Patents

Literature

58results about How to "Avoid counting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

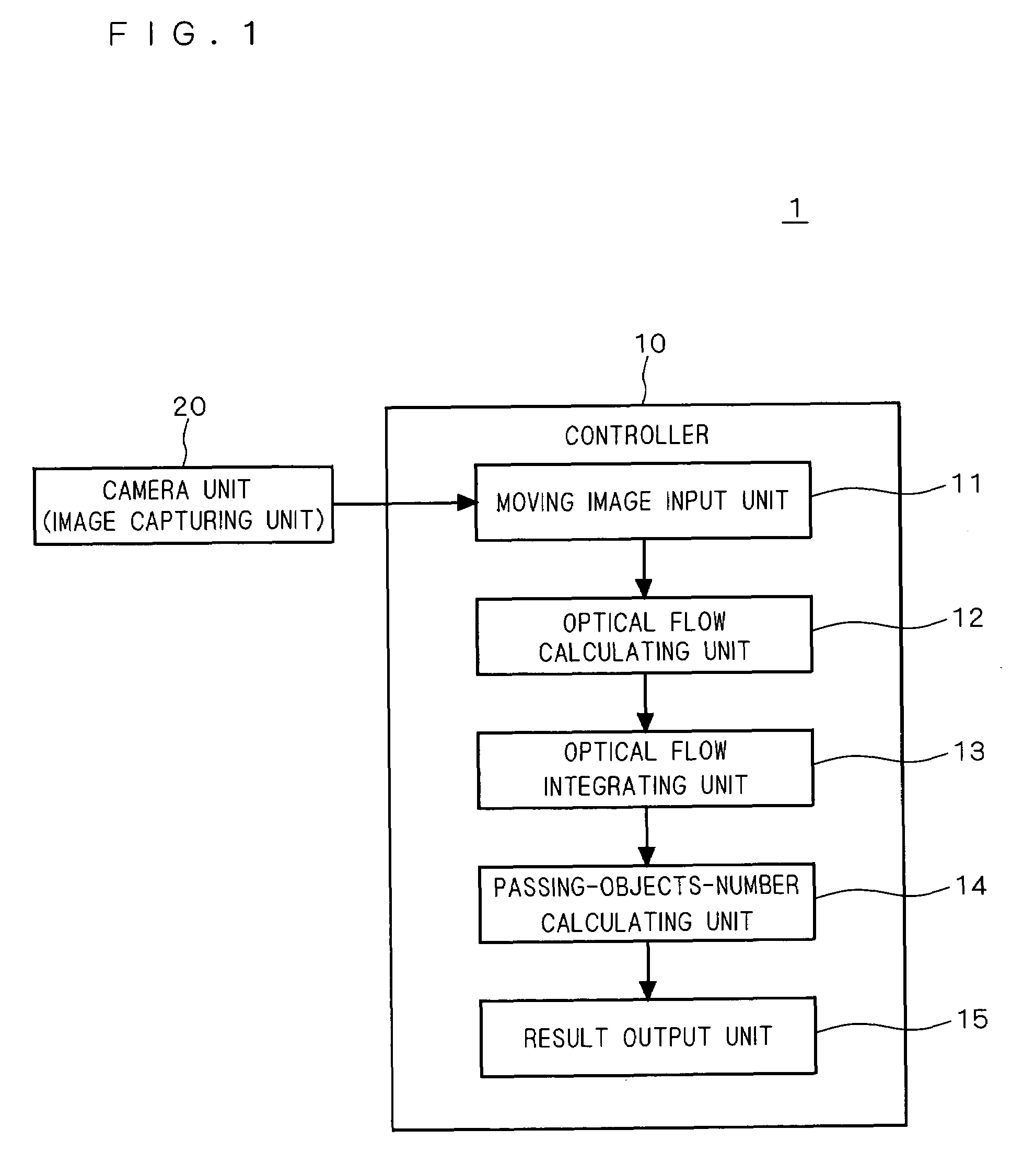

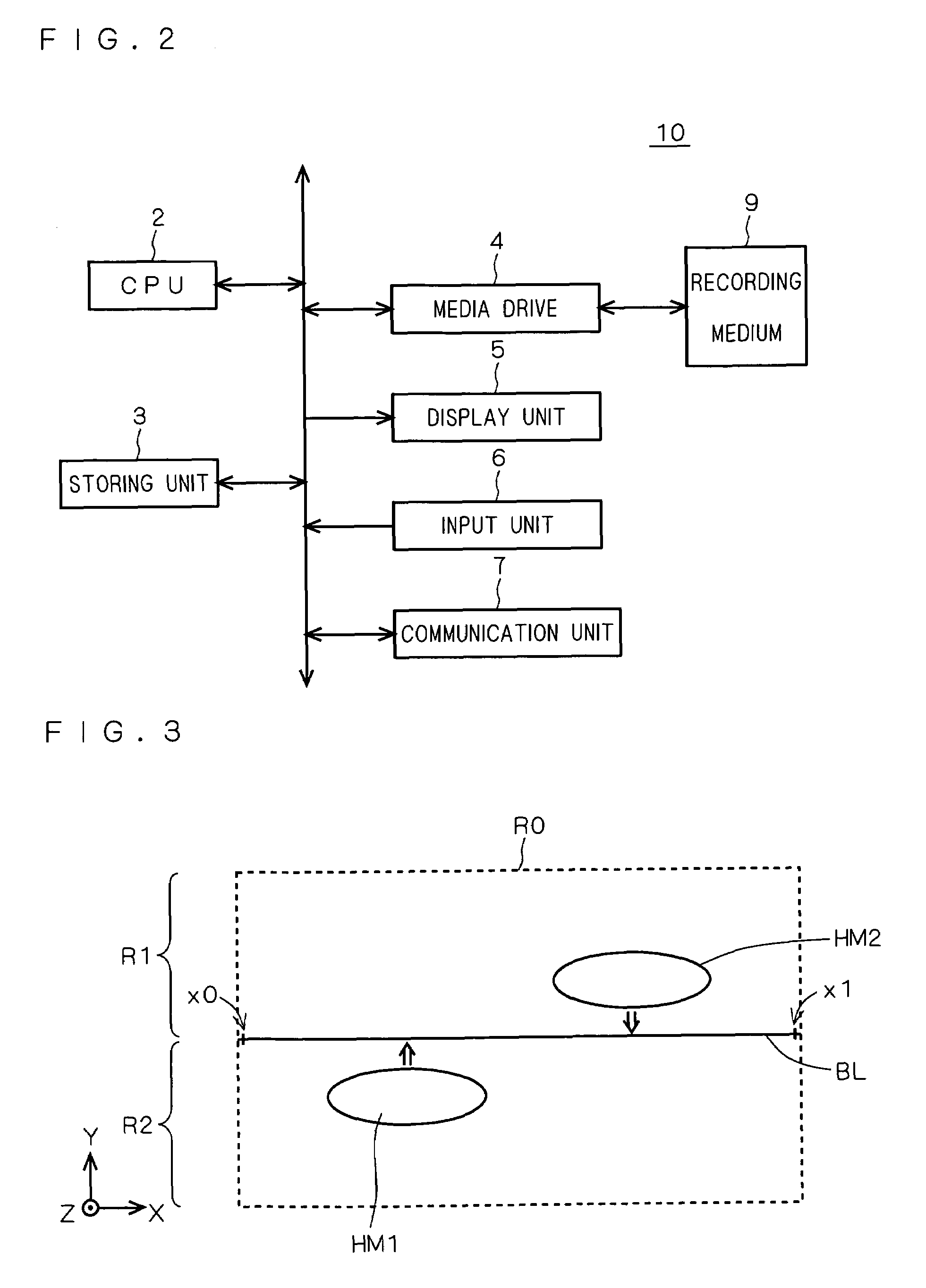

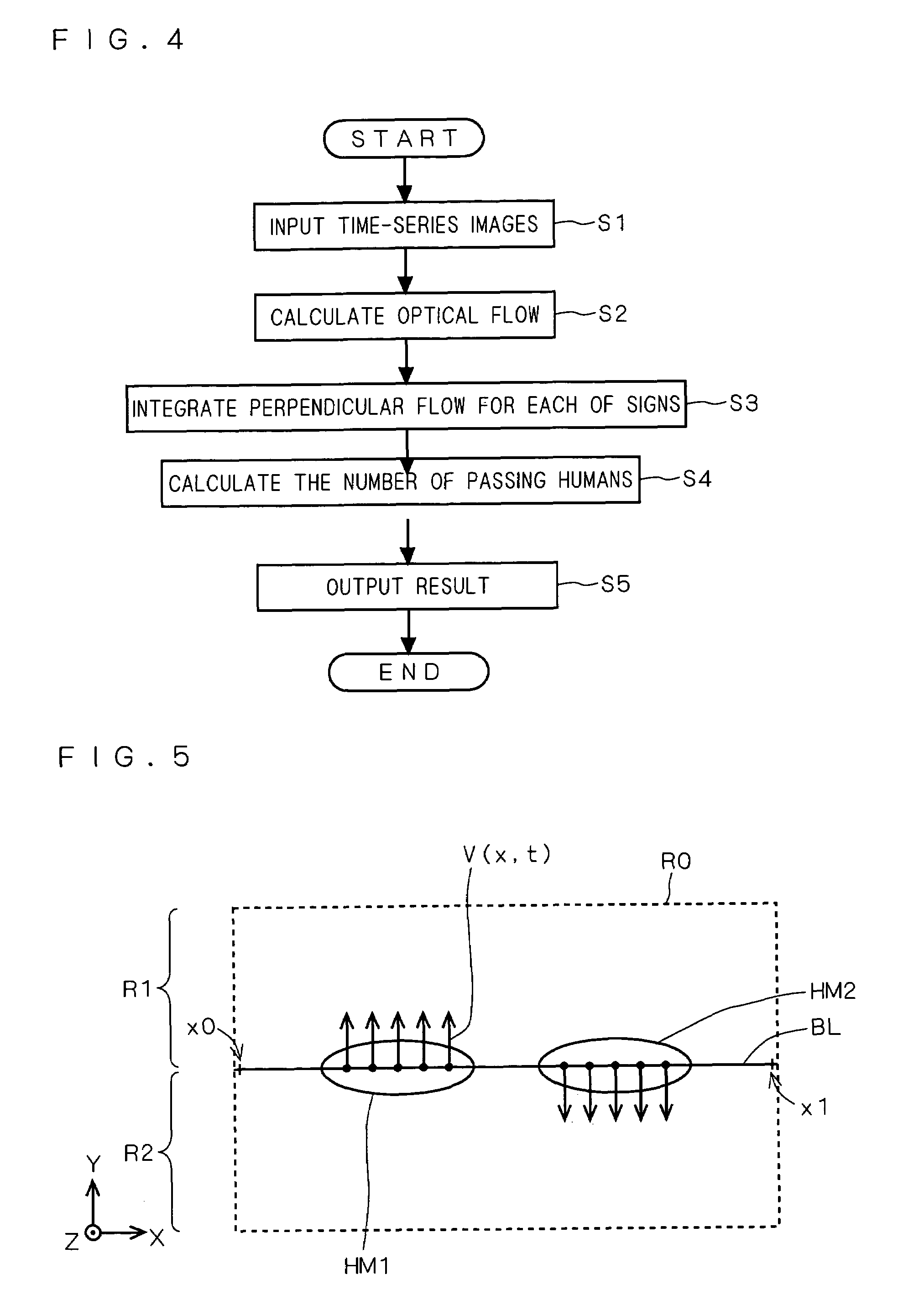

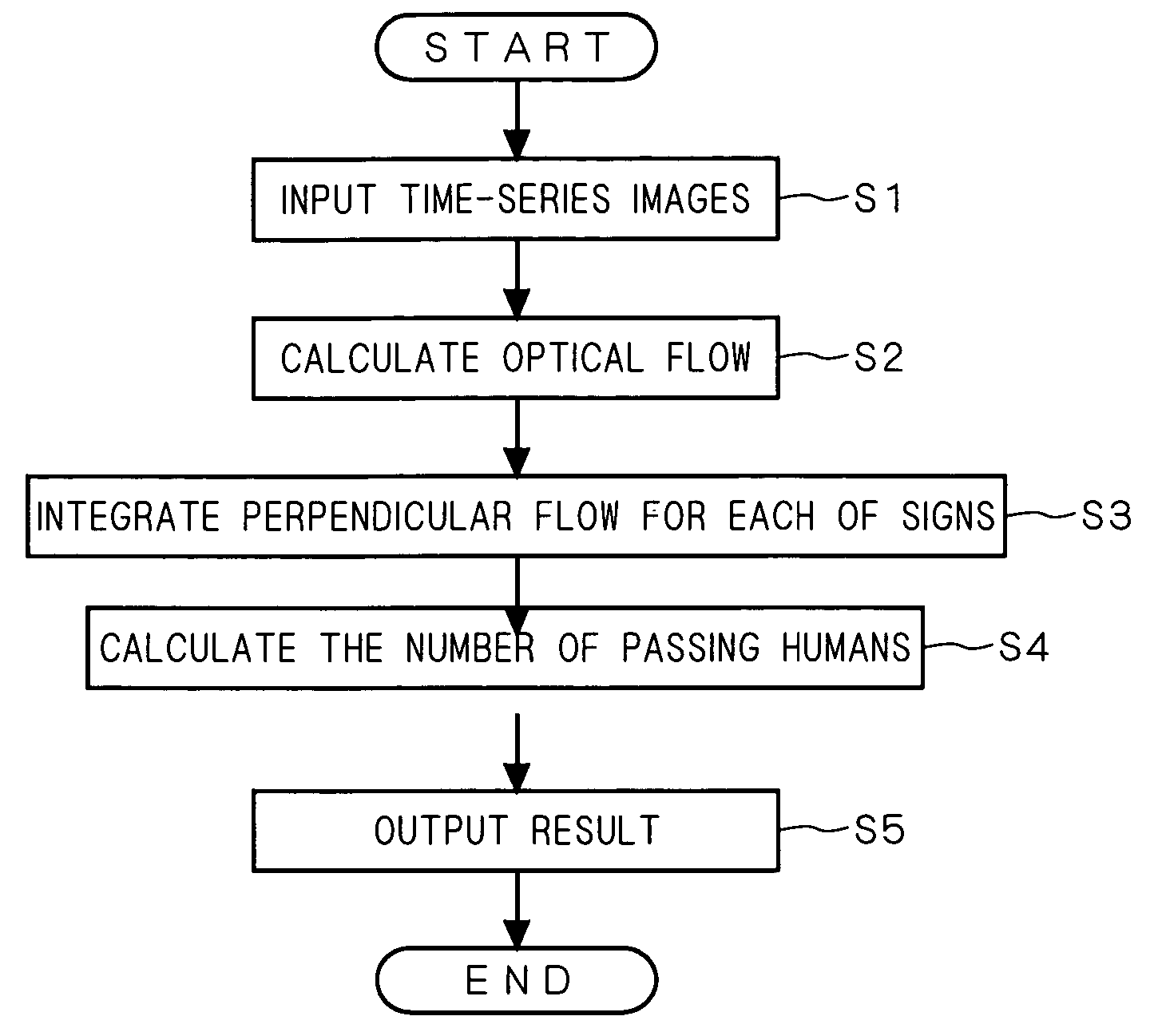

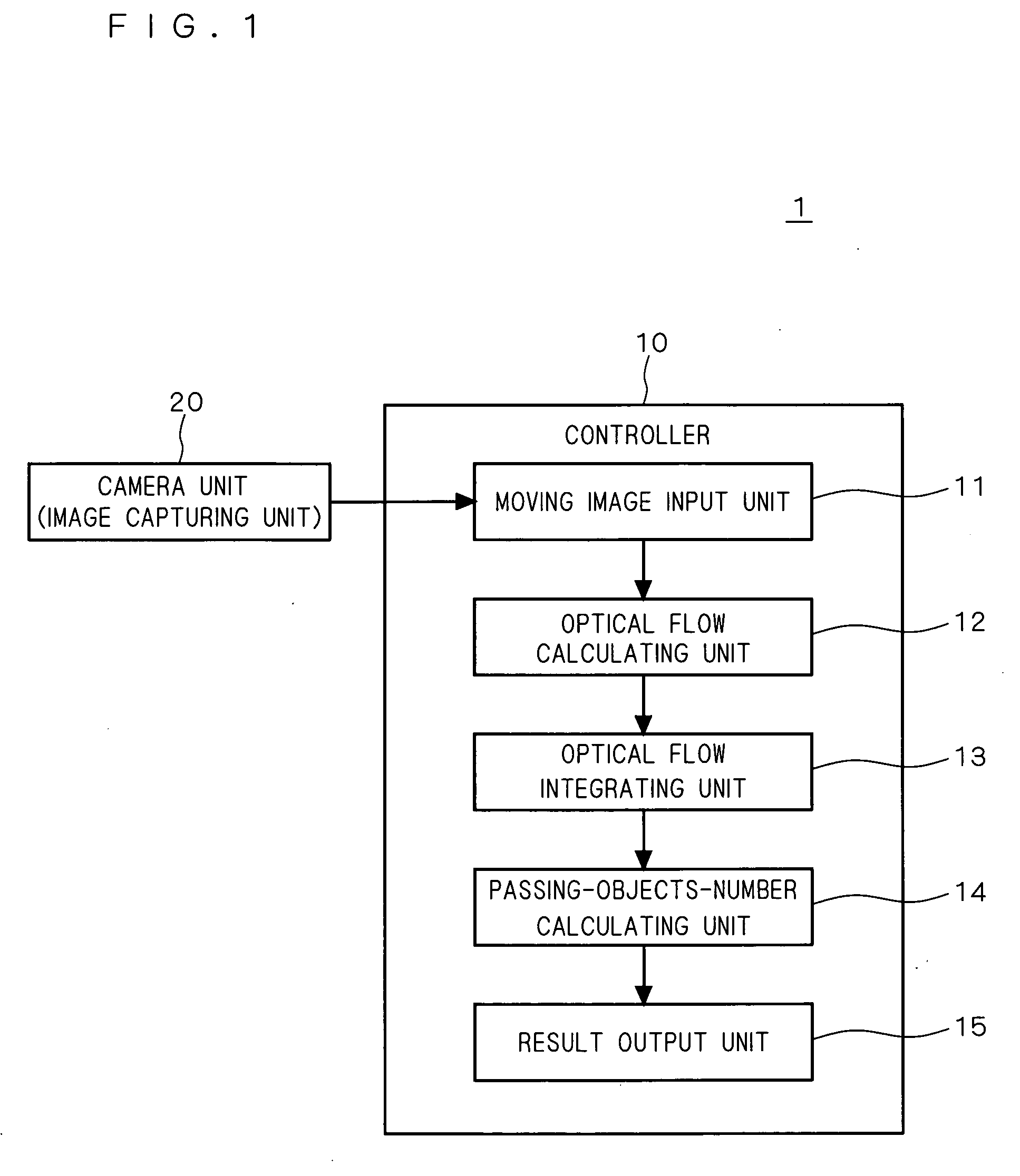

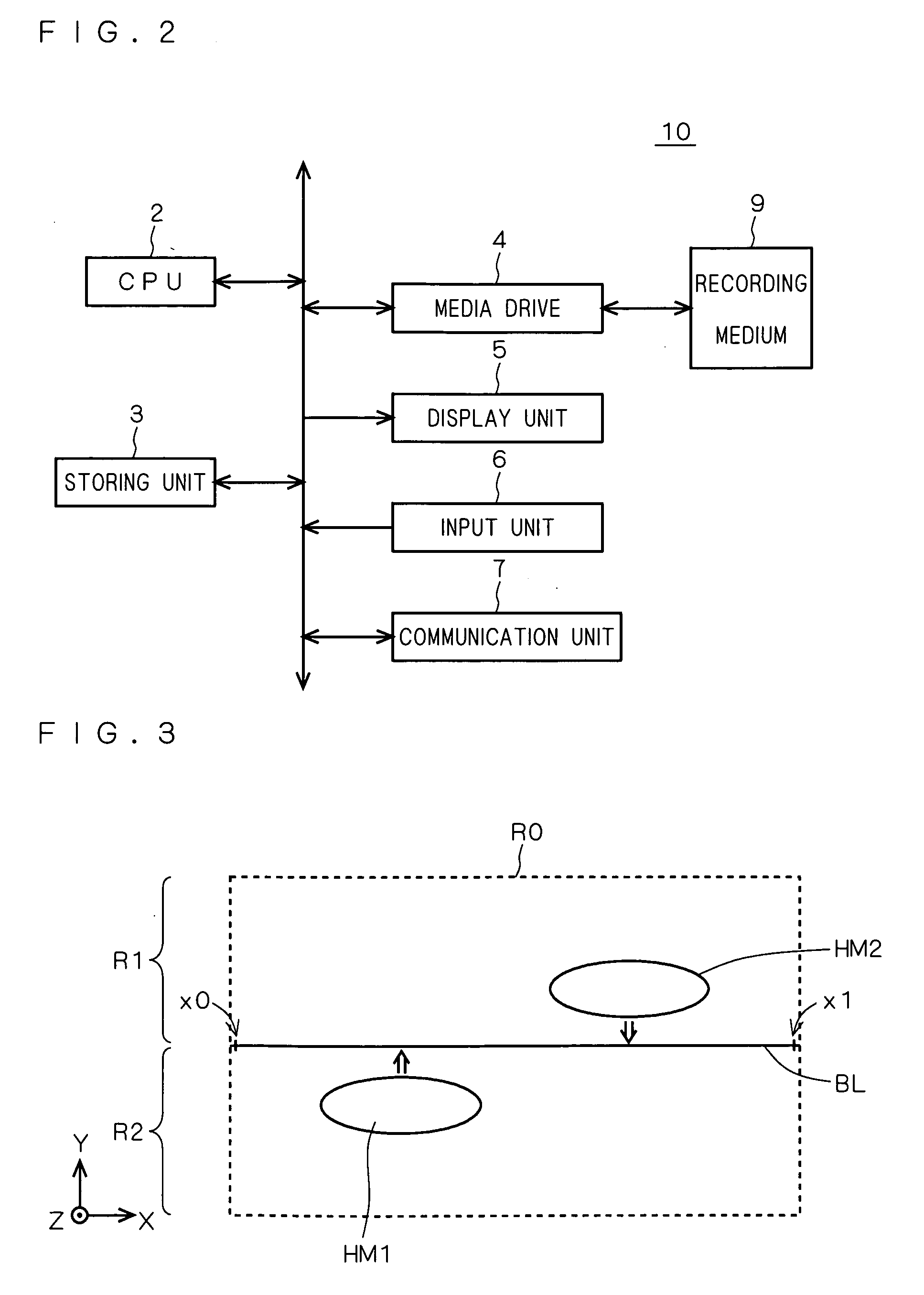

Object measuring apparatus, object measuring method, and program product

InactiveUS7221779B2Accurate countHigh speed machiningTelevision system detailsImage analysisMeasurement deviceMotion vector

The present invention provides an object measuring apparatus capable of performing high-speed process and accurately counting the number of a plurality of objects even in the case where the plurality of objects pass a boundary line simultaneously. The object measuring apparatus extracts motion vectors at a plurality of times in each of a plurality of positions on a boundary line on the basis of a plurality of images. The object measuring apparatus obtains at least one integral value by integrating components perpendicular to the boundary line of the motion vectors. As the at least one integral value, for example, an integral value derived by integrating the perpendicular components of one of positive and negative signs is obtained. The object measuring apparatus calculates the number of moving objects (people and the like) passing the boundary line on the basis of the integral value.

Owner:KONICA MINOLTA INC

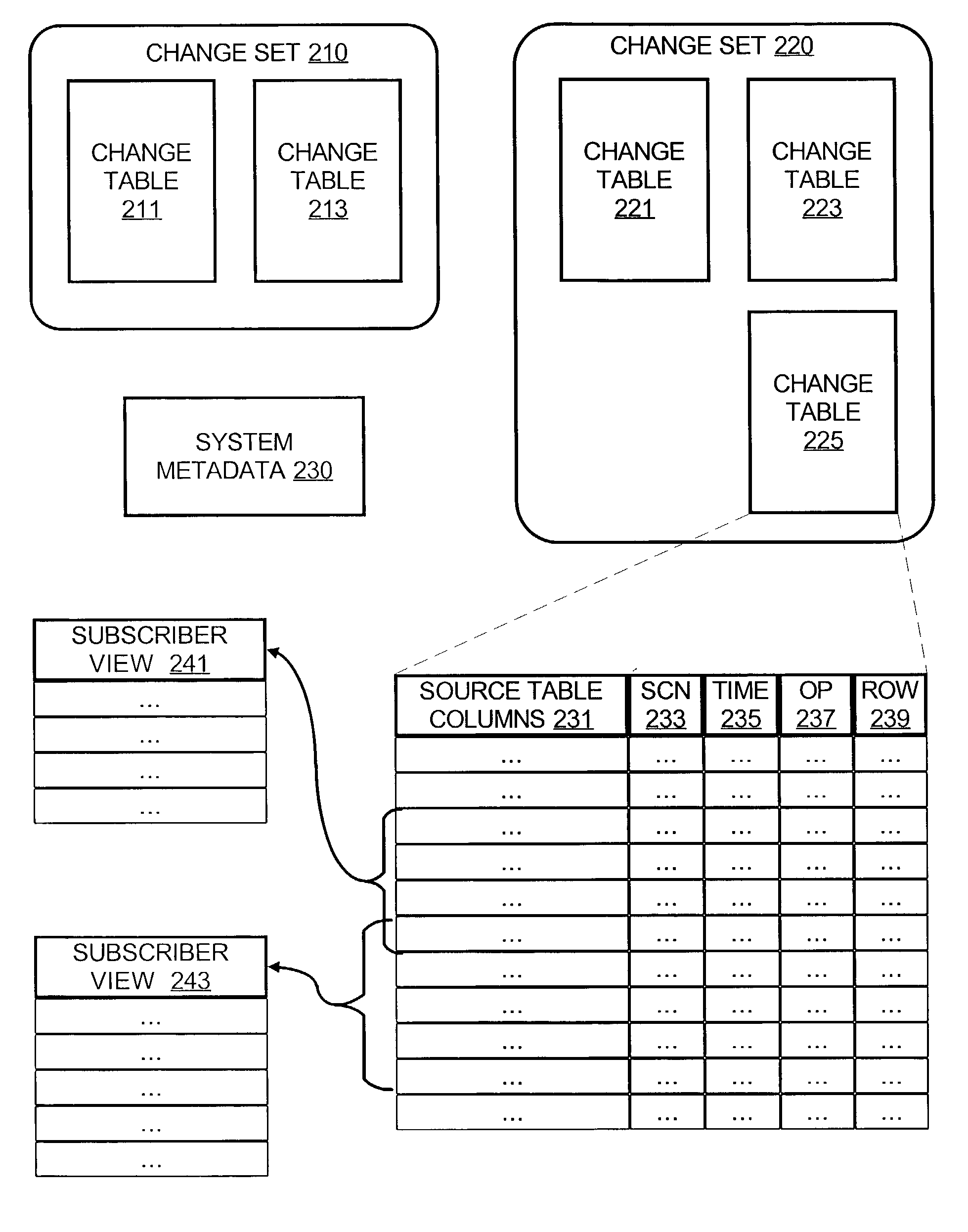

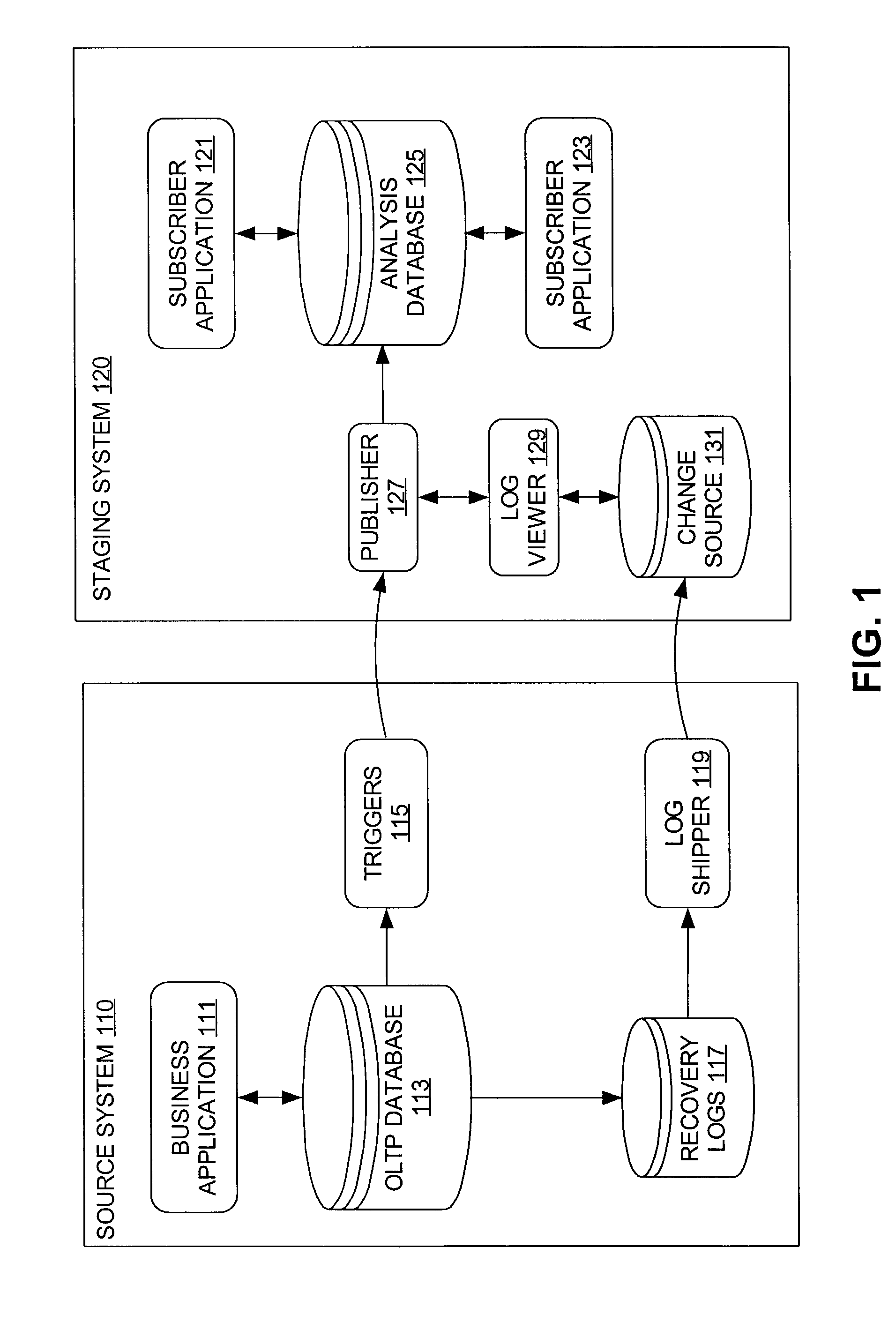

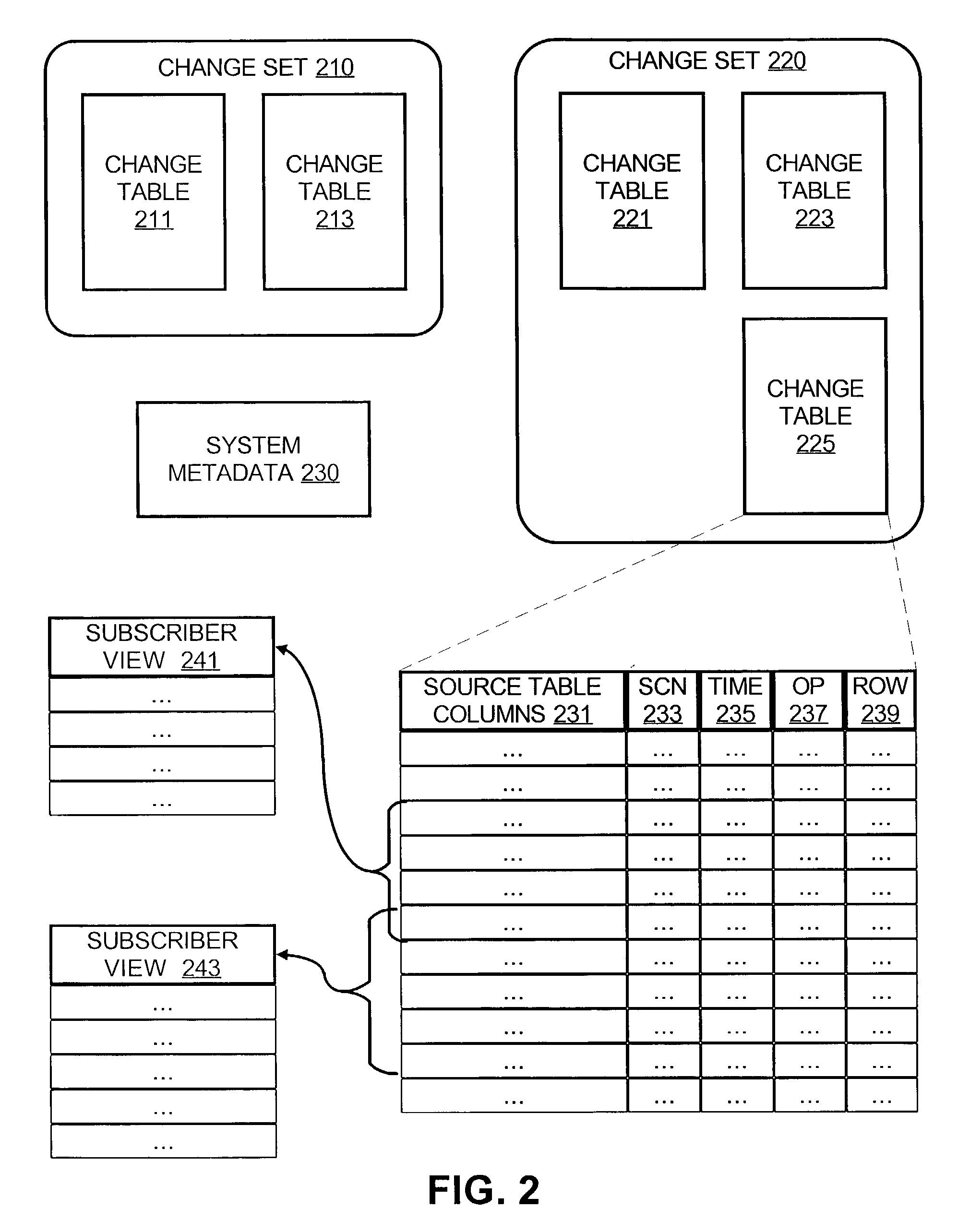

Method and apparatus for change data capture in a database system

InactiveUS6999977B1Task is complicatedPrevent loss and double countingData processing applicationsDigital data information retrievalControl mannerApplication software

A method of change data captured is disclosed, in which modifications made to on-line transaction processing (OLTP) tables (e.g. inserts, updates, and deletes) are maintained in a database object, referred to as a change table. The change data in the change table is then made available to analysis applications in a controlled manner, such as in accordance with a publication-subscription model.

Owner:ORACLE INT CORP

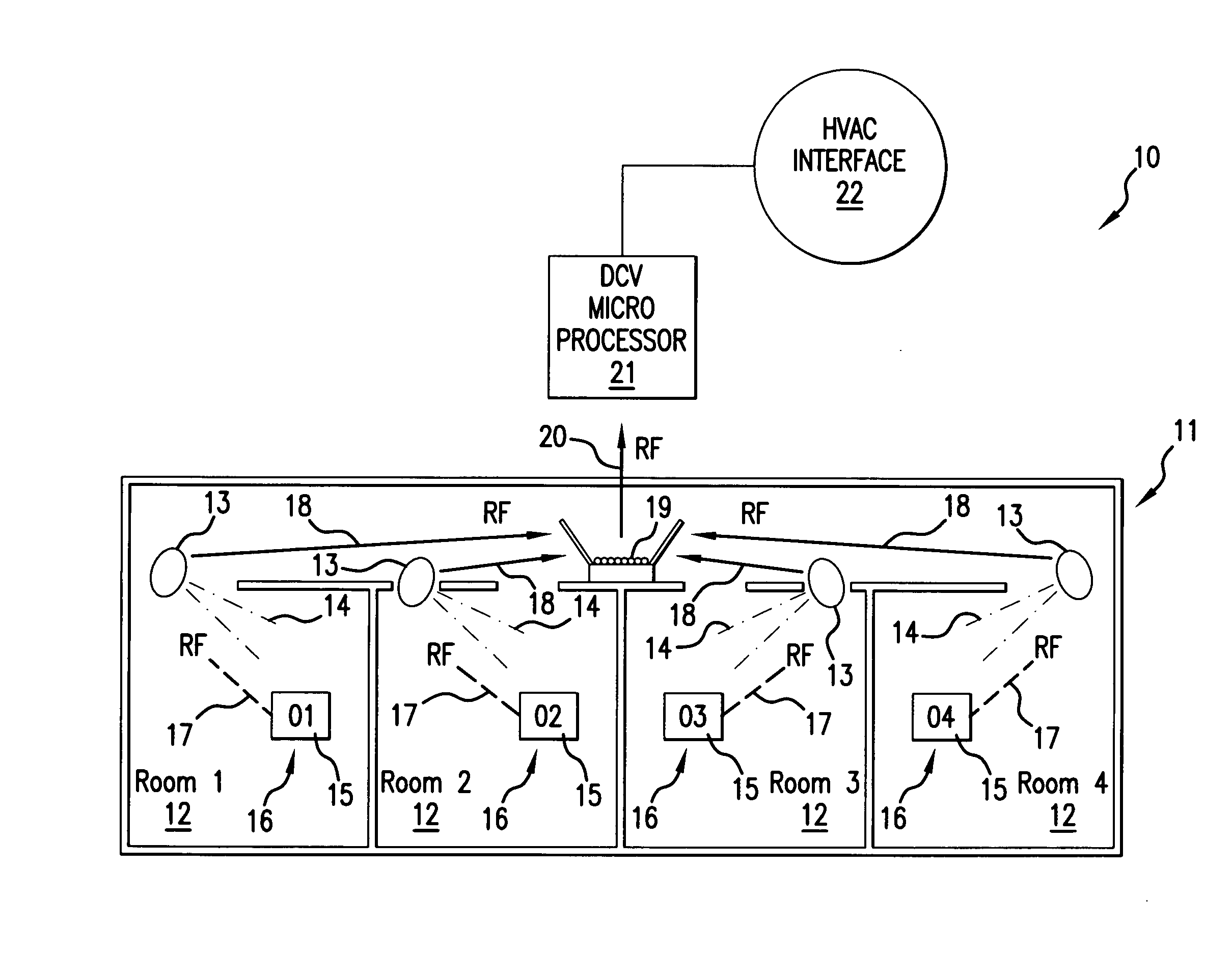

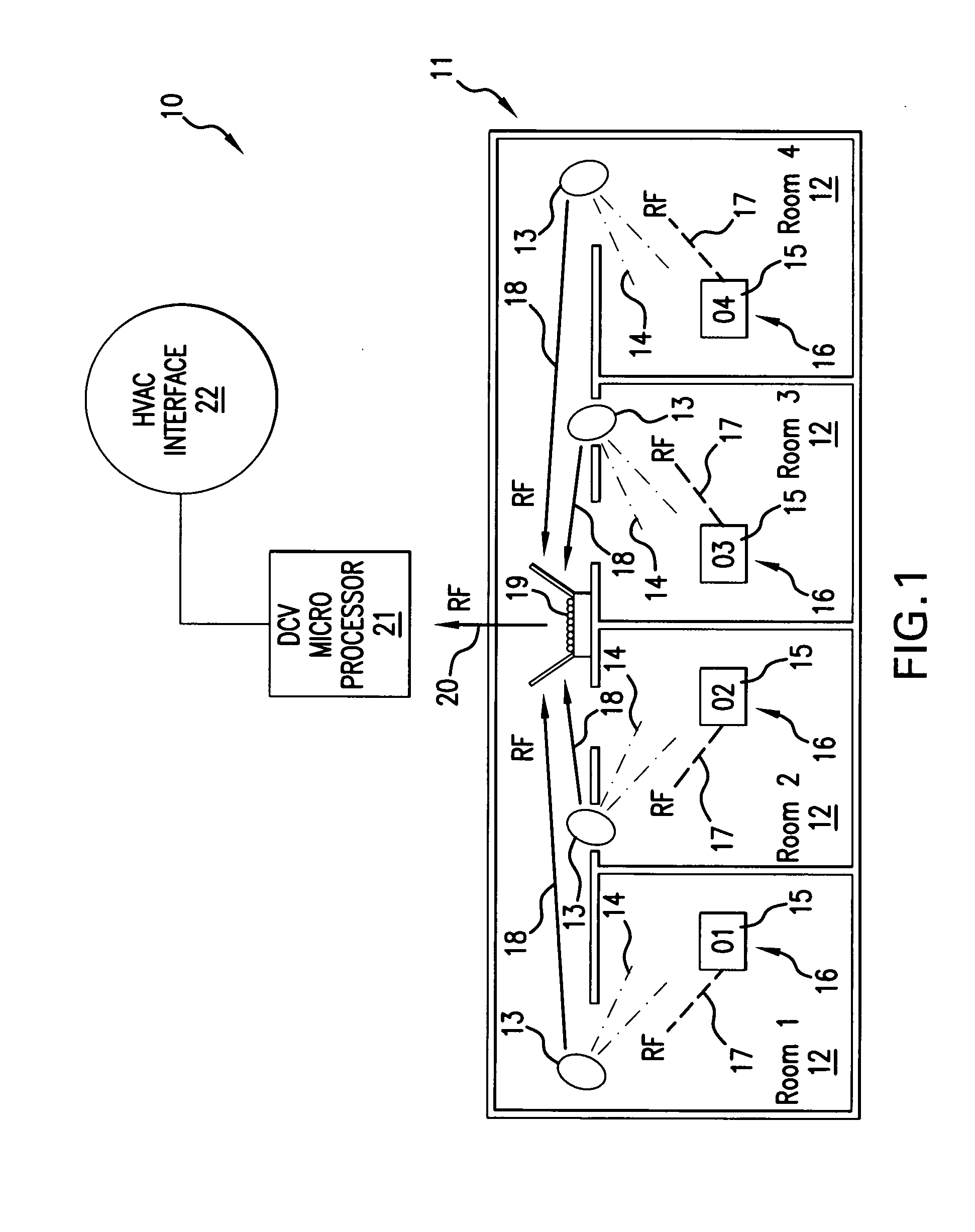

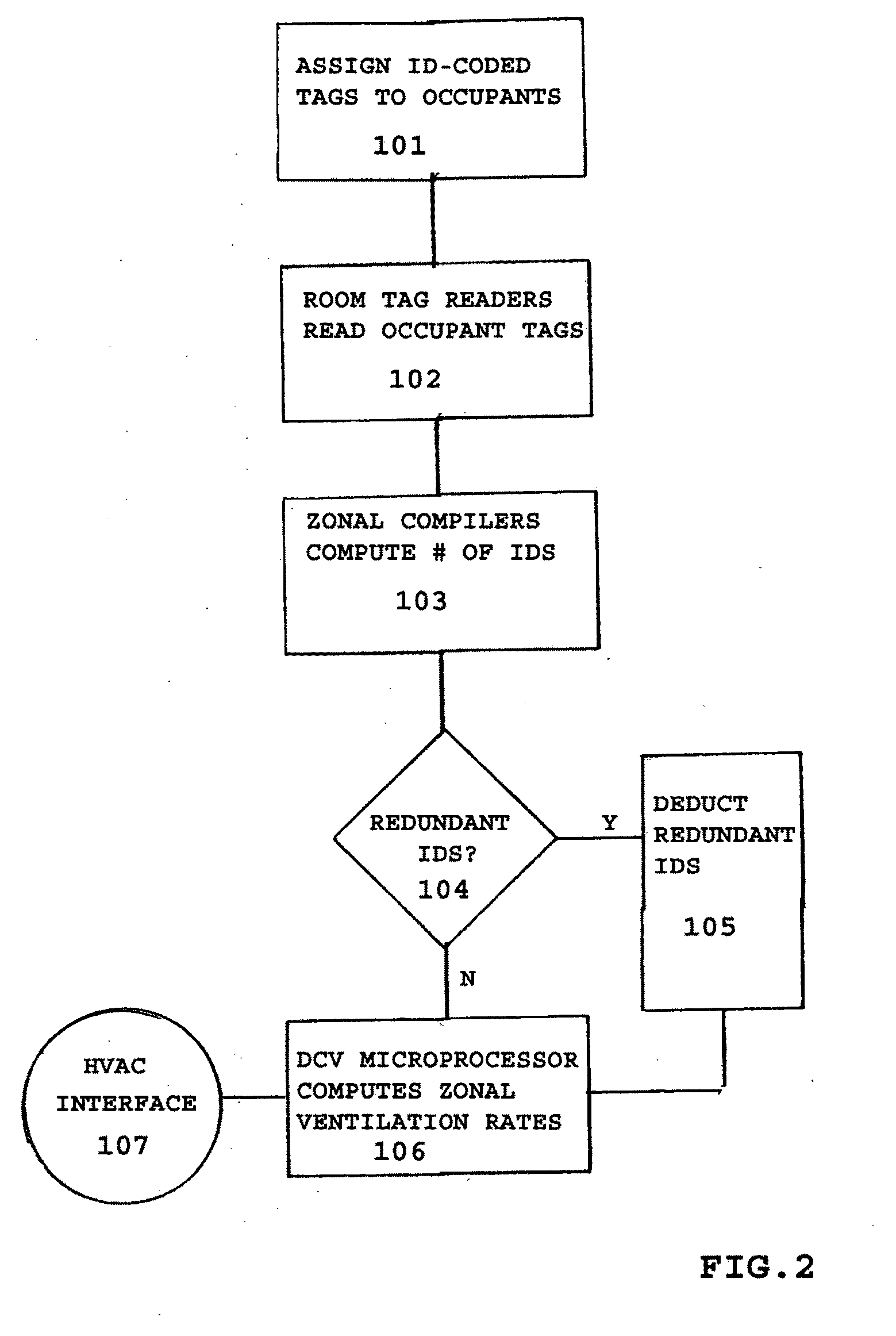

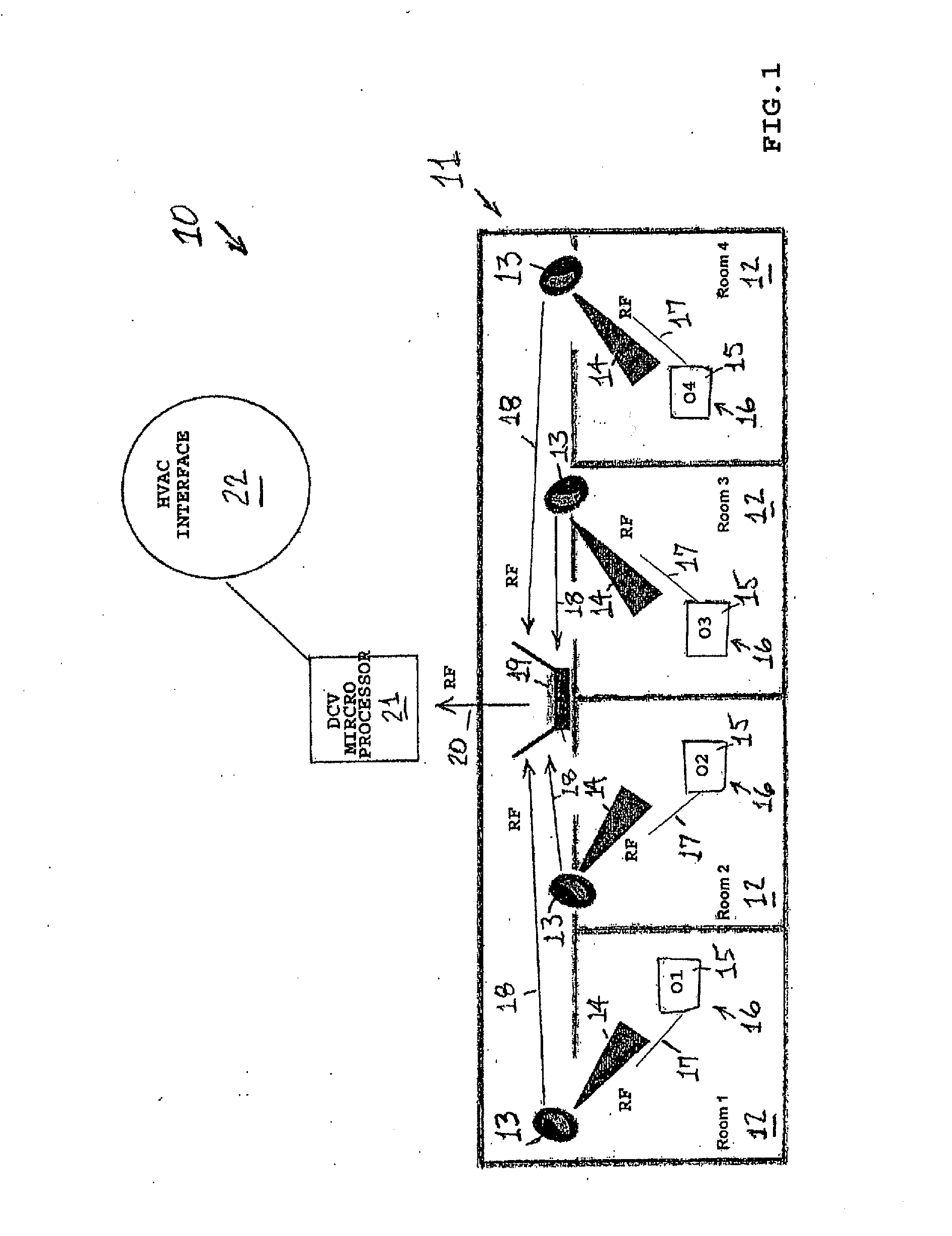

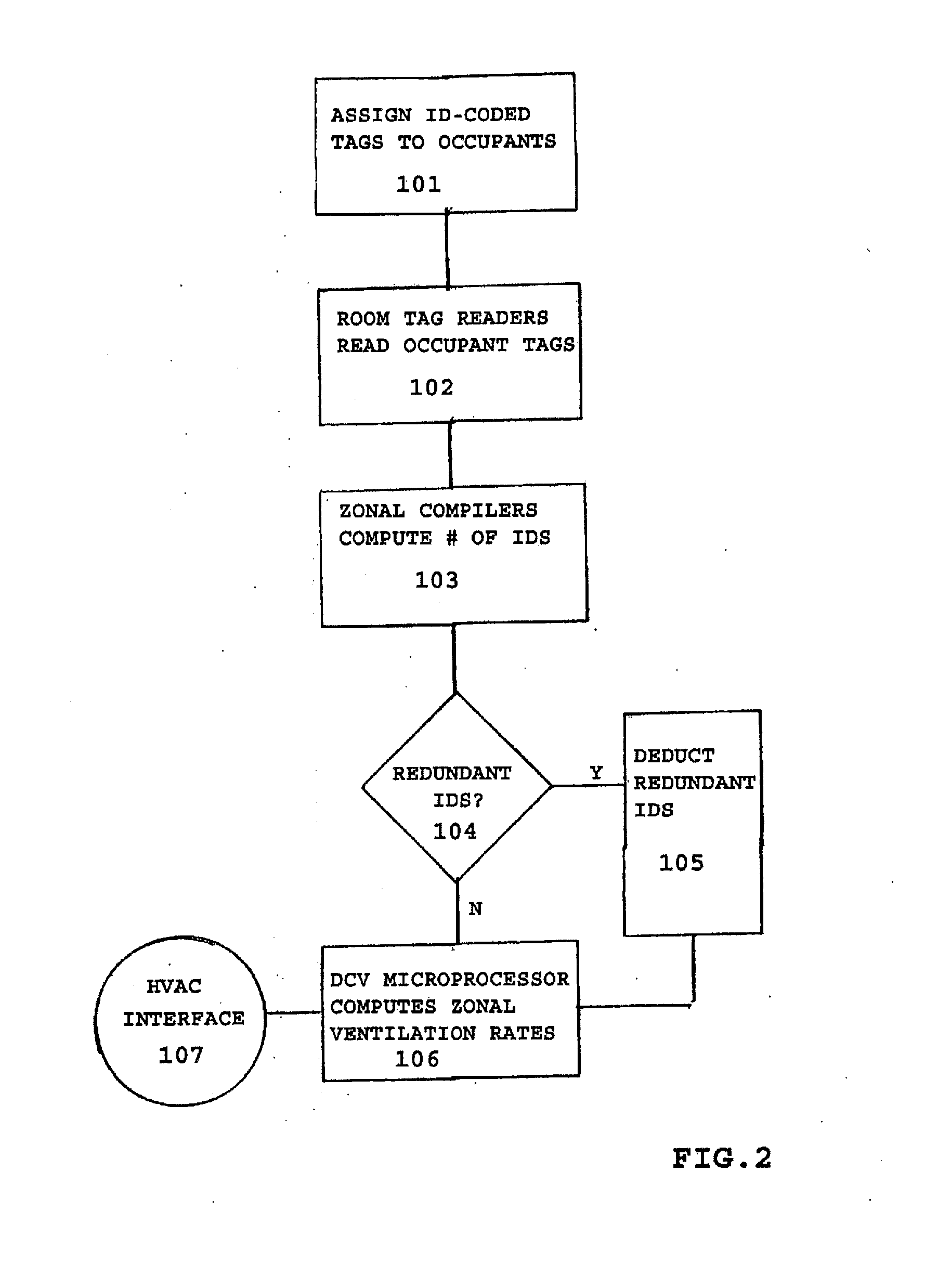

Occupancy-based demand controlled ventilation system

ActiveUS20110127340A1Maximum energy efficiencySimple and inexpensive implementationSampled-variable control systemsMechanical apparatusControl of respirationControlled ventilation

In a demand control ventilation (DCV) system, ID codes of tags worn by occupants are detected in each room by a tag detector and wirelessly communicated to a zonal occupancy compiler. The zonal occupancy count arrived at by the compiler is transmitted to a DCV microprocessor, which interfaces with the ventilation controller of the building's HVAC system and sets the zonal ventilation rate based on the occupancy count and applicable ASHRAE standards.

Owner:AIKEN THOMAS DAVID

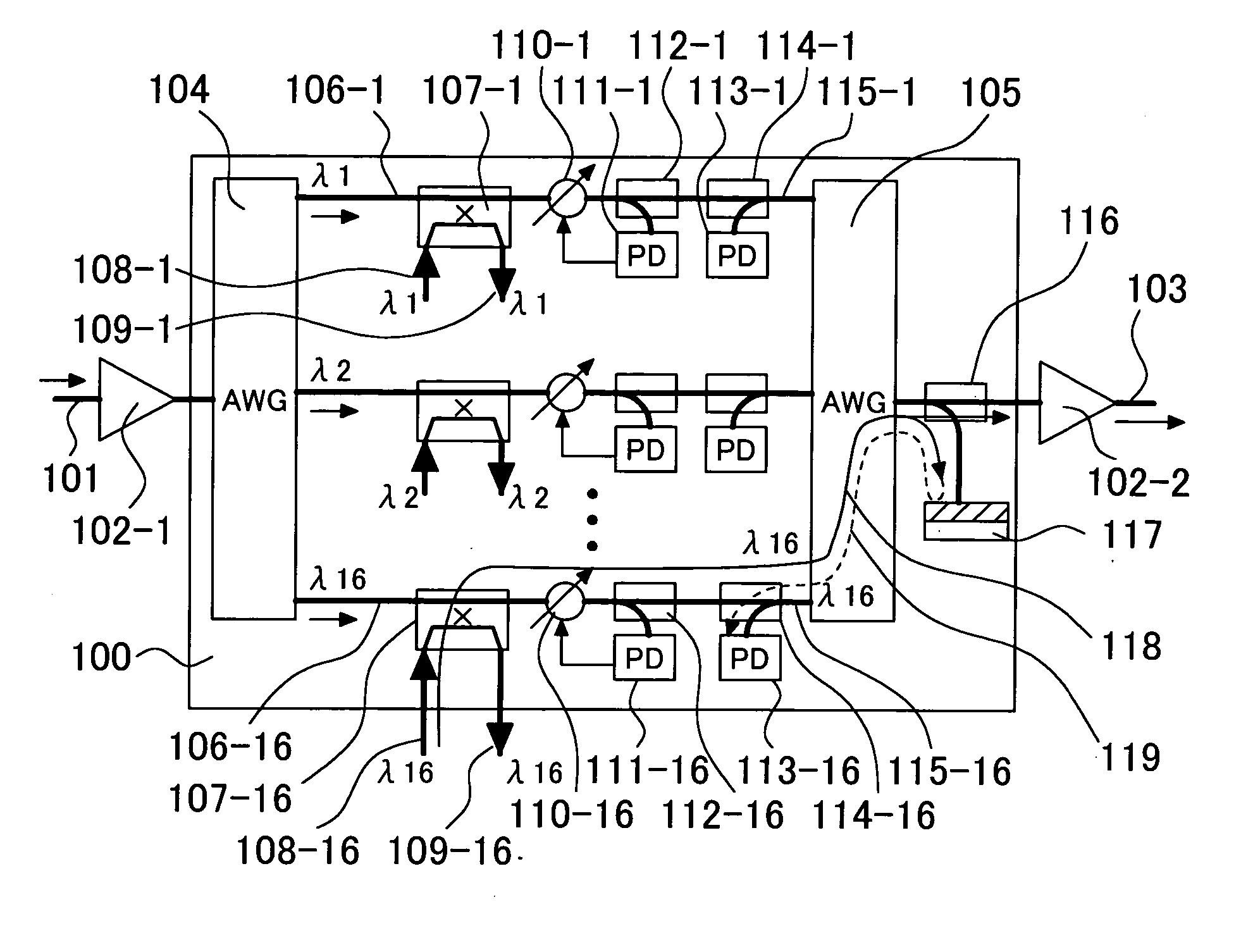

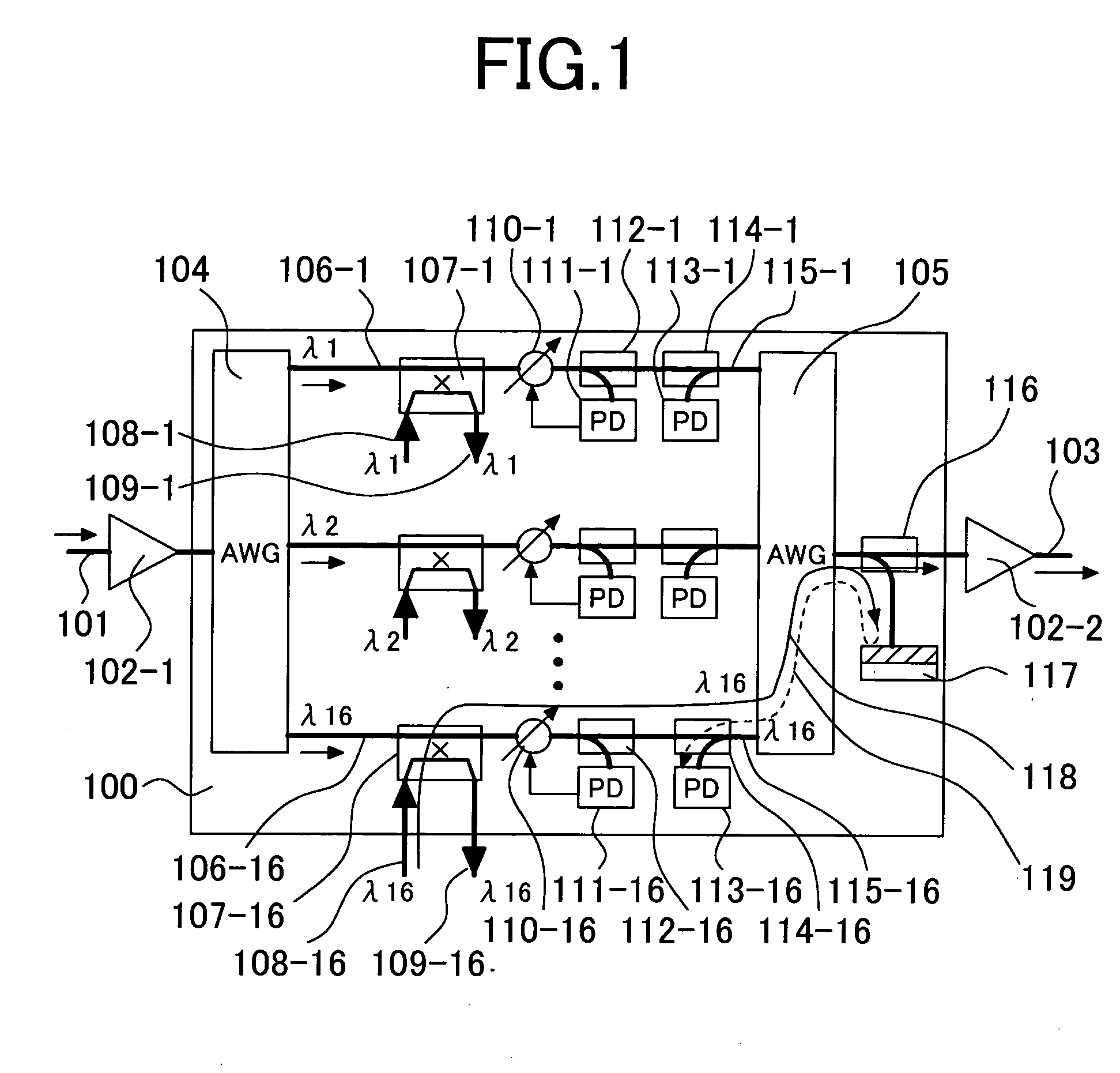

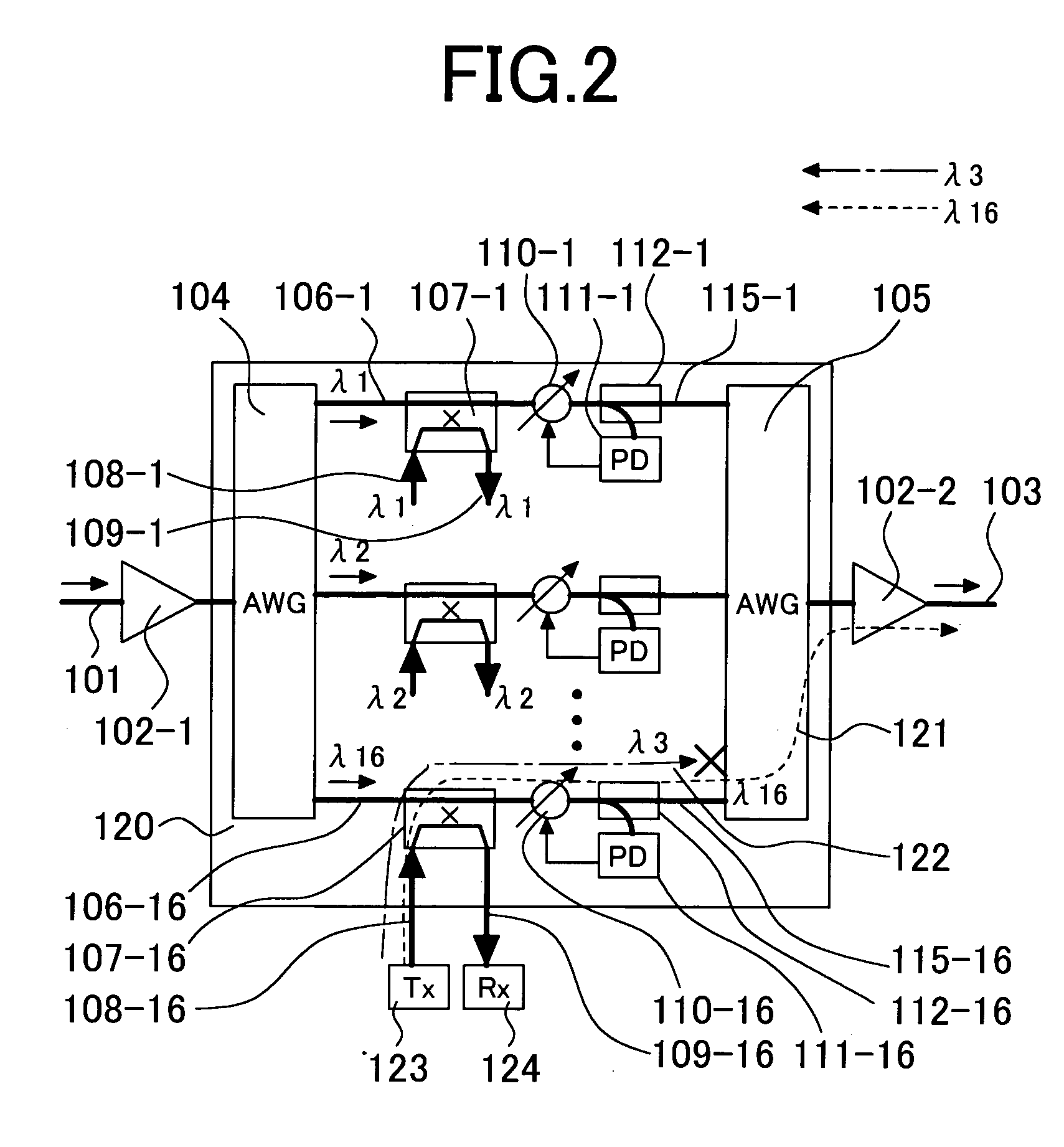

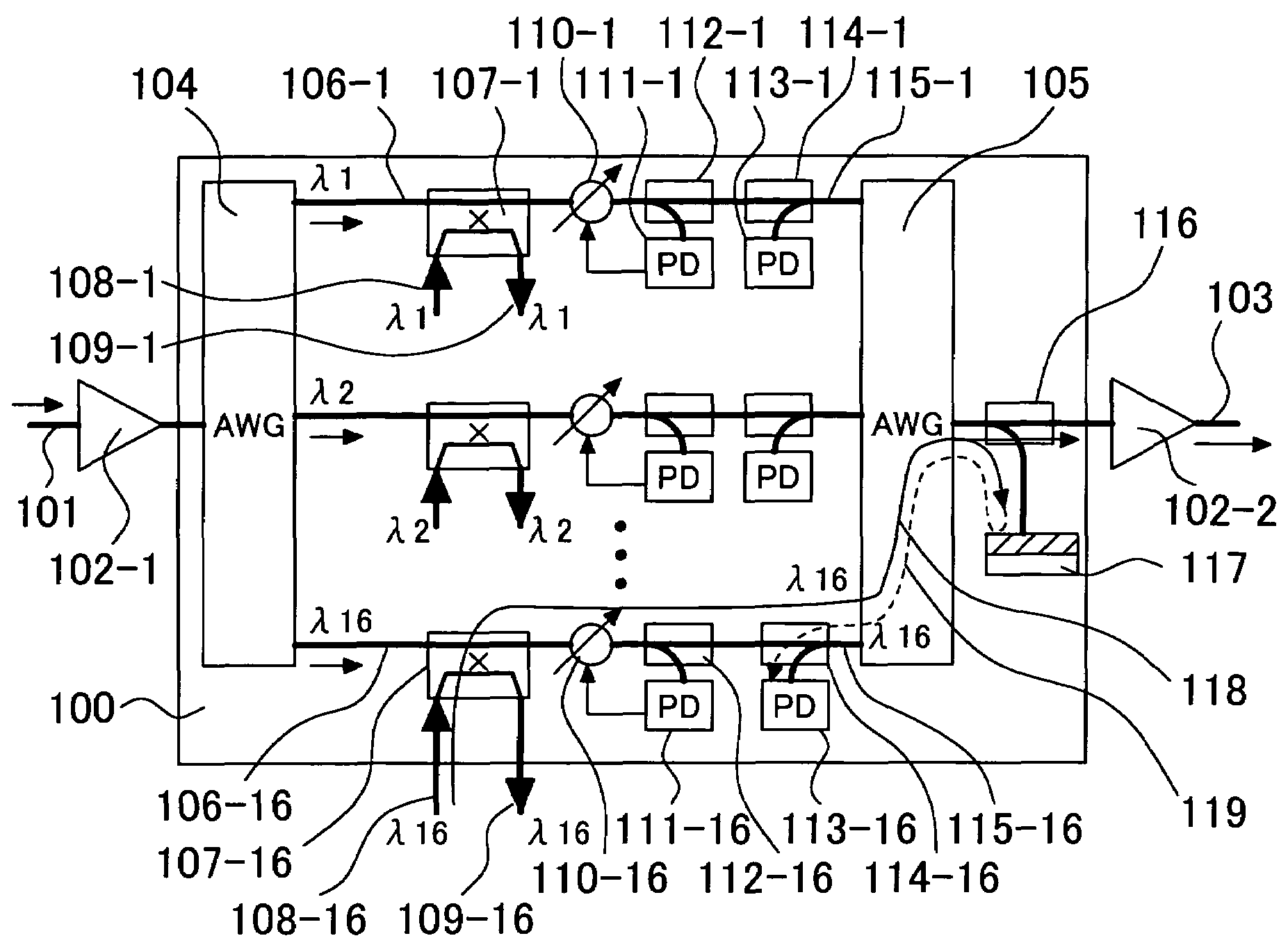

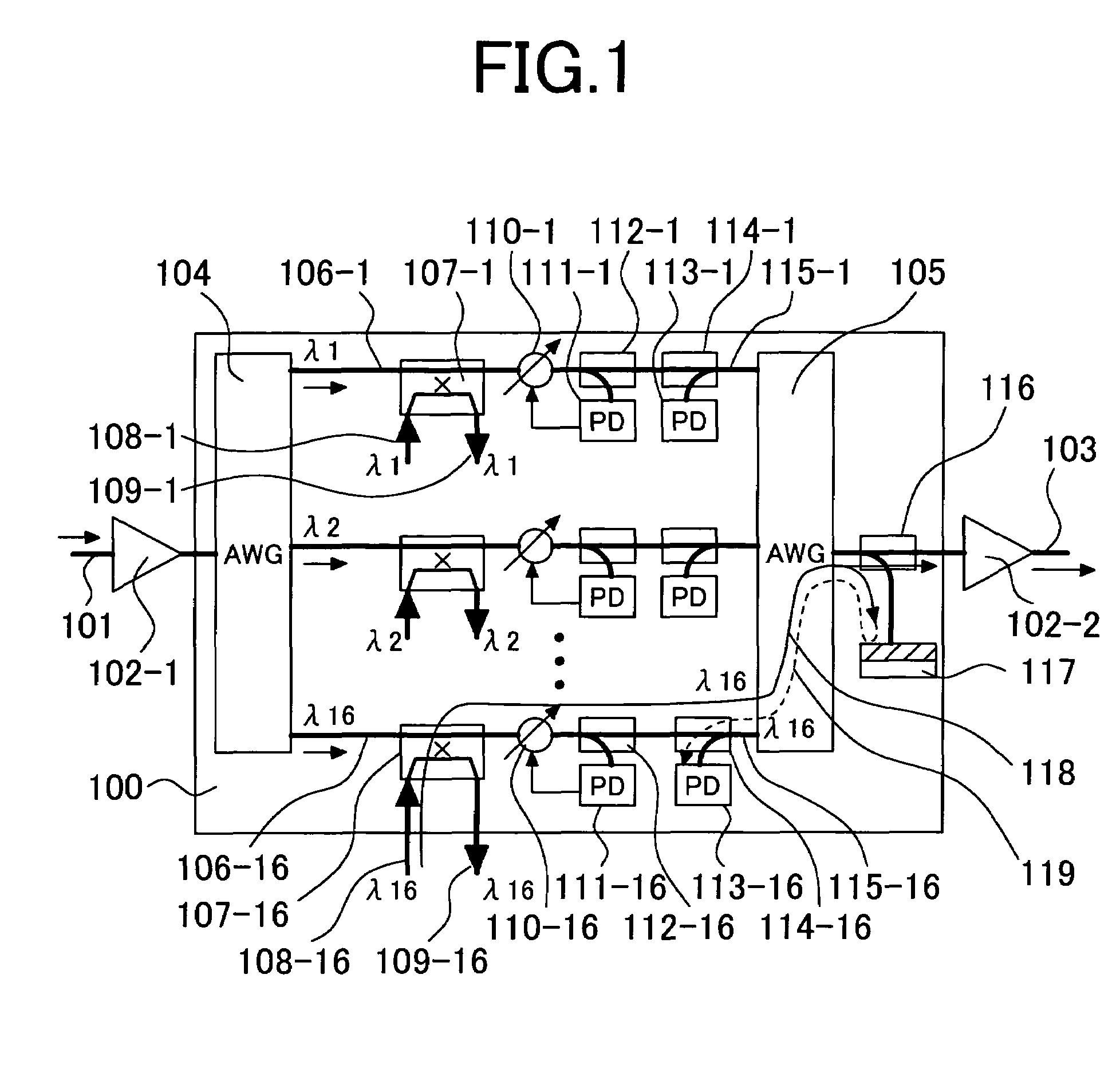

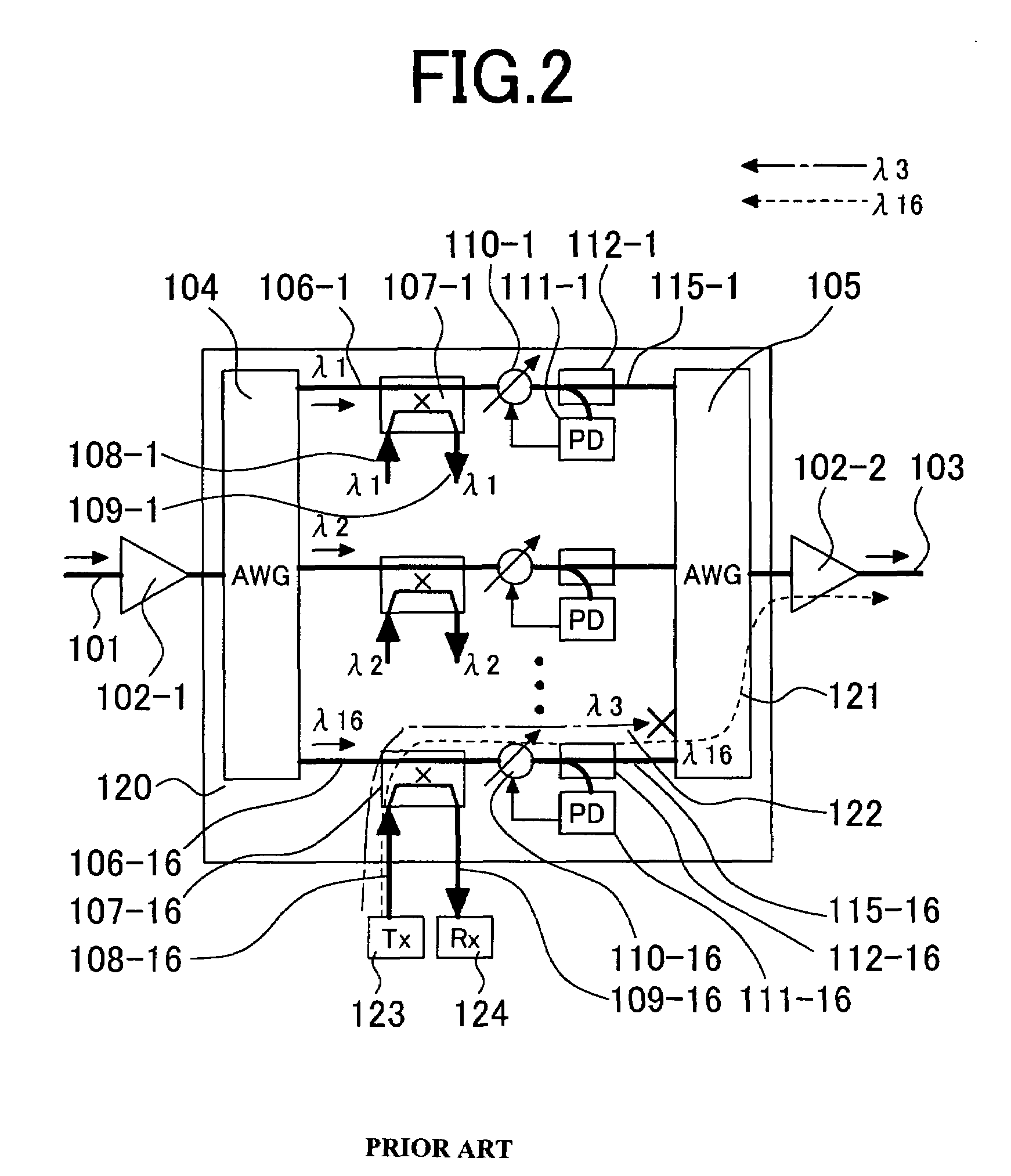

Optical wavelength add-drop multiplexer

InactiveUS20050226621A1Accurately notifiedEfficient solutionWavelength-division multiplex systemsCoupling light guidesMultiplexerCalculation error

It was difficult to detect a wavelength error. Further, a wavelength error of an optical add signal is accompanied by a calculation error of the number of wavelengths of a wavelength division multiplexing signal, which causes a set value of an optical signal level to become abnormal, resulting in the degradation of the optical signal. According to the present invention, part of an inputted optical add signal 118 is reflected by a mirror 117, and is thereby inputted into an optical wavelength multiplexer 105 in the reverse direction so that the optical add signal is returned to paths 115-1 through 115-16 corresponding to wavelengths λ1 through λ16. If the returned optical add signal is an optical add signal having a correct wavelength (in FIG. 1, λ16), the optical signal enters its corresponding backward direction optical detector 113-16. Accordingly, it is possible to check whether or not a wavelength of the optical add signal is correct.

Owner:HITACHI LTD

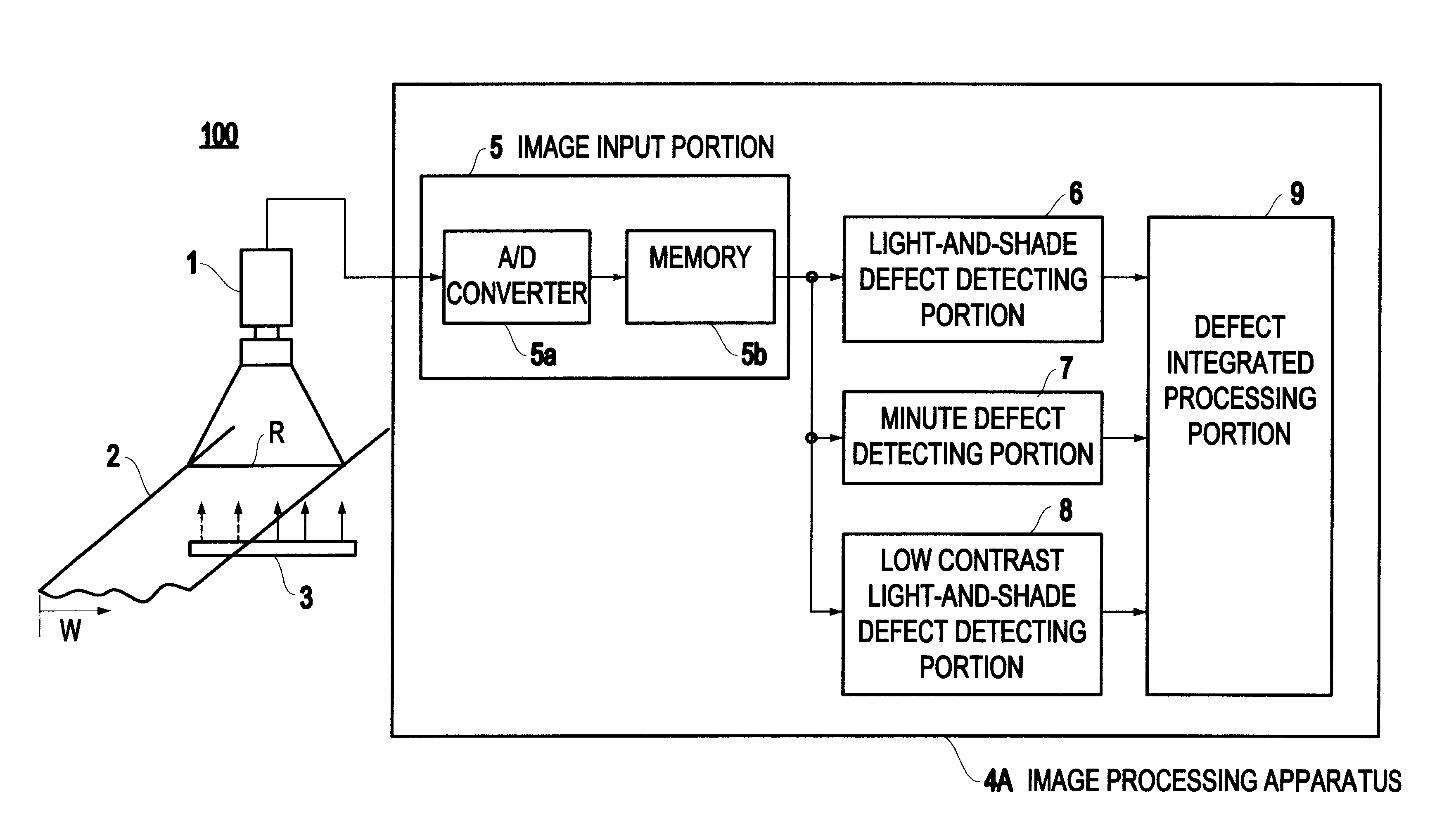

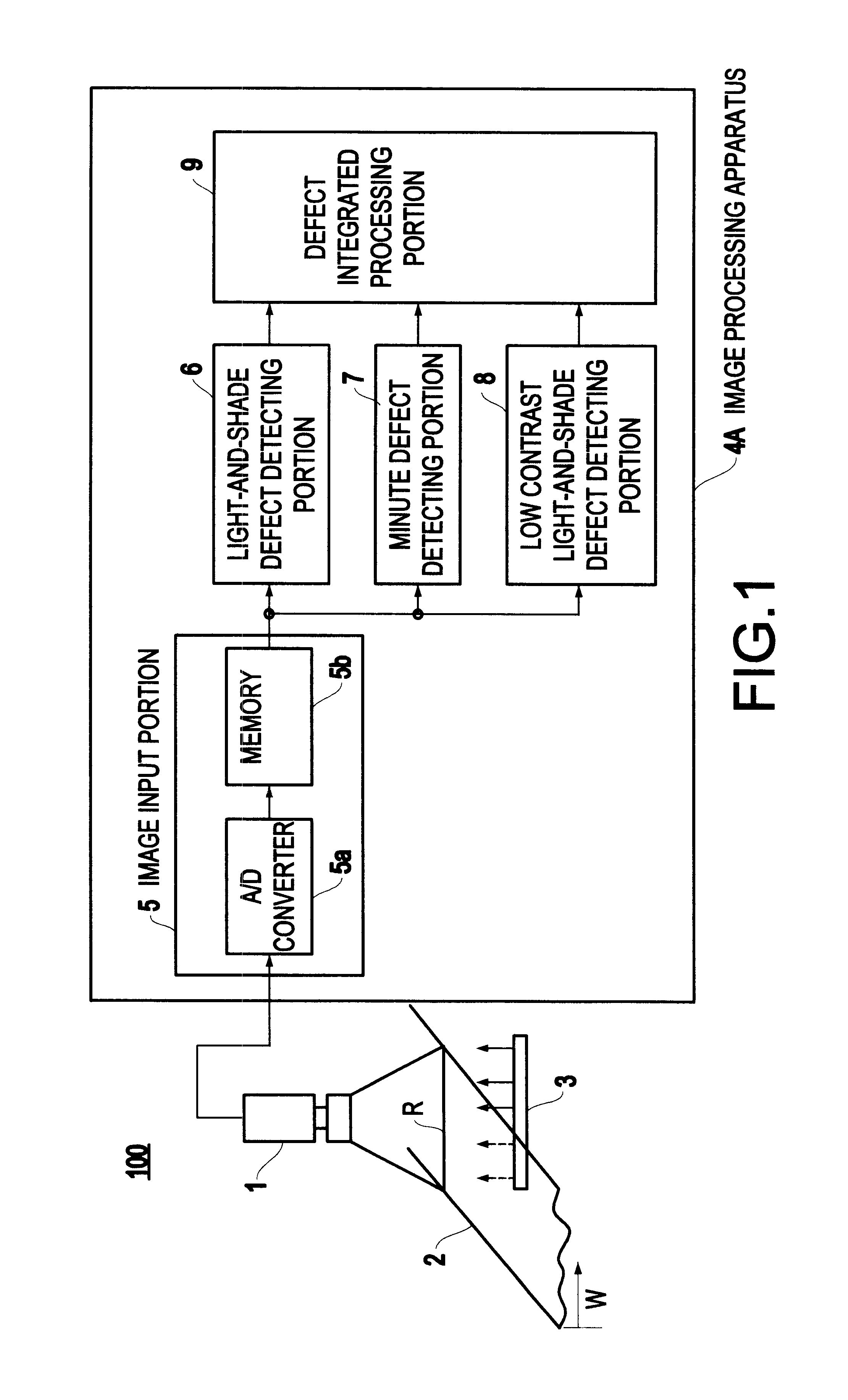

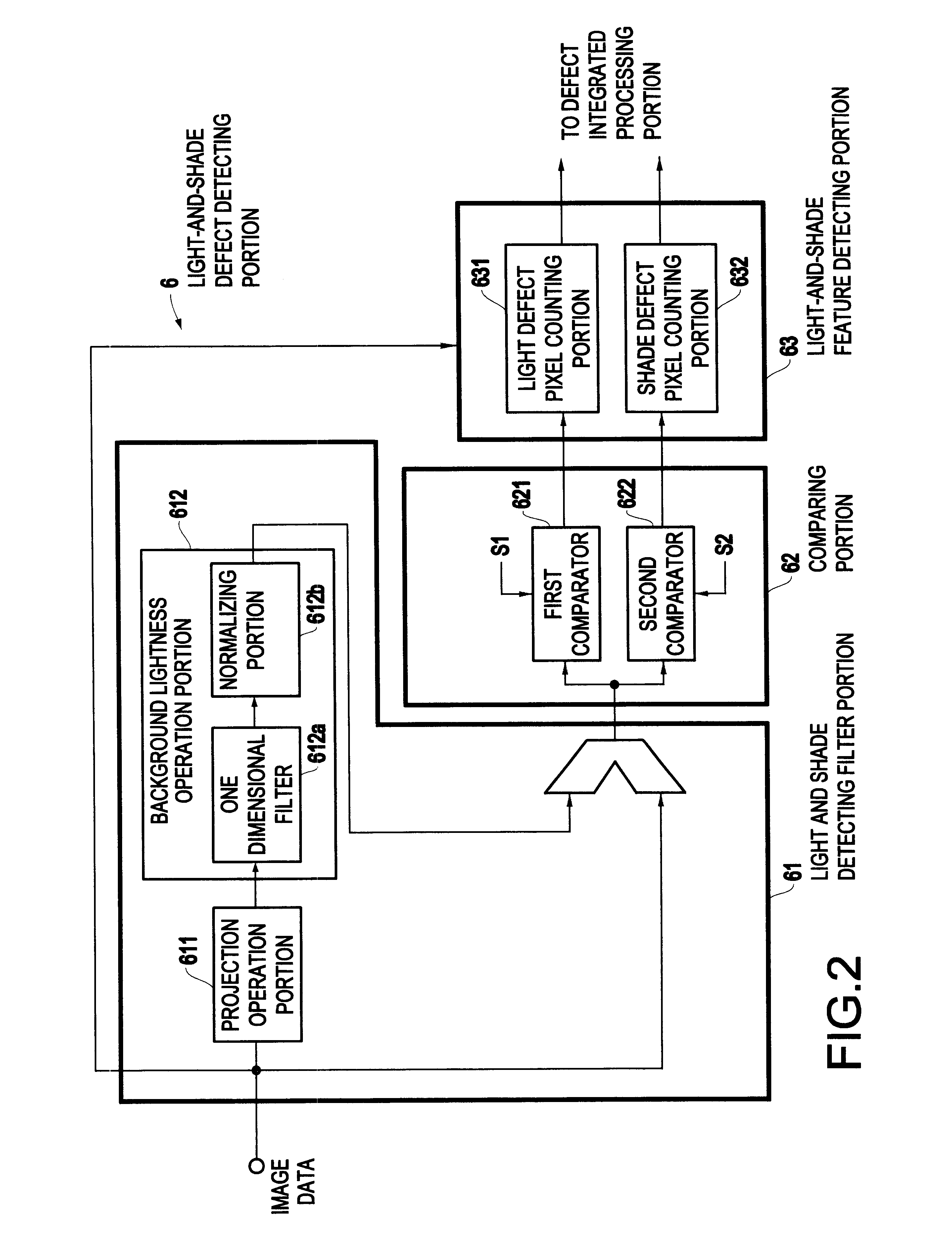

Defect integrated processing apparatus and method thereof

InactiveUS6535621B1Highly reliable defect integrated processingIncrease the lengthImage enhancementInvestigating moving sheetsLow contrastIntegrated processing

A defect integrated processing apparatus and method for performing a processing in an integrated fashion of various kinds of edfect and then detecting the accurate number, positions, sizes, etc. of the defects in detail, includes detecting light-and-shade defects based on an image data obtained by picking up an object to be inspected. Edges and minute defect on the object are detected by performing a differential processing of the image data, low contrast light-and-shade defects are detected by performing an integral processing of the image data obtained through the image pick-up device and then a differential processing of an obtained integrated image, and an integrated information of defects is obtained by performing a processing in an integrated fashion of detected defects.

Owner:TOSHIBA ENG

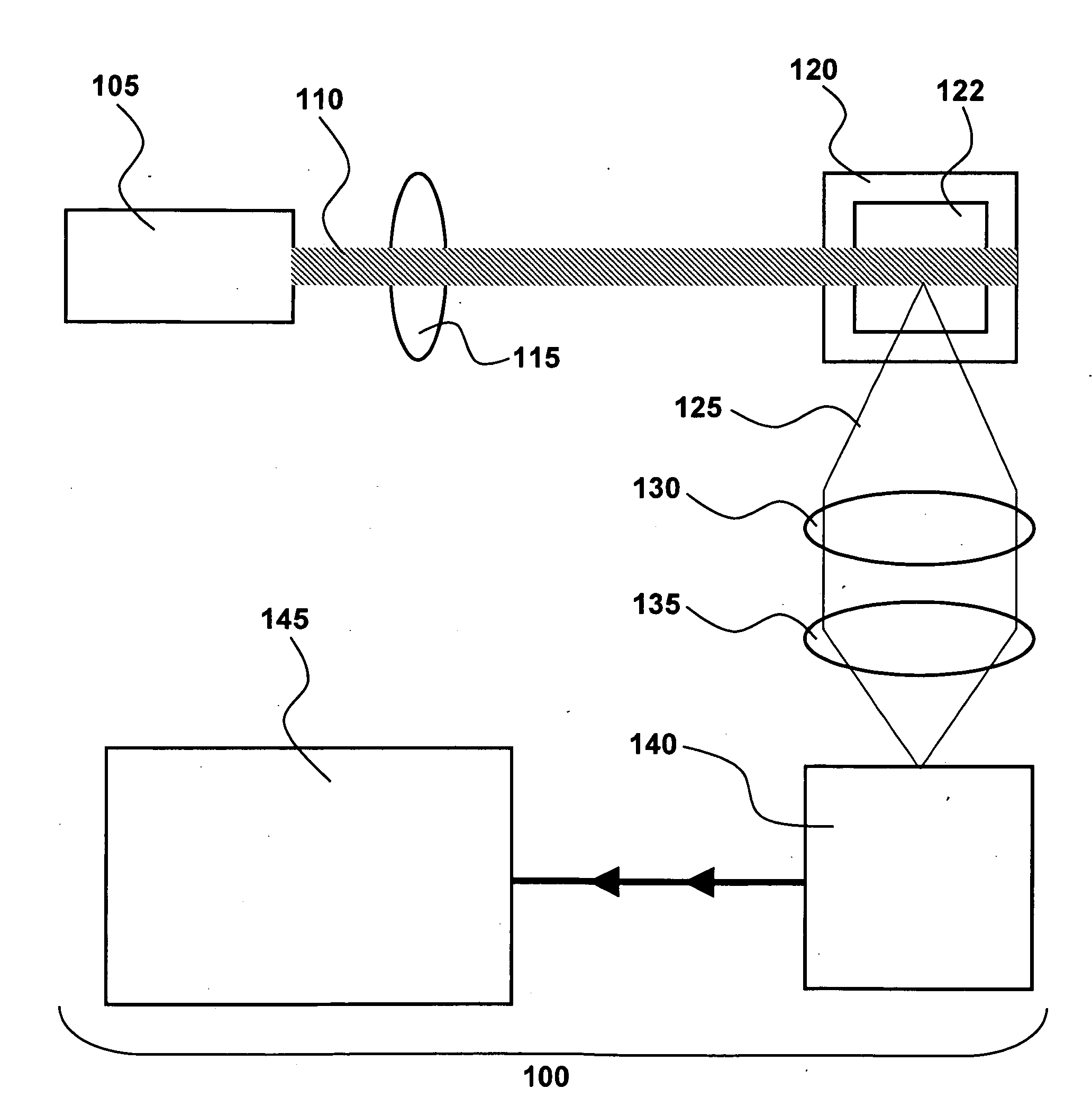

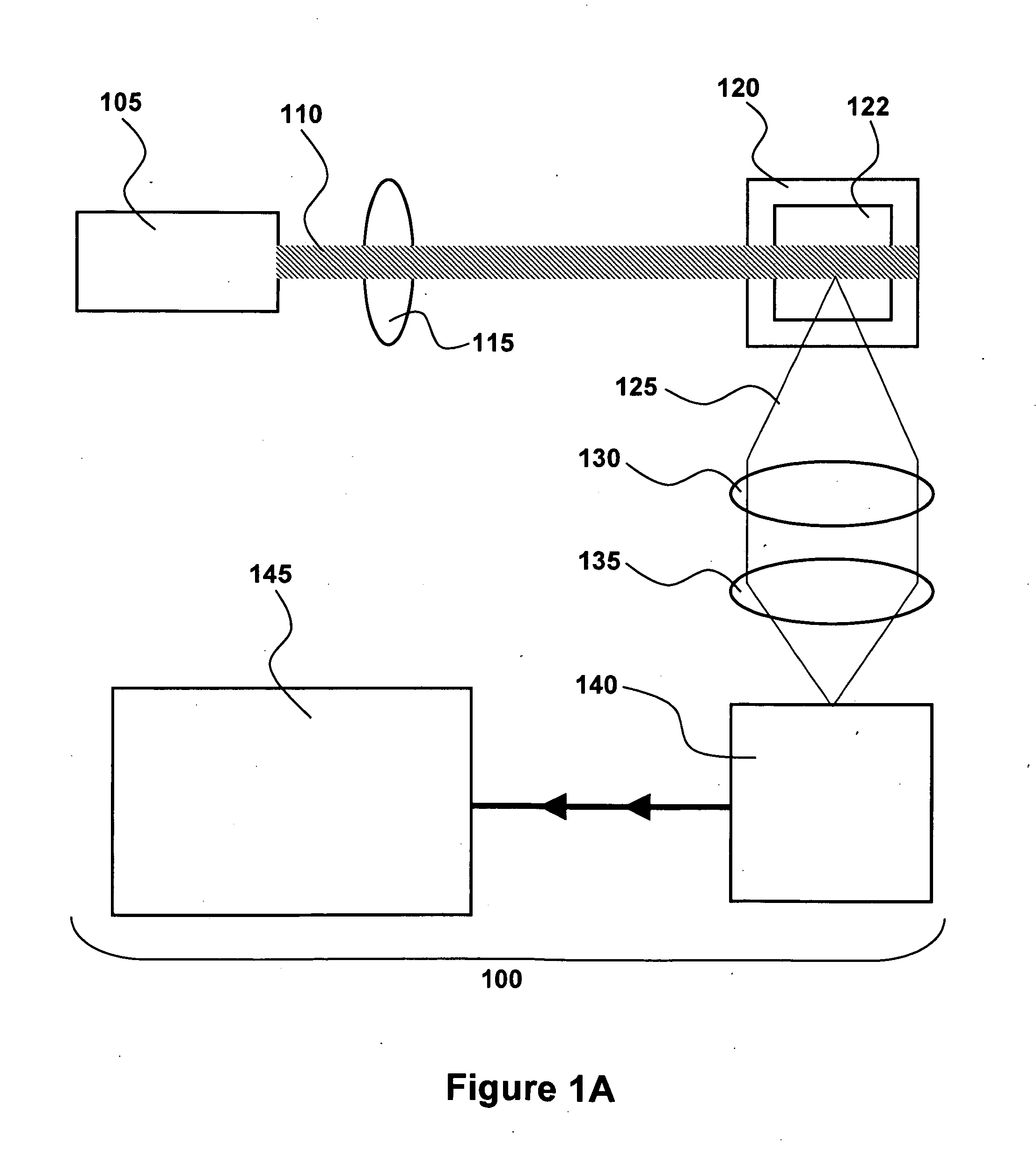

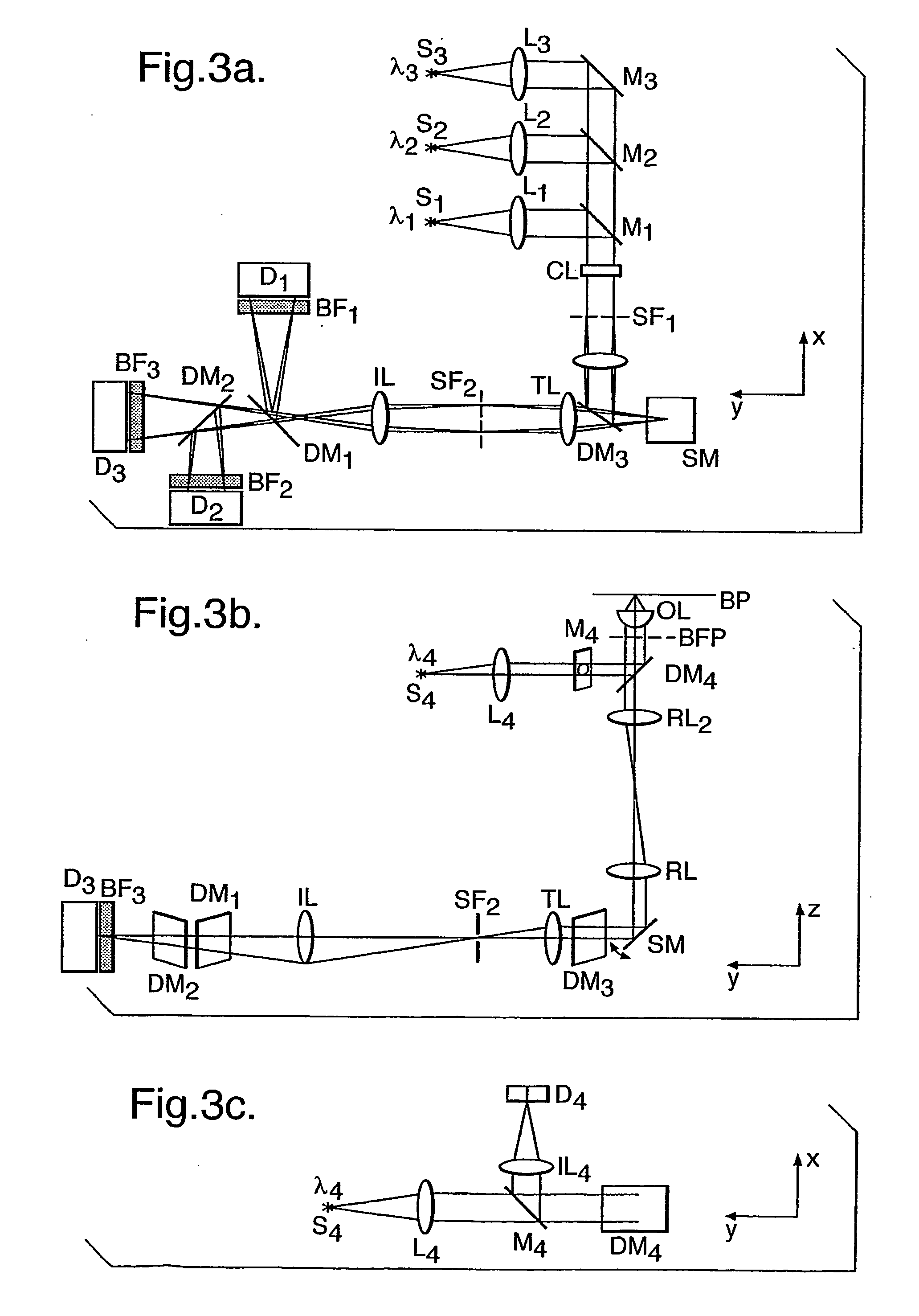

Two-dimensional optical imaging methods and systems for particle detection

ActiveUS20090244536A1Accurate detectionEfficiently generating and identifyingNanoparticle analysisInvestigating moving fluids/granular solidsGas phaseSelection system

The present invention provides methods and systems for particle detection and analysis using two-dimensional optical imaging to access enhanced detection sensitivity and expanded sensing functionality relative to conventional point and array detection-based optical particle counters. Methods and systems of the present invention provide a two-dimensional optical imaging-based particle sensing platform wherein system components and specifications are selected to generate reproducible and readily identifiable signals, including particle detection signatures, from optical scattering or emission from particles provided to the system. Systems and methods of the present invention are capable of accurately and sensitively detecting, identifying, and characterizing (e.g., determining the size of) particles in liquid phase or gas phase samples.

Owner:PARTICLE MEASURING SYST

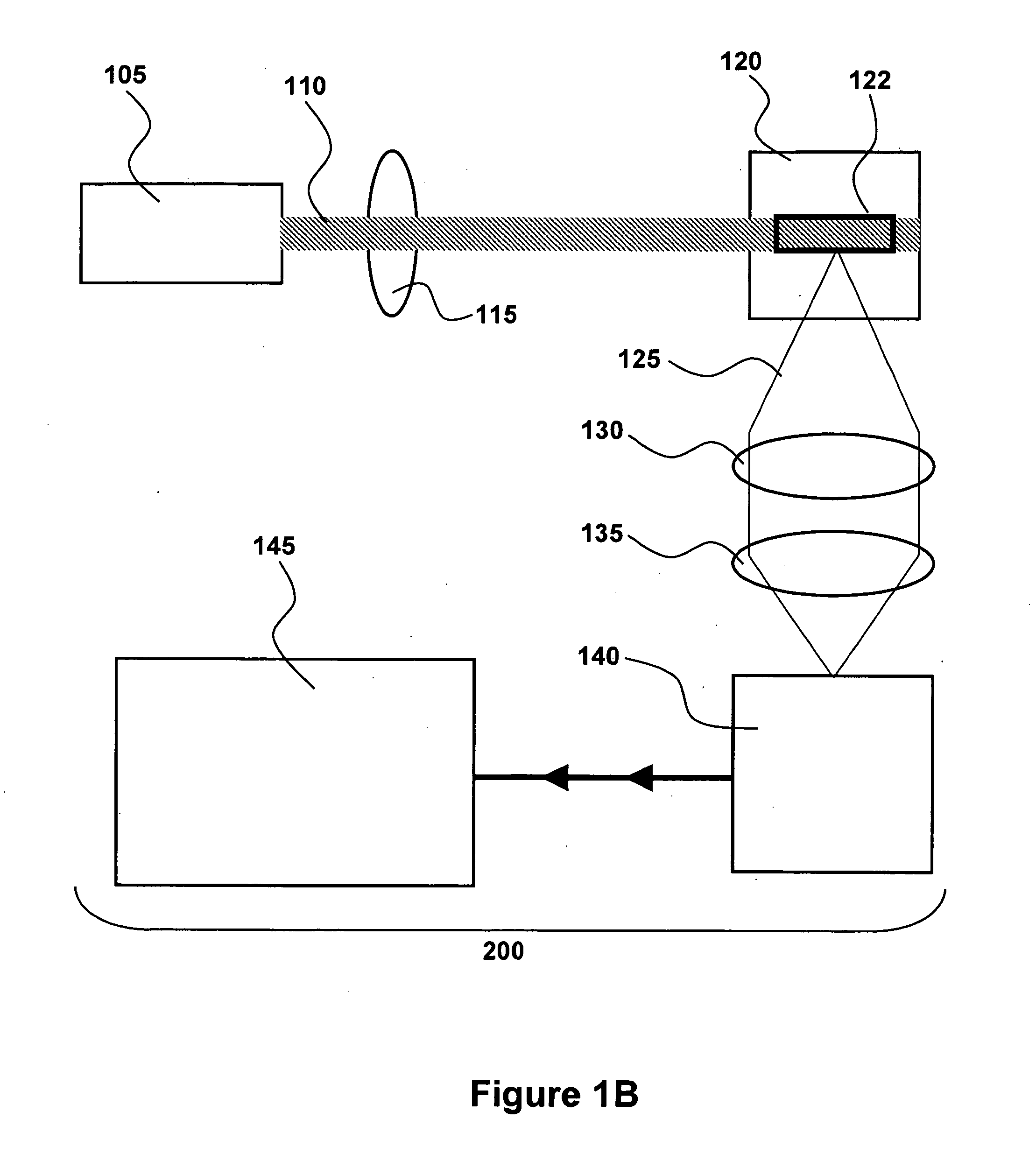

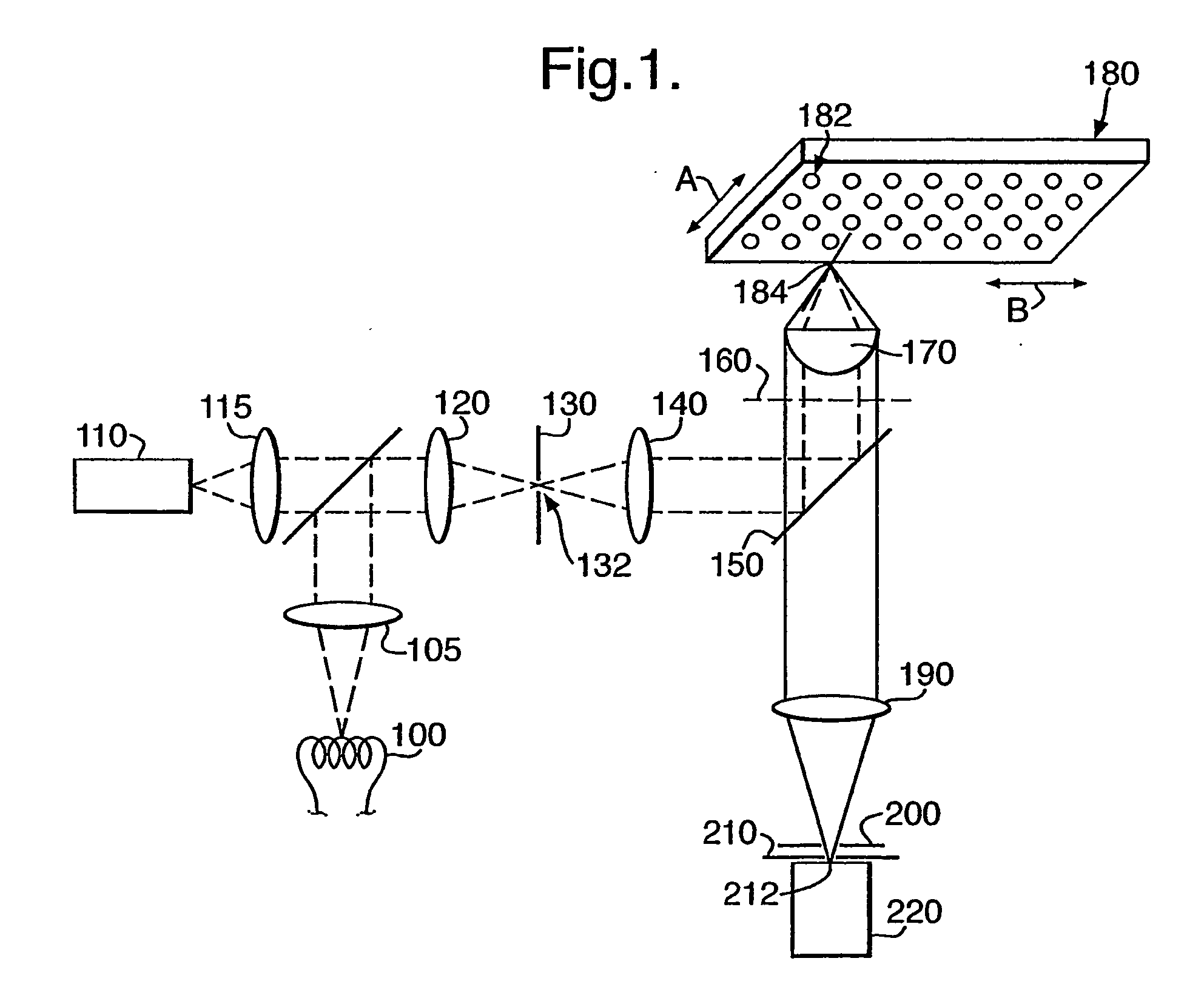

Method for assessing biofilms

InactiveUS20060275847A1Larger effective field-of-viewResolution is sacrificedMicrobiological testing/measurementMicroscopesFluorescenceElectromagnetic radiation

An automated method for measuring the development of a biofilm, containing one or more fluorescent moieties, on a plurality of surfaces using a confocal imaging system including: a) a radiation source system for forming a beam of electromagnetic radiation including one or more wavelengths; b) an optical system for directing and focusing said beam onto one or more planes of the object; c) a detection system for detecting electromagnetic radiation emitted from the object and producing image data; and d) a scanning system for scanning the object in a plurality of planes with the electromagnetic radiation, the method comprising the steps of: i) growing said biofilm on said plurality of surfaces; ii) detecting the presence of said one or more fluorescent moieties within the biofilm by scanning the biofilm with electromagnetic radiation in a plurality of planes and collecting fluorescent emissions to produce a plurality of images; and iii) analysing said images by means of a data processing system under the control of computer software to determine the structure of the biofilm.

Owner:GE HEALTHCARE LTD

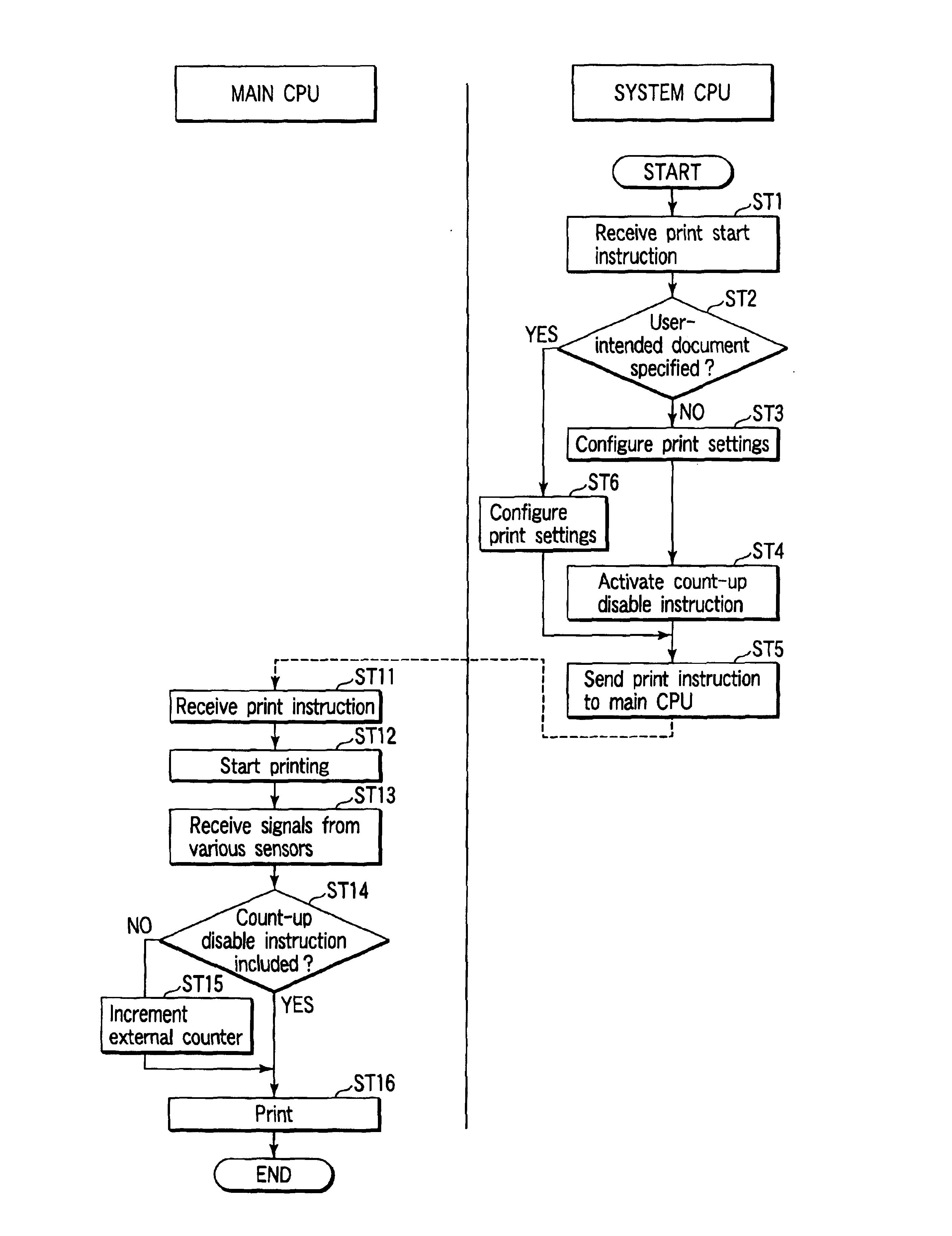

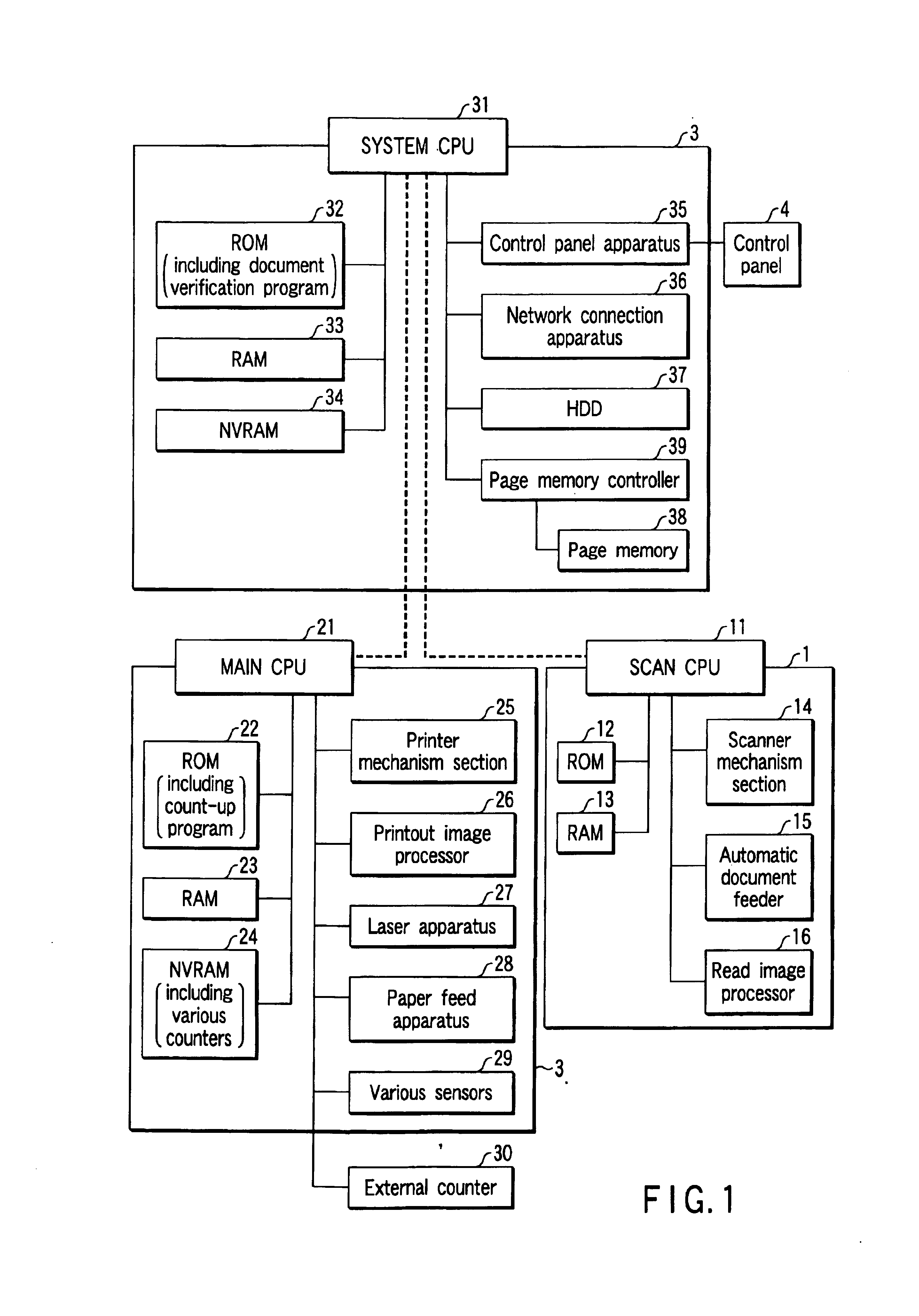

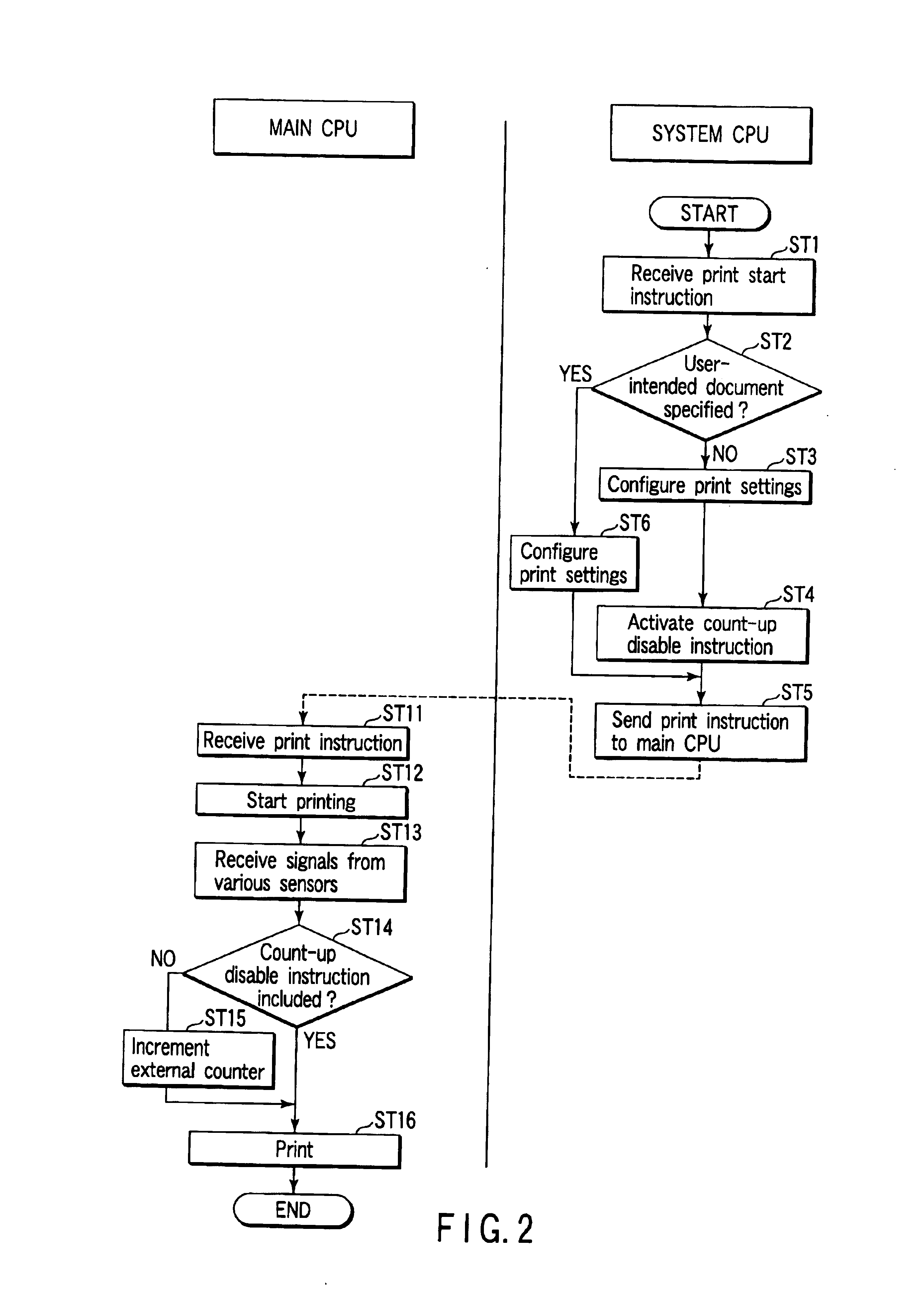

Image forming apparatus

InactiveUS6873807B2Disabling chargingLow costElectrographic process apparatusPictoral communicationOperating instructionImage formation

Owner:KK TOSHIBA +1

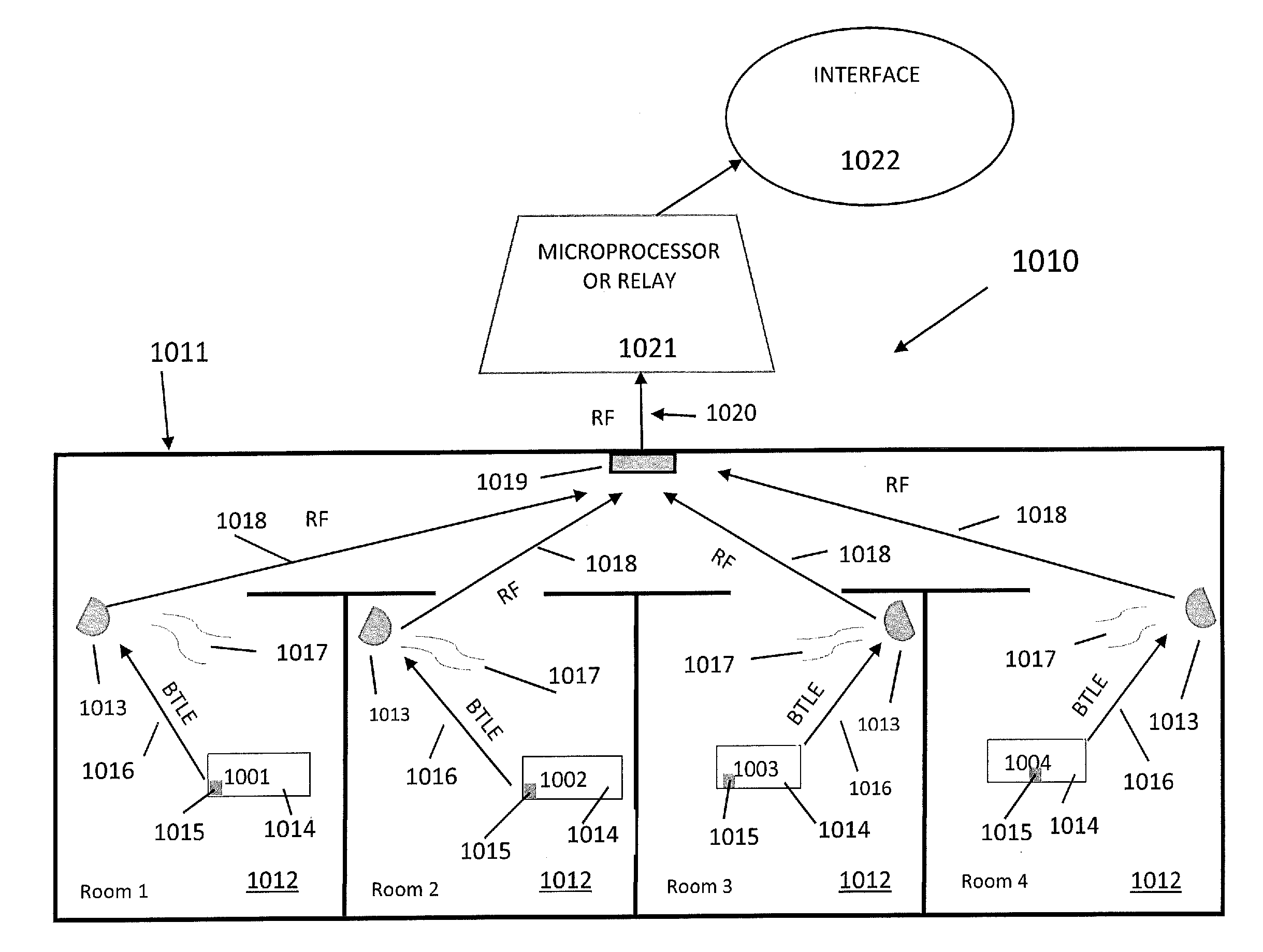

Occupancy based demand controlled utility system

ActiveUS20160139576A1Maximum energy efficiencySimple and inexpensive implementationMechanical apparatusTemperatue controlControl systemOperating energy

To control lighting and other utilities in buildings based upon occupancy, mountable sensors are used to detect low energy radio frequencies emitted from devices, or tags, worn or carried by occupants. In a demand control system, identification (ID) codes embedded in tags worn by occupants are detected in each room by a tag sensor and may wirelessly communicate to a zonal compiler that determines zonal occupancy. The zonal occupancy count is transmitted to an interface relay that immediately adjusts the intensity and rate of the specific utility. HVAC systems may also be tied into the system to have adjustments made to the intensity and rate of ventilation as done with the lighting in this system. This system has many advantages over current systems such as not being dependent upon movement of an occupant or following the heat signature of an occupant that both may lead to false readings and delay in adjusting the specific building utility to save energy and costs.

Owner:AIKEN THOMAS DAVID +1

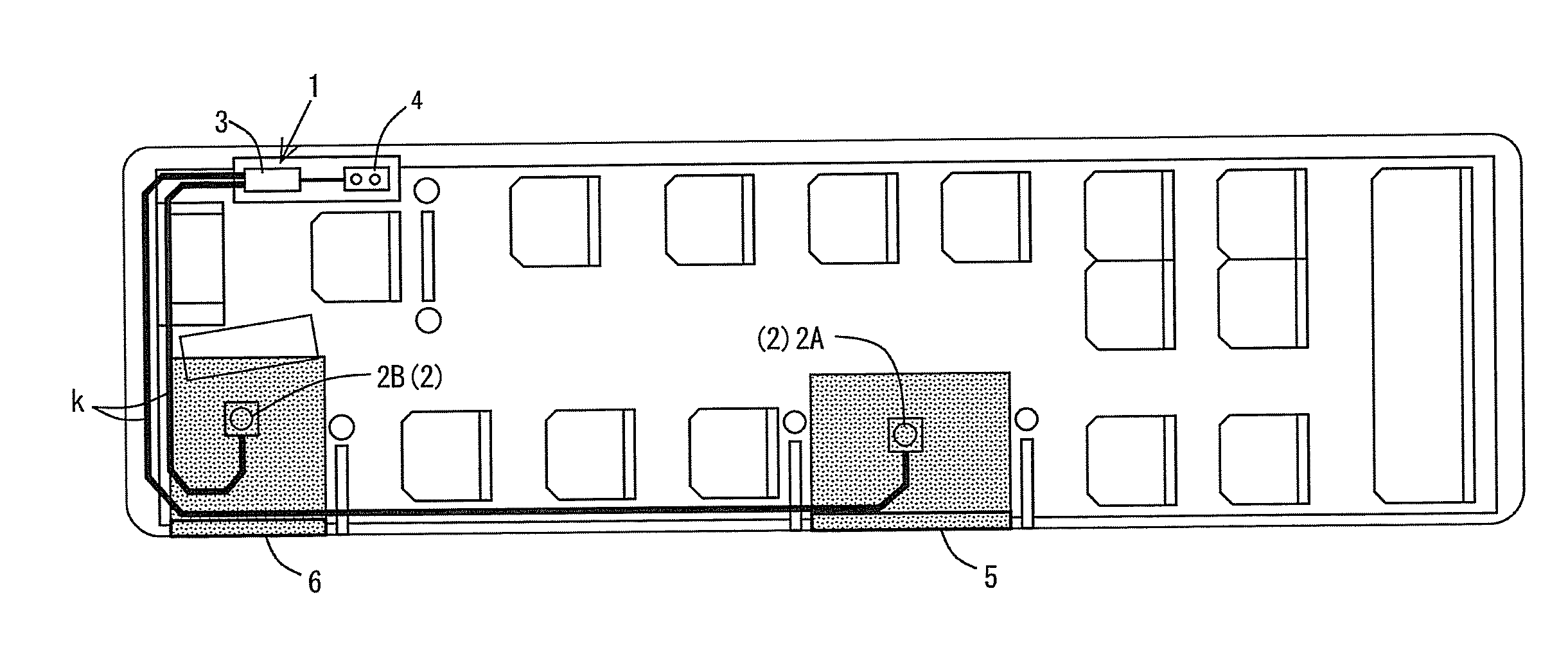

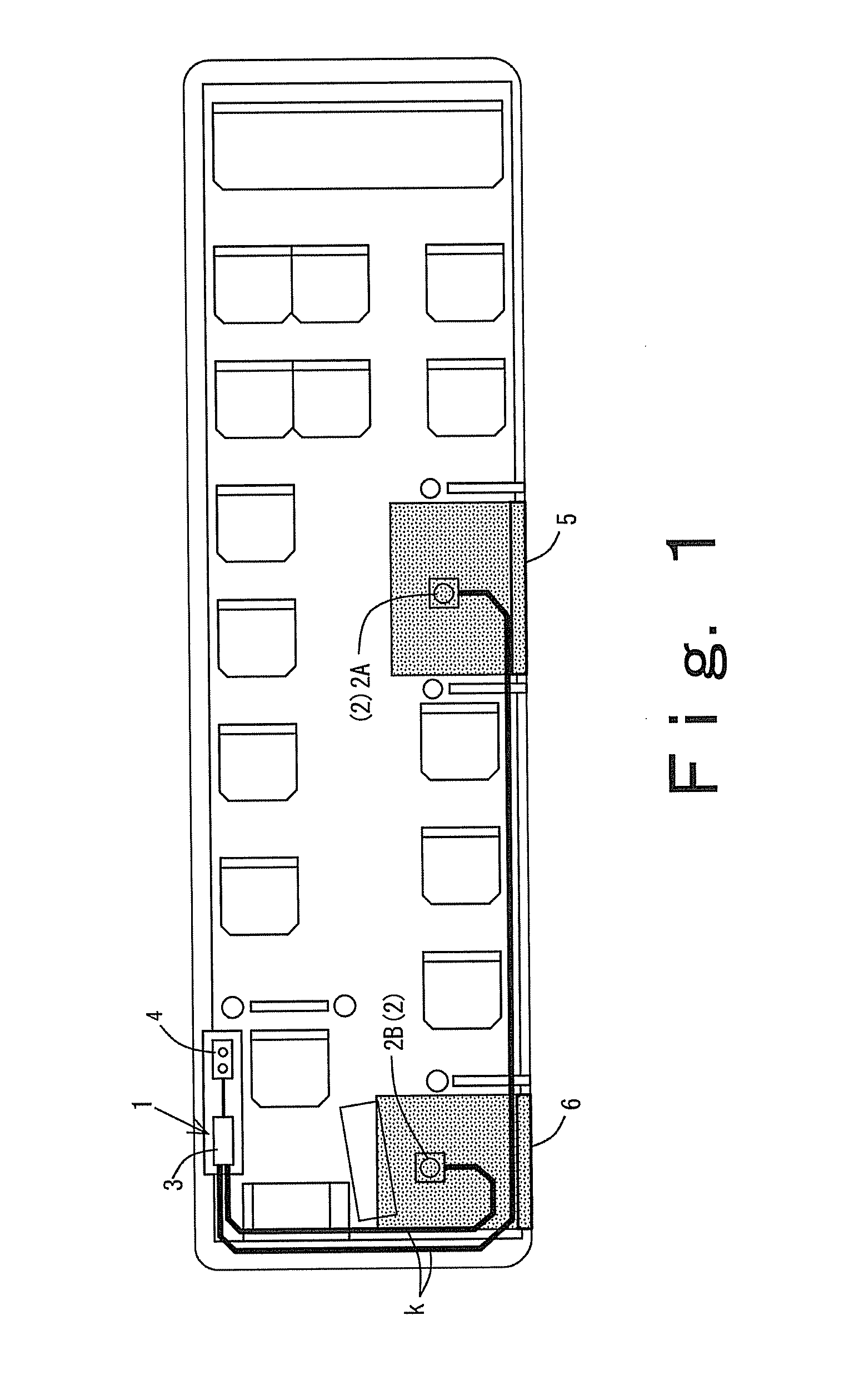

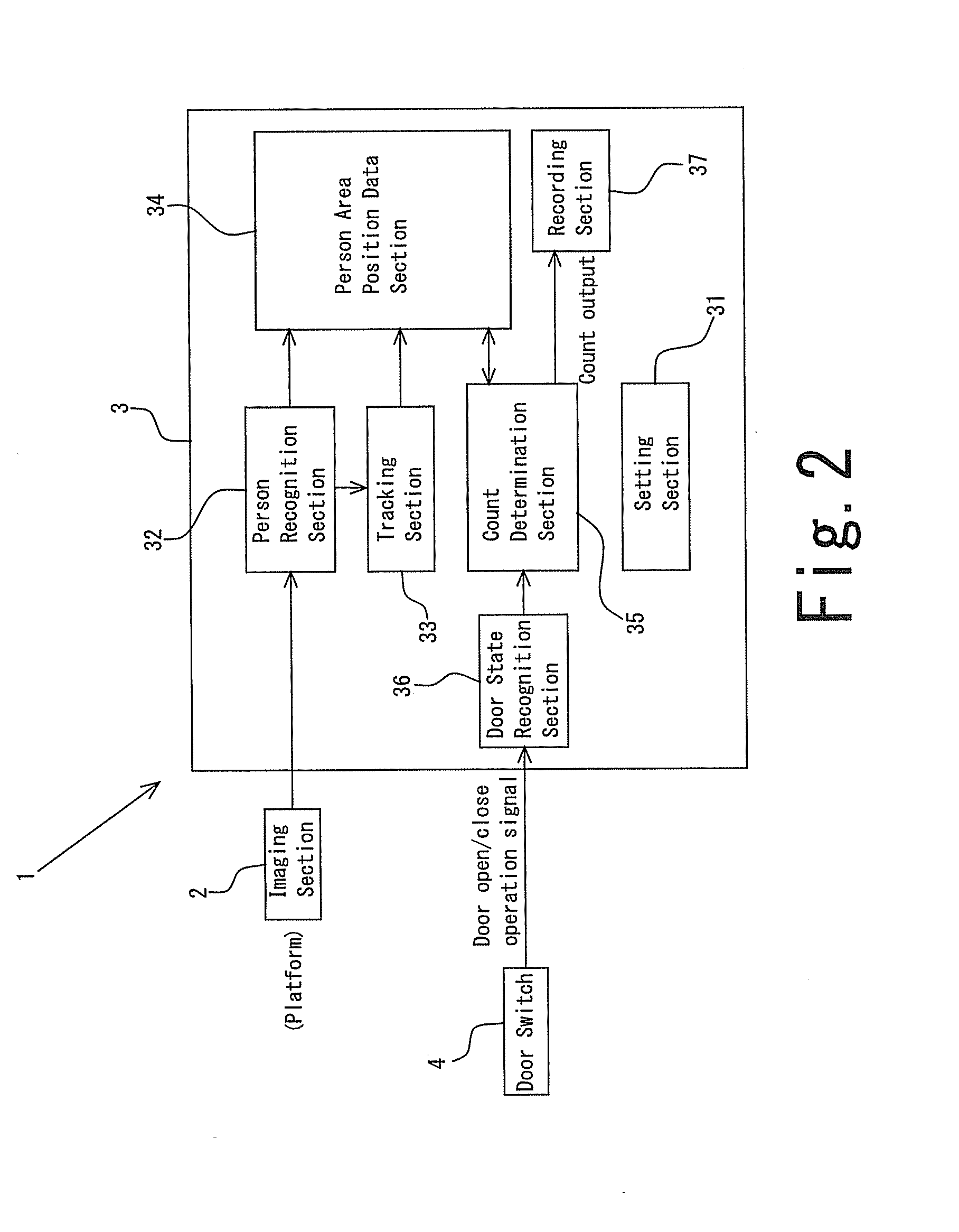

Passenger counter

ActiveUS20140333769A1Reliably recognizeExact numberCharacter and pattern recognitionColor television detailsEngineeringInner ear

A passenger counter that counts the number of persons who get on / off a vehicle comprising an imaging unit 2 installed at an inside of a vehicle platform; a setting unit 31 configured to set an inner area I corresponding to a passage inside the vehicle, one outer areas B surrounding the inner area I and inside the vehicle and other outer area A surrounding the inner area I and outside the vehicle; and a count determination unit 35 configured to count the number of persons who move from one outer area A(B) to the other outer area B(A) through the inner area I while a door of the platform is opened, not to count the number of persons while the door is closed, and to perform processing of determining a person existing in the inner area I when the opened (closed) door is closed (opened) to be counted.

Owner:GIKEN TRASTEM

Optical wavelength add-drop multiplexer

InactiveUS7653311B2Accurately notifiedEfficient solutionWavelength-division multiplex systemsCoupling light guidesMultiplexerLength wave

Part of an inputted optical add signal 118 is reflected by a mirror 117, and is thereby inputted into an optical wavelength multiplexer 105 in the reverse direction so that the optical add signal is returned to paths 115-1 through 115-16 corresponding to wavelengths λ1 through λ16. If the returned optical add signal is an optical add signal having a correct wavelength, the optical signal enters its corresponding backward direction optical detector 113-16. Accordingly, it is possible to check whether or not a wavelength of the optical add signal is correct.

Owner:HITACHI LTD

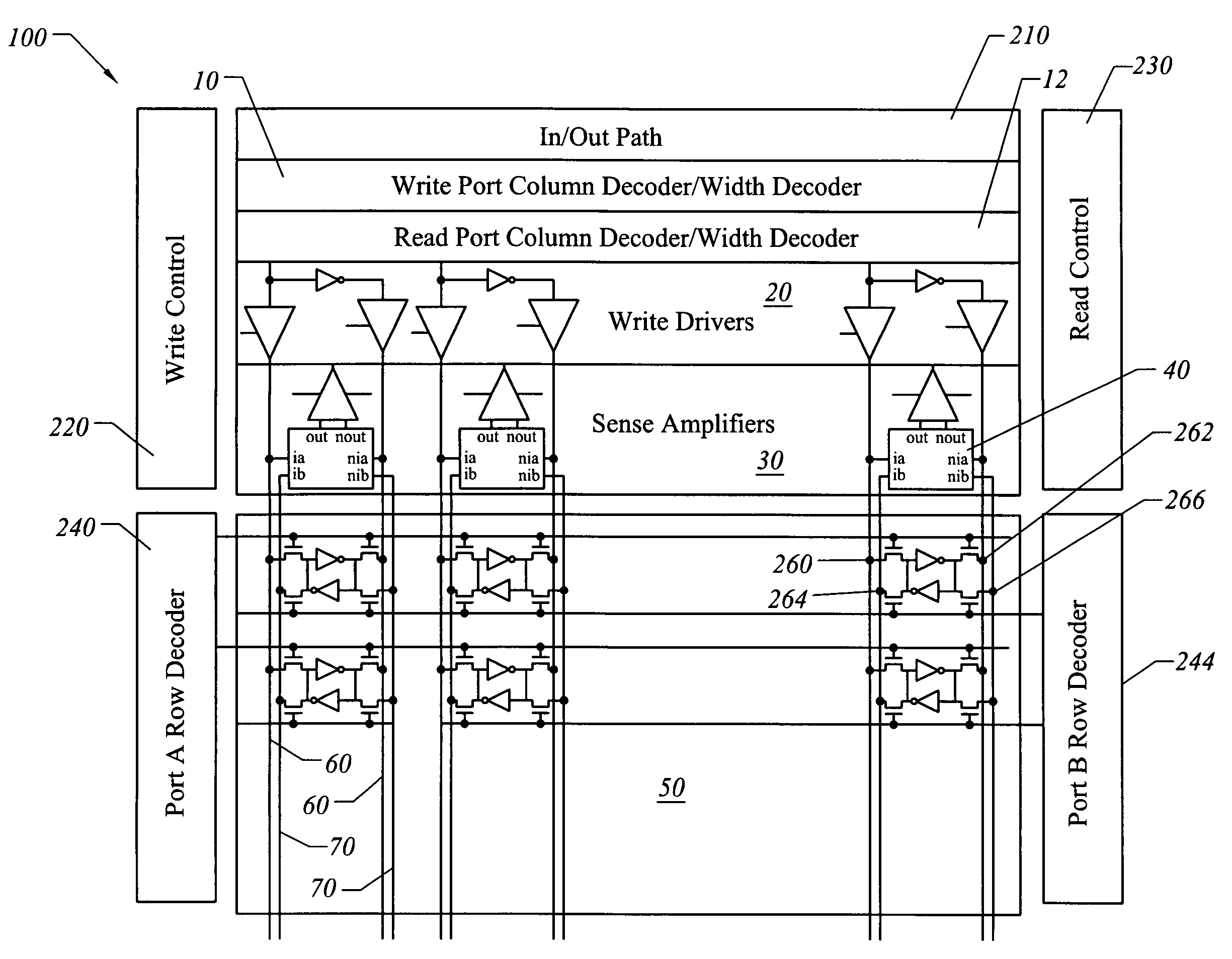

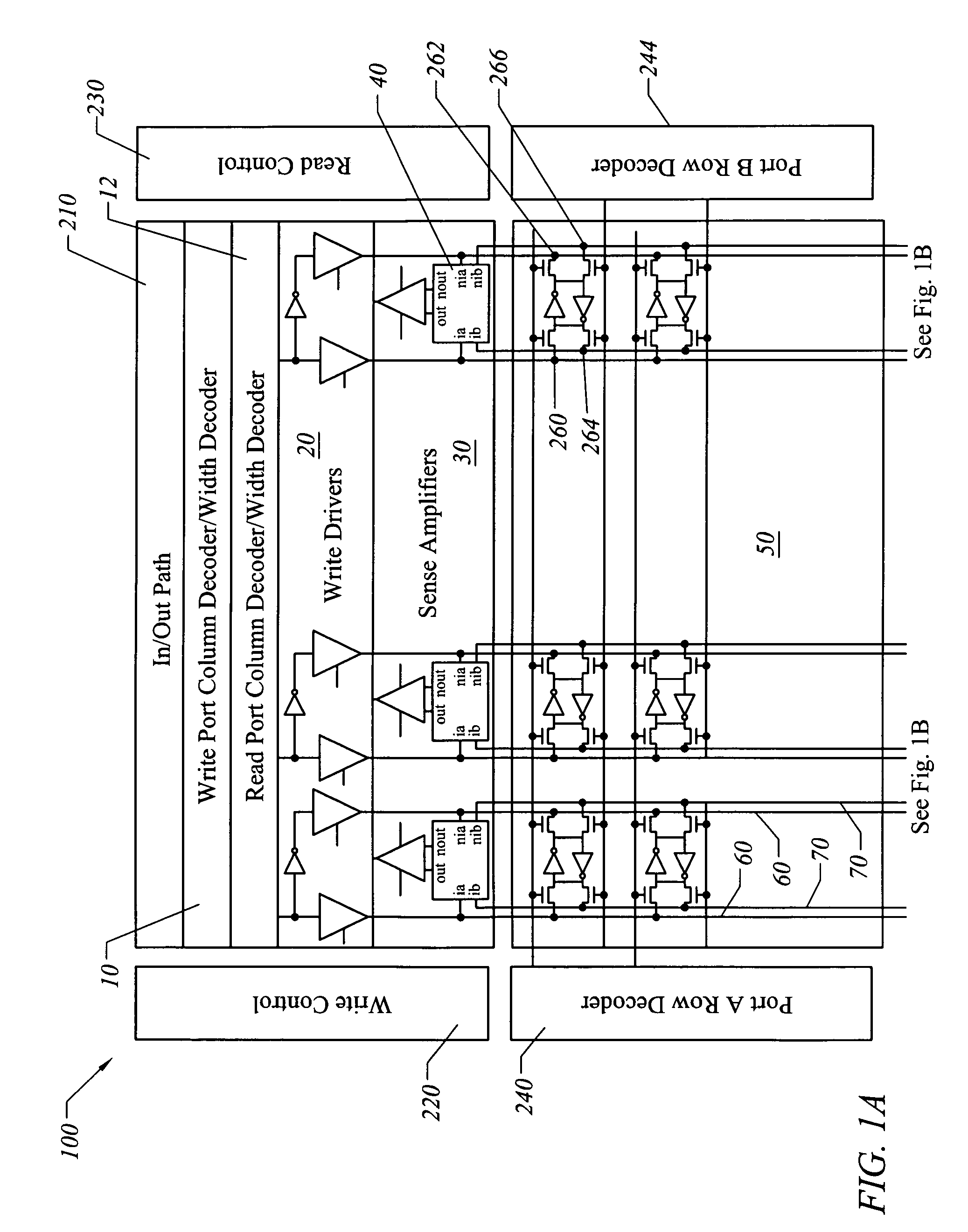

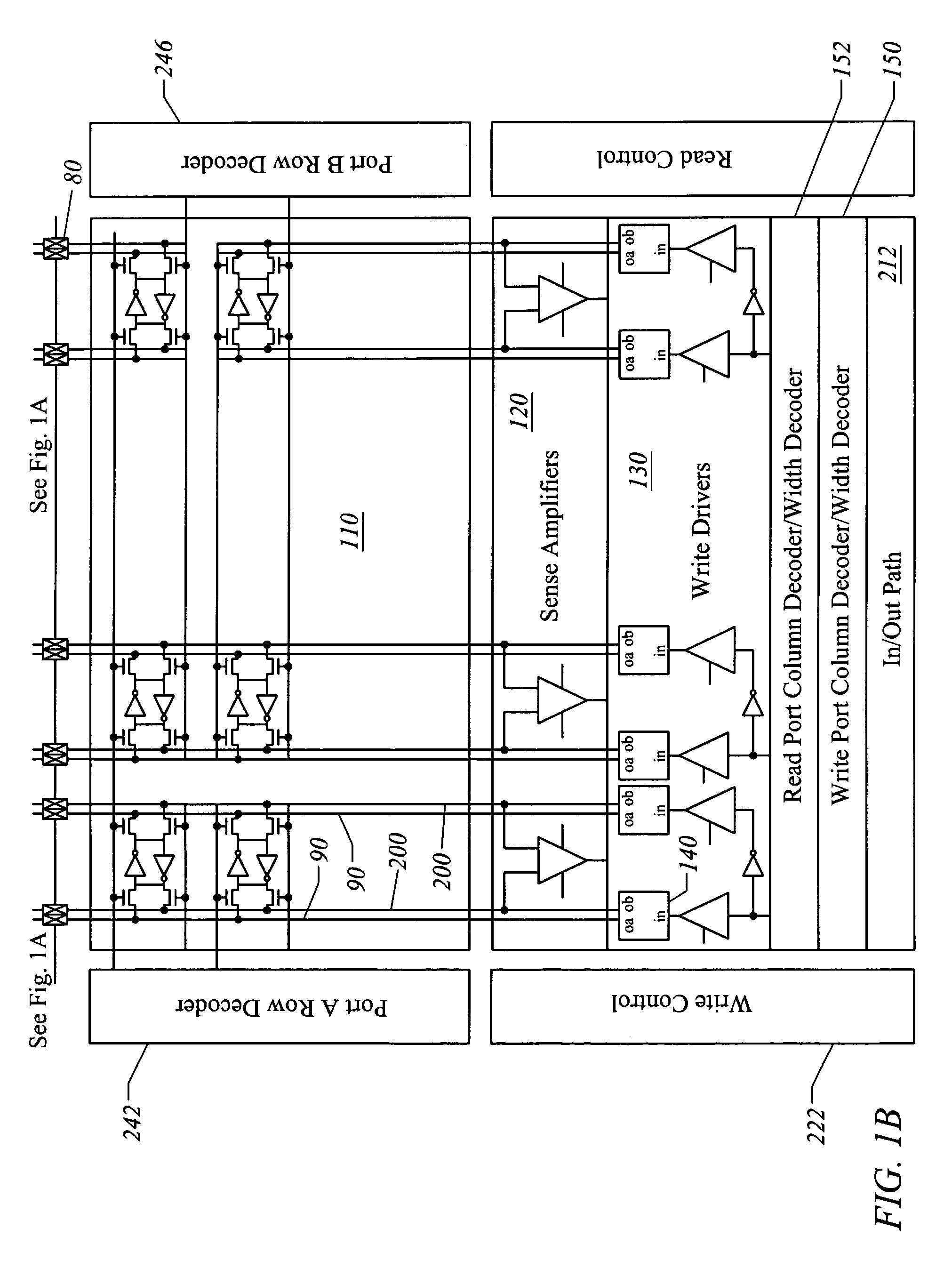

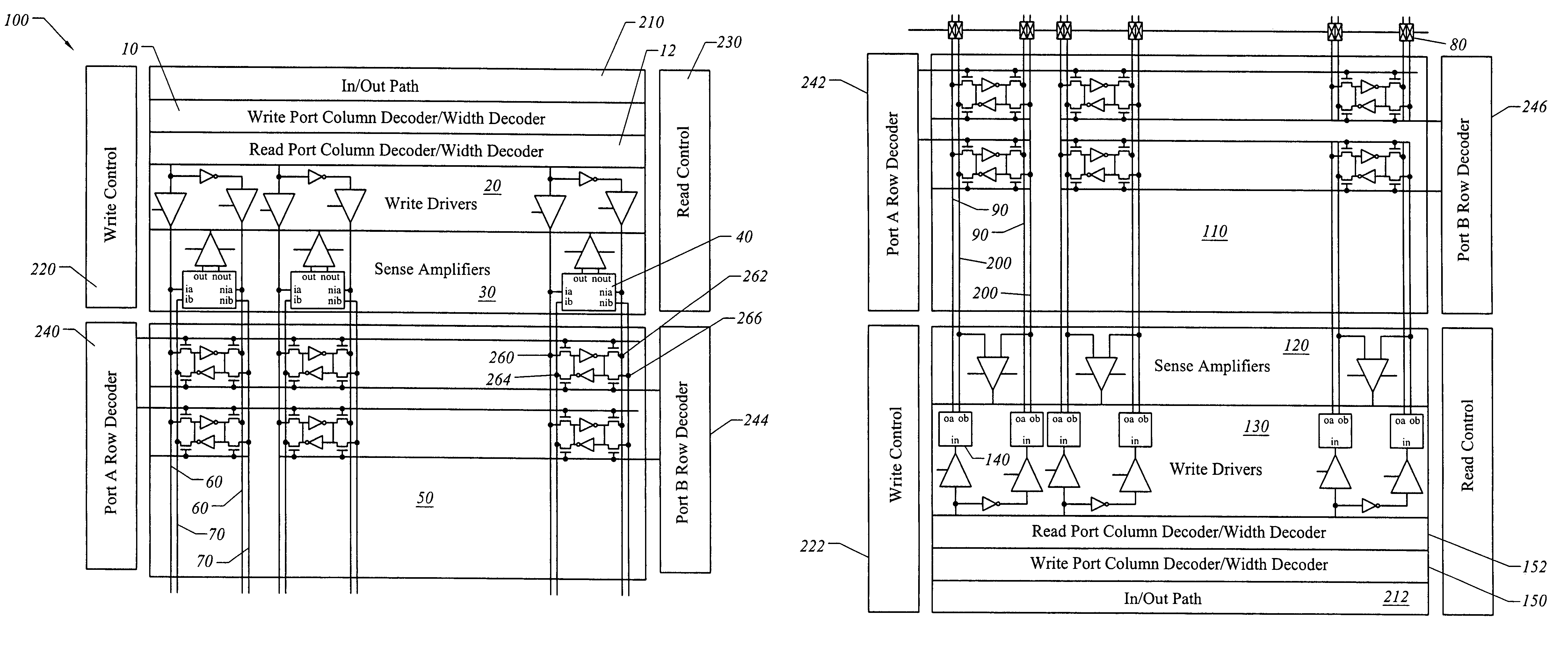

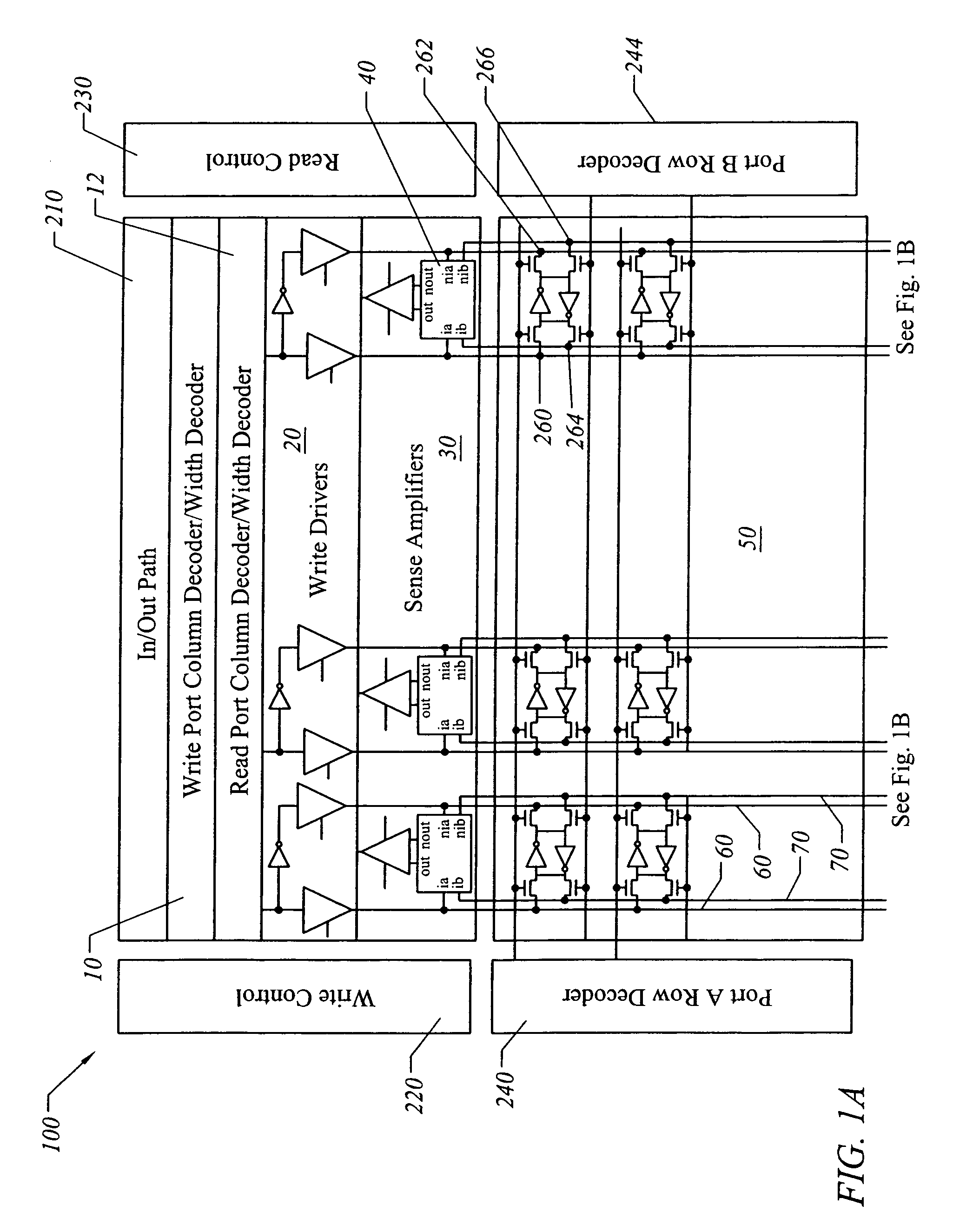

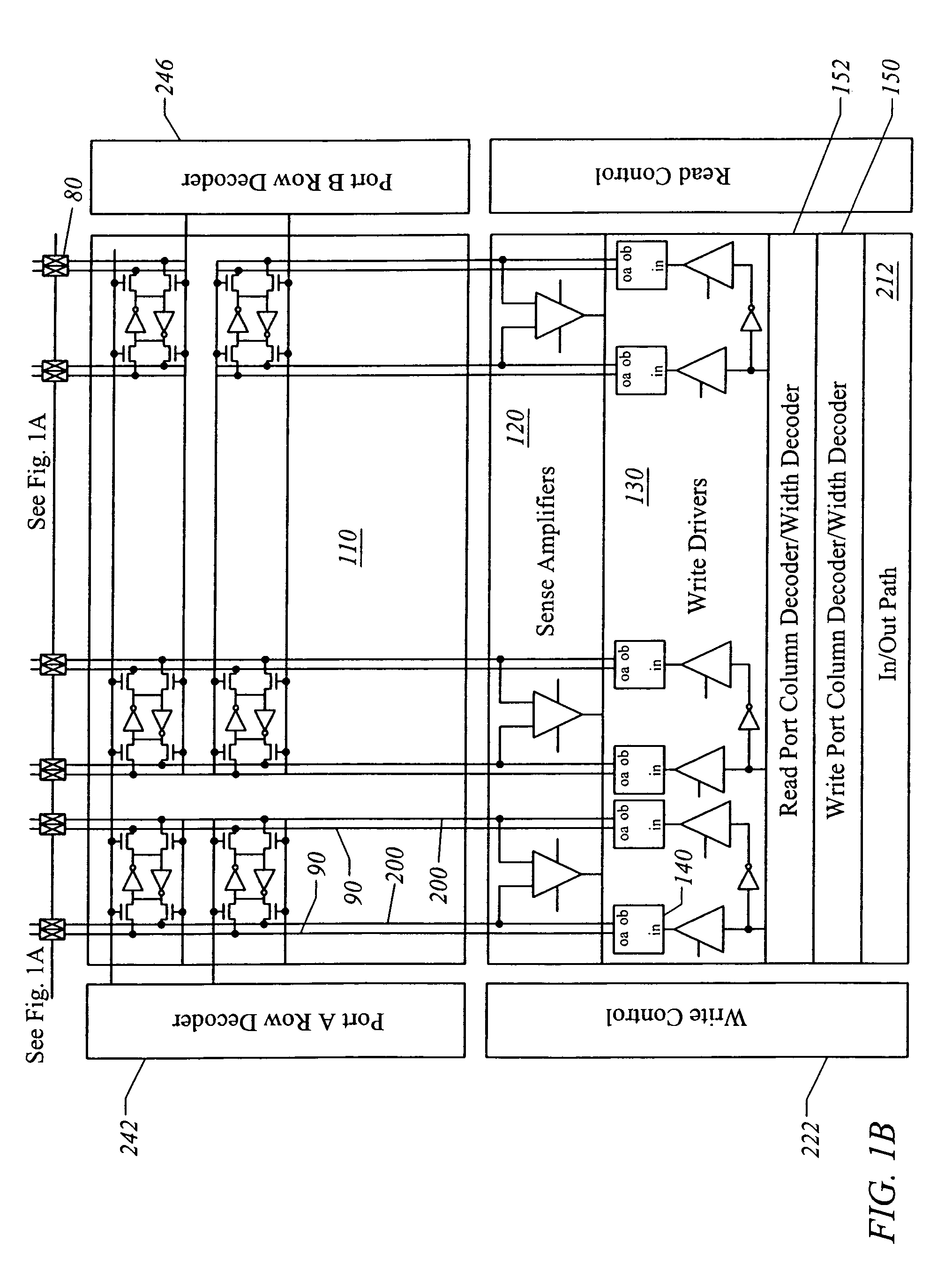

Divisible true dual port memory system supporting simple dual port memory subsystems

InactiveUS7130238B1Increase bit densityAvoid countingDigital storageLogic circuitsAudio power amplifierRandom access memory

A random access memory circuit and a method for configuring the same. The circuit includes a first array of memory cells including a first plurality of ports and a second plurality of ports, and a second array of memory cells including a third plurality of ports and a fourth plurality of ports. Additionally, the circuit includes a plurality of switches connected to the first plurality of ports and the third plurality of ports respectively or connected to the second plurality of ports and the fourth plurality of ports respectively. Moreover, the circuit includes a plurality of sense amplifiers and a plurality of write drivers.

Owner:ALTERA CORP

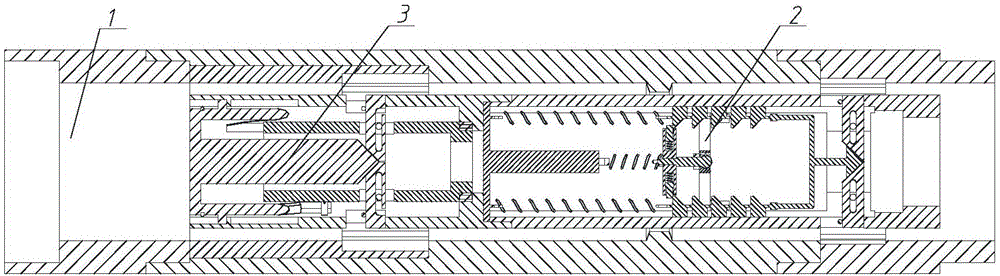

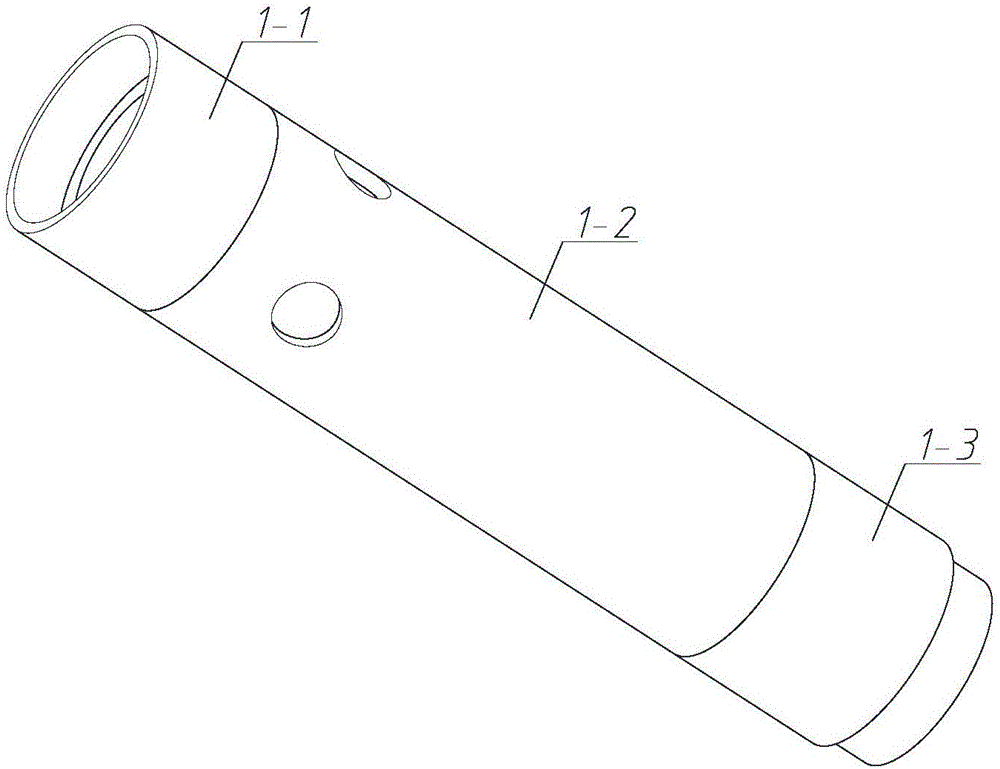

Downhole full-bore infinite sliding-pin slide bushing switch

ActiveCN106761640AAvoid wear and tearEasy to replaceFluid removalWell/borehole valve arrangementsMechanical engineeringEngineering

The invention discloses a downhole full-bore infinite sliding-pin slide bushing switch and solves the problems of inconvenience in maintenance and the like due to the fact that the conventional fracturing slide bushing needs to be wholly lowered into downhole. The downhole full-bore infinite sliding-pin slide bushing switch specifically comprises a main slide bushing body and a tenon block mechanism, wherein the tenon block mechanism comprises a tenon block recognition mechanism and a tenon block switch mechanism, during use, the main slide bushing body is lowered into the downhole, and the tenon block mechanism is lowered for recognizing a fracture layer when a fracture channel needs to be opened or closed. The slide bushing switch has high recognition degree for different fracture layers, parts are convenient and simple to replace and maintain, and the working stability and accuracy are enhanced greatly.

Owner:黑龙江赛恩思科技信息咨询服务有限公司

Object measuring apparatus, object measuring method, and program product

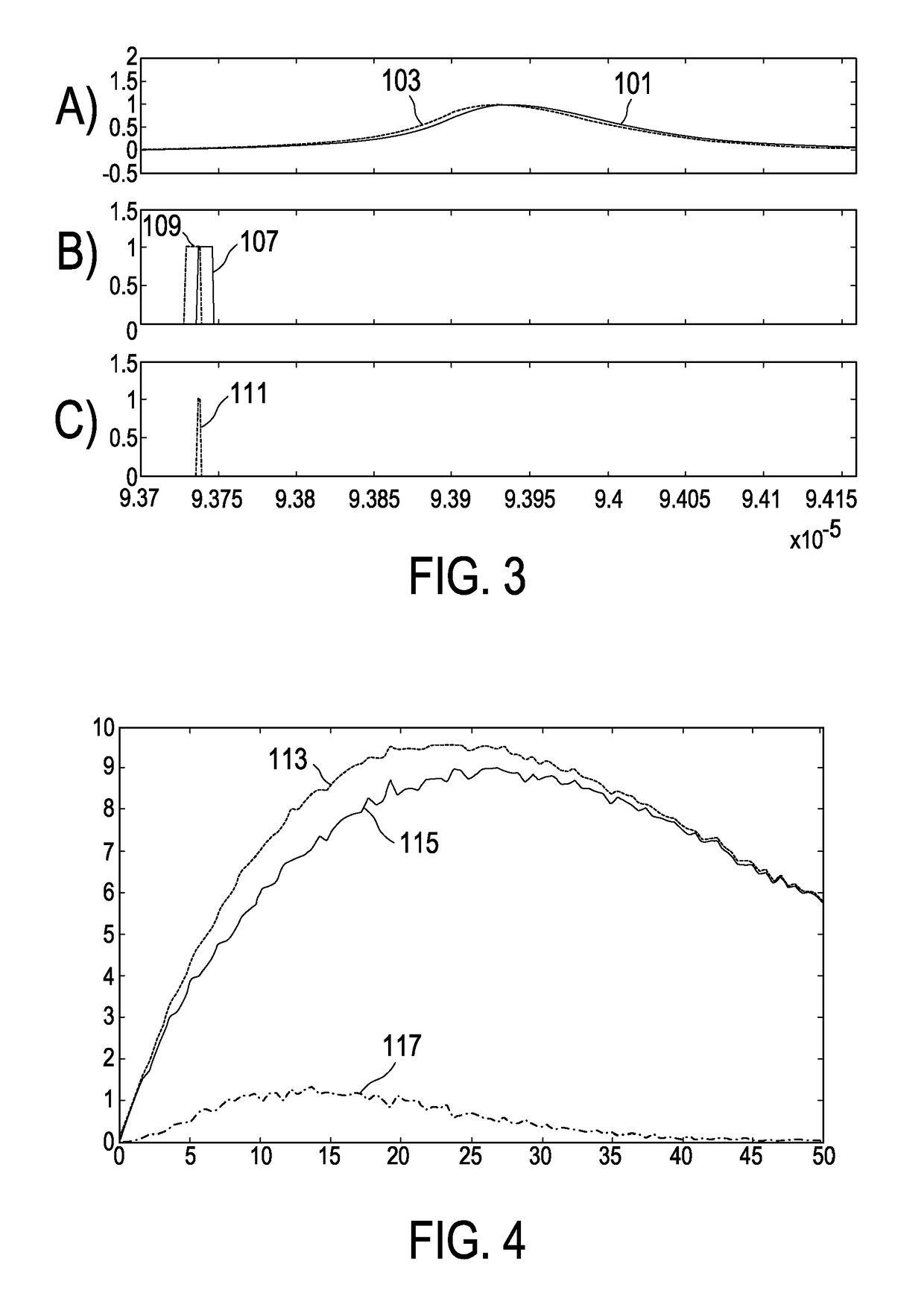

InactiveUS20050084133A1Accurate countHigh speed machiningTelevision system detailsImage analysisMeasurement deviceMotion vector

The present invention provides an object measuring apparatus capable of performing high-speed process and accurately counting the number of a plurality of objects even in the case where the plurality of objects pass a boundary line simultaneously. The object measuring apparatus extracts motion vectors at a plurality of times in each of a plurality of positions on a boundary line on the basis of a plurality of images. The object measuring apparatus obtains at least one integral value by integrating components perpendicular to the boundary line of the motion vectors. As the at least one integral value, for example, an integral value derived by integrating the perpendicular components of one of positive and negative signs is obtained. The object measuring apparatus calculates the number of moving objects (people and the like) passing the boundary line on the basis of the integral value.

Owner:KONICA MINOLTA INC

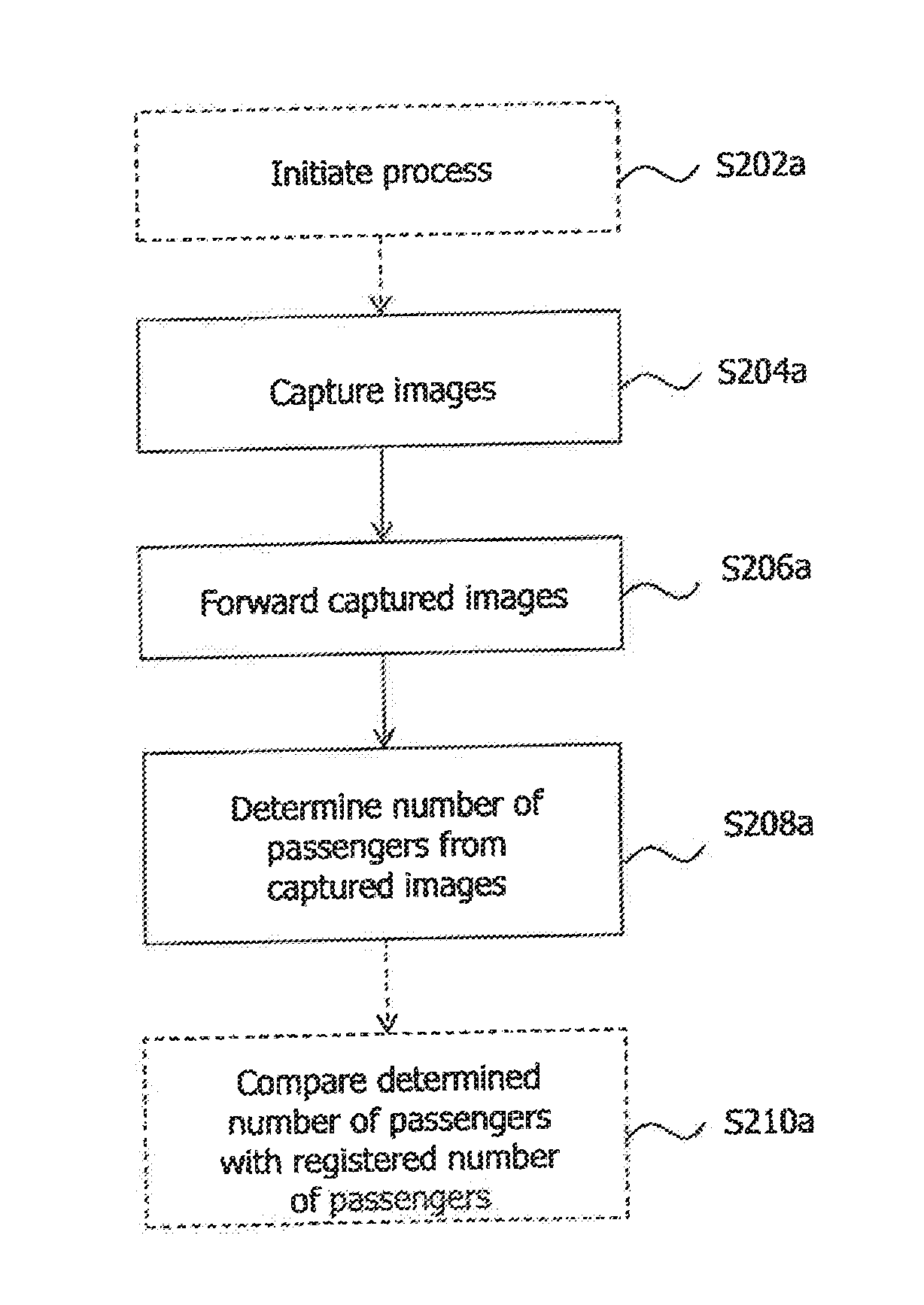

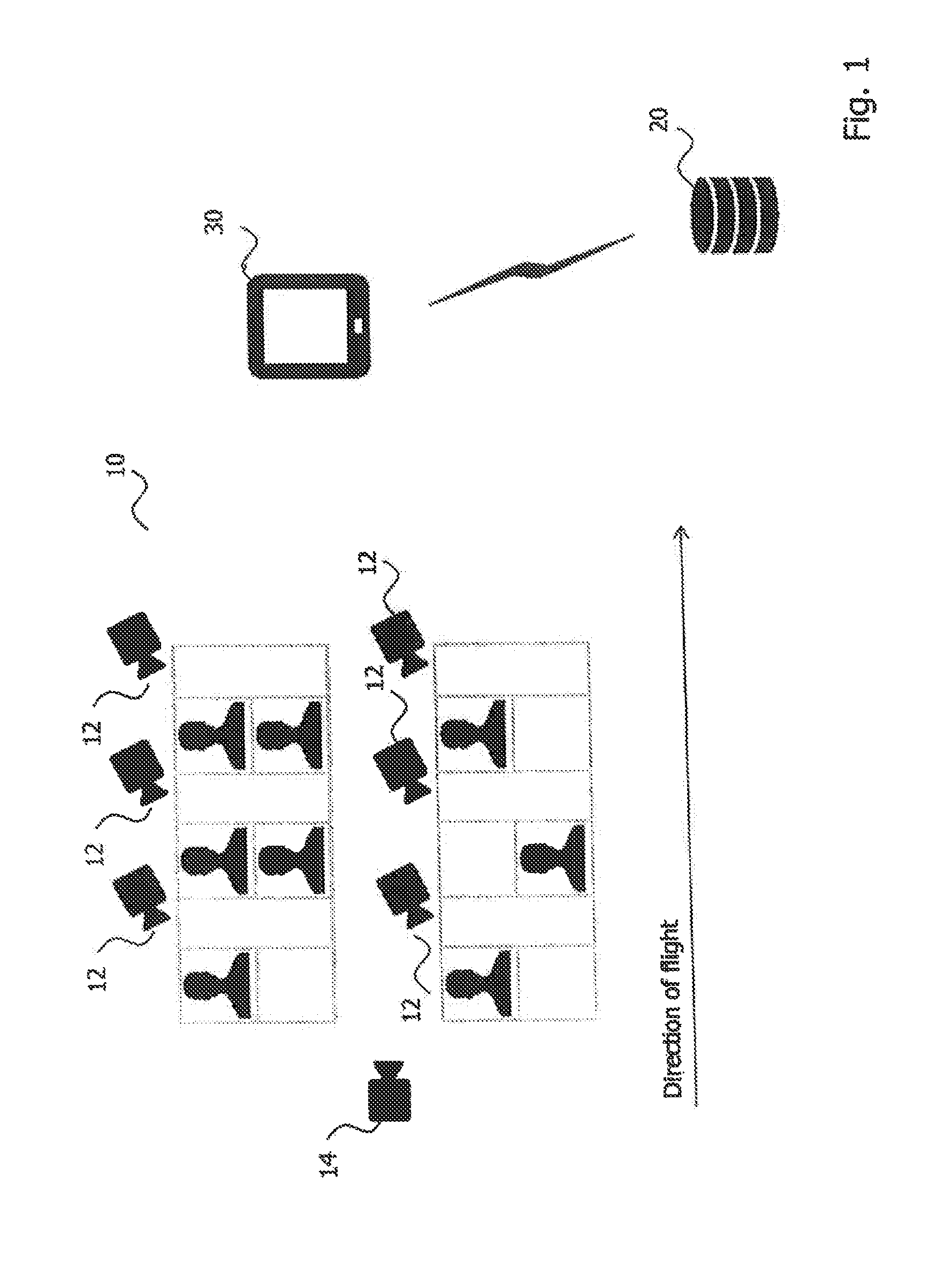

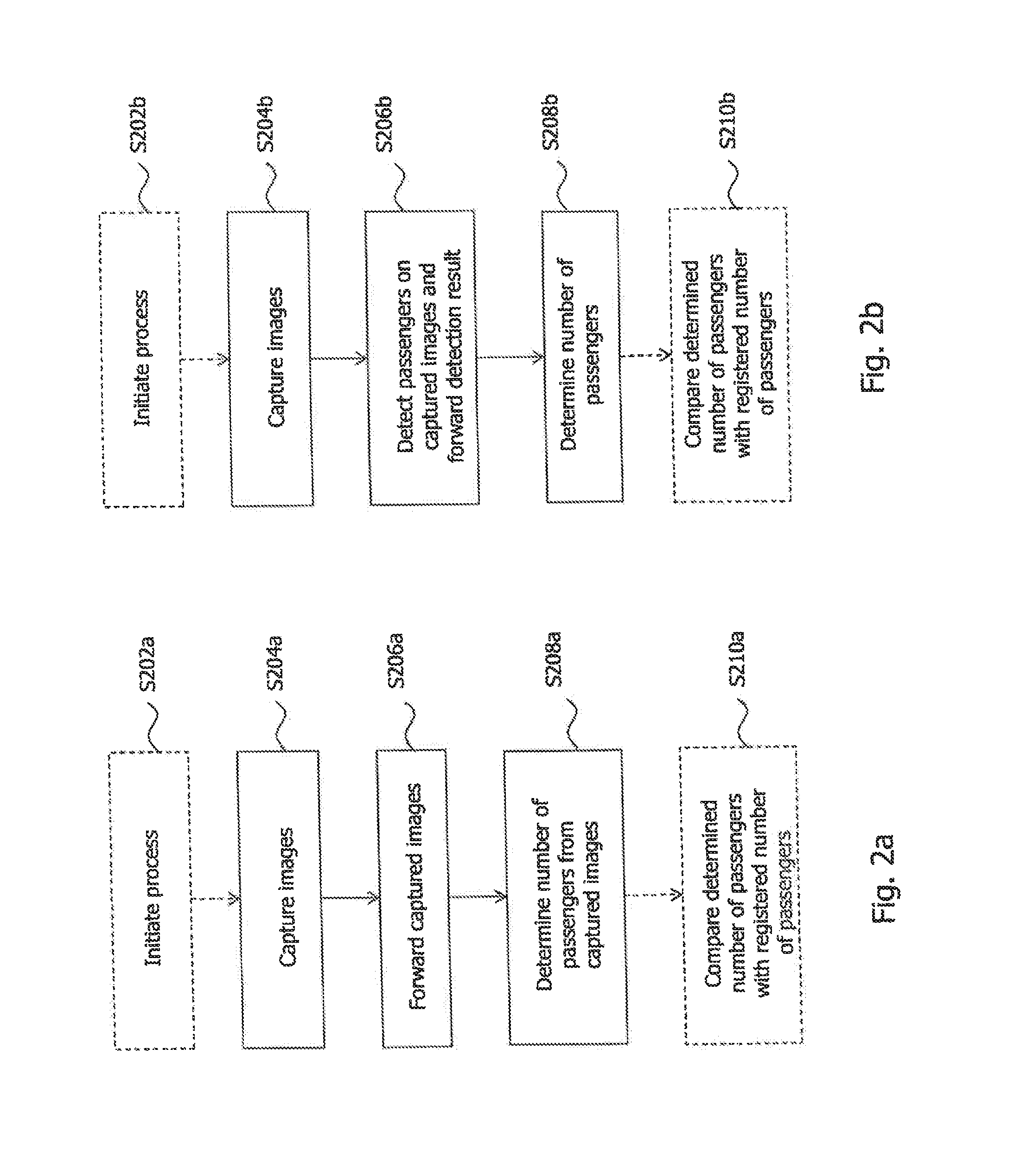

Automatic head count determination on board a means of transport

InactiveUS20150278618A1Avoid countingRegistering/indicating working of vehiclesCharacter and pattern recognitionNacelleOn board

A technique of determining an actual number of passengers on board a means of transport, for example on board an aircraft. A system embodiment comprises a camera arrangement configured to acquire image data on board the means of transport, and a processing unit configured to determine the actual number of passengers on board the means of transport, based on the acquired image data. The camera arrangement comprises at least one of one or more cabin corridor cameras and one or more cabin door cameras. The one or more cabin corridor cameras are configured and arranged to acquire image data of at least one or more cabin corridors of the means of transport. The one or more cabin door cameras are configured and arranged to acquire image data of one or more cabin doors of the means of transport.

Owner:AIRBUS OPERATIONS GMBH

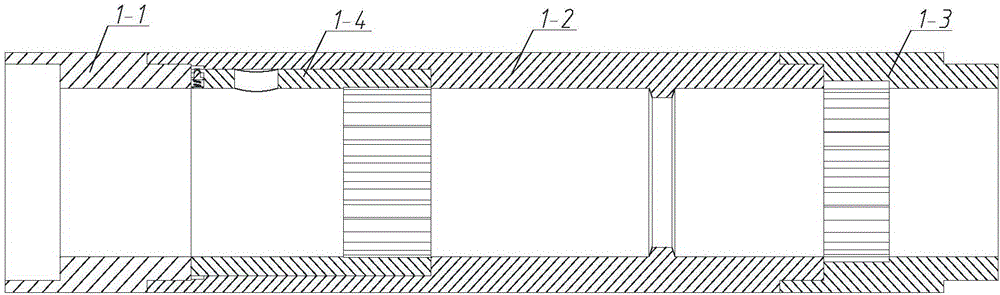

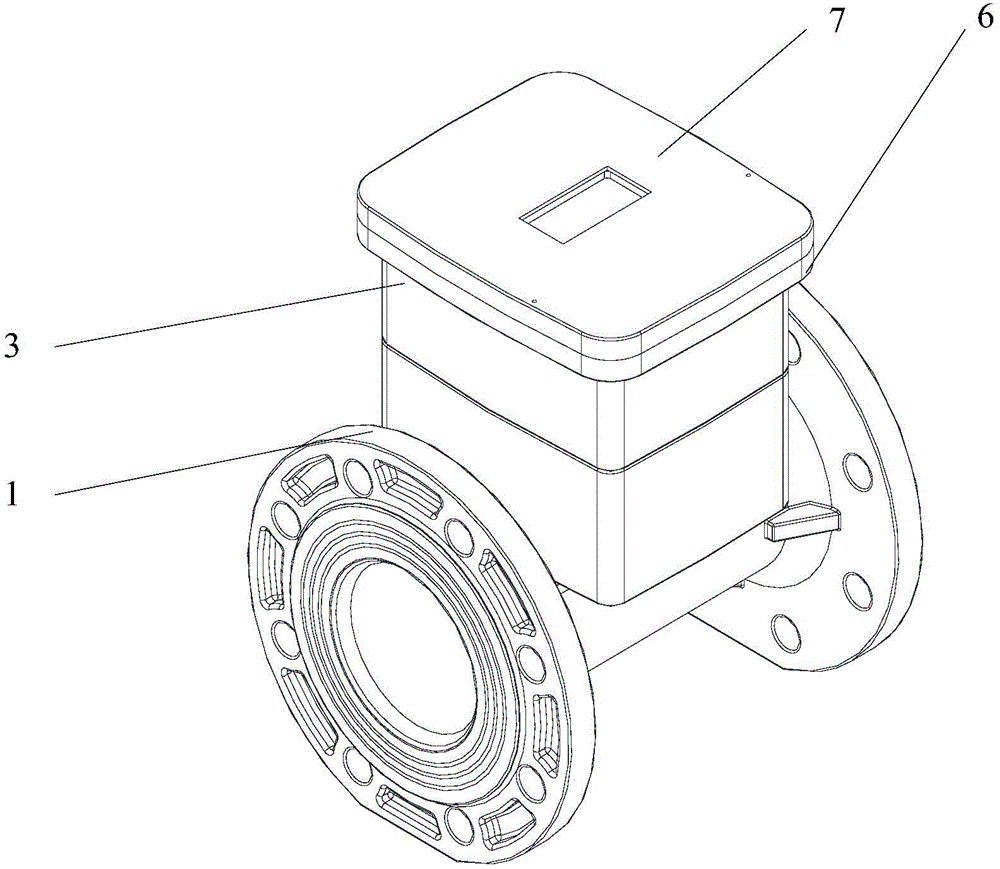

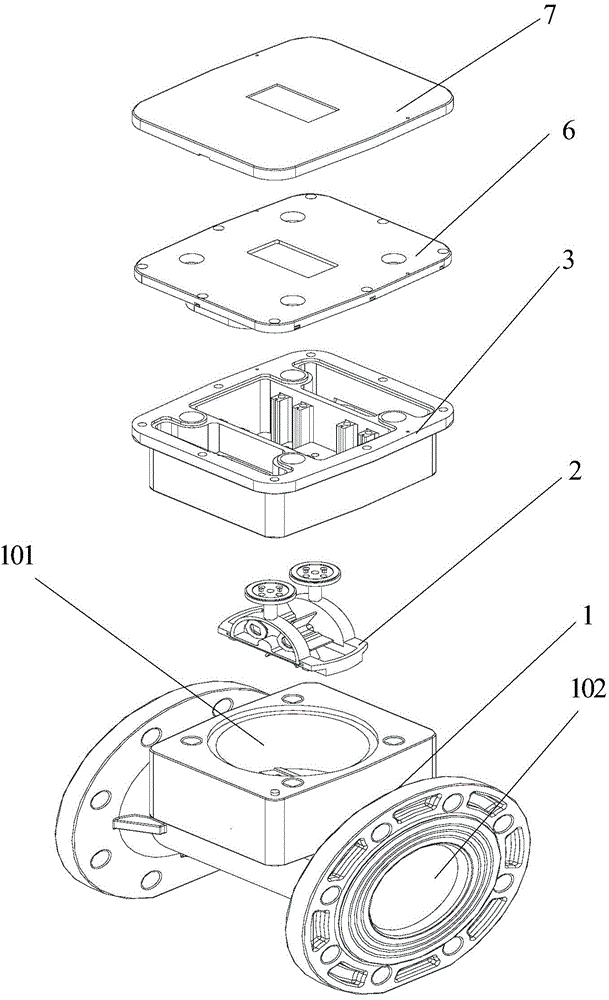

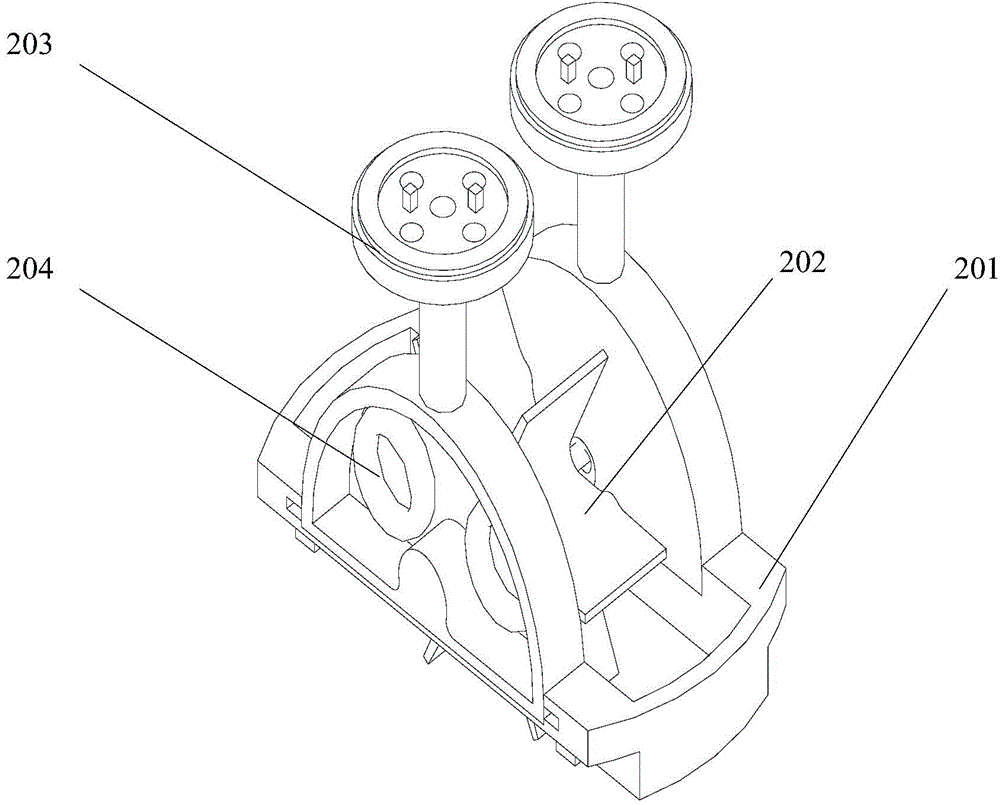

Magneto-electrical flow meter

ActiveCN104568032AAvoid malfunctioningAvoid countingVolume/mass flow by electromagnetic flowmetersMagnetoMagnetic line

The invention discloses a magneto-electrical flow meter. The magneto-electrical flow meter comprises a flow meter body, a hydraulic wheel sensing mechanism and an electronic device chamber; when in work, liquid flows through a pipeline at the lower end of the flow meter body to enter a hydraulic wheel container in the upper end of the flow meter body; a permanent magnet is mounted on a hydraulic wheel blade of a hydraulic wheel; when the hydraulic wheel is pushed by the liquid to rotate, a magnetic line produced by a coil cutting the permanent magnet generates an induced electromotive force; a first signal of the induced electromotive force is transmitted to a first processing circuit into the electronic device chamber mounted in the upper end of the hydraulic wheel sensing mechanism through a connection terminal, and then a produced second signal is transmitted to a micro-controller after processing; the micro-controller acquires the second signal and converts the acquired second signal into flow rate to display. According to the magneto-electrical flow meter, the magnetic line produced by the coil cutting the permanent magnet is utilized to meter the flow rate, so that the problem of dead clamping caused by measuring the flow rate by the worm gear and worm transmission can be avoided.

Owner:北京奥特美克科技股份有限公司

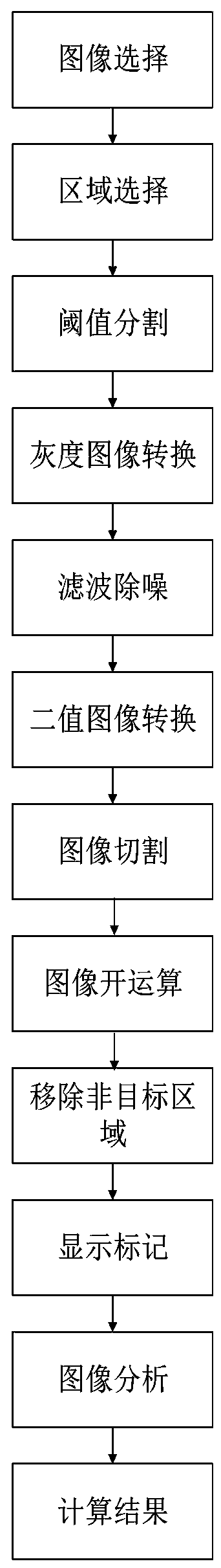

A fast counting method of wheat basic seedlings based on machine vision and graphics processing

ActiveCN109447945AAppropriate statisticsAvoid countingImage enhancementImage analysisGraphicsMachine vision

A fast counting method of wheat basic seedlings based on machine vision and graphics processing is proposed to solve the technical problem of low counting efficiency of wheat basic seedlings, and includes the following steps of acquiring basic seedling images, enhancing image restoration and performing target count. In the target count, the image processed by the step S8 is counted by using the connected area comparison method to obtain the number of wheat basic seedlings, so that the blocking adhesion of the wheat seedlings can be read and recognized, and the number of wheat basic seedlings is equal to the number of wheat seedlings counted in each connected area. By using machine vision and graphics processing method, the counting efficiency is high, and the method is suitable for large-scale statistics of wheat planting or germination.

Owner:HENAN AGRICULTURAL UNIVERSITY

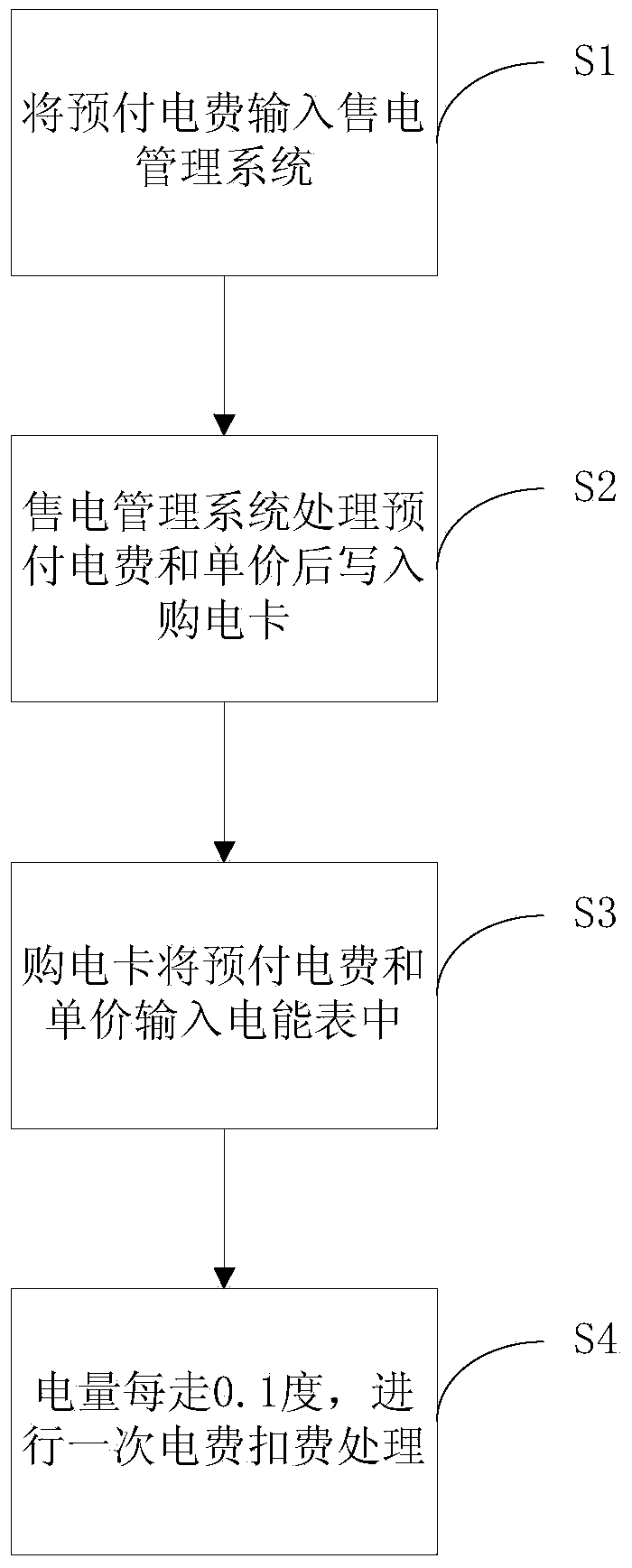

Charge-control processing method of electric power meter for prepayment

ActiveCN104299323ALighten the computational burdenImprove the display effectApparatus for hiring articlesElectricityElectric power system

The invention discloses a charge-control processing method of an electric power meter and relates to the field of charging with the electric power meter. The charge-control processing method includes that firstly, prepaid electricity is inputted into an electricity selling management system; the electricity selling management system magnifies the prepaid electricity to be 10N+1 times and converts the prepaid electricity into a hexadecimal value and magnifies unit price to be 1-N times and converts the unit price into a hexadecimal value; secondly, the converted prepaid electricity and unit price are inputted into the electric power meter storing total electricity and the unit price which are hexadecimal; electricity deduction processing is performed by the electric power meter each time 0.1-degree electric quantity is consumed according to the formula: remaining electricity=remaining electricity before deduction-unit price, and the hexadecimal remaining electricity and unit price are stored in the electric power meter. Multiply operation of decimal floating points in electricity deduction is simplified to be hexadecimal addition and subtraction calculation operation, and burden of the electric power meter is reduced.

Owner:武汉阿迪克电子股份有限公司

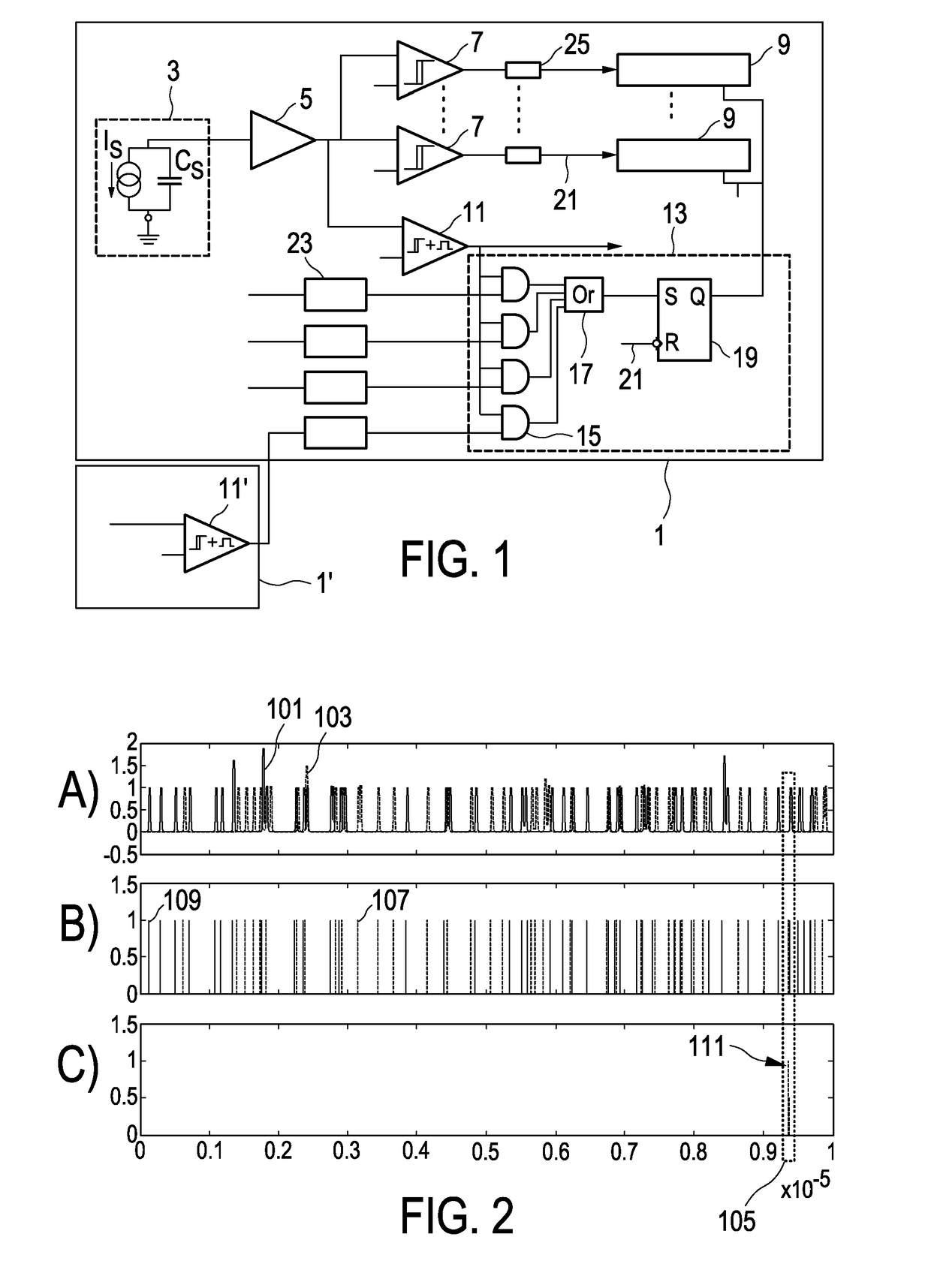

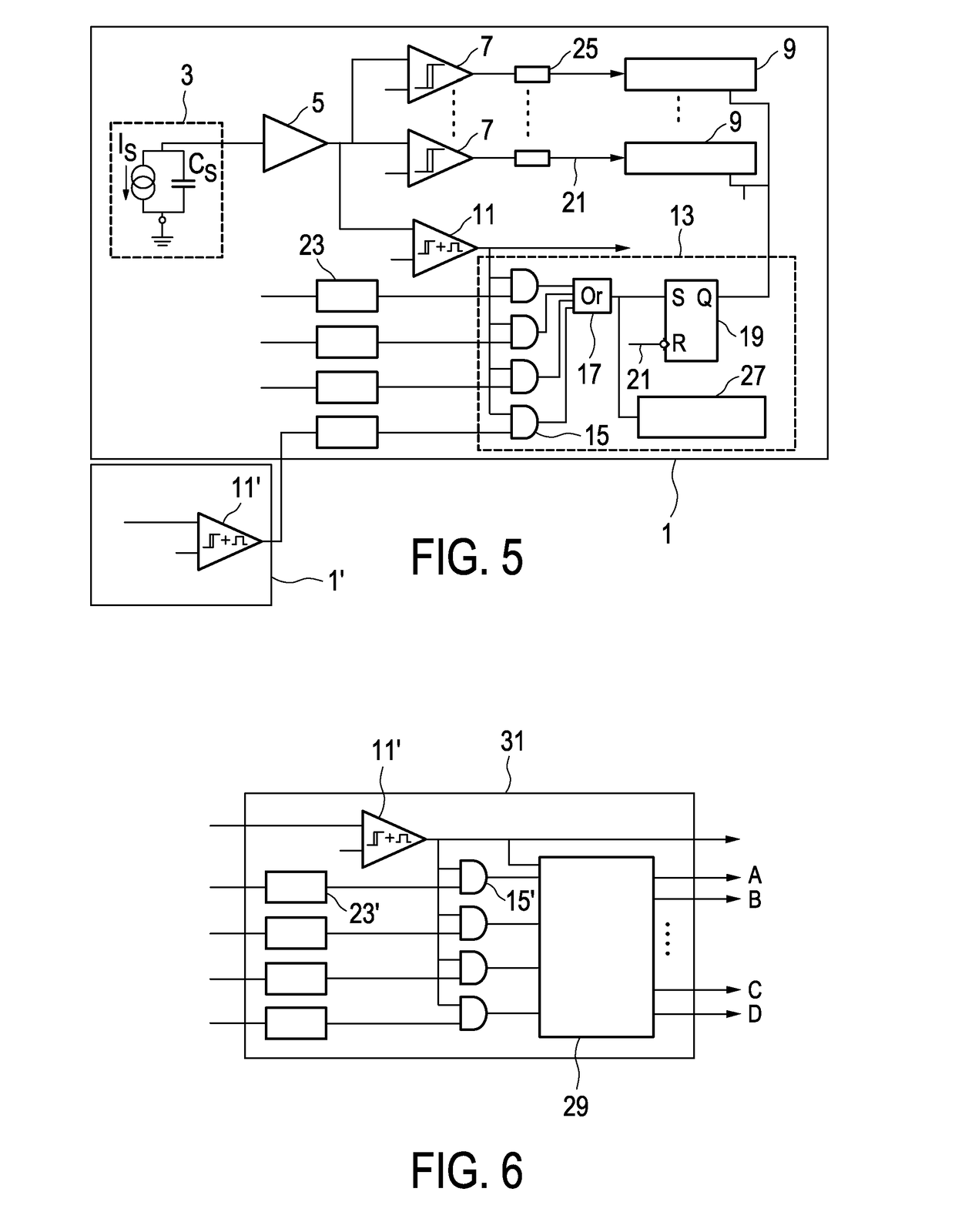

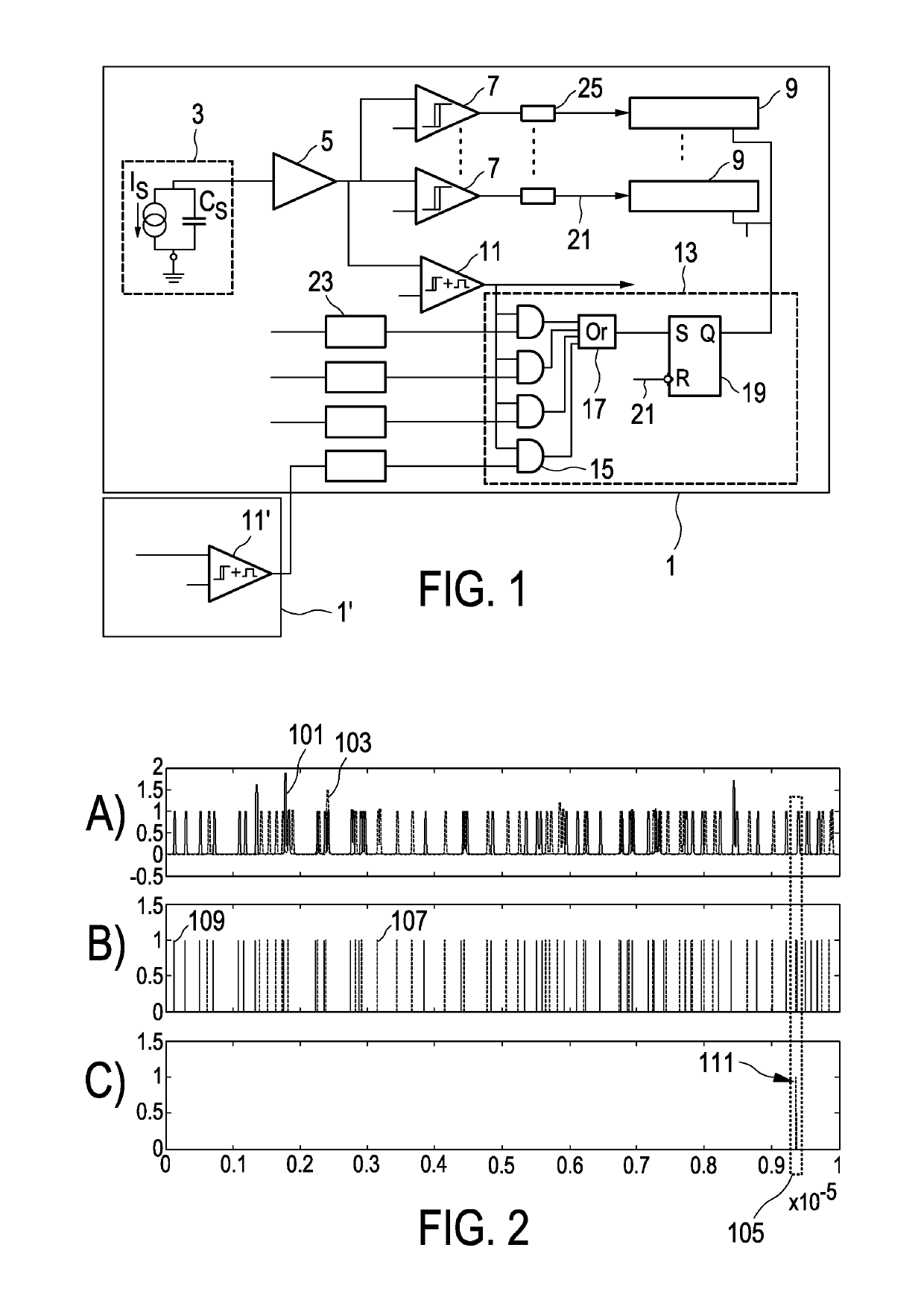

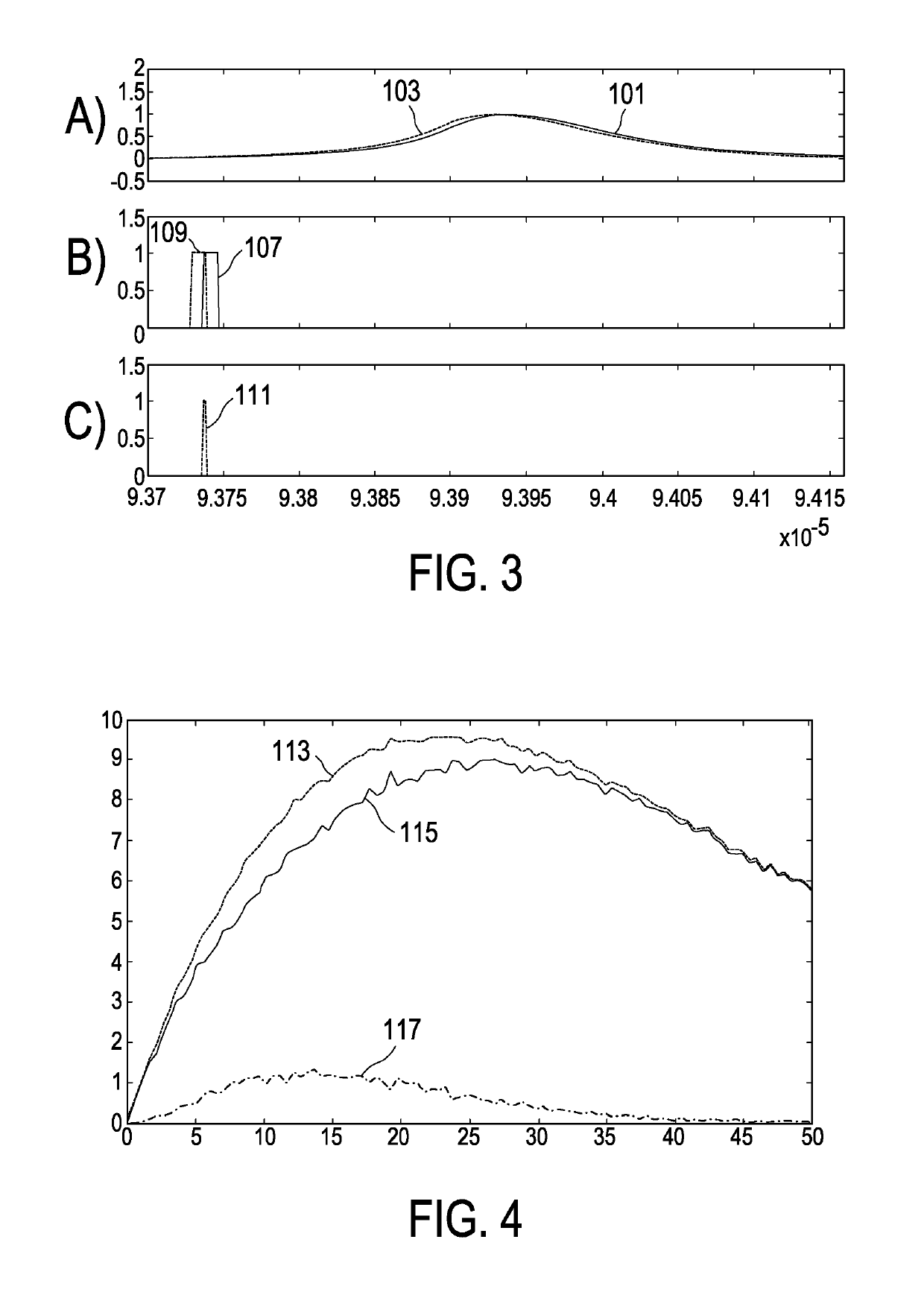

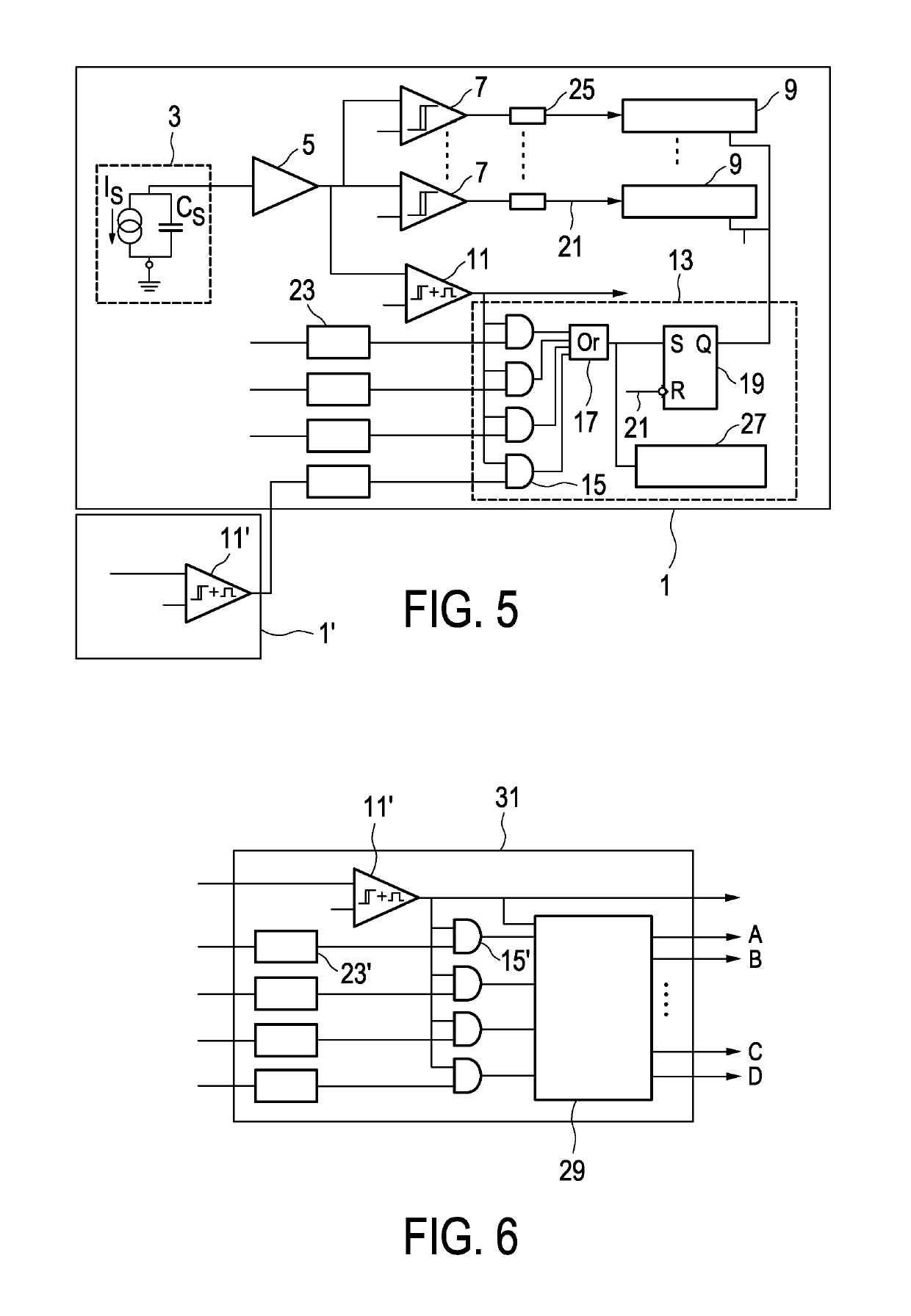

Photon counting device and method

ActiveUS20190025440A1Reduce decreaseAvoid countingTelevision system detailsPhotometryCharge sharingCoincidence

The invention relates a photon counting device and method for counting photon interactions in a piece of converter material and addressing the issue of charge sharing. The occurrence of a charge sharing event is already detected upon the onset of the pulse, taking into consideration an onset of a pulse in a neighboring pixel within a preferably very short coincidence window. According to the invention, it is detected whether a pulse is being processed and one or more neighboring pixels are scouted to decide whether a simultaneous interaction has been registered within a very short coincidence window.

Owner:KONINKLJIJKE PHILIPS NV

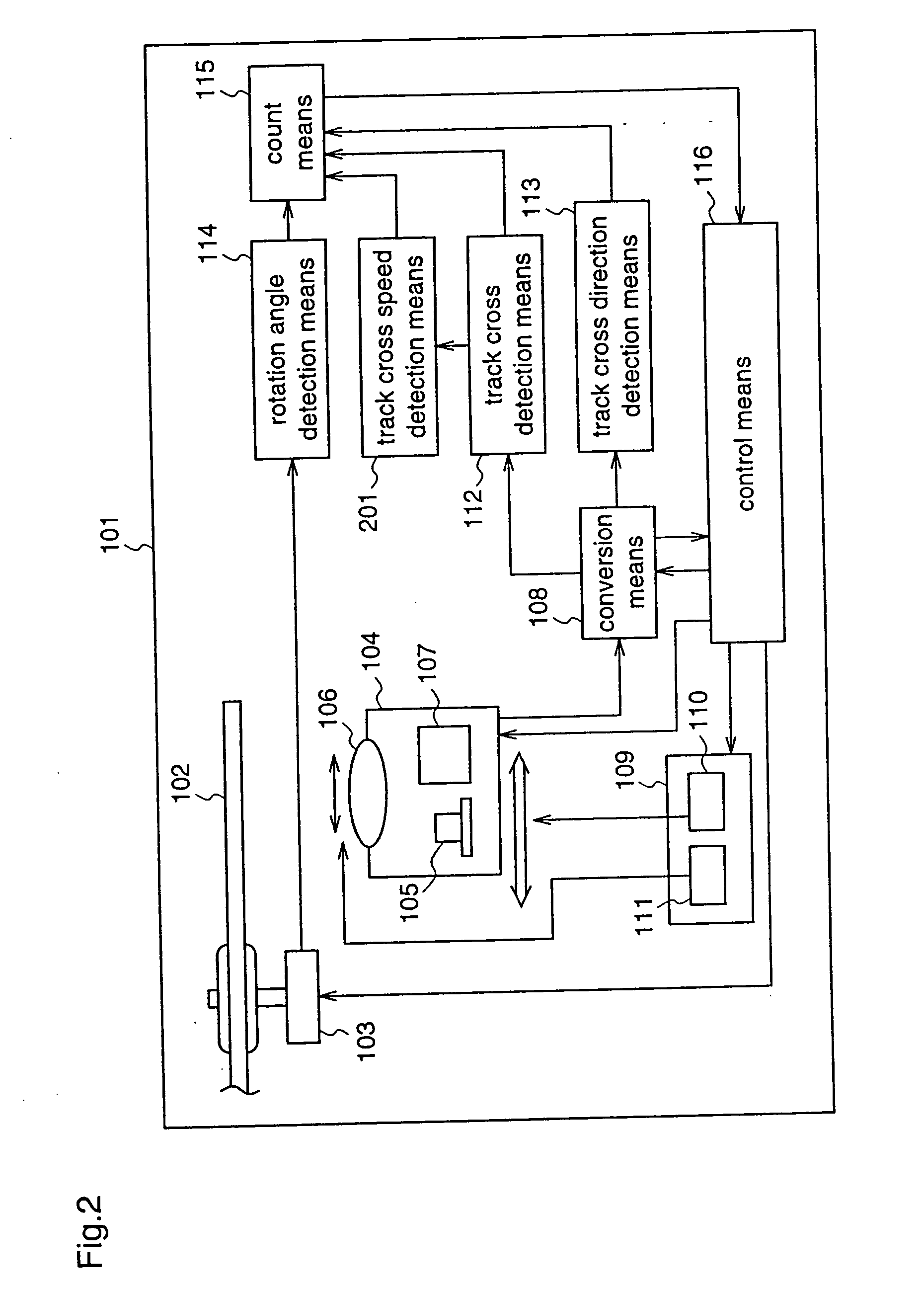

Information disc recording/playback apparatus, and vibration detection method for information disc recording/playback apparatus

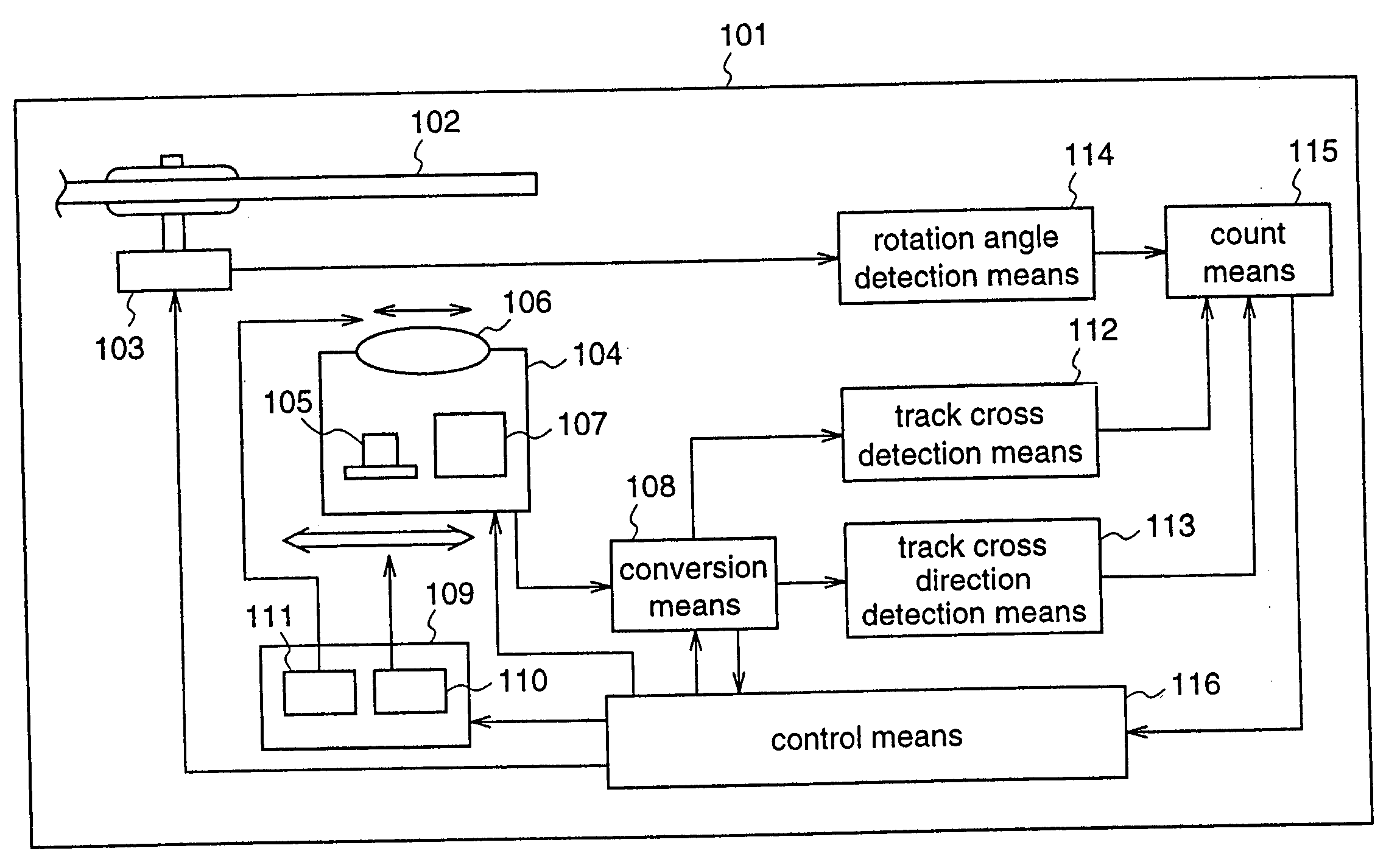

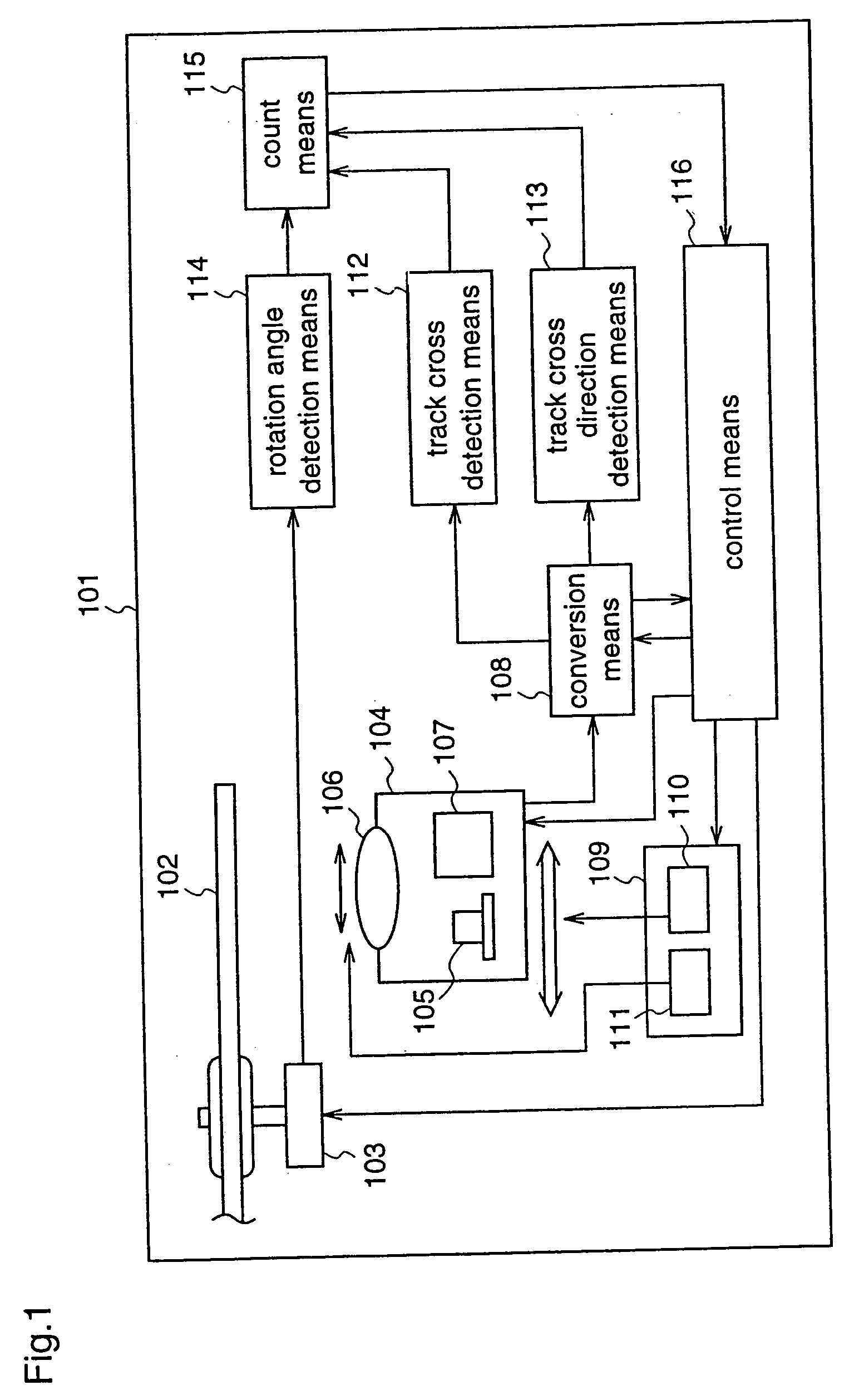

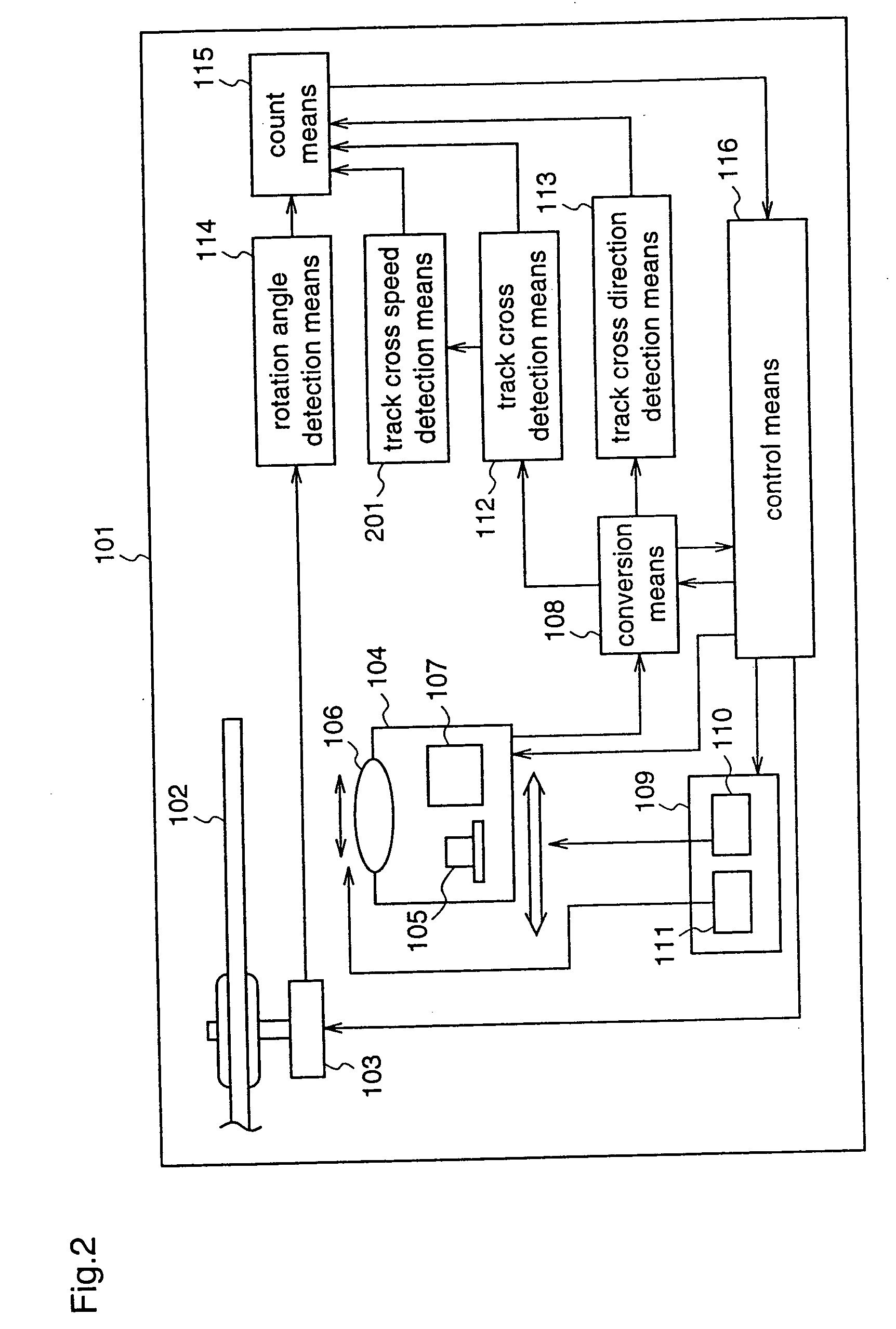

InactiveUS20060044963A1Accurately carry-outAvoid countingRecord information storageCarrier monitoringVibration amplitudeVibration acceleration

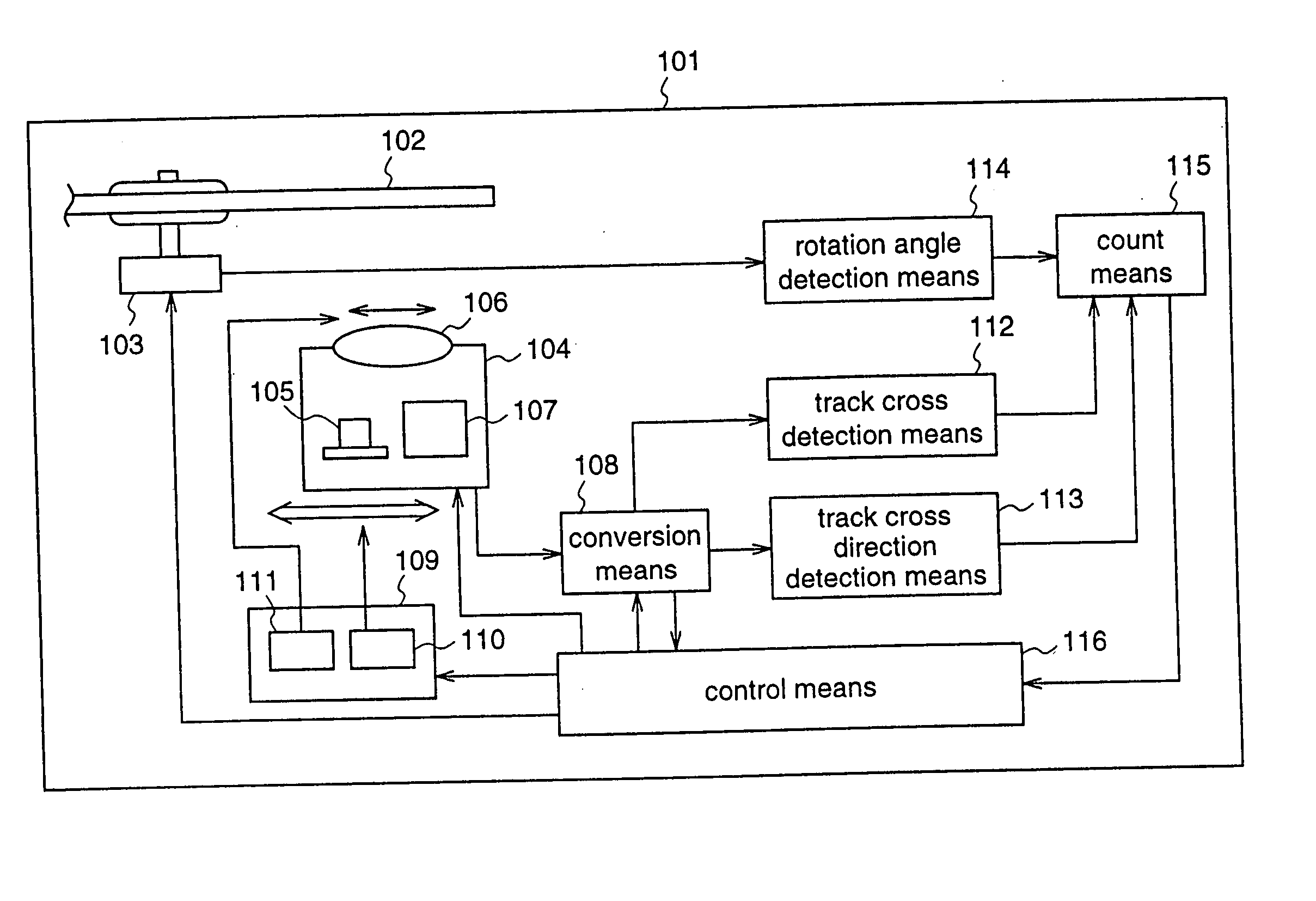

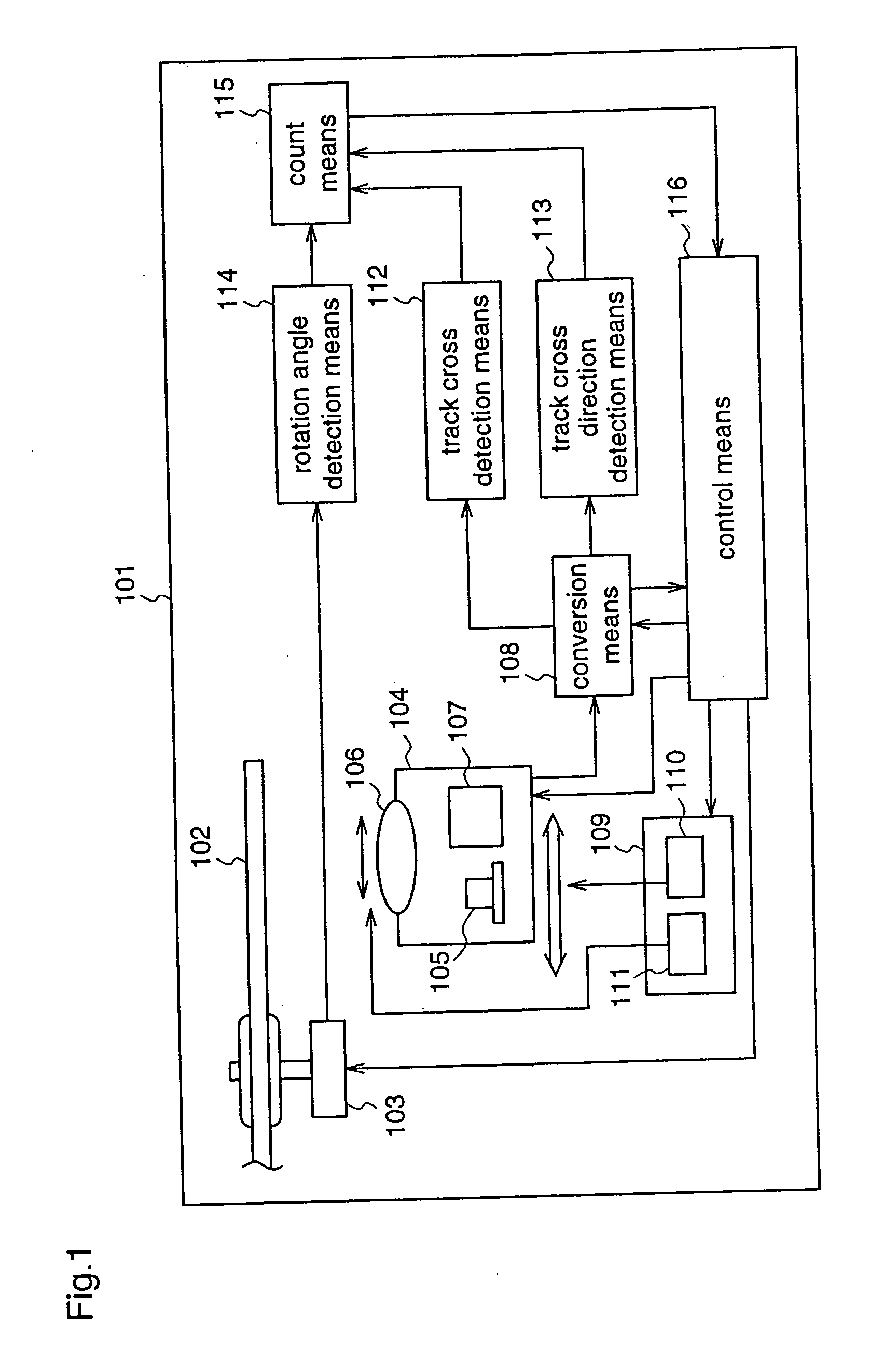

The present invention provides an information disc recording / playback apparatus which includes a track cross detection means (112), a track cross direction detection means (113), a rotation angle detection means (114), and a count means (115), detects the track pitch of a disc, evaluates the vibration amount, or vibration speed, or vibration acceleration considering the track pitch of the disc, and determines a maximum rotation speed that is lower than the allowable vibration amplitude, vibration speed, or vibration acceleration of the information disc recording / playback apparatus; as well as a vibration detection method for the information disc recording / playback apparatus. This information disc recording / playback apparatus can perform vibration detection using a single threshold value that is independent of the type of the disc, without using an acceleration sensor, and further, the apparatus can accurately perform vibration detection even when direction detection is difficult.

Owner:TAKAHASHI YORIO

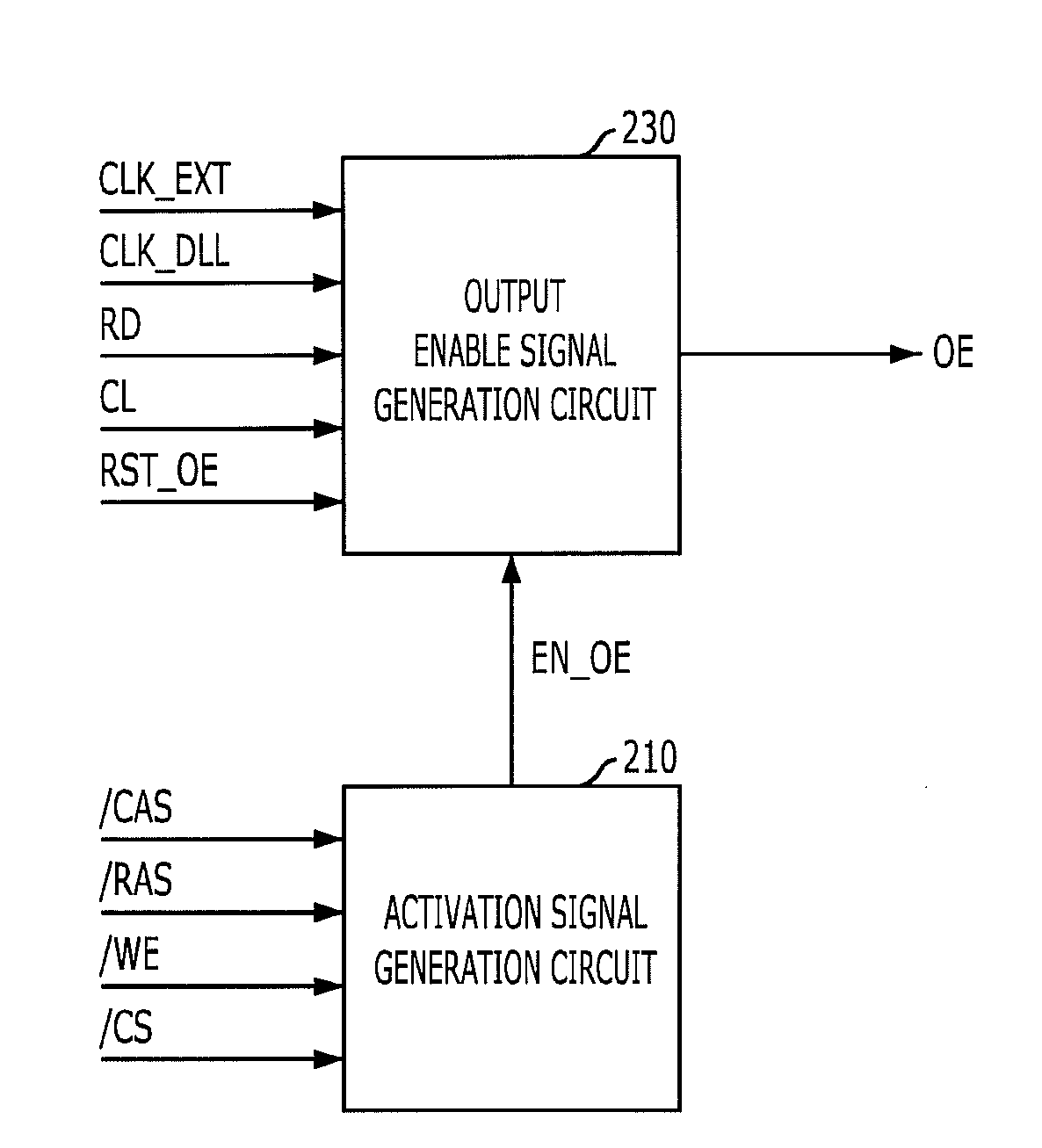

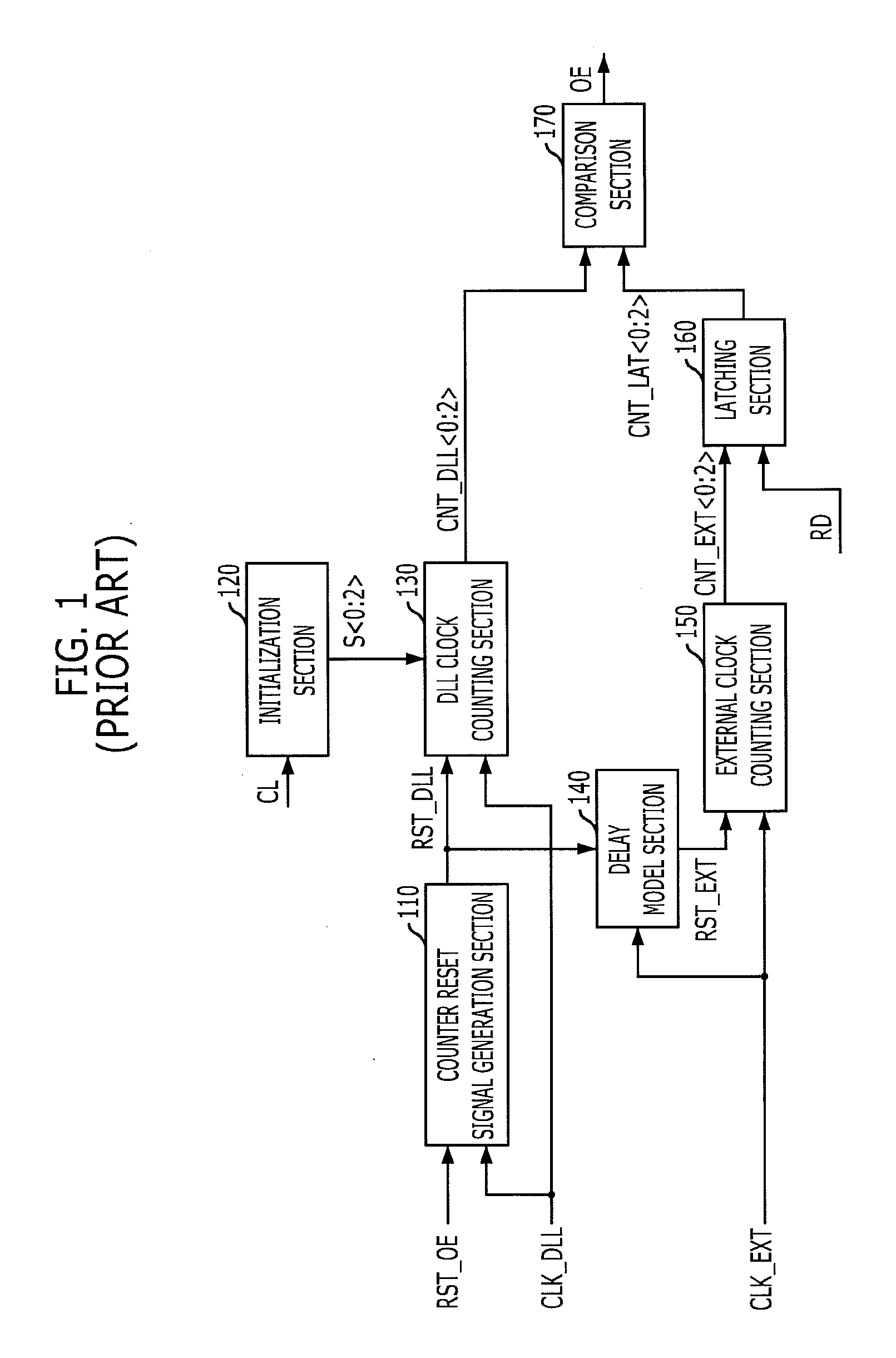

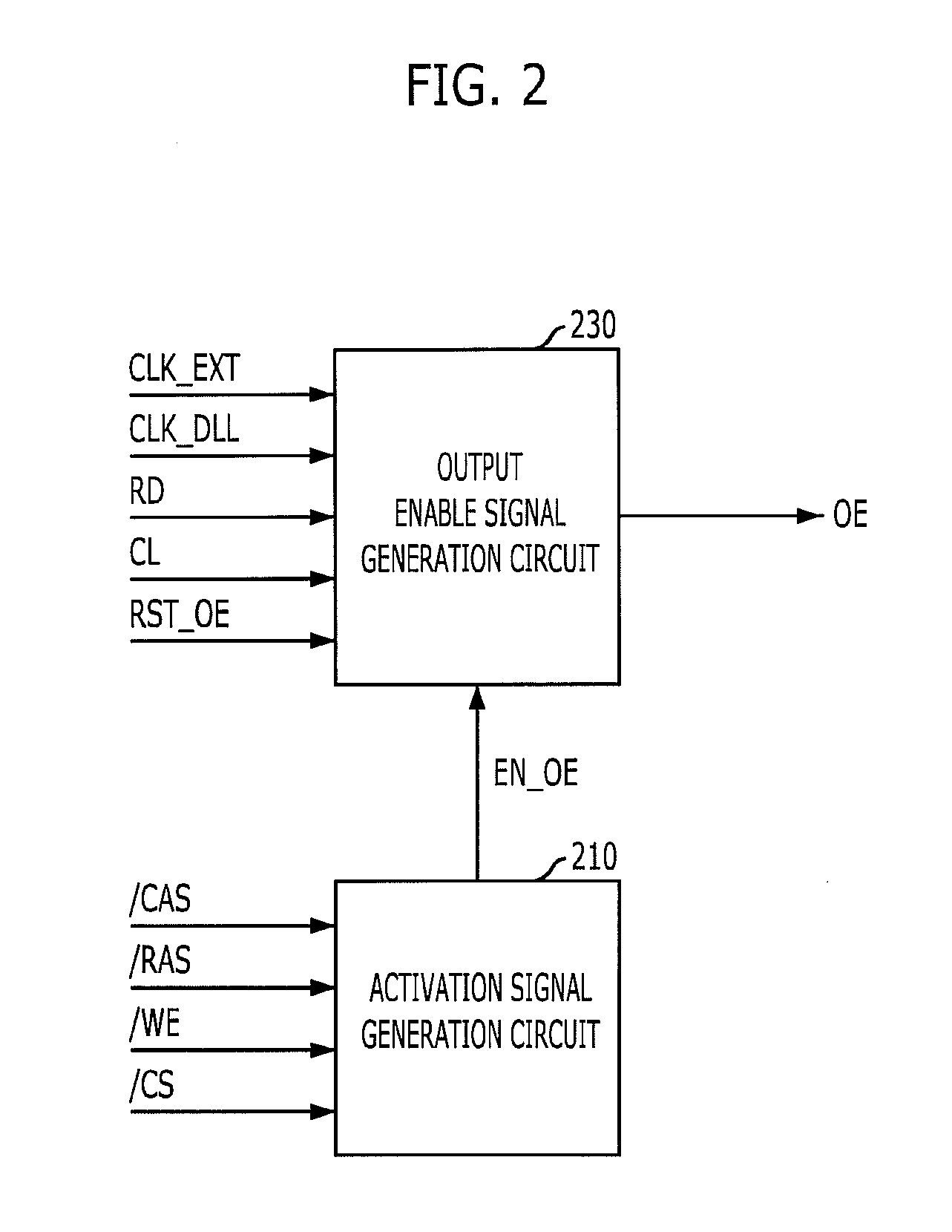

Semiconductor memory device and driving method thereof

ActiveUS20100277992A1Limit counting operationAvoid countingDigital storageEngineeringBiological activation

A semiconductor memory device includes output enable signal generation means configured to be reset in response to an output enable reset signal, count a DLL clock signal and an external clock signal, and generate an output enable signal in correspondence to a read command and an operating frequency; and activation signal generation means configured to generate an activation signal for inactivating the output enable signal generation means during a write operation interval.

Owner:SK HYNIX INC

Information disc recording/playback apparatus, and vibration detection method for information disc recording/playback apparatus

InactiveUS20060028944A1Accurately carry-outAvoid countingRecord information storageUsing detectable carrier informationVibration amplitudeVibration acceleration

The present invention provides an information disc recording / playback apparatus which includes a track cross detection means (112), a track cross direction detection means (113), a rotation angle detection means (114), and a count means (115), detects the track pitch of a disc, evaluates the vibration amount, or vibration speed, or vibration acceleration considering the track pitch of the disc, and determines a maximum rotation speed that is lower than the allowable vibration amplitude, vibration speed, or vibration acceleration of the information disc recording / playback apparatus; as well as a vibration detection method for the information disc recording / playback apparatus. This information disc recording / playback apparatus can perform vibration detection using a single threshold value that is independent of the type of the disc, without using an acceleration sensor, and further, the apparatus can accurately perform vibration detection even when direction detection is difficult.

Owner:TAKAHASHI YORIO

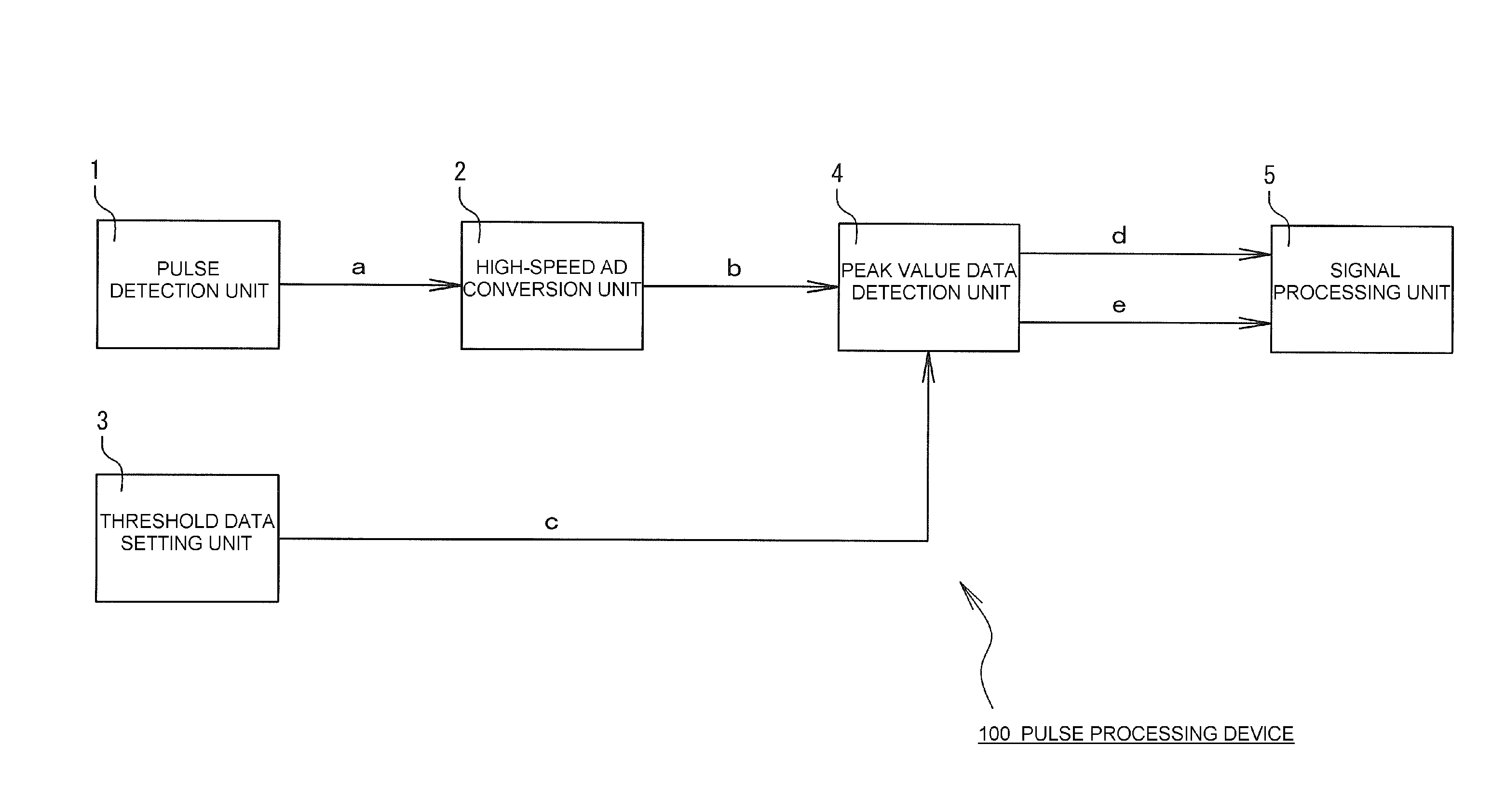

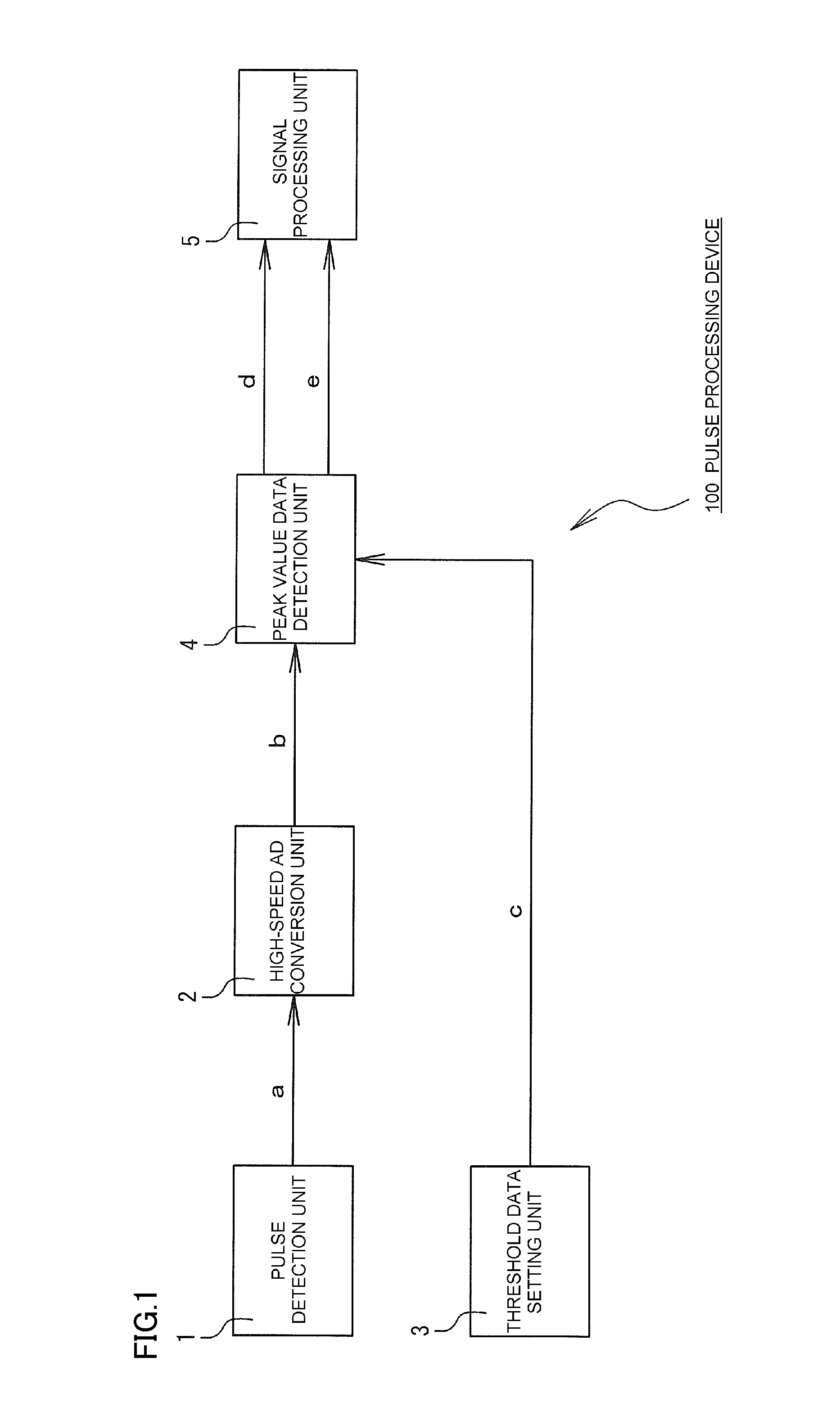

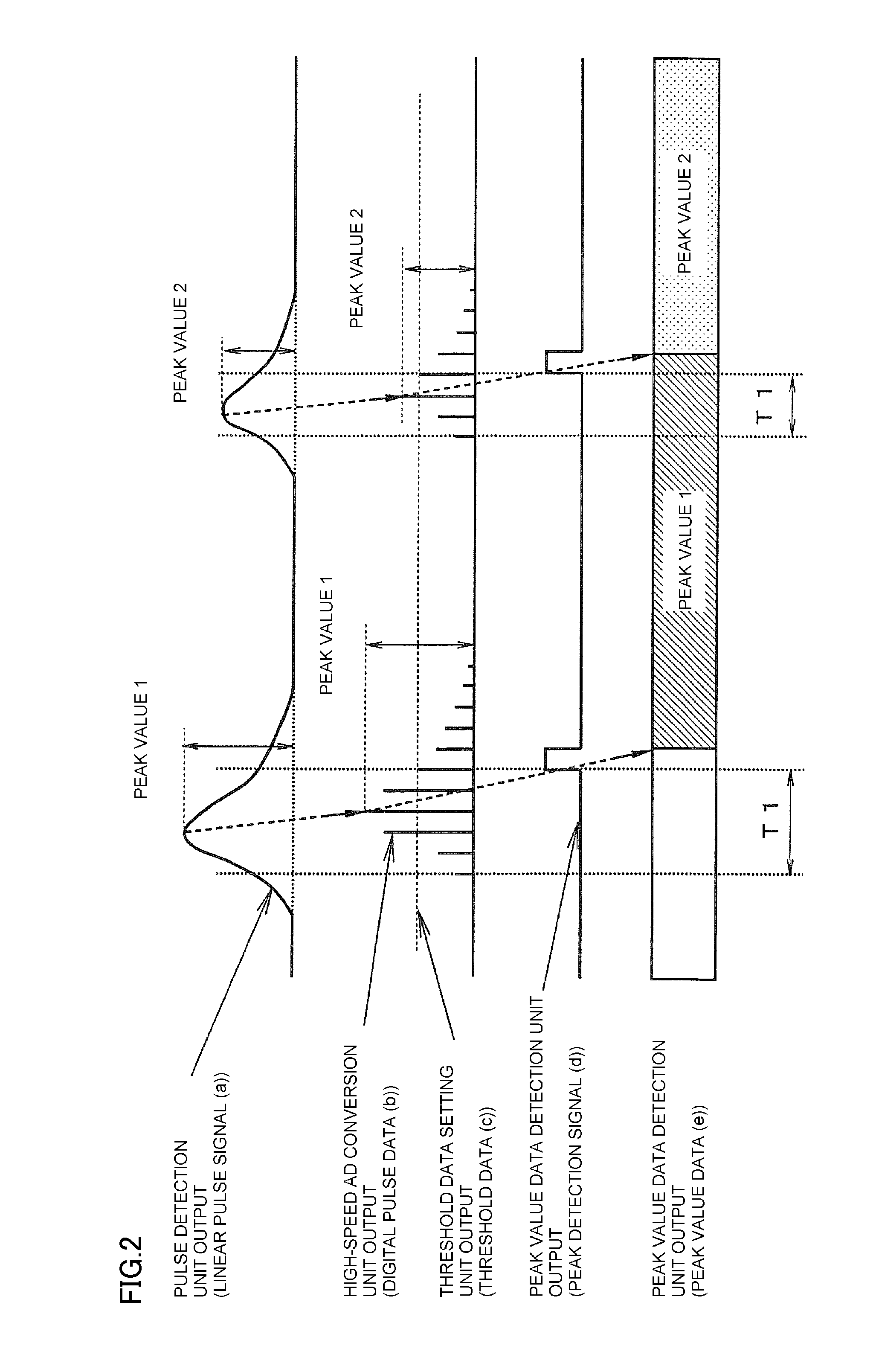

Pulse processing device and radiation measuring device

ActiveUS20140188418A1Cancel noiseEasy to analyzeDigital variable/waveform displayX/gamma/cosmic radiation measurmentData setMeasurement device

Provided is a pulse processing device that accelerates signal processing and prevents counting loss. Provided also is a radiation measuring device in which counting loss is prevented and counting capacity is increased by installing the pulse processing device. The processing device is in a form of a pulse processing device including a pulse detection unit that outputs a linear pulse signal in response to a physical event, a high-speed AD conversion unit that converts the linear pulse signal into digital pulse data, a threshold data setting unit that outputs preset threshold data, a peak value data detection unit that compares the digital pulse data with the threshold data and outputs the maximum digital pulse data, from among the digital pulse data continuously exceeding the threshold data, as maximum peak value data, and a signal processing unit that inputs the peak value data as a pulse wave height.

Owner:FUJI ELECTRIC CO LTD

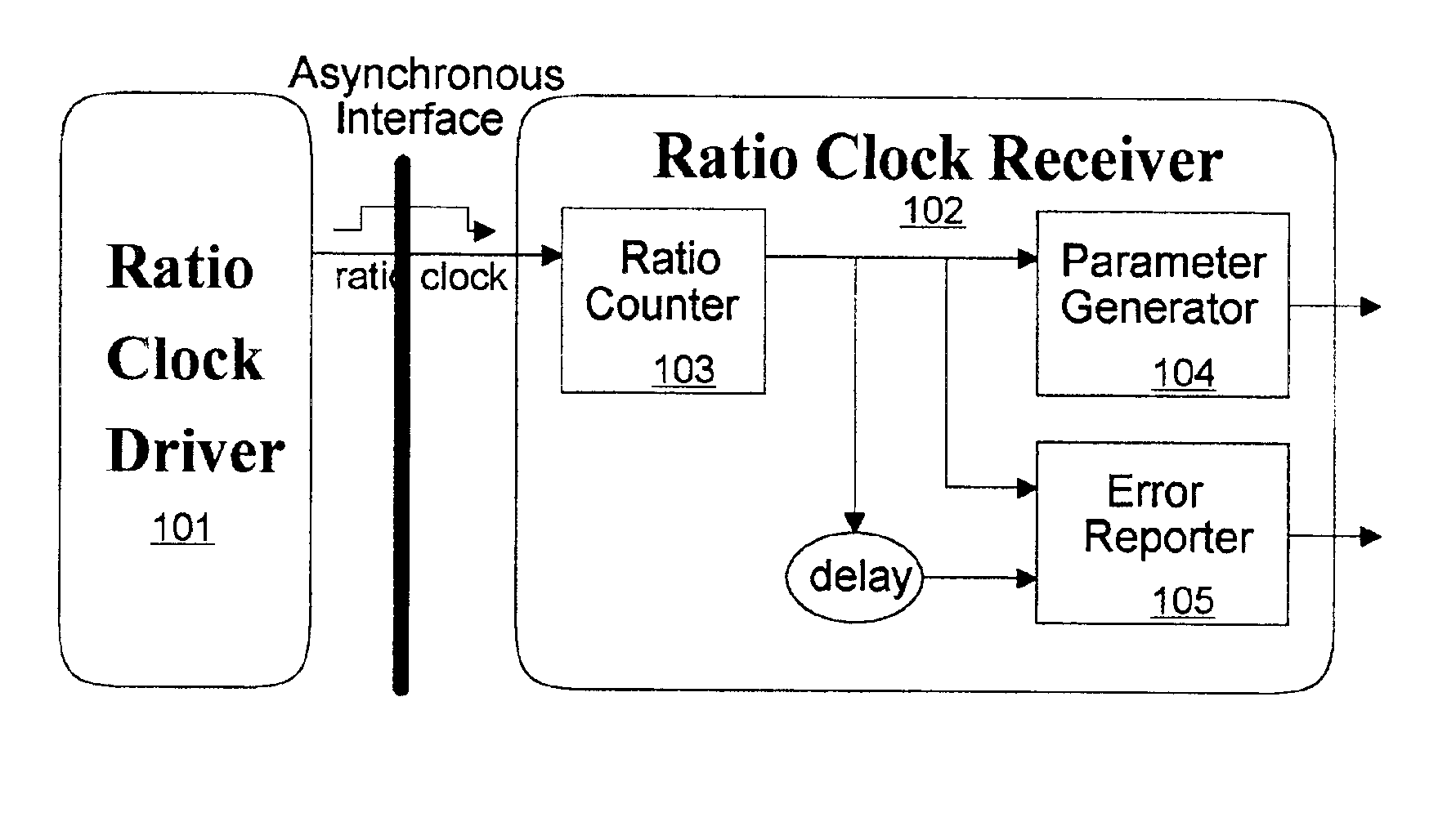

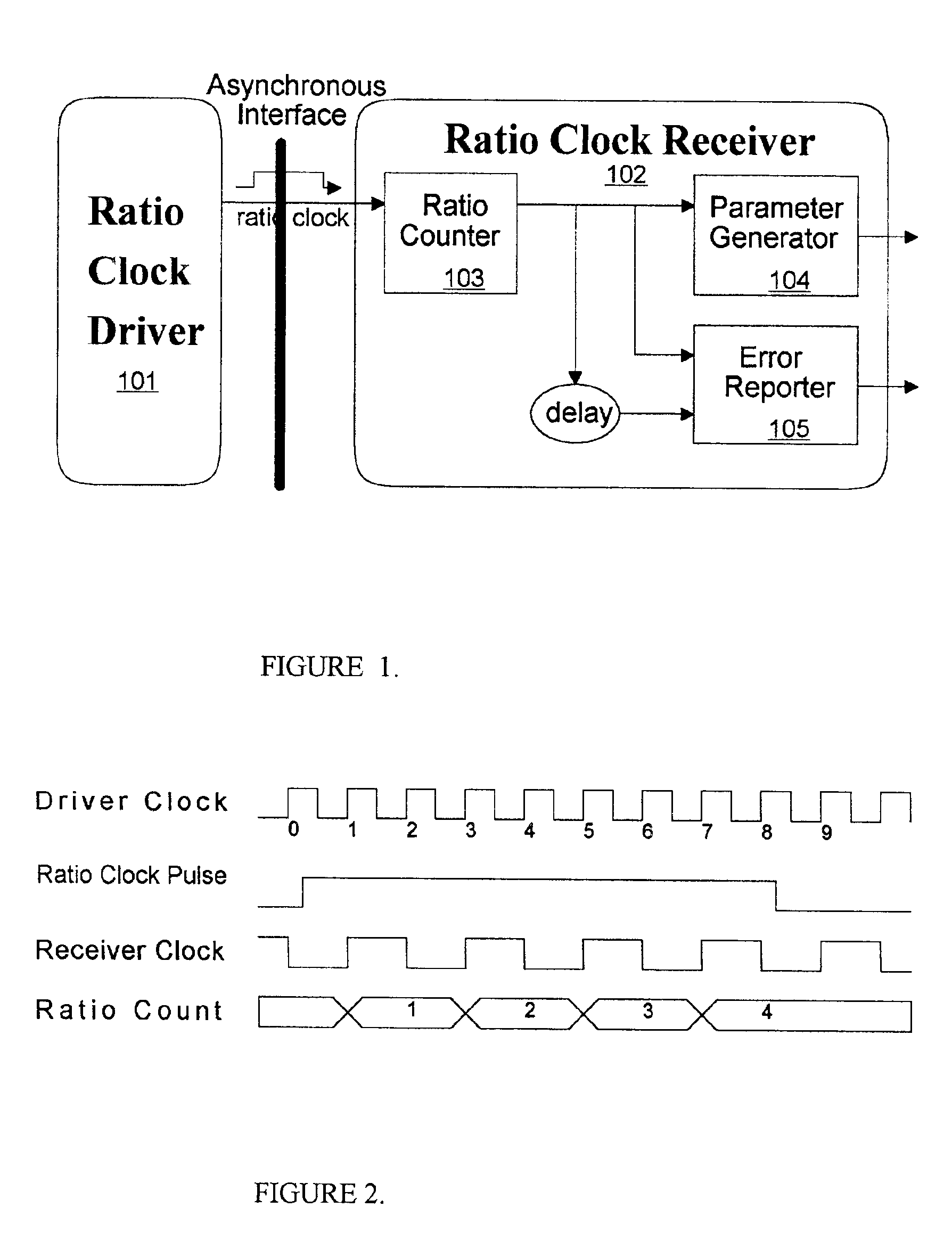

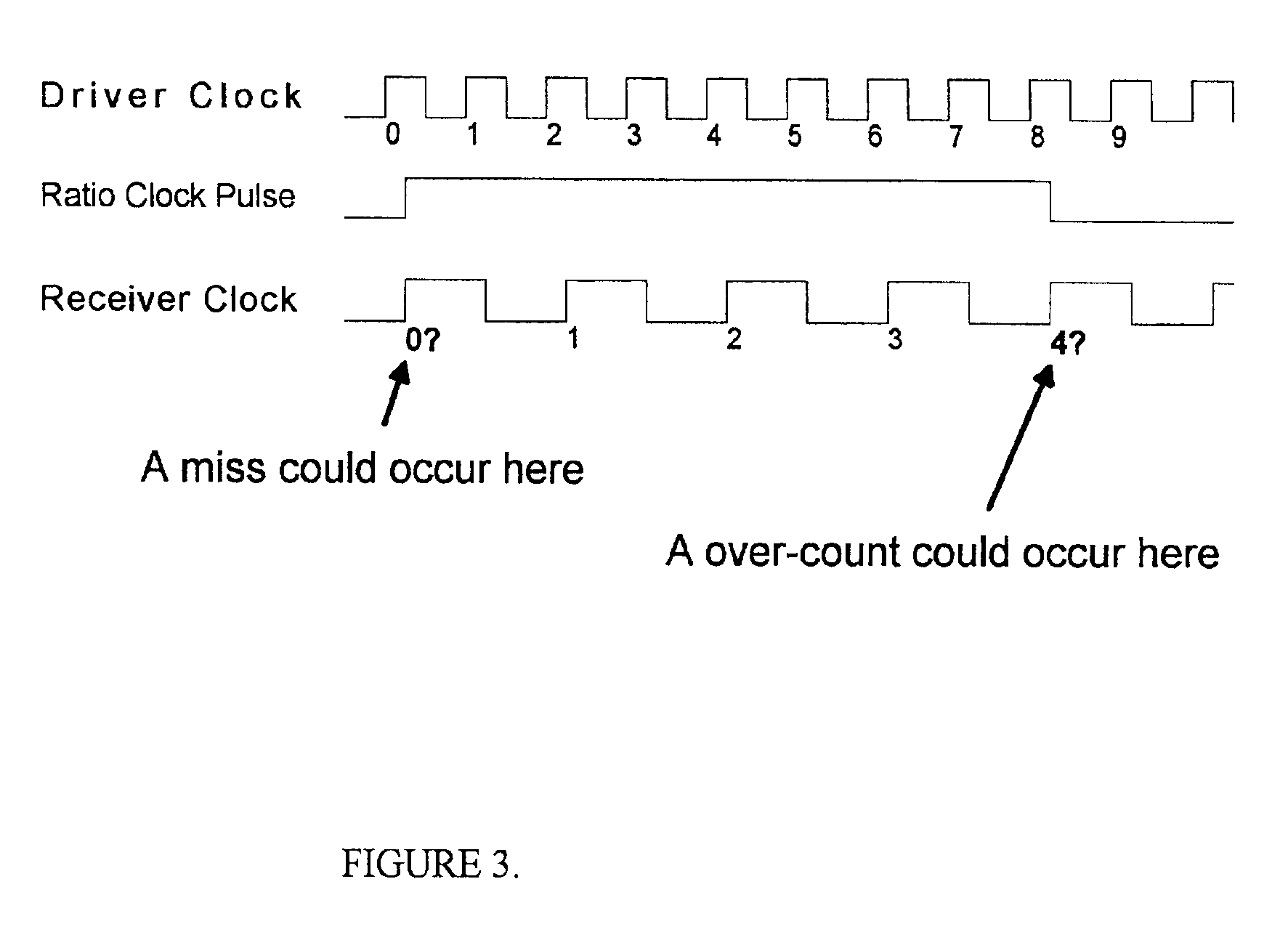

Method for adjusting system clocks using dynamic clock ratio detector to detect clock ratio between clock domain of driver and counting receiver clock domain

InactiveUS6898725B2Prevent outputAvoid countingGenerating/distributing signalsTransmission path multiple useEngineeringCircuit design

Disclosed is a method and a computer circuit design for a dynamic clock ratio detector. The detector is used to determine the ratio between two clock domains. The detector has a driver 101 and a receiver, which reside in different clock domains. The driver 101 constantly produces a ratio clock pulse to the receiver. The ratio-counter in the receiver counts the pulse width based on its local clock cycles. The clock ratio detector has many features, including absorbing the meta-stability effect when the pulse crosses an asynchronous interface. The clock ratio detector prevents output counts oscillation, provides an adjustable ratio-detecting coverage range, a programmable system-parameter generator 104, and a programmable error reporter 105.

Owner:IBM CORP

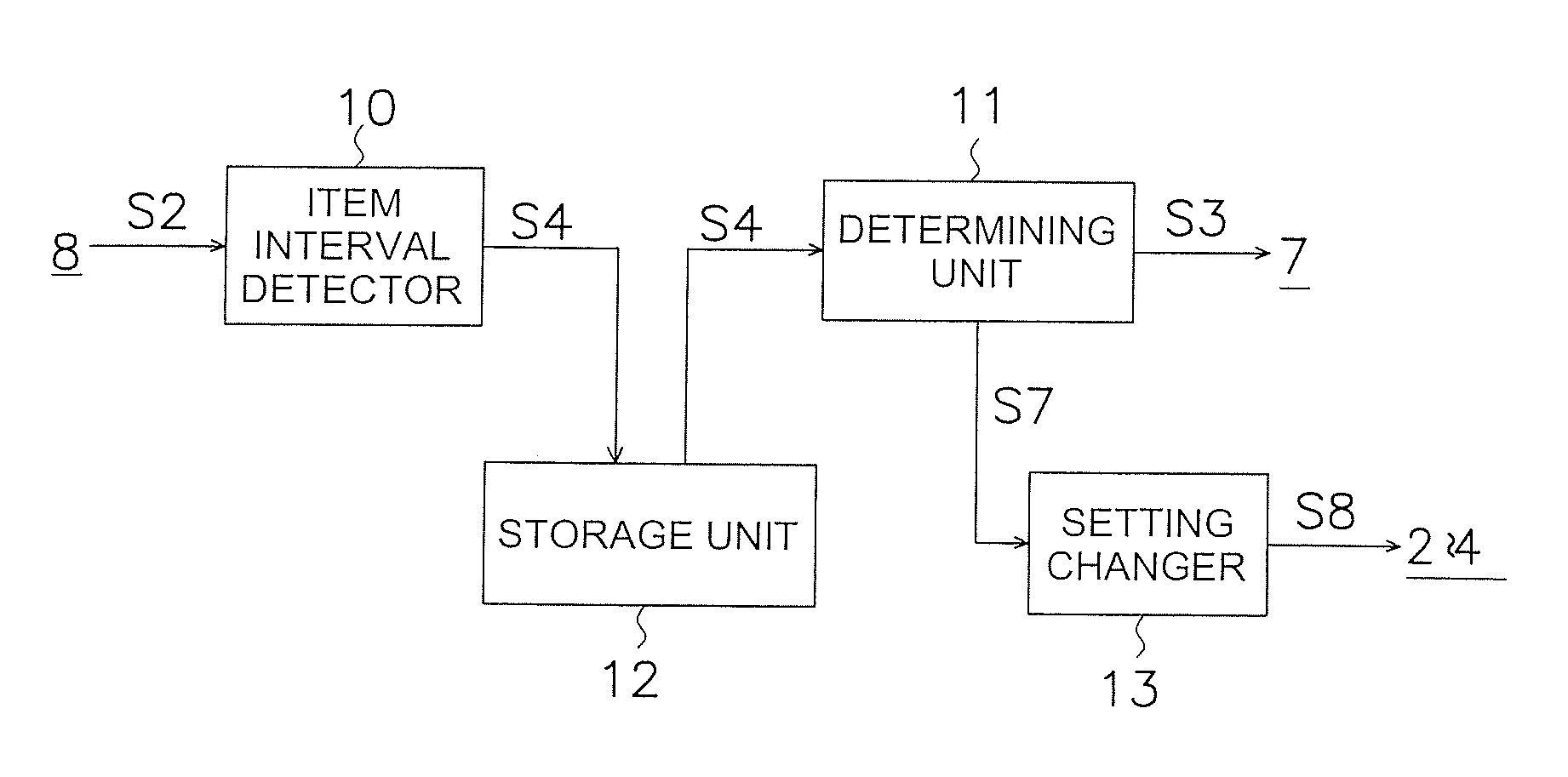

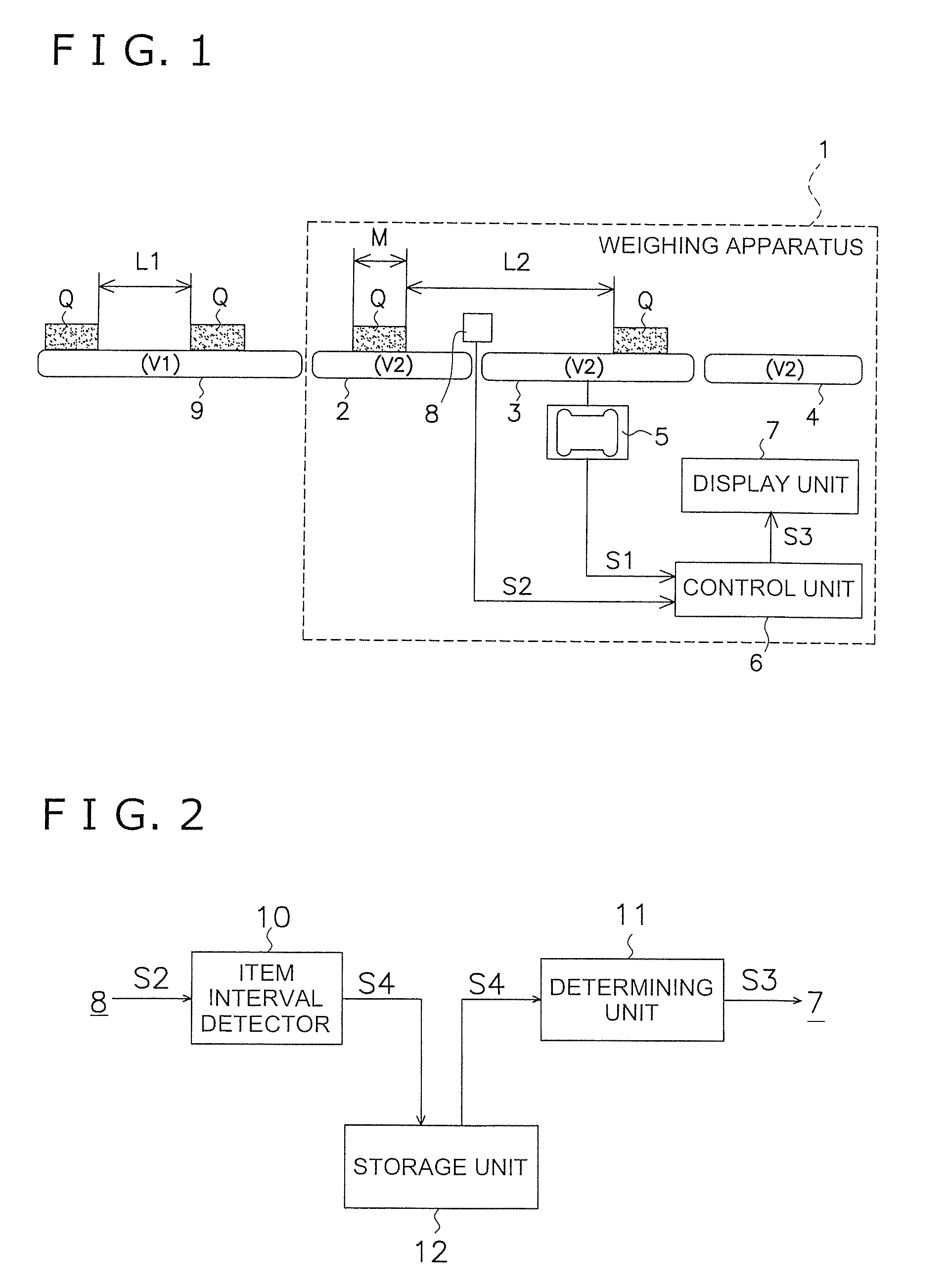

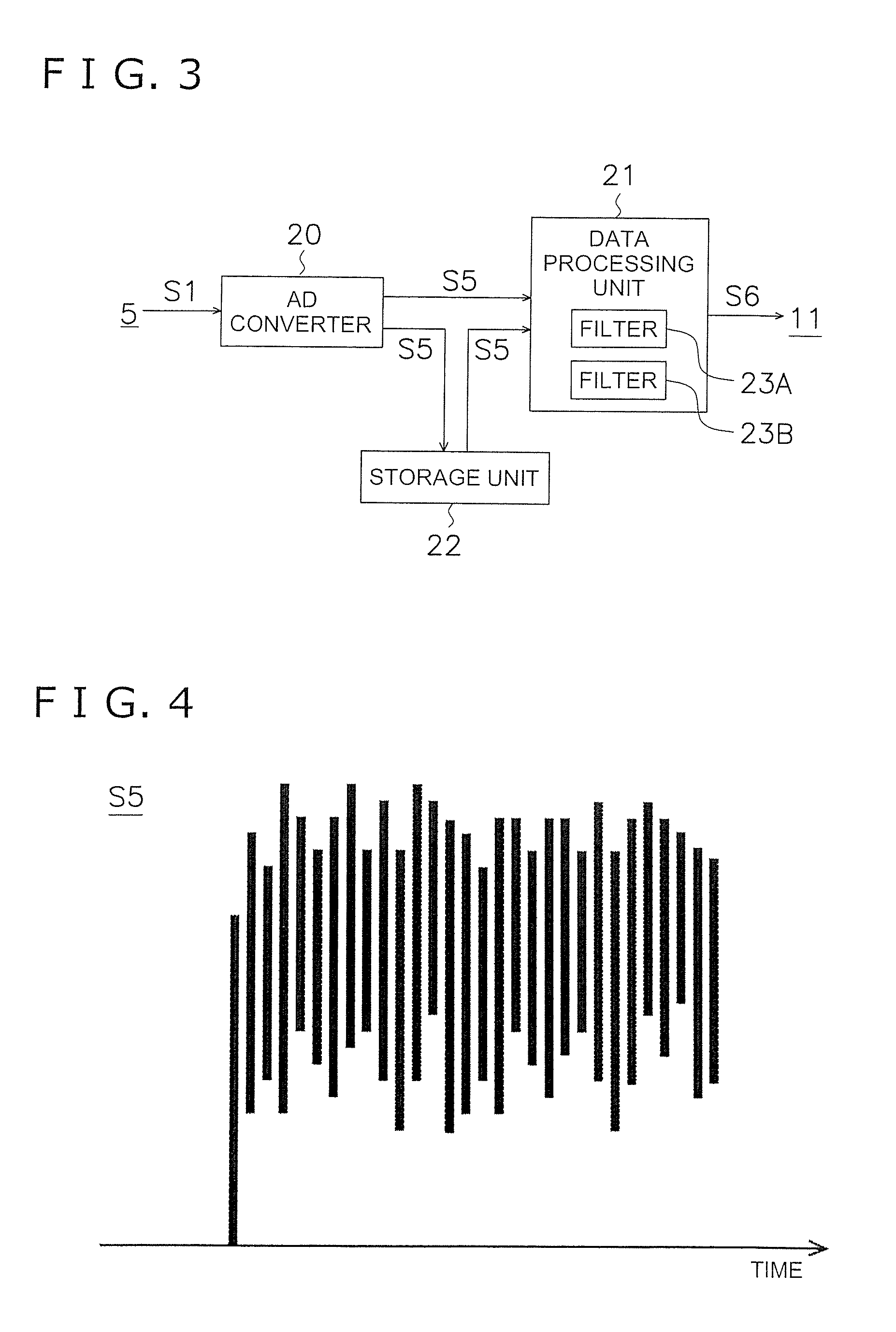

Weighing apparatus

InactiveUS20110196877A1Avoid countingProcess is performedDigital data processing detailsControl devices for conveyorsEngineeringStorage cell

Owner:ISHIDA CO LTD

Photon counting device and method

ActiveUS10365380B2Reduce decreaseAvoid countingTelevision system detailsColor television detailsCharge sharingCoincidence

The invention relates a photon counting device and method for counting photon interactions in a piece of converter material and addressing the issue of charge sharing. The occurrence of a charge sharing event is already detected upon the onset of the pulse, taking into consideration an onset of a pulse in a neighboring pixel within a preferably very short coincidence window. According to the invention, it is detected whether a pulse is being processed and one or more neighboring pixels are scouted to decide whether a simultaneous interaction has been registered within a very short coincidence window.

Owner:KONINKLJIJKE PHILIPS NV

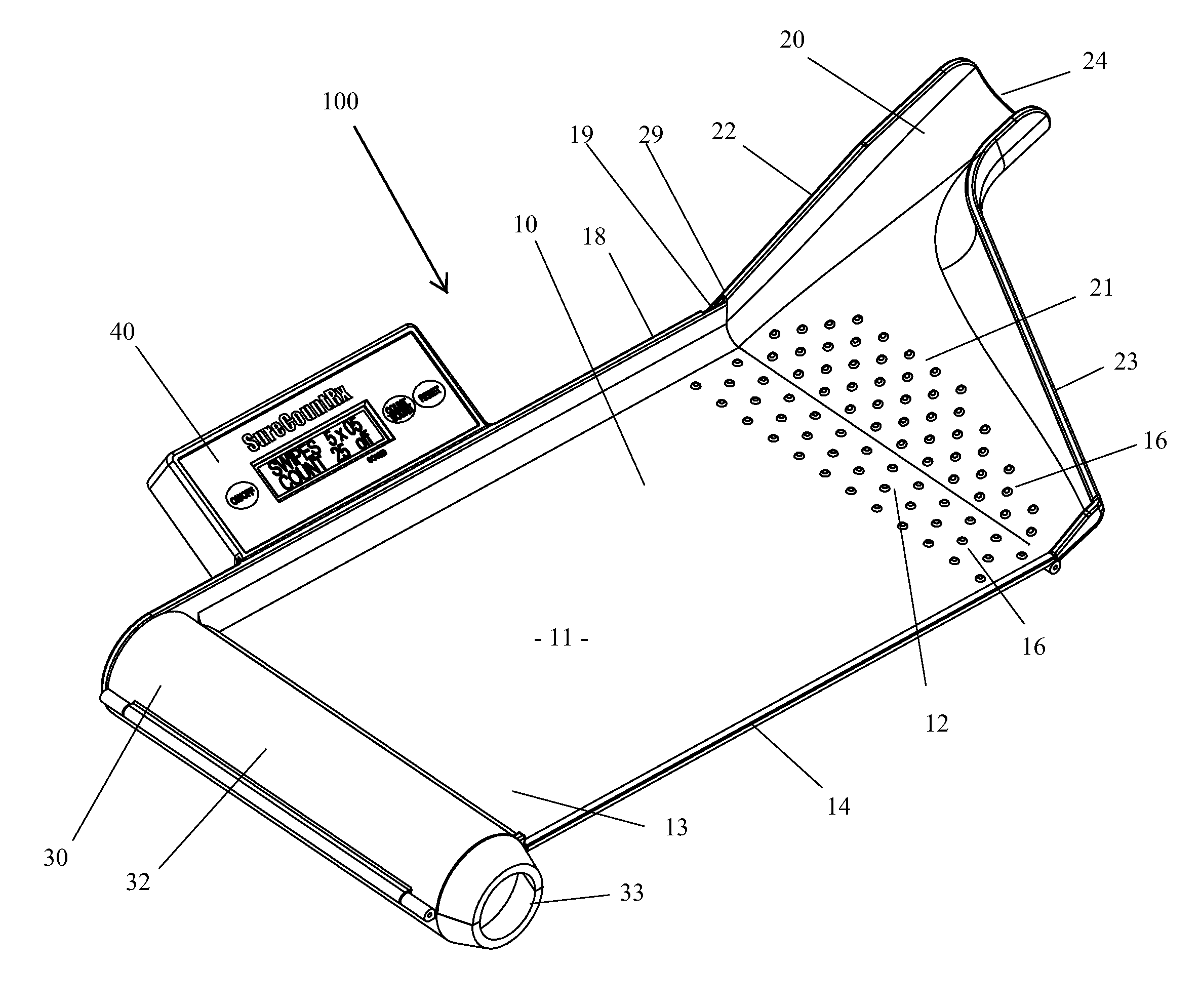

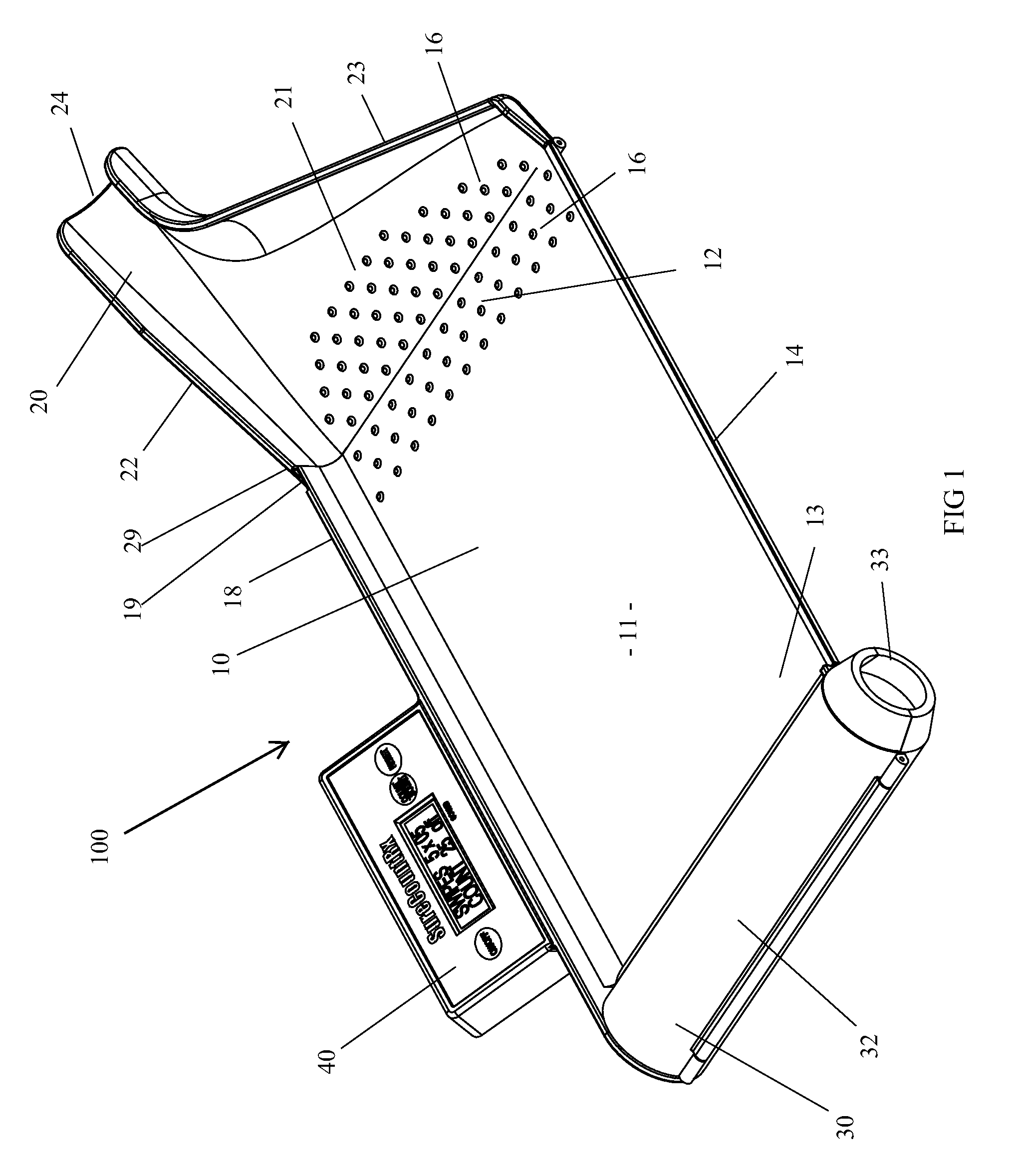

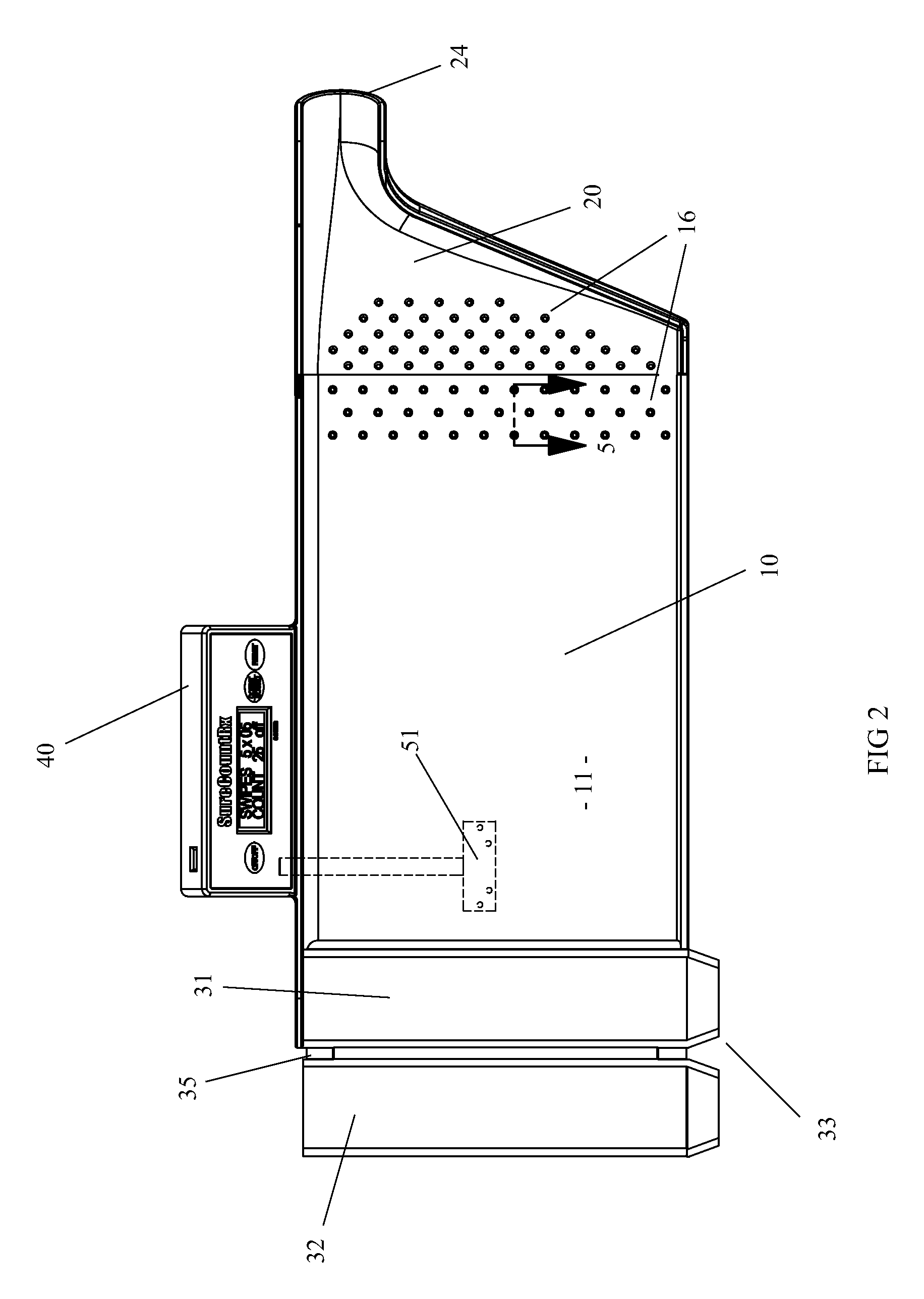

Pill counting tray with digital counter

ActiveUS9241877B2Facilitates ergonomic returnPreventing pill clusteringOral administration deviceTerrainPill count

Owner:EVOLVING INNOVATIONS

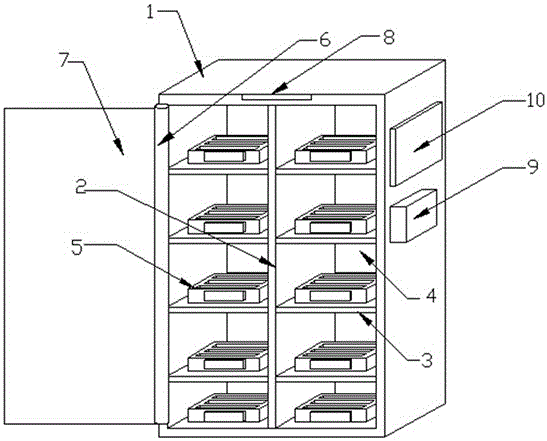

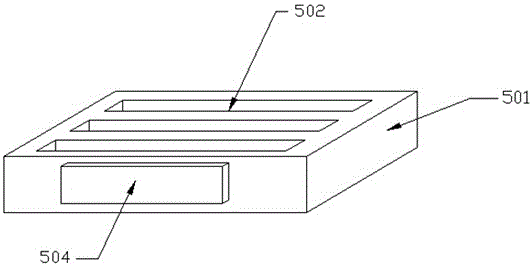

Electric power safety sign board intelligent storage cabinet

The invention discloses an electric power safety sign board intelligent storage cabinet. A plurality of storage tanks are arranged in each storage box, the bottom in each storage tank is provided with a pressure inductor, and a display screen is arranged on one side of each storage box; an electric rotary shaft is arranged on the side edge of a storage cabinet body, a cabinet door is fixed to one side of the electric rotary shaft, and a distance inductor is arranged on the top of the storage cabinet body. When sign boards are placed in the storage tanks of the storage boxes, pressure is exerted on the pressure inductors, a controller can know the number of the sign boards according to pressure of the pressure inductors and displays the number on the display screens and an LED display screen, after a user observes that the number of the sign boards is reduced through the display screens, the number of the sign boards in the storage boxes is increased, and use convenience is improved; the situation that the sign boards are counted manually is avoided; when the distance inductor senses that a person gets close to the storage cabinet, the controller controls the electric rotary shaft to rotate so that the person can conveniently obtain the sign boards.

Owner:STATE GRID CORP OF CHINA +1

Divisible true dual port memory system supporting simple dual port memory subsystems

InactiveUS7269089B1Increase bit densityAvoid countingDigital storageLogic circuitsAudio power amplifierRandom access memory

A random access memory circuit and a method for configuring the same. The circuit includes a first array of memory cells including a first plurality of ports and a second plurality of ports, and a second array of memory cells including a third plurality of ports and a fourth plurality of ports. Additionally, the circuit includes a plurality of switches connected to the first plurality of ports and the third plurality of ports respectively or connected to the second plurality of ports and the fourth plurality of ports respectively. Moreover, the circuit includes a plurality of sense amplifiers and a plurality of write drivers.

Owner:ALTERA CORP

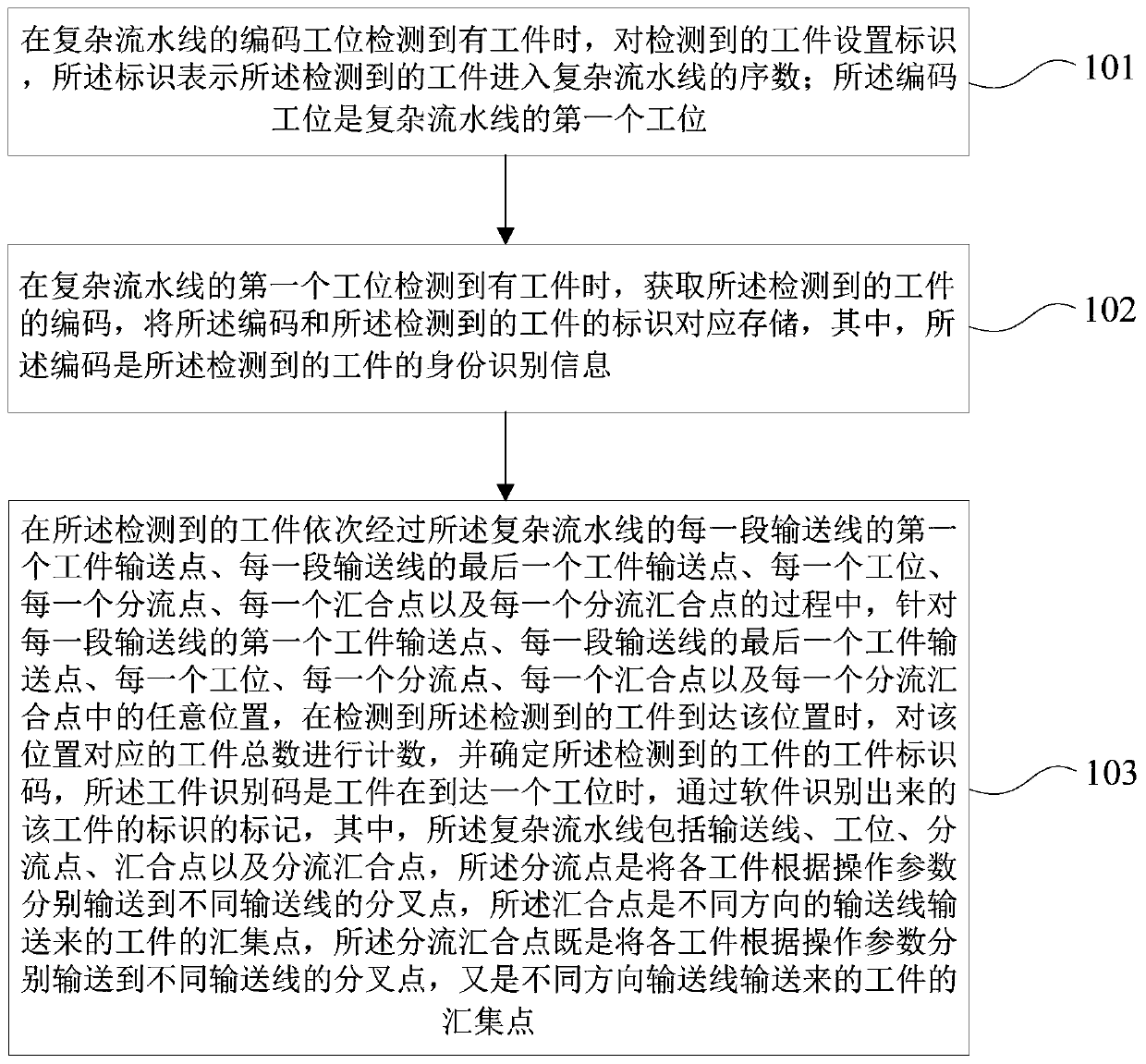

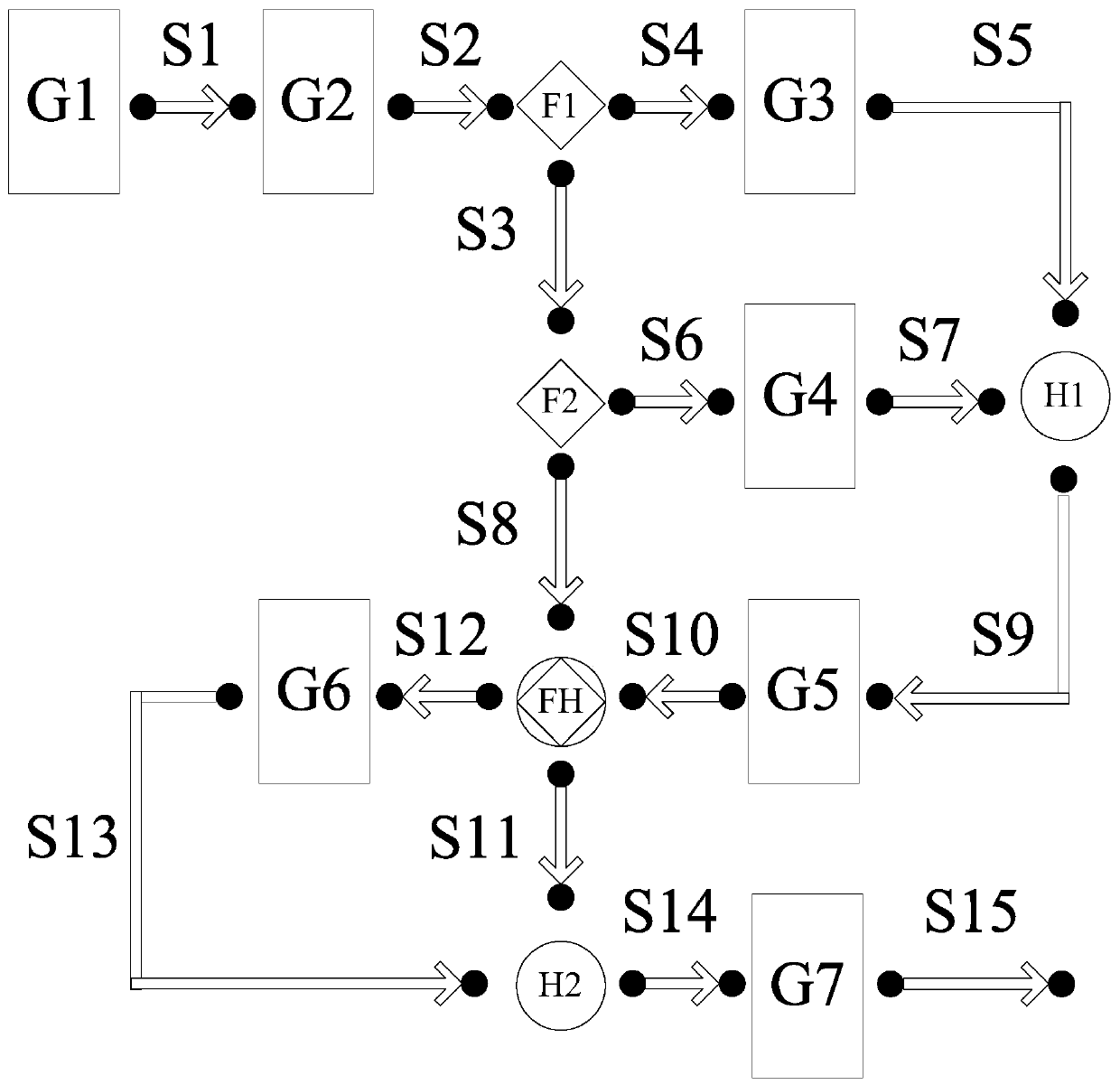

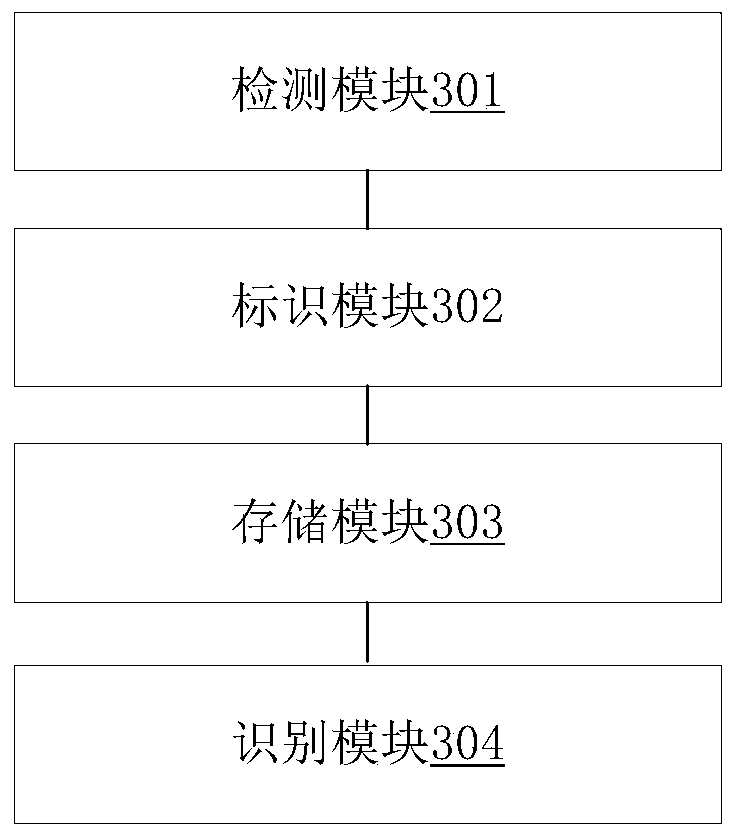

Workpiece detection and intelligent identification method and system for complex assembly line

PendingCN110282405AHigh degree of automationRealize intelligent identificationConveyor partsMechanical conveyorsEngineeringAssembly line

The embodiment of the invention provides a workpiece detection and intelligent identification method and system for a complex assembly line. The method includes the steps that when it is detected that workpieces exist at a first station of the complex assembly line, identifiers are set for the detected workpieces, and the identifiers of the coded and detected workpieces are correspondingly stored; and as for first and last conveying points of each section of the complex assembly line, each station, each flow dividing point, each convergence point and each flow dividing and convergence point, when it is detected that the detected workpieces reach the position, the total number of the workpieces corresponding to the position is counted, and workpiece identification codes of the detected workpieces are determined. By means of the scheme, through station counting and logical deduction calculation, the functions of workpiece quantity measurement, workpiece identification, workpiece inspection and maintenance information querying and workpiece automatic flow dividing and convergence are achieved, the automation degree of the complex assembly line can be improved, the labor cost is reduced, and the error rate caused by manual operation is reduced.

Owner:CHINA OILFIELD SERVICES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com