Patents

Literature

48results about How to "Easy to automate jobs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

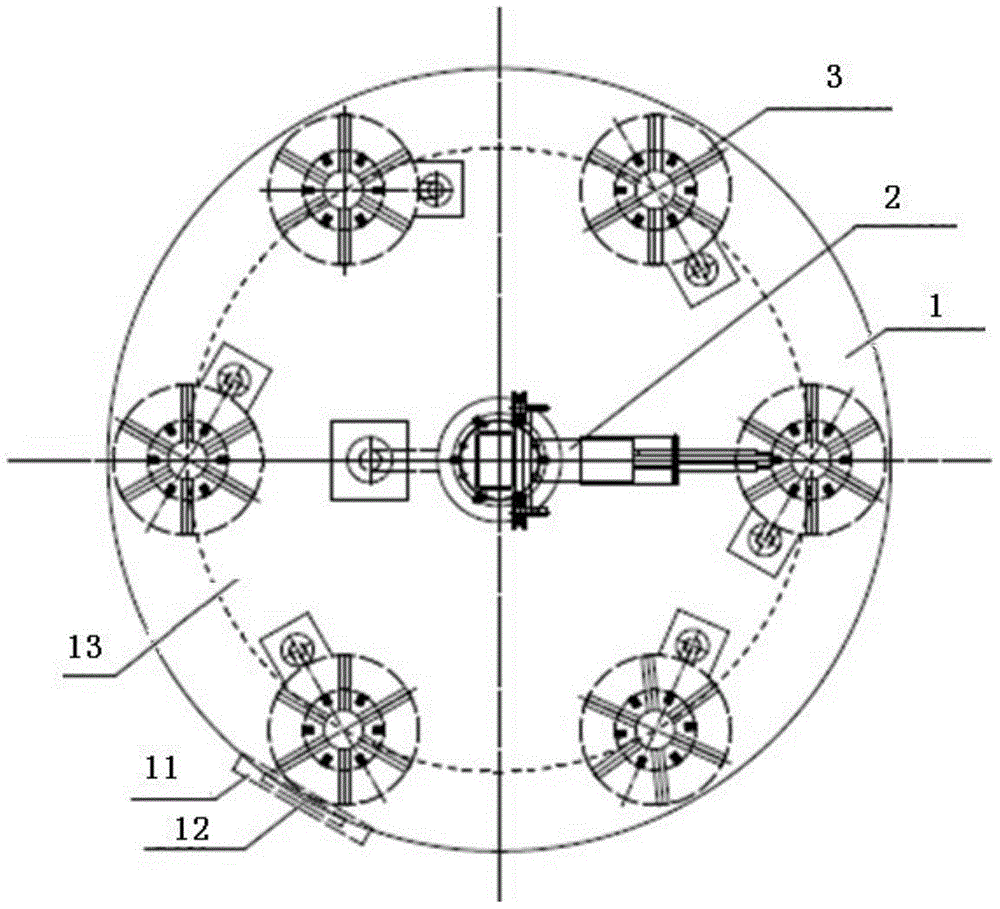

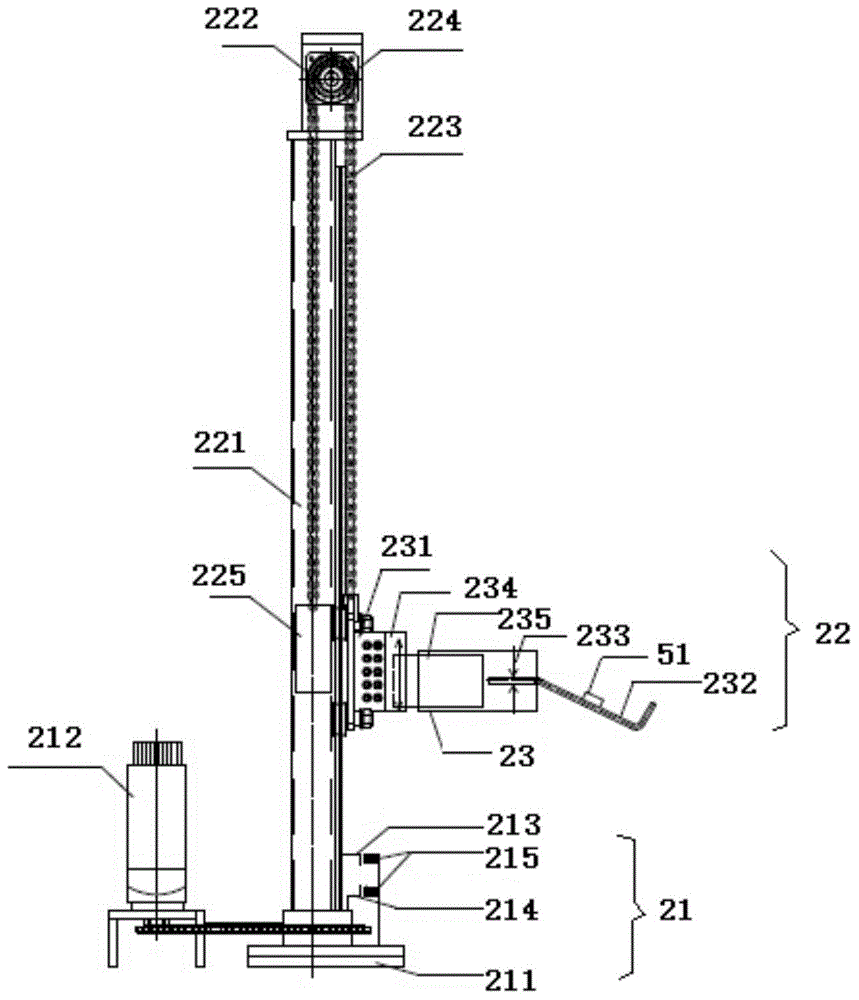

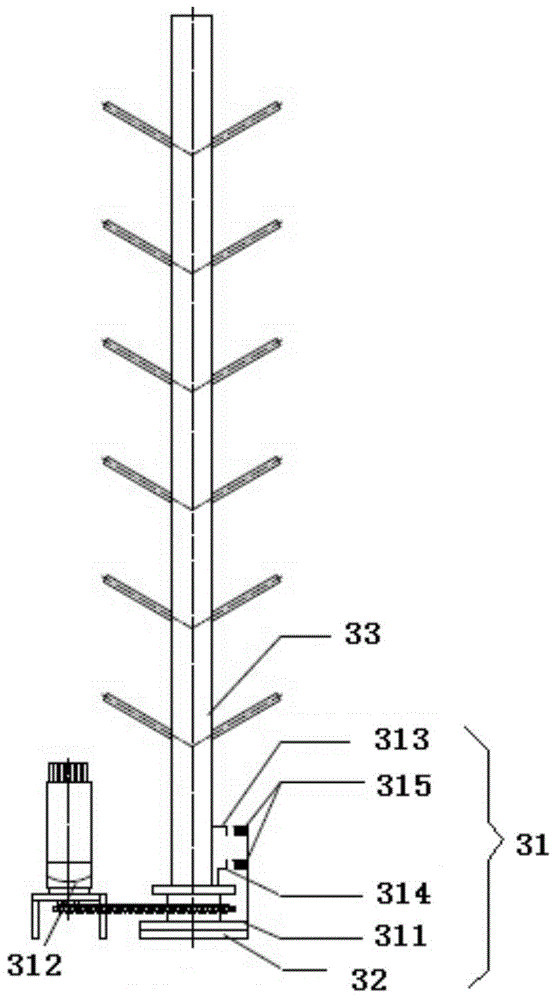

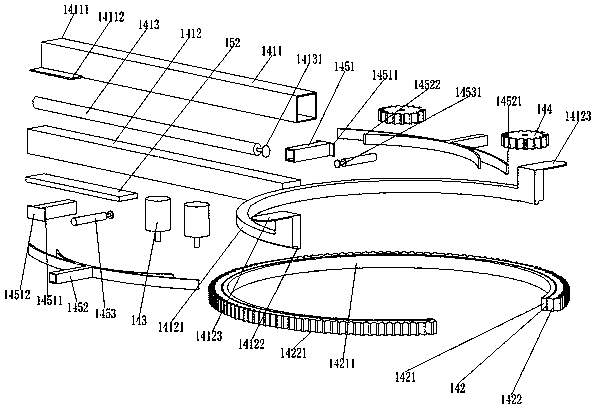

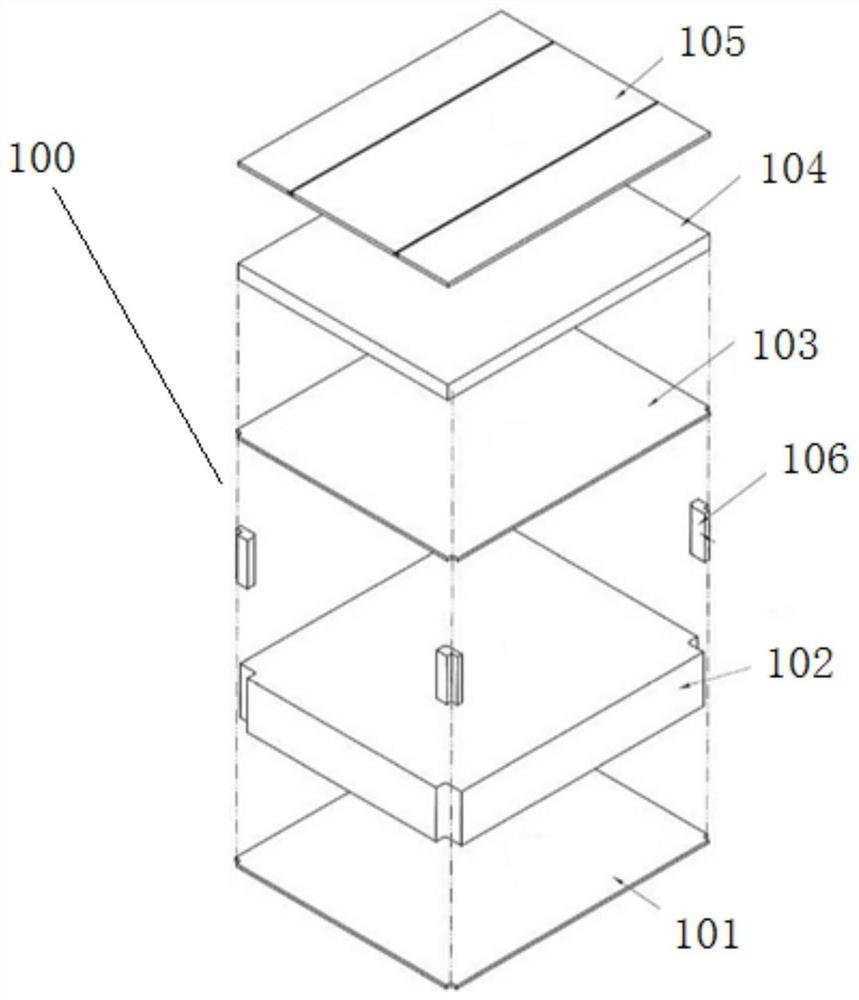

Rotary type automatic goods storing and taking device and method

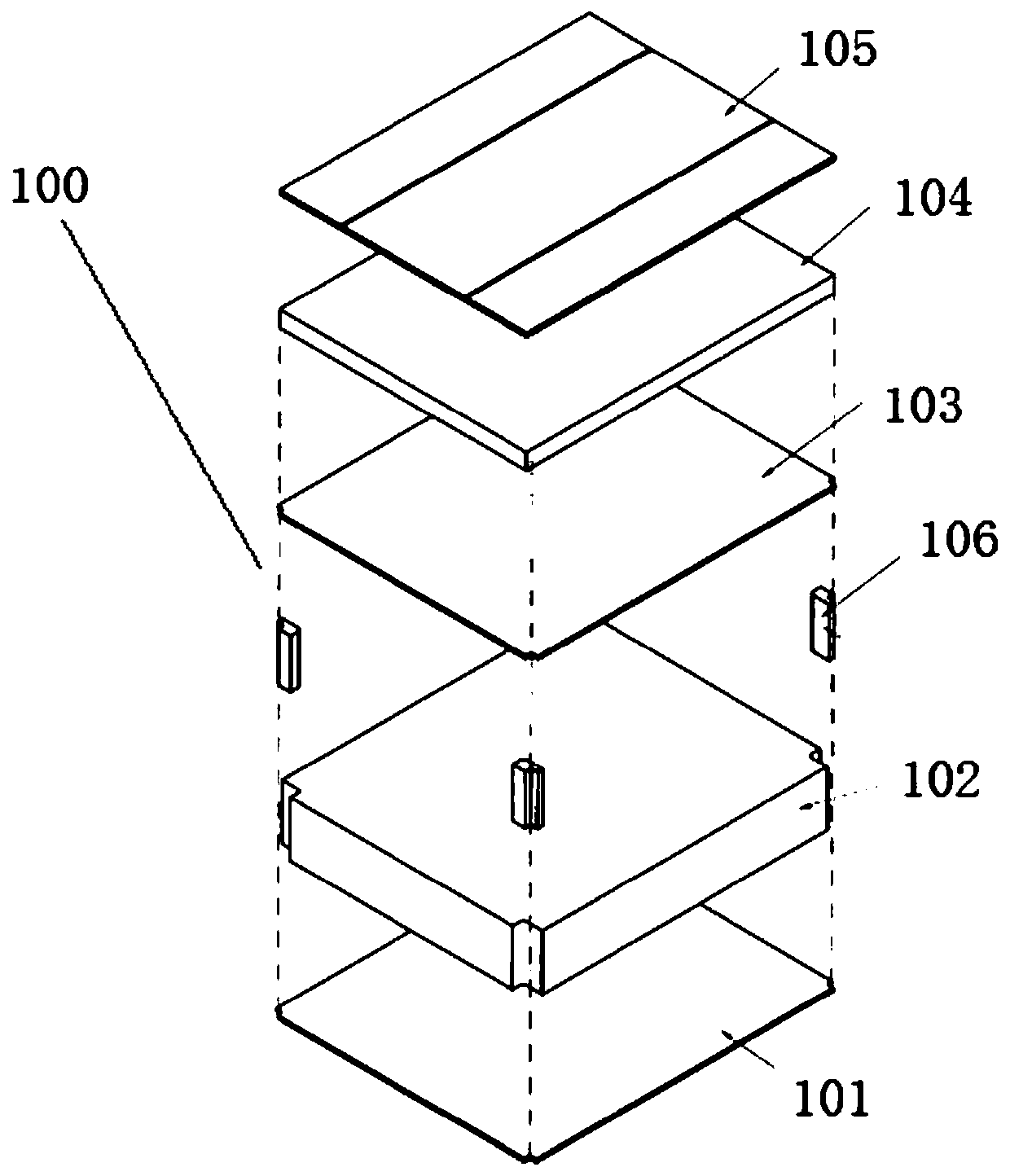

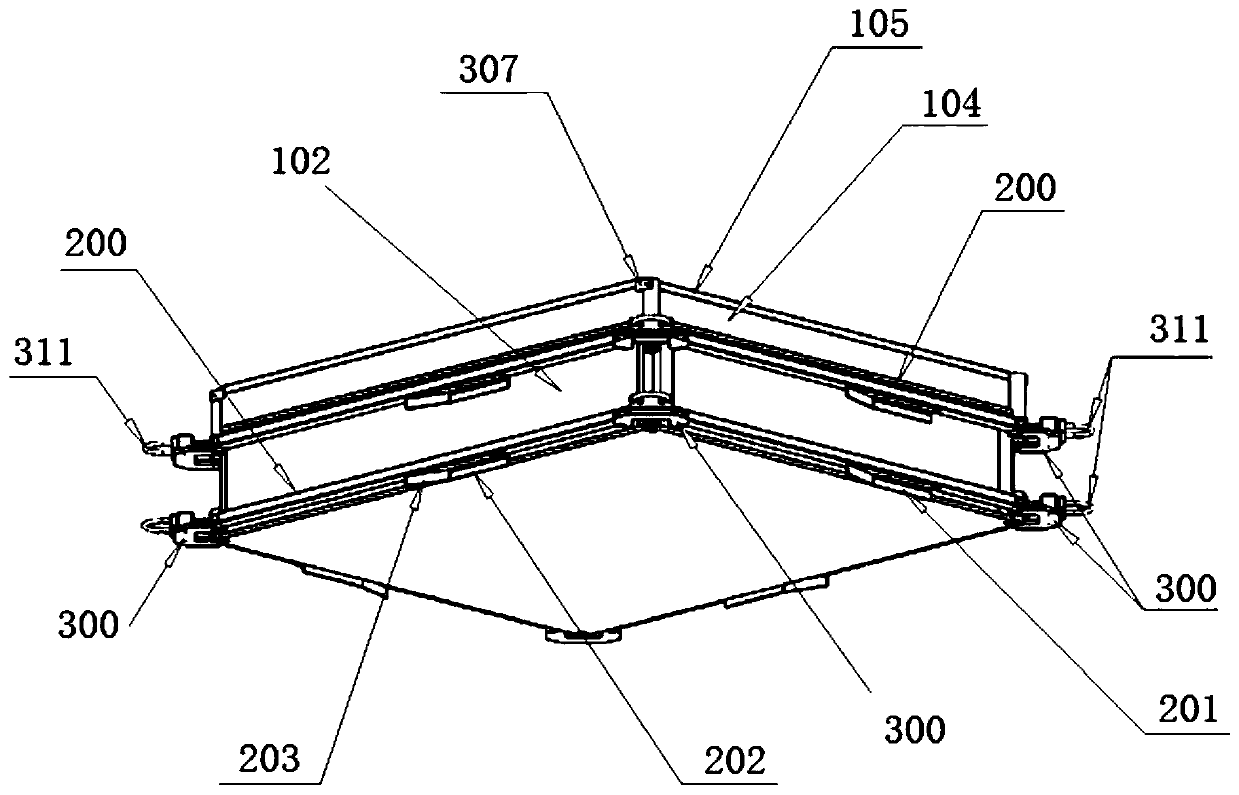

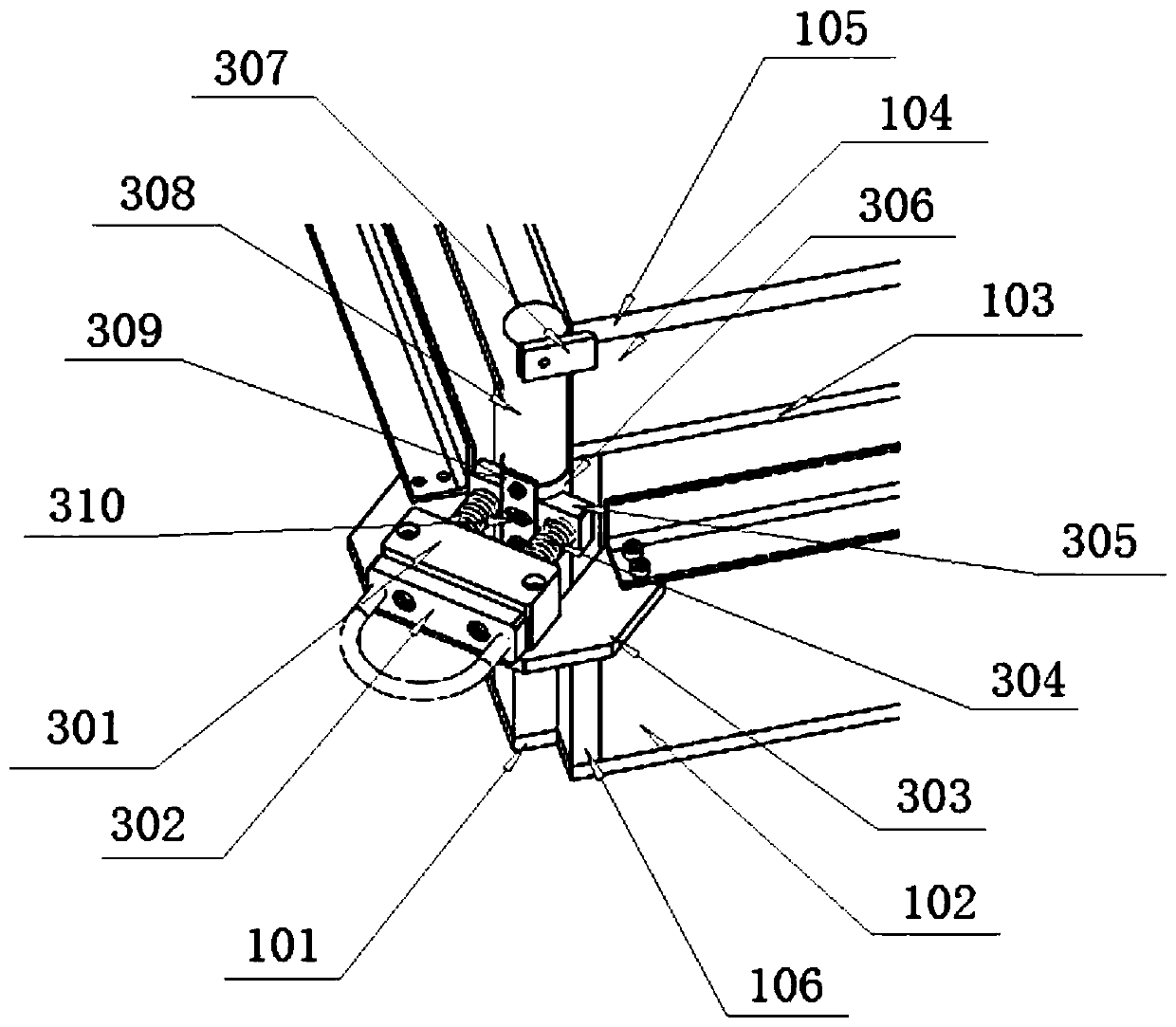

InactiveCN104443977ASmall footprintImprove space utilizationStorage devicesIdentity recognitionOperation mode

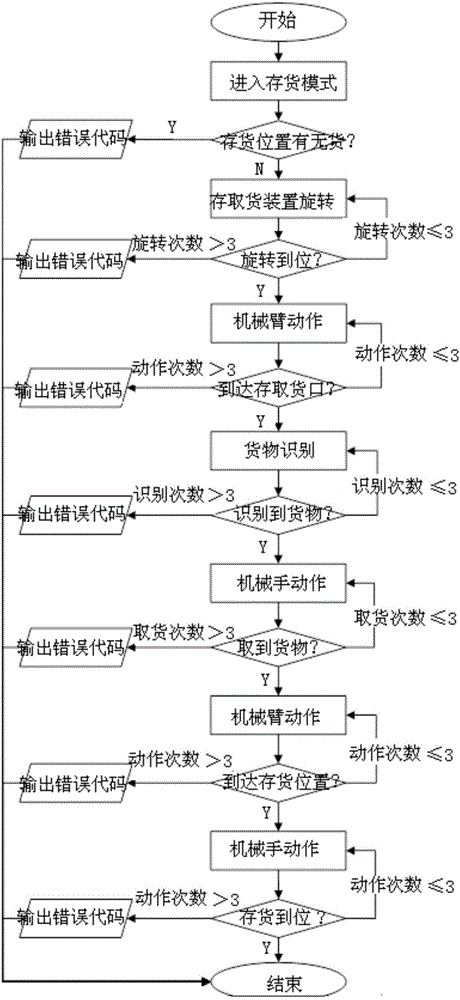

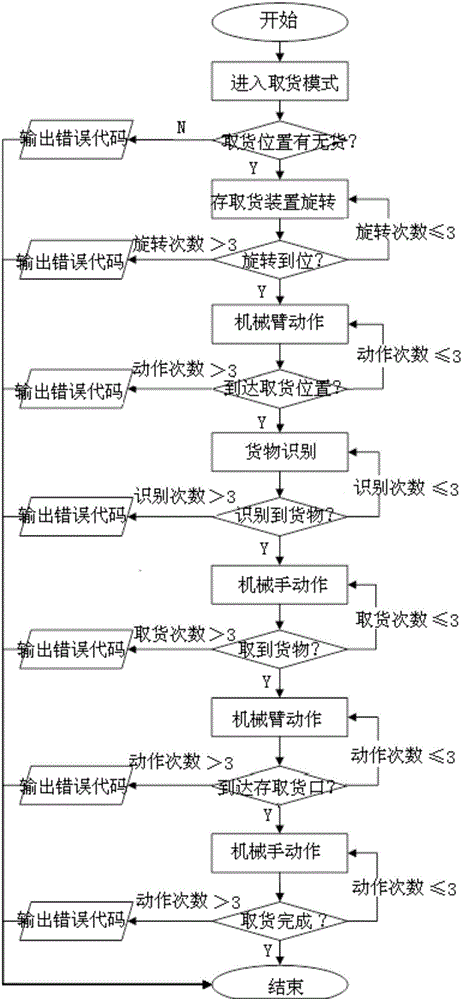

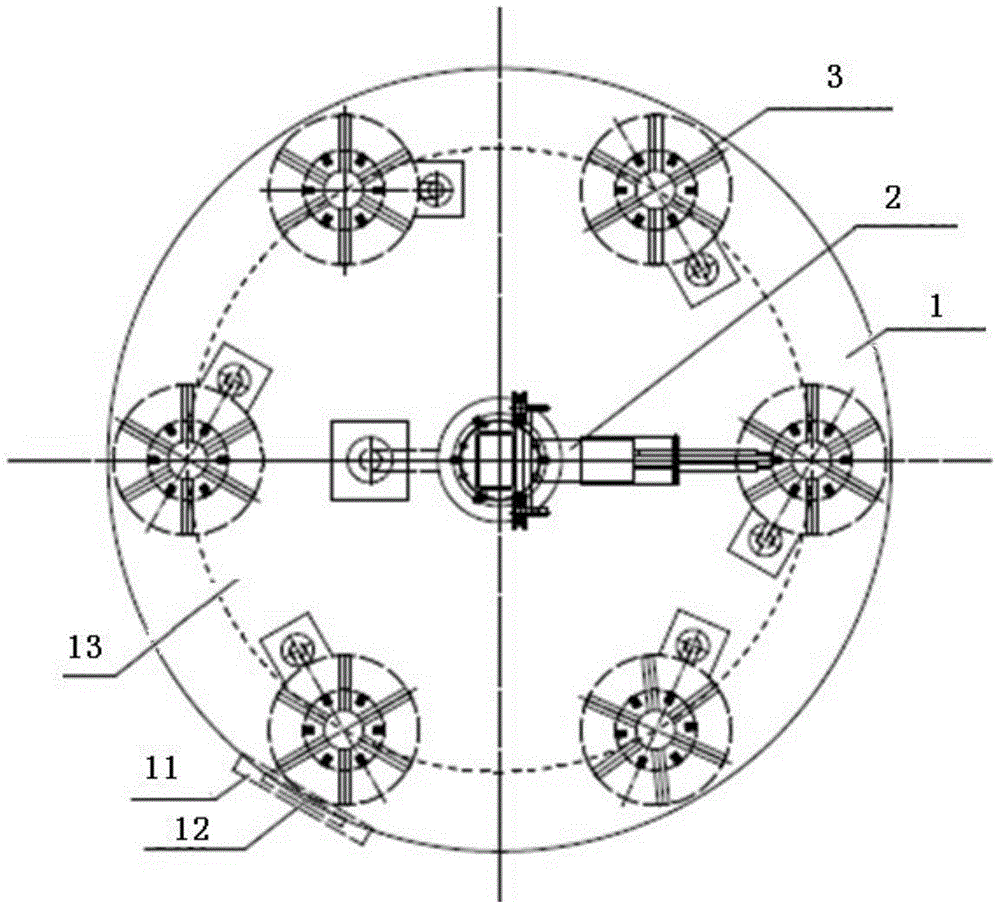

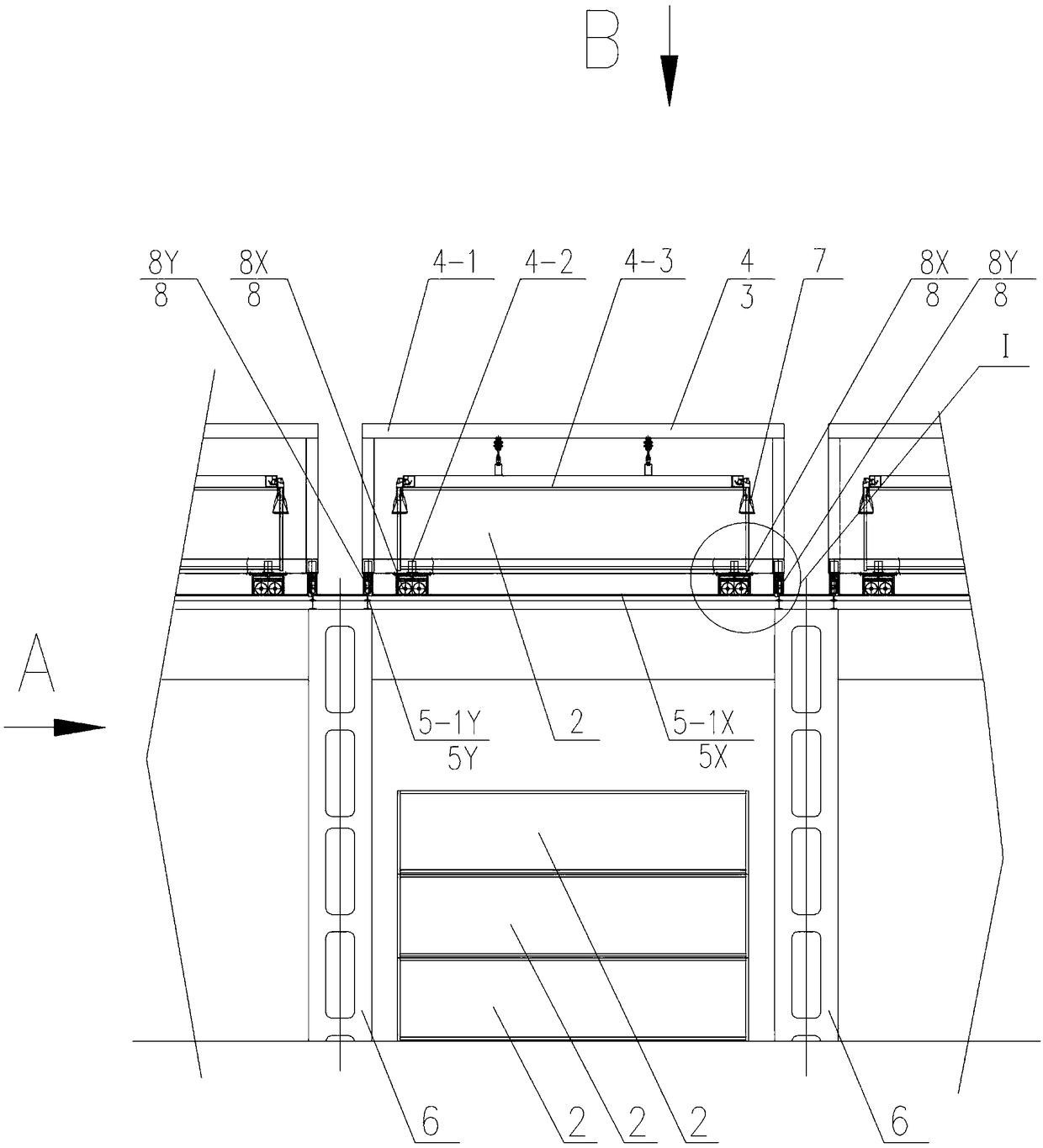

The invention discloses a rotary type automatic goods storing and taking device and method. The device comprises a system closing, supporting and assisting unit, a mechanical arm, a rotary type goods storing and taking device, a control unit, an identity recognition unit and the like. The space utilization rate of the device is greatly increased, the goods secrecy is improved, modulation assembling and controlling are achieved, and the device is convenient to transport, easy to operate and convenient to maintain; goods can be stored, taken and conveyed through the mechanical arm, the repeated labor sum is reduced, and the storing and taking efficiency is improved. A goods storing mode, a goods taking mode, a fault mode and an initialization mode are involved in the rotary type automatic goods storing and taking method and correspond to the four operation modes or states of goods storing, goods taking, faults and initialization, automation of goods storing, taking and conveying is achieved, human factors are eliminated basically, man-made interference is reduced greatly, the goods storing and taking positions are calculated intelligently, authentication is needed in the storing and taking process, and the accuracy of goods storing and taking is ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

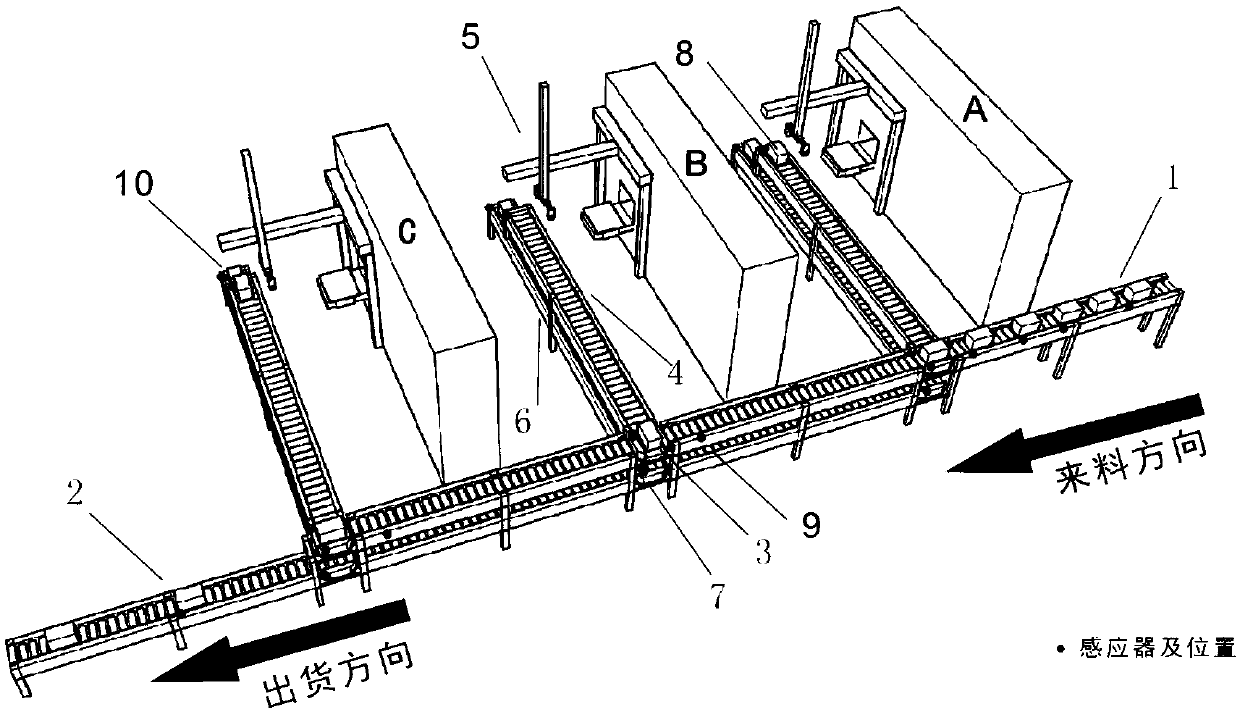

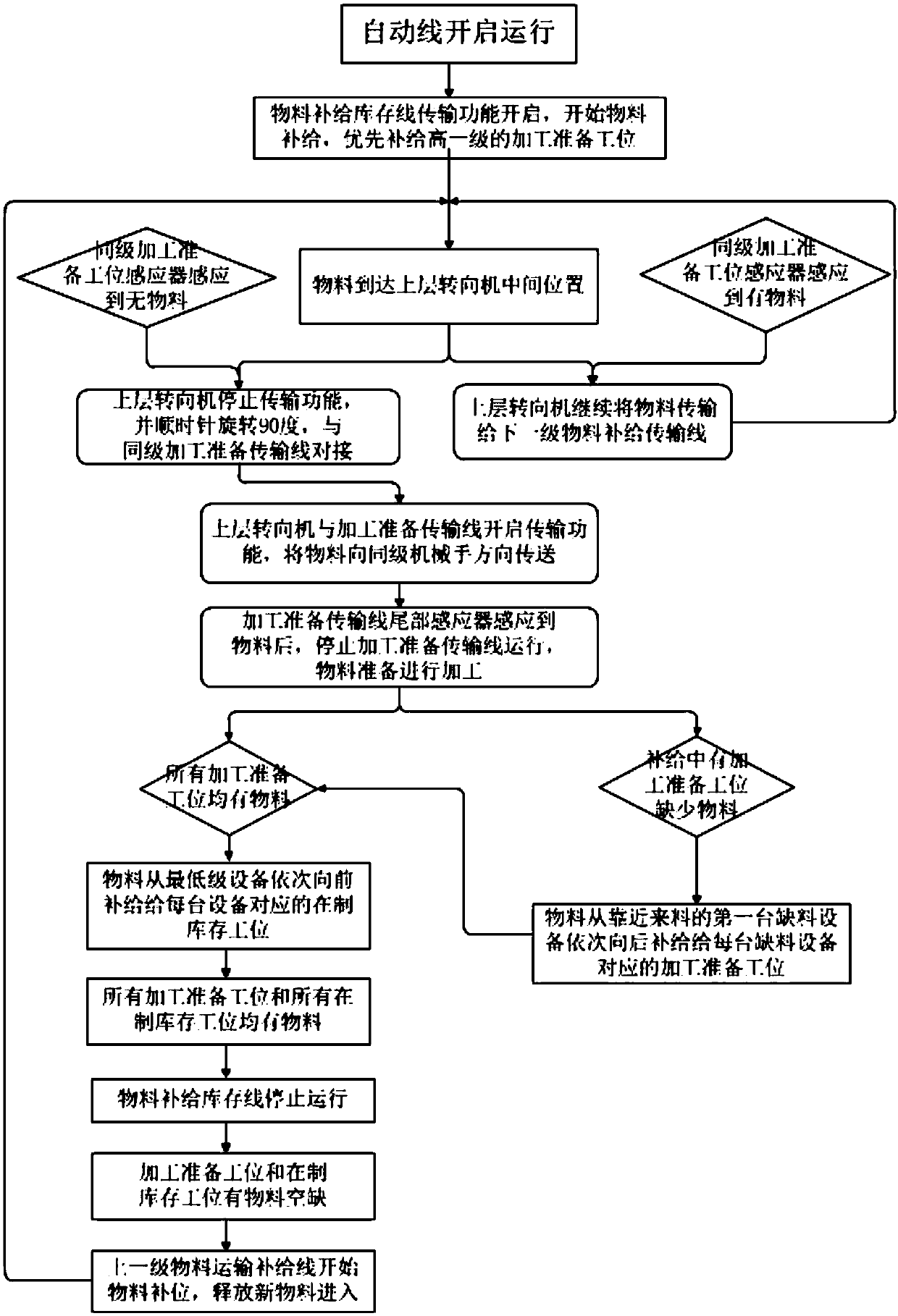

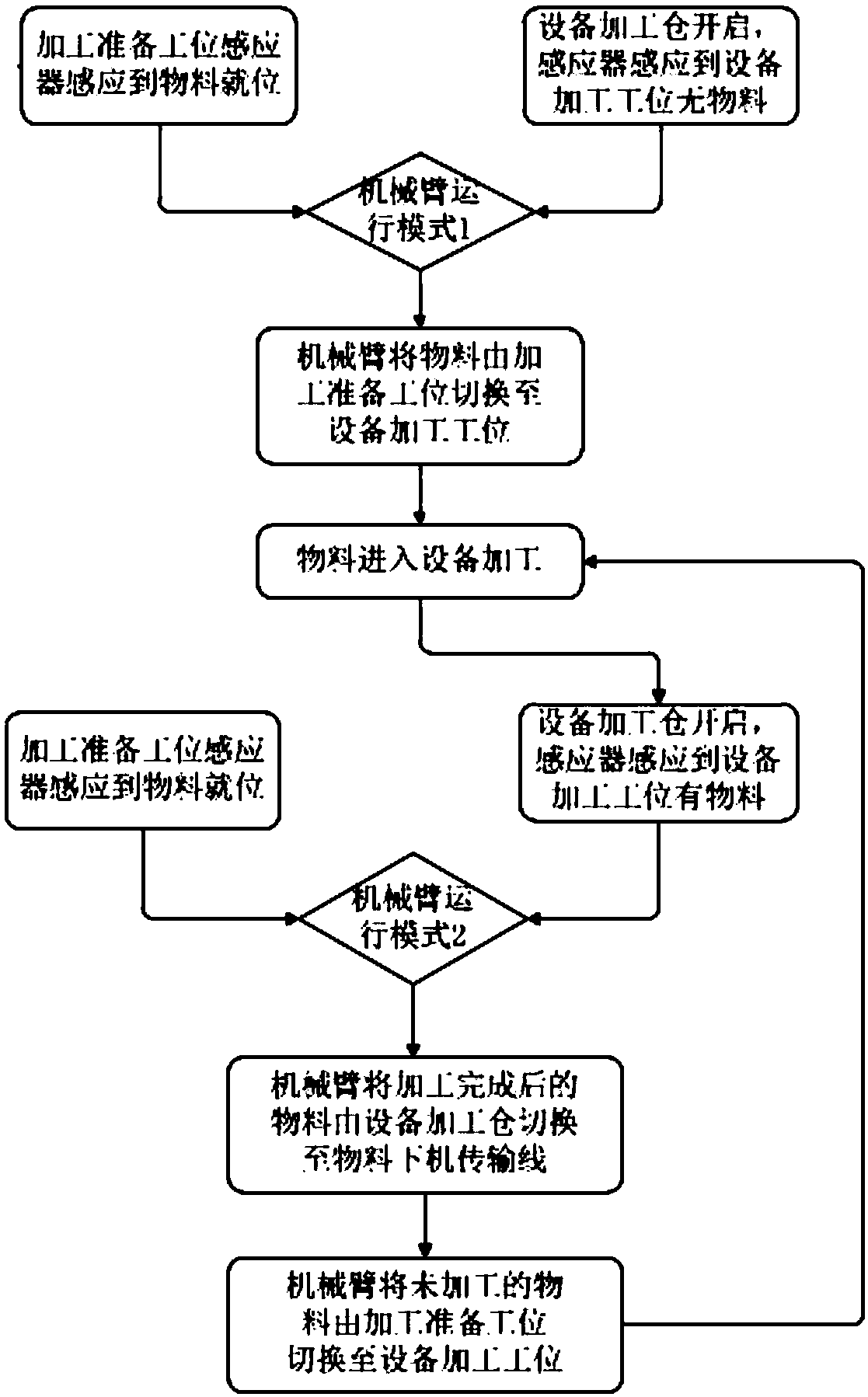

Modular automatic production and processing line and production and processing method

PendingCN109634222AHigh degree of automationEasy to automate jobsTotal factory controlProgramme total factory controlMaterials preparationTransport system

The invention provides a modular automatic production and processing line and production and processing method. In a line device, a conveying line responsible for material transportation is divided into two layers in total, an upper-layer material supplying and distributing system is composed of a material supply conveying line, several upper-layer steering machines, several station material preparation conveying lines and a matched control program, and is mainly responsible for automatically distributing and conveying unprocessed materials to each piece of equipment in a module; and a lower-layer material discharge conveying system is composed of a material discharge conveying line, several material lower machine conveying lines, several lower-layer steering machines and a matched controlprogram, and is mainly responsible for automatically transferring and conveying the materials after being processed by the equipment to the next working procedure. According to the modular automaticproduction and processing line and production and processing method, discrete cluster type production is converted into modular line type production, and in the case of the operation mode and the implementation mode of a processing system, the original discrete type production is converted into the modular line type production by using the device.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

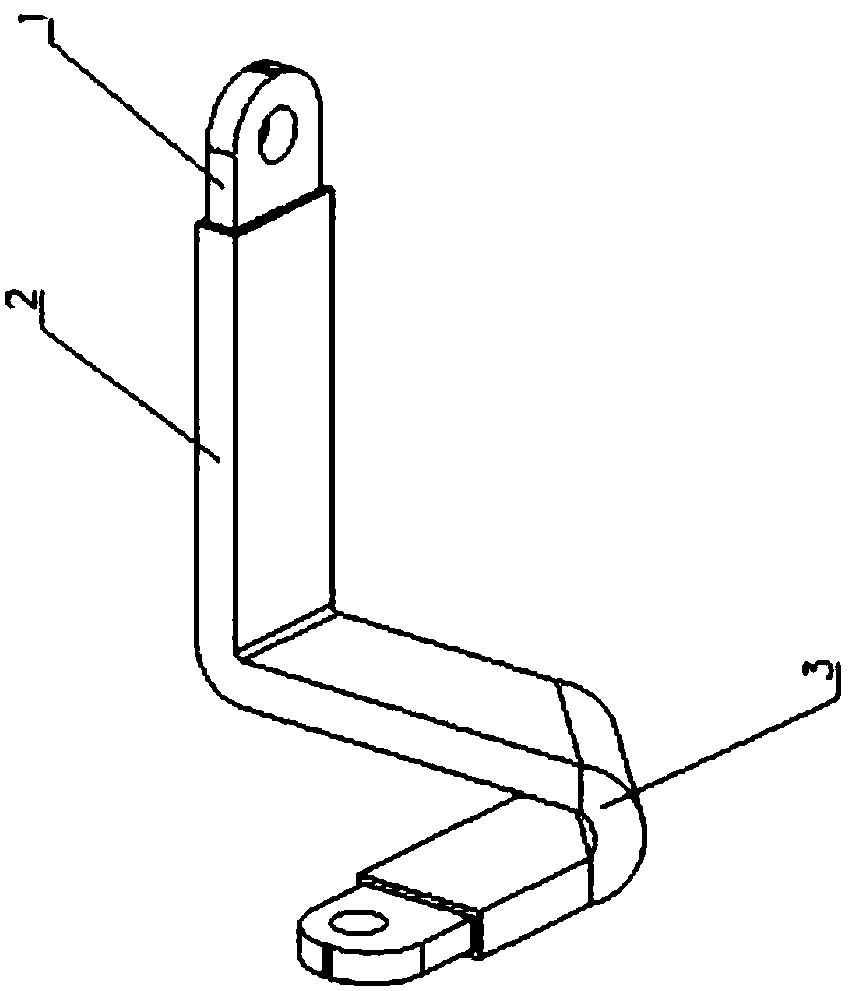

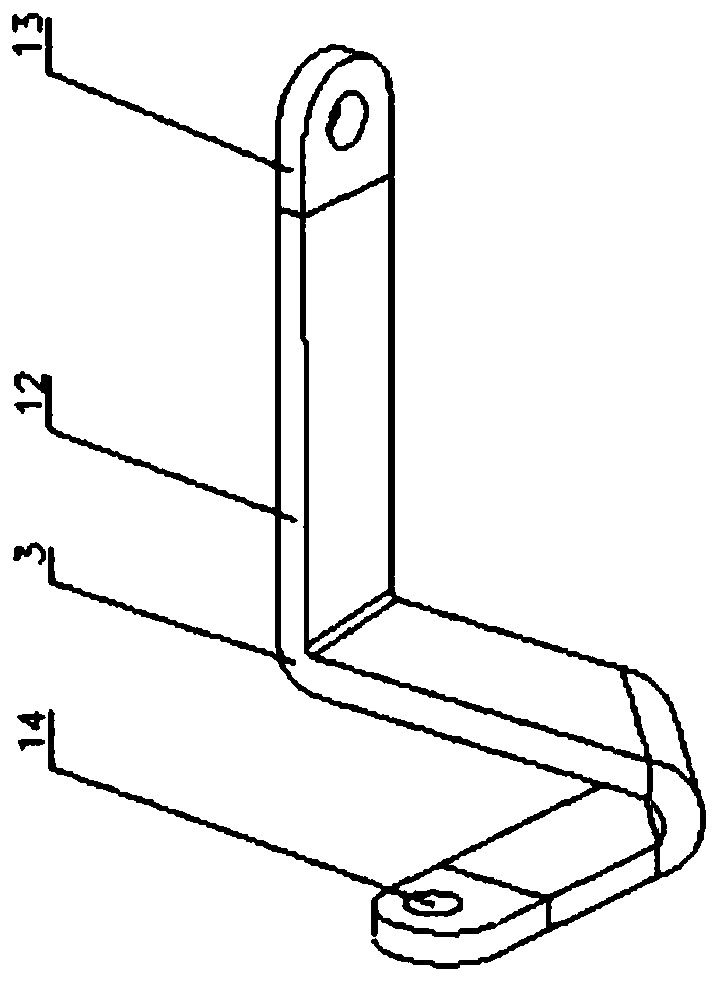

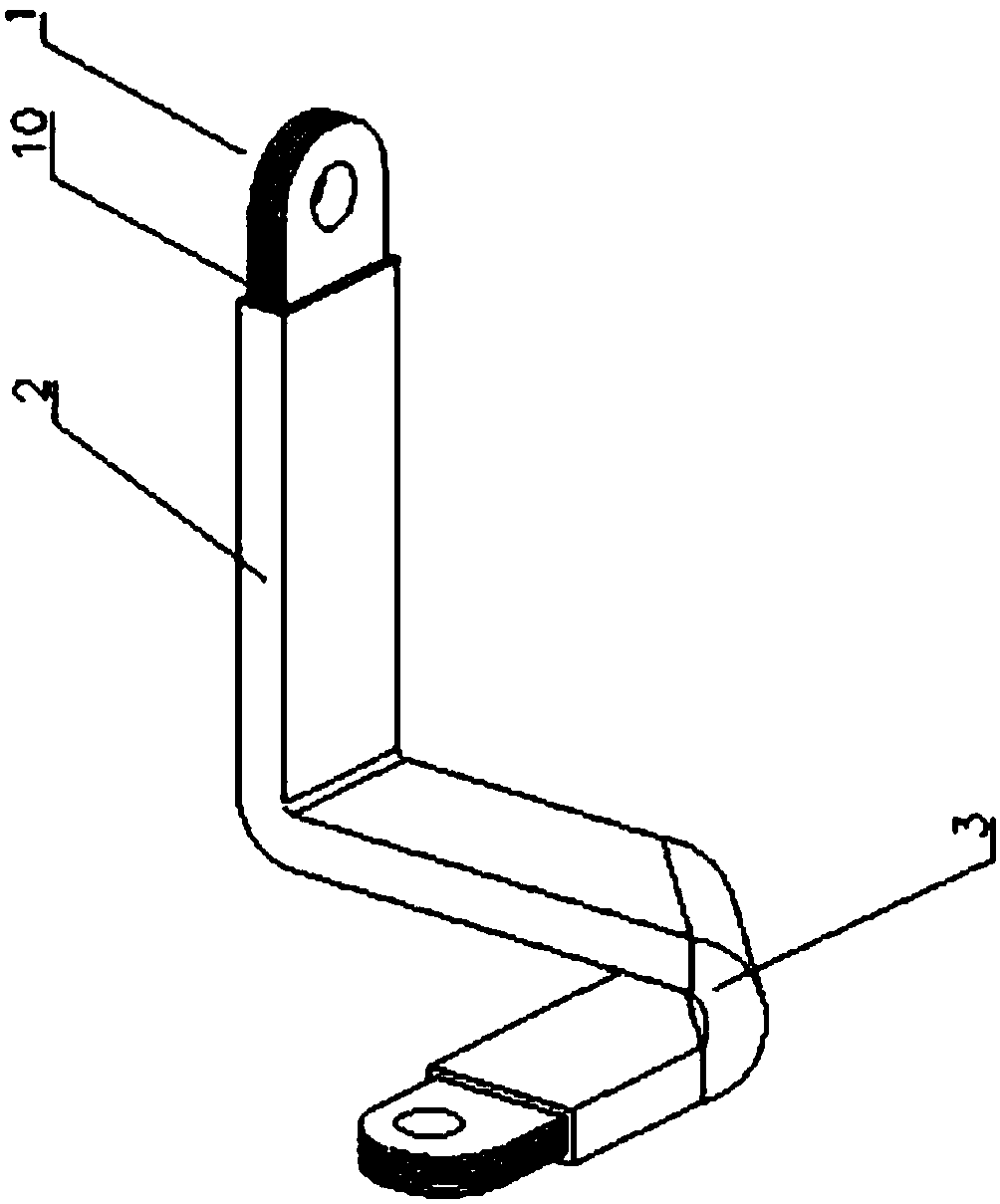

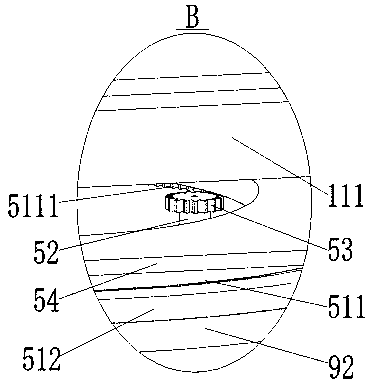

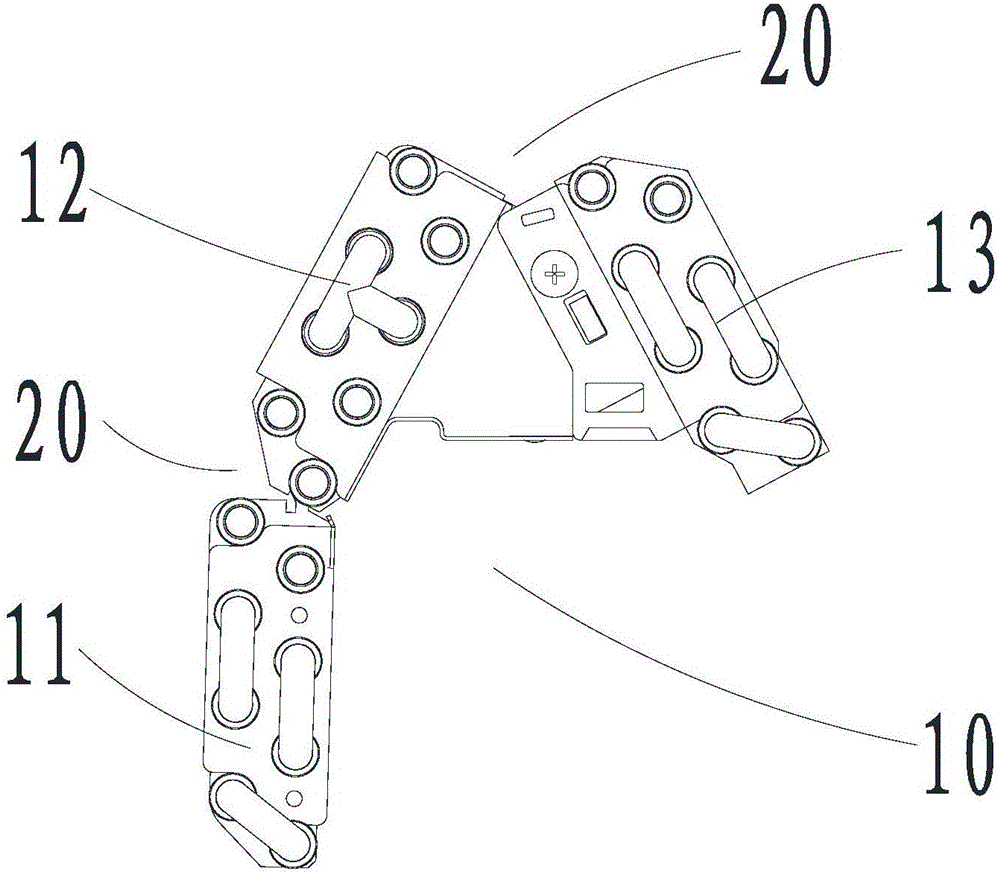

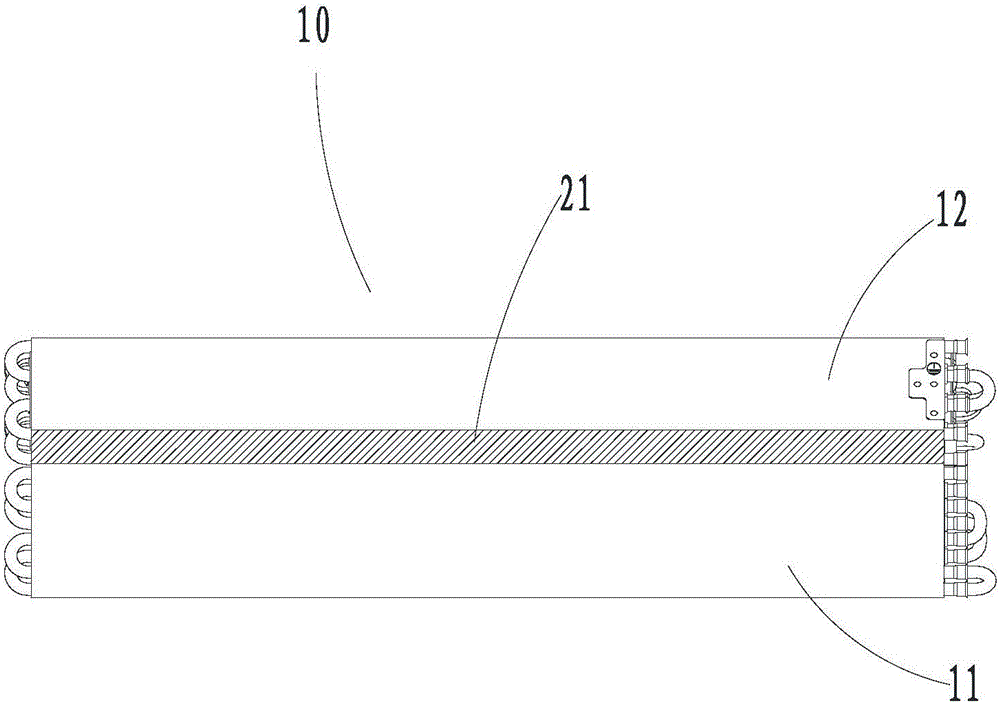

Non-welded power battery soft connection wire manufacturing method

InactiveCN107845453AAvoid breakingImprove yieldCurrent conducting connectionsInsulating conductors/cablesPower batteryElectrical conductor

The invention discloses a non-welded power battery soft connection wire manufacturing method, which has the advantages that the process is simple; the manufacturing is quick and convenient; and a plastic insulating sleeve can be prevented from being broken. The non-welded power battery soft connection wire comprises a metal conductor (1) and a plastic insulator (2) extruded together with the metalconductor (1), wherein multiple bent parts (3) are arranged on the metal conductor (1). The method comprises steps of slitting, continuous electroplating, insulating layer co-extrusion, cutting, bending and edge cutting and hole manufacturing. The method of the invention can be widely applied to the field of power battery packs.

Owner:东莞市佳超五金科技有限公司

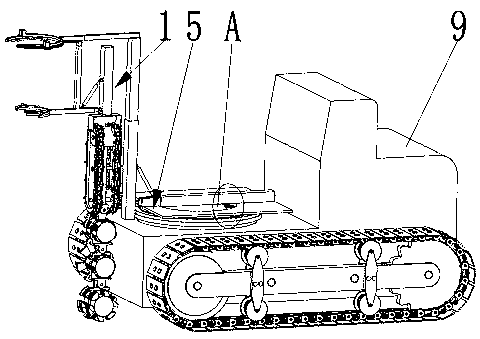

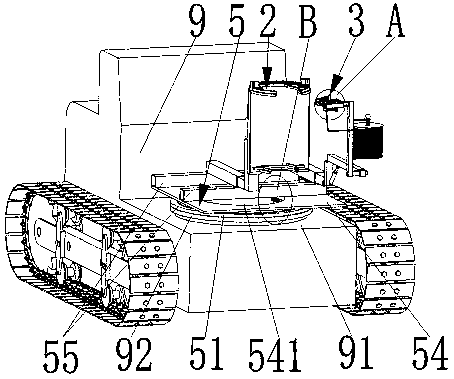

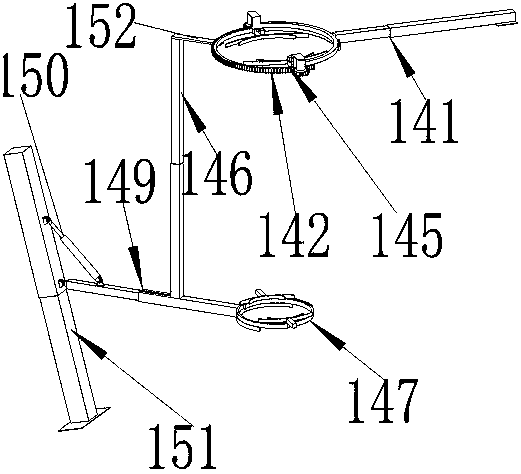

Upland tree mover capable of cutting main roots

InactiveCN108849369AQuick alignmentSpecification is goodForestryDiameter at breast heightSlope angle

The invention discloses an upland tree mover capable of cutting main roots. The upland tree mover is composed of a tree digging device, a rotary table device, a tracked vehicle and a slope sensor, wherein the tree digging device is composed of a first telescopic assembly, a first variable-amplitude hydraulic cylinder, a second telescopic assembly, a tool rotary motion driving assembly and a combined cutter device; the cylinder body of the first variable-amplitude hydraulic cylinder is provided with a double-lug ring, and a piston rod of the first variable-amplitude hydraulic cylinder is provided with a single-lug ring; according to a slope angle signal of the slope sensor, the first variable-amplitude hydraulic cylinder can automatically adjust the angle of the tree digging device, so thatthe tree digging device is ensured to quickly align seedlings; the diameter at breast height of the trunk can be automatically measured, so that the diameter and taper angle of soil balls are automatically adjusted; main root cutting and soil ball cutting are completed simultaneously, and the standard quality of the soil balls is good; the intelligent control and automatic operation are achievedeasily, the operation is convenient, and the working efficiency of seedling lifting is high.

Owner:KUNMING UNIV

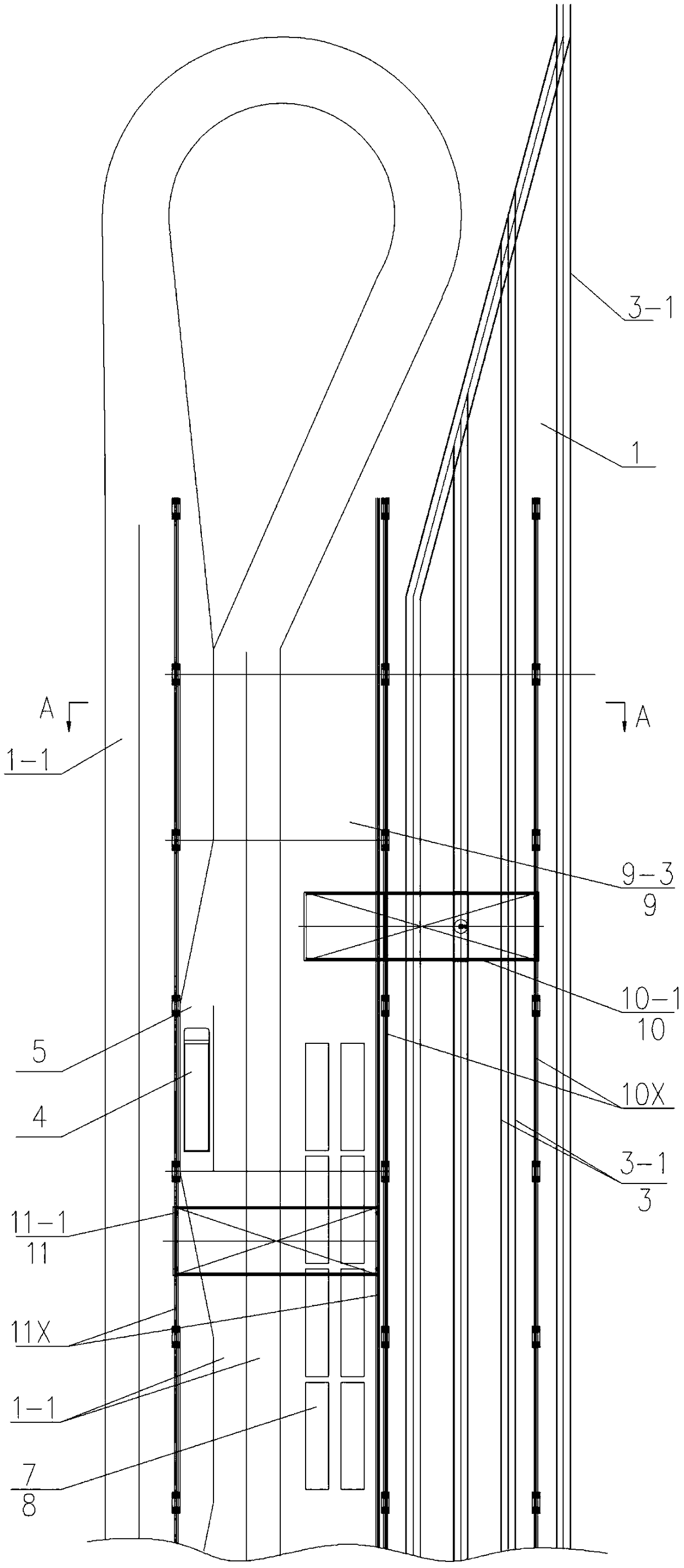

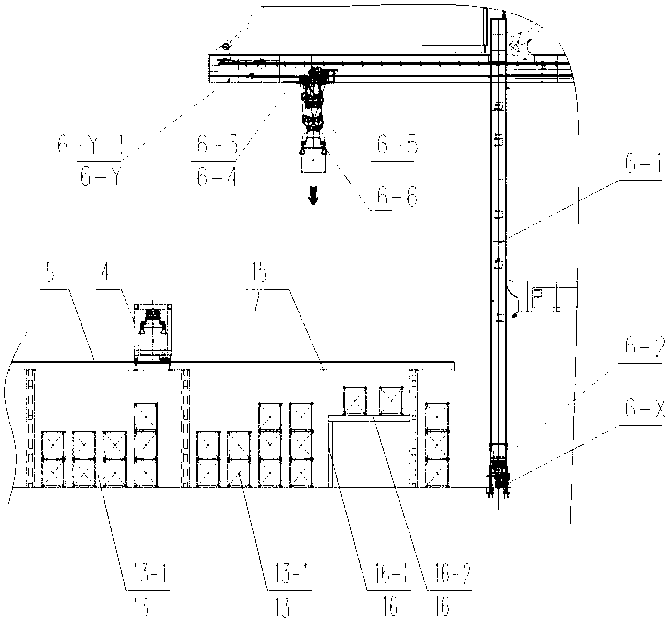

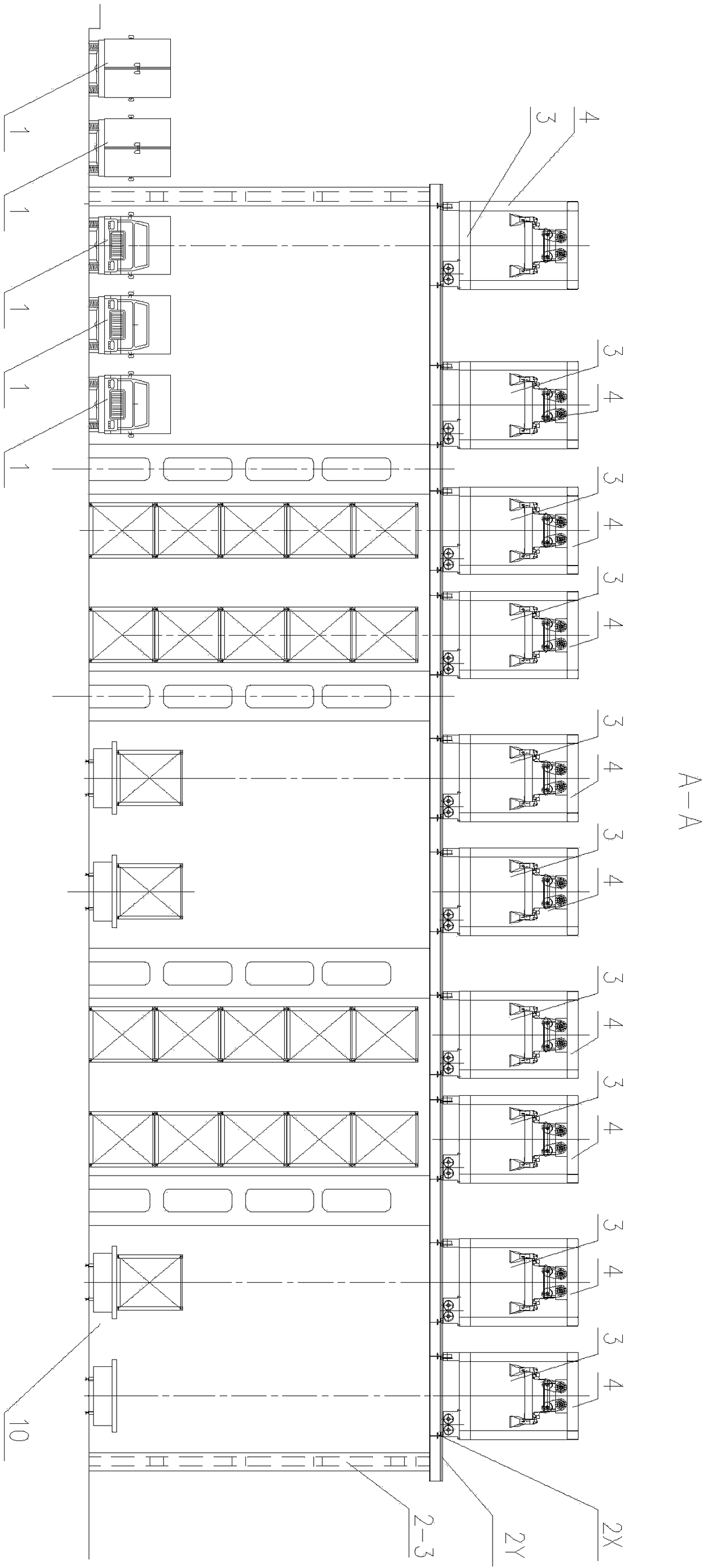

Railway container freight yard and delivery device thereof

The invention provides a railway container freight yard and a delivery device thereof. A railway container freight yard 1 comprises a vehicle gathering loading unloading region 3 of railway containervehicles 2, a truck loading uploading region 5 of container trucks 4, a container storage region 8 of a container delivery device 6 and containers 7, the truck gathering loading unloading region 5 comprises a plurality of truck gathering lanes 1-1 for the operation of the container trucks 4, the container storage region 8 comprises a container buffering region 9, the delivery device 6 comprises avehicle gathering crane 10 and a truck gathering crane 11, the vehicle crane 10 is a delivery machine above the vehicle loading unloading region 3 used for the railway container vehicles 2, a vehiclegathering buffering region 9-1 or a vehicle truck buffering region 9-3, and the truck gathering crane 11 is a delivery machine above the truck gathering loading unloading region 5, a truck gathering buffering region 9-2 and the vehicle truck buffering region 9-3. The delivery device has the advantages that the vehicle gathering loading unloading region 3, the truck gathering loading unloading region 5 and the container storage region 8 can be covered by the container delivery device 6, all operation regions can be connected as a whole, the containers 7 can be transferred in all of the regions,full-coverage logistic transportation can be achieved, automatic operation is easily achieved, and the efficiency is high.

Owner:王燏斌

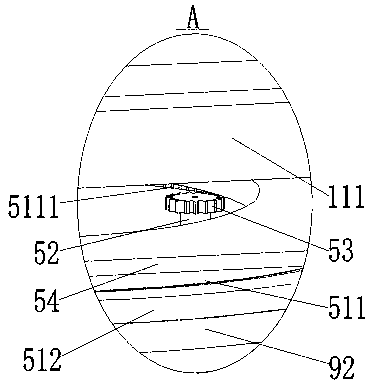

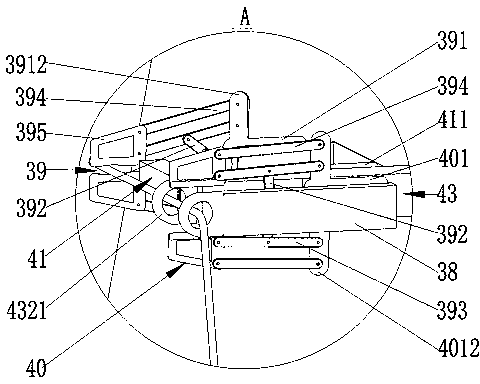

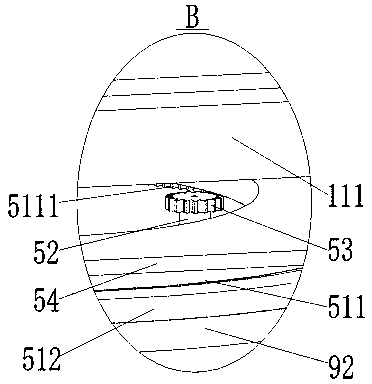

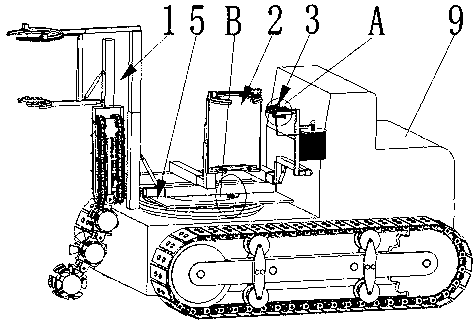

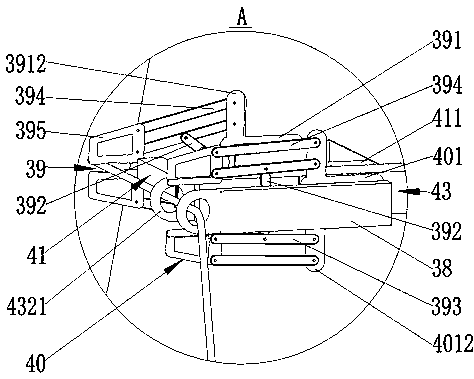

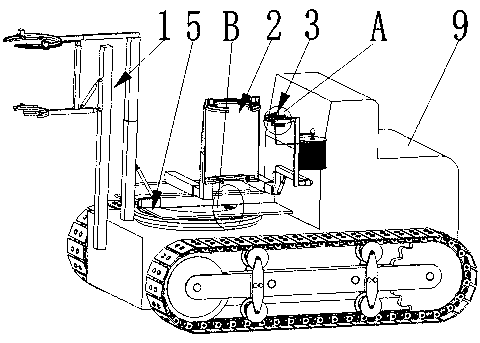

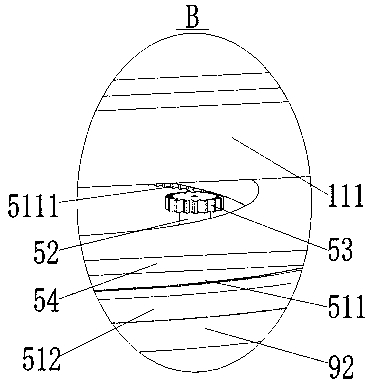

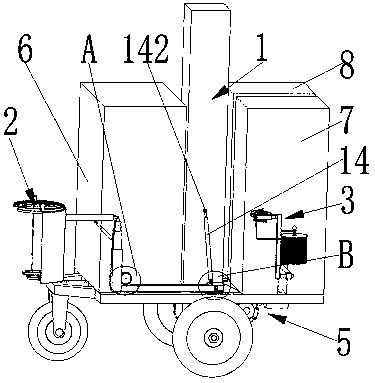

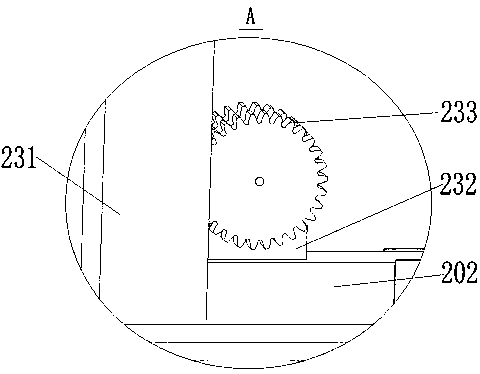

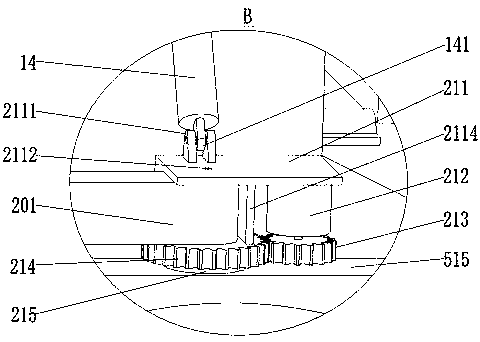

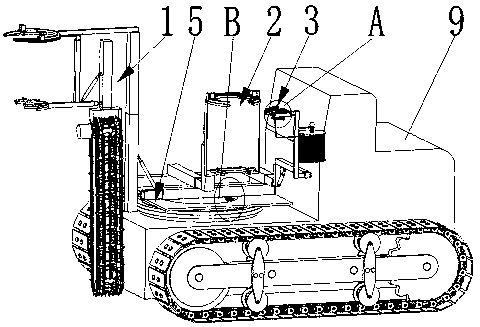

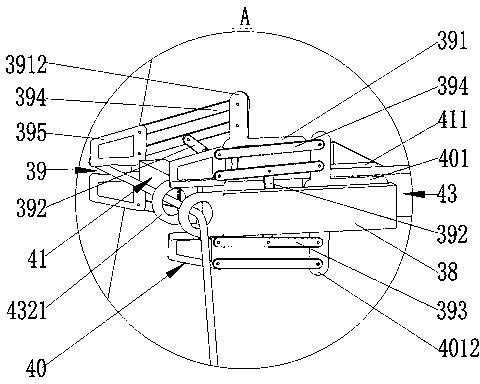

Soil ball lifting and rope-winding automated machine

InactiveCN108750972AEasy to control intelligentlyEasy to automate jobsForestryCranesEngineeringConductor Coil

The invention discloses a soil ball lifting and rope-winding automated machine. The soil ball lifting and rope-winding automated machine consists of a soil ball lifting and rotating device, a rope winding device, a rotary table device and a creeper truck, wherein the creeper truck is equipped with a chassis and a flange plate; and the soil ball lifting and rotating device consists of a first telescopic assembly, a second telescopic assembly, a lifting assembly, a first amplitude-change hydraulic oil cylinder, an outer extending beam, a hanger and a soil ball rotating assembly. The soil ball lifting and rope-winding automated machine can automatically lift a soil ball and can complete soil ball rope-winding work, can automatically load nursery-grown plant onto a transport vehicle, easily realizes intelligent control and automatic operation, is convenient to operate, and is high in nursery-grown plant lifting working efficiency.

Owner:KUNMING UNIV

Main root cutoff mountainous region automatic tree mover

InactiveCN108812169AQuick alignmentSpecification is goodForestryHydraulic cylinderDiameter at breast height

The invention discloses a main root cutoff mountainous region automatic tree mover which is composed of a tree digging device, a rotary table device, a crawler and a gradient sensor. The tree diggingdevice is composed of a first stretchable assembly, a first amplitude changing hydraulic oil cylinder, a second stretchable assembly, a tool cycle motion driving assembly and a combination tool device; a cylinder body of the first amplitude changing hydraulic oil cylinder is provided with dual earrings, and a piston rod is provided with a single earring; the first amplitude changing hydraulic oilcylinder can automatically adjust the angle of the tree digging device according to a gradient angle signal of the gradient sensor, and it is ensured that the tree digging device can be rapidly aligned to nursery stock; the diameter at breast height can be automatically measured, and the diameter and the taper angle of soil balls can be automatically adjusted; main root cutoff and soil ball cutting can be completed at the same time, and the specification quality of the soil balls is good; the nursery stock can be automatically loaded to a transport vehicle; intelligent control and automatic operation can be achieved easily, operation is convenient, and the seedling lifting efficiency is high.

Owner:KUNMING UNIV

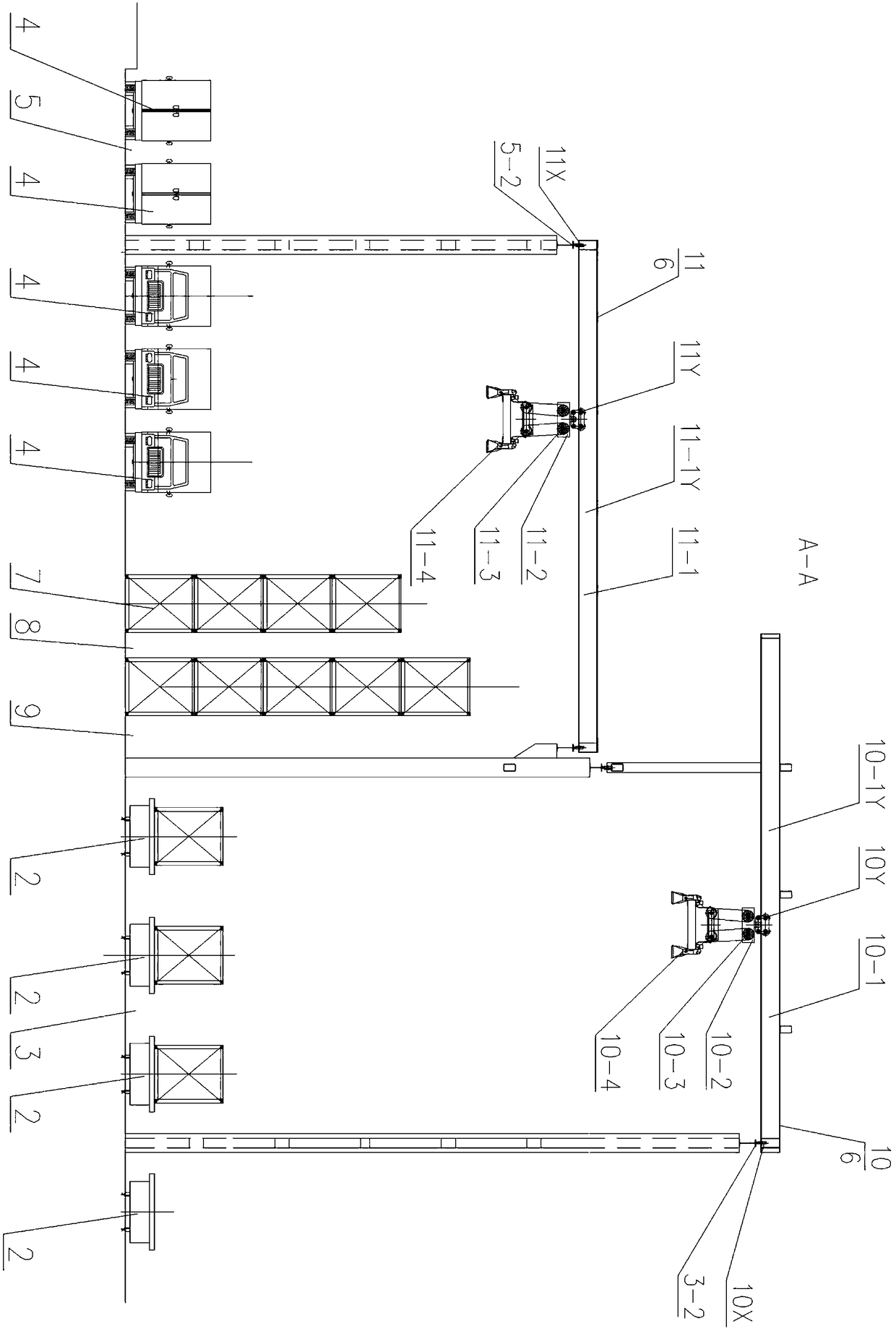

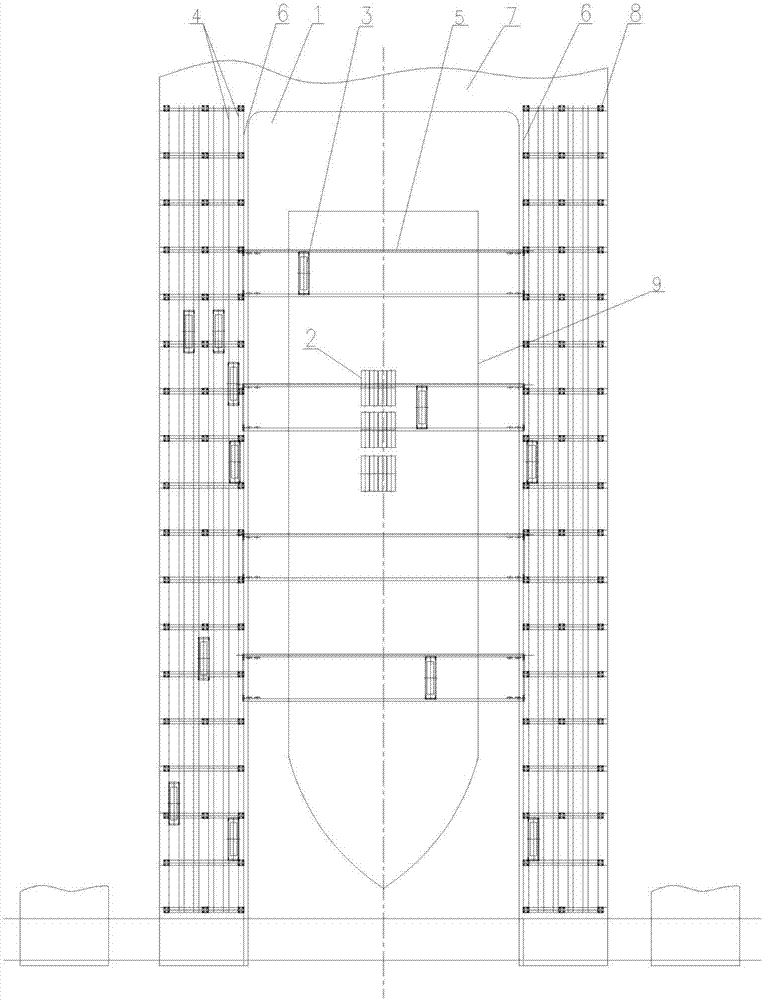

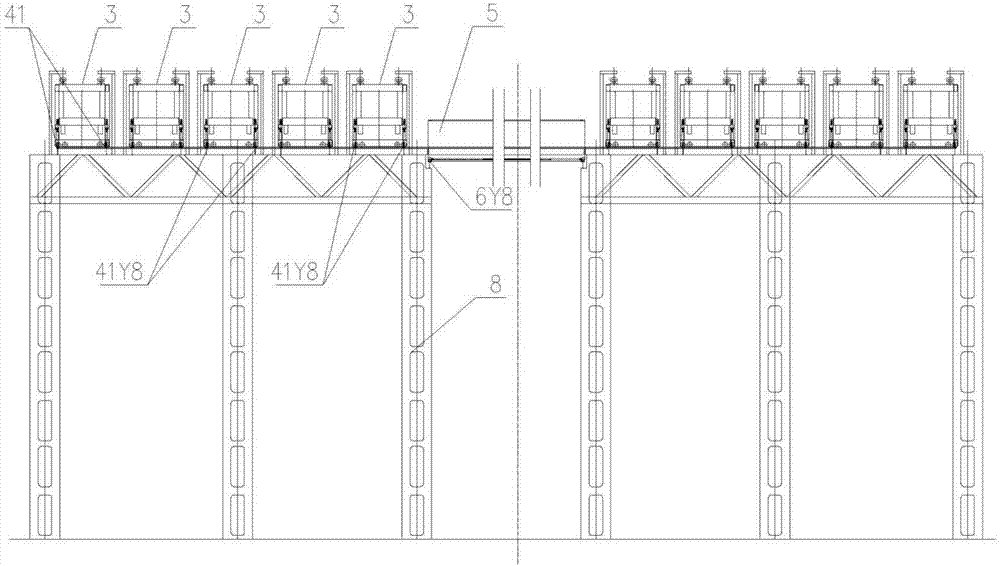

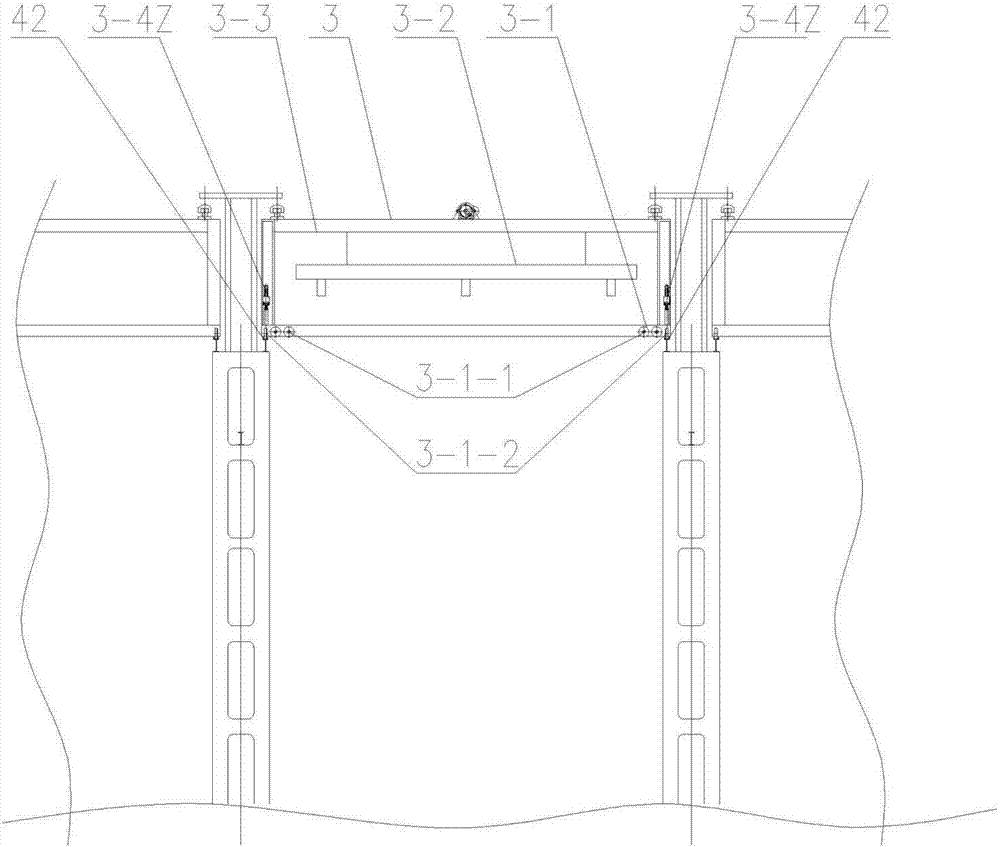

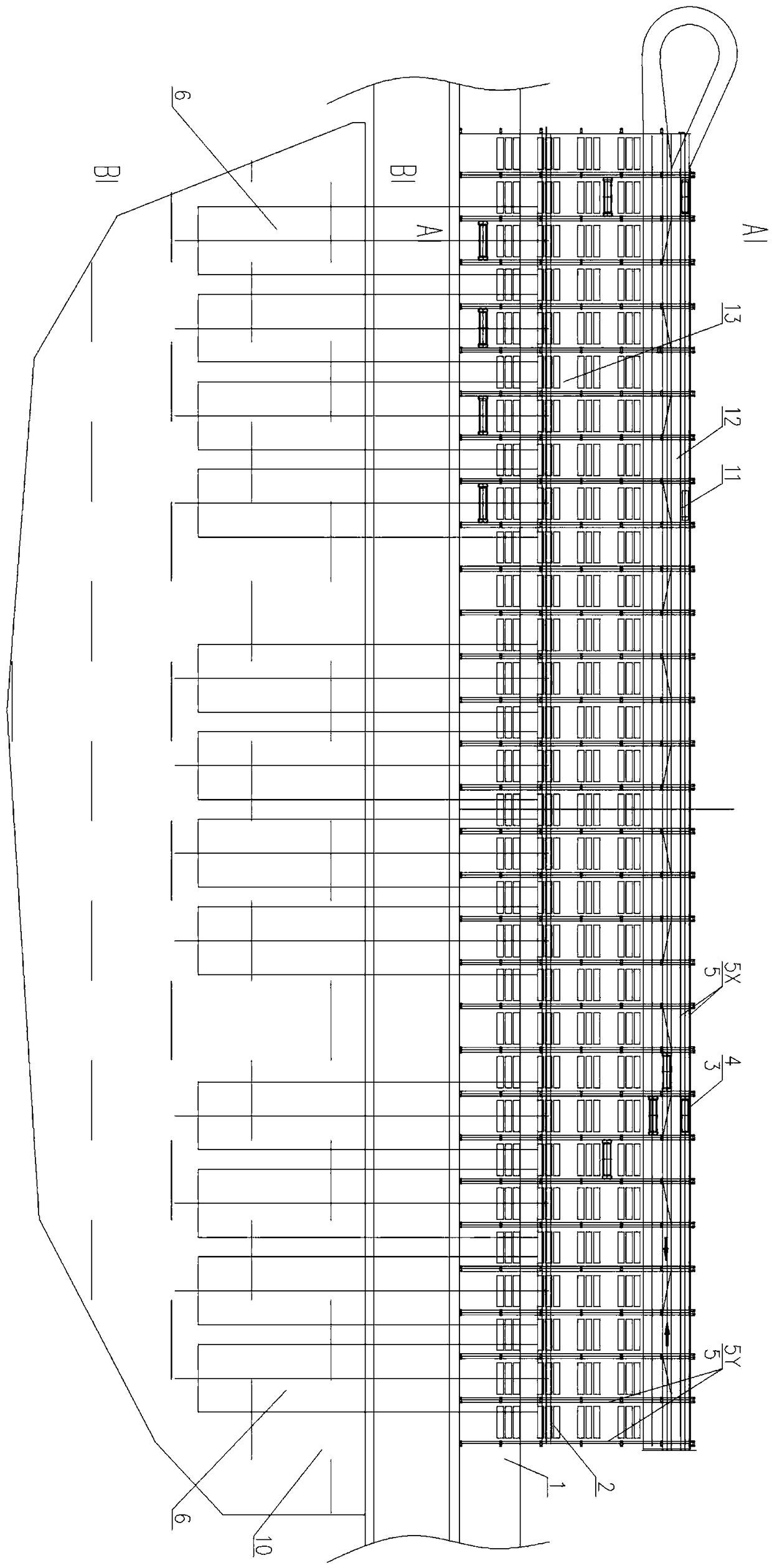

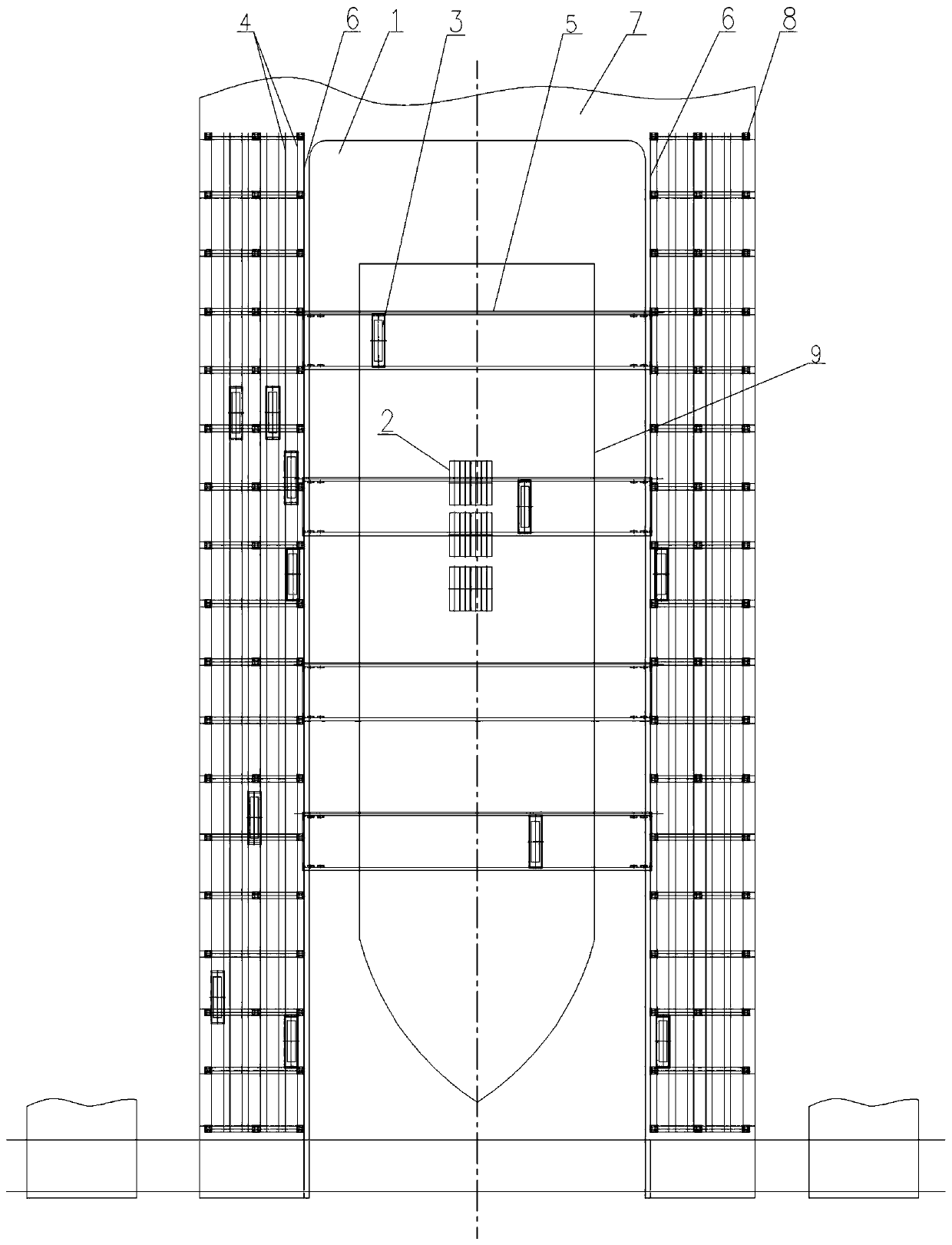

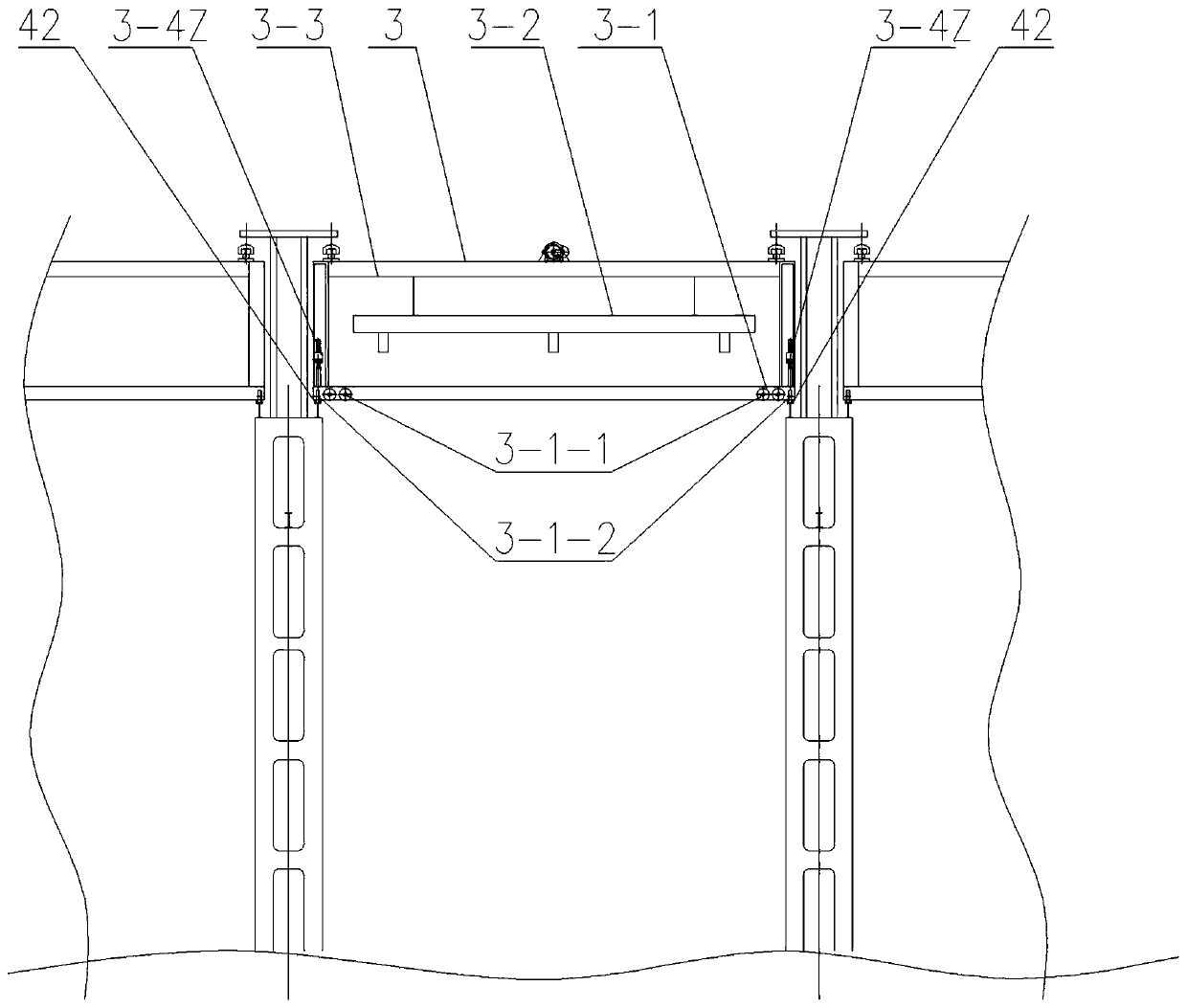

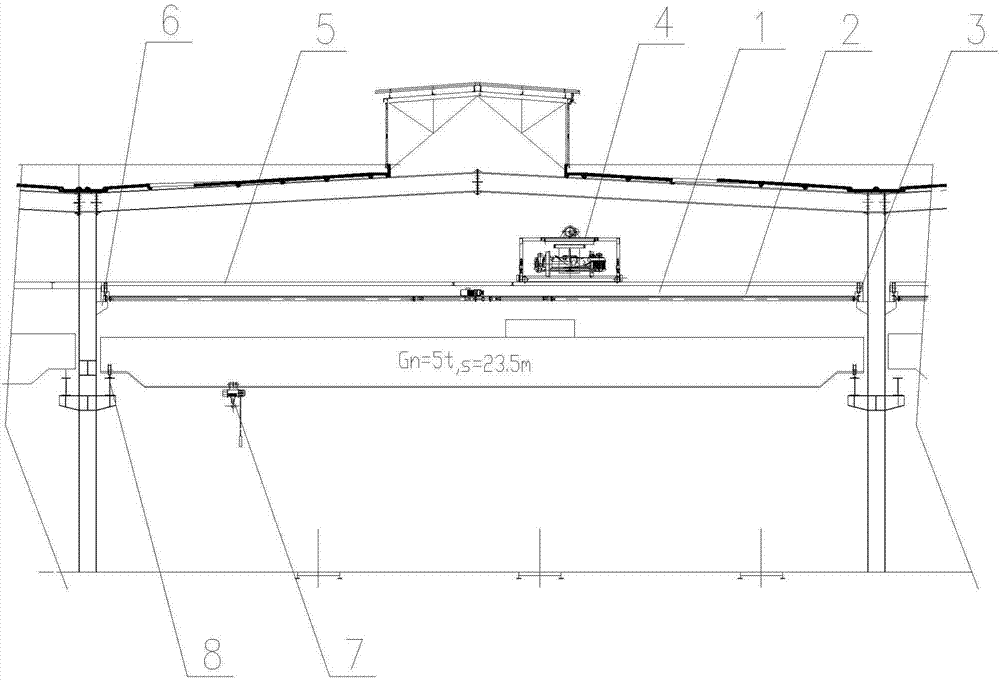

Container crane used for U-shaped berth

ActiveCN107500143AEasy to automate jobsImprove efficiencyTrolley cranesTravelling gearVertical edgeContainer crane

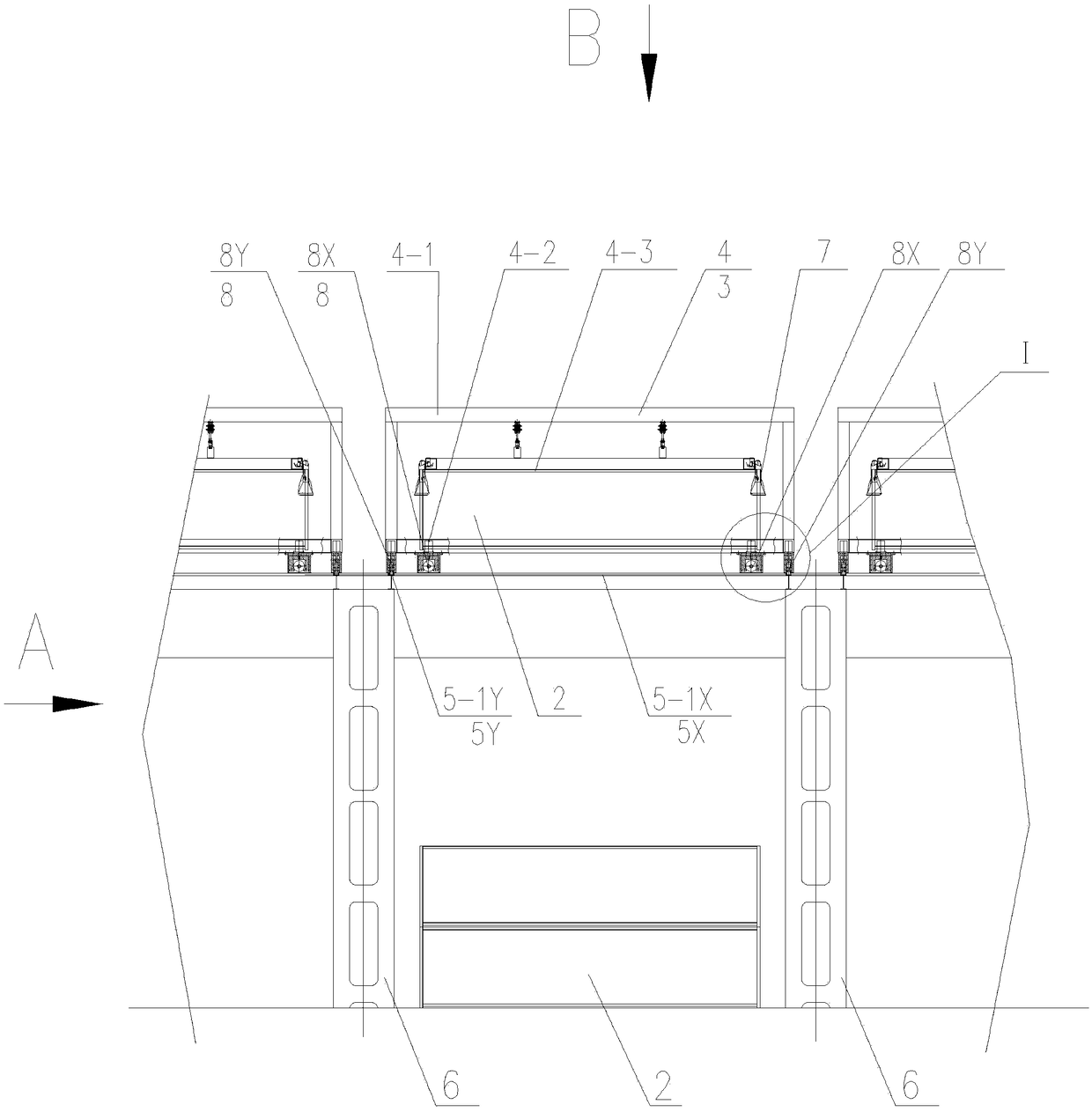

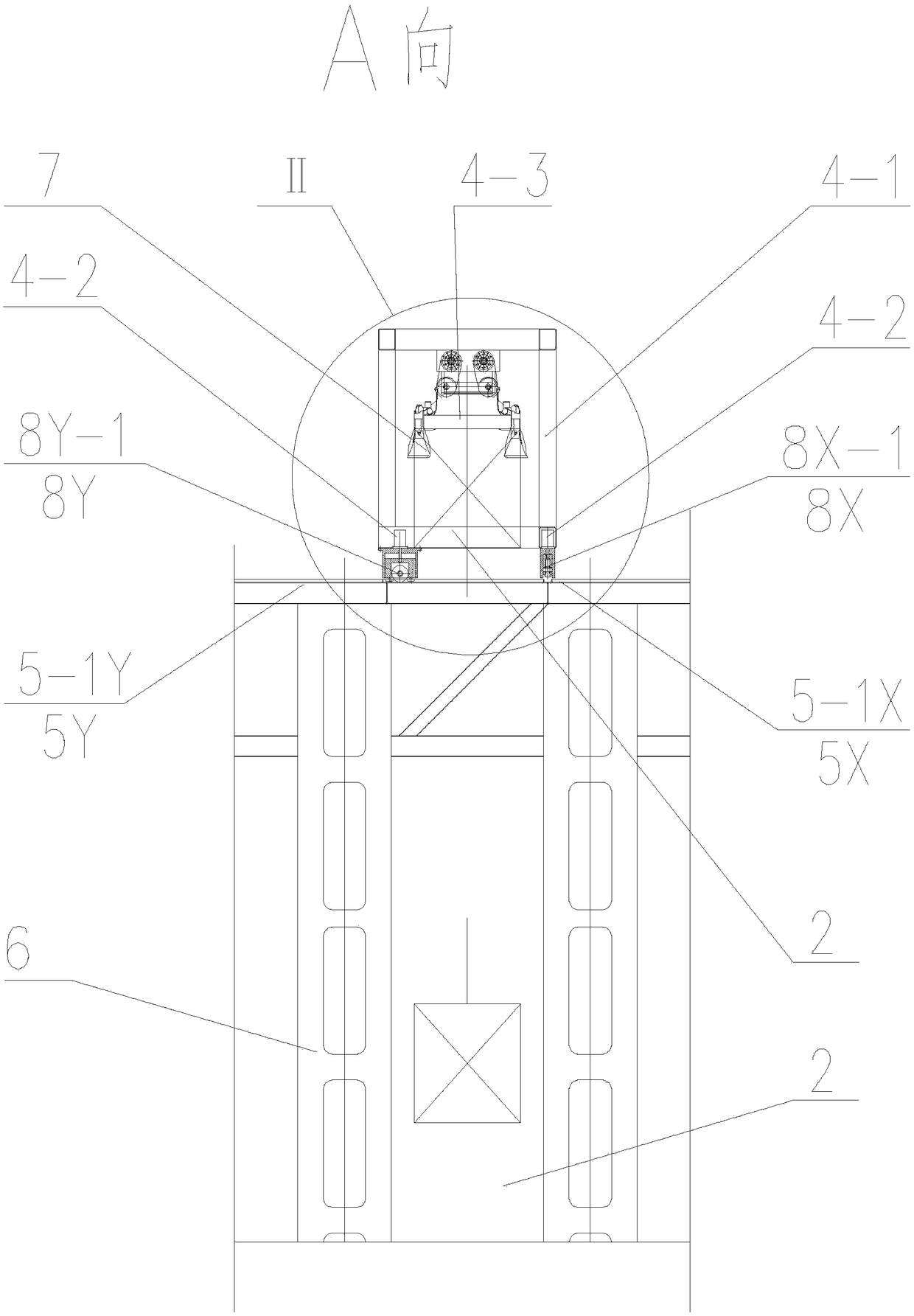

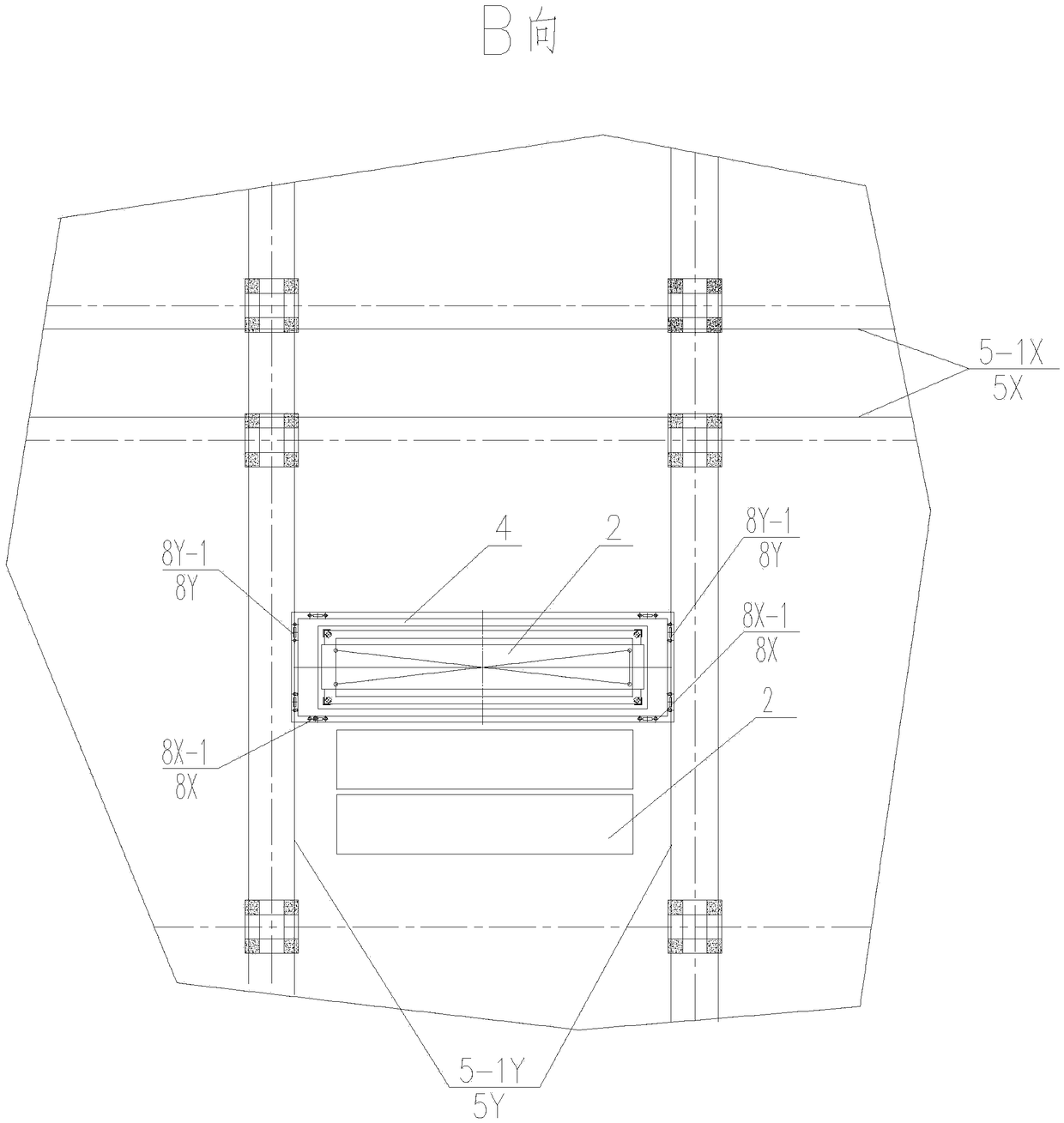

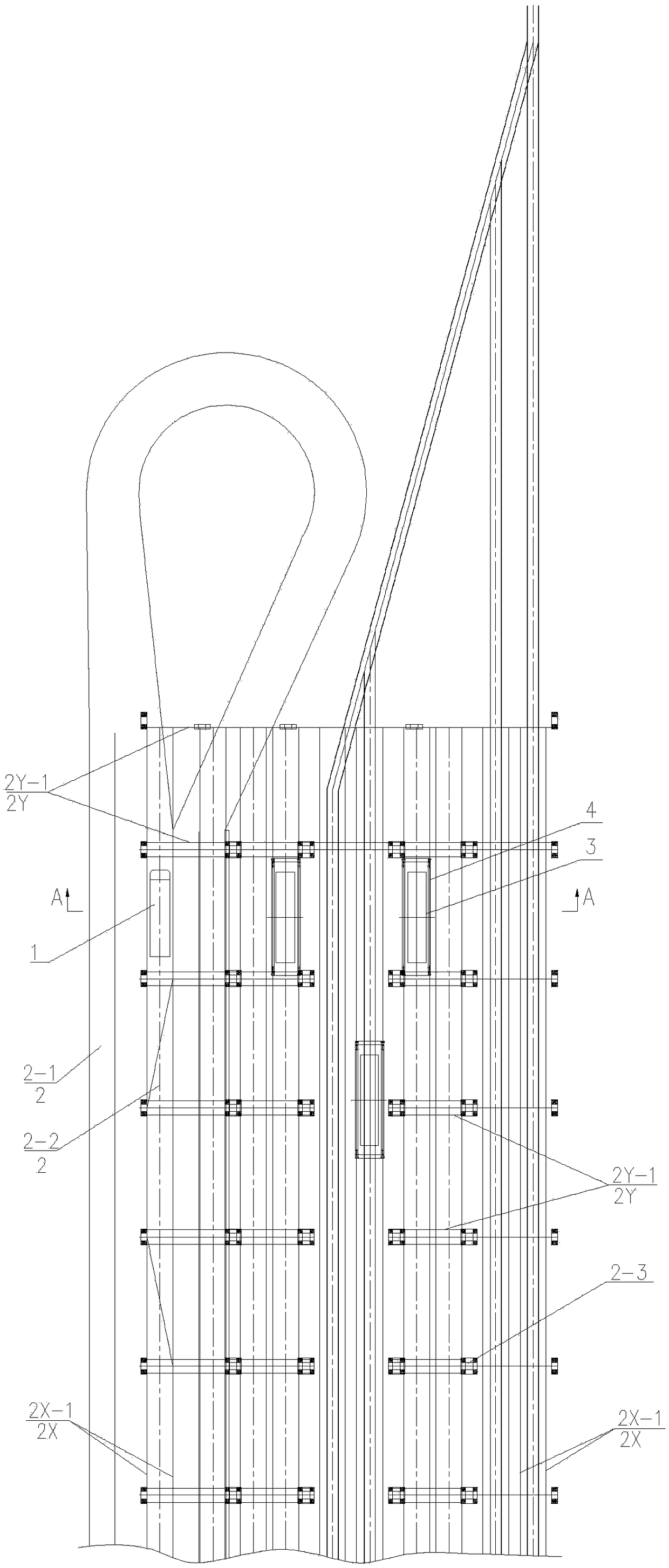

The invention provides a container crane used for a U-shaped berth. The container crane 1 comprises conveying trolleys 3 of containers 2, tracks 4 for the trolleys 3 to run, large trolleys 5, tracks 6 for the large trolleys 5 to run, the U-shaped berth 7 and components 8 on the U-shaped berth 7; it is set that the length direction of the bottom edges of the U-shaped berth 7 is the X direction; the length of a bottom edge 7X is larger than the width of a container ship 9; the length of a vertical edge 7Y of the U-shaped berth is larger than that of the ship 9; the length direction of each container 2 on the ship 9 is parallel to the length direction of the ship 9; each trolley 3 comprises a walking device 3-1, a sling and lifting device 3-2, a frame 3-3 and a switching device 3-4; each walking device 3-1 is located on the lower portion of the corresponding frame 3-3; each device 3-2 is located on the upper portion of the corresponding frame 3-3; each frame 3-3 is a cavity with an opening in the bottom; and each container 2 below the corresponding frame 3-3 is hoisted and hung by a sling device 3-2-1 of the corresponding device 3-2 into the cavity of the frame 3-3. The container crane used for the U-shaped berth has the beneficial effects that the ship 9 is berthed in the U-shaped berth 7, a shoreside container loading and unloading bridge is not needed, each container 2 is hoisted into the cavity of the corresponding frame 3-3 by means of the corresponding conveying trolley 3 on the corresponding large trolley 5, running is performed on air tracks, full-covering logistics conveying can be achieved, automatic operation can be easily achieved, and efficiency is high.

Owner:王燏斌

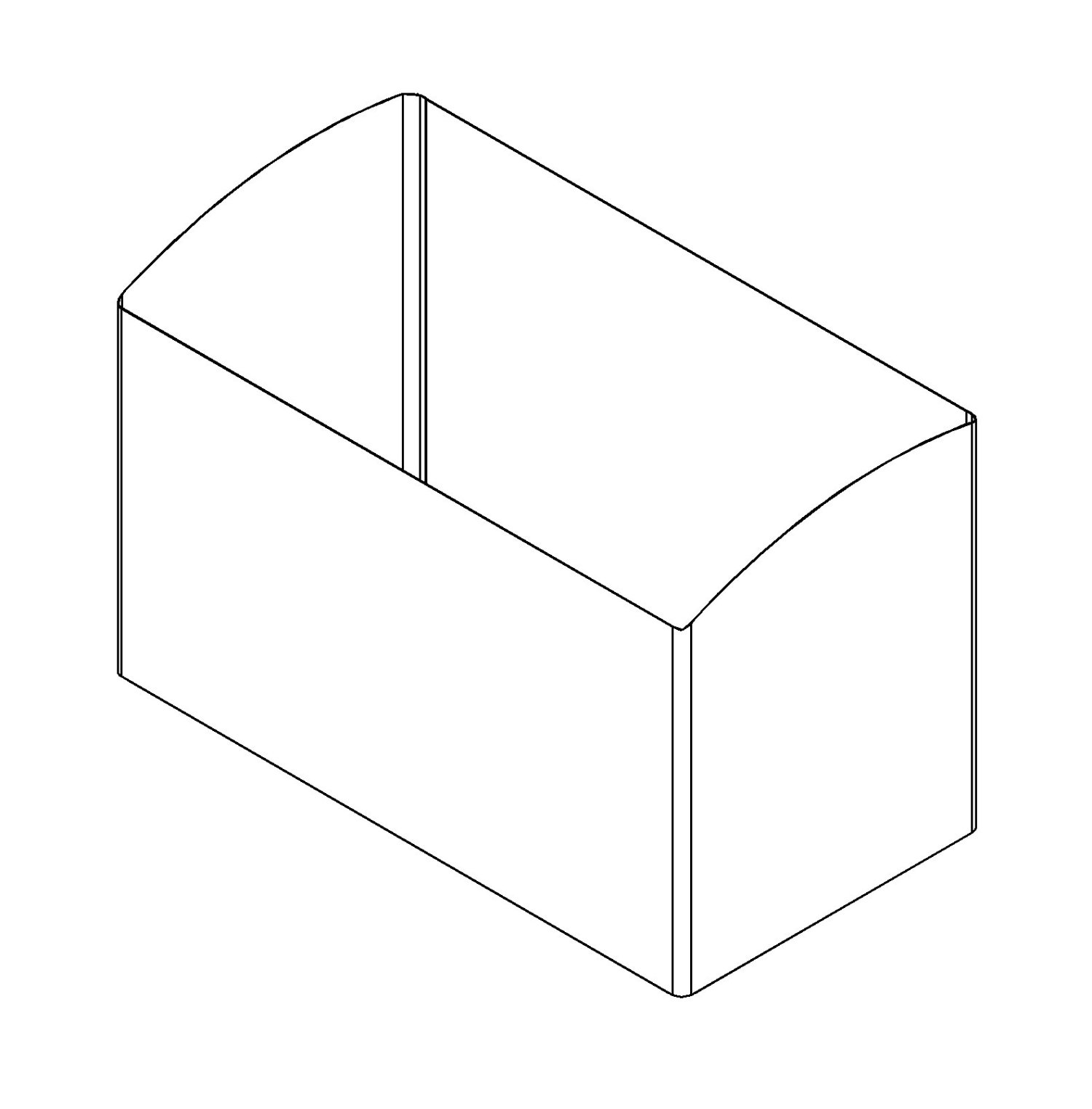

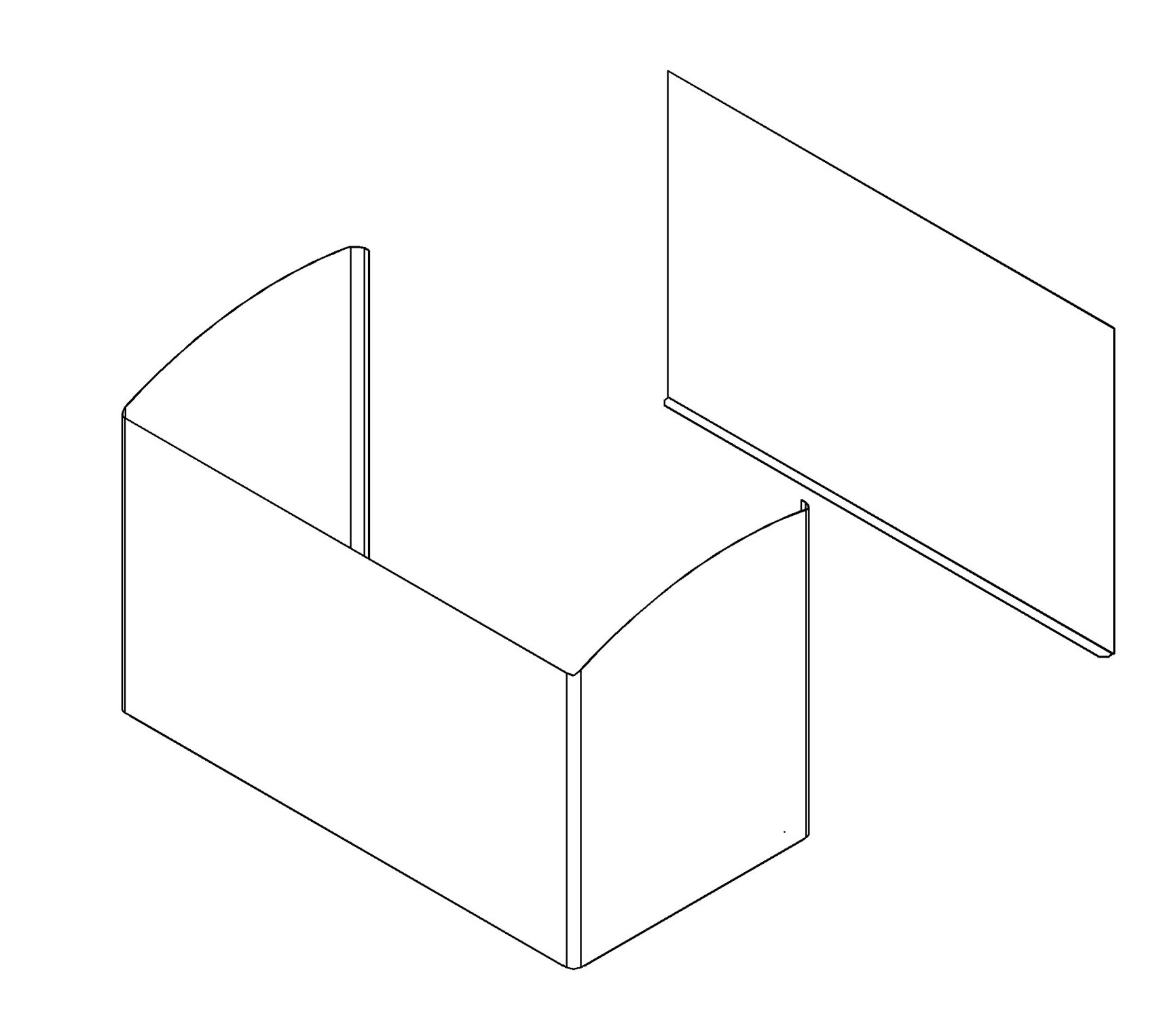

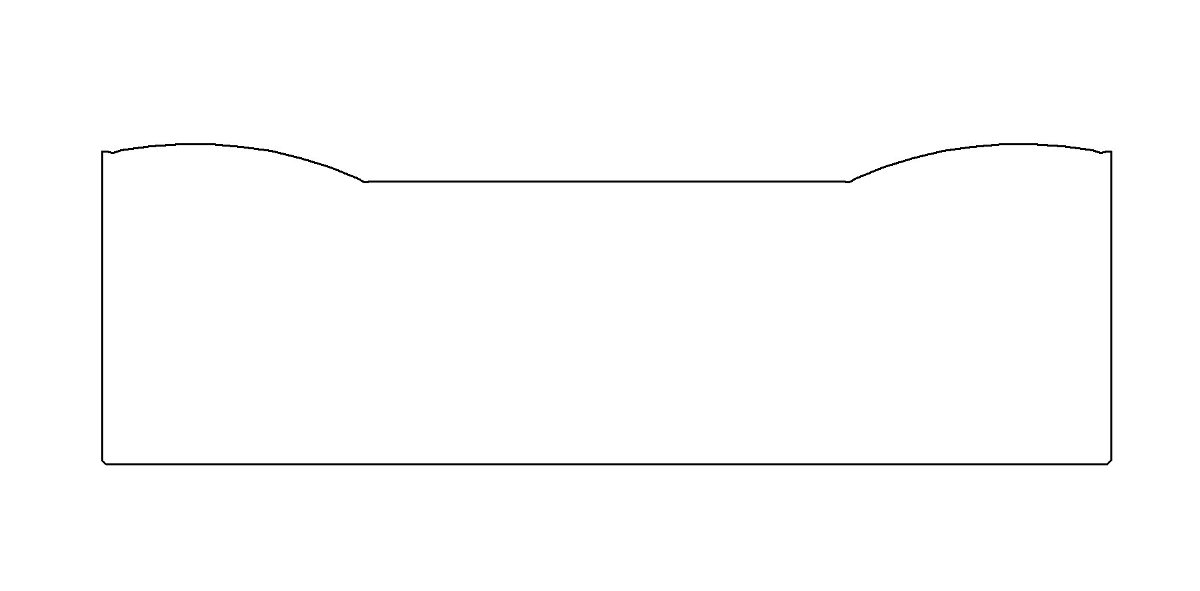

Processing method and device of metal shell brattice for cambered refrigerator

The invention discloses a processing method and a device of a metal shell brattice for a cambered refrigerator. The device comprises a first station and a second station which are arranged front and back along the conveying direction, wherein two pressure punching machines which are arranged at intervals are arranged at the first station, and a linear plate shearing machine is installed at the second station. When a brattice workpiece is processed, firstly, the two pressure punching machines are used for punching the excess materials of the cambered parts at the two sides of the workpiece to form cambered line segments at the two sides of the workpiece; and then, the linear plate shearing machine is used for shearing off the excess materials of the linear part in the middle of the workpiece. The processing device is relatively portable and has small space occupation and low manufacturing cost. Moreover, the excess materials of the workpiece in the processing procedure are divided intothree parts, the excess materials can be discharged easily, the automated operation can be realized easily, and the production efficiency can be greatly improved. In addition, by adjusting the distance between the two pressure punching machines and controlling the shearing stroke of the linear plate shearing machine, the device can be used for processing brattice workpieces of various specifications and has strong universality.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

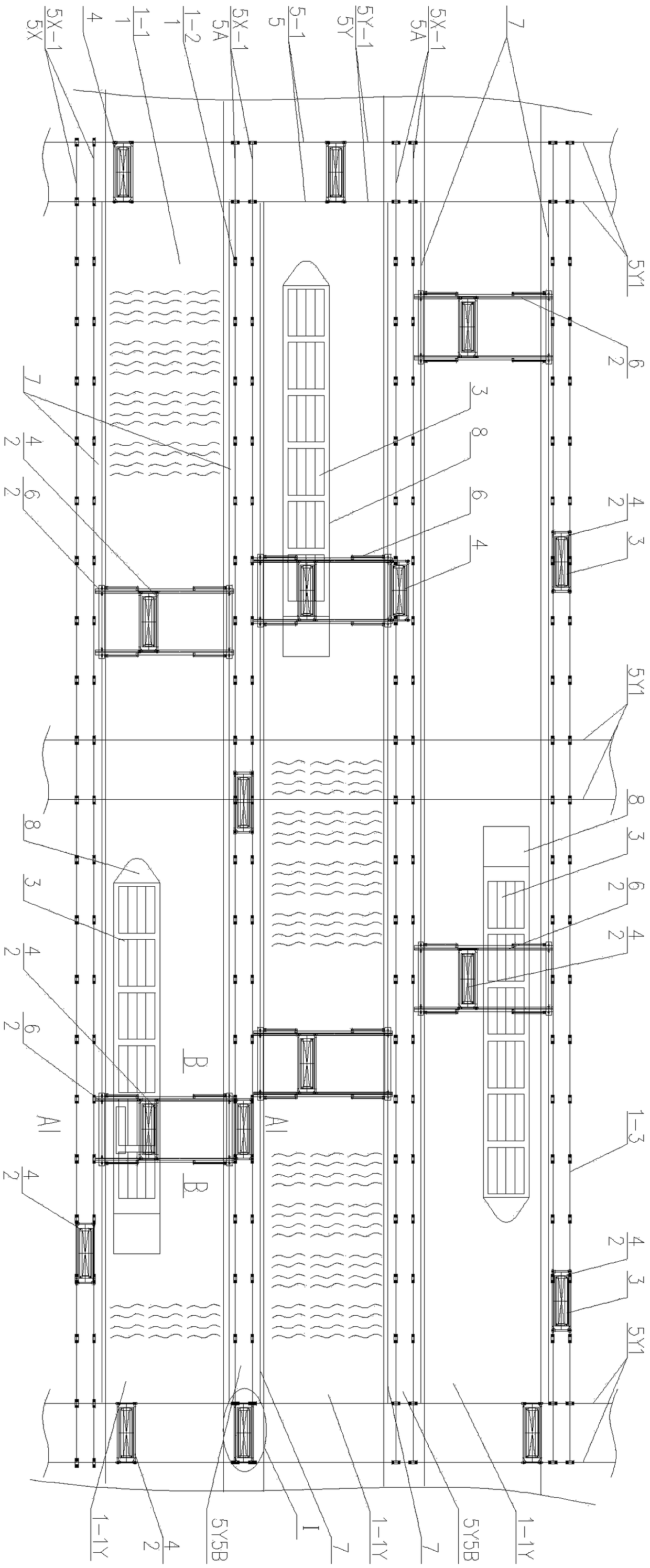

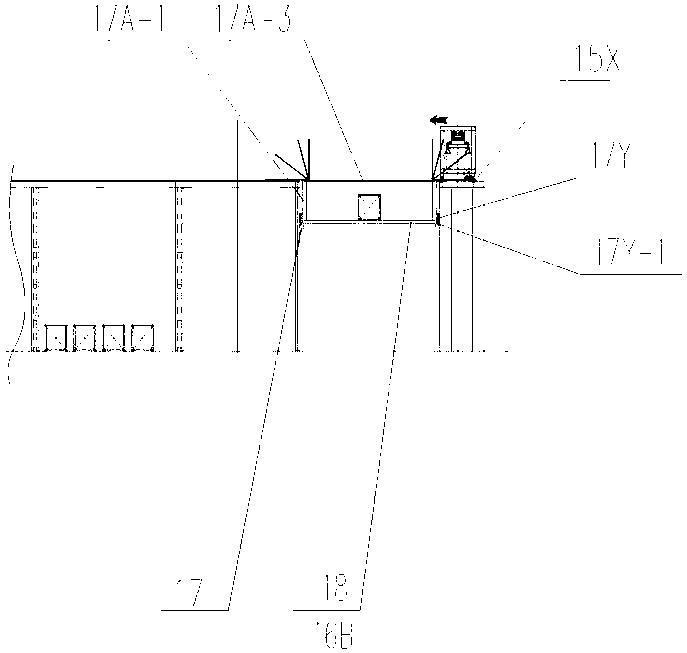

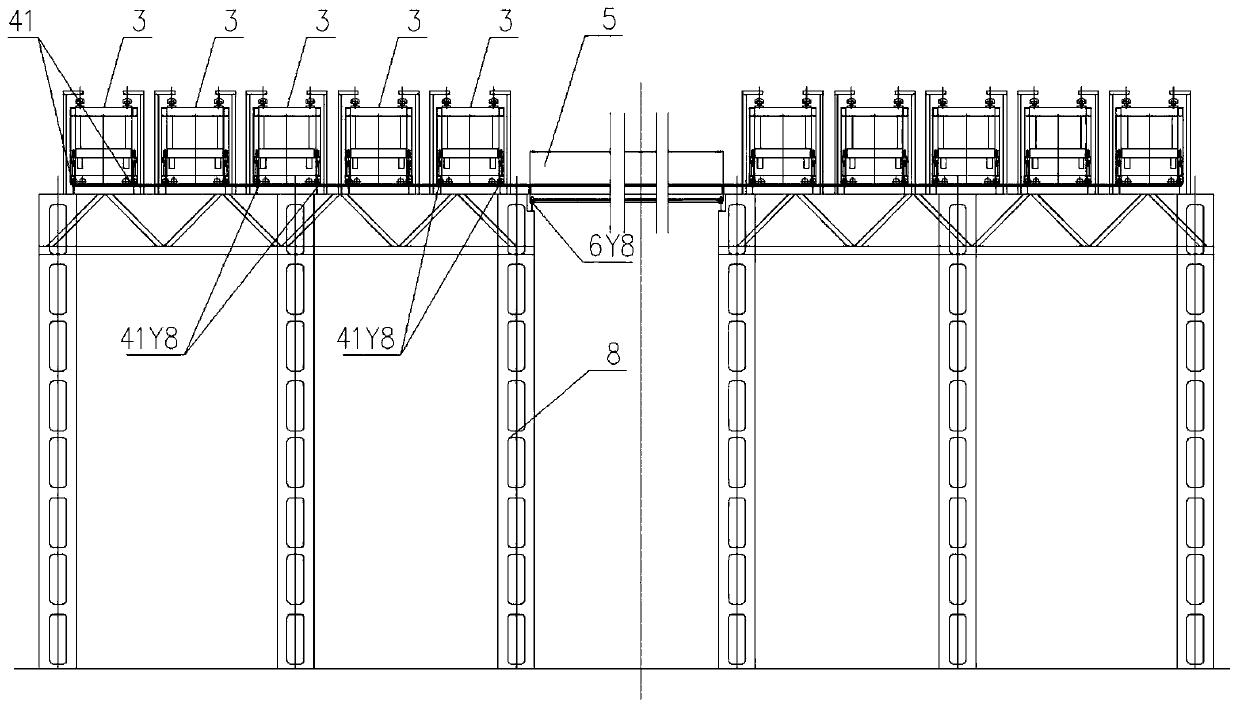

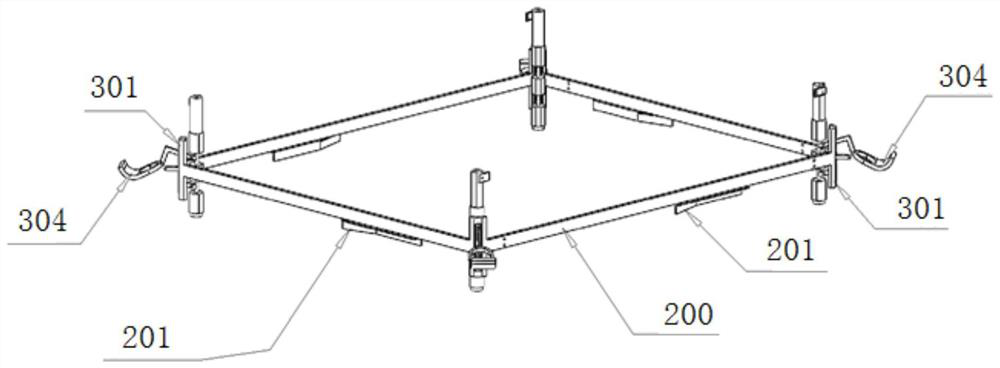

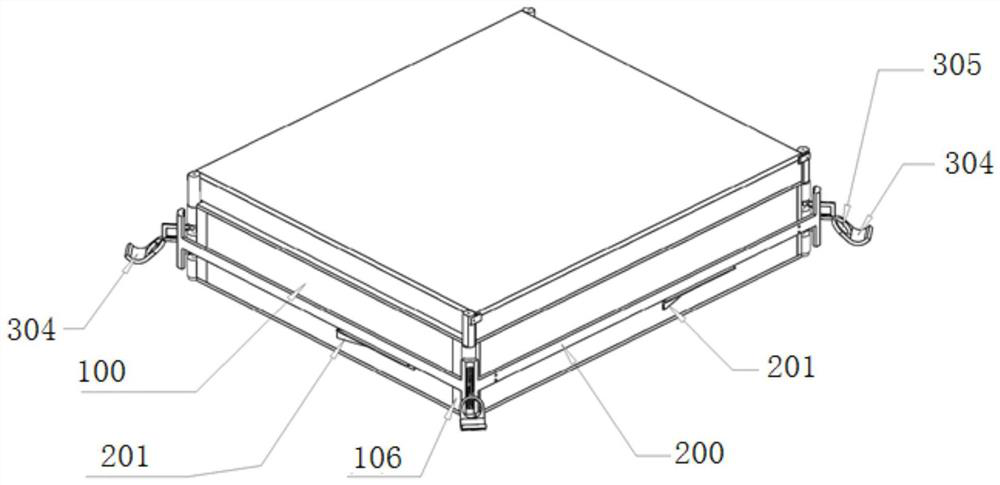

Conveying device for container port

PendingCN109436856AEasy to automate jobsImprove efficiencyConveyorsStorage devicesMechanical engineeringContainer port

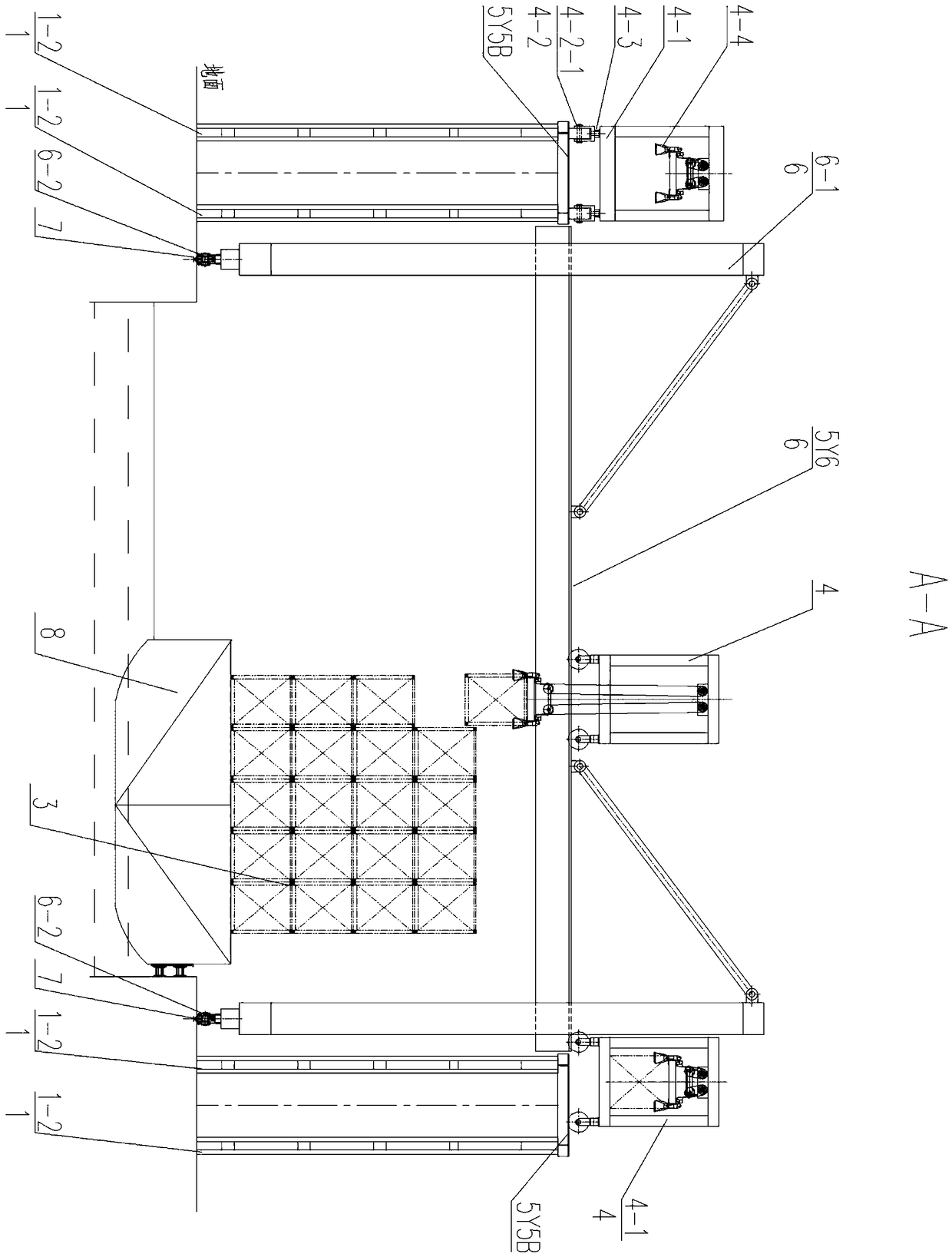

The invention provides a conveying device for a container port. The conveying device 2 for the port 1 comprises a conveying vehicle 4 of a container 3, a conveying vehicle track 5, a transverse movingmachine 6 and a transverse moving machine track 7, wherein the port 1 comprises a berth 1-1, a stand column component 1-2 and a conveying vehicle track grid 1-3; the conveying vehicle 4 comprises a frame 4-1, a travelling device 4-2, a switching device 4-3 and a hoisting hanging device 4-4; the conveying vehicle track 5 comprises a transverse track 5X arranged in the X direction and a longitudinal track 5Y arranged in the Y direction; and the transverse moving machine 6 comprises a rack 6-1, a movable longitudinal track 5Y6, transverse travelling wheels 6-2. The conveying device for the container port has the advantages that the conveying vehicle 4 of the container 3 of the conveying device 2 runs on an air track, the container can be automatically taken and placed, the conveying vehicle4 of the container runs on the track 5 to realize travelling in the X direction and in the Y direction, loading and unloading operation of the container 3 in a ship 8 is realized through the conveyingvehicle 4 and the transverse moving machine 6, so that full-coverage logistics conveying at the berth 1-1 can be realized, the automatic operation is easy to realize, and the efficiency is high.

Owner:王燏斌

Intelligent tree mover

InactiveCN108684485AQuick alignmentAutomatic diameter measurementForestryDiameter at breast heightTree trunk

The invention discloses an intelligent tree mover. The intelligent tree mover is composed of a tree moving device, a soil ball hoisting and rotating device, a rope winding device, a rotary table device, a crawler and a gradient sensor. The tree moving device is composed of a first telescopic assembly, a first amplitude-variable hydraulic oil cylinder, a second telescopic assembly, a tool cycling motion driving assembly and a tree moving assembly, the first amplitude-variable hydraulic oil cylinder is provided with a double-lug ring, and a piston rod is provided with a single-lug ring; according to a gradient angle signal of the gradient sensor, the angle of the tree mover can be automatically adjusted through the first amplitude-variable oil cylinder, and it is ensured that the tree moverrapidly aligns with nursery stocks; the diameter at breast height of a tree trunk can be automatically measured, and the diameter and the taper angle of a soil ball can be automatically adjusted; thesoil ball can be cut rapidly, and is complete and good in quality; the soil ball can be automatically hoisted and wound with a rope, and the nursery stocks can be automatically loaded onto a transportation vehicle. The intelligent tree mover realizes intelligent control and automatic operation easily, and is convenient to operate and high in working efficiency in nursery stock hoisting.

Owner:KUNMING UNIV

Small mechanical fast tree digging machine

The invention discloses a small mechanical fast tree digging machine. The machine consists of a tree digging device, a soil ball diameter adjustment and hoisting rotation device, a rope winding device, a trolley, a charging battery pack, an inverter, a hydraulic system box and a control system box. The tree digging device is composed of a first cubic fixing arm, a first cubic retractable arm, an end cover, a first amplitude-changeable hydraulic oil cylinder, a first multilevel retractable sleeving-type oil cylinder and a double-row sprocket tooling assembly. The diameter at breast height of atrunk can be automatically measured, and the diameter and taper angle of each soil ball are automatically adjusted. The soil balls can be quickly cut, and the standard quality of the soil balls is high. The soil balls can be automatically hoisted up and wound by ropes; nursery stocks can be automatically loaded onto conveying vehicles. Intelligent control and automated operation are easily achieved, operation is convenient, and the work efficiency during seedling lifting is high.

Owner:KUNMING UNIV

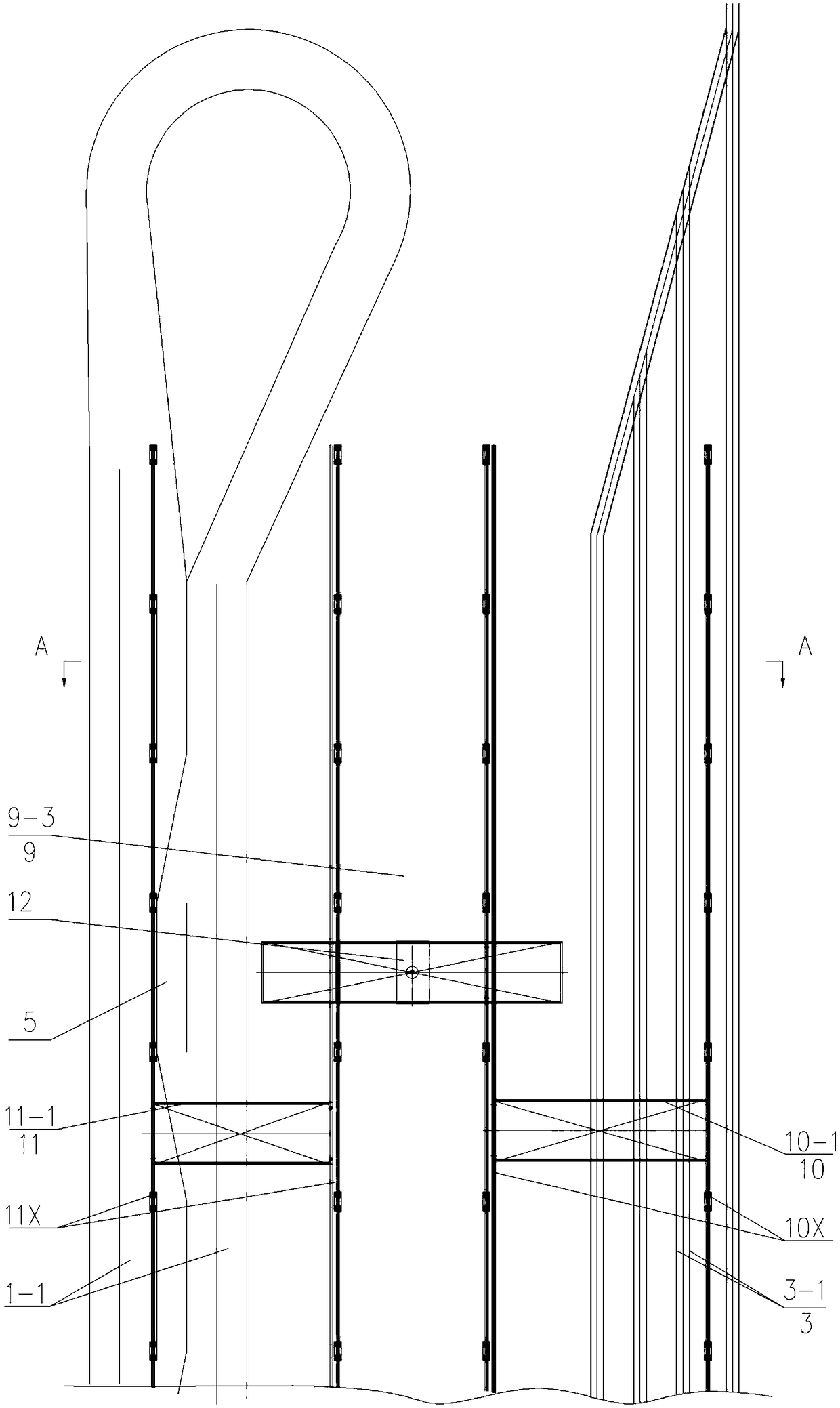

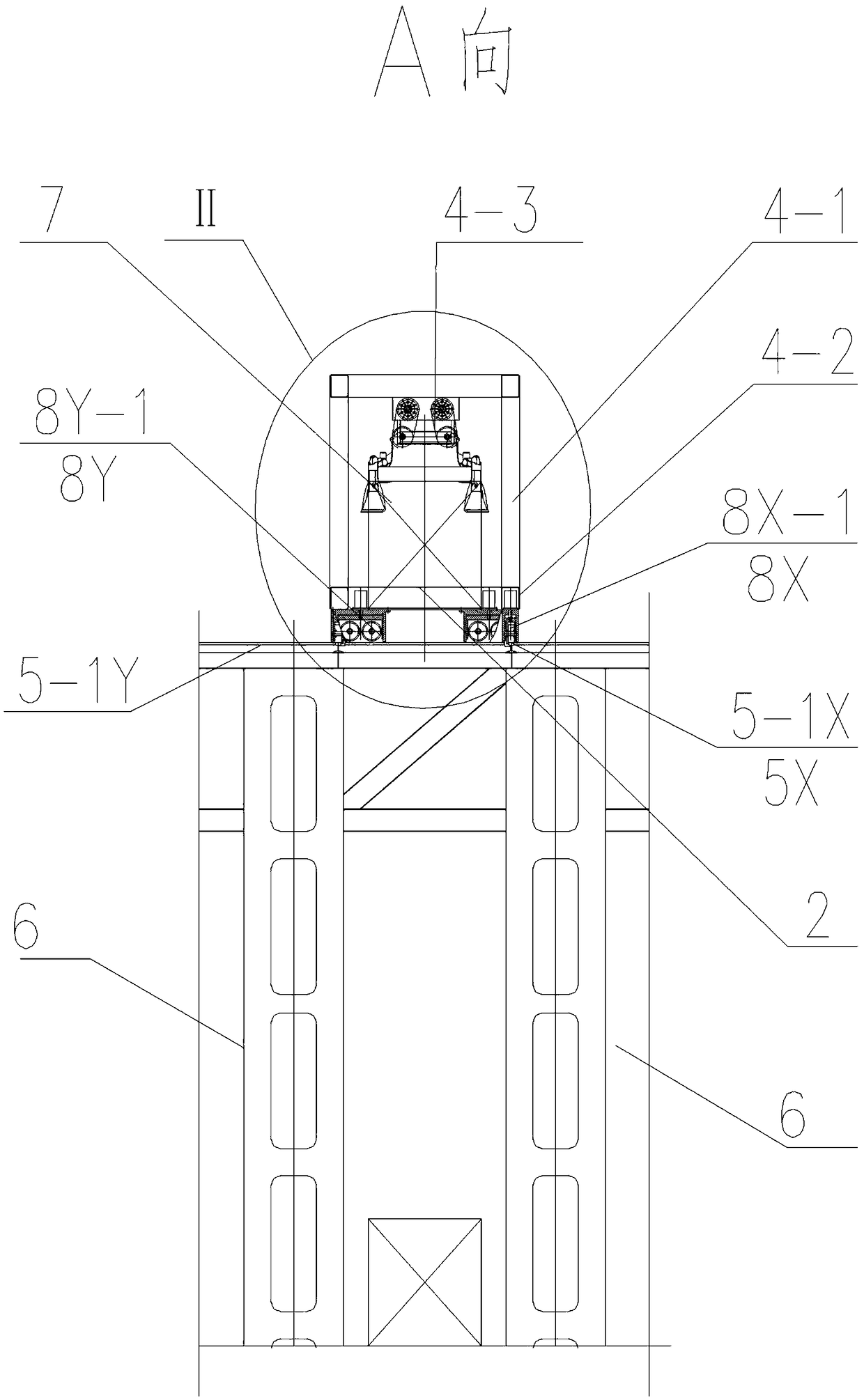

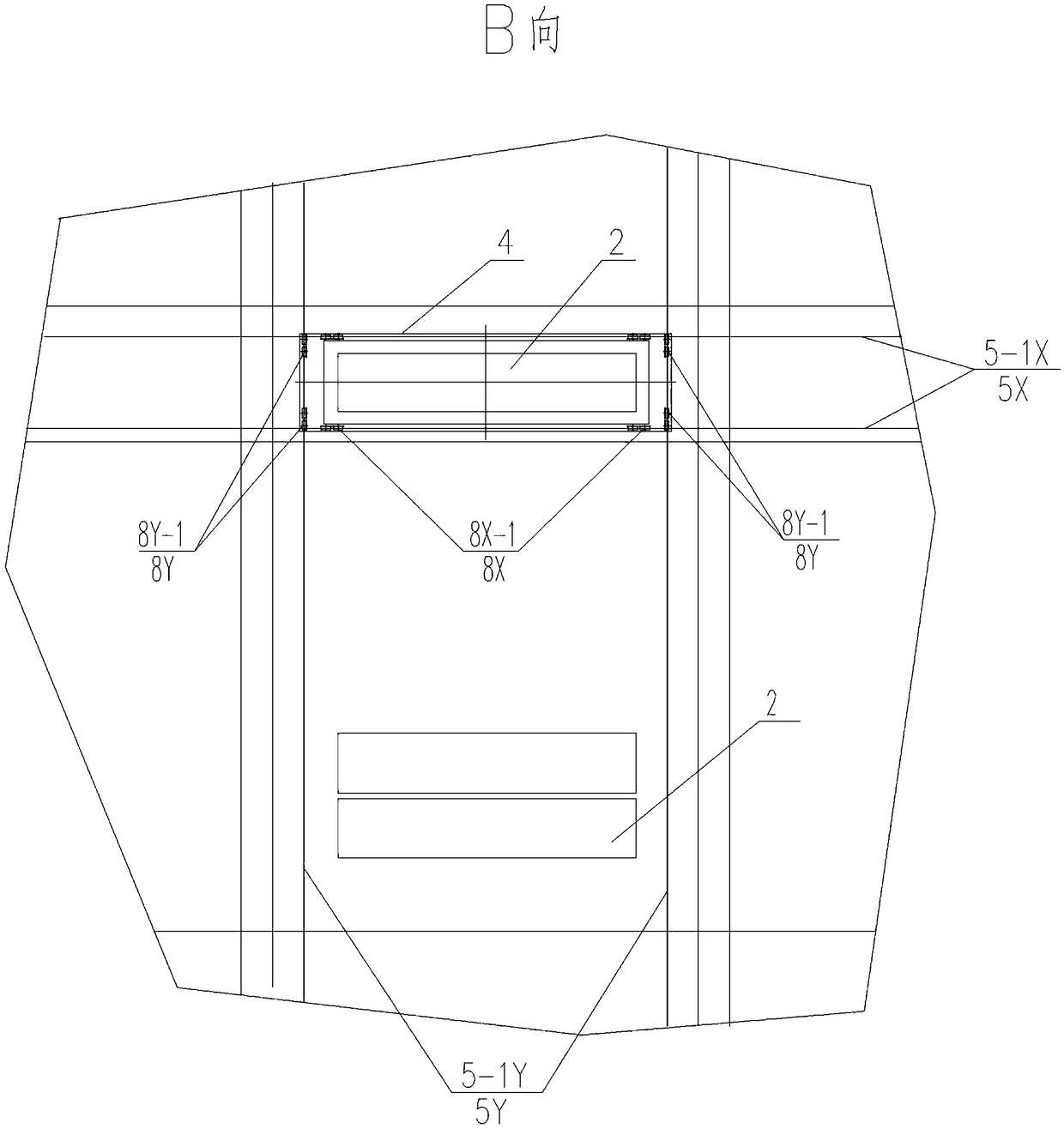

Railway container yard and conveying device thereof

PendingCN108792485AEasy to automate jobsImprove efficiencyStorage devicesMechanical conveyorsLogistics managementYard

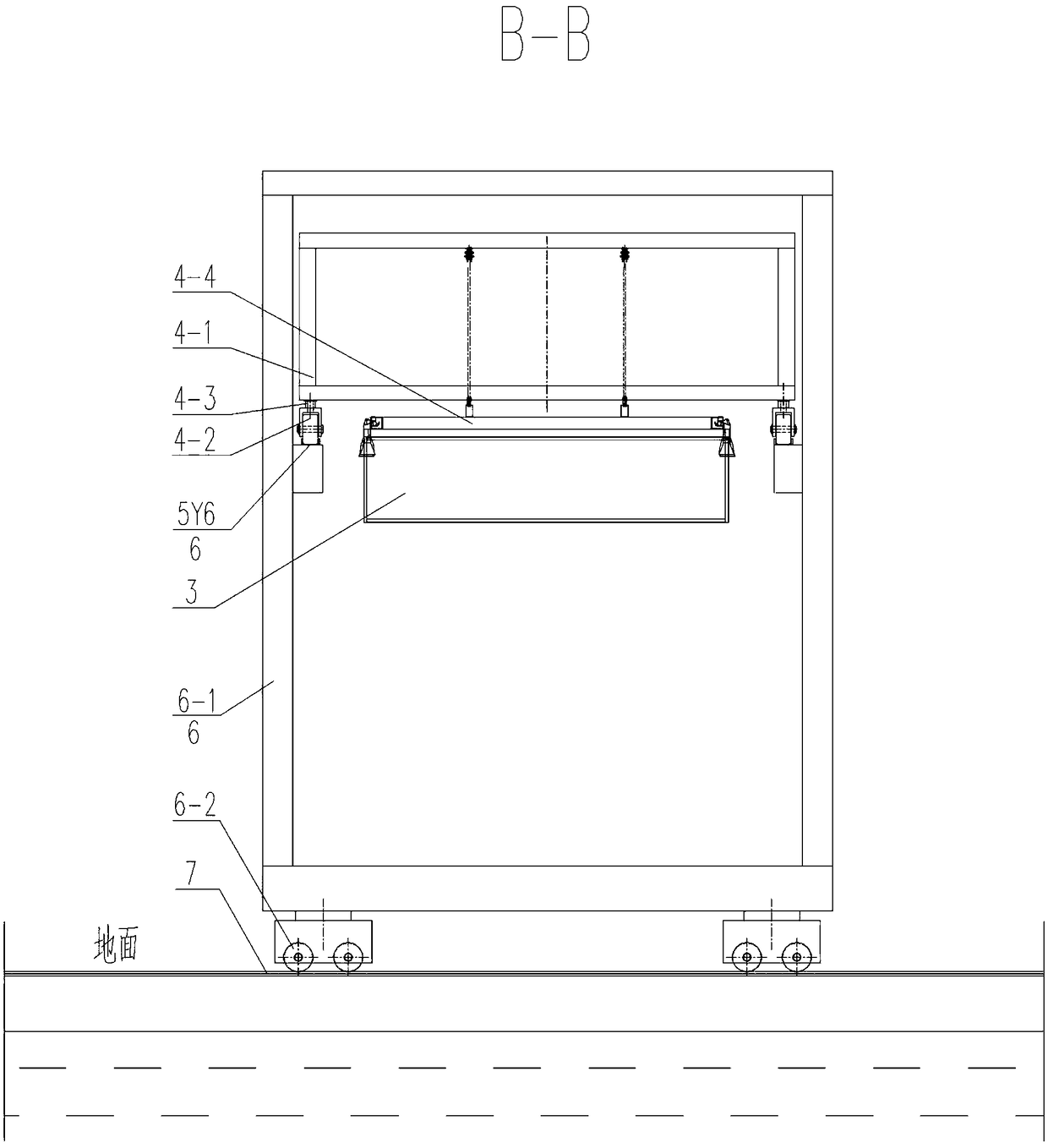

The invention provides a railway container yard and a conveying device thereof. The conveying device 3 of a container 2 in the railway container yard 1 comprises a container conveying vehicle 4, a yard track 5 where the conveying vehicle 4 operates, and vertical post components 6. The conveying vehicle 4 comprises a frame 4-1, a jacking switching device 4-2, a lifting device 4-3, a hanging device7 and a traveling device 8, wherein the frame 4-1 is a cavity with a bottom opening, the traveling device 8 is located at the bottom of the frame 4-1, the lifting device 4-3 is located at the top of the frame 4-1, and the lifting device 4-3 is used for hanging the container 2 below the frame 4-1 into the frame 4-1 through the hanging device 7 or placing the container 2 in the frame 4-1 below the frame 4-1. The railway container yard and the conveying device thereof have the advantages that the container conveying vehicle 4 of the conveying device 3 operates on the aerial track, and the container can be taken and placed automatically; and the container conveying vehicle 4 travels on the track 5 in the X direction and the Y direction, so that full coverage logistics conveying can be achieved, automatic operation is achieved easily, and efficiency is high.

Owner:王燏斌

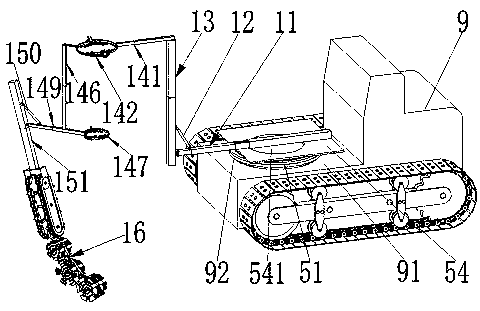

Automatic tree mover

The invention discloses an automatic tree mover. The automatic tree mover is composed of a tree moving device, a soil ball hoisting and rotating device, a rope winding device, a rotary table device, acrawler and a gradient sensor. The tree moving device is composed of a first telescopic assembly, a first amplitude-variable hydraulic oil cylinder, a second telescopic assembly, a tool cycling motion driving assembly and a dual-row sprocket tool assembly, the first amplitude-variable hydraulic oil cylinder is provided with a double-lug ring, and a piston rod is provided with a single-lug ring; according to a gradient angle signal of the gradient sensor, the angle of the tree mover can be automatically adjusted through the first amplitude-variable oil cylinder, and it is ensured that the treemover rapidly aligns with nursery stocks; the diameter at breast height of a tree trunk can be automatically measured, and the diameter and the taper angle of a soil ball can be automatically adjusted; the soil ball can be cut rapidly, and is standard and good in quality; the soil ball can be automatically hoisted and wound with a rope, and the nursery stocks can be automatically loaded onto a transportation vehicle. The automatic tree mover realizes intelligent control and automatic operation easily, and is convenient to operate and high in working efficiency in nursery stock hoisting.

Owner:KUNMING UNIV

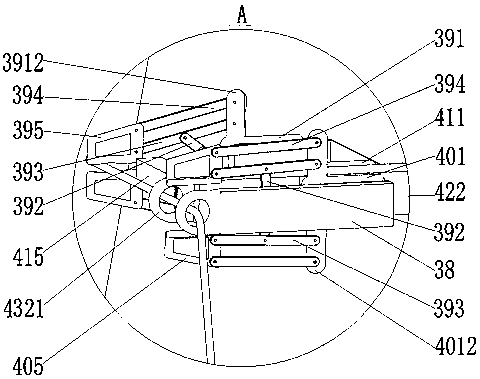

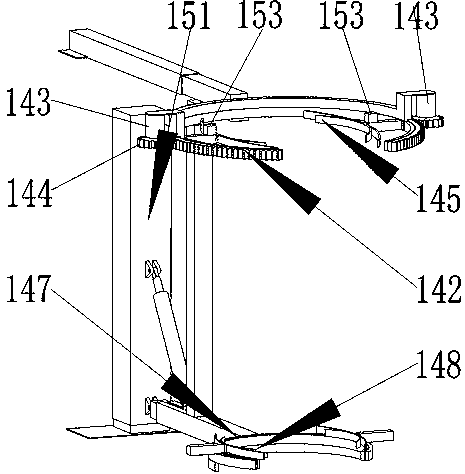

Driving device for cycle motion of tree digging cutter

The invention discloses a driving device for cycle motion of a tree digging cutter. The device is composed of a first retractable component, a first C-shaped slewing supporting component, two low-speed large-torque hydraulic motors, two first gears, two first clamping components, a second retractable component, a second C-shaped slewing supporting component, two second clamping components, a thirdretractable component, an amplitude-variation hydraulic oil cylinder, a fourth retractable component, a plate-type cantilever beam and two laser displacement sensors. A cylinder body of the amplitude-variation hydraulic oil cylinder is provided with double lugs, and a piston rod is provided with a single lug; the diameter at breast height of a tree trunk can be automatically measured, and the diameter and taper angle of soil balls can be automatically and conveniently adjusted; the cutter can be supported and conduct circular motion of different diameters and taper angles, and the soil ballsof different diameters and taper angles are cut; intelligent control and automatic operation are easily achieved, and the driving device for cycle motion is convenient to operate and high in working efficiency.

Owner:KUNMING UNIV

Single component crylic acid anaerobic stick glue and production method and construction method of single component crylic acid anaerobic stick glue

ActiveCN104312460ALow viscosityImprove the level ofNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveLeveling effectAdhesive

The invention relates to the field of chemical adhesives, in particular to single component crylic acid anaerobic stick glue and a production method and a construction method of the single component crylic acid anaerobic stick glue. The single component crylic acid anaerobic stick glue is low in viscosity, good in leveling effect and capable of guaranteeing that paint film on a gluing face is uniform and coincident, can be solidified at the room temperature, is high in speed and strength, small in shrinking percentage and capable of being disassembled after solidification, saves energy, is excellent in performance, and has the performance of heat resistance, voltage resistance, lower temperature resistance, drug resistance, impact resistance, shock absorption, corrosion prevention, fog resistance and the like. Glue overflowed from glue seams cannot be solidified and is easy to remove. The production method for preparing the single component crylic acid anaerobic stick glue is simple in process and low in cost. According to the construction method of the single component crylic acid anaerobic stick glue, anaerobic solidification is used, construction is simple, weighing, mixing and glue preparation are not needed, the single component crylic acid anaerobic stick glue is quiet convenient to use, and the automation operation is easily achieved.

Owner:GUANGZHOU SHUANGKE NEW MATERIAL

Wharf container yard and conveying device thereof

PendingCN108792482AEasy to automate jobsImprove efficiencyStorage devicesMechanical conveyorsCooperative workWharf

The invention discloses a wharf container yard and a conveying device thereof. The conveying device for containers 2 in the wharf container yard 1 comprises a container conveying cart 4, a goods rail5 for running of the conveying cart 4, a bank crane 6 and a connector device 7; the conveying cart 4 comprises a framework 4-1, an ejection switching device 4-2, a craning device 4-3, a hanging device4-4 and a walking devices 8; bottoms of a horizontal walking device 8X and a longitudinal walking device 8Y are separately provided with walking wheels 8-1; the walking wheels 8-1 are guided throughguiding flanges 8-1-1 which are lower than the upper plane of a yard guide rail 5-1. The wharf container yard and the conveying device thereof have the advantages that the container conveying cart 4 of the conveying device 3 runs on the air guide rail; the containers can be automatically fetched and taken; walking of the container conveying cart 4 on the rail 5 in the X and Y directions is realized; and through cooperative work of the bank crane 6 and the connector device 7, full-coverage logistic conveying can be realized; automatic work is easy to realize; and the efficiency is high.

Owner:王燏斌

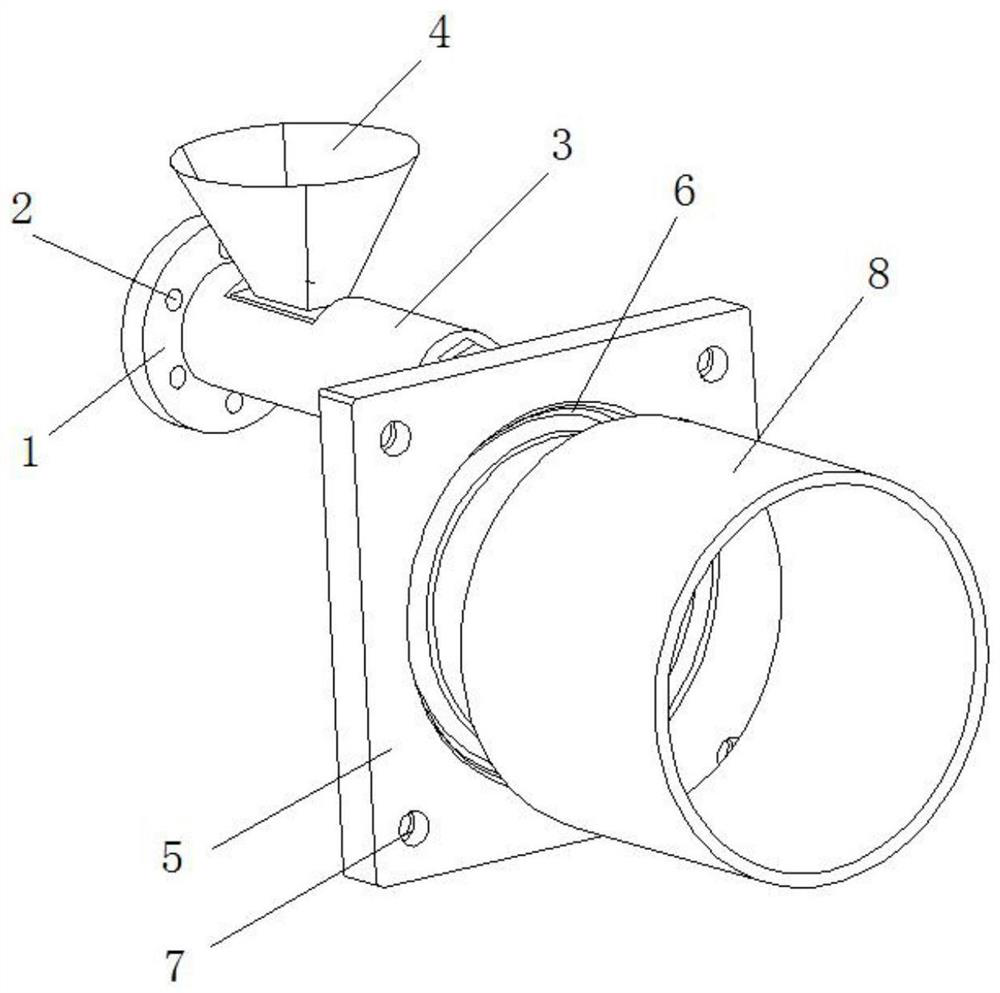

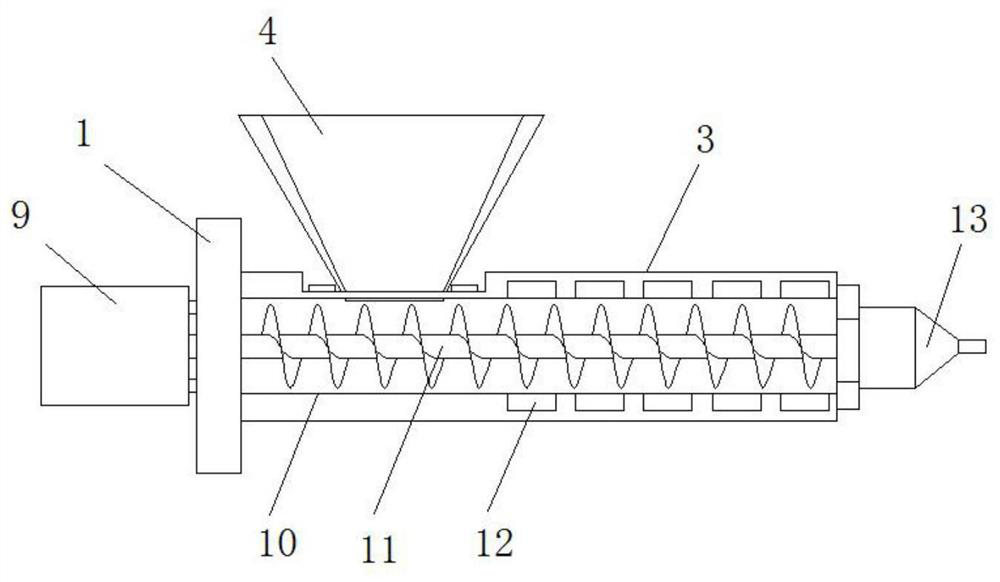

Steel-plastic composite pipe port middle layer metal steel wire injection molding edge sealing device and method

PendingCN113843960AAutomate operationsEasy to automate jobsTubular articlesElectric machineEngineering

The invention discloses a steel-plastic composite pipe port middle layer metal steel wire injection molding edge sealing device. The steel-plastic composite pipe port middle layer metal steel wire injection molding edge sealing device comprises a fixing disc, an outer protective barrel is coaxially fixed to one circumferential side face of the fixing disc, a material conveying barrel is coaxially fixed in the outer protective barrel, a material conveying screw is coaxially installed in the material conveying barrel, a constant-speed motor is coaxially fixed to the other circumferential side face of the fixing disc, the output end of the constant-speed motor is coaxially and fixedly connected with one end of the material conveying screw, a nozzle is arranged at the other end of the material conveying barrel, an annular heater is arranged on the outer side wall of the material conveying barrel, a feeding hopper is fixed to the side wall of the outer protective barrel, the discharging end of the nozzle is fixedly connected with a pipe edge sealing mold, a limiting forming ring groove is formed in the other side face of the pipe edge sealing mold, and a steel-plastic composite pipe is in butt joint with the limiting forming ring groove. The invention has the technical effects of being integrally formed through mold injection molding, being time-saving and labor-saving, being easier to realize automatic operation, being simple and convenient in operation method, and ensuring the edge sealing quality.

Owner:天津壹川智能科技有限公司

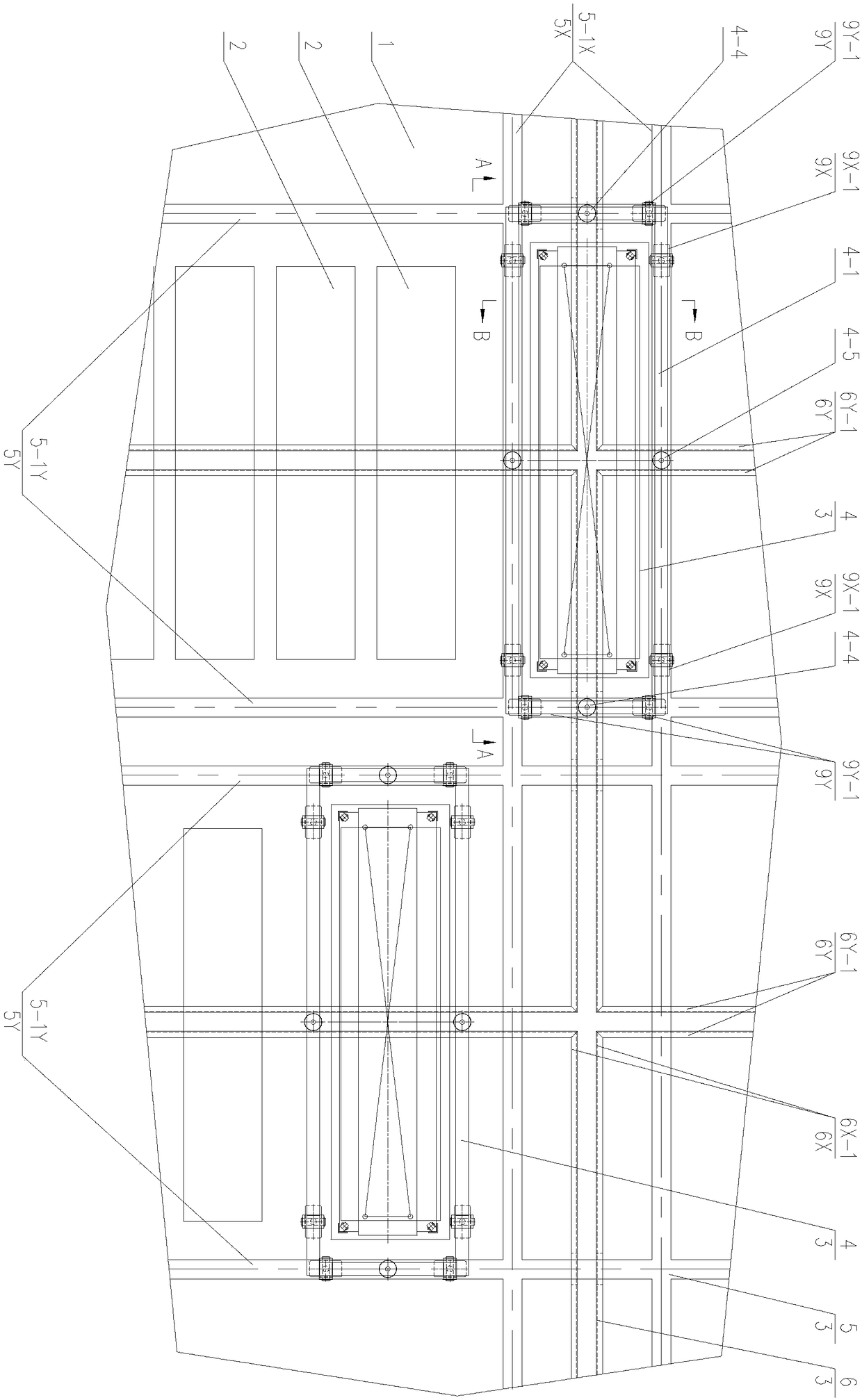

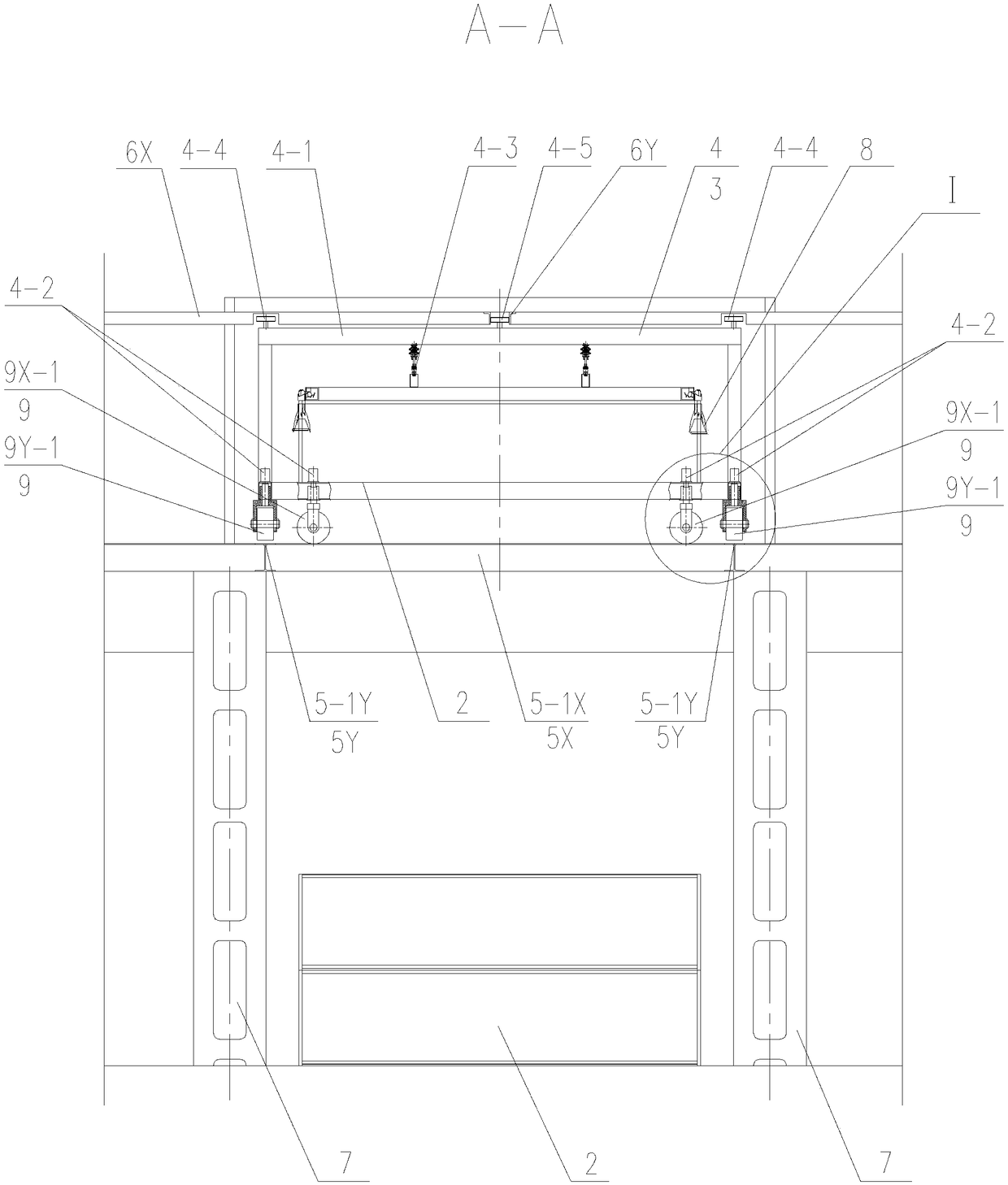

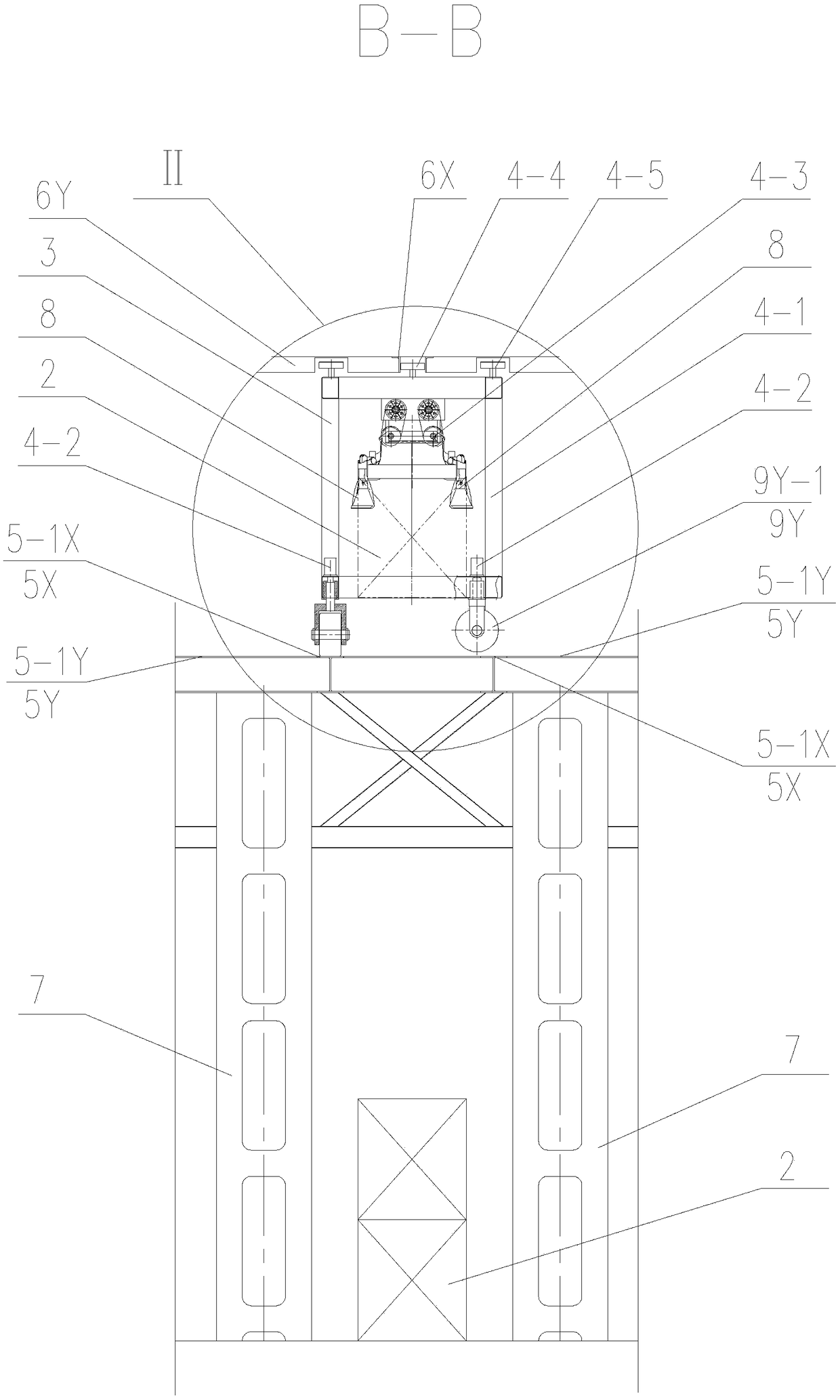

Conveying device for container yard

The invention provides a conveying device for a container yard. The conveying device 3 of a container 2 of a wharf and a railway container yard 1 comprises a container conveying vehicle 4, a bearing track 5, a guide track 6 and a vertical column component 7, wherein the conveying vehicle 4 comprises a frame 4-1, a jacking switching device 4-2, a hoisting device 4-3, X guide wheels 4-4, Y guide wheels 4-5, a hanging device 8 and a travelling device 9; the guide track 6 is located above the bearing track 5 to be positioned on the vertical column component 7 and is composed of a guiding guide track 6-1; and the jacking switching device 4-2 extends and retracts to change height different between transverse travelling wheels 9X-1 and longitudinal travelling wheels 9Y-1 and realize running switching of the travelling device 9 on a transverse guide track 5X and on a longitudinal guide track 5Y. The conveying device for the container yard has the advantages that the frame 4-1 is a cavity provided with a bottom opening, the container 2 can be taken and placed automatically through the hanging device 8, the travelling device 9 realizes running in the X direction and the Y direction through the jacking switching device 4-2 and the conveying device 4, full-automatic operation is easy to realize, and the efficiency is high.

Owner:王燏斌

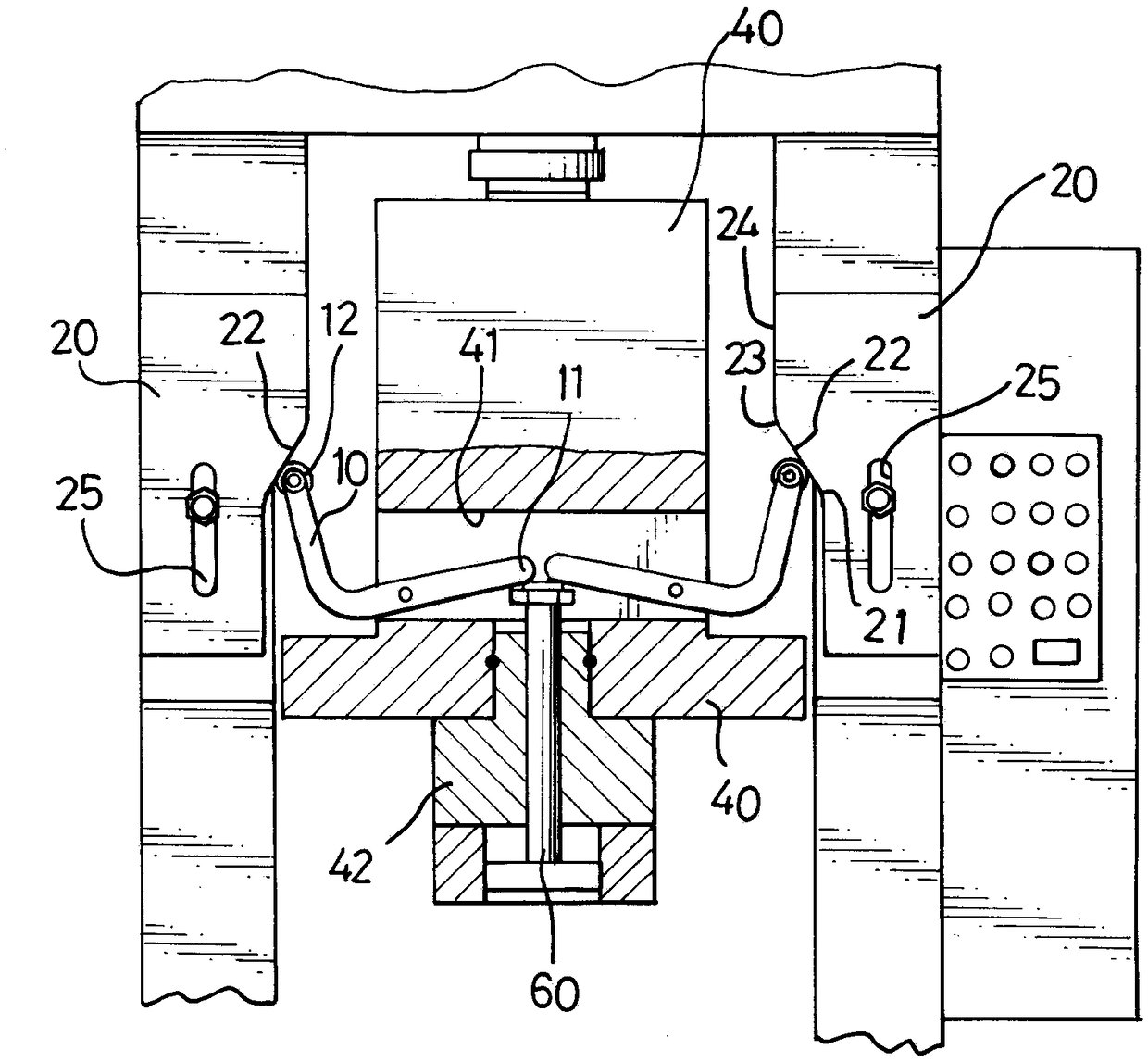

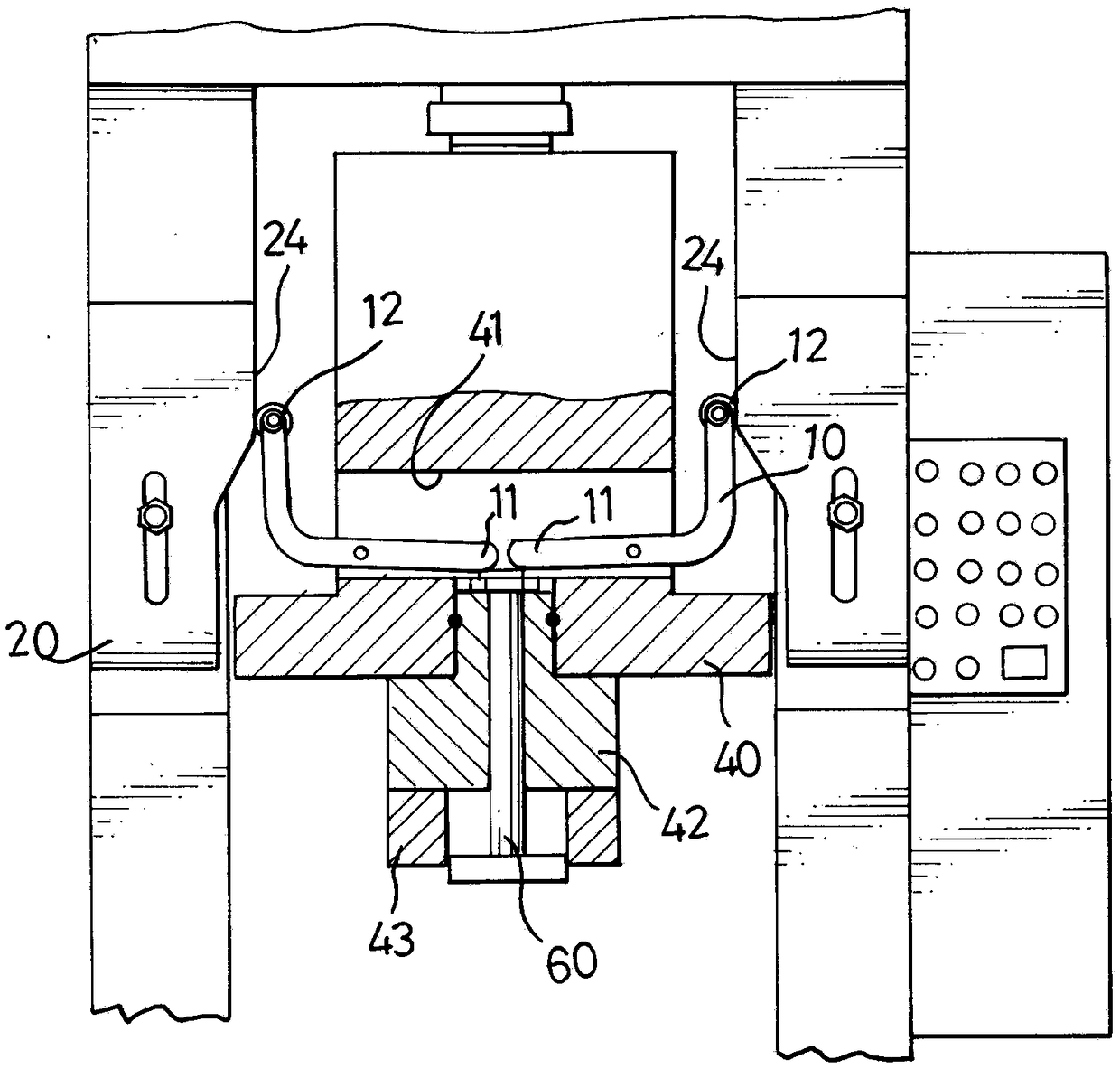

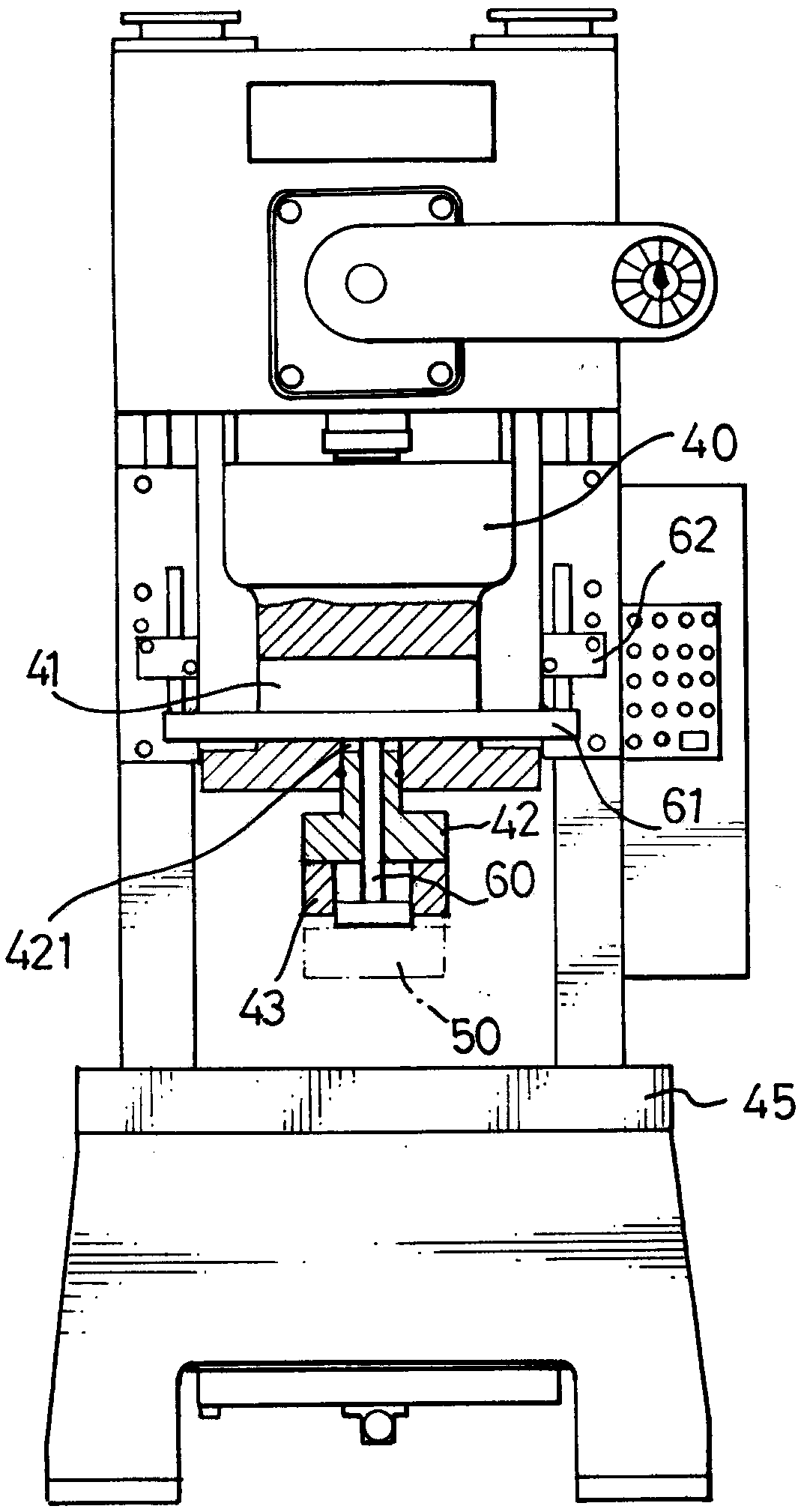

Material part quick demolding structure of anchor chain transverse stop punch

The invention relates to the field of anchor chains, in particular to a material part quick demolding structure of an anchor chain transverse stop punch. A transverse long hole area is formed in a punch hammer; the punch hammer is connected with a mold head; a pushing rod and a pair of molding arms are placed in the mold head; the demolding arms are similarly L-shaped support arm rods, movable wheel type guide wheels are pivoted at the tail ends of vertical ends, and horizontal ends are collision ends; orienting blocks are locked on a punch body and near two sides of the punch hammer; the inner sides of the orienting blocks are near the punch hammer; a lower corner with a slight upper arc is formed in a non-rising normal state position of the punch hammer; the lower corner aslant extends to gradually approach an inclined wall of the punch hammer; and the upper part of the inclined wall is a vertical wall type priming wall. The demolding design cannot cause great framework change of thepunch body, and is easy to install, low in cost and simple in element; and through the structure with practicability and advancement, the excellent effect easier to cooperate with automatic operationis achieved.

Owner:青岛天顺达机械制造有限公司

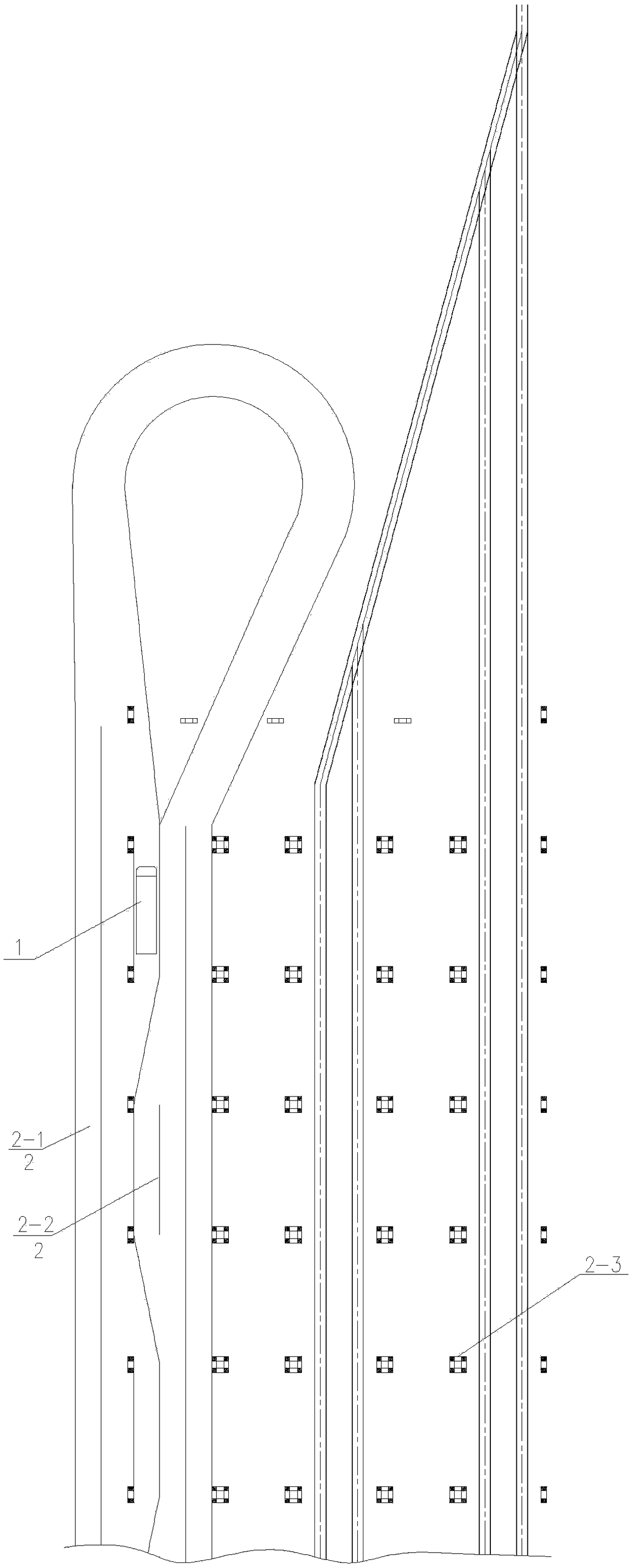

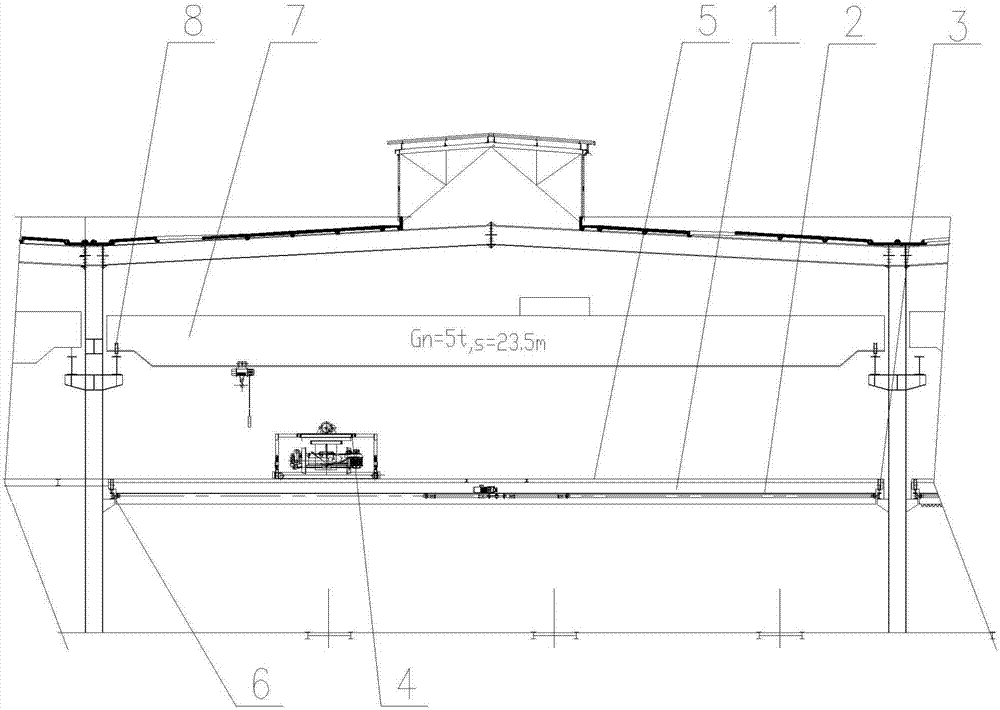

Loading and unloading operation area for container truck

InactiveCN108820932AEasy to automate jobsImprove efficiencyLoading/unloadingMechanical conveyorsParking spaceYard

The invention provides a loading and unloading operation area for a container truck. The loading and unloading operation area 2 used for the container truck 1 in railway or wharf goods yards comprisesconveying devices 4 for containers 3. The loading and unloading operation area 2 comprises lanes 2-1, loading and unloading truck spaces 2-2, vertical column members 2-3, transverse tracks 2X and longitudinal tracks 2Y. The conveying devices 4 comprise frames 5, switching devices 6, transverse operation devices 7, longitudinal operation devices 8 and lifting hanging devices 9. The frames 5 are frames with the open bottoms. The transverse operation devices 7 and the longitudinal operation devices 8 are both mounted on the bottoms of the frames 5. The loading and unloading operation area has the advantages that the conveying devices operate on the air tracks, the containers can be taken and placed automatically, automation operation is easy to realize, and the efficiency is high; the front-back direction of doors of the containers on the truck is changed during loading through the travelling direction of the container truck; and by changing the left-right position of the loading and unloading parking spaces on the lanes, the left-right direction of the doors of the containers on the truck is changed.

Owner:王燏斌

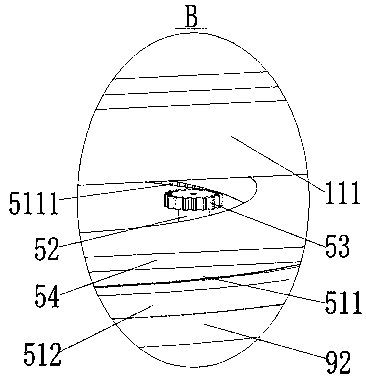

A container crane for U-shaped berth

ActiveCN107500143BEasy to automate jobsImprove efficiencyTrolley cranesTravelling gearContainer craneEngineering

A container crane for a U-shaped berth, said container crane comprising transport machines (3) for containers (2), tracks (4) for the transport machines (3) to move along, large machines (5), tracks (6) for the large machines (5) to move along, the U-shaped berth (7), and components (8) on the U-shaped berth (7). Each transport machine (3) comprises a locomotion apparatus (3-1), a spreader and lifting apparatus (3-2), a frame (3-3), and a switching apparatus (3-4), the locomotion apparatus (3-1) being located beneath the frame (3-3), the spreader and lifting apparatus (3-2) being located above the frame (3-3), the frame (3-3) being a hollow cavity with an opening at the bottom. The transport machines (3) on the large machines (5) are used to suspend the containers (2) in the hollow cavities of the frames (3-3), and move along the aerial tracks. The present invention implements full-coverage logistical transportation, and easily achieves automated operations and high efficiency.

Owner:王燏斌

A corner splint positioning and tensioning device

ActiveCN109954634BPrecise positioningEven by forcePretreated surfacesCoatingsHigh densityStructural engineering

The invention relates to a corner clamping plate locating tensioning device. The corner clamping plate locating tensioning device includes an outer frame with inner side size not less than the side surface contour size of an insulation box and corner frames distributed on the four corners of the outer frame, wherein the corner frames include corner plates fixed to the outer frame, compression rollers located on the inner sides of the corner plates and connecting rod mechanisms connected with the compression rollers and used for driving the compression rollers to compress second concave right-angle grooves. Compared with the prior art, the quality and the efficiency of corner clamping plate assembling can be effectively improved through the corner clamping plate locating tensioning device,installation and disassembling works are more easy and can be operated by one person, furthermore, the corner clamping plate locating tensioning device can be neatly stacked with high density, and fully automated operation and the logistic circulation efficiency are convenient to achieve.

Owner:SHANGHAI JIAO TONG UNIV +1

A corner splint positioning and tensioning device

ActiveCN109954633BPrecise positioningEven by forcePretreated surfacesCoatingsHigh densityEngineering

Owner:SHANGHAI JIAOTONG UNIV +2

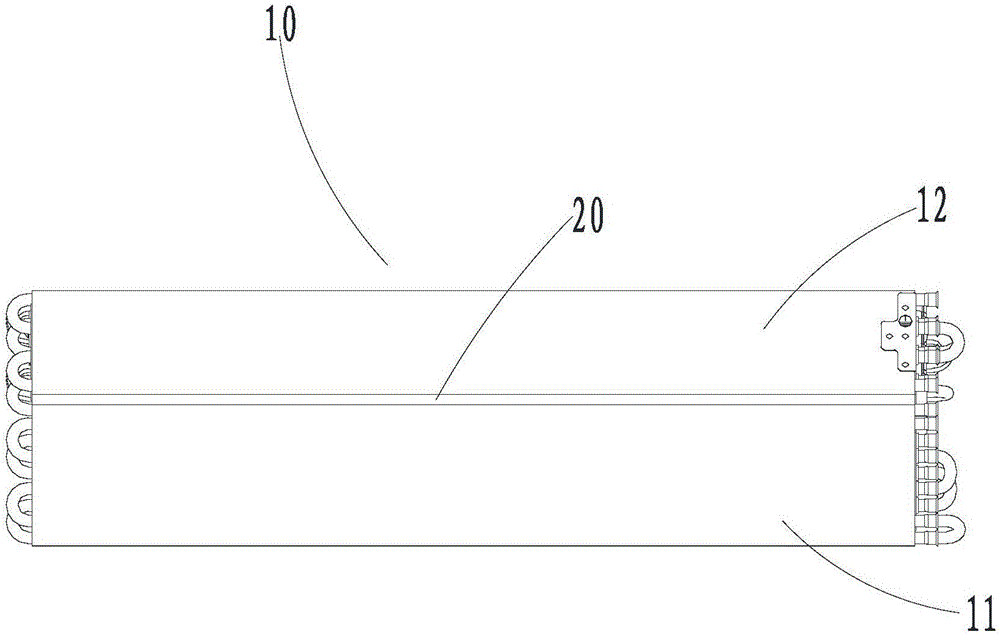

Heat exchanger assembly splicing and sealing method and heat exchanger

InactiveCN106195266AImprove energy efficiencyReduce dosageEngine sealsSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention provides a heat exchanger assembly splicing and sealing method. The method comprises the steps that heat exchanger assemblies are spliced together, and a splicing gap of the heat exchanger assemblies is coated with a hot melt adhesive, wherein the hot melt adhesive contains gas. According to the heat exchanger assembly splicing and sealing method and the heat exchanger, the hot melt adhesive is used for replacing sponge and butyl rubber to be used for sealing the splicing gap of the heat exchanger assemblies, and the quality problems such as warping and disengagement of sponge and butyl rubber materials can be avoided due to the fact that the hot melt adhesive has viscidity. The hot melt adhesive is filled with gas, so that the hot melt adhesive with air holes is formed, the using amount of the hot melt adhesive can be reduced, and the cost can be reduced. In addition, due to the fact that the heat conductivity coefficient of gas is generally small, the energy efficiency of the heat exchanger can be better improved.

Owner:GREE ELECTRIC APPLIANCES INC

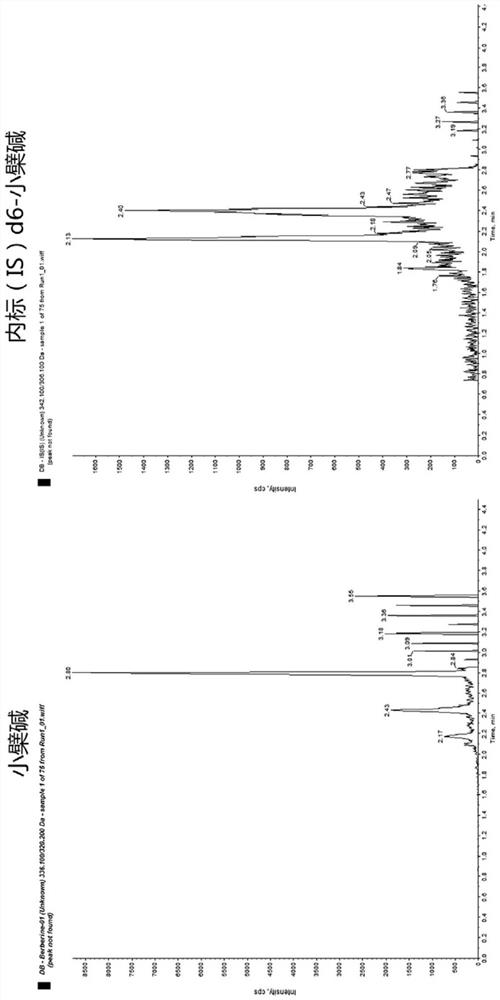

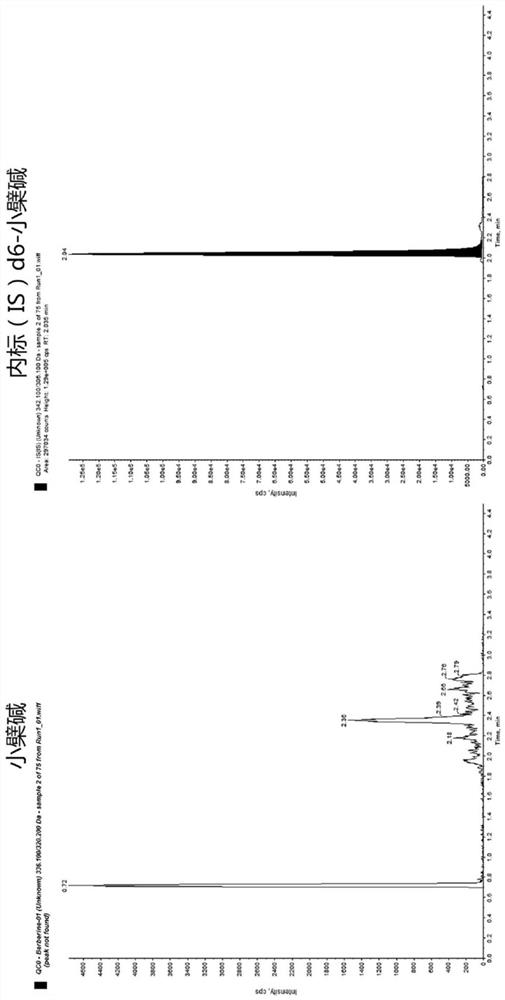

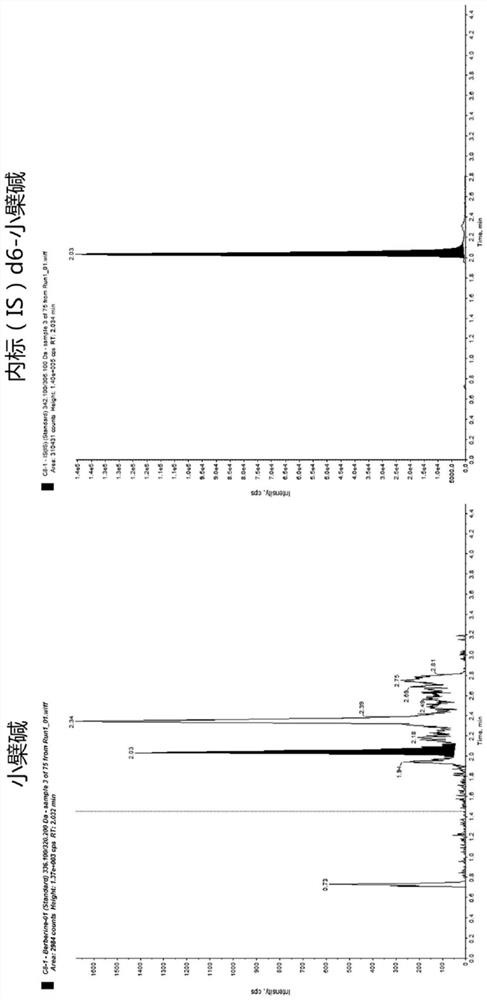

Quantitative analysis method of berberine in blood plasma

InactiveCN111929380ASimple and fast operationEasy to automate jobsComponent separationBerberineFluid phase

The invention discloses a quantitative analysis method of berberine in blood plasma. The method comprises the following steps: S1, carrying out pretreatment on plasma through a solid-phase supported liquid-liquid extraction method, wherein the method specifically comprises the following steps: diluting plasma, performing implantation adsorption in solid filler, eluting berberine by using an esterorganic solvent, drying, and finally uniformly mixing berberine in an analysis column by using an organic solvent mixed solution serving as a mobile phase to obtain an organic solvent mixed solution containing berberine; and S2, carrying out liquid-phase secondary mass spectrometry analysis on the organic solvent mixed solution by using a mass spectrometer. The method is easy and convenient to operate, automatic operation is easy, labor is saved, and the yield is high; the extraction effect is ultra-clean, and no latex liquid is formed; a large number of materials and equipment for traditionalextraction operation are omitted, cost is saved, and environmental protection is facilitated.

Owner:苏州圣临医药科技有限公司

Conveying device used for railway vehicle maintenance and production

InactiveCN107499850ARealize full coverage of logistics transportationEasy to automate jobsConveyor partsMechanical conveyorsEngineeringLogistics management

Owner:王燏斌

A rotary automatic storage and retrieval device and method

InactiveCN104443977BSmall footprintImprove space utilizationStorage devicesIdentity recognitionControl engineering

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Railway container yard and conveying device thereof

PendingCN108792484AEasy to automate jobsImprove efficiencyStorage devicesMechanical conveyorsLogistics managementYard

The invention provides a railway container yard and a conveying device thereof. The conveying device (3) for each container (2) in the railway container yard (1) comprises a container transport truck(4), a yard track (5) and stand column components (6), wherein each transport truck (4) operates on the corresponding yard track (5). Each transport truck (4) comprises a frame (4-1), a jacking switching device (4-2), a hoisting device (4-3), a hanging device (4-4) and walking devices (8). Each frame (4-1) is a cavity with the bottom being open. Each walking device (8) is located at the bottom ofthe corresponding frame (4-1). Each hoisting device (4-3) is located at the top of the corresponding frame (4-1). Each walking device (8) comprises a transverse walking device (8X) and a longitudinalwalking device (8Y). The railway container yard (1) comprises a container vehicle loading and unloading area (10) for the railway container vehicles (9), a container truck loading and unloading area (12) for container trucks (11) and a container piling area (13). The railway container yard and the conveying device thereof have the advantages that the container transport truck (4) of each conveyingdevice (3) operates on the corresponding overhead track, the corresponding container can be picked and placed automatically, and each container transport truck (4) can walk on the corresponding track(5) in the X direction and the Y direction; full-coverage logistics transport can be achieved; and automated operation can be achieved easily, and efficiency is high.

Owner:王燏斌

Process for local chemical plating long pipe surface

ActiveCN1900357BAvoid ingredient gradientsUniform thicknessLiquid/solution decomposition chemical coatingTopical surfaceCompound (substance)

The present invention relates to a partial chemical plating long tube whole or partial surface method used for raising inner bore surface coating uniformity and workpiece service life. Said method includes 1, adopts plating solution trough having electroless plating liquid, plating solution drive unit, connecting chemical plating long tube to form loop through pipe and valve; 2, starting up plating solution drive unit to fill chemical plating liquid in long tube simultaneously adopting heater relatively moving outside long tube to heat chemical plating liquid in long tube, making chemical plating to long tube inner surface; 3, continue circulation using chemical plating liquid back flown to plating solution trough until long tube inner surface whole or partial chemical plating ending. Heater and workpiece relatively move at 0.1-500mm / min speed; chemical plating liquid continuously pass through workpiece inner bore at 0-500mm / s speed.

Owner:GRIMAT ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com