Patents

Literature

34results about How to "Power drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

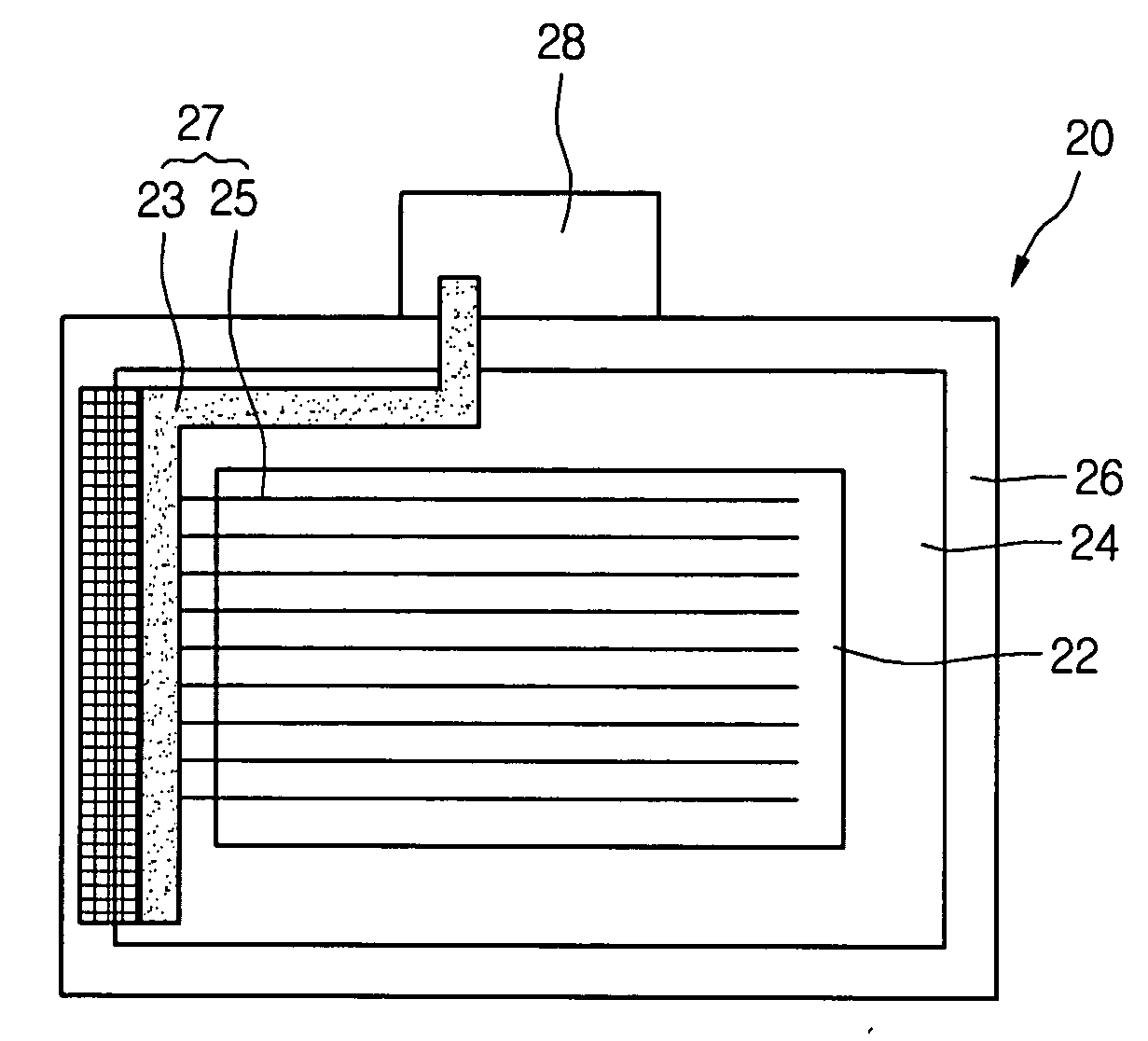

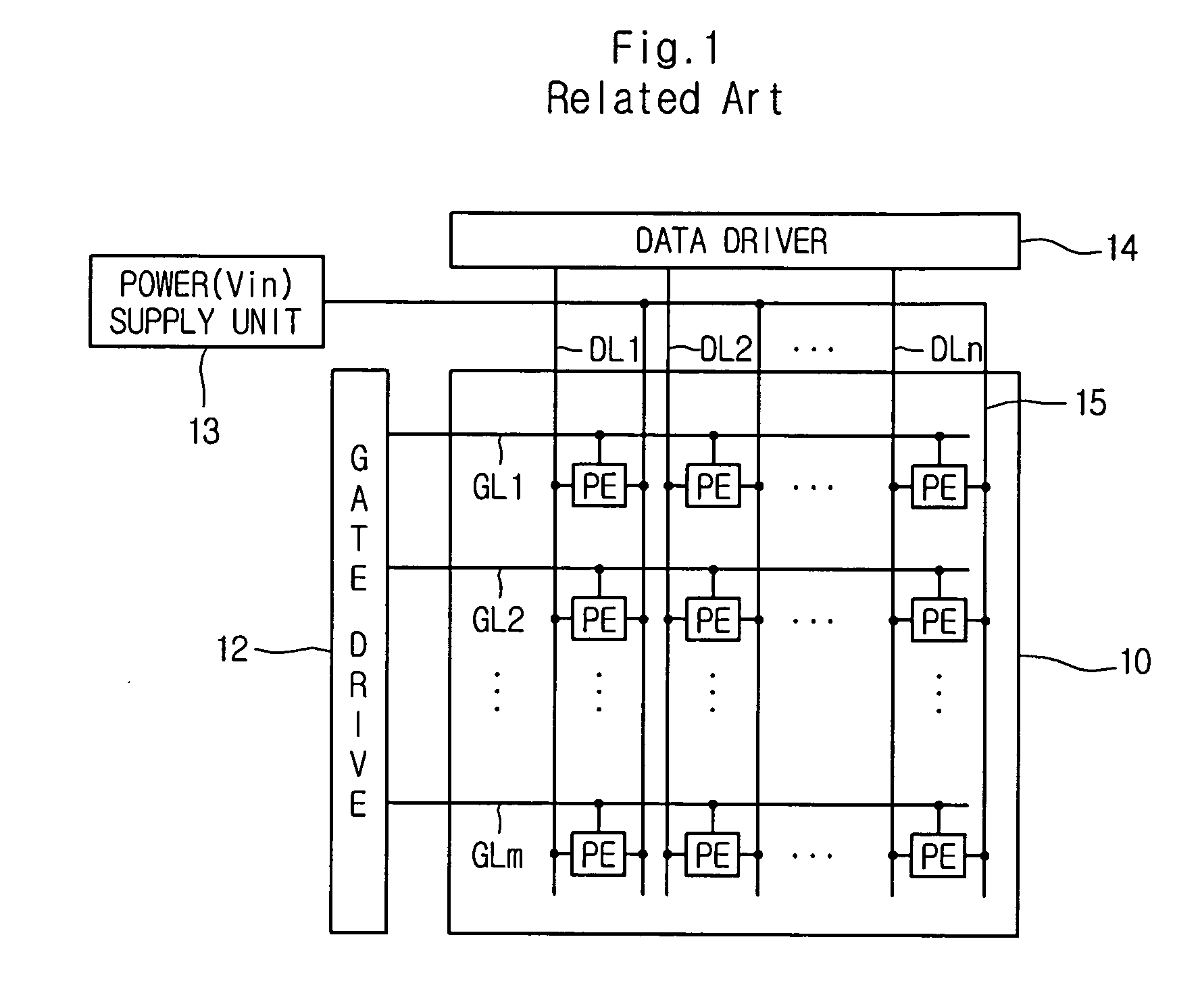

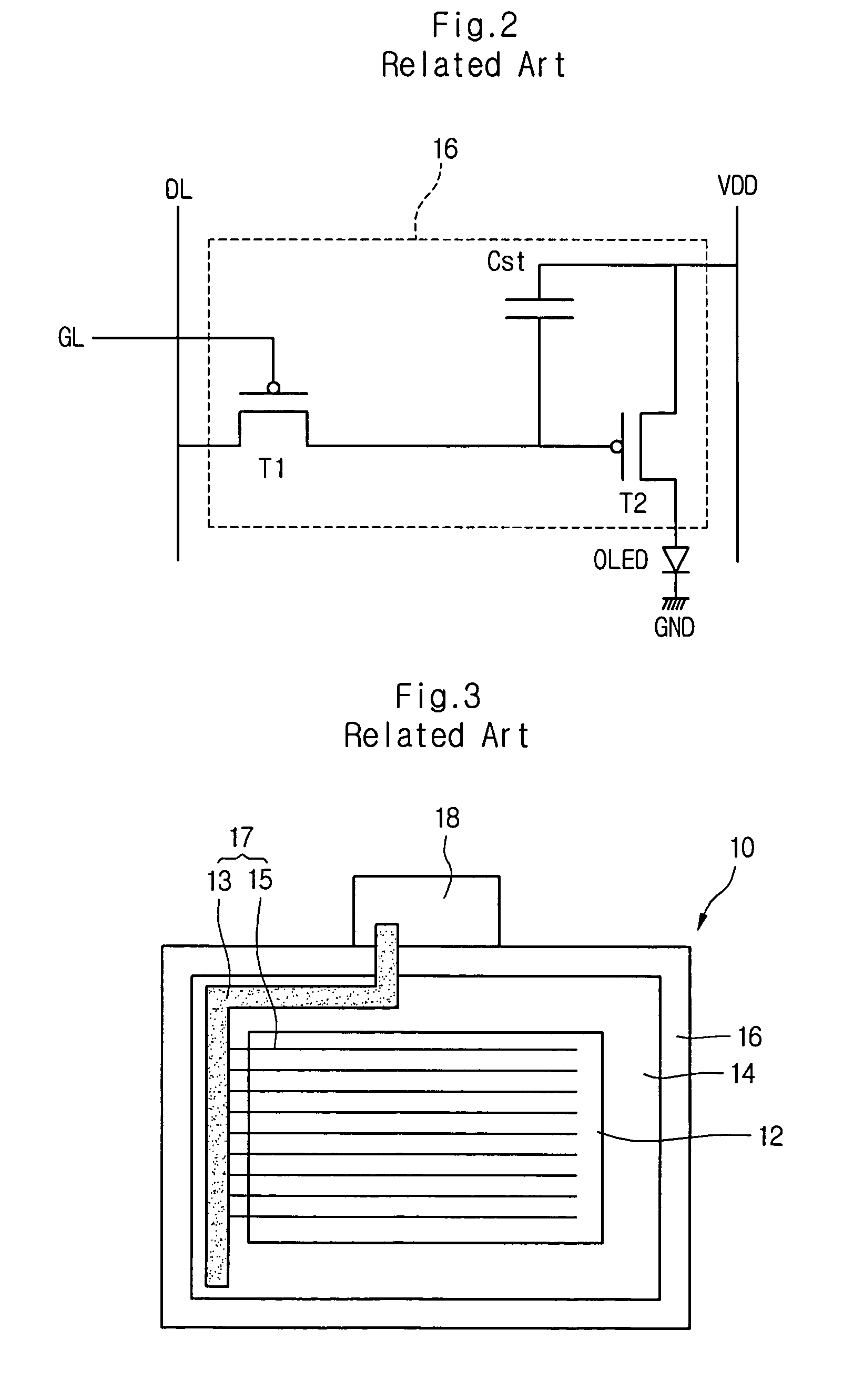

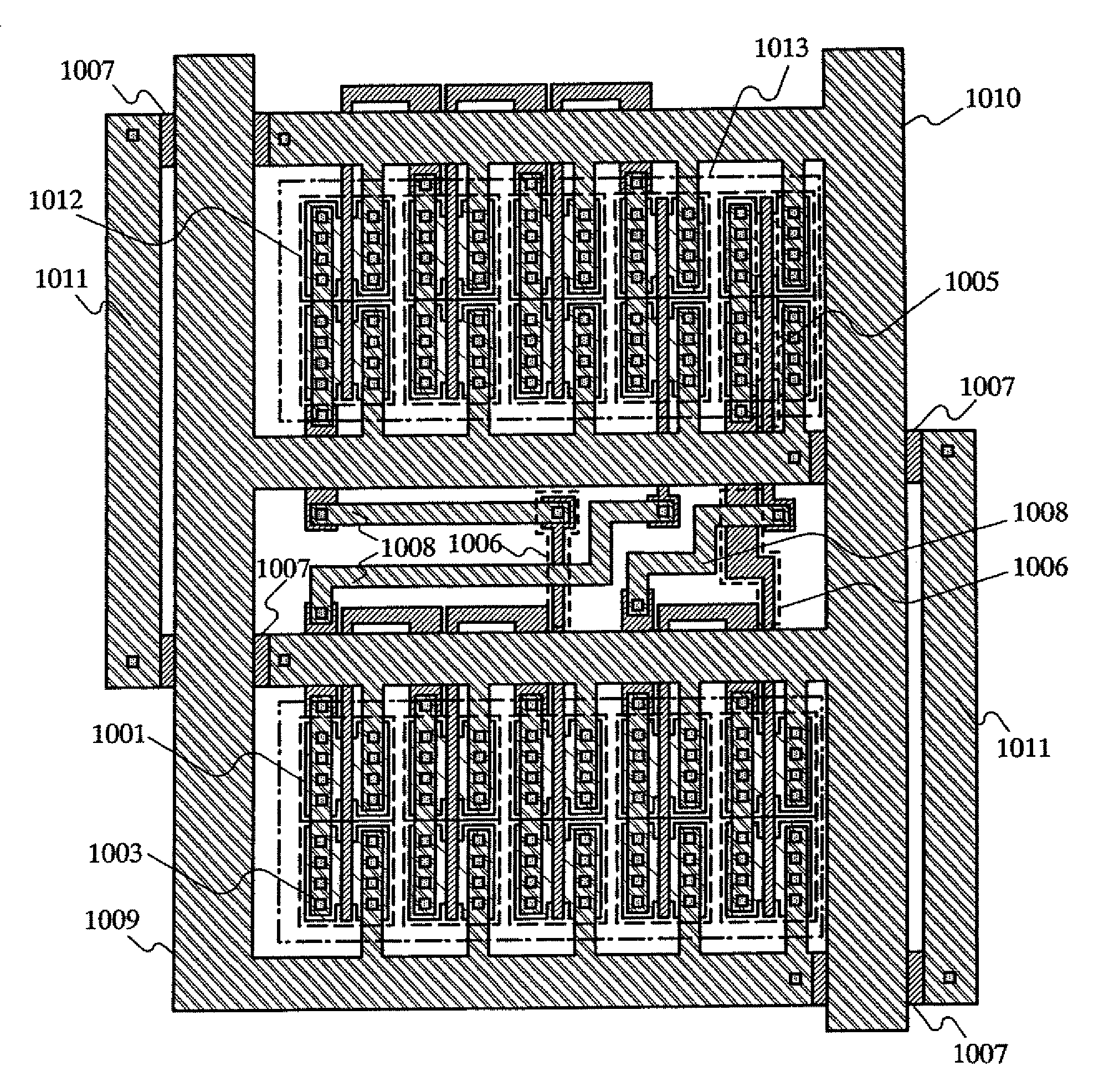

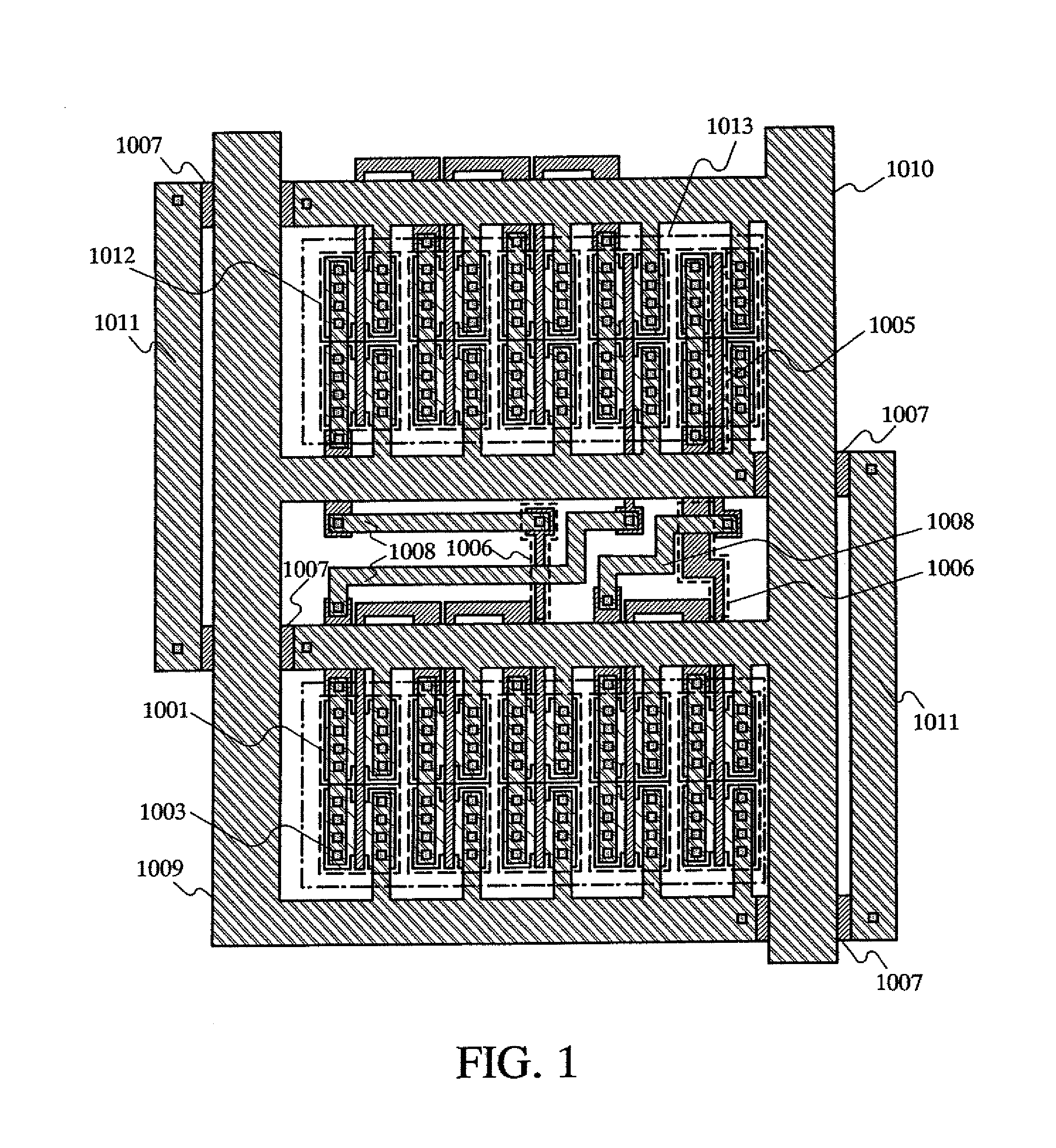

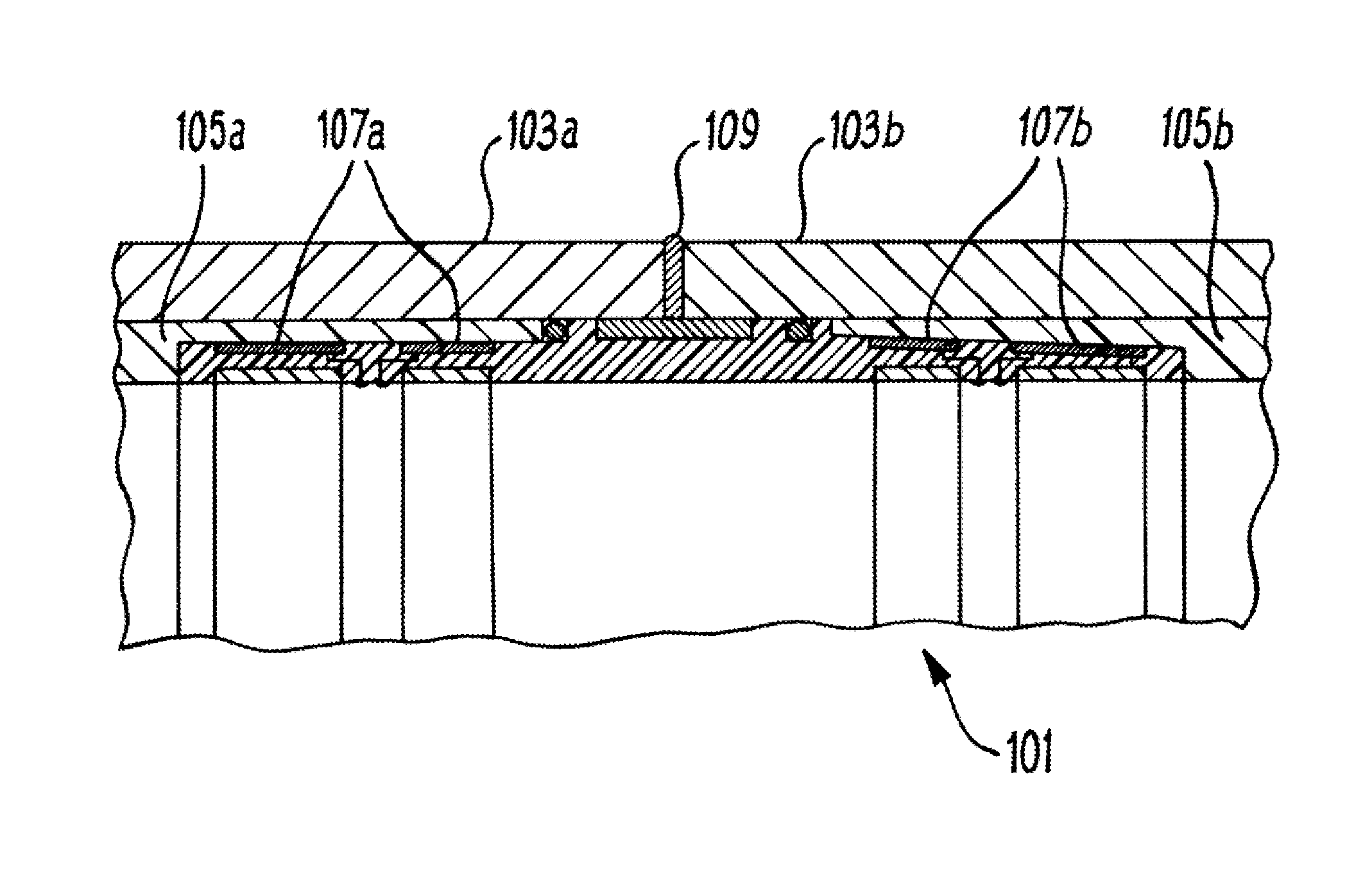

Active matrix organic light emitting display panel

ActiveUS20060250083A1Reduce voltage dropPower dropDischarge tube luminescnet screensStatic indicating devicesActive matrixVoltage

An active matrix organic light emitting display panel includes a first substrate including a seal pattern region, a non-display region, and a display region, the non-display region being between the display region and the seal pattern region, a pad connected to the first substrate, and a power line including a routing line connected directly to the pad, and a pixel line for applying a pixel voltage to a plurality of pixels, the routing line having a first portion being in the non-display region and a second portion being in the seal pattern region, and the pixel line being in the display region.

Owner:LG DISPLAY CO LTD

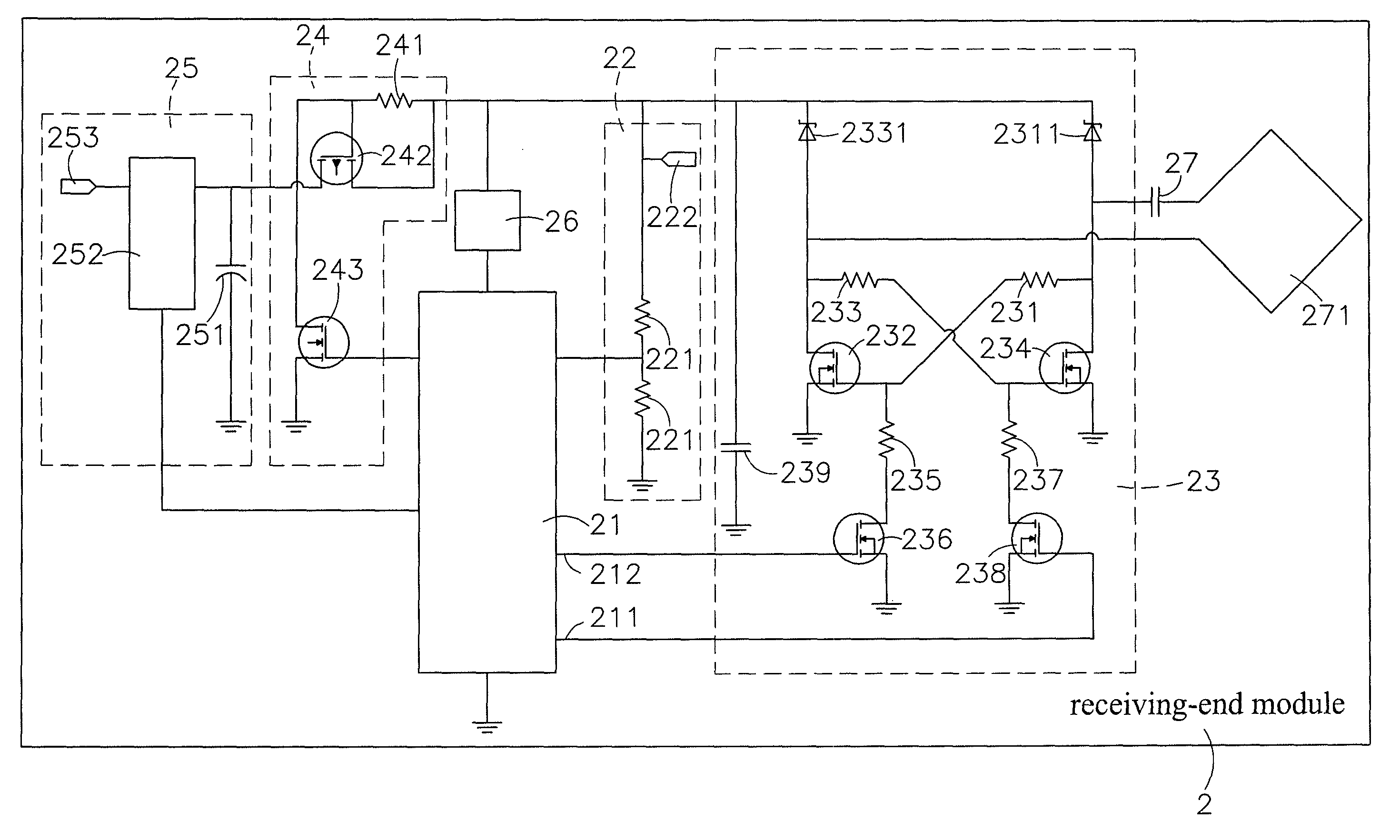

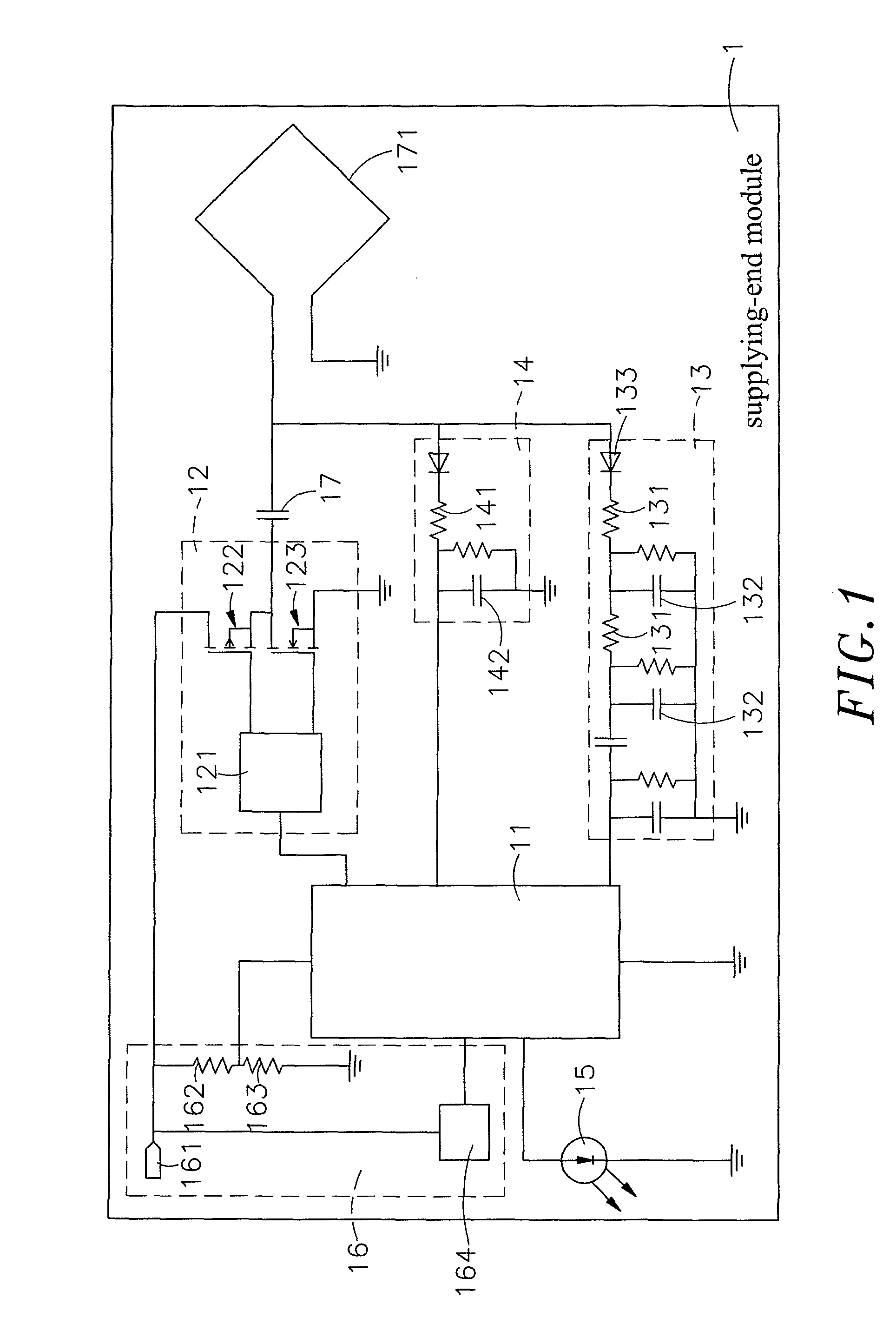

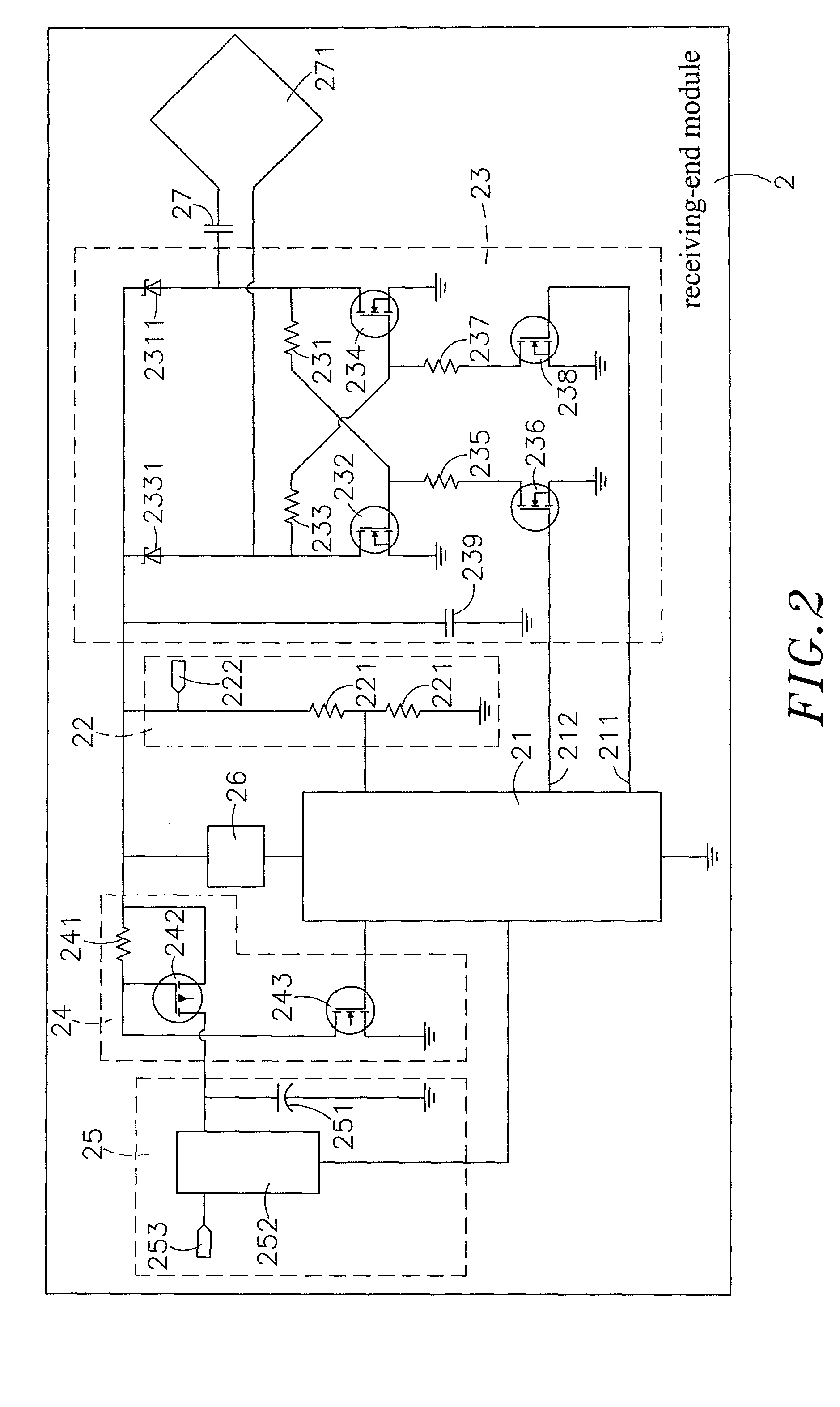

Induction type power supply system with synchronous rectification control for data transmission

ActiveUS9075587B2Improve the level ofIncrease power levelNear-field transmissionTransformersElectric power transmissionTransfer procedure

An induction type power supply system with synchronous rectification control for data transmission is disclosed to include a supplying-end module with a supplying-end coil and a receiving-end module with a receiving-end coil for receiving power supply from the supplying-end coil and providing a feedback data signal to the supplying-end coil during power supply transmission subject to the operation of a rectifier and signal feedback circuit of the receiving-end module that breaks off electric current transiently to change the load characteristics of the receiving-end coil, assuring a high level of data signal transmission stability and a high level of power transmission efficiency.

Owner:FU TONG TECH

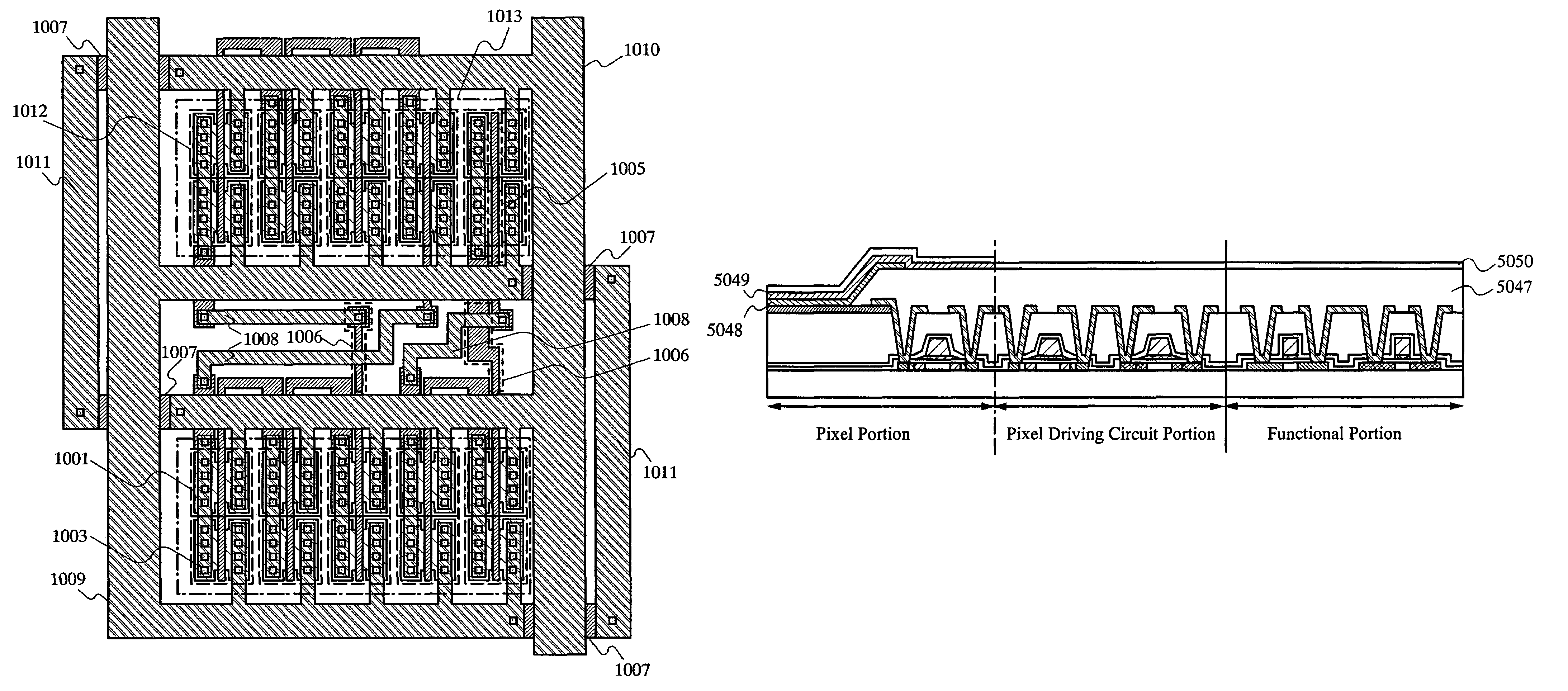

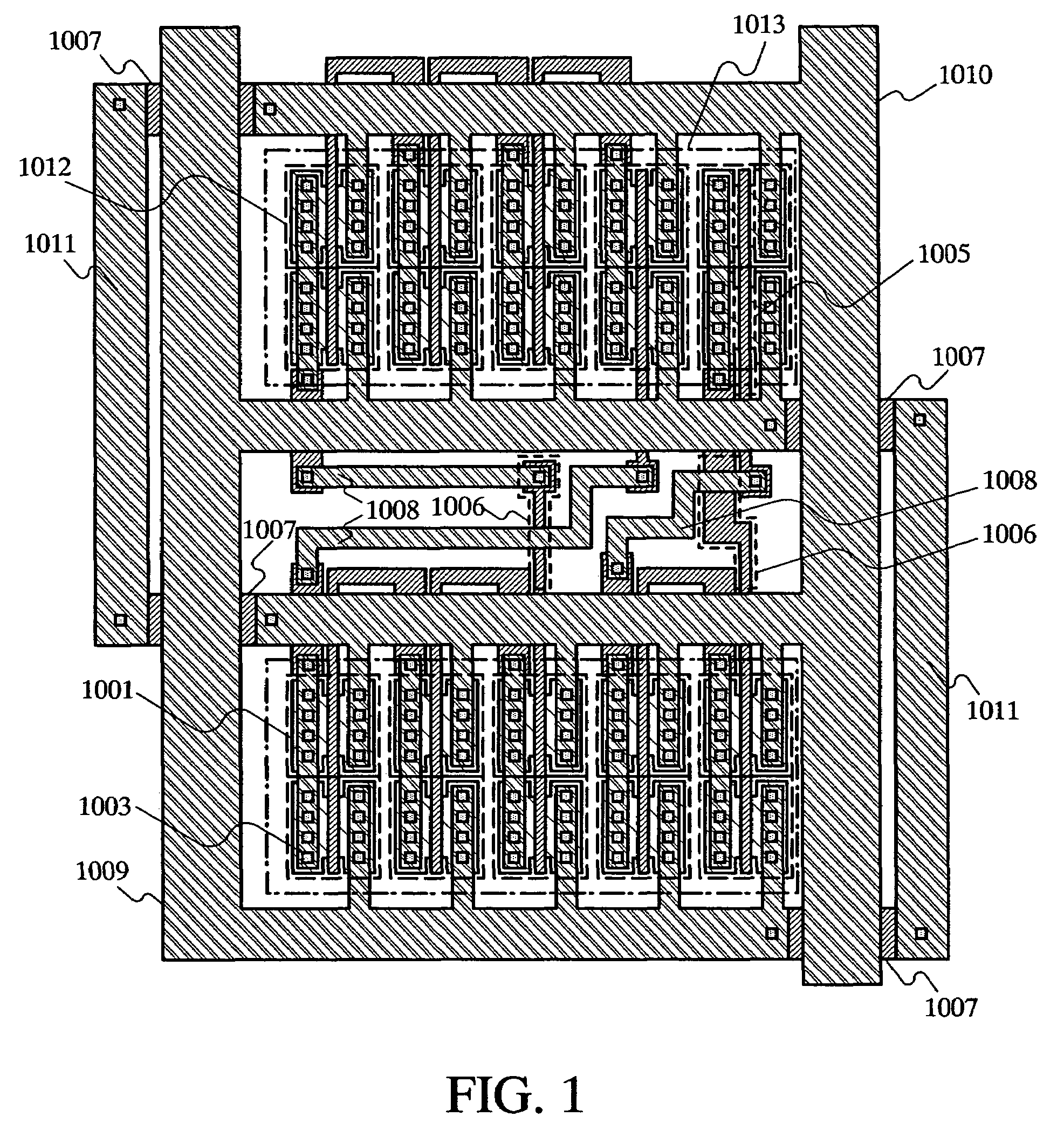

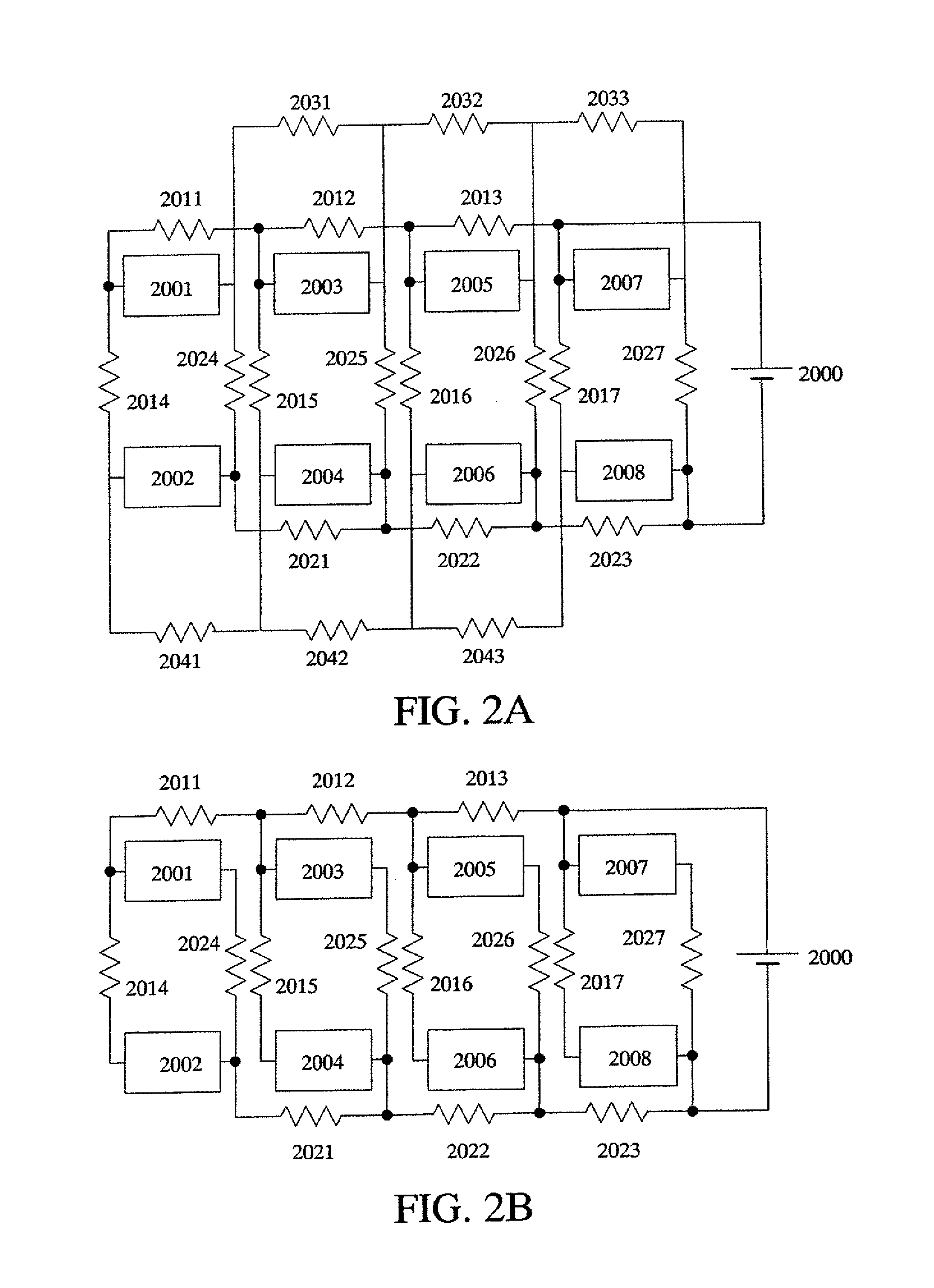

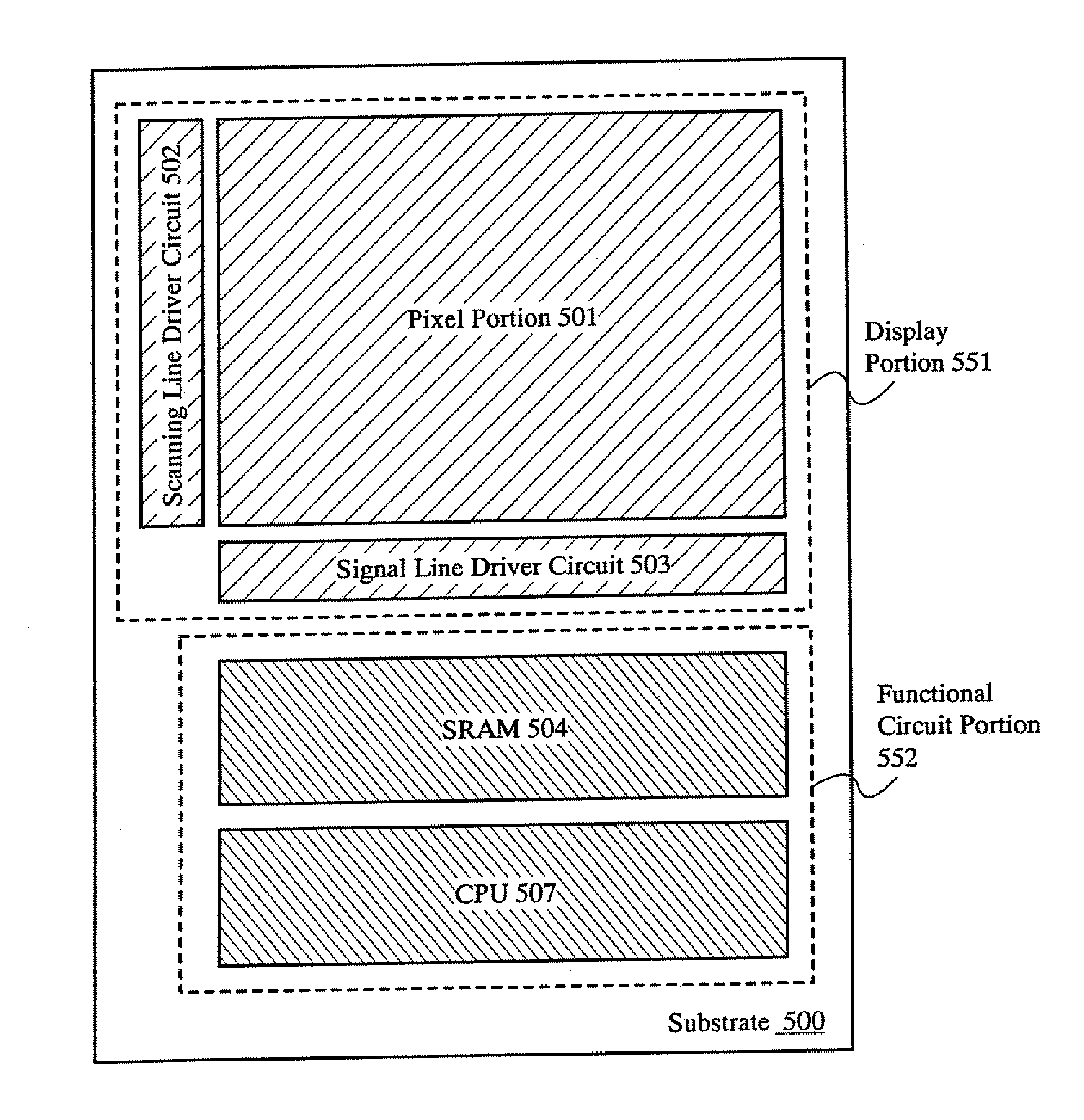

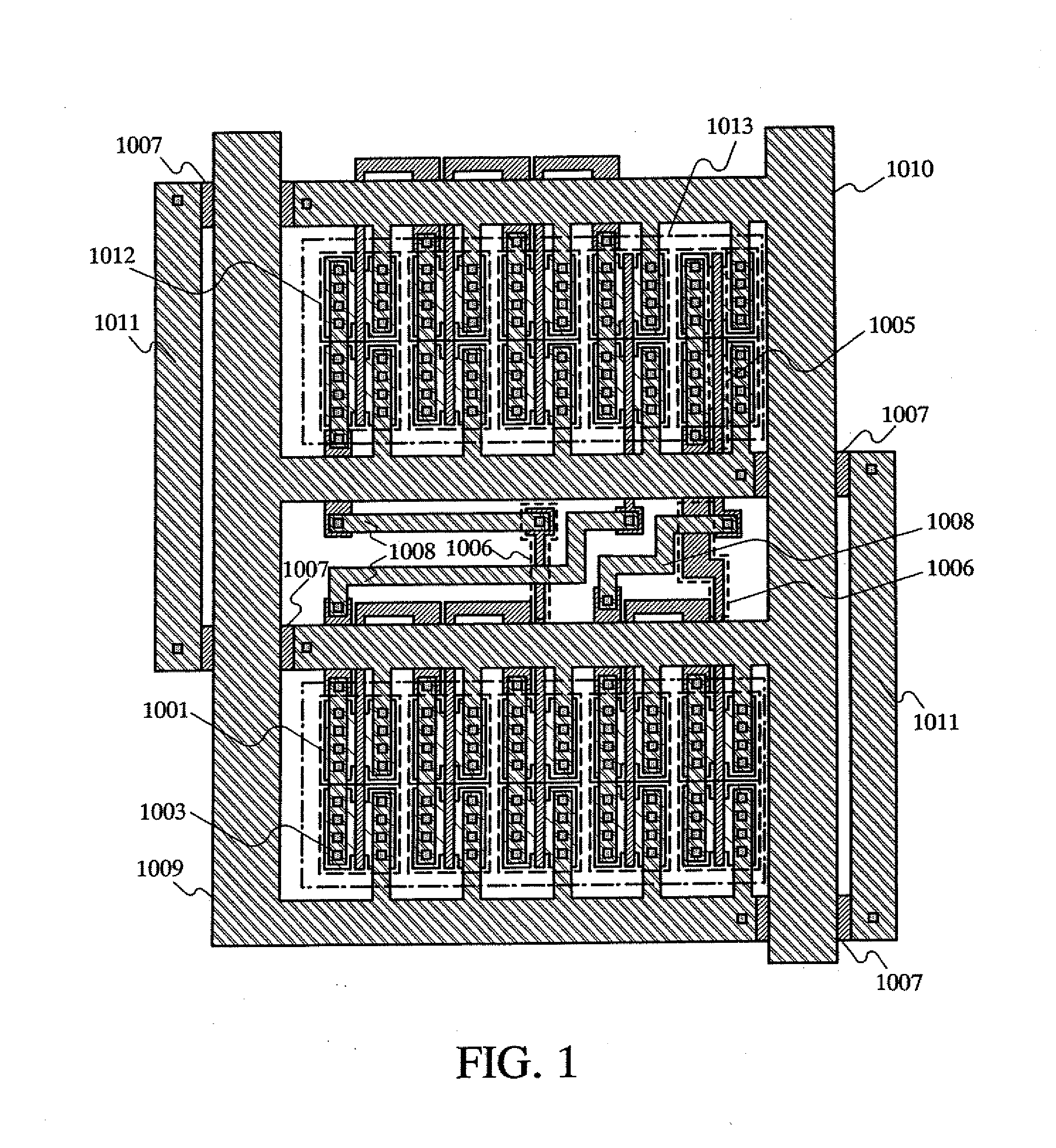

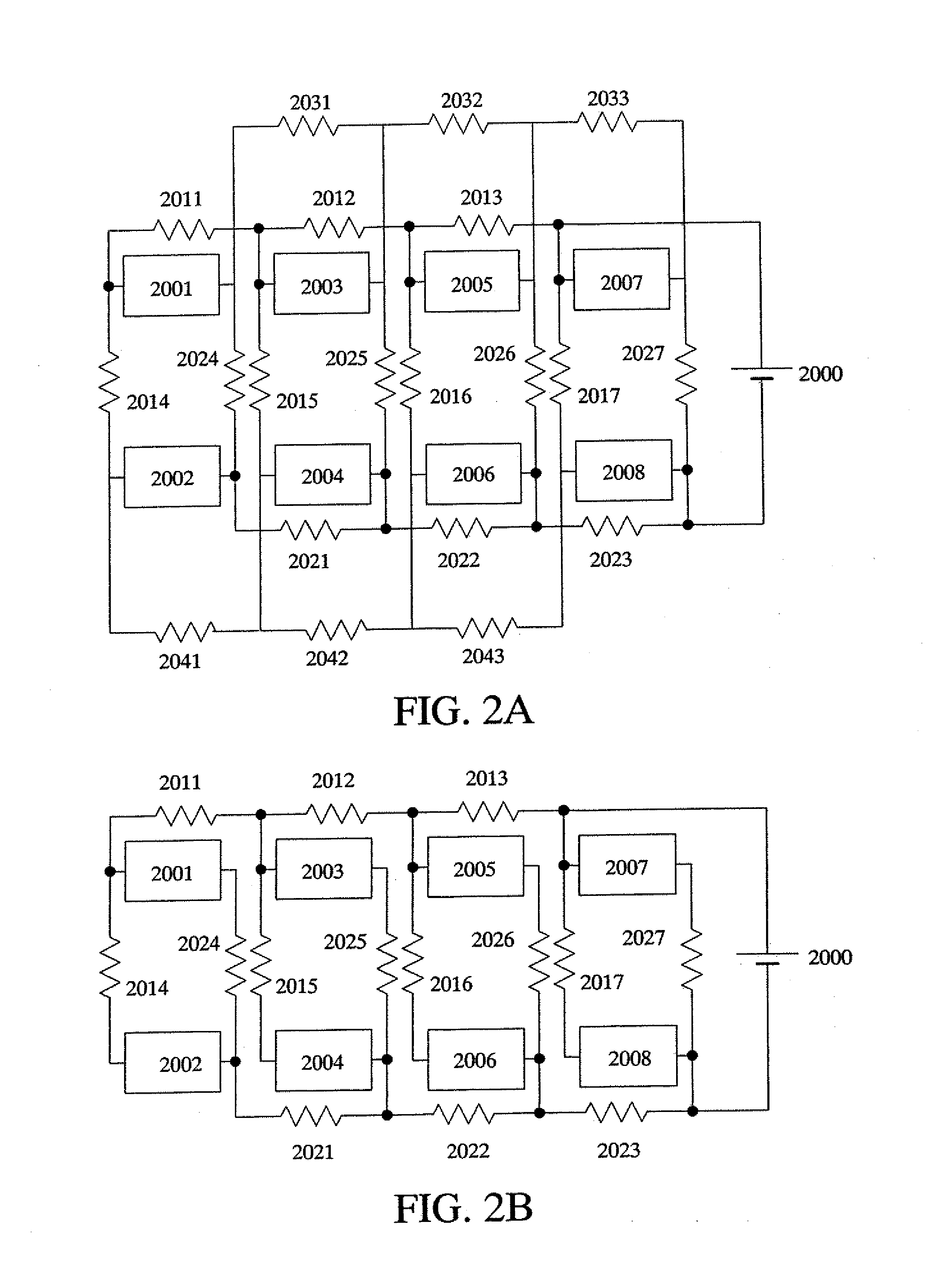

Semiconductor device and display device

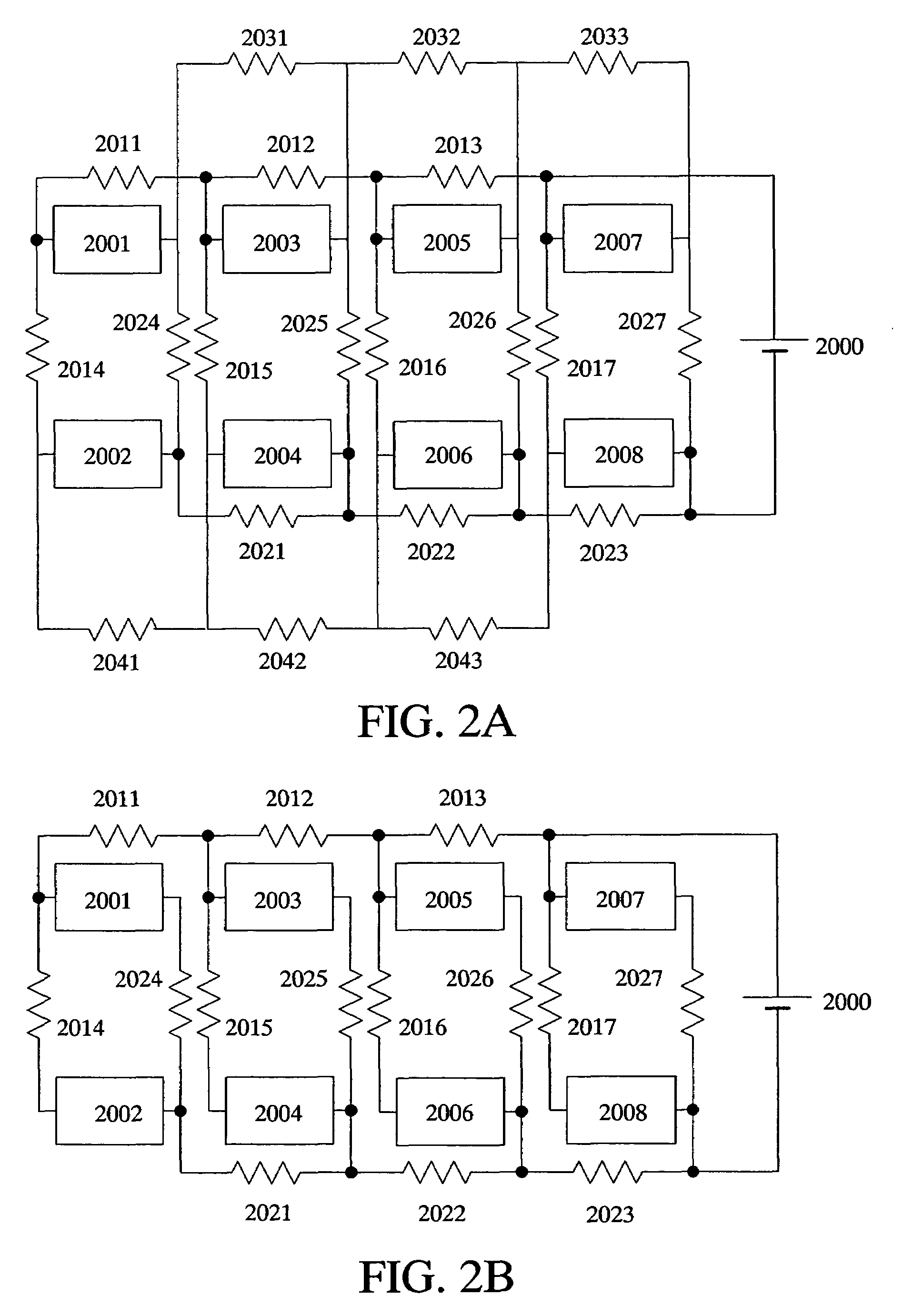

ActiveUS7408196B2Reduce areaIncreased ground voltageSemiconductor/solid-state device detailsSolid-state devicesElectricityPower semiconductor device

It is an object of the invention to provide a thin, lightweight, high performance, and low in cost semiconductor device and a display device by reducing an arrangement area required for a power supply wiring and a ground wiring of a functional circuit and decreasing a drop in power supply voltage and a rise in ground voltage.In the functional circuit of the semiconductor device and the display device, a power supply wiring and a ground wiring are formed in a comb-like arrangement, and the tips thereof are electrically connected with a first wiring, a second wiring, and a contact between the first wiring and the second wiring, thereby forming in a grid-like arrangement. The drop in power supply voltage and the rise in ground voltage can be decreased and the arrangement area can be decreased in the grid-like arrangement.

Owner:SEMICON ENERGY LAB CO LTD

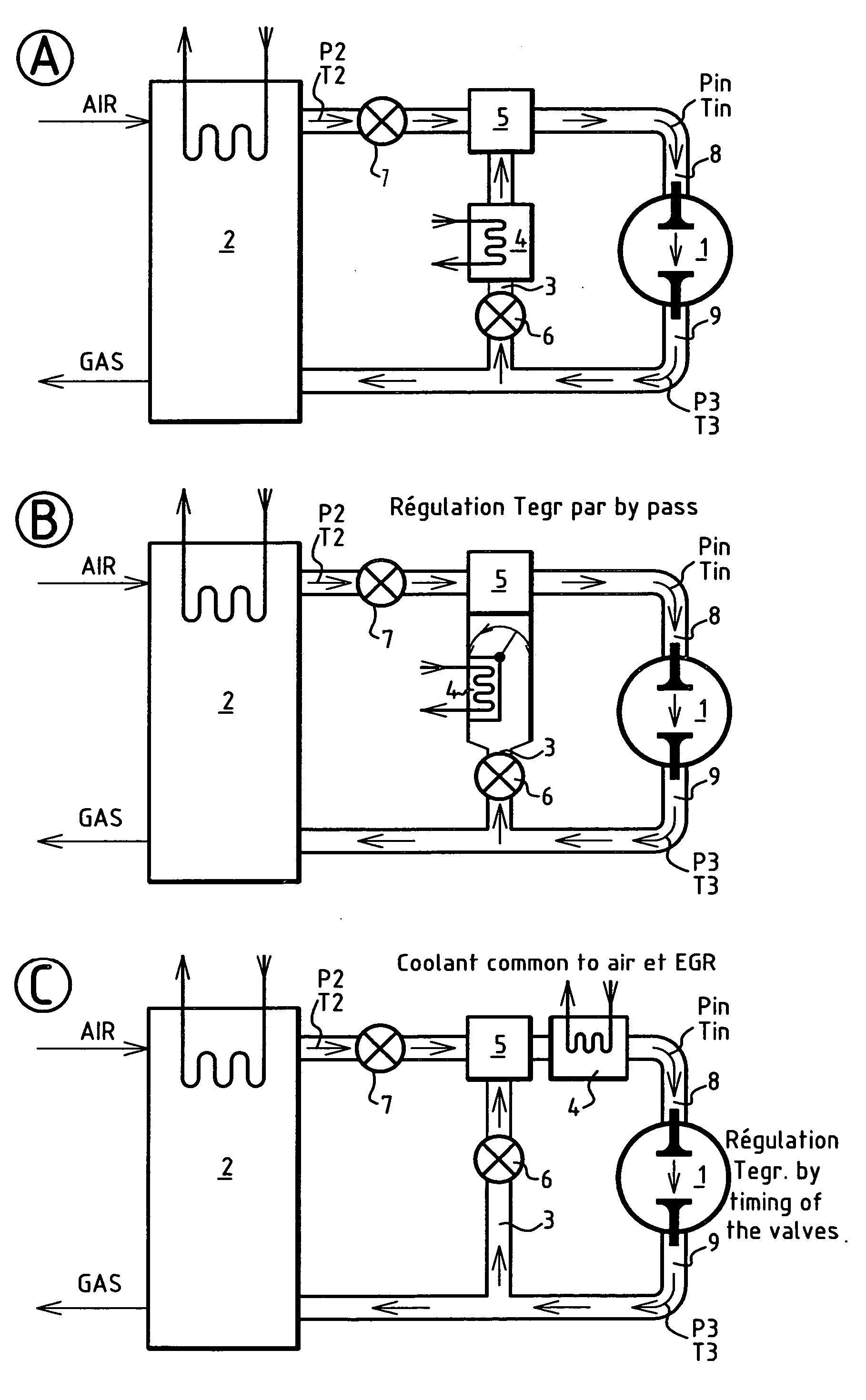

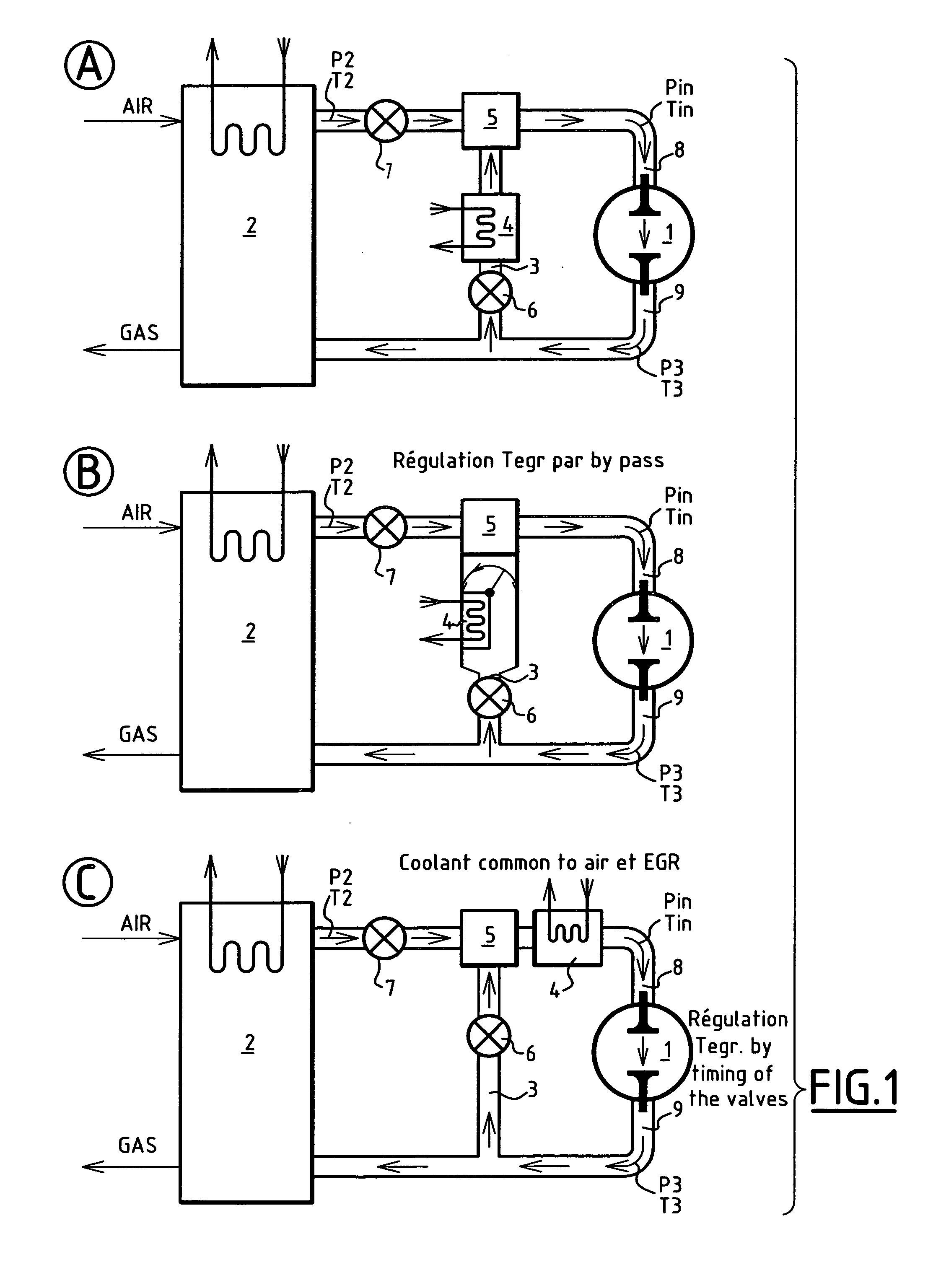

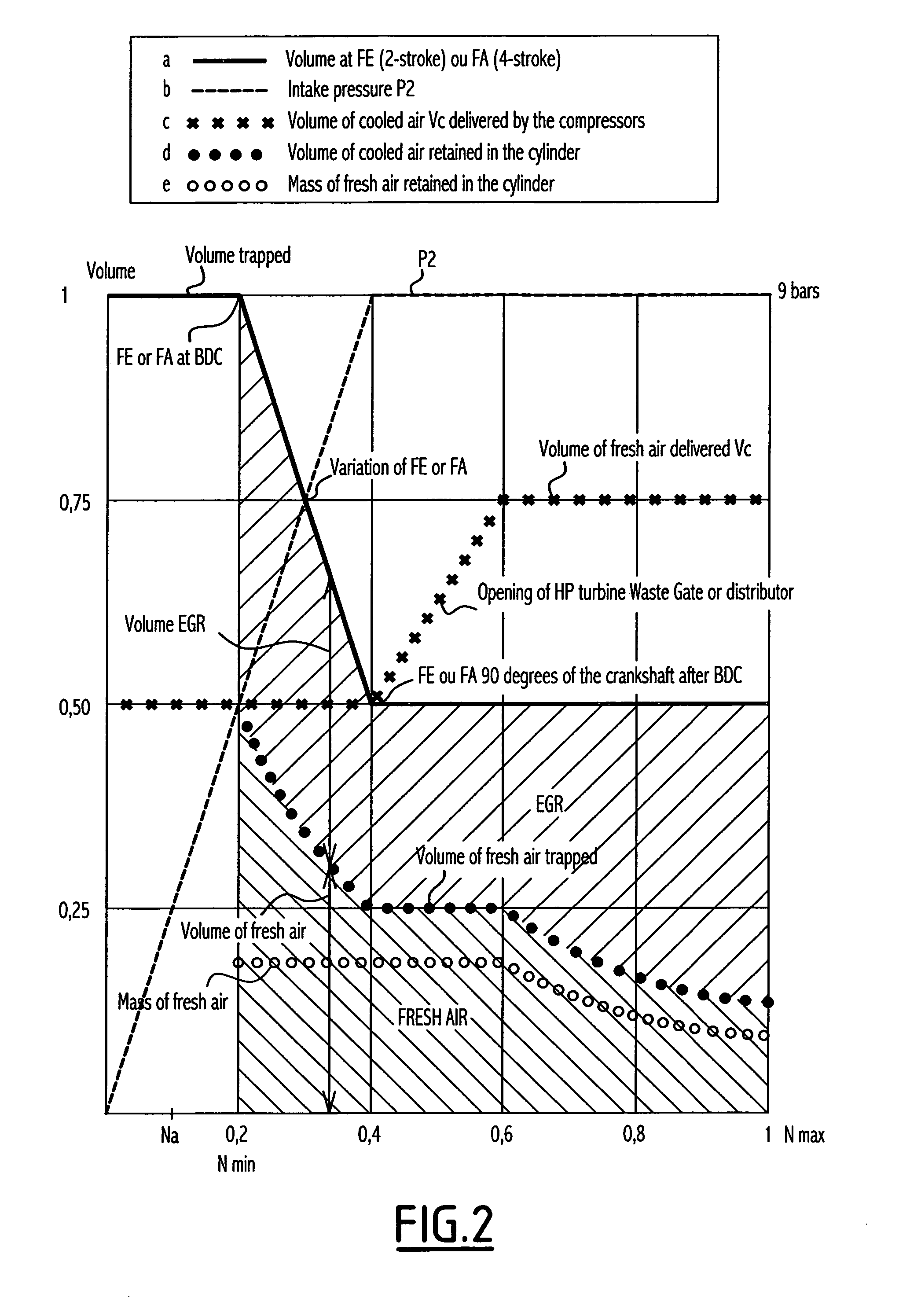

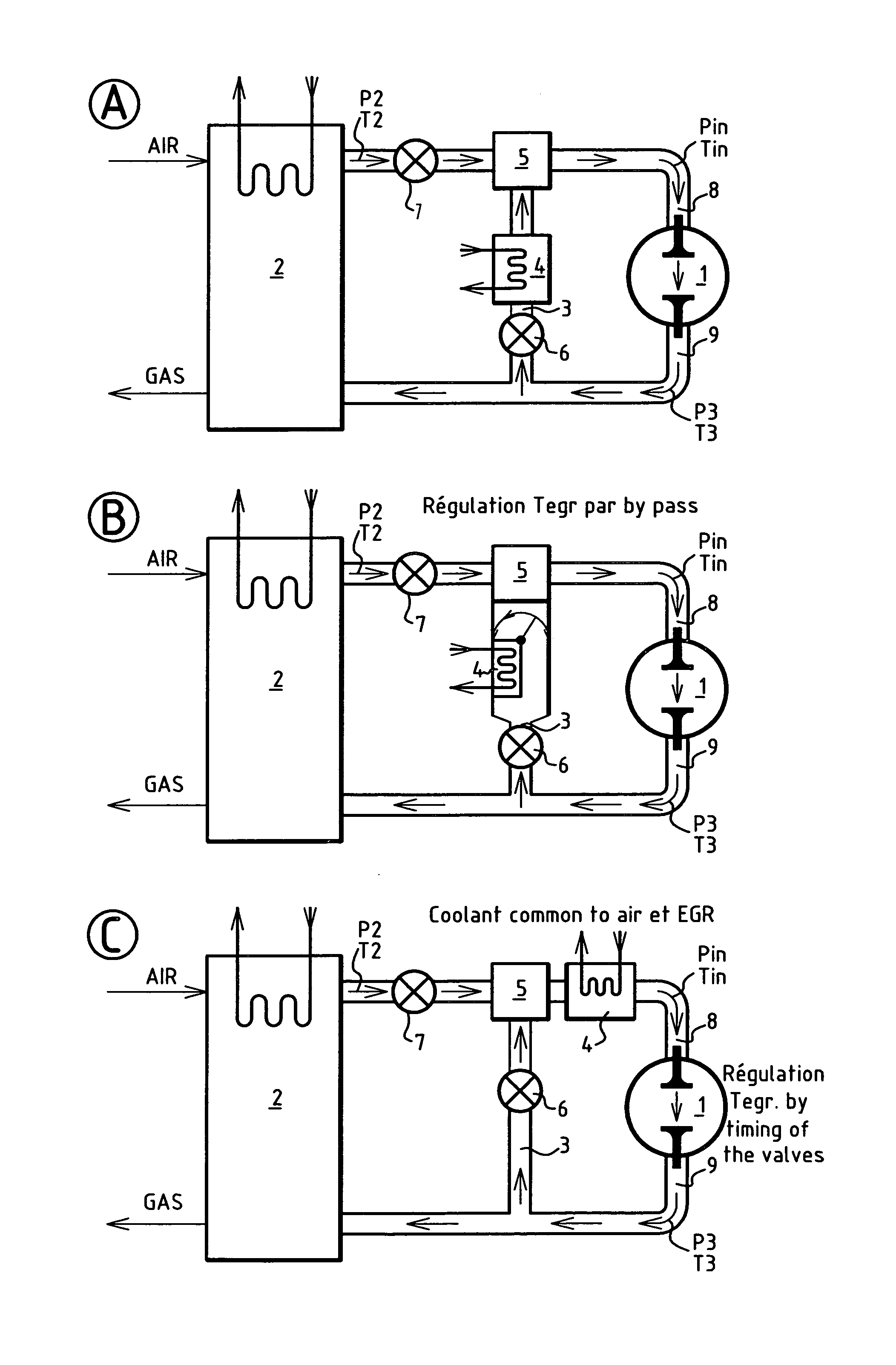

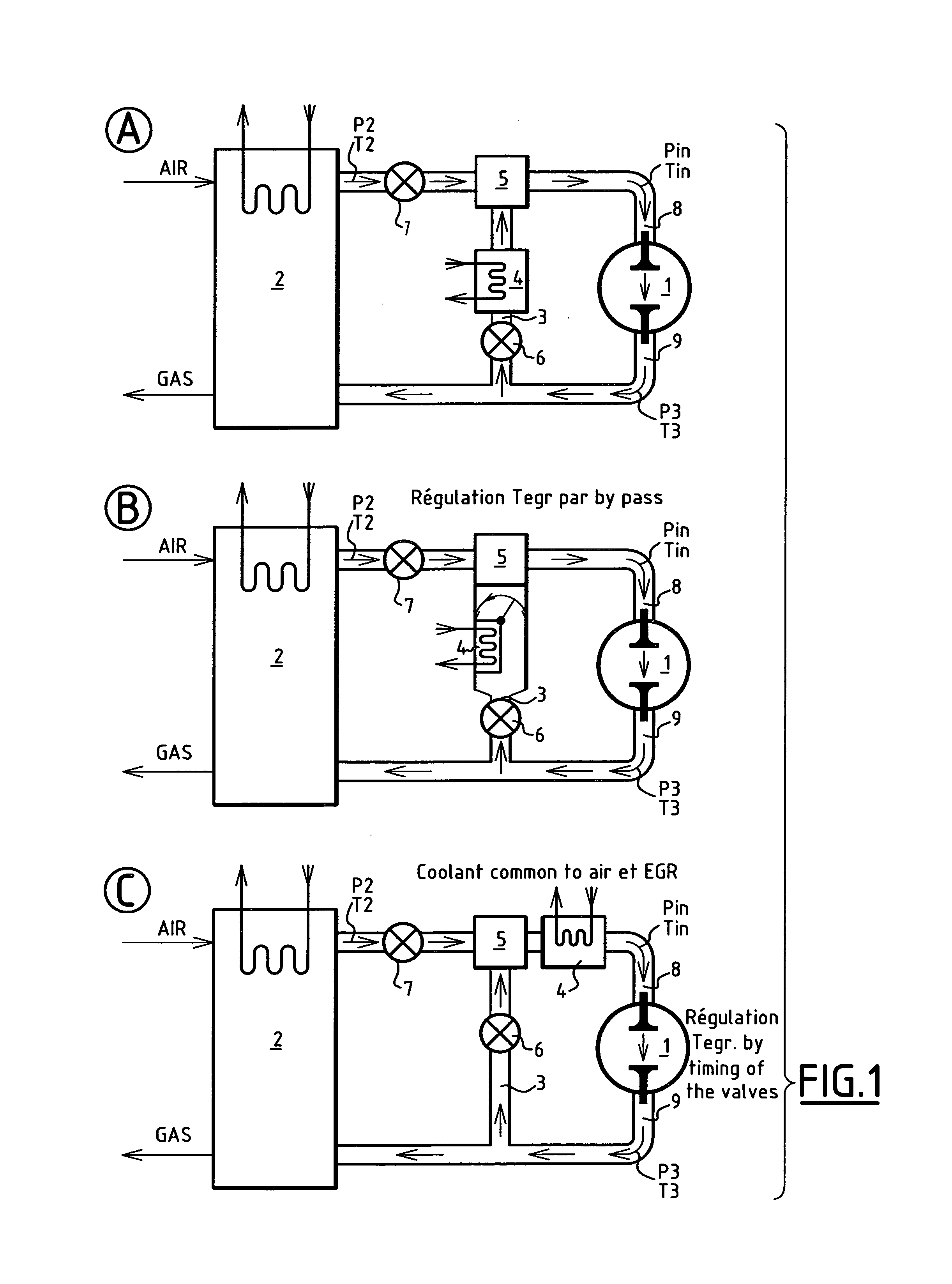

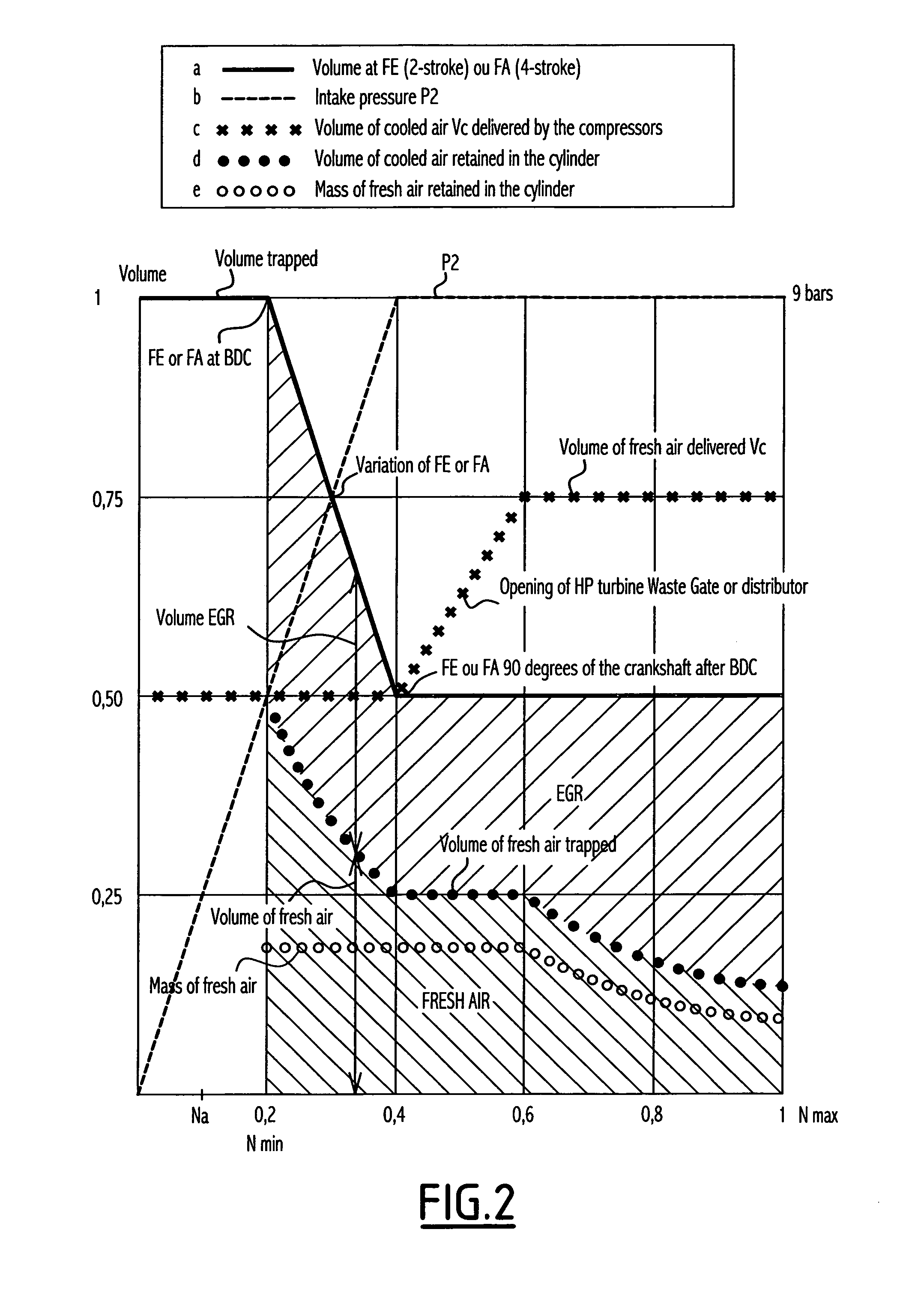

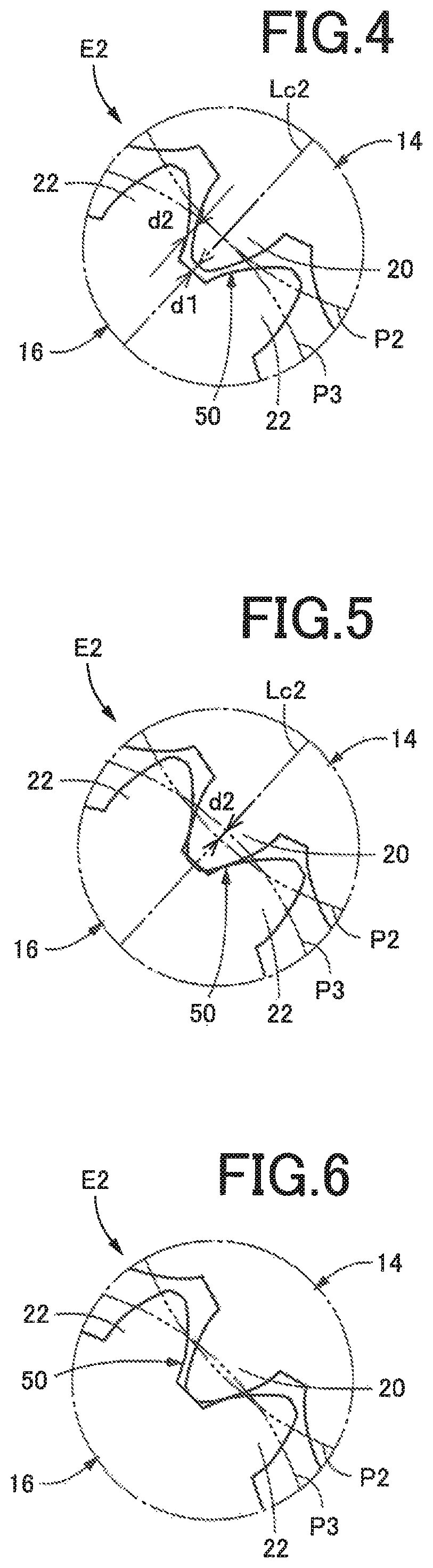

Alternative (reciprocating) engine with recirculation of exhaust gases intended for the propulsion of automobiles and method turbocharging these motors

InactiveUS20070271919A1Power dropReduce time lagNon-fuel substance addition to fuelInternal combustion piston enginesTurbineDischarge pressure

A reciprocating engine includes a turbocharging unit that: supplies the intake manifold with air via a coolant; is supplied with gas by the exhaust manifold; and has the turbine supply pressure substantially equal to the compressor discharge pressure. At constant air temperature, the turbocharging unit delivers a substantially constant volume of cooled air when the pressure varies, and the volume is substantially proportional to the turbine outlet section. The turbine pressure is maintained substantially equal to compressor pressure by a EGR bypass between the intake and exhaust manifold. In addition, the volume of air is less than the volume drawn in at the speed so that a flow of hot gases is drawn in again via the bypass above the speed, where the volume drawn in is equal to the volume, and a flow of air is deflected towards the turbine below the speed.

Owner:MELCHIOR

Alternative (reciprocating) engine with recirculation of exhaust gases intended for the propulsion of automobiles and method turbocharging these motors

InactiveUS7313918B2Increase the proportion of EGR and/or the engine torqueIncrease boost pressureNon-fuel substance addition to fuelInternal combustion piston enginesDischarge pressureTurbine

A reciprocating engine includes a turbocharging unit that: supplies the intake manifold with air via a coolant; is supplied with gas by the exhaust manifold; and has the turbine supply pressure substantially equal to the compressor discharge pressure. At constant air temperature, the turbocharging unit delivers a substantially constant volume of cooled air when the pressure varies, and the volume is substantially proportional to the turbine outlet section. The turbine pressure is maintained substantially equal to compressor pressure by a EGR bypass between the intake and exhaust manifold. In addition, the volume of air is less than the volume drawn in at the speed so that a flow of hot gases is drawn in again via the bypass above the speed, where the volume drawn in is equal to the volume, and a flow of air is deflected towards the turbine below the speed.

Owner:MELCHIOR

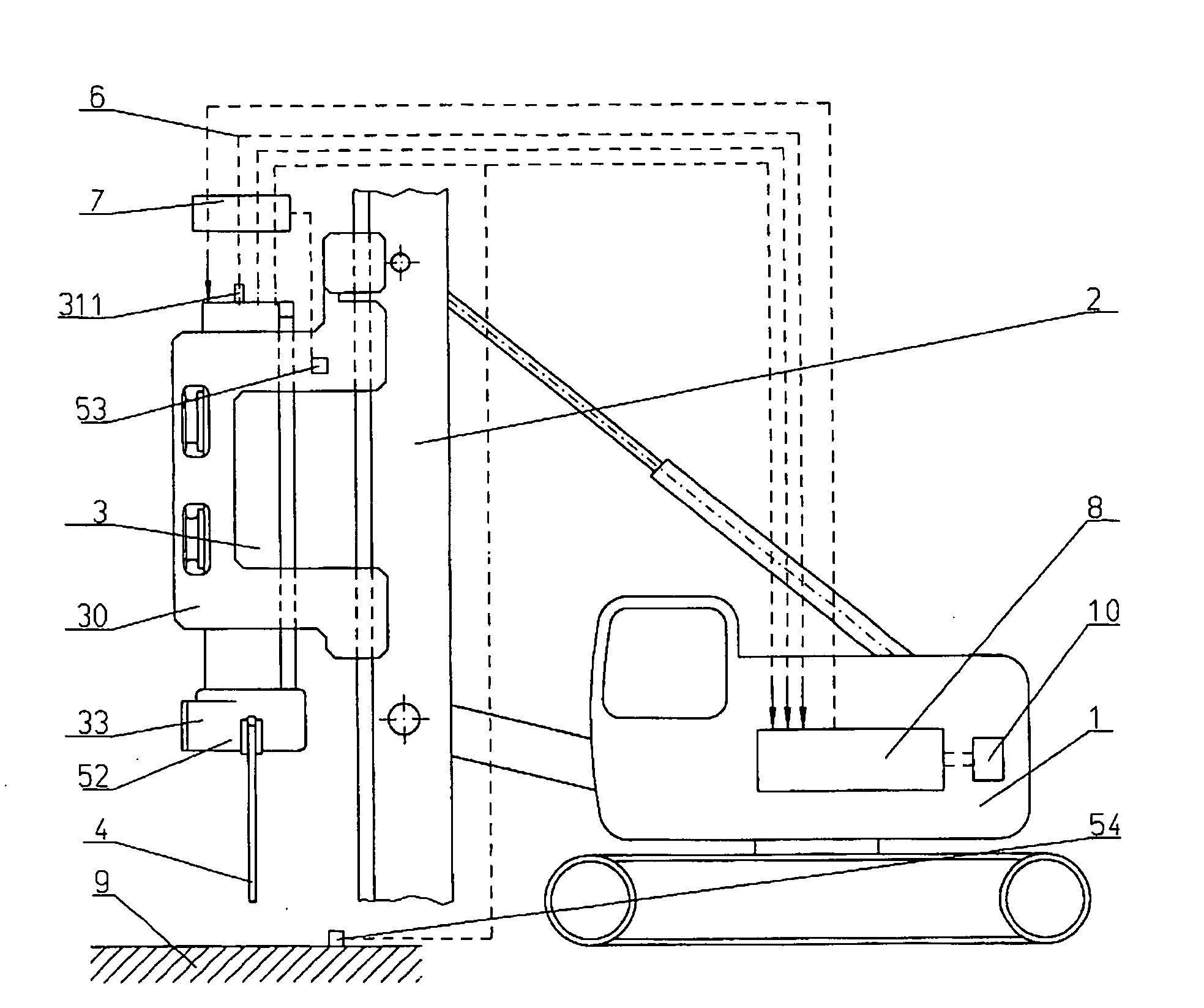

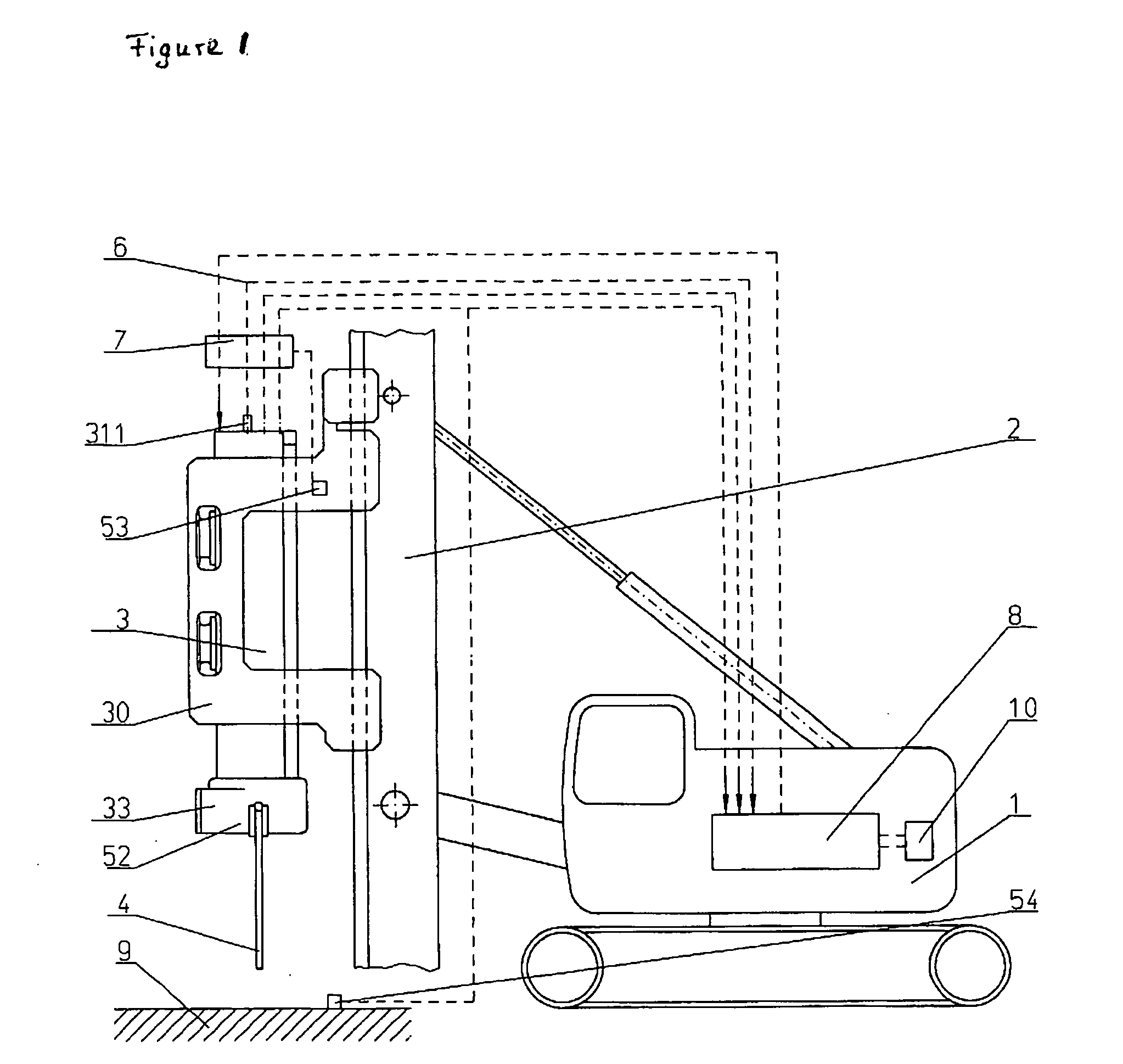

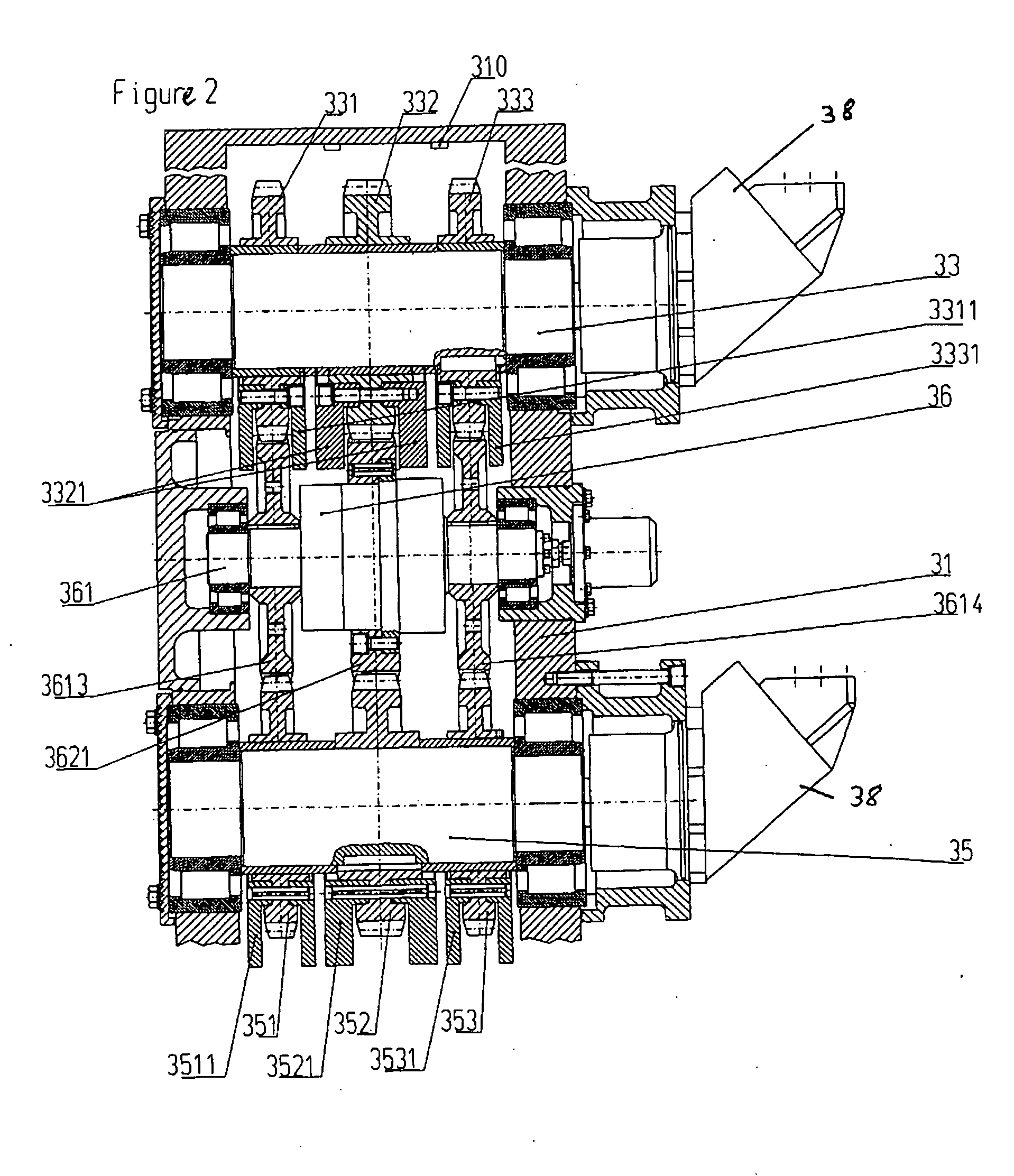

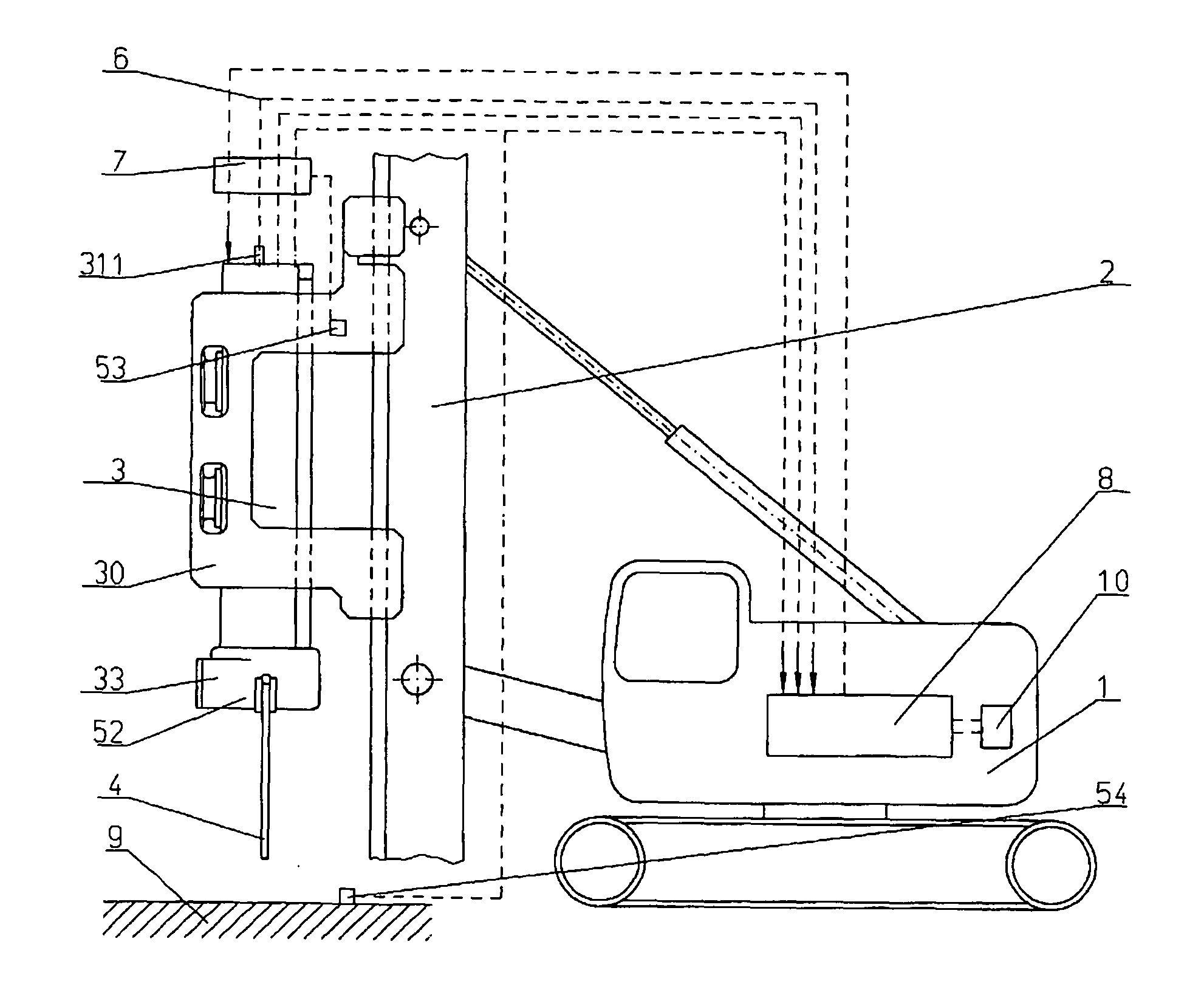

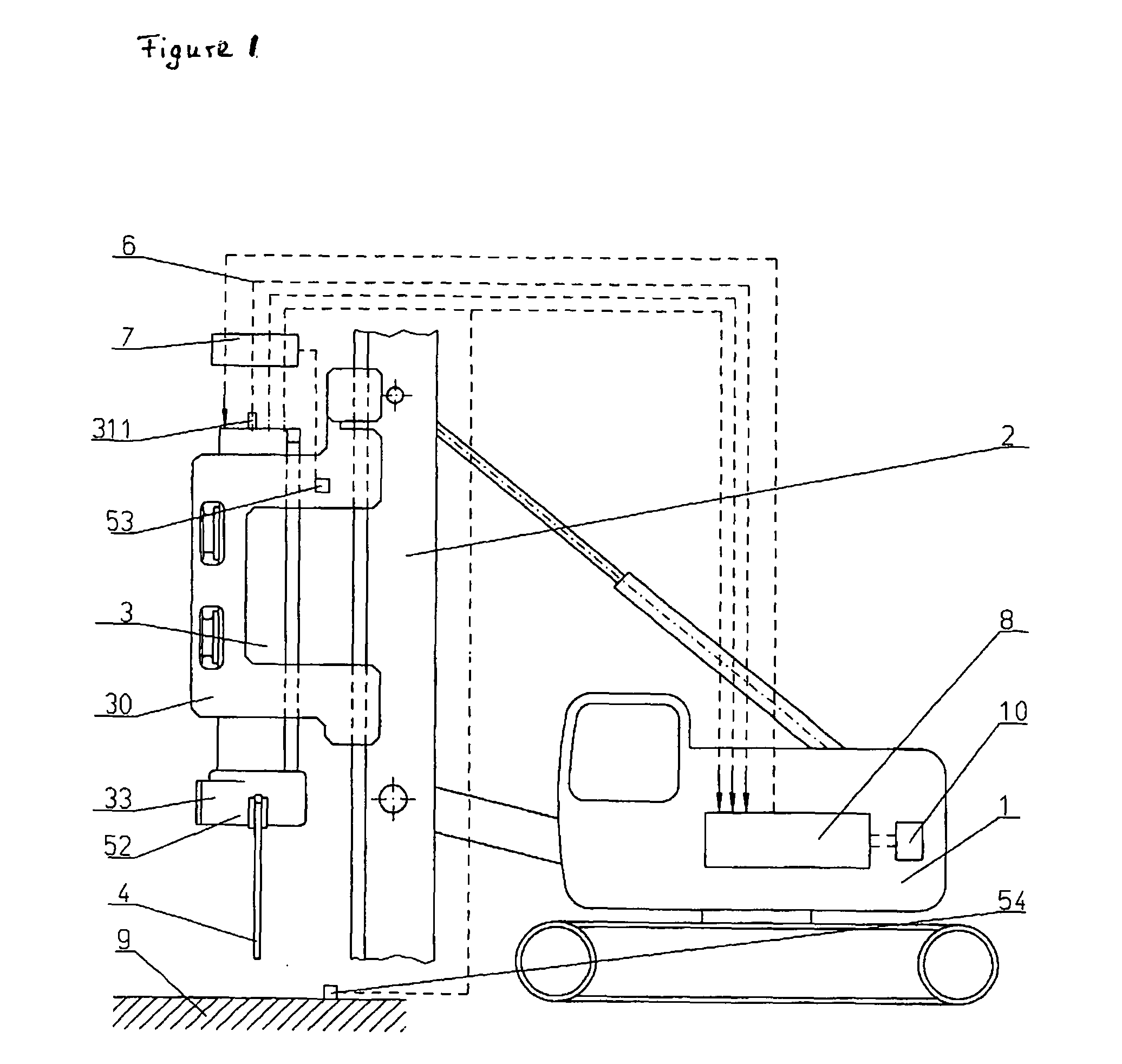

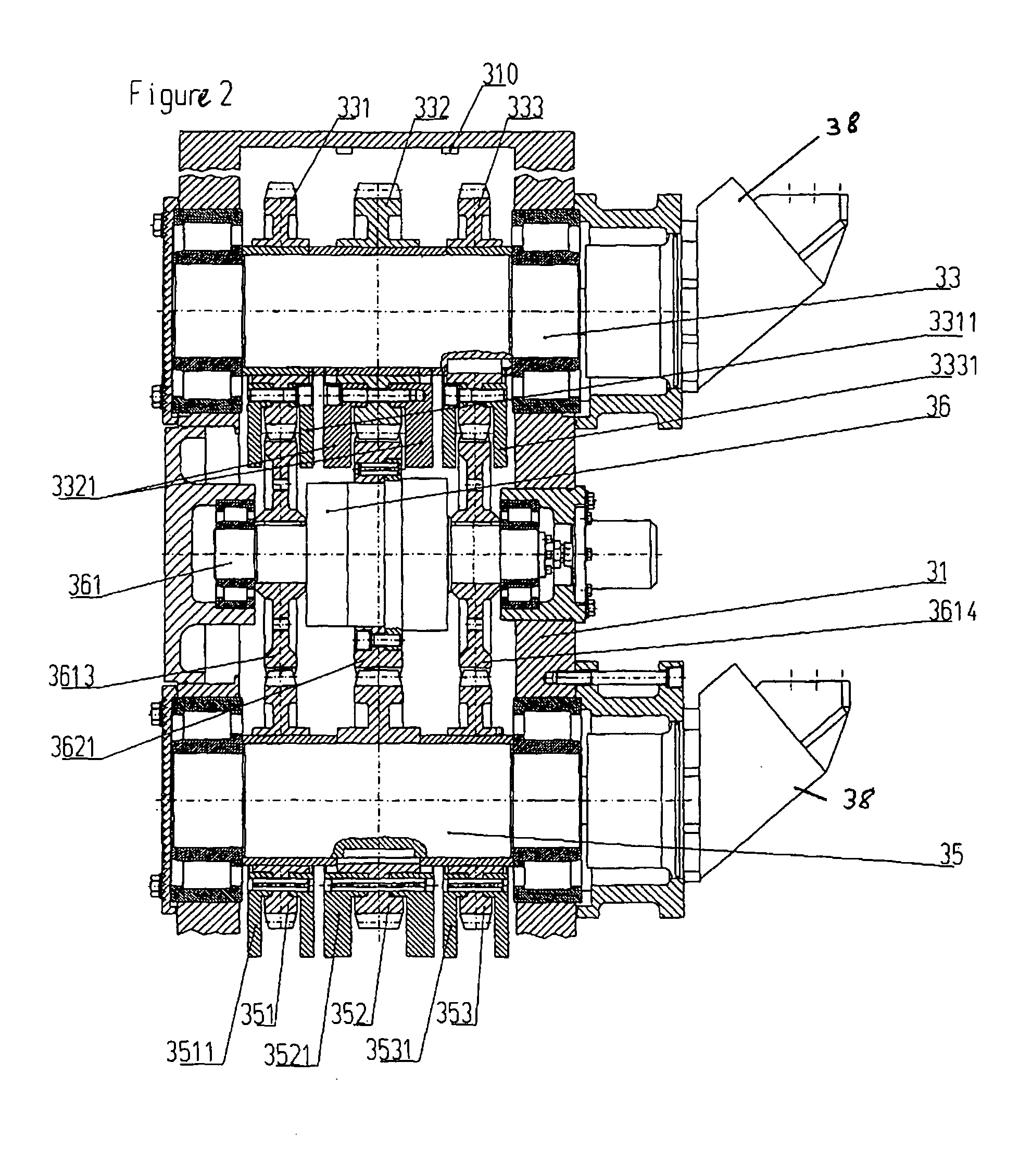

Vibration generator for a vibration pile driver

ActiveUS20090189467A1Without drop in powerDrop in power of drivePortable percussive toolsMechanical vibrations separationEngineeringPile driver

A vibration generator for a vibration pile driver, comprises imbalance masses that can rotate, which are disposed on shafts. A hydraulic drive having a changeable suction volume is disposed on the generator. A vibration pile driver consists of the vibration generator and a mast for movably supporting the vibration generator and / or an accommodation for a pile-driven material.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

Semiconductor device and display device

InactiveUS8058672B2Reduce areaHigh voltageSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectricity

It is an object of the invention to provide a thin, lightweight, high performance, and low in cost semiconductor device and a display device by reducing an arrangement area required for a power supply wiring and a ground wiring of a functional circuit and decreasing a drop in power supply voltage and a rise in ground voltage. In the functional circuit of the semiconductor device and the display device, a power supply wiring and a ground wiring are formed in a comb-like arrangement, and the tips thereof are electrically connected with a first wiring, a second wiring, and a contact between the first wiring and the second wiring, thereby forming in a grid-like arrangement. The drop in power supply voltage and the rise in ground voltage can be decreased and the arrangement area can be decreased in the grid-like arrangement.

Owner:SEMICON ENERGY LAB CO LTD

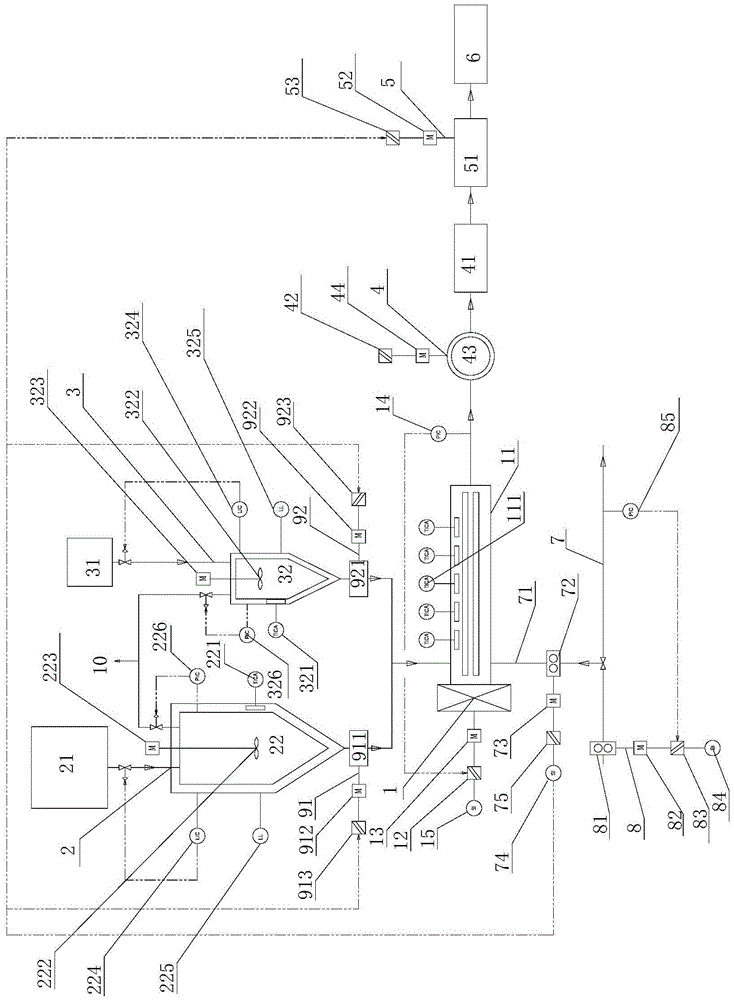

Broadband Power Amplifier with A High Power Feedback Structure

InactiveUS20090231042A1High power feedback structureLarge optimum load impedanceSemiconductor/solid-state device detailsSolid-state devicesBroadband power amplifierPower over

A broadband power amplifier using a novel high power feedback structure is disclosed in this patent. Feedback is widely used in amplifier design to broaden the bandwidth of the amplifier. Traditionally, the feedback resistor is either an axial resistor placed over the top of the transistor or a surface mount resistor with a long PCB trace making up the rest of the feedback path. However, each of these methods has it's limitations. The axial resistor doesn't have good heat sinking capability and therefore cannot handle high power. The feedback on PCB makes the feedback path long and becomes positive feedback at high frequency, thus limiting the high end frequency of operation of the amplifier in a stable region. The feedback structure disclosed in this patent has a good heat sinking path, has very short feedback path; allowing for higher frequency operation. We successfully applied the feedback structures to a Gallium Nitride (GaN) transistor, which is a new type of power transistor that has low parasitic capacitance and high optimum load impedance, and demonstrated an amplifier with very high output power over extraordinarily broad bandwidth. Matching networks have been optimized to improve performance and stability. We have demonstrated that unconditional stability is achievable while operating over a broad bandwidth using this feedback structure.

Owner:JIA PENGCHENG +1

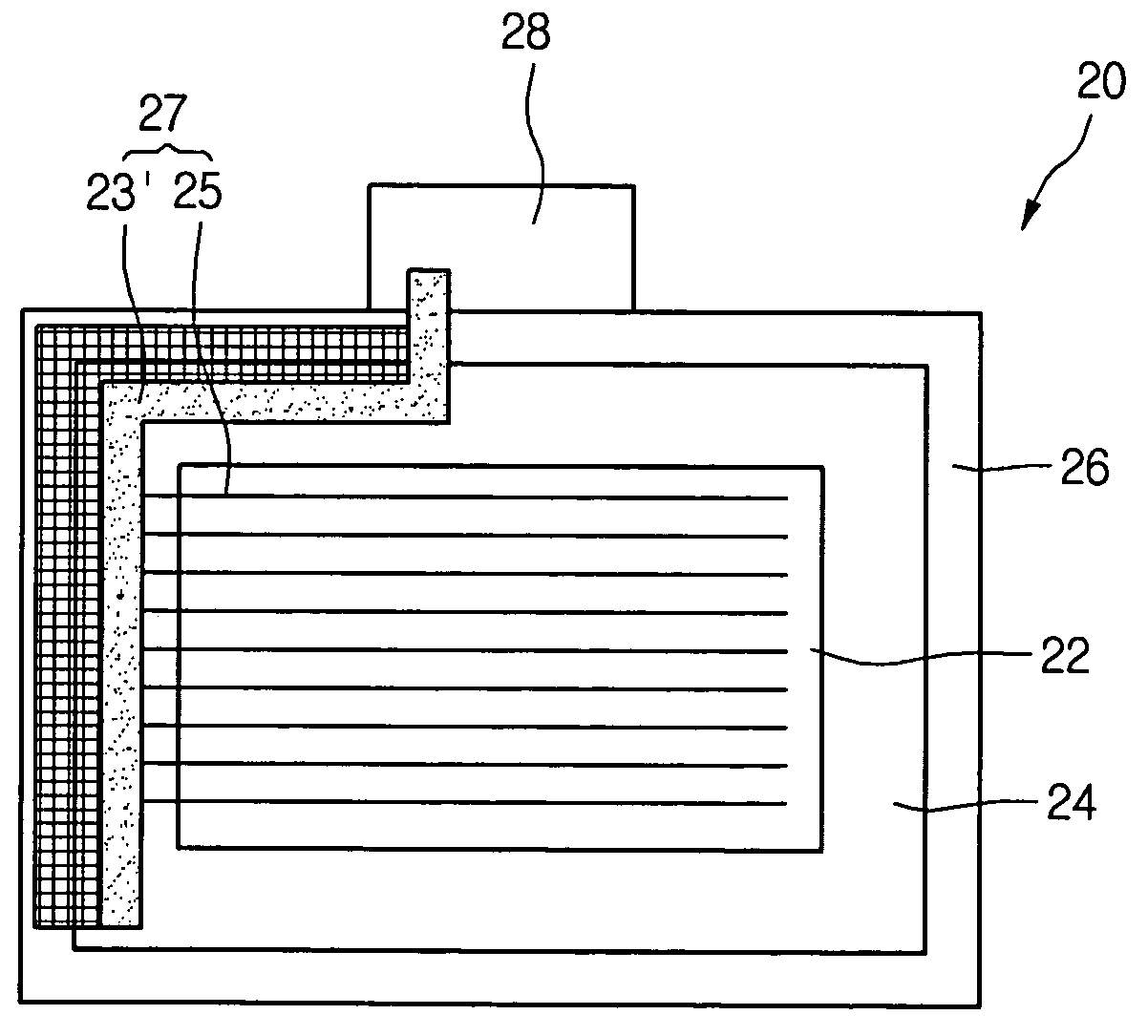

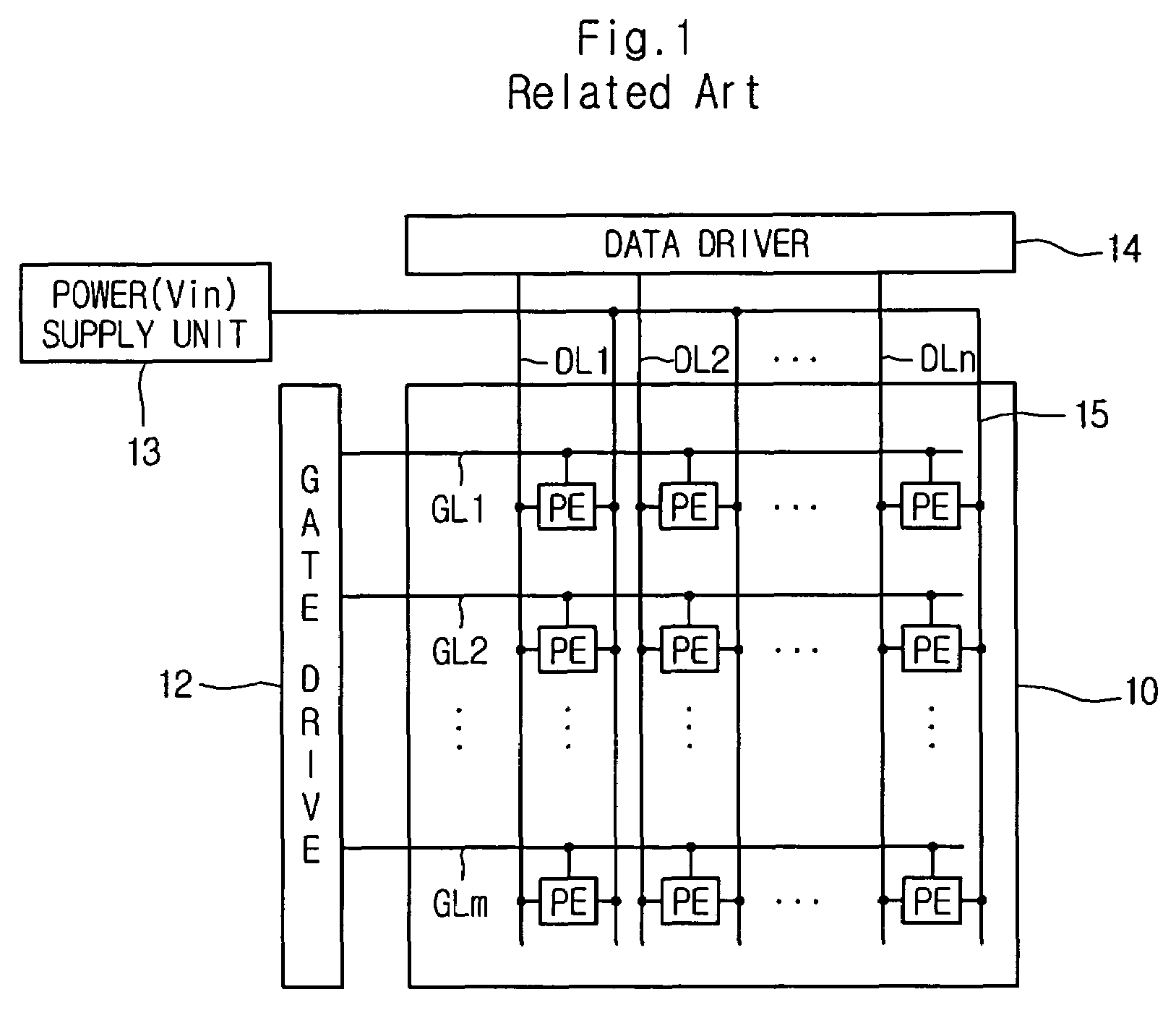

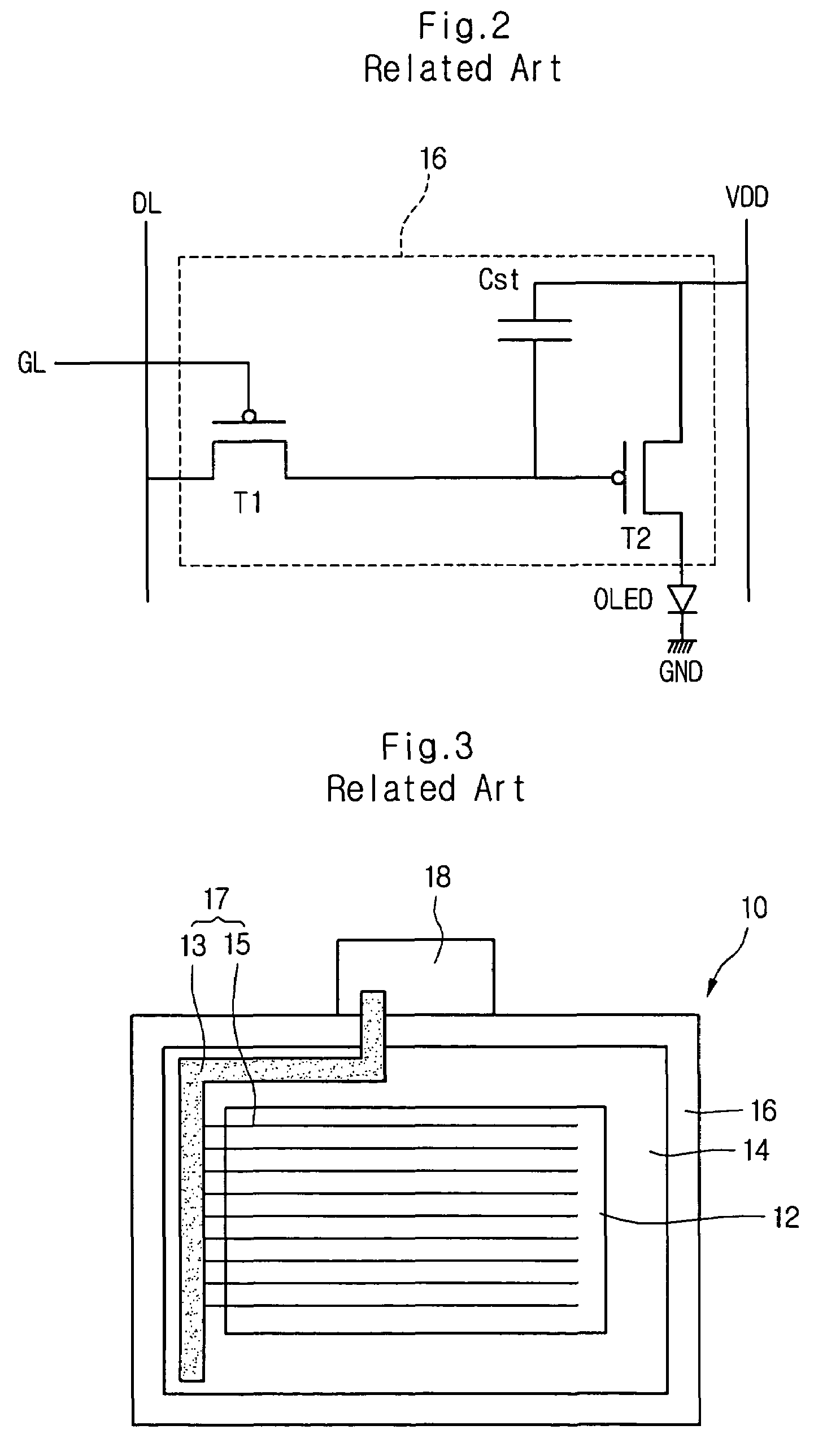

Active matrix organic light emitting display panel

ActiveUS7221096B2Power dropDischarge tube luminescnet screensStatic indicating devicesActive matrixVoltage

An active matrix organic light emitting display panel includes a first substrate including a seal pattern region, a non-display region, and a display region, the non-display region being between the display region and the seal pattern region, a pad connected to the first substrate, and a power line including a routing line connected directly to the pad, and a pixel line for applying a pixel voltage to a plurality of pixels, the routing line having a first portion being in the non-display region and a second portion being in the seal pattern region, and the pixel line being in the display region.

Owner:LG DISPLAY CO LTD

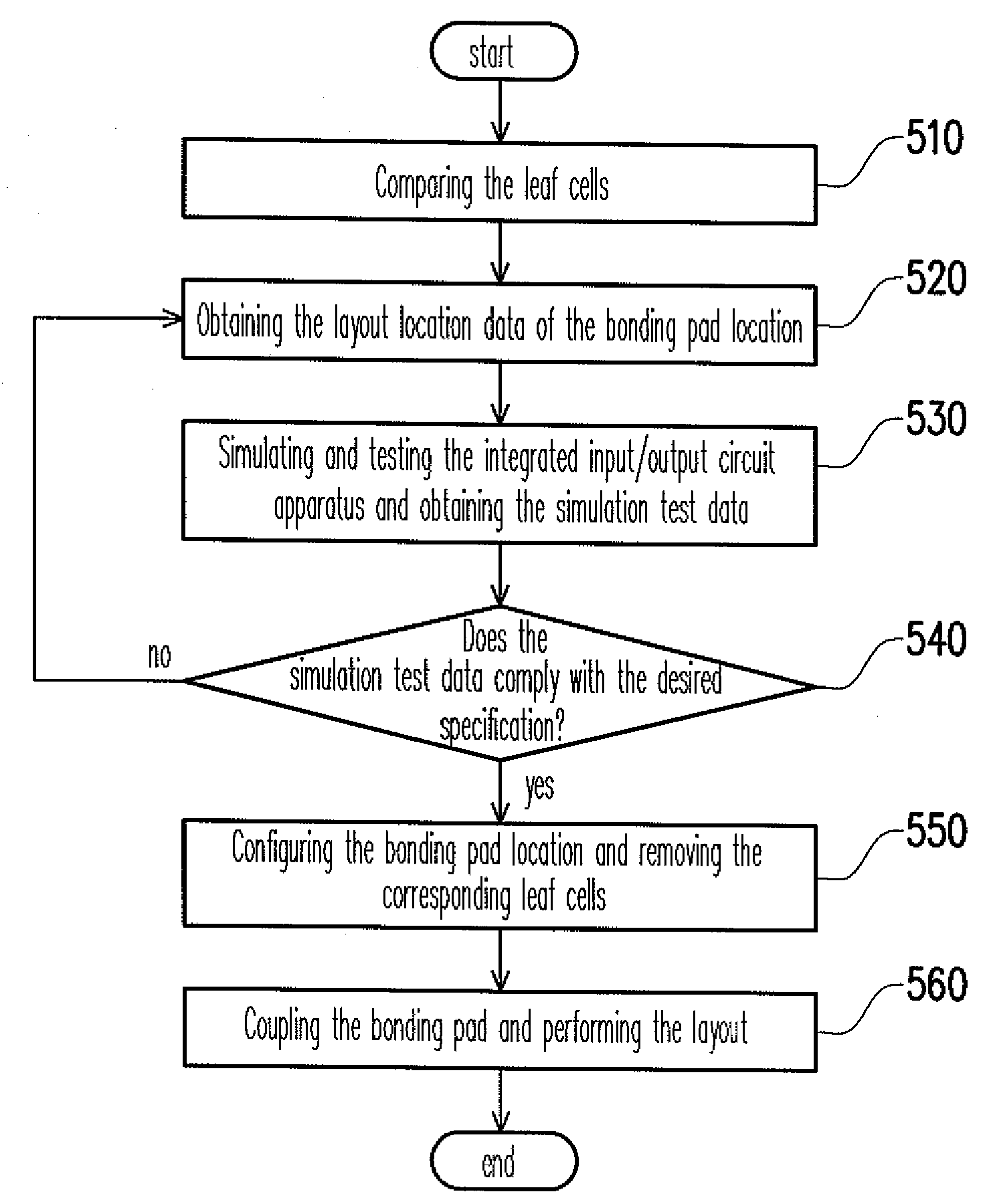

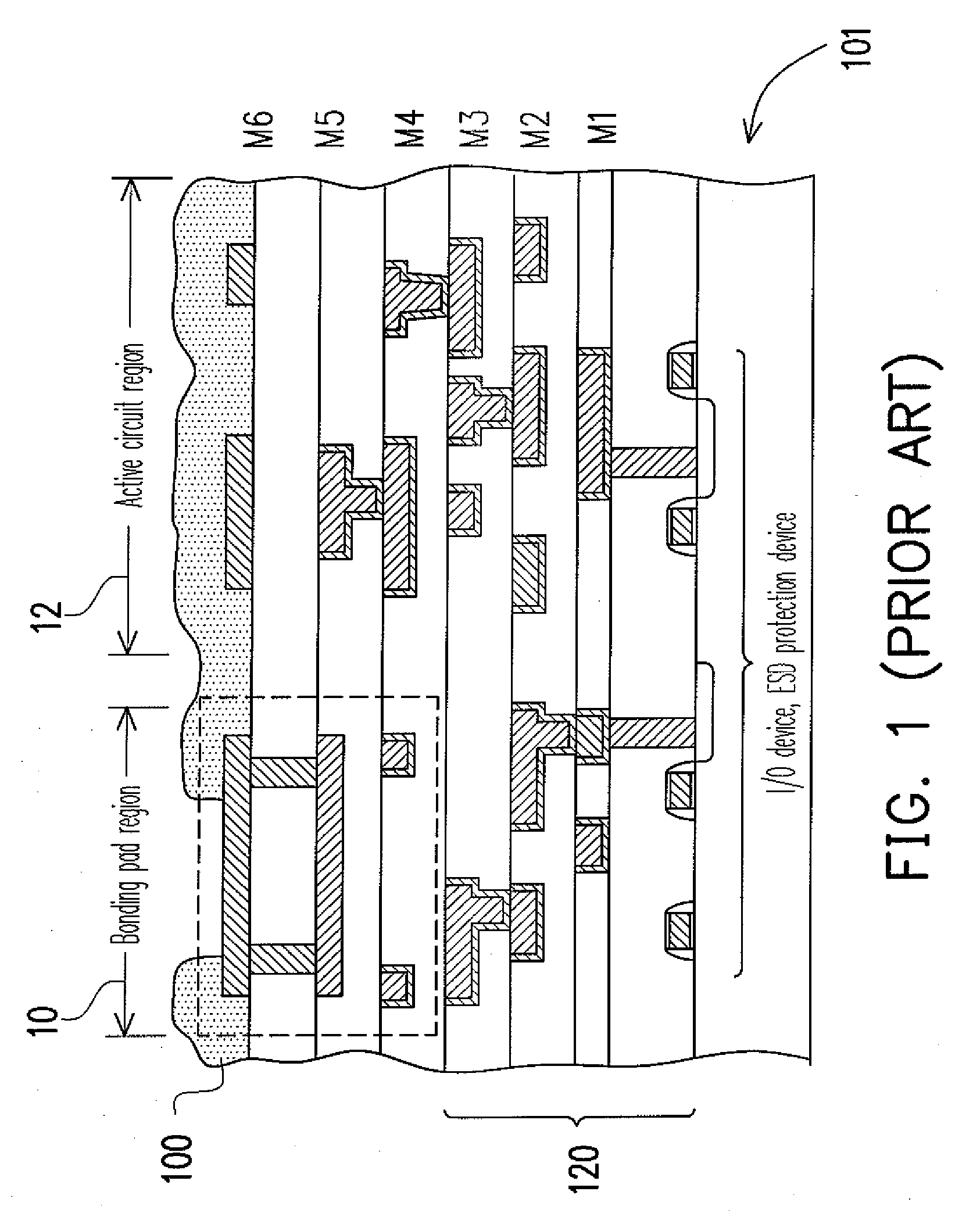

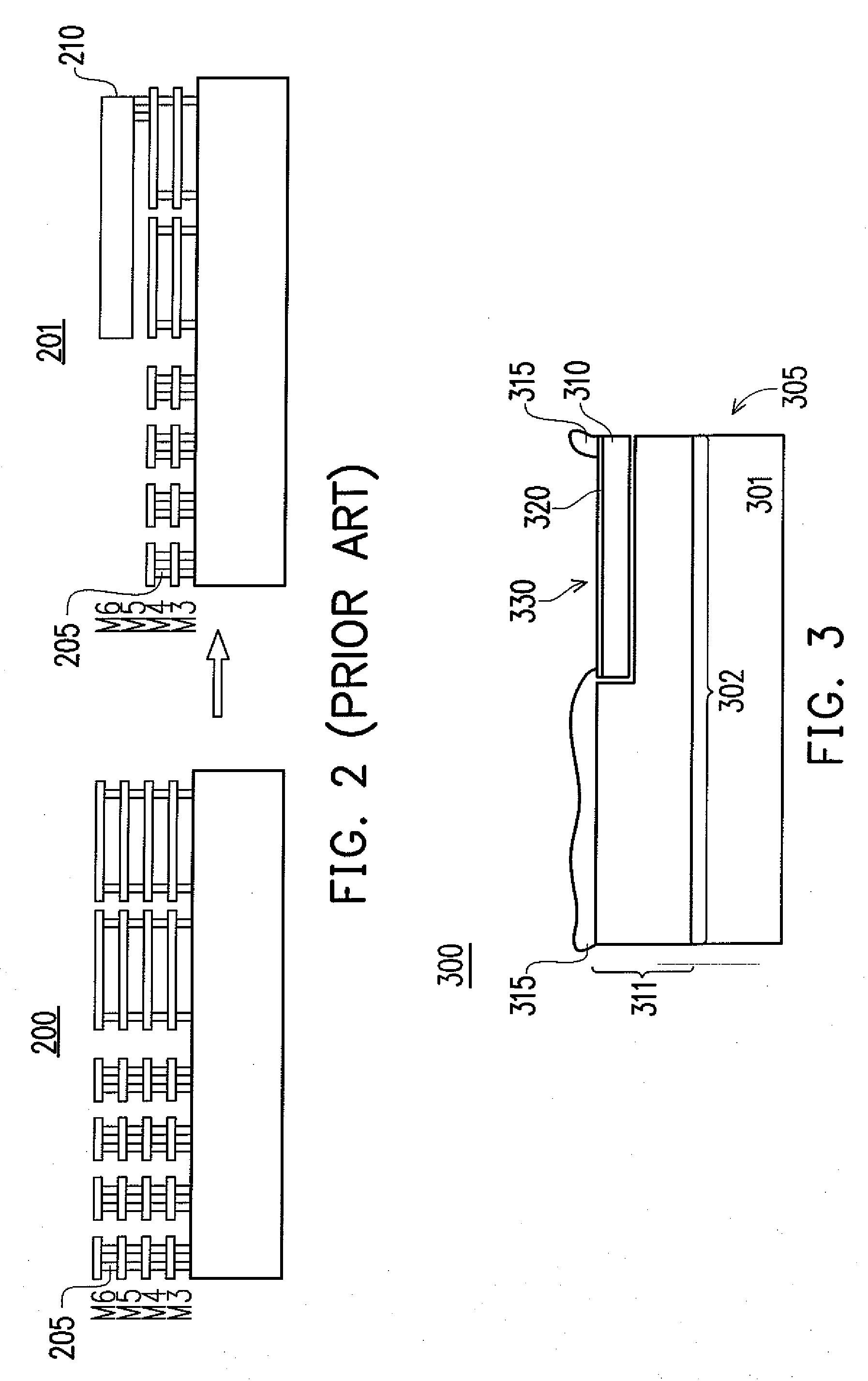

Apparatus for integrated input/output circuit and verification method thereof

InactiveUS20080163146A1Reduce occupancyReduce resistanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical resistance and conductanceElectricity

An apparatus for integrated input / output circuit and a verification method thereof are provided. The apparatus effectively reduces the chip area occupation and cost, and decreases the resistance on an electrical transmission path of the integrated input / output circuit to improve the circuit efficiency. The apparatus comprises a metal structure and a plurality of integrated circuit components. Wherein, the integrated circuit comprises the integrated circuit components and the metal structure that has a bonding pad. In addition, the integrated circuit components are disposed directly under the metal structure and coupled to the metal structure. In which, the metal structure provides an electrical transmission path for the integrated circuit.

Owner:WU CHIH HUNG +1

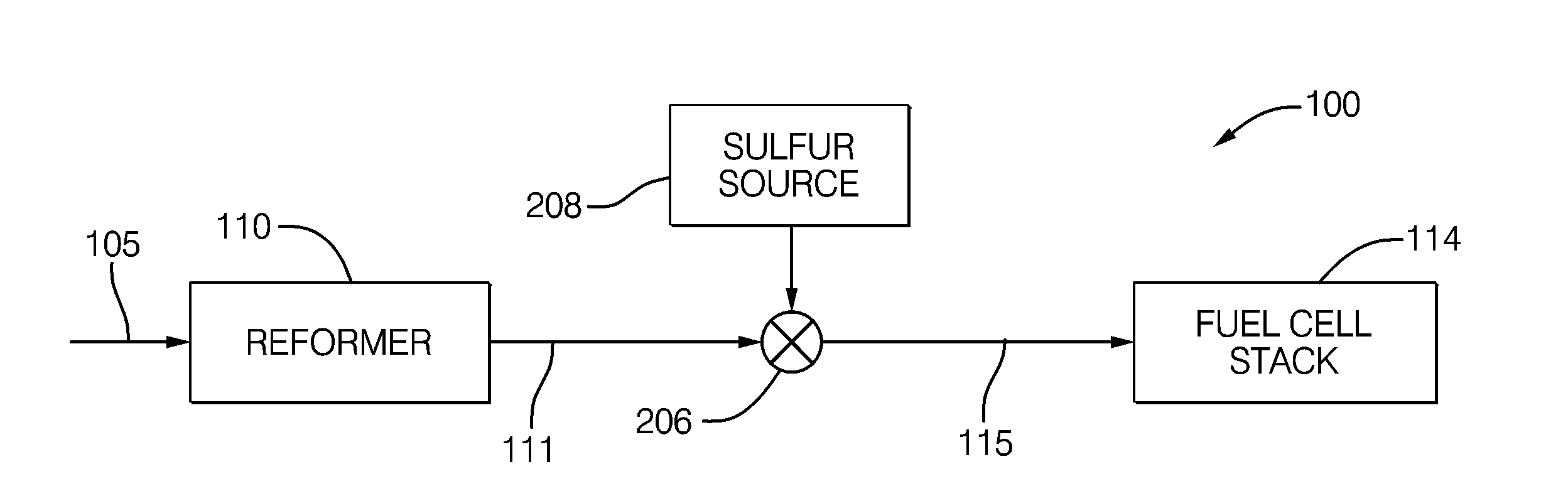

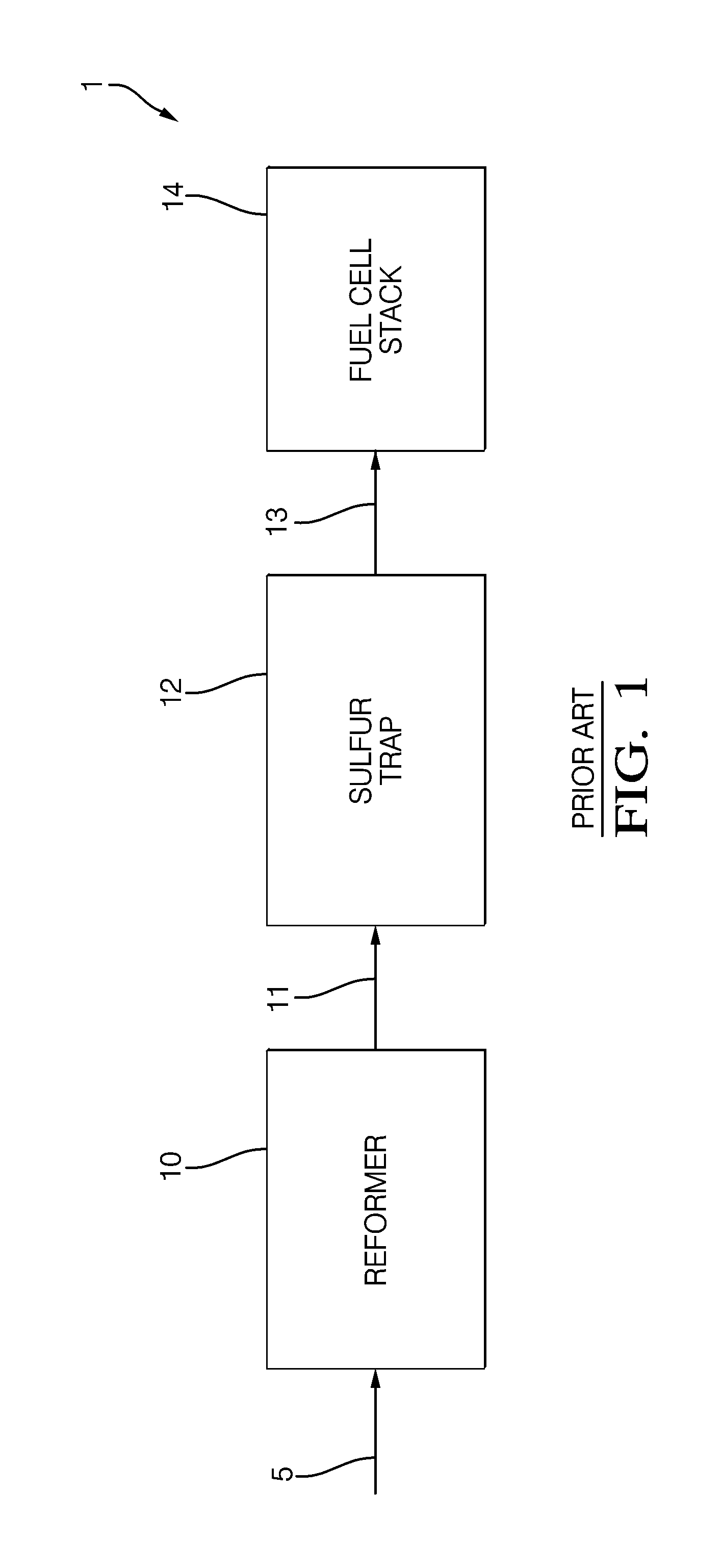

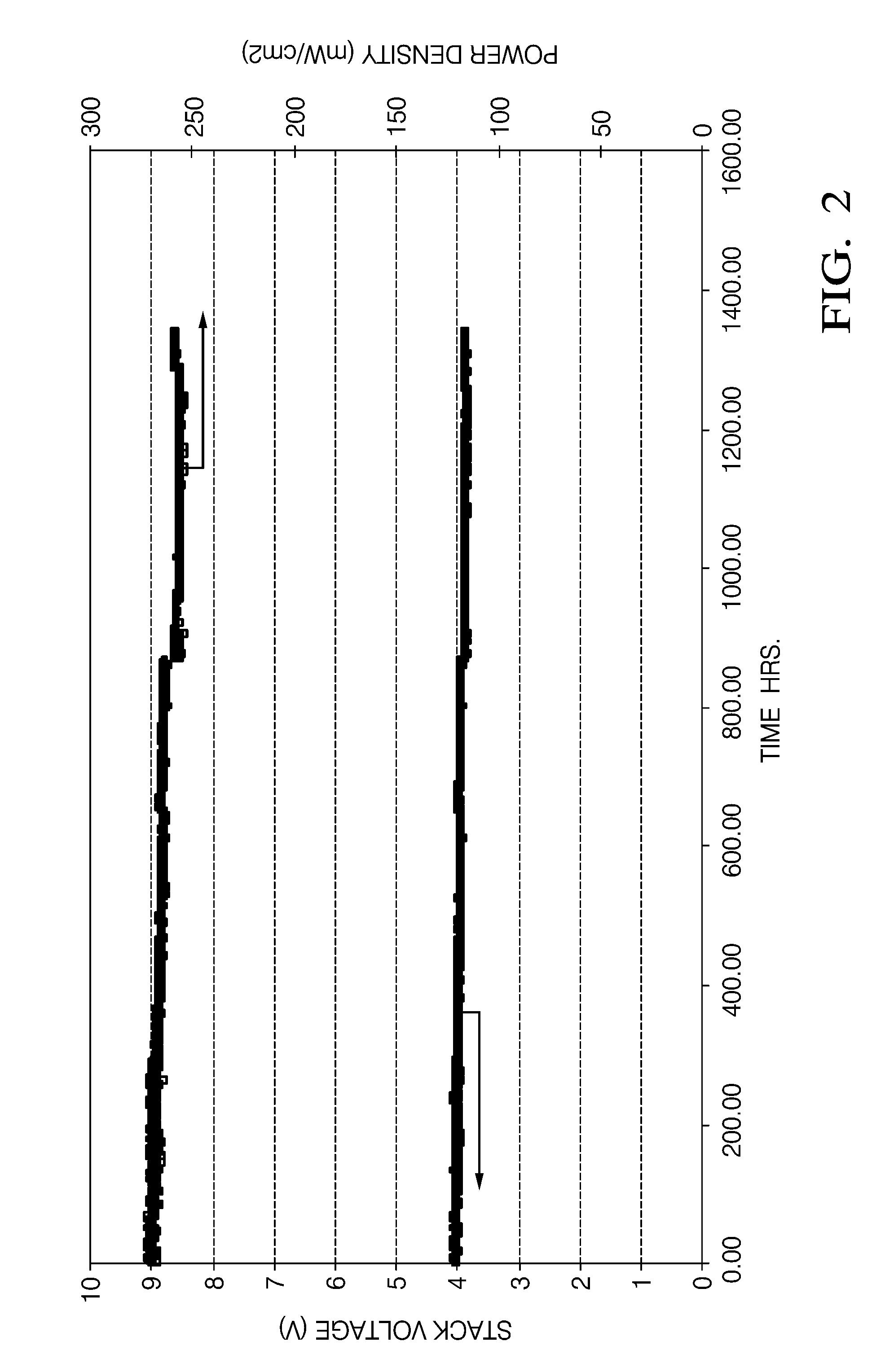

System for Adding Sulfur to a Fuel Cell Stack System for Improved Fuel Cell Stability

InactiveUS20110269033A1Extended service lifePerformance degradation can be minimizedFuel cellsChemistryPollutant

A system for adding sulfur to a fuel cell stack, having a reformer adapted to reform a hydrocarbon fuel stream containing sulfur contaminants, thereby providing a reformate stream having sulfur; a sulfur trap fluidly coupled downstream of the reformer for removing sulfur from the reformate stream, thereby providing a desulfurized reformate stream; and a metering device in fluid communication with the reformate stream upstream of the sulfur trap and with the desulfurized reformate stream downstream of the sulfur trap. The metering device is adapted to bypass a portion of the reformate stream to mix with the desulfurized reformate stream, thereby producing a conditioned reformate stream having a predetermined sulfur concentration that gives an acceptable balance of minimal drop in initial power with the desired maximum stability of operation over prolonged periods for the fuel cell stack.

Owner:DELPHI TECH INC

Vibration generator for a vibration pile driver

ActiveUS8522891B2Without drop in powerDrop in power of drivePortable percussive toolsMechanical vibrations separationEngineeringPile driver

A vibration generator for a vibration pile driver, comprises imbalance masses that can rotate, which are disposed on shafts. A hydraulic drive having a changeable suction volume is disposed on the generator. A vibration pile driver consists of the vibration generator and a mast for movably supporting the vibration generator and / or an accommodation for a pile-driven material.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

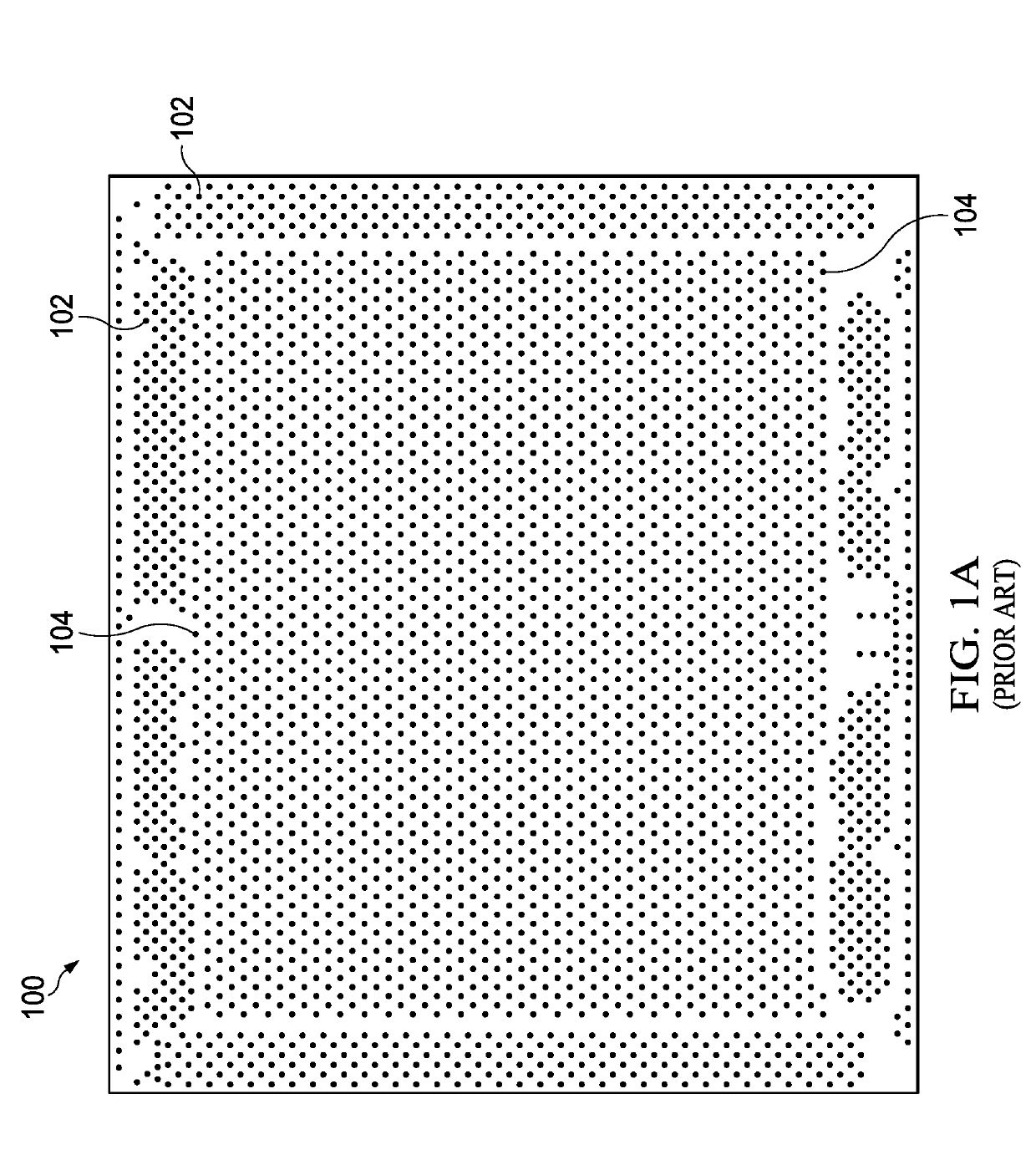

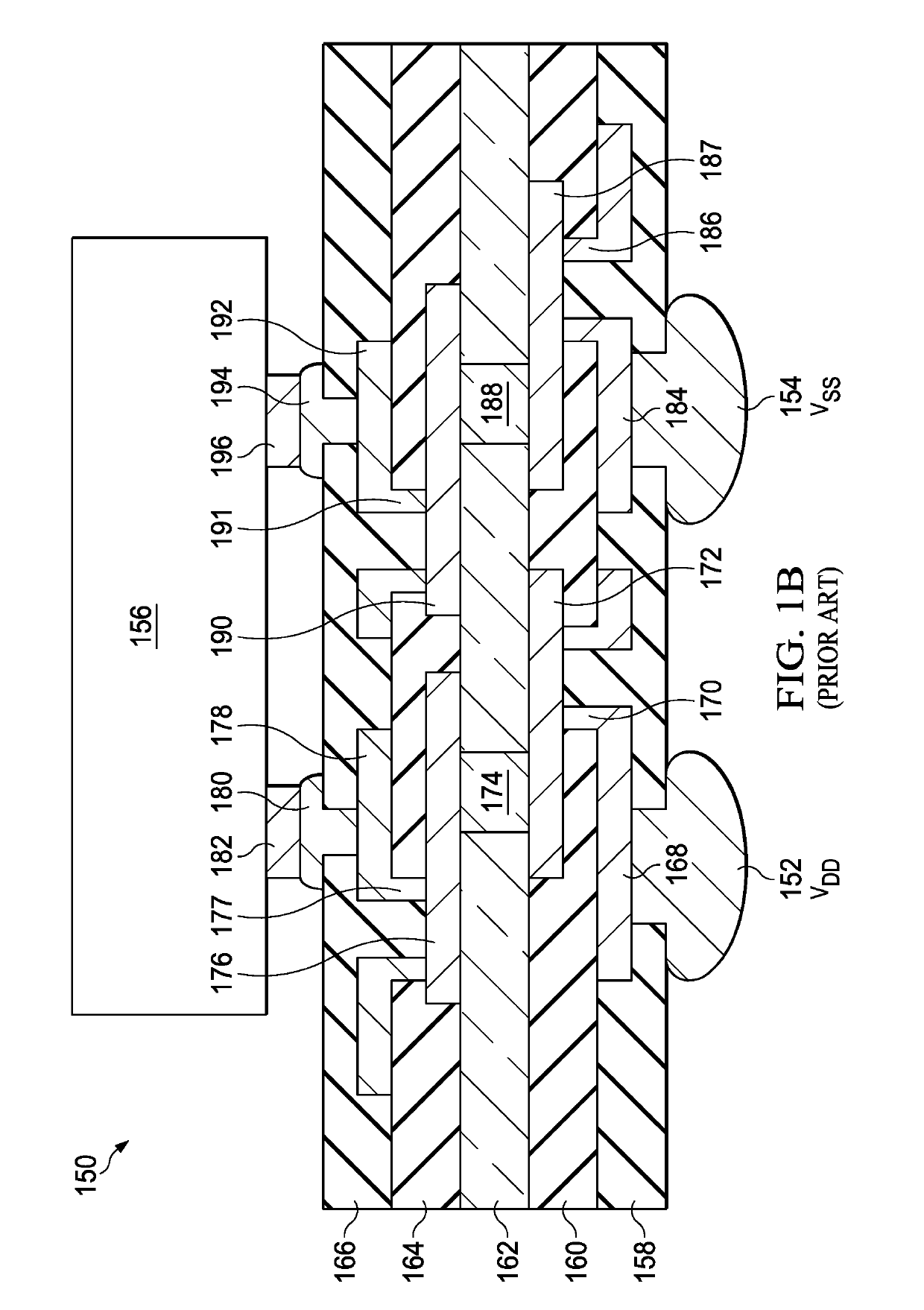

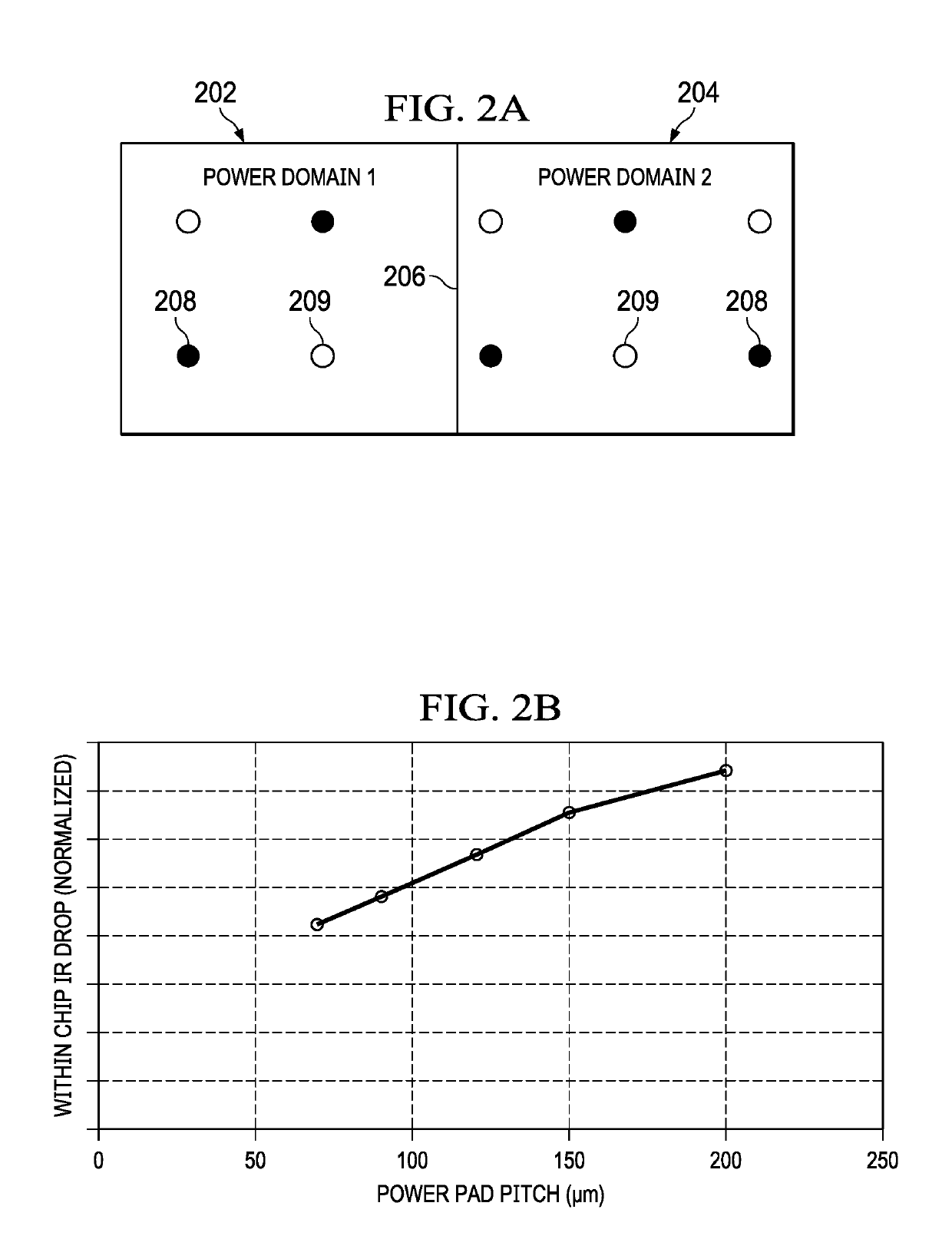

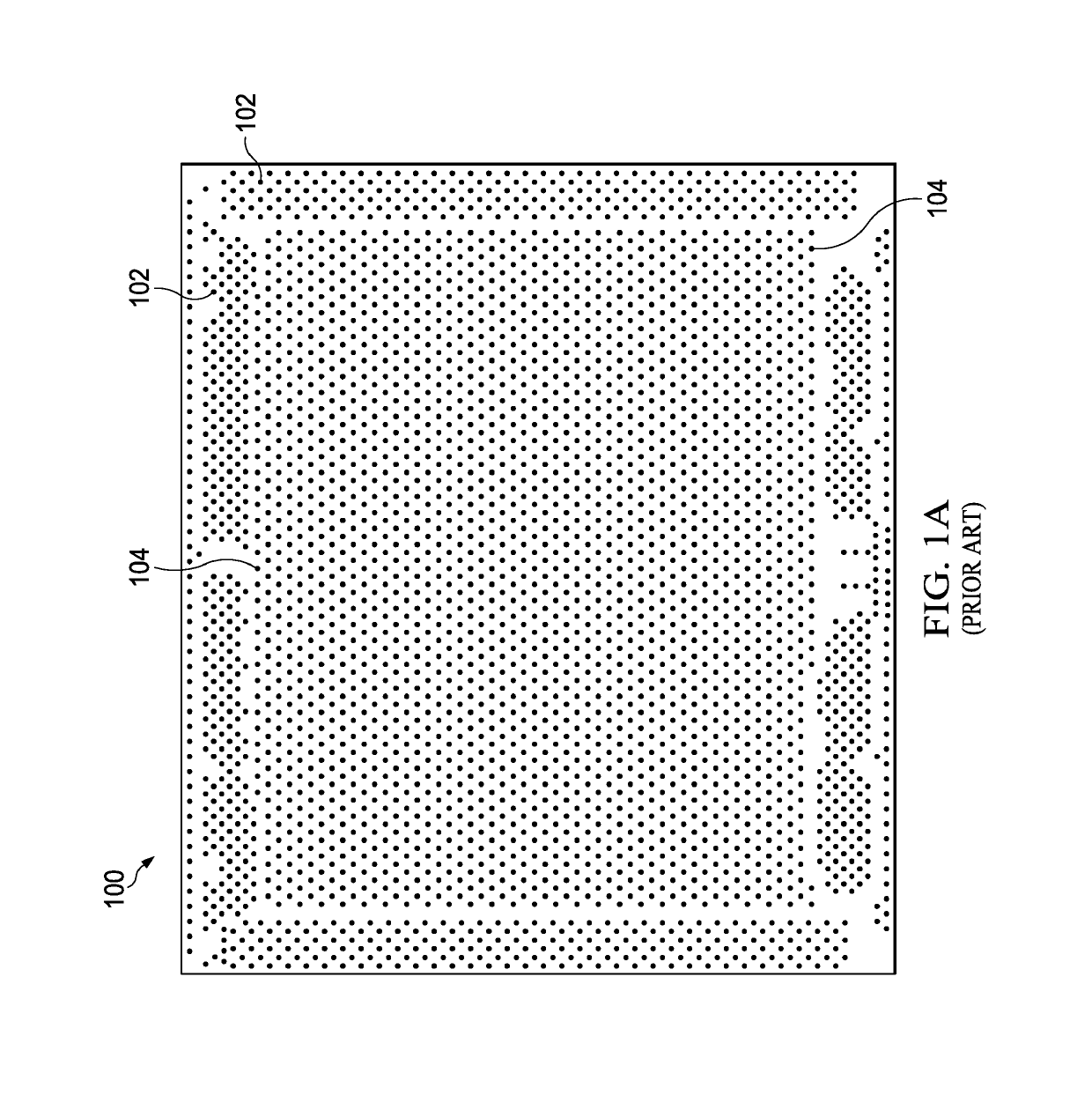

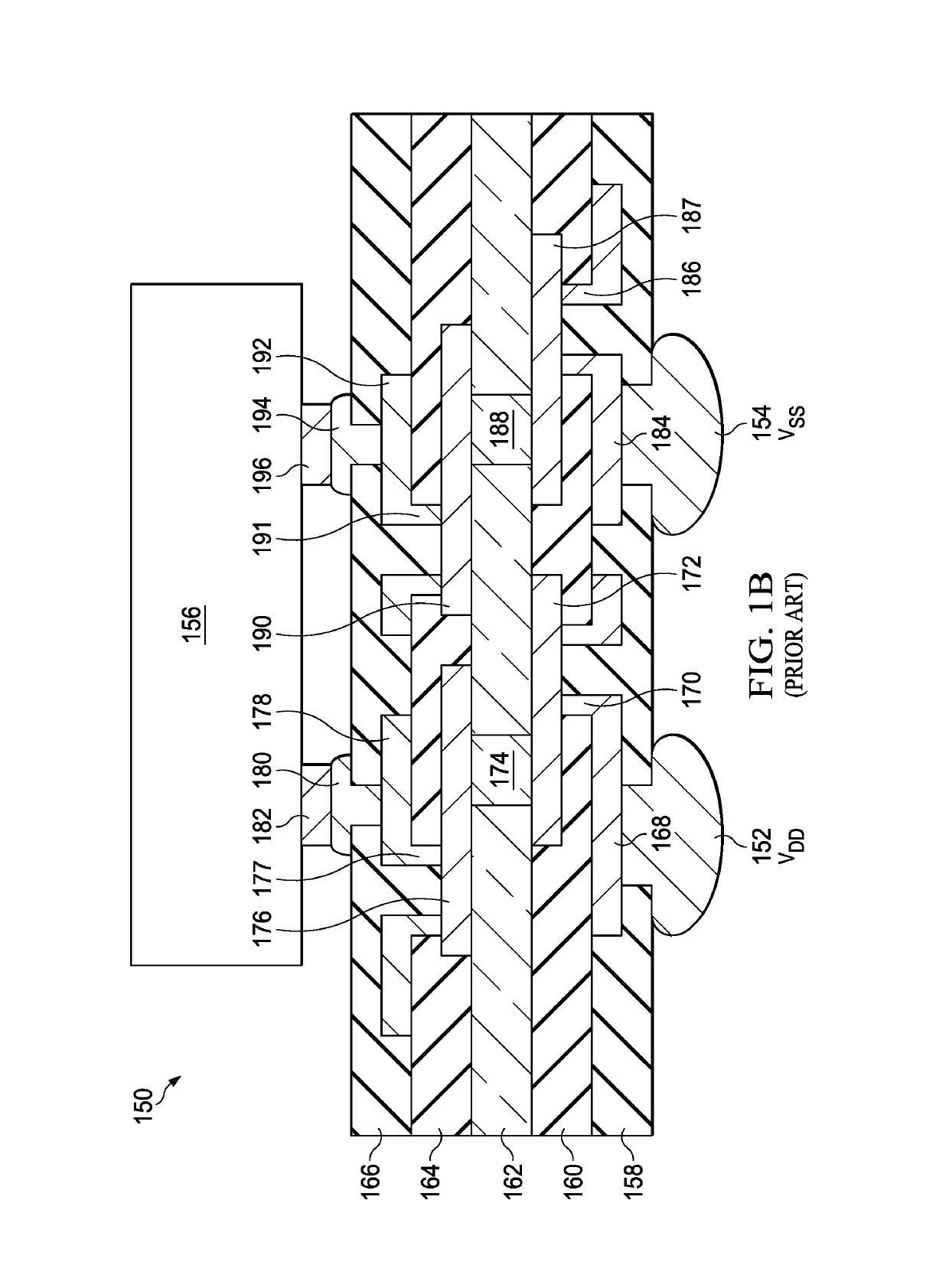

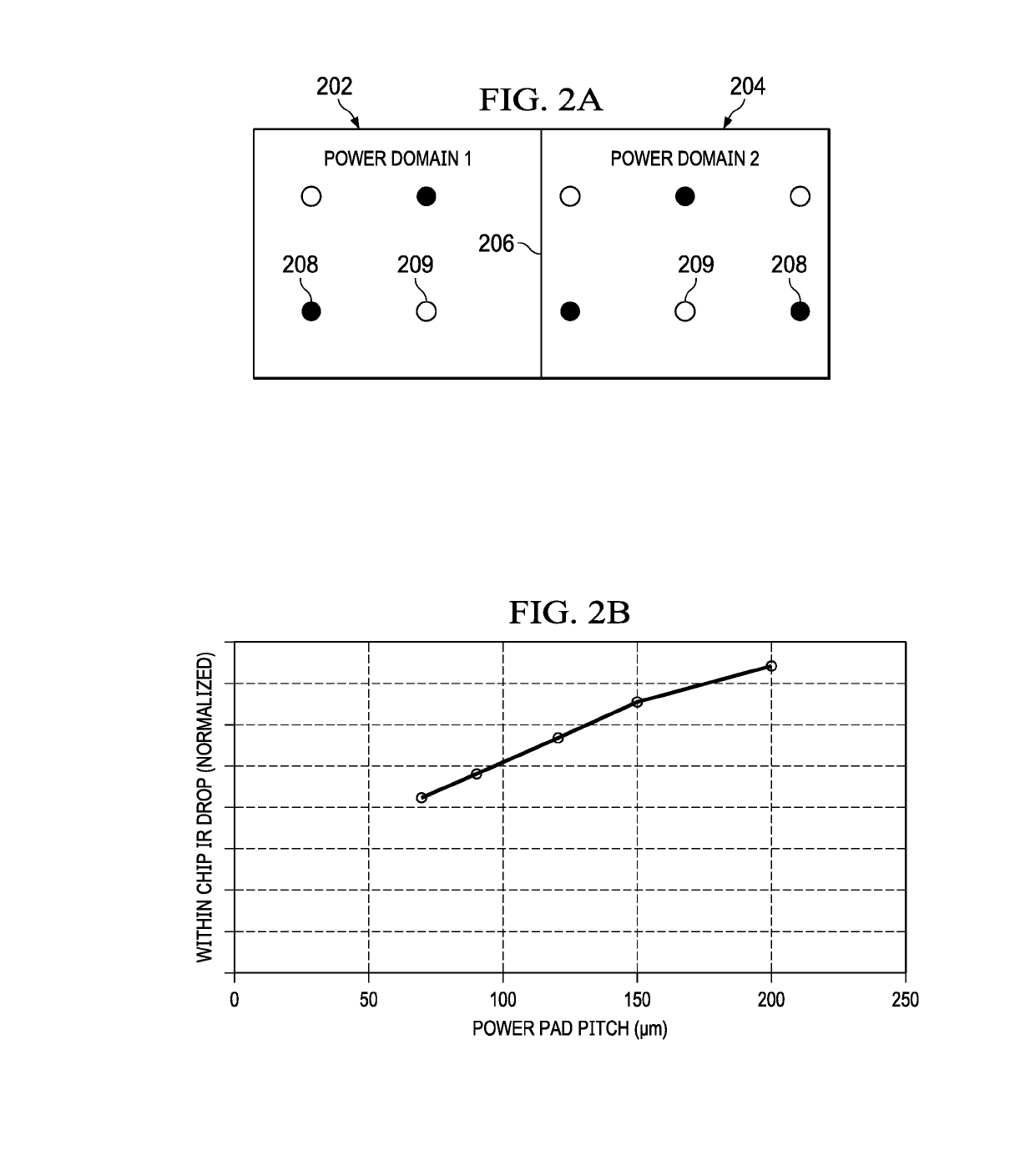

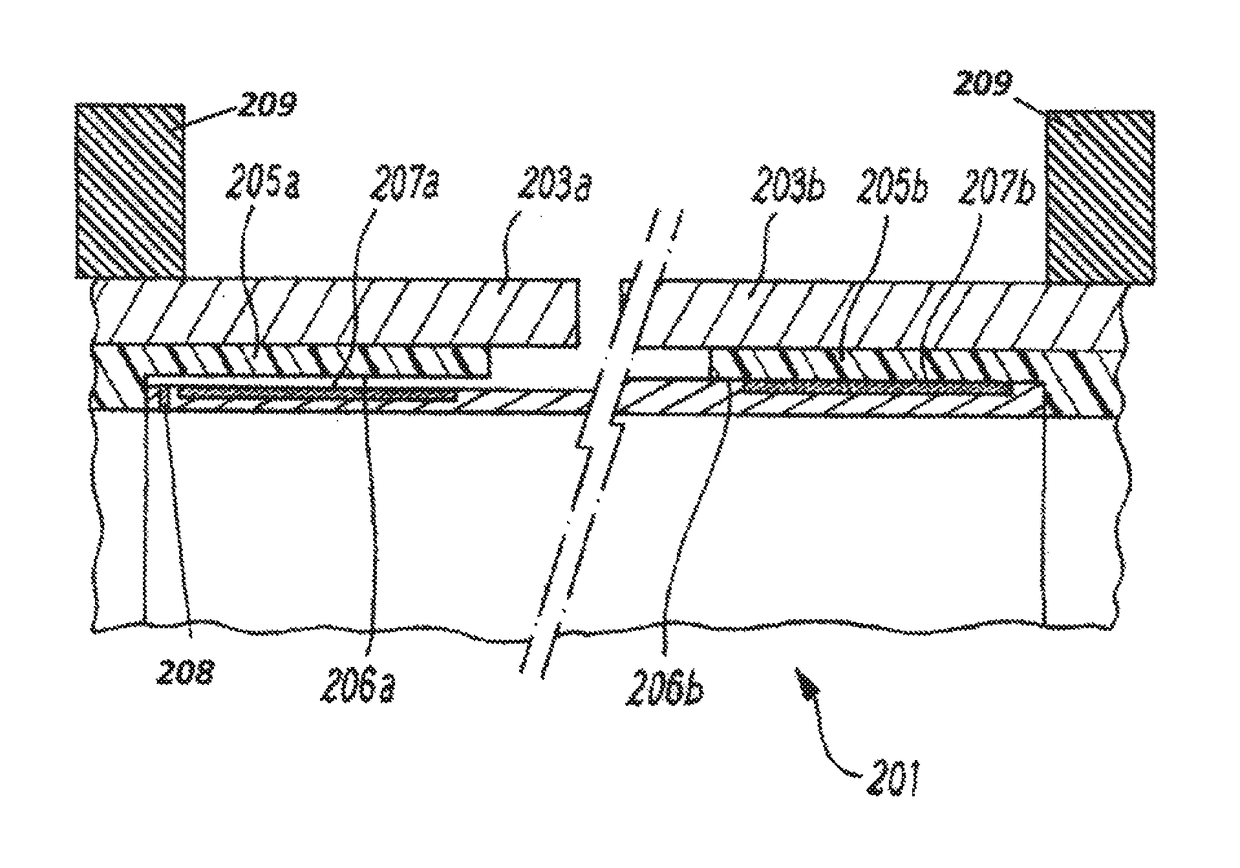

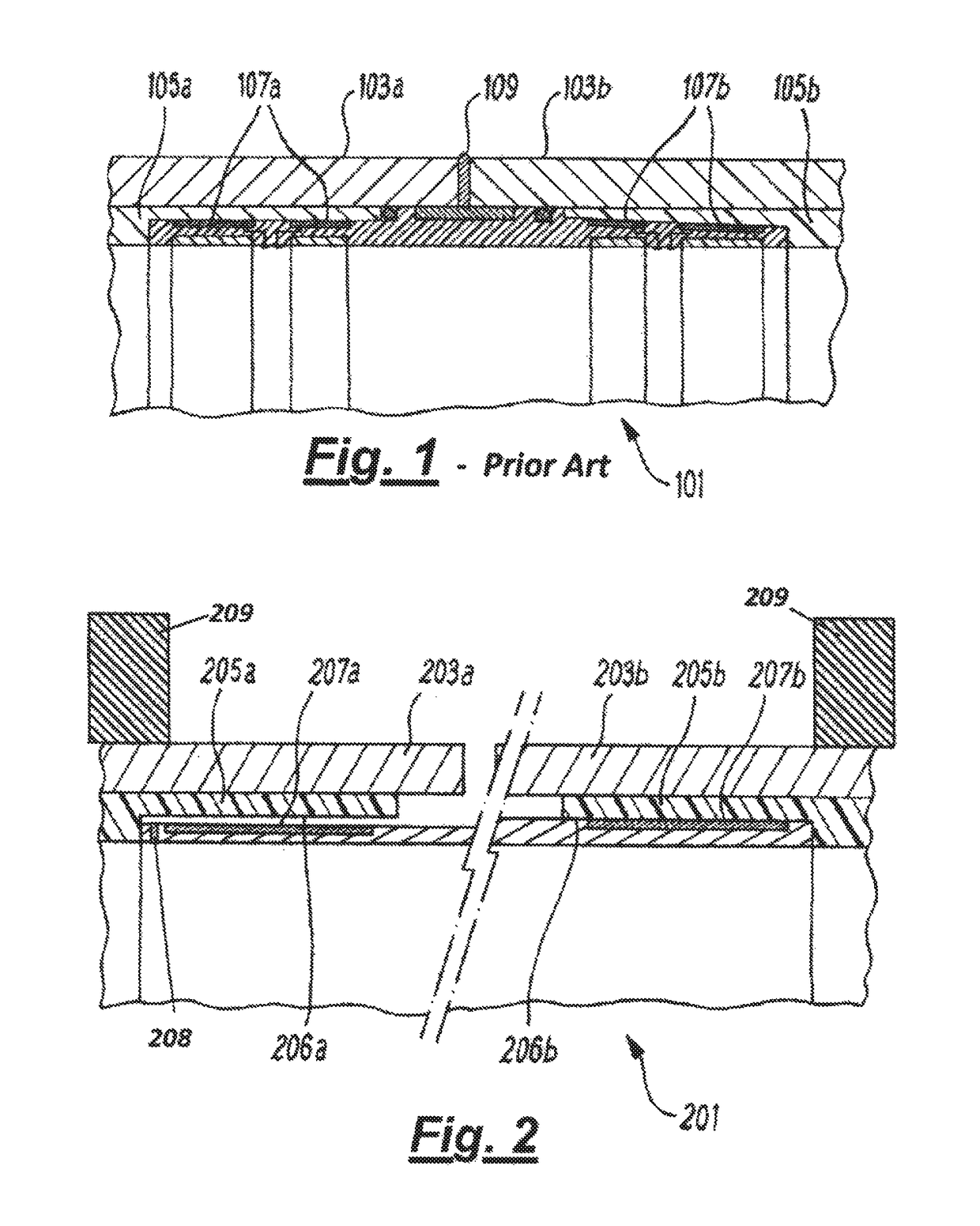

Semiconductor package having reduced internal power pad pitch

ActiveUS20190148323A1Reduction of lateral separationLarge transistor voltageSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor package

A packaged Integrated Circuit (IC) includes an IC and a package. The package has a bottom dielectric layer and a plurality of redistribution layers (RDLs) formed on the bottom dielectric layer. Each the RDLs includes patterned conductors, a dielectric layer, and a plurality of vias that extend between the patterned conductors to a differing RDL or to external connections. The package includes a plurality of package pads that have a first lateral separation pitch. The IC includes a plurality of IC pads that electrically connect to the plurality of package pads that have a first lateral separation pitch. The package also includes a plurality of Printed Circuit Board (PCB) pads that extend through the bottom dielectric layer and contact the plurality of patterned conductors of the first RDL. Power PCB pads and ground PCB pads of the plurality of PCB pads have a second lateral separation pitch that exceeds the first lateral separation pitch.

Owner:FUTUREWEI TECH INC

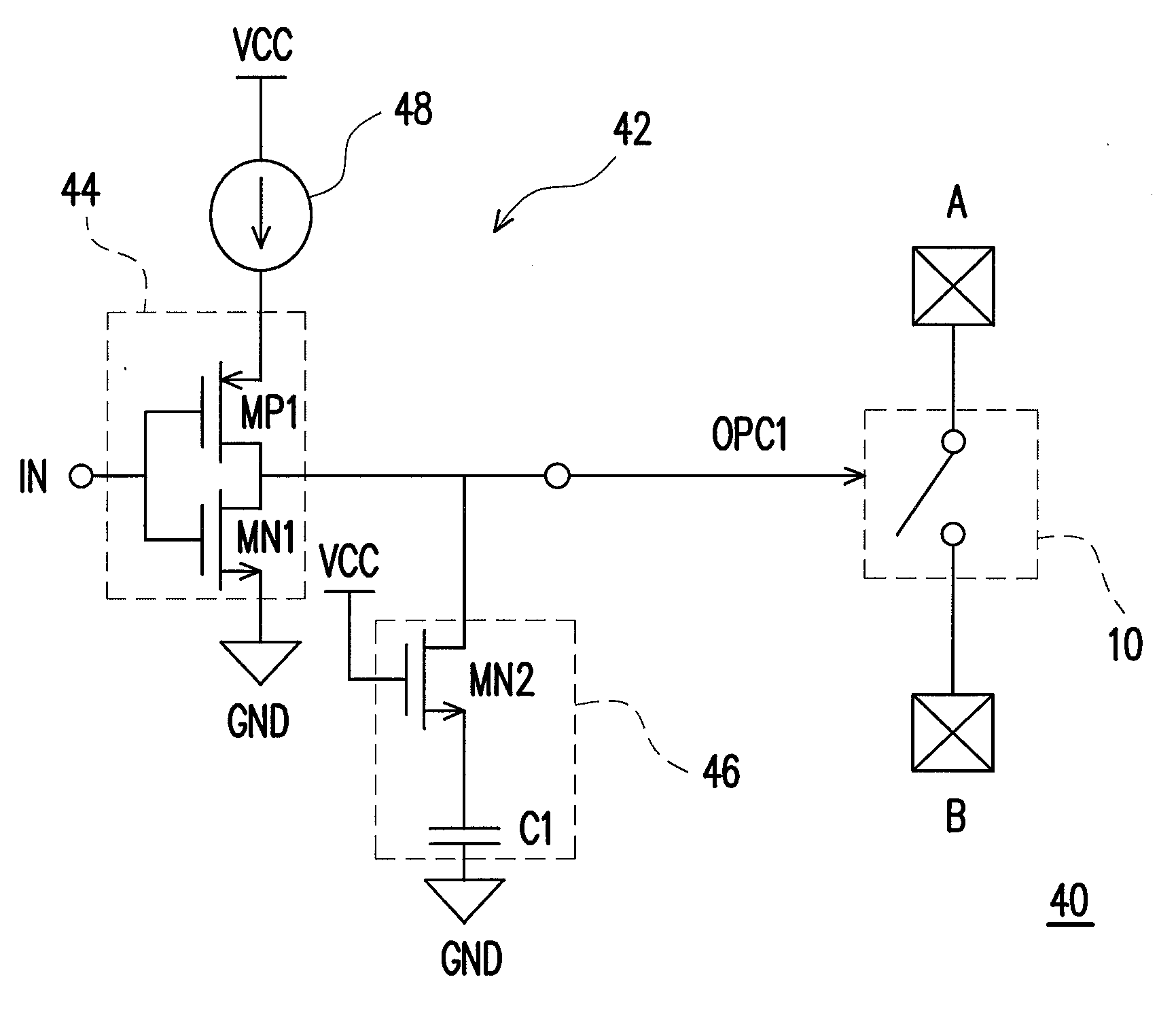

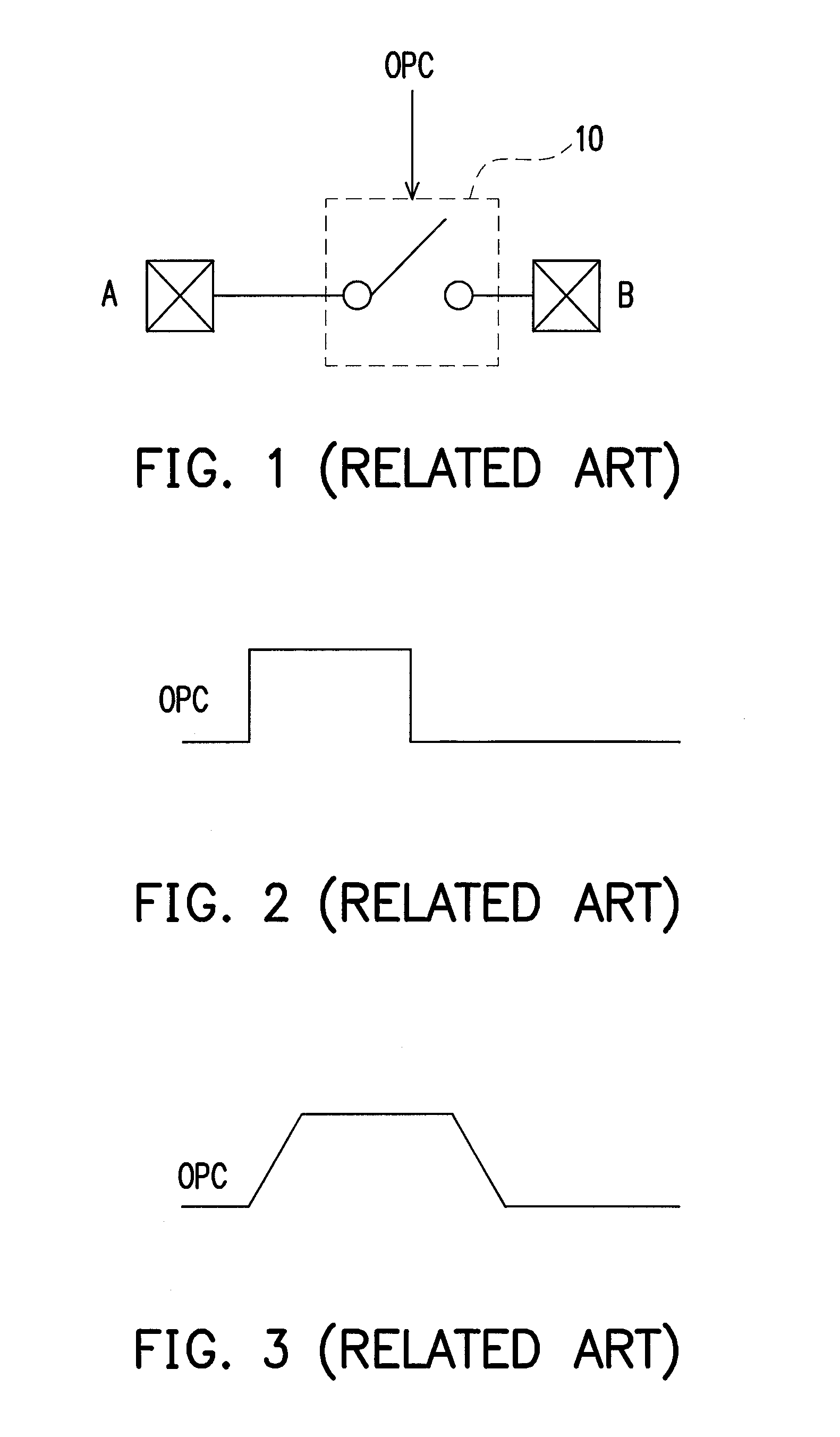

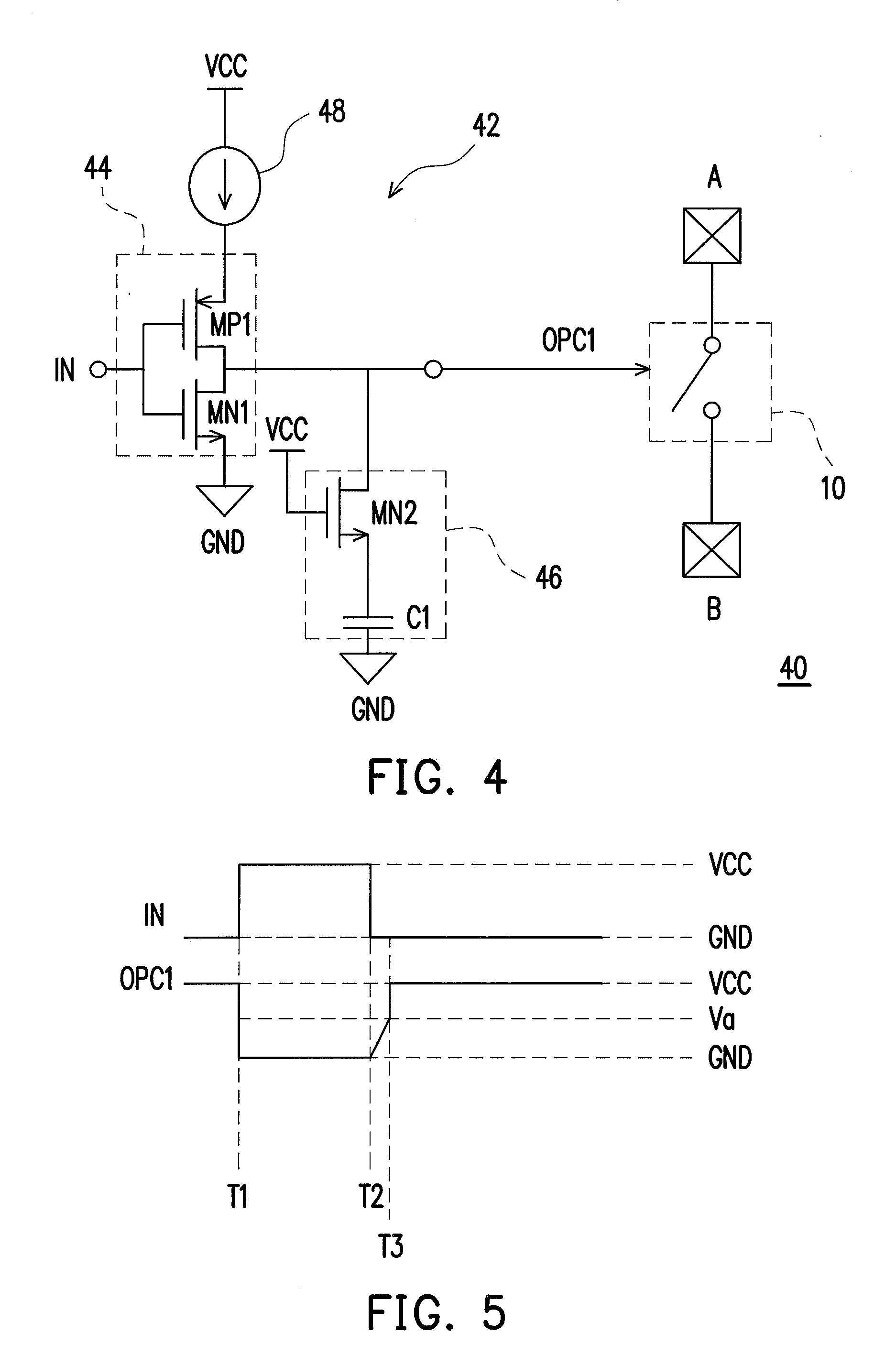

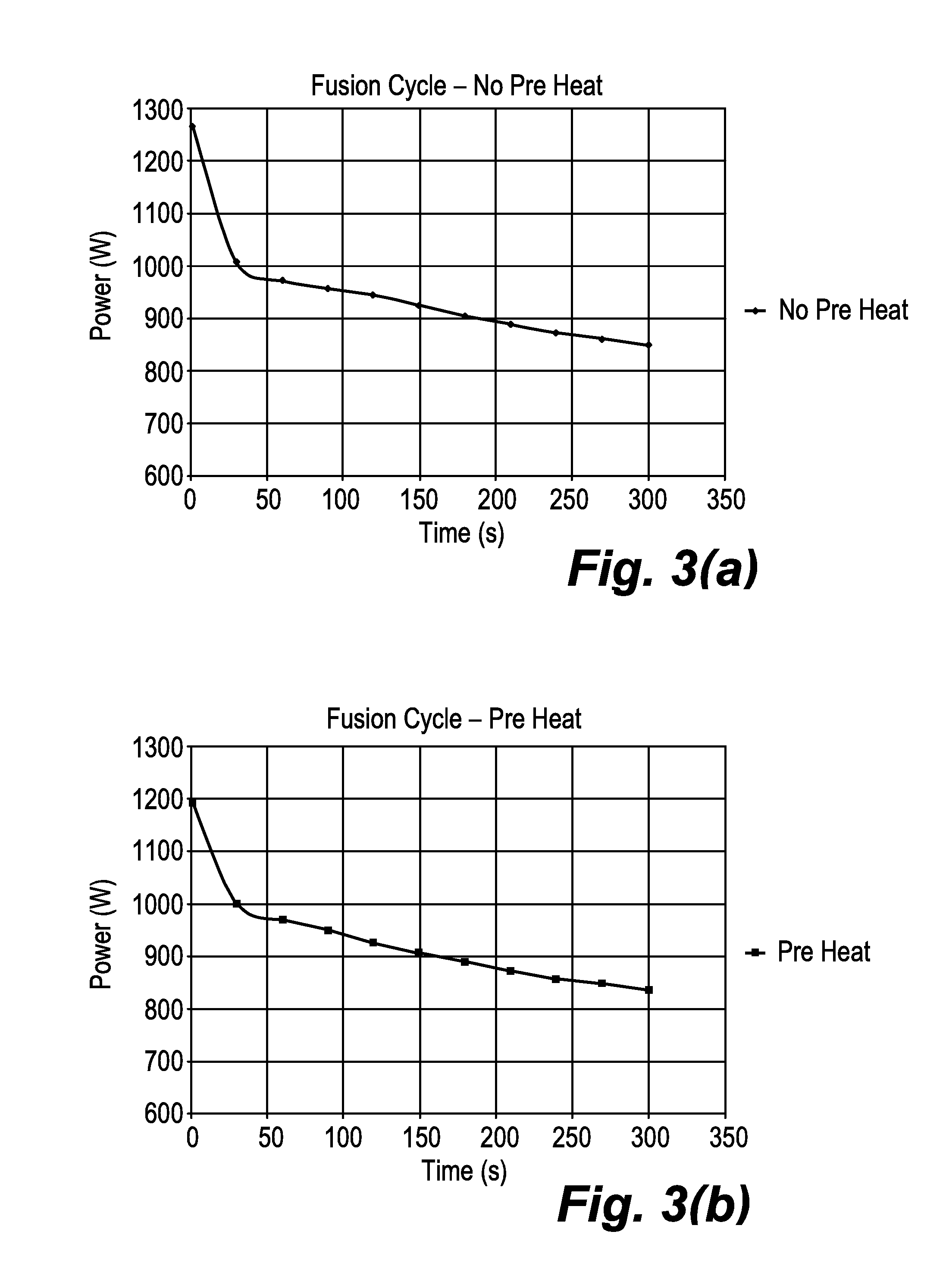

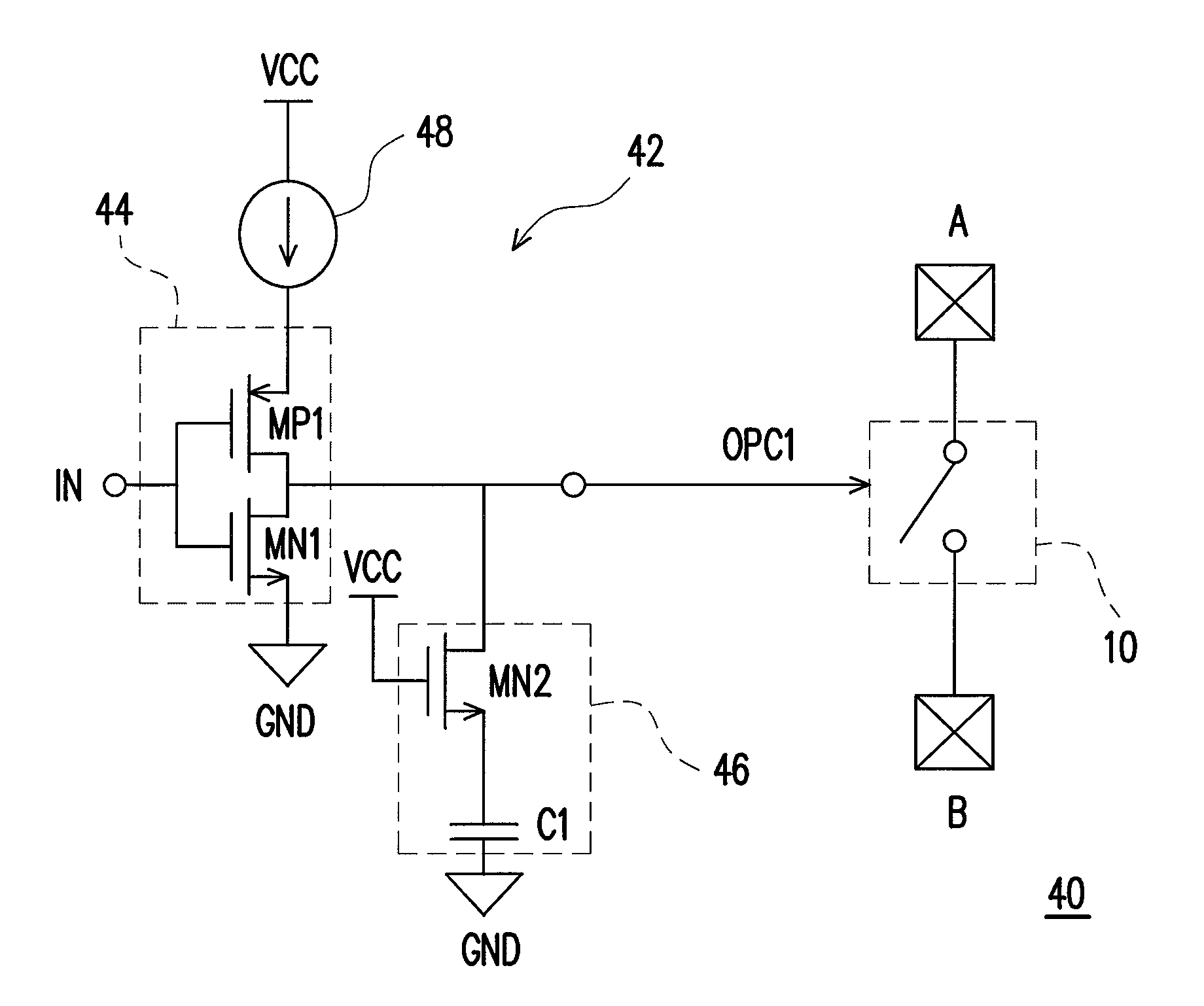

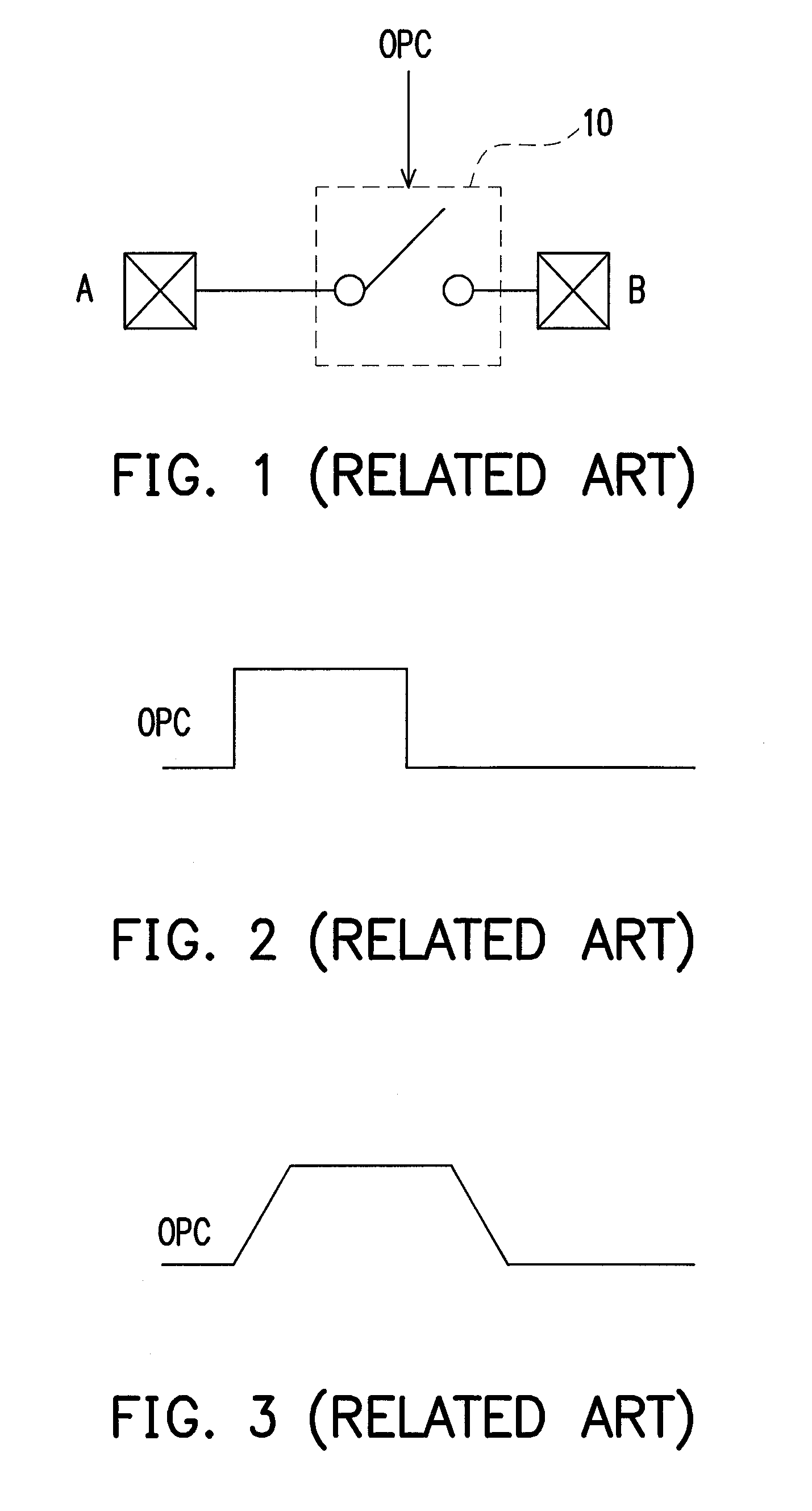

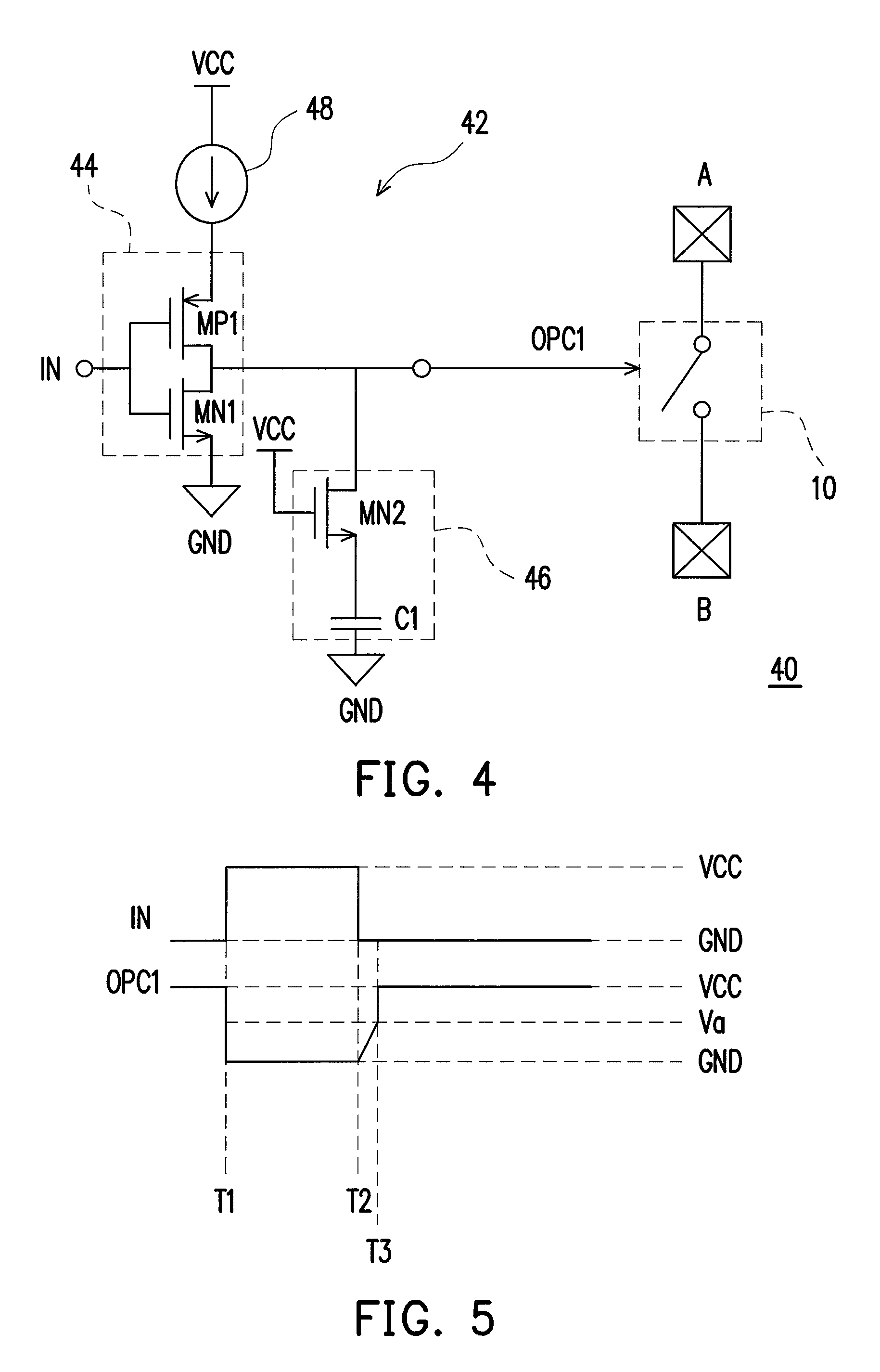

Switching apparatus and control signal generator thereof

InactiveUS20110062924A1Fast switching responseSlow changeTransistorElectronic switchingCapacitanceControl signal

A switching apparatus has a switch and a control signal generator. The control signal generator is configured to generate a control signal applied to the switch to control the operations of turning on and off of the switch. The control signal generator has an inverter and a regulating circuit. The input end of the inverter receives an input signal, and the output end of the inverter outputs the control signal. The regulating circuit has a switching unit and a capacitor. A first end of the switching unit is coupled to the output end of the inverter, a second end of the switching unit is coupled to a first system voltage, a third end of the switching unit is coupled to a first end of the capacitor, and a second end of the capacitor is coupled to a second system voltage.

Owner:NOVATEK MICROELECTRONICS CORP

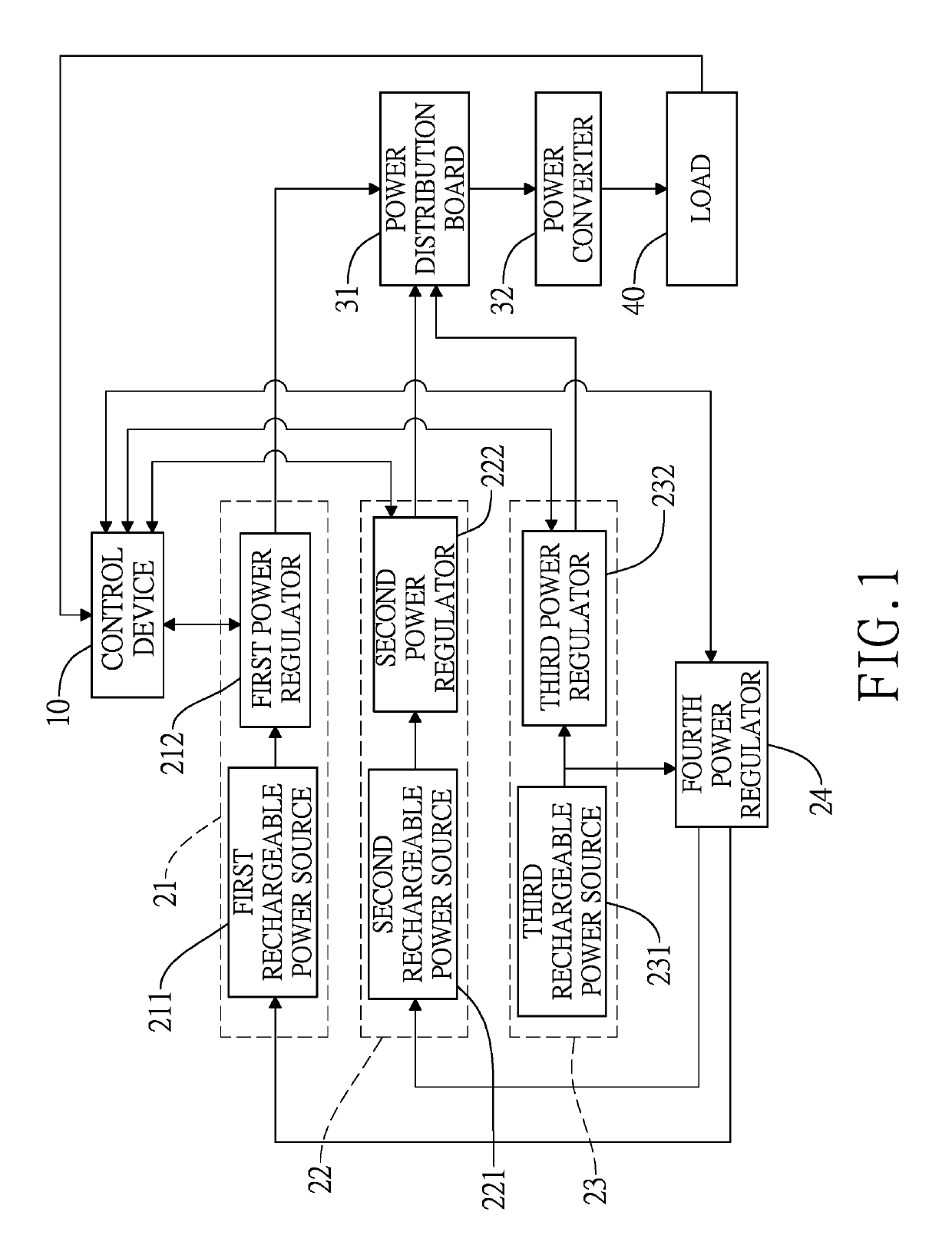

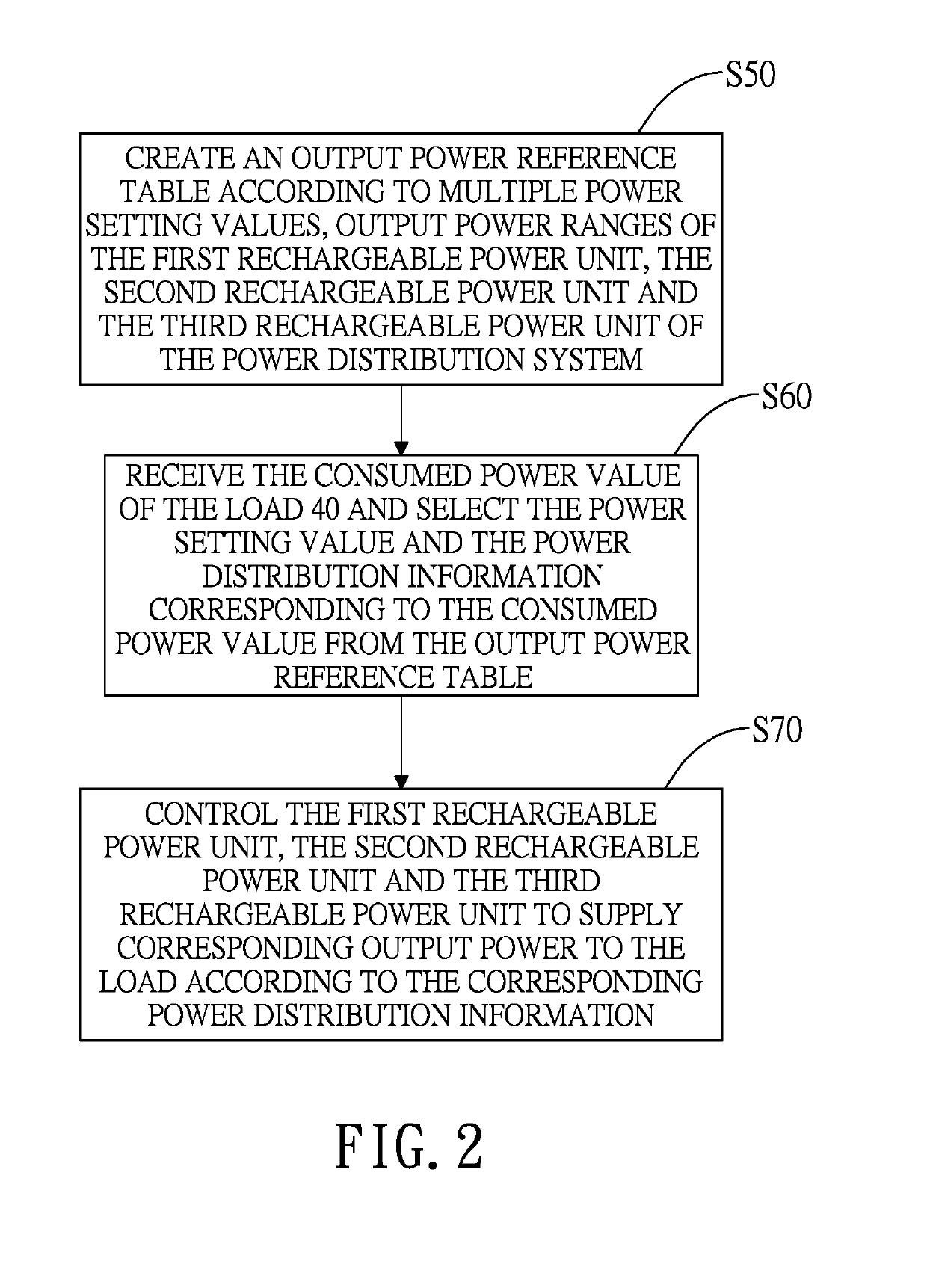

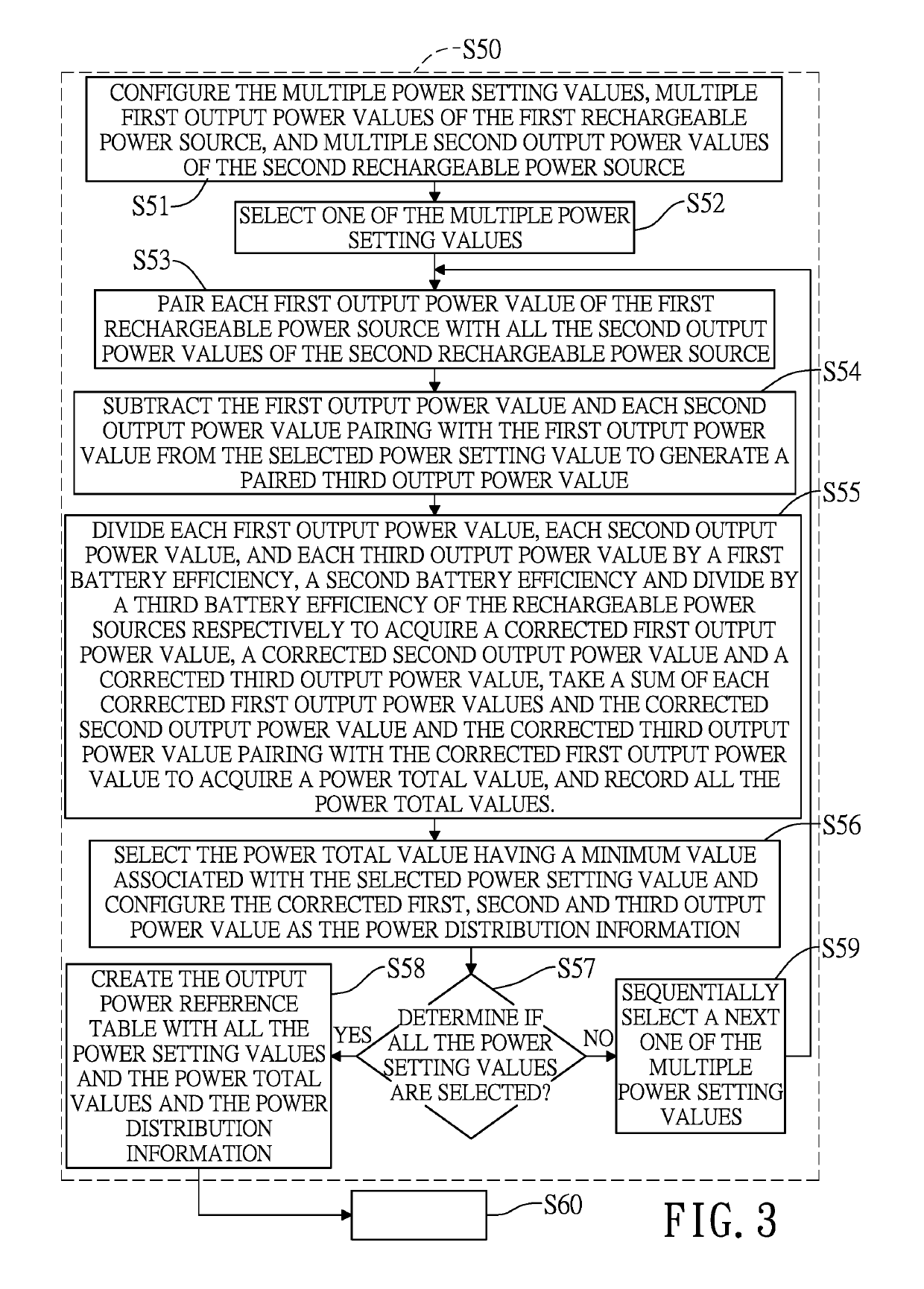

Power distribution system using multiple rechargeable power sources and method for distributing power using multiple rechargeable power sources

ActiveUS20190199121A1Improve power utilizationPower dropCharge equalisation circuitCharging stationsElectricityElectrical battery

A method for distributing power using multiple power sources is performed by a control device electrically connected to multiple rechargeable power units and a load. The control device creates an output power reference table according to multiple power setting values, output power ranges and battery efficiencies of the multiple rechargeable power units. The output power reference table includes the power setting values and power distribution information corresponding to the power setting values. When receiving a consumed power value of the load, the control device selects corresponding power setting value and power distribution information in the output power reference table and controls the multiple rechargeable power units to simultaneously output power to the load according to the power distribution information. By referring to the output power values of all the rechargeable power units and allocating power outputted from all the rechargeable power units, power utilization efficiency can be enhanced.

Owner:AUTOMOTIVE RES & TESTING CENT

Semiconductor device and display device

ActiveUS20080303065A1Reduce areaHigh voltageSemiconductor/solid-state device detailsSolid-state devicesElectricityDisplay device

It is an object of the invention to provide a thin, lightweight, high performance, and low in cost semiconductor device and a display device by reducing an arrangement area required for a power supply wiring and a ground wiring of a functional circuit and decreasing a drop in power supply voltage and a rise in ground voltage. In the functional circuit of the semiconductor device and the display device, a power supply wiring and a ground wiring are formed in a comb-like arrangement, and the tips thereof are electrically connected with a first wiring, a second wiring, and a contact between the first wiring and the second wiring, thereby forming in a grid-like arrangement. The drop in power supply voltage and the rise in ground voltage can be decreased and the arrangement area can be decreased in the grid-like arrangement.

Owner:SEMICON ENERGY LAB CO LTD

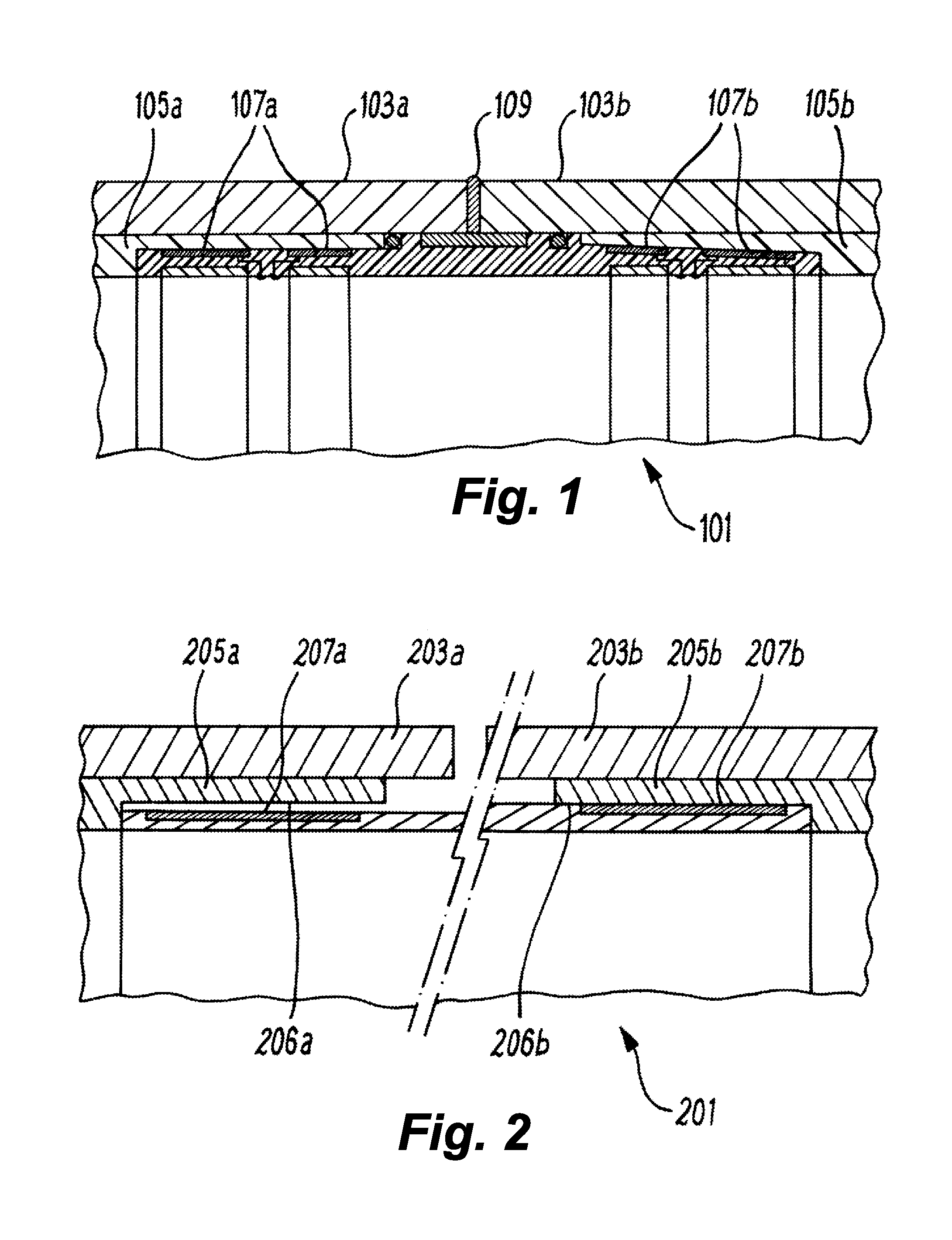

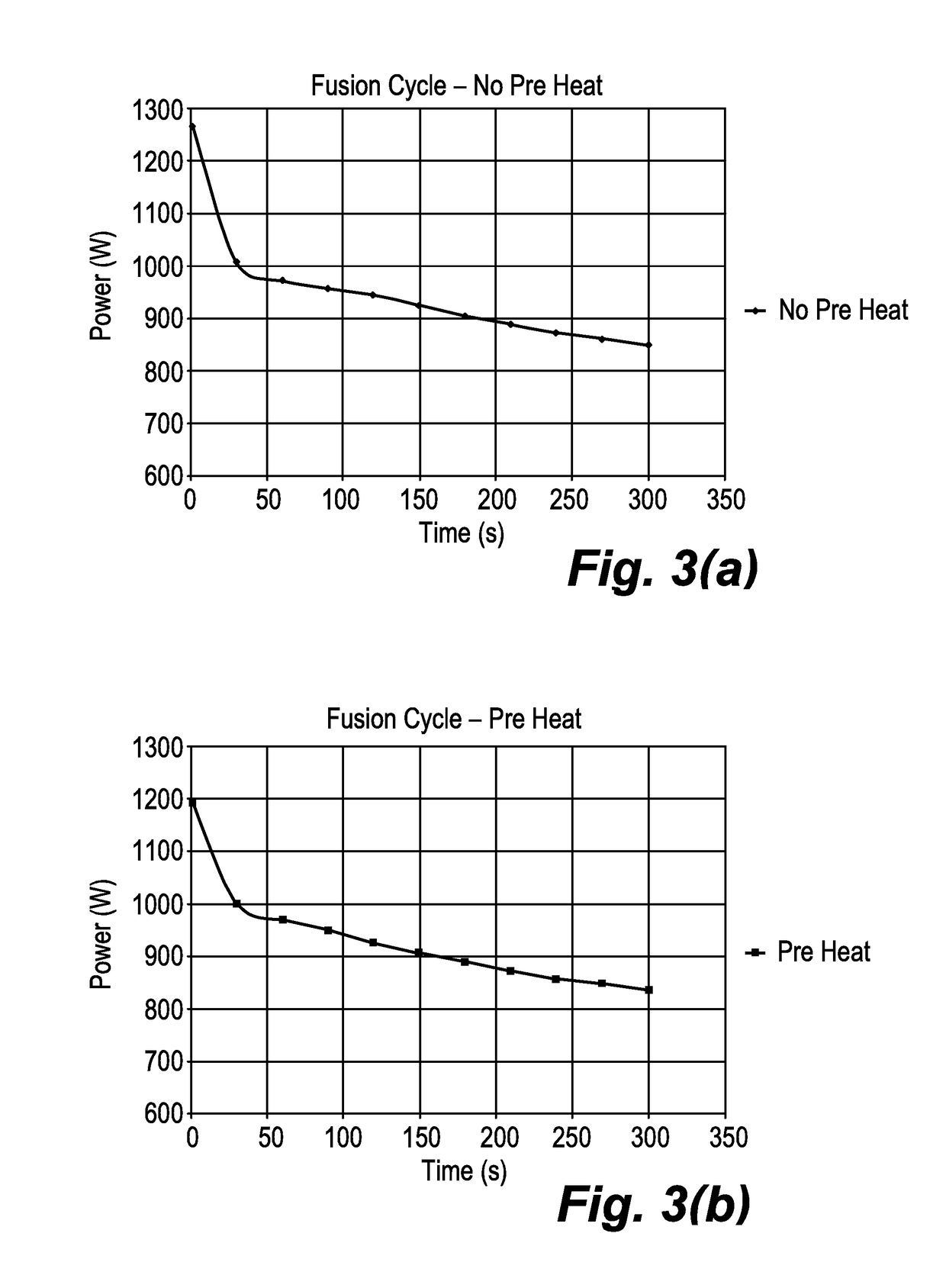

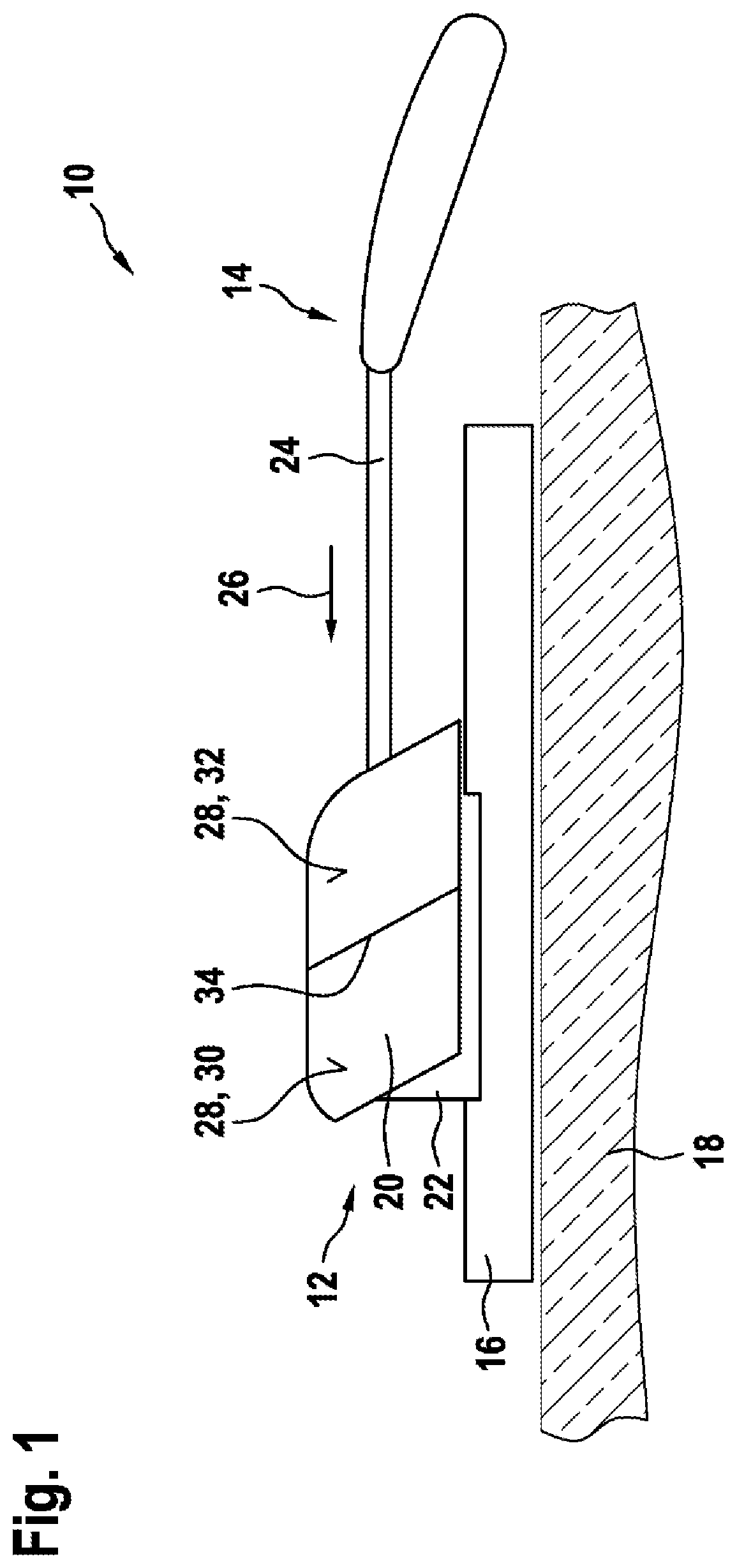

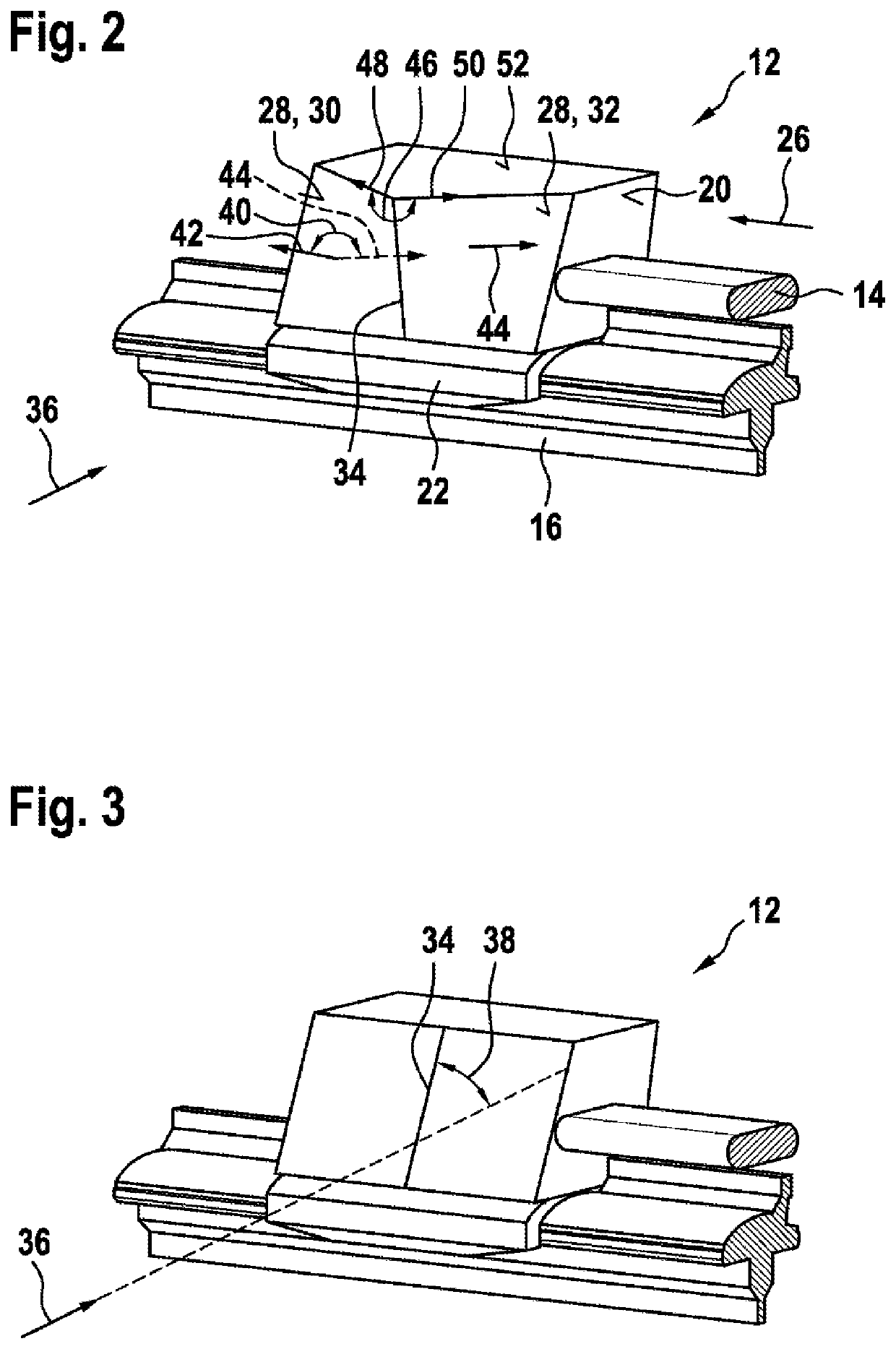

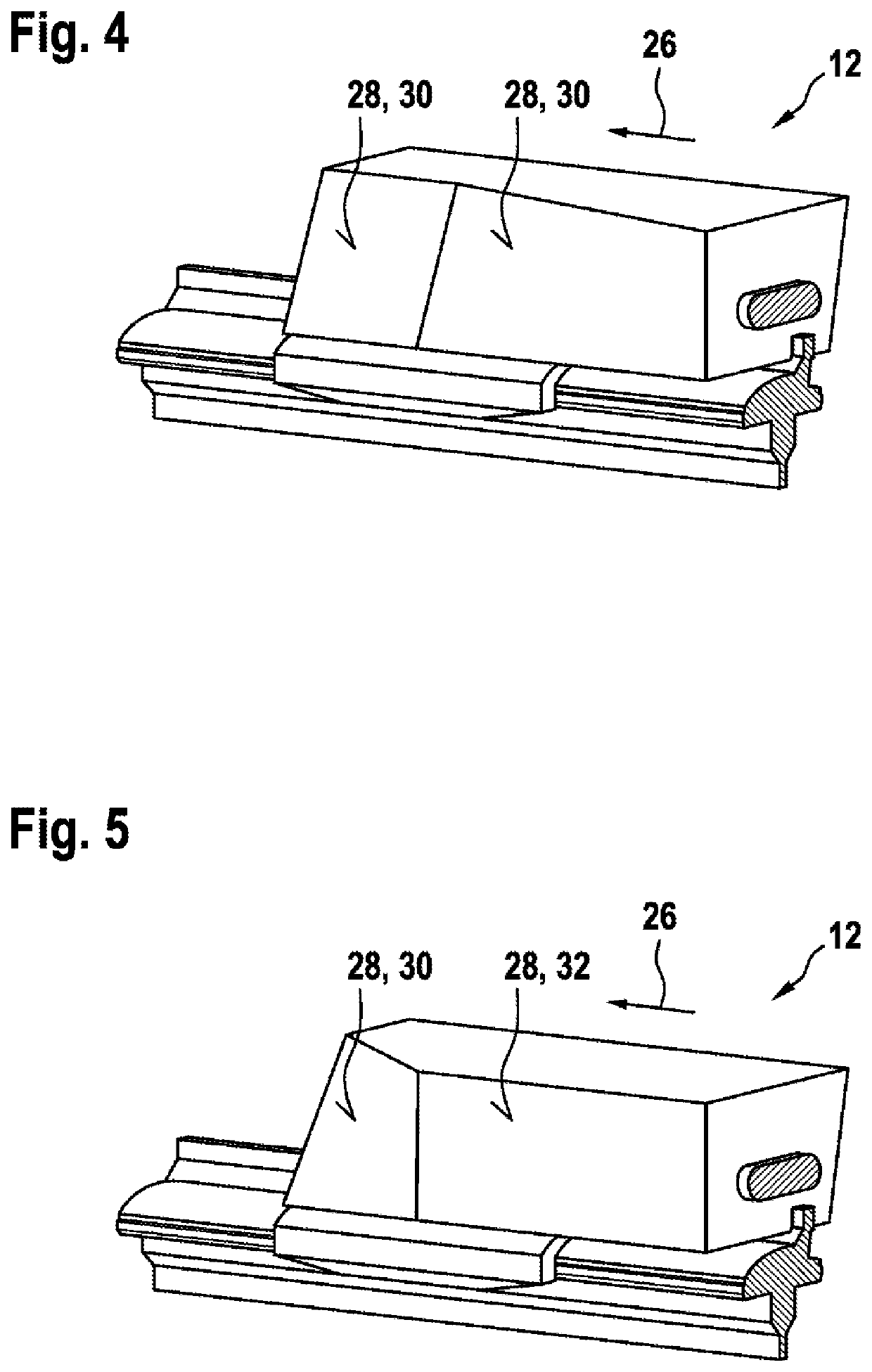

Electrofusion fitting methods

ActiveUS20160161039A1Increase likelihoodImprove reliabilityFilament handlingSoldering apparatusEngineeringCycle time

The invention provides improvements to electrofusion fitting methods that allow for continuity and repeatability of welds between an electrofusion fitting and a pipe lining (or stand-alone pipe). An electrofusion fitting for joining sections of lined pipe has heating elements configured to create at least one weld between the electrofusion fitting and a pipe lining, however prior to the weld step taking place the electrofusion fitting is heated and expands accordingly to ensure contact with the pipe lining. Preheating the electrofusion fitting also provides a predetermined starting temperature for the fitting and the lining which results in improved fusion cycle reliability. Furthermore, the need for clamps or support frames to support the electrofusion fitting in situ is removed, with corresponding reductions in cycle times, complexity, and hence cost.

Owner:PIONEER LINING TECH

Switching apparatus and control signal generator thereof

A switching apparatus has a switch and a control signal generator. The control signal generator is configured to generate a control signal applied to the switch to control the operations of turning on and off of the switch. The control signal generator has an inverter and a regulating circuit. The input end of the inverter receives an input signal, and the output end of the inverter outputs the control signal. The regulating circuit has a switching unit and a capacitor. A first end of the switching unit is coupled to the output end of the inverter, a second end of the switching unit is coupled to a first system voltage, a third end of the switching unit is coupled to a first end of the capacitor, and a second end of the capacitor is coupled to a second system voltage.

Owner:NOVATEK MICROELECTRONICS CORP

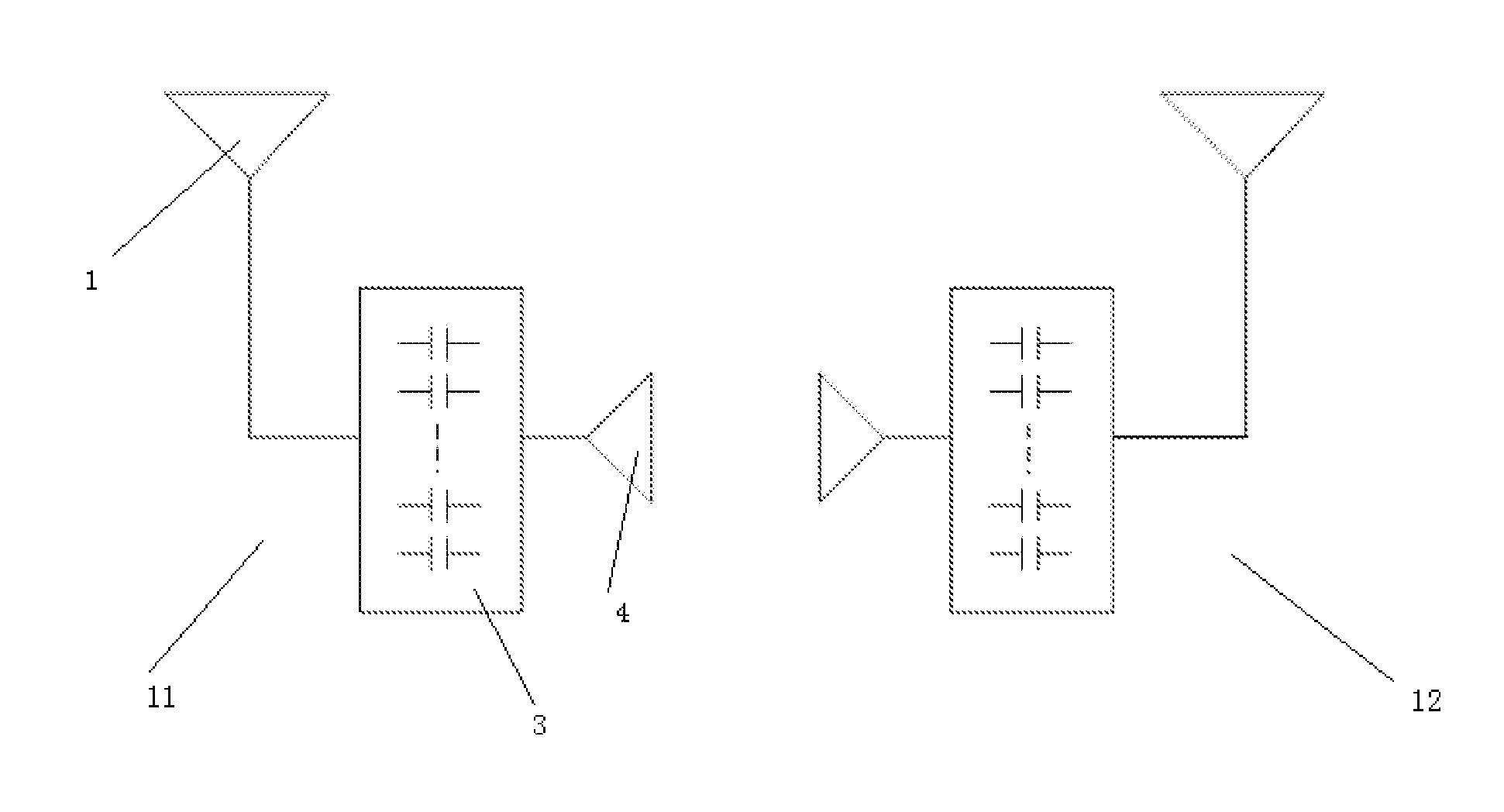

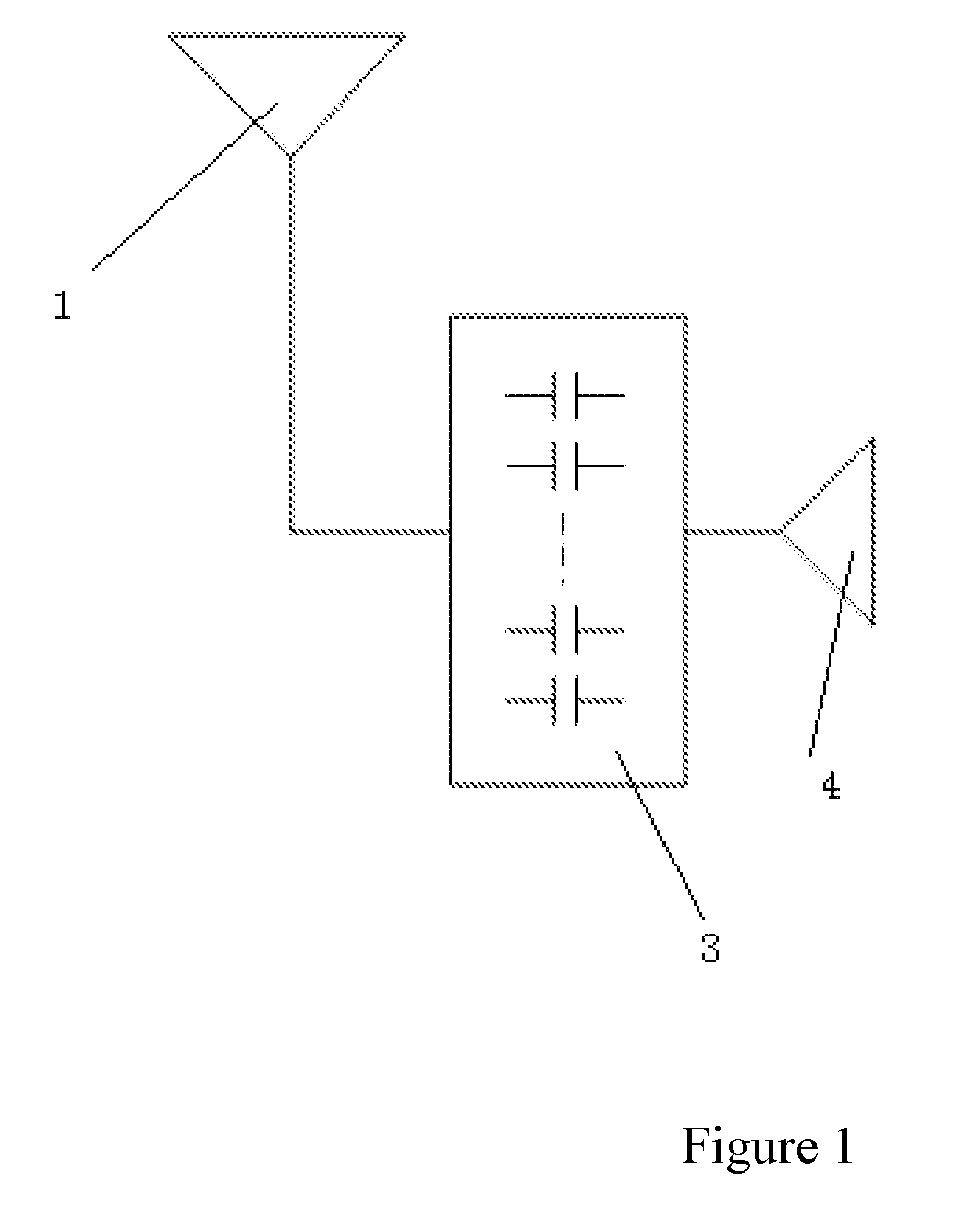

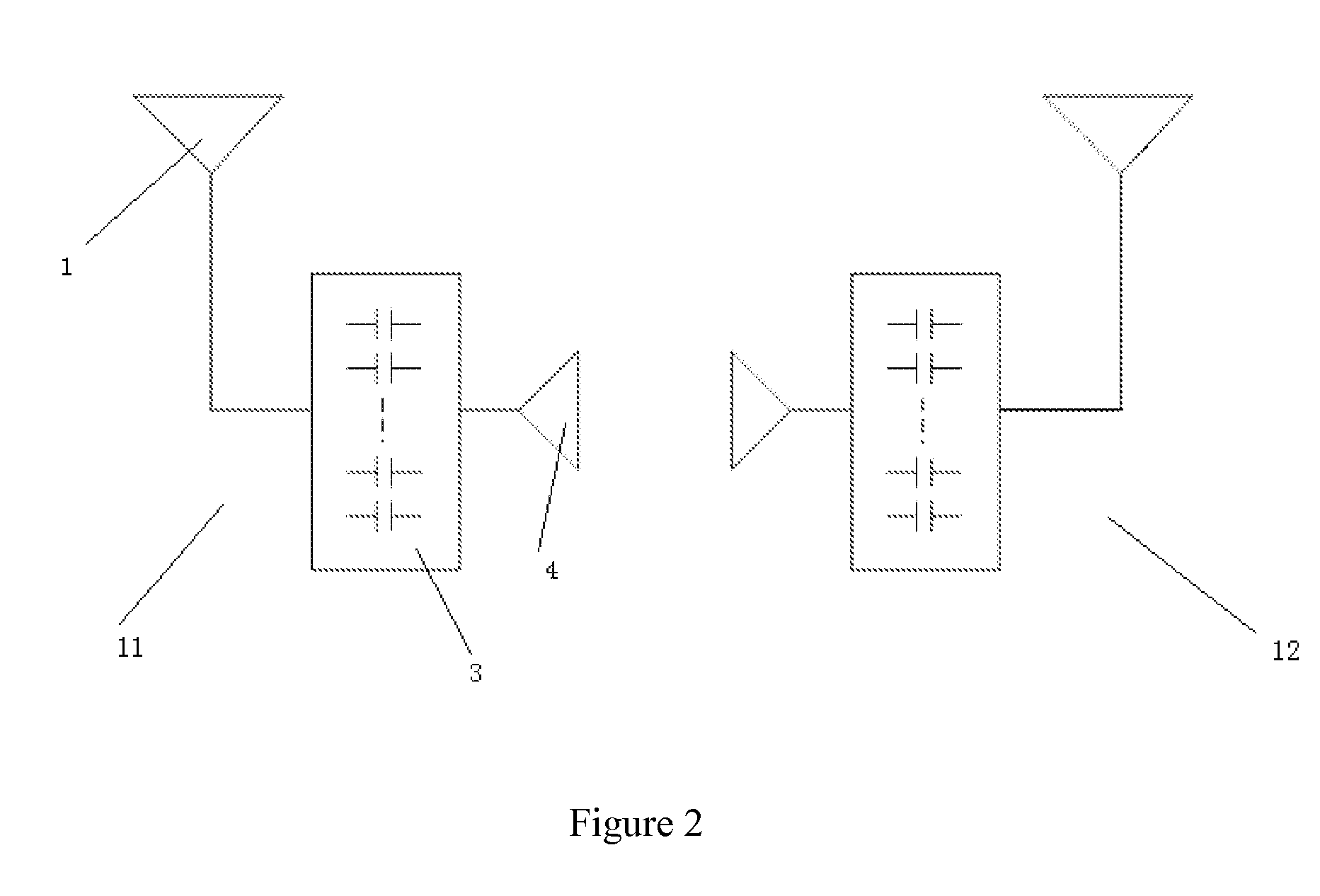

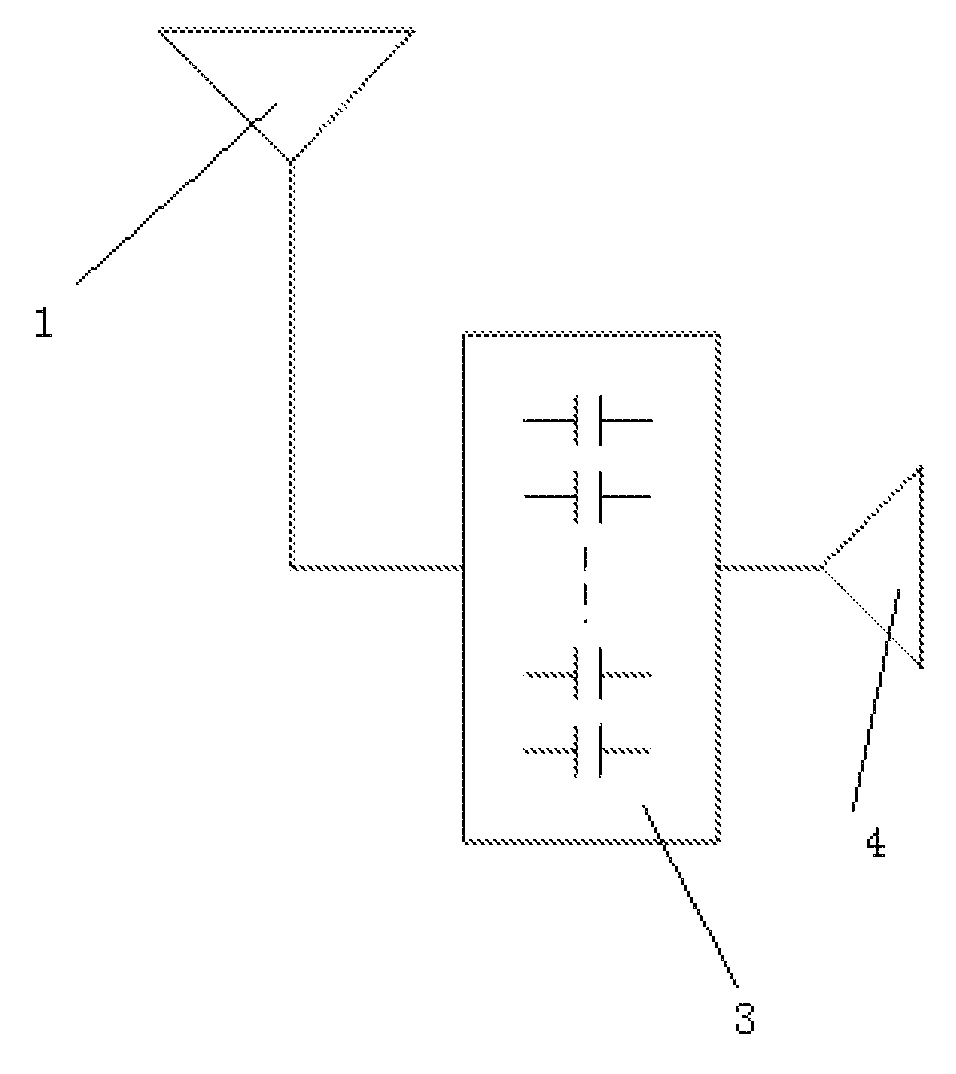

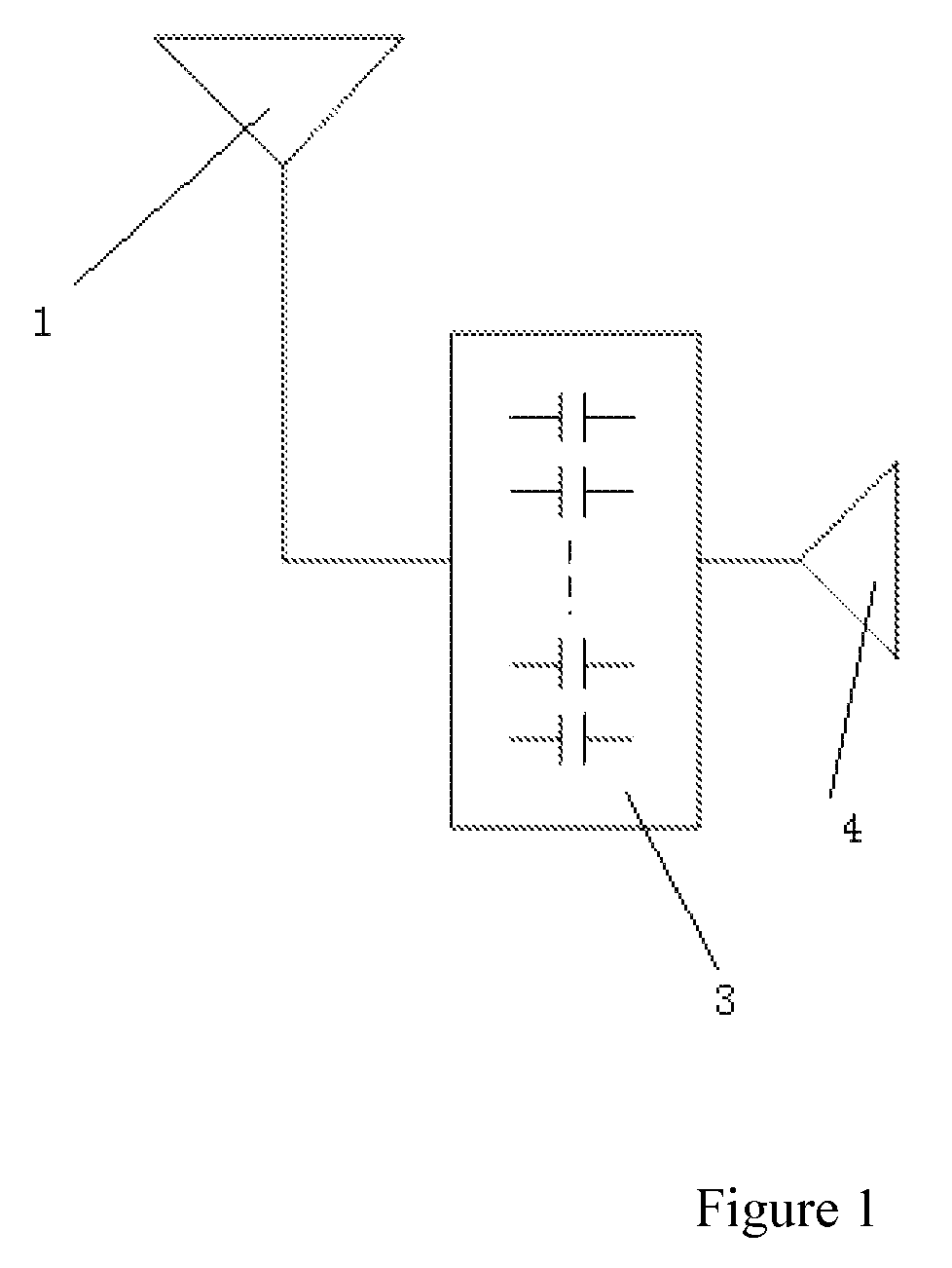

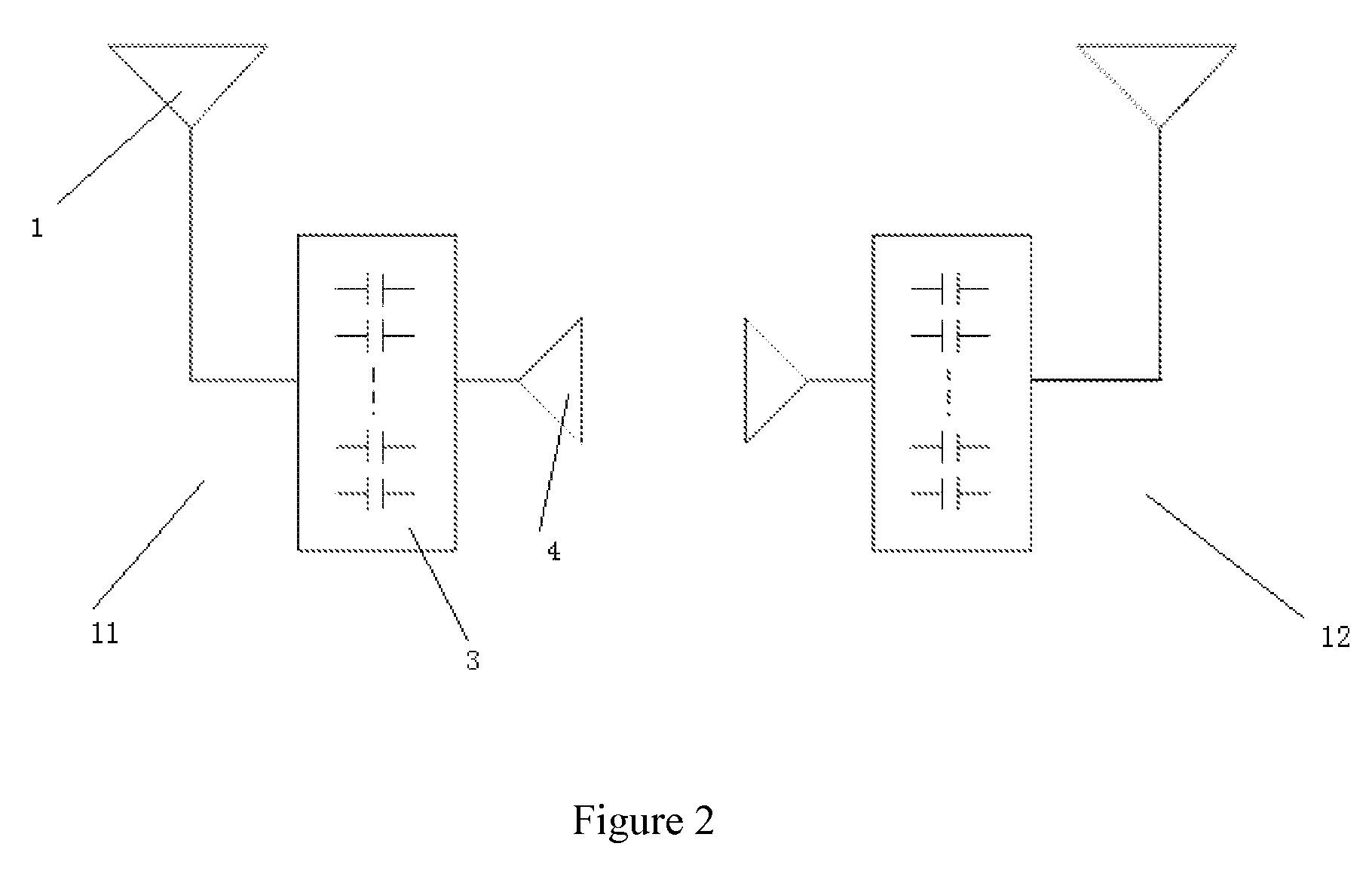

Device for improving the stray isolation between the antennas in the bilateral antenna and the method thereof

ActiveUS20150118975A1Improving stray isolationReduce the required powerTransmissionWireless communicationRadianceComputer module

The present invention relates to the communication technology field, more specifically, to a scheme of bilateral antenna. A device for improving the stray isolation between the antennas in the bilateral antenna comprises a plurality of communication modules having an antenna and a power amplification module; at least one of the communication modules further comprises a tuning module. The power amplification module is connected to the antenna directly or through the tuning module. The stray isolation between the communication module and other communication module is improved by adjusting the communication modules comprising the tuning module. This invention increases the stray isolation between the communication modules in different frequency bands, specifically, when a long interval exits between working frequency bands. Consequently, the radiance performance of the bilateral antenna of the mobile termination is satisfied, and the capacity of resisting disturbance between the systems is enhanced.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

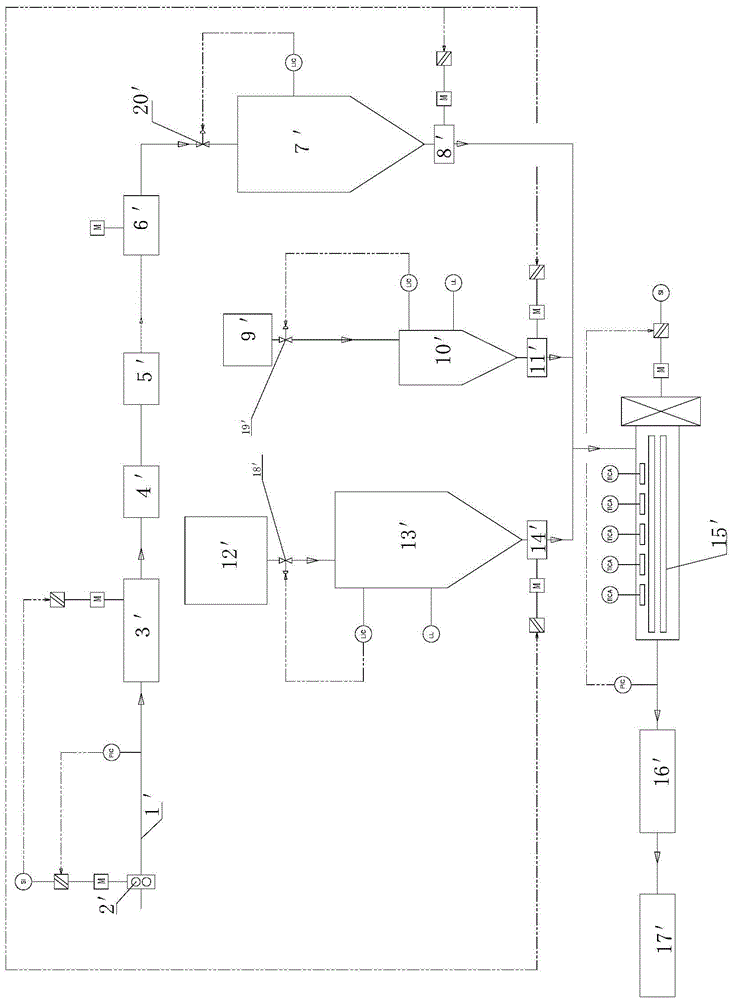

Method for preparing master batches through direct PET melt mixing and equipment special for method

Provided are a method for preparing master batches through direct PET melt mixing and equipment special for the method. The method comprises the steps that melt is introduced from a main melt pipeline, a delustering agent and a dispersing agent are mixed in proportion, and the mixture enters a double-screw extruder in a negative-pressure state for low-speed preliminary mixing; and then blending is carried out through an ultrasonic dynamic mixer, dicing, drying and packaging are carried out after water cooling, and the corresponding master batches are prepared. The equipment comprises an extruder assembly, an auxiliary material bin assembly, a dispersing agent bin assembly, an ultrasonic dynamic mixing assembly, a dicing assembly, a drying and packaging machine and a control box. The main melt pipeline is connected to a discharging opening of a discharging assembly, and communicates with a first feeding opening pipeline of the extruder assembly through a branch melt pipeline, and a discharging opening of a corresponding feeding assembly communicates with a second feeding opening pipeline of the extruder assembly. The method and the equipment have the beneficial effects that viscosity is lowered, the quality is stable, and good spinnability is achieved; and the procedures of slicing and dicing, drying, solid phase condensation polymerization, grinding and the like are omitted, and cost is reduced.

Owner:新凤鸣江苏新拓新材有限公司

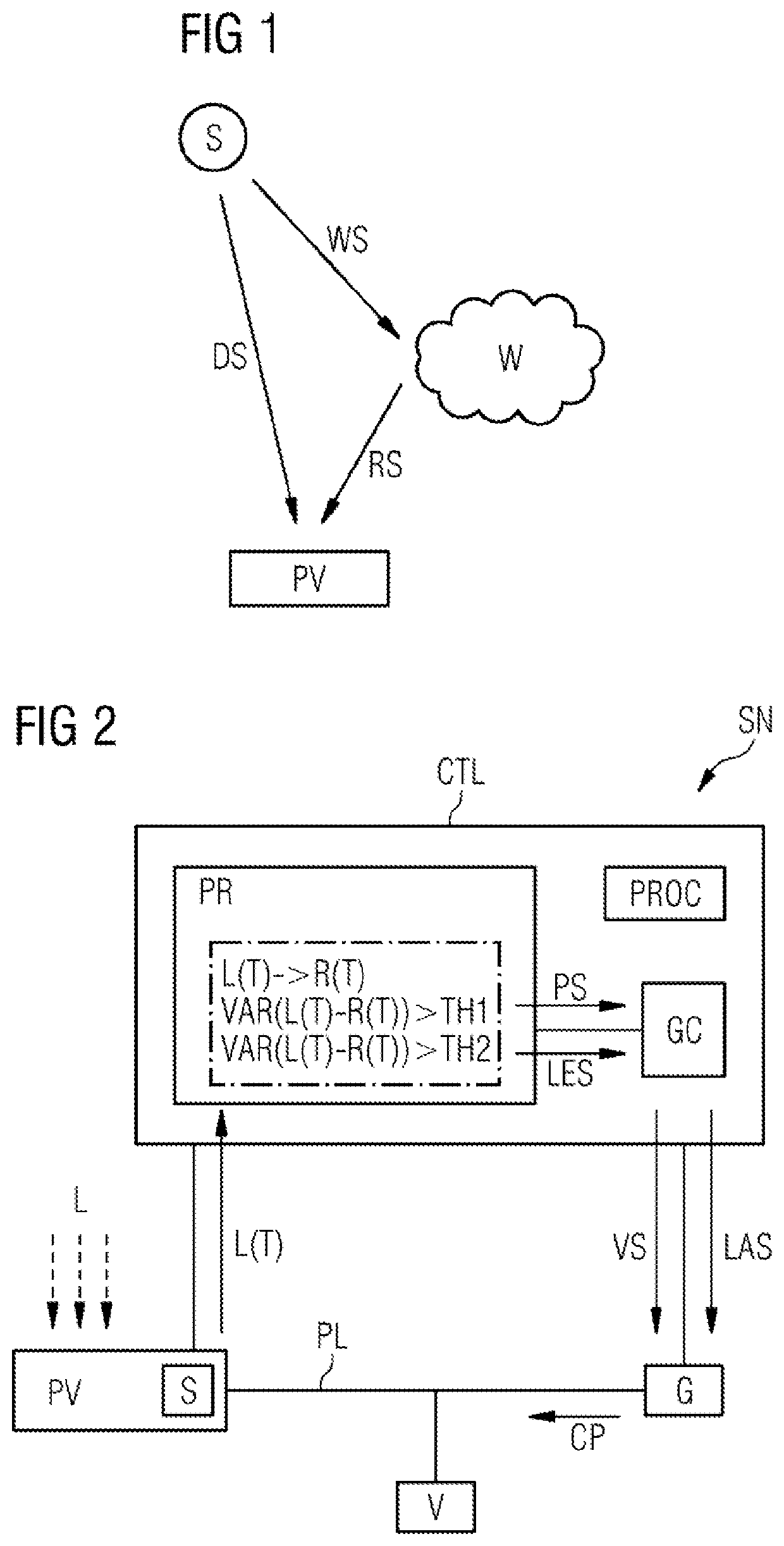

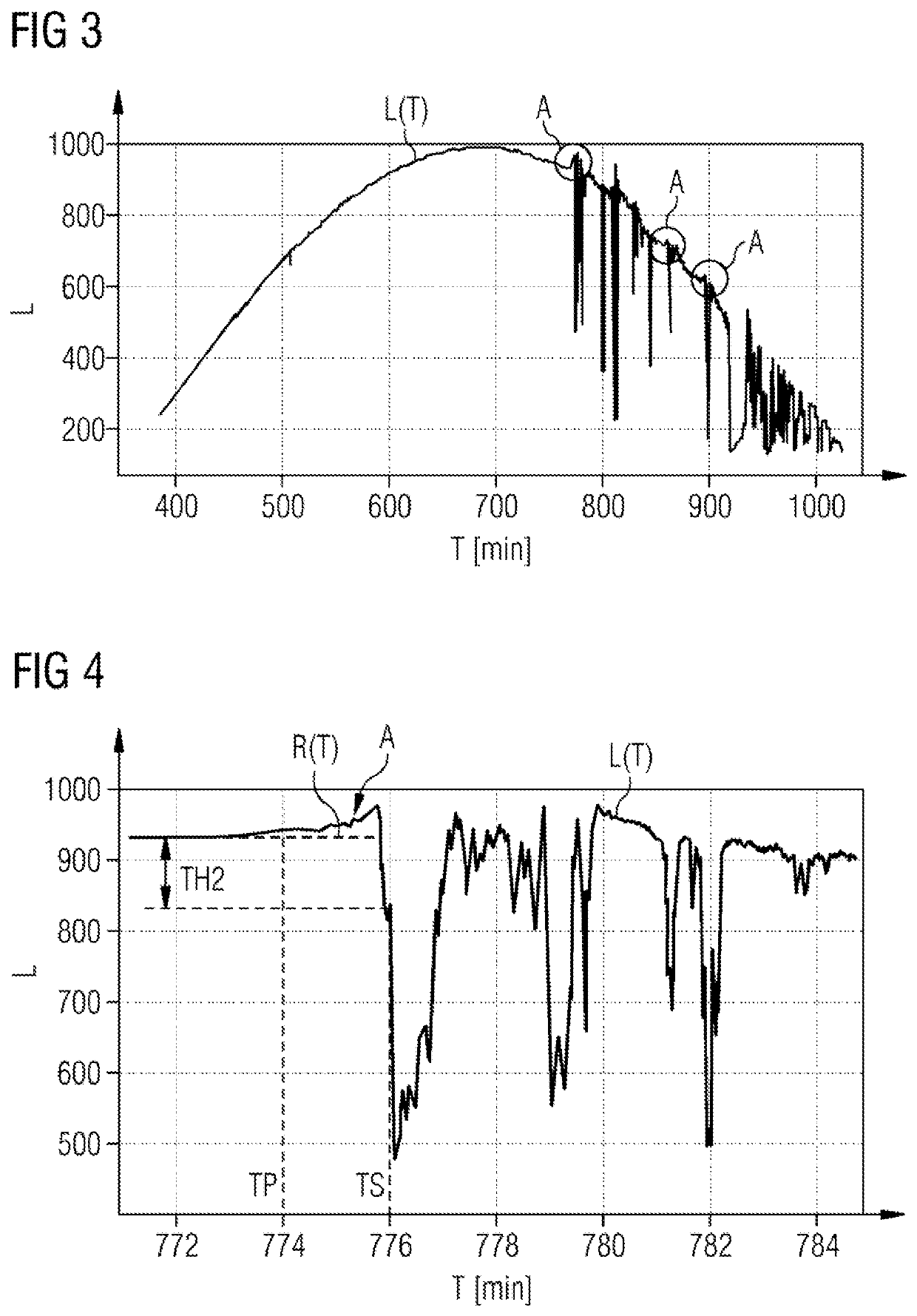

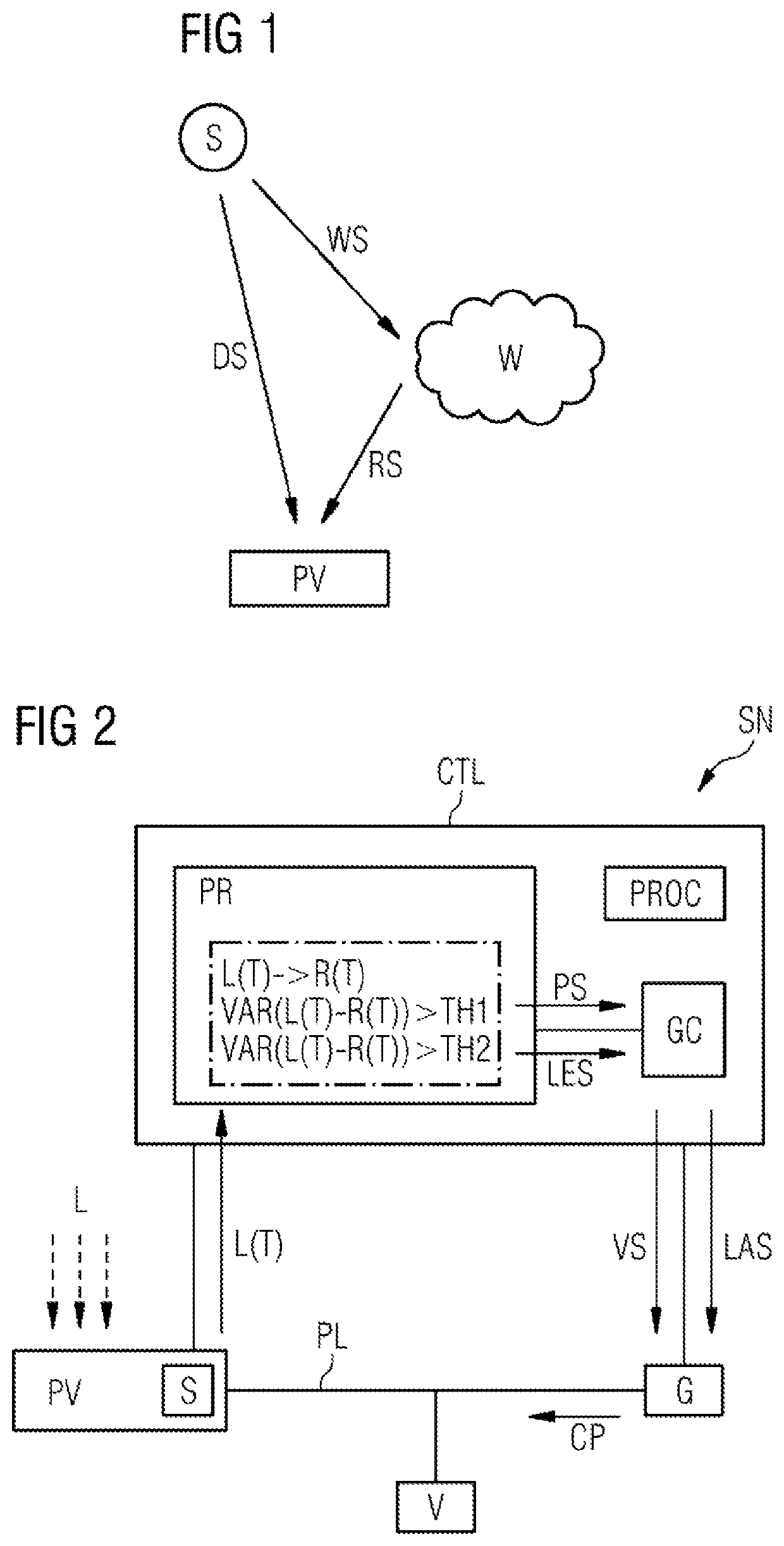

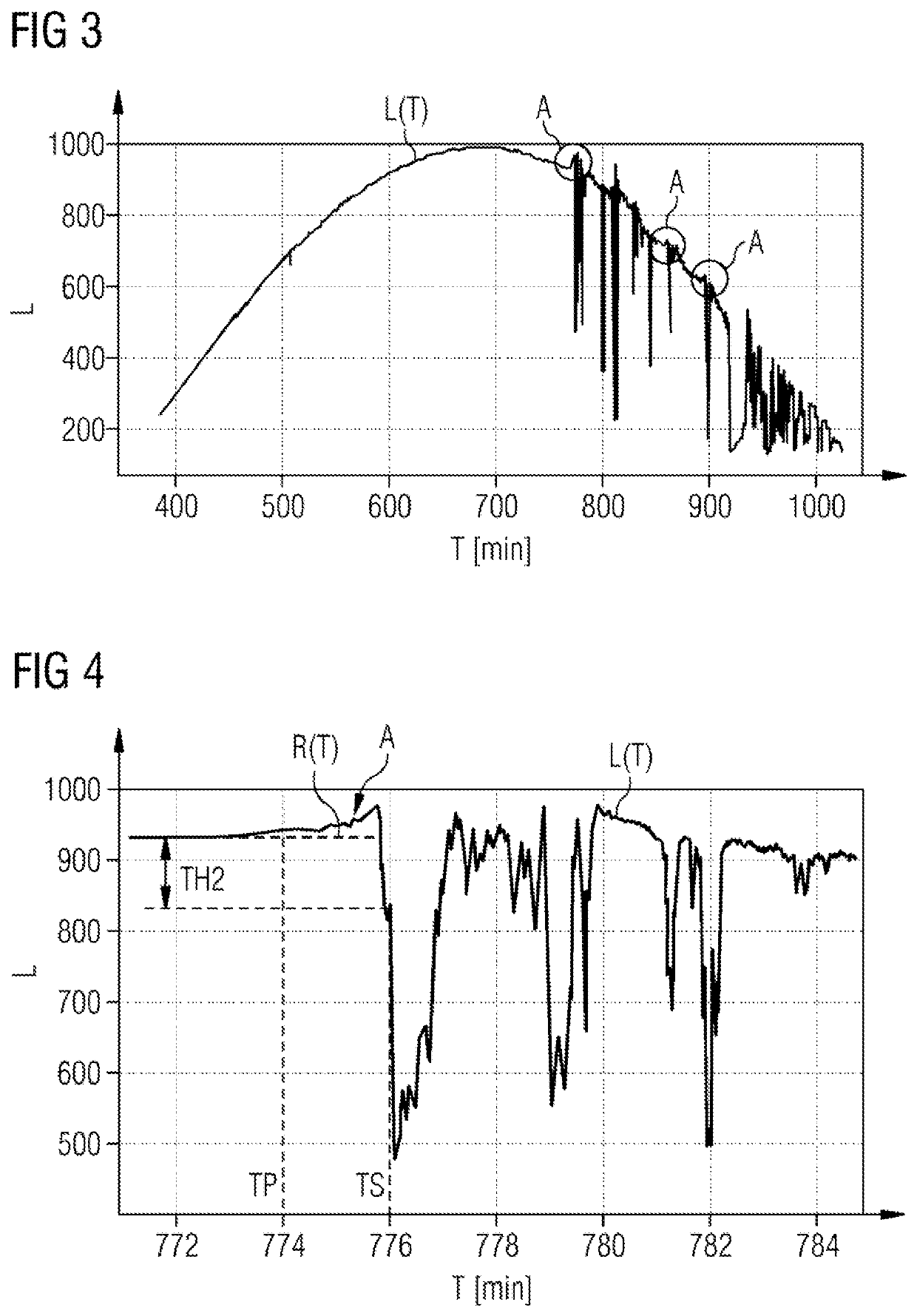

Method, forecasting device and control device for controlling a power network with a photovoltaic system

ActiveUS20200251898A1Improve time resolutionPower dropSunshine duration recordersGeneration forecast in ac networkOptical radiationEngineering

To control a power network having a photovoltaic system, a time curve of a light radiation of the photovoltaic system is determined, wherein an increase of the time curve in relation to a reference curve of the light radiation is detected. As a result of the detection of the increase, a preparatory measure is then introduced to prepare the power network for an upcoming power drop of the photovoltaic system.

Owner:SIEMENS AG

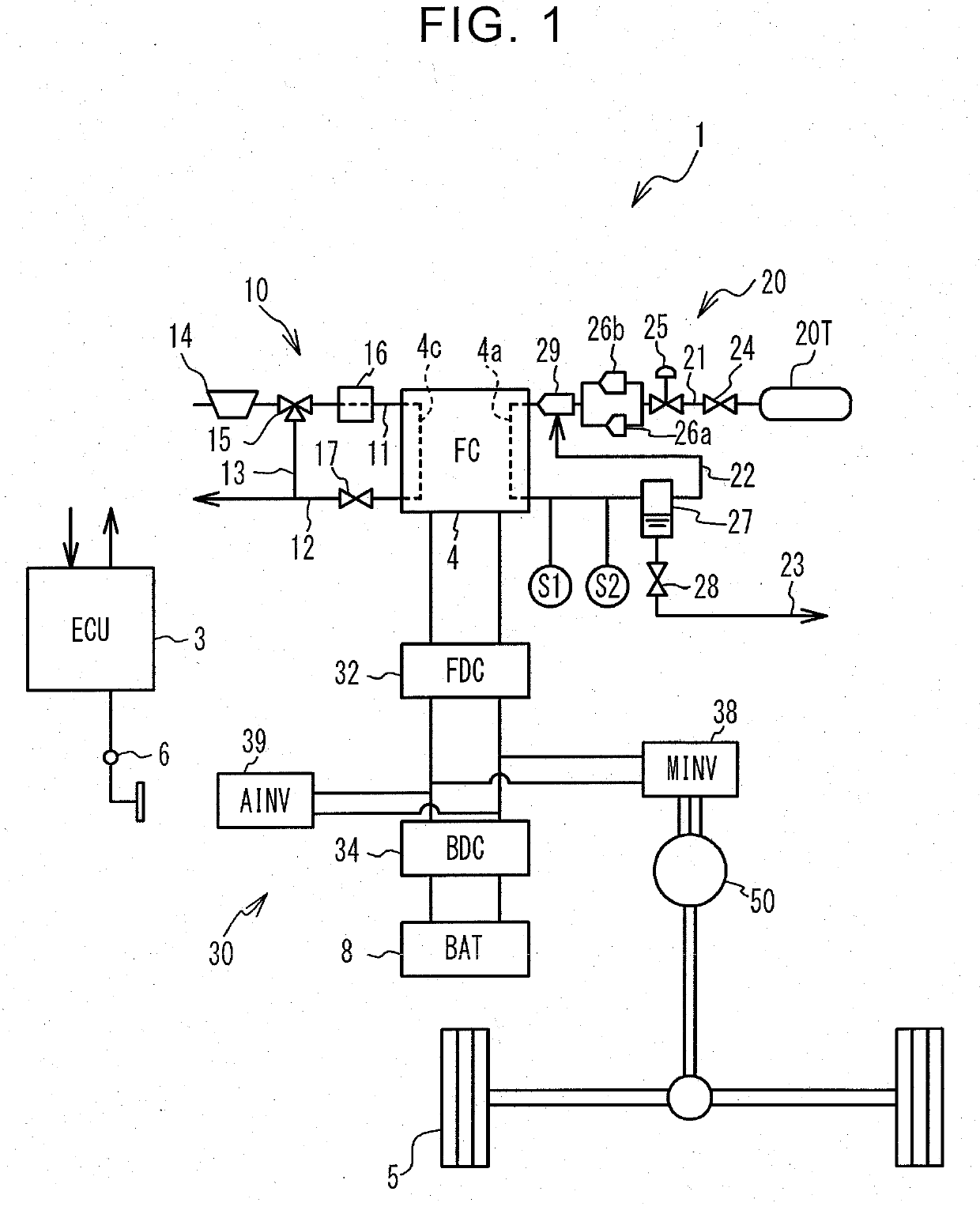

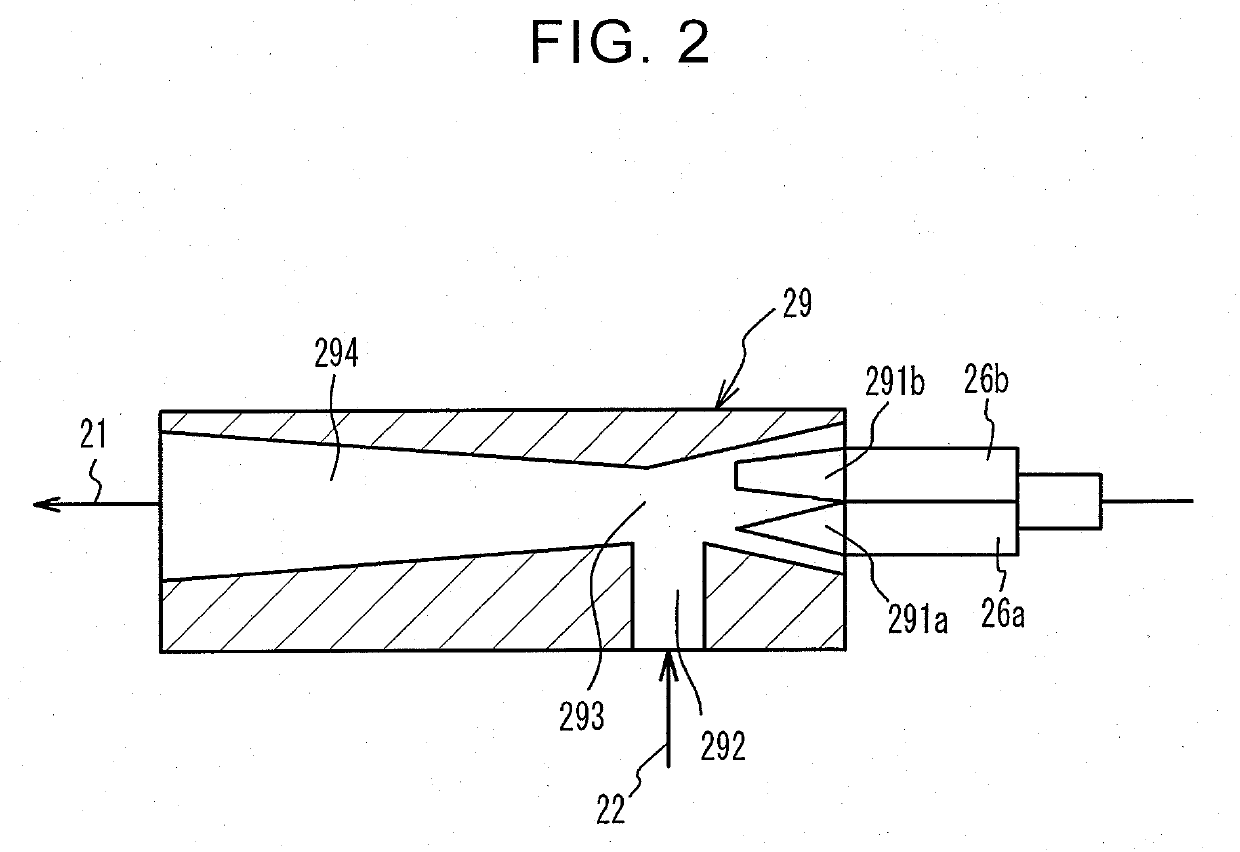

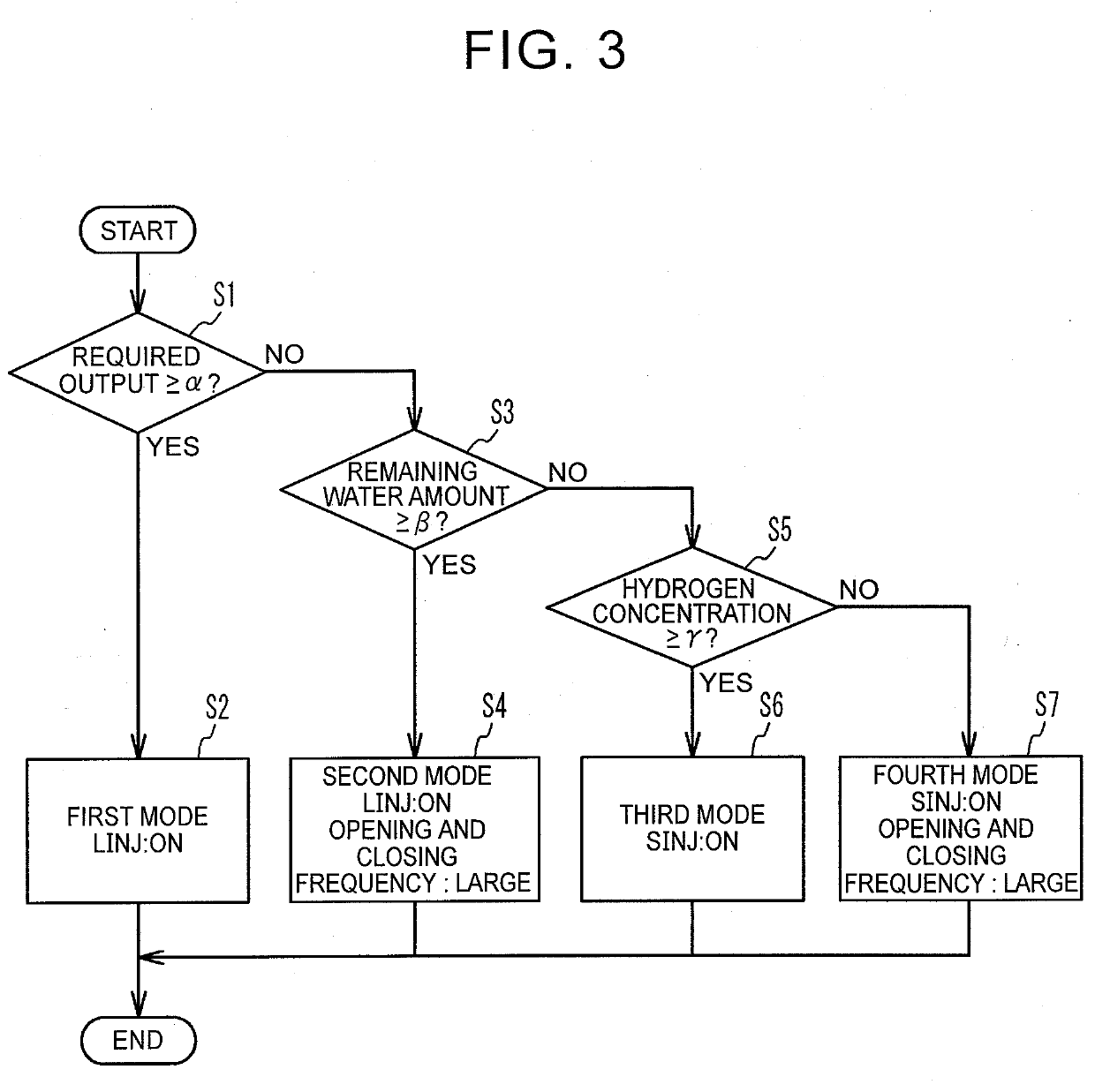

Fuel cell system and control method of fuel cell system

InactiveUS20200243879A1Deterioration of power generation performancePower generation performance is deterioratedReactant parameters controlFuel cellsGas passing

A fuel cell system includes a fuel cell, a first injector configured to inject fuel gas, a second injector configured to inject the fuel gas at an injection flow rate that is larger than that of the first injector, an ejector mechanism through which the fuel gas injected from each of the first injector and the second injector passes, a supply passage configured to supply the fuel gas passing through the ejector mechanism to the fuel cell, and a circulation passage configured to return the fuel gas discharged from the fuel cell to the ejector mechanism.

Owner:TOYOTA JIDOSHA KK

Semiconductor package having reduced internal power pad pitch

ActiveUS10304792B1Easy to separatePower dropSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor package

A packaged Integrated Circuit (IC) includes an IC and a package. The package has a bottom dielectric layer and a plurality of redistribution layers (RDLs) formed on the bottom dielectric layer. Each the RDLs includes patterned conductors, a dielectric layer, and a plurality of vias that extend between the patterned conductors to a differing RDL or to external connections. The package includes a plurality of package pads that have a first lateral separation pitch. The IC includes a plurality of IC pads that electrically connect to the plurality of package pads that have a first lateral separation pitch. The package also includes a plurality of Printed Circuit Board (PCB) pads that extend through the bottom dielectric layer and contact the plurality of patterned conductors of the first RDL. Power PCB pads and ground PCB pads of the plurality of PCB pads have a second lateral separation pitch that exceeds the first lateral separation pitch.

Owner:FUTUREWEI TECH INC

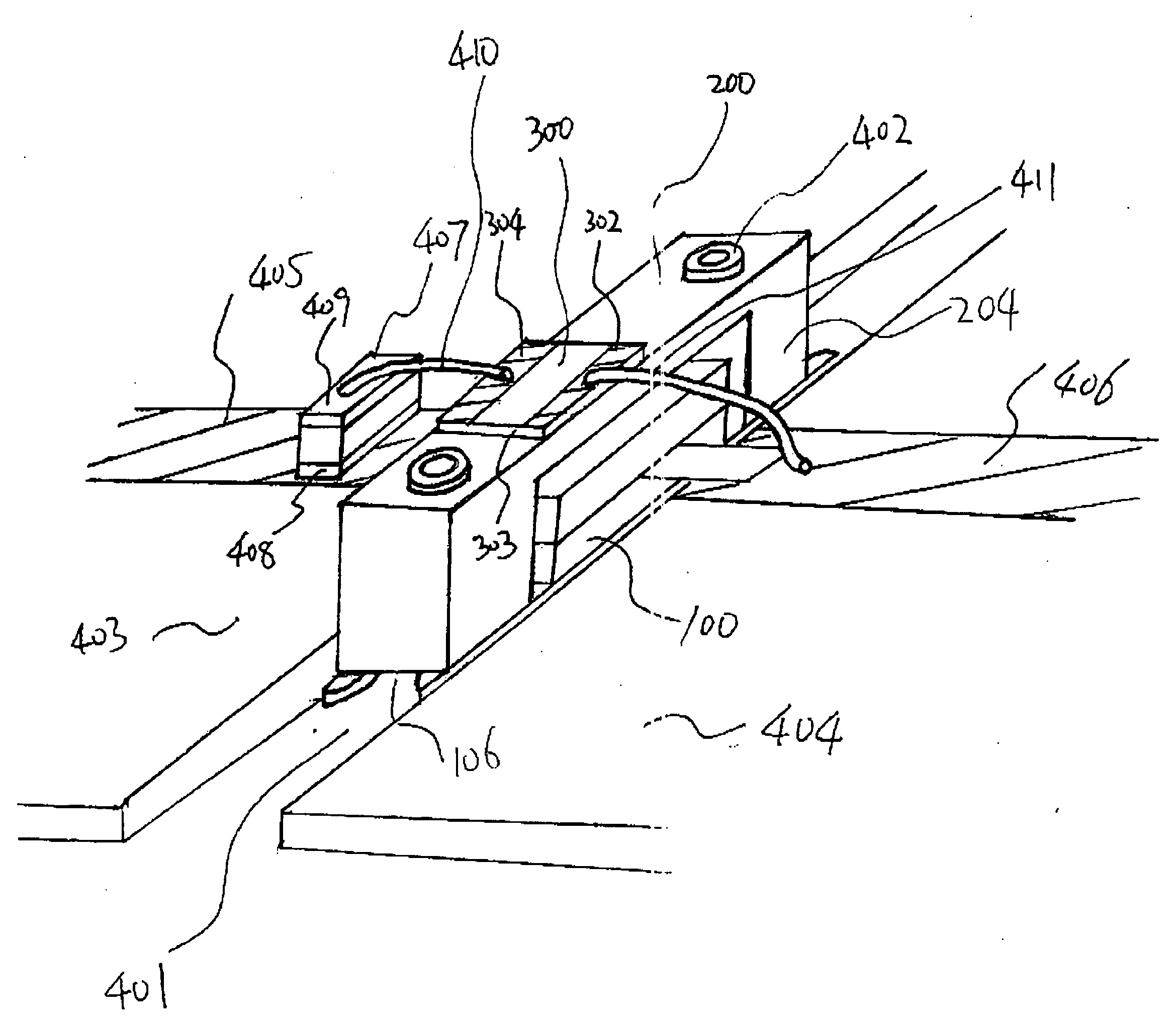

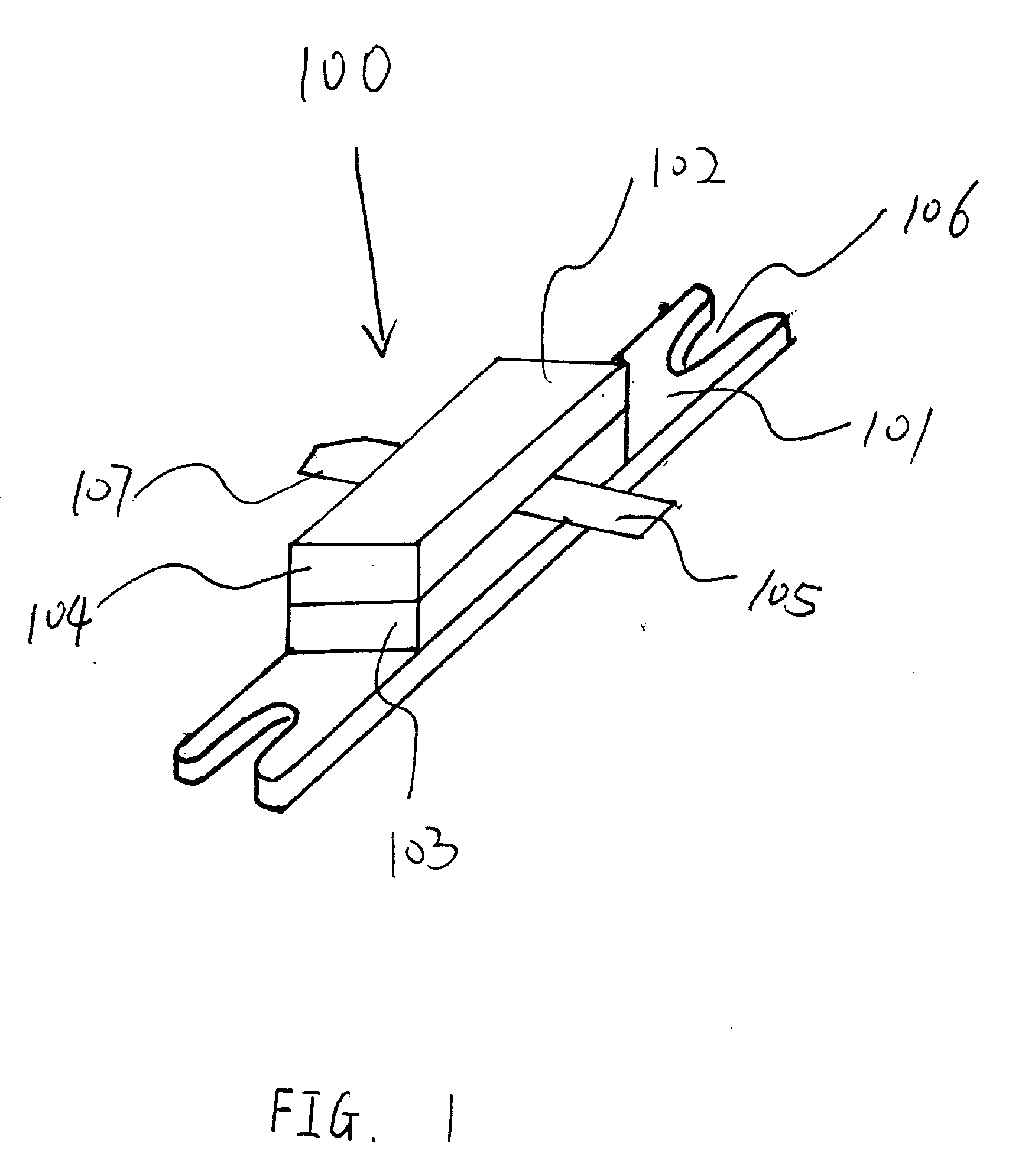

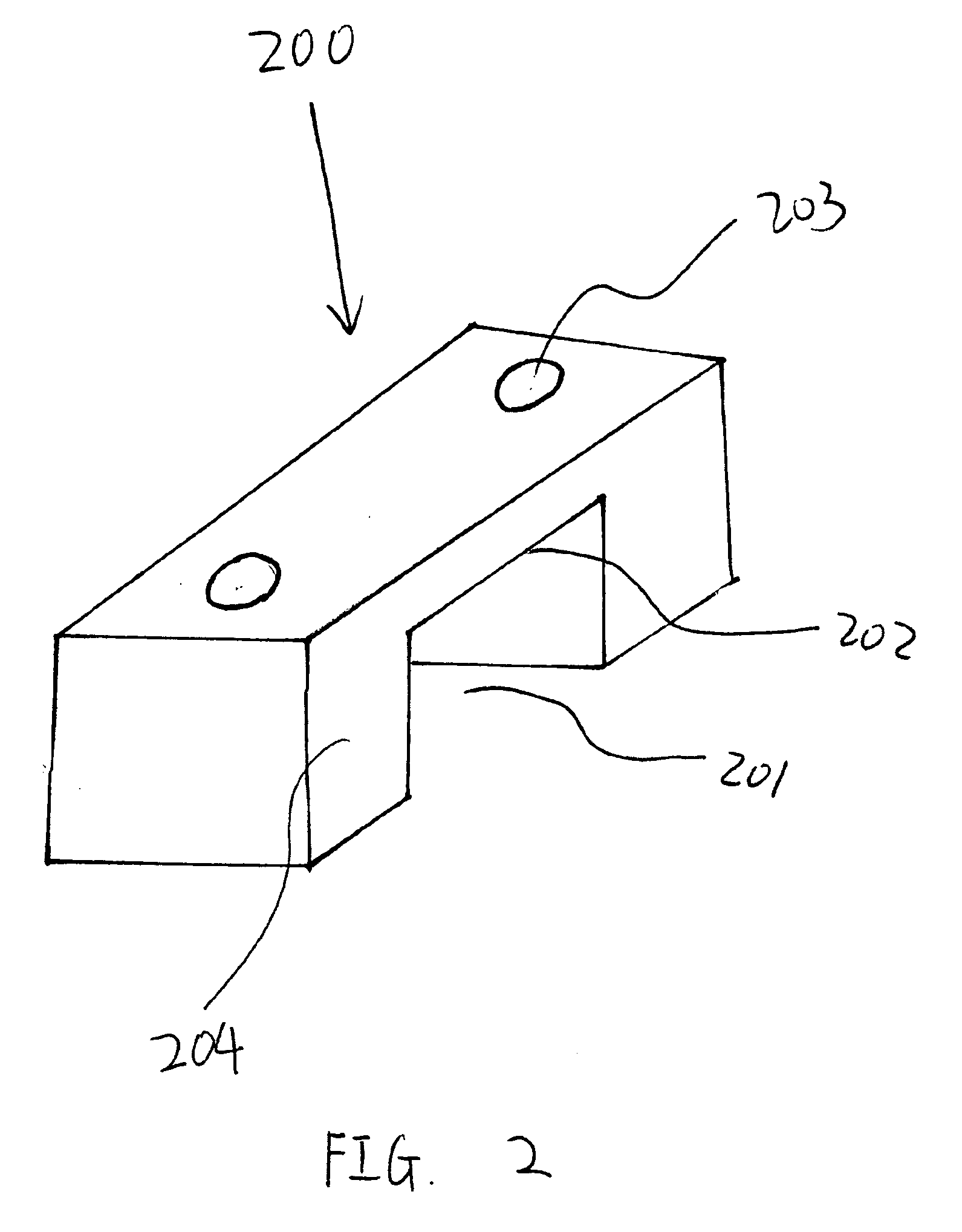

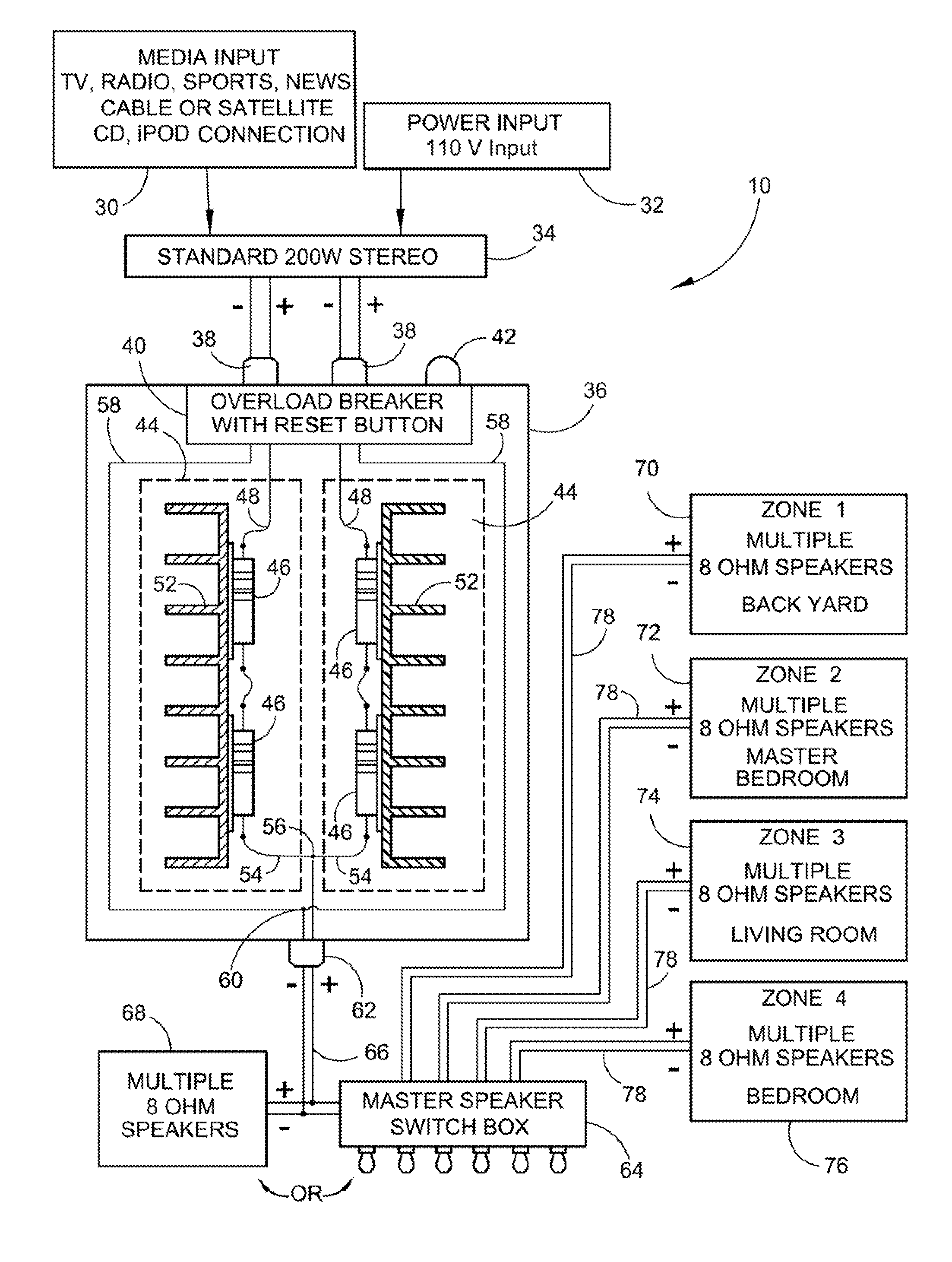

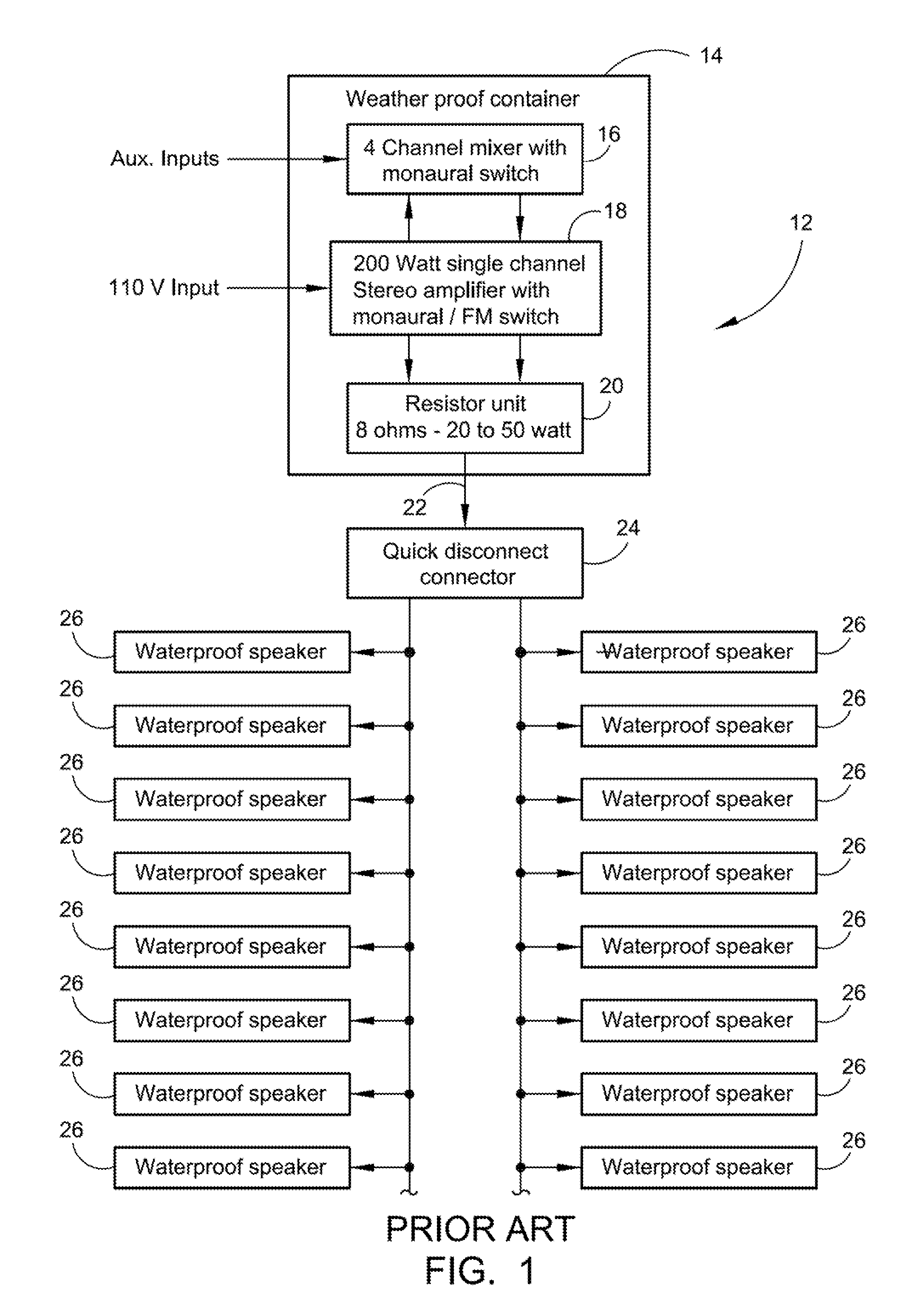

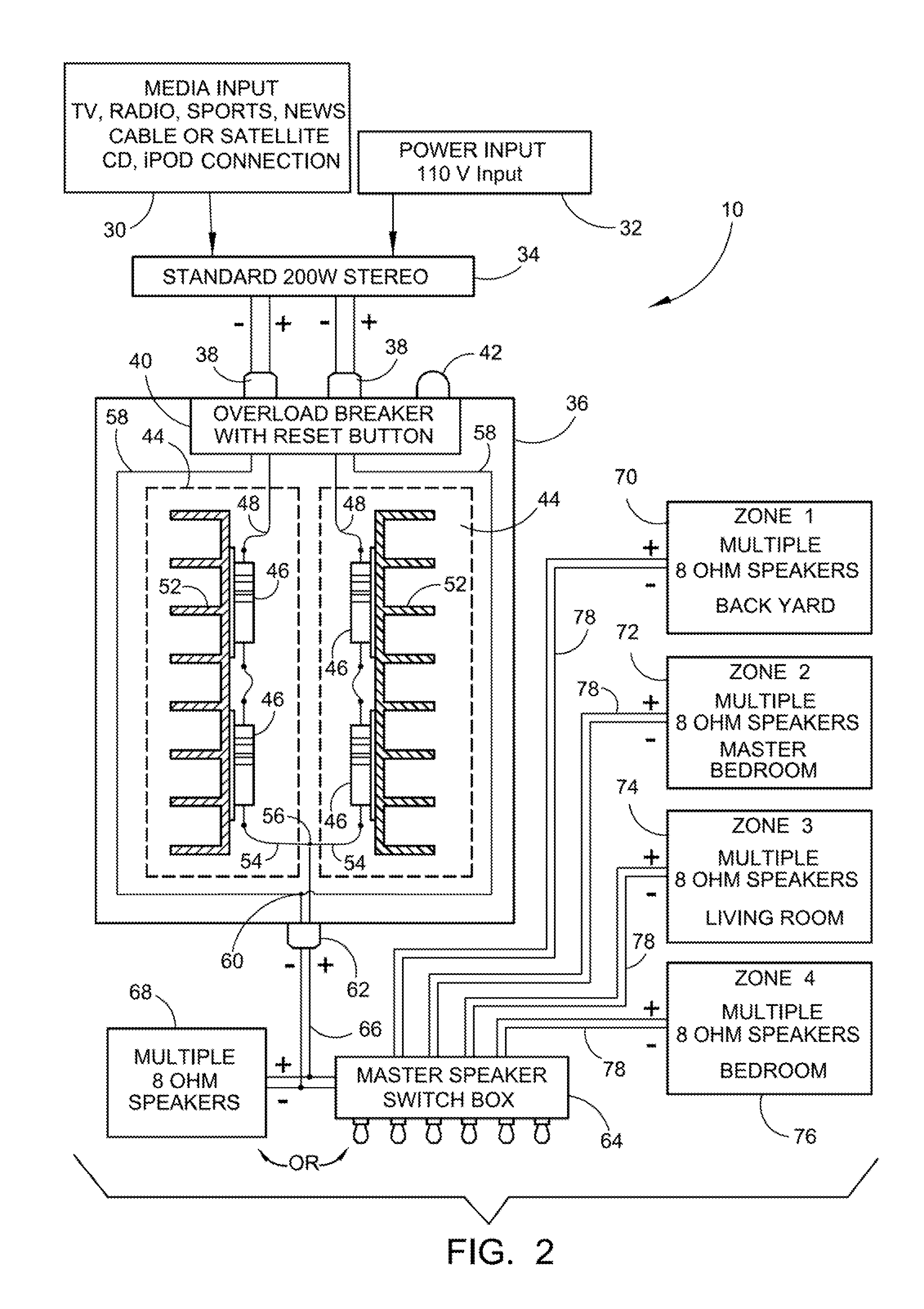

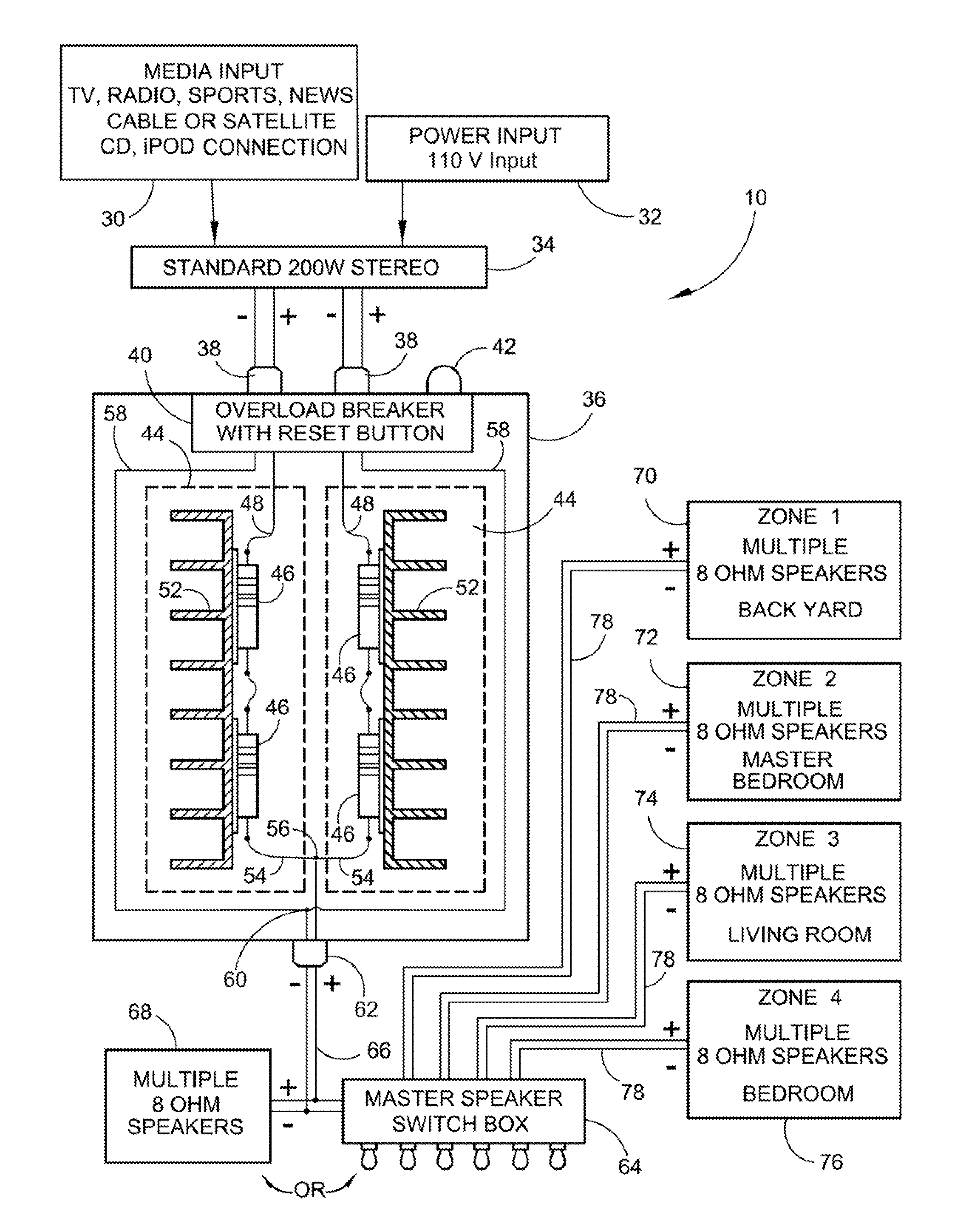

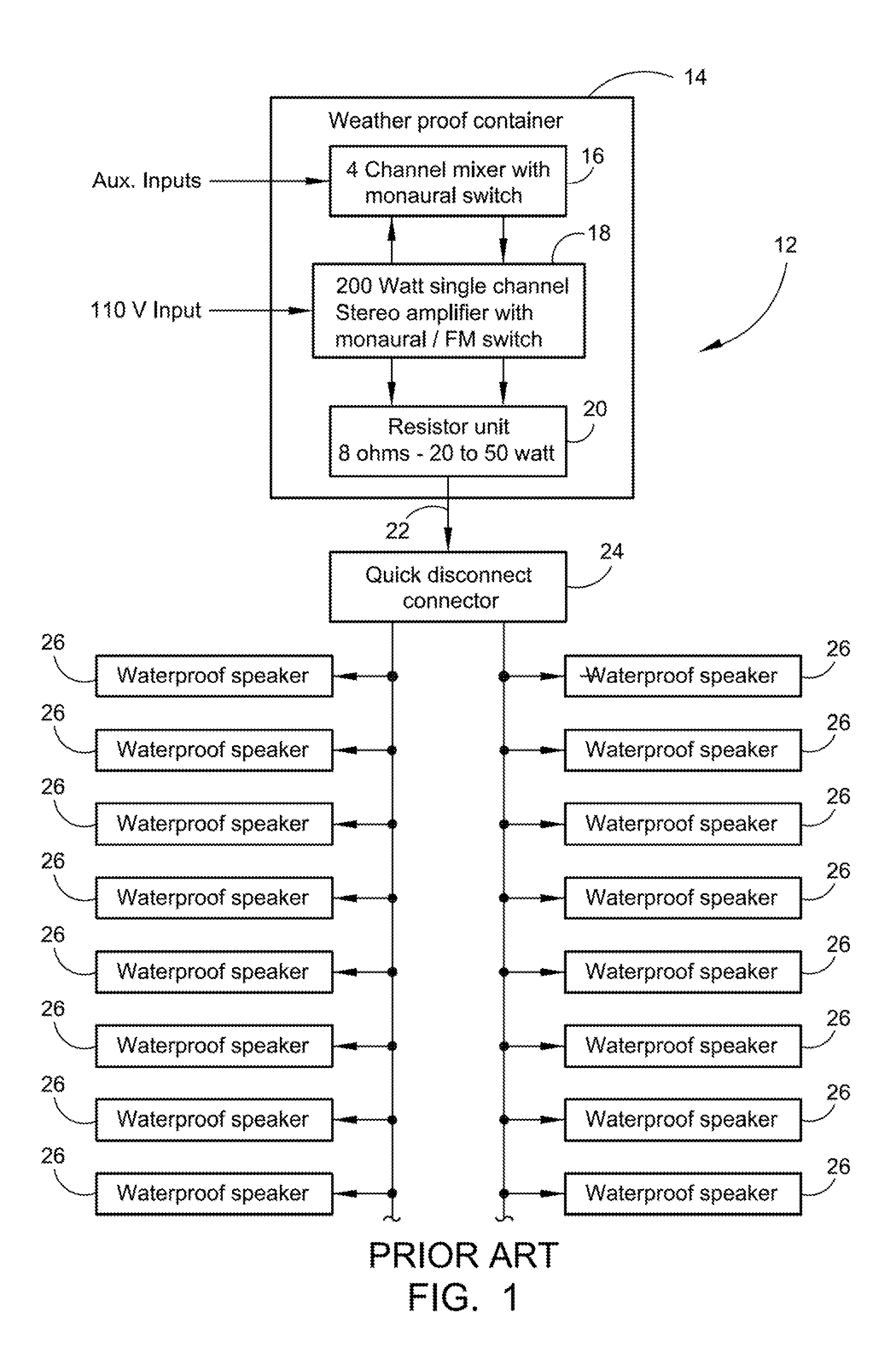

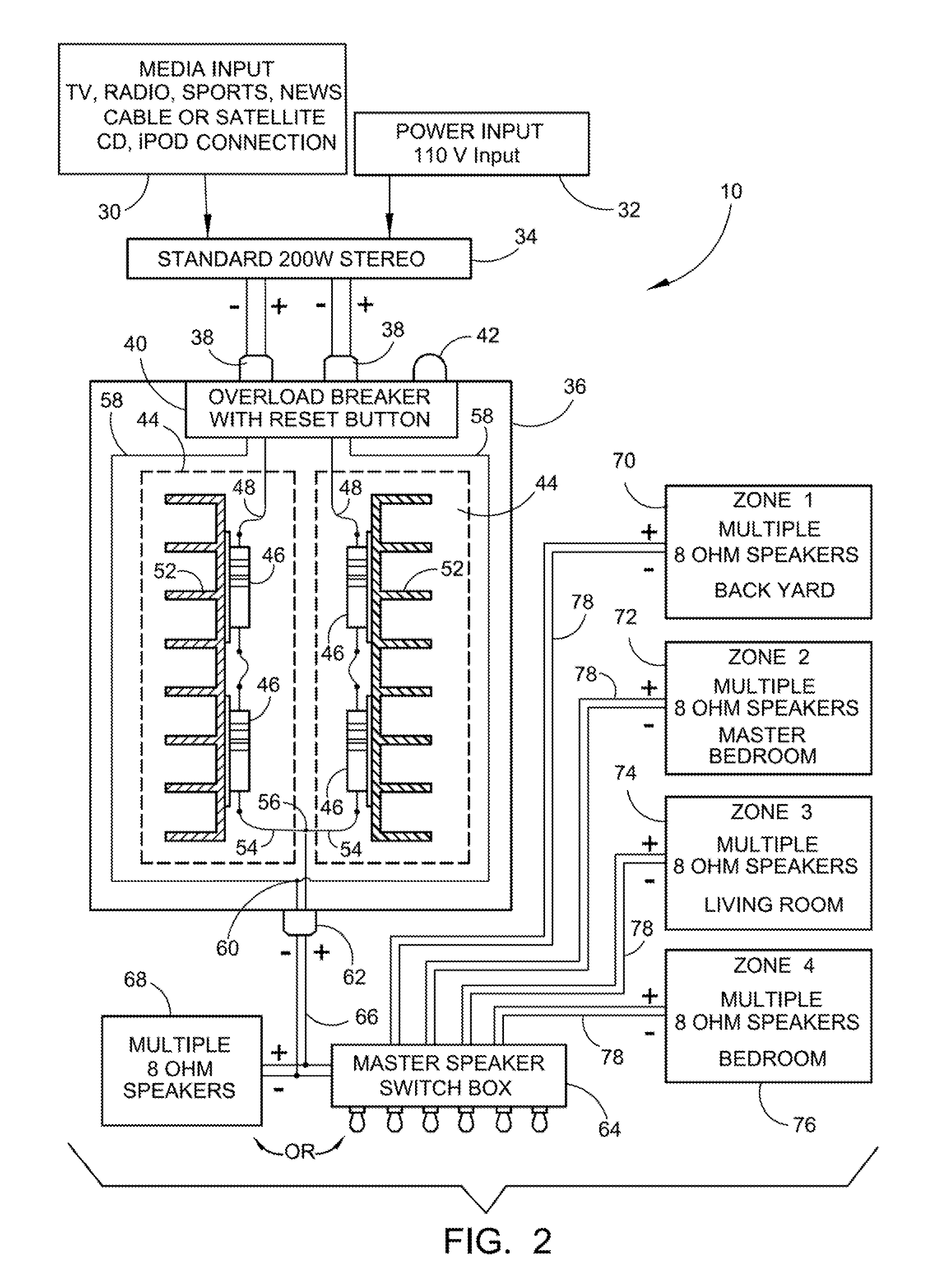

Stereo to monaural multi-speaker parallel wiring system

InactiveUS9161130B2Easy to installPower dropContact members penetrating/cutting insulation/cable strandsLoudspeaker spatial/constructional arrangementsSwitch boxVocal tract

The present invention is directed to a Stereo to Monaural Multi-speaker Parallel Wiring System that uses a standard 200 watt stereo and a whole sound impedance corrector to greatly reduce the wiring connections, the installation time and the overall cost of the system. A whole or complete sound comes from each speaker and will overlap from speaker to speaker so that moving around in different areas or zones within a house or yard, a person will receive the same whole and complete sound. With the master speaker switch box included, different areas or zones can be turned off or on as desired.

Owner:ADAM RON R

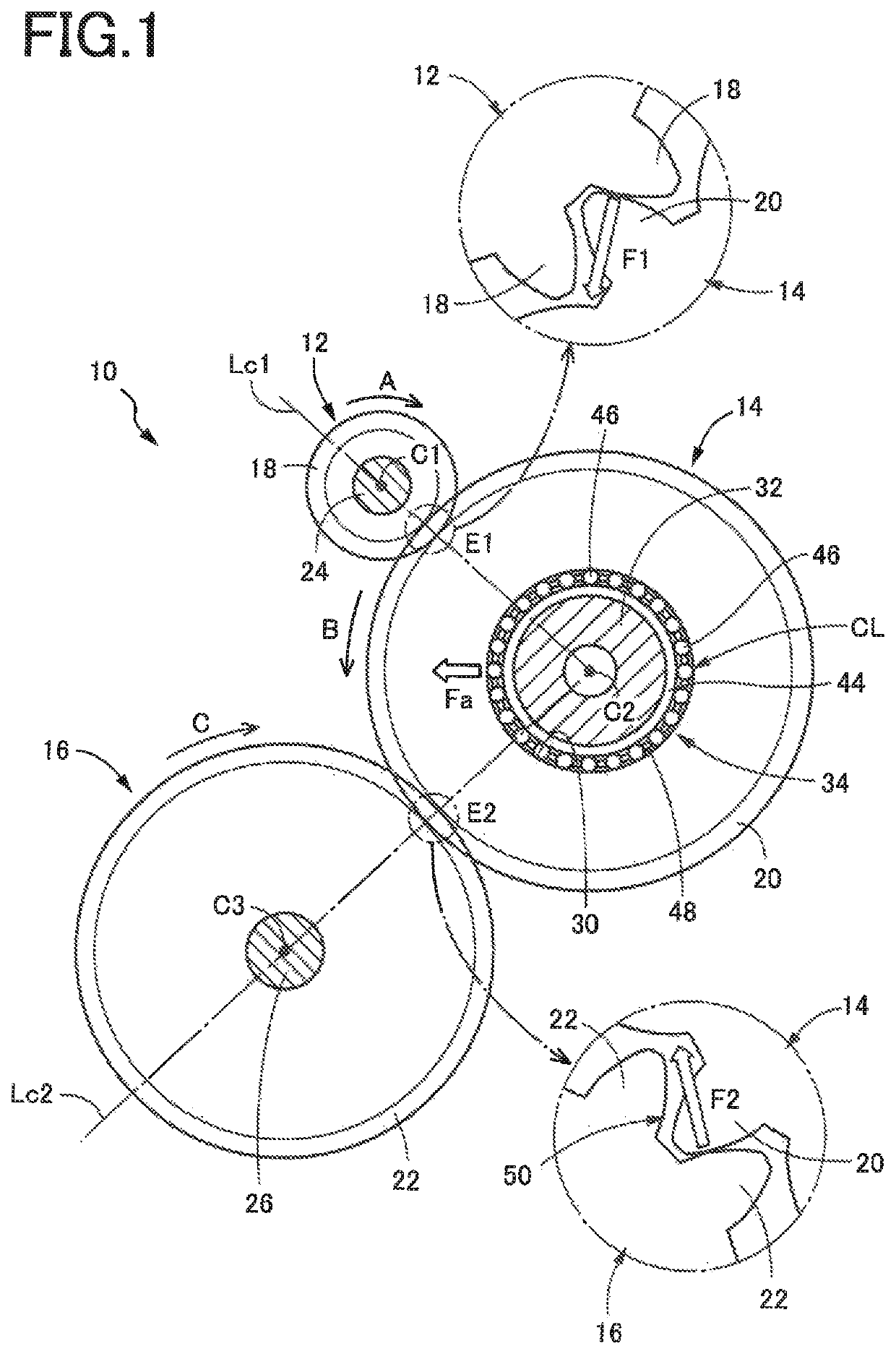

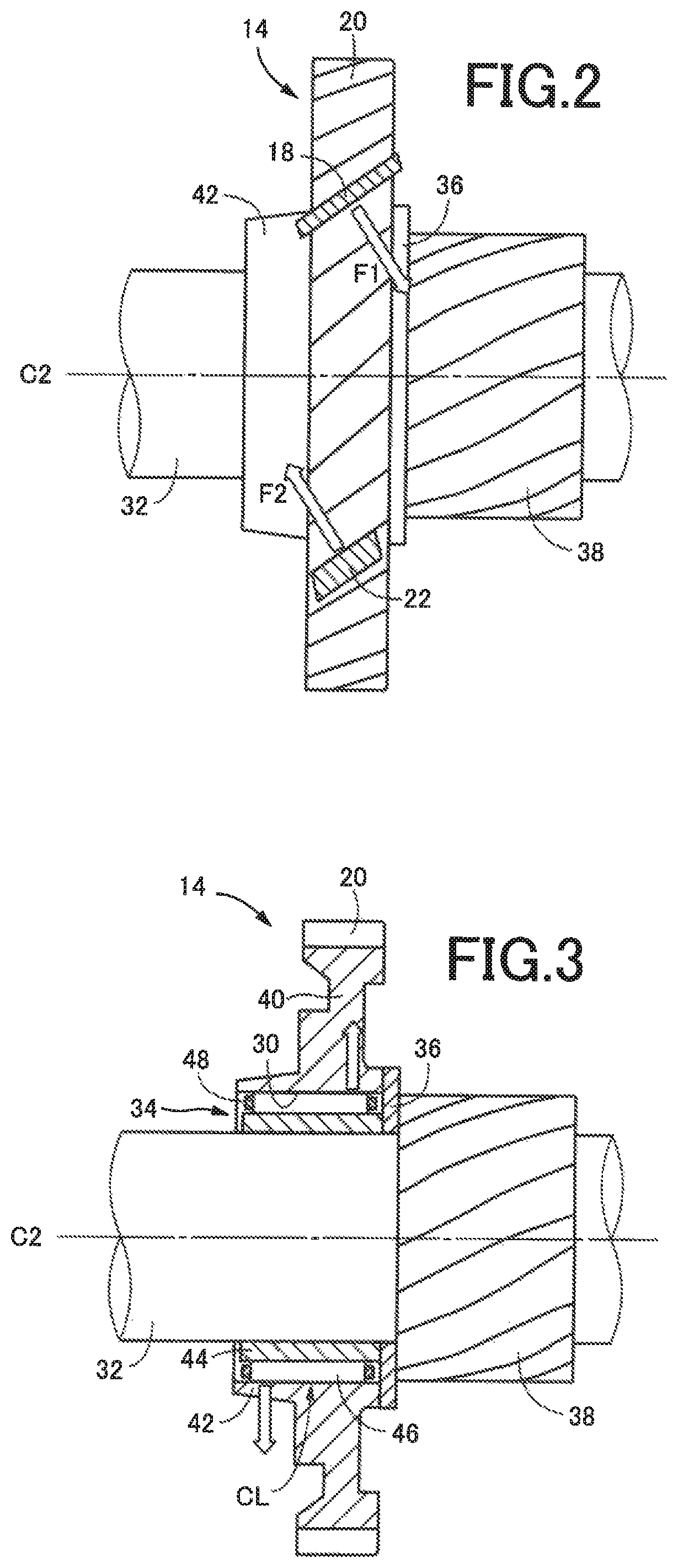

Helical gear device

ActiveUS10663037B2Power dropAvoid it happening againToothed gearingsPortable liftingGear wheelEngineering

A helical gear device includes: first and second helical gear respectively and rotatably disposed about first and third mutually parallel axes; a second helical gear meshing with the first and third helical gears so that a rotary motion is transmitted from the first to the third helical gear through the second, the second helical gear having a center bore; a support shaft disposed coaxially with a second axis parallel to the first, and extending through the center bore with a predetermined amount of radial play between the support shaft and the second helical gear, rotatably supporting the second helical gear. The second and third helical gears have a predetermined radial clearance in their reference meshing state in which their pitch circles contact. The radial clearance is smaller than a radial gap of a backlash between the second and third helical gears in the reference meshing state.

Owner:TOYOTA JIDOSHA KK

Device for improving the stray isolation between the antennas in the bilateral antenna and the method thereof

ActiveUS9407316B2Improving stray isolationReduce the required powerTransmissionRadianceComputer module

The present invention relates to the communication technology field, more specifically, to a scheme of bilateral antenna. A device for improving the stray isolation between the antennas in the bilateral antenna comprises a plurality of communication modules having an antenna and a power amplification module; at least one of the communication modules further comprises a tuning module. The power amplification module is connected to the antenna directly or through the tuning module. The stray isolation between the communication module and other communication module is improved by adjusting the communication modules comprising the tuning module. This invention increases the stray isolation between the communication modules in different frequency bands, specifically, when a long interval exits between working frequency bands. Consequently, the radiance performance of the bilateral antenna of the mobile termination is satisfied, and the capacity of resisting disturbance between the systems is enhanced.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

Method, forecasting device and control device for controlling a power network with a photovoltaic system

ActiveUS11128133B2Power dropComponent with highSunshine duration recordersGeneration forecast in ac networkOptical radiationEngineering

Owner:SIEMENS AG

Electrofusion fitting methods

ActiveUS10047892B2Increase likelihoodImprove reliabilityCorrosion preventionPipe protection against corrosion/incrustationElectricityEngineering

The invention provides improvements to electrofusion fitting methods that allow for continuity and repeatability of welds between an electrofusion fitting and a pipe lining (or stand-alone pipe). An electrofusion fitting for joining sections of lined pipe has heating elements configured to create at least one weld between the electrofusion fitting and a pipe lining, however prior to the weld step taking place the electrofusion fitting is heated and expands accordingly to ensure contact with the pipe lining. Preheating the electrofusion fitting also provides a predetermined starting temperature for the fitting and the lining which results in improved fusion cycle reliability. Furthermore, the need for clamps or support frames to support the electrofusion fitting in situ is removed, with corresponding reductions in cycle times, complexity, and hence cost.

Owner:PIONEER LINING TECH

Adapter unit

PendingUS20210347334A1Minimize turbulenceSufficient pressing pressureVehicle cleaningEngineeringPhysics

The invention relates to an adapter unit which is provided for coupling, in particular releasably coupling, a wiper blade to a wiper arm, having a wind deflecting surface which is designed to deflect inflowing air and press the wiper blade against a vehicle windshield. According to the invention, the wind deflecting surface has at least one first sub-surface and a second sub-surface, wherein the first sub-surface has a different orientation than the second sub-surface and / or the first sub-surface has a different geometry than the second sub-surface.

Owner:ROBERT BOSCH GMBH

Stereo to monaural multi-speaker parallel wiring system

InactiveUS20130216048A1Easy to installPower dropElectrically conductive connectionsLoudspeaker spatial/constructional arrangementsSwitch boxVocal tract

The present invention is directed to a Stereo to Monaural Multi-speaker Parallel Wiring System that uses a standard 200 watt stereo and a whole sound impedance corrector to greatly reduce the wiring connections, the installation time and the overall cost of the system. A whole or complete sound comes from each speaker and will, overlap from speaker to speaker so that moving / around in different areas or zones within a house or yard, a person will receive the same whole and complete sound. With the master speaker switch box included, different areas or zones can be turned off or on as desired.

Owner:ADAM RON R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com