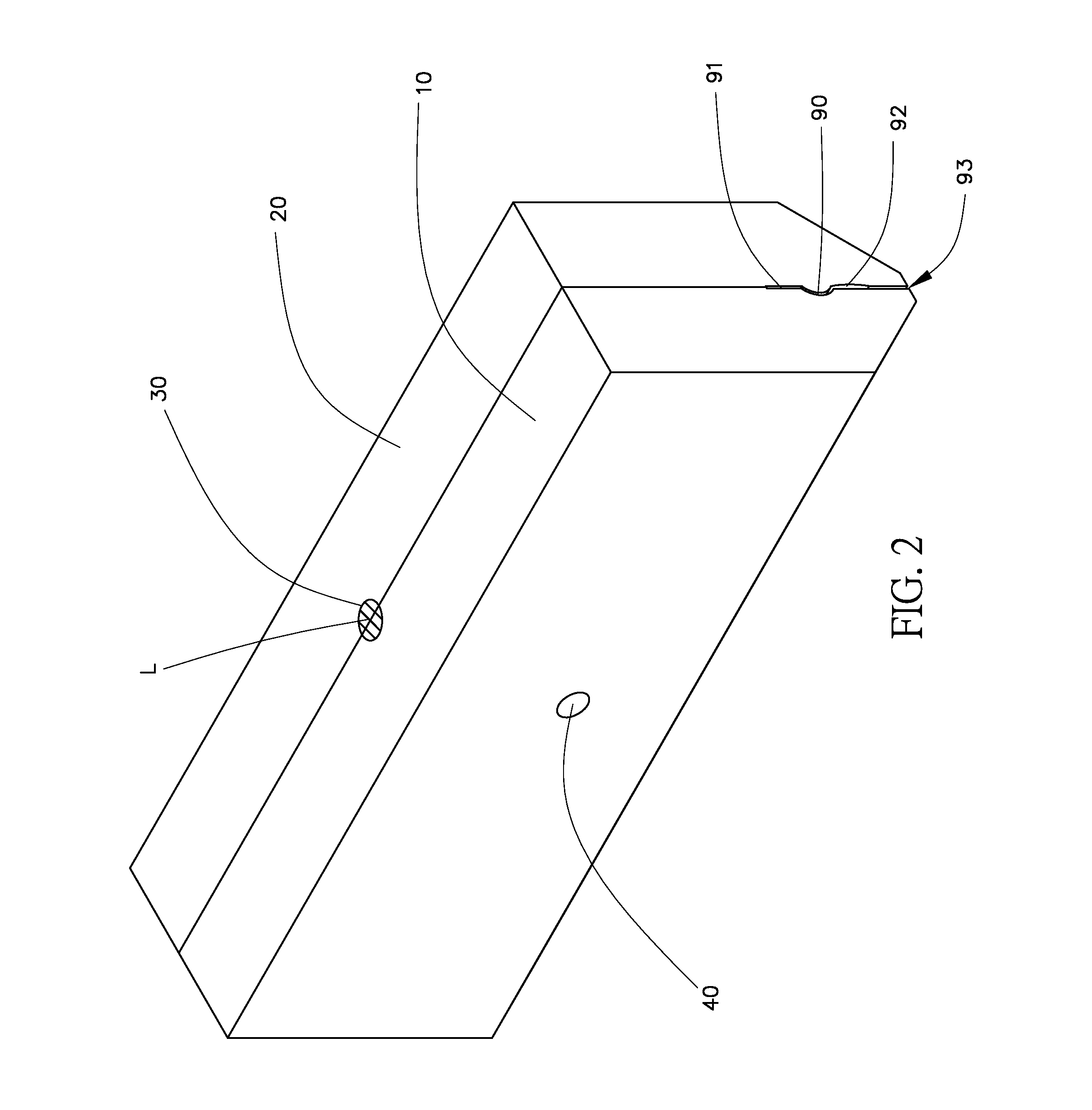

Ink supply system, recording apparatus, recording head, and liquid supply system

InactiveUS20050068394A1Compact configurationWasteful ink consumption can be suppressedPrintingEngineeringMechanical engineering

An ink supply system comprises an ink tank which contains ink, and a liquid chamber which is connected to the ink tank through a plurality of communication paths, and supplies ink taken from the ink tank to a recording head, wherein the liquid chamber, except the plurality of communication paths and a connection section to the recording head, forms a substantially sealed space; the liquid chamber is provided with a filter which can partition the inside of the liquid chamber into a first region at the side of the ink tank and a second region at the side of the recording head, and can form a meniscus of ink which is broken by a pressure of gas in the second region.

Owner:CANON KK

Ink supply system, recording apparatus, recording head, and liquid supply system

An ink supply system comprises an ink tank which contains ink, and a liquid chamber which is connected to the ink tank through a plurality of communication paths, and supplies ink taken from the ink tank to a recording head, wherein the liquid chamber, except the plurality of communication paths and a connection section to the recording head, forms a substantially sealed space; the liquid chamber is provided with a filter which can partition the inside of the liquid chamber into a first region at the side of the ink tank and a second region at the side of the recording head, and can form a meniscus of ink which is broken by a pressure of gas in the second region.

Owner:CANON KK

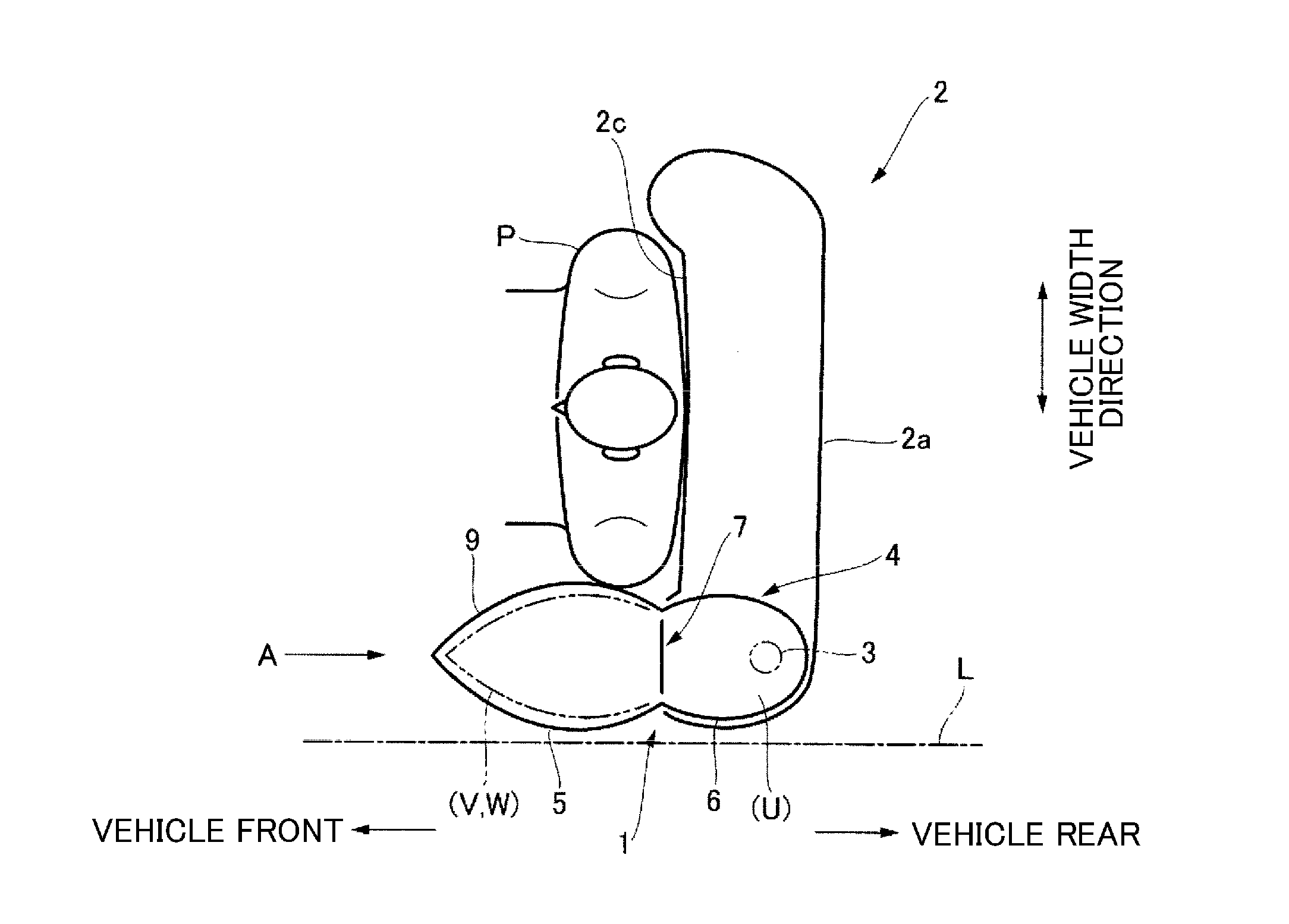

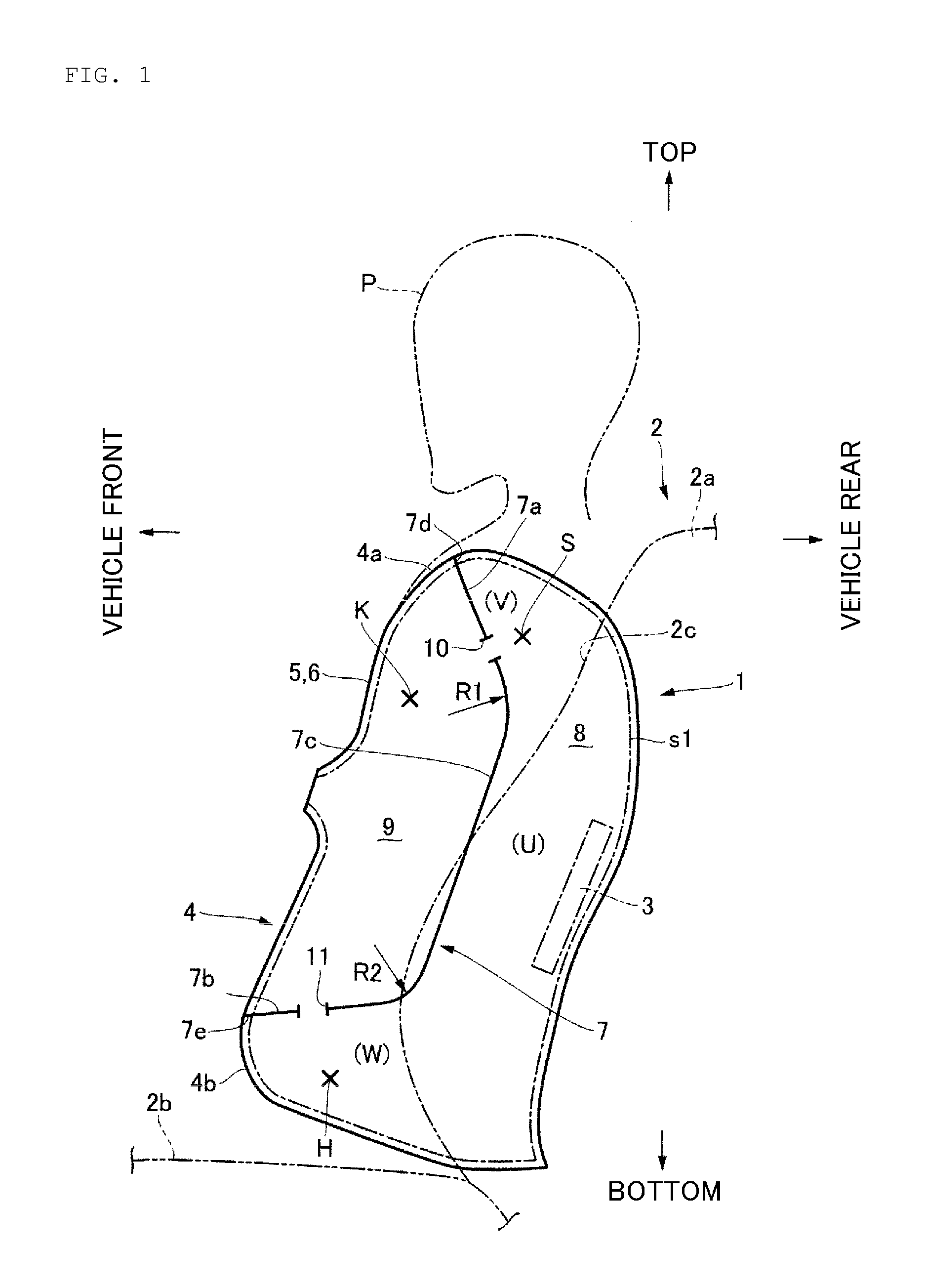

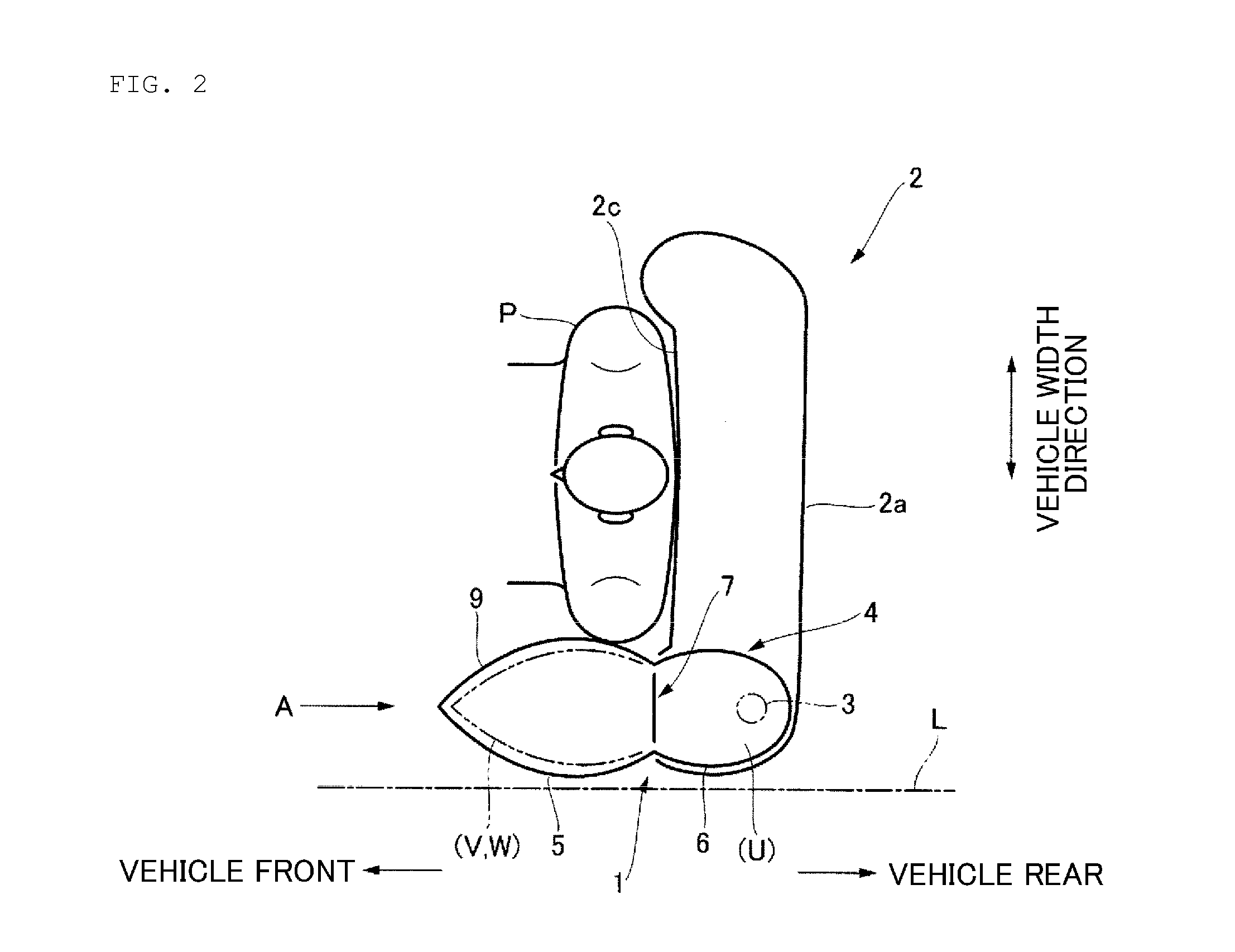

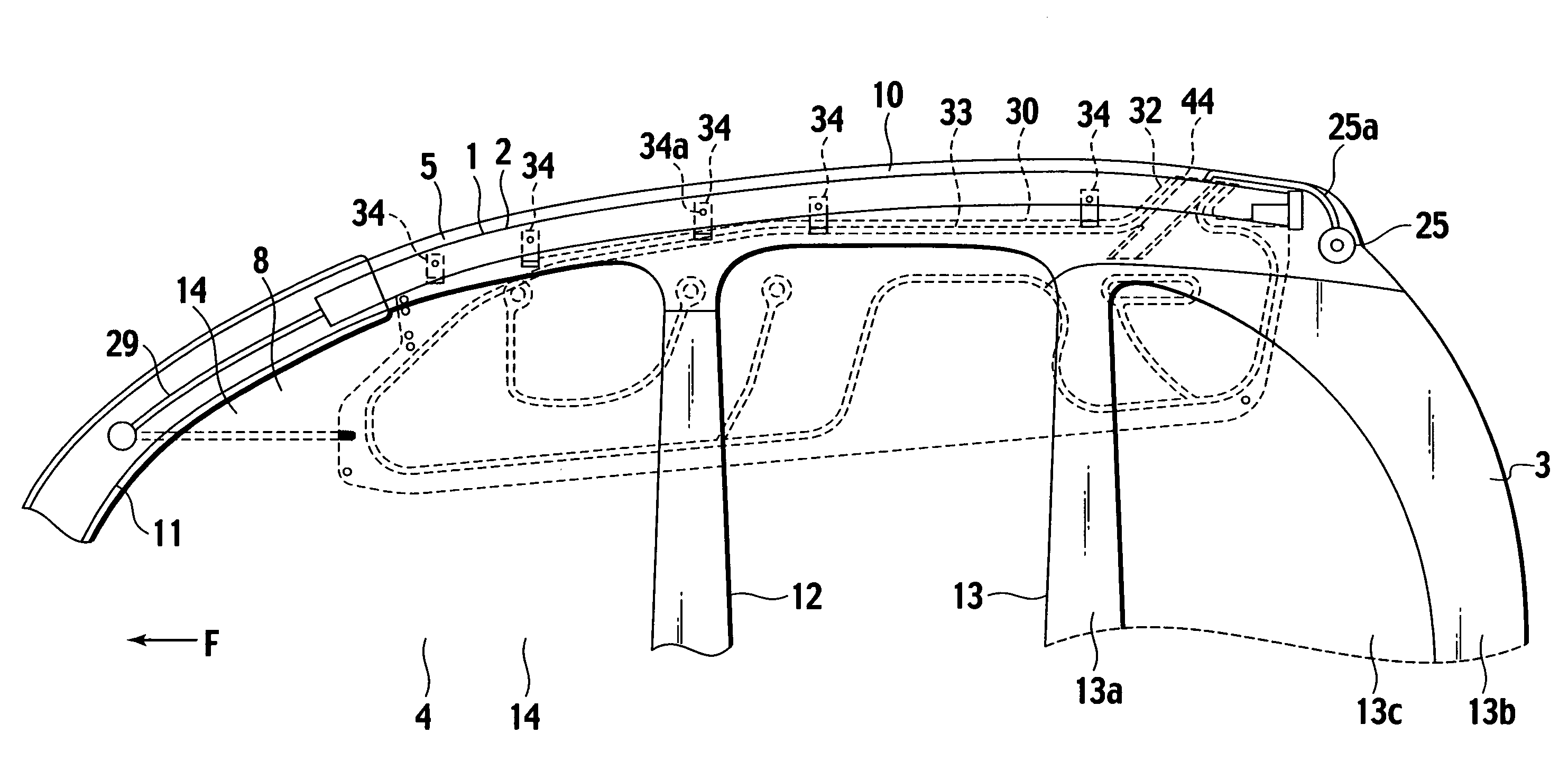

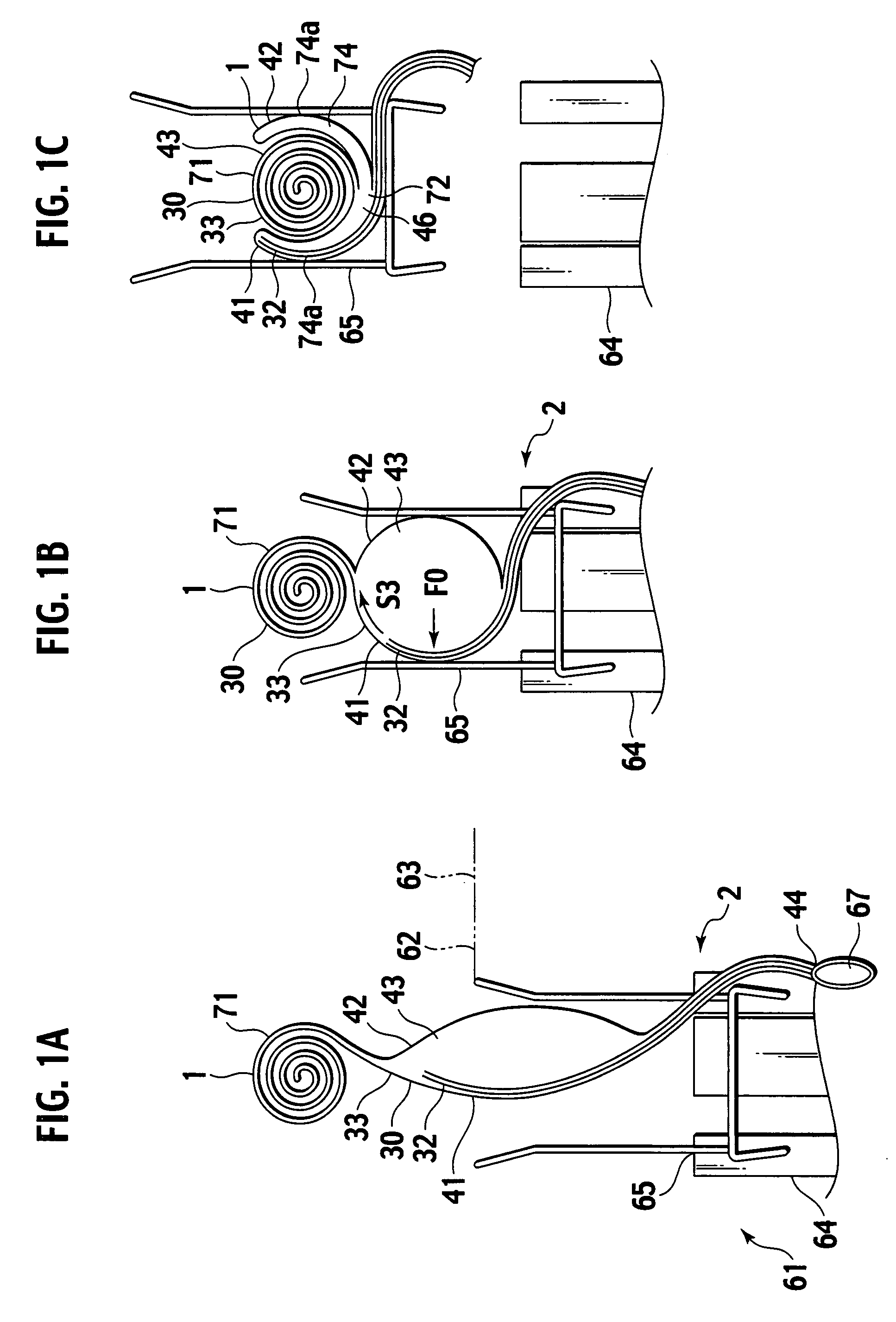

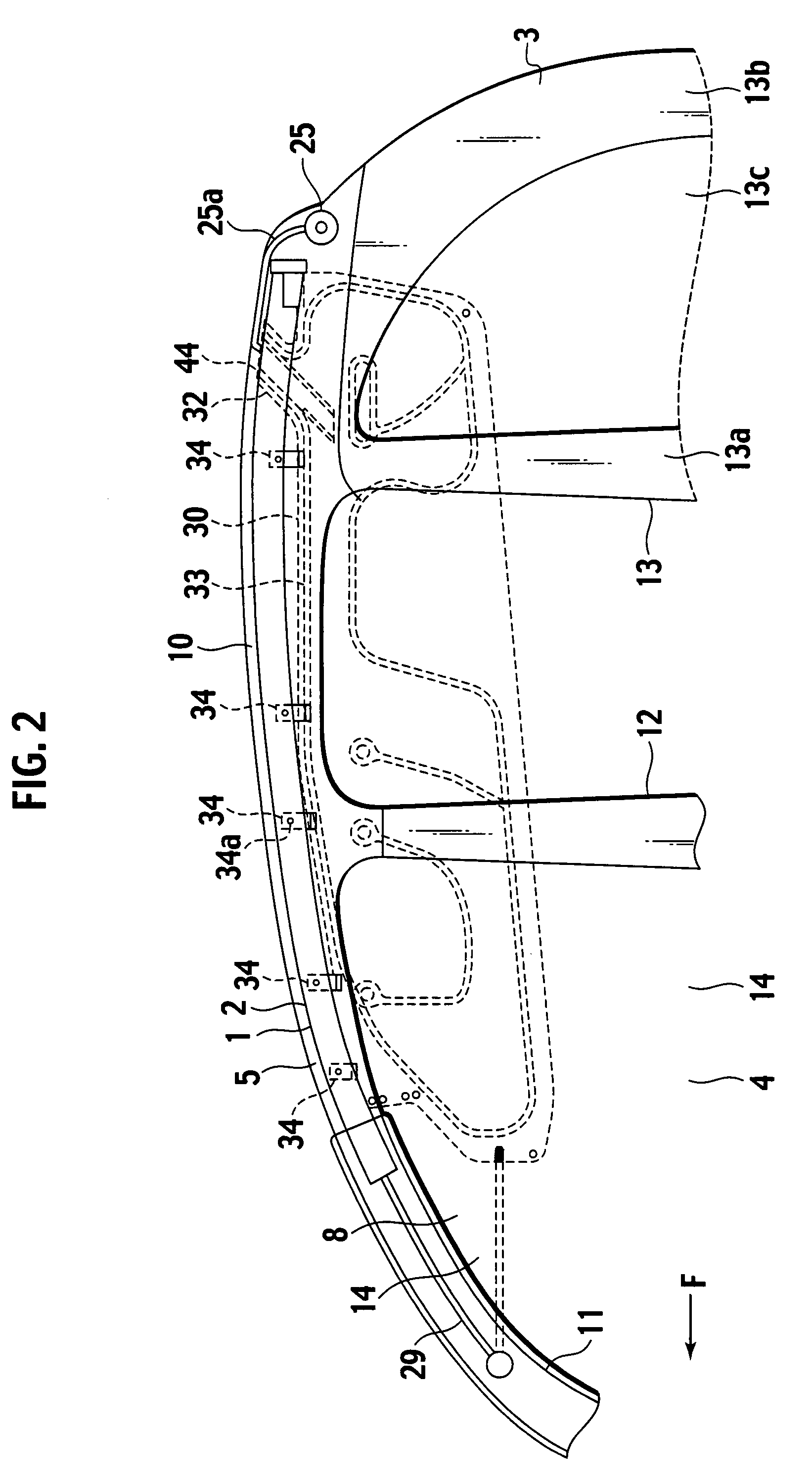

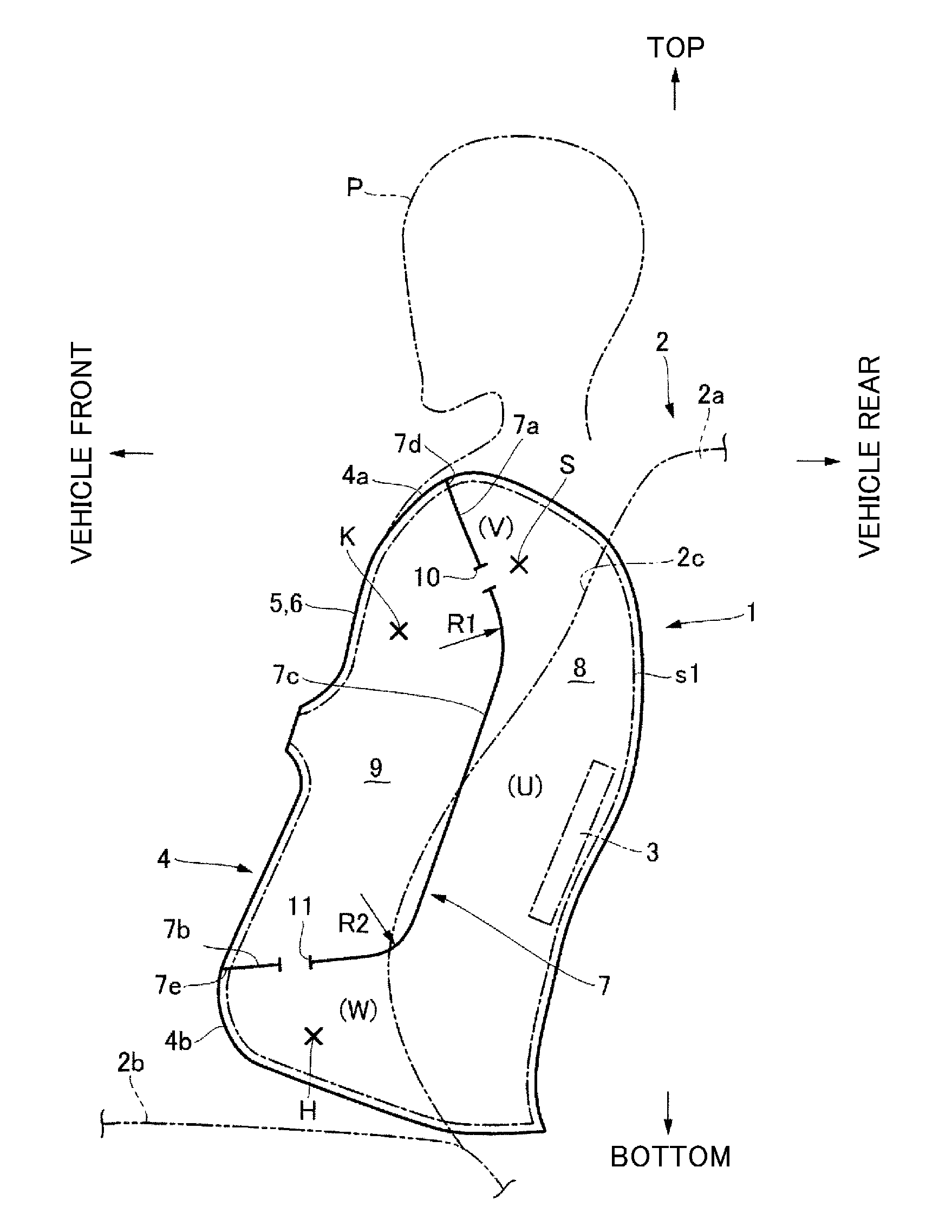

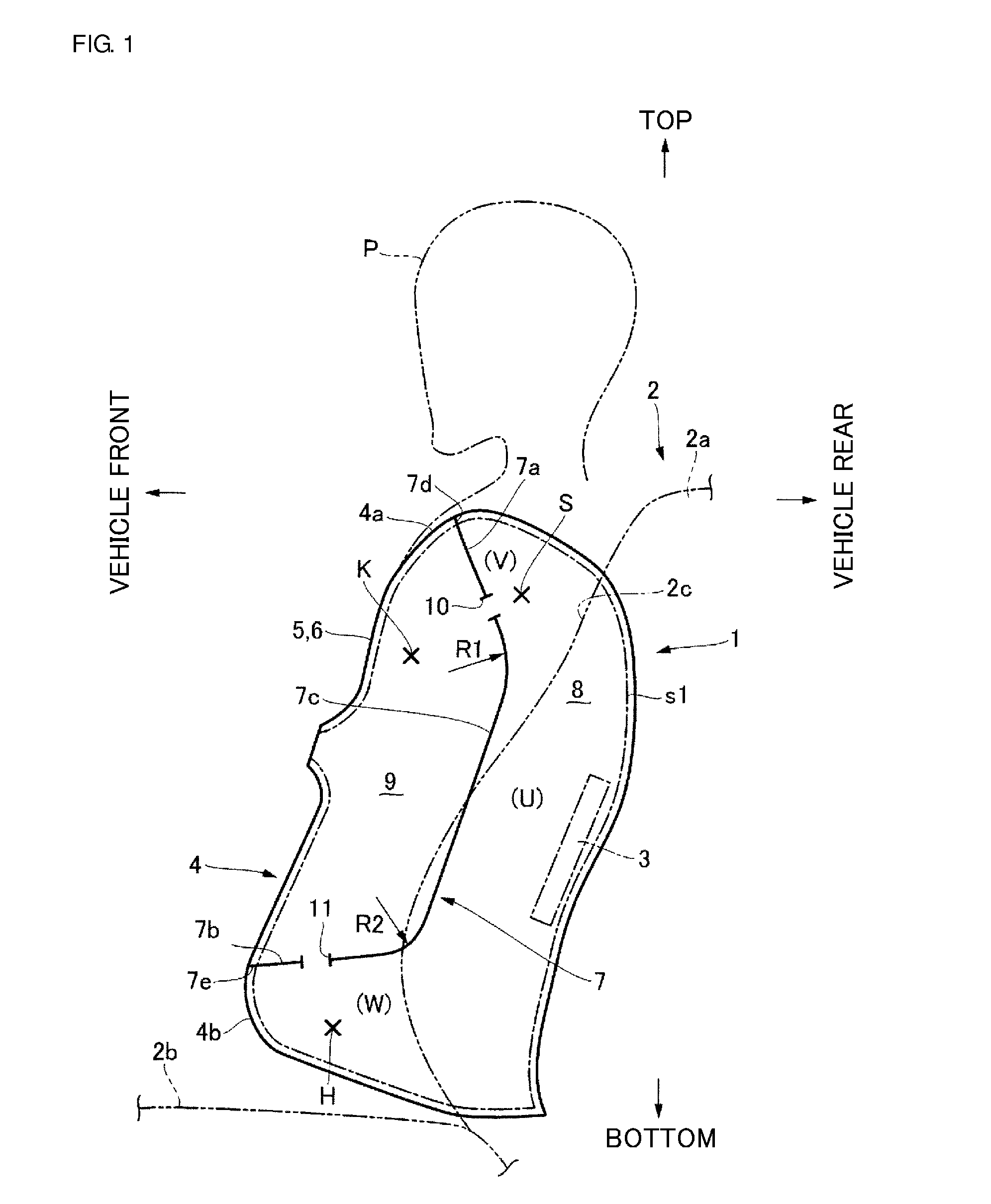

Vehicular Side Airbag Device

ActiveUS20150367811A1Smoothly and quicklySmall thicknessPedestrian/occupant safety arrangementChest regionLateral airbag

A side airbag device having a side airbag that can slide between an occupant and a vehicle side section, and allows occupant restraint by reaching. The side airbag can be inflated with the thickness of the portion that protects the peripheries of the occupant shoulder and waist is small and the thickness of the portion that protects the periphery of the chest region is large. Inside a side airbag, a rapid chamber extends from a seat back region over a top region and a bottom region and tapers towards the vehicle front; a delay chamber is positioned between the top region and bottom region, and a partitioning member partitions the interior of the side airbag into the delay chamber and the rapid chamber. An inflator is provided inside the rapid chamber.

Owner:AUTOLIV DEV AB

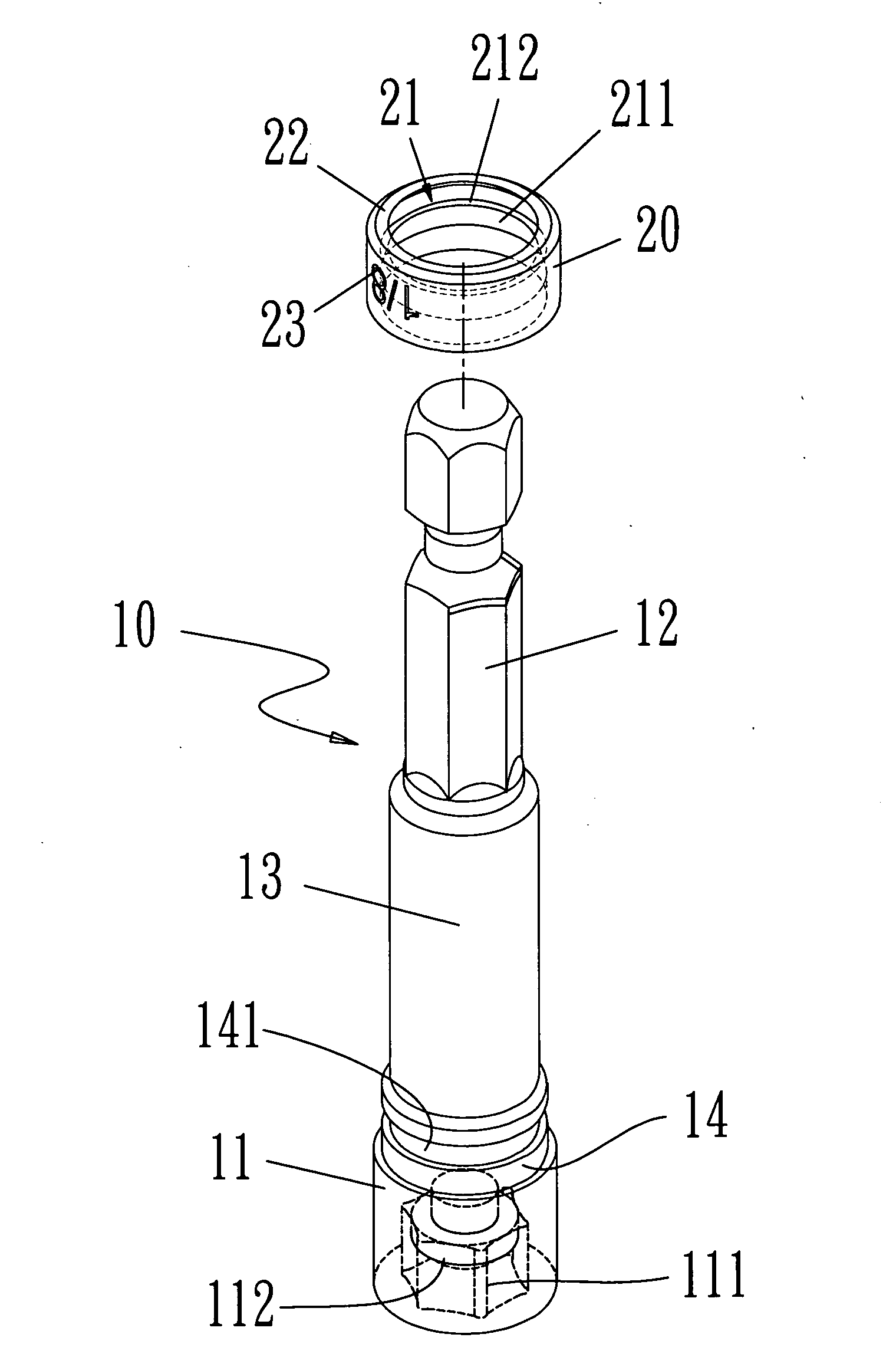

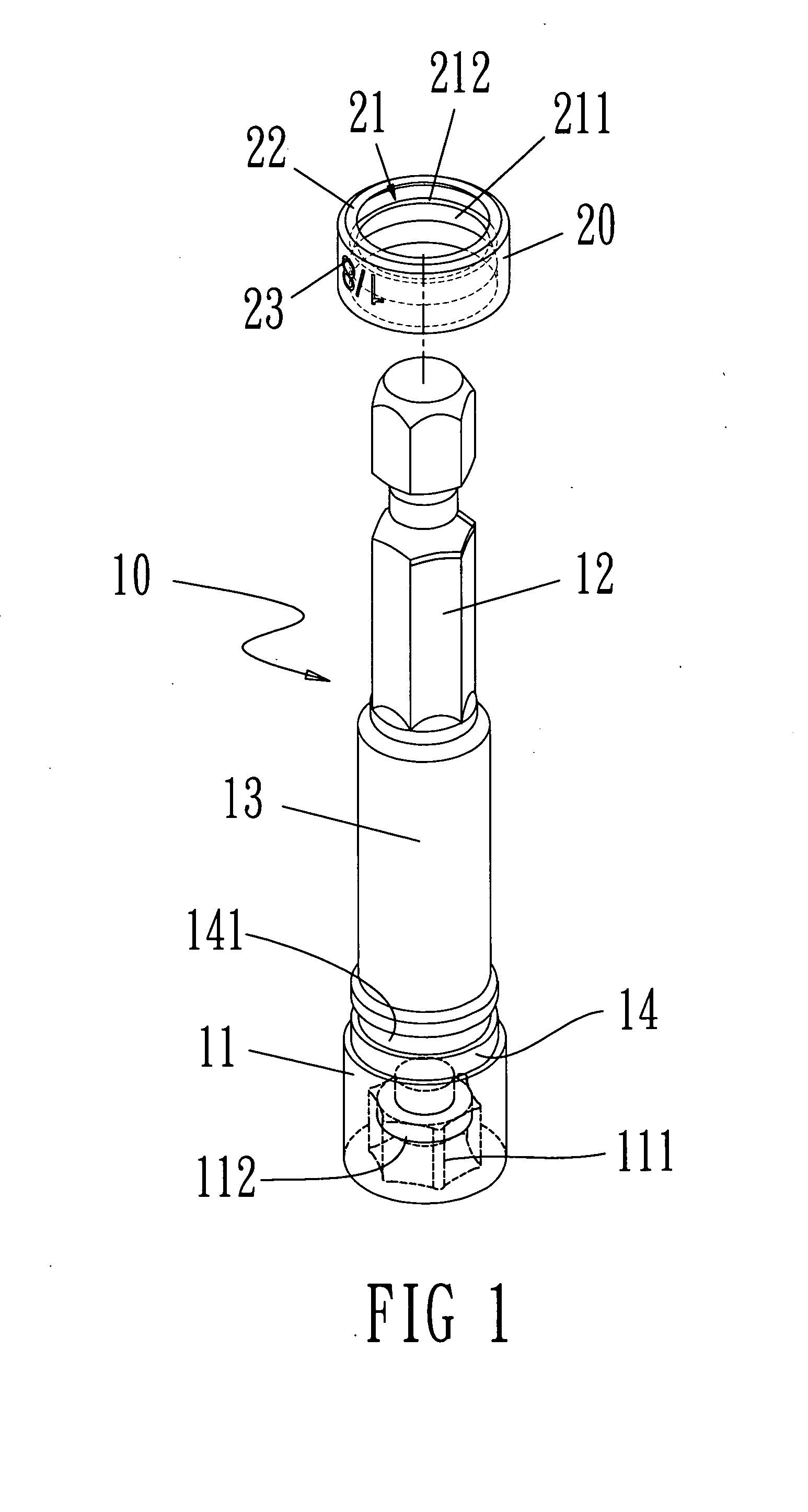

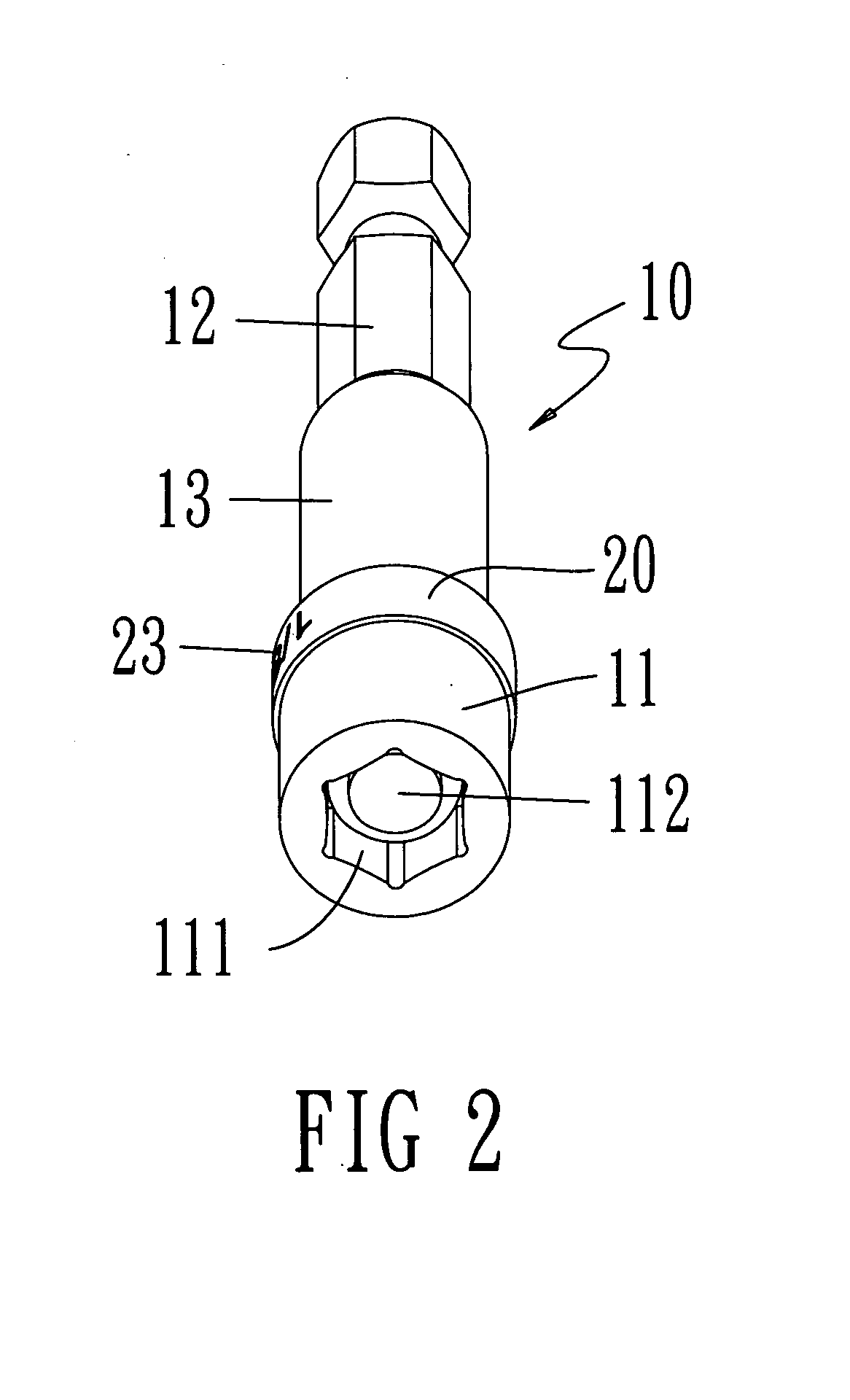

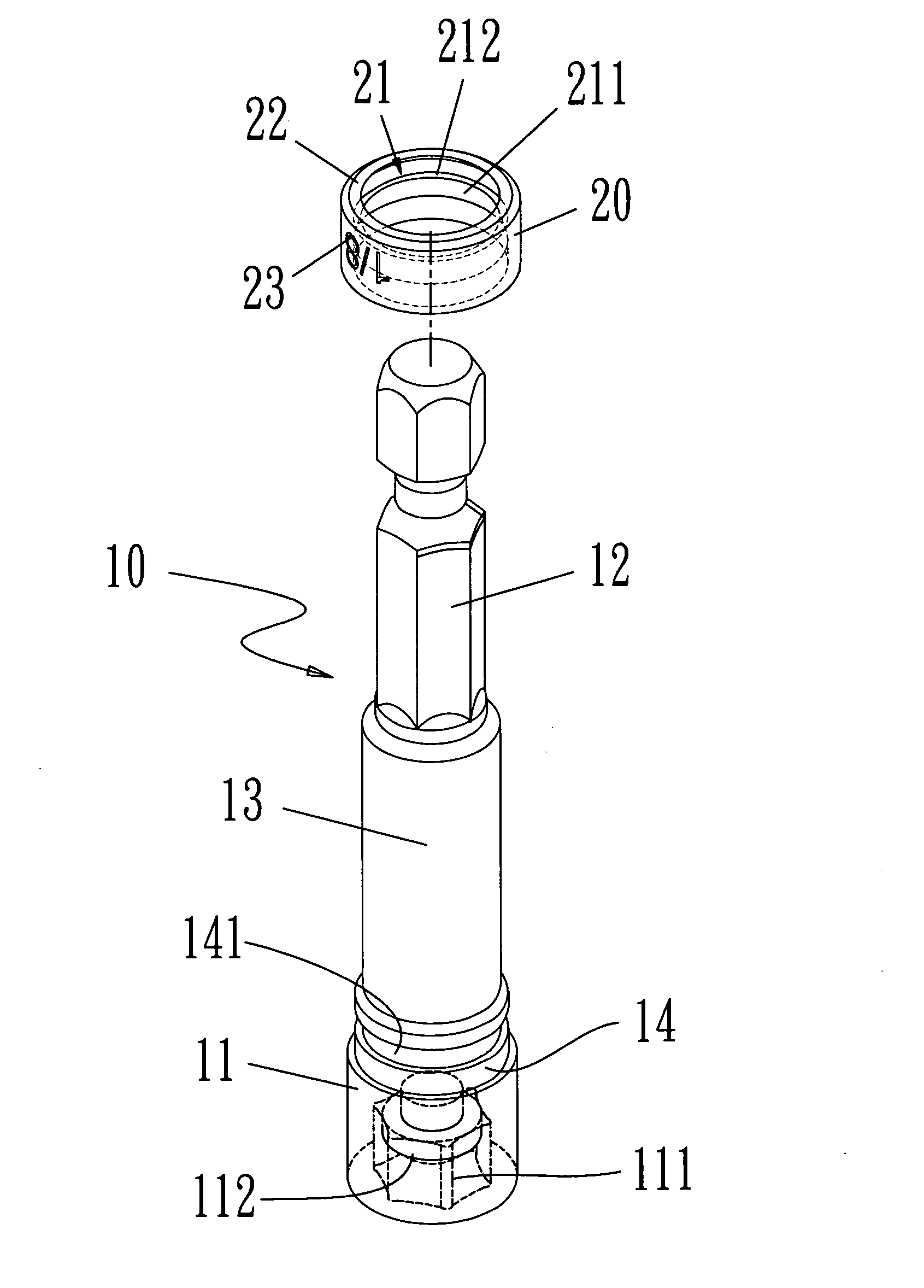

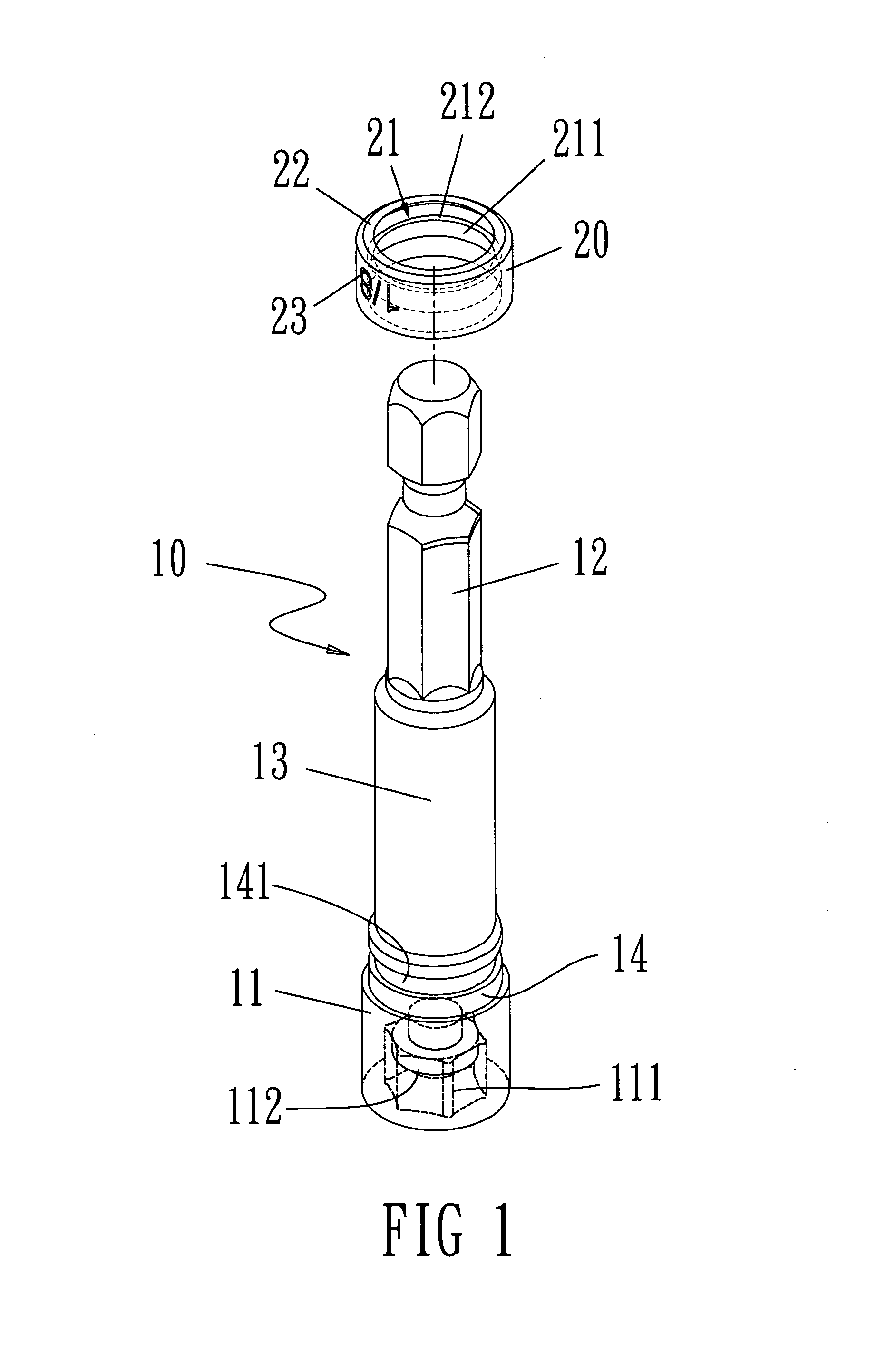

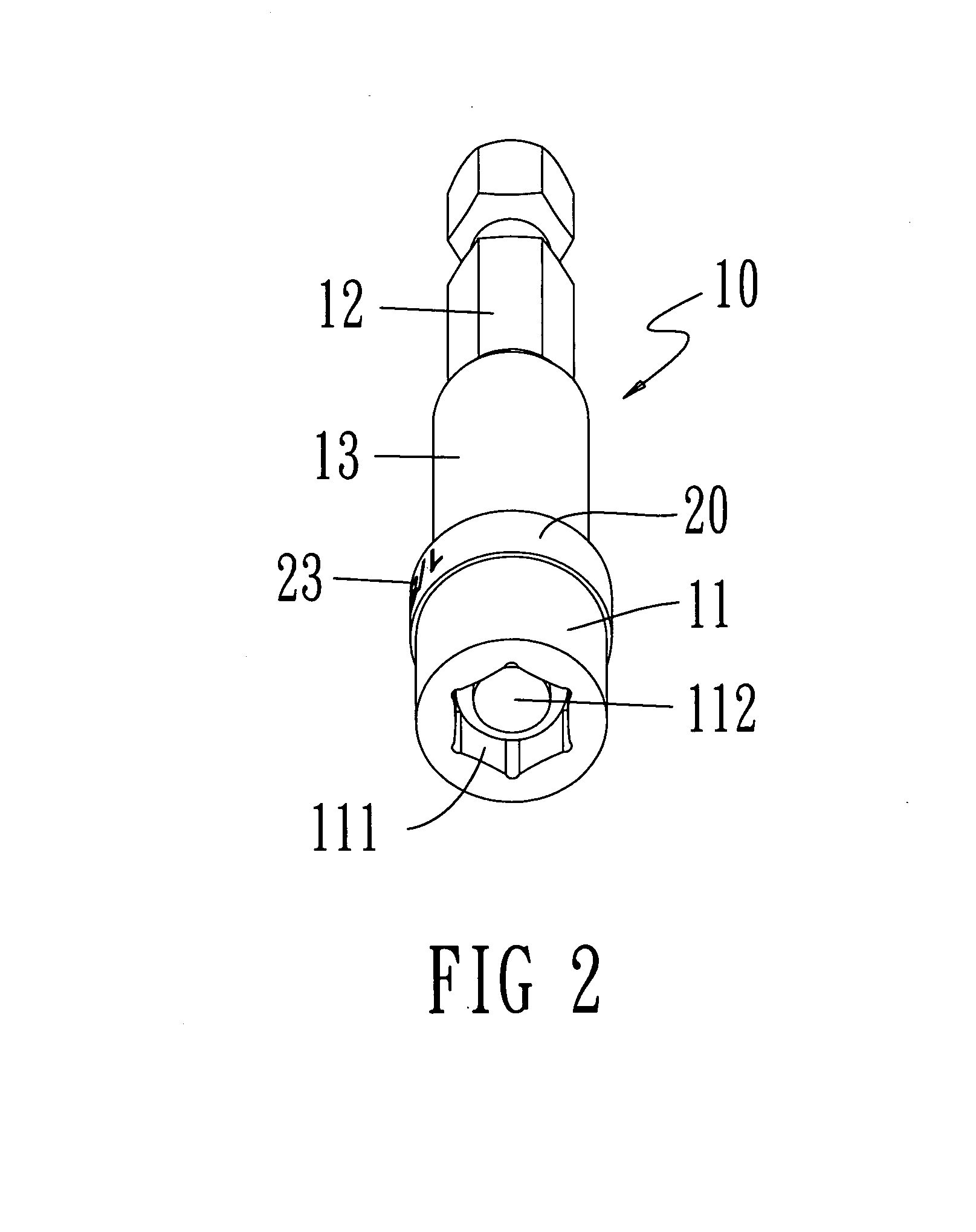

Joint recognition member

A joint recognition member is revealed. The joint recognition member includes a joint body formed by a cylinder connected with a polygonal prism. A polygonal hole with a magnet part is set on the cylinder so as to attract driver bits by magnetic force. The device features on that: a narrow neck part with a ring groove is arranged at one end of the cylinder near the polygonal prism. The ring is wrapped around the narrow neck part and outside diameter of the ring is no smaller than that of the cylinder. A protruding ring on the ring is mounted and moved freely in the ring groove. An outer surface of the ring is labeled with words such as size. According to the corresponding polygonal hole, the ring has different shapes and sizes in various colors for fast recognition.

Owner:ROTE MATE IND

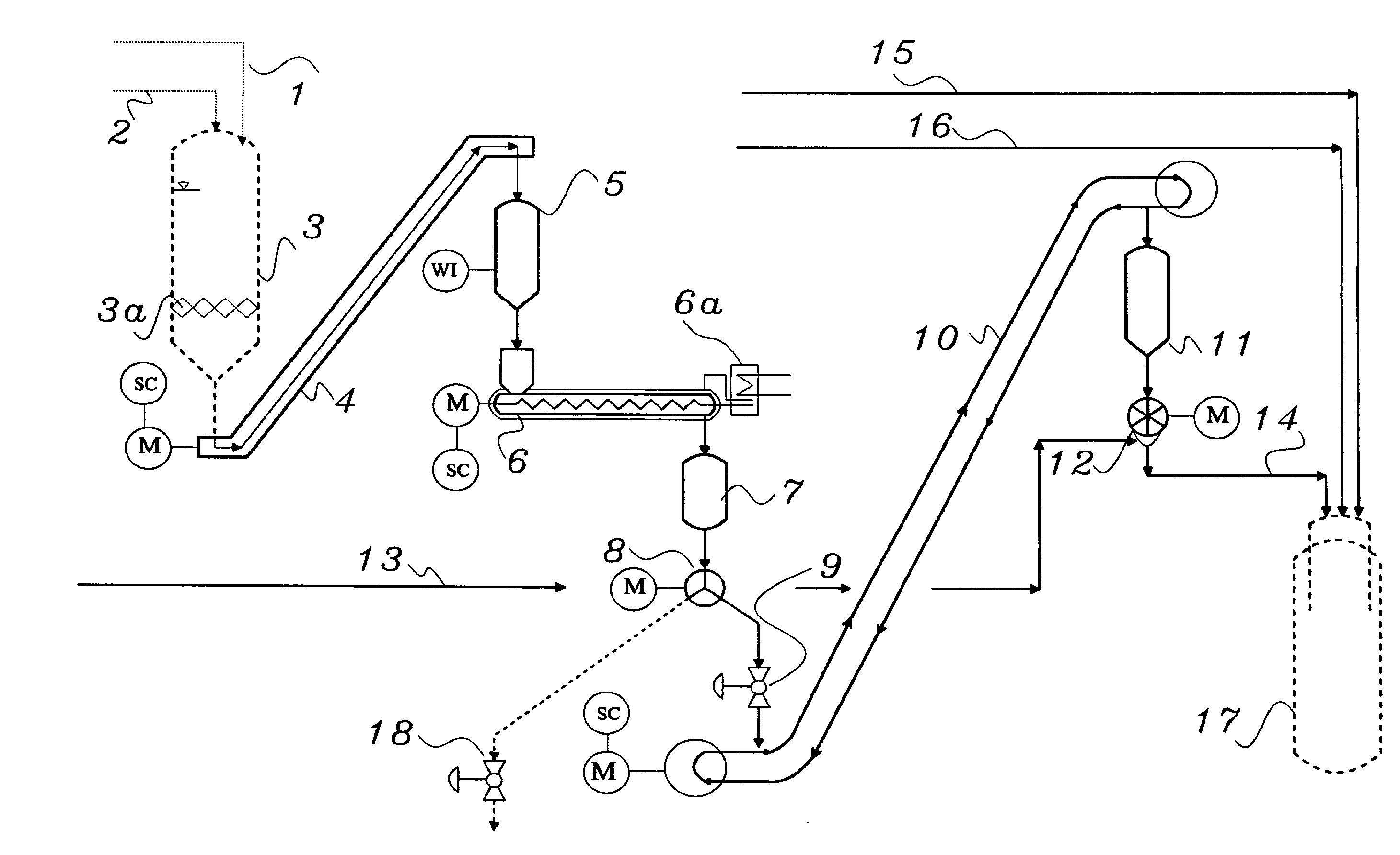

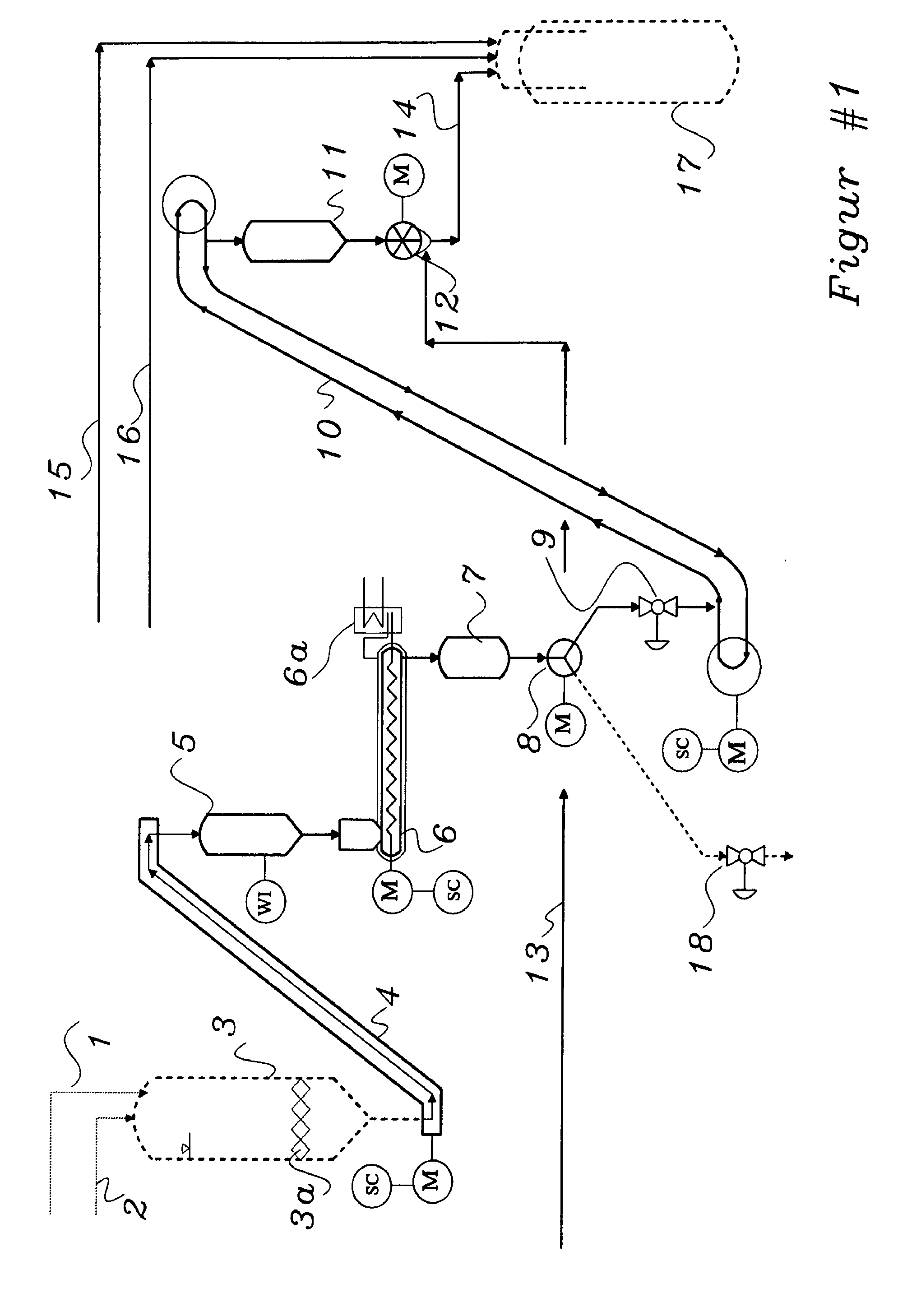

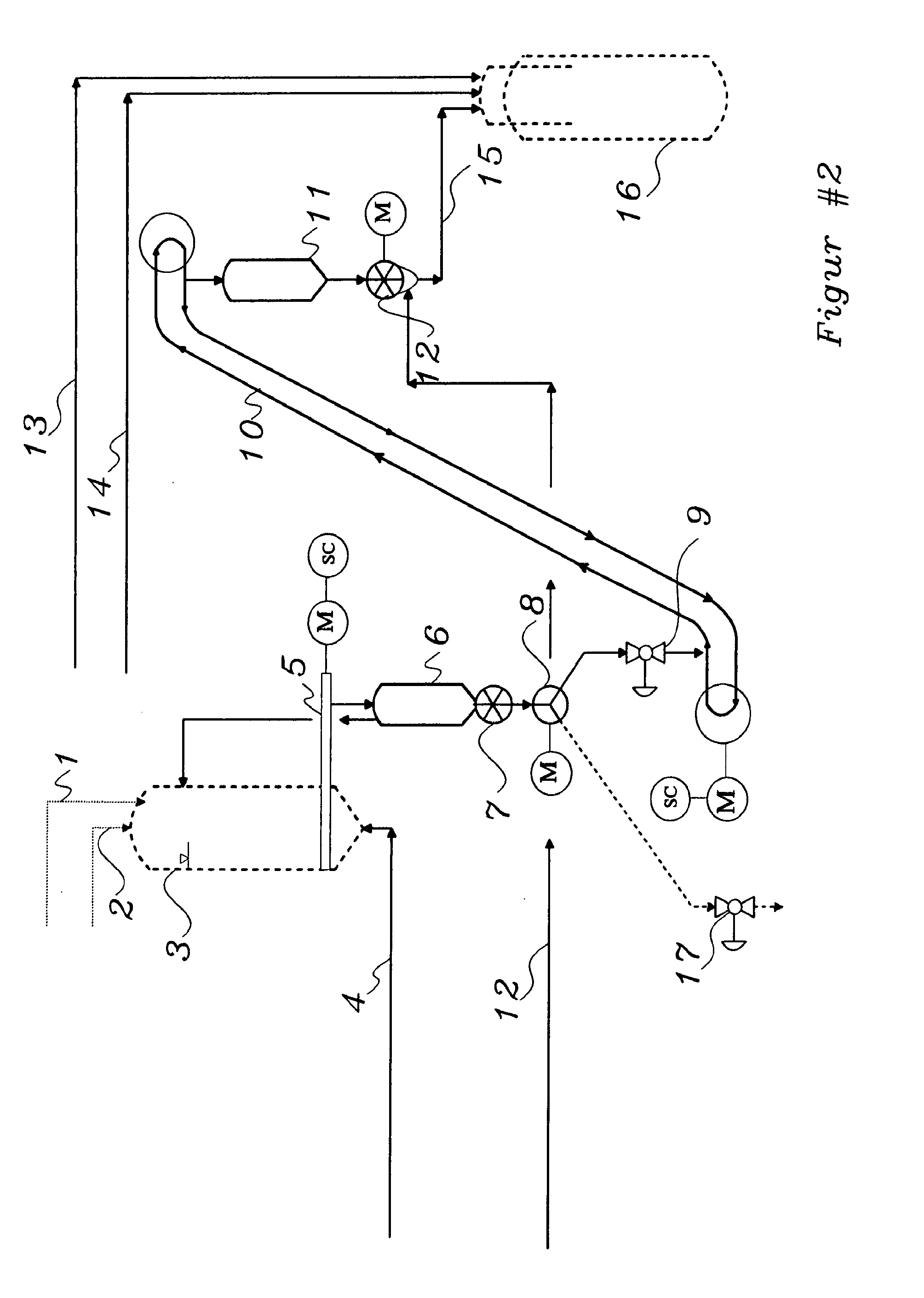

Process for continuous dry conveying of carbonaceous materials subject to partial oxidization to a pressurized gasification reactor

InactiveUS20120182827A1Smoothly and quicklyMaximum flexibilityControlling ratio of multiple fluid flowsMixer accessoriesSlagPartial oxidation

The present invention demonstrates a continuous process for dry conveying of powdered coal either a blend of carbonaceous material subject to partial oxidization whereby the conveying feed will be transferred via a suitable conveyer from an atmospheric silo to a or a number of extruder's LP Feeder Vessel and be fed over extruder's inlet chute in continuo to a or a number of extruder(s), in which the dry feed material will be densificated along the compression zone of that extruder up to high pressure and will be discharged over outlet chute into a downstream said First Pressurized Vessel, wherefrom the feeding precursor will be transported via a or a number of in series pressurized tubular-drag conveyor to the said Second Pressurized Vessel, which is equipped with one or more Reactor Feeding Unit(s), referred to Splitter(s), each one consisting of a Star Valve, Reactor-Feed-Line and a said Injection-Line for pneumatic conveying individually, whereby the feed carbonaceous material will be exposed to with injection gaseous media (saturated steam, superheated steam, inter gases, natural gas, N2, CO2, purge gas from synthesis section of ammonia, methanol plant, purge gas from PSA of hydrogen purification section, hydrogen or a blend of those gaseous media in any composition) by the formation of any pneumatic bulk conveying mechanism into a downstream pressurized reactor, preferably a gasification reactor, wherein the transported precursor will be converted chemically under high temperature and elevated pressure via partial oxidization reactions to process gas, slag and ash.

Owner:BAIRAMIJAMAL FARAMARZ

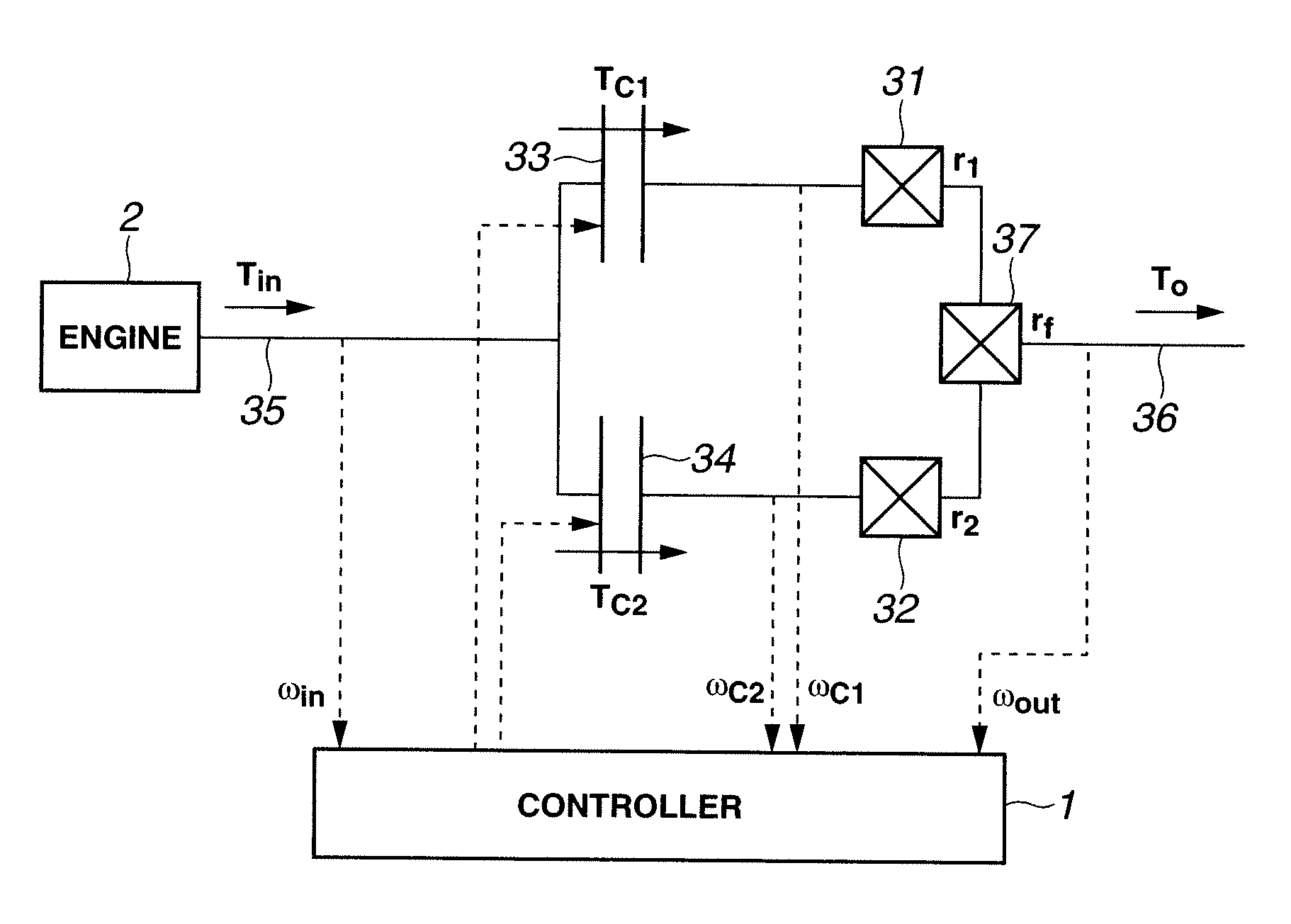

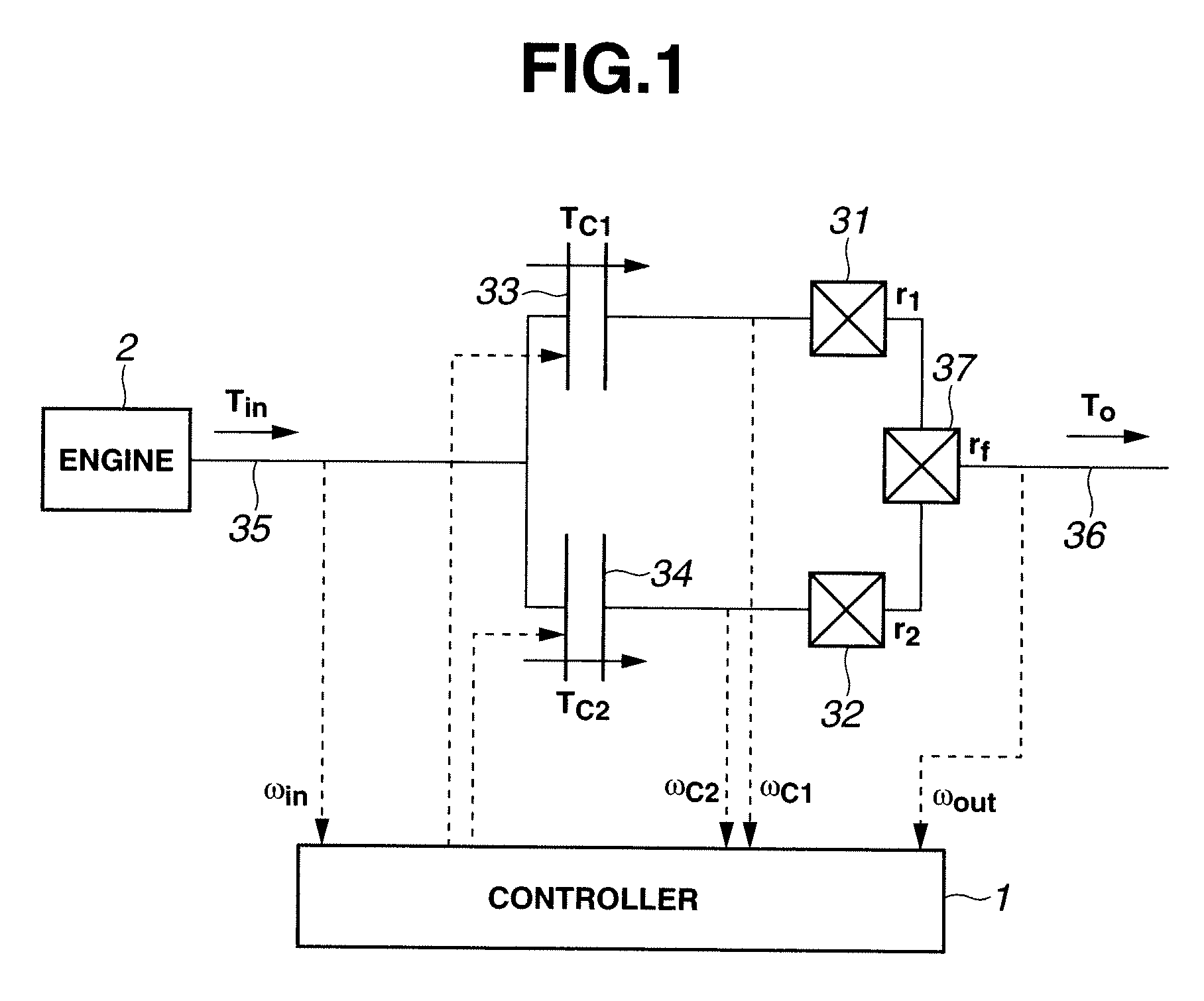

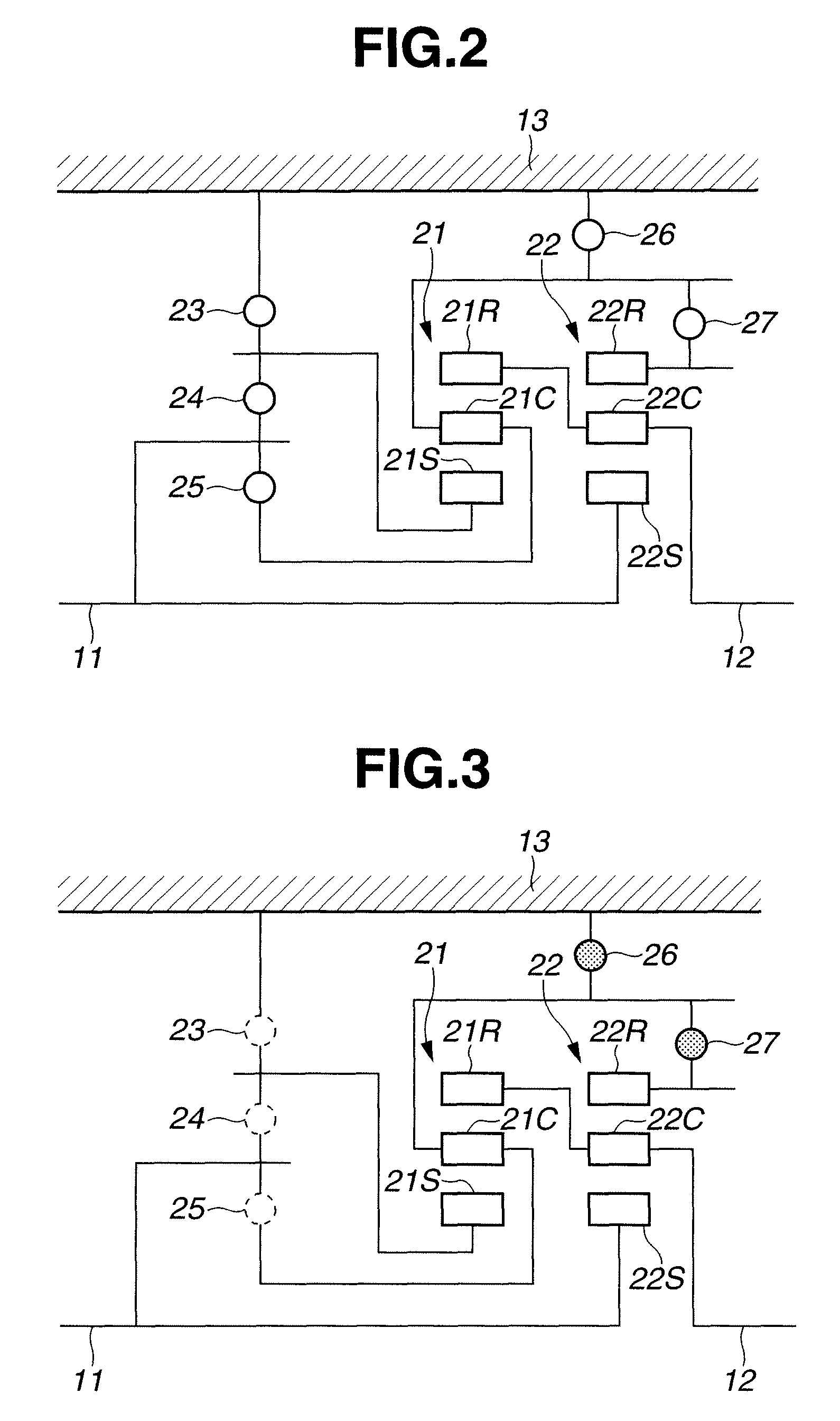

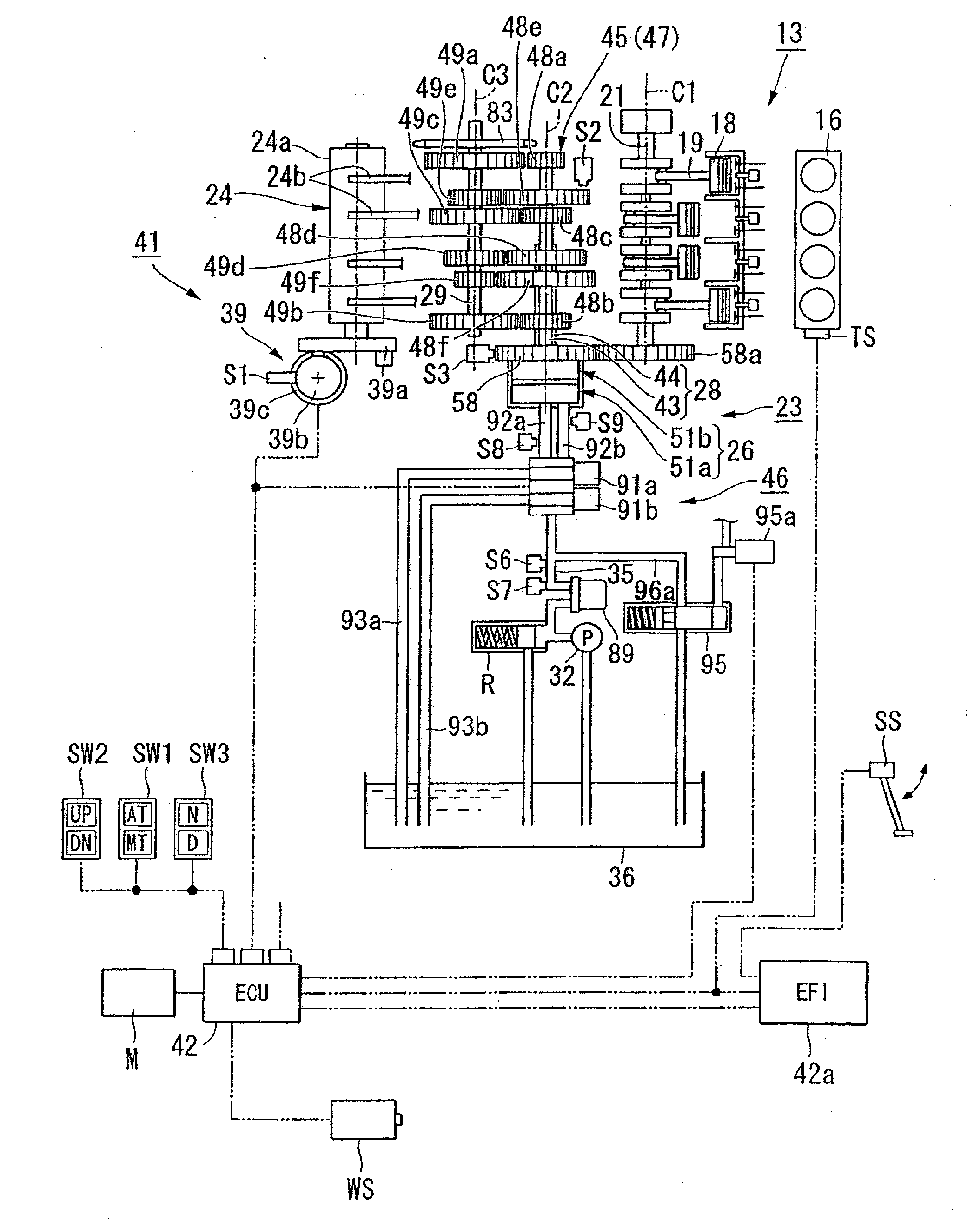

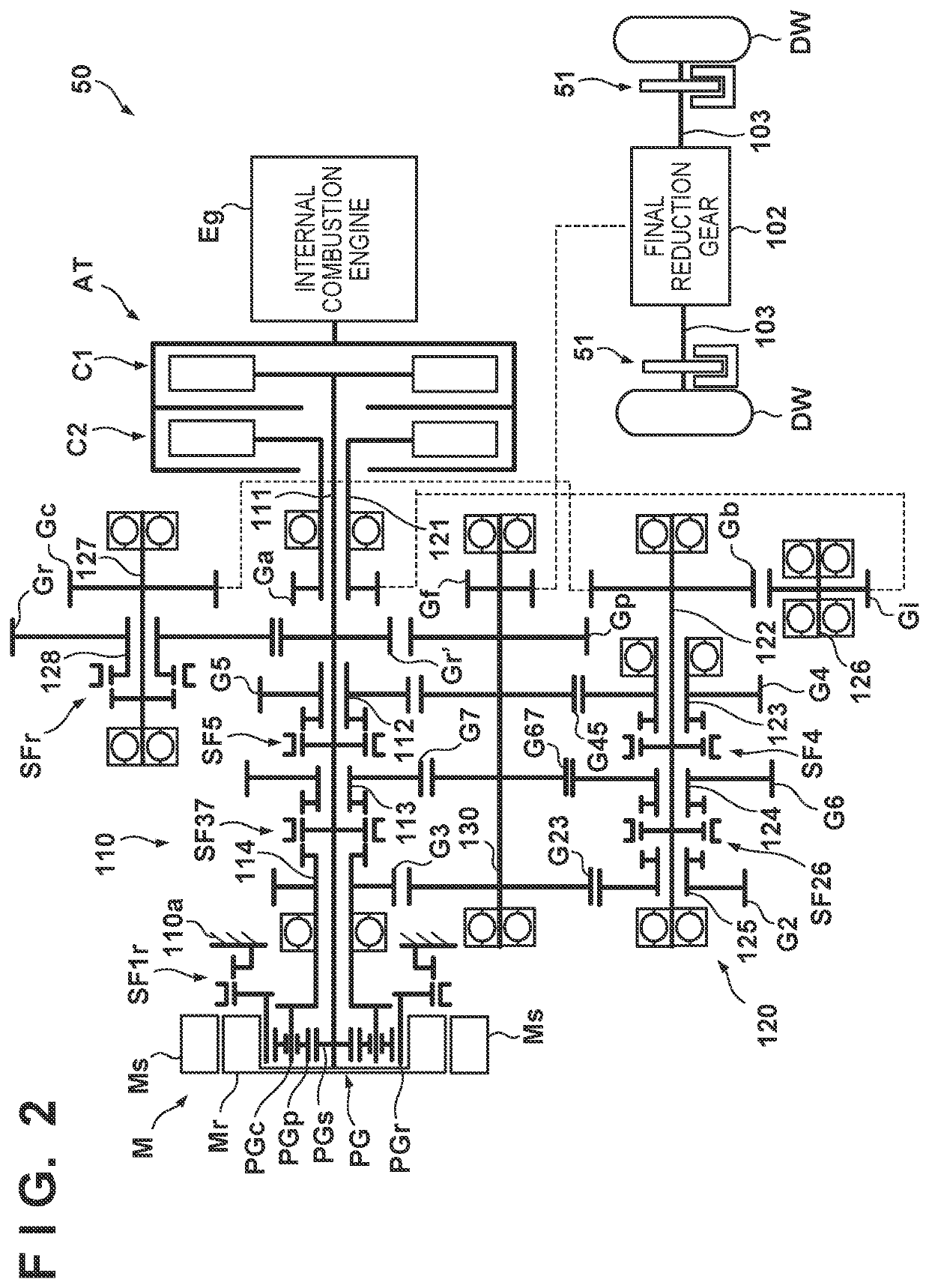

Automatic transmission, and apparatus and method of controlling the same

InactiveUS7840329B2Smoothly and quicklyDigital data processing detailsGearing controlAutomatic transmissionEngineering

An automatic transmission includes at least an input section, an output section, first and second frictional engagement elements, and a controller. The input section receives an input torque from a drive unit. The first frictional engagement element has an engaged state allowing the output section to rotate at a first transmission gear ratio with respect to the input section. The second frictional engagement element has an engaged state allowing the output section to rotate at a second transmission gear ratio with respect to the input section. The controller controls at least a gear shift from the first transmission gear ratio to the second transmission gear ratio. The controller controls the first and second frictional engagement elements and the drive unit so as to cancel an inertia torque resulting from the gear shift.

Owner:JATCO LTD

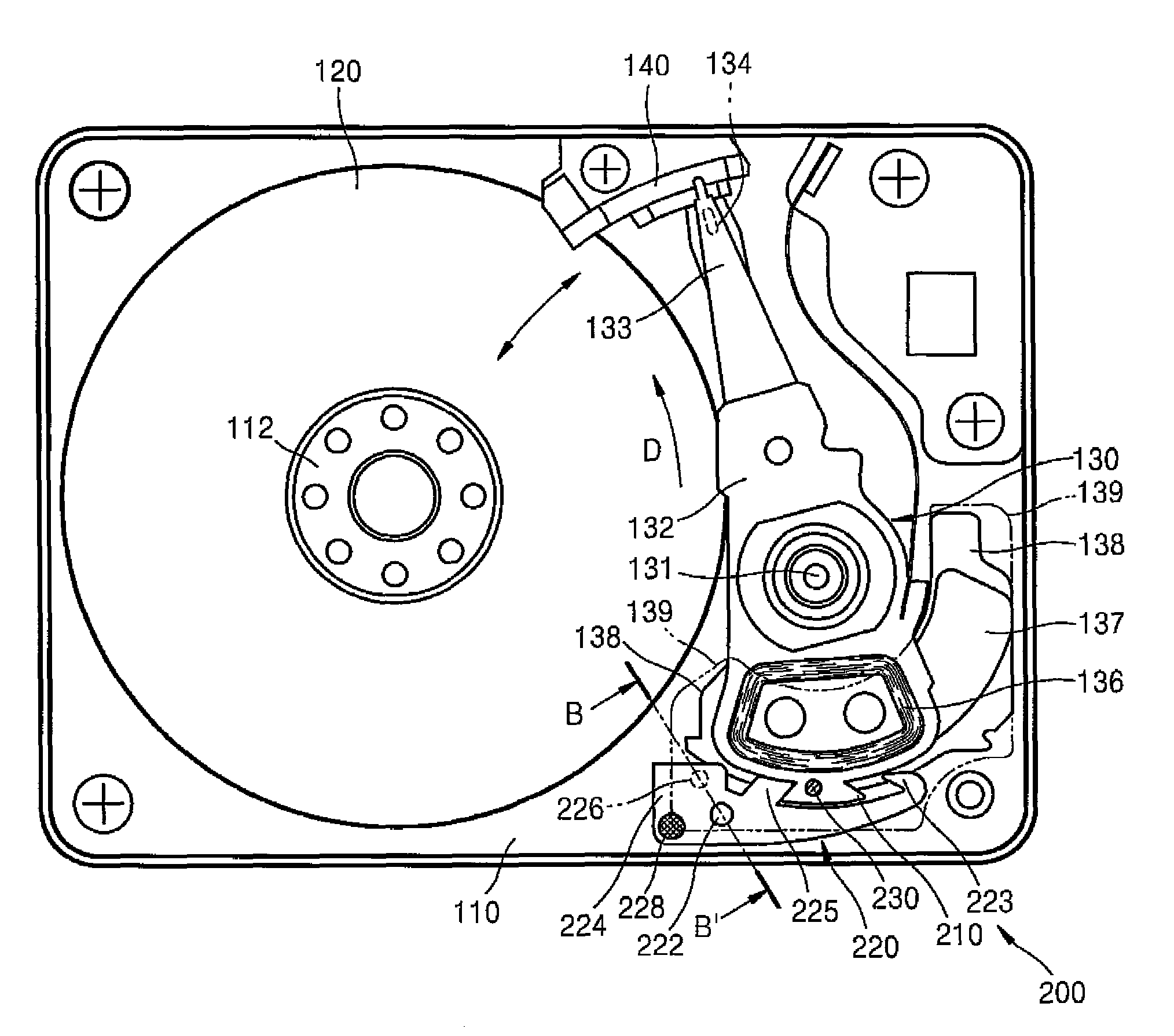

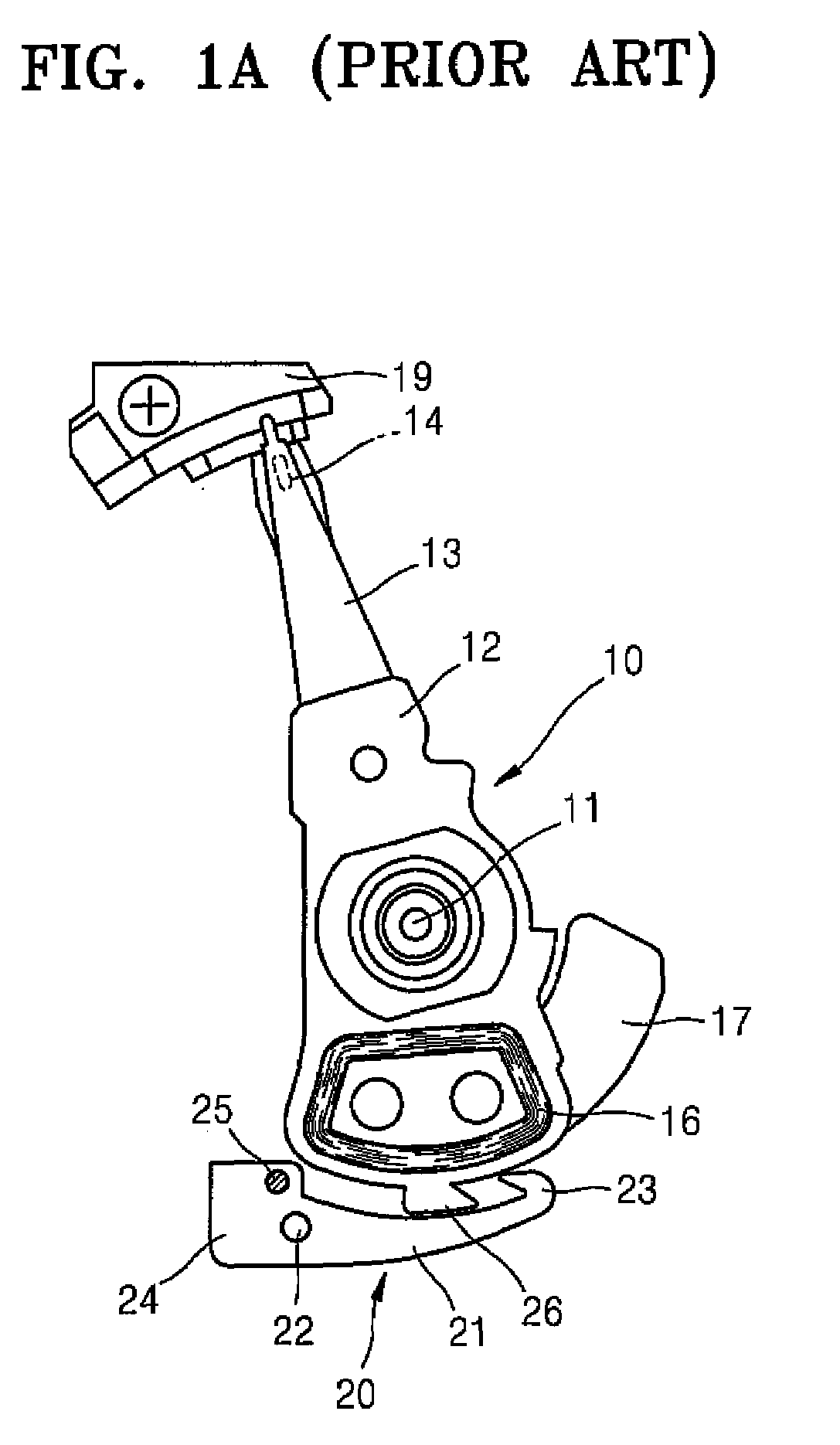

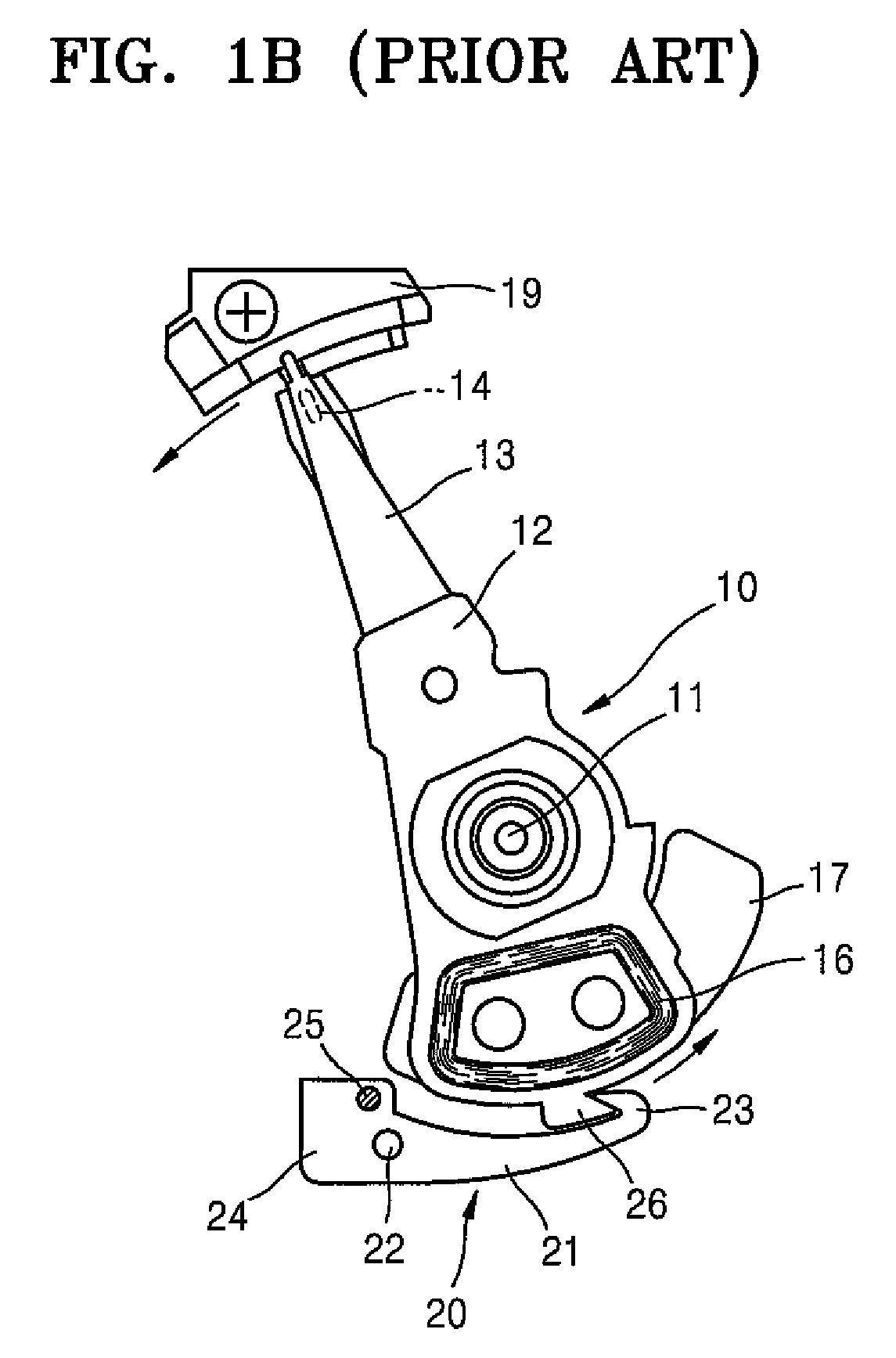

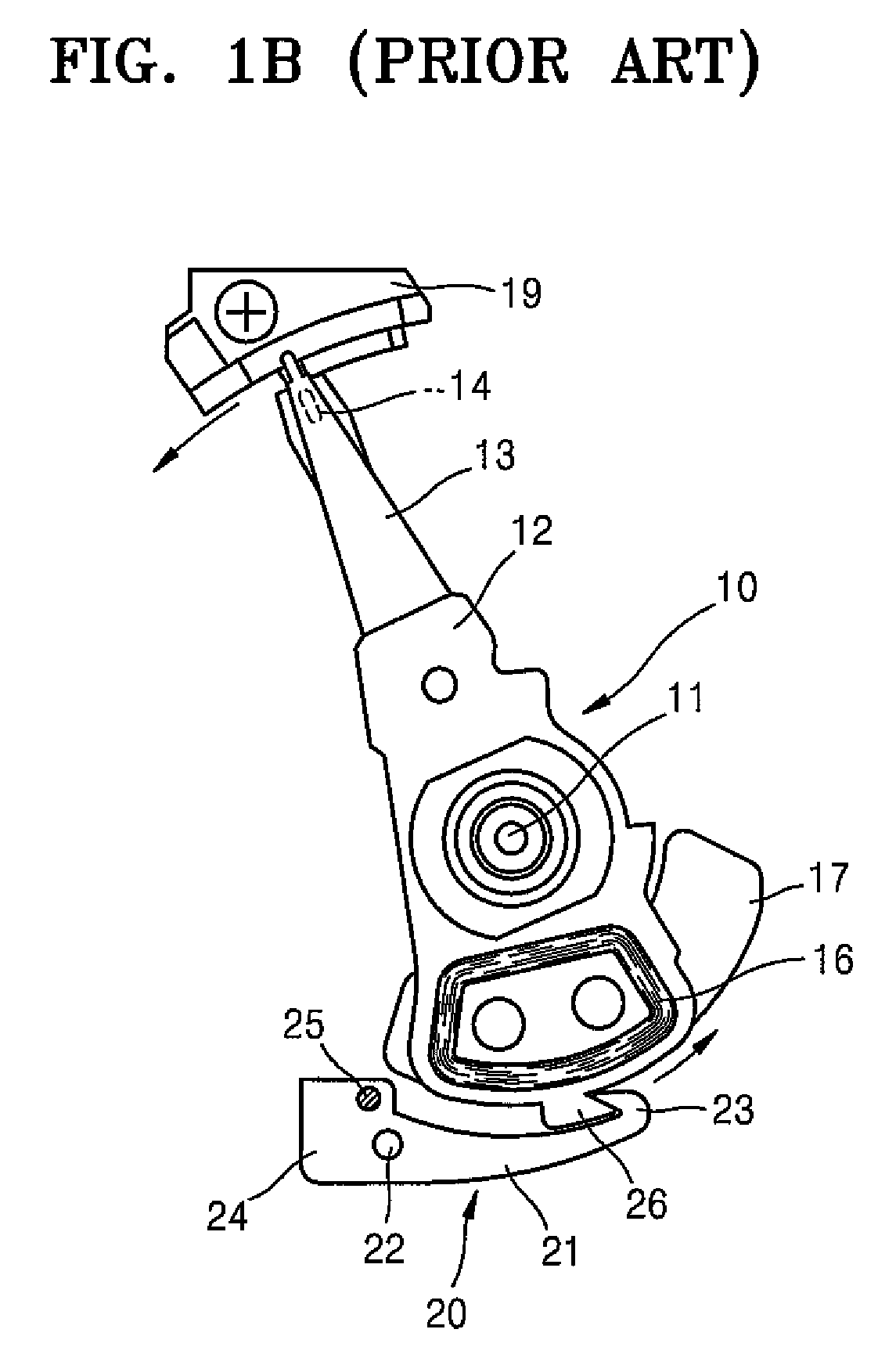

Actuator latch system of hard disk drive

InactiveUS20080192385A1Guaranteed uptimeSmoothly and quicklyDisposition/mounting of recording headsDriving/moving recording headsMagnetic tension forceHard disc drive

An HDD includes a base, a swing arm having a notch at a rear end portion and mounted to the base so as to be rotatable, a VCM coil disposed on the rear end portion of the swing arm, a lower yoke and an upper yoke disposed below and above the VCM coil, at least one magnet attached to the yokes, and a latch lever levitated by the at least one magnet. The latch lever is mounted to the base so as to be rotatable, and includes a hook at one end and a counterbalance at another end. The latch lever is mounted to the base so as to be rotatable. A first magnetic retractor is installed on the counterbalance to apply torque to the latch lever. The first retract member is disposed such that the vertical component of the net magnetic force applied to the first retractor by the magnet(s) is 0 or negligible when the latch lever is located at a position at which a first air gap and a second air gap exist, respectively, immediately below and above the latch lever.

Owner:SEAGATE TECH INT

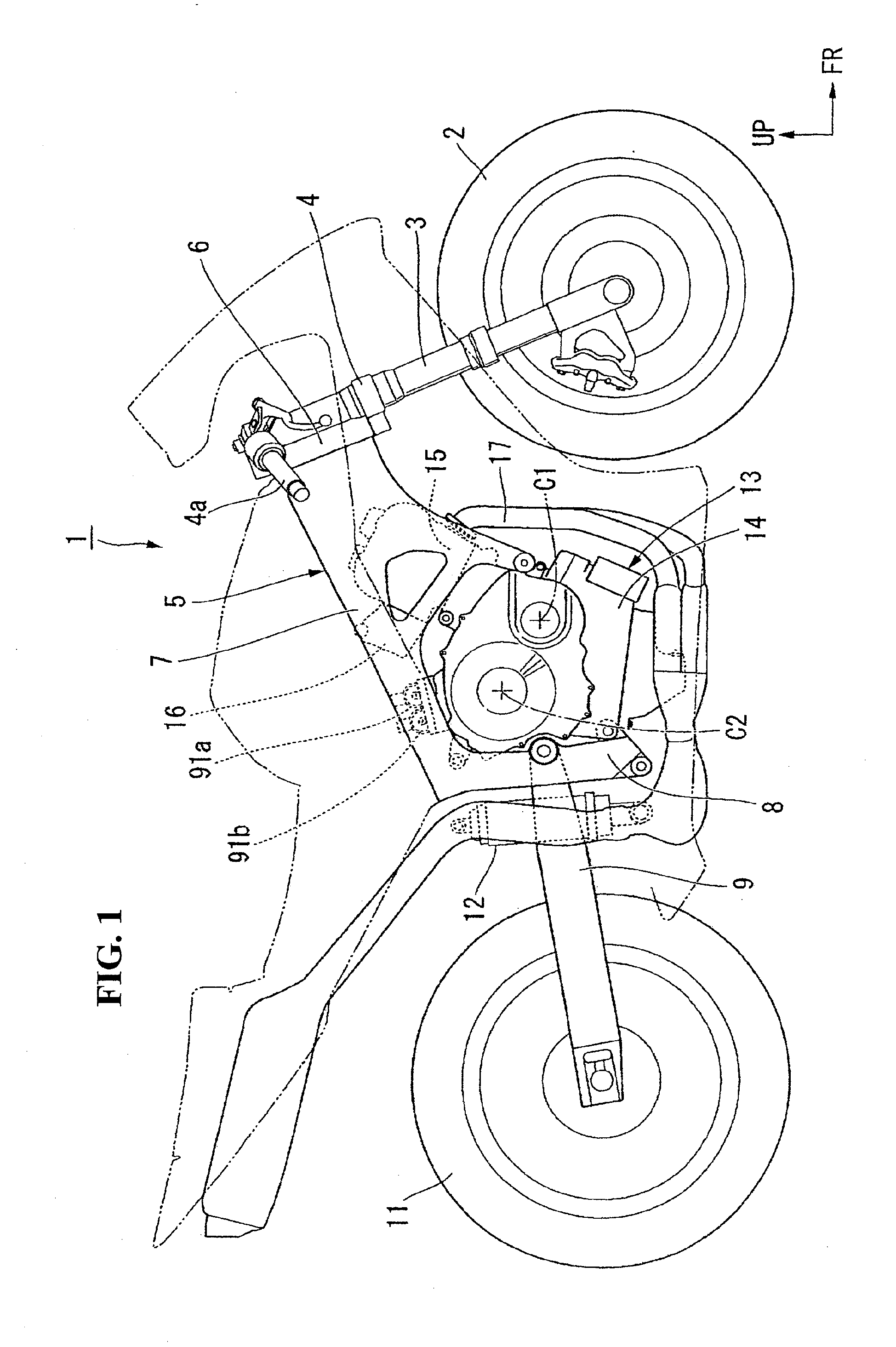

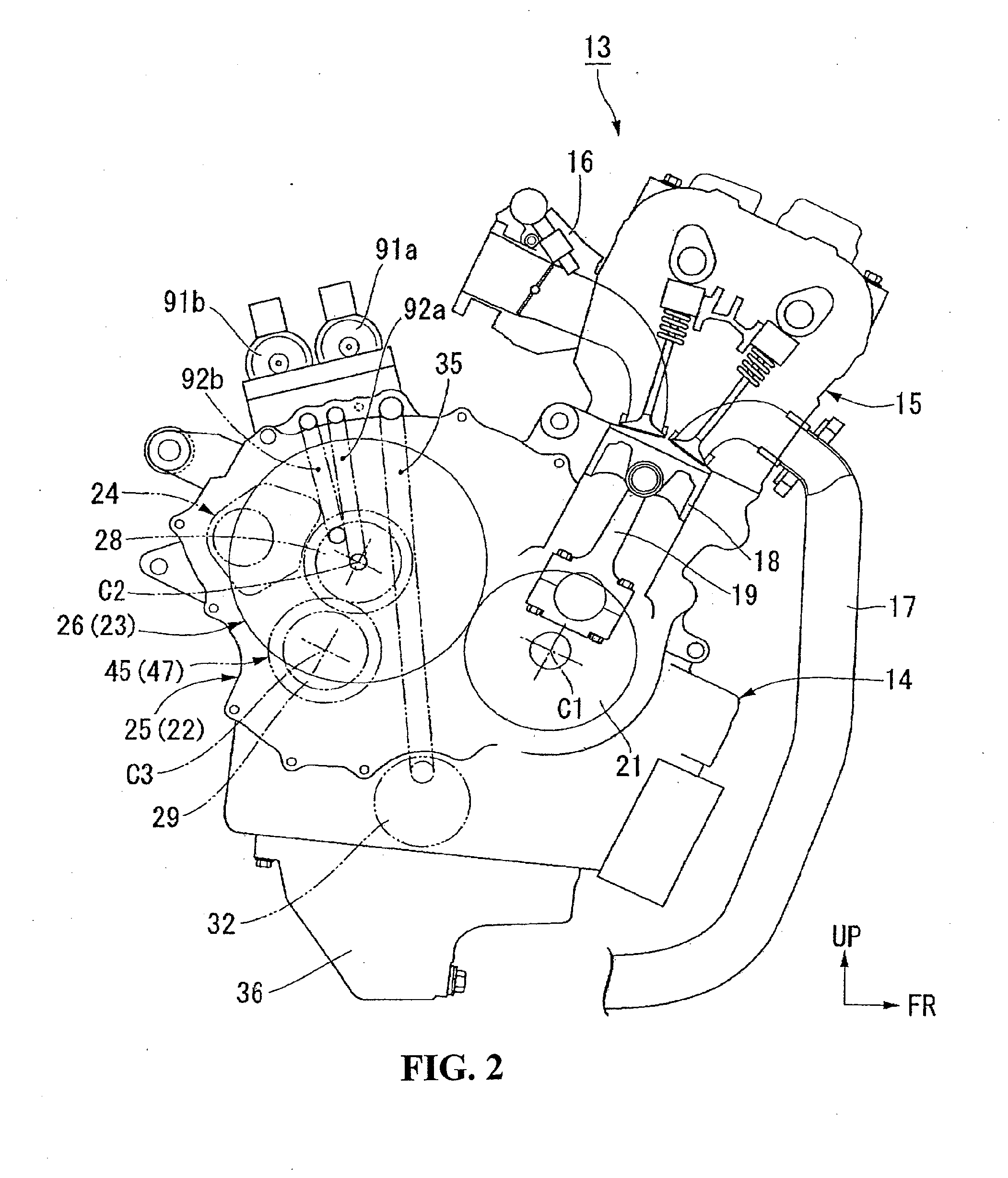

Clutch control apparatus for vehicle

ActiveUS20090111653A1Smoothly and quicklyMechanical actuated clutchesFluid actuated clutchesEngineeringSeparated state

A clutch control apparatus for a vehicle provided with a hydraulic clutch in the middle of a power transmission path between an engine and a drive wheel. Before the clutch of the vehicle is brought into an engagement state, intermittent hydraulic pressure Y is applied to the clutch while maintaining the clutch in a disengagement state, and thereafter a predetermined hydraulic pressure is applied to the clutch to bring it into the engagement state. A solenoid valve is provided to control hydraulic pressure supplied to the clutch. Before the clutch is brought into the engagement state, a pulsed drive current D is supplied to the solenoid valve. The clutch control apparatus so configured suppresses a motion delay at the time of engaging the clutch, thereby allowing a quick and smooth start and shifting of the clutch.

Owner:HONDA MOTOR CO LTD

Airbag, airbag apparatus, and method for folding airbag

ActiveUS20080030011A1Stable deployment performanceSmoothly and quicklyPedestrian/occupant safety arrangementEngineeringAirbag

An airbag, which is folded and assembled elongatedly, is deployed along a side window. The airbag has a folded portion and a pleated portion which wraps the folded portion under the assembled condition. The airbag also has an inner tube which is provided from the inside of an infusion portion to the inside of an upstream portion of an inflating portion. The inner tube prevents that the airbag is damaged by heat of inflation gas. When the airbag is assembled, the inner tube is positioned along a first fabric, which is developed so that the surface of the first fabric faces an inside of a vehicle compartment, by the infused fluid. Deployment performance of the airbag (curtain airbag deploying along a side window of an automobile) is improved.

Owner:NIHON PLAST CO LTD

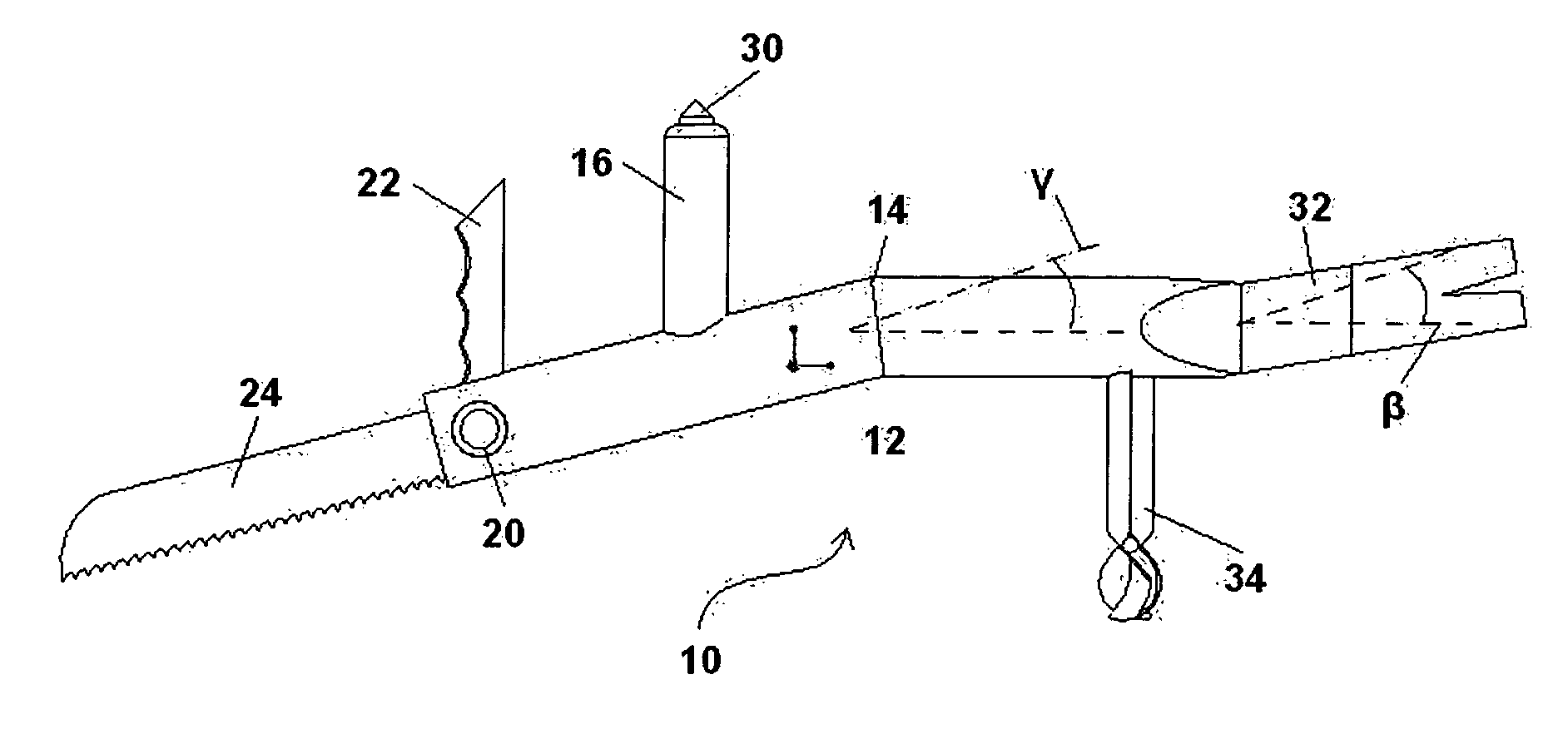

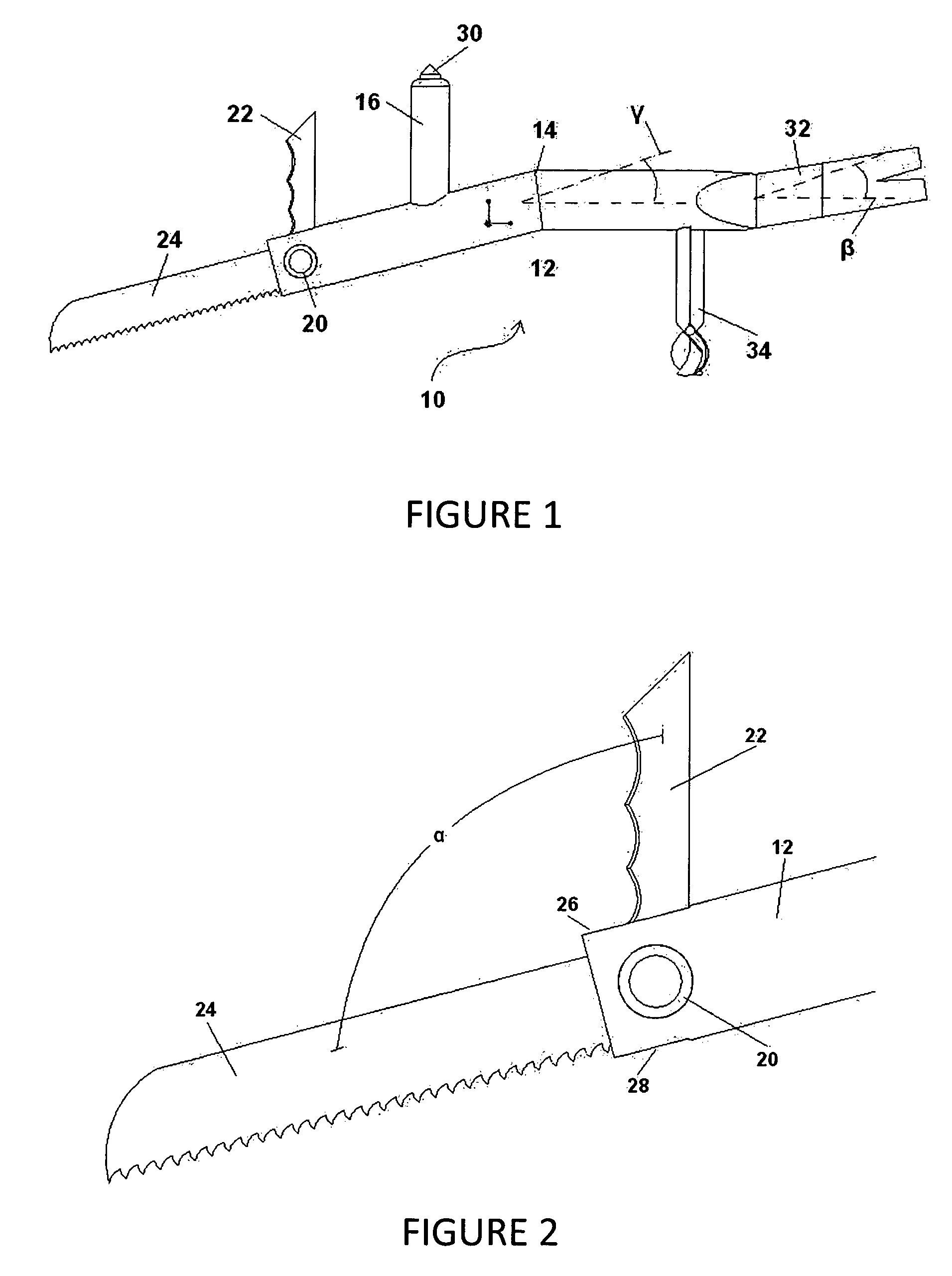

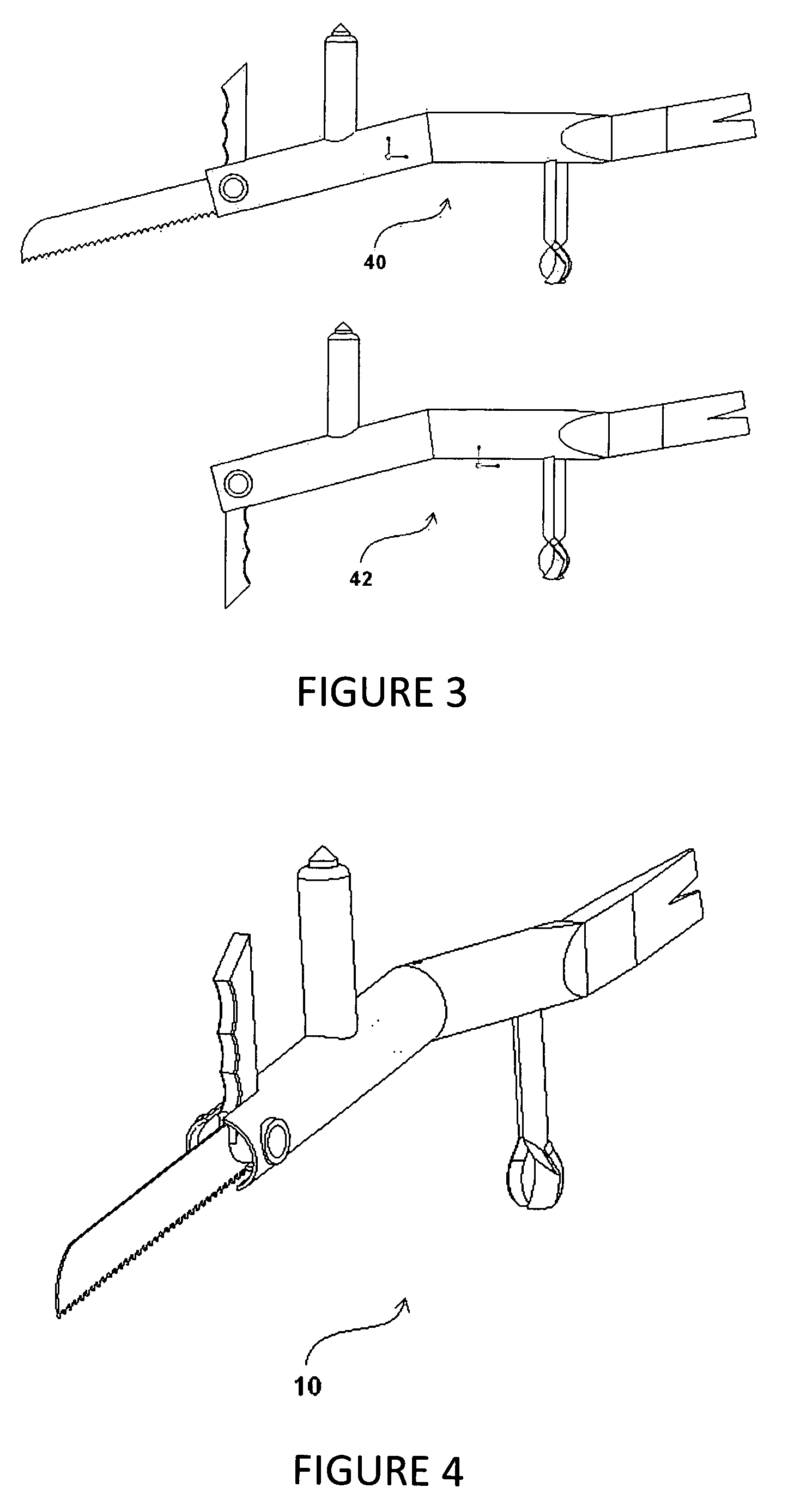

Vehicle extrication preparatory tool

InactiveUS7703161B1Safe wayFast and reliableThrusting weaponsPortable percussive toolsEngineeringWindshield

A vehicle extrication preparatory tool includes an elongated body portion with an ergonomic bend in the middle. A handle is provided forward of the bend extending in an upward direction perpendicularly to the rear section of the body. Incorporated into the upward end of the handle is a window punch. A pry bar is attached to the rearward end of the body portion. Incorporated into the forward end of the tool is a swivel segment. The swivel segment incorporates both a windshield spike and a windshield saw blade. In the open position, the saw blade extends from the swivel segment, running parallel with the front section of the body and the spike extends upward from the swivel segment perpendicular to the rear section of the body. When closed, the saw blade fits inside a slot in the body portion extending from the swivel segment inline with the front section of the body and the spike extends downward perpendicular to the rear section of the body from the swivel segment.

Owner:HANDSHAW DARRAN MICHAEL

Joint recognition member

Owner:ROTE MATE IND

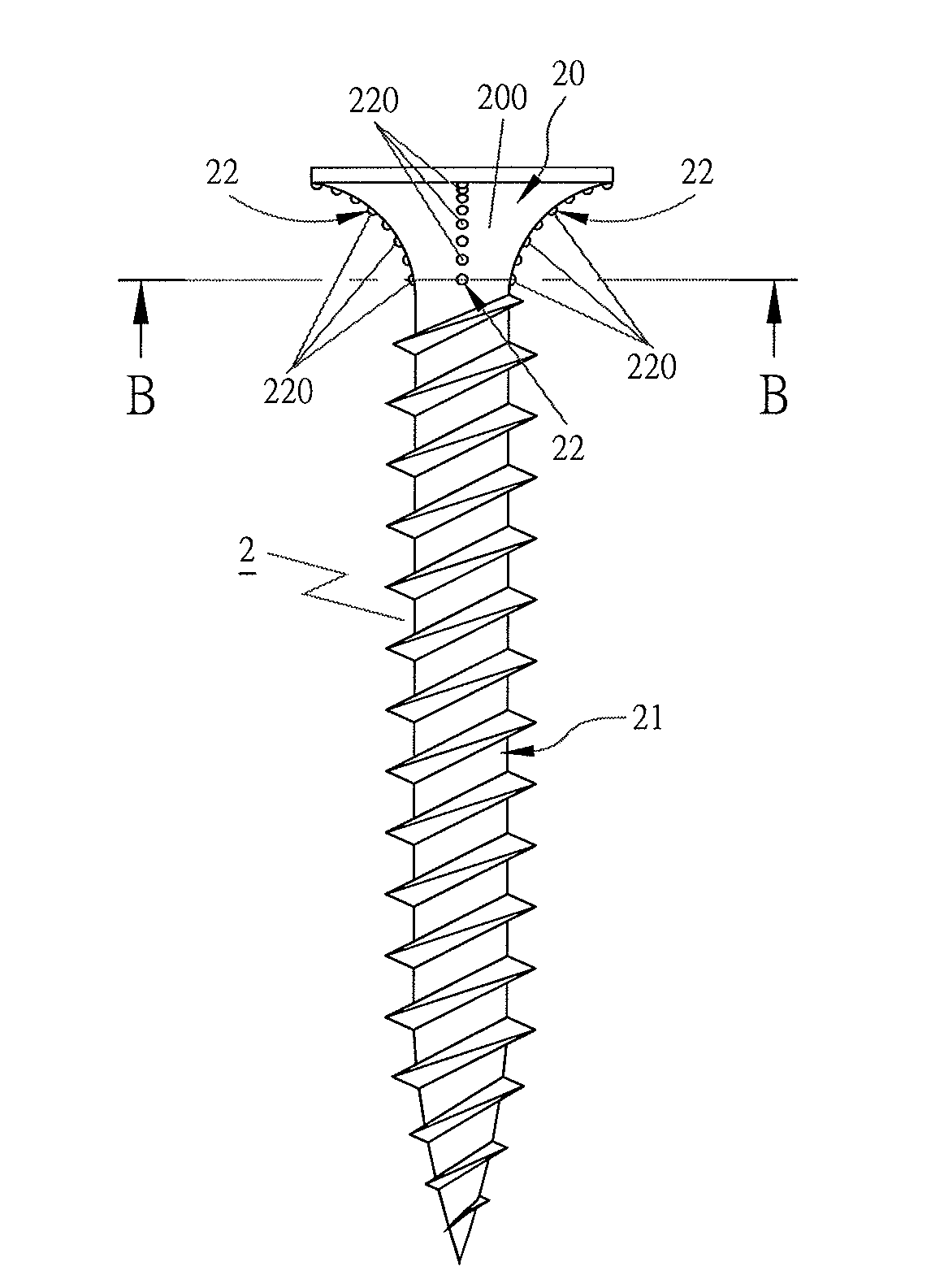

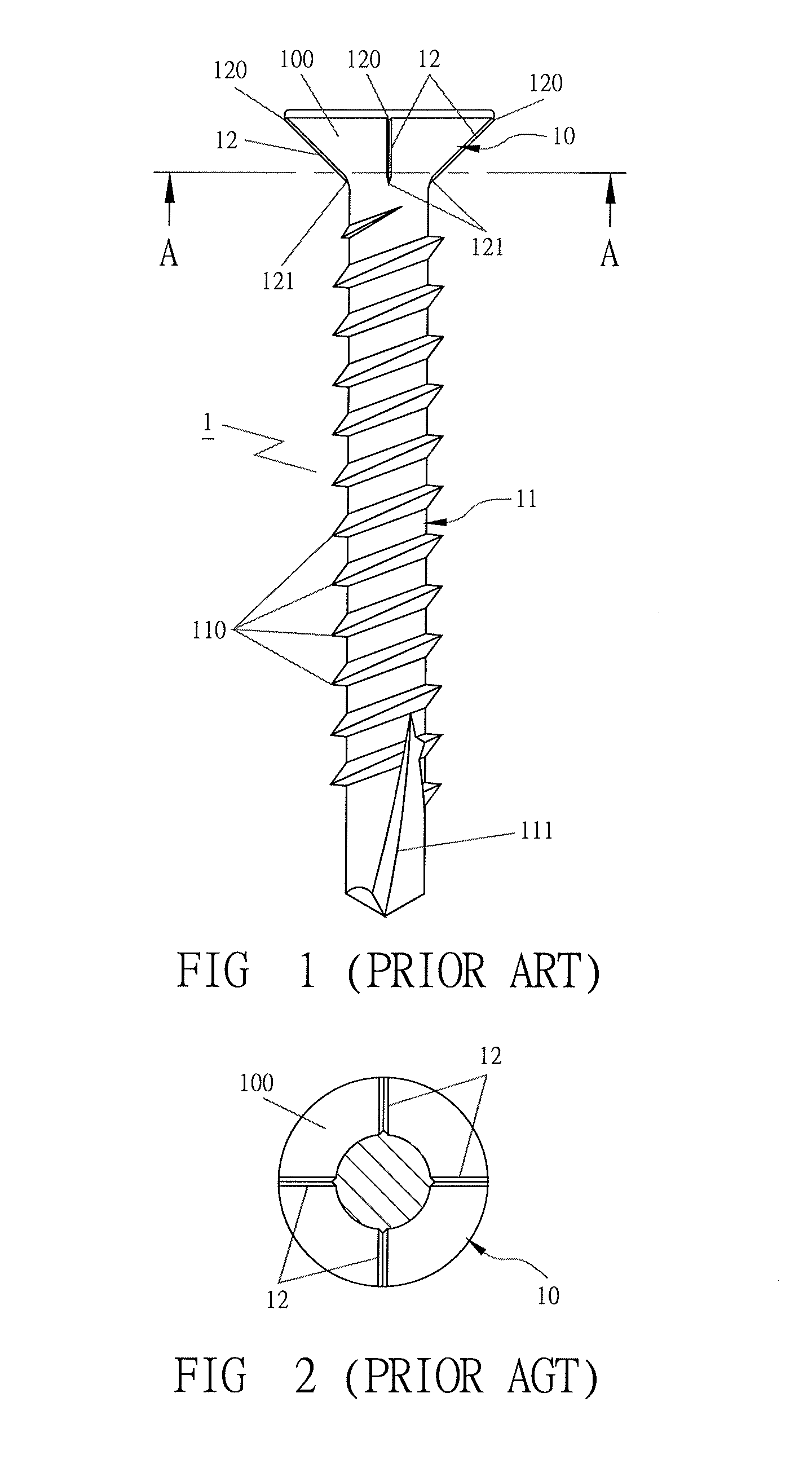

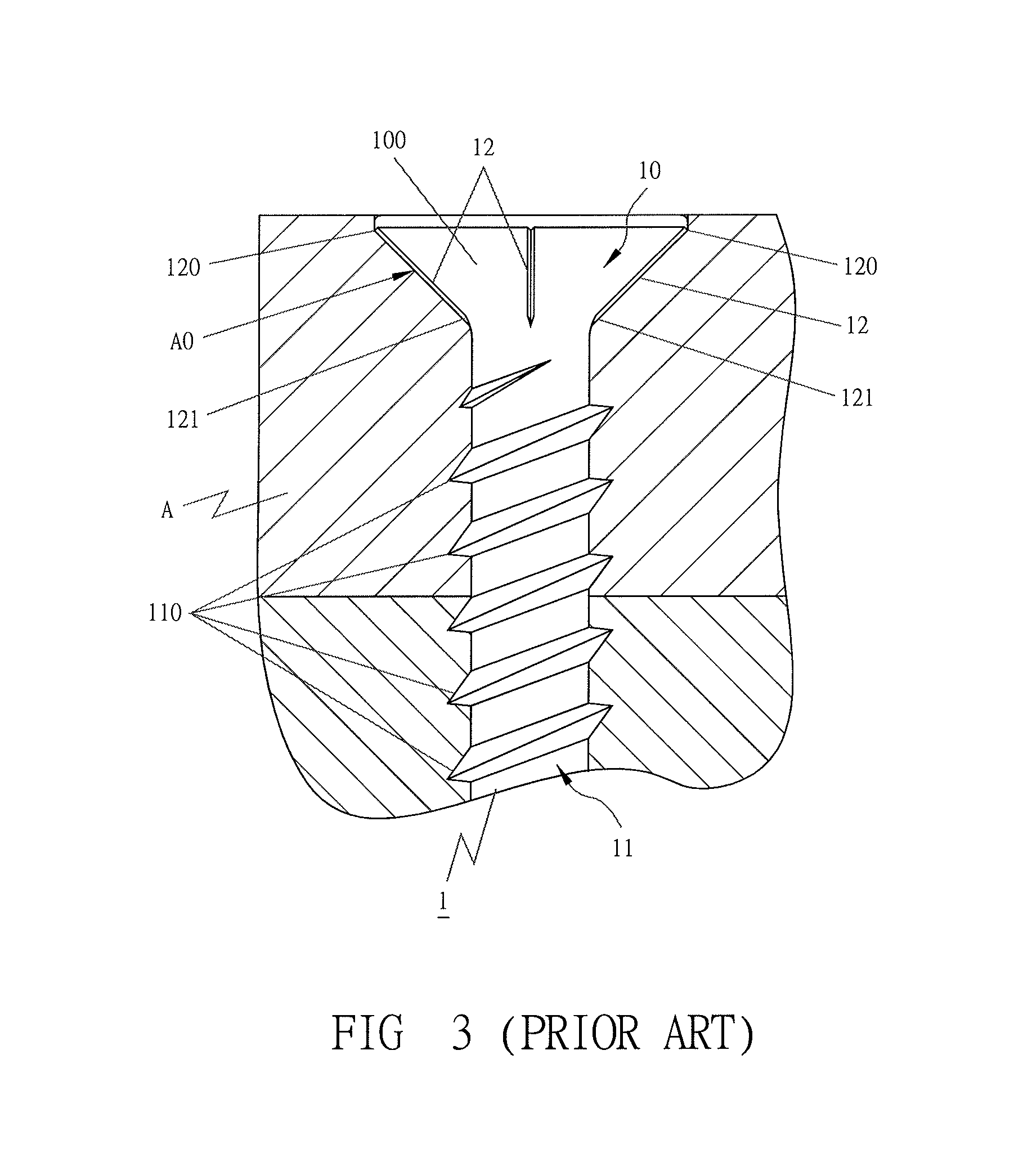

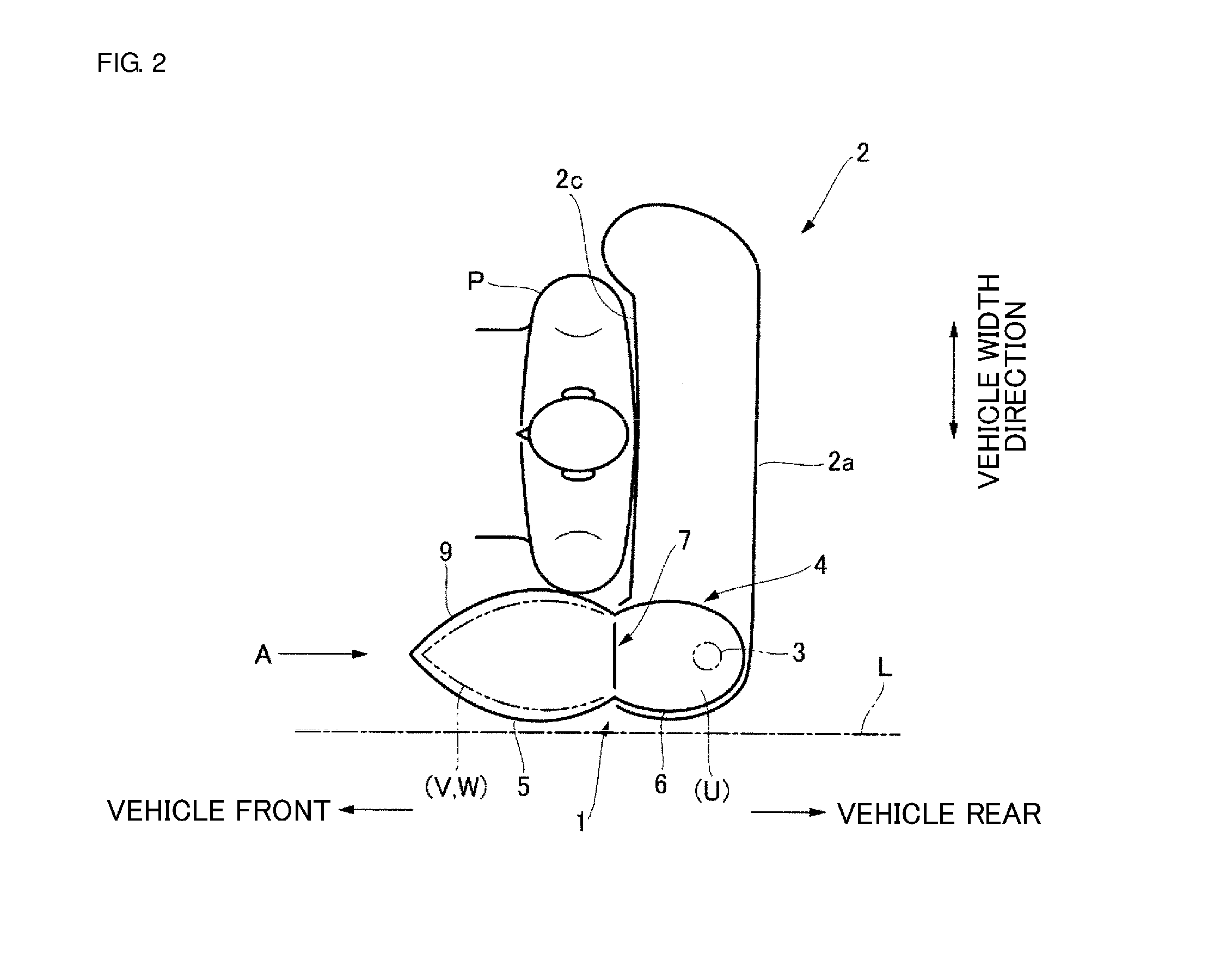

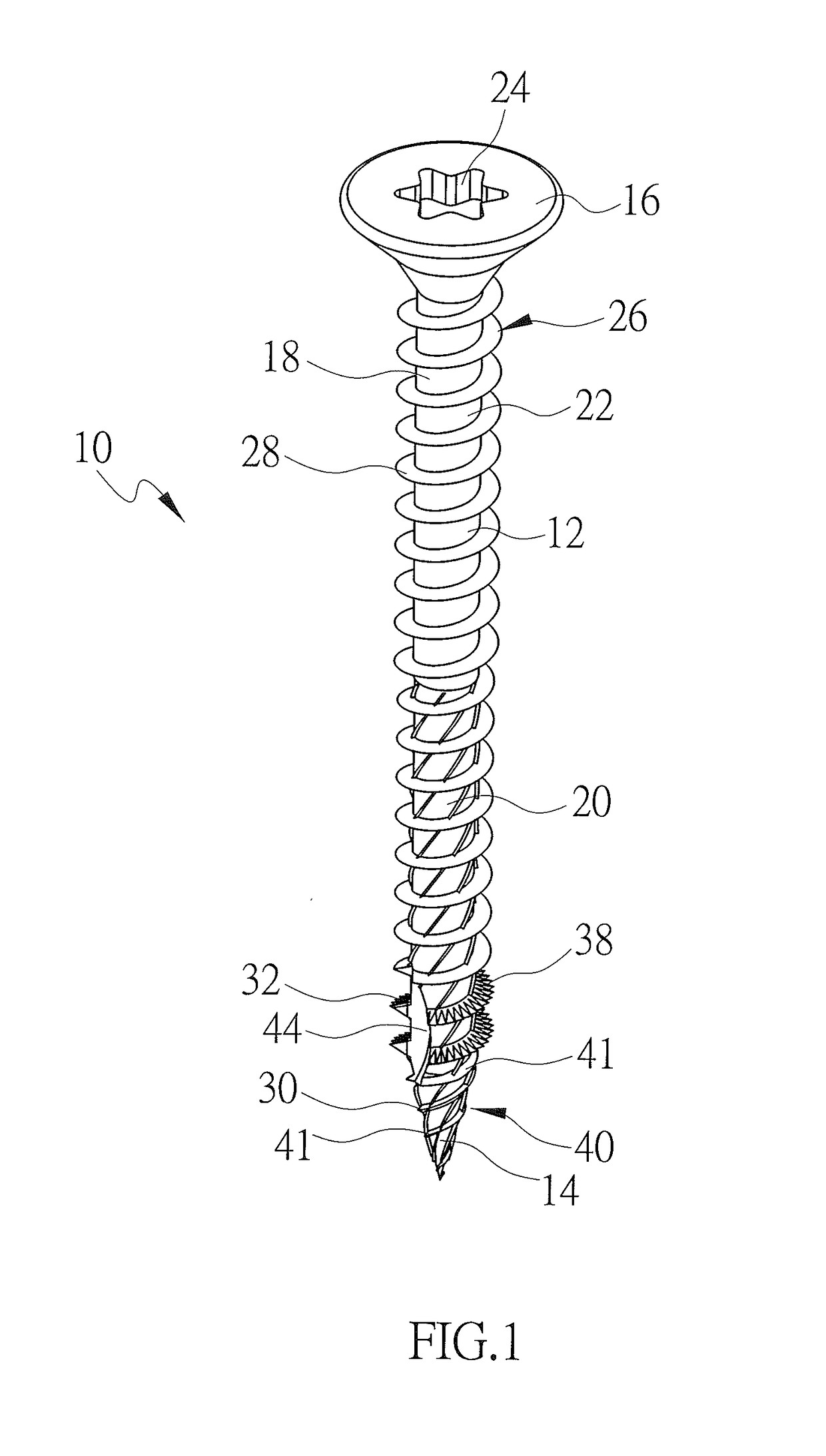

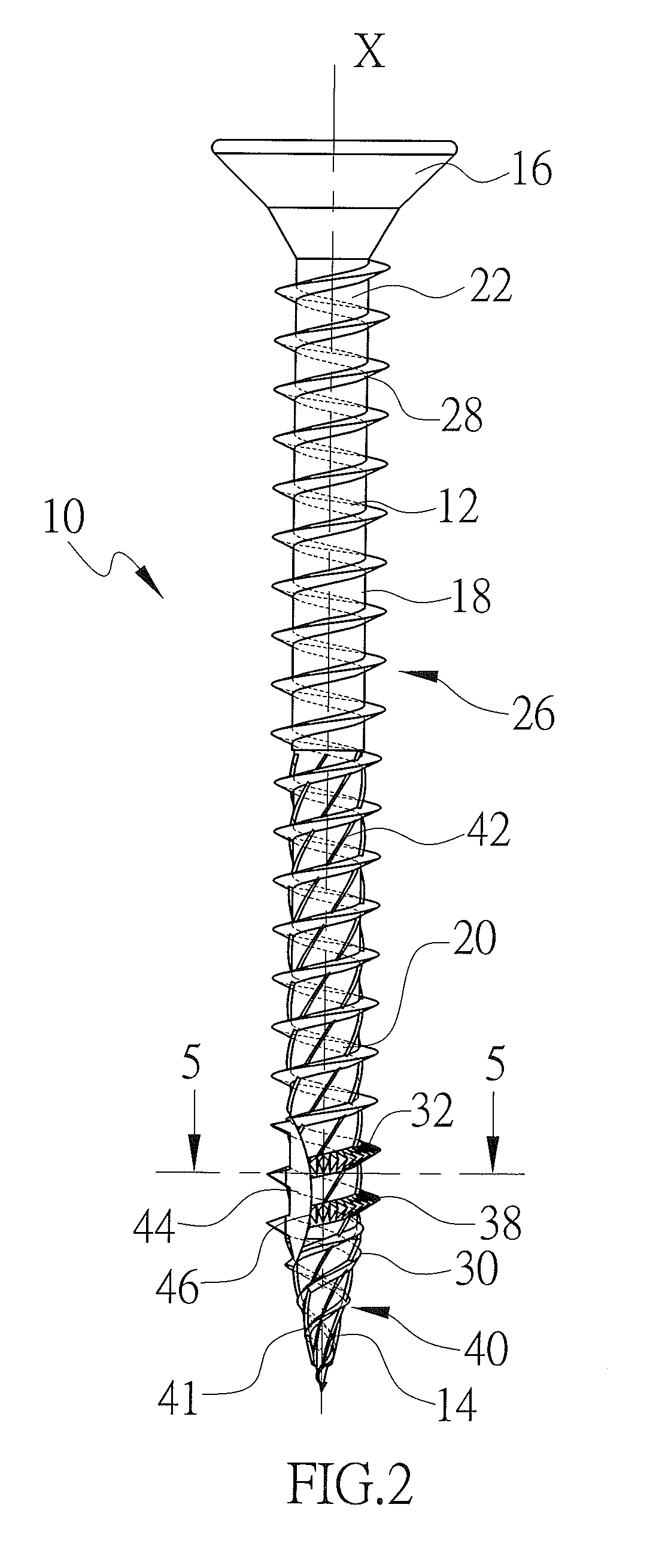

Screw

Owner:YIH SHWEI BOLT INDAL

Vehicular side airbag device

ActiveUS9505375B2Smoothly and quicklySmall thicknessPedestrian/occupant safety arrangementChest regionLateral airbag

A side airbag device having a side airbag that can slide between an occupant and a vehicle side section, and allows occupant restraint by reaching. The side airbag can be inflated with the thickness of the portion that protects the peripheries of the occupant shoulder and waist is small and the thickness of the portion that protects the periphery of the chest region is large. Inside a side airbag, a rapid chamber extends from a seat back region over a top region and a bottom region and tapers towards the vehicle front; a delay chamber is positioned between the top region and bottom region, and a partitioning member partitions the interior of the side airbag into the delay chamber and the rapid chamber. An inflator is provided inside the rapid chamber.

Owner:AUTOLIV DEV AB

Screw

A screw includes a shank, a first thread, and a second thread. The shank includes a screw-in portion, a head portion, and a straight rod portion between the screw-in portion and the head portion. The first thread surrounds the shank spirally and includes an upper thread portion formed around the straight rod portion, a lower thread portion formed around the screw-in portion, and a middle thread portion continuously connected between the upper and lower thread portions. A plurality of serrate cutting teeth is provided on the middle thread portion of the first thread. The second thread is helically formed around the screw-in portion of the shank and includes a plurality of thread convolutions spaced from thread convolutions of the lower thread portion of the first thread. The screw can be quickly driven into articles to be joined without degradation of binding capacity between the screw and the articles.

Owner:HSU KUO TAI

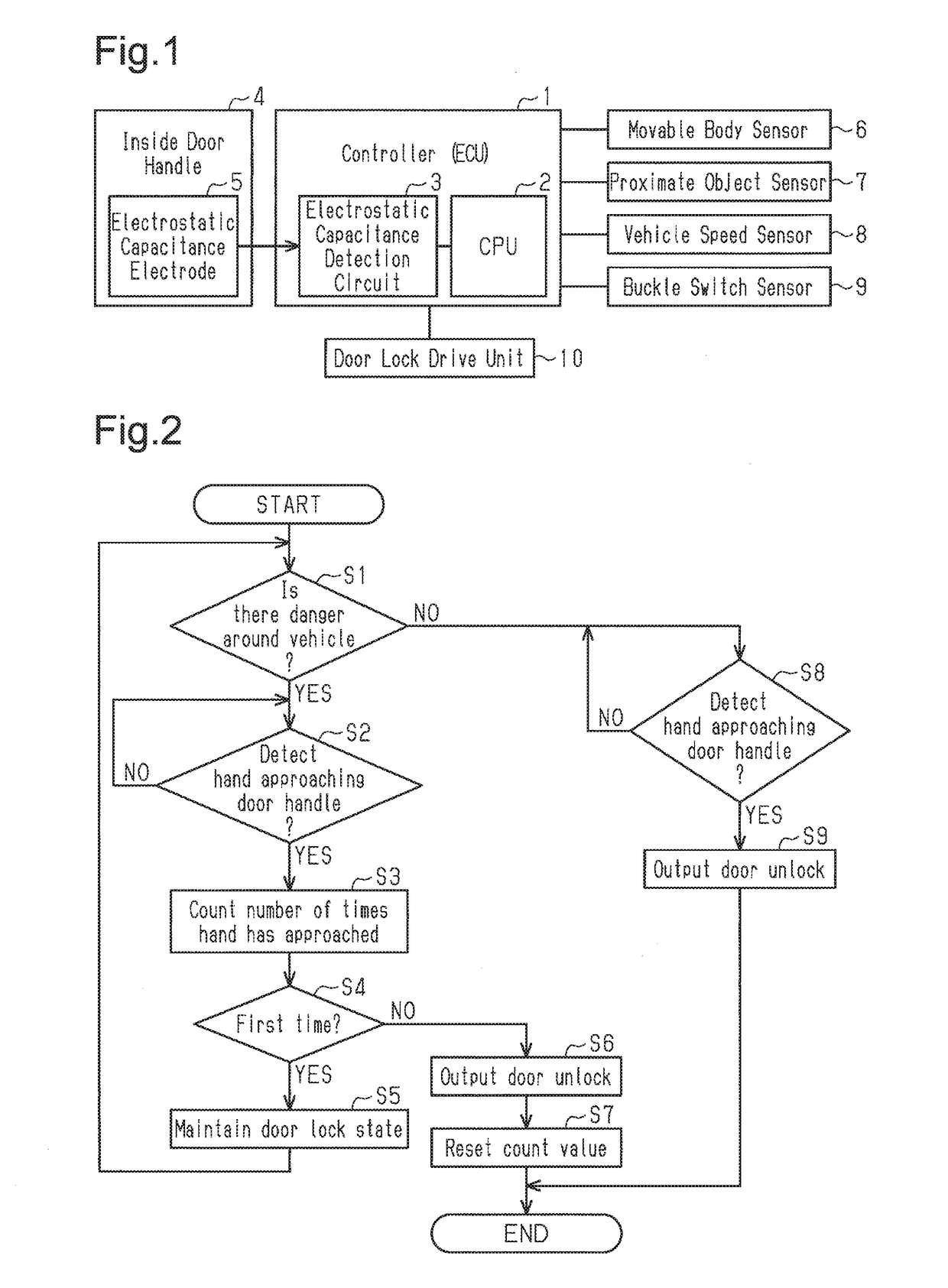

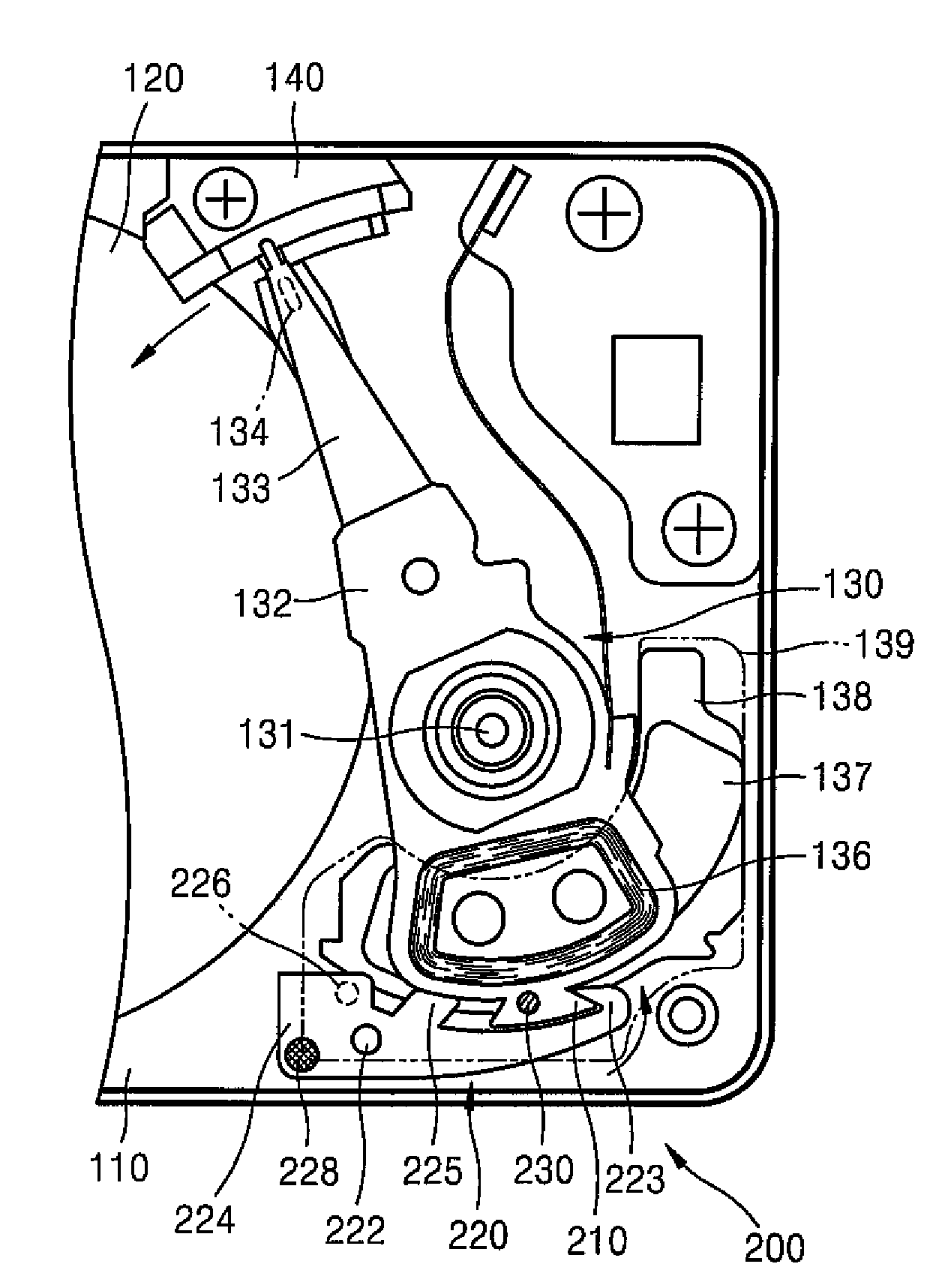

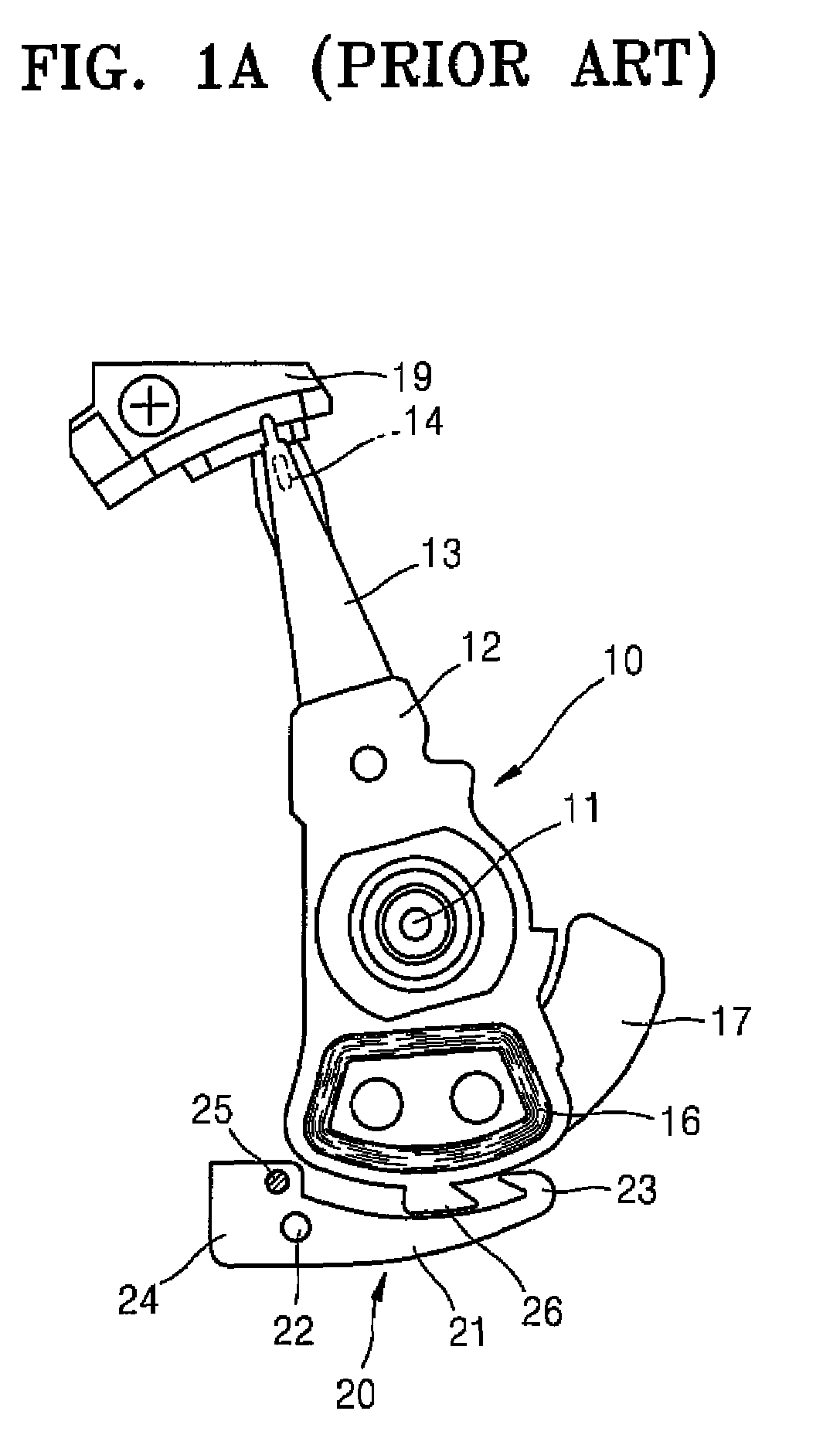

Door lock device for vehicles

InactiveUS20190010735A1Safe openSmoothly and quicklyElectrical locking circuitsElectrical locking actuatorsControl unitElectrical and Electronics engineering

A door lock device for vehicles is provided with sensors for detecting whether or not a door of a vehicle can be opened safely; a door lock drive unit for switching the door between a lock state and an unlock state; and a control unit for controlling the door lock drive unit. When determining on the basis of detection signals from the sensors that the safety of opening the door cannot be ensured, the control unit maintains the door in the lock state through the door lock drive unit, and when the number of operations of the inside door handle of the door is more than or equal to a predetermined value, the control unit forcibly switches the door to the unlock state through the door lock drive unit independent of the detection signals from the sensors.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

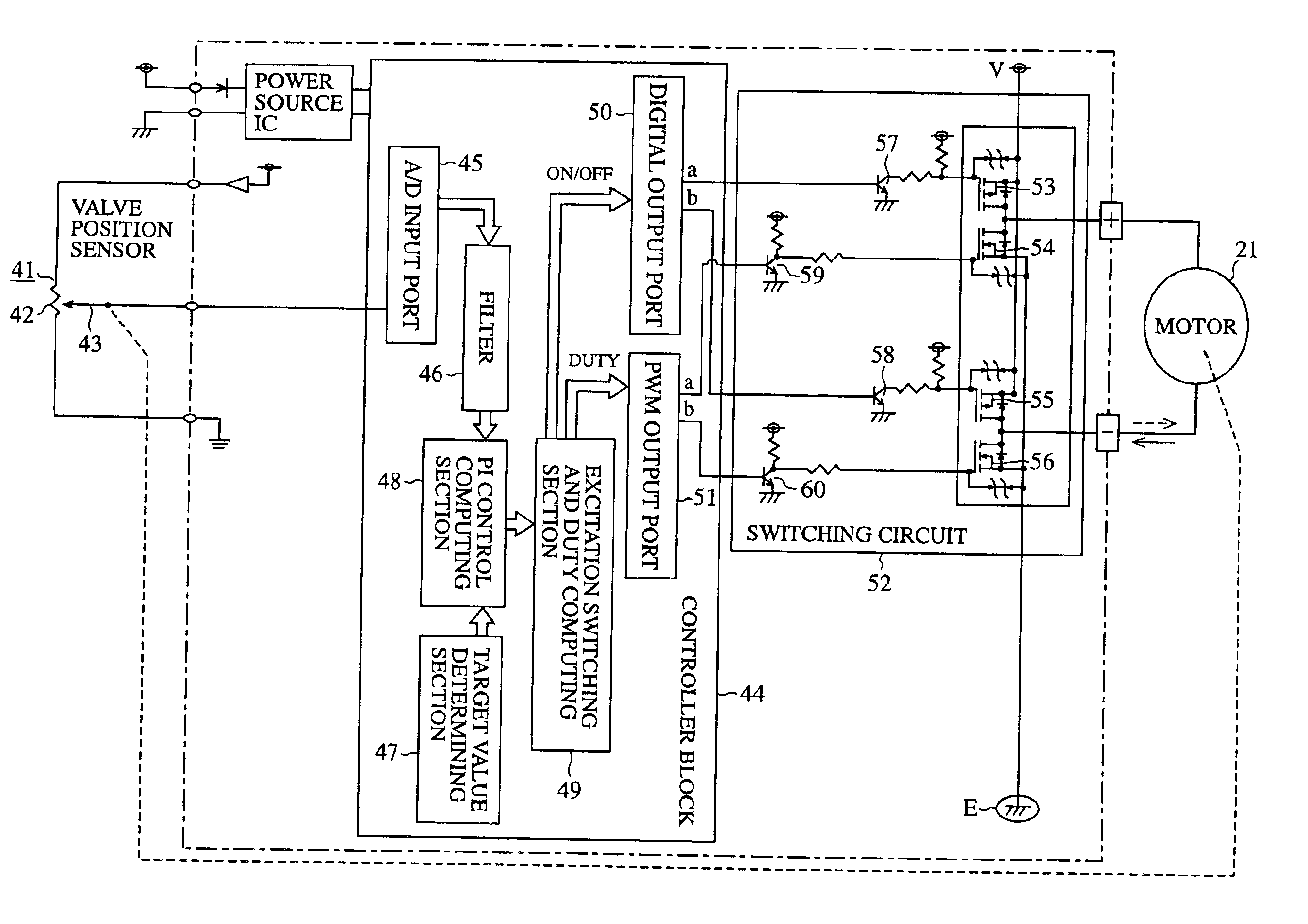

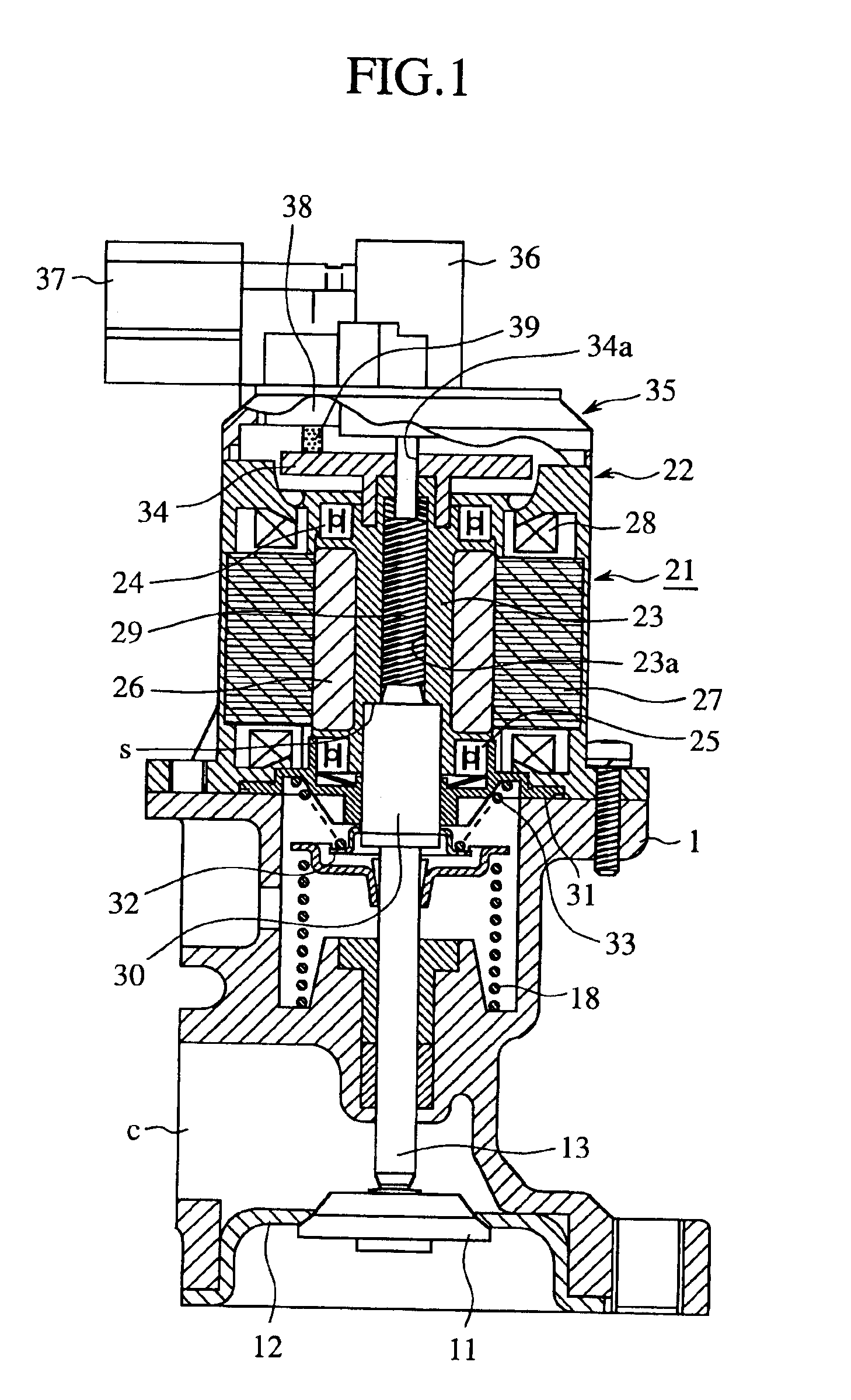

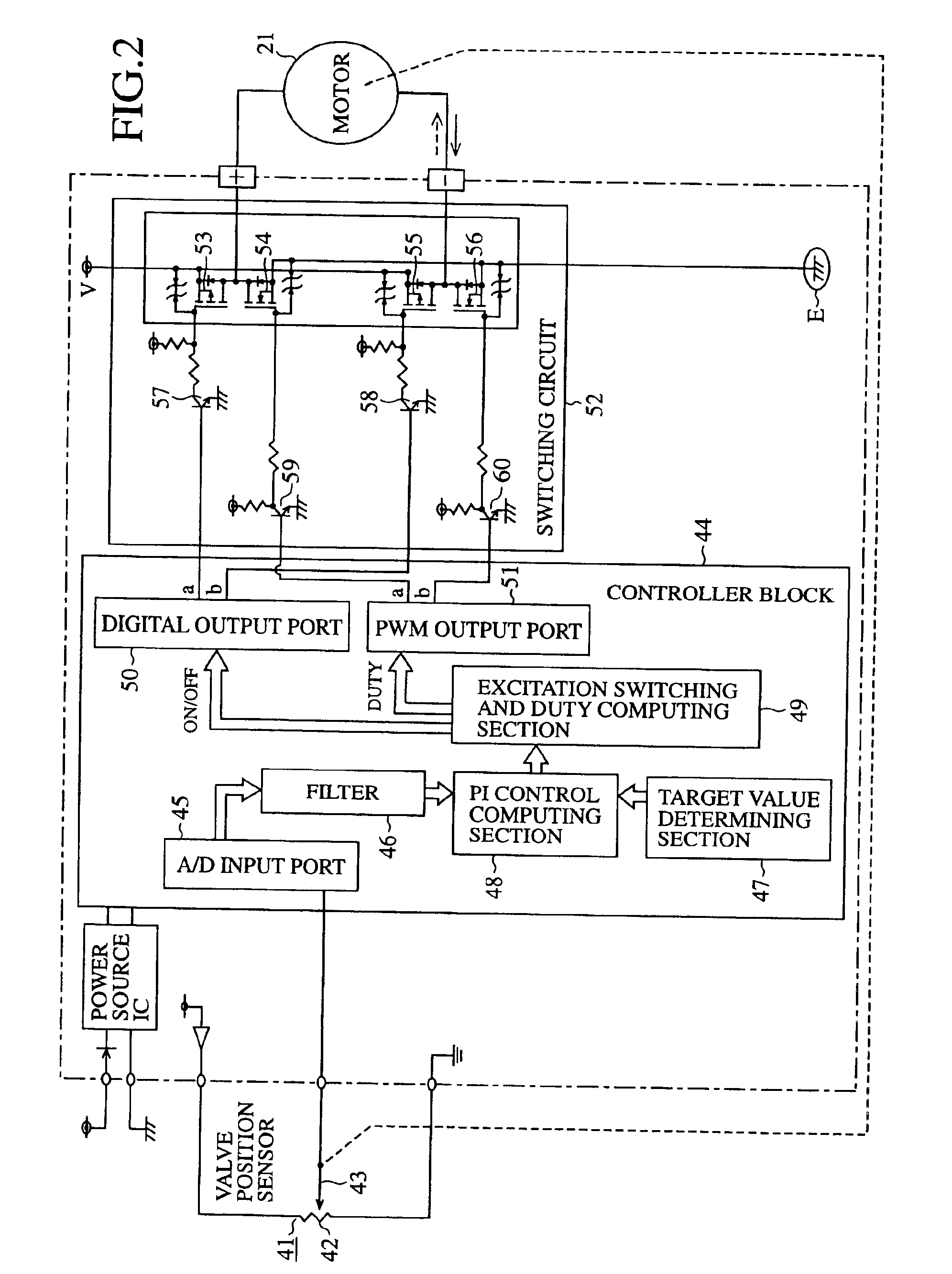

Brake for DC motor

InactiveUS6913122B2Smoothly and quicklyOperating means/releasing devices for valvesInternal combustion piston enginesLocation detectionMotor shaft

A braking device of a DC motor has a position detecting means to detect a position of a motor shaft, a rotational speed detecting means to detect a rotational speed of the motor and a braking means to generate a braking force based on a position signal and a speed signal detected by both of the means, and stops the motor shaft quickly and smoothly without making the motor shaft collide with a stopper.

Owner:MITSUBISHI ELECTRIC CORP

Actuator latch system of hard disk drive including magnetically levitated latch lever

InactiveUS8159787B2Guaranteed uptimeSmoothly and quicklyDisposition/mounting of recording headsDriving/moving recording headsMagnetic tension forceHard disc drive

An HDD includes a base, a swing arm, a VCM coil disposed on the rear end portion of the swing arm, a lower yoke and an upper yoke disposed below and above the VCM coil, at least one magnet attached to the yokes, and a latch lever levitated by the at least one magnet. The latch lever includes a hook at one end and a counterbalance at another end. A first magnetic retractor is installed on the counterbalance to apply torque to the latch lever. The first retract member is disposed such that the vertical component of the net magnetic force applied to the first retractor by the magnet(s) is about 0 when the latch lever is located at a position at which a first air gap and a second air gap exist, respectively, immediately below and above the latch lever.

Owner:SEAGATE TECH INT

Hybrid electric vehicle

InactiveUS9079485B2No energy lossSmoothly and quicklyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingLine shaftElectric vehicle

Owner:DUAN ZHIHUI +1

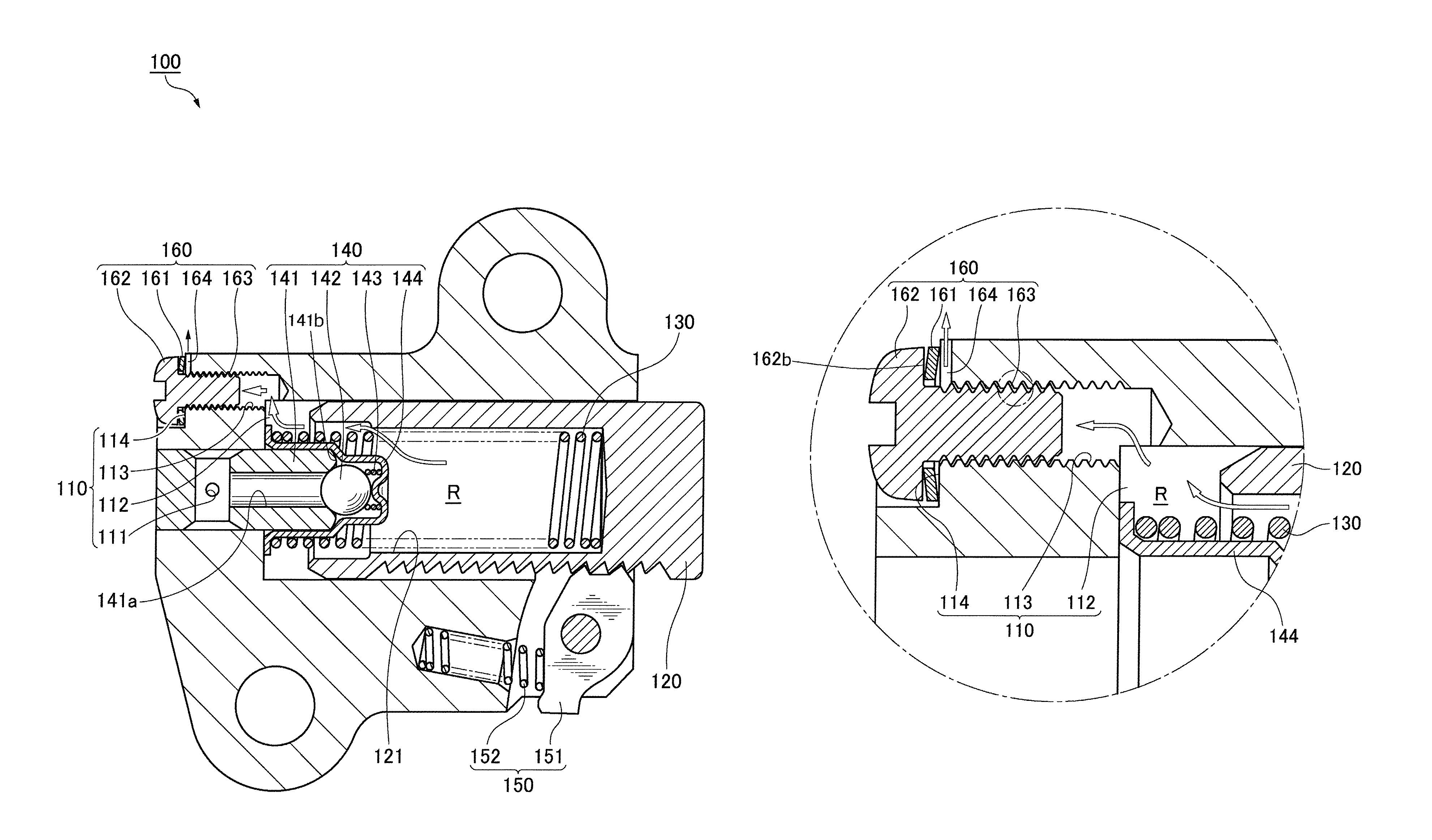

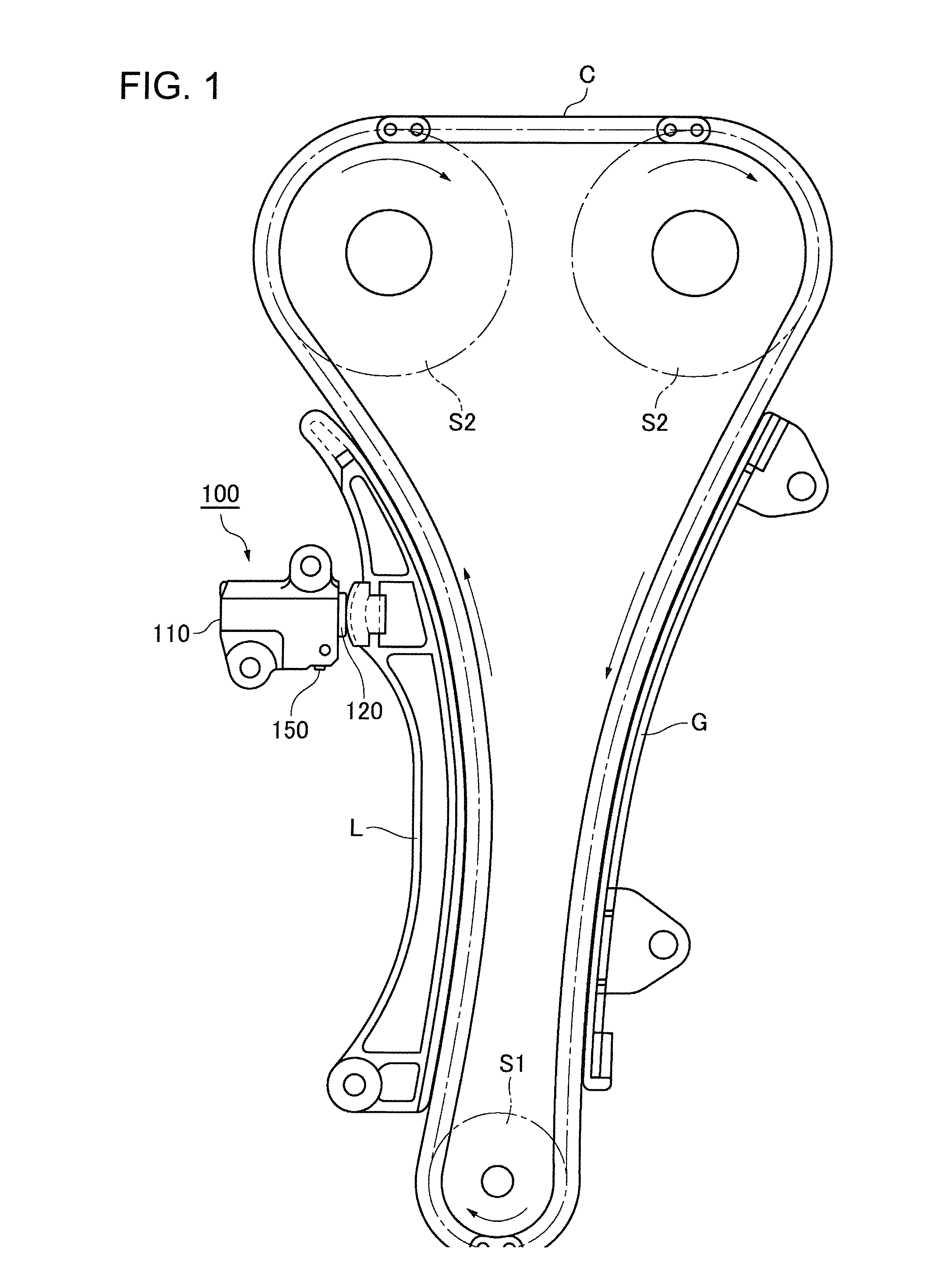

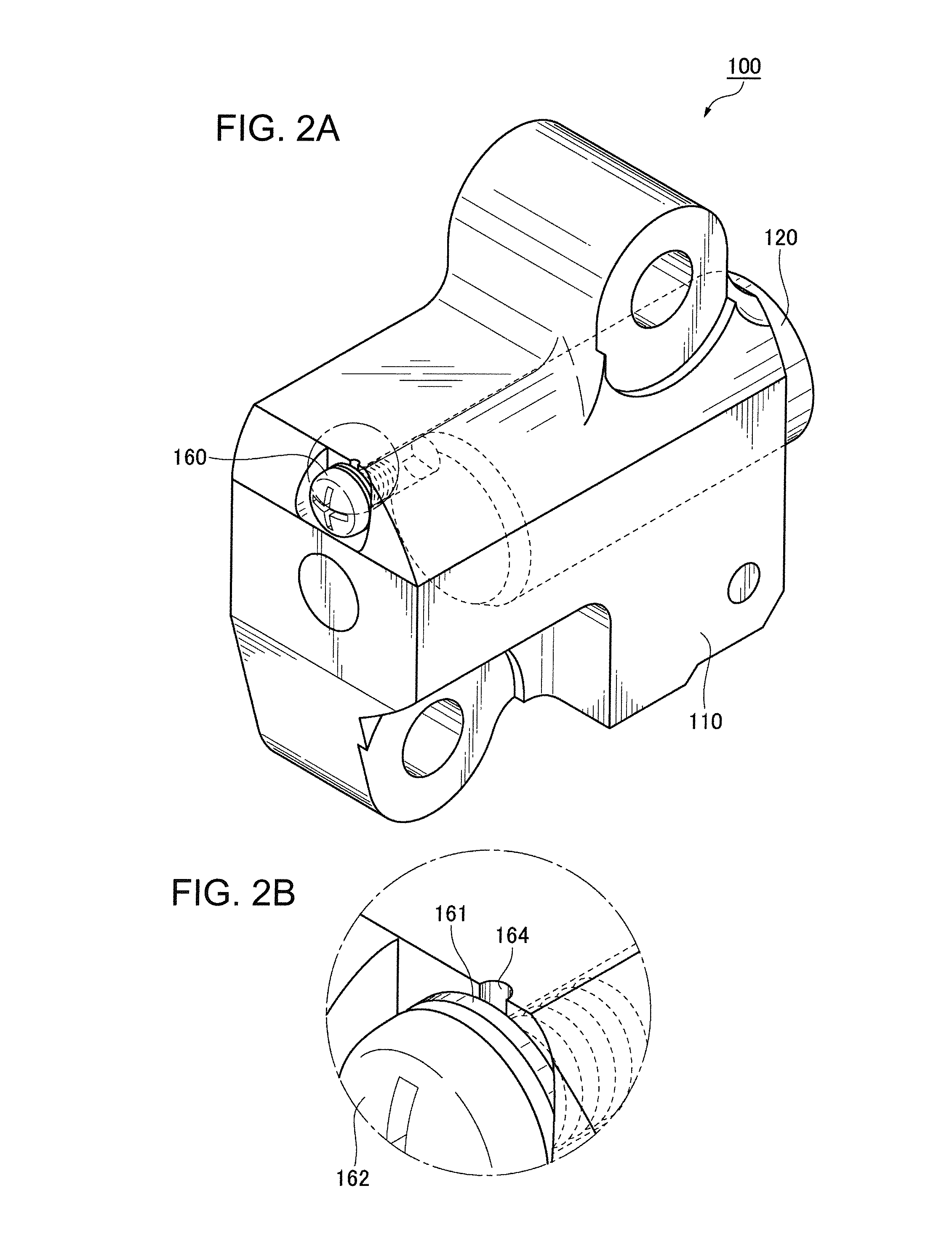

Hydraulic tensioner

Deaeration of the high pressure oil chamber of a hydraulic tensioner takes place though a helical orifice formed by opposed flanks of the threads of a threaded hole in the tensioner housing and the threads of a screw inserted into the hole. The opposed flanks are maintained in spaced relationship by a force exerted by a spring washer disposed between the head of the screw and a surface of the tensioner housing surrounding the opening of the threaded hole. The flank of the thread of the hole that forms part of the boundary of the helical orifice can have a concave curvature in order to increase the aperture of the air flow path. A groove in the surface surrounding the opening of the threaded hole prevents the washer from sealing off the flow of air. This groove is disposed with its exit end at a level above its entry end.

Owner:TSUBAKIMOTO CHAIN CO

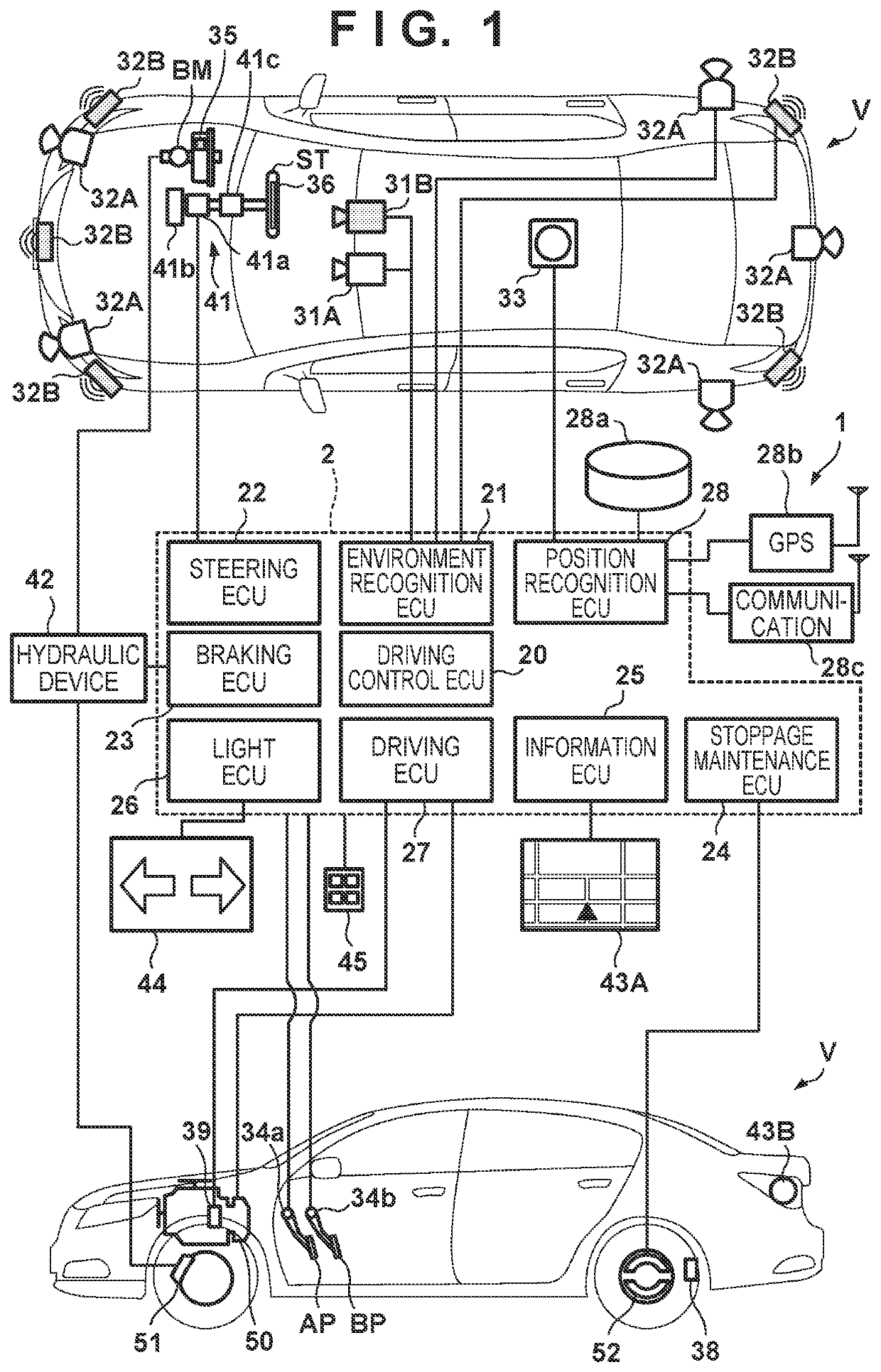

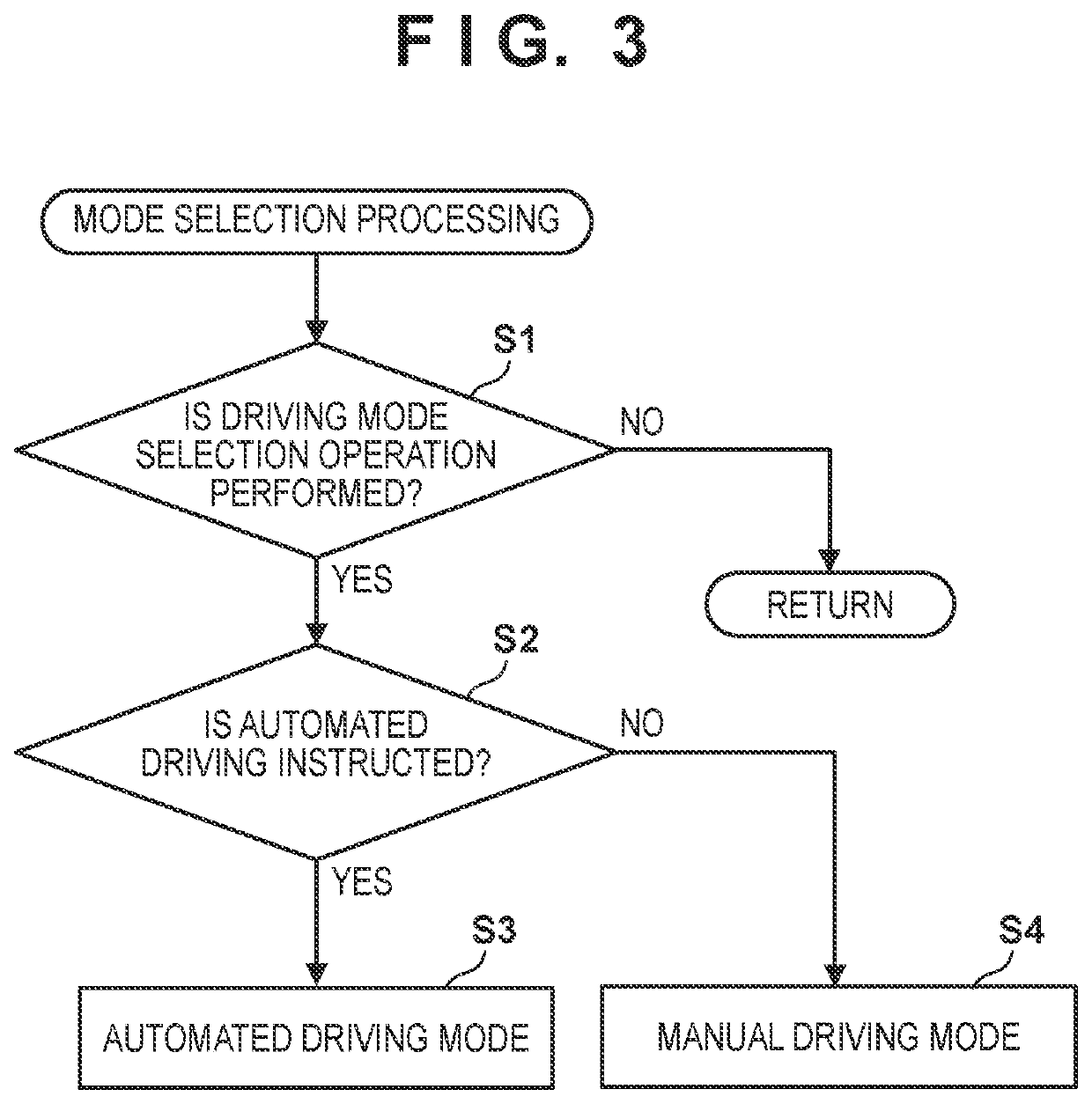

Vehicle and control apparatus

ActiveUS10836387B2Smoothly and quicklyHybrid vehiclesToothed gearingsAutomatic transmissionControl theory

A vehicle includes: an automatic transmission configured to select a gear from a plurality of gears by switching engagement of a plurality of friction engaging mechanisms; a determination unit configured to determine whether a predetermined deceleration condition is satisfied during traveling; and an engagement control unit configured to control the plurality of friction engaging mechanisms. If the determination unit determines that the predetermined deceleration condition is satisfied, the engagement control unit decelerates the vehicle by controlling, in addition to a friction engaging mechanism corresponding to a current gear among the plurality of friction engaging mechanisms, a degree of engagement of another friction engaging mechanism that can generate interlock of the automatic transmission.

Owner:HONDA MOTOR CO LTD

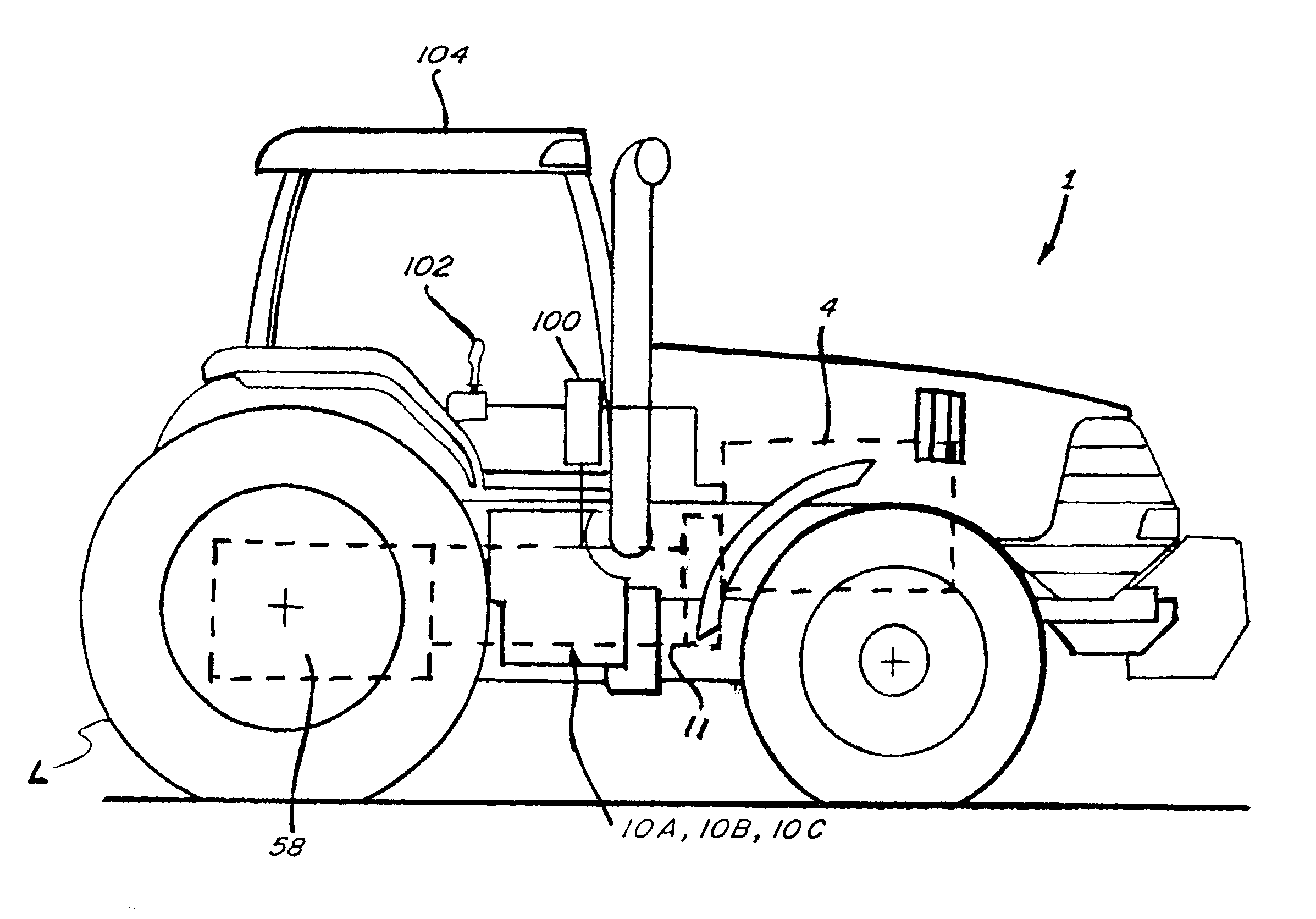

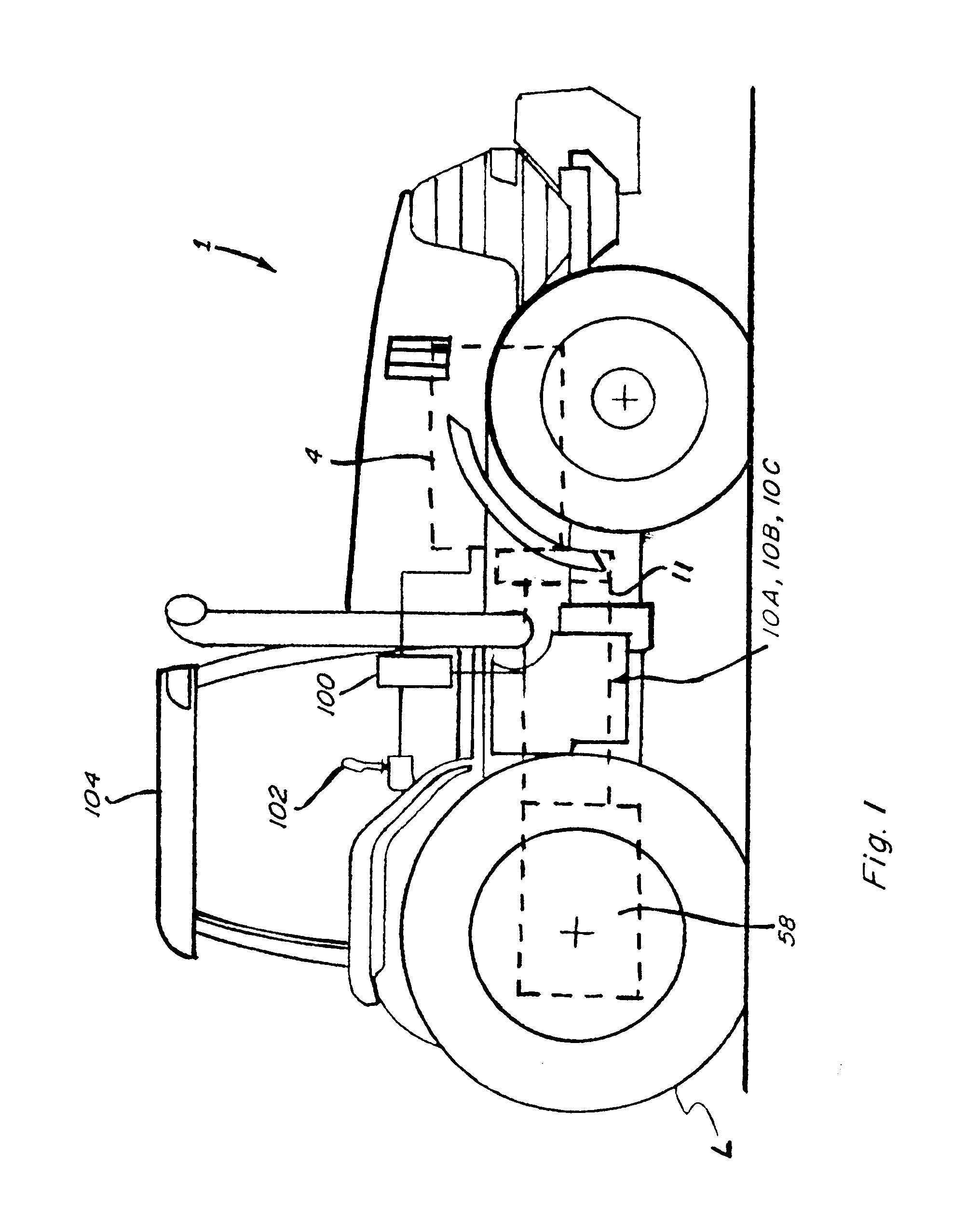

Proportional Parking Brake Control In Cooperation With Operation Of A Conntinuously Variable Transmission

ActiveUS20140187381A1Move quickly and easilySmoothly and quicklyBraking element arrangementsGearing controlMobile locationVariator

A parking brake is controlled in concert with operation of a hydrostatic power unit of a continuously variable transmission, particularly when engaging, disengaging and shuttle shifting the transmission, to provide advantages, particularly when on hills. When particular commands are received, such as shifting to a non-moving position, the parking brake is automatically engaged to hold the vehicle position. A swash plate of the hydrostatic unit can be automatically positioned to anticipate the next command. If that command is received, the brake is automatically gradually or proportionally released and the transmission engaged to effect the commanded movement of the vehicle. If a different command is received, the brake remains engaged as the transmission is configured for the commanded movement, such that no machine movement results. Then the brake is automatically gradually or proportionally released and the transmission engaged to effect that commanded movement.

Owner:BLUE LEAF I P

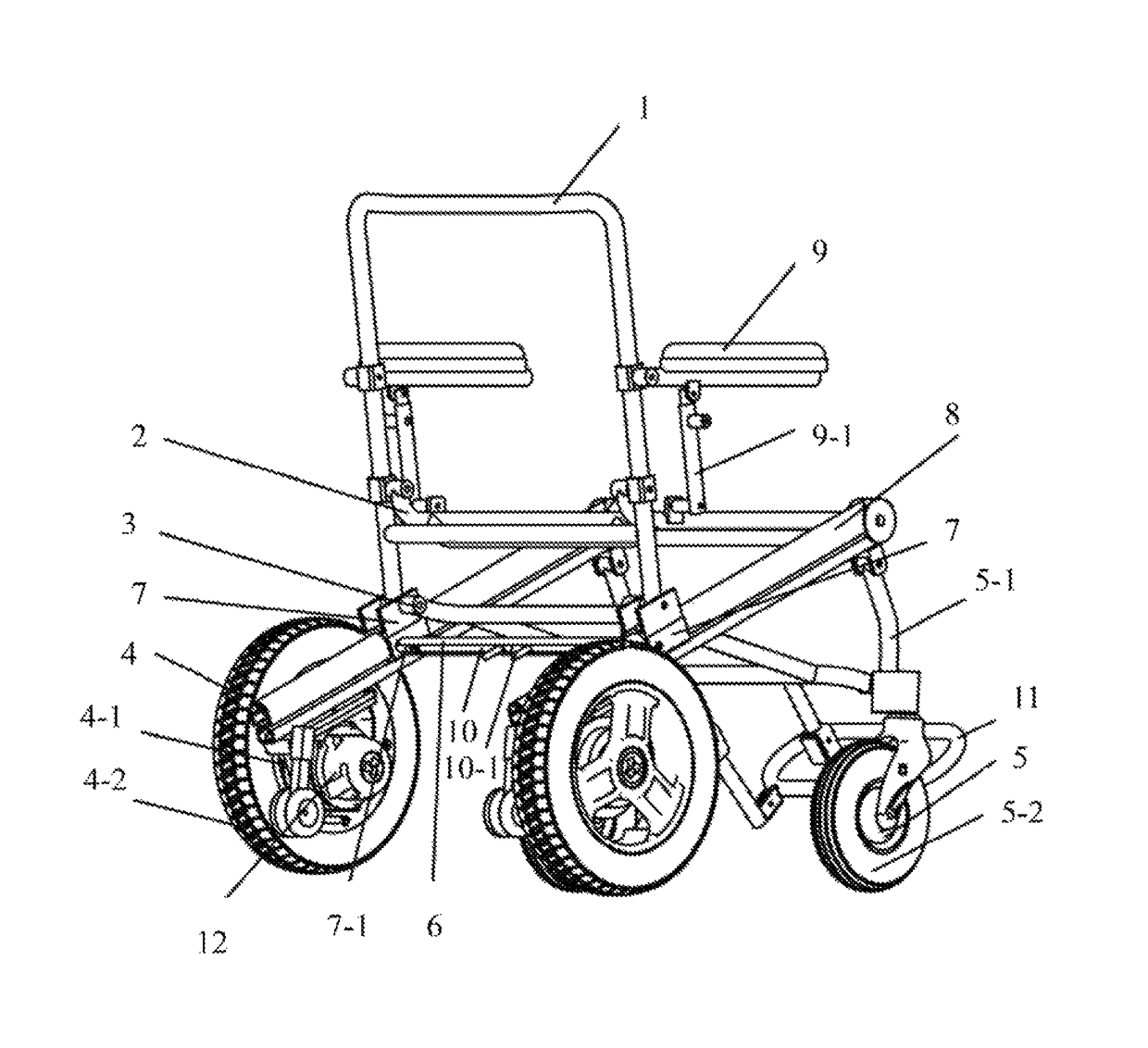

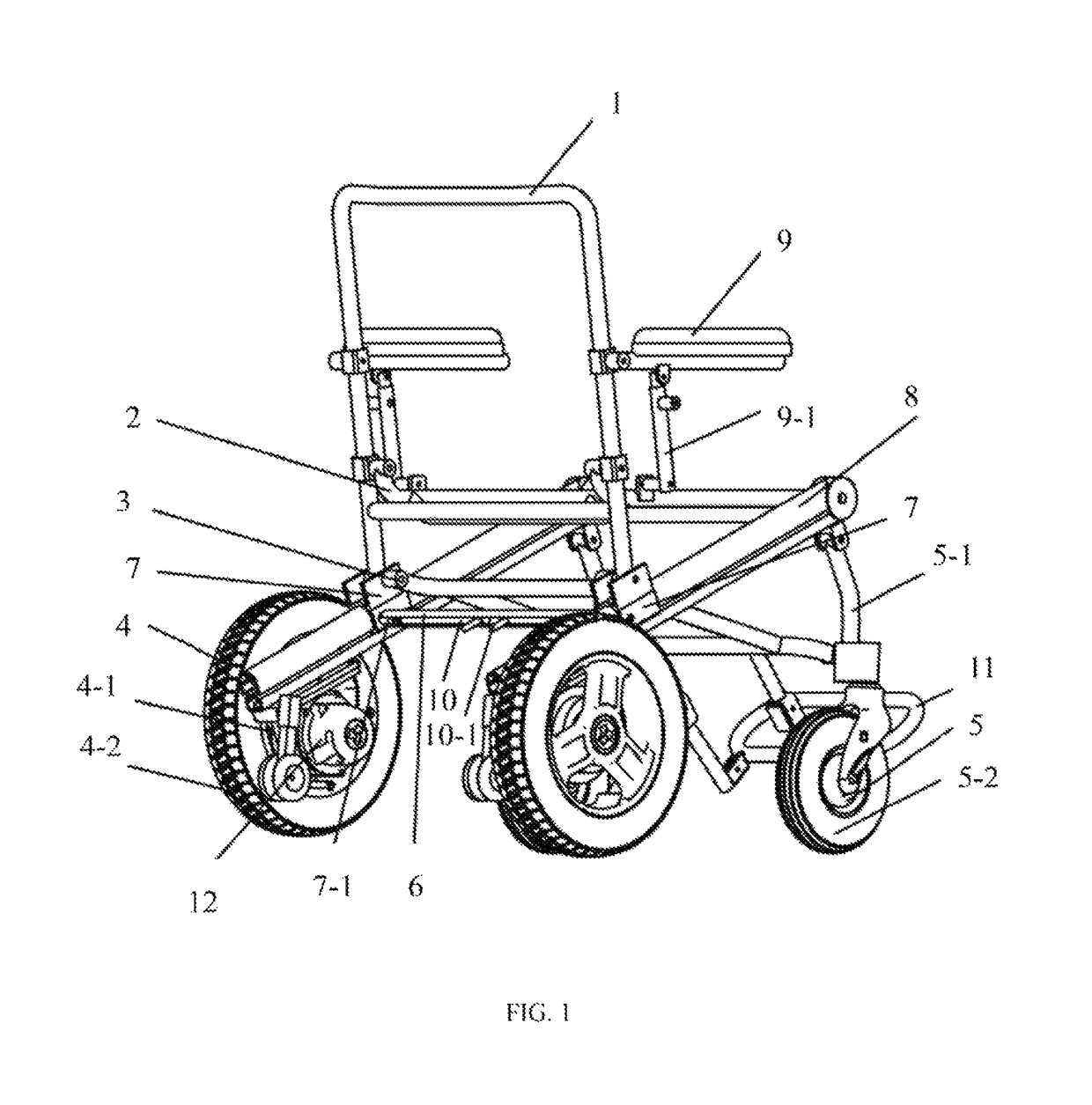

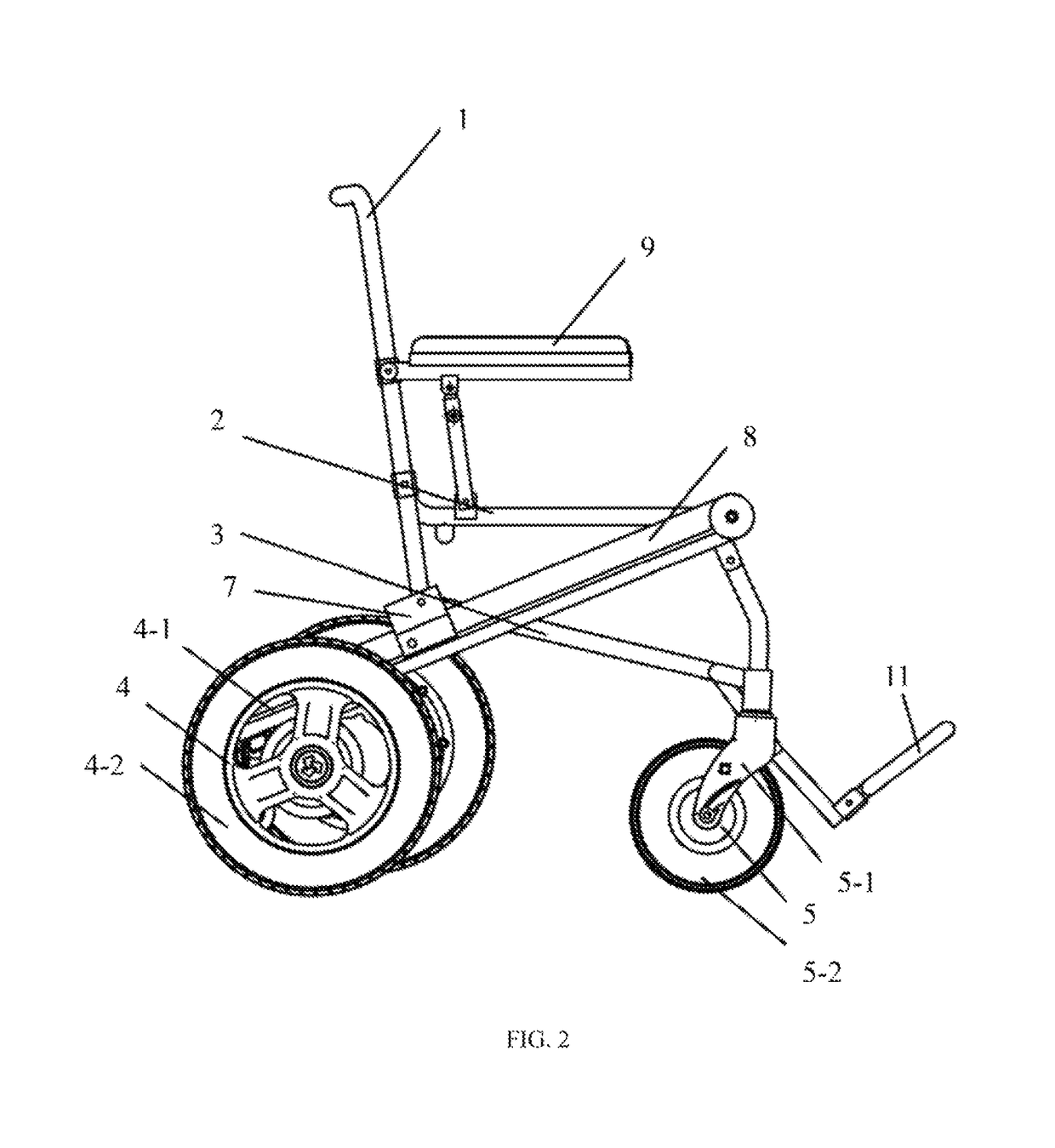

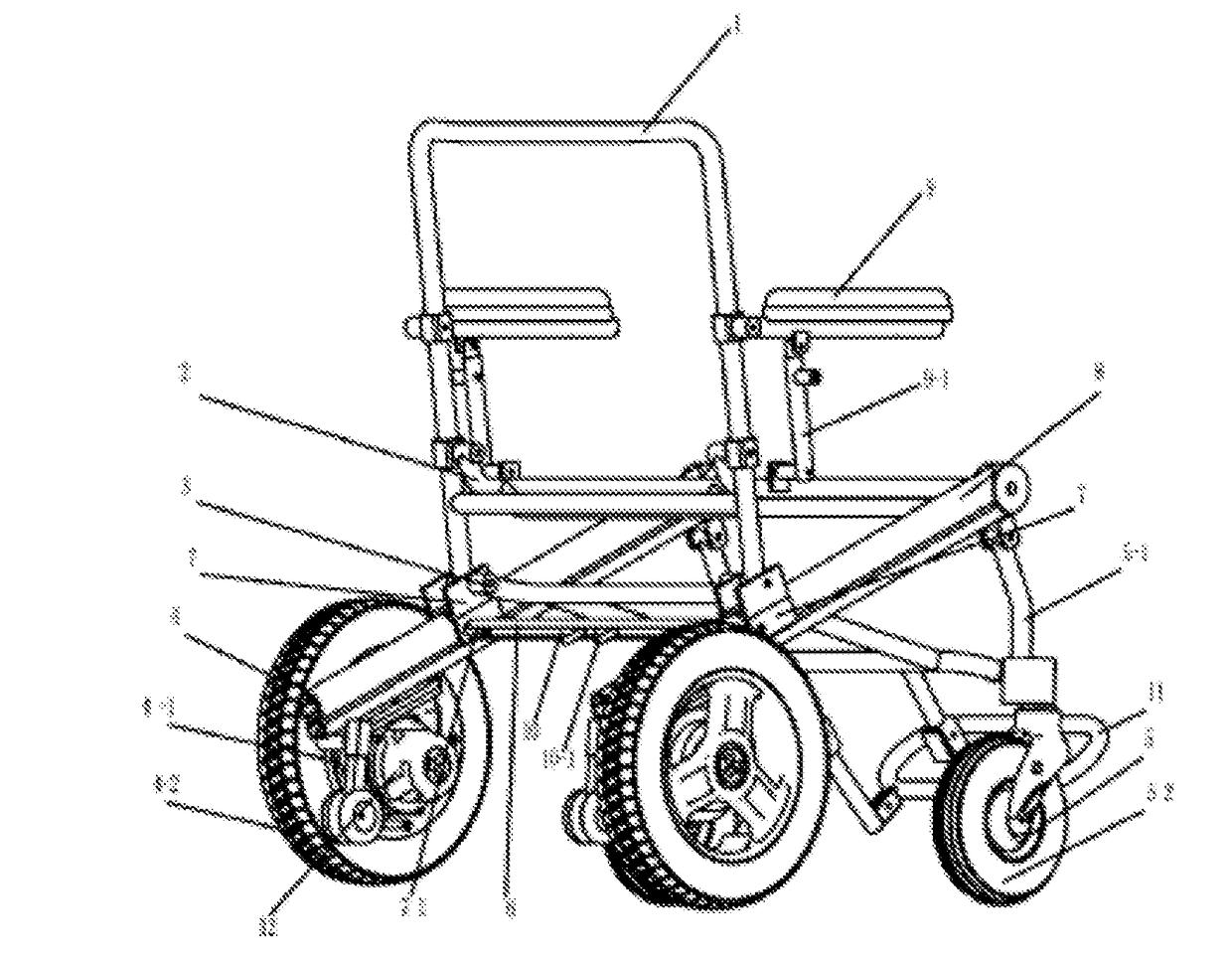

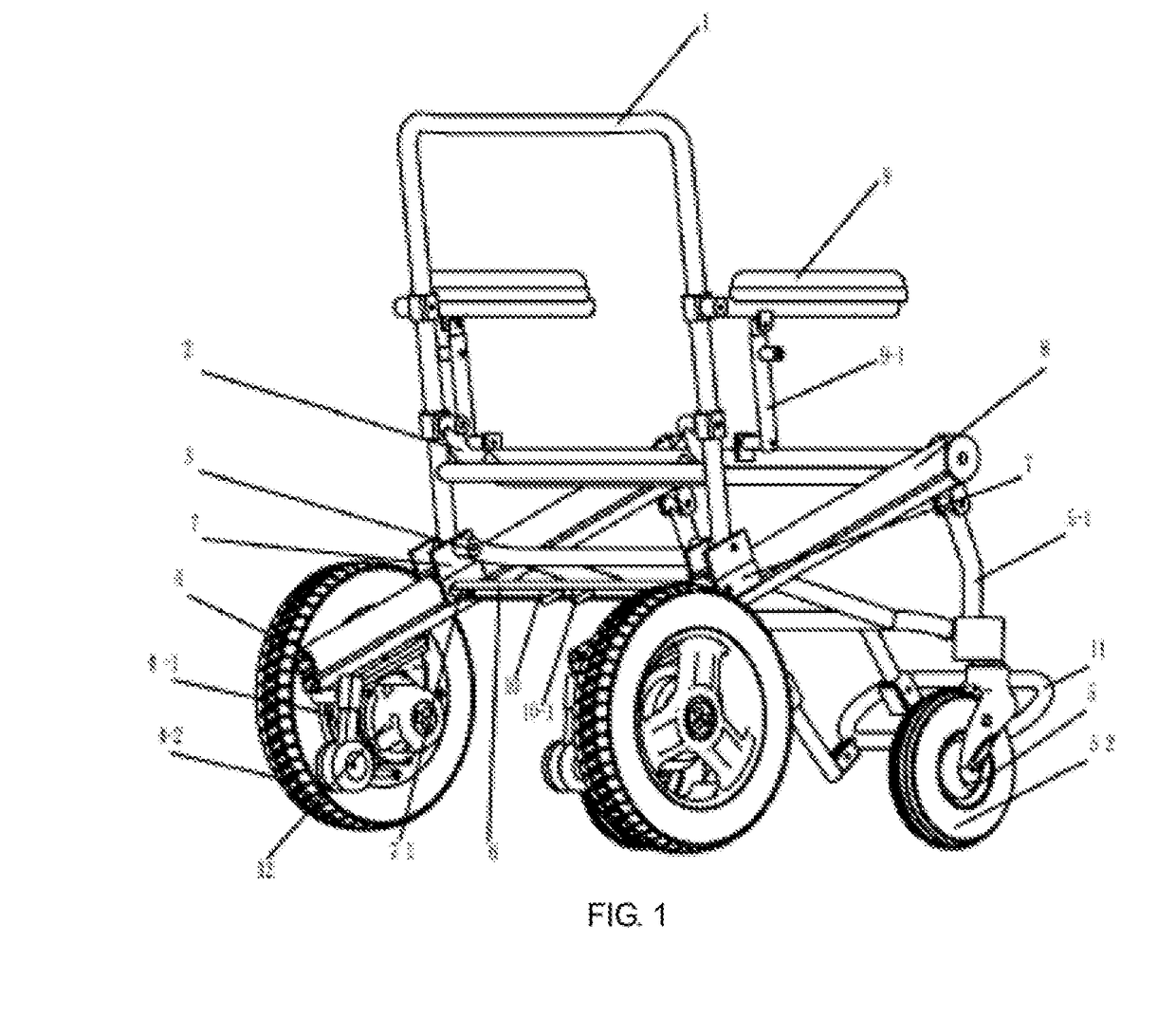

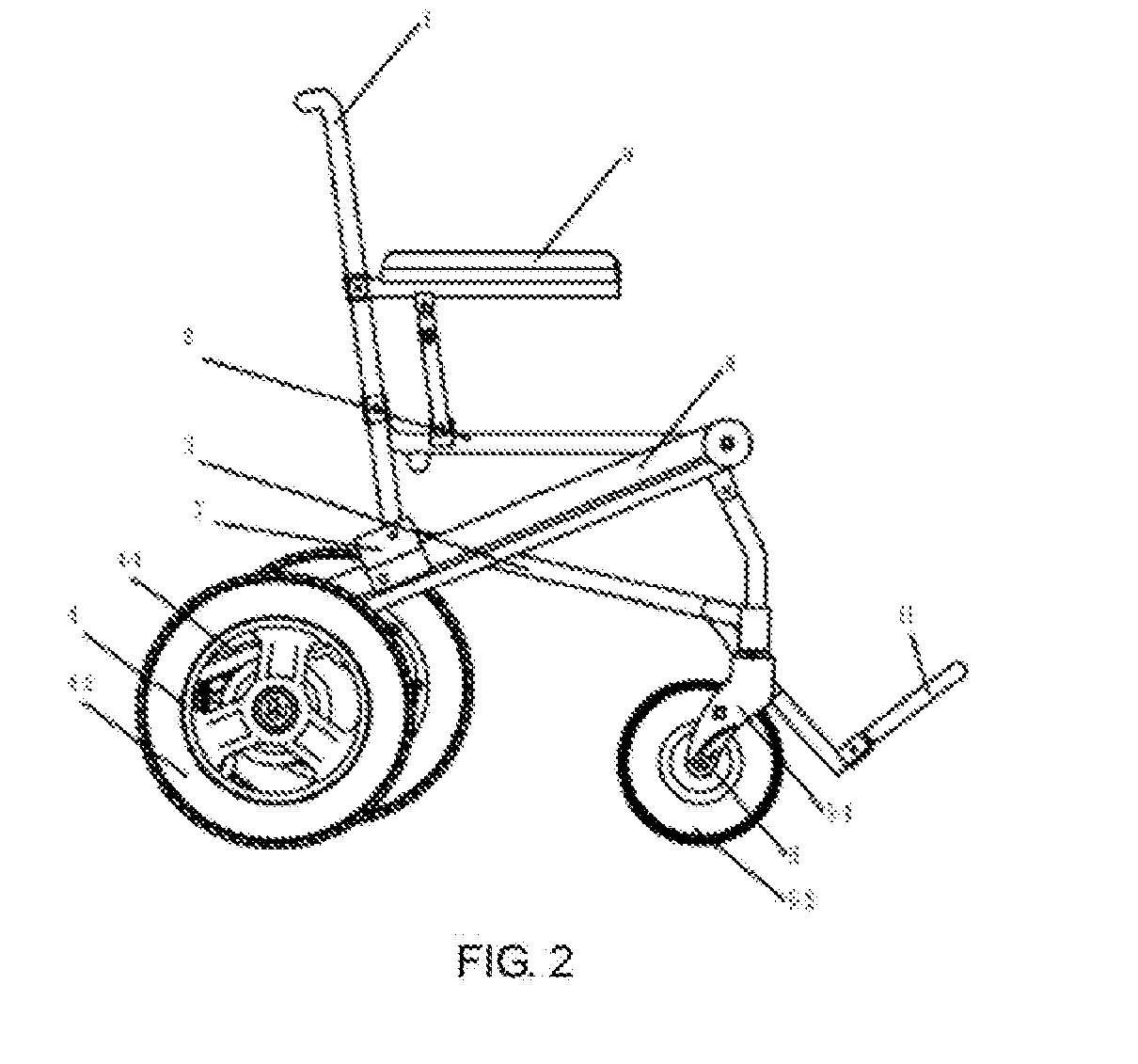

Folding wheelchair

A folding wheelchair, including a back frame a seat frame a lower frame, two rear wheel assemblies, two front wheel assemblies and an armrest; the armrest and the seat frame are hingedly connected to the back frame from top to bottom in a sequence; the two front wheel assemblies is connected to the lower frame; a sliding guide rail is provided between one end of the seat frame and each rear wheel assembly, and is provided with a sliding block thereon in a sliding fit manner; the sliding block is hingedly connected to a lower end of the back frame and the lower frame or the lower end of the back frame is hingedly connected to the sliding block and the lower frame; or the lower frame is hingedly connected to the lower end of the back frame and the sliding block The folding wheelchair is safe and reliable touse, and can be folded smoothly and quickly; in addition, the folded wheelchair has a small size, and is convenient to lean, against a wall, occupies a small space in a vehicle trunk or under a bed, and is convenient to use when going out.

Owner:CHANGZHOU GOLDEN MOTOR TECH CO LTD

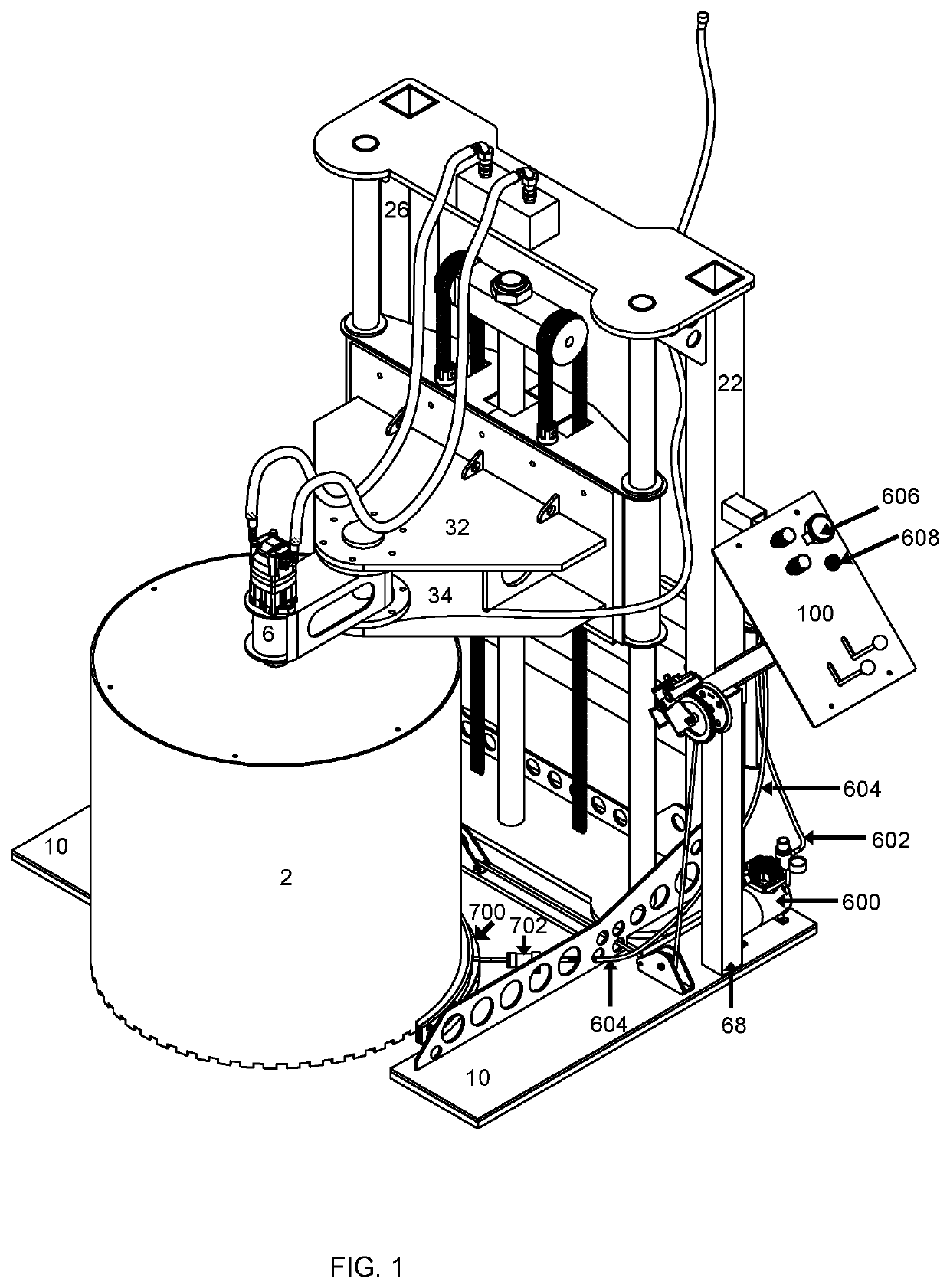

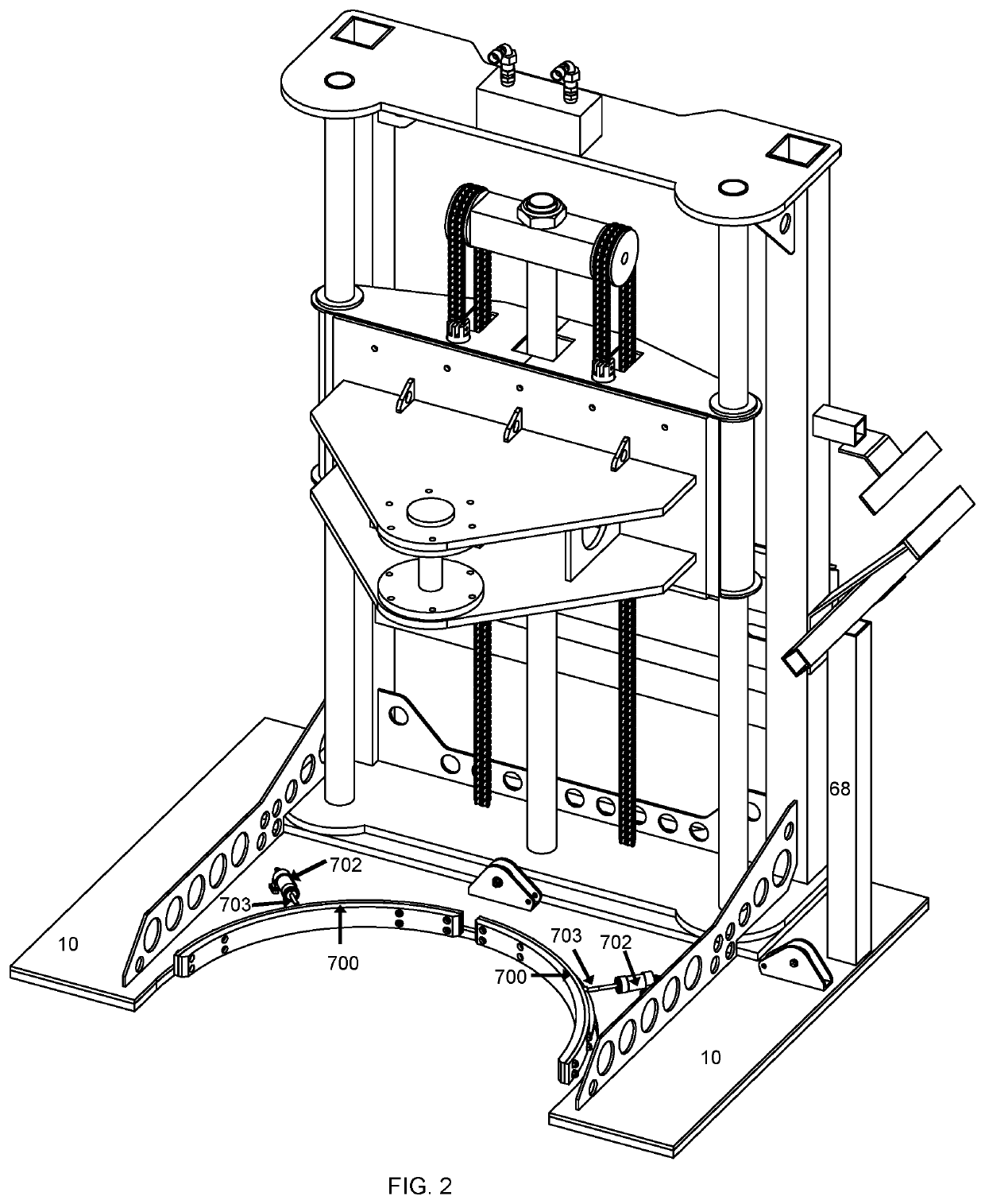

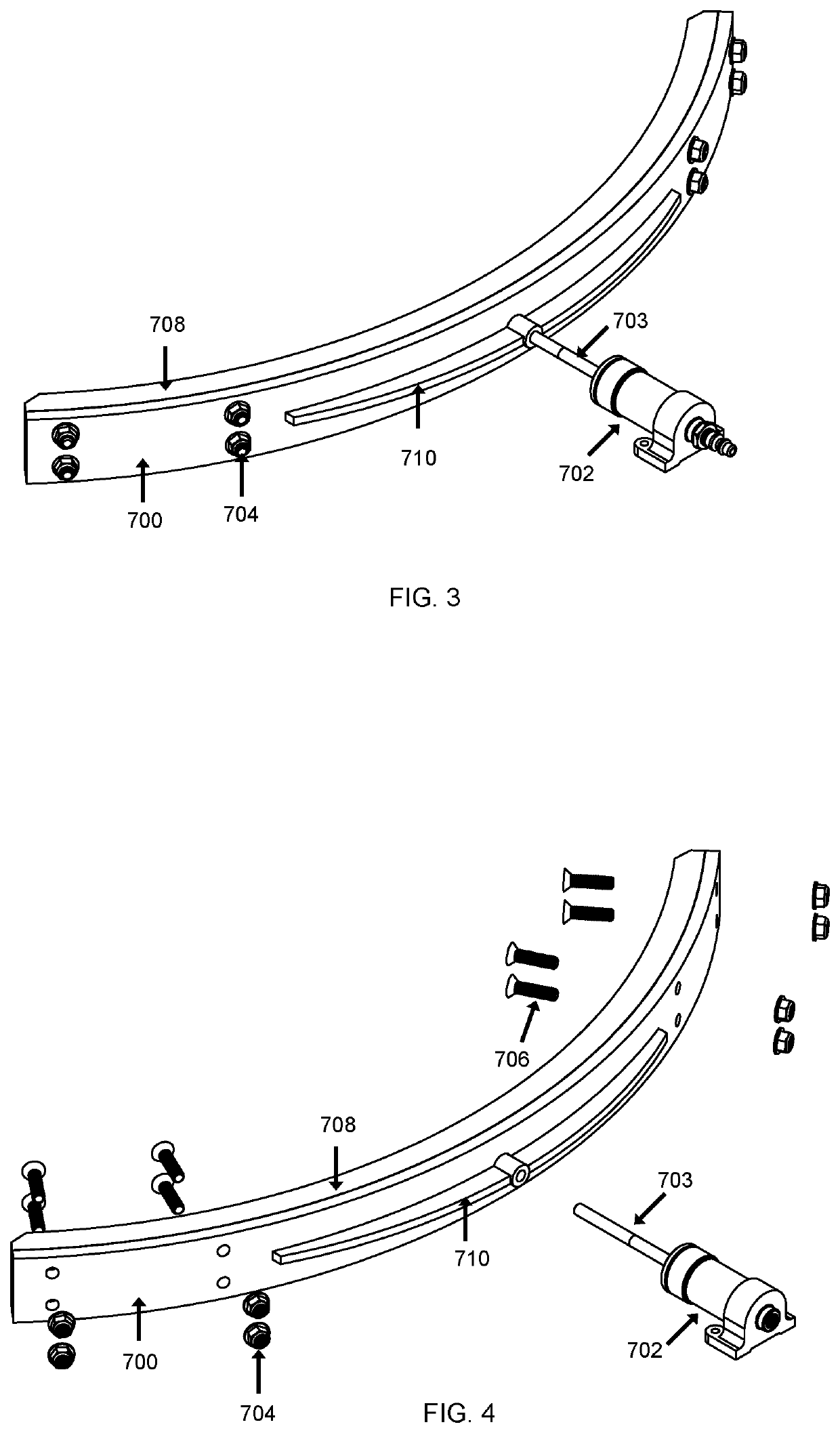

Heavy equipment concrete core drill bit stabilizer

ActiveUS20190360273A1Reduce the binding forceSmoothly and quicklyDrill bitsDrilling rodsEngineeringAir compressor

The present invention is an accessory device that hole coring machine, wherein the hole coring machine is utilized to quickly and efficiently core holes in concrete and asphalt. The accessory device comprises a stabilizer assembly that is coupled to a base of the hole coring machine. The stabilizer assembly includes at least one stabilizing frame that is formed to the outside diameter of a drill saw bit of the hole coring machine. The at least one stabilizing frame is coupled to an air compressor that causes the stabilizing frame to move relative to the drill saw bit during operation of the hole coring machine. The at least one stabilizing frame aids in maintaining the shape of the drill saw bit and reduces vibration and binding of the drill saw bit while forming a hole in concrete and / or asphalt.

Owner:THORNTON LEE C

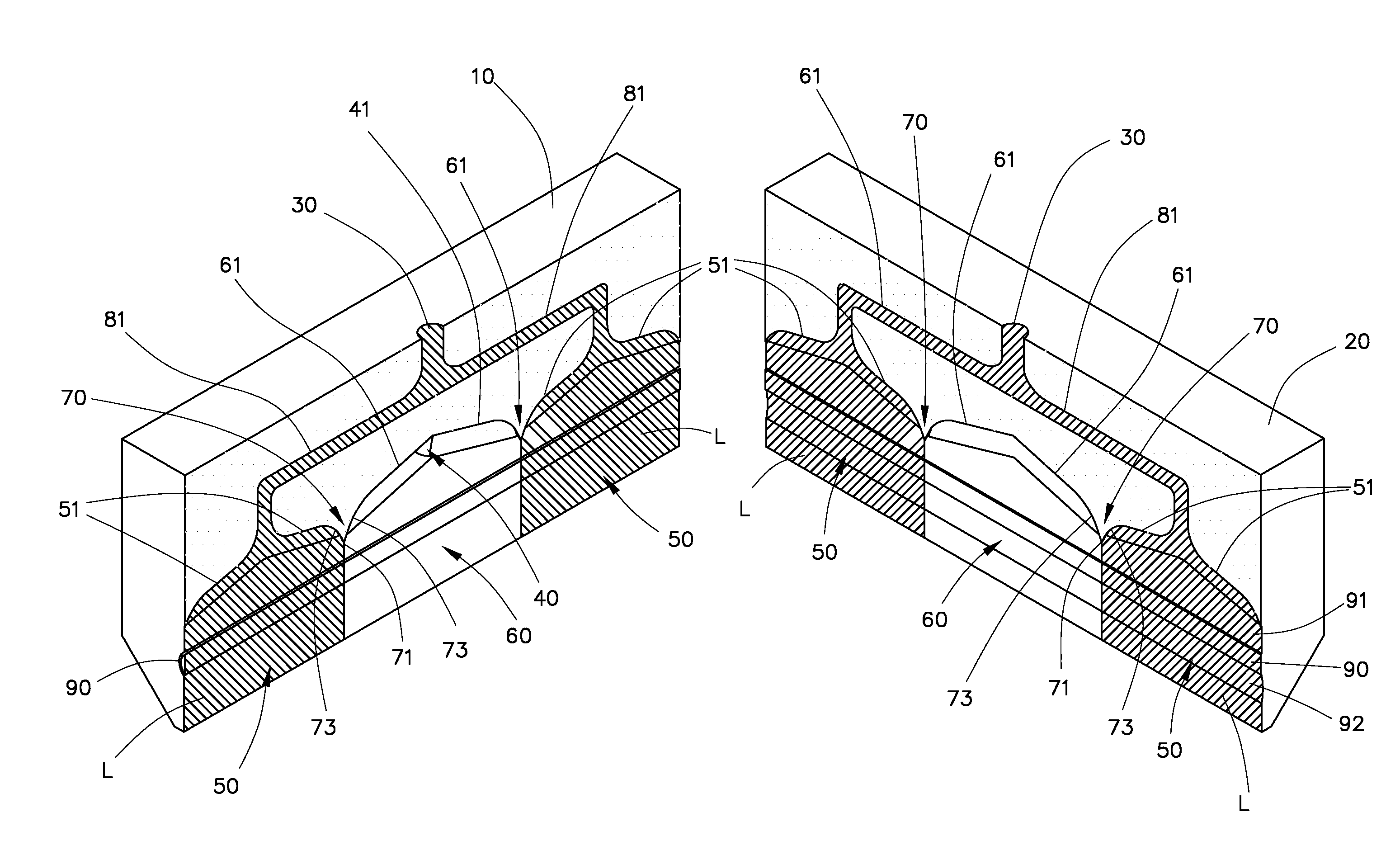

Extrusion die for producing bicolor plastic sheets

InactiveUS20160067902A1Avoid mixing colorsSpeed up the flowConfectionerySweetmeatsEngineeringPlastic film

An extrusion die includes a first metal plate and a second metal plate. The first and second metal plates define a first entrance for receiving a first plastic flow, a first cavity including two first distributing channels, and a second cavity including two second distributing channels. The first entrance communicates with the first cavity. The first metal plate further defines a second entrance for receiving a second plastic flow of different color. The second entrance communicates with the second cavity. The first cavity communicates with the second cavity through a common side therebetween. An exit is defined at bottoms of the cavities, from which bicolor plastic sheets can be delivered. One of the first distributing channels and one of the second distributing channels are respectively curved downwardly to join to the common side between the cavities, so that the plastic flows can flow more smoothly to prevent color mixing therebetween.

Owner:CHING HSING IRON WORKS

Polishing slurry for polishing aluminum film and polishing method for polishing aluminum film using the same

ActiveUS20070141957A1Smoothly and quickly polishSmoothly and quicklyPigmenting treatmentOther chemical processesColloidal silicaAluminium

A polishing slurry for polishing an aluminum film used for LSI or the like and a method for polishing an aluminum film using the same are provided. A polishing slurry for polishing an aluminum film comprising a polyvalent carboxylic acid having a first stage acid dissociation exponent at 25° C. of 3 or lower, colloidal silica, and water, and having a pH from 2 to 4, and a polishing method for polishing an aluminum film using the polishing slurry.

Owner:SHOWA DENKO MATERIALS CO LTD

Folding wheelchair

A folding wheelchair, including a back frame a seat frame a lower frame, two rear wheel assemblies, two front wheel assemblies and an armrest; the armrest and the seat frame are hingedly connected to the back frame from top to bottom in a sequence; the two front wheel assemblies is connected to the lower frame; a sliding guide rail is provided between one end of the seat frame and each rear wheel assembly, and is provided with a sliding block thereon in a sliding fit manner; the sliding block is hingedly connected to a lower end of the back frame and the lower frame or the lower end of the back frame is hingedly connected to the sliding block and the lower frame; or the lower frame is hingedly connected to the lower end of the back frame and the sliding block The folding wheelchair is safe and reliable touse, and can be folded smoothly and quickly; in addition, the folded wheelchair has a small size, and is convenient to lean, against a wall, occupies a small space in a vehicle trunk or under a bed, and is convenient to use when going out.

Owner:CHANGZHOU GOLDEN MOTOR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com