Patents

Literature

34results about How to "Improve job controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selecting method of primary positioning reference of engine connecting rod

The invention discloses a selecting method of a primary positioning reference of an engine connecting rod. The method comprises the following steps of firstly, selecting the upper end surfaces and the lower end surfaces of head holes as first positioning references, and respectively selecting a small head hole and the outer side as a second positioning reference and a third positioning reference; roughly grinding the upper end surfaces and the lower end surfaces, adopting a mutual reference method to process, and meanwhile during drilling and rough boring of the small head hole, selecting the end surfaces of the small head hole and the contour of a small head as reference surfaces; during finishing operation, adopting a uniform reference method to process, processing the small head hole by taking the end surfaces of a large head hole and the small head hole and the outer side surface of a large head as the uniform precise references, and grinding the upper end surface and the lower surface of the small head hole by taking the upper end surface and the lower surface of the small head hole as the precise references; and selecting the size, direction and action points of clamping force, wherein the direction of the clamping force faces the main positioning surface and the end surfaces of the large head and the small head. The method has the beneficial effects that the stability and easy speed adjusting in the linear movement are realized, the running precision of a machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Simulation experiment method for drilling-blocking prevention of rock drill in cave

InactiveCN102926683AEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesEngineeringDrill

The invention discloses a simulation experiment method for drilling-blocking prevention of a rock drill in a cave. The method comprises the following steps of: firstly, controlling a rod-disassembling mechanism to pressurize a drilling rod to cause a pressure value of rotary pressure to be stabilized to 12MPa; in the process of the simulation of drilling rocks by a down-the-hole drill, controlling a propulsion handle in an operator cab to pressurize a propulsion mechanism to cause a pressure value of propulsion pressure to be stabilized to 8MPa, and simulating a normal propulsion state of the down-the-hole drill in the process of drilling the rocks; controlling the propulsion handle to depressurize the propulsion mechanism to reduce the propulsion pressure to 5MPa suddenly, and simulating a drilling-blocking phenomenon in the cave and wherein a setting value of a pressure relay of a propulsion circuit is 3MPa, which is less than a critical propulsion pressure value of the drilling-blocking prevention in the cave; and drawing a change curve of the propulsion pressure with changes with time in the process. The method provided by the invention has the beneficial effects that the drilling-blocking problem is solved, the normal drilling operation of the rock drill is ensured, the service life of the rock drill is prolonged, and the body of the rock drill can be assisted to be stressed.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Speed adjusting method of hydraulic system transmission mechanism

InactiveCN102954055AMeet the process requirementsHigh movement precisionServomotorsHydraulic motorLogical combination

The invention discloses a speed adjusting method of a hydraulic system transmission mechanism, and the speed adjusting method is characterized by comprising the following steps of installing and determining a hydraulic actuation element, adopting a reversing valve or a logic control unit to control the direction, and adopting a logical combination structure of a cartridge valve and a pilot control valve; adopting a quantitative pump to supply oil, utilizing a flow control valve to change the flow inputting or outputting from the hydraulic actuation element to adjust the speed, and adjusting the speed by changing the displacement of a hydraulic pump or a hydraulic motor; a variable pump is used for supplying the oil in the volume throttling speed adjusting process, utilizing the flow control valve to adjust the flow inputted into or outputted from the hydraulic actuation element, ensuring the oil supply quantity to be equivalent to the oil demand quantity, and determining a circulating form of a loop; and adopting an open circulating way to make the hydraulic pump suck oil from an oil tank, and returning the pressure oil back to the oil tank after releasing the energy through the system. The method has the beneficial effects that different technique requirements of a pressing workpiece can be completely and accurately satisfied, the movement precision of the machine is improved, the abrasion situation is reduced, the service life is prolonged, and the stress of the machine body is assisted.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connecting method of load control dual-pressure system for high-speed punching machine

The invention discloses a connecting method of a load control dual-pressure system for a high-speed punching machine. The connecting method comprises the following steps: firstly, double pressure pumps, namely a high-pressure large-flow pump and a low-pressure small-flow pump, are respectively arranged inside a hydraulic system; an energy accumulator is additionally arranged on an oil path between the low-pressure small-flow pump and a hydraulic cylinder; meanwhile, another energy accumulator is additionally arranged on the oil path between the high-pressure large-flow pump and the hydraulic cylinder as an auxiliary power source; then the set load control dual-pressure system is adopted; rapid movement and punching action of the hydraulic cylinder are achieved by alternative use of the double pumps; simultaneously, a differential connection circuit is additionally arranged on the hydraulic system, and a hydraulically operated direction control valve is additionally arranged to achieve the on / off the differential connection circuit and the unloading of a low-pressure pump. The connecting method has the beneficial effects that the system is stable to move, the speed is easy to adjust, the travel is controllable and the noise is low; the stamping frequency is improved, and the service life is prolonged. Meanwhile, the operation controllability can be improved, and the labor intensity is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Anti-blocking method for hydraulic propulsion circuit of rock drilling machine and rotary circuit in series connection

InactiveCN102926657AEnsure normal drilling workHigh movement precisionDrilling drivesRotary valveFuselage

The invention discloses an anti-blocking method for a hydraulic propulsion circuit of a rock drilling machine and a rotary circuit in series connection. The method comprises the following steps: firstly, arranging an anti-blocking circuit comprising an impactor, a propulsion motor and a rotary motor, wherein an oil way of the impactor is connected with an impacting propulsion pump, a pressure reducing value is arranged outside the propulsion motor, and the rotary motor is connected with a rotary valve; and arranging an anti-blocking valve between the propulsion motor and the rotary motor, wherein the propulsion circuit is that pressure oil of a pump are depressurized to go into a forwarding oil-taking cavity of the propulsion motor, and return oil of the propulsion circuit and the pressure oil of the pump are combined to go into the rotary motor, thus rotary pressure become backpressure, propulsion and rotation of the propulsion motor, thereby forming a series circuit. The method provided by the invention has the beneficial effects of solving drilling-blocking problem advantageously, ensuring normal drilling operation of the rock drilling machine, improving production efficiency, strengthening movement accuracy of the rock drilling machine and reducing wear degree favorably, prolonging the service life and assisting the stress of the body of the rock drilling machine.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Processing method for hydraulic oil tank cylinder barrel of lifter

InactiveCN103016429AImprove work performanceImprove job controllabilityPump assembliesFuel tankChromium coating

The invention discloses a processing method for a hydraulic oil tank cylinder barrel of a lifer. The method comprises the following steps: selecting the material of No.35 or No.45 steel to process the cylinder barrel, adopting No.35 steel with better welding performance when the cylinder barrel, a cylinder cover, a hanging connector and other components are welded together, and modulating after rough processing; adopting a rubber seal ring structure for the cylinder barrel and a piston, adopting H9 / f8 for the matching of the cylinder barrel and the piston, adopting H7 / g6 for the matching if a piston ring is used for sealing, and grinding the inner diameter of the cylinder barrel; and applying a metal chromium coating with the thickness of 30 to 35mMu to the inner surface of the cylinder barrel, and polishing the inner surface of the cylinder barrel after chromeplating; and setting the errors of roundness and cylindricity of the inner diameter of the cylinder barrel to be not greater than a half of the diameter tolerance. The invention has the benefits that the processing method facilitates the improvement on the working effect of an oil tank, is good in safety, can be used in various different occasions, and facilitates the improvement on the operation controllability and the energy-saving effect.

Owner:WUXI YANGGONG MACHINERY MFG

Connecting method of hydraulic parallel type speed transition circuit

InactiveCN102966614AReliable actionHigh positioning accuracyServomotorsHydraulic cylinderDifferential pressure

The invention discloses a connecting method of a hydraulic parallel type speed transition circuit. The connecting method comprises the following steps that firstly, two speed adjusting valves connected in parallel are additionally arranged in a circuit consisting of a hydraulic cylinder and a variable pump, so as to realize a transition circuit with two feeding speeds, and the feeding speeds of the two speed adjusting valves are respectively adjusted; then, hydraulic circuits of the two speed adjusting valves connected in parallel are externally provided with a fixed differential pressure reducing valve, and when one speed adjusting valve works and the other speed adjusting valve has no hydraulic fluid passing, the fixed differential pressure reducing valve is adjusted to the maximum opening position; and a travel valve is additionally arranged in a hydraulic circuit between the two speed adjusting valves and the hydraulic cylinder. The connecting method has the beneficial effects that the hydraulic circuit is simplified, the action is reliable, the precision of the converted position is higher, and the sufficient transition precision is realized.

Owner:无锡九条龙汽车设备有限公司

High-speed punch hydraulic system connection method capable of realizing fast direction change

InactiveCN102950805AHigh movement precisionEasy to processServomotor componentsFluid-pressure actuator componentsHydraulic cylinderPunch press

The invention discloses a high-speed punch hydraulic system connection method capable of realizing fast direction change. Firstly, with a plunger pump in a hydraulic system as a center, a motor and an air filter are respectively arranged on both sides of the peripheral oil circuit of the plunger pump, and meanwhile, a pressure meter is mounted on each component; a valve subsystem which comprises an electromagnetic reversing valve, a check valve, an overflow valve, an energy accumulator and a proportional servo valve is arranged in the oil circuit area between a hydraulic cylinder and the plunger pump, wherein a filter and a cooler are sequentially mounted on the oil circuit between the energy accumulator and the plunger pump; the electromagnetic reversing valve and the check valve are connected in series in the valve subsystem to form a direction control loop, the overflow valve is connected in parallel with the direction control loop, and both ends of the proportional servo valve are directly connected into the peripheral oil circuit of the hydraulic cylinder. The high-speed punch hydraulic system connection method has the advantages that: the system can stably move, the speed of the system can be easily regulated, moreover, the travel of the system can be controlled, noise is reduced, the punching frequency is increased, and the service life is prolonged; meanwhile, the controllability of operation can be enhanced, and labor intensity can be decreased.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Method for setting manipulator rotating mechanism of hydraulic system

InactiveCN102966621AHigh movement precisionEasy to processServomotor componentsServomotorsFuel tankHydraulic circuit

The invention discloses a method for setting a manipulator rotating mechanism of a hydraulic system. The method comprises the following steps that firstly, a section of valve control circuit is additionally arranged between a variable pump and a hydraulic cylinder, a hydraulic control reversing valve is arranged in the valve control circuit, and a swinging motor is arranged in a manipulator rotating hydraulic system; then, a one-way valve and an overflow valve are additionally arranged in a hydraulic circuit connected with the periphery of the motor, and when an electromagnetic valve returns to the middle position, because the pressures at both ends of the cycloidal motor are unbalanced, if the pressure at the left end of the cycloidal motor is larger, the hydraulic fluid flows to a hydraulic tank through the one-way valve and the overflow valve; a three-position and four-way one-way valve is adopted as the one-way valve, and the locking of the hydraulic motor and the buffering of the hydraulic fluid are realized by the additional one-way valve and the overflow valve. The method has the beneficial effects that the stability and the easy speed adjustment in the linear movement are realized, the running precision of the machine is favorably improved, and the service life of the machine is prolonged; and meanwhile, the convenient and flexible arrangement is favorably realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Creation method for simulation model of anti-jamming hydraulic control system of rocker driller

InactiveCN102996109AEnsure normal drilling workHigh movement precisionAutomatic control for drillingAnti jammingEngineering

The invention discloses a creation method for a simulation model of an anti-jamming hydraulic control system of a rocker driller, comprising the following steps of: firstly, setting an analogue load input value of a feed mechanism and an analogue input value of a slewing mechanism to cause the feed mechanism and the slewing mechanism to work in a normal state, and to cause feed pressure to stabilize at 8MPA and slewing pressure to stabilize at 12MPA; inputting a process that the feed pressure is reduced from a normal value into the analogue load of the feed mechanism to carry out cave jammed drilling simulation, wherein when the feed pressure is reduced to a setting value of a pressure relay signal of a feeding loop, an electromagnetic reversing valve acts, a multi-way valve changes direction to push a motor to slew, and the feed mechanism retreats; observing whether the anti-jamming hydraulic control system is capable of preventing cave jammed drilling; and inputting a process that the slewing pressure is increased slowly from a normal value into the analogue load of the slewing mechanism to carry out simulated slow varying jammed drilling. The method disclosed by the invention has the beneficial effects that the method is conductive to solving the problem of jammed drilling, ensures normal drilling work of the rock driller, and is conductive to prolonging service life and assisting driller stressing.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Slowly-varying drilling sticking preventing simulation experimental method of rock chiseling machine

InactiveCN102953692AEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesExperimental methodsFuselage

The invention discloses a slowly-varying drilling sticking preventing simulation experimental method of a rock chiseling machine, and the method comprises the following steps that a down-the-hole drill device is started to work at a normal rock chiseling state and is normally rotated after being normally propelled; then a breakout mechanism is controlled to slowly pressurize a drill rod, so that the rotation pressure is slowly increased to 6MPa so as to simulate the slowly-varying drilling sticking, and the applied pressure is smaller than 20 percent of an adjustment value of a pressure relay of a rotation circuit and greater than 30 percent of an adjustment value of a jamming prevention valve; and through the test, a variation curve of the propelling pressure along the time is drawn in the process. The method has the beneficial effects that the drilling sticking problem is solved, the normal drilling work of the rock chiseling machine is guaranteed, the service life is prolonged, and the stress of a machine body can be assisted.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Method for selecting hydraulic power source of hydraulic system

InactiveCN102966640AMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsFiltrationHydraulic circuit

The invention discloses a method for selecting a hydraulic power source of a hydraulic system. The method comprises the following steps that firstly, a working medium of the hydraulic system is supplied by the hydraulic source, a throttle speed adjusting system is supplied with hydraulic fluid by a quantitative pump, the hydraulic fluid supply quantity of a hydraulic pump is greater than the quantity of hydraulic fluid required by the system, and the excessive redundant hydraulic fluid flows back to a hydraulic tank through an overflow valve; a volume speed adjusting system is supplied with hydraulic fluid by a variable pump, the maximum pressure of the system is limited by a safety valve, the hydraulic fluid supply quantity of the hydraulic pump is matched with the quantity of hydraulic fluid required by the system, and in each phase of work circulation, the hydraulic fluid is supplied by multiple pumps; an accumulator is additionally arranged and is used as an auxiliary hydraulic source, an inlet of the pump is provided with a coarse filter, and according to the requirements of protected elements, the hydraulic fluid entering the system is subjected to secondary filtration by a corresponding fine filter; and a magnetic filter is arranged on a hydraulic circuit, and according to the environments of the hydraulic equipment and the requirements of on temperature raising, the heating and cooling measures are additionally carried out. The method has the beneficial effects that the running precision of the machine is favorably improved, the abrasion is reduced, the service life is prolonged, the force on the machine body is assisted, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Hydraulic anti-sticking method of rock drill propulsion loop

InactiveCN102943644AEnsure normal drilling workHigh movement precisionBorehole/well accessoriesHydraulic motorSpool valve

The invention discloses a hydraulic anti-sticking method of a rock drill propulsion loop. Firstly, a hydraulic control reversing valve is arranged between a working propulsion oil cylinder and a hydraulic motor, and meanwhile, a hydraulic control anti-sticking valve is additionally arranged between the outer end of an oil passage of the hydraulic control reversing valve and the propulsion oil cylinder. The end of the anti-sticking valve is connected with a hydraulic control loop, and is connected with the hydraulic control valve, one of two loops of the hydraulic control valve is connected with a propulsion loop, and the other of the two loops of the hydraulic control valve is connected with a rotary loop by the hydraulic control loop. The hydraulic system is provided with an anti-sticking loop which is connected with a rock impact system, and then a rock drill is automatically in the light impact state. Meanwhile, a valve core of an upper slide valve of the hydraulic control valve is provided with a sealing structure. The hydraulic anti-sticking method has the beneficial effects that the drill sticking problem is favorably solved, the normal drilling operation of the rock drill is ensured, the production efficiency is improved, the operation precision of the machine is favorably improved, the abrasion condition is favorably reduced, the service life is prolonged, the force on a machine body is assisted to bear, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Load calculation method of elevator executive component

InactiveCN102979786AEnsure smooth motionEnsure correctnessFluid-pressure actuator componentsEngineeringCutting force

The invention discloses a load calculation method of an elevator executive component. The load calculation method of the elevator executive component is used for analyzing the load of the actuating component, namely, the main total resistance of four hydraulic cylinders. The total resistance of the oil cylinders to be calculated comprises cutting force resisting working movement, frictional resistance among moving parts, frictional resistance of seal devices, inertia force in a starting and braking or steering process, and resistance generated in an oil return cavity due to crushed effect. The cutting force is the gravity of rated load and the gravity of a support and an upper top board, the seal resistance of the seal devices and the inertia force of the moving parts are calculated, and the seal resistance of the seal devices is relevant to the inertia force of the moving parts. The resistance which each hydraulic cylinder needs to overcome can be known, and the action on a lifting platform from a constant load can be further known. The load calculation method of the elevator executive component has the advantages of being beneficial for guaranteeing the moving stability and accuracy of an executive portion, reasonable in structure, excellent in safety, suitable for various occasions, and meanwhile beneficial for improving operation controllability, and improving energy-saving effect.

Owner:WUXI YANGGONG MACHINERY MFG

Method of sequential acting of execution assemblies of hydraulic system transmission mechanism

InactiveCN102966616AMeet the process requirementsHigh movement precisionServomotorsSolenoid valveHydraulic circuit

The invention discloses a method of sequential acting of execution assemblies of a hydraulic system transmission mechanism. An operation mechanism of an engineering machinery is manually operated, and is controlled by a manual multiway reversing valve, and the sequential acting of each execution mechanism of a processing machinery is controlled by travels. When a working part moves to certain position, an electric signal sent by an electrical travel switch is transmitted to an electromagnet, and the electromagnet is pushed to control the continuous action. A travel valve is arranged and is connected with a corresponding hydraulic circuit, and meanwhile, a time control unit and a pressure control unit are additionally arranged. After a pump normally runs, a delay relay sends an electrical signal to close an unloading valve, and a normal work pressure is established. When one execution element completes the preset action, the pressure in a circuit reaches certain value, and the hydraulic fluid passes through in a way of sending an electrical signal by a pressure relay or opening a sequence valve, so as to start the next action. The method has the beneficial effects that the running precision of the machine is favorably improved, the abrasion is reduced, the service life is prolonged, the force on the machine body is assisted, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connection method for hydraulic direction control valve of hydraulic machine

InactiveCN102937122AHigh movement precisionReduce wear and tearServomotor componentsInlet valveHigh pressure

The invention discloses a connection method for a hydraulic direction control valve of a hydraulic machine. A water inlet valve and a water outlet valve are chosen, the two valves choose balanced pressure relief valves, a guide pressure relief valve with a small diameter is arranged in a main valve, and an upper cavity of the main valve is communicated with high pressure liquids outside a valve cup through holes opened in the valve cup; a valve rod is jacked upward by a lever or a cam, the pressure relief valves are opened, high pressure liquids in the upper cavity are discharged rapidly through a pressure relief valve opening, and the open area of a water guide hole is controlled to be 15% of that of the pressure relief valve opening, so that liquids discharged form the pressure relief valve opening is more than liquids complemented by the water guide hole; and the pressure of the upper cavity restrict the on and off of the main valve after pressure relief, and the open area of the water guide hole is increased increasing strokes of the pressure relief valves. The connection method has the advantages that the improvement of machine operation accuracy and the decrease of abrasion conditions are facilitated, the service life is increased, the machine body stress is assisted, and the like.

Owner:WUXI YANGGONG MACHINERY MFG

Control method for automatic anti-jamming hydraulic system of rock driller

InactiveCN102996091AEnsure normal drilling workHigh movement precisionBorehole/well accessoriesRotary pumpAnti jamming

The invention discloses a control method for an automatic anti-jamming hydraulic system of a rock driller, comprising the following steps that: firstly, an anti-jamming loop which is composed of a propel motor and a rotary motor is arranged, an oil path area which is composed of the propel motor and a propel pump is connected with a sub-system which is composed of an electromagnetic reversing valve, a one-way valve, a control oil supply pump and a handle, the part between the outer side of the rotary motor and a rotary pump is orderly connected with a pressure relay and a hydraulic control multi-way valve; and pressure oil is introduced into the multi-way valve between a rotary loop and the rotary pump, the pressure oil entering the rotary motor positively turns into an oil chamber to cause the rotary motor to rotate forwardly, the pressure relay does not move, and the oil introduced by the control pump orderly passes through the reversing valve, the control handle, and then the control multi-way valve. The control method disclosed by the invention has the beneficial effects that the method is conductive to solving the problem of jammed drilling, ensures normal drilling work of the rock driller, is capable of improving production efficiency, is conductive to improving driller movement precision and reducing wear condition, and is capable of prolonging service life and assisting driller stressing.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Precise basis type production processing flow for engine connecting rod

The invention discloses a precise reference type production processing flow for an engine connecting rod. The production processing flow comprises the following steps of firstly, carrying out the first phase of processing before cutting of a connecting rod body and a cover, respectively carrying out blank inspection, magnetic particle inspection and rough drilling of a small-end hole, and preparing for the processing of upper and lower end surfaces, the small-end hole, two planes at bolt hole ends, an outer surface of a large-end hole, and the like in the precise basis way; then, carrying out processing after cutting of the connecting rod body and the cover, roughening the large-end hole, except for precise referencebasis, and preparing for the roughening of the bolt hole and the combining surface, and the processing of a bearing counterbored groove; and carrying out processing after cutting of the connecting rod body and the cover, and sequentially carrying out the finishing of the large-end hole after the assembly of the connecting rod, the finishing of the upper and lower end surfaces, and the finishing of the large-end hole and the small-end hole. The production processing flow has the beneficial effects that the speed of the linear movement can be smoothly adjusted, the running precision of the machine is favorably improved, the service life of the machine is prolonged, the arrangement is conveniently and flexibly realized according to requirements, the operation controllability is improved, and the labor strength is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connecting method of hydraulic system pressure reducing loop of hydraulic test bench

InactiveCN102927090AReliable actionHigh positioning accuracyFluid-pressure actuator componentsHydraulic cylinderWorking pressure

The invention discloses a connecting method of a hydraulic system pressure reducing loop of a hydraulic test bench. The connecting method comprises the following steps : a constant-value pressure reducing valve is connected in series with peripheral branch of a low-pressure pump of a hydraulic system oil channel; a second pressure reducing valve is connected in parallel to a branch opposite to the constant-value pressure reducing valve; the second pressure reducing valve can be adjusted so as to provide a stable working pressure to a branch, wherein the stable working pressure is less than the pressure setting value of the system; the branch is connected with a control oil channel of a working clamping, guide rail lubricating and hydraulic system; an one-way valve is arranged at one side of the second pressure reducing valve in the pressure reducing loop, so that the pressure of a hydraulic cylinder can be prevented from being interfered by the pressure of a main oil channel once the pressure of the main oil channel is less than the setting value of the constant-value pressure reducing valve. The connecting method has the beneficial effects that the oil channel is simplified, the reliability in action is ensured, higher precision in switching position is achieved, and sufficient changing-over precision can be obtained.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

A method for setting up a manifold block of a hydraulic device

ActiveCN102954065BMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsSuperimpositionControl valves

The invention discloses a method for setting up an integrated block of a hydraulic device, and the method is characterized by comprising the following steps that cast iron or forged steel is adopted as an integrated material, a block body is machined into a cubic structure, and a superimposition form of multiple integrated blocks is adopted for the situation that the hydraulic system is complicated and multiple control valves exist; an upper surface and a lower surface of each superimposed integrated block are respectively set as a superimposition joint surface and simultaneously provided with a common pressure oil hole, a leak oil hole and three bolt holes; and one side surface of four surfaces of the integrated block is communicated with an oil pipe of a hydraulic actuation element, the other three side surfaces are used for installing a hydraulic valve, and a hole which is communicated with each valve is drilled inside the block body according to the requirement of a system diagram; and the installation position of the valve makes the communicated oil holes stay on the same horizontal plane as far as possible. The method has the beneficial effects that the movement precision of the machine is improved, the service life is prolonged, and the stress of the machine body is assisted; and the operation controllability is improved, and the labor intensity is alleviated.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connection method for upper top plate structure of lift

InactiveCN102942094AImprove manufacturing precisionImprove job controllabilityBuilding liftsEngineeringControllability

The invention discloses a connection method for an upper top plate structure of a lift. The upper top plate is directly contacted with a load, the structure is welded by a plurality of mutually intersected perpendicular hot rolling channel steels in a welding manner, and auto sheets of 4000mmx2000mmx3mm are spread on the four side faces and the upper top face of each channel steel; four NO.16 hot rolling channel steels are arranged along the length direction of the upper top face of a platform, six NO.10 hot rolling channel steels are arranged along the width direction of the upper top face of the platform, and thus the upper top plate is formed; and a sliding groove for assembling an upper support and a lower support is processed on the foremost outer periphery along the length direction to facilitate the assembly of the upper support and the lower support. The connection method has the beneficial effects that the movement stability and correctness of execution parts are facilitated to be guaranteed, the manufacture precision is improved, the cost is lowered, meanwhile the improvement of operation controllability and energy-saving effect are facilitated.

Owner:WUXI YANGGONG MACHINERY MFG

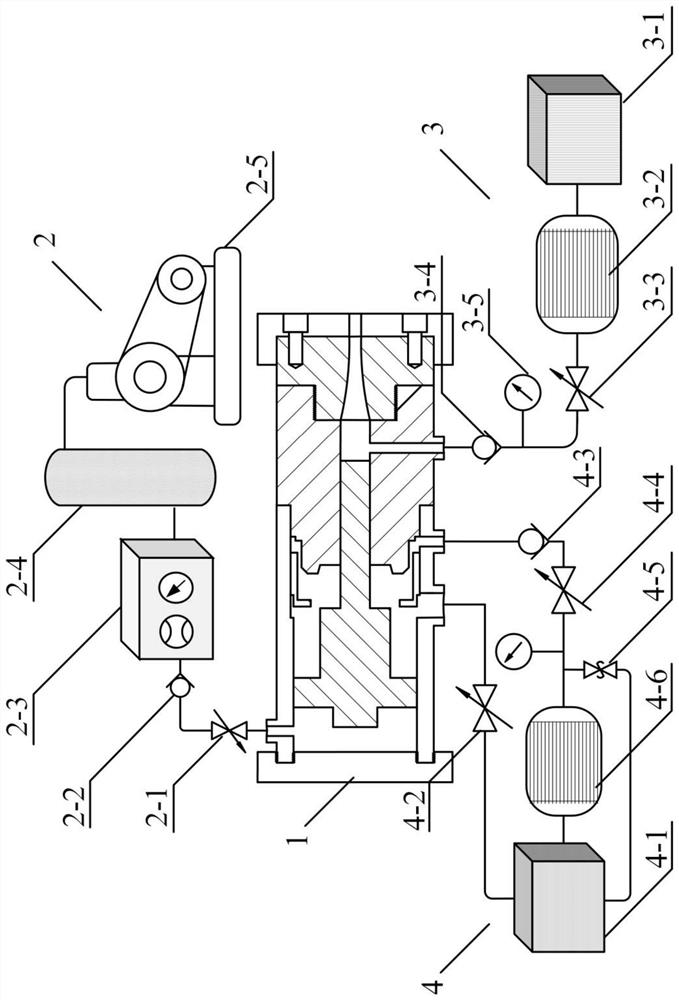

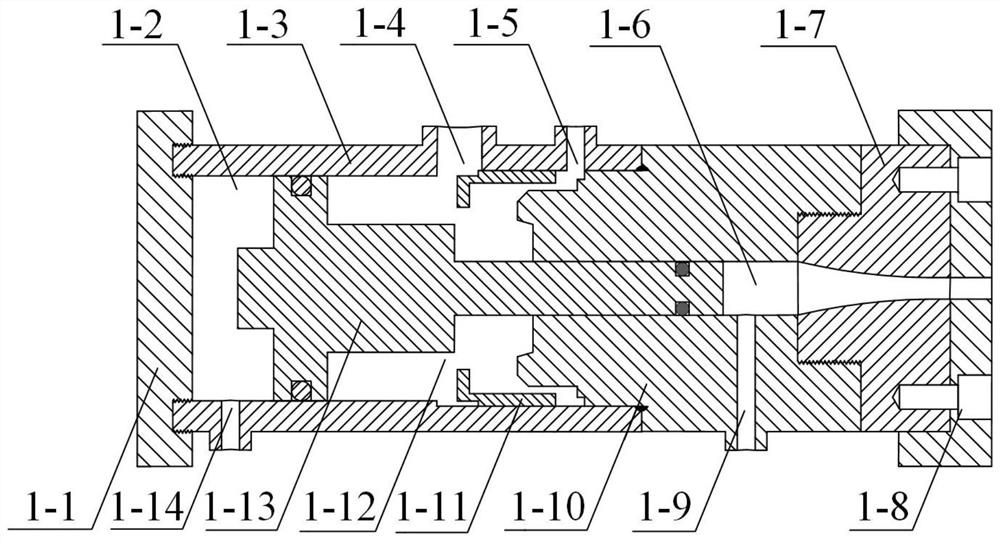

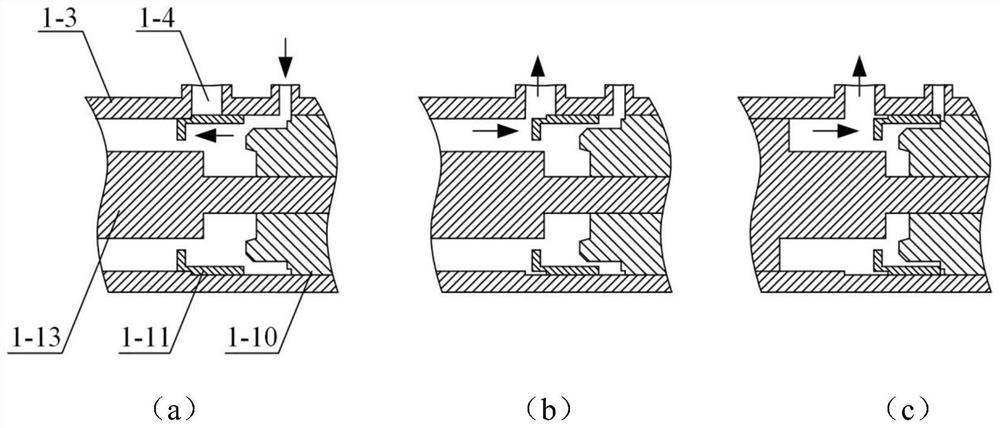

A high-voltage pulse-focused jet generating system and its application method

ActiveCN111520076BImprove crushing effectReduce energy consumptionLiquid/gas jet drillingFlushingEngineeringHigh voltage pulse

The invention discloses a high-voltage pulse energy-gathering jet generating system and its application method. The system includes a high-pressure pulse energy-gathering jet generator, a gas supply system, a fluid supply system and a hydraulic oil supply system. The high-voltage pulse energy-gathering generator includes a rear End cover, pressure cylinder, piston, sliding sleeve, piston sleeve, energy-concentrating nozzle and front end cover, this system can adjust the delivery pressure of the air source supply system according to different rock hardness conditions, and can form the maximum pressure without increasing power consumption The high-pressure pulsed energy-concentrating jet that is several times stronger than the rock can achieve efficient crushing of hard rock formations and improve the efficiency of hard rock roadway excavation.

Owner:JIANGSU ZHONGJI MINE EQUIP

Simulation experiment method for drilling-blocking prevention of rock drill in cave

InactiveCN102926683BEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesEngineeringDrill

The invention discloses a simulation experiment method for drilling-blocking prevention of a rock drill in a cave. The method comprises the following steps of: firstly, controlling a rod-disassembling mechanism to pressurize a drilling rod to cause a pressure value of rotary pressure to be stabilized to 12MPa; in the process of the simulation of drilling rocks by a down-the-hole drill, controlling a propulsion handle in an operator cab to pressurize a propulsion mechanism to cause a pressure value of propulsion pressure to be stabilized to 8MPa, and simulating a normal propulsion state of the down-the-hole drill in the process of drilling the rocks; controlling the propulsion handle to depressurize the propulsion mechanism to reduce the propulsion pressure to 5MPa suddenly, and simulating a drilling-blocking phenomenon in the cave and wherein a setting value of a pressure relay of a propulsion circuit is 3MPa, which is less than a critical propulsion pressure value of the drilling-blocking prevention in the cave; and drawing a change curve of the propulsion pressure with changes with time in the process. The method provided by the invention has the beneficial effects that the drilling-blocking problem is solved, the normal drilling operation of the rock drill is ensured, the service life of the rock drill is prolonged, and the body of the rock drill can be assisted to be stressed.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connection method of hydraulic system by adopting hydraulic control one-way locking loop

InactiveCN102996573AReliable actionHigh positioning accuracyServomotor componentsHydraulic cylinderInlet channel

The invention discloses a connection method of a hydraulic system by adopting a hydraulic control one-way locking loop. The connection method is that hydraulic locks are connected in series with oil channels on two sides of a hydraulic cylinder; pistons are adjusted to realize the capacity of being locked for a long time in any positions in the route and can not move due to external reasons; the locking precision is adjusted according to the leaking and the oil compressing performance of the hydraulic cylinder; a reversing valve is connected with the outer part of a variable pump and can be used for switching off an oil inlet channel and an oil outlet channel of an executive element so as to prevent moving due to the external reasons after stopping moving; an O-shaped structure of a three-way reversing valve is adopted and is used for sealing two chambers of the hydraulic cylinder; and the arranged reversing valve is provided with an H shaped structure. The connection method has the beneficial effects that the oil channels are simplified, the reliability of action is ensured, the position reversing precision is relatively high, and the sufficient switching precision can be gained.

Owner:无锡九条龙汽车设备有限公司

Method for increasing energy utilization rate of hydraulic system in field of ship building

InactiveCN102963025AHigh movement precisionMeet the process requirementsPressesWorking fluidEngineering

The invention discloses a method for increasing the energy utilization rate of a hydraulic system in the field of ship building. In the aspect of operation, a piston type main work cylinder is arranged for hydraulic press and return; a floating ejector cylinder is arranged for reversely pulling a hydraulic flange and respectively carrying out micro adjustment operation, manual operation and semiautomatic operation; in the aspect of travel speed, the assisting time is saved by quick idle running motion and a pressure-maintaining and time-delaying system is required to be arranged so as to meet the specific process requirement; the pressure of work fluid is maintained at 25-30MPa or a lower work pressure value or higher work pressure value of an interval is selected according to the difference of unit deformation pressure of a workpiece; the a hydraulic pressure is subjected to pressure classification; and finally, pressure pre-relieving is carried out on the main cylinder so as to reduce the impact vibration during return. The method disclosed by the invention has the beneficial effects that due to the adoption of the mode, various process requirements of pressed workpieces can be met comprehensively and accurately, the improvement of the motion precision of the machine and the reduction of wear conditions are facilitated, the service life can be prolonged, the stress of the machine body is assisted and the like.

Owner:WUXI YANGGONG MACHINERY MFG

A method for preventing jamming in series with hydraulic propulsion circuit and slewing circuit of rock drilling machine

InactiveCN102926657BEnsure normal drilling workHigh movement precisionDrilling drivesRotary valveFuselage

The invention discloses an anti-blocking method for a hydraulic propulsion circuit of a rock drilling machine and a rotary circuit in series connection. The method comprises the following steps: firstly, arranging an anti-blocking circuit comprising an impactor, a propulsion motor and a rotary motor, wherein an oil way of the impactor is connected with an impacting propulsion pump, a pressure reducing value is arranged outside the propulsion motor, and the rotary motor is connected with a rotary valve; and arranging an anti-blocking valve between the propulsion motor and the rotary motor, wherein the propulsion circuit is that pressure oil of a pump are depressurized to go into a forwarding oil-taking cavity of the propulsion motor, and return oil of the propulsion circuit and the pressure oil of the pump are combined to go into the rotary motor, thus rotary pressure become backpressure, propulsion and rotation of the propulsion motor, thereby forming a series circuit. The method provided by the invention has the beneficial effects of solving drilling-blocking problem advantageously, ensuring normal drilling operation of the rock drilling machine, improving production efficiency, strengthening movement accuracy of the rock drilling machine and reducing wear degree favorably, prolonging the service life and assisting the stress of the body of the rock drilling machine.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Method for setting up integrated block of hydraulic device

ActiveCN102954065AMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsSuperimpositionEngineering

The invention discloses a method for setting up an integrated block of a hydraulic device, and the method is characterized by comprising the following steps that cast iron or forged steel is adopted as an integrated material, a block body is machined into a cubic structure, and a superimposition form of multiple integrated blocks is adopted for the situation that the hydraulic system is complicated and multiple control valves exist; an upper surface and a lower surface of each superimposed integrated block are respectively set as a superimposition joint surface and simultaneously provided with a common pressure oil hole, a leak oil hole and three bolt holes; and one side surface of four surfaces of the integrated block is communicated with an oil pipe of a hydraulic actuation element, the other three side surfaces are used for installing a hydraulic valve, and a hole which is communicated with each valve is drilled inside the block body according to the requirement of a system diagram; and the installation position of the valve makes the communicated oil holes stay on the same horizontal plane as far as possible. The method has the beneficial effects that the movement precision of the machine is improved, the service life is prolonged, and the stress of the machine body is assisted; and the operation controllability is improved, and the labor intensity is alleviated.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Method for drawing combined hydraulic system diagram

InactiveCN102966638AMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsEngineeringControllability

The invention discloses a method for drawing a combined hydraulic system diagram. The hydraulic system diagram of an overall unit is formed by combination of control circuits and a hydraulic source, repeated and redundant elements are eliminated when the circuits are combined together, and an interlocking relationship of the elements is drawn; a stage for maintenance and monitoring the hydraulic system is set, and necessary detection elements are arranged on major paths of the system; standard pieces are adopted by hydraulic elements, the diagram is drawn according to normal states of the specified functional symbols of the hydraulic elements, self-designed non-standard elements are added, and a structural schematic drawing is drawn; and finally, the name and the action of every hydraulic actuating element are marked in the system diagram, the serial number of every hydraulic element and the code of every electromagnet are marked, and a table of actions of the electromagnets, stroke valves and control elements are attached. The method has the beneficial effects that: the method is conducive to improvement of the accuracy of machine movement, the service life can be prolonged, the force-bearing condition of the machine body can be improved, the operational controllability can be enhanced, and the labor intensity can be reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Hydraulic oil tank structure of milling device

InactiveCN102954054AHigh movement precisionEasy to processPump assembliesMilling equipment detailsAir filterFlange

The invention discloses a hydraulic oil tank structure of a milling structure, and the hydraulic oil tank structure is characterized in that an entire oil tank body is in a box body structure formed by a hexagonal structure, the volume of the oil tank is set to be 40L, the ratio of the length, to the width and to the height is 2:1:1, preferably the length, the width and the height are respectively of 500mm, 250mm and 250mm, and simultaneously meanwhile the thickness of the tank wall is 3mm; the bottom of the box body is fixedly provided with a heater through two U-shaped pipes, and the end surfaces of the heater is are fixedly connected through a flange; and an air filter is installed above an oil tank cover, a filter device is installed inside the air filter, an oil filling port filter screen is arranged on the corresponding position, and the size of the filter screen is 0.4mm. The hydraulic oil tank structure has the beneficial effects that the linear movement is steady and easy for adjusting the speed, and the movement precision of the machine can be improved; and meanwhile, convenience and flexibility in arrangement can be favored.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Hydraulic cylinder piston rod seal structure of punch hydraulic system

InactiveCN102943881AHigh movement precisionImprove mechanical propertiesEngine sealsHydraulic cylinderPunch press

The invention discloses a hydraulic cylinder piston rod seal structure of a punch hydraulic system. Firstly, a piston rod and an end cover are sealed by utilizing a bilabial shaft Y-shaped seal ring with the model of MA39; the Y-shaped seal ring is provided with a cut angle less than 45 degrees; double lips are asymmetrical; a baffle ring is arranged outside one sealing lip so as to facilitate the upward sealing effect of the piston rod; and the Y-shaped seal ring is made of polyurethane AU92, the maximum working pressure is set as 50MPa, the temperature is between minus 30 DEG C and 800 DEG C, the movement velocity is less than 0.4m / s. The hydraulic cylinder piston rod seal structure has the beneficial effects of improving the mechanical property, avoiding the abrasion, ensuring the stable movement, easy speed regulation and controllable stroke of a system, reducing noises, improving the stamping frequency, improving the movement accuracy of machines and prolonging the service life; and meanwhile, the hydraulic cylinder piston rod seal structure is conductive to adapting to the requirements of transportation, installation and rack regulation, and can be used for improving the operation controllability and reducing the labor intensity.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com