Patents

Literature

39results about How to "Miniaturization possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

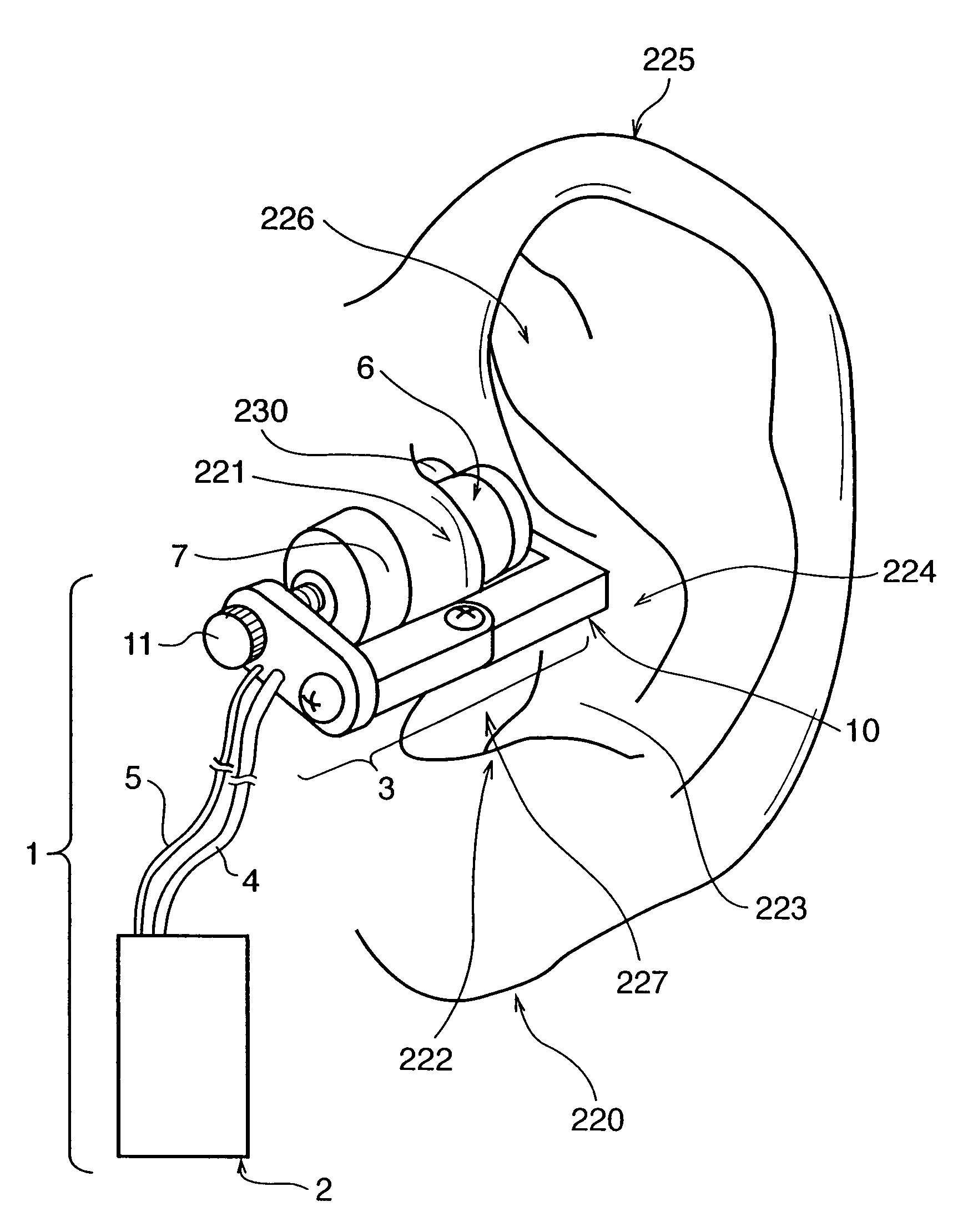

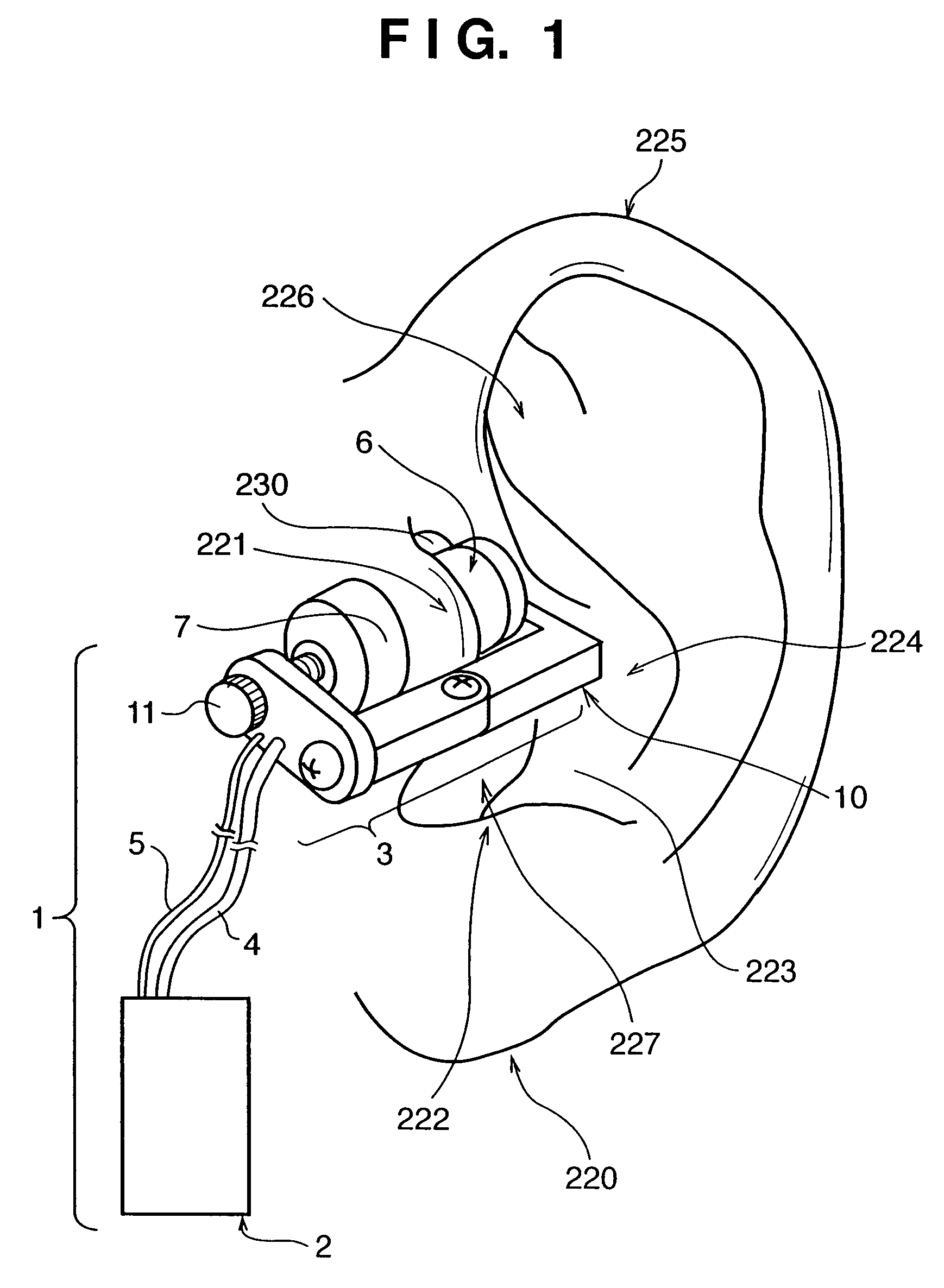

Blood pressure measuring apparatus

ActiveUS7695440B2Easy to installAccurate blood pressureCatheterDiagnostic recording/measuringBlood pressure kitMedicine

A blood pressure measurement apparatus which can install cuffs at a tragus that has differences includes a holding member 3 having a shape part 52 to be installed in a space between an auricular concha and an antihelix, a first protrusion 54 extended from the shape part such that the first protrusion is directed towards the ear hole, a second protrusion 55 extended from the shape part such that the second protrusion is nearly right-angled with respect to the first protrusion and the second protrusion steps over the tragus, an integral member 50 having an ear hook part 51 that is extended from the shape part, the ear hook is integrally made with the integral member or made as an independent member, inner cuff 6 is supported at the end portion of the first protrusion, support member 15 is attached at the end portion of the second protrusion, cuffs 6,7 are attached to the support member through a clamping width adjustment part 11 that makes a clamping width adjustment against the tragus possible.

Owner:TERUMO KK +1

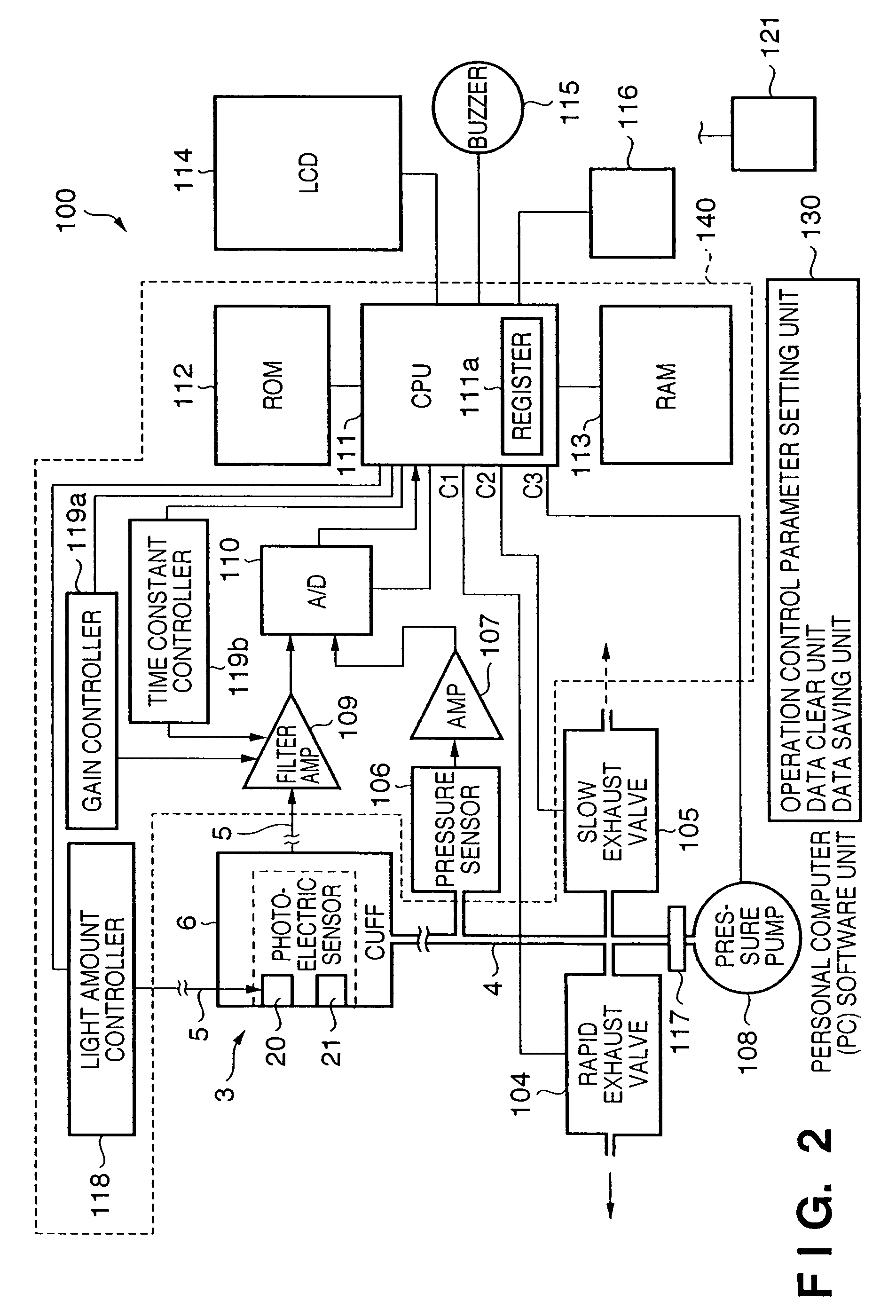

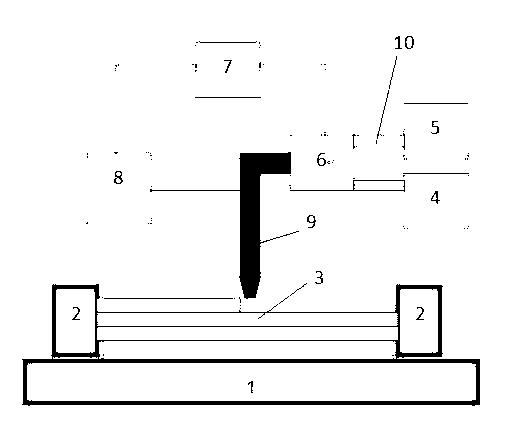

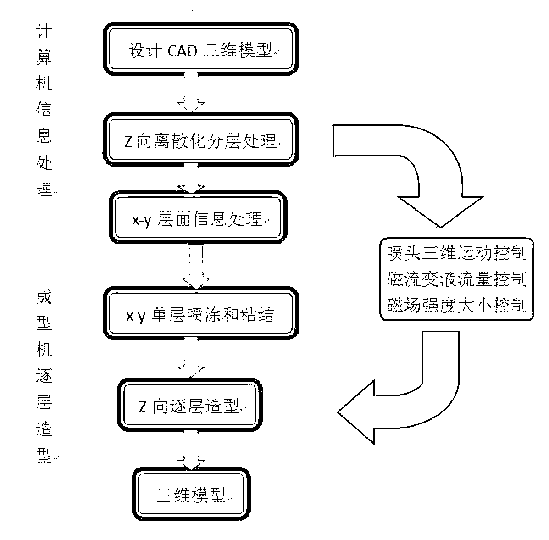

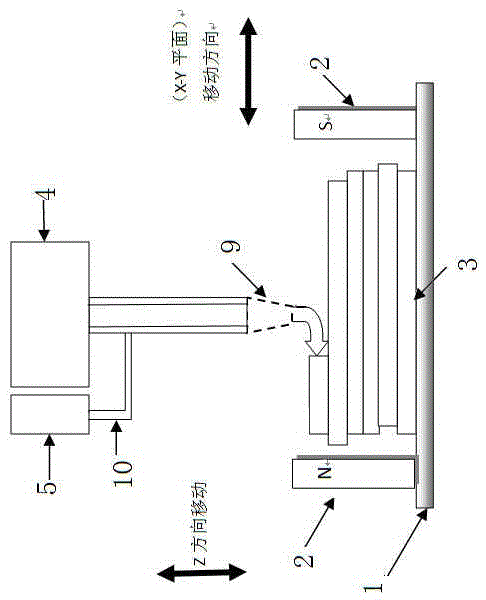

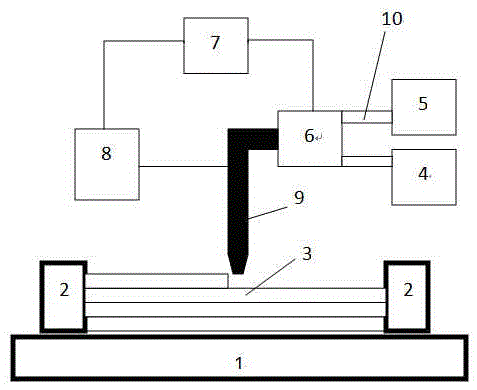

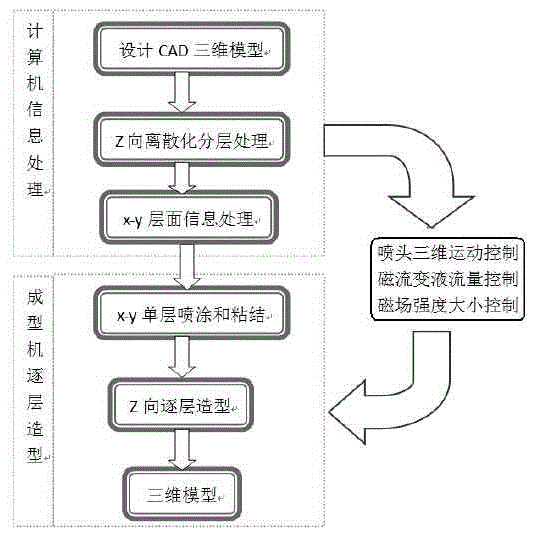

Magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping device and method

The invention relates to a magnetorheological-material-based 3D (Three-Dimensional) printing type rapid prototyping method and device. According to the principle of magnetorheological effect, a magnetorheological material is used as a 3D printing raw material; and a 3D solid model is constructed by spraying the magnetorheological material on a workbench with a magnetic field, rapidly solidifying and prototyping the sprayed magnetorheological material, and then depositing the treated material layer by layer. A computer is provided with three control circuits; one circuit is used for controlling the flow of a driving pump, namely the flow at a spray head; another circuit is used for controlling the 3D motion of the spray head through a servo mechanism; and the rest circuit is used for controlling colour mixing and allocating of a colourized ink box. The magnetorheological material is solidified and prototyped by utilizing the magnetic field generated by an electromagnet. According to the magnetorheological effect of the magnetorheological material, a temperature control module in the traditional melting, spraying and rapid prototyping type 3D printing method is replaced by the magnetic field; in addition, the device disclosed by the invention is also different from a high-pressure electric field required by an electrorheological fluid effect, has the advantages of being simple in structure, low in energy consumption and cost, capable of realizing the microminiaturization and the like, and can be applicable to the fields of process design, art and entertainment, prosthesis model and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

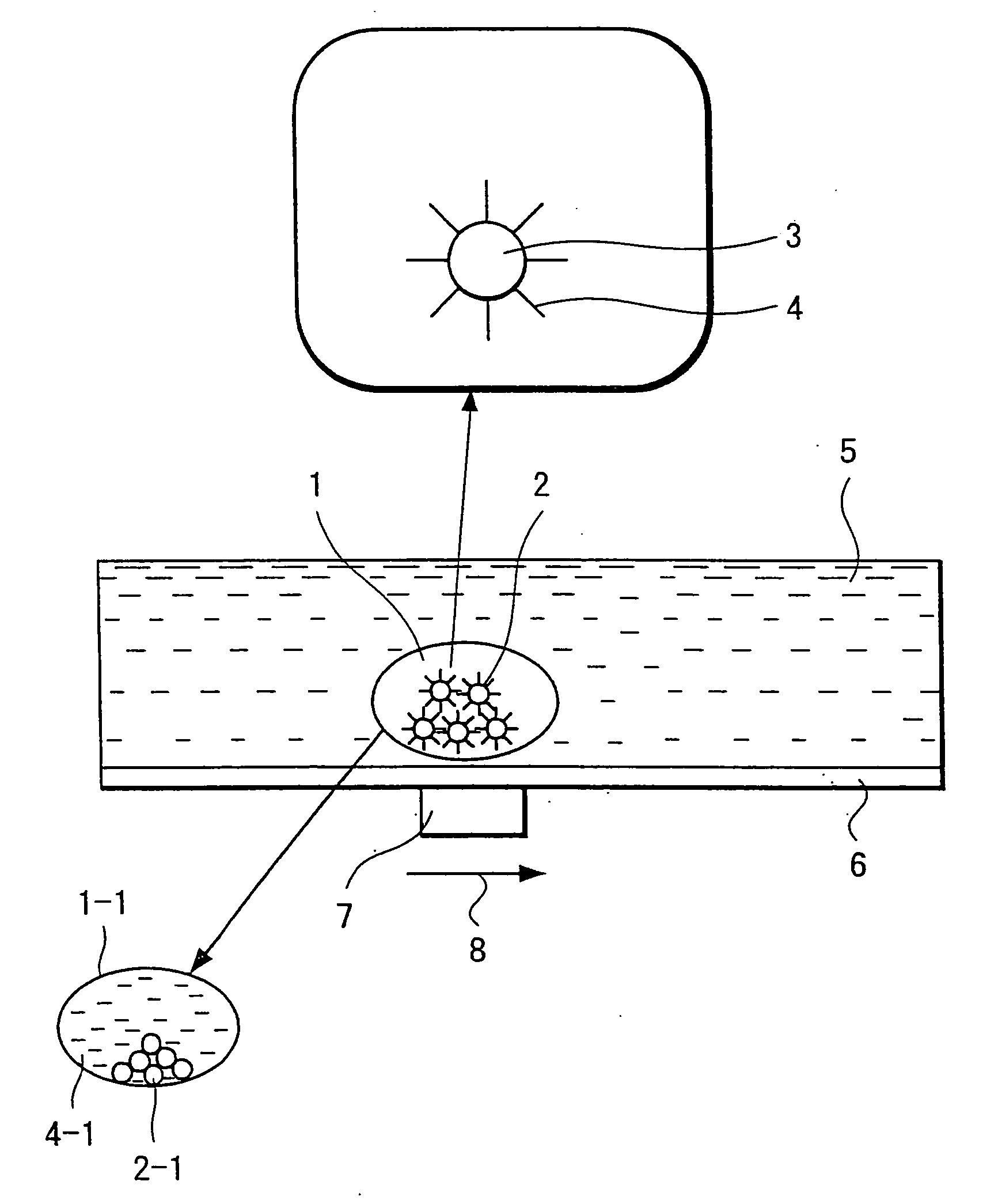

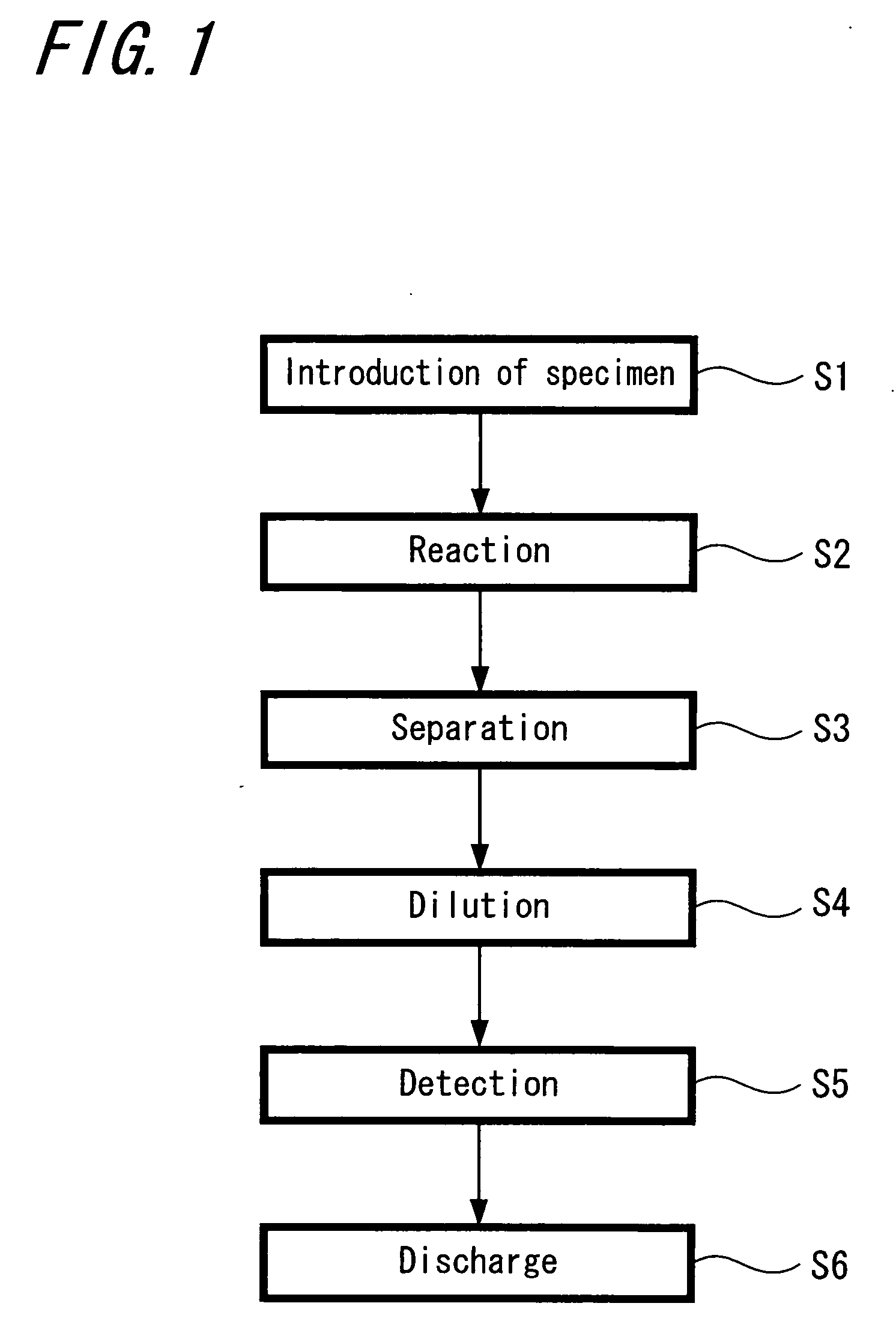

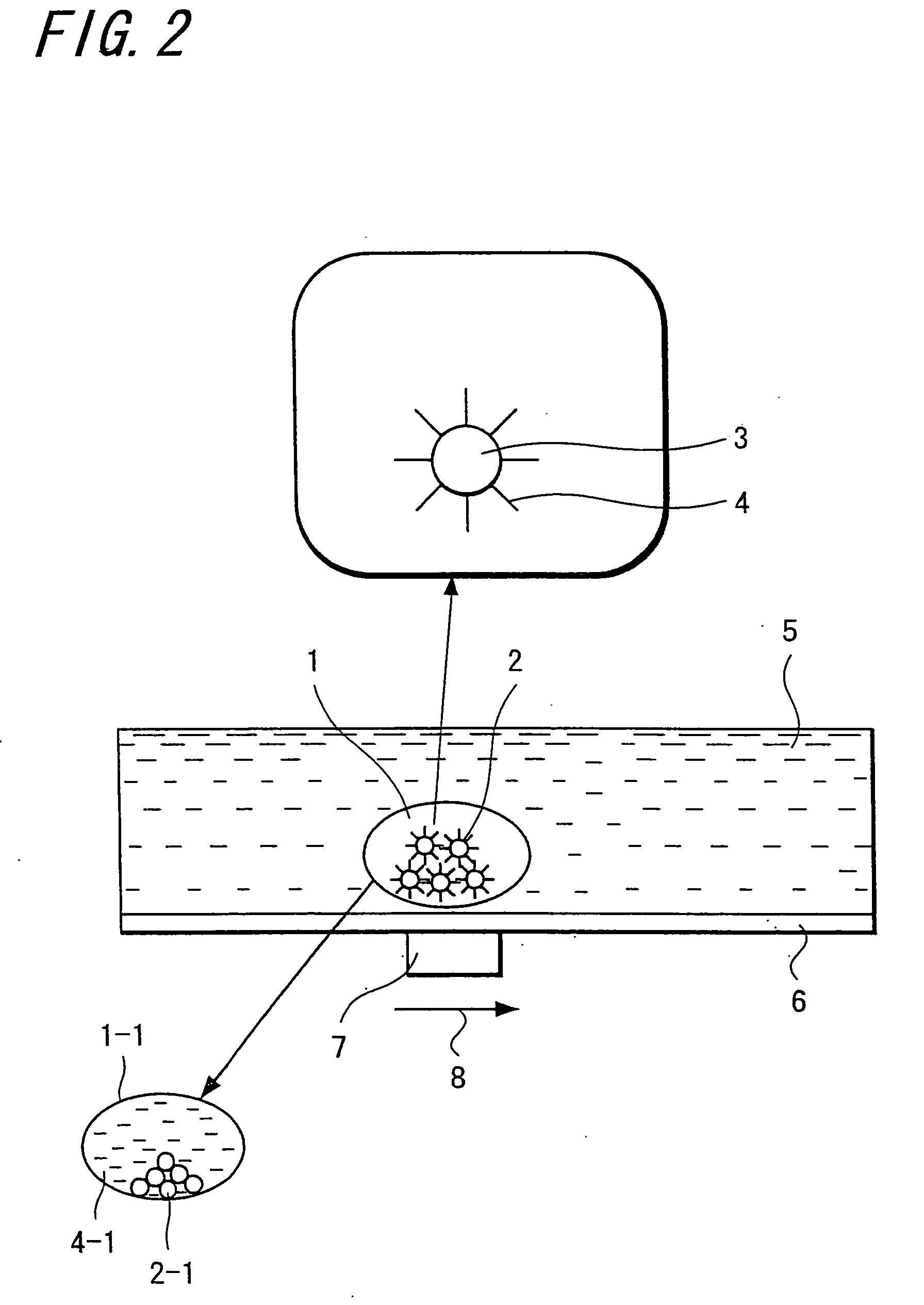

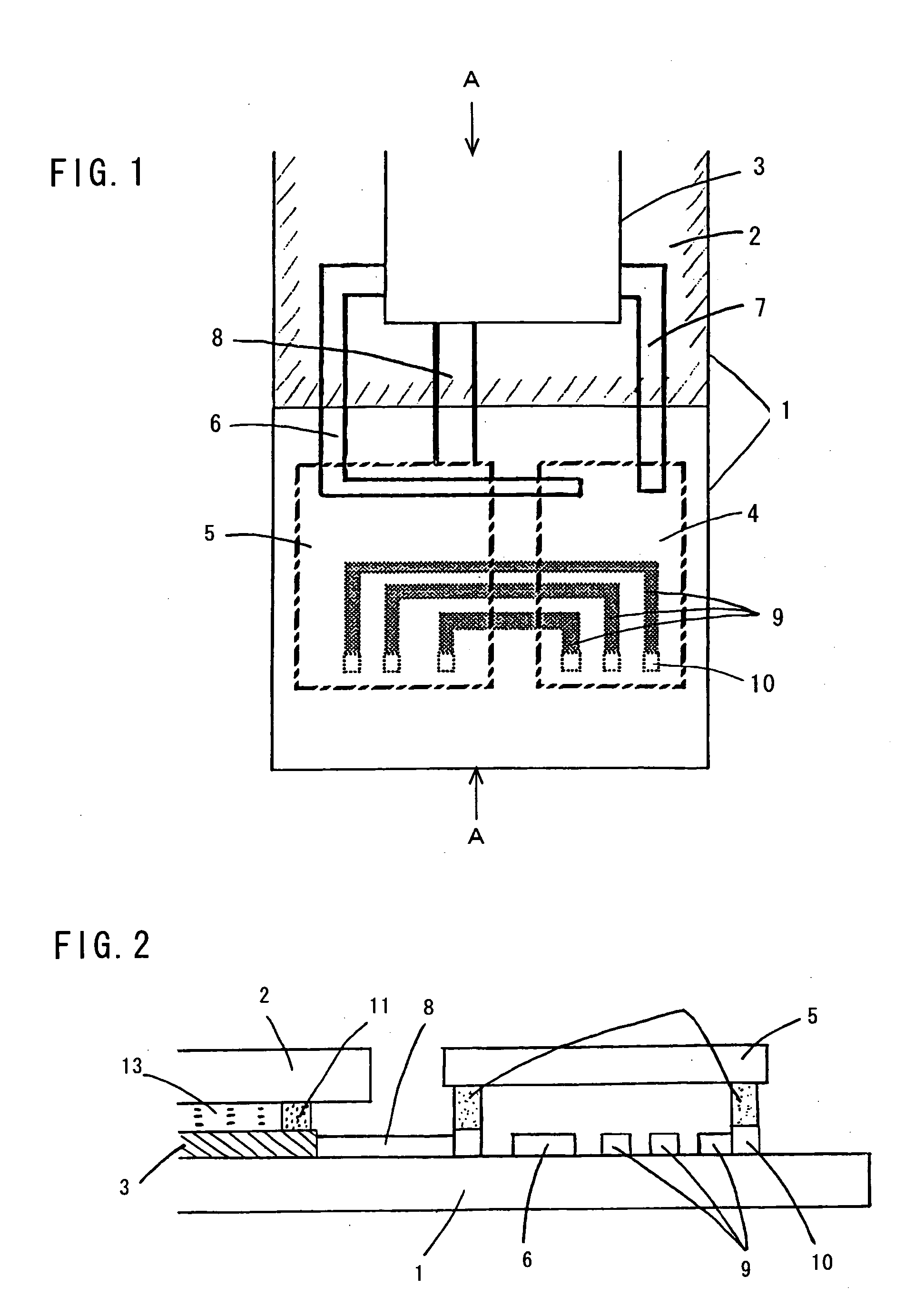

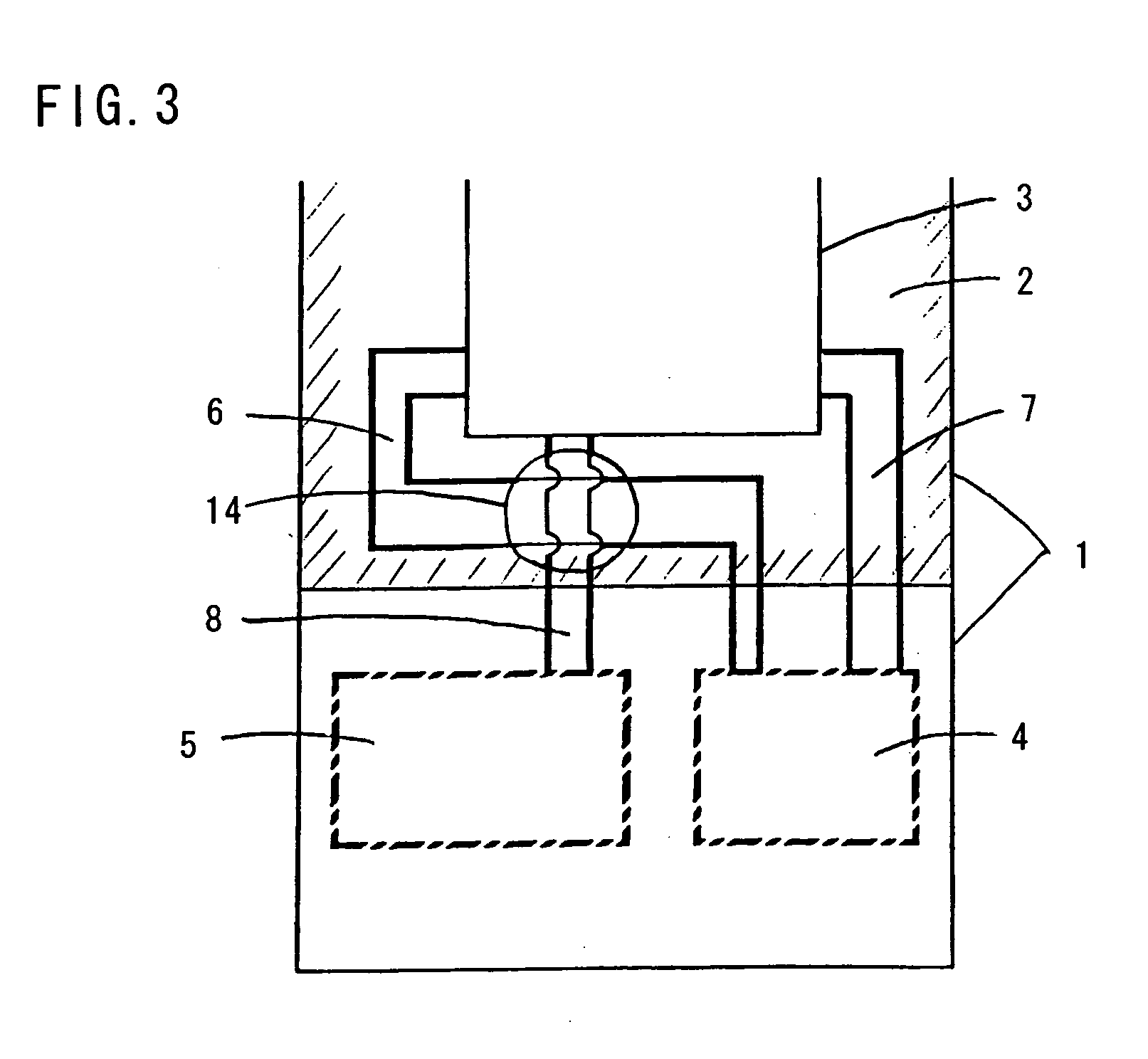

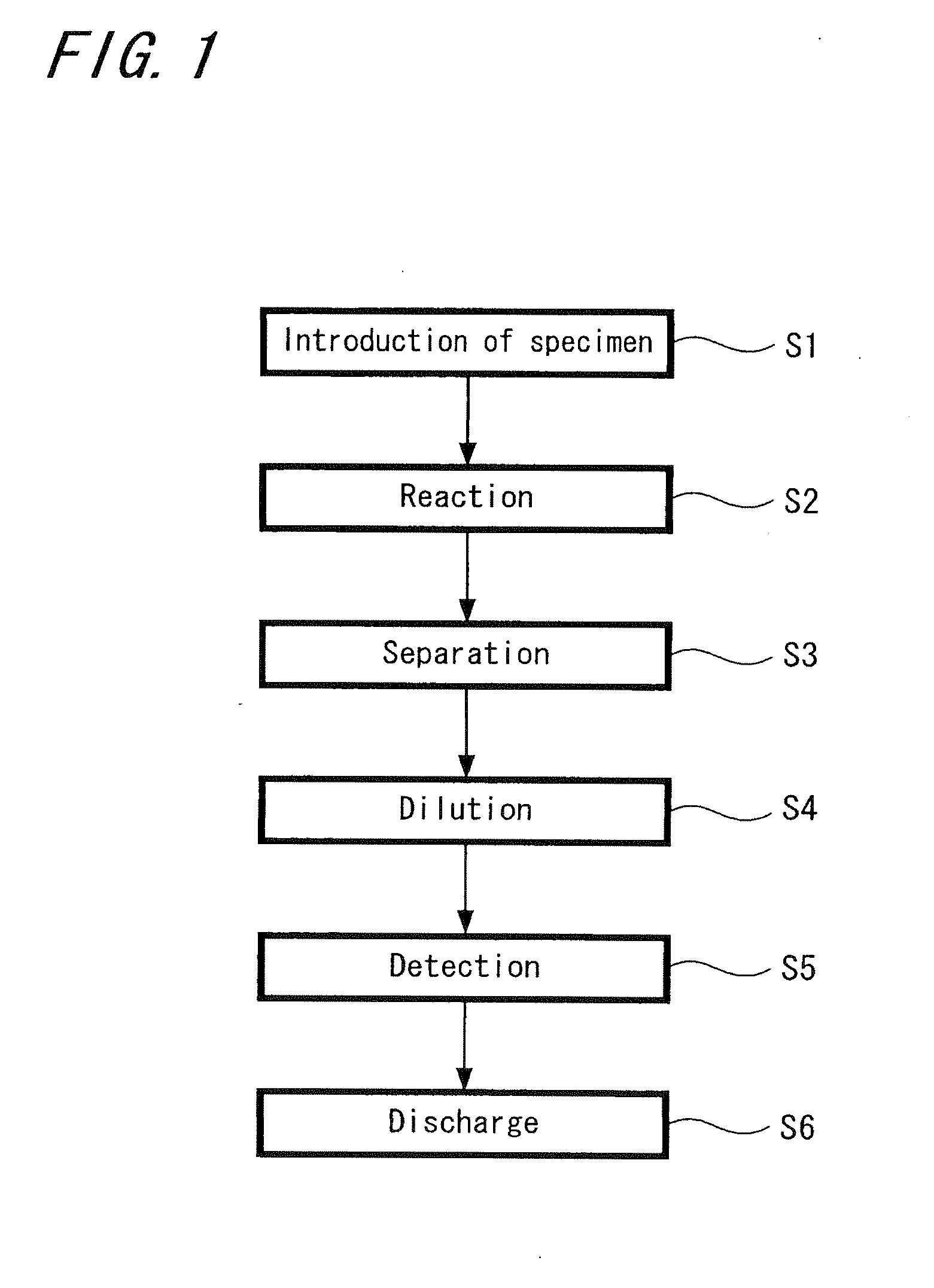

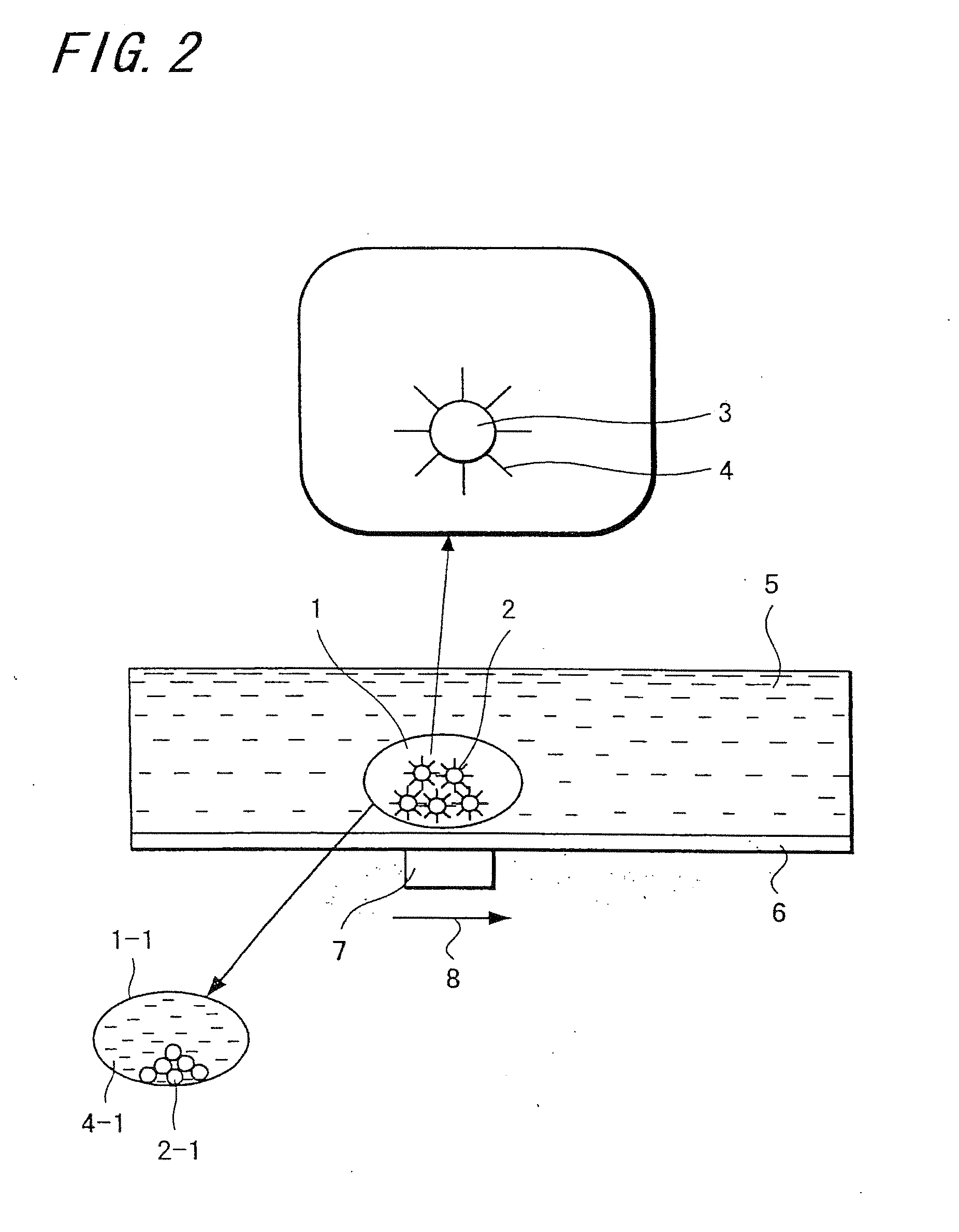

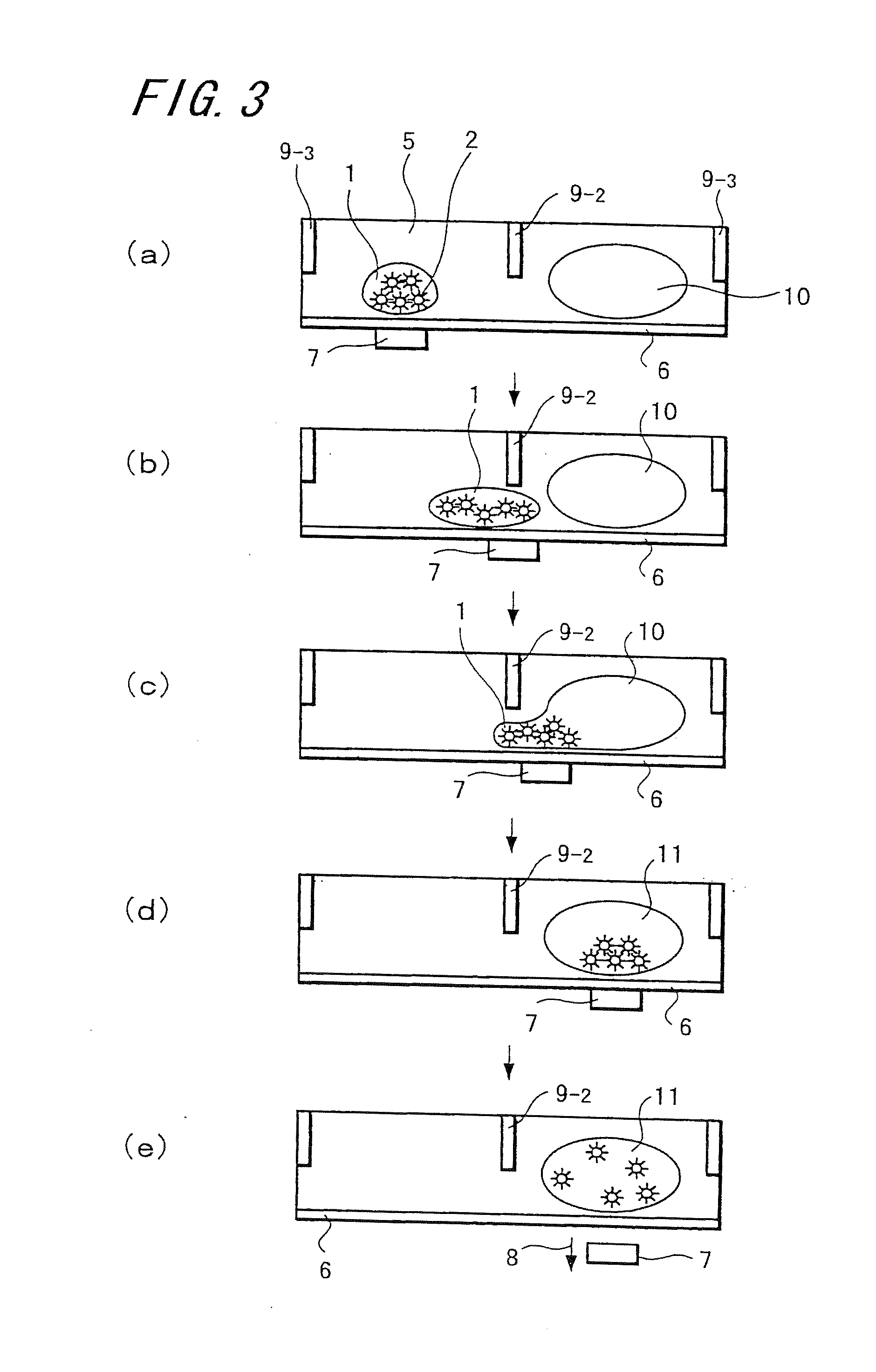

Chemical Analytic Apparatus and Chemical Analytic Method

InactiveUS20080226500A1Improve magnetic efficiencyImprove accuracyLaboratory glasswaresBiological testingCompound (substance)Miniaturization

A chemical analytic apparatus of the present invention is the one which proposes that a miniaturization, a making low-cost and portability are possible and also the operation of each process of separation, concentration and dilution of specimen is possible, and which includes: an introduction means (S1) that introduces a droplet to which magnetic ultrafine particles are mixed into another liquid that differs from the droplet while maintaining a single droplet; a conveyance means by which the droplet that includes the magnetic particles is conveyed in another liquid of the introduction means by applying magnetic field externally to the magnetic ultrafine particles; and processing means (S2 to S6) by which operations for processing of chemical analysis are performed one by one in the process in which the droplet to which the magnetic ultrafine particles are mixed is conveyed by the conveyance means

Owner:JAPAN SCI & TECH CORP

Fluid Identification Device and Fluid Identification Method

InactiveUS20080184775A1Miniaturization possibleStable identification performanceDetection of fluid at leakage pointVolume/mass flow by thermal effectsEngineeringHeating element

A fluid identification device includes a fluid detection part which is equipped with a temperature detector for fluid detection and a heating element disposed in the vicinity of the temperature detector and disposed on the identification target fluid side, a fluid detection circuit connected to the fluid detection part and an identification operation part which performs identification of an identification target fluid based on the output of the fluid detection circuit are contained in an identification sensor module main body.

Owner:MITSUI MINING & SMELTING CO LTD

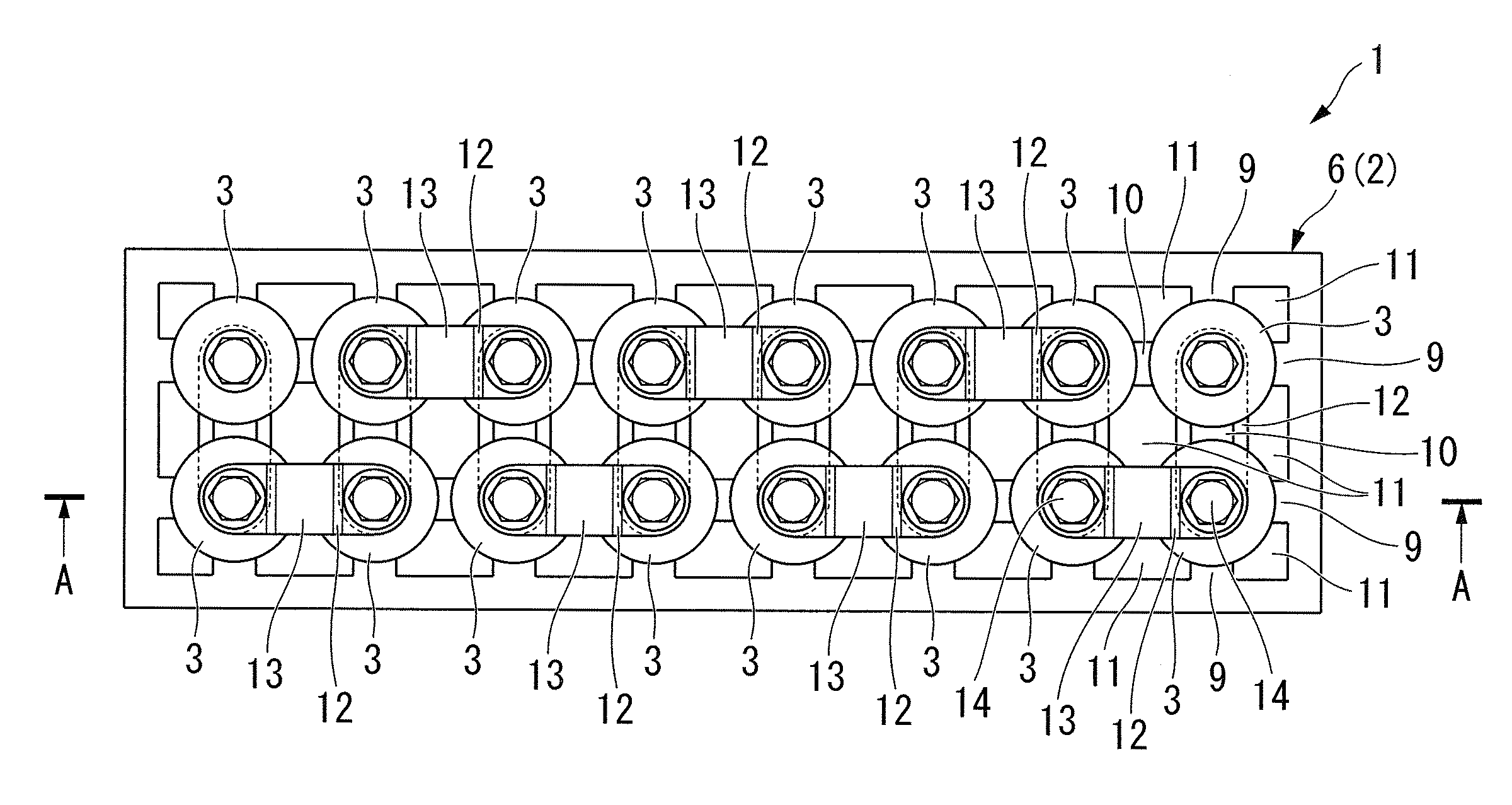

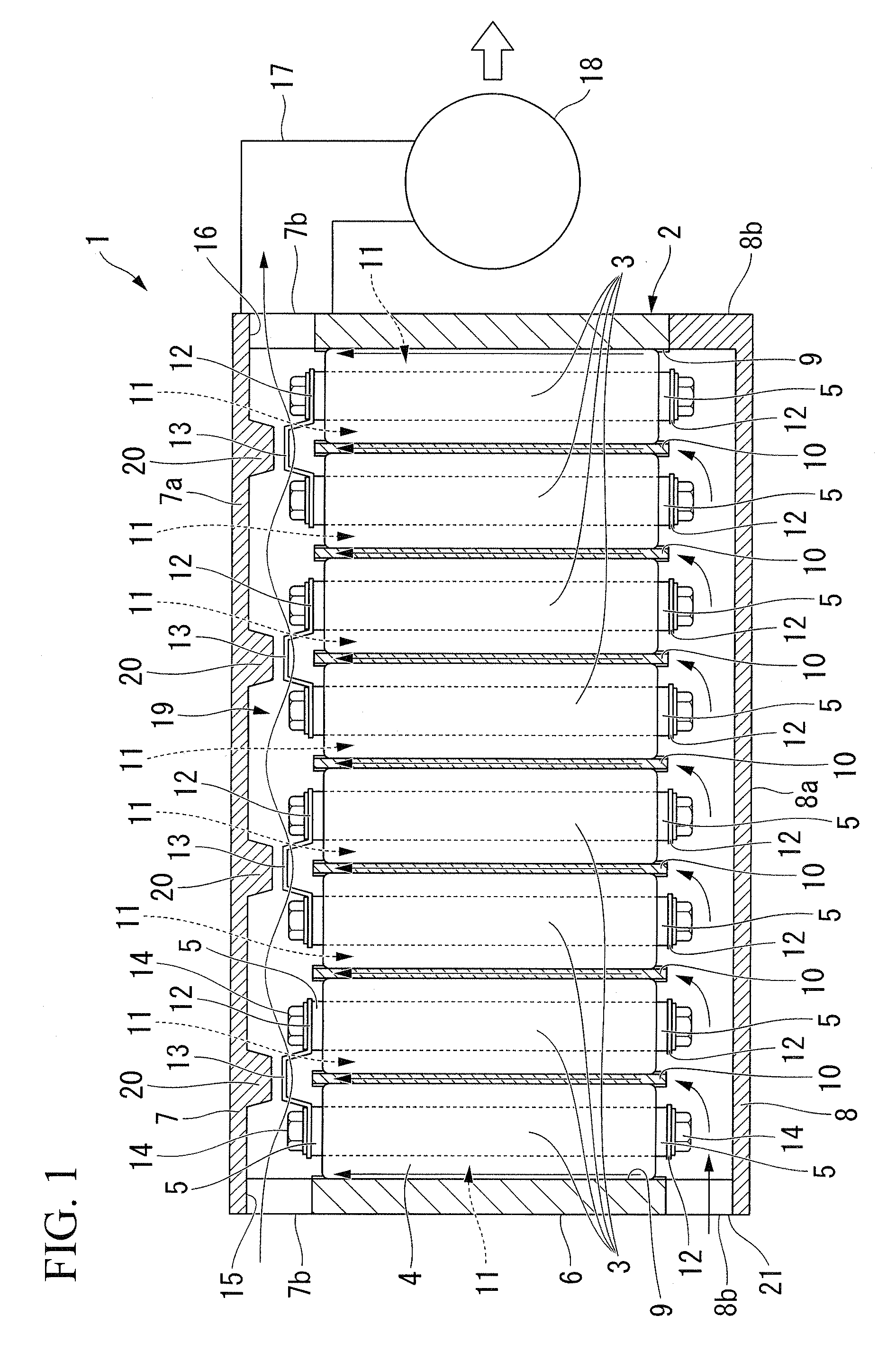

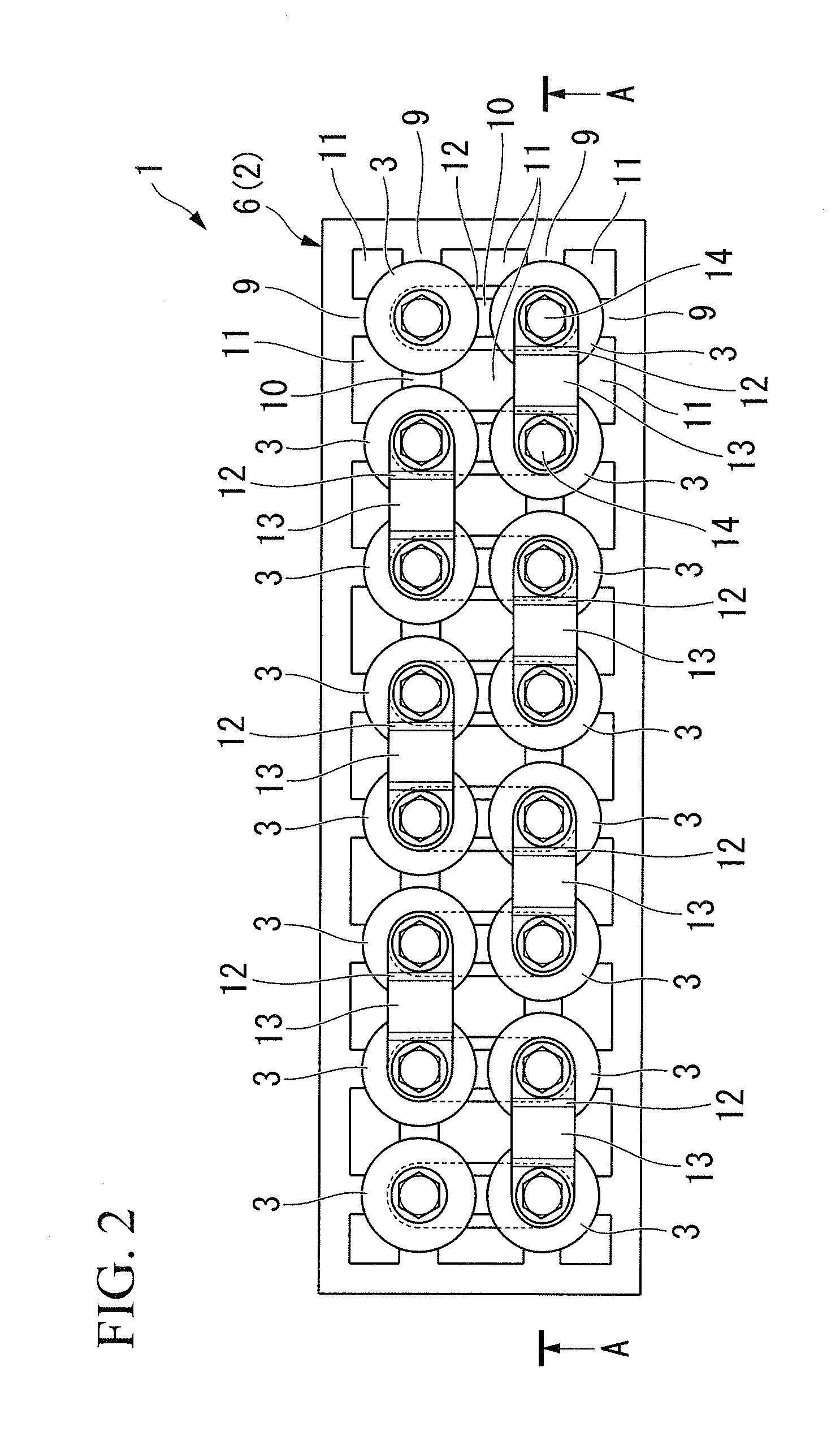

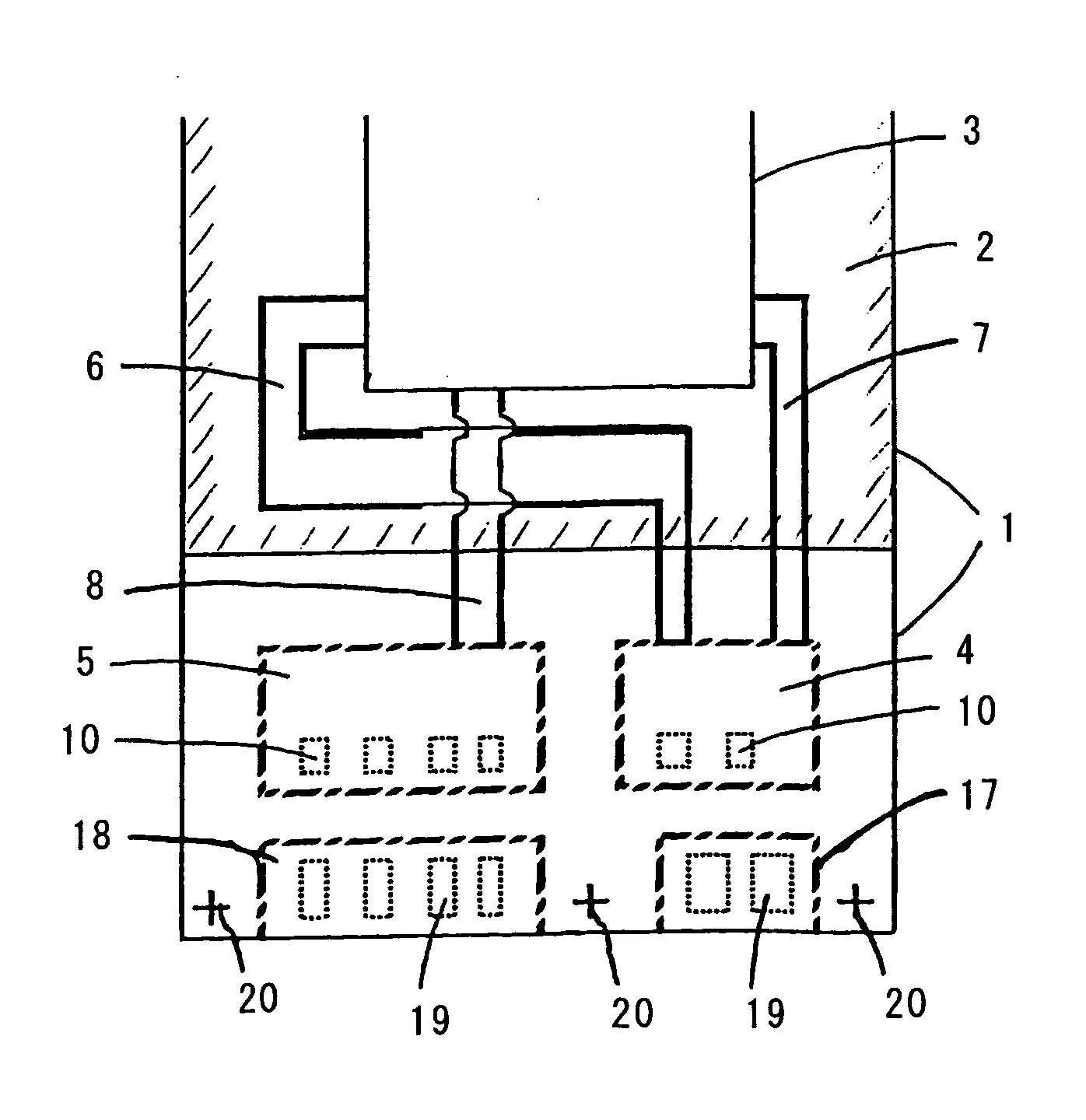

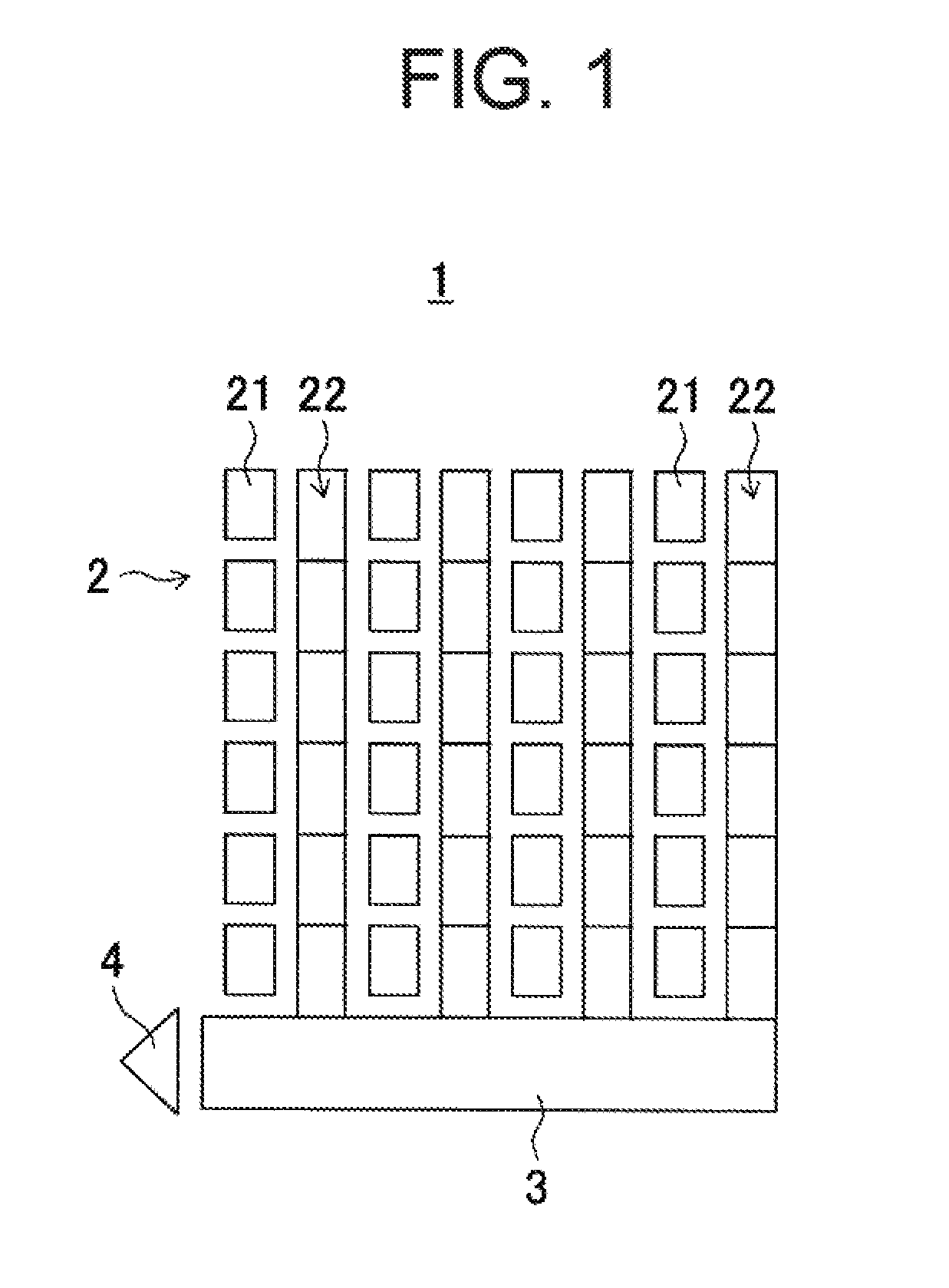

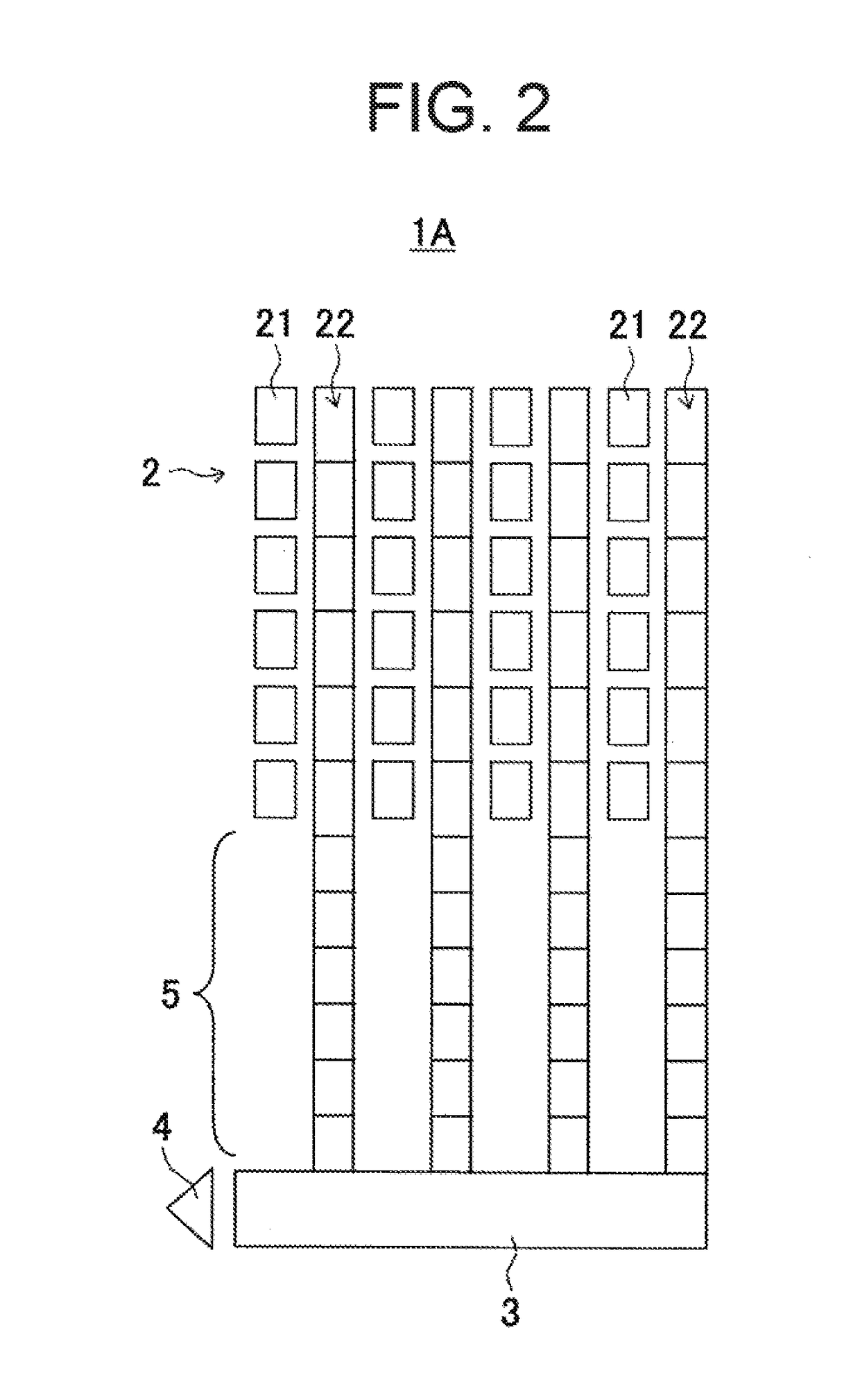

Battery container unit

InactiveUS20090061305A1Improve cooling effectMiniaturization possibleSecondary cellsCell component detailsCooling mediumElectrical and Electronics engineering

A battery container unit including: an enclosure; and a plurality of battery modules of cylindrical shape, wherein each adjacent pair of the electrode terminals is serially connected by a conductive linking member, the plurality of battery modules are provided in matrix form within the enclosure by a support member, a first cooling medium flow path is provided which linearly flows a cooling medium along in parallel with the electrode terminals and the conductive linking members of the plurality of battery modules in a region within the enclosure near an end in the axial direction of the plurality of battery modules, and a second cooling medium flow path is provided in a gap along the axial direction of the battery modules, between adjacent battery modules within the enclosure, which flows the cooling medium toward the first cooling medium flow path.

Owner:HONDA MOTOR CO LTD

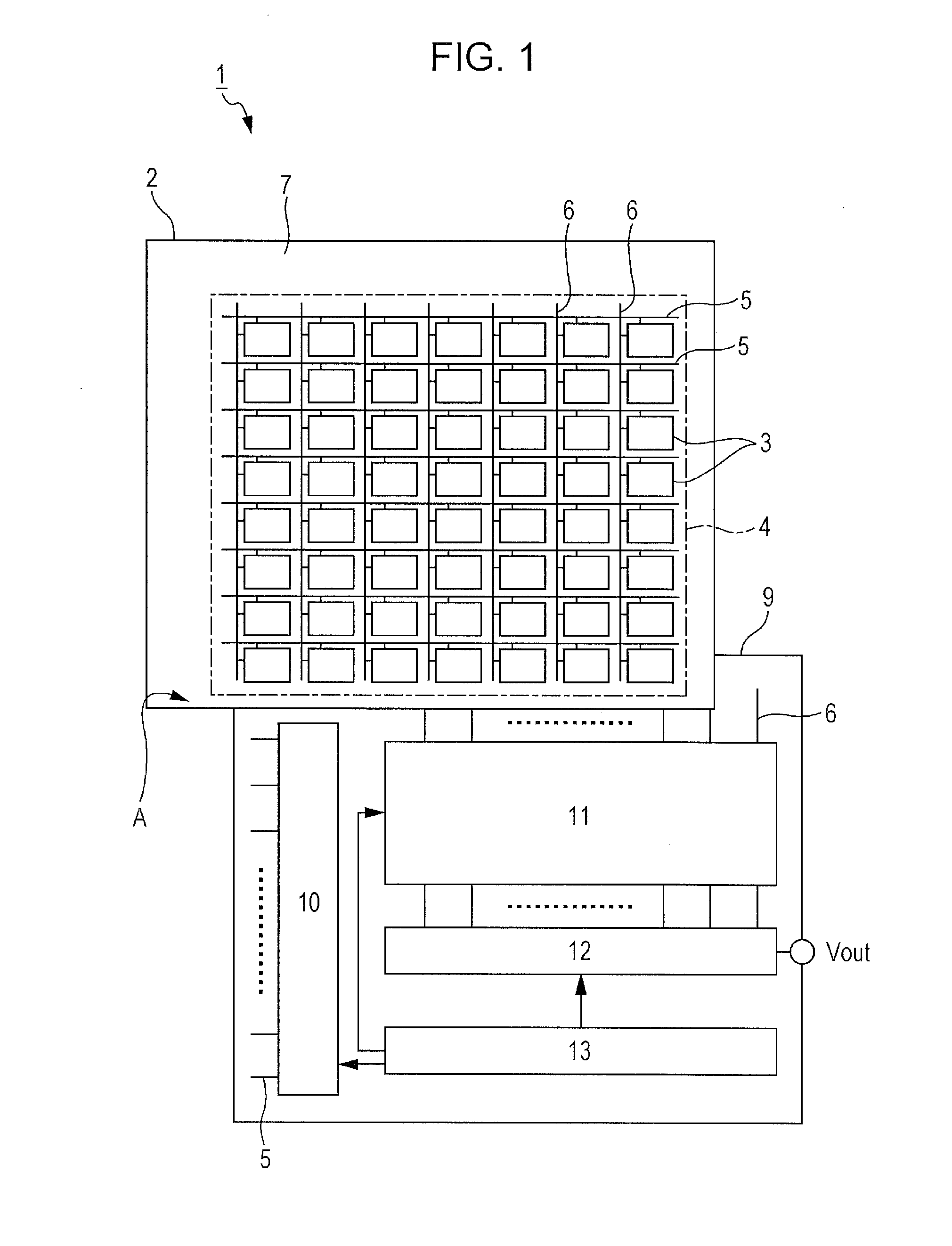

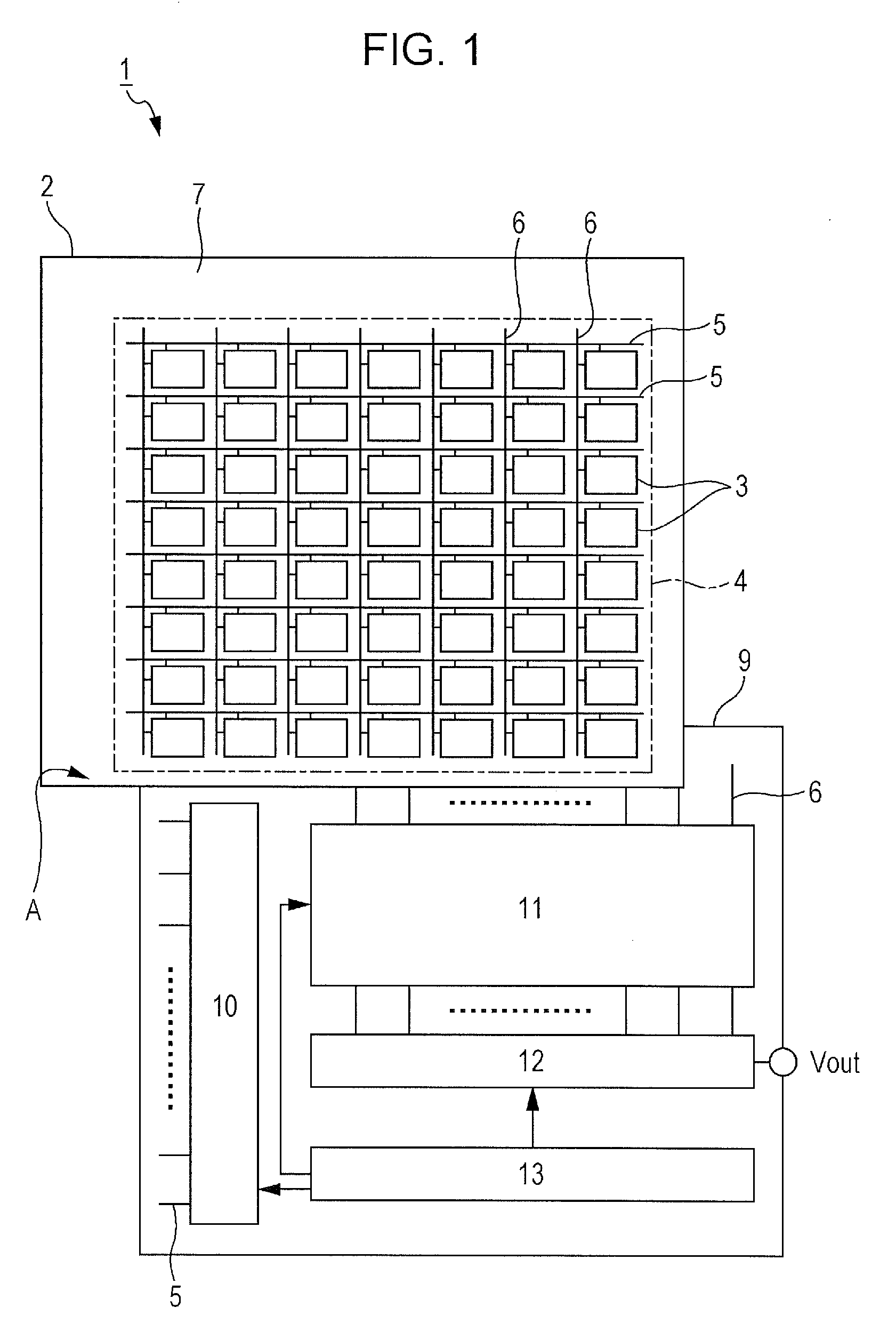

Display device

InactiveUS20050248713A1Miniaturization possibleReduction in display characteristic and manufacturing yieldStatic indicating devicesNon-linear opticsSignal linesScan line

A display device comprises scan lines on a insulating substrate, signal lines intersecting with the scan lines with an insulating film interposed therebetween, a display area comprising pixel electrodes connected to the signal lines, a scan line driver circuit connected to the scan lines, a signal line driver circuit connected to the signal lines. The scan line driver circuit and the signal line driver circuit are mounted directly on the insulating substrate outside of the display area and close to one side of the display area. Lines connecting the scan line driver circuit and the signal line driver circuit are formed in an area in which the scan line driver circuit and the signal line driver circuit are mounted.

Owner:MITSUBISHI ELECTRIC CORP

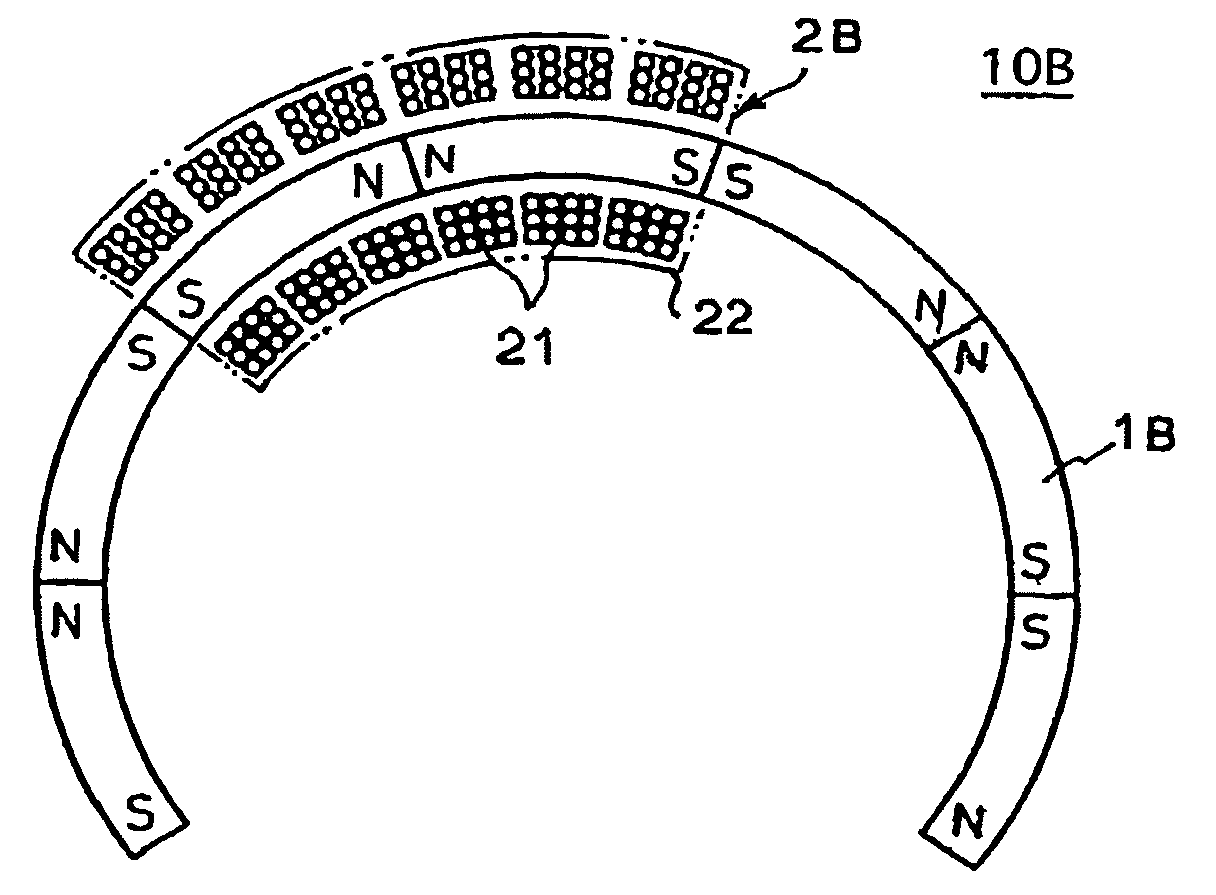

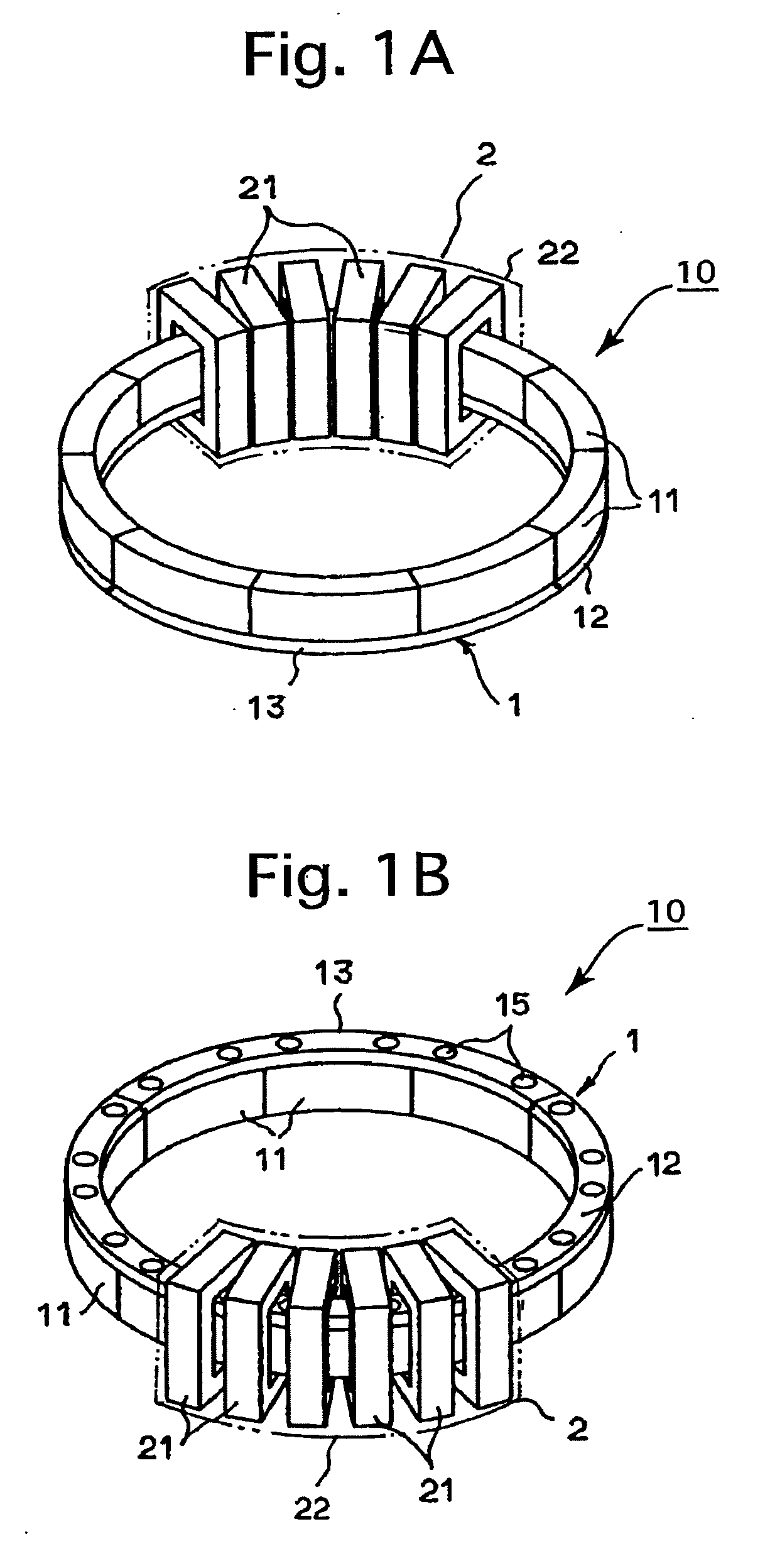

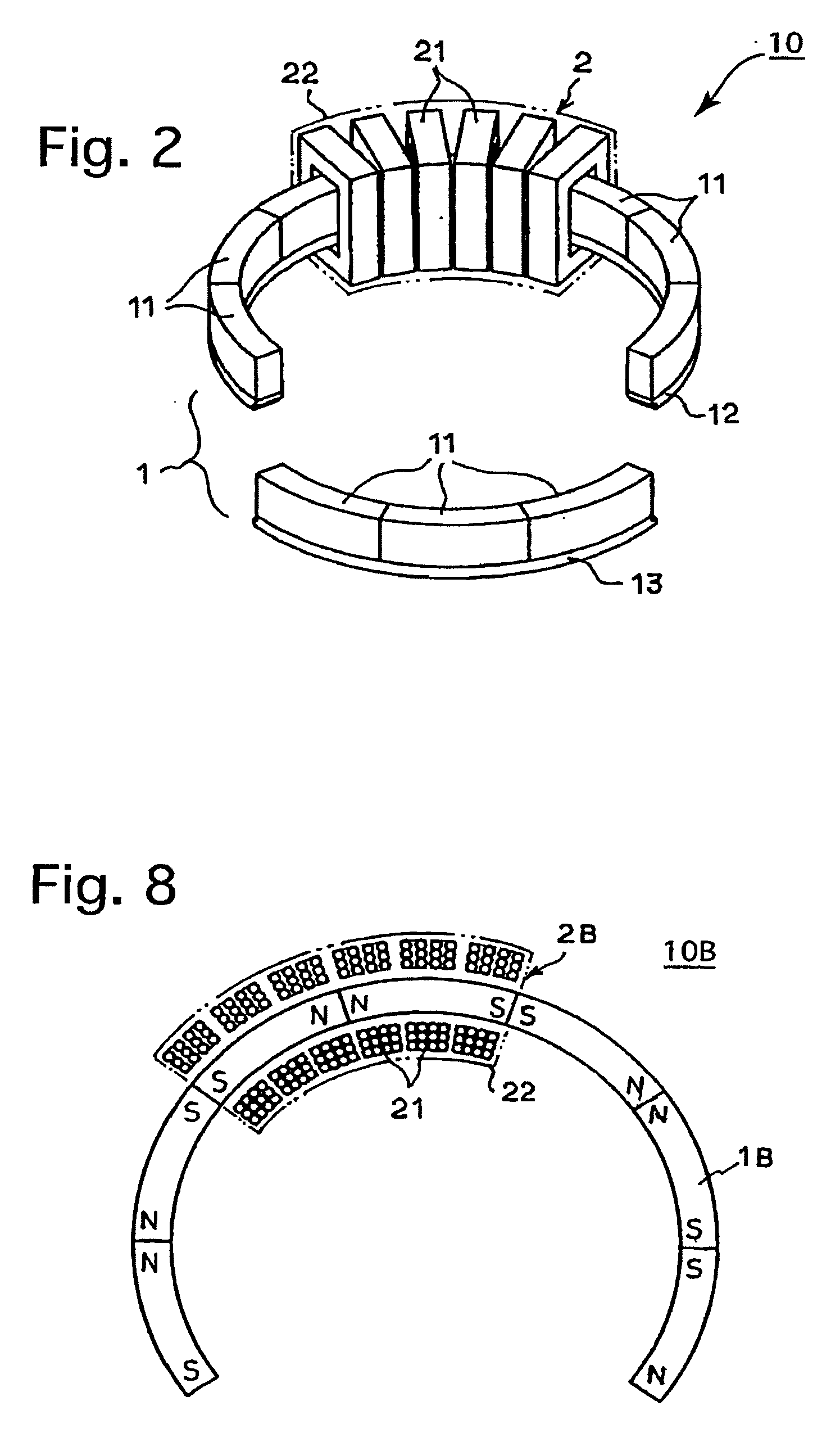

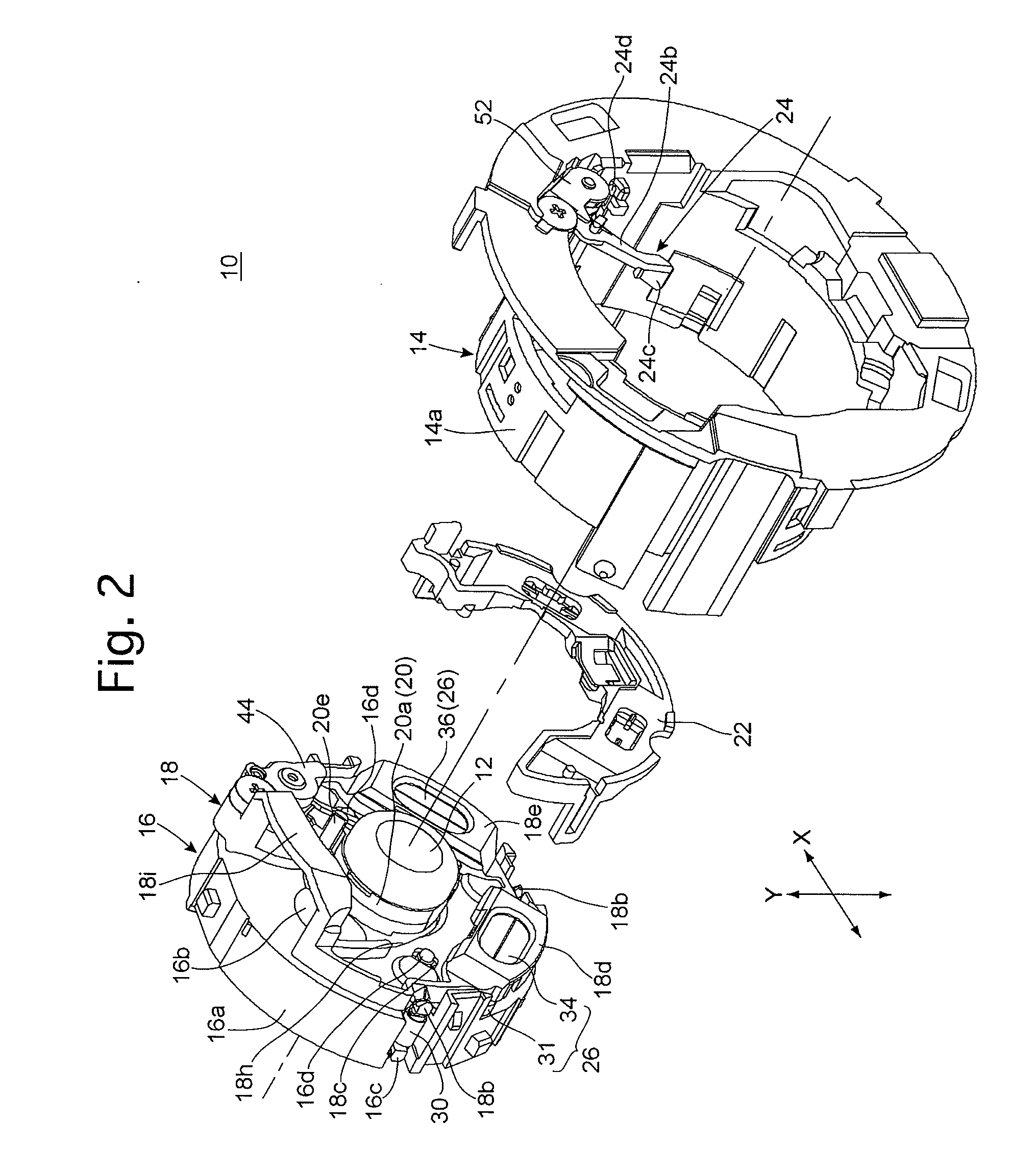

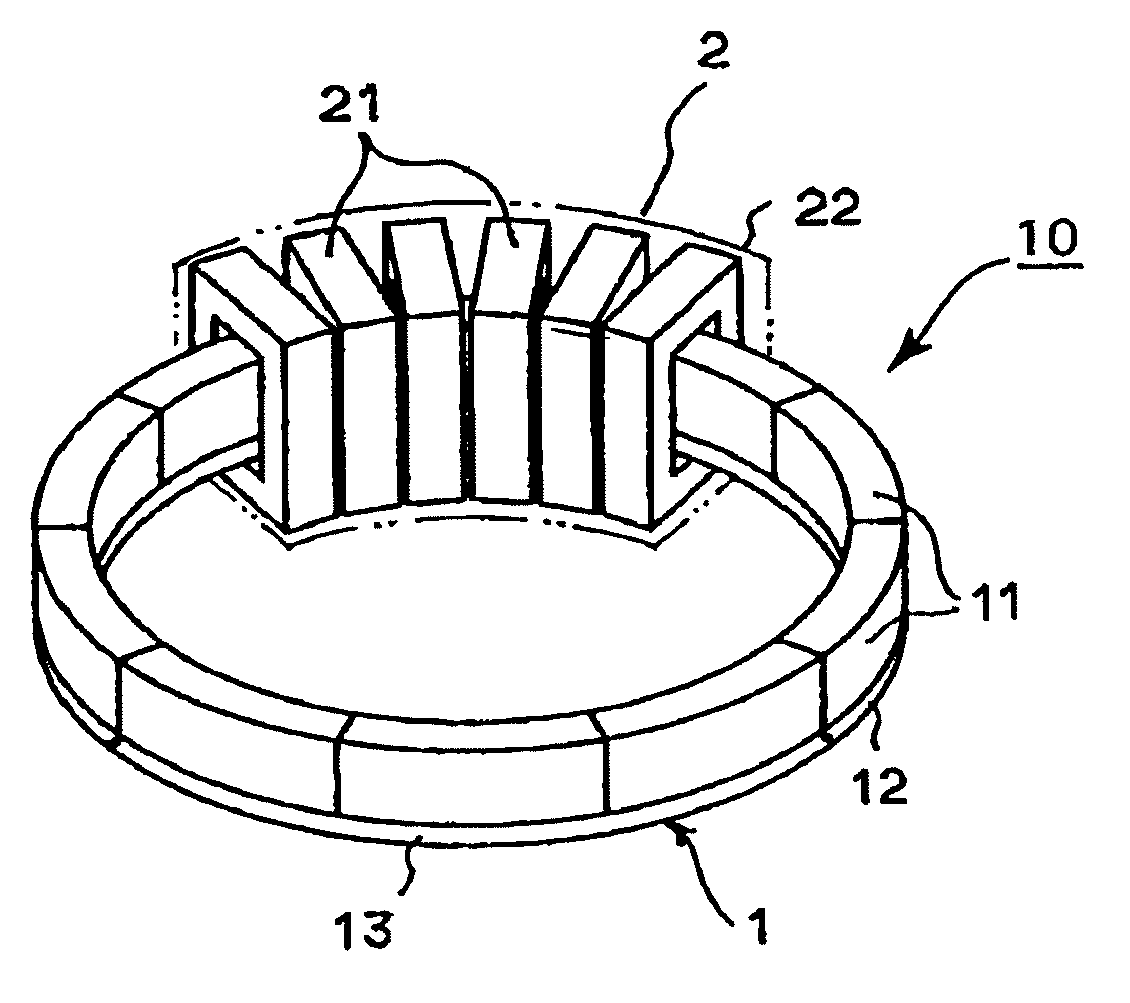

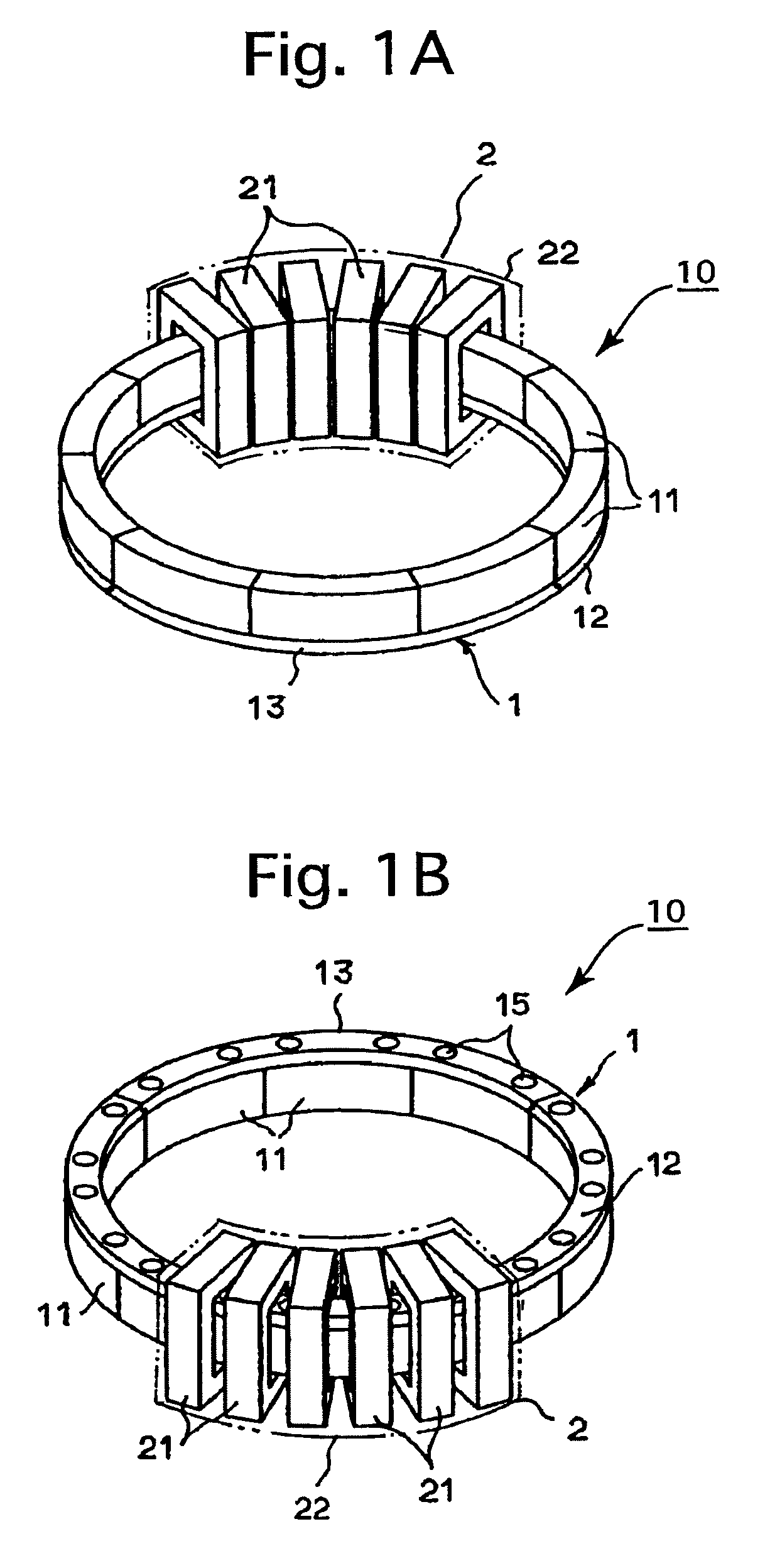

Rotary actuator

InactiveUS20090323208A1Reduce weightMiniaturization possibleSynchronous generatorsWindingsRotary actuatorMagnet

A rotary actuator includes a multi-polar magnet, in which north and south poles are alternately arranged in a circumferential direction, the multi-polar magnet being shaped into one of a circular ring and a circular arc member; and a coil body having coils which are provided around the multi-polar magnet to be capable of moving in the circumferential direction of the multi-polar magnet, each of the coils substantially lying on a plane that extends in a radial direction of the multi-polar magnet and orthogonal to the circumferential direction of the multi-polar magnet. The north and south poles of the multi-polar magnet are positioned apart from each other by a predetermined interval in the circumferential direction. Dimensions of each coil are predetermined so that length of each coil in the circumferential direction is associated with the predetermined interval. Predetermined currents are passed through the coils in a properly phased manner.

Owner:RICOH IMAGING COMPANY

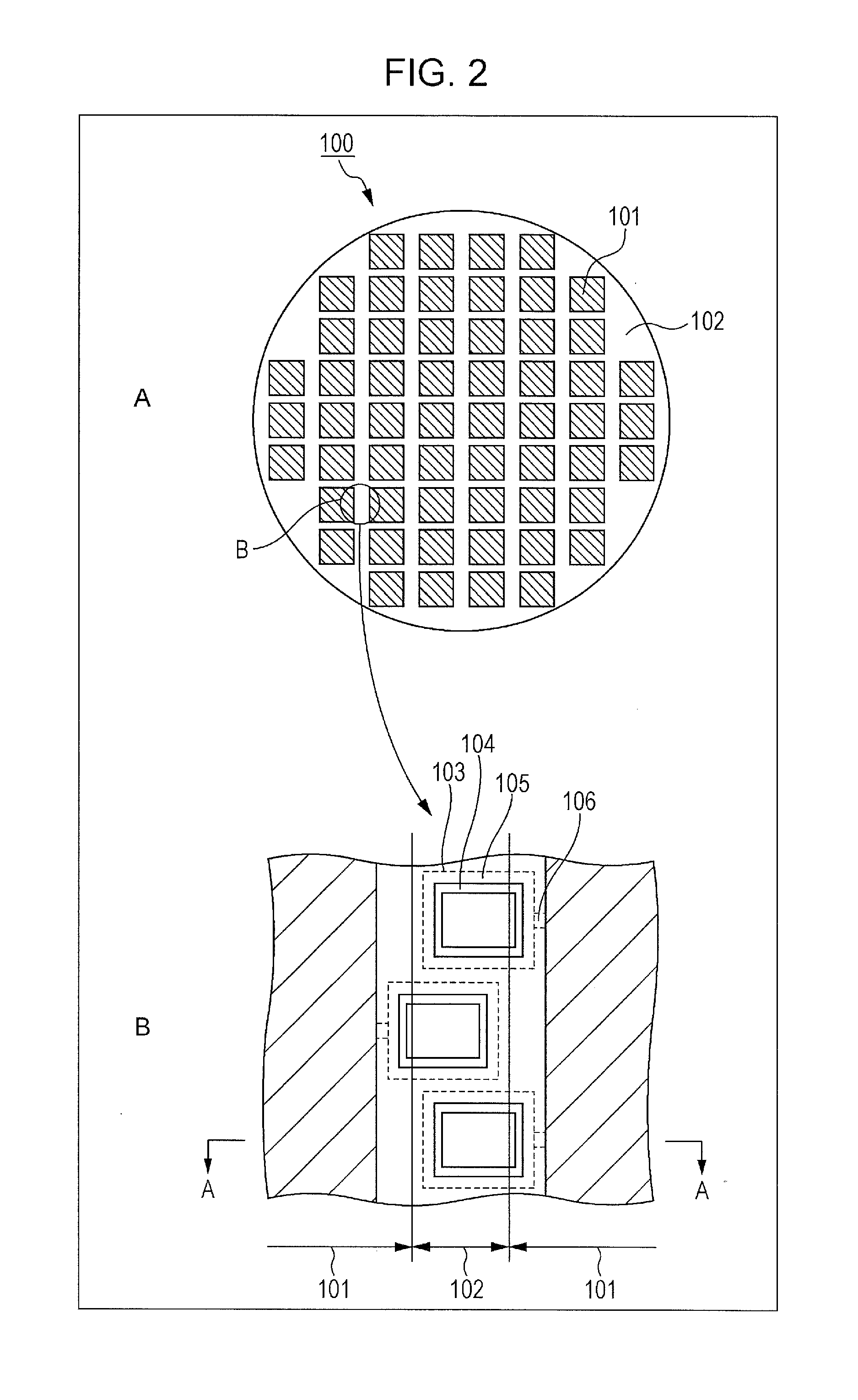

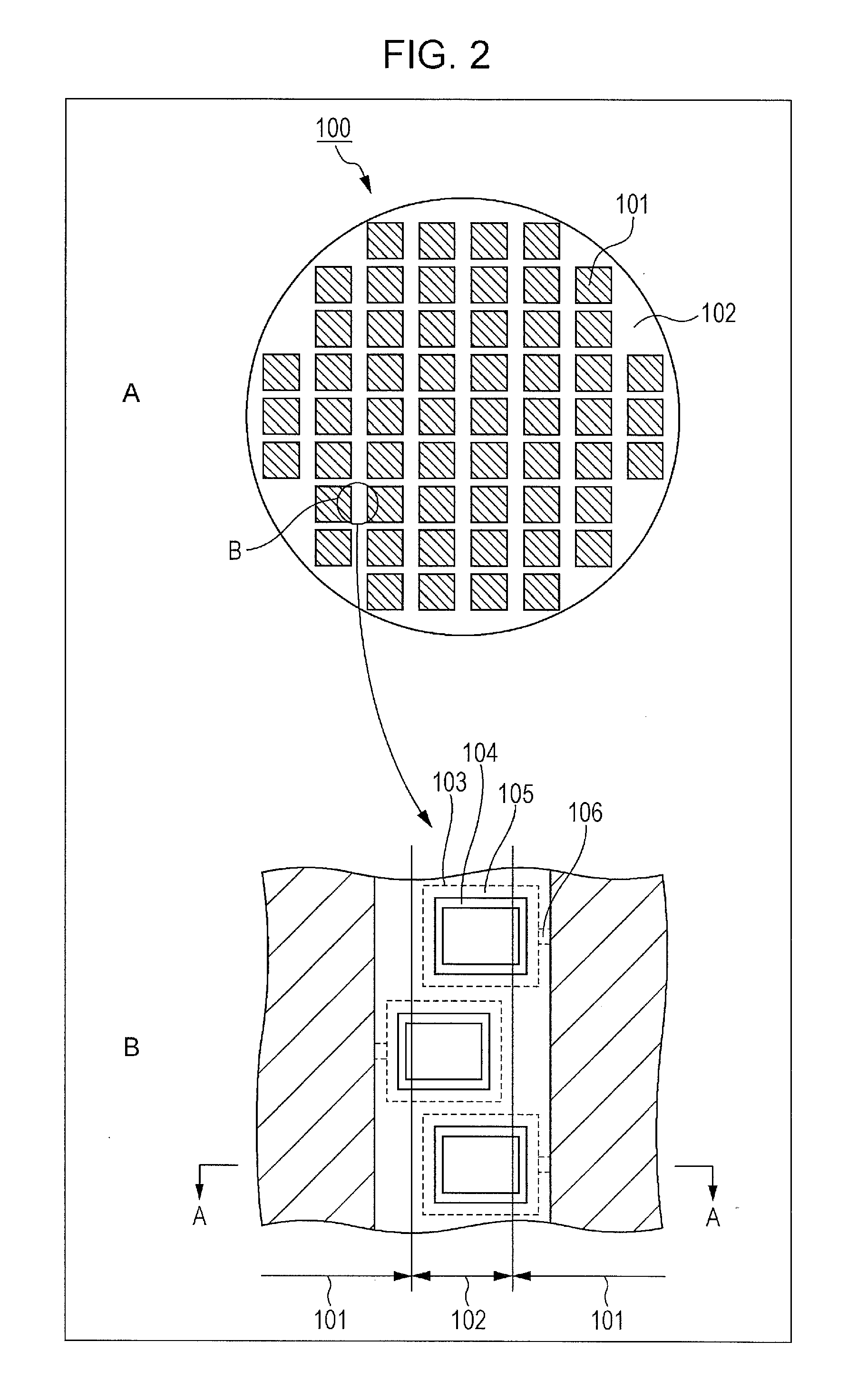

Semiconductor device, manufacturing method of semiconductor device, semiconductor wafer, and electronic equipment

ActiveUS20150035109A1Miniaturization possibleSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPower semiconductor deviceMiniaturization

The present technology relates to a semiconductor device, a manufacturing method of a semiconductor device, a semiconductor wafer, and electronic equipment, which allow a semiconductor device, in which miniaturization is possible, to be provided.A semiconductor device includes a semiconductor substrate, a wiring layer that is formed on the semiconductor substrate, and a drive circuit that is provided in a circuit forming region of the semiconductor substrate. Then, the semiconductor device 110 is configured to include a pad electrode 103 that is electrically connected to the drive circuit and exposed from the side surface of the wiring layer, and an external connection terminal 108 that is provided in side surfaces of the semiconductor substrate and the wiring layer, and is electrically connected to the pad electrode 103.

Owner:SONY CORP

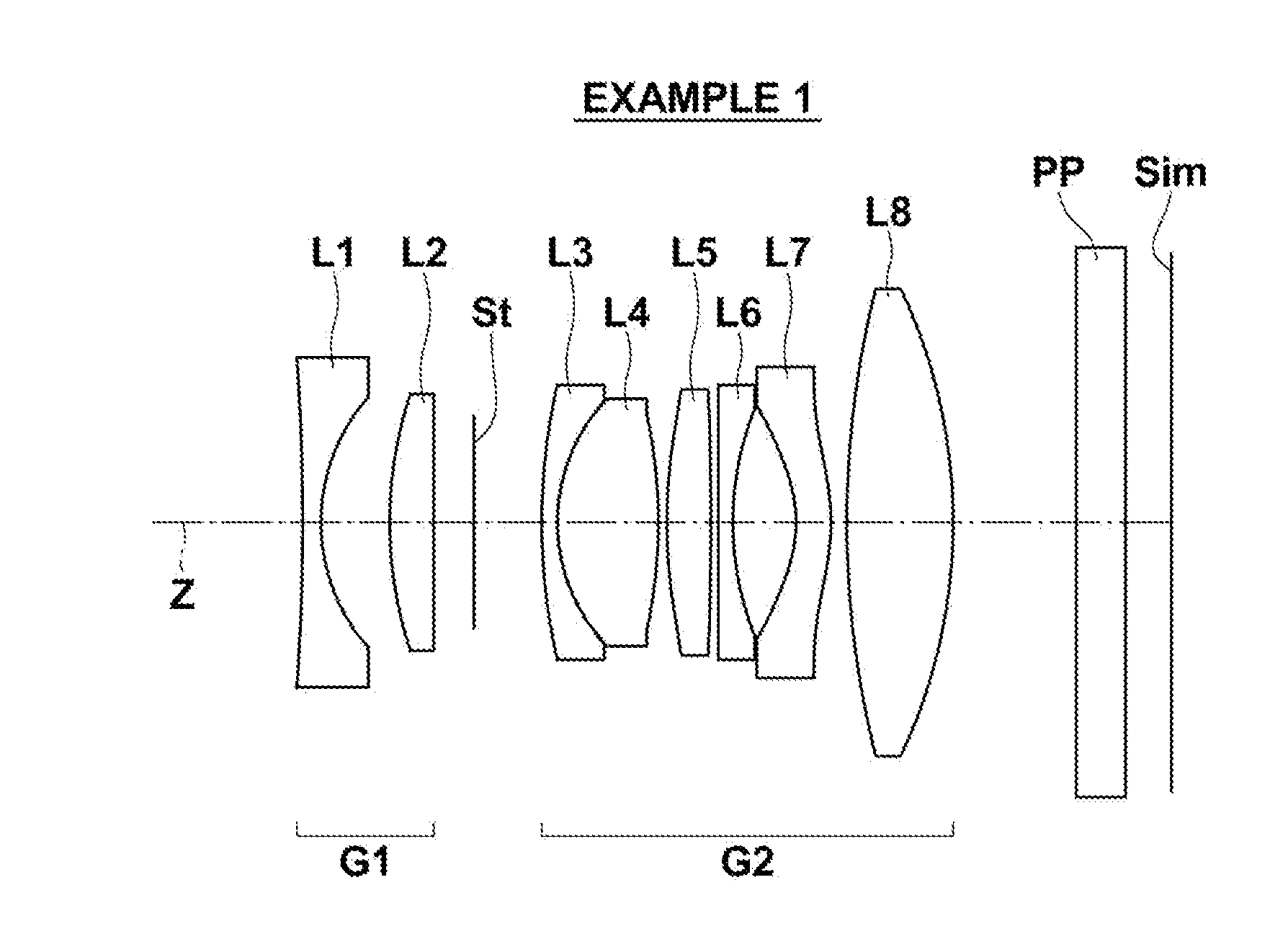

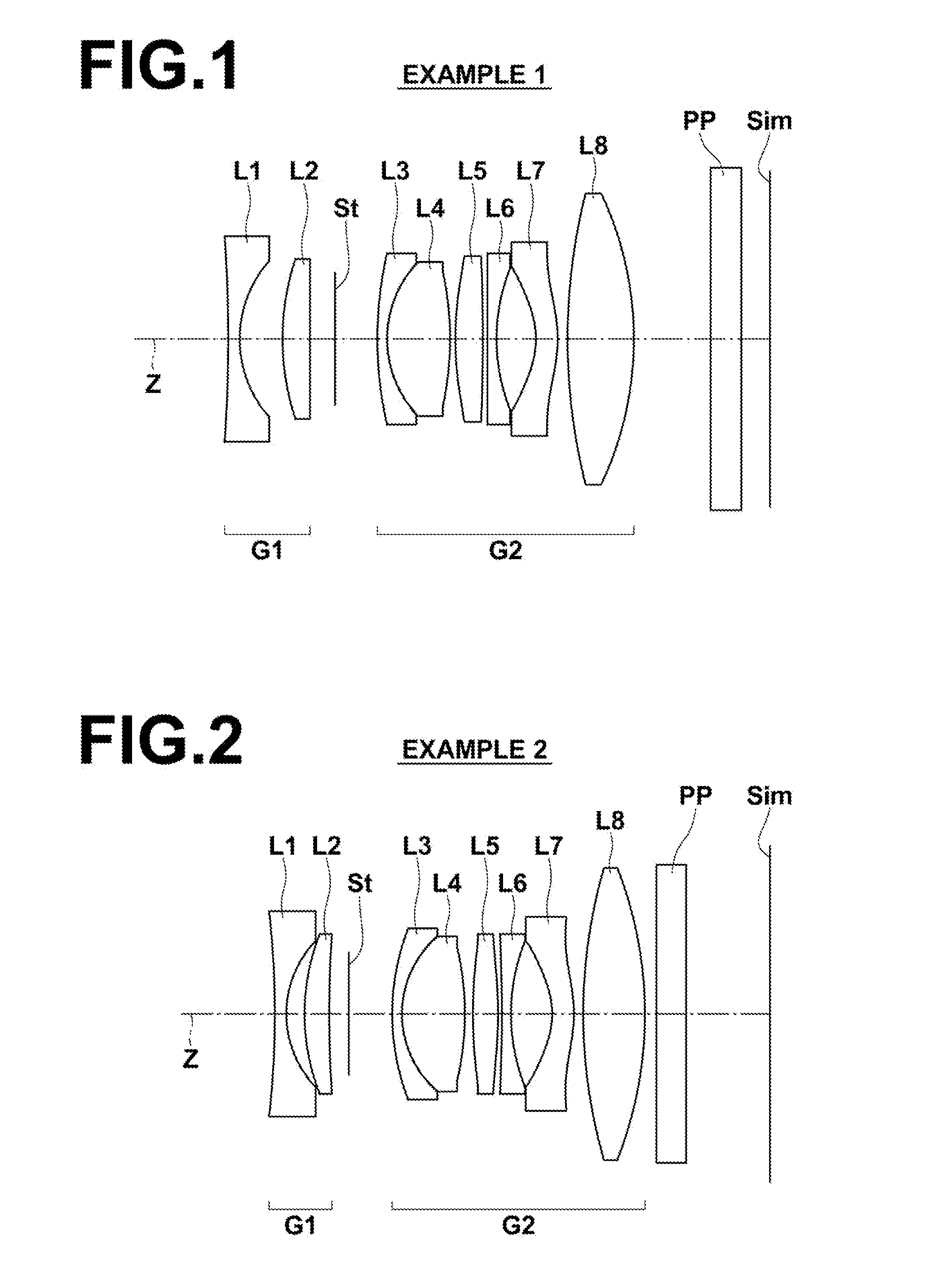

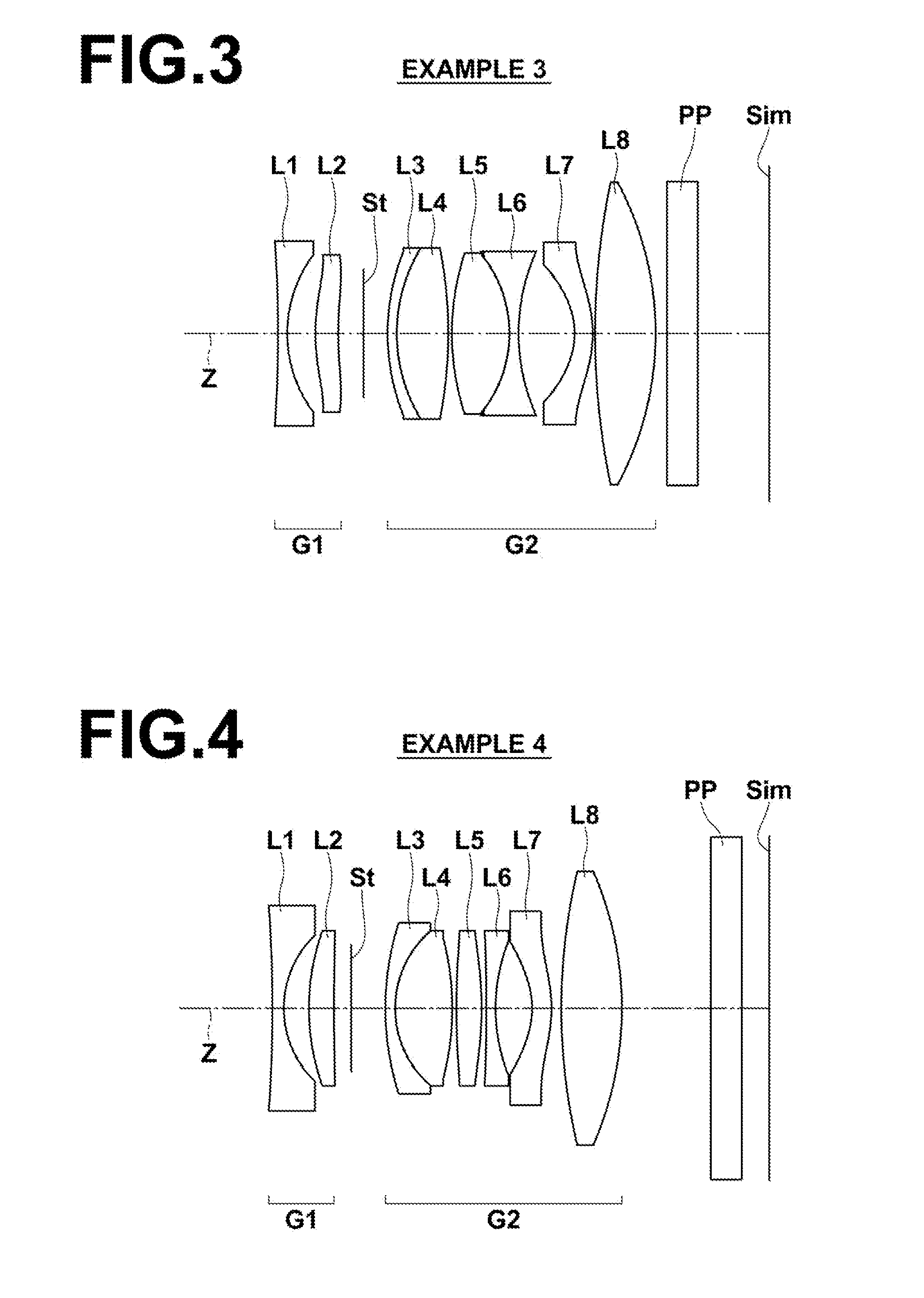

Imaging lens and imaging apparatus

An imaging lens includes: a first lens group; an aperture stop; and a second lens group having a positive refractive power, in this order from an object side. The first lens group includes a negative first lens provided most toward the object side. The second lens group includes a positive lens, provided most toward an imaging surface, and a negative lens having a concave surface and an aspherical surface at least toward the object side. The following Conditional Formulae are satisfied:0.03<(|Sagsp1|−|Sagas1|) / Re1<0.35; and1.819≦NdAB wherein Sagsp1 is the sag of a reference spherical surface at the edge of the effective diameter of the object side surface of the negative lens, Sagas1 is the sag of the aspherical surface of the lens, Re1 is the effective diameter of the object side surface of the lens, and NdAB is the average refractive index of the positive lens and the negative lens.

Owner:FUJIFILM CORP

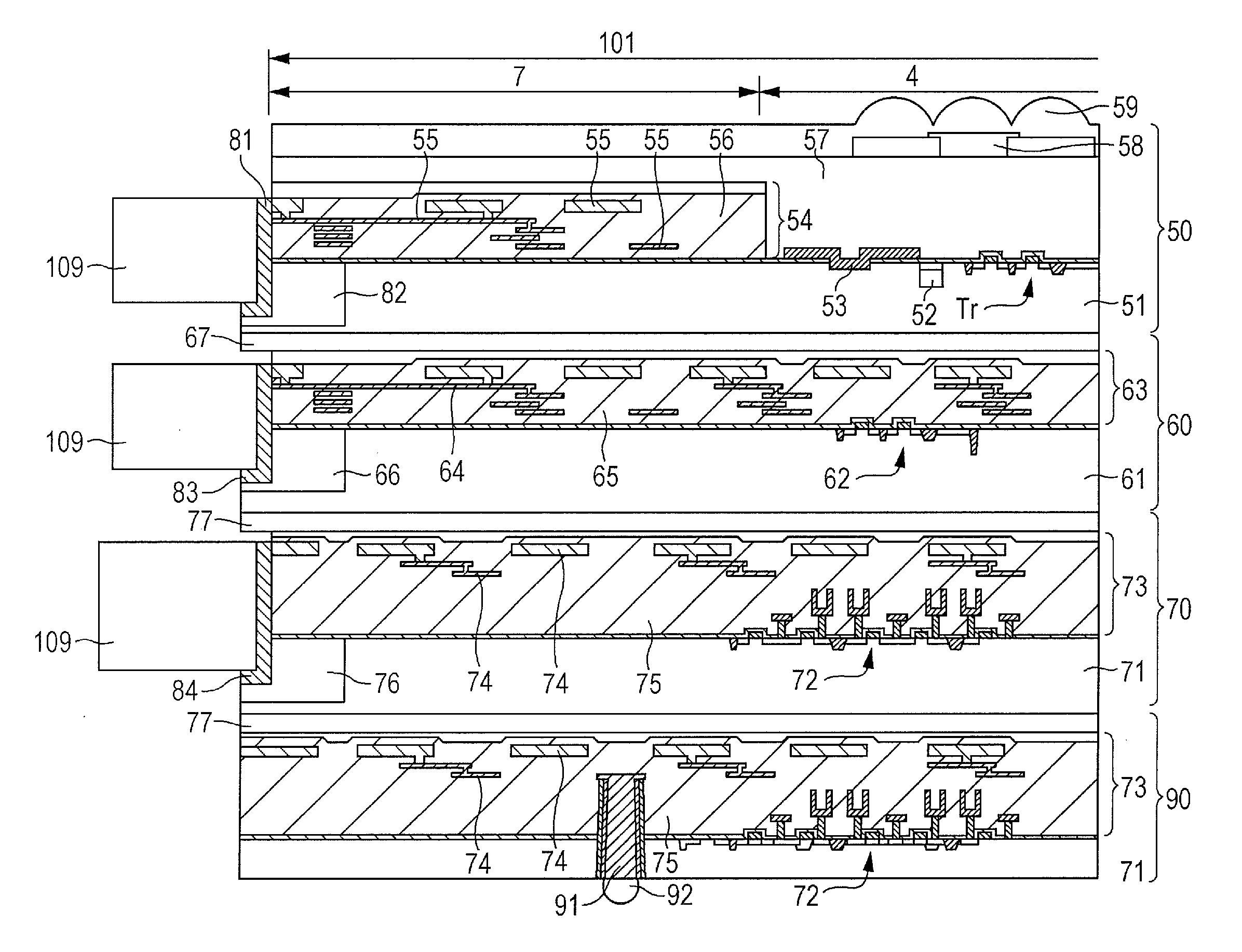

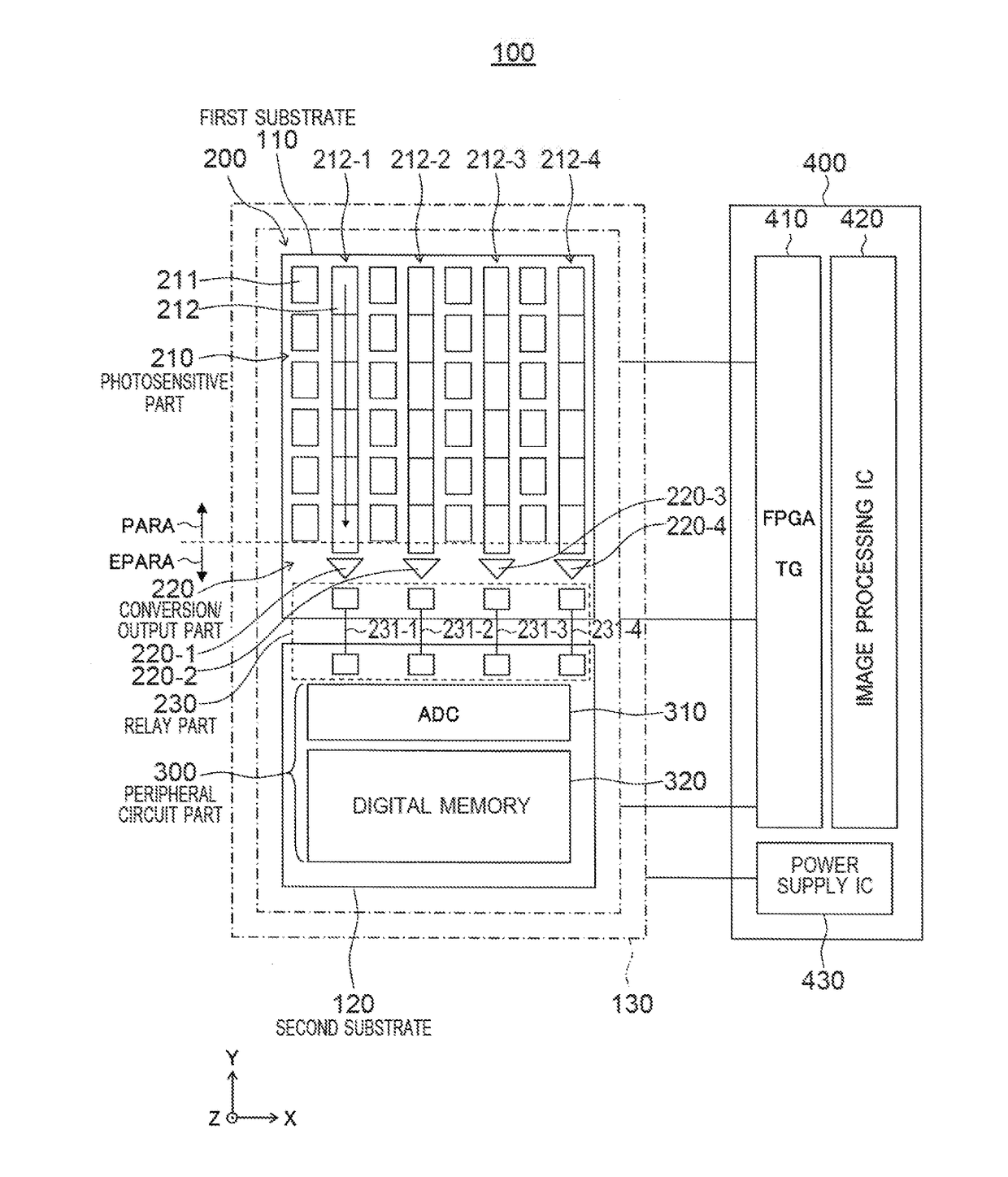

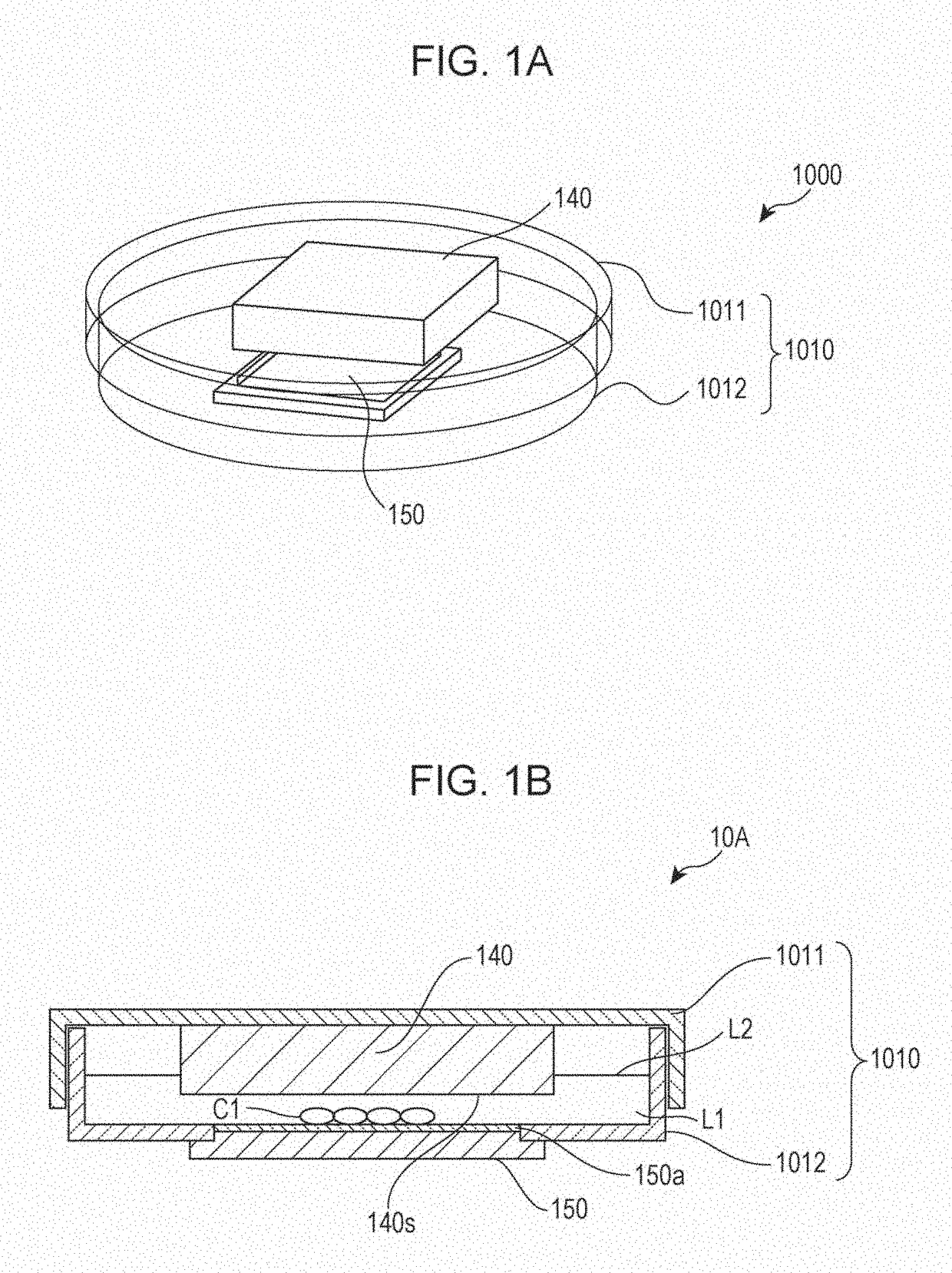

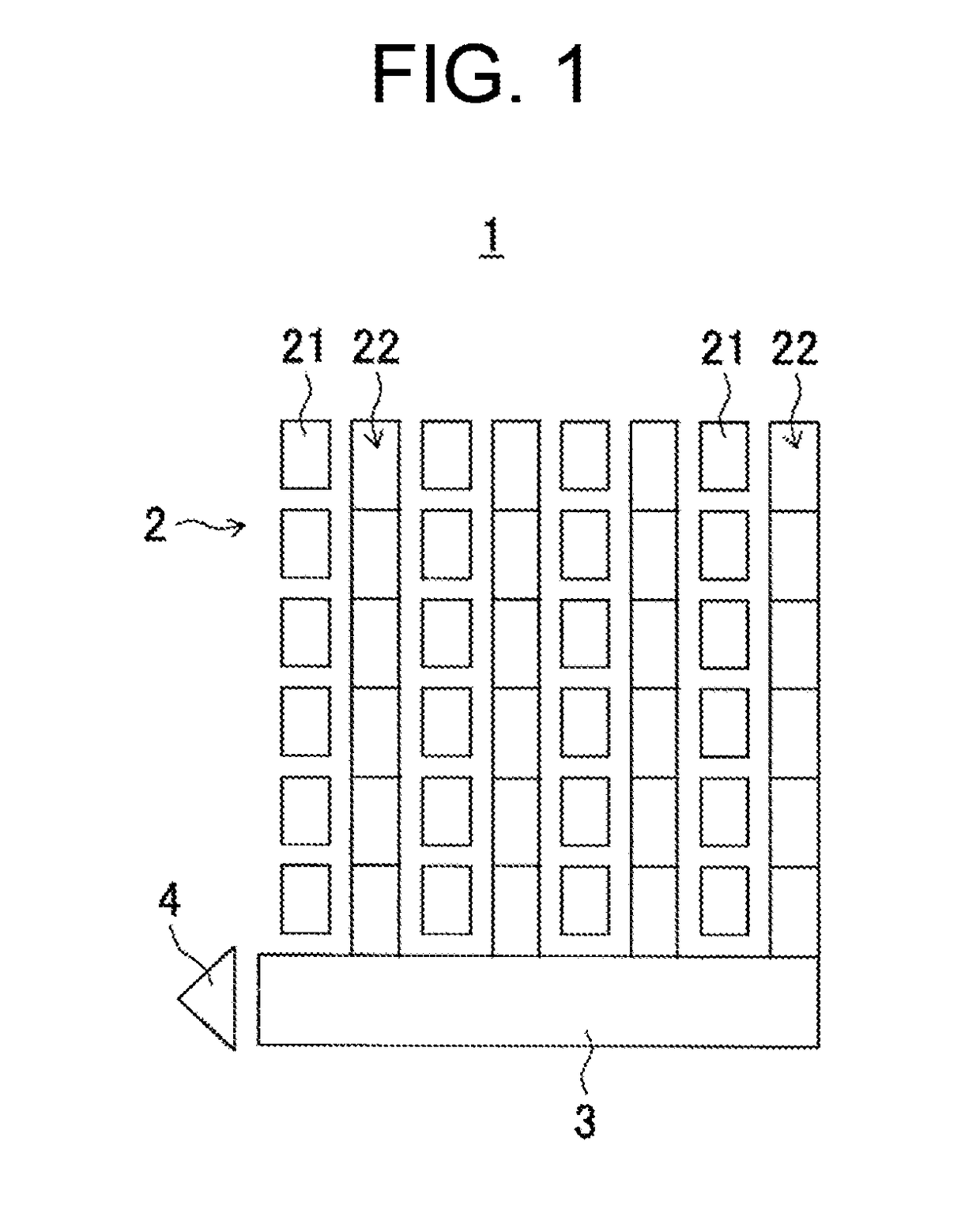

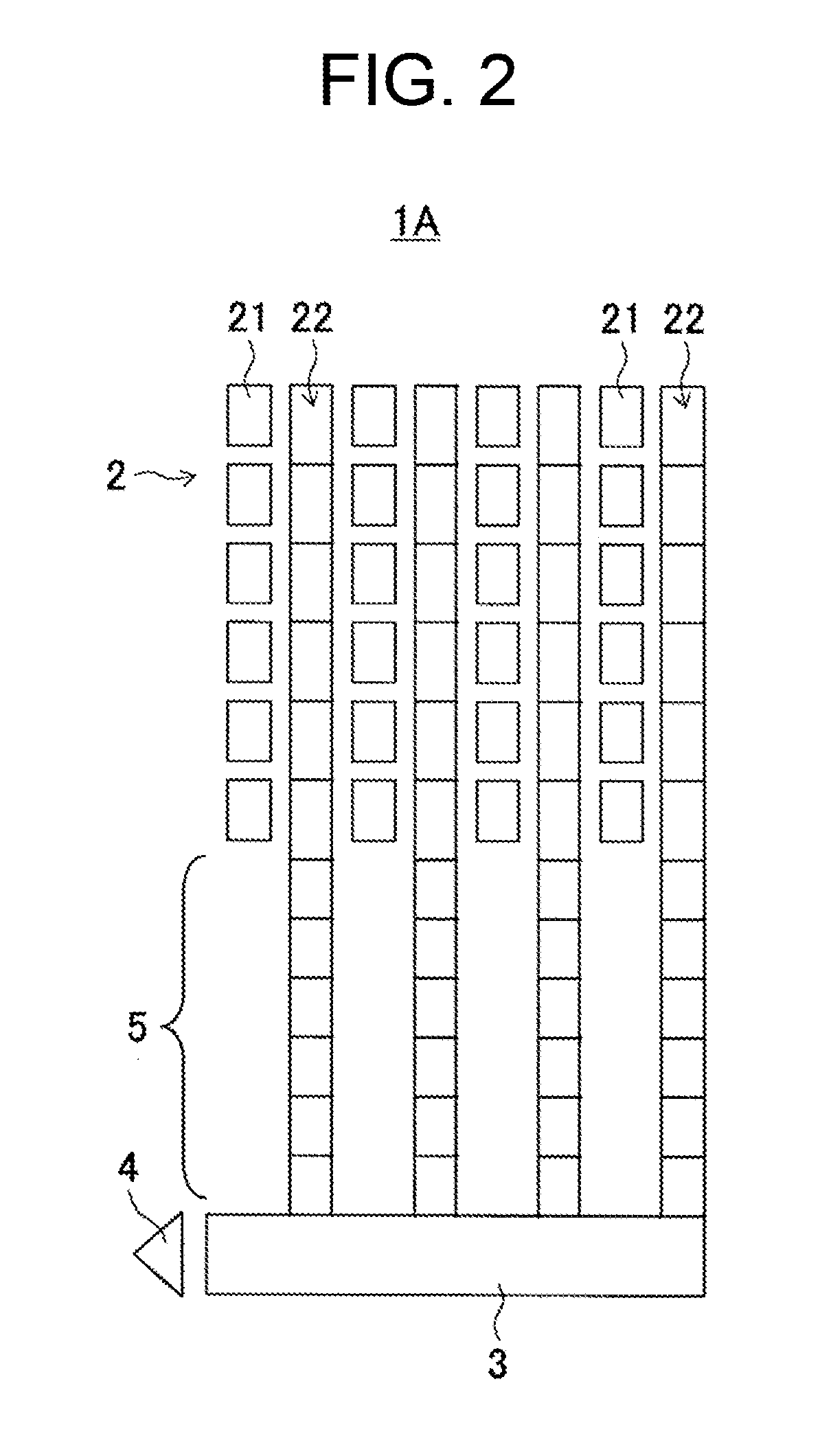

Solid-state imaging device, method for producing solid-state imaging device, and electronic apparatus

ActiveUS20170230598A1Little restrictionIncrease speedTelevision system detailsSolid-state devicesPhotoelectric conversionEngineering

A solid state imaging device has: a photosensitive part containing a plurality of charge transfer parts that transfer, in column units, the signal charges of a plurality of photoelectric conversion elements disposed in a matrix; a conversion / output unit that converts, to an electrical signal, the signal charges forwarded by the charge transfer parts; a peripheral circuit part that performs a predetermined process with respect to the electrical signals from the conversion / output part; a relay part that relays the forwarding to the peripheral circuit part of the electrical signal from the conversion / output part; a first substrate where a photosensitive part and the conversion / output part are formed; and a second substrate where the peripheral circuit part is formed. The first and second substrates are stacked together, and the relay part electrically connects the conversion / output part formed at the first substrate to the peripheral circuit part formed at the second substrate.

Owner:BRILLNICS JAPAN

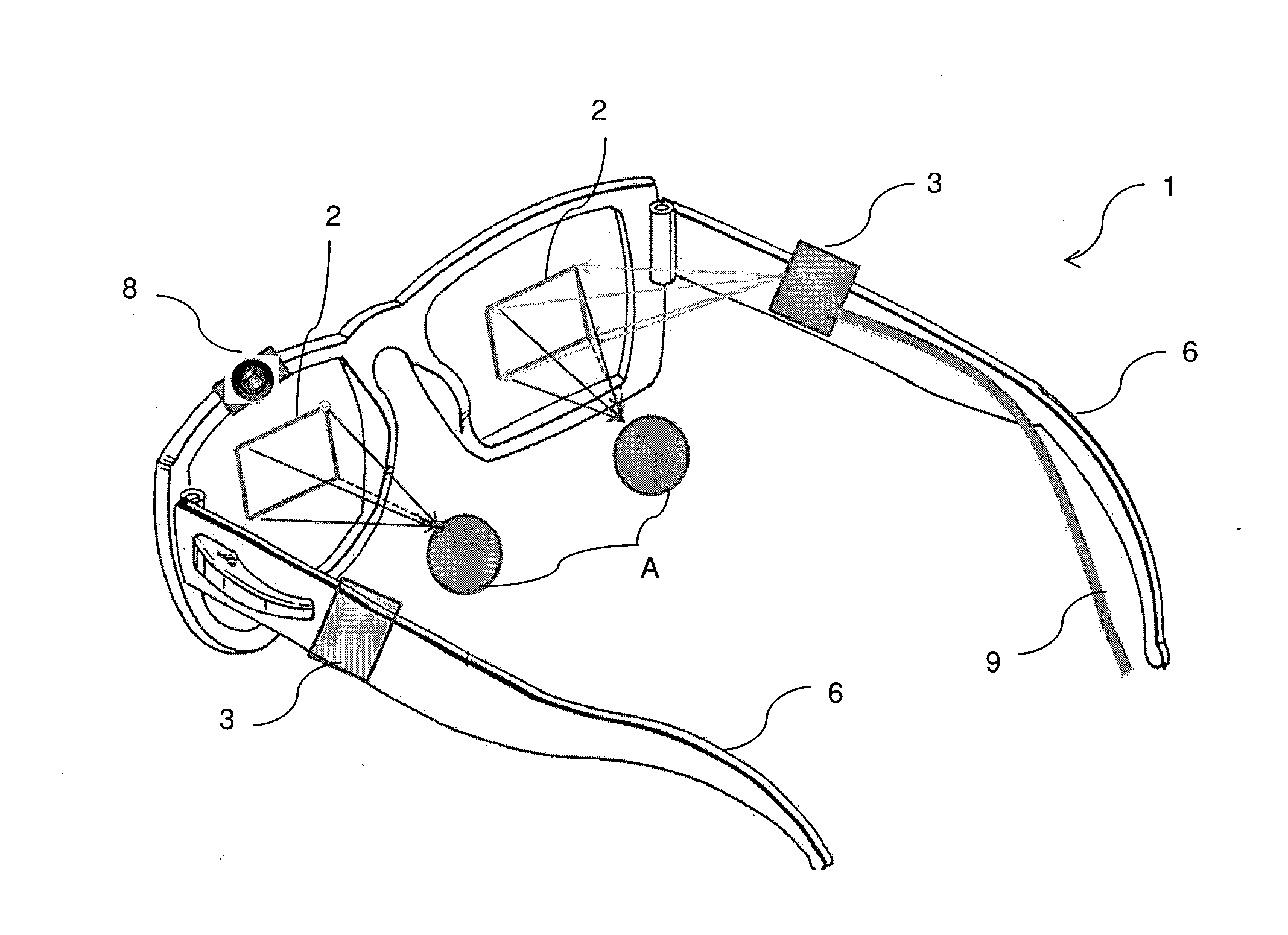

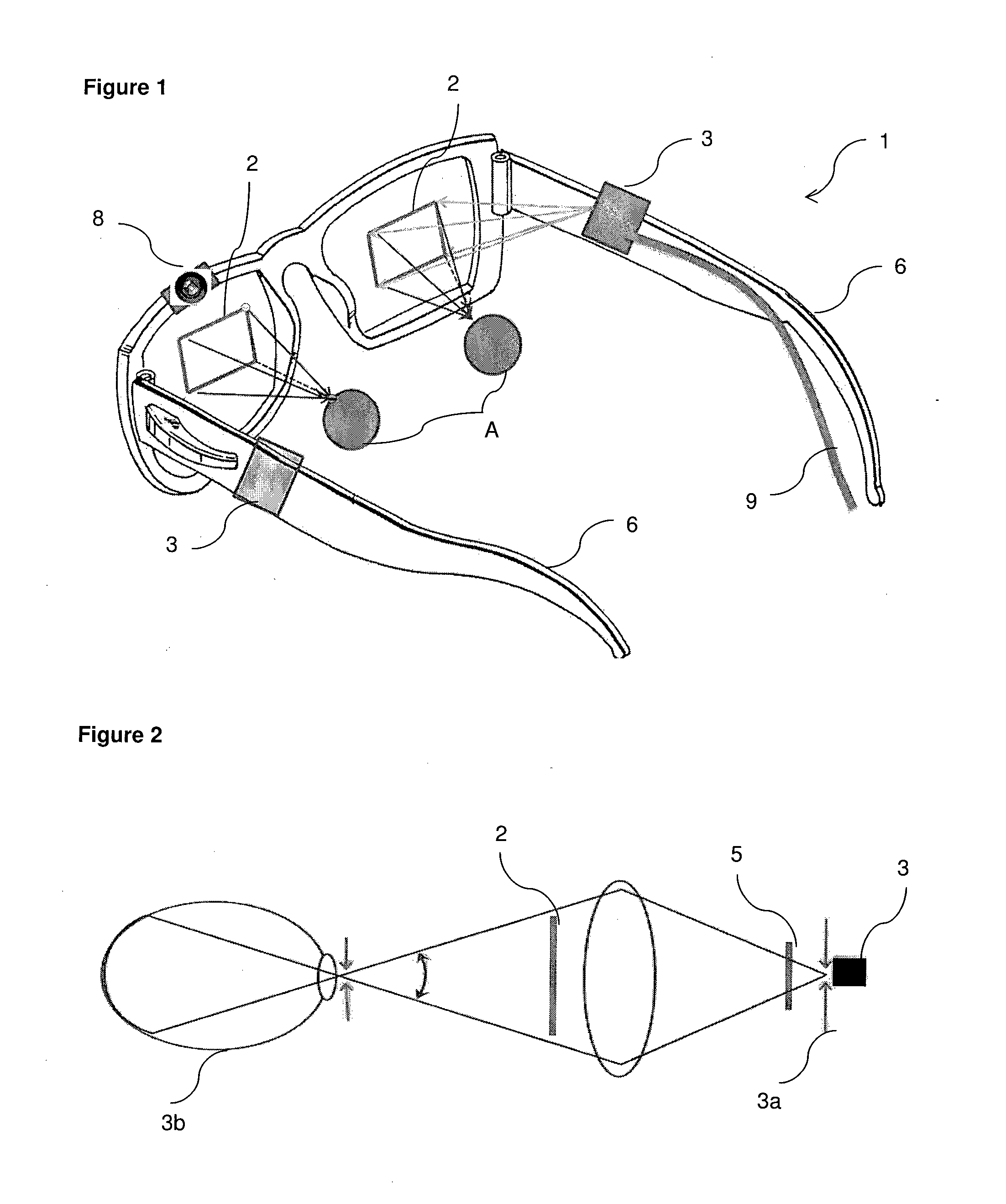

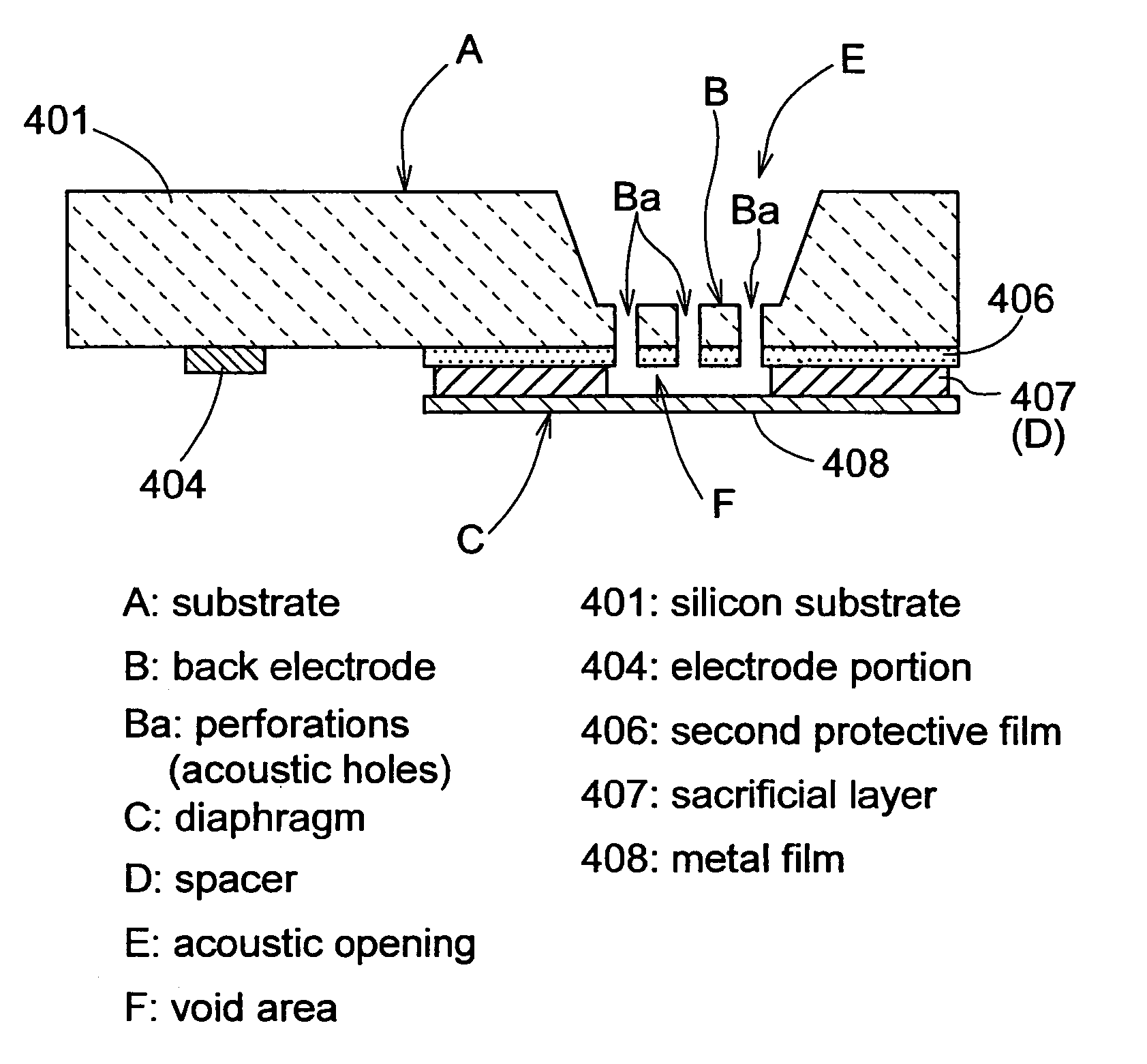

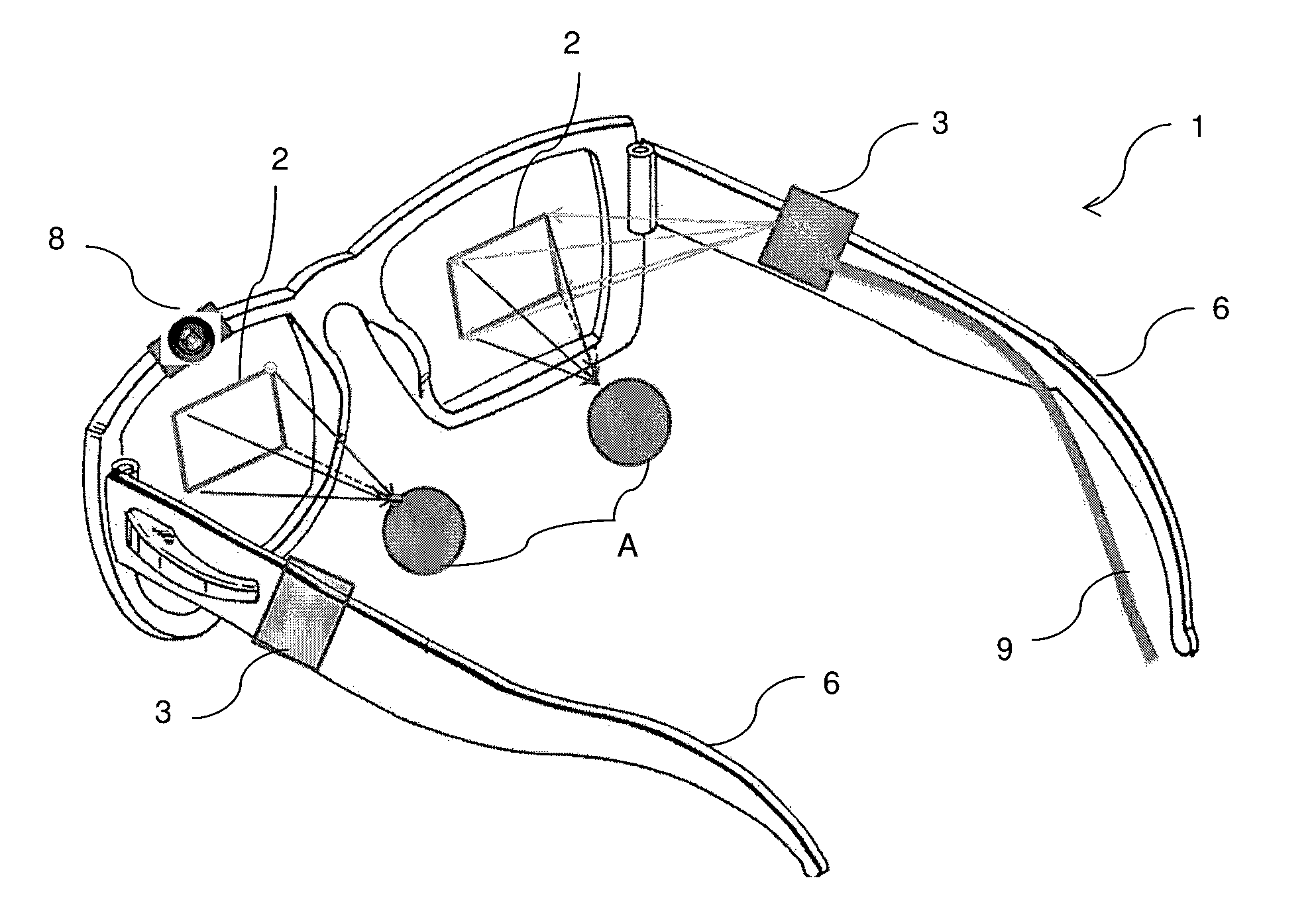

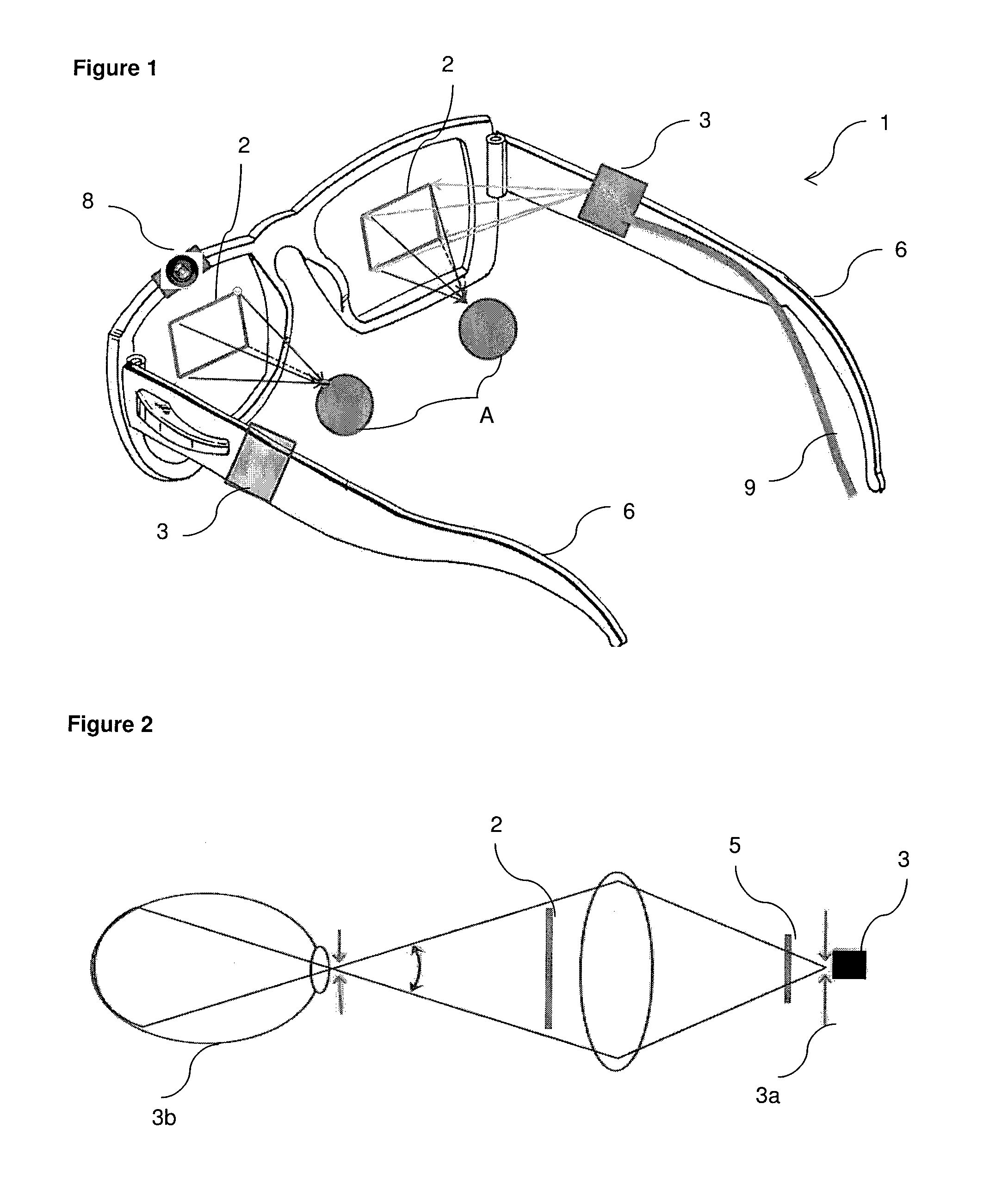

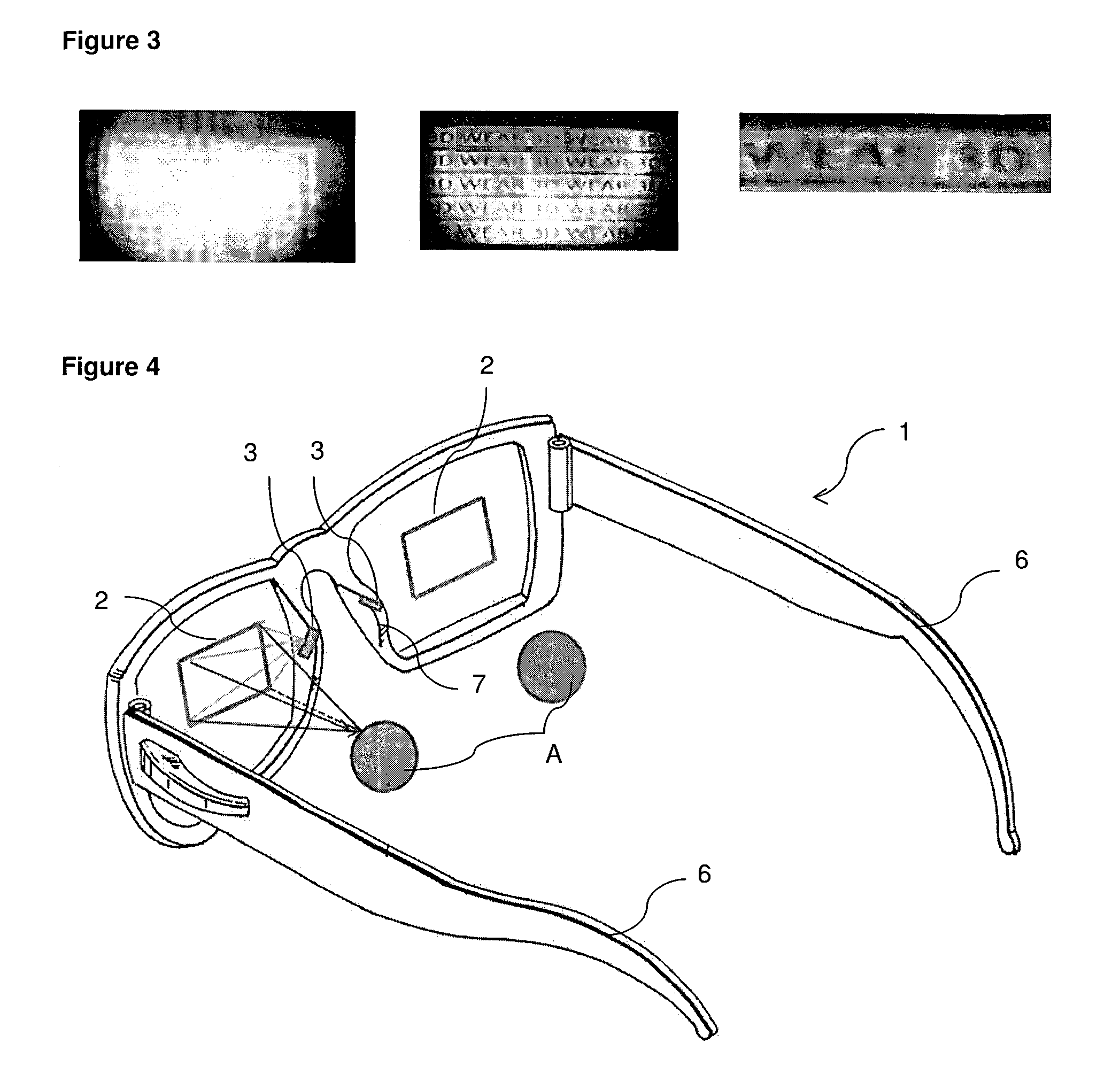

Image display device in the form of a pair of eye glasses

ActiveUS20160209656A1Large field of viewViewing comfortMirrorsNon-linear opticsEyes glassPoint light source

The present invention relates to an image display device (1) comprises at least one spatial light modulator (2), at least one point light source (3), wherein the light source (3) is placed in front of the spatial light modulator (2). The display device is suitable for wearable Augmented Reality (AR) and 3D displays.

Owner:CY VISION INC

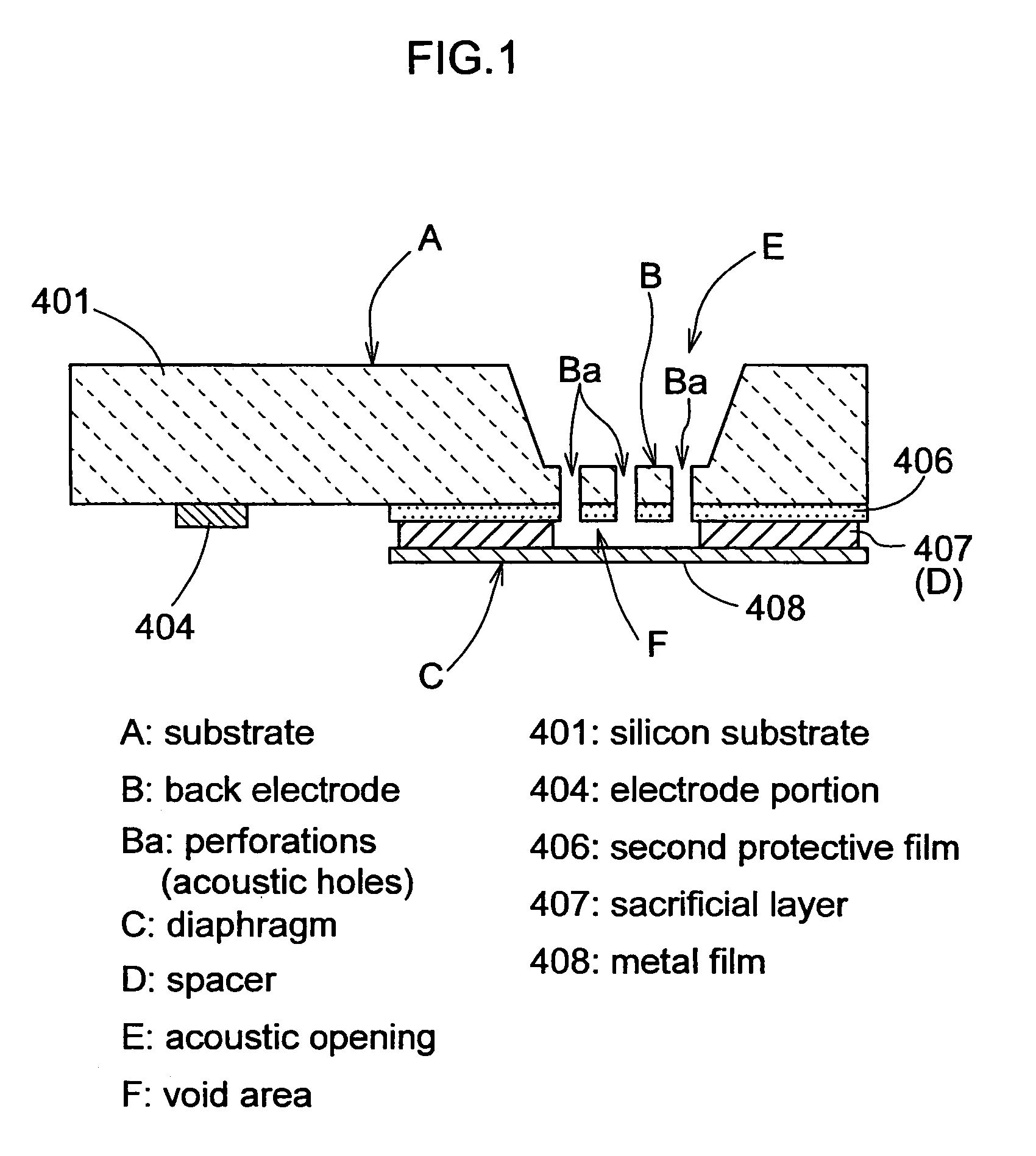

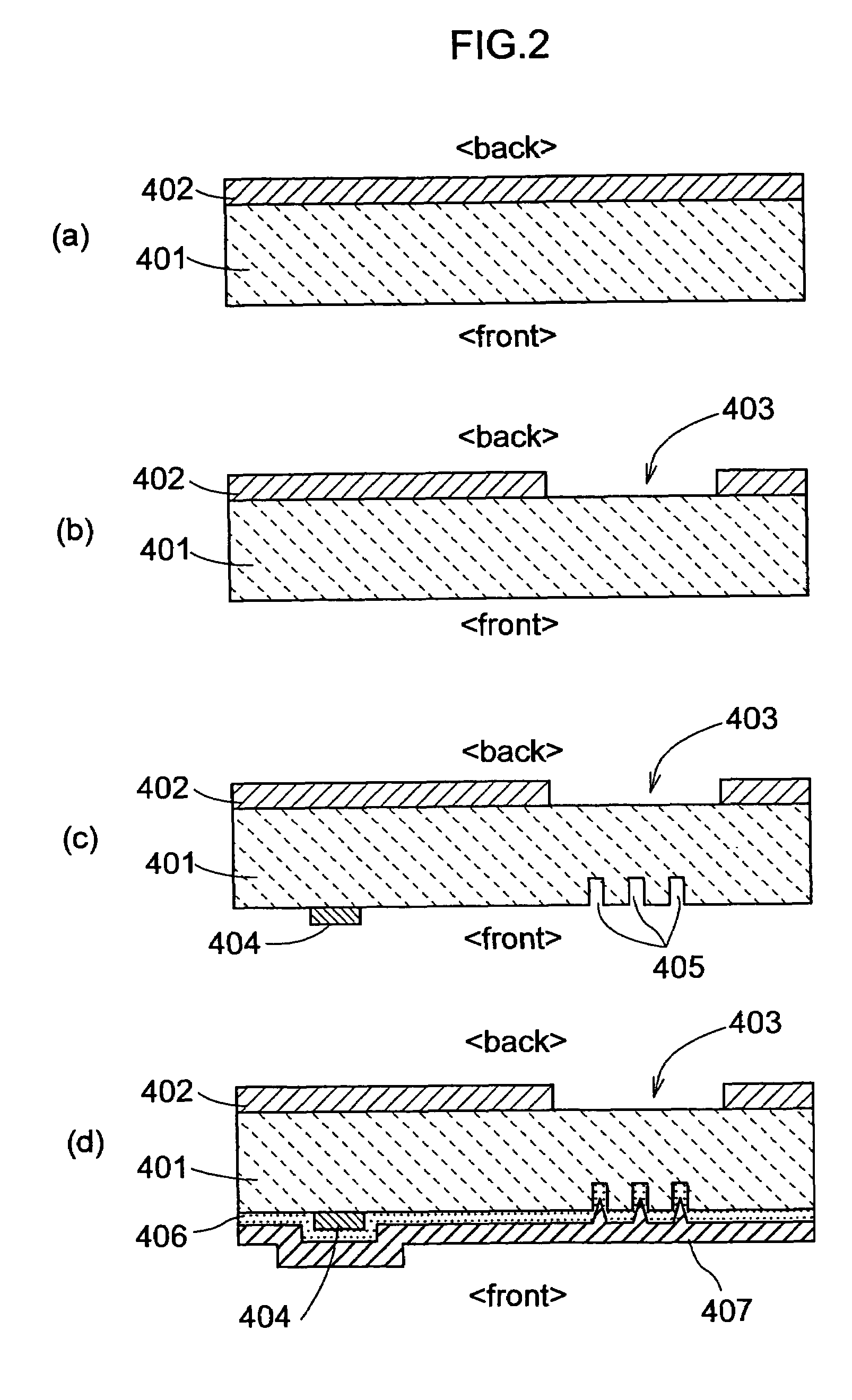

Sound detecting mechanism

InactiveUS7570773B2Miniaturization possibleReduce distancePiezoelectric/electrostriction/magnetostriction machinesElectrostatic transducer microphonesSound detectionTectorial membrane

A sound detecting mechanism capable of forming a diaphragm and a back electrode on a substrate by a simple process includes acoustic holes corresponding to perforations formed on a front surface of a substrate. A second protective film, a sacrificial layer and a metal film are laminated on the front surface in a portion corresponding to the acoustic holes. The substrate is etched from the back surface thereof to a depth reaching the acoustic holes to form an acoustic opening. Subsequently, by effecting an etching from the back surface of the substrate through the acoustic holes, the sacrificial layer is removed and a void area is formed between the diaphragm made of the metal film, the substrate and the formed perforations. The sacrificial layer that remains after the etching is used as a spacer for maintaining a gap between the back electrode and the diaphragm.

Owner:HOSIDEN CORP +1

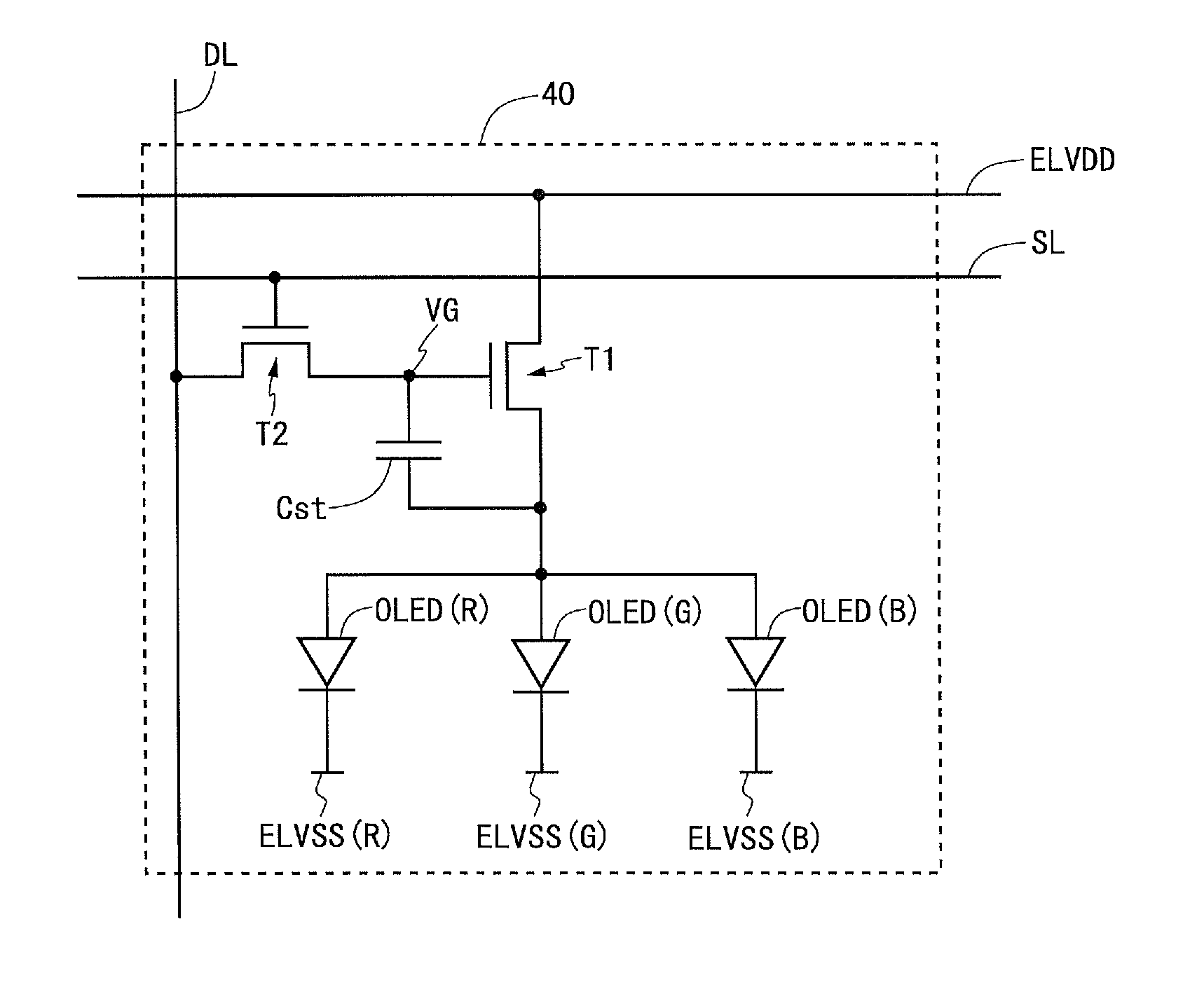

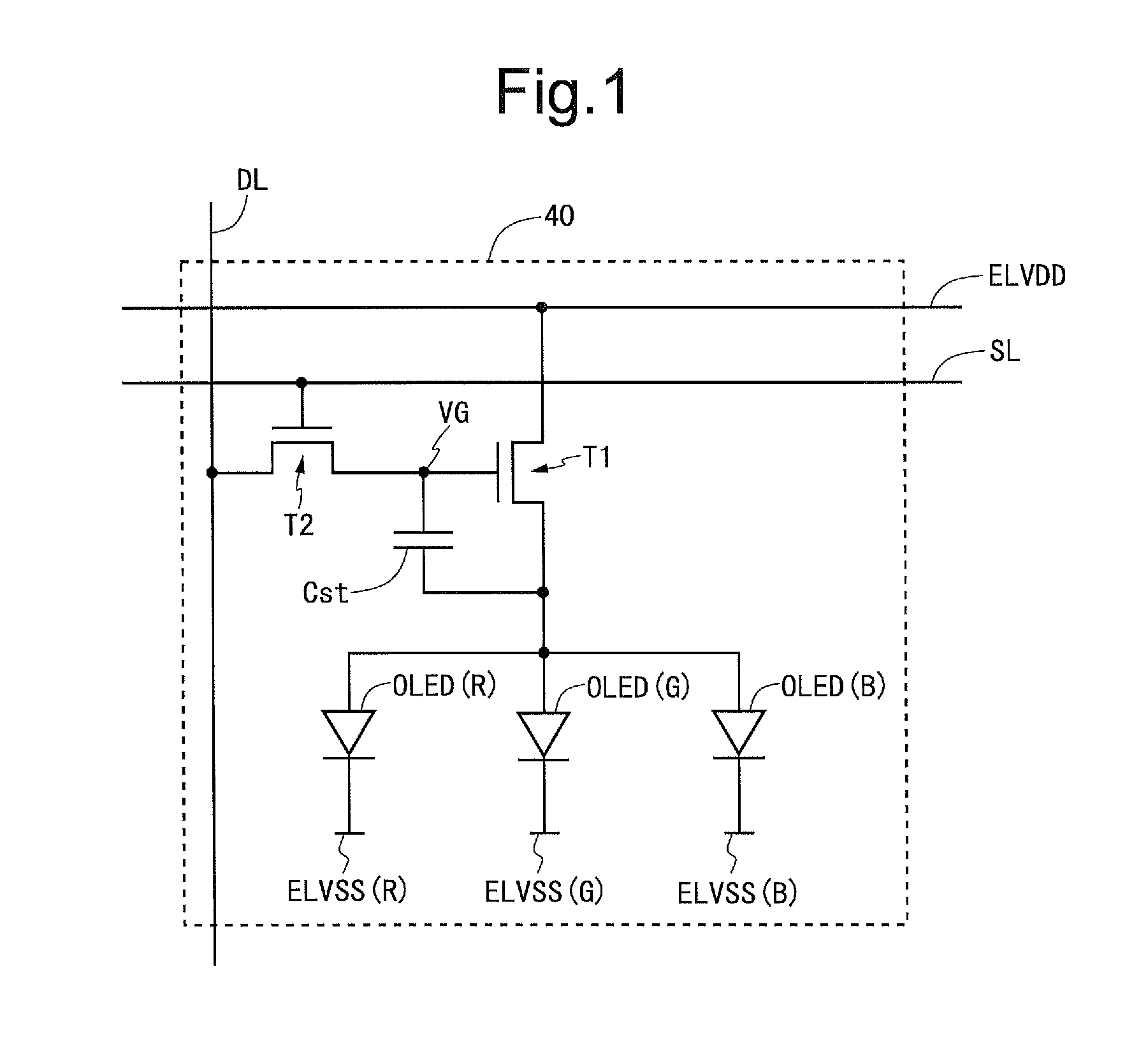

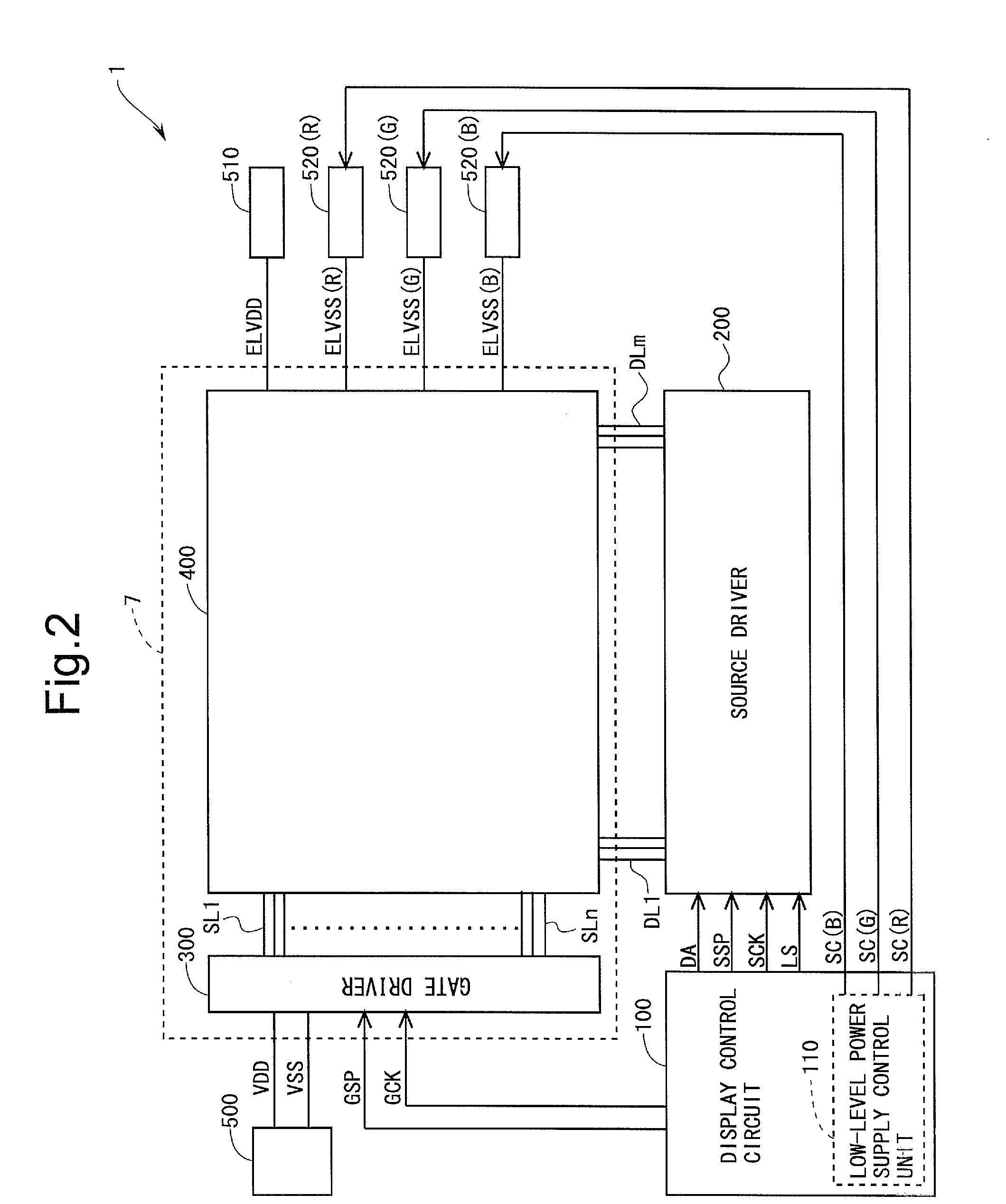

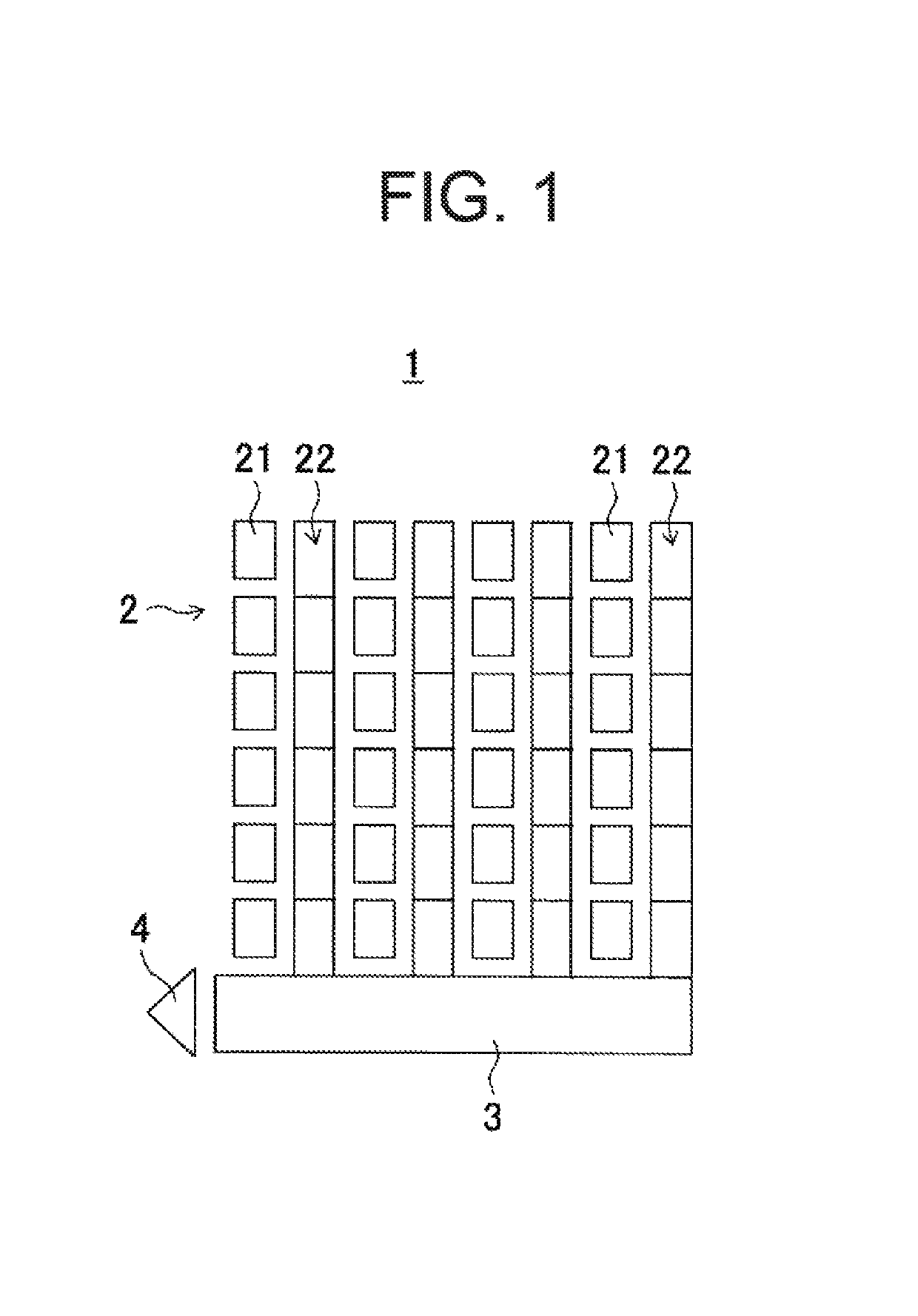

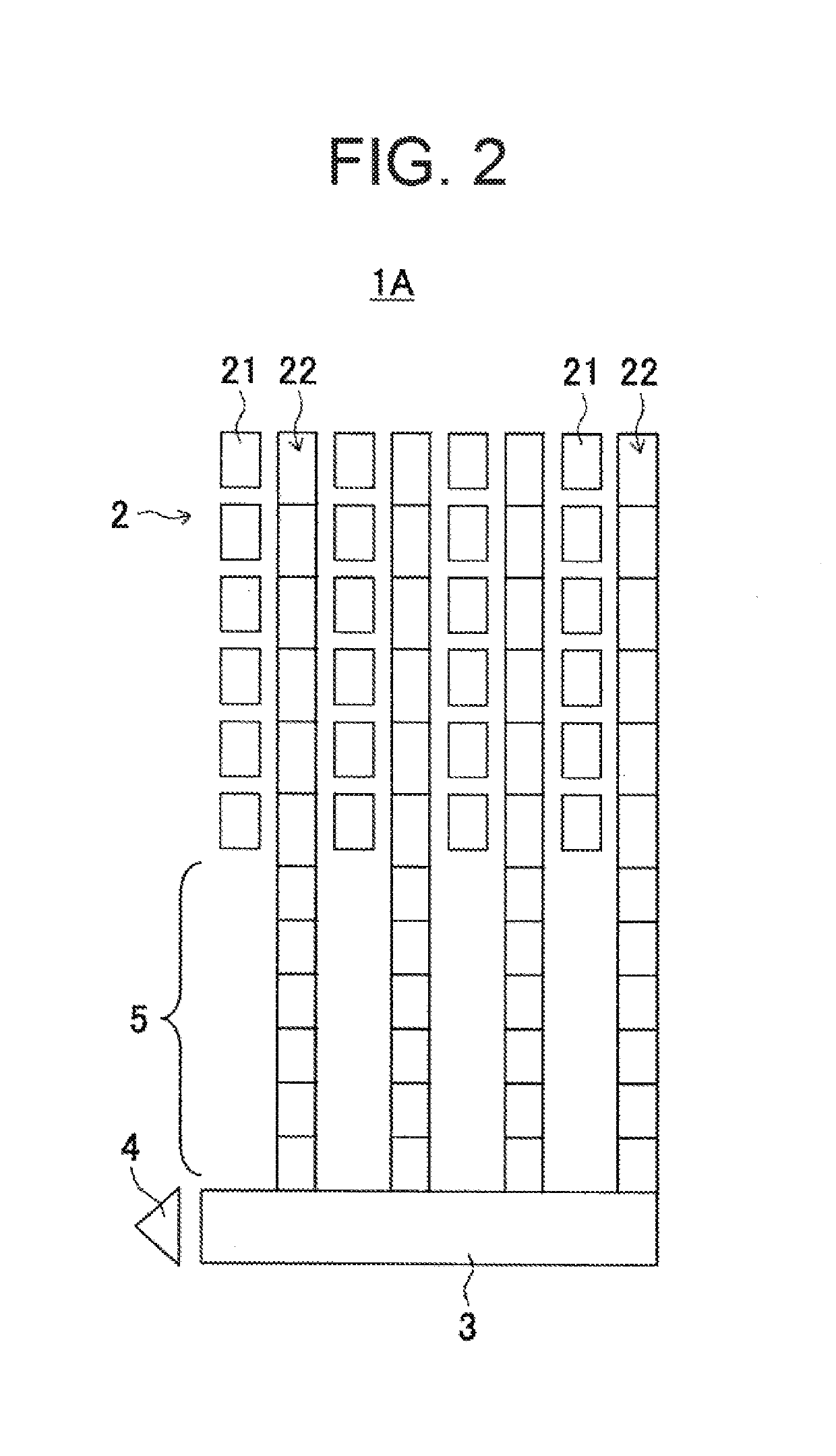

Display device and method for driving same

ActiveUS20150317952A1Reduce in quantitySimple configurationCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceHemt circuits

An embodiment of the present invention realizes a display device equipped with a self light-emitting type display element driven by a current, by using a pixel circuit having a configuration simpler than a conventional configuration. A pixel circuit includes a driving transistor (T1), an input transistor (T2), a capacitor (Cst), and three organic EL elements (OLED(R), OLED(G), and OLED(B)). Cathode terminals of the organic EL elements (OLED(R), OLED(G), and OLED(B)) are respectively connected to low-level power supply lines (ELVSS(R), ELVSS(G), and ELVSS(B)). In such a configuration, in each sub-frame, only a low-level power supply voltage (ELVSS) corresponding to the sub-frame is set to a relatively low level, and the other low-level power supply voltages (ELVSS) are set to relatively high levels.

Owner:SHARP KK

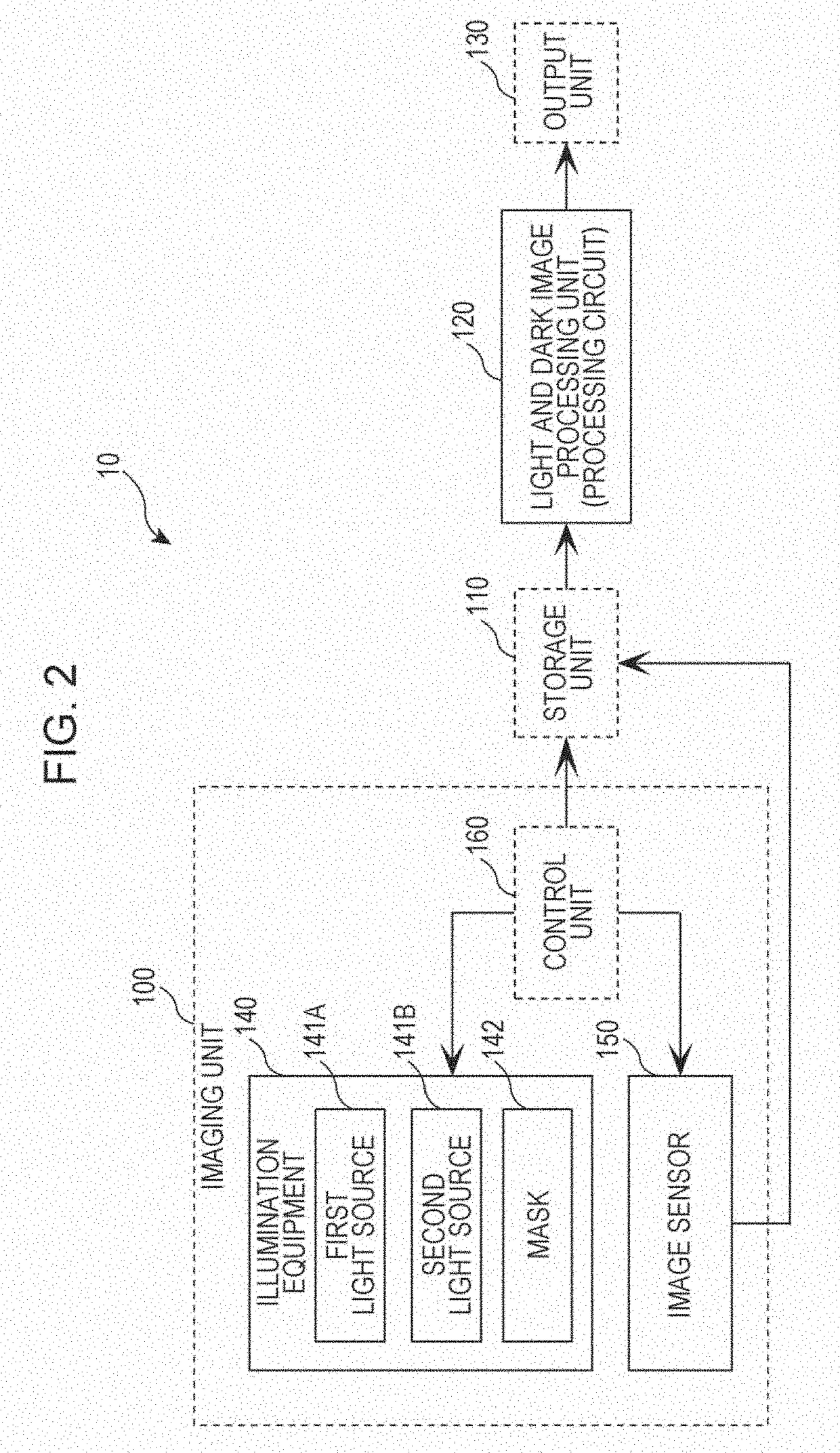

Image generating apparatus and image generating method

ActiveUS20180025475A1Miniaturization possibleTelevision system detailsImage enhancementImaging processingTransmitted light

An image generating apparatus is provided with: first and second light sources that illuminate a material; an image sensor on which the material is disposed; a mask which includes a light-transmitting part that transmits light and a light-blocking part that blocks light, and which is positioned between the image sensor and the first and second light sources; and a light and dark image processing unit. The image sensor acquires first and second images of the material when illuminated by the first and second light sources, respectively. The light and dark image processing unit derives a difference between a luminance value of a pixel included in the first image and a luminance value of a pixel included in the second image at the same position as the pixel included in the first image, and thereby generates a third image of the material.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

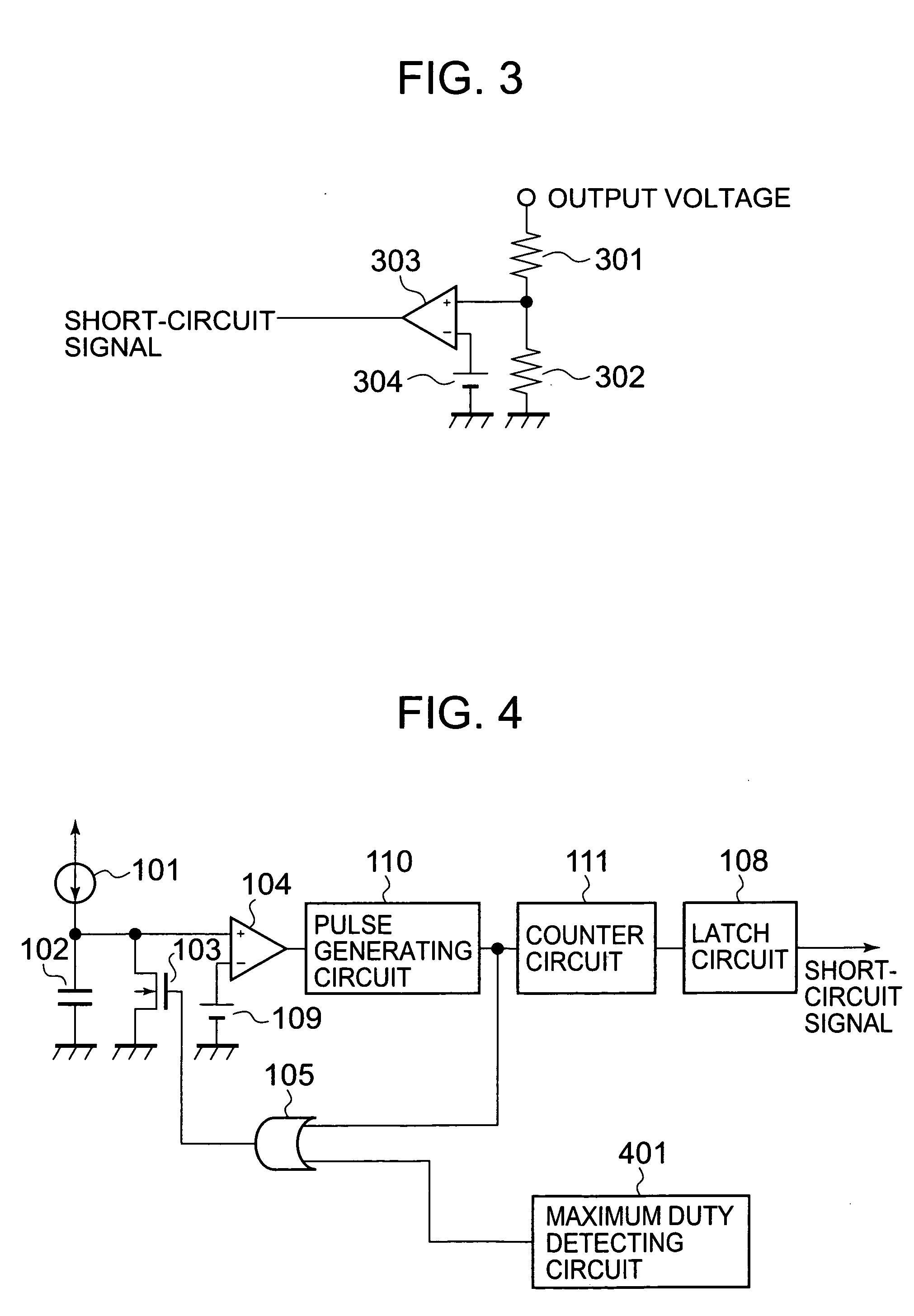

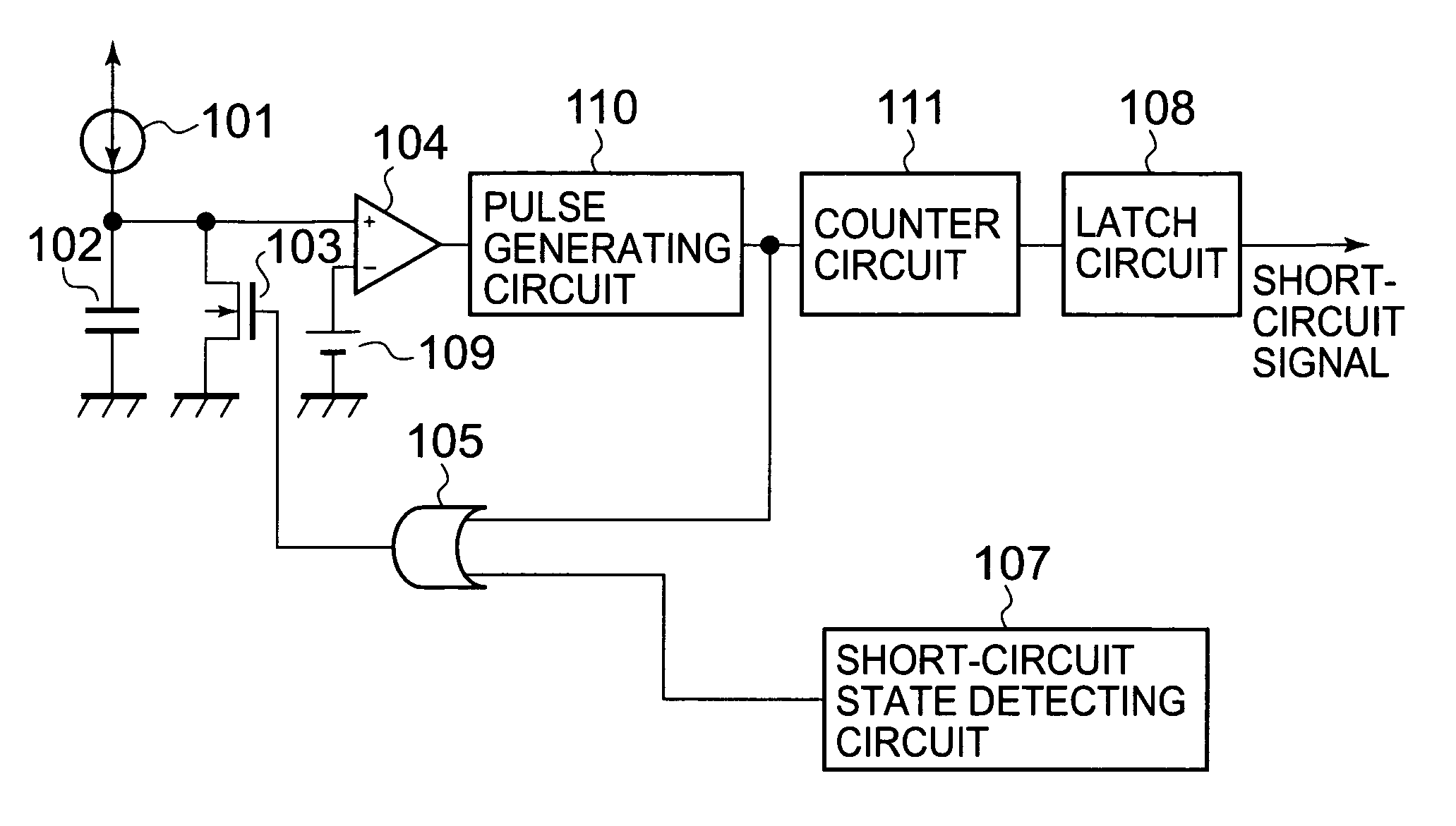

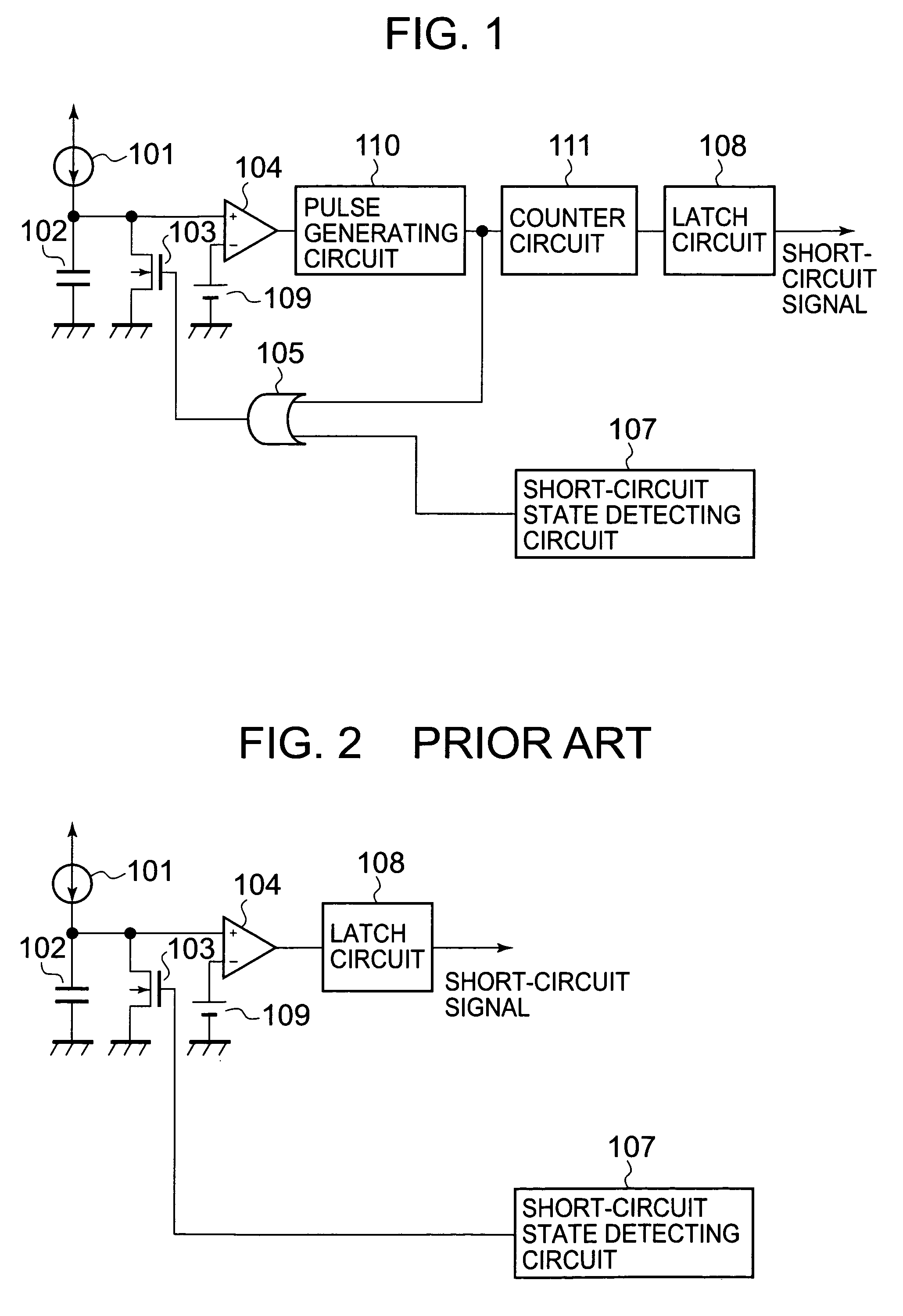

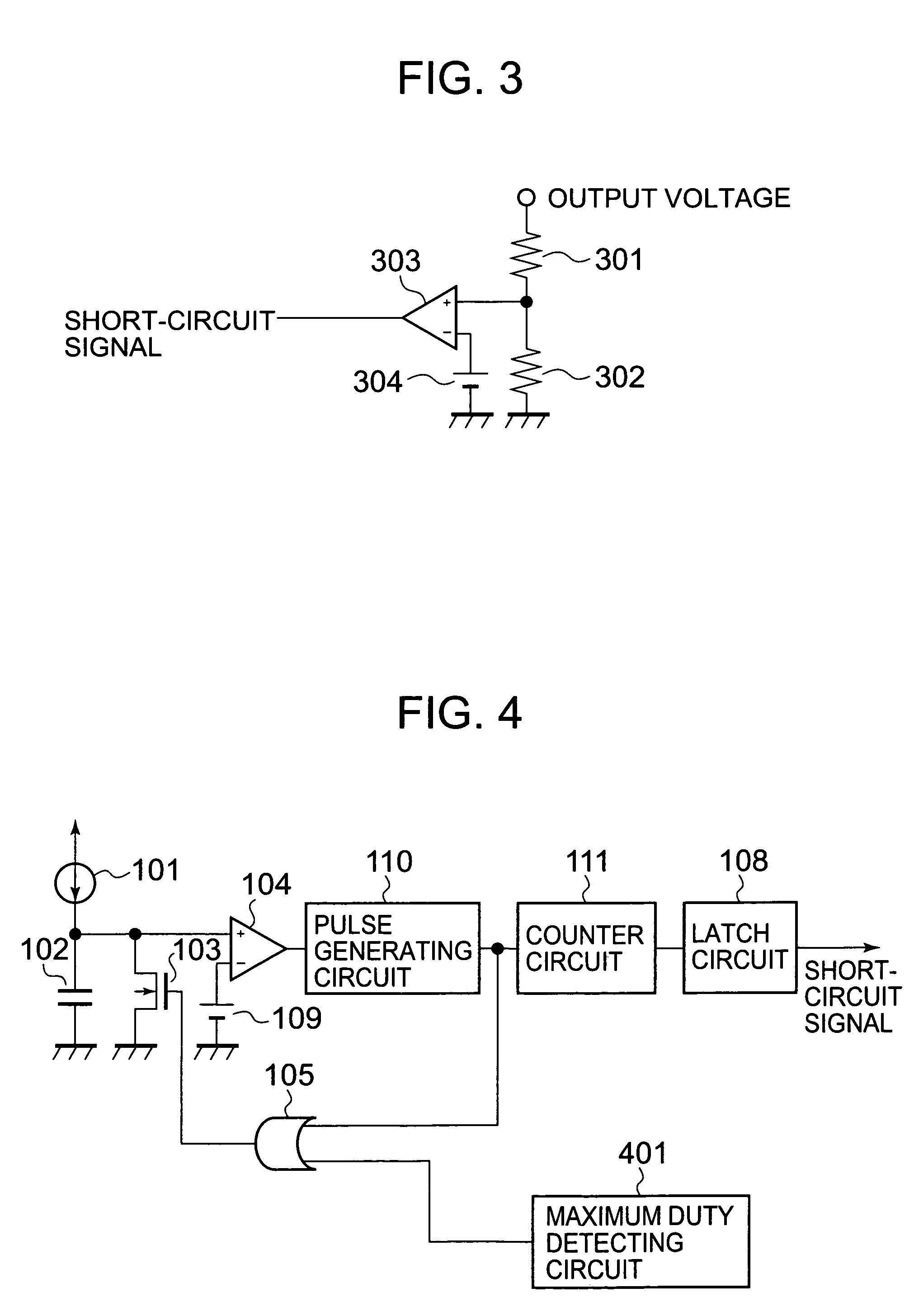

Switching regulator

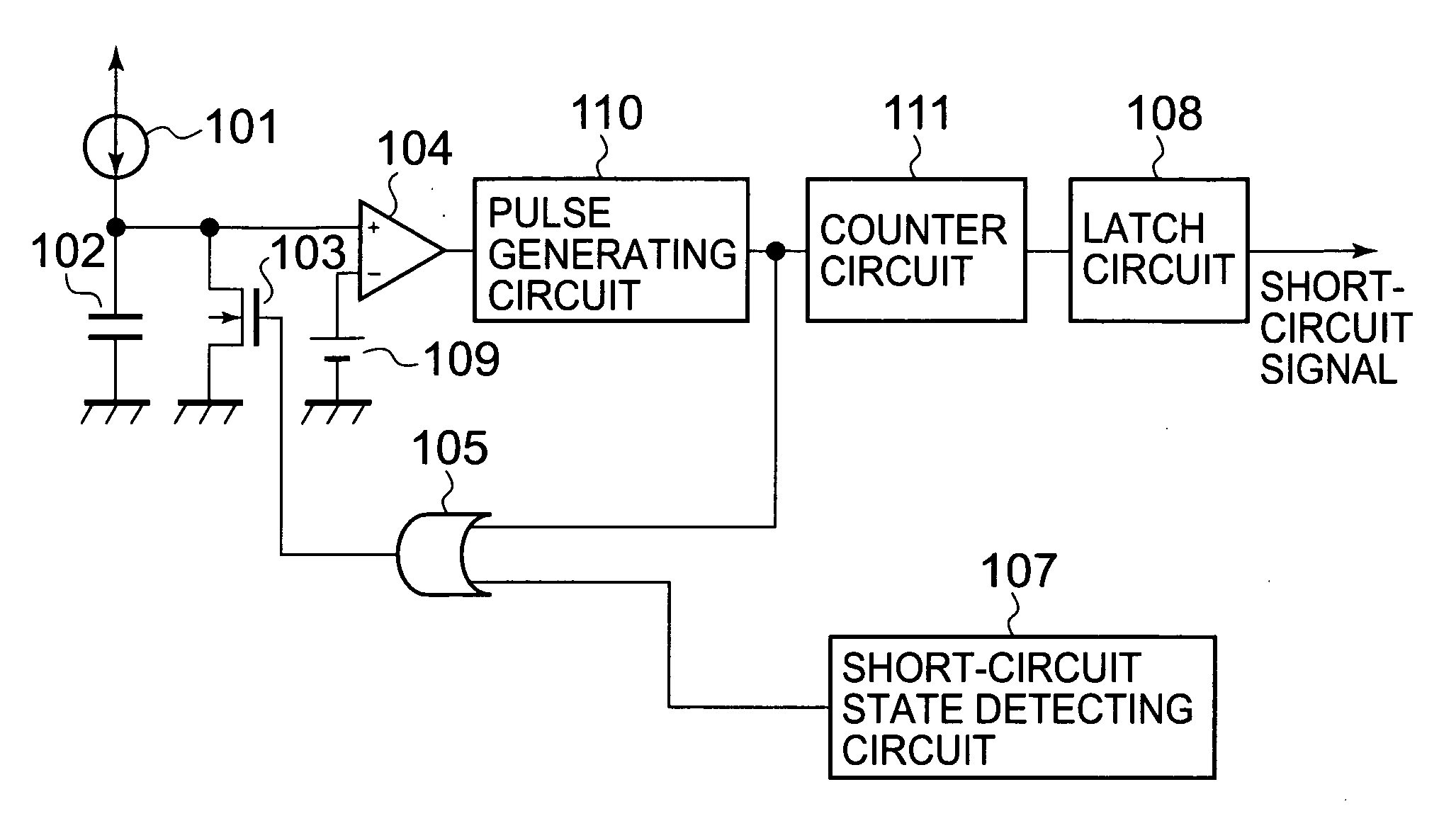

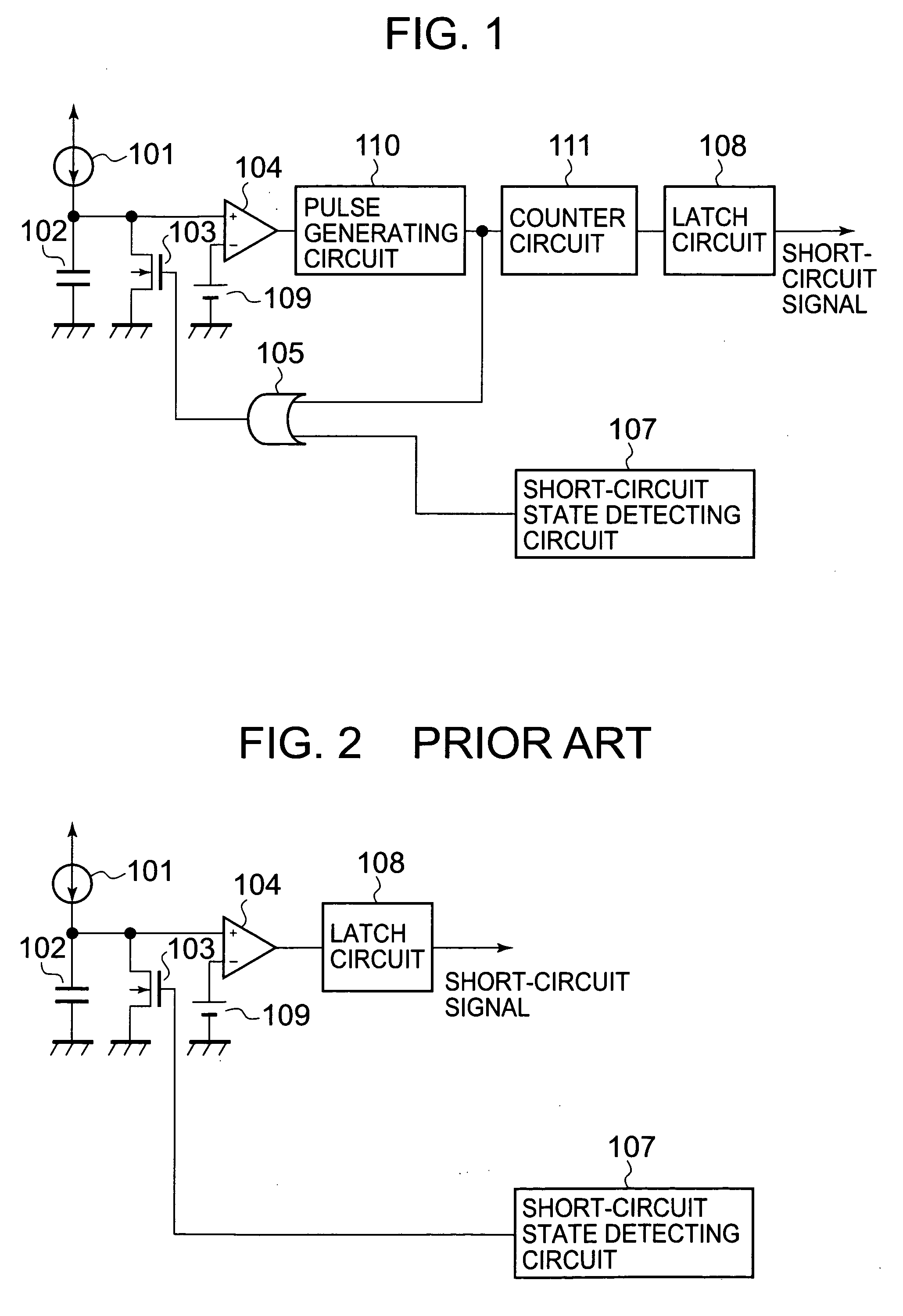

ActiveUS20060076941A1Long delay timeMiniaturization possibleDc-dc conversionElectronic switchingWork periodDelayed time

The present invention provides a short-circuit protecting circuit of a switching regulator which does not require a capacitor having a large capacity in order to obtain a sufficient duty time. A pulse generating circuit for generating one clock with a short-circuit detection signal as a trigger signal is added, and a counter circuit for counting clock pulses of a clock signal is further inserted between a comparator and a latch circuit, whereby it becomes possible to produce a sufficient delay time based on a signal having a short period using a capacitor having a small capacity.

Owner:ABLIC INC

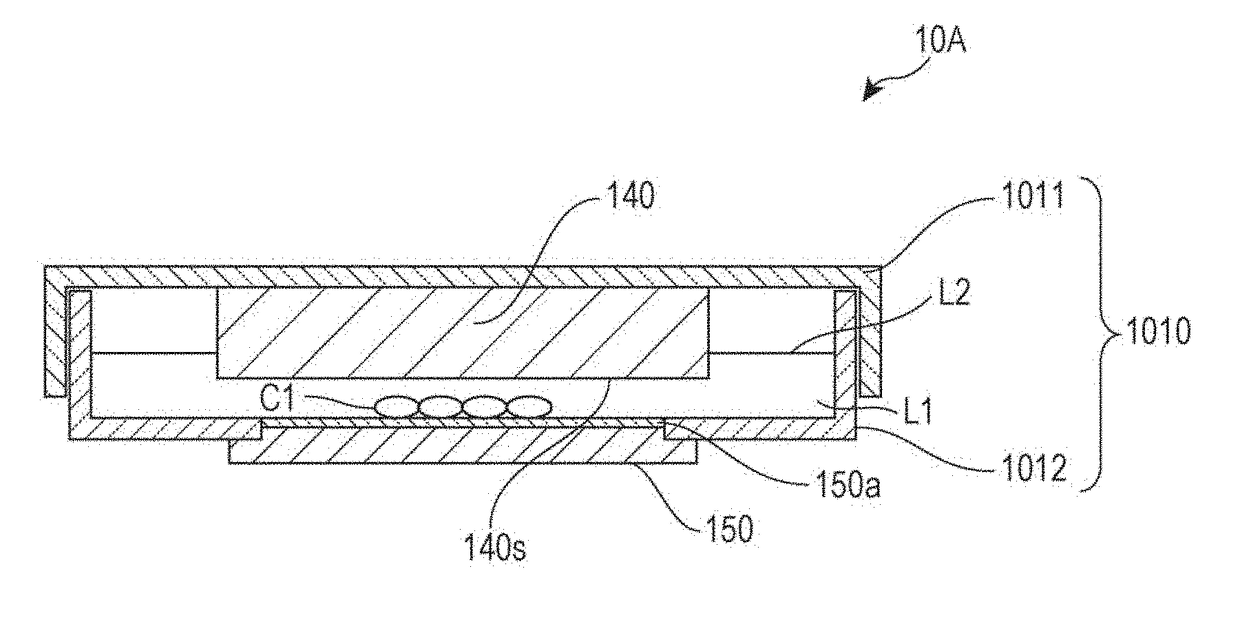

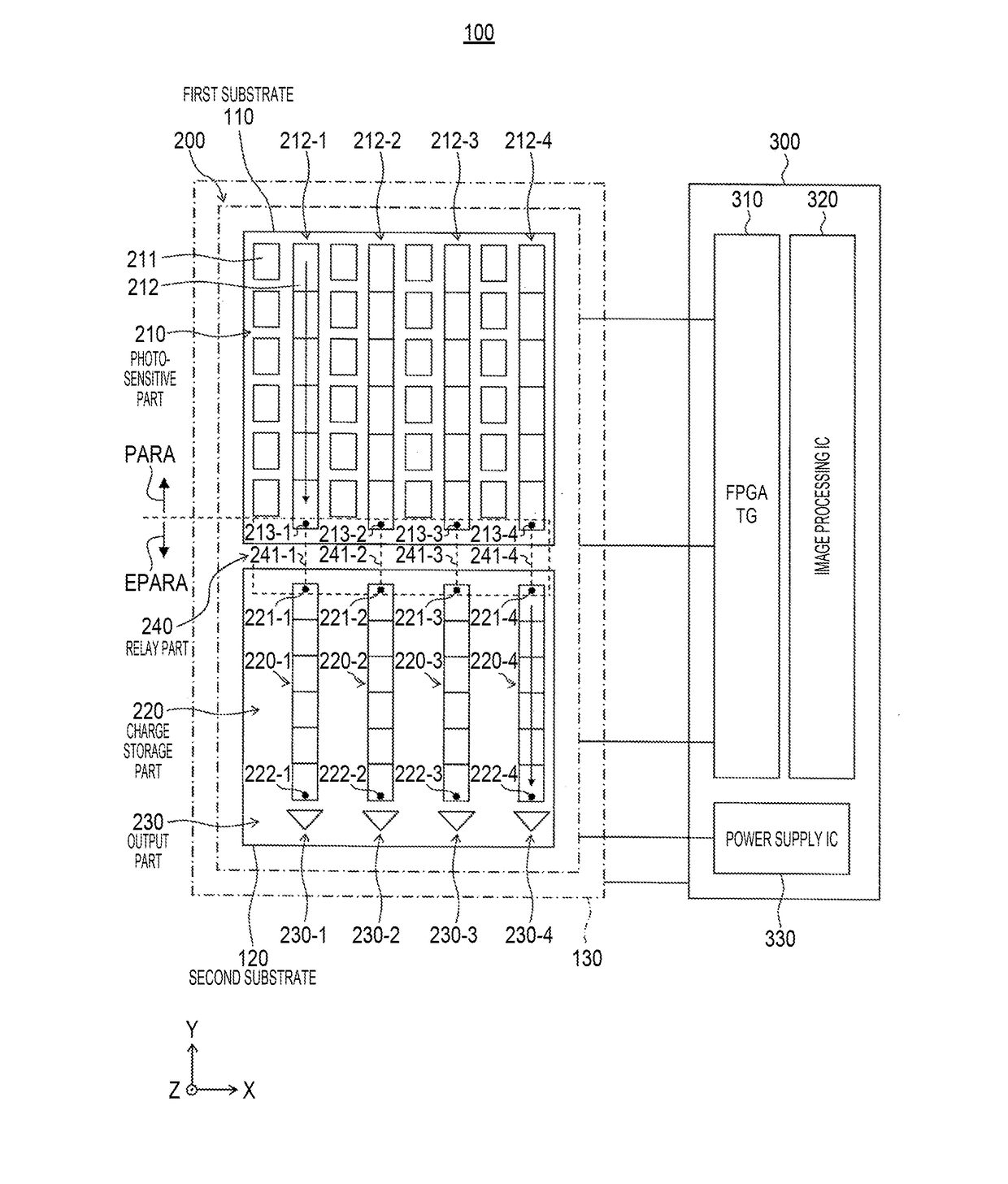

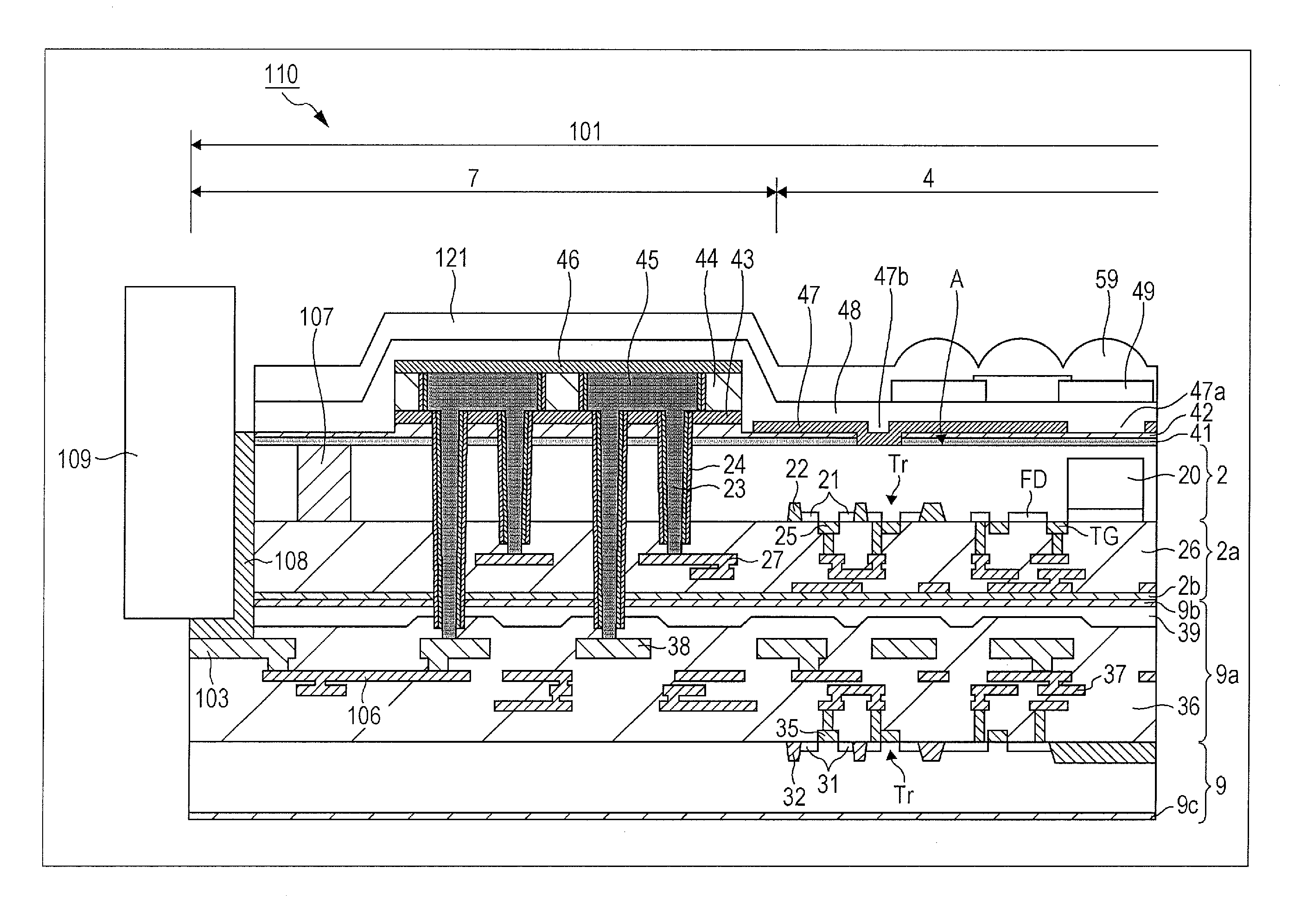

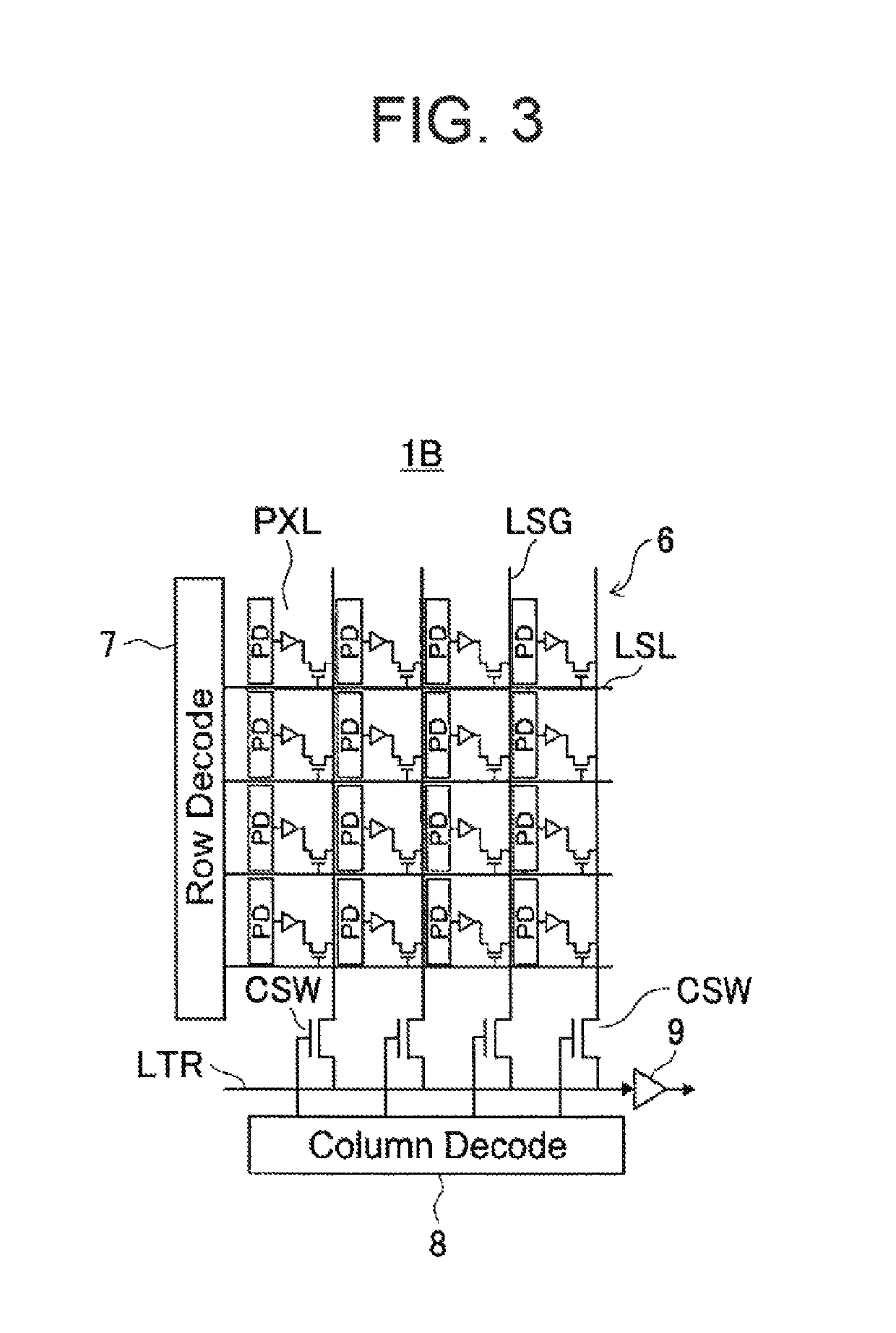

Solid-state imaging device, method for producing solid-state imaging device, and electronic apparatus

ActiveUS20170162625A1High speed readLittle restrictionTelevision system detailsSemiconductor/solid-state device detailsElectricityEngineering

This solid-state imaging device 100 has: a photosensitive part that includes pixel portions 211, which are disposed in a matrix, and charge transfer parts 212 for transferring, by the column, the signal charge of the pixel portions; a plurality of charge storage parts 220 that accumulate the signal charges transferred by the plurality of charge transfer parts of the photosensitive part; a relay part 240 that relays the transfer of the signal charges transferred by the plurality of charge transfer parts to each charge storage part; an output part 230 that outputs the signal charges of the plurality of charge storage parts as electric signals; a first substrate 110 at which the photosensitive unit 210 is formed; and a second substrate 120 at which the charge storage part 220 and output unit 230 are formed. The first substrate and second substrate are stacked together, and the relay part 240 electrically couples the charge transfer parts of the first substrate to the charge storage parts of the second substrate by means of a connecting parts passing through the substrates outside the photosensitive region of the photosensitive part.

Owner:BRILLNICS JAPAN

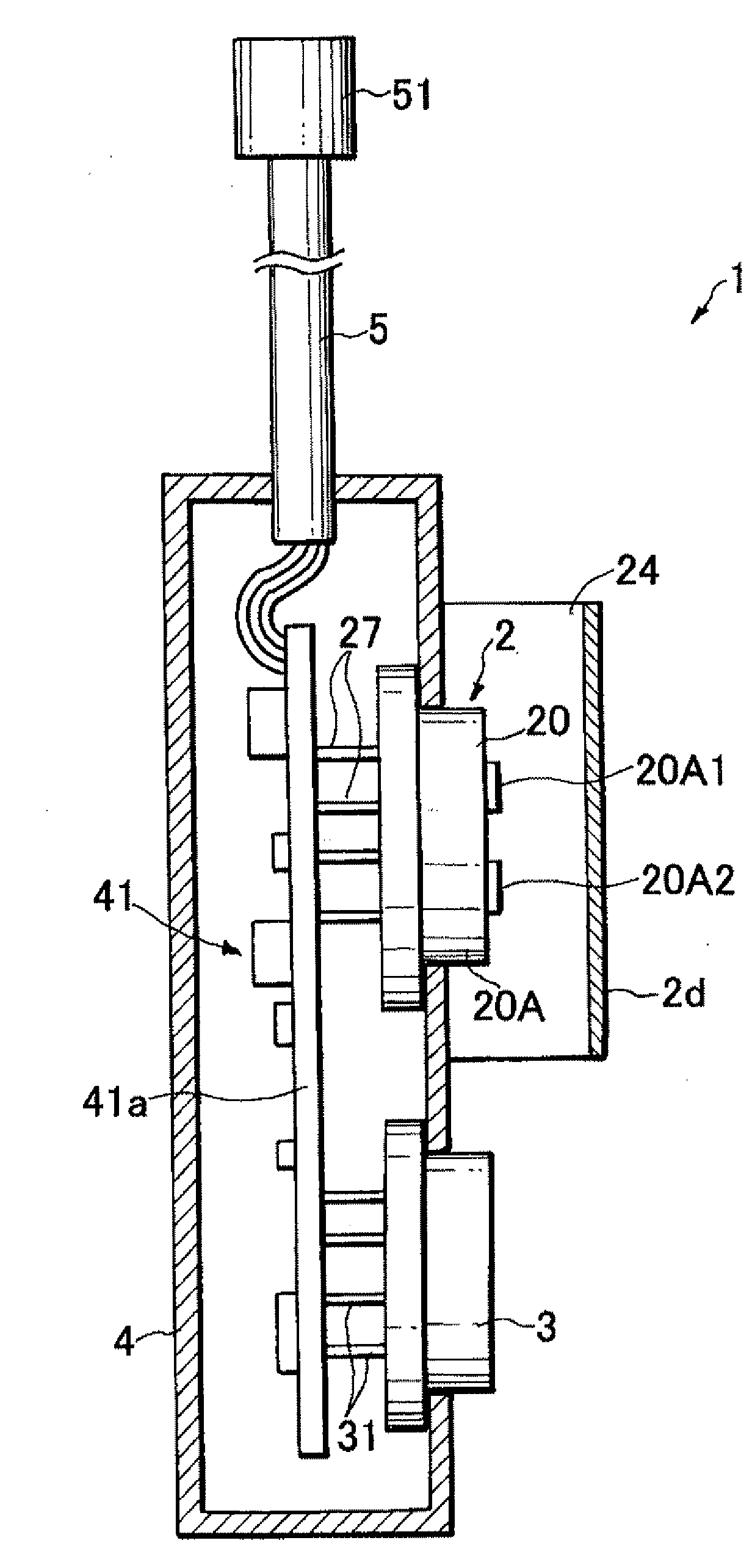

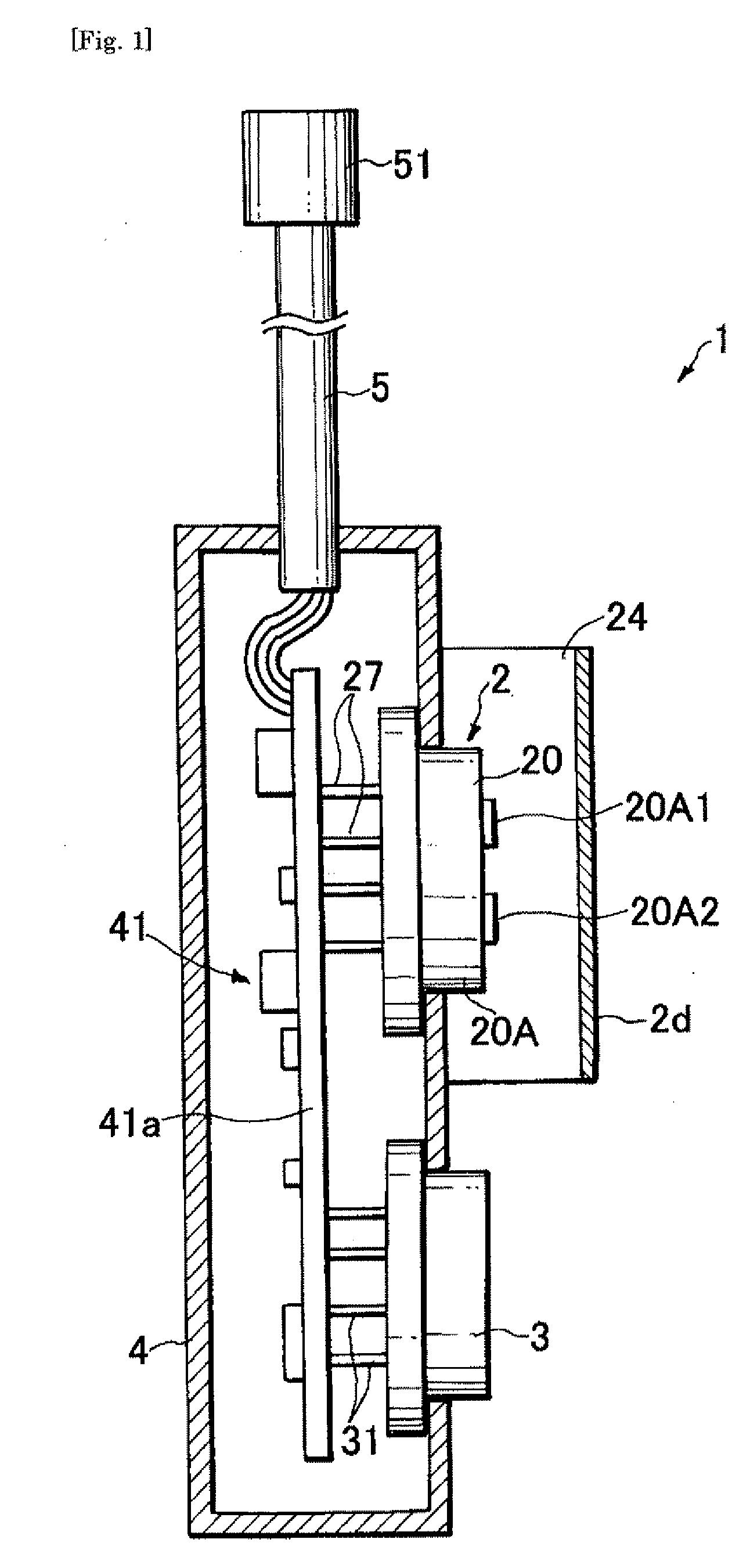

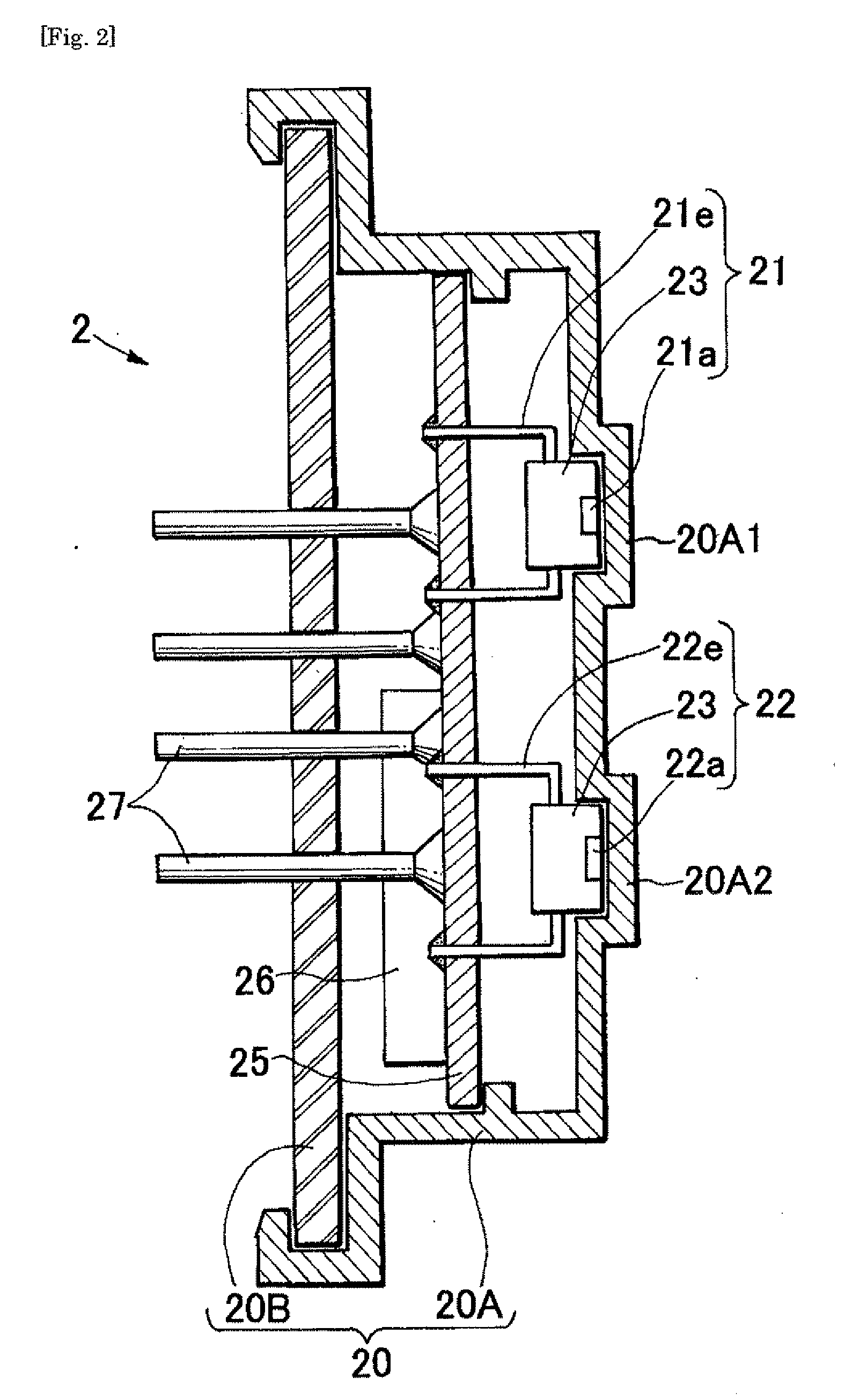

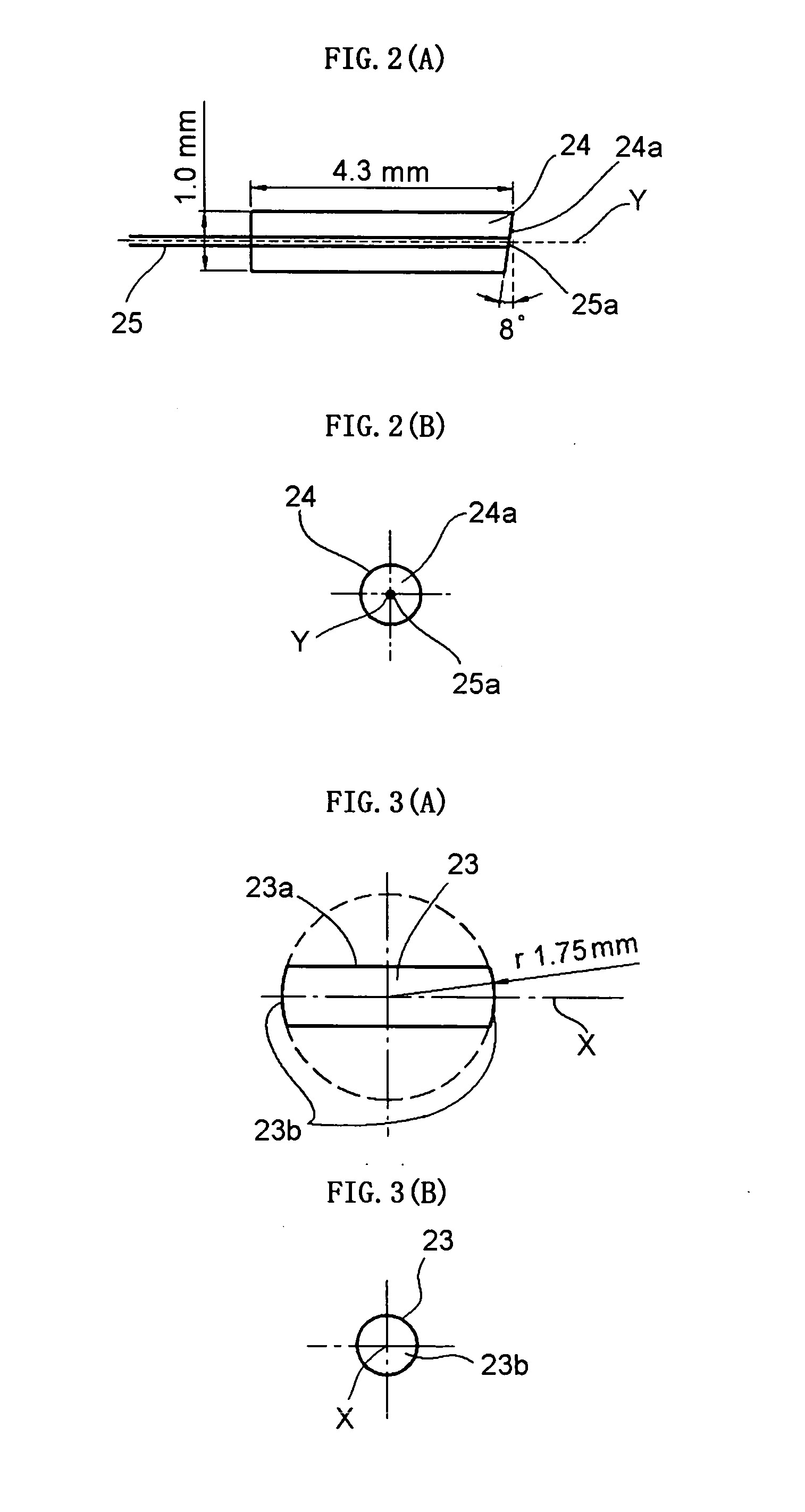

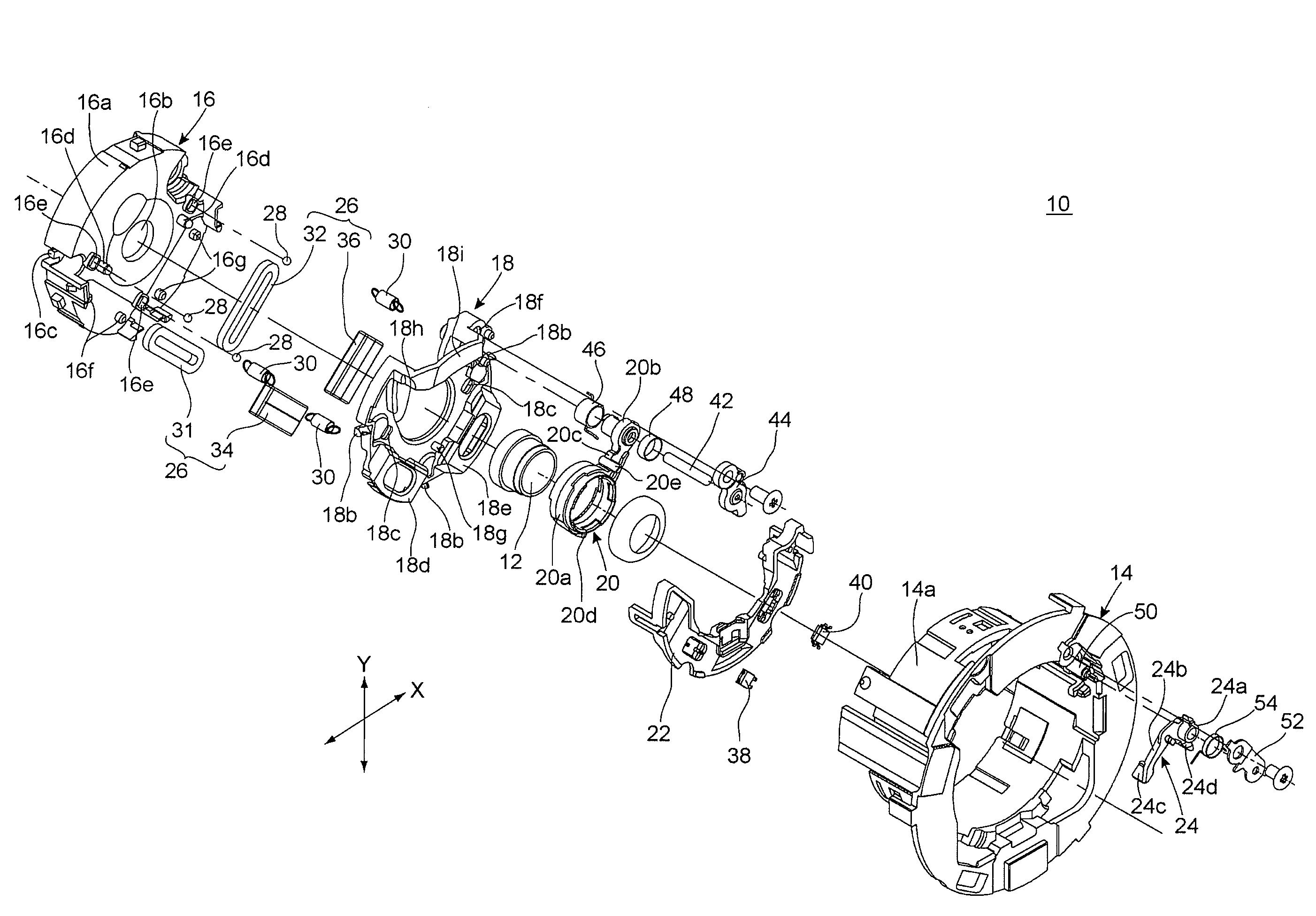

Lens barrel having an image-stabilizing insertable/removable optical element

InactiveUS8773762B2Improve imaging stabilityMiniaturization possibleTelevision system detailsPrintersEngineeringActuator

Owner:HOYA CORP

Chemical Analytic Apparatus and Chemical Analytic Method

InactiveUS20120135533A1Miniaturization possibleEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsMiniaturizationEngineering

A chemical analytic apparatus of the present invention is the one which proposes that a miniaturization, a making low-cost and portability are possible and also the operation of each process of separation, concentration and dilution of specimen is possible, and, which includes: an introduction means (S1) that introduces a droplet to which magnetic ultrafine particles are mixed into another liquid that differs from the droplet while maintaining a single droplet; a conveyance means by which the droplet that includes the magnetic particles is conveyed in another liquid of the introduction means by applying magnetic field externally to the magnetic ultrafine particles; and processing means (S2 to S6) by which operations for processing of chemical analysis are performed one by one in the process in which the droplet to which the magnetic ultrafine particles are mixed is conveyed by the conveyance means

Owner:JAPAN SCI & TECH CORP

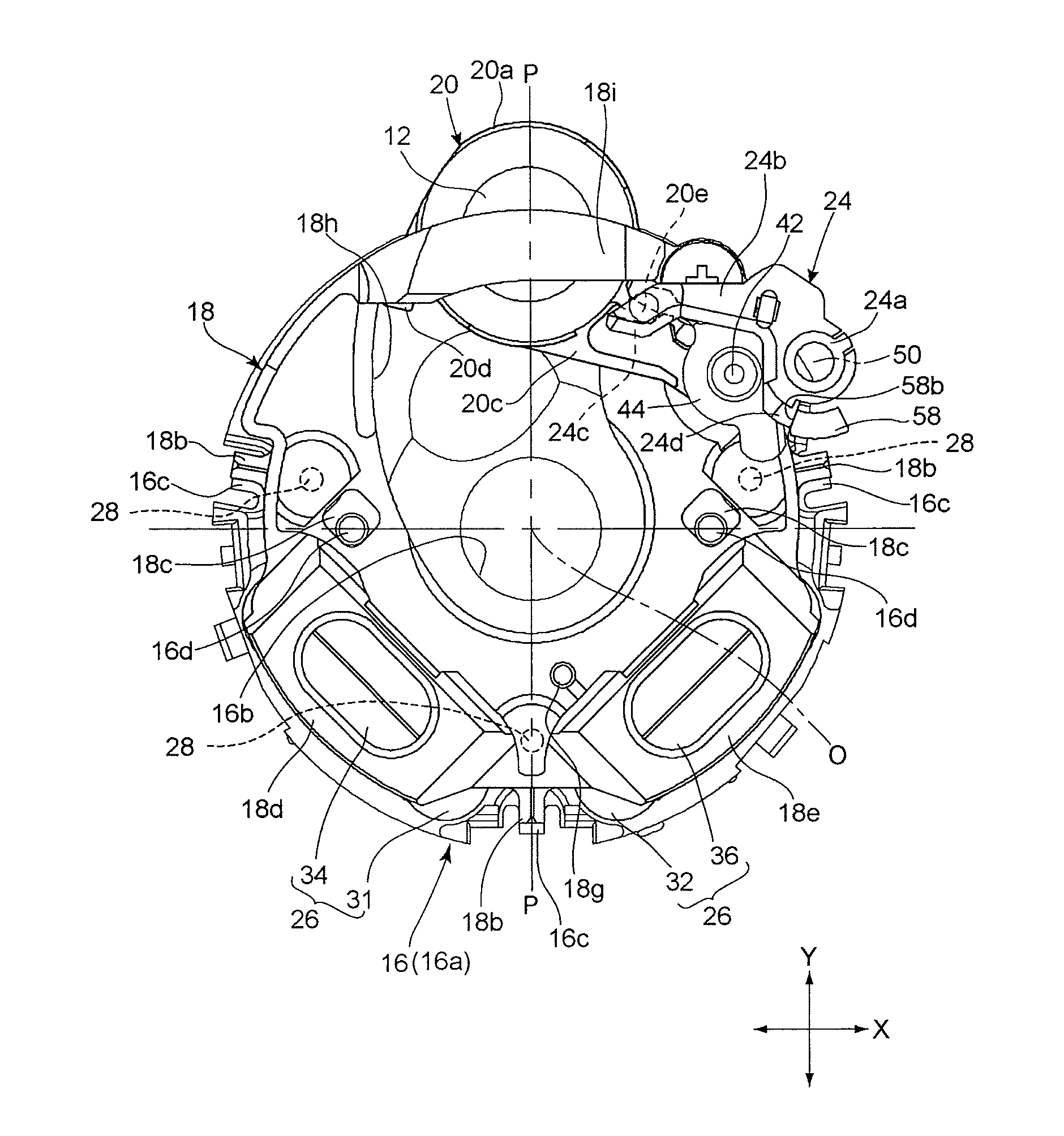

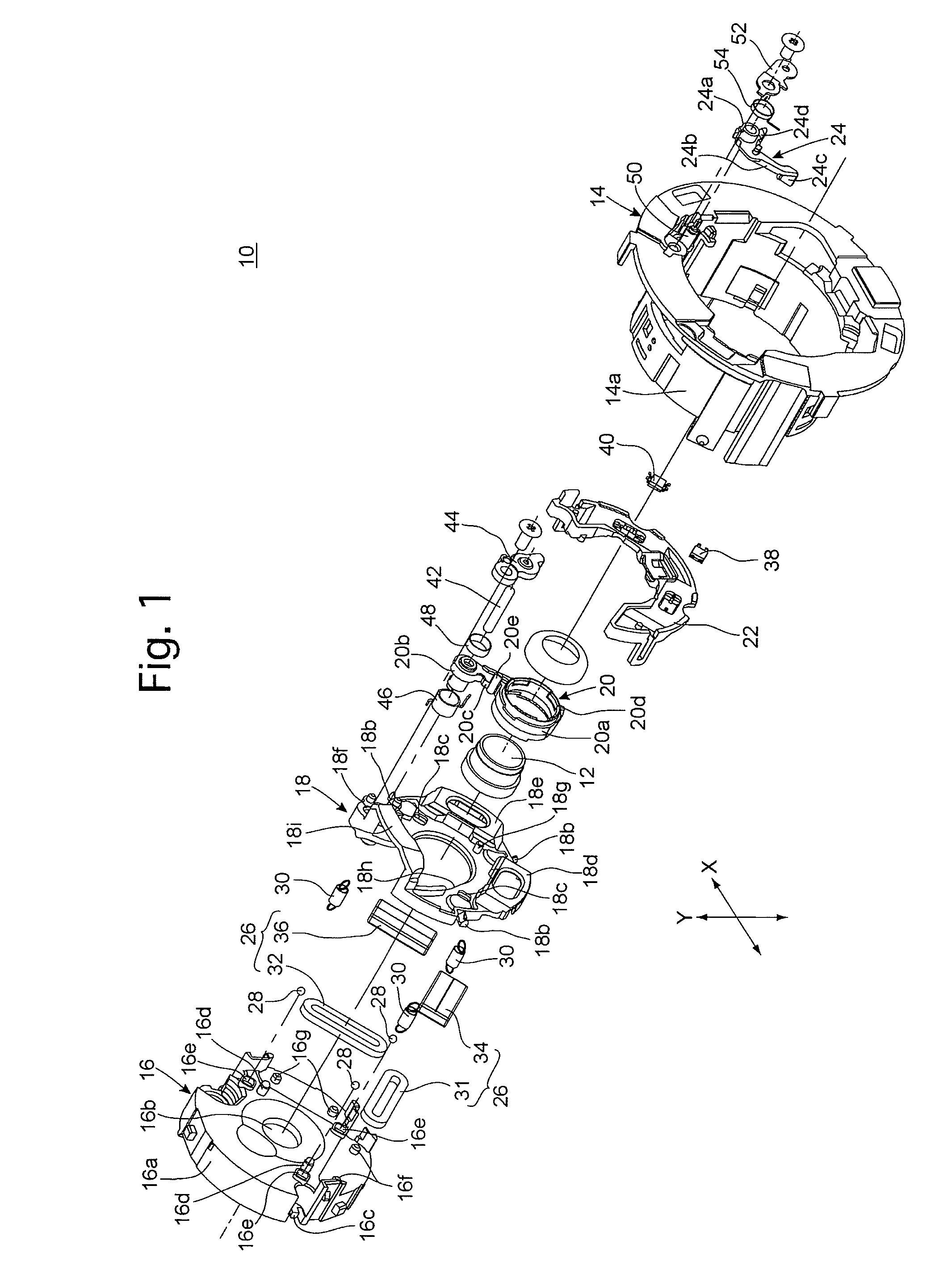

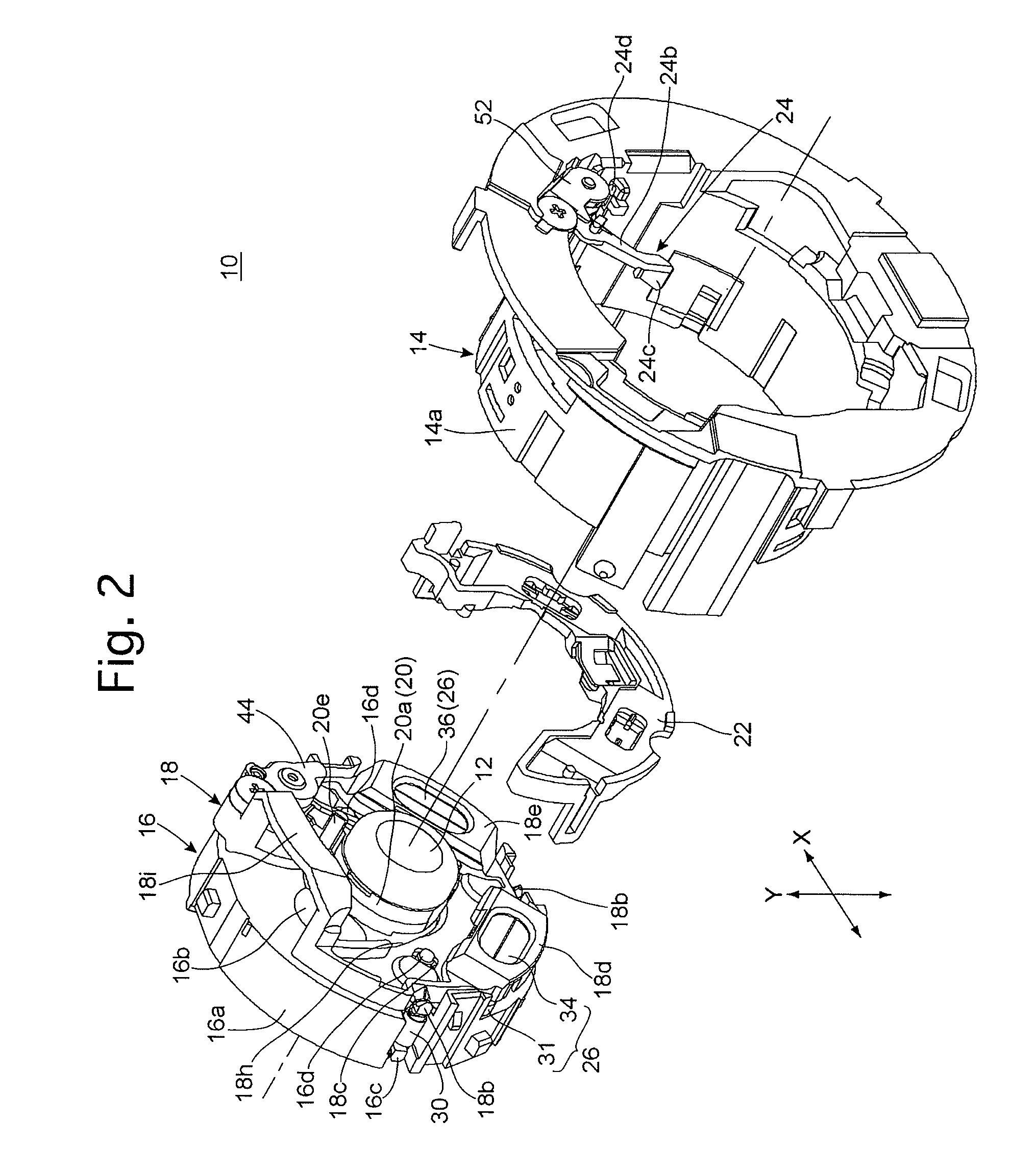

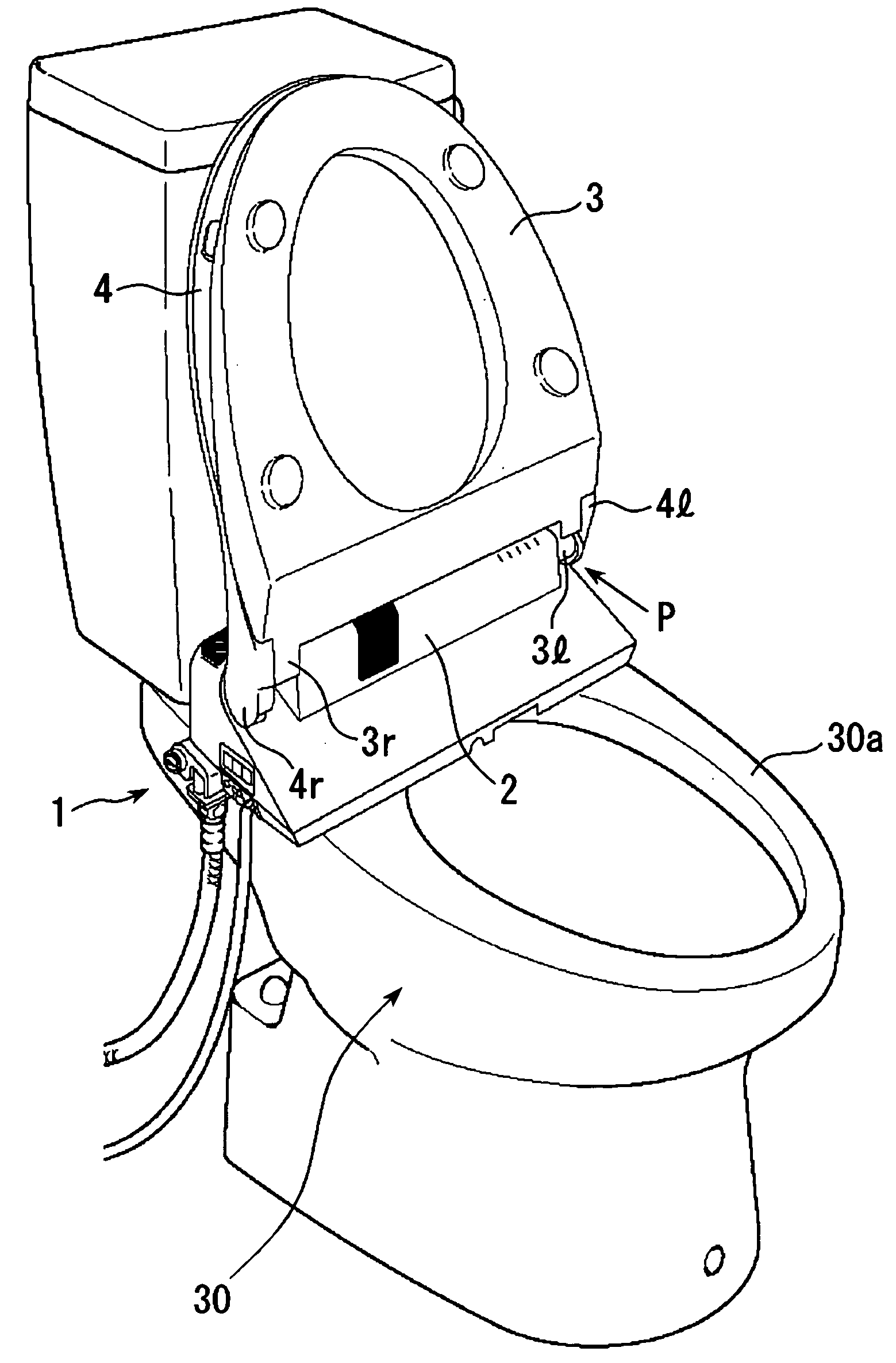

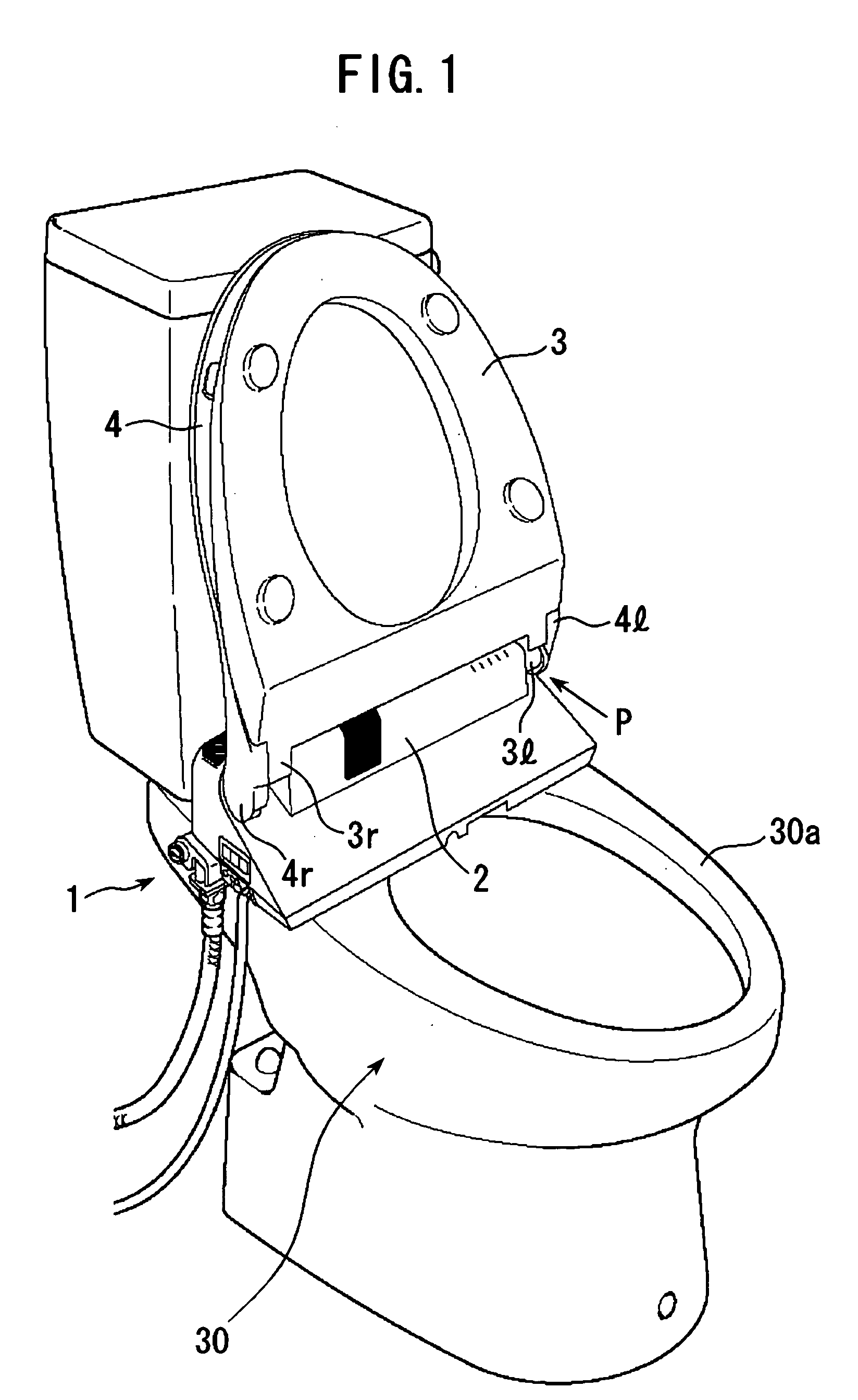

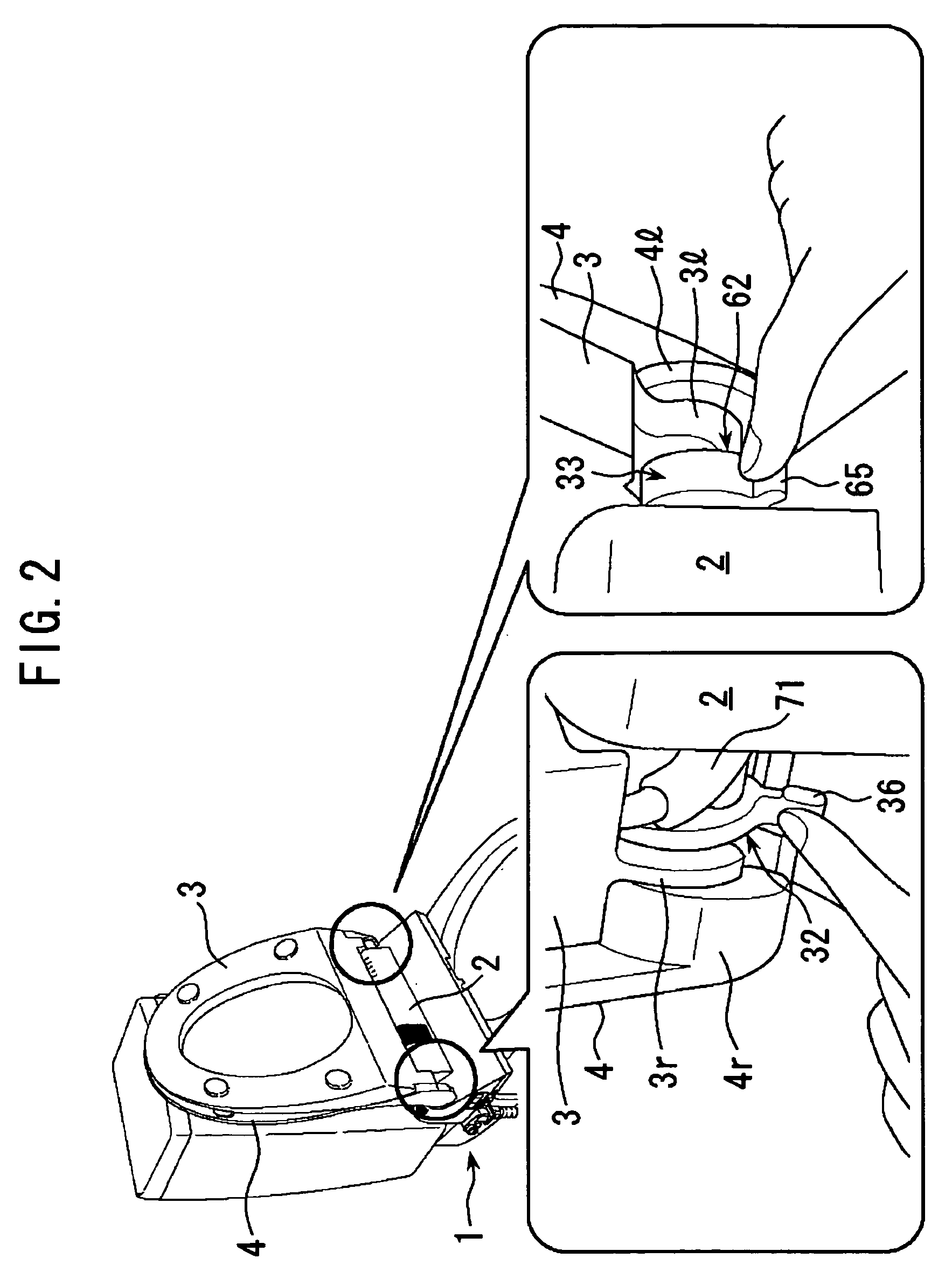

Opening/closing device for toilet seat or toilet lid, and transmission unit for the device

A lifting and lowering device (31) for a toilet seat or a toilet cover has a swing shaft (17) provided on a swing center line (C) of a toilet seat (3) or a toilet cover (4) that swings around base end portions (3l, 4l), respectively, and rises. The device comprises a lifting and lowering control unit (5) indirectly fixed to a toilet bowl main body (30); an output shaft (12) that is provided on the swing center line (C), one end portion of which shaft being removably connected to the swing shaft (17) of the lifting and lowering control unit (5) and the other end portion being detacheably connected to the base end portion (3l) of the toilet seat (3); and a toilet seat transmission unit (9) containing a tortion spring (13) that urges the output shaft (12) in a lifting direction of the toilet seat (3). The lifting and lowering device (31) for the toilet seat of toilet cover is relatively small in size and able to stabely hold the toilet seat or toilet cover in a raised position. Commonality of structural parts can be achieved depending on the magunitude of torque caused by the self weight of the toilet seat or toilet cover.

Owner:TOTO LTD

Image display device in the form of a pair of eye glasses comprising micro reflectors

ActiveUS9442294B2Large field of viewViewing comfortMirrorsNon-linear opticsUses eyeglassesSpatial light modulator

The present invention relates to an image display device (1) comprises at least one spatial light modulator (2), at least one point light source (3), wherein the light source (3) is placed in front of the spatial light modulator (2). The display device is suitable for wearable Augmented Reality (AR) and 3D displays.

Owner:CY VISION INC

3D printing rapid prototyping device and method based on magnetorheological materials

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

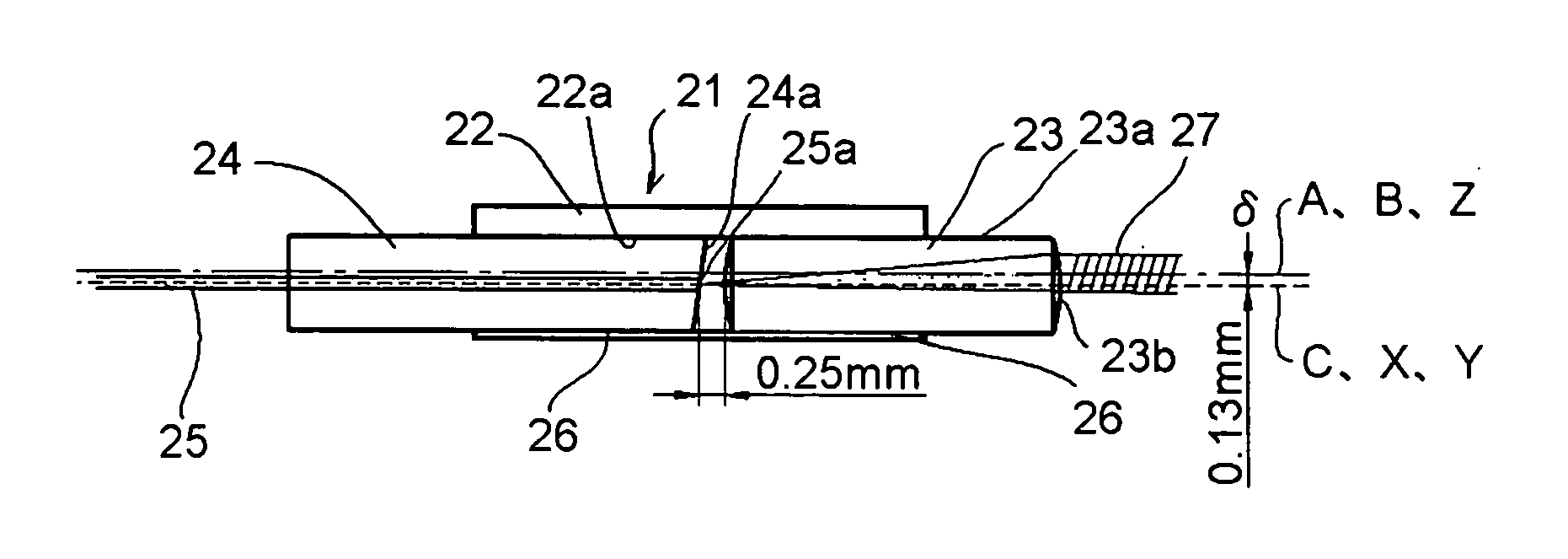

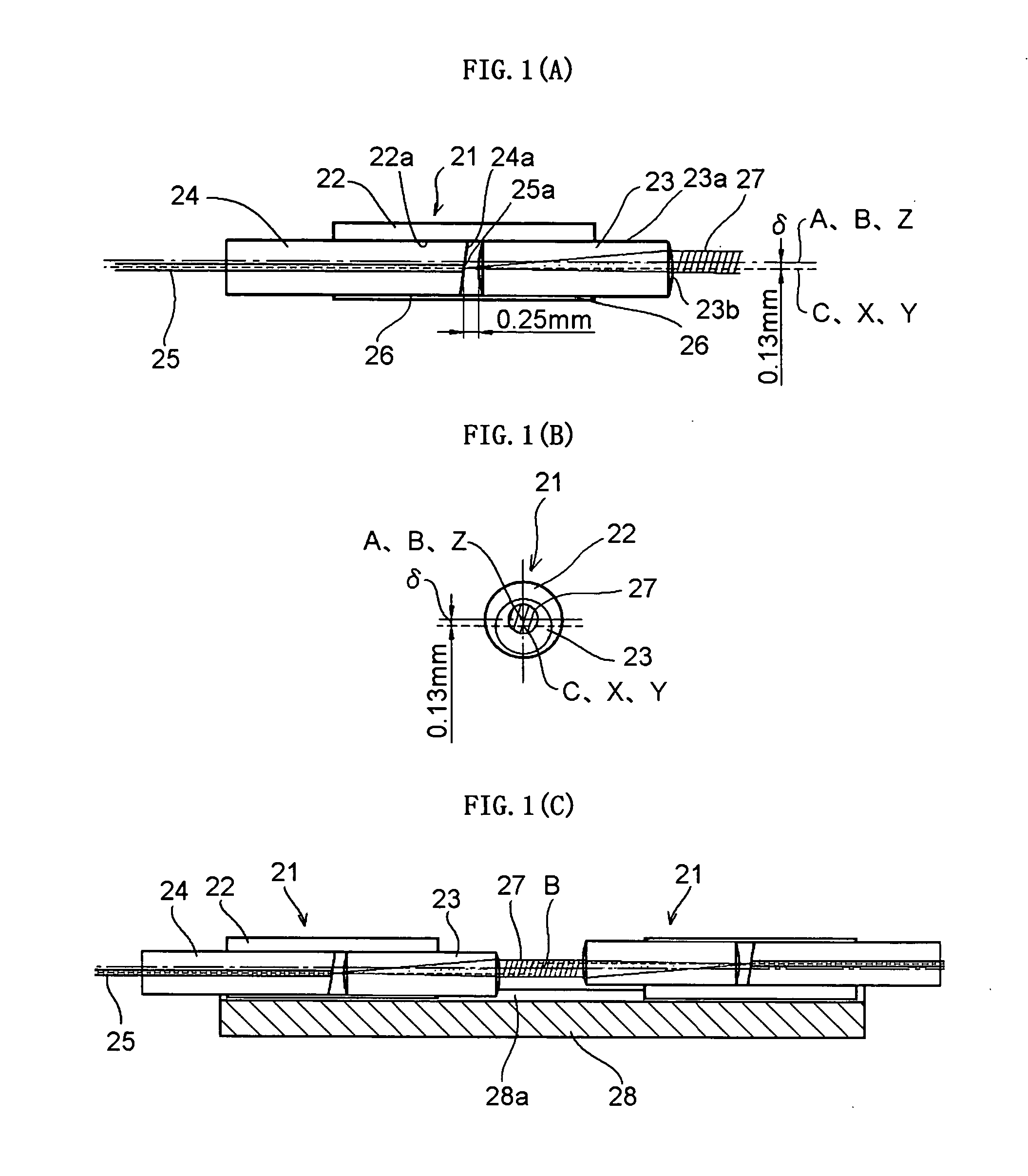

Optical collimator

InactiveUS20060256446A1Miniaturization possibleReduce degradationCoupling light guidesOptical axisSpherical form

An optical collimator 21 includes a glass-made partially spherical lens 23 having translucent spherical surfaces 23b with approximately the same center of curvature at both ends of a columnar portion 23a, a glass-made or crystallized glass-made capillary tube 24 holding an optical fiber 25 with an angled end face 25a at a center, and a glass-made or crystallized glass-made cylindrical eccentric sleeve 22 having an inner hole 22a for fixing the partially spherical lens 23 and the capillary tube 24 therein. An optical axis Z of collimated beam 27 is in a round with radius range of 0.02 mm or less, and is in an angle range of 0.2° or less with respect to the center axis B of the outer surface of the eccentric sleeve 22.

Owner:NIPPON ELECTRIC GLASS CO LTD

Lens barrel having an image-stabilizing insertable/removable optical element

InactiveUS20120218636A1Improve imaging stabilityIncrease in sizeTelevision system detailsPrintersEngineeringActuator

A lens barrel having an insertable / removable optical element includes an advancing / retracting member, an anti-shake frame supported by the advancing / retracting member, an insertable / removable frame holding the insertable / removable optical element and supported by the anti-shake frame, an anti-shake drive mechanism, and a removal drive mechanism which moves the insertable / removable frame between the insertion and the removed positions. The anti-shake drive mechanism includes first and second anti-shake drive actuators positioned on the opposite side of the insertion position from the removed position and are respectively positioned on opposite sides of a straight line connecting a center of the insertable / removable optical element at the insertion position and at the removed position. Directions of driving forces produced by the first and second anti-shake drive actuators are at right angles to each other.

Owner:HOYA CORP

Semiconductor device, manufacturing method of semiconductor device, semiconductor wafer, and electronic equipment

ActiveUS9263488B2Miniaturization possibleSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMiniaturizationEngineering

The present technology relates to a semiconductor device, a manufacturing method of a semiconductor device, a semiconductor wafer, and electronic equipment, which allow a semiconductor device, in which miniaturization is possible, to be provided. A semiconductor device includes a semiconductor substrate, a wiring layer that is formed on the semiconductor substrate, and a drive circuit that is provided in a circuit forming region of the semiconductor substrate. Then, the semiconductor device is configured to include a pad electrode that is electrically connected to the drive circuit and exposed from the side surface of the wiring layer, and an external connection terminal that is provided in side surfaces of the semiconductor substrate and the wiring layer, and is electrically connected to the pad electrode.

Owner:SONY CORP

Switching regulator

ActiveUS7088083B2Long delay timeMiniaturization possibleDc-dc conversionElectronic switchingWork periodDelayed time

Owner:ABLIC INC

Rotary actuator for auto-focusing a camera lens

InactiveUS8149520B2Reduce weightMiniaturization possibleSynchronous generatorsWindingsCamera lensPower flow

A rotary actuator includes a multi-polar magnet, in which north and south poles are alternately arranged in a circumferential direction, the multi-polar magnet being shaped into one of a circular ring and a circular arc member; and a coil body having coils which are provided around the multi-polar magnet to be capable of moving in the circumferential direction of the multi-polar magnet, each of the coils substantially lying on a plane that extends in a radial direction of the multi-polar magnet and orthogonal to the circumferential direction of the multi-polar magnet. The north and south poles of the multi-polar magnet are positioned apart from each other by a predetermined interval in the circumferential direction. Dimensions of each coil are predetermined so that length of each coil in the circumferential direction is associated with the predetermined interval. Predetermined currents are passed through the coils in a properly phased manner.

Owner:RICOH IMAGING COMPANY

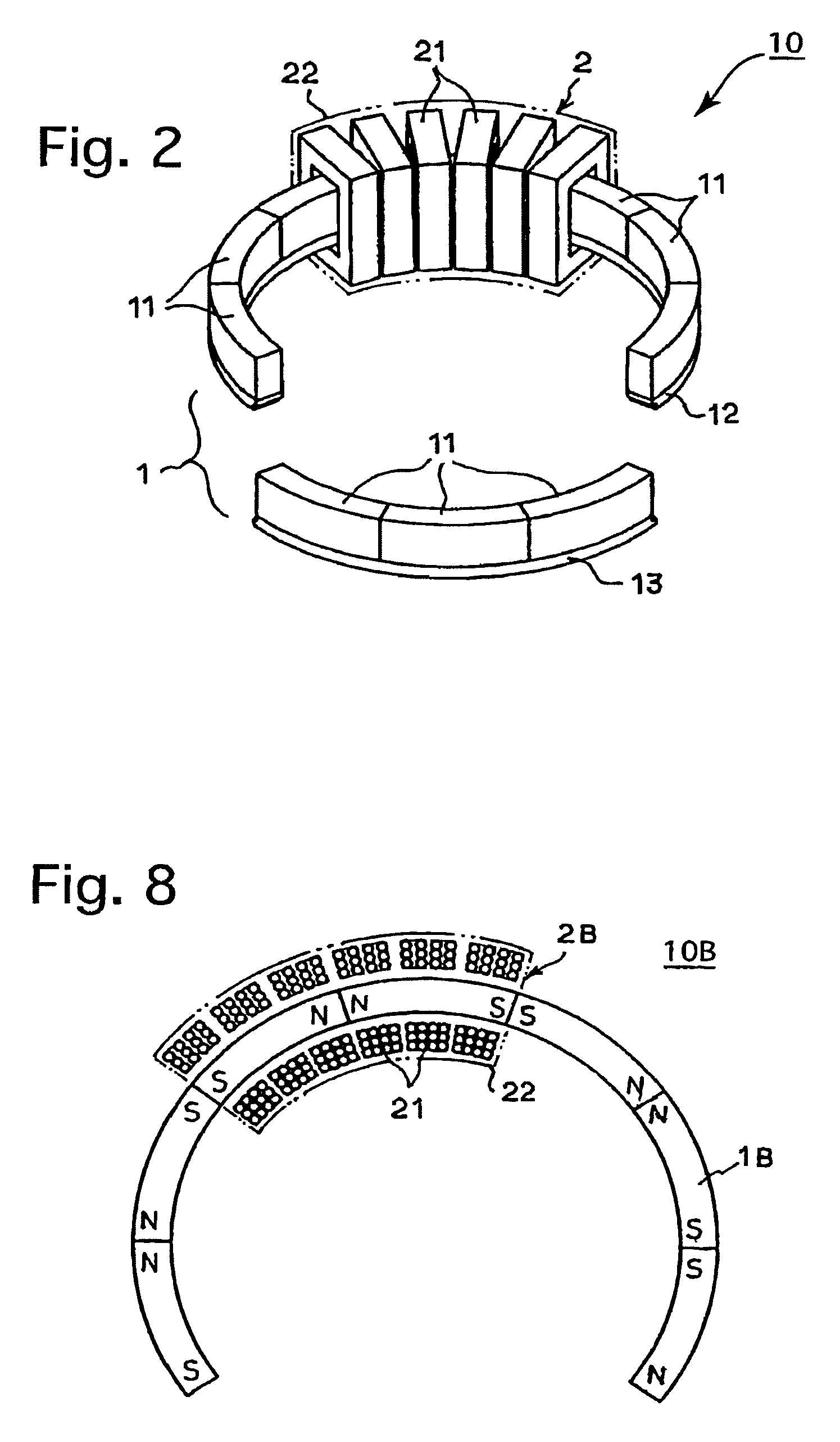

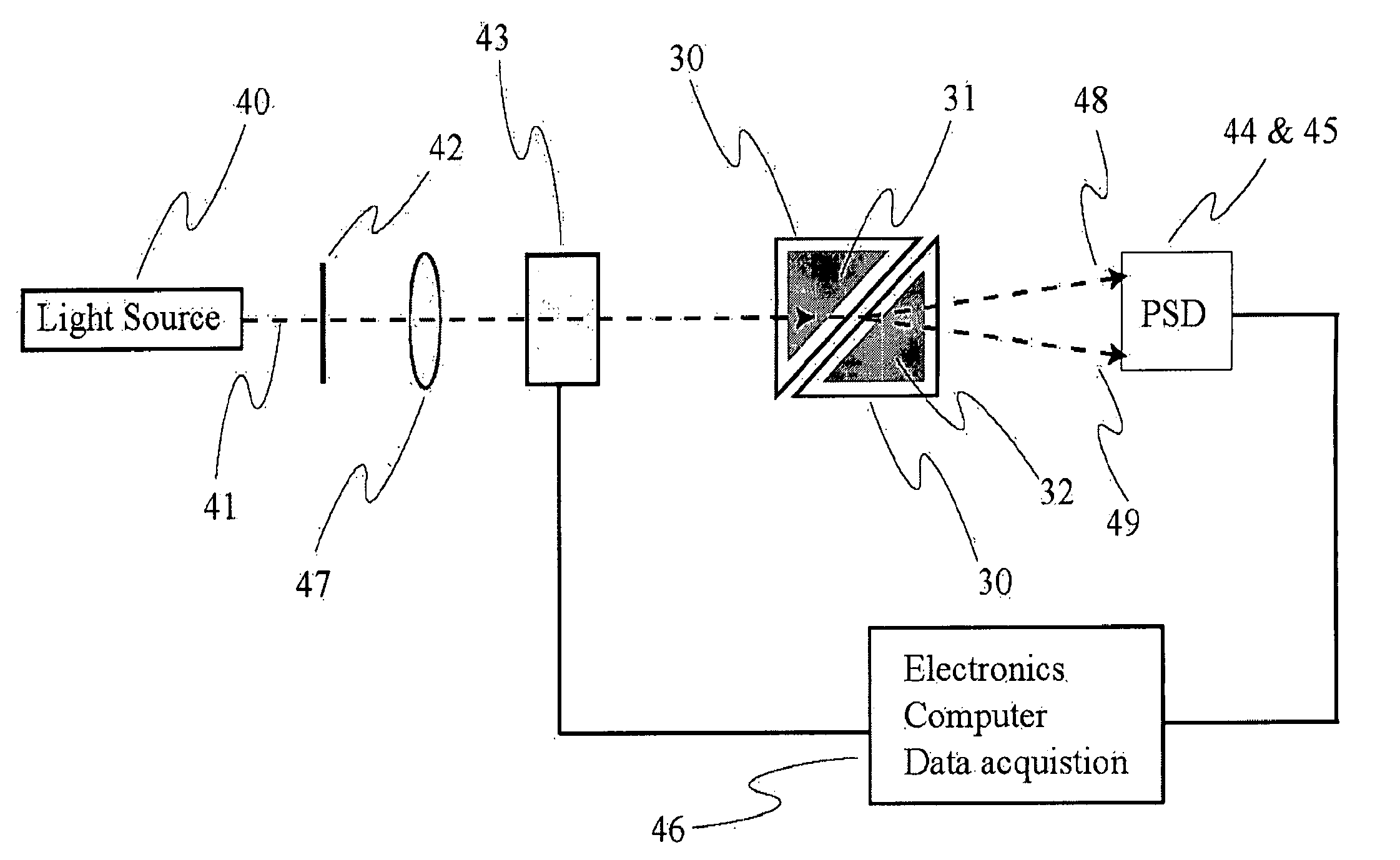

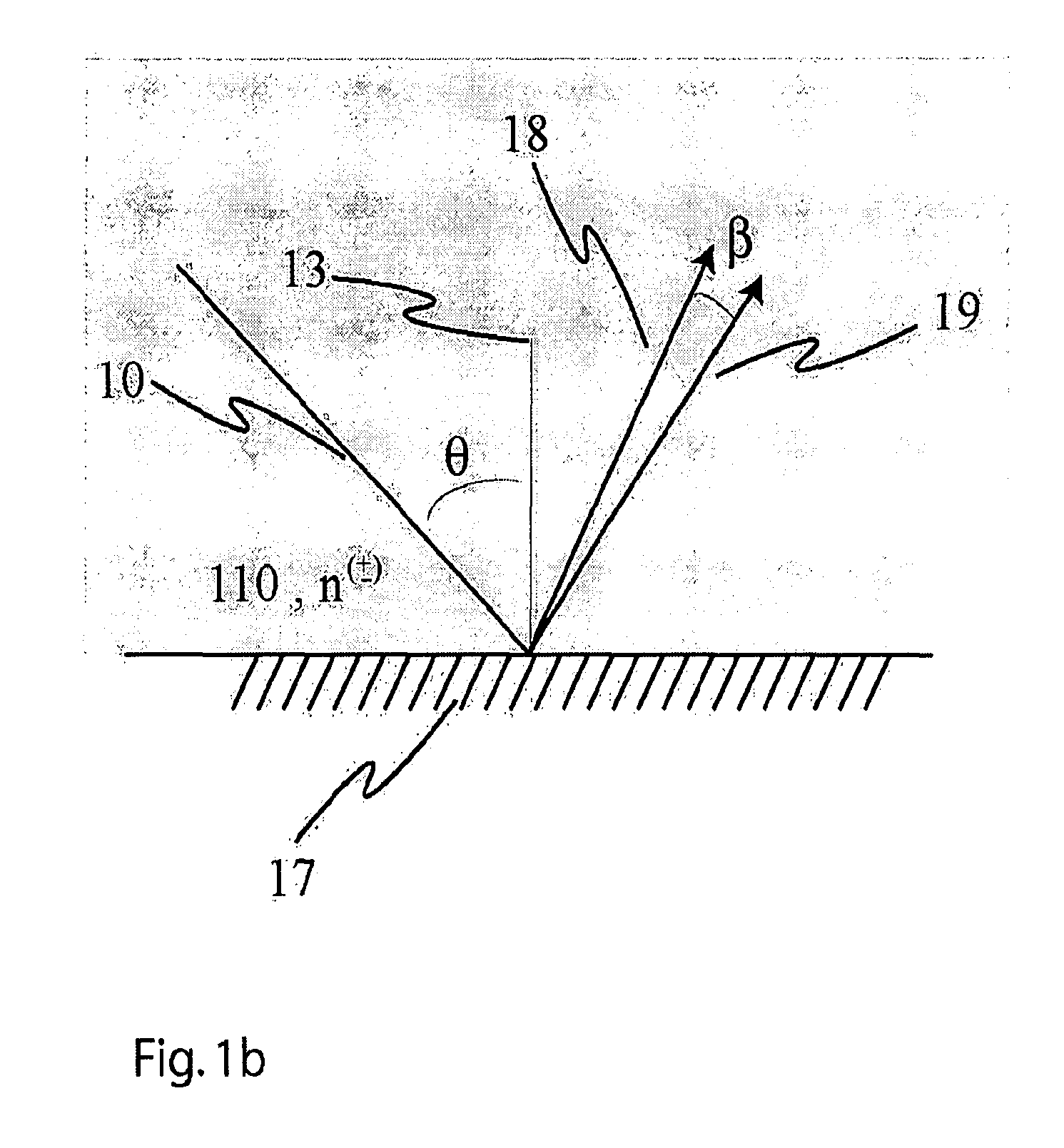

Circular birefringence refractometer: method and apparatus for measuring optical activity

InactiveUS7961318B2Suitable for miniaturizationMiniaturization possibleWithdrawing sample devicesMaterial analysis by optical meansSinistral and dextralLight beam

A system and method for detection and measurement of circular birefringences in materials that exhibit the Faraday effect. The method and apparatus permit detection of optical activities via the difference in the directions of propagation the left- and the right-circularly polarized light (components). A beam of light is directed at an interface formed by the optically active medium and another medium such that a difference in the angles of refraction and / or reflection and / or diffraction between the left- and the right-circularly polarized components of the light beam can be detected. The difference in the propagation directions between the two circularly polarized light components is measured on a position sensitive detector and / or is detected as an intensity difference.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Solid-state imaging device, method for producing solid-state imaging device, and electronic apparatus using photoelectric conversion elements

ActiveUS10264199B2Little restrictionIncrease speedTelevision system detailsSolid-state devicesPhotoelectric conversionElectron

A solid state imaging device has: a photosensitive part containing a plurality of charge transfer parts that transfer, in column units, the signal charges of a plurality of photoelectric conversion elements disposed in a matrix; a conversion / output unit that converts, to an electrical signal, the signal charges forwarded by the charge transfer parts; a peripheral circuit part that performs a predetermined process with respect to the electrical signals from the conversion / output part; a relay part that relays the forwarding to the peripheral circuit part of the electrical signal from the conversion / output part; a first substrate where a photosensitive part and the conversion / output part are formed; and a second substrate where the peripheral circuit part is formed. The first and second substrates are stacked together, and the relay part electrically connects the conversion / output part formed at the first substrate to the peripheral circuit part formed at the second substrate.

Owner:BRILLNICS JAPAN

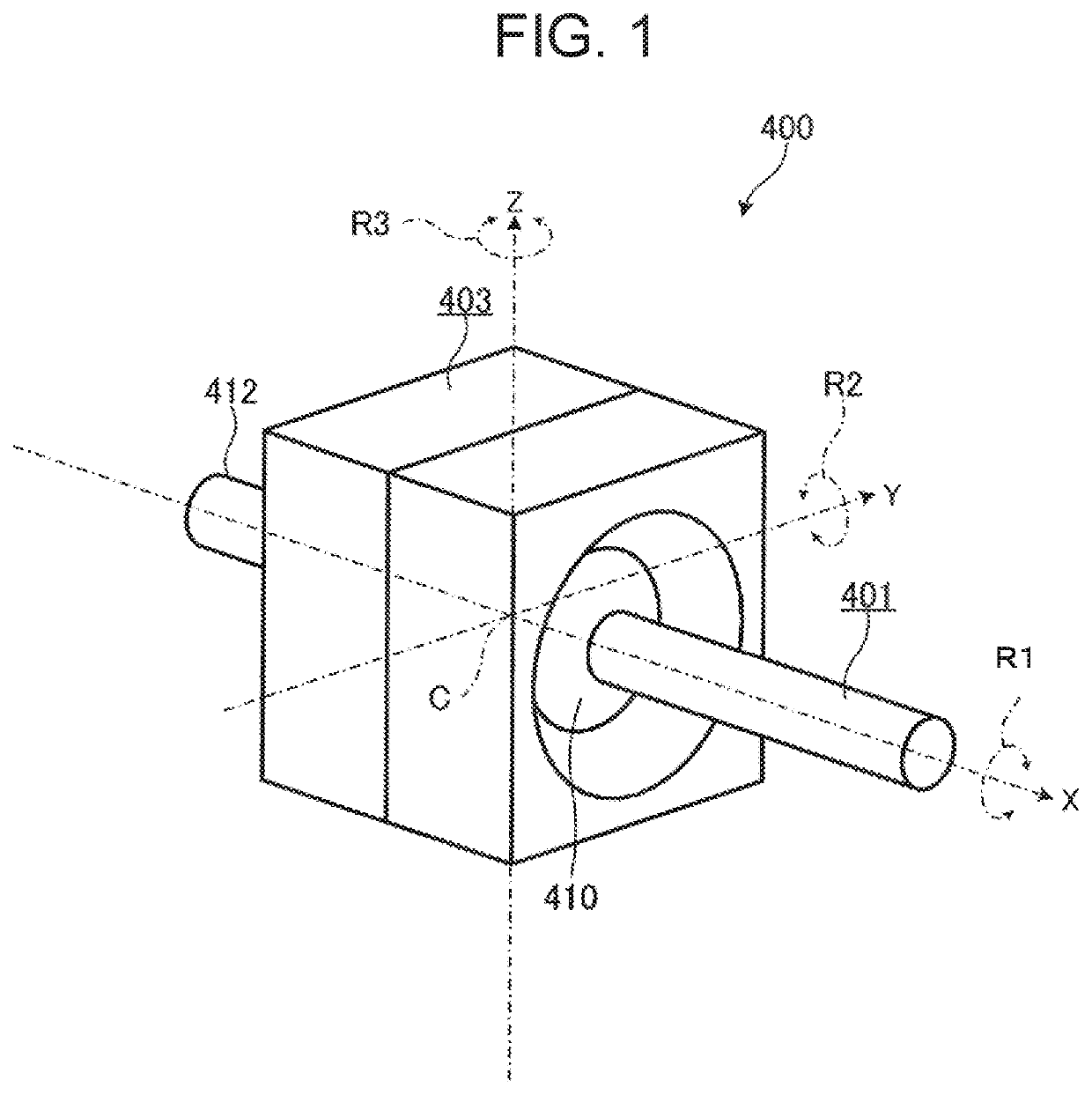

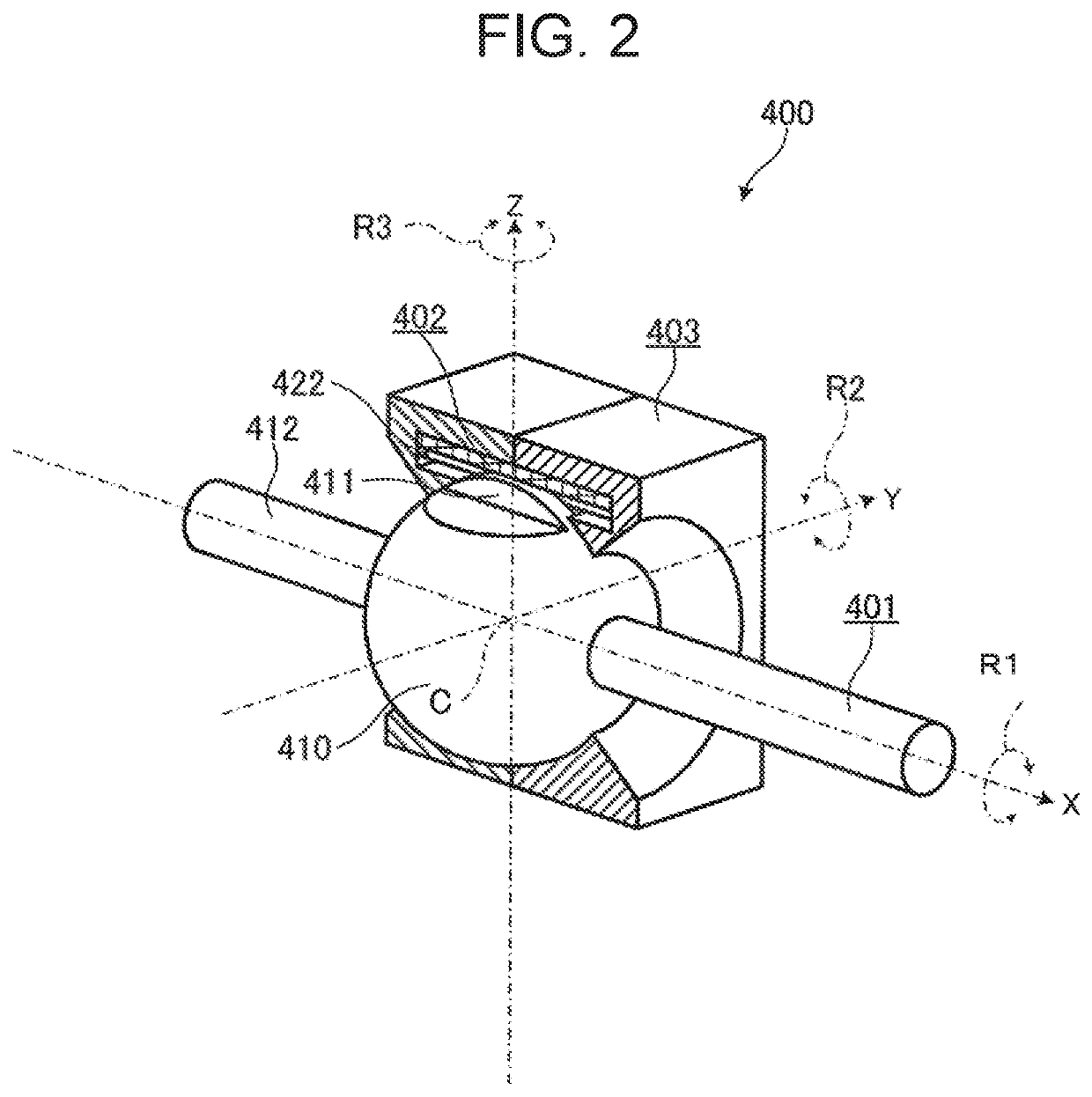

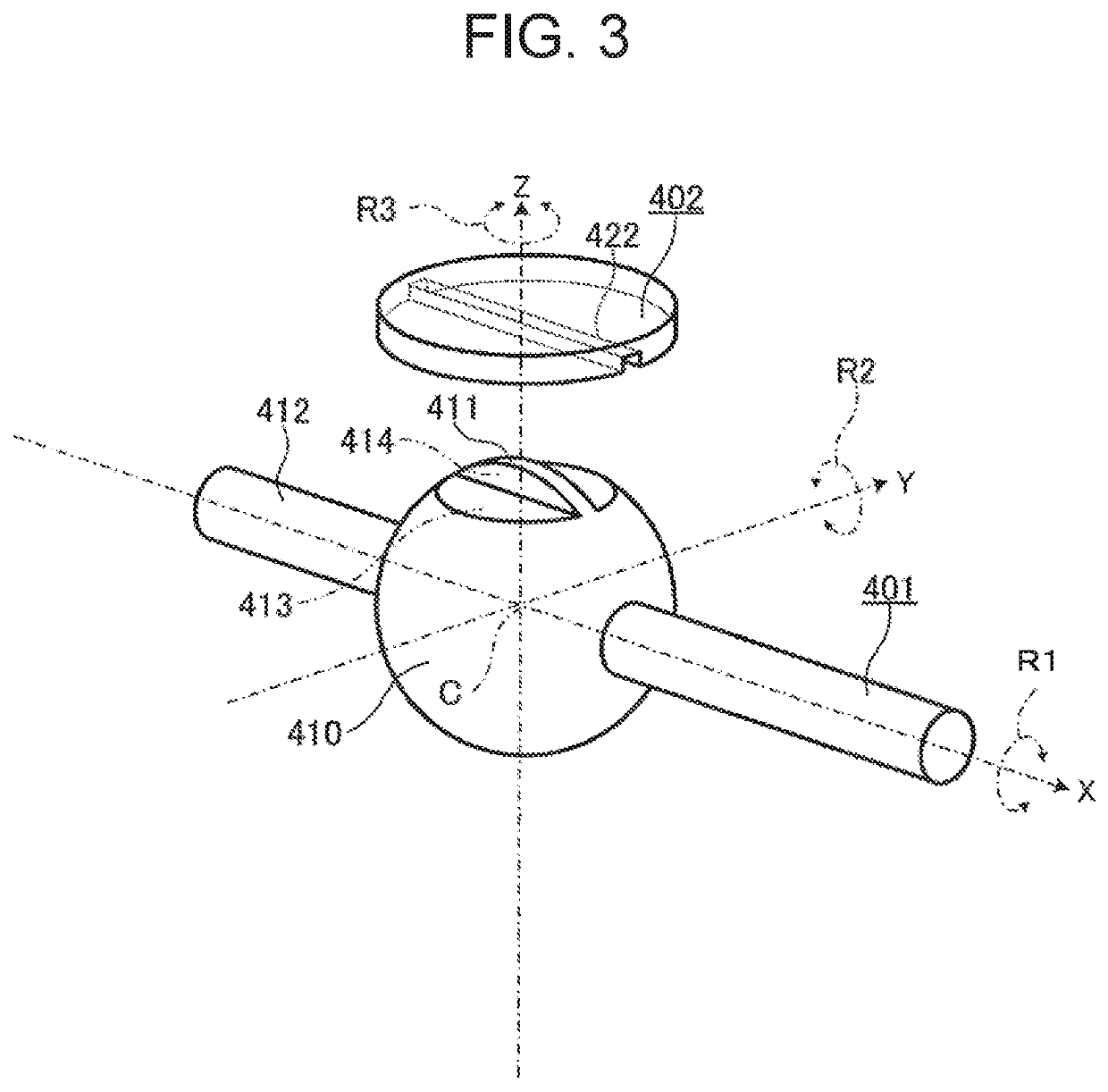

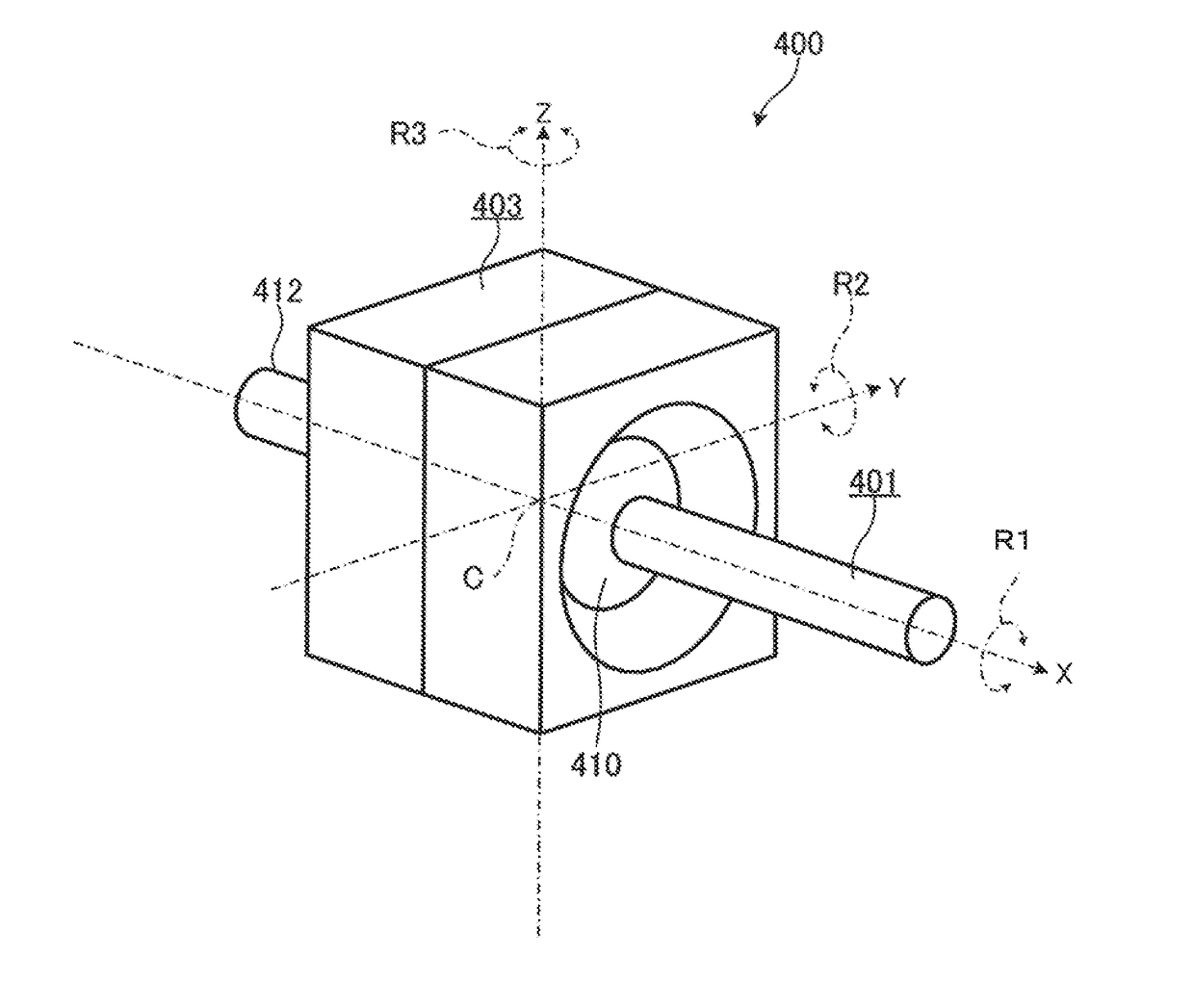

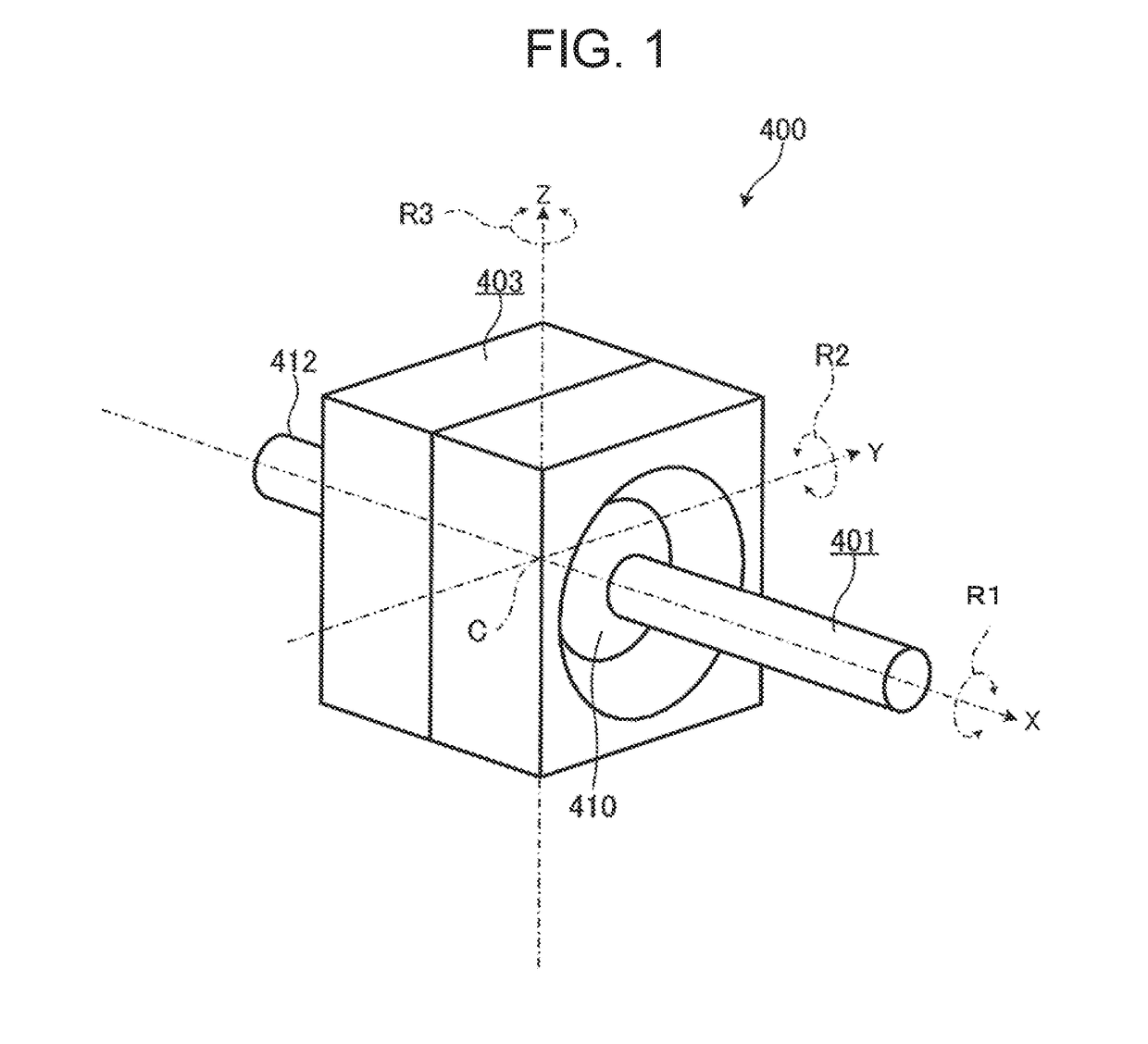

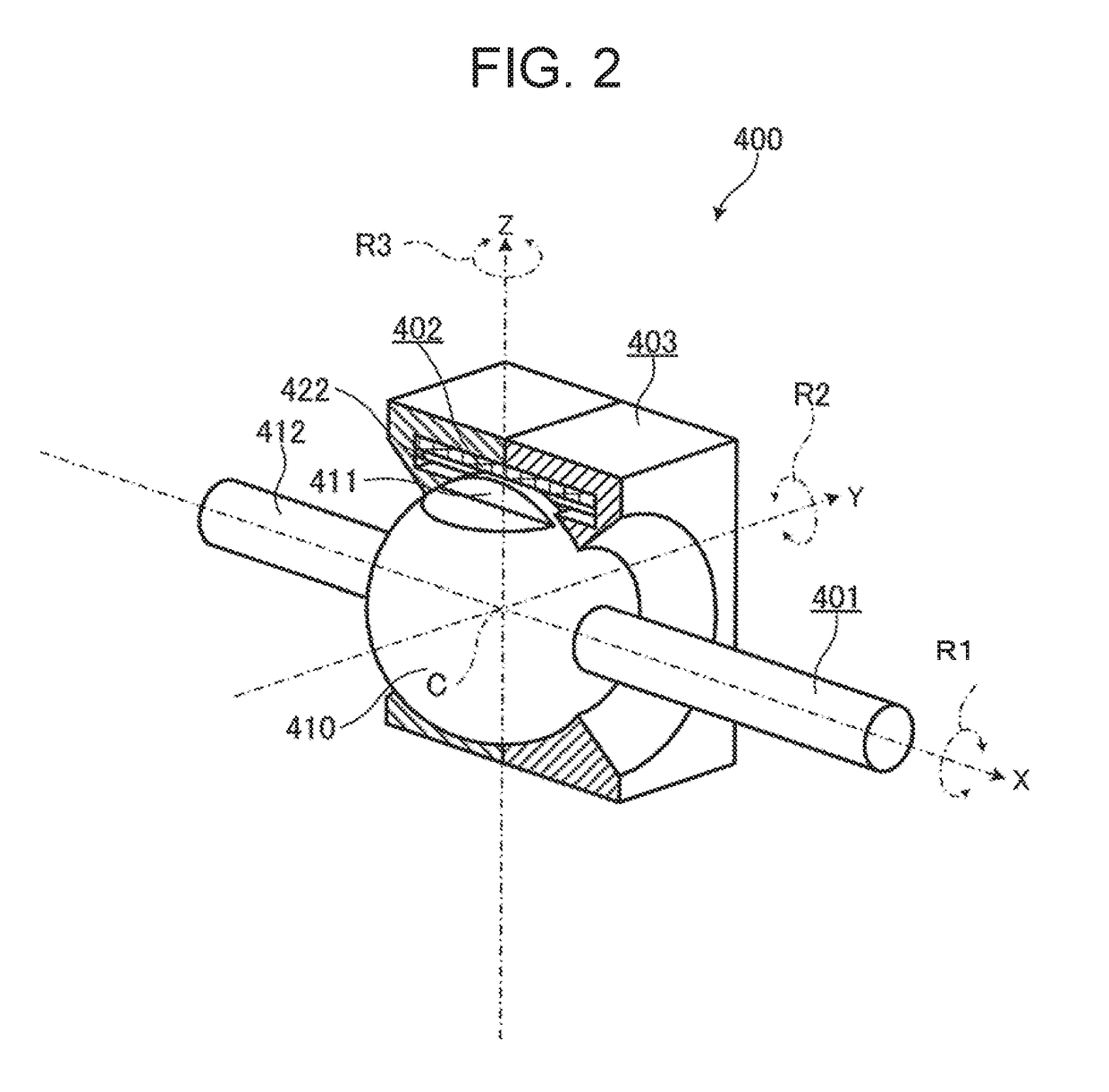

Spherical bearing device and switch

ActiveUS10626914B2Increase the number ofComplex structureElectronic switchingElectric switchesRotational axisSpherical bearing

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Spherical bearing device and switch

ActiveUS20170314610A1Increase the number ofComplex structureElectronic switchingElectric switchesSpherical bearingEngineering

A spherical bearing device includes a shaft member, a turnable body, and a bearing. The shaft member has a shaft body and a spherical body having a first engaging portion. The turnable body has a second engaging portion that is engaged with the first engaging portion in a first rotational direction about a first axis passing through a center of the spherical body, and allows other rotations. The bearing is provided with a first space and a second space. The first space accommodates the spherical body spherically slidably. The second space accommodates the turnable body such that the turnable body is turnable, and allows the shaft body to move.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com