Patents

Literature

54 results about "Virtual particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, a virtual particle is a transient quantum fluctuation that exhibits some of the characteristics of an ordinary particle, while having its existence limited by the uncertainty principle. The concept of virtual particles arises in perturbation theory of quantum field theory where interactions between ordinary particles are described in terms of exchanges of virtual particles. A process involving virtual particles can be described by a schematic representation known as a Feynman diagram, in which virtual particles are represented by internal lines.

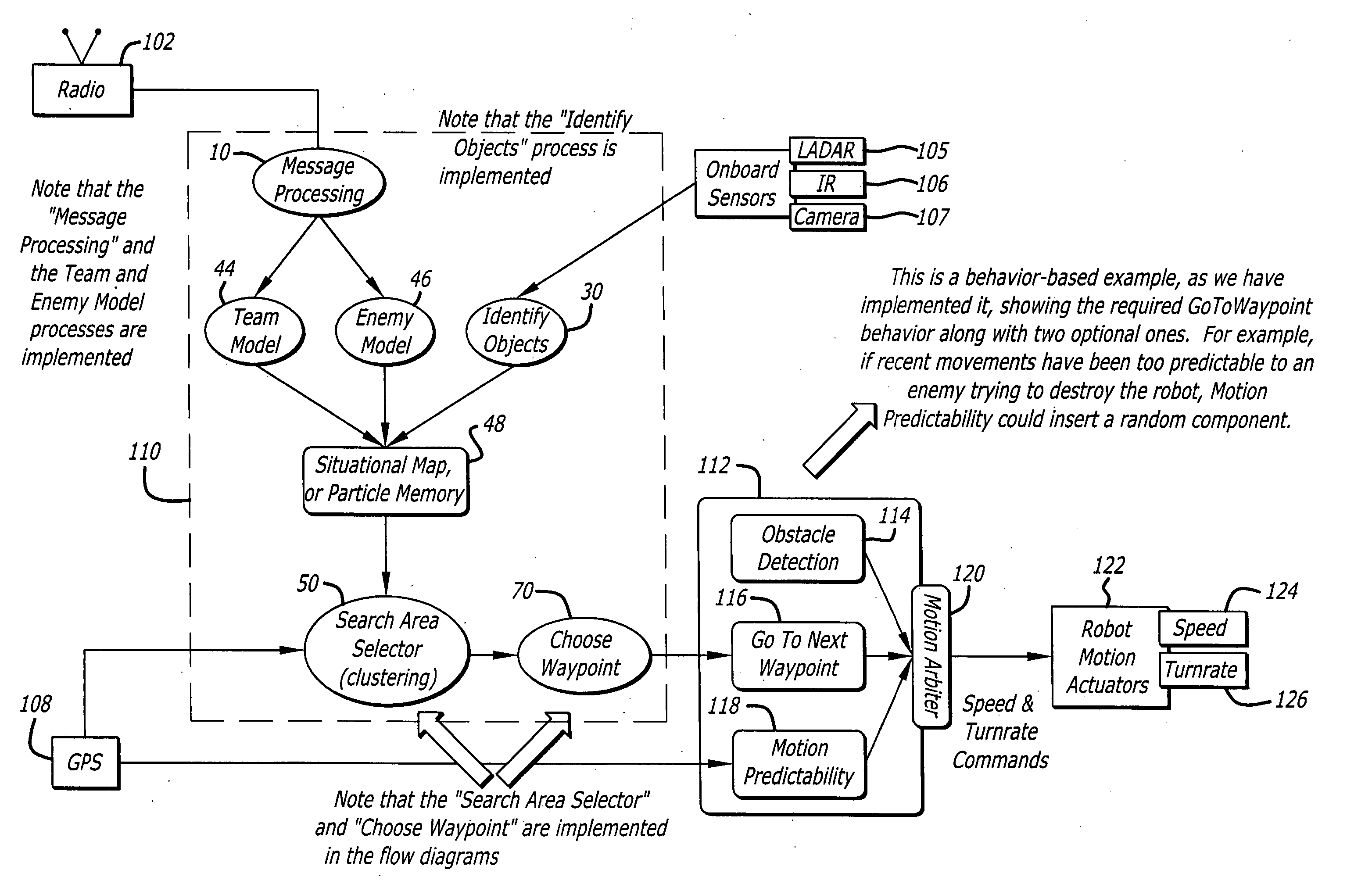

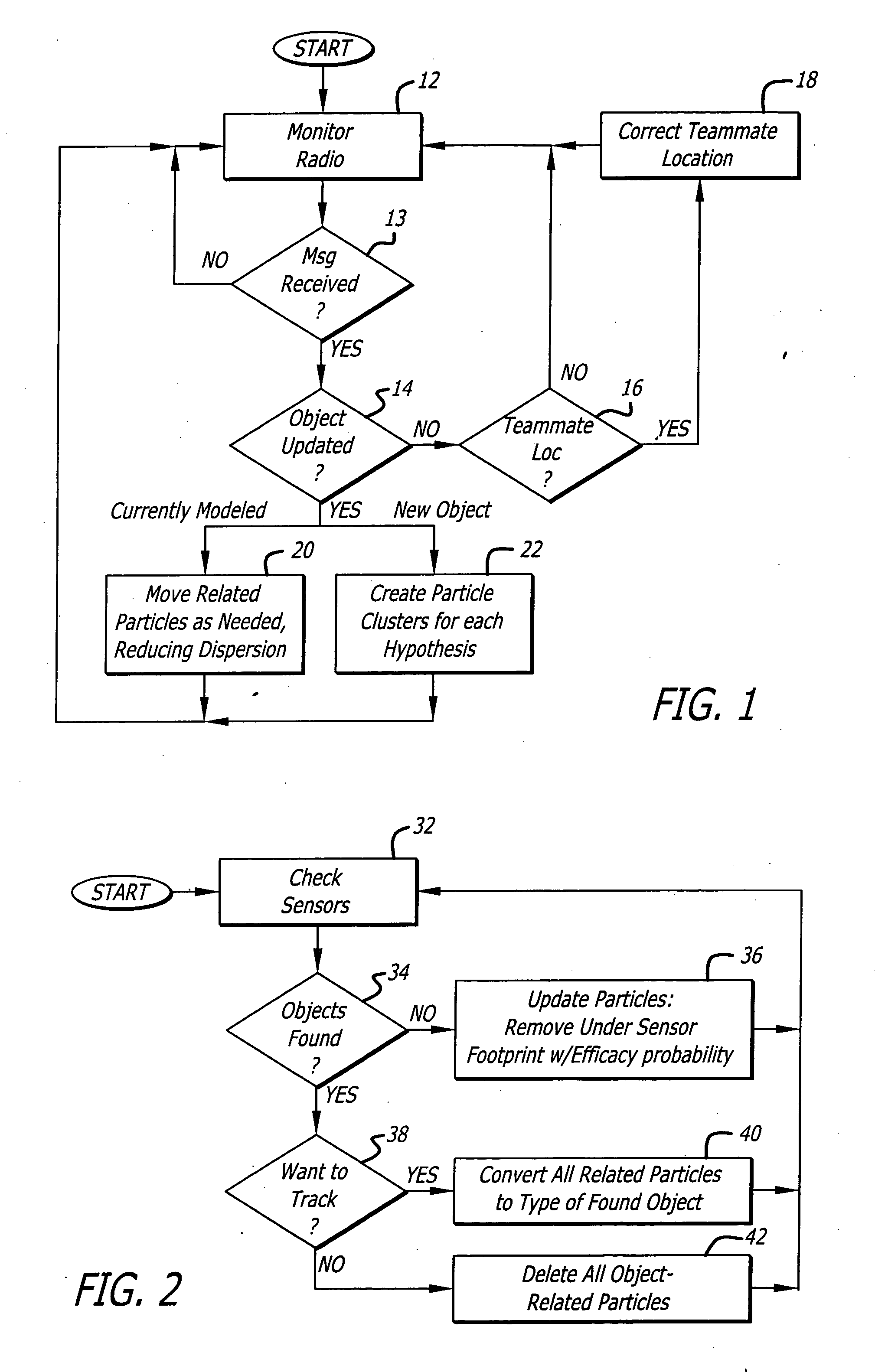

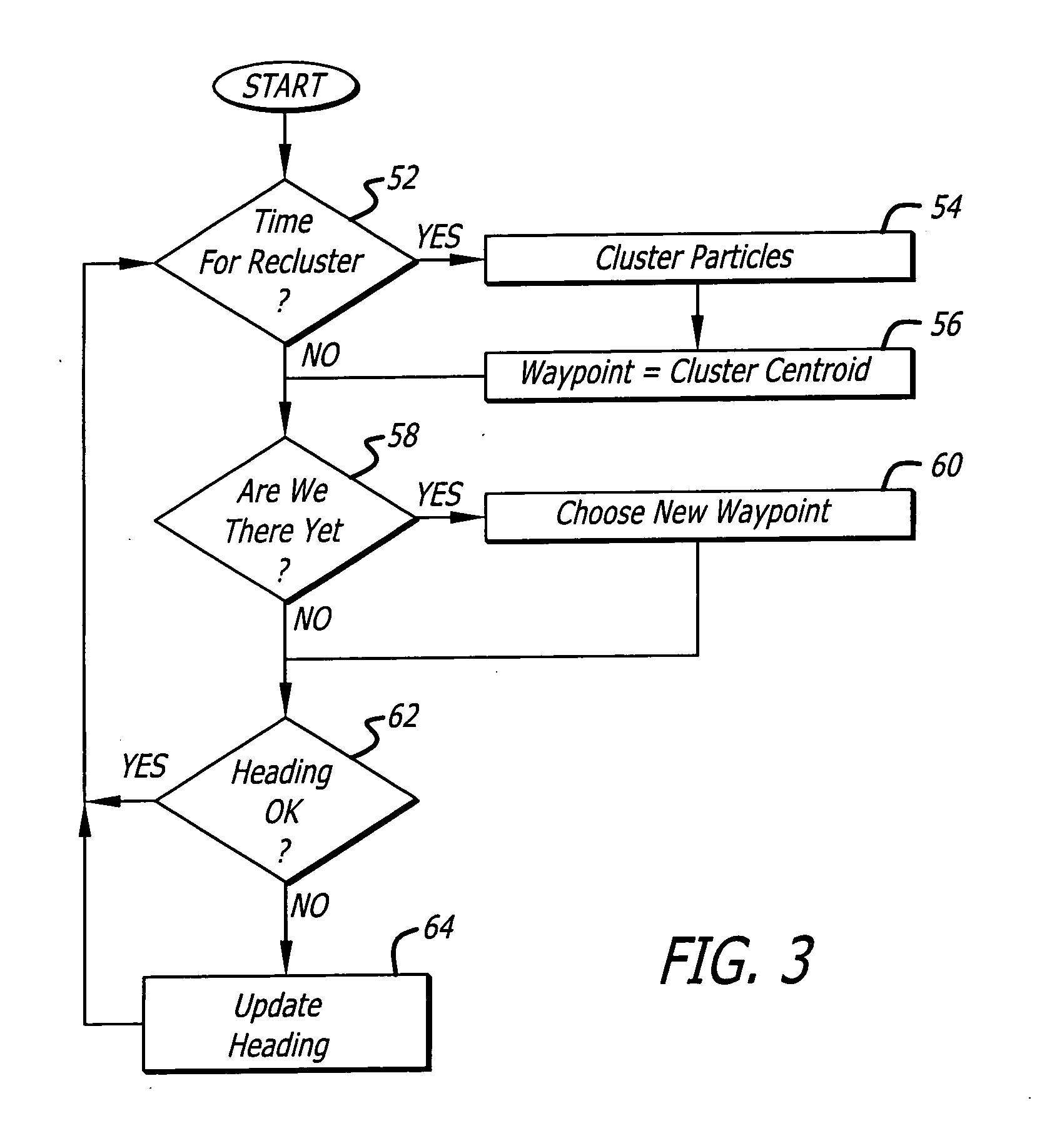

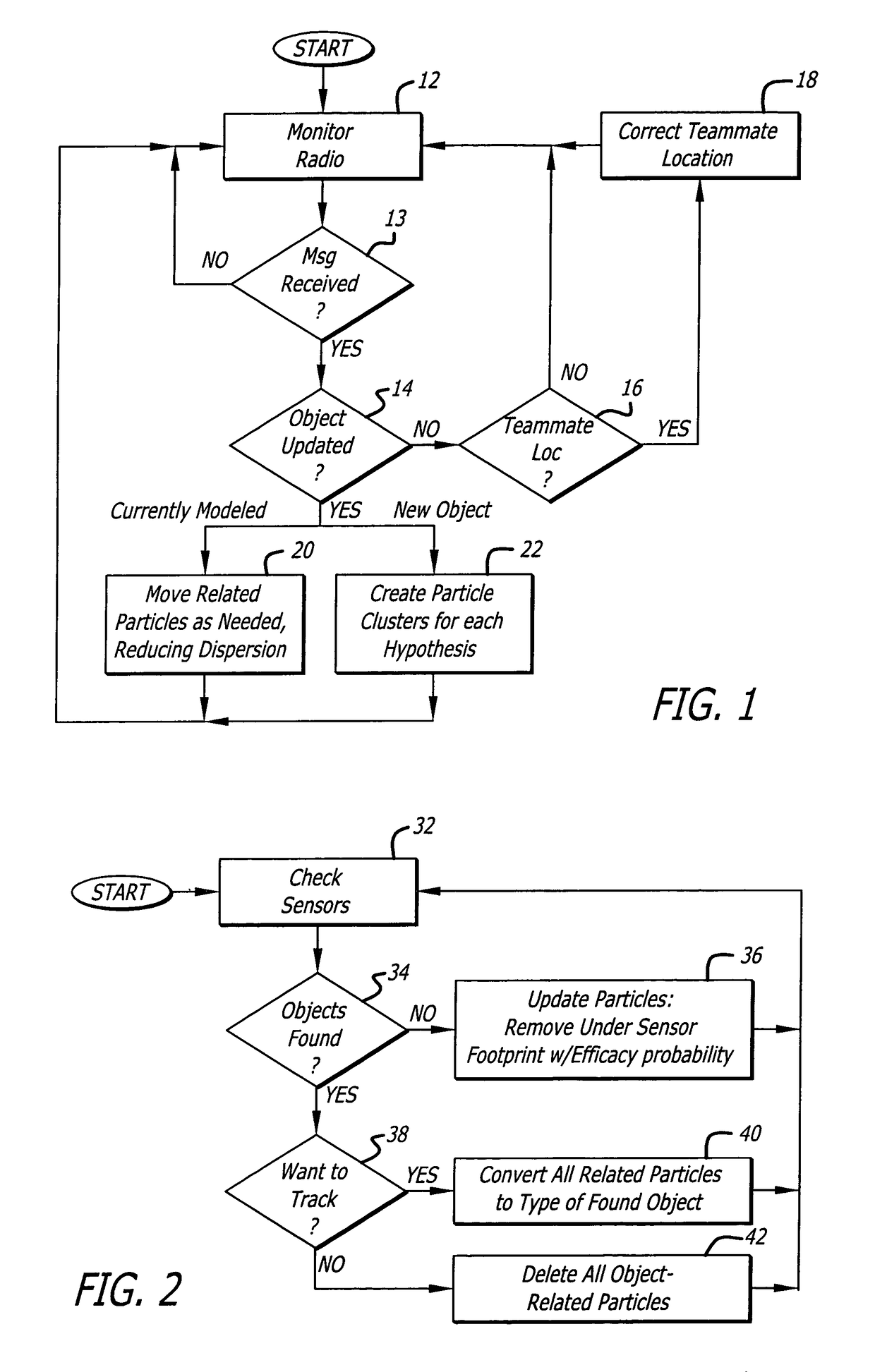

System and method for automated search by distributed elements

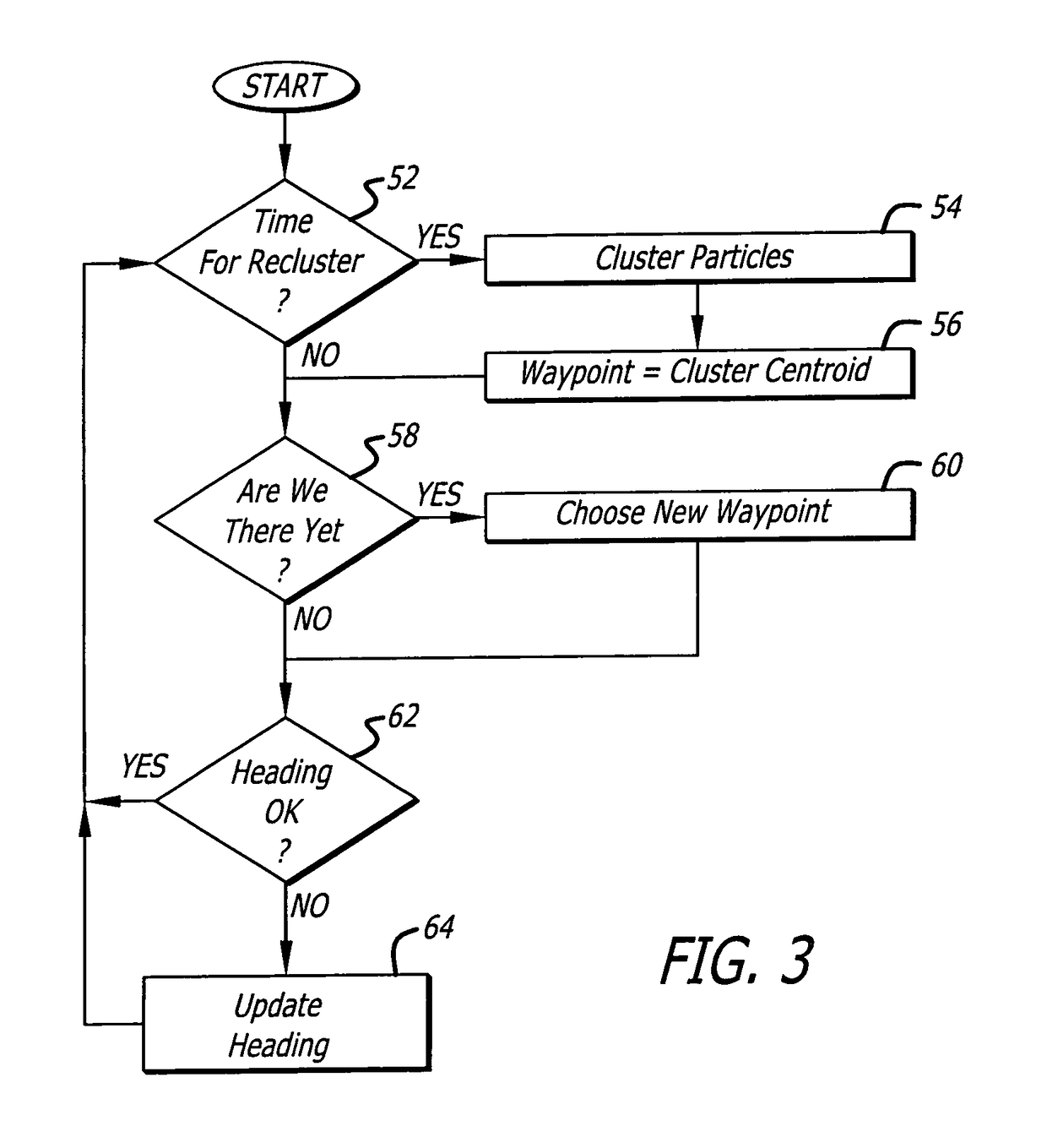

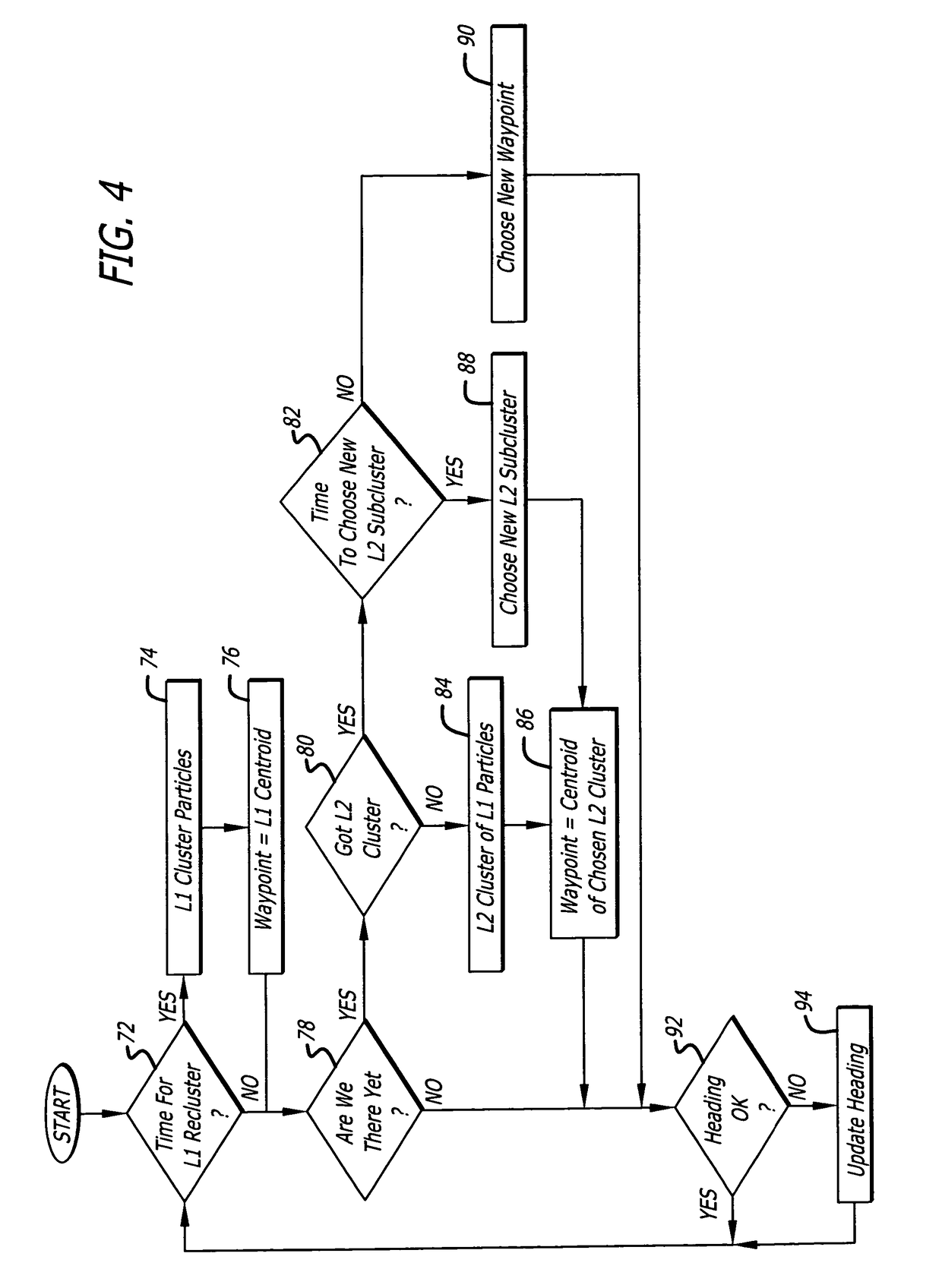

InactiveUS20060015215A1Autonomous decision making processPosition fixationSearch problemProbability representation

A system and method for decentralized cooperative control of a team of agents for geographic and other search tasks. The approach is behavior-based and uses probability particle approach to the search problem. Agents are attracted to probability distributions in the form of virtual particles of probability that represent hypotheses about the existence of objects of interest in a geographic area or a data-space. Reliance on dependable, high-bandwidth communication is reduced by modeling the movements of other team members and the objects of interest between periodic update messages.

Owner:RAYTHEON CO

System and method for automated search by distributed elements

InactiveUS7908040B2Autonomous decision making processDigital data processing detailsSearch problemHigh bandwidth

Owner:RAYTHEON CO

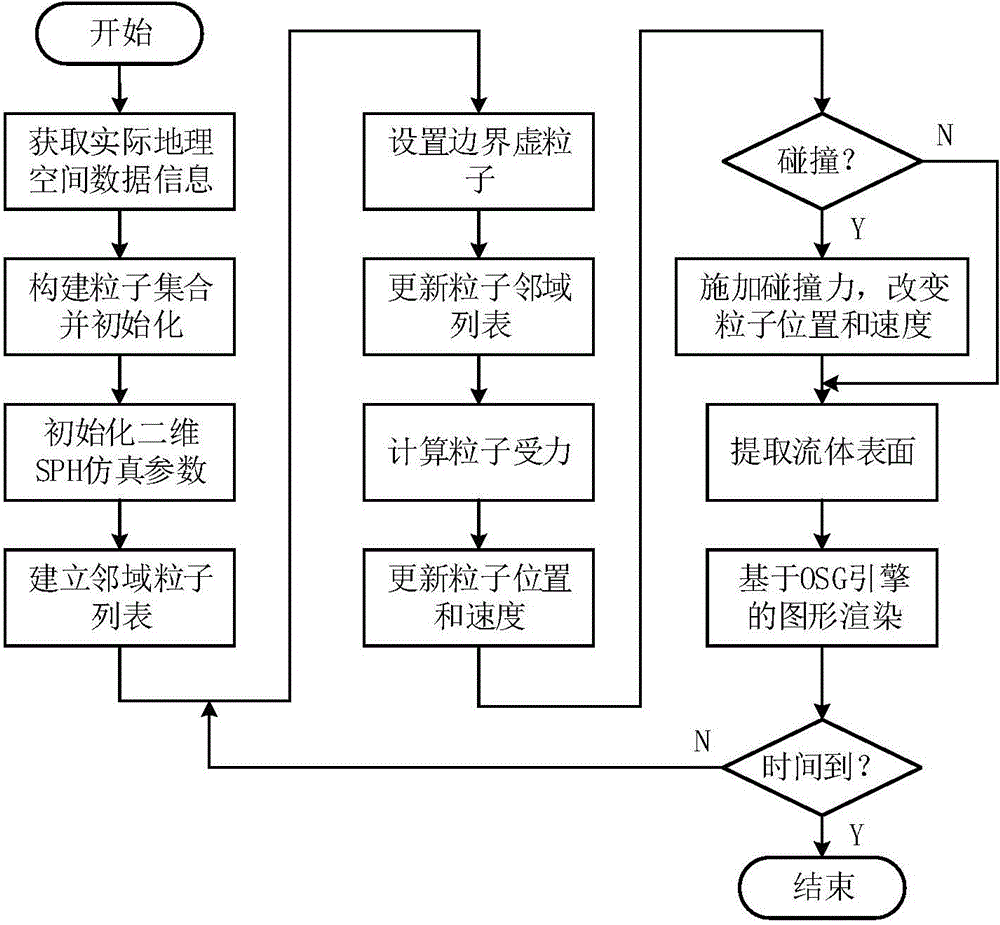

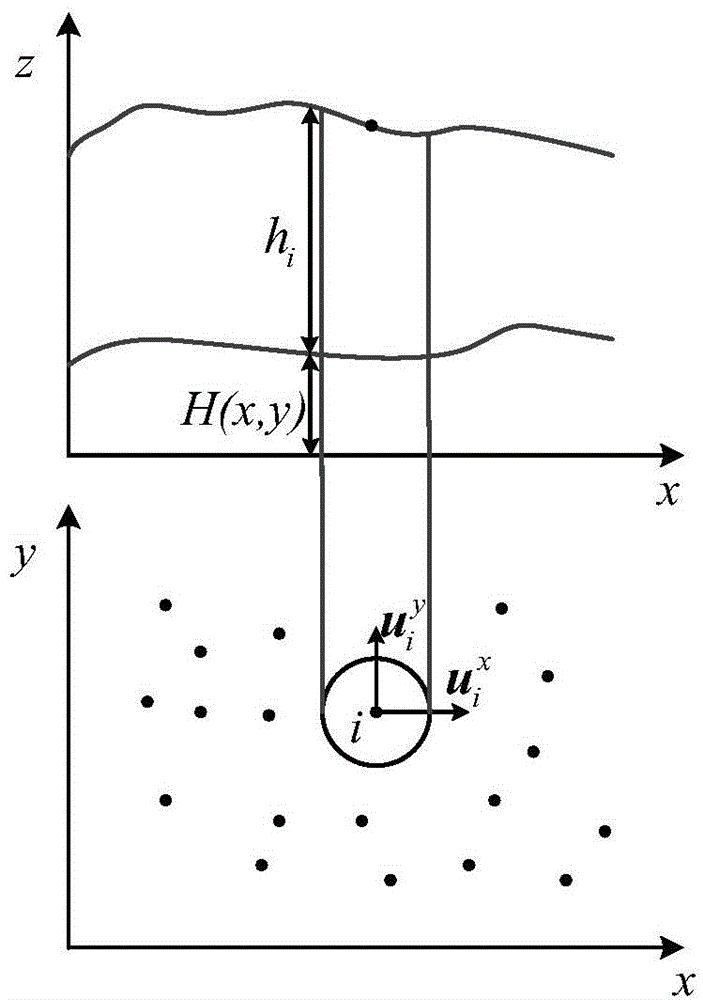

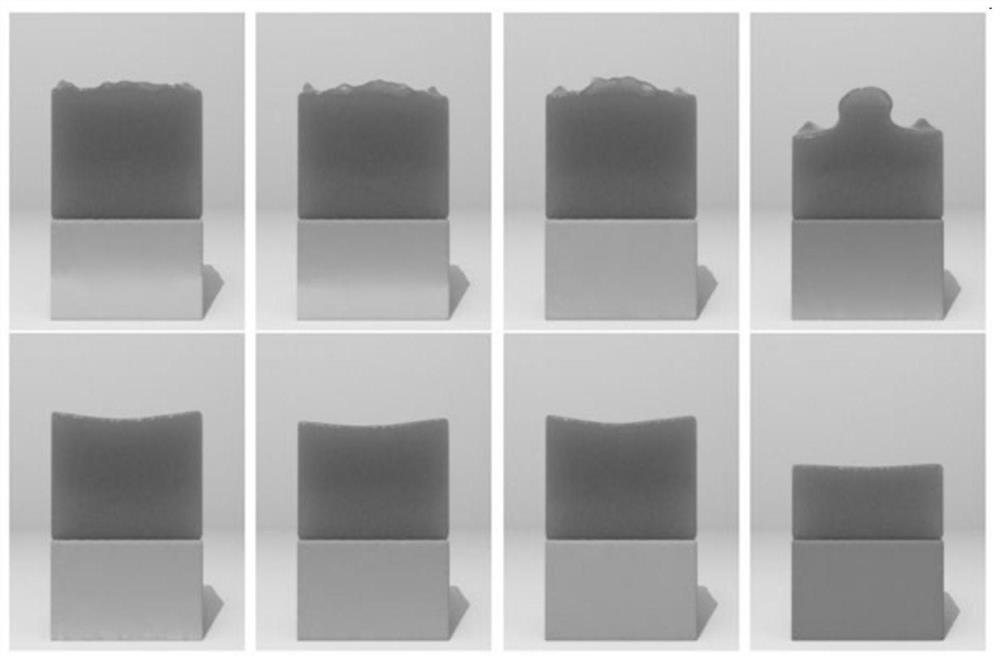

Dam bursting flood routing simulation method based on two-dimensional SPH

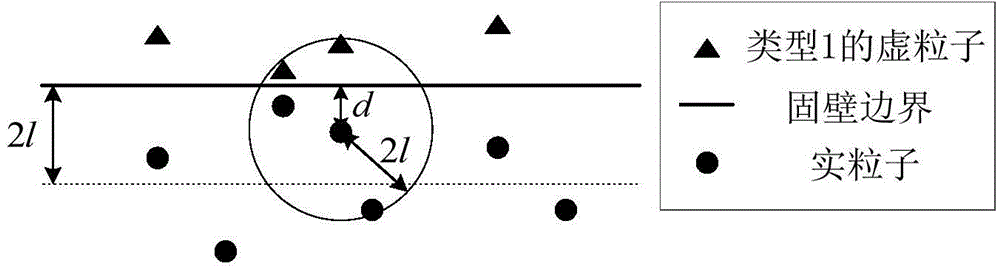

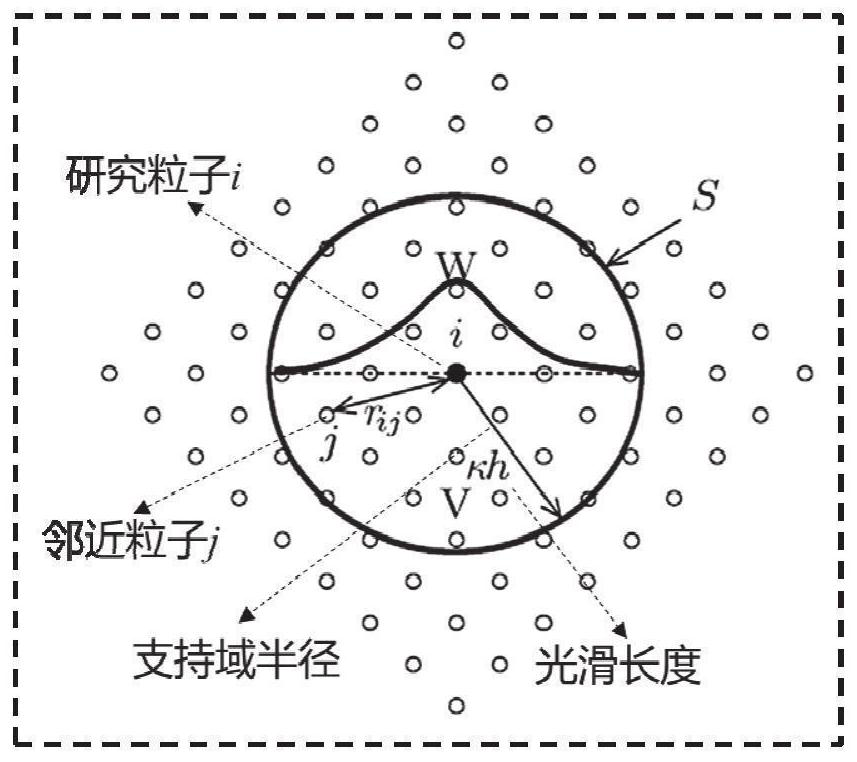

InactiveCN104991999AMake up for lack of precisionMake up for the huge amount of calculationClimate change adaptationSpecial data processing applicationsData informationCollision detection

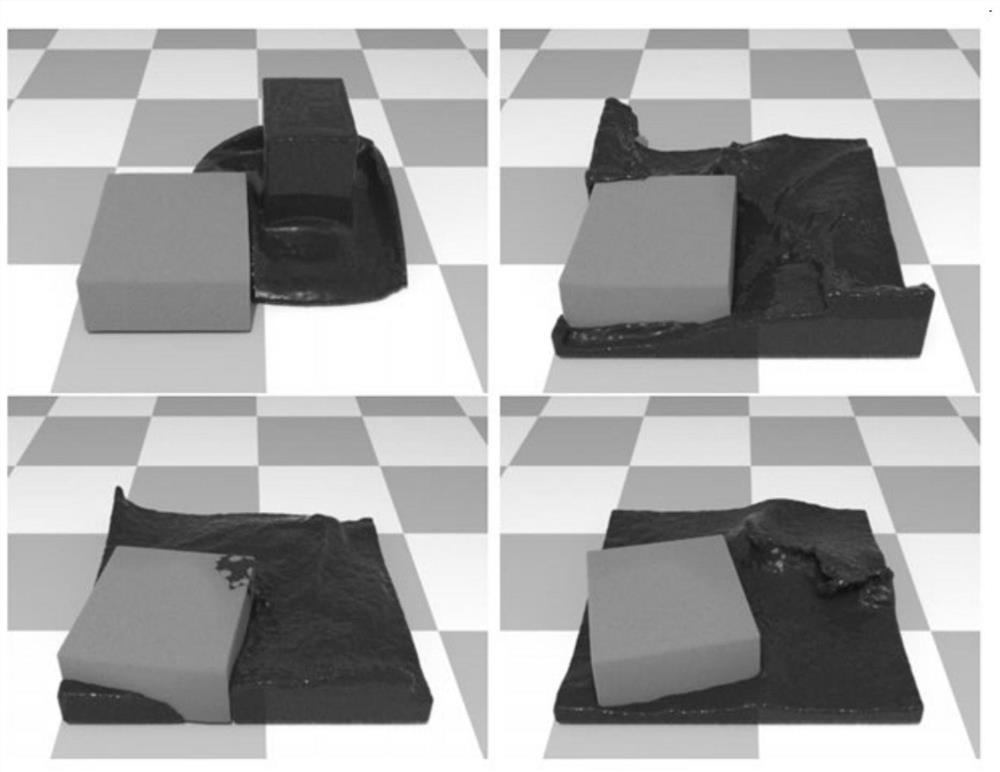

A dam bursting flood routing simulation method based on two-dimensional SPH belongs to the technical field of geographic-science course simulation and geographic information systems. By the method, data information of a reservoir and downstream geographic space is obtained firstly, a flood routing two-dimensional mode based on a shallow water equation is established according to the obtained data, and a simulation course undergoes initialization which comprises initial configuration of particle properties, establishment of a neighborhood particle list of particles and setting of parameters; simulation circulation is started then, wherein whether boundary virtual particles are set is determined according to positions of the particles, and the neighborhood particle list of each water particle is updated; force borne by each water particle is calculated, and then the position and the speed of each water particle at the next time step are calculated; and collision detection is carried out, boundary punishment force is applied to change the position and the speed of the particle in case of a boundary, a fluid surface is extracted according to particle distribution, and the extracted fluid surface is rendered. The method provided by the invention can realize the relatively real analogue simulation of the large-scale dam bursting flood routing situations.

Owner:DALIAN UNIV OF TECH

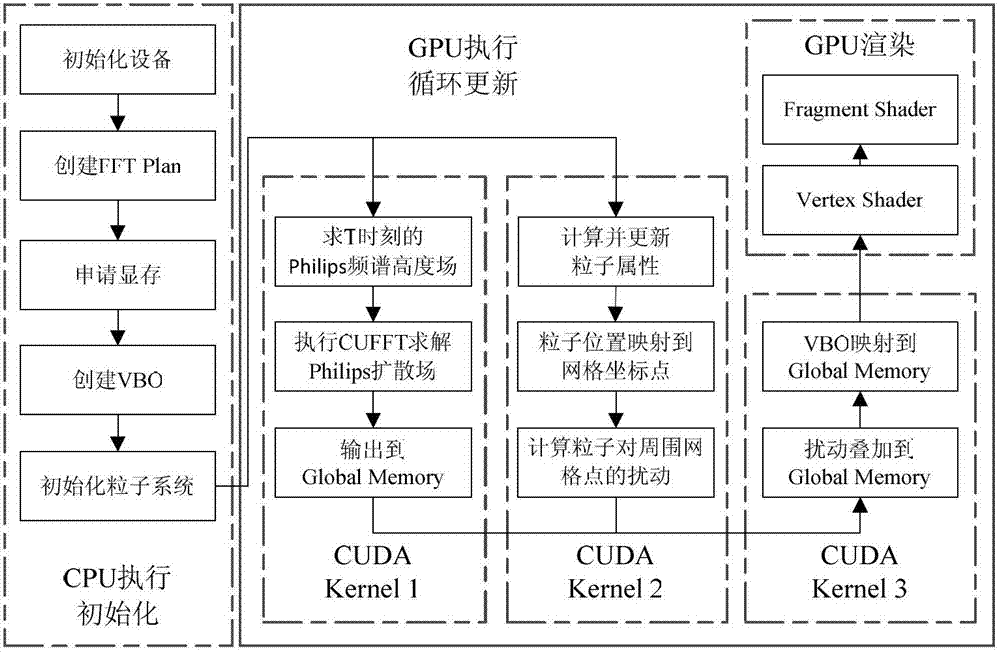

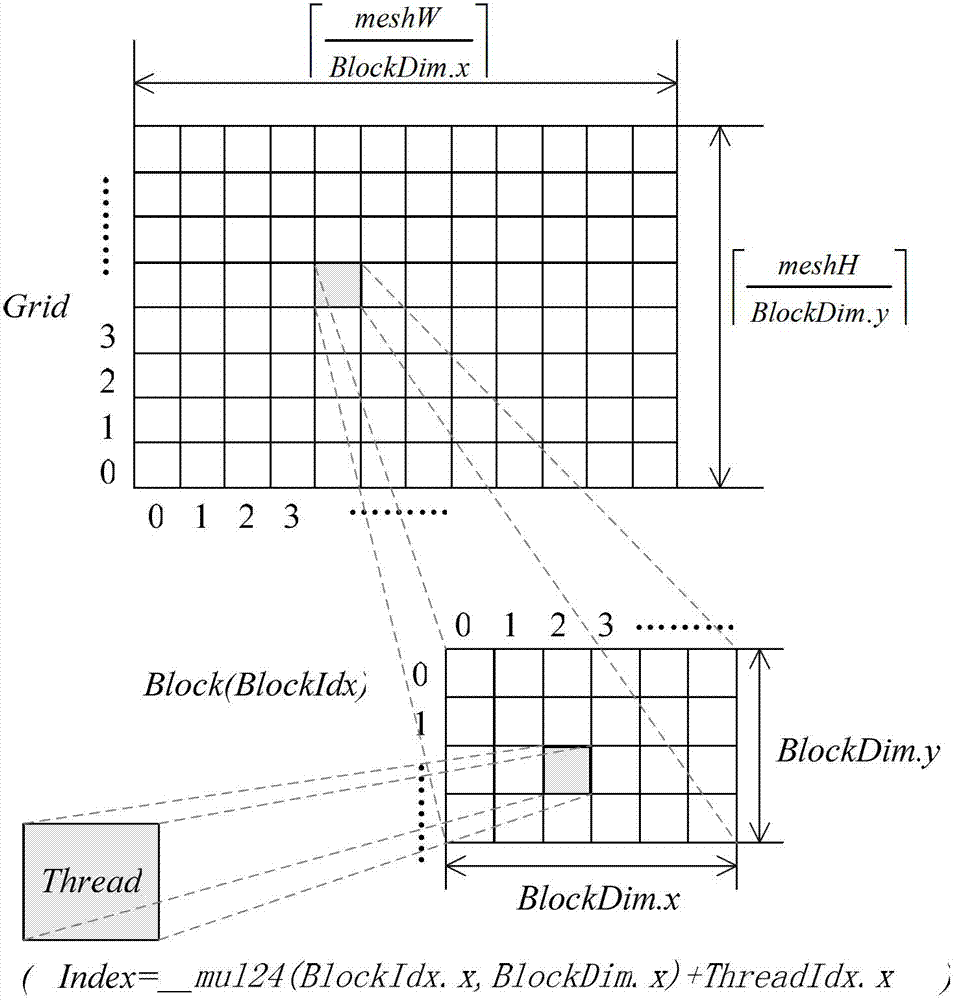

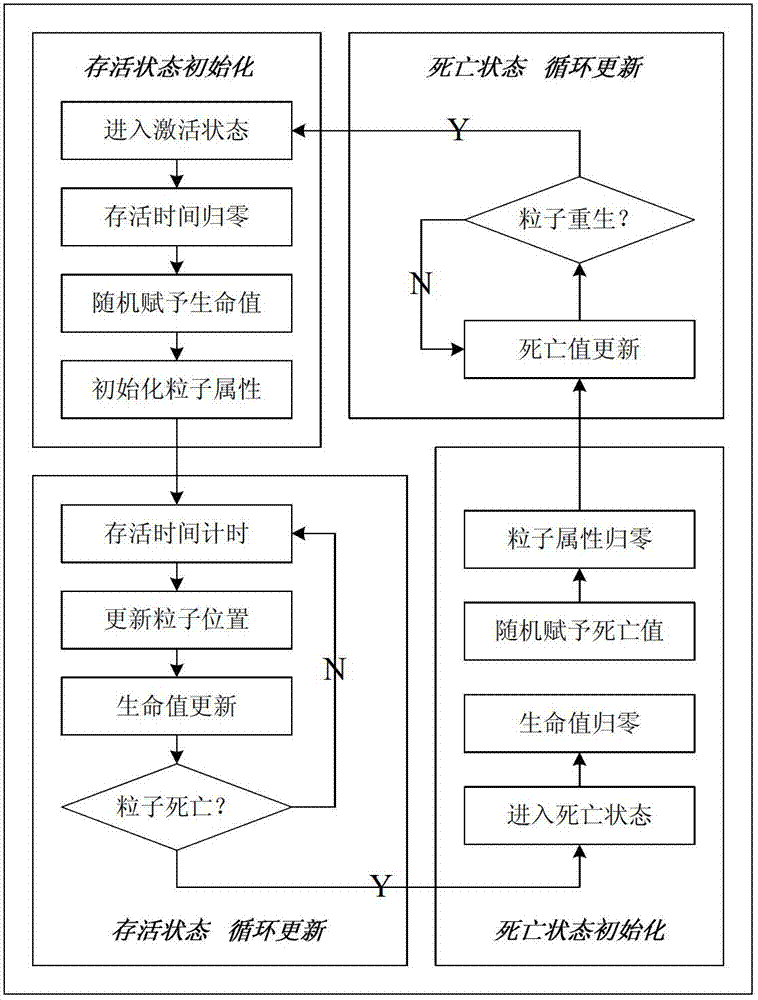

Sea surface track parallel simulation method based on particle system

The invention relates to a sea surface track parallel simulation method based on a particle system. A sea surface track is generated by the method combining a real grid and a virtual particle, the parallel operation of the grid and a particle model is realized on the basis of CUDA (Compute Unified Device Architecture), and sea surface and track rendering in GPU (Programmable Graphics Processing Unit) is realized by GLSL (OpenGL Shading Language). According to the method disclosed by the invention, all the core computations and rendering are carried out in the GPU, the model computation and the rendering constitute a whole process in the GPU, the communication between the internal memory and the video memory is reduced, and the parallel processing capacity of the GPU is fully exerted. The experiment of the inventor proves that the simulation efficiency can be obviously improved under the condition of ensuring a good simulation effect.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

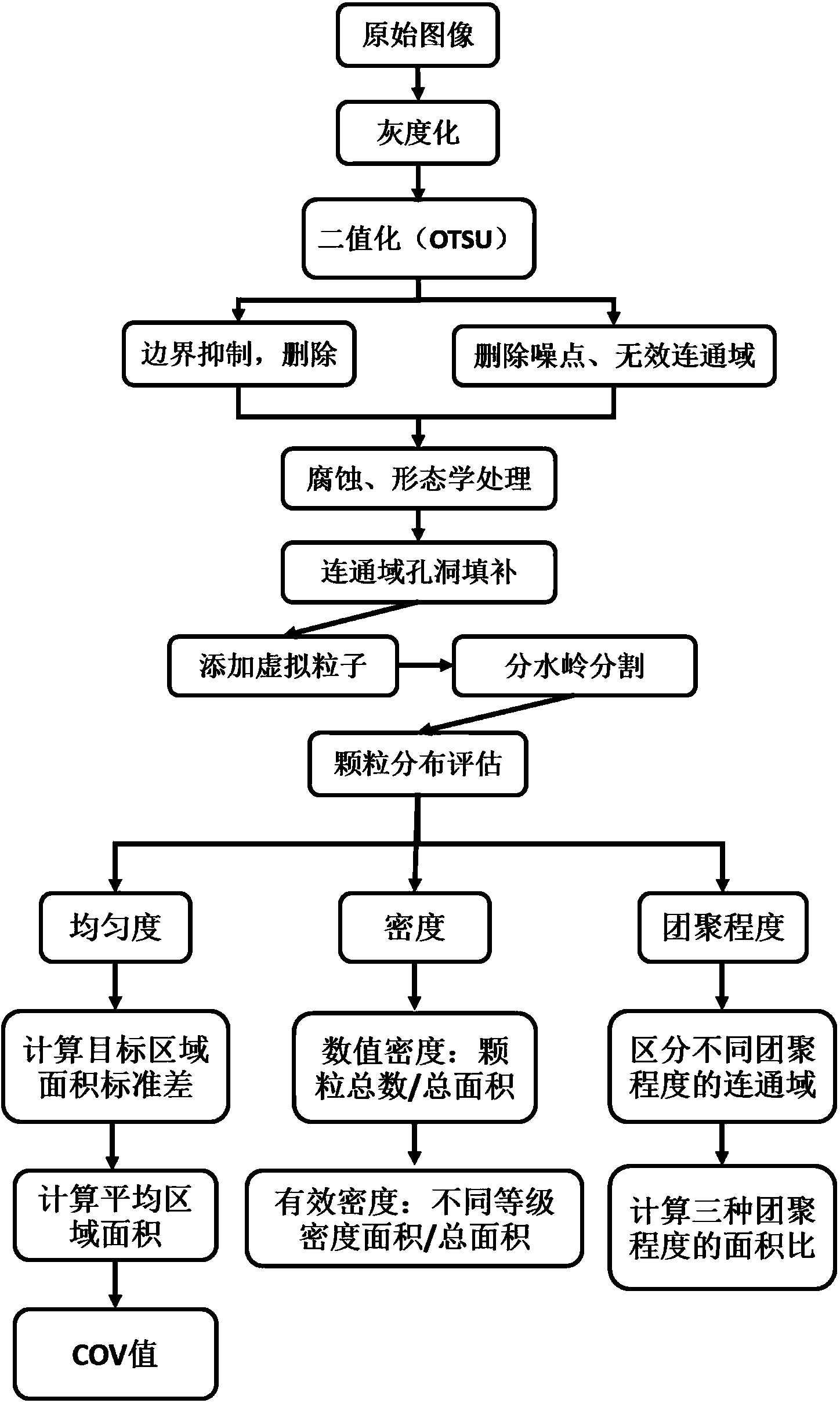

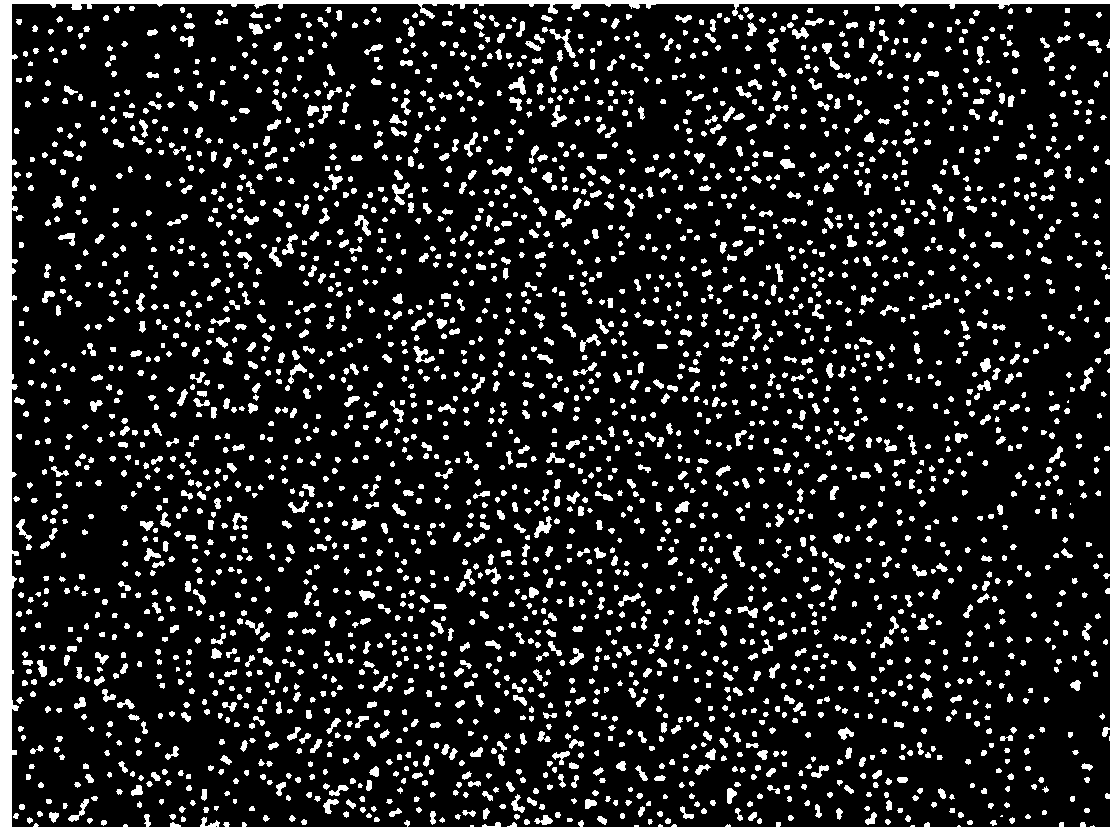

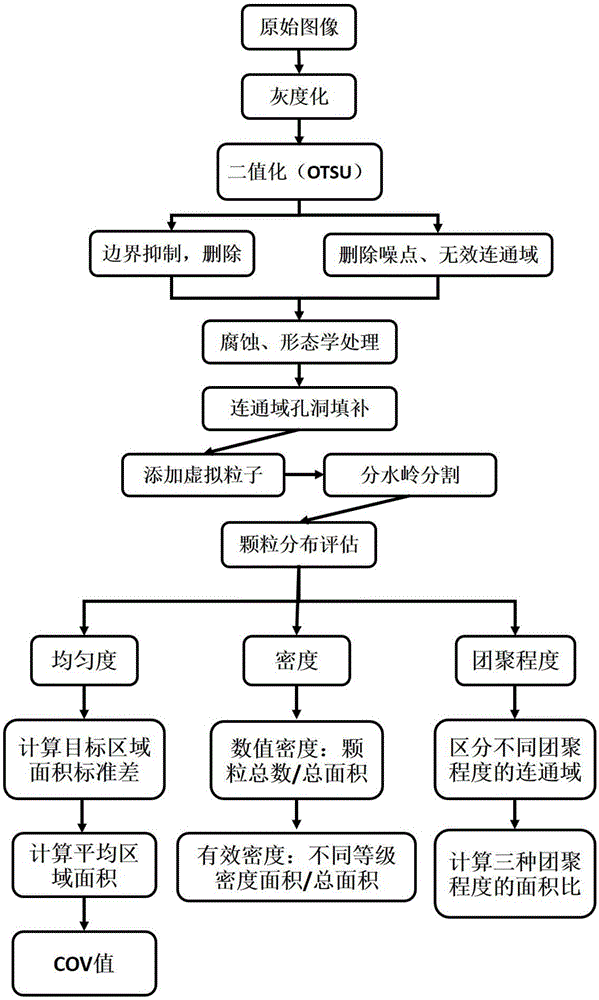

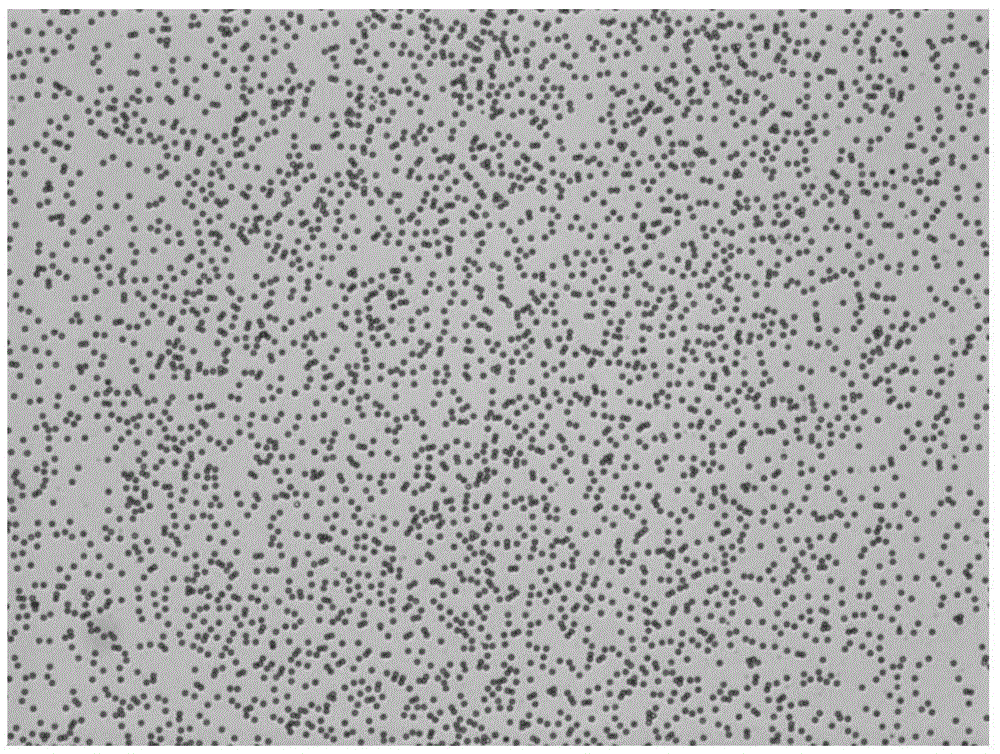

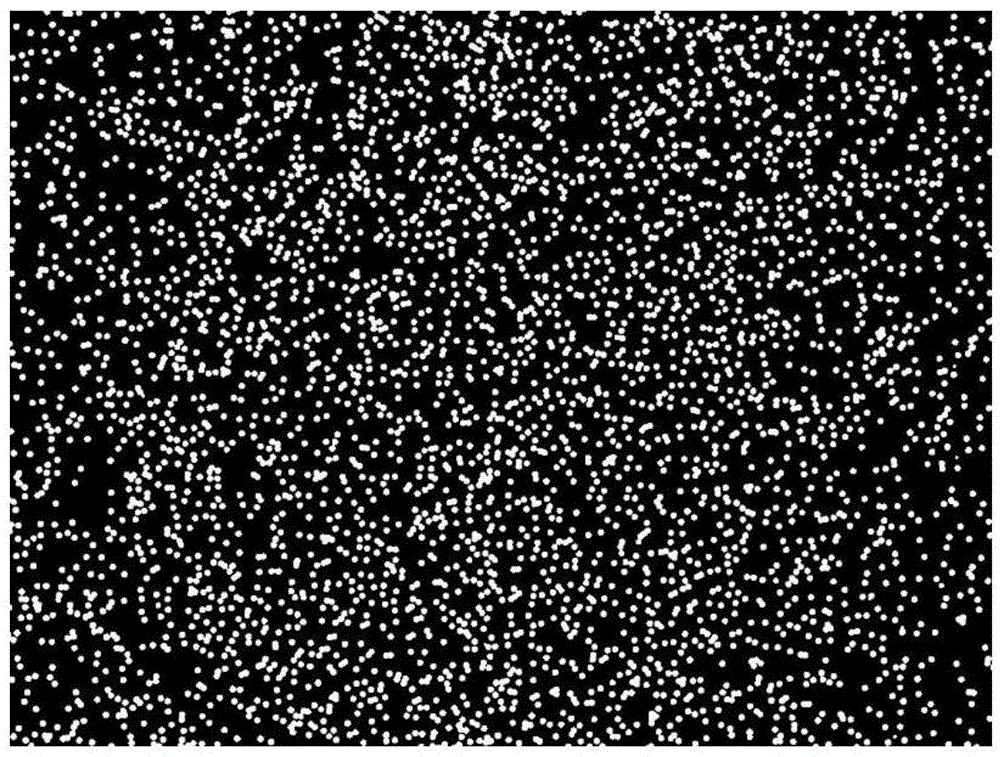

Method for analyzing and evaluating micro-nano particle dispersion and distribution

The invention provides a method for analyzing and evaluating micro-nano particle dispersion and distribution. The method includes the following steps of firstly, collecting a micro-nano particle microscopic image, and graying the image; secondly, conducting binaryzation on the image through an OTSU method, and removing impure points and ineffective communication domains in the image; thirdly, separating the connected communication domains through the morphological algorithm, and filling holes in the communication domains; fourthly, adding virtual particles, segmenting the image through the watershed algorithm, and obtaining segmented characteristic communication domains; fifthly, calculating related data of the characteristic communication domains; sixthly, evaluating micro-nano particle dispersion and distribution. By means of the method, the more accurate result can be obtained; a large number of micro-nano particle distribution microscopic images can be rapidly processed in a batched mode; the micro-nano particle distribution condition can be analyzed and evaluated comprehensively from the aspects of uniformity, density and clustering degree.

Owner:SHANGHAI JIAO TONG UNIV

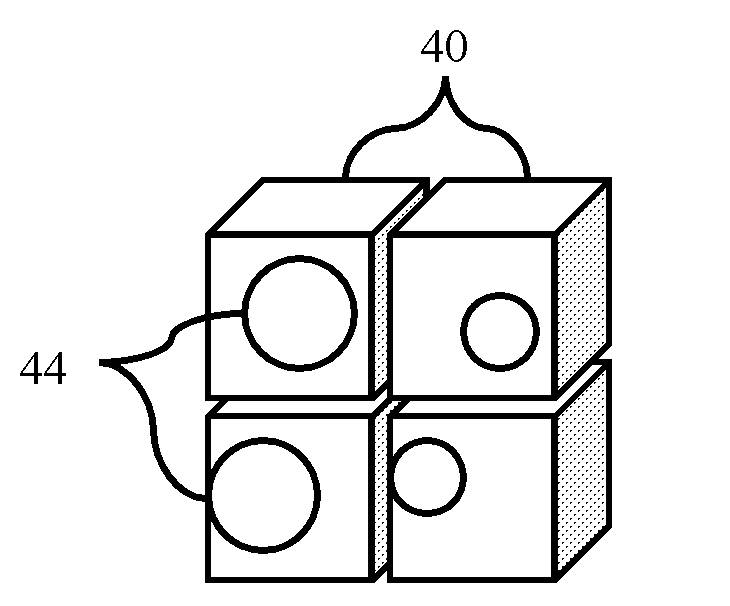

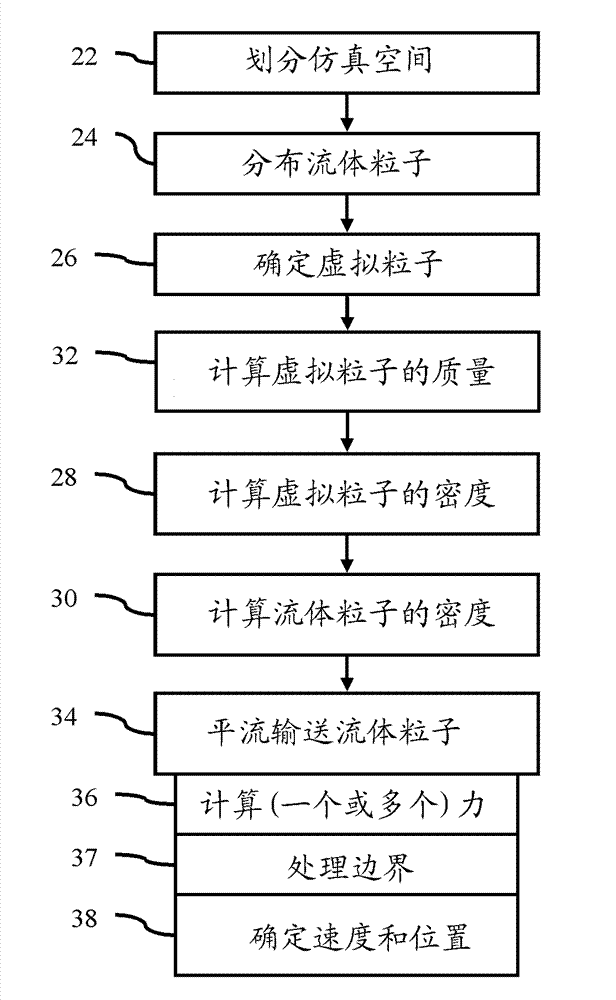

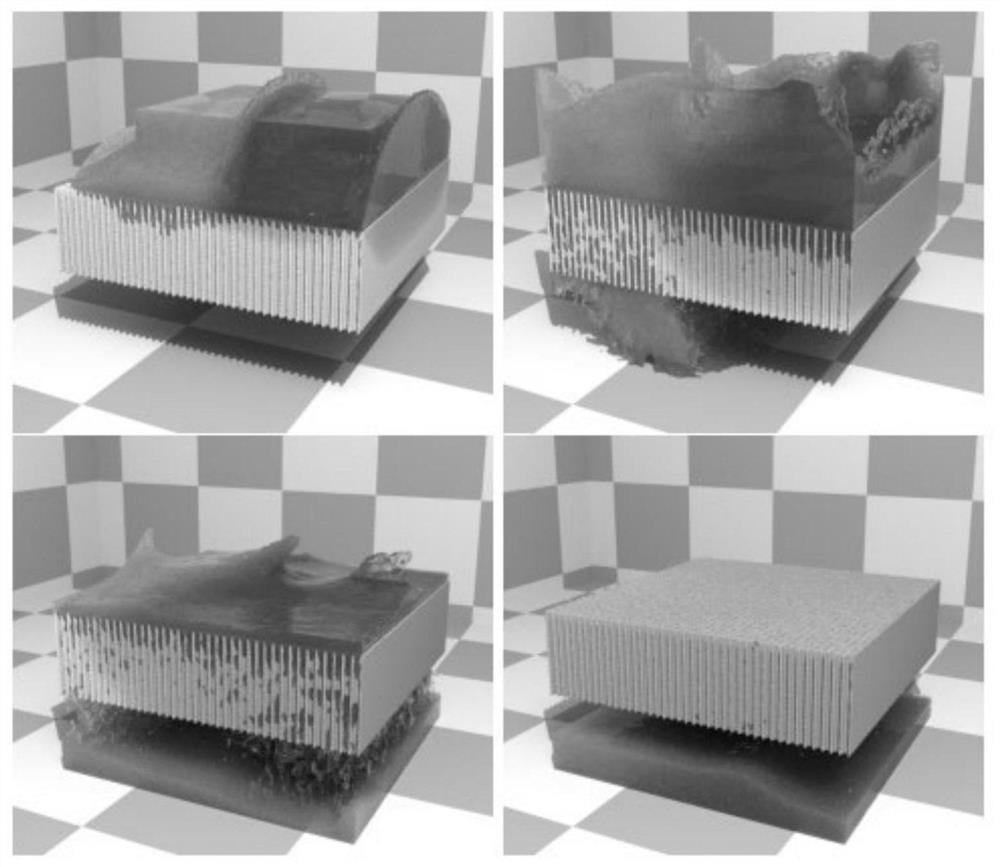

Simplified smoothed particle hydrodynamics

InactiveCN102768698ADesign optimisation/simulationEducational modelsSmoothed-particle hydrodynamicsParticle physics

The invention relates to simplified smoothed particle hydrodynamics. For efficient smooth particle hydrodynamics using more particle information, virtual particles are created. Each virtual particle represents an averaging of properties for the fluid particles in a cell. For density, force, or other calculations for a given fluid particle, the interaction between the particles within a cell are calculated. For calculating the influence of particles outside the cell on the particle in the cell, the virtual particles from the neighboring cells are used. The interaction with these aggregate particles reduces the number of calculations while still including the influence from particles of other cells.

Owner:SIEMENS AG

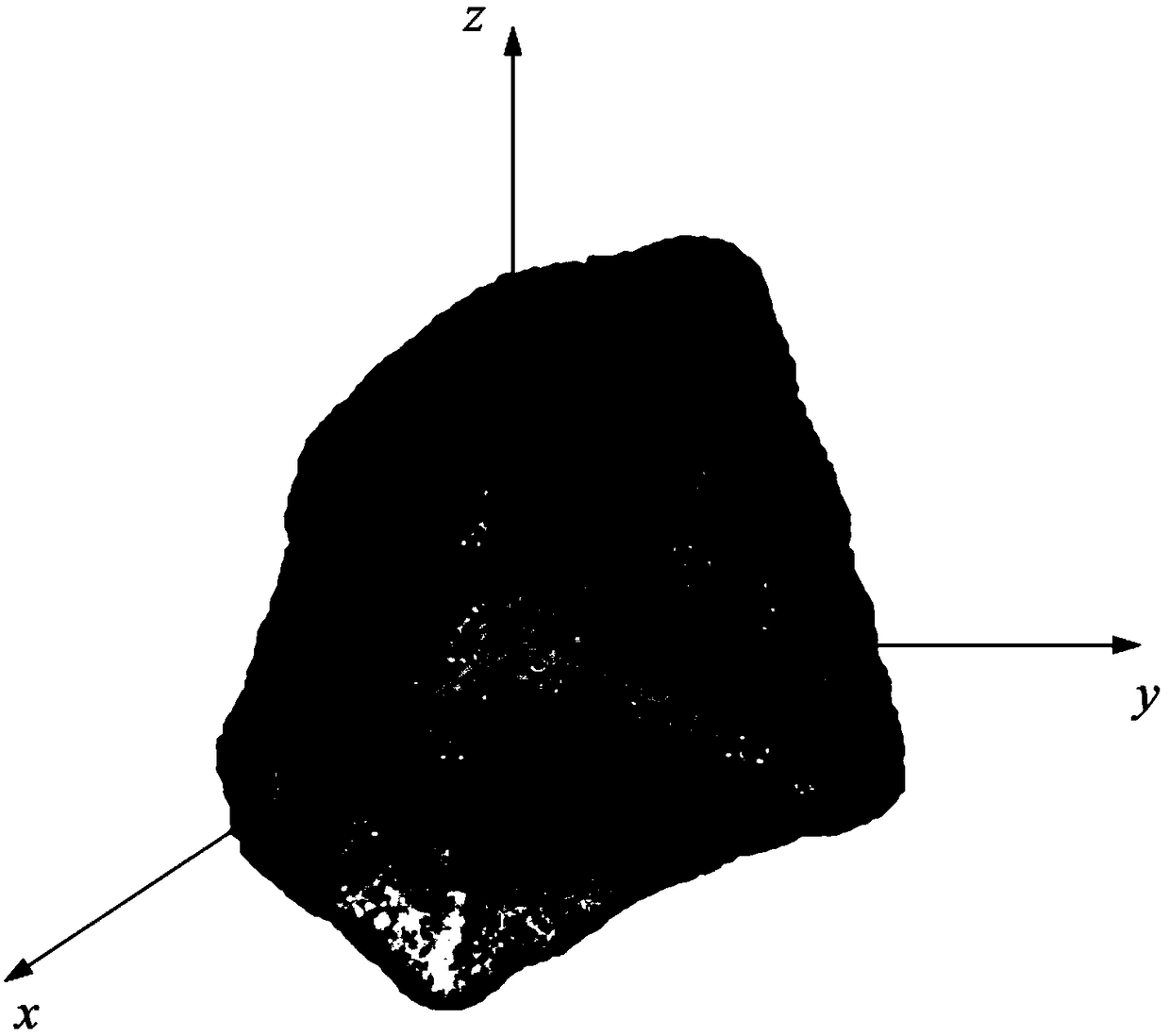

A method for evaluating the the overall roughness of the surface of three-dimensional irregular particles

The invention provides a method for evaluating the overall roughness of the surface of three-dimensional irregular particles, comprising the following steps: S1, scanning the three-dimensional irregular particles by a three-dimensional scanner to obtain the point cloud data of the surface of the particles; S2, carrying out 3D geometrical reconstruction of the particle surface by using the coordinates of the particle surface points obtained by scanning with the spherical harmonic function with the highest degree n=25, using the reconstructed virtual particles as the reference smooth particles,and evaluating the overall roughness of the particles based on the difference between the real particles and the reference particles; S3, using the reconstructed virtual particles as the reference smooth particles, evaluating the roughness of the real particles based on the volume enclosed between the actual particle surface and the reference particle surface and the reference particle surface area. The invention has the advantages that the whole roughness of the whole particle can be evaluated; The influence of the whole geometry of three-dimensional irregular particles can be considered.

Owner:SHENZHEN UNIV

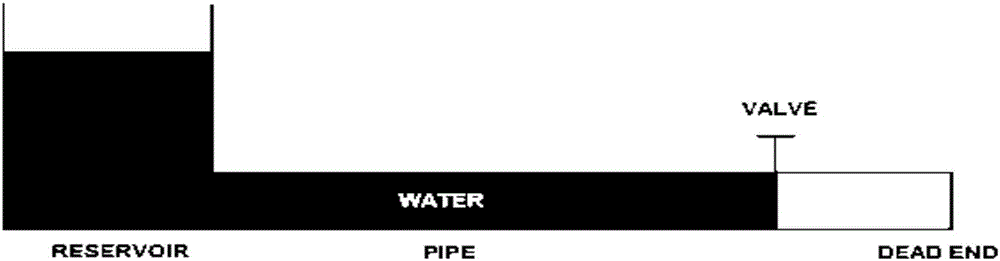

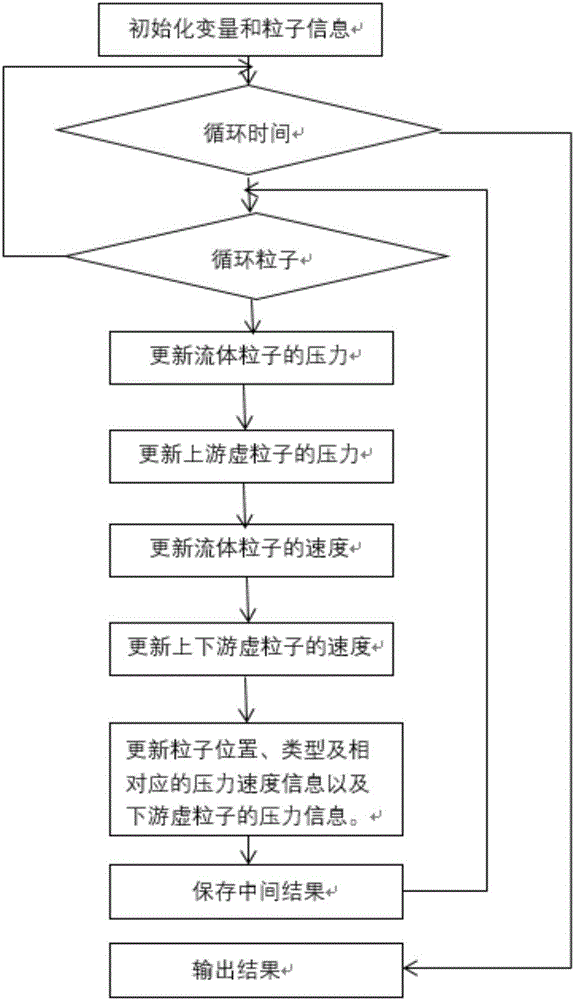

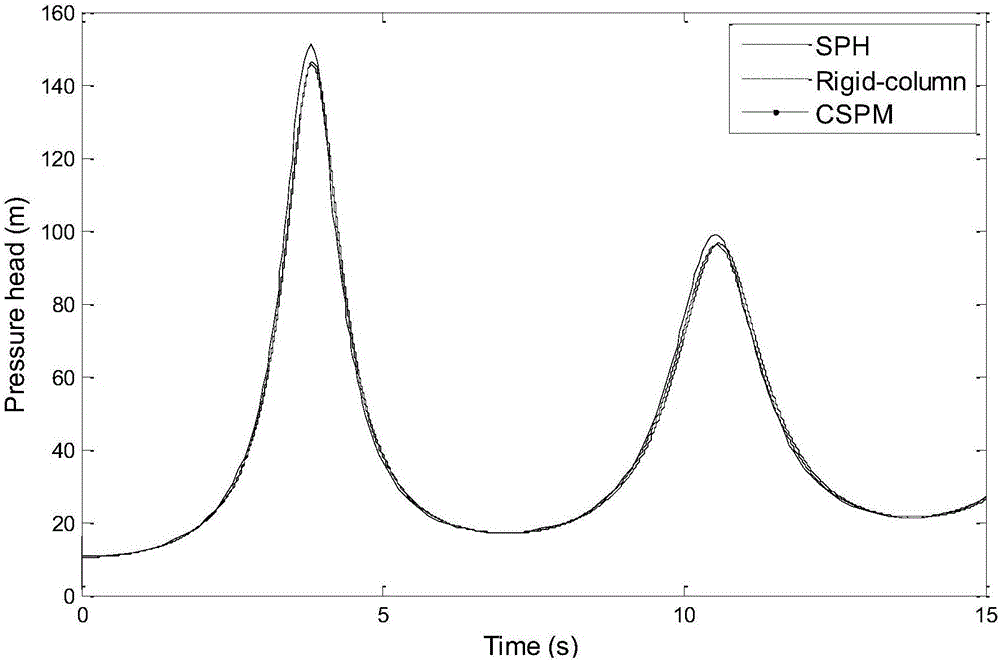

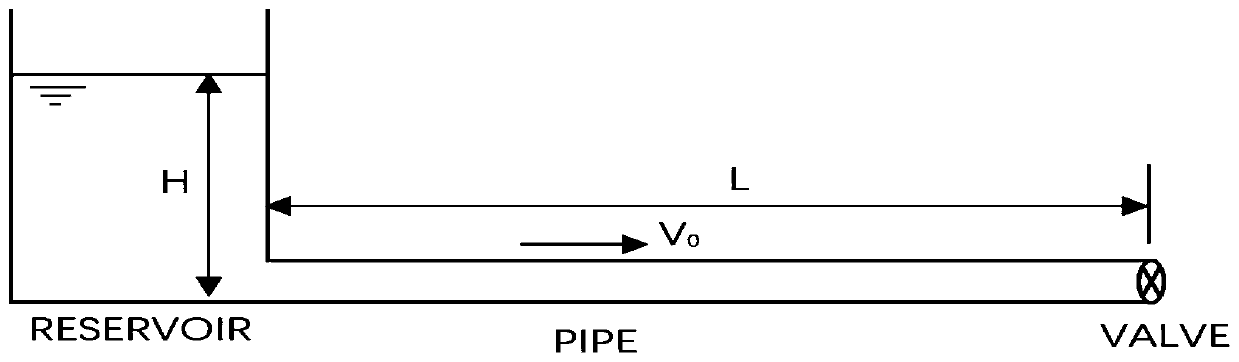

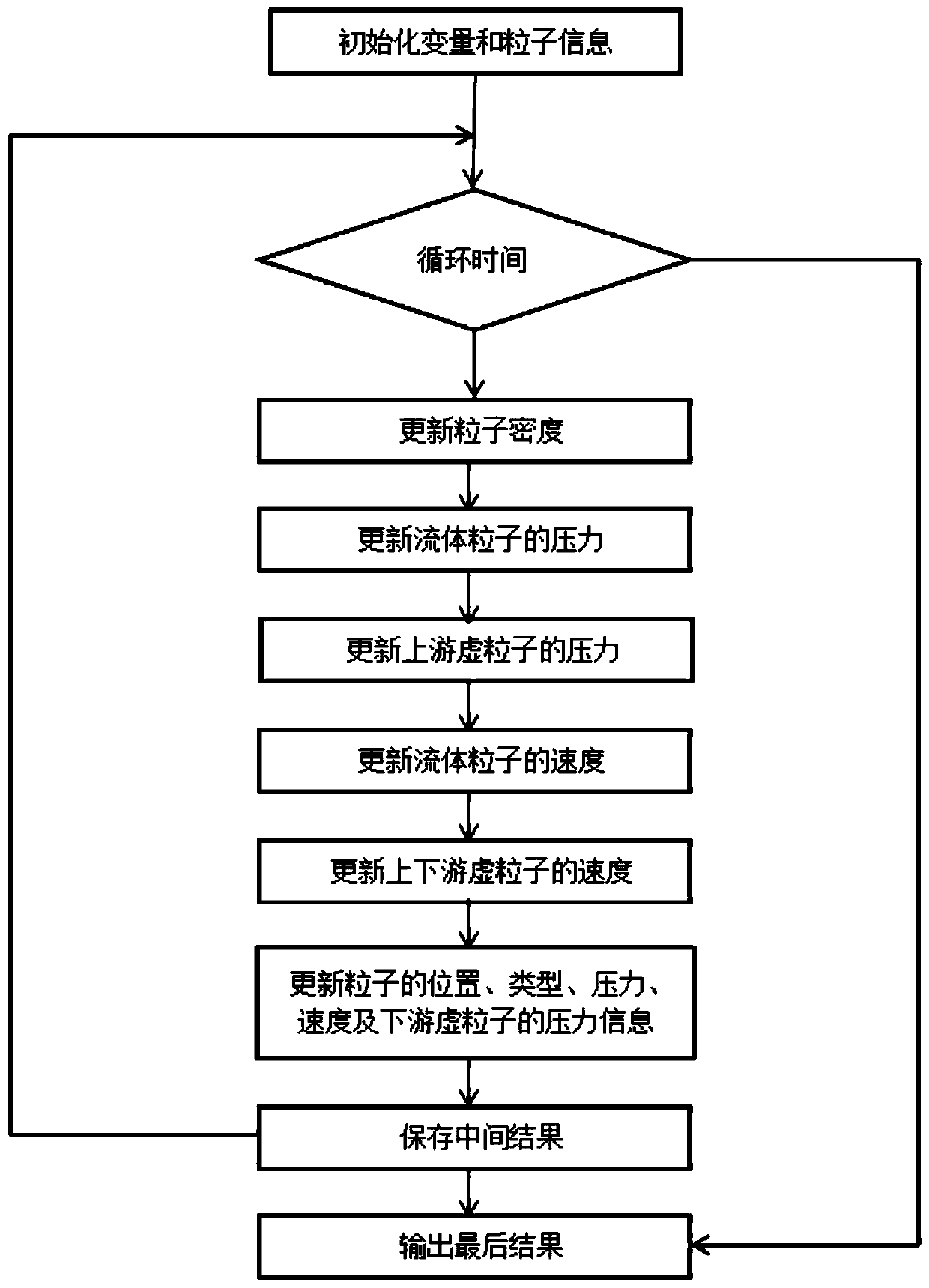

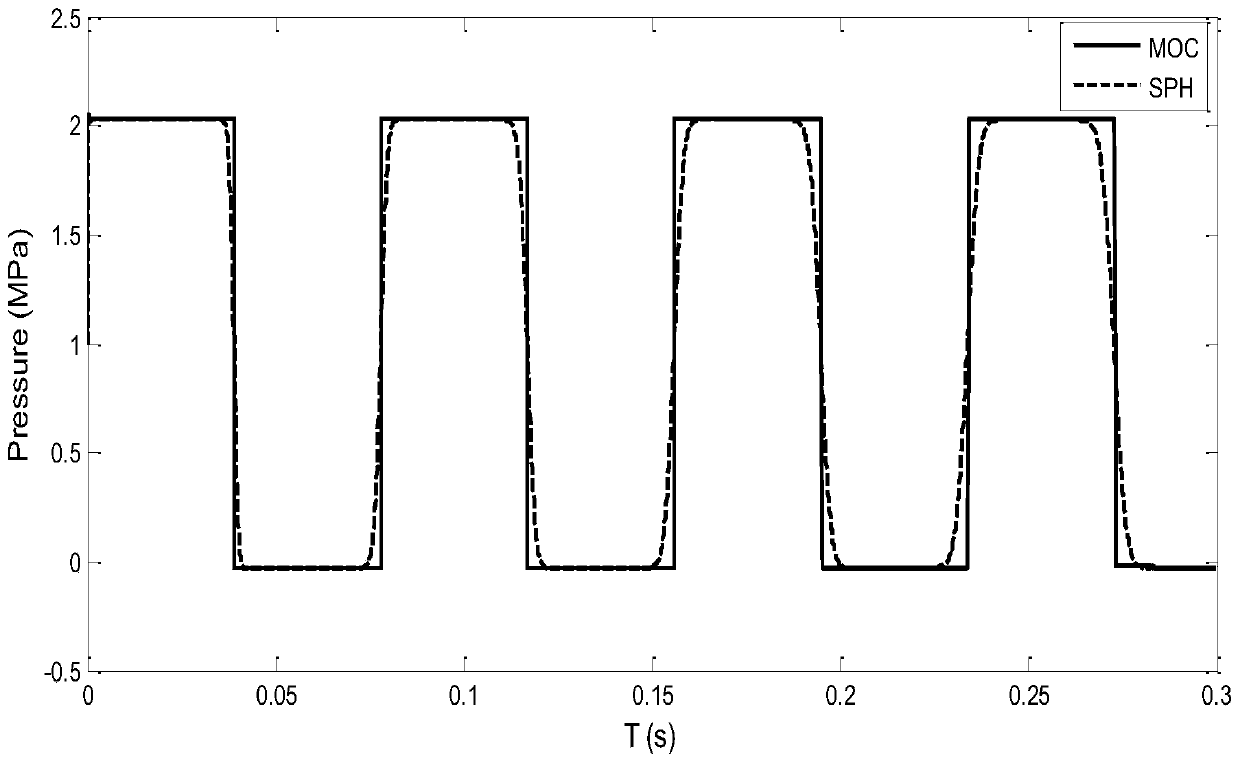

Meshless particle method for analyzing trapped air mass-containing transient pipe flow

InactiveCN106570308AHigh simulationReduce mistakesSpecial data processing applicationsInformaticsSmoothed-particle hydrodynamicsCompressibility

The invention discloses a meshless particle method for analyzing trapped air mass-containing transient pipe flow. The meshless particle method comprises the following steps of (1) initializing relevant variable and particle information; (2) carrying out iterative computation, namely circulating a time variable, circulating particles, calculating pressure information of fluid particles of the initialized particles and updating the pressure information of the fluid particles, the pressure information of upstream virtual particles, speed information of the fluid particles, speeds of upstream and downstream virtual particles, particle positions and corresponding pressure and speed information and the pressure information of downstream virtual particles; and (3) outputting the result. A water hammer equation under a lagrange system is solved by adopting a smoothed particle hydrodynamics method; the influences caused by movement of a gas-liquid interface and weak compressibility of water are fully considered; various errors caused by interpolation and gas-liquid interface tracking technologies are reduced; and the trapped air mass-containing transient pipe flow can be more conveniently simulated on the premise of meeting the numerical precision.

Owner:TIANJIN UNIV

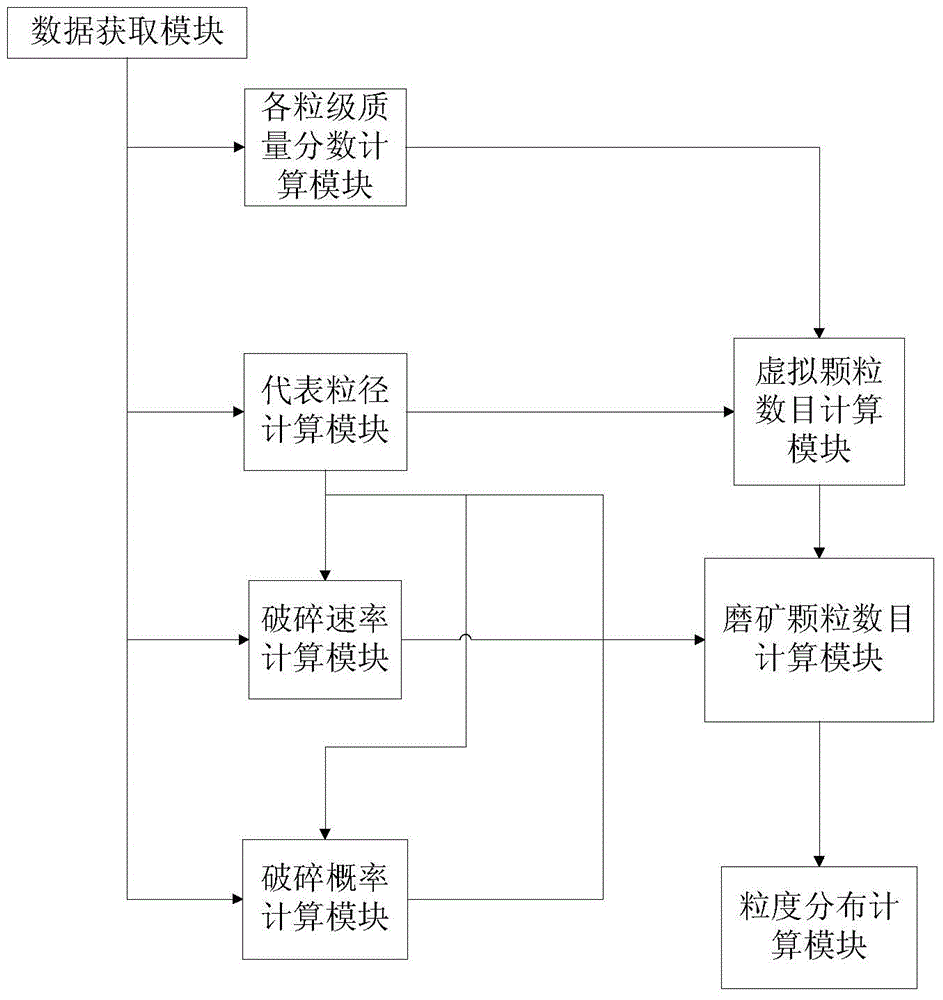

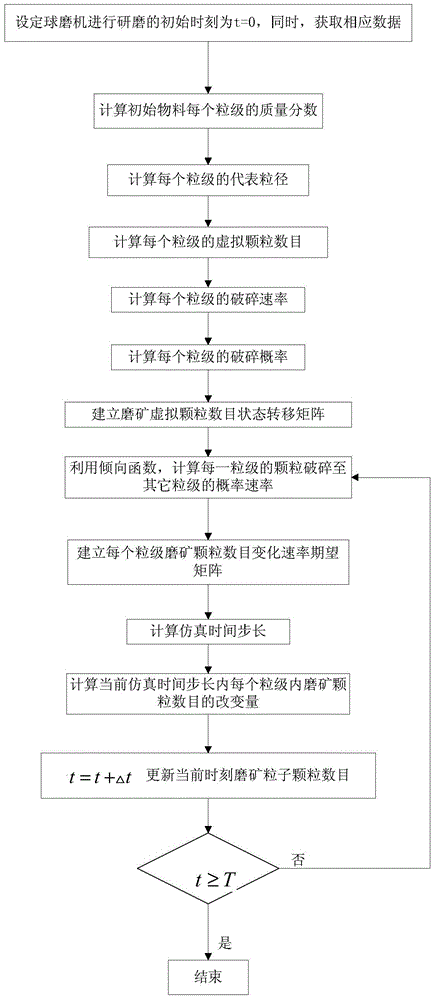

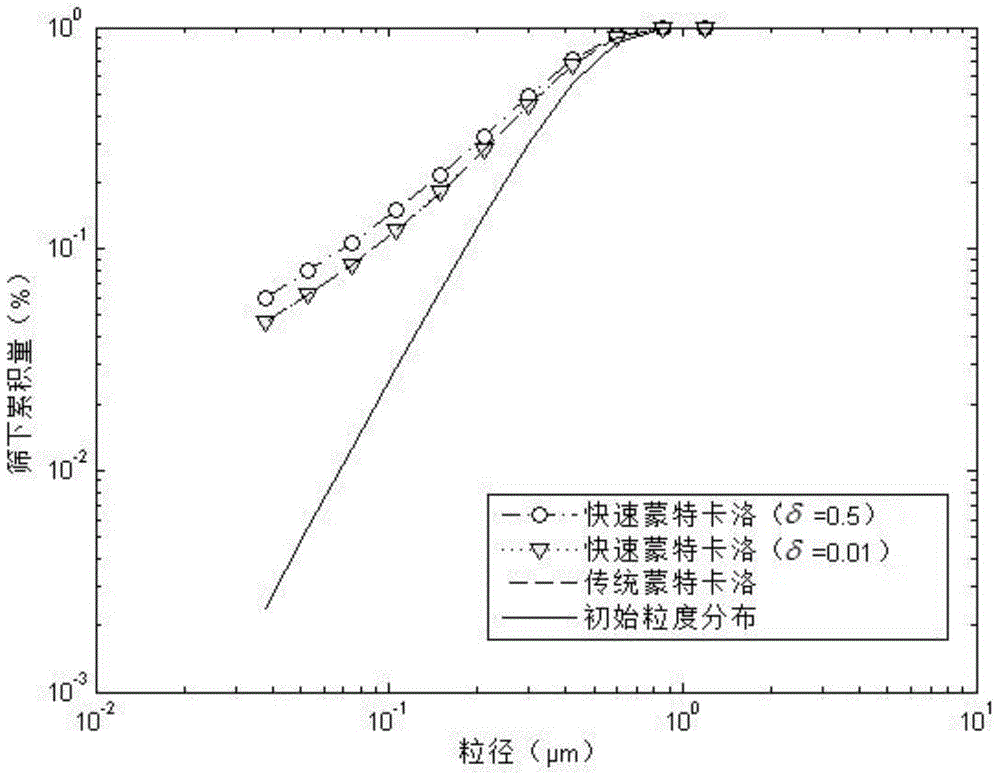

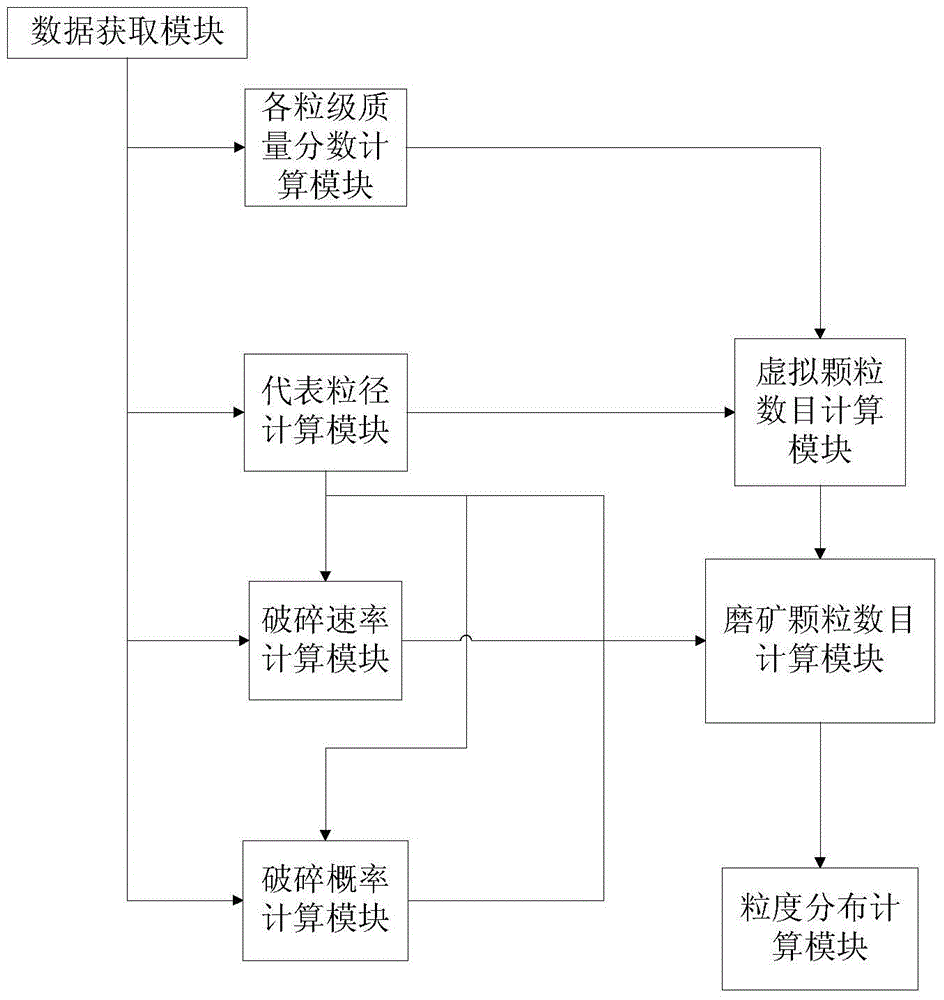

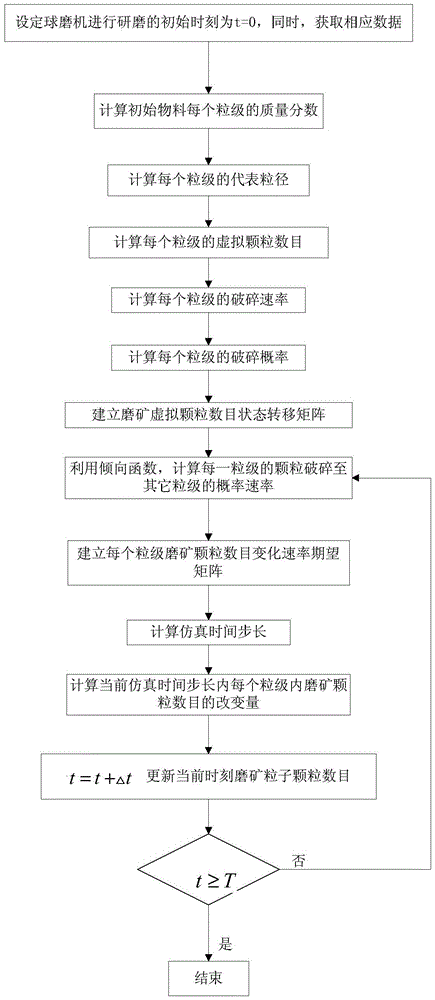

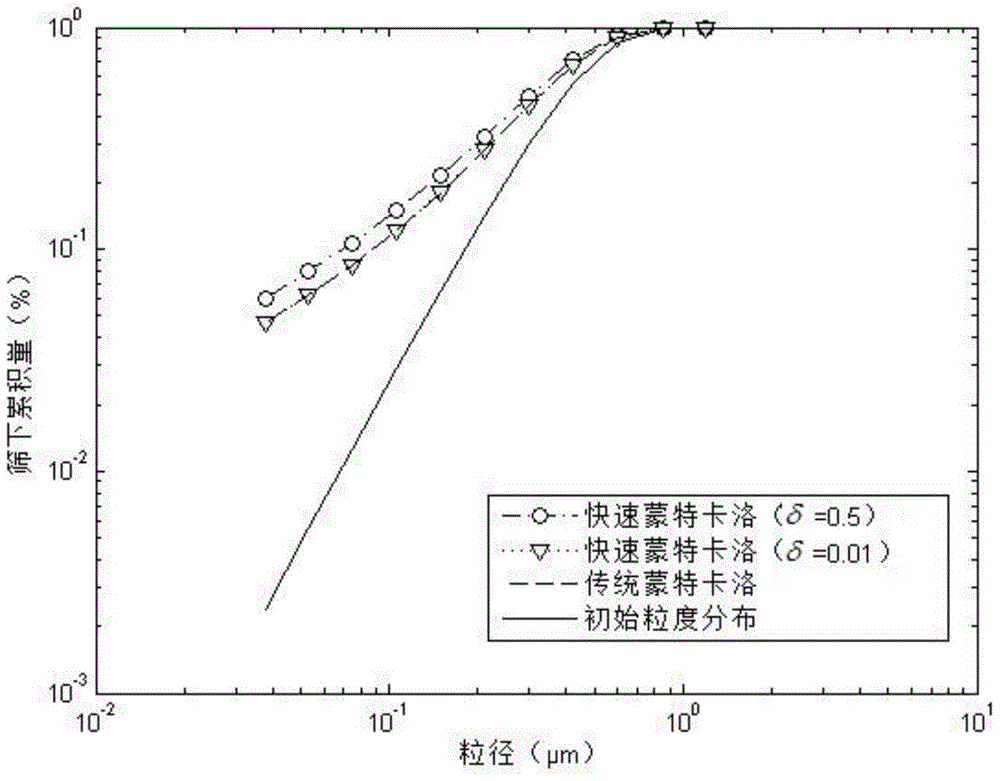

System and method for predicating ball mill grind size distribution by fast Monte Carlo method

The invention discloses a system for predicating ball mill grind size distribution by a fast Monte Carlo method and a method thereof, and the system comprises a data acquiring module, a particle size mass fraction calculating module, a representative particle diameter calculating module, a virtual particle number calculating module, a breaking rate calculating module, a breaking probability calculating module, a grinding particle number calculating module and a size distribution calculating module; the method comprises the following steps of: setting the initial time (t=0) of the ball mill, and acquiring relative data; calculating the mass fraction of each particle size of each initial material; calculating the representative particle diameter of each particle size; calculating the virtual particle number of each particle size; calculating the breaking rate of each particle size; calculating the breaking probability of each particle size; acquiring the number of grinding particles in each particle size after grinding by the ball mill; calculating grinded size distribution. In the system and the method, many breaking events are allowed to occur in each time interval, thereby precisely observing a microscopic grinding process and obtaining the size distribution change of the material in the ball mill before and after grinding.

Owner:NORTHEASTERN UNIV LIAONING

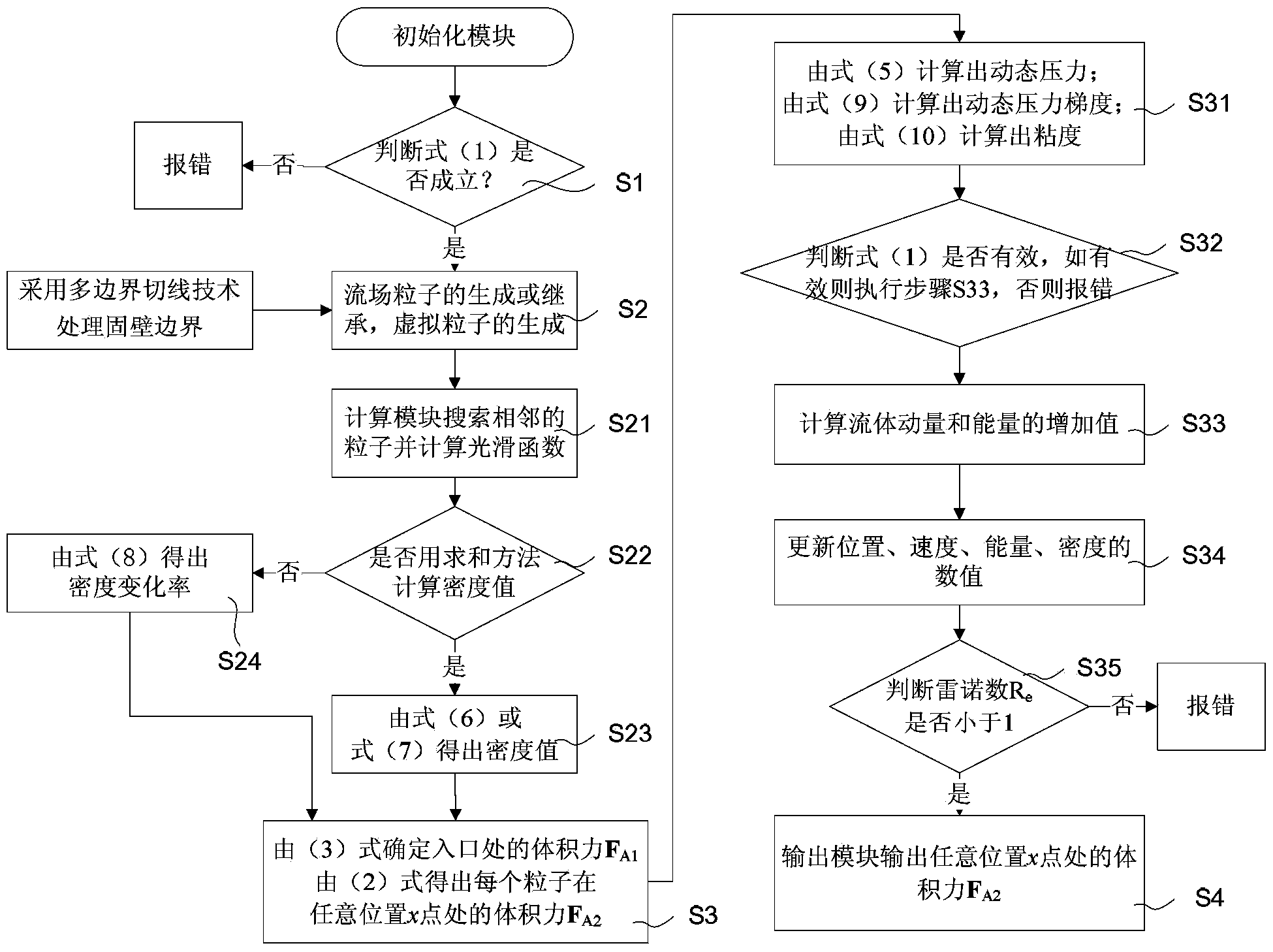

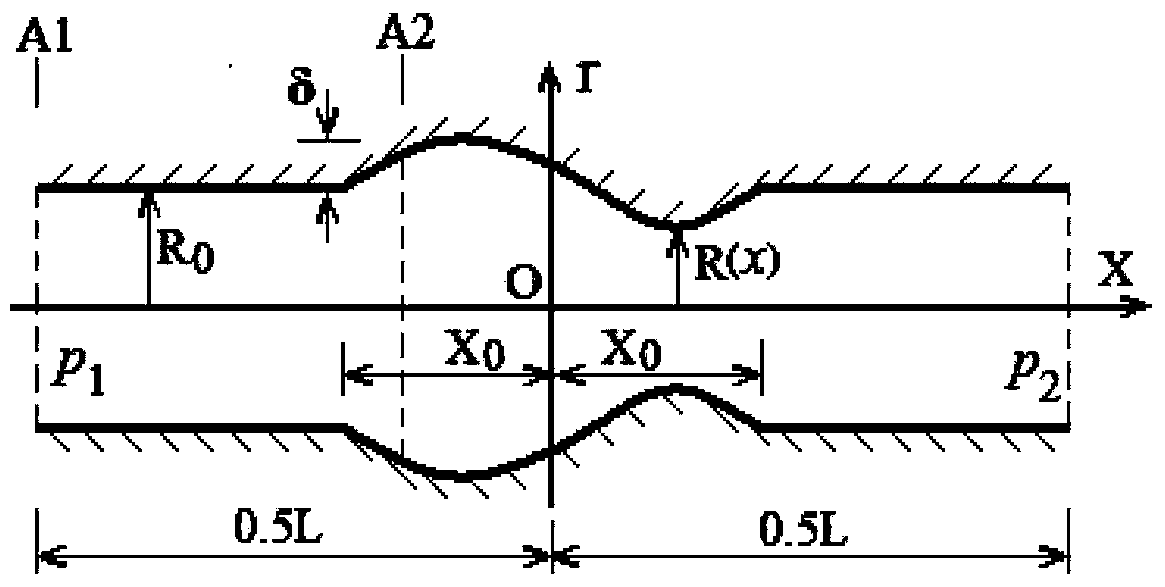

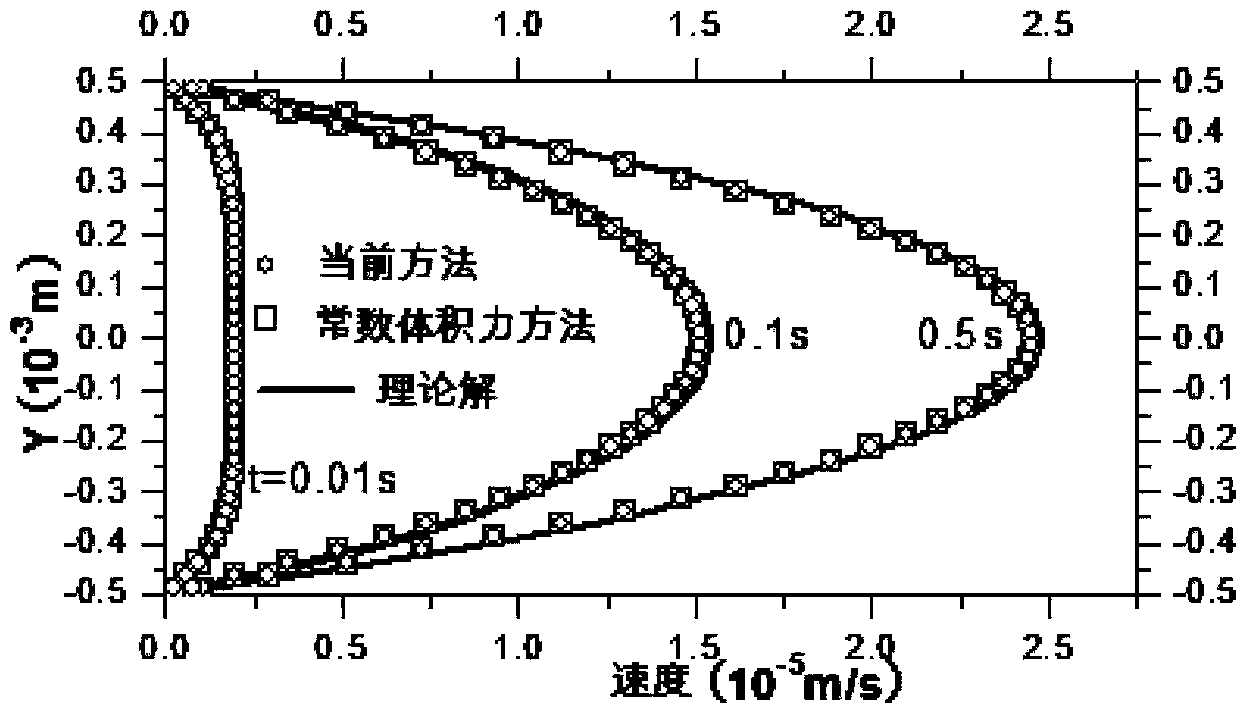

Simulation method of pressure difference in low Reynolds number incompressible flow at bending boundaries

InactiveCN103473418APromote conversionSpecial data processing applicationsPressure differenceComputer science

The invention relates to a simulation method of pressure difference in low Reynolds number incompressible flow at bending boundaries. The method comprises the following steps of S1, enabling a calculation module to determine if the formula (1) is met or not for the given low Reynolds number incompressible flow, or R0<<x0, L>>R0, Re<1; S2, if the formula (1) in the step S1 is met, enabling the calculation module to generate or inherit particles in a simulation flow field, and adopting a multi-boundary tangential technology to process the fixed-wall boundary and generating virtual particles according to the requirement of the technology; S3, enabling the calculation module to calculate the volume force FA2 of each particle at the x point of any position according to the formula (2), and calculating the volume force FA1 at an inlet by the formula (3); S4, enabling an output module to output the volume force FA2 at the x point in the step S3. The method can conveniently convert the pressure difference in the low Reynolds number incompressible flow at the bending boundaries into the volume force at any part.

Owner:WUZHOU UNIV

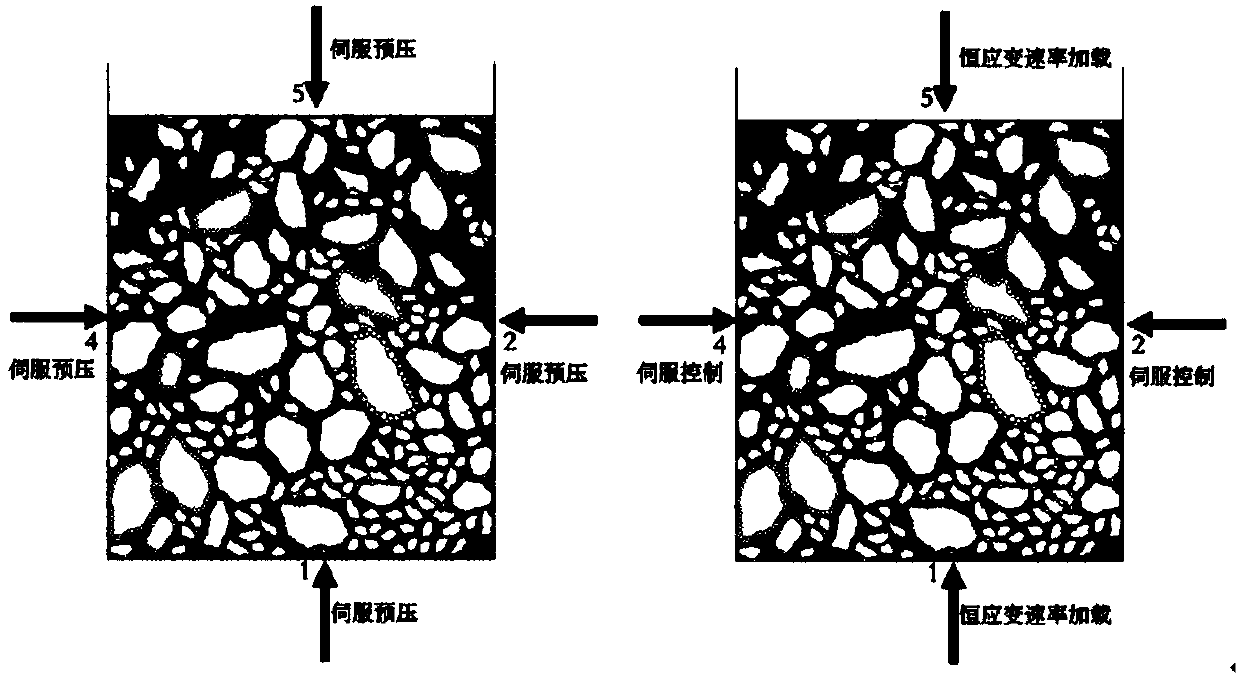

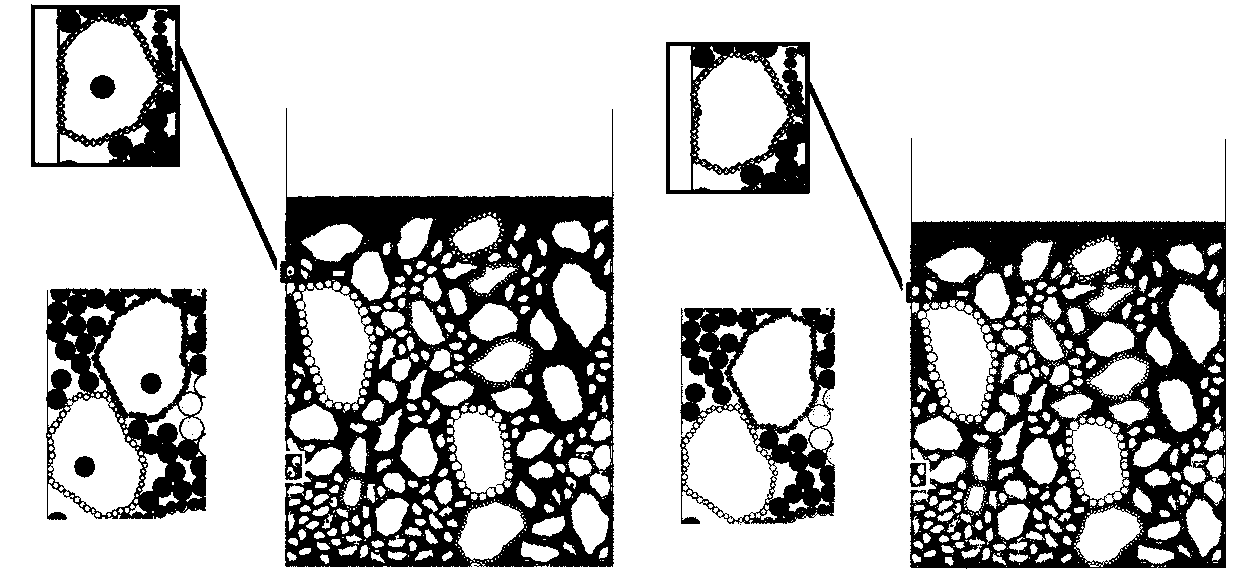

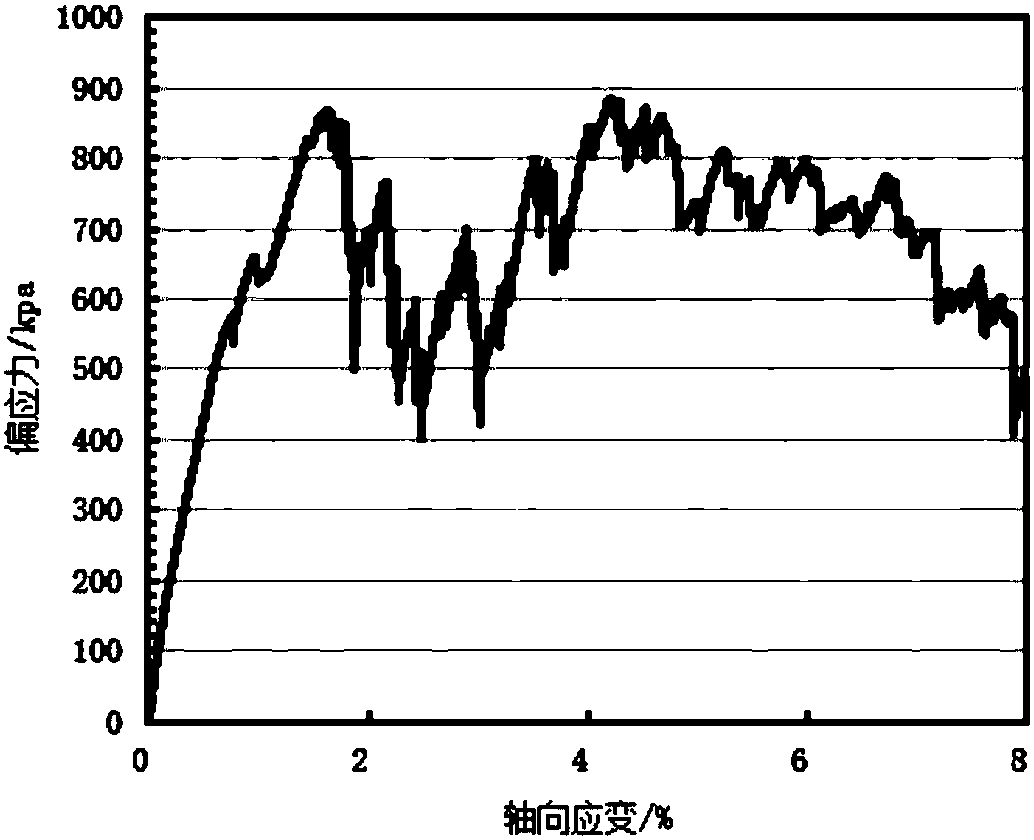

Method for building graded broken stone shear resistance number value prediction models

ActiveCN107796713AReduce capacitySatisfy the experimental simulation taskMaterial strength using steady shearing forcesDesign optimisation/simulationCrushed stoneComputer science

The invention discloses a method for building graded broken stone shear resistance number value prediction models. The method includes the steps: (1) selecting sample particles; (2) virtual modeling of coarse aggregate particles: acquiring contour coordinates of the sample particles and building virtual particle matrix samples to form large-batch particles; (3) virtual modeling of shear test parts: building wall models to simulate test models, and removing error escape particles in a screened manner; (4) virtual shear model loading: giving a servo operation mechanism and a constant-speed operation mechanism to the wall models in different stages to simulate stress and strain control modes in a shear-resistant test; (5) test result counting and arrangement: recording stress and strain curves in shear-resistant test processes and stress and strain data in the limit breaking state. According to the method, the graded broken stone shear resistance number value prediction models are built in a batch manner, numerical simulation of shear-resistant evaluation is achieved, and shear-resistant characteristics of graded broken stones can be rapidly evaluated.

Owner:SOUTHEAST UNIV

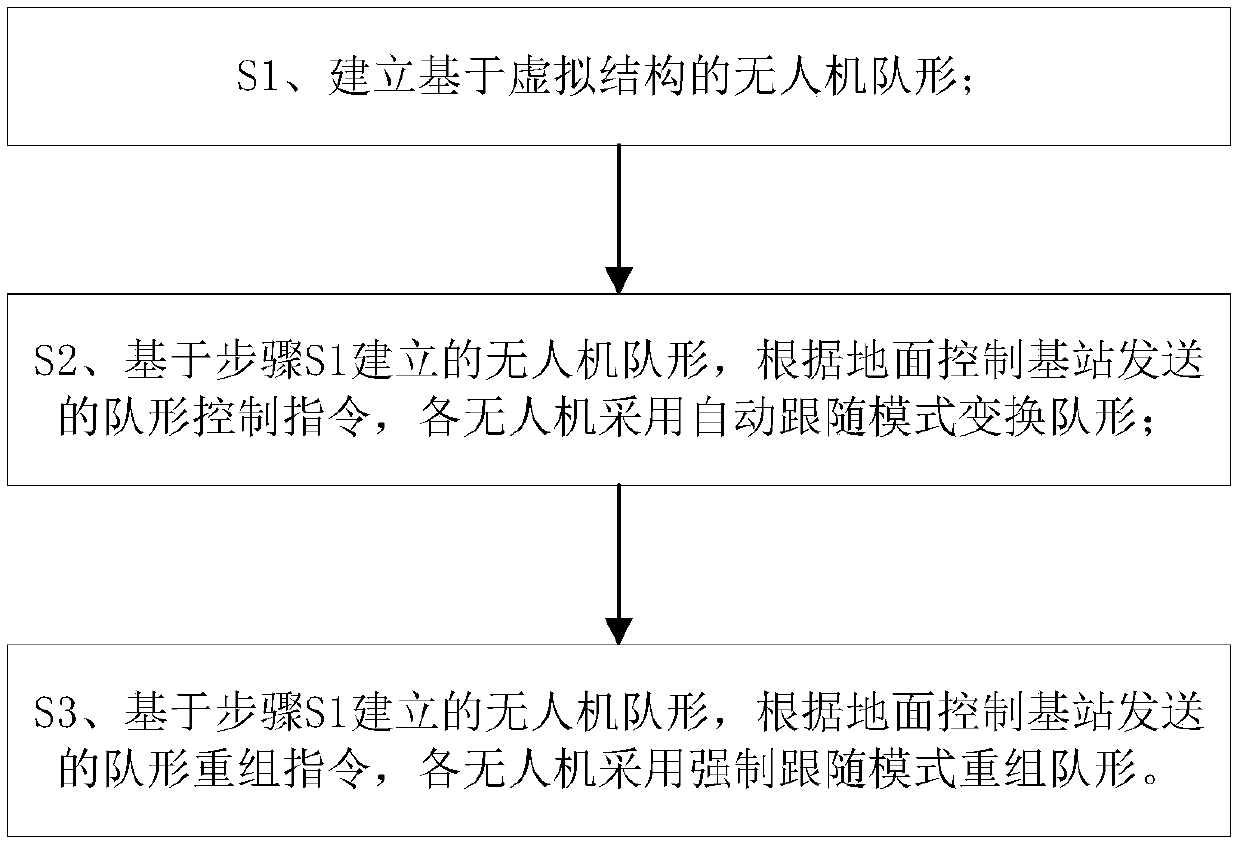

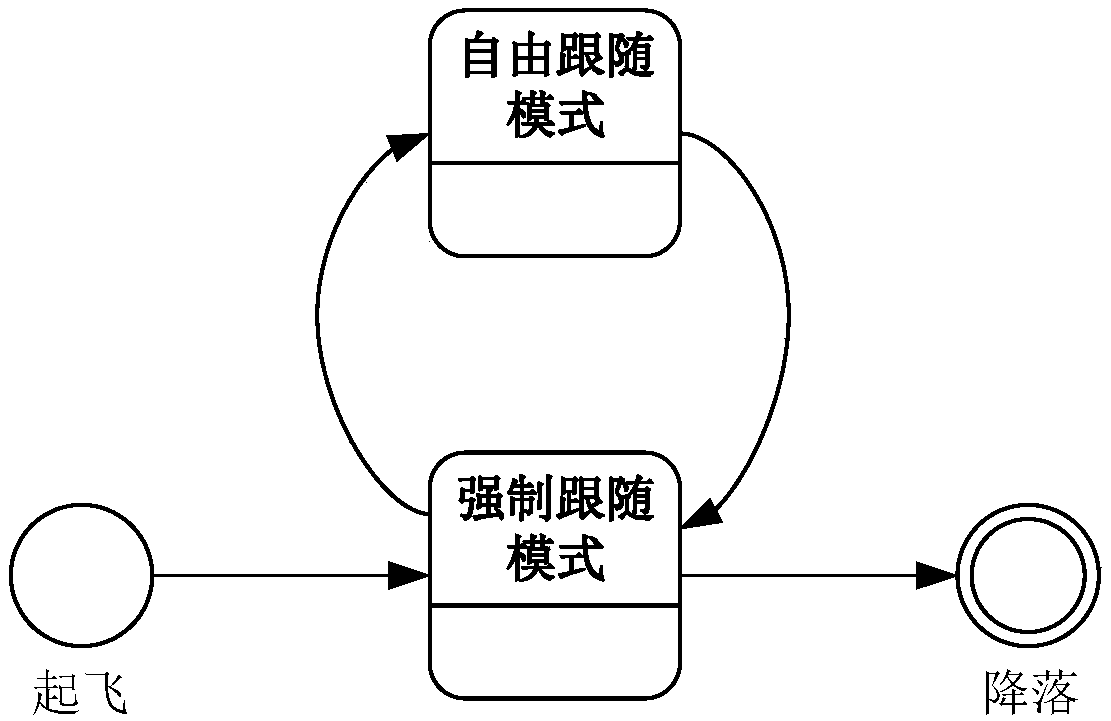

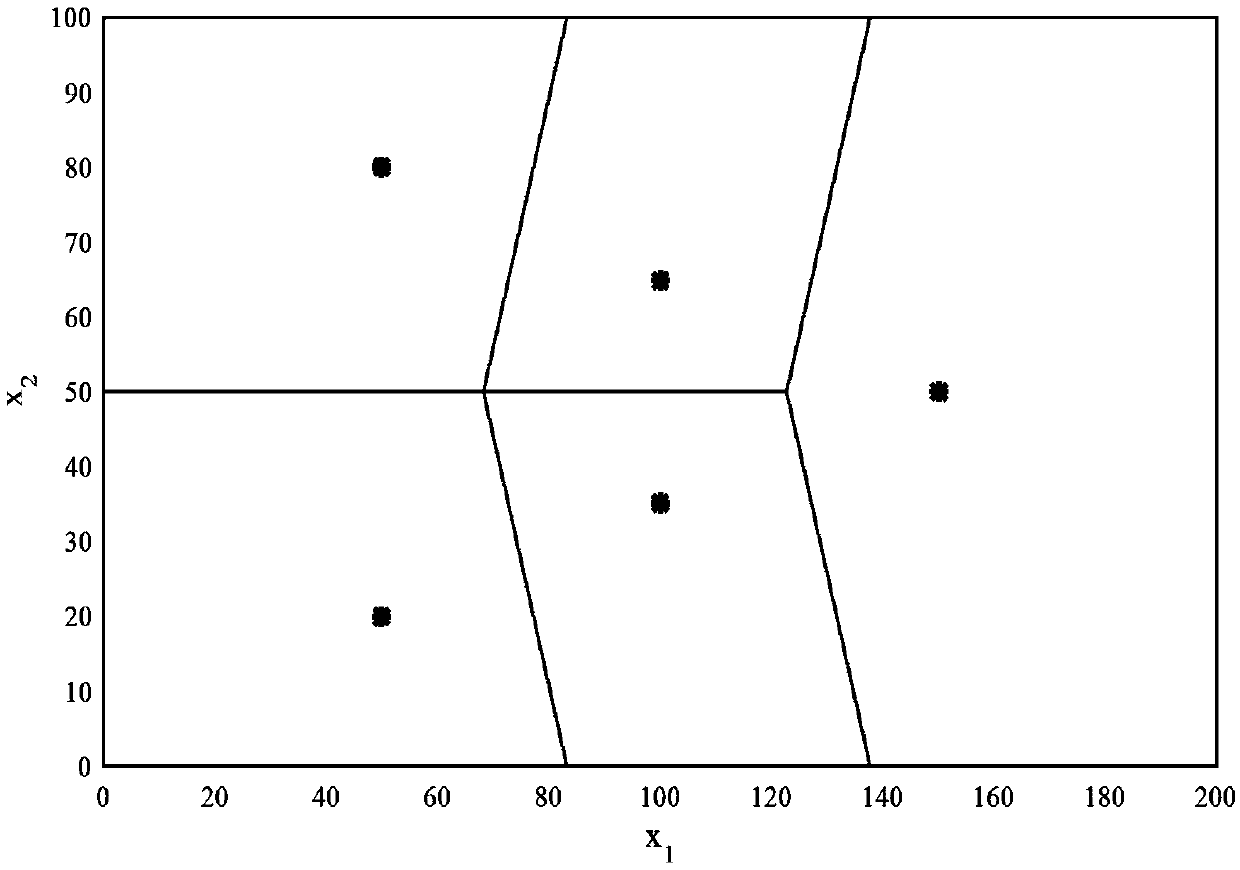

Unmanned aerial vehicle formation transformation method based on virtual structure

ActiveCN108983818AGood formation control effectReduce trafficPosition/course control in three dimensionsUncrewed vehicleVirtual structure

The invention discloses an unmanned aerial vehicle (UAV) formation transformation method based on a virtual structure, applied to the UAV formation and control field for solving the problems that in an existing virtual structure method, each UAV follows a virtual particle, and the virtual structure is limited, so that flexible formation transformation cannot be realized. The UAV formation transformation method based on a virtual structure firstly establishes a UAV formation based on the virtual structure, and then controls the flight state of the entire formation by controlling the flight state of the virtual structure, and the UAV moves around the virtual particle to which the UAV belongs, so as to realize flexible transformation of the UAV formation based on the virtual structure.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

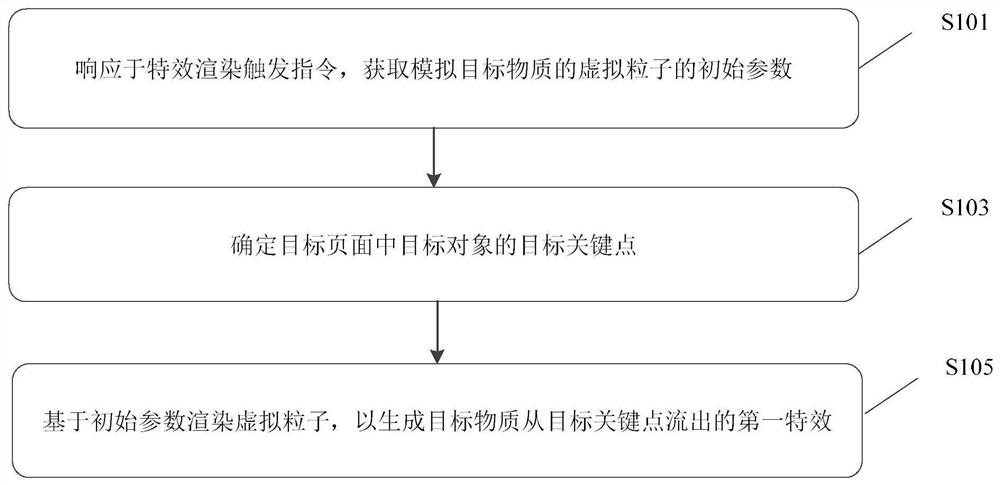

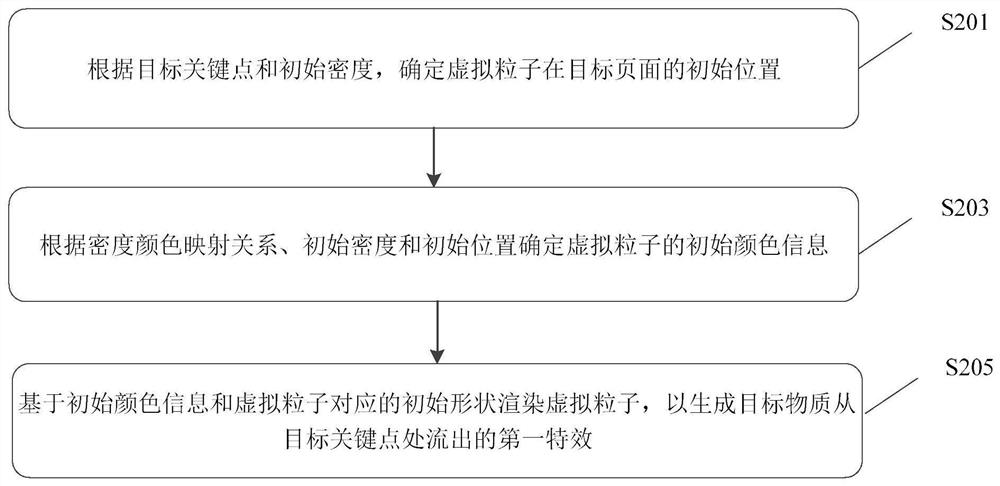

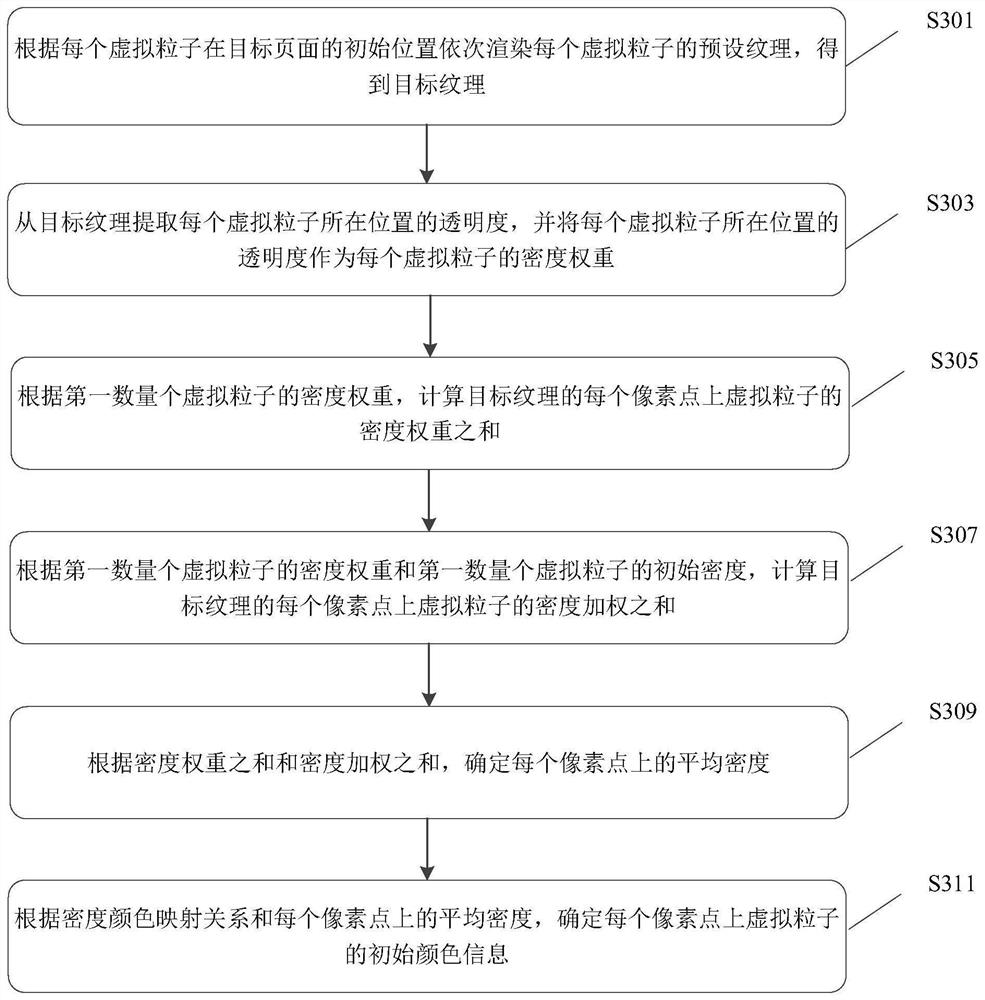

Special effect rendering method and device, electronic equipment and storage medium

PendingCN112446942AIncrease authenticityImprove the simulation effectImage analysis3D-image renderingComputer graphics (images)Simulation

The invention relates to a special effect rendering method and device, electronic equipment and a storage medium, and the method comprises the steps of responding to a special effect rendering triggering instruction, and obtaining the initial parameters of virtual particles simulating a target substance, the initial parameters representing the layout information and motion information of the virtual particles in an initial state; determining a target key point of a target object in the target page; and rendering the virtual particles based on the initial parameters to generate a first specialeffect that the target substance flows out of the target key point. By utilizing the embodiment of the invention, real-time online special effect rendering can be realized, the authenticity of the rendered special effect is improved, and the simulation effect is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

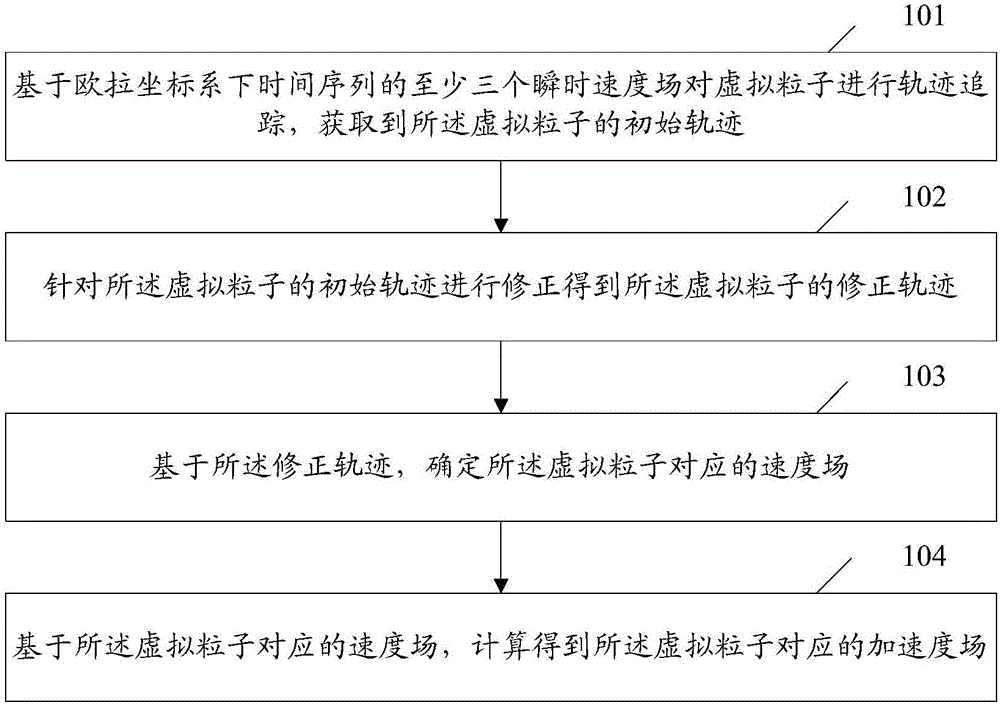

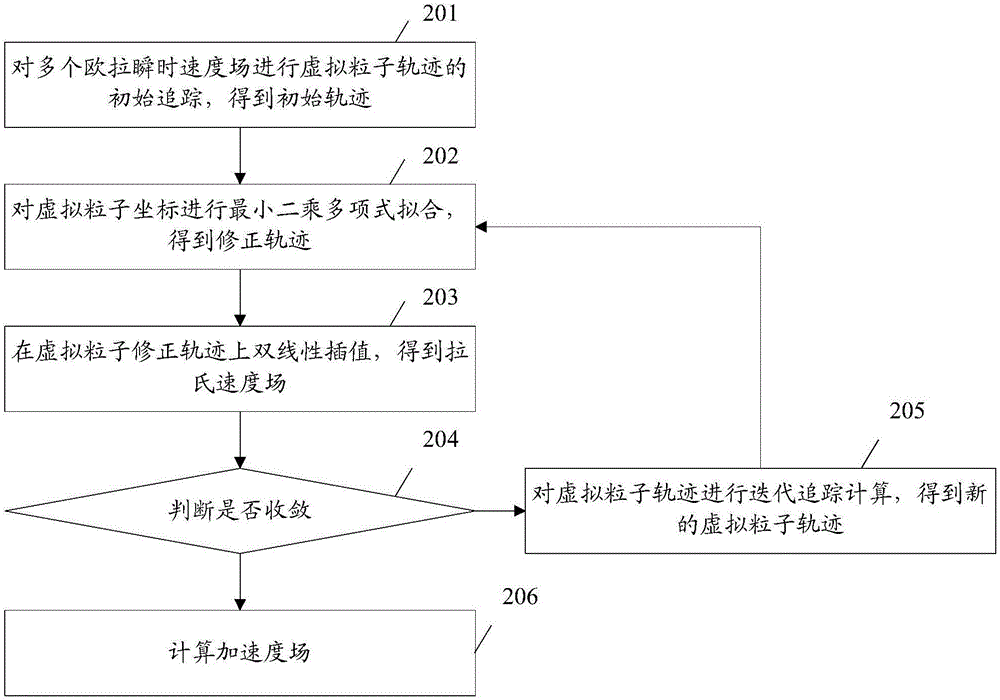

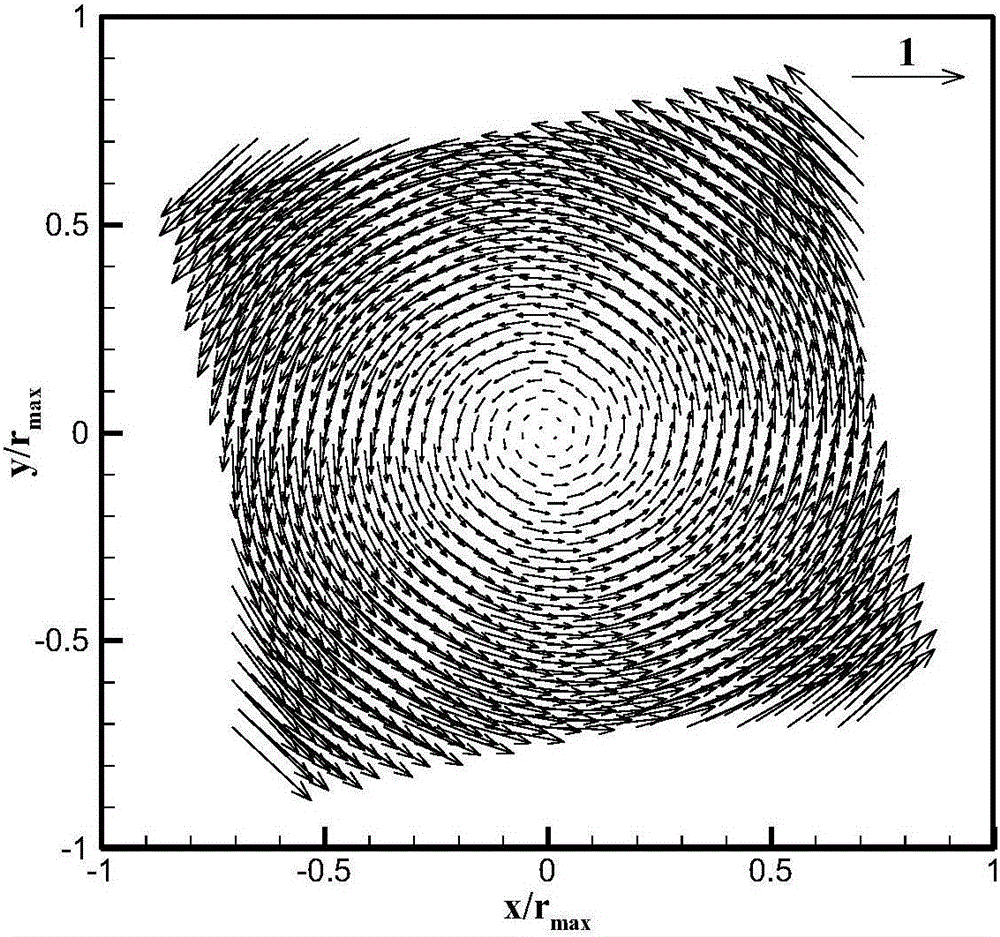

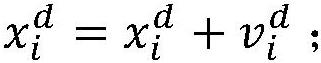

Acceleration measurement method and device based on particle image velocimetry technology

ActiveCN105807093AImprove calculation accuracyGuaranteed Physical PropertiesAcceleration measurementClassical mechanicsVirtual particle

The invention discloses an acceleration measurement method and device based on a particle image velocimetry technology.The method comprises the steps that trajectory tracking is conducted on virtual particles based on at least three instantaneous velocity fields of a time sequence of an Eulerian coordinate system, and initial trajectories of the virtual particles are obtained; correction is conducted on the initial trajectories of the virtual particles, and corrected trajectories of the virtual particles are obtained, wherein the corrected trajectories at least comprise coordinates corresponding to the virtual particles at all times in the time sequence;the velocity fields corresponding to the virtual particles are determined based on the corrected trajectories, wherein the velocity fields comprise velocity information corresponding to the virtual particles at all the coordinates; on the basis of the velocity fields corresponding to the virtual particles, acceleration fields corresponding to the virtual particles are obtained through calculation, wherein the acceleration fields comprise acceleration information corresponding to the virtual particles at all the coordinates.

Owner:BEIHANG UNIV +1

Method for analyzing pipeline water hammer

PendingCN110569541AFully consider weak compressibilityHigh simulationSpecial data processing applicationsAnalysis methodWater hammer

The invention relates to the technical field of fluid mechanics, and provides a new method for analyzing a pipeline water hammer, a water hammer equation under a moving coordinate system is solved, and simulation of a water hammer phenomenon in a pipeline is achieved. Meanwhile, the pipeline water hammer problem can be more conveniently simulated on the premise that the numerical precision is met.Therefore, the technical scheme adopted by the invention is as follows: the method comprises the following steps: step 1, initialization: initializing related variables, particles and upstream and downstream virtual particle information; step 2, listing a solving equation and performing iterative computation; and step 3, outputting a result. The method is mainly applied to fluid mechanics engineering design occasions.

Owner:TIANJIN UNIV

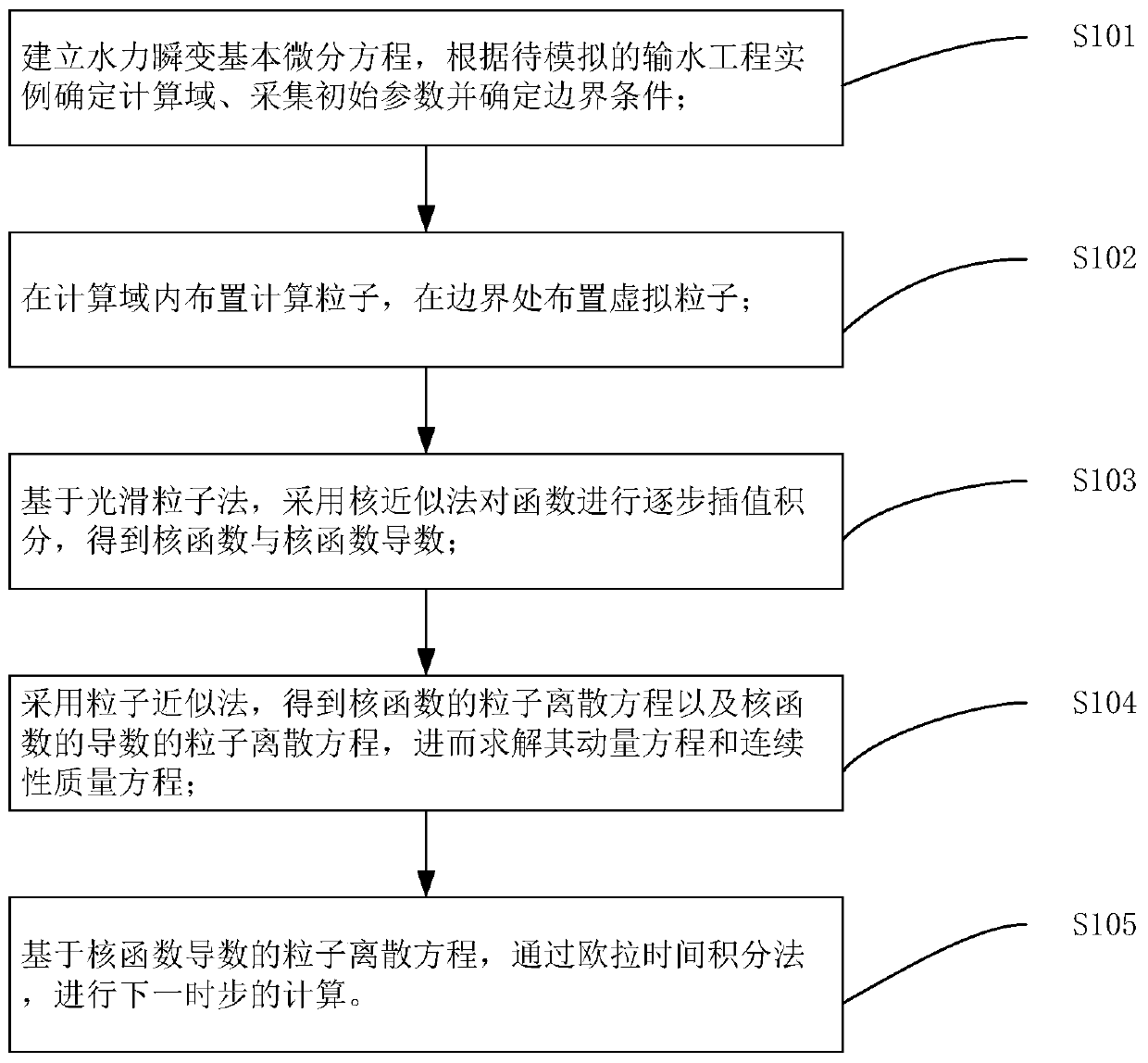

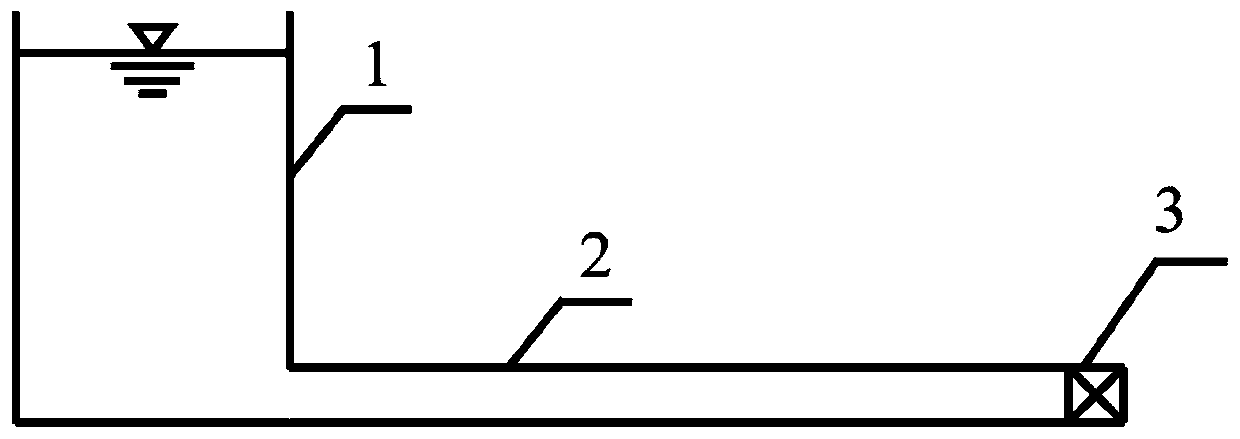

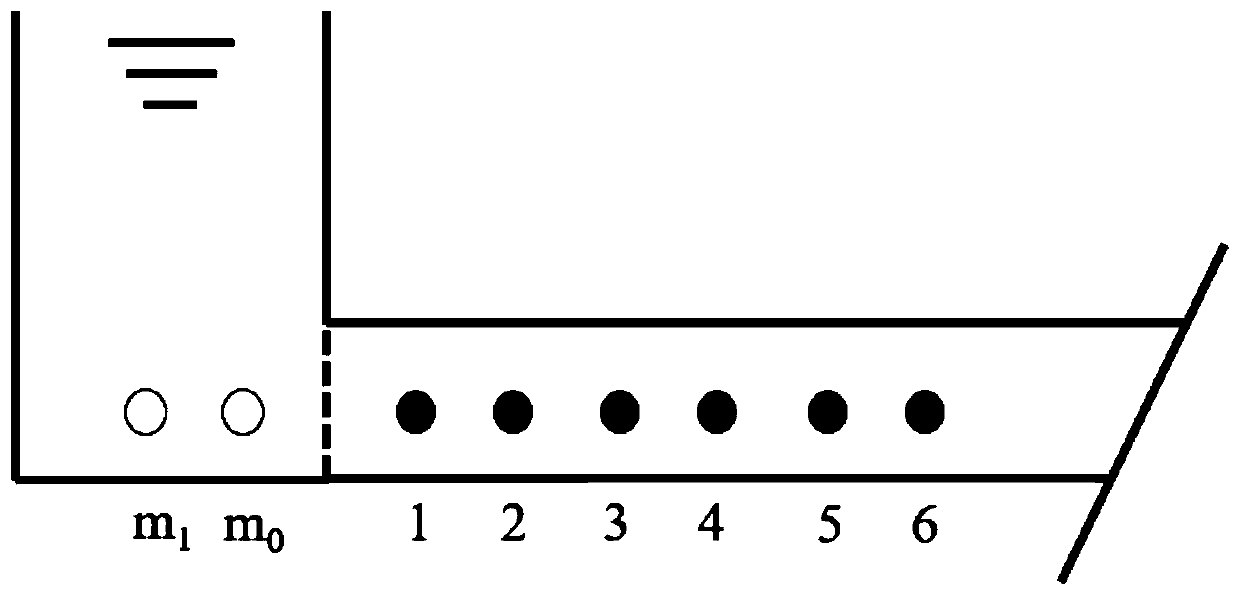

Hydraulic transient simulation method and device based on Lagrange meshless particle method

InactiveCN111339658ASolve computational difficultiesEasy to implementArtificial lifeDesign optimisation/simulationEngineeringParticle method

The invention discloses a hydraulic transient simulation method based on a Lagrange meshless particle method, which comprises the following steps: establishing a hydraulic transient basic differentialequation, determining a computational domain according to a to-be-simulated water conveyance project instance, collecting initial parameters and determining boundary conditions; arranging calculationparticles in the calculation domain, and arranging virtual particles at the boundary; based on a smooth particle method, performing step-by-step interpolation integration on the function by adoptinga kernel approximation method to obtain a kernel function and a kernel function derivative; adopting a particle approximation method to obtain a particle discrete equation of a kernel function and a particle discrete equation of a kernel function derivative, and further solving a momentum equation and a continuity quality equation; and based on a particle discrete equation of a kernel function derivative, calculating the next time step through an Euler time integral method. Accurate numerical simulation can be performed on hydraulic transient in a water delivery pipeline system, artificial viscosity is introduced to suppress false numerical oscillation, engineering risks can be avoided, and the safety of a hydraulic system is protected.

Owner:HOHAI UNIV

Method for carrying out porous medium and multiphase fluid mixed simulation by using virtual particle phase

ActiveCN113486566AAvoid delete/insertConsistent qualityDesign optimisation/simulationPorous mediumModelSim

The invention relates to a method for carrying out porous medium and multiphase fluid mixed simulation by using a virtual particle phase, which comprises the following steps of: calculating absorption phases of solid external fluid and solid internal fluid by using the virtual particle phase, further calculating mass and momentum transmission among different phases, and obtaining discretization implementation based on an SPH method. According to the method, the internal fluid and the external fluid are modeled in a unified mode through the volume fraction and the mixing model, constant particle deletion and insertion are avoided, the real solid fluid mixing simulation effect is achieved, an artistic control scheme is provided, and the porous medium and fluid mixing simulation efficiency and effect are comparable to the effect of a current advanced method in the industry.

Owner:NANKAI UNIV

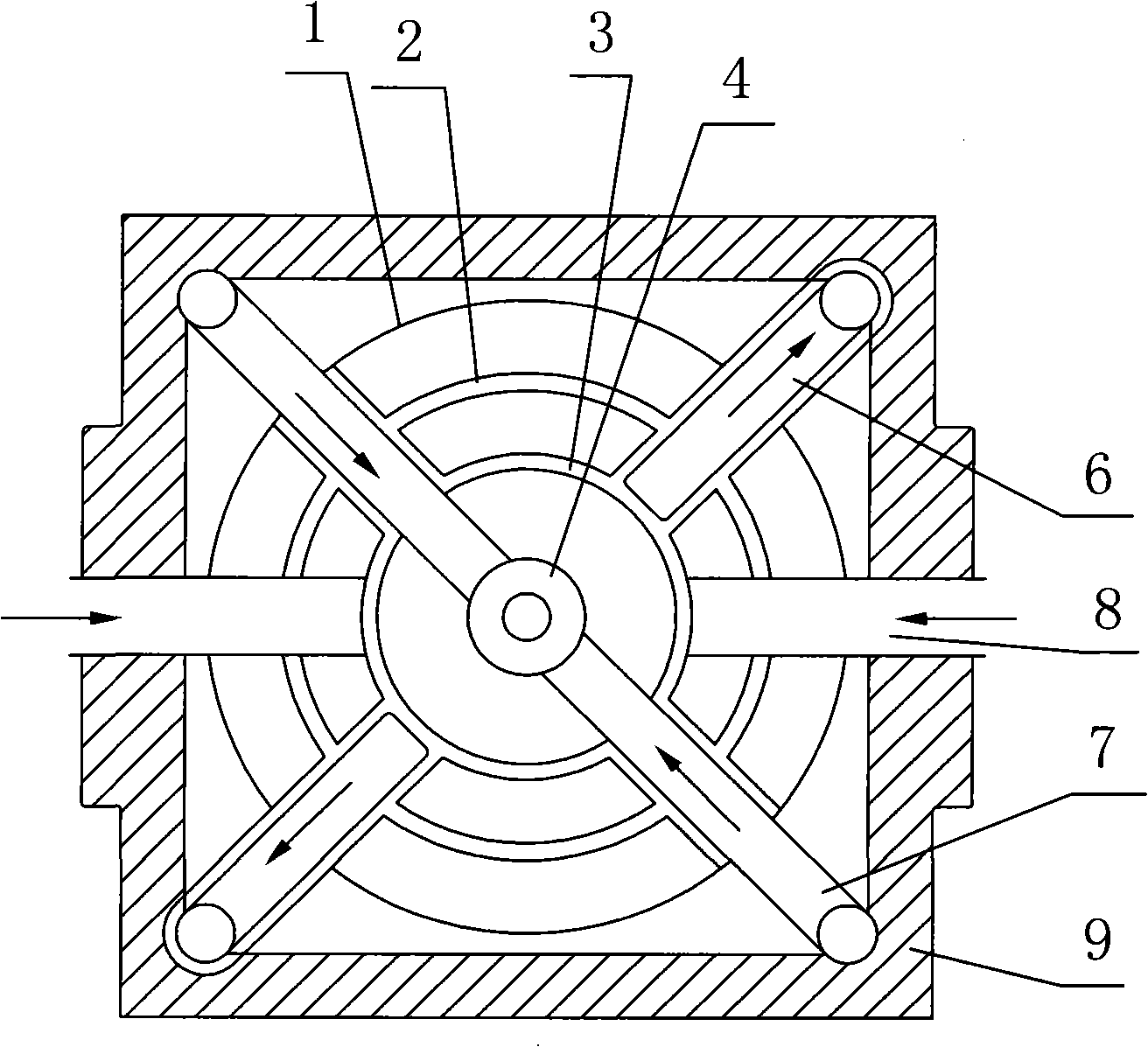

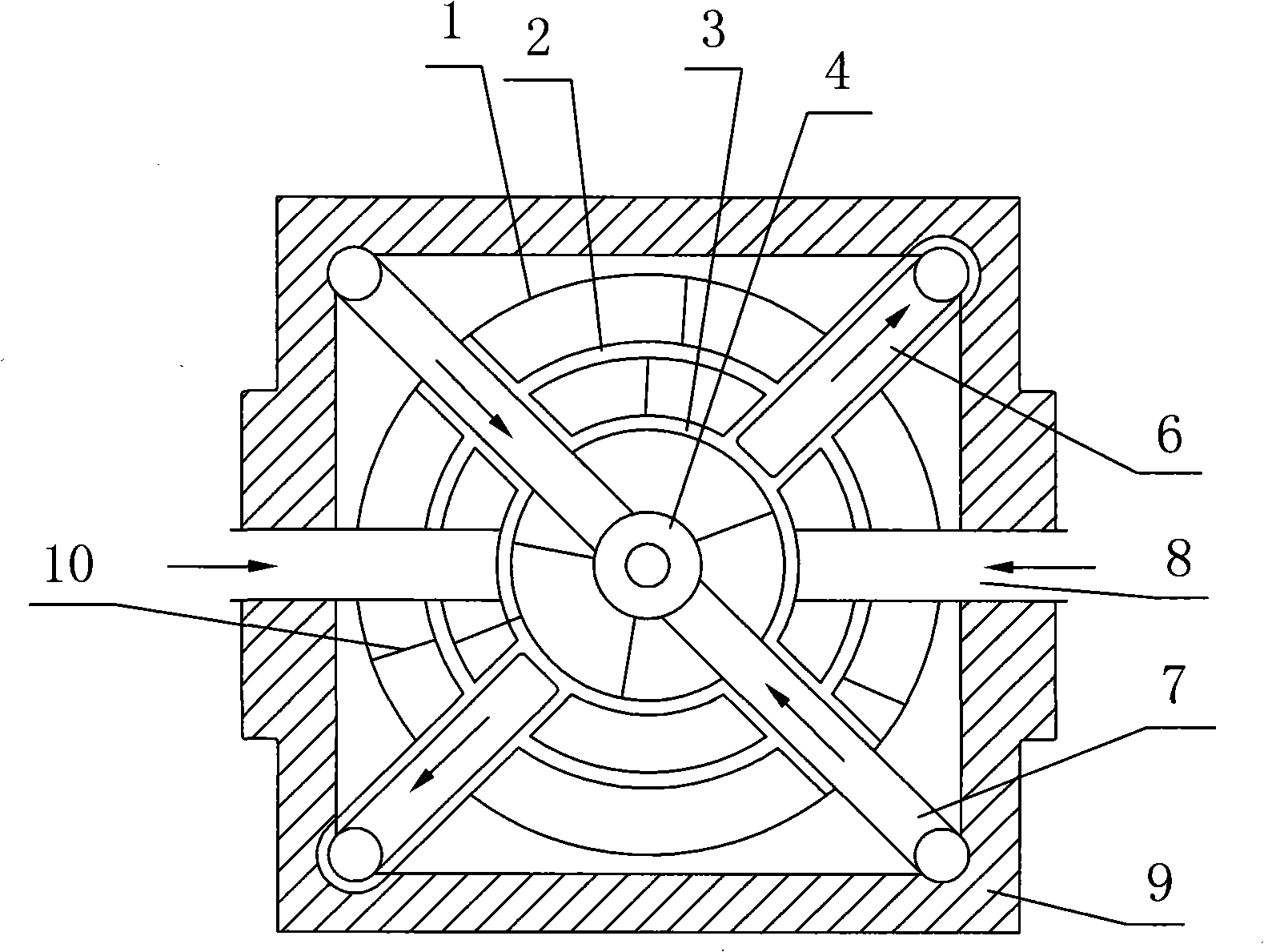

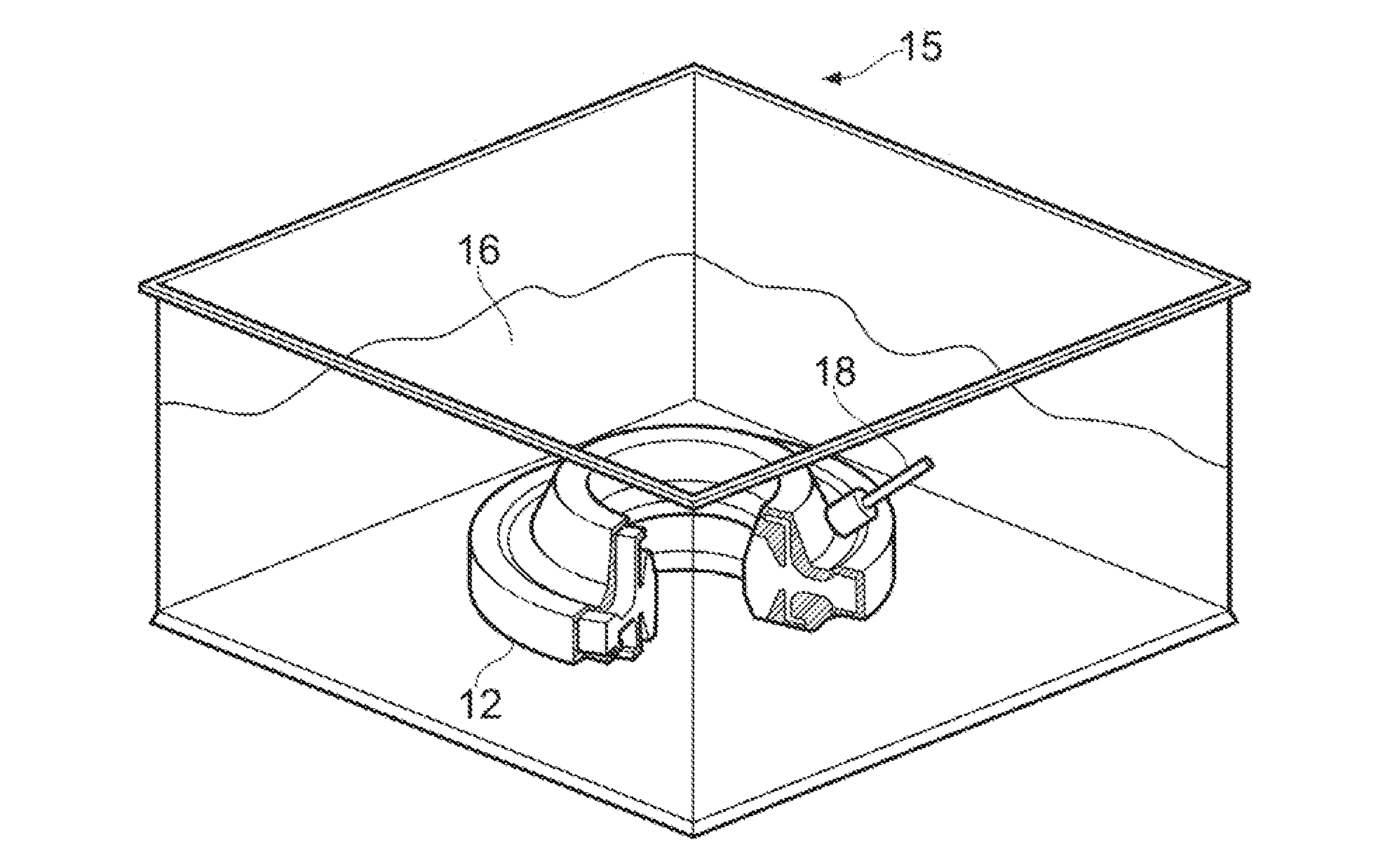

Virtual particle plasma generating device

InactiveCN101540210AStrong nuclear forceAvoid pollutionNuclear energy generationDynamo-electric machinesNuclear forceElectric power

The invention discloses a virtual particle plasma generating device which comprises a spherical strong nuclear force closing body, a strong nuclear force white hole ball sleeved in the spherical strong nuclear force closing body, a weak nuclear force bug hole ball sleeved in the strong nuclear force white hole ball, a strong nuclear force black hole ball sleeved in the weak nuclear force bug hole ball, a fuel input channel used for inputting composite fuel formed by positive charge electrical materials and negative charge electrical materials, and a drive energy channel used for inputting drive energy with 10<3>Gev-10<5>Gev. The diameter proportion of the spherical strong nuclear force closing body, the strong nuclear force white hole ball, the weak nuclear force bug hole ball and the strong nuclear force black hole ball is 4:3:2:1, and the centers of sphere of the four balls are the same center of sphere 0; and the black hole ball is a Q-G particle sieve ball generated by the composite fuel in the spherical strong nuclear force closing body after the annihilation reaction under the action of the drive energy. The invention has simple and reasonable structure, convenient operation and good use effect, not only can continuously stably output the highest electric power, but also is low in cost, consumes little fuel, and has the function of cleaning fuel.

Owner:周先德

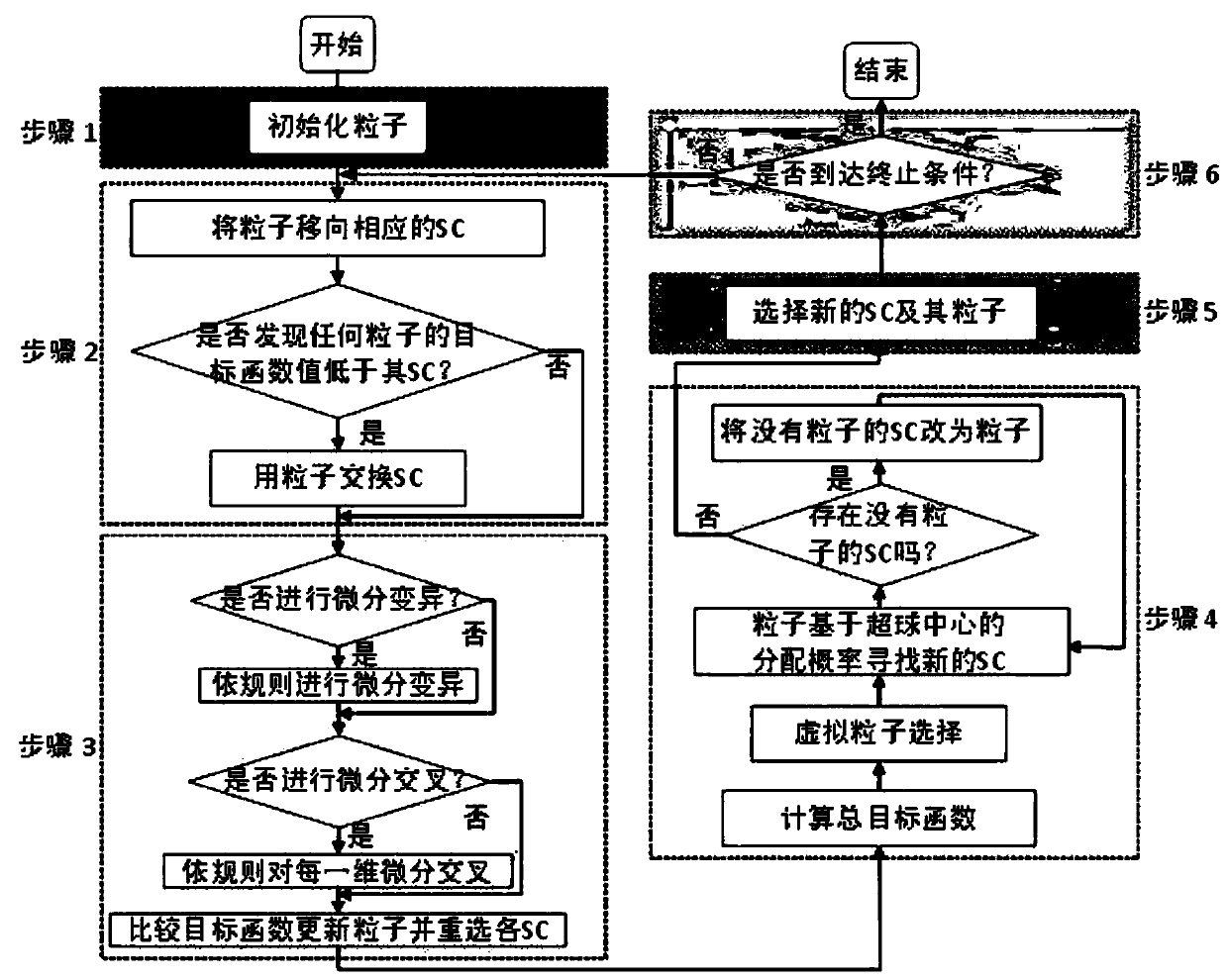

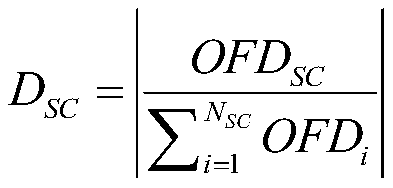

Hypersphere search algorithm based on differential evolution

PendingCN110751258ASimple designImprove global search performanceMathematical modelsArtificial lifeHypersphereRail transit

The invention discloses a hypersphere search algorithm based on differential evolution. An initial population number Npop, the number of hypersphere centers NSC; the upper and lower limits rmin and rmax of the hypersphere searching radius, a hypersphere motion angle change probability Prangle, a differential evolution crossover probability MR and a differential evolution mutation probability CR are defined, the algorithm comprise six steps of algorithm initialization, result optimal movement, differential evolution, virtual particle recovery, hypersphere center re-determination and judgment convergence, the six steps are closely related, the overall algorithm design is simplified, the process is clear, and the practicability is high. According to the algorithm, under the condition that theoptimal solution is not lost, the global search capability is improved, the accuracy of the obtained solution is enhanced, and a new optimization technology is provided for the field of rail transit.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

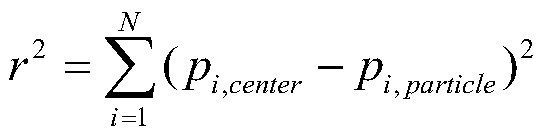

SPH simulation display method and system for whole submarine landslide catastrophe evolution process

PendingCN113761775AEffective simulationEffective visualizationDesign optimisation/simulationClassical mechanicsEngineering

The invention discloses an SPH simulation display method and system for a whole submarine landslide catastrophe evolution process. The method comprises the following steps: dispersing a calculation region of a submarine slope body and seawater into a set number of particles with different physical state attributes, and endowing each physical state particle with corresponding physical and mechanical parameters; on an outer side of a boundary, arranging a non-slip boundary layer in which repulsive particles and virtual particles are combined; applying infinite covering seawater gravity and periodic wave action to seawater particles, converting land slope acting force and structural acting force borne by the slope body into stress boundary conditions of a slope body particle calculation area, applying the stress boundary conditions to boundary particles composed of the repulsive particles and the virtual particles, and applying displacement boundary conditions; in each calculation time step, determining a catastrophe evolution stage of the submarine slope body, selecting a system constitutive equation set corresponding to the catastrophe evolution stage, carrying out calculation solving in the single time step, and completing updating of particle physical and mechanical information of a solving domain; and displaying the particle physical and mechanical information at set time steps.

Owner:SHANDONG UNIV

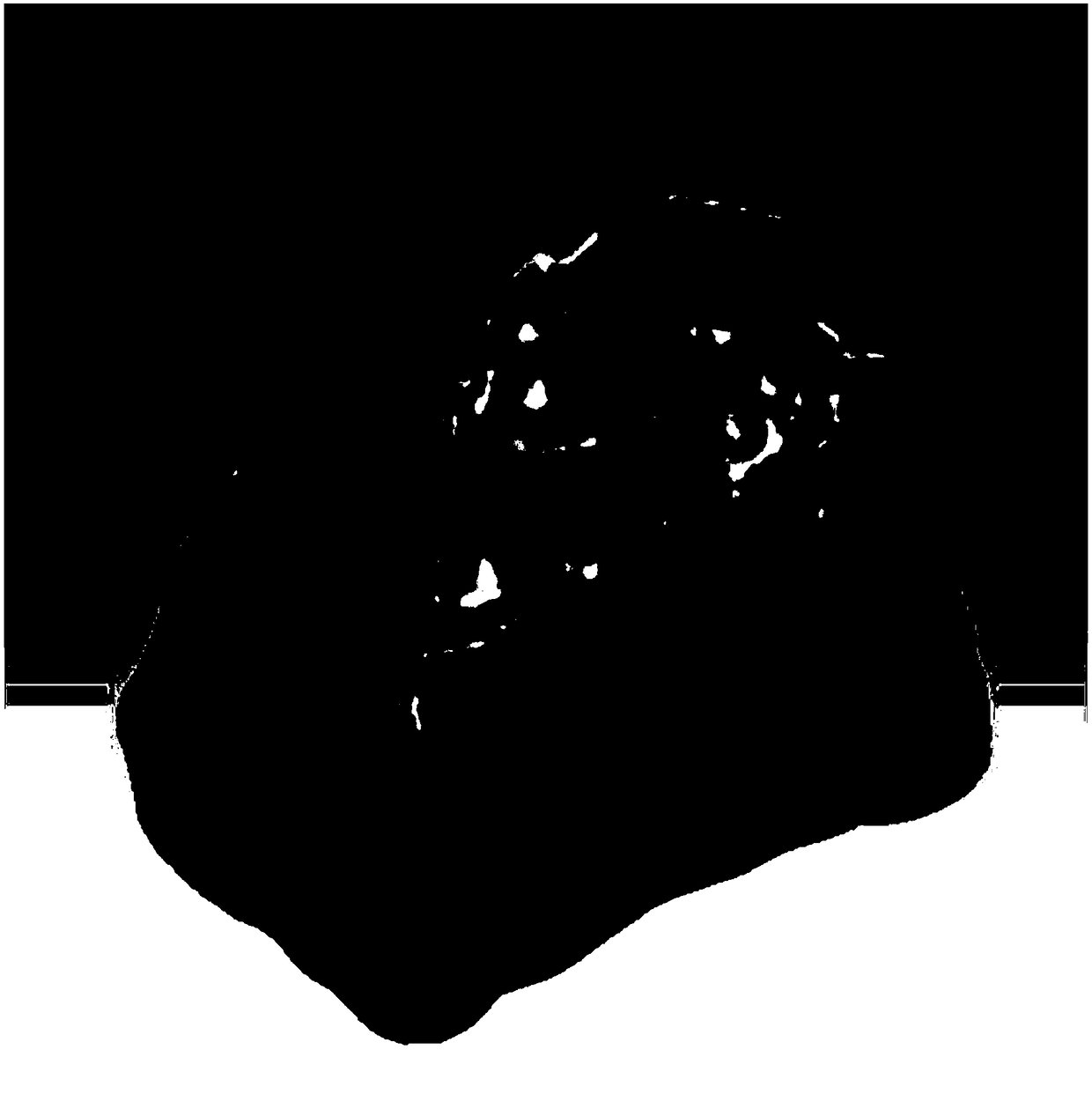

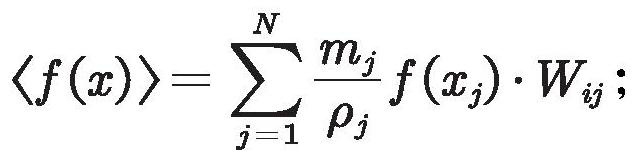

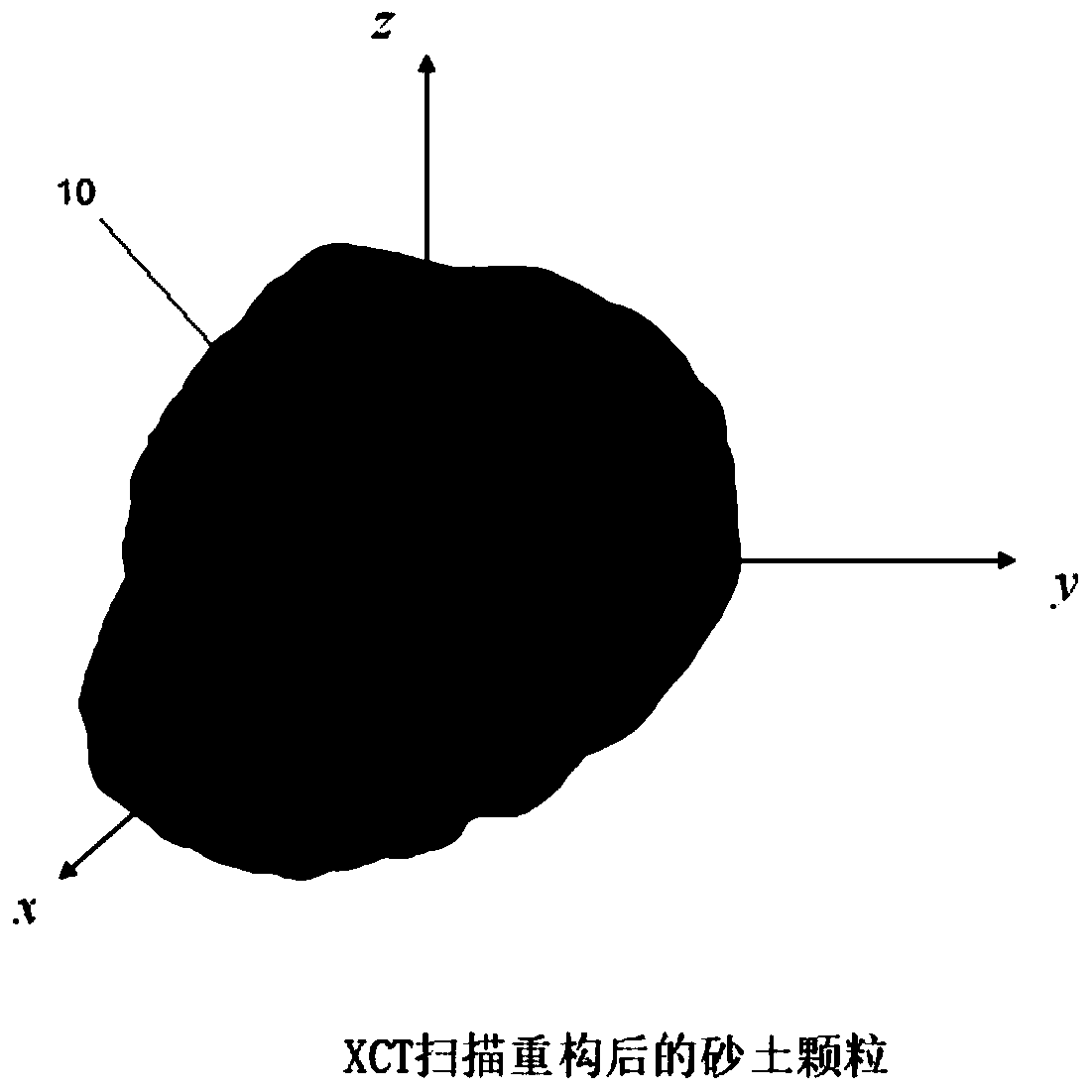

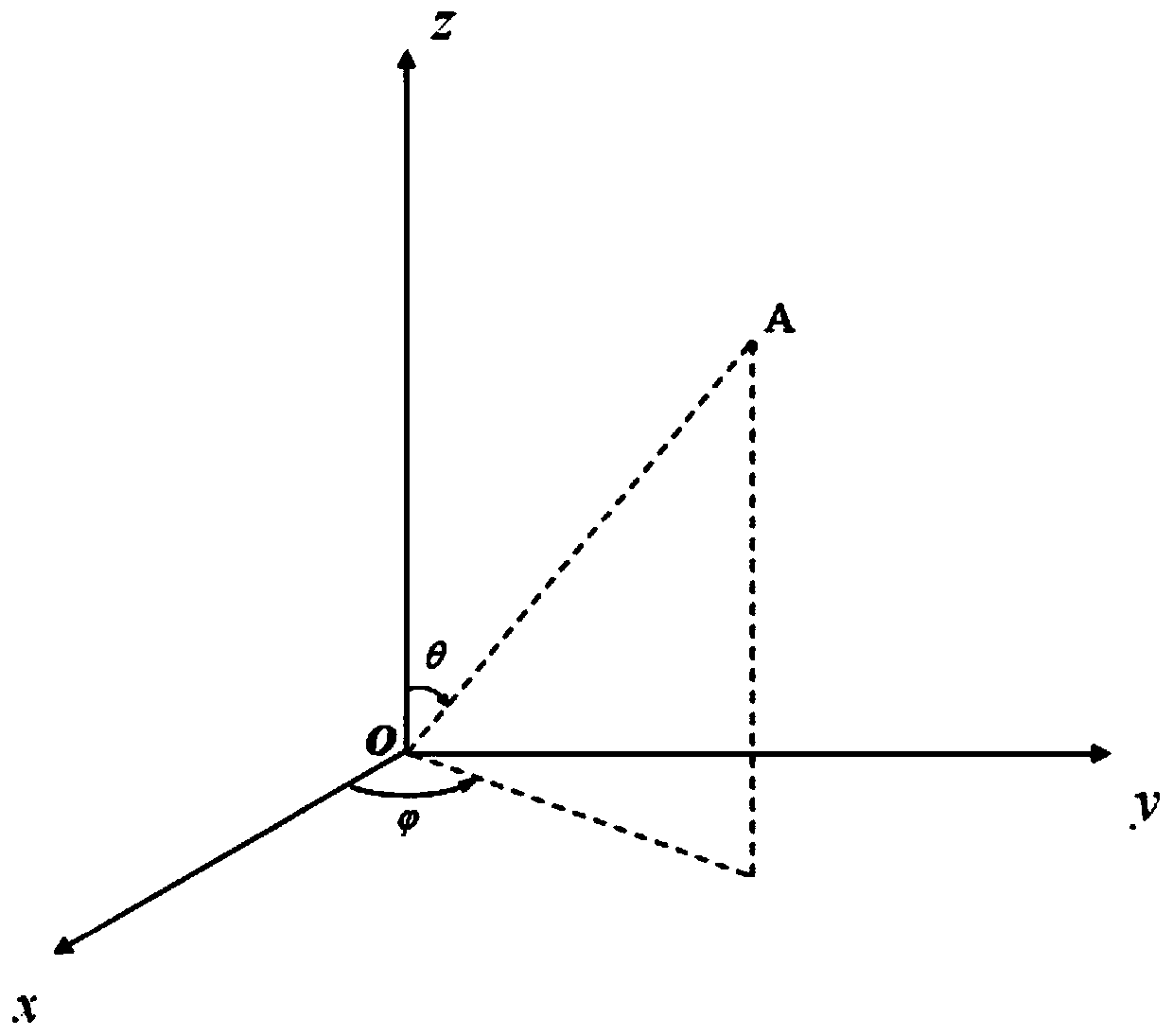

Three-dimensional virtual particle generation method

The invention discloses a three-dimensional virtual particle generation method, which comprises the following steps of step S10, obtaining a sectional image of particles, and reconstructing a three-dimensional pixel image corresponding to the particles based on the sectional image; step S20, determining a quality center of the three-dimensional pixel image; step S30, determining a semi-major axisa, a semi-middle axis b and a semi-minor axis c to establish an approximate external ellipsoid corresponding to the three-dimensional pixel image; step S90, calculating the radiuses of the virtual approximate external ellipsoid at different polar angles, and obtaining the radiuses of the virtual particles at different polar angles according to the radiuses of the virtual approximate external ellipsoid at different polar angles and the second compensation radius; and step S100, calculating according to the radiuses of the virtual particles for different polar angles to obtain three-dimensionalrectangular coordinates of surface points of the three-dimensional virtual particles so as to generate the three-dimensional virtual particles. The difference between the generated three-dimensional virtual particles and real particles is small, and the method can be suitable for generation of a large number of particles.

Owner:SHENZHEN UNIV

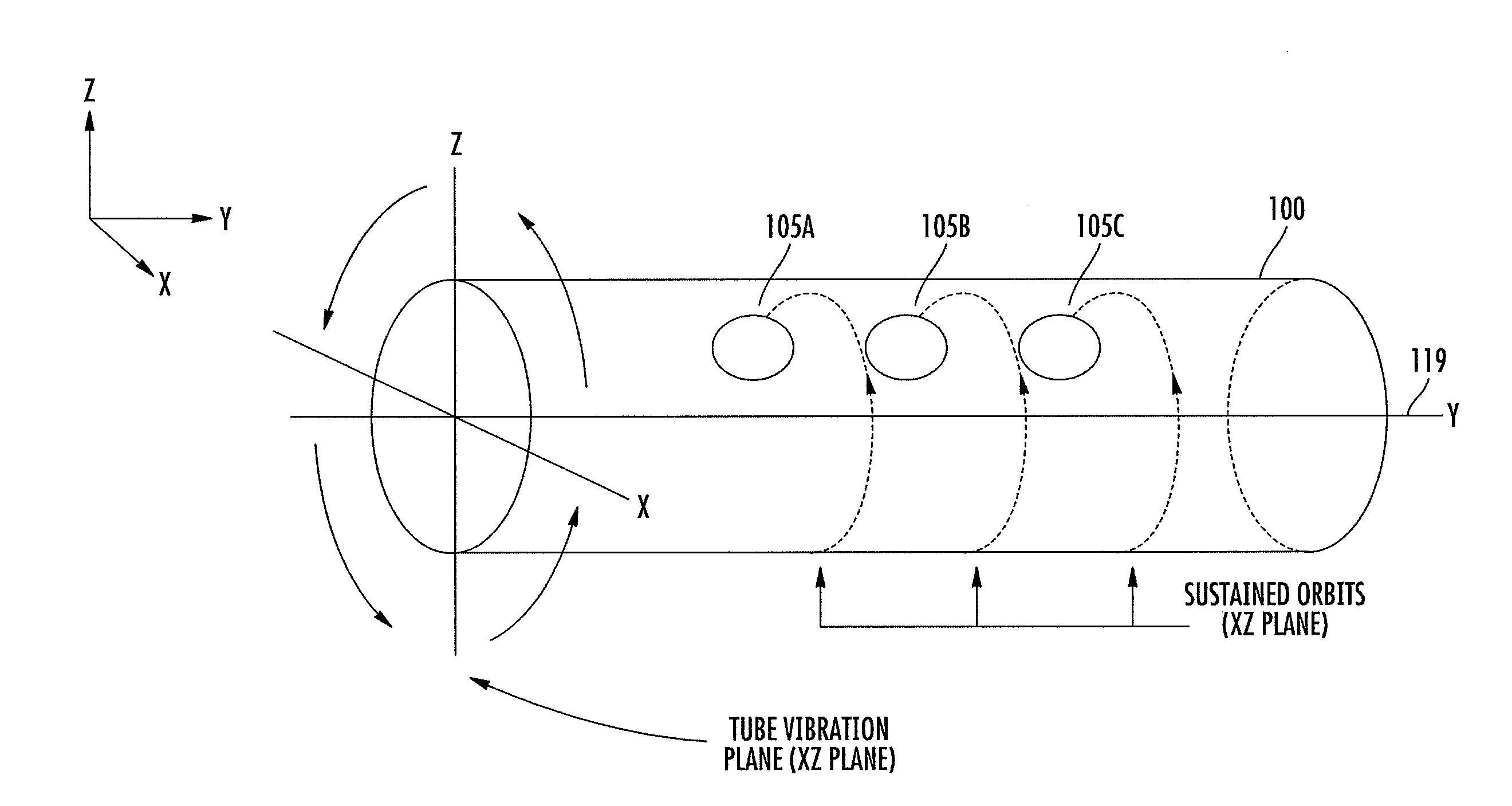

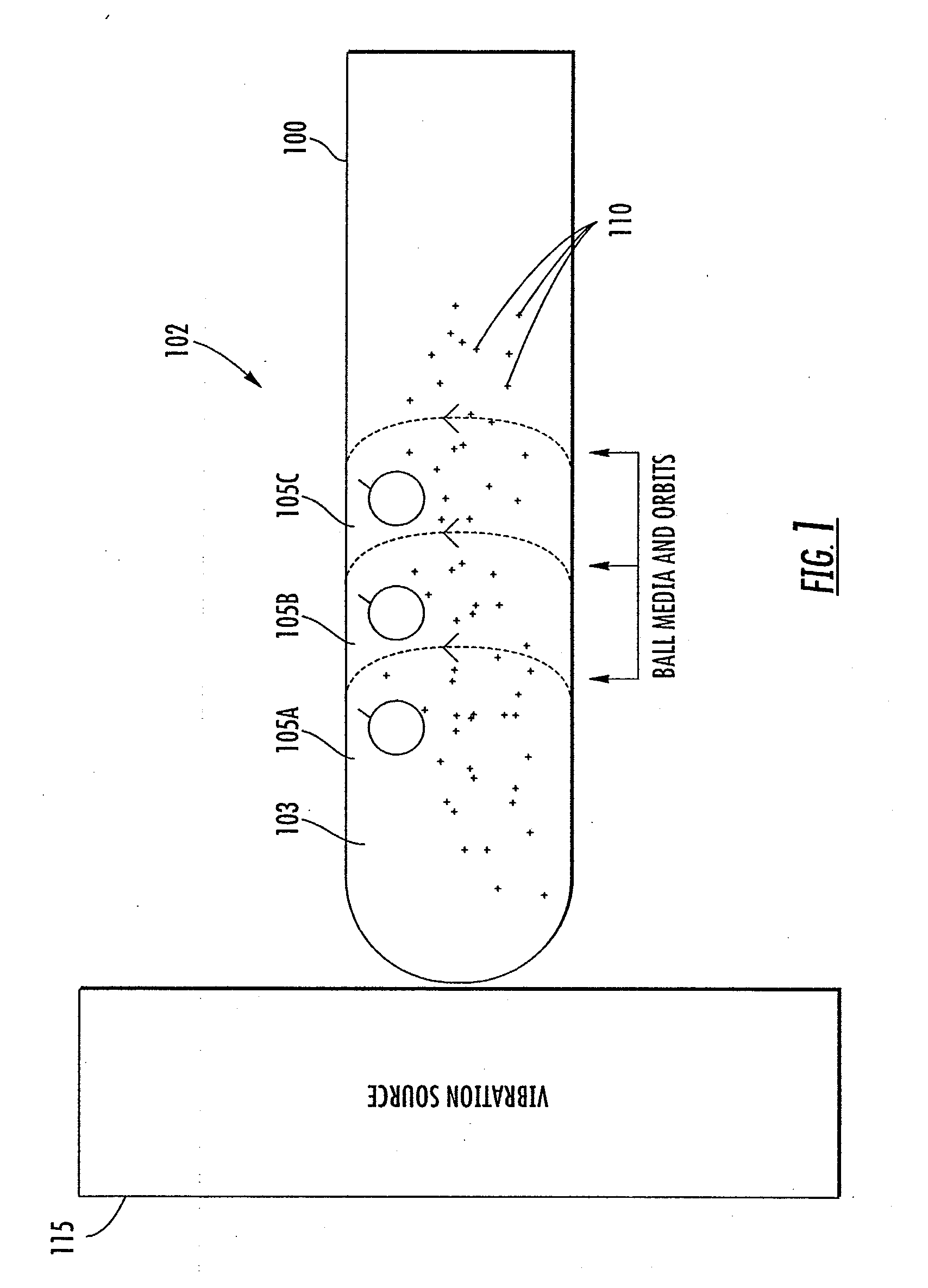

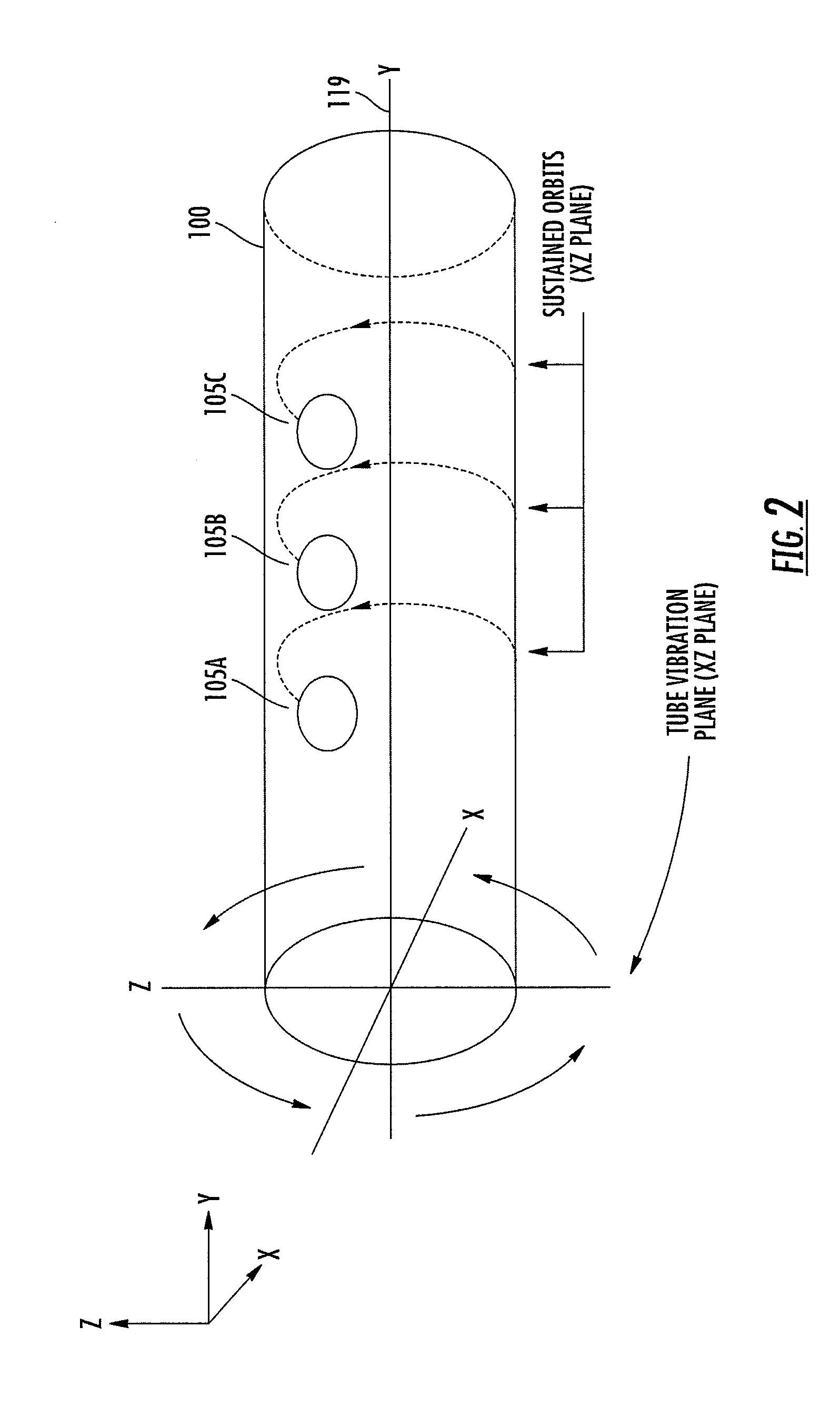

High speed orbiting ball media processors

According to one embodiment, a ball mill for working generally spherically shaped target particles into a flake-shaped end product is provided. The ball mill includes a milling tube, one or more milling balls disposed within the milling tube, and a vibration source that is positioned and adapted to move the milling tube such that its central axis follows along a substantially circular path. The continuously changing direction of the acceleration of the milling tube results in each of the milling balls following a respective, substantially orbital path about the milling tube's central axis. As the milling balls follow the respective, orbital paths, the milling balls come into contact with and transform the target particles into flakes. In a further embodiment, the ball mill may further include a virtual particle separator configured to route intermediate particles back to an inlet portion of the milling tube for additional processing time.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

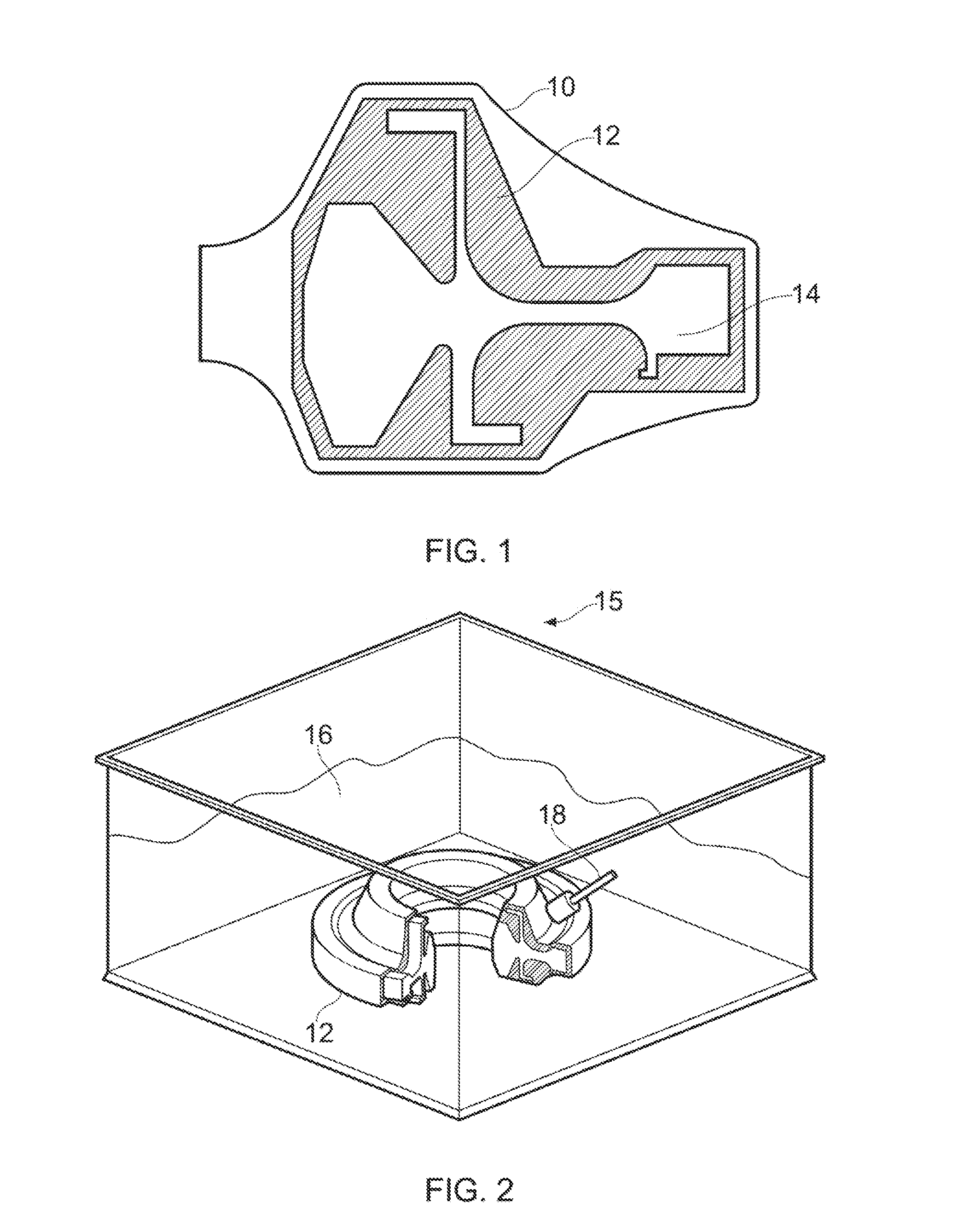

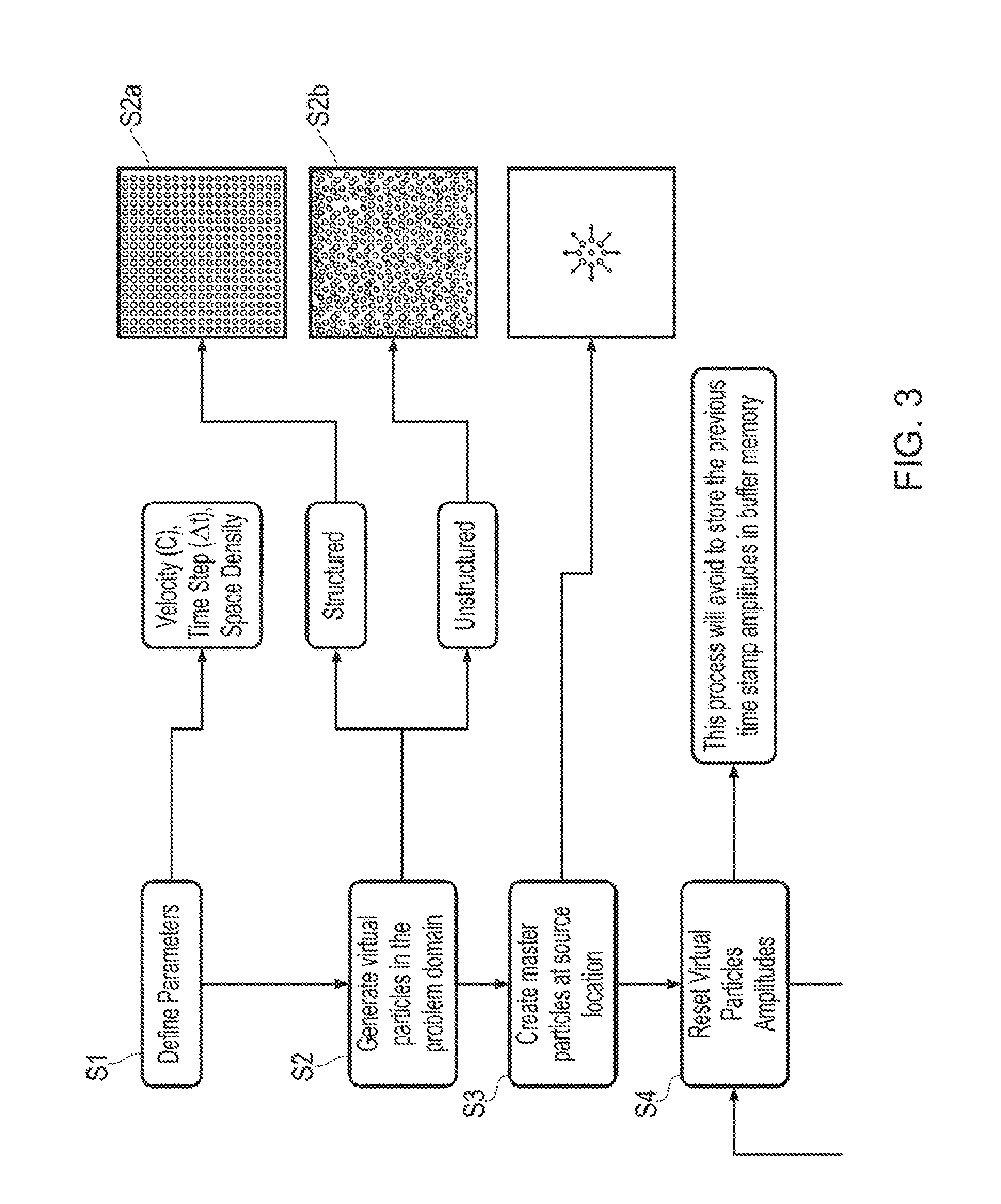

Method of determining the magnitude of a field variable of an energy wave

ActiveUS20160139087A1Analysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalReal variableClassical mechanics

Determining magnitude of a field variable of an energy wave through domain of interest, including steps of: defining plurality of master-particles spaced within domain, master-particles being representative of field variables of energy wave at location of respective master-particle, and defining supporting domain Ωm for each master-particle; computing field variables including position, magnitude and direction of propagation of each master-particle at predetermined time; defining plurality of virtual-particles within domain representative of magnitude of field variable of wave at location of respective virtual-particle; calculating magnitude uv of field variable of each virtual-particle at time of interest by applying formula:uv=∑m=1Numf(q1)×g(q2)Wherev∈Ωmwhere N is total number of master-particles, um is magnitude of respective master-particle, f(q1) is an envelope function relating magnitude of virtual-particle to distance from master-particle in direction of propagation of master-particle, and g(q2) is a smoothing function relating magnitude of virtual-particle to distance from master-particle normal to direction of propagation of master-particle.

Owner:ROLLS ROYCE PLC

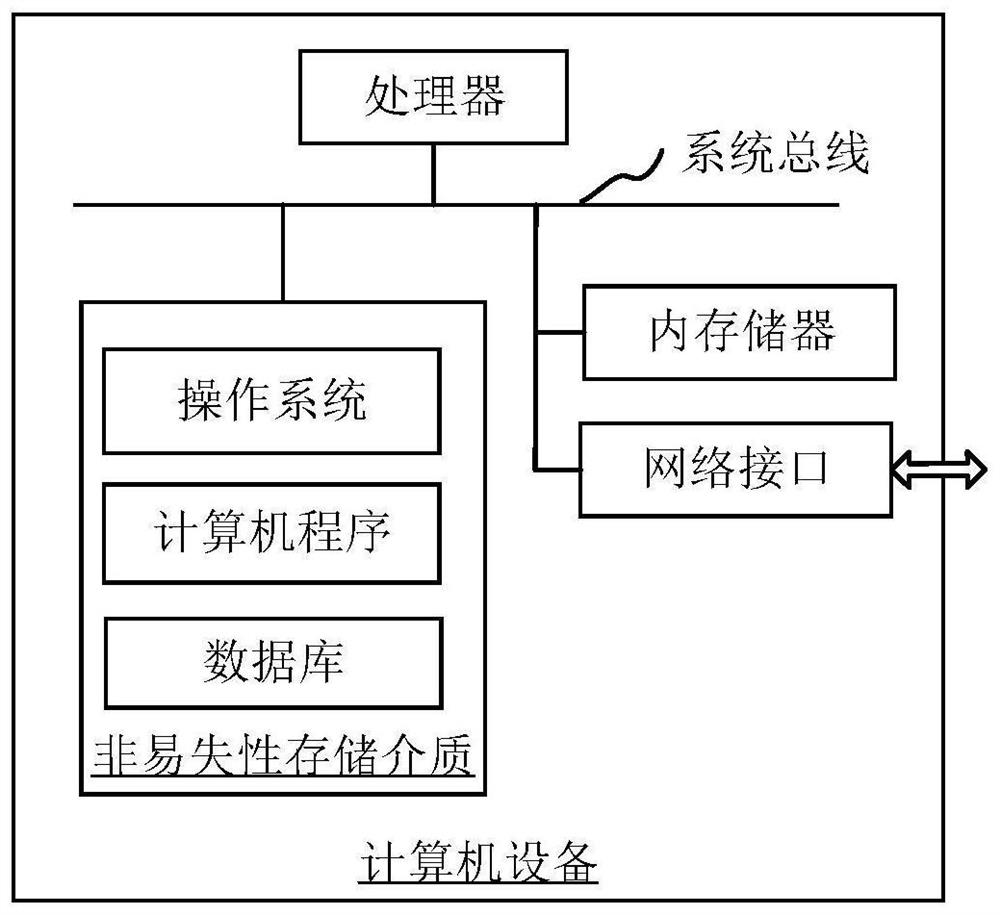

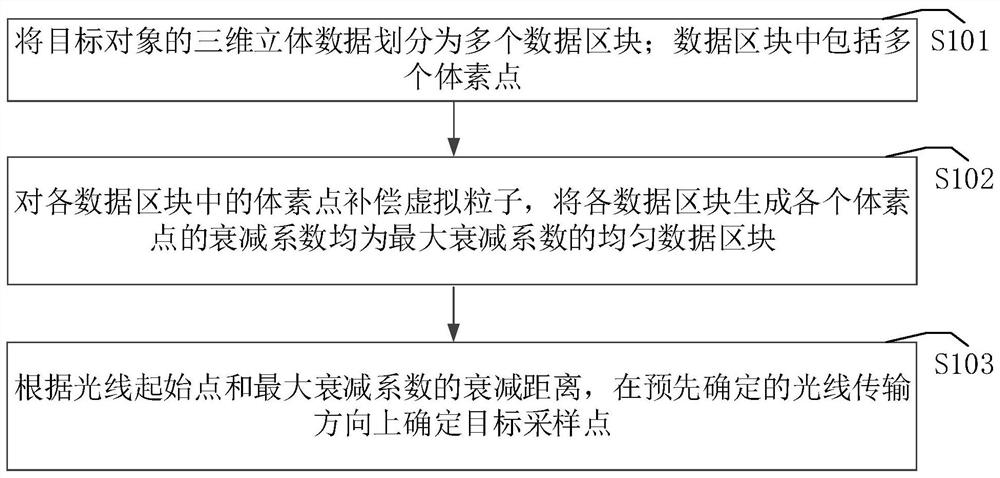

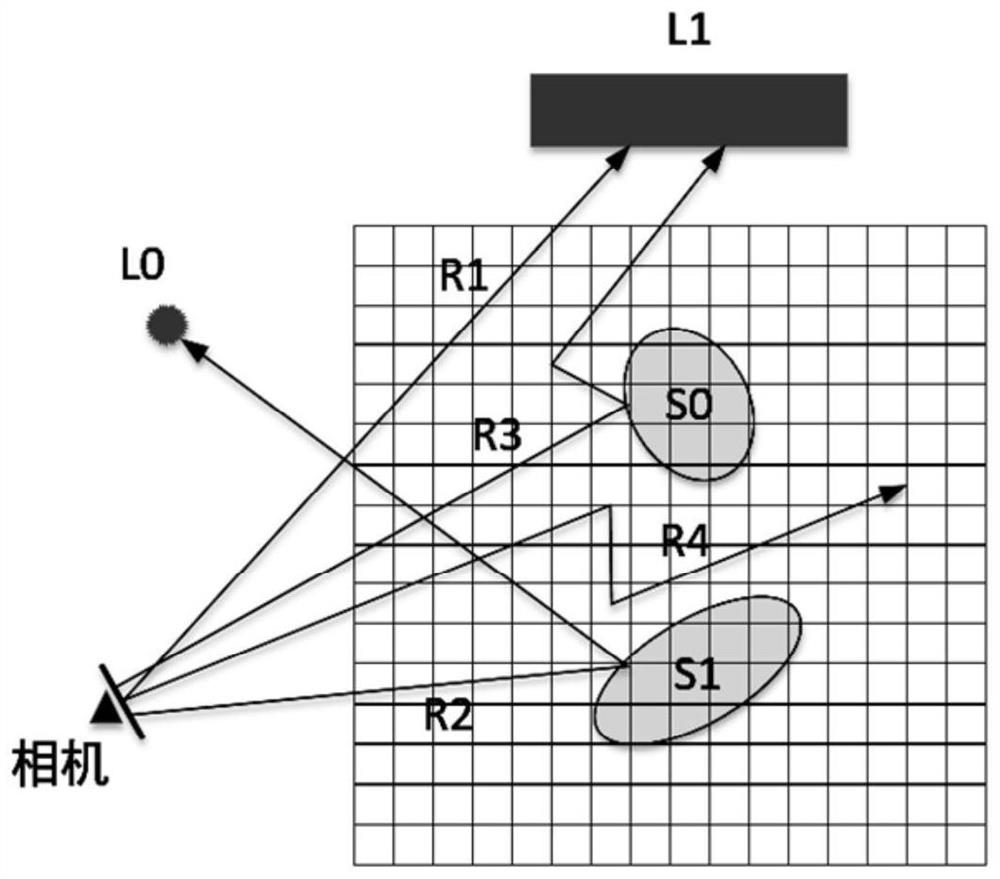

Distance sampling method and device, equipment and storage medium

The invention relates to a distance sampling method and device, computer equipment and a storage medium. The method comprises the steps: dividing three-dimensional data of a target object into a plurality of data blocks, compensating virtual particles for voxel points in each data block, enabling each data block to generate a uniform data block of which the attenuation coefficient of each voxel point is the maximum attenuation coefficient, and storing the uniform data block in the storage medium; and then determining a target sampling point in a predetermined light transmission direction according to the attenuation distance between the light starting point and the maximum attenuation coefficient, and if the target sampling point is a real particle of an uncompensated virtual particle, determining distance sampling as effective distance sampling. According to the method, quick positioning of the target sampling point is realized, the distance sampling speed is quickly increased, and the overall performance of a physical rendering algorithm is greatly improved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

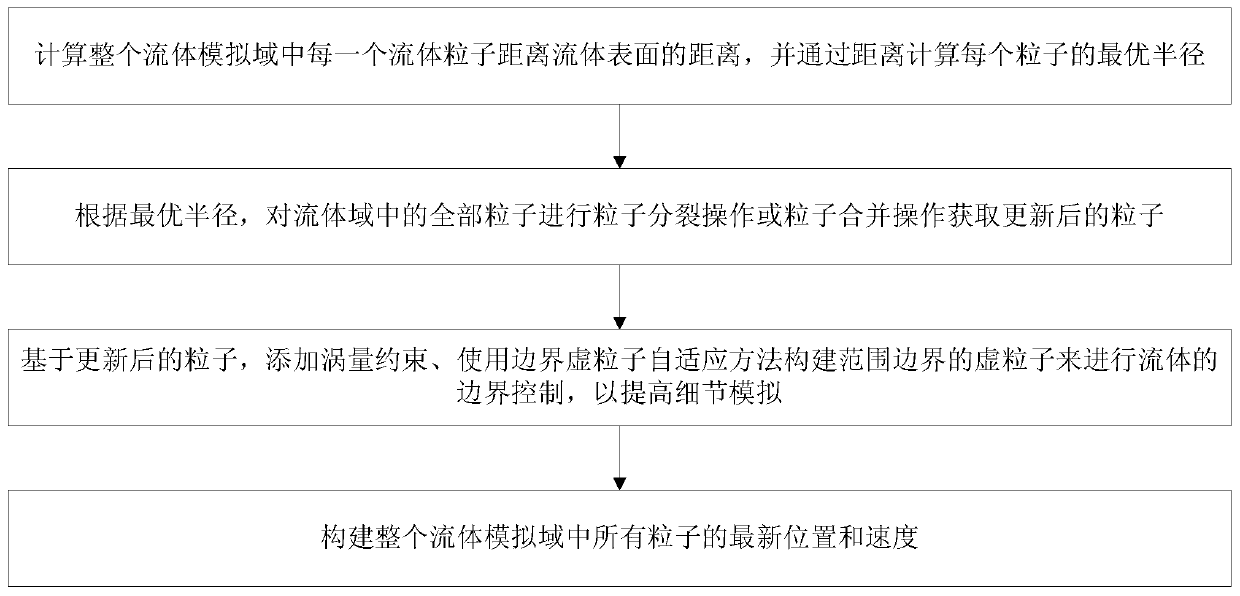

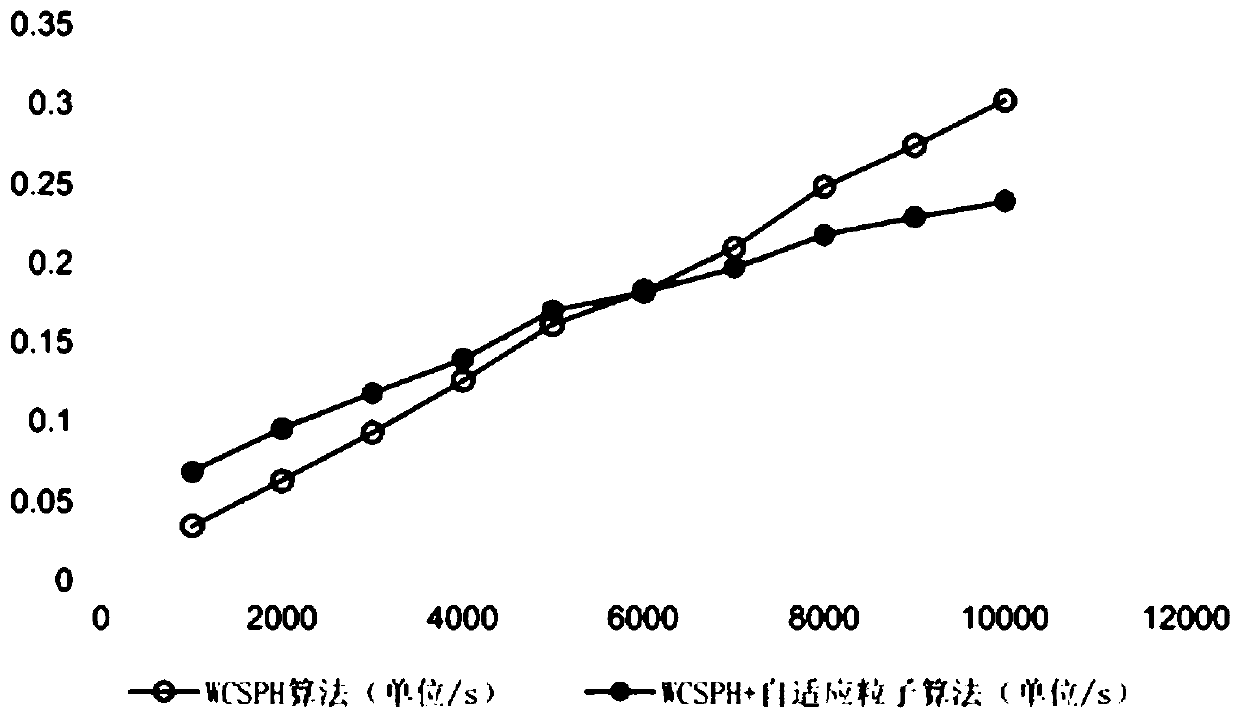

Computer simulation method for self-adaptive particle fluid

PendingCN111581875AImprove efficiencyCalculation speedDesign optimisation/simulationEngineeringComputational physics

The invention discloses a self-adaptive particle fluid computer simulation method for a self-adaptive particle fluid, which comprises the following steps: calculating the distance from each fluid particle to the fluid surface in the whole fluid simulation domain, and calculating the optimal radius of each particle through the distance; according to the optimal radius, performing particle splittingoperation or particle merging operation on all particles in the fluid domain to obtain updated particles; adding a vorticity constraint based on the updated particles, and constructing virtual particles of a range boundary by using a boundary virtual particle adaptive method to perform boundary control of the fluid so as to improve detail simulation; and constructing the latest positions and speeds of all particles in the whole fluid simulation domain. According to the invention, the radius of the fluid particle can be automatically adjusted to adapt to the resolution simulation meeting the requirement, and rich fluid details can still be provided while the fluid simulation efficiency is improved.

Owner:TIANJIN UNIV

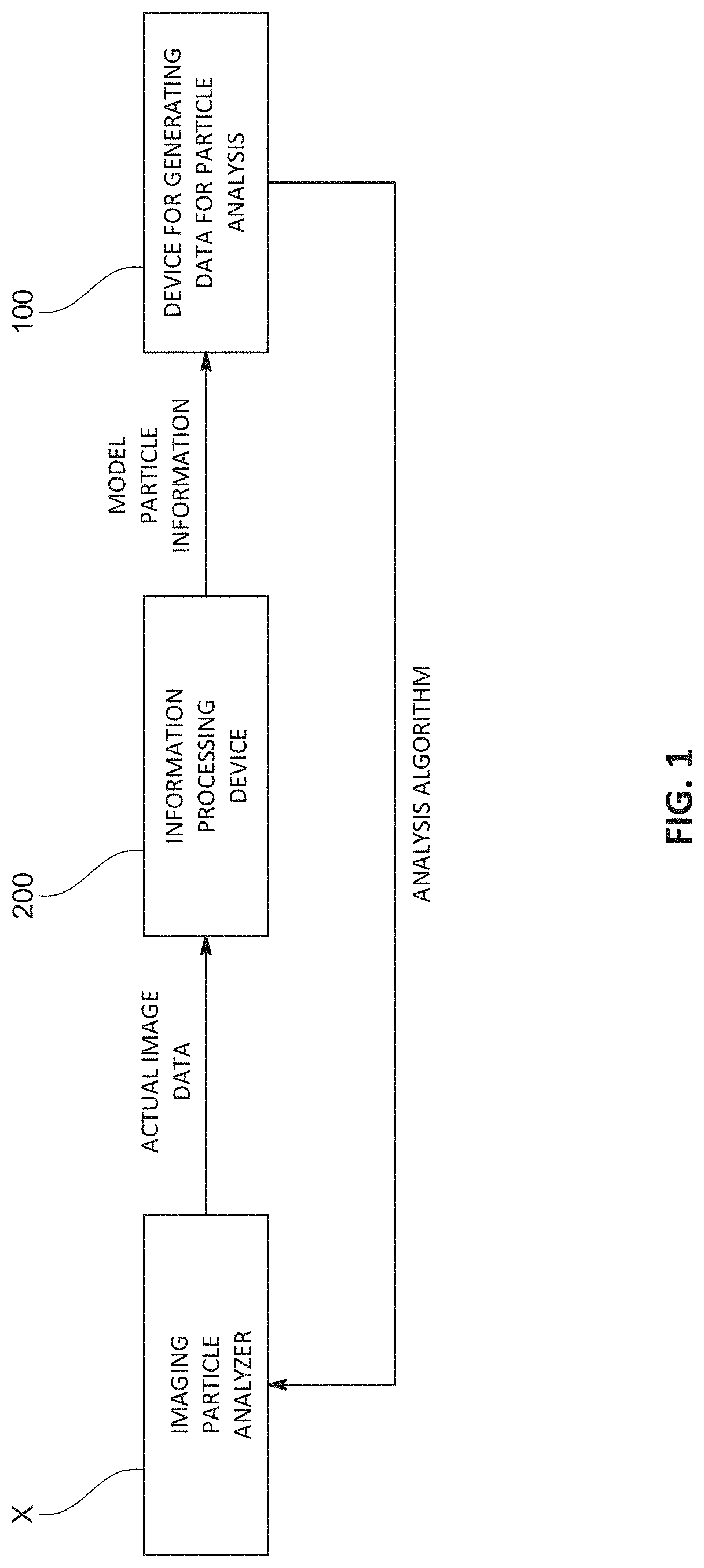

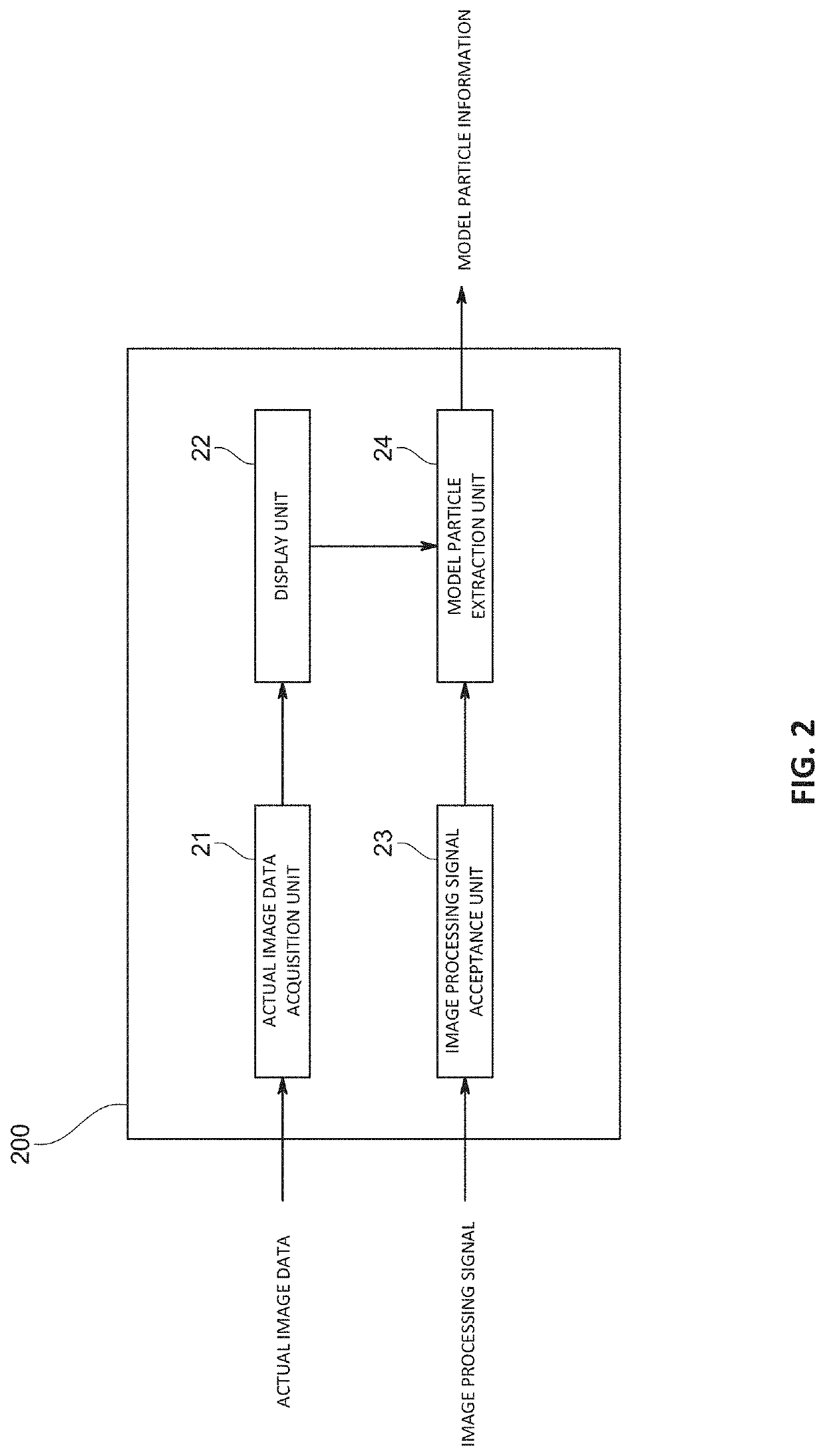

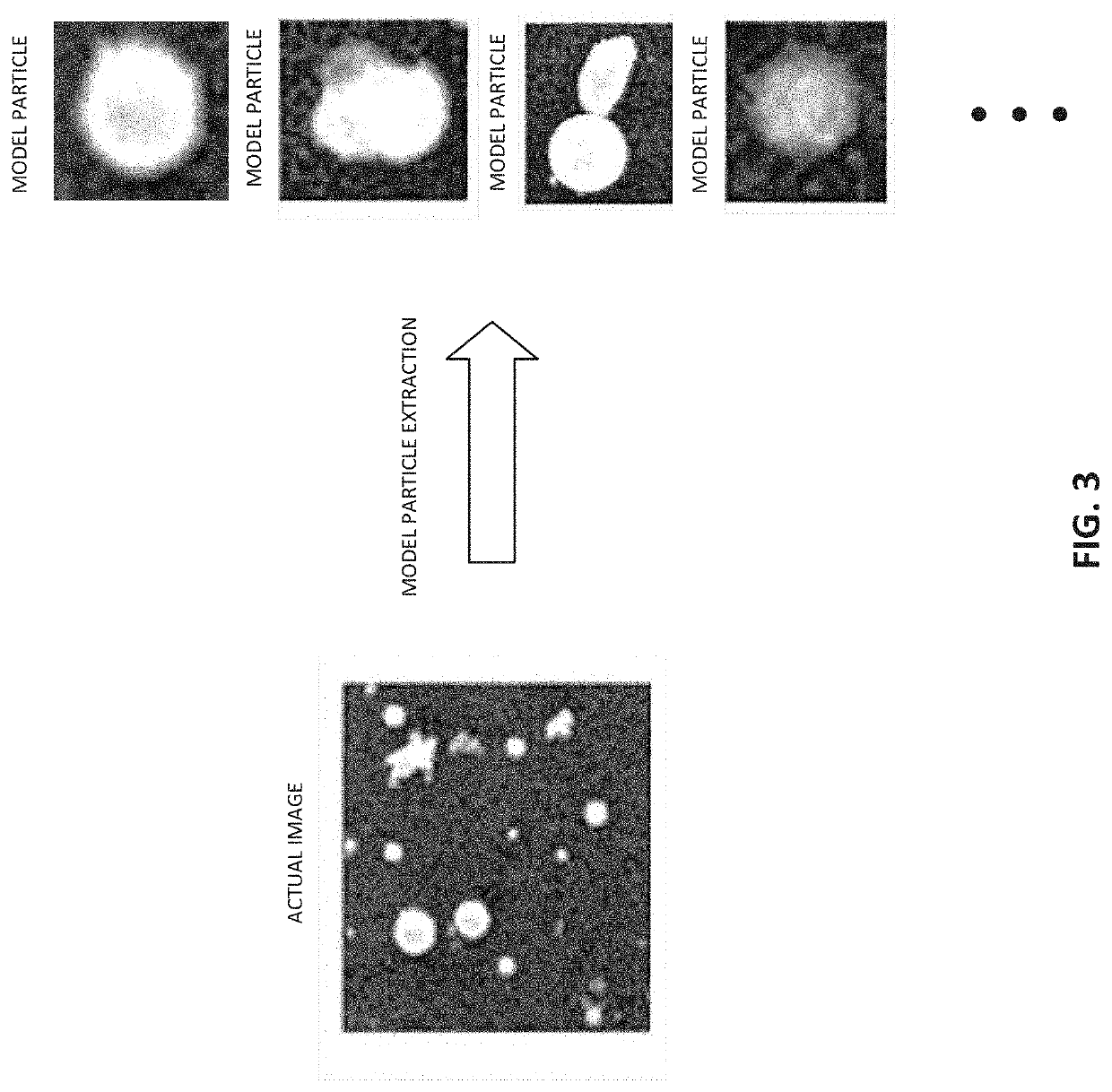

Method for generating data for particle analysis, program for generating data for particle analysis, and device for generating data for particle analysis

PendingUS20210349007A1Reduce overall man-hoursAcquiring/recognising microscopic objectsIndividual particle analysisApplications of artificial intelligenceComputer graphics (images)

In relation to application of artificial intelligence to image analysis of particles, to make it possible to provide data for machine learning corresponding to user demands while making it possible to reduce, as much as possible, man-hours taken to, for example, prepare vast amounts of actual image data obtained by actually capturing images of particles, the present invention generates virtual particle image data, which is image data of a virtual particle, on the basis of a predetermined condition, generates label data corresponding to the virtual particle, and associates the virtual particle image data with the label data.

Owner:HORIBA LTD

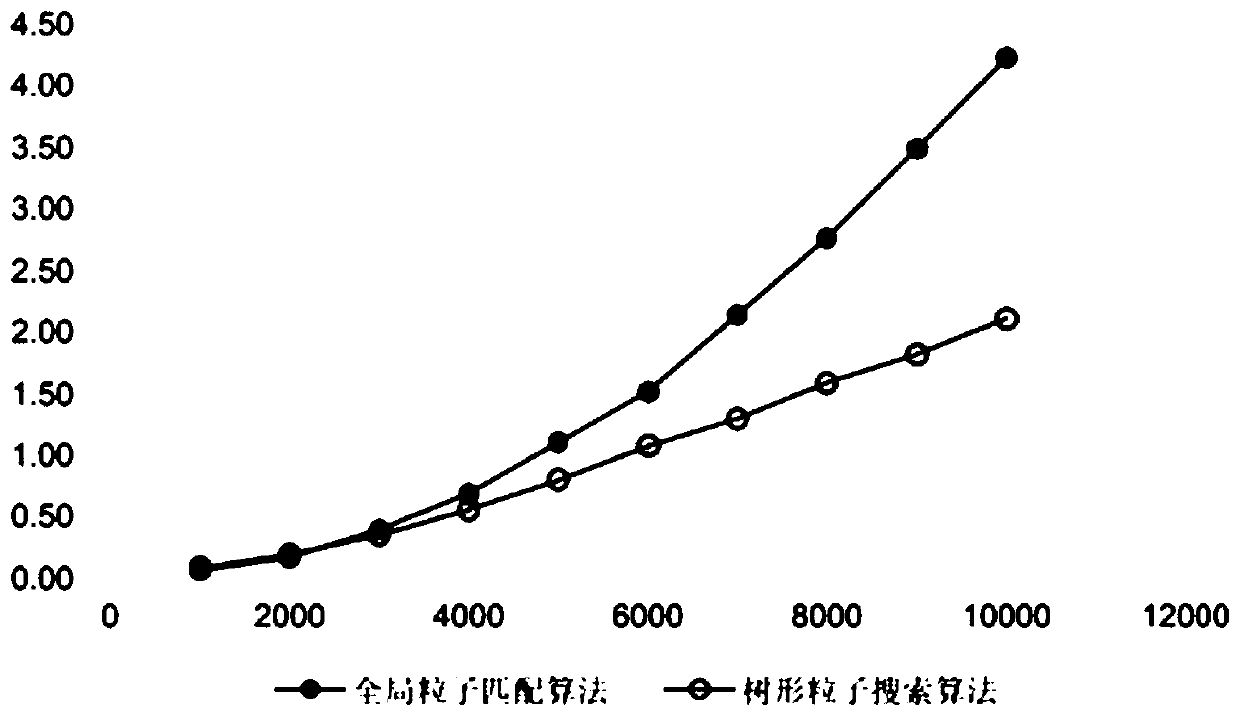

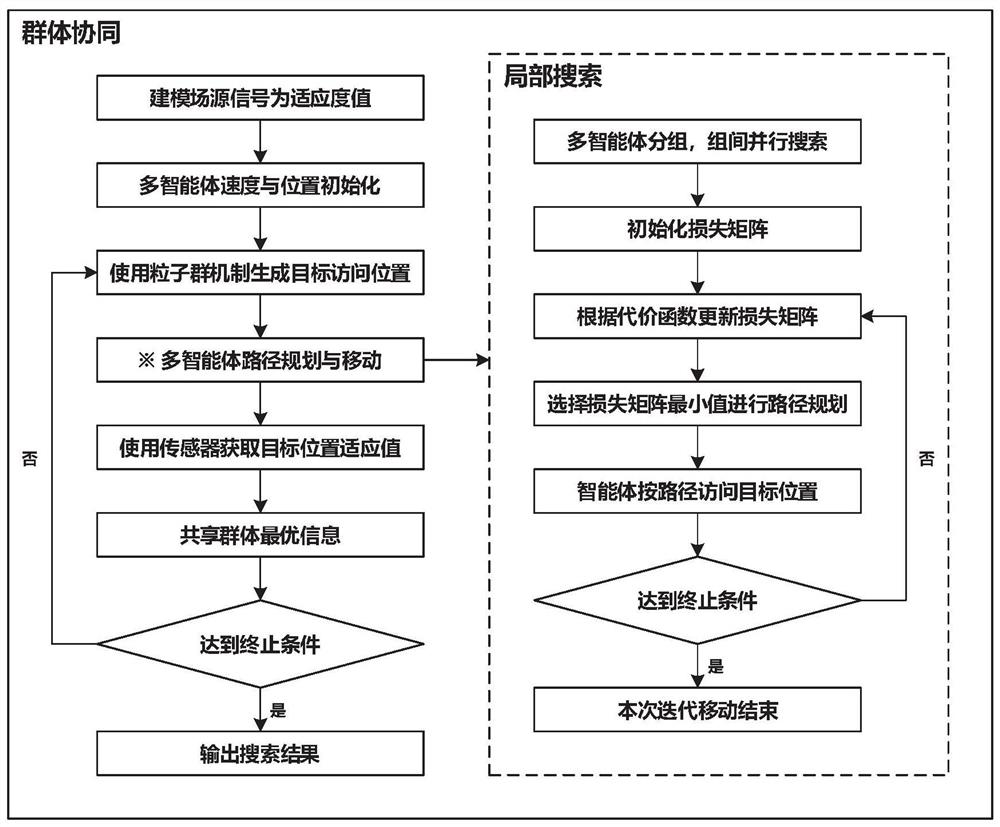

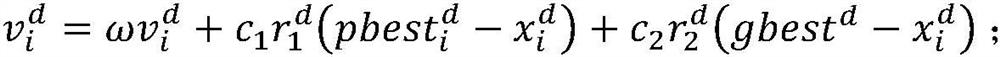

A multi-agent cooperative target search method based on particle swarm optimization

ActiveCN112966803BAchieve synergyReduce energy consumptionDigital data information retrievalForecastingLocal search (optimization)Simulation

The present invention proposes a multi-agent cooperative target search method based on the particle swarm algorithm, which introduces the particle swarm algorithm for virtual navigation, and uses entity agents with certain communication and perception capabilities to replace the virtual particle realization source in the particle swarm algorithm Location search. For the first time in the particle swarm algorithm, the moving distance and search time of the particles are considered, and the weight cost function is established. According to the target position generated by each generation of the particle swarm, the path with the least cost is planned for the agent through the local search strategy. Accordingly, the multi-agent system can greatly reduce energy consumption, enhance battery life, and improve search efficiency without affecting the target search accuracy. The invention is a multi-agent target search method with generality, and the particle swarm algorithm based on it can be any particle swarm variant.

Owner:TONGJI UNIV

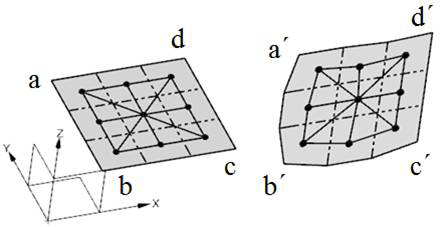

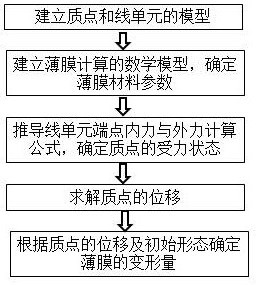

Virtual Particle Method for Calculating Deformation of Plastic Film

The invention relates to a virtual particle method for calculating plastic film deformation, which is characterized in that the following steps are adopted: 1) establishing a particle and line unit model, and clarifying the function and connection of the mass point and line unit; 2) establishing a mathematical model for plastic film calculation, and determining the film Material parameters; 3) Combining the path unit and virtual reverse motion to obtain the calculation formula of the internal force of the end point of the line unit, and deriving the calculation formula of the external force of the film according to the line unit model, and obtaining the force state of the particle; 4) Combining Newton's second law , using the explicit central difference formula, write a calculation program to solve the displacement of the particle after being stressed; 5) Determine the deformation of the film according to the displacement of the particle and the initial shape, and then obtain the deformation of the plastic film after being stressed. The invention can obtain the deformation amount of the wind-selected plastic film in the sorting process, improve the precision of theoretical research and sorted plastic film, thereby laying a foundation for optimizing and improving the sorting machine of the plastic film.

Owner:SHANDONG UNIV OF TECH

System and method for predicting grinding particle size distribution of ball mill by fast Monte Carlo method

A system and method for predicting ball mill grinding particle size distribution using a fast Monte Carlo method. The system includes: a data acquisition module, a mass fraction calculation module for each particle size, a representative particle size calculation module, a virtual particle number calculation module, and a crushing rate calculation module. , crushing probability calculation module, grinding particle number calculation module and particle size distribution calculation module; the method includes: setting the initial time of the ball mill to t=0, and at the same time, obtaining corresponding data; calculating the mass fraction of each particle size of the initial material; Calculate the representative particle size of each particle size; calculate the number of virtual particles for each particle size; calculate the crushing rate of each particle size; calculate the crushing probability of each particle size; obtain the internal grinding of each particle size after ball mill grinding Number of particles; calculate particle size distribution after grinding. The invention allows multiple crushing events to occur within each time interval, and can accurately observe the microscopic grinding process, thereby obtaining changes in the particle size distribution of materials in the ball mill before and after grinding.

Owner:NORTHEASTERN UNIV LIAONING

A Method for Analyzing and Evaluating the Dispersion Distribution of Micro-Nano Particles

The invention provides a method for analyzing and evaluating micro-nano particle dispersion and distribution. The method includes the following steps of firstly, collecting a micro-nano particle microscopic image, and graying the image; secondly, conducting binaryzation on the image through an OTSU method, and removing impure points and ineffective communication domains in the image; thirdly, separating the connected communication domains through the morphological algorithm, and filling holes in the communication domains; fourthly, adding virtual particles, segmenting the image through the watershed algorithm, and obtaining segmented characteristic communication domains; fifthly, calculating related data of the characteristic communication domains; sixthly, evaluating micro-nano particle dispersion and distribution. By means of the method, the more accurate result can be obtained; a large number of micro-nano particle distribution microscopic images can be rapidly processed in a batched mode; the micro-nano particle distribution condition can be analyzed and evaluated comprehensively from the aspects of uniformity, density and clustering degree.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com