Patents

Literature

30results about How to "Color deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

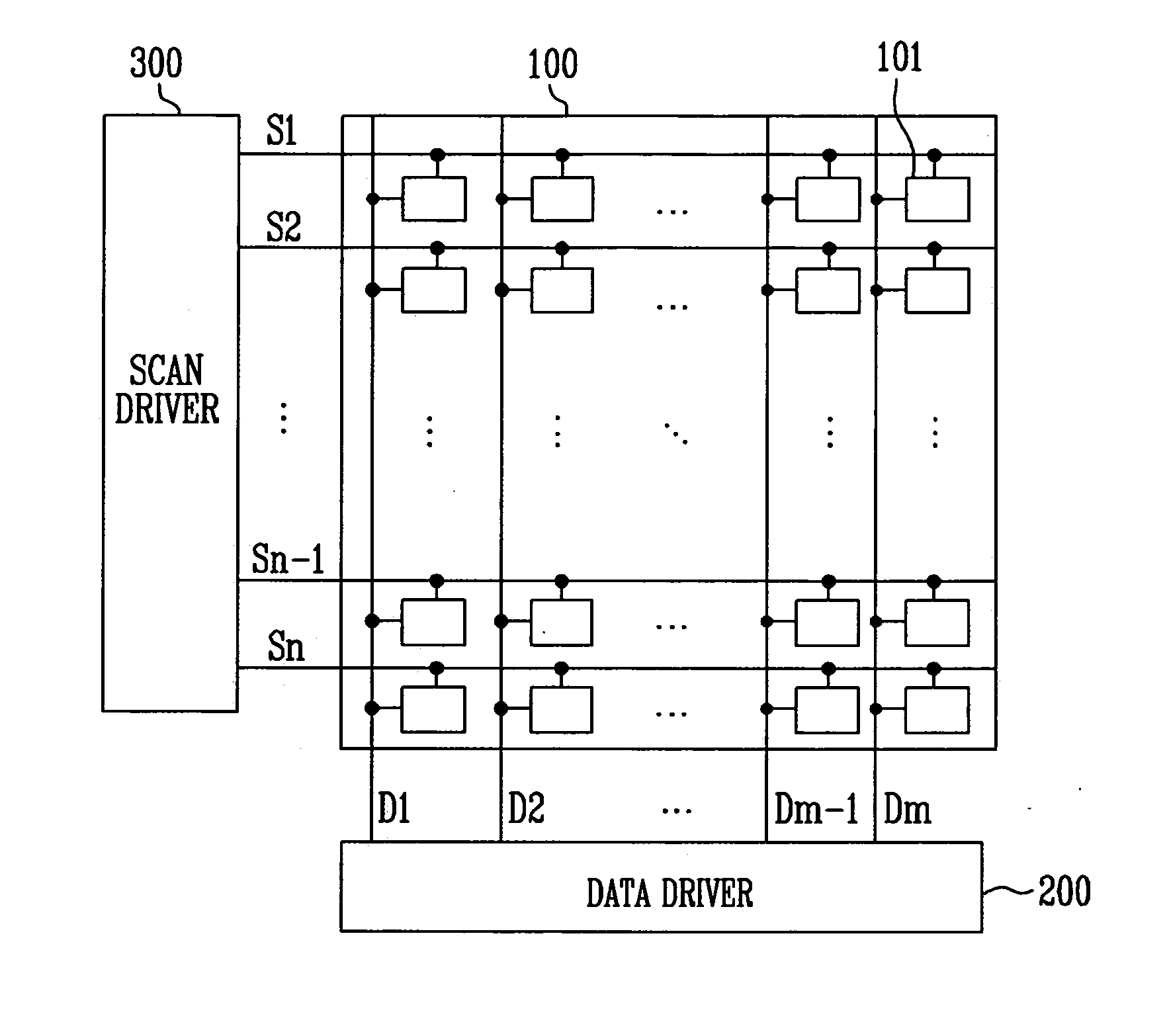

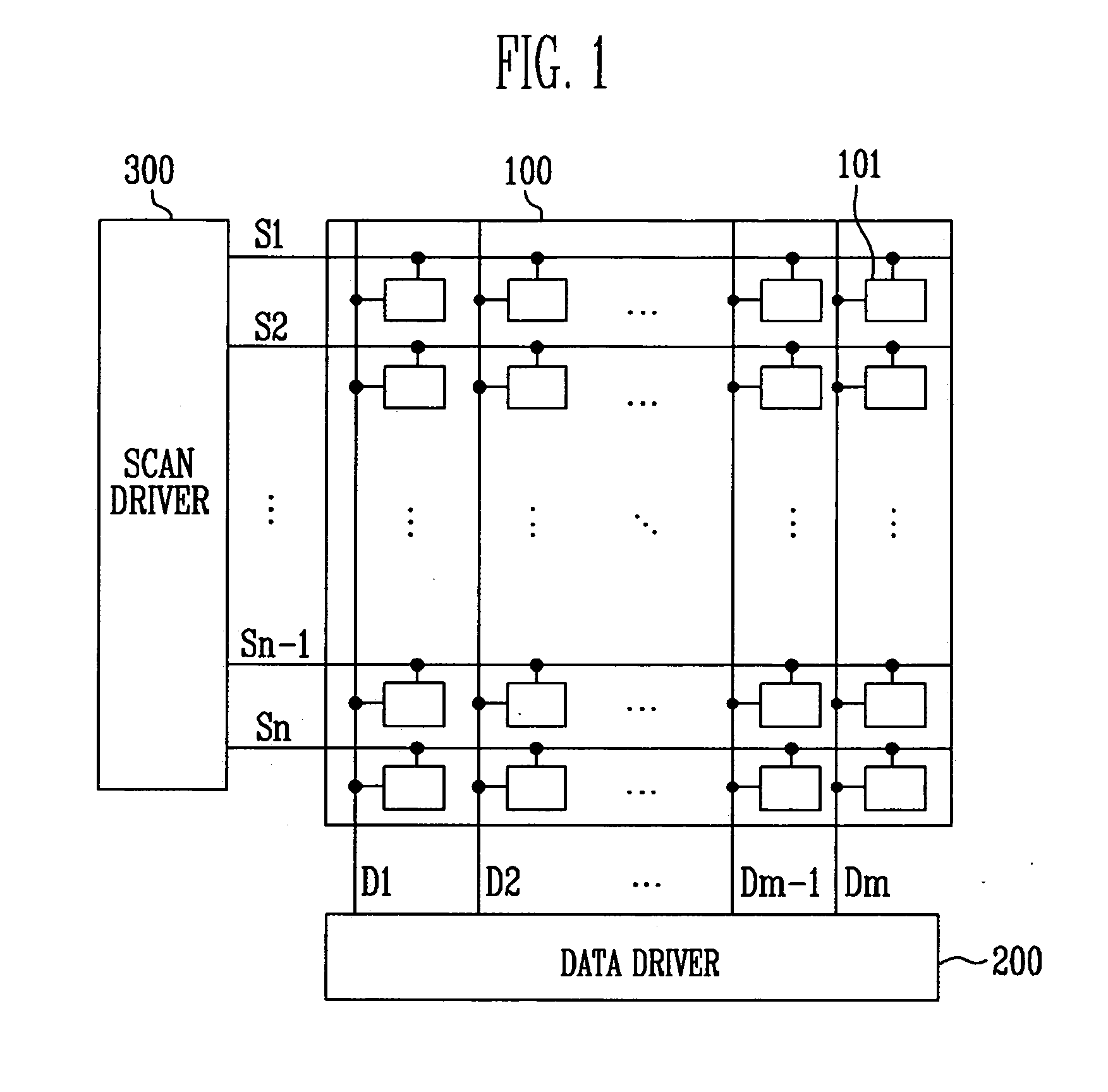

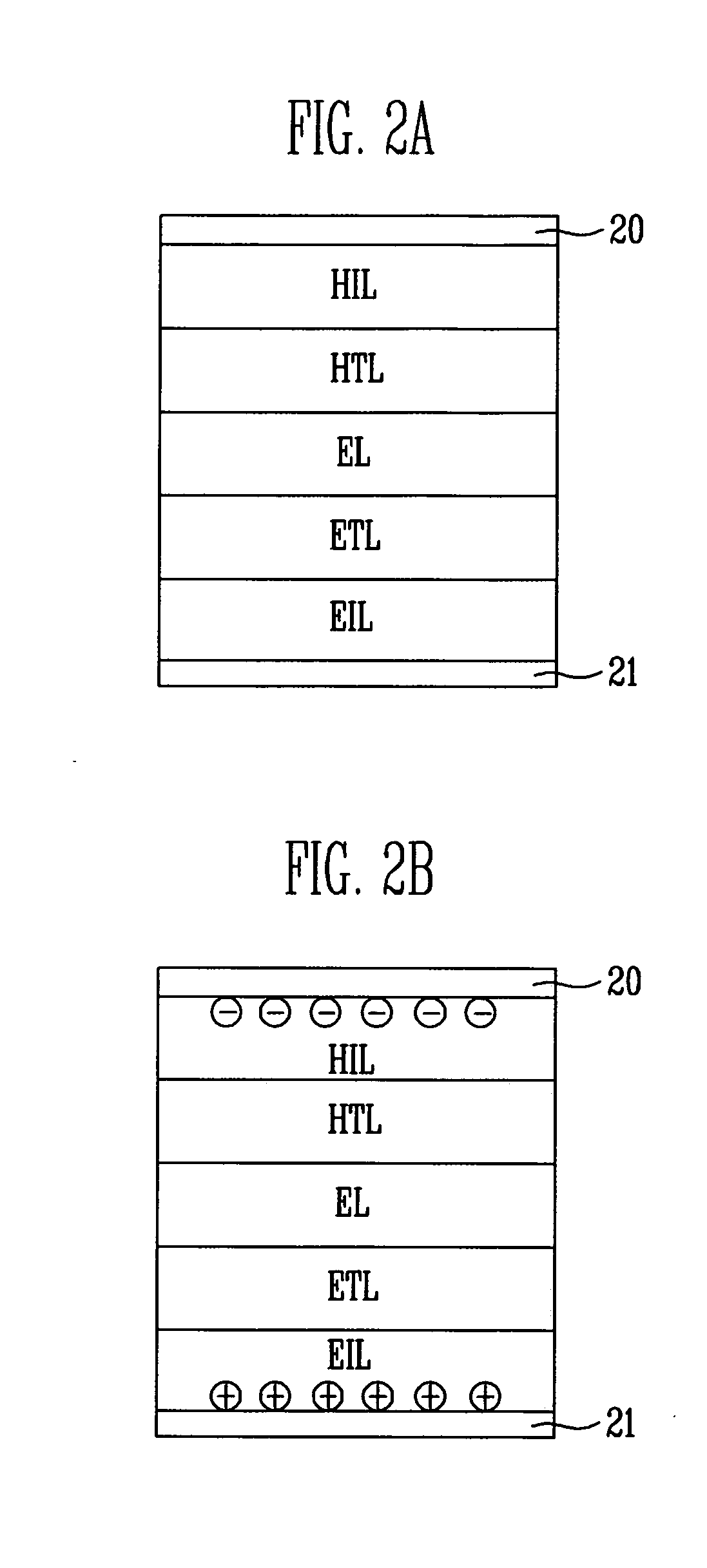

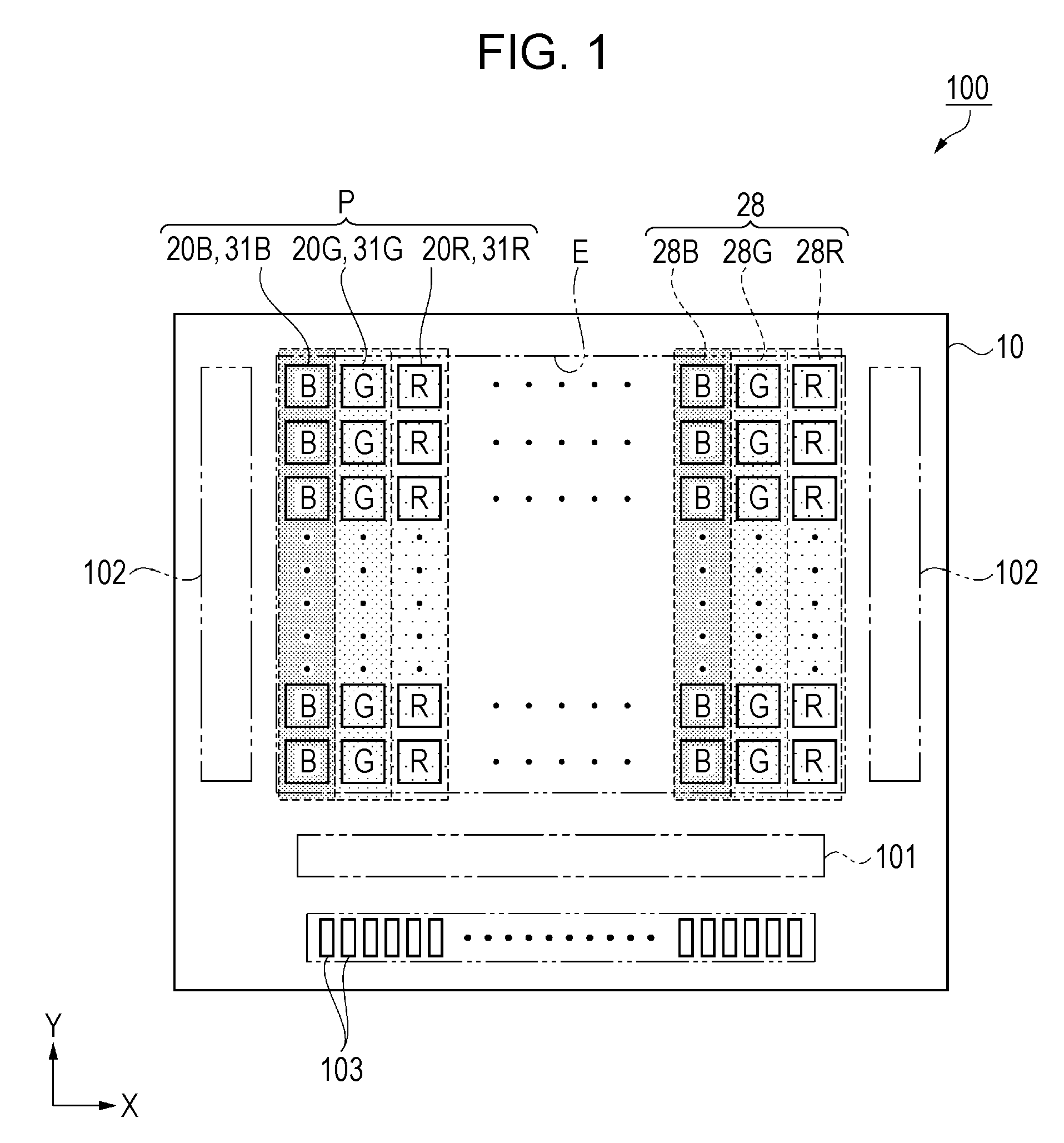

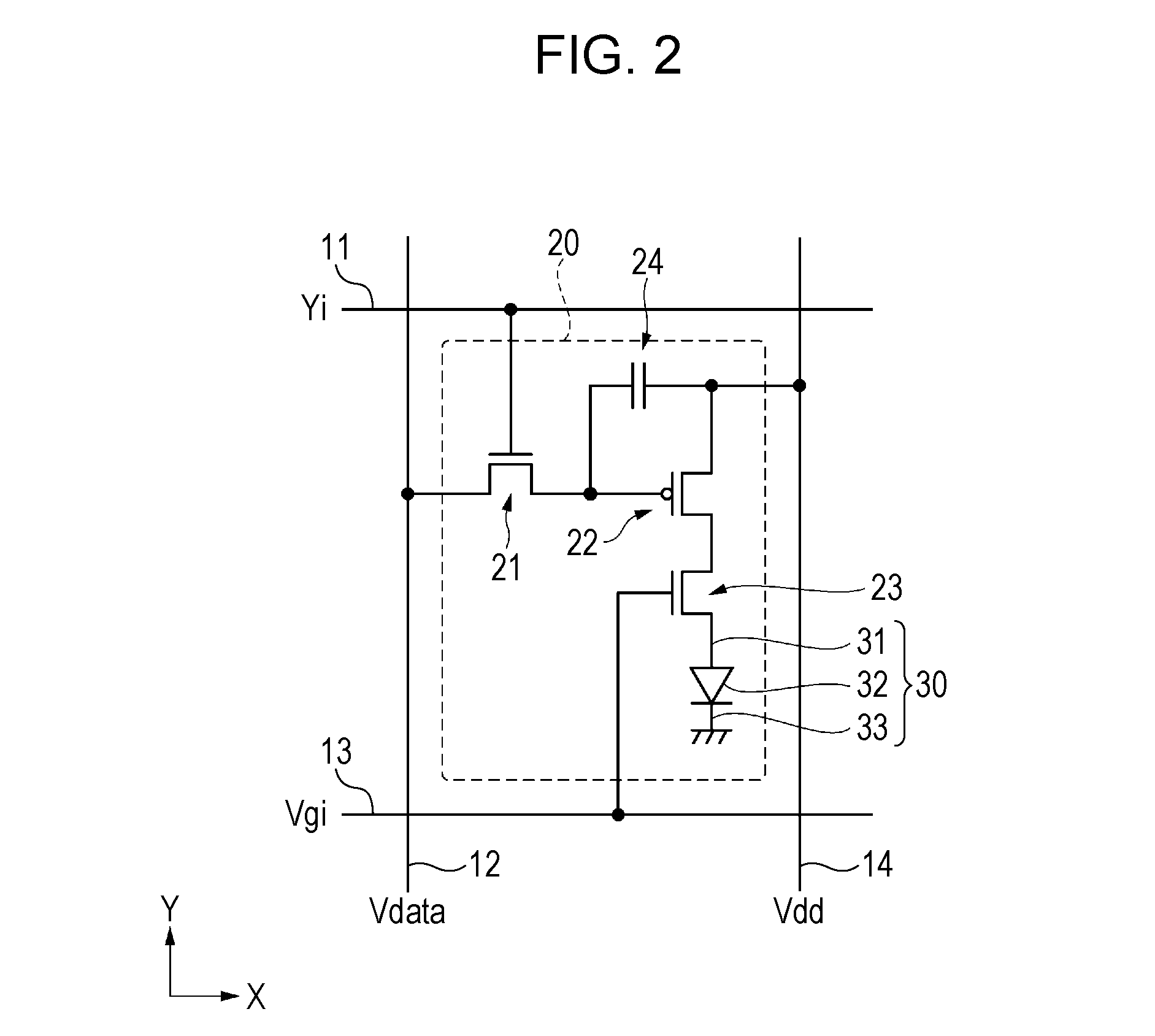

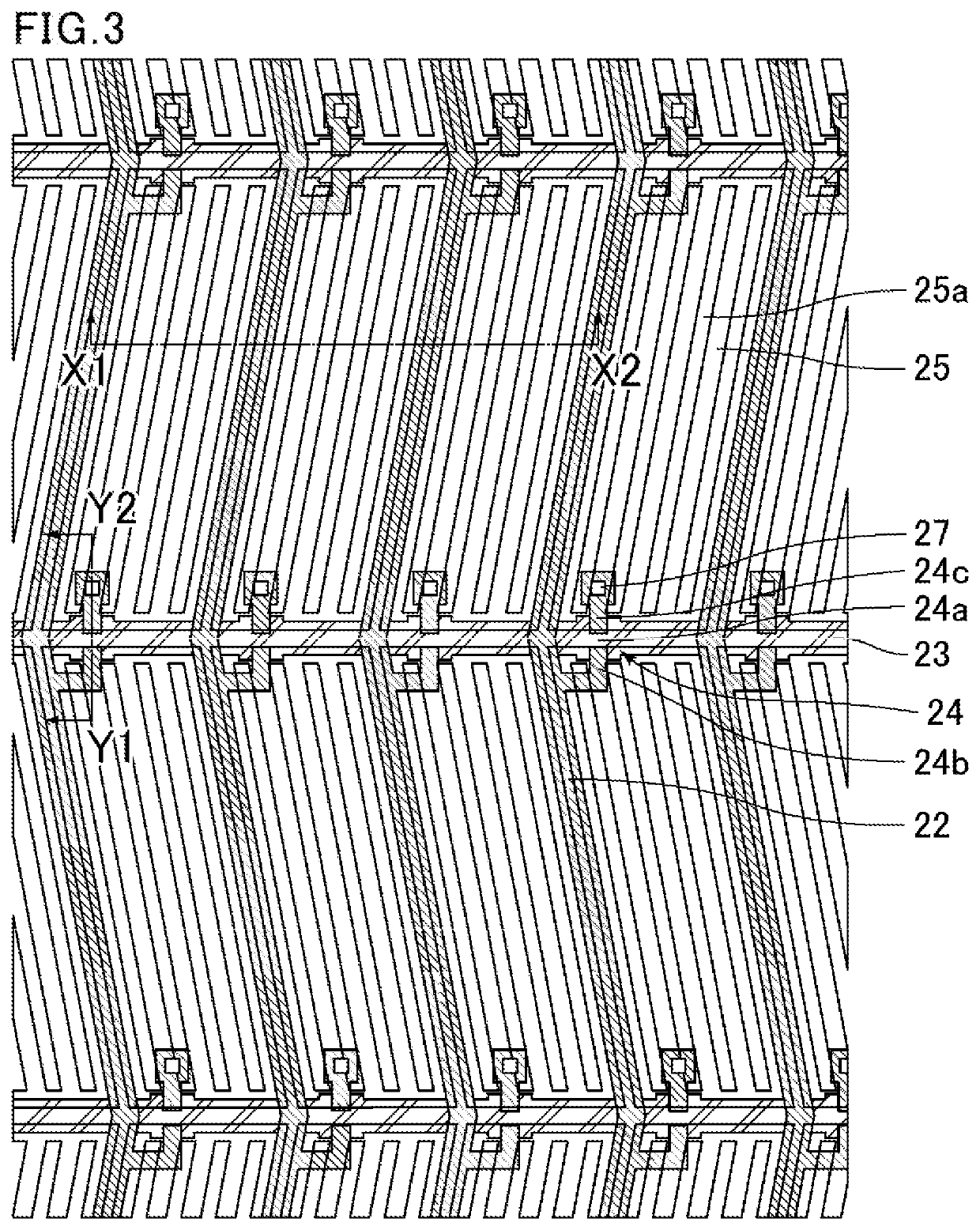

Pixel structure and organic light emitting display using the same

InactiveUS20110025723A1Extend your lifeSmall sizeSolid-state devicesCathode-ray tube indicatorsPhysicsOptoelectronics

A pixel that is adapted for implementing higher definition and an organic light emitting display using such a pixel are provided. The pixel includes a red sub-pixel including a red emitting layer, a green sub-pixel including a green emitting layer, a first blue sub-pixel including a first blue emitting layer, and a second blue sub-pixel including a second blue emitting layer. The red emitting layer and the green emitting layer are symmetrically arranged and the first blue emitting layer and the second blue emitting layer are symmetrically arranged.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Enzymatic process for interesterification of fats and oils using distillation

InactiveUS6090598AIncrease concentrationEfficientlyFermentationEdible oils/fats with aqeous phaseMultiple stagesDistillation

There is disclosed a process for modifying fats and oils by an interesterification reaction to efficiently increase concentrations of the desired triglycerides. In the process, a step for subjecting a fat or oil to an interesterification reaction with a fatty acid or its lower alcohol ester in the presence of an enzyme catalyst and then a step for removing the fatty acid or its lower alcohol ester by distillation are repeated in multiple stages. The process is characterized by leaving the fat or oil and a feedstock fatty acid or its ester selectively in the distillation steps preceding the one in the final stage. According to this process, the amount of the fatty acid or its ester to be used can be reduced and the formation of by-products can be inhibited, thereby enabling to increase concentrations of the desired triglycerides more efficiently than conventional multistage interesterification processes.

Owner:FUJI OIL CO LTD

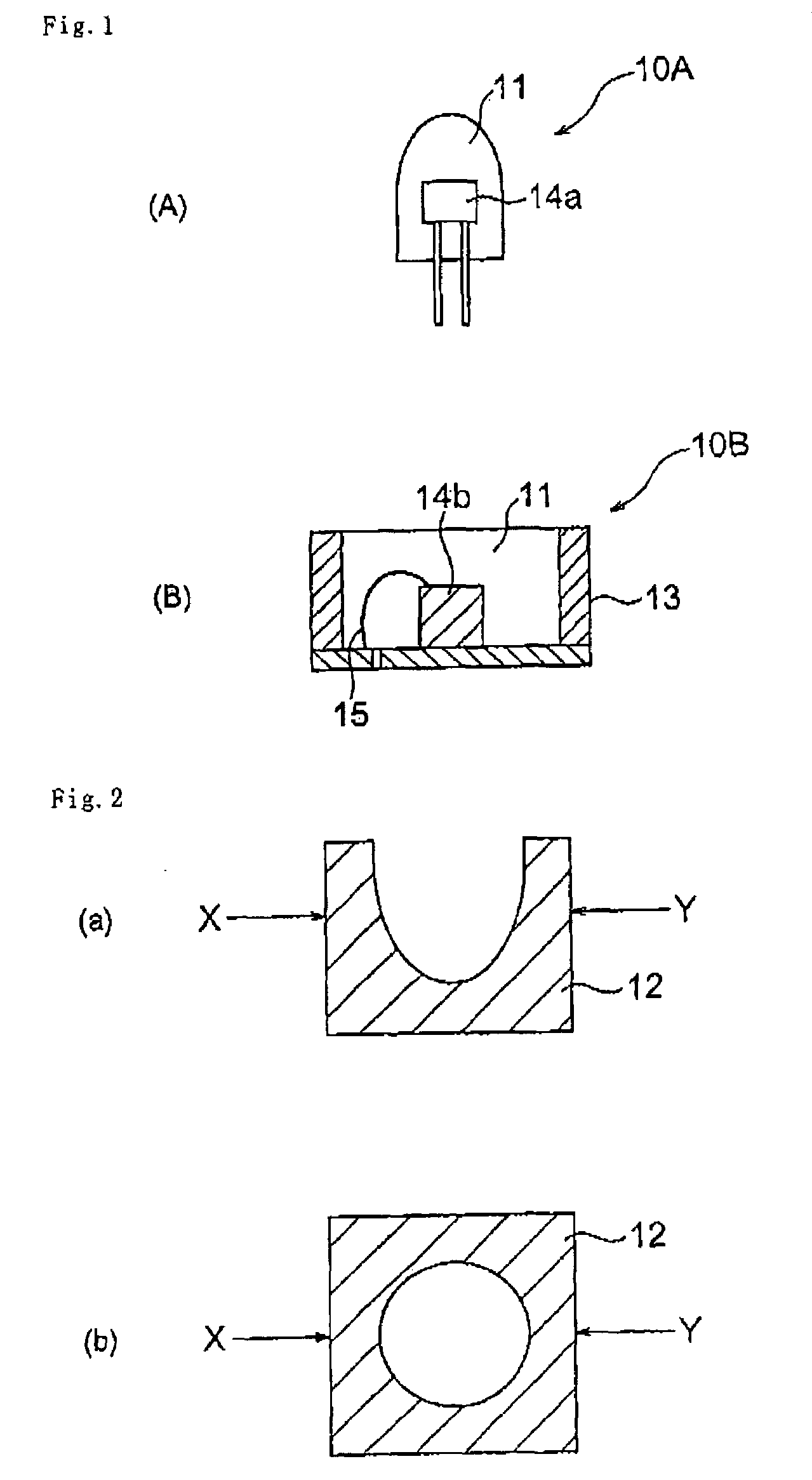

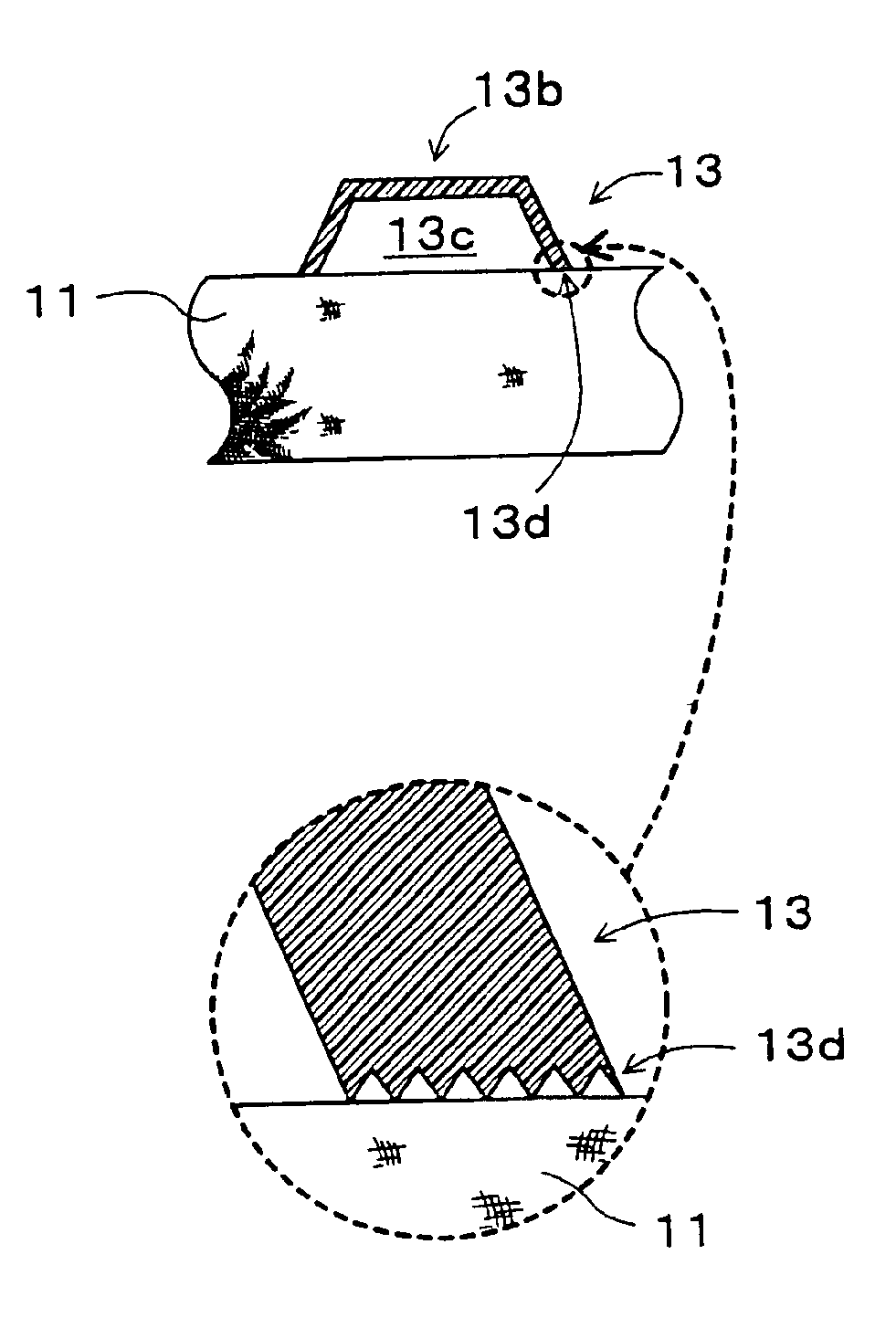

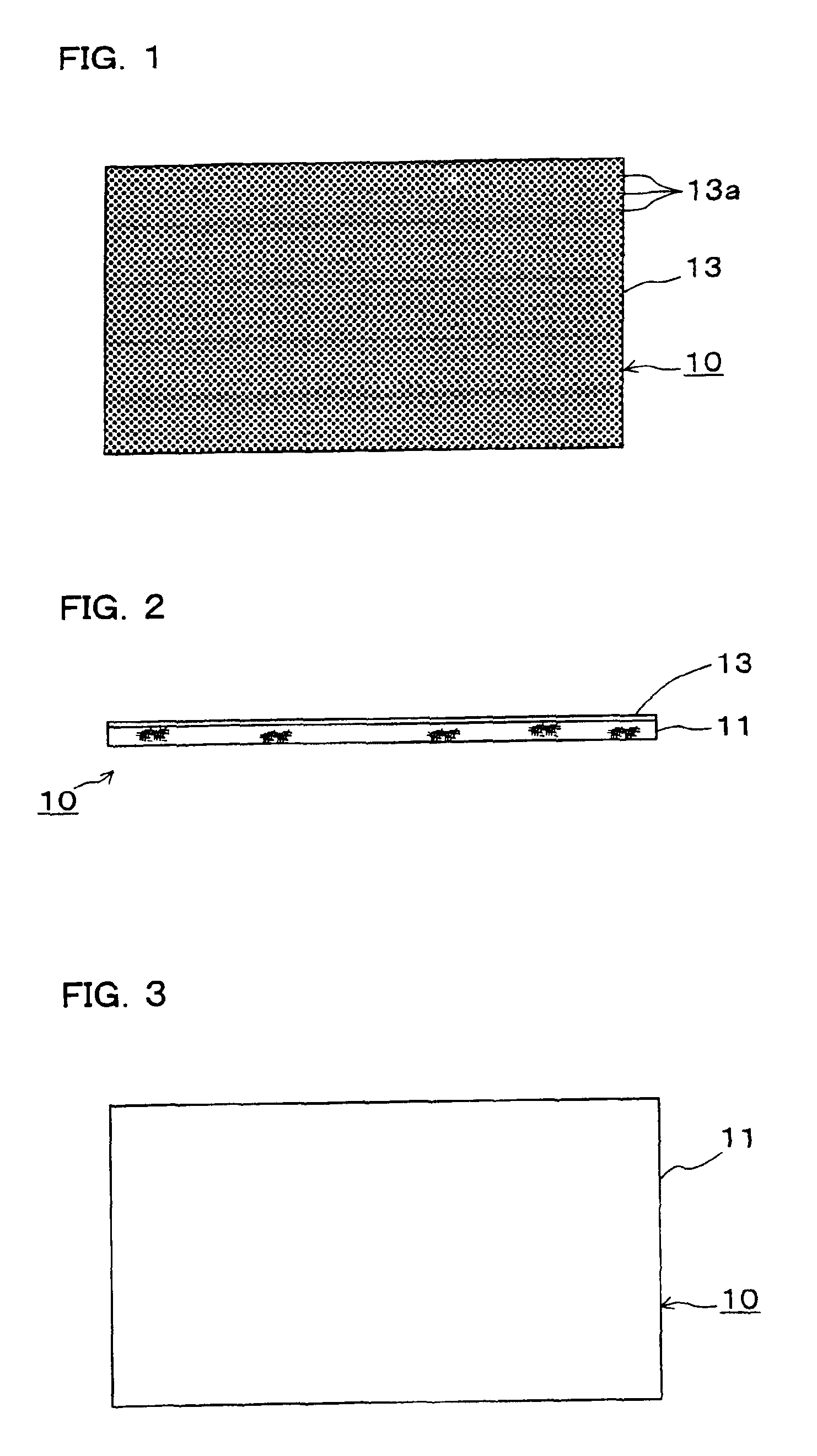

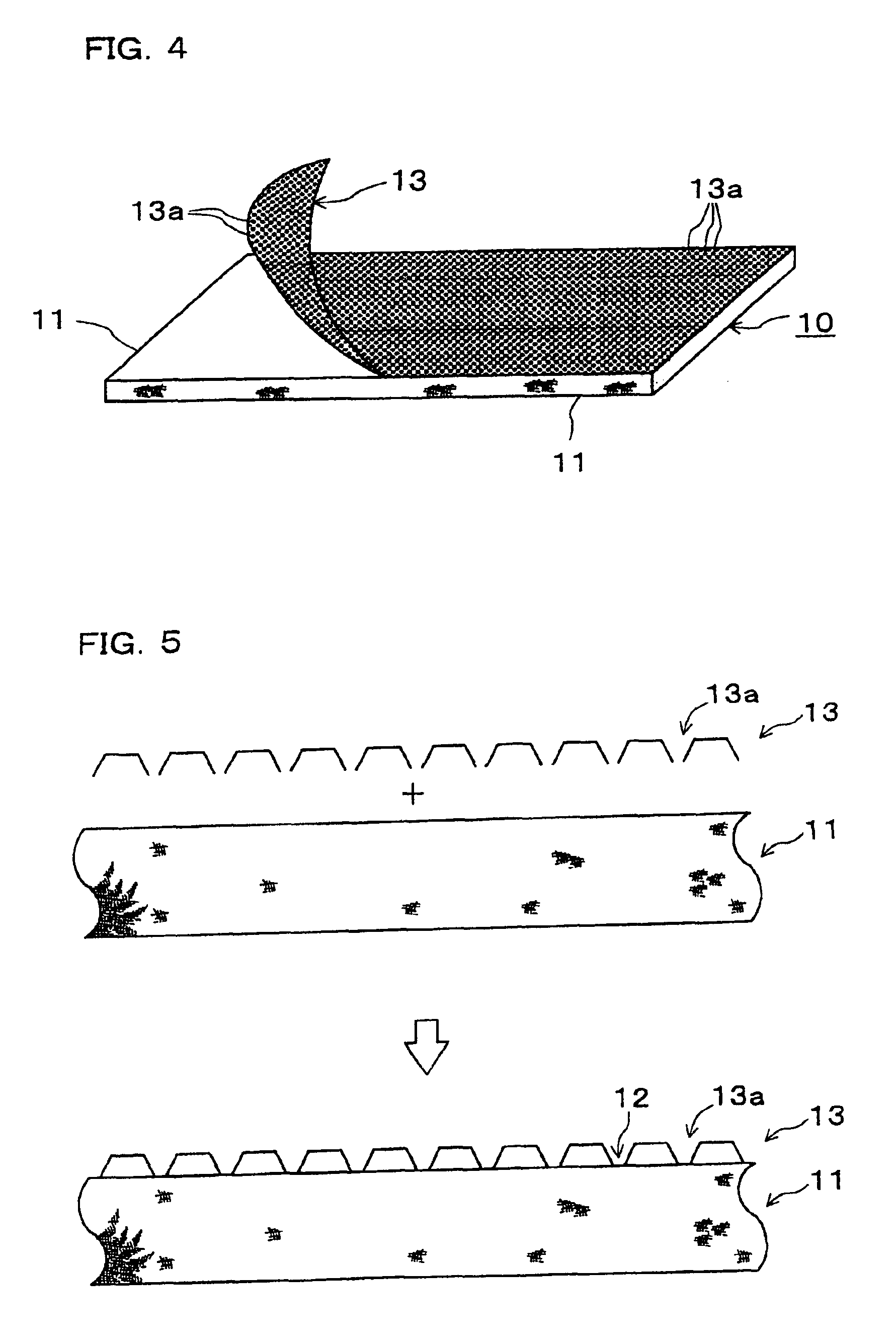

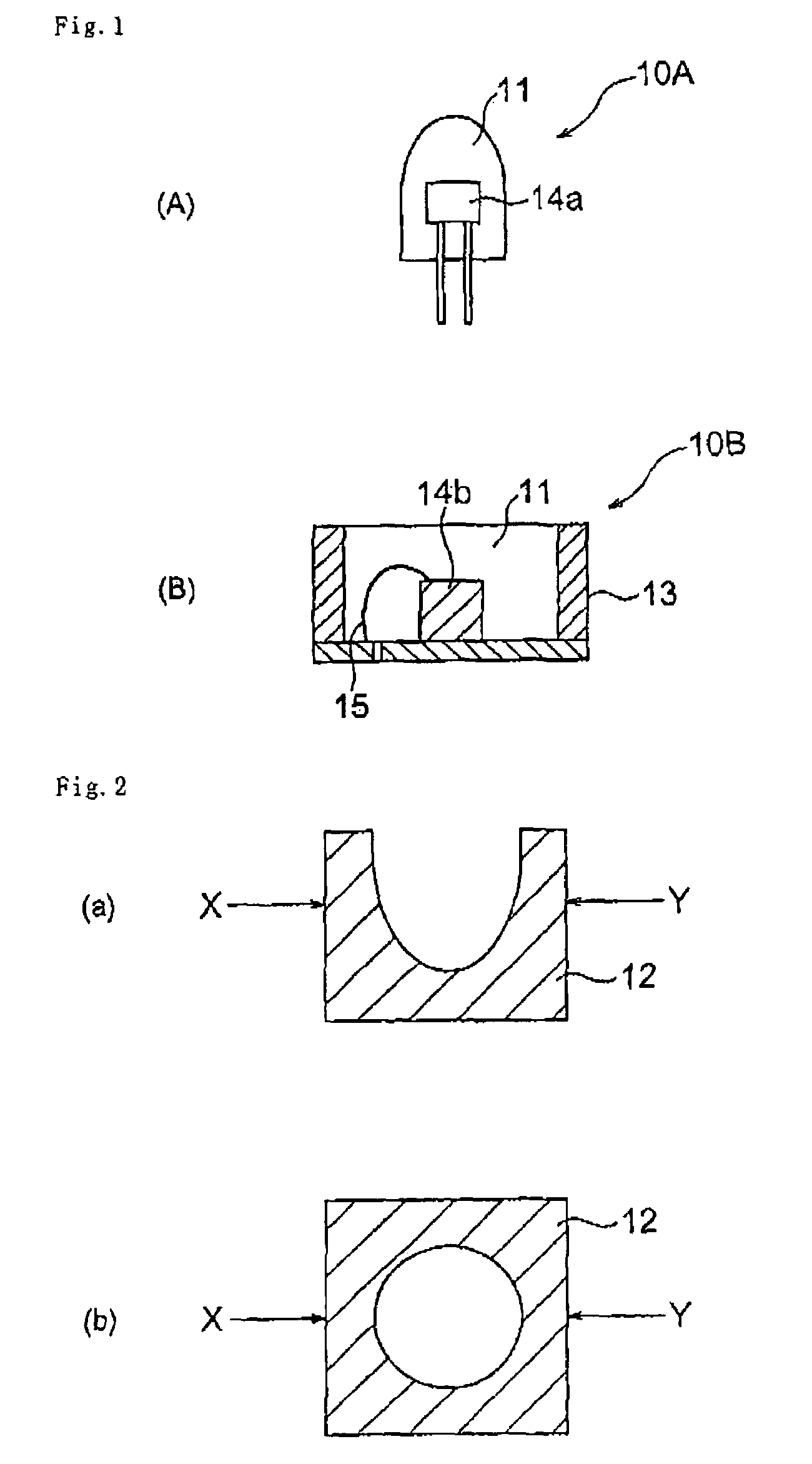

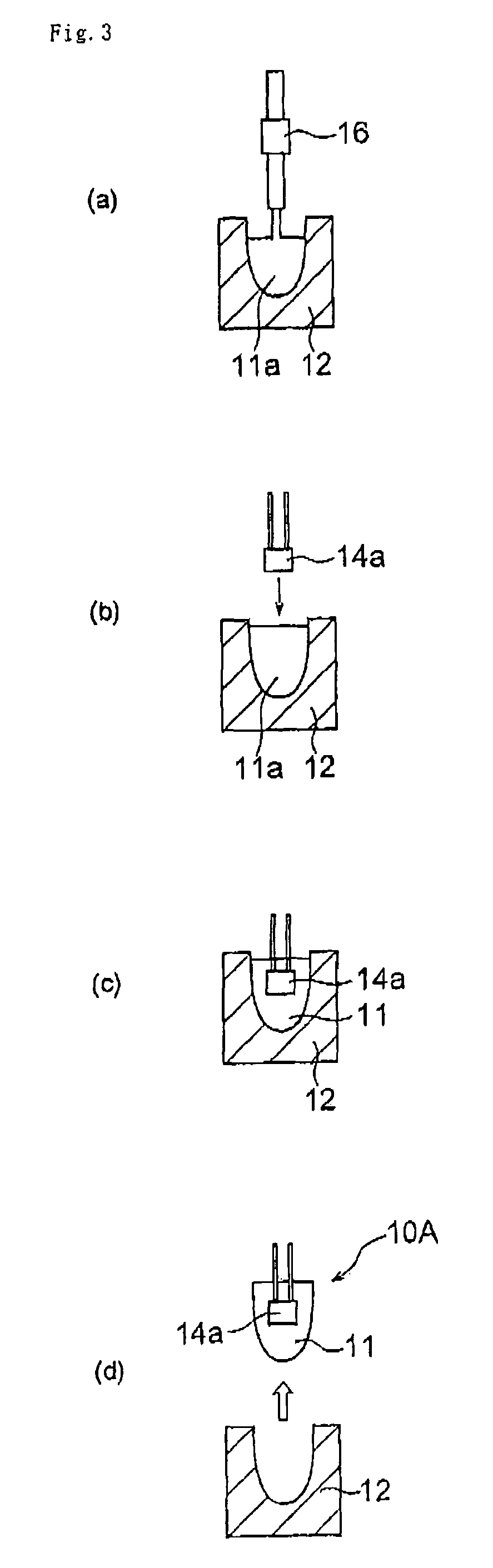

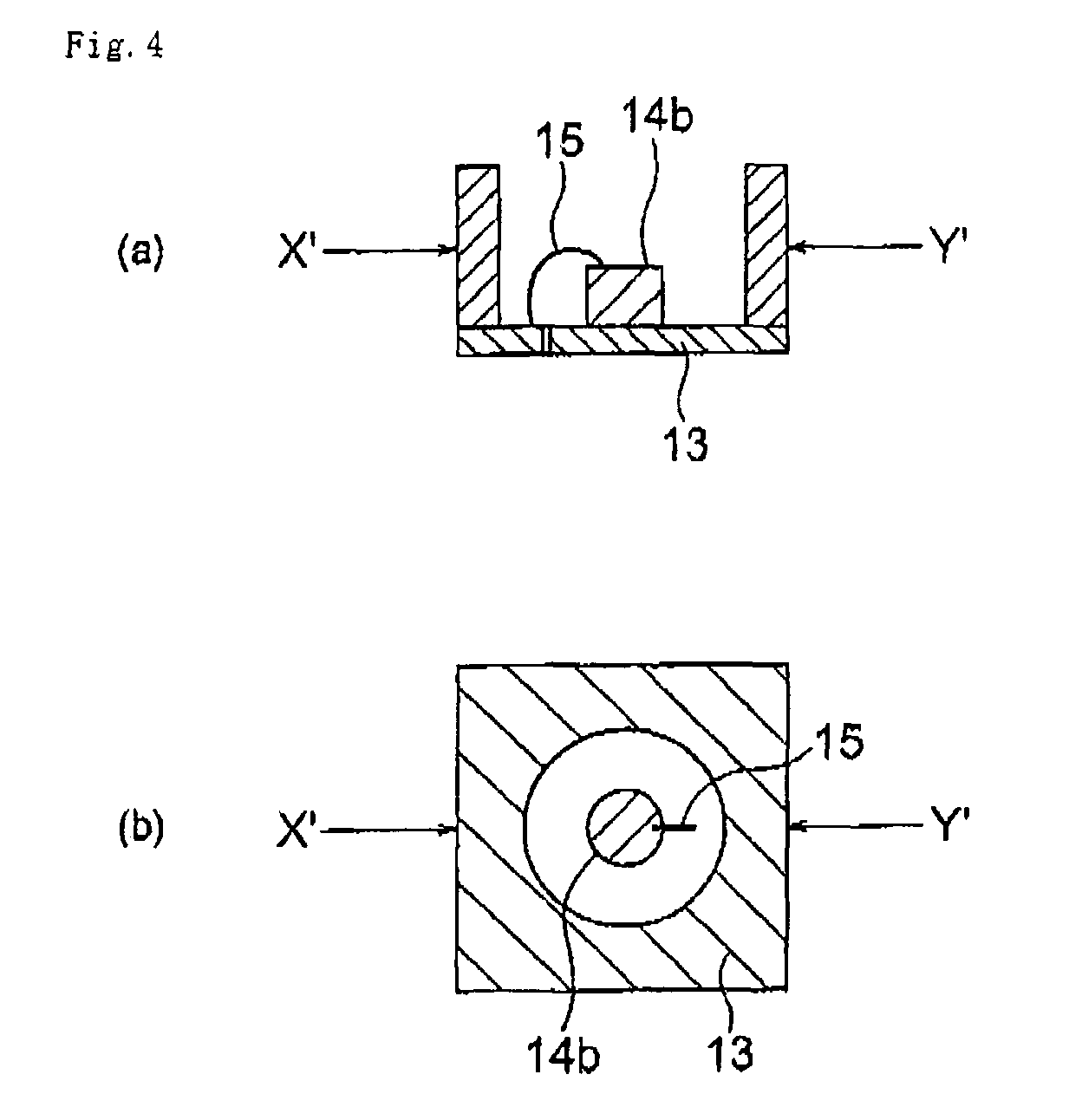

Molding material comprising polysilsesquioxane compound, sealing material, and sealed optical element

ActiveUS20090005530A1Improve heat resistanceHigh transparencyLayered productsSemiconductor/solid-state device manufacturingHeat resistanceShell molding

A molding material which can produce cured products with long-lasting excellent transparency and heat resistance, a sealing material in which the molding material is used, and a sealed optical element are provided. The molding material comprises a polysilsesquioxane compound with a ladder structure having a repeating unit of the following formula (I) in the molecule as a major component.wherein R1 represents a group shown by the formula AO—(CH2)r— (wherein A indicates a protective group for a hydroxyl group and r is an integer of 1 to 10), R2 represents a substituted or unsubstituted phenyl group, a substituted or unsubstituted (excluding substitution with OA in the above formula) alkyl group having 1 to 20 carbon atoms, or an alkenyl group having 2 to 20 carbon atoms, and l, m, and n individually represent 0 or an arbitrary integer, provided that l and n are not 0 at the same time.

Owner:LINTEC CORP

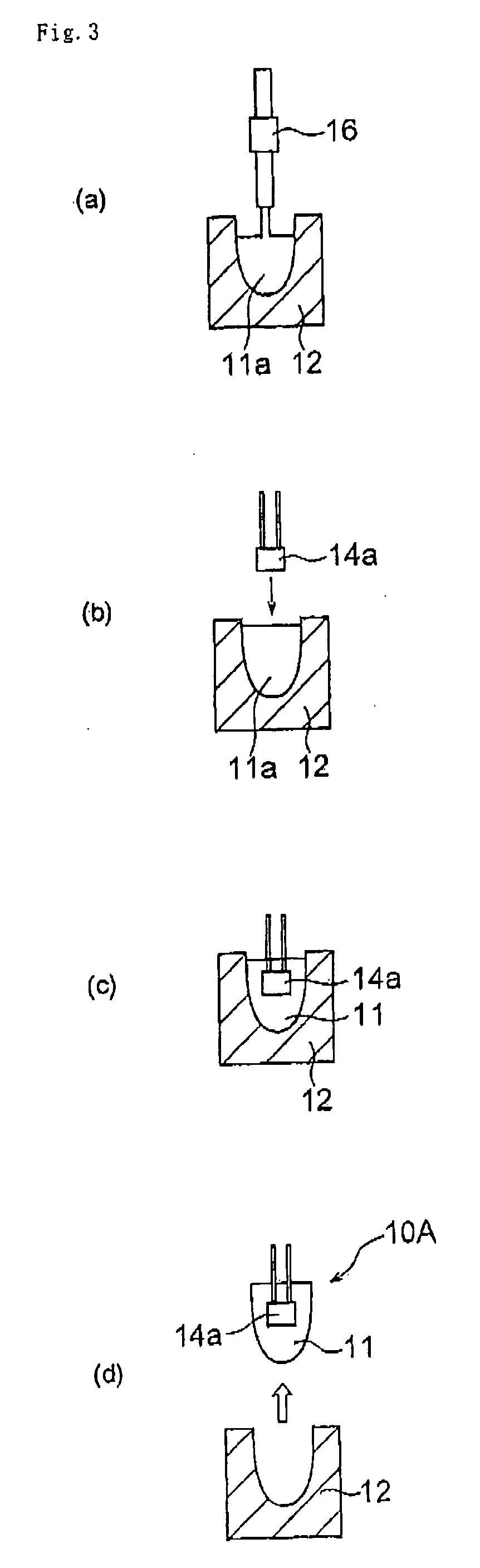

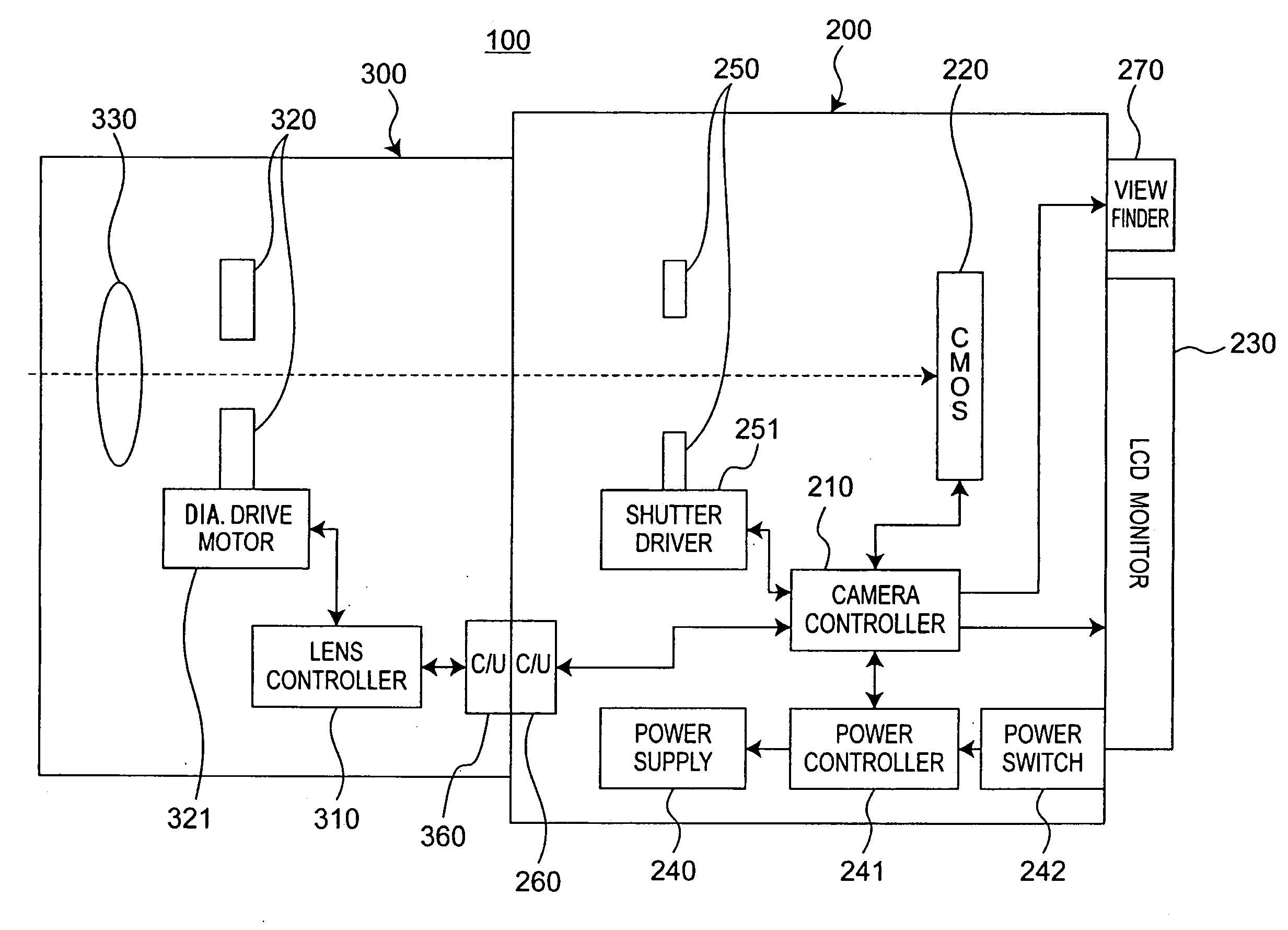

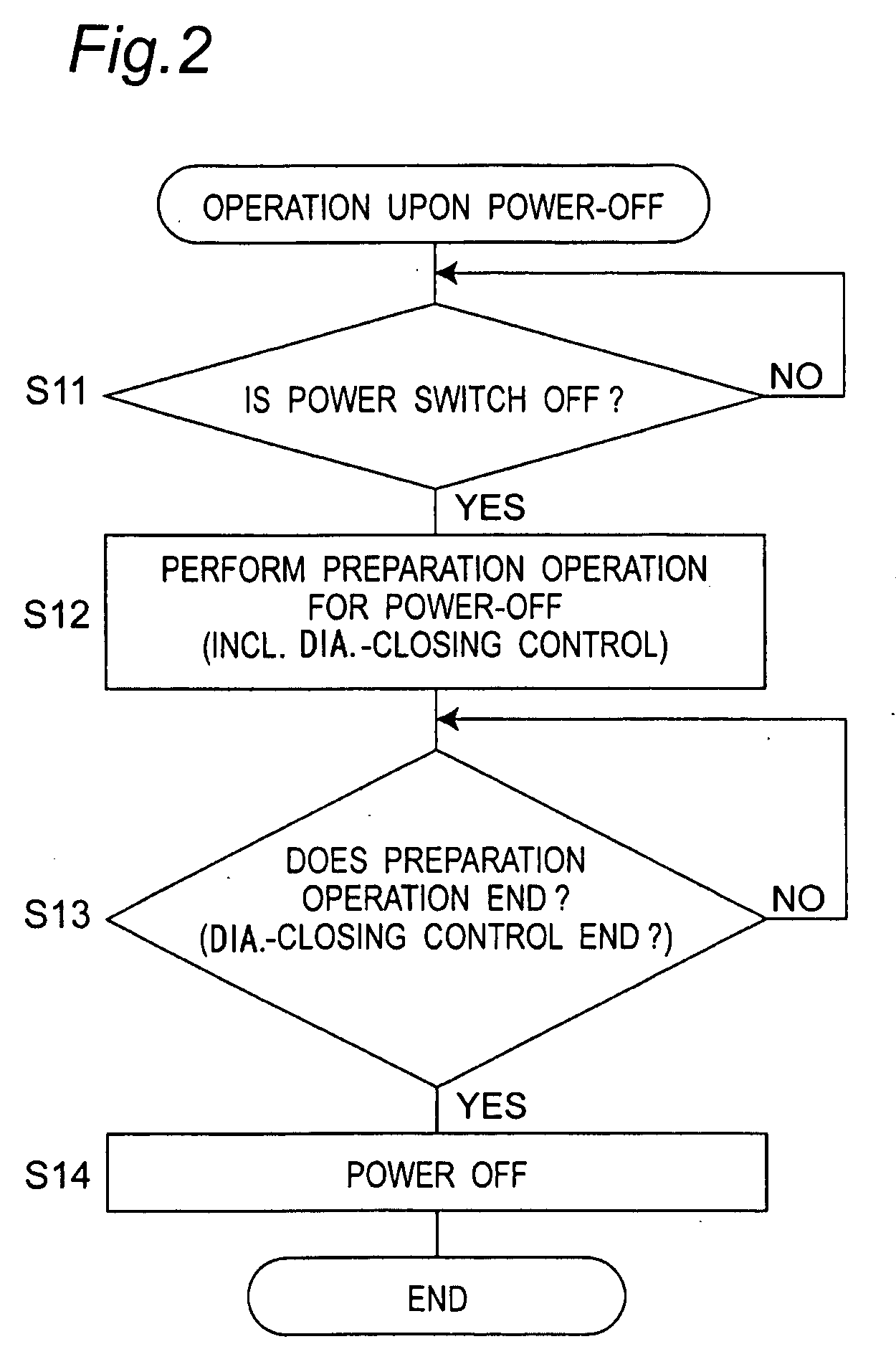

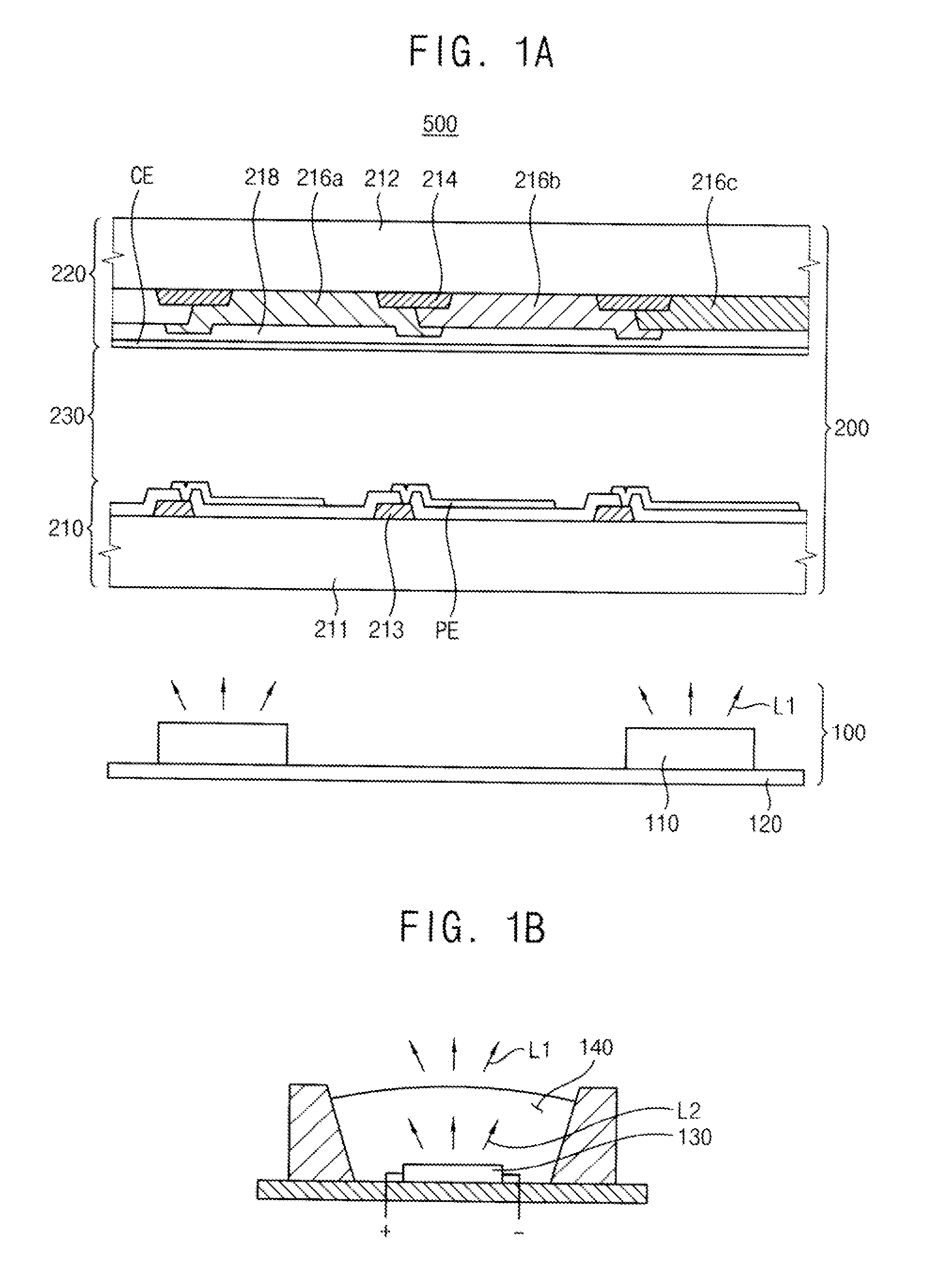

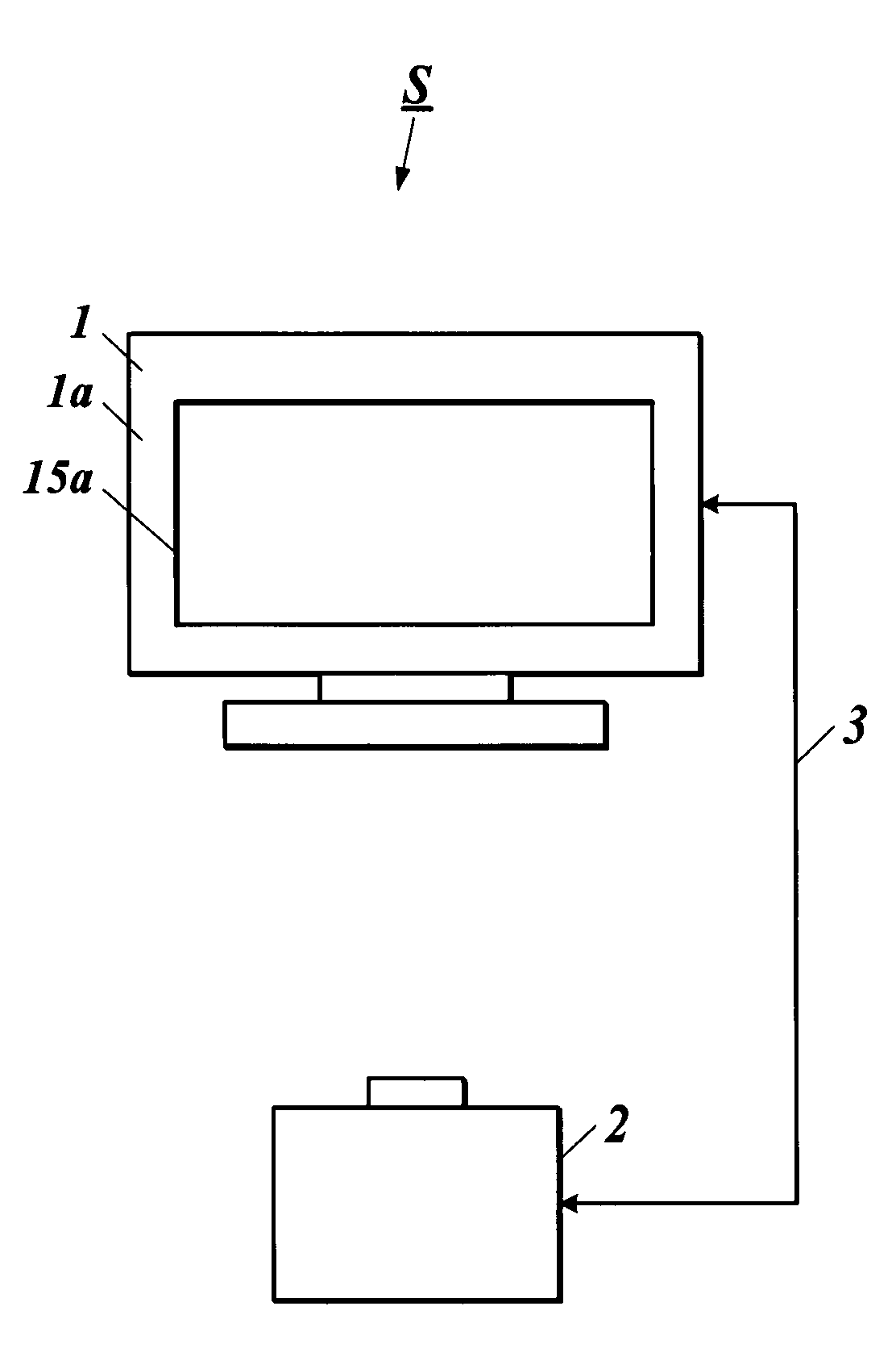

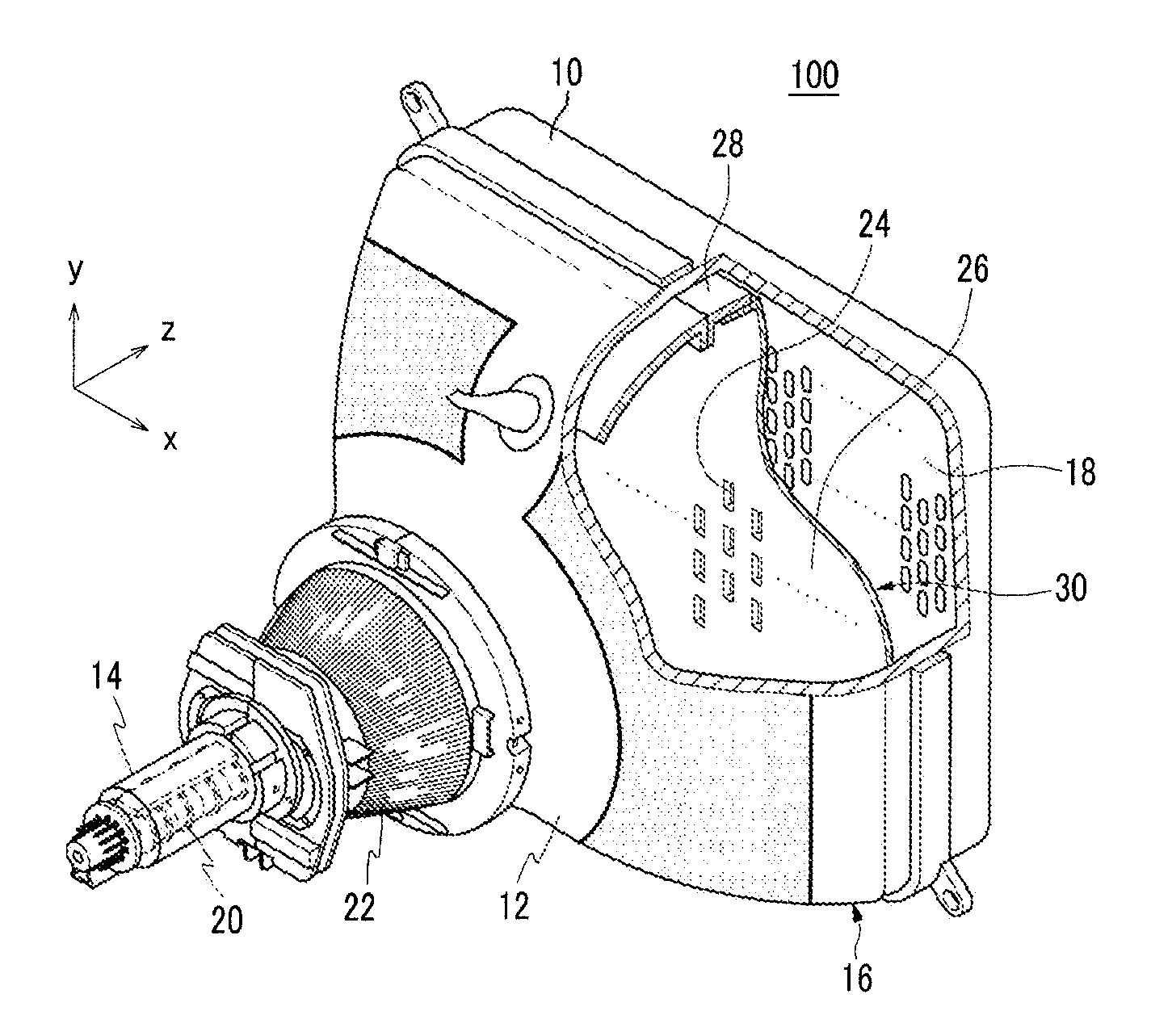

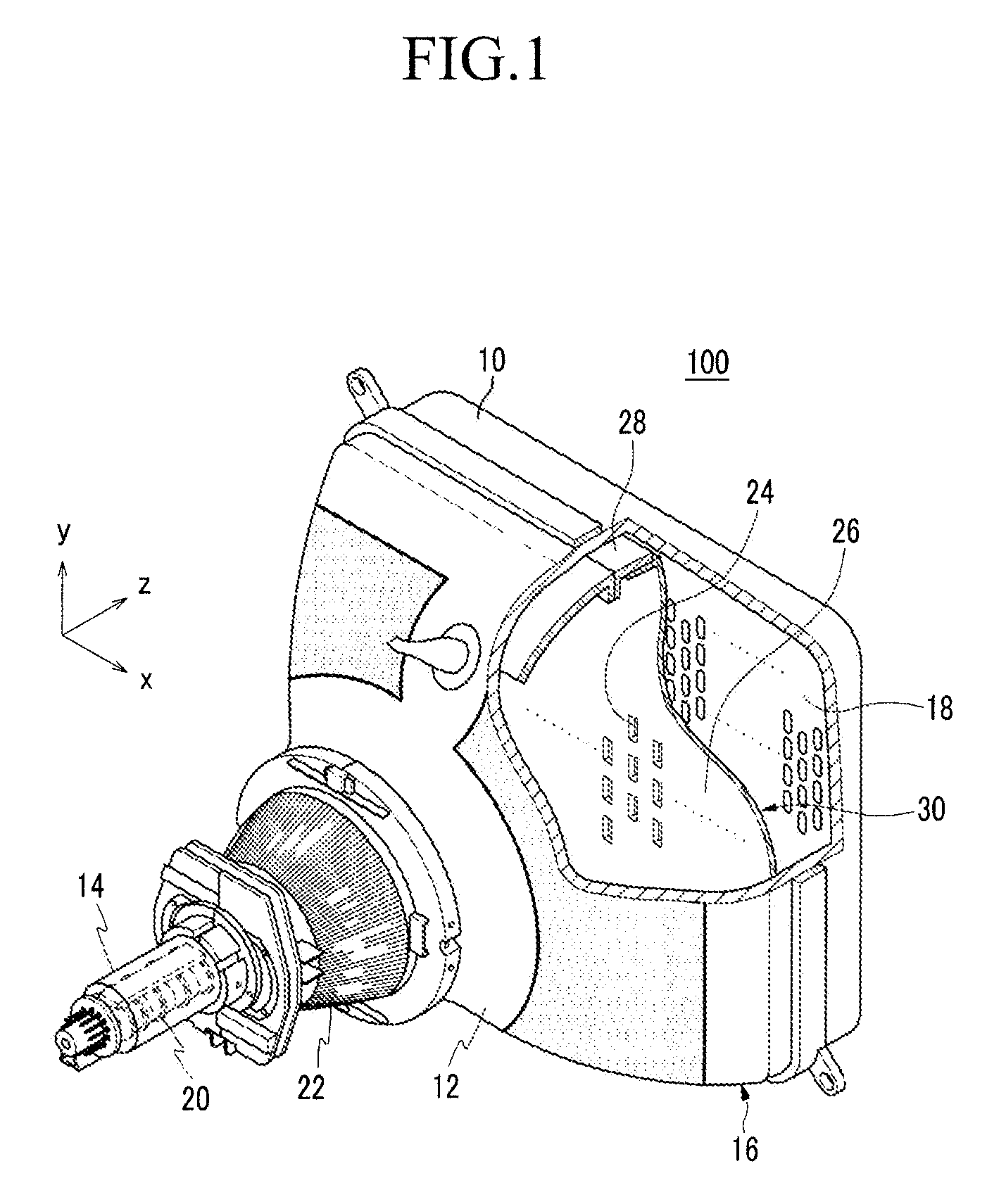

Camera System And Camera Body Composing The Same

InactiveUS20090244360A1Reduce deteriorationColor deteriorationTelevision system detailsColor television detailsCamera lensExecution control

A camera system includes a controller operable to control operations of a camera body and an interchangeable lens. When supply of power from a power supply of the camera body is requested to be stopped, the controller performs control to adjust an aperture of the diaphragm such that an amount of light passing through the diaphragm is no greater than a predetermined value, and thereafter, to stop the supply of power.

Owner:PANASONIC CORP

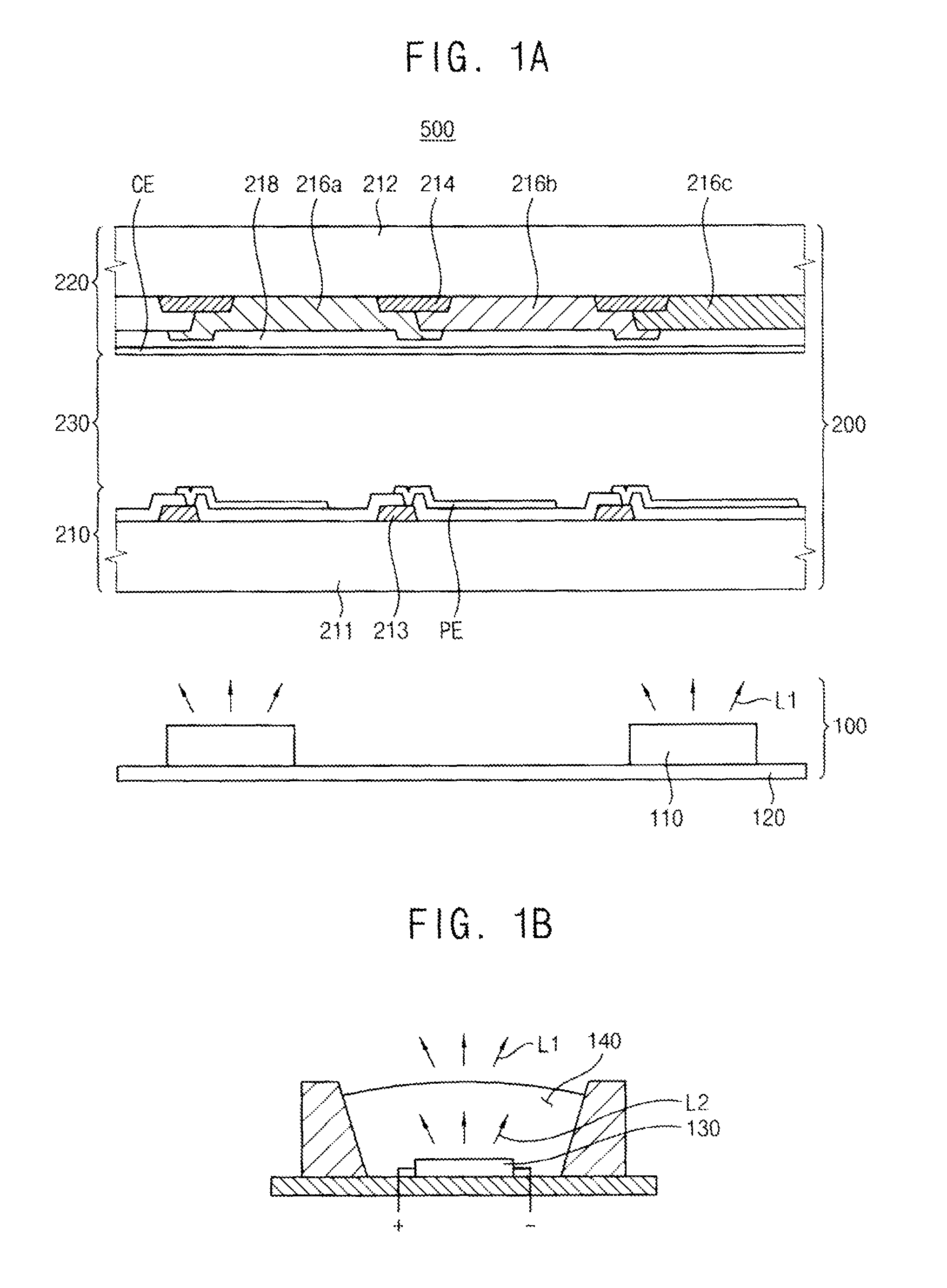

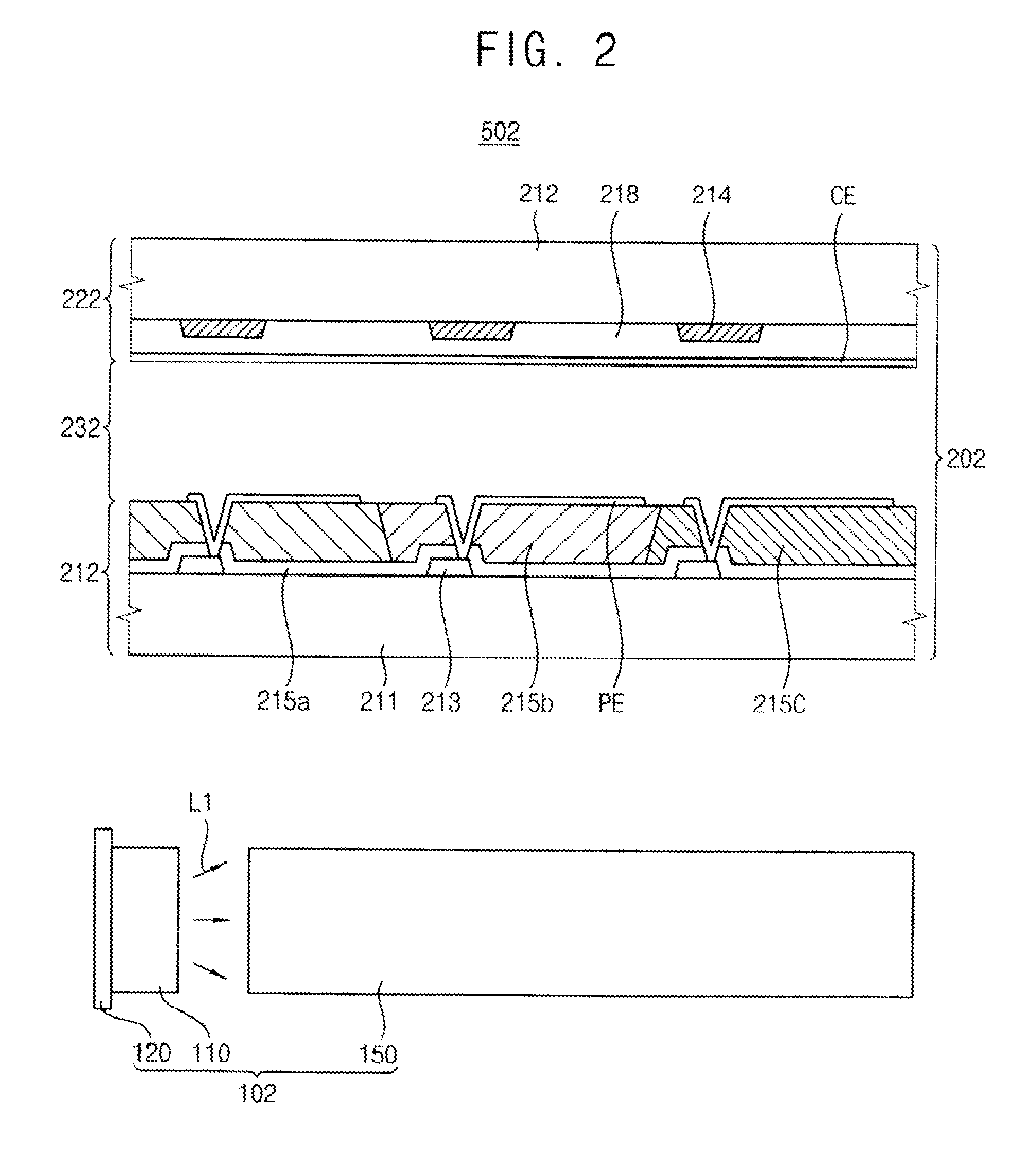

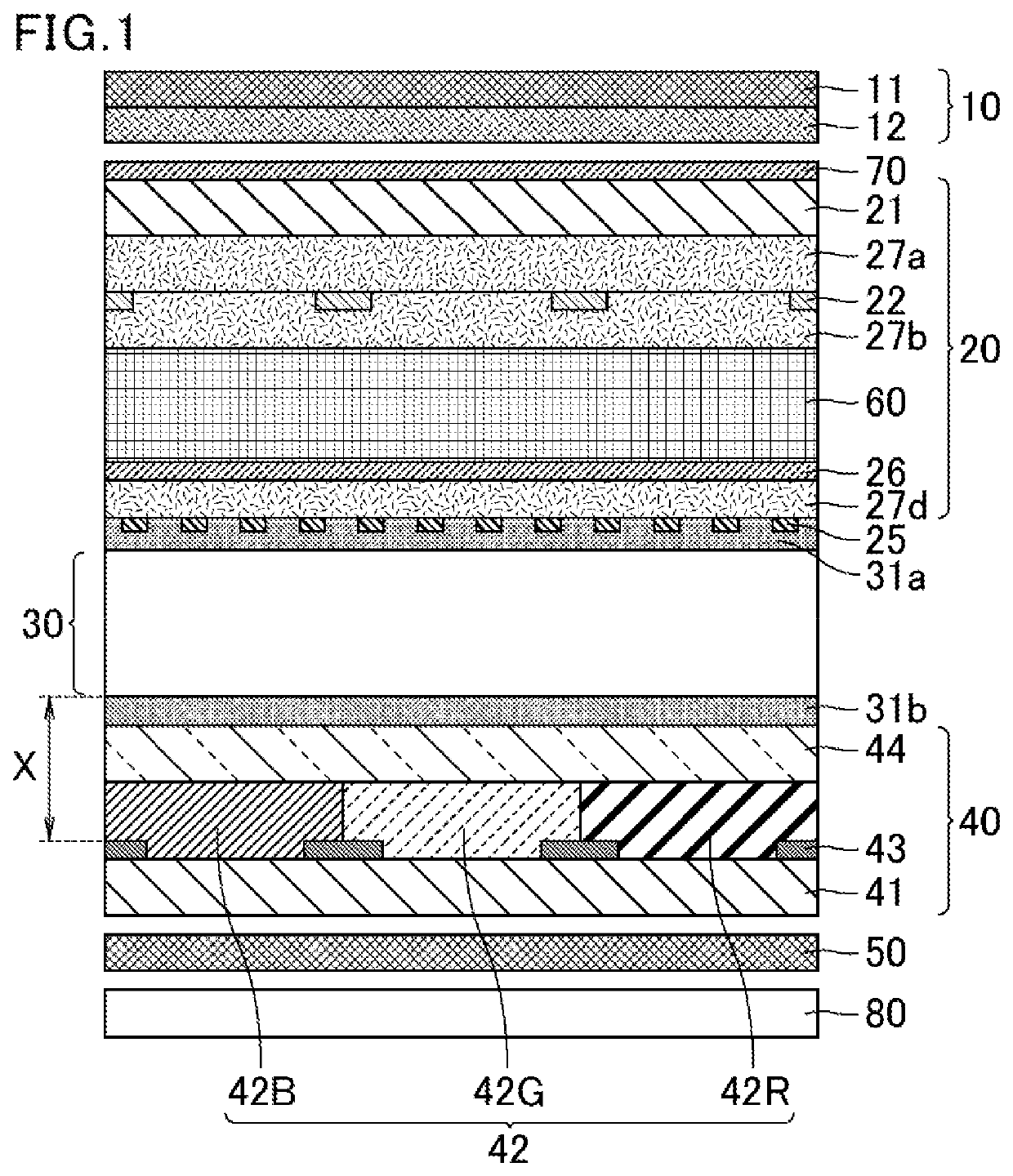

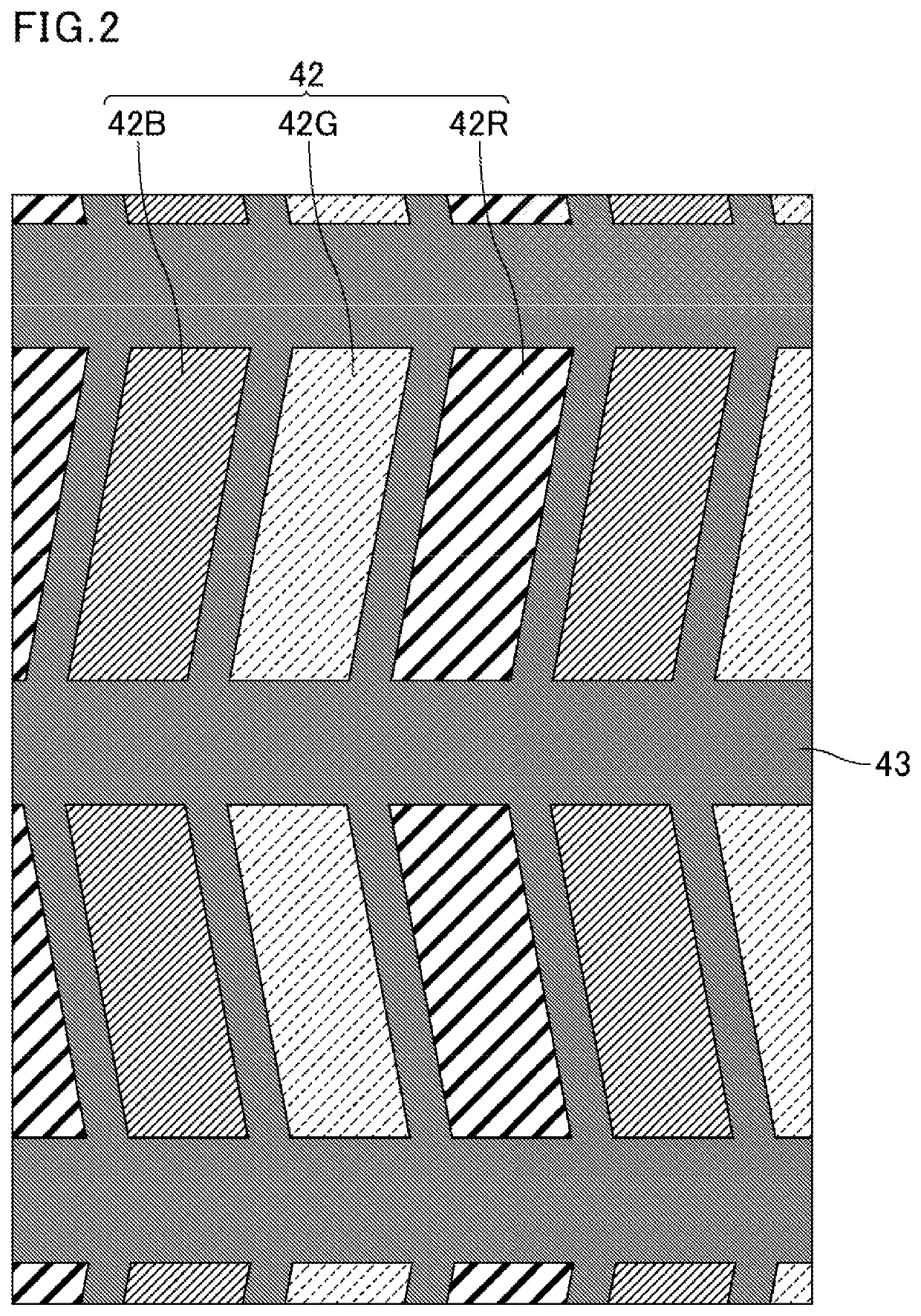

Display device

ActiveUS9122089B2Color deteriorationAvoid problemsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLength wave

A display device includes a light emitting unit and a display panel including a first color filter. The light emitting unit includes a light source generating a blue light, and a light-converting part converting the blue light into a white light and emitting the white light to an exterior. The first color filter, through which the white light passes, includes a first coloring agent that absorbs about 95% to about 100% of light having wavelength of about 420 nm to about 470 nm in the white light. Thus, a color reproducibility of the display device may be improved.

Owner:SAMSUNG DISPLAY CO LTD

Drip absorption mat

InactiveUS6936342B2Inhibit coloringAvoid foodLiving organism packagingMeat/fish preservationEngineering

Owner:UNI CHARM CORP

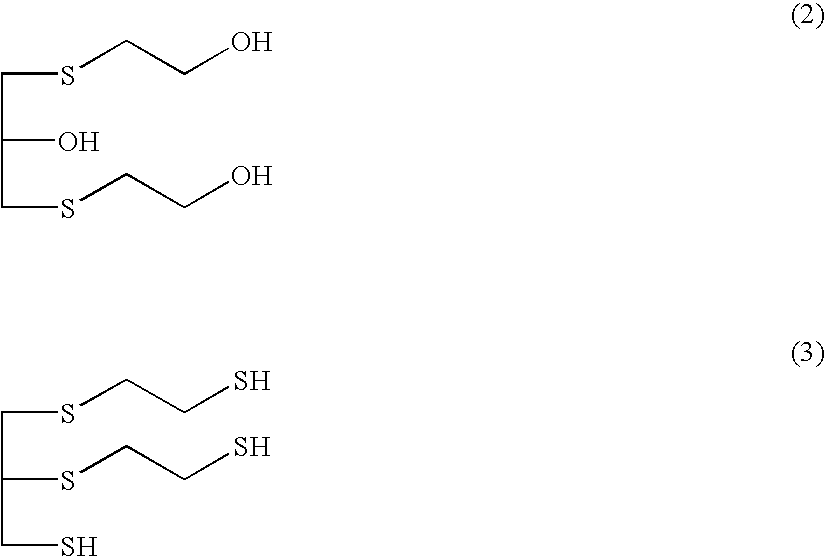

Process for producing polythiol compound for optical materials, and polymerizable composition containing polythiol compound

InactiveUS20090082544A1Good colorColor deteriorationThiol preparationOrganic compound preparationPolyol2-Mercaptoethanol

Owner:MITSUI CHEM INC

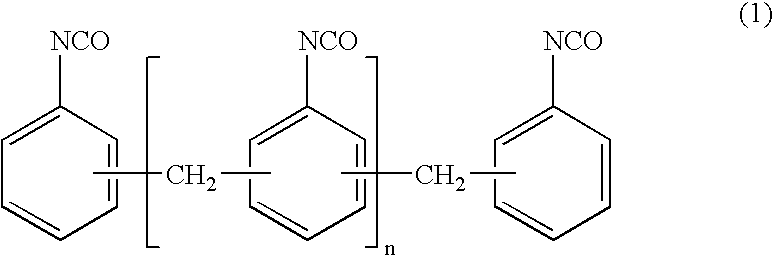

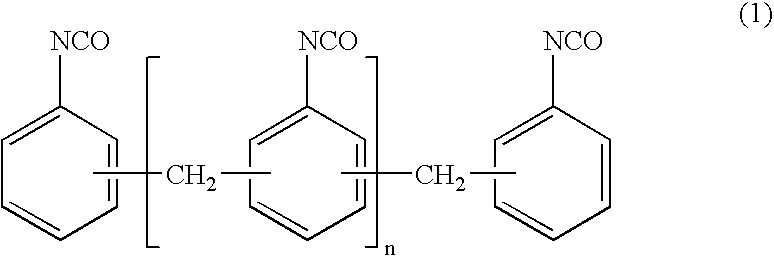

Multicolored thermally recording medium

InactiveUS20060072429A1Sharp thermal sensitive characteristicImprove heat resistanceMechanical record carriersRecord information storageBenzenePolymer

In the multi colored thermally sensitive recording medium, at least one kind of dye precursor is contained in complex fine particles which contain dye precursor and polymer of multi valence isocyanate compound, further contain 4,4′-diisocyanate-3,3′-dimethyl-1,1′biphenyl and / or polymethylene.polyphenyl.polyisocyanate.

Owner:NIPPON PAPER IND CO LTD

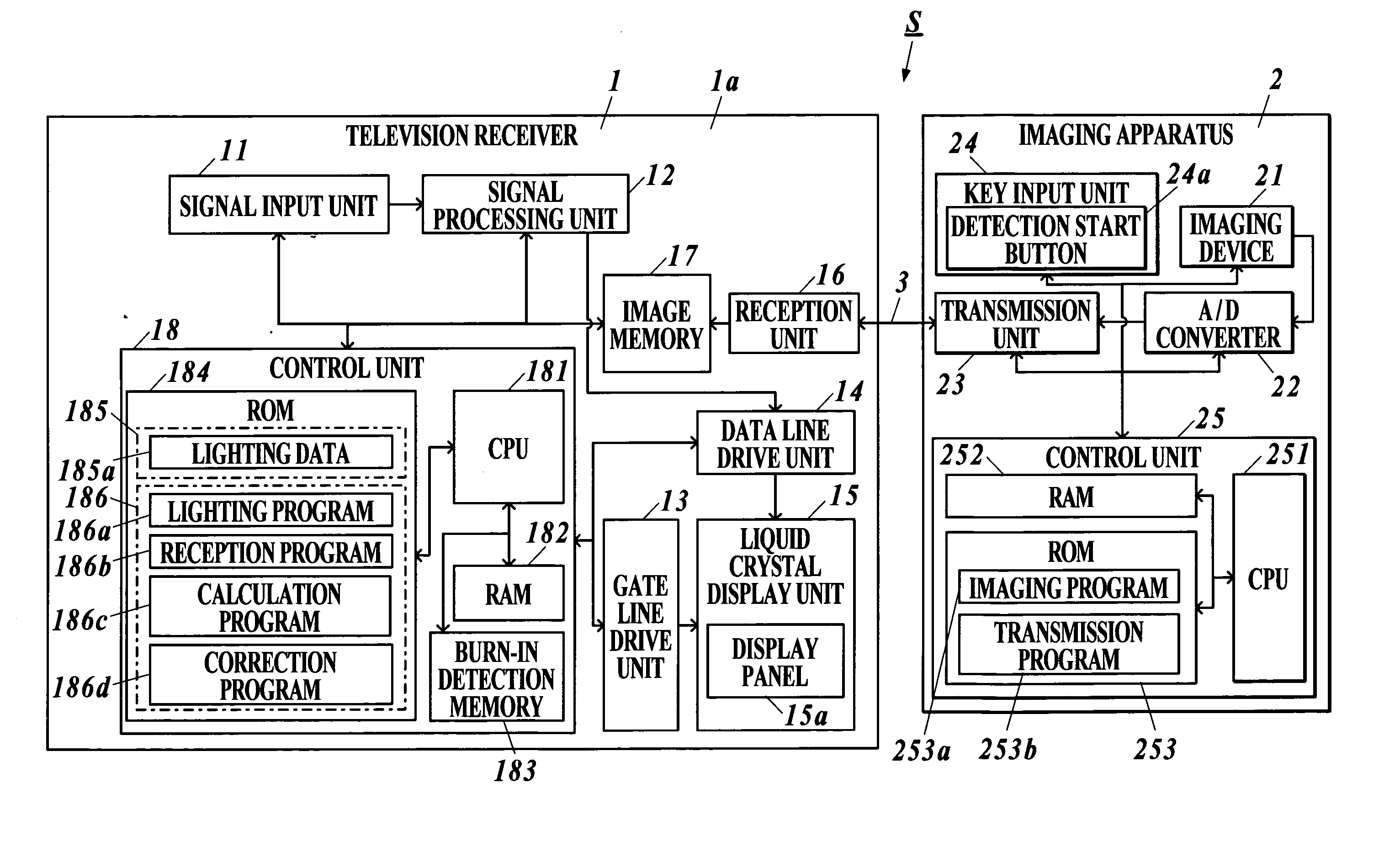

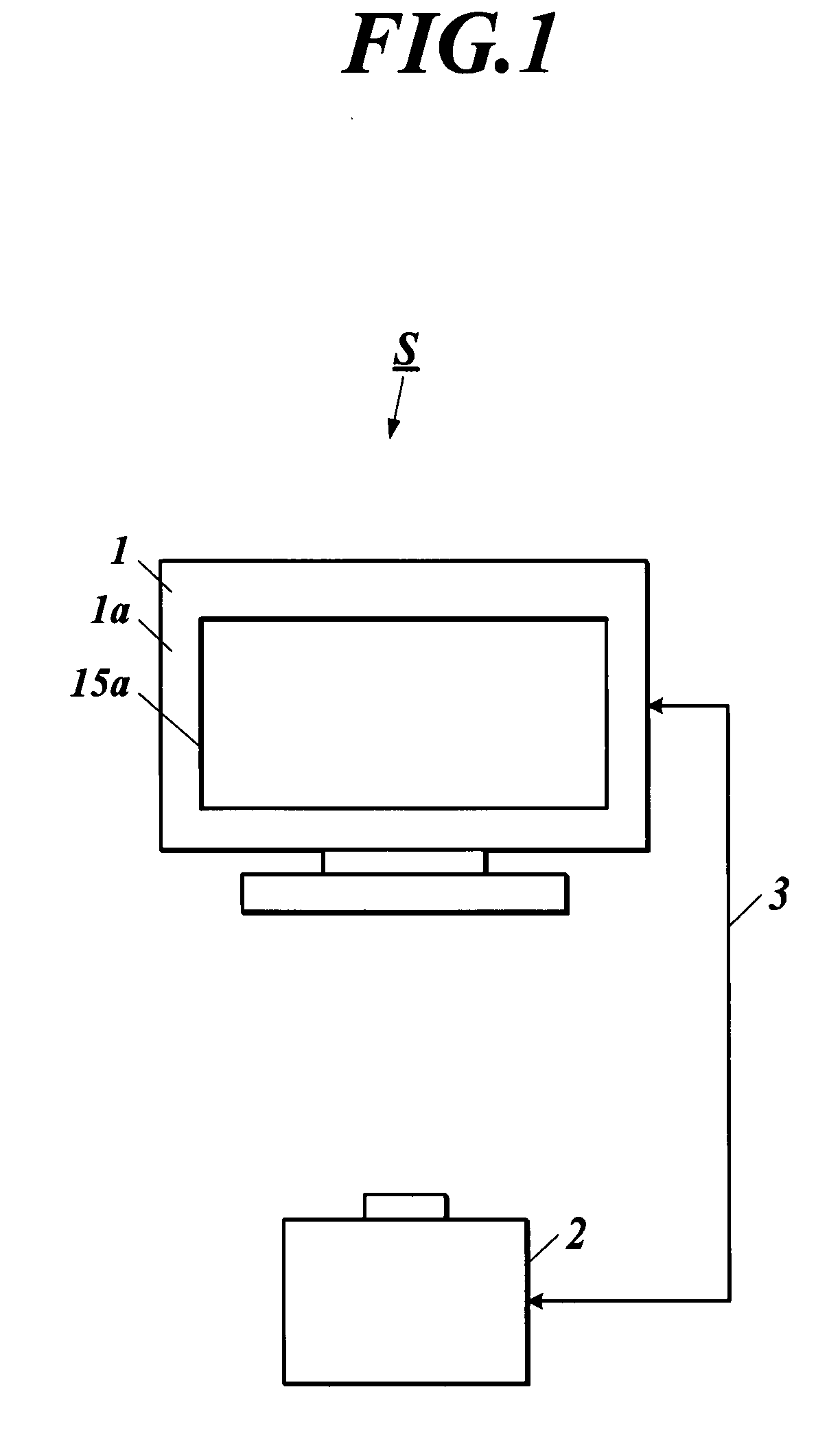

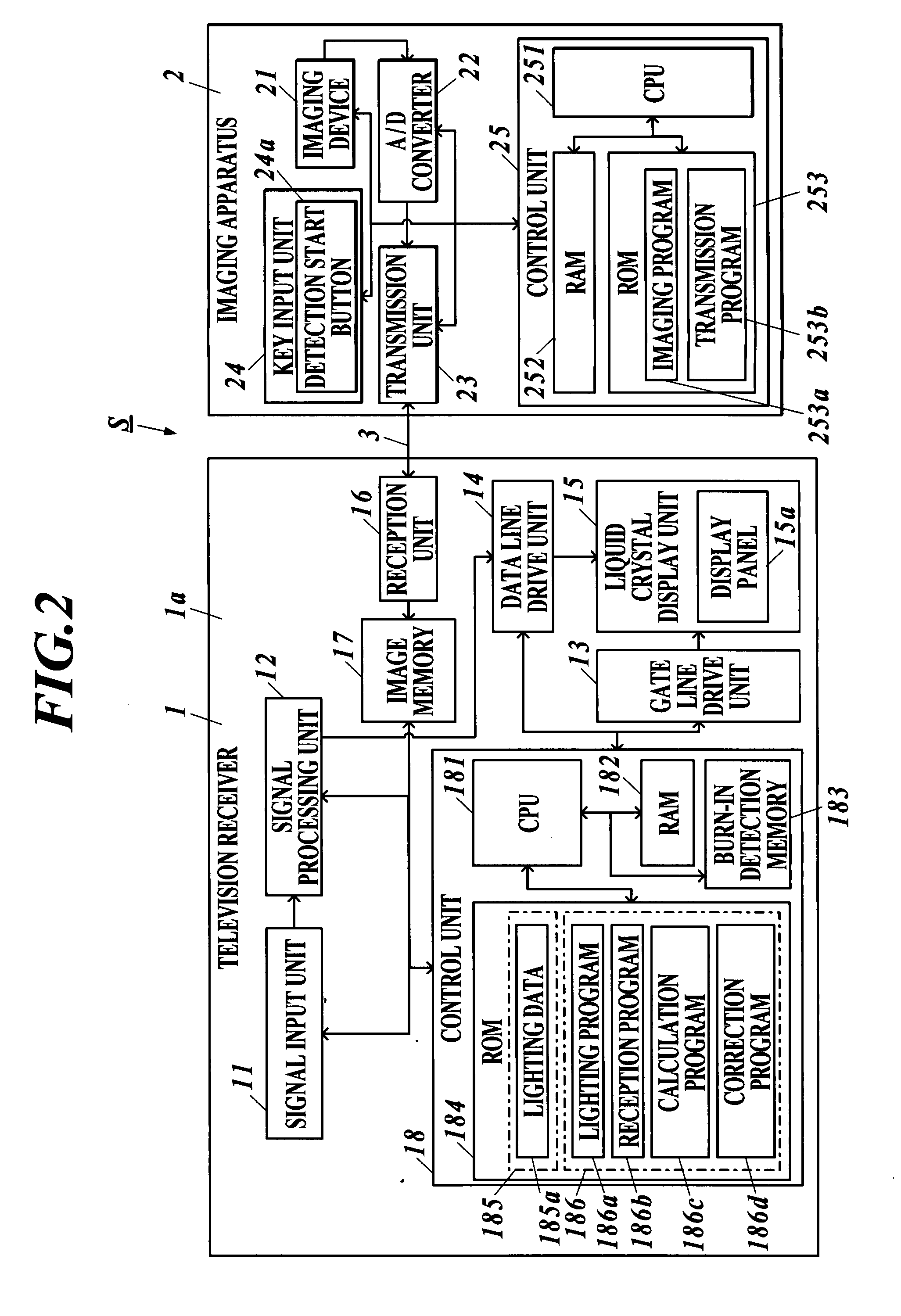

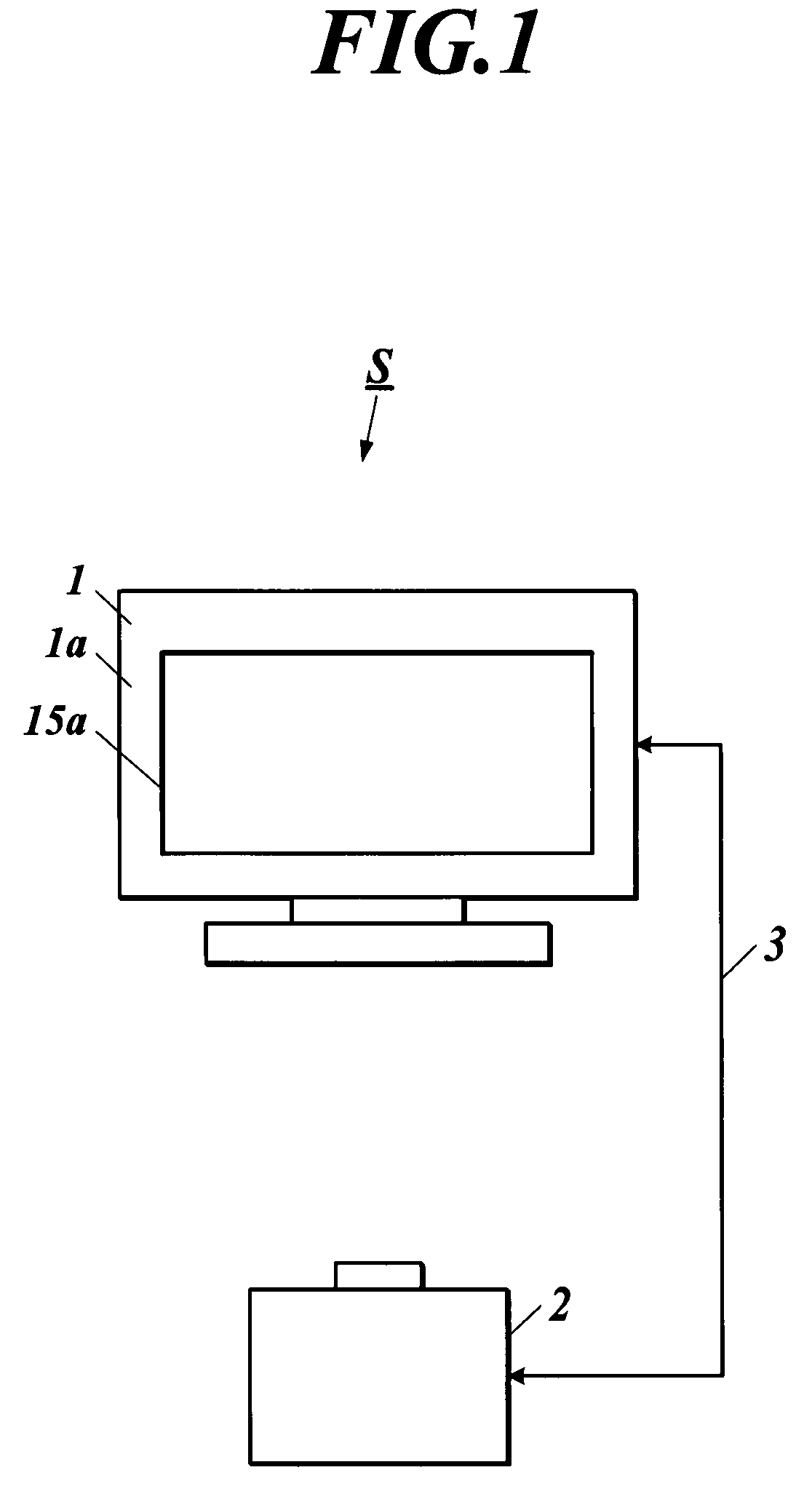

Display apparatus, burn-in correction system and burn-in correction method

InactiveUS20070222860A1Accurately correctAccurate detectionTelevision system detailsTelevision system scanning detailsCorrection methodImaging data

A burn-in correction system including a display unit equipped with a display panel displaying an image according to input image data, and an imaging unit acquiring imaged image data by imaging the display panel from a viewing side, the system correcting burn-in on the display panel. The system further includes: a lighting unit lighting each pixel constituting the display panel in order under a preset lighting condition; a calculation unit calculating a difference value between luminance of the imaged image data of each pixel lighted by the lighting unit, the imaged image data acquired by imaging each lighted pixel with the imaging unit, and luminance preset in the lighting condition; and a correction unit correcting luminance of each pixel based on the input image data, the correcting performed based on the difference value calculated by the calculation unit.

Owner:FUNAI ELECTRIC CO LTD

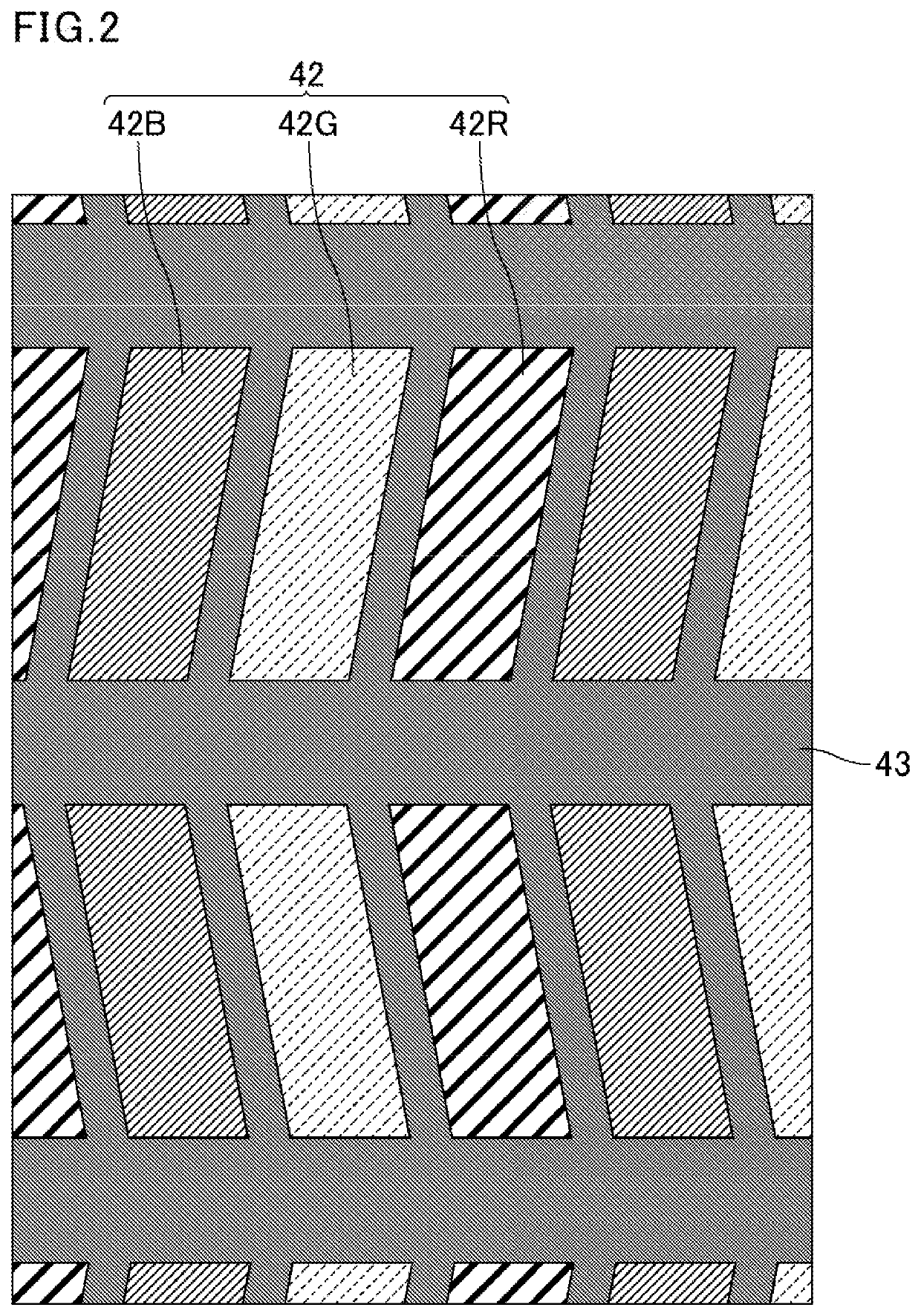

Color filter substrate and display device

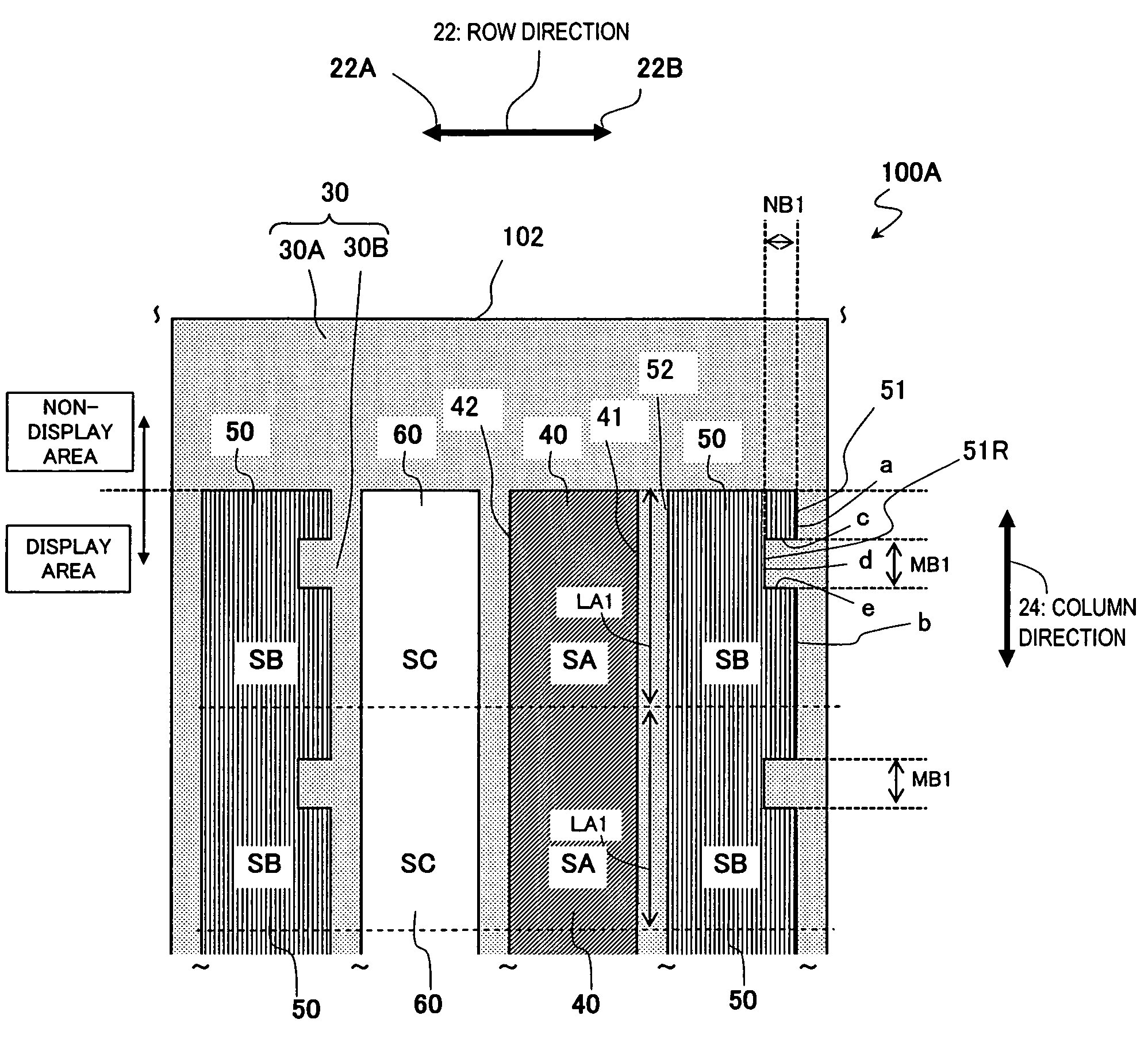

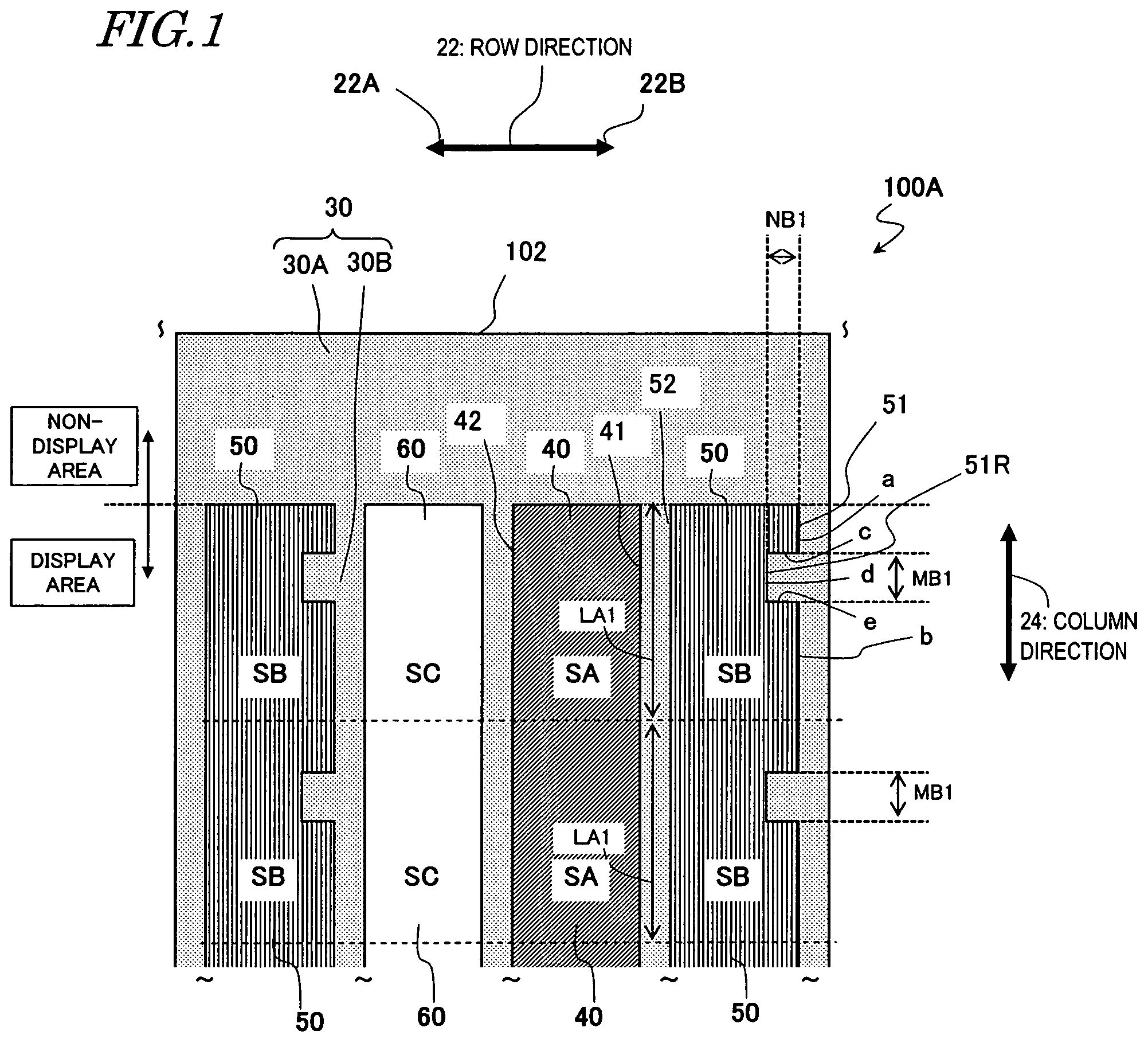

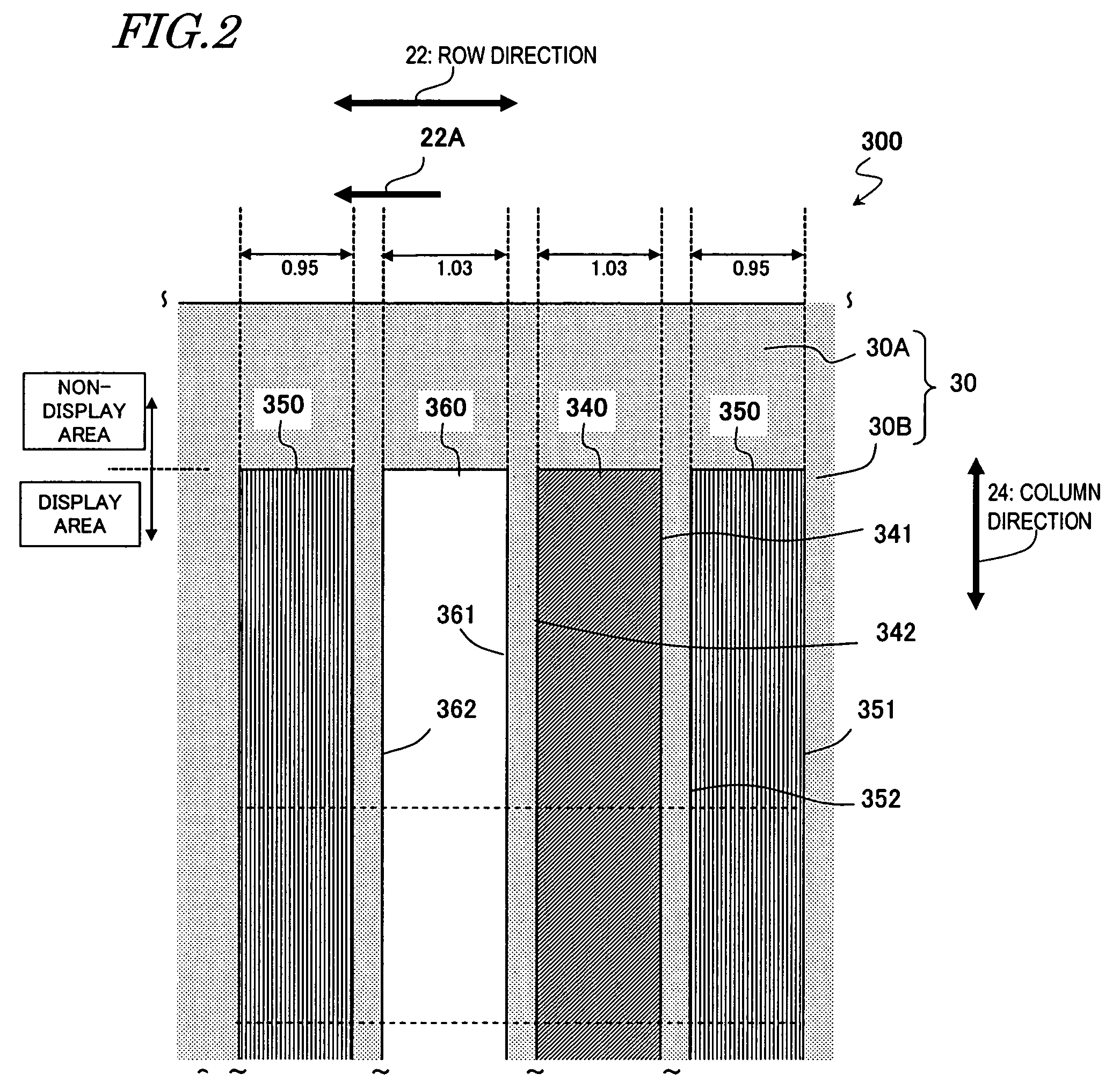

ActiveUS7015506B2Minimize unwanted deterioration in display qualityDrop in display qualityOptical filtersSolid-state devicesColor gelDisplay device

A color filter substrate for a display device includes pixels arranged in columns and rows. The substrate includes color filters, each being associated with one of the pixels and including at least two A-color filters in a first color and at least two B-color filters in a second color. Each row is associated with a group of color filters including at least one of the A-color filters and at least one of the B-color filters. Each of the A-color and B-color filters has first and second sides defining a width in the row direction. The area SA of each A-color filter is greater than the area SB of each B-color filter. The first side of each B-color filter has at least one recess, and the first side of each B-color filter has a shape that is defined by forming a recess on the first side of each A-color filter toward the second side thereof in the row direction.

Owner:SHARP KK

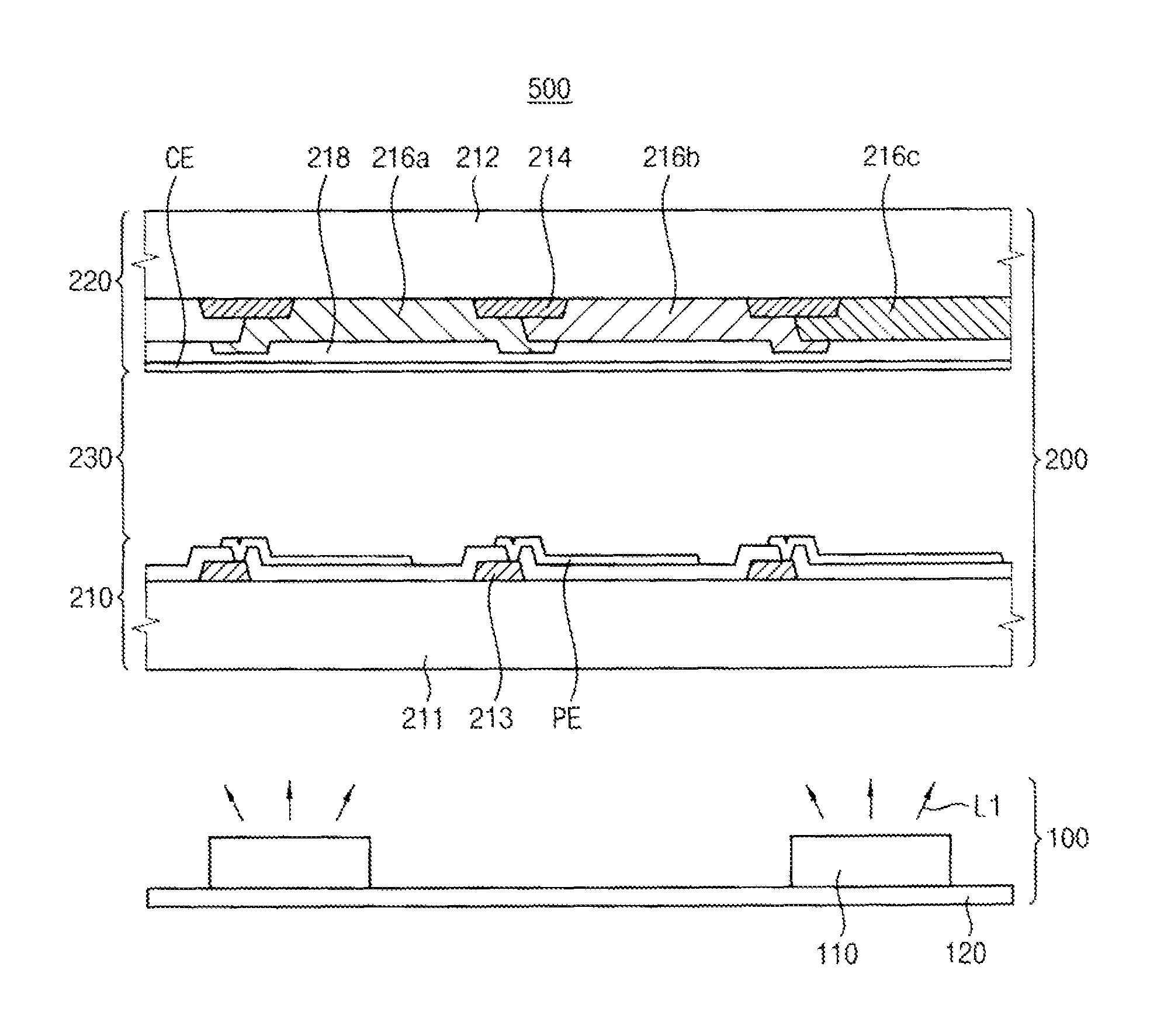

Display device

ActiveUS20110304804A1Avoid mixing colorsColor deteriorationSolid-state devicesGas discharge lamp usageWhite emissionLight source

A display device includes a light emitting unit and a display panel including a first color filter. The light emitting unit includes a light source generating a blue light, and a light-converting part converting the blue light into a white light and emitting the white light to an exterior. The first color filter, through which the white light passes, includes a first coloring agent that absorbs about 95% to about 100% of light having wavelength of about 420 nm to about 470 nm in the white light. Thus, a color reproducibility of the display device may be improved.

Owner:SAMSUNG DISPLAY CO LTD

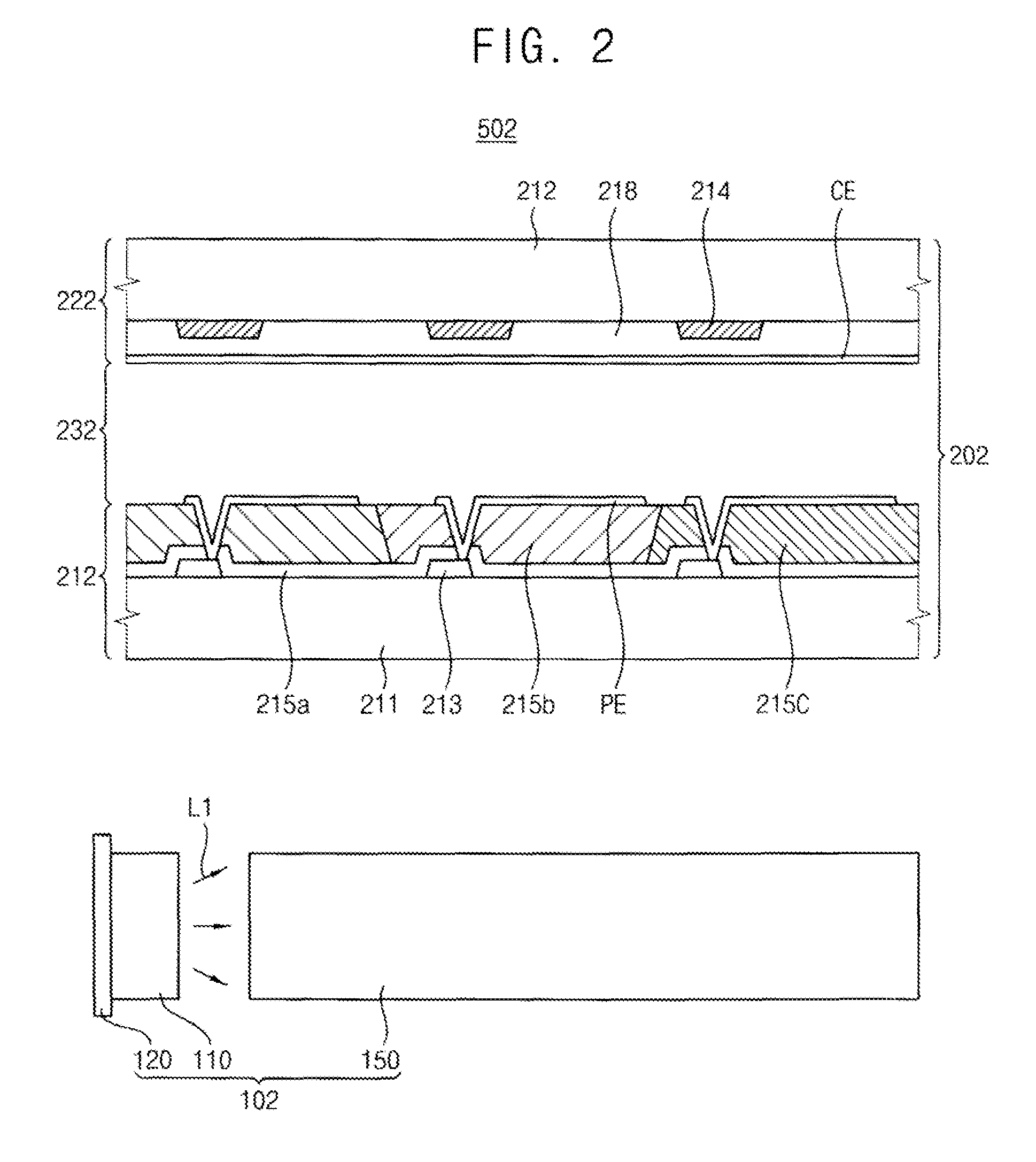

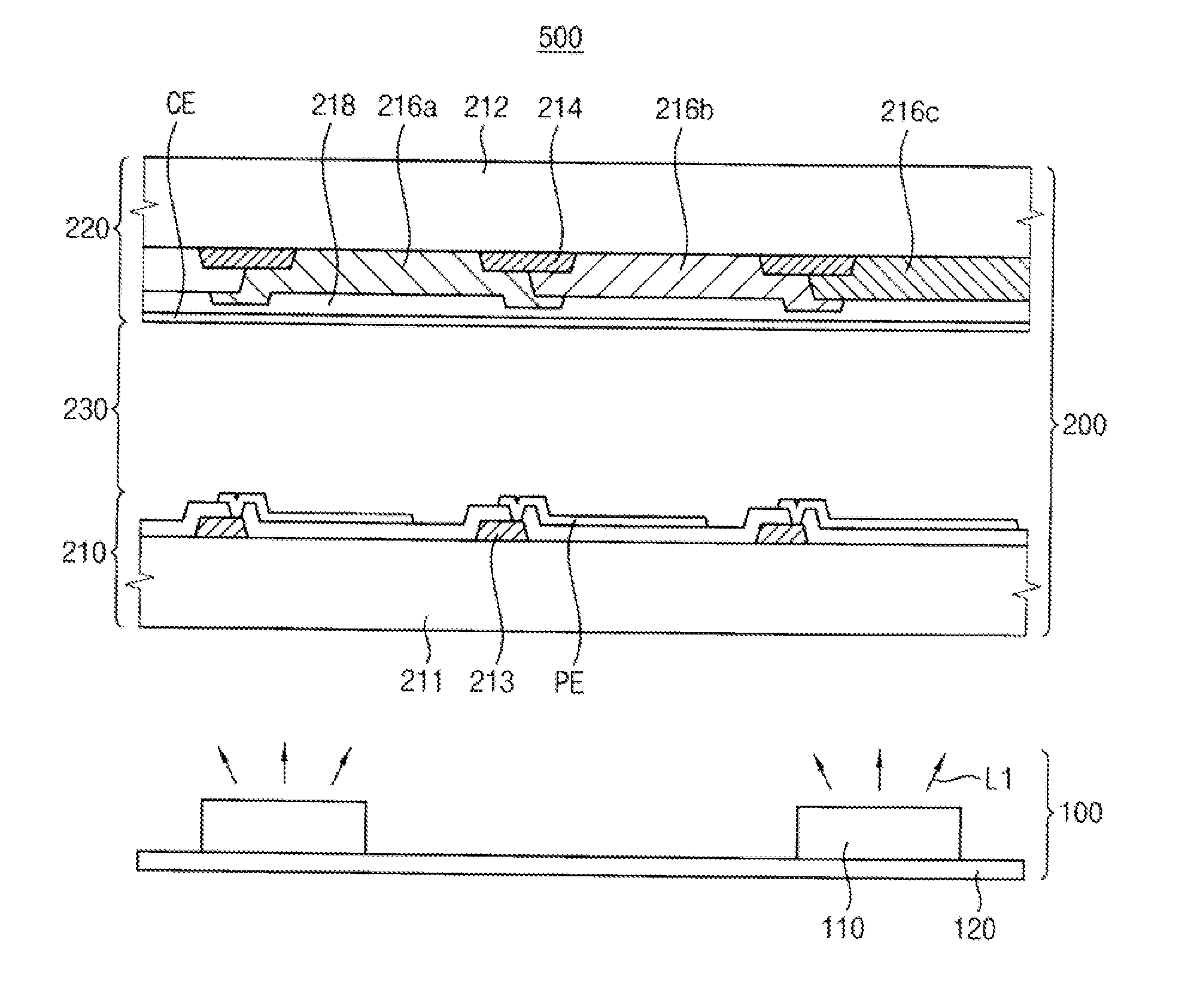

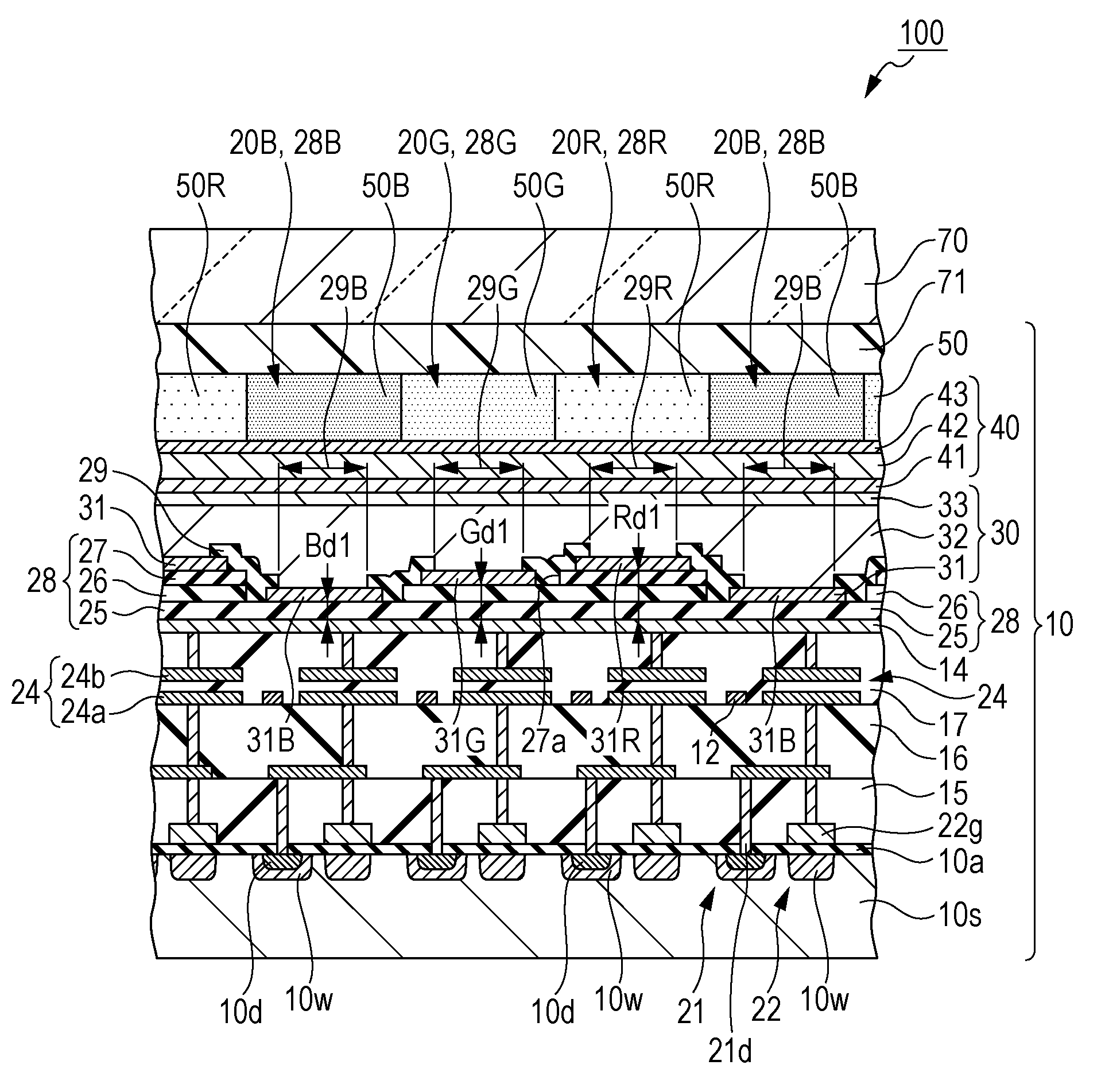

Light emitting device, method of manufacturing light emitting device, and electronic equipment

ActiveUS9142599B2High color purityHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerLight reflection

A light emitting device includes a transistor, a light reflection layer, a first insulation layer that includes a first layer thickness part, a second layer thickness part, and a third layer thickness part, a pixel electrode that is provided on the first insulation layer, a second insulation layer that covers a peripheral section of the pixel electrode, a light emission functional layer, a facing electrode, and a conductive layer that is provided on the first layer thickness part. The pixel electrode includes a first pixel electrode which is provided in the first layer thickness part, a second pixel electrode which is provided in the second layer thickness part, and a third pixel electrode which is provided in the third layer thickness part. The first pixel electrode, the second pixel electrode, and the third pixel electrode are connected to the transistor through the conductive layer.

Owner:SEIKO EPSON CORP

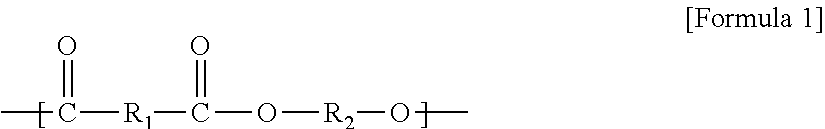

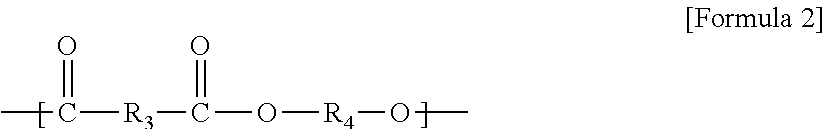

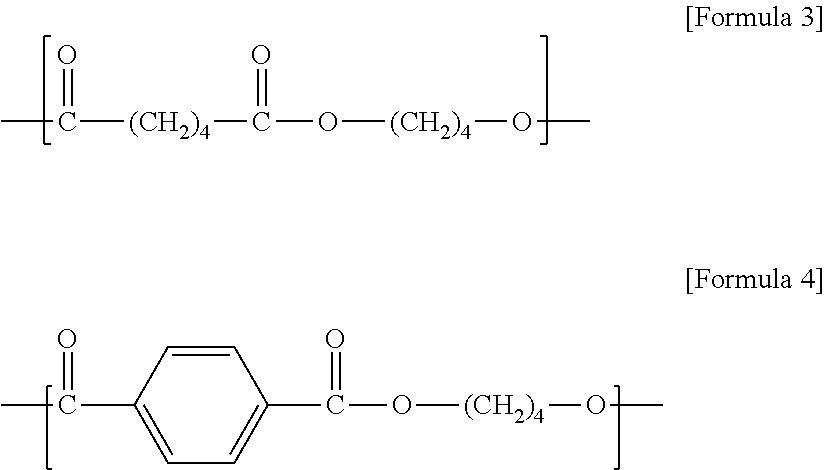

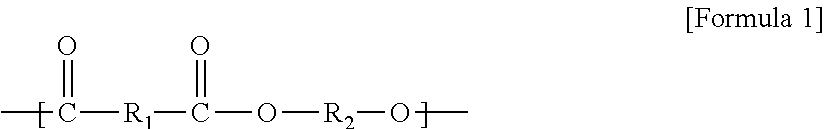

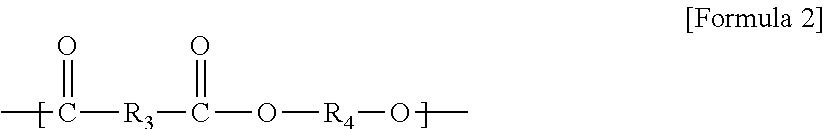

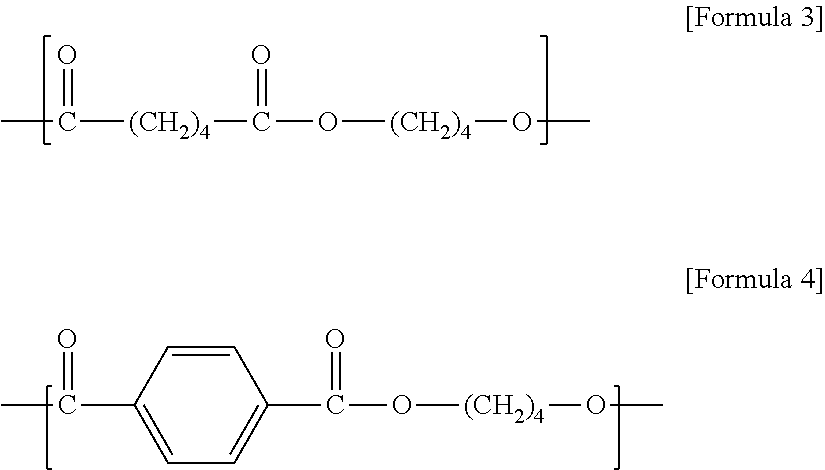

Method for continuous production of biodegradable aliphatic/aromatic polyester copolymer

ActiveUS20150315335A1Good formabilityImproved in processibilityPolyesterManufacturing cost reduction

A continuous preparation method of a biodegradable aliphatic / aromatic polyester copolymer includes: performing a first esterification reaction of an aliphatic dihydroxy compound with an aliphatic dicarboxylic acid at a temperature of 185° C. or less; continuously performing a second esterification reaction of a reaction product from the first esterification reaction; continuously performing a first polycondensation reaction of a reaction product from the second esterification reaction to obtain a prepolymer having a weight average molecular weight of about 6,900 to about 14,000; continuously performing a second polycondensation reaction of the prepolymer to obtain a second polycondensation reaction product; and continuously performing a third polycondensation reaction of the second polycondensation reaction product to prepare the biodegradable aliphatic / aromatic polyester copolymer, wherein the performing of the first esterification reaction or the continuously performing of the second esterification reaction includes adding an aromatic carboxylic acid. The biodegradable aliphatic / aromatic polyester copolymer prepared by the continuous method may be improved in processibility, film formability, tensile / tearing strength, and blending ability with another polymer resin. Use of a less amount of the aliphatic dihydroxy compound as a starting material may reduce manufacturing costs.

Owner:ANKOR BIOPLASTICS CO LTD

Color keeping slip-resisting solution

InactiveUS20060117997A1Increase in friction coefficientIncrease coefficient of frictionOther chemical processesBathsFrictional coefficientColor changes

An aqueous solution for treatment of colored concrete, glazed enamel or porcelain surfaces to increase the coefficient of friction of that surface, whether dry or wet, to about 0.8 without deteriorating the color of the surface comprises about 1.5 to 1.9 wt % of ammonium bifluoride, 1.5 to 3.0 wt % of tri-ethylamine and a wetting agent in water. The degree of change of the color of the surface, treated seven minutes with the solution of the current application, measured by a color meter shows only 0.56 while the result of a commercial solution to increase the frictional coefficient shows 2.22. This means that the color change by the solution of the current application is undetectable by human eyes. Meanwhile, the change by the commercial solution product is detectable.

Owner:KIM E E +2

Display apparatus, burn-in correction system and burn-in correction method

InactiveUS7719596B2Accurate detectionAccurate correctionTelevision system detailsTelevision system scanning detailsData displayPixel based

A burn-in correction system including a display unit equipped with a display panel displaying an image according to input image data, and an imaging unit acquiring imaged image data by imaging the display panel from a viewing side, the system correcting burn-in on the display panel. The system further includes: a lighting unit lighting each pixel constituting the display panel in order under a preset lighting condition; a calculation unit calculating a difference value between luminance of the imaged image data of each pixel lighted by the lighting unit, the imaged image data acquired by imaging each lighted pixel with the imaging unit, and luminance preset in the lighting condition; and a correction unit correcting luminance of each pixel based on the input image data, the correcting performed based on the difference value calculated by the calculation unit.

Owner:FUNAI ELECTRIC CO LTD

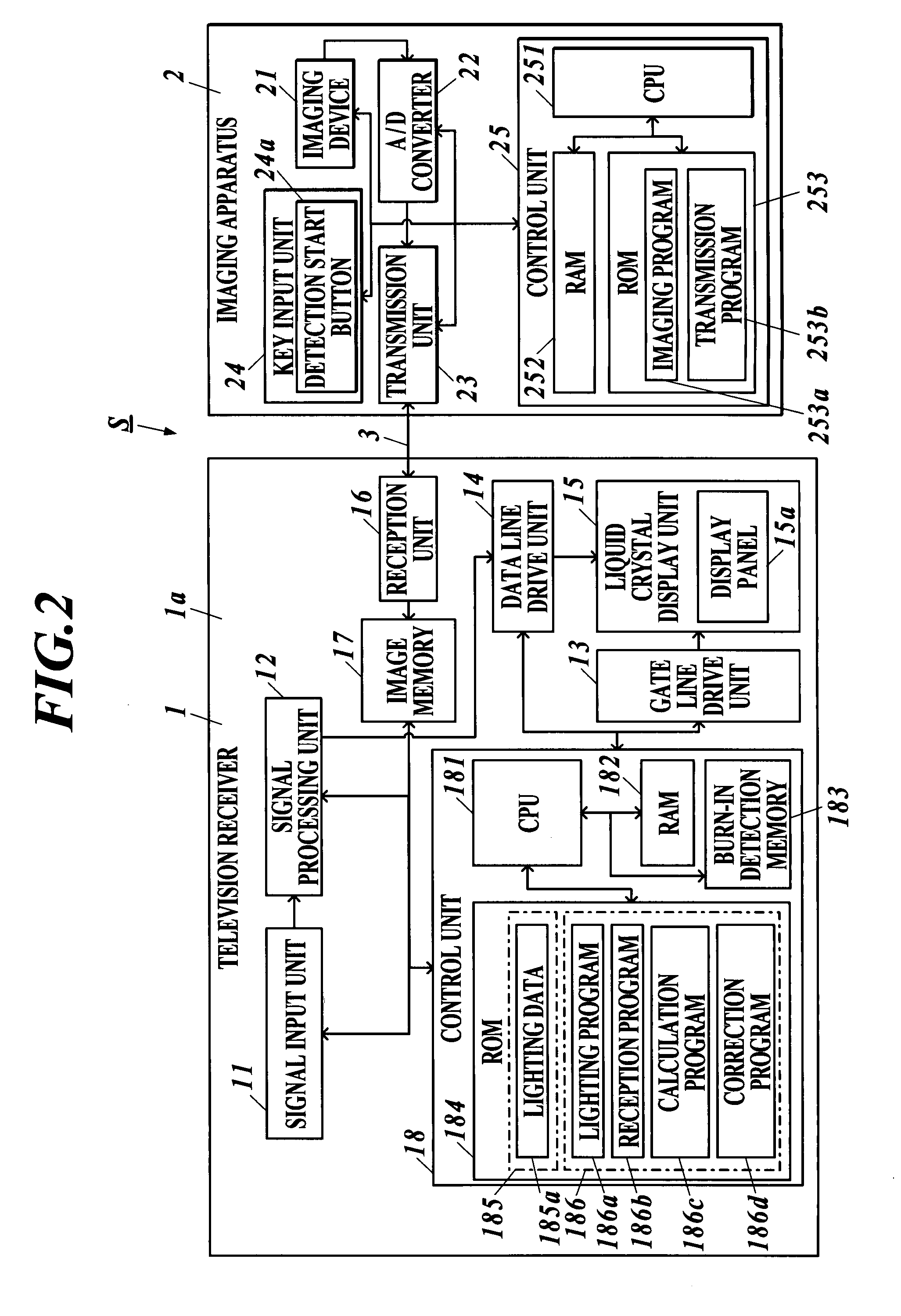

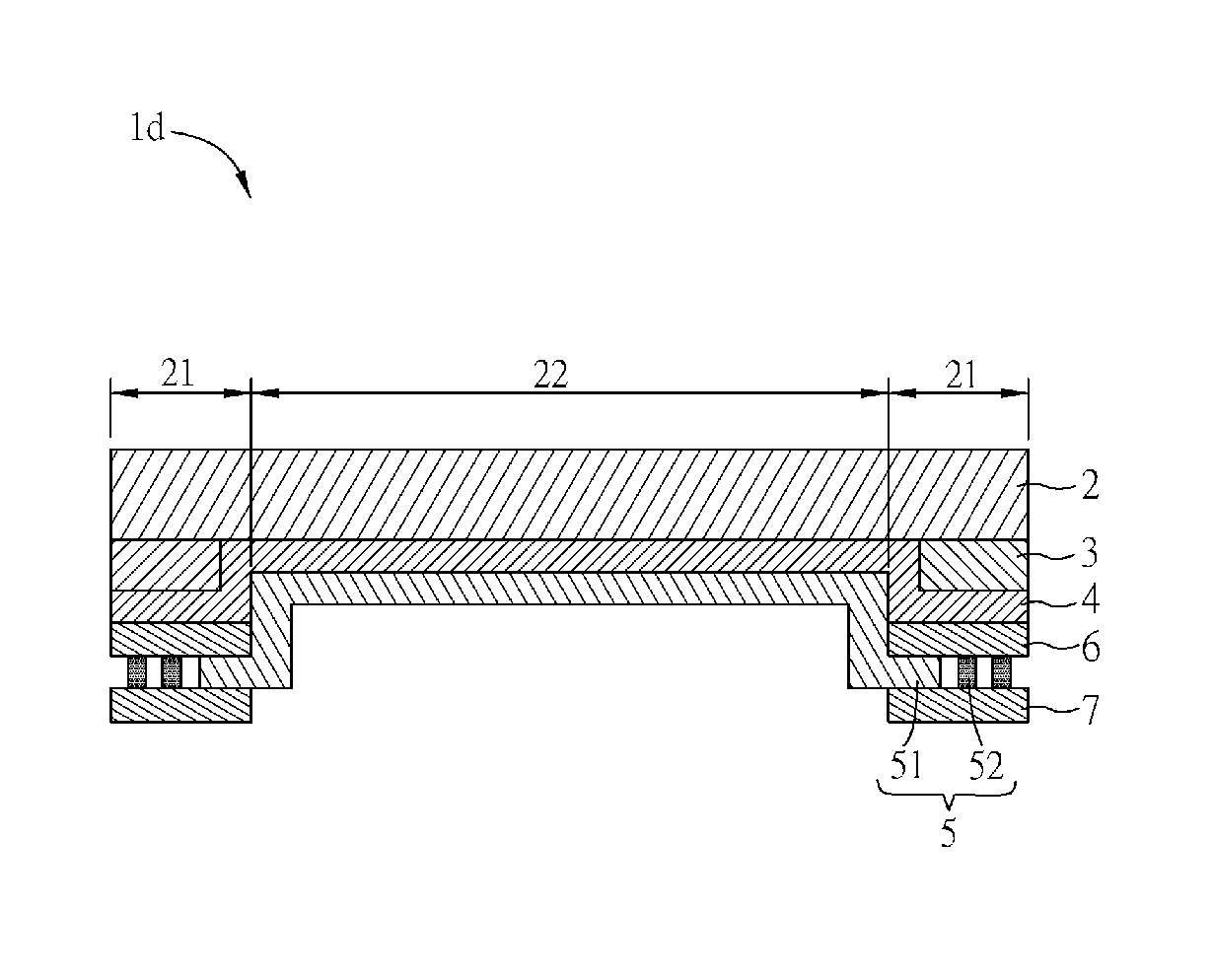

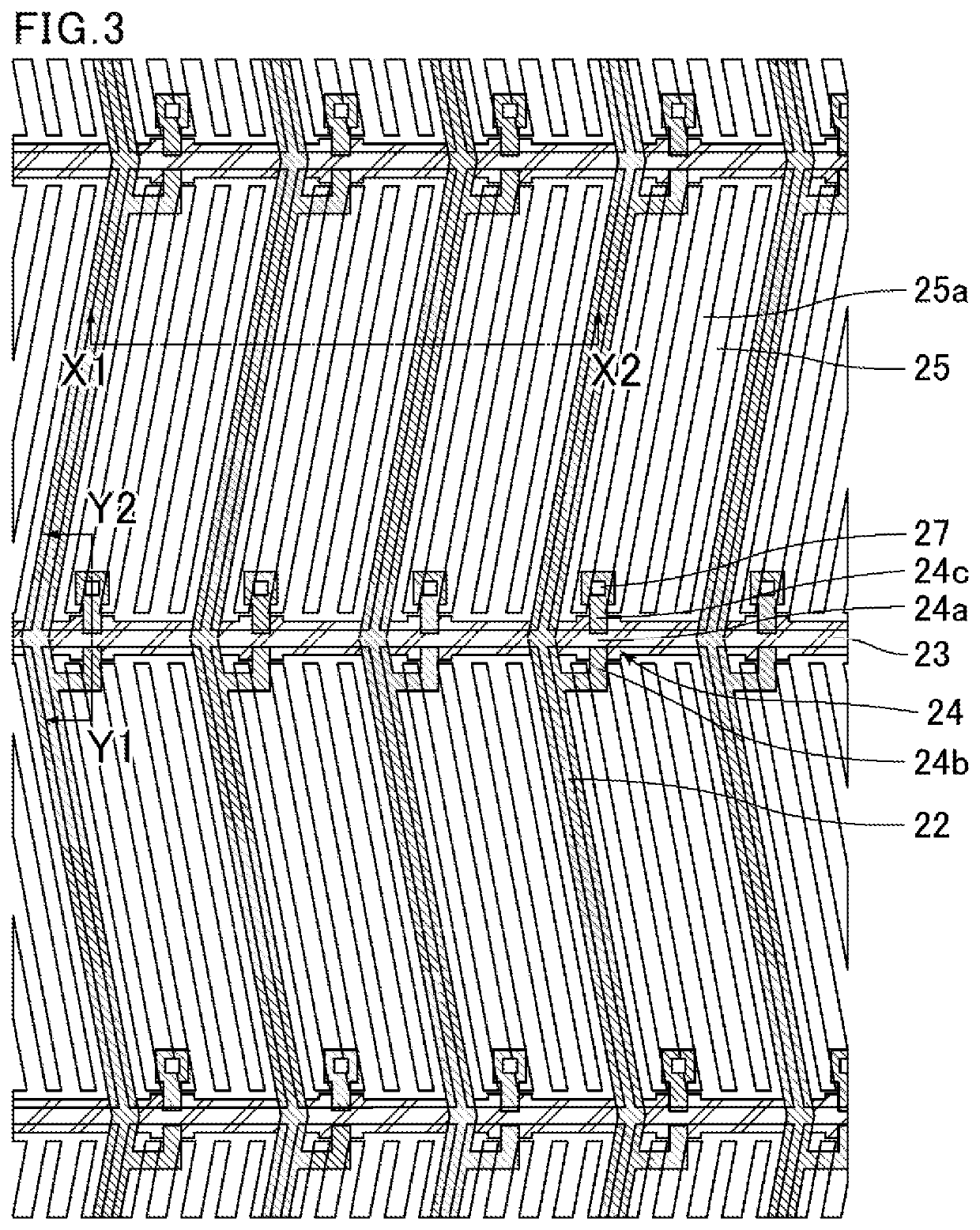

Liquid crystal display device

ActiveUS20200159066A1Reducing of outside lightImprove visibilityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes a liquid crystal panel and a circularly polarizing plate disposed on a viewing side of the liquid crystal panel. The circularly polarizing plate sequentially includes, from a viewing side, a linearly polarizing plate and an out-cell retarder. The liquid crystal panel includes a thin-film transistor substrate, a color filter substrate facing the thin-film transistor substrate and including black matrix, a horizontal alignment liquid crystal layer disposed between the thin-film transistor substrate and the color filter substrate, and an in-cell retarder disposed in one substrate disposed on the viewing side selected from the thin-film transistor substrate and the color filter substrate. The in-cell retarder is disposed outside a region between the black matrix and the horizontal alignment liquid crystal layer.

Owner:SHARP KK

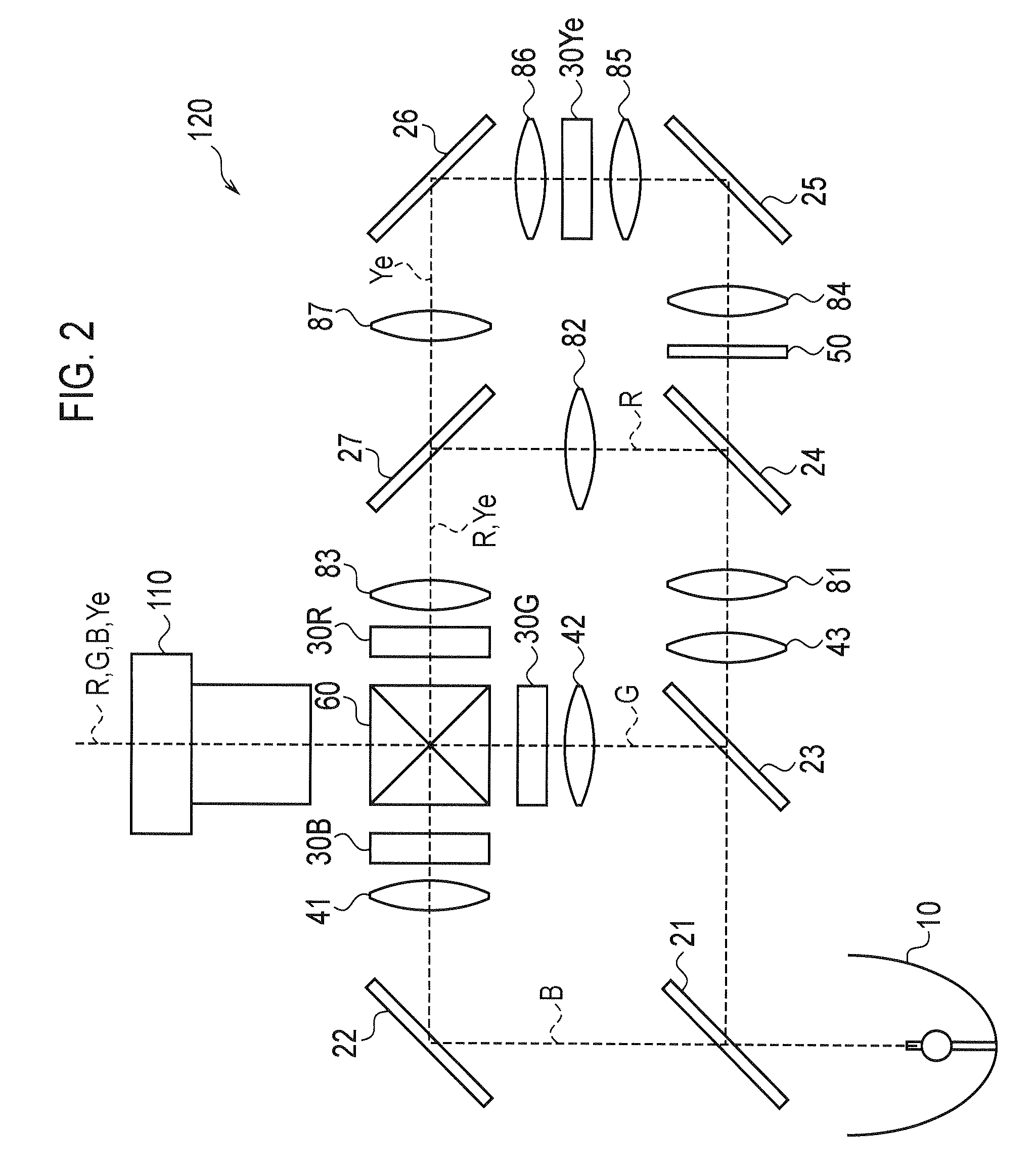

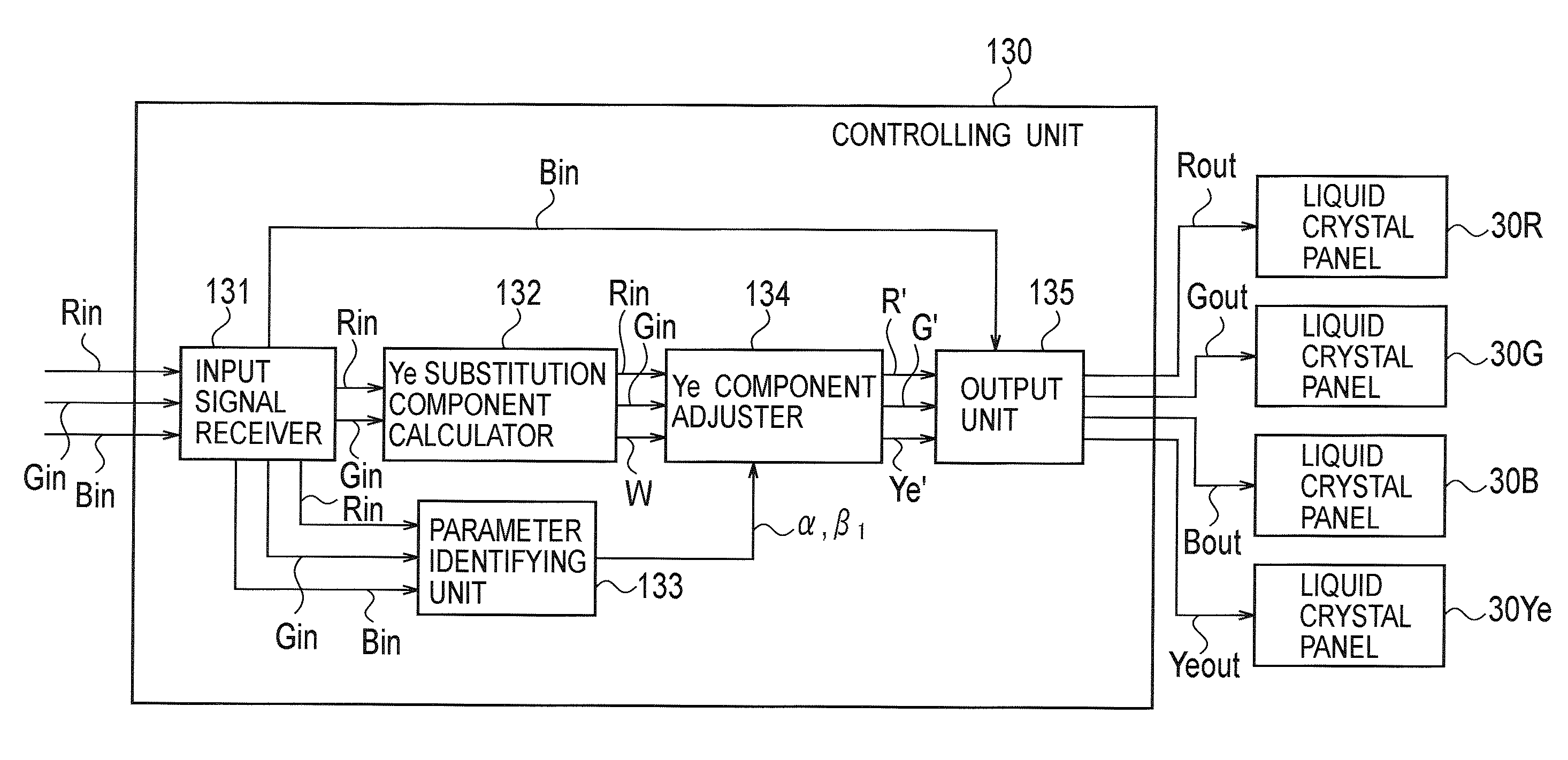

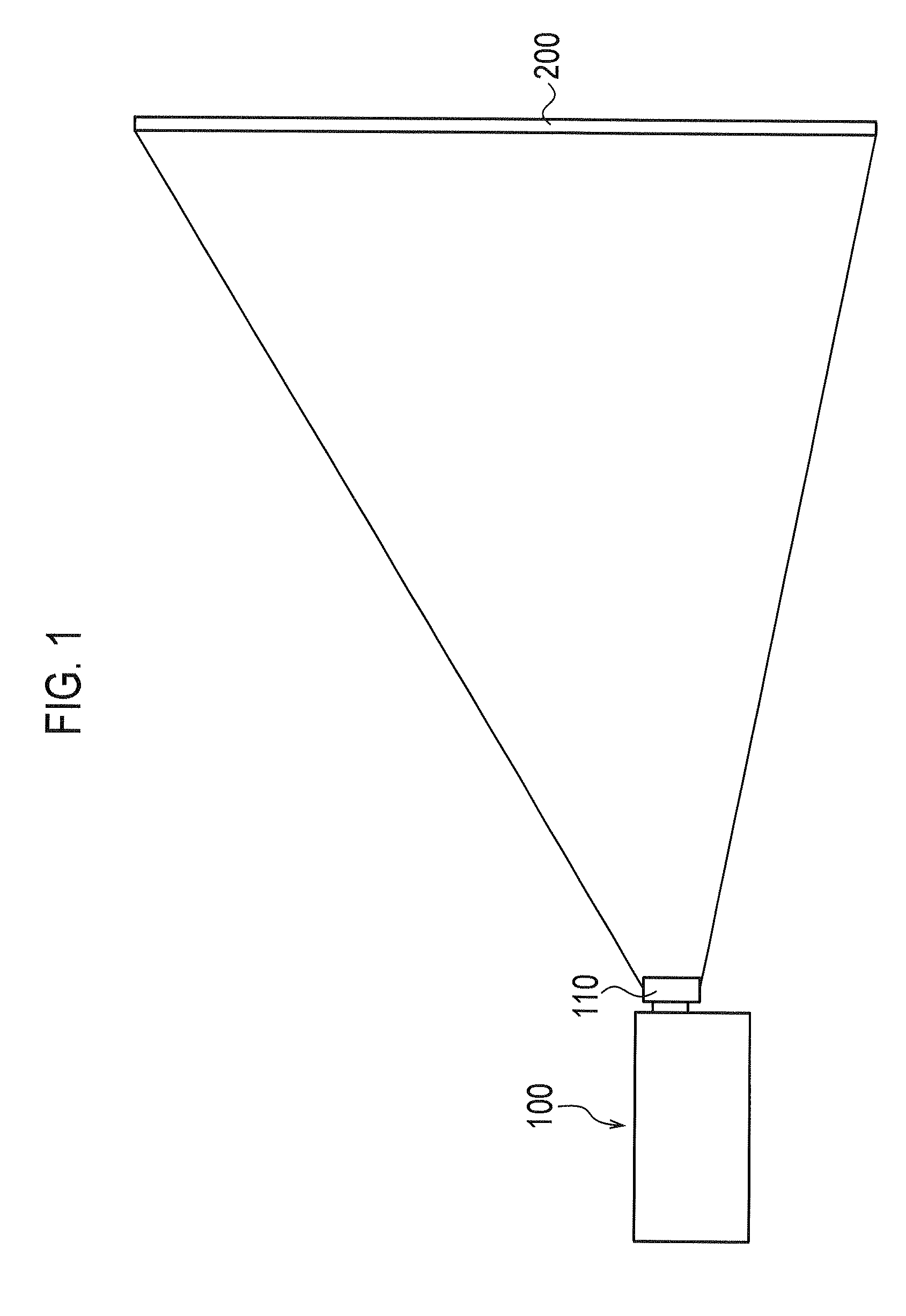

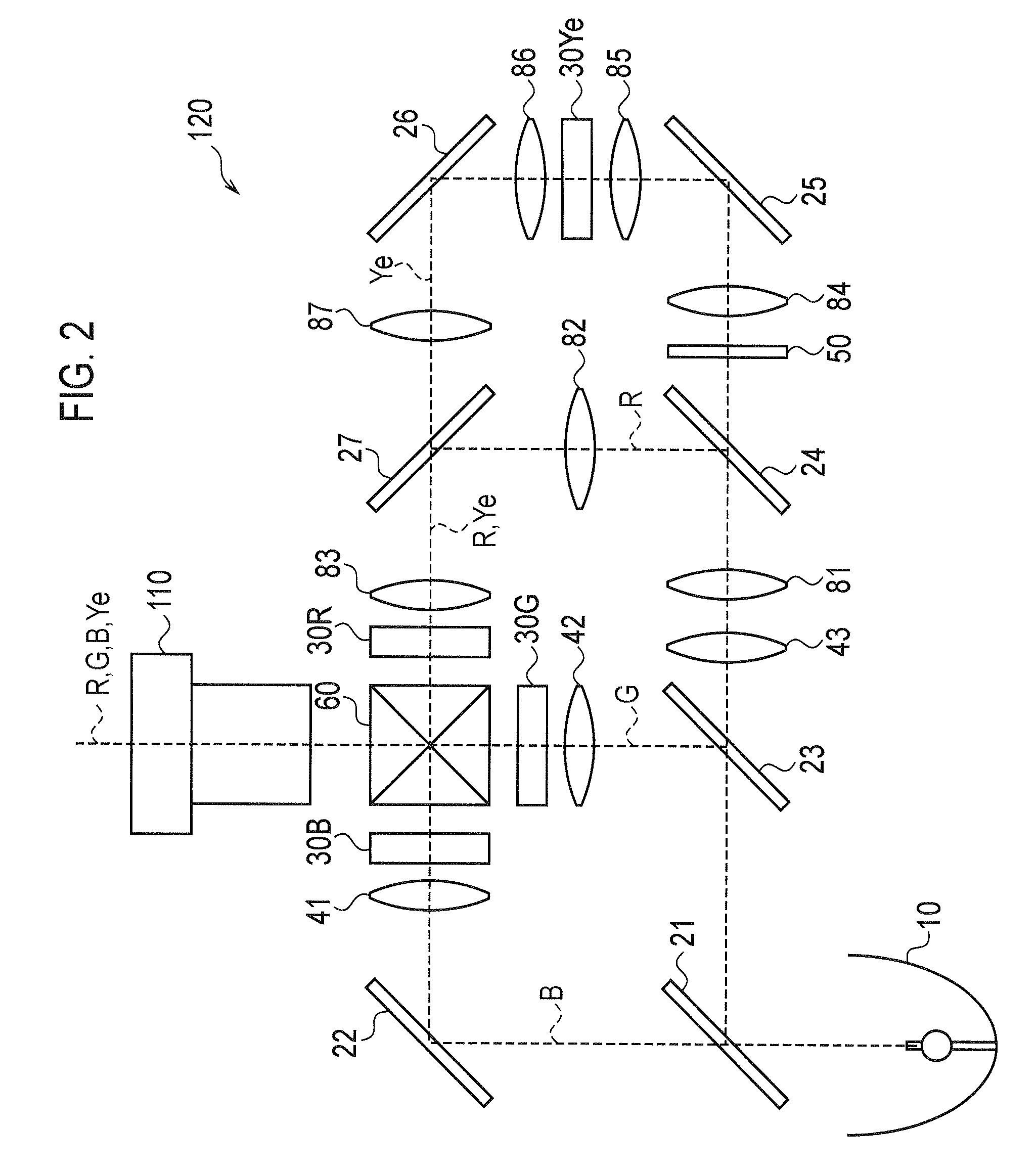

Image Signal Converting Apparatus And Image Display Apparatus

ActiveUS20090096806A1Increase brightnessColor deteriorationCathode-ray tube indicatorsColor television detailsSuperimpositionHue

The image signal converting apparatus is used in a lighting unit. The lighting unit includes a liquid crystal panel modulating a red component light according to a red image signal, a liquid crystal panel modulating a green component light according to a green image signal, and a liquid crystal panel modulating a blue component light according to a blue image signal. Yellow component light is superimposed on any of the red component light, the green component light and the blue component light. The image signal converting apparatus includes a controlling unit which controls a superimposition amount of yellow component light based on a specific image signal among a red image signal, a green image signal, and a blue image signal. A color corresponding to the specific image signal has a hue adjacent to a hue corresponding to the yellow component light. The controlling unit controls a reduction amount of the specific image signal based on the superimposition amount.

Owner:SANYO ELECTRIC CO LTD

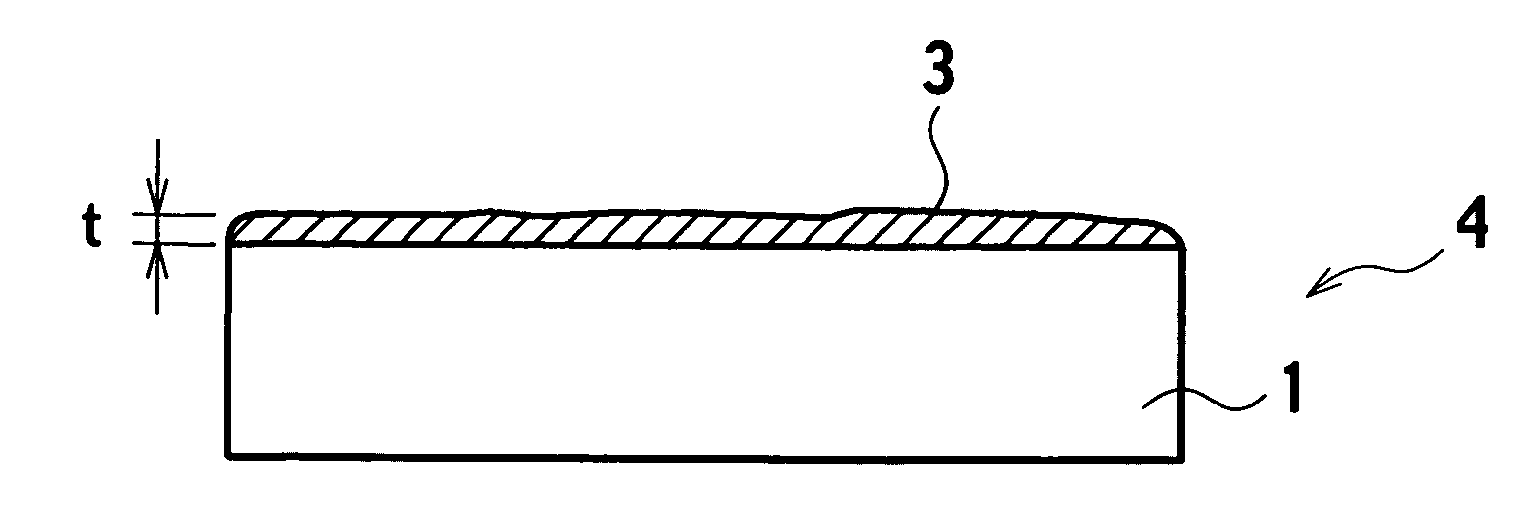

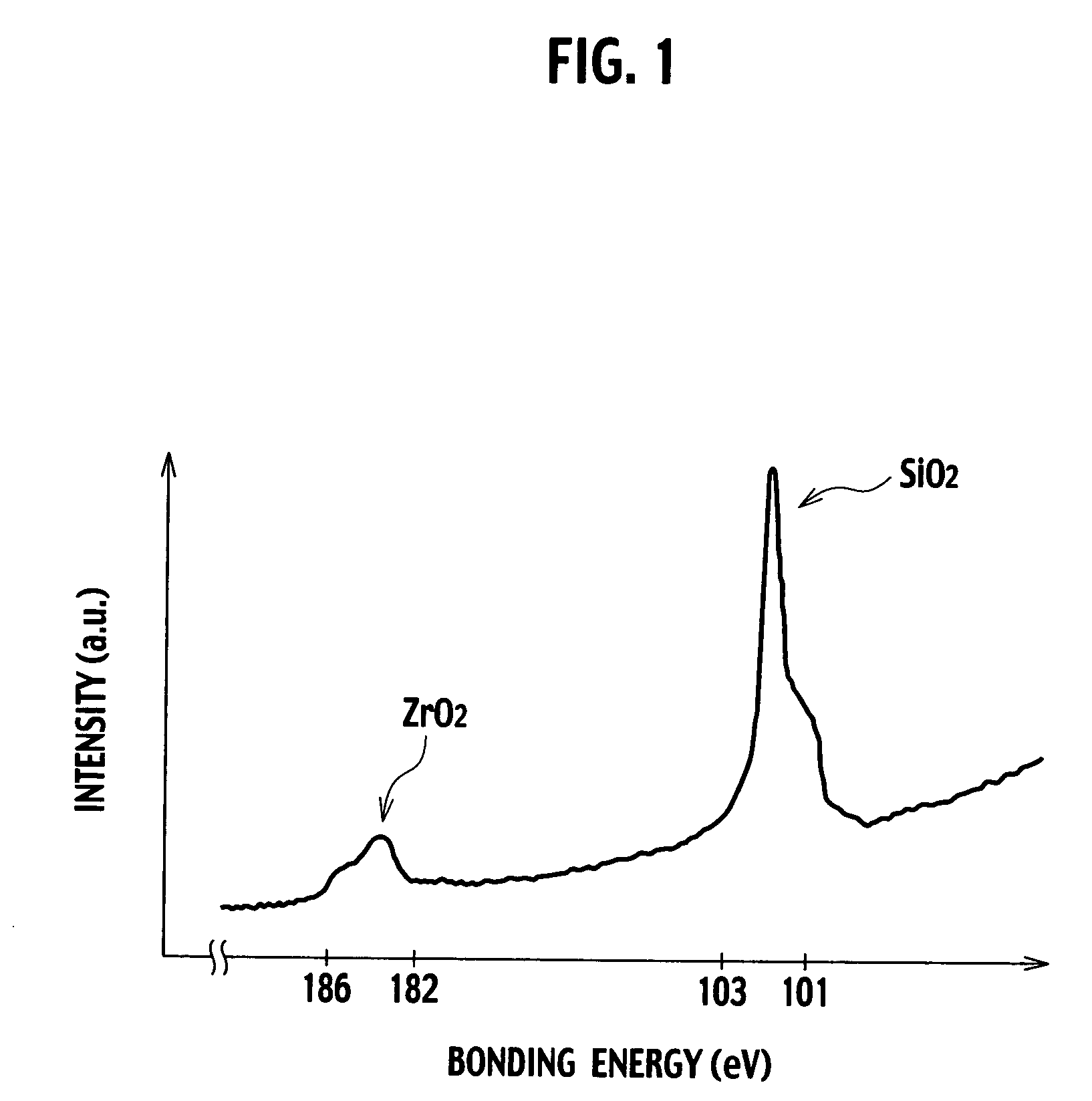

Method Of Forming Film On Zirconium-Based Metallic Glass Surface, And Zirconium-Based Metallic Glass Component

InactiveUS20080014447A1Improve corrosion resistanceColor deteriorationAutomatic/semiautomatic turning machinesMetallic material coating processesAlcoholOxygen

A method of forming a film on a zirconium-based metallic glass surface, including the steps of forming a film including oxygen, silicon and zirconium, which has a post-drying thickness of 10 μm or less, by drying an alcohol solution containing silicon dioxide in a content of 3% or more and less than 25%, after the alcohol solution is applied to a surface of a zirconium-based metallic glass.

Owner:NGK INSULATORS LTD +1

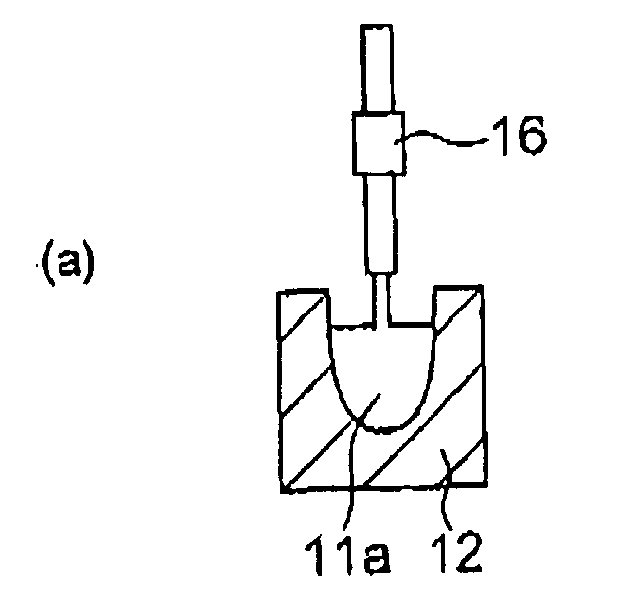

Molding material comprising polysilsesquioxane compound, sealing material, and sealed optical element

ActiveUS8481669B2Improve heat resistanceColor deteriorationLayered productsSemiconductor/solid-state device manufacturingHeat resistanceShell molding

A molding material which can produce cured products with long-lasting excellent transparency and heat resistance, a sealing material in which the molding material is used, and a sealed optical element are provided. The molding material comprises a polysilsesquioxane compound with a ladder structure having a repeating unit of the following formula (I) in the molecule as a major component.wherein R1 represents a group shown by the formula AO—(CH2)r— (wherein A indicates a protective group for a hydroxyl group and r is an integer of 1 to 10), R2 represents a substituted or unsubstituted phenyl group, a substituted or unsubstituted (excluding substitution with OA in the above formula) alkyl group having 1 to 20 carbon atoms, or an alkenyl group having 2 to 20 carbon atoms, and l, m, and n individually represent 0 or an arbitrary integer, provided that l and n are not 0 at the same time.

Owner:LINTEC CORP

Process for production of bleached pulp

InactiveUS8900408B2Reduce the amount of solutionColor deteriorationPulp bleachingPulping with halogen compoundsCelluloseChlorine dioxide

Owner:MITSUBISHI GAS CHEM CO INC

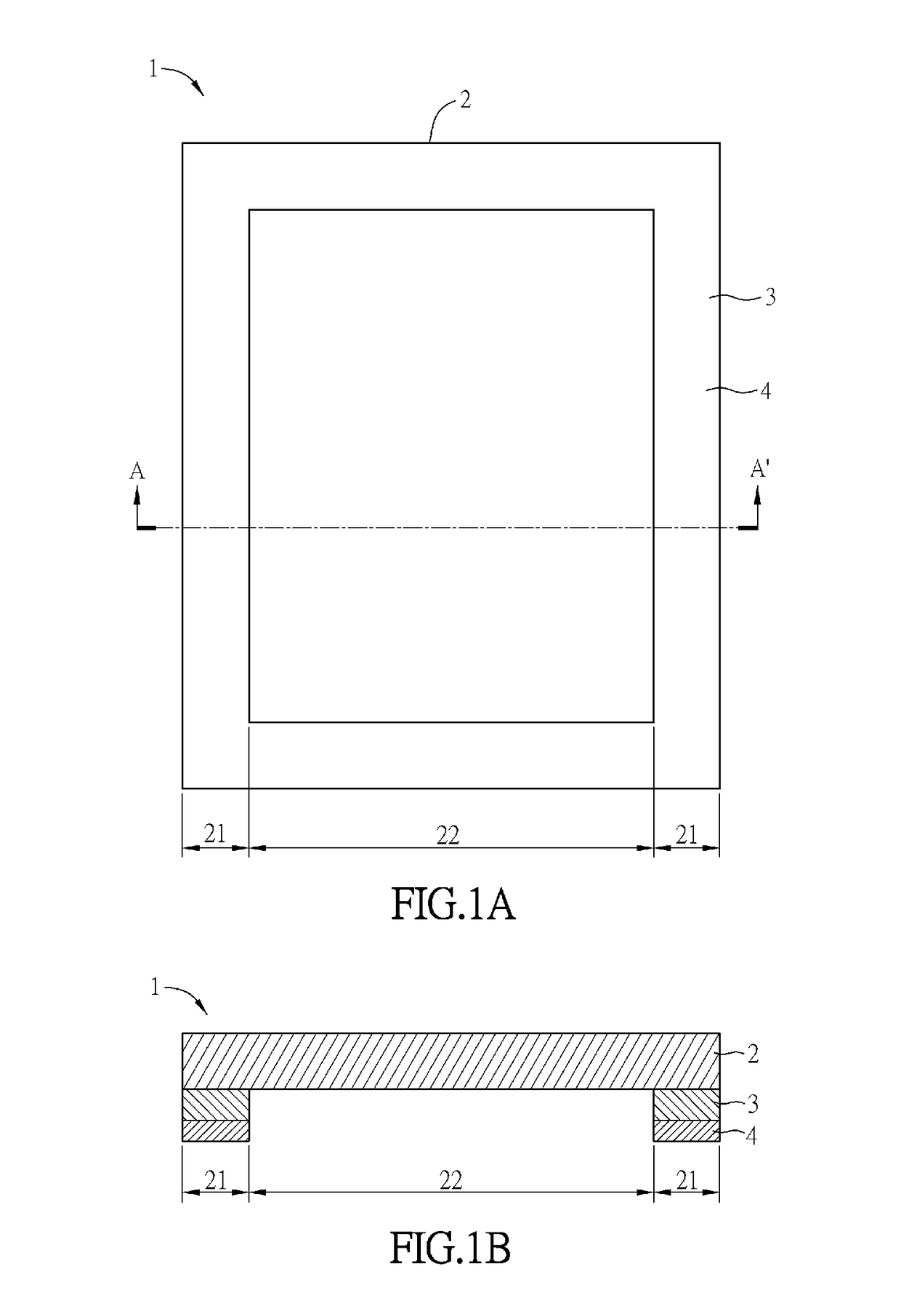

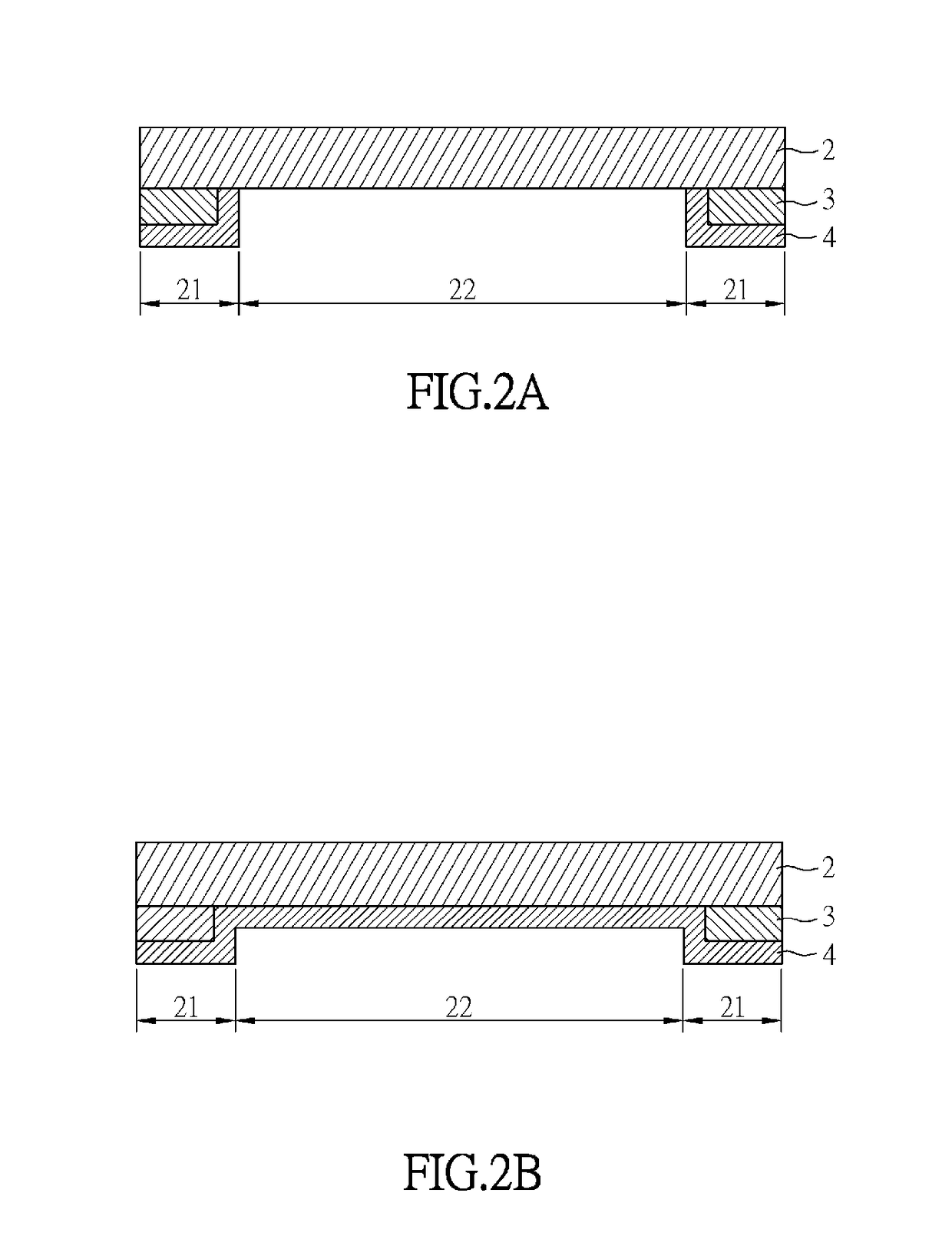

Touch panel

ActiveUS10001849B2Change colorHigh degreeInput/output processes for data processingEngineeringTouch panel

A touch panel comprises a substrate, a first mask structure and a dense structure. The first mask structure is disposed on a surface of the substrate and divides the substrate into a mask area and a visible area disposed adjacent to the mask area. The first mask structure is disposed in the mask area. The dense structure at least masks a surface of the first mask structure farther from the substrate.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Method for continuous production of biodegradable aliphatic/aromatic polyester copolymer

A continuous preparation method of a biodegradable aliphatic / aromatic polyester copolymer includes: performing a first esterification reaction of an aliphatic dihydroxy compound with an aliphatic dicarboxylic acid at a temperature of 185° C. or less; continuously performing a second esterification reaction of a reaction product from the first esterification reaction; continuously performing a first polycondensation reaction of a reaction product from the second esterification reaction to obtain a prepolymer having a weight average molecular weight of about 6,900 to about 14,000; continuously performing a second polycondensation reaction of the prepolymer to obtain a second polycondensation reaction product; and continuously performing a third polycondensation reaction of the second polycondensation reaction product to prepare the biodegradable aliphatic / aromatic polyester copolymer, wherein the performing of the first esterification reaction or the continuously performing of the second esterification reaction includes adding an aromatic carboxylic acid. The biodegradable aliphatic / aromatic polyester copolymer prepared by the continuous method may be improved in processibility, film formability, tensile / tearing strength, and blending ability with another polymer resin. Use of a less amount of the aliphatic dihydroxy compound as a starting material may reduce manufacturing costs.

Owner:ANKOR BIOPLASTICS CO LTD

Image signal converting apparatus and image display apparatus

ActiveUS8487953B2Increase brightnessColor deteriorationCathode-ray tube indicatorsColor television detailsSuperimpositionHue

The image signal converting apparatus is used in a lighting unit. The lighting unit includes a liquid crystal panel modulating a red component light according to a red image signal, a liquid crystal panel modulating a green component light according to a green image signal, and a liquid crystal panel modulating a blue component light according to a blue image signal. Yellow component light is superimposed on any of the red component light, the green component light and the blue component light. The image signal converting apparatus includes a controlling unit which controls a superimposition amount of yellow component light based on a specific image signal among a red image signal, a green image signal, and a blue image signal. A color corresponding to the specific image signal has a hue adjacent to a hue corresponding to the yellow component light. The controlling unit controls a reduction amount of the specific image signal based on the superimposition amount.

Owner:SANYO ELECTRIC CO LTD

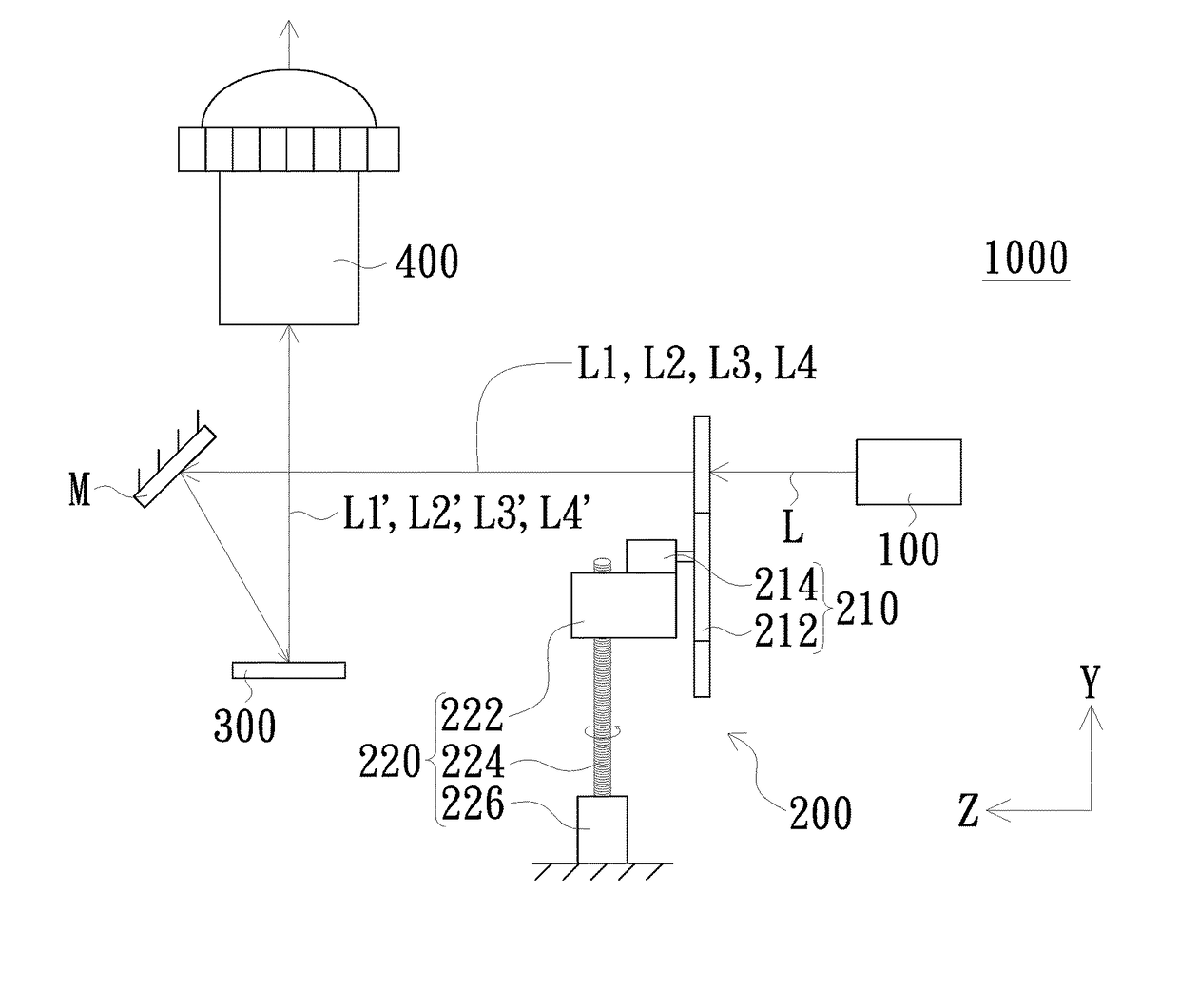

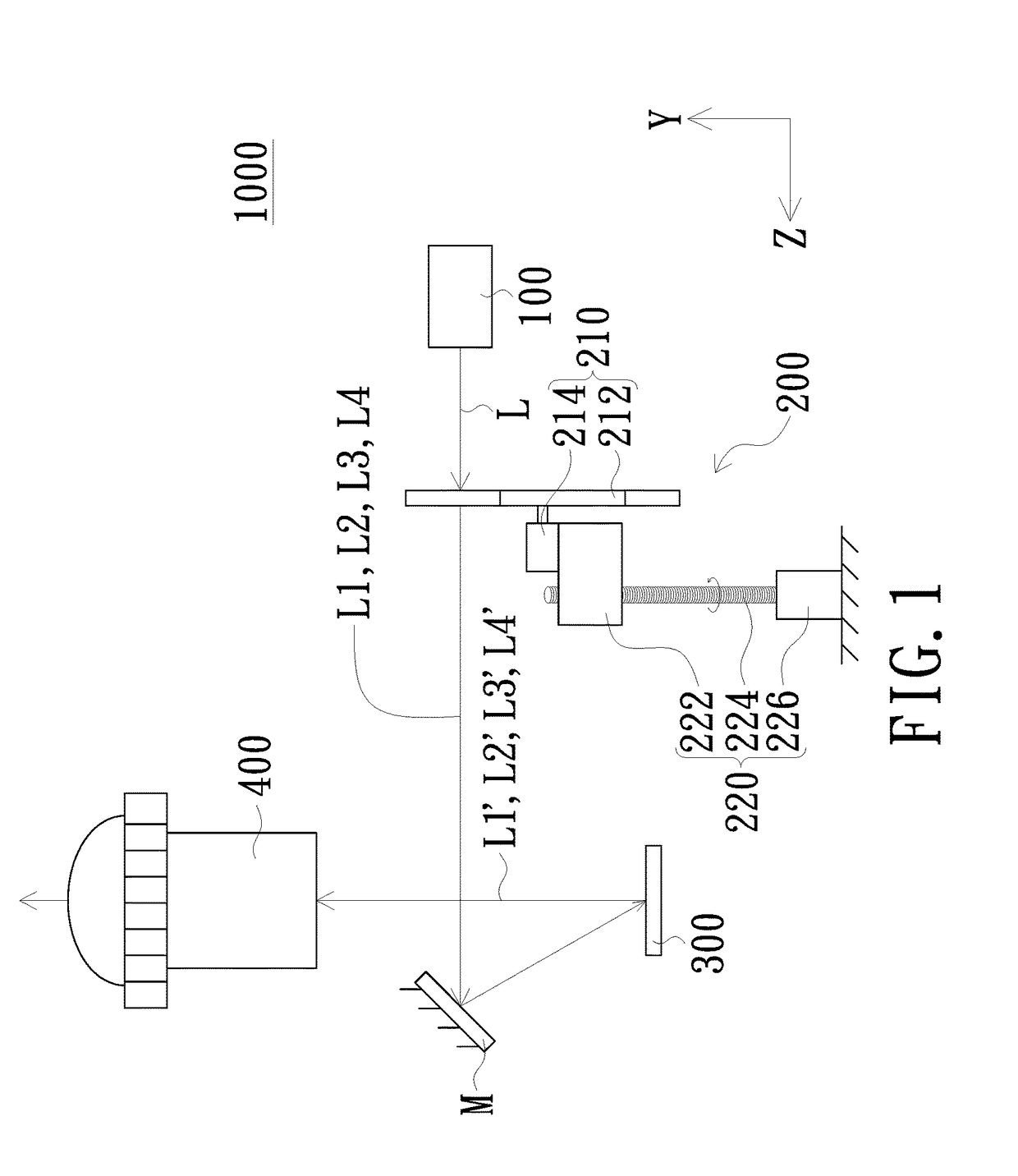

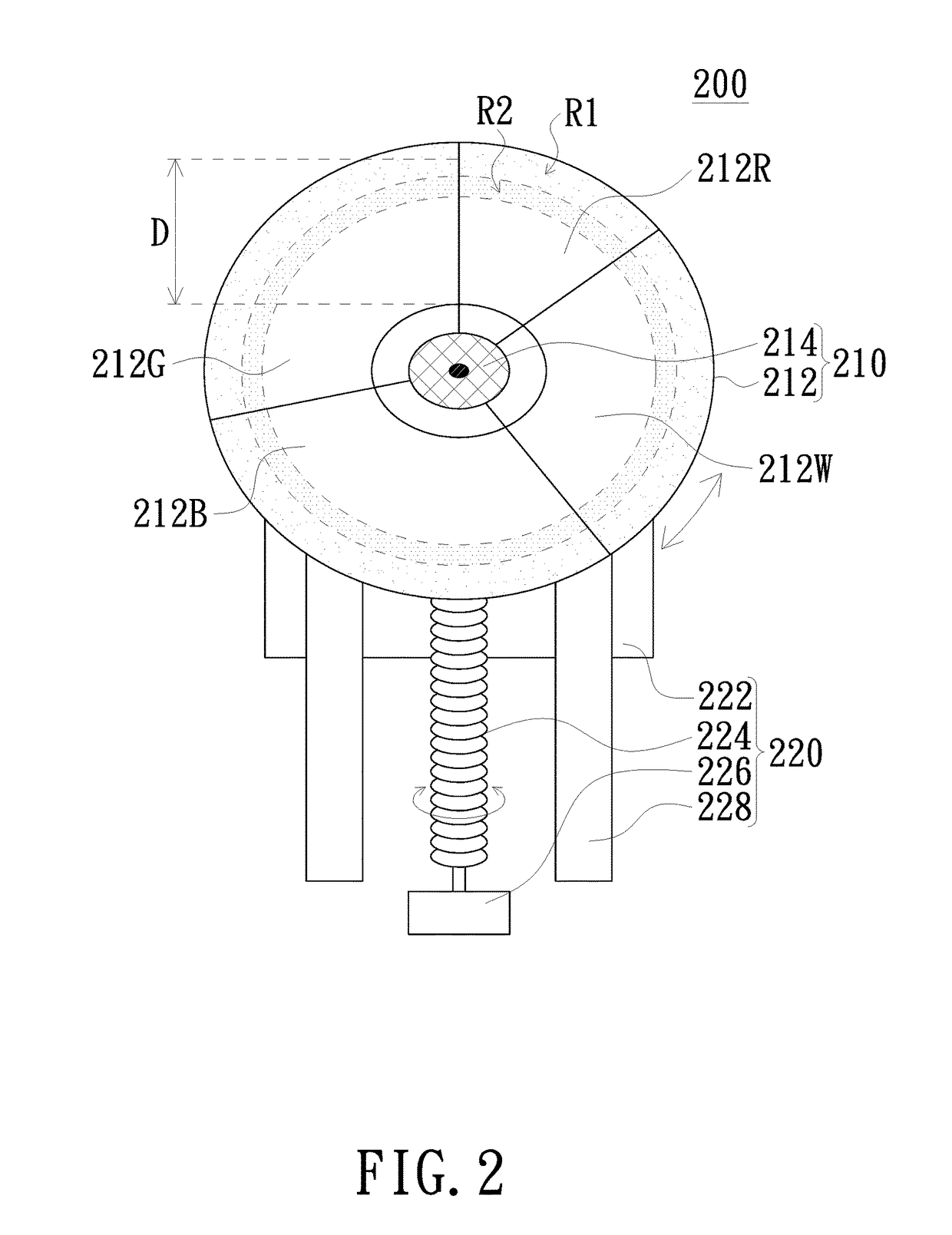

Color light generating assembly, projection apparatus using the same and projection method thereof

InactiveUS20170302894A1Heat riseColor deteriorationProjectorsPicture reproducers using projection devicesPhysicsColor wheel

A color light generating assembly includes a color wheel module and a reciprocating module. The color wheel module includes a color wheel and a first driving device. The color wheel is disposed on a transmission path of an illumination beam of the projection apparatus. An optical axis of the illumination beam irradiates the color wheel along a predetermined direction. The first driving device is configured to drive the color wheel to rotate so as to sequentially convert the illumination beam into a plurality of sub-illumination beams of different colors. The reciprocating module is connected to the color wheel module and configured to drive the color wheel module to reciprocate along a predetermined path when the color wheel is being driven to rotate by the first driving device. The predetermined direction is non-parallel to the predetermined path. A projection apparatus using the assembly and a projection method are also provided.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

Color keeping slip-resisting solution

InactiveUS7179328B2Increase frictionIncrease coefficient of frictionOther chemical processesBathsFrictional coefficientColor changes

An aqueous solution for treatment of colored concrete, glazed enamel or porcelain surfaces to increase the coefficient of friction of that surface, whether dry or wet, to about 0.8 without deteriorating the color of the surface comprises about 1.5 to 1.9 wt % of ammonium bifluoride, 1.5 to 3.0 wt % of tri-ethylamine and a wetting agent in water. The degree of change of the color of the surface, treated seven minutes with the solution of the current application, measured by a color meter shows only 0.56 while the result of a commercial solution to increase the frictional coefficient shows 2.22. This means that the color change by the solution of the current application is undetectable by human eyes. Meanwhile, the change by the commercial solution product is detectable.

Owner:KIM E E +2

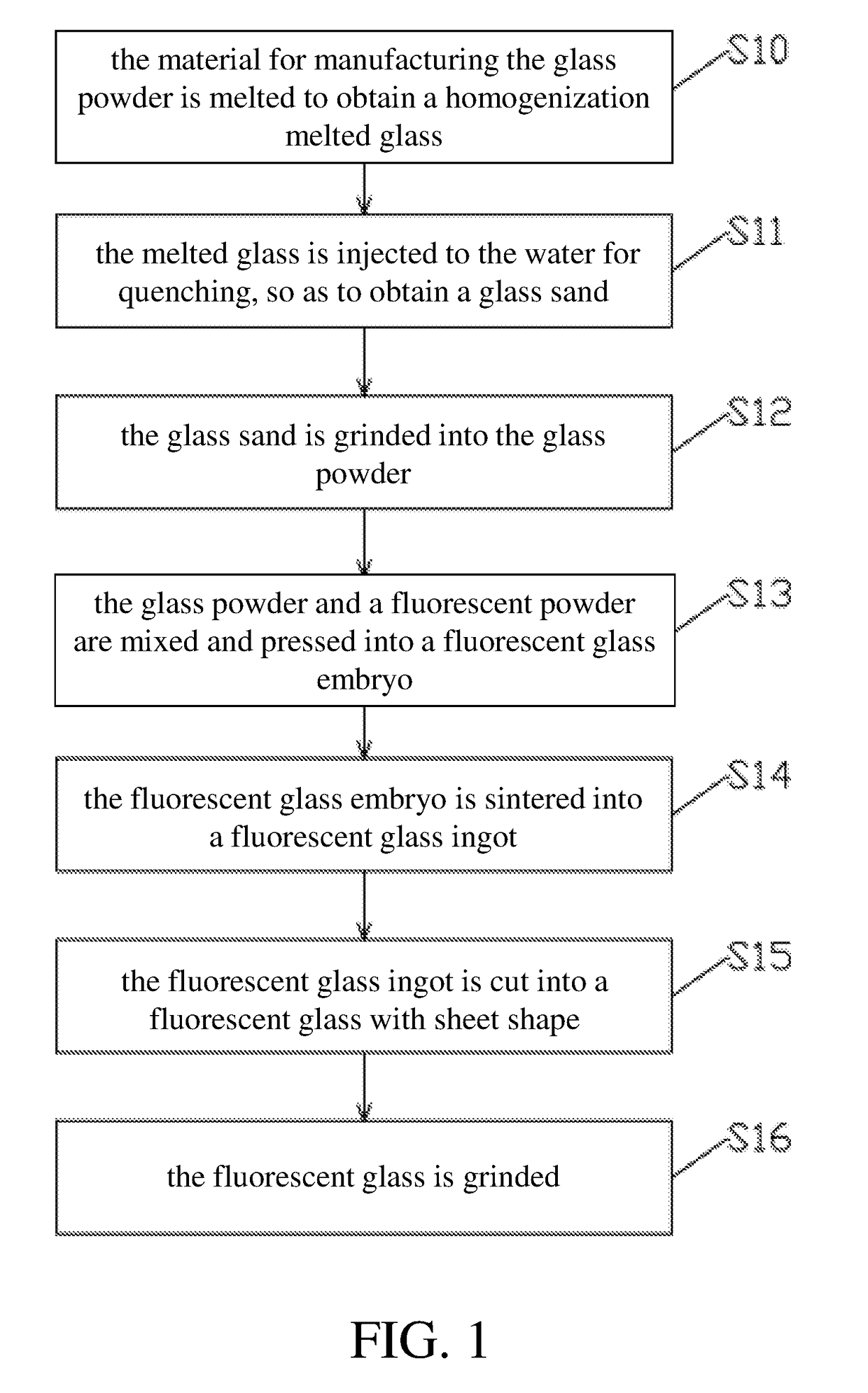

Fluorescent Glass For Light Emitting Diode And Manufacturing Method Thereof

InactiveUS20190010079A1Avoid light lossLight efficiencyGlass shaping apparatusLuminescent compositionsFluorescenceFritted glass

The present disclosure is related to a fluorescent glass for a light emitting diode and a manufacturing method thereof. The fluorescent glass for the light emitting diode includes a glass powder and a fluorescent powder, wherein the glass powder and the fluorescent powder are mixed to form a fluorescent glass, the material for manufacturing the glass powder comprises silicon dioxide with 20 wt % to 37 wt %, diboron trioxide with 31 wt %-47 wt % and calcium oxide with 16 wt %˜35 wt %, and the material of the fluorescent powder is selected from one of Ce-YAG, LuAG, silicate, and nitrides / oxynitrides fluorescent powder. The fluorescent glass of the present disclosure is formed by mixing and sintering the glass powder and the fluorescent powder and has low sintering temperature, so as to avoid the deterioration of color of the fluorescent powder due to high temperature. Therefore, the fluorescent glass of the present disclosure has good transparency, and the light emitting diode applying this fluorescent glass has good lighting efficiency.

Owner:PLATINUM OPTICS TECH SUZHOU INC +1

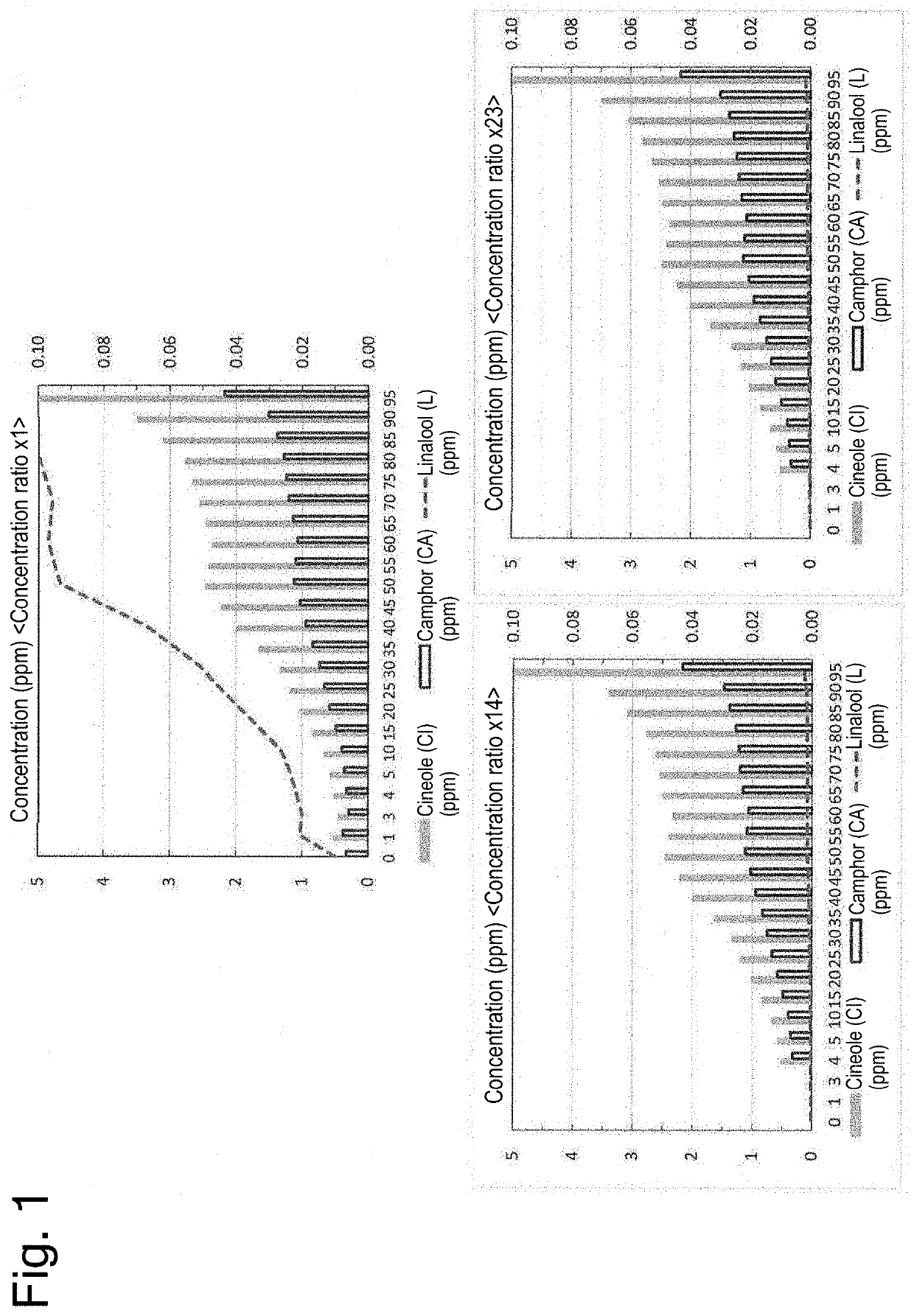

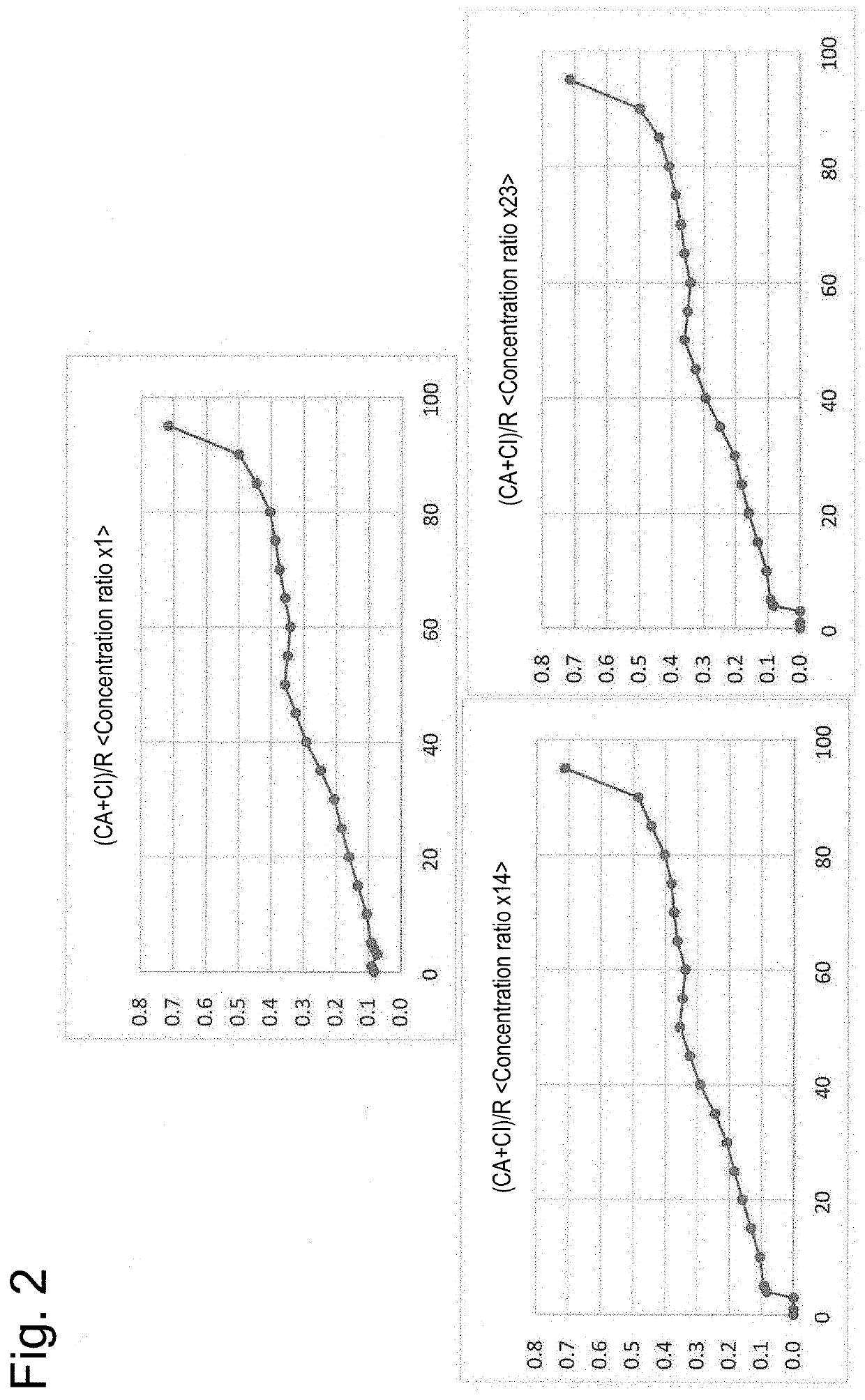

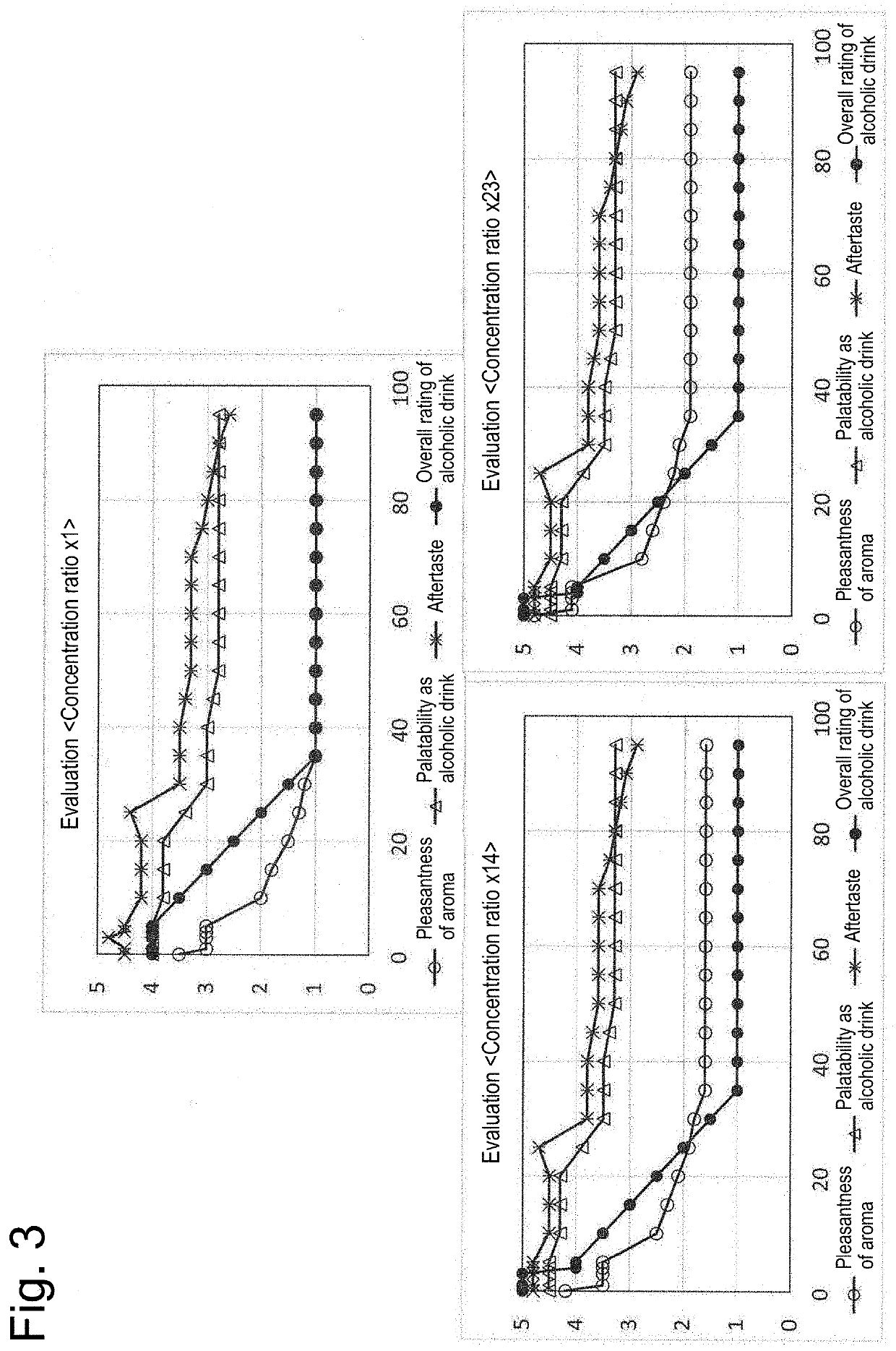

Packed beverages suppressed in the fading of dyes

ActiveUS11484046B2Suppressing fadingGreat tasteNatural extract food ingredientsFood ingredient functionsBiotechnologyRosemary extract

The present invention aims at providing packed beverages in which the effect of rosmarinic acid for suppressing the fading of dyes is maintained and yet any undesirable flavor that is characteristic of rosemary extracts as exemplified by their undesirable smell or aftertaste is suppressed. To this end, the contents of cineole and camphor are reduced.

Owner:SUNTORY HLDG LTD

Multicolored thermally recording medium

InactiveUS7232791B2Easy to controlColor is not hurtMechanical record carriersRecord information storageBenzenePhotochemistry

In the multi colored thermally sensitive recording medium, at least one kind of dye precursor is contained in complex fine particles which contain dye precursor and polymer of multi valence isocyanate compound, further contain 4,4′-diisocyanate-3,3′-dimethyl-1,1′biphenyl and / or polymethylene.polyphenyl.polyisocyanate.

Owner:NIPPON PAPER IND CO LTD

Liquid crystal display device

A liquid crystal display device includes a liquid crystal panel and a circularly polarizing plate disposed on a viewing side of the liquid crystal panel. The circularly polarizing plate sequentially includes, from a viewing side, a linearly polarizing plate and an out-cell retarder. The liquid crystal panel includes a thin-film transistor substrate, a color filter substrate facing the thin-film transistor substrate and including black matrix, a horizontal alignment liquid crystal layer disposed between the thin-film transistor substrate and the color filter substrate, and an in-cell retarder disposed in one substrate disposed on the viewing side selected from the thin-film transistor substrate and the color filter substrate. The in-cell retarder is disposed outside a region between the black matrix and the horizontal alignment liquid crystal layer.

Owner:SHARP KK

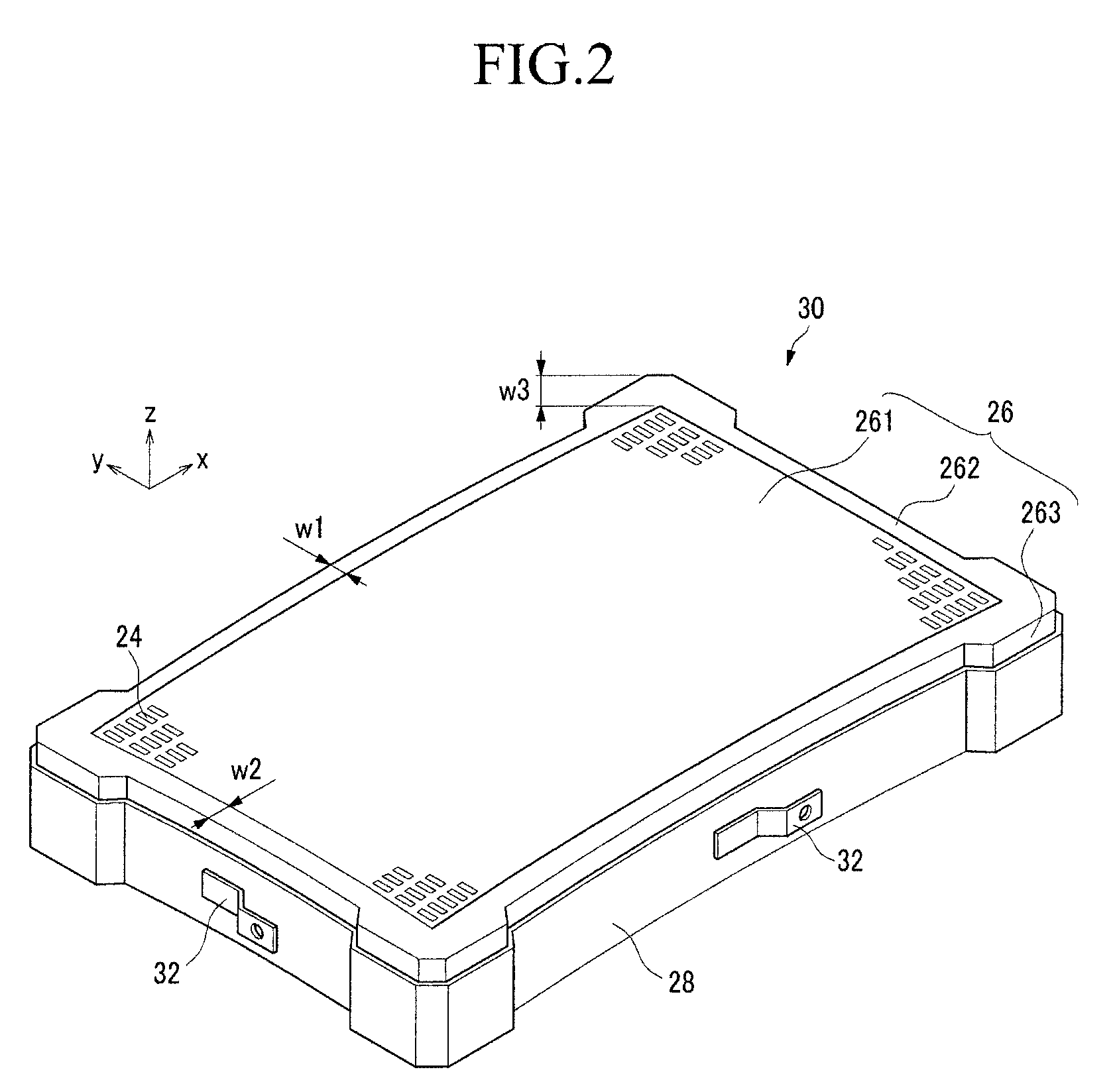

Cathode ray tube with improved mask assembly

InactiveUS20090072699A1Easy to shapeSuppressing a doming phenomenon of the shadow maskTransit-tube electron/ion gunsElectrode and associated part arrangementsEngineeringElectron

A cathode ray tube including a shadow mask. The shadow mask includes an aperture portion including a plurality of beam guide holes, a non-aperture portion surrounding the aperture portion, and a skirt portion that is bent from an edge of the non-aperture portion toward an electron gun. The non-aperture portion includes a pair of longer sides, a pair of shorter sides, and four corner portions, and a first width of the non-aperture portion measured at the longer side and a second width of the non-aperture portion measured at the shorter side are formed to be less than a third width of the non-aperture portion measured at the corner portions. The shadow mask satisfies the following conditions: 2 mm≦w1<w3, and 2 mm≦w2<w3, where w1 denotes the first width of the non-aperture portion, w2 denotes the second width of the non-aperture portion, and w3 denotes the third width of the non-aperture portion.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com