Patents

Literature

84 results about "Sequential test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

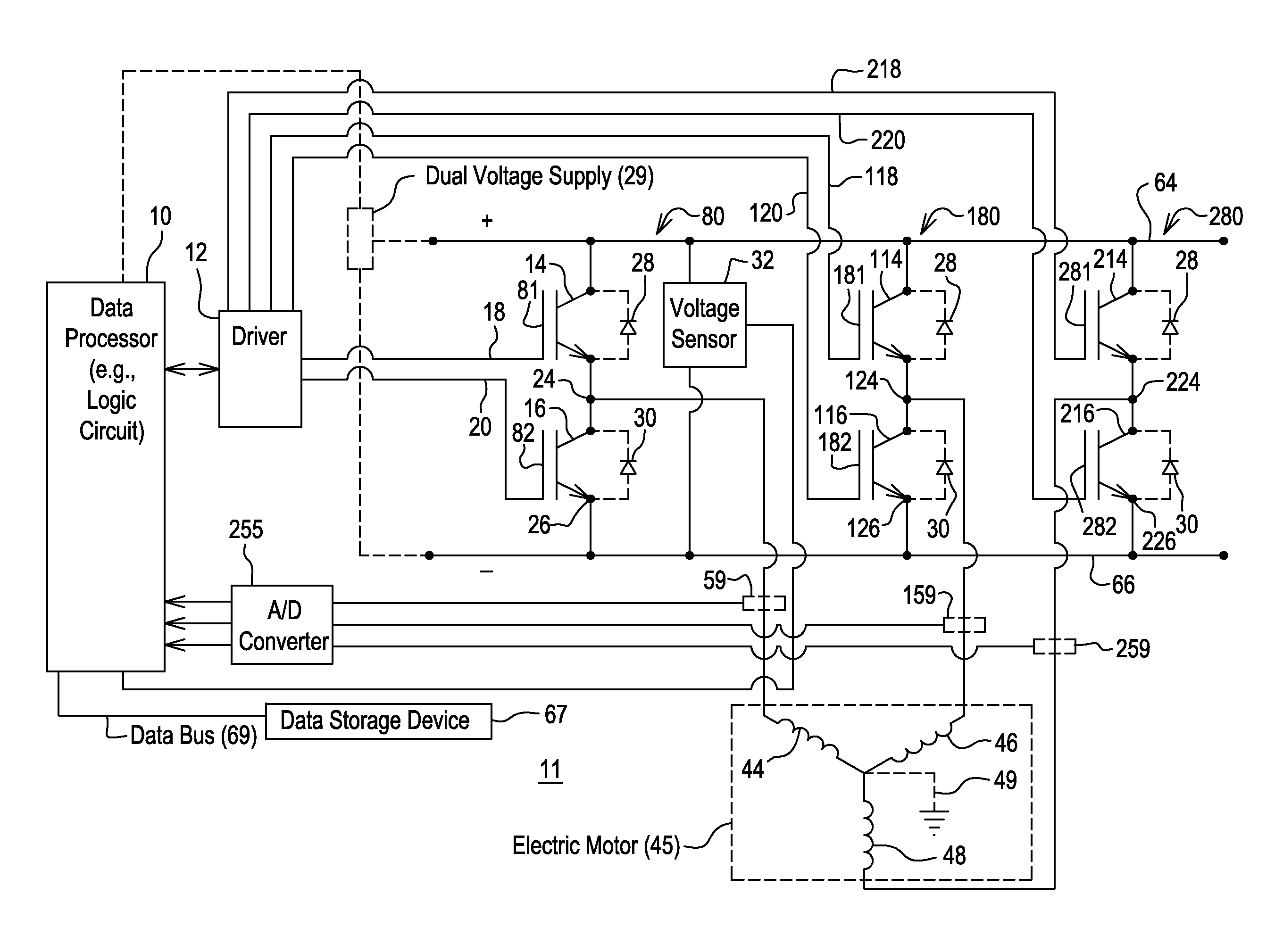

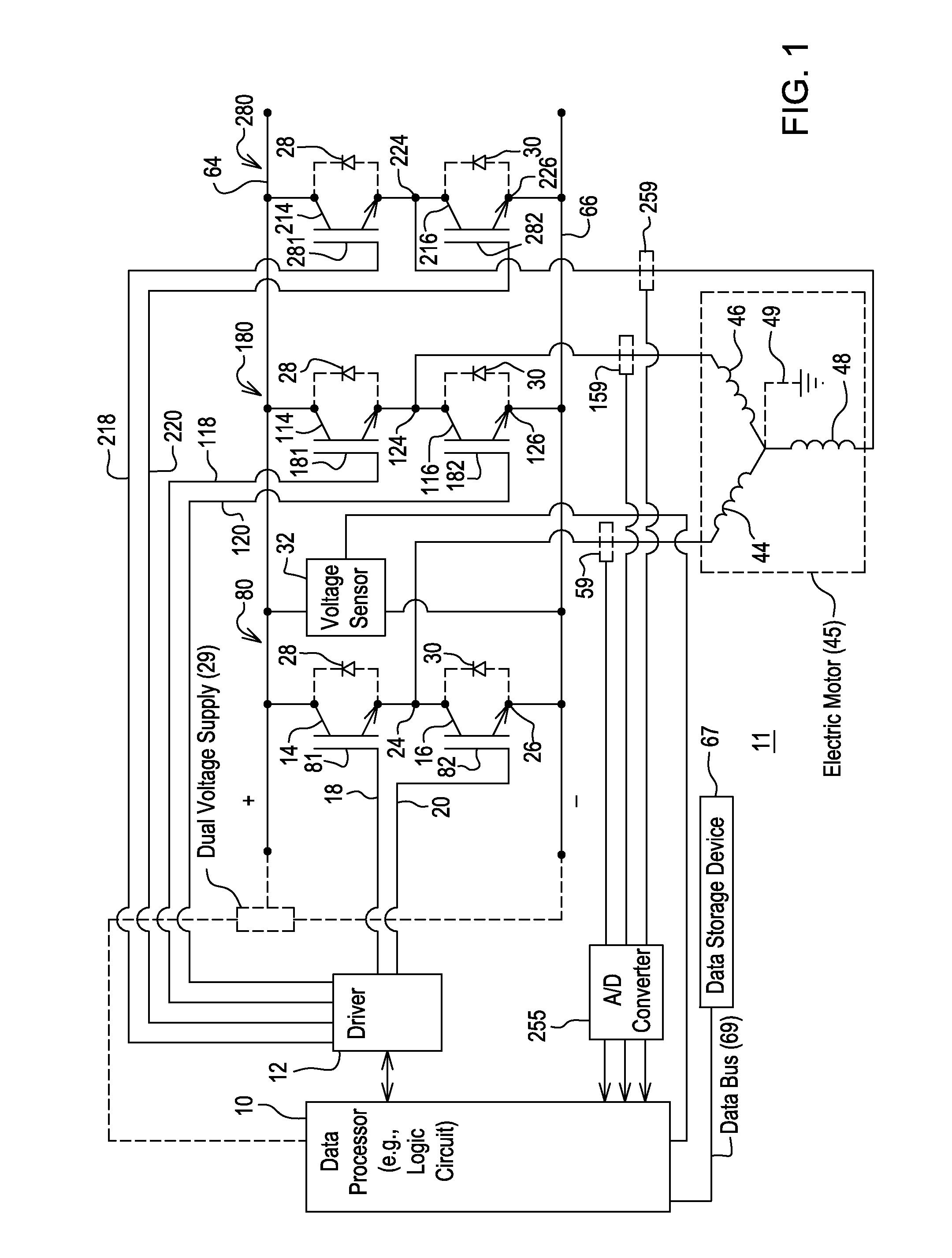

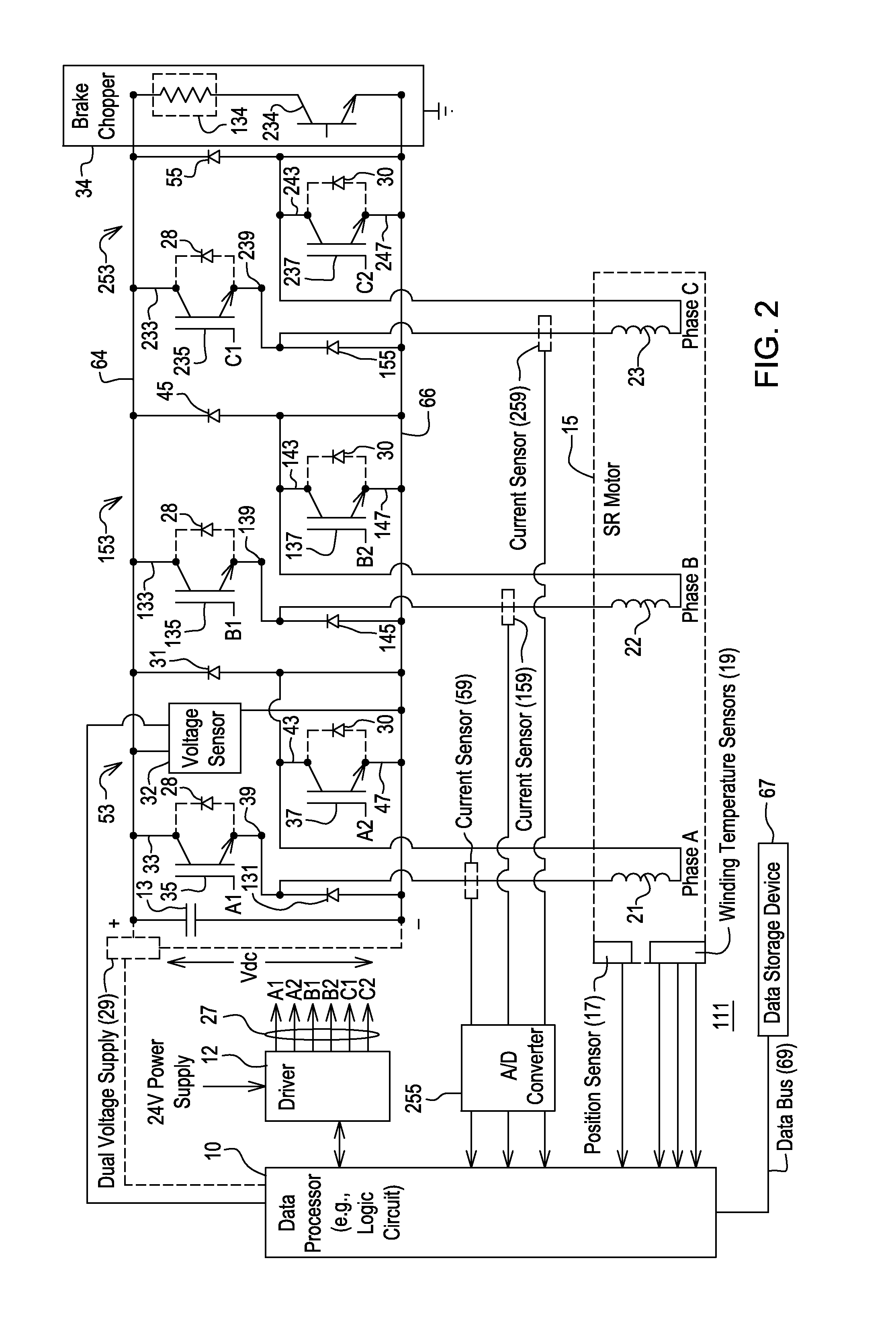

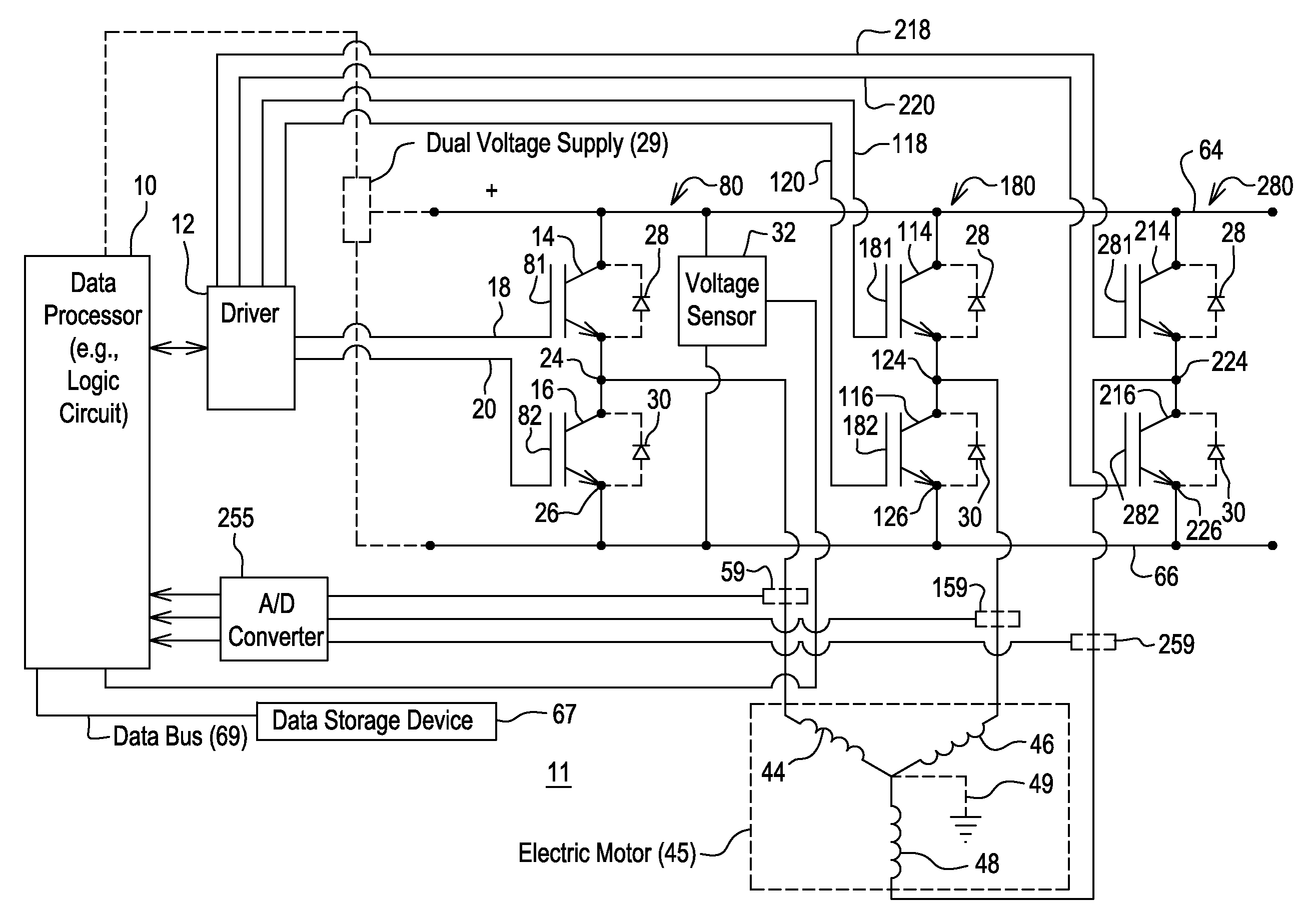

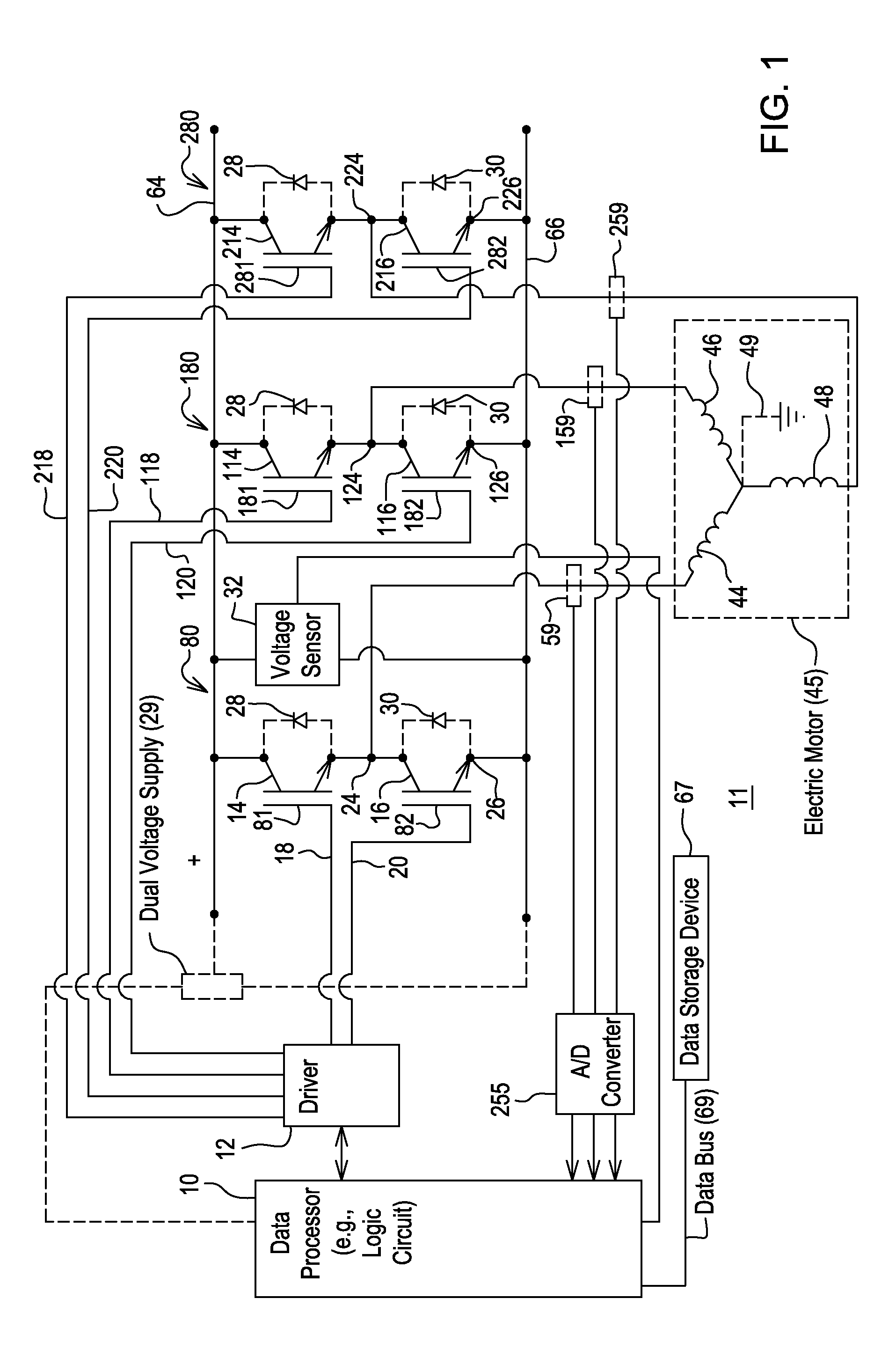

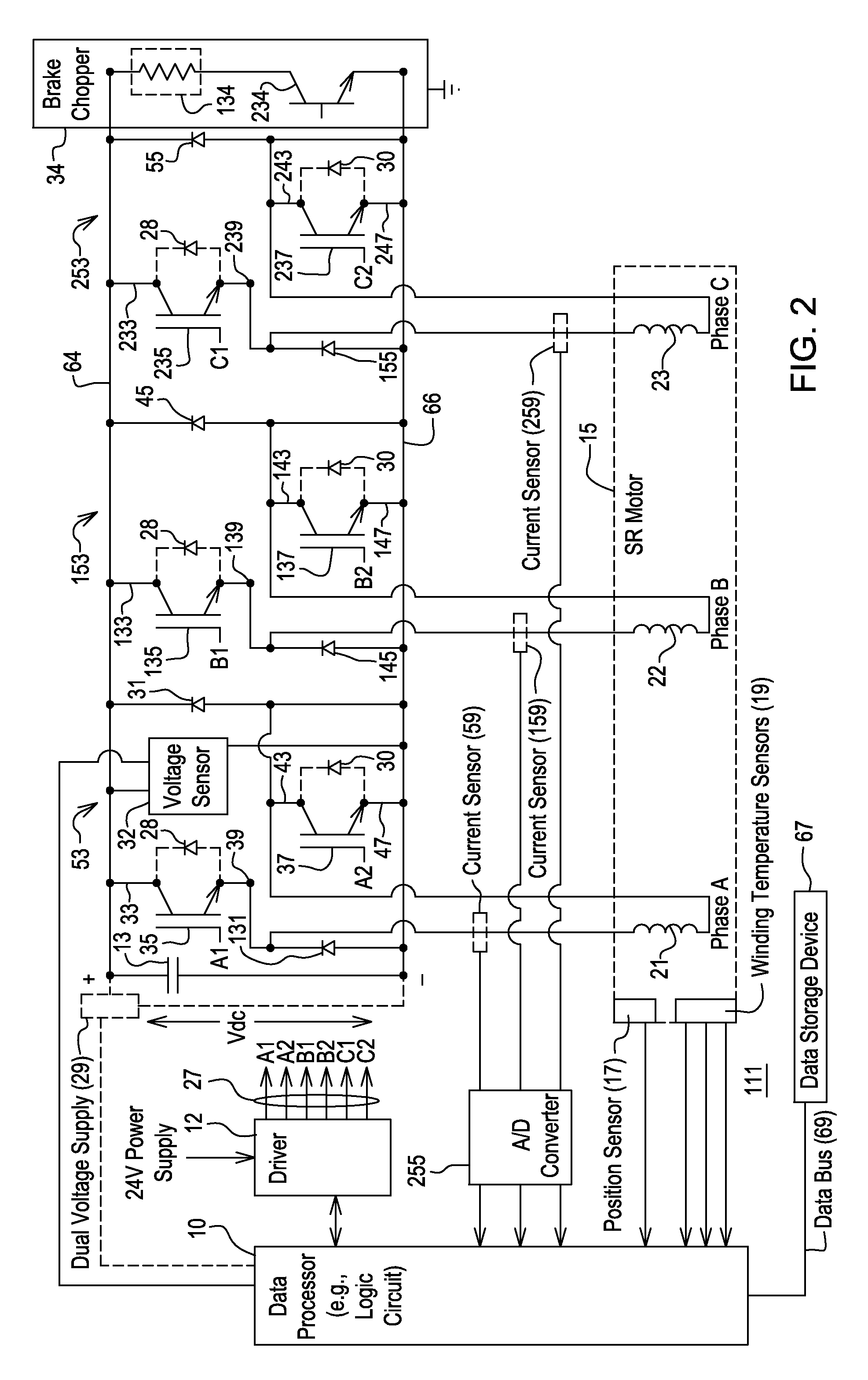

Method and controller for an electric motor with switch testing

ActiveUS20130320903A1Avoid damageMotor/generator/converter stoppersDC motor speed/torque controlBiological activationSemiconductor

For each phase of a controller, a pair of semiconductor switches comprises a high side switch and a low side switch. A direct current voltage bus provides electrical energy to the semiconductor switches at a test voltage level less than a full operational voltage level. A measuring circuit is adapted to measure the direct current bus voltage. A data processor determines that a deficiency in a tested, related semiconductor switch is present if the measured direct current bus voltage decreases or collapses upon activation of a particular semiconductor switch in the same phase of the controller, or if other sequential test results indicate a deficiency. If the deficiency in the related semiconductor switch is present the processor may prevent the voltage supply from providing the full operational voltage to the direct current data bus to prevent damage to the motor or the controller, for example.

Owner:DEERE & CO

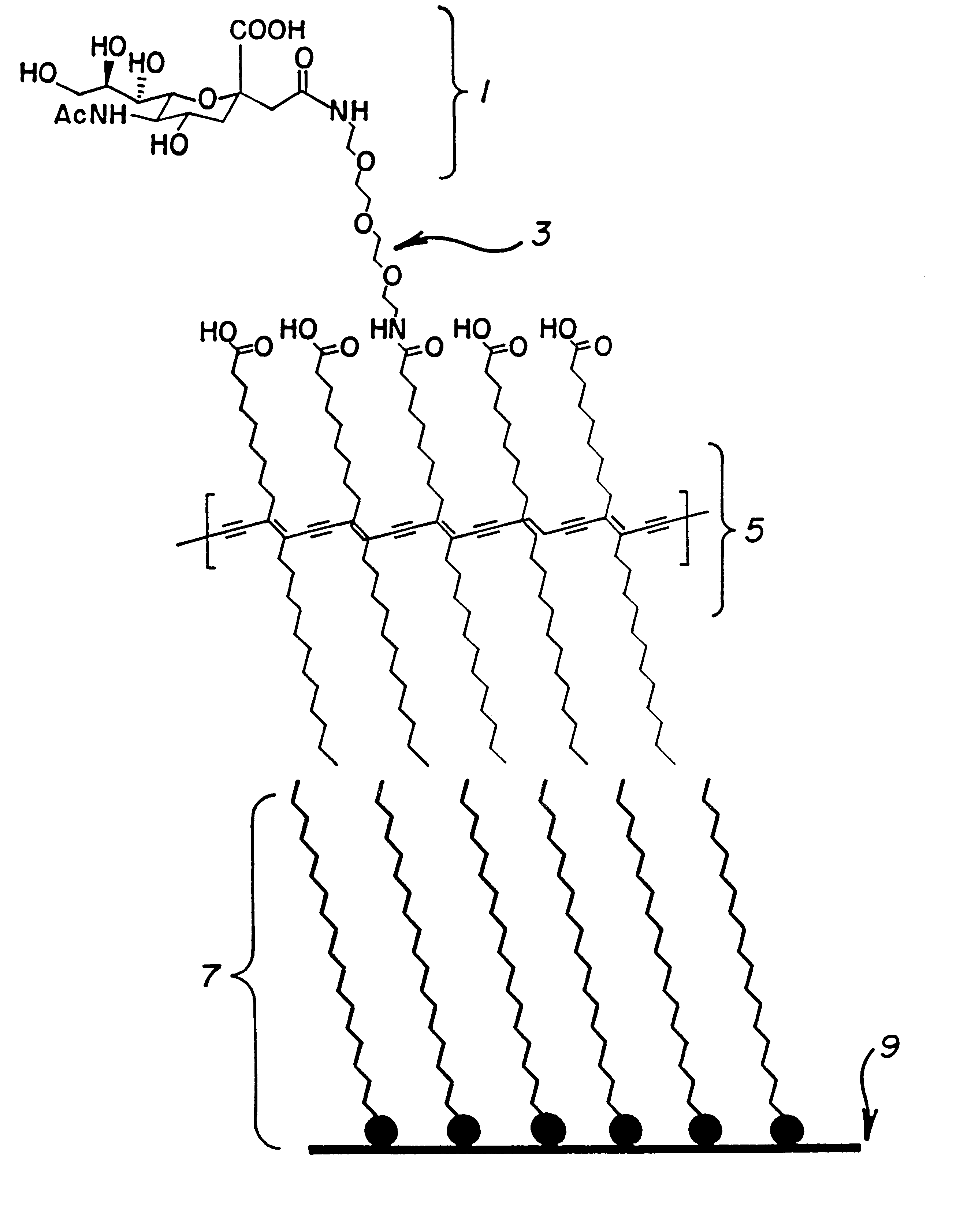

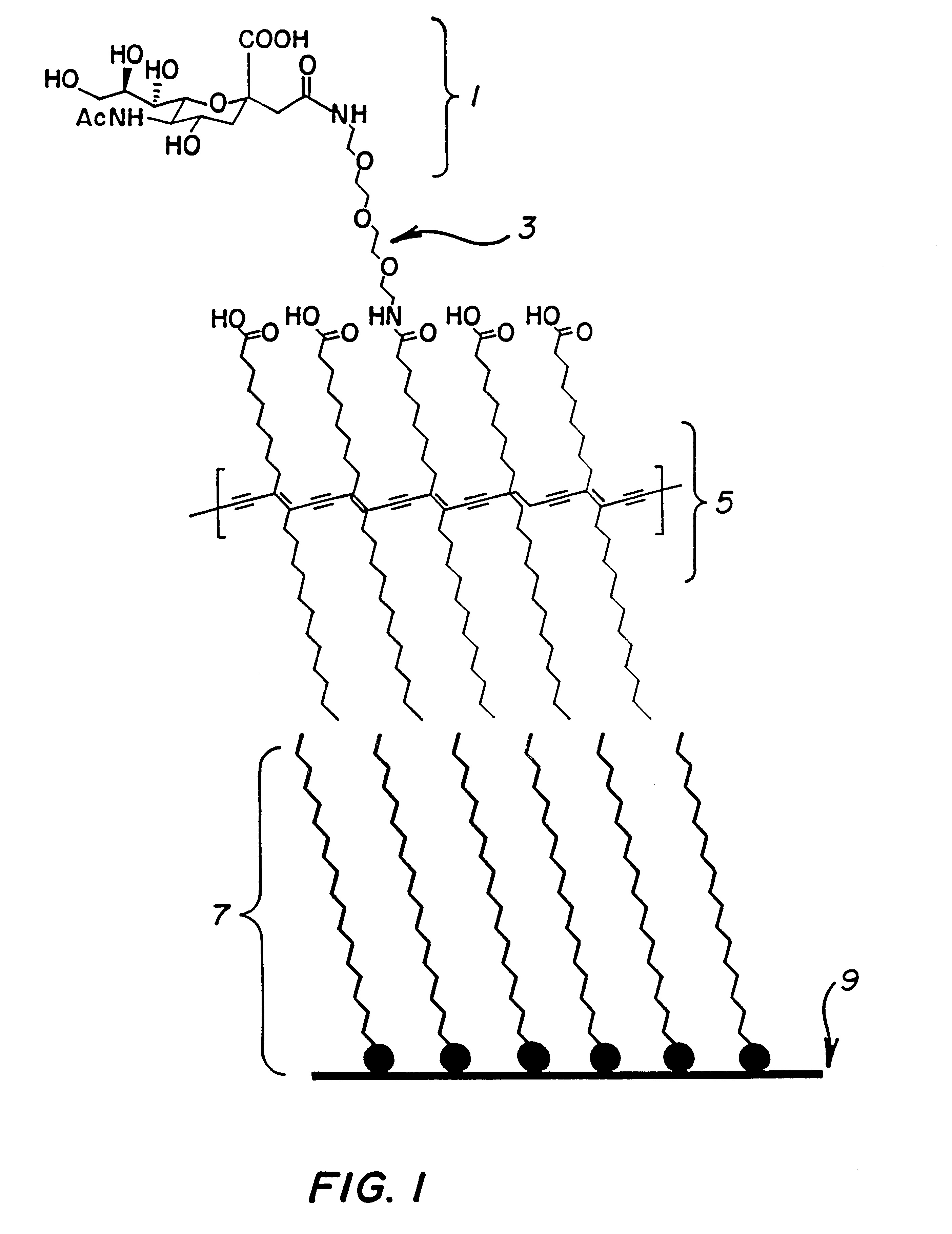

Polymeric assay film for direct colorimetric detection

InactiveUS6395561B1Limited applicabilityMaintain its infectivityMaterial nanotechnologyMicrobiological testing/measurementAnalyteDrug development

A lipid bilayer with affinity to an analyte, which directly signals binding by a changes in the light absorption spectra. This novel assay means and method has special applications in the drug development and medical testing fields. Using a spectrometer, the system is easily automated, and a multiple well embodiment allows inexpensive screening and sequential testing. This invention also has applications in industry for feedstock and effluent monitoring.

Owner:RGT UNIV OF CALIFORNIA

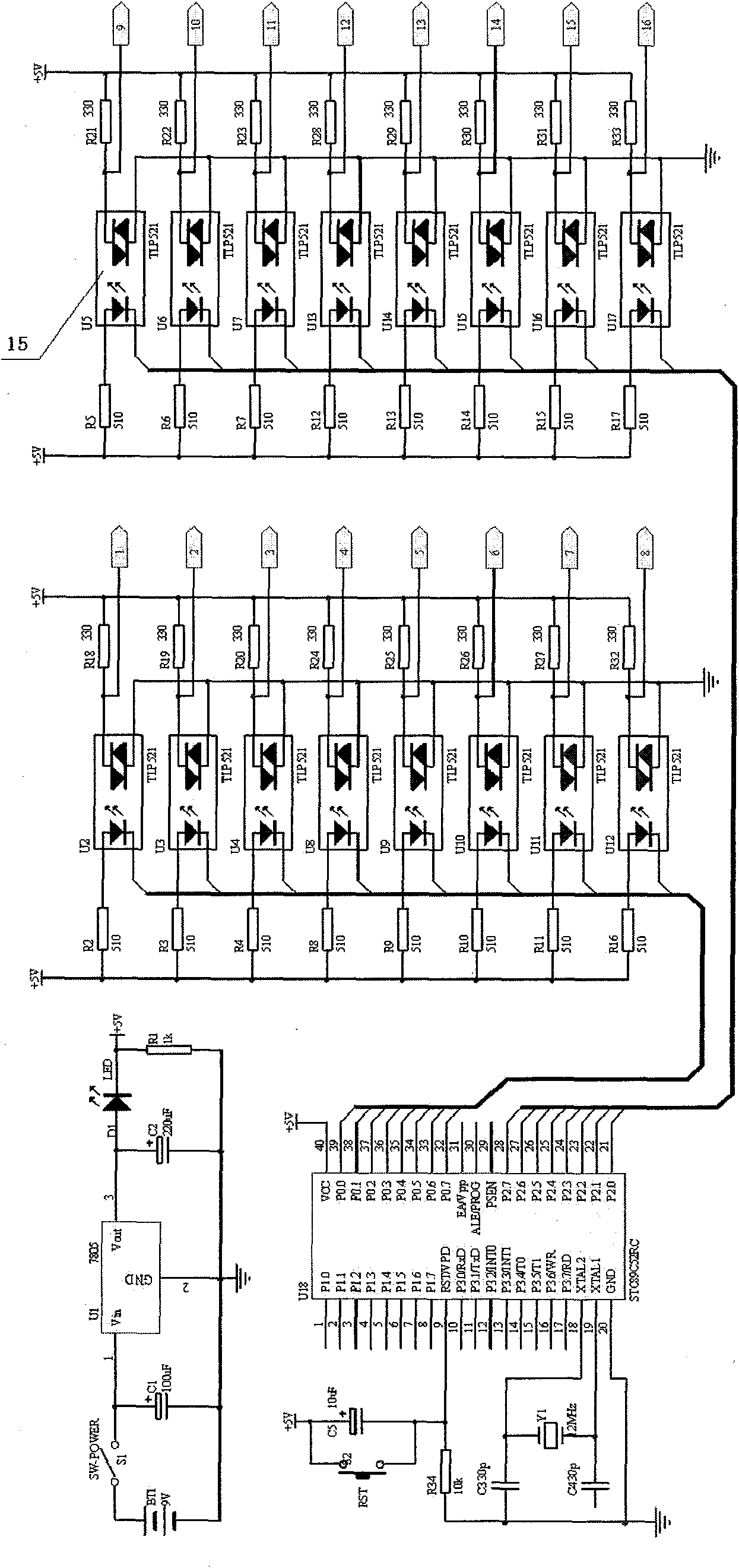

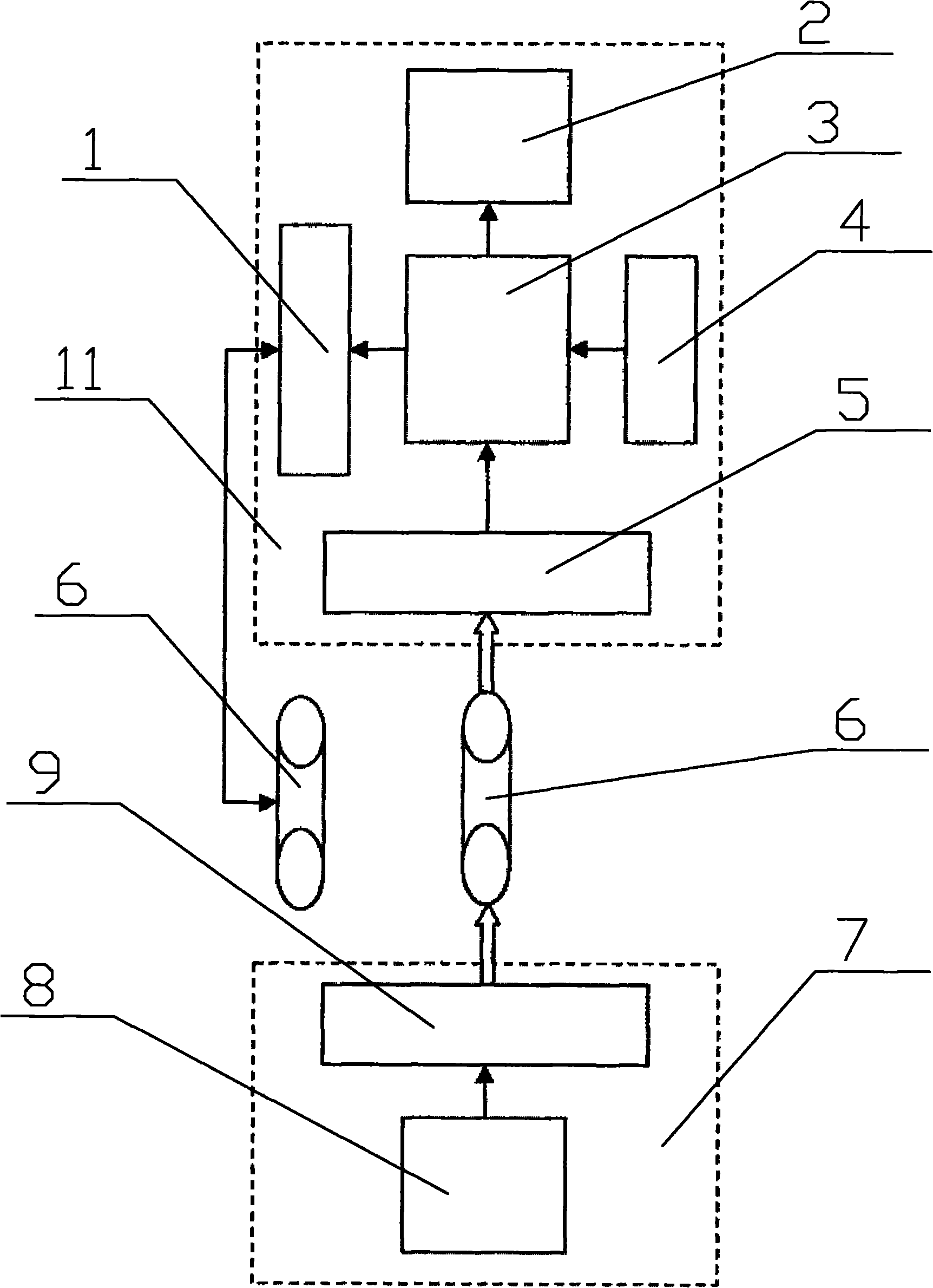

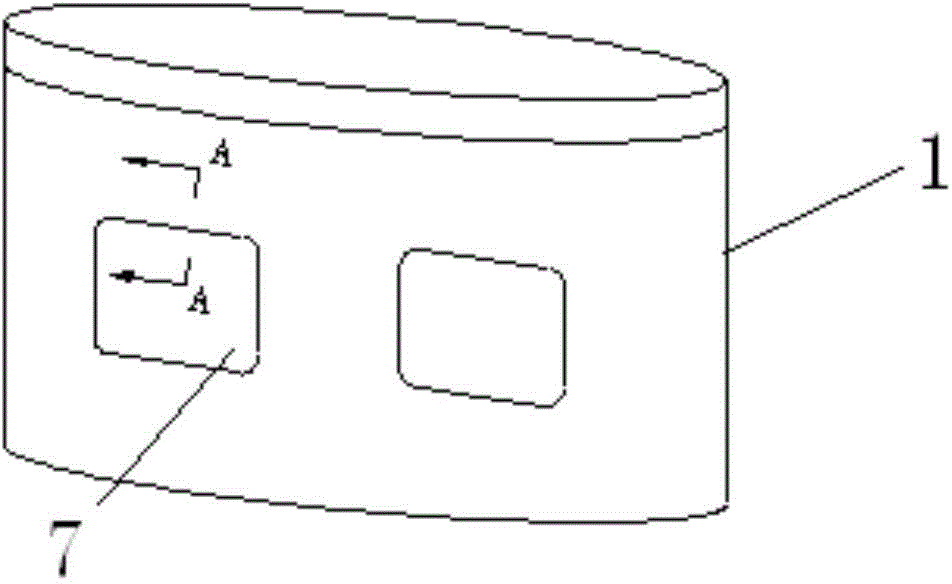

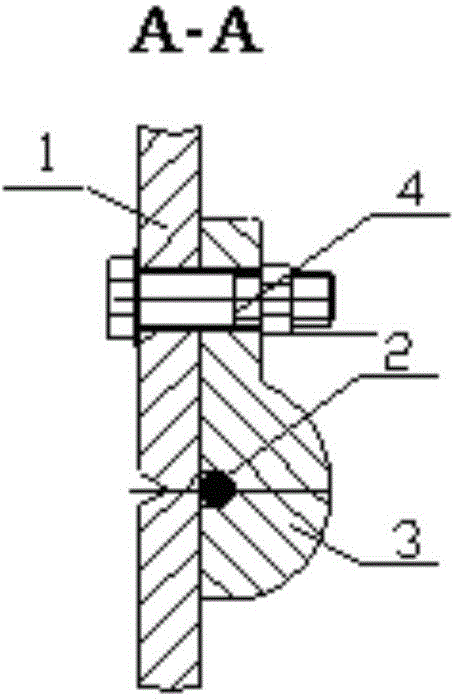

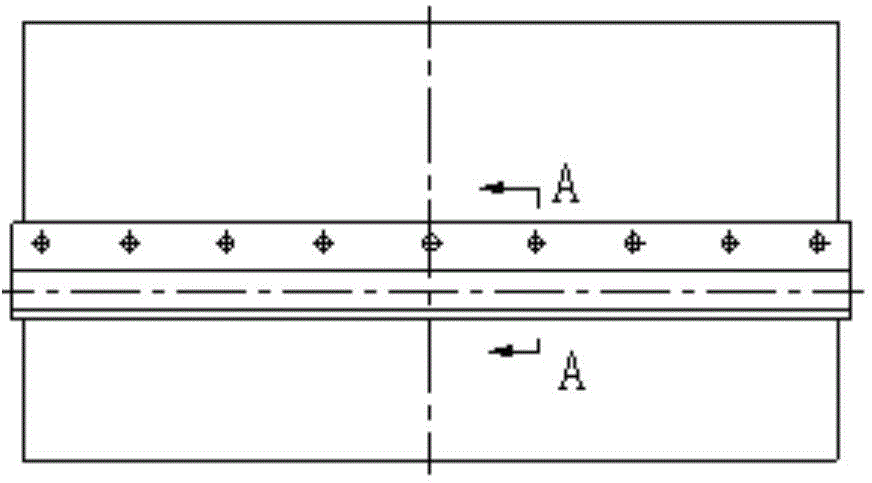

Multicore communication cable comprehensive tester

InactiveCN101799513AIncrease the lengthLow priceFault location by pulse reflection methodsLow speedTester device

The invention relates to a multicore communication cable comprehensive tester. The tester comprises a line-sequential test signal transmitter and a host. The tester is characterized in that the line-sequential test signal transmitter comprises a coding CPU and a code-sending circuit which is connected with the coding CPU and controlled by the coding CPU; the host comprises a decoding CPU, a code-receiving circuit, a fault range-finding signal transmitting / receiving circuit, a monitor and a keyboard; and the code-receiving circuit, the fault range-finding signal transmitting / receiving circuit, the monitor and the keyboard are separately connected with the decoding CPU, the code-receiving circuit adopts a low-speed AD chip, and the code-receiving circuit and the code-receiving circuit are provided with optocouplers which are separated from a cable to be tested. The tester of the invention has simple structure, low cost, high reliability and high anti-interference performance, and can be used to test long cables and be applicable to the connection and maintenance projects of various cables.

Owner:姚晴洲 +1

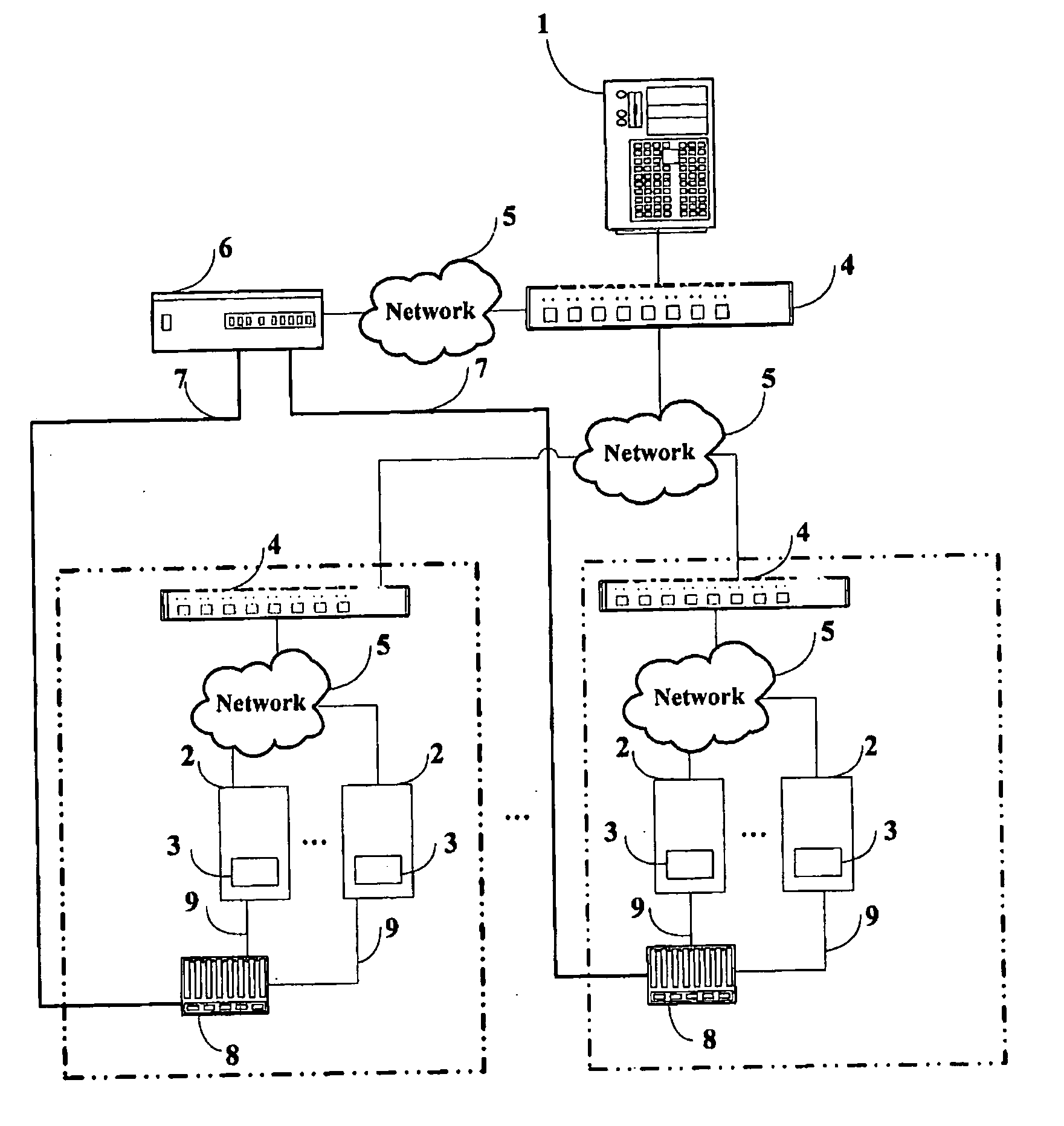

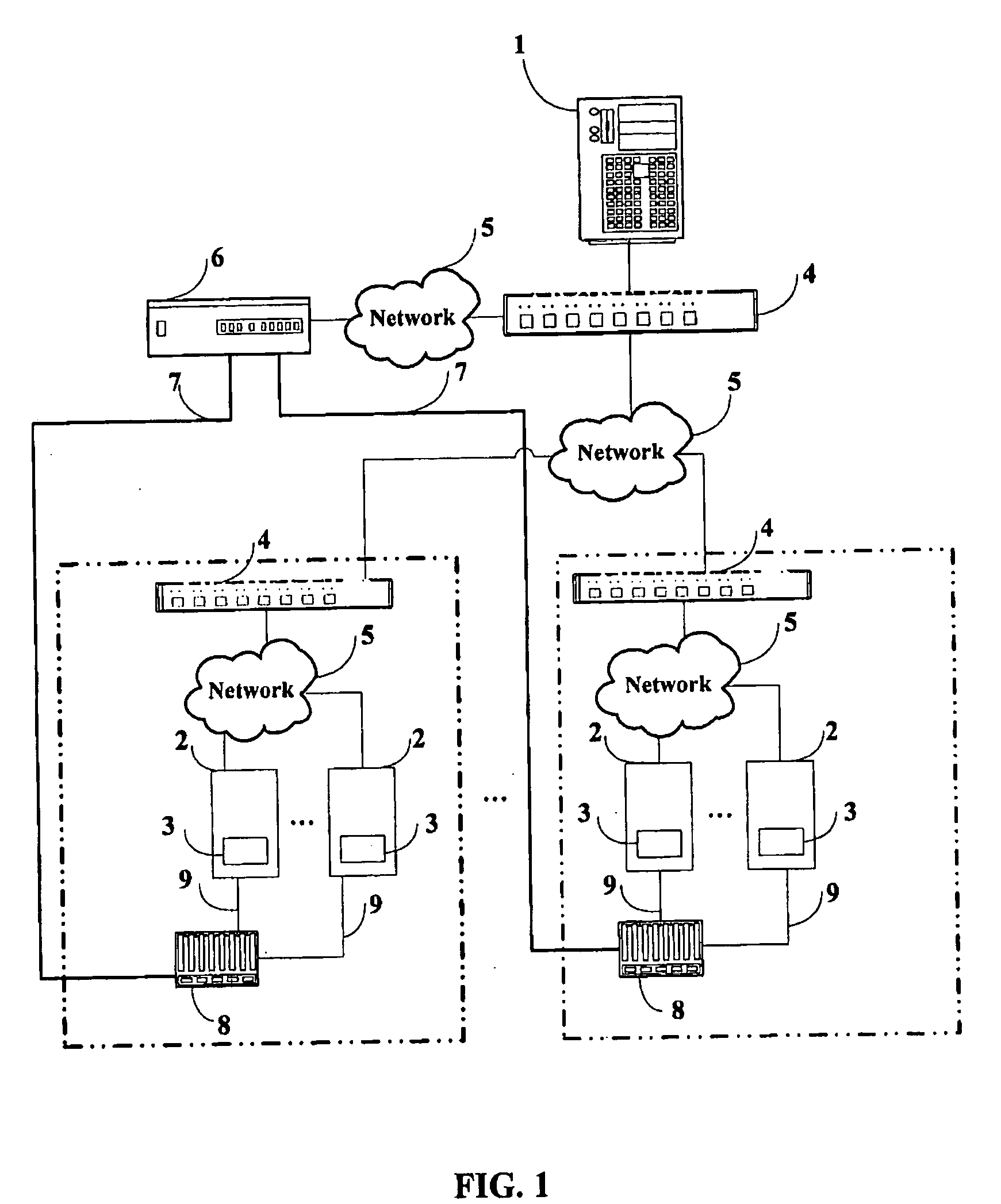

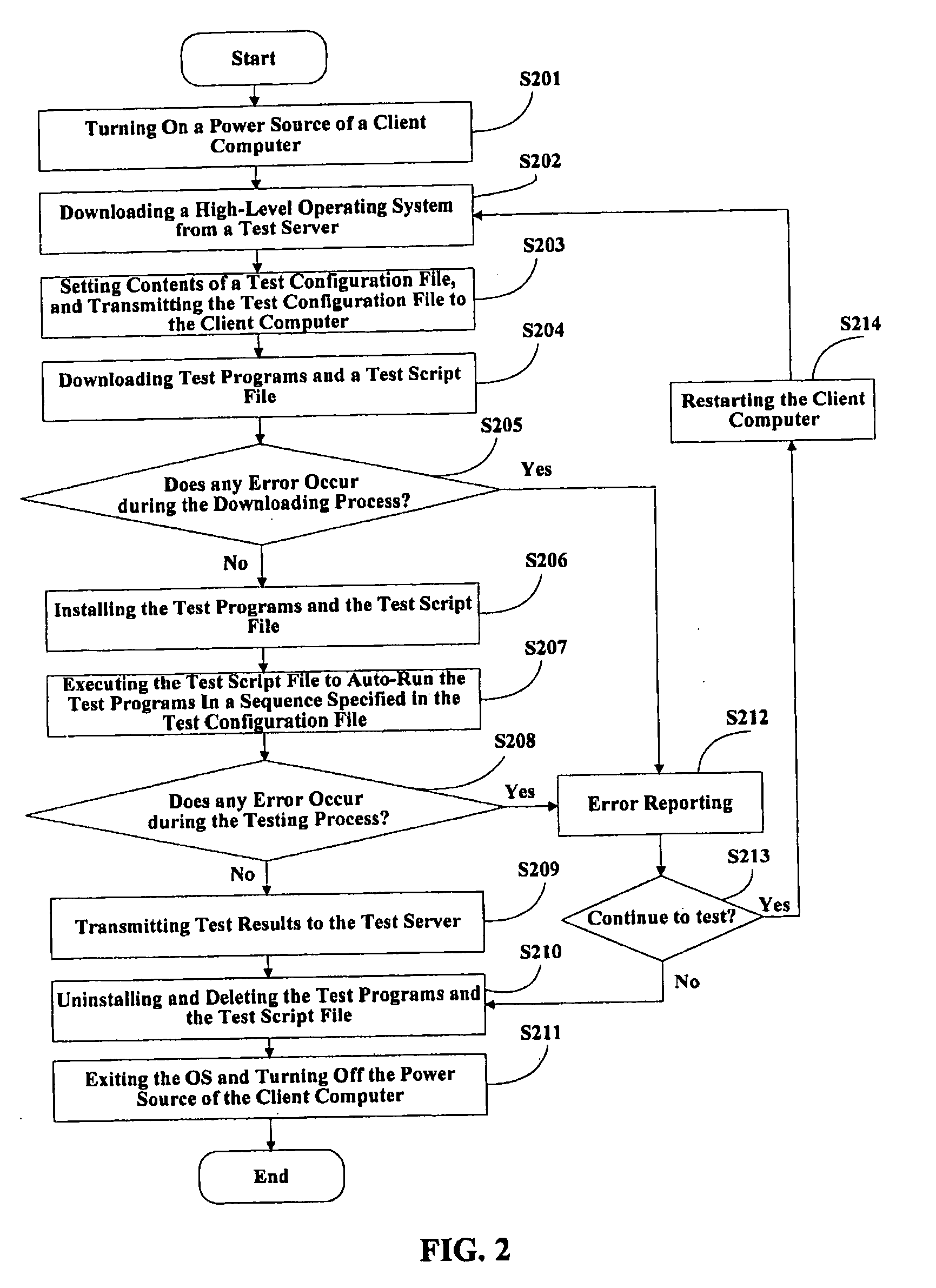

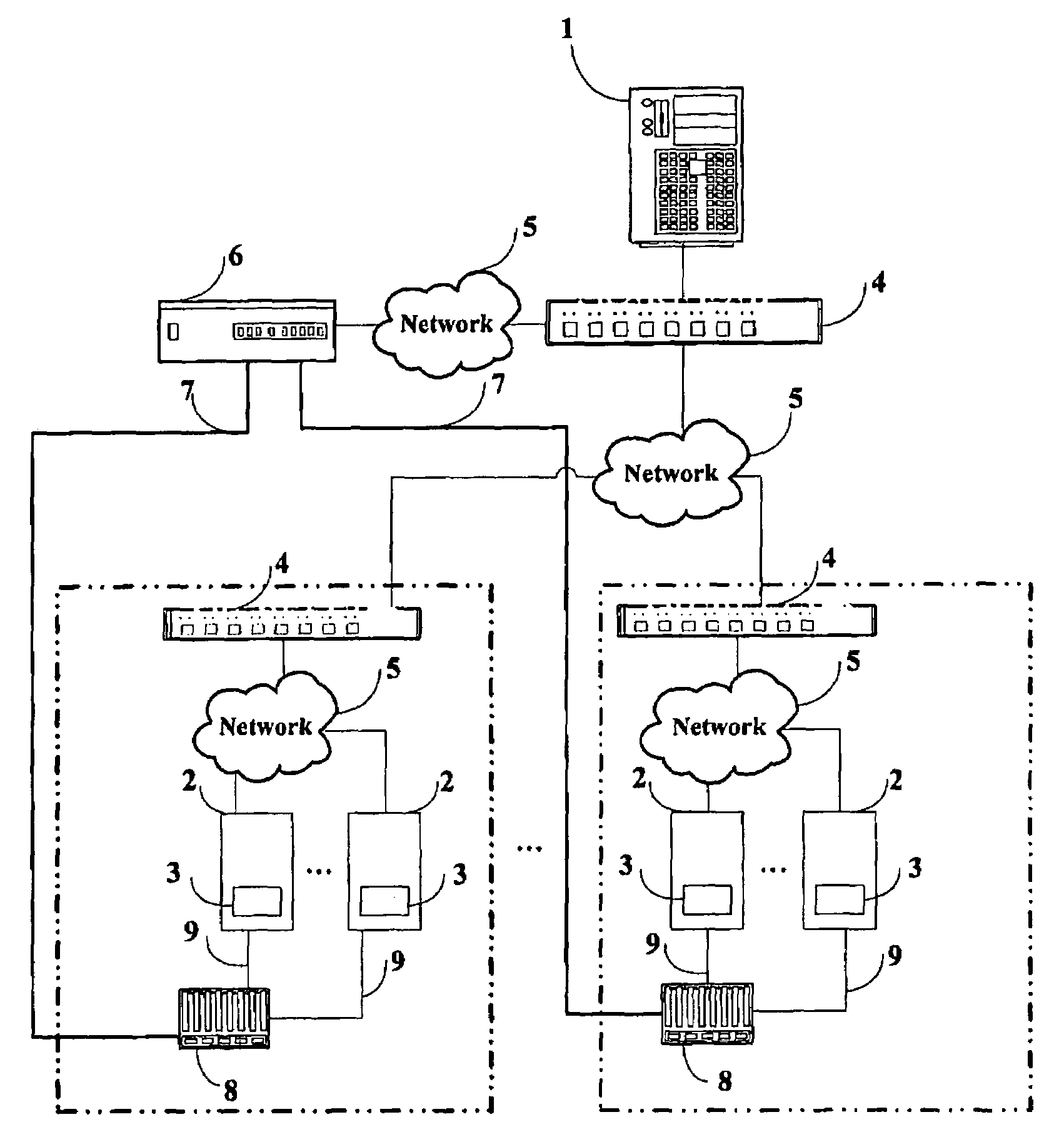

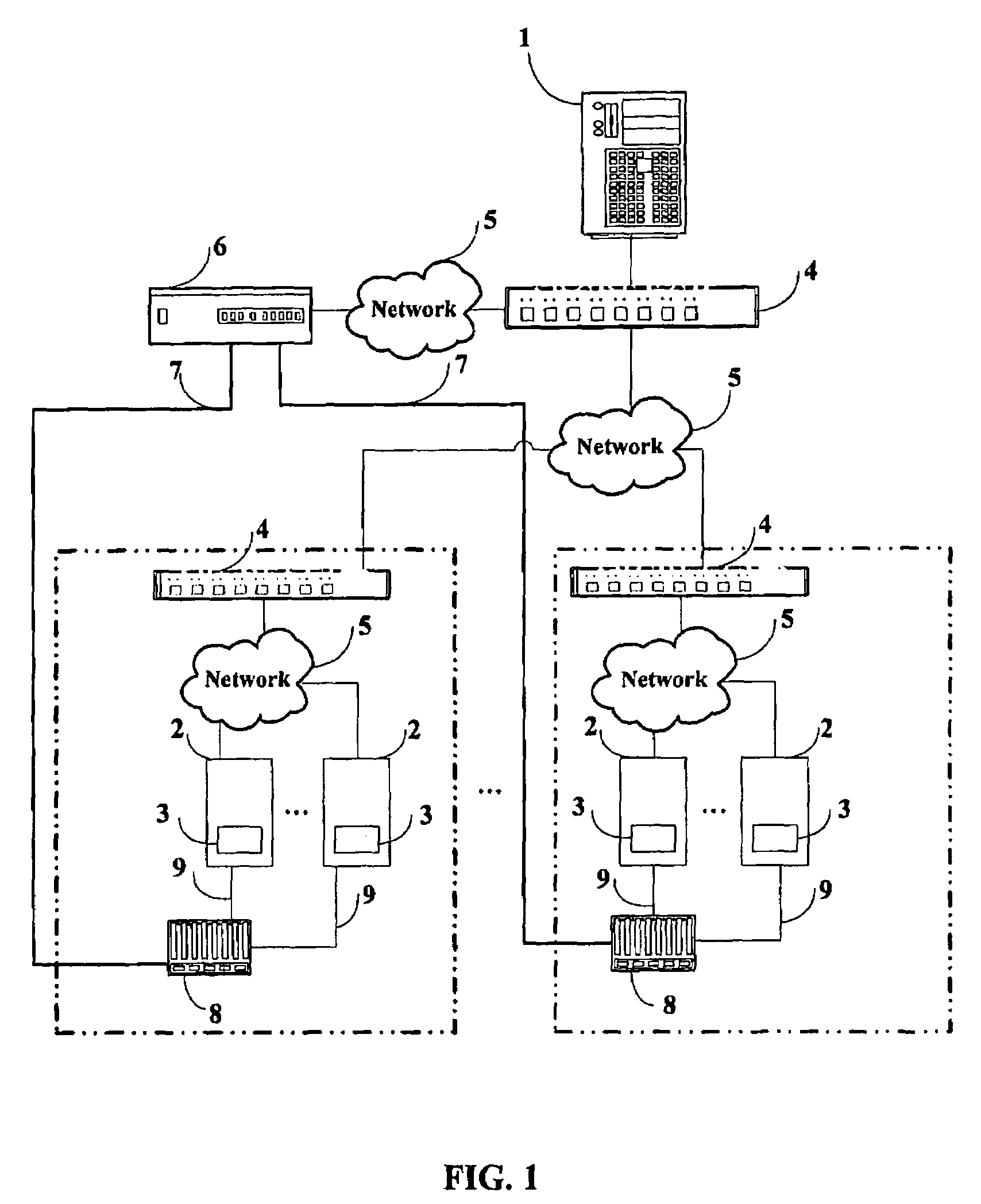

System and method for automatically testing motherboards

InactiveUS20050246589A1Resistance/reactance/impedenceDetecting faulty hardware by remote testTest scriptOperational system

A system for automatically testing motherboards includes a test server (1), client computers (2), and a network (5) connecting the test server with the client computers. The test server is for storing a plurality of high-level OSs (Operating Systems), test programs and test script files, for setting contents of test configuration files, and for storing test results. Each client computer has a motherboard installed therein, and is operated under a DOS (Disk Operating System). The client computer downloads and installs a high-level OS from the test server, downloads and installs one or more test programs and a test script file according to a test configuration file set by the test server, executes the test script file to auto-run test programs in a sequence specified in the test configuration file, and then transmits test results to the test server.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

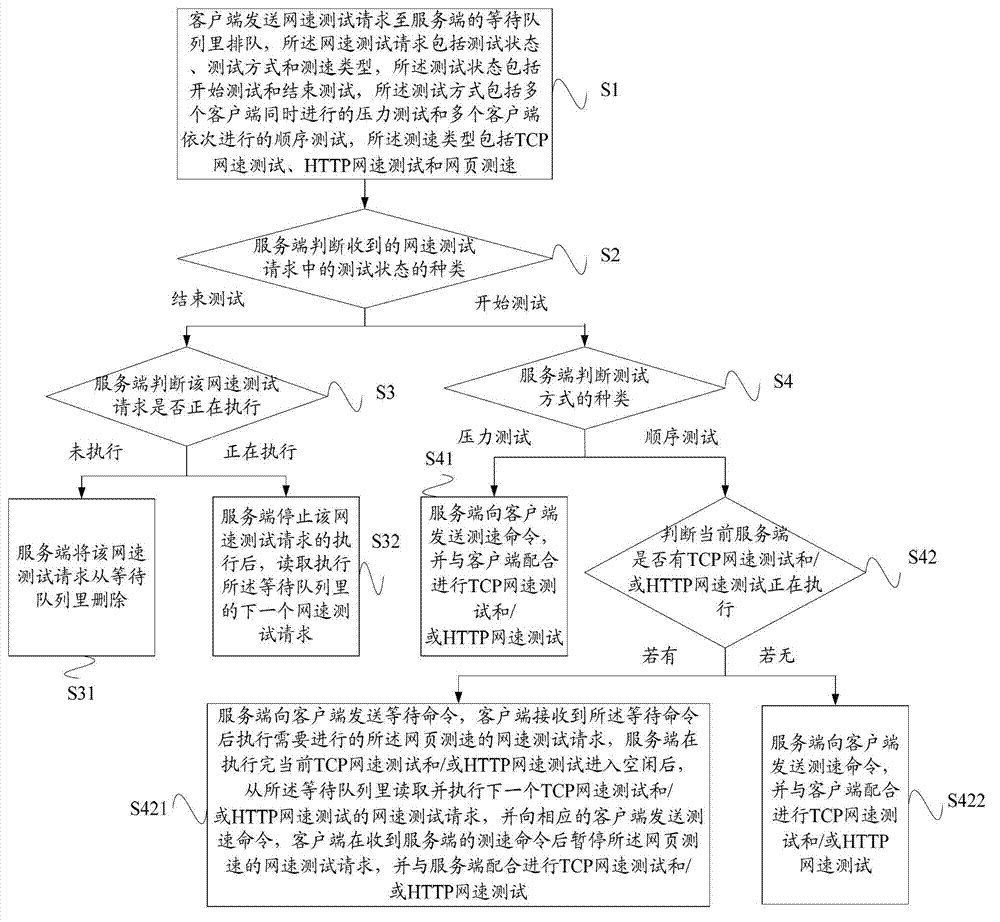

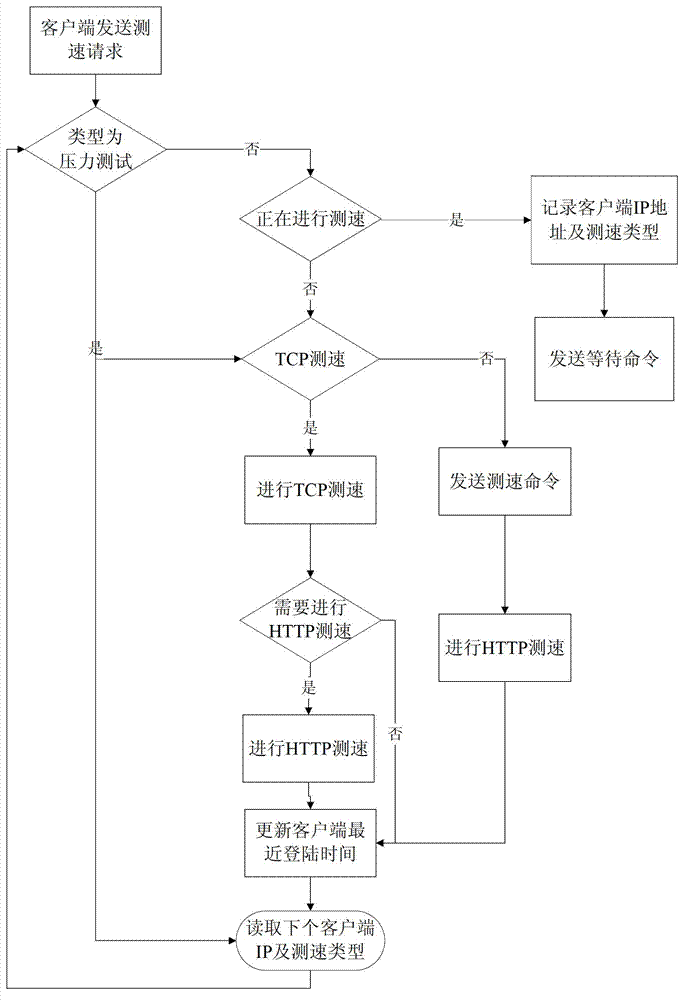

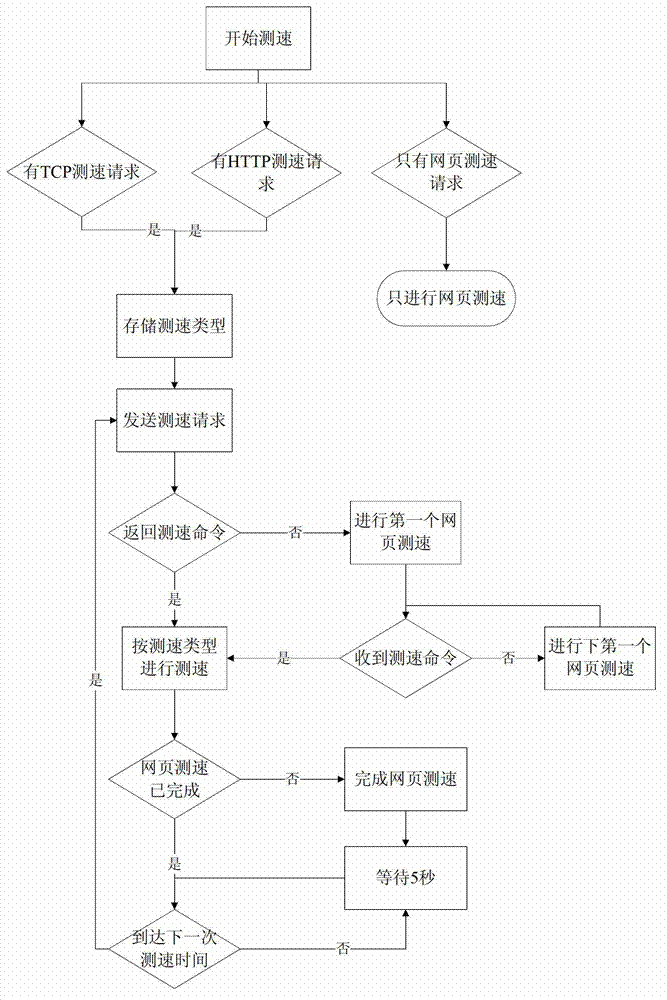

Network speed test method and network speed test system

ActiveCN103051498AIntuitive and objective detectionAccurate Bandwidth DataData switching networksSpeed testClient-side

The invention relates to a network speed test method and a network speed test system. The method includes the following steps: a network speed test request is sent into a waiting queue of a server by a client to be queued; if the judgment result of the server is test starting, then the server judges the variety of a test mode; if the test mode is pressure test, then the server sends a speed-testing command to the client, and cooperates with the client to carry out a TCP (transfer control protocol) network speed test and / or an HTTP (hypertext transfer protocol) network speed test; if the test mode is sequence test, whether the TCP network speed test and / or the HTTP network speed test are / is executed by the current server is judged, if so, then a waiting command is sent to the client, and if not, then the server cooperates with the client to carry out the TCP network speed test and / or the HTTP network speed test. The invention can visually and objectively test the speed of all broadband networks to provide reliable technical support for users to obtain accurate bandwidth data of operators.

Owner:上海泰峰检测认证有限公司

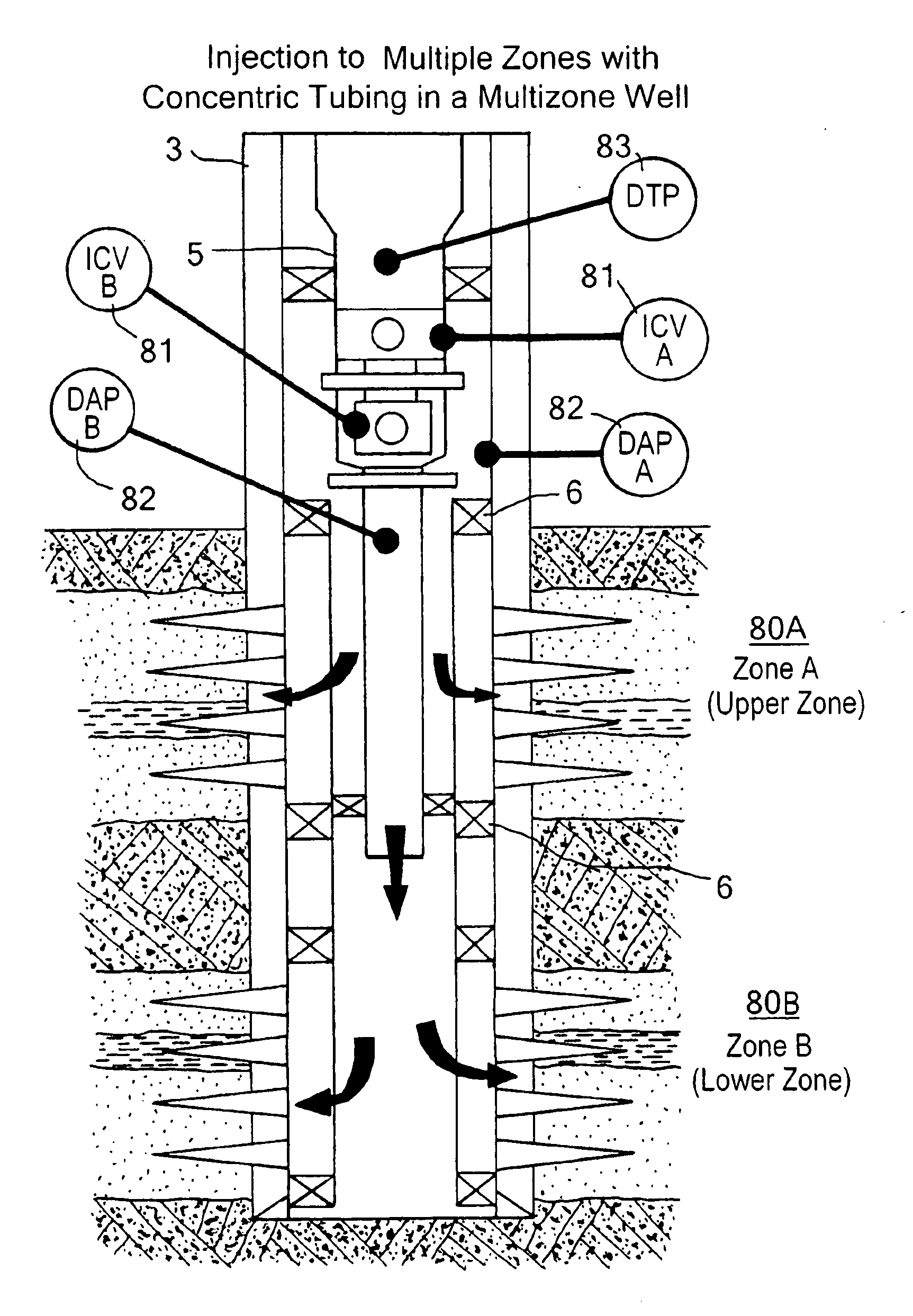

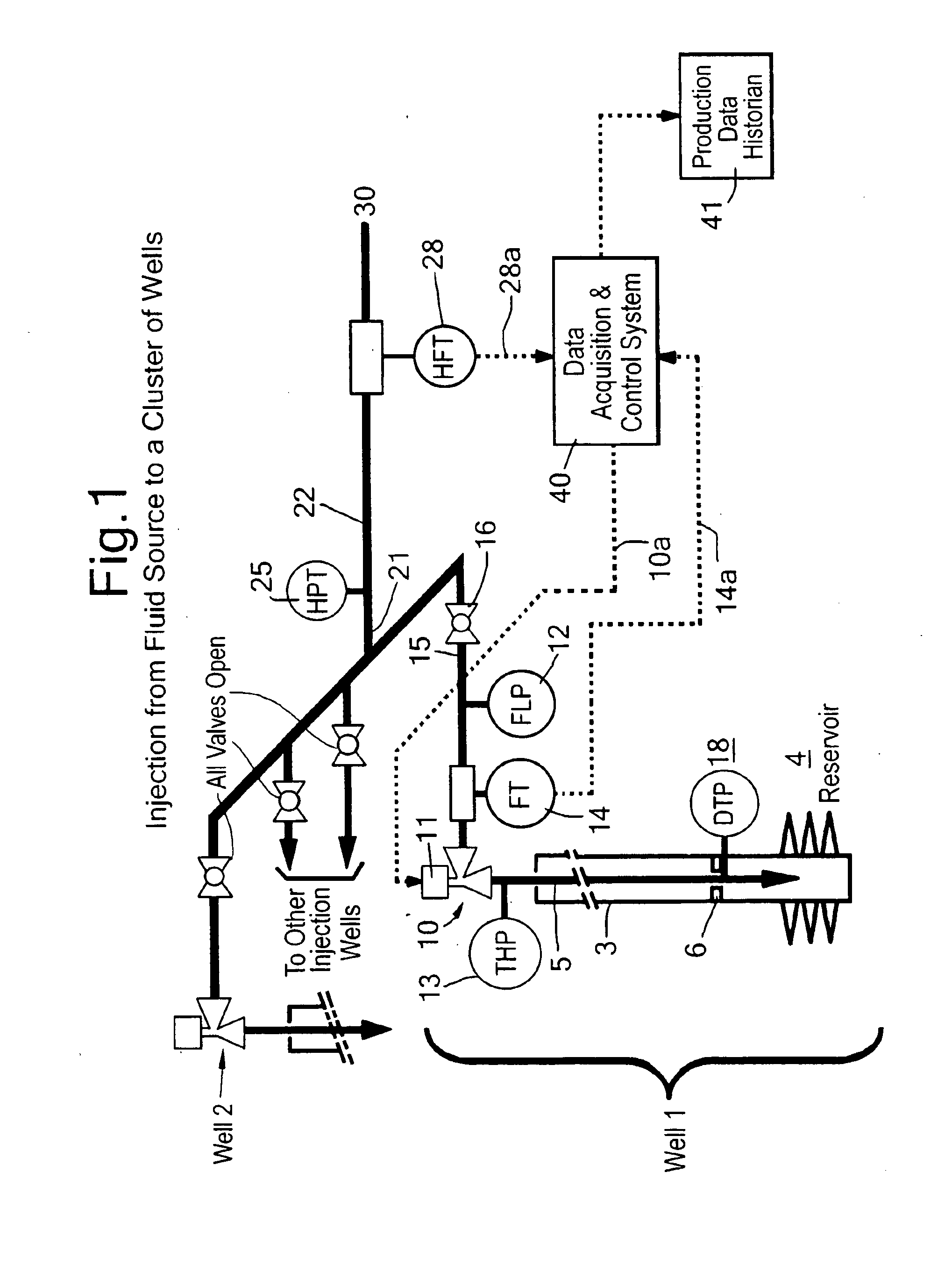

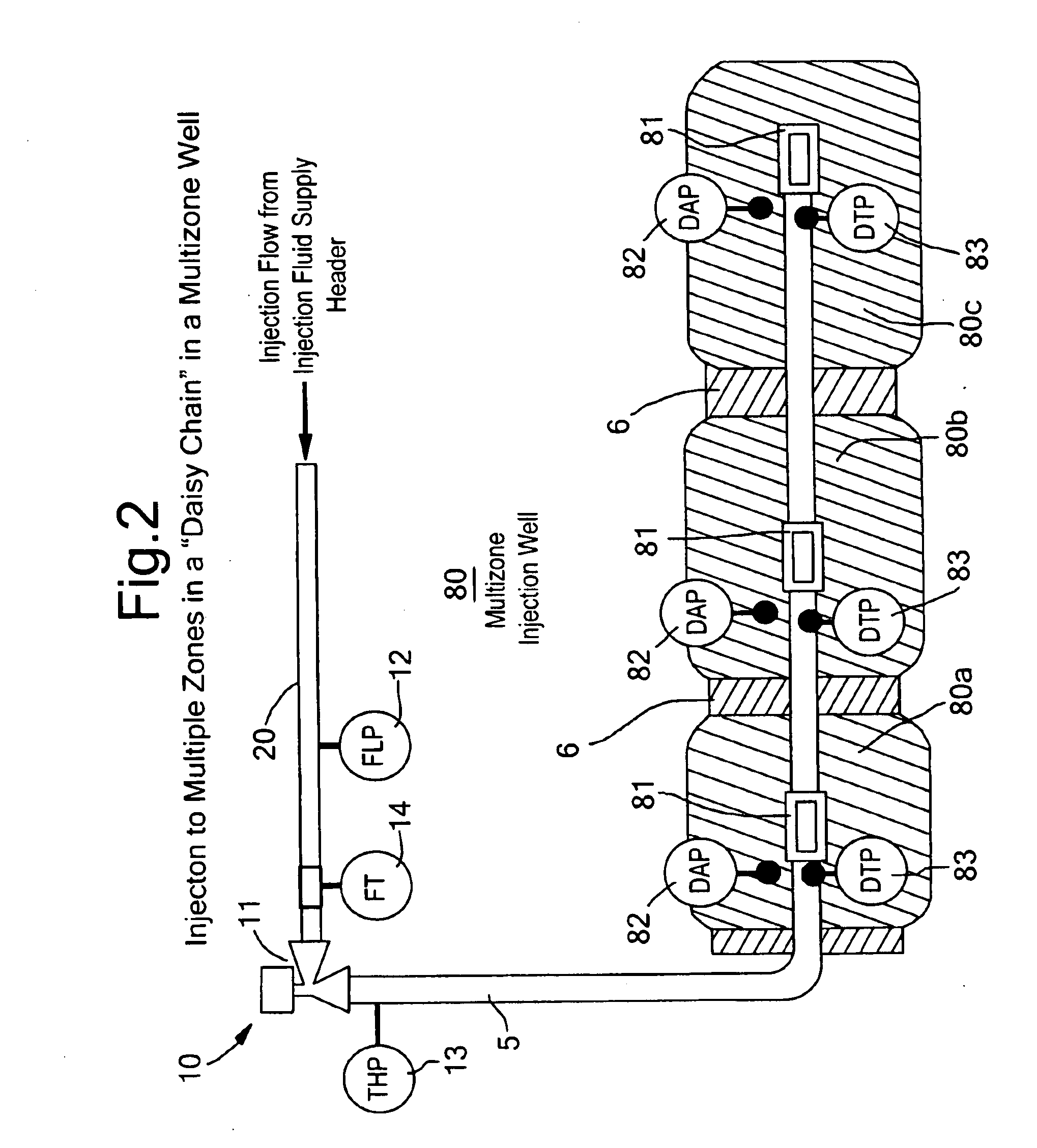

Method for virtual metering of injection wells and allocation and control of multi-zonal injection wells

ActiveUS20110301851A1Electric/magnetic detection for well-loggingVolume/mass flow measurementEngineeringInjection well

A method for virtual metering of fluid flow rates in a cluster of fluid injection wells which are connected to a collective fluid supply header conduit assembly comprises: a) sequentially testing each of the injection wells of the cluster by closing in that well and then performing a dynamically disturbed injection well test (DDIT) on the tested well, during which test the injection rate to the tested well is varied over a range of flows whilst the fluid flowrate in the header conduit assembly and one or more injection well variables, including tubing head pressure, of the well under test and of the other wells in the cluster are monitored, and the other wells in the cluster are controlled such as to cause their tubing head pressures or flow meter readings to be approximately constant for the duration of the test; b) deriving from step a a well injection estimation model for each tested well, which model provides a correlation between variations of the fluid flowrate attributable to the well under consideration in the header conduit assembly, and variations of one or more well variables monitored during each dynamically disturbed injection well test (DDIT); c) injecting fluid through the header conduit assembly into the cluster of wells whilst a dynamic fluid flow pattern in the header conduit assembly and one or more well variables of each injection well are monitored; d) calculating an estimated injection rate at each well on the basis of dynamic fluid flow pattern in the header conduit and the monitored well variables and the well injection estimation model of step b.

Owner:SHELL USA INC

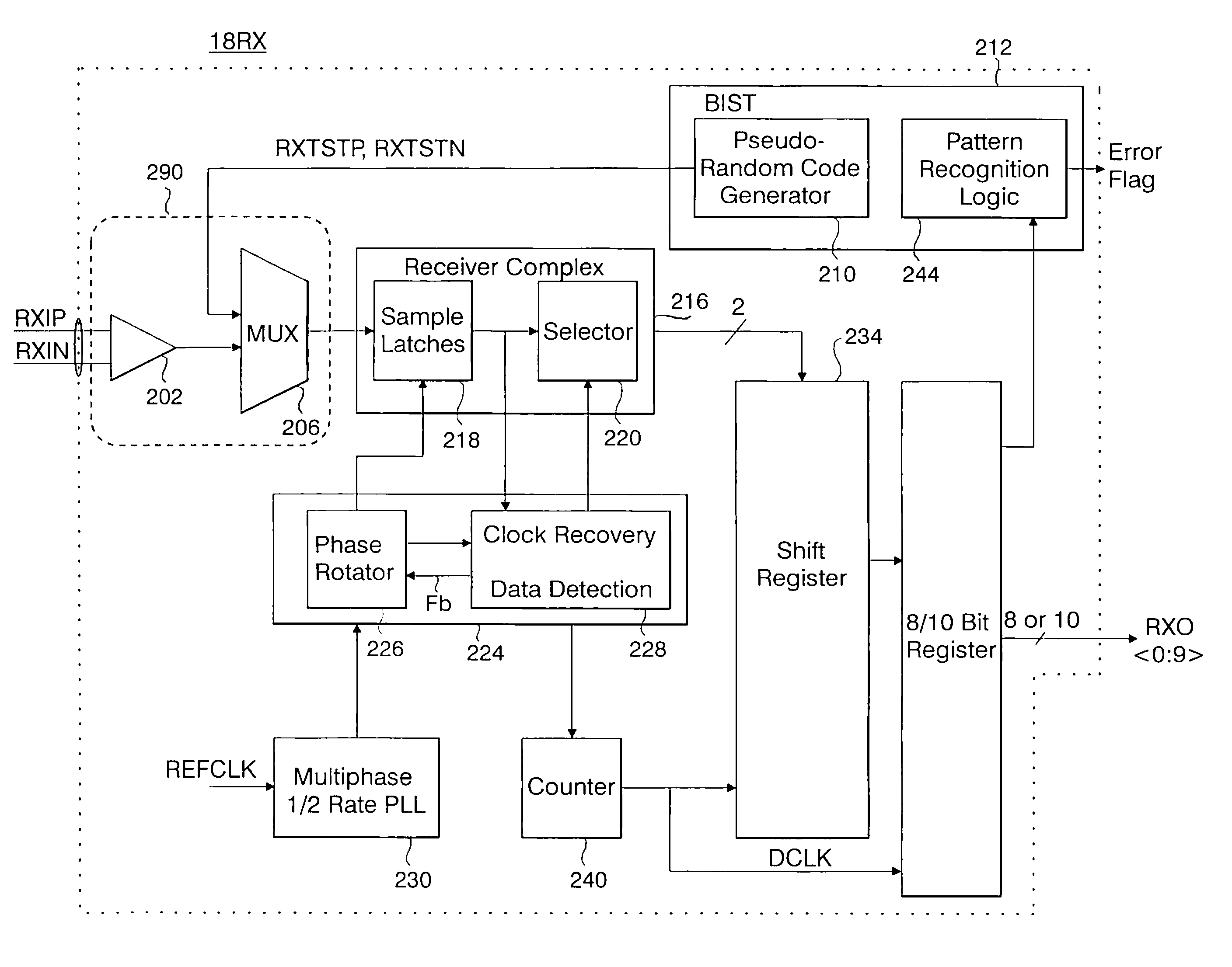

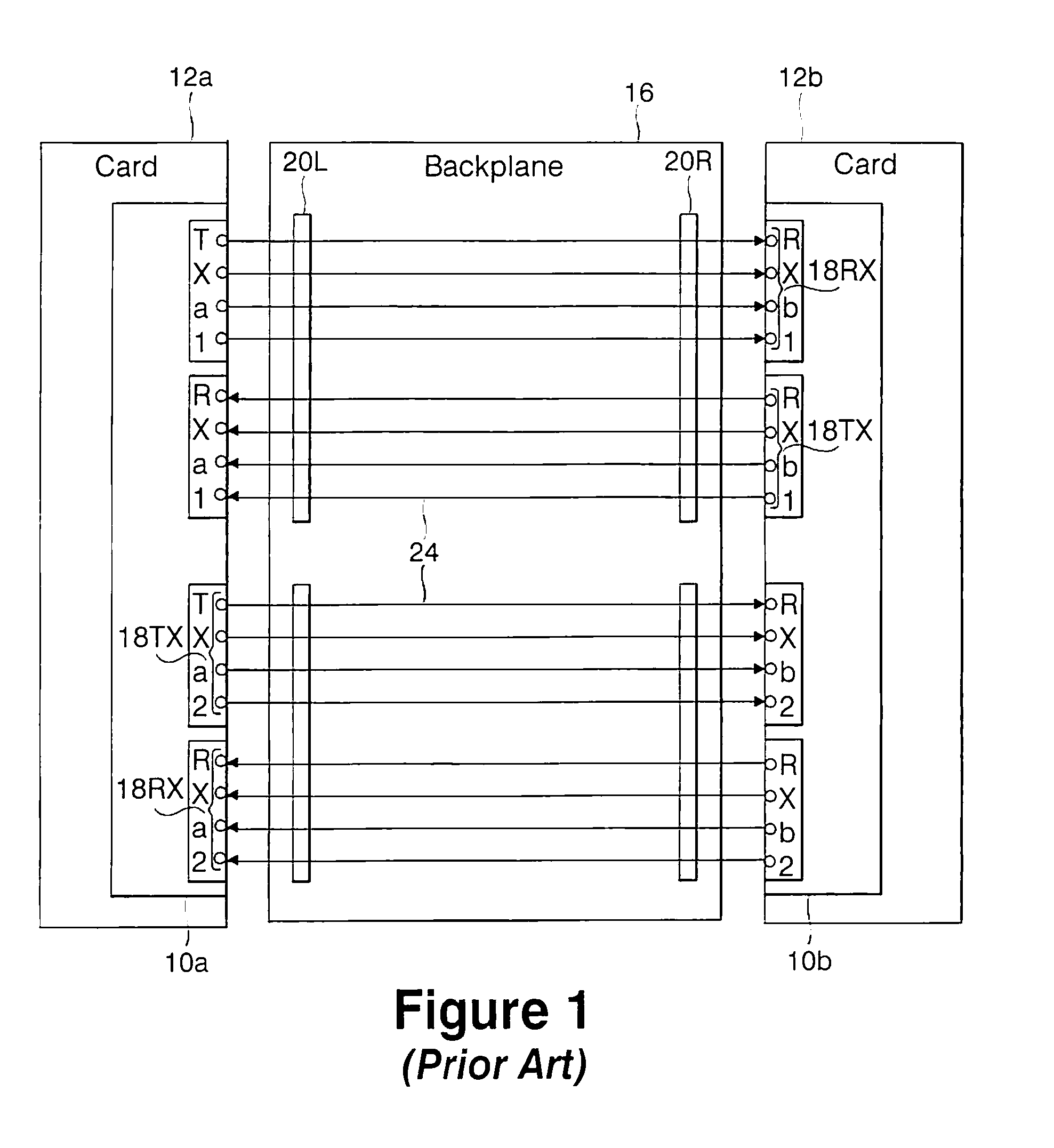

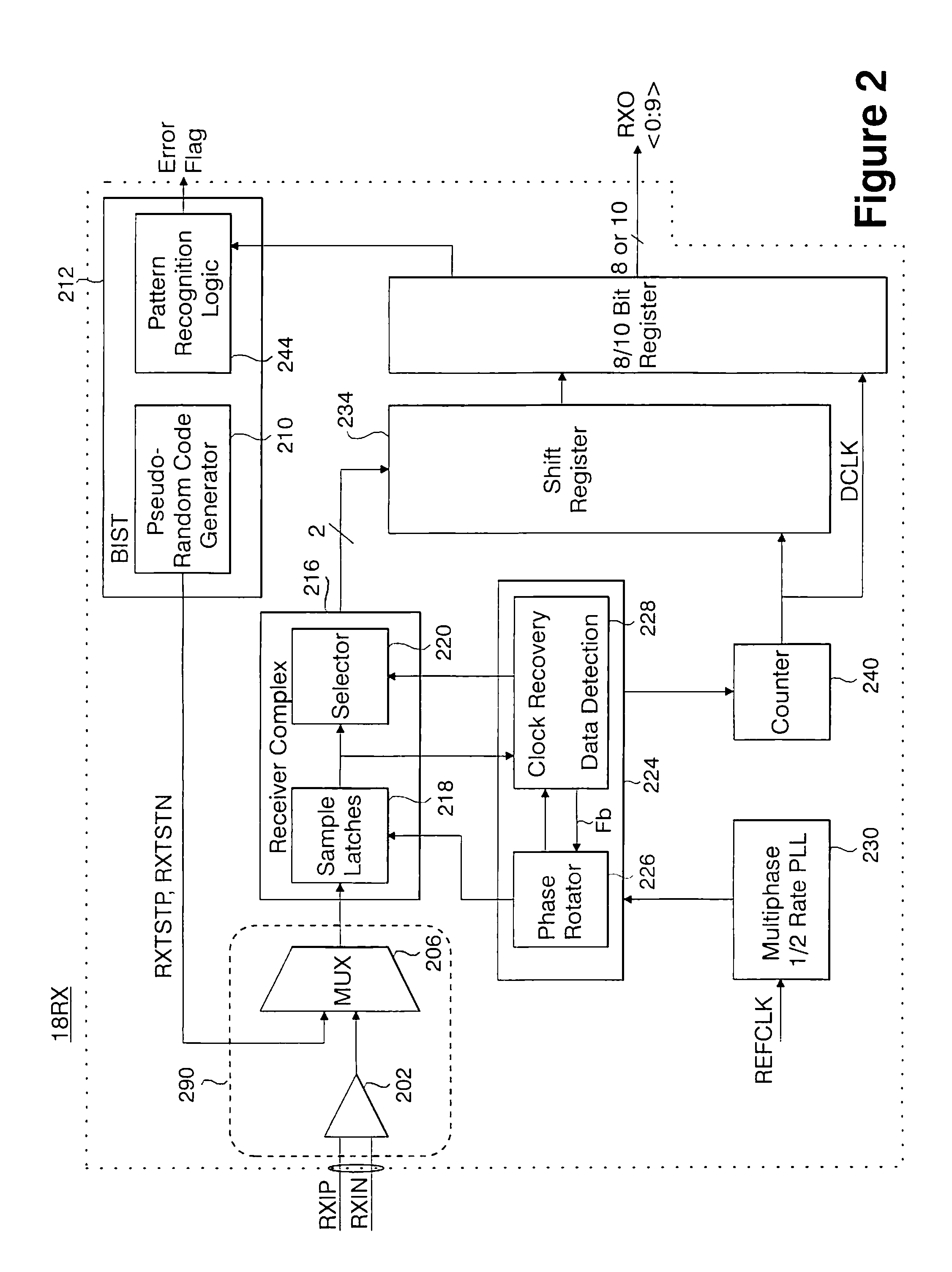

System and method for sequential testing of high speed serial link core

ActiveUS7191371B2Minimize test timeMinimized in sizeCorrect operation testingTransmission systemsEngineeringHigh speed serial link

A testing circuit for testing a series of at least three alternating transmitter and receiver links. The testing circuit including a built-in-self-test (BIST.) macro for generating test data and transmitting the test data to a first link of the series of transmitter and receiver links, and for receiving processed test data from a last link of the series of transmitter receiver links; and at least one test transmission line for transmitting test data received by a link of the series of transmitter and receiver links to a next link of the series of transmitter and receiver links, wherein the at least one test transmission line connects the at least three transmitter and receiver links. A method for testing a series of links having at least three alternating transmitter and receiver links of a plurality of transmitter and receiver links in a SerDes core including generating at least one test data signal; transmitting the at least one test data signal sequentially through the transmitter and receiver links of the series of links; receiving the at least one test data signal from a last link of the series of transmitter and receiver links; and checking the at least one test data signal received.

Owner:GLOBALFOUNDRIES US INC

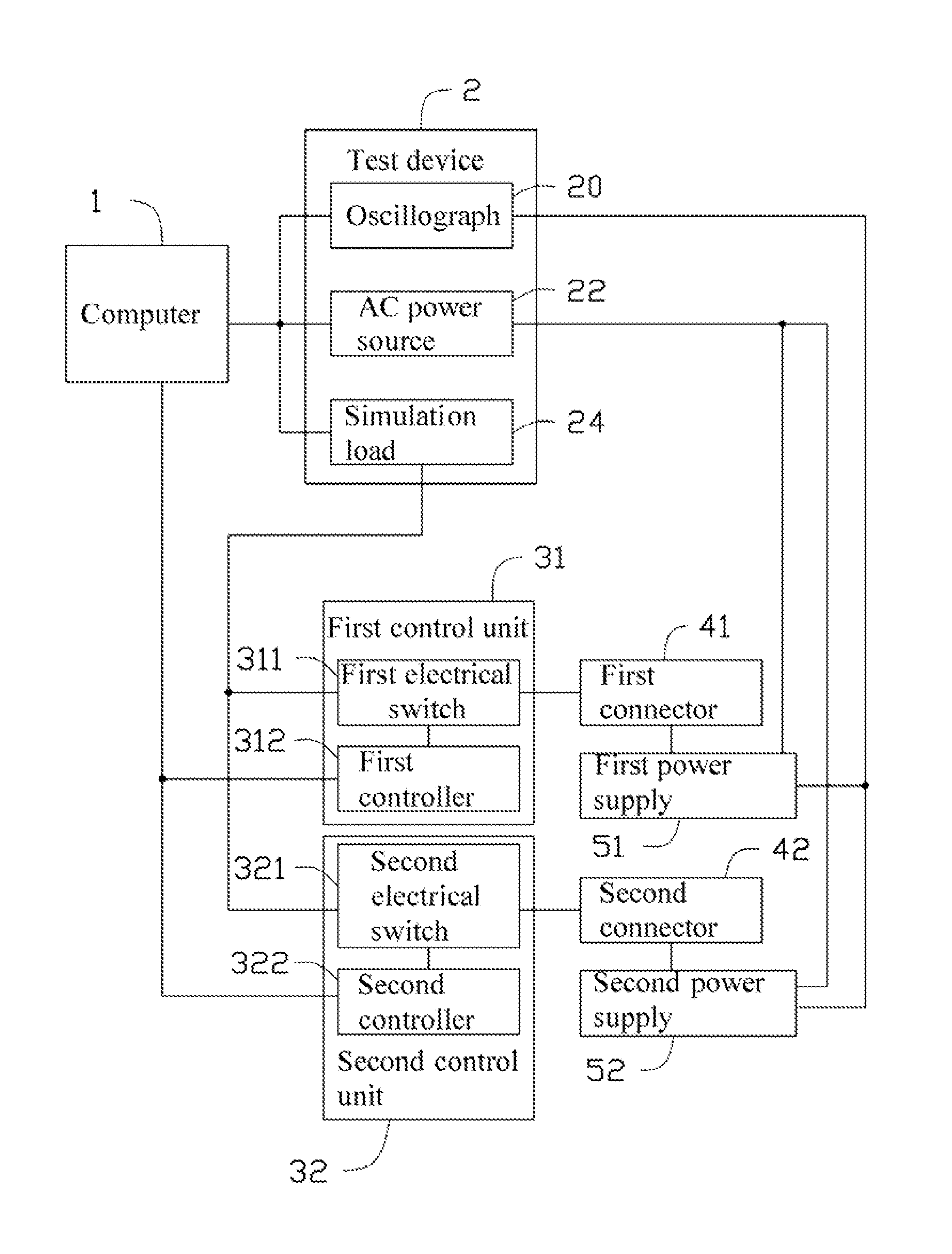

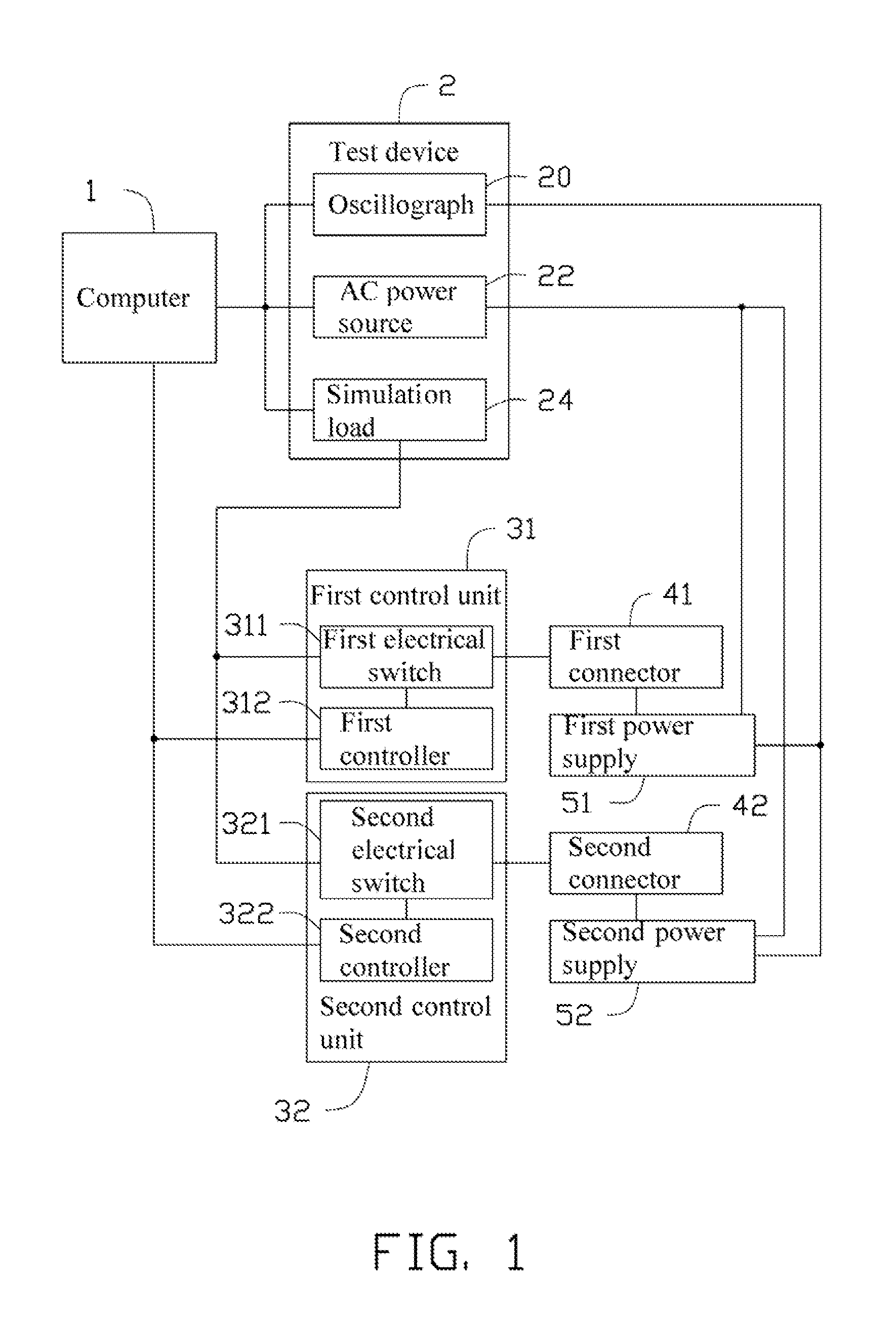

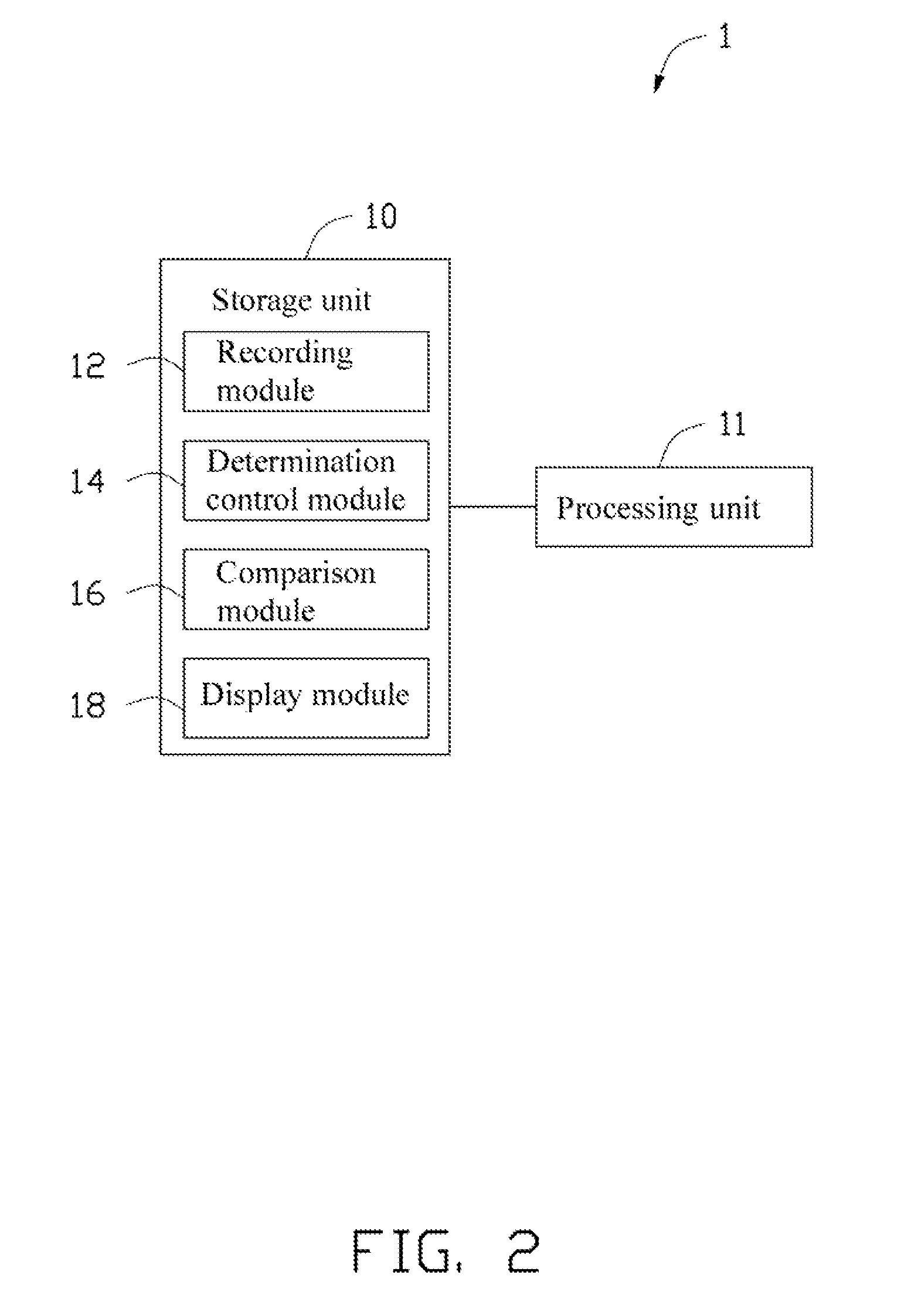

Automatic power supply testing system and method

InactiveUS20120185201A1Resistance/reactance/impedencePower supply testingEngineeringElectrical stability

An automatic power supply testing system records a preset test order of first and second power supplies with a recording module. The automatic power supply testing system controls a first control unit to connect a first connector connected to the first power supply to a simulation load to test the first power supply according to the preset test order by a determination control module and obtains a first test result. The automatic power supply testing system controls a second control unit to connect a second connector connected to the second power supply to the simulation load to test the second power supply after determining that the first test result is displayed and obtain a second test result. A display module displays the electrical stability of the first and second power supplies.

Owner:HON HAI PRECISION IND CO LTD

System and method for automatically testing motherboards

InactiveUS7451349B2Resistance/reactance/impedenceDetecting faulty hardware by remote testTest scriptOperational system

A system for automatically testing motherboards includes a test server (1), client computers (2), and a network (5) connecting the test server with the client computers. The test server is for storing a plurality of high-level OSs (Operating Systems), test programs and test script files, for setting contents of test configuration files, and for storing test results. Each client computer has a motherboard installed therein, and is operated under a DOS (Disk Operating System). The client computer downloads and installs a high-level OS from the test server, downloads and installs one or more test programs and a test script file according to a test configuration file set by the test server, executes the test script file to auto-run test programs in a sequence specified in the test configuration file, and then transmits test results to the test server.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

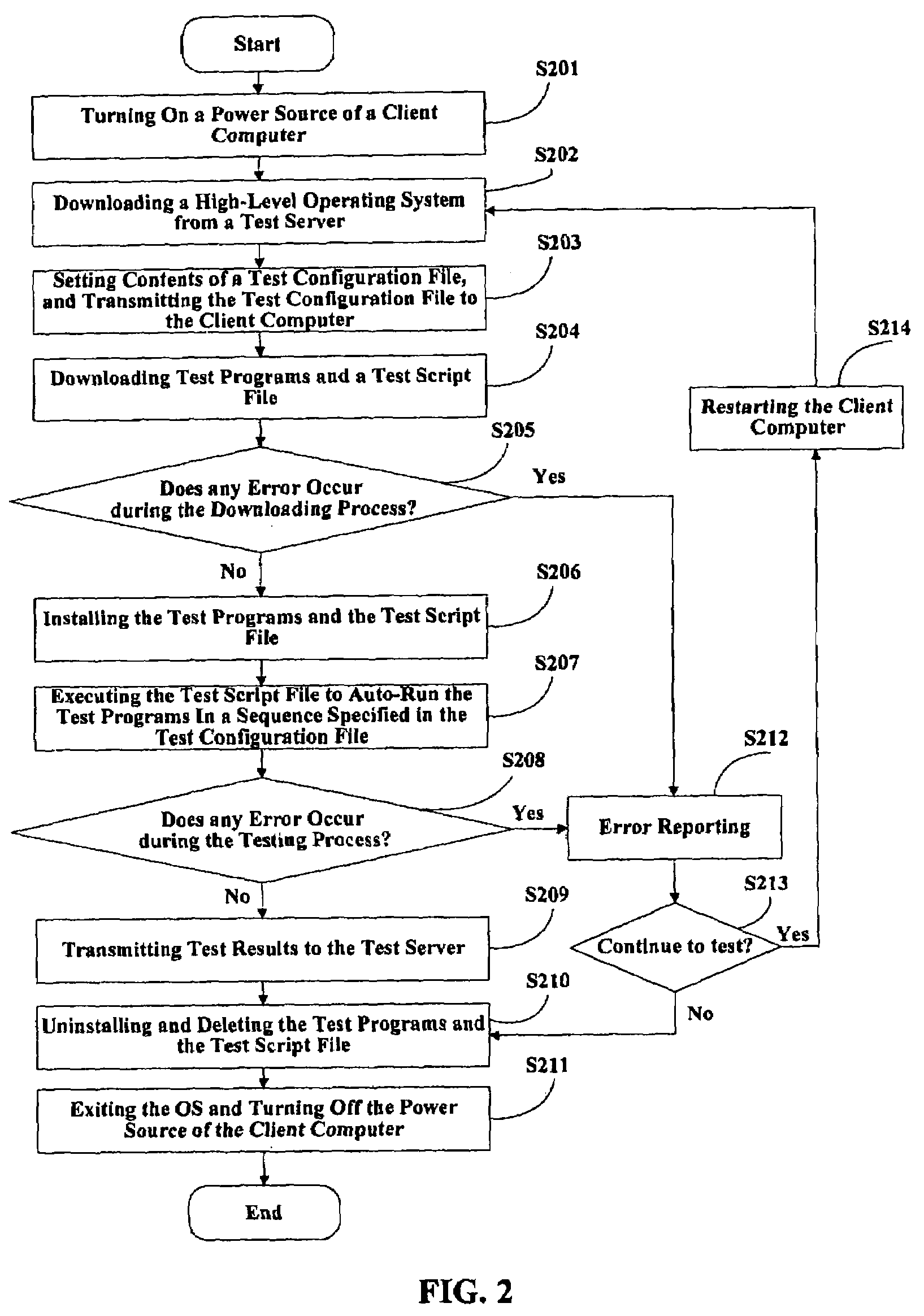

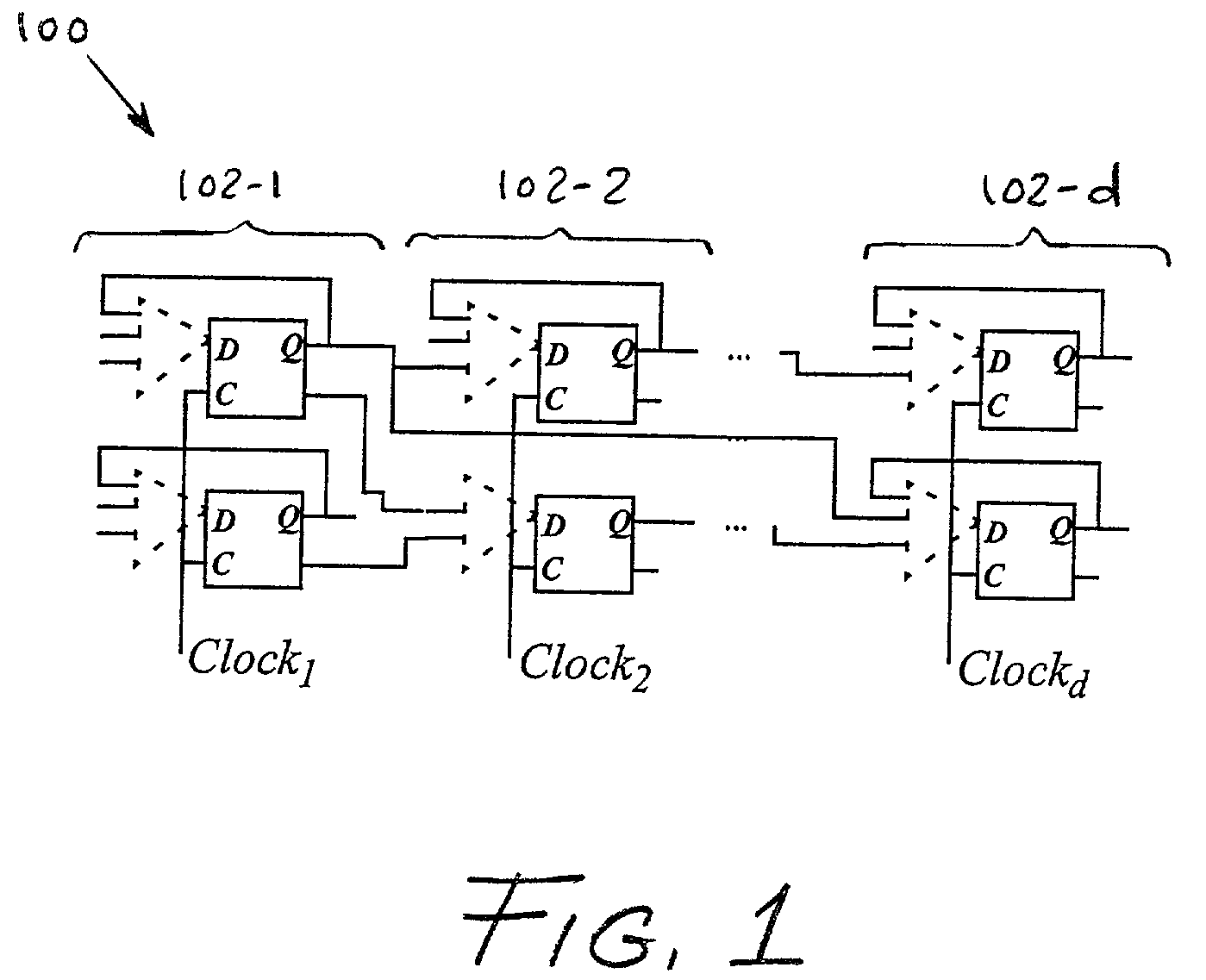

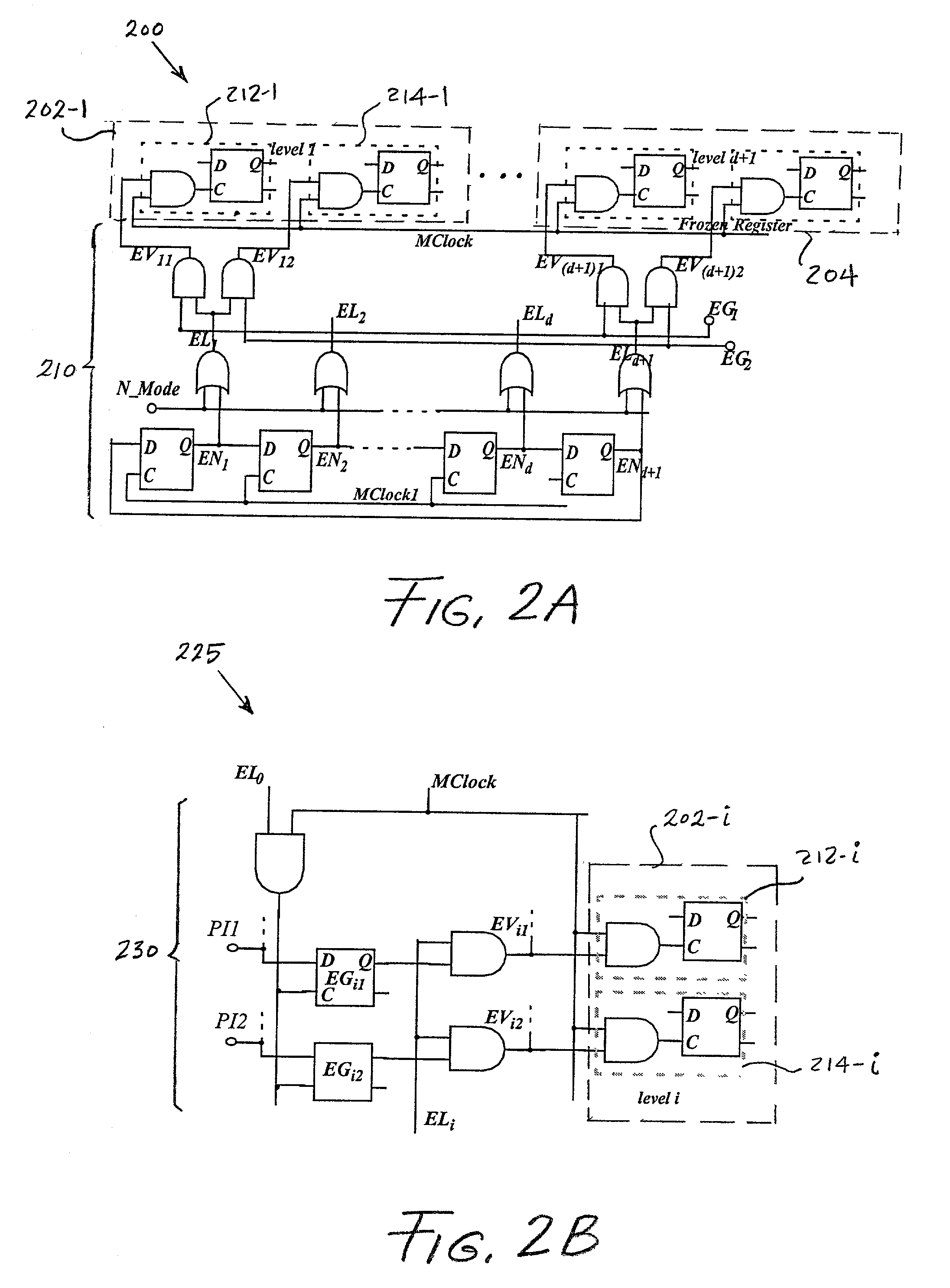

Sequential test pattern generation using clock-control design for testability structures

InactiveUS7017096B2No delay penaltiesSmall area overheadDigital circuit testingError detection/correctionProcessor registerPattern generation

Techniques for testing a sequential circuit comprising a plurality of flip-flops or other types of registers. The circuit is first configured such that substantially all feedback loops associated with the registers, other than one or more self-loops each associated with a corresponding one of the registers, are broken. Test patterns are then generated for application to the circuit. The test patterns are applied to the circuit in conjunction with partitioned clock signals each of which is associated with a corresponding level of the circuit containing at least one of the self-loops.

Owner:BELL SEMICON LLC

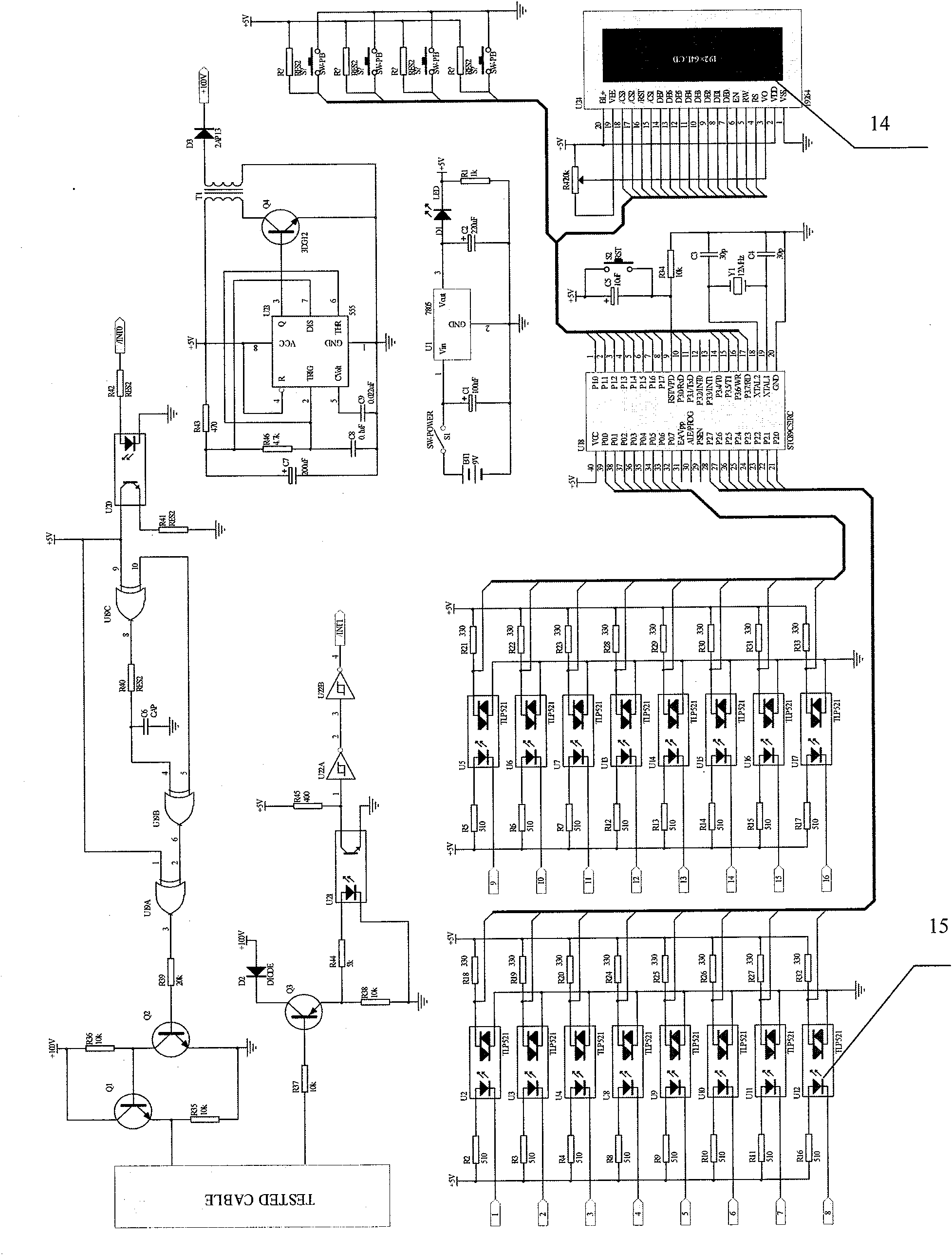

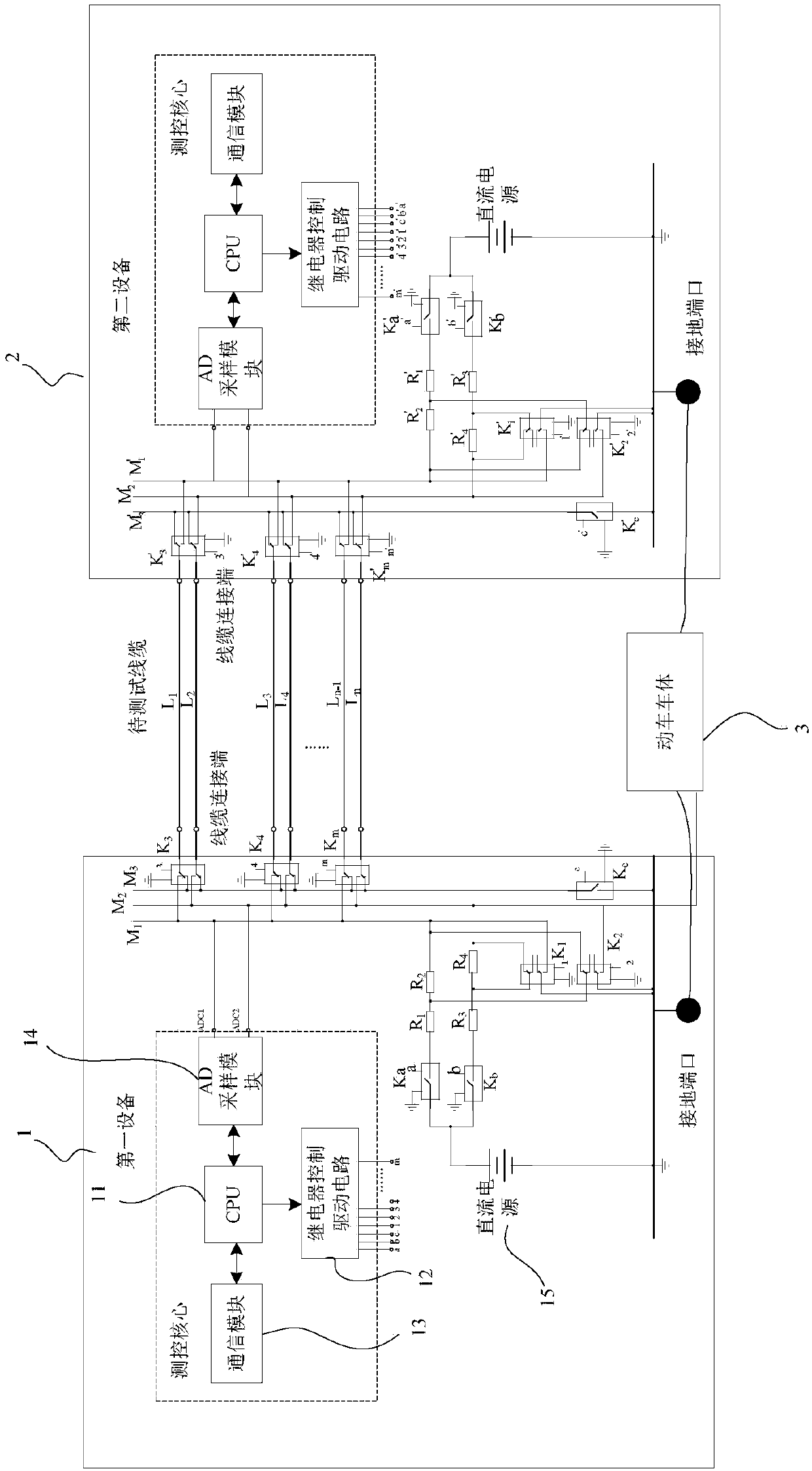

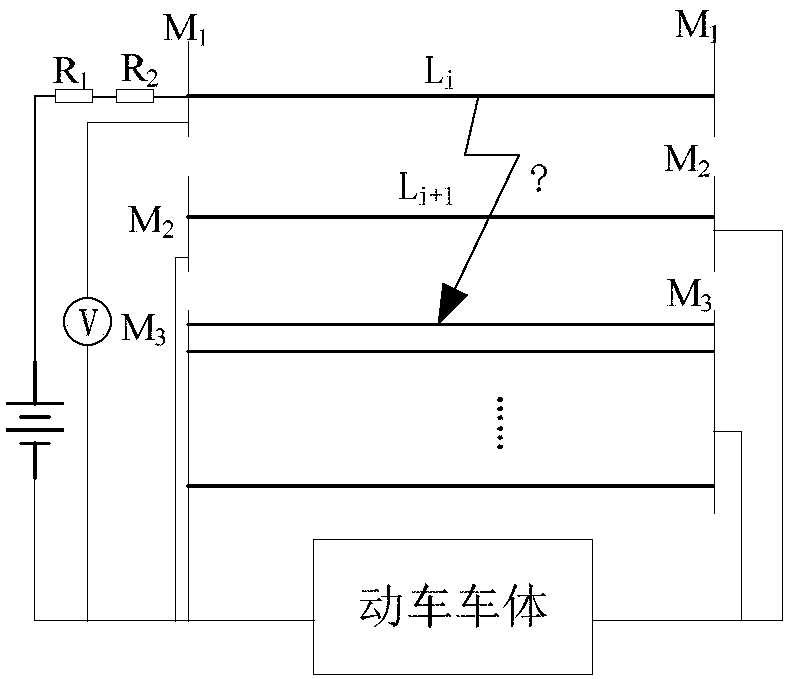

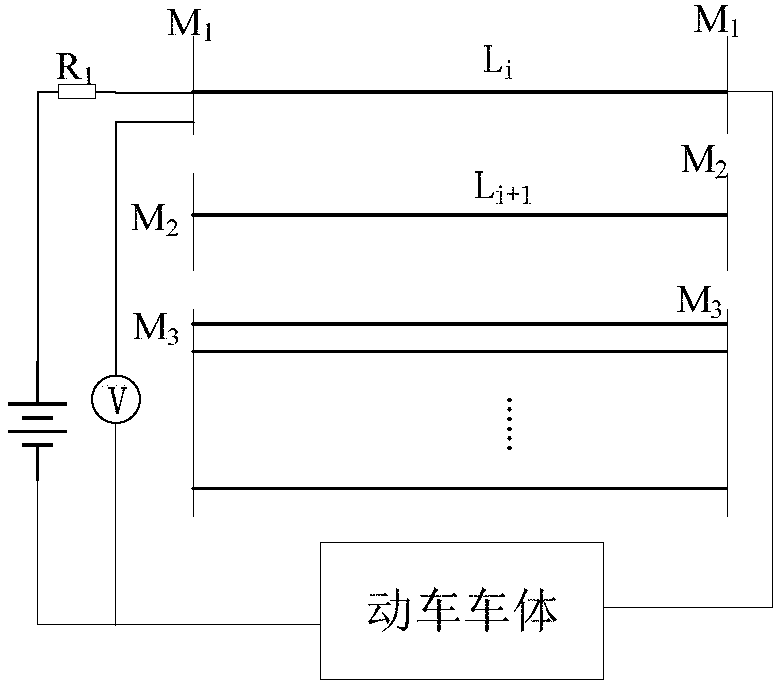

Hand-held cable continuity test device and system and test method for rail vehicle

ActiveCN107907779AReduce the number of movementsReduce in quantityElectrical testingReverse orderHand held

The invention provides a hand-held cable continuity test device for a rail vehicle. The bus switch module (A) of the device is provided with a cable end. The contacts of A are connected with an idle bus and a test bus respectively. Each bus is connected with a grounding end through the contacts of grounding switch modules (B). Drive and grounding ports are arranged. Each switch module is providedwith an enable end and contacts. The slave device of the system comprises the hand-held cable continuity test device, control and communication modules, a power supply, a power supply switch module (C) and a voltage measurement circuit. The power supply is connected with the test bus through the contacts of C. The control module is connected with the drive. The enable end is connected with contacts and the drive. Short circuit and continuity test is carried out on a connected first cable. A master device determines a corresponding test result. Next cables on the same A are tested in reverse order until the last one. The test comprises the steps that the master device sends a test signal to the slave device; and the slave device controls the contact action of the slave device, and notifiesthe master device to control the contact action after switching. The test result is determined according to voltage. The volume is small, and the speed is fast.

Owner:CRRC QINGDAO SIFANG CO LTD

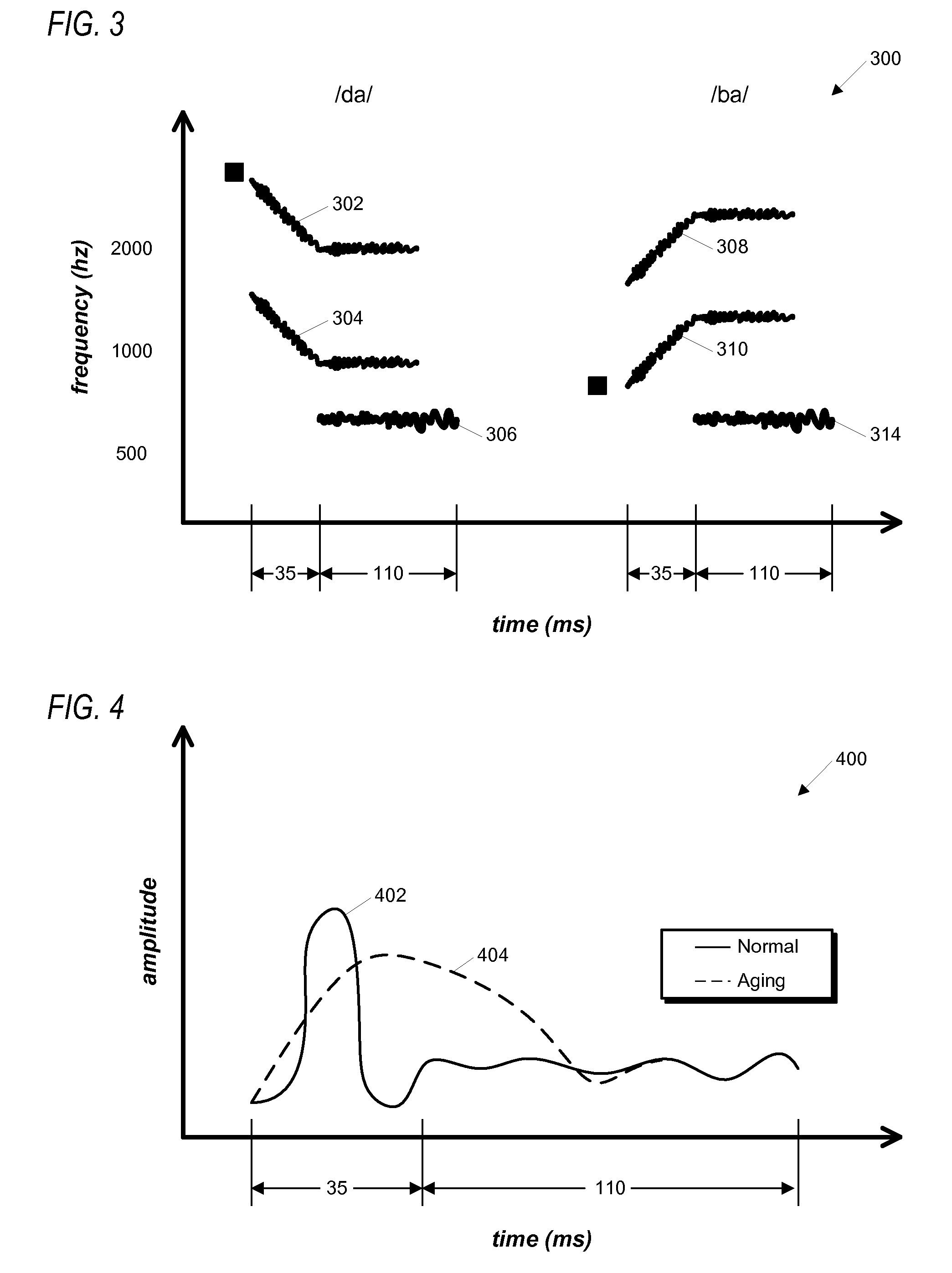

Cognitive training using a maximum likelihood assessment procedure

InactiveUS20070134636A1Easy to useImproving the cognitive skills of the adult subjectEducational modelsElectrical appliancesExercise performanceUltimate tensile strength

Computer-implemented method for improving cognition and memory in an aging adult, utilizing a computing device to present stimuli to the adult, and to record responses from the adult. A psychophysical threshold for an aging adult with respect to stimuli in a cognitive development exercise is determined using a maximum likelihood procedure, such as QUEST (quick estimation by sequential testing) or ZEST (zippy estimation by sequential testing). The threshold is a stimulus intensity value associated with a specified performance level of the adult. A plurality of trials in the exercise are then performed with stimuli at or near the determined threshold to improve the adult's cognition and memory skills. This threshold determination and exercise performance may be repeated in an iterative manner to further improve the adult's cognition and memory skills.

Owner:POSIT SCI CORP

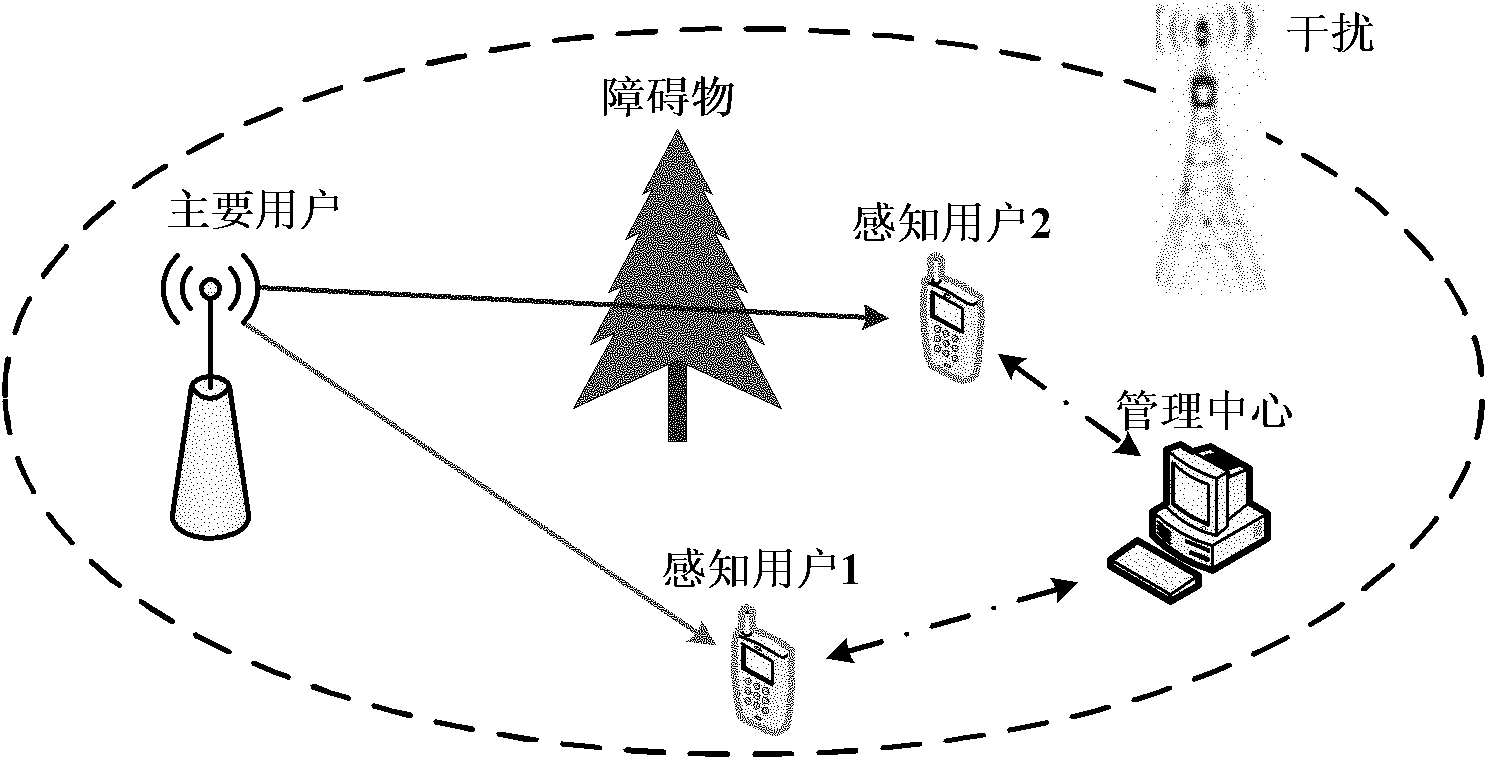

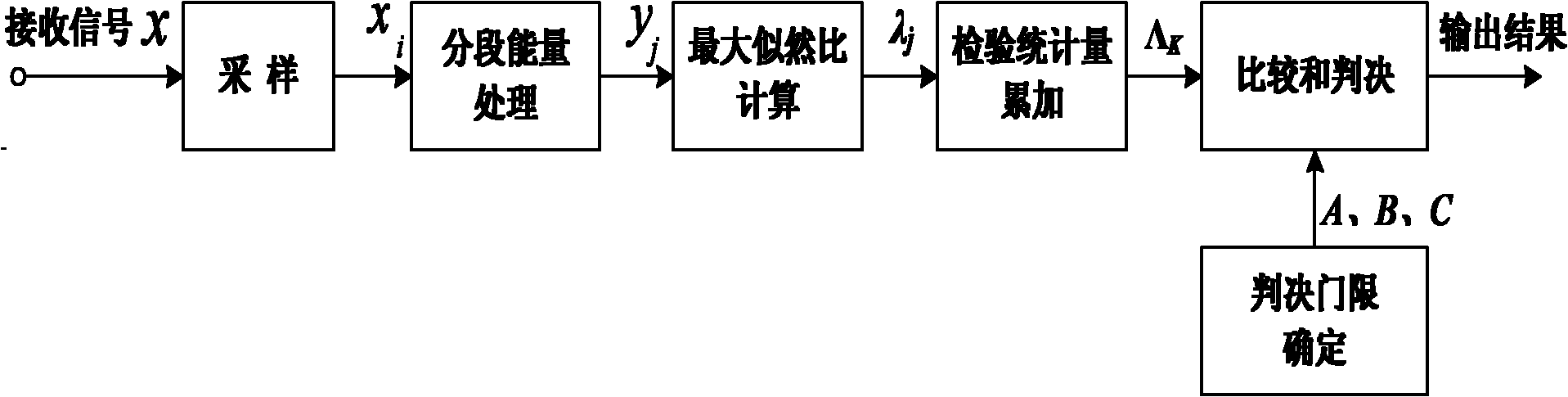

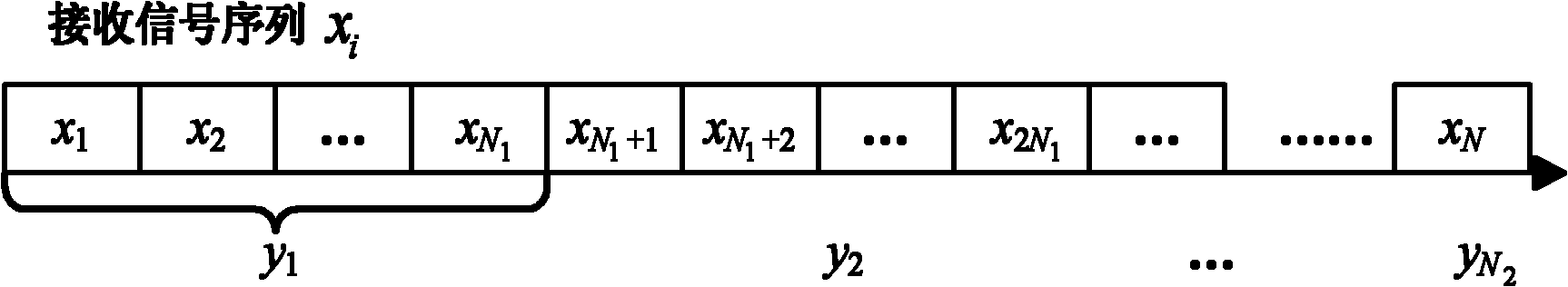

Segmented energy processing-based truncated sequential test method

InactiveCN102075263AFast perceptionPerceived effectiveTransmission monitoringComputation complexityFrequency spectrum

The invention discloses a segmented energy processing-based truncated sequential test method, which mainly solves the problem that the conventional spectrum sensing algorithm has poor detection performance and high computational complexity in a complex electromagnetic environment. The method comprises the following steps of: (1) sampling a received signal; (2) averagely segmenting the sequence ofthe sampled received signal, and calculating energy of each segmented sequence; (3) calculating the maximum likelihood ratio lambda j of the energy of each segmented sequence; (4) calculating test statistics Lambda K of the likelihood ratio lambda j of the energy of each segmented sequence; (5) determining an upper limit and a lower limit of a decision threshold; (6) determining the optimal truncated threshold; and (7) comparing and deciding the test statistics Lambda K, the upper and lower limits of the decision threshold and the optimal truncated threshold to obtain an output result. The method has the advantages of low computational complexity and short spectrum detection time, and can be used for improving the spectrum sensing performance of a cognitive radio network in the complex electromagnetic environment.

Owner:XIDIAN UNIV

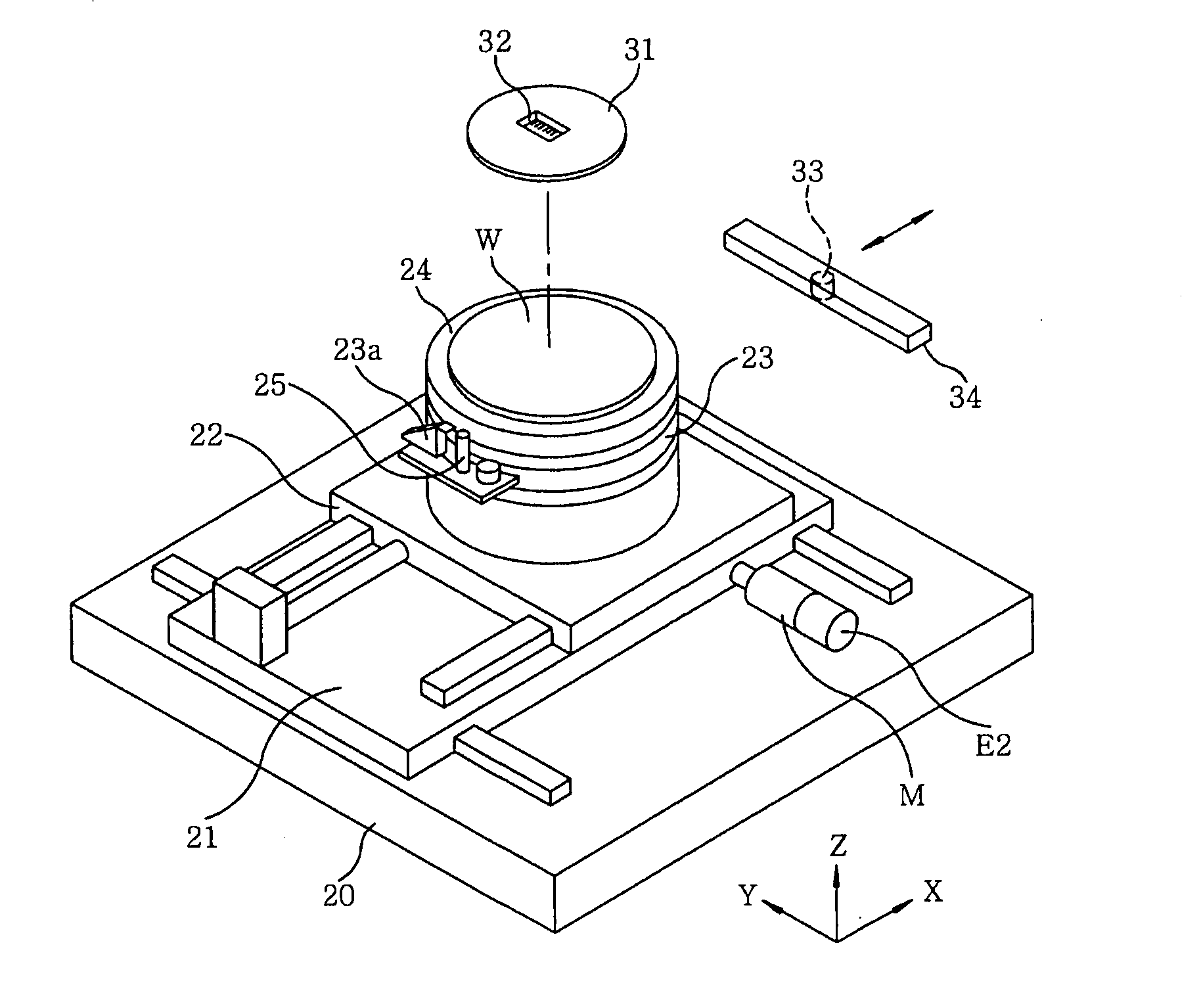

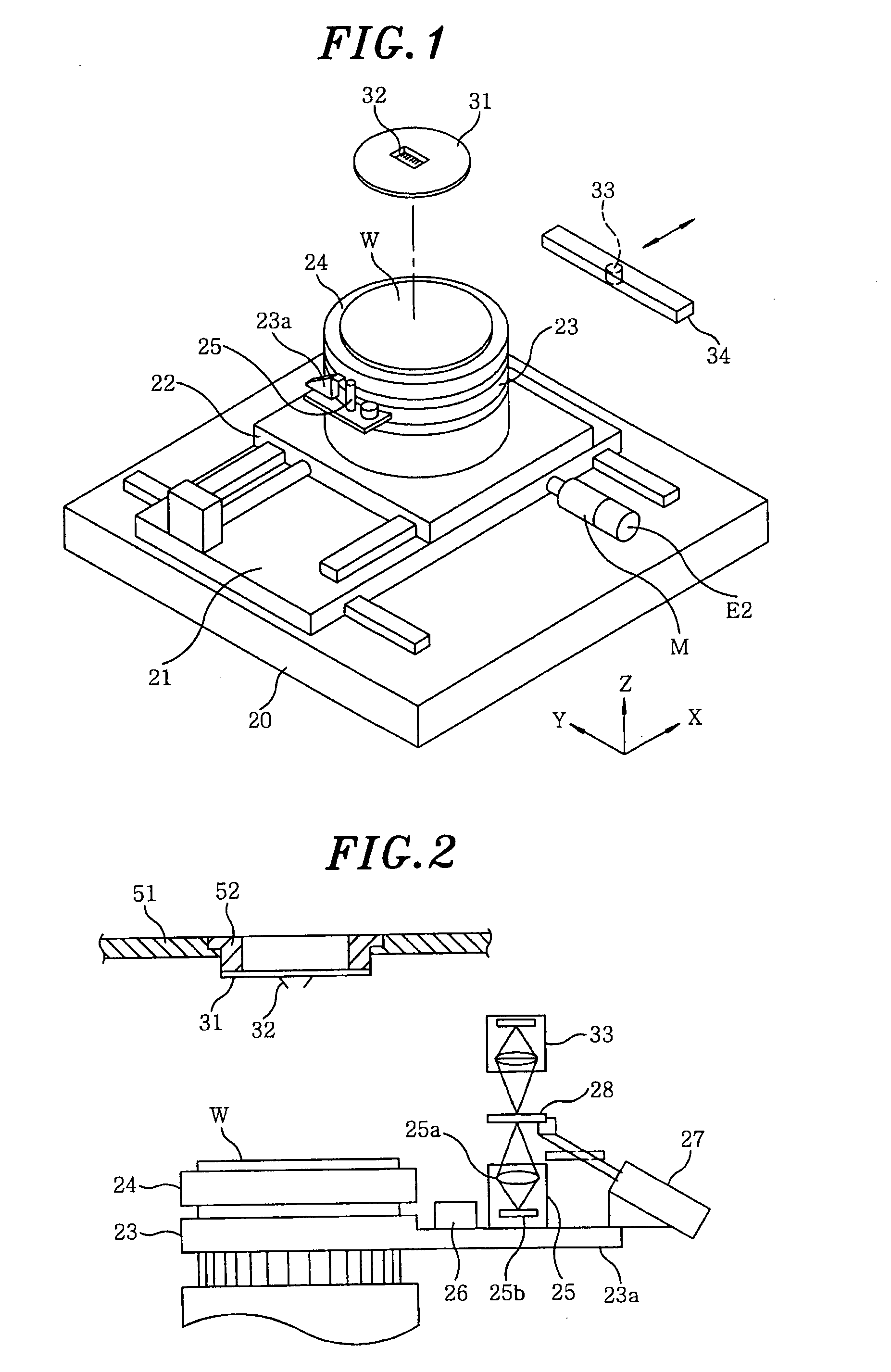

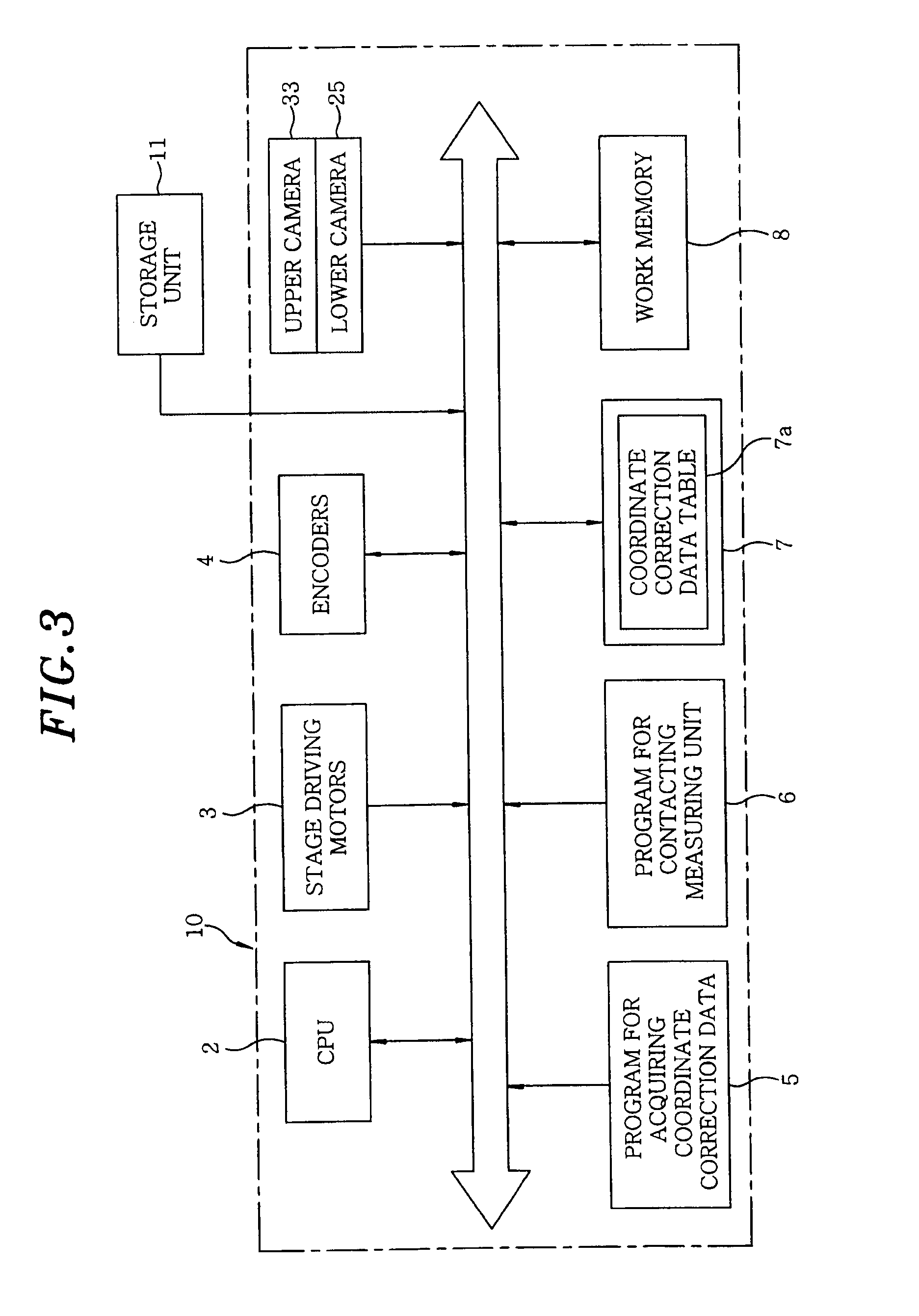

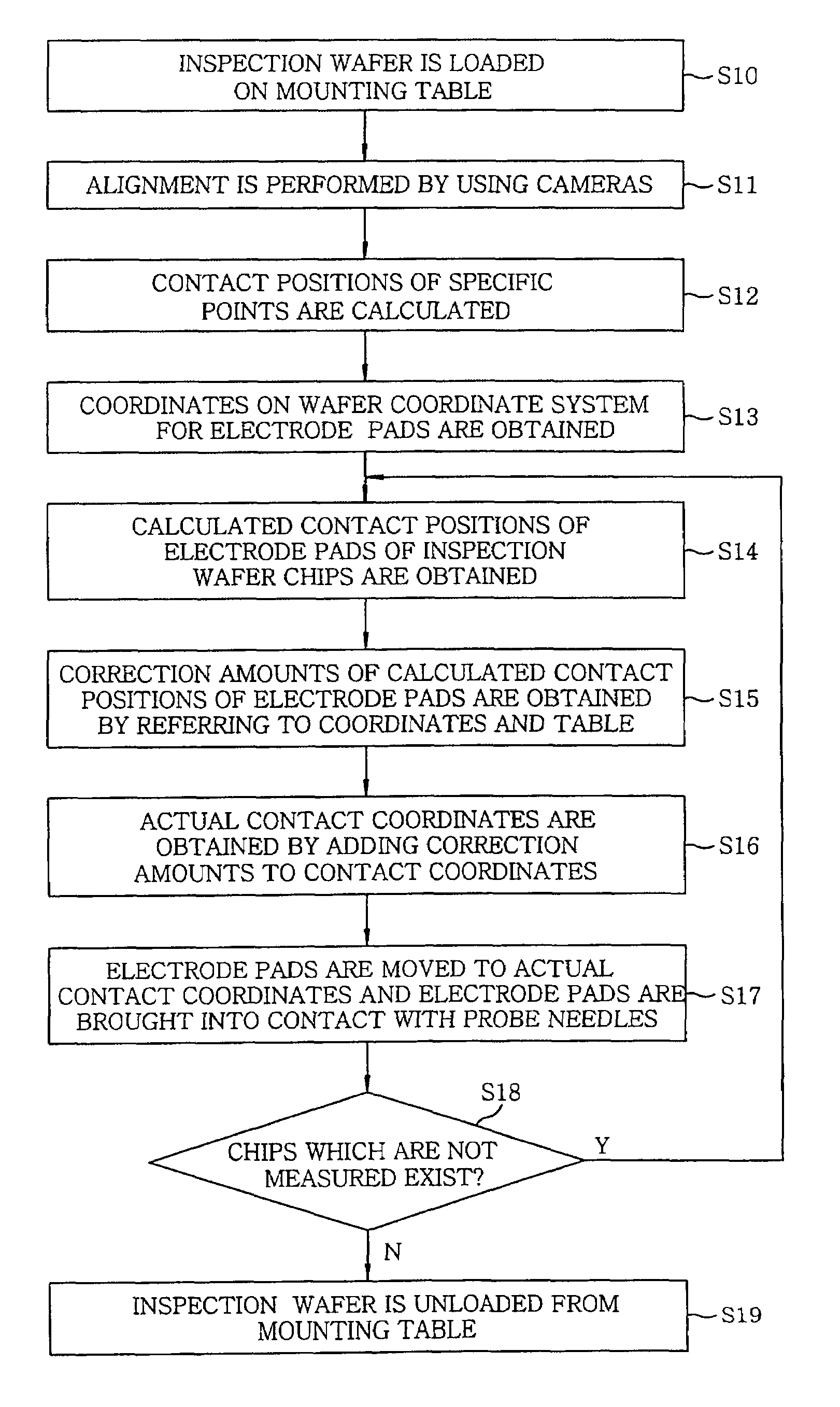

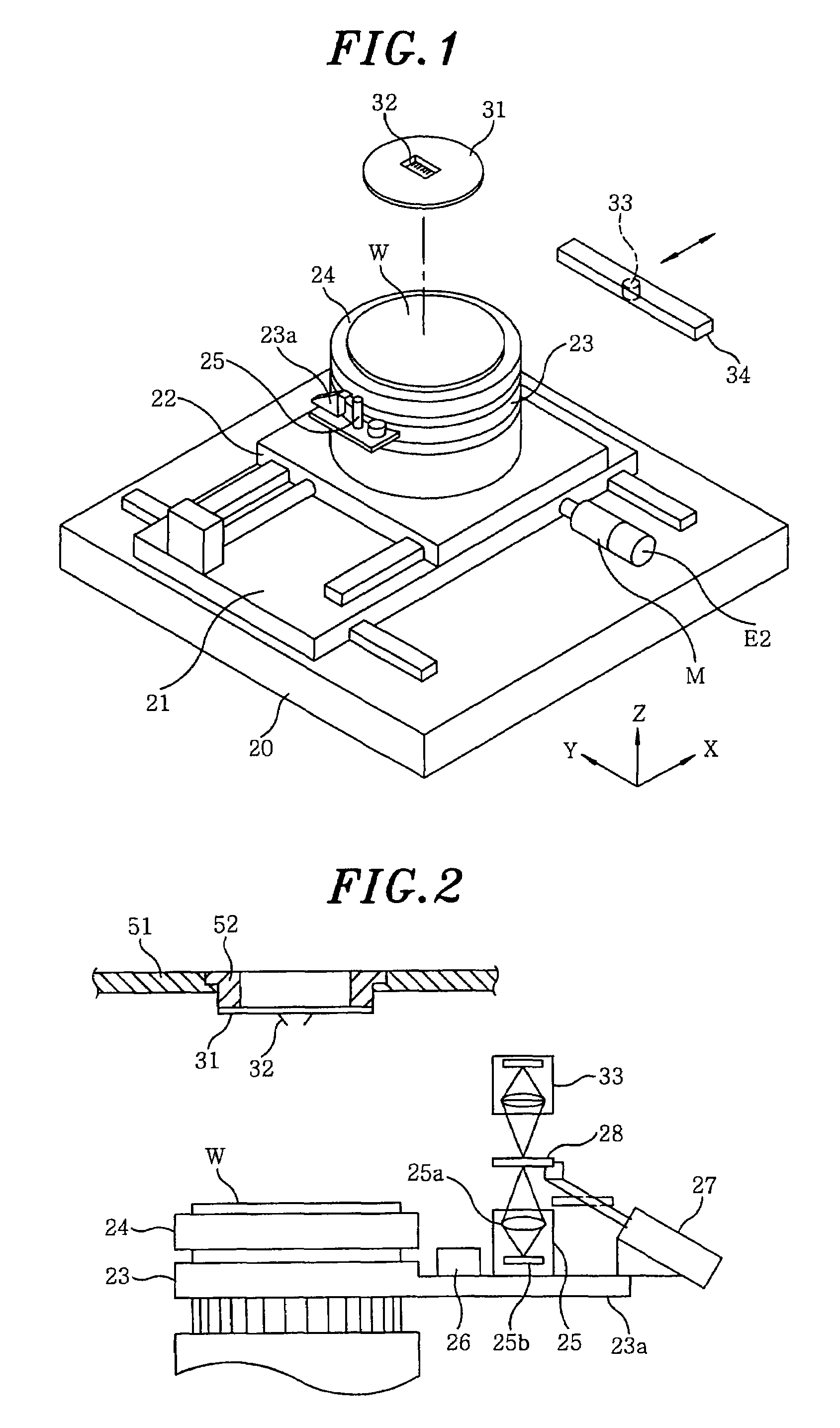

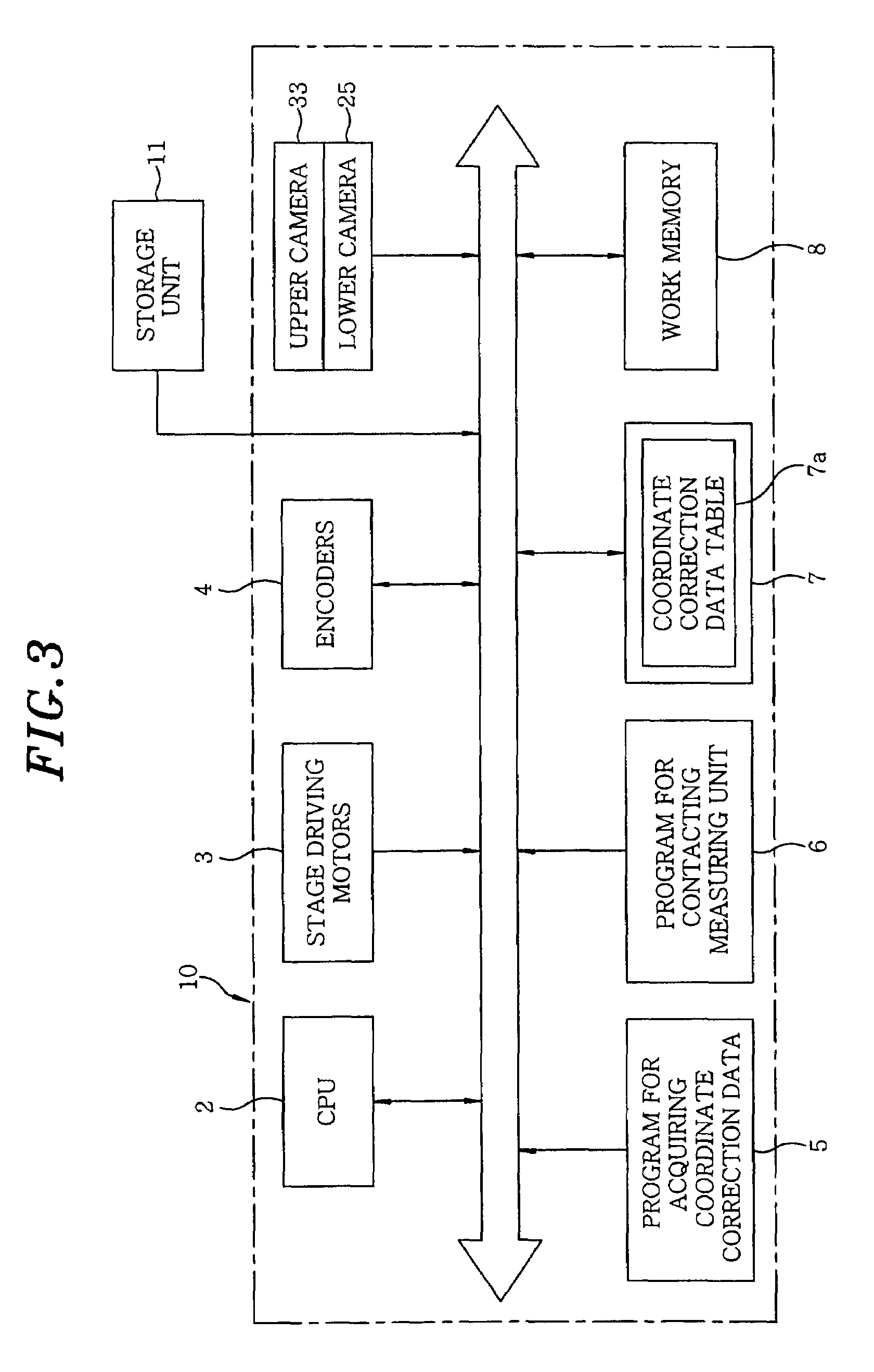

Probe apparatus, probing method and storage medium

ActiveUS20080238463A1Improve accuracySemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsEngineeringContact position

A probe apparatus for sequentially testing electrical characteristics of chips includes an imaging unit for capturing images of the electrode pads of the inspection substrate, and a unit for calculating contact positions at which the probes are expected to contact with the electrode pads. The probe apparatus further includes a storage unit for storing correction data in which reference points on a reference substrate are associated with correction amounts corresponding to differences between actual and calculated contact positions of the reference points, and a unit for obtaining actual contact positions for the electrode pads by measuring relative positions of the electrode pads with respect to the reference points and correcting the calculated contact positions of the electrode pads based on the relative positions and the correction data.

Owner:TOKYO ELECTRON LTD

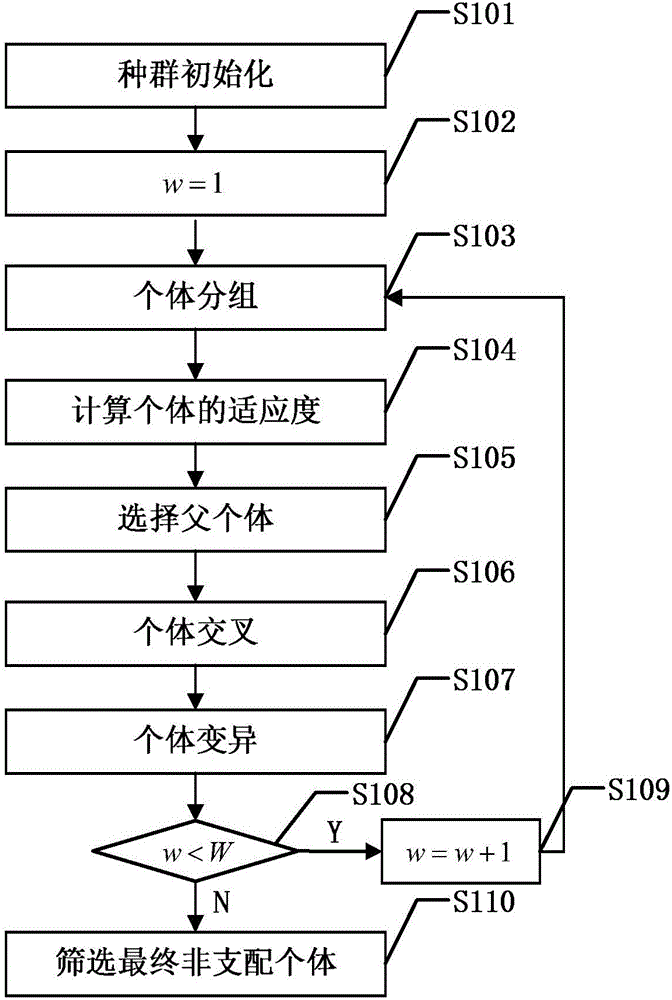

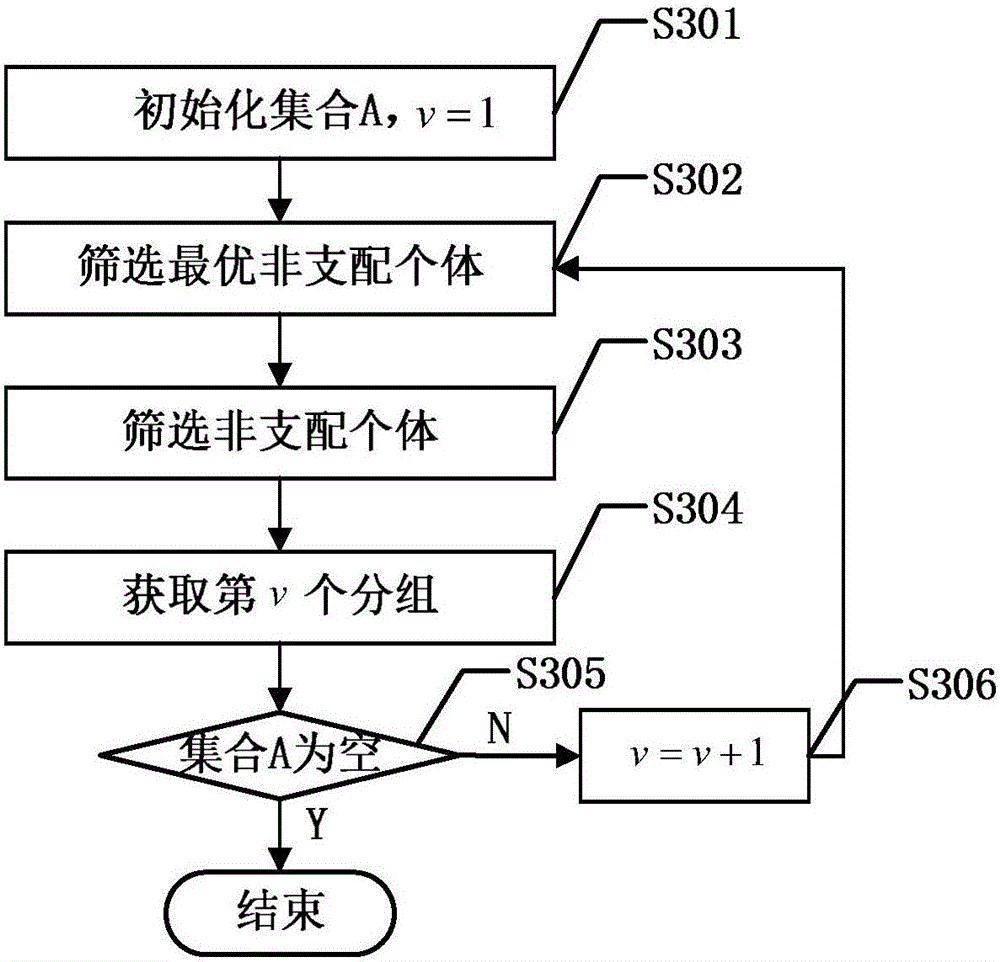

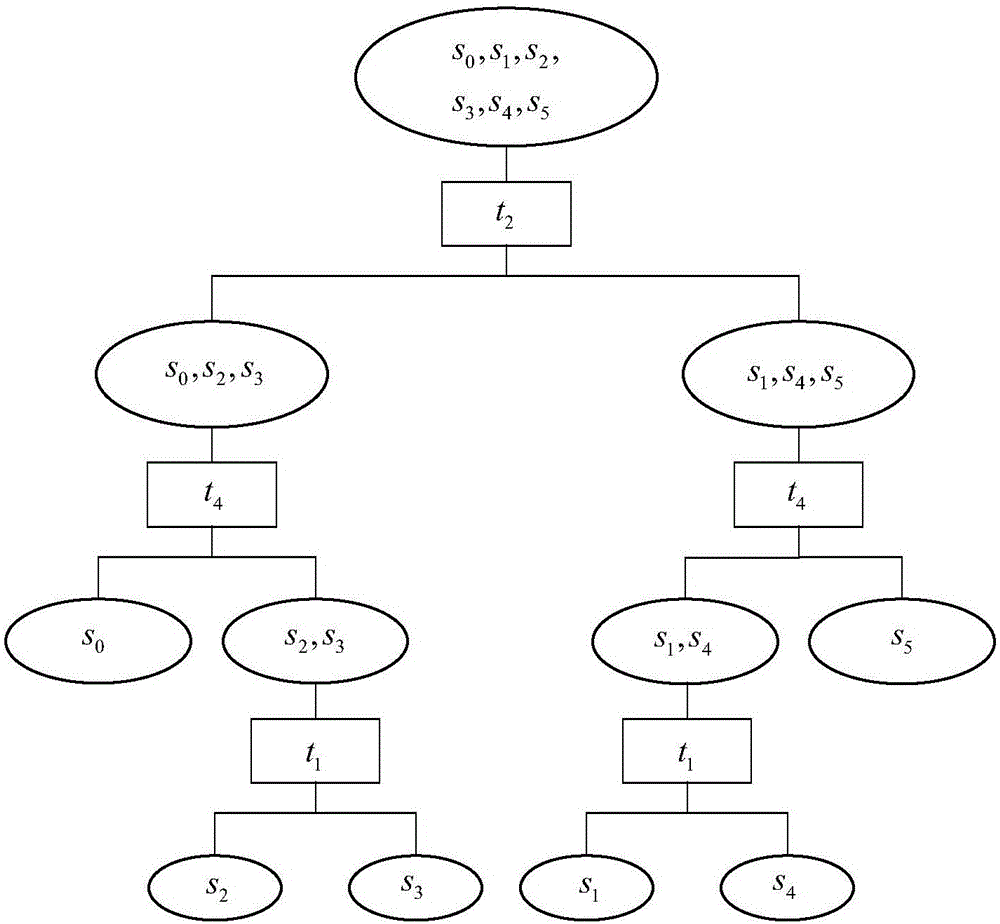

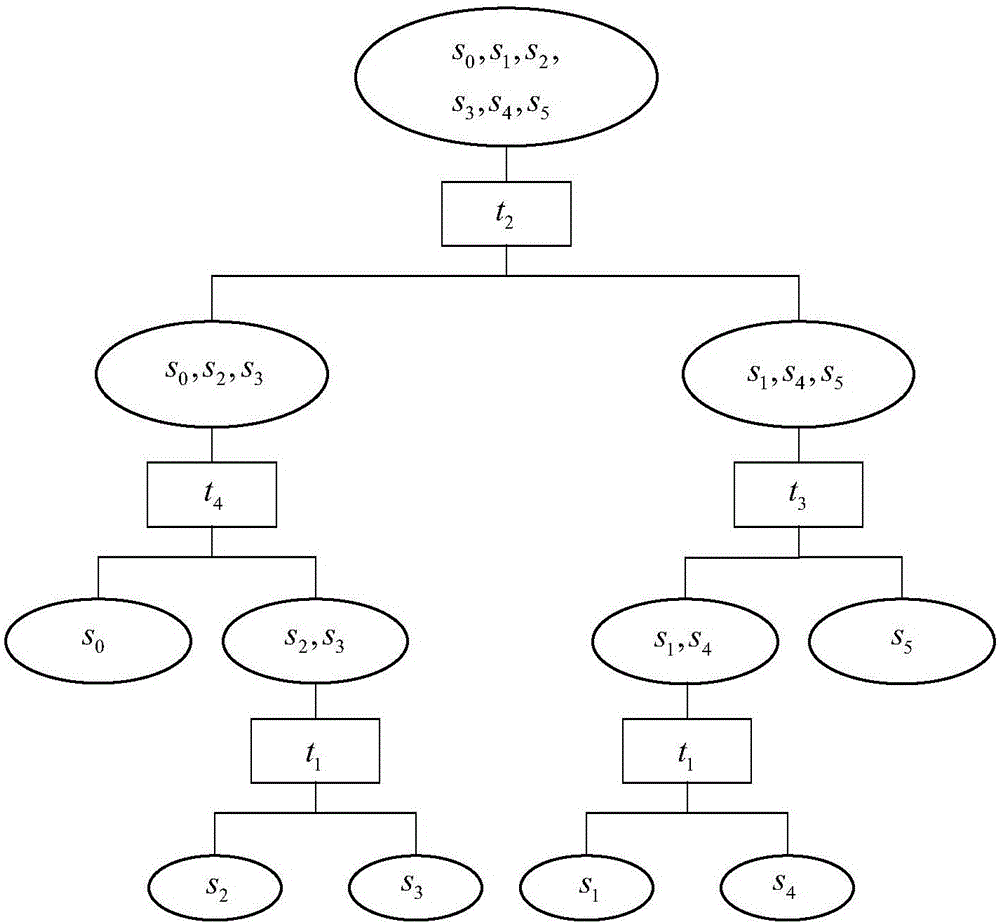

Sequential test optimization method based on multi-objective genetic programming algorithm

InactiveCN106682448AGenetic modelsSpecial data processing applicationsSystem testingCrowding distance

The invention discloses a sequential test optimization method based on a multi-objective genetic programming algorithm. The method comprises the steps of firstly initializing to obtain a fault diagnostic tree population, using the multi-objective genetic programming method to select, cross and mutate a fault diagnostic tree, during the iteration of each generation, grouping the fault diagnosis tree individuals, wherein, the adaptability of each individual is calculated by using grouping adaptability and a crowding distance; after multiple iterations, selecting non-domination individuals from a final generation population as a non-domination fault diagnosis tree of the sequential test of the system. The sequential test optimization method based on the multi-objective genetic programming algorithm can be used for acquiring a Pareto optimum solution of the fault diagnosis tree of the sequential test for which multiple test indexes can be used as optimized targets, the optimum solutions can be selected by testers to provide guidance for system testers.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

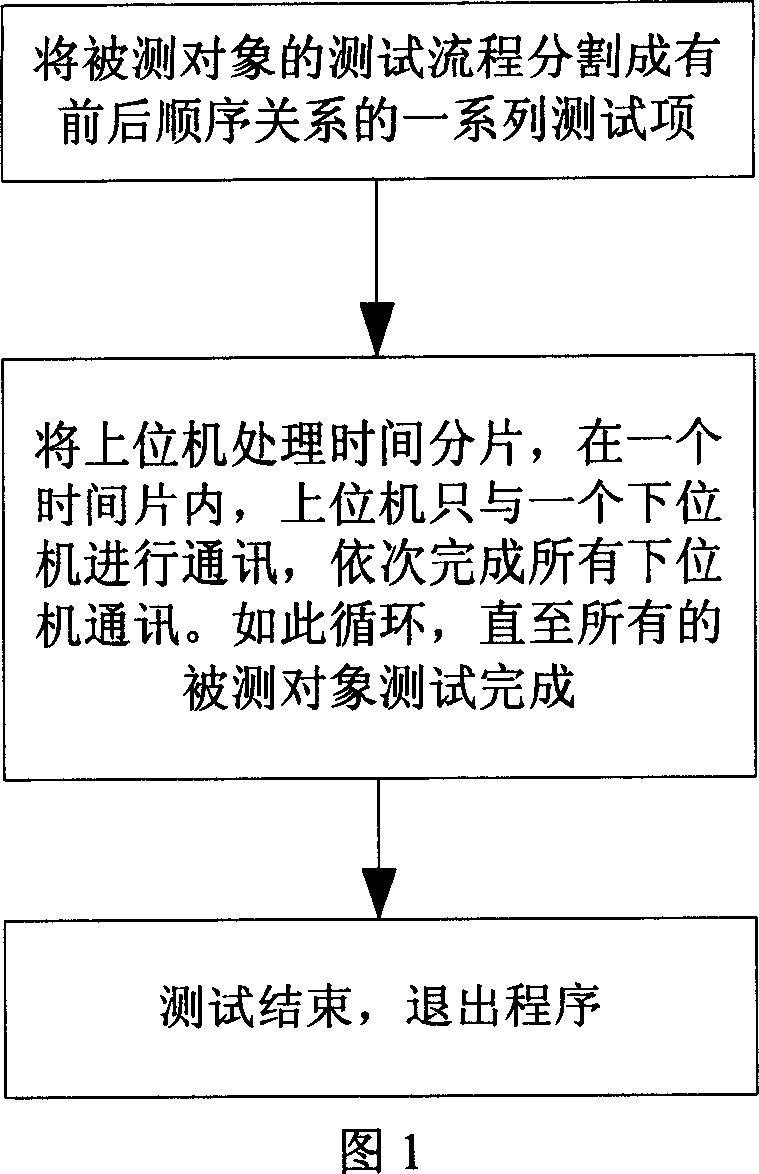

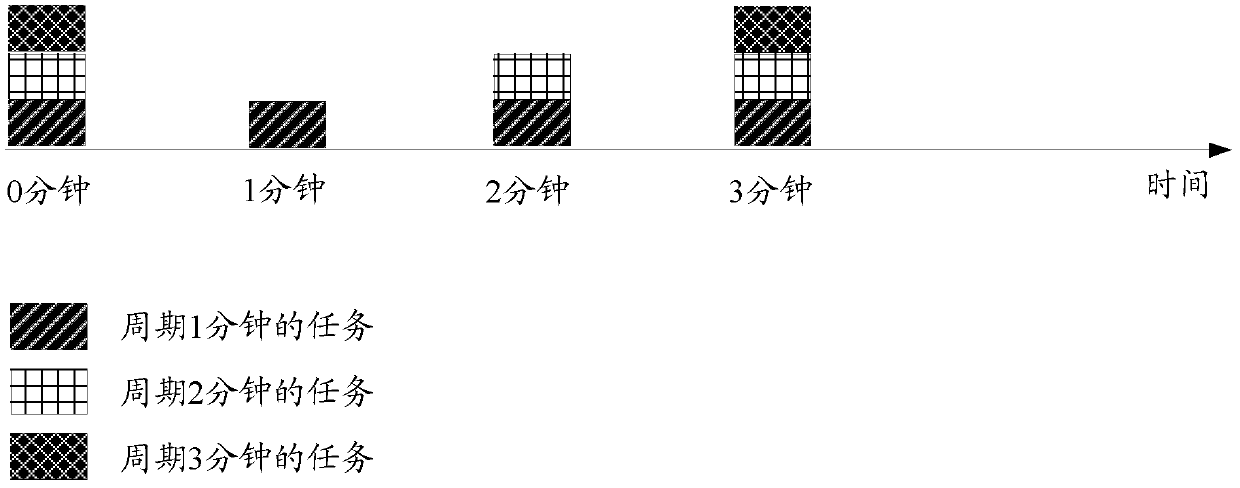

Time sharing test approach for tester

ActiveCN101098359AImprove test efficiencyLow costError detection/correctionSupervisory/monitoring/testing arrangementsTest efficiencySoftware engineering

The invention discloses a time-sharing test method used in tester, comprising that according to the test character and method of tested object, dividing the test process of the tested object into independent sequential test items, dividing the software processing time of superior machine, in single time sheet, the superior machine only communicates with one inferior machine, to complete all inferior machine communications, circulating until all tested objects are tested, the superior machine software inquires the completion of all tested objects, ending the test and receding the test program. The inventive method via time-sharing test can fully utilize superior machine, to interact with a plurality of inferior machines, and complete multiple tests, to improve test efficiency, compared with traditional tester which tests object one by one. The time-sharing test can fully utilize the resource of tester and reduce tester cost.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER

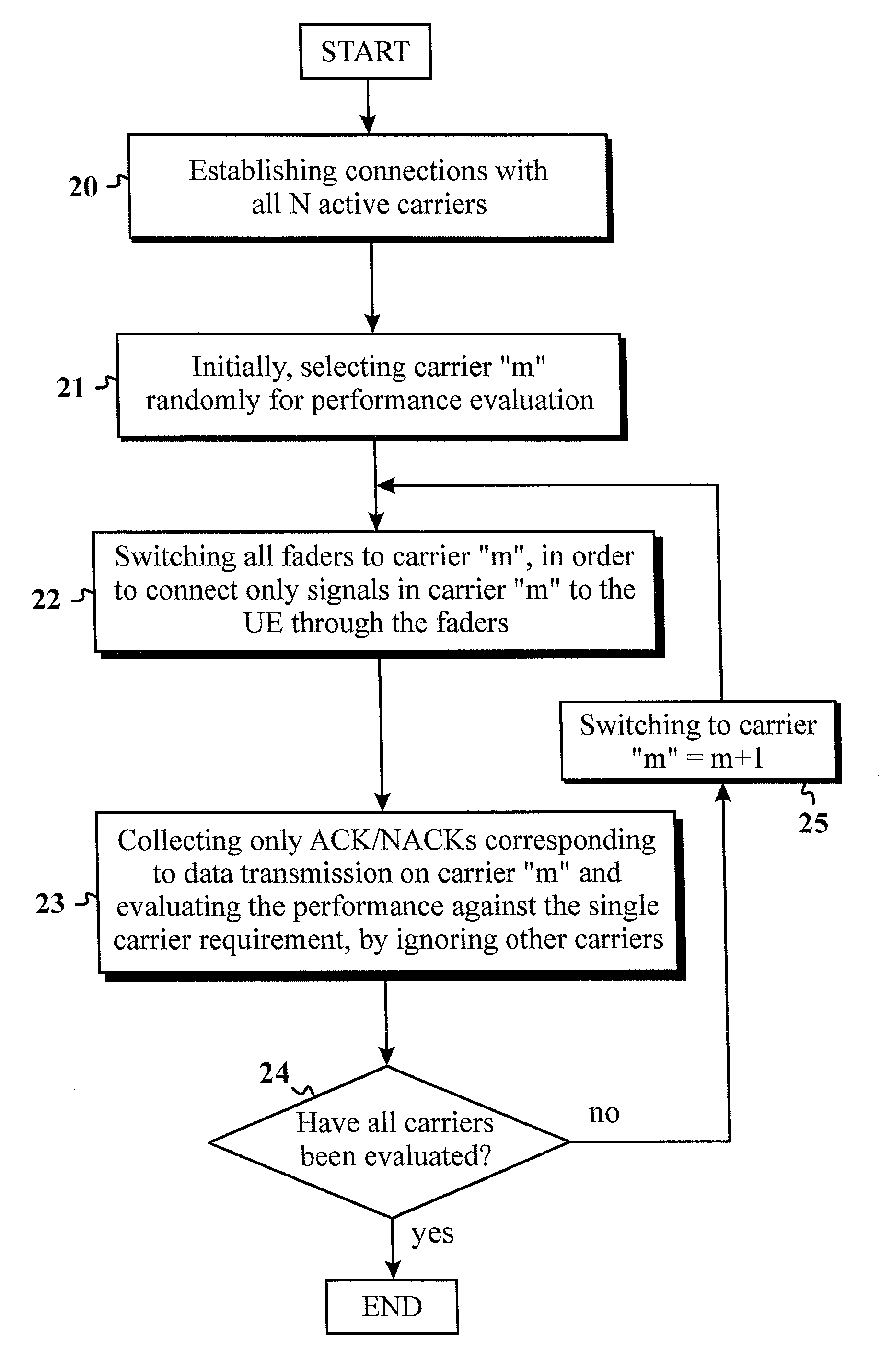

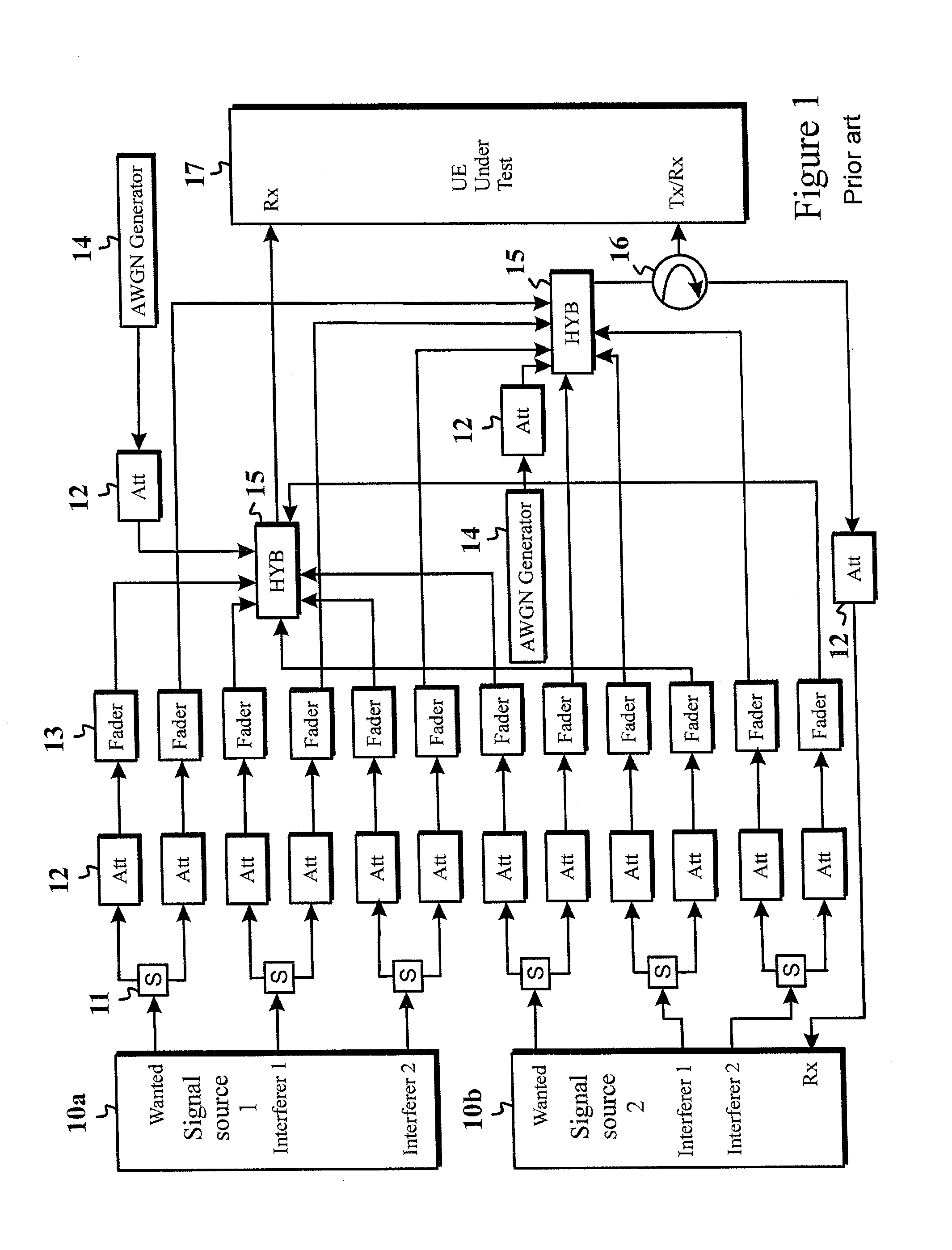

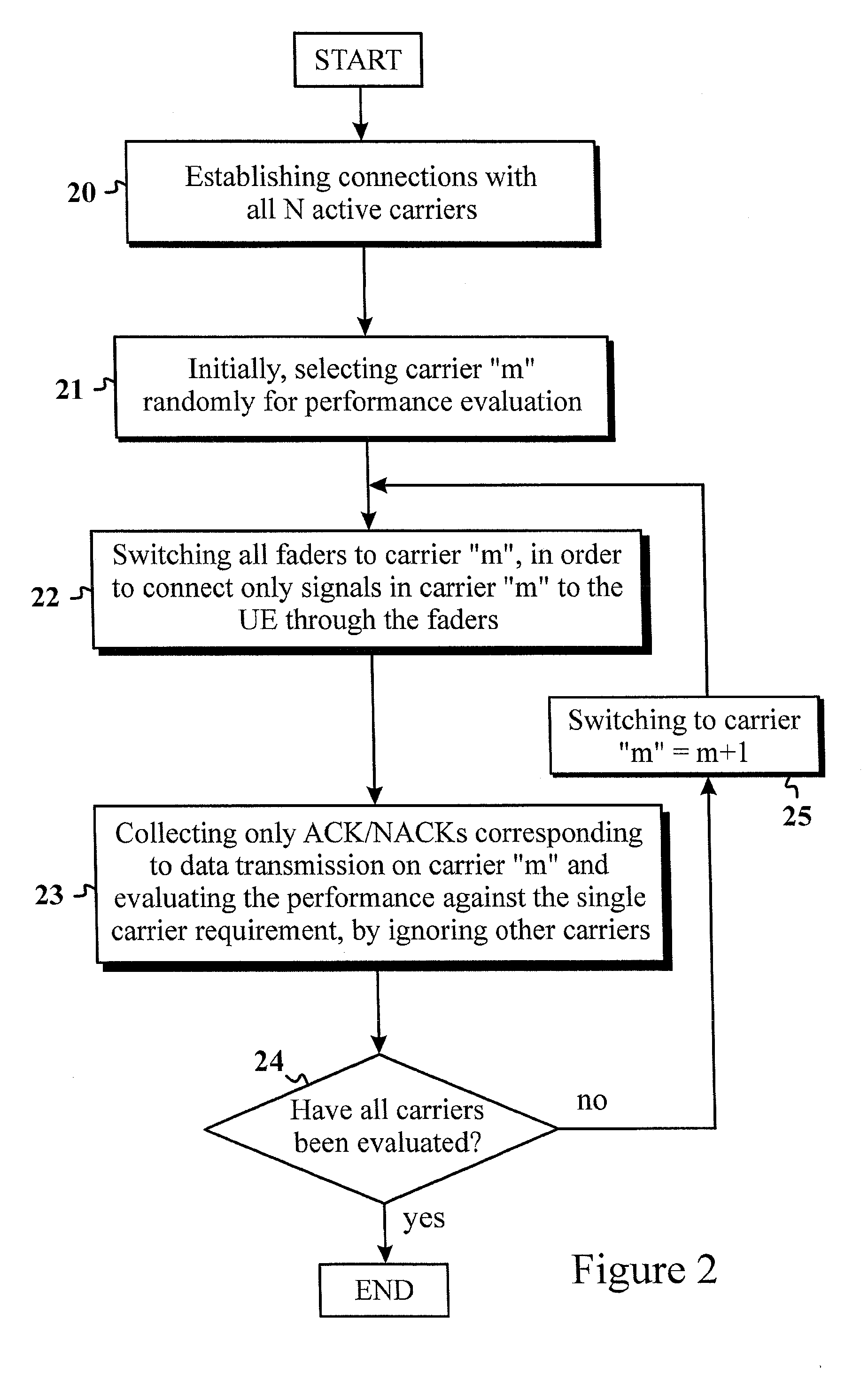

Test Method for Type 3I Receiver in Multicarrier Configuration

The present invention discloses a test method and a testing apparatus for type 3i receivers which use multicarrier operation in HSDPA. The method sequentially tests each carrier, one at a time. Applying multi-switches, channel emulators and efficient wirings, performance tests can be performed without any need for changing the User Equipment to be tested. In case a single carrier test is passed, the next carrier is selected for the test. All carriers are thus tested sequentially against a single carrier throughput requirement until all carriers have been processed.

Owner:AVAGO TECH INT SALES PTE LTD

Method and controller for an electric motor with switch testing

ActiveUS9291678B2Avoid damageDC motor speed/torque controlShort-circuit testingEngineeringBiological activation

Owner:DEERE & CO

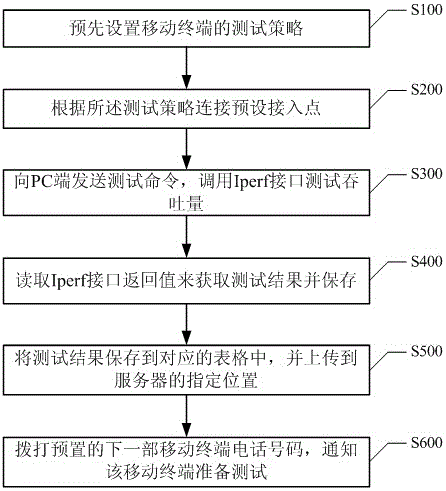

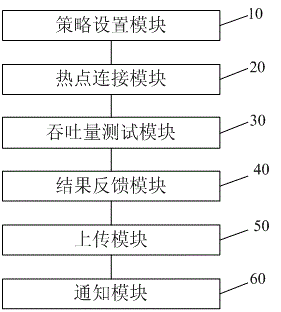

Method and system for testing throughput of mobile terminal

The invention discloses a method and a system for testing throughput of a mobile terminal. The method comprises the following steps: presetting a testing strategy of the mobile terminal; linking a preset access point according to the testing strategy; sending a test command to a PC terminal, and invoking an Iperf interface to test the throughput; and reading a returned value of the Iperf interface, so as to acquire a test result, and storing. In a test process, a corresponding automatic adjustment strategy is set according to preset test conditions by the mobile terminal without being manually executed, and when a corresponding condition is reached, the testing strategy is automatically adjusted through the communication of the mobile terminal and the PC terminal, so that the automatic and sequential testing of multiple mobile terminals can be realized; and after each test item is finished, corresponding results are stored for being viewed and analyzed by testers, so that the testing manpower and the testing time are saved, and great convenience is realized.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

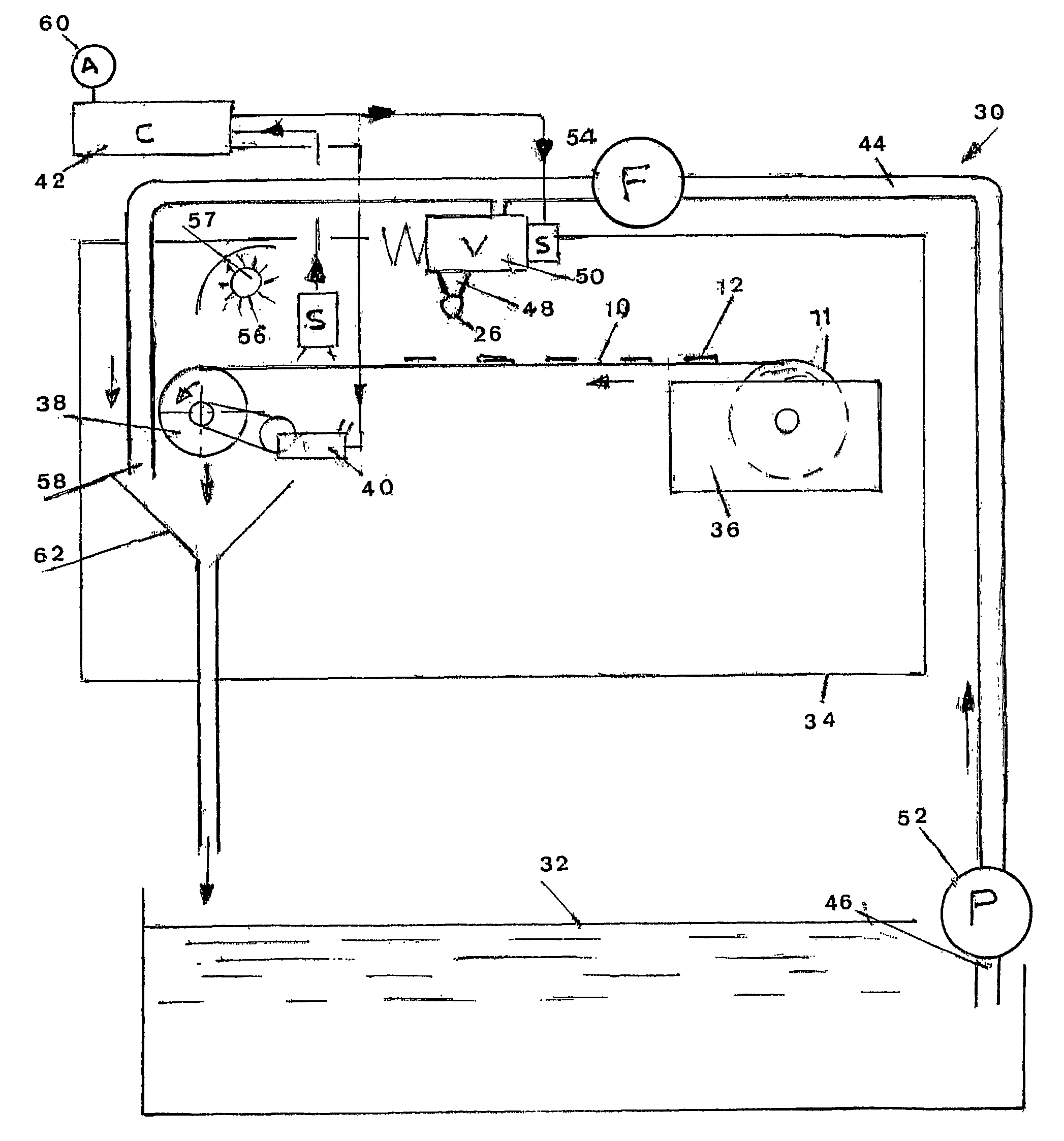

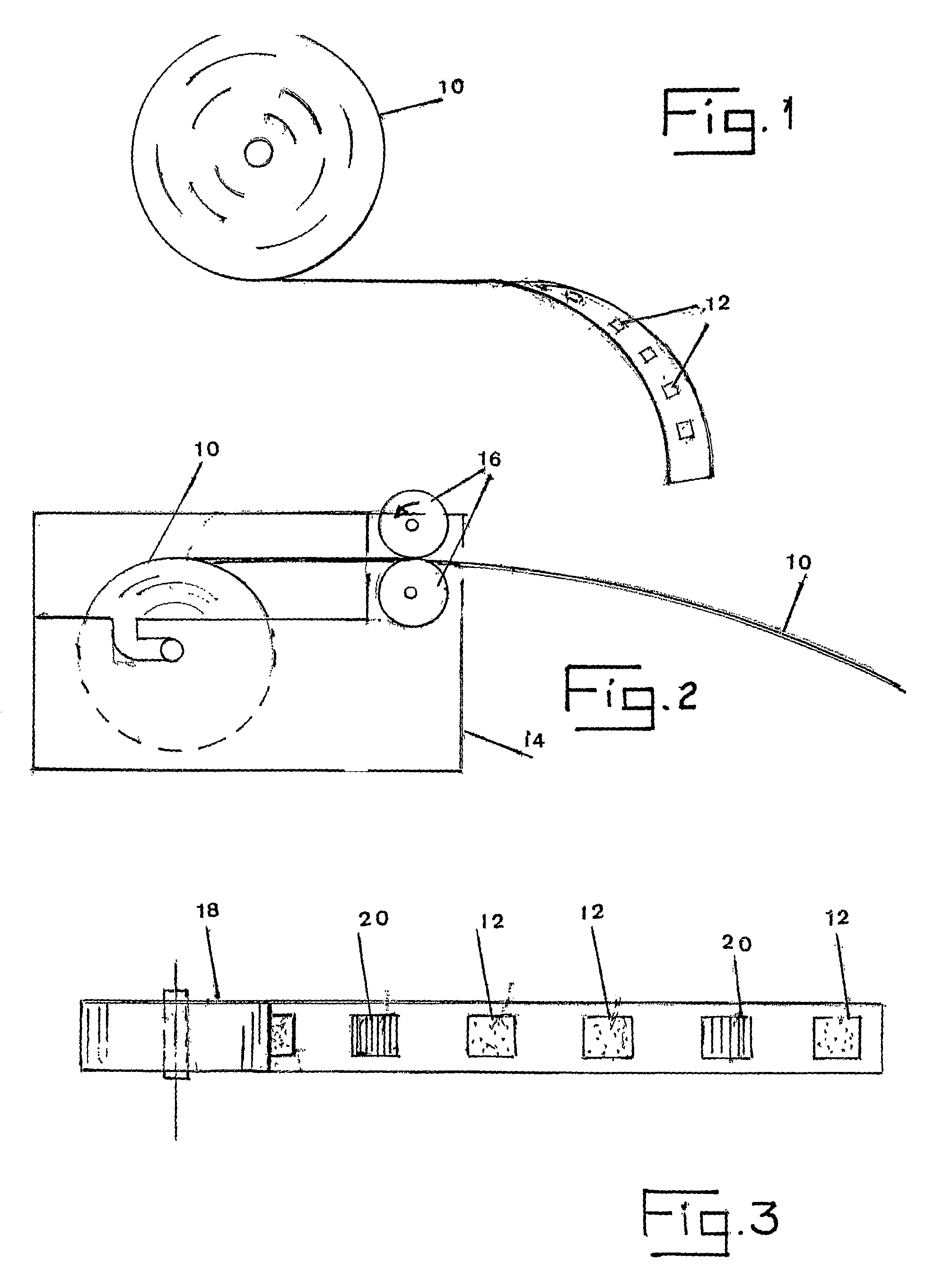

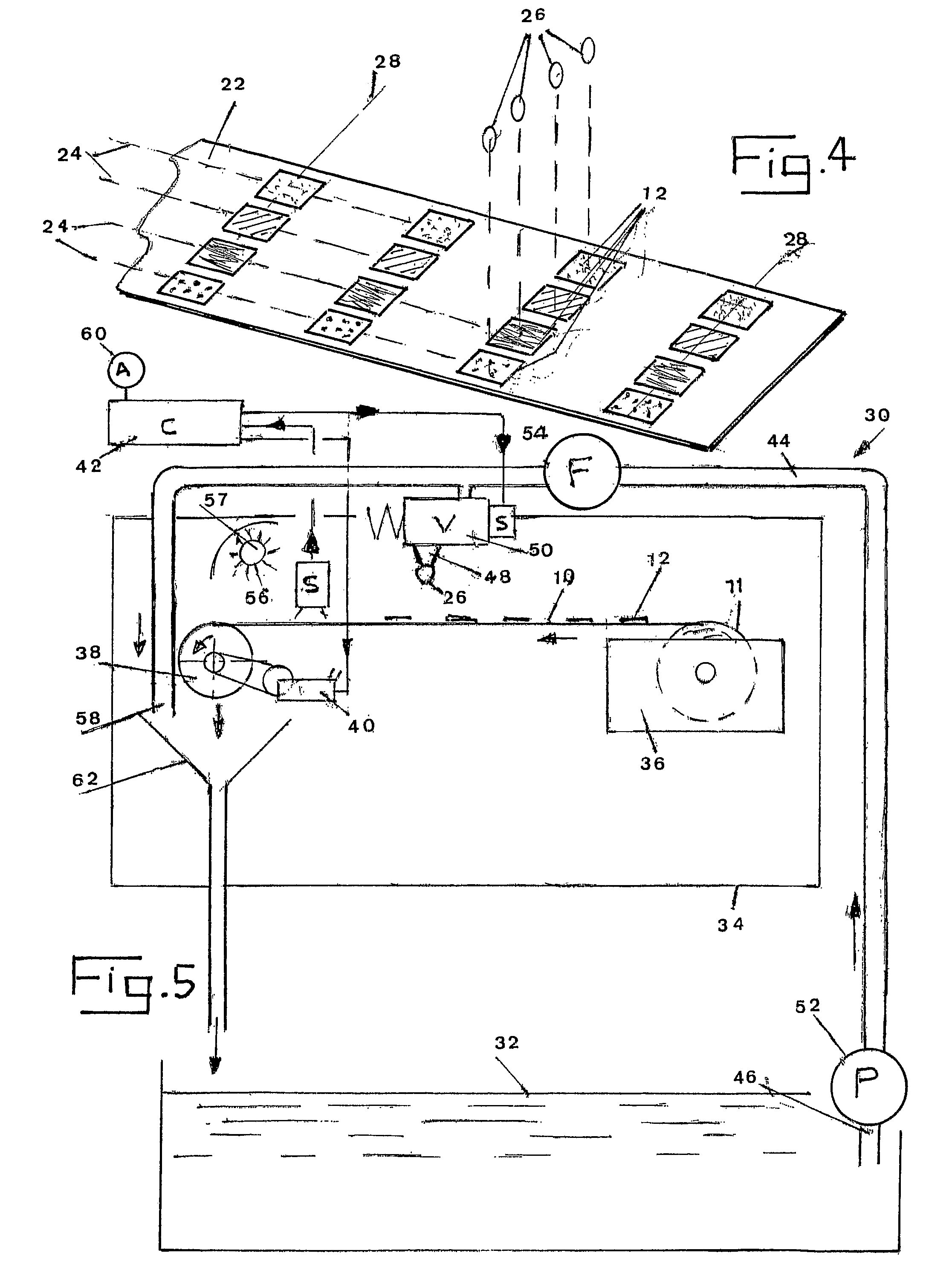

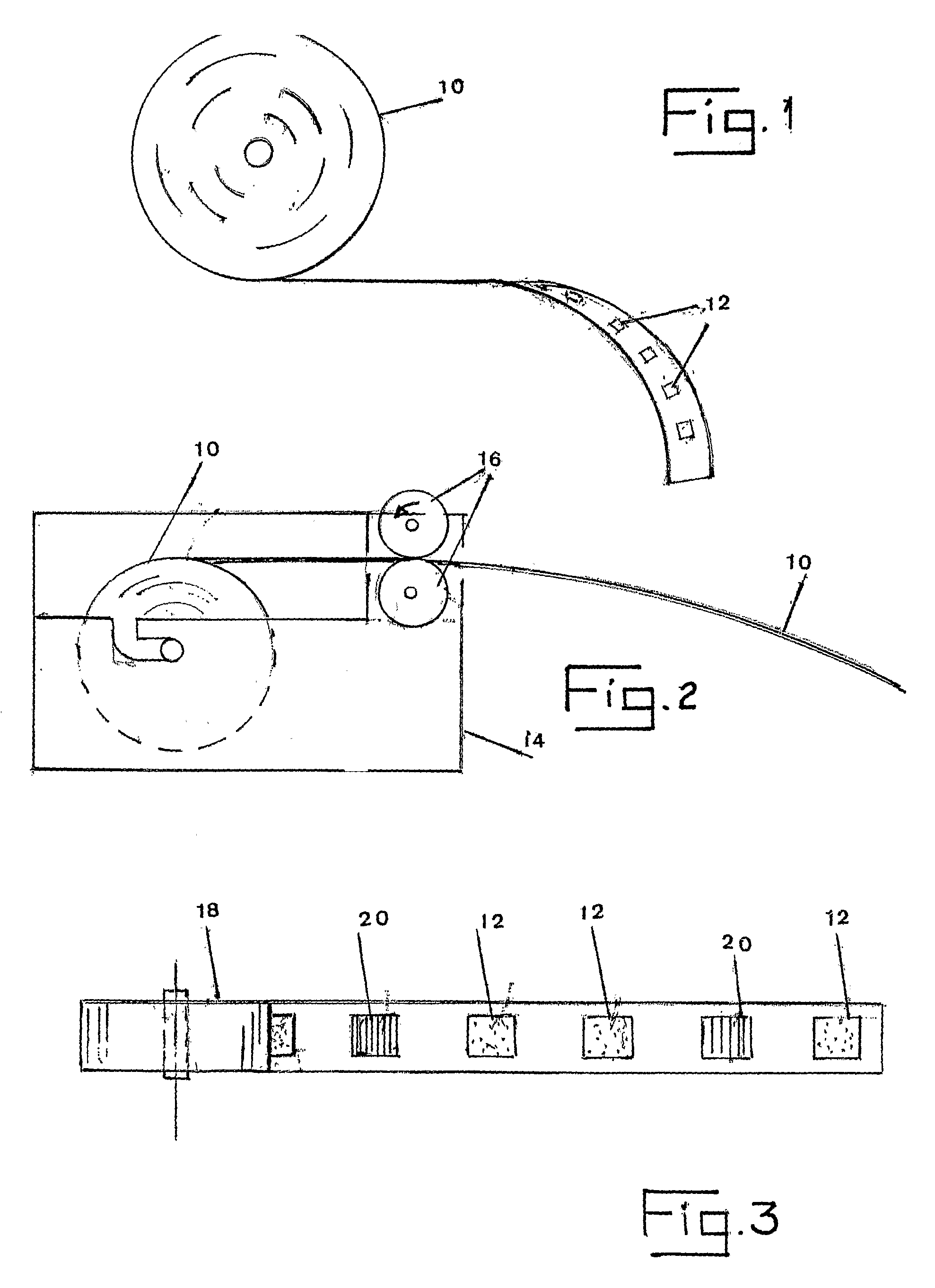

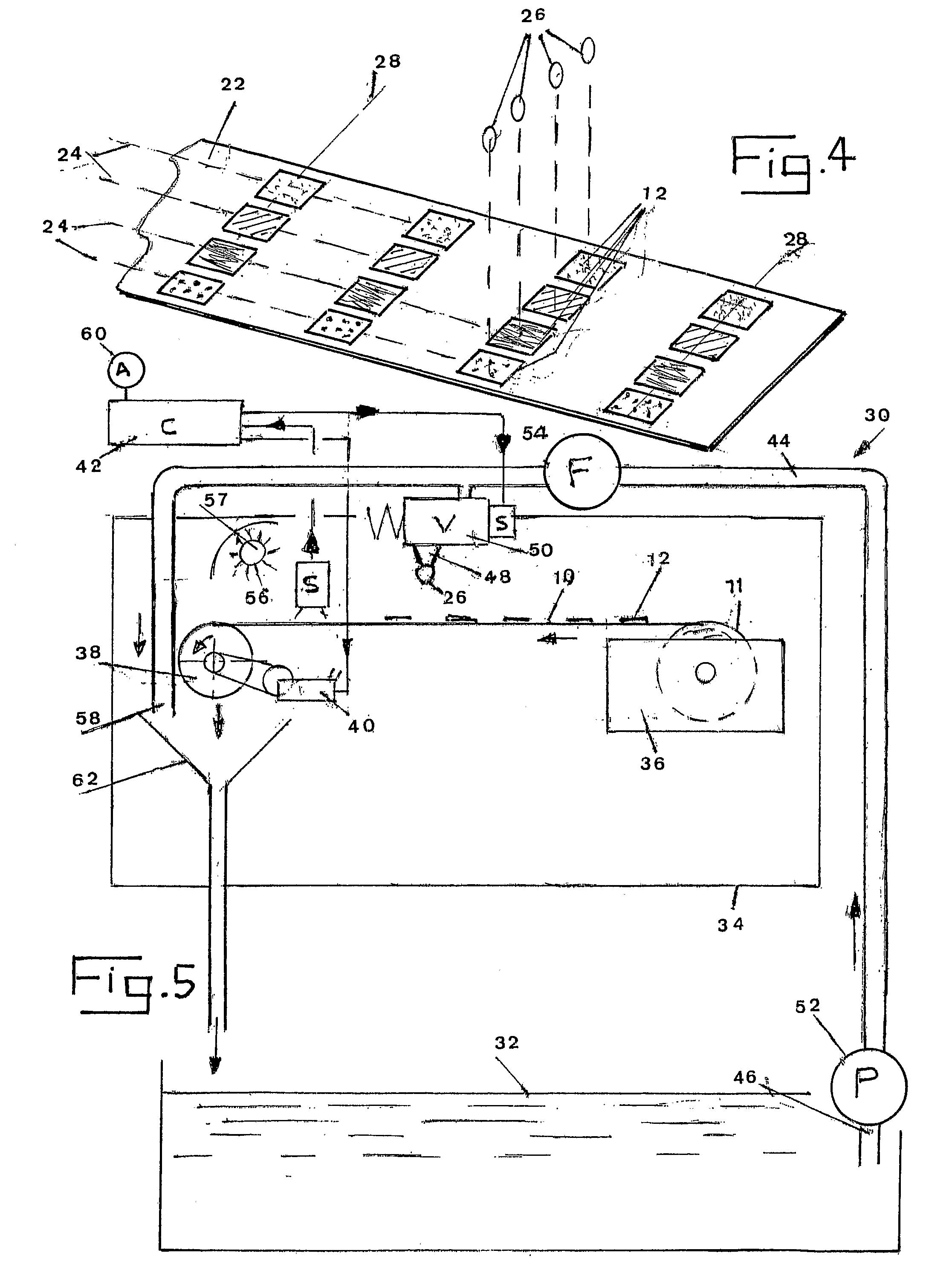

Indicator strip and a device for automatic testing of liquids

ActiveUS8197755B2Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorEngineeringAutomatic testing

A continuous indicator strip having a multiplicity of separate individual sequential test sections along the surface thereof, wherein a plurality of test sections are impregnated with the same indicator enabling the utilization of the strip for sequential repetitive testing of samples, the strip being provided with at least 20 such test sections.

Owner:TSUR BEN DAVID

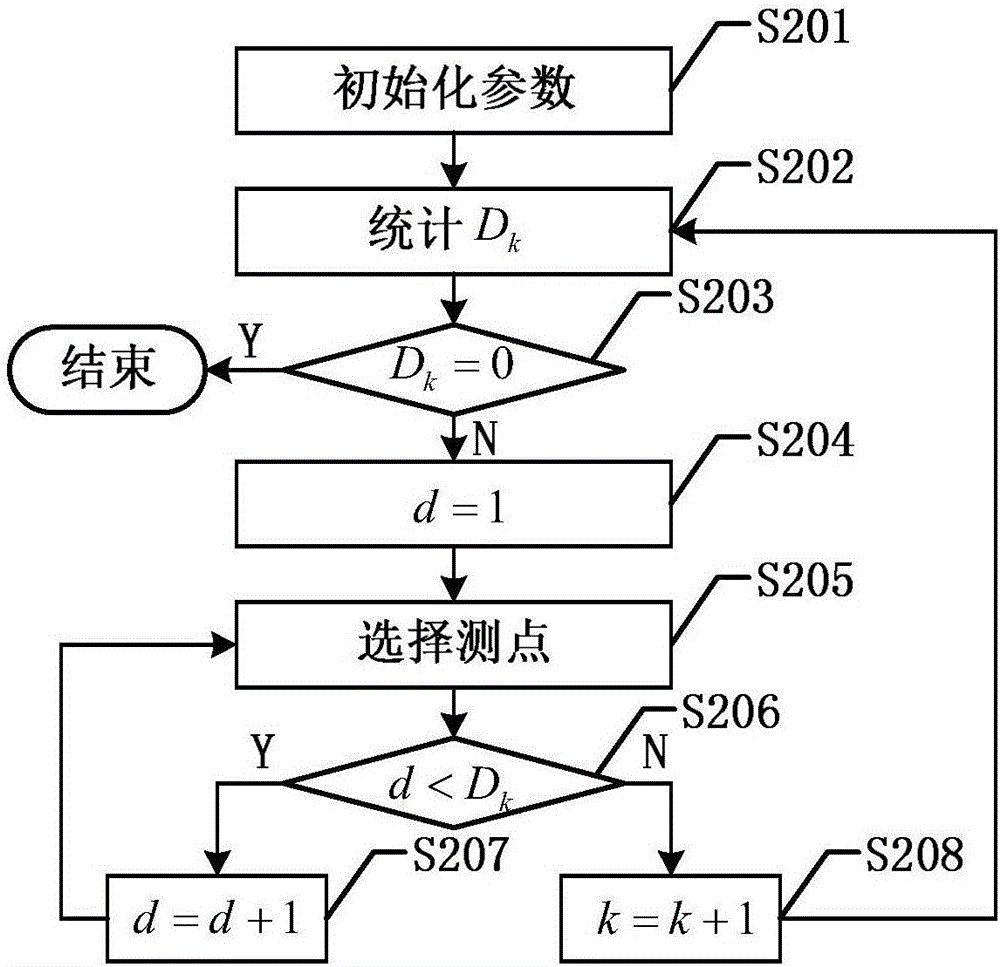

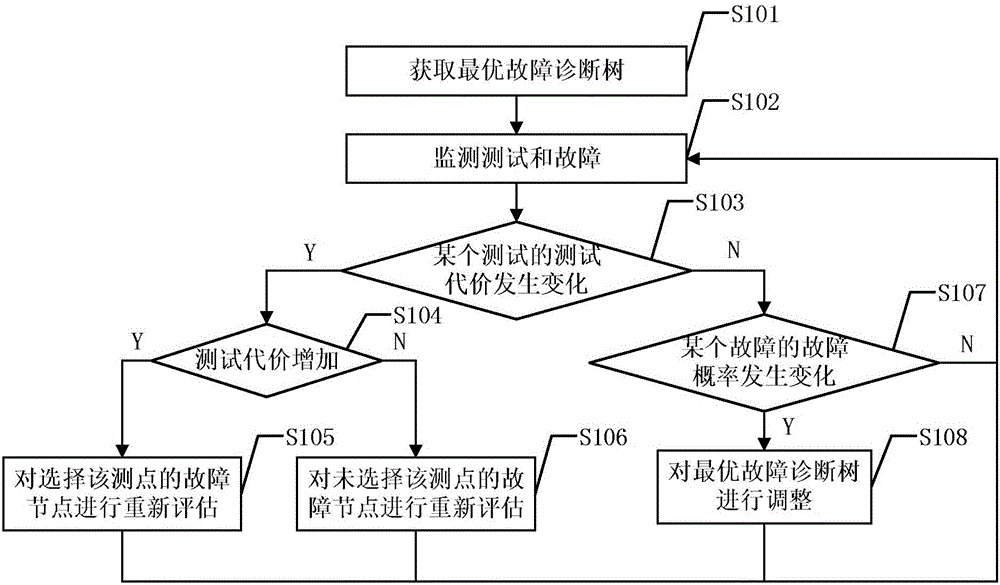

Sequential-test dynamic adjustment method based on AO* algorithm

ActiveCN106095608AAchieving Adaptive Dynamic AdjustmentFault responseDetecting faulty computer hardwareElectronic systemsComputer science

The invention discloses a sequential-test dynamic adjustment method based on the AO* algorithm. The sequential-test dynamic adjustment method includes the steps that an optimal fault diagnosis tree of an electronic system is obtained through the AO* algorithm; then the testing cost of a test and the probability dynamic condition of a fault are monitored, and when the testing cost of the test is increased, a fault node selecting a test point is reevaluated; when the testing cost of the test is reduced, a fault node which does not select the test point is reevaluated, and the optimal fault diagnosis tree is adjusted; when the probability of the fault is changed, the optimal fault diagnosis tree is adjusted. According to changes of the testing cost and changes of the fault probability in the electronic system, the present optimal fault diagnosis tree is correspondingly adjusted, the new optimal fault diagnosis tree is rapidly obtained, and adaptive dynamic adjustment of the sequential test is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Mild detonation fuse separation device design verification test method

ActiveCN105571632AThe influence of boundary effects is smallThe condition of the test piece is reasonableMachine part testingHigh temperature storageDetonation

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Website service quality testing method and device

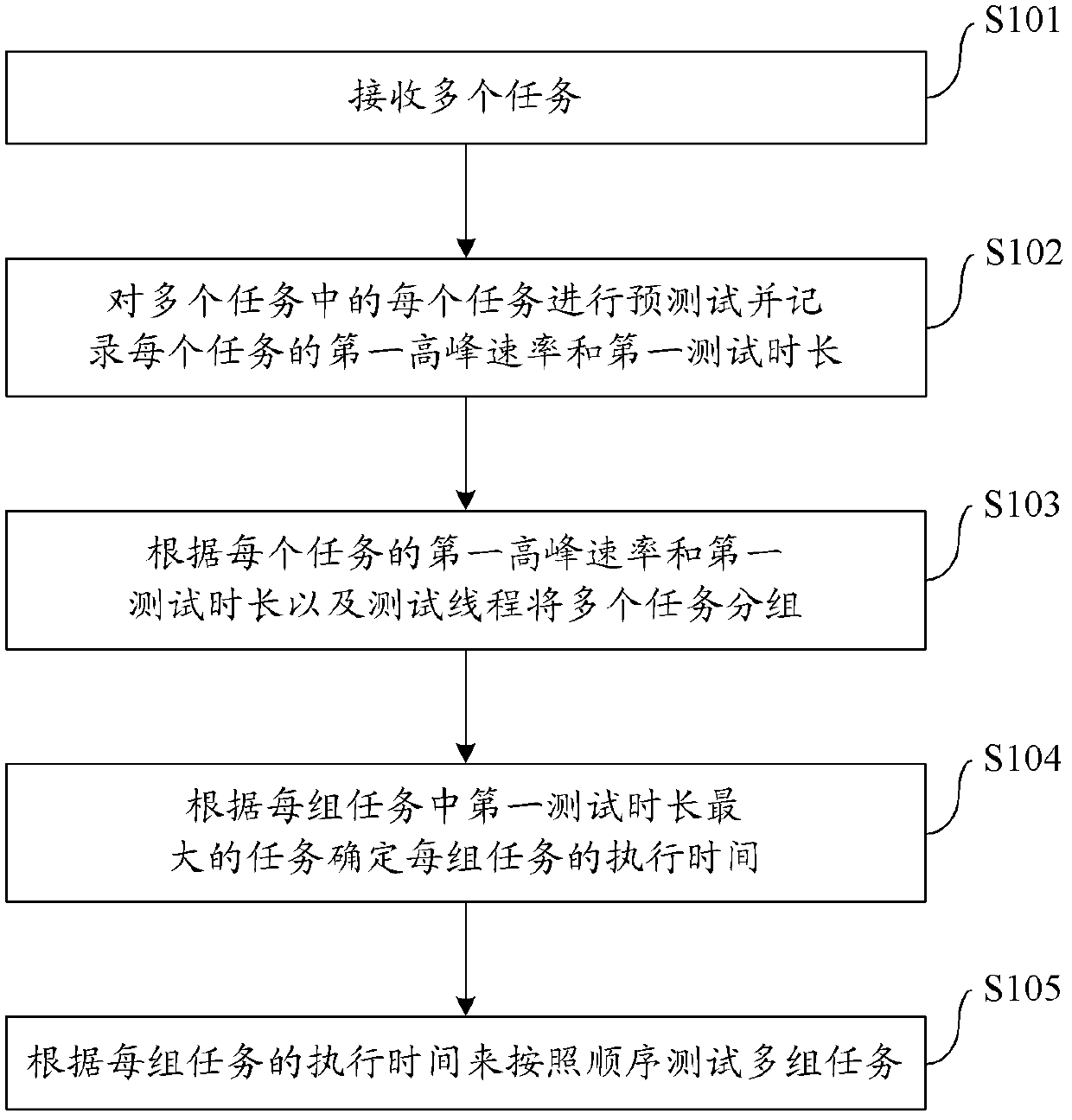

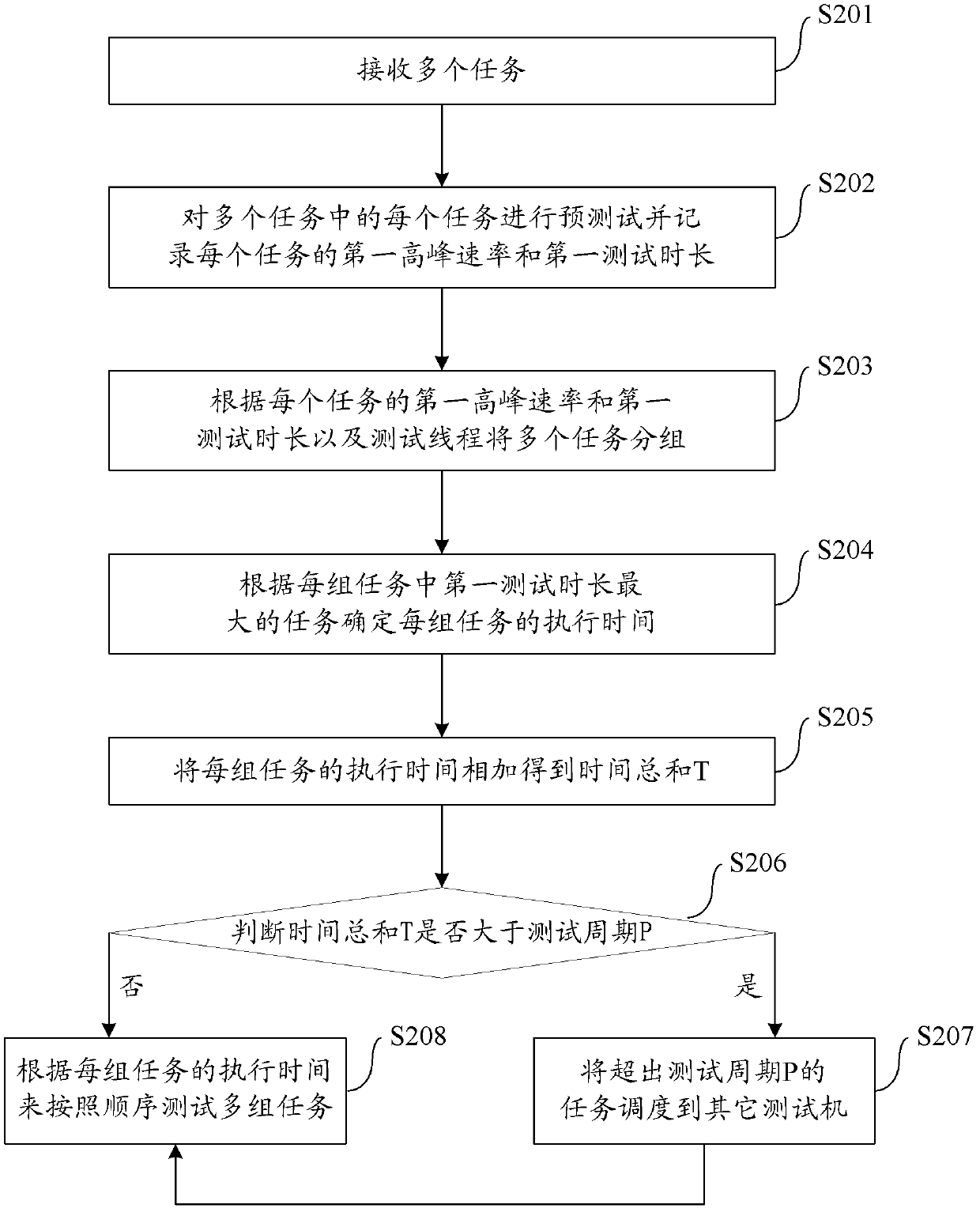

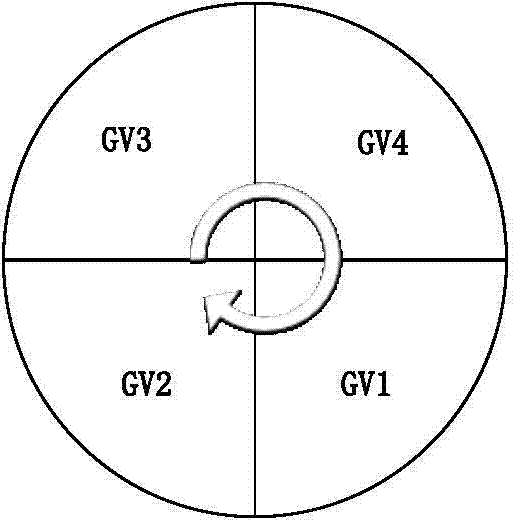

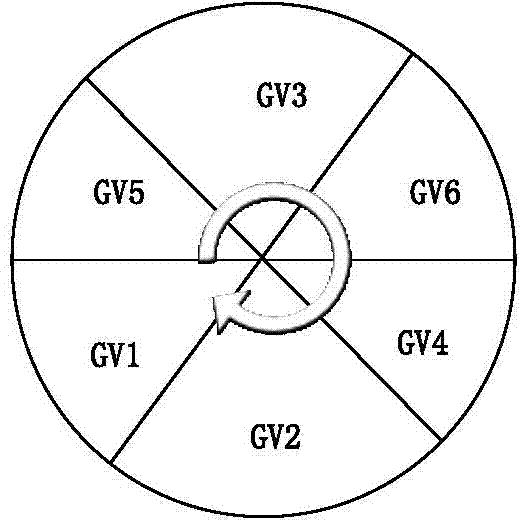

The invention provides a website service quality testing method and a device. The method comprises the following steps: receiving a plurality of tasks; pretesting each task in the plurality of tasks, and recording the first peak rate and first testing duration of each task; grouping the plurality of tasks according to the first peak rate and the first testing duration of each task and a testing thread; determining the implementing time of each group of tasks according to a task of which the first testing duration is longest in each group of tasks; testing multiple groups of tasks in sequence according to the implementing time of each group of tasks. According to the method in the embodiment of the invention, a detecting machine can be protected from being blocked in a testing process; moreover, a peak bandwidth is not over high, so that more tasks can be borne on the premise of ensuring the quality of a testing result, and more large and small file hybrid tasks can be borne on the other hand; the method is not only suitable for website service quality testing based on an http protocol, but can also be applied to various other similar website service quality testing.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Method for optimizing steam turbine high pressure regulating valve steam inlet sequence testing experiment

ActiveCN104849055ASolve problems with a huge amount of engineering practiceShorten test timeEngine testingControl mannerEngineering

The invention relates a method for testing the high pressure regulating valve steam inlet sequence, and particularly relates to a method for optimizing a steam turbine high pressure regulating valve steam inlet sequence testing experiment. The invention aims to solve a problem that a traditional high pressure regulating valve steam inlet sequence testing experiment method is too long in experimental time. According the test scheme which is designed and optimized according to nozzle set arrangement information of different numbers of high pressure regulating valves, repetitive steps in a traditional testing process are optimized and combined, and a process of unnecessary repeated opening or repeated closing existing in multiple groups of experiments is removed; then running parameters and control modes of a unit are regulated so as to meet experimental conditions, and a regulating valve on-off experiment is carried out. The method provided by the invention can effectively shorten the experimental time, and solves the problem that the traditional test method requires a very long time in allusion to a unit experiment. The method is applicable to the test field of steam turbine high pressure regulating valve steam inlet sequence optimization.

Owner:HARBIN INST OF TECH

Downhole, single trip, multi-zone testing system and downhole testing method using such

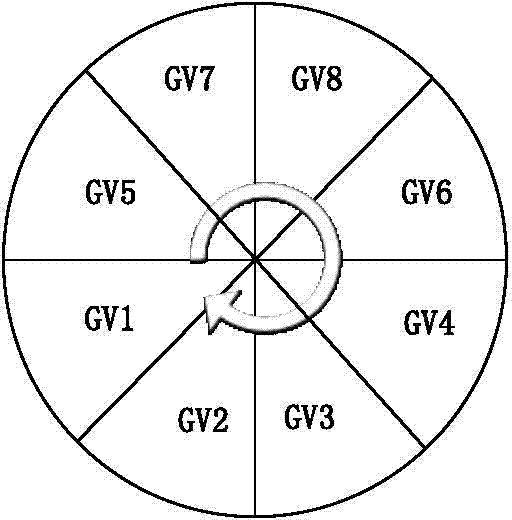

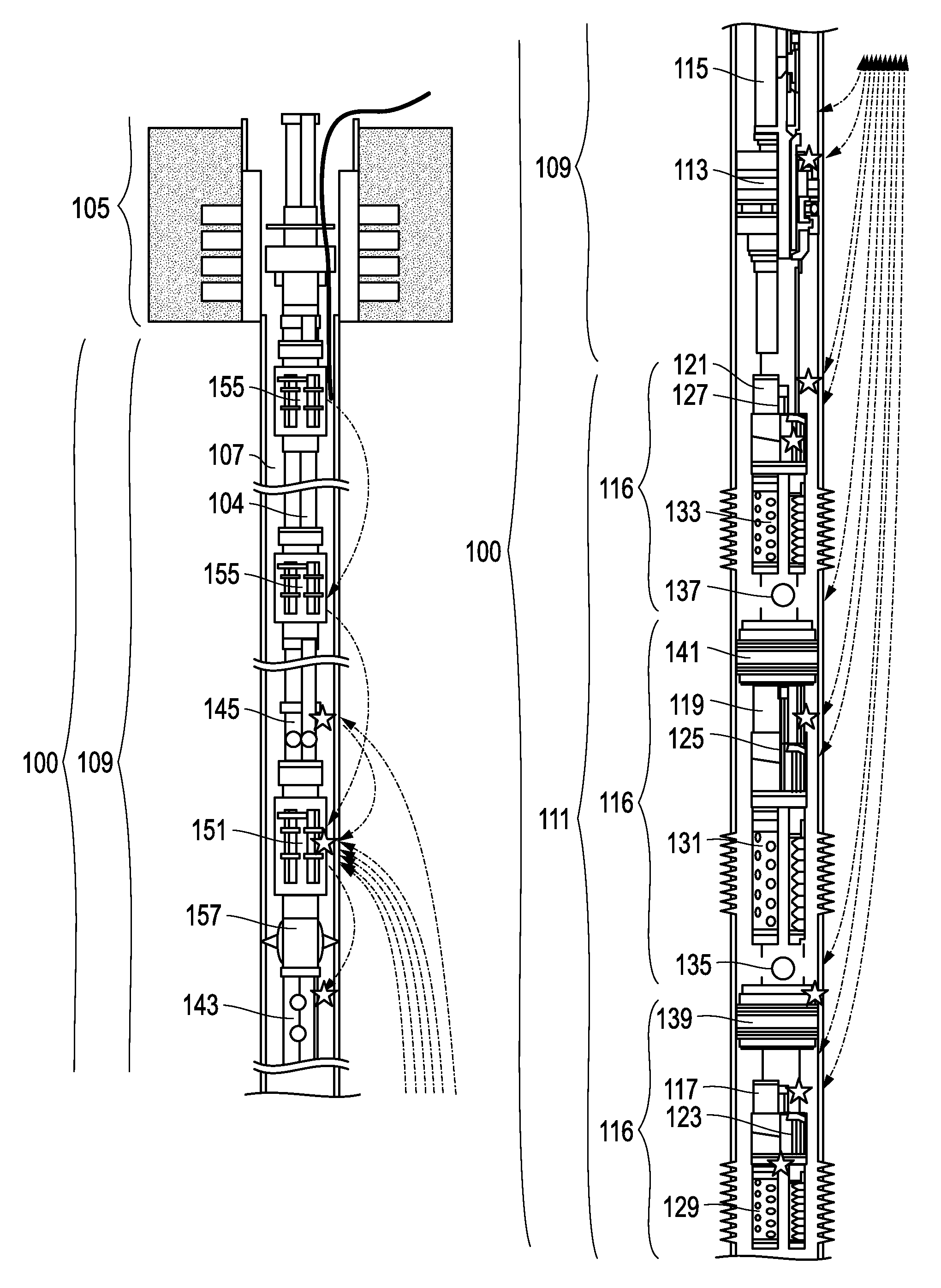

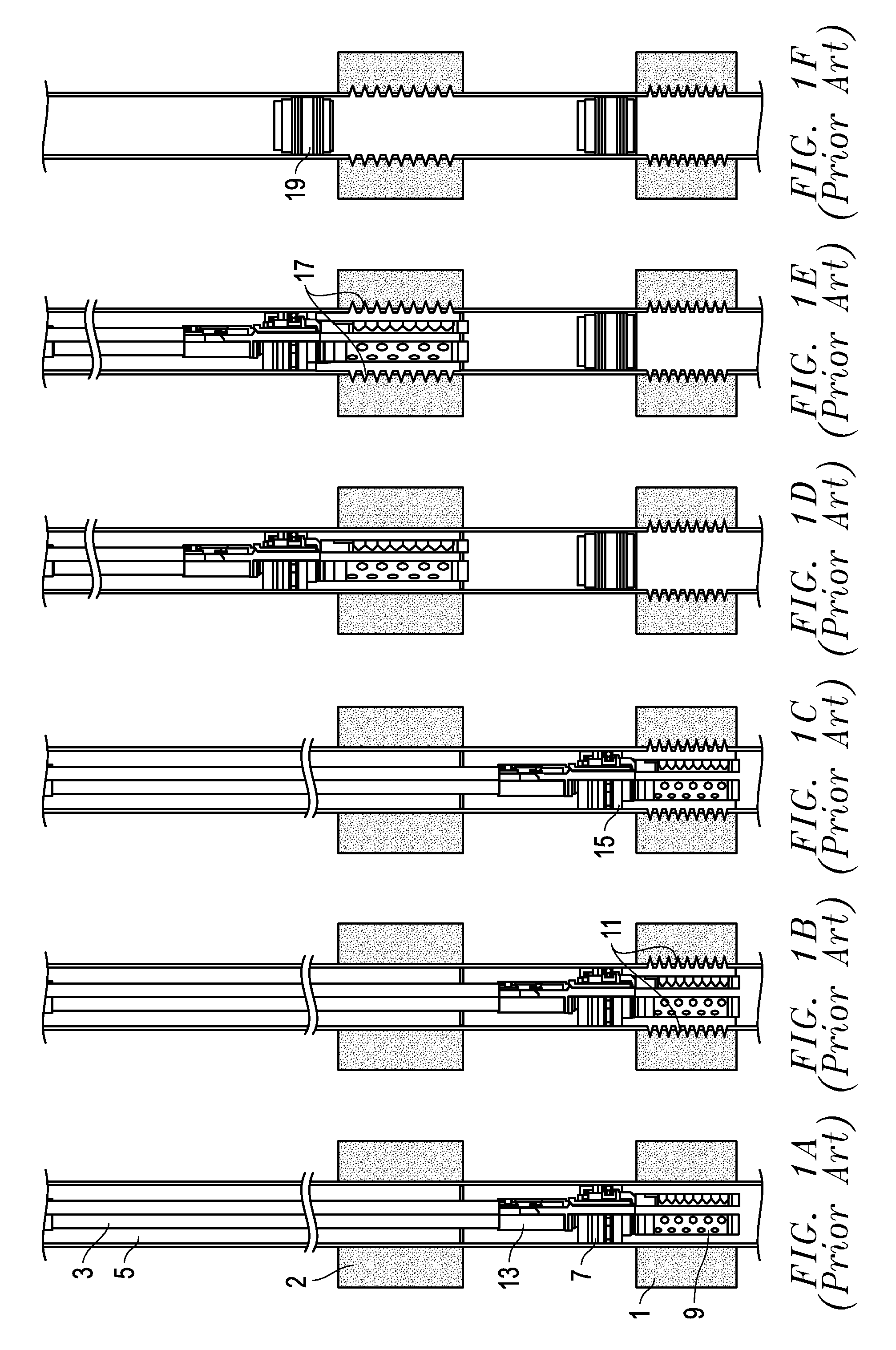

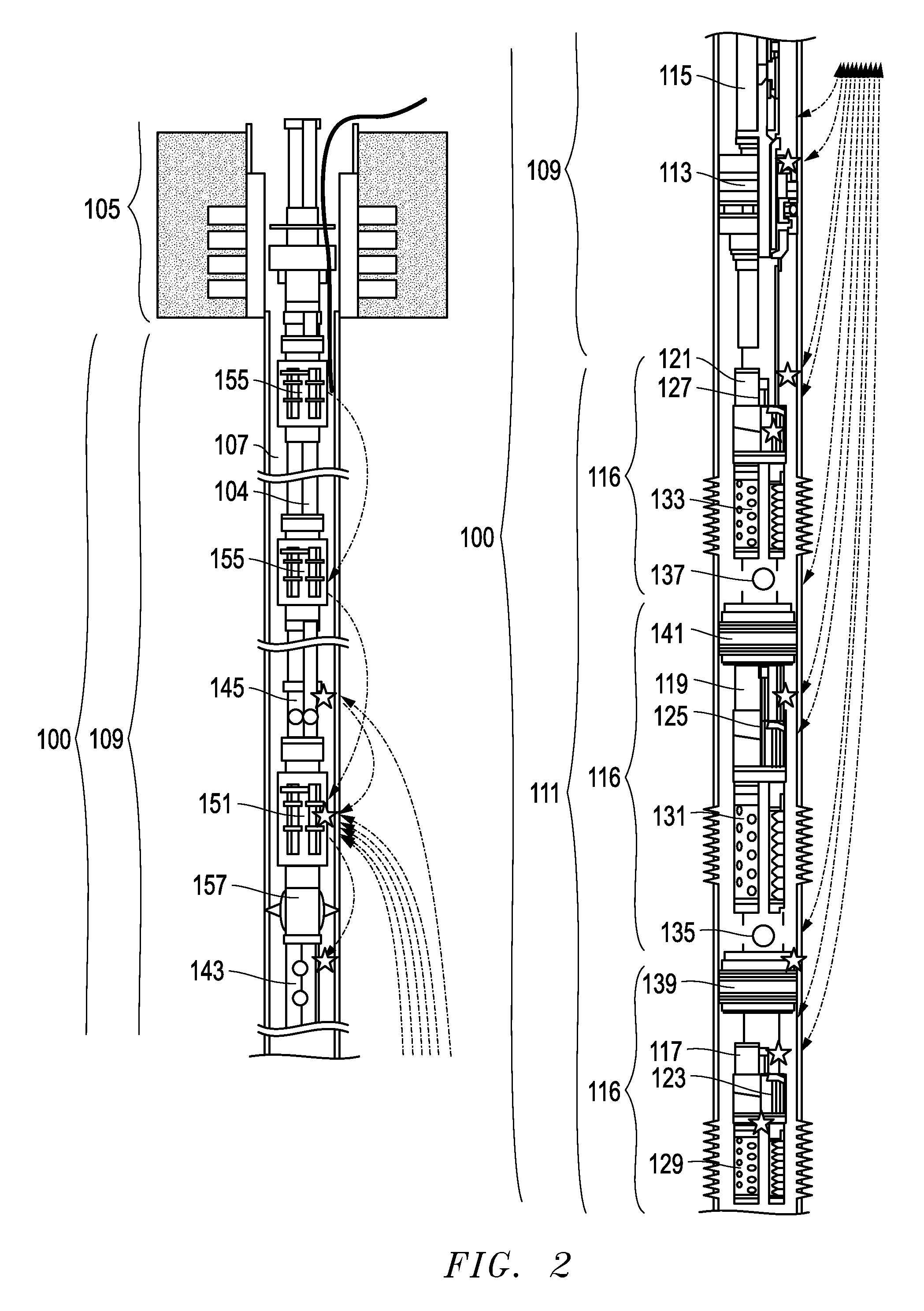

A multizone testing system (100), for the testing of subterranean layers, comprises an upper subsystem (109) comprising a control station (151), a main isolation packer (113) for isolating the upper subsystem (109) from the lower subsystem (111), a lower subsystem (111) comprising an array of individual apparatuses (116) connected in series, each apparatus (116) being adapted for the testing of one layer and comprising a series of remotely activated tools for hydraulically isolating and testing the corresponding layer and a communication system comprises communication means between the control station (151) and the surface and between the control station (151) and each of the individual apparatuses (116) in order to control the remotely activated tools of the individual apparatuses for sequential testing of the layers. A multizone testing method for the testing of a plurality of subterranean layers intersected by a well, using a multizone testing system (100) comprises the steps of running and positioning said system (100) into the well such that each individual apparatus (116) is adjacent to a layer to be tested and controlling the remotely activated tools of the individual apparatuses for a sequential test of the layers.

Owner:SCHLUMBERGER TECH CORP

Indicator Strip and a Device for Automatic Testing of Liquids

ActiveUS20080193331A1Analysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorEngineeringTest fixture

A continuous indicator strip having a multiplicity of separate individual sequential test sections along the surface thereof, wherein a plurality of test sections are impregnated with the same indicator enabling the utilization of the strip for sequential repetitive testing of samples, the strip being provided with at least 20 such test sections.

Owner:TSUR BEN DAVID

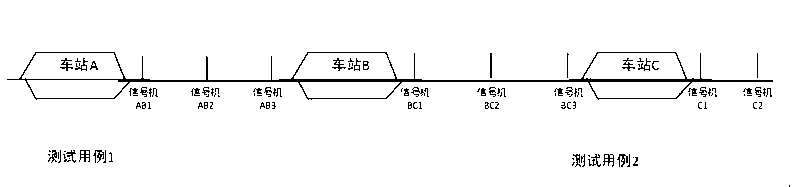

Test script automatic linking method and storage medium

ActiveCN109684223AReduce workloadReduce errorsSoftware testing/debuggingTest scriptSoftware engineering

The invention discloses a test script automatic linking method and a storage medium, and the method comprises the steps: (1), pre-establishing a multi-dimensional state conversion matrix composed of different working states, (2), sequentially searching test scripts for lines which need to be tested according to the spatial sequence relationship of the lines, and obtaining a test script sequence ofthe test scripts with the sequential test sequence; (3) analyzing the working state of each test script, searching a state conversion matrix, obtaining a conversion condition required for convertingthe working state of the previous test script into the working state of the next test script in the test script sequence, and writing the conversion condition into the next test script; And (4) sequentially combining a plurality of test scripts in the test script sequence to form a new complete test script. The test of one line can be automatically carried out, the workload of manual operation isreduced, and the occurrence of errors is reduced.

Owner:HENAN THINKER TRACK TRAFFIC TECH RES INST

Probe apparatus and method for measuring electrical characteristics of chips and storage medium therefor

ActiveUS7719297B2Improve accuracySemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsContact positionBiomedical engineering

A probe apparatus for sequentially testing electrical characteristics of chips includes an imaging unit for capturing images of the electrode pads of the inspection substrate, and a unit for calculating contact positions at which the probes are expected to contact with the electrode pads. The probe apparatus further includes a storage unit for storing correction data in which reference points on a reference substrate are associated with correction amounts corresponding to differences between actual and calculated contact positions of the reference points, and a unit for obtaining actual contact positions for the electrode pads by measuring relative positions of the electrode pads with respect to the reference points and correcting the calculated contact positions of the electrode pads based on the relative positions and the correction data.

Owner:TOKYO ELECTRON LTD

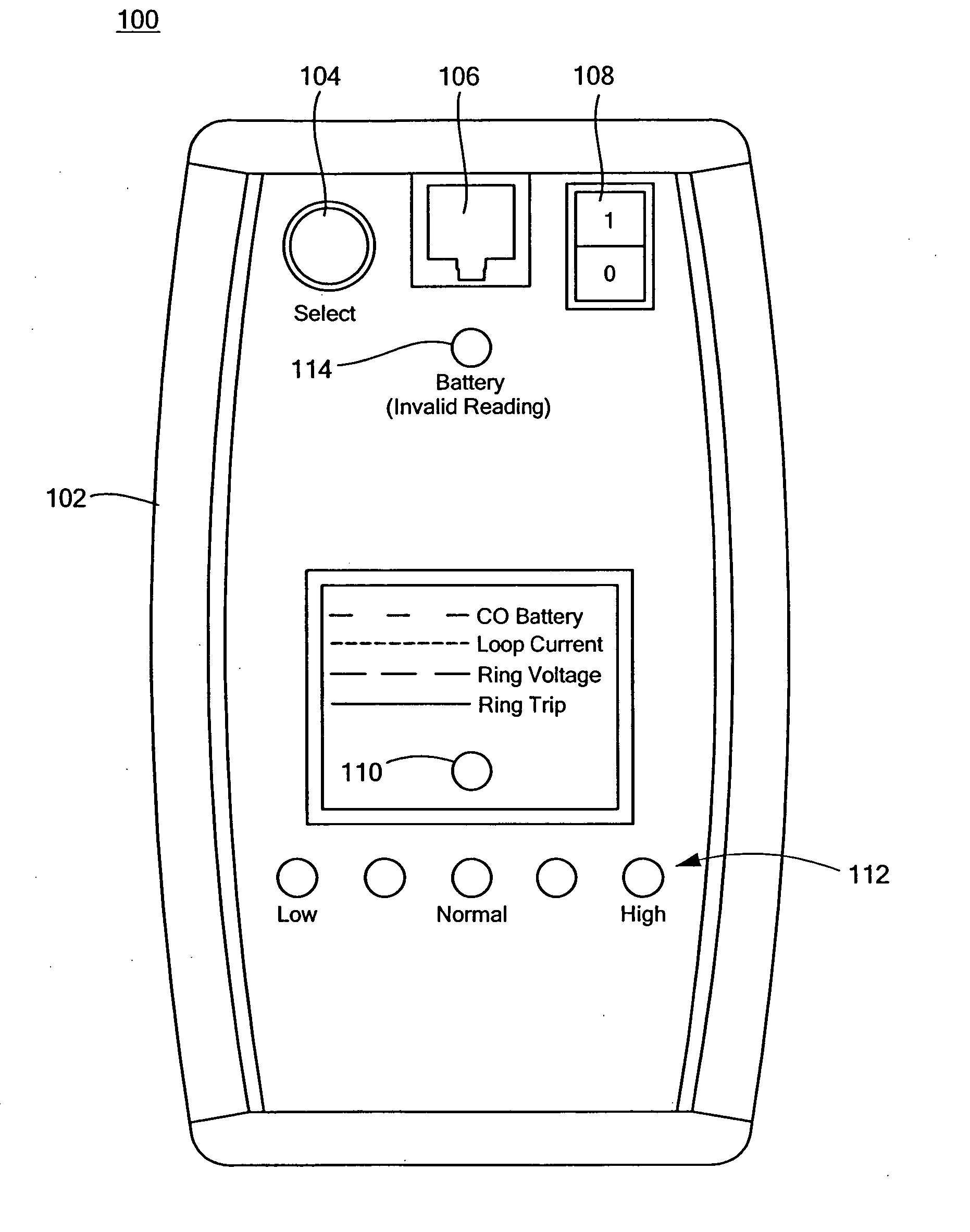

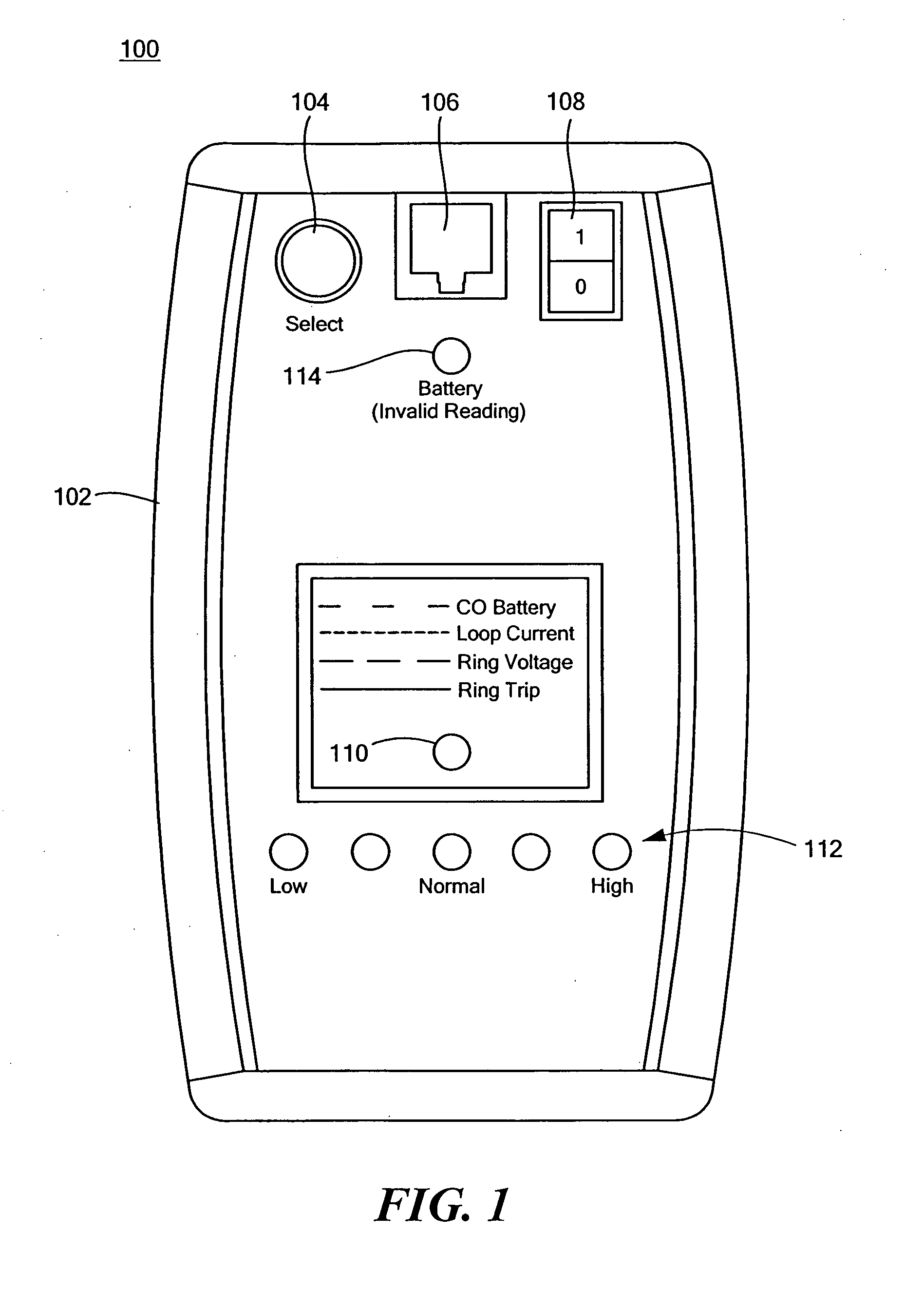

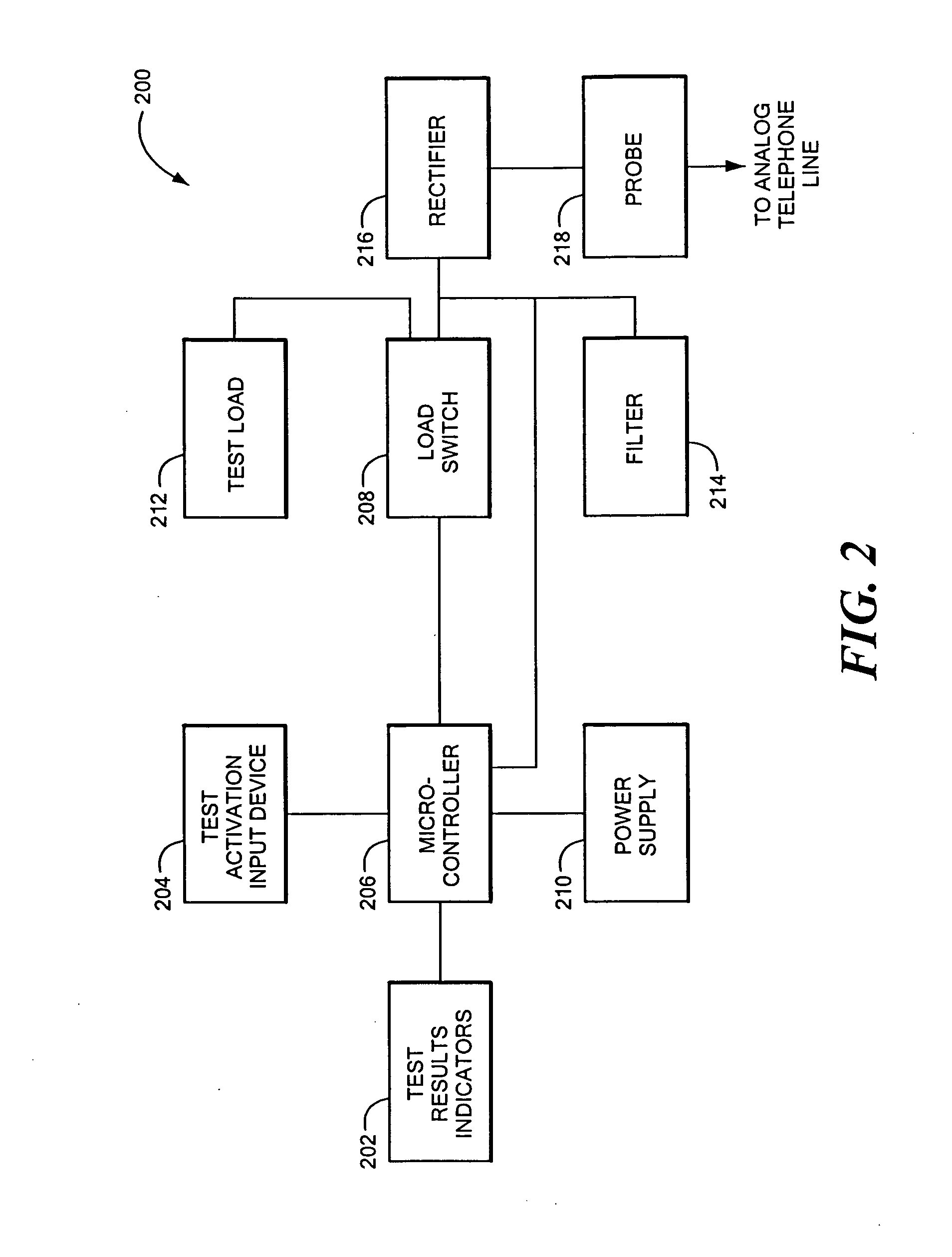

Method and system for evaluating analog telephone lines

InactiveUS20080080676A1Quick SetupMinimal trainingSupervisory/monitoring/testing arrangementsSubstation equipmentBiological activationVoltage

A method and apparatus for determining a plurality of parameters indicative of performance of an analog telephone line is disclosed. The method includes sequentially performing a plurality of tests on the analog telephone line. The method further includes sequentially indicating results of the plurality of tests using a same set of visual indicators. In one embodiment, the performing the plurality of tests includes performing a second and a third sequential test upon detection of sequential activation of a test initiation input device. In another embodiment, the determining a plurality of parameters includes determining any one of loop current, ring voltage and ring trip energy of the analog telephone line.

Owner:NORTEL NETWORKS LTD

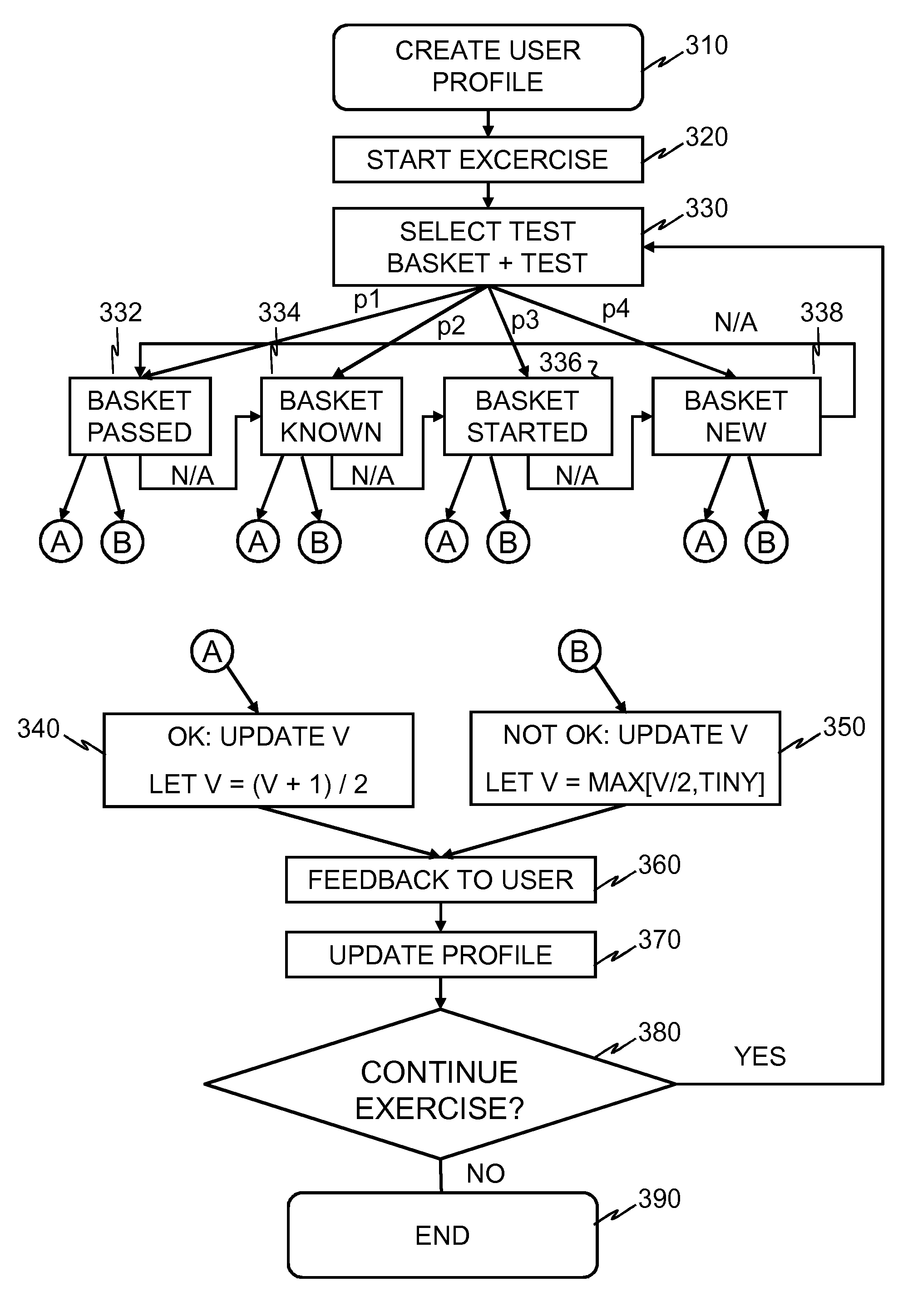

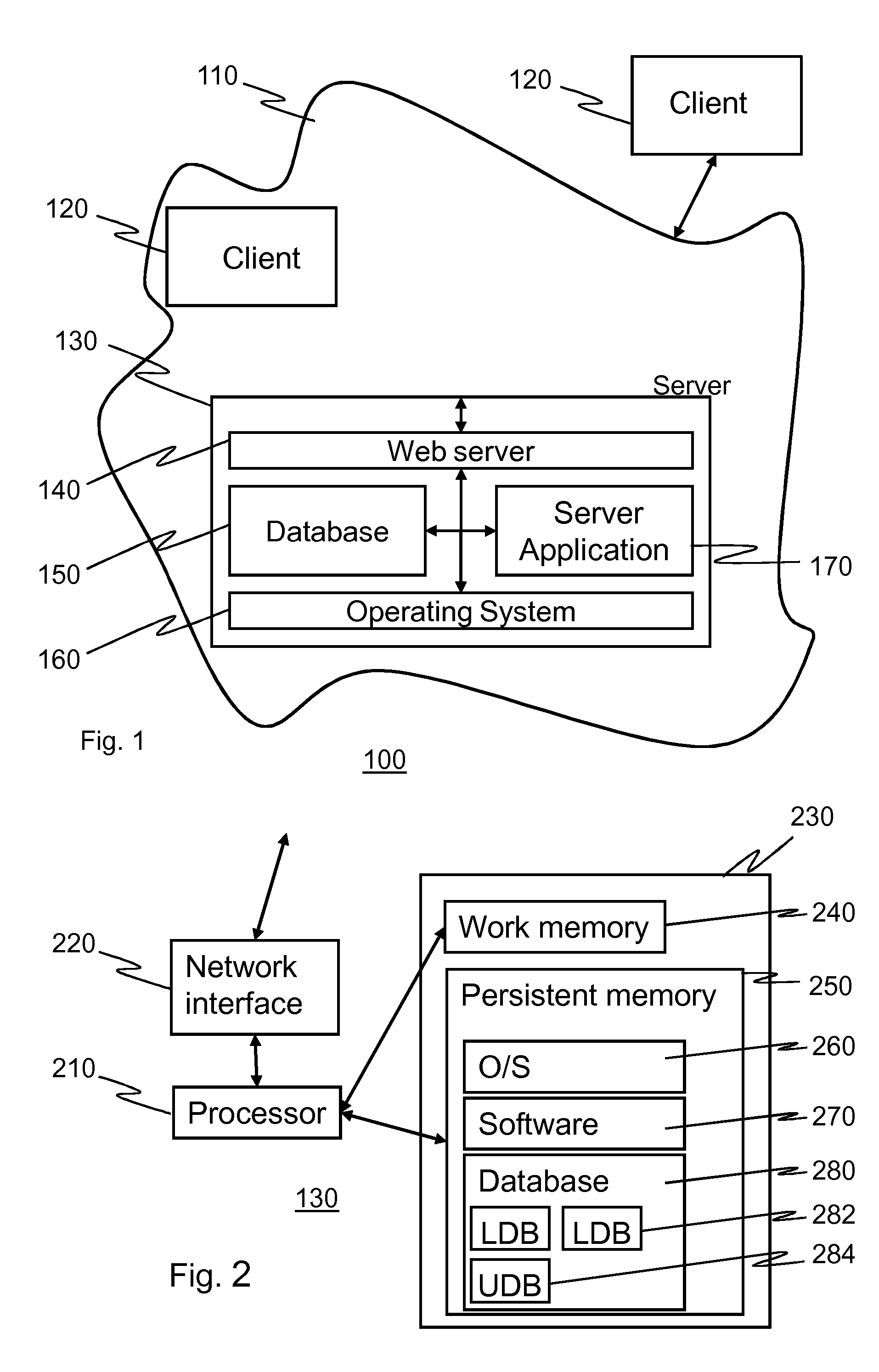

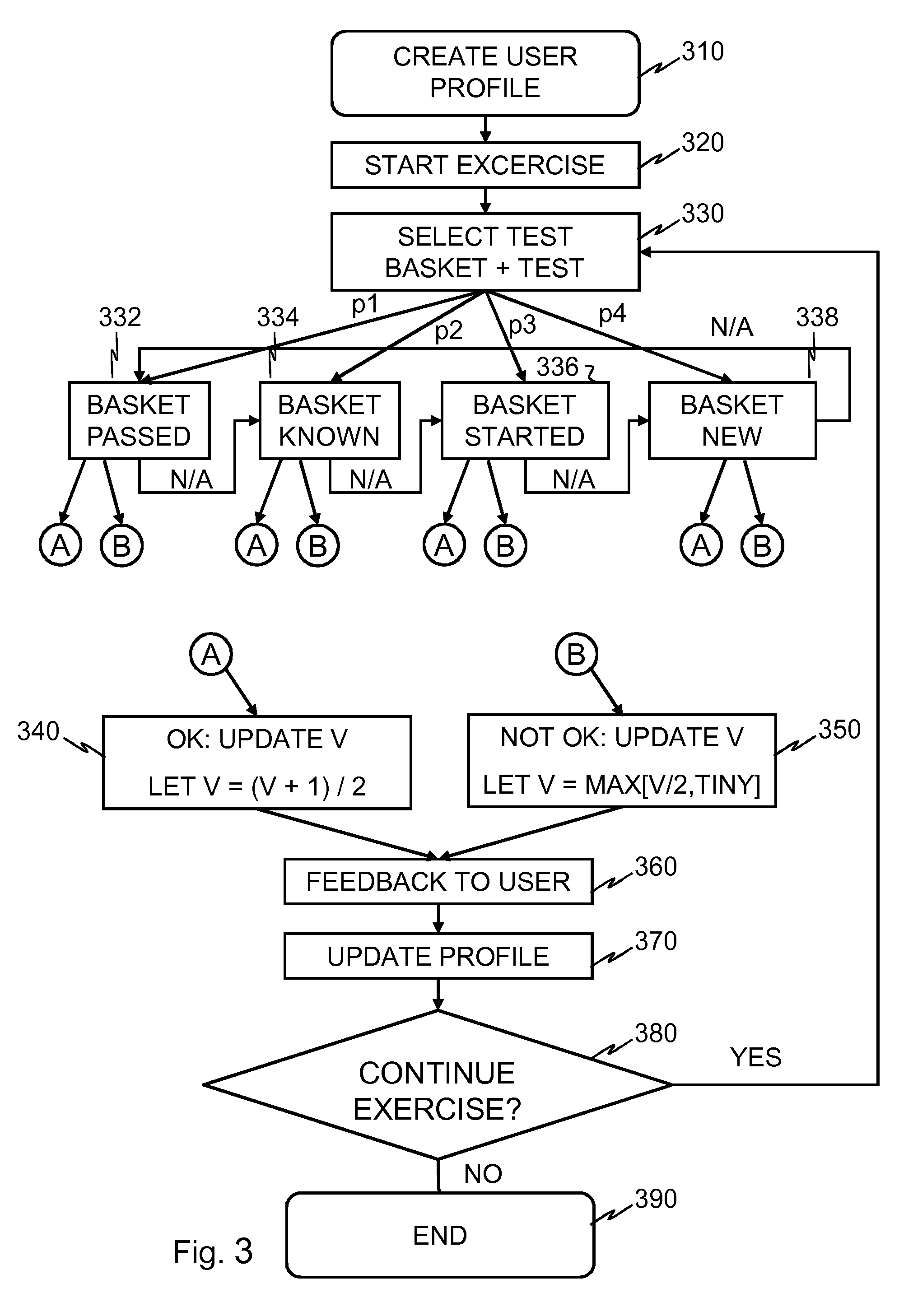

Language training apparatus, method and computer program

ActiveUS20120308968A1Small costSmall requirementSpecial data processing applicationsTeaching apparatusData miningUser profile

An apparatus with a memory that has a learning database and a user database. The learning database has a set of details to be learned and the user database has a user profile. The user profile has a weighing vector of weighing parameters corresponding to the set of details. The apparatus further has a processor configured to test a user for particular details in an order that is at least partly based on the weighing parameters. The processor is further configured to adjust the weighing parameter corresponding to a given detail depending on whether the user has passed the test. Also corresponding methods and computer programs are disclosed.

Owner:VOCTRAINER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com