Patents

Literature

35results about How to "Avoid neurotoxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for treating amyloid-related diseases

InactiveUS20050038117A1Increase the gapReduce depositionBiocideOrganic active ingredientsMedicineAmyloid

Owner:BELLUS HEALTH (INT) LTD (CH)

Compounds for the treatment of CNS and amyloid associated diseases

InactiveUS20060167057A1Increase the gapInhibition of activationBiocideNervous disorderAmyloid betaDisease cause

Methods, compounds, pharmaceutical compositions and kits are described for treating or preventing CNS and amyloid associated disease. Also described are methods, compounds, pharmaceutical compositions and kits for detecting, diagnosing, monitoring and treating or preventing CNS and amyloid associated disease.

Owner:BELLUS HEALTH (INT) LTD (CH)

Methods and compositions for the treatment of amyloid-and epileptogenesis-associated diseases

InactiveUS20050038000A1Neurodegeneration and reduced and inhibitedToxicity reduced and inhibitedBiocideOrganic chemistryConvulsionDisease

Methods of treating or preventing an amyloid-related disease in a subject by administering to a subject a therapeutic amount of a compound of the invention are described. Also included are methods for inhibiting epileptogenesis in a subject, by administering to a subject an effective amount of an anti-epileptogenic agent. Methods for treating a subject suffering from an epileptogenesis-associated condition, by administering to the subject an effective amount of an anti-epileptogenic agent are also included. Methods for treating convulsions in a subject by administering to the subject an effective amount of a therapeutic amount of a compound of the invention are also described.

Owner:BELLUS HEALTH (INT) LTD (CH)

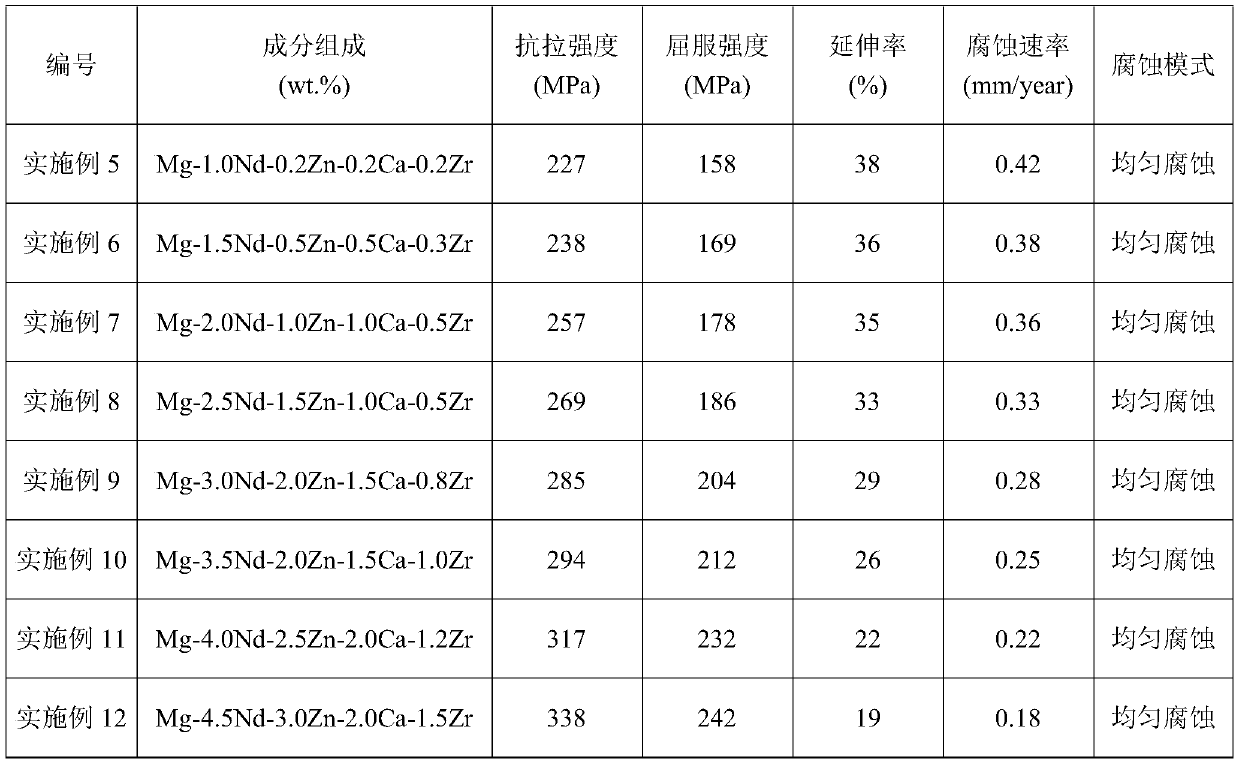

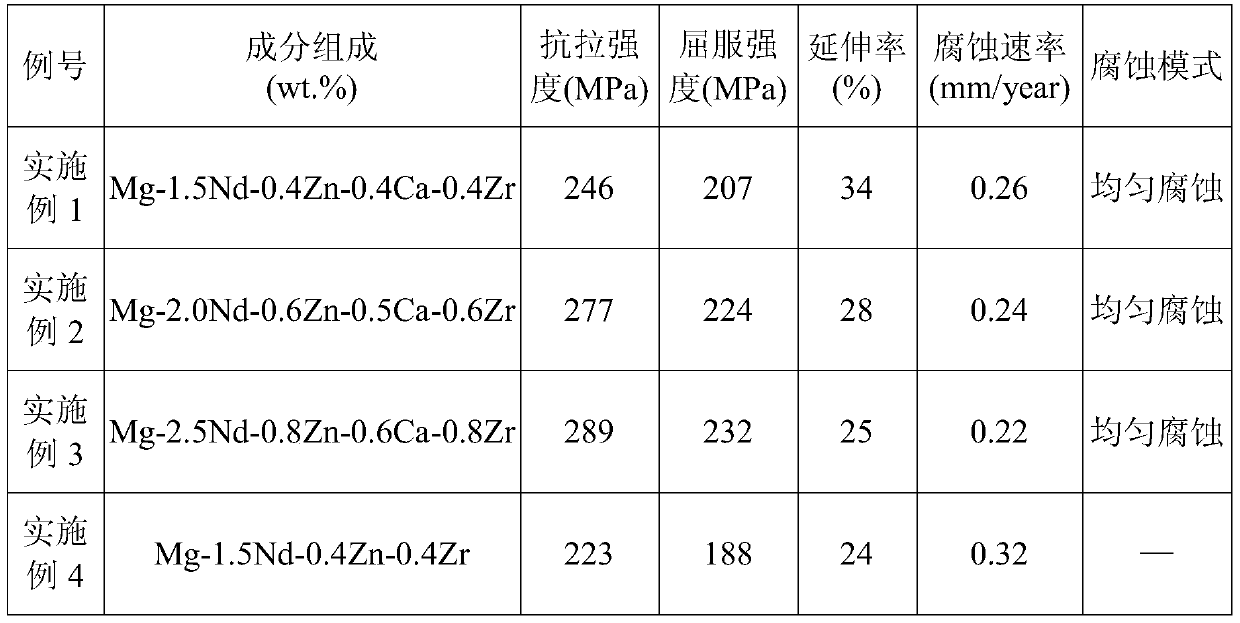

High-toughness corrosion-resistant magnesium alloy implanted material capable of being degraded in organism

The invention relates to a high-toughness corrosion-resistant magnesium alloy implanted material capable of being degraded in an organism, belonging to the technical field of biological materials. The material of the invention comprises the following components in percentage by weight: 1-4% of Nd, 0.1-1.0% of Zn, 0.1-1.0% of Ag, 0.3-0.8% of Zr and balance of Mg. The invention strengthens magnesium alloy through alloy elements, refines grains, improves plasticity, and further strengthens the magnesium alloy through extrusion deformation and heat treatment processes. The corrosion rate of the magnesium alloy provided by the invention in the simulated body fluid is 0.22-0.28mm / year, meeting the requirement of the implanted material for the corrosion rate; and the material of the invention does not have obvious cytotoxicity and has good blood compatibility, thereby meeting the requirements of the implanted material for biological compatibility. The high-plasticity medium-strength magnesium alloy provided by the invention can be used for support intravascular stent materials, and the high-strength medium-plasticity magnesium alloy provided by the invention can be used for implanted materials in orthopaedics.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

Methods and compositions for treating amyloid-related diseases

InactiveUS7244764B2Increase the gapReduce depositionBiocideOrganic active ingredientsMedicineAmyloid

Owner:BELLUS HEALTH (INT) LTD (CH)

Methods and compositions for treating amyloid-related diseases

InactiveUS20050096385A1Increase the gapReduce depositionBiocideGroup 5/15 element organic compoundsMedicineAmyloid

Owner:BHI

Methods and compositions for treating amyloid-related diseases

InactiveUS7414076B2Increase the gapReduce depositionBiocideGroup 5/15 element organic compoundsMedicineAmyloid

Owner:BHI LLP

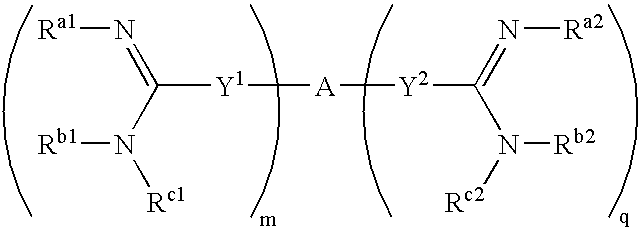

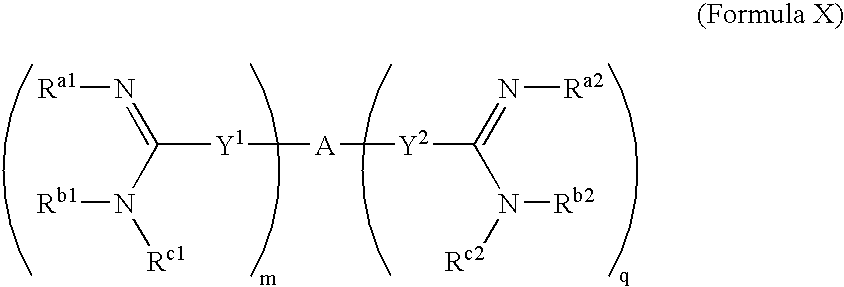

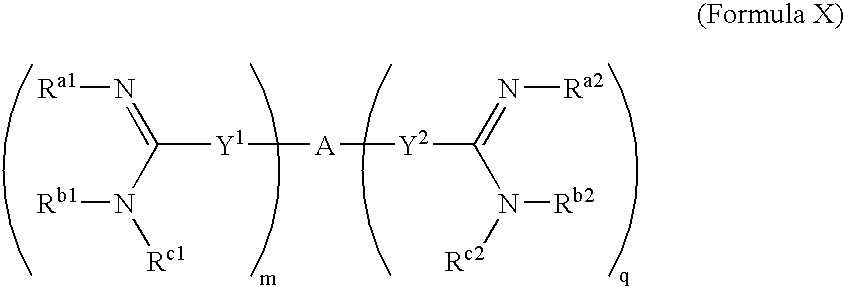

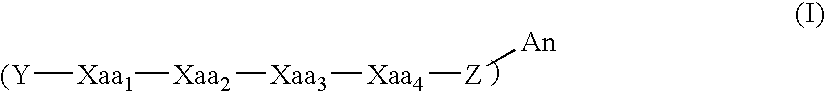

Amidine derivatives for treating amyloidosis

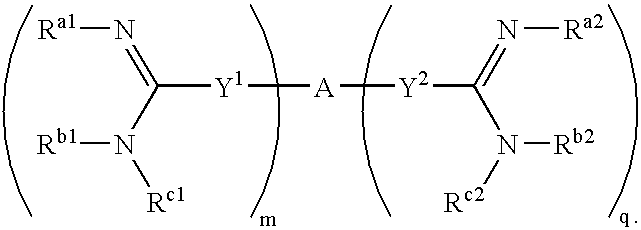

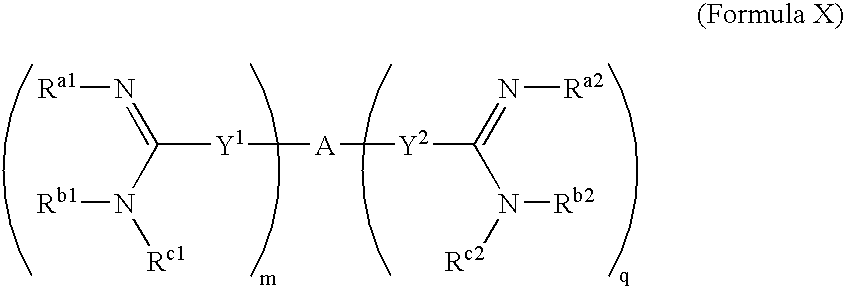

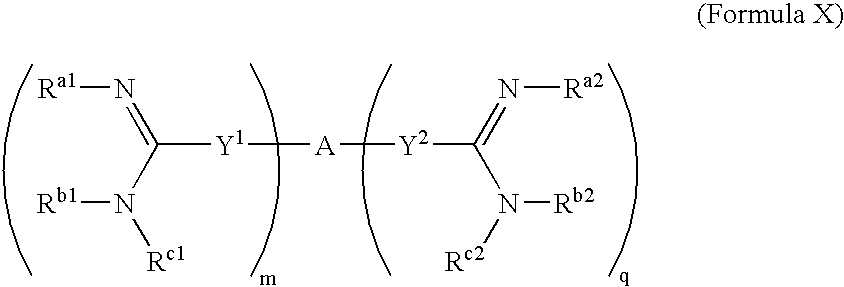

The present invention relates to the use of amidine compounds in the treatment of amyloid-related diseases. In particular, the invention relates to a method of treating or preventing an amyloid-related disease in a subject comprising administering to the subject a therapeutic amount of an amidine compound. Among the compounds for use according to the invention are those according to the following Formula, such that, when administered, amyloid fibril formation, neurodegeneration, or cellular toxicity is reduced or inhibited:

Owner:BELLUS HEALTH (INT) LTD (CH)

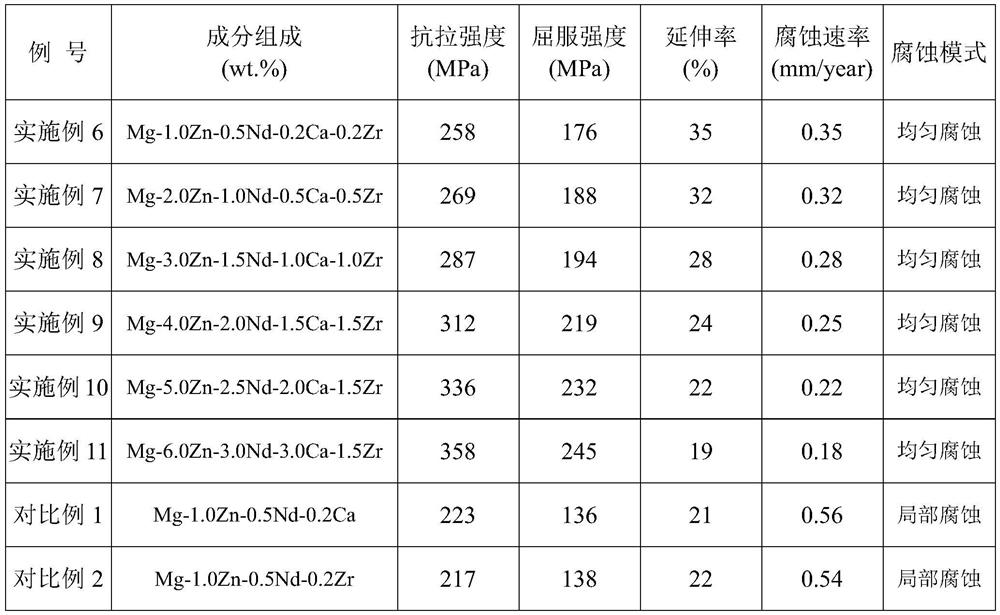

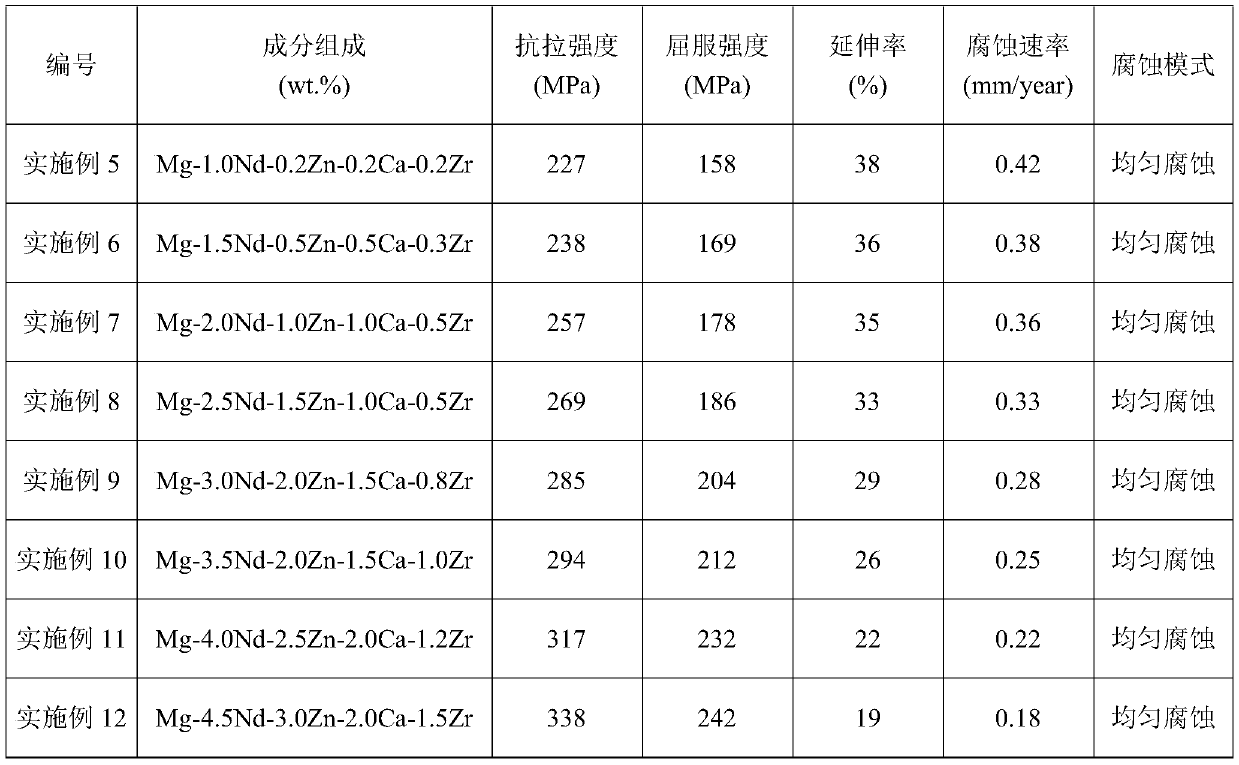

High-strength-and-toughness and corrosion-resistance magnesium alloy and preparation method thereof

ActiveCN110144503ASolve the problem of difficult plastic processingStable supportToughnessCorrosion resistant

The embodiment of the invention provides high-strength-and-toughness and corrosion-resistance magnesium alloy and a preparation method thereof. The alloy solves the problems in the prior art that thedeformation capability of the magnesium alloy is poorer and the plasticity processing is difficult when the magnesium alloy is used for preparing stents, the stents can be uniformly degraded in the body while the ideal supporting effect of alloy is achieved, better corrosion resistant performance is achieved, the corrosion-resistance rate is significantly reduced, and the corrosion is more uniform.

Owner:珠海中科先进技术研究院有限公司

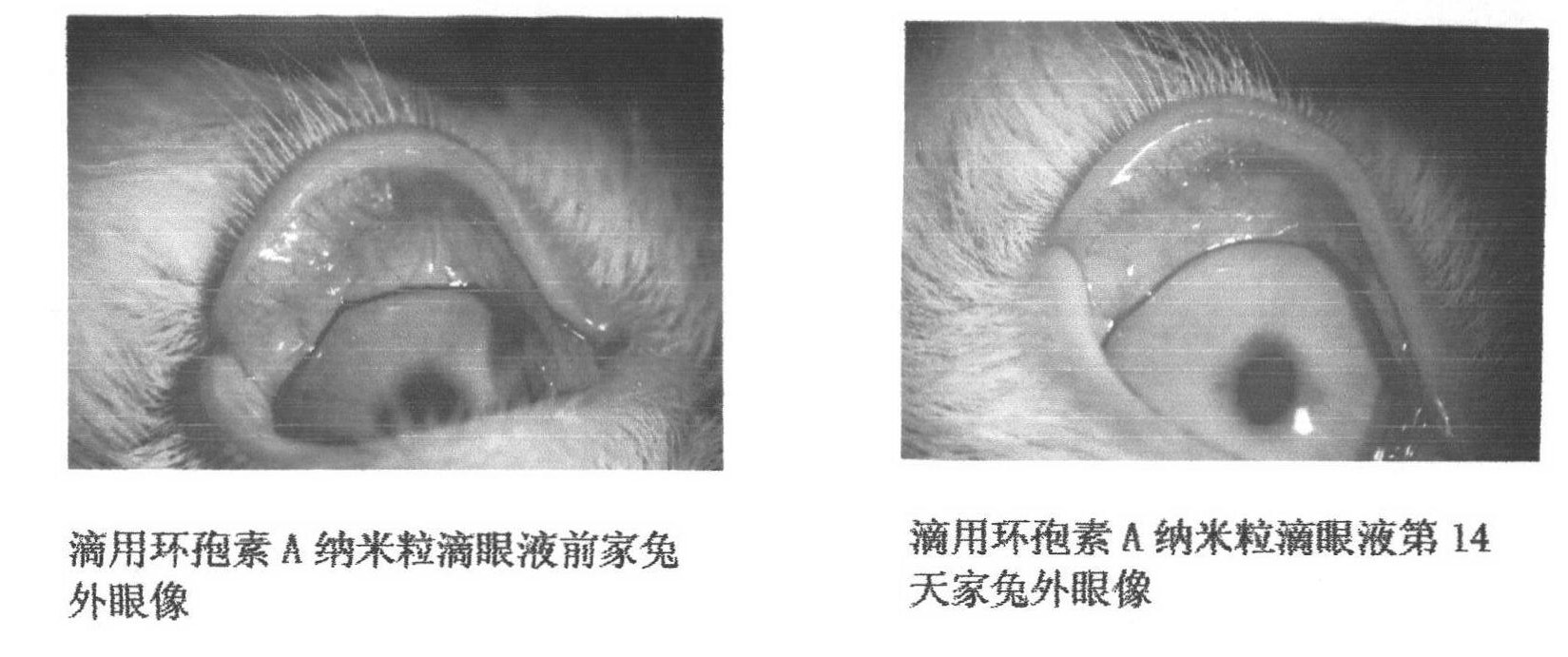

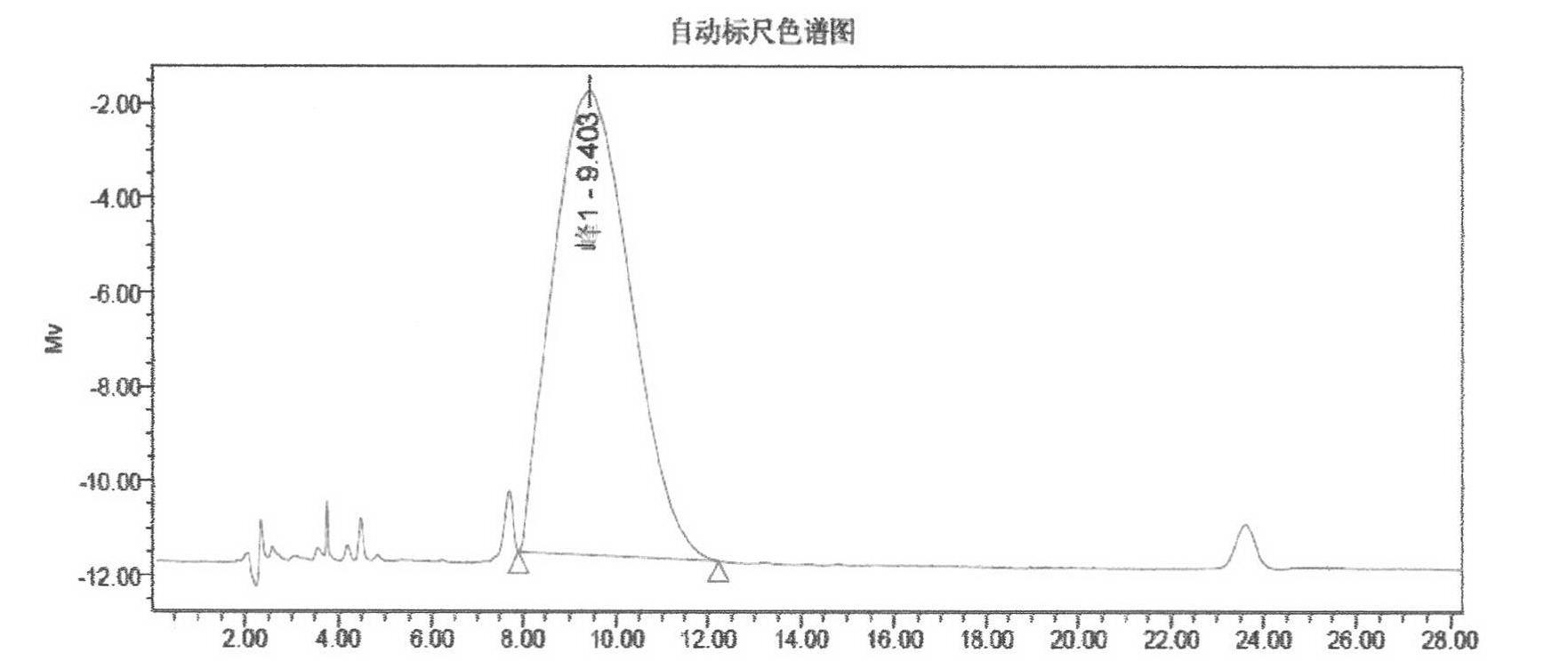

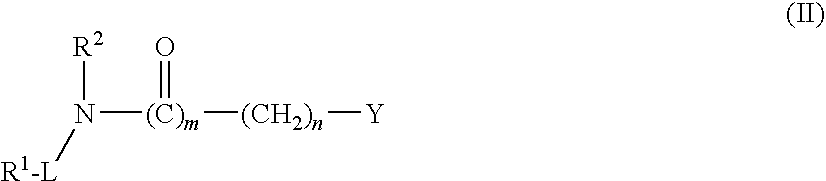

Preparation of cyclosporine A nano-particle eye drop

InactiveCN102210849AImprove bioavailabilitySmall toxicitySenses disorderPharmaceutical delivery mechanismSolubilityRotary evaporator

The invention relates to cyclosporine A-carrying polyethylene glycol-polylactic acid copolymer nano eye drop, prepared by the following two methods: method 1: dissolving a polymer and cyclosporine A in an organic solvent, magnetically stirring the organic solvent with a water solution containing a surfactant, breaking by a high pressure homogenizer to prepare an emulsion, then removing the organic solvent by a rotary evaporator, centrifuging, and re-dissolving in normal saline to obtain the cyclosporine A-carrying polyethylene glycol-polylactic acid copolymer nano eye drop; and method 2: dissolving a polymer and cyclosporine A in an organic solvent, and slowly dropwise adding into water while magnetically stirring to prepare the cyclosporine A-carrying polyethylene glycol-polylactic acid copolymer nano eye drop. The drug-carrying nano eye drop prepared by the methods can obviously improve the water solubility of cyclosporine A.

Owner:BEIJING INST OF OPHTHALMOLOGY

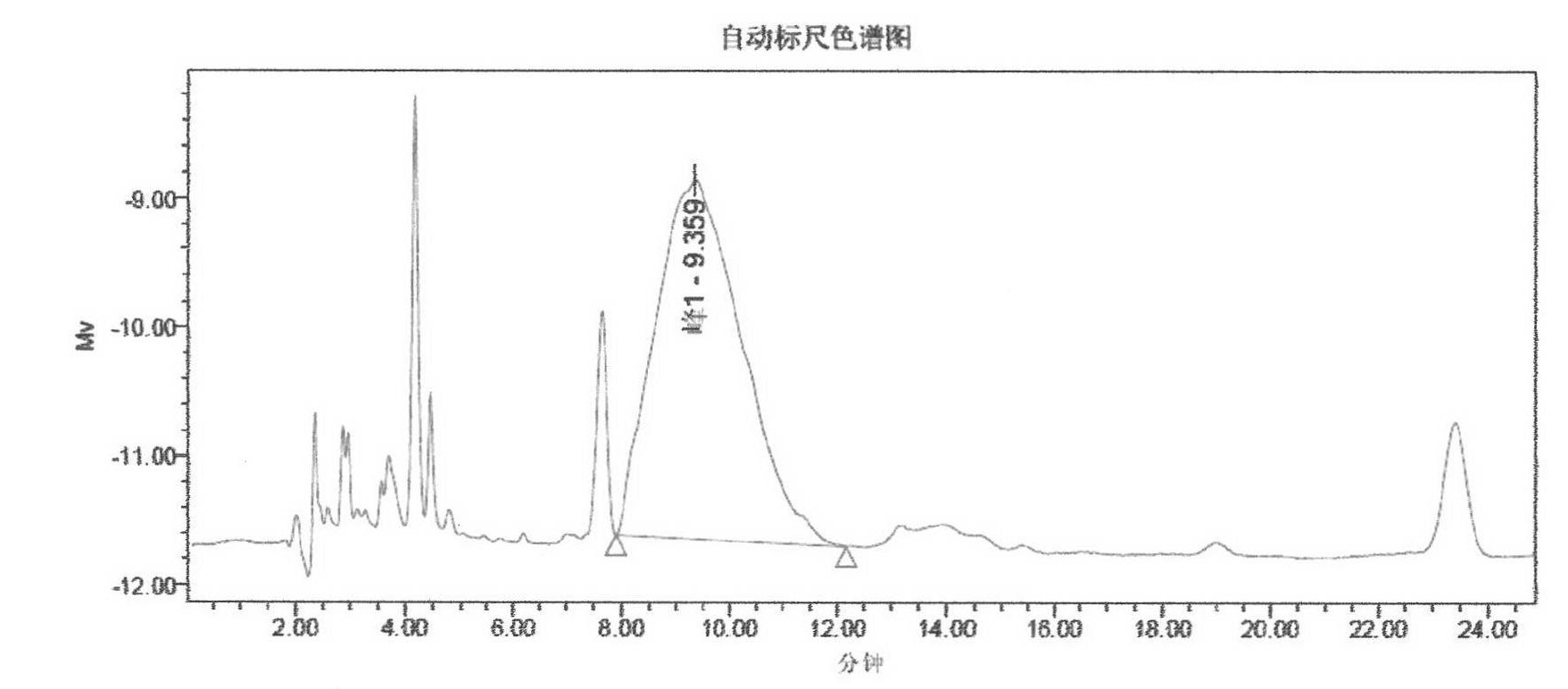

Taxol nanometer particle and preparation method and application thereof

InactiveCN101167716AGood curative effectReduce toxic and side effectsOrganic active ingredientsPowder deliveryChitosan nanoparticlesOrganic solvent

The invention relates to paclitaxel nanometer particles, which can be made by the following preparation process: putting the paclitaxel alcoholic solution containing surface activator under the room temperature, by which paclitaxel nanometer particles are gained as the volatilization of alcoholic solution, dissolving the paclitaxel nanometer particles in chitose solution as aqueous phase, mixing the aqueous phase with the oil phase under the temperature of 25-35 DEG C, and chuning for 1-4 hours, by which emulsion is prepared, solidifying and precipitating chitose nanometer particles of paclitaxel from the emulsion by cross linking agent, washing the particles by organic solvent, by which the nanometer particles carrying paclitaxel is made after vacuum drying. The process doesn't need any chemical modification to the chitose. The prepared nanometer particles carrying medicament has explicit slow-release effect on the death of tumour cell.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

Methods and compositions for treating amyloid-related diseases

InactiveUS20100113591A1Reduce depositionInhibition of activationBiocideNervous disorderDiseaseAmyloid

Owner:BHI LLP

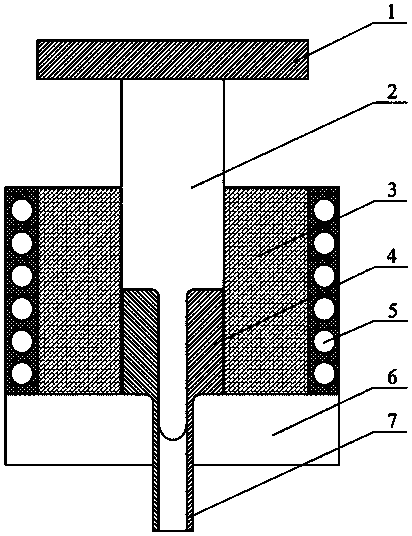

Corrosion-resistant high strength and toughness magnesium alloy tubular product and preparation process

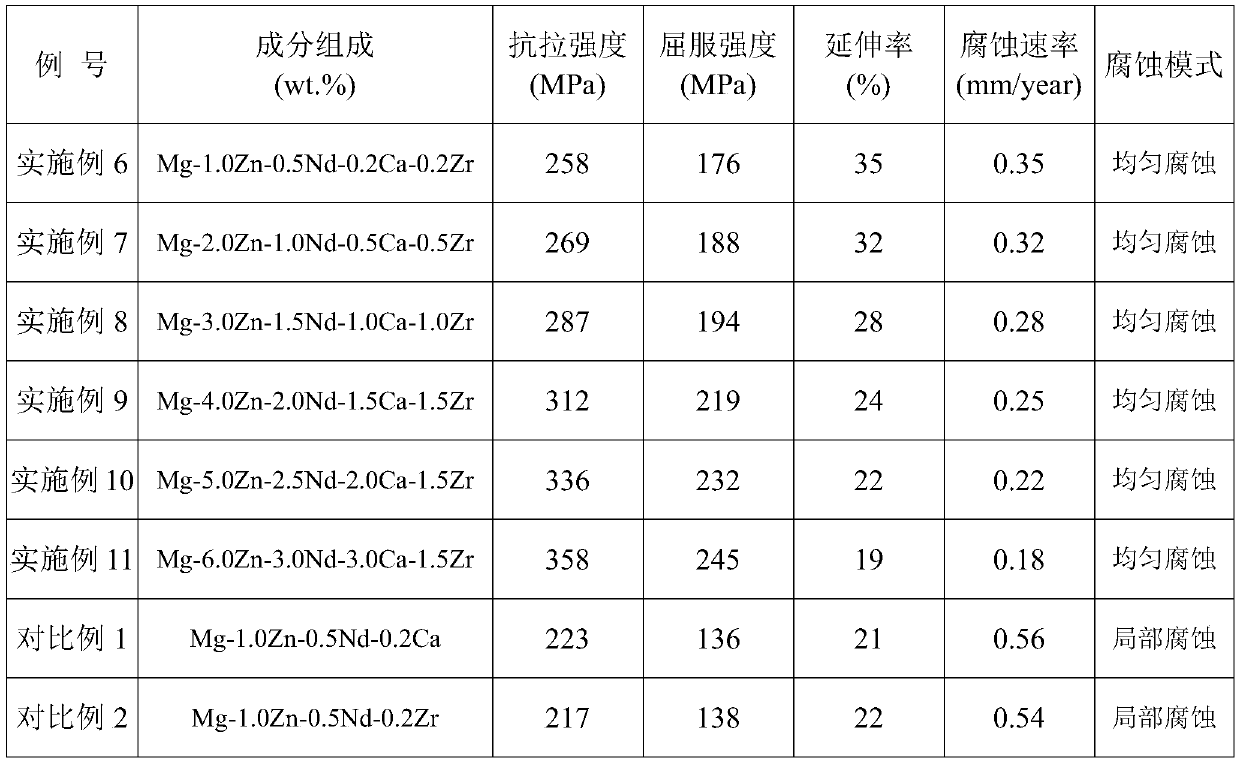

ActiveCN110117743ASolve the problem of difficult plastic processingStable supportExtrusion diesRoom temperatureIngot

The embodiment of the invention provides a corrosion-resistant high strength and toughness magnesium alloy tubular product and a preparation process. The alloy tubular product is prepared from the following elements in percent by mass: 1.0-6.0% of Nd, 0.1-5.0% of Zn, 0.1-5.0% of Ca, 0.1-4.0% of Zr and the balance Mg. The preparation process comprises the following steps: successively preparing a magnesium alloy cast ingot, a magnesium alloy blank, a magnesium round bar and a magnesium hollow round ingot through a series of steps: vacuum semicontinuous casting, solid solution homogenizing, barextrusion processing, hollow round ingot processing and the like; and finally, extruding the hollow round ingot to obtain the corrosion-resistant high strength and toughness magnesium alloy tubular product. The corrosion-resistant high strength and toughness magnesium alloy tubular product solves the problem of hard plastic processing for preparing a bracket as the magnesium alloy tubular productis relatively poor in deformability at room temperature in the prior art, can be degraded uniformly in vivo while achieving an ideal supporting effect of the alloy, and meanwhile, has better corrosionresistance and is relatively uniform to corrode, wherein the corrosion rate is 0.18-0.42 mm / year.

Owner:ZHUHAI INST OF ADVANCED TECH

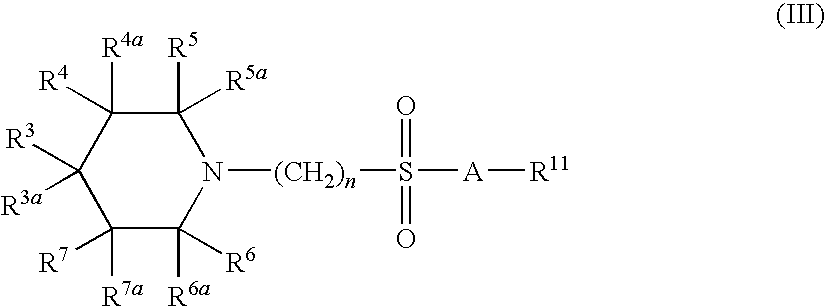

Amidine derivatives for treating amyloidosis

InactiveUS20050182118A1Prevent and inhibit assemblyInhibition of activationBiocideOrganic chemistryMedicineCytotoxicity

The present invention relates to the use of amidine compounds in the treatment of amyloid-related diseases. In particular, the invention relates to a method of treating or preventing an amyloid-related disease in a subject comprising administering to the subject a therapeutic amount of an amidine compound. Among the compounds for use according to the invention are those according to the following Formula, such that, when administered, amyloid fibril formation, neurodegeneration, or cellular toxicity is reduced or inhibited:

Owner:BELLUS HEALTH (INT) LTD (CH)

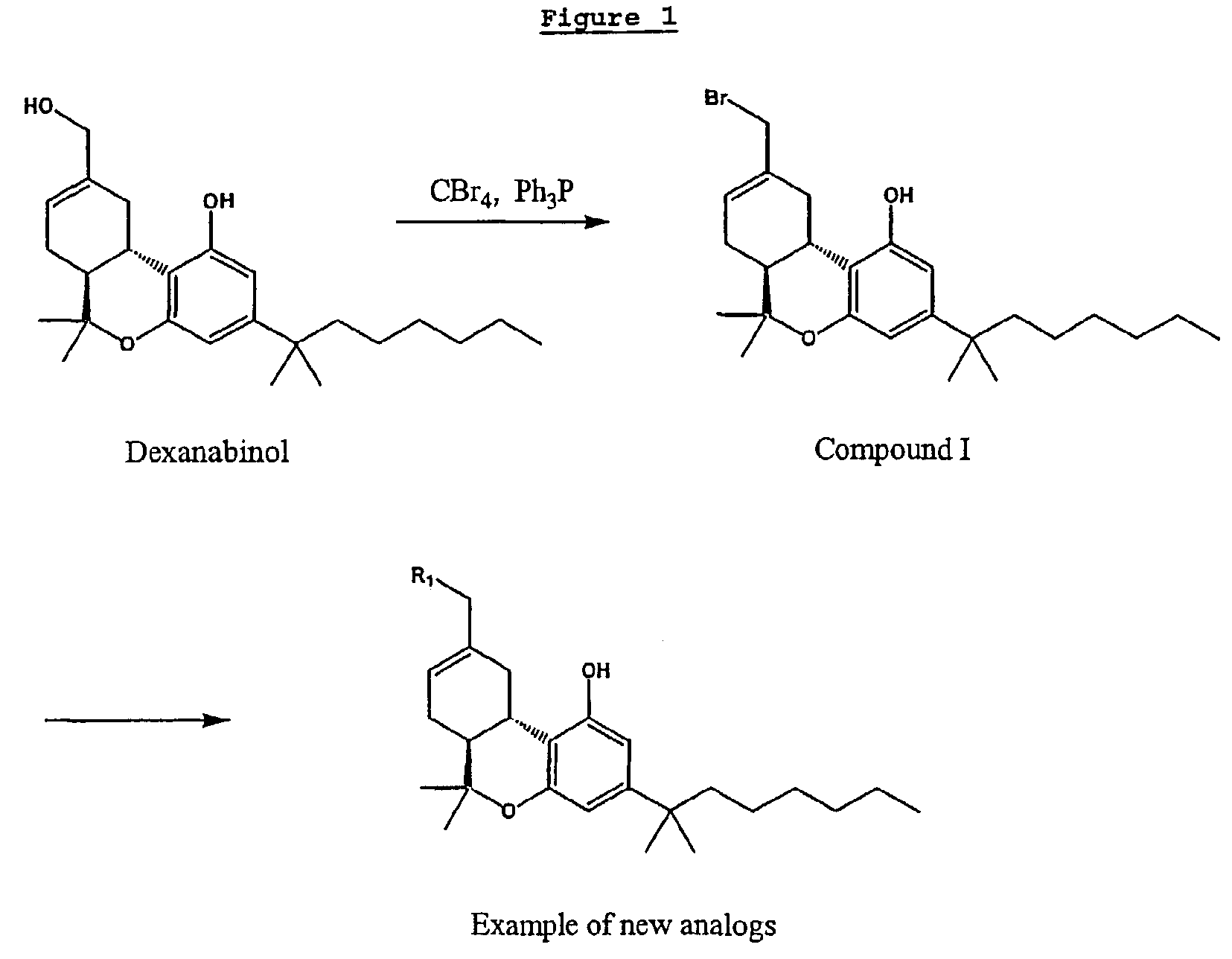

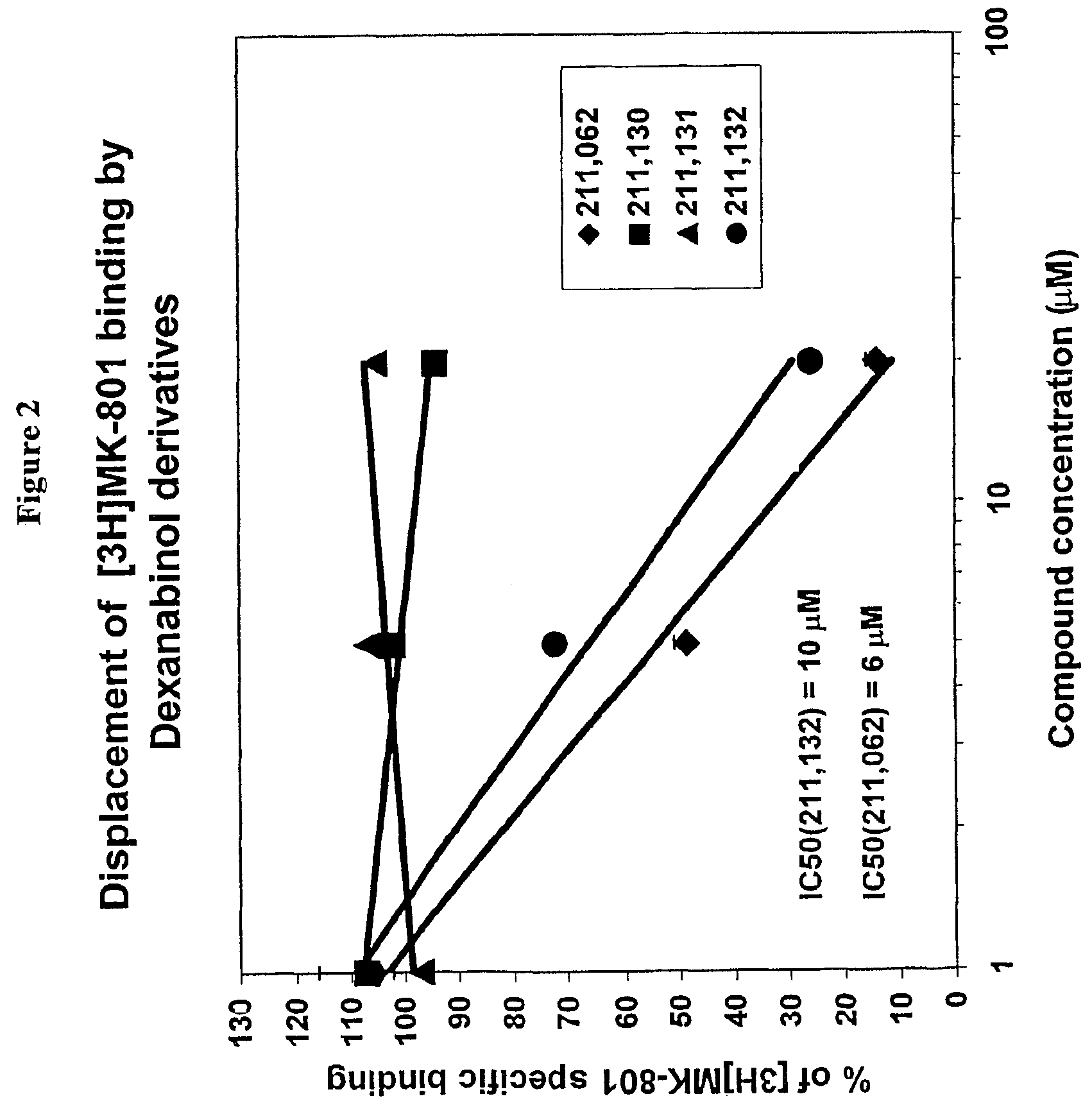

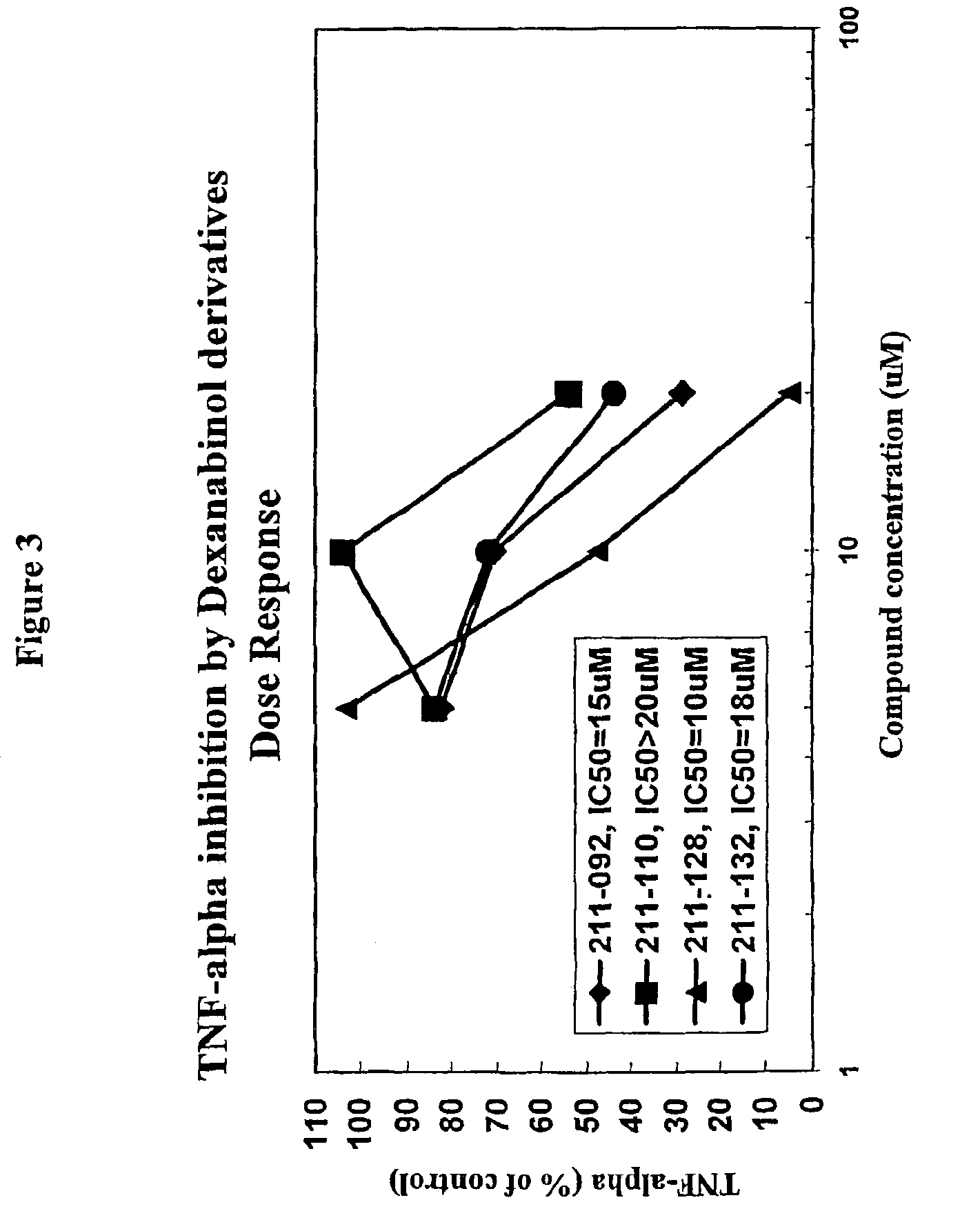

Non-psychotropic cannabinoids

InactiveUS7235584B2Avoid neurotoxicityReduce harmBiocideOrganic chemistryChronic degenerative diseasePain chronic

Novel non-psychotropic cannabinoids are disclosed and pharmaceutical compositions comprising these novel compounds are described for preventing neurotoxicity, neuroinflammation, immune or inflammatory disorders comprising as active ingredient the stereospecific (+) enantiomer, having (3S,4S) configuration of Δ6 tetrahydrocannabinol type compounds. The compositions are particularly effective in alleviating and even preventing neurotoxicity due to acute injuries to the central nervous system, including mechanical trauma, compromised or reduced blood supply as may occur in cardiac arrest or stroke, or poisonings. They are also effective in the treatment of certain inflammatory disorders and chronic degenerative diseases characterized by neuronal loss and chronic pain including neuropathic pain.

Owner:PHARMOS

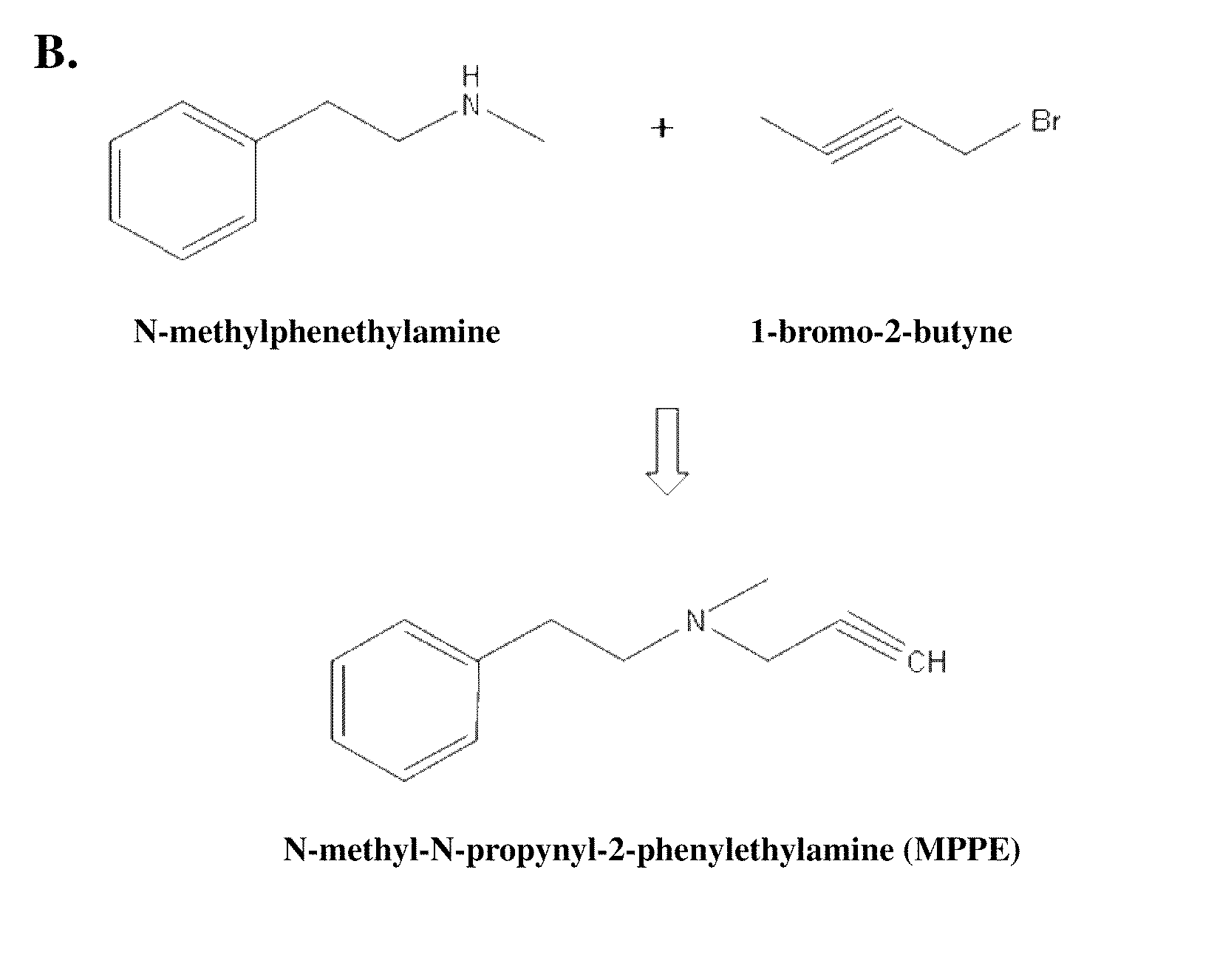

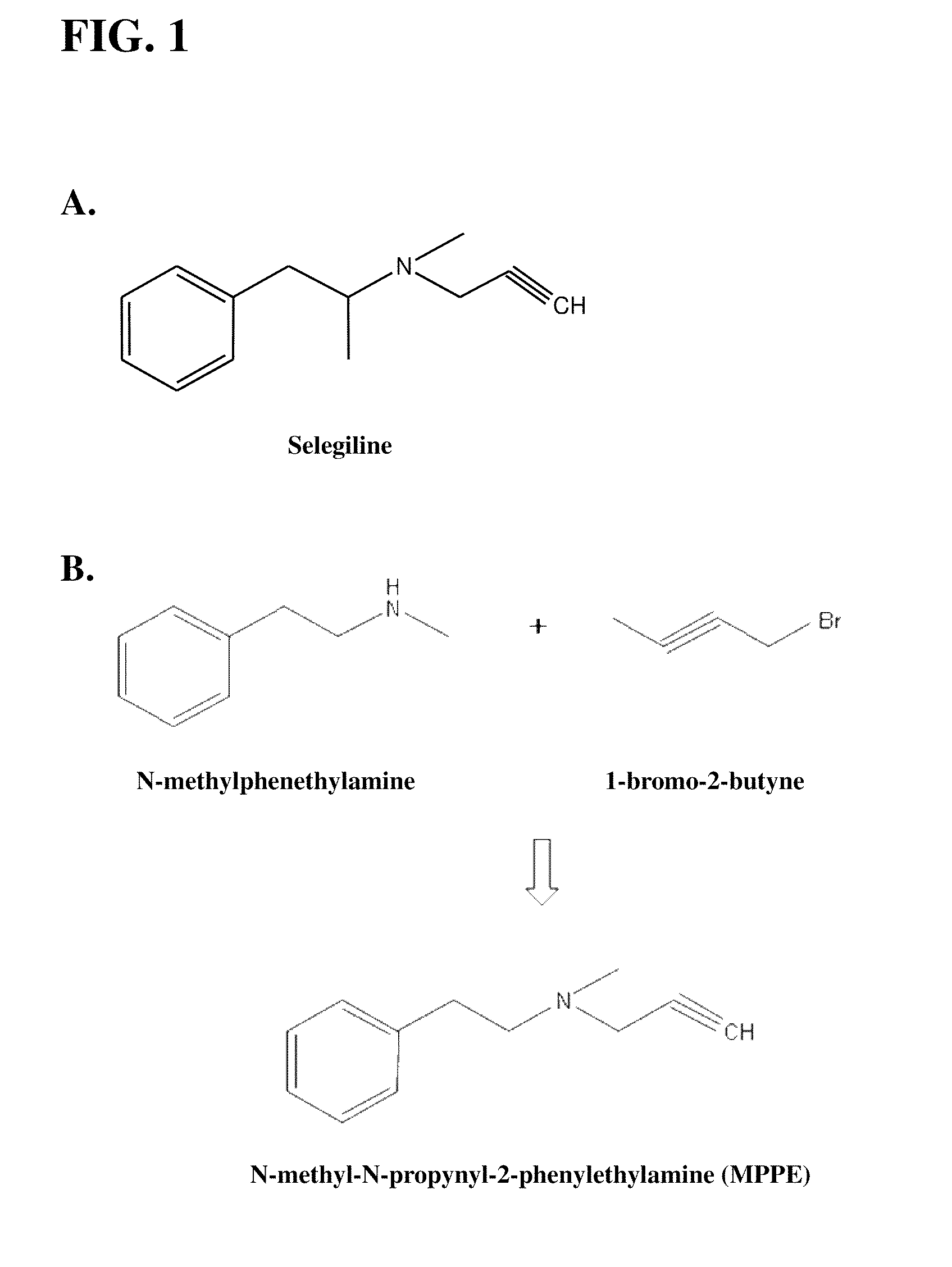

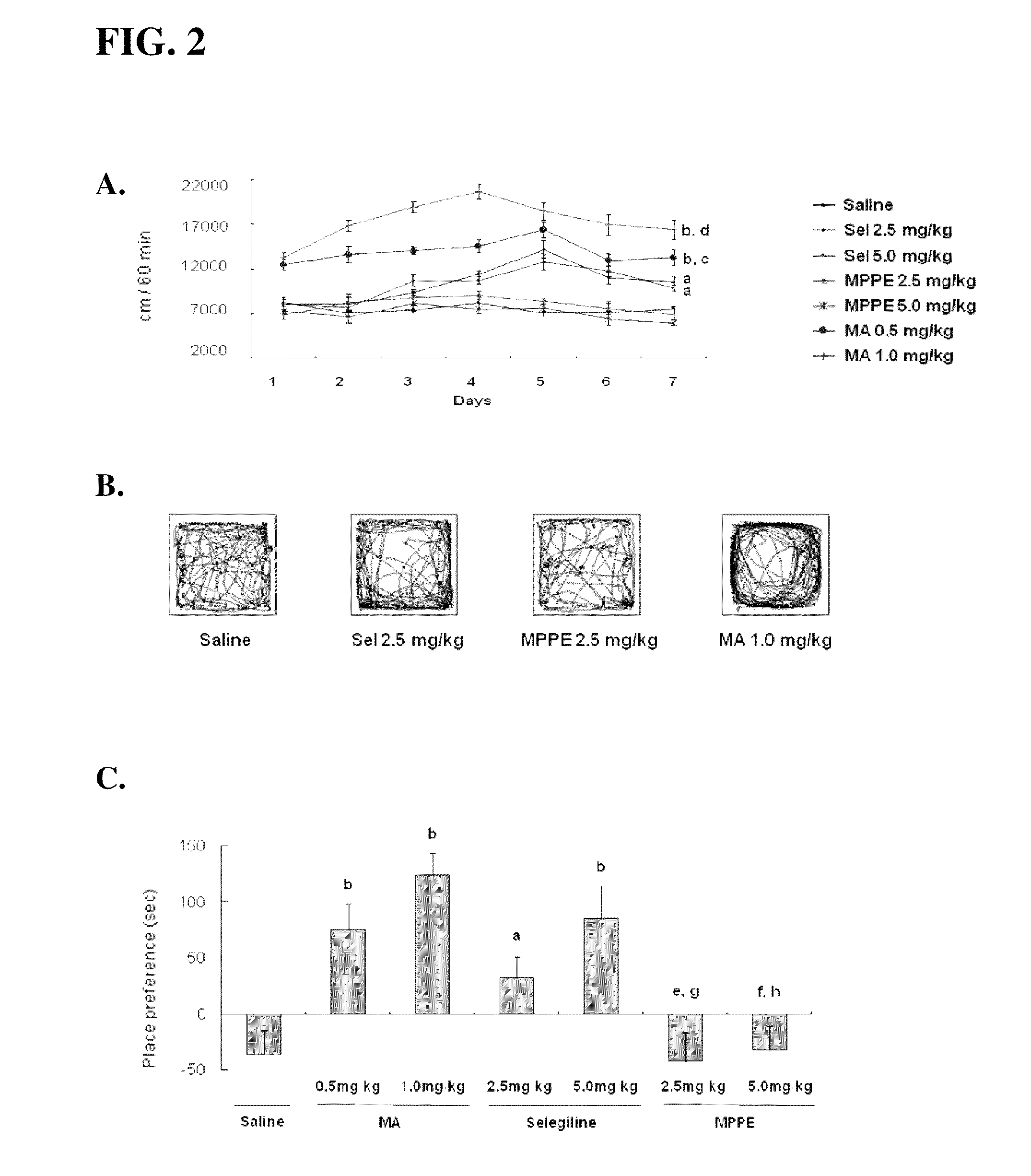

Anti-parkinsonian compounds

InactiveUS20110027354A1Antioxidant effectAvoid neurotoxicityOrganic active ingredientsBiocideCompound (substance)Methyl group

The present application describes a composition comprising a neuroprotective effective amount of N-methyl-N-propynyl-2-phenylethylamine (MPPE).

Owner:KANGWON NATIONAL UNIVERSITY +1

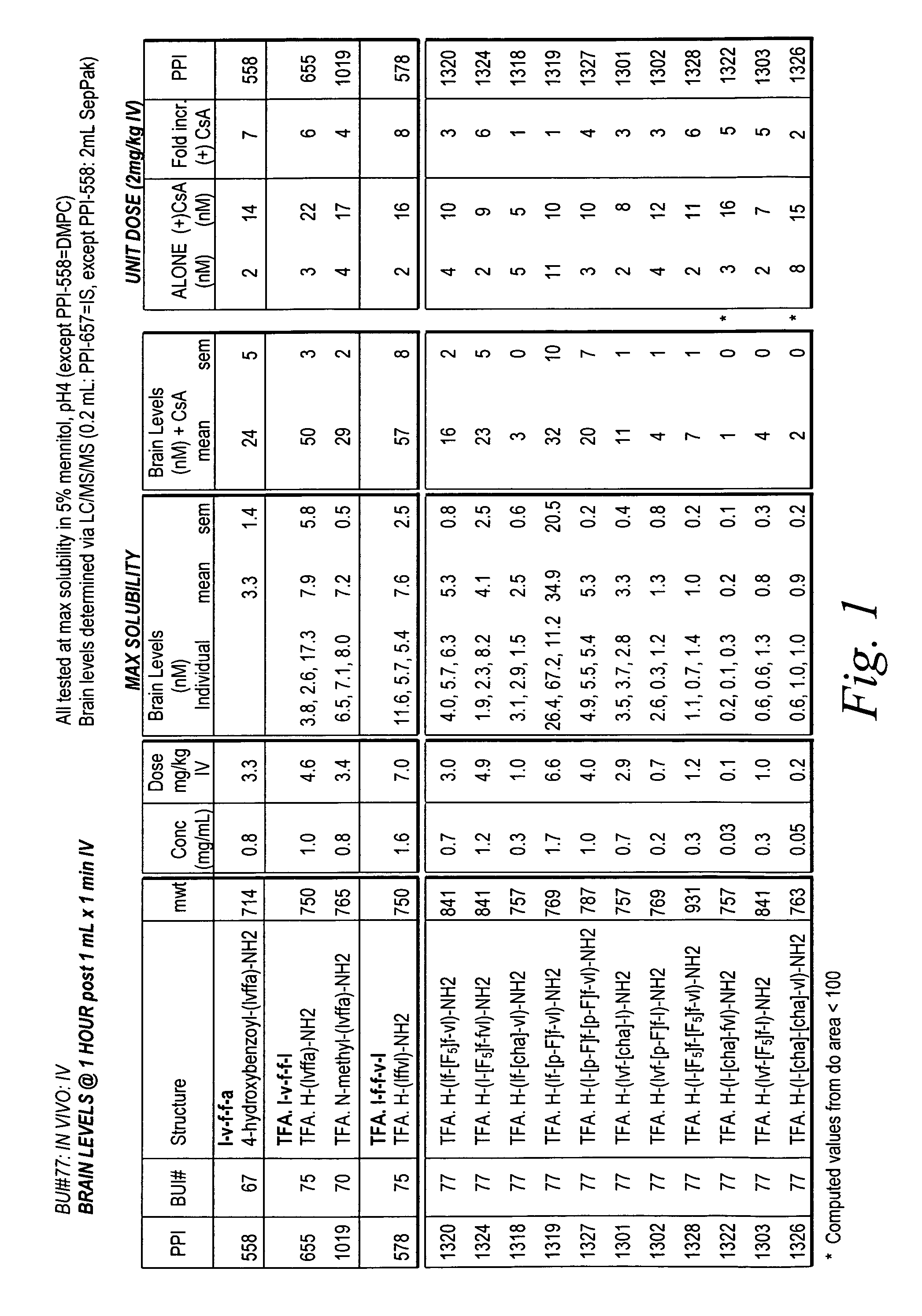

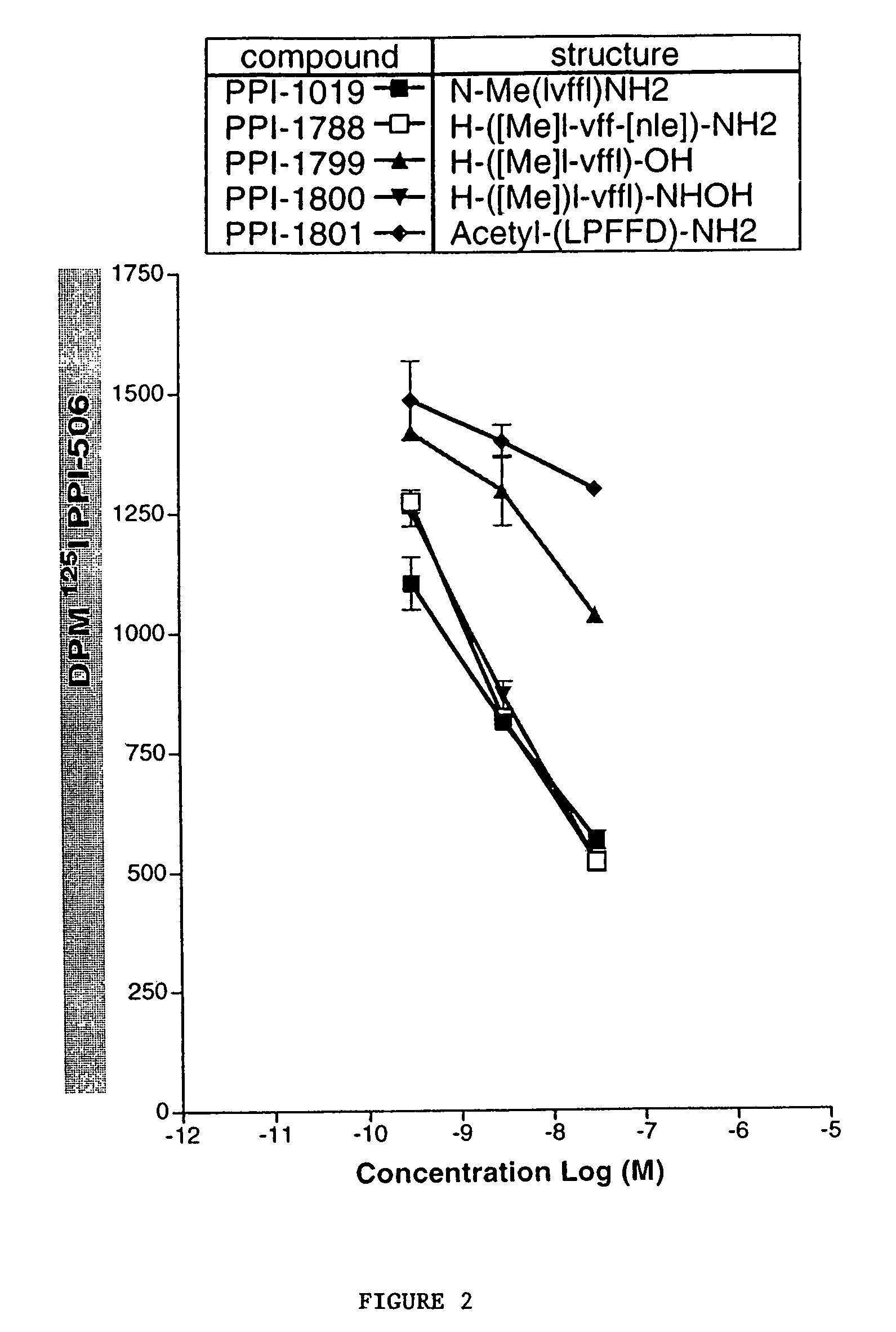

Modulators of β-amyloid peptide aggregation

InactiveUS7803774B2Increase brain levelAvoid neurotoxicityNervous disorderIn-vivo radioactive preparationsDiseaseTert-leucine

Compounds that modulate natural β amyloid peptide aggregation are provided. The modulators of the invention comprise a peptide, preferably based on a β amyloid peptide, that is comprised entirely of D-amino acids. Preferably, the peptide comprises 3-5 D-amino acid residues and includes at least two D-amino acid residues independently selected from the group consisting of D-leucine, D-phenylalanine and D-valine. In a particularly preferred embodiment, the peptide is a retro-inverso isomer of a β amyloid peptide, preferably a retro-inverso isomer of Aβ17-21. In certain embodiments, the peptide is modified at the amino-terminus, the carboxy-terminus, or both. Preferred amino-terminal modifying groups alkyl groups. Preferred carboxy-terminal modifying groups include an amide group, an acetate group, an alkyl amide group, an aryl amide group or a hydroxy group. Pharmaceutical compositions comprising the compounds of the invention, and diagnostic and treatment methods for amyloidogenic diseases using the compounds of the invention, are also disclosed.

Owner:GLAXO SMITHKLINE LLC

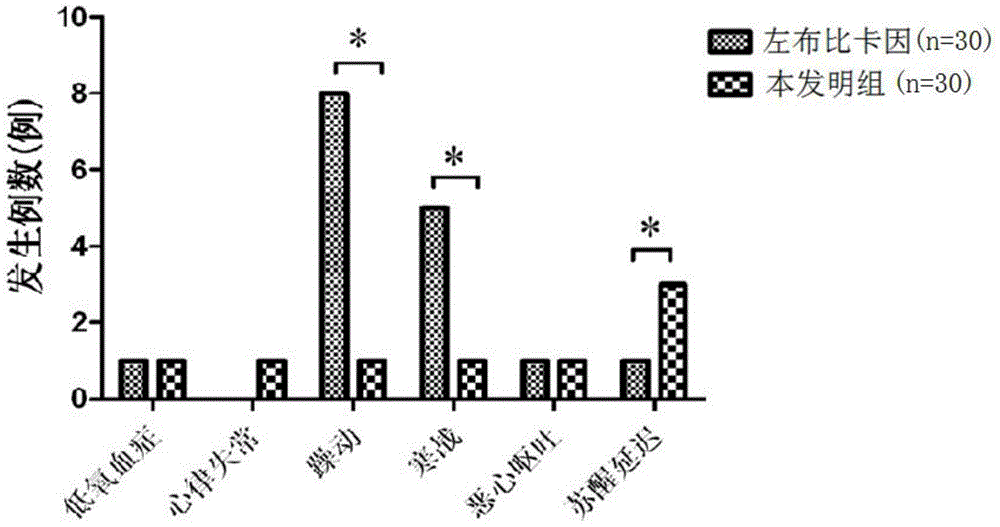

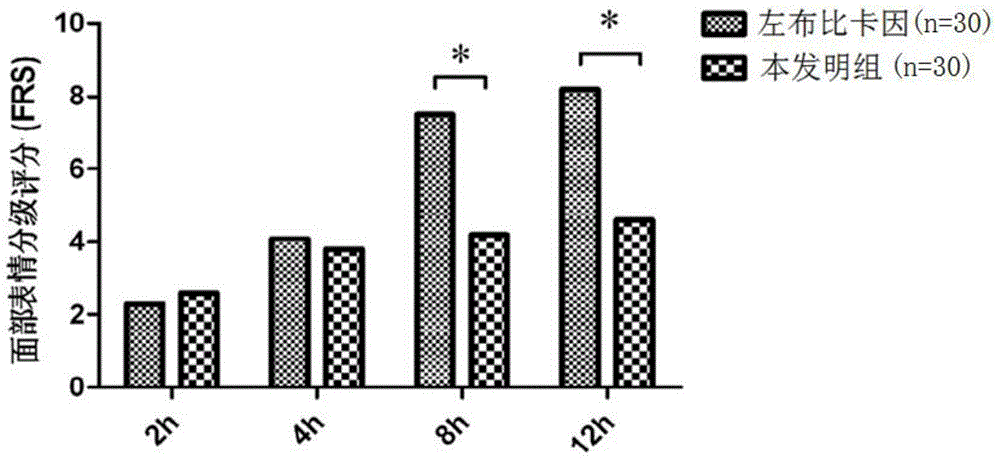

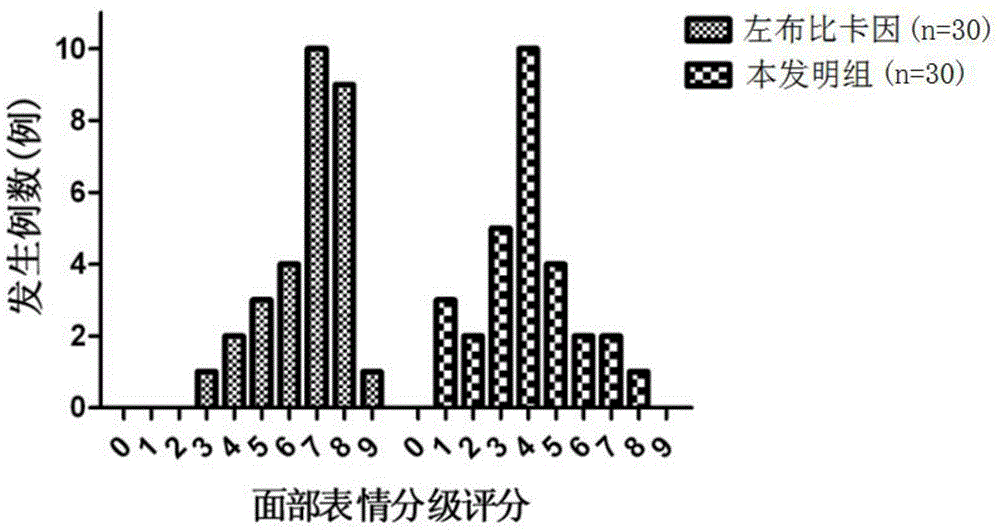

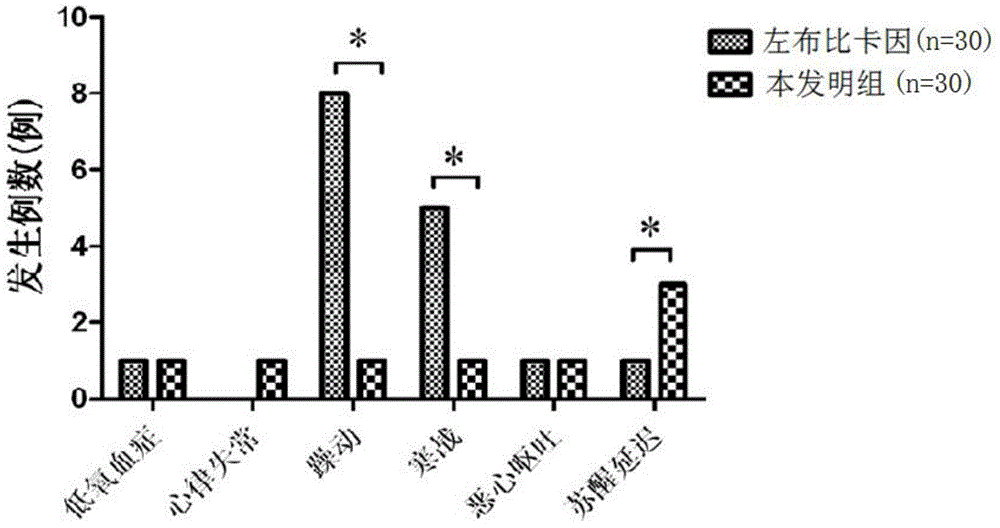

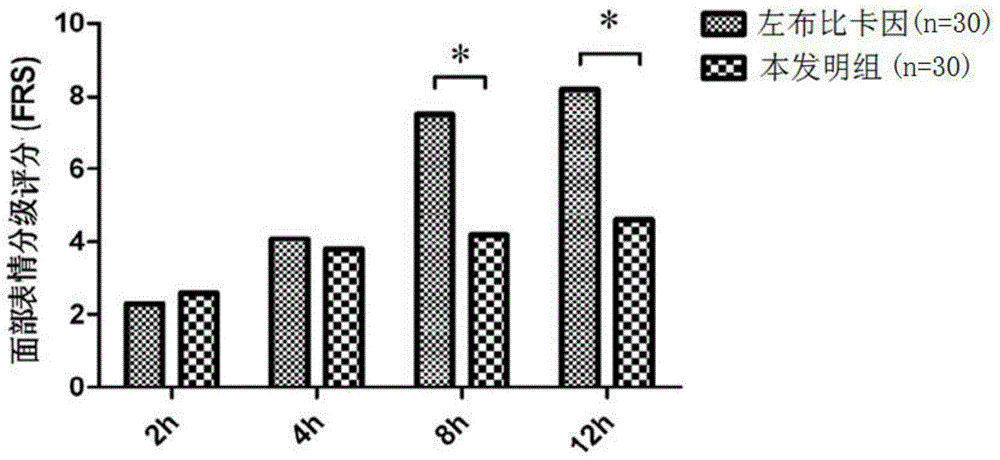

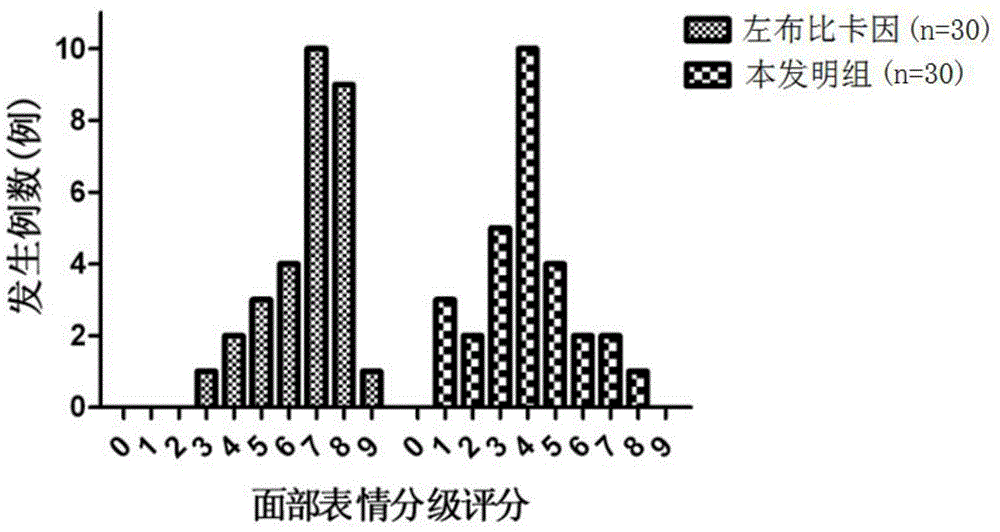

Intraspinal anesthetic and preparation method and application thereof

ActiveCN104814966AAvoid neurotoxicityAvoid nerve damageOrganic active ingredientsAnaestheticsNeurotoxic effectLocal anesthetic

The invention discloses an intraspinal anesthetic and a preparation method and an application thereof. The intraspinal anesthetic comprises dexmedetomidine, epinephrine, betamethasone and water for injection. The preparation method comprises the following steps: (1) after the betamethasone and the epinephrine are mixed and 50% of water for injection of the full dose are added, uniformly mixing; (2) after the dexmedetomidine is mixed in a mixing solution in step (1), adding the water for injection to full dose, and uniformly mixing; (3) filtrating and sterilizing the mixing solution in step (2) to obtain the intraspinal anesthetic. The invention further provides the application of the intraspinal anesthetic in the preparation of the intraspinal anesthetic. According to the intraspinal anesthetic provided by the invention, the neurovirulent effect caused by using local anesthetics to the intraspinal anesthesia can be prevented; furthermore, the intraspinal anesthetic has the effects of analgesia, calm, muscle relaxation and adverse areflexia and shiver prevention, can evade the adverse effects of the vein use and can be used for special patients.

Owner:宋兴荣

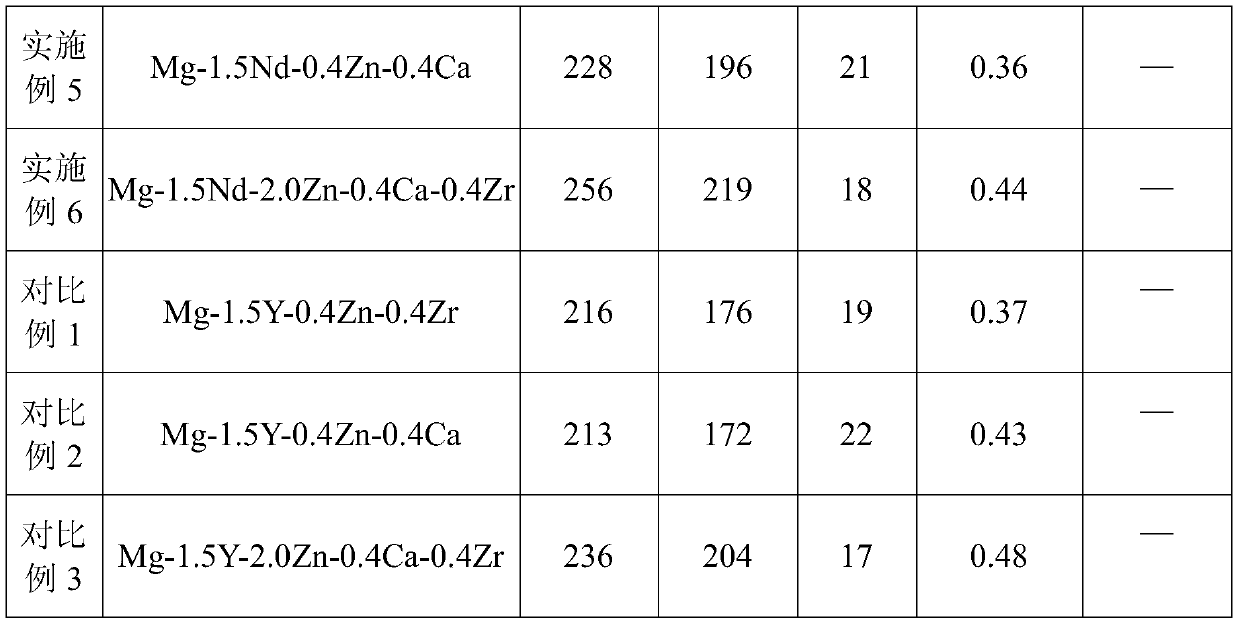

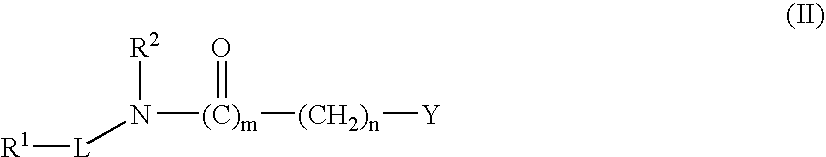

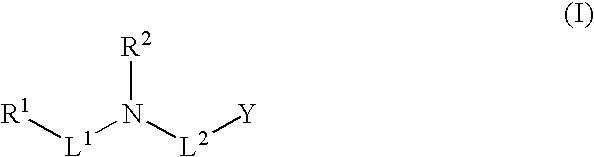

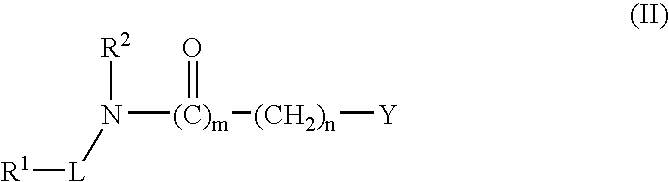

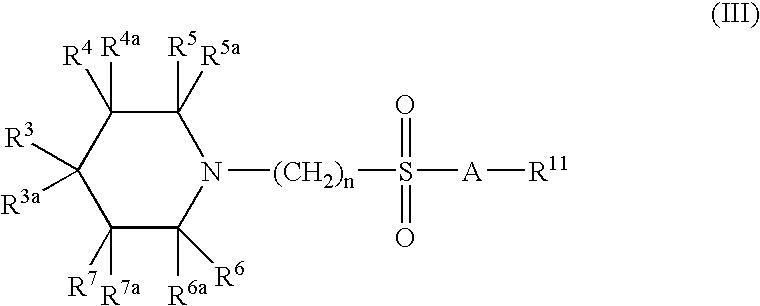

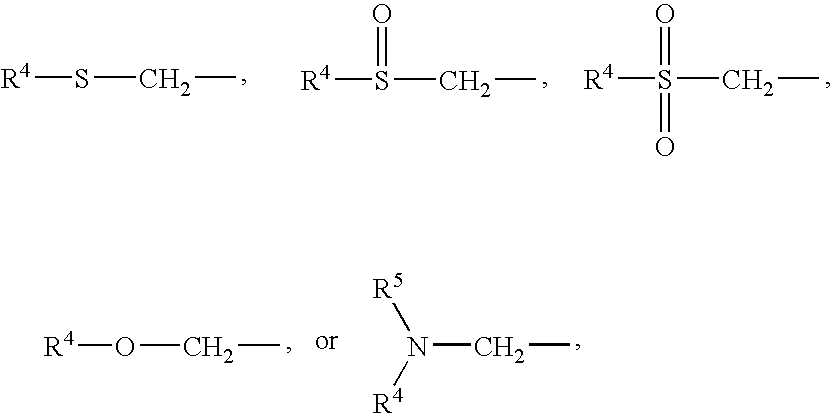

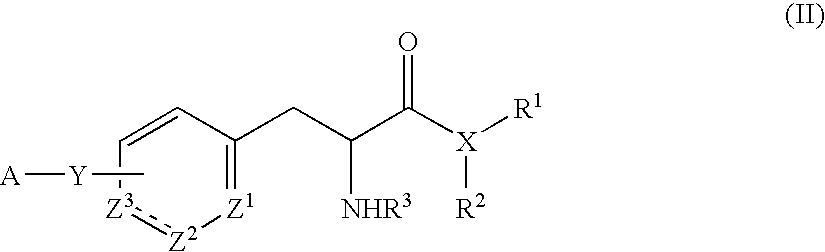

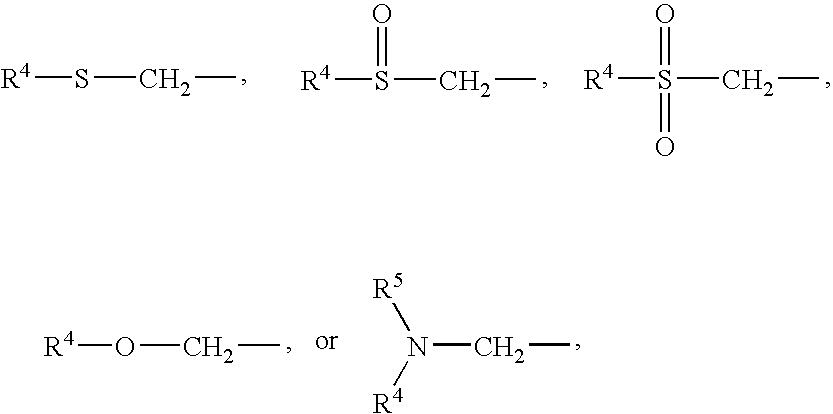

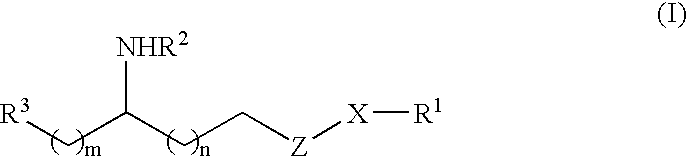

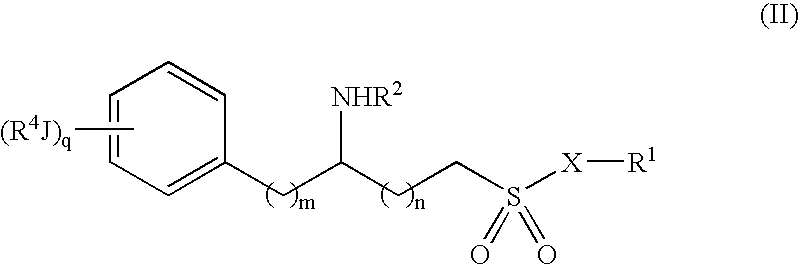

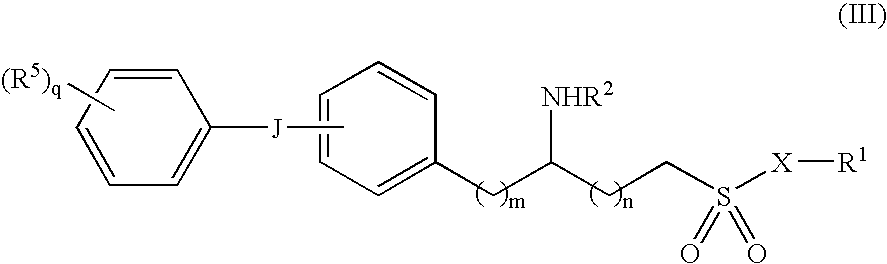

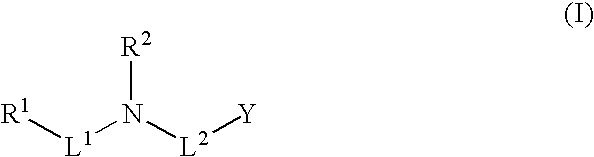

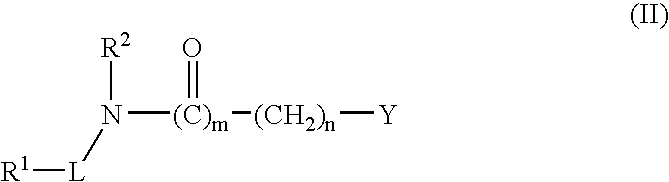

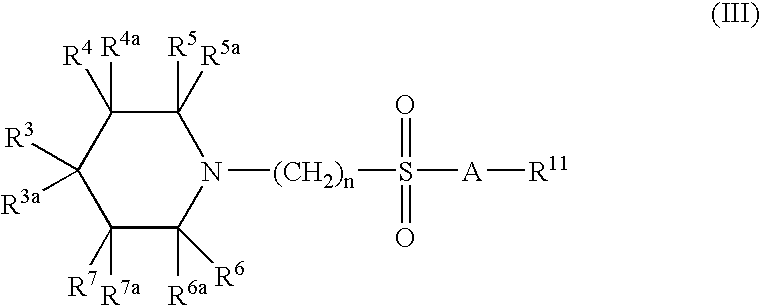

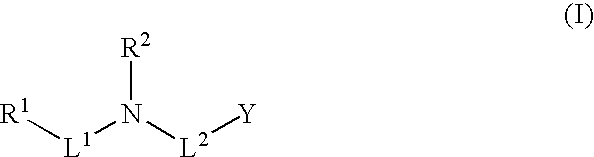

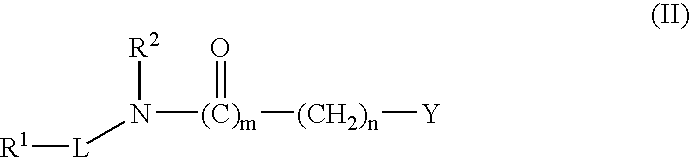

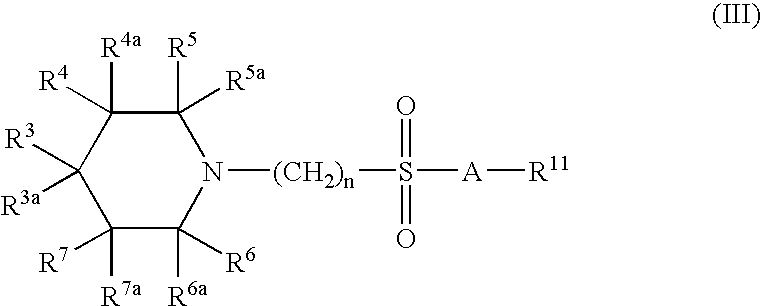

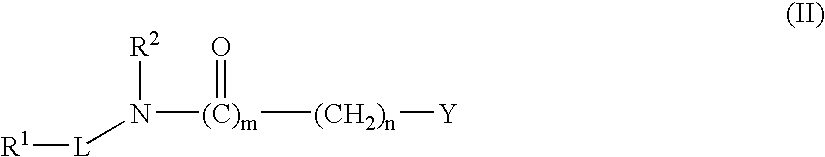

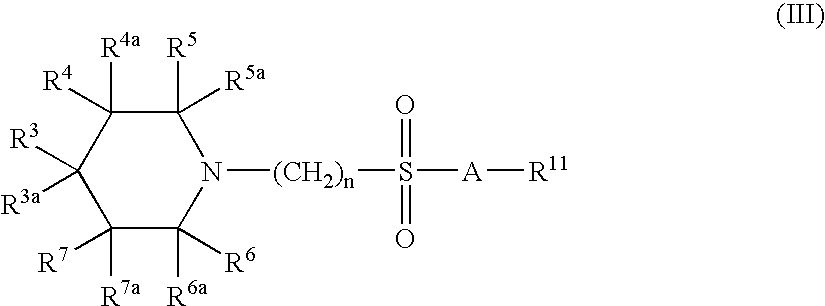

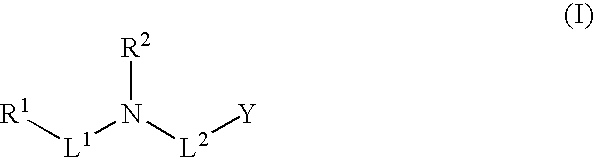

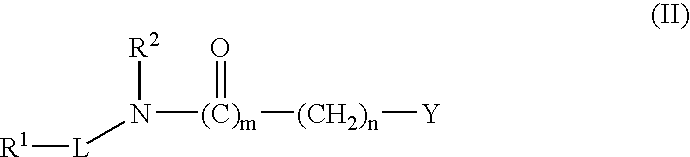

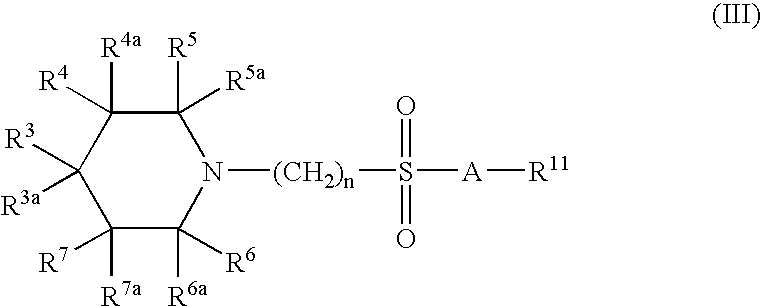

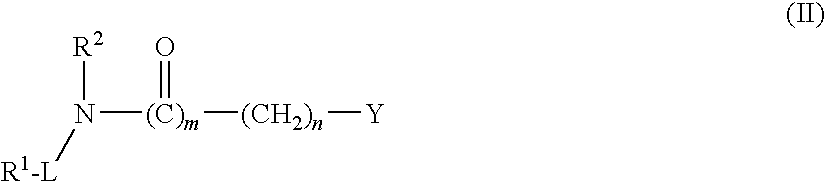

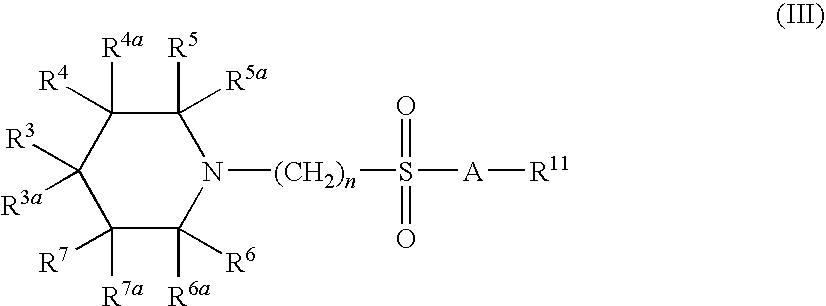

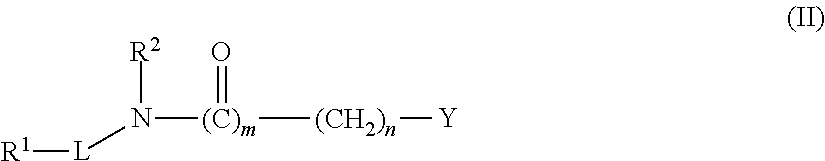

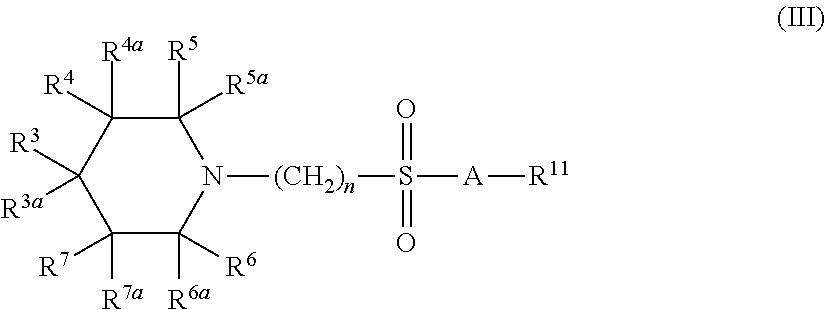

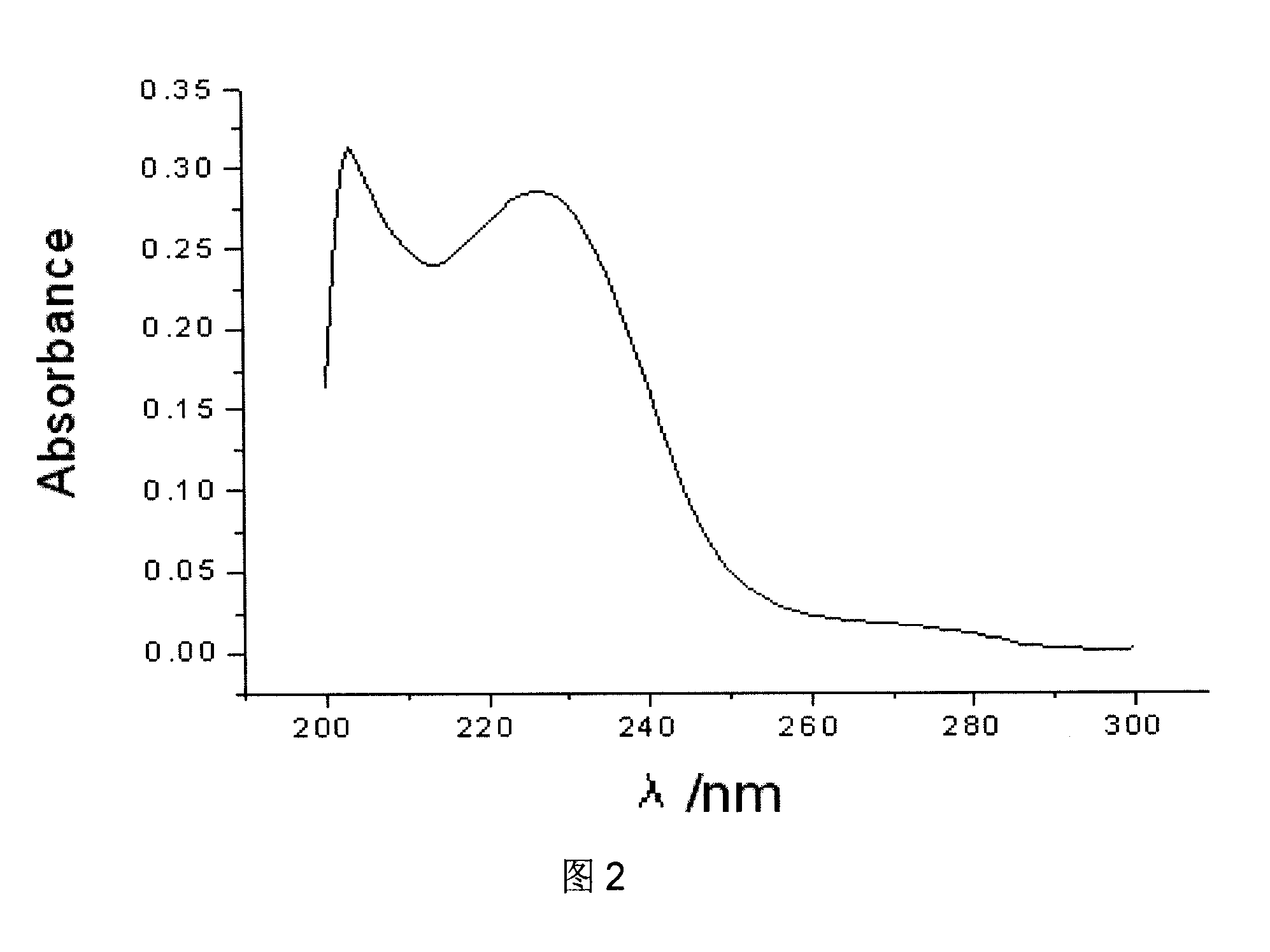

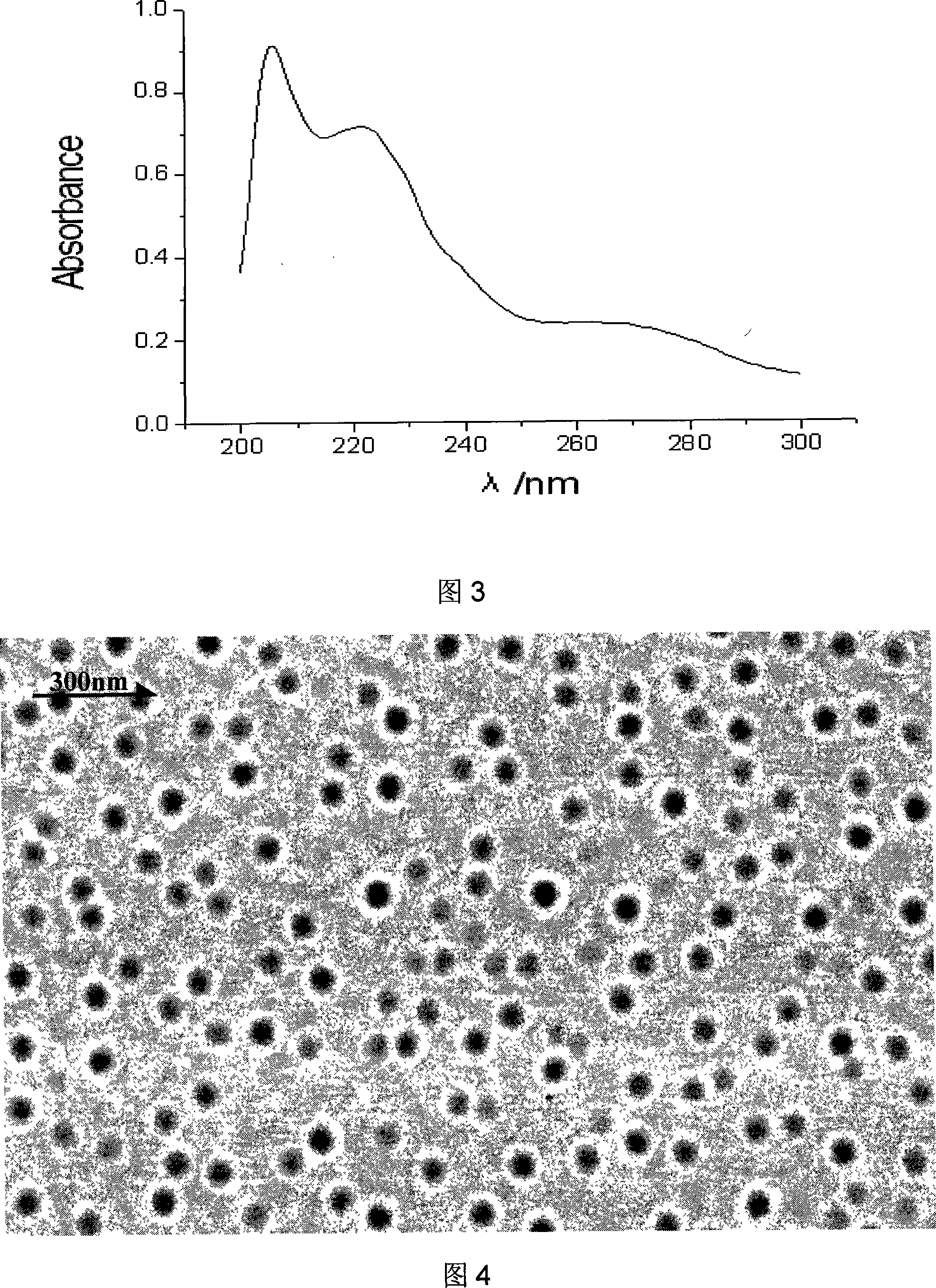

Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents

The use of a compound of formula (I), is disclosed in treating and / or preventing 5 chemotherapy-induced peripheral neurotoxicity (CIPN). The invention includes pharmaceutical compositions wherein the compound of formula (I) is present in a mixture with anticancer agents. An improved anticancer treatment with reduced CIPN-related side effects is also provided.

Owner:NEUROTUNE AG

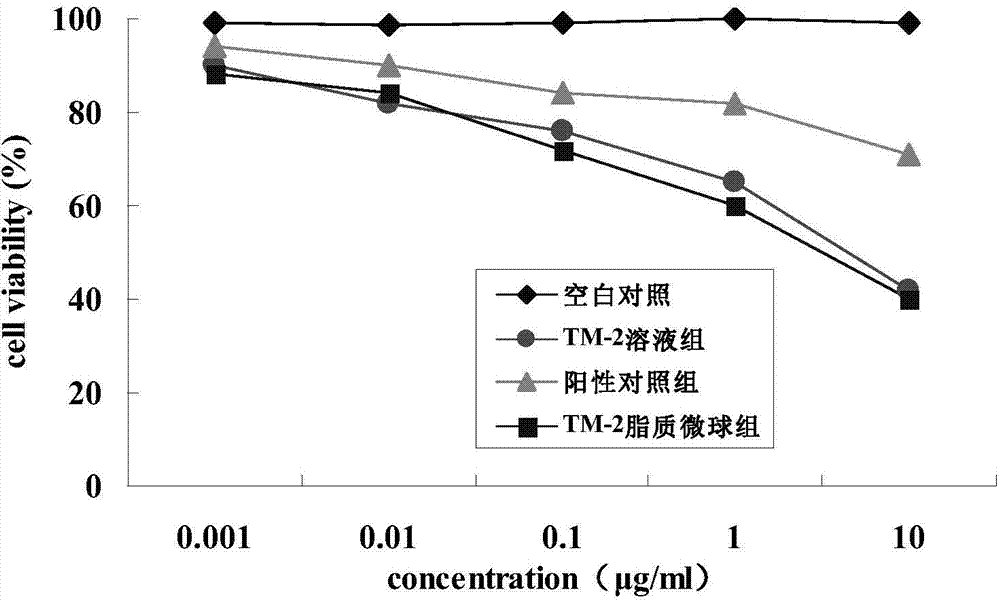

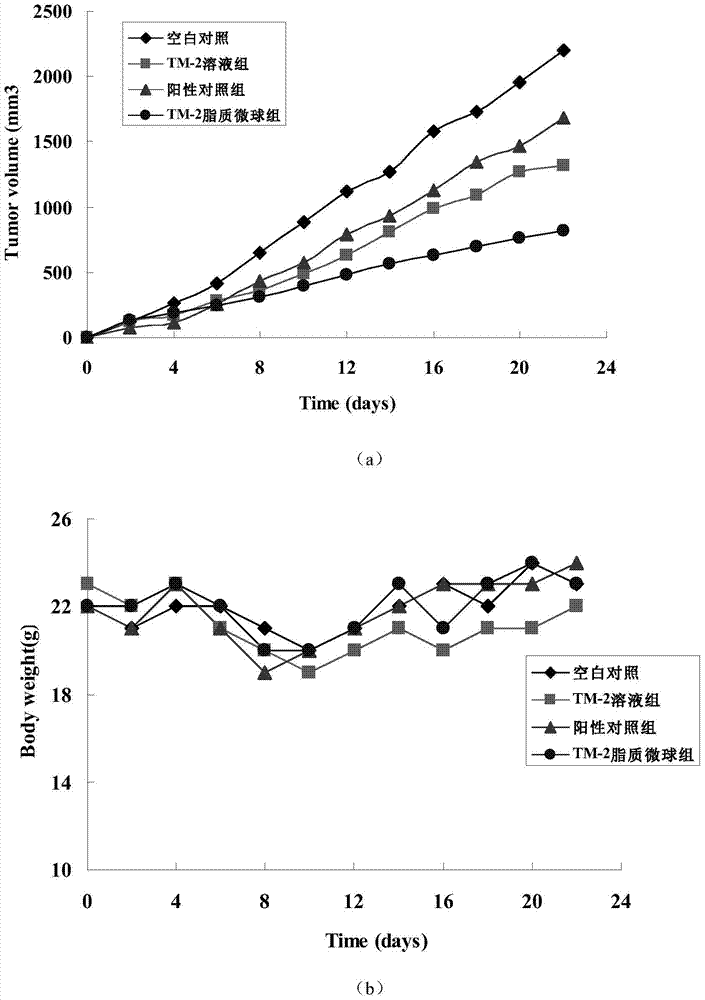

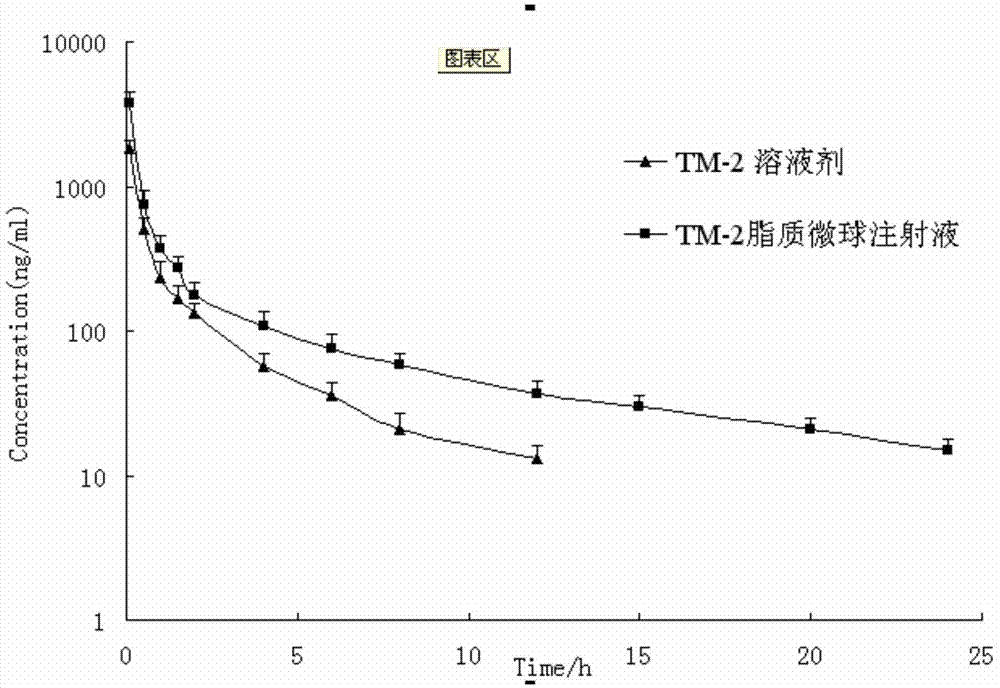

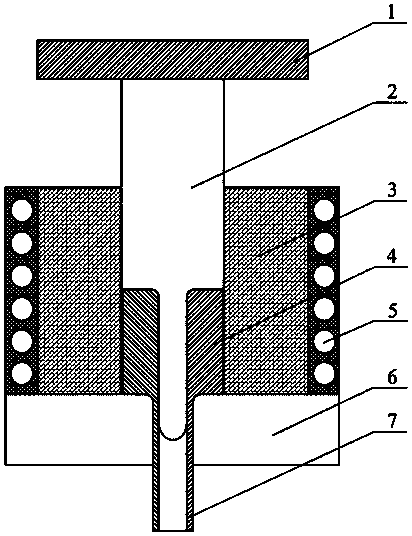

Lipid microsphere injection of taxane derivative TM-2 and preparation method thereof

InactiveCN104323990AReduce localReduce vascular irritationOrganic active ingredientsPharmaceutical non-active ingredientsMicrosphereCholesterol

A lipid microsphere injection of taxane derivative TM-2 and preparation method thereof belong to the technical field of medicines. The lipid microsphere injection includes following components: the TM-2, oil for injection, an emulsifier, cholesterol, a polyethylene glycol-polyaspartic acid co-polymer, an auxiliary emulsifier, a stabilizing agent, an isoosmotic adjusting agent and water for injection. The preparation method comprises following steps: (1) uniformly mixing the TM-2 with an oil-soluble medium and dispersing the mixture in a water phase; (2) performing high-speed stirring to prepare a primary emulsion; and (3) performing high-pressure homogenization to obtain a preparation and then sterilizing the preparation through a high-pressure rotational sterilizing method. Compared with a reference preparation taxane lipid microsphere injection, The TM-2 lipid microsphere injection shows a better antitumor activity. The TM-2 lipid microsphere injection not only is better than the reference preparation taxane lipid microsphere injection in effectives, but also is good in stability. The TM-2 lipid microsphere injection reduces toxicity of the TM-2 and is enhanced in curative effects. Meanwhile, the TM-2 lipid microsphere injection is tolerant of high-temperature pressurized sterilization and is suitable for industrialized production.

Owner:SHENYANG PHARMA UNIVERSITY

A corrosion-resistant high-strength toughness magnesium alloy pipe and its preparation process

ActiveCN110117743BSolve the problem of difficult plastic processingStable supportExtrusion diesIngotRound bar

The embodiment of the invention provides a corrosion-resistant high strength and toughness magnesium alloy tubular product and a preparation process. The alloy tubular product is prepared from the following elements in percent by mass: 1.0-6.0% of Nd, 0.1-5.0% of Zn, 0.1-5.0% of Ca, 0.1-4.0% of Zr and the balance Mg. The preparation process comprises the following steps: successively preparing a magnesium alloy cast ingot, a magnesium alloy blank, a magnesium round bar and a magnesium hollow round ingot through a series of steps: vacuum semicontinuous casting, solid solution homogenizing, barextrusion processing, hollow round ingot processing and the like; and finally, extruding the hollow round ingot to obtain the corrosion-resistant high strength and toughness magnesium alloy tubular product. The corrosion-resistant high strength and toughness magnesium alloy tubular product solves the problem of hard plastic processing for preparing a bracket as the magnesium alloy tubular productis relatively poor in deformability at room temperature in the prior art, can be degraded uniformly in vivo while achieving an ideal supporting effect of the alloy, and meanwhile, has better corrosionresistance and is relatively uniform to corrode, wherein the corrosion rate is 0.18-0.42 mm / year.

Owner:ZHUHAI INST OF ADVANCED TECH

High-toughness corrosion-resistant magnesium alloy implanted material capable of being degraded in organism

ActiveCN101837145BAvoid painAvoid troubleSurgeryTissue regenerationBiocompatibility TestingBiological materials

Disclosed is a magnesium alloy used for degradable stent material in vivo and preparation method thereof. The components and their weight ratio of magnesium alloy are: Nd 1-2.49%, Zn 0.1-2%, Zr 0-0.6%, impurities 0-0.2% and balance Mg. The magnesium alloy has better mechanical property and plastic deformation property than WE43, desired uniform corrosion resistance and good biocompatibility. The magnesium alloy can be applied to prepare lumen support which is used for short-term intervention therapeutic of vessel, biliary duct, pancreatic duct, and esophagus and so on.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

A kind of intraspinal anesthetic and its preparation method and application

ActiveCN104814966BAvoid neurotoxicityAvoid nerve damageOrganic active ingredientsAnaestheticsReflexSpinal anesthetic

The invention discloses a spinal canal anesthetic and its preparation method and application. The spinal canal anesthetic comprises dexmedetomidine, epinephrine, betamethasone and water for injection. The preparation method comprises the following steps: (1) after mixing betamethasone and epinephrine, adding 50% of the total amount of water for injection, and mixing uniformly; (2) adding dexmedetomidine to the mixed solution in step (1) , then add water for injection to the full amount, and mix evenly; (3) filter and sterilize the mixed solution in step (2) to obtain. The present invention also proposes the application of the spinal canal anesthetic in the preparation of spinal canal anesthetic drugs. The intraspinal anesthetic of the present invention avoids the neurotoxic effect caused by local anesthetics used in intraspinal anesthesia, has the effects of analgesia, sedation, muscle relaxation, and disappearance of adverse reflexes, and prevents shivering, and can avoid the adverse reactions of its intravenous use , can also be used for special patients.

Owner:宋兴荣

A kind of high-strength and toughness corrosion-resistant magnesium alloy and preparation method thereof

ActiveCN110144503BSolve the problem of difficult plastic processingStable supportCorrosion resistantMagnesium alloy

The embodiment of the invention provides high-strength-and-toughness and corrosion-resistance magnesium alloy and a preparation method thereof. The alloy solves the problems in the prior art that thedeformation capability of the magnesium alloy is poorer and the plasticity processing is difficult when the magnesium alloy is used for preparing stents, the stents can be uniformly degraded in the body while the ideal supporting effect of alloy is achieved, better corrosion resistant performance is achieved, the corrosion-resistance rate is significantly reduced, and the corrosion is more uniform.

Owner:ZHUHAI INST OF ADVANCED TECH

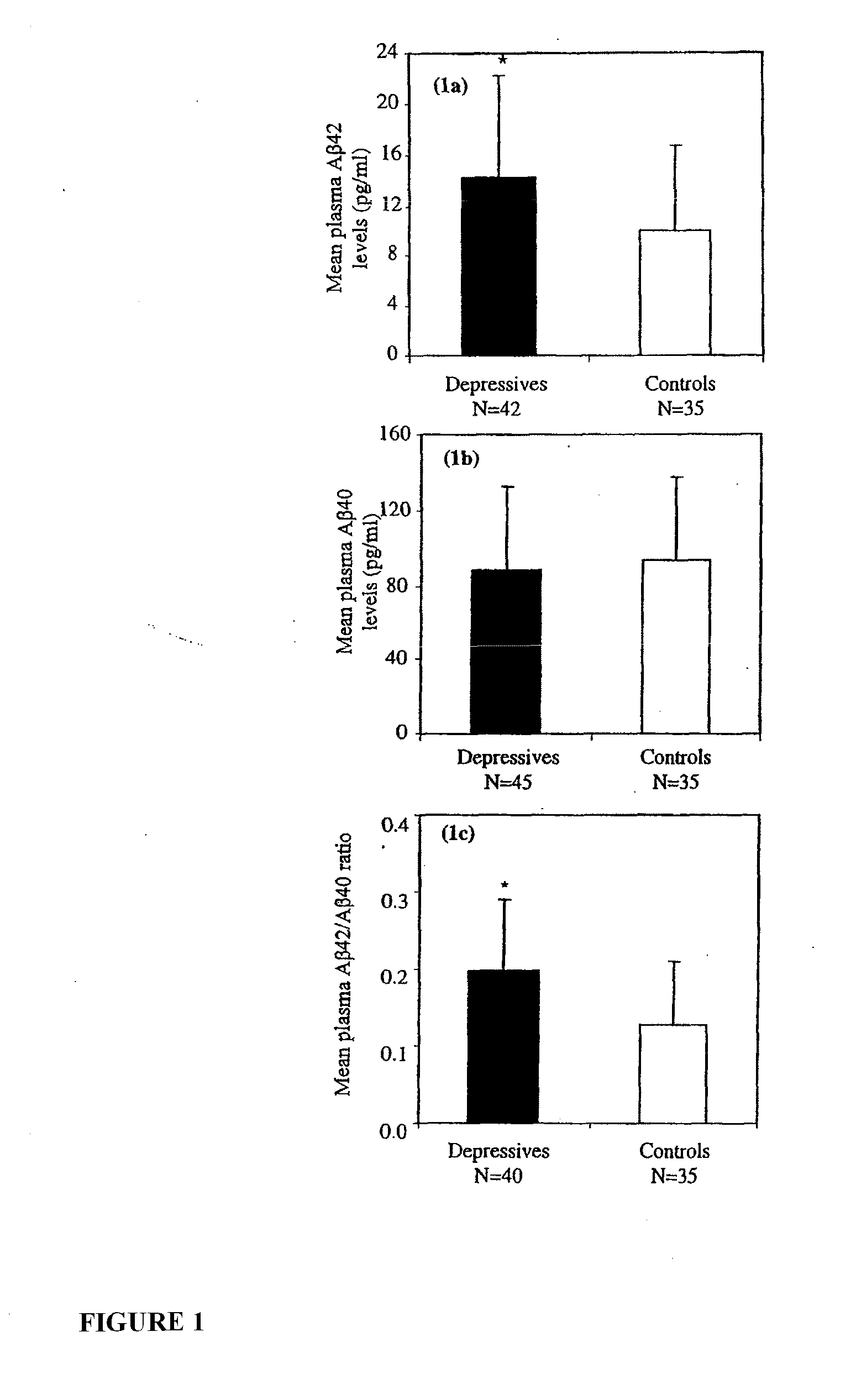

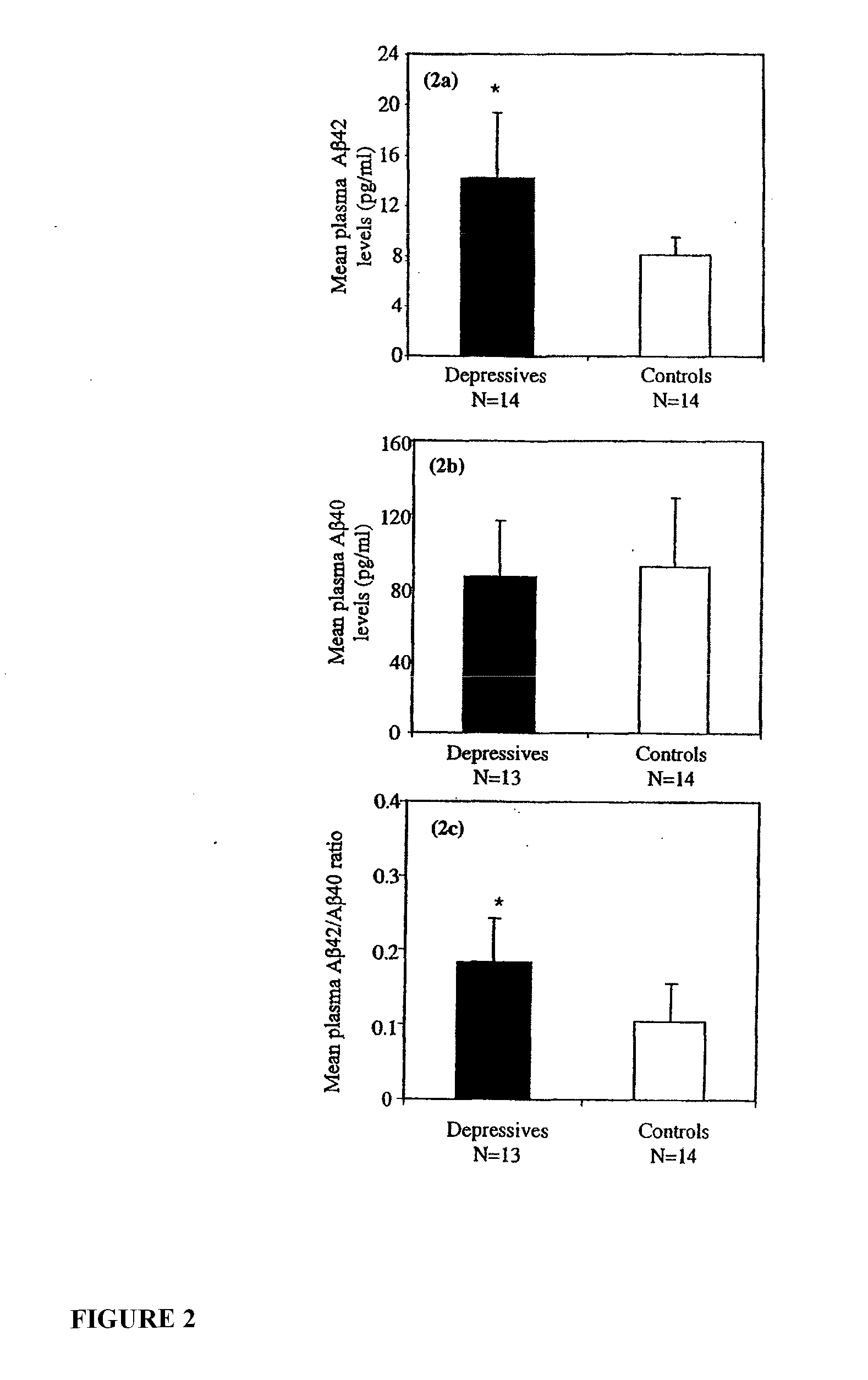

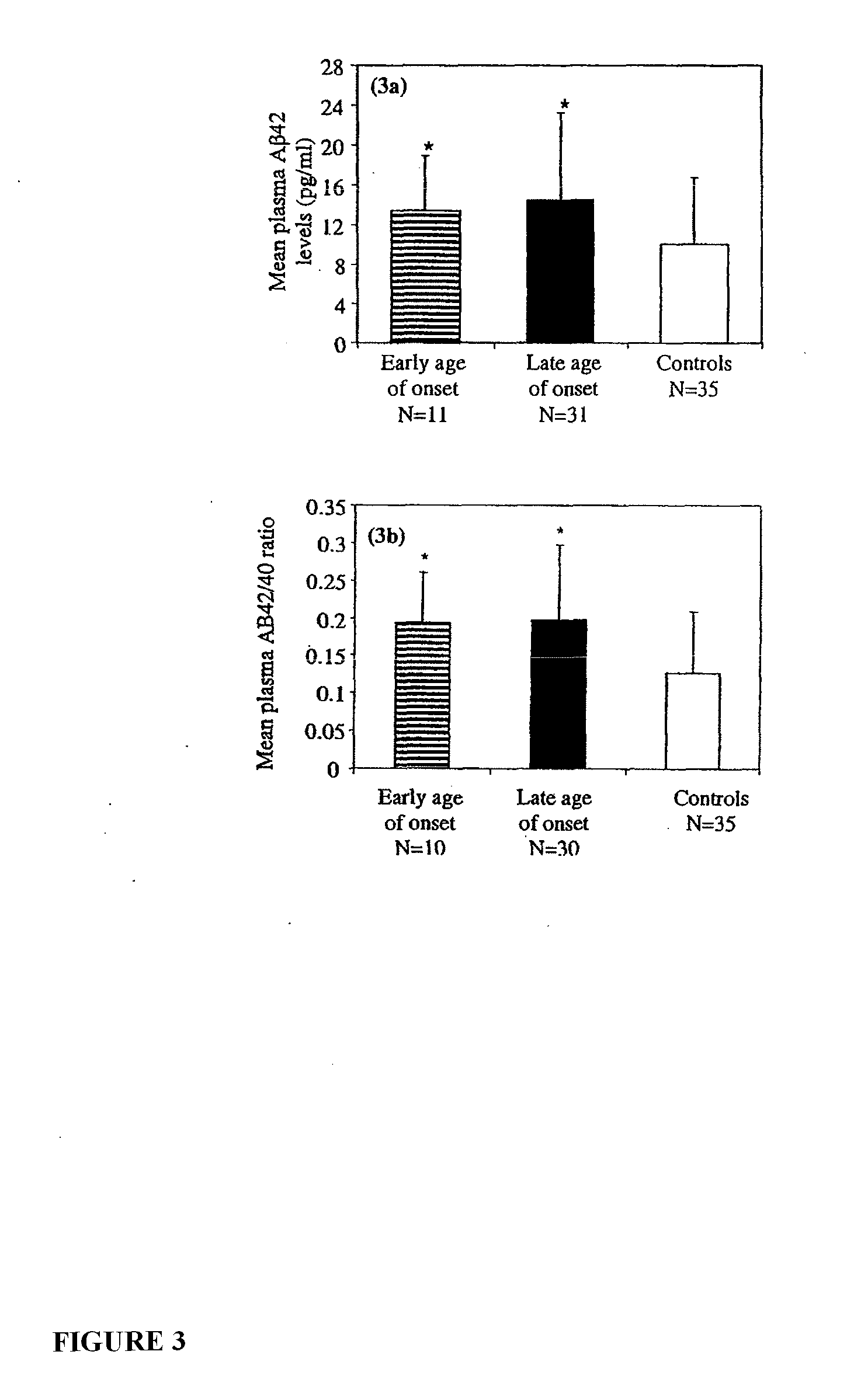

Methods and compositions for diagnosing and treating mood disorders

InactiveUS20130236919A1Promote degradationImprove the level ofDisease diagnosisBiological testingDiseaseFibril

The present invention relates to methods of diagnosing, prognosing or treating diseases or disorders in which elevated or reduced levels of Aβ protein, including Aβ1-42 are prevalent. In particular, the present invention relates to methods of diagnosing, prognosing or treating a major or minor depressive episode / disorder attributed to elevated or reduced levels of Aβ protein, including Aβ1-42, found particularly in body fluids including whole blood, blood cells, serum, plasma, urine and CSF as well as in the brain. The invention also relates to the treatment of these disorders by administering an agent that either prevents production of Aβ, prevents aggregation of Aβ fibrils, or that increases the degradation or clearance of Aβ. In addition, the invention provides a method of treating or preventing a major or minor depressive disorder by administering an agent that prevents or interferes with Aβ-induced neurotoxicity. The present invention also relates to pharmaceutical compositions containing such agents and methods of screening for novel agents.

Owner:NEW YORK UNIV

A biomedical degradable corrosion-resistant high-strength magnesium alloy and its preparation method

ActiveCN107541631BIdeal in vivo corrosion resistanceAvoid failureSurgerySolution treatmentMetallurgy

The invention provides a biomedical degradable anti-corrosion high strength and ductility magnesium alloy and a preparation method thereof. With the total weight of the magnesium alloy being 100%, thecomponents of the magnesium alloy comprise, by weight, 1.0-4.5% of Nd, 0.2-2.0% of Zn, 0-1.0% of Ca, 0-1.0% of Zr and the balance Mg. The preparation method of the magnesium alloy includes the stepsthat by adopting a mode of vacuum semi-continuous casting, a magnesium alloy cast ingot is prepared according to the components and the weight percentage of the magnesium alloy, then solid solution treatment and extrusion are conducted on the magnesium alloy cast ingot, and the magnesium alloy is prepared. The biomedical degradable anti-corrosion high strength and ductility magnesium alloy has theadvantages of being nontoxic, capable of being degraded completely, good in anti-corrosion property, high in strength and ductility and the like, and can be used for preparing intravascular stents.

Owner:BEIJING AMSINO MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents](https://images-eureka.patsnap.com/patent_img/f49f6188-722b-4e7e-9be3-4b2872a63c02/US07973066-20110705-D00001.png)

![Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents](https://images-eureka.patsnap.com/patent_img/f49f6188-722b-4e7e-9be3-4b2872a63c02/US07973066-20110705-D00002.png)

![Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents Pyrrolo[1,2-A]imidazoledione effective in the treatment of peripheral neurotoxicity induced by chemotherapeutic agents](https://images-eureka.patsnap.com/patent_img/f49f6188-722b-4e7e-9be3-4b2872a63c02/US07973066-20110705-D00003.png)