Patents

Literature

31results about How to "Simplification and improvement of process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

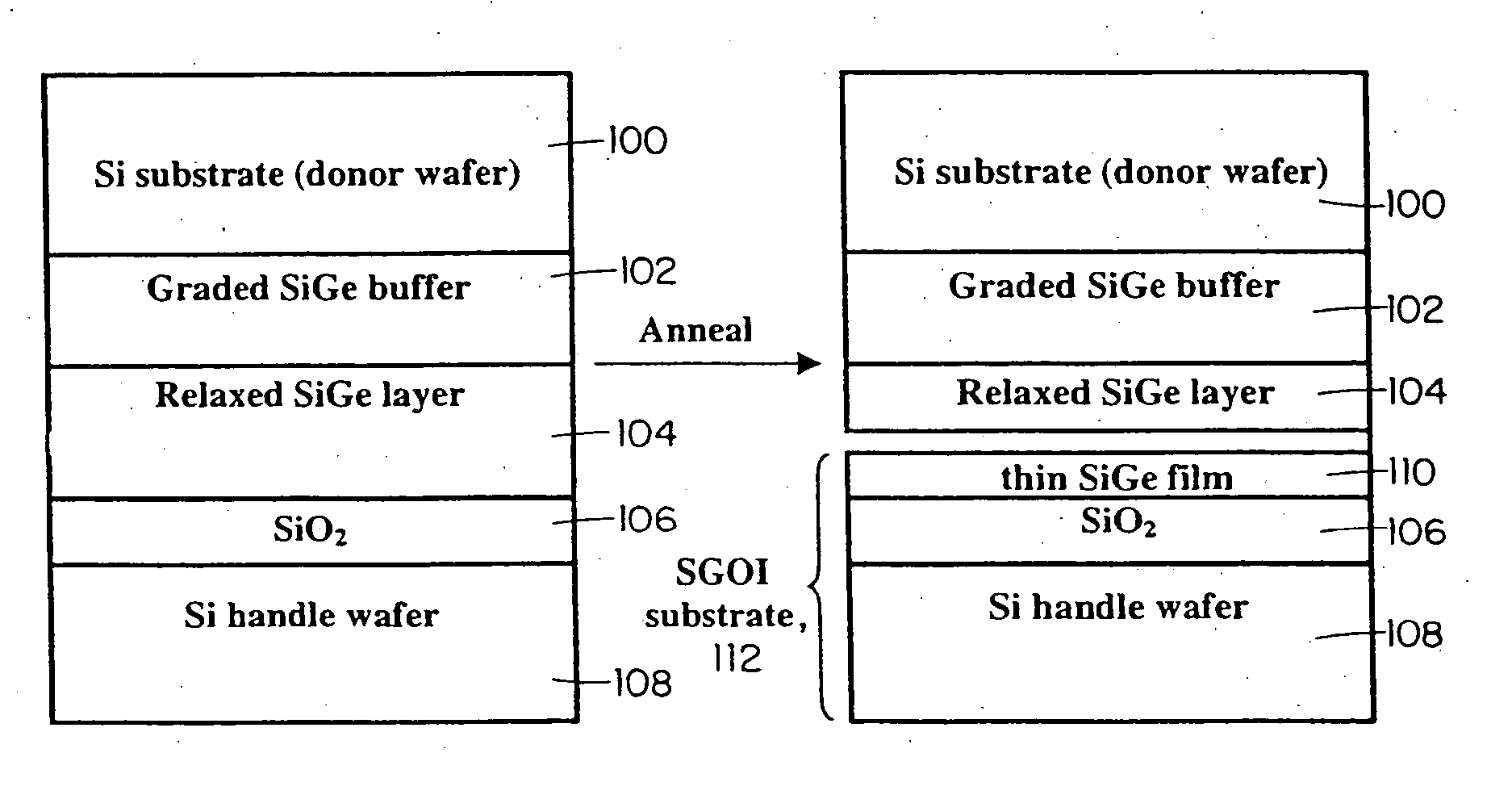

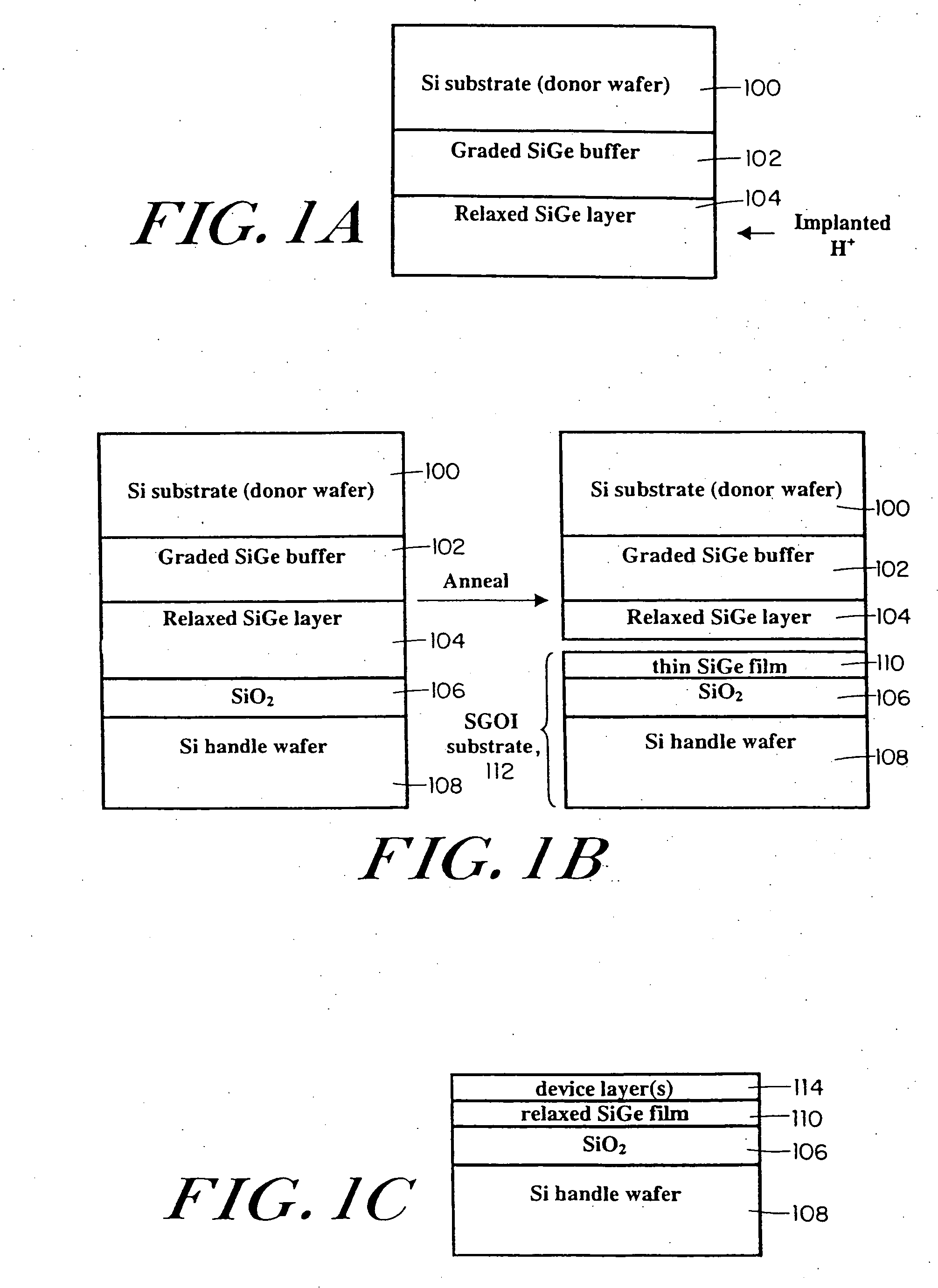

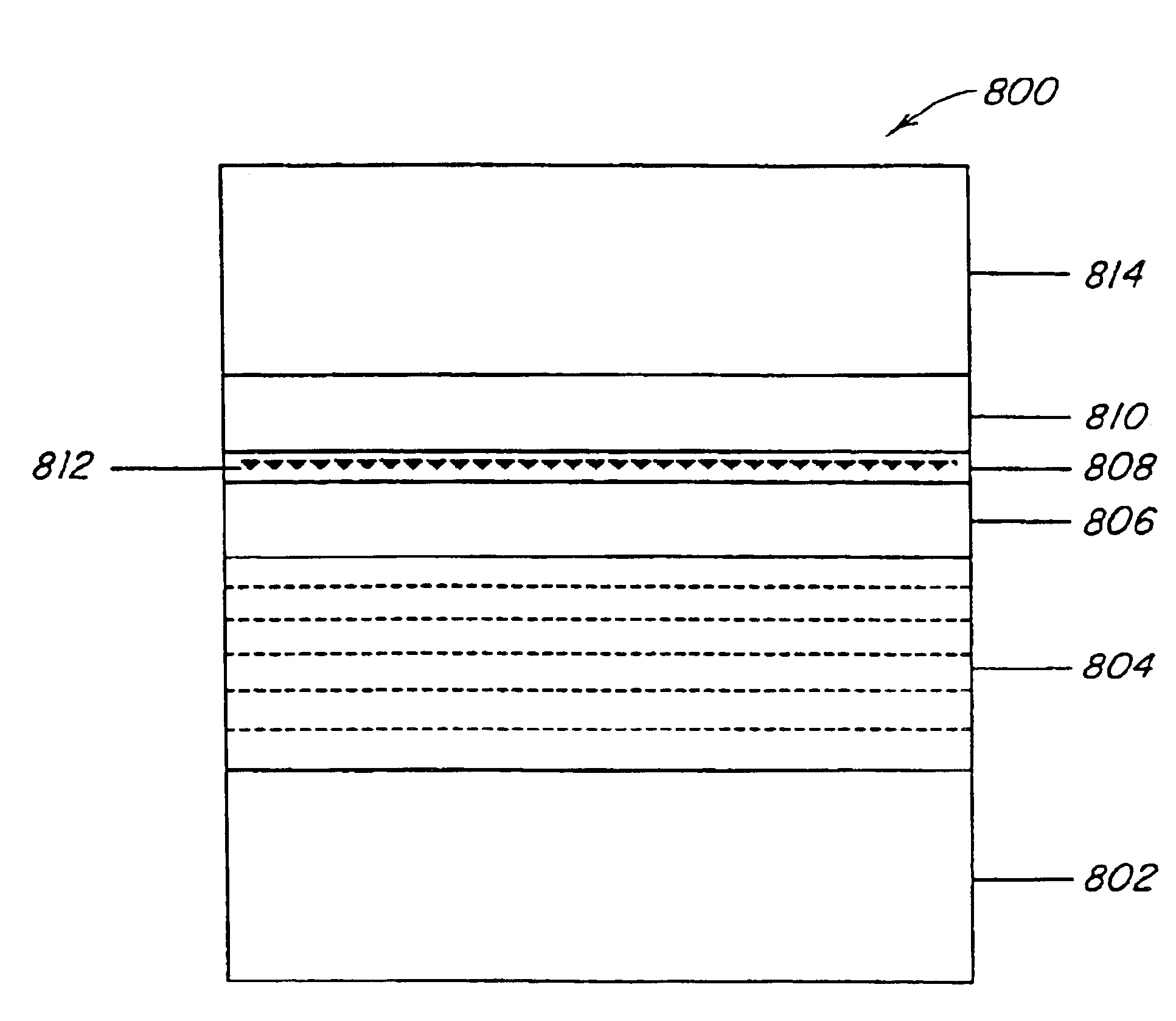

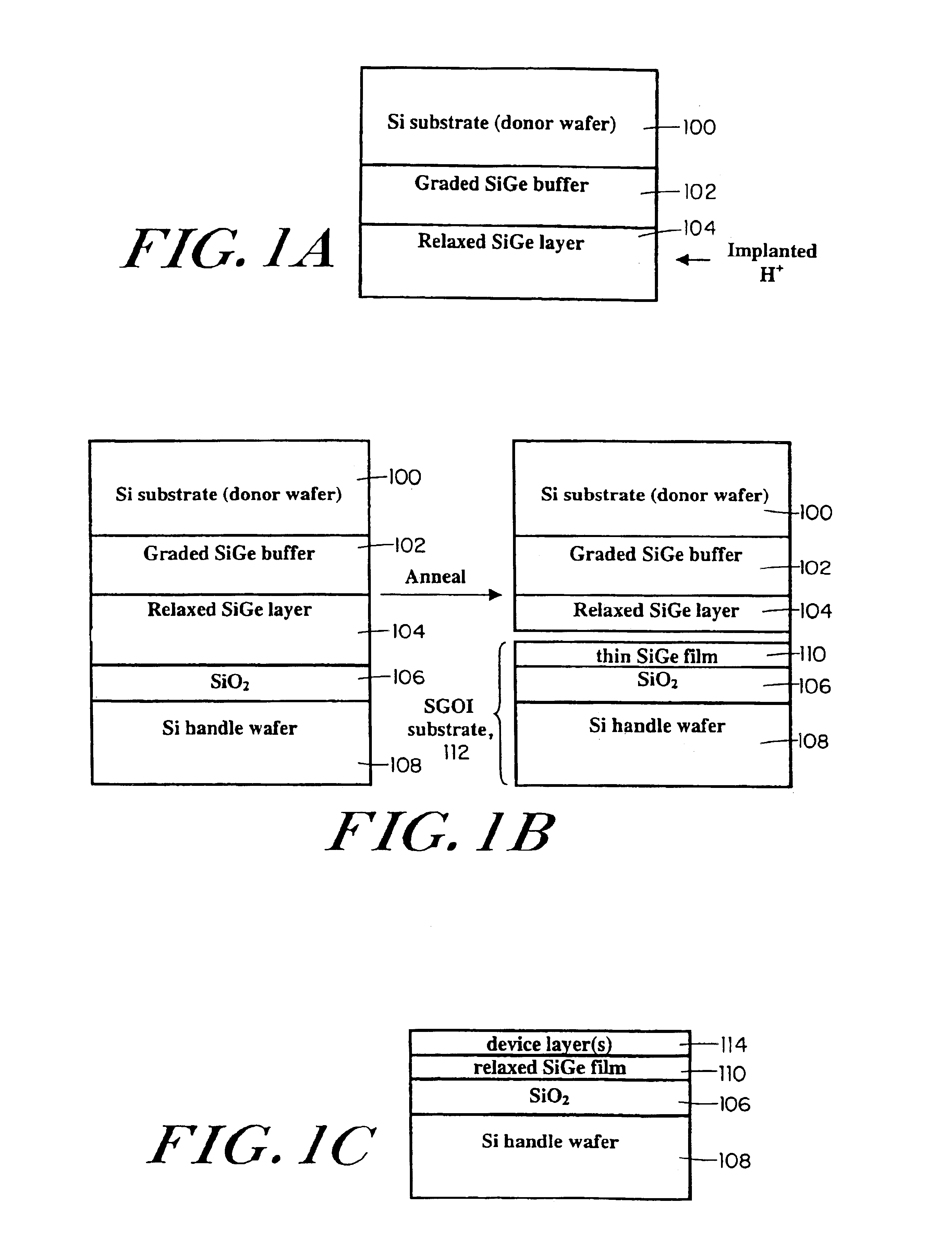

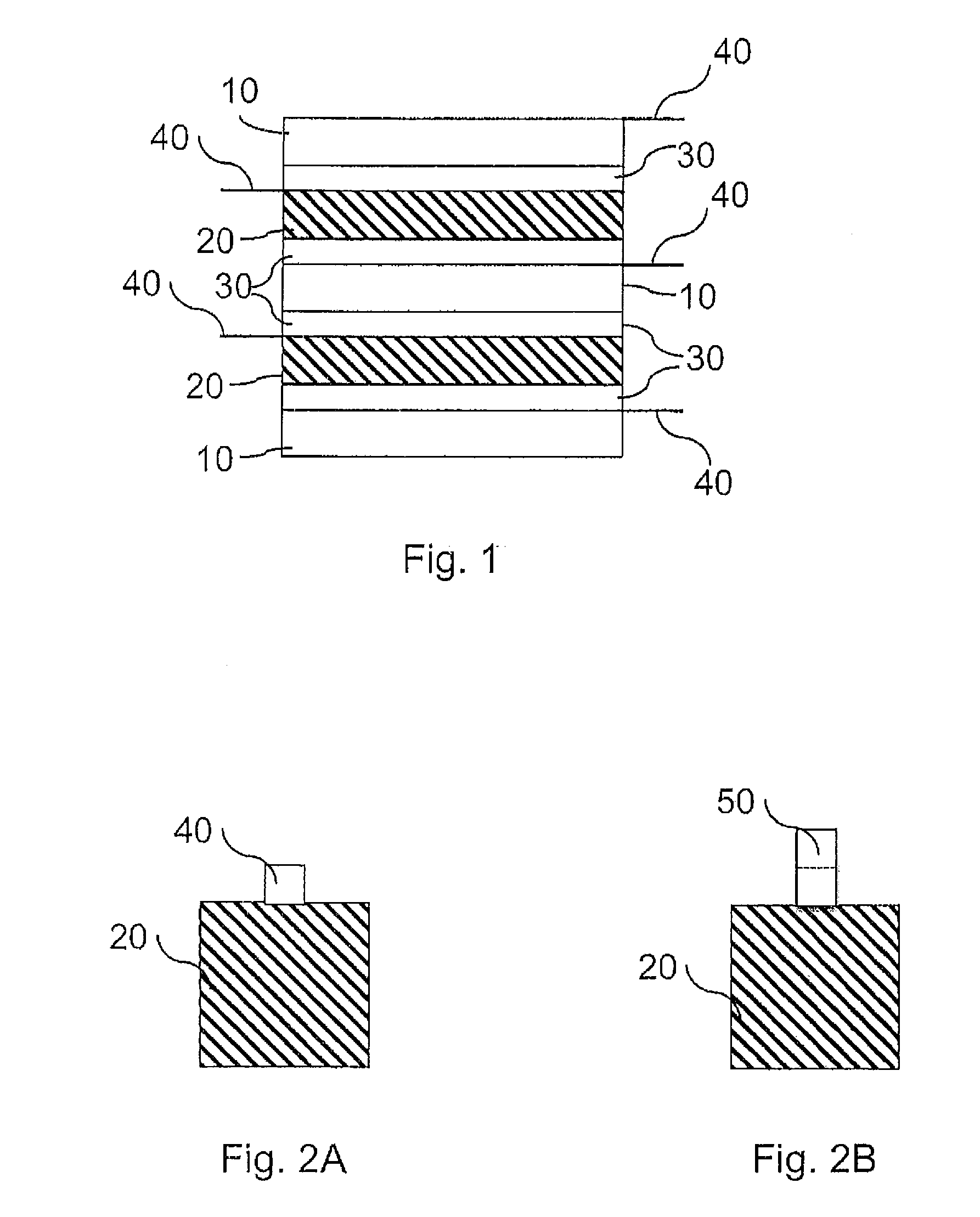

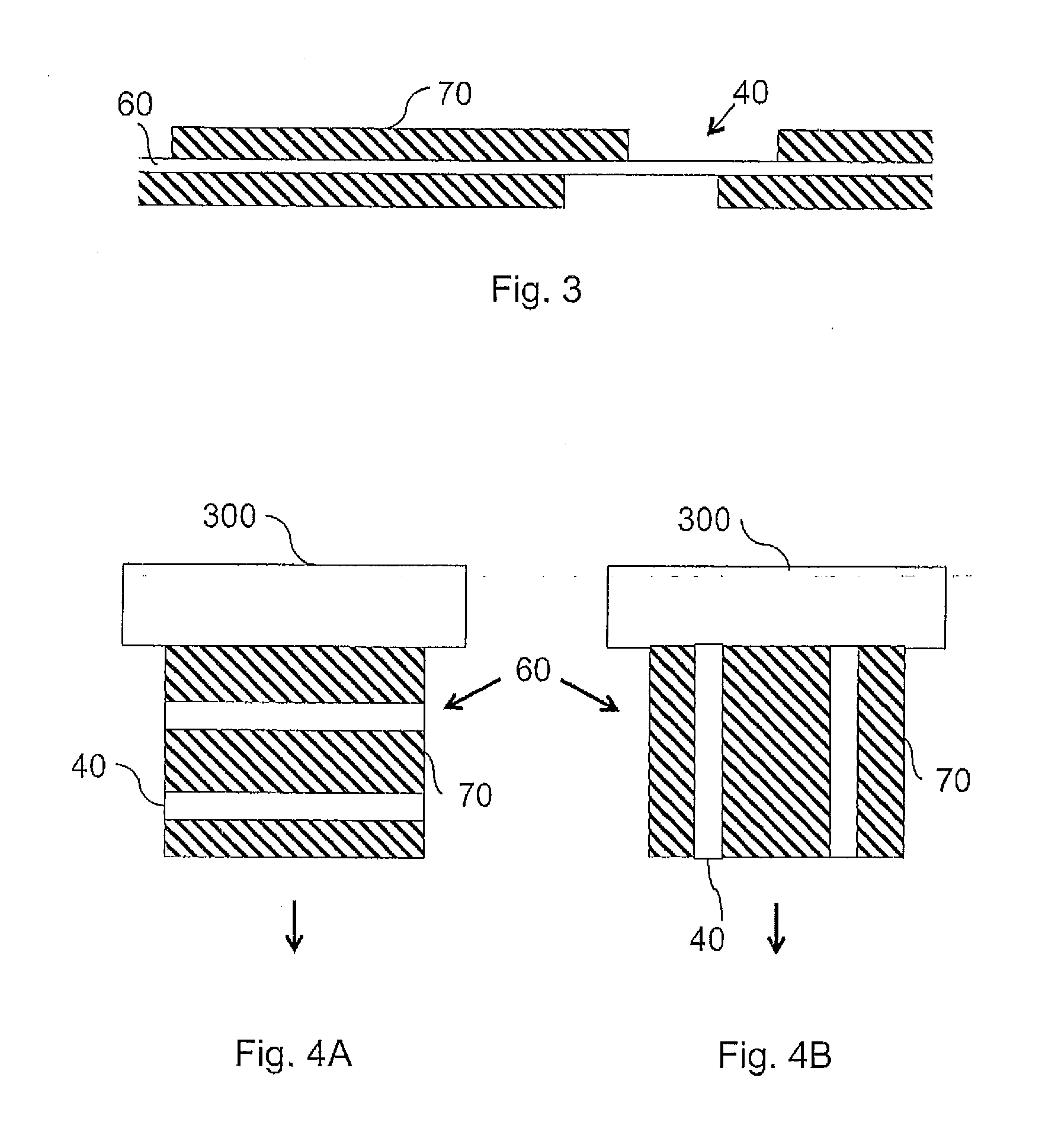

Process for producing semiconductor article using graded epitaxial growth

InactiveUS20050009288A1Simplified and improved processHigh materialFrom solid stateSolid-state devicesHydrogenSingle crystal

A process for producing monocrystalline semiconductor layers. In an exemplary embodiment, a graded Si1-xGex (x increases from 0 to y) is deposited on a first silicon substrate, followed by deposition of a relaxed Si1-yGey layer, a thin strained Si1-zGez layer and another relaxed Si1-yGey layer. Hydrogen ions are then introduced into the strained SizGez layer. The relaxed Si1-yGey layer is bonded to a second oxidized substrate. An annealing treatment splits the bonded pair at the strained Si layer, such that the second relaxed Si1-yGey layer remains on the second substrate. In another exemplary embodiment, a graded SixGex is deposited on a first silicon substrate, where the Ge concentration x is increased from 0 to 1. Then a relaxed GaAs layer is deposited on the relaxed Ge buffer. As the lattice constant of GaAs is close to that of Ge, GaAs has high quality with limited dislocation defects. Hydrogen ions are introduced into the relaxed GaAs layer at the selected depth. The relaxed GaAs layer is bonded to a second oxidized substrate. An annealing treatment splits the bonded pair at the hydrogen ion rich layer, such that the upper portion of relaxed GaAs layer remains on the second substrate.

Owner:MASSACHUSETTS INST OF TECH

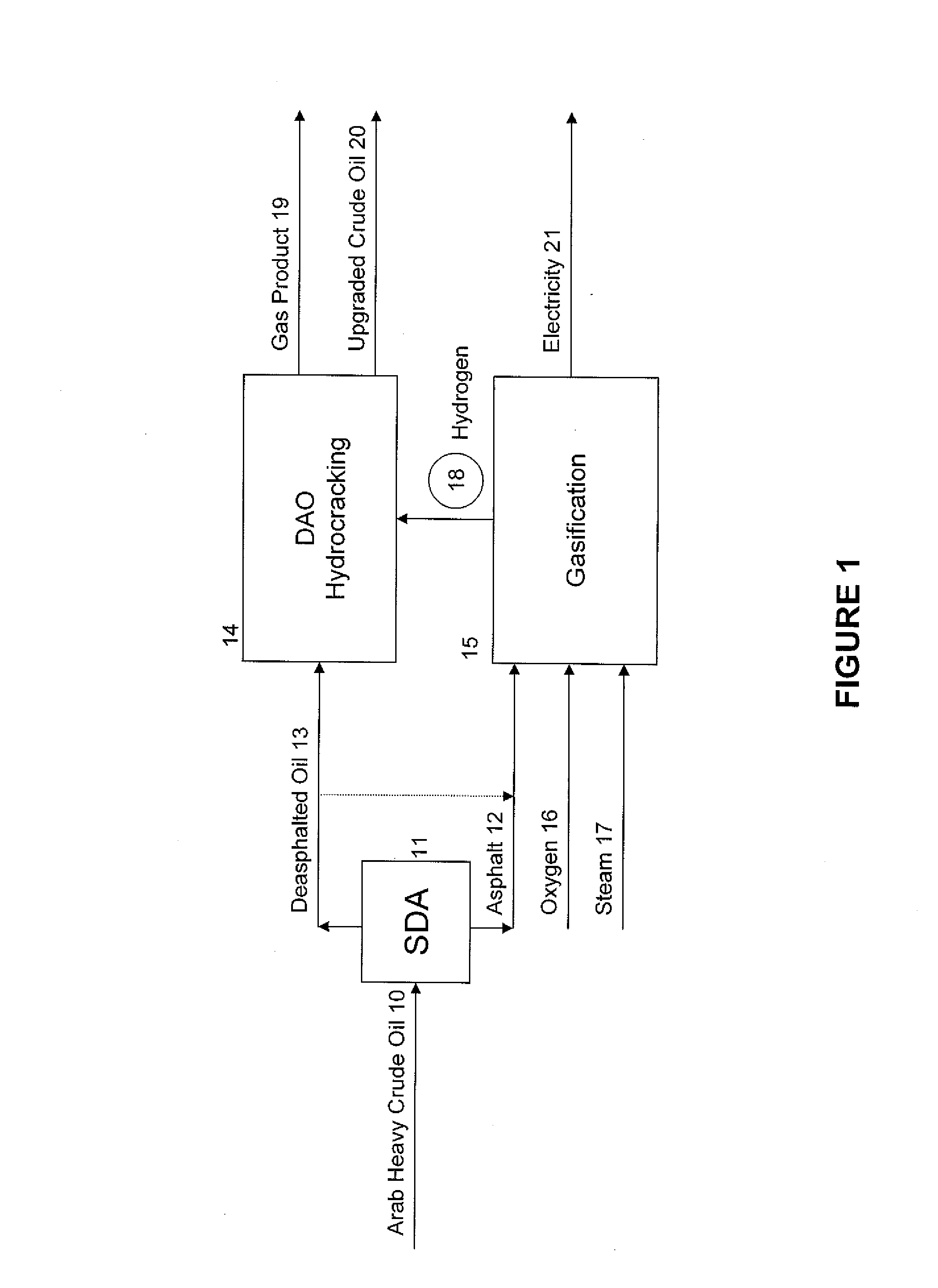

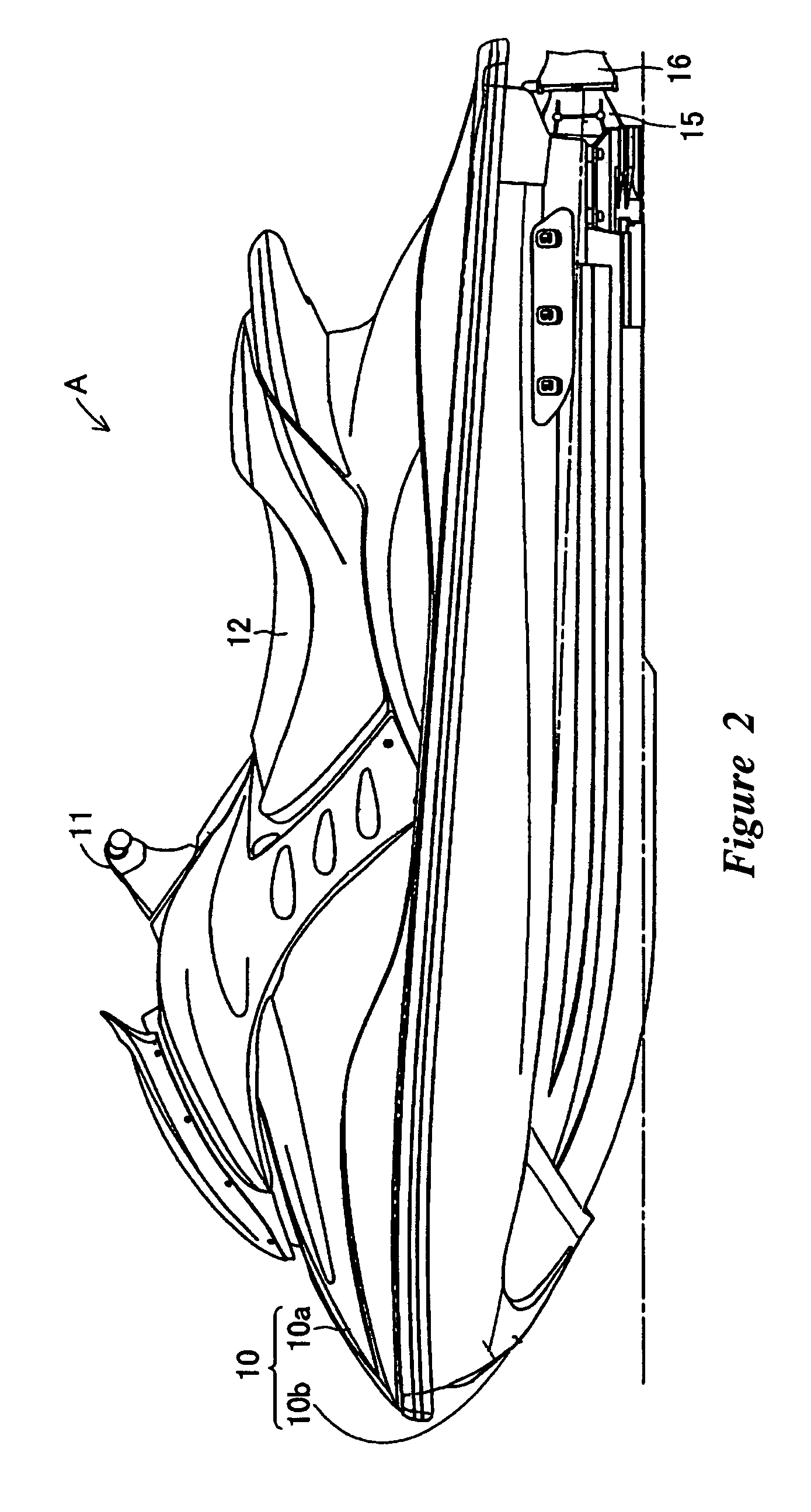

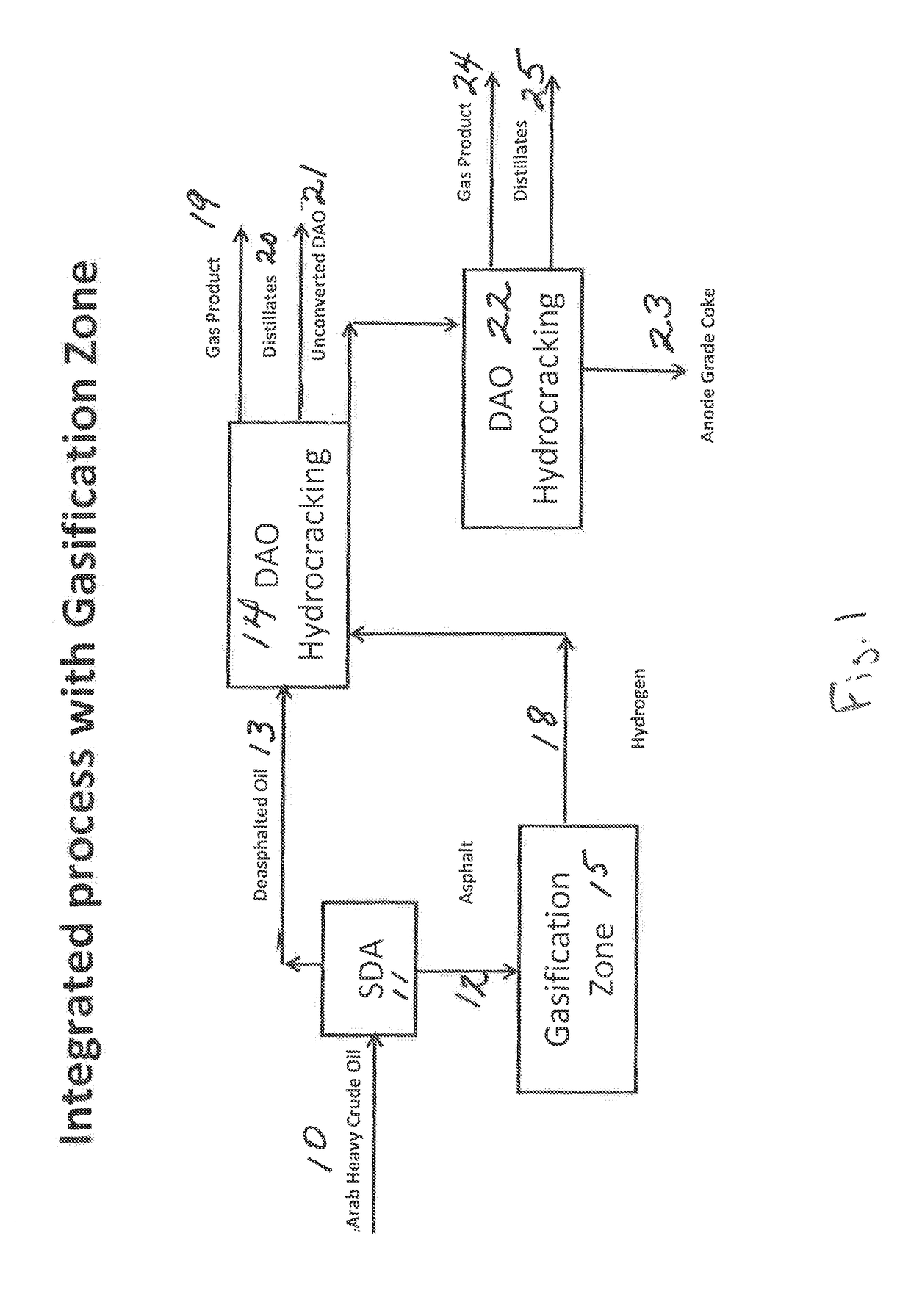

Integrated process for deasphalting and desulfurizing whole crude oil

InactiveUS20130319910A1Simplification and improvement of processSimple processWorking-up pitch/asphalt/bitumenGasification processes detailsSulfurAsphalt

The invention relates to processes for removing impurities, such as asphalt, from whole crude oil. The invention is accomplished by first deasphalting a feedstock, followed by processing resulting DAO and asphalt fractions. The DAO fraction is hydrocracked, resulting in removal of sulfur and hydrocarbons which boil at temperatures over 370° C., and gasifying the asphalt portion.

Owner:JGC CATALYSTS & CHEM LTD +2

Process for producing semiconductor article using graded epitaxial growth

InactiveUS6921914B2Quality improvementSimplification and improvement of processSolid-state devicesSemiconductor/solid-state device manufacturingHydrogenSingle crystal

A process for producing monocrystalline semiconductor layers. In an exemplary embodiment, a graded Si1-xGex (x increases from 0 to y) is deposited on a first silicon substrate, followed by deposition of a relaxed Si1-yGey layer, a thin strained Si1-zGez layer and another relaxed Si1-yGey layer. Hydrogen ions are then introduced into the strained SizGez layer. The relaxed Si1-yGey layer is bonded to a second oxidized substrate. An annealing treatment splits the bonded pair at the strained Si layer, such that the second relaxed Si1-yGey layer remains on the second substrate. In another exemplary embodiment, a graded Si1-xGex is deposited on a first silicon substrate, where the Ge concentration x is increased from 0 to 1. Then a relaxed GaAs layer is deposited on the relaxed Ge buffer. As the lattice constant of GaAs is close to that of Ge, GaAs has high quality with limited dislocation defects. Hydrogen ions are introduced into the relaxed GaAs layer at the selected depth. The relaxed GaAs layer is bonded to a second oxidized substrate. An annealing treatment splits the bonded pair at the hydrogen ion rich layer, such that the upper portion of relaxed GaAs layer remains on the second substrate.

Owner:MASSACHUSETTS INST OF TECH

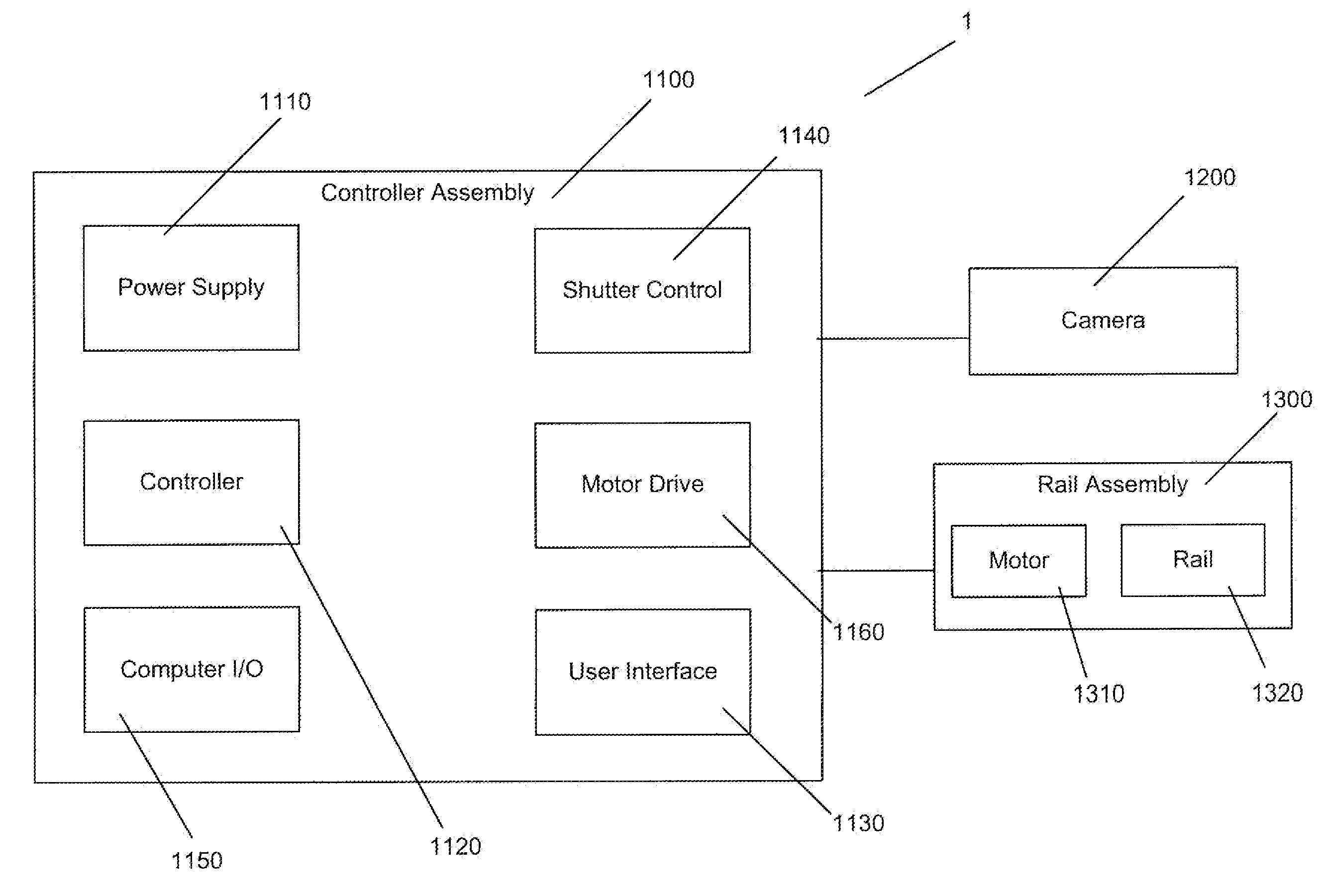

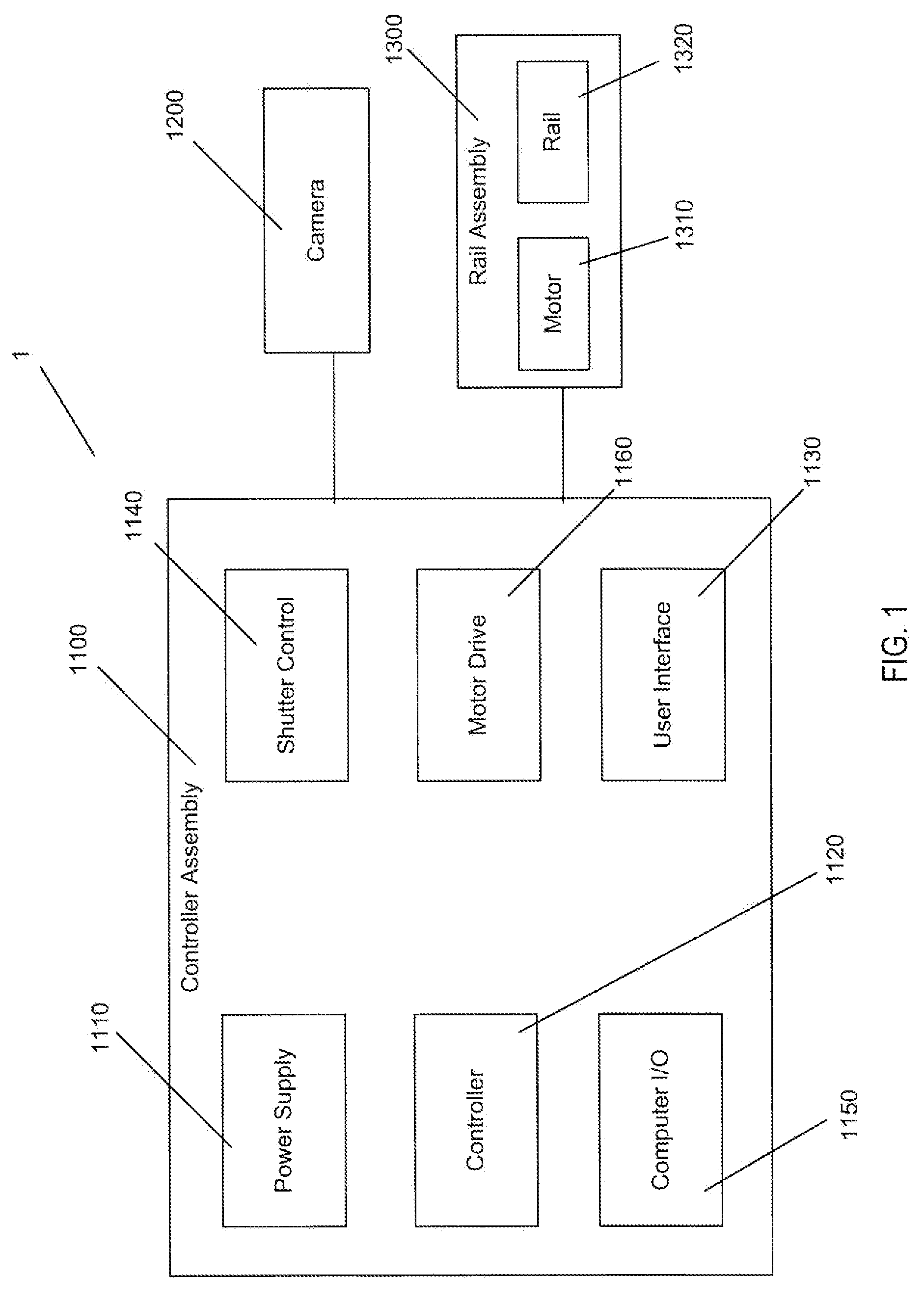

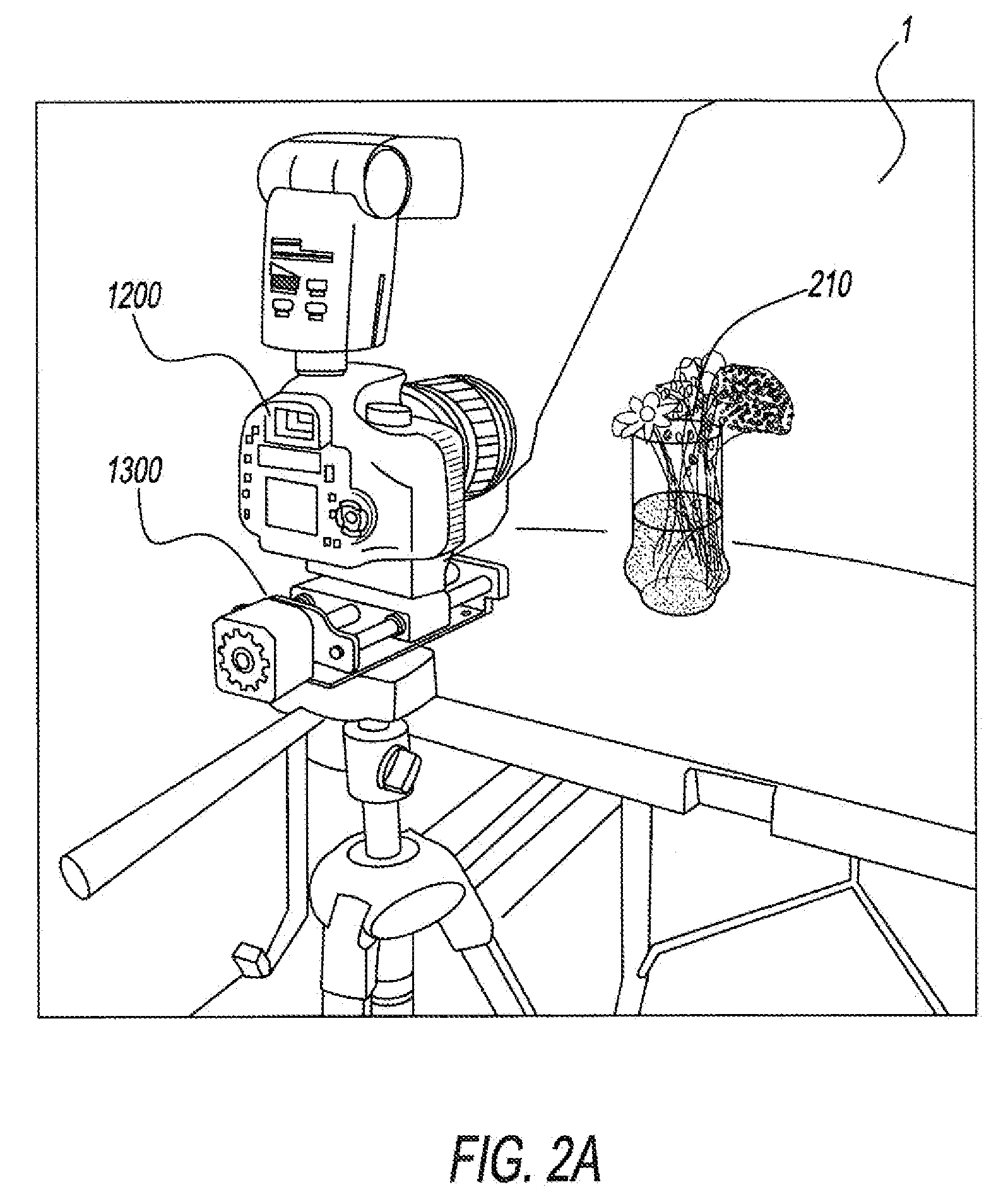

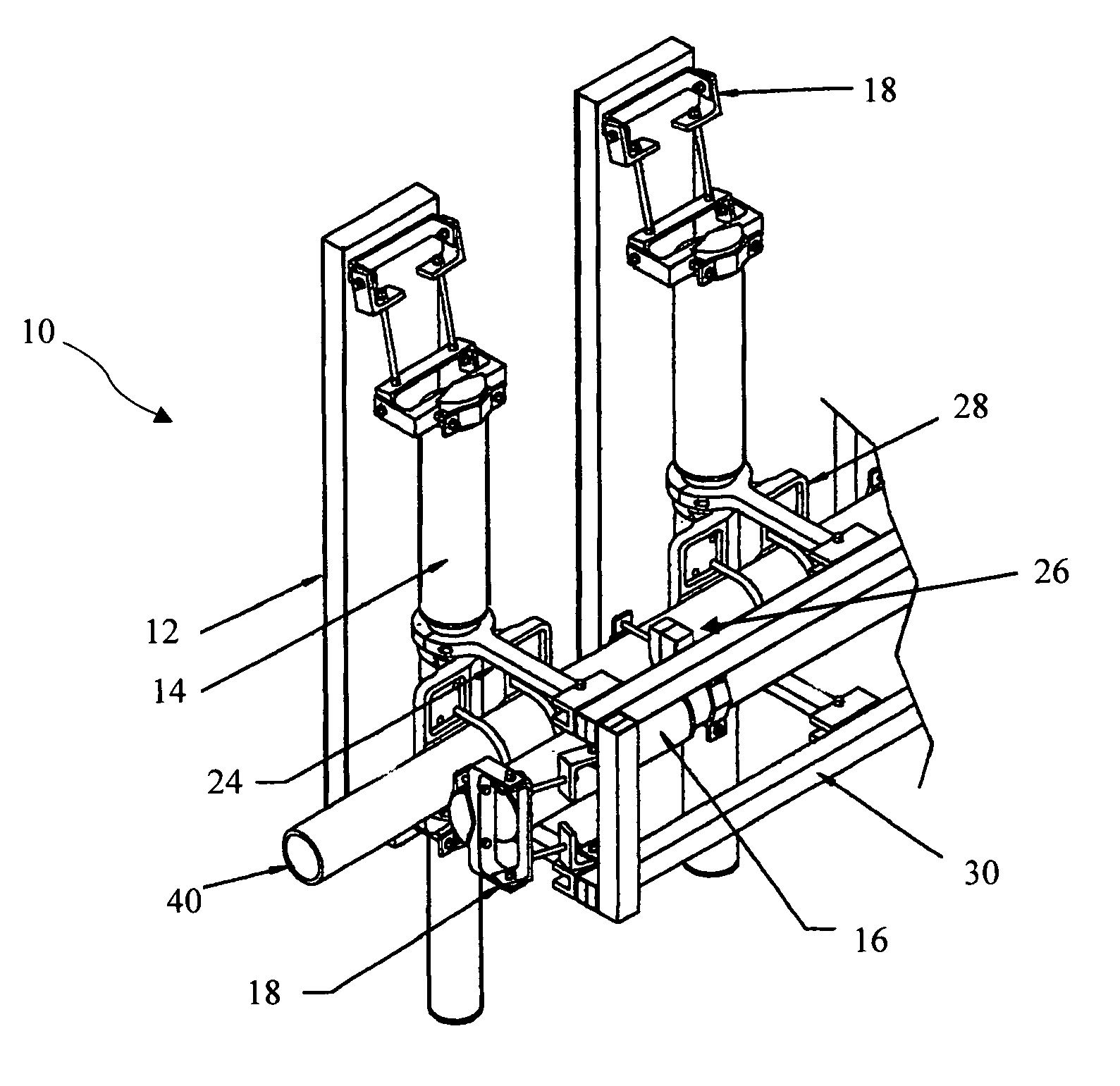

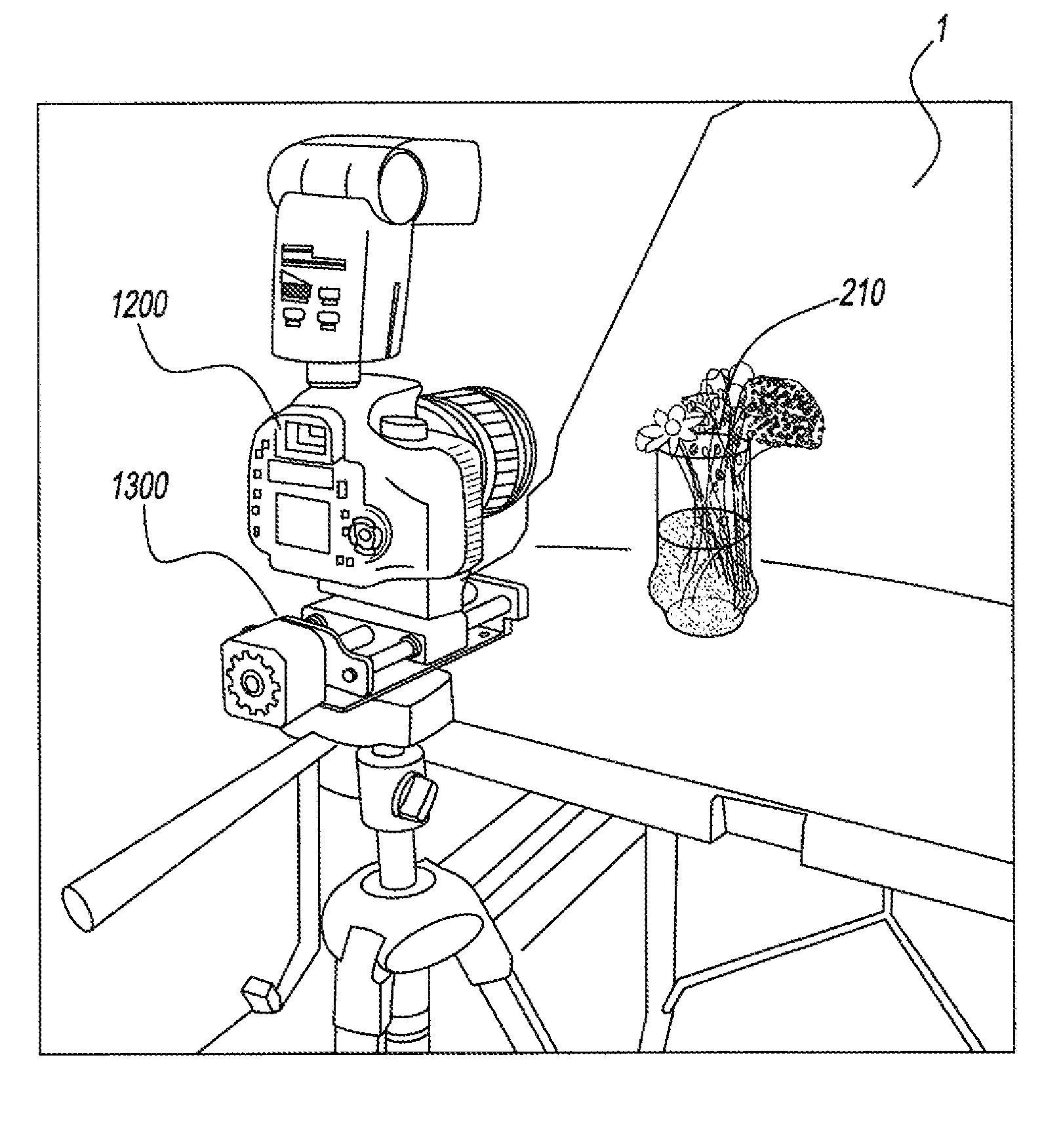

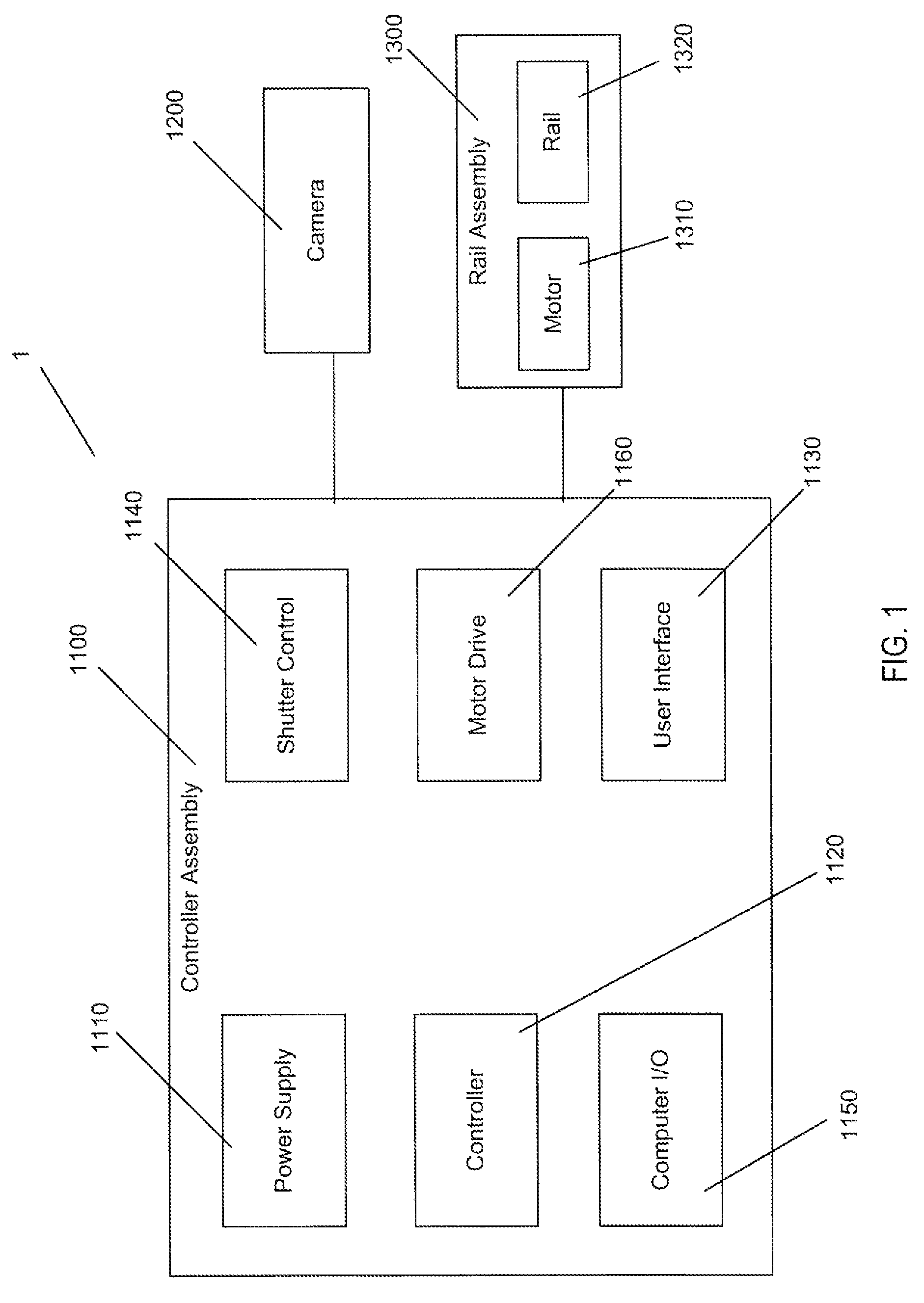

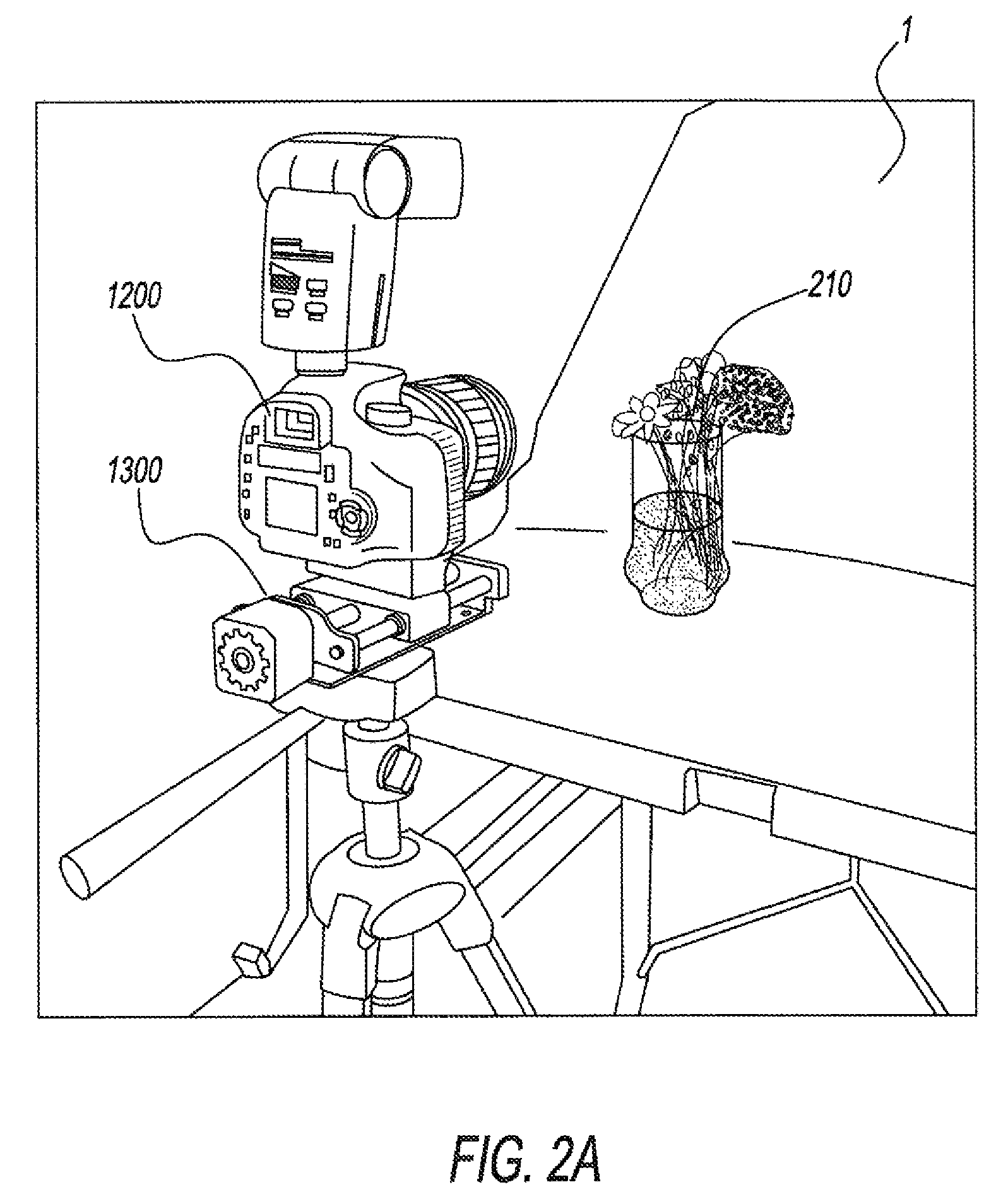

Motor controlled macro rail for close-up focus-stacking photography

ActiveUS20110123188A1Simplification and improvement of processTelevision system detailsColor television detailsCamera lensClose-up

A motor controlled rail assembly is provided which simplifies and automates the process of taking focus-stacked pictures. This device can be used to incrementally move a camera or other photographic device a programmable distance forward or backward in precise steps relative to an external object to facilitate focus-stacked photography. The device may include a motor-driven macro rail assembly, a controller assembly and a camera, which, generally speaking, are configured as follows: a camera is attached to a macro rail carriage which is driven by the motor and controller. The device may have different modes of operation (an automatic step mode, an automatic distance mode, a total distance mode, a distance per step mode, a continuous mode and a manual mode) to yield improved results in different situations.

Owner:DEZEEUW PAUL +2

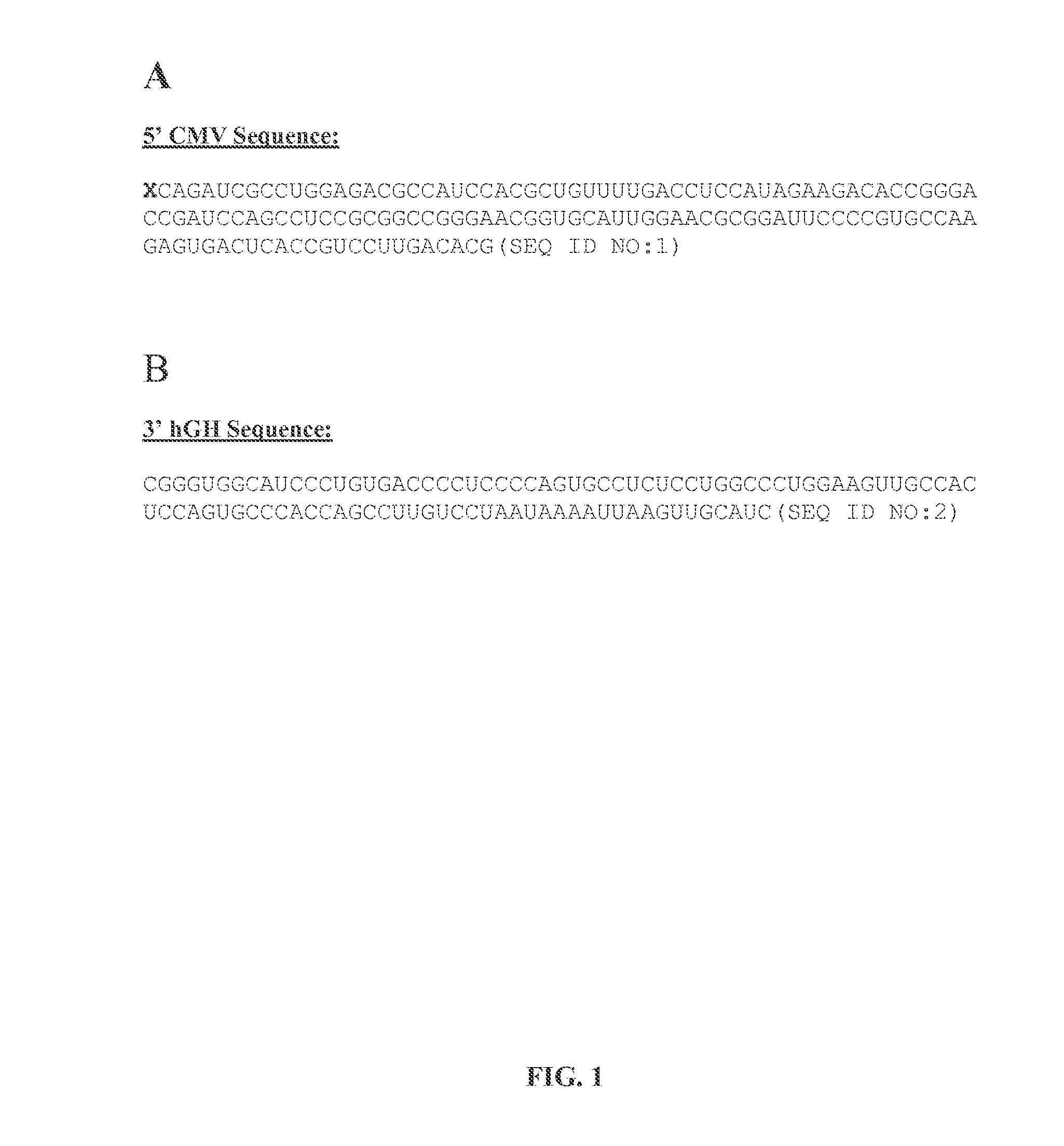

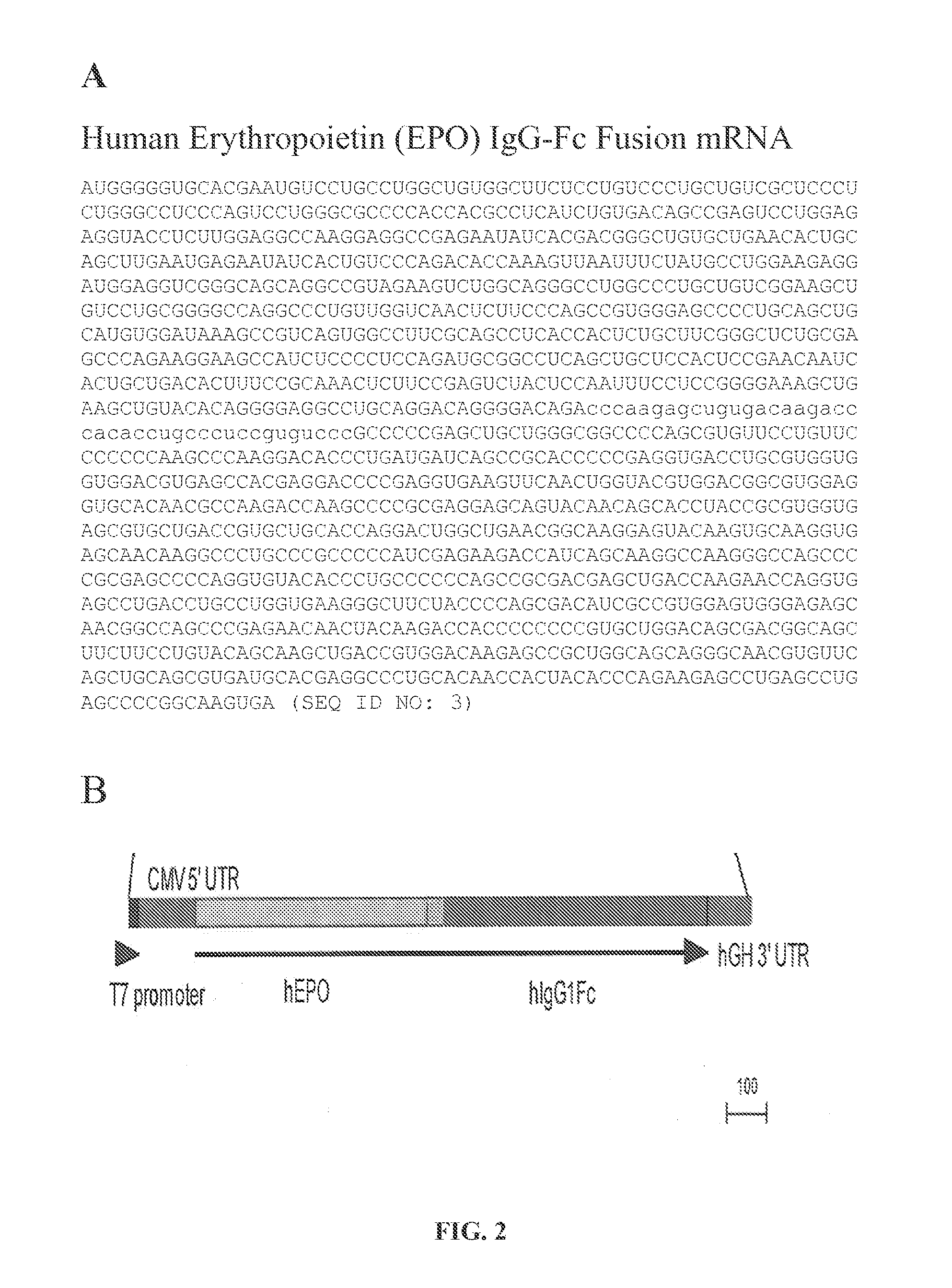

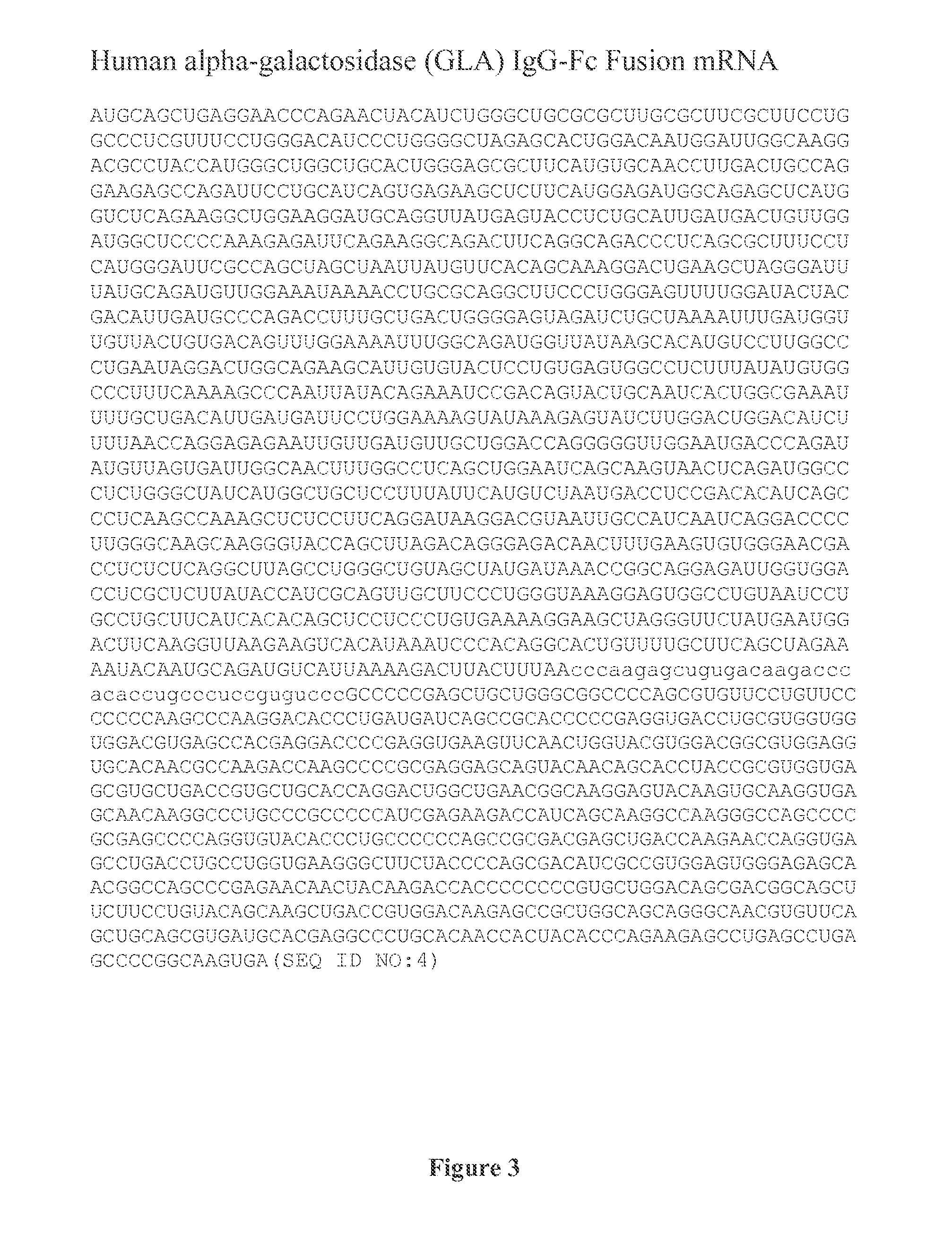

mRNA therapeutic compositions and use to treat diseases and disorders

InactiveUS20160184458A1Reduce immunogenicitySimplification and improvement of processAntibody mimetics/scaffoldsMicroencapsulation basedTherapeutic proteinDisease

Disclosed are compositions and methods for producing therapeutic fusion proteins in vivo. The compositions and methods disclosed herein are capable of ameliorating diseases by providing therapeutic protein delivery.

Owner:TRANSLATE BIO INC

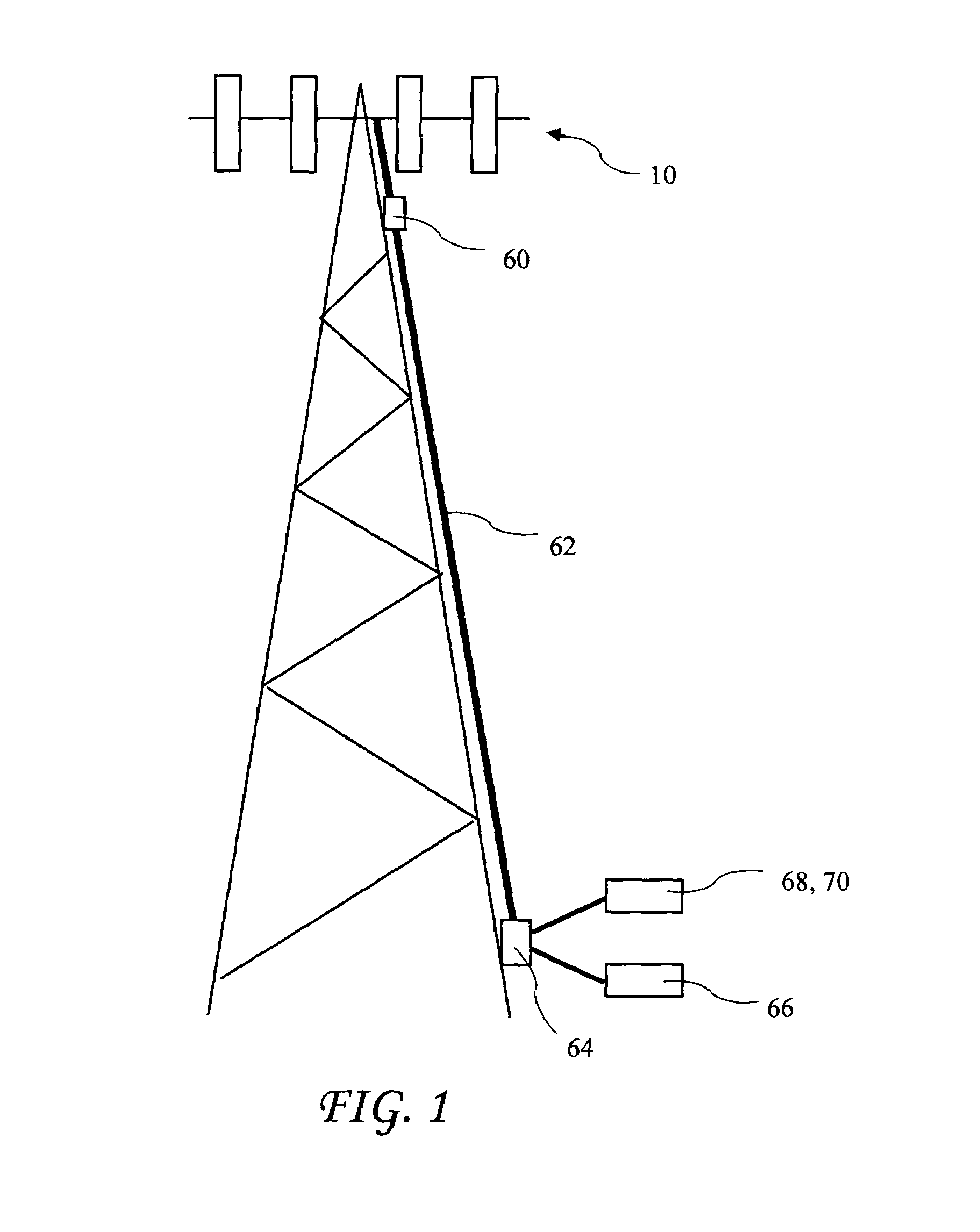

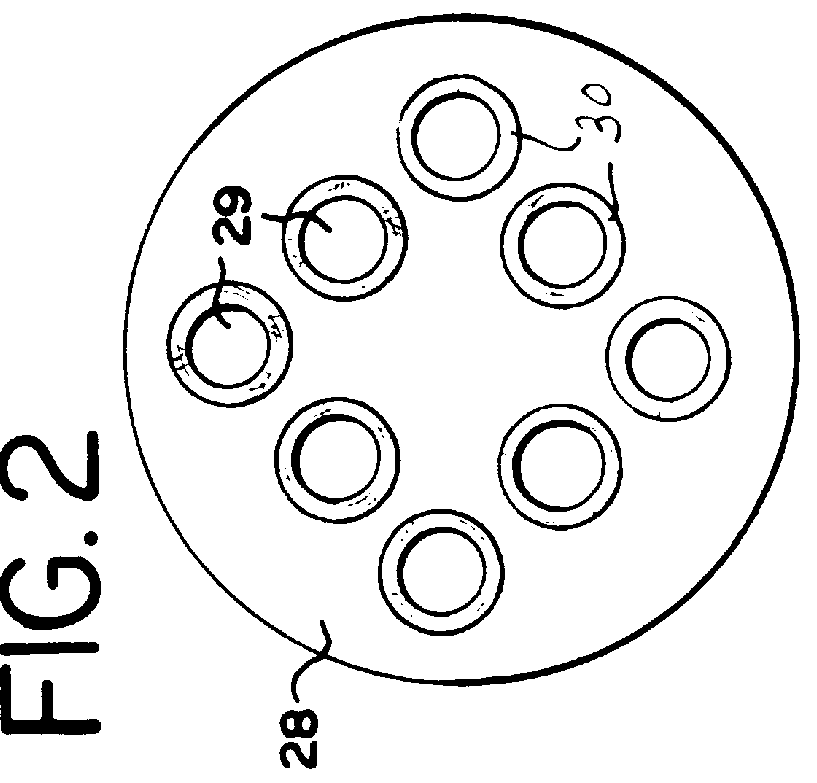

System for remotely adjusting antennas

InactiveUS7183996B2Economical and efficientImprove efficiencyAntenna supports/mountingsEngineeringVertical motion

A mounting apparatus for remotely adjusting the tilt and heading of cell antennas. Antenna tilt is provided by the cooperation of a hinged lower tilt bracket and an upper tilt bracket connected to the antenna by links. The upper tilt bracket is mounted to a vertically translating dust cover. Vertical motion of the dust cover is translated to tilting motion of the antenna by the links. Heading adjustment may be provided uniformly to entire sectors of antennas using a Pitman arm arrangement, or may be provided to each cell antenna individually using a helix heading adjustment apparatus.

Owner:WENSINK JAN B

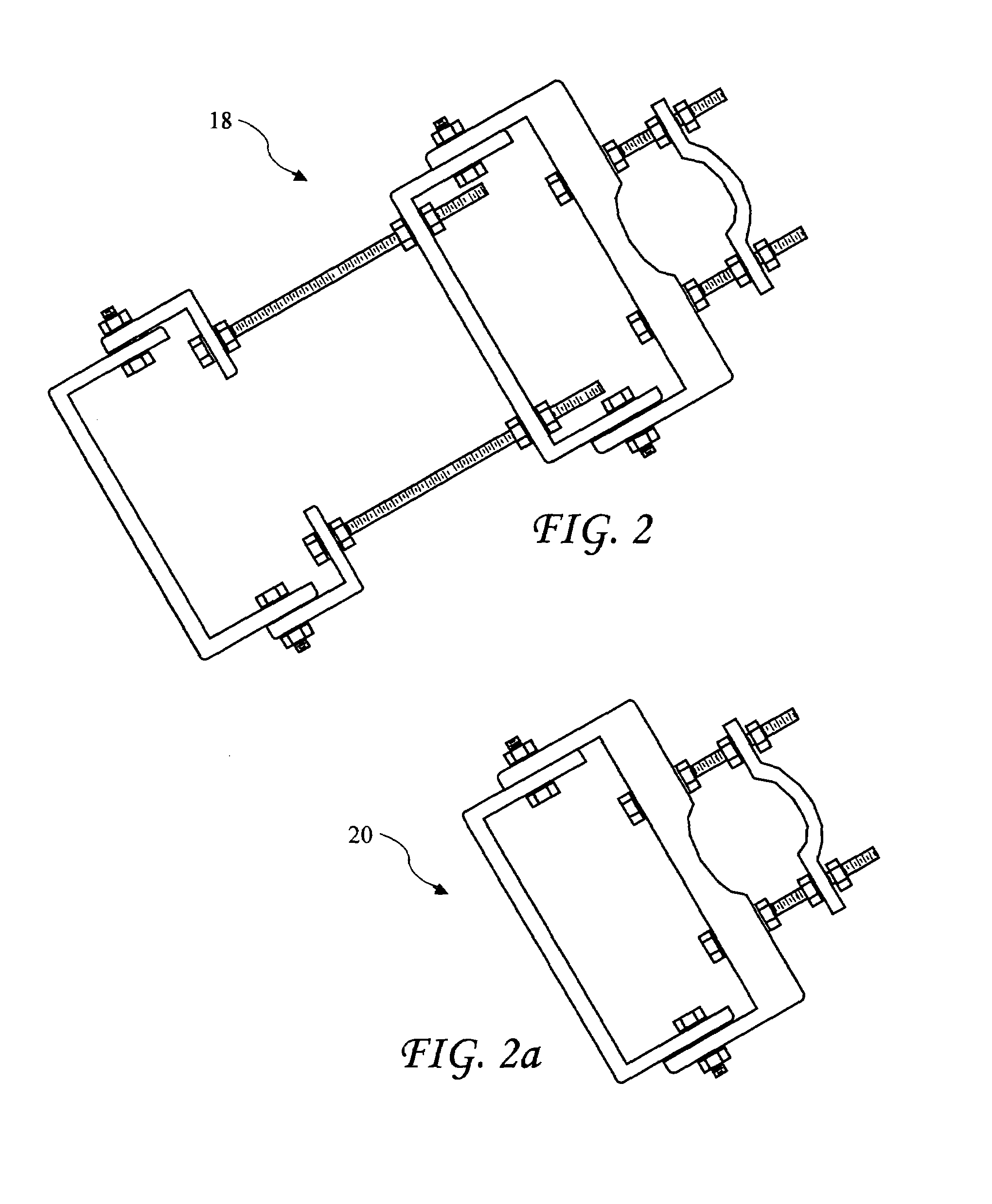

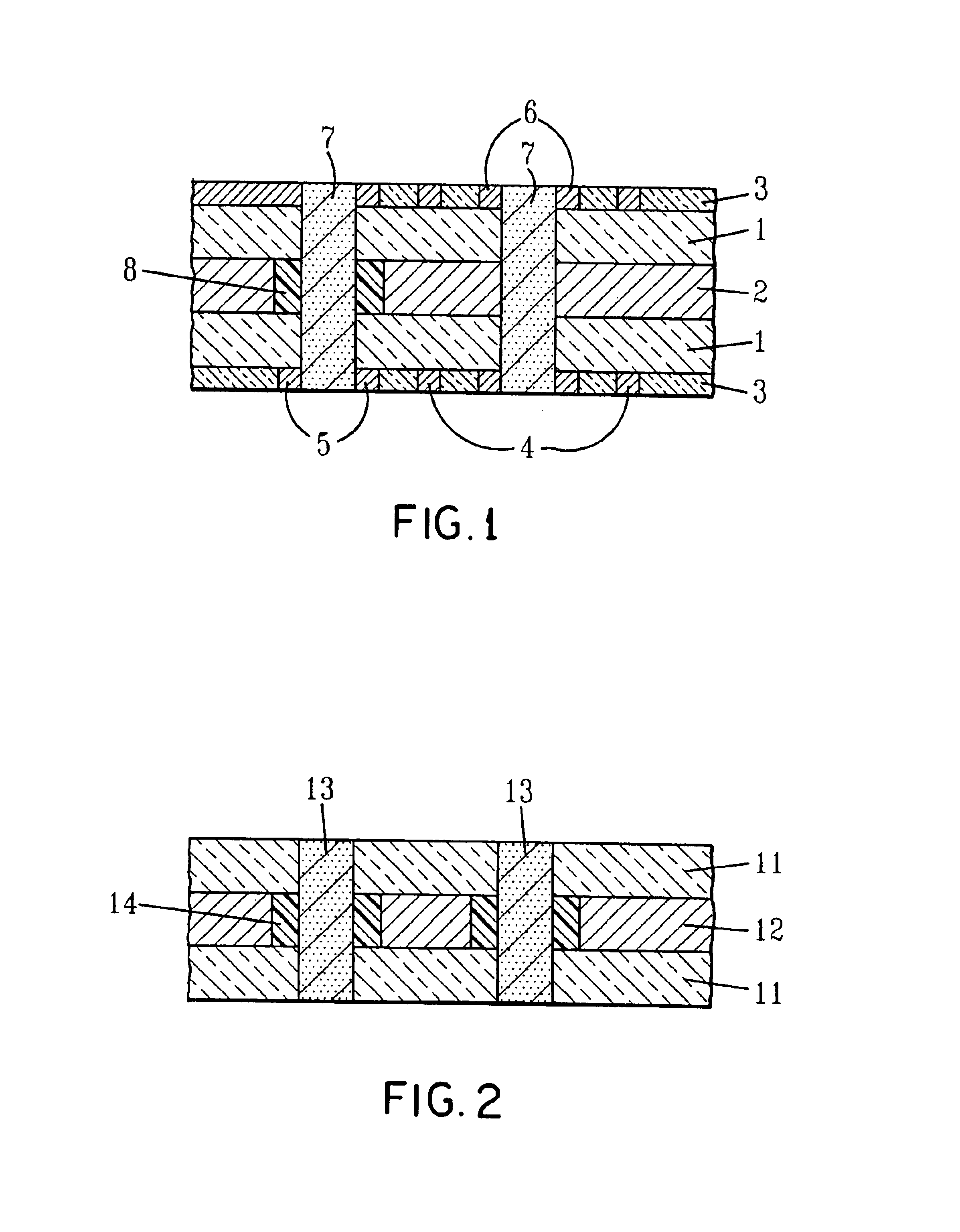

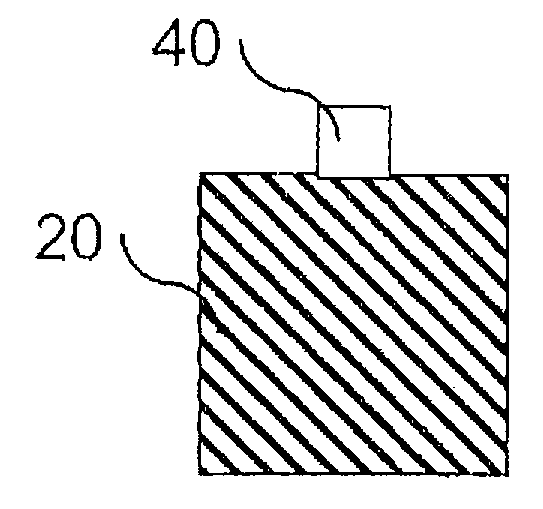

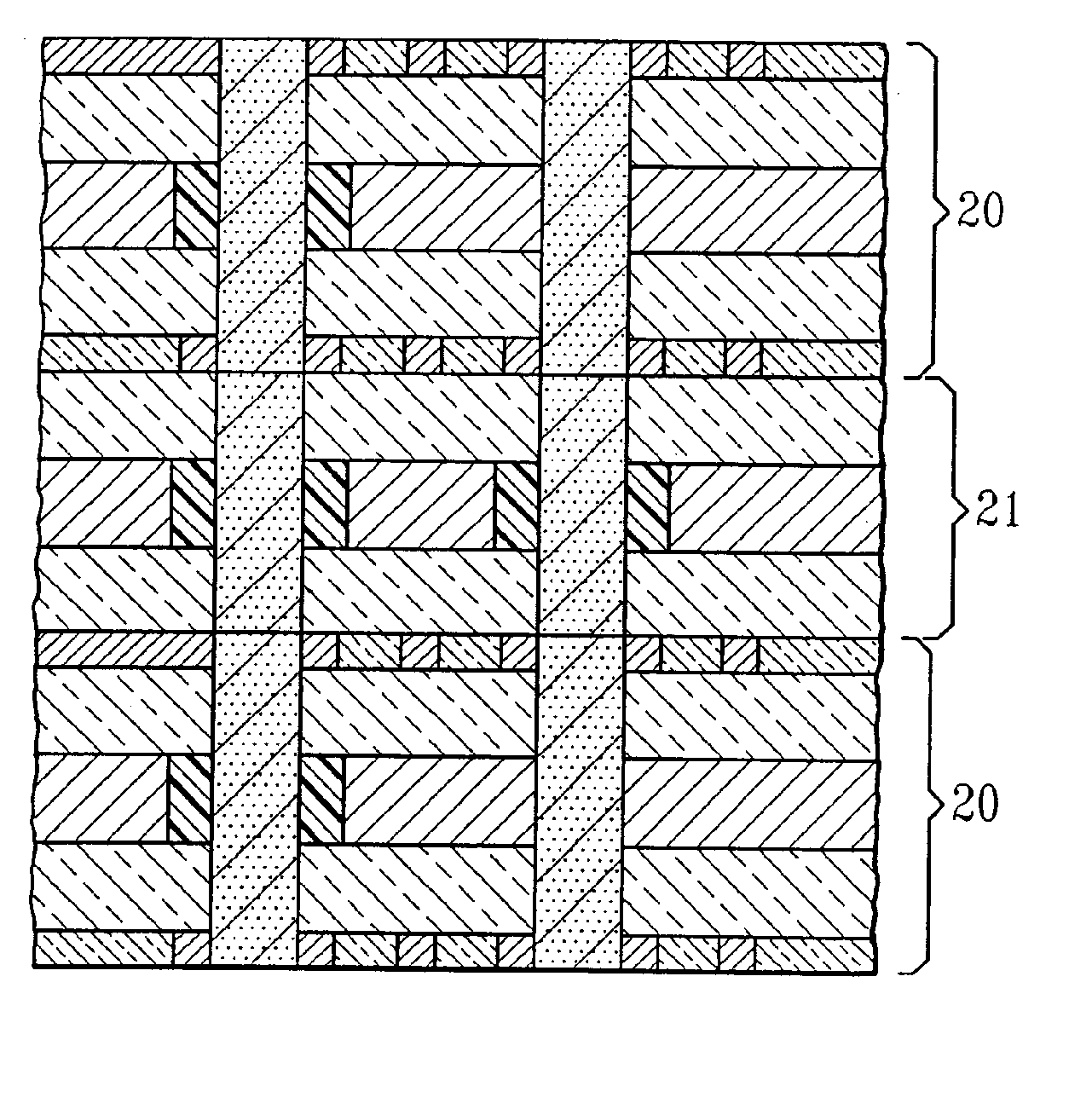

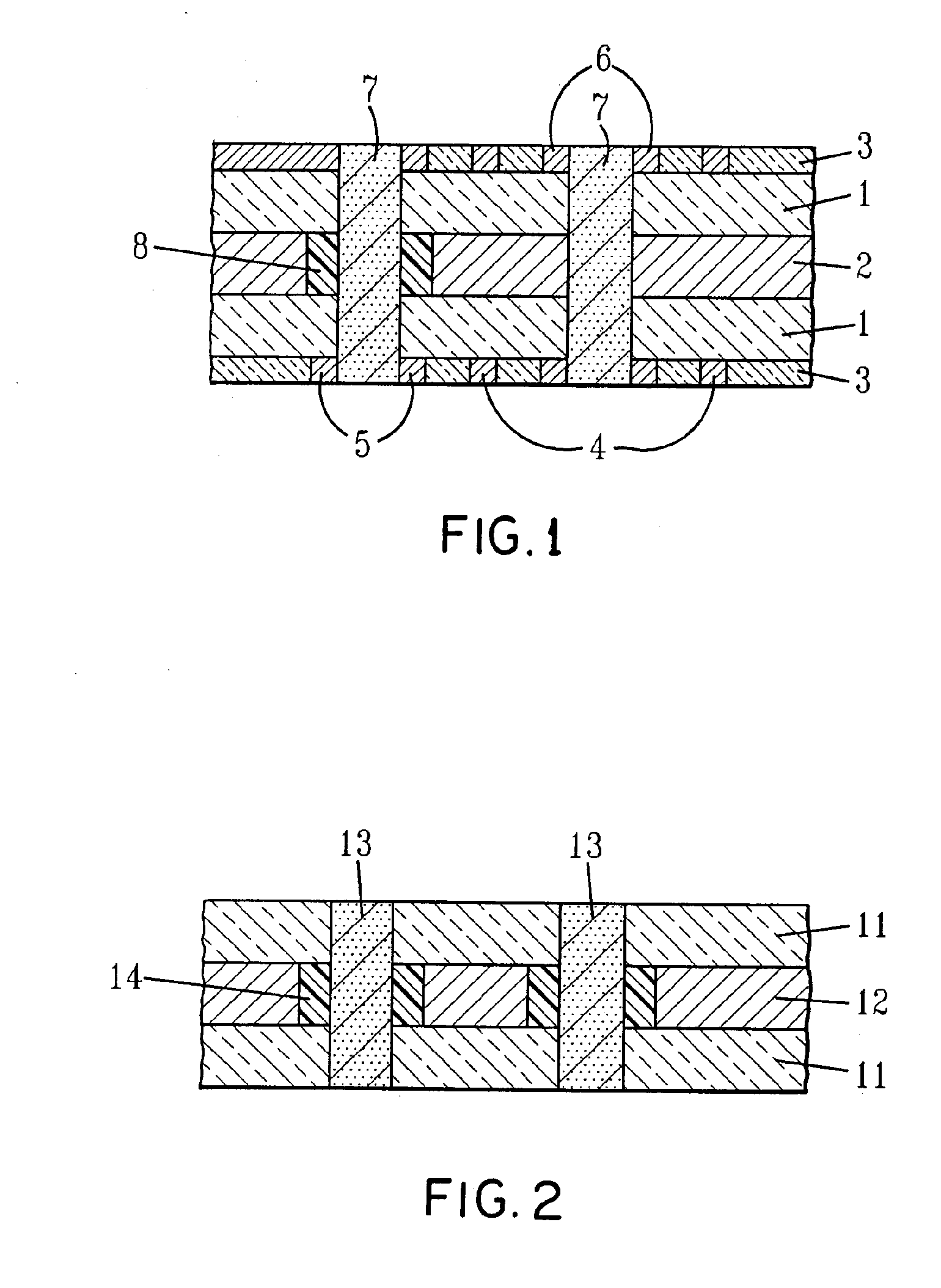

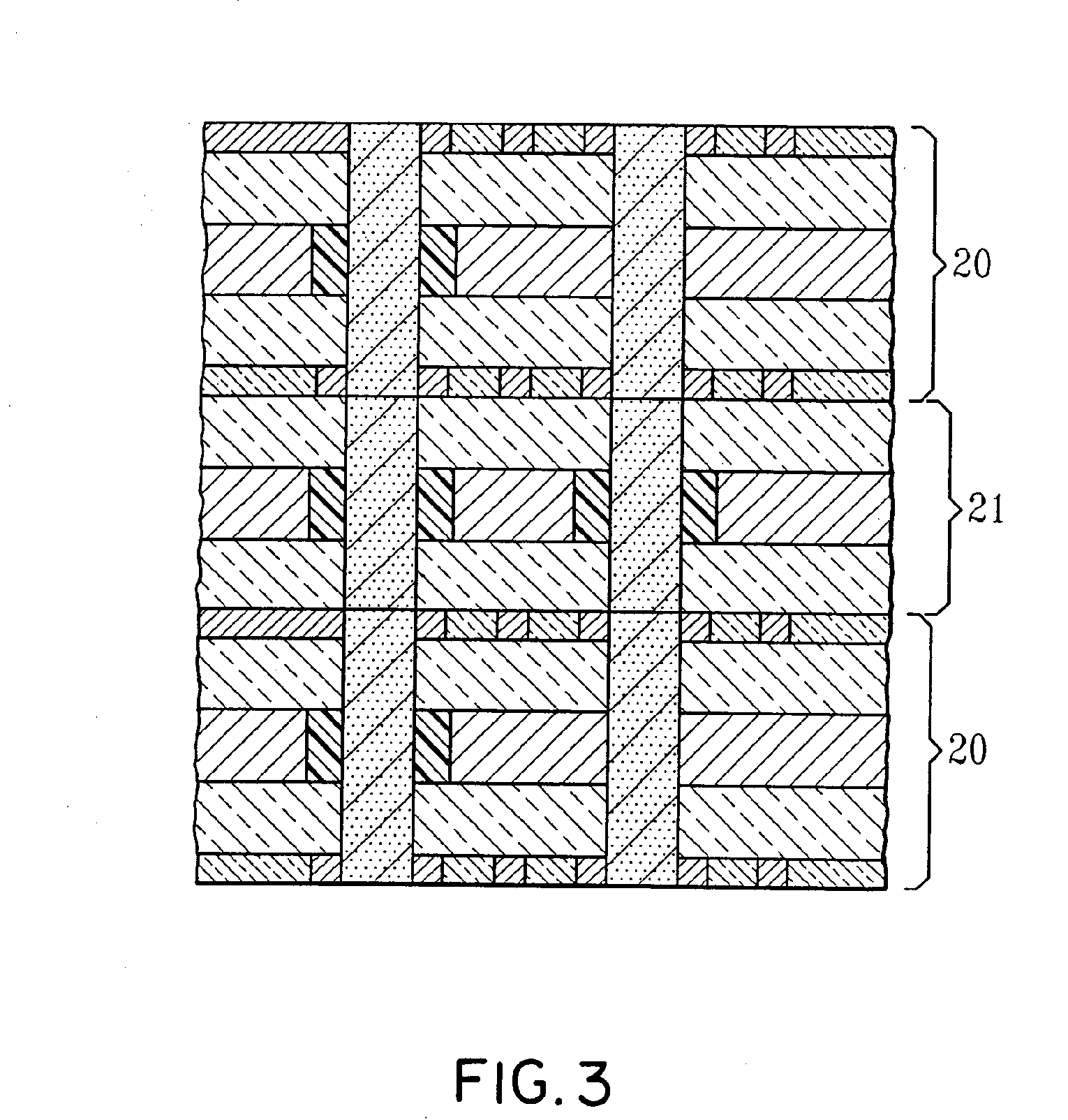

Method of fabricating a laminate circuit structure

InactiveUS6834426B1Thinner laminate circuit structureHigh densityPrinted circuit assemblingPrinted circuit aspectsDielectricVoltage

A method for fabricating a laminate circuit structure is provided. The method comprises: providing at least two modularized circuitized voltage plane subassemblies wherein each of the subassemblies comprise at least two signal planes having an external and internal surface disposed about an internal voltage plane; providing a dielectric material between the signal and voltage planes; and providing dielectric on each external surface of each signal plane; and providing a non-cured or partially cured curable dielectric composition between the subassemblies wherein the dielectric composition comprises, dielectric material that is of the same material as the dielectric material used in said subassemblies, aligning the subassemblies, and then laminating to cause bonding of the subassemblies.

Owner:IBM CORP

Process for the Preparation of Sevelamer Hydrochloride and Formulation Thereof

InactiveUS20090280178A1Cost reductionEliminate useMetabolism disorderDigestive systemPhosphateSevelamer Hydrochloride

Disclosed herein is an improved process for preparation of Sevelamer hydrochloride having phosphate binding capacity of 4.7 to 6.4 mmol / g. Further, the invention discloses Sevelamer hydrochloride compositions and a novel process for preparation of said compositions comprising high shear non-aqueous granulation.

Owner:USV LTD

Process for the preparation of sevelamer hydrochloride and formulation thereof

InactiveUS7846425B2Eliminate useSimplification and improvement of processOrganic active ingredientsMetabolism disorderPhosphateMedicinal chemistry

Disclosed herein is an improved process for preparation of Sevelamer hydrochloride having phosphate binding capacity of 4.7 to 6.4 mmol / g. Further, the invention discloses Sevelamer hydrochloride compositions and a novel process for preparation of said compositions comprising high shear non-aqueous granulation.

Owner:USV LTD

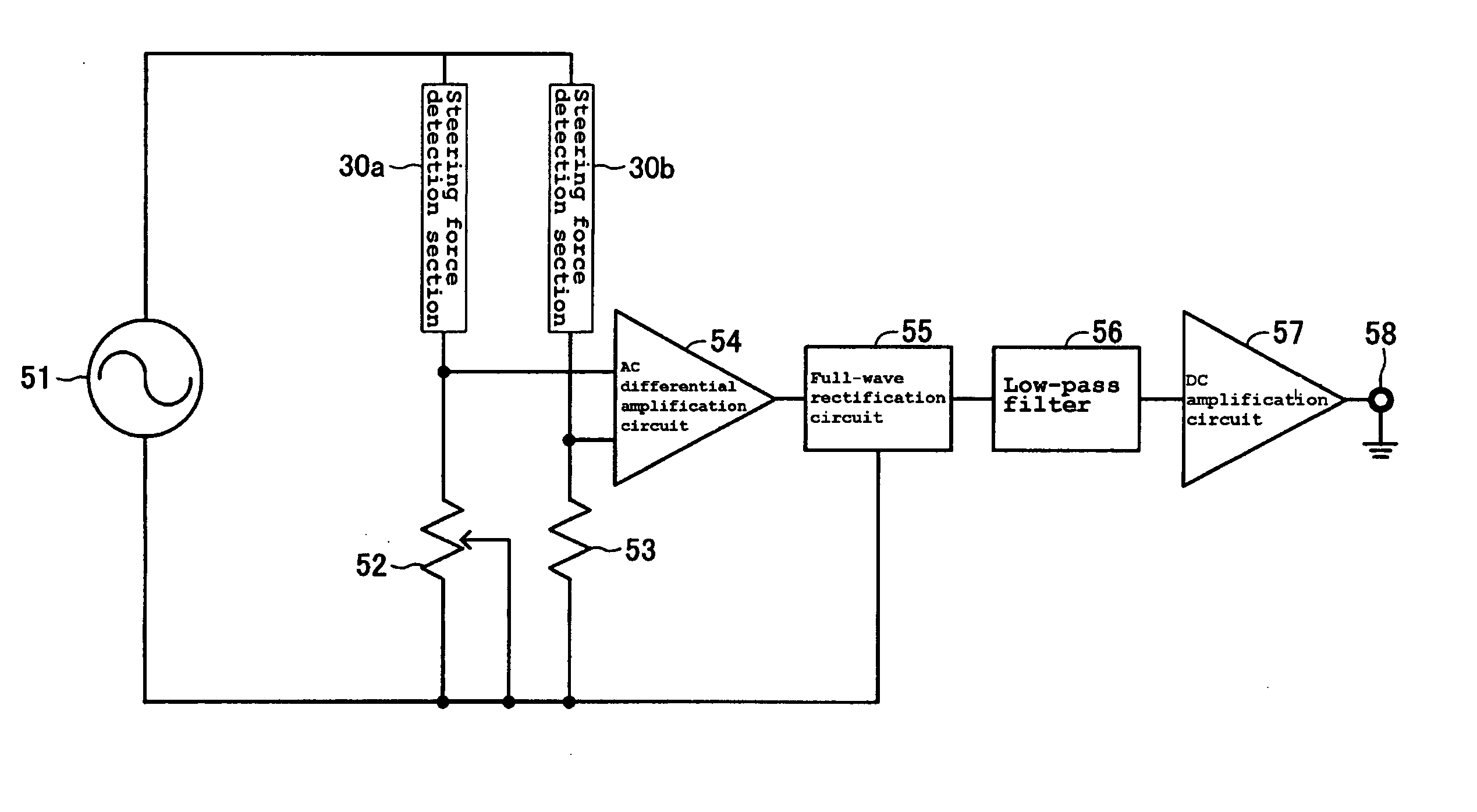

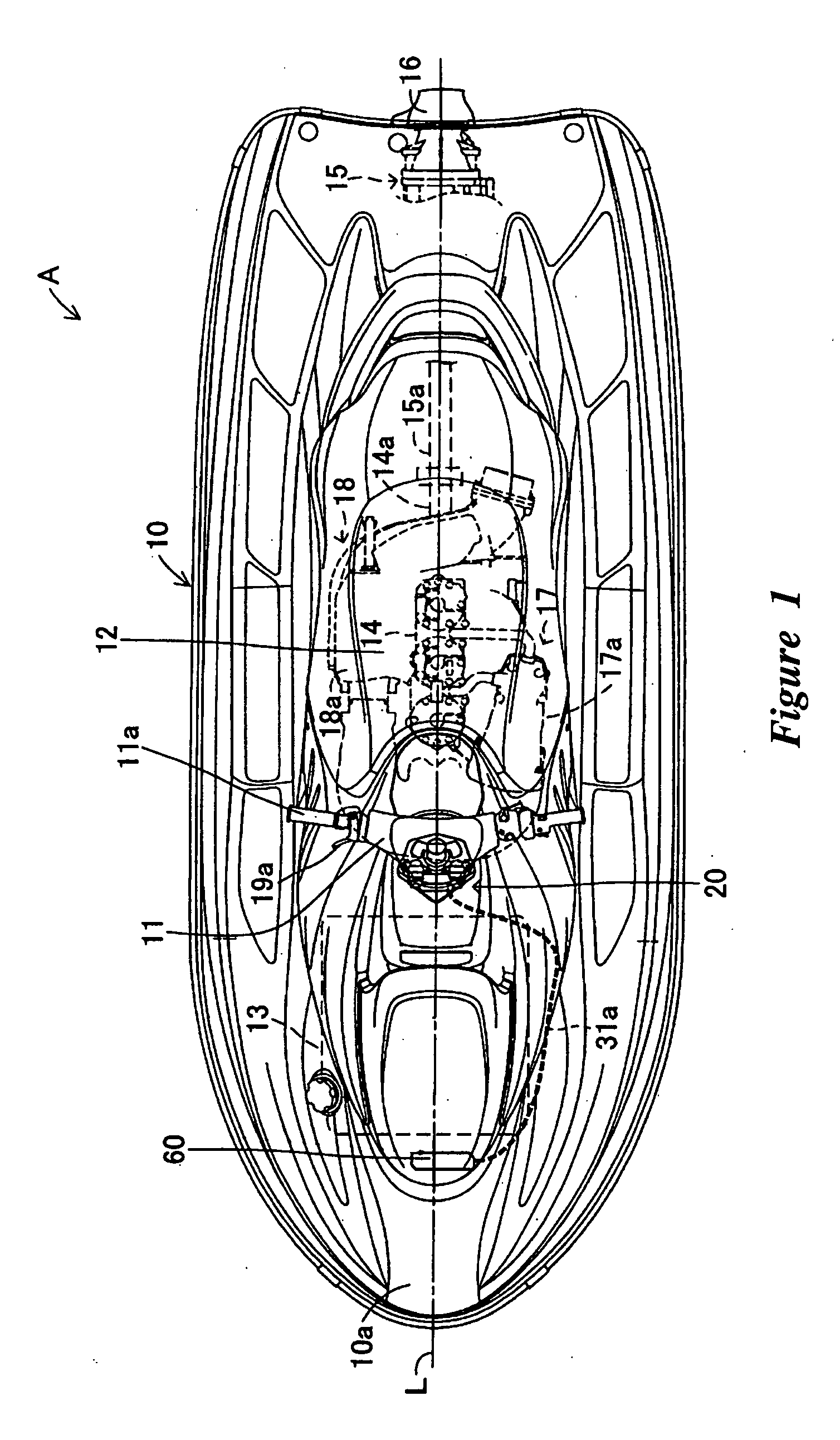

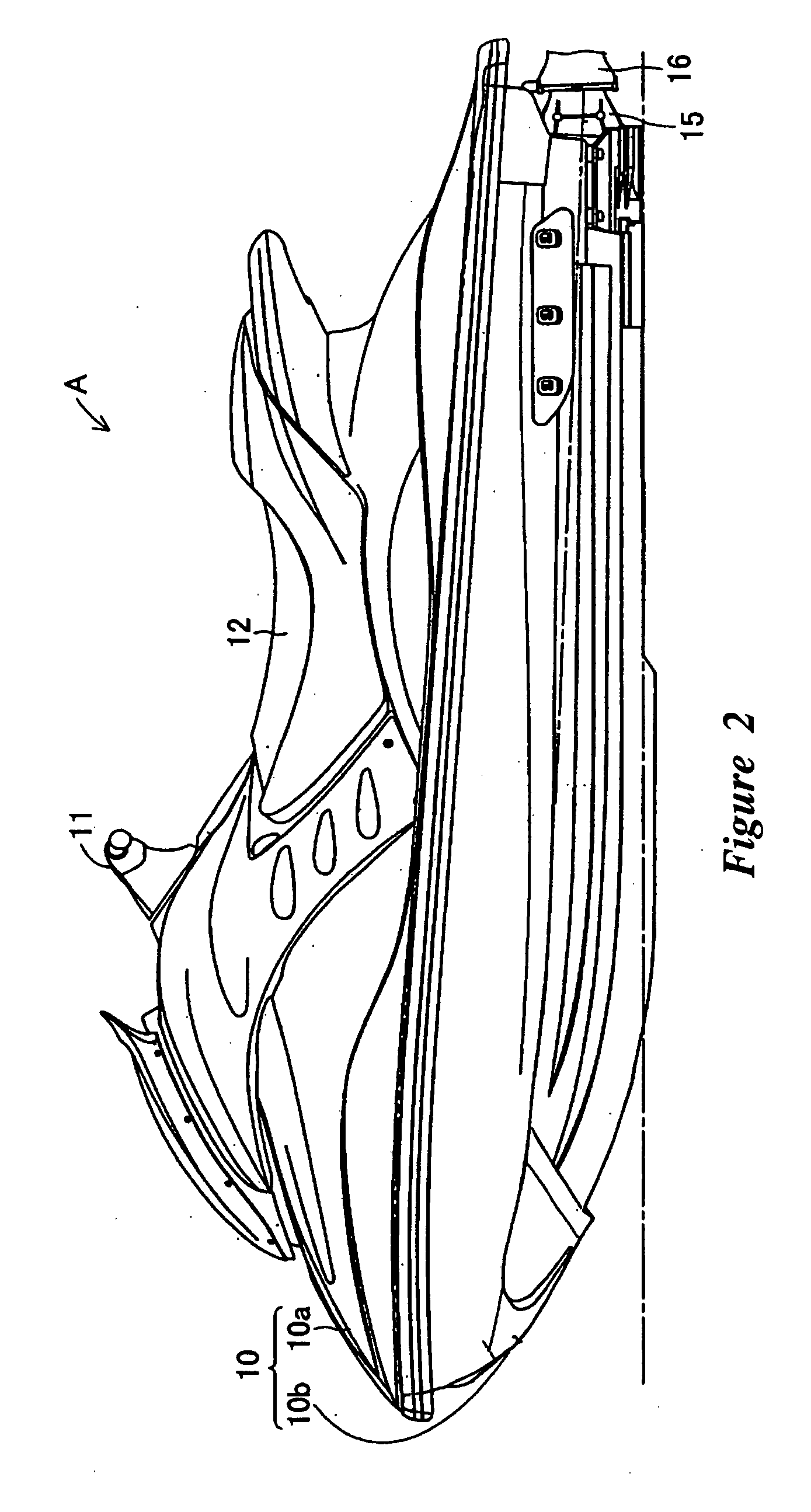

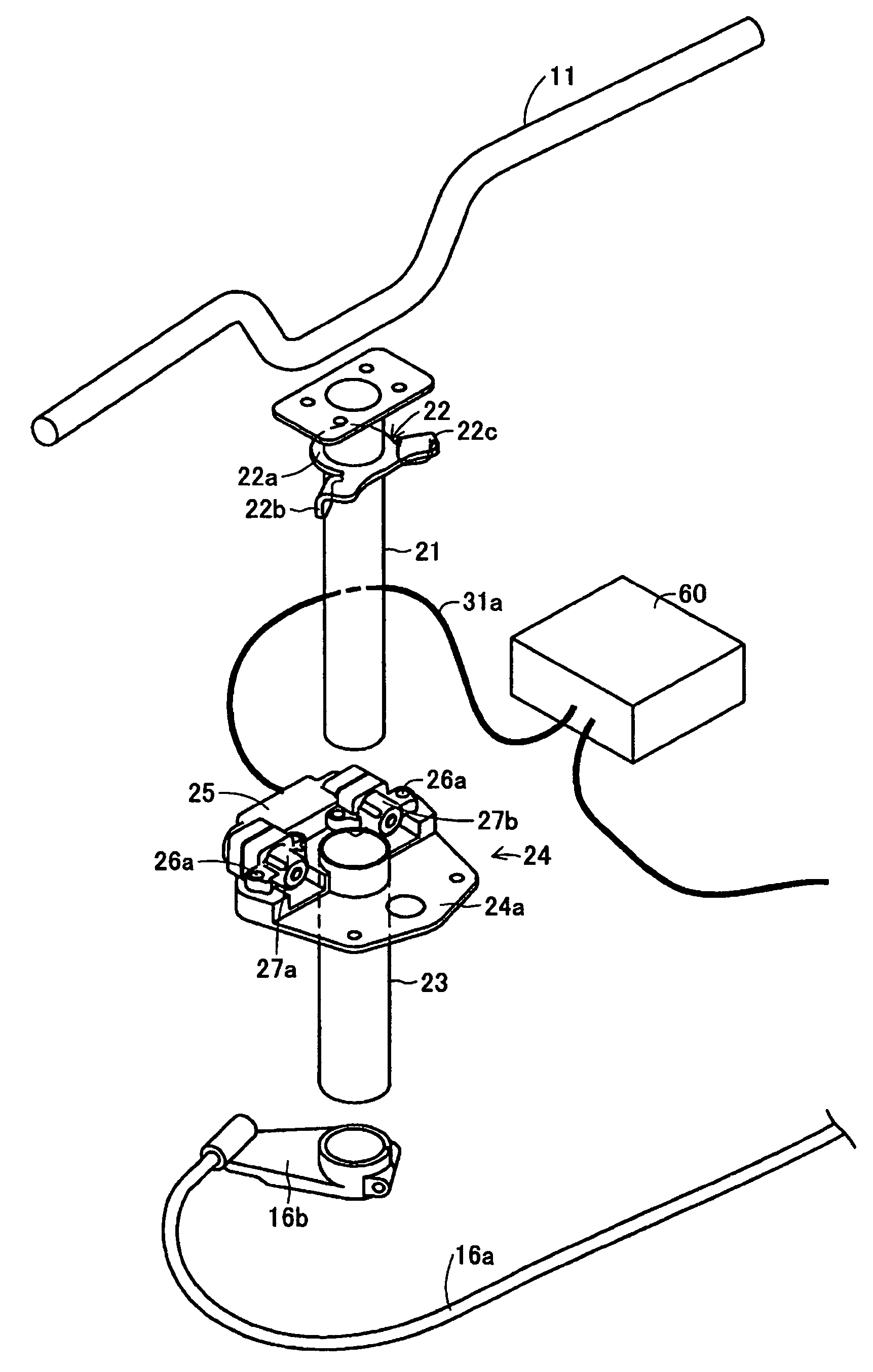

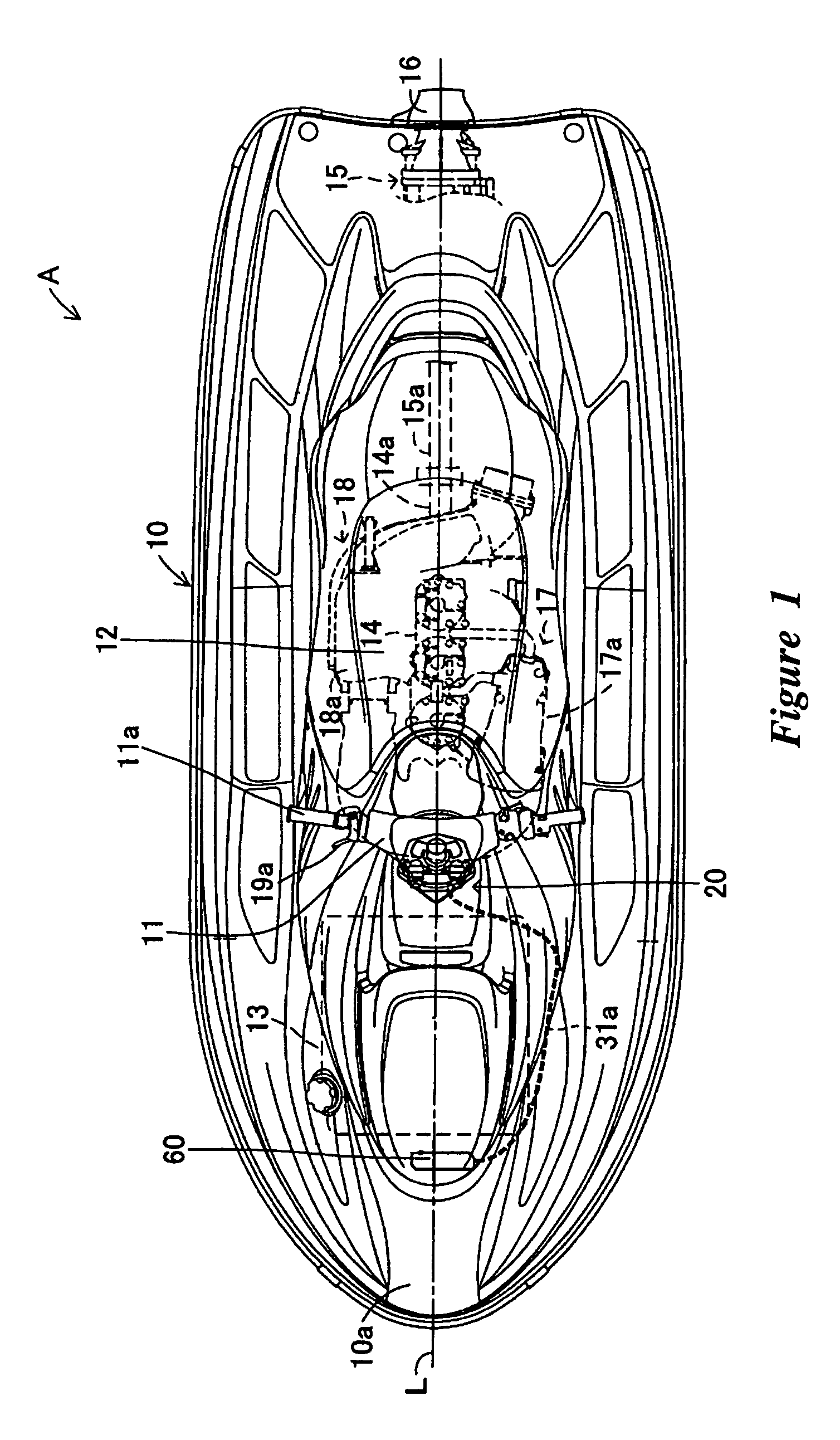

Steering force detection device for steering handle of vehicle

InactiveUS20060004502A1Easy alignmentImprove assembly accuracyDigital data processing detailsSteering initiationsSteering angleWatercraft

A watercraft has steering force detection sections. Each steering force detection section includes a pressure receiving section. The pressure receiving sections are spaced from each other and are in the vicinity of a steering shaft. A pressing member is coupled to the steering shaft. The pressing member can press on at least one of the pressure receiving sections when the steering handlebars are rotated to a maximum steering angle. A received pressure detection section detects the pressure applied to the pressure receiving section. The pressure receiving section and the received pressure detection section are coaxially mounted in a pressure receiving section casing and a detection section casing. A guide tube can engage the pressure receiving section and the received pressure detection section. The guide tube is formed with ribs and grooves. The pressure receiving section has a pressure receiving member, a bolt, a plain washer, and a spring member.

Owner:YAMAHA MARINE KK

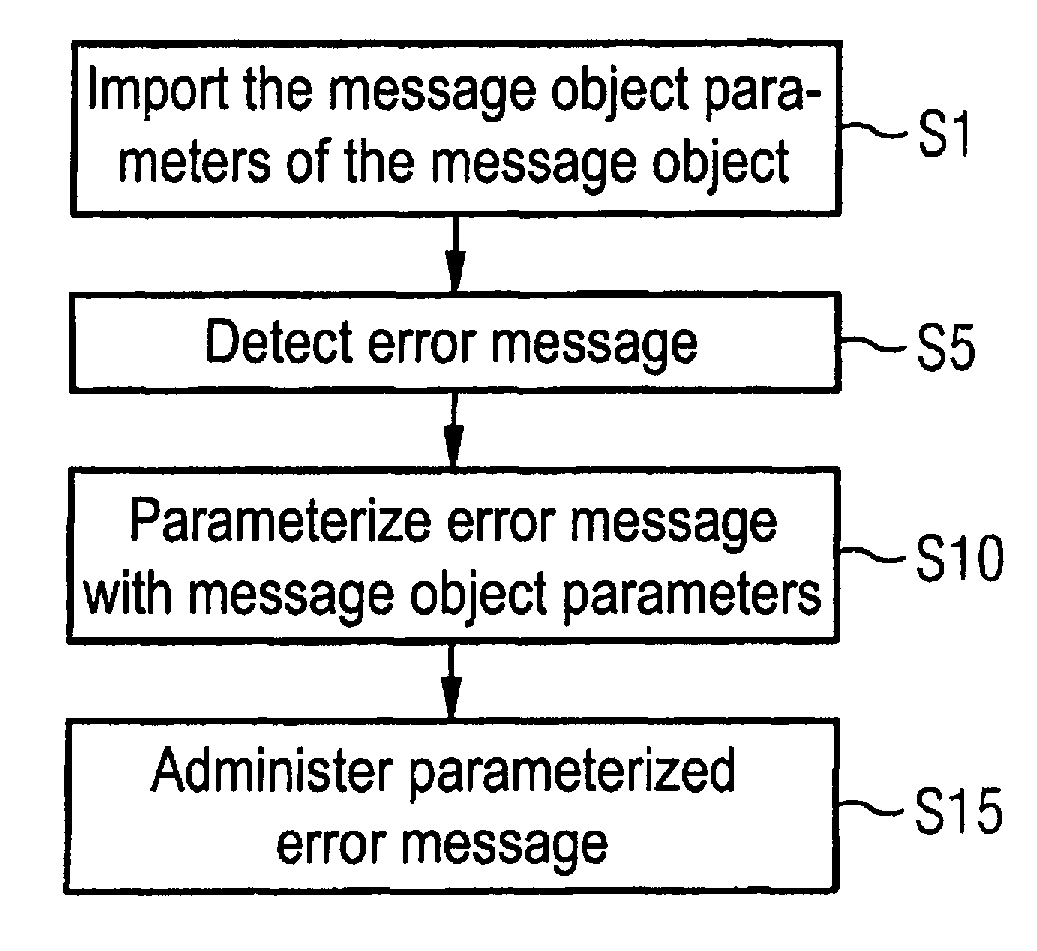

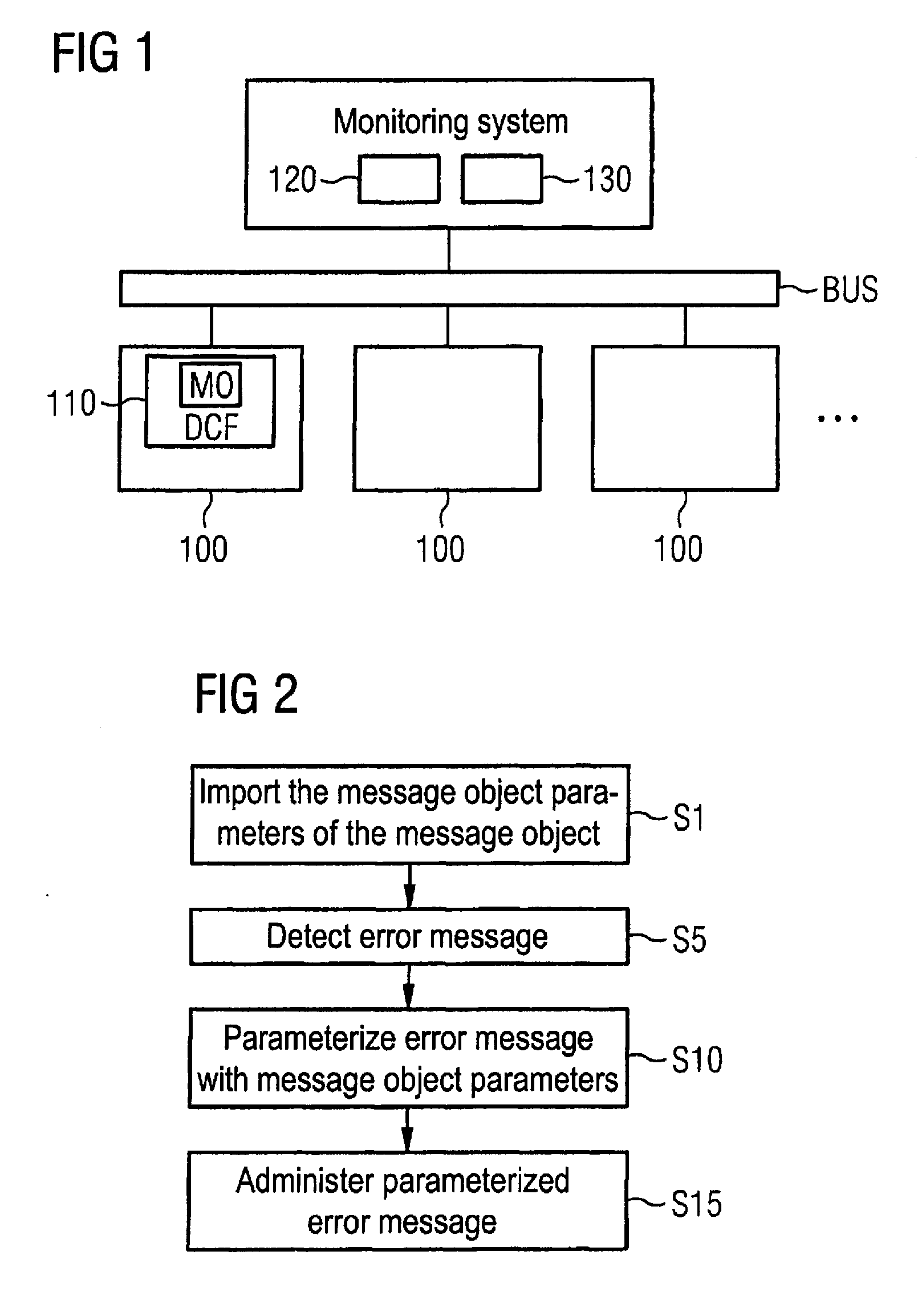

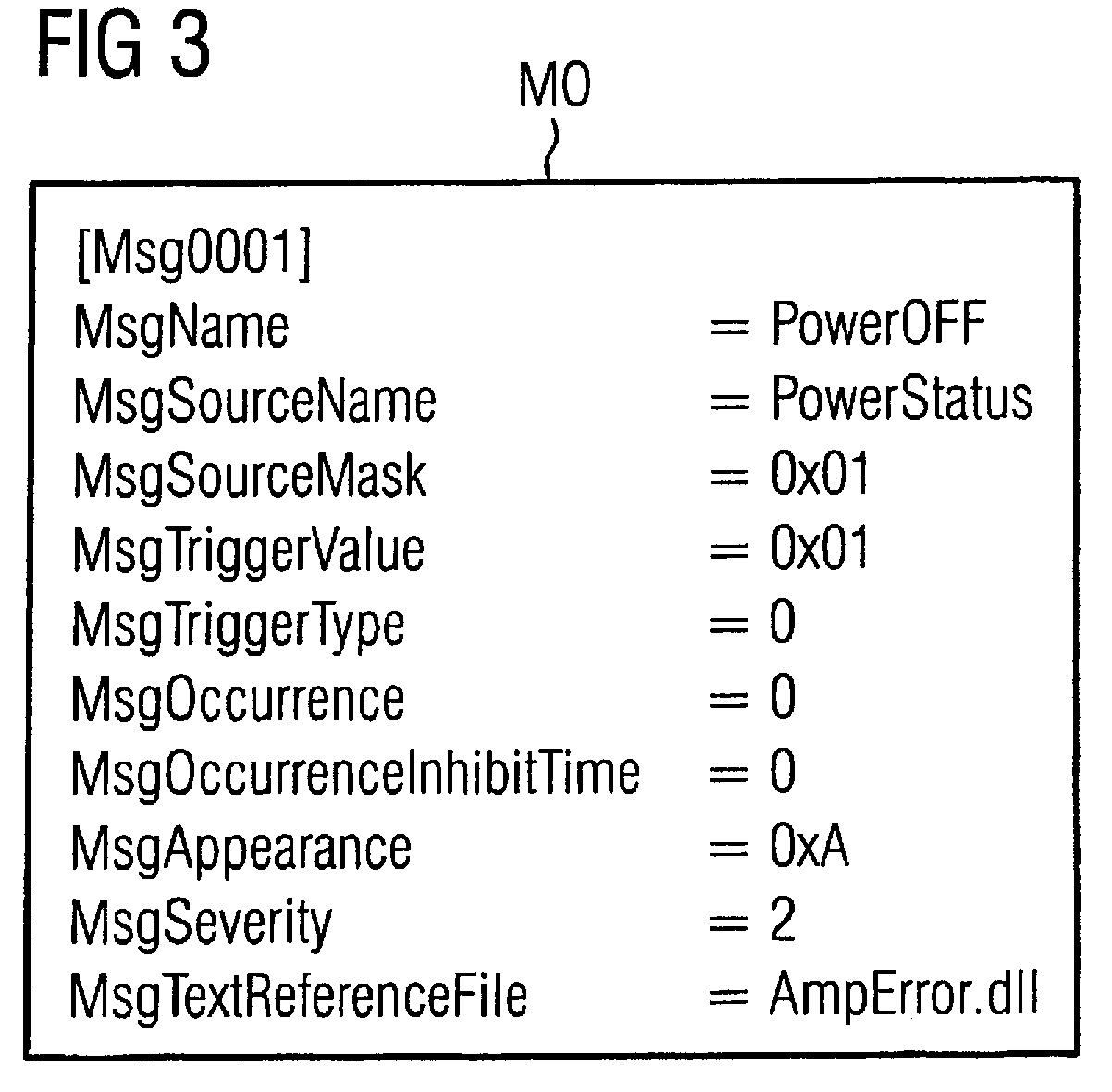

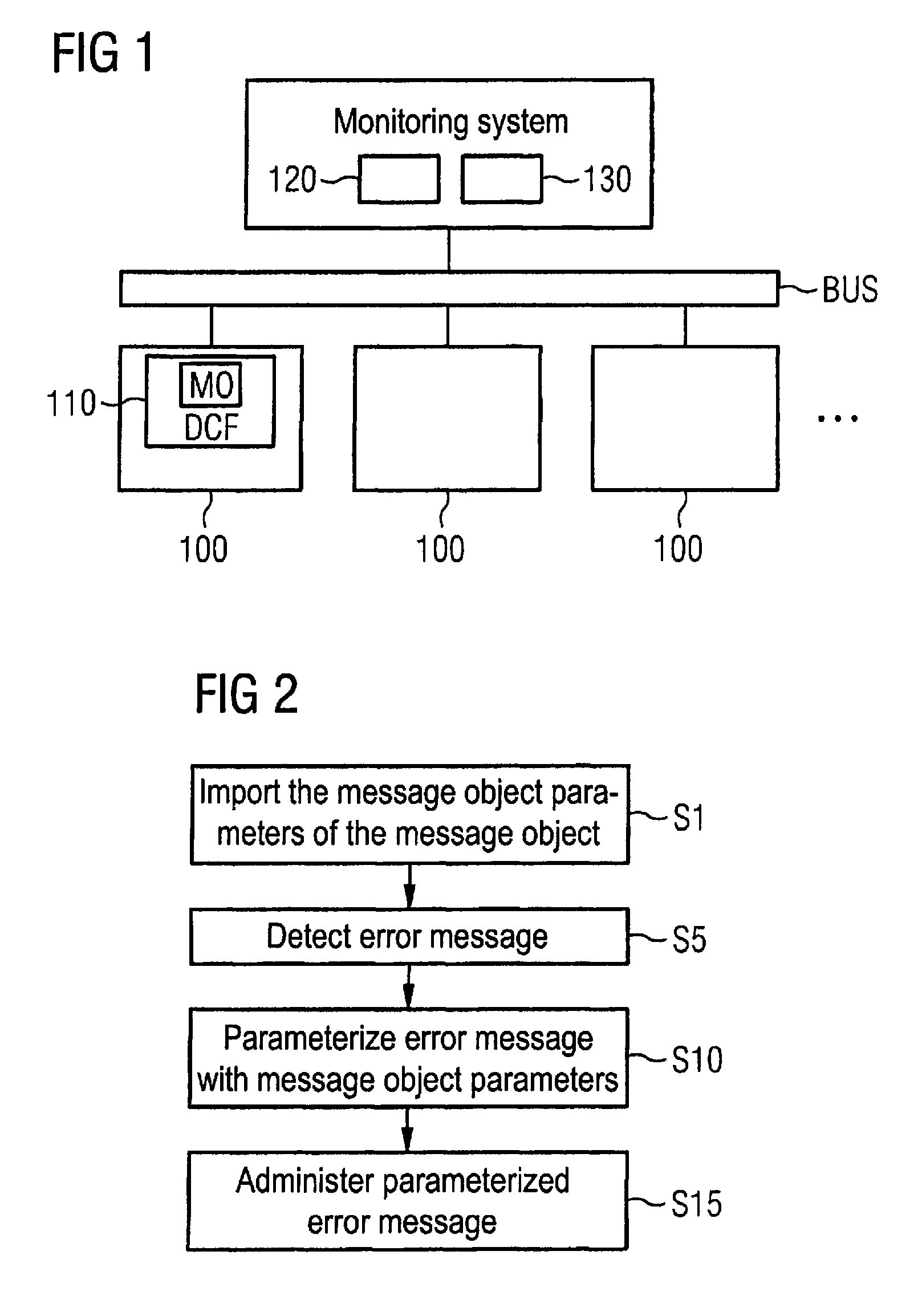

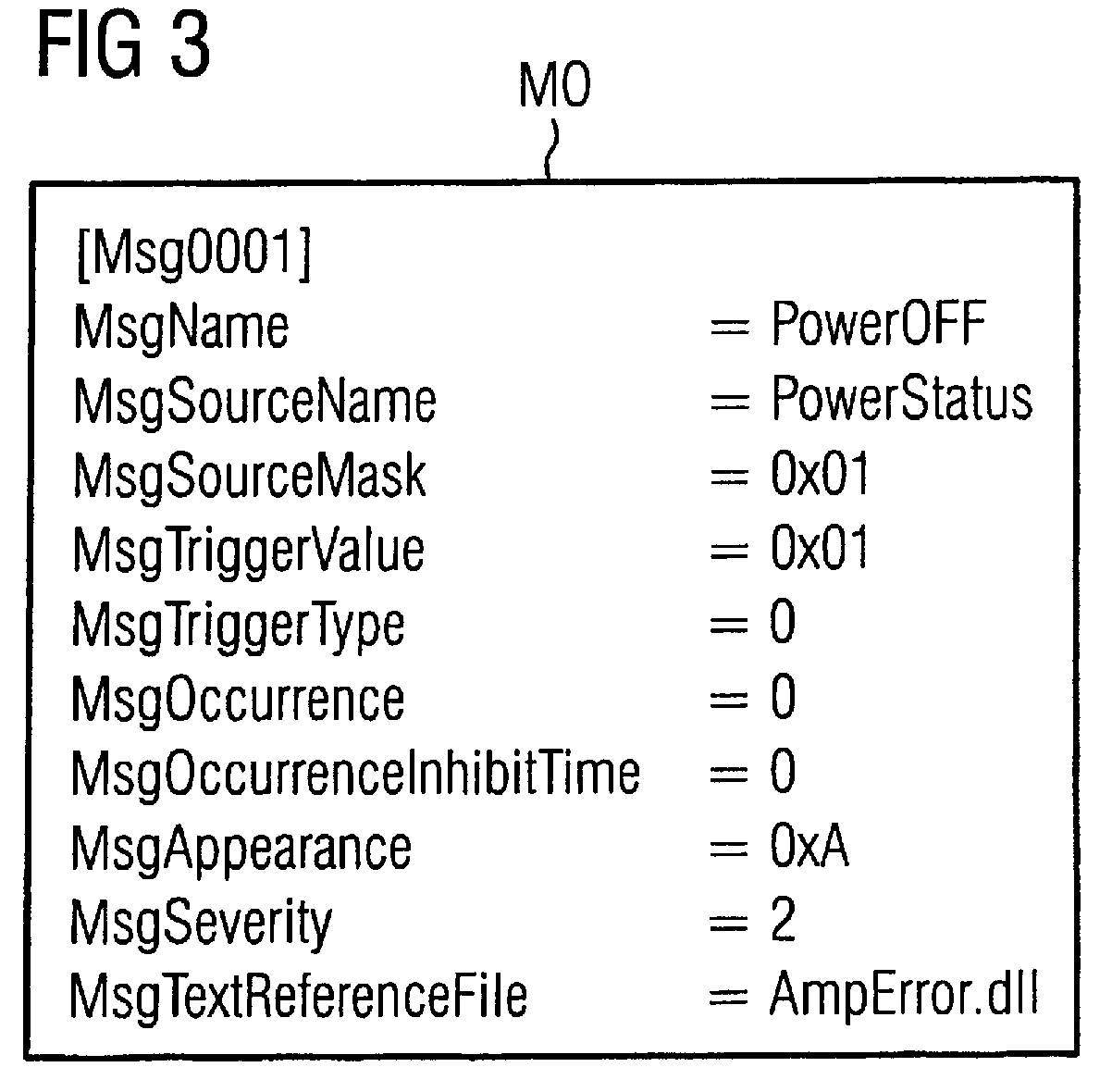

Communications administration method and system for an electronic apparatus

ActiveUS20100037103A1Avoid the correction processSimplification and improvement of processNon-redundant fault processingComputer hardwareCANopen

In a method, a computer-readable medium encoded with programming instructions, and a system for the administration of error messages of electronic, medical technology peripheral apparatuses (100) that are in communication via a CANopen interface, a device configuration file is extended by a message object. The message object can be configured in advance. At run time the message object is then imported and used in the processing or in the administration of a detected error message. The detected error message is parameterized (and thus specifically processed) using the detected message object.

Owner:SIEMENS HEALTHCARE GMBH

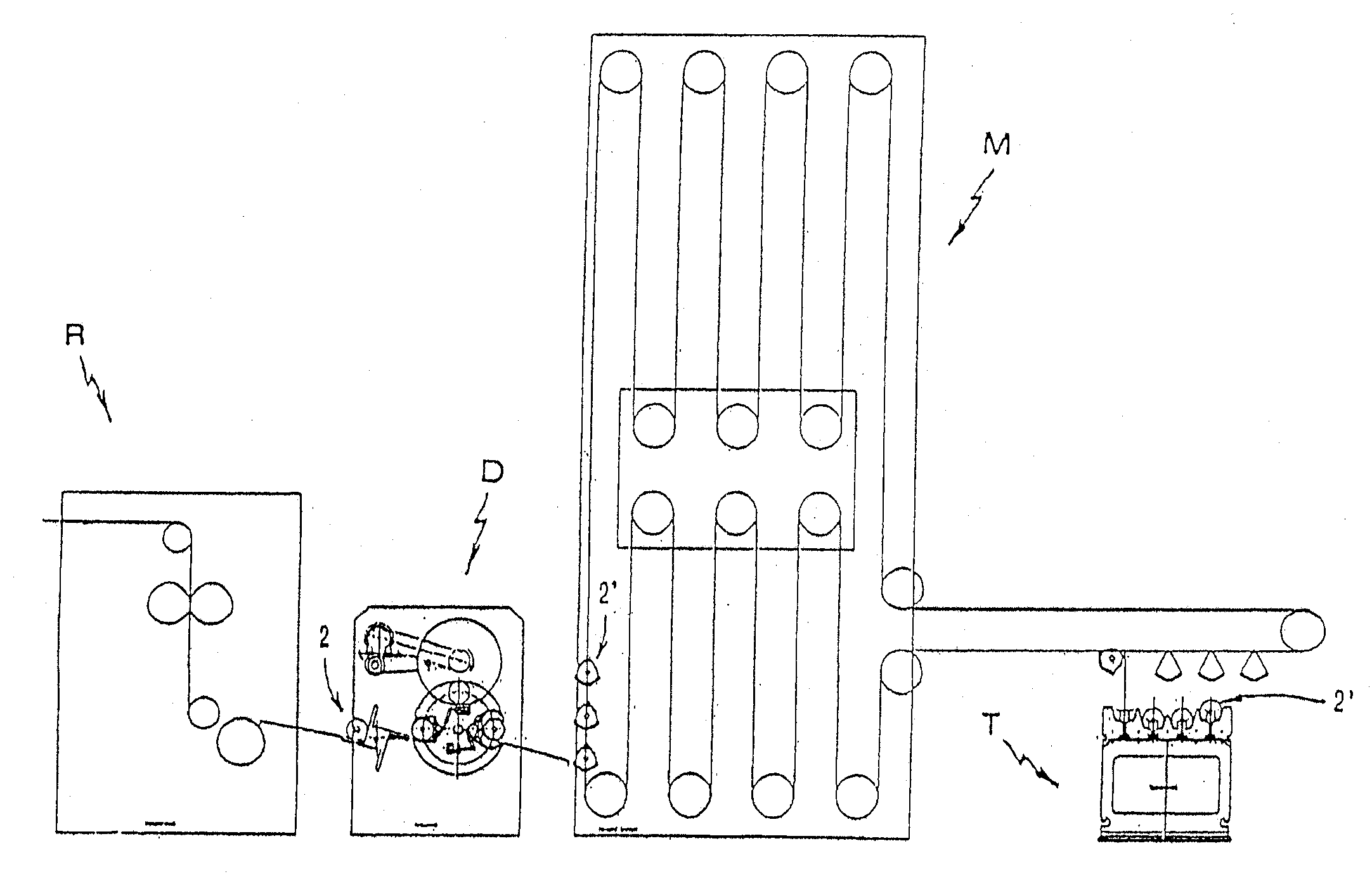

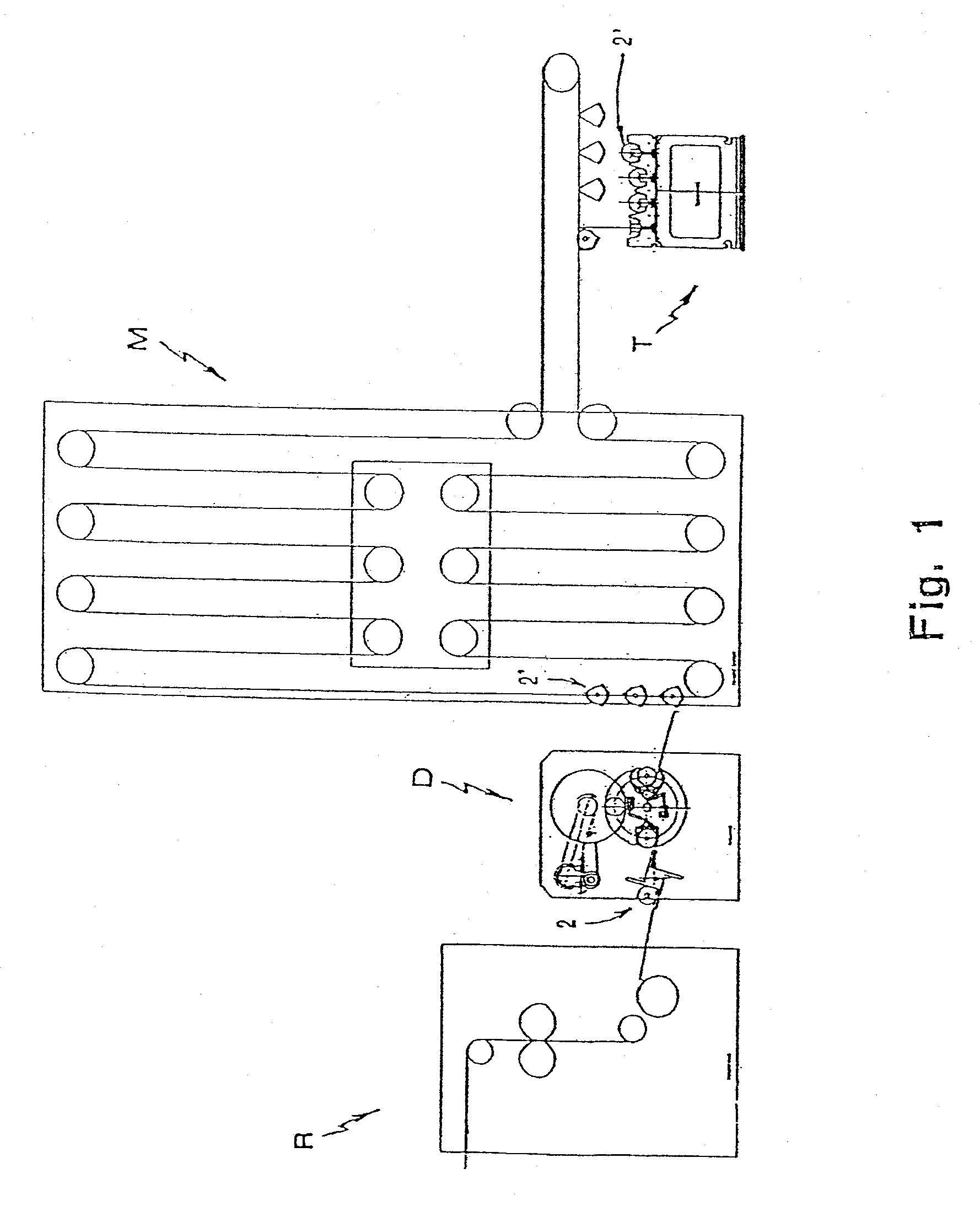

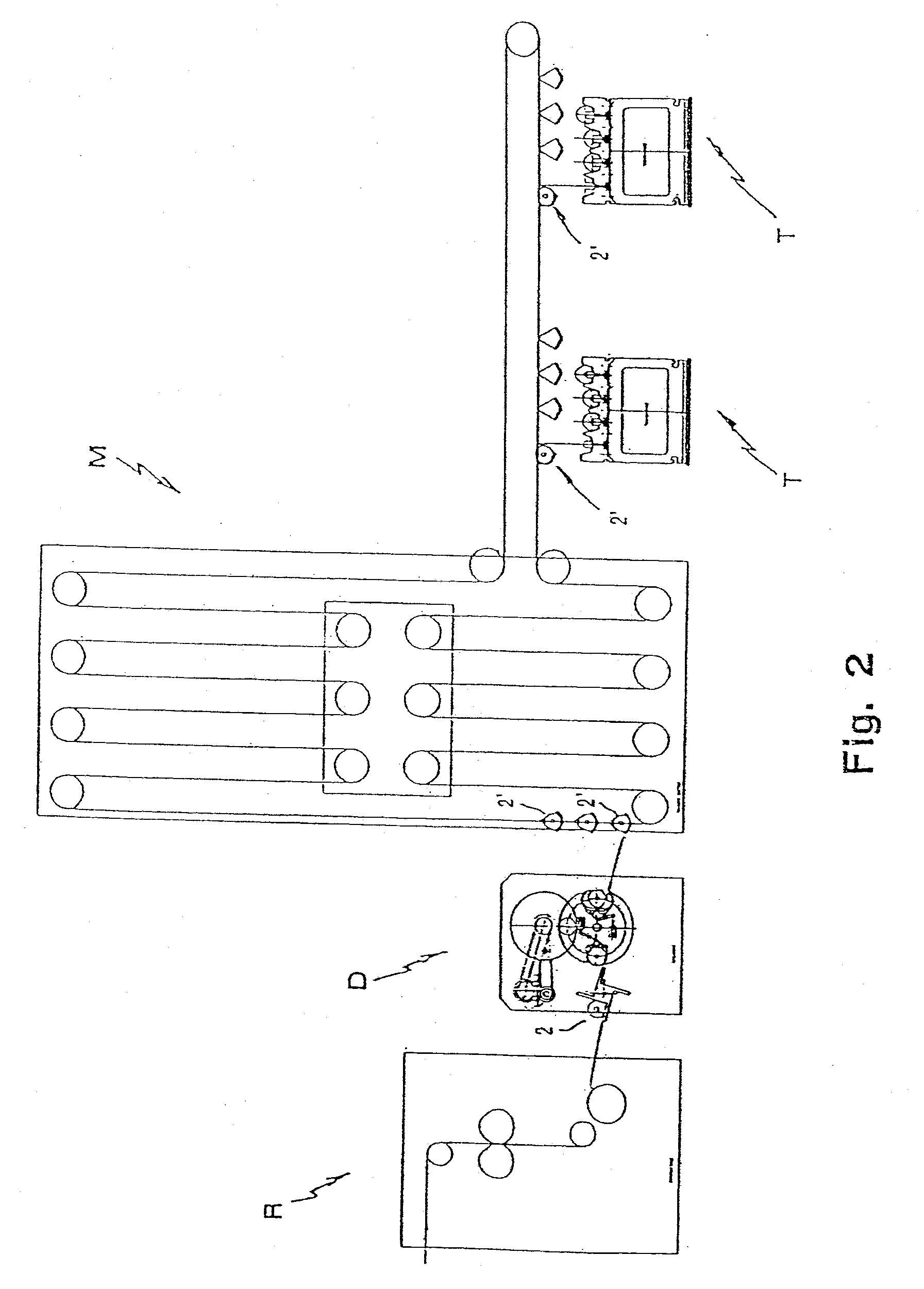

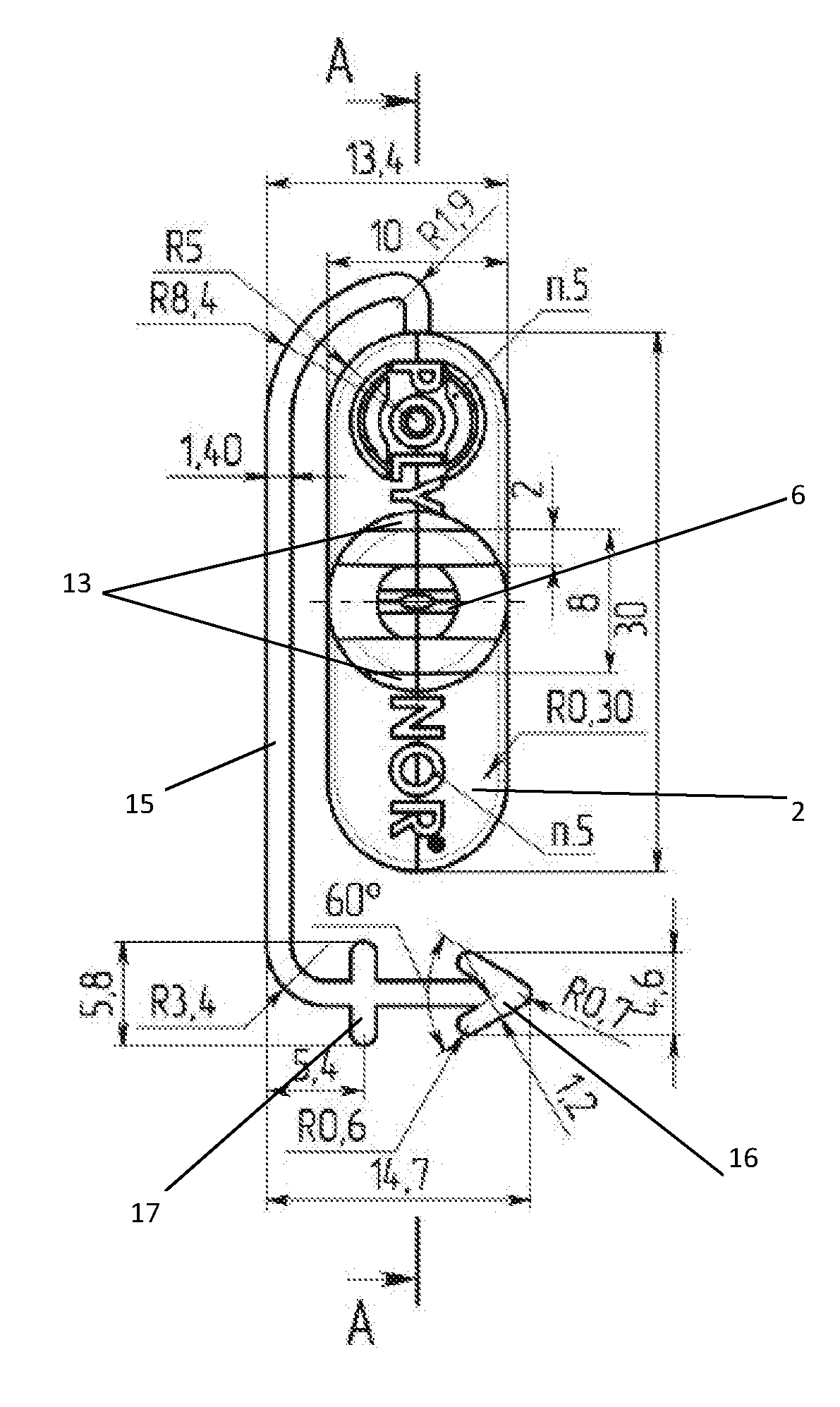

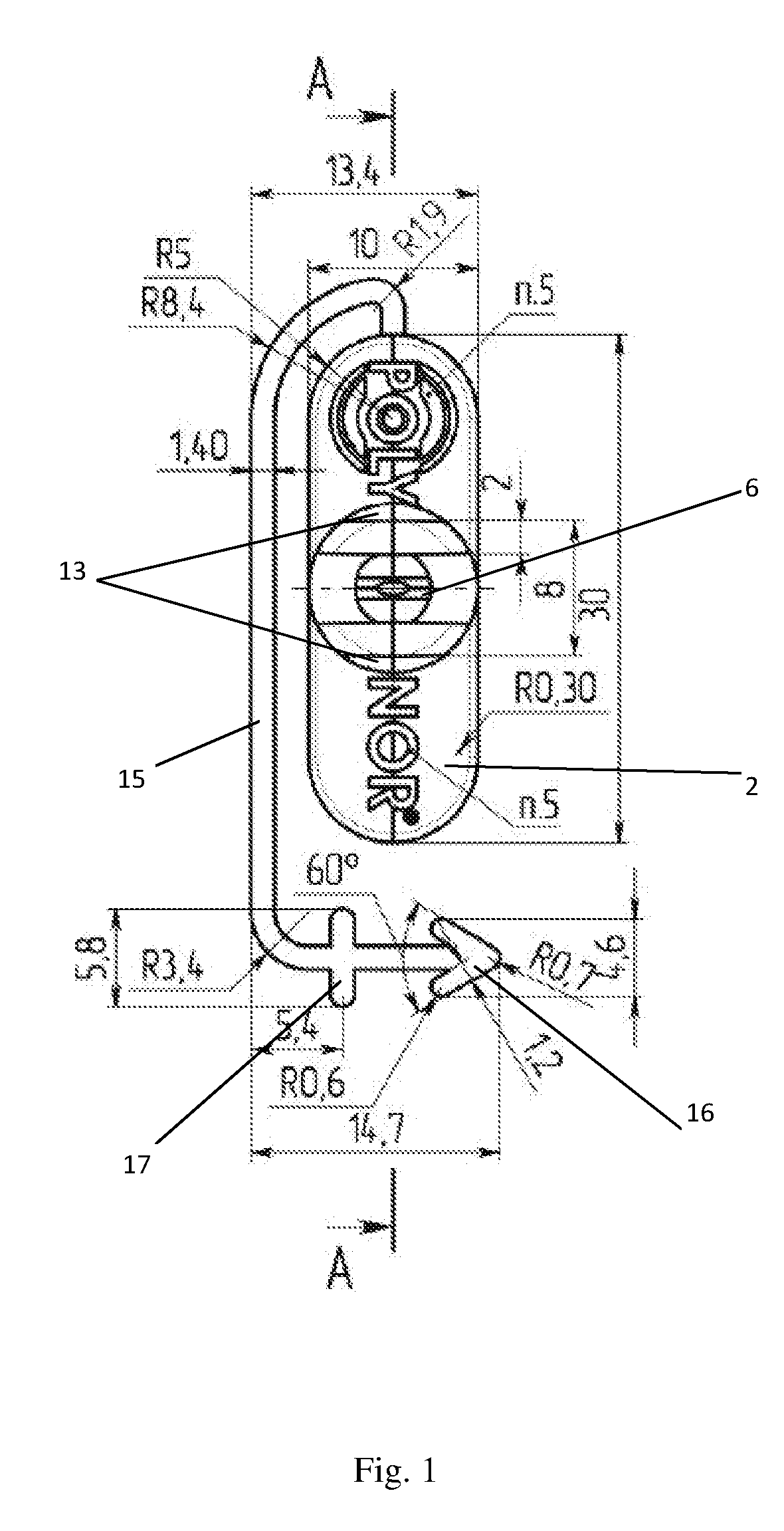

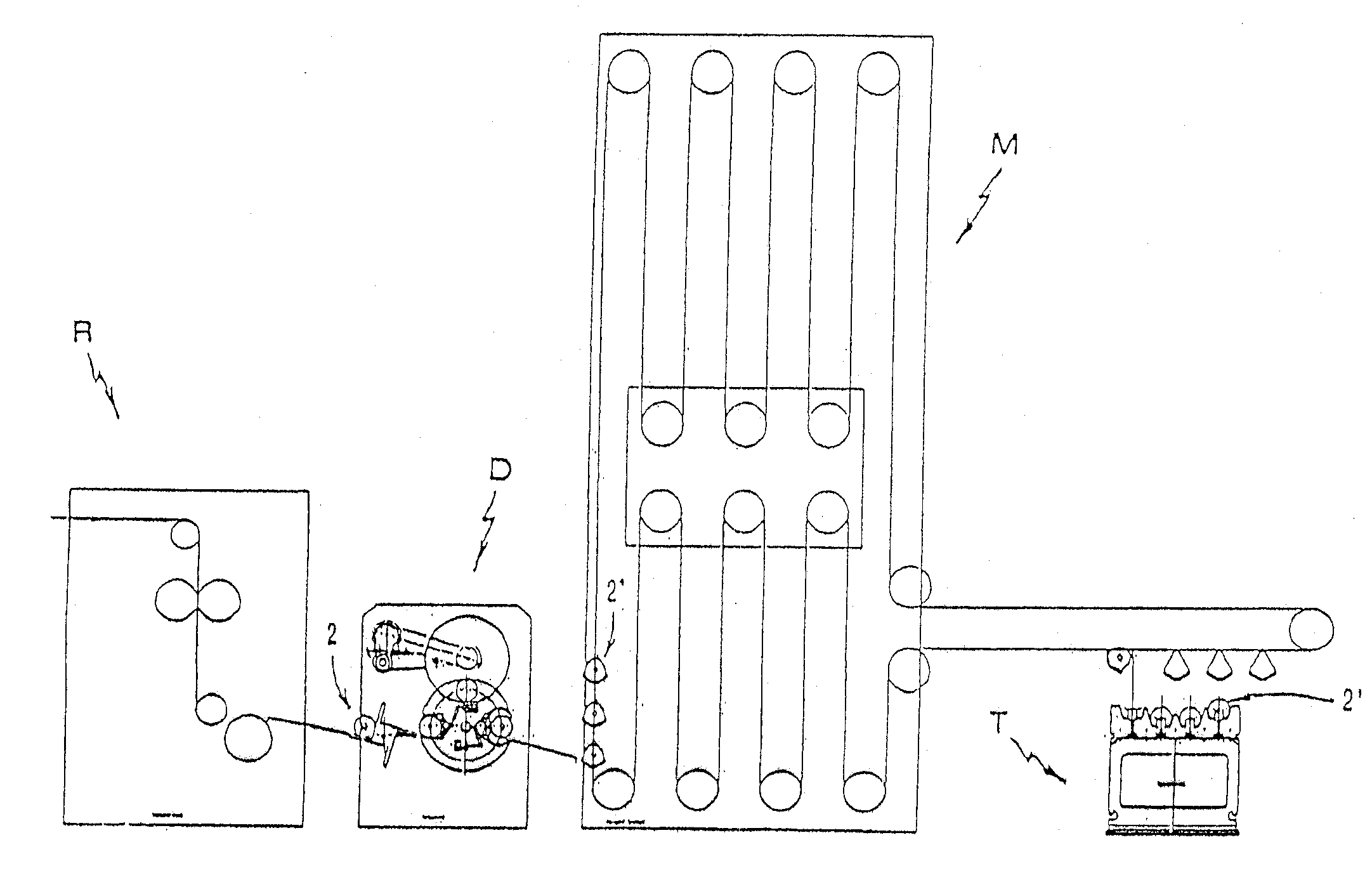

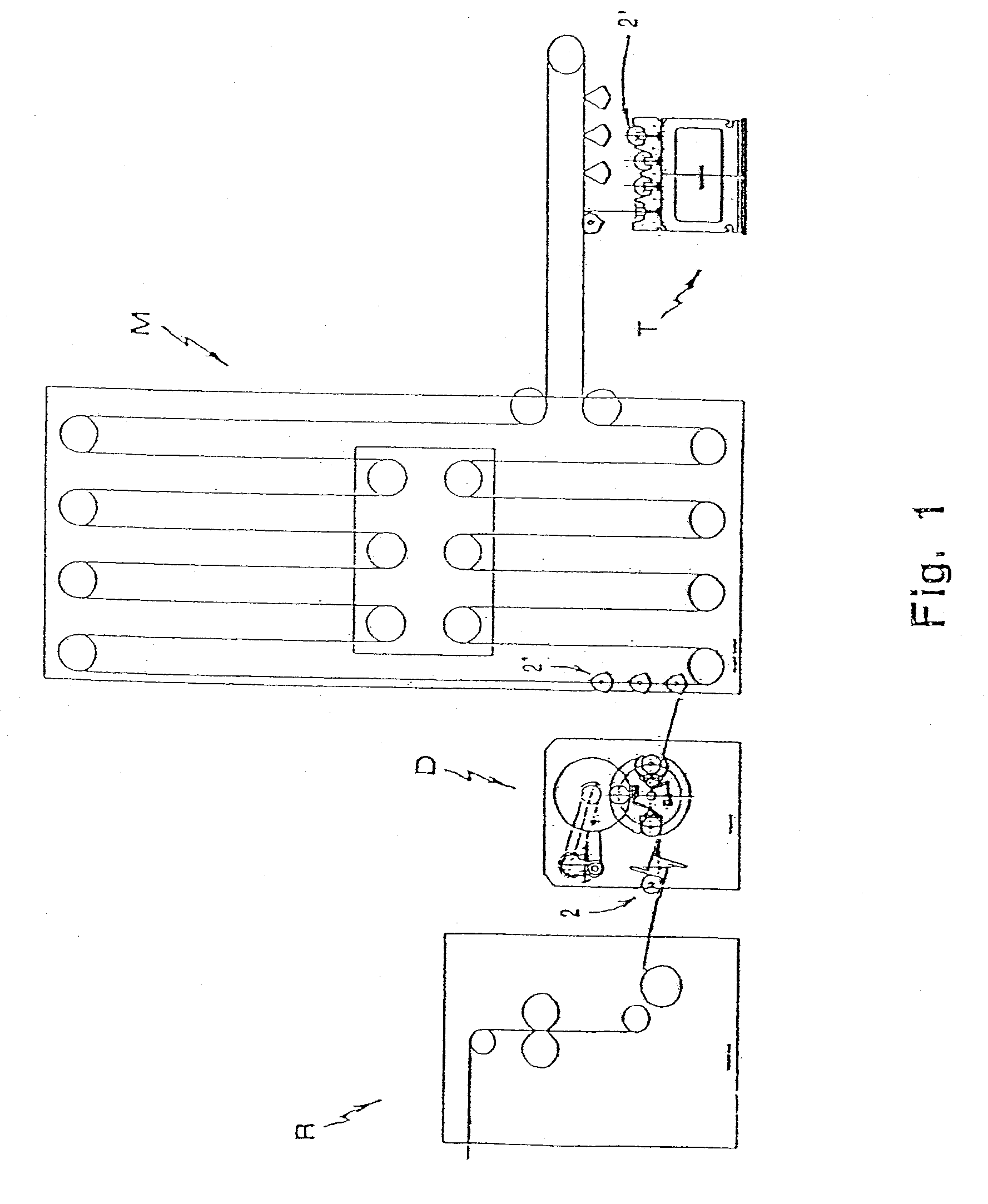

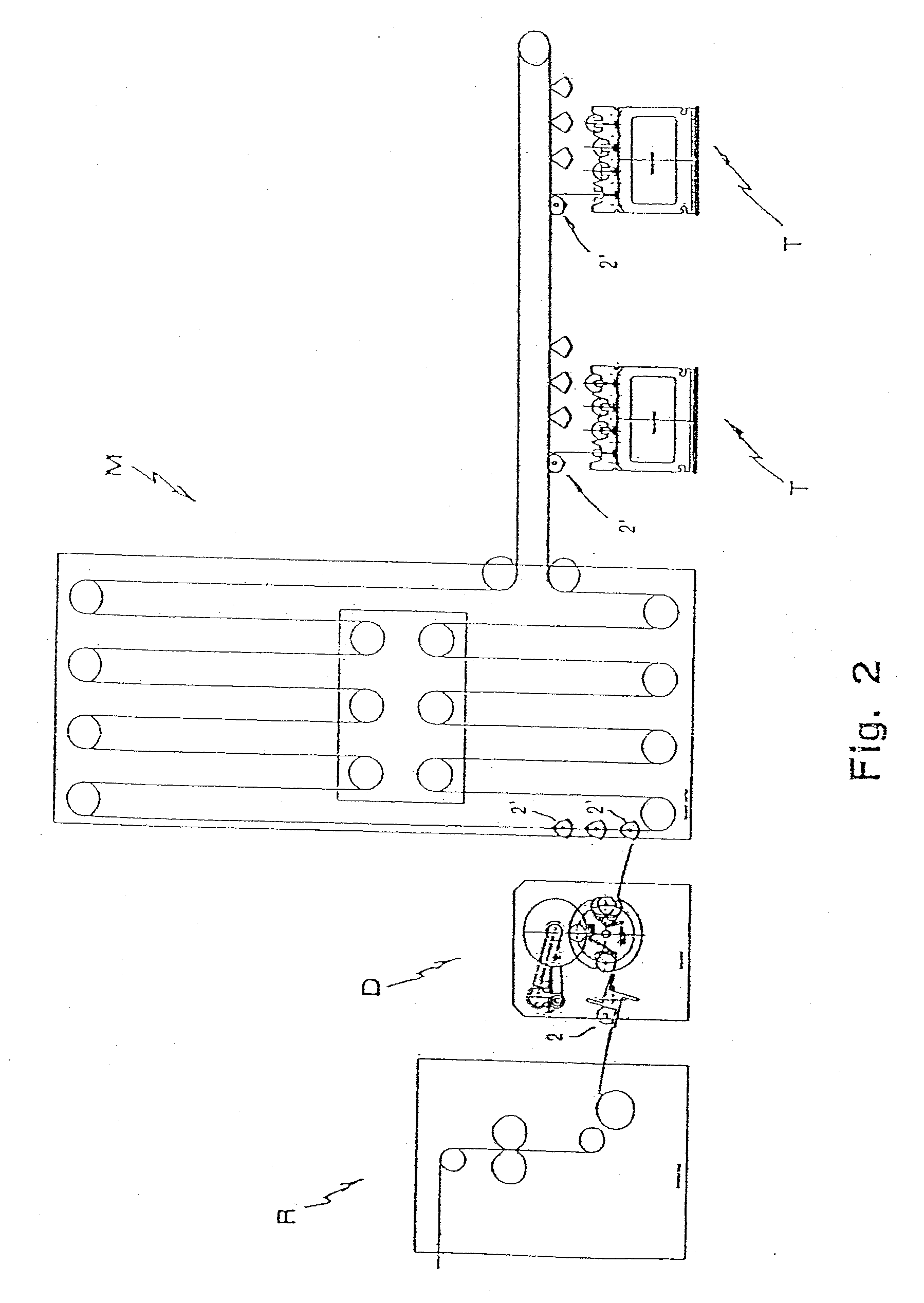

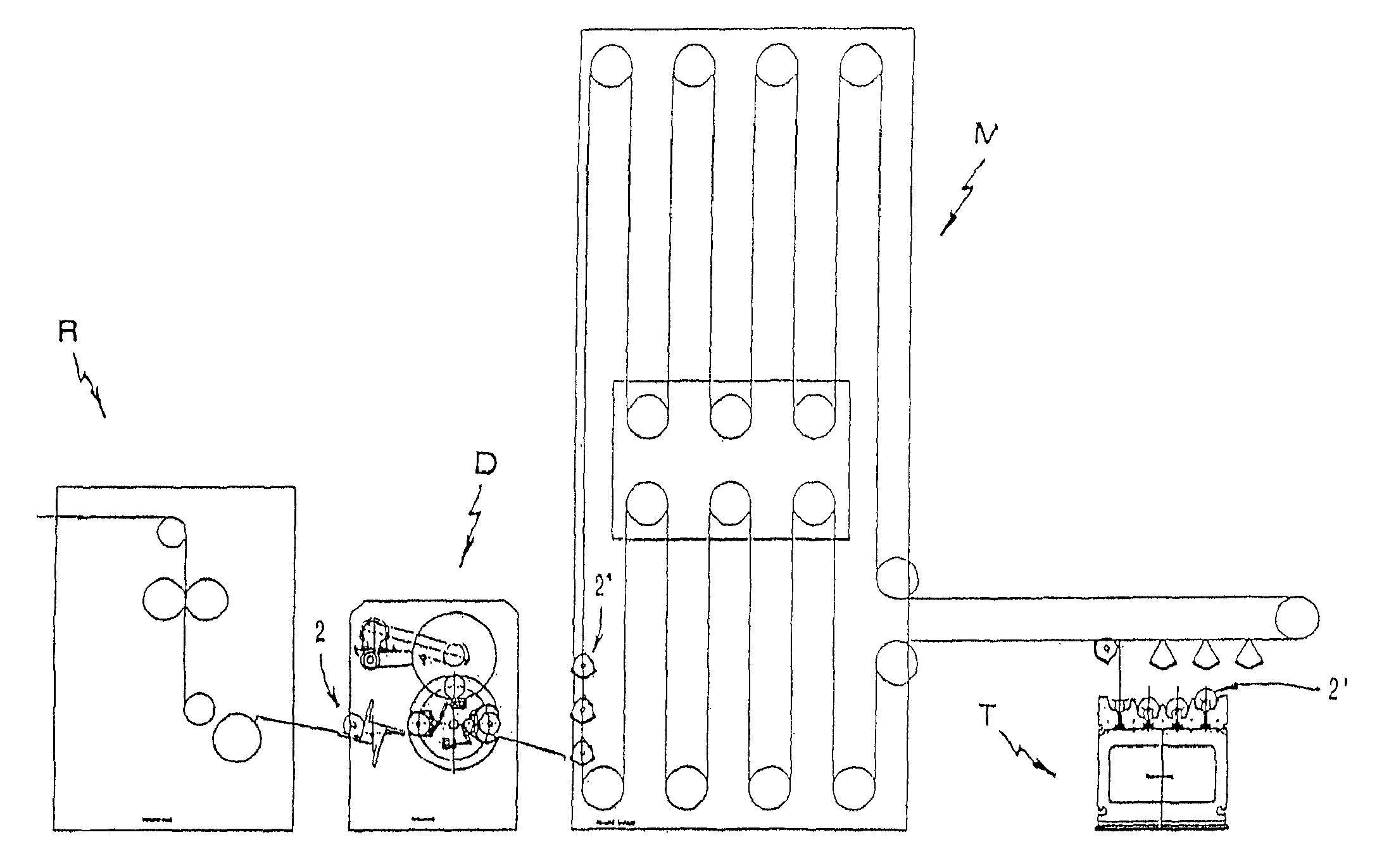

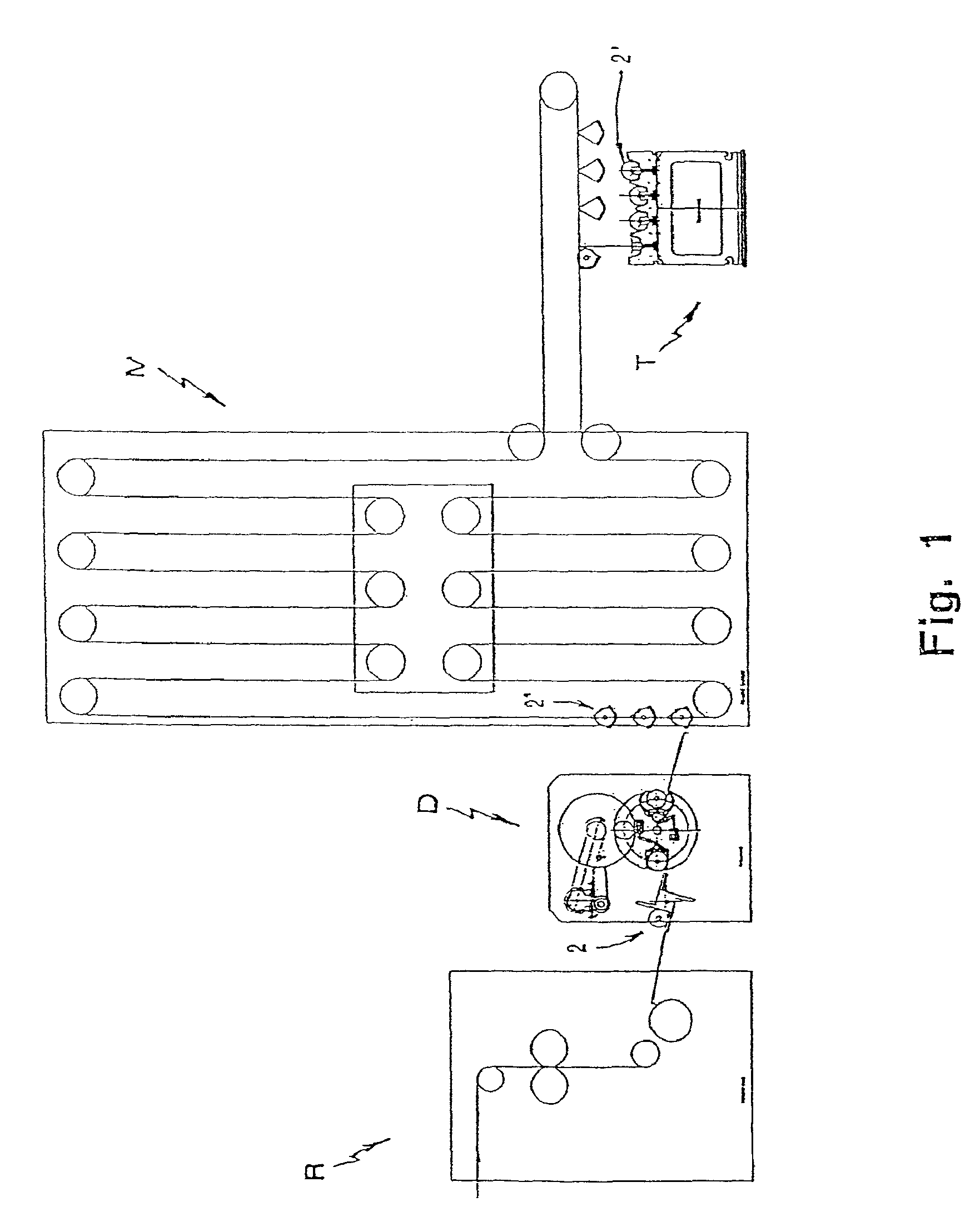

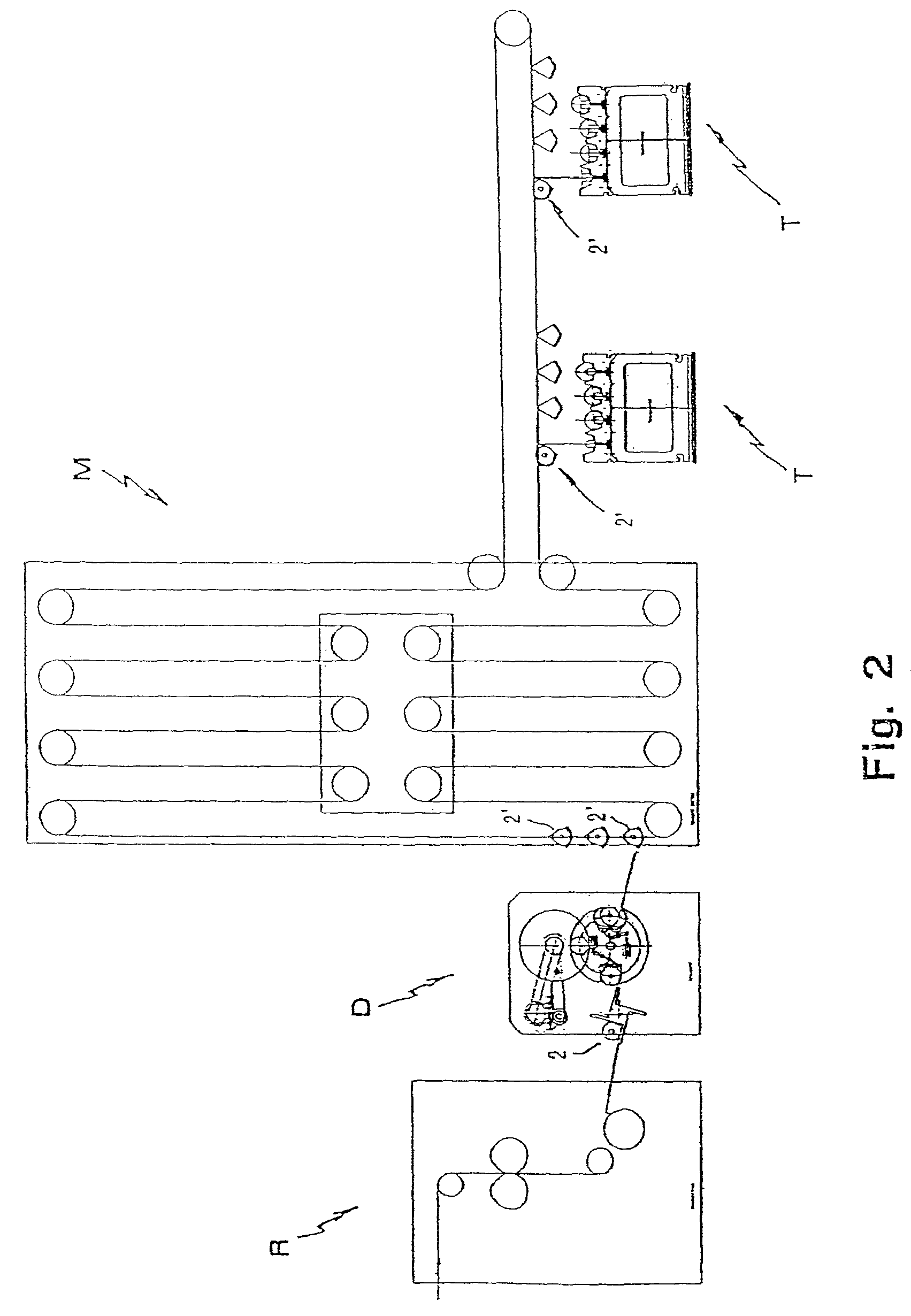

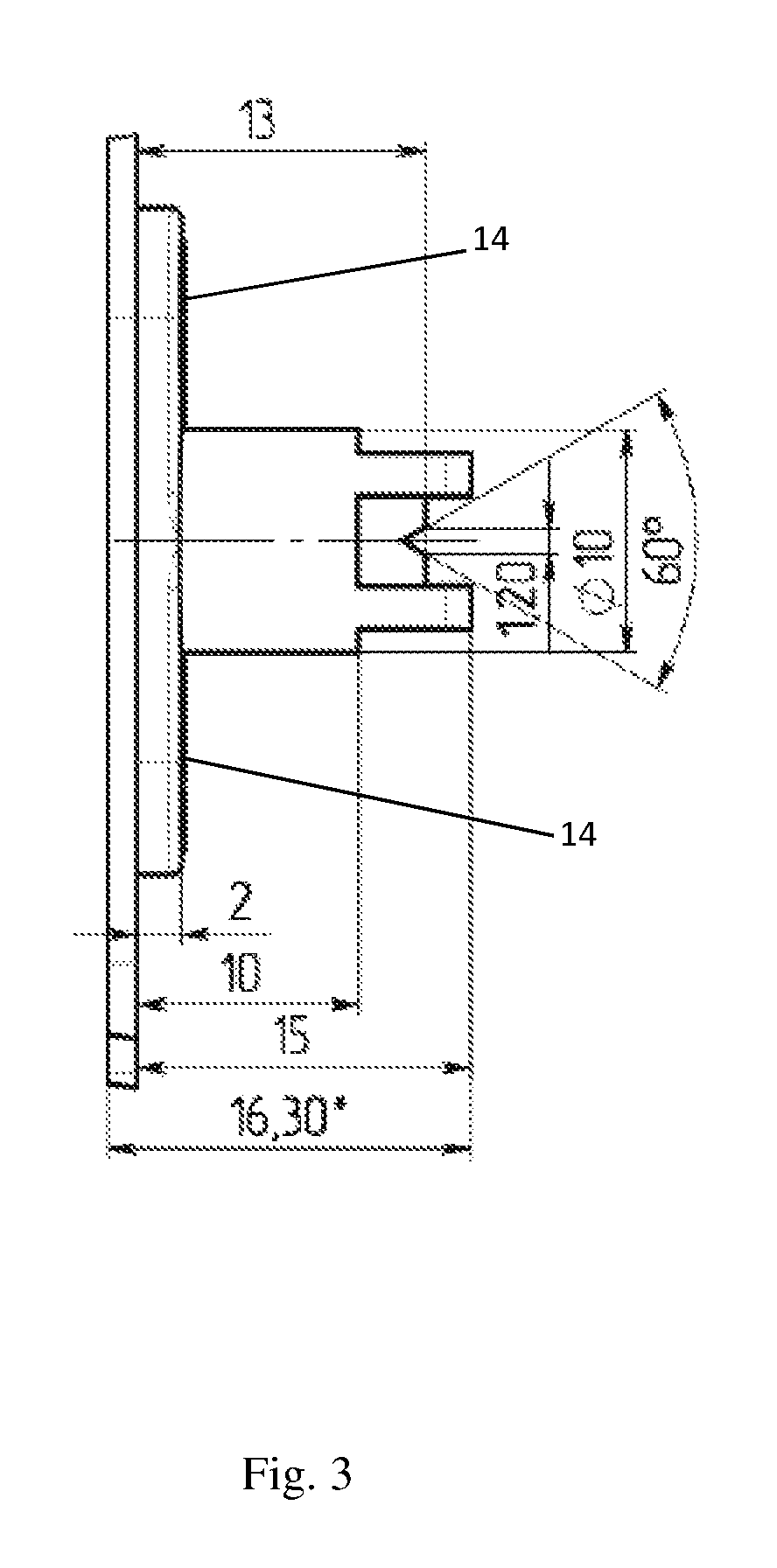

Apparatus for trimming paper rolls or logs and an operating method for treating the logs

InactiveUS20090000438A1Simplify and improve log-cutting processSimple processMetal working apparatusEngineeringMechanical engineering

Apparatus for trimming paper rolls or logs (2) characterized in that it comprises: a section for the entry of the logs (2) to be trimmed; a section for the exit of the trimmed logs (2′); a station with cutting means (6) for trimming the logs (2); means (3) for moving the logs (2, 2′) between the entry section, the cutting station and the exit section; means (4), associated with the log-moving means (3), for retaining the logs when subjected to movement.

Owner:PERINI

Pelletized shortening

InactiveUS6054167AReduce processPromote lowerDough treatmentBakery battersParticulatesRoom temperature

A pelletized shortening is prepared by a process which includes melting, cooling, solidifying and extruding natural and / or synthetic shortening materials to provide shortening pellets or chunks which, without requiring further processing, resist clumping together at at least moderate temperatures of about 70 DEG F. (about 21 DEG C.). The pelletized shortening has a hardness or solids profile which is especially suitable for baking applications and imparts a tenderizing effect in bakery type products while still providing a shortening in a form that is easy to handle inasmuch as it is pourable or able to be metered in a flowing particulate style. While it has relatively high solids at room temperature or storage conditions, the solids content of the pelletized shortening dissipates rapidly enough such that the solids reduction will provide the desired tenderizing effect in dough products including biscuits and pizza crusts.

Owner:BUNGE FOODS

Battery electrode and a method for producing same

ActiveUS20130302674A1Improve edge qualityReduce energy inputRadiation applicationsFinal product manufactureEnergy densityBattery electrode

In order to allow for a compact configuration of a battery with an increased energy density / volume ratio together with low production costs, the invention specifies a battery electrode and a method for producing same, wherein an arrester region is arranged on a collector substrate such that it is predominantly surrounded by a coating film.

Owner:ZENT FUR SONNENENERGIE & WASSERSTOFF FORSCHUNG BADEN WURTTEMBERG GEMEINNUTZIGE STIFTUNG

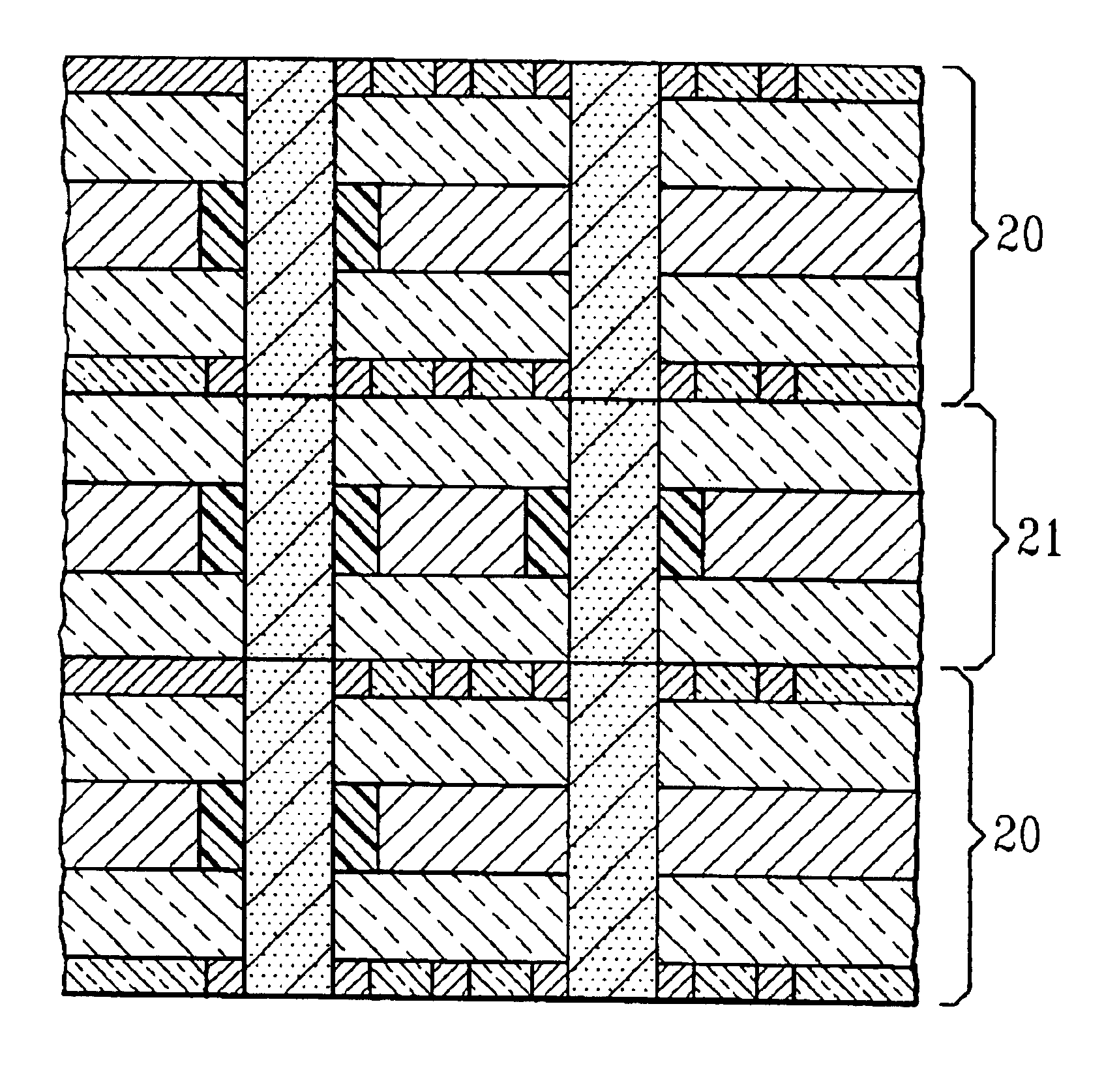

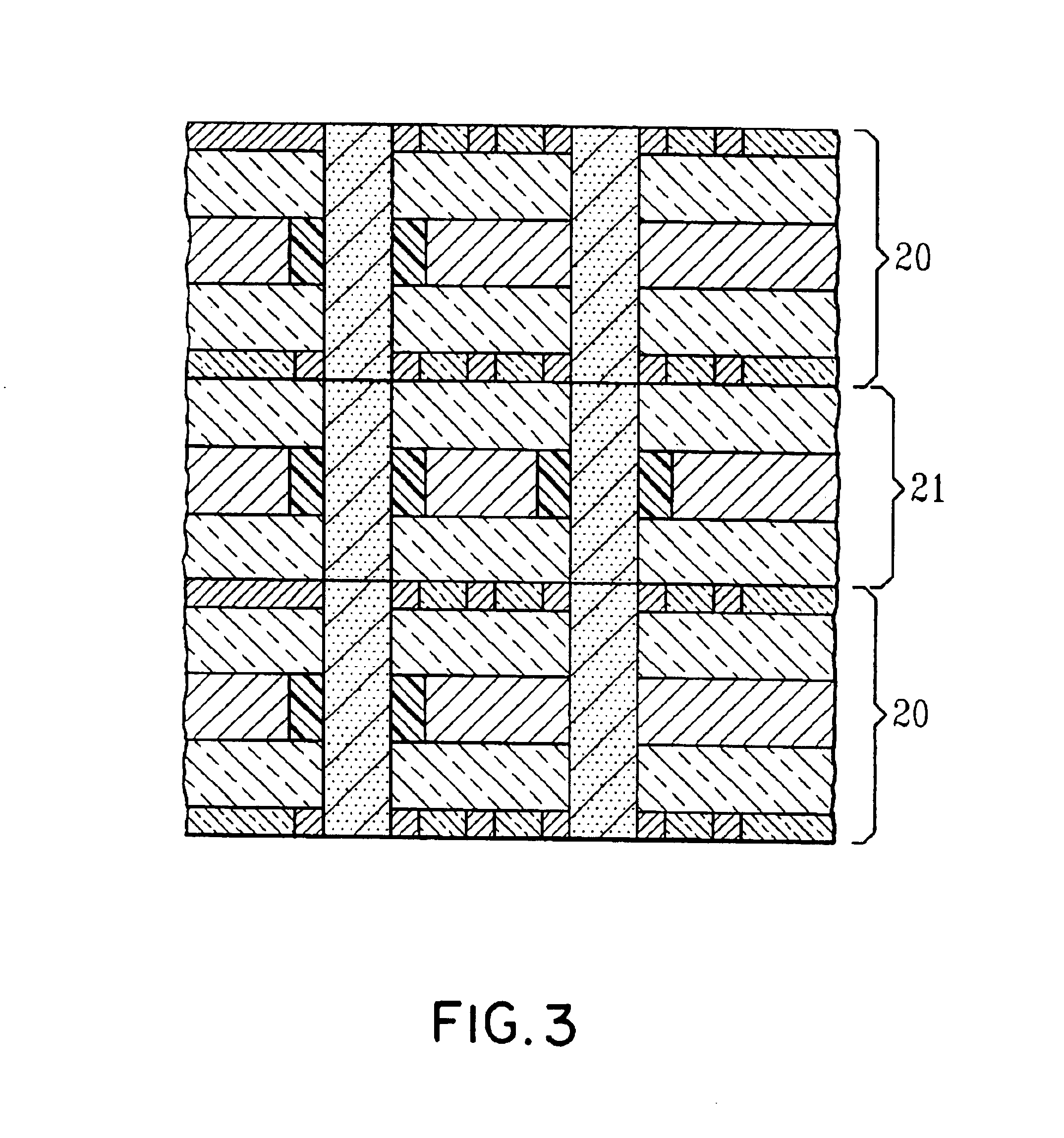

Composite laminate circuit structure

InactiveUS20050048408A1High densitySimplify and solve problemPrinted circuit aspectsPhotomechanical apparatusComposite laminatesInterposer

A laminate circuit structure assembly is provided that comprises at least two modularized circuitized voltage plane subassemblies; optionally an interposer located between each of the subassemblies, and wherein the subassemblies and interposer, if present, are bonded together with a cured dielectric coating. The interposer comprises dielectric layers disposed about an internal electrically conductive layer.

Owner:INT BUSINESS MASCH CORP

Steering force detection device for steering handle of vehicle

InactiveUS7430466B2Simplification and improvement of processEasy to assembleDigital data processing detailsSteering initiationsSteering angleWatercraft

A watercraft has steering force detection sections. Each steering force detection section includes a pressure receiving section. The pressure receiving sections are spaced from each other and are in the vicinity of a steering shaft. A pressing member is coupled to the steering shaft. The pressing member can press on at least one of the pressure receiving sections when the steering handlebars are rotated to a maximum steering angle. A received pressure detection section detects the pressure applied to the pressure receiving section. The pressure receiving section and the received pressure detection section are coaxially mounted in a pressure receiving section casing and a detection section casing. A guide tube can engage the pressure receiving section and the received pressure detection section. The guide tube is formed with ribs and grooves. The pressure receiving section has a pressure receiving member, a bolt, a plain washer, and a spring member.

Owner:YAMAHA MARINE KK

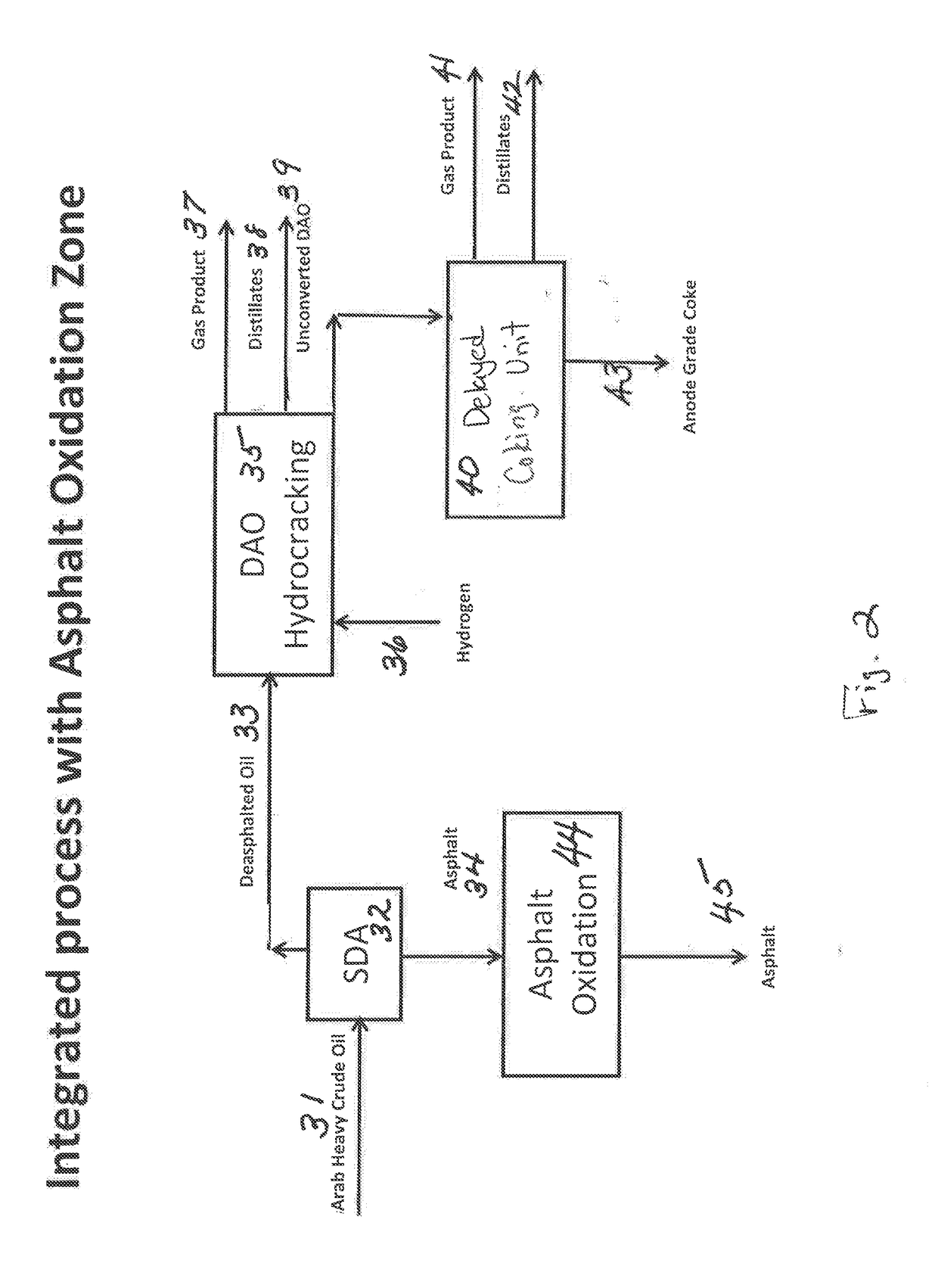

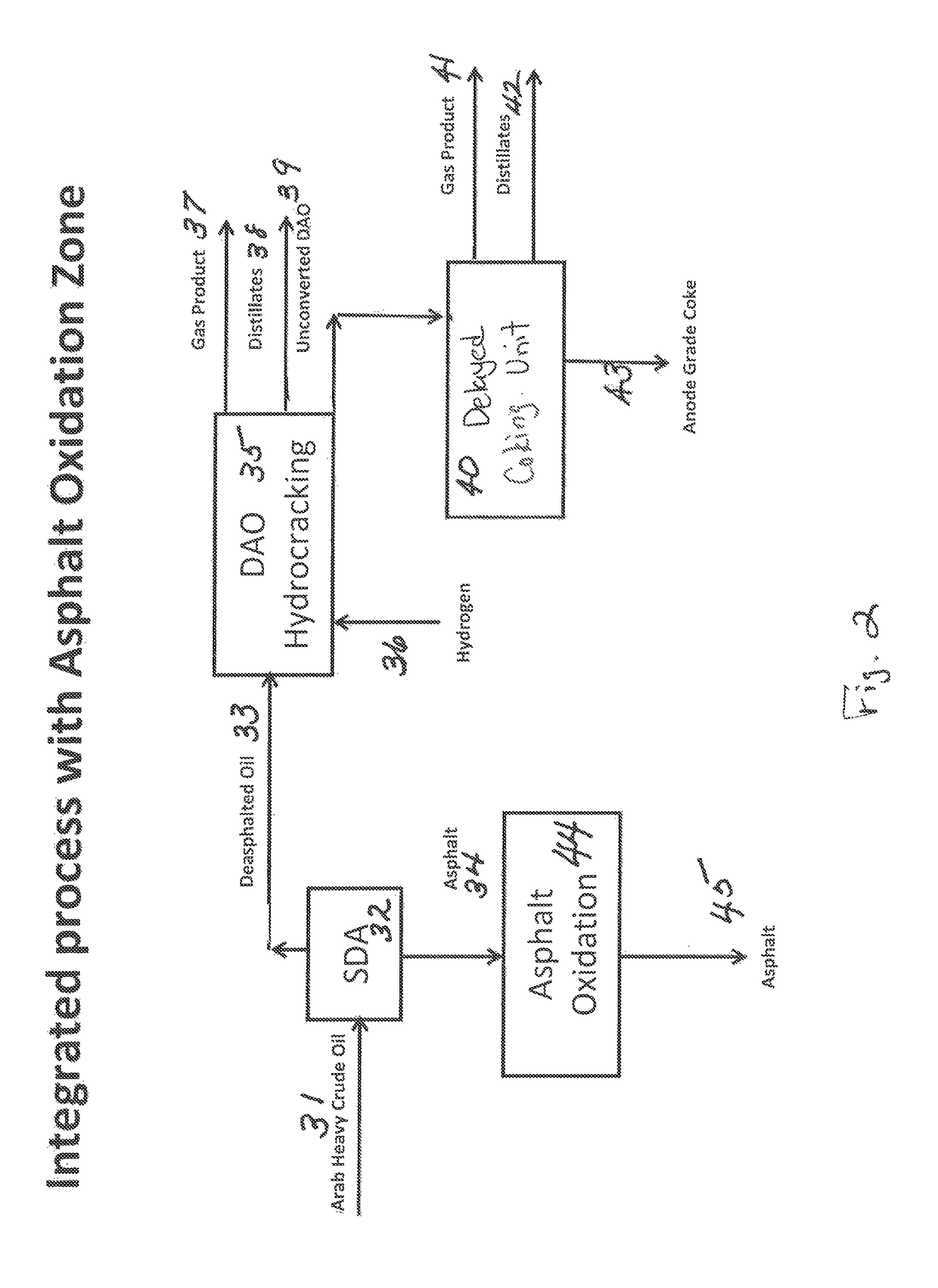

Integrated process for producing anode grade coke

ActiveUS20170066971A1Slow cokingSimplification and improvement of processThermal non-catalytic crackingHydrocarbon oil crackingAsphaltMaterials science

The invention relates to processes for producing anode grade coke from whole crude oil. The invention is accomplished by first deasphalting a feedstock, followed by processing resulting DAO and asphalt fractions. The DAO fraction is hydrotreated or hydrocracked, resulting in removal of sulfur and hydrocarbons, which boil at temperatures over 370° C., and gasifying the asphalt portion in one embodiment. This embodiment includes subjecting hydrotreated and / or unconverted DAO fractions to delayed coking. In an alternate embodiment, rather than gasifying the asphalt portion, it is subjected to delayed coking in a separate reaction chamber. Any coke produced via delayed coking can be gasified.

Owner:SAUDI ARABIAN OIL CO

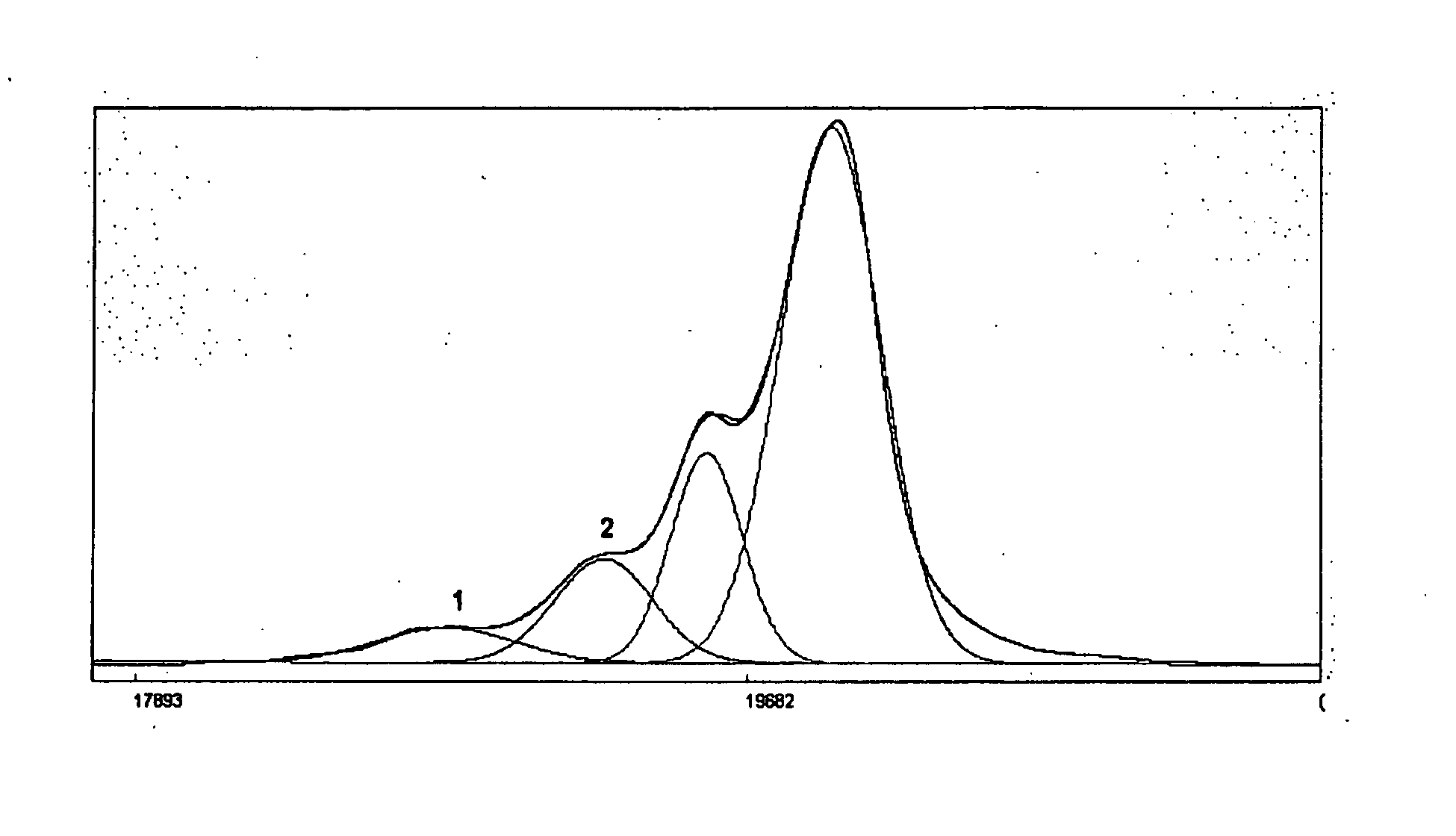

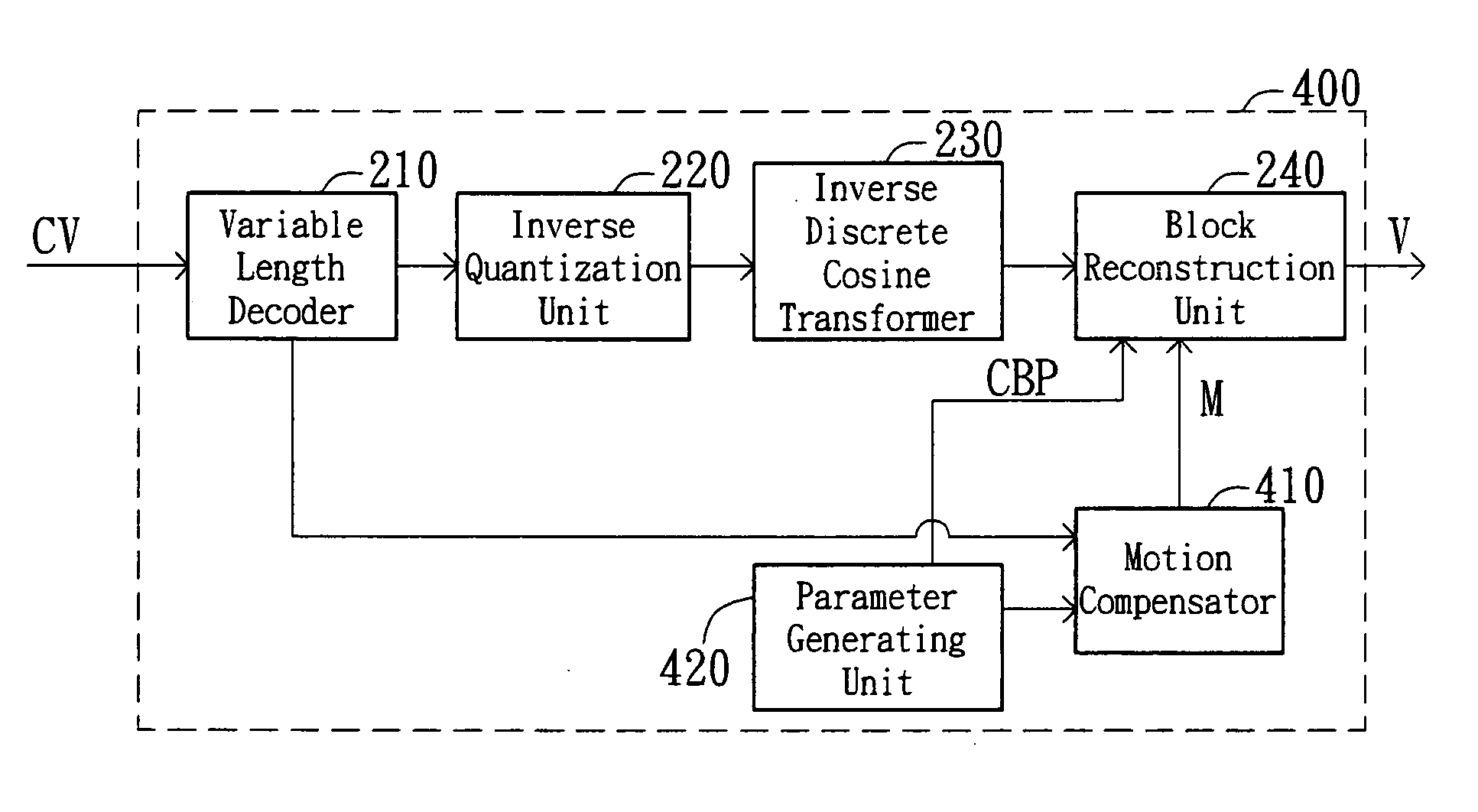

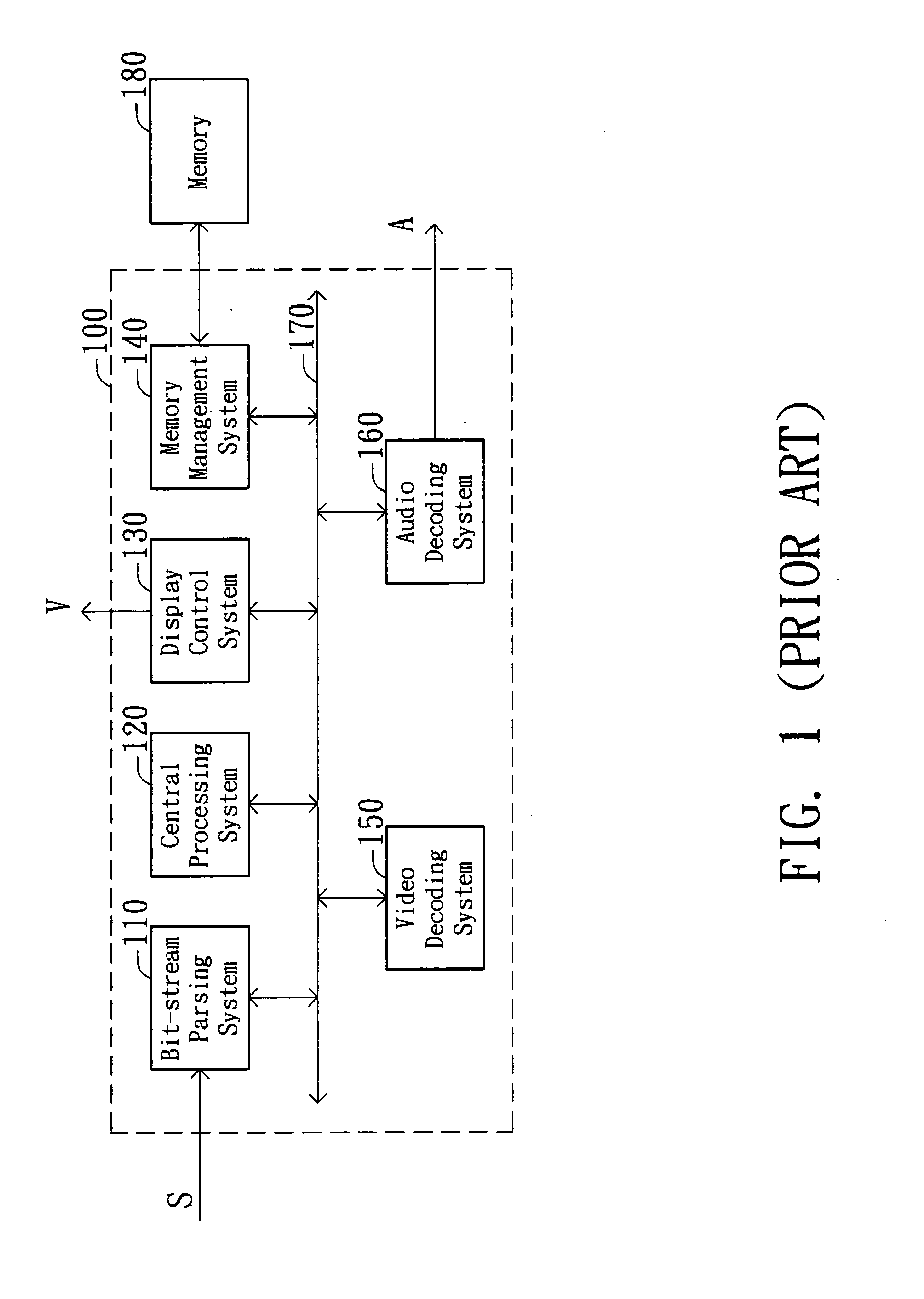

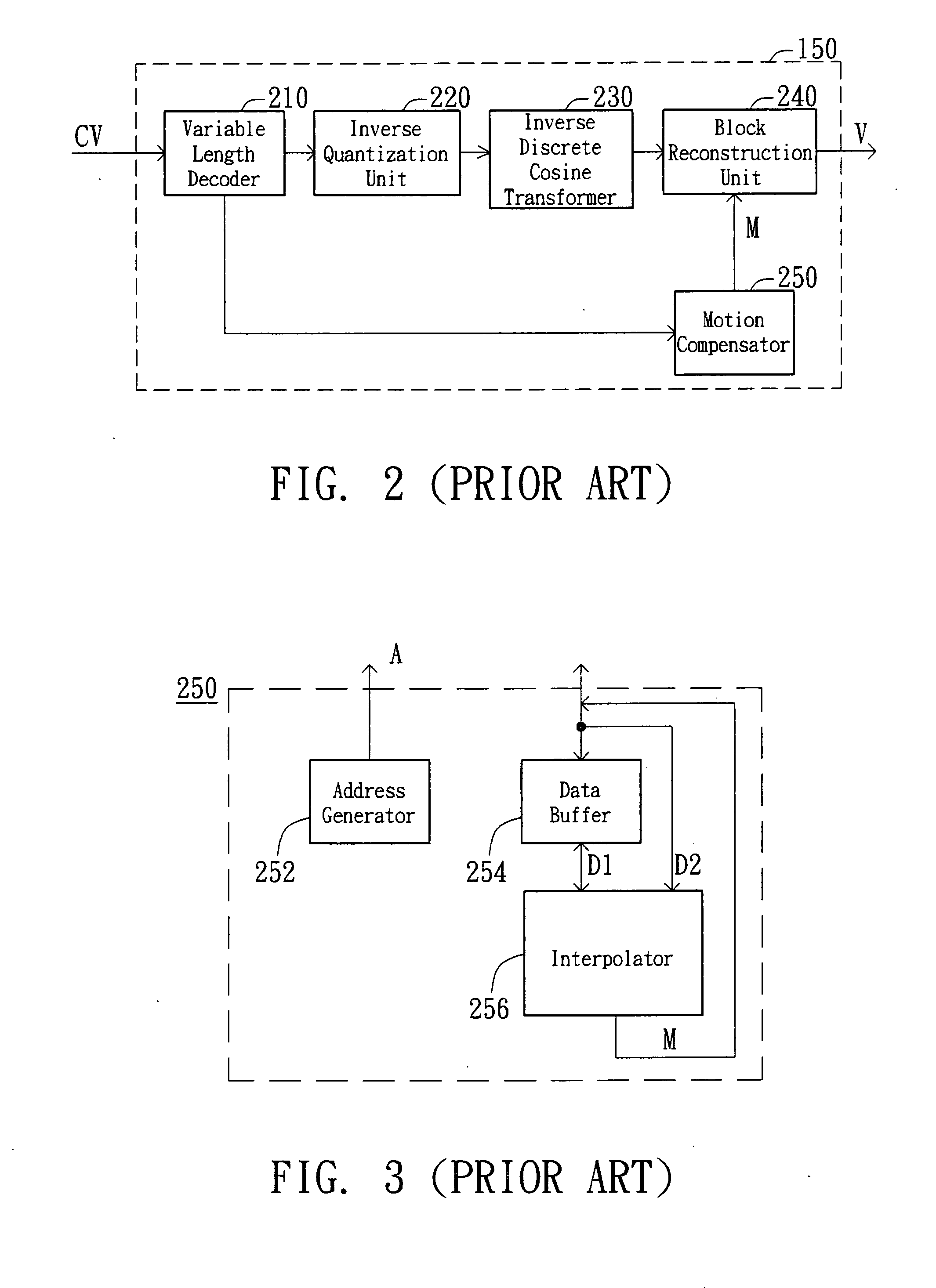

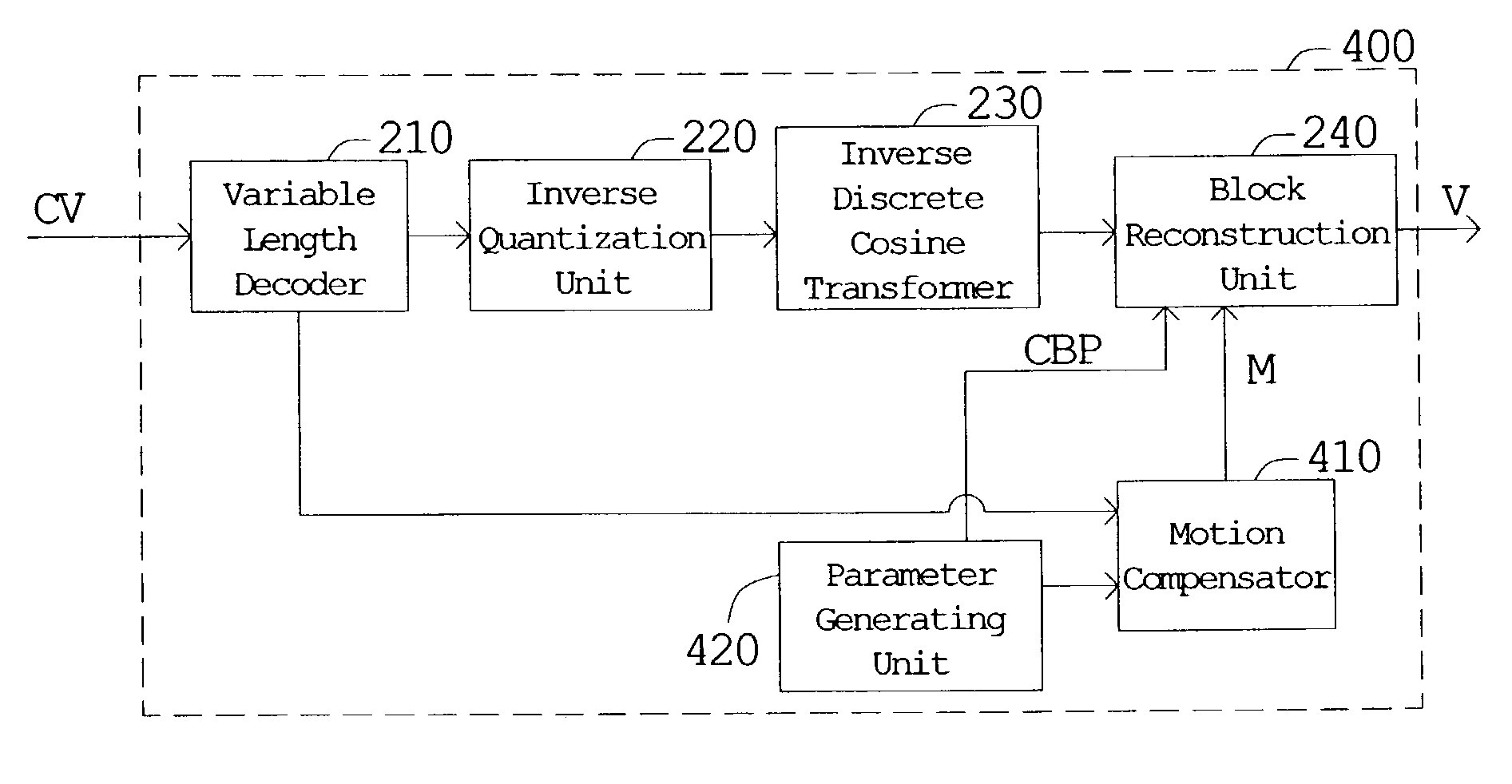

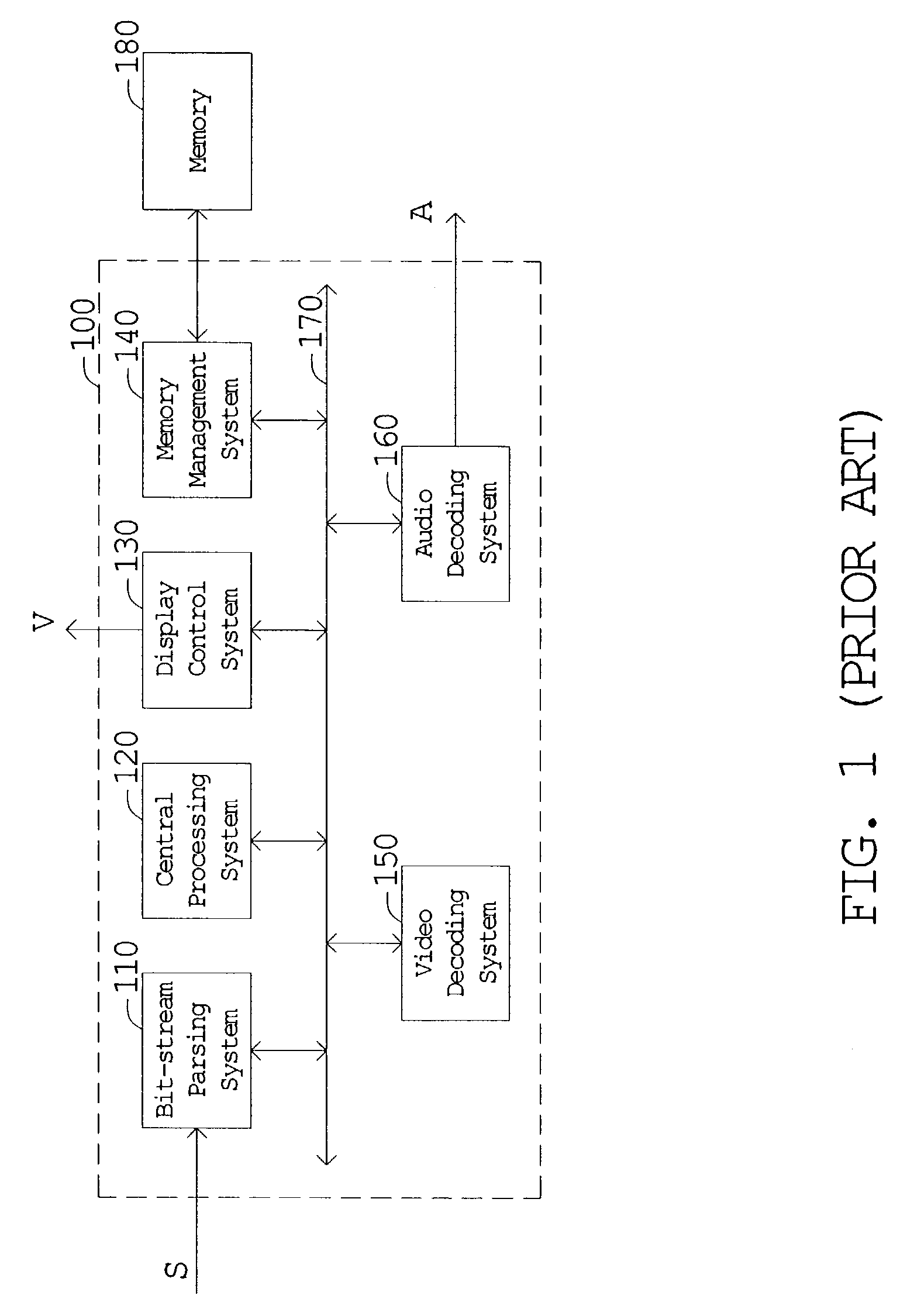

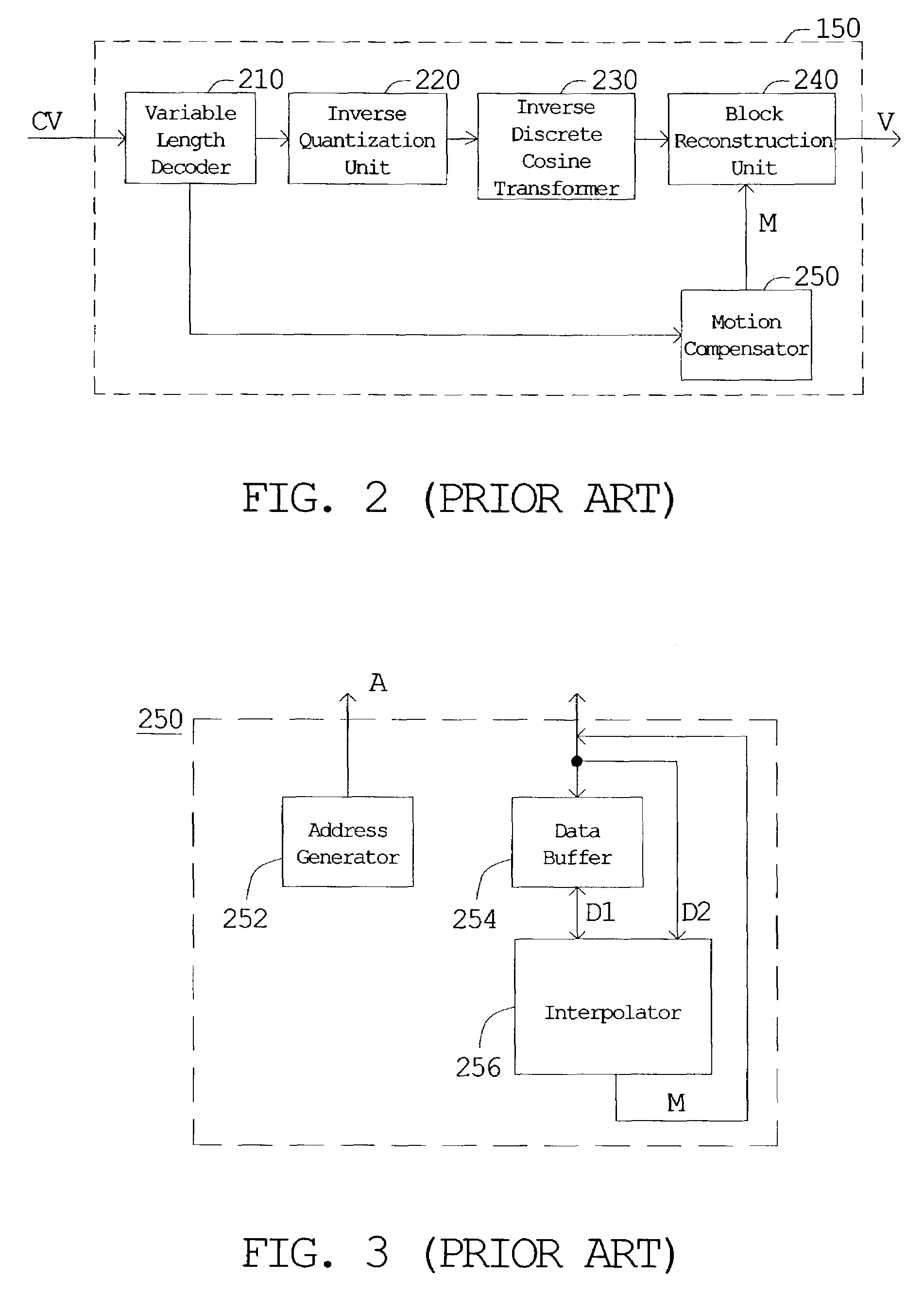

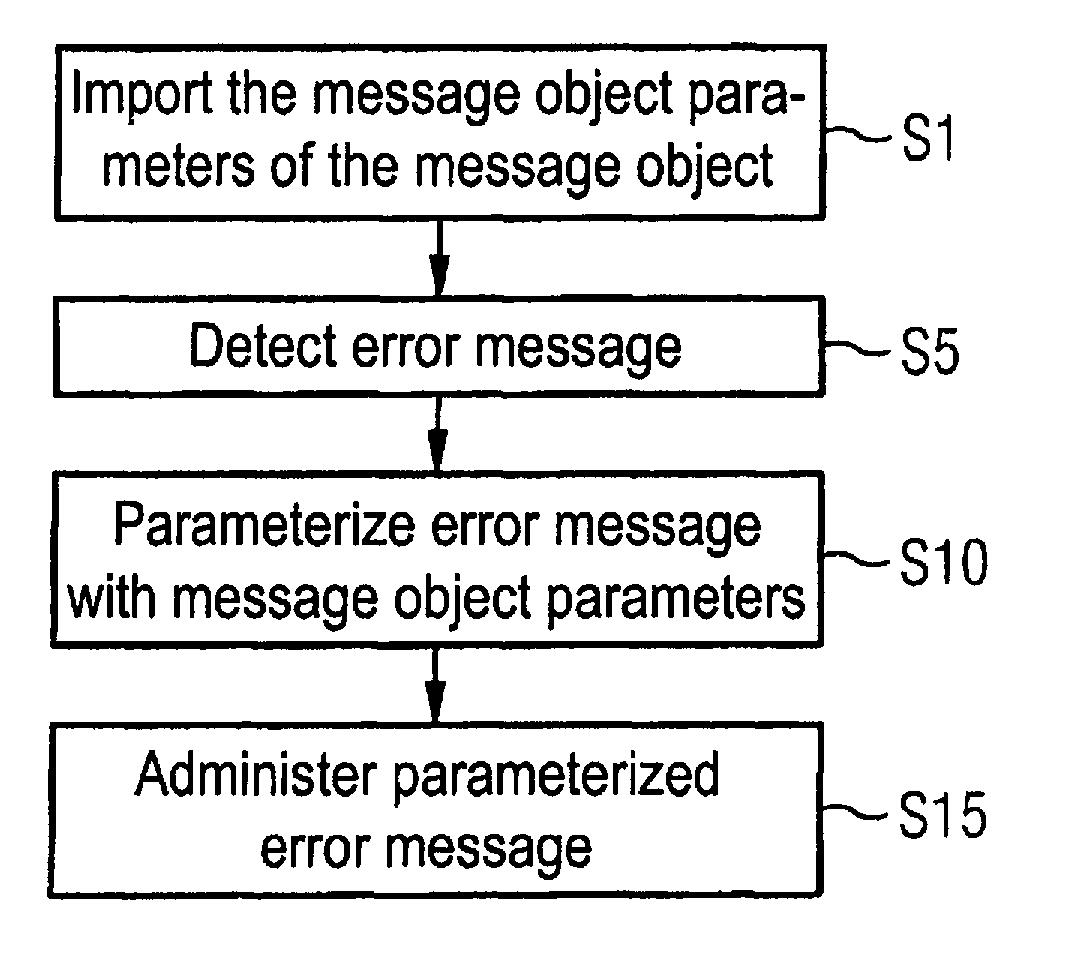

Method and apparatus of picture display

InactiveUS20070263729A1Simplification and improvement of processReduce hardware costsTelevision system detailsColor television with pulse code modulationComputer graphics (images)Image display

A method and an apparatus of picture display. The invention displays the first picture and the second picture and displaying at least one virtual picture in between the first and the second picture. The motion compensator is included in a DVD player. The method includes: decoding the first and the second pictures from the received bit-stream; creating the virtual picture parameter according to the transition effect; and generating the virtual picture according to the virtual picture parameter by the motion compensator.

Owner:XUESHAN TECH INC

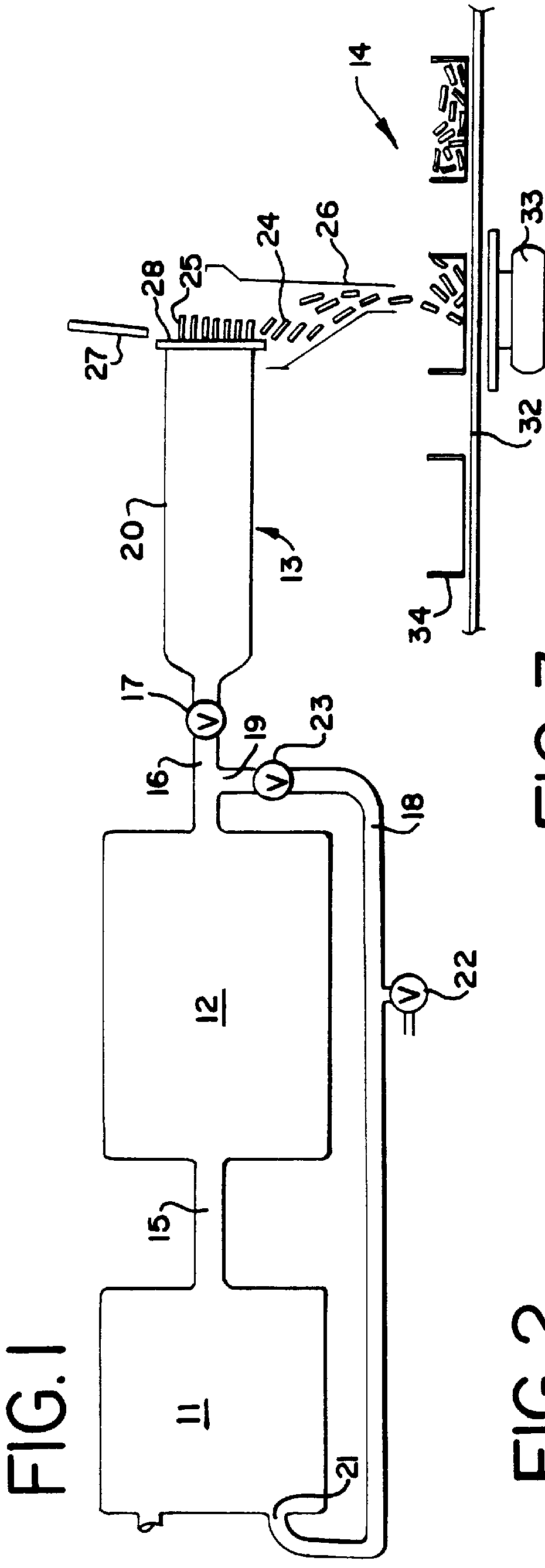

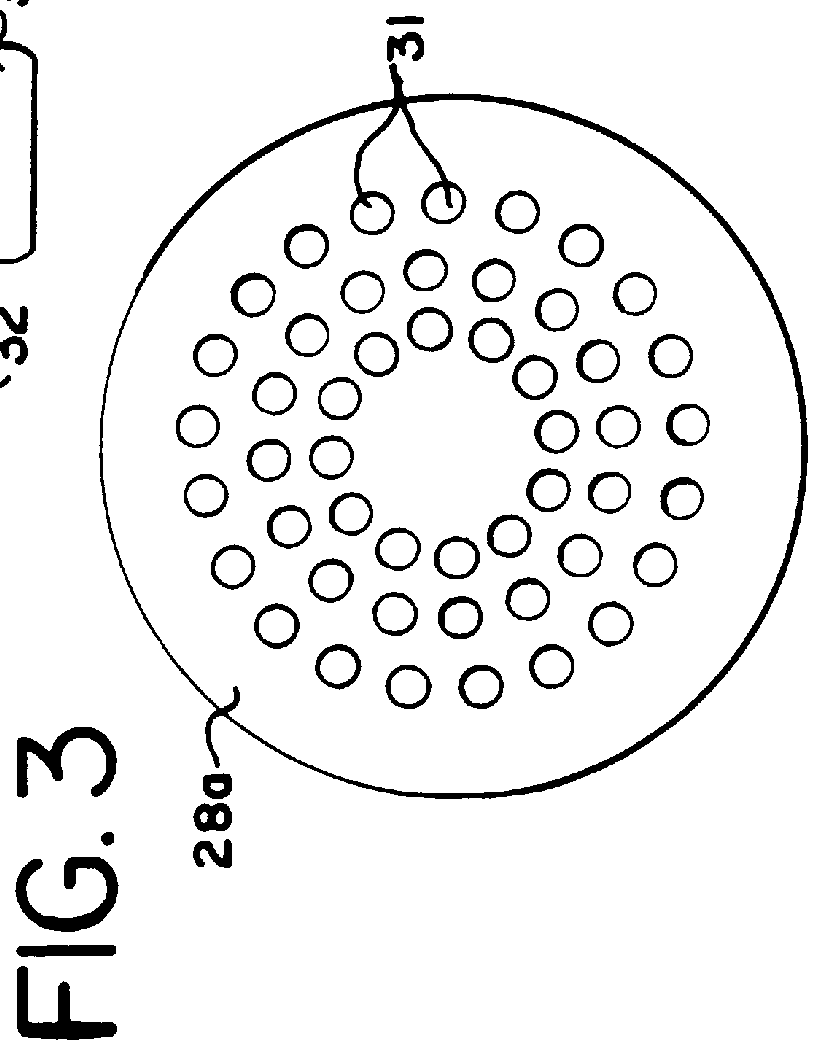

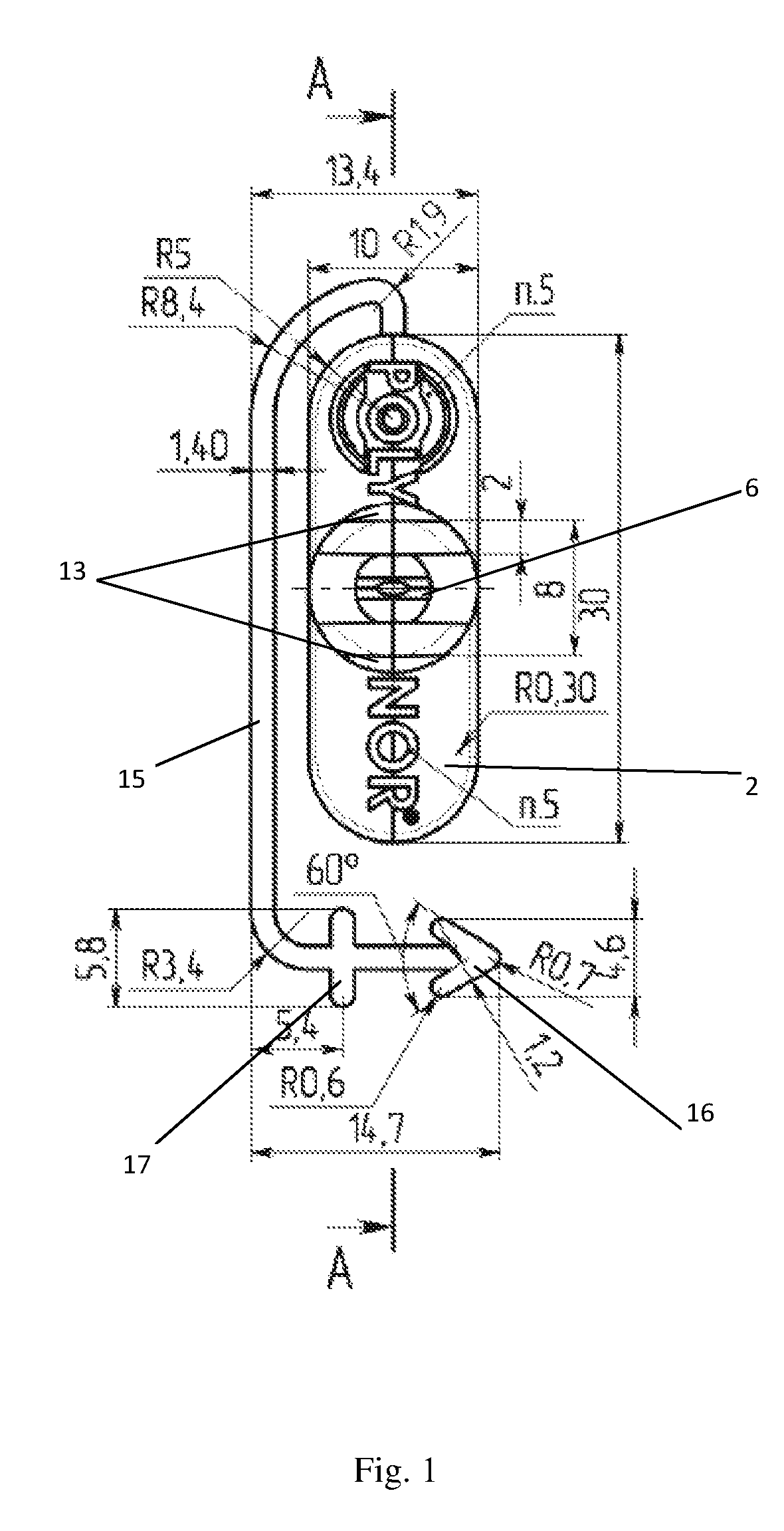

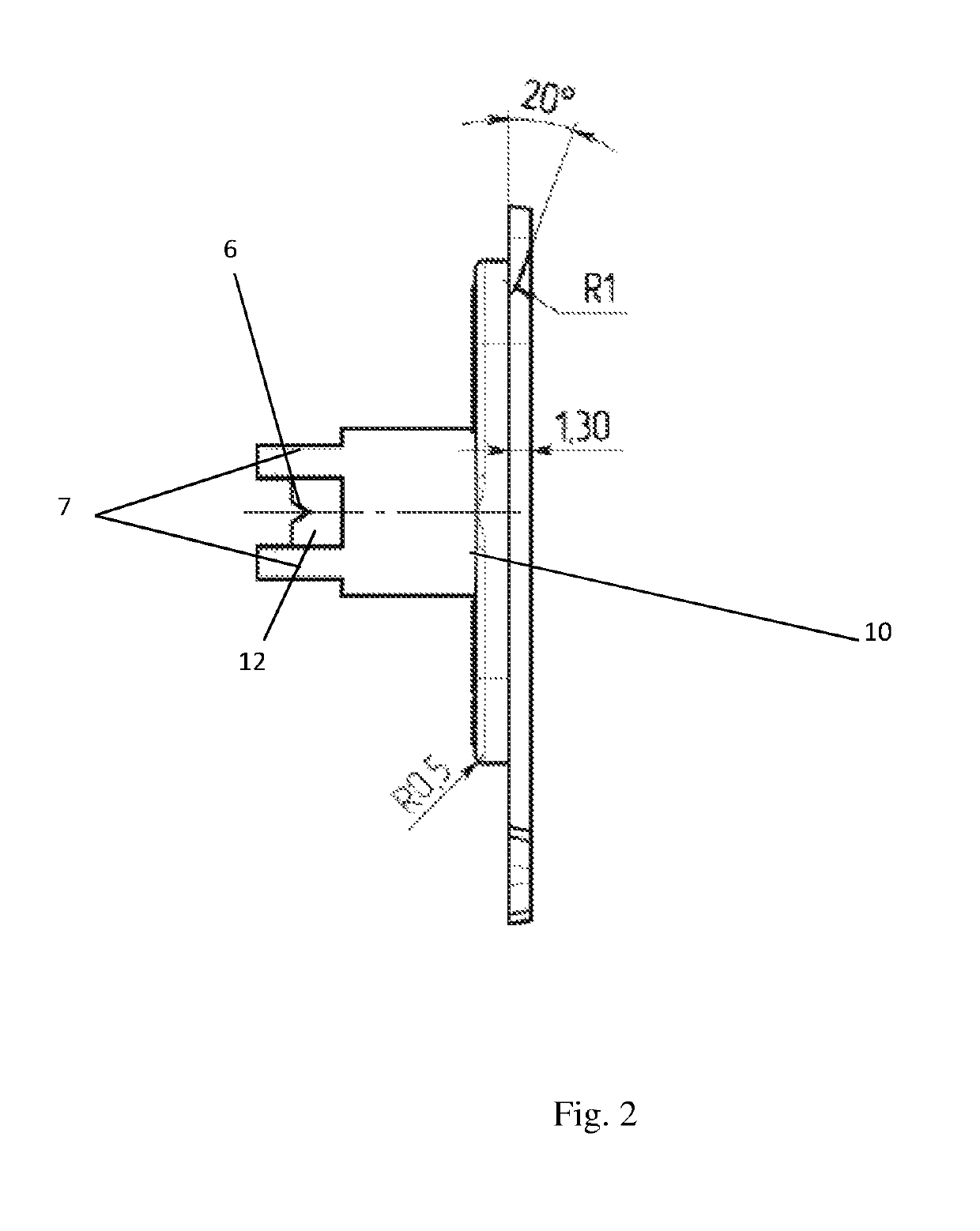

Device for Spraying Pressurized Material

InactiveUS20180043376A1Simplification and improvement of processEasy to replaceLiquid surface applicatorsDispensing apparatusEngineeringAerosol

Spraying heads may be used in spray guns for applying a pressurized aerosol material in the form of jets or spray. A spraying nozzle for spraying a polyurethane material includes a cylindrical body provided, on a first end, with a base having a mounting aperture extending into the cylindrical body, forming a cavity for arranging a head of a gun. The base of the nozzle is in the form of oppositely-disposed leaves. A second end of the body is provided with a cylindrical shoulder, a through-bore of which is communicated with a V-shaped and laterally non-closed recess at the region of an outlet of the sprayed material. Oppositely arranged plate-like protrusions adjoin a lateral surfaces of the cylindrical shoulder. A mounting aperture end which adjoins the base has a circumferential cut. The spraying nozzle is provided with an attachment means used when in an inoperative position.

Owner:DRAGAN KONSTANTIN MARATOVICH +1

Integrated process for producing anode grade coke

ActiveUS9909068B2Slow cokingSimplification and improvement of processThermal non-catalytic crackingEnergy inputSulfurAsphalt

The invention relates to processes for producing anode grade coke from whole crude oil. The invention is accomplished by first deasphalting a feedstock, followed by processing resulting DAO and asphalt fractions. The DAO fraction is hydrotreated or hydrocracked, resulting in removal of sulfur and hydrocarbons, which boil at temperatures over 370° C., and gasifying the asphalt portion in one embodiment. This embodiment includes subjecting hydrotreated and / or unconverted DAO fractions to delayed coking. In an alternate embodiment, rather than gasifying the asphalt portion, it is subjected to delayed coking in a separate reaction chamber. Any coke produced via delayed coking can be gasified.

Owner:SAUDI ARABIAN OIL CO

Process for the Preparation of Sevelamer Hydrochloride and Formulation Thereof

InactiveUS20100092421A1Eliminate useSimplification and improvement of processOrganic active ingredientsMetabolism disorderPhosphateMedicinal chemistry

Owner:USV LTD

Apparatus for trimming paper rolls or logs and an operating method for treating the logs

ActiveUS20090000447A1Simplify and improve log-cutting processSimple processGang saw millsMetal working apparatusEngineeringMechanical engineering

Apparatus for trimming paper rolls or logs (2) characterized in that it comprises: a section for the entry of the logs (2) to be trimmed; a section for the exit of the trimmed logs (2′); a station with cutting means (6) for trimming the logs (2); means (3) for moving the logs (2, 2′) between the entry section, the cutting station and the exit section; means (4), associated with the log-moving means (3), for retaining the logs when subjected to movement.

Owner:PERINI

Method and apparatus of picture display

ActiveUS7257160B2Simplification and improvement of processReduce hardware costsTelevision system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Computer science

A method and an apparatus of picture display. The invention displays the first picture and the second picture and displaying at least one virtual picture in between the first and the second picture. The motion compensator is included in a DVD player. The method includes: decoding the first and the second pictures from the received bit-stream; creating the virtual picture parameter according to the transition effect; and generating the virtual picture according to the virtual picture parameter by the motion compensator.

Owner:XUESHAN TECH INC

Communications administration method and system for an electronic apparatus

ActiveUS8156384B2Avoid the correction processSimplification and improvement of processNon-redundant fault processingComputer hardwareCANopen

Owner:SIEMENS HEALTHCARE GMBH

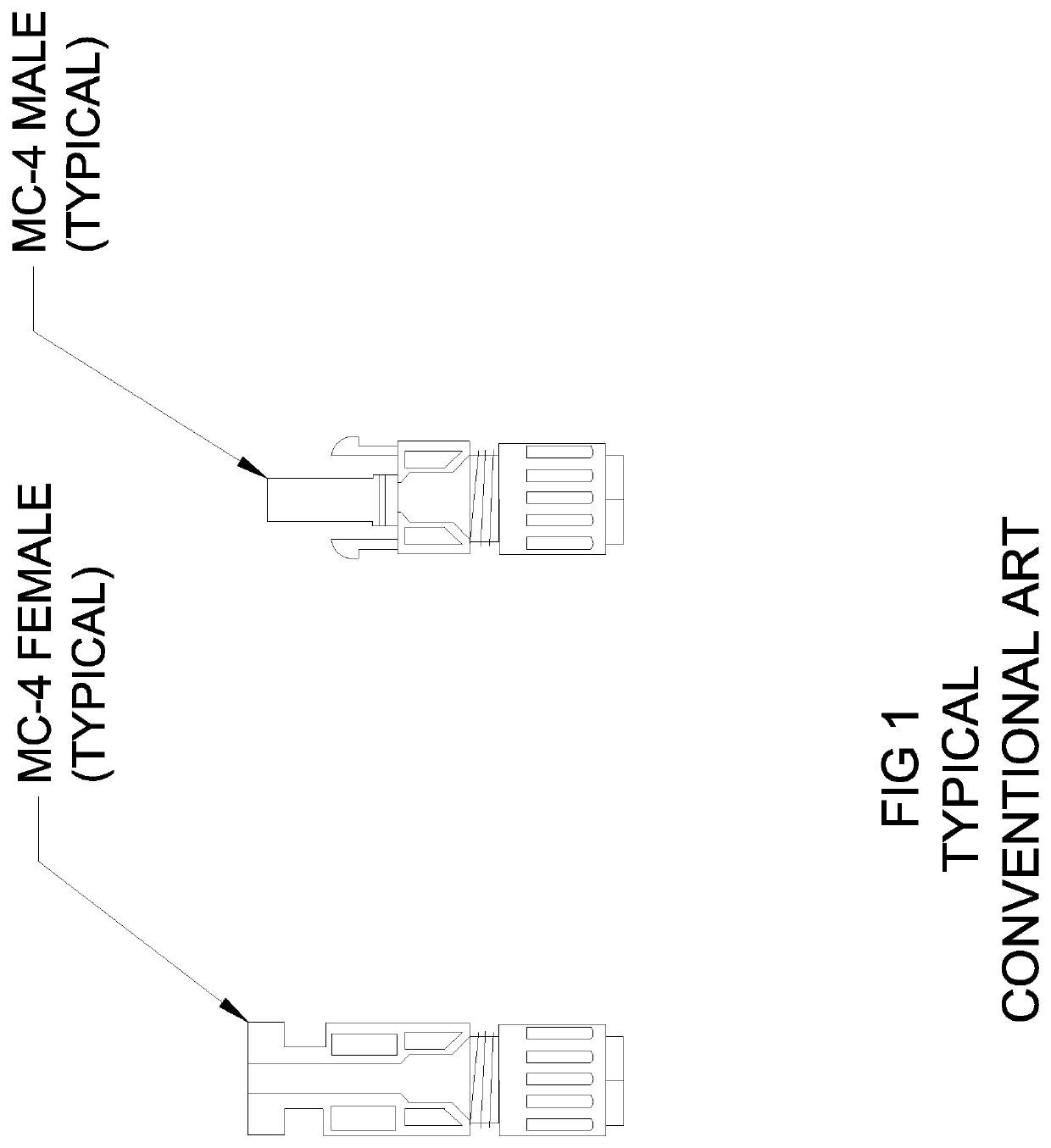

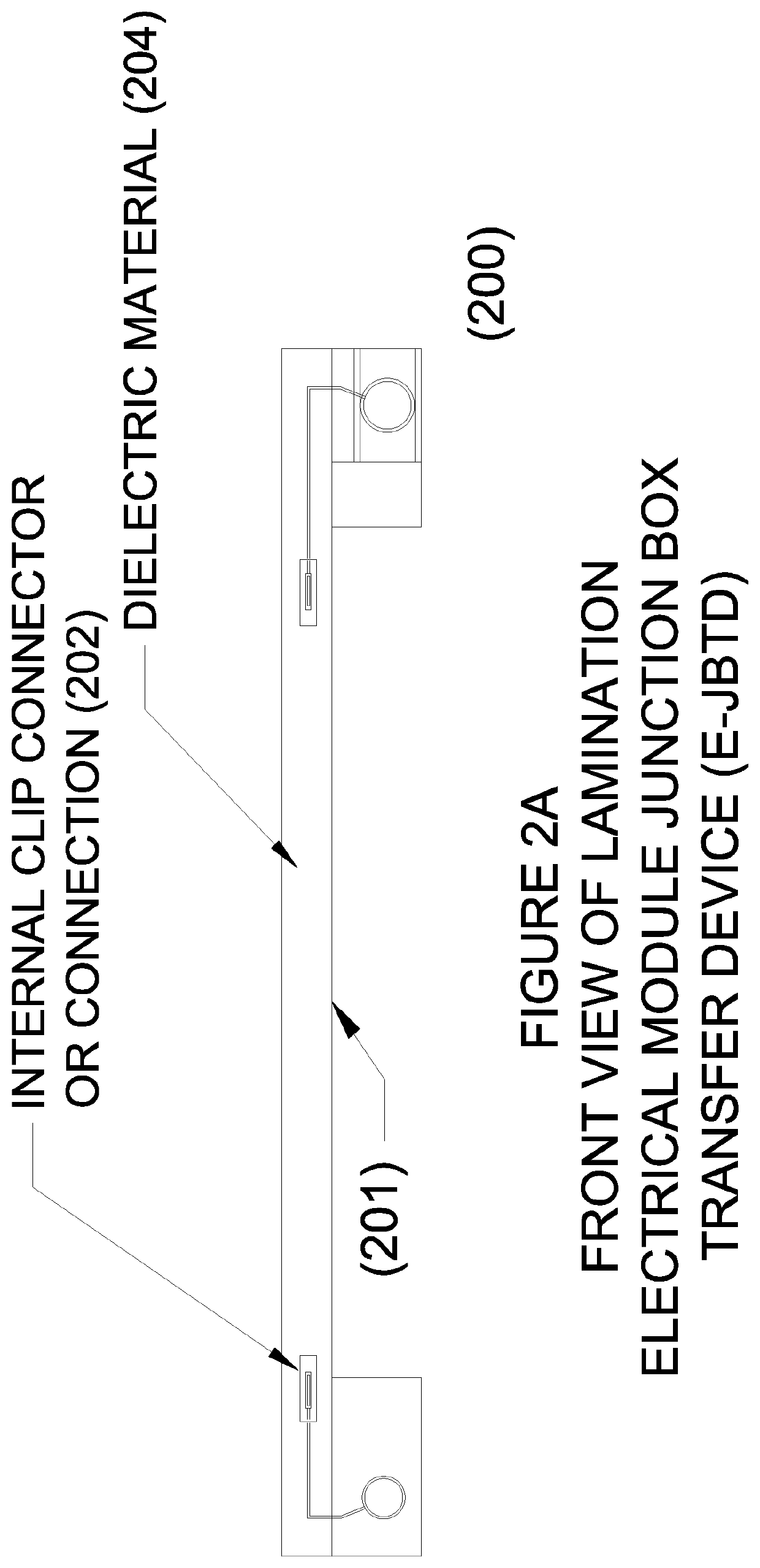

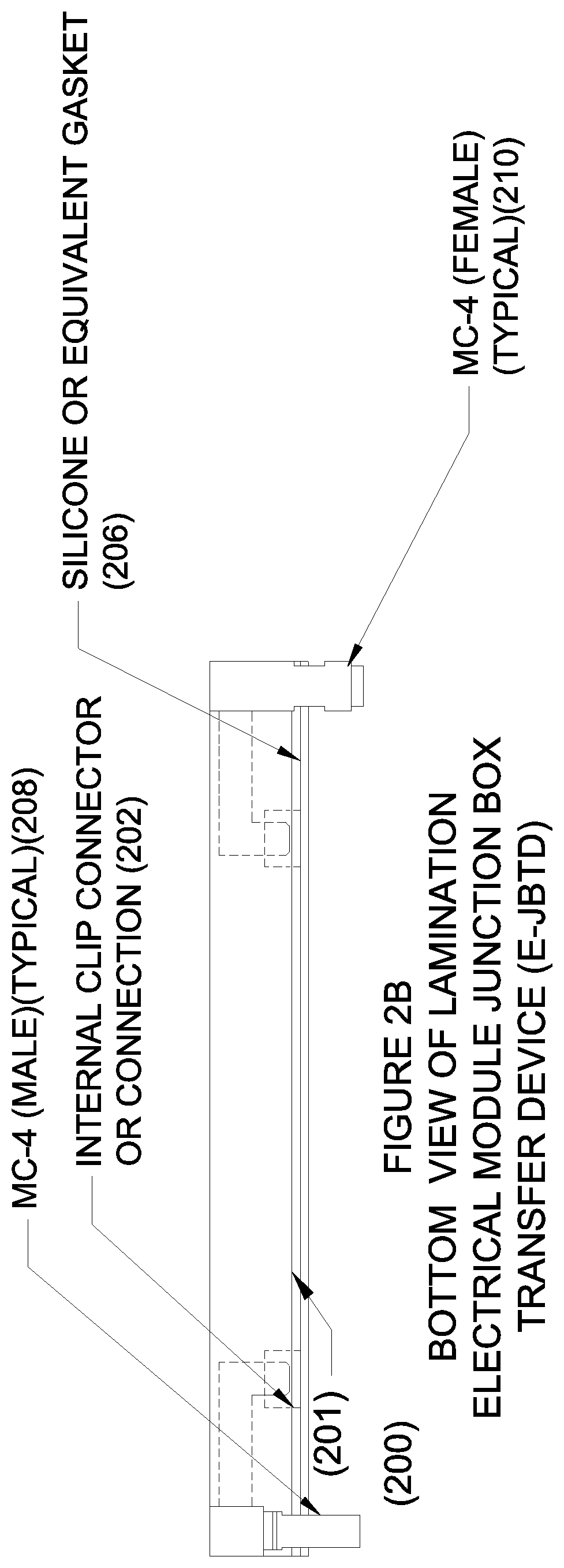

Electrical module junction box transfer device (e-jbtd) system having electrical energy internal and external connections

PendingUS20210044096A1OptimizationSafely securedPhotovoltaicsPhotovoltaic energy generationElectrical junctionElectrical connection

An Electrical Module Junction Box Transfer Device (E-JBTD) includes one or more electrical connectors, and a non-conductive dielectric insulating material protecting the one or more electrical connectors. A system includes an electricity-generating glass (EGP) device, and an Electrical Junction Box Electron Transfer Device (E-JBTD) on the electricity-generating glass (EGP) device. The Electrical Module Junction Box Transfer Device (E-JBTD) is water and weather tight, maintains a secure electrical connection between modules or electricity-generating glass (EGP) devices, and may not be removed after installation and reinstalled on another module or electricity-generating glass (EGP) device.

Owner:SOLARWINDOW TECH

Apparatus for trimming paper rolls or logs and method for treating the logs

ActiveUS7827892B2Simplify structure and operationSimple processShearing machinesGang saw millsMechanical engineeringEngineering

An apparatus for trimming paper rolls or logs (2) including: a section for the entry of the logs (2) to be trimmed; a section for the exit of the trimmed logs (2′); a station with a cutting device (6) for trimming the logs (2); a device (3) for moving the logs (2, 2′) between the entry section, the cutting station and the exit section; a device (4), associated with the log-moving device (3), for retaining the logs when subjected to movement.

Owner:PERINI

Motor controlled macro rail for close-up focus-stacking photography

ActiveUS8287195B2Simplification and improvement of processTelevision system detailsColor television detailsMotor driveEngineering

A motor controlled rail assembly is provided which simplifies and automates the process of taking focus-stacked pictures. This device can be used to incrementally move a camera or other photographic device a programmable distance forward or backward in precise steps relative to an external object to facilitate focus-stacked photography. The device may include a motor-driven macro rail assembly, a controller assembly and a camera, which, generally speaking, are configured as follows: a camera is attached to a macro rail carriage which is driven by the motor and controller. The device may have different modes of operation (an automatic step mode, an automatic distance mode, a total distance mode, a distance per step mode, a continuous mode and a manual mode) to yield improved results in different situations.

Owner:DEZEEUW PAUL +2

Device for spraying pressurized material

InactiveUS10239064B2Simplification and improvement of processEasy to replaceLiquid surface applicatorsSpray nozzlesSpray nozzleEngineering

Spraying heads may be used in spray guns for applying a pressurized aerosol material in the form of jets or spray. A spraying nozzle for spraying a polyurethane material includes a cylindrical body provided, on a first end, with a base having a mounting aperture extending into the cylindrical body, forming a cavity for arranging a head of a gun. The base of the nozzle is in the form of oppositely-disposed leaves. A second end of the body is provided with a cylindrical shoulder, a through-bore of which is communicated with a V-shaped and laterally non-closed recess at the region of an outlet of the sprayed material. Oppositely arranged plate-like protrusions adjoin a lateral surfaces of the cylindrical shoulder. A mounting aperture end which adjoins the base has a circumferential cut. The spraying nozzle is provided with an attachment means used when in an inoperative position.

Owner:DRAGAN KONSTANTIN MARATOVICH +1

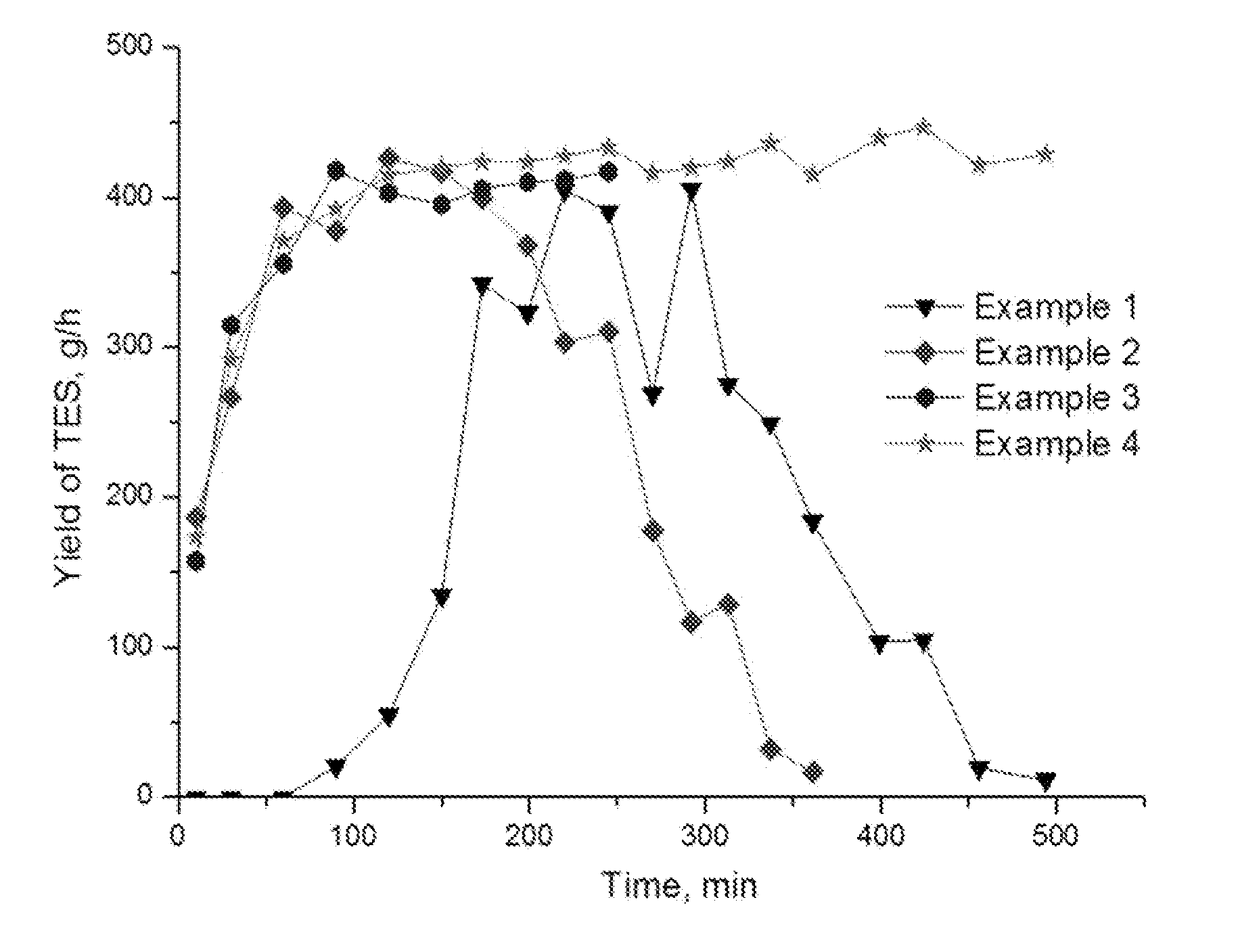

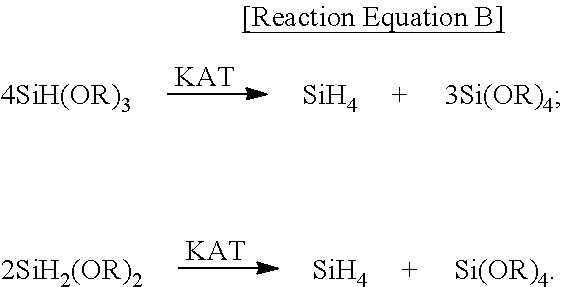

Method for preparing monosilane using trialkoxysilane

ActiveUS9278864B2Improve performanceSufficient feasibilitySilicon hydridesMetal/metal-oxides/metal-hydroxide catalystsCrystallographySemiconductor structure

Provided is a method for preparing monosilane, more particularly a method for economically preparing monosilane, which is useful for the composition of a thin semiconductor structure and multipurpose high-purity polycrystalline silicon, by preparing monosilane with high purity and high yield using trialkoxysilane.

Owner:OCI +1

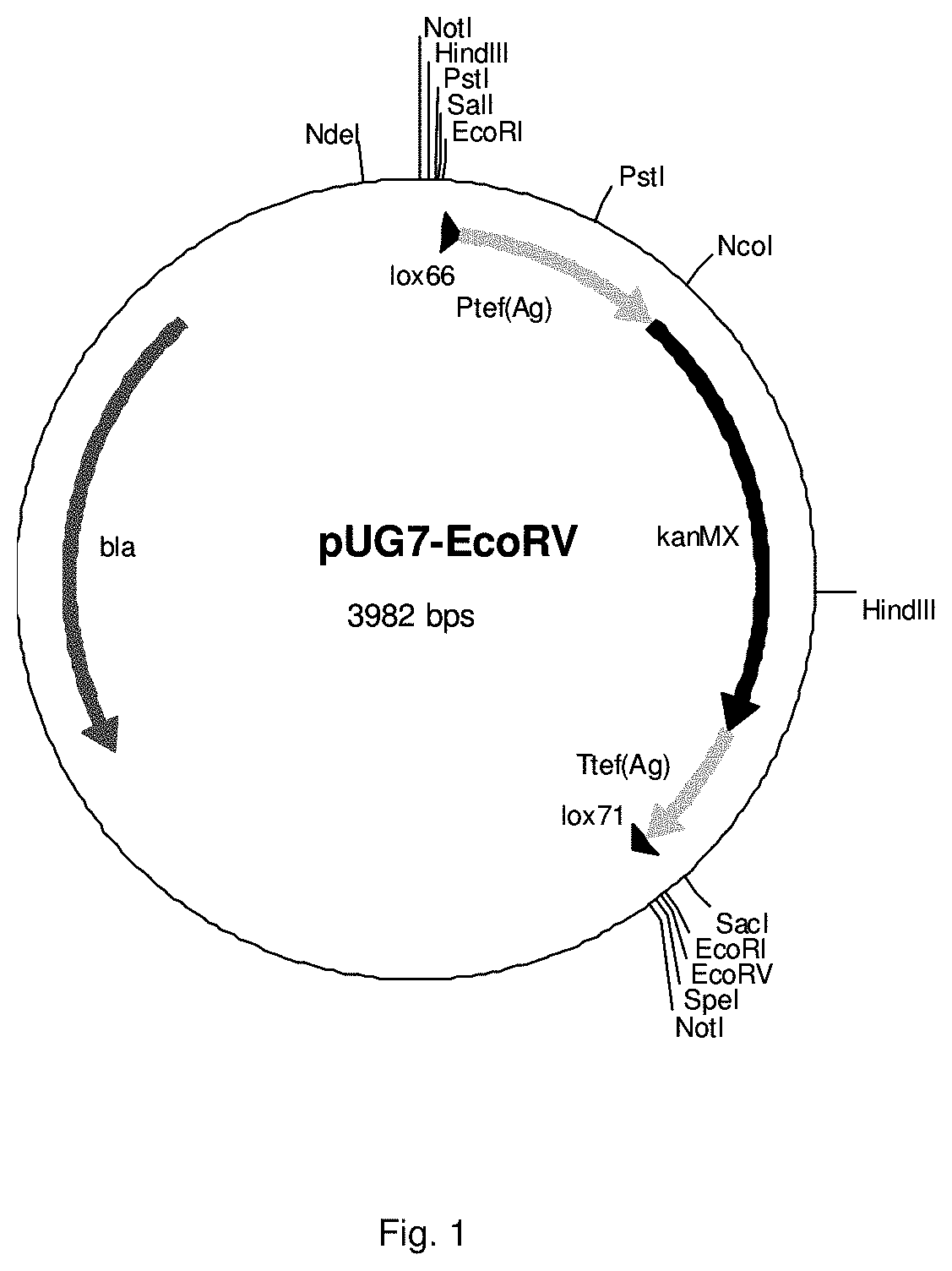

Recovery of steviol glycosides

ActiveUS10689410B2Simplification and improvement of processSugar derivativesSugar derivatives preparationGlycosideFluid phase

The present invention relates a process for the recovery of one or more steviol glycosides from a steviol glycoside-containing fermentation broth, which method comprises (a) providing a fermentation broth comprising one or more steviol glycosides and one or more non-steviol glycoside components; (b) separating the liquid phase of the broth from the solid phase of the broth; (c) providing an adsorbent resin; (d) contacting the liquid phase of the broth with the adsorbent resin in order to separate at least a portion of the one or more steviol glycosides from the non-steviol glycoside components, thereby to recover one or more steviol glycosides from the fermentation broth containing one or more steviol glycosides. The invention also relates to a purified steviol glycoside composition prepared using such a process.

Owner:DSM IP ASSETS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com