Patents

Literature

44results about How to "Small jump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for obtaining character segment of video data and electronic equipment

ActiveCN110119711AQuality improvementSmall jumpCharacter and pattern recognitionPattern recognitionTimestamp

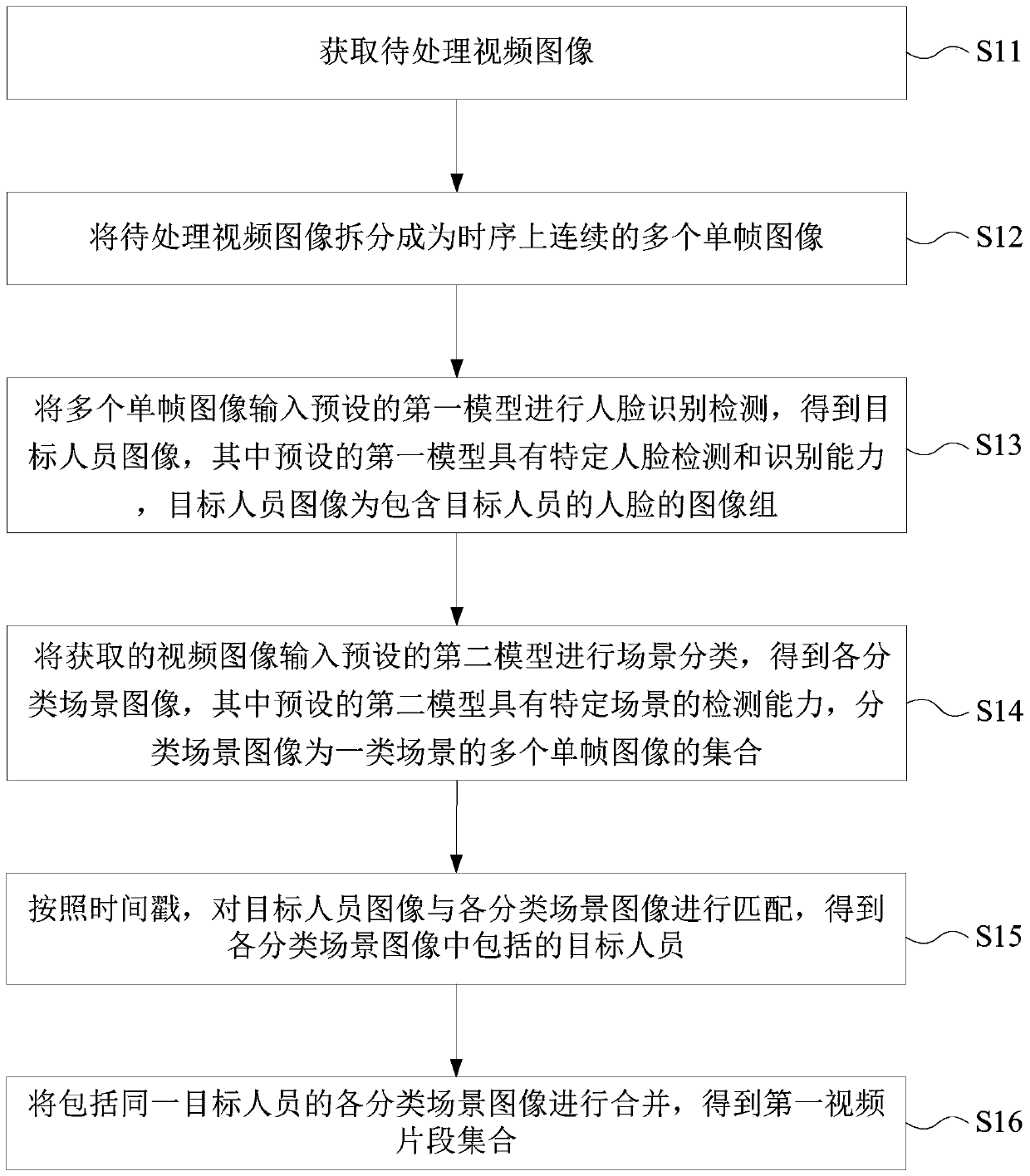

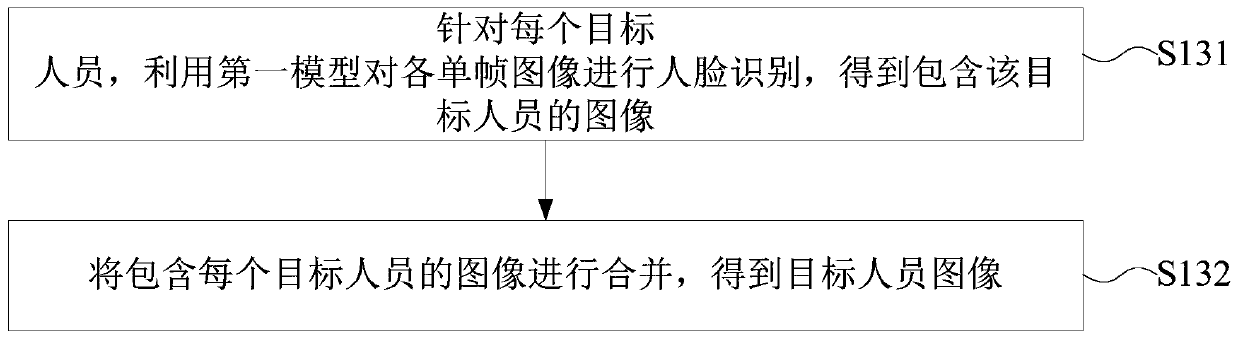

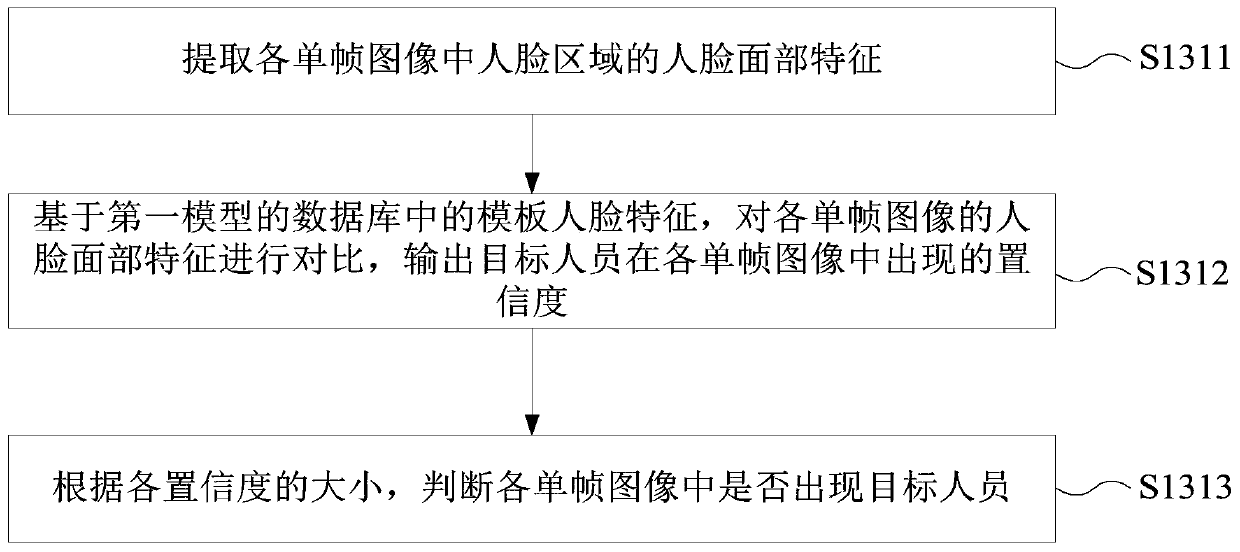

The embodiment of the invention provides a method and device for obtaining video data character fragments and electronic equipment, and the method comprises the steps: obtaining a to-be-processed video image; splitting the video image to be processed into a plurality of single-frame images which are continuous in time sequence; inputting the plurality of single-frame images into a preset first model for face recognition detection to obtain a target person image; inputting the obtained video images into a preset second model for scene classification to obtain classified scene images; matching the target person image with each classification scene image according to the timestamp to obtain a target person included in each classification scene image; and combining the classification scene images including the same target person to obtain a first video clip set. The human face recognition technology and the scene detection technology are combined together to generate the presentation segment of the target person, time is saved, and meanwhile scene type images are combined, so that the hops of actors in movie and television drama segments become small.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Dyeing process of nylon fiber

InactiveCN104711874AMild handling environmentReduce damageBiochemical fibre treatmentFibre typesColour fastnessPolymer chemistry

The invention provides a dyeing process of nylon fiber. The dyeing process comprises the following steps: pretreatment, presetting, dyeing soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that in the dyeing procedure, disperse dyes and acidic dyes are used for carrying out dyeing according to the own property of the nylon fiber, so that the dyeing effect is improved; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:袁英英

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Mixed cascading type multilevel stored energy charging-discharging and voltage-equalizing circuit

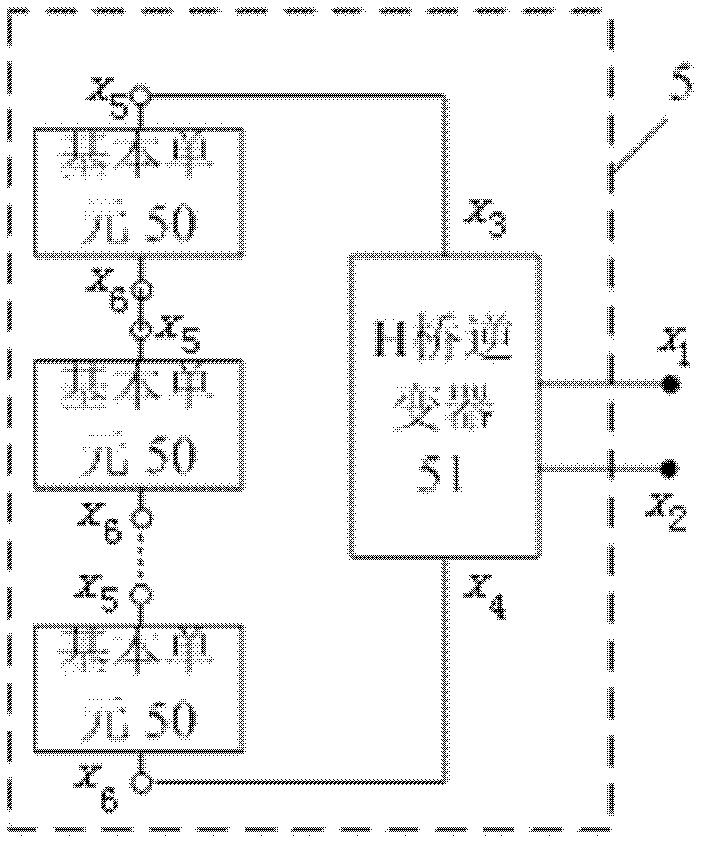

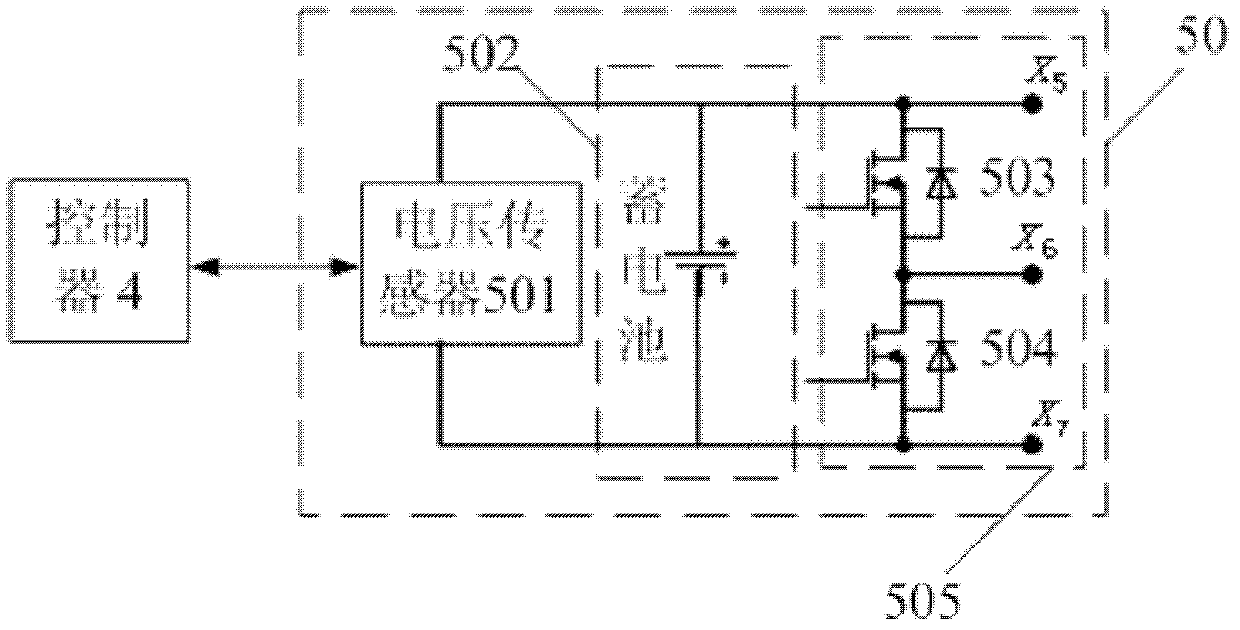

ActiveCN102185487AReduce direct series and parallel connectionSimple structureElectrical storage systemAc-dc conversionCapacitanceElectricity

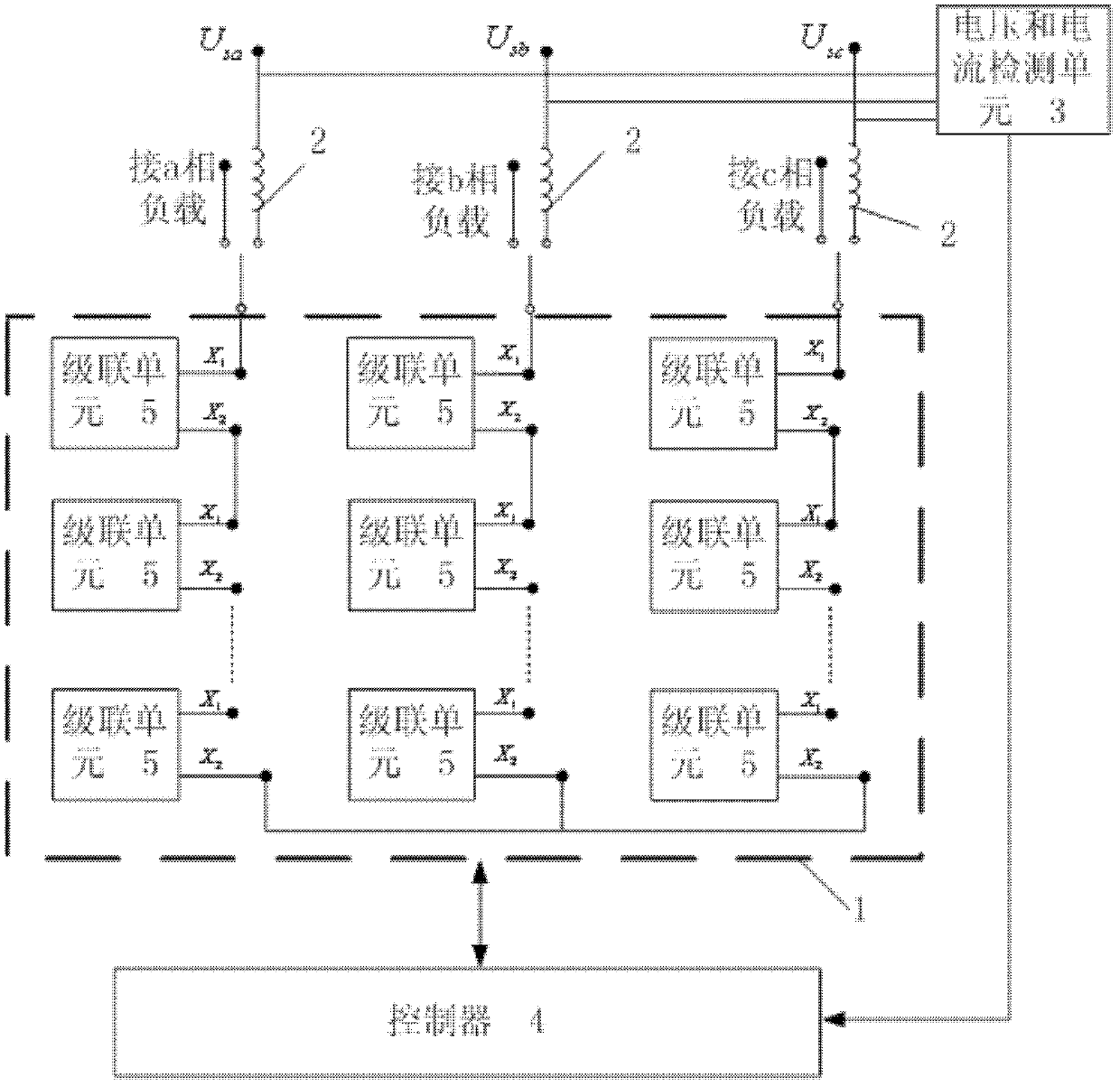

The invention relates to a mixed cascading type multilevel stored energy charging-discharging and voltage-equalizing circuit, which is characterized by comprising a multilevel converter, inductors, a voltage and current detection unit and a controller, wherein the multilevel converter comprises a three-phase circuit, each phase circuit comprises a plurality of tandem cascading units, and two connectors of each cascading unit are respectively connected with connectors of the adjacent cascading unit in series; three-phase output ends of the multilevel converter are connected with loads and three-phase input ends of the multilevel converter are respectively connected with an external power grid by the inductors; and power-grid input sides of each inductor are respectively connected with the voltage and current detection unit, the voltage and current detection unit is used for transmitting detected power-grid voltage and current signals to the controller, and the controller carries out information interaction with the multilevel converter. In the circuit, a stored energy structure with a mixed structure of storage batteries and a super capacitor is adopted, thus decreasing direct series-parallel connection of stored energy units, and being simpler in circuit structure. The circuit can be widely applied to stored energy of electric systems, electric automobiles and other systems.

Owner:TSINGHUA UNIV

Process of dyeing silk fabric

InactiveCN104727165AMild handling environmentReduce damageBiochemical fibre treatmentHeating/cooling textile fabricsColour fastnessPolymer chemistry

The invention provides a process for dyeing a silk fabric. The process comprises the steps of pre-treatment, pre-shaping, modifying treatment, dyeing, soaping, color fixing, post-arrangement, drying, shaping, calendering and rolling. According to the method, the fabric is modified in advance by chitosan to improve the dyeing rate, and the difficulty of the subsequent dyeing step is reduced; in the dyeing step, the chitosan is used as a mordant, and mangosteen hull serving as a natural dye is used and is free of poison and environmentally friendly; the dyeing firmness is good by additionally arranging the soaping and color fixing steps, environment-friendly formaldehyde-free TCD-R is adopted in the color fixing step, color-fixed fibers are stepwise dried, so that the fiber firmness degree is greatly improved; the post-arrangement process is additionally added, so that the color firmness and softness of the fabric is improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for polyamide fabric

InactiveCN105177987AProcess temperature changeLow processing temperatureBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPolyamideAmmonium chloride mixture

The invention discloses a dyeing and finishing process for polyamide fabric. The provided process comprises pretreatment, pre-setting, modified processing, dyeing, soaping, dye fixation, post-finishing, drying, setting, calendering and rolling. Supersonic waves are employed for pretreatment, fabric is subjected to low temperature plasma processing before the dyeing step, then 2,3-epoxy propyl trimethyl ammonium chloride is employed for modification processing of the fabric, the dyeing degree of the fabric is raised, and difficulty of the subsequent dyeing step is lowered. During the dyeing step, a lot of alkaline substances and inorganic salt are not used, natural dyes are employed, colophony powder is added as a dye-fixing agent, the dye-fixing effect is enhanced, environment pollution is avoided, and green environmental protection requirements are met. Montmorillonite is employed for modification processing and flame retardation processing of the fabric, and thus the flame retardation of the fabric is high. Anti-yellowing reagents are used both in the pre-setting and setting steps, and thus the final fabric is not easy to turn yellow.

Owner:TAICANG TIANLONG CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Dyeing process of polyester cotton fiber fabric

ActiveCN103993487AAvoid wrinklesAvoid severe shrinkageHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention provides a dyeing process of a polyester cotton fiber fabric. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, washing, soaping, color fixing, drying, forming and winding. According to the dyeing process, a high-temperature leveling agent is added during dyeing, so that the problem that level dyeing effect and penetration dyeing effect are affected and even generate color dots and color patches occur caused by gathering of dyes because the heat stability resistance of fuel is reduced due to temperature increase is avoided, and the dyeing effect is good; the temperature is increased in a stepped progressive mode in the dyeing procedure, and the temperature increase and decrease velocity and the dyeing time are strictly controlled, so that high dyeing fastness, dyeing uniformity and good dyeing stability of the polyester cotton fiber fabric are achieved; the dyes with single property are not used and dispersed dyes and neutral dyes are compounded in the dyeing procedure, and the dispersed dyes and the neutral dyes supplement each other, so that good dyeing fastness is achieved; the traditional two-bath two-step method dyeing is abandoned, and the one-bath one-step method dyeing is adopted, so that the energy is saved, and the emission amount is reduced.

Owner:广东欣薇尔服装有限公司

Antistatic finishing process of chemical fiber fabric

InactiveCN103993473AImprove comfort performanceImprove overall performanceSynthetic fibresDyeing processDyeingPolymer chemistry

The invention provides an antistatic finishing process of a chemical fiber fabric. The antistatic finishing process comprises the following steps of pretreatment, preforming, dyeing, drying, padding, drying, baking, forming, calendering and winding. According to the antistatic finishing process, the chemical fiber fabric is firstly refined and then subjected to alkali weight reduction treatment during the pretreatment, so that the comfortable property of the chemical fiber fabric is enhanced, the integral property of the chemical fiber fabric is enhanced and the stability of the chemical fiber fabric is enhanced under the condition that the chemical fiber fabric is not damaged, and the stability of subsequent steps, namely the dyeing, the padding, the forming and the calendaring is guaranteed; an antistatic agent is added to the padding procedure, so that the antistatic property of the chemical fiber fabric is effectively improved, and the waterproof property and softening property of the chemical fiber fabric are both greatly enhanced through added waterproof agent and softener, the chitosan is also added to the padding procedure, the chitosan is a high-molecular substance with natural antibacterial and deodorant property, is safe and environmentally friendly, can also be used as the antistatic agent, and the antistatic property and antibacterial and deodorant property of the chemical fiber fabric are all greatly enhanced after the chitosan is added.

Owner:TAICANG MENGFAN CHEM FIBER

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

High-fixation high-flame retardation polyester fabric dyeing and finishing technology

InactiveCN105113286AProcess temperature changeLow processing temperatureFibre typesUltrasonic/sonic fibre treatmentPolyesterFlame resistance

The invention discloses a high-fixation high-flame retardation polyester fabric dyeing and finishing technology. The technology comprises pre-treatment, pre-setting, modification treatment, dyeing, soaping, dye fixation, after finishing, drying, setting, calendering and rolling. Supersonic wave is used for pre-treatment and a modification treatment process is used. In dyeing, a lot of alkaline substances and inorganic salts are avoided, natural dye is adopted and colophony powder is used as a dye-fixing agent so that dye fixation effects are improved, environmental pollution is avoided and environmental protection requirements are satisfied. Through modification and flame retardation treatment on the fabric by montmorillonite, fabric fire resistance is high. Through the dyeing and finishing technology, the high-fixation high-flame retardation polyester fabric is obtained.

Owner:太仓市宝明化纤有限公司

Dyeing and finishing process for mulberry silk fabric

InactiveCN105064074ALow processing temperatureTime changeUltrasonic/sonic fibre treatmentBleaching apparatusInorganic saltsEngineering

The invention discloses a dyeing and finishing process for a mulberry silk fabric. The process comprises the following steps: pretreatment; pre-setting; modification; dyeing; soaping; dye fixation; afterfinishing; drying; setting; calendering; and rolling. According to the invention, supersonic waves are used for pretreatment, and the step of modification is increased; and natural dyes instead of a great amount of alkaline substances and inorganic salts are employed in dyeing, and rosin powder is added as a fixing agent, so dye fixation effect is reinforced, environmental pollution is avoided, and requirements of greenness and environmental protection are met. Through treatment by using the process, the mulberry silk fabric with high rubbing fastness and high dye fixation degree can be obtained.

Owner:太仓市宝明化纤有限公司

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Efficient dyeing and finishing process for chemical fiber fabric

InactiveCN104975498AImprove hydrophilicityImprove dye uptakeHeating/cooling textile fabricsDry-cleaning apparatus for textilesInorganic saltsFiber

The invention discloses an efficient dyeing and finishing process for a chemical fiber fabric, which comprises the procedures of modification treatment, one-bath scouring dyeing, soaping, fixation, after finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave; before the procedure of dyeing, the fabric is subjected to low-temperature plasma treatment, and then 2, 3-glycidyl trimethyl ammonium chloride is adopted for carrying out modification treatment on the fiber fabric, so that the degree of dyeing of the fabric is increased, and the difficulty of subsequent dyeing step is lowered; since one-bath scouring dyeing is adopted, the efficiency is increased, and the cost is lowered; in the dyeing procedure, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedure of sizing, so that the final fabric cannot become yellow easily.

Owner:TAICANG TIANLONG CHEM FIBER

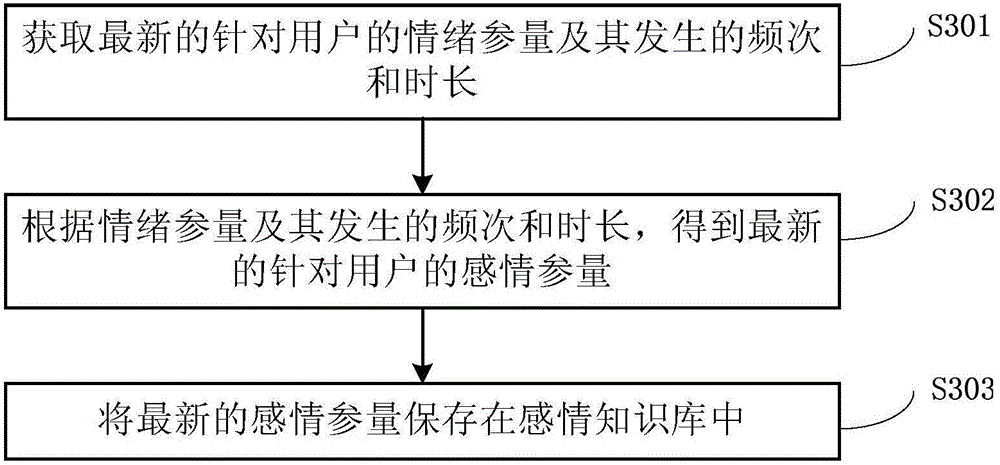

Information processing method and system for intelligent robot

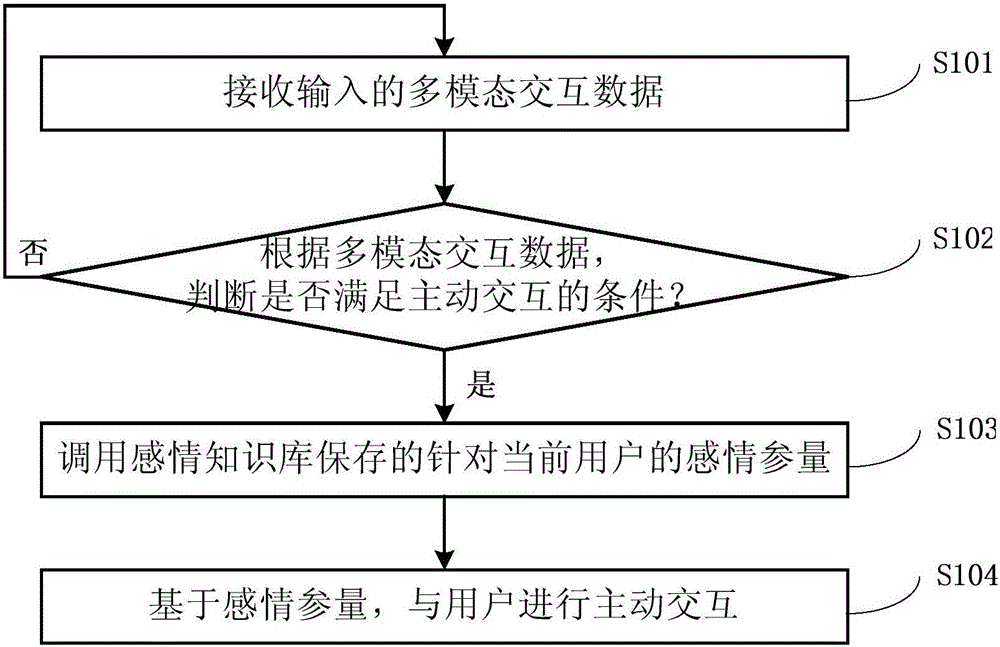

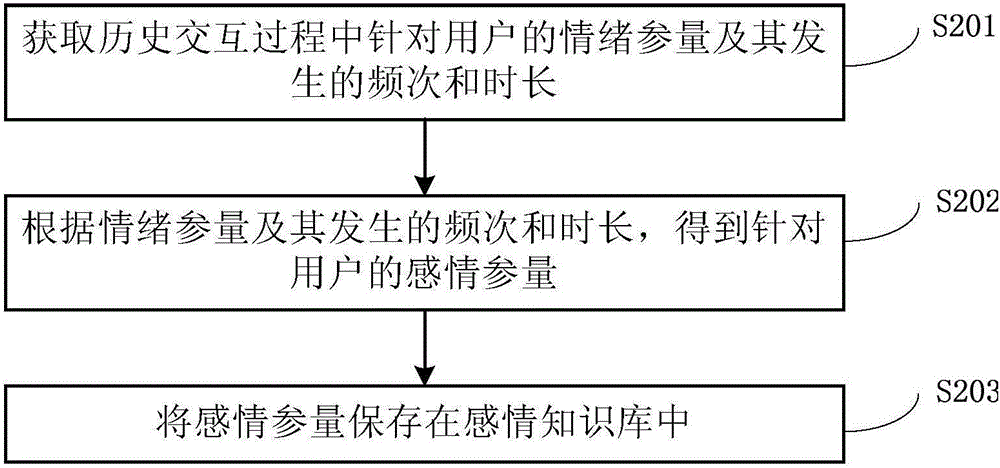

InactiveCN105945949ASmall jumpImprove experienceInput/output for user-computer interactionProgramme-controlled manipulatorKnowledge baseInformation processing

The invention discloses an information processing method and system for an intelligent robot. The method comprises steps as follows: input multi-modal interactive data are received; whether active interaction conditions are met or not is judged according to the multi-modal interactive data; if the active interaction conditions are met, emotion parameters which are used for a current user and stored in an emotion knowledge base are called; and active interaction with the user is performed on the basis of the emotion parameters. With the adoption of the information processing method and system, the intelligent robot can interact with the user actively on the basis of the emotion parameters and can express emotional states actively to the user; besides, with the adoption of the emotion parameters which are used as quantized integration of historical emotions, the intelligent robot expresses the emotions step by step, the jumping is small, the experience effect of the user is greatly improved, and dependence of the user on the intelligent robot and the use adhesiveness can be cultivated.

Owner:BEIJING GUANGNIAN WUXIAN SCI & TECH

Dyeing process of mulberry silk fabrics

InactiveCN104711873AMild handling environmentReduce damageBiochemical fibre treatmentDry-cleaning apparatus for textilesColour fastnessPolymer chemistry

The invention provides a dyeing process of mulberry silk fabrics. The dyeing process comprises the steps of: pretreatment, presetting, low-temperature freezing treatment, dyeing, soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that the step of low-temperature freezing treatment is added, so that the modifying treatment is carried out on the properties of the mulberry silk fabrics fundamentally; a salt-free dyeing additive is added in the dyeing procedure, so that the use of inorganic salts is reduced on the premise of guaranteeing the dyeing effect; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:太仓市宝明化纤有限公司

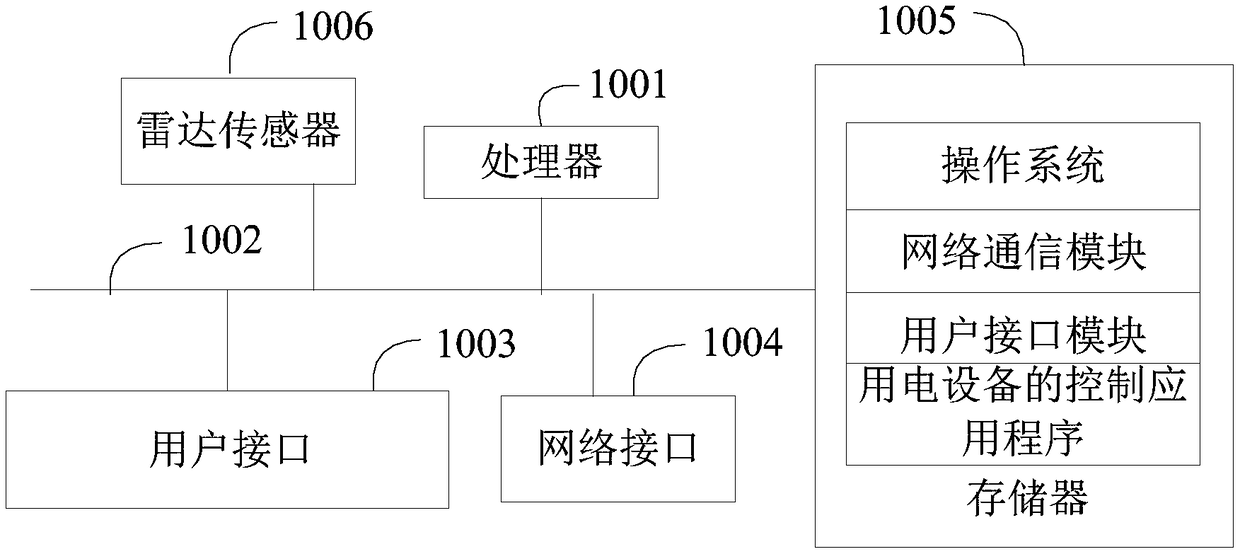

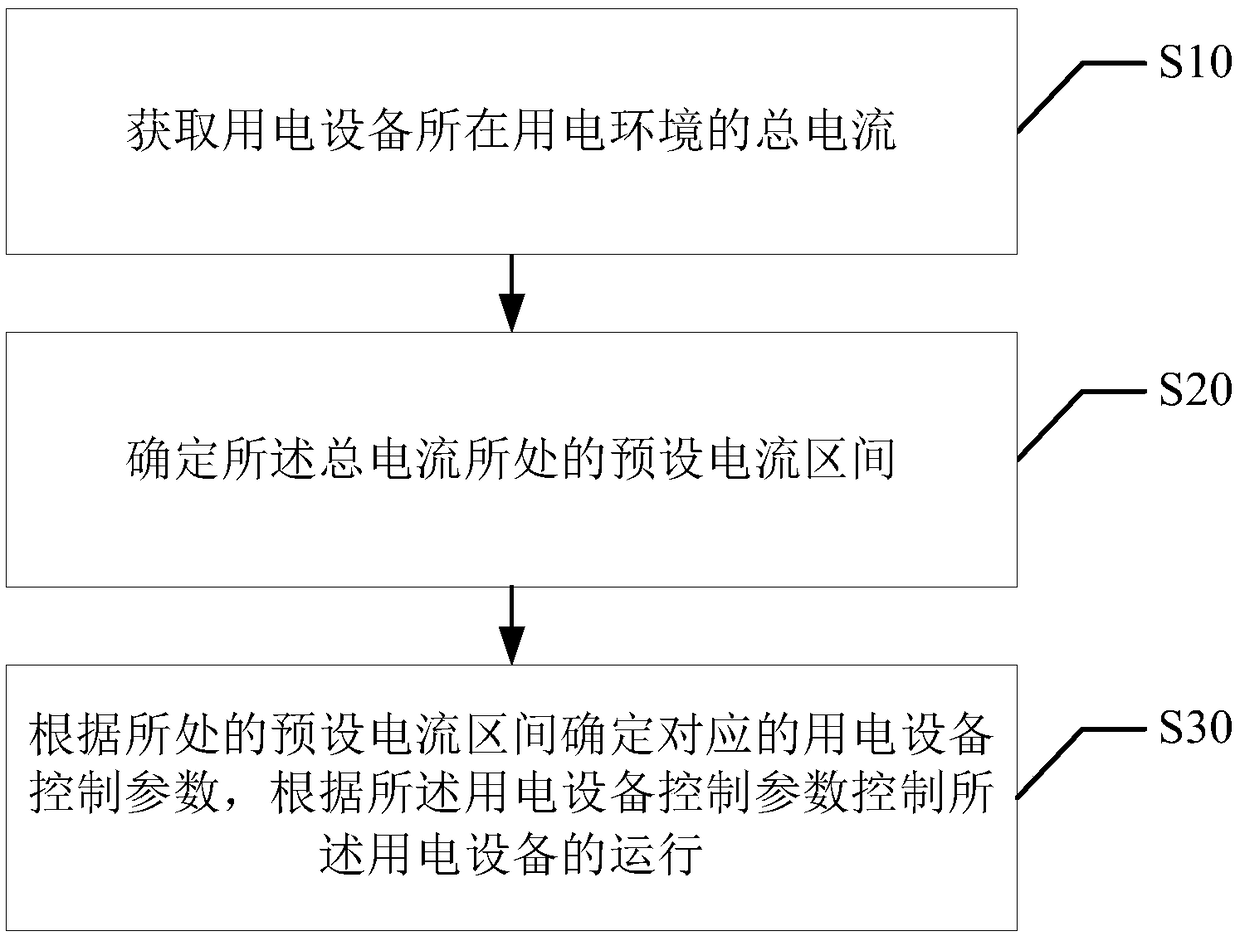

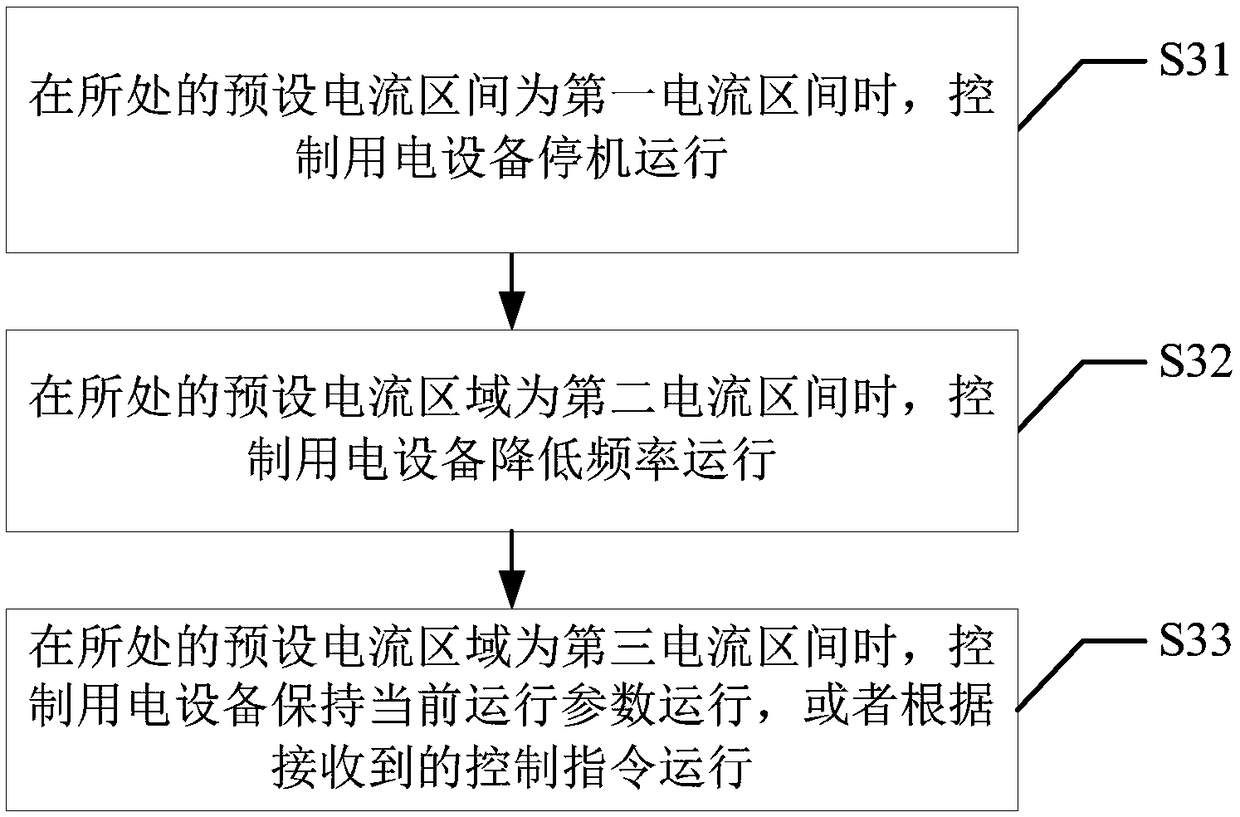

Power utilization equipment control method and device, power utilization equipment and readable storage medium

InactiveCN108731185AStable controlImprove accuracyMechanical apparatusSpace heating and ventilation safety systemsTotal currentControl parameters

The invention discloses a power utilization equipment control method. The method comprises the following steps that the total current of the power utilization environment where power utilization equipment is located is obtained; the preset current section where the total current is located is determined; and according to the located preset current section, corresponding power utilization equipmentcontrol parameters are determined, and running of the power utilization equipment is controlled according to the power utilization equipment control parameters. The invention further discloses a power utilization equipment control device, the power utilization equipment and a readable storage medium. According to the power utilization equipment control method and device, the power utilization equipment and the readable storage medium, stable power utilization equipment control is achieved, the situation of shortening of the service life due to constant start / stop is avoided, accuracy of powerutilization equipment control is improved, and accordingly the service life of the power utilization equipment is prolonged.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

Dyeing process of chinlon-containing blended fiber

ActiveCN103993478AAvoid wrinklesAvoid severe shrinkageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a dyeing process of a chinlon-containing blended fiber. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, drying, finished product forming and winding. According to the dyeing process, the preforming is carried out before the pretreatment, so that the phenomenon that crumples appear on the chinlon-containing blended fiber; a high-temperature leveling agent is added in the dyeing procedure, so that the problem that level dyeing effect and penetration dyeing effect are influenced and even color dots and color patches occur caused by the gathering of dyes because the heat stability resistance of fuel is lowered due to temperature increase is prevented, and good dyeing effect is achieved; the final dye-uptake rate of the chinlon-containing blended fiber can achieve 75%, the soaping color fastness of the dyed fiber achieves 5 level, and good water shrinkage and washing fastness and low strength loss of the dyed fiber are achieved.

Owner:中山敦明纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com