Patents

Literature

33results about How to "Improve the speed of handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

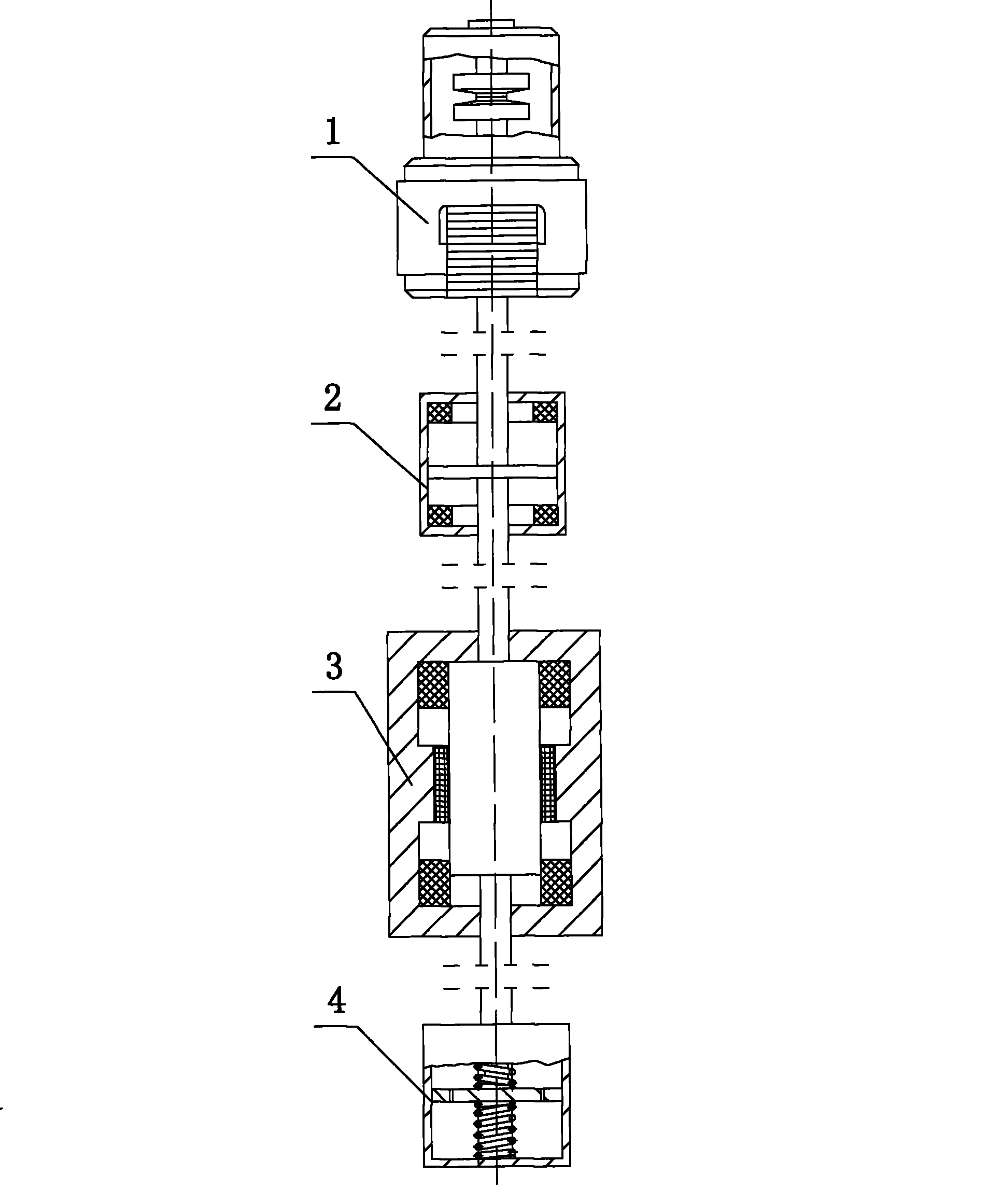

Ultra rapid operation mechanism for high voltage switch

InactiveCN101510475ALarge initial accelerationSmooth motionSwitch power arrangementsAir-break switch detailsEngineeringEddy current

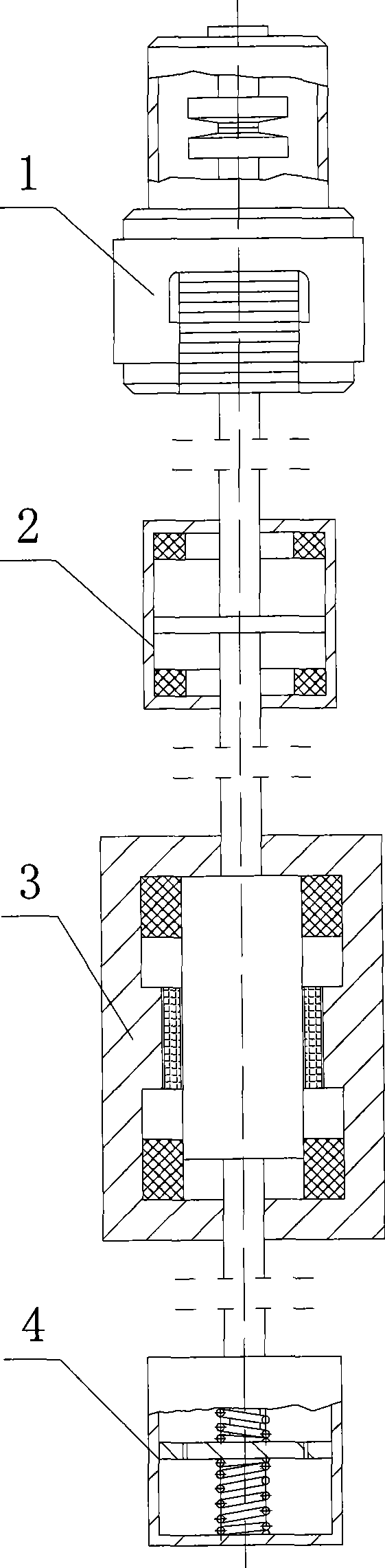

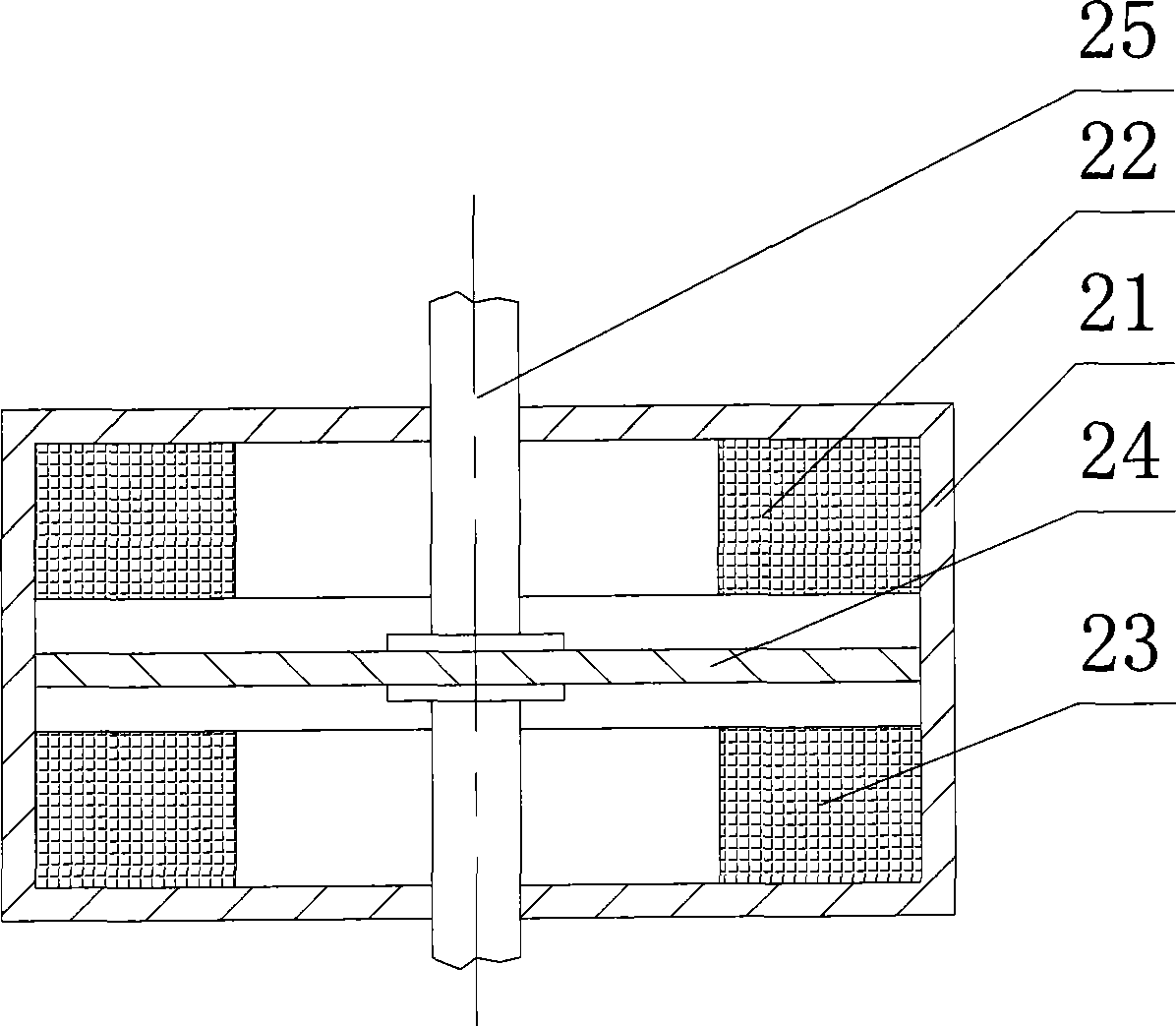

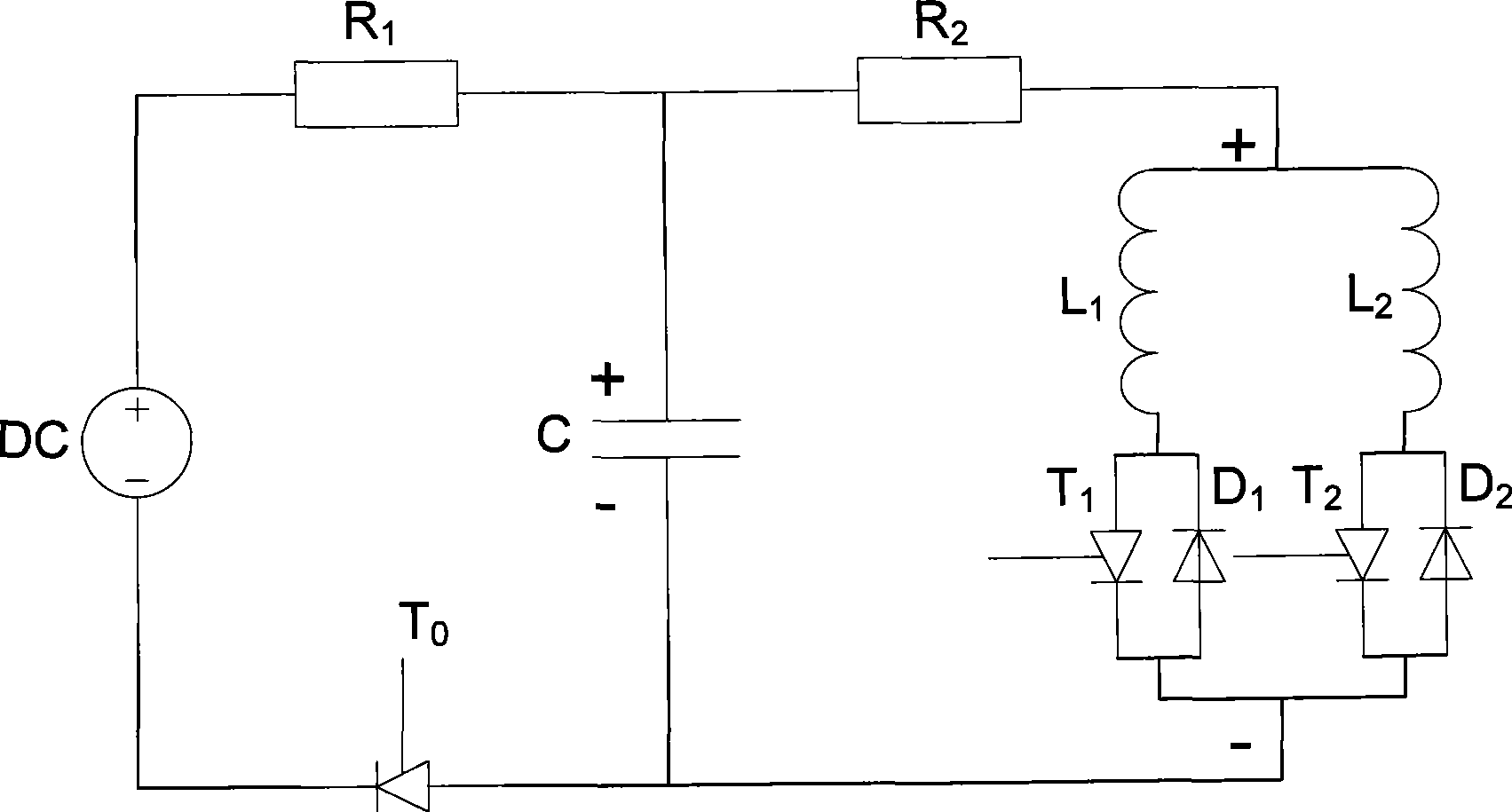

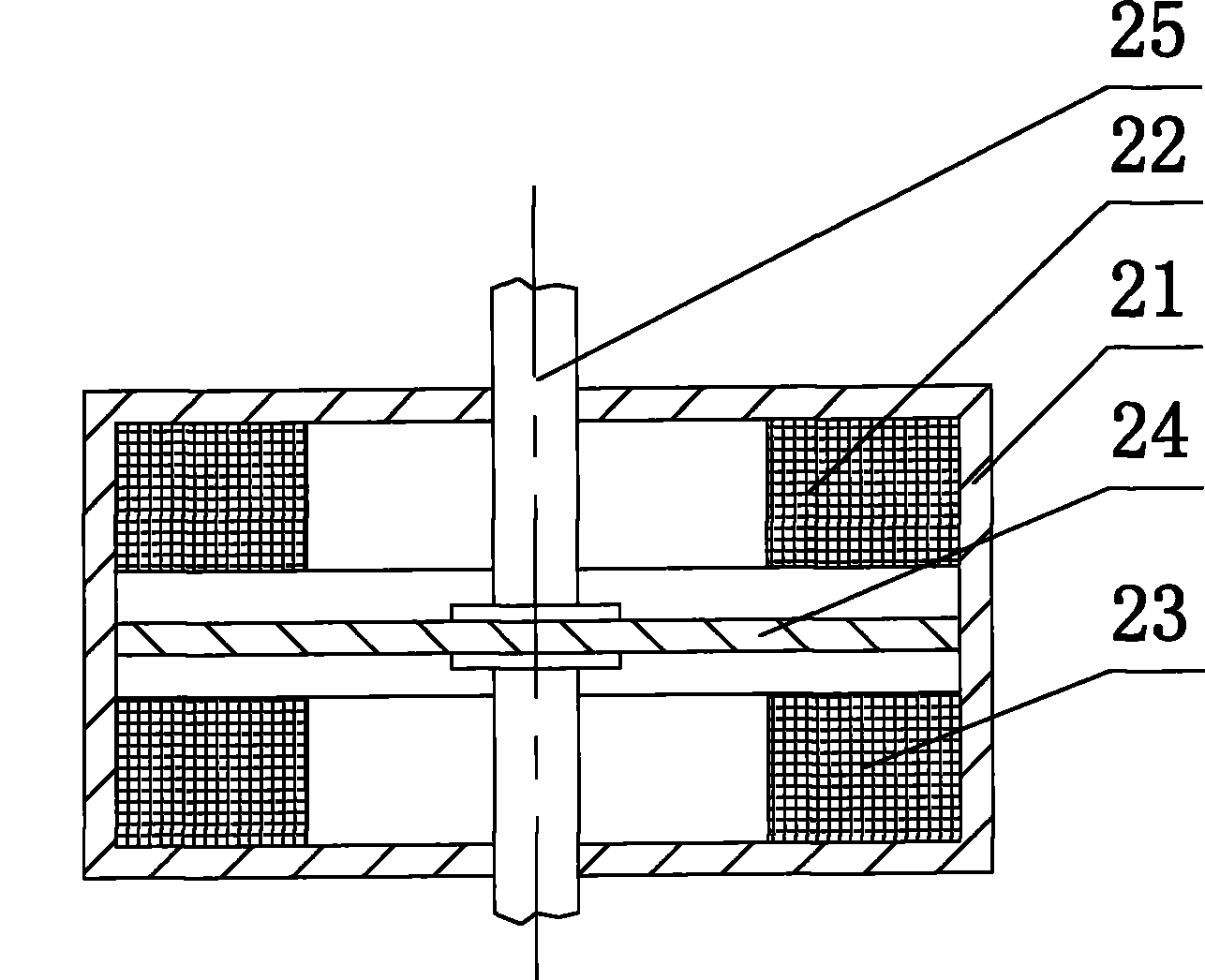

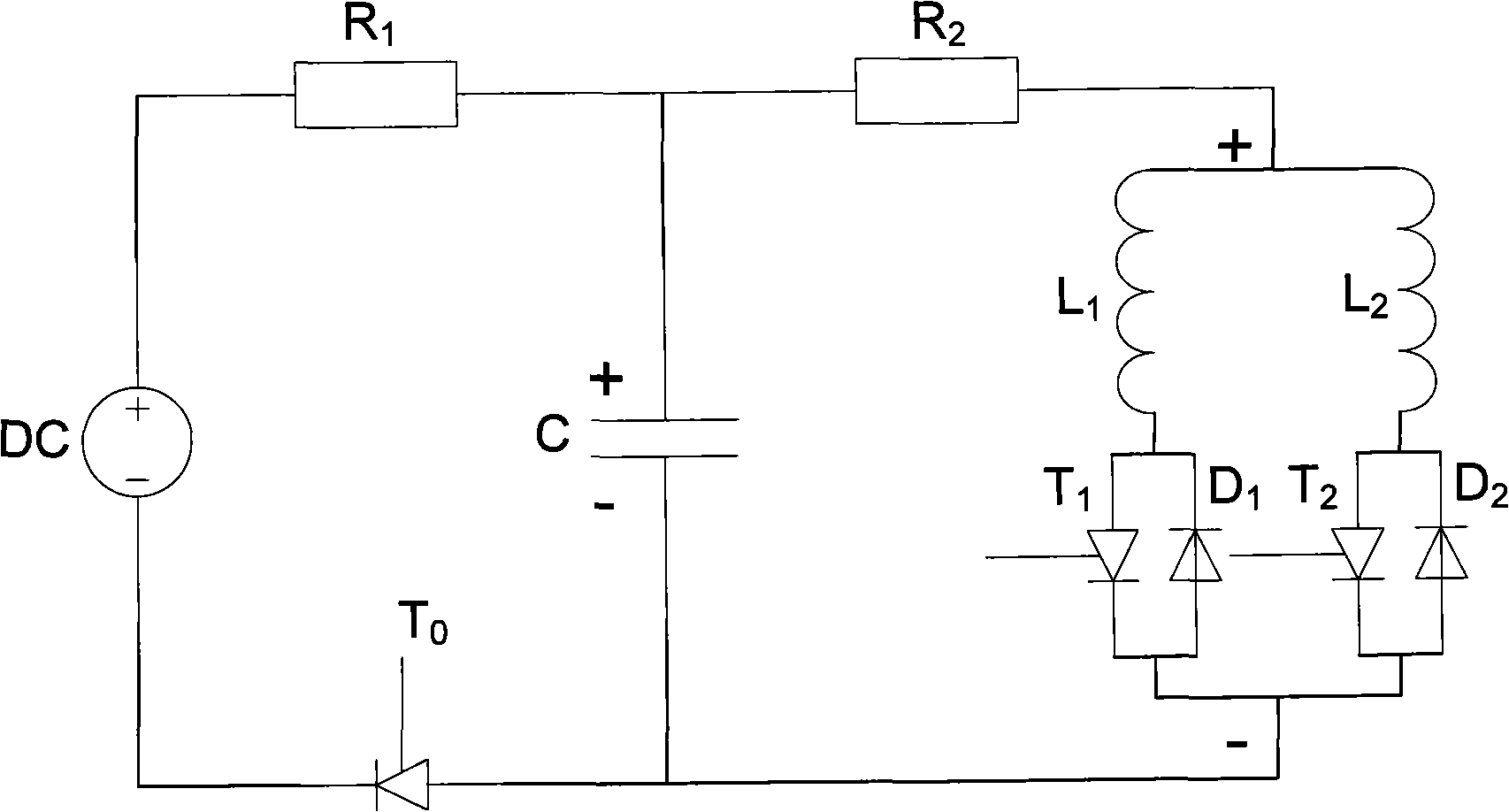

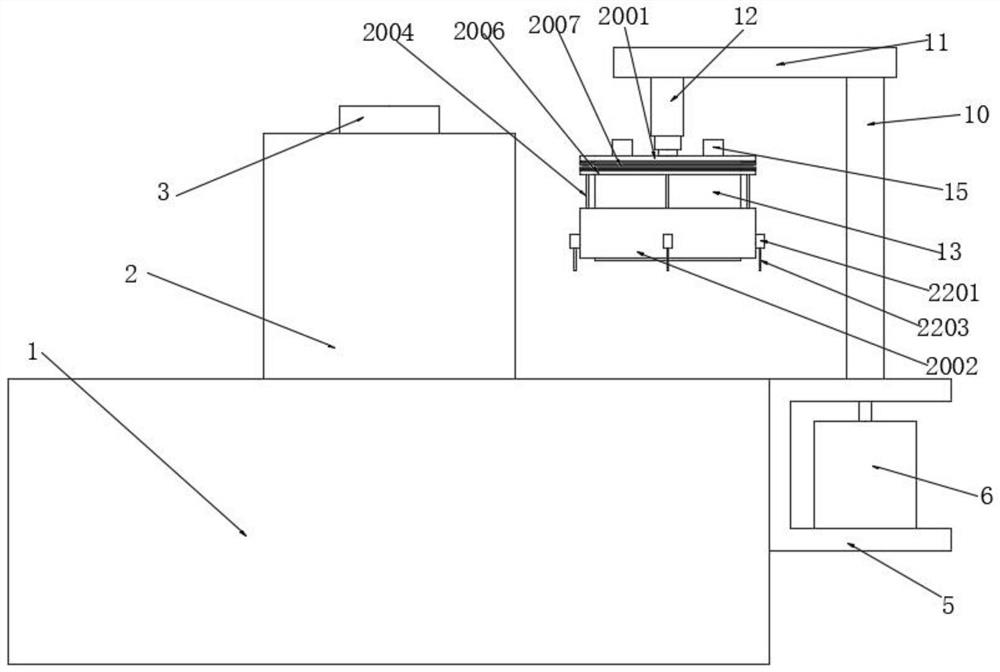

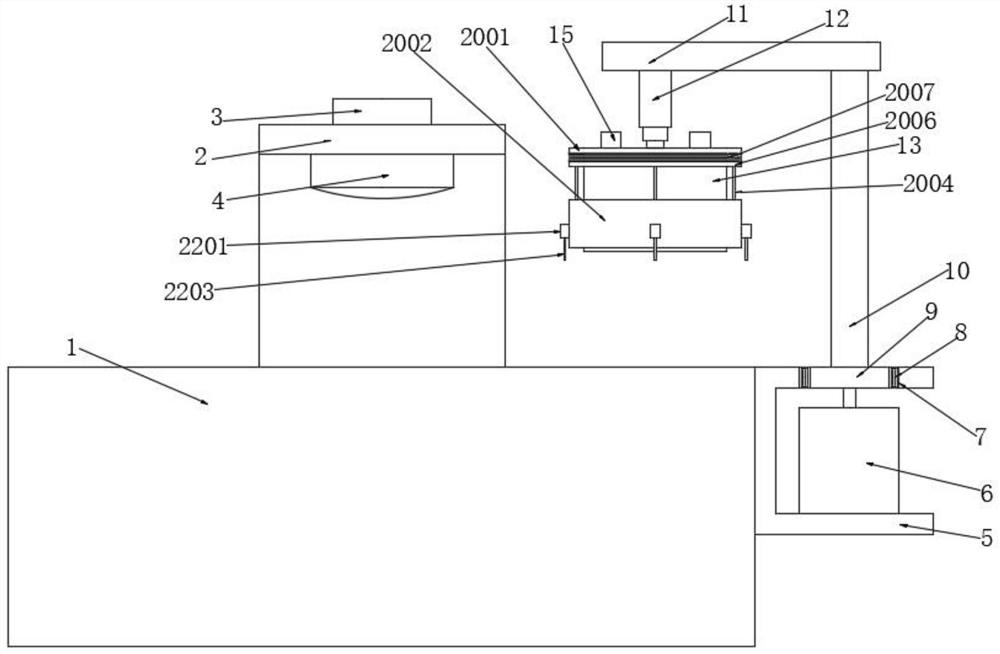

The invention discloses a super-fast operating mechanism for a high-voltage switch, which comprises a permanent magnetic position-keeping auxiliary drive device (3) and a buffer and energy storage device (4), wherein, one end of a movable core push rod (36) of the permanent magnetic position-keeping auxiliary drive device (3) is connected with a tube-type push rod of the buffer and energy storage device (4); the super-fast operating mechanism is characterized in that the other end of the movable core push rod (36) of the permanent magnetic position-keeping auxiliary drive device (3) is connected with an electromagnetic eddy current repulsion main drive device (2) which is used for providing initial operating force for operating the switch; the permanent magnetic position-keeping auxiliary drive device is used for providing stable and reliable power when a switch contact moves to the position of 5mm and keeping the switch contact in position when the movement of the switch is over; the buffer and energy storage device is used for reducing the impact of the operating mechanism to the shell of the mechanism and the switch contact during the operating process and storing the energy in the form of spring energy for next switching operation .

Owner:SOUTHEAST UNIV

Camera remote control method, device thereof and system thereof

InactiveCN102665044AQuick controlPrecise handlingTelevision system detailsColor television detailsVideo monitoringCamera lens

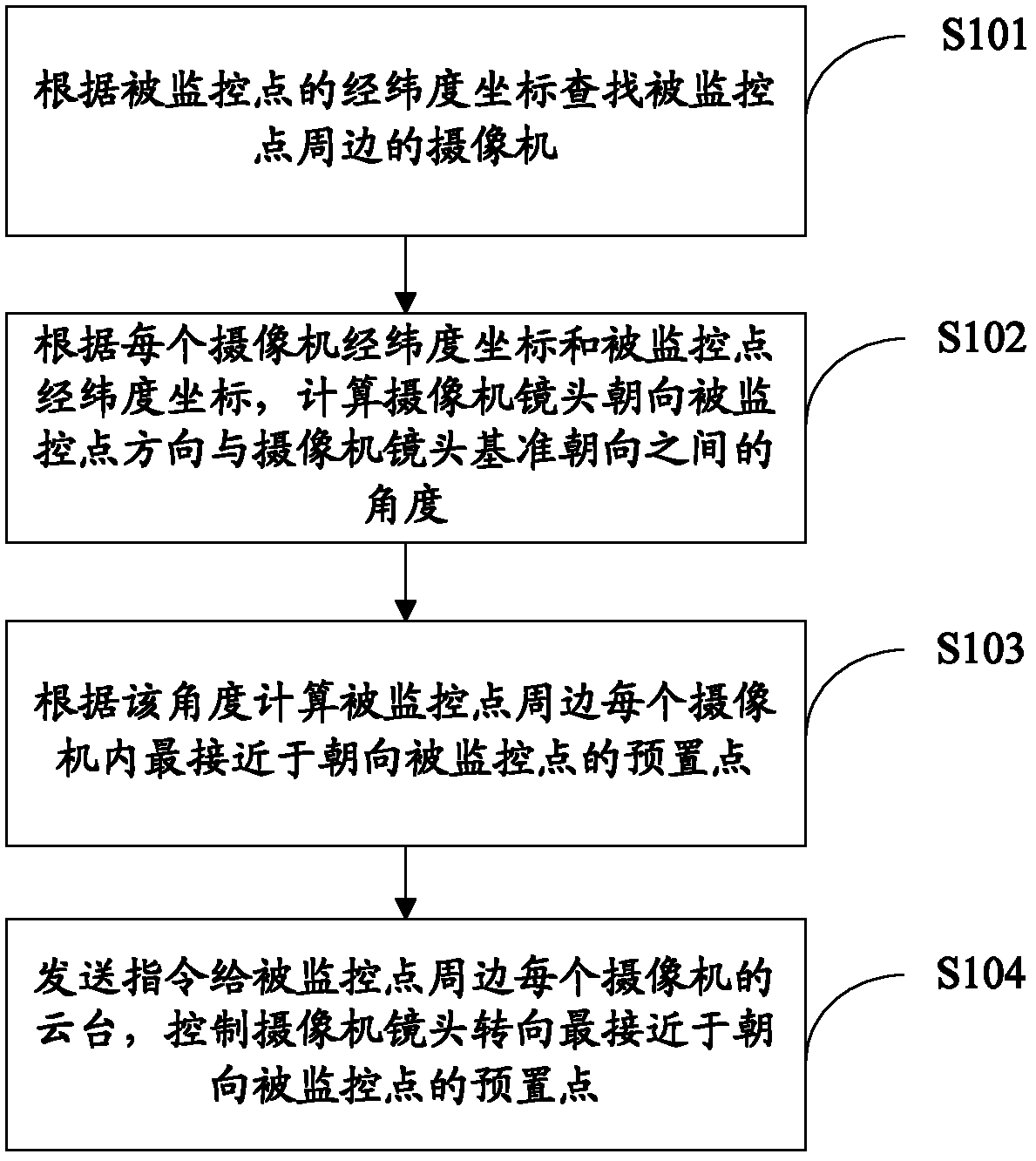

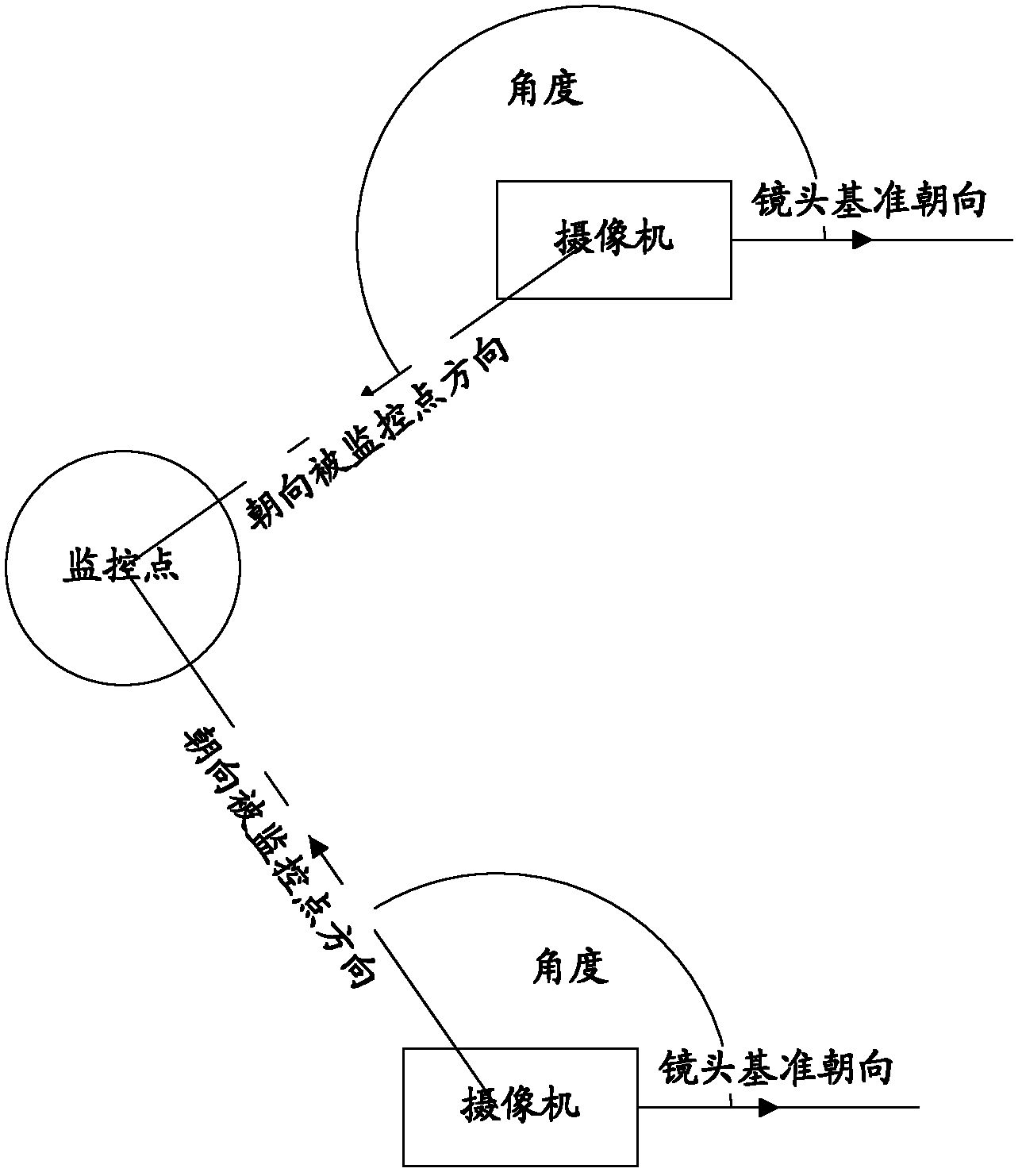

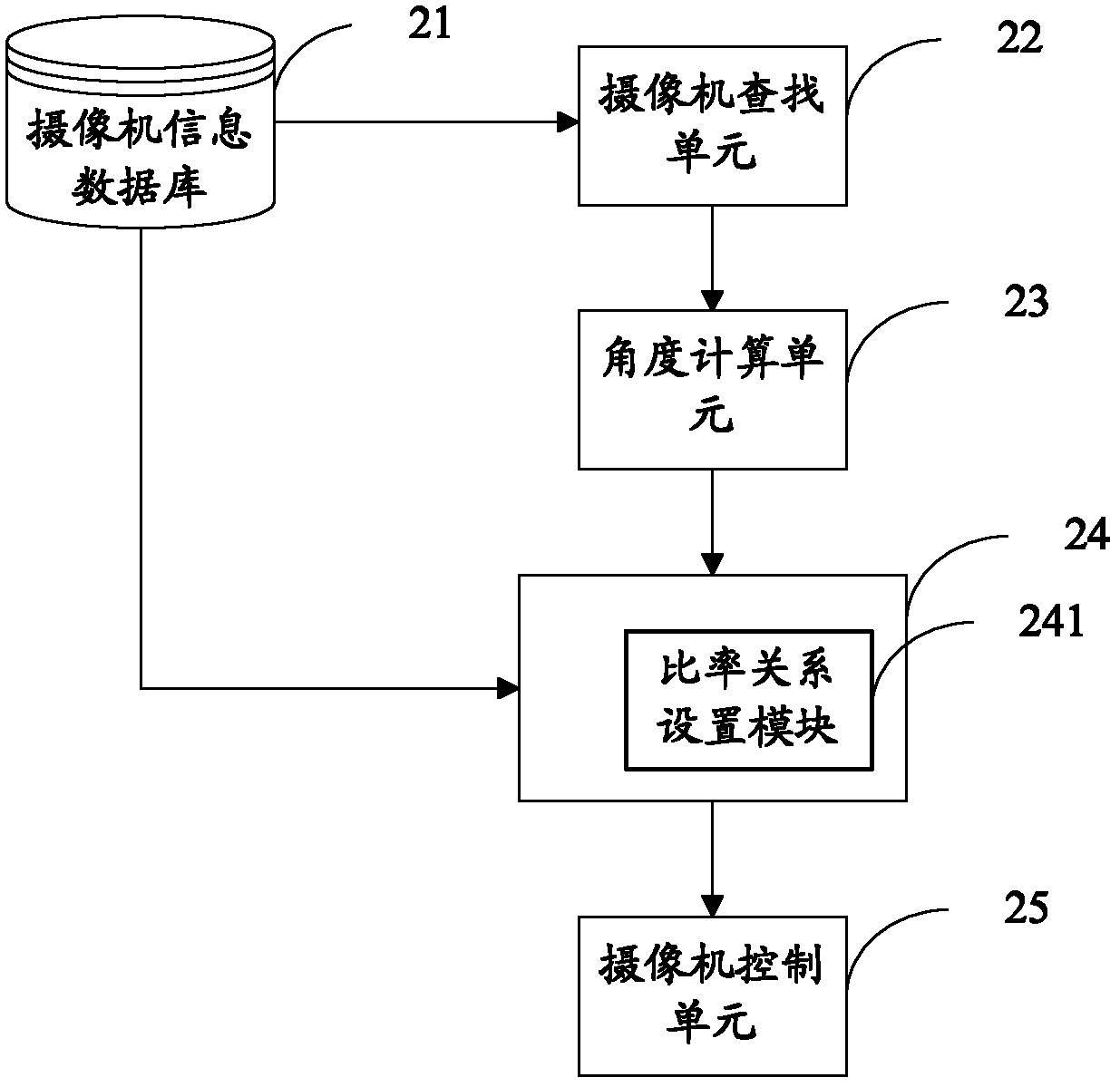

The invention is applicable to the field of video monitoring, and provides a camera remote control method, a device thereof and a system thereof. The method comprises the following steps of: searching cameras around a monitored point according to latitude and longitude coordinates of the monitored point; according to latitude and longitude coordinates of each camera around the monitored point and the latitude and longitude coordinates of the monitored point, calculating an angle between a direction of lens orientation monitored point of each camera around the monitored point and a camera lens reference orientation; according to the angle, calculating a preset point closest to the orientation monitored point in each camera around the monitored point; sending an instruction carrying the information of the preset point closest to the orientation monitored point to a tripod head of each camera around the monitored point, and controlling a lens of the camera to turn to the preset point closest to the orientation monitored point. According to the method, the device and the system, carrying out simultaneous fast, accurate, intuitive control on a plurality of cameras is realized, and control speed of monitoring personnel to the plurality of cameras is greatly raised.

Owner:杭州天视智能系统有限公司 +1

Method for achieving mass operation under terminal and touch screen

InactiveCN104731491AImprove the speed of handlingExperience natureInput/output processes for data processingTouchscreenClosed pattern

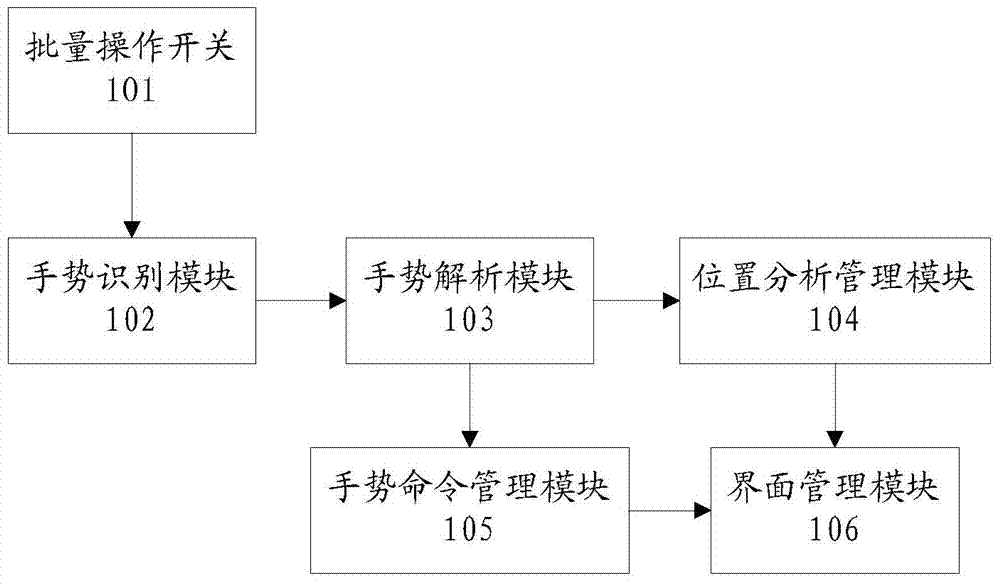

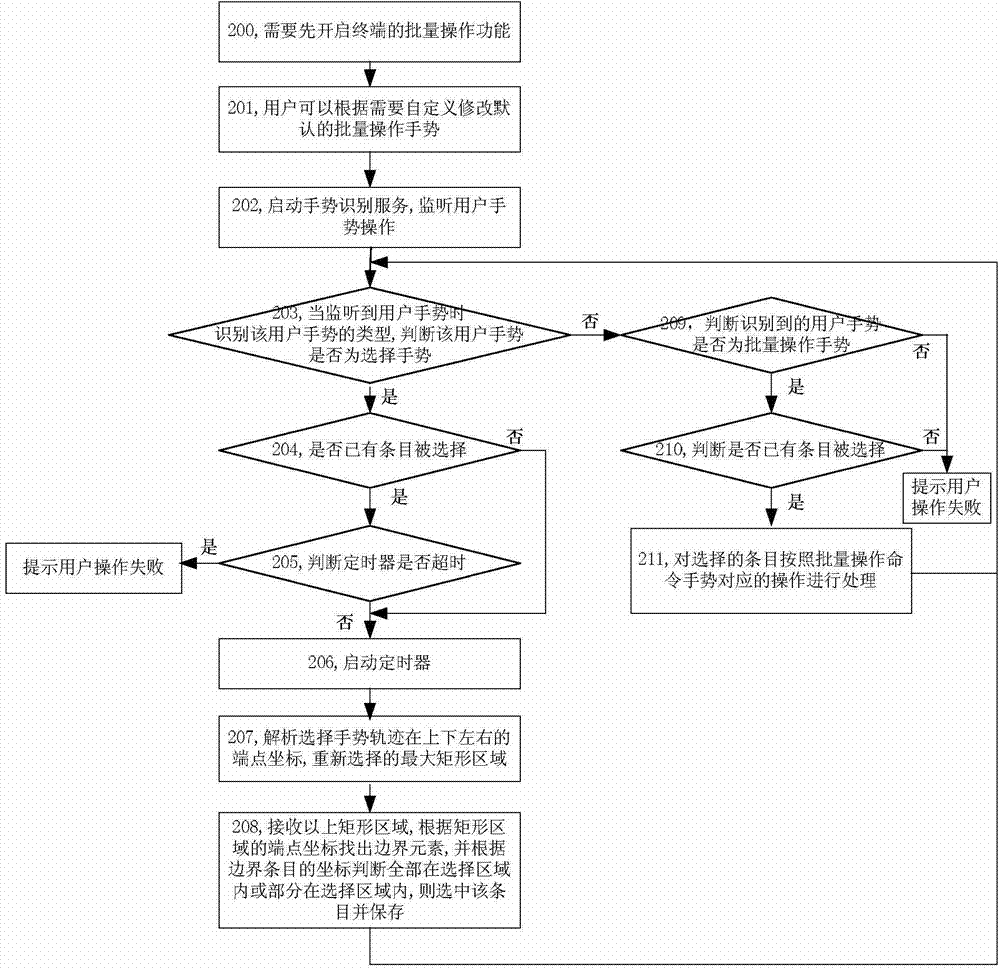

A terminal and a method for realizing a bulk operation under a touchscreen, which relate to the field of terminals with touchscreens. The method disclosed in the present invention comprises: after a terminal enables a bulk operation function according to a user operation, monitoring and recognizing a user gesture; when it is recognized that the user gesture indicates a closed pattern, determining the type of the gesture as a selected gesture, converting a closed range indicated by the selected gesture into a touchscreen selection range, and determining all entries displayed in the touchscreen selection range as bulk operation objects; and when it is recognized that the user gesture is a set bulk operation gesture, conducting operation processing corresponding to the bulk operation gesture on the determined bulk operation objects. Also disclosed is a terminal. The technical solution of the present application allows a user to quickly conduct bulk operations such as selection and reproduction, and deletion on any multi-entry (multi-object) interface, thereby making the user experience more natural and more convenient while increasing the manipulation speed of the user.

Owner:ZTE CORP

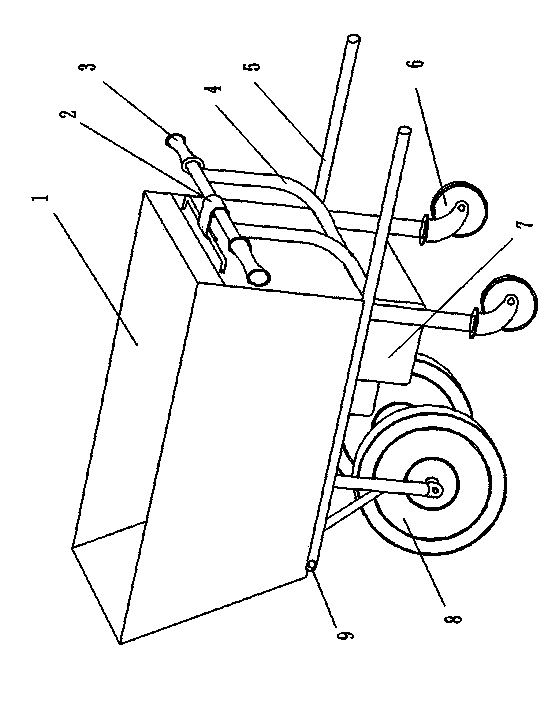

Electric power-assisting cart

The invention relates to an electric power-assisting cart which comprises a vehicle hopper, a frame and wheels, wherein a cart body is formed by the vehicle hopper, the frame and the wheels; the wheels comprise front wheels and rear wheels; the vehicle hopper is arranged on the frame; a driving device is arranged at the bottom of the frame; the driving device is connected with the front wheels; one end of the frame is fixedly connected with handle struts perpendicular to the frame; the handle struts are fixedly connected with a control handle which is horizontally arranged; the control handle is connected with the driving device and is controlled by the driving device; one end of the vehicle hopper is connected with the middle part of the control handle by a hook; the bottom of the other end of the vehicle hopper is hinged to the frame by a connecting piece. The cart can enter a building elevator and a door along a barrier-free path, is convenient to operate, is stable to operate, is flexible to turn and can make a turn or turn around in a corridor; compared with conventional manual carrying, the bulk electric power-assisting cart reduces labor intensity and improves carrying speed and efficiency; due to adoption of non-fuel power, the electric power-assisting cart has zero emission and low noise, is civilized to construct and is green and environmental-friendly.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

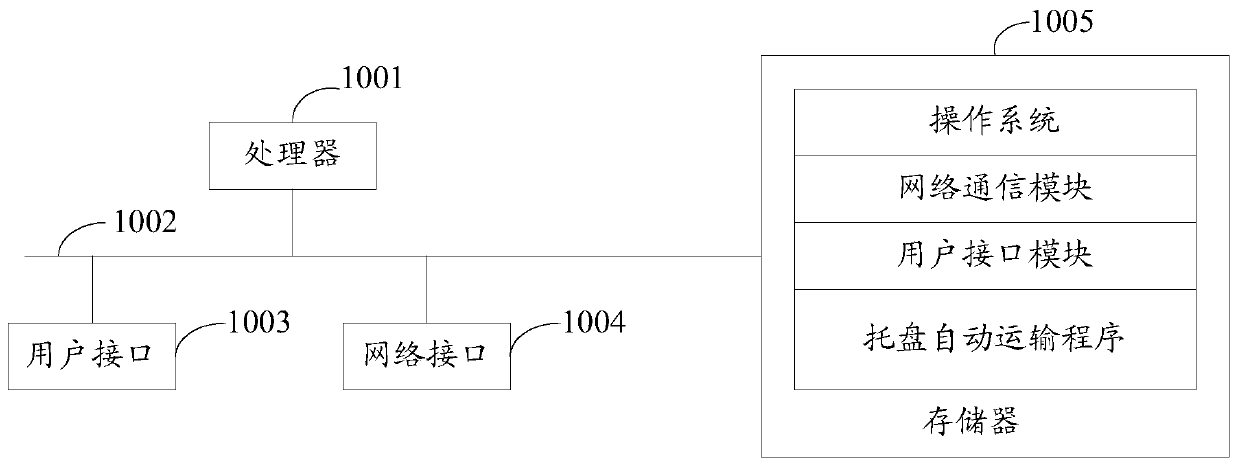

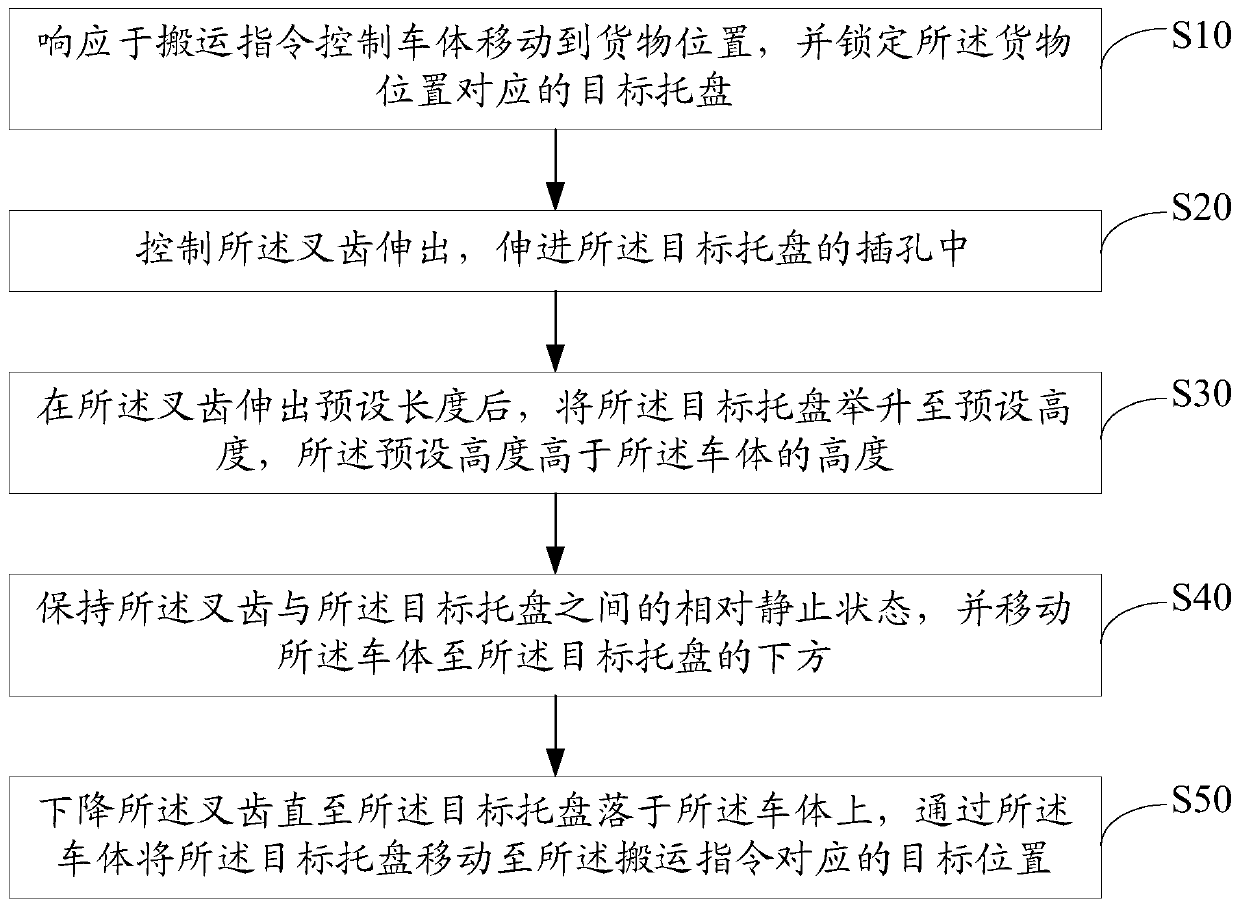

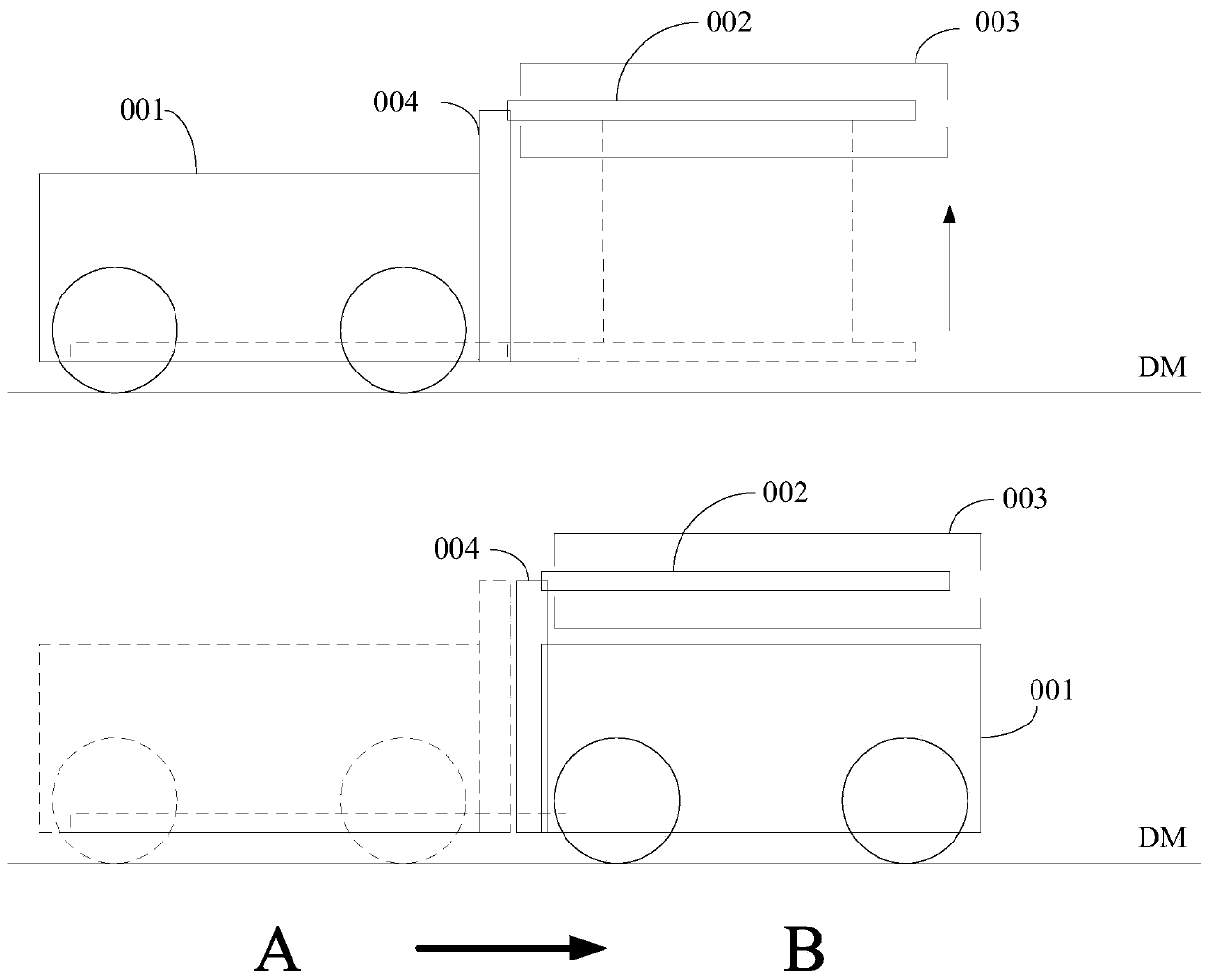

Automatic tray transportation method, system and facility

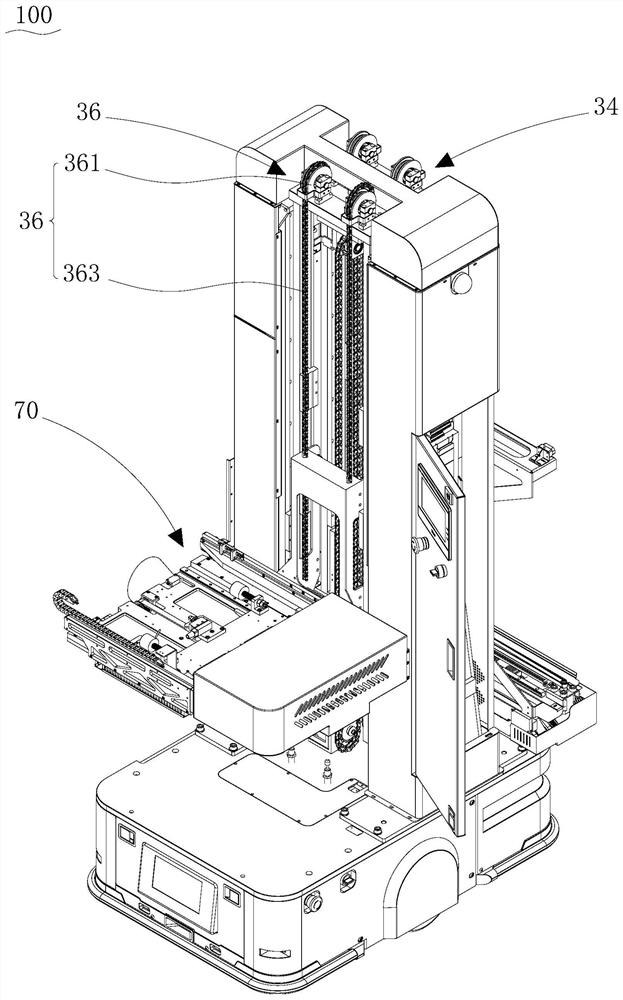

PendingCN110642187ARealize automation and unmannedReduce use costLifting devicesPosition/course control in two dimensionsStorage garageForklift truck

The invention discloses an automatic tray transportation method, system and facility. A controller is used for responding to a carrying instruction to control a vehicle body to move to the goods position, and a target tray corresponding to the goods position is locked; fork teeth stretch out and stretch into inserting holes of the target tray; after the fork teeth completely stretch in, the targettray is elevated to the preset height, and the preset height is larger than the height of the vehicle body; the fork teeth and the target tray are kept in a static state, and the vehicle body is moved to the position under the target tray; the fork teeth are lowered till the target tray falls onto the vehicle body, the target tray is moved to the target position corresponding to the carrying instruction, assistance through manual work, a forklift or other corresponding auxiliary facilities is not needed, unmanned and automatic tray carrying can be achieved, the usage cost is reduced, the sizeis reduced, more lightweight is achieved, a spacious transportation channel is not needed, and the warehouse utilization rate is increased; and cluster-type collaborative operation can be achieved, the carrying speed and efficiency are improved, the tray type is not limited, and the universal rate can be increased.

Owner:HANGZHOU EIOROBOT TECH CO LTD

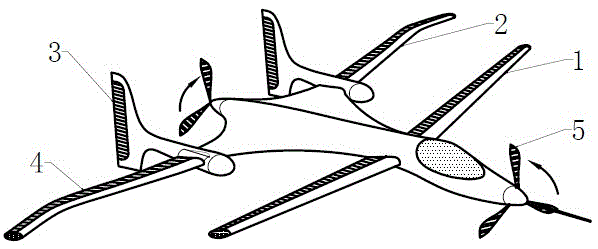

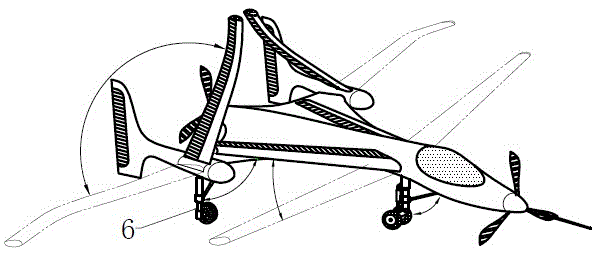

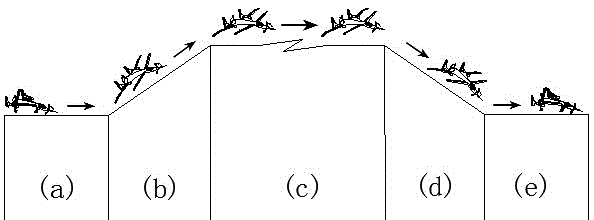

Deformable airplane with front-rear double propeller and front-rear double wing

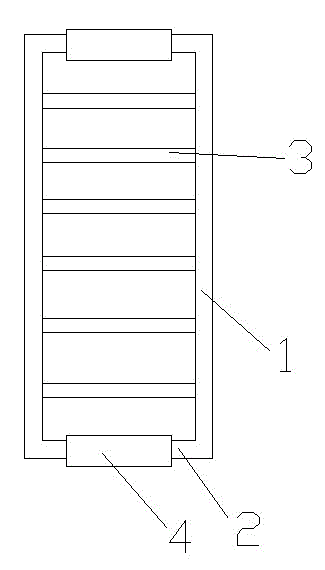

InactiveCN105539807AAvoid wing root stress concentrationAvoid rolling momentLayered productsFuselage bulkheadsJet aeroplaneLow speed

The invention discloses a deformable airplane with a front-rear double propeller and a front-rear double wing. A front wing (1) and a rear wing (1) form the front-rear double wing. The structure is compact, stiffness and strength are good, enough lift force is provided by a large wing face, two rudders (3) and four horizontal rudders (4) provide good controllability, and the airplane is suitable for low-speed large-load cruising. The front-back double wing can deform, the front wing (1) can rotate, the rear wing (2) can be folded, the wingspan of the whole plane is adjustable to adapt to cruising at different speeds, and running on the ground, traction, transport and storage are also facilitated. The head and the tail of the airplane are each provided with a propeller (5), and the propellers are combined into a pair of reversing propellers to generate push force and pull force in the same direction. A power shaft is in the center and coincides with the propellers to offset torque, the weight of the whole airplane is moderate, the rolling inertia is small, rolling maneuverability is facilitated, and no wing face airflow interference exists. An airplane body upper shell and four wing upper shell structures are obtained through the photovoltaic assembly skin and honeycomb composite material lamination technology, the two wings and wing bodies are fused to provide large lighting area, the photovoltaic effect is facilitated, a secondary battery is charged in time, power is supplied to a system, long flight endurance is facilitated, and the airplane is environmentally friendly and safe.

Owner:杨汉波

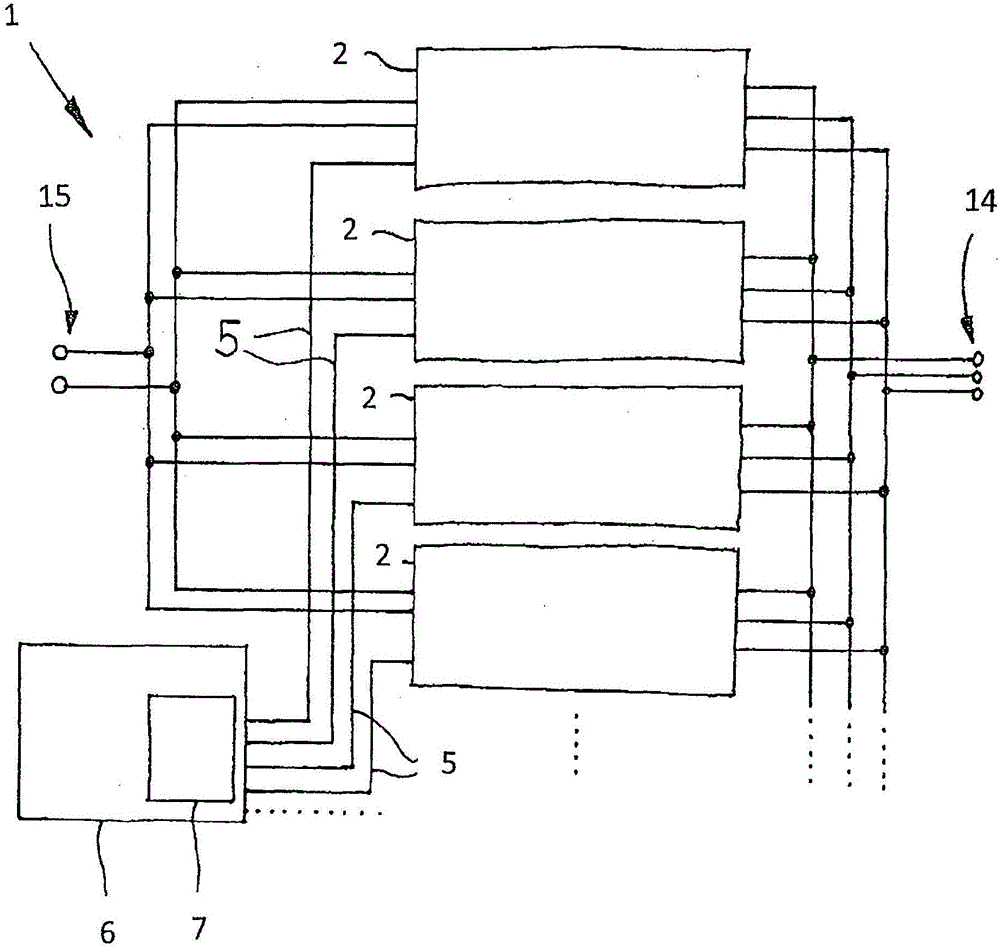

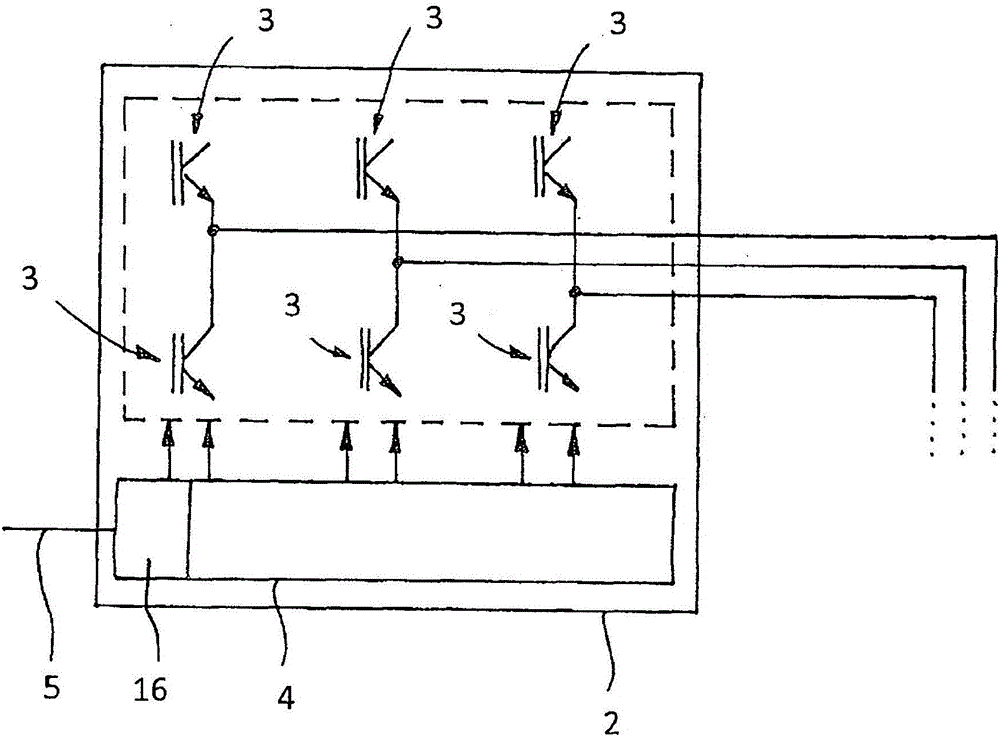

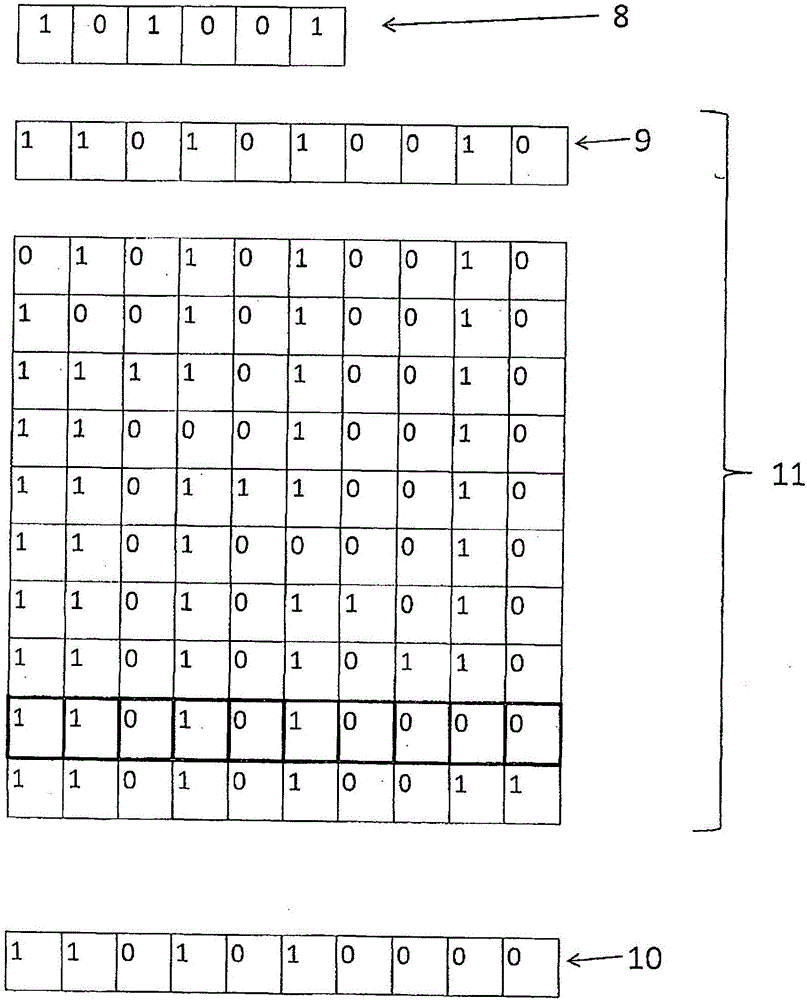

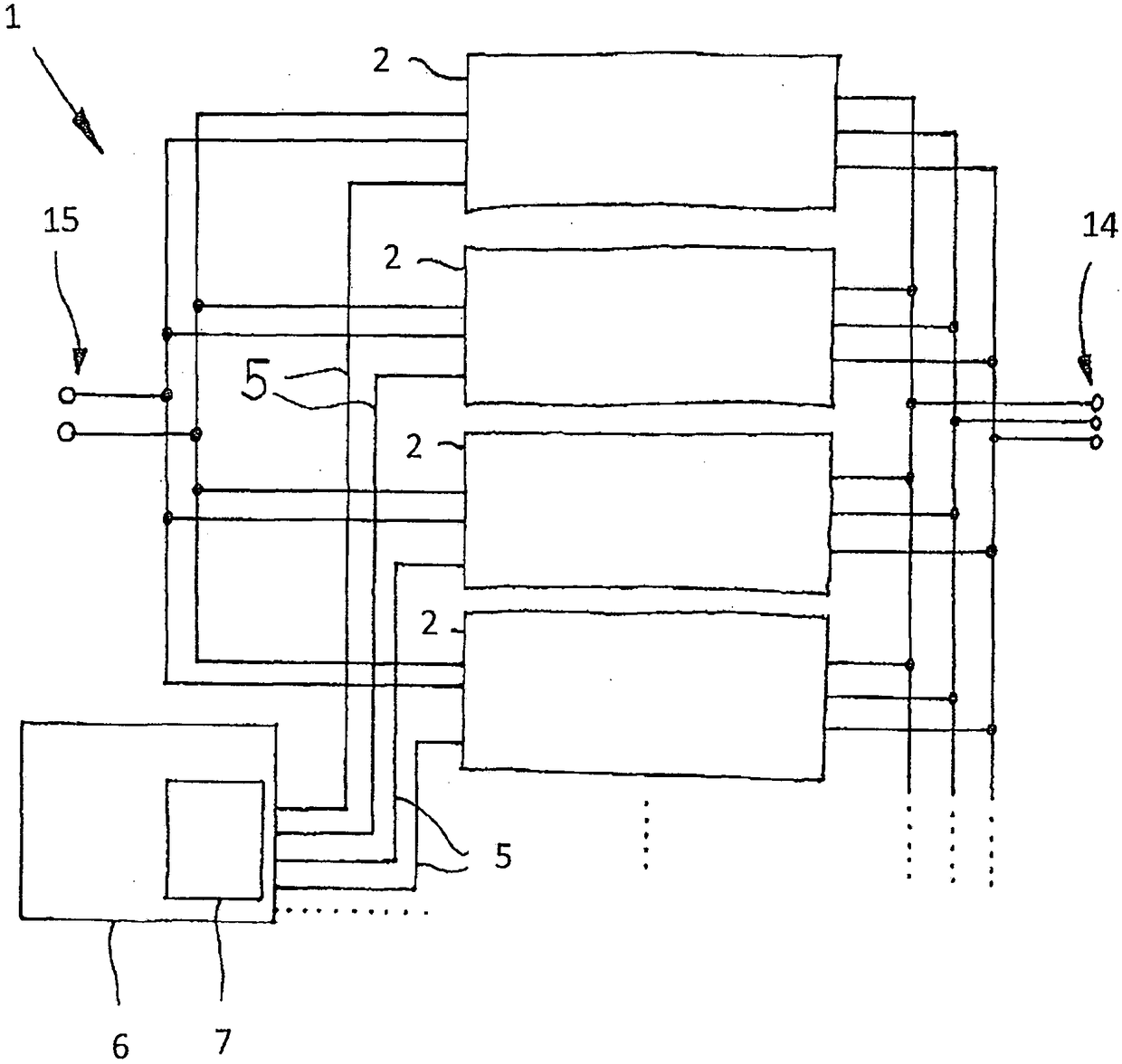

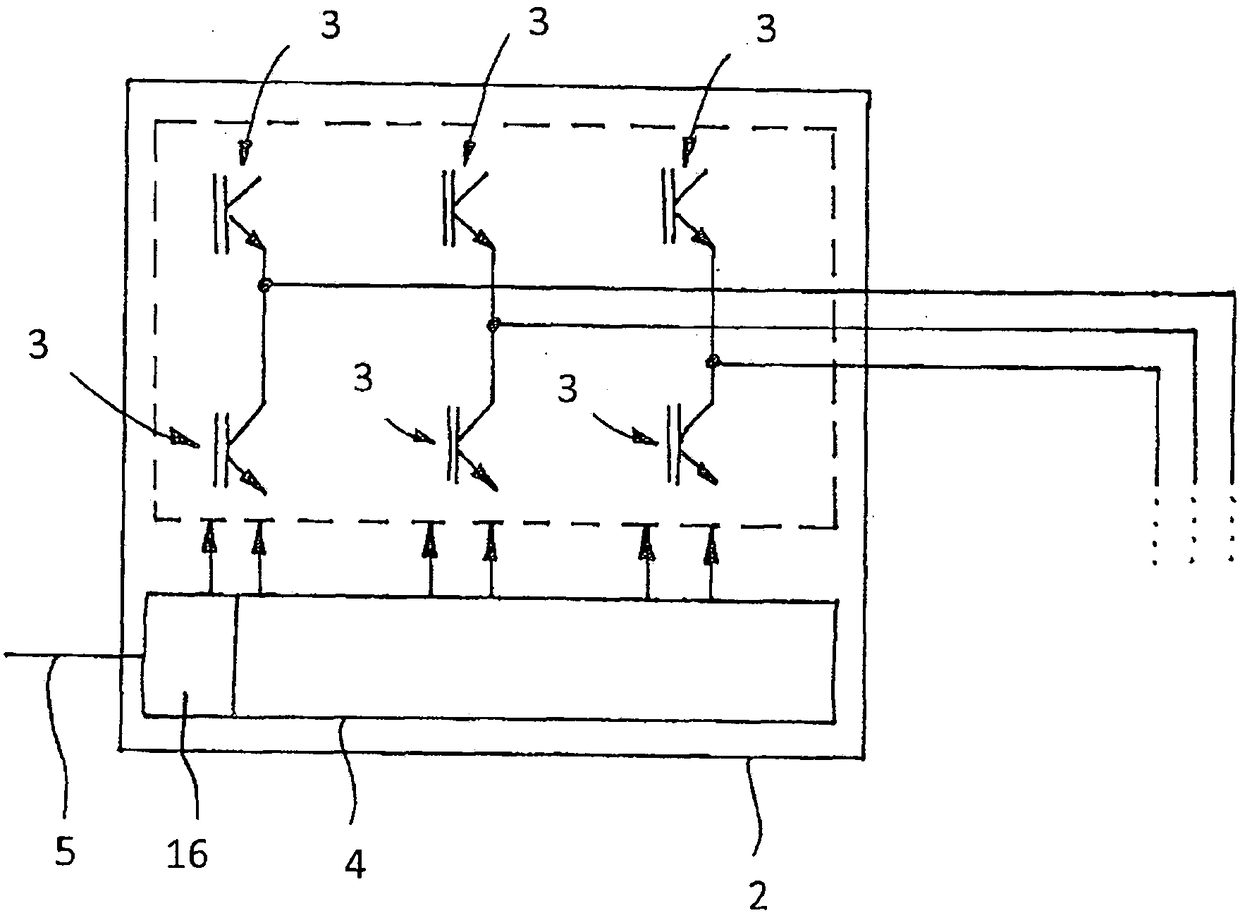

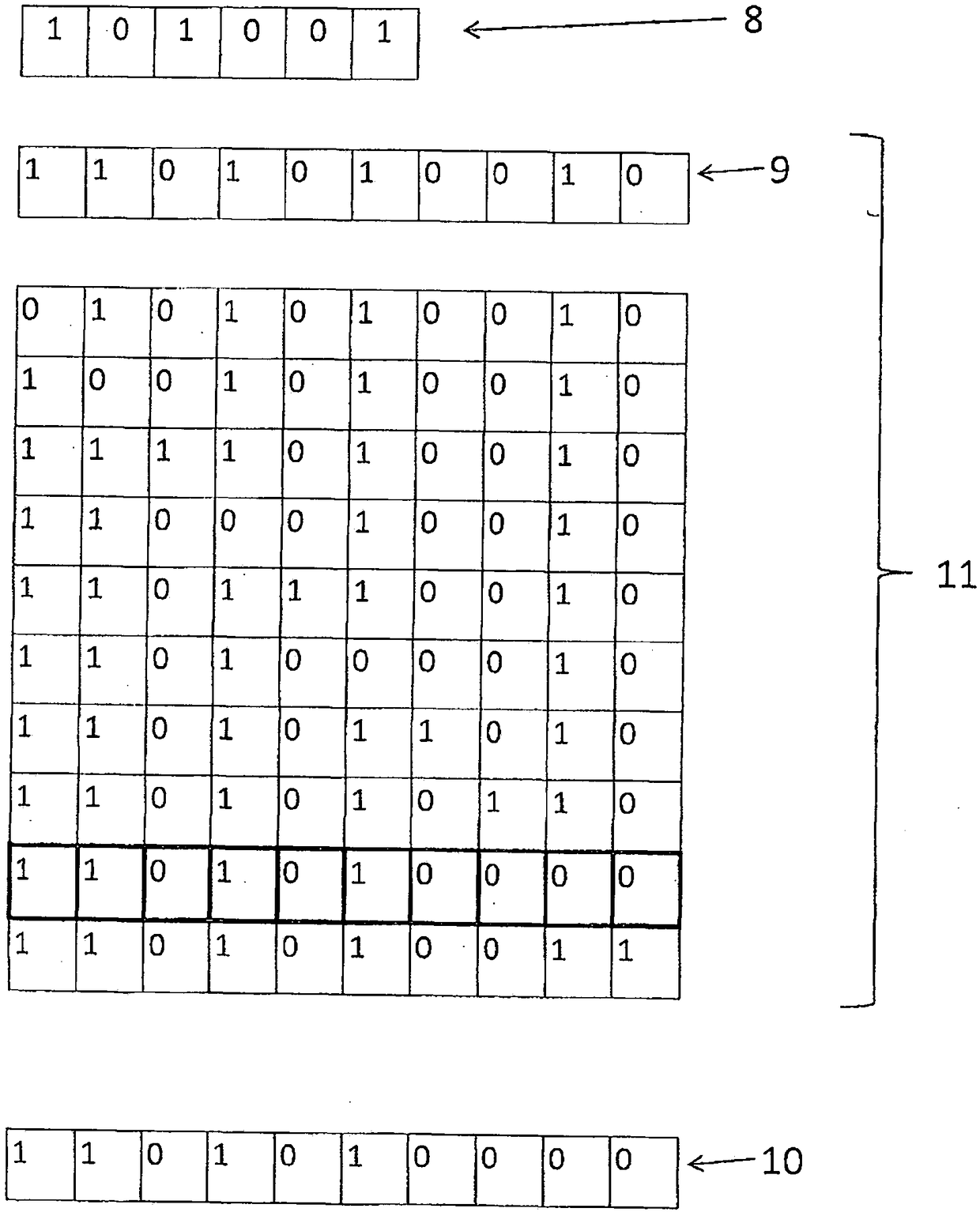

Method for actuating inverters connected in parallel

ActiveCN105850023AReduced wiring costsEnsure reliabilityAc-dc conversionElectric variable regulationFunctional impairmentData transmission

The invention relates to a method for actuating inverter stages (2) connected in parallel, wherein each inverter stage (2) comprises a plurality of switching elements (3), each having two switching states. In accordance with the invention, the actuation of the inverter stages (2) takes place via a central regulation unit (6), which is connected to each inverter stage (2) via a serial data transmission path (5). For the transmission of the selected switching states from the central regulation unit (6) to the corresponding inverter stage (2), measures are proposed firstly for ensuring safe operation of the inverter stages (2) via a multiplicity of switching operations and reliably avoiding functional impairments of the switching elements (3) owing to faulty actuation, but secondly for performing the actuation of the switching elements (3) of the inverter stages (2) also sufficiently quickly in order not to impair the quality of the output current formed by the inverter stage (2).

Owner:SCHNEIDER ELECTRIC POWER DRIVES GMBH

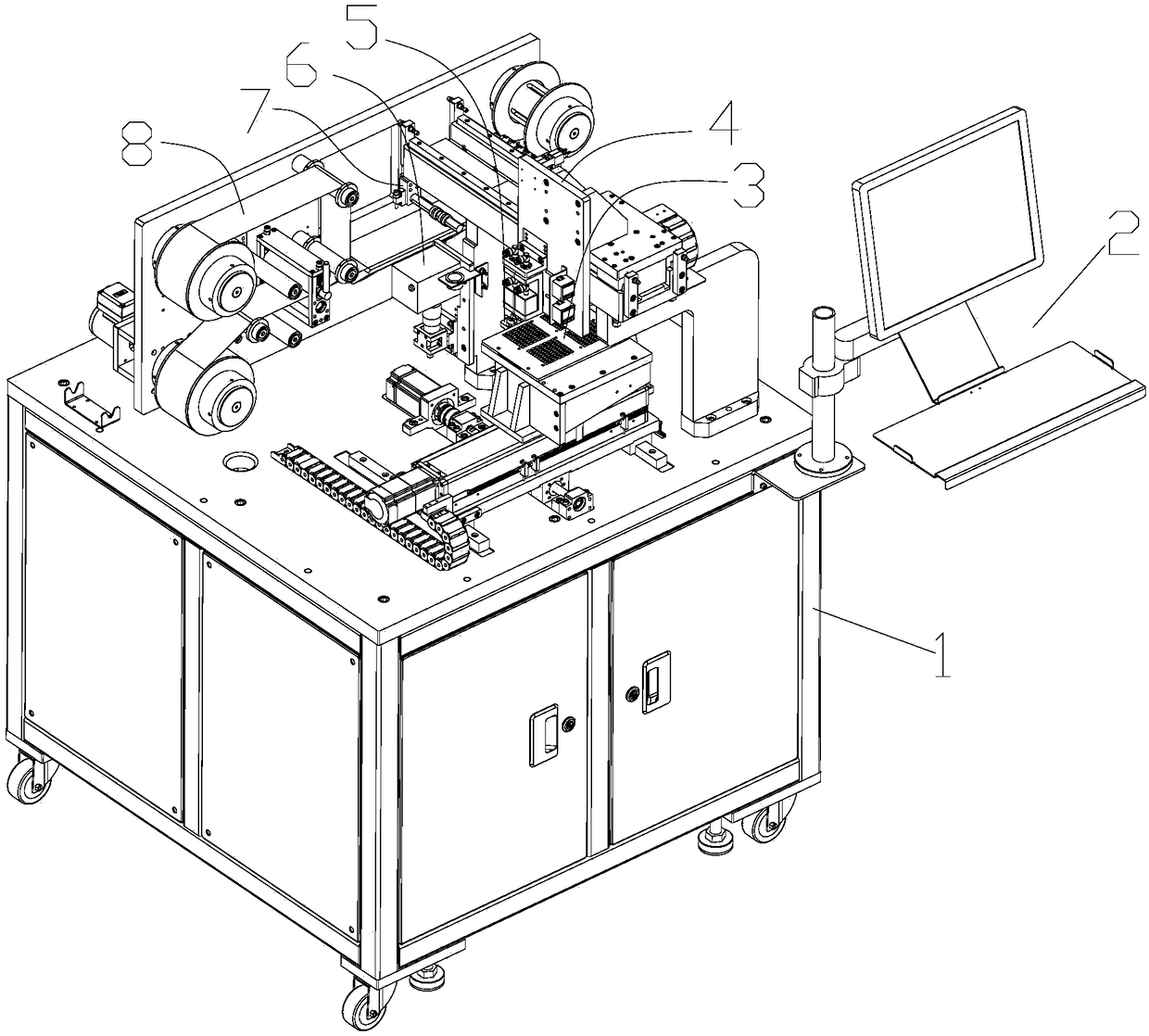

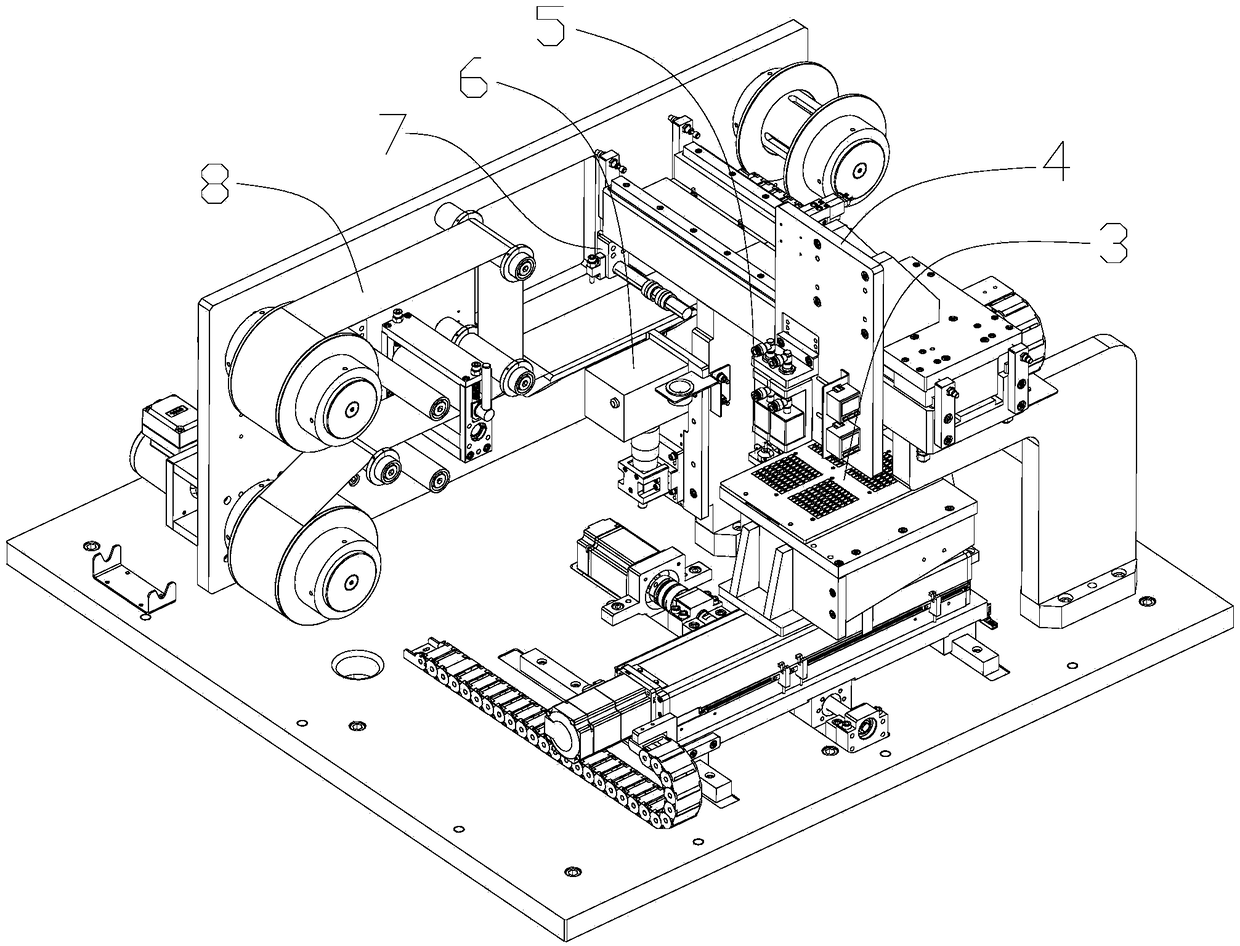

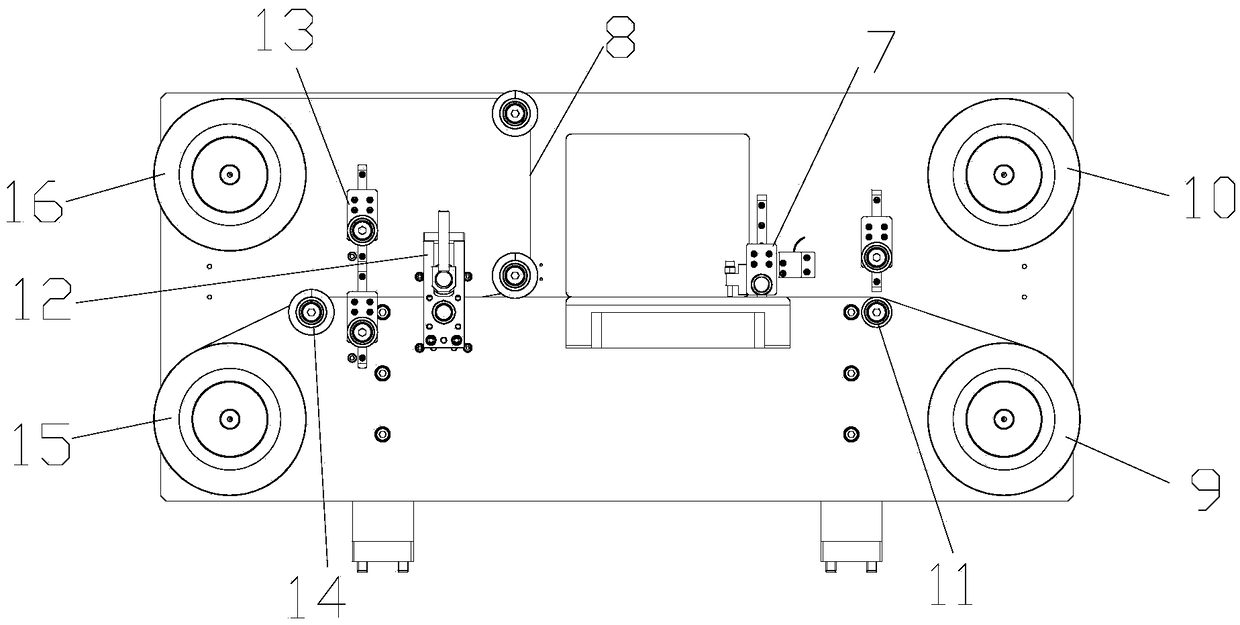

Steel sheet rolling and packaging machine

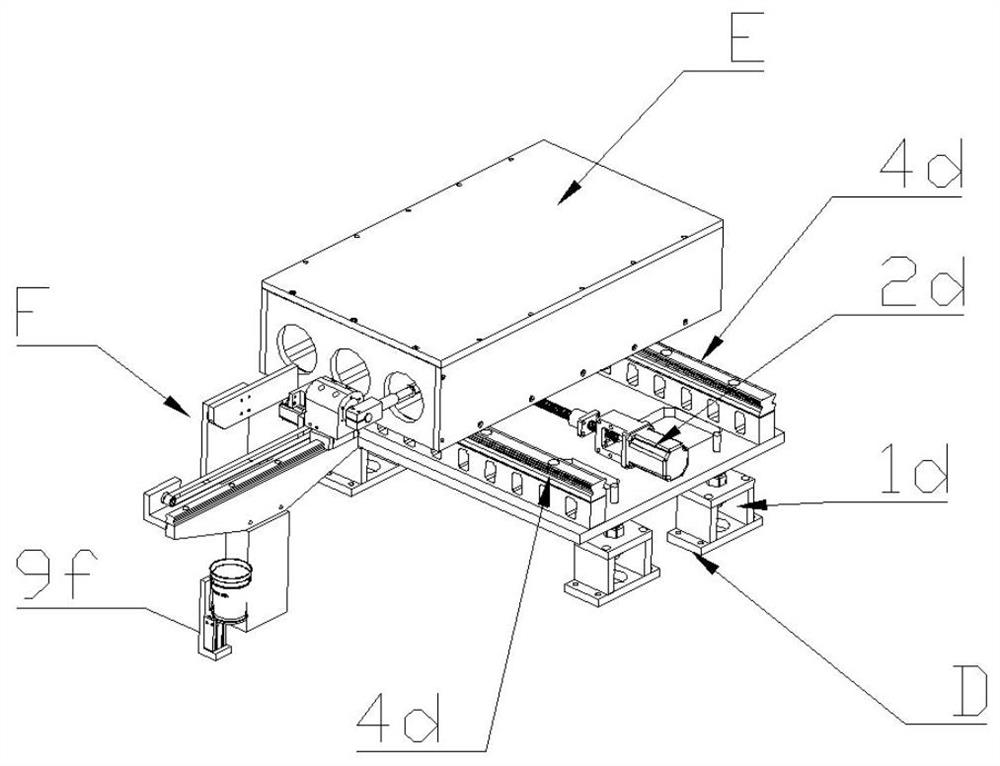

PendingCN108820317AImprove the speed of handlingImprove handling efficiencyPackaging automatic controlEngineeringLinear motor

The invention discloses a steel sheet rolling and packaging machine. The steel sheet rolling and packaging machine comprises a frame and a manipulation device. A feeding mechanism, a carrying mechanism and a packaging mechanism, which are controlled by the manipulation device comprehensively, are arranged on the frame. A carrying platform of the feeding mechanism can do planar movement. Carrying positions used for holding steel sheets are arranged on the carrying platform. The carrying mechanism comprises a sucker device and a linear motor, and carries the steel sheets to a belt of the packaging mechanism from the carrying positions. The packaging mechanism comprises a first conveying mechanism, a tensioning device, a collecting mechanism and the belt. The belt is conveyed by the first conveying mechanism, tensioned by the tensioning device and rolled by the collecting mechanism. An adhering layer for fixing the steel sheets is arranged on the bearing surface of the belt. The steel sheet rolling and packaging machine has the advantages that carrying speed and efficiency of the steel sheets are improved by the linear motor, the structure is compact, the occupied space is small, andthe degree of automation, integration and intelligence is high; the multiple carrying positions can be provided to shorten feeding time; the steel sheets can be detected, and production quality control and improvement are benefited.

Owner:YUXINDA (SHENZHEN) INTELLIGENT EQUIP CO LTD

A method for operating parallel-connected inverters

ActiveCN105850023BExtended service lifeAvoid faulty circuitsAc-dc conversionElectric variable regulationData transmissionEngineering

The invention relates to a method for operating parallel-connected inverter stages (2), wherein each inverter stage (2) has a plurality of switching elements (3) each having two switching states. According to the invention, the inverter stages (2) are actuated via a central regulation unit (6) which communicates with each inverter stage (2) via a serial data transmission path (5) )connect. In order to transmit the selected switching states from the central control unit (6) to the corresponding inverter stage (2), measures are provided to ensure the reliability of the inverter stage (2) on the one hand via a plurality of switching processes operation and reliably avoids functional influences on the switching elements (3) due to incorrect actuation, while on the other hand the actuation of the switching elements (3) of the inverter stage (2) remains This is done quickly enough so as not to affect the quality of the output current formed by said inverter stage (2).

Owner:SCHNEIDER ELECTRIC POWER DRIVES GMBH

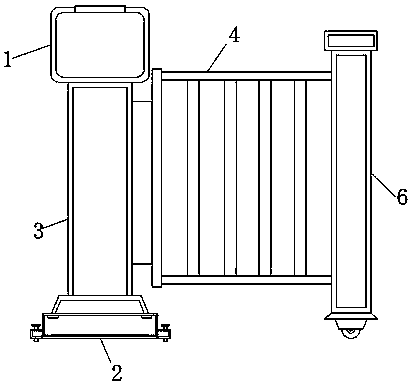

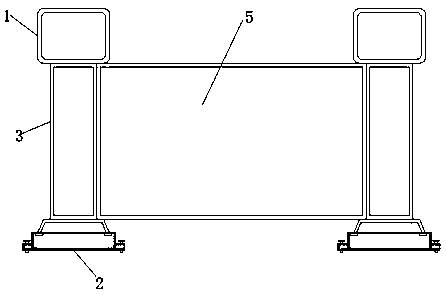

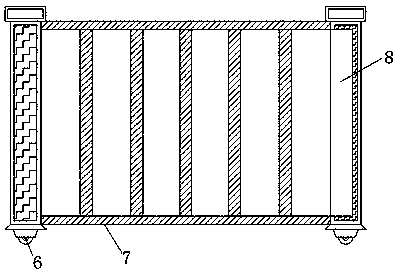

Intelligent gateway for bus station

The invention discloses an intelligent gateway for a bus station. The intelligent gateway for the bus station comprises main uprights, base devices, first rubber cushions and a barrier gate handle; the base devices are arranged at the bottom ends of the main uprights; pulleys are fixed at the parts, on the internal sides of the base devices, of the bottom ends of the main uprights; the first rubber cushions and second rubber cushions correspondingly coat the main uprights; and clamping grooves are fixed on the internal sides of the first rubber cushions. According to the intelligent gateway for the bus station, as the base devices and the pulleys are arranged, the device can be stably fixed on the base devices under the mutual action of the first cushions, first soft plates and springs inthe base devices; and therefore, the device cannot easily shake even though suffering a collision; and meanwhile, under the mutual effect of bases, fixing doors, fixing blocks and screws in the base devices, the device is convenient to move so that the working intensity of mounting personnel is reduced, time and labor are saved, the mounting and conveying speed of the device is increased, and theworking efficiency of the device cannot be affected.

Owner:江苏艾华美陈科技股份有限公司

Ultra rapid operation mechanism for high voltage switch

InactiveCN101510475BLarge initial accelerationSmooth motionSwitch power arrangementsAir-break switch detailsEngineeringEddy current

The invention discloses a super-fast operating mechanism for a high-voltage switch, which comprises a permanent magnetic position-keeping auxiliary drive device (3) and a buffer and energy storage device (4), wherein, one end of a movable core push rod (36) of the permanent magnetic position-keeping auxiliary drive device (3) is connected with a tube-type push rod of the buffer and energy storagedevice (4); the super-fast operating mechanism is characterized in that the other end of the movable core push rod (36) of the permanent magnetic position-keeping auxiliary drive device (3) is connected with an electromagnetic eddy current repulsion main drive device (2) which is used for providing initial operating force for operating the switch; the permanent magnetic position-keeping auxiliarydrive device is used for providing stable and reliable power when a switch contact moves to the position of 5mm and keeping the switch contact in position when the movement of the switch is over; thebuffer and energy storage device is used for reducing the impact of the operating mechanism to the shell of the mechanism and the switch contact during the operating process and storing the energy inthe form of spring energy for next switching operation .

Owner:SOUTHEAST UNIV

Warehouse carrying device with sorting function

PendingCN114772122AAchieve the effect of automatic sortingImprove the speed of handlingStorage devicesData informationElectric machinery

The warehouse carrying device with the sorting function comprises a conveying machine body, a controller and a scanner are installed on the conveying machine body, a fixing plate is fixedly installed at the conveying tail end of the conveying machine body, a driving motor and a rotating disc are installed on the fixing plate, and the rotating disc is connected with the driving motor; a rotating rod is installed on the rotating disc, a hydraulic lifter is installed on the rotating rod, a clamping body is fixedly installed at the telescopic end of the hydraulic lifter, after goods are scanned through the scanner, data information is transmitted into the controller, and after the goods reach the carrying position, the controller controls the hydraulic lifter to drive the clamping body to move downwards, and the clamping body moves downwards; according to the automatic sorting device, the suction cup is driven to make contact with goods, at the moment, the air pump is started to conduct air suction on the suction cup, then the goods are grabbed, meanwhile, the controller starts the driving motor to drive the rotating disc to rotate, the clamping bodies are driven to rotate to the position, at the corresponding angle, of the conveying belt, and therefore the automatic sorting effect is achieved.

Owner:南京骆驼储运集团有限公司

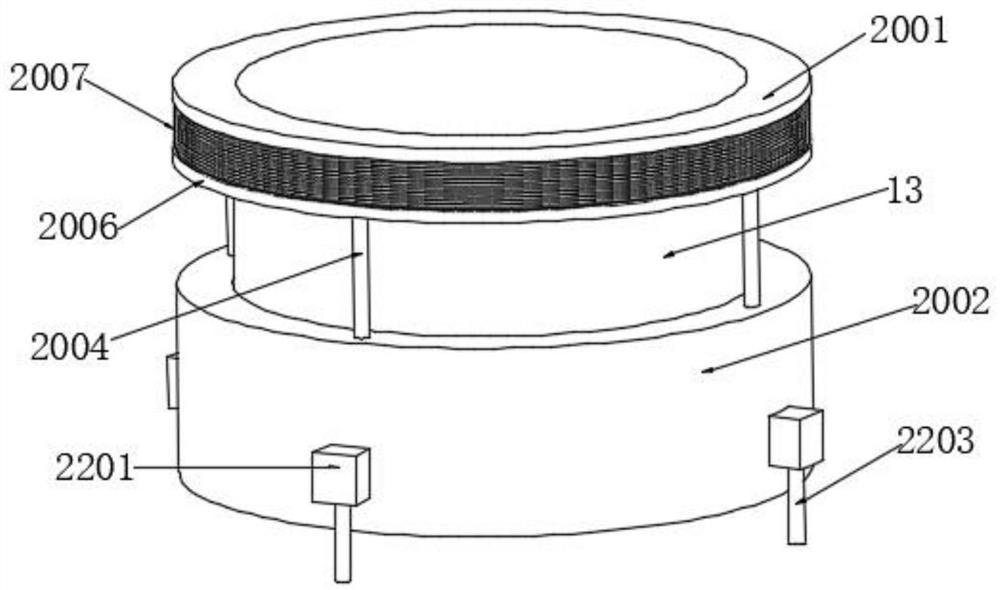

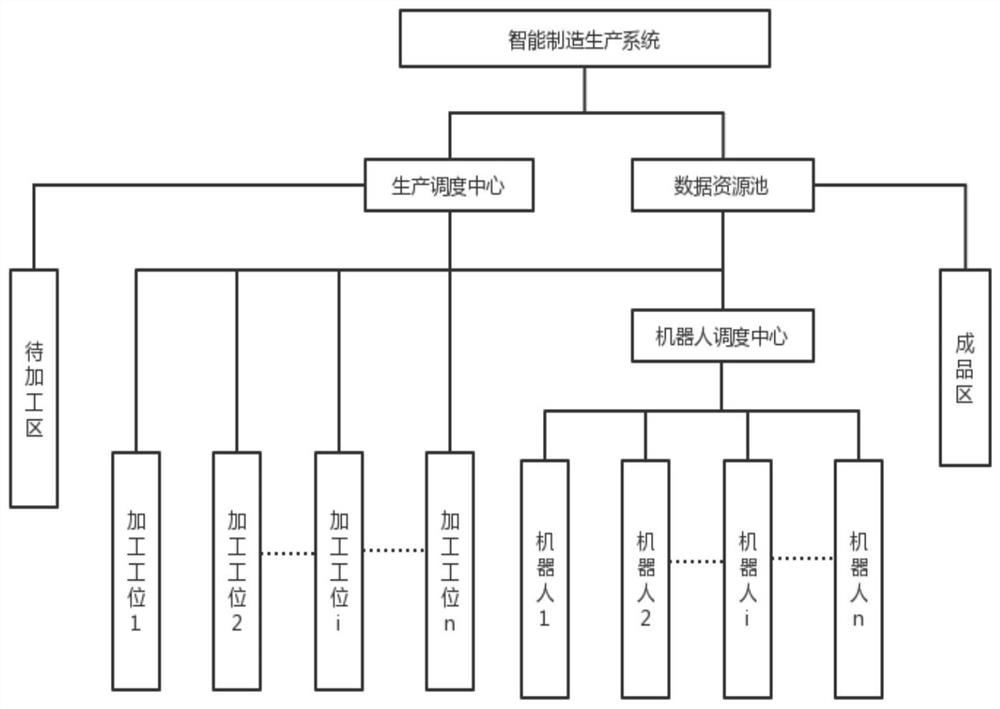

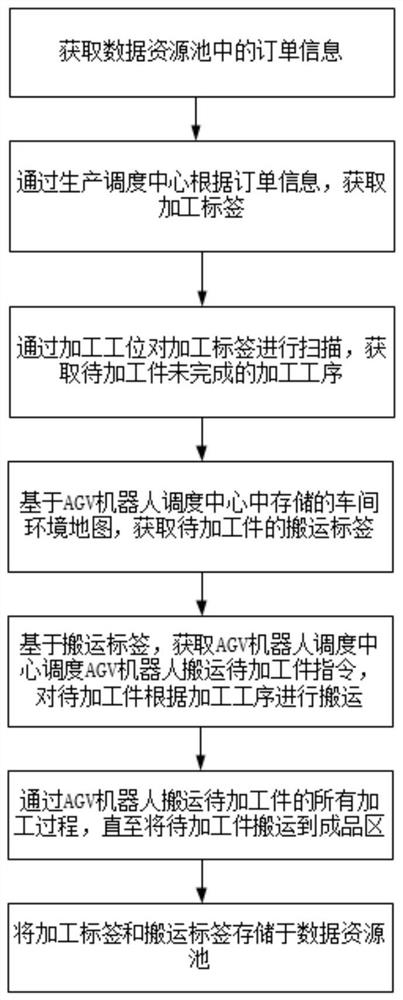

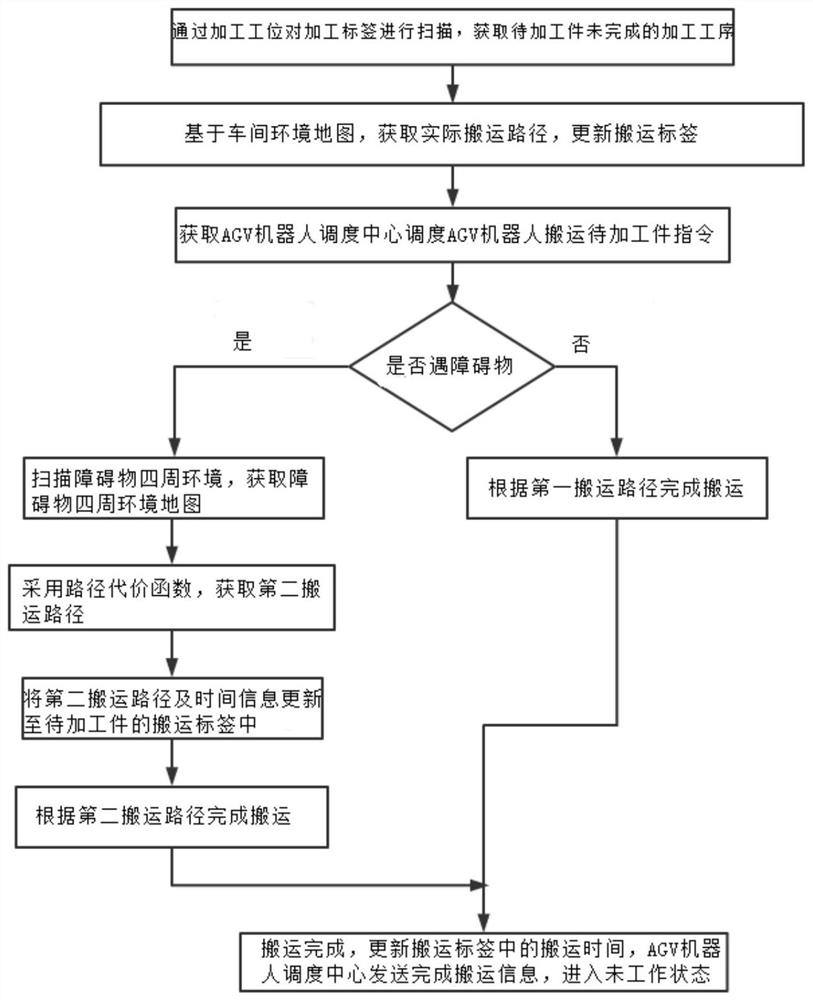

Method for improving processing efficiency of intelligent manufacturing system based on labels

PendingCN114815751AImprove processing efficiencyImprove processing speedProgramme total factory controlResource poolProcess engineering

The invention provides a method for improving the processing efficiency of an intelligent manufacturing system based on labels, the intelligent manufacturing system comprises a data resource pool, a production scheduling center, an AGV robot scheduling center, an AGV robot, a processing station, a to-be-processed area and a finished product area, the labels are configured in the data resource pool, the labels comprise processing labels and carrying labels, and the processing labels are configured in the production scheduling center. The machining labels comprise the machining sequence, the machining procedures, the machining stations and the machining time of all the to-be-machined workpieces and are used for the machining and tracking machining processes of all the procedures of the to-be-machined workpieces at the different machining stations, and the to-be-machined workpieces enter the to-be-machined area after being attached with the machining labels; and the carrying labels are used for the AGV robot to carry out carrying among different positions of the raw material area, the machining area and the finished product area according to the planned path and the self-searching path, and the problems that the whole machining time is long and the production efficiency is reduced due to the fact that the carrying time of each working procedure in the production scheduling process of AGV workpiece carrying in the machining process in existing intelligent manufacturing is long are solved.

Owner:SHENYANG POLYTECHNIC UNIV

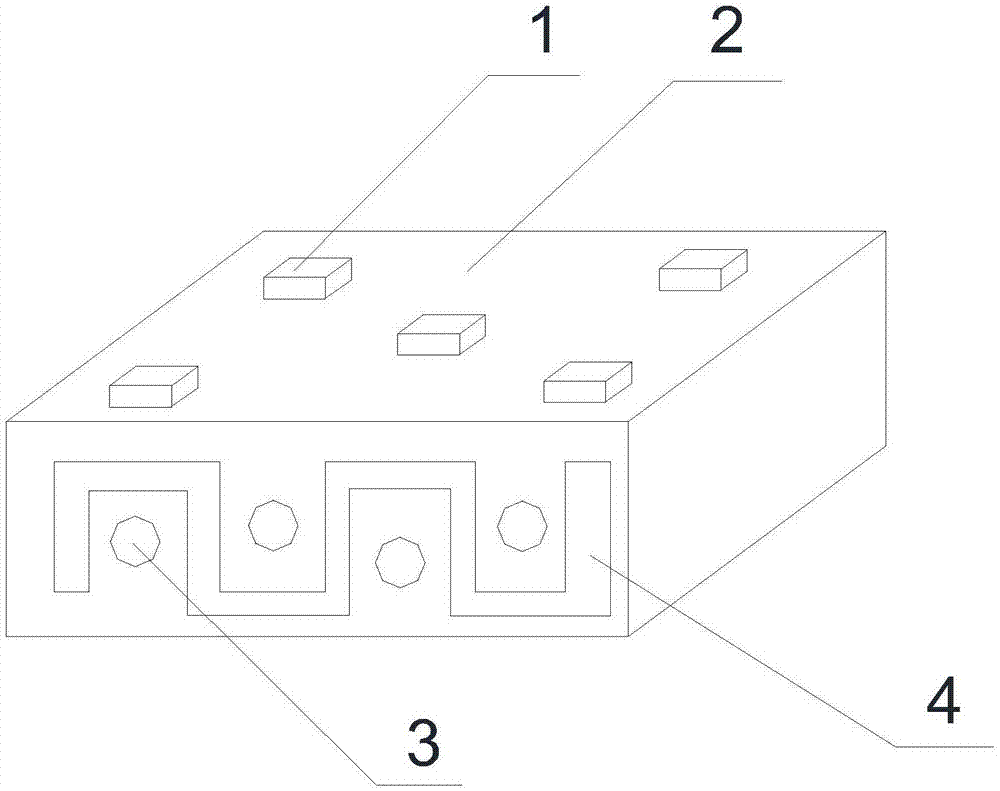

Gangue hollow insulating brick

InactiveCN107447909AAccurate and fast positioningClosely positionedConstruction materialWallsBrickEngineering

The invention relates to a gangue hollow insulating brick. The gangue hollow insulating brick comprises a brick body, wherein a bulged block is arranged on the upper surface of the brick body, a groove which corresponds to the bulged block in position is formed in the lower surface of the brick body, a first through hole and a second through hole are formed in the front and back surfaces of the brick body, and the second through hole is filled with insulating materials. The gangue hollow insulating brick is positioned by adopting the bulged block, when workers build a wall, the connection between bricks is simple, only the bulged block is embedded into the groove, so that two connected bricks are positioned, the positioning is quick and accurate, and the connection between the two bricks is tight, so that a good sound insulation effect is achieved; secondly, the through holes are formed in the brick body, so that the weight of the brick body is reduced, the conveying and carrying speed is increased relatively, and the working efficiency is effectively improved. In addition, the through hole of the brick body of the gangue hollow insulating brick is filled with the insulating materials, so that the insulation of a house is good, and the modern housing requirements of people are met. The gangue hollow insulating brick has the advantages of simple structure, easiness in manufacturing and low manufacturing cost.

Owner:徐州市恒基伟业建材发展有限公司

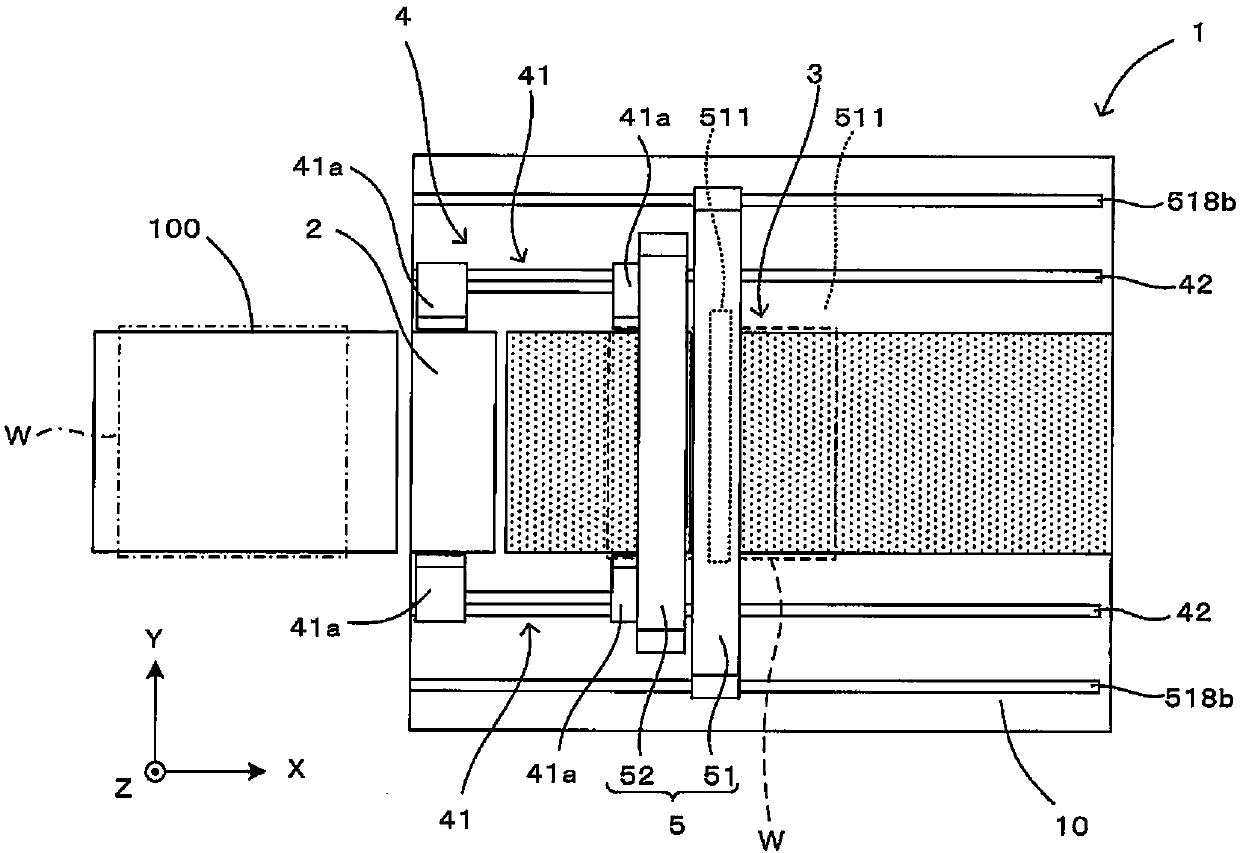

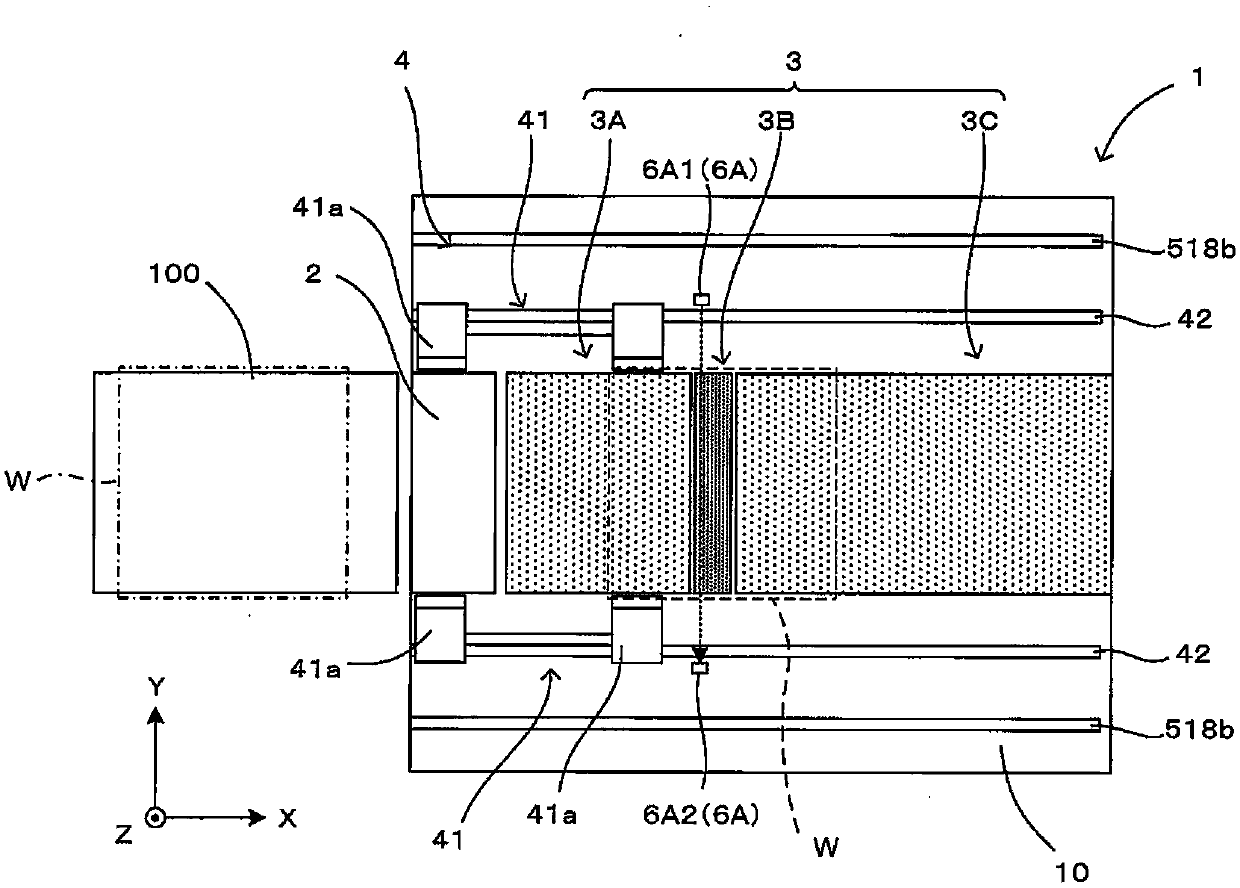

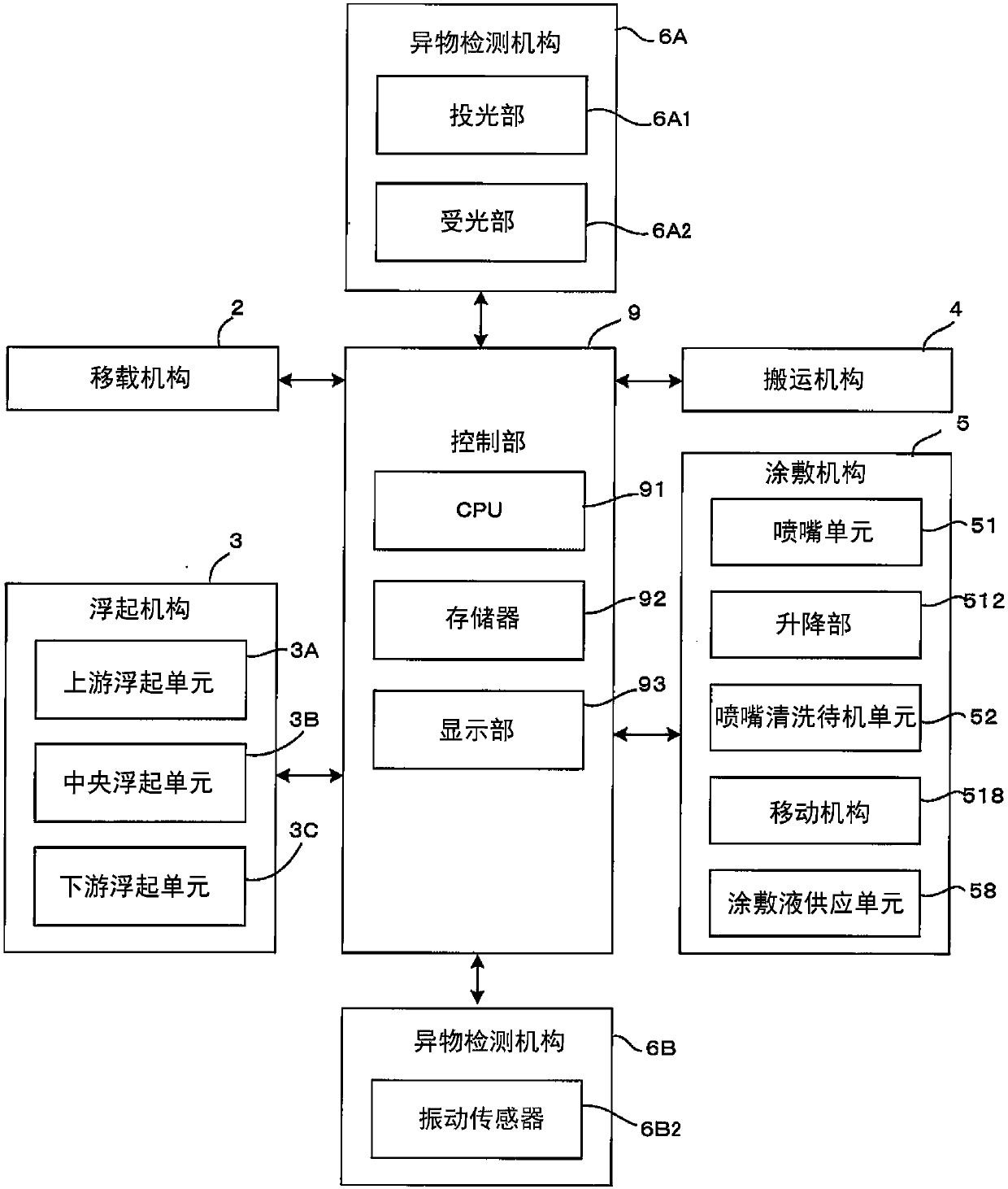

Coating device and coating method

PendingCN107824392AFast handlingImprove the speed of handlingLiquid surface applicatorsCoatingsMoving speedEngineering

The present invention relates to a coating device and a coating method, which shorten the tact time of the coating process and stably apply the coating liquid to the substrate. The coating apparatus includes a floating portion for floating the substrate with the main surface of the substrate facing upward, and a conveying portion for conveying the substrate floated by the floating portion in a predetermined conveyance direction at a substrate conveying speed; a nozzle which sprays the coating liquid onto the main surface of the substrate conveyed by the conveying section to apply the coating liquid; and a moving section moves the nozzle that is ejecting the coating liquid in the conveying direction at a nozzle moving speed that is lower than the substrate conveying speed.

Owner:DAINIPPON SCREEN MTG CO LTD

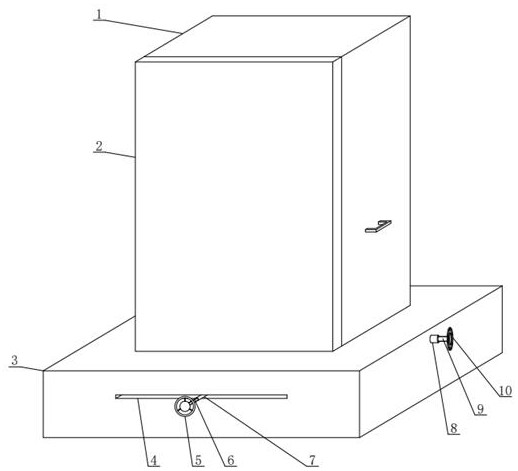

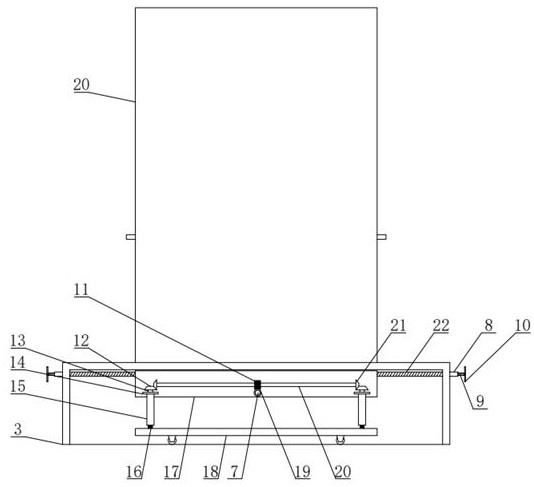

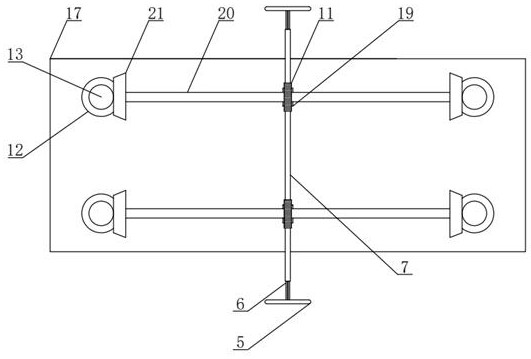

Electrical control equipment convenient to move

PendingCN113412008AReduce supportImprove the speed of handlingCasings/cabinets/drawers detailsElectrical controlStructural engineering

Electrical control equipment convenient to move comprises an electrical control cabinet (1) body and a base (3), and is characterized in that a cabinet door (2) is arranged on the front face of the electrical control cabinet (1) body; the base (3) is arranged at the bottom of the electrical control cabinet body; the base comprises a sliding groove (4) and a movable and lifting unit; a rotating threaded rod (22) is horizontally arranged at the top in the base, the movable block is a rectangular block body, a screw hole matched with the rotating threaded rod is formed in the movable block, the first connecting rod (6) is elastically connected with the first rotating rod through a spring, the second connecting rod (9) is also elastically connected with the second rotating rod through a spring, and clamping blocks are arranged at the upper end and the lower end of the first connecting rod and the upper end and the lower end of the second connecting rod respectively. The power distribution cabinet has the advantages that the power distribution cabinet is convenient to move, manpower is saved, the base absorbs impact force through the two first rotating wheels and the second rotating wheels, the springs can absorb most energy, and the effect of protecting the cabinet body is achieved.

Owner:CHINA MCC5 GROUP CORP

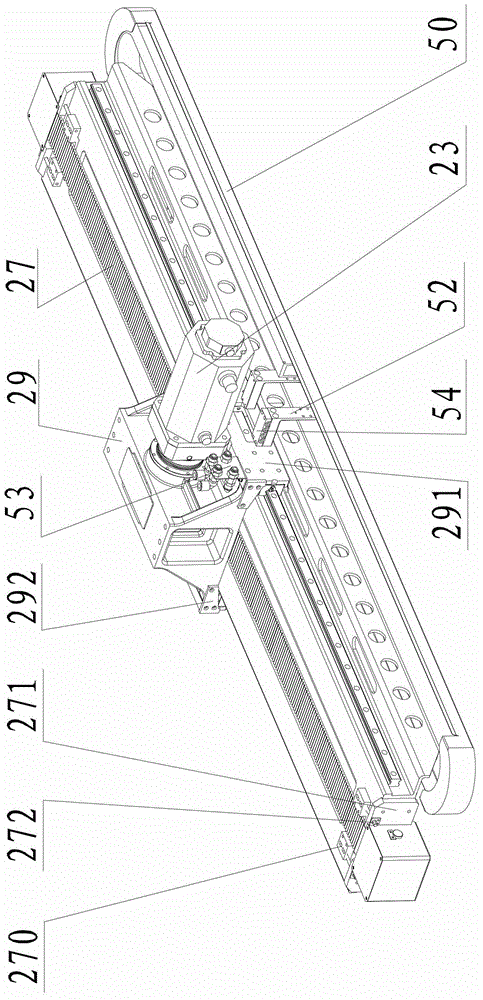

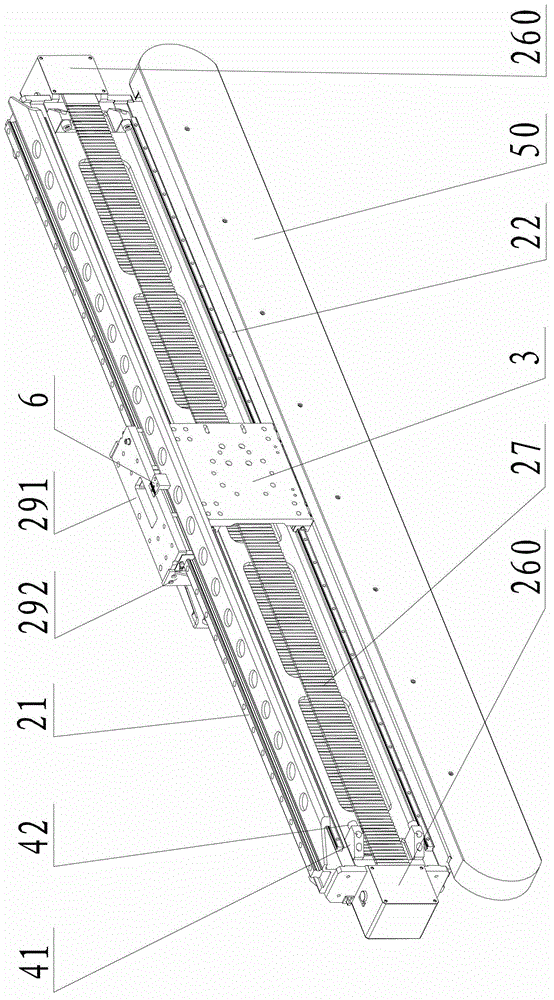

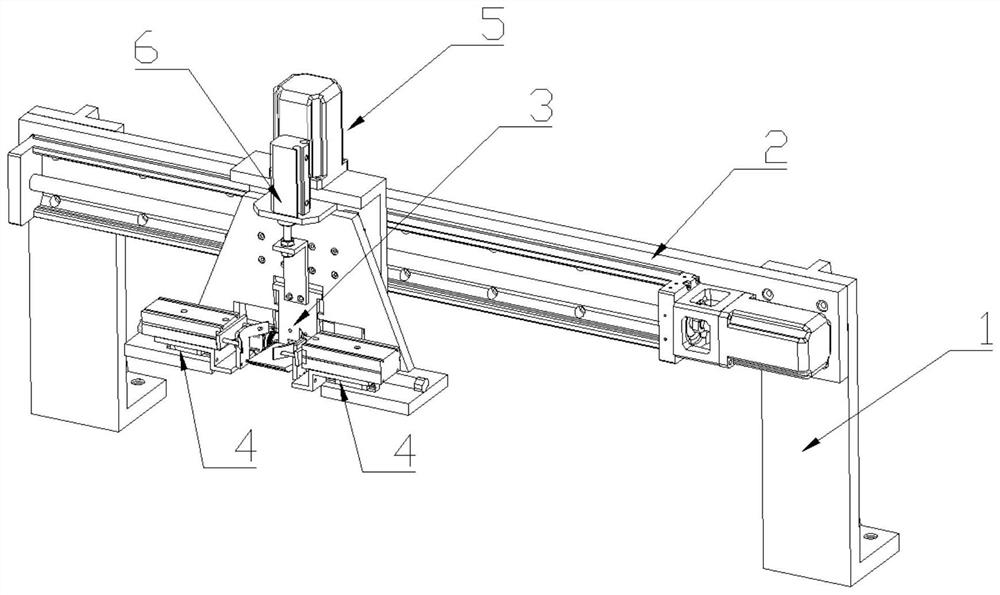

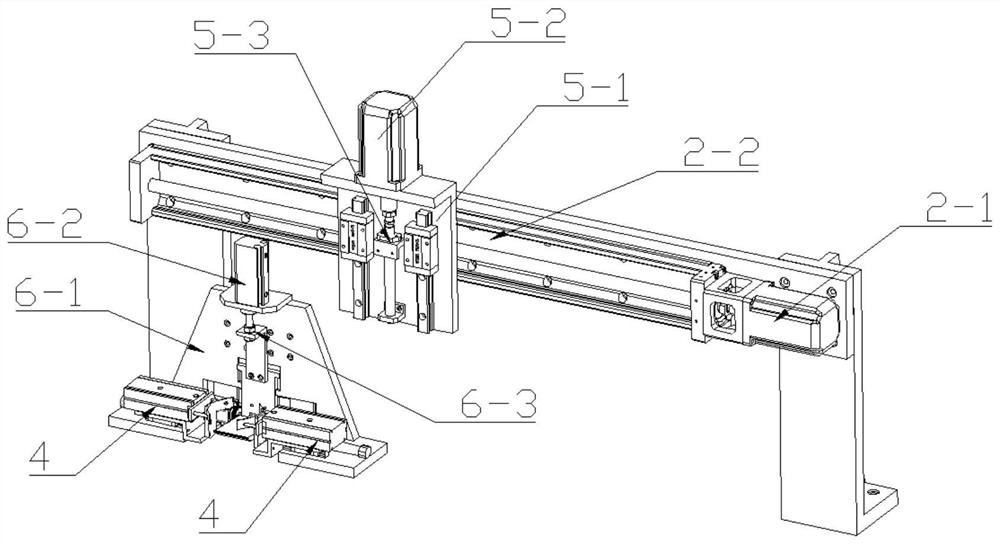

Linear seven-axis transfer robot for stamping

ActiveCN103358319BSimplify handling trajectoryHigh weight light stiffnessProgramme-controlled manipulatorArmsEngineeringMechanical engineering

The invention discloses a linear seven-shaft device of a handling robot for stamping, wherein the linear seven-shaft device has the advantages of light weight, high rigidity, small inertia and fast moving speed. The linear seven-shaft device comprises a main arm, a linear moving device and an end picking-up device installation plate. The main arm comprises a main arm main body with a cross section which is of a rectangular frame body, and a front supporting plate and a rear supporting plate which are respectively connected on the front side and the rear side of the lower end of the main arm main body. The linear moving device comprises a pair of side surface guide rails, a pair of bottom surface guide rails, a servo motor, a main belt wheel, a pair of guide wheels, a pair of auxiliary belt wheels, a main belt and an auxiliary belt. The pair of side surface guide rails is respectively installed on the front side surface and the rear side surface of the main arm main body. The pair of bottom surface guide rails is installed on the lower end surface of the main arm main body. The servo motor is installed on a power support. The power support is installed on the pair of side surface guide rails and above the main arm main body and is connected onto the main belt. The main belt wheel is installed on the servo motor. The pair of guide wheels is arranged below the left side and the right side of the main belt wheel. The end picking-up device installation plate is installed on the pair of bottom surface guide rails and is connected onto the auxiliary belt.

Owner:SHANGHAI FANUC ROBOTICS

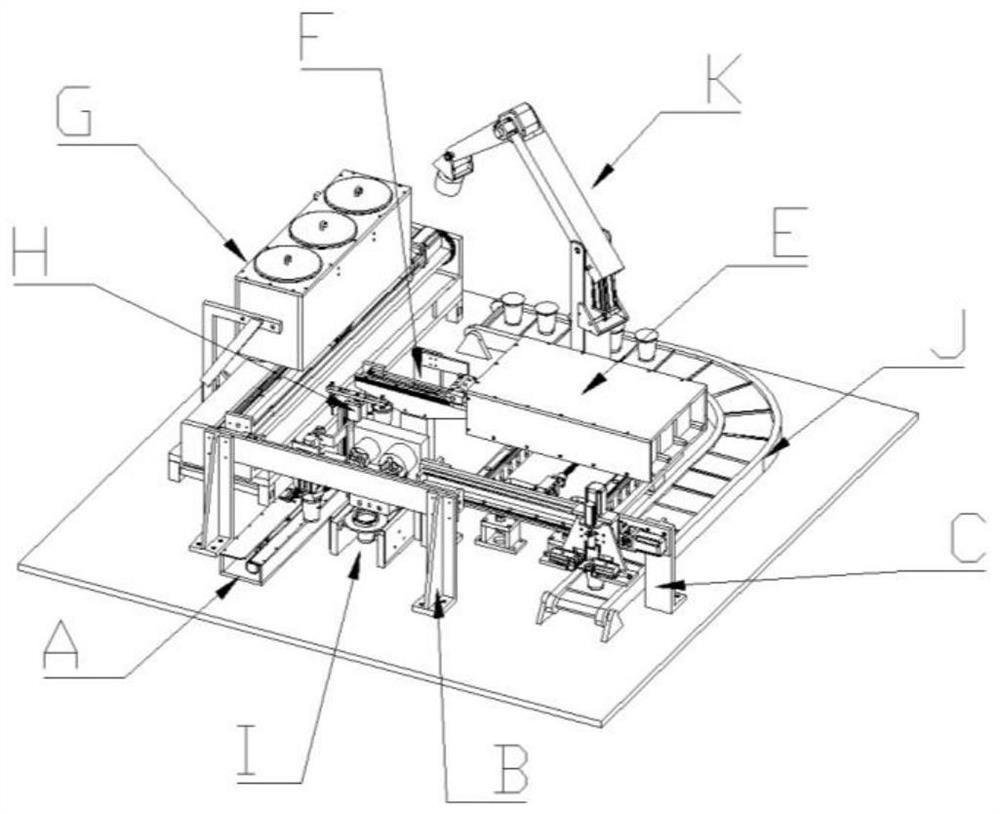

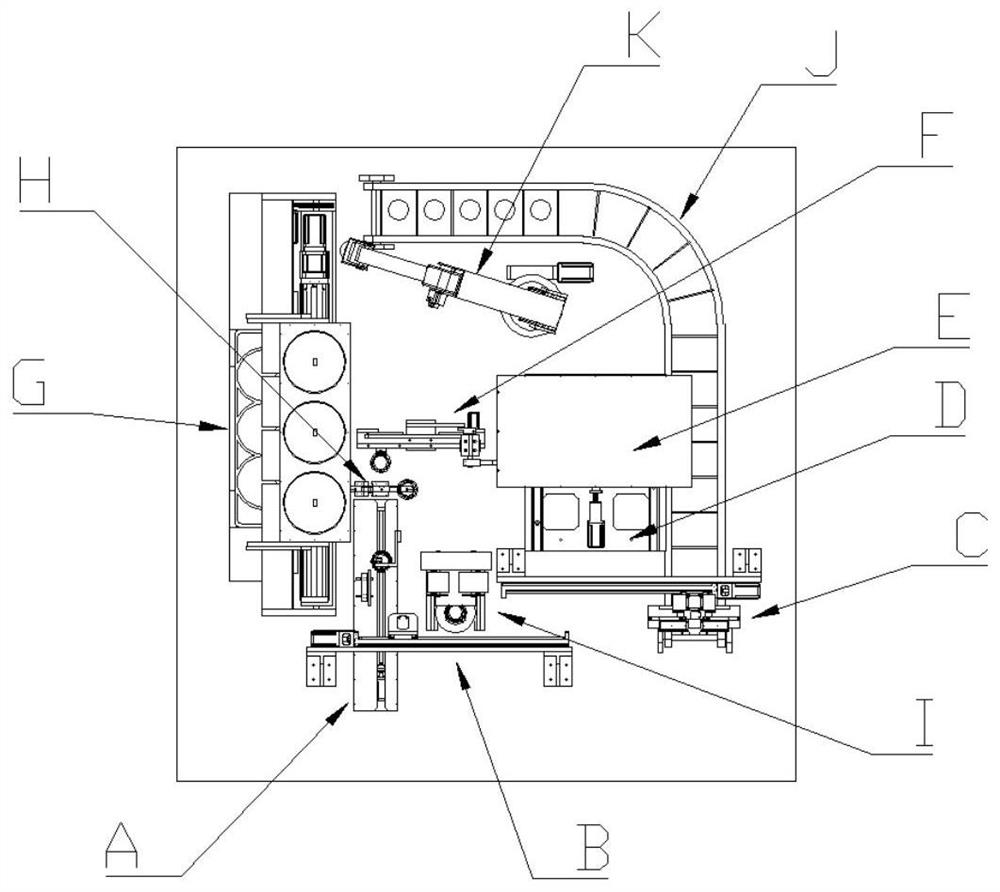

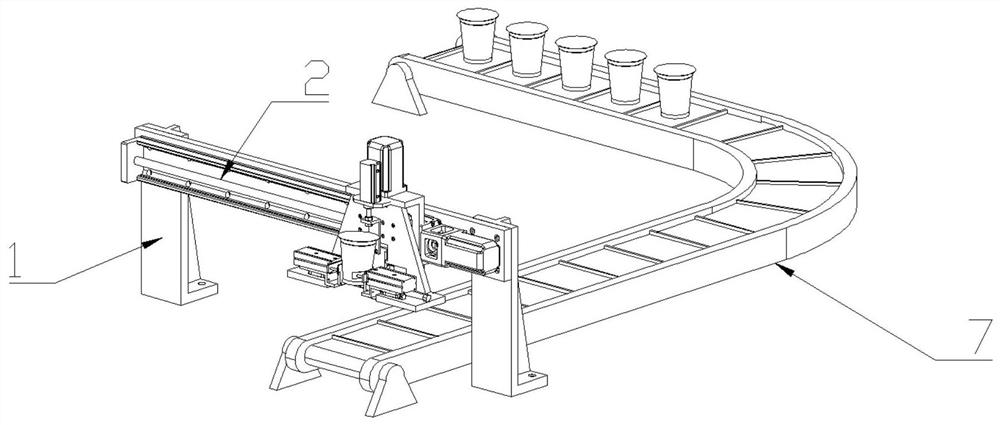

A fully automatic milk tea machine

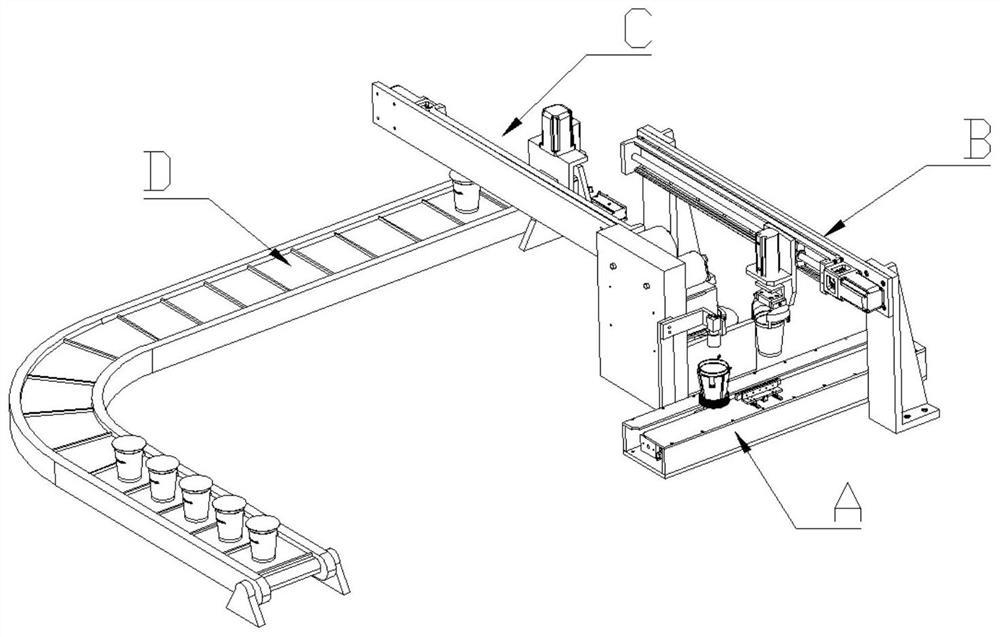

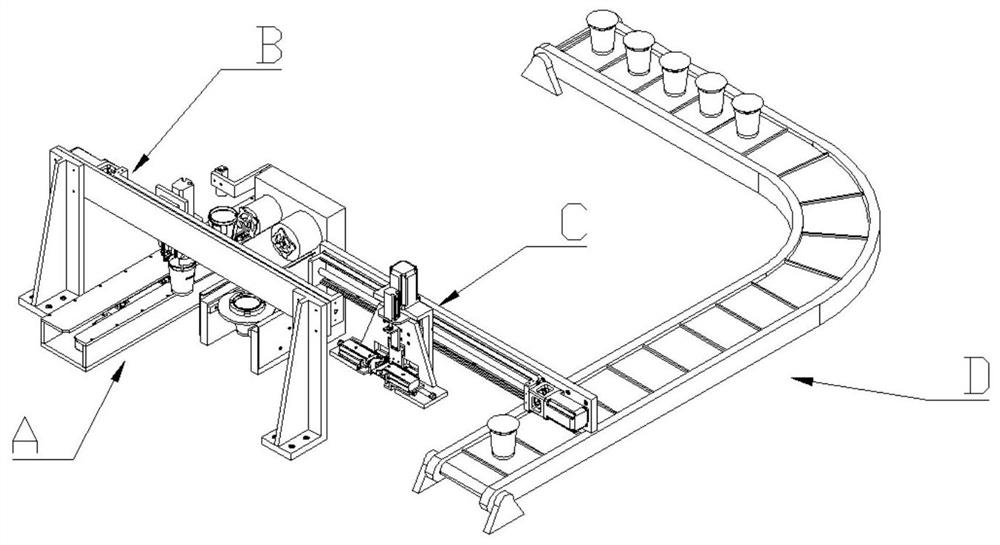

ActiveCN111891478BSimple structureReduce manufacturing costLiquid materialConveyor partsProcess engineeringMaterial resources

The invention discloses a full-automatic milk tea machine, comprising a material reclaiming system, a shaking system, a material pouring system, a capping system, a cup taking system and a conveying system; Different, the raw materials corresponding to the milk tea are automatically fed into the receiving container; the cup taking system is used to take out the milk tea cups one by one; the conveying system includes a first handling device, a second handling device, and a finished product conveying device. and a third conveying device; the feeding system is used for conveying the receiving container to the position where it is handed over to the shaking system, and at the same time conveying the receiving container that has completed the shaking process to the first conveying position The cup taking station of the handover of the device; the shaking system is used for shaking the milk tea raw material in the feeding container; the capping system is used to realize the capping of the milk tea cup. The automatic milk tea machine of the invention can realize the automatic production of milk tea, thereby saving manpower and material resources.

Owner:昆山弗兰德机电工程技术有限公司

Plastic support frame for engineering

ActiveCN103470061BEasy to operateImprove securityBuilding material handlingEngineering plasticEngineering

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

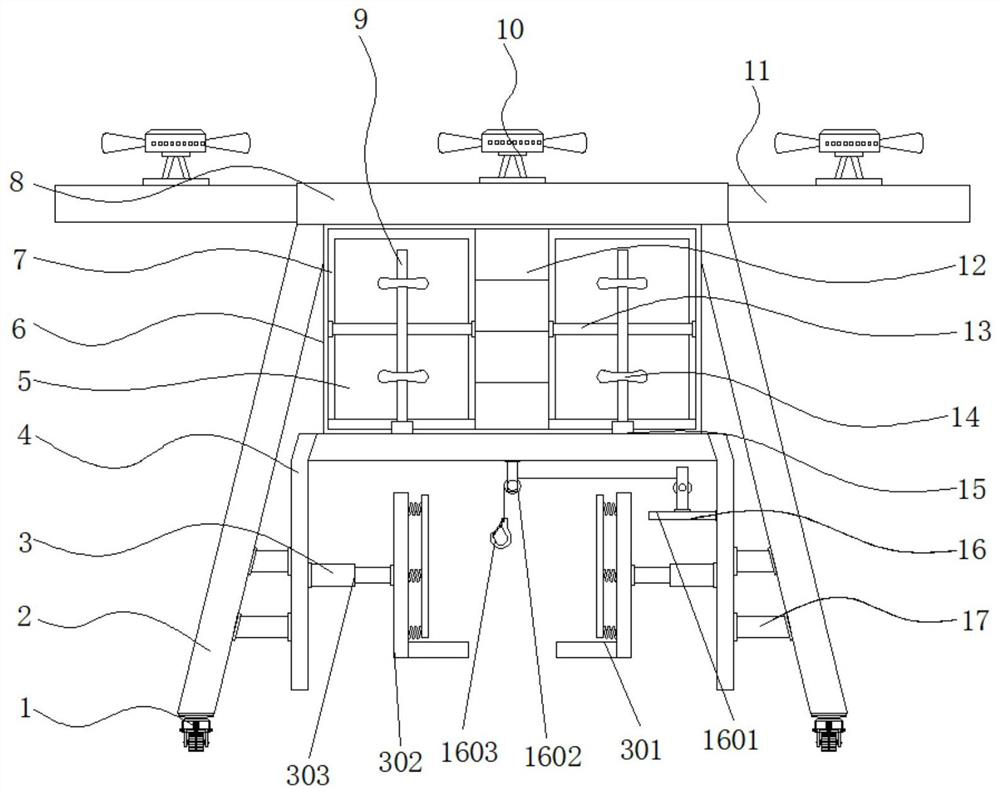

Unmanned aerial vehicle for carrying expresses

ActiveCN112918679AEffective classificationEffective limitFreight handlingRotocraftMarine engineeringUncrewed vehicle

The invention discloses an unmanned aerial vehicle for carrying expresses, and particularly relates to the technical field of unmanned aerial vehicle transportation. The unmanned aerial vehicle comprises lifting frames and a vehicle body, four corners of the bottom end of each lifting frame are fixedly connected with the corresponding lifting frames, moving trundles are arranged at the bottom ends of the lifting frames, the bottom end of the vehicle body is fixedly connected with a placing shell, and a connecting rod is fixedly connected to the outer part of the machine body. By arranging a supporting plate, a movable roller, a lifting hook, a servo motor, a rotating shaft, a supporting rod, a lifting rope and a winding roller, an express needing to be carried is hung in the lifting hook, when the express needs to be put down, the servo motor is started, the servo motor drives the winding roller to rotate through the rotating shaft, and the lifting rope can drive the lifting hook to descend through rotation of the winding roller; and the lifting hook descends to place an express at the bottom end of the lifting hook on the ground, the carrying speed can be increased by placing the express on the ground from the high position, the practicability of the device can be improved by arranging the lifting hook, and the movable roller can facilitate winding of the lifting rope through the winding roller.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

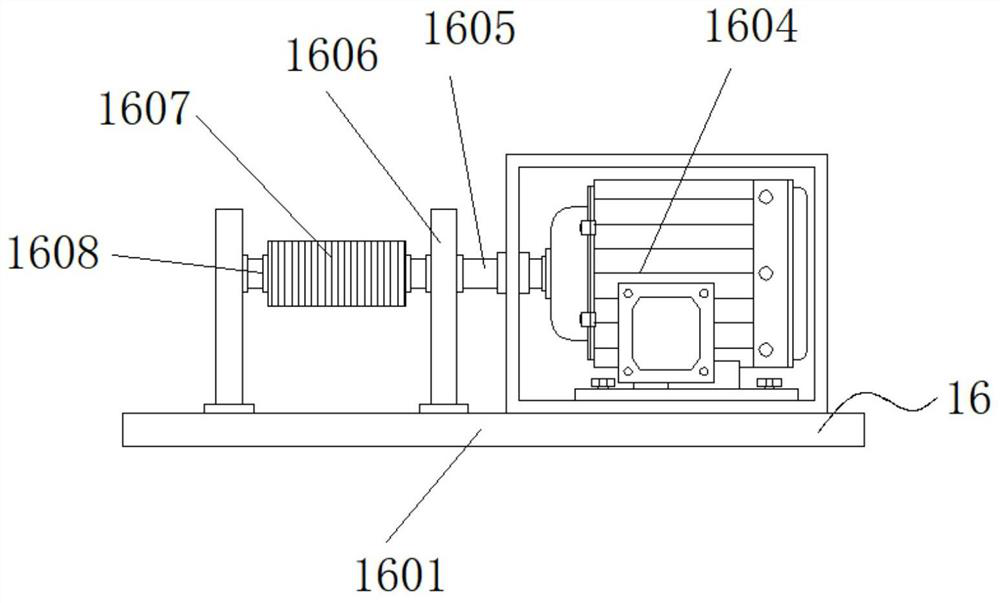

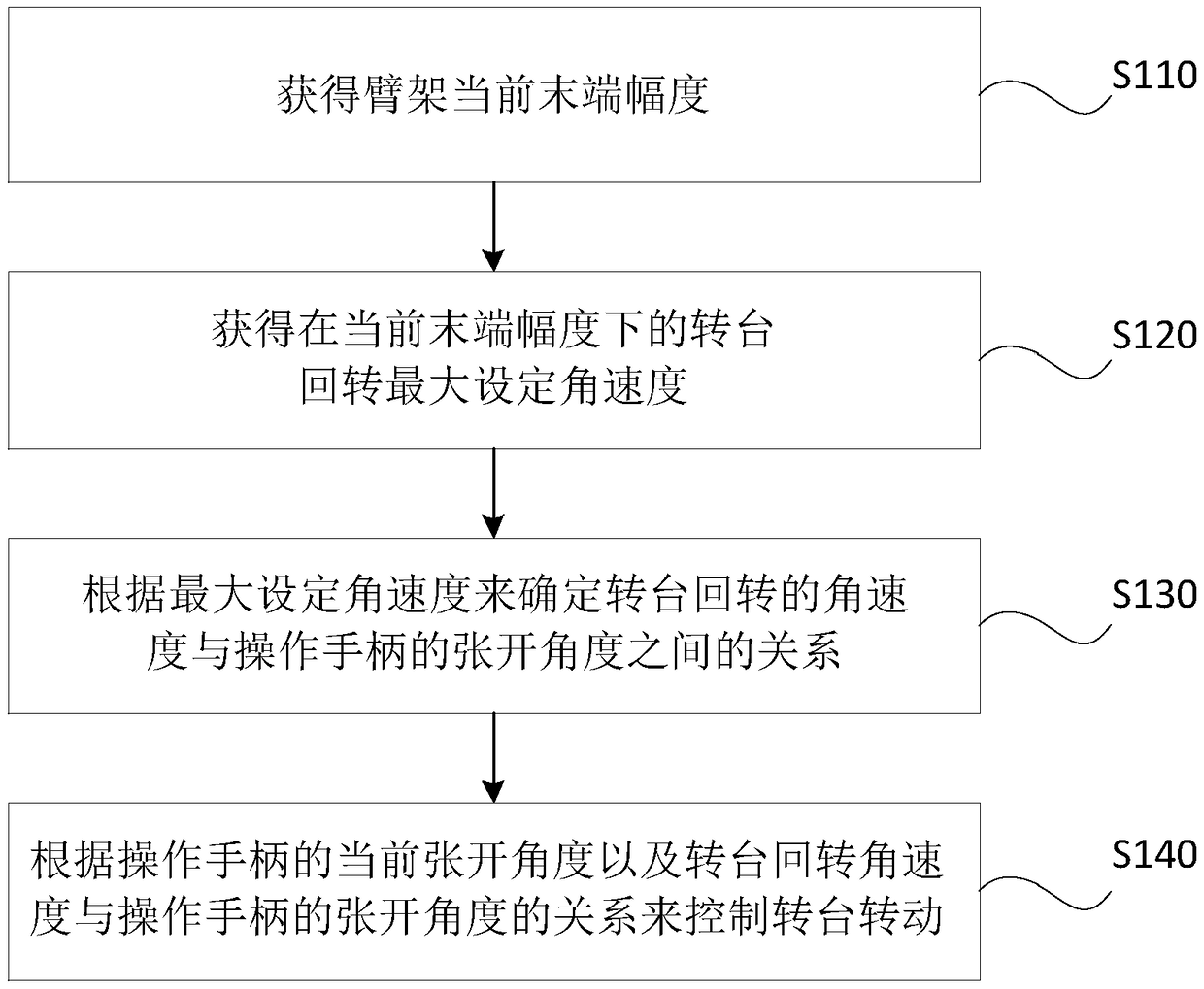

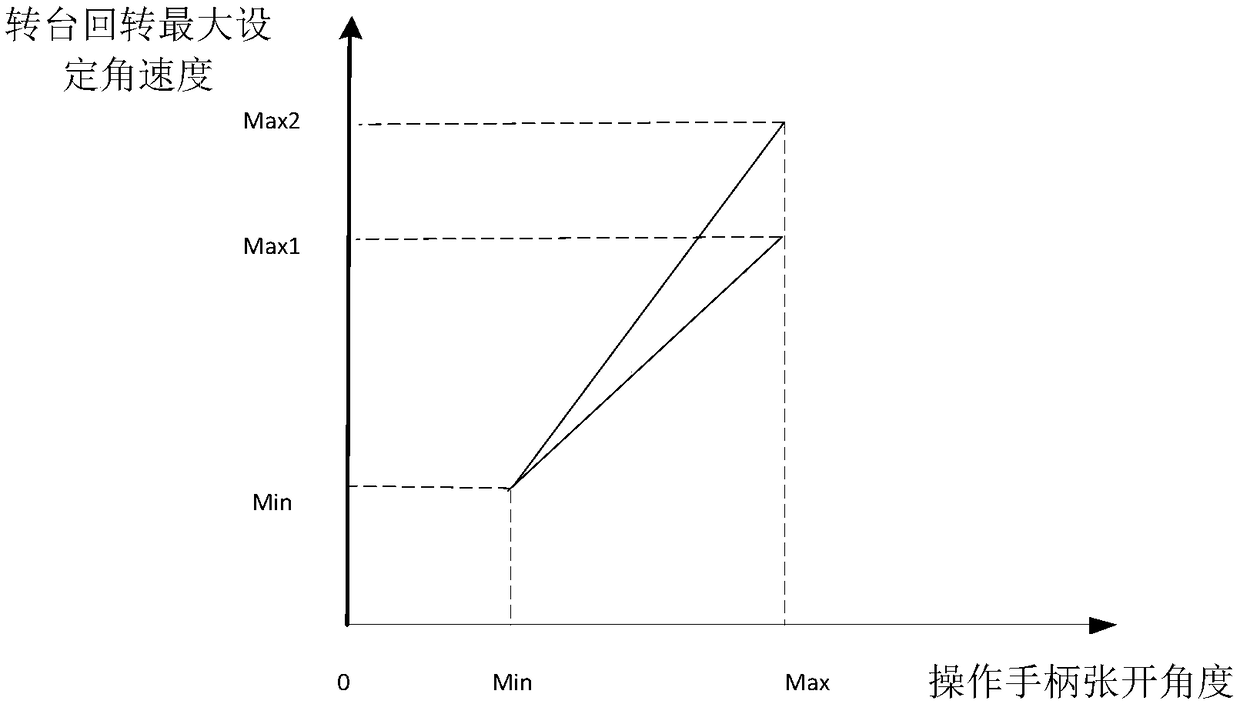

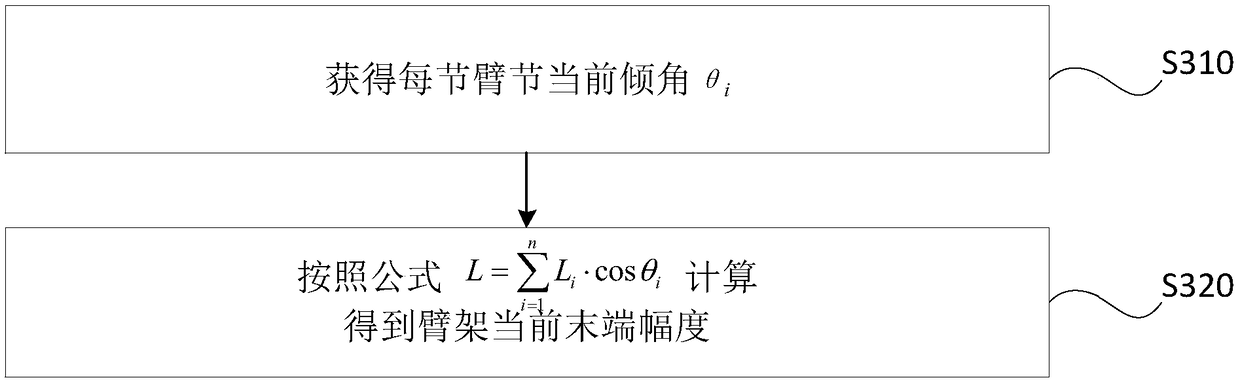

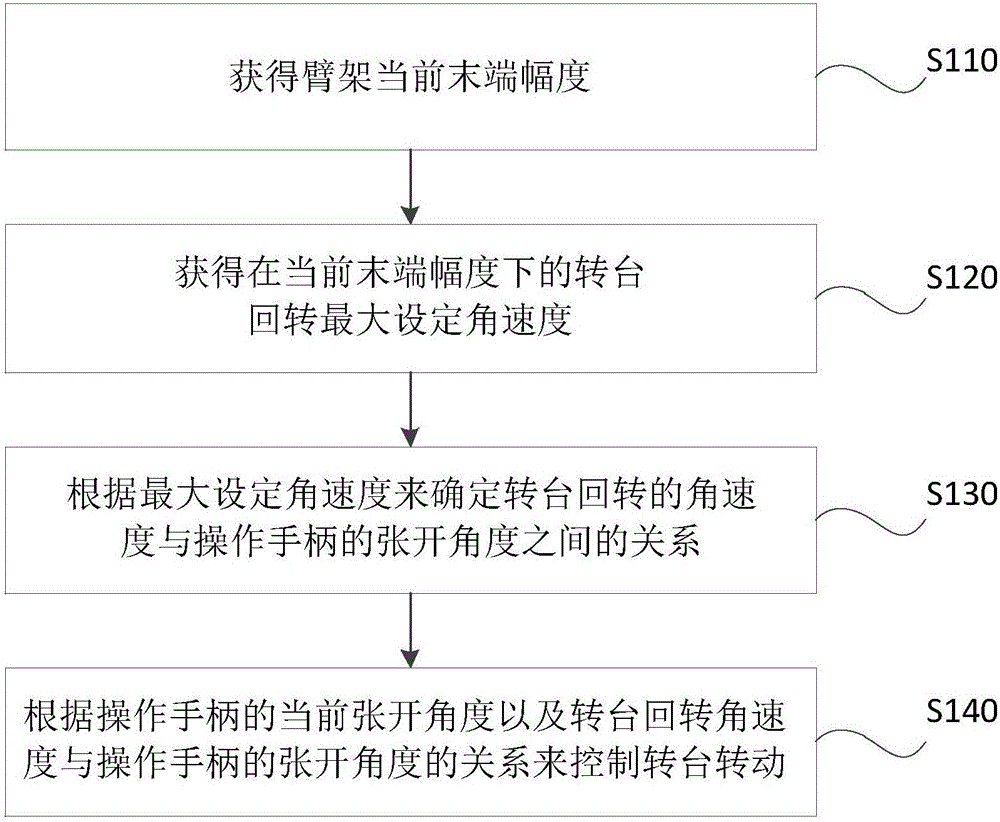

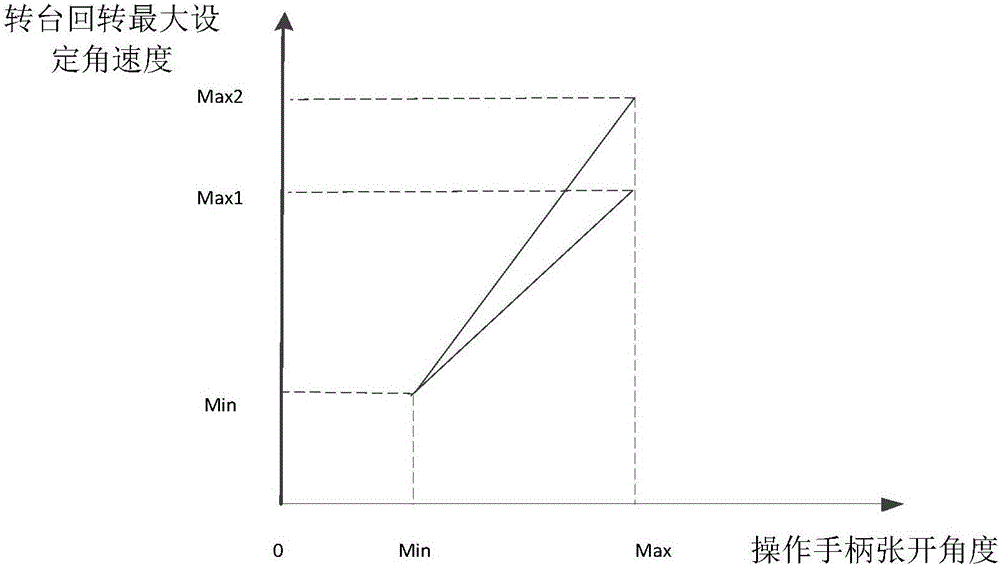

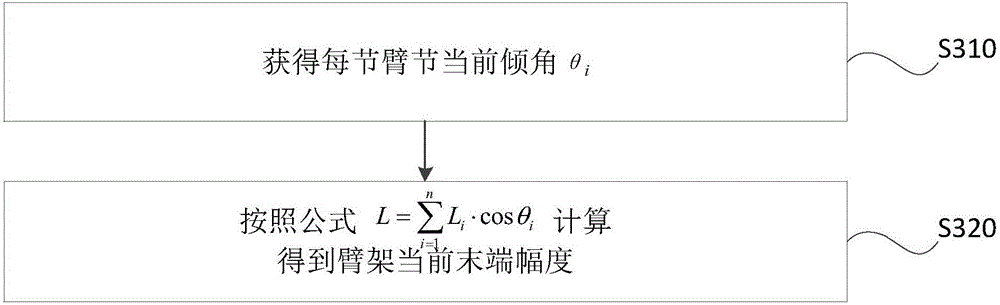

Control method, control device and pump truck for rotary table rotation of pump truck

ActiveCN106481080BEnsure safetyImprove the speed of handlingBuilding material handlingAngular degreesAngular velocity

The invention discloses a control method and a control device for controlling rotation of a turnplate of a pump truck and the pump truck. The control device comprises the following steps: acquiring the current boom tail end amplitude; according to the current boom tail end amplitude and the maximum boom tail end linear velocity, acquiring the turnplate rotating maximum set angular velocity under the current tail end amplitude; according to the maximum set angular velocity, determining the relationship between the turnplate rotating angular velocity and the opening angle of an operating handle; according to the current opening angle of the operating handle and the determined relationship between the turnplate rotating angular velocity and the opening angle of the operating handle, controlling the turnplate to rotate at the corresponding angular velocity. By the control device, the maximum turnplate rotating set angular velocity can be dynamically controlled according to the boom tail end amplitude, and the control rapidness of a boom of the pump truck is improved on the basis that the safety of users and equipment is ensured.

Owner:雷萨股份有限公司

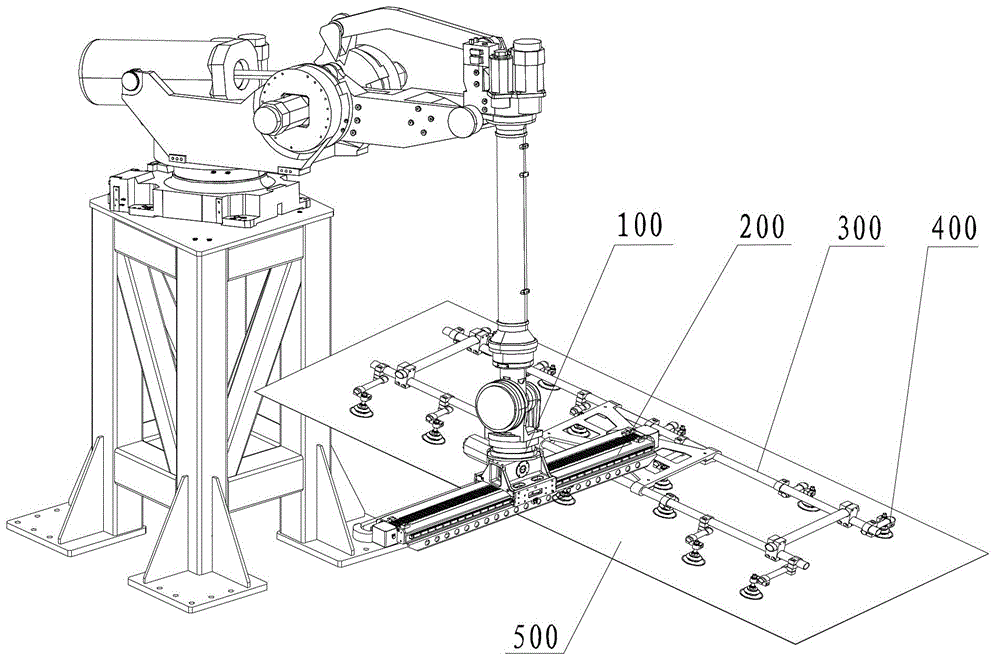

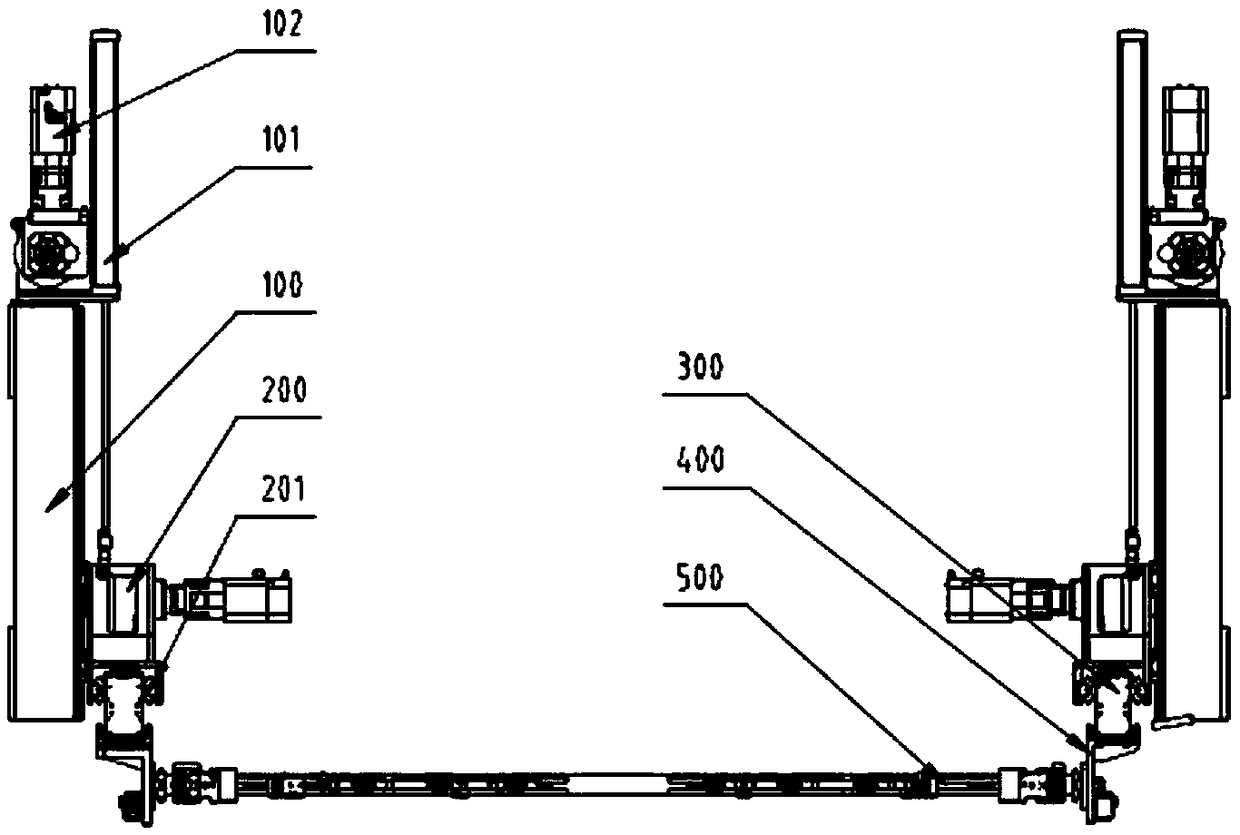

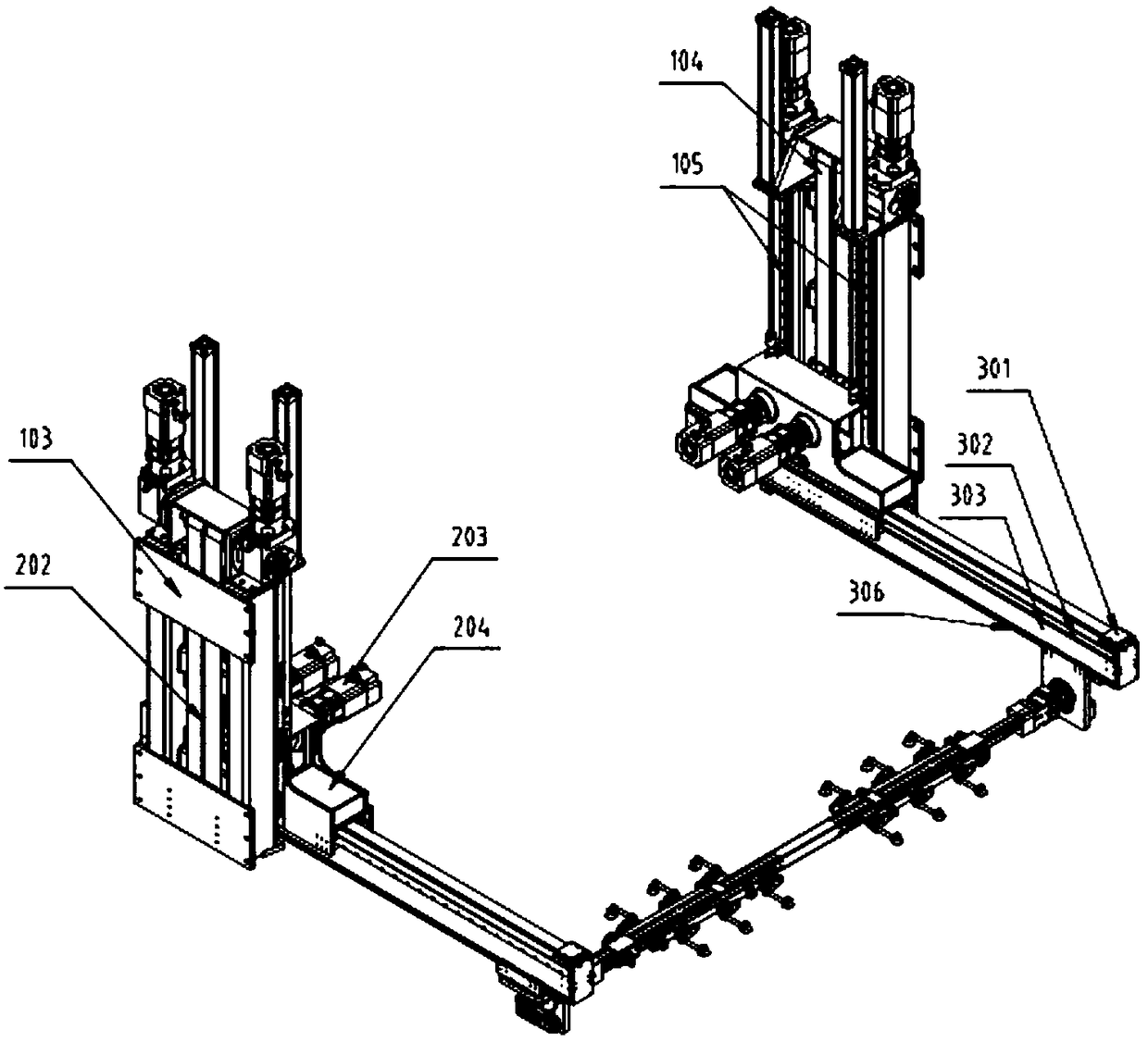

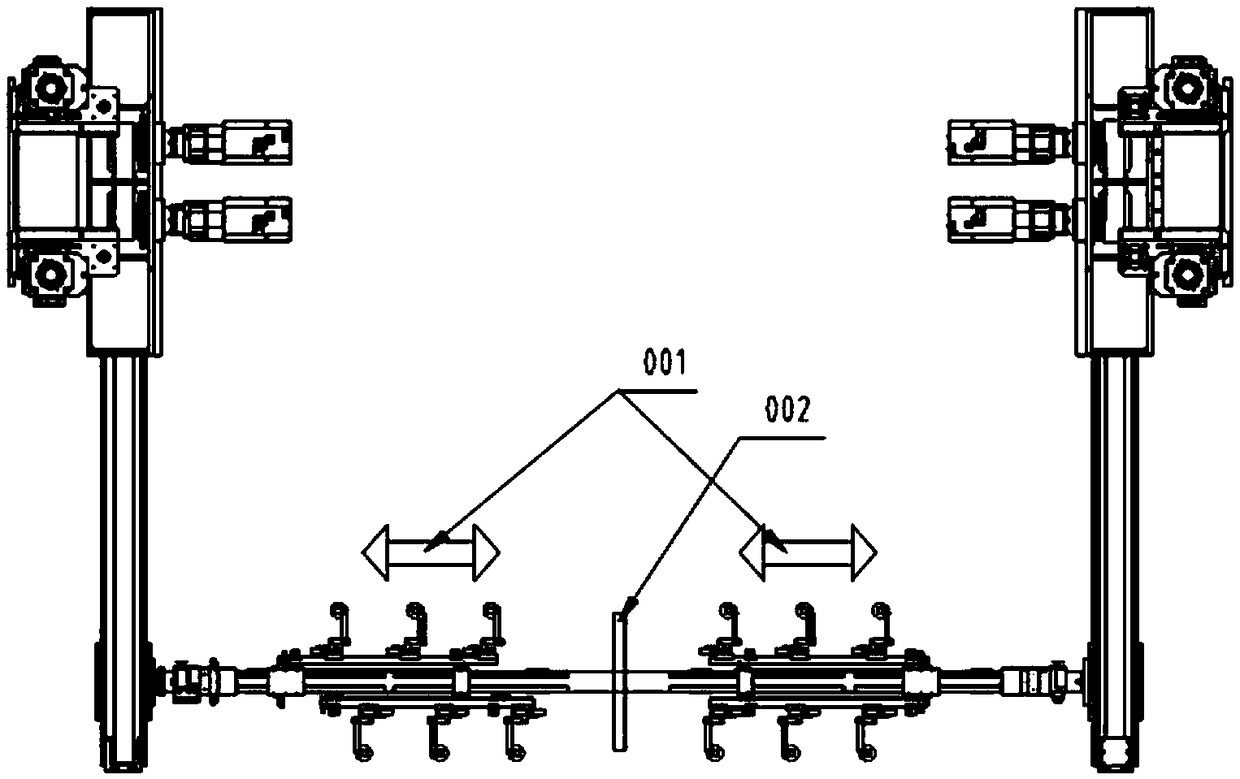

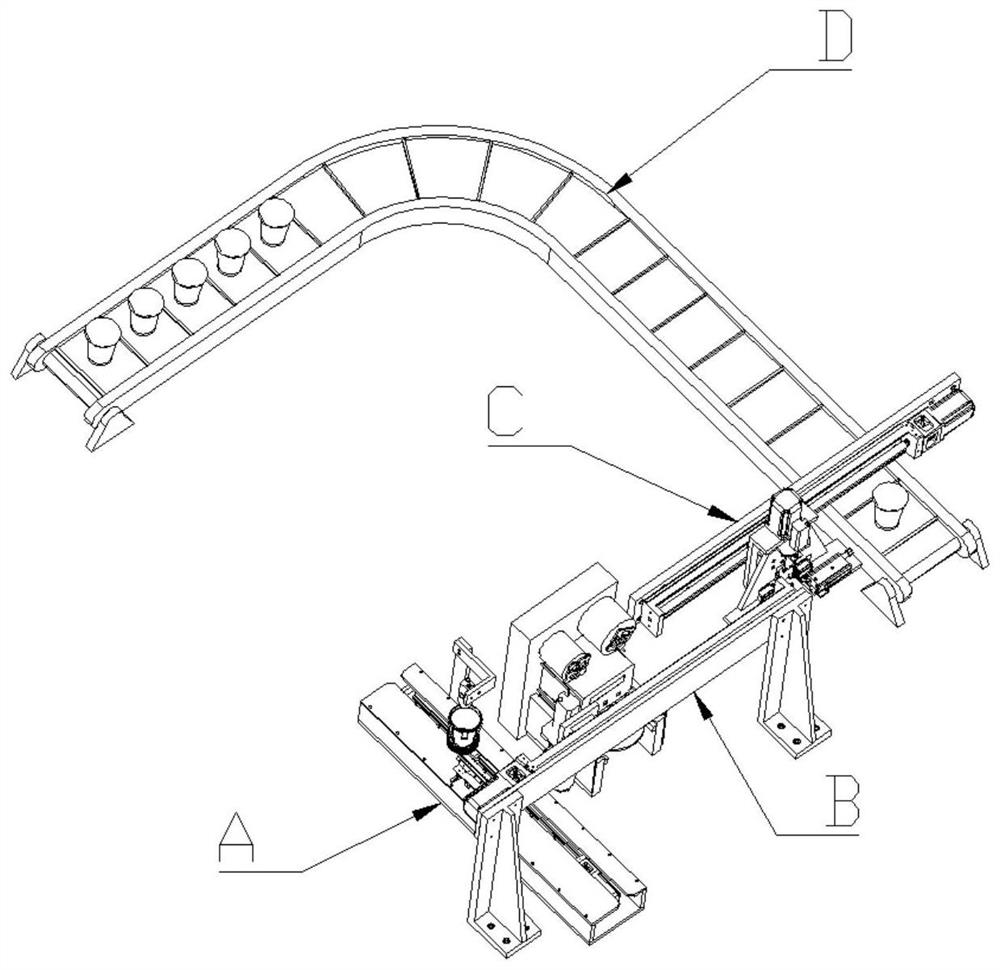

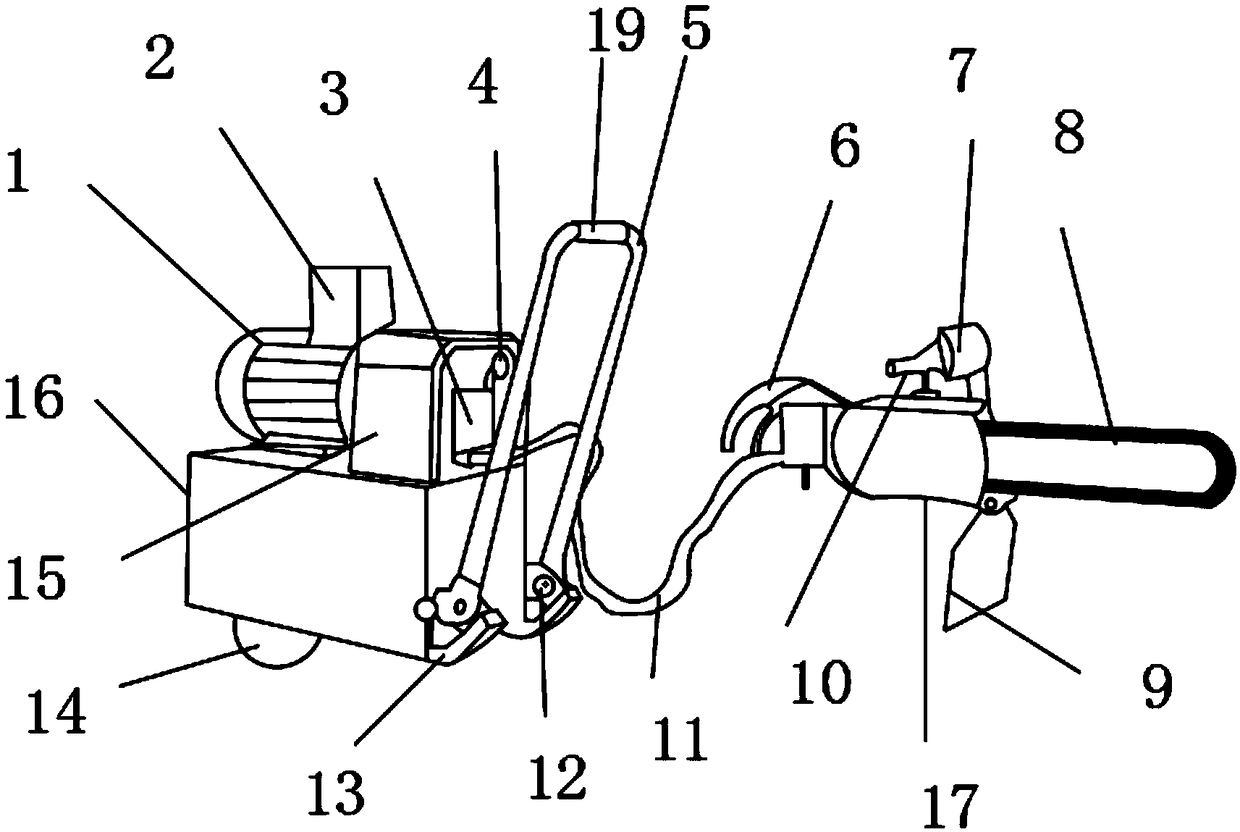

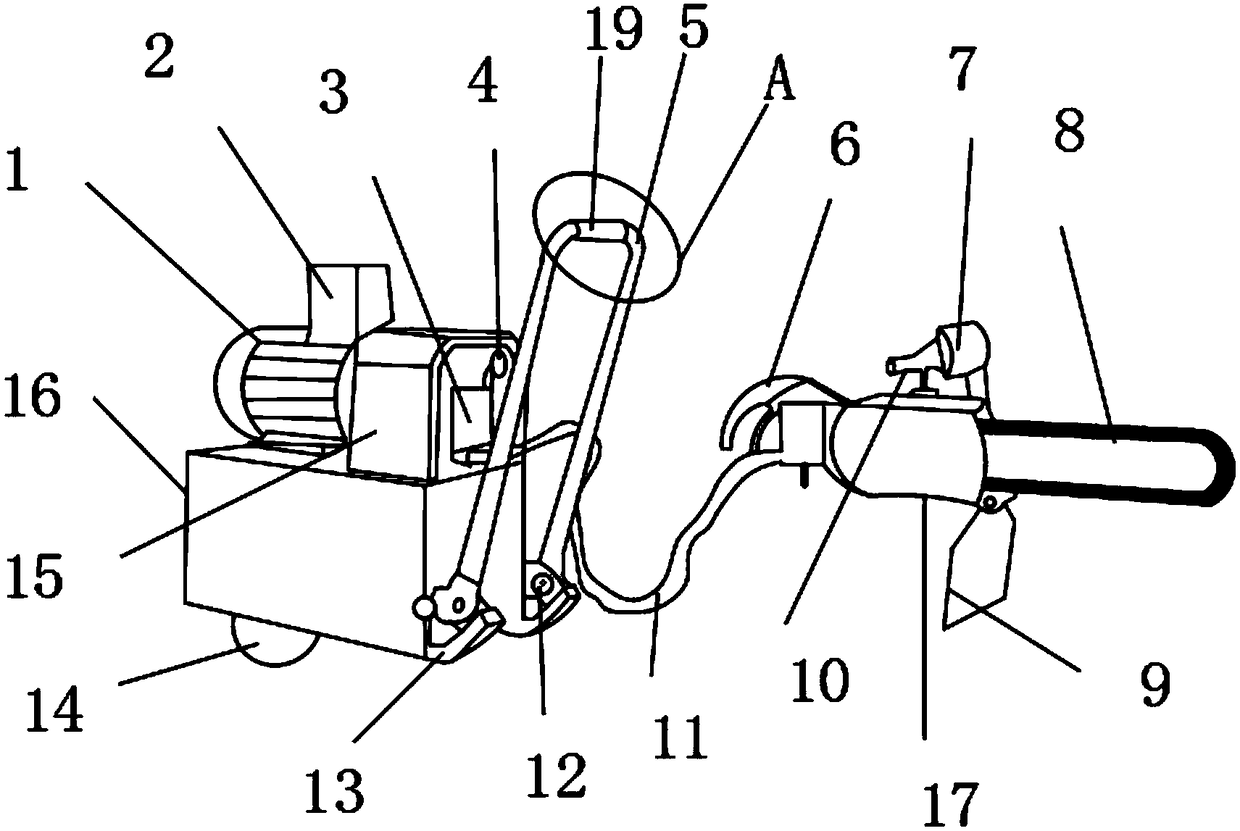

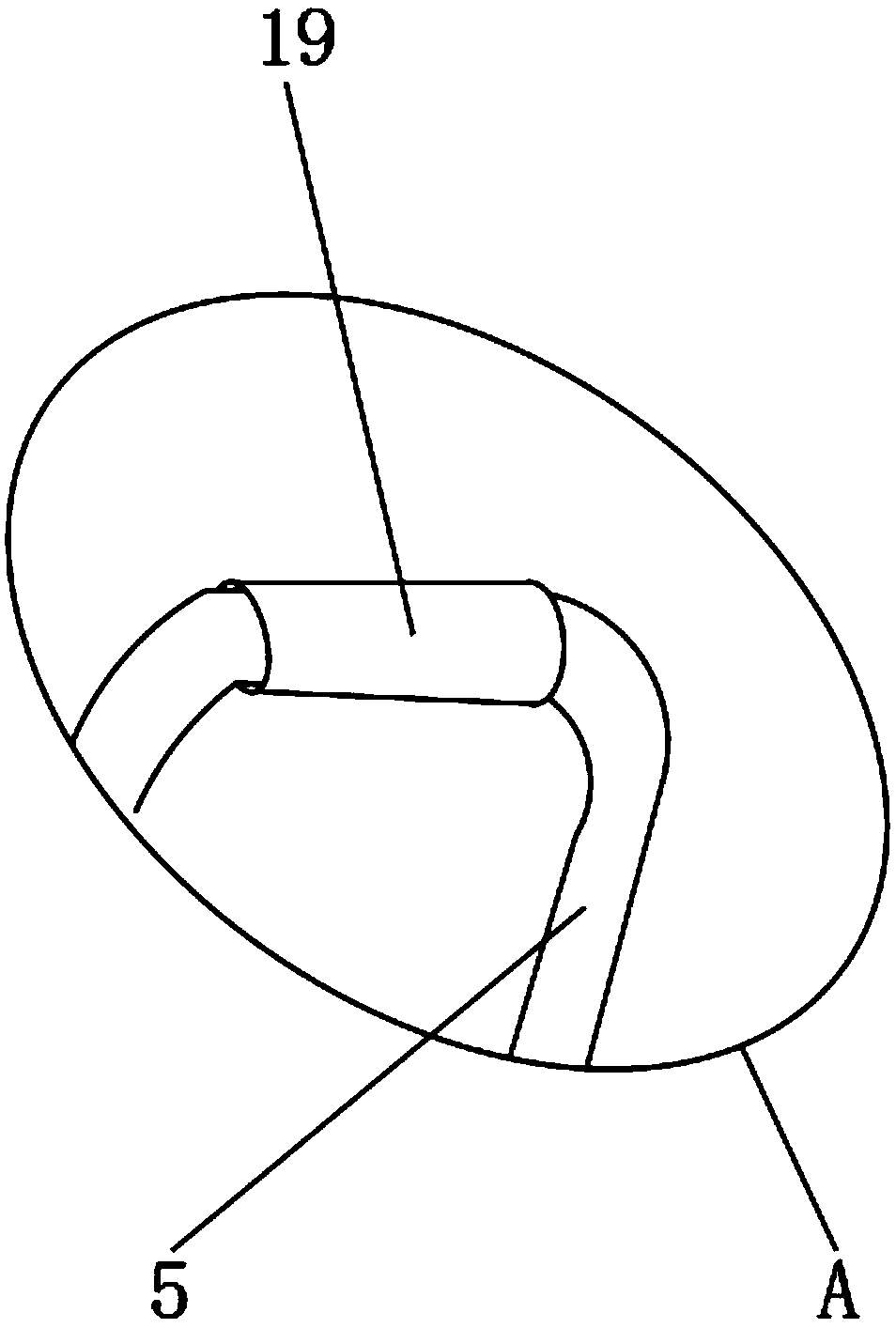

Conveying device, system and method used for press line pressing machine room or multi-station pressing machine

PendingCN108856549ASimple structureThe overall structure is simpleMetal-working feeding devicesPositioning devicesMachine pressFeeding drive

The invention discloses a conveying device, system and method used for a press line pressing machine room or a multi-station pressing machine. The conveying device includes mounting brackets, liftingbox bodies, cross girders, follow-up devices, cross bars and suction devices. The conveying system includes two or more conveying devices which are continuously arranged and used for the press line pressing machine room or the multi-station pressing machine. The conveying device, system and method are used for conveying platy components of a pressing machine room of a high-speed automated pressingproduction line, and the platy components can be conveyed from a previous work station to a next work station more quickly. The structure and control of the conveying device are simplified, the wholestructure of the conveying device is simple and compact, there is certain interchangeability between a promoting drive and a feeding drive, maintenance is easy, the speed of conveying the platy components is increased, and the efficiency of conveying the platy components is improved. A novel servo pressing machine production line can be more effectively matched, the production cost is reduced forautomobile manufacturing enterprises, and the production efficiency and quality are improved.

Owner:JIER MACHINE TOOL GROUP

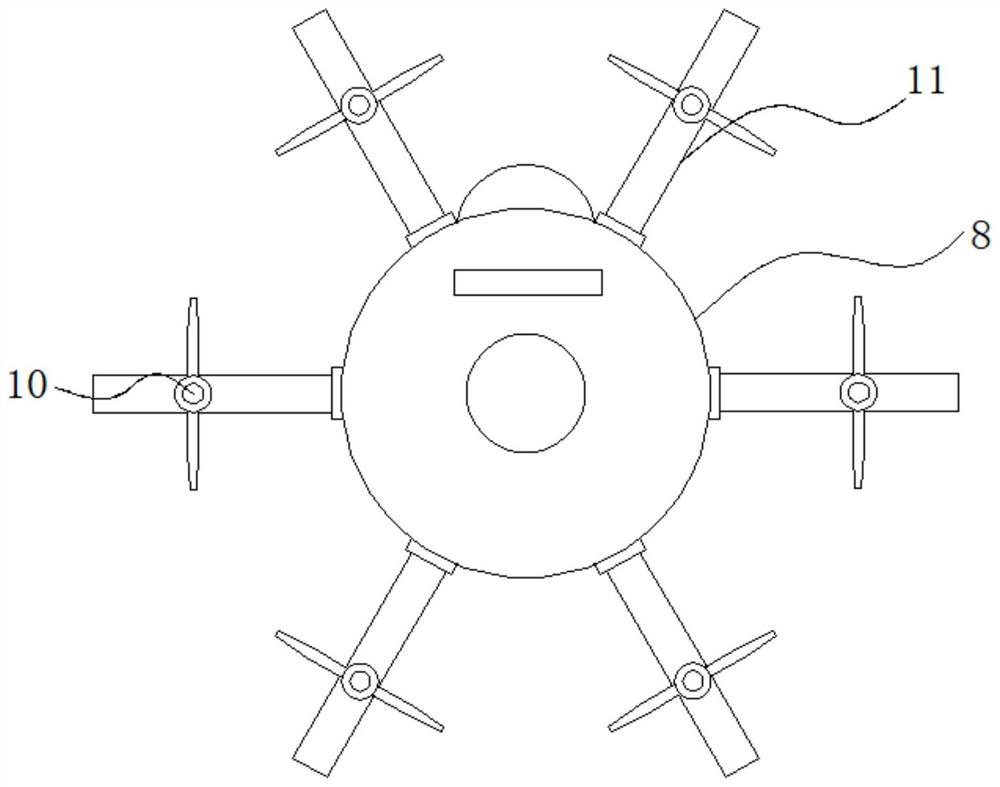

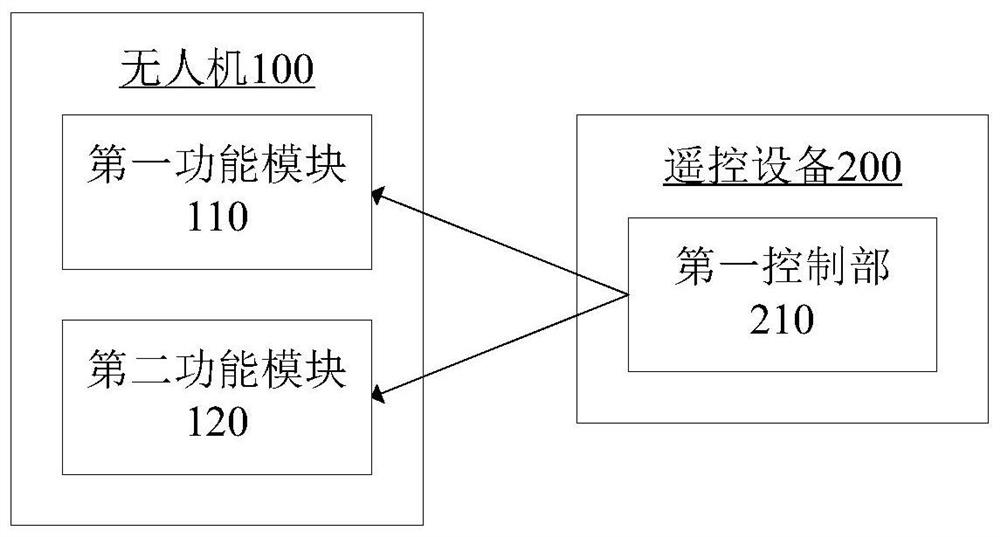

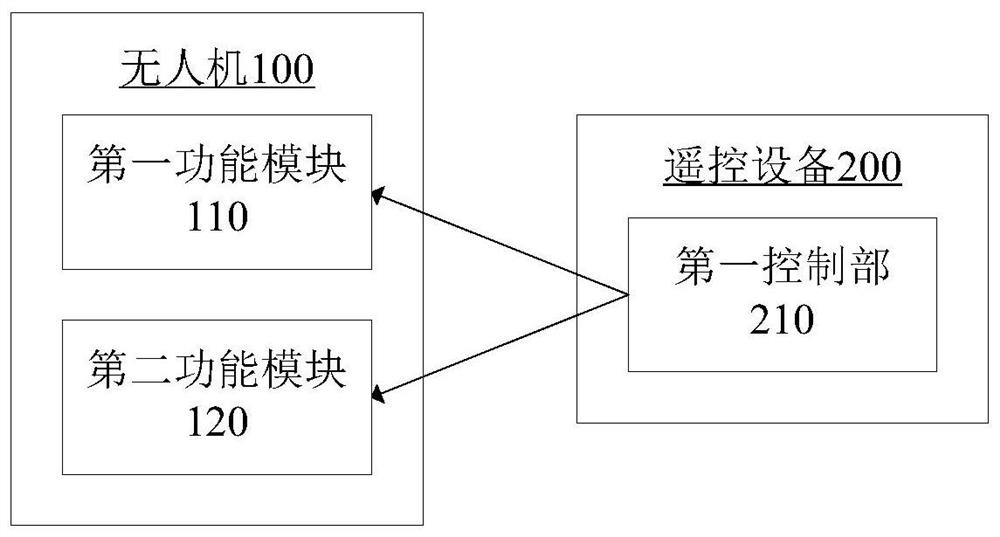

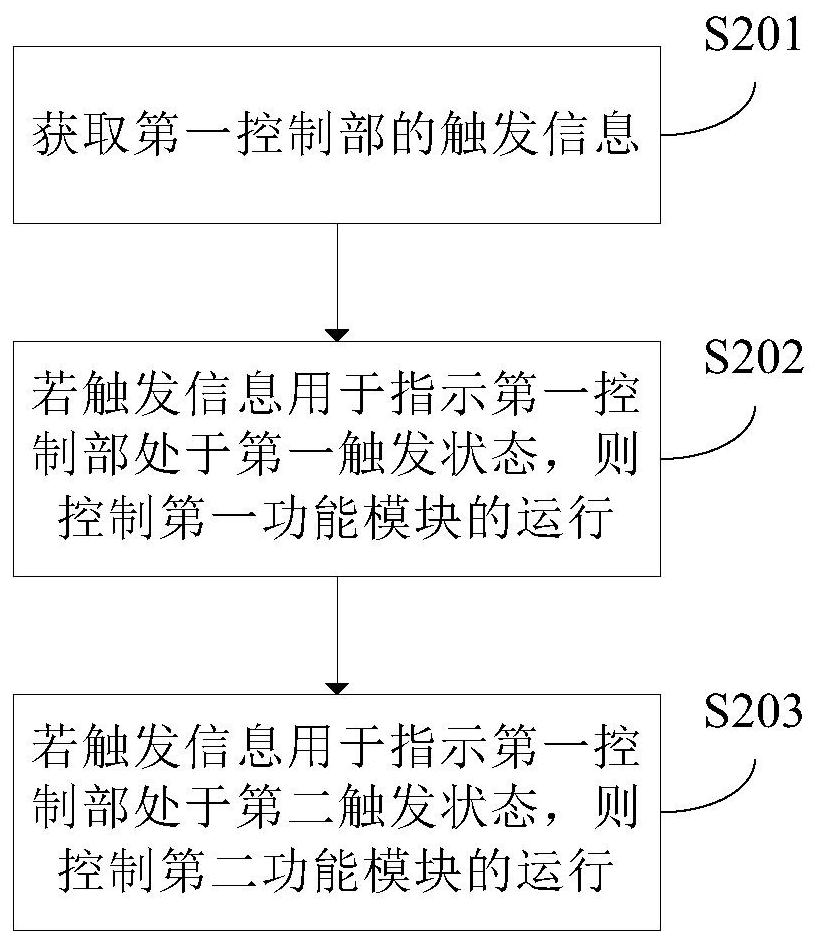

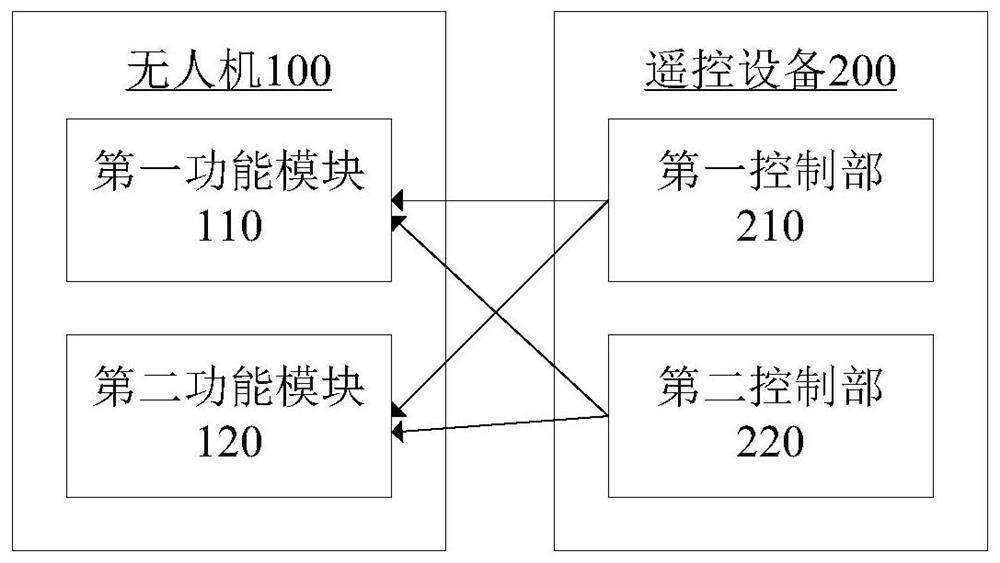

Movable platform control method, remote control device, and movable platform component

ActiveCN112189331BEasy to controlImprove operating experienceTelevision system detailsColor television detailsMultiplexingRemote control

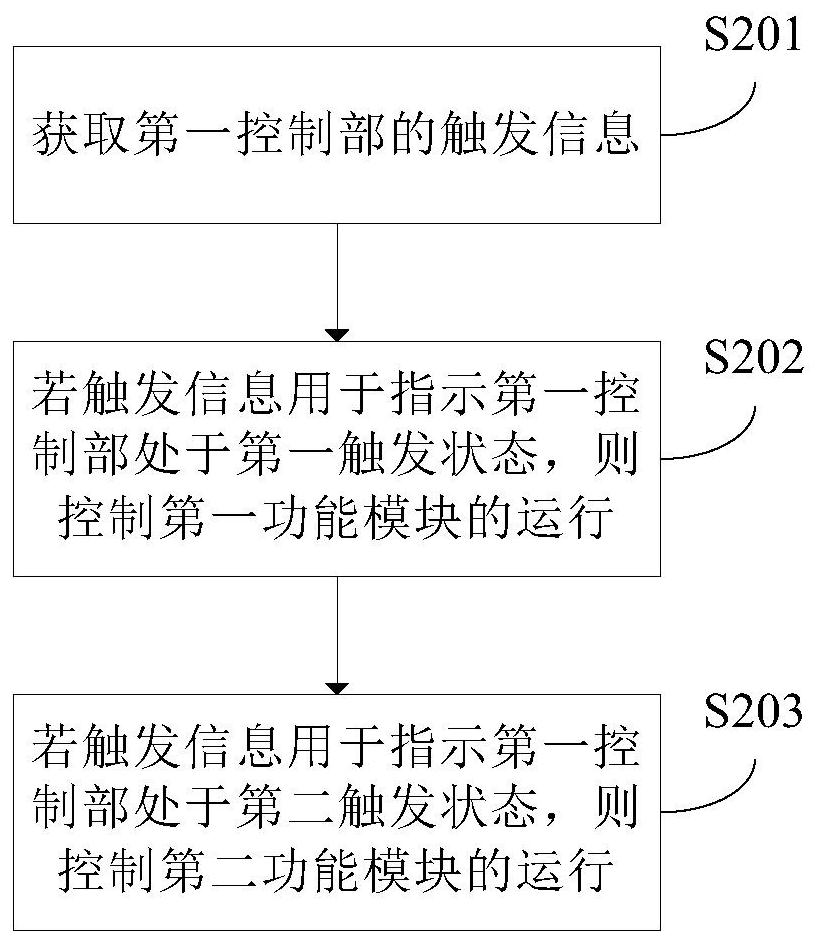

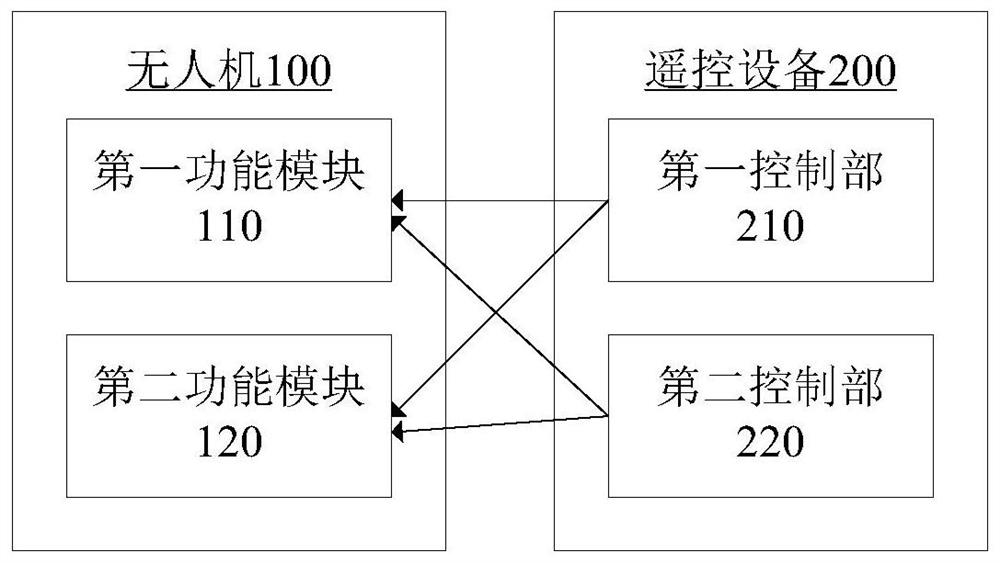

A method for controlling a movable platform, its remote control device (200), and a movable platform component, wherein the movable platform includes a first functional module (110) and a second functional module (120), and the remote control device (200) includes a first A control unit (210); the method is applied to the remote control device (200), and the method includes: acquiring trigger information of the first control unit (210) (S201); if the trigger information is used to indicate that the first control unit (210) is in the first trigger state, then control the operation of the first functional module (110) (S202); if the trigger information is used to indicate that the first control part (210) is in the second trigger state, then control the operation of the second functional module (120) (S203 ). Through the multiplexing control of the first control part (210) of the remote control device (200), the control of the first functional module (110) and the second functional module (120) is realized, which improves the control speed and convenience, and increases the control Stability and reliability bring users a better operating experience.

Owner:SZ DJI TECH CO LTD

A milk tea cup automatic handling system

Owner:广州酷库智能科技有限公司

Hydraulic saw for convenient electric bed cutting

InactiveCN108817540AIncrease frictionAvoid damageMetal sawing devicesMetal sawing accessoriesHydraulic pumpFuel tank

The invention discloses a hydraulic saw for convenient electric bed cutting. The hydraulic saw comprises an electric motor, an oil pipe, bolts and a hydraulic saw body. A control box is arranged abovethe electric motor, and a protective plate is arranged on one side of the electric motor. A fuel tank is arranged at the bottom end of the electric motor, and a rectangular pull rod is arranged at the upper ends of anti-collision frames. The protective plate is internally provided with a hydraulic pump and a cooling fan, and a pressure indicator gauge is fixedly mounted at the upper end of the hydraulic pump. A portable switch and a portable handle are arranged on the outer surface of the hydraulic saw body. The hydraulic saw for convenient electric bed cutting is provided with an anti-slip rubber sleeve, the cooling fan and a saw blade speed regulating device, the friction between a worker and the rectangular pull rod can be increased, the heat during the working of the hydraulic saw isdischarged, the hydraulic saw is kept at a certain temperature, and the speed of a saw blade is adjusted; and the hydraulic saw is suitable for cutting various large objects, is suitable for differentworking conditions, and brings better use prospects.

Owner:JIAXING WEITELA ELECTRICAL SCI & TECH CO LTD

High-throughput multi-modal characterization system and method based on micro-nano manipulation robot

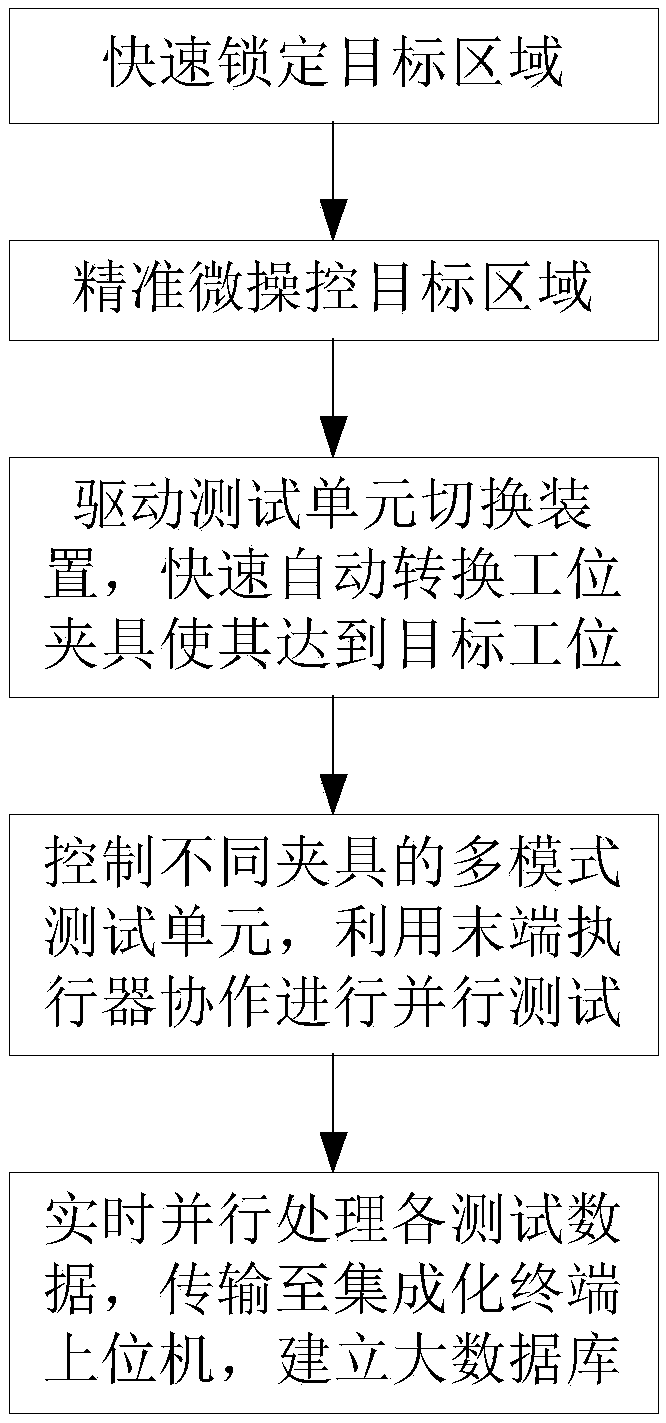

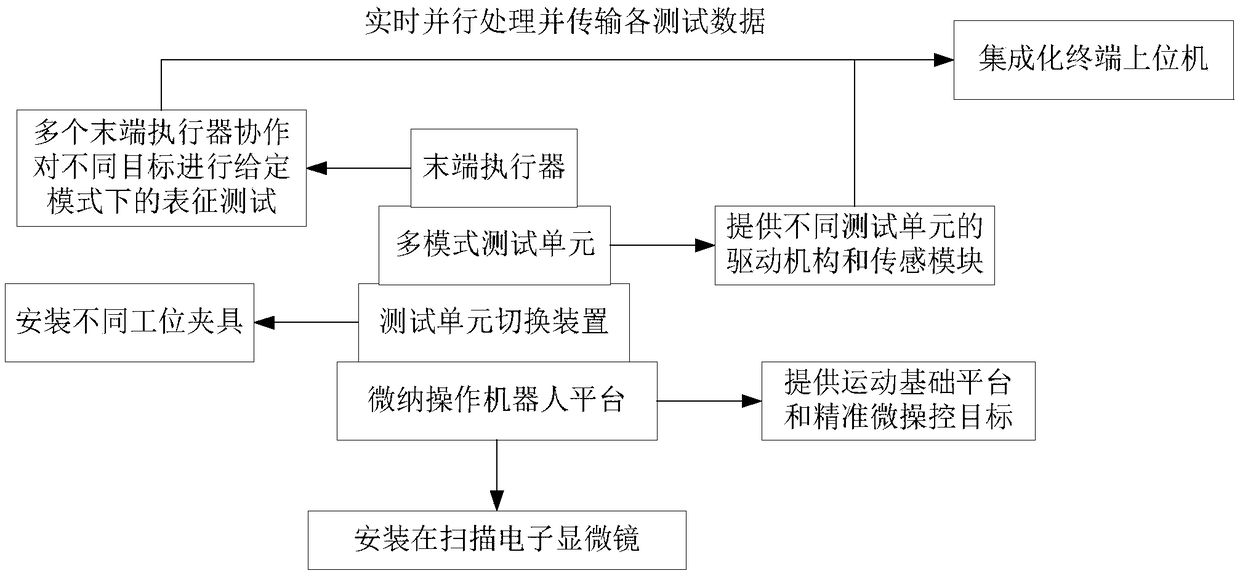

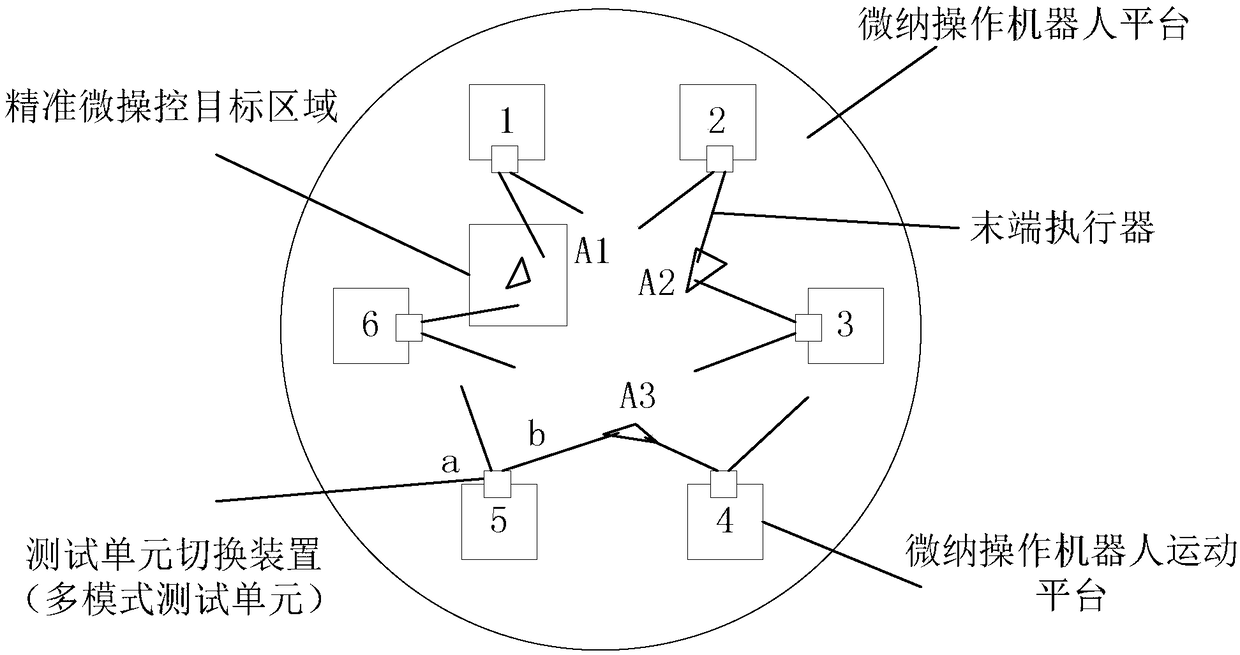

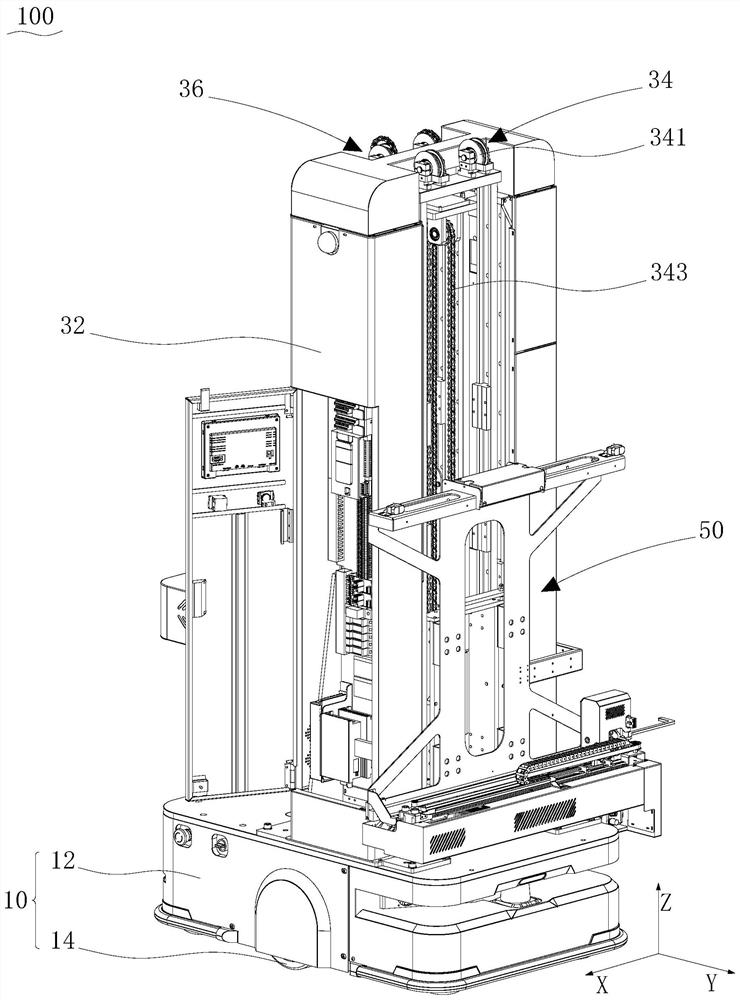

ActiveCN106426085BQuick searchImprove characterization efficiencyMicromanipulatorMicro nanoVisual field loss

The invention discloses a high-throughput multi-mode representation system and method based on a micro-nano manipulation robot. The high-throughput multi-mode representation system based on the micro-nano manipulation robot is applied under a scanning electron microscope and mainly comprises the micro-nano manipulation robot, a testing unit switching device and multi-mode testing units. The method adopted by the system comprises the following steps of: quickly locking a destination by using the large visual field search capability of the scanning electron microscope; driving the micro-nano manipulation robot to carry out accurate micro manipulation on represented objects; and realizing rapid switching of the multi-mode testing units by controlling the testing unit switching device to achieve the purposes of automatic change of end effectors and concurrent implementation of multiple performance representation, thereby realizing high-throughput multi-mode representation testing. The high-throughput multi-mode representation system has the characteristics of high-throughput multi-mode representation capability, fast manipulation speed, high representation efficiency and the like.

Owner:SHANGHAI UNIV

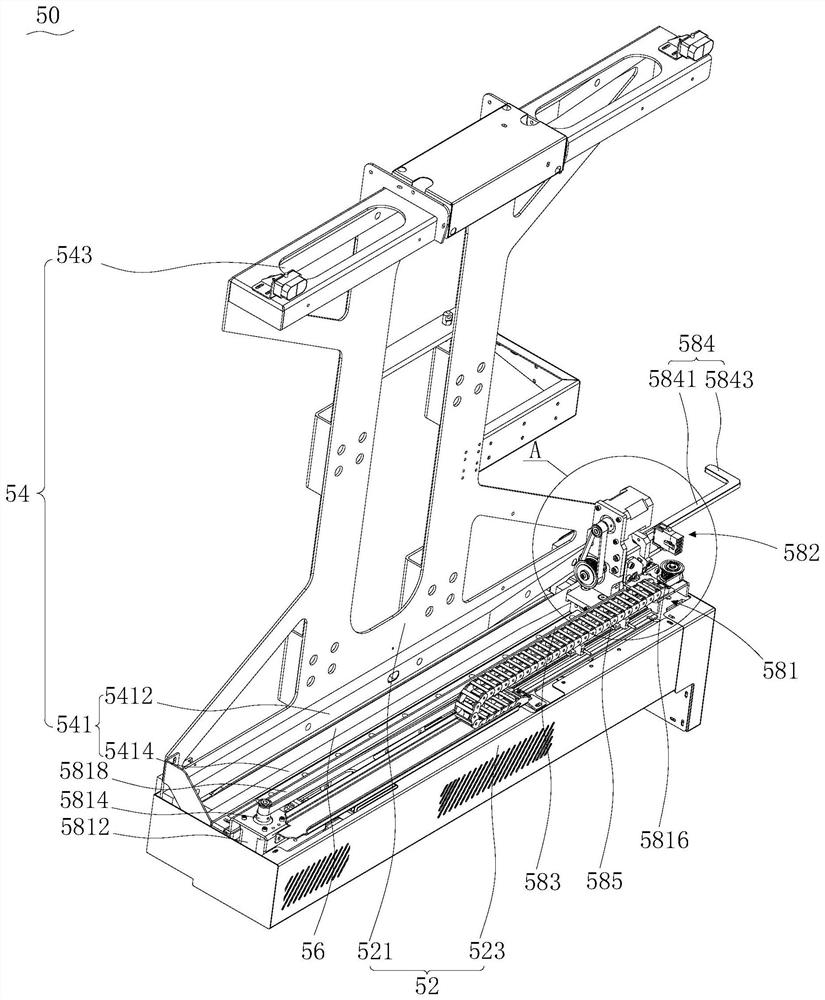

Material taking and placing equipment

InactiveCN112978349AImprove the speed of handlingImprove handling efficiencyConveyor partsStructural engineeringMechanical engineering

Owner:STANDARD ROBOTS CO LTD

Transitional transfer carrying device for milk tea machine

ActiveCN111891743AIncrease inclusivenessHandling will not affectConveyorsPackagingEngineeringVertical motion

The invention discloses a transitional transfer carrying device for a milk tea machine. The transitional transfer carrying device comprises a rack, a carrying mechanism and a transverse driving mechanism; the carrying mechanism comprises a carrying seat, a clamping seat arranged on the carrying seat, a clamping mechanism arranged on the clamping seat and a first vertical driving mechanism used fordriving the clamping seat to do vertical motion, and the carrying mechanism further comprises a bearing mechanism used for bearing the bottom of a milk tea cup; and the bearing mechanism comprises abearing seat, a bearing plate arranged on the bearing seat, a second vertical driving mechanism used for driving the bearing seat to do vertical motion, and a bearing driving mechanism used for driving the bearing plate to rotate so as to realize the separation of the bottom of the milk tea cup. According to the transitional transfer conveying device for the milk tea machine, transitional transferof milk tea cups with other conveying devices can be realized, and a transfer platform is not required to be additionally arranged, so that the conveying speed and the conveying efficiency are improved.

Owner:临沂市高新汽车租赁服务有限公司

Control method and control device for controlling rotation of turnplate of pump truck and pump truck

ActiveCN106481080AEnsure safetyImprove the speed of handlingBuilding material handlingAngular velocityTruck

The invention discloses a control method and a control device for controlling rotation of a turnplate of a pump truck and the pump truck. The control device comprises the following steps: acquiring the current boom tail end amplitude; according to the current boom tail end amplitude and the maximum boom tail end linear velocity, acquiring the turnplate rotating maximum set angular velocity under the current tail end amplitude; according to the maximum set angular velocity, determining the relationship between the turnplate rotating angular velocity and the opening angle of an operating handle; according to the current opening angle of the operating handle and the determined relationship between the turnplate rotating angular velocity and the opening angle of the operating handle, controlling the turnplate to rotate at the corresponding angular velocity. By the control device, the maximum turnplate rotating set angular velocity can be dynamically controlled according to the boom tail end amplitude, and the control rapidness of a boom of the pump truck is improved on the basis that the safety of users and equipment is ensured.

Owner:雷萨股份有限公司

Control method of movable platform, remote control device of movable platform and movable platform assembly

ActiveCN112189331AEasy to controlImprove operating experienceTelevision system detailsColor television detailsRemote controlControl engineering

The invention relates to a control method of a movable platform, a remote control device (200) of the movable platform and a movable platform assembly. The movable platform comprises a first functionmodule (110) and a second function module (120), and the remote control device (200) comprises a first control part (210); the method is applied to the remote control device (200). The method comprises: acquiring trigger information of a first control unit (210) (S201); if the trigger information is used to indicate that the first control unit (210) is in the first trigger state, controlling the operation of the first function module (110) (S202); and if the trigger information is used to indicate that the first control unit (210) is in the second trigger state, controlling the operation of the second function module (120) (S203). Through multiplexing control of the first control part (210) of the remote control device (200), control over the first function module (110) and the second function module (120) is achieved, the control speed and convenience are improved, the control stability and reliability are improved, and good operation experience is brought to a user.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com