Patents

Literature

171 results about "Corneum stratum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

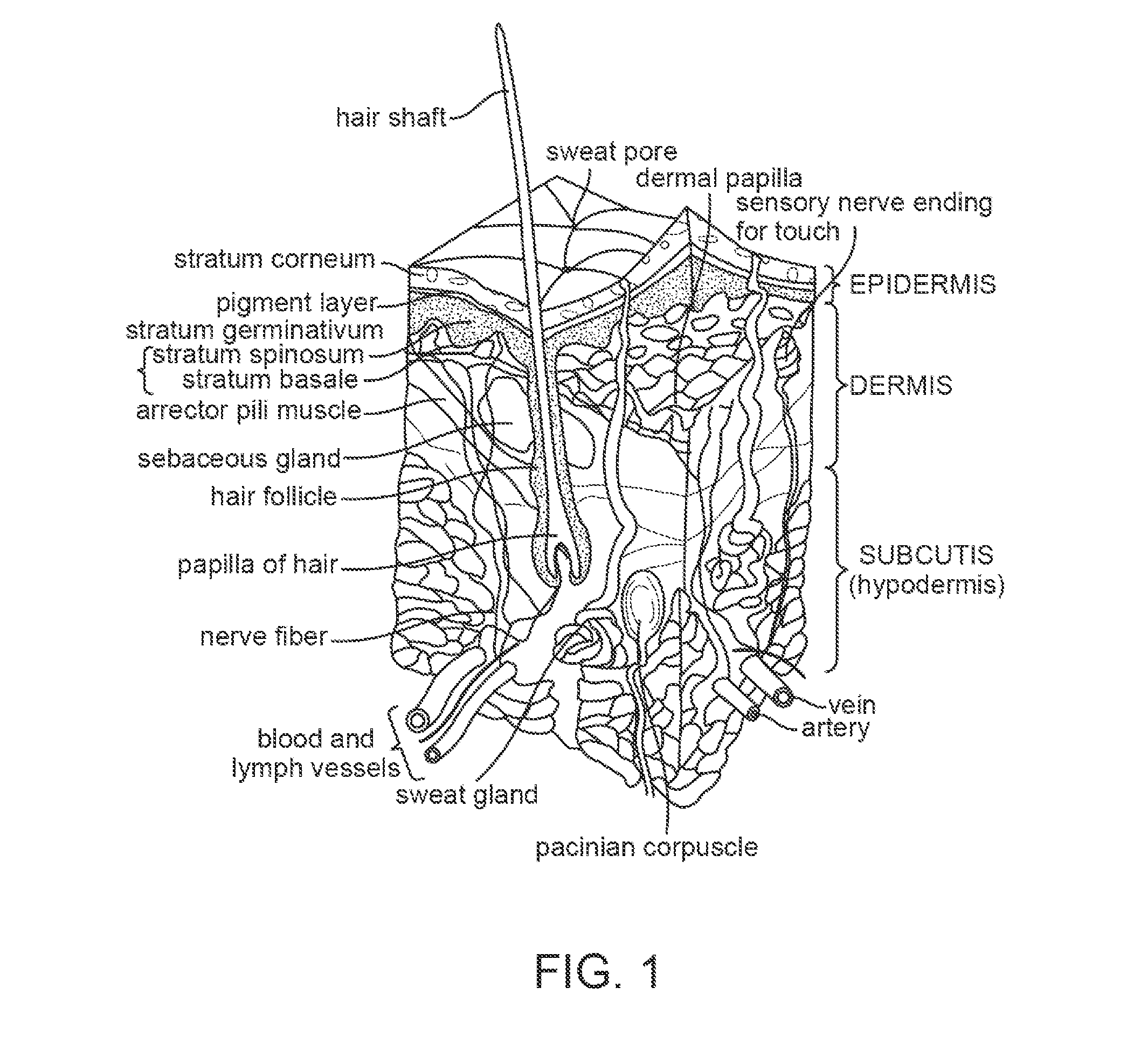

The stratum corneum (Latin for 'horny layer') is the outermost layer of the epidermis, consisting of dead cells (corneocytes). This layer is composed of 15–20 layers of flattened cells with no nuclei and cell organelles.

Self-actuating applicator for microprojection array

Owner:ALZA CORP

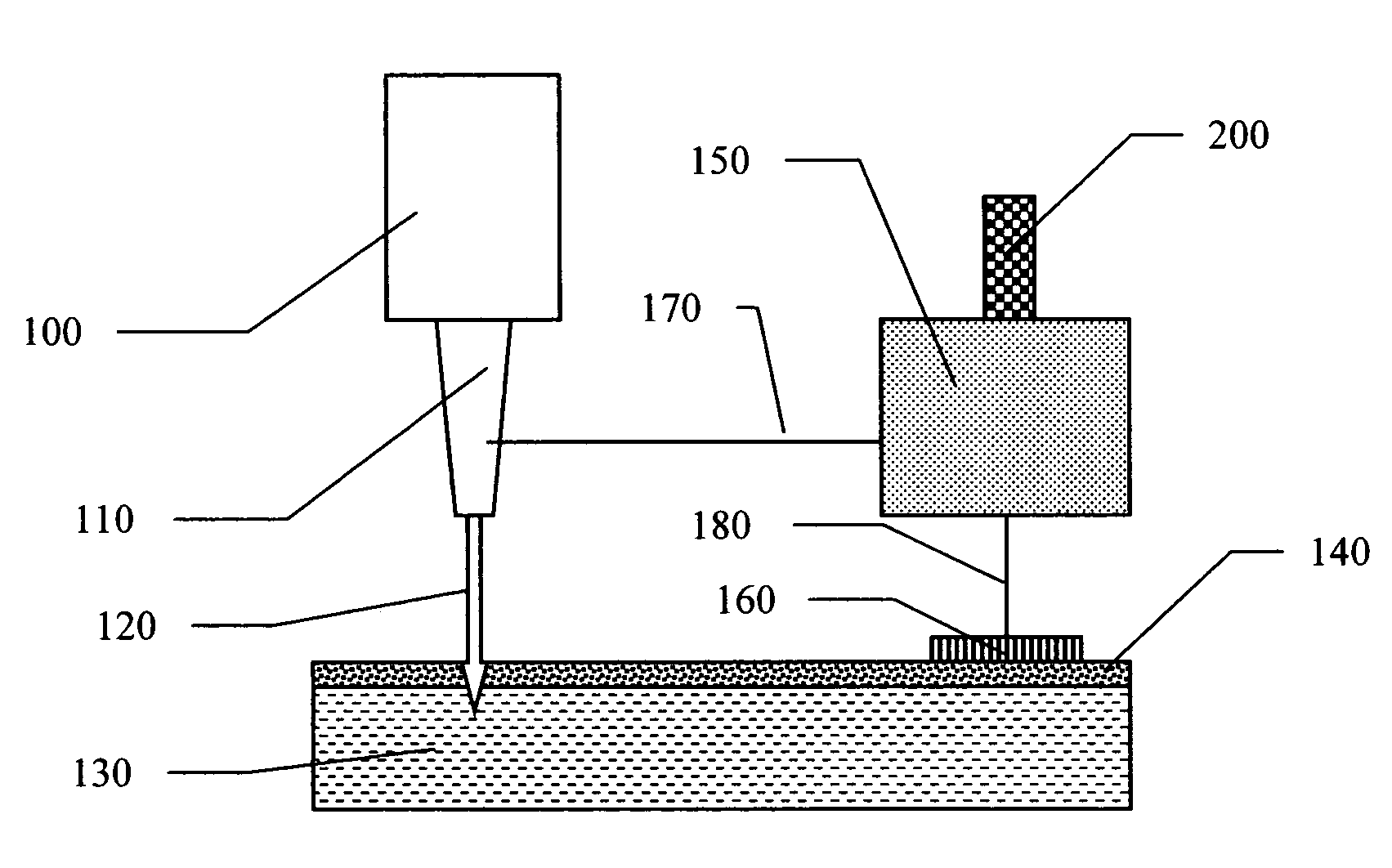

Intracutaneous microneedle array apparatus

InactiveUS20050209565A1Sufficient separation distanceGreater transdermal fluxElectrotherapySurgical needlesEngineeringBiological fluids

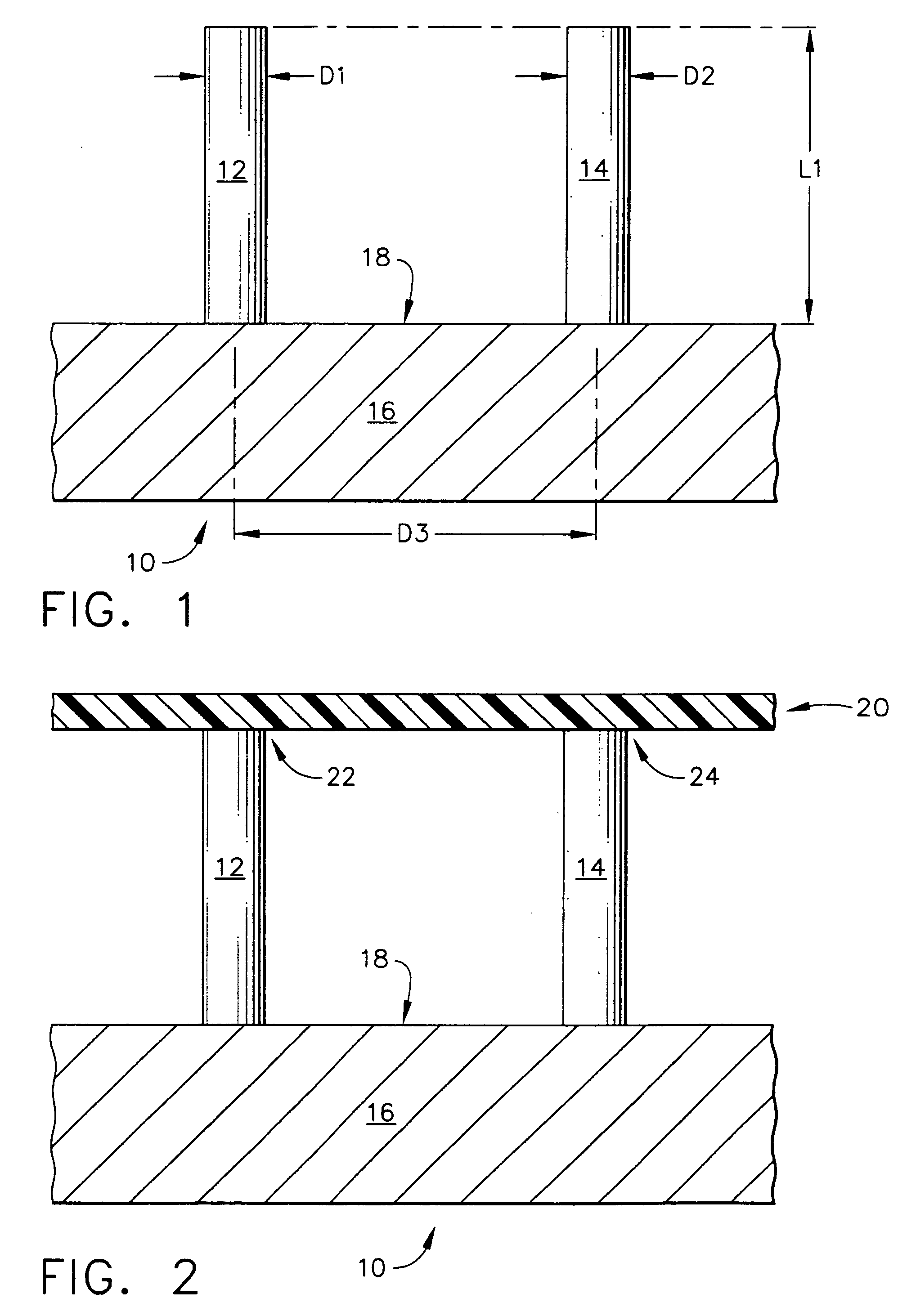

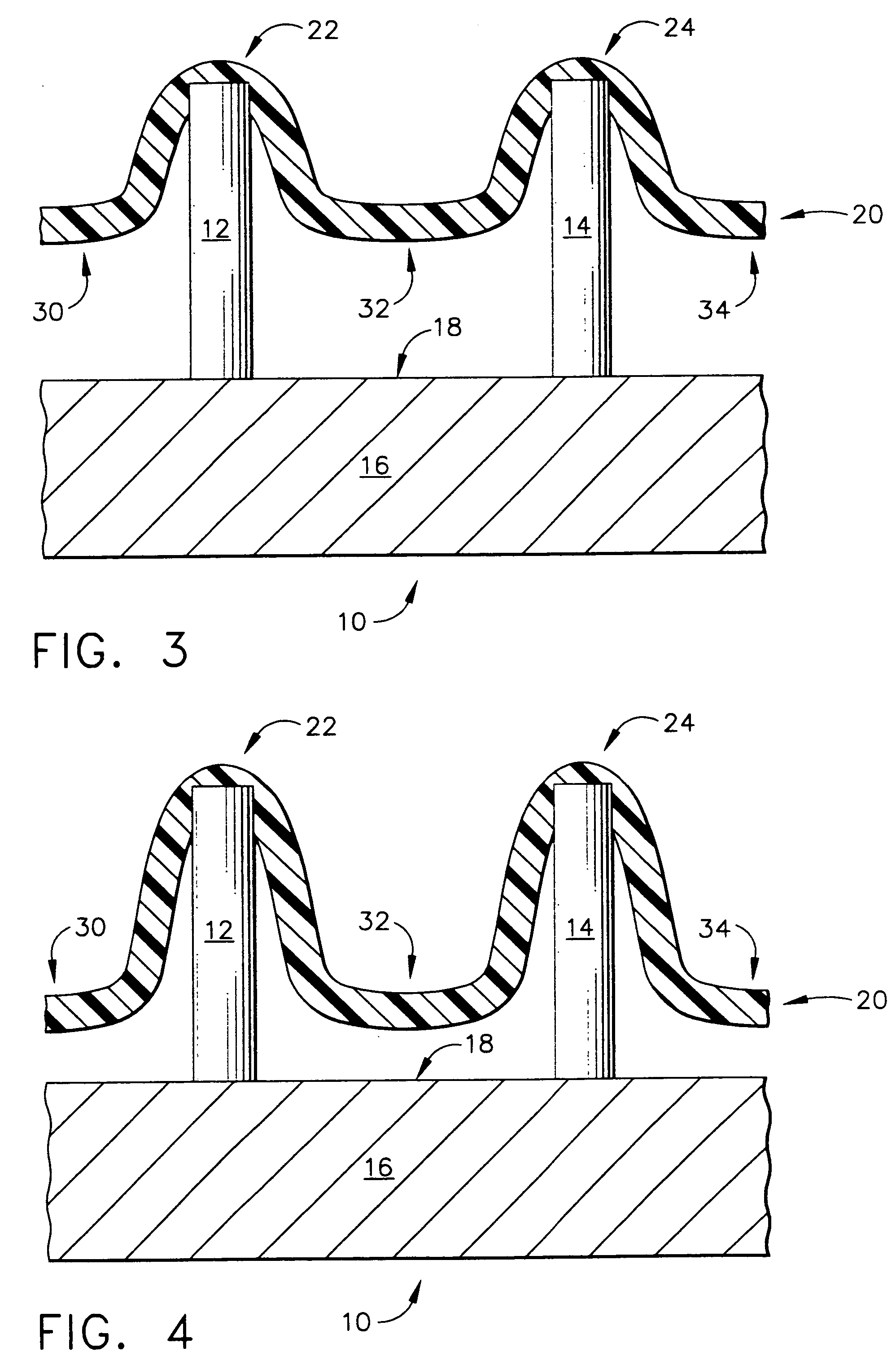

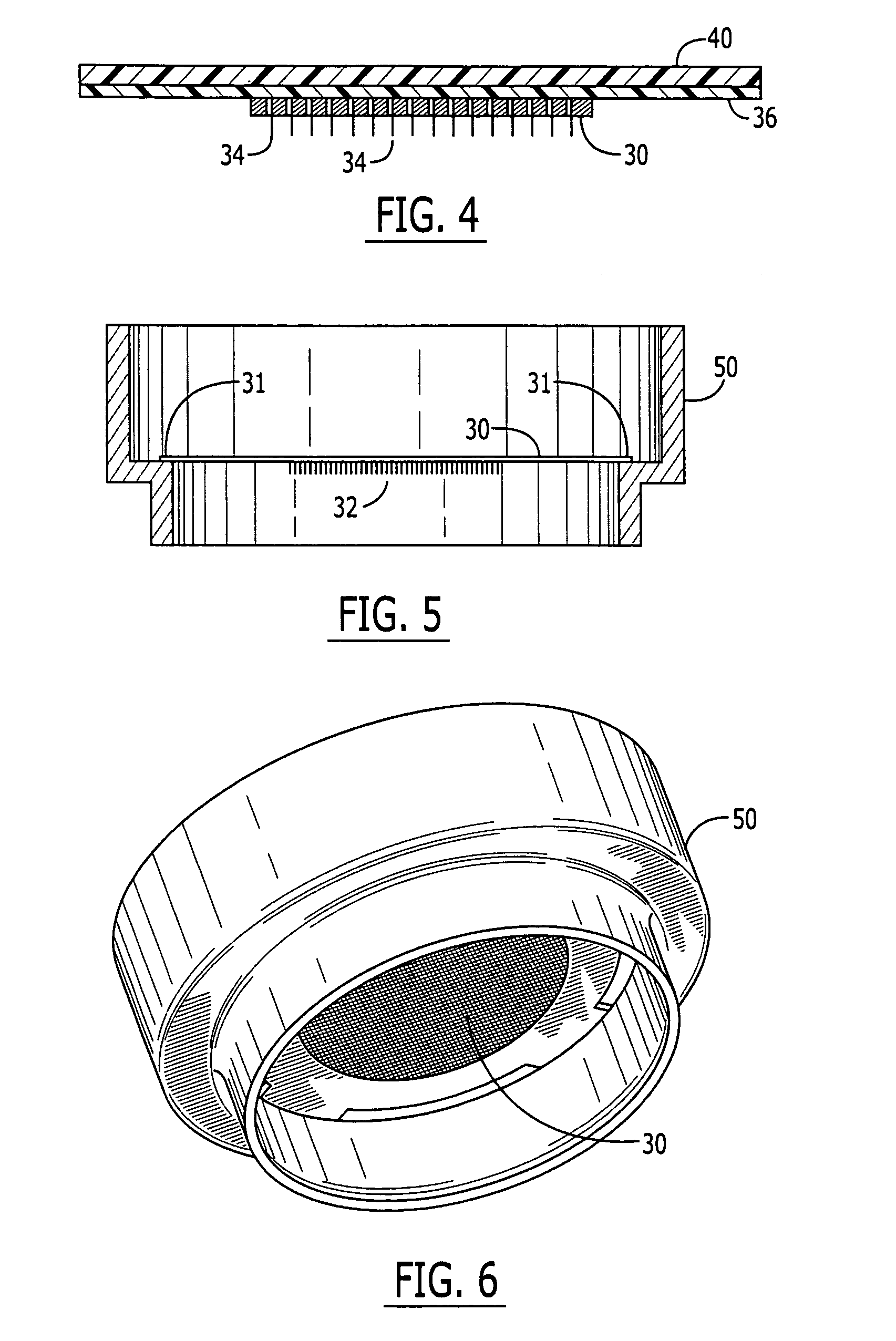

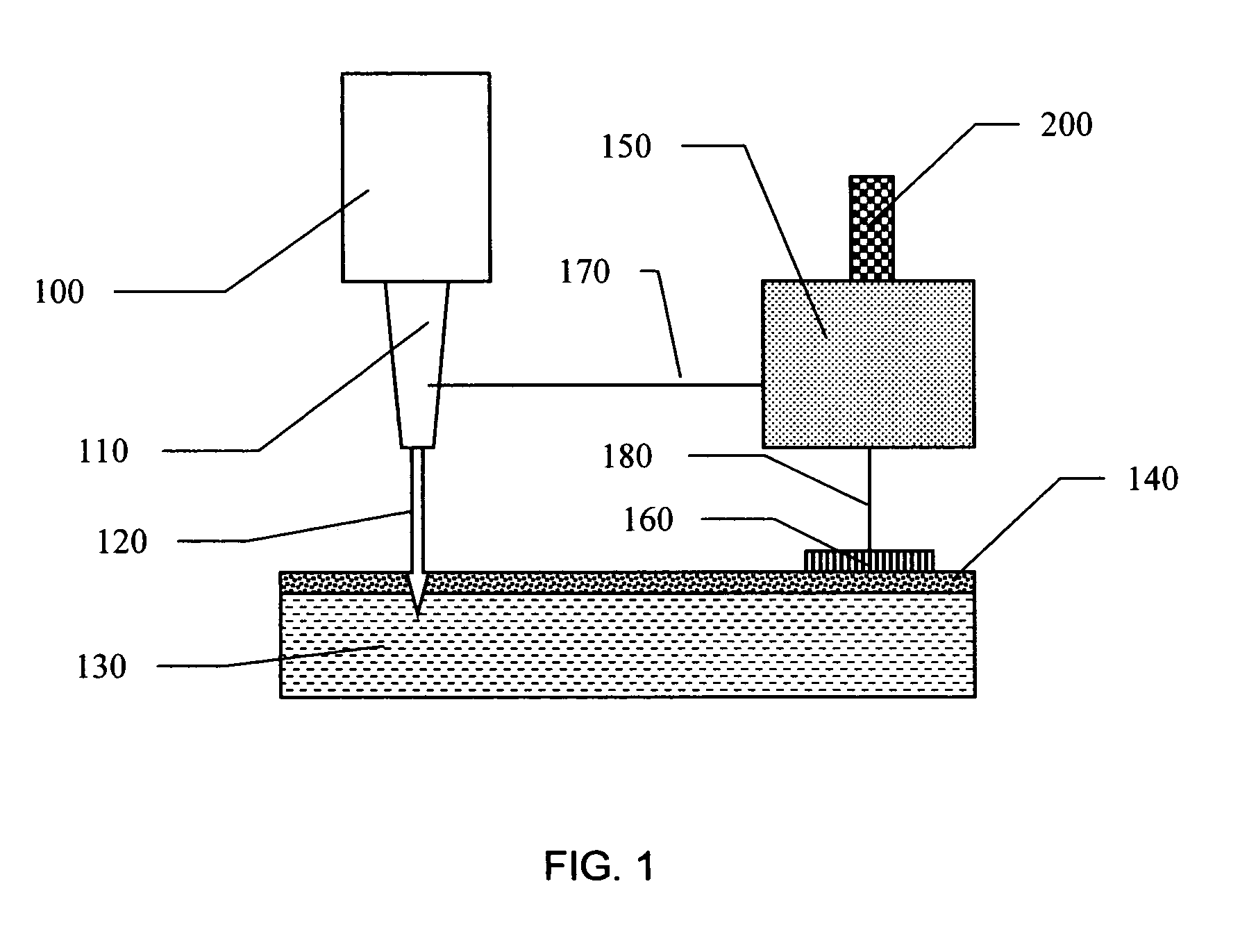

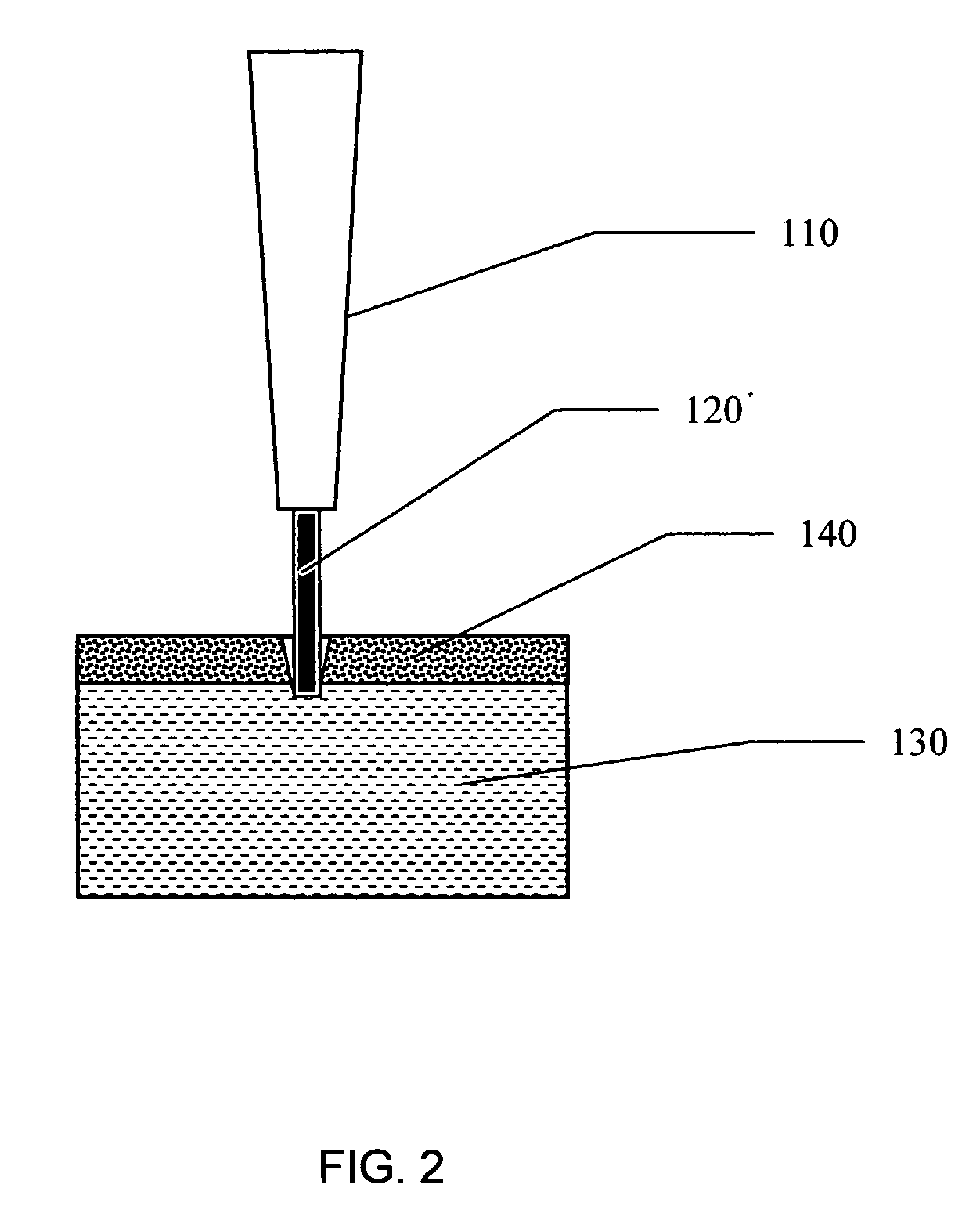

Improved microneedle arrays are provided having a sufficiently large separation distance between each of the individual microneedles to ensure penetration of the skin while having a sufficiently small separation distance to provide high transdermal transport rates. A very useful range of separation distances between microneedles is in the range of 100-300 microns, and more preferably in the range of 100-200 microns. The outer diameter and microneedle length is also very important, and in combination with the separation distance will be crucial as to whether or not the microneedles will actually penetrate the stratum corneum of skin. For circular microneedles, a useful outer diameter range is from 20-100 microns, and more preferably in the range of 20-50 microns. For circular microneedles that do not have sharp edges, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 100-150 microns; for use with other biological fluids, a useful length is in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns. For circular microneedles having sharp side edges, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 80-150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns. For solid microneedles having a star-shaped profile with sharp edges for its star-shaped blades, a useful length for use with interstitial fluids is in the range of 50-200 microns, and more preferably in the range of 80-150 microns; for use with other biological fluids, a useful length is again in the range of 200 microns—3 mm, and more preferably in the range of 200-400 microns, while the radius of each of its blades is in the range of 10-50 microns, and more preferably in the range of 10-15 microns.

Owner:CORIUM INC

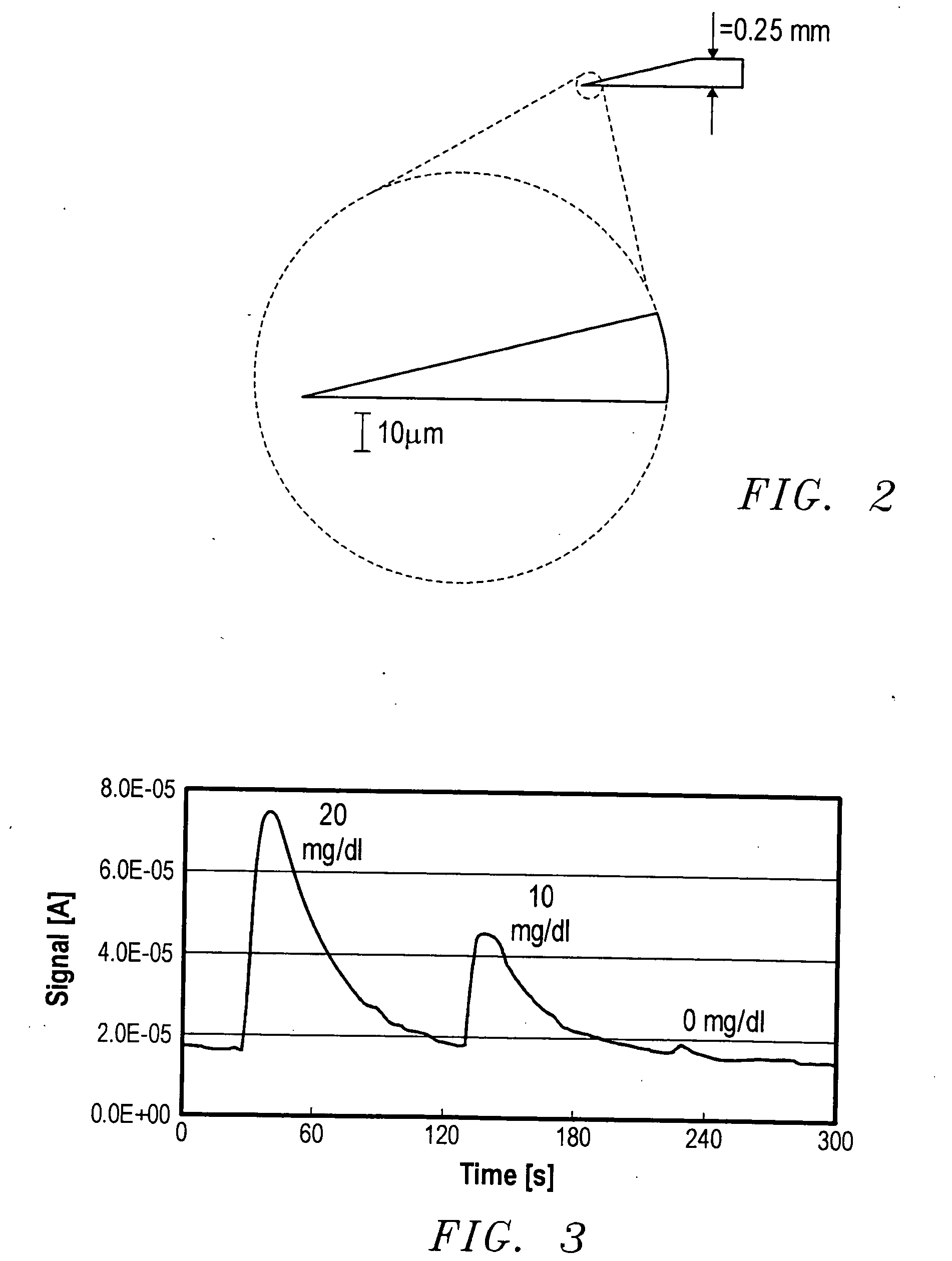

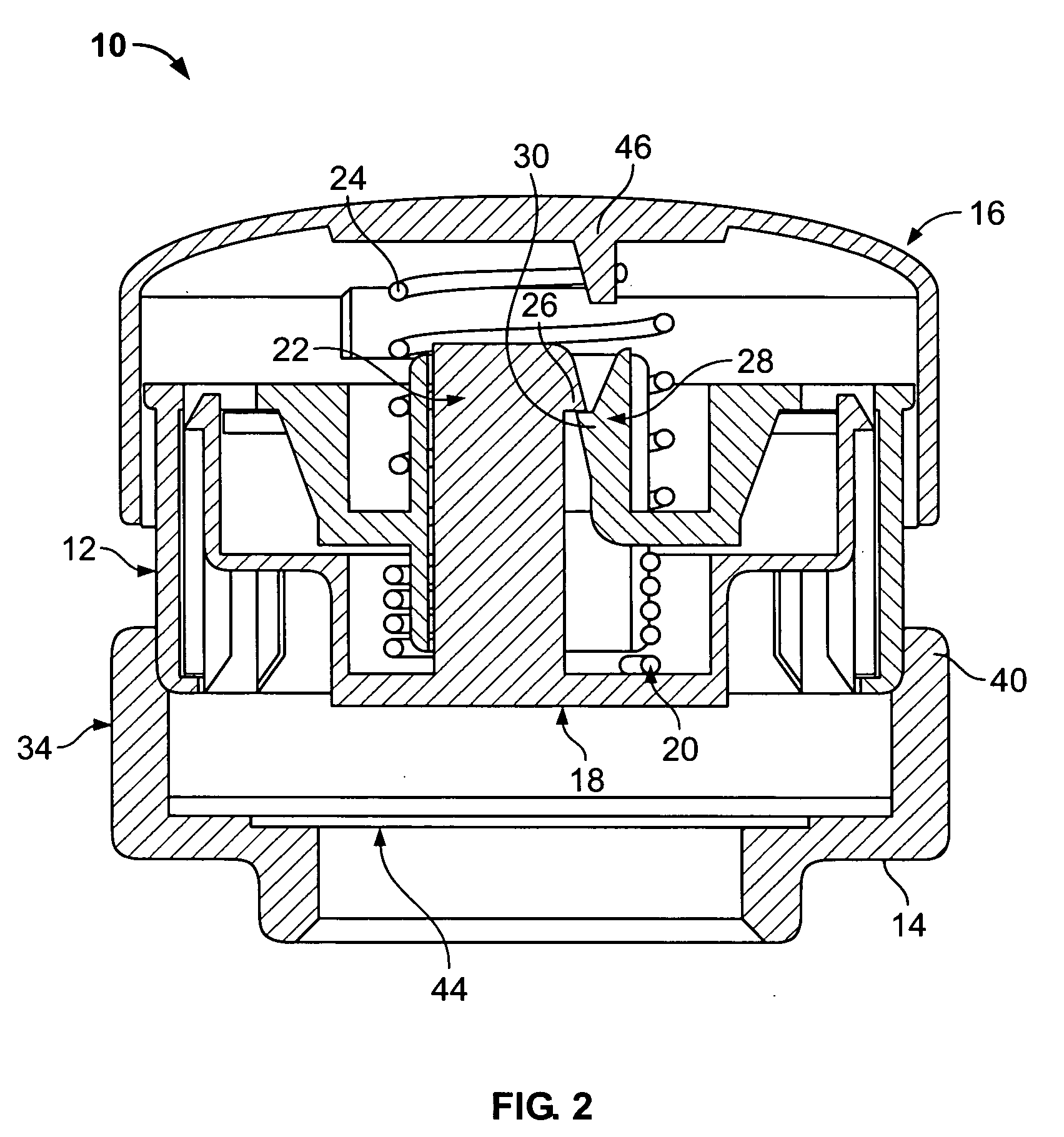

Interstitial fluid analyzer

A device useful for measuring an analyte in the interstitial fluid of an animal comprising an array chamber having an array of one or more microprojections and a detection compartment comprising a sensor in selective fluid communication with the array chamber. Also included are two extraction electrodes for inducing electrotransport of the interstitial fluid from the animal into the array chamber. A method includes the steps of forming a plurality of microchannels through a stratum corneum layer of an epidermis of the animal, inducing electrotransport of interstitial fluid containing the analyte through the microchannels and mixing one or more materials with the interstitial fluid to form a mixture, contacting the mixture with detection electrodes and analyzing the mixture with the detection electrodes.

Owner:LYNNTECH

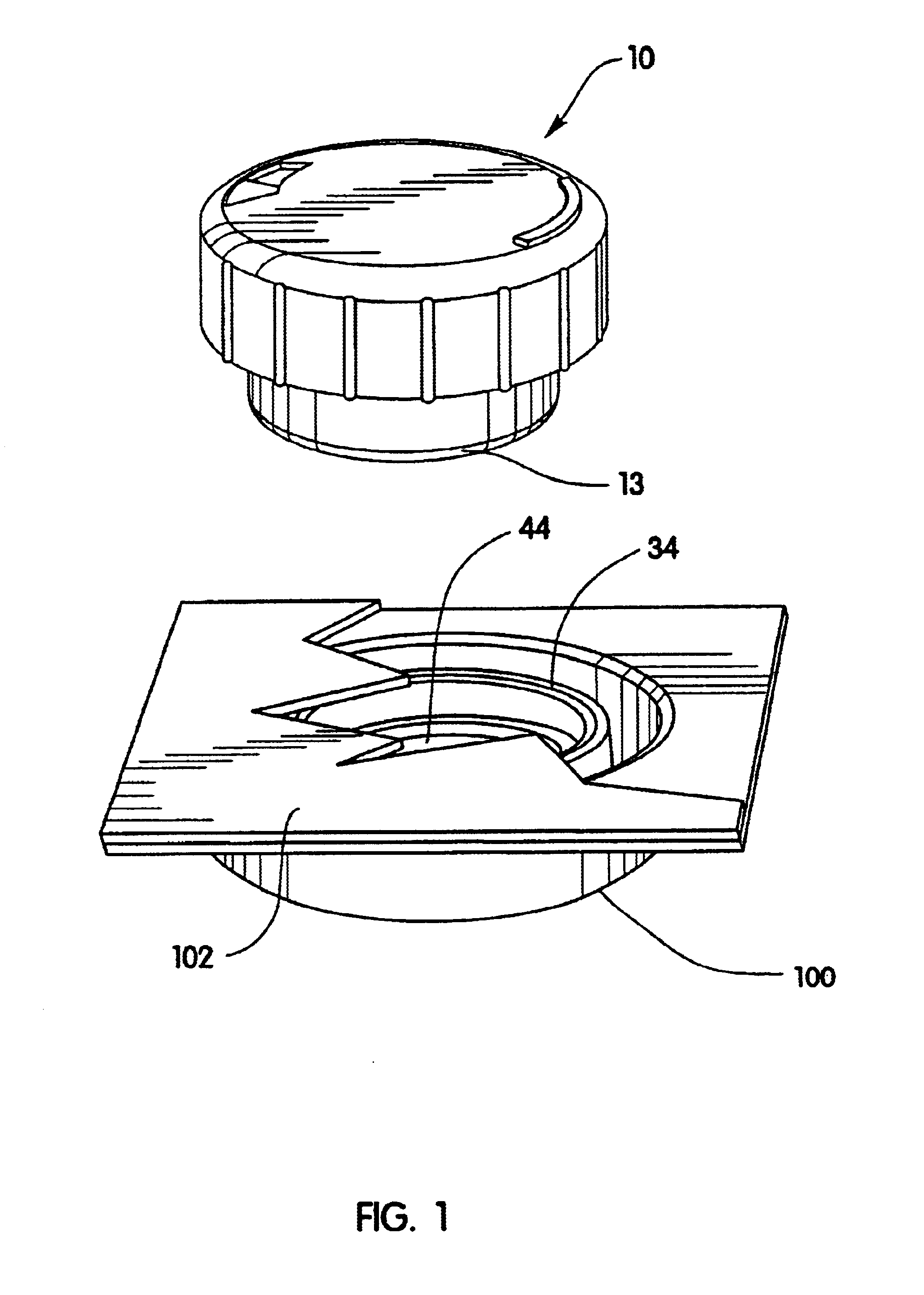

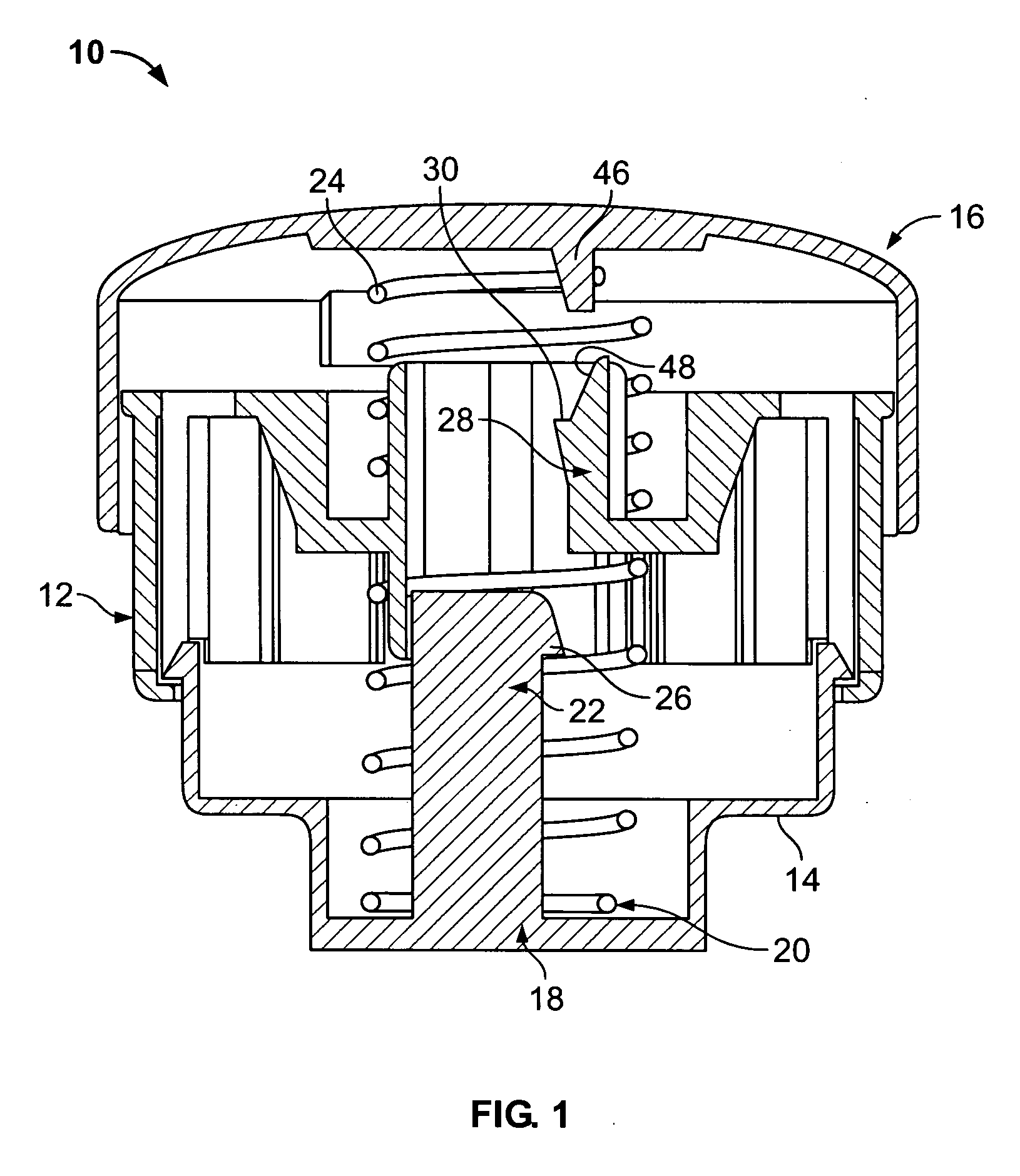

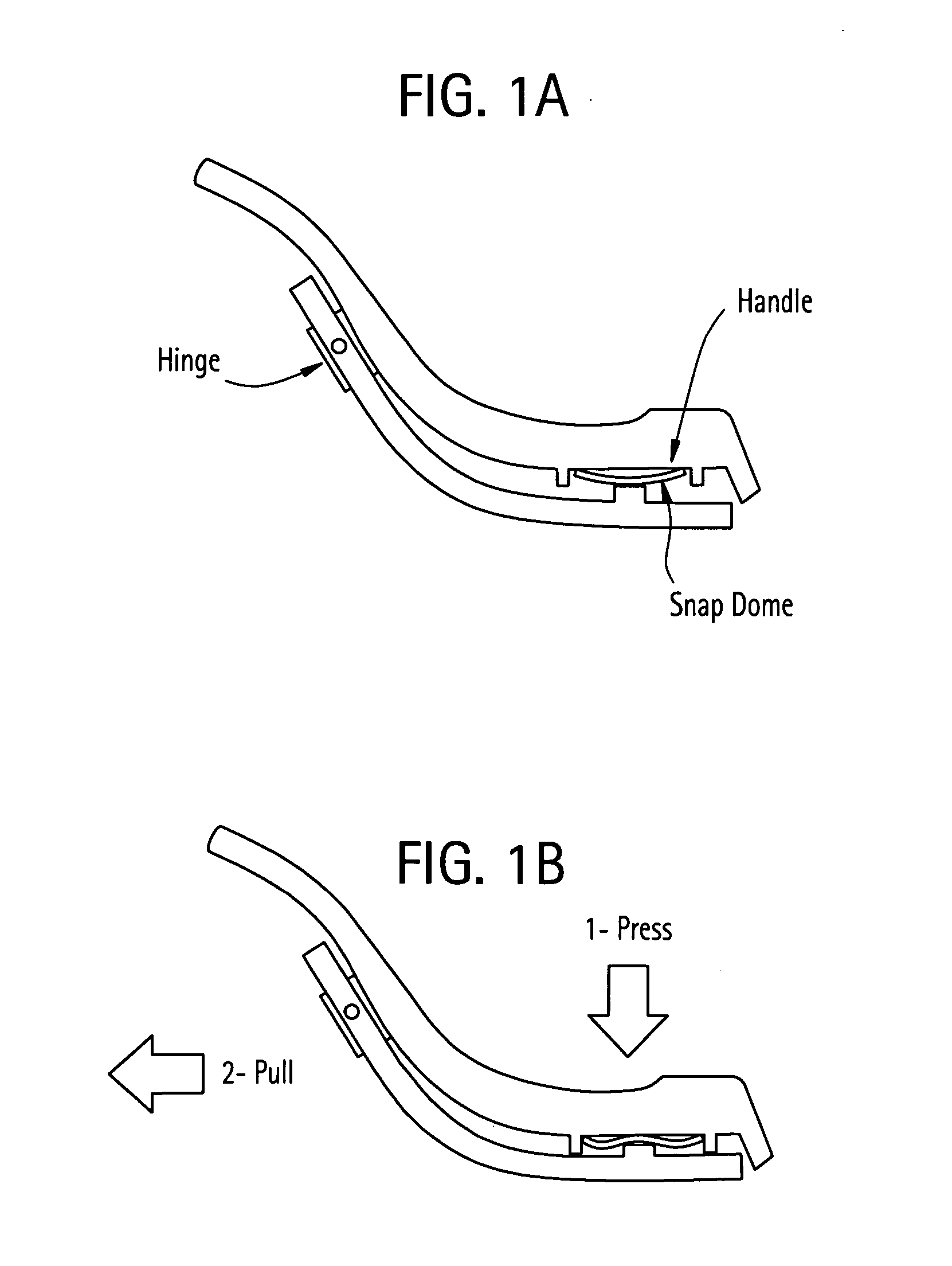

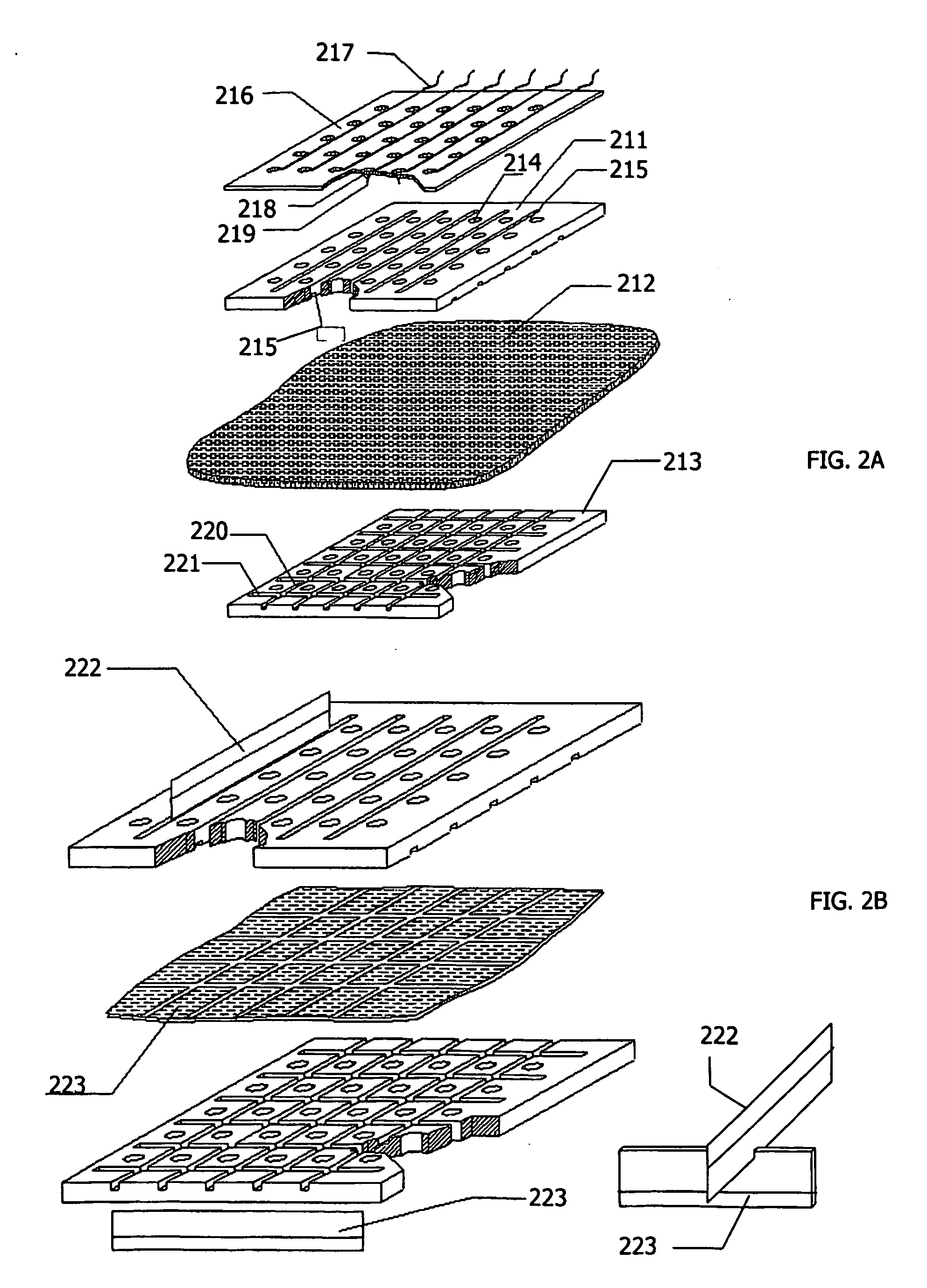

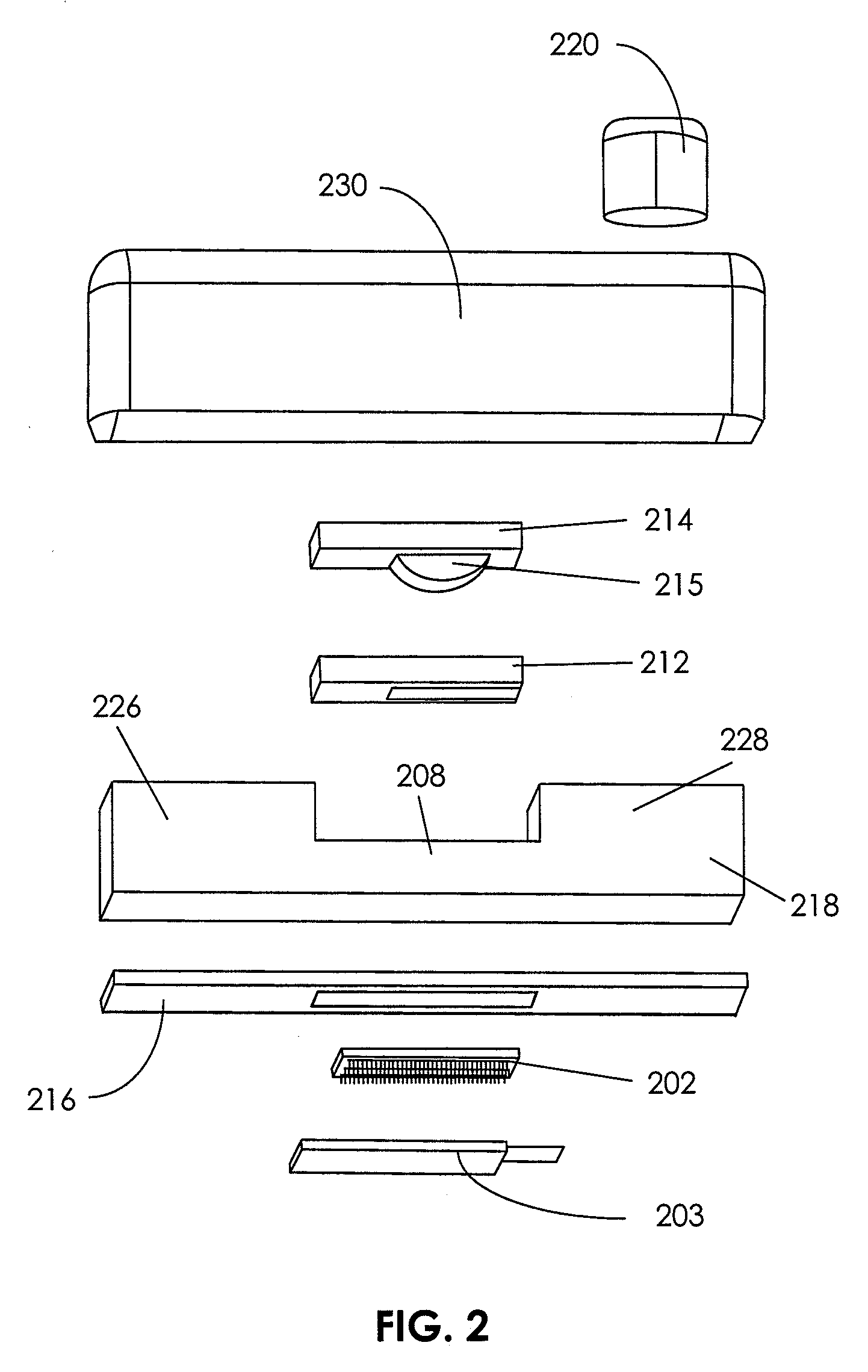

Self-actuating applicator for microprojection array

An applicator for applying a microprojection member to the stratum corneum of a patient having a housing, a piston moveable within the housing and a cap adapted to activate the applicator. The applicator is self-setting and auto-triggering, which allows the applicator to be used by patient's having neither the strength, nor the manual dexterity to pre-set and activate other types of applicator devices.

Owner:ALZA CORP

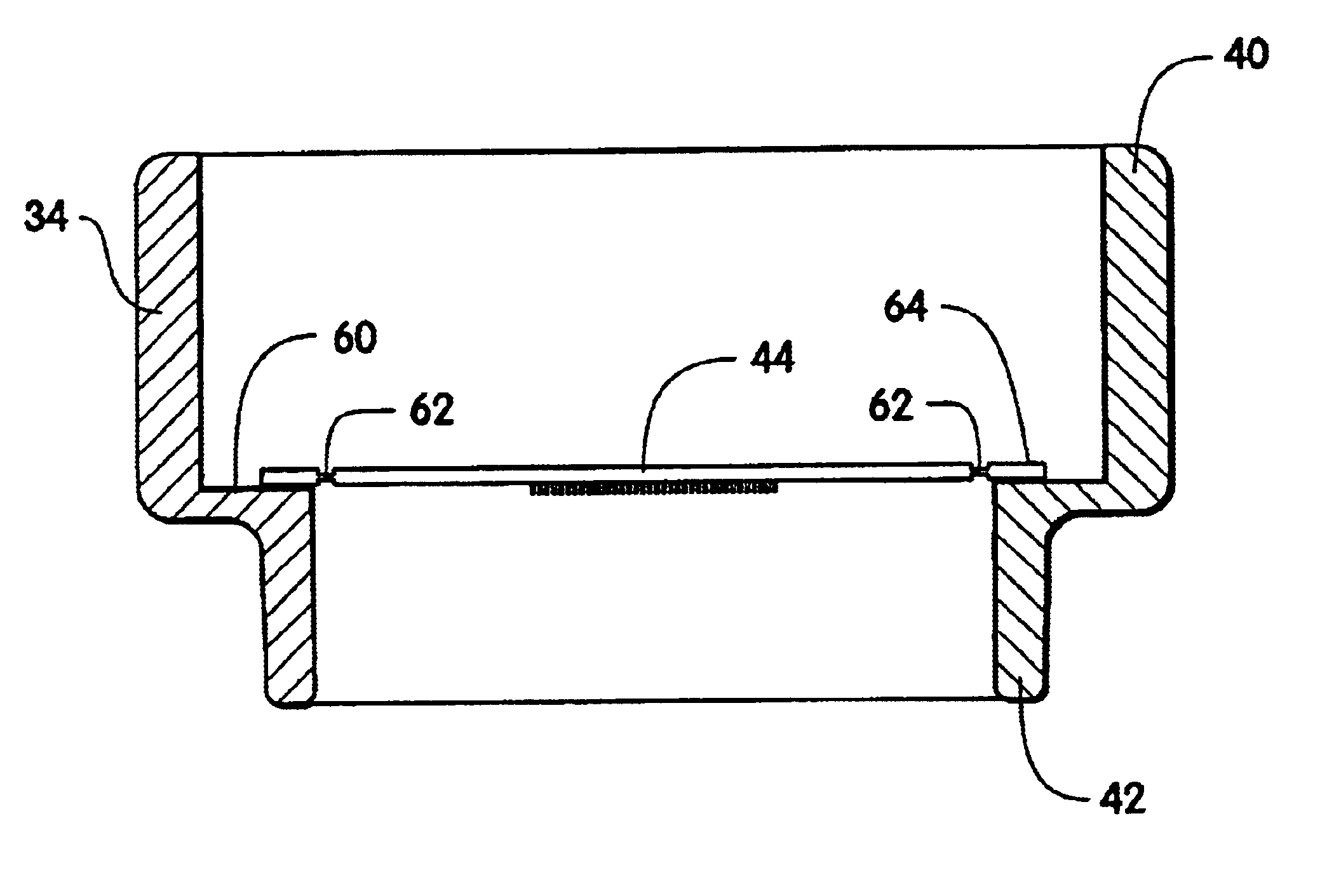

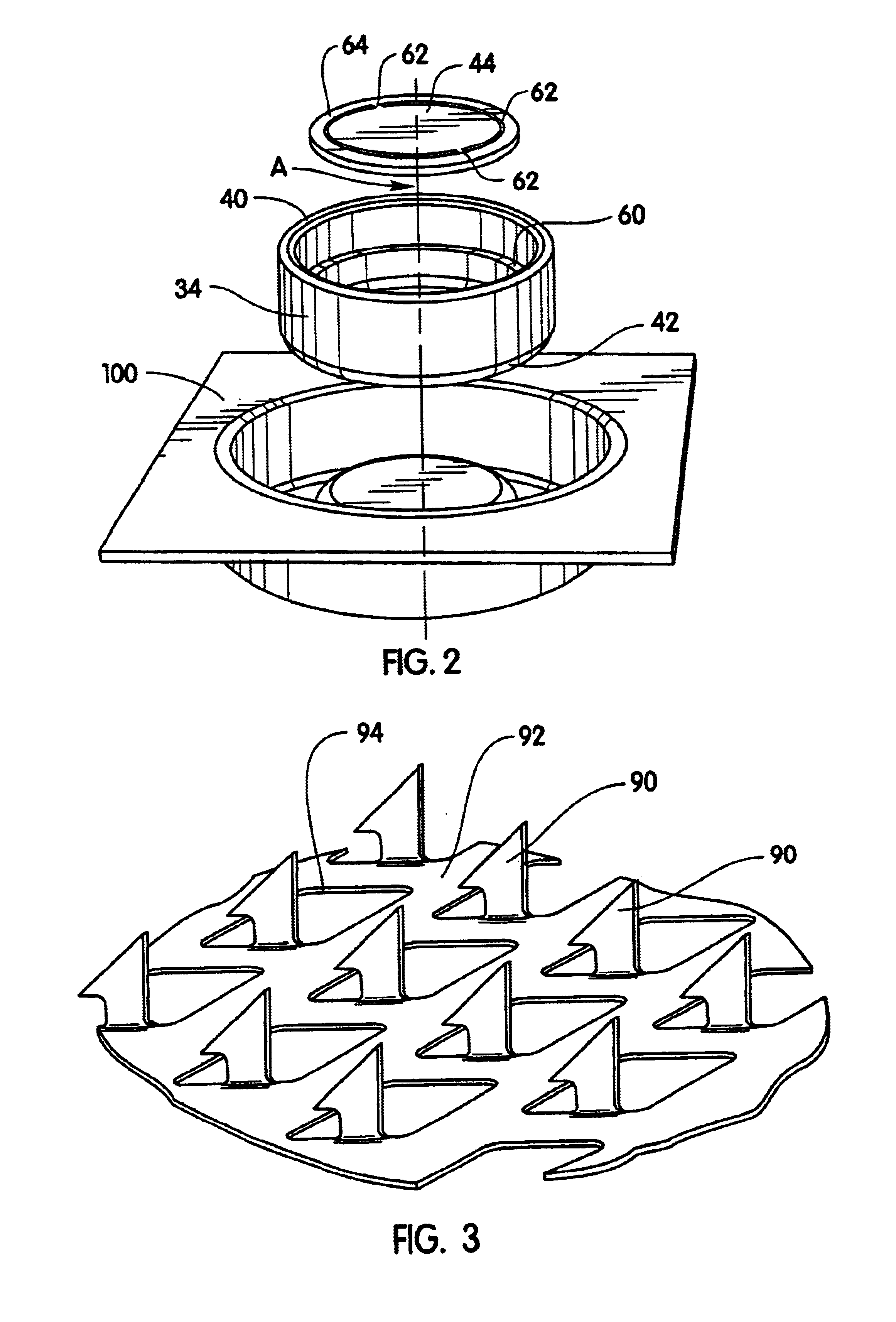

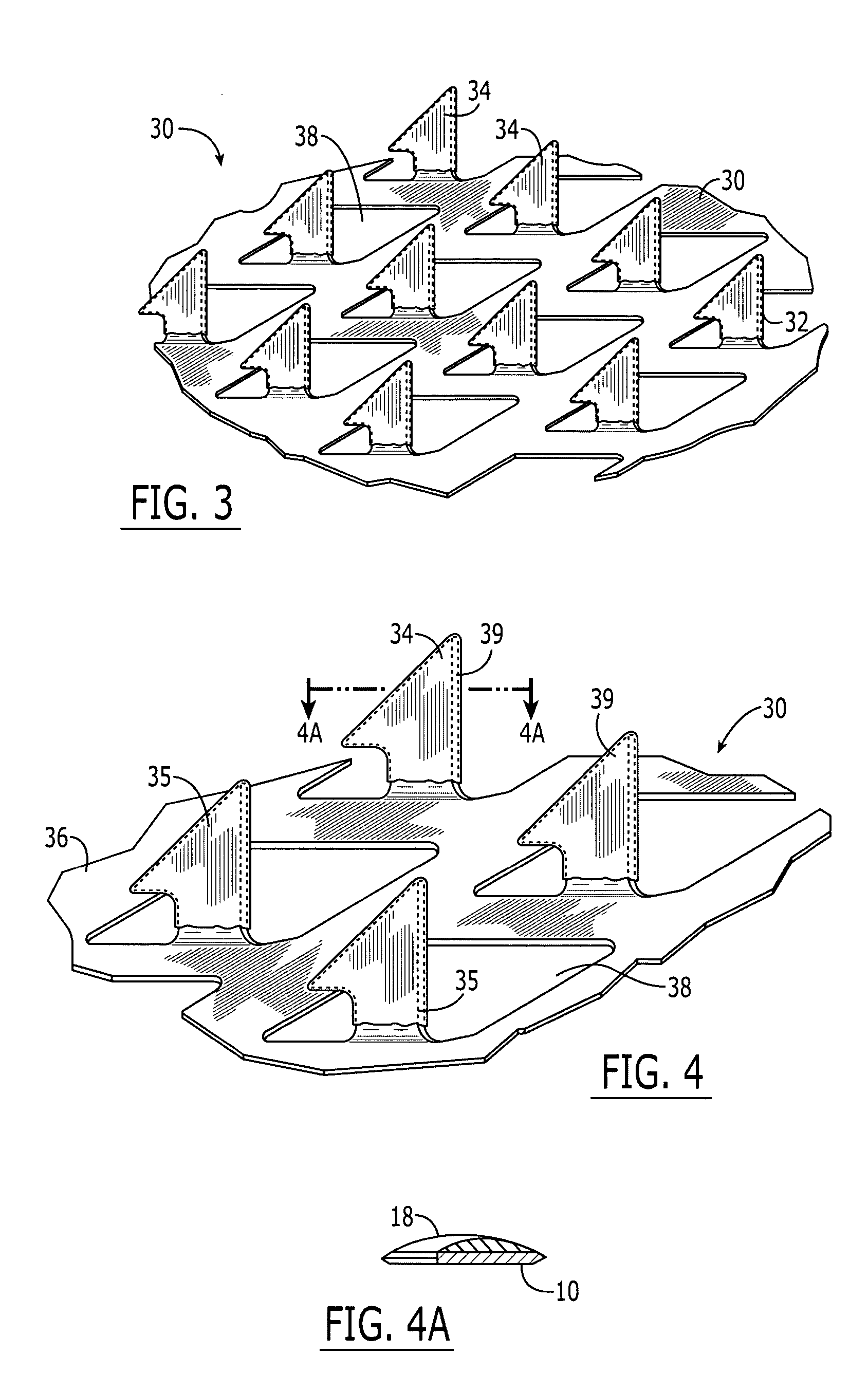

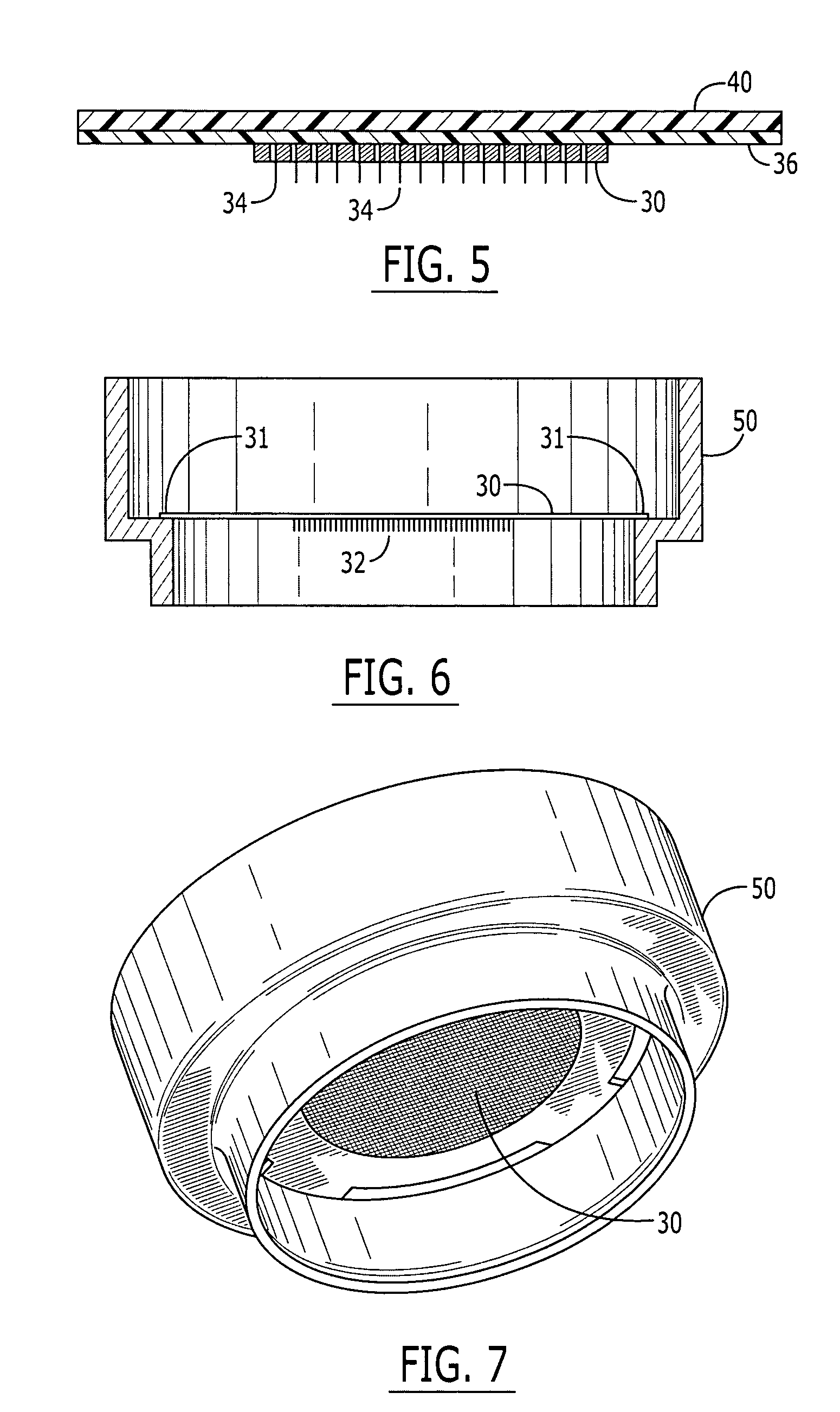

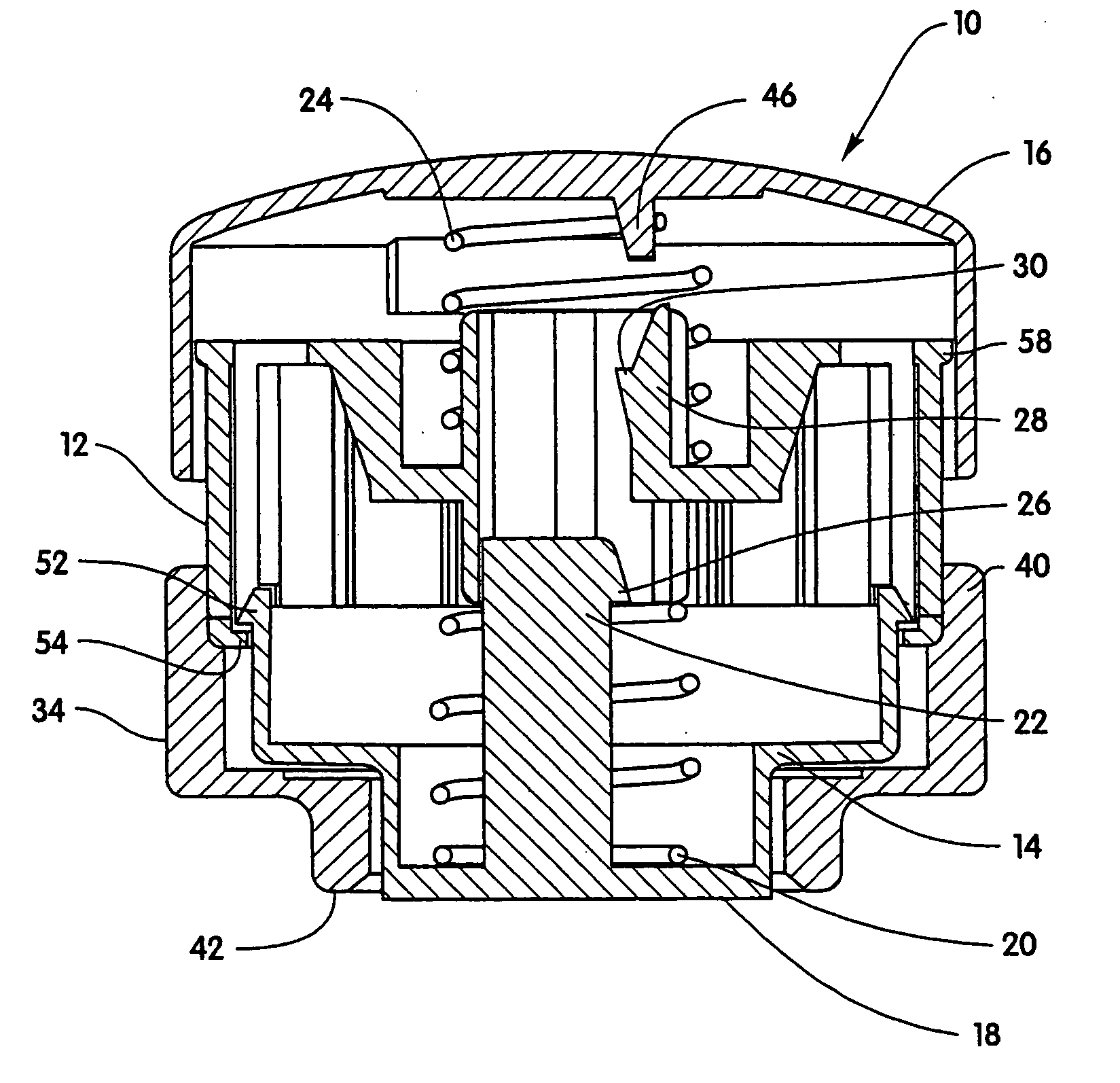

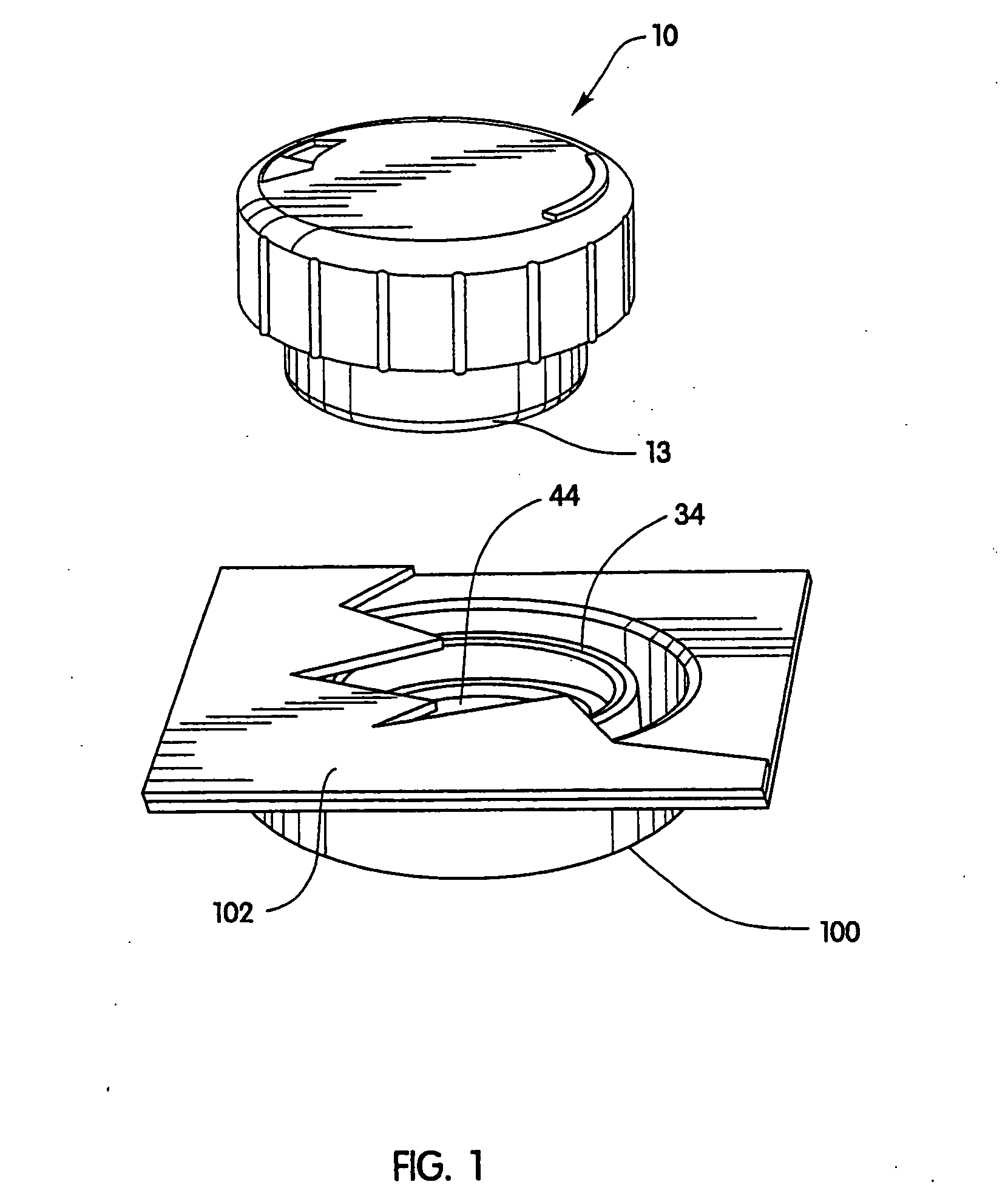

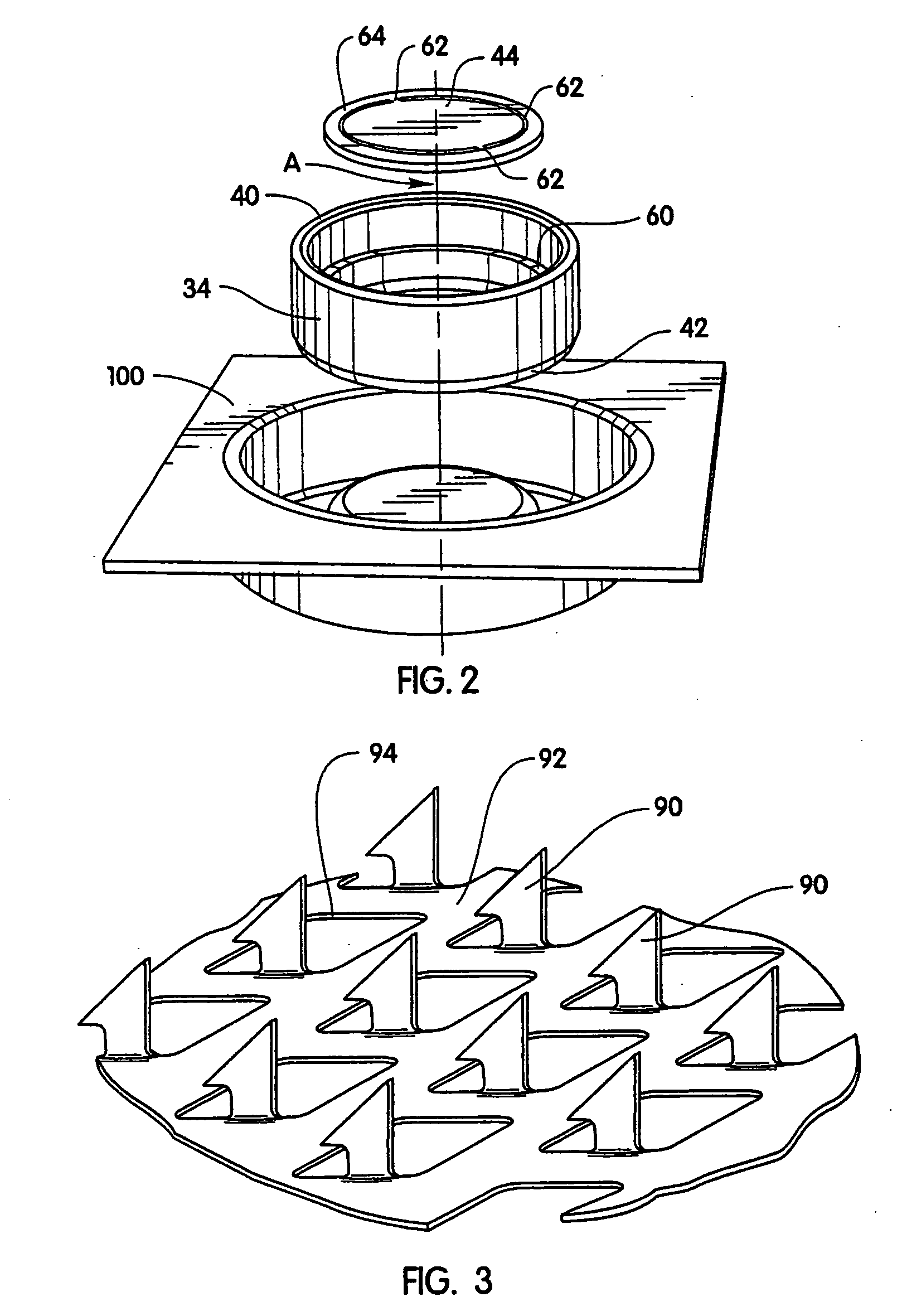

Microprotrusion member retainer for impact applicator

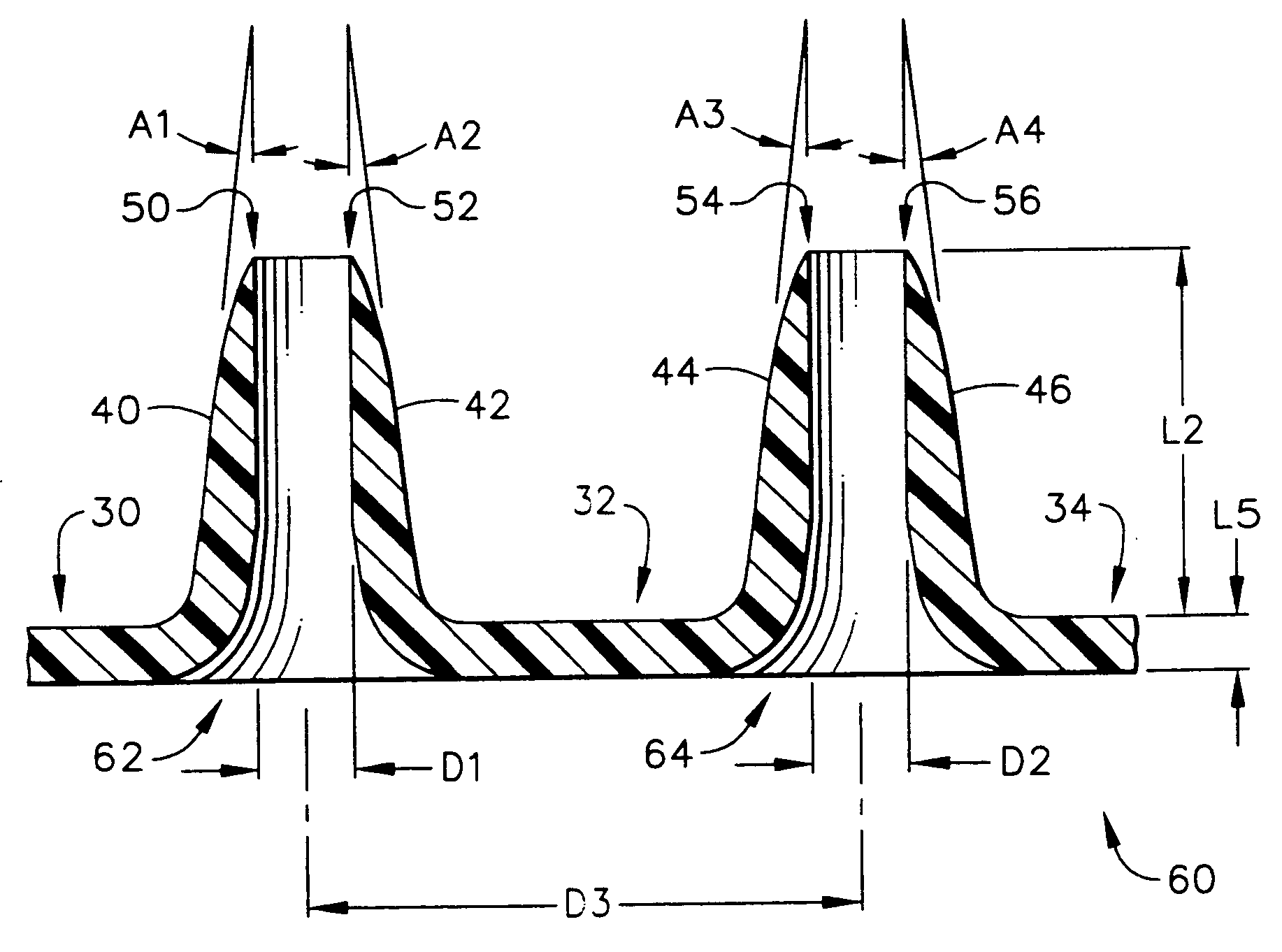

A retainer (34) is provided for holding a microprotrusion member (44) for application of the microprotrusion member (44) to the stratum corneum with an impact applicator (10). The microprotrusion member (44) includes a plurality of microprotrusions (90) which penetrate the stratum corneum to improve transport of an agent across the stratum corneum.

Owner:ALZA CORP

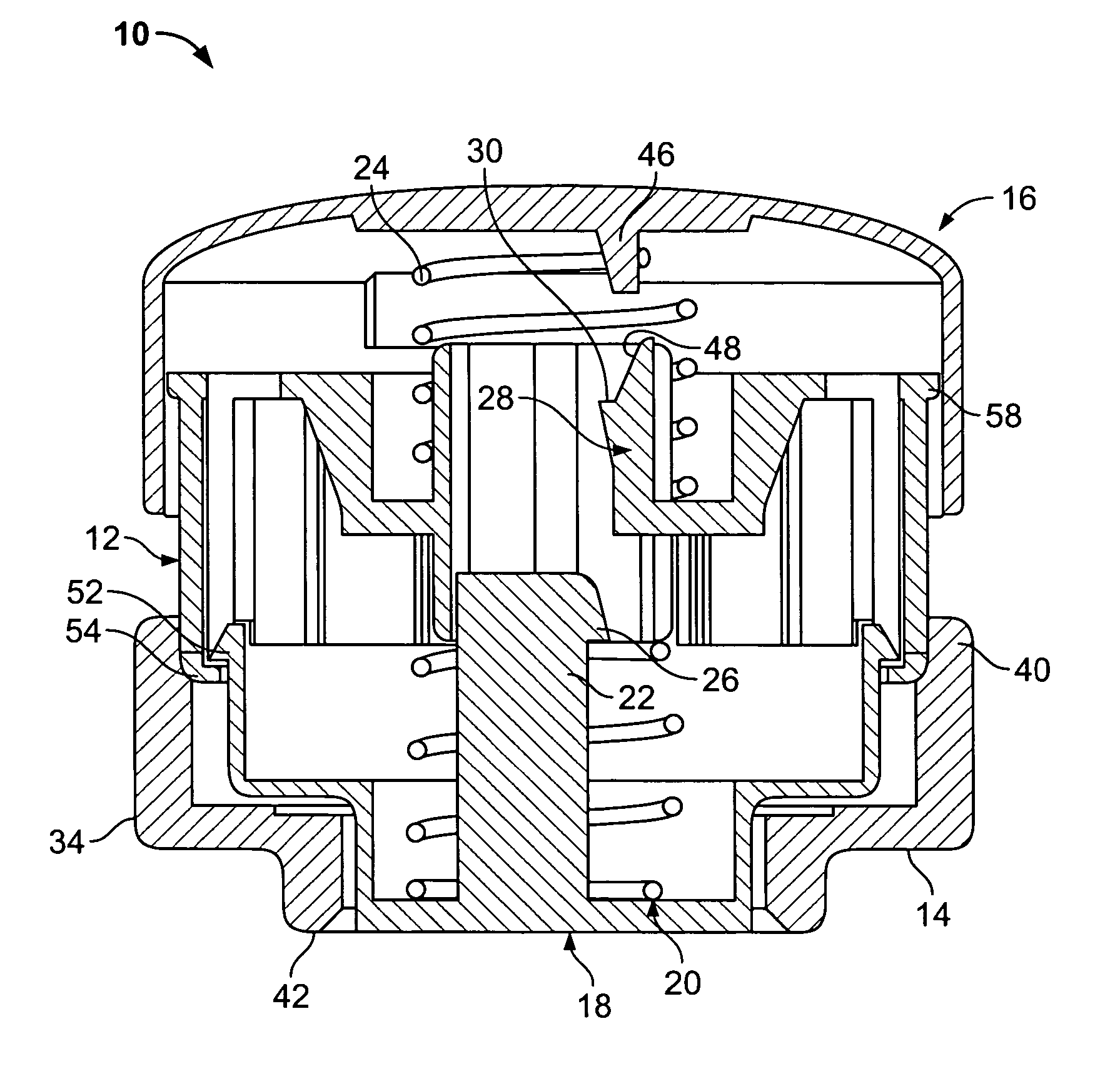

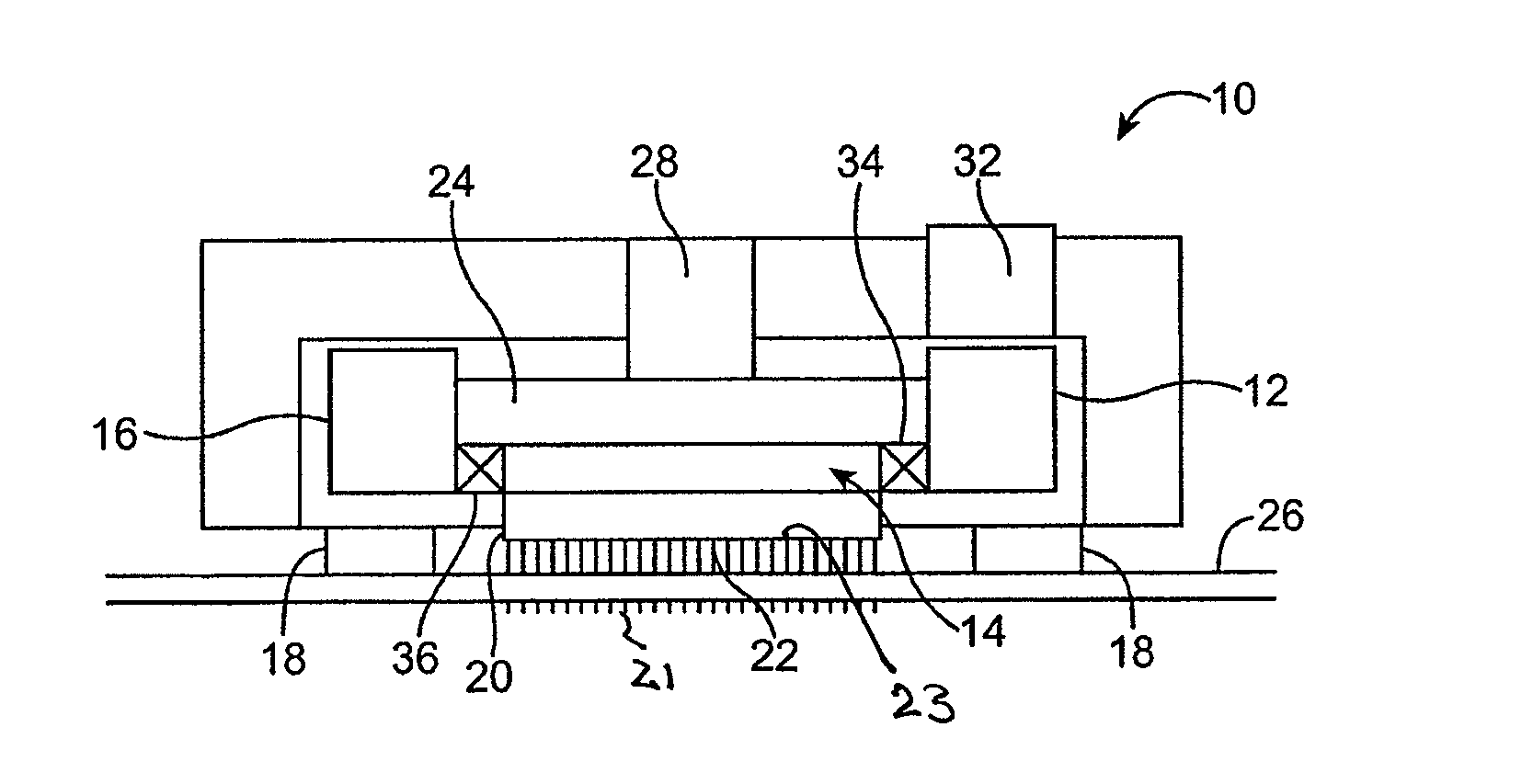

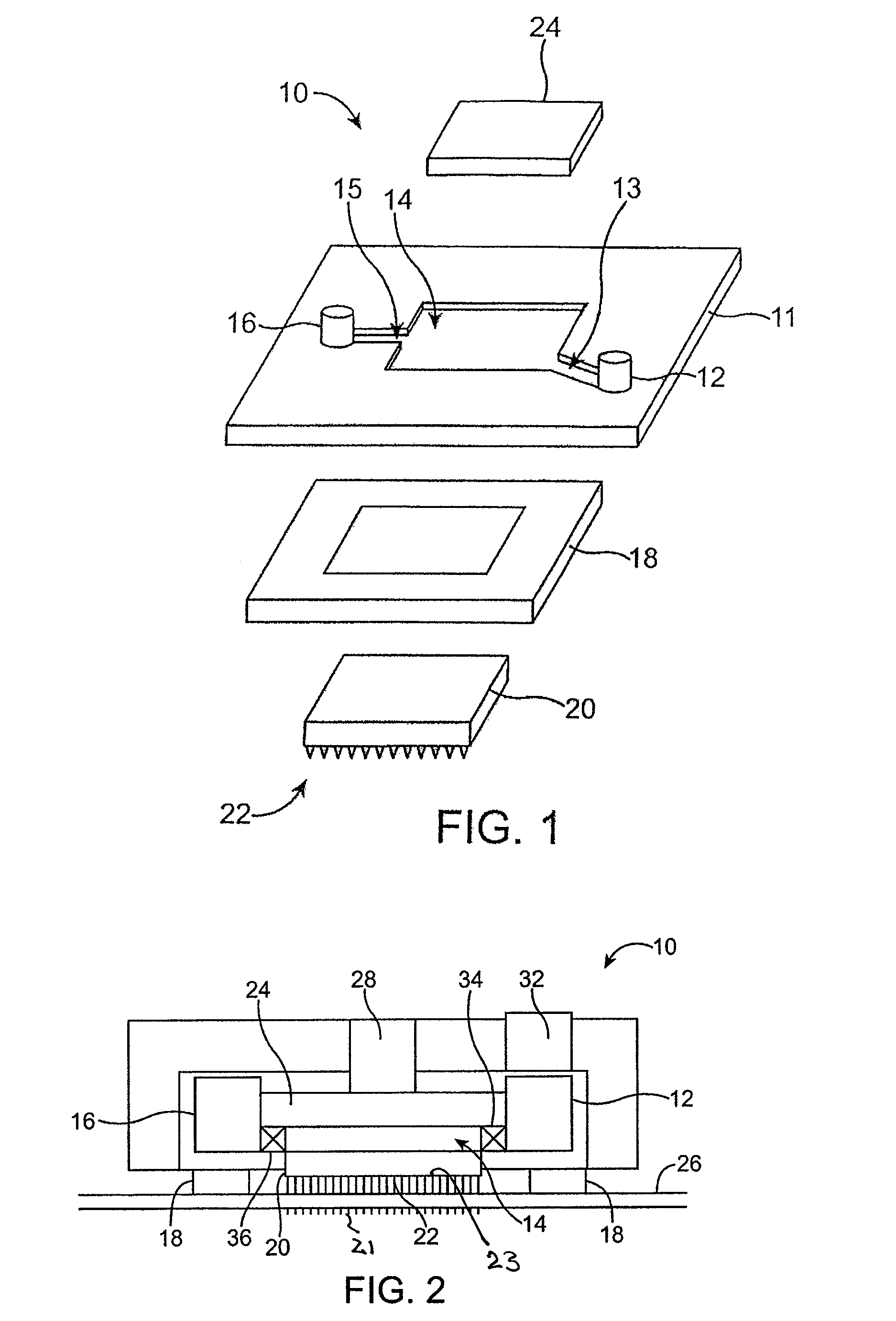

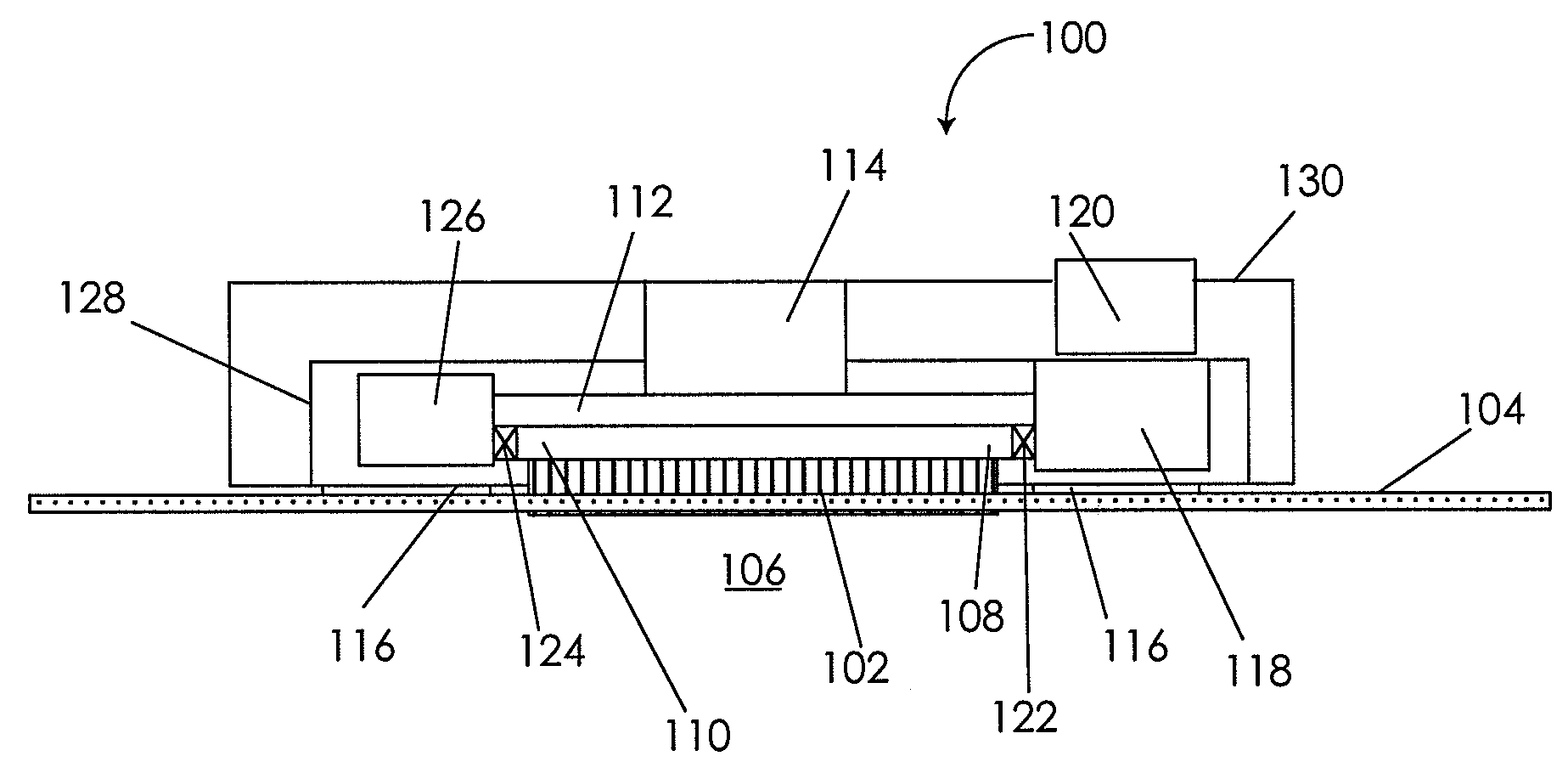

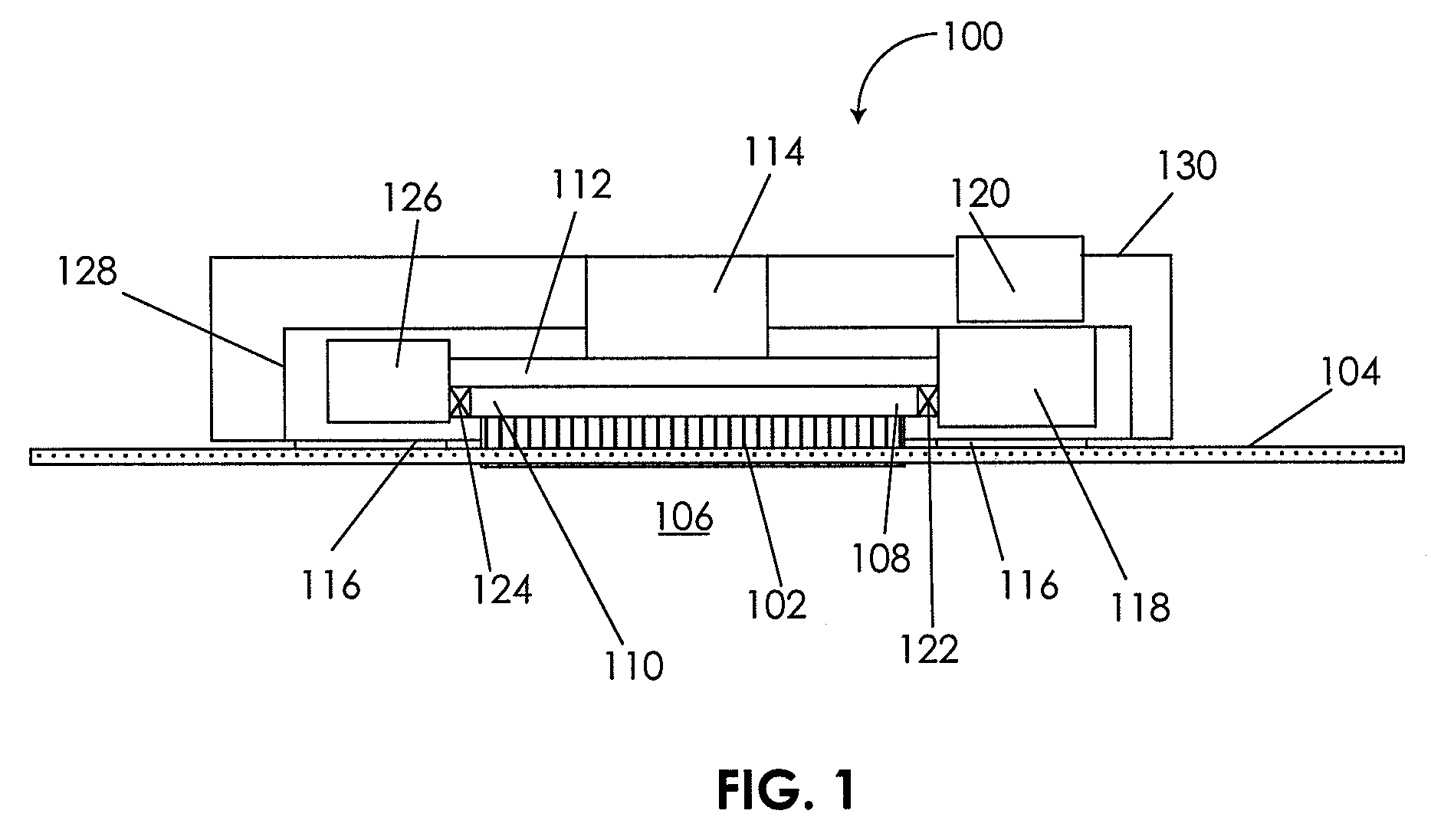

Microblade array impact applicator

ActiveUS20060095061A1Easy to transportMinimal strengthSurgical needlesMicroneedlesEngineeringBiomedical engineering

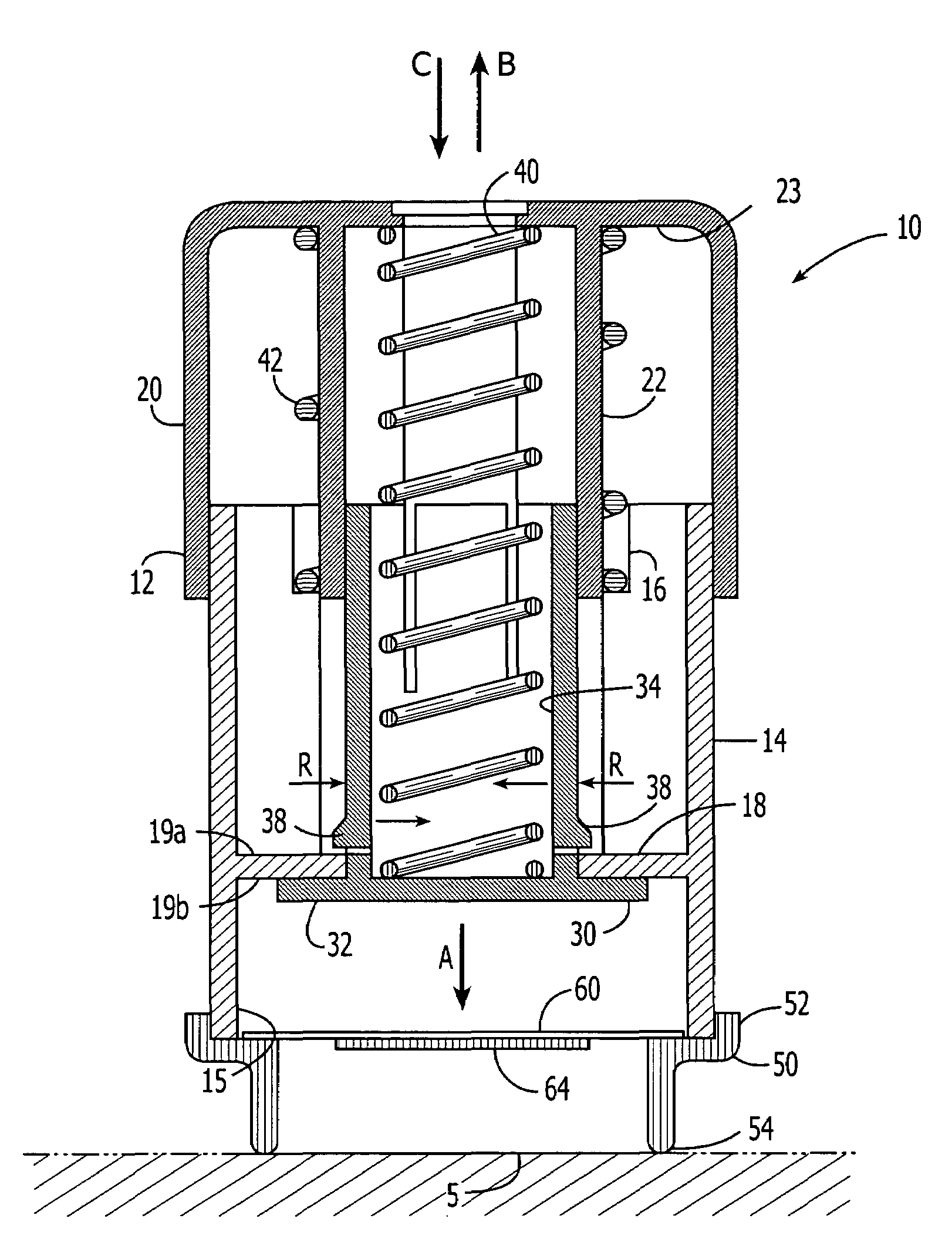

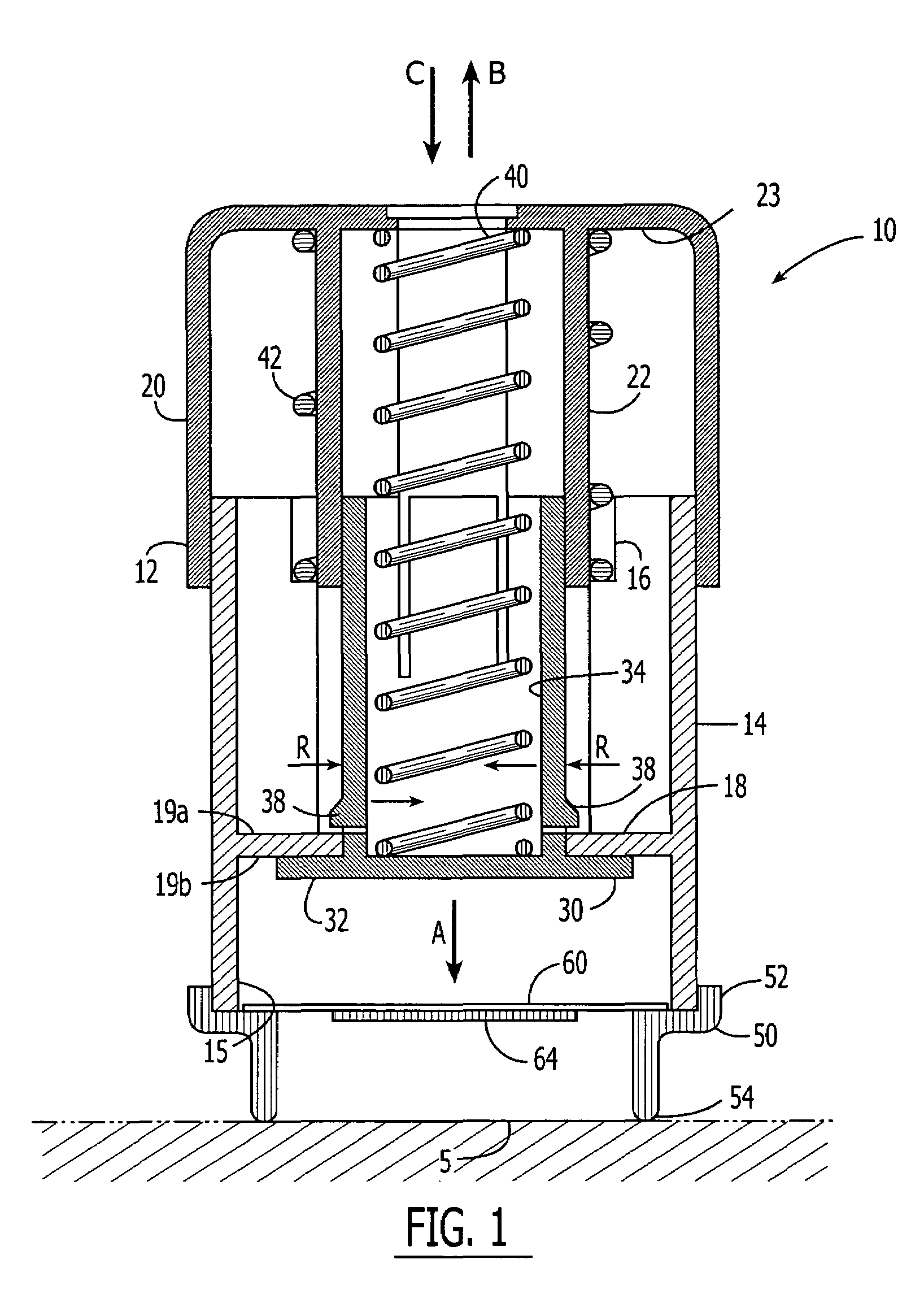

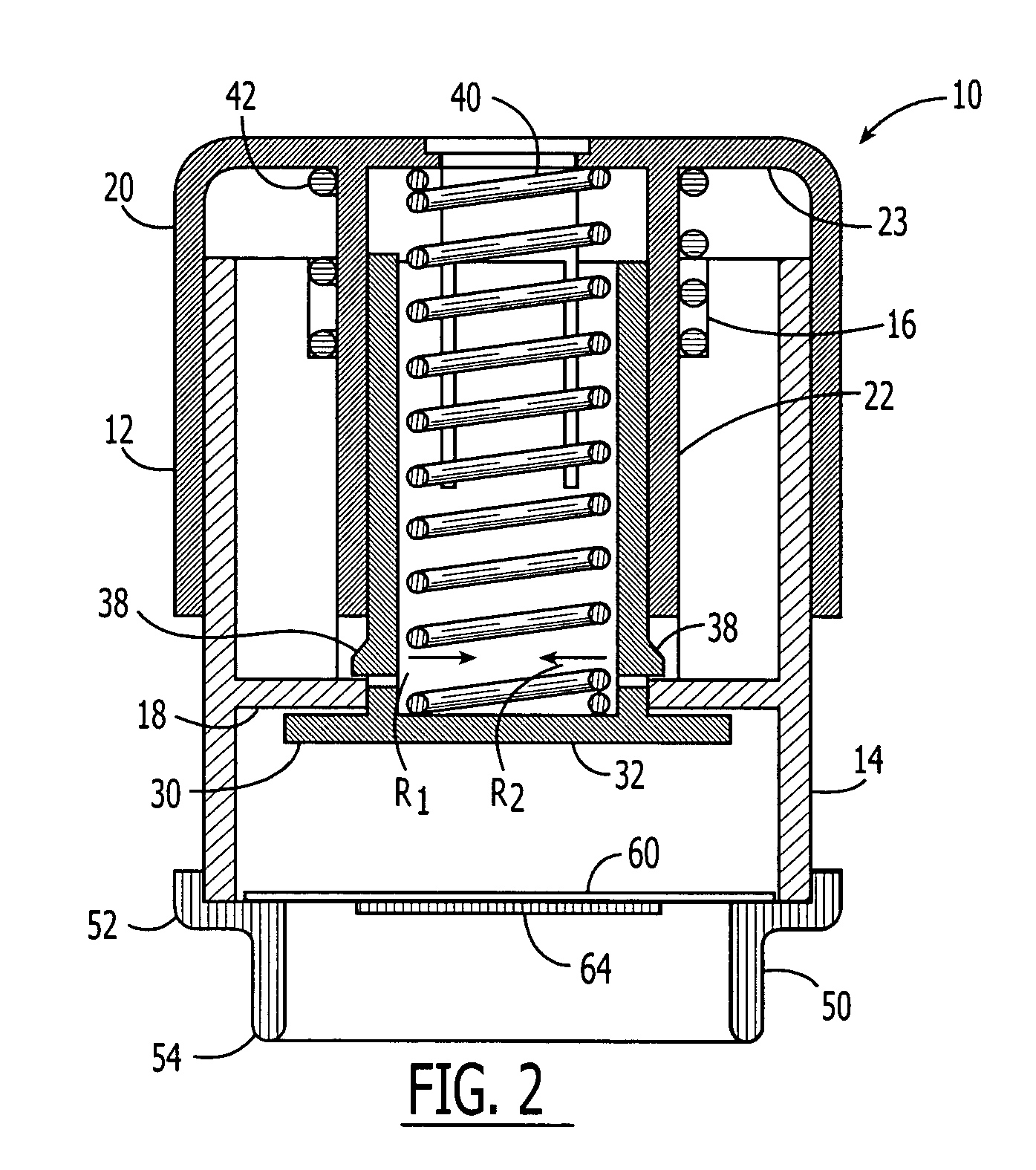

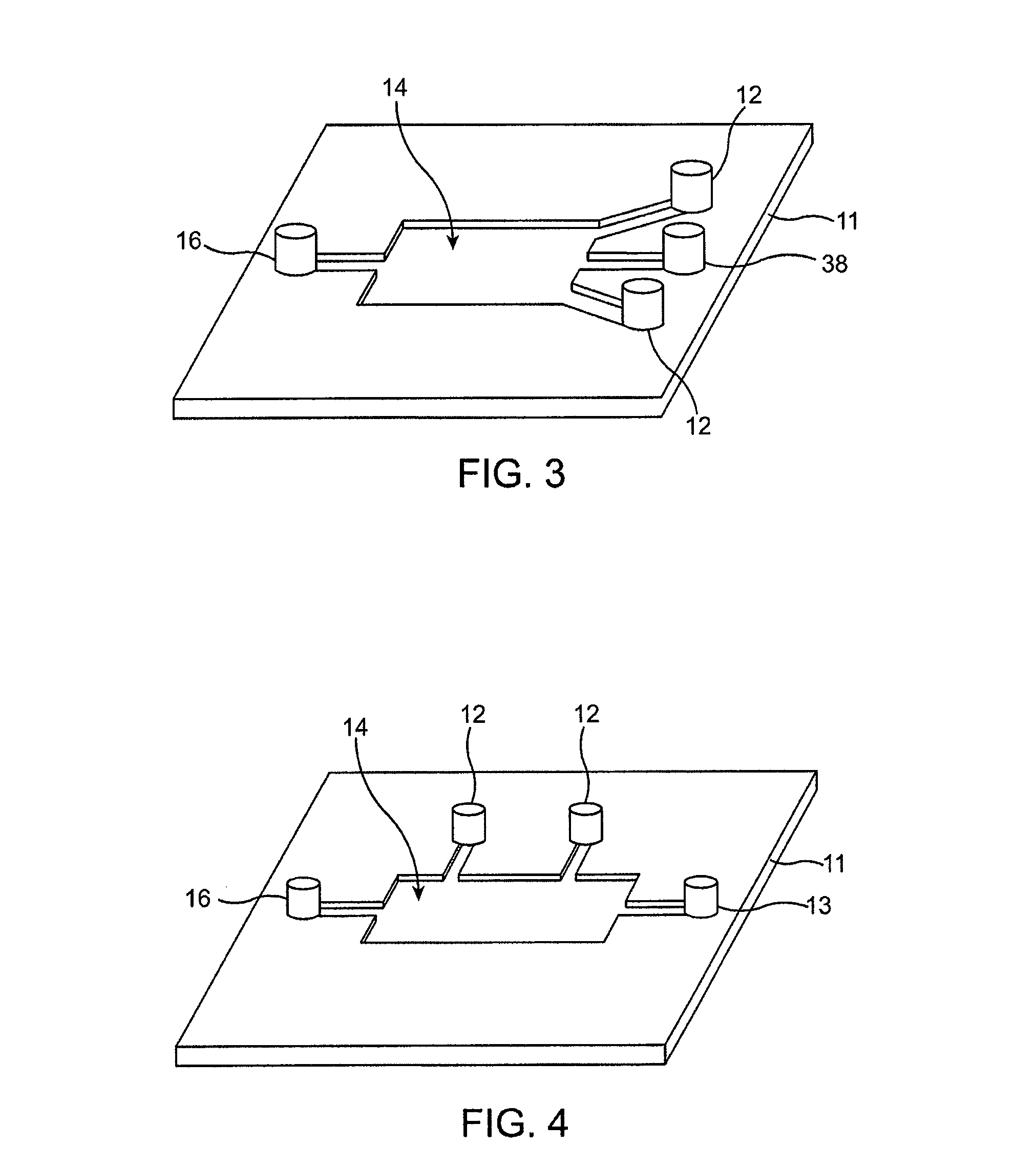

An applicator device (10) is provided for applying a patch (44) having an array of microprotrusions (90) to the stratum corneum. The applicator device (10) includes a device body (12) and a piston moveable within the device body (12). A cap (16) is provided on the device body (12) for activating the device (10) to impact the stratum corneum with a microprotrusion array (44,90). The device (10) is capable of being cocked by one handed operation of the user which allows the device (10) to be used by patients having neither the strength nor the manual dexterity to cock other types of applicator devices.

Owner:ALZA CORP

Ultrasound assisted transdermal vaccine delivery method and system

InactiveUS20050112135A1Adequate buffering capacityHigh viscosityViral antigen ingredientsSurgeryVaccine deliveryBiocompatible coating

An apparatus and method for transdermally delivering a vaccine comprising a delivery system having (i) a microprojection member (or system) that includes a plurality of microprojections (or array thereof) that are adapted to pierce through the stratum corneum into the underlying epidermis layer, or epidermis and dermis layers and (ii) an ultrasonic device. In one embodiment, the vaccine is contained in a biocompatible coating that is applied to the microprojection member. In a further embodiment, the delivery system includes a gel pack having a vaccine-containing hydrogel formulation that is disposed on the microprojection member after application to the skin of a patient. In an alternative embodiment, the vaccine is contained in both the coating and the hydrogel formulation.

Owner:ALZA CORP

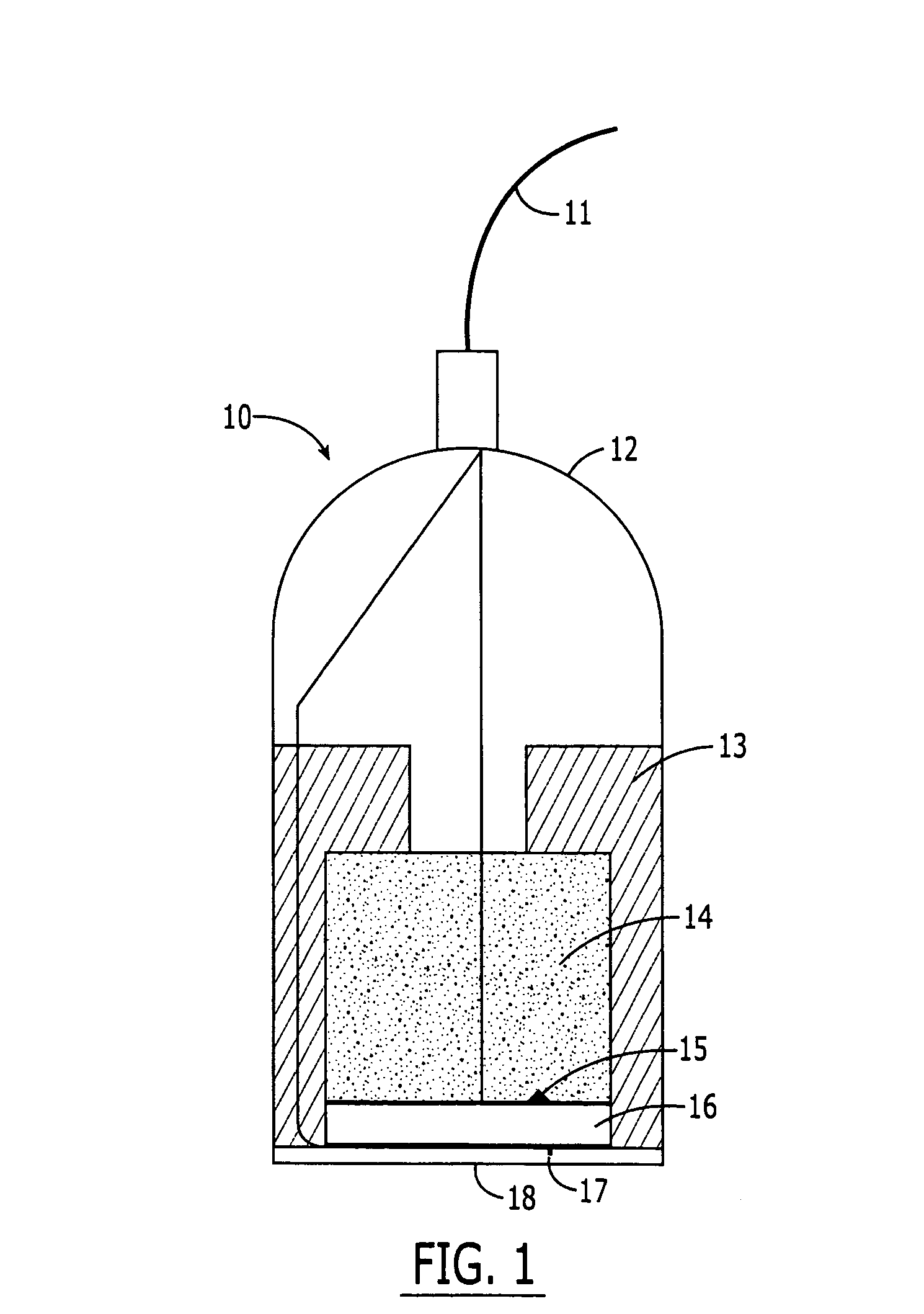

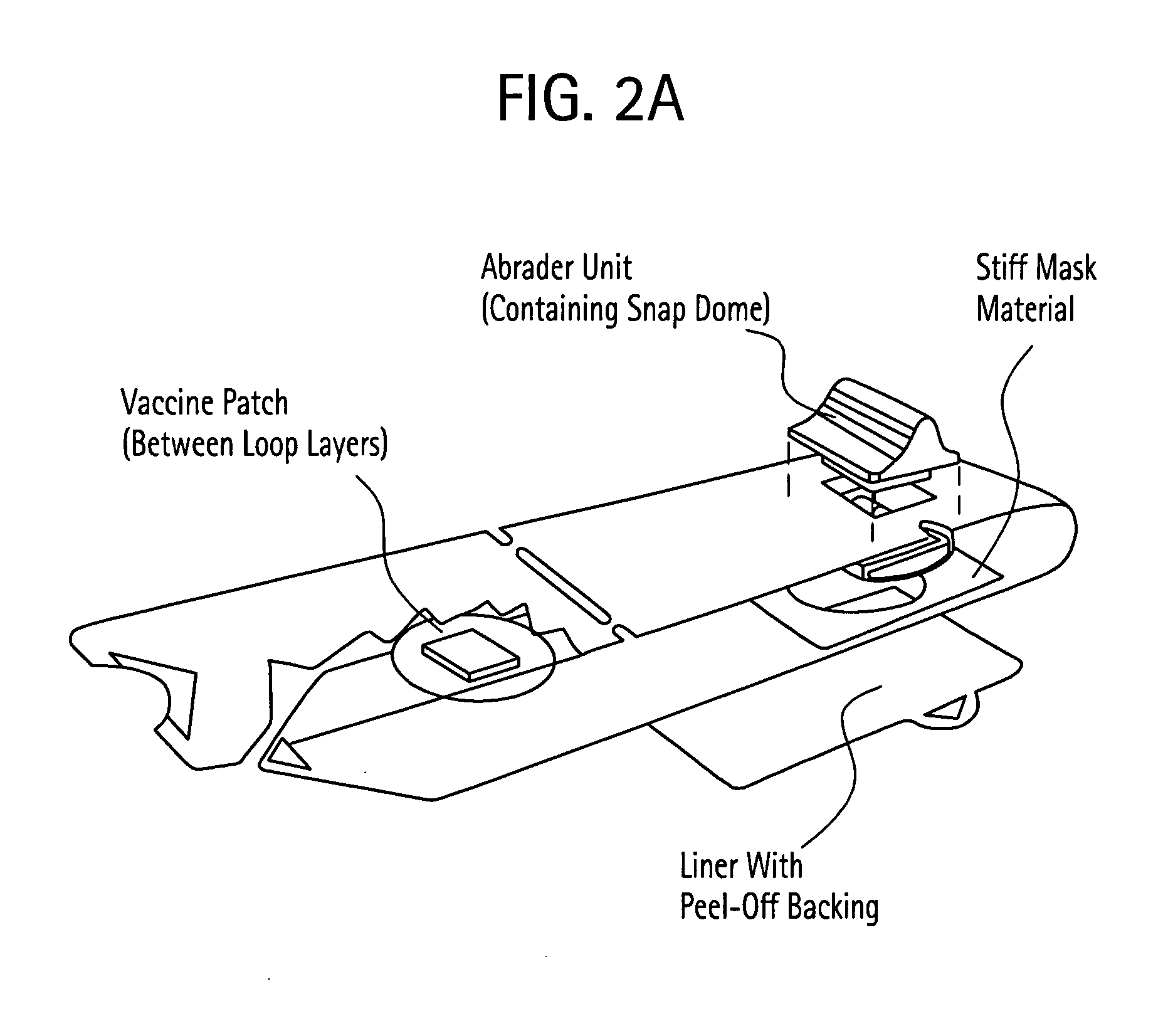

Devices for transcutaneous delivery of vaccines and transdermal delivery of drugs and uses thereof

The invention provides devices for the disruption of one or more layers of skin and methods of their use to administer therapeutic agents, e.g., antigens or drugs. The devices are designed to disrupt a defined area of skin. The defined area can approximate the area that a patch or other suitable vehicle for therapeutic agent, e.g., drug or vaccine, delivery is designed to contact. Exemplary devices employ a mask to define the area to be disrupted. Other devices disrupt a defined area by rotating in place. For devices that employ a mask that is secured to the skin, the invention provides methods of disrupting the stratum corneum by first securing the mask to the skin and then disrupting the skin. For rotating devices, the disrupting member is simply placed against the skin and actuated to effect disruption.

Owner:INTERCELL USA

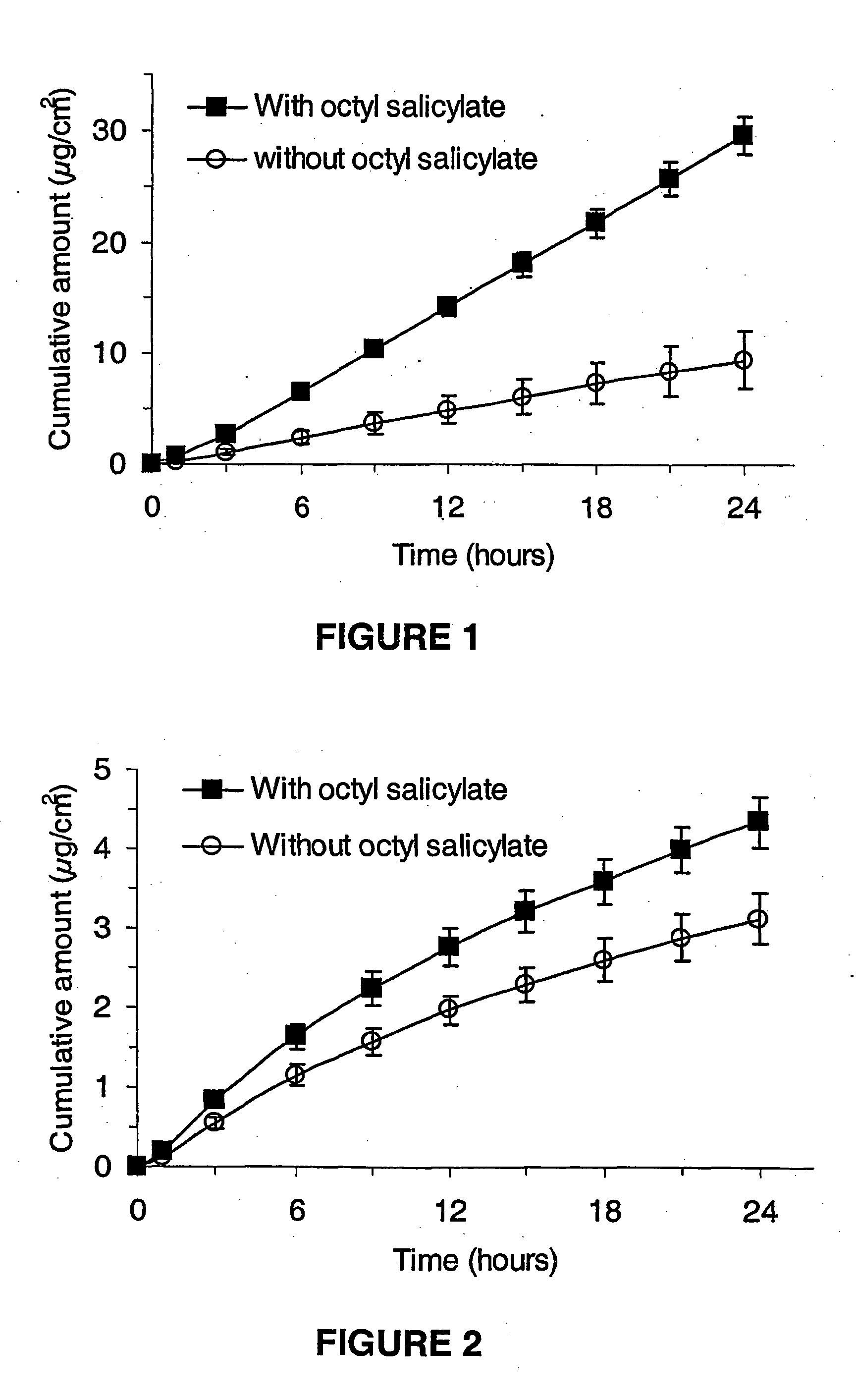

Apparatus and method for enhancing transdermal drug delivery

Owner:ALZA CORP

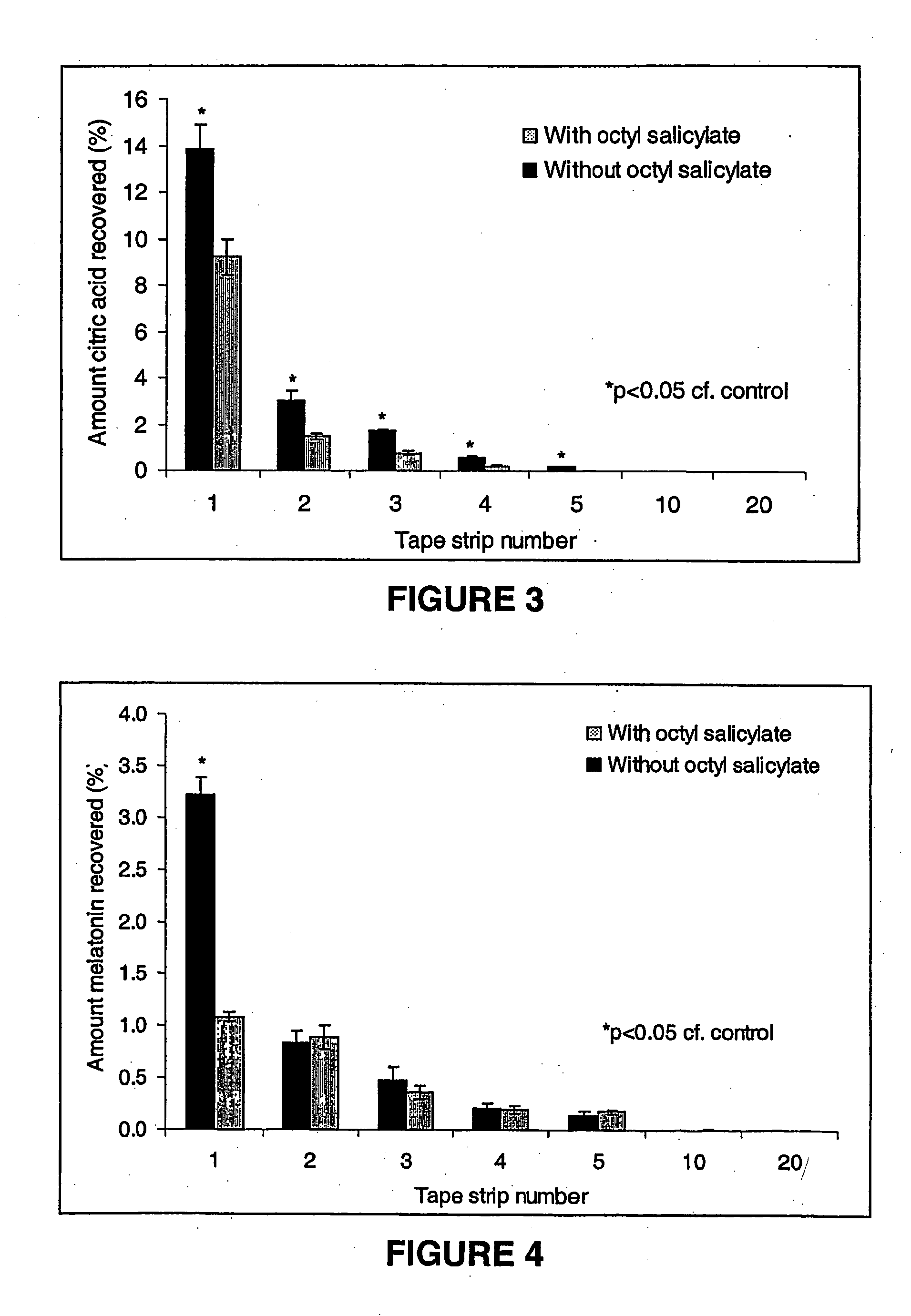

Topical cosmetic compositions

InactiveUS20050271692A1Improve skinDiminishing, reducing or preventing the effects of one or more of the skin conditionsCosmetic preparationsHair cosmeticsWater solubleDermatology

A topical cosmetic composition including: at least one water-soluble cosmetic agent; at least one oil-soluble cosmetic agent; and a dermal penetration enhancer, wherein topical application of the composition results in the delivery of the water-soluble and oil-soluble cosmetic agents into the stratum corneum as well as delivery of the oil-soluble cosmetic agent into the epidermis and dermis.

Owner:COSMECEUTIC SOLUTIONS

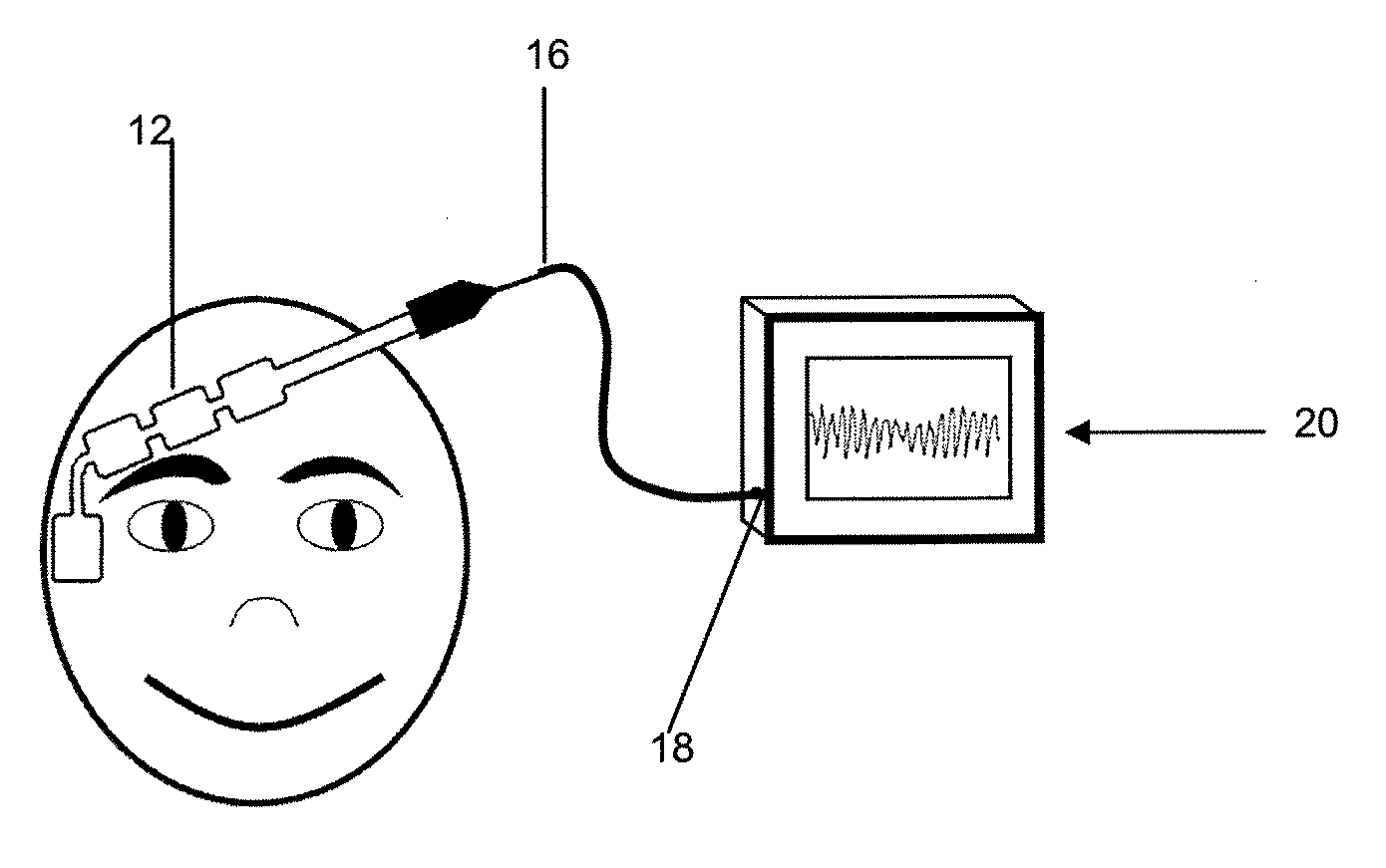

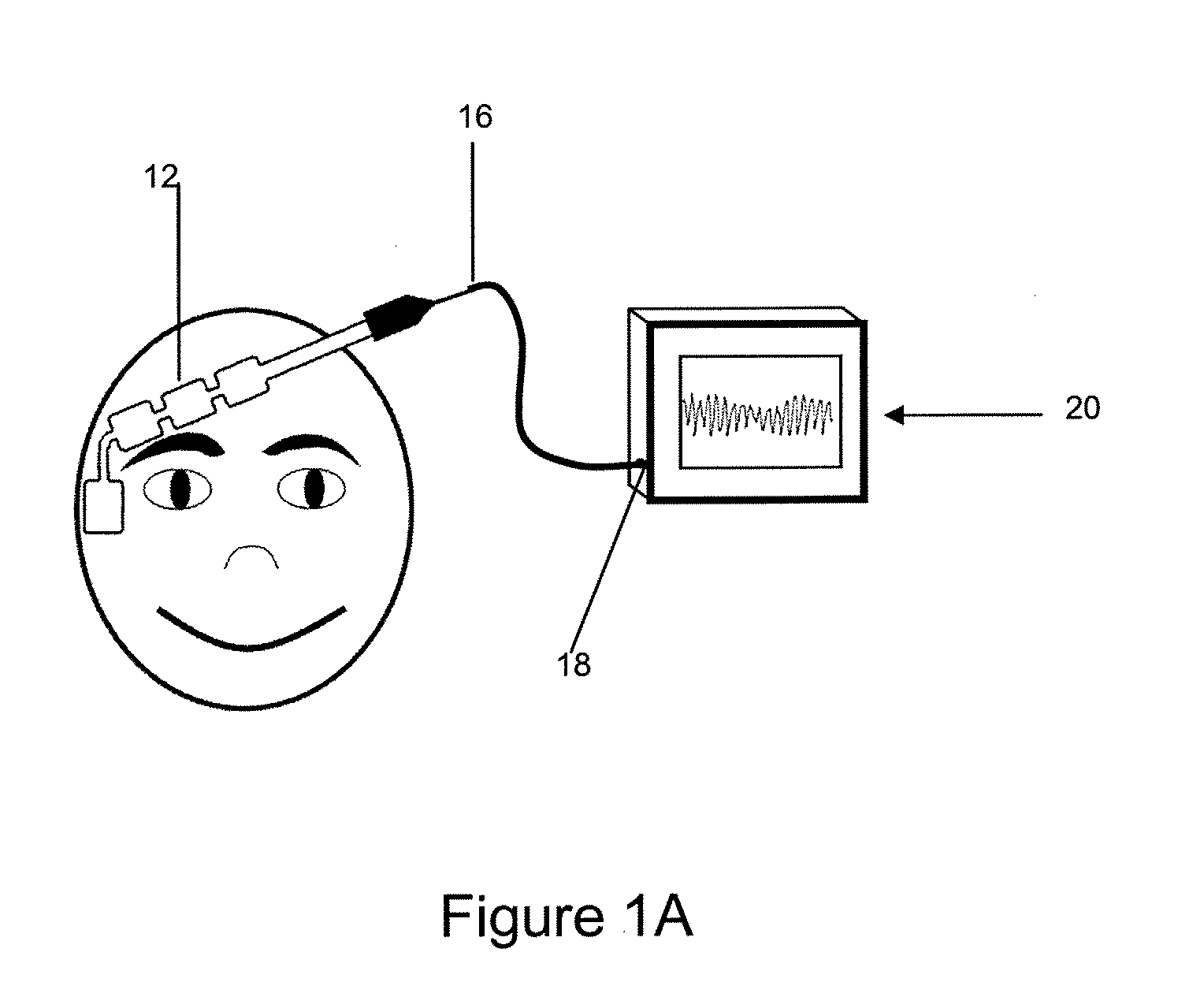

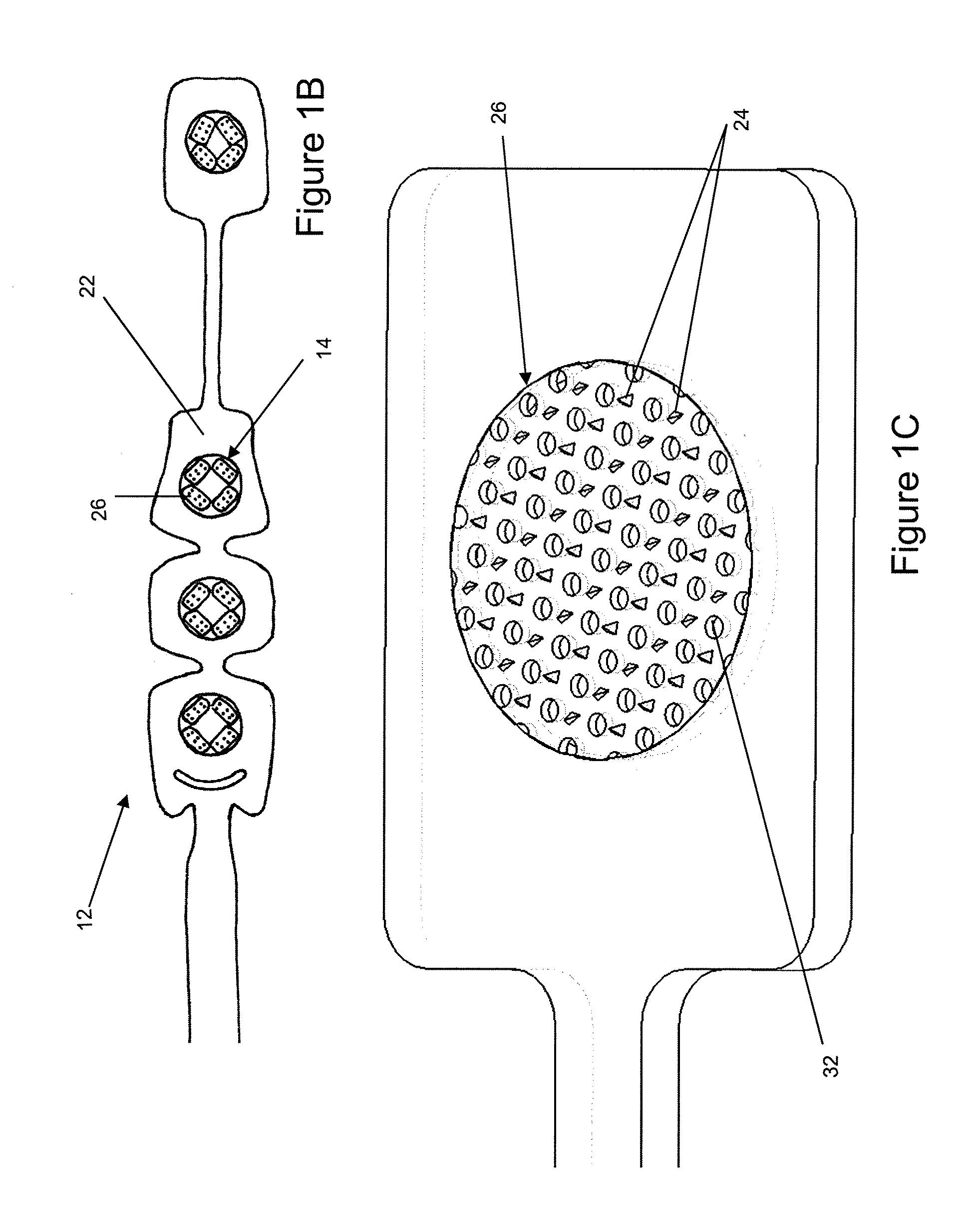

Microneedle electrode

InactiveUS20110295100A1Improve conductivityEasy to detectElectroencephalographyElectrocardiographyElectrical impedanceMicro-needle

In certain variations, methods, systems and / or devices for enhancing conductivity of an electrical signal through a subject's skin using one or more microneedle electrodes are provided. A microneedle electrode may be applied to the subject's skin by placing the microneedle electrode in direct contact with the subject's skin. The microneedles of the microneedle electrode may be inserted into the skin such that the microneedles pierce stratum corneum of the skin up to or through dermis of the skin. An electrical signal passes or is conducted through or across the microneedle electrode and the subject's skin, where impedance of the microneedle electrode is minimal and greatly reduced compared to existing technologies.

Owner:EMKINETICS

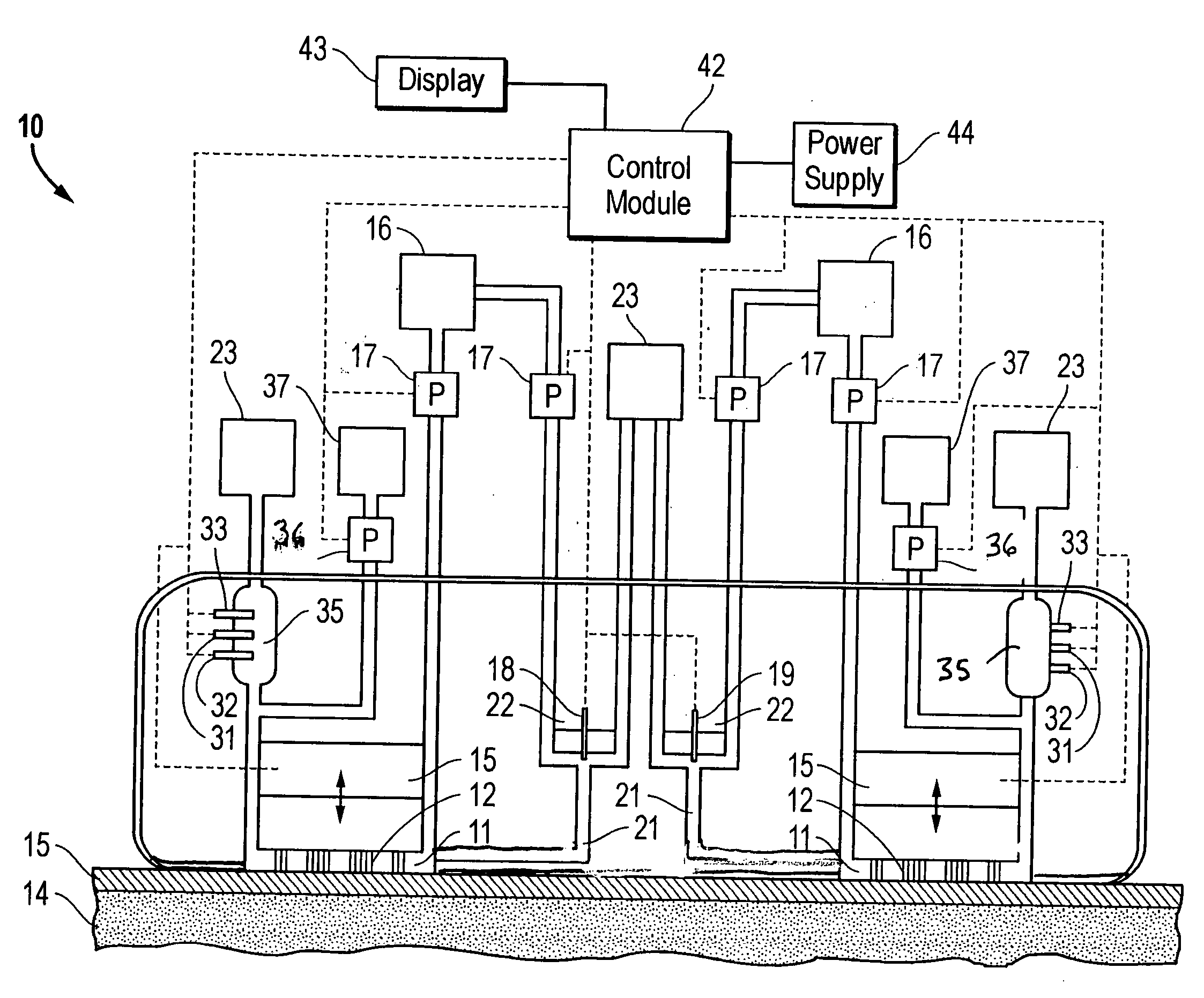

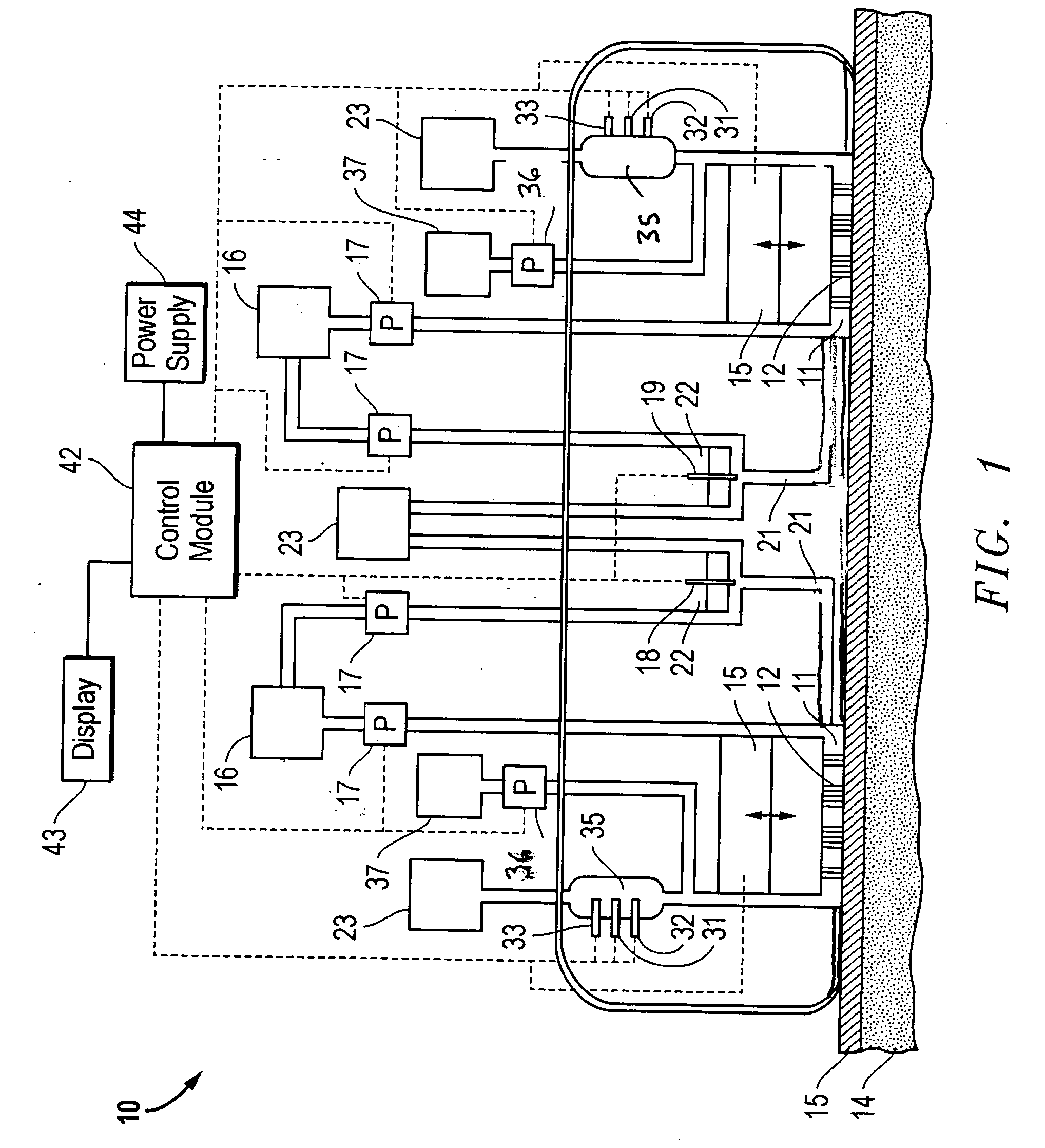

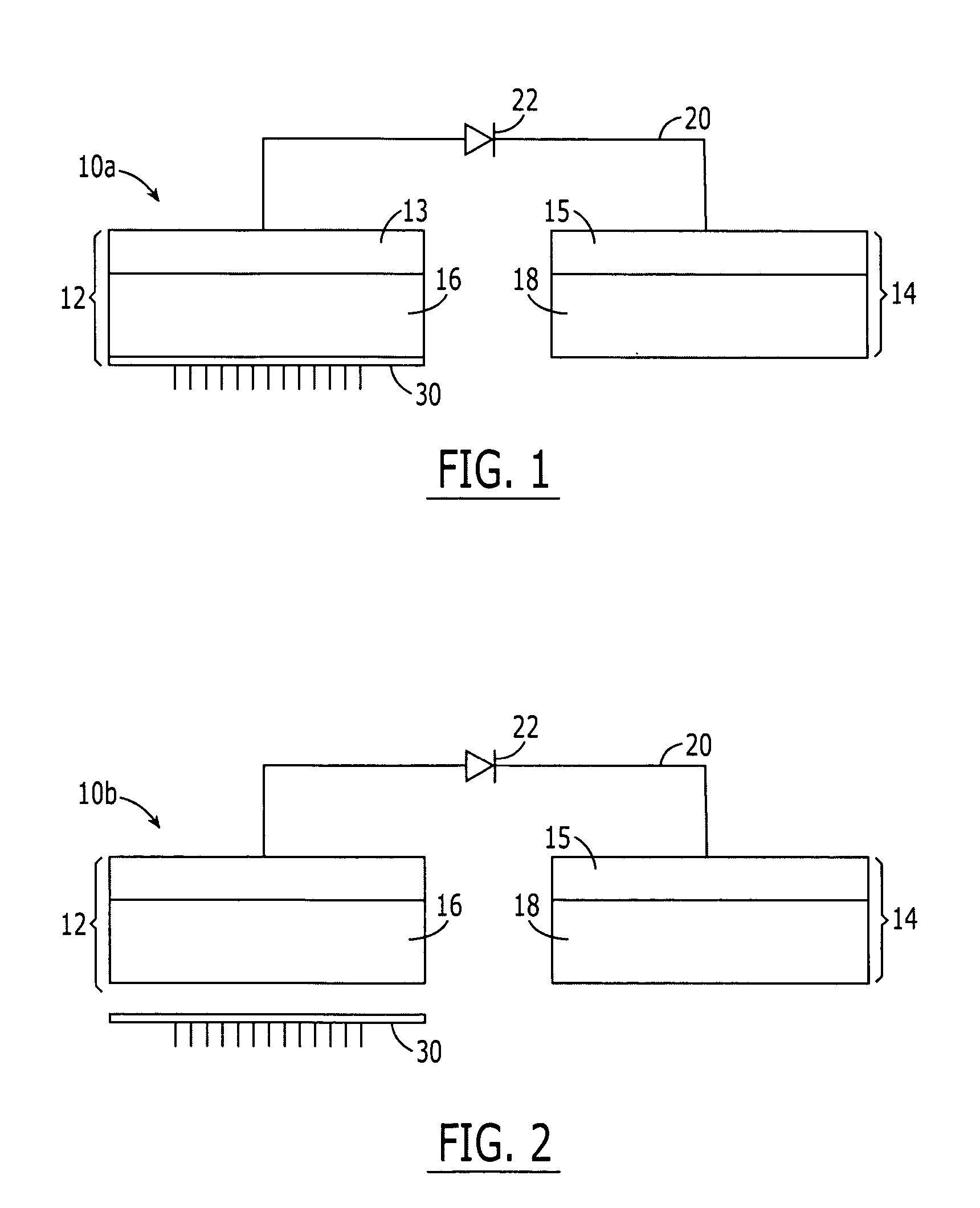

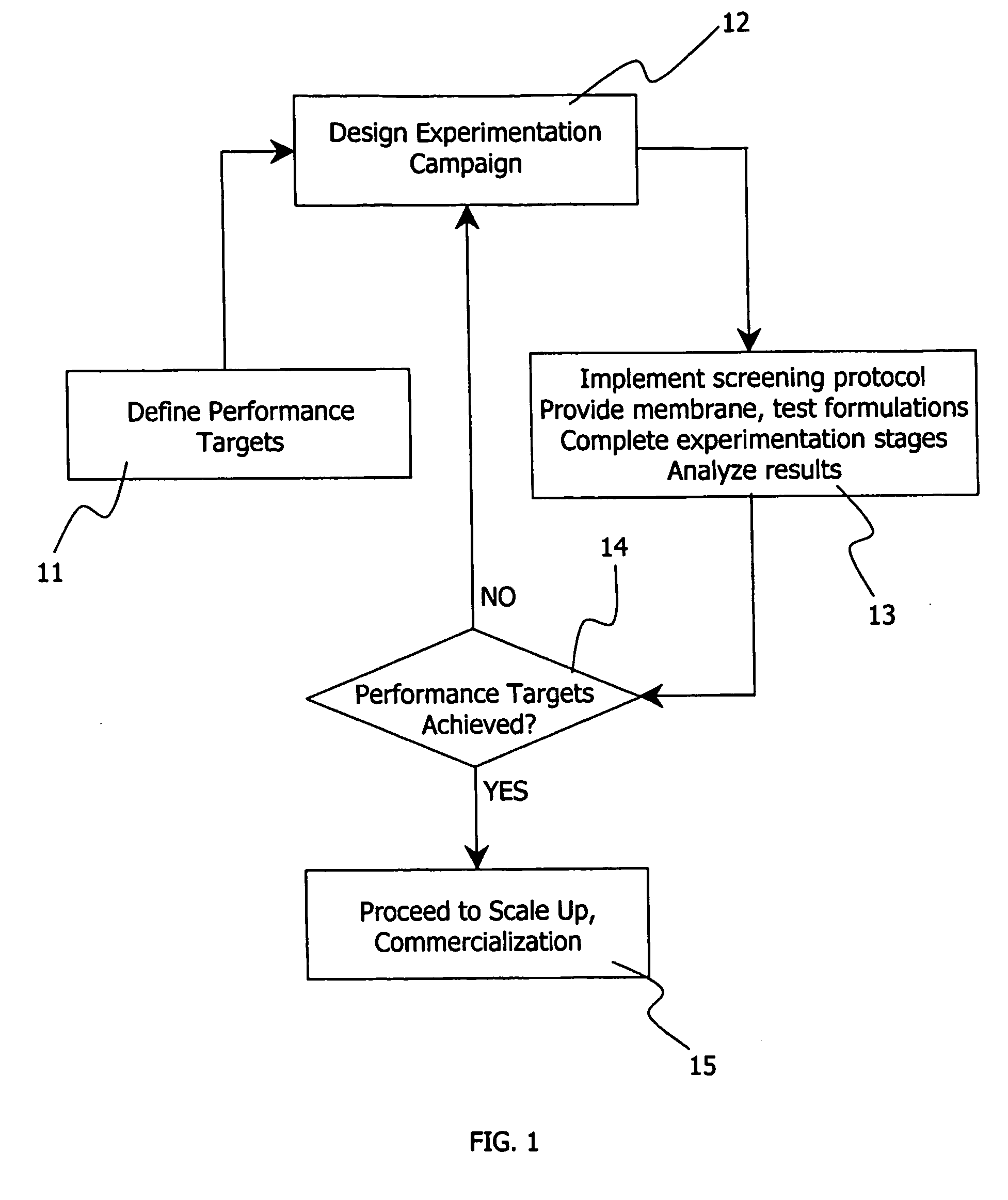

System and method for transdermal vaccine delivery

InactiveUS20050123565A1Ease of conditionsBacterial antigen ingredientsElectrotherapyVaccine deliveryBiocompatible coating

A system and method for transdermally delivering a vaccine to a patient including an iontophoresis delivery device having a donor electrode, a counter electrode, and electric circuitry for supplying iontophoresis energy to the electrodes, and a non-electroactive microprojection member having a plurality of stratum corneum-piercing microprojections extending therefrom. The vaccine can be contained in a hydrogel formulation in an agent reservoir disposed proximate the donor electrode, in a biocompatible coating that is disposed on the microprojections or in both.

Owner:ALZA CORP

Skin preparation device and biopotential sensor

ActiveUS20100022864A1Lower impedanceLower skin resistanceElectroencephalographyMicroneedlesSignal qualityCombined use

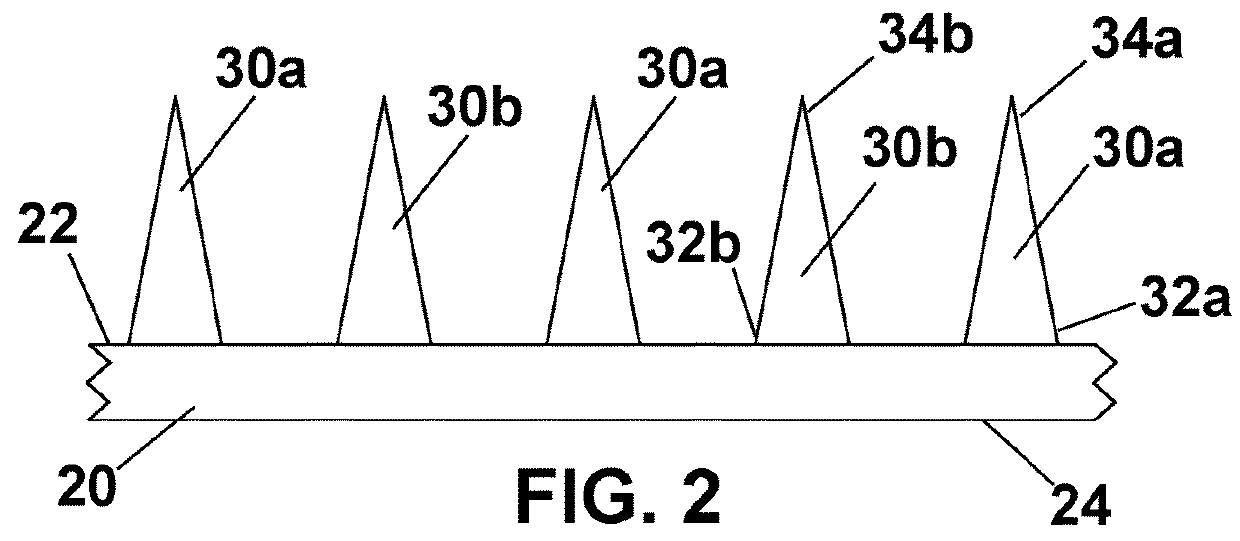

The skin preparation device and sensor of the present invention include an array of rigid tines. The tines serve to “self-prepare” the skin at each electrode site. These tines, when pressed against the skin, penetrate the stratum corneum, thereby reducing skin impedance and improving signal quality. A self-prepping device of the present invention is an optimized array of short non-conductive rigid tines in which the individual tines are created in a geometry that allows for a sharp point at the tip when molding, machining or etching is used as a method of fabrication. This non-conductive array with rigid penetrating structures may, therefore, be used in combination with a conductive medium, preferably an ionic conductive gel. In penetrating the stratum corneum, micro-conduits are created in the layers of the skin enabling the conductive medium to reach the low impedance layers and to transmit bioelectrical signals from the skin to the electrode surface. Such a self-prepping device can be readily mass produced using molding methods or possibly other manufacturing methods, thereby providing for a low cost means of achieving improved performance of the biopotential sensor. Additionally this invention includes the integration of this self-prepping device into a biopotential sensor comprising an array of one or more electrodes.

Owner:TYCO HEALTHCARE GRP LP

Needleless hypodermic jet injector apparatus and method

InactiveUS7347851B1Less painful experienceLess discomfortJet injection syringesAutomatic syringesLiquid jetJet flow

In the present invention, the impedance between patient's body and the jet injection drug delivery device is measured through the liquid jet during the drug delivery process. The liquid jet completes the electrical circuit formed by impedance monitor, drug delivery device, and the patient's body. When the jet pierces stratum corneum, the impedance in the circuit immediately decreases, thus an indicating the successful drug delivery. The impedance monitor then provides a signal, visible, audible, or electronic, indicating that the process of the drug delivery through skin was successful.

Owner:KRIKSUNOV LEO B

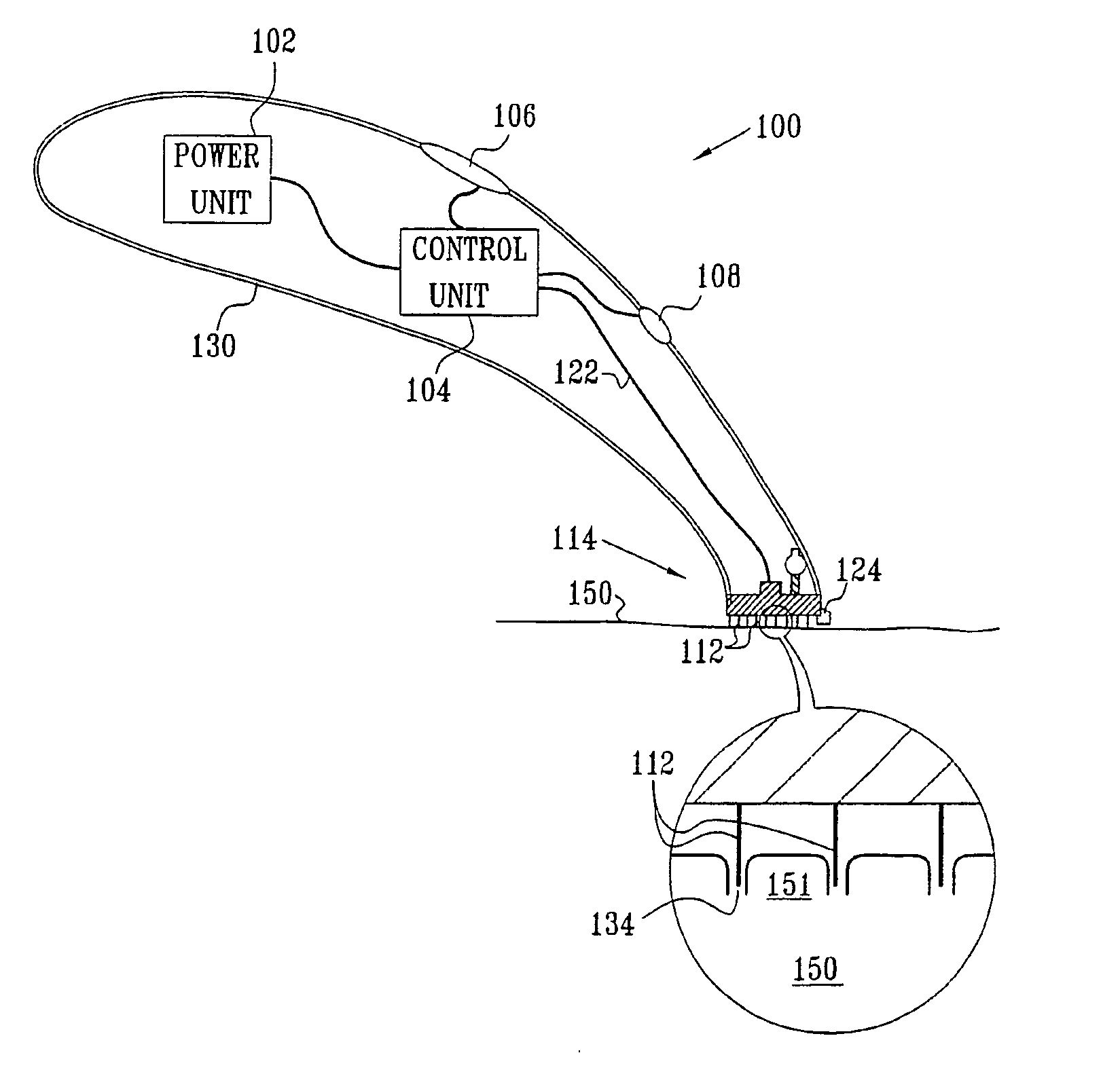

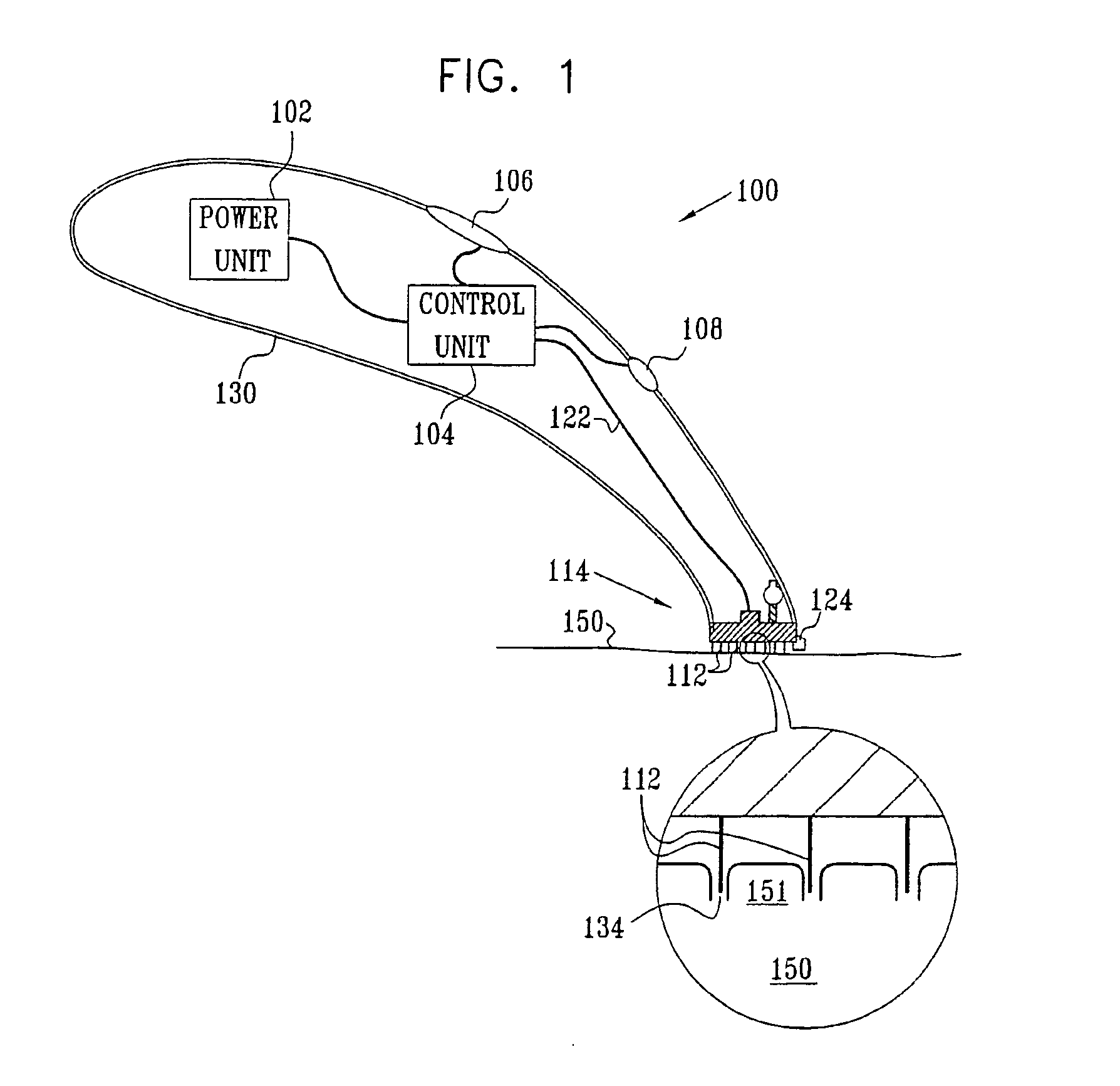

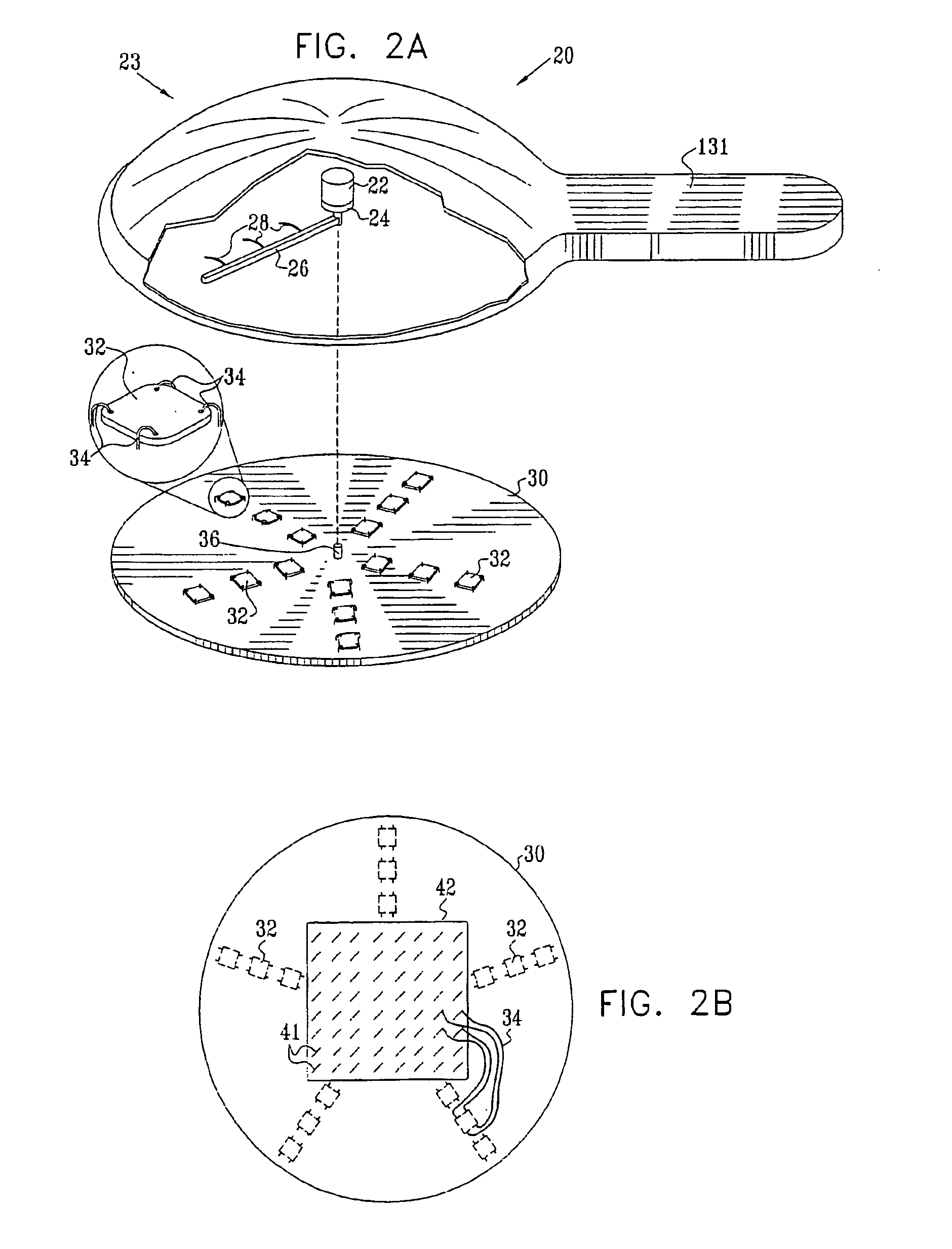

Handheld transdermal drug delivery and analyte extraction

InactiveUS20050119605A1Facilitate transdermal transportMaximize minimum distanceElectrotherapyMedical devicesContact padAnalyte

Apparatus (20) for application to skin of a subject is provided. The apparatus includes a board (30) having a first surface and a second surface, the first surface including a plurality of ablation electrodes (41), which are adapted to be applied to the skin, and the second surface including one or more contact pads (32), each one of the contact pads electrically coupled to at least one of the ablation electrodes. The apparatus further includes one or more driving electrodes (28). An energy applicator (e.g., motor 22), coupled to the driving electrodes, is adapted to pass the driving electrodes over the contact pads. A power source (e.g., power unit 102) is adapted to drive a current from the driving electrodes, to the contact pads, and to the ablation electrodes. The current is capable of ablating at least a portion of stratum corneum of the skin in a vicinity of the ablation electrodes, so as to facilitate transdermal transport of a substance.

Owner:TRANSPHARMA MEDICAL

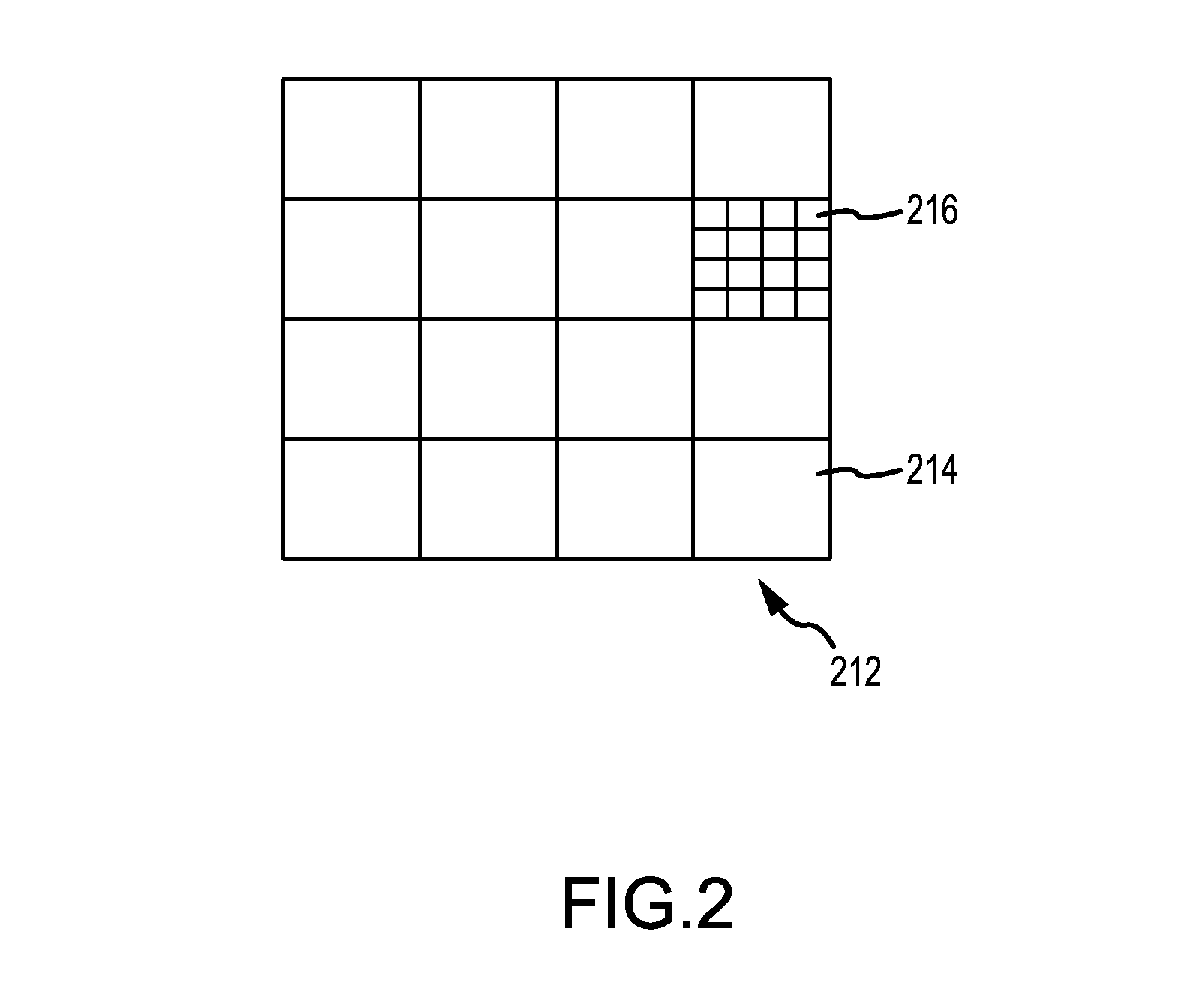

High dynamic range capacitive sensing

InactiveUS20140267659A1Improve fingerprint image measurementReduce waiting timeColor television detailsClosed circuit television systemsCapacitanceCapacitive sensing

Improving fingerprint image measurement despite damage to the stratum corneum. Determining whether a fingerprint image is adequate for matching with a database. If not, re-measure those image portions that are inadequate (overexposed or underexposed), such re-measuring a minimal selection of image portions. An amount of time or power to re-measure is minimized. Improving fingerprint image data collection despite fixed pattern noise like saturated bars in blocks of picture elements. Determining a histogram of grayscale values, removing fixed pattern noise, and expanding real histogram values to obtain more bits of precision.

Owner:APPLE INC

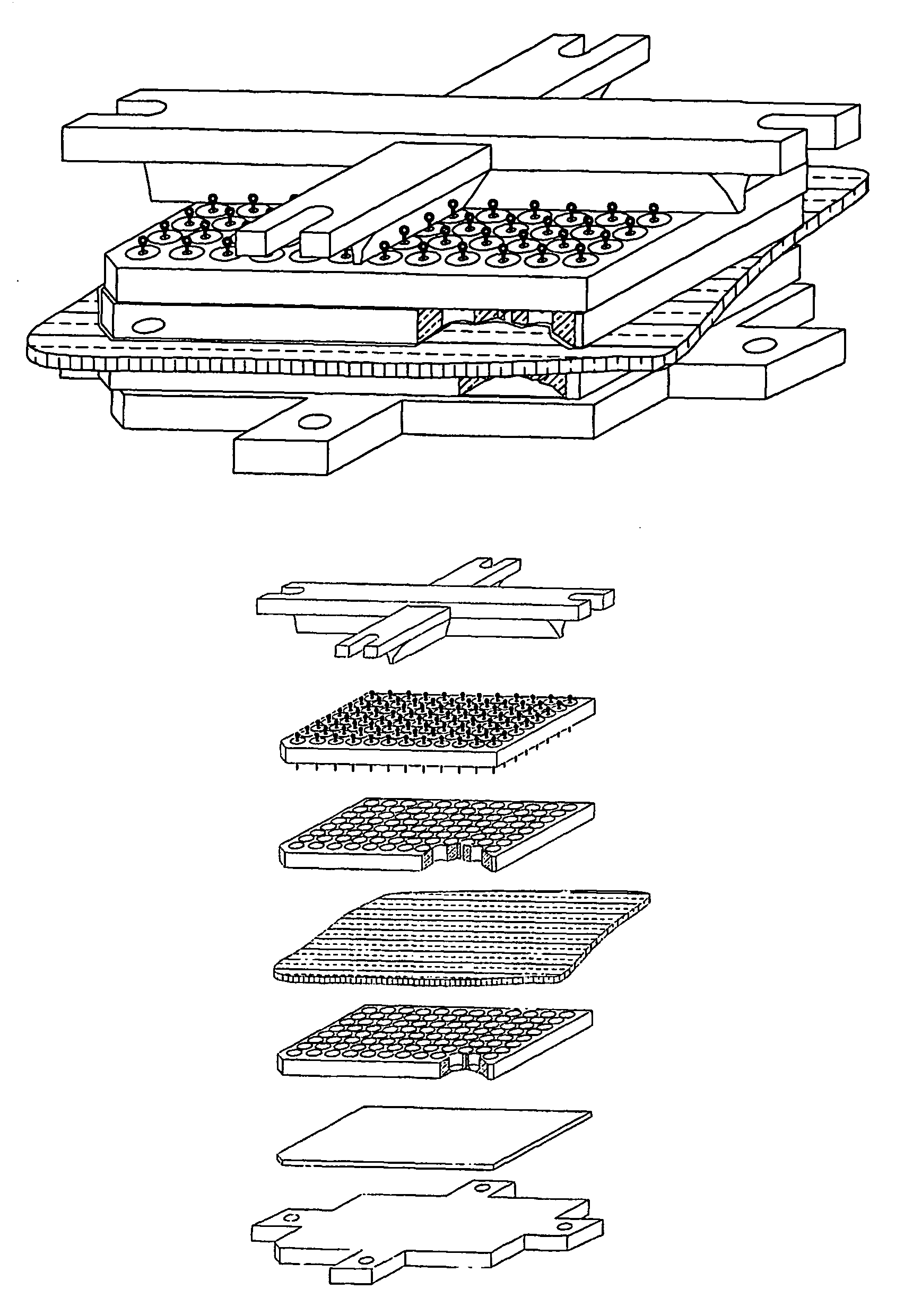

Apparatus and methods for evaluating the barrier properties of a membrane

InactiveUS20070183936A1MeasurementsSimple and robust and scalableMaterial analysis by observing effect on chemical indicatorRotary centrifugesElectricityAdditive ingredient

Owner:TIOGA RES

Microprotrusion member retainer for impact applicator

Owner:ALZA CORP

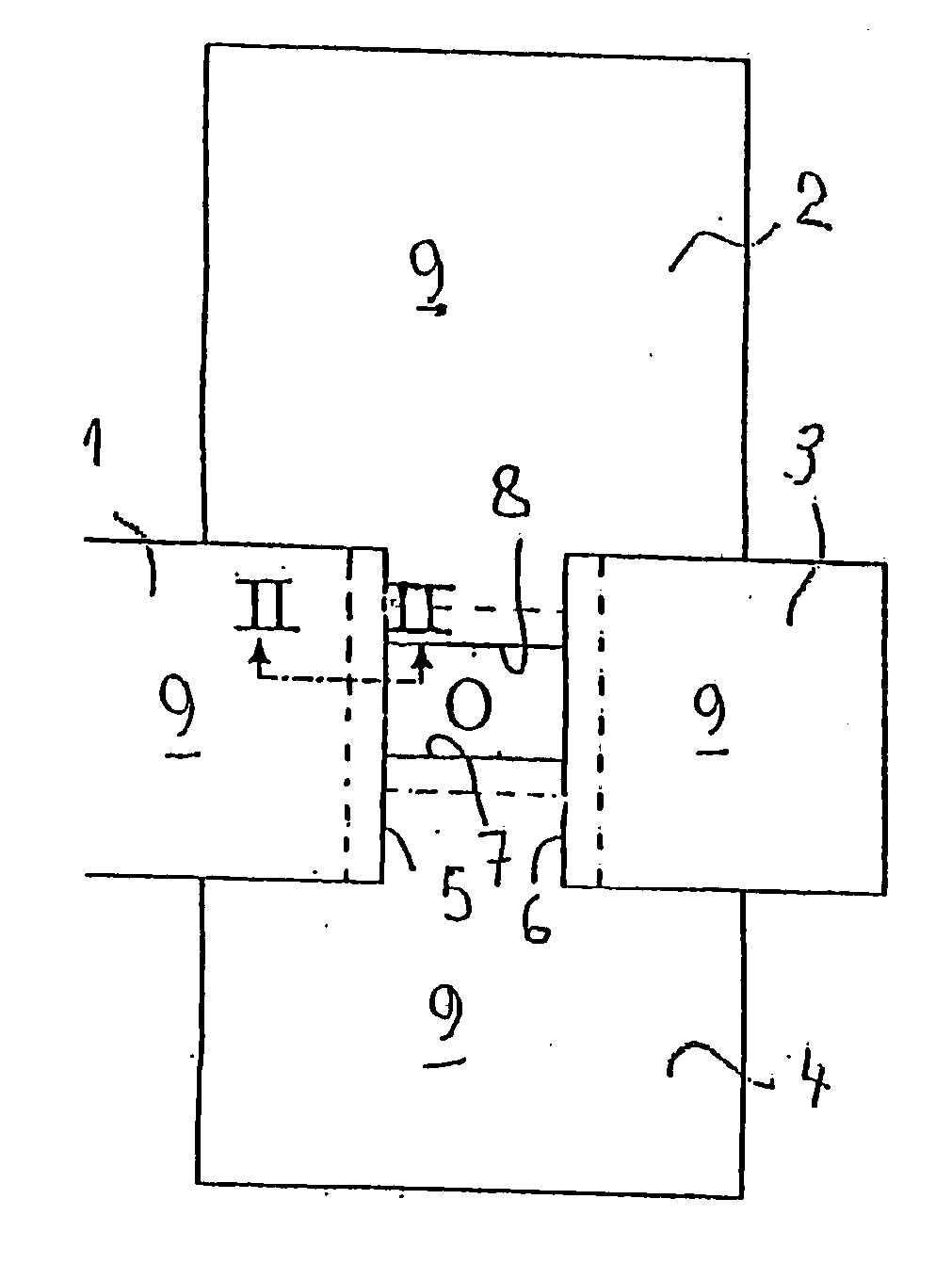

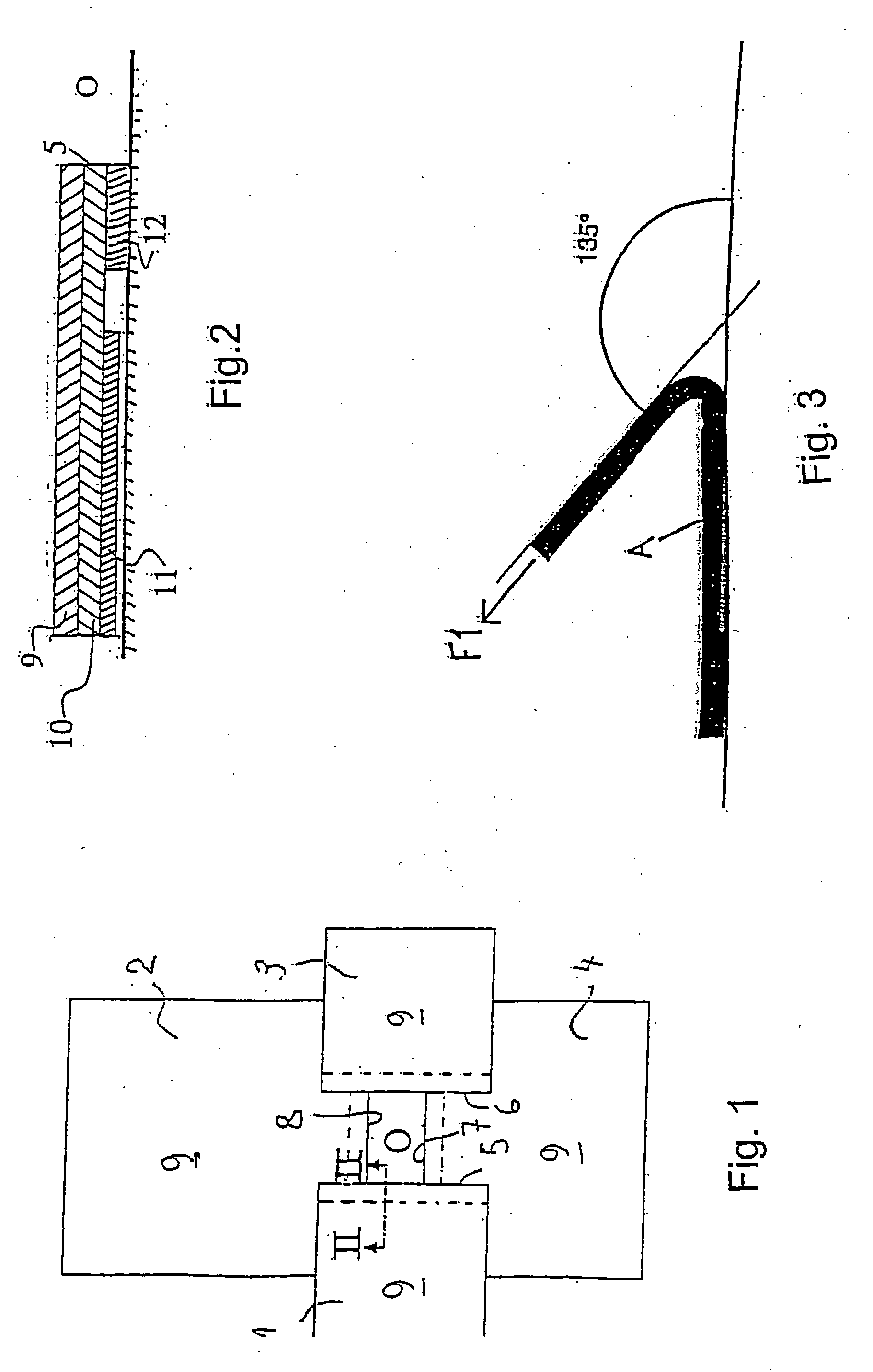

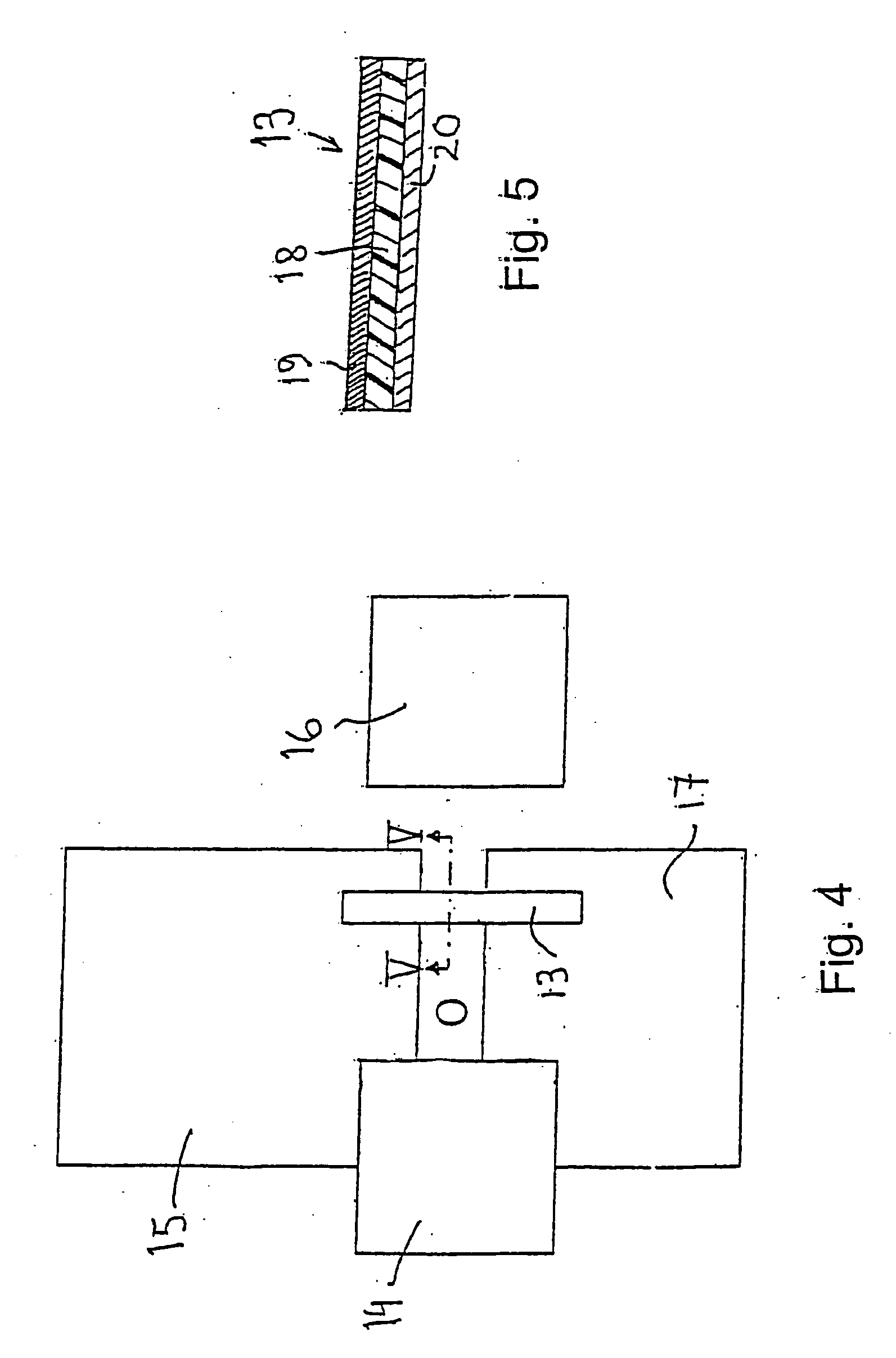

Draping product with adhesive edge

A draping product (1-4) for surgical interventions, which on its underside is coated with adhesive along at least one edge thereof (5, 6, 7 and 8, respectively), the coating (12) extending fully or partly along the edge. According to the invention, the adherence force against skin of the adhesive is greater than 0.5 N / 25 mm and the damage to Stratum Corneum of the part of the skin covered by the adhesive is, after removal of a draping product (1-4) attached to the skin, less than 30 % measured with SCT (Spectroscopic Colour Test).

Owner:MOLNLYCKE HEALTH CARE AB

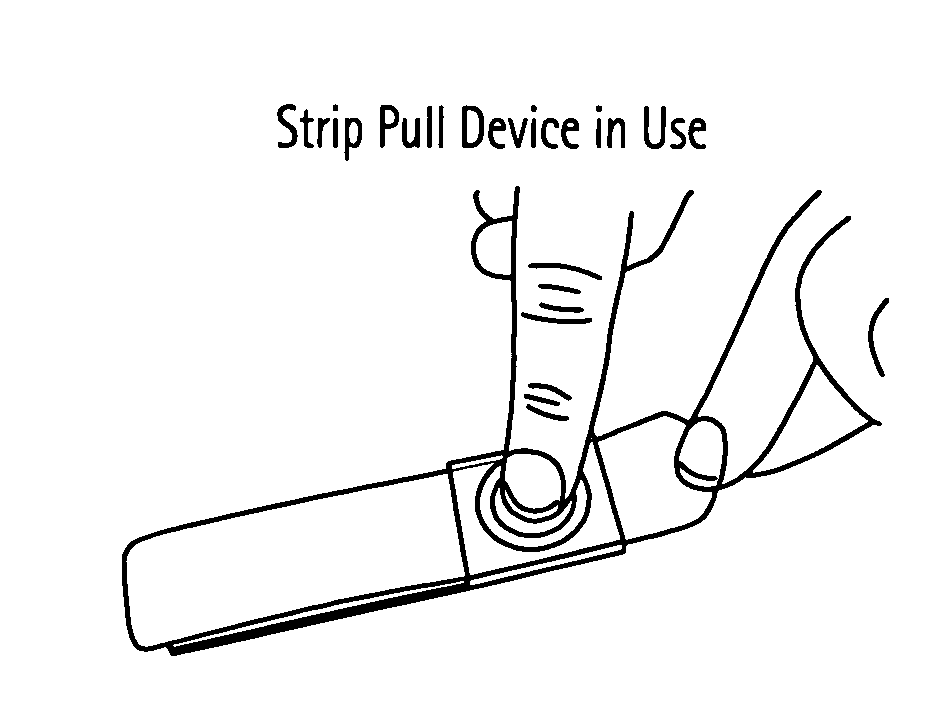

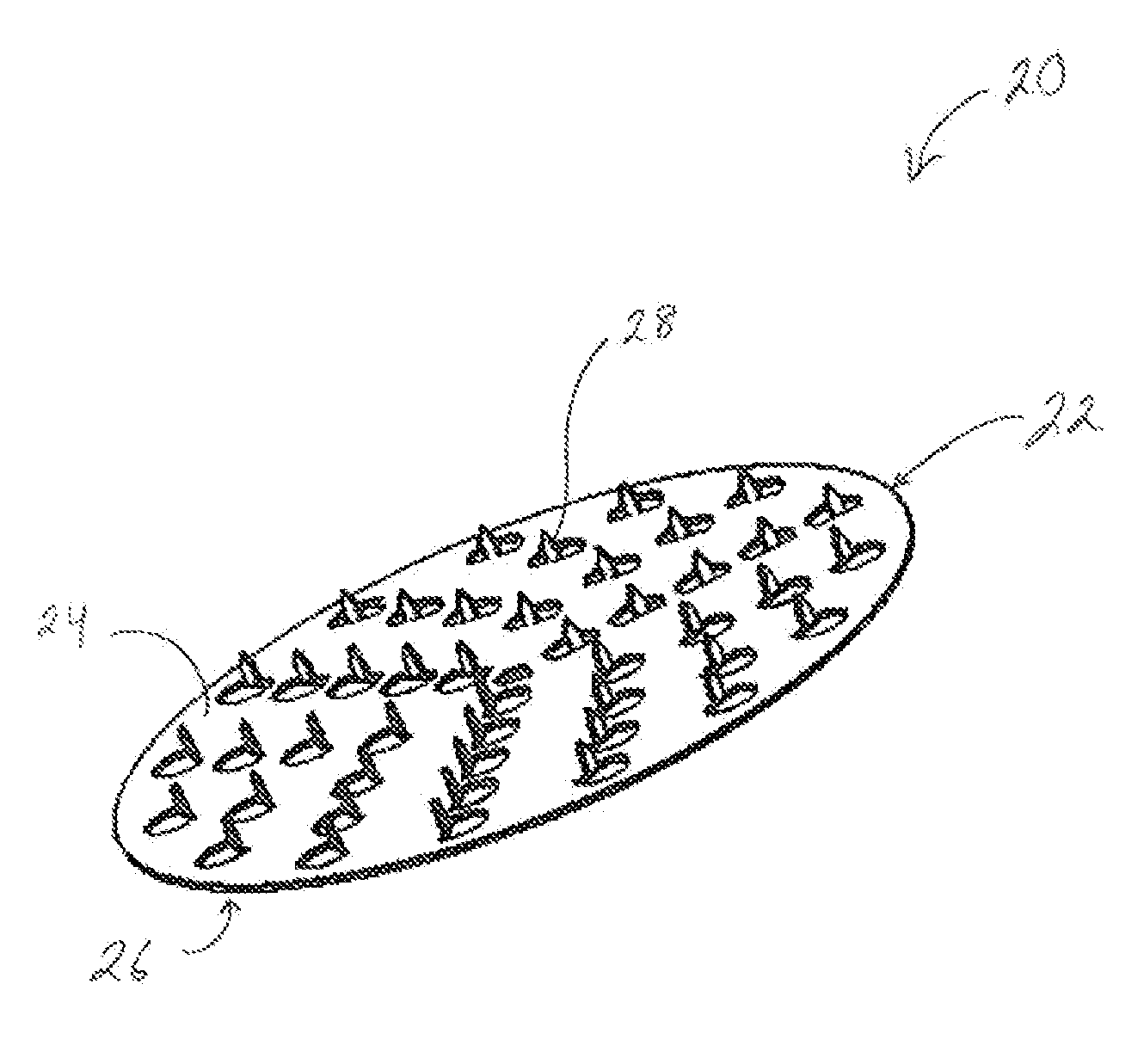

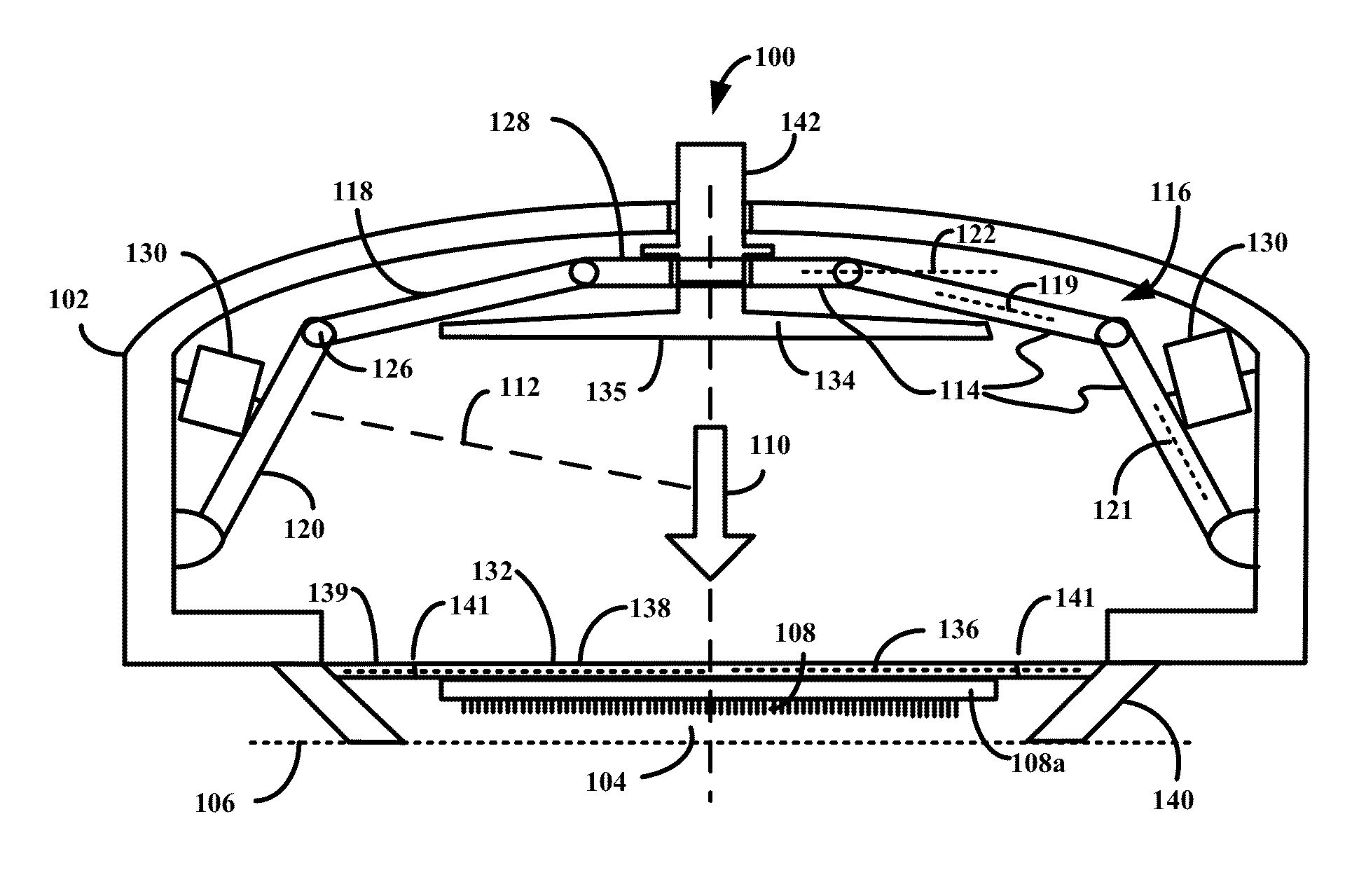

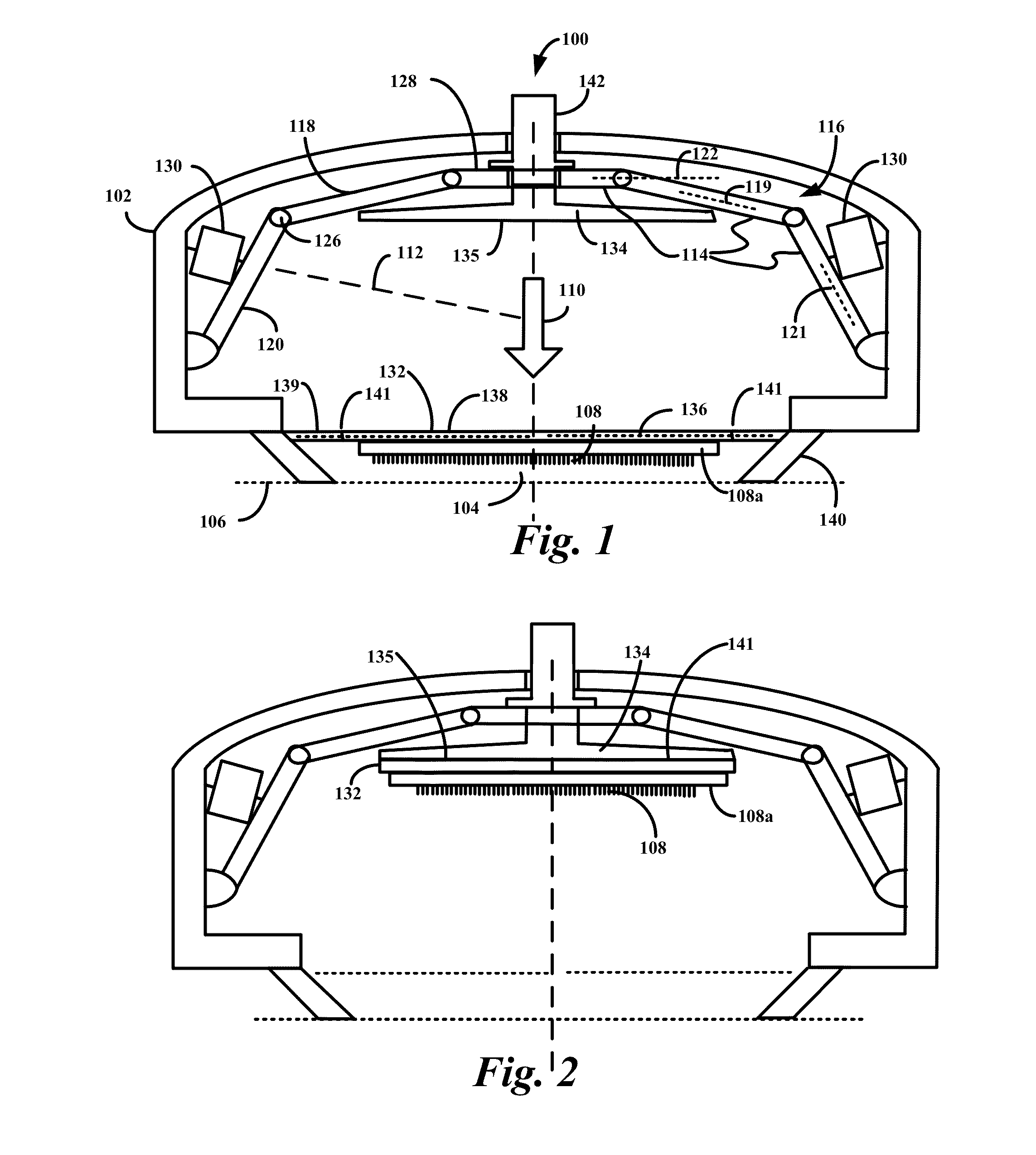

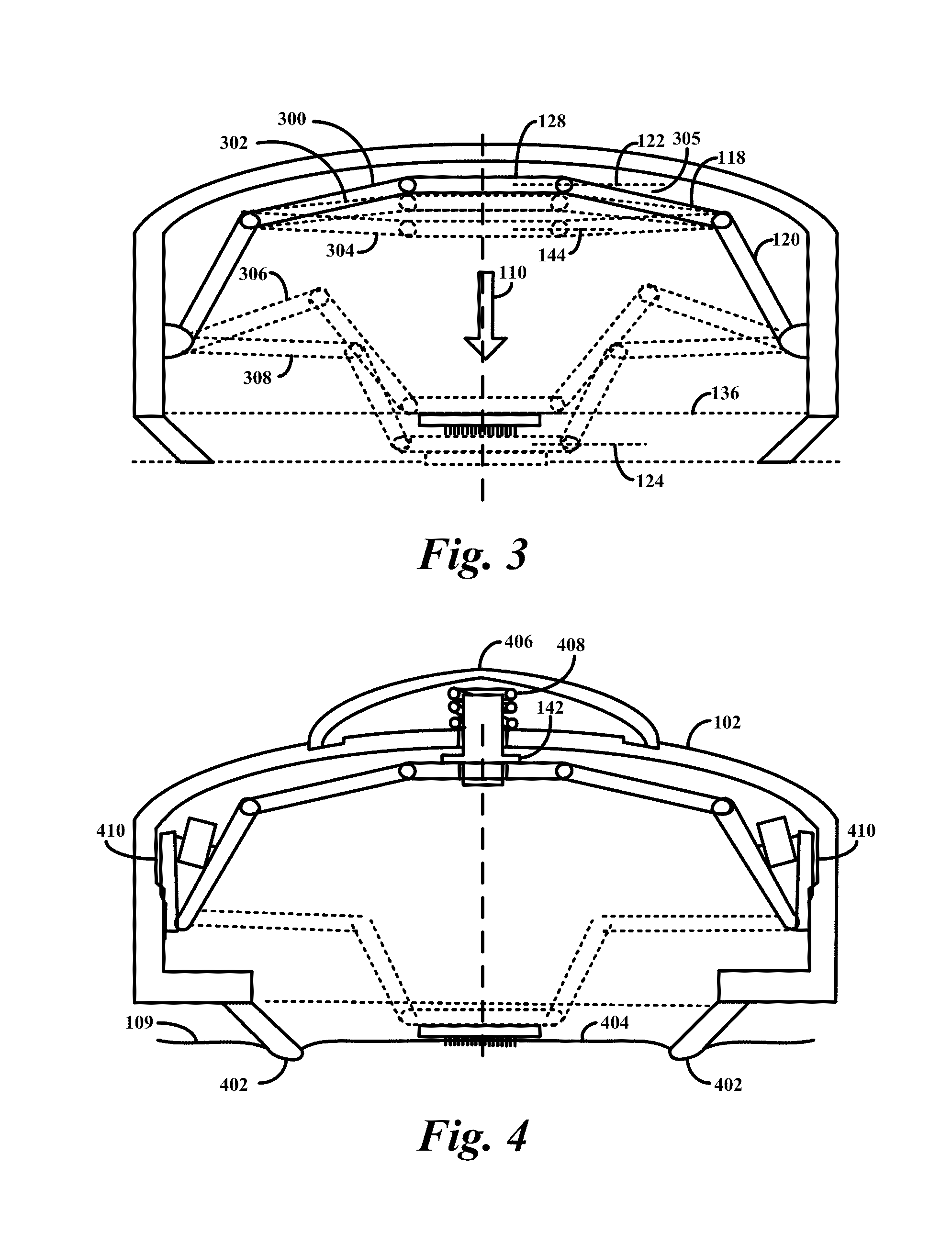

Low-Profile Microneedle Patch Applicator

A low-profile applicator, and a method of manufacturing and use thereof, for impacting microneedles against the stratum corneum of a person having a housing, a diaphragm member having the microneedles, a folding member having interlinking members that hinge-ably rotate with a force member, operatively attached thereto, between a resting position and an extended position. The folding member translates energy stored within the force member when release while retaining the force member in an energized state when in the resting position.

Owner:ZP OPCO INC

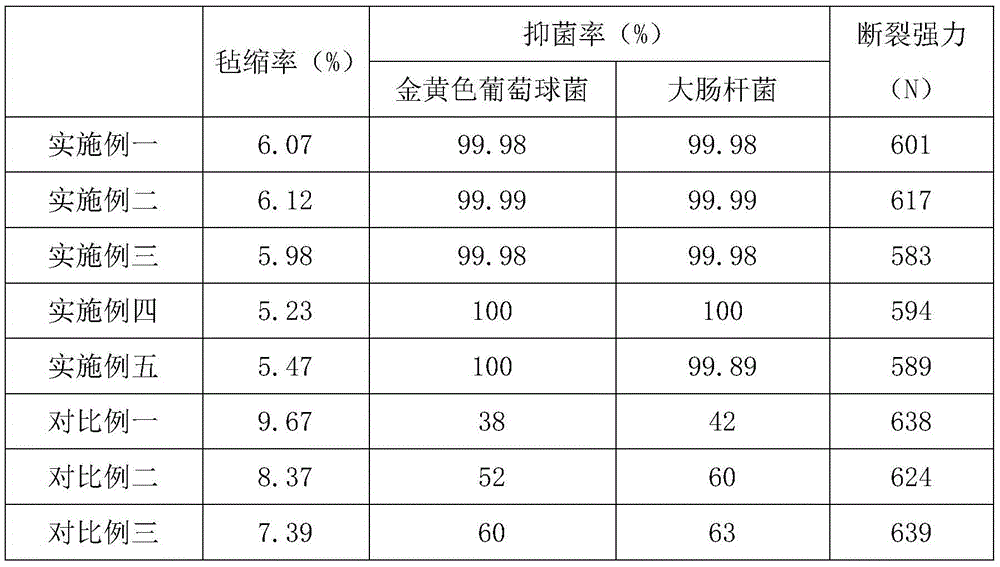

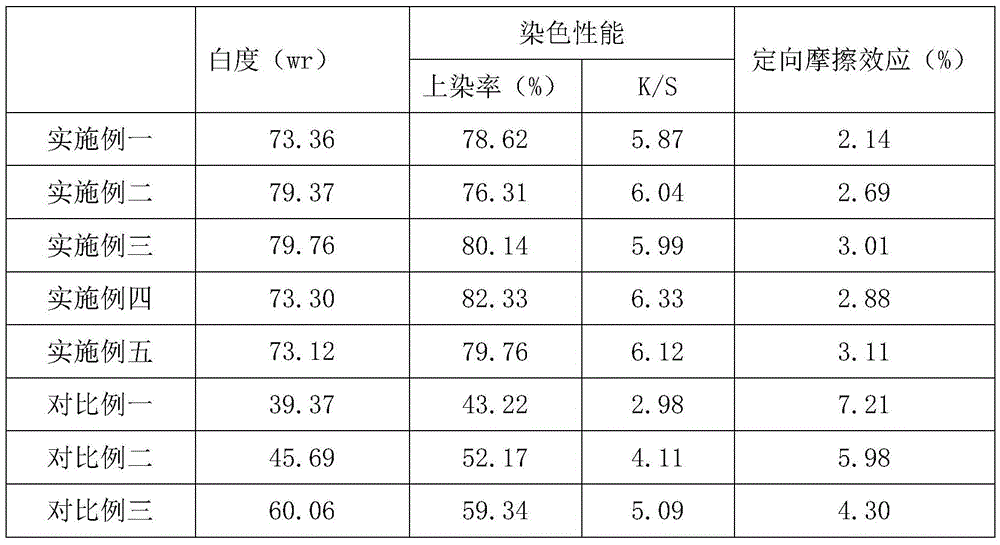

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

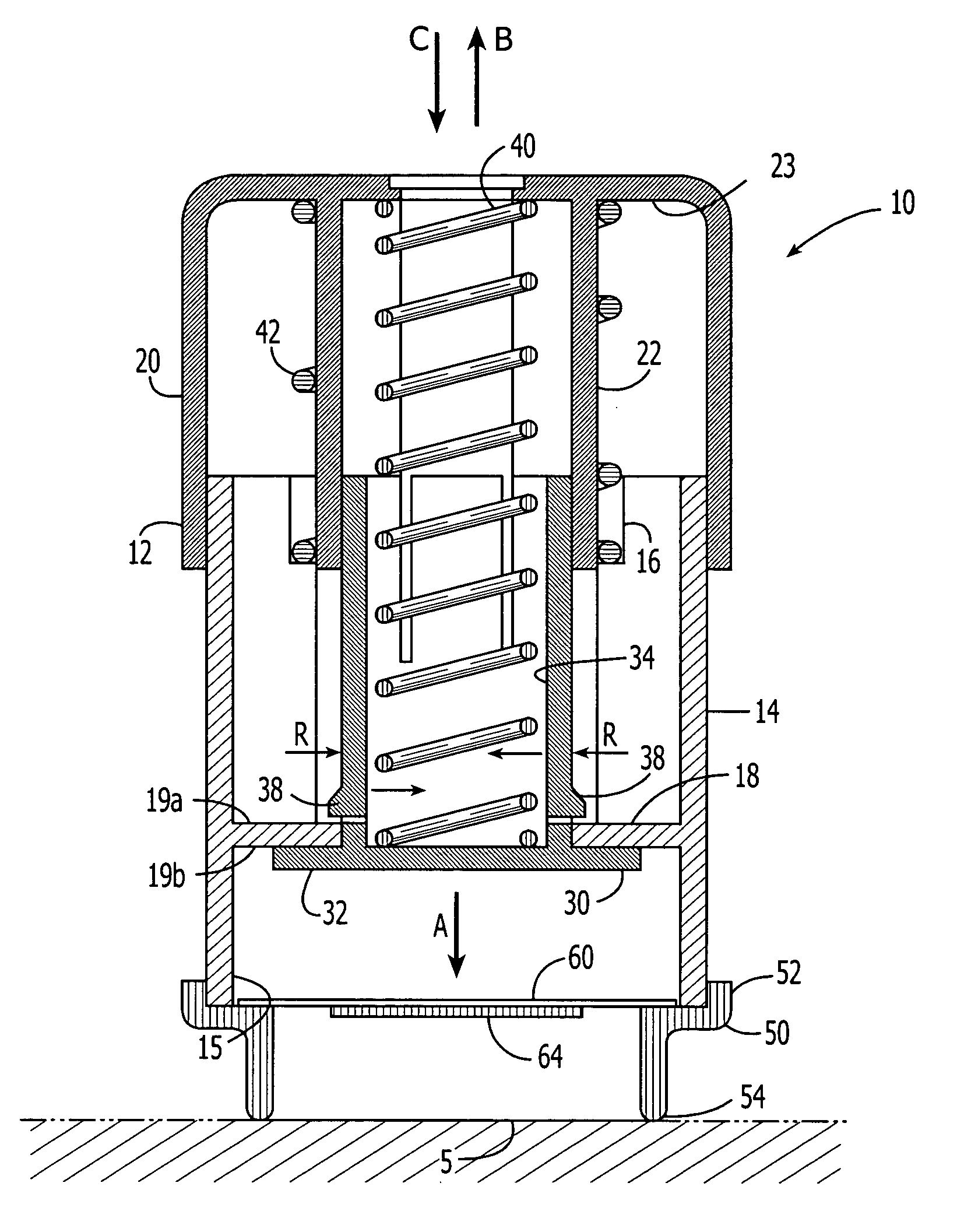

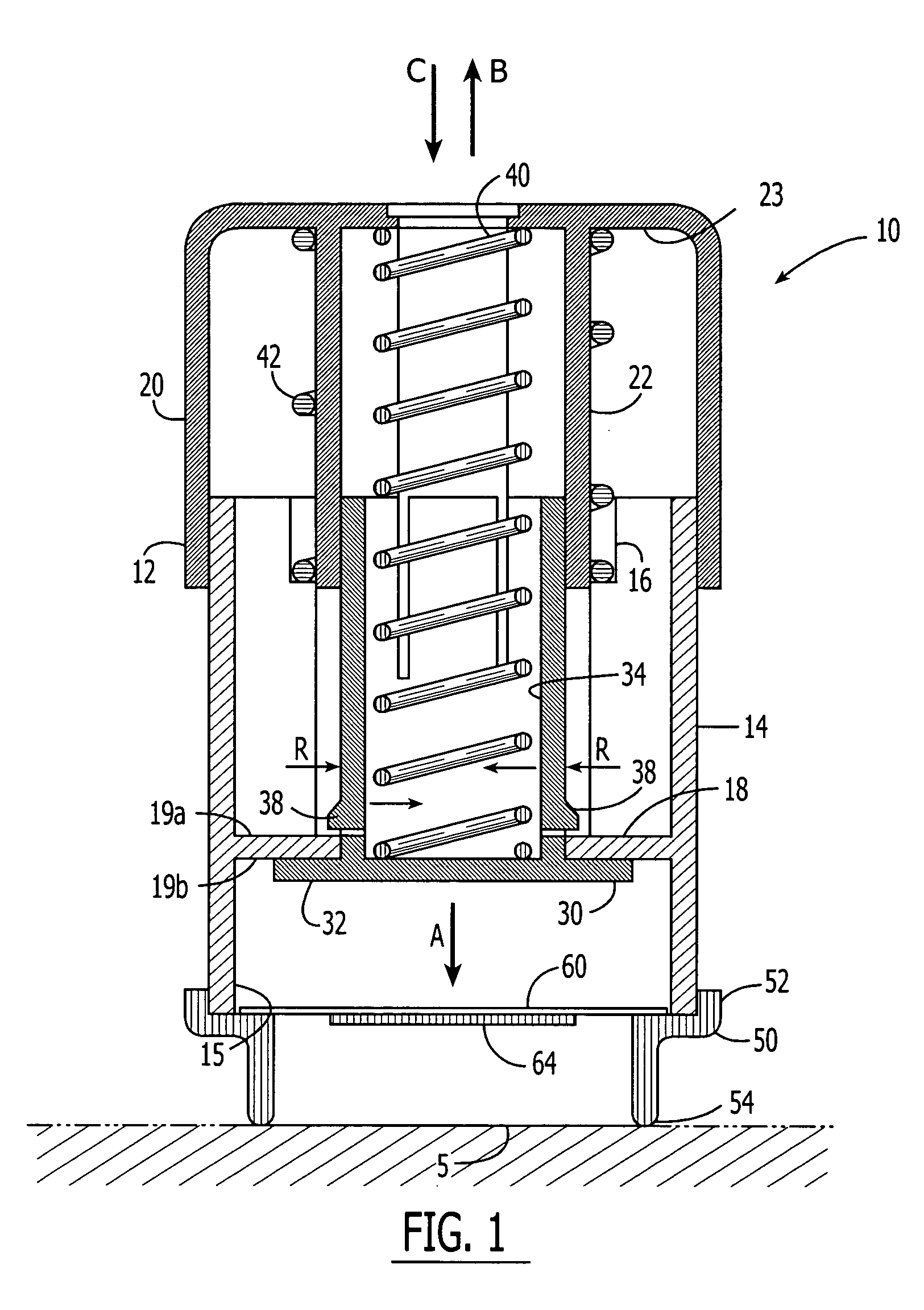

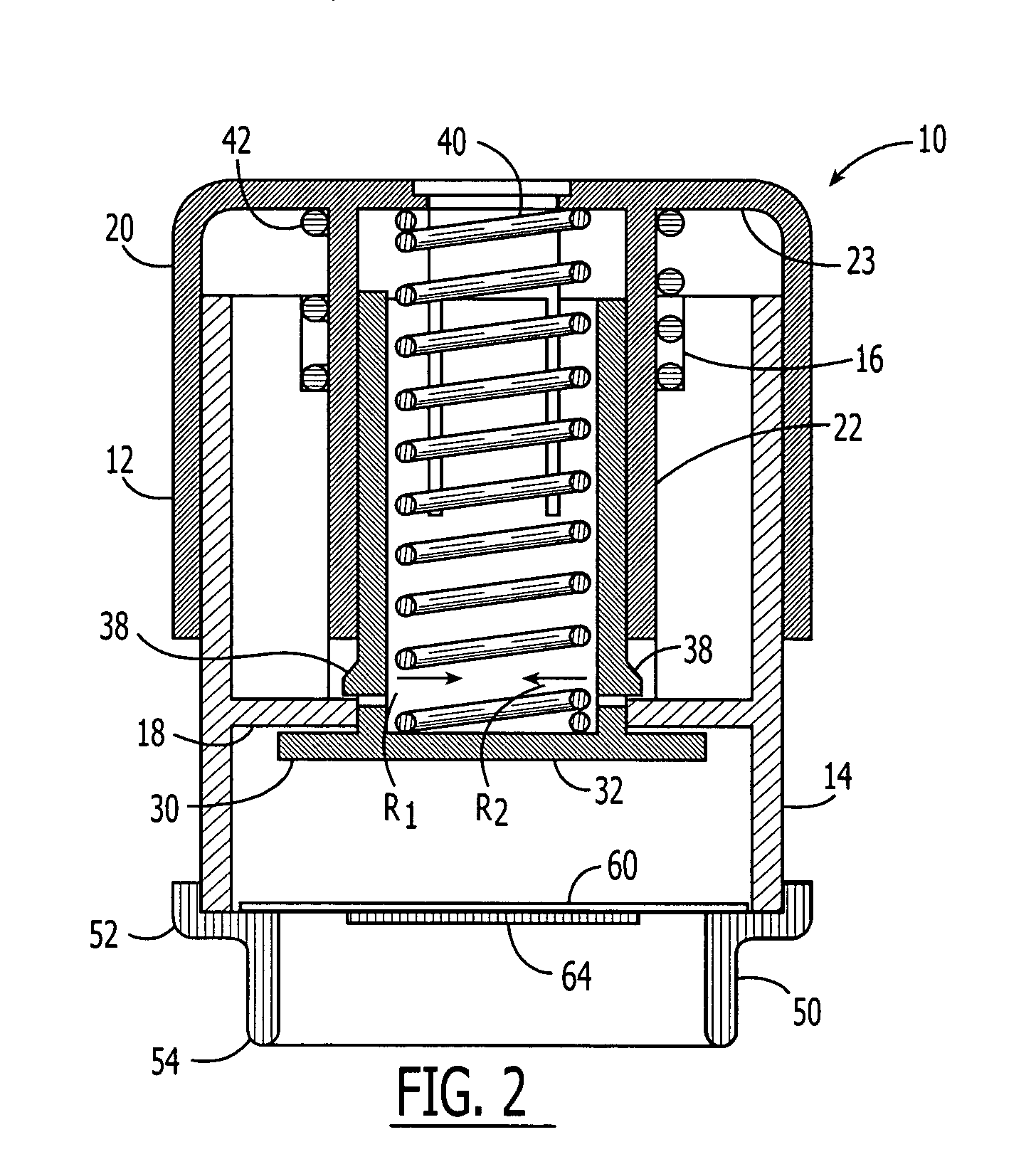

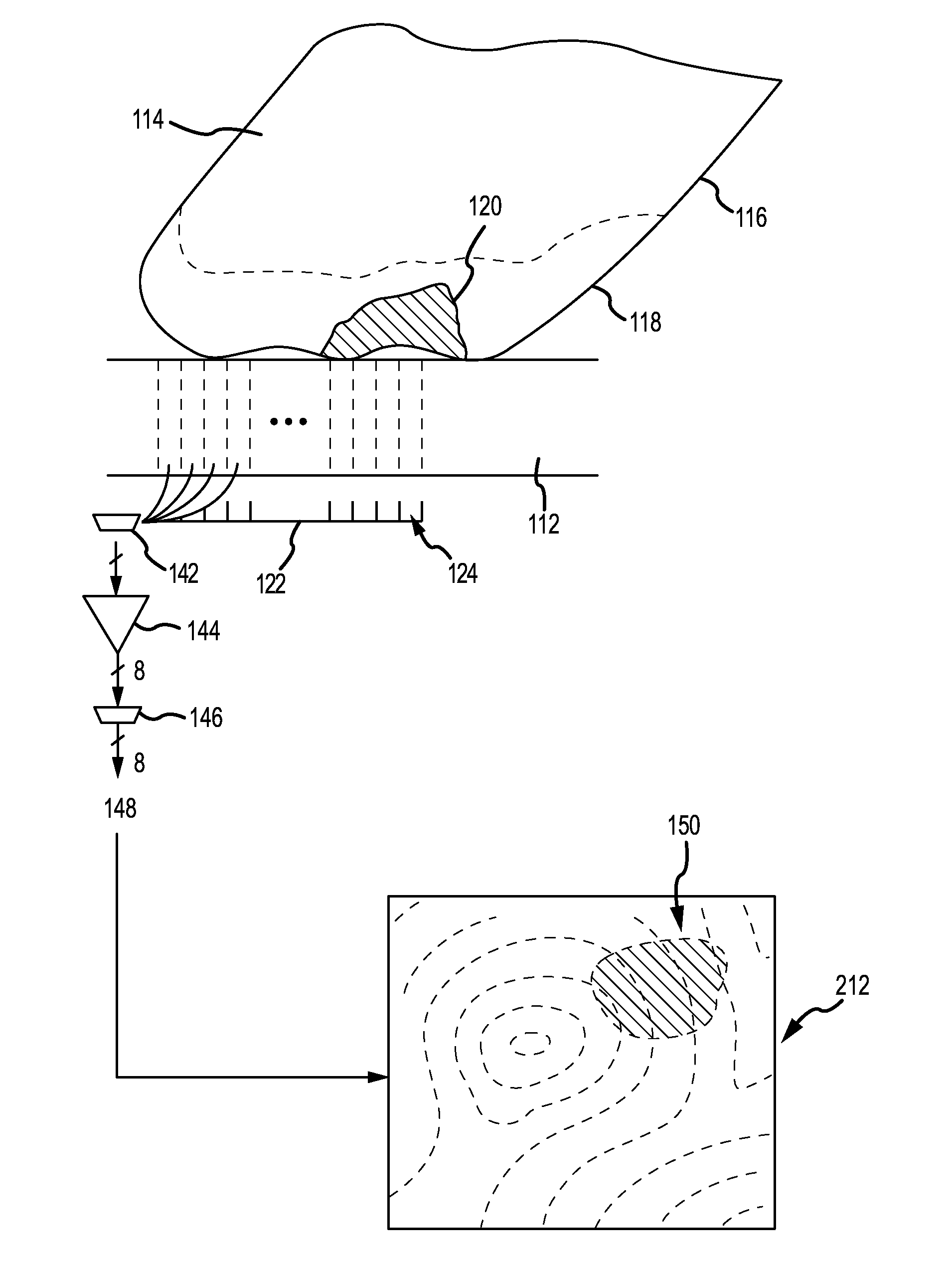

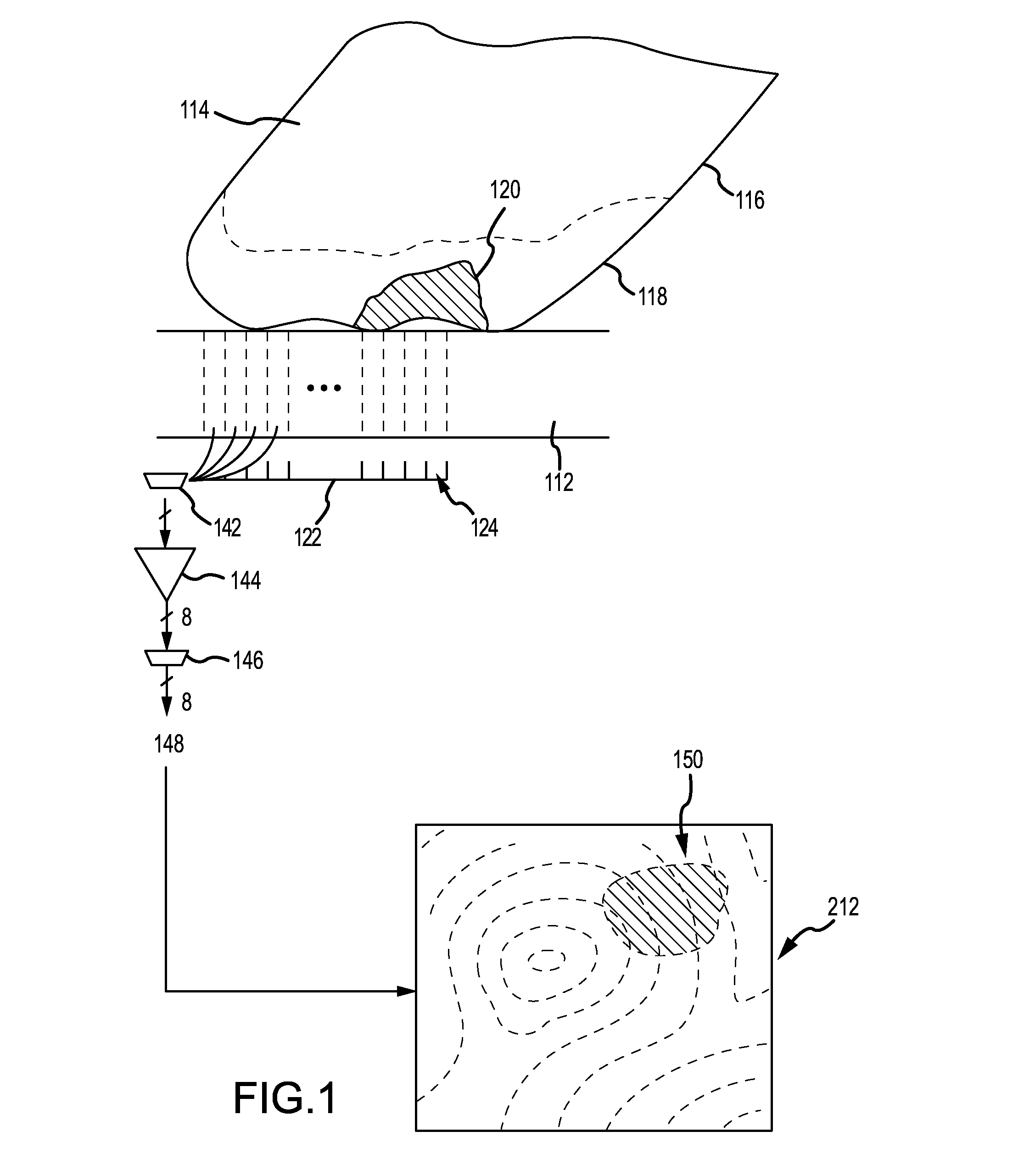

Sensing Fluid Concentration for Continuous Glucose Monitoring

An analyte monitor having a plurality of fluid paths, each fluid path having a distal opening adapted to be disposed on one side of a stratum corneum layer of a user's skin, a proximal opening adapted to be disposed on another side of the stratum corneum layer and an interior space extending between the distal and proximal openings; a sensing zone in fluid communication with the proximal openings of the fluid paths; sensing fluid extending from the sensing zone into substantially the entire interior space of the fluid paths; and an analyte sensor adapted to detect a concentration of analyte in the sensing fluid within the sensing zone, wherein at least one of the sensing fluid and the analyte sensor comprises a catalyst for mutarotation of glucose. The invention also includes a method of using the monitor.

Owner:ARKAL MEDICAL

Method

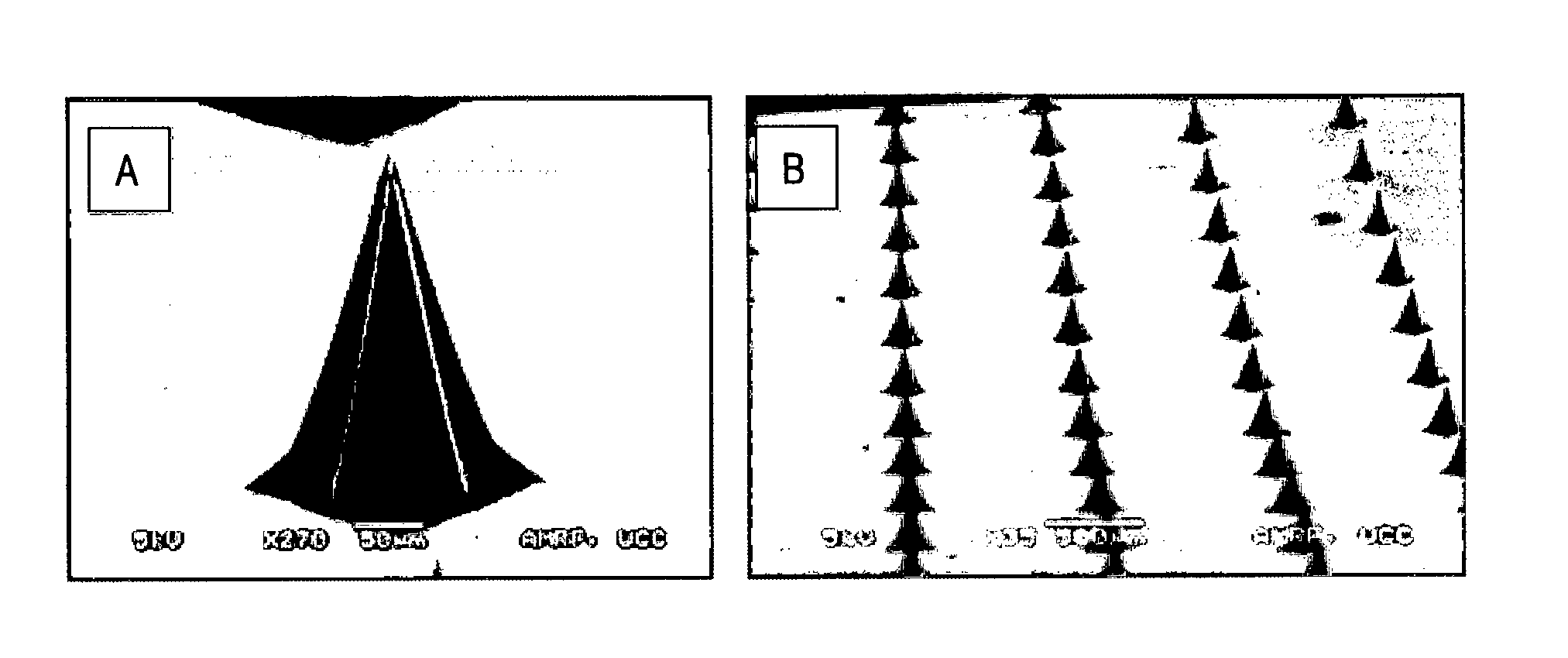

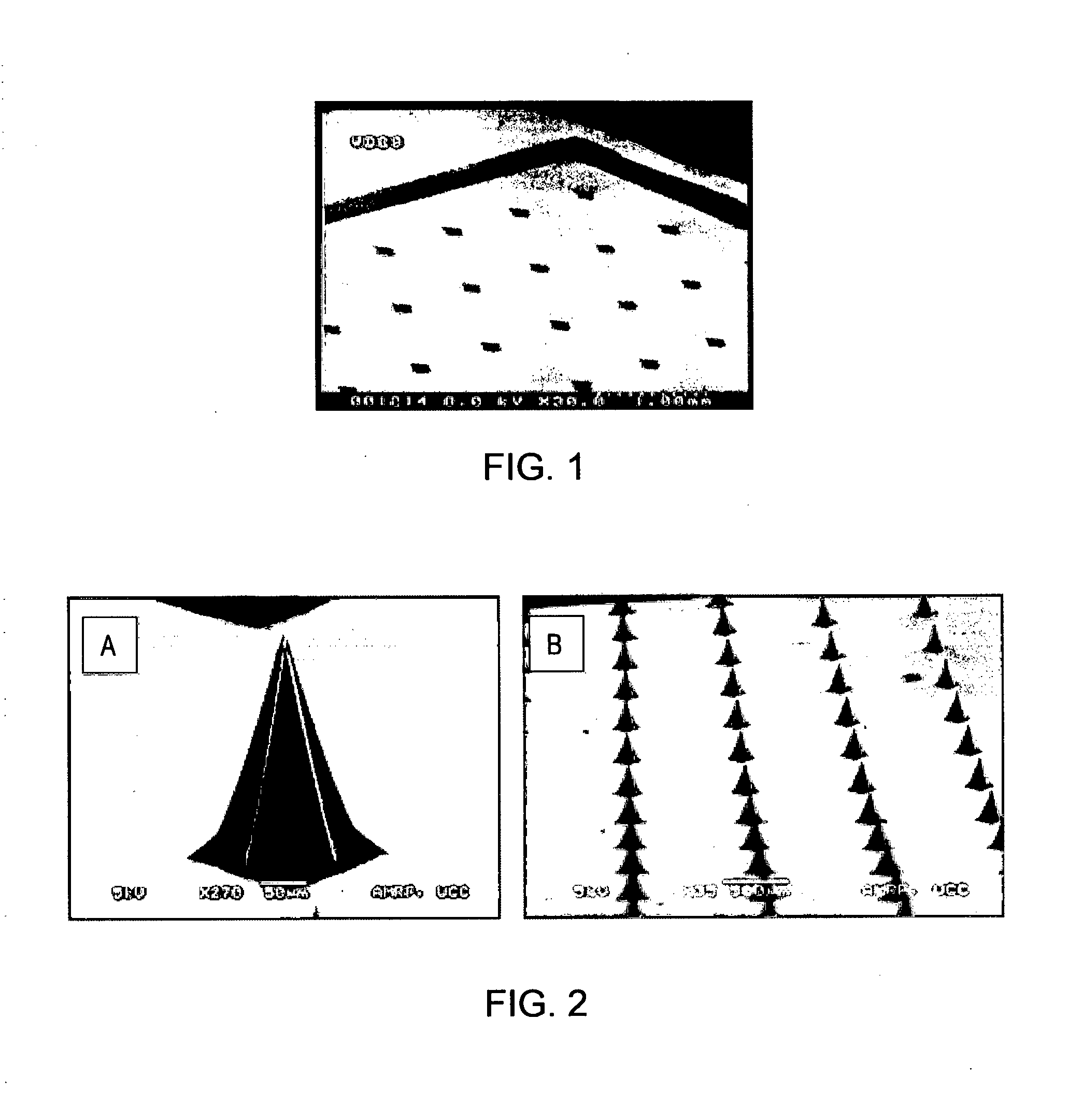

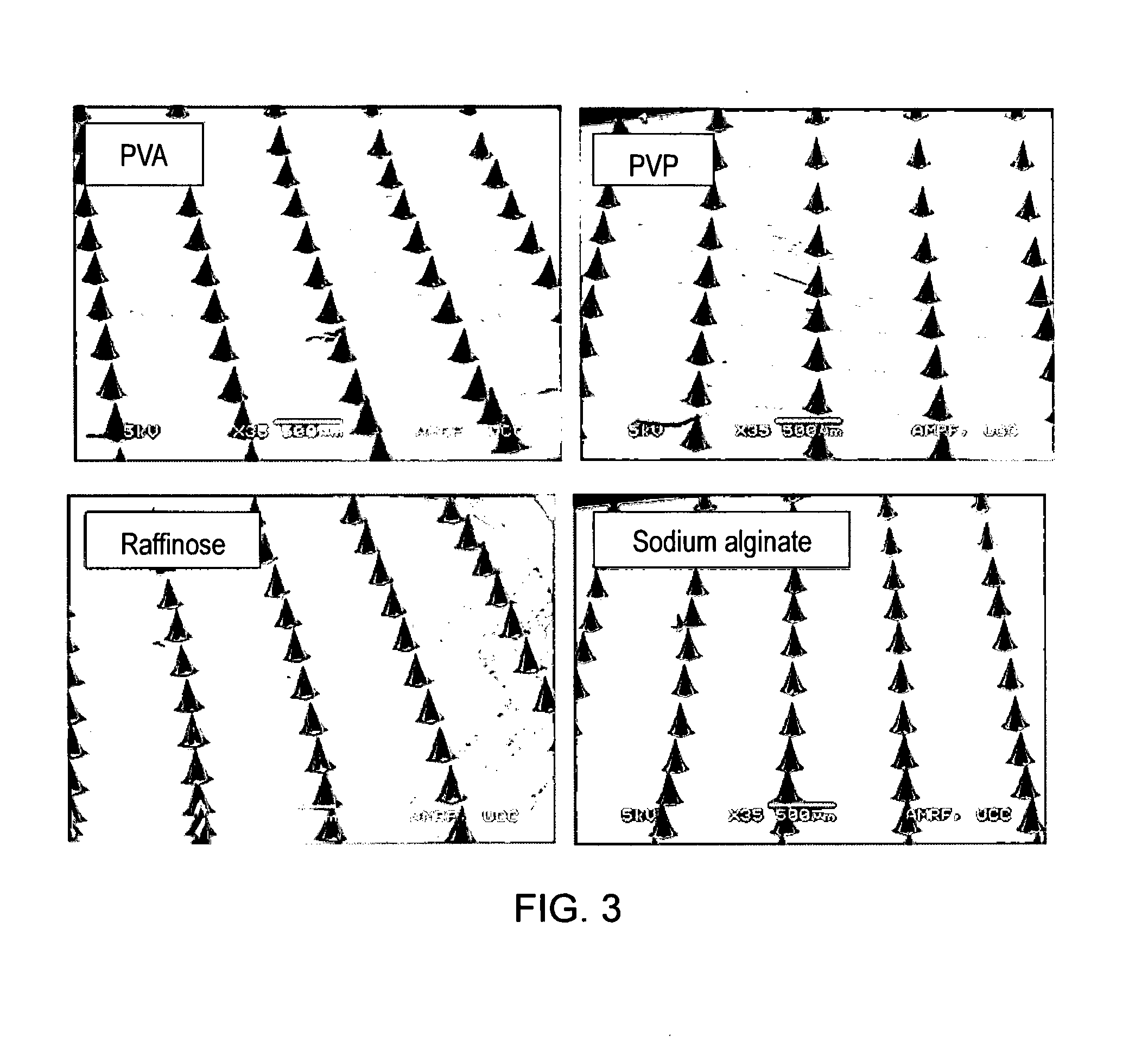

InactiveUS20130310665A1Easy to manufactureMicroneedlesPretreated surfacesCutinBiomedical engineering

The present invention relates to a method for fabricating a microneedle which comprises the steps of spraying a composition into a mould, drying the composition and removal of the dried composition from the mould, thereby forming a microneedle that, when applied to the skin of a subject, pierces the stratum corneum to access the underlying tissue of the subject. The present invention also relates to a method for coating a microneedle which comprises the steps of spraying a composition onto a microneedle and drying the composition at an ambient temperature, thereby forming a coated microneedle that, when applied to the skin of a subject, pierces the stratum corneum to deliver the sprayed material to the underlying tissue of the subject.

Owner:UNIV COLLEGE CORK NAT UNIV OF IRELAND CORK

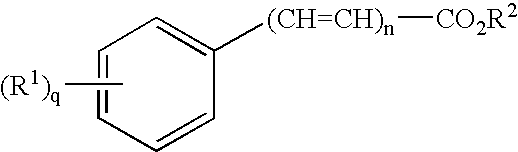

Delivery of hydroxy carboxylic acids

The present invention provides greater than 99% pure bis(triorganosilyl)hydroxycarboxylates of the general formulae: R3SiO-CHR1-COO-SiR3 R3SiO-CHR1-R2COO-SiR3wherein each R is independently a monovalent straight or branched chain alkyl or alkenyl group having from 1 to about 6 carbon atoms, or an aryl group, R1 may be hydrogen, a monovalent straight or branched chain alkyl group having from 1 to about 18 carbon atoms, or an aryl group, and R2 is a divalent straight or branched chain alkyl group having from 1 to about 18 carbon atoms, an aryl group, or a straight or branched chain alkaryl group having from 7 to about 18 carbon atoms; a process for producing the bis(trimethylsilyl)hydroxycarboxylates comprising the trimethylsilylation with hexamethyldisilazane of the corresponding hydroxy carboxylic acids; cosmetic formulation comprising the greater than 99% pure bis(trimethylsilyl)hydroxycarboxylates dissolved in aprotic media; and a method of delivering hydroxycarboxylic acids to the epidermis without apparent irritation or inflammation of the epidermis or stratum corneum.

Owner:SIVANCE

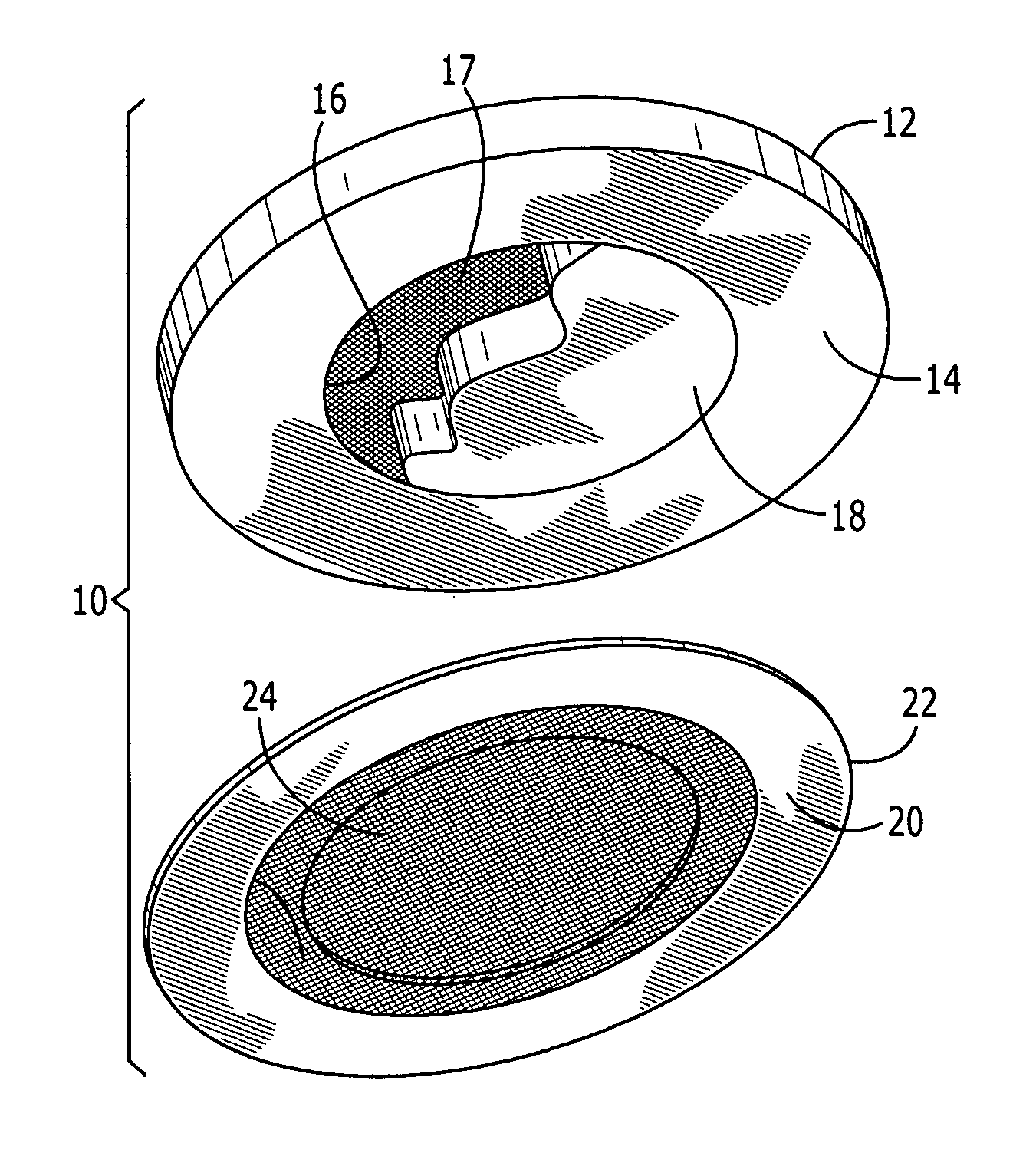

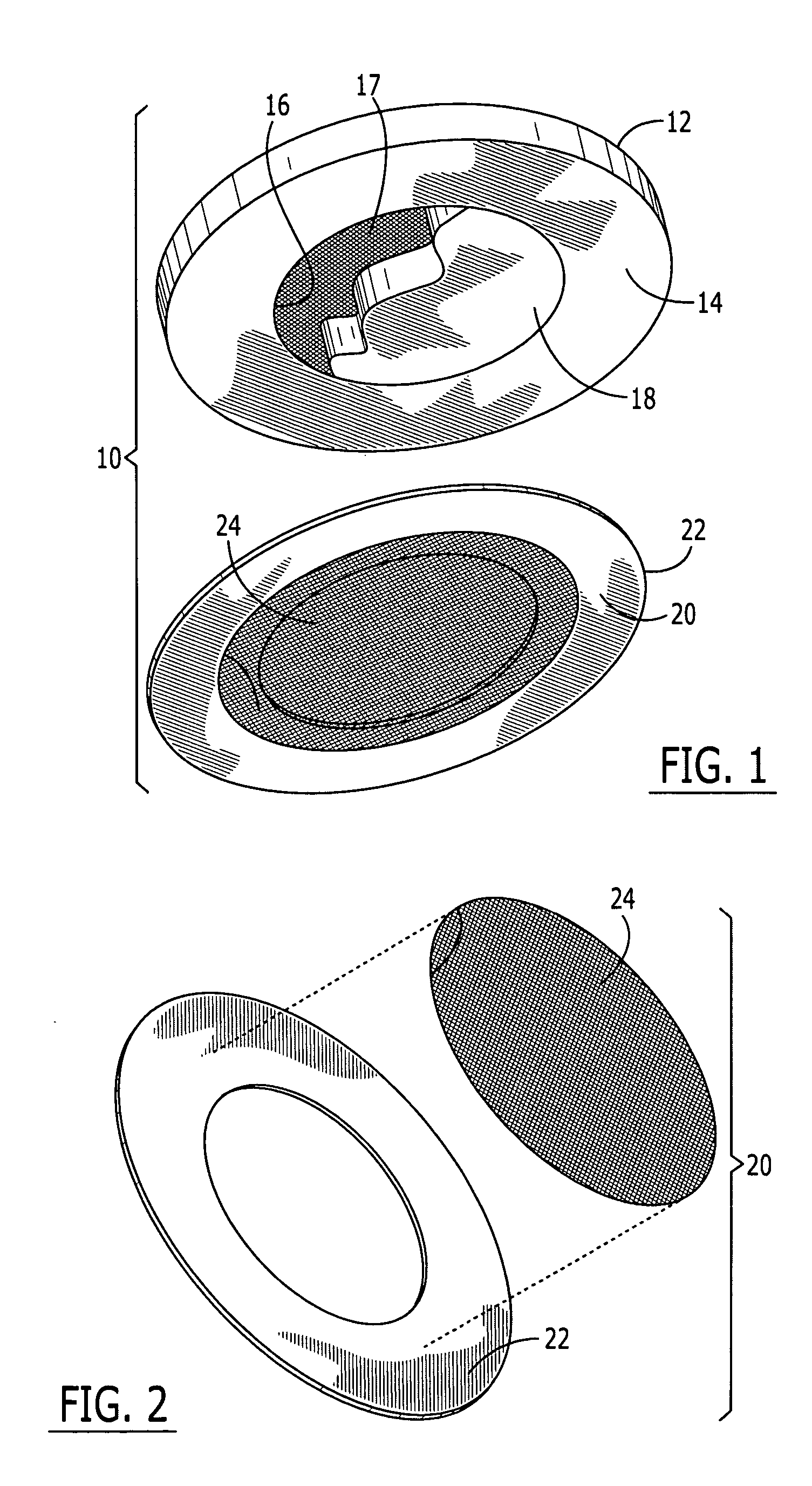

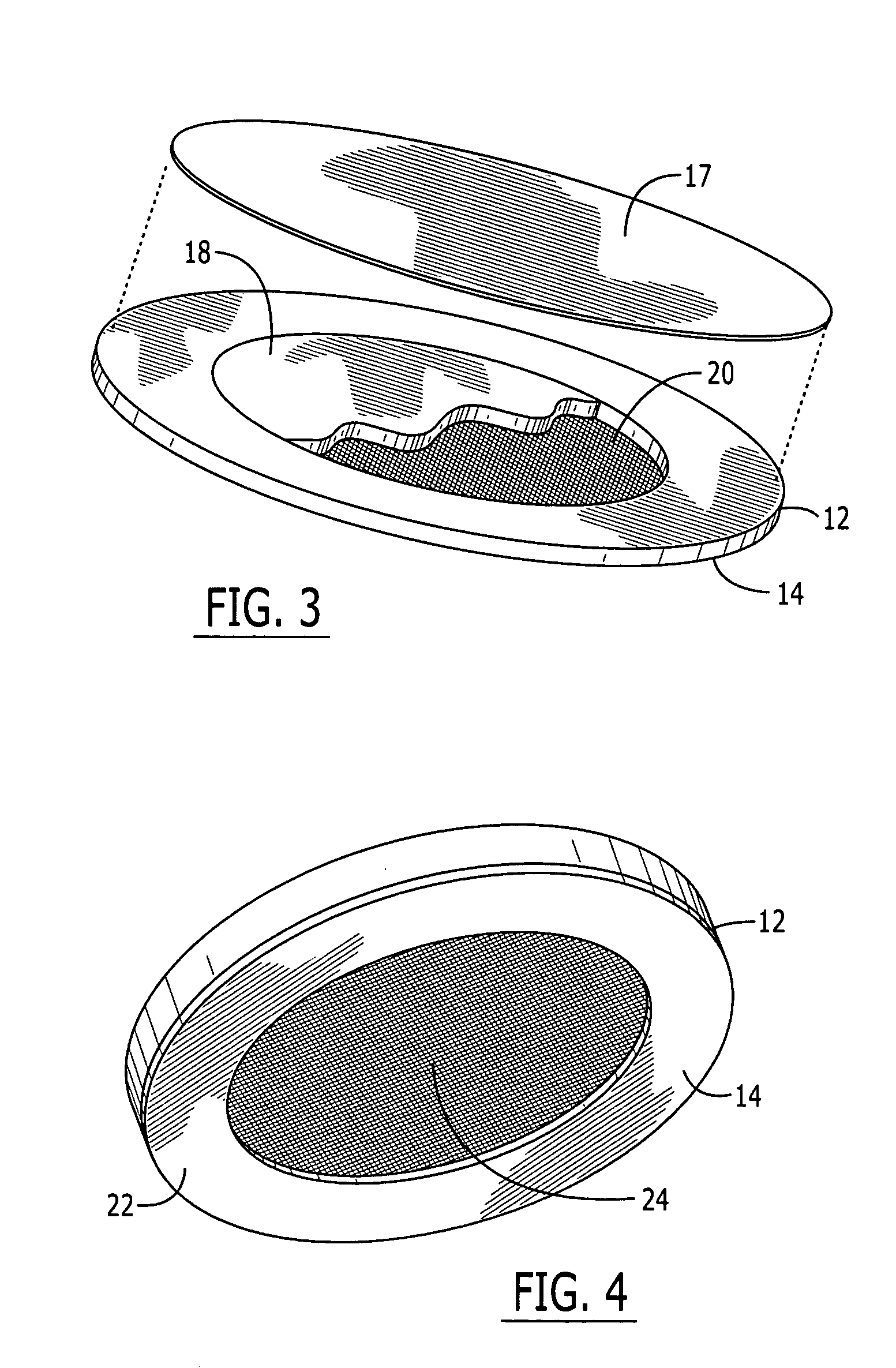

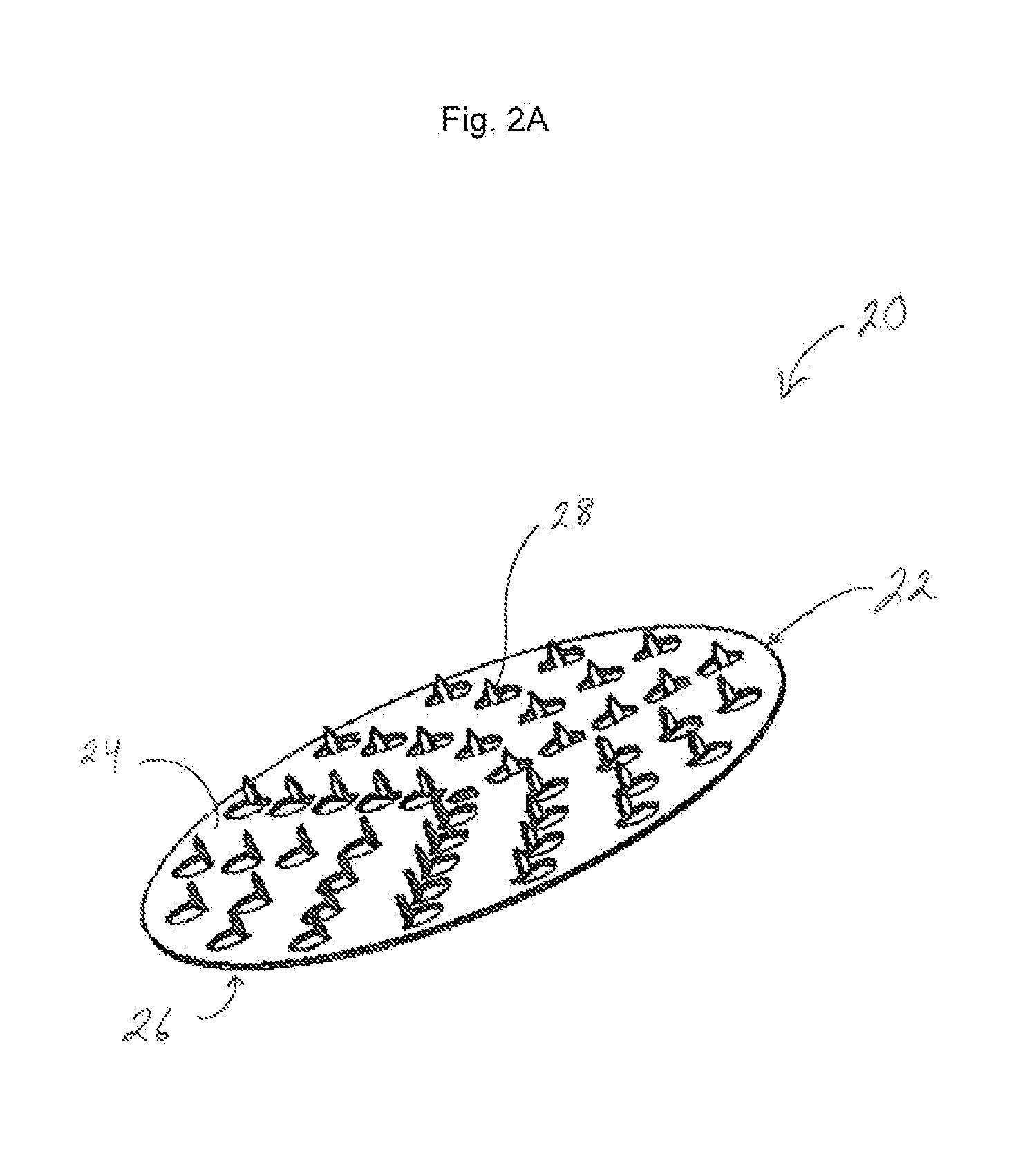

Medical devices and kits including same

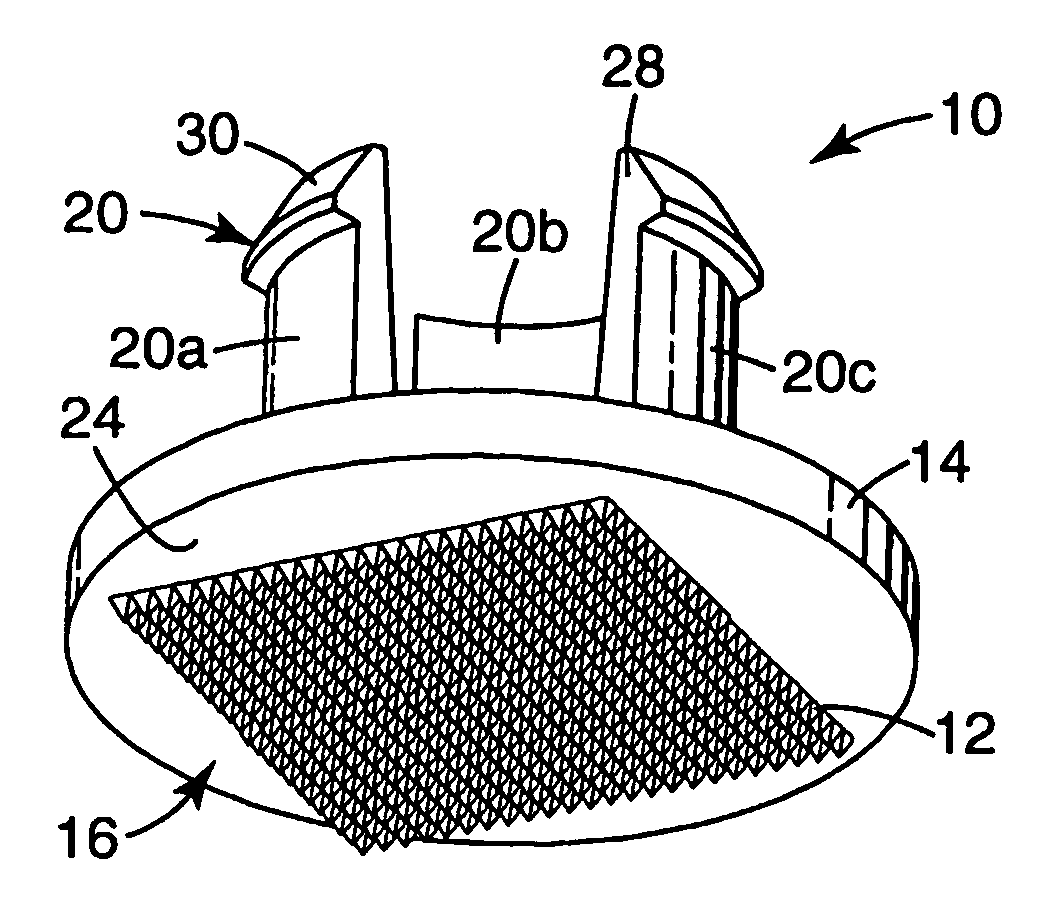

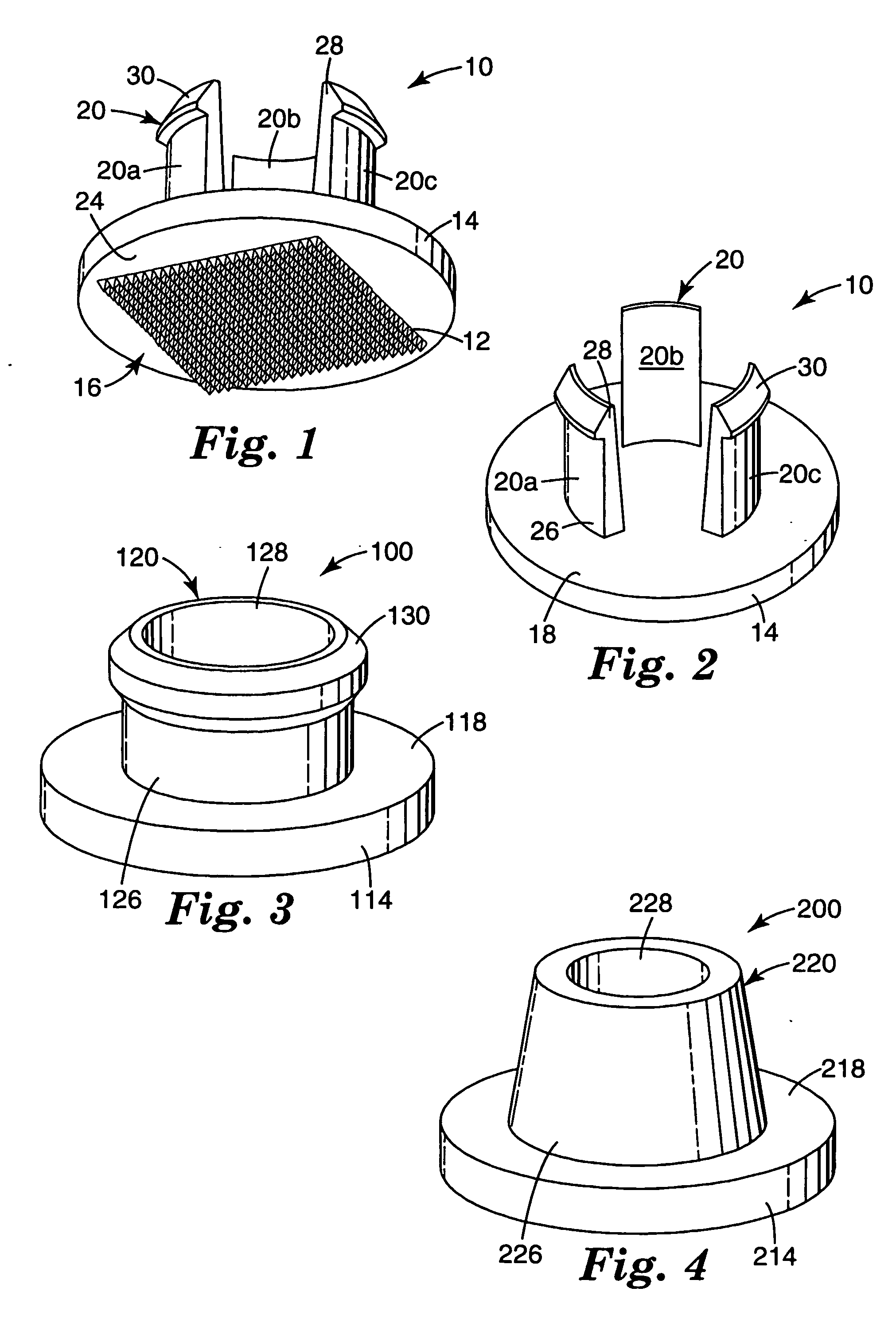

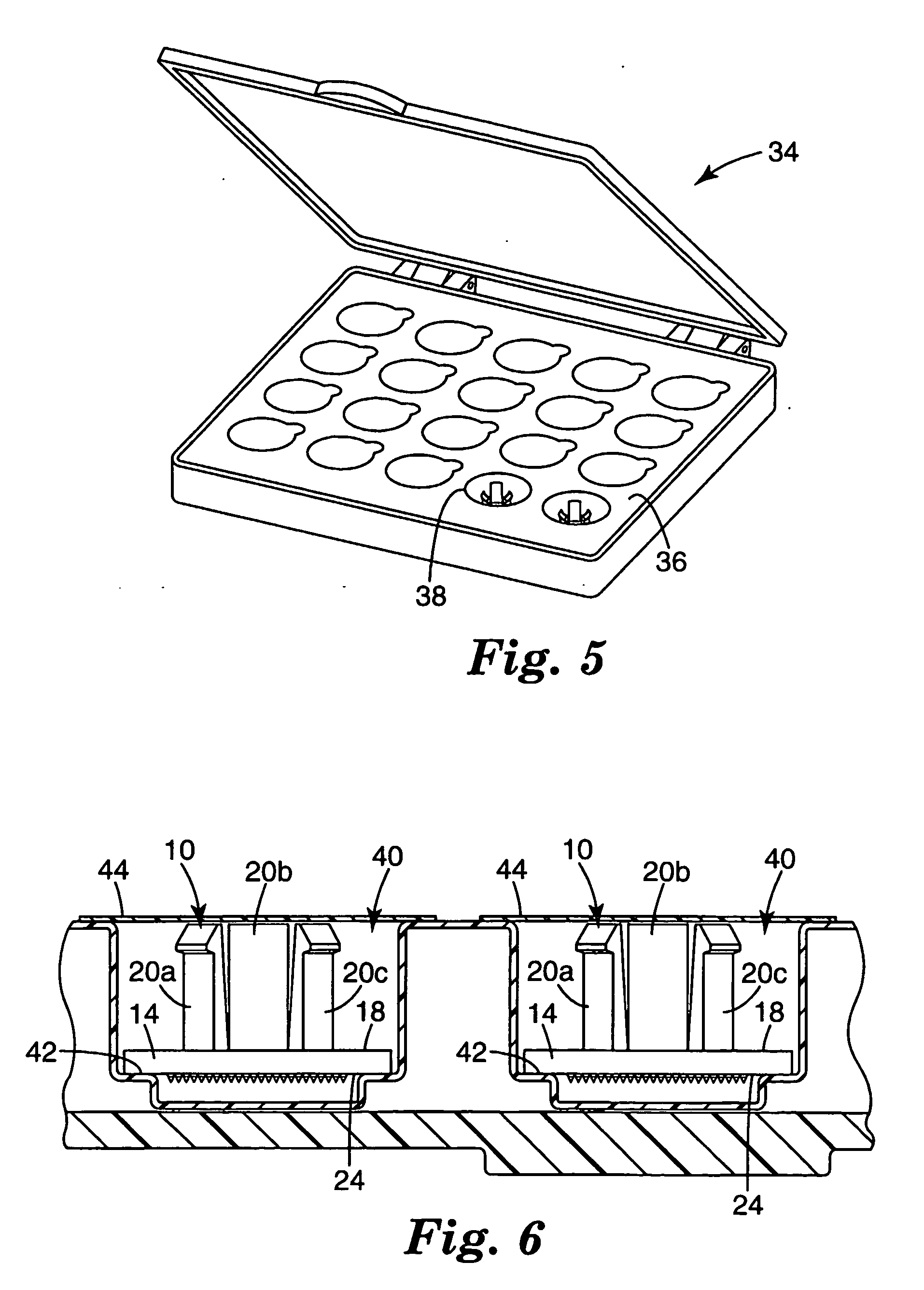

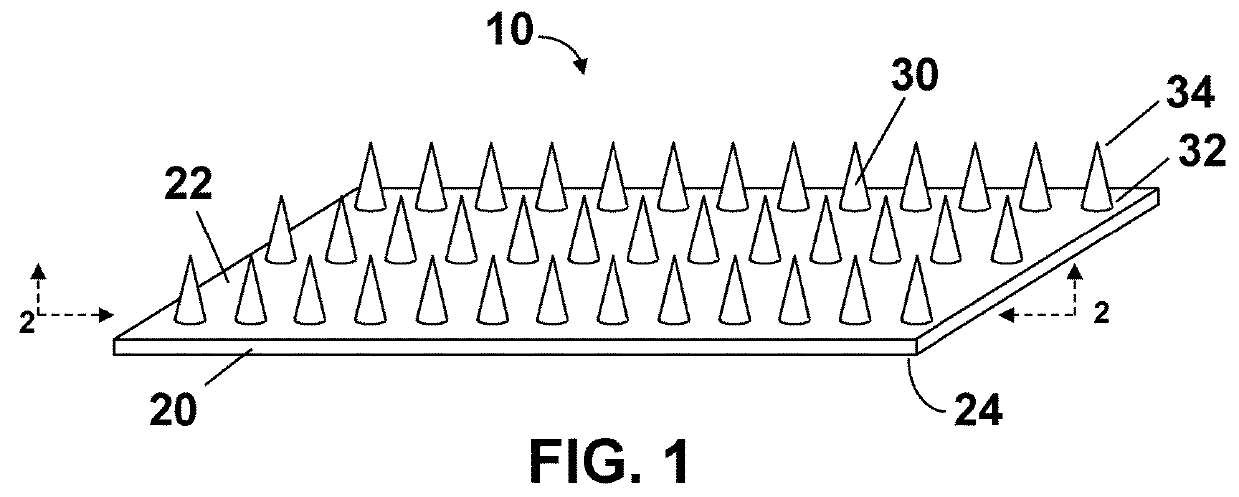

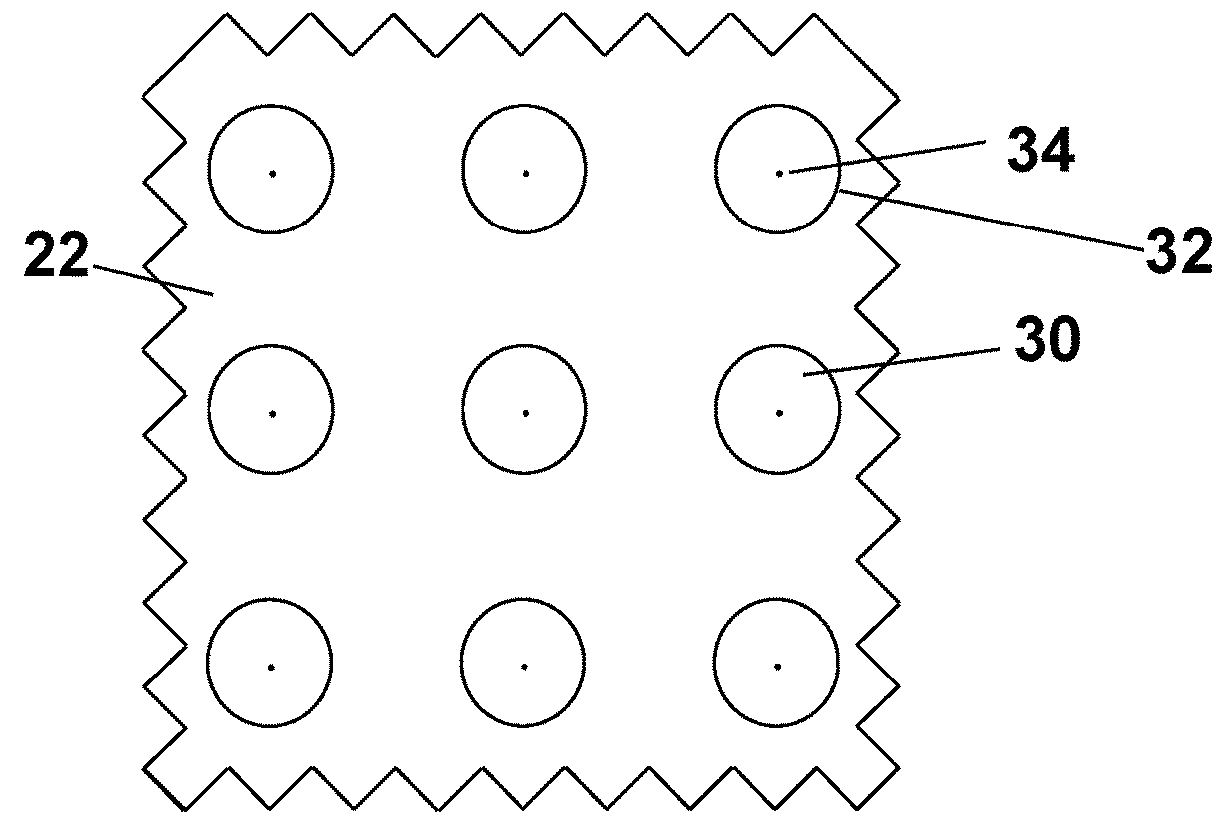

A medical device is described, comprising an array (10) comprising microstructures (12) configured to penetrate the stratum corneum upon impact, and a connection member (20) affixed to the array in a one piece construction, the connection member configured to reversibly connect the medical device to an applicator. The medical devices of the invention may be used in methods requiring the penetration of skin to deliver medicaments or other substances and / or extract blood or tissue through the skin. In use, it is generally desirable to provide the microstructures at a height sufficient to penetrate the stratum corneum. A medical kit is also described, comprising the foregoing medical device and a tray (34) configured to hold the medical device.

Owner:3M INNOVATIVE PROPERTIES CO

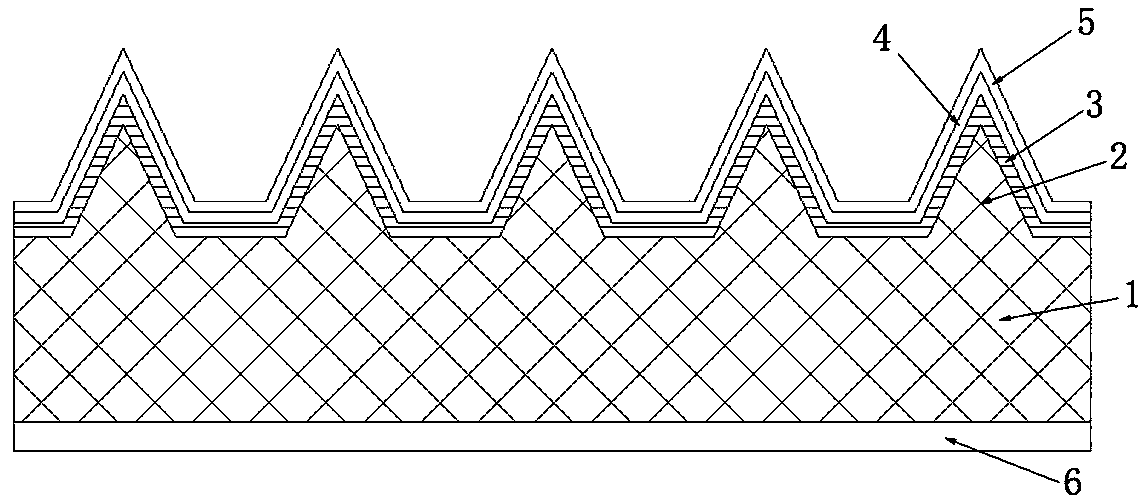

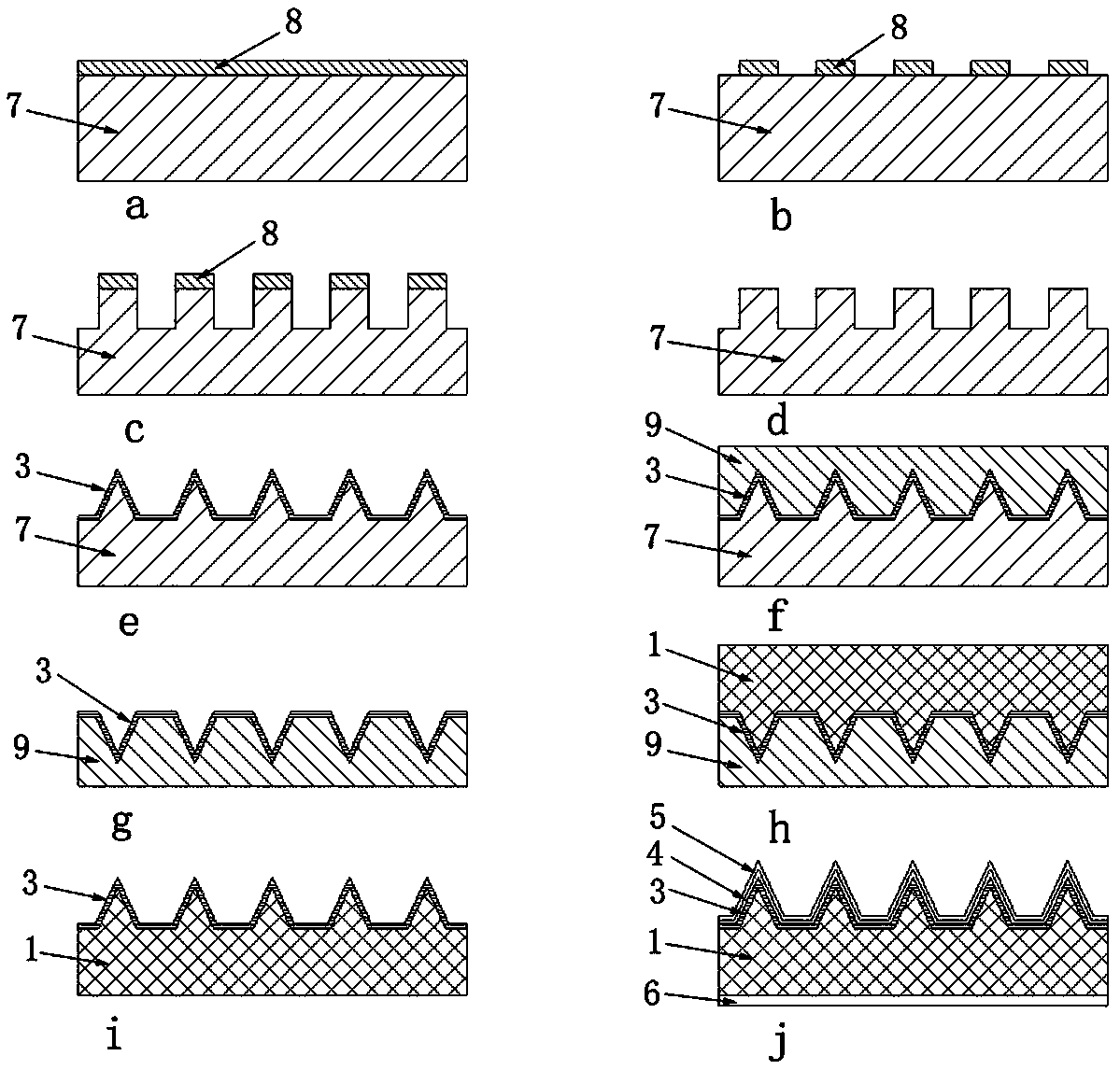

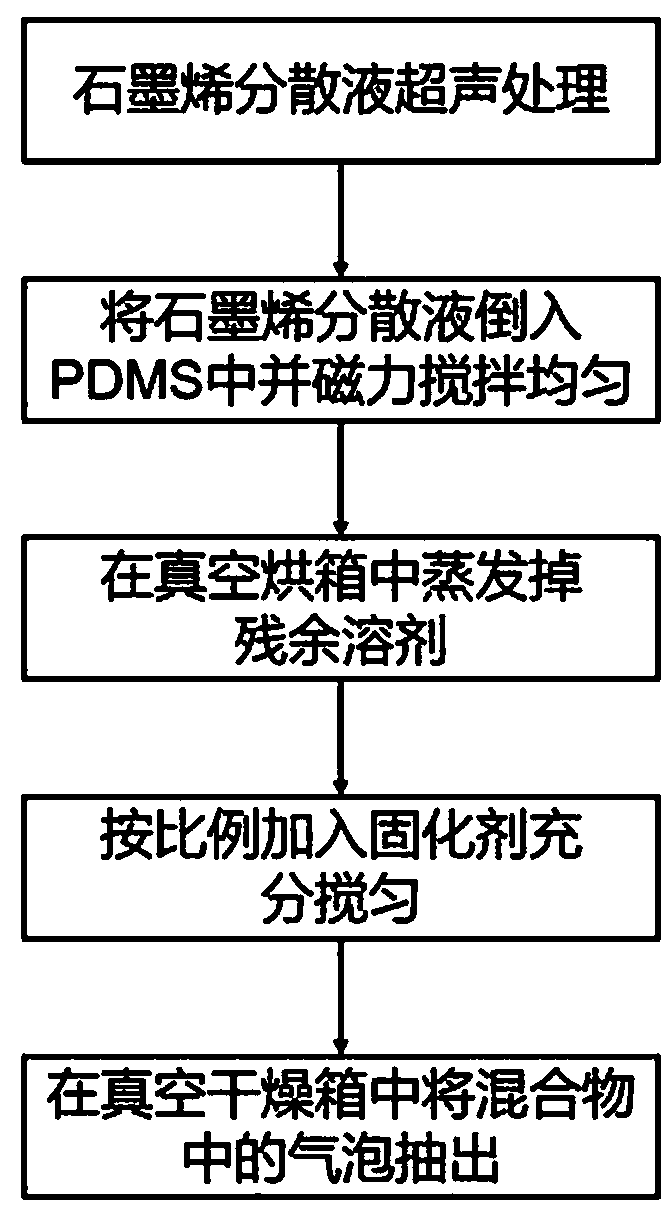

Graphene-PDMS flexible substrate electrocardiogram dry electrode based on tip array structure and preparation method thereof

ActiveCN108975266AReduce contact resistanceImprove stabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEcg signalSputtering

The invention relates to a graphene-PDMS flexible substrate electrocardiogram dry electrode based on a tip array structure and a preparation method thereof. a graphene-PDMS flexible substrate is designed on a top surface thereof, a paraxylene film is deposited on tip array structure, metal seed layer is sputtered on paraxylene film, a metal lalyer is sputtered on the metal seed layer. The bottom surface of the graphene-PDMS flexible conductive substrate is coated with a conductive silver paste layer. The process of the invention is simple, the cost is low, and the production of the mould is favorable for batch production. The materials such as conductive silver colloid, PDMS, graphene, paraxylene film and sputtered titanium and gold have good biological compatibility, and can effectively inhibit bacteria and reduce skin irritation. The tip array structure designed by the invention has a larger contact area, and can pass through the stratum corneum by directly contacting with the skin,so that contact impedance of the skin-electrode can be effectively reduced, thus obtaining a stable ECG signal.

Owner:ZHONGBEI UNIV

Devices, systems, methods and tools for continuous glucose monitoring

One aspect of the invention provides a glucose monitor having a plurality of tissue piercing elements, each tissue piercing element having a distal opening, a proximal opening and interior space extending between the distal and proximal openings; a sensing volume in fluid communication with the proximal openings of the tissue piercing elements; sensing fluid extending into the sensing volume; and a glucose sensor adapted to detect a concentration of glucose in the sensing fluid within the sensing volume. Another aspect of the invention provides A method of in vivo monitoring of an individual's interstitial fluid glucose concentration comprising: inserting distal ends of a plurality of tissue piercing elements through a stratum corneum area of the individual's skin, the tissue piercing elements each comprising a distal opening, a proximal opening, and an interior space extending between the distal and proximal opening; allowing interstitial fluid to flow into the interior space of the tissue piercing elements to substantially fill the interior space; filling substantially the entire interior space of the sensing area; and sensing a glucose concentration of the sensing fluid.

Owner:ARKAL MEDICAL

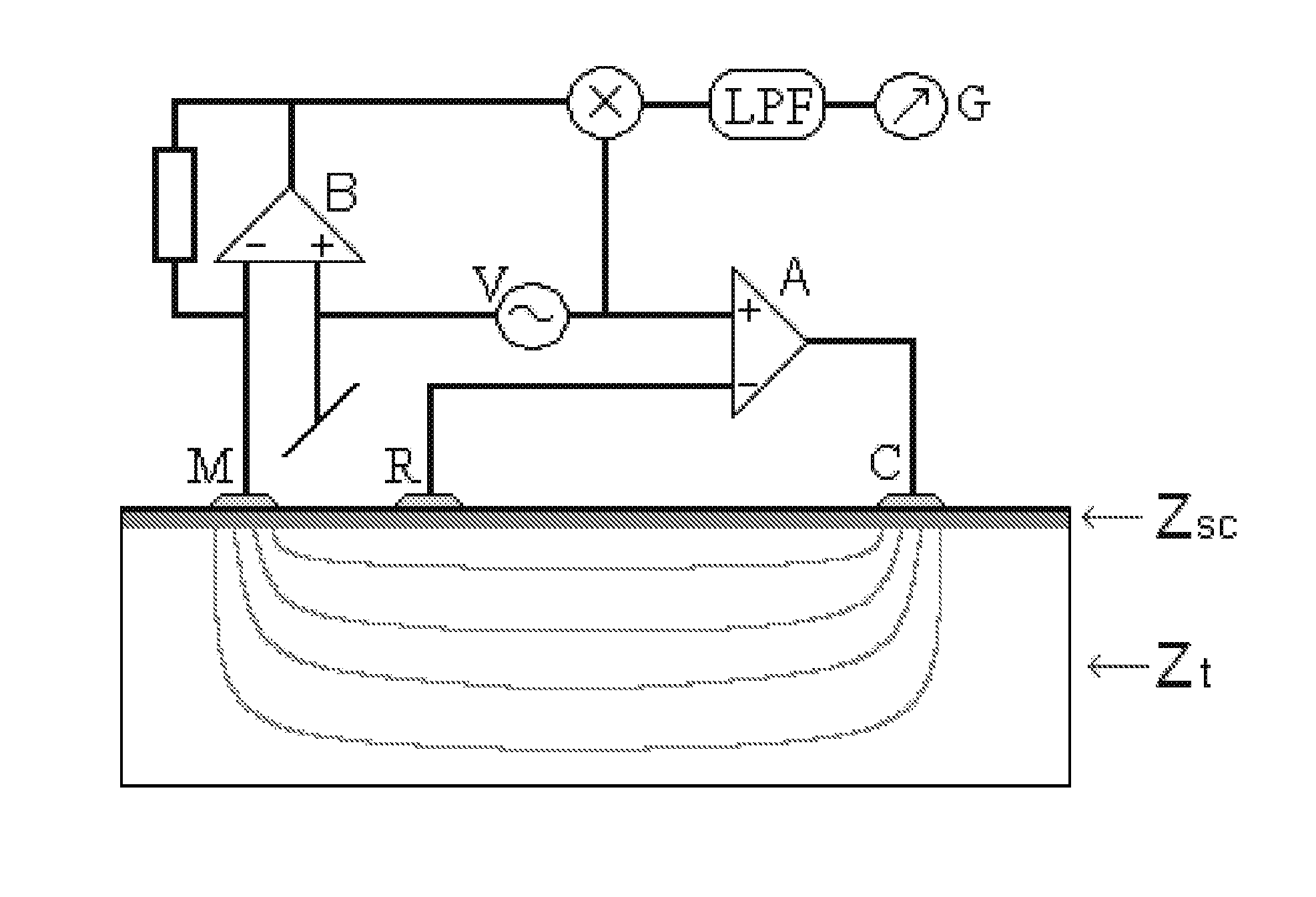

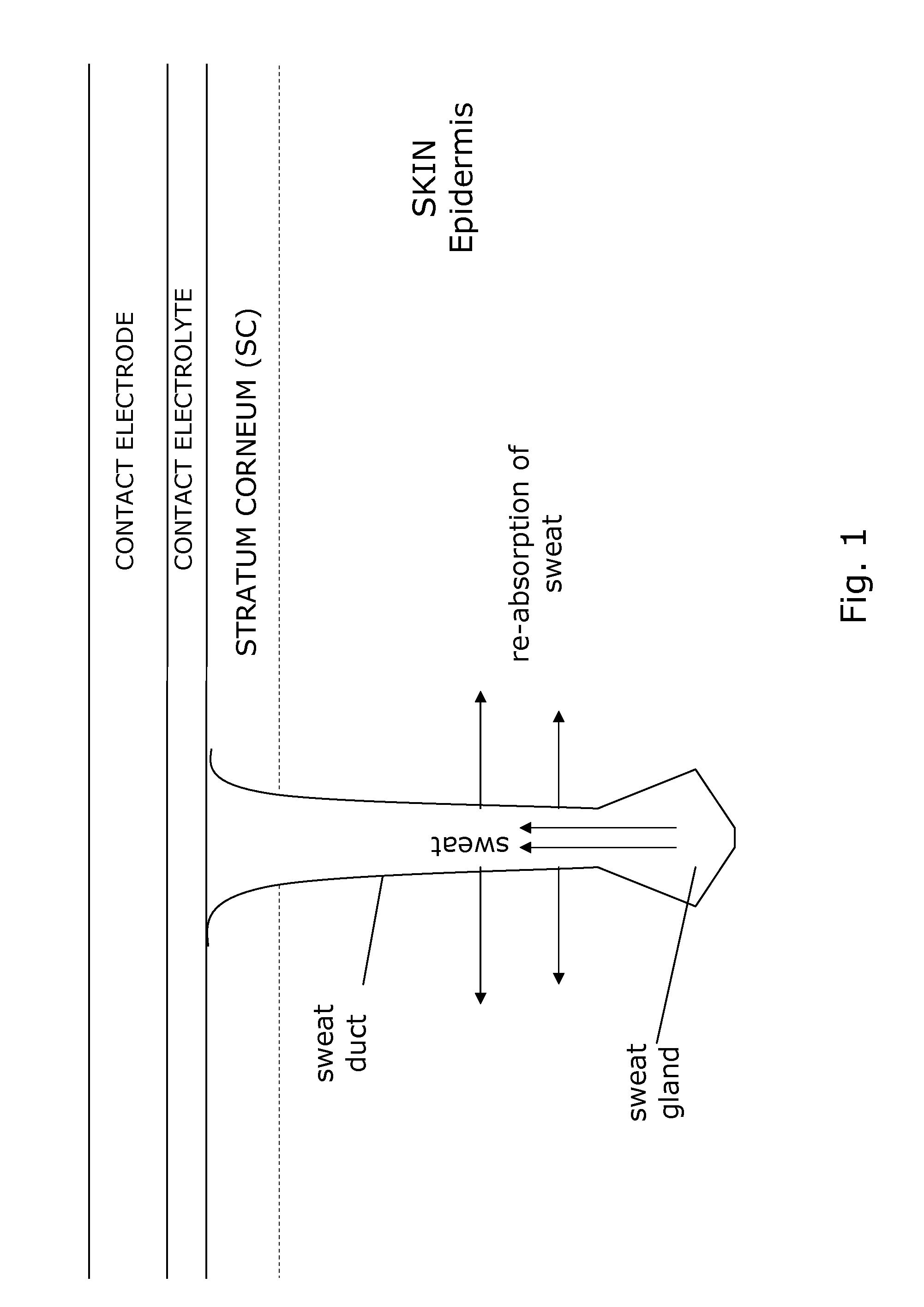

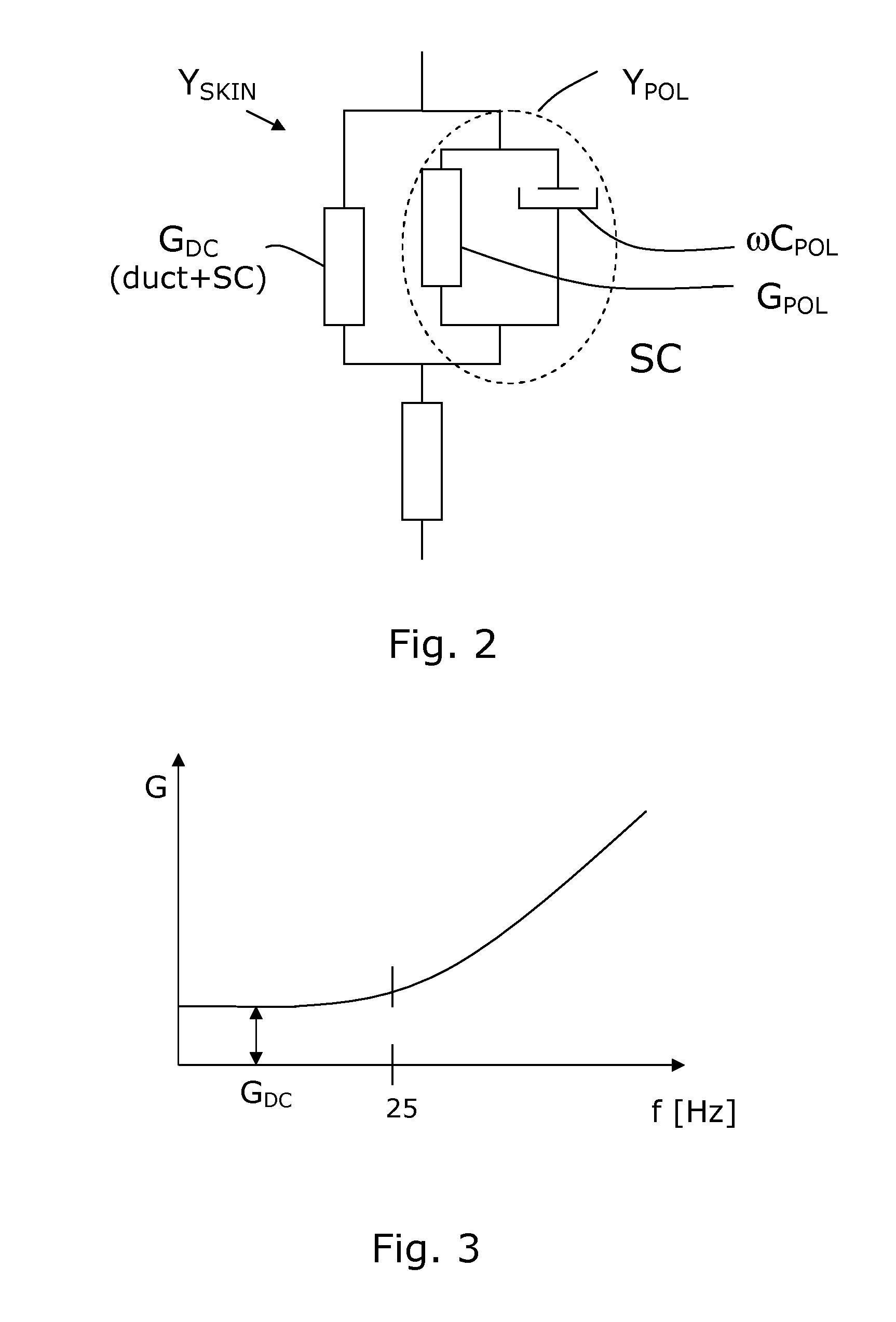

Method and kit for sweat activity measurement

InactiveUS8565850B2Simple and robustSimple technologySensorsTelemetric patient monitoringEngineeringRe absorption

The invention relates to sweat activity measurement, e.g. for determining a physiological state of a subject, embodied by a method as well as a kit with an immittance measuring circuit and electrodes with contact electrolyte. Sweat activity is considered a transport phenomenon and can be defined as a flux, e.g. gram water per skin area per second. Prior art methods determining water absorbed per gram dry stratum corneum measures skin moisture and do not truly reflect sweat activity. A periodic signal with frequency of 60 Hz or lower is applied to reduce contribution from complex admittance of the skin, and skin conductance is measured as a degree of sweat activity. The contact electrolyte allows filling of sweat ducts with sweat from sweat glands, this may be characterized in that it does not substantially fill the sweat ducts when being positioned on the skin and / or in that it has a re-absorption time constant from the sweat ducts into the Epidermis of less than 15 min.

Owner:UNIVERSITY OF OSLO

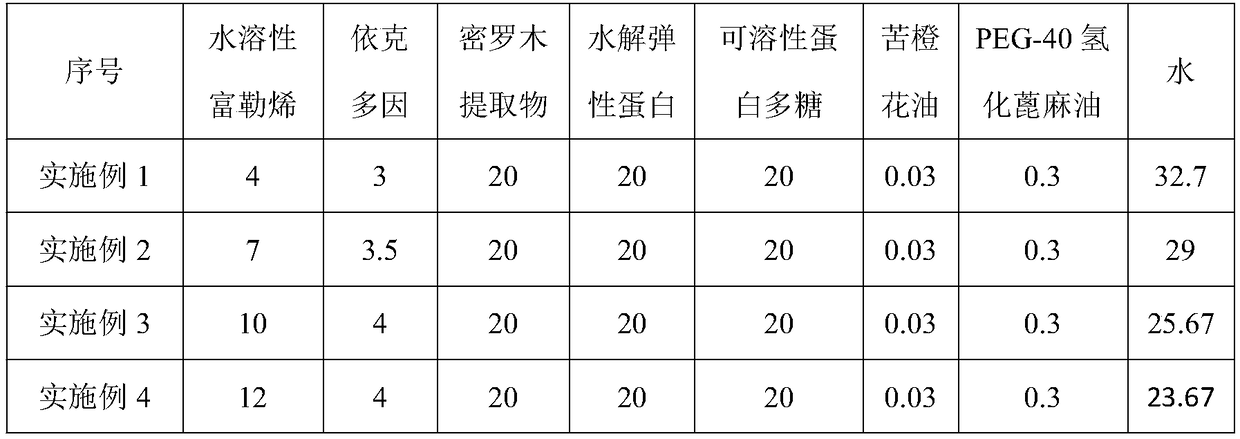

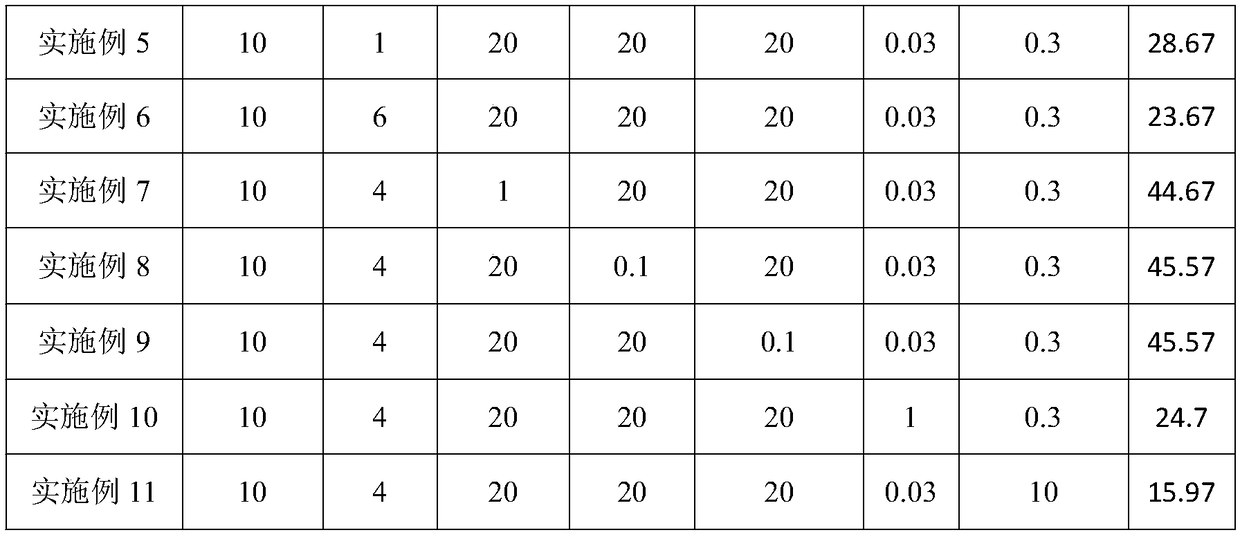

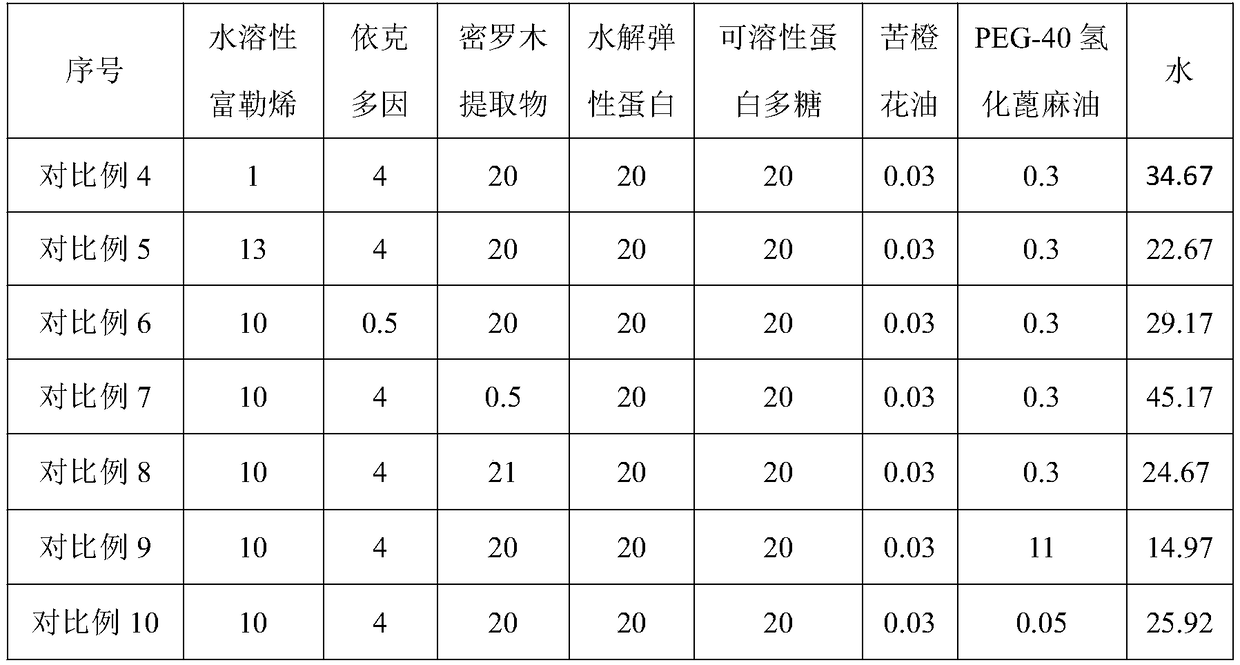

Skincare base with effects of preserving moisture, improving wrinkles and resisting oxidation as well as preparation method and application of skincare base

The invention discloses a skincare base with effects of preserving moisture, improving wrinkles and resisting oxidation as well as a preparation method and an application of the skincare base. The skincare base comprises components in parts by mass as follows: 2-12 parts of water soluble fullerene, 1-6 parts of Ectoin, 1-20 parts of myrothamnus flabellifolia extract, 0.1-20 parts of soluble proteoglycan, 0.1-20 parts of hydrolyzed elastin, 0.01-1 part of bitter orange flower oil, 0.1-10 parts of PEG-40 hydrogenated castor oil and 10-35 parts of water. By means of interaction of the components,active components of the skincare base can be completely absorbed by skin, moisture content of stratum corneum epidermidis is increased by about 30% after 4-week application and is increased by 35% or more when the skincare base is applied to cosmetics, capacity of resisting oxidation free radicals is increased by 30% and is increased by 40% or more when the skincare base is applied to the cosmetics, and wrinkle reduction rate of the skincare base can reach 20% and is 32% when the skincare base is applied to the cosmetics.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

Microneedle arrays and methods for making and using

An array of differing microneedles can be accurately achieved including a film having first and second, outwardly facing major surfaces. The first, outwardly facing major surface has a plurality of stratum corneum piercing microneedles extending therefrom, and the plurality of microneedles includes a plurality of first microneedles having a first benefit agent and a plurality of second microneedles having a second benefit agent.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com