Patents

Literature

48results about How to "Conducive to full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

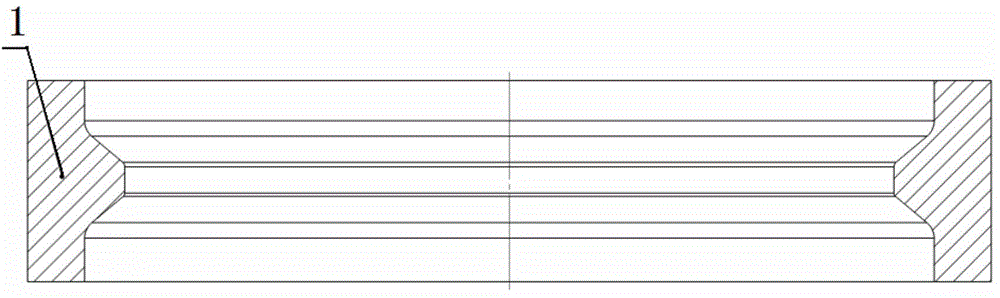

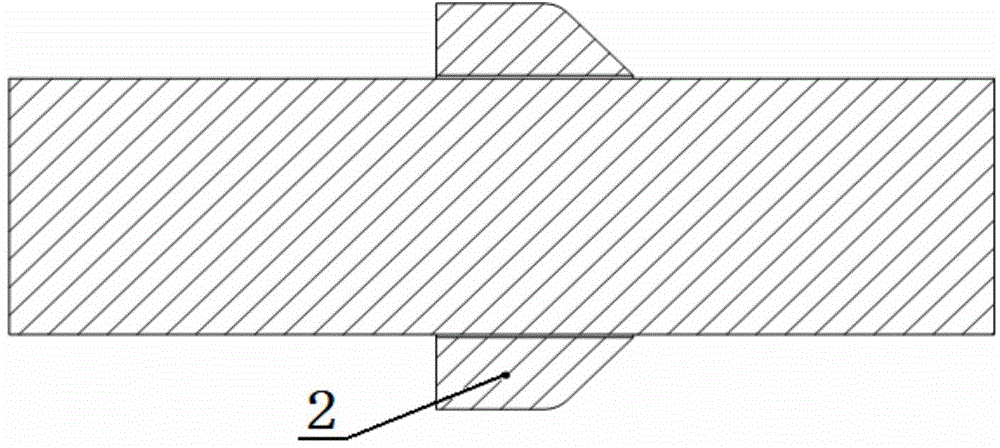

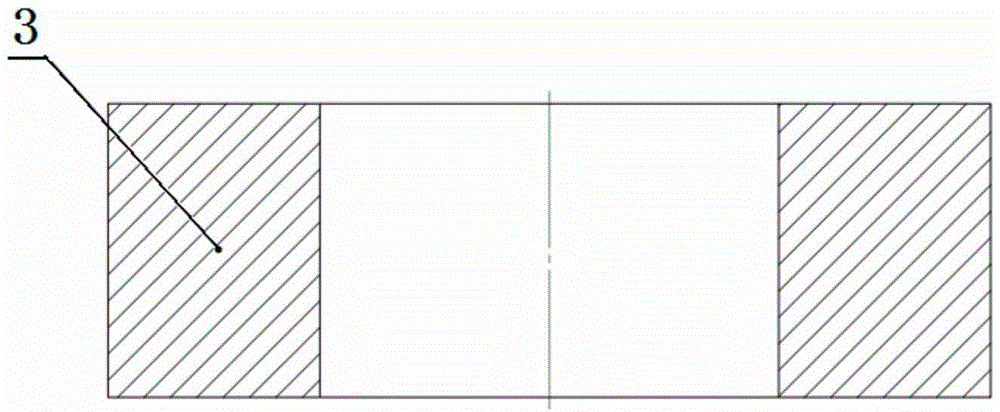

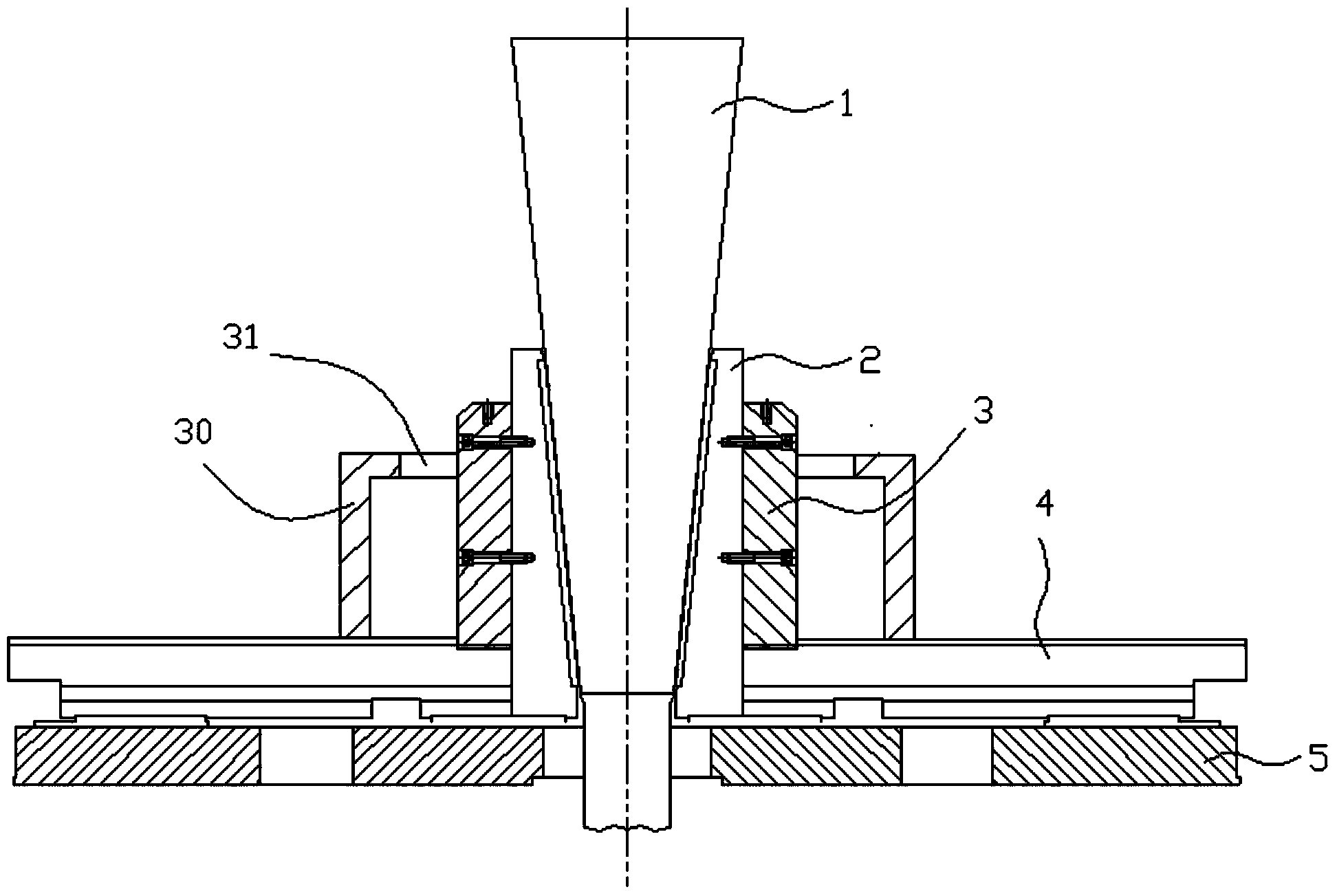

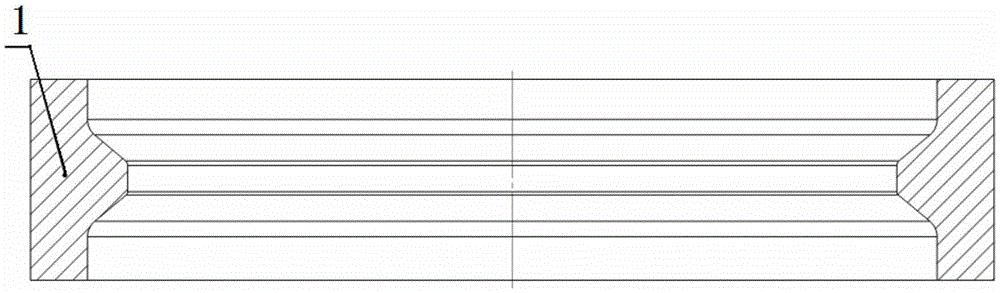

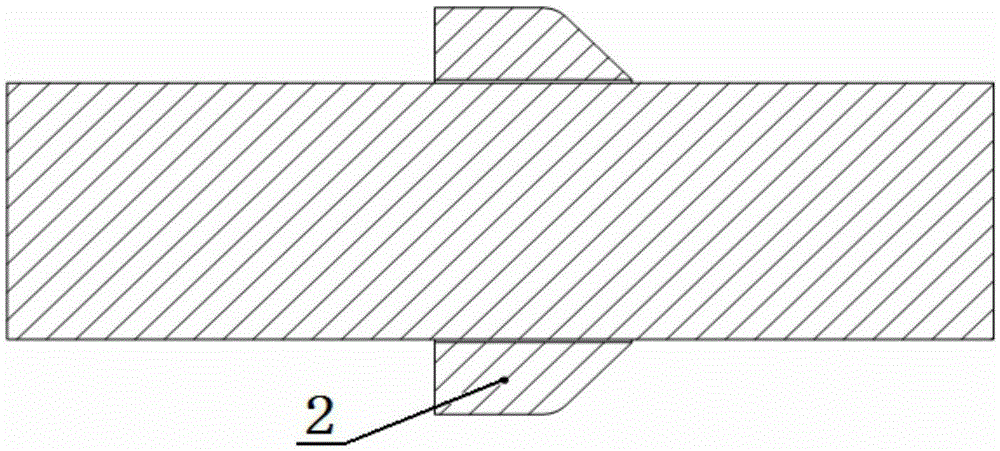

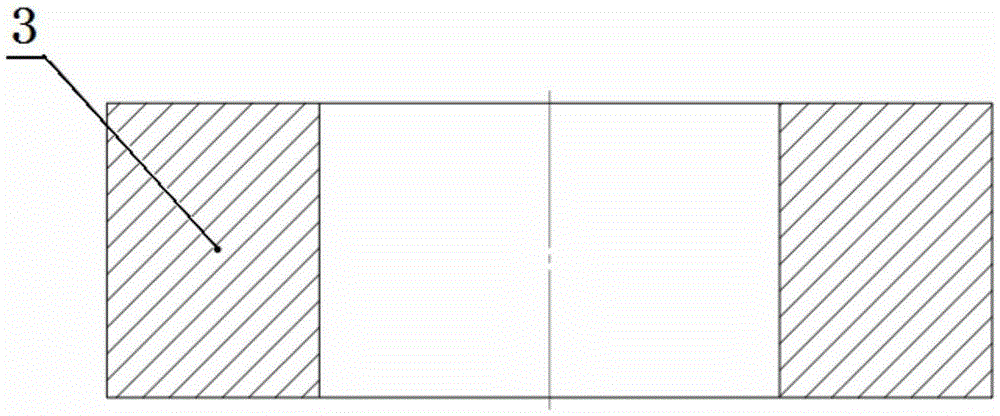

Manufacturing method for large internal T-shaped ring forge piece blank of SB564UNS N06690 alloy

The invention discloses a manufacturing method for a large internal T-shaped ring forge piece blank of SB564UNS N06690 alloy. Firstly, upsetting and drawing are performed through a hydraulic forging press, a punch with the diameter of 300mm is used for punching, then chambering and rounding are performed, twice rolling is performed on a ring rolling mill by the aid of a step mold, an original blank with a rectangular section is circularly rolled into a middle blank with a step, then the middle blank is rotated by 180 degrees, and second rolling is performed, so that the internal T-shaped annular forge piece blank is obtained. According to the manufacturing method for the large internal T-shaped annular forge piece blank of the SB564UNS N06690 alloy, the structure of the manufactured forge piece blank is uniform, grains are refined, shapes are rectangular, and the forge piece quality and the production efficiency are high.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Process for fabricating template pipe-containing cast part in manner of pre-embedding stainless steel pipeline

ActiveCN104384443AImprove corrosion resistanceExtended service lifeFoundry mouldsFoundry coresPre embeddingSteel pipeline

The invention discloses a process for fabricating a template pipe-containing cast part in a manner of pre-embedding a stainless steel pipeline. The process comprises the following steps: 1) fabricating a wood pattern according to a drawing, and manufacturing a water outlet pipe groove in an inner cavity of the wood pattern; 2) selecting an appropriate sand box according to the wood pattern, and fabricating a sand mold of a lower box with the water pipe groove surface being upwards; 3) selecting an appropriate special upper box after finishing the sand mold of the lower box, fixing the upper box on the lower box, and then assembling an appropriate quantity of tooling bars into a track groove in a sand box; 4) fixing the tooling bars, and then beginning to fabricate a sand mold of the upper box; 5) bending a water pipe; 6) dividing the fabricated sand mold; 7) fixing the tooling bars with a stainless steel pipe, so that the periphery of the stainless steel pipe cannot directly contact the sand mold, and reserving a gap; 8) closing the boxes, and casting; and 9) solidifying and cooling a to-be-cast part, taking out the to-be-cast part, separating the upper box, and transporting the cast part to a cleaning region. According to the process disclosed by the invention, fastening and connection between the water pipe and the sand boxes are ensured, stress deformation of the stainless steel pipe caused by heating is removed, and thus not only is the geometrical tolerance of the water pipe ensured, but also the yield is improved.

Owner:滁州鑫诺实业有限公司

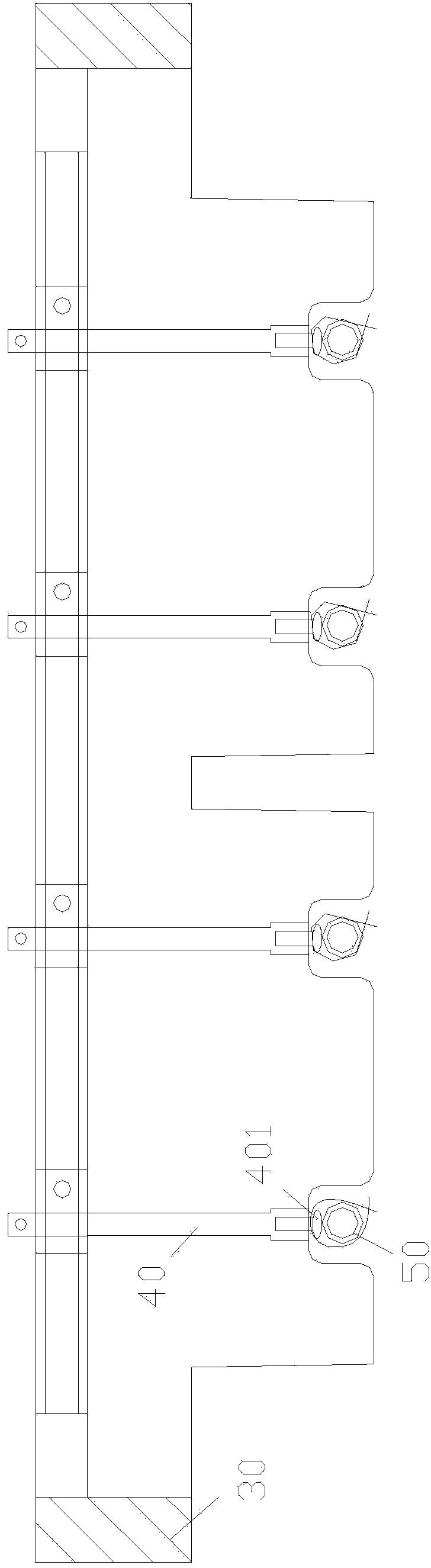

Generator magnetic pole precision forging method

The present invention relates to a dynamo magnetic pole finish forging and forming method. Said method includes the following steps: (a), blanking raw material and cutting raw material into material part; (b), preforging, placing the material part into heating furnace, heating to predefined temperature 1000-1200deg.C, preforging the material part in the preforging die to obtain the preforged piece, its heating time is 30-90 sec. the lower portion of said preforged piece is circular cylinder body and the upper portion of said preforged piece is conical body; (c). forging the preforged piece in a closed precision hot forging die to obtain forged piece, its forging temperature is 1150-950deg.C and forging time is 4-10 sec.; (d). edging forged piece; and (e). machining said forged piece to obtain the dynamo magnetic pole product.

Owner:武汉经开科创运营有限公司

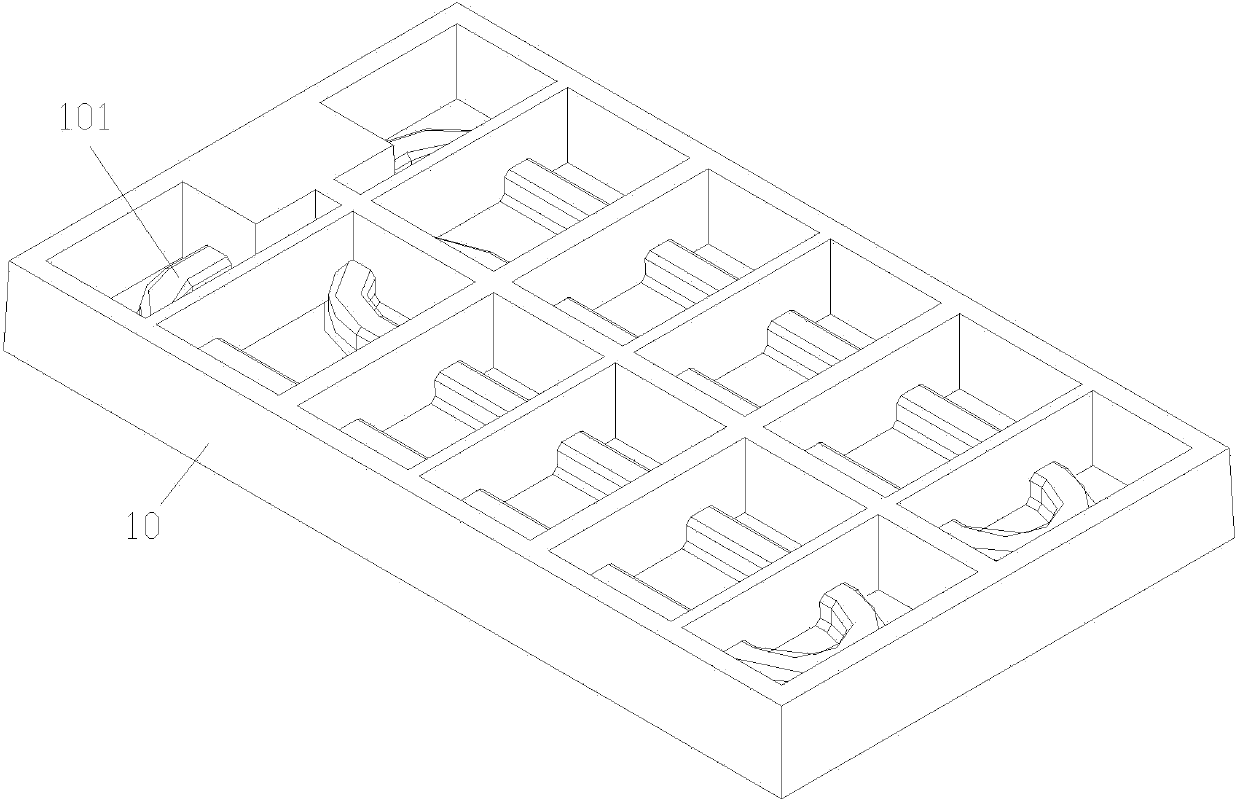

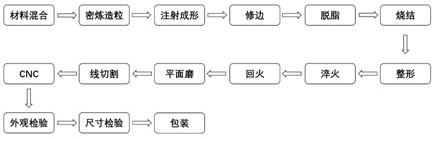

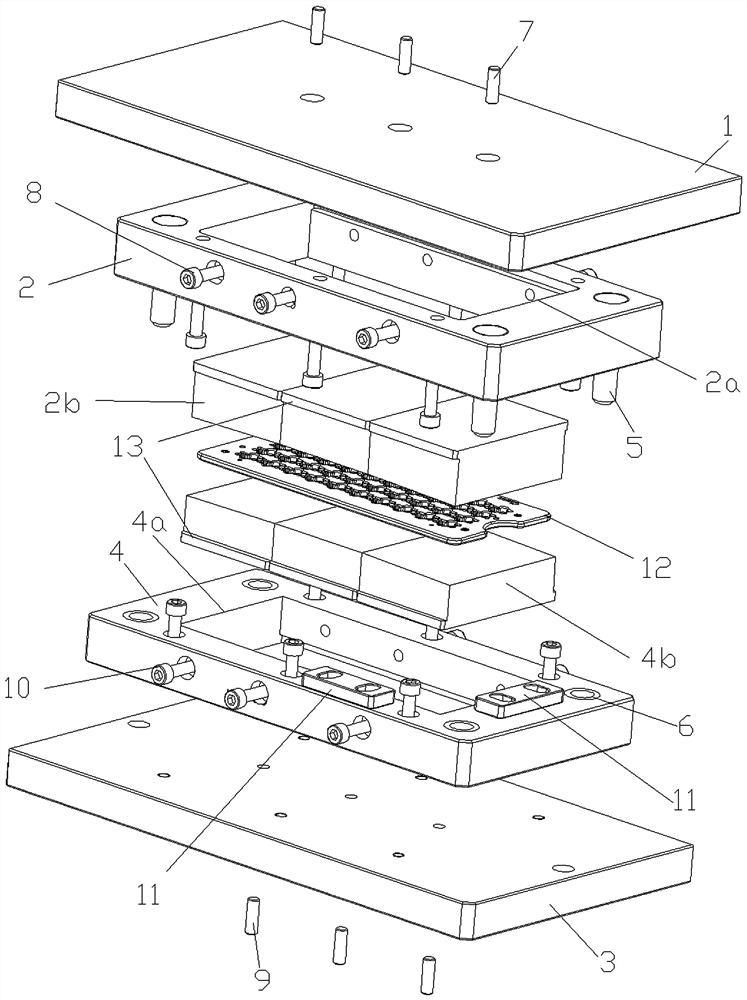

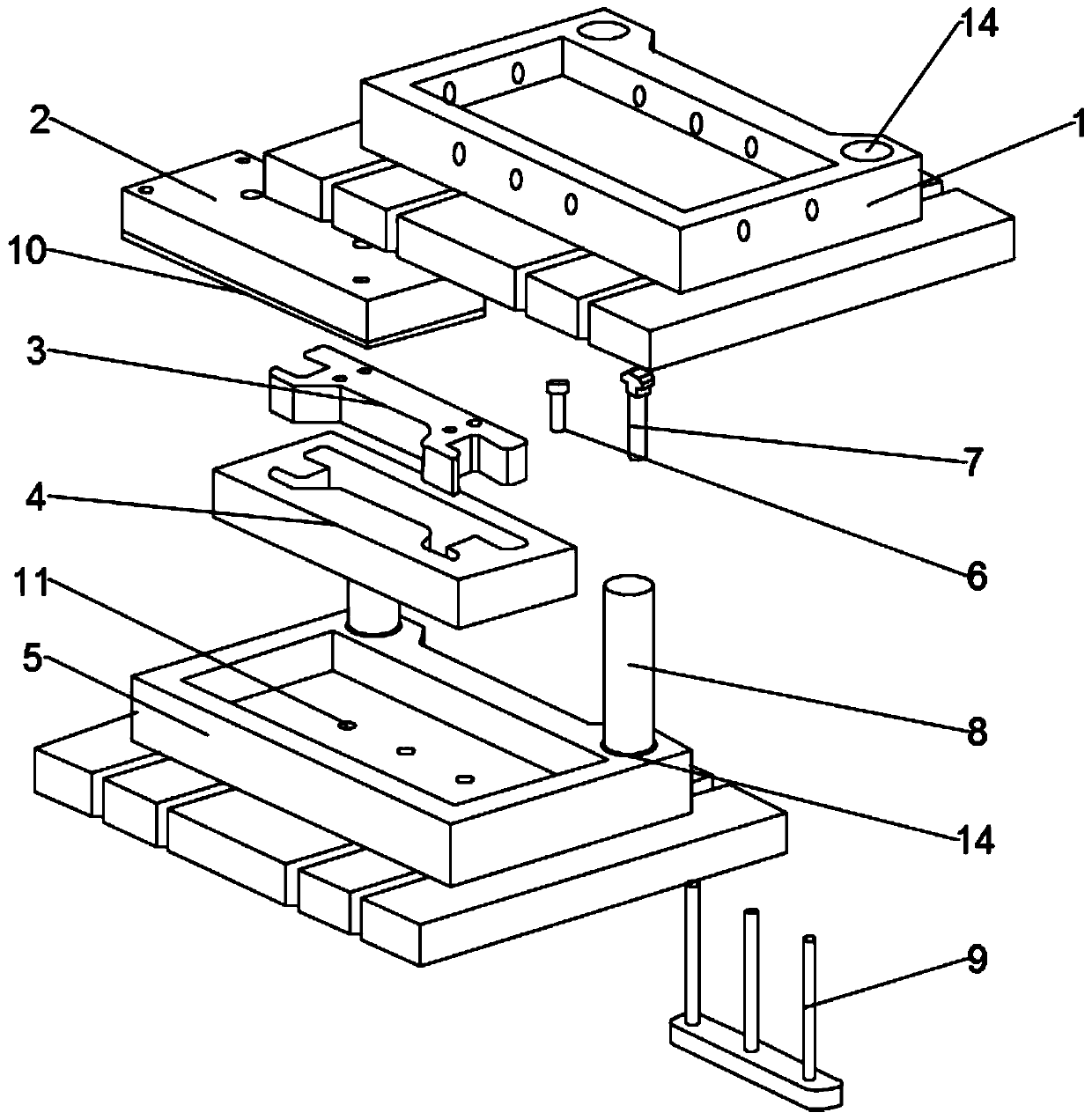

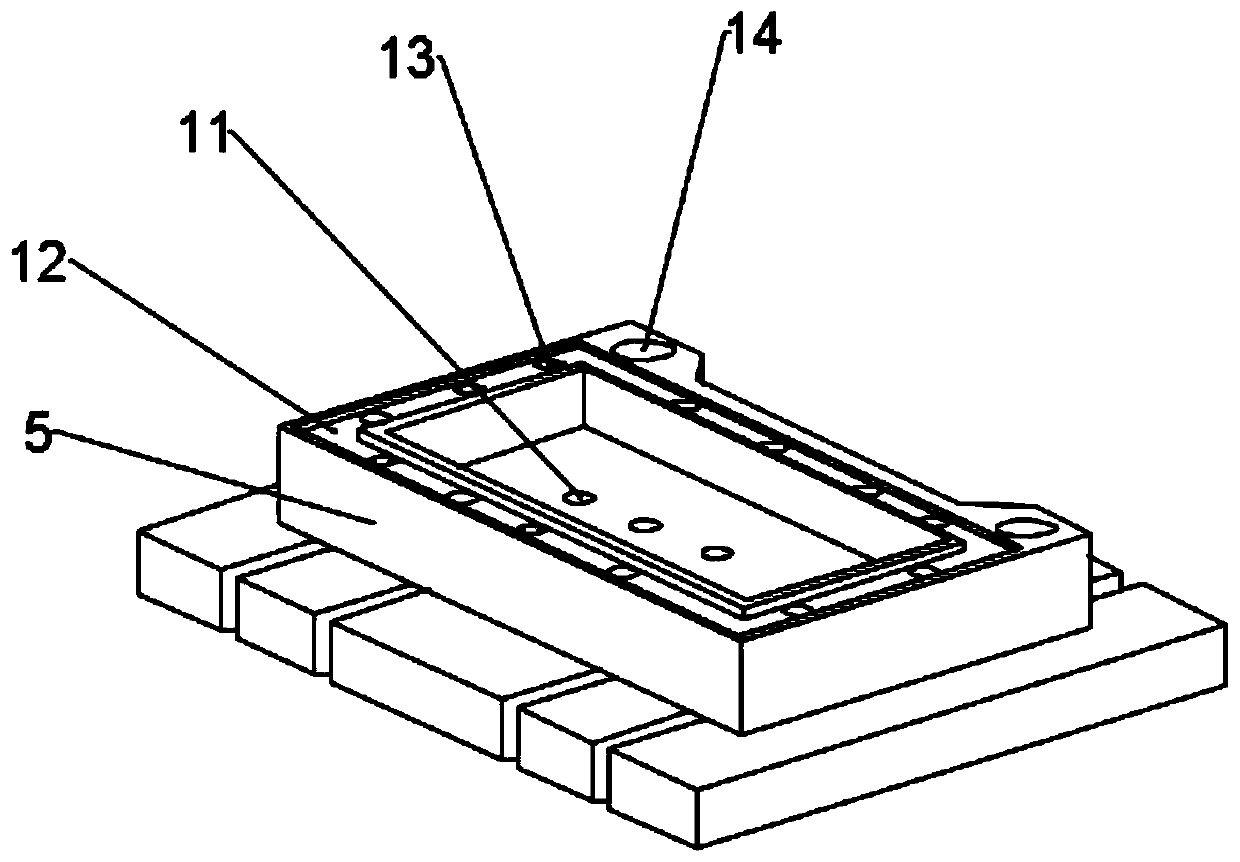

Preparation method of mobile phone middle plate jig

ActiveCN112427641AGood liquidityReduce porosityTransportation and packagingMetal-working apparatusParaffin waxMechanical engineering

The invention discloses a preparation method of a mobile phone middle plate jig. The preparation method is characterized by comprising the following steps: selecting metal powder to obtain mixed alloypowder; weighing binders, wherein the binders are mainly composed of polyformaldehyde 7520, polyethylene 6098, high-density polyethylene 7200, Brazilian wax T3 and sliced paraffin wax, and all the binders are independently weighed and contained; performing banburying and granulating to obtain a feed which can be used for injection; performing injection molding: adding the feed into an injection machine and injecting the feed into a mold to obtain a middle plate jig injection blank; performing trimming; performing degreasing to obtain a middle plate jig degreased blank; performing sintering toobtain a middle plate jig sintered blank; performing shaping to obtain a shaped blank; performing quenching to obtain a middle plate jig quenched blank; performing tempering to obtain a middle platejig tempered blank; and obtaining the mobile phone middle plate jig through plane grinding, linear cutting of positioning holes and CNC finish machining.

Owner:ANHUI HAOFANG ELECTROMECHANICS

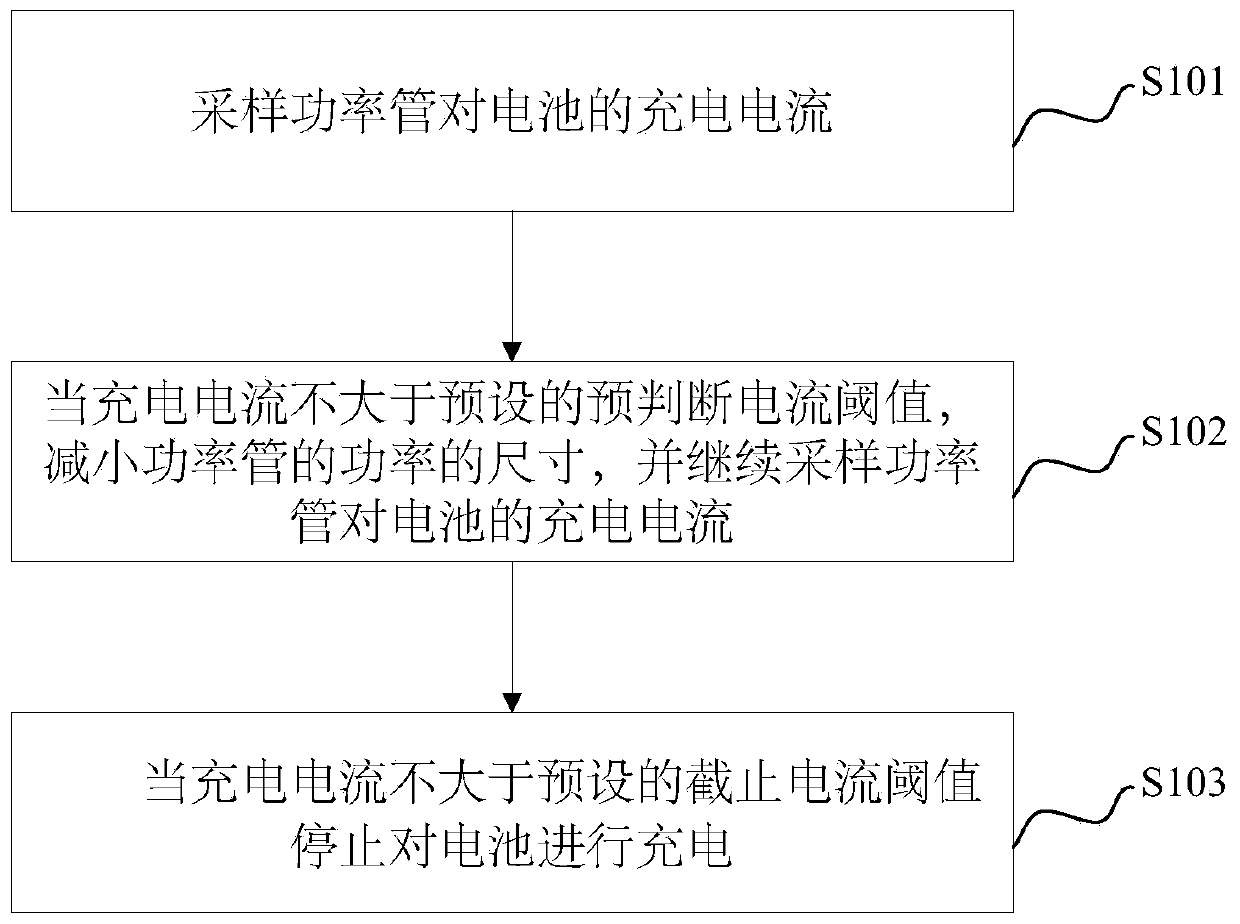

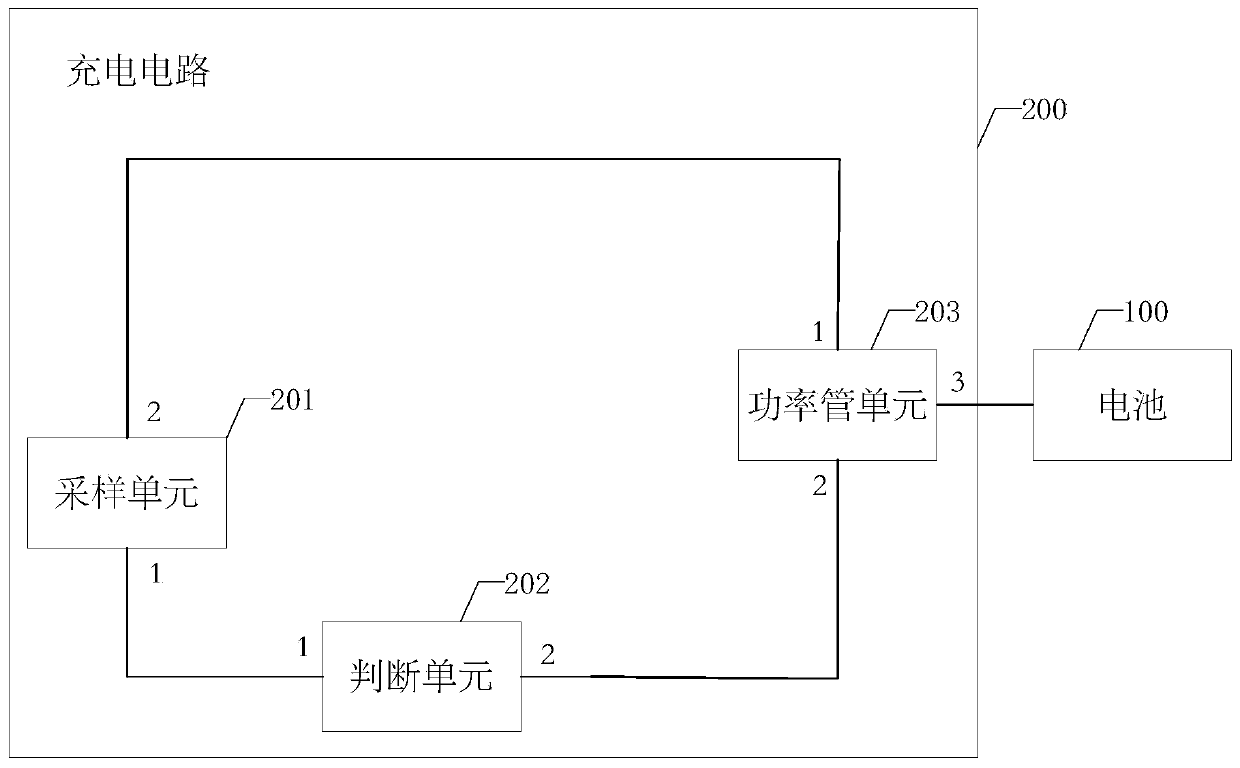

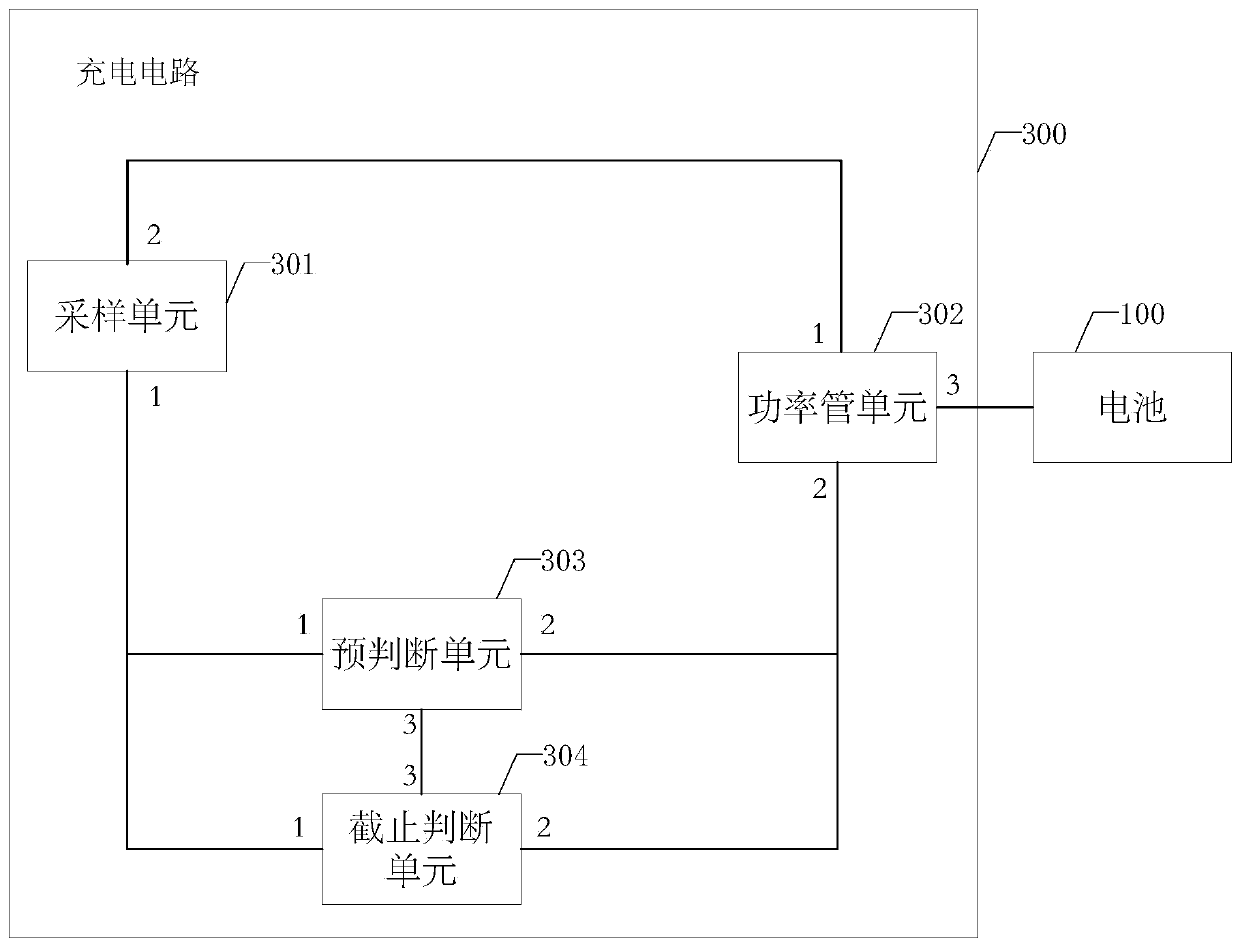

Charging method of charging circuit, charging circuit, charging chip and equipment

ActiveCN111463849AAccurate charging currentHigh precisionBatteries circuit arrangementsElectric powerCurrent thresholdCharge current

The invention discloses a charging method of a charging circuit, the charging circuit, a charging chip and equipment. The charging circuit comprises a power tube unit which is used for charging a battery and is variable in size. The charging method comprises the steps of sampling the charging current of the power tube unit to the battery, wherein the sampling precision is inversely proportional tothe size of the power tube unit; if the charging current is equal to or less than a preset pre-judged current threshold, reducing the size of the power tube unit and continuously sampling the charging current of the power tube unit to the battery; and if the charging current is equal to or less than a preset cut-off current threshold, stopping charging the battery, wherein the cut-off current threshold is less than the pre-judged current threshold. According to the charging method provided by the invention, the sampling precision can be improved by reducing the size of the power tube unit, and the charging current obtained by sampling can be more accurate, so that the cut-off current threshold can be designed to be smaller, the battery is facilitated to be fully charged, and the technicalproblem of weak endurance of the battery is further solved.

Owner:无锡艾为集成电路技术有限公司

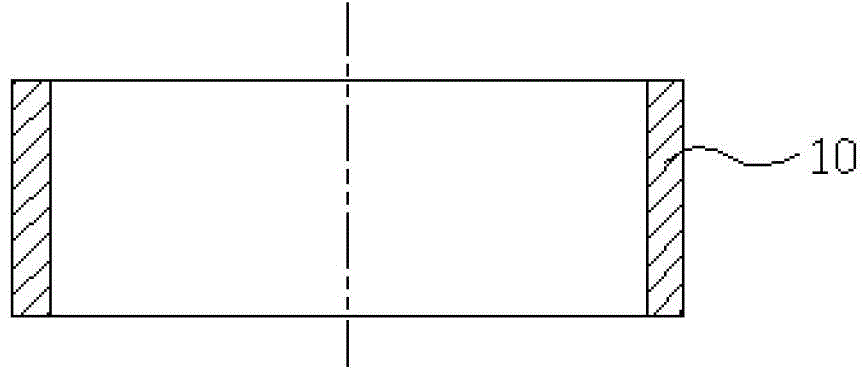

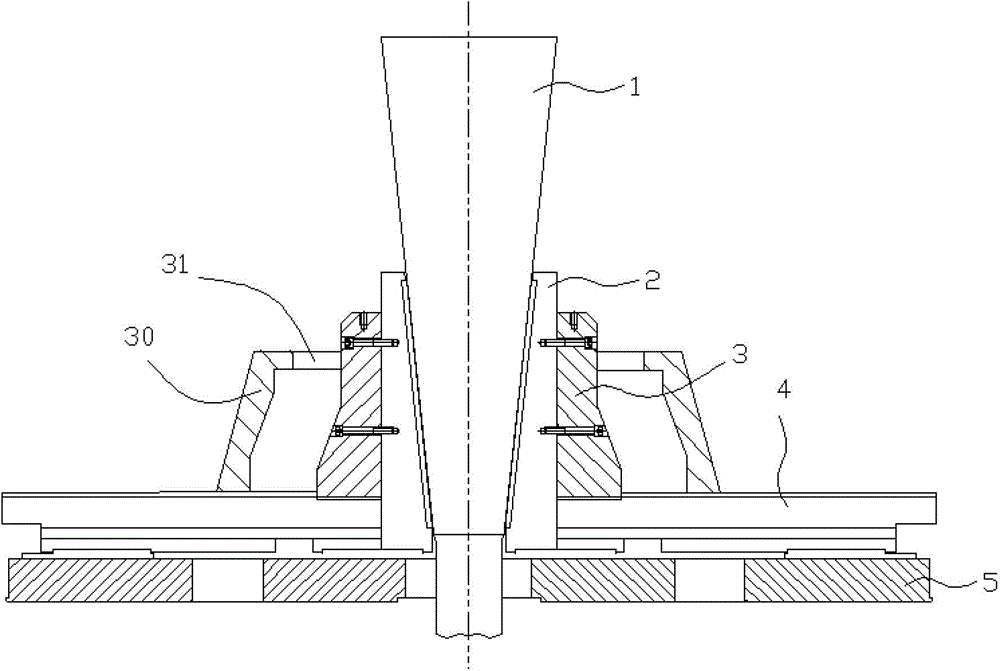

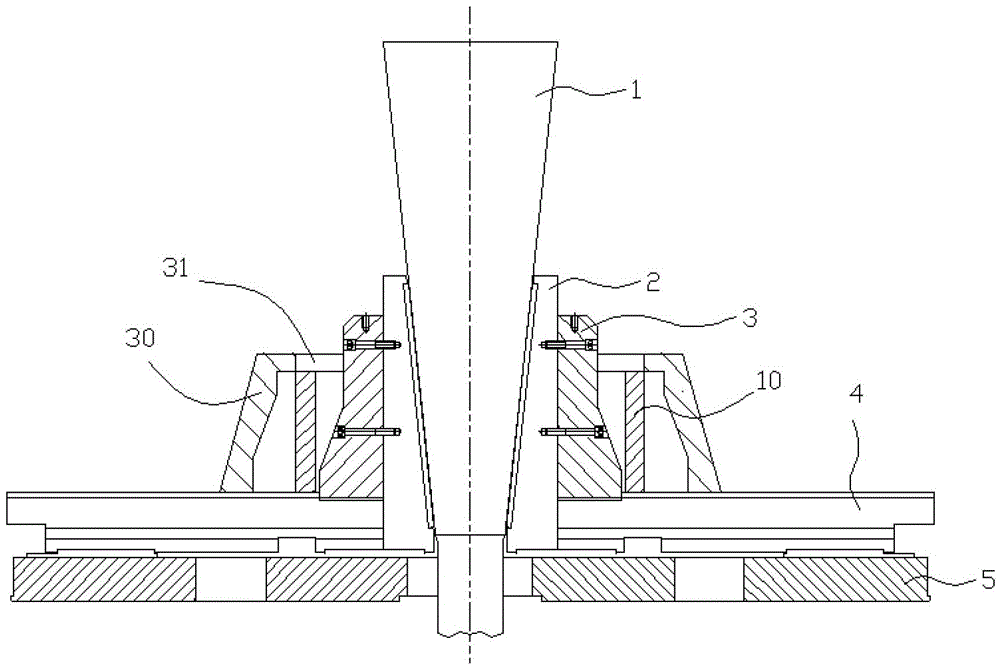

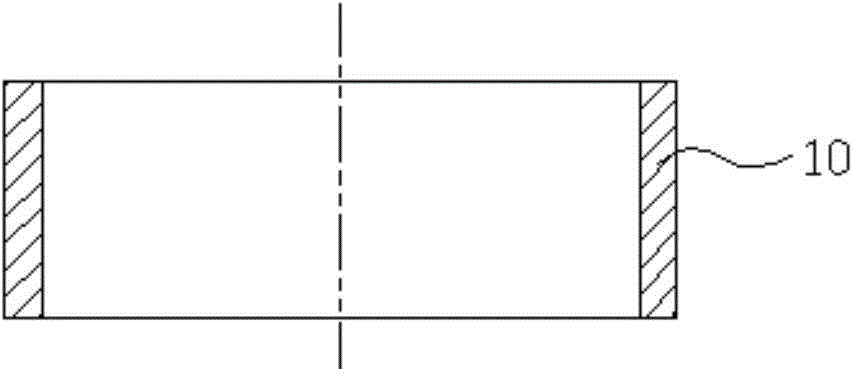

Heat bulging forming method for stainless steel rectangular cross section annular elements

ActiveCN103447377AHigh dimensional accuracyAchieve precision bulge formingShaping toolsProduction rateLarge deformation

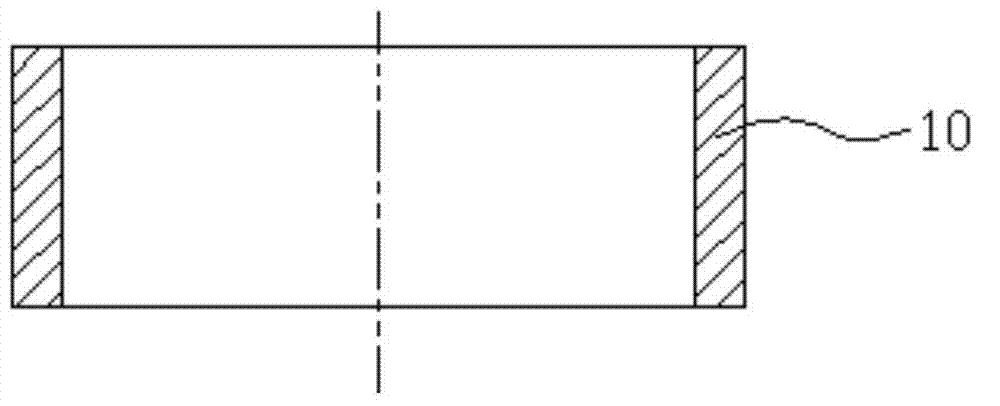

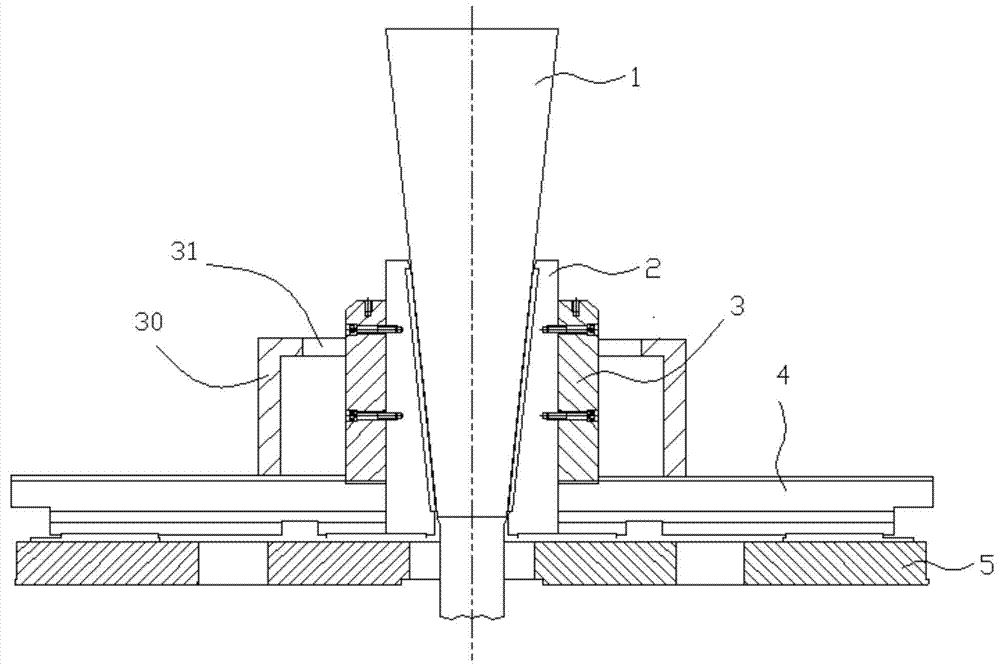

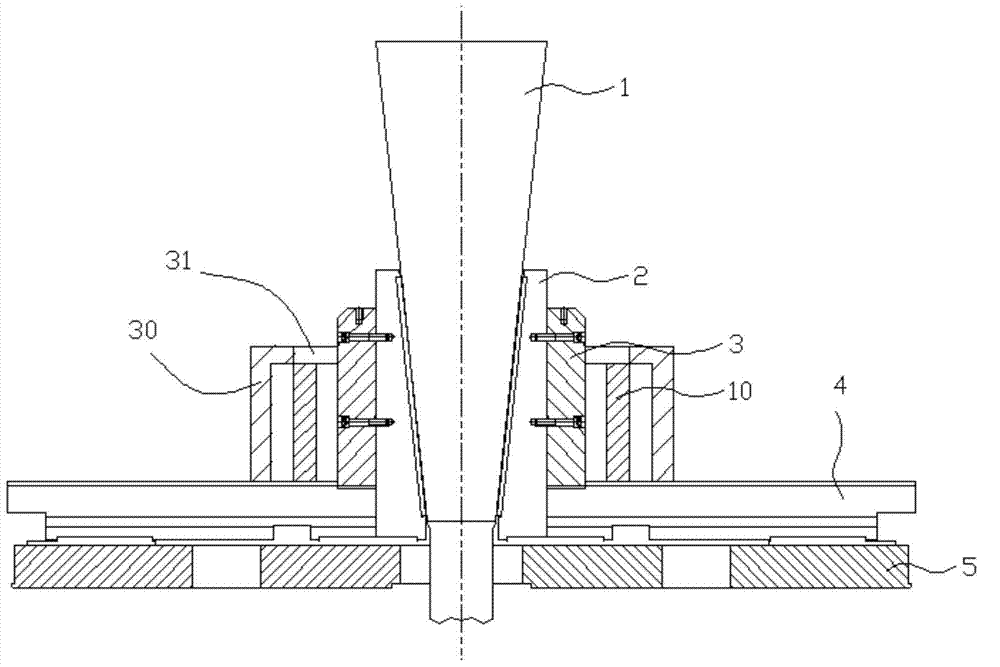

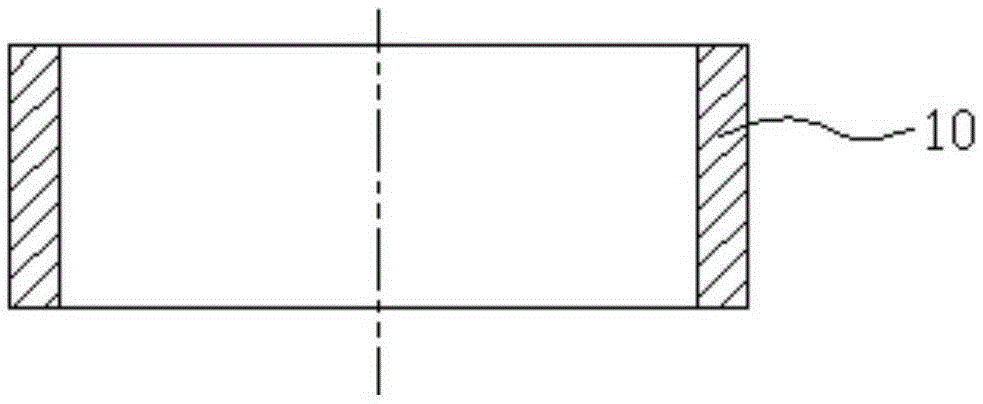

The invention discloses a heat bulging forming method for stainless steel rectangular cross section annular elements. The method comprises the following steps that a preheated mold sleeve is fixed on a work table of a bulging machine, then, a heated stainless steel rectangular cross section annular element is sheathed on the periphery of a preheated bulging block in the bulging machine so that the heated stainless steel rectangular cross section annular element is positioned in an annular space surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve, the bulging machine is started so that the bulging block extrudes the annular element from the inner circumference surface of the annular element in the radial direction, deforms 10 percent to 13 percent, and is then extruded into the inner annular surface of the mold sleeve, a sealed die cavity surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve is fully filled, and the bulged rectangular cross section annular element is formed after the pressure preservation. The method adopts one-step large-deformation-quantity bulging forming, the operation is simplified, and the bulged rectangular cross section annular element with high dimension precision, high product quality and high productivity is obtained. The bulged rectangular cross section annular element is mainly used for rotating body parts of tubular casings and the like used in the fields of aeronautics and astronautics and the like.

Owner:GUIZHOU AVIATION TECHN DEV

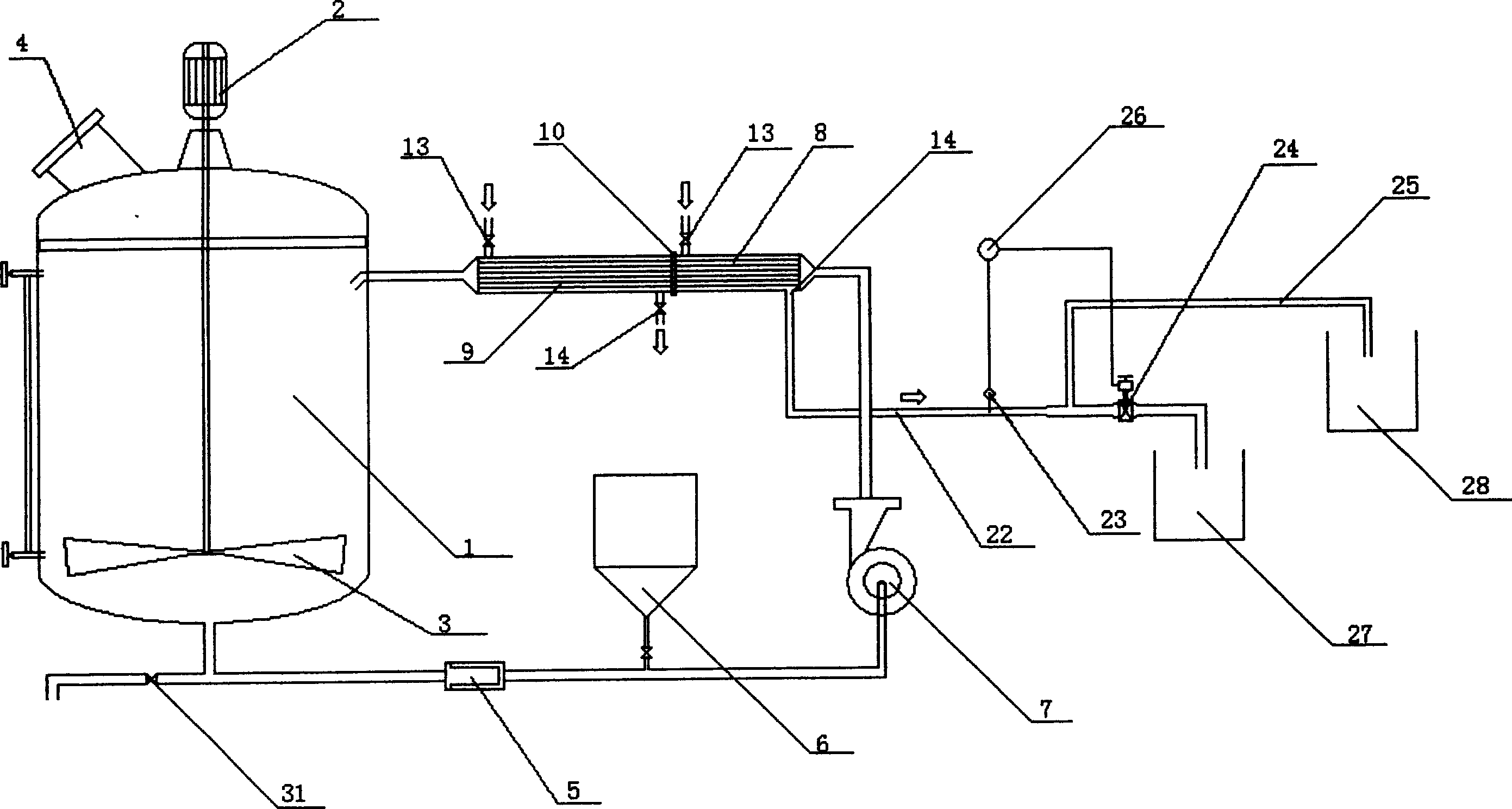

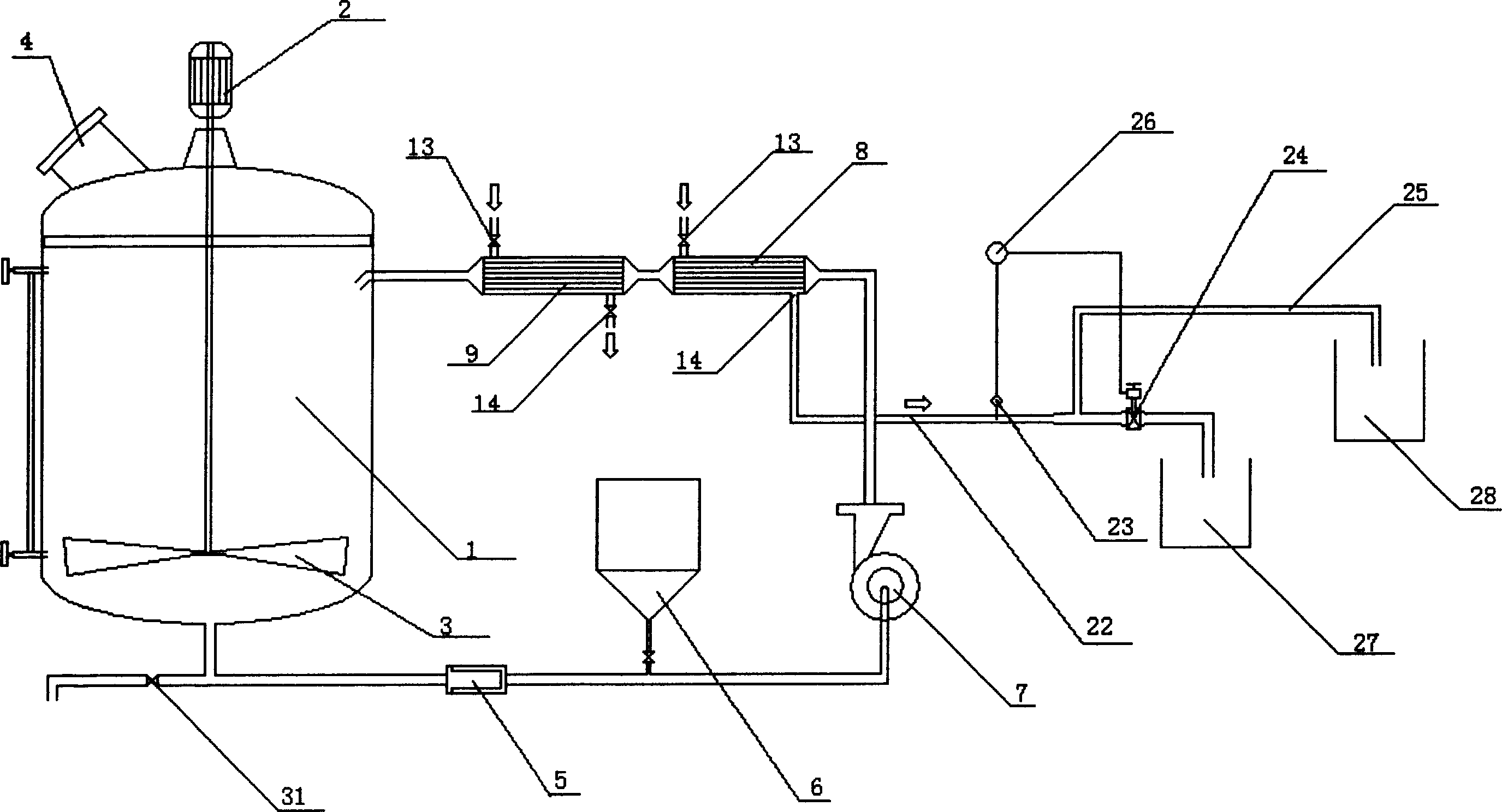

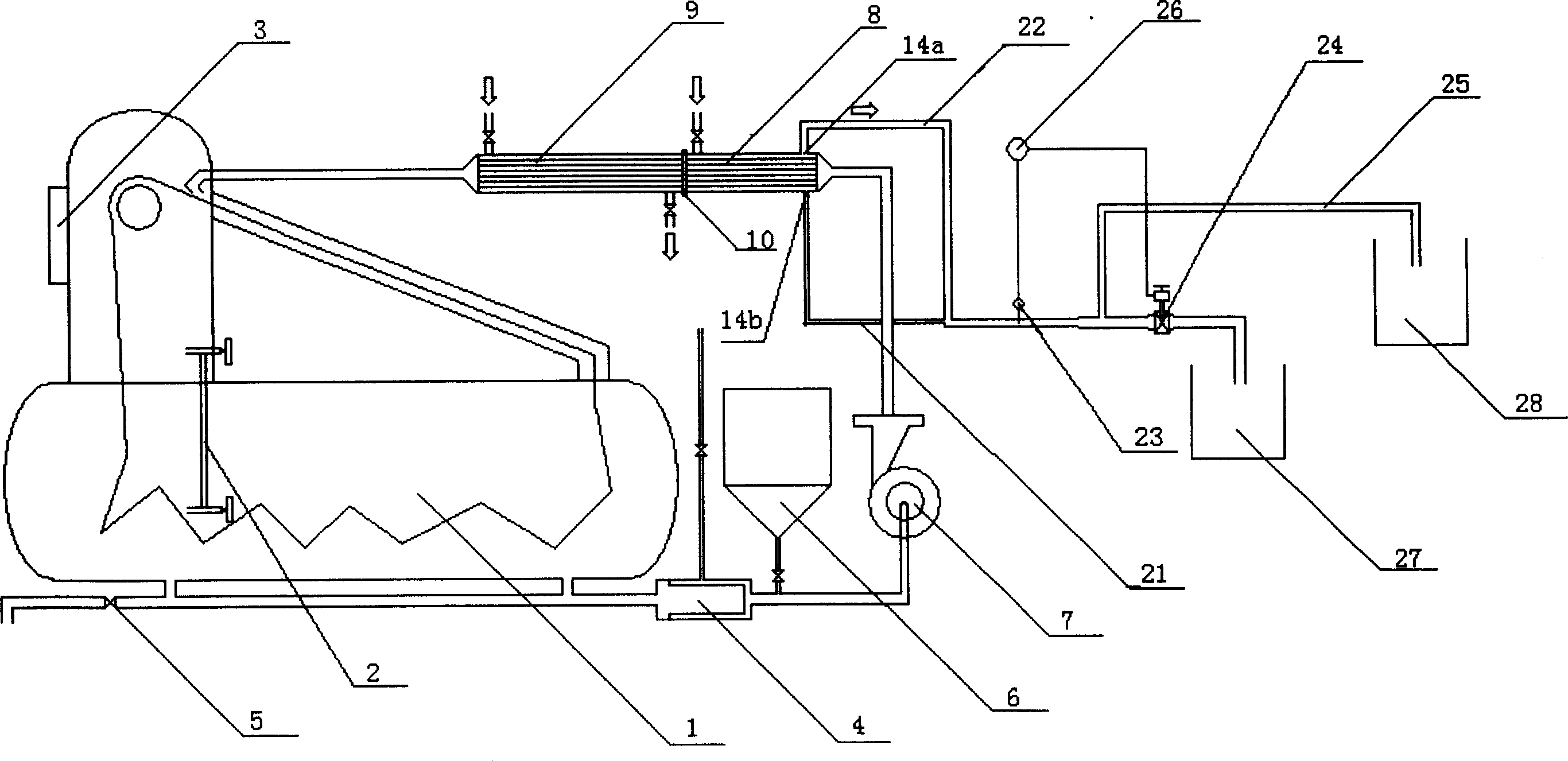

Oil heating and heat recovering reaction pot

InactiveCN1772367AReduce volumeRelieve pressureFlow mixersRotary stirring mixersThermal energyEngineering

The present invention discloses one kind of oil heating and heat recovering reaction pot, and belongs to the field of chemical material processing apparatus technology. The oil heating and heat recovering reaction pot includes a pot body, a filter and a circulating water pump connected successively, as well as combined or serially connected water cooling heat exchanger with shunt and oil heating heat exchanger connected between the pot body and the circulating water pump. By means of the water cooling heat exchanger and the oil heating heat exchanger, the mixed liquid may be cooled and heated to the required temperature, and the water exhausted from the heat exchanger may be made to flow into the hot water or cold water returning unit to utilize the heat energy fully.

Owner:劳关明

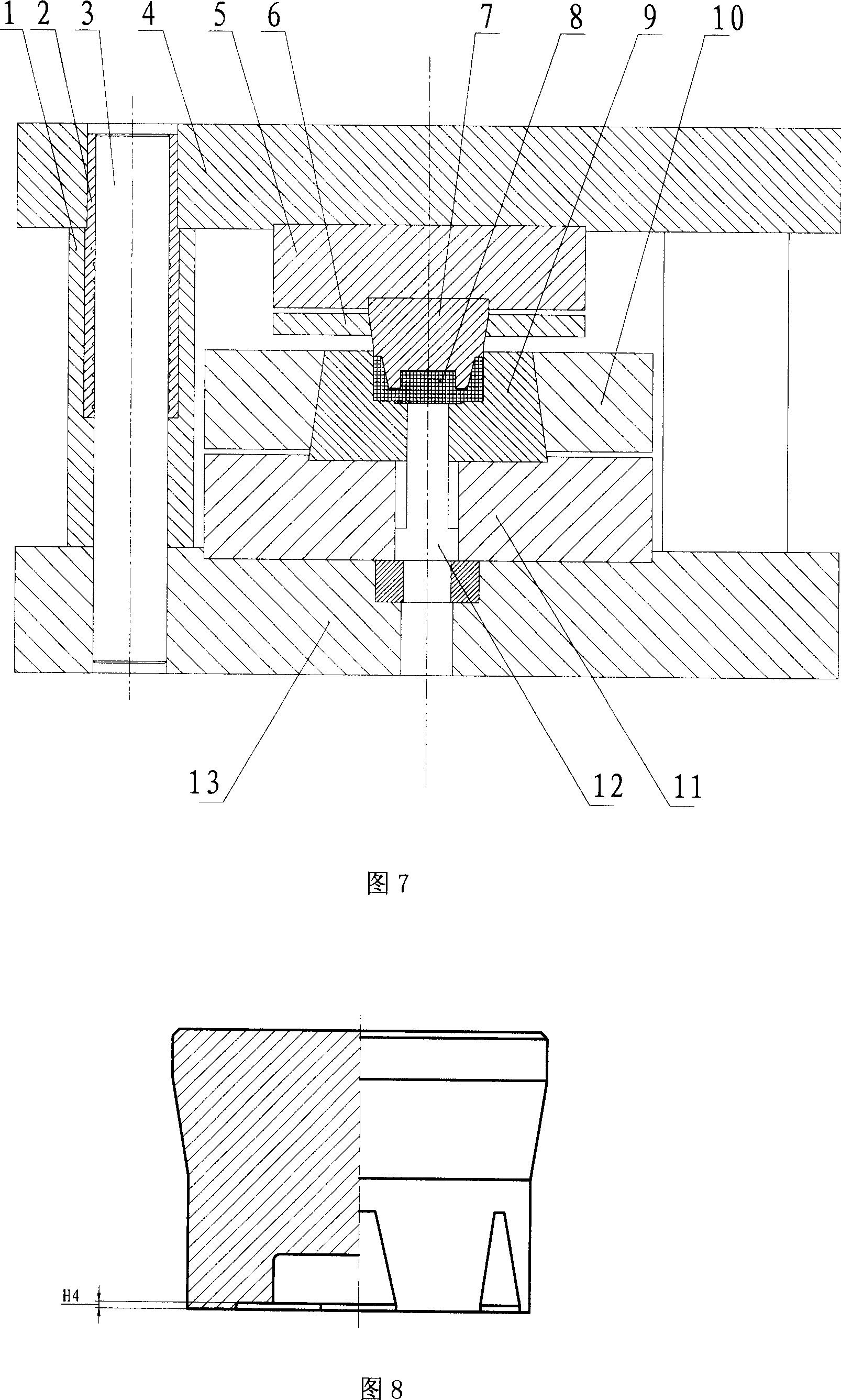

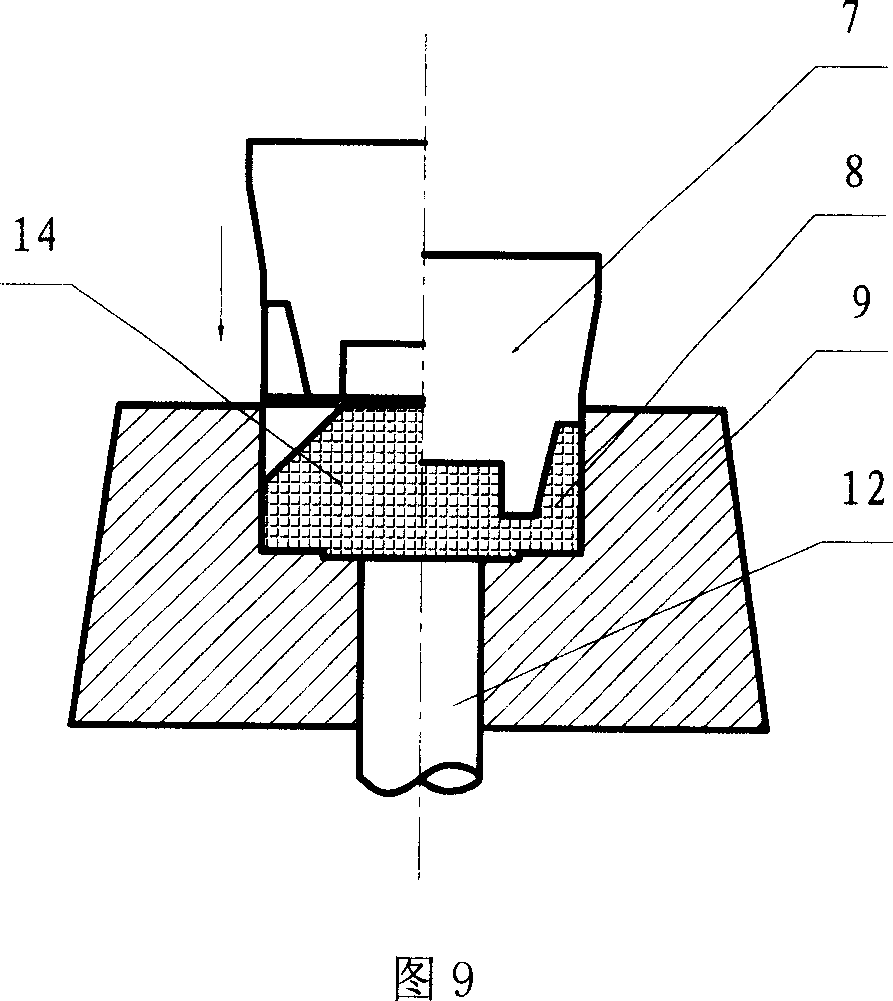

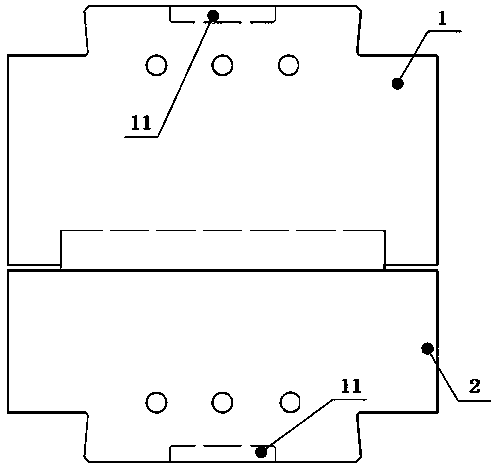

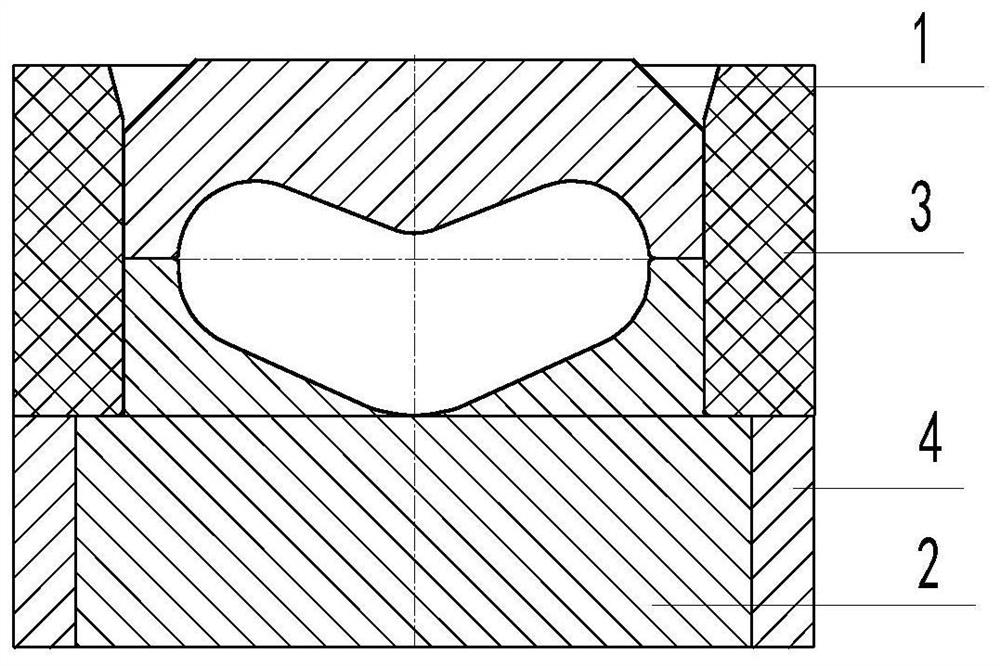

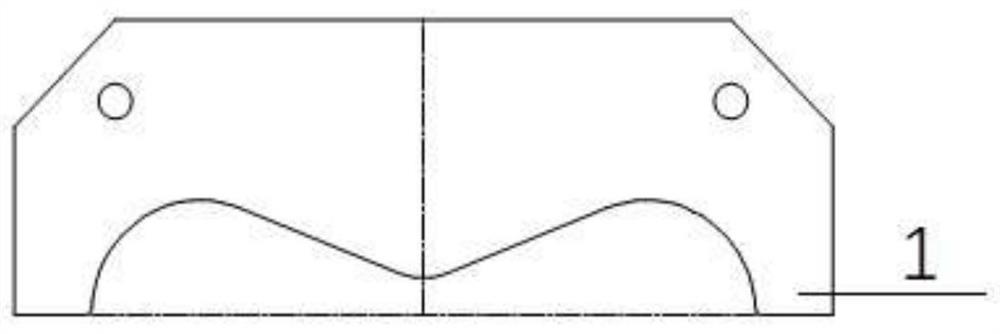

Passenger vehicle steering knuckle precise forging die for hammer forging

InactiveCN103406481AEasy to processEasy to install and adjustForging/hammering/pressing machinesKnuckleEngineering

The invention discloses a passenger vehicle steering knuckle precise forging die for hammer forging. The passenger vehicle steering knuckle precise forging die comprises an upper forging die and a lower forging die, the upper forging die is provided with an upper pre-forging cavity and an upper final-forging cavity, the lower forging die is provided with a lower pre-forging cavity matched with the upper pre-forging cavity and a lower final-forging cavity matched with the upper final-forging cavity, the periphery of the lower forging die at the lower pre-forging cavity and the lower final-forging die is provided with a resistance dam. The passenger vehicle steering knuckle precise forging die disclosed by the invention is suitable for the precise forging of the passenger vehicle steering knuckle for the hammer forging, the sufficient forming of the forge piece is satisfied, and the demands of size precision of misplacement of die and the surface quality and the long service life are satisfied.

Owner:ANHUI ANHUANG MACHINERY

Hot bulging forming method for bearing steel rectangular cross-section ring unit

ActiveCN103447378AHigh dimensional accuracySimplified bulging processShaping toolsProduction rateLarge deformation

The invention discloses a hot bulging forming method for a bearing steel rectangular cross-section ring unit. The hot bulging forming method comprises the following steps of fixing a preheated die sleeve on a worktable of a bulging machine, then, sleeving the periphery of a preheated bulging block in the bulging machine with the preheated bearing steel rectangular cross-section ring unit, and enabling the bearing steel rectangular cross-section ring unit to locate in an annular space formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve; starting the bulging machine to enable the bulging block to extrude the ring unit along a radial direction from the inner circumferential surface of the ring unit and extruding into the inner ring surface of the die sleeve after the ring unit is deformed by 9-11 percent to fill a closed mold cavity formed by encircling the outer circumferential surface of the bulging block and the inner ring surface of the die sleeve, and retaining the pressure of the ring unit to enable the ring unit to become the bulged rectangular cross-section ring unit. According to the method, by adopting one-time large-deformation bulging forming, the operation is simplified, and the bulged rectangular cross-section ring unit which is high in dimensional accuracy, good in product quality and high in production rate is obtained. The bulged rectangular cross-section ring unit is mainly used for revolved body parts used in the fields of wind power generation and the like.

Owner:GUIZHOU AVIATION TECHN DEV

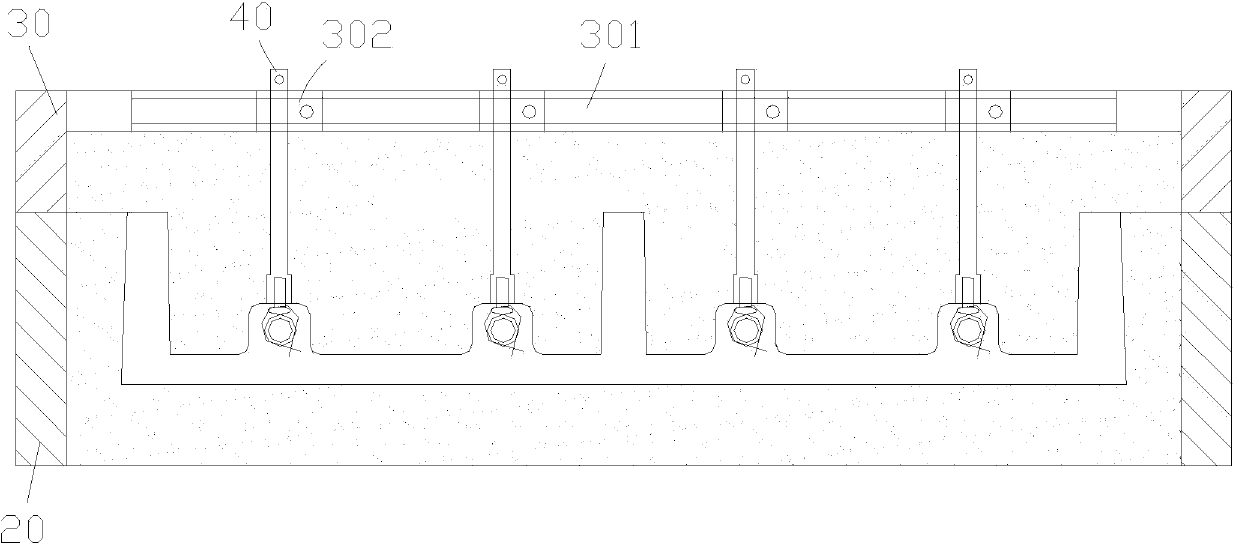

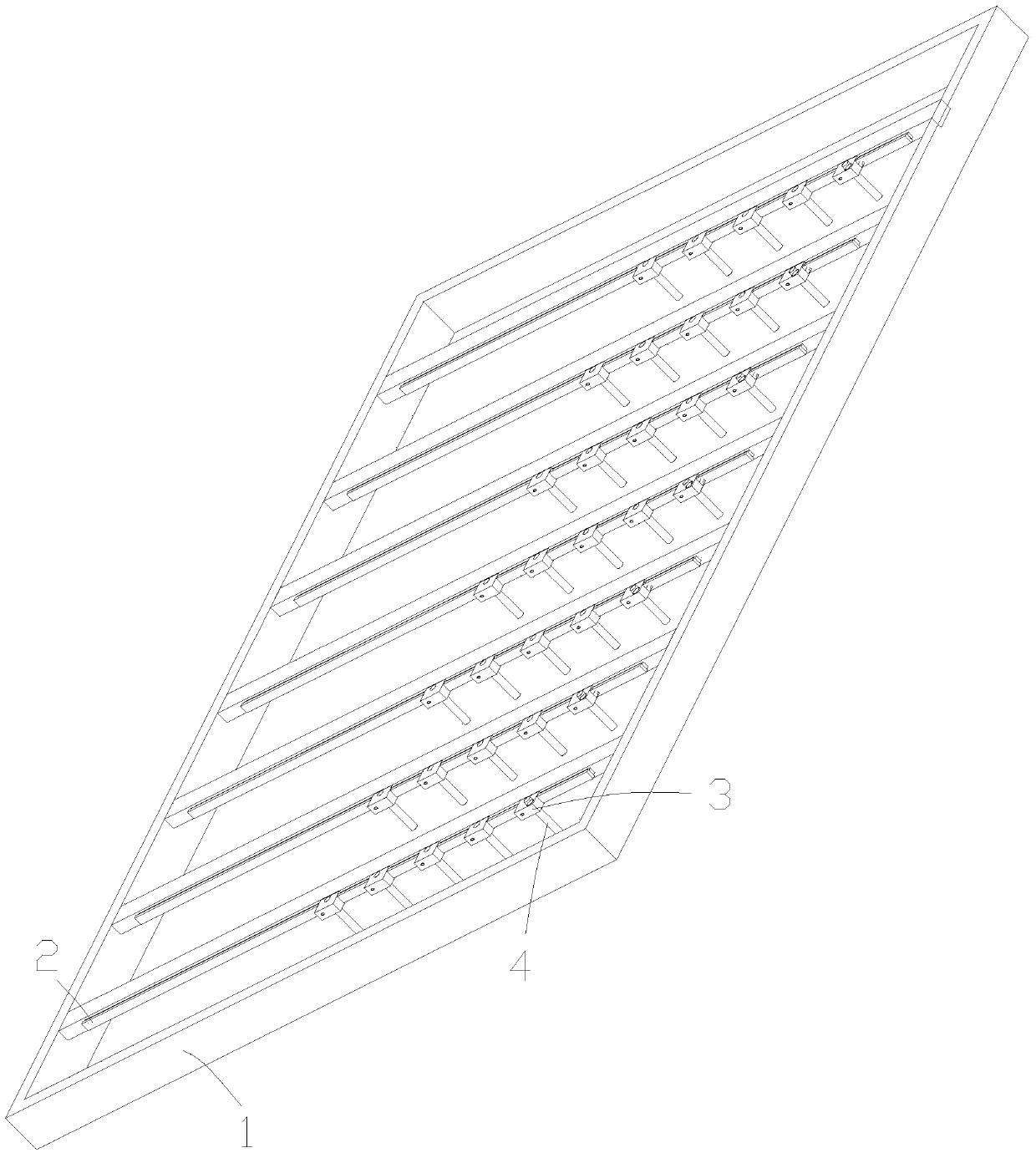

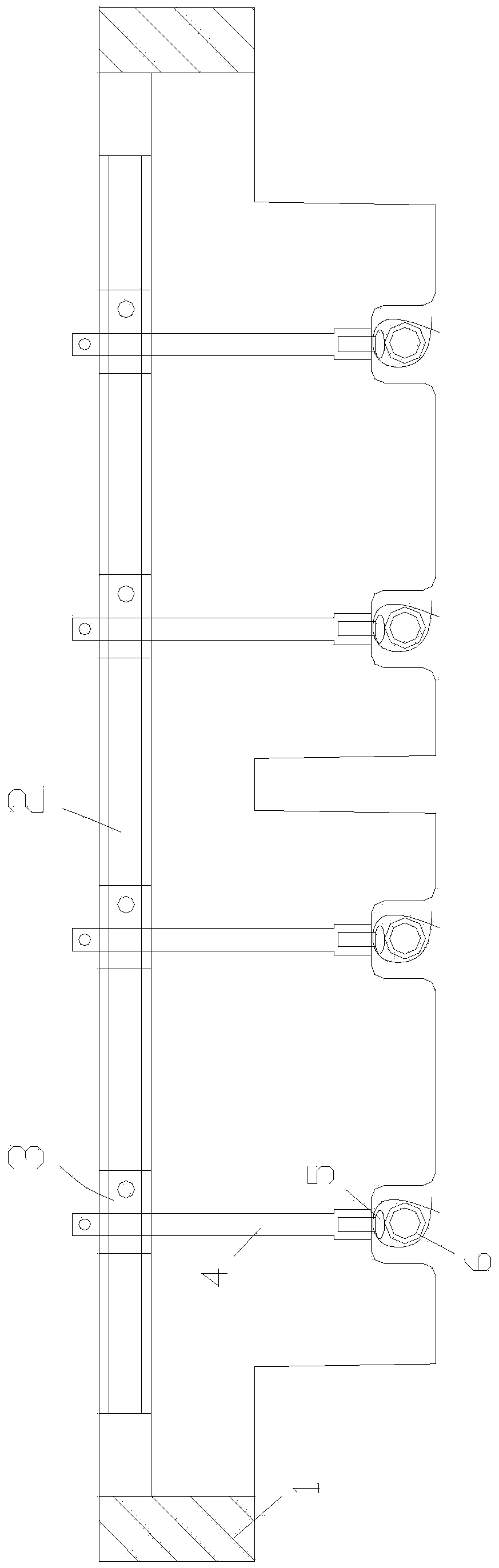

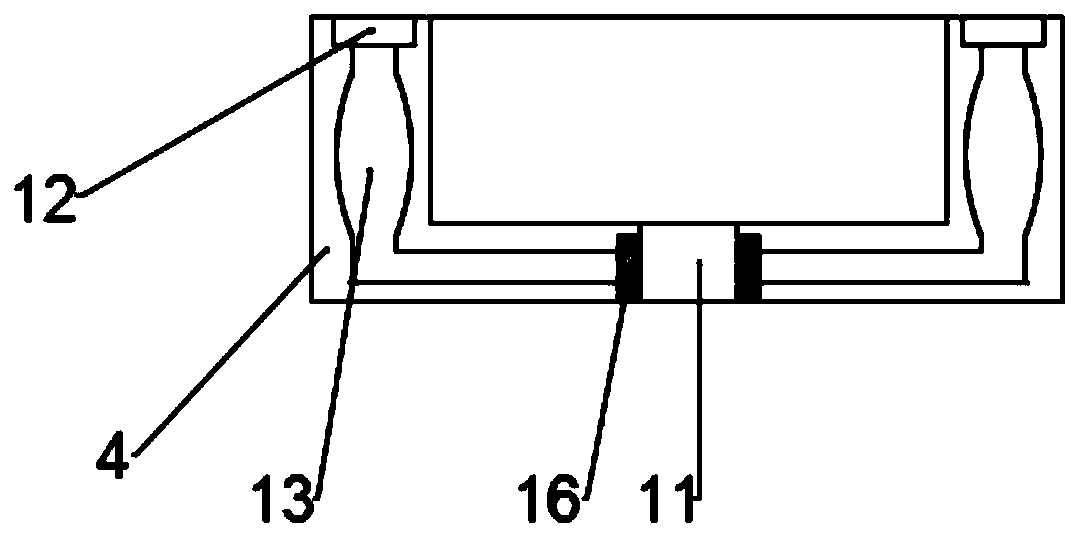

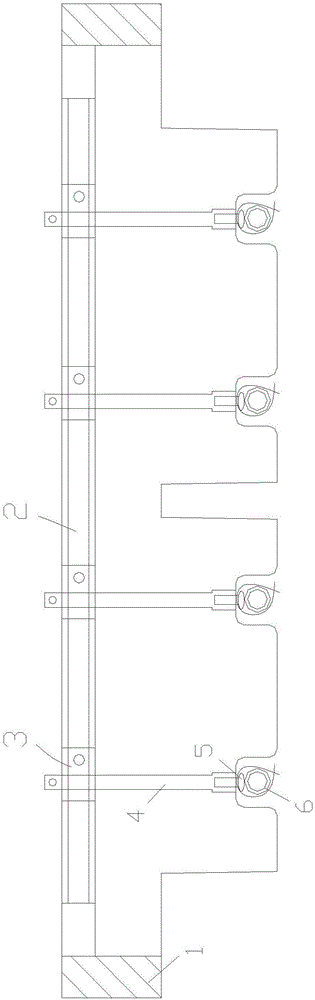

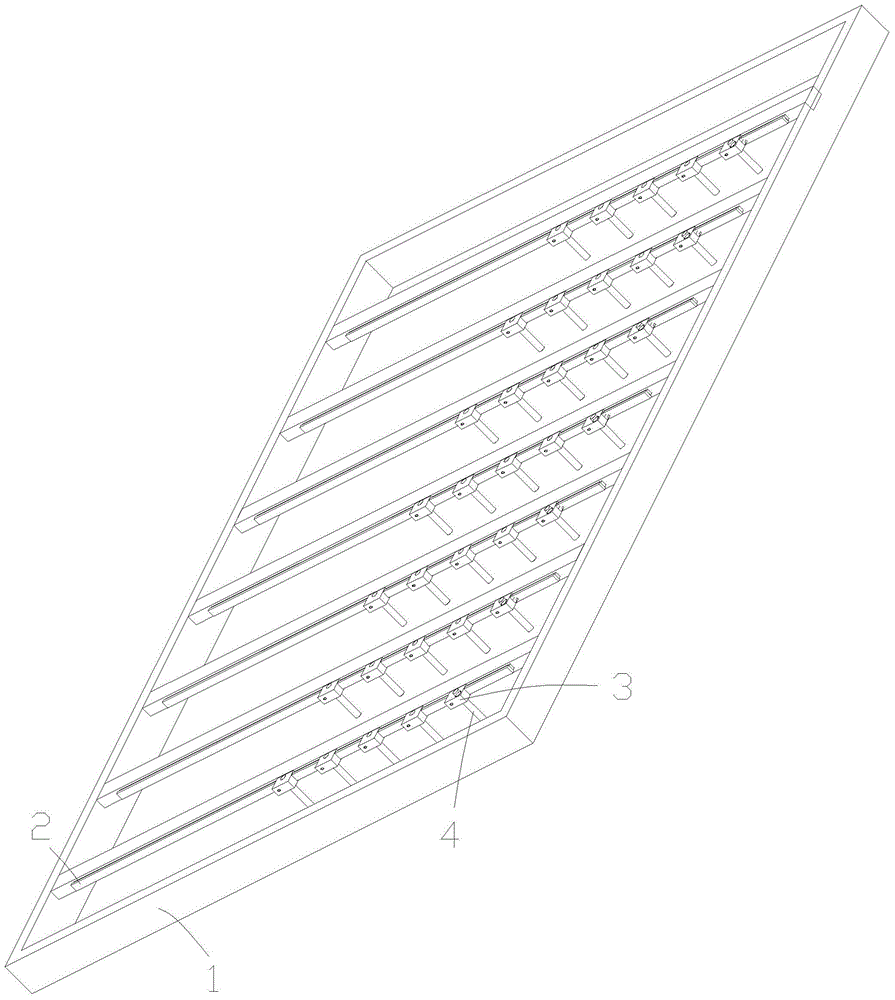

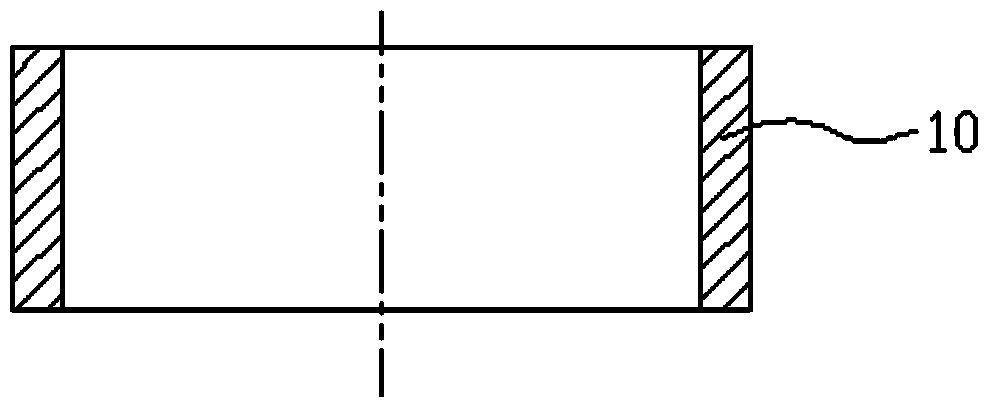

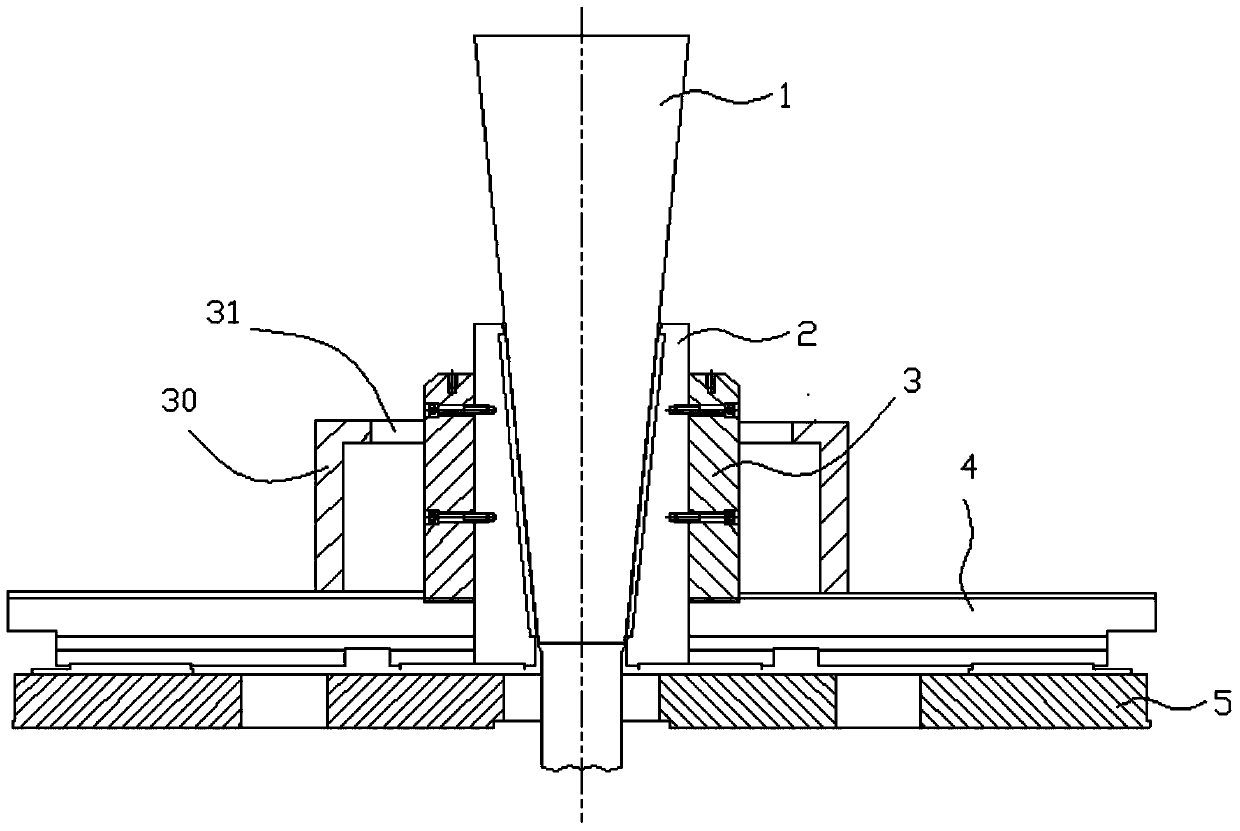

Template type pipe casting-containing stainless steel water pipe fixing structure

ActiveCN104399942AEliminate the process of milling groove buried pipeShorten the timeMoulding flasksEngineeringScrew thread

The invention discloses a template type pipe casting-containing stainless steel water pipe fixing structure. The structure comprises a sand mold upper box, wherein a rail is arranged at the upper end of the sand mold upper box; slide blocks are arranged in the rail at intervals; a through hole is formed in the middle of each slide block; a connecting rod is connected into each through hole; one end of each connecting rod is connected in the through hole in the corresponding slide block through screw threads and extends into the upper part of the corresponding through hole; the lower end of each connecting rod is positioned at the bottom of the sand mold upper box; a screw hole is formed in the lower end of each connecting rod; a fixing screw with the diameter of 1mm binding wire penetrates through each screw hole; a clearance with the diameter of 3 to 5mm is formed between the end part of each fixing screw and the bottom end of the corresponding connecting rod; the fixing screw is used for connecting a stainless steel water pipe; a binding wire on each fixing screw is used for fixing the stainless steel water pipe; the fixed stainless steel water pipe is in a suspension state; the surrounding of the stainless steel water pipe is not in direction contact with the sand mold upper box and a clearance is reserved, otherwise, the cast steel pipe is exposed on the surface of a casting.

Owner:CHUZHOU JINNUO INDAL

Oil-heating and heat-recovery type dyeing machine

InactiveCN1766195AReached temperatureEnhanced agitationTextile treatment machine arrangementsTextile/flexible product manufactureShunt DevicePulp and paper industry

The invention discloses a oil-heat thermal recovery dyeing machine, which comprises: a dyeing cylinder body connected with a filtrator that links to a circulating water pump, linking a water-cool exchanger with a shunt device and oil-heat exchangeer integrated by flange or in series between said cylinder body and pump. This invention can make good use of hot water, and increases utility for heat energy.

Owner:劳关明 +1

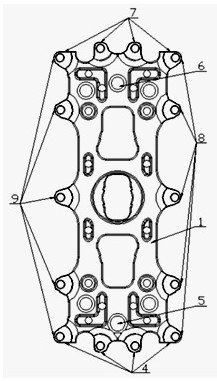

Preparation method for metal injection molding of SMT (Surface Mount Technology) carrier plate jig

The invention provides a preparation method for metal injection molding of an SMT (Surface Mount Technology) carrier plate jig. The preparation method is characterized by comprising the following steps: preparing metal powder; blending a binder; preparing feed; injection molding; trimming is conducted; degreasing is conducted; sintering is performed; shaping is conducted; straightening is conducted; performing double-sided grinding; cNC1 processing is carried out; cNC2 processing is carried out; rolling and polishing; performing cleaning; and fully inspecting the size. According to the method, by optimizing parameters such as raw material selection and preparation, mold design, degreasing and sintering processes, products which are good in flatness, free of cracking, good in use performance and meet the requirements of customers are produced, and by combining the metal injection molding (MIM) process and CNC finish machining, the production efficiency is improved, and the cost is reduced.

Owner:ANHUI HAOFANG ELECTROMECHANICS

Blocker-type forging method of travelling block lifting ring for petroleum drilling machine lifting system

ActiveCN112264567ASmall machining allowanceSave raw materialsForging/hammering/pressing machinesHeat conservationEngineering

The invention discloses a blocker-type forging method of a travelling block lifting ring for a petroleum drilling machine lifting system. The method comprises the following steps that a blocker-type forging die is designed according to the shape and size of a forge piece; a blank is heated to the initial forging temperature, and free forging upsetting and rounding are conducted after heat preservation; and the blank is placed in the die to be forged, and after die stripping, cooling in heap and normalizing are conducted to obtain the lifting ring. According to the blocker-type forging method of the travelling block lifting ring for the petroleum drilling machine lifting system, the flowing direction of metal is limited by means of a blocker-type die in a forging process, the shape of a final forge piece is close to that of a part, the machining allowance of the forge piece is small, raw materials are saved, and after forging is completed, a lower die is subjected to automatic die stripping under the dead weight without overturning the blocker-type die and an ejection device, the operation is simple and convenient, the production efficiency is high, and the safety and reliability are achieved; and a metal streamline in the forged piece conforms to the shape of the part, the metal streamline is not cut off in subsequent machining, the mechanical property is excellent, and the userequirement of the travelling block lifting ring can be well met.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

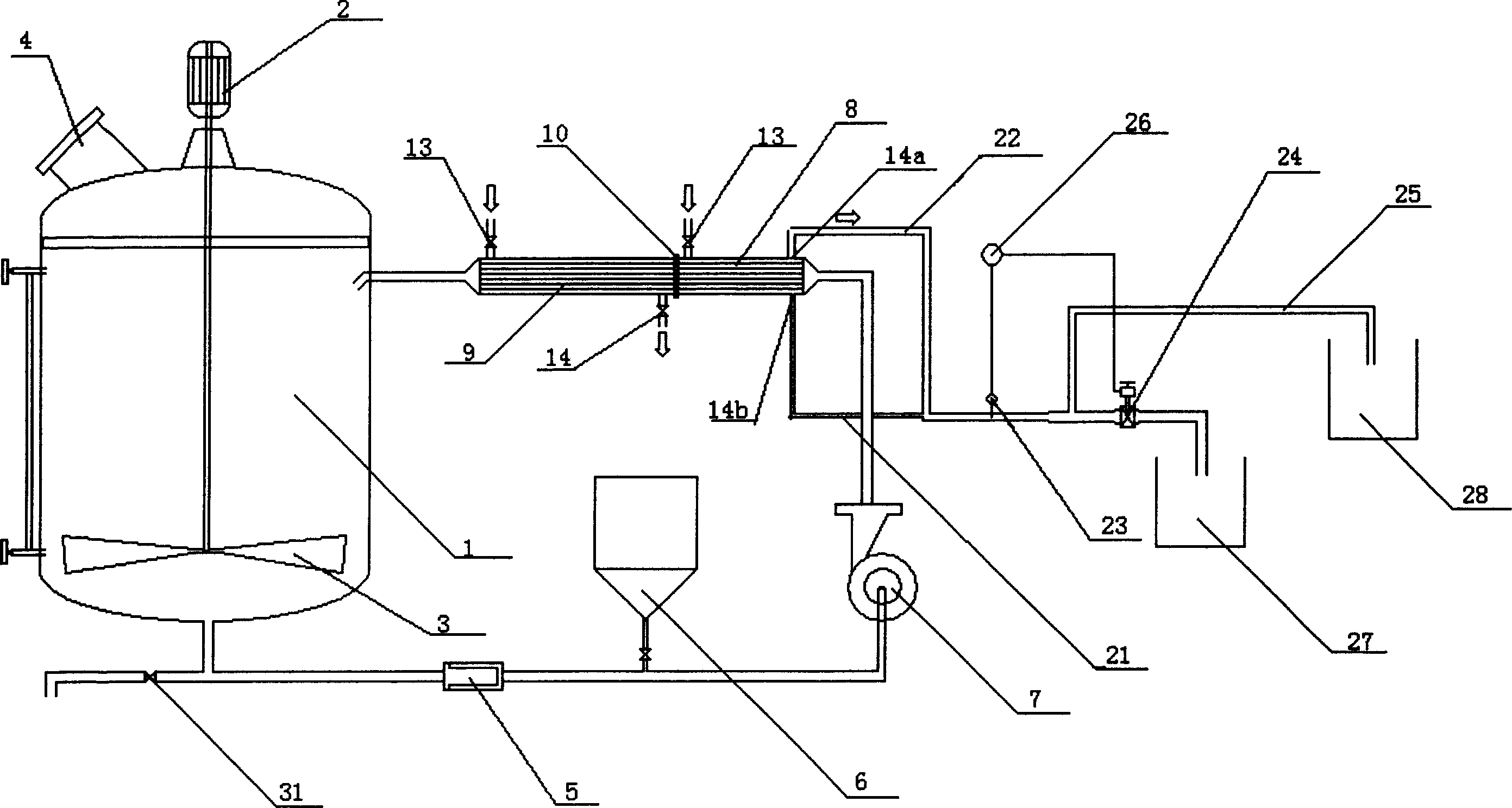

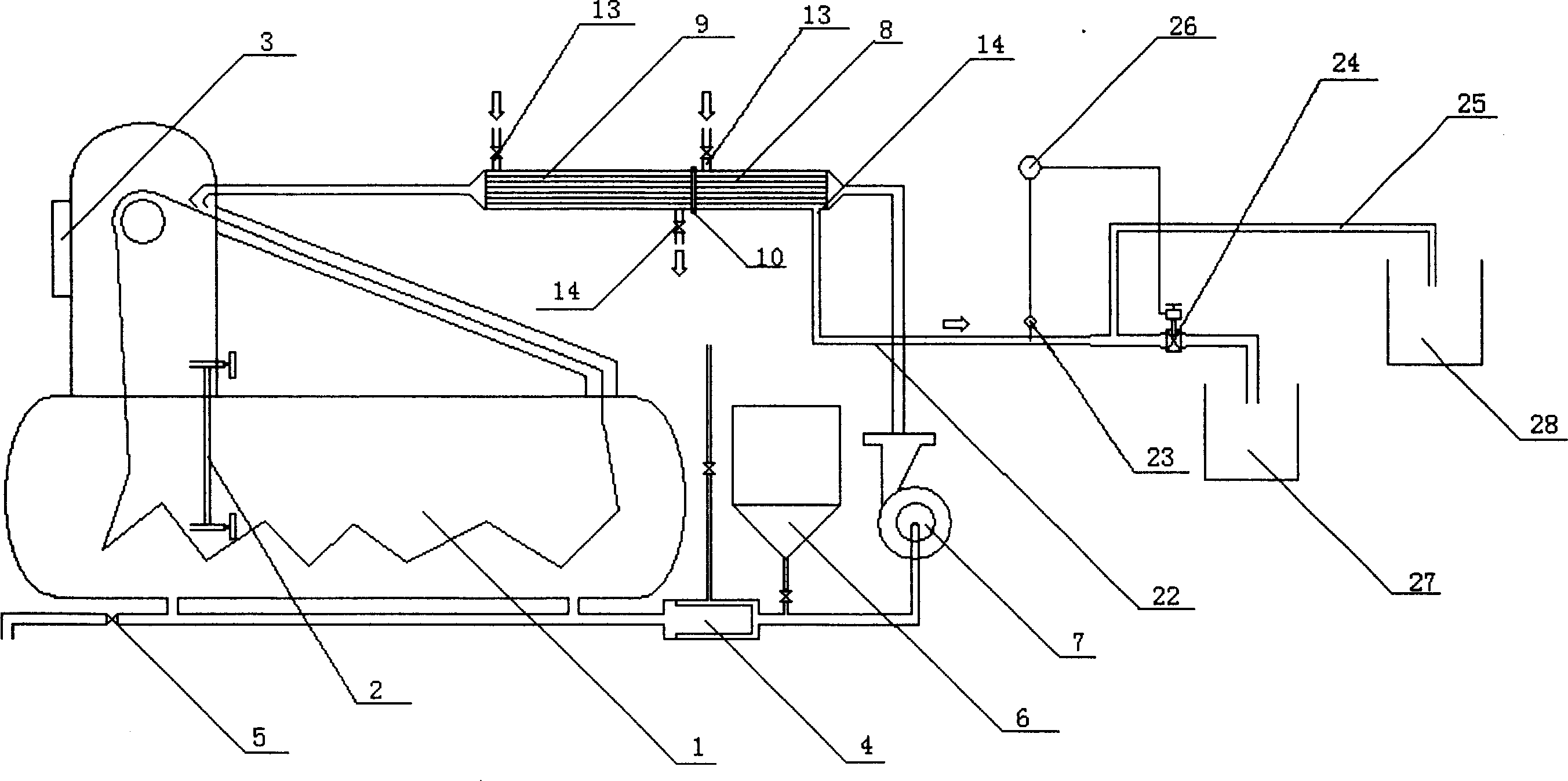

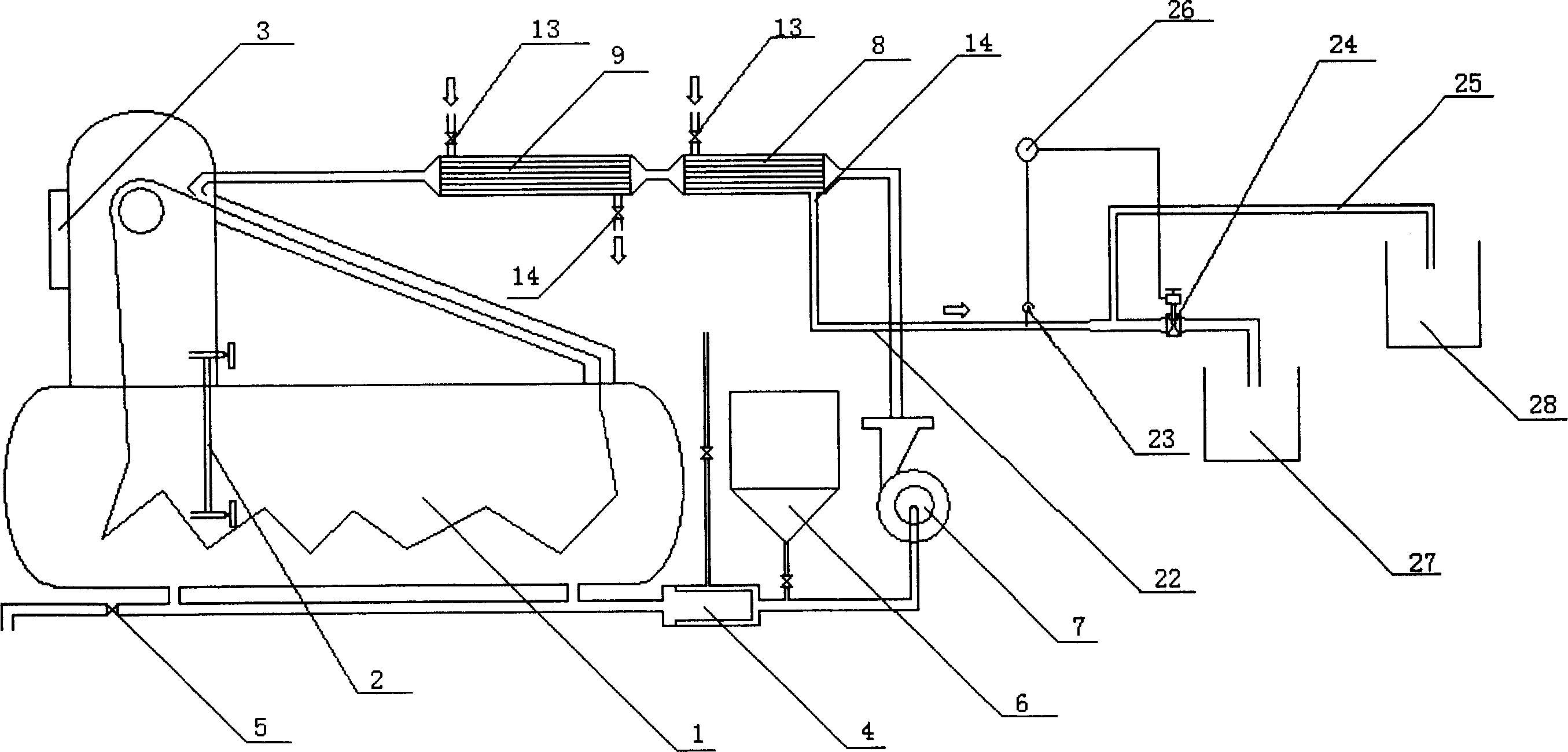

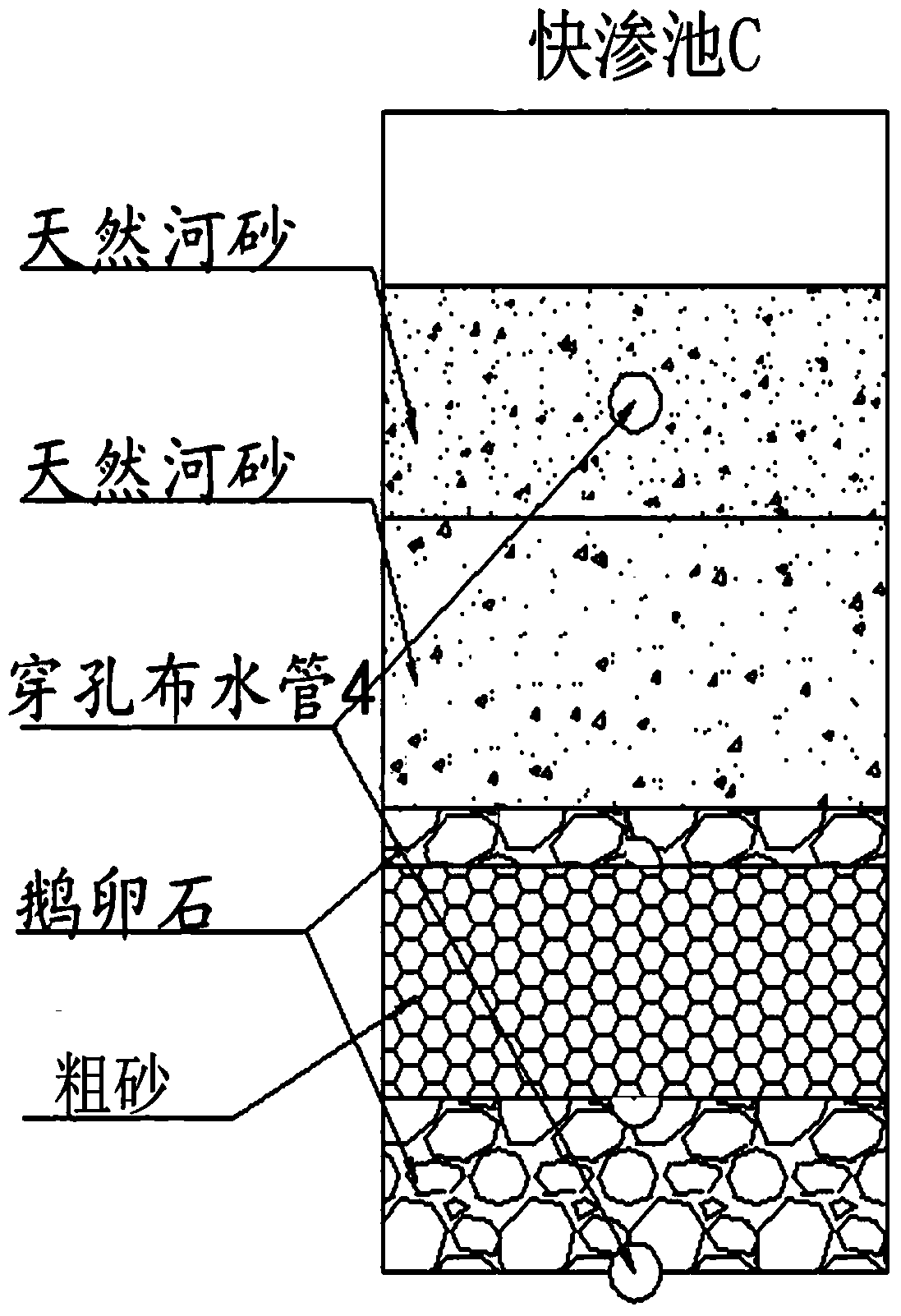

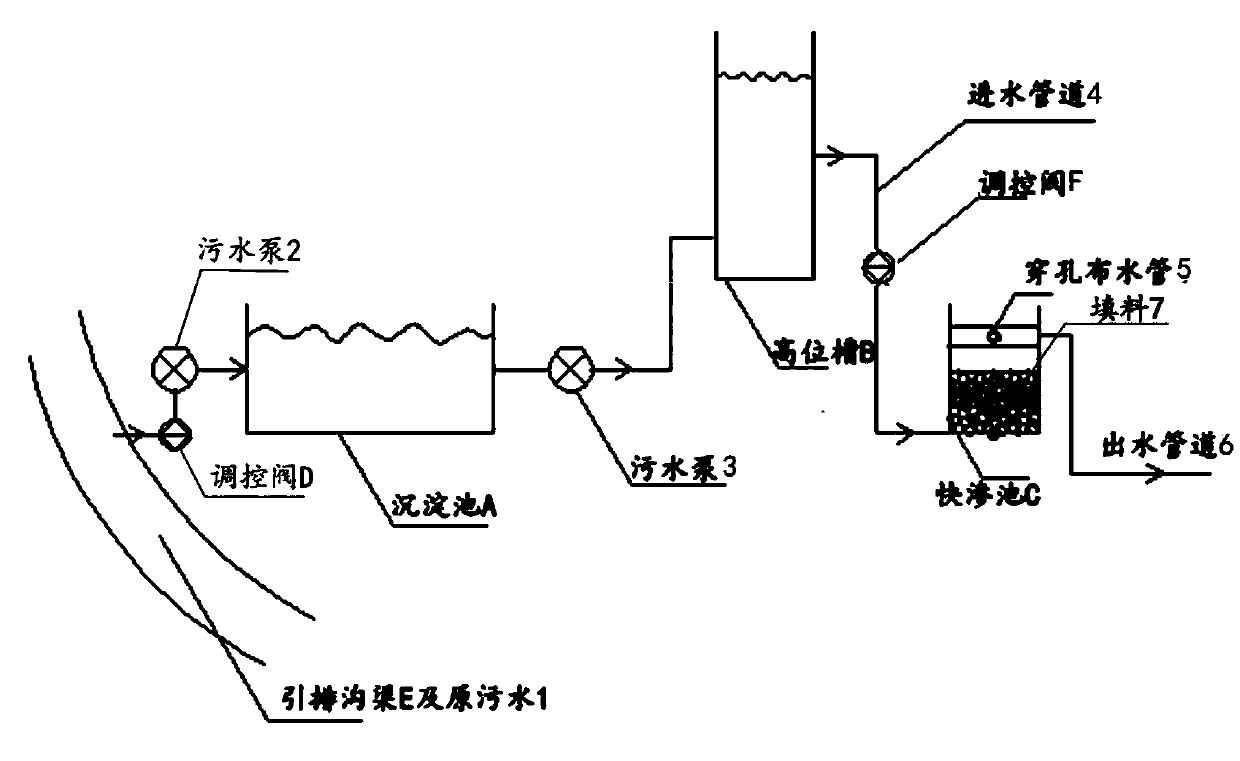

A water inlet method and device for improving the denitrification efficiency of an artificial percolation system

ActiveCN104176882BImprove nitrogen removal efficiencyRefining and Improving Processing EffectsMultistage water/sewage treatmentChemical oxygen demandSedimentation

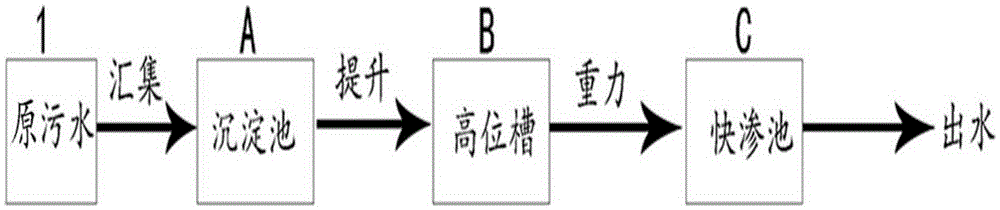

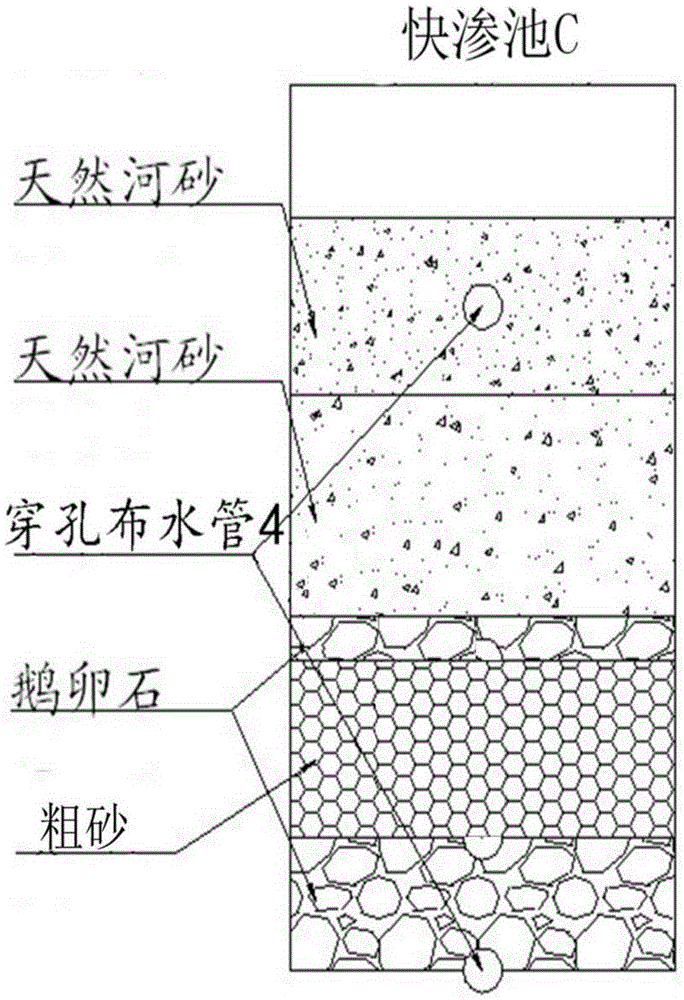

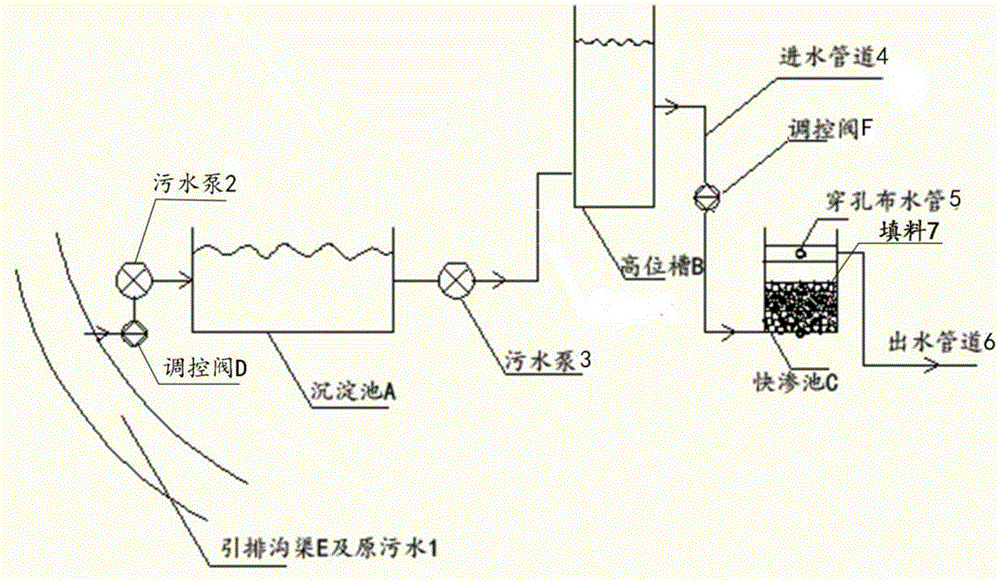

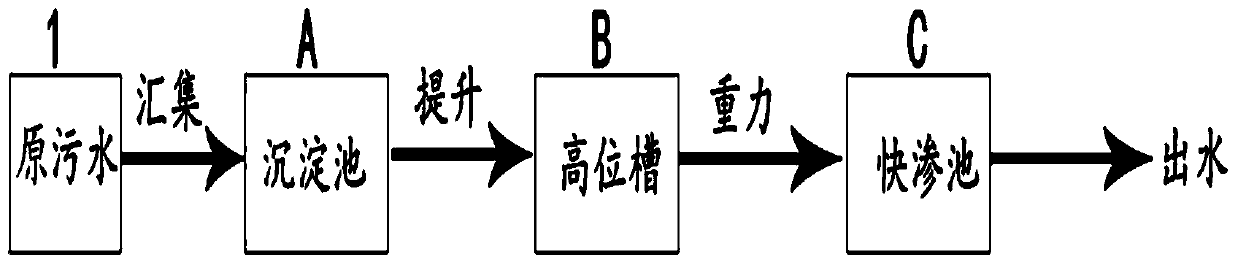

The invention discloses a water feeding method and device for improving the nitrogen removal efficiency of a constructed infiltration system. The method comprises the following steps: A, collection and pretreatment of original sewage: pumping the original sewage in a drainage ditch into a sedimentation tank through a control valve and a sewage pump which are connected with the sedimentation tank, and removing suspended matters and sand from the original sewage in the sedimentation tank; B, water lift: lifting the pretreated original sewage in the sedimentation tank to an elevated tank by the sewage pump; and C, deep treatment: controlling the effluent in the elevated tank by the control valve, discharging the pretreated water to a packing layer of a rapid infiltration tank, thus achieving sewage treatment. The sedimentation tank is connected with the drainage ditch through the sewage pump and the control valve on a pipeline, the sewage pump is connected with the sedimentation tank, the effluent is connected with the elevated tank through the sewage pump, the elevated tank is connected with a water inlet pipeline, the water inlet pipeline is connected with the rapid infiltration tank through the control valve on the pipeline, and a perforated water distribution pipe is connected with a water outlet pipeline. Nitrogen, phosphorus and COD (chemical oxygen demand) can be removed by the CRI (Constructed Rapid Infiltration) system. The device is simple in structure and convenient to use, and can be used for realizing efficient purification of sewage.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Water feeding method and device for improving nitrogen removal efficiency of constructed infiltration system

ActiveCN104176882AImprove nitrogen removal efficiencyRefining and Improving Processing EffectsMultistage water/sewage treatmentChemical oxygen demandSedimentation

The invention discloses a water feeding method and device for improving the nitrogen removal efficiency of a constructed infiltration system. The method comprises the following steps: A, collection and pretreatment of original sewage: pumping the original sewage in a drainage ditch into a sedimentation tank through a control valve and a sewage pump which are connected with the sedimentation tank, and removing suspended matters and sand from the original sewage in the sedimentation tank; B, water lift: lifting the pretreated original sewage in the sedimentation tank to an elevated tank by the sewage pump; and C, deep treatment: controlling the effluent in the elevated tank by the control valve, discharging the pretreated water to a packing layer of a rapid infiltration tank, thus achieving sewage treatment. The sedimentation tank is connected with the drainage ditch through the sewage pump and the control valve on a pipeline, the sewage pump is connected with the sedimentation tank, the effluent is connected with the elevated tank through the sewage pump, the elevated tank is connected with a water inlet pipeline, the water inlet pipeline is connected with the rapid infiltration tank through the control valve on the pipeline, and a perforated water distribution pipe is connected with a water outlet pipeline. Nitrogen, phosphorus and COD (chemical oxygen demand) can be removed by the CRI (Constructed Rapid Infiltration) system. The device is simple in structure and convenient to use, and can be used for realizing efficient purification of sewage.

Owner:INST OF AQUATIC LIFE ACAD SINICA

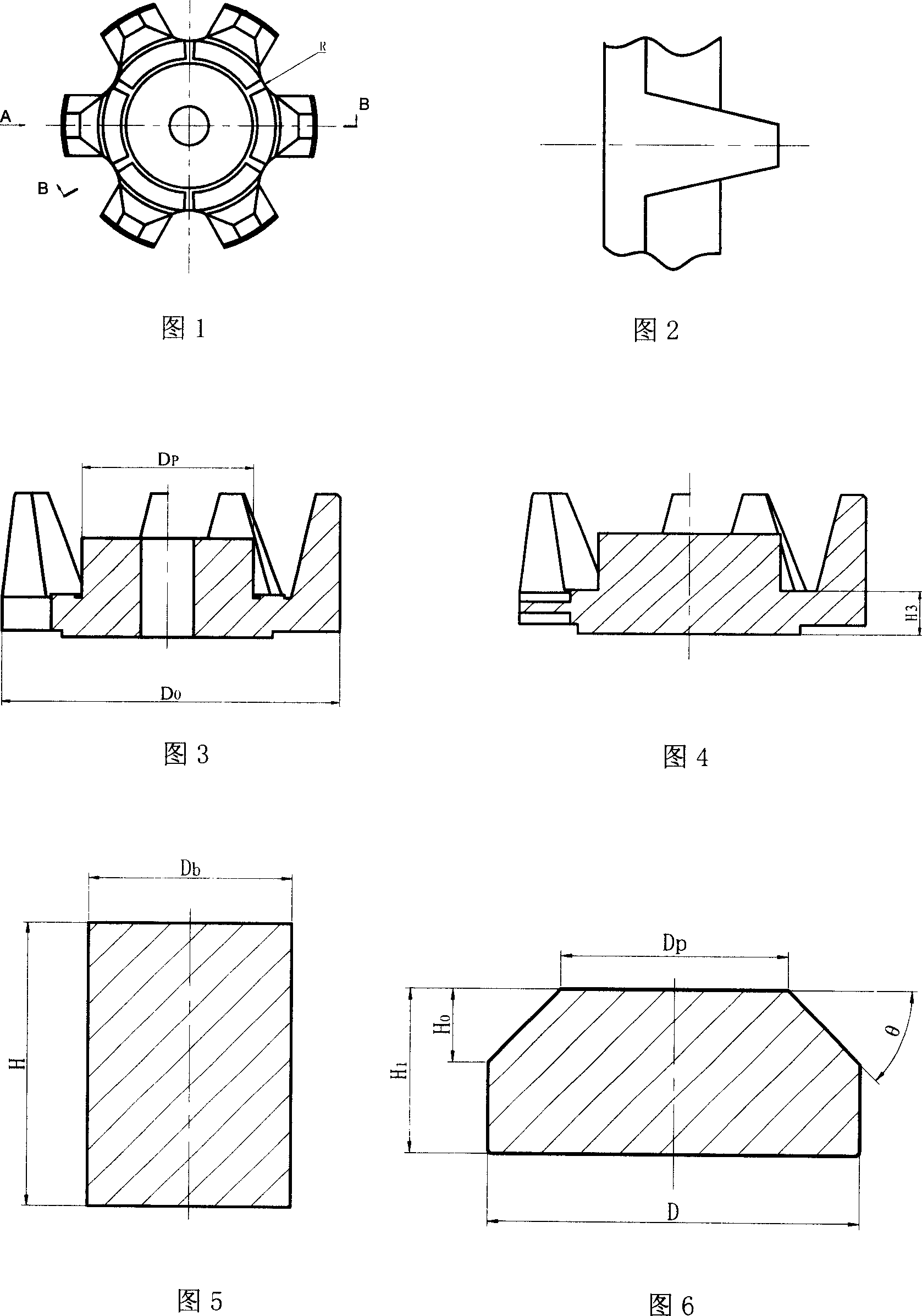

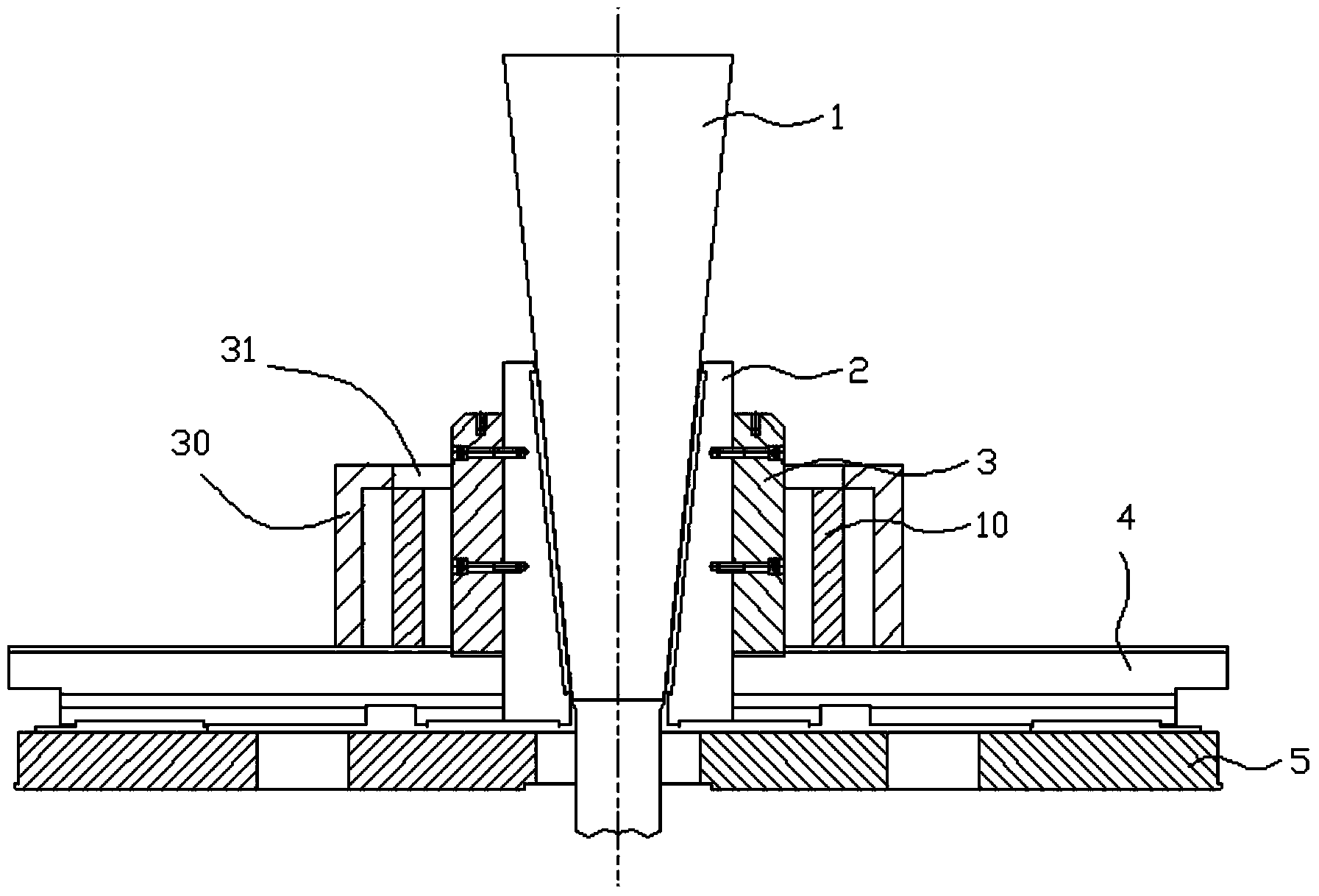

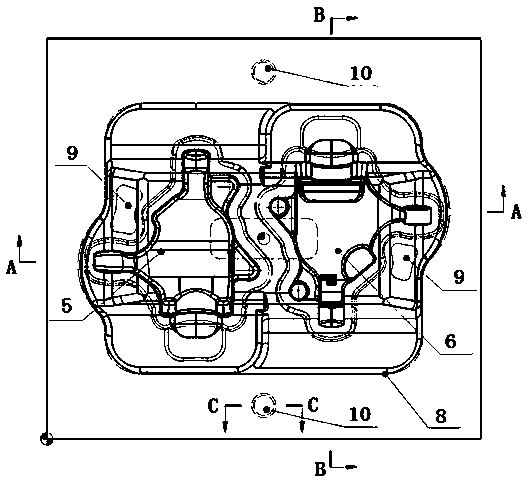

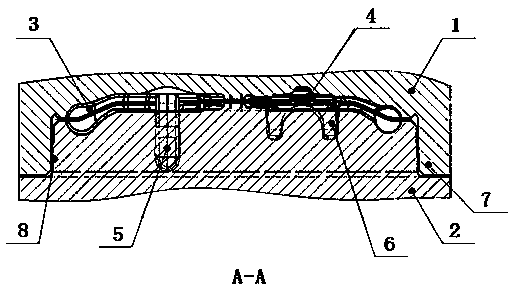

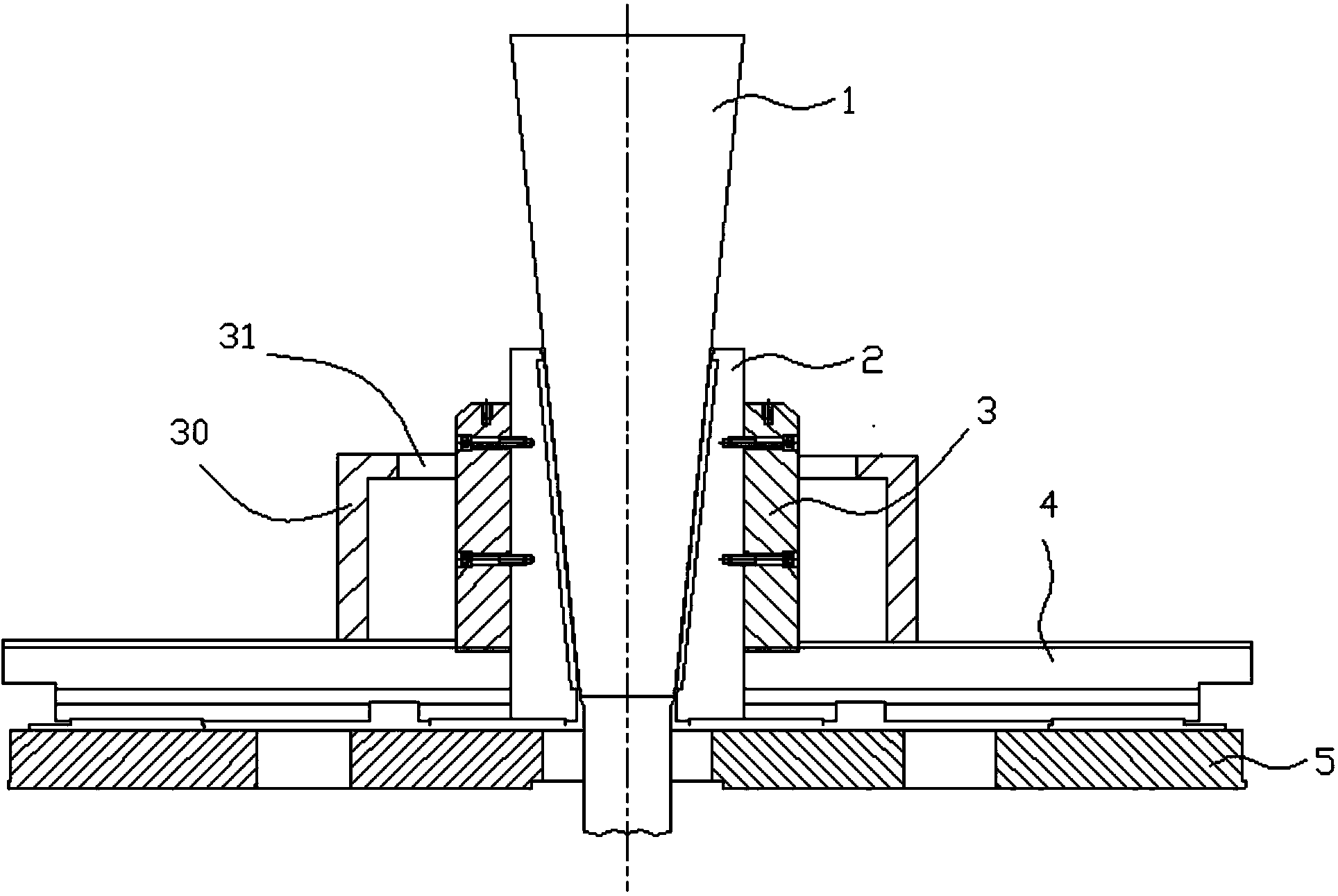

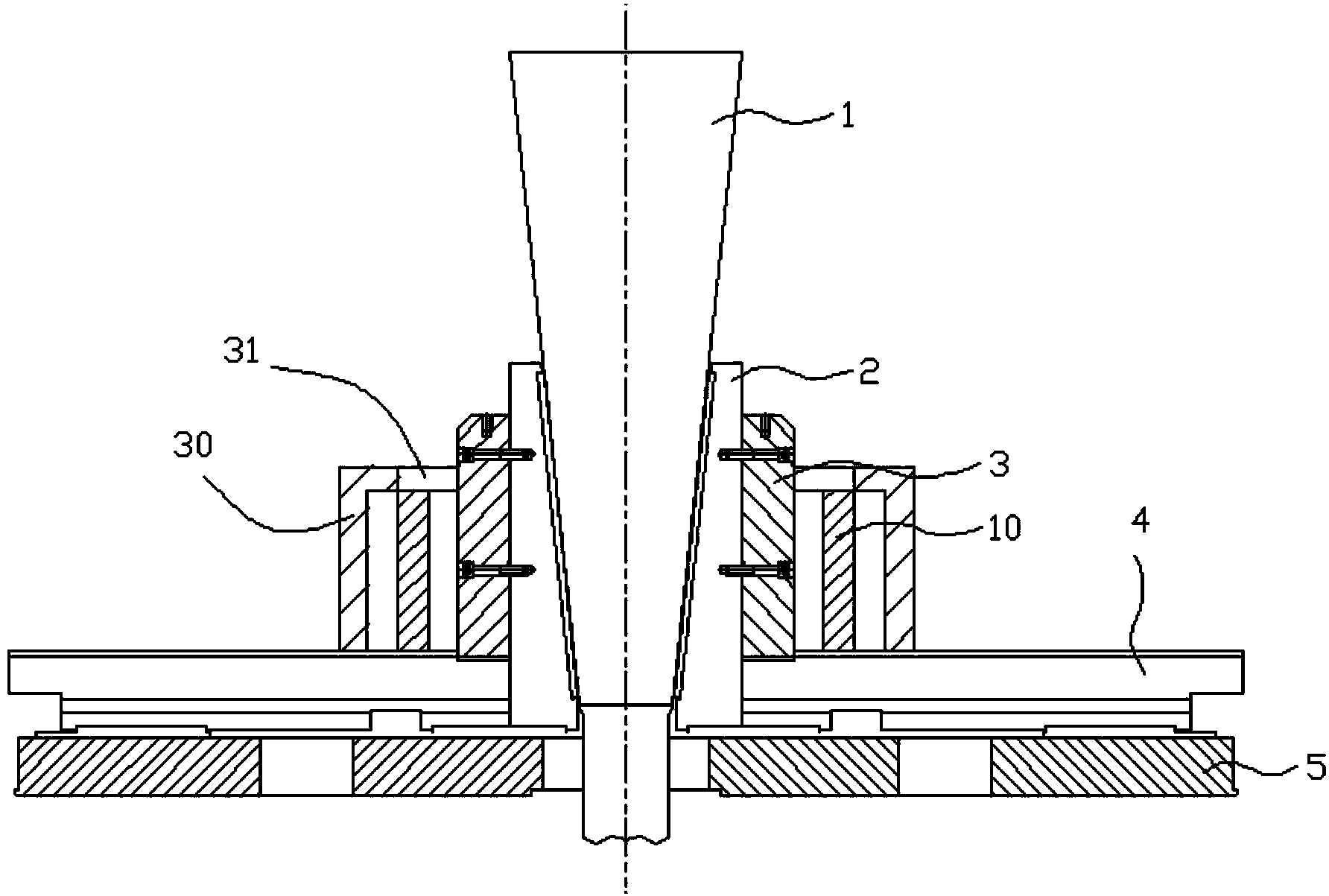

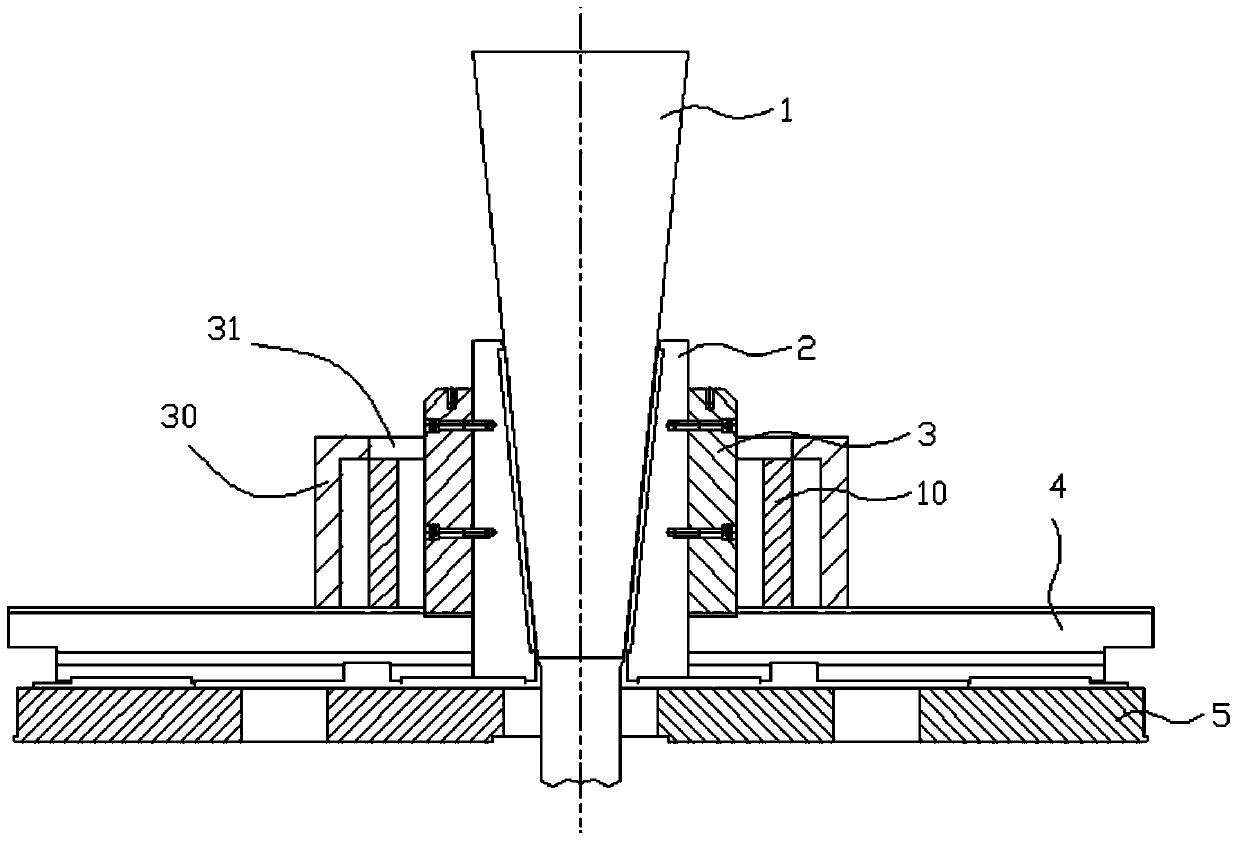

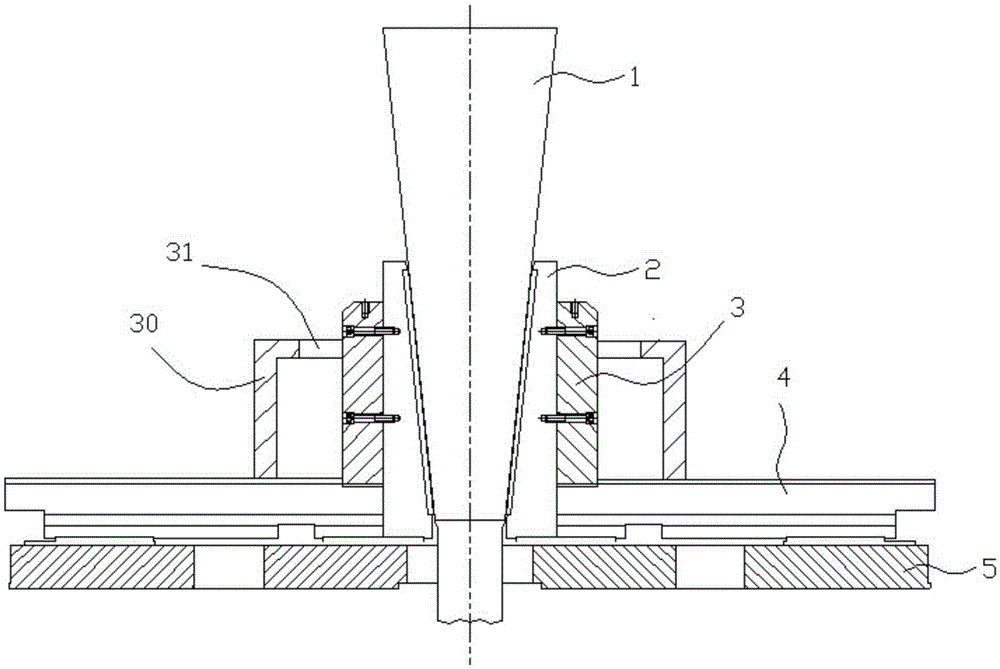

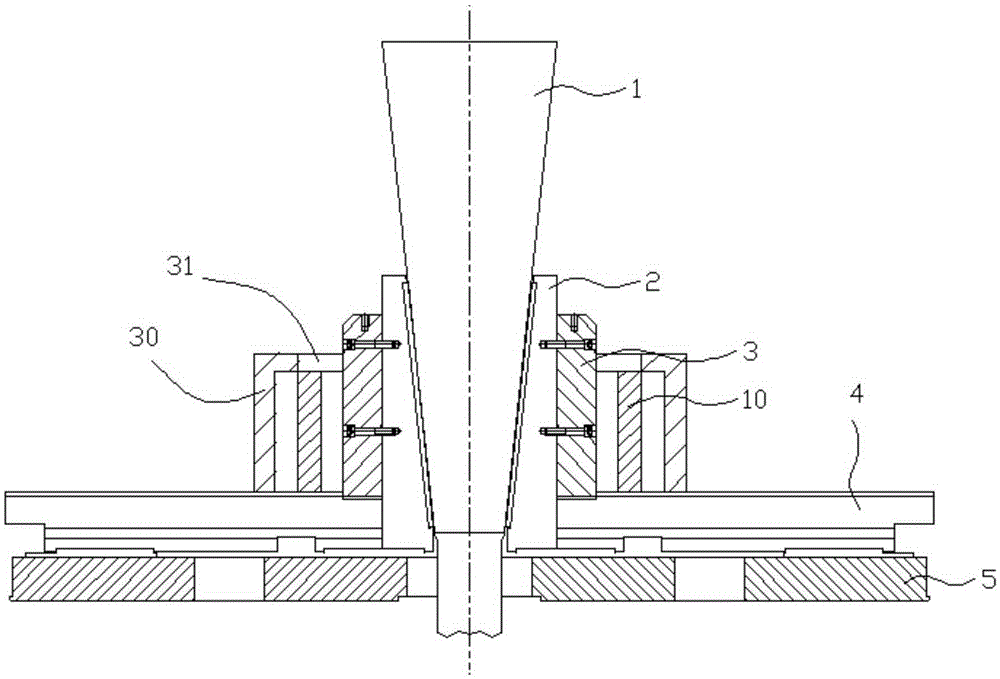

Grate closed-die forging technology and forming closed die

PendingCN110405125AIncrease profitLow costForging/hammering/pressing machinesAir compressionMedium frequency

The embodiment of the invention discloses a grate closed-die forging technology. The grate closed-die forging technology comprises the steps that material selecting and feeding are conducted; multi-stage medium frequency heating is conducted, and oxide skins are removed; a lubricant and a releasing agent are used, and bar stocks are put into a die after the die is preheated; and after the surfacesof the bar stocks are lubricated through the glass lubricant, the die is closed. The closed die is included and comprises an upper die sleeve connected with an upper die, a lower die sleeve connectedwith a lower die, a concave die and a convex die; the upper die sleeve is provided with a fixing plate for being connected with the upper die sleeve and the convex die, an elastic cushion is arrangedbetween the convex die and the fixing plate, and the convex die is installed on the fixing plate through a hold-down nut; the bottom of the lower die sleeve is provided with a plurality of ejector rods at equal intervals, through column holes for installing the ejector rods are formed in the lower die sleeve, and the edge of the periphery of the upper surface of the lower die sleeve is provided with an air compression groove, air inflation holes are formed in the position, at the bottom of the interior of the air compression groove, of the lower die sleeve, and the air inflation holes extendto the through column holes; and the structure strength of existing grates during forging is improved, and the number of times of forging in the forging process is decreased.

Owner:中机精密成形产业技术研究院(安徽)股份有限公司

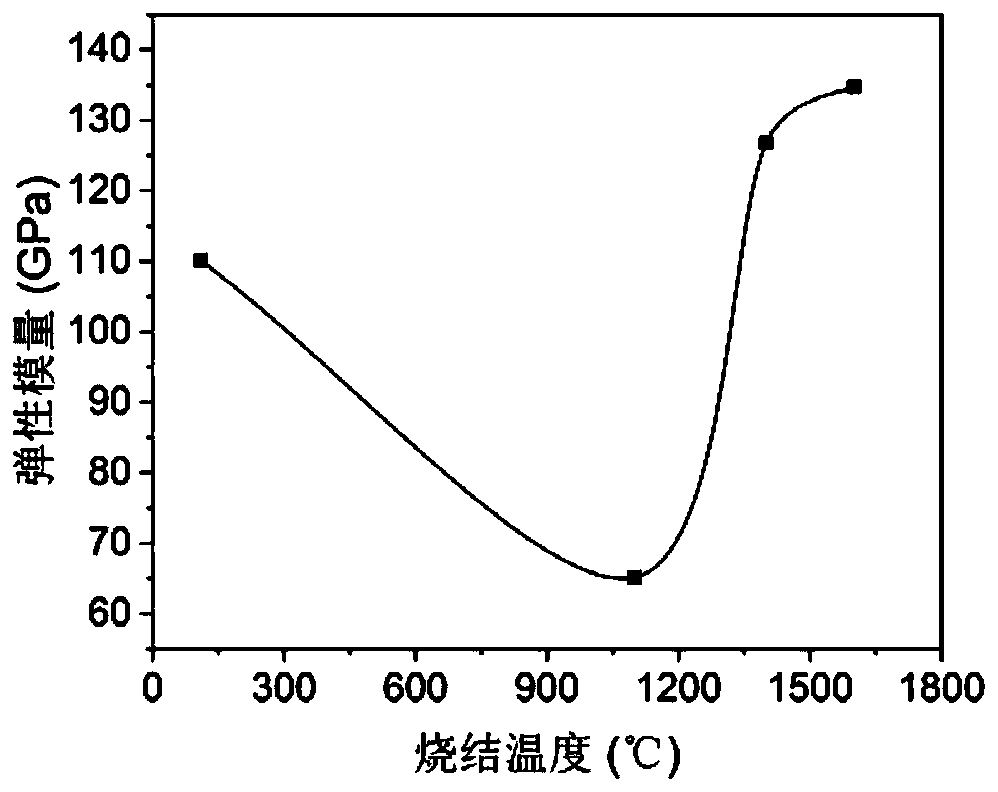

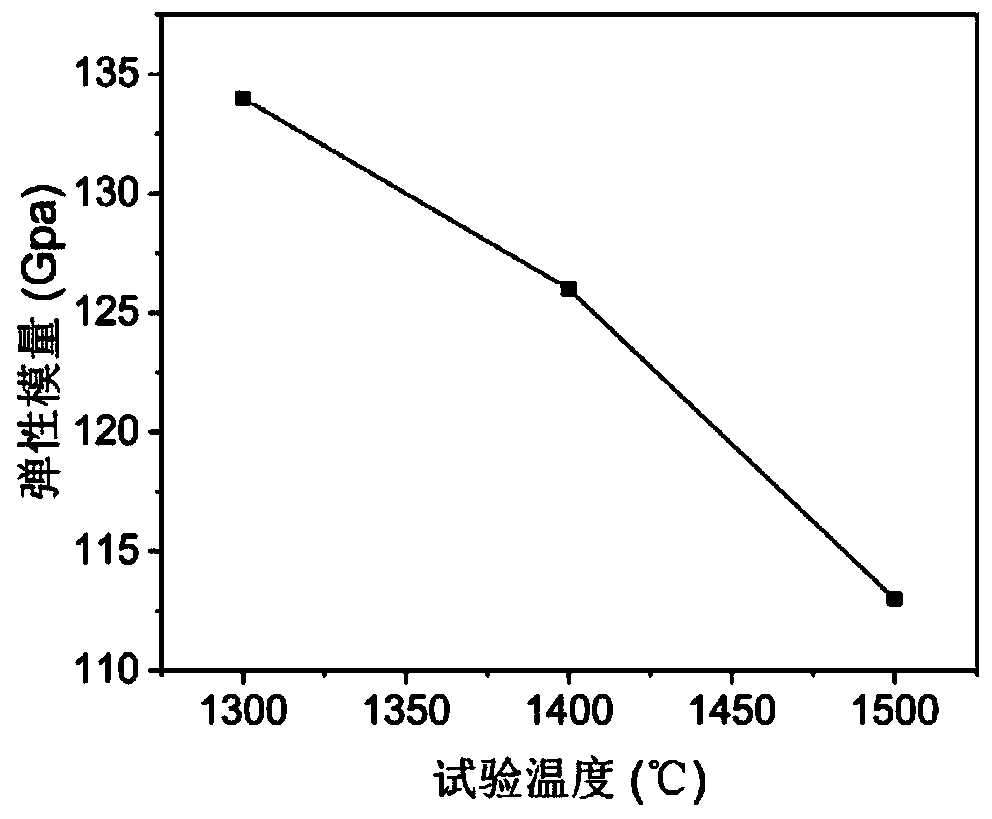

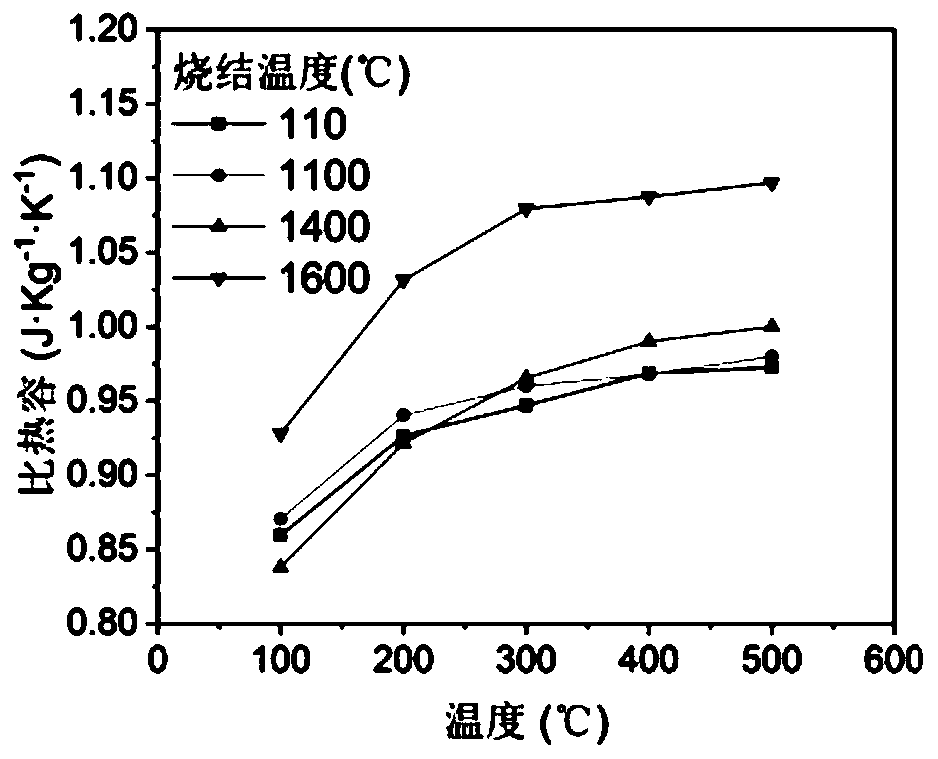

Light casting material for steel ladle gas-permeable plug, and preparation method thereof

The invention provides a light casting material for a steel ladle gas-permeable plug, and a preparation method thereof, wherein the raw materials comprise, by weight, 20-24% of tabular corundum with aparticle size of 3-5 mm, 26-30% of tabular corundum with a particle size of 1-3 mm, 17-19% of tabular corundum with a particle size of 0-1 mm, 13-15% of tabular corundum with a particle size of 60-75[mu]m, 6-9% of tabular corundum with a particle size of 30-45 [mu]m and 6-9% of alpha-Al2O3 with a particle size of 1-2 [mu]m. The preparation method comprises three steps of raw material mixed powder preparation, injection molding curing and roasting treatment, wherein the sintering temperature of the roasting treatment is 1350-1450 DEG C. According to the invention, the prepared light casting material has good slag resistance; and with the preparation method, the mass of the light casting material can be reduced while the compactness of the structure is increased, the stability and the service life of the gas-permeable plug are improved, and the maintenance is convenient.

Owner:WUHAN UNIV OF SCI & TECH

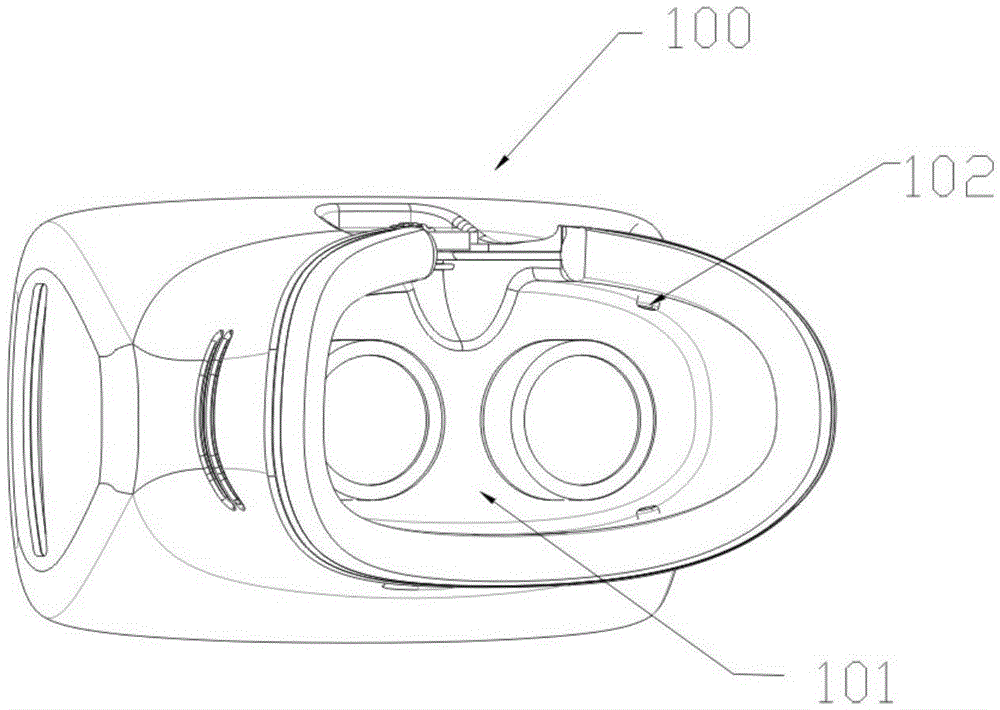

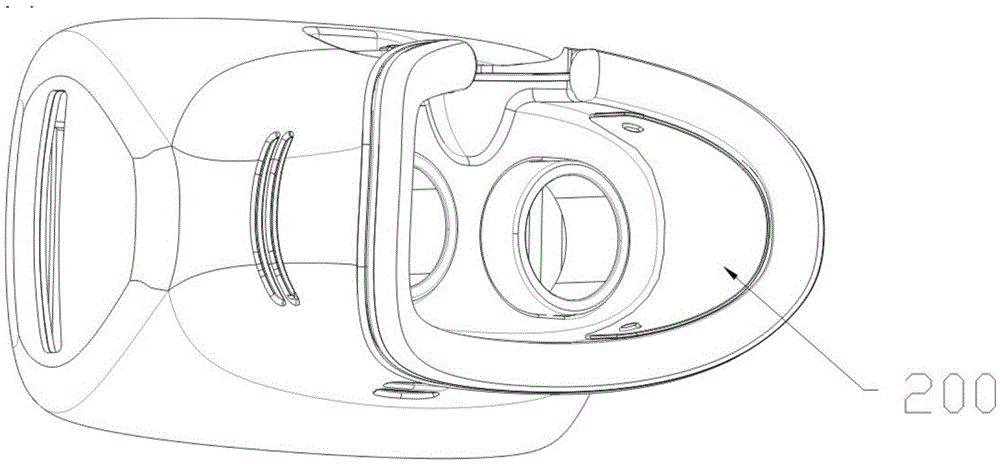

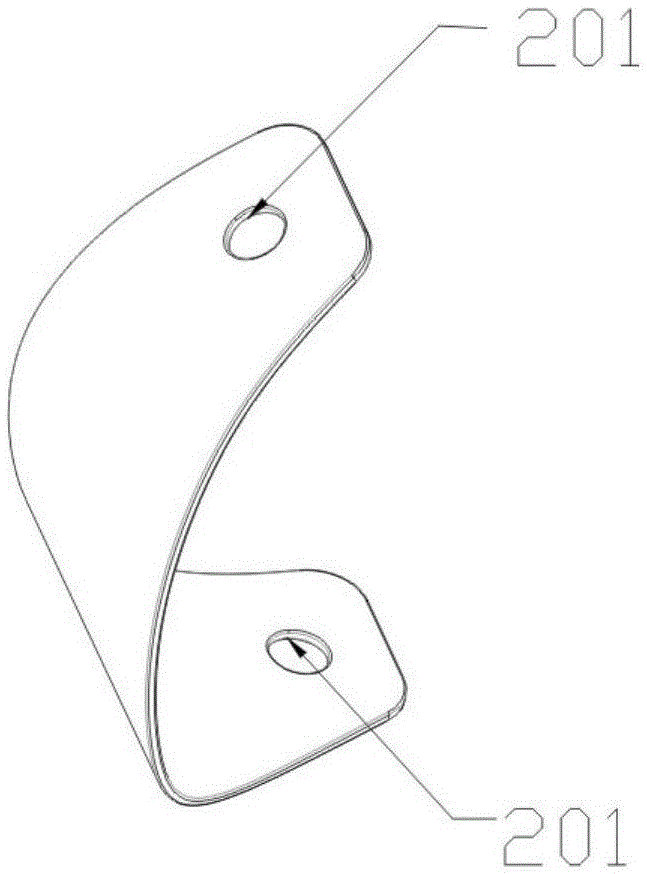

Volatile medicine dosing device with eye health caring effect

InactiveCN105534638APlay a health functionConducive to fullEye treatmentVolatile drugsBiomedical engineering

The invention provides a volatile medicine dosing device with the eye health caring effect. The medicine dosing device is a head-wearing-type device. The head-wearing-type device is worn to the head and comprises a body structure and a fixing device. The body structure comprises a shell surrounding the two eyes at the same time; the fixing device is wound around the back of the head or is hung to the double ears; volatile medicine storing devices are arranged at the portions, corresponding to the peripheries of the eyes of the human body, of the interior of the shell. According to the medicine dosing device, traditional dosing modes such as an eye hot-compressing mode or an eye liquid dropping mode are broken through, the head-wearing-type device is adopted, volatile medicine is stored to the portions, corresponding to the peripheries of the eyes of the human body, of the interior of the shell of the head-wearing-type device, the medicine dosing device can be used for various myopia therapeutic apparatuses and particularly can be used for various amblyopia therapeutic apparatuses, the effect of the medicine is developed while the eyes are trained,, and convenience and practicality are achieved.

Owner:HANGZHOU LUKE TECH CO LTD

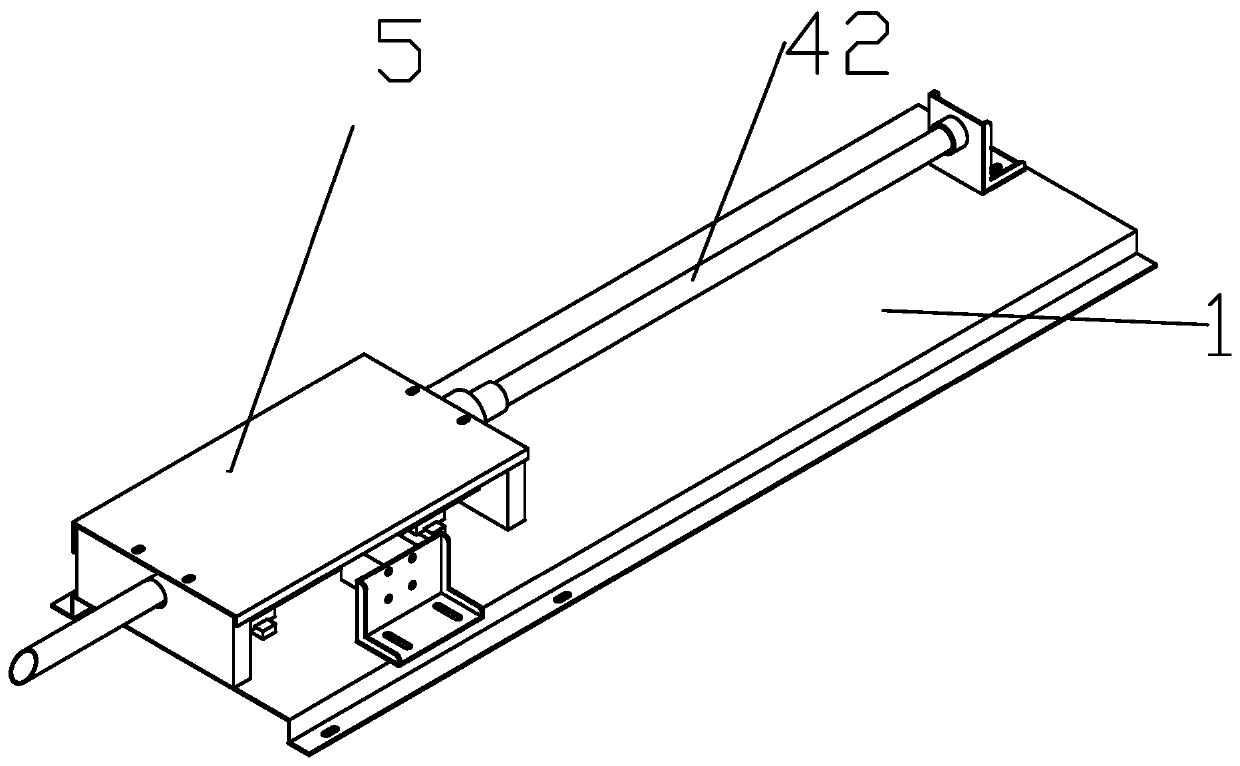

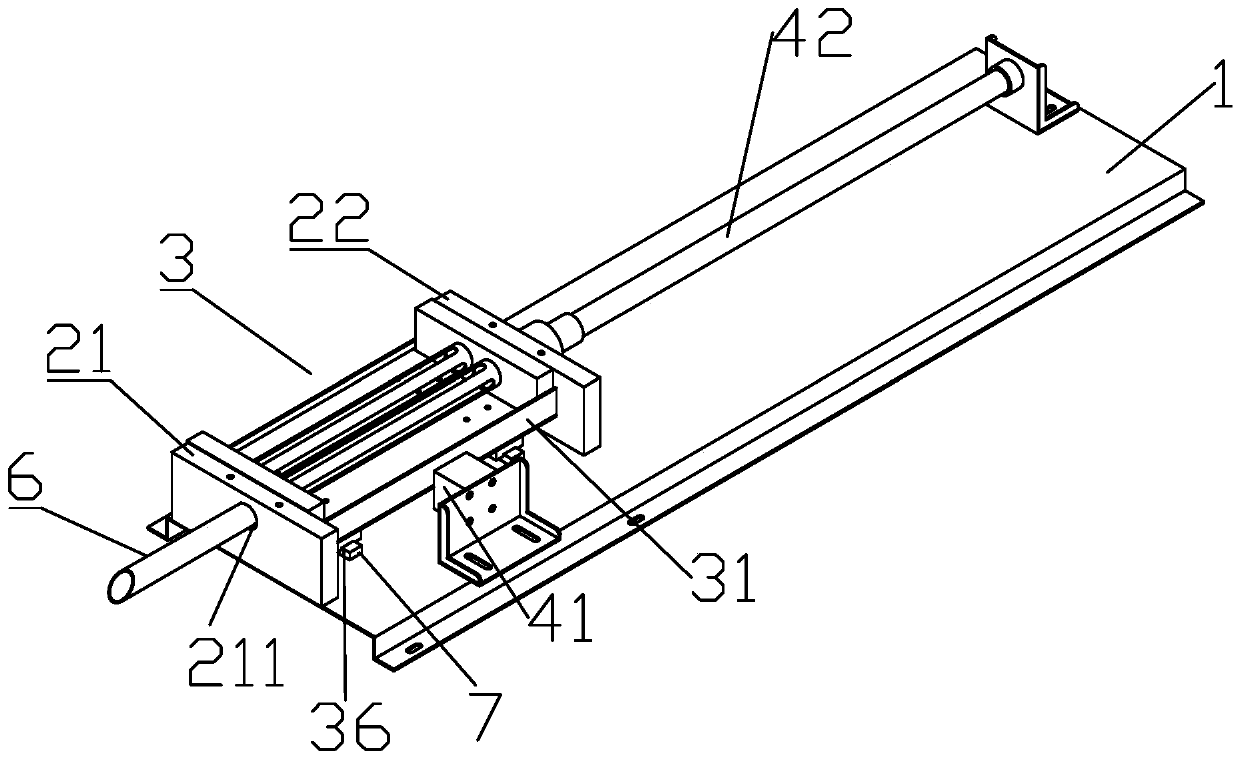

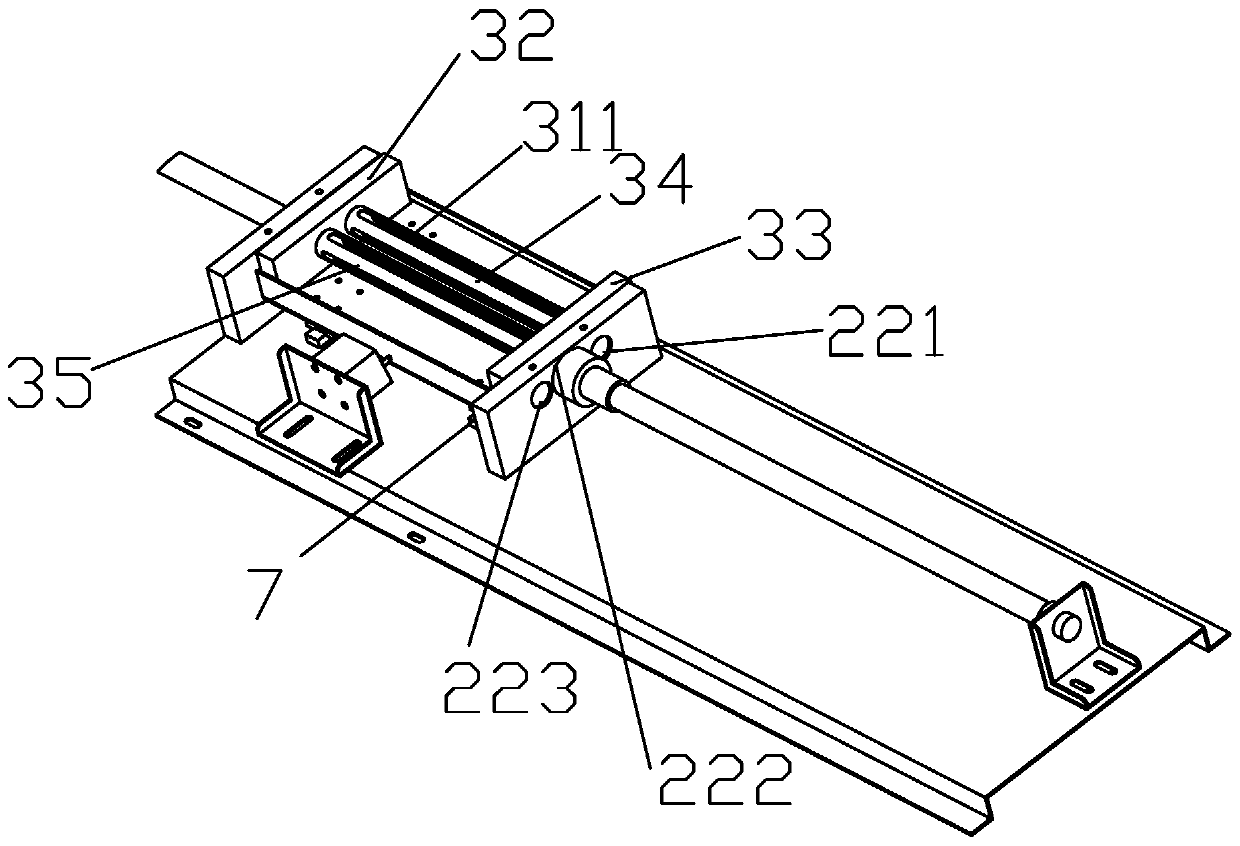

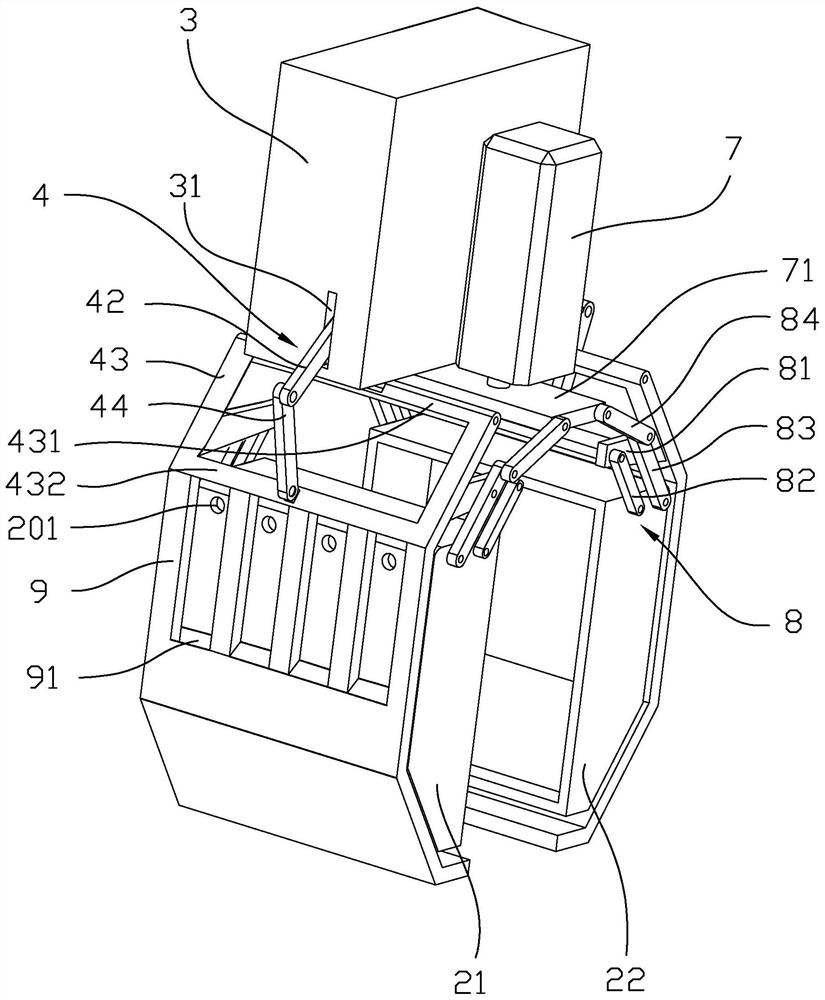

Double-pipe down filling gun for down filling machine

PendingCN111115546AReduce waiting timeImprove work efficiencyUpholstery manufactureClothes making applicancesStructural engineeringPower apparatus

The invention provides a double-pipe down filling gun for a down filling machine. The double-pipe down filling gun comprises a base, supporting pieces, a double-pipe down storage device, a power device, a cover plate and a down filling head. The supporting pieces are installed on the base in parallel. A guide rail is arranged on the base, and a guide groove matched with the guide rail is formed inthe bottom of the double-pipe down storage device. The double-pipe down storage device is connected to the power device, and the power device provides power for the double-pipe down storage device tomove on the guide rail. By means of the switchable structure of the two down storage pipes, one down storage pipe feeds down into the other down storage pipe while pushing down, the down filling andstoring waiting time is greatly shortened, and the working efficiency is greatly improved. The problems of down running and down leakage caused by damage to down fabric during down filling of cut-parts are solved, and down filling of airtight cut-parts can be achieved.

Owner:上海推罗智能设备科技有限公司

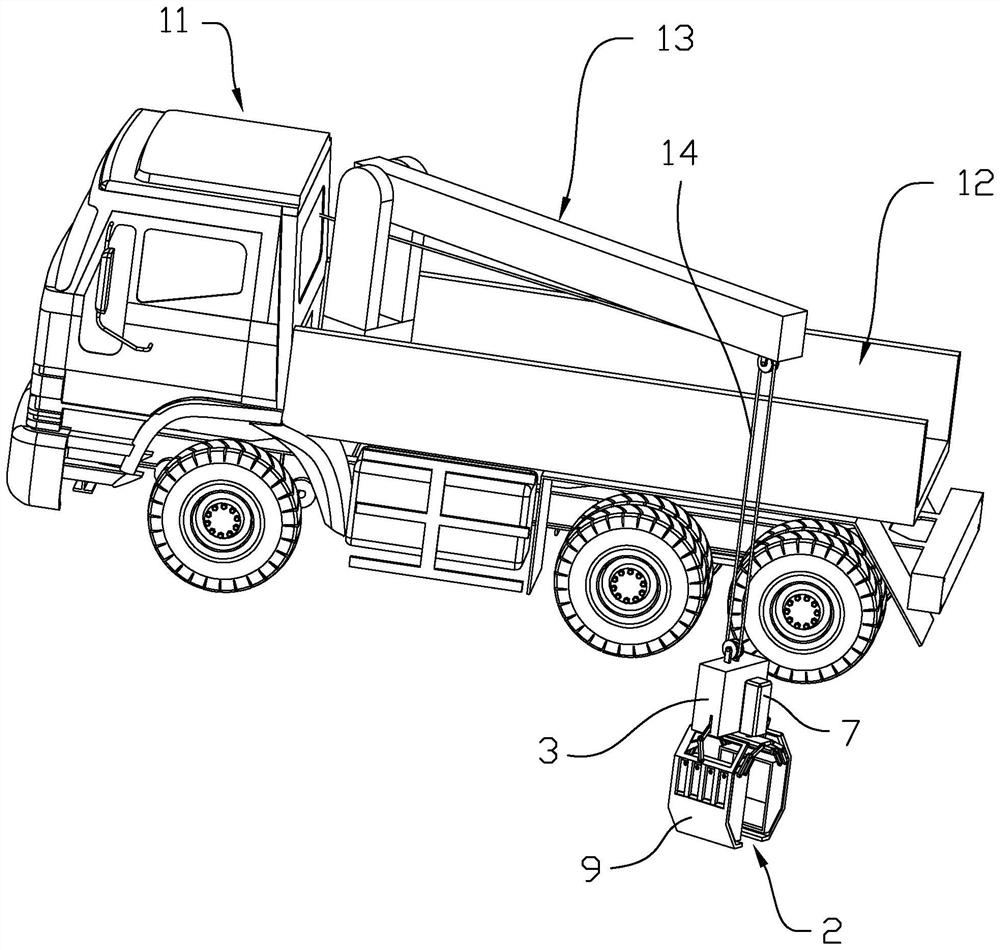

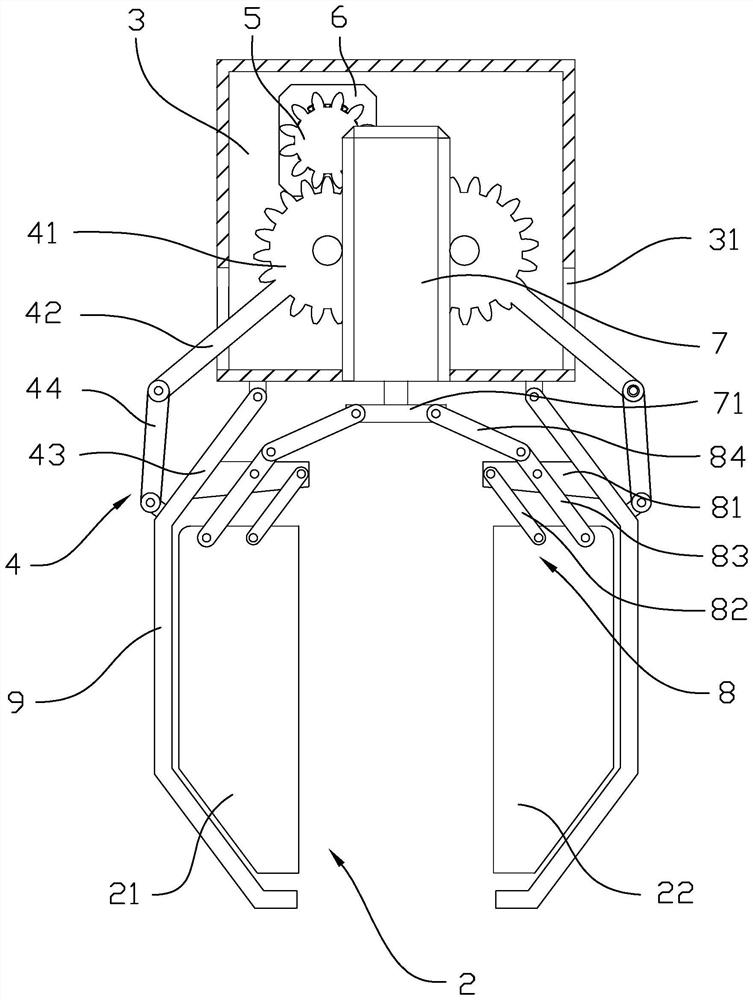

Regular dredging device for pond bottom

InactiveCN112726714ANot easy to dropImprove cleaning efficiencyMechanical machines/dredgersSludgeGear wheel

The invention discloses a regular dredging device for pond bottom. The regular dredging device comprises a vehicle body, a sludge hopper and a mechanical arm, wherein a sling is arranged at the end, away from the vehicle body, of the mechanical arm, a shoveling hopper is arranged at the end, away from the mechanical arm, of the sling, the shoveling hopper comprises a left hopper body and a right hopper body which are matched with each other, a mounting frame is arranged between the shoveling hopper and the sling, two sets of clamping mechanisms are arranged on the mounting frame, symmetrically arranged and used for driving the left hopper and the right hopper correspondingly, and each clamping mechanism comprises a gear I rotationally arranged on the mounting frame, a connecting rod I with one end fixedly connected with the gear I, a connecting rod II with one end hinged to the bottom of the mounting frame and a connecting rod III hinged between the connecting rod II and the connecting rod I, the hoppers are arranged on the connecting rods II, the connecting rods II are located between the hoppers and the connecting rods III, the gears I in the two sets of clamping mechanisms are meshed with each other, a gear II meshed with one of the first gears is rotationally arranged on the mounting frame, and a submersible motor for driving the gear II to rotate is arranged on the mounting frame. According to the device, the sludge cleaning efficiency can be improved.

Owner:安徽丰达园林工程有限公司

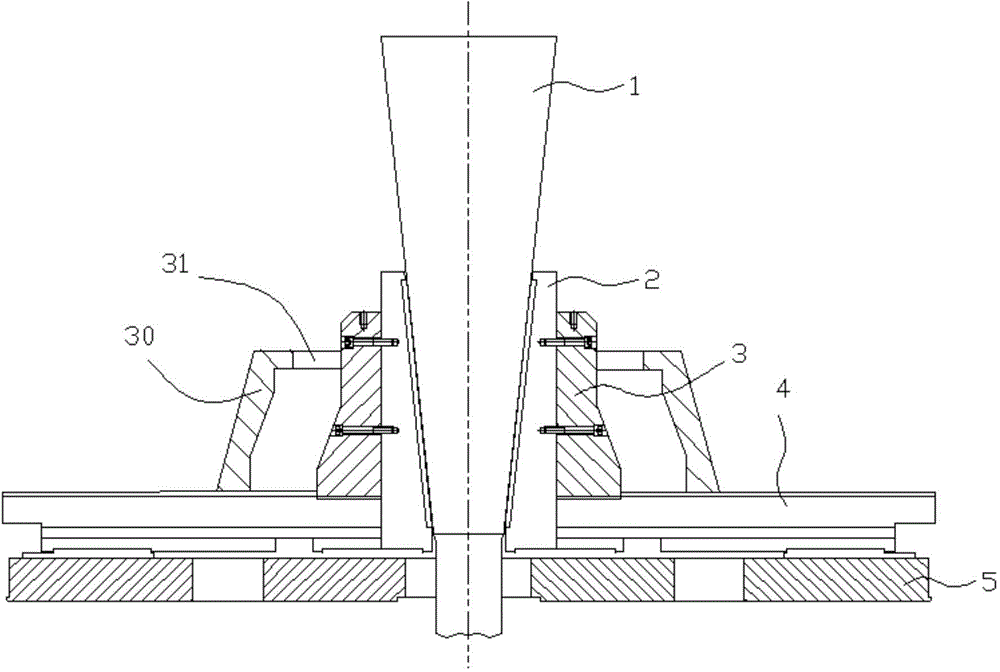

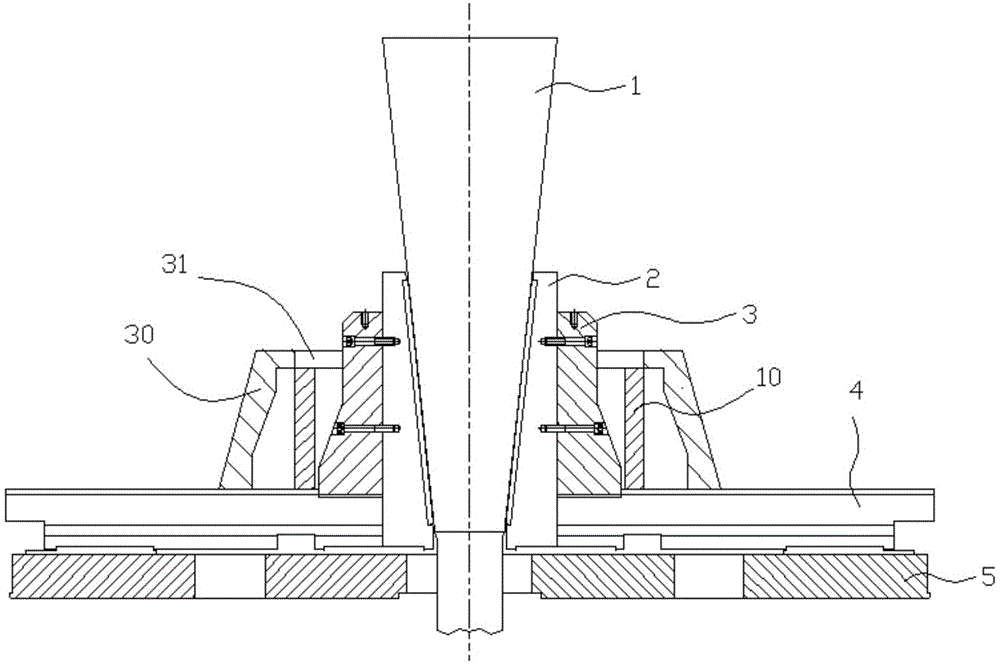

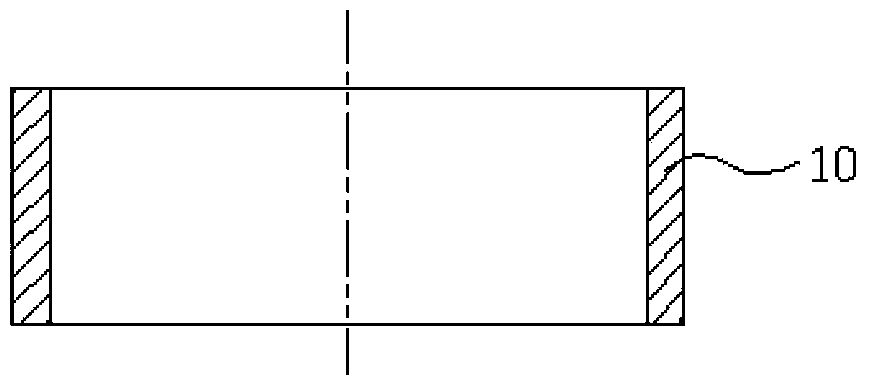

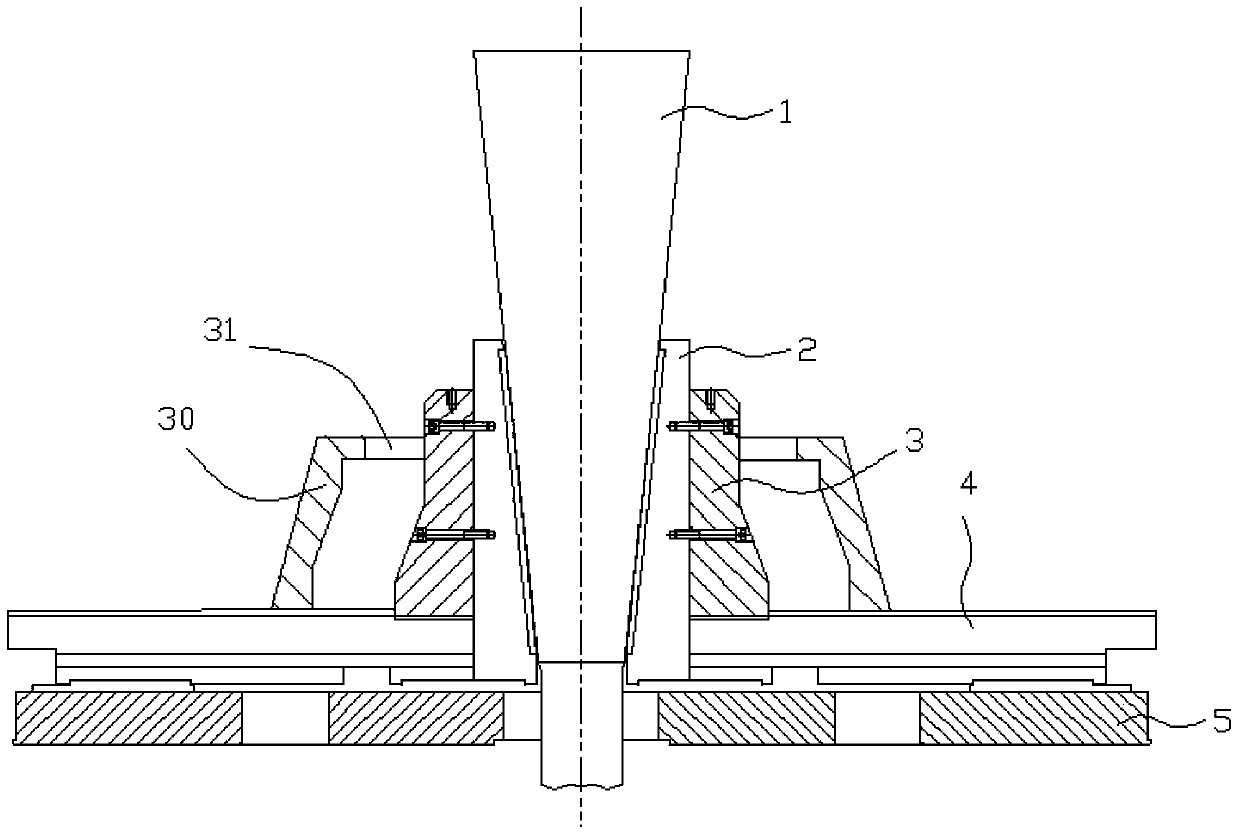

Production method of sb564 UNS N06690 alloy large inner T-shaped annular forging billet

The invention discloses a manufacturing method for a large internal T-shaped ring forge piece blank of SB564UNS N06690 alloy. Firstly, upsetting and drawing are performed through a hydraulic forging press, a punch with the diameter of 300mm is used for punching, then chambering and rounding are performed, twice rolling is performed on a ring rolling mill by the aid of a step mold, an original blank with a rectangular section is circularly rolled into a middle blank with a step, then the middle blank is rotated by 180 degrees, and second rolling is performed, so that the internal T-shaped annular forge piece blank is obtained. According to the manufacturing method for the large internal T-shaped annular forge piece blank of the SB564UNS N06690 alloy, the structure of the manufactured forge piece blank is uniform, grains are refined, shapes are rectangular, and the forge piece quality and the production efficiency are high.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

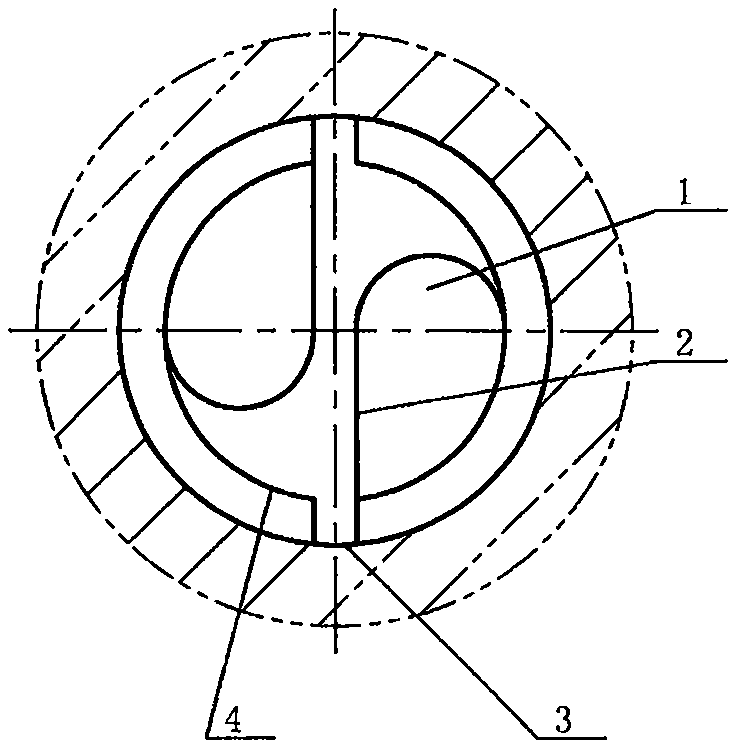

Method for thermal expansion of superalloy rectangular cross-section ring to form special-shaped cross-section ring

The invention discloses a method for forming an irregular section ring unit by using a high-temperature alloy rectangular section ring unit in a thermal-bulging mode. The method includes the steps that 1, a preheated die sleeve is fixed to a work table of a bulging machine, the heated high-temperature alloy rectangular section ring unit is arranged on the periphery of a preheated bulging block in the bulging machine in a sleeved mode, and the heated high-temperature alloy rectangular section ring unit is located in an annular space formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve; 2, the bulging machine is started, the ring unit can be extruded by the bulging block from the inner circumference surface of the ring unit in the radial direction and extruded into the inner ring face of the die sleeve after the ring unit deforms by 12%-15%, a closed cavity formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve is full of the ring unit, and the ring unit becomes the irregular section ring unit after pressure maintaining. According to the method, bulging forming is achieved by one-shot large deformation, operation is simplified, and the bulged irregular section ring unit which is high in size accuracy, good in product quality and high in productivity can be obtained. The irregular section ring unit is mainly applied to revolved body components and parts like cylindrical shells in the fields like aerospace.

Owner:GUIZHOU AVIATION TECHN DEV

Method for Thermal Expansion of Stainless Steel Rectangular Cross-section Ring to Form Special-shaped Cross-section Ring

The invention discloses a method for forming a deformed section annular part from a stainless steel rectangular section annular part in a thermal expansion mode. The method includes the steps that a die sleeve which is preheated is fixed on a worktable of a bulging machine, the heated stainless steel rectangular section annular part is arranged on the periphery of a preheated bulging block in the bulging machine in a sleeved mode, and therefore the stainless steel rectangular section annular part is located in an annular space defined by the outer circumference face of the bulging block and the inner ring face of the die sleeve; the bulging machine is started so as to enable the bulging block to extrude the annular part in the radial direction from the surface of the inner circumference of the annular part, the annular part is deformed by 11-14 percent and extruded into the inner ring face of the die sleeve, and a closed cavity defined by the outer circumference face of the bulging block and the inner ring face of the die sleeve is filled with the annular part. After the stainless steel rectangular section annular part undergoes pressure maintaining, the deformed section annular part is formed. According to the method, one-time large deformation bulging forming is adopted, operation is simplified, and the bulging deformed section annular part which is high in size precision, good in product quality and high in productivity is obtained. The deformed section annular part is mainly used in revolution body parts such as cylindrical shell bodies which are used in the fields such as aerospace.

Owner:GUIZHOU AVIATION TECHN DEV

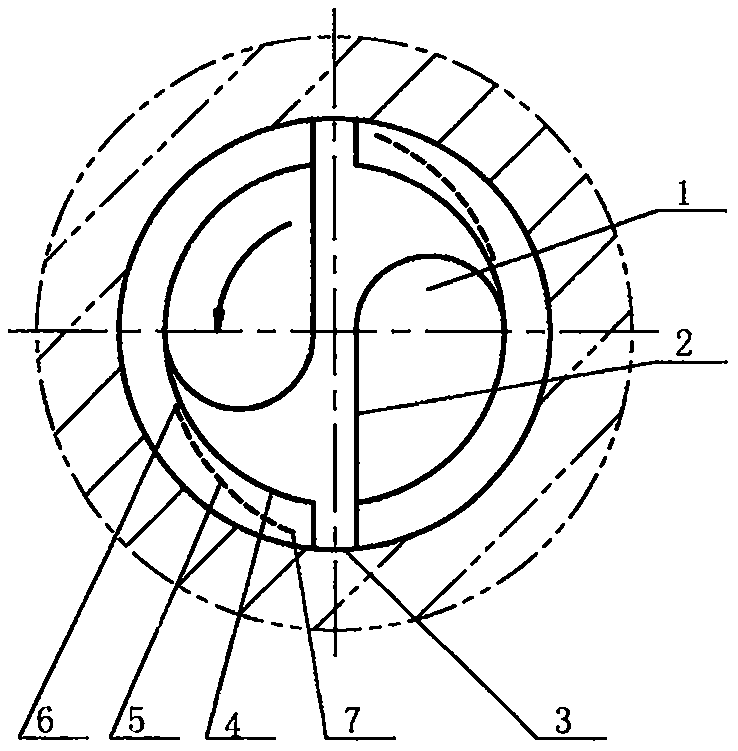

Method for forming irregular section ring unit by using high-temperature alloy rectangular section ring unit in thermal-bulging mode

ActiveCN103433363AClosed bulgingImprovement of inner diameter dimensional accuracyShaping toolsProduction rateAlloy

The invention discloses a method for forming an irregular section ring unit by using a high-temperature alloy rectangular section ring unit in a thermal-bulging mode. The method includes the steps that 1, a preheated die sleeve is fixed to a work table of a bulging machine, the heated high-temperature alloy rectangular section ring unit is arranged on the periphery of a preheated bulging block in the bulging machine in a sleeved mode, and the heated high-temperature alloy rectangular section ring unit is located in an annular space formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve; 2, the bulging machine is started, the ring unit can be extruded by the bulging block from the inner circumference surface of the ring unit in the radial direction and extruded into the inner ring face of the die sleeve after the ring unit deforms by 12%-15%, a closed cavity formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve is full of the ring unit, and the ring unit becomes the irregular section ring unit after pressure maintaining. According to the method, bulging forming is achieved by one-shot large deformation, operation is simplified, and the bulged irregular section ring unit which is high in size accuracy, good in product quality and high in productivity can be obtained. The irregular section ring unit is mainly applied to revolved body components and parts like cylindrical shells in the fields like aerospace.

Owner:GUIZHOU AVIATION TECHN DEV

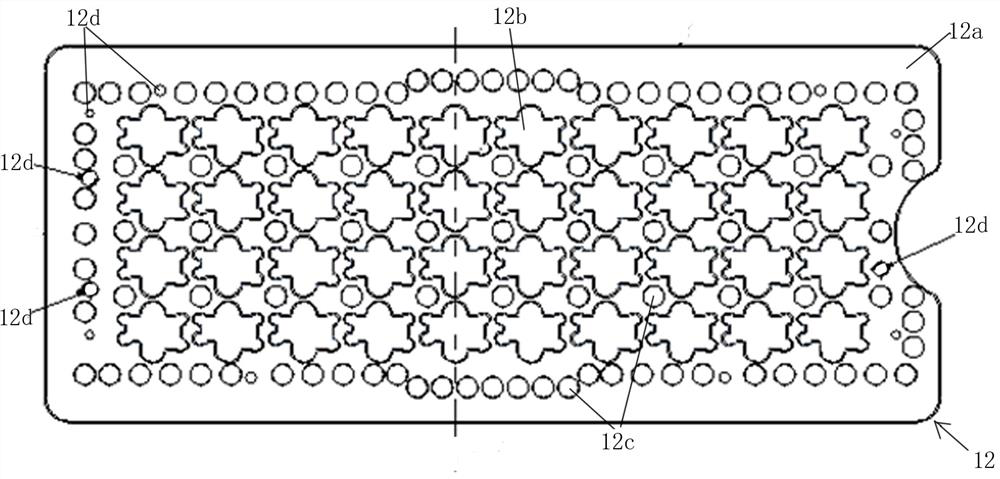

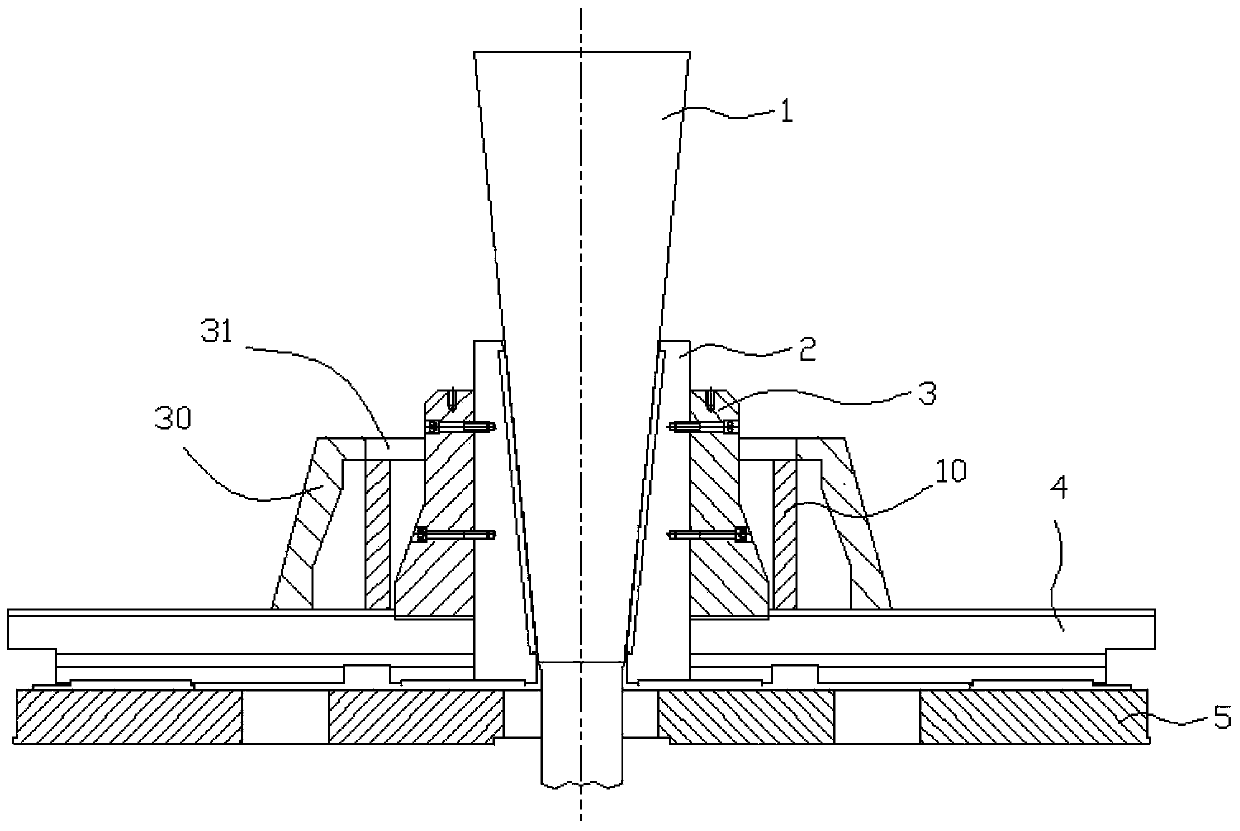

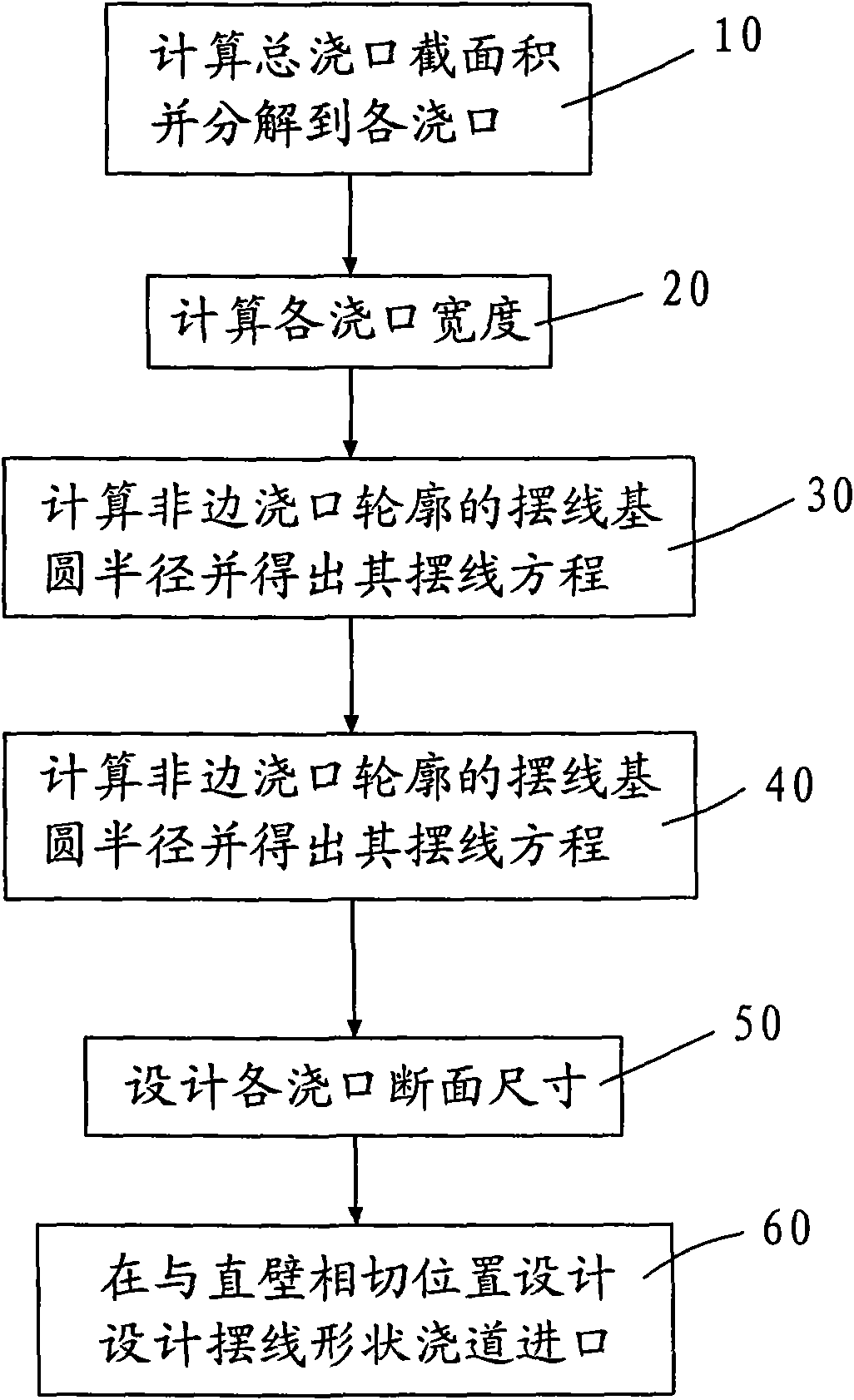

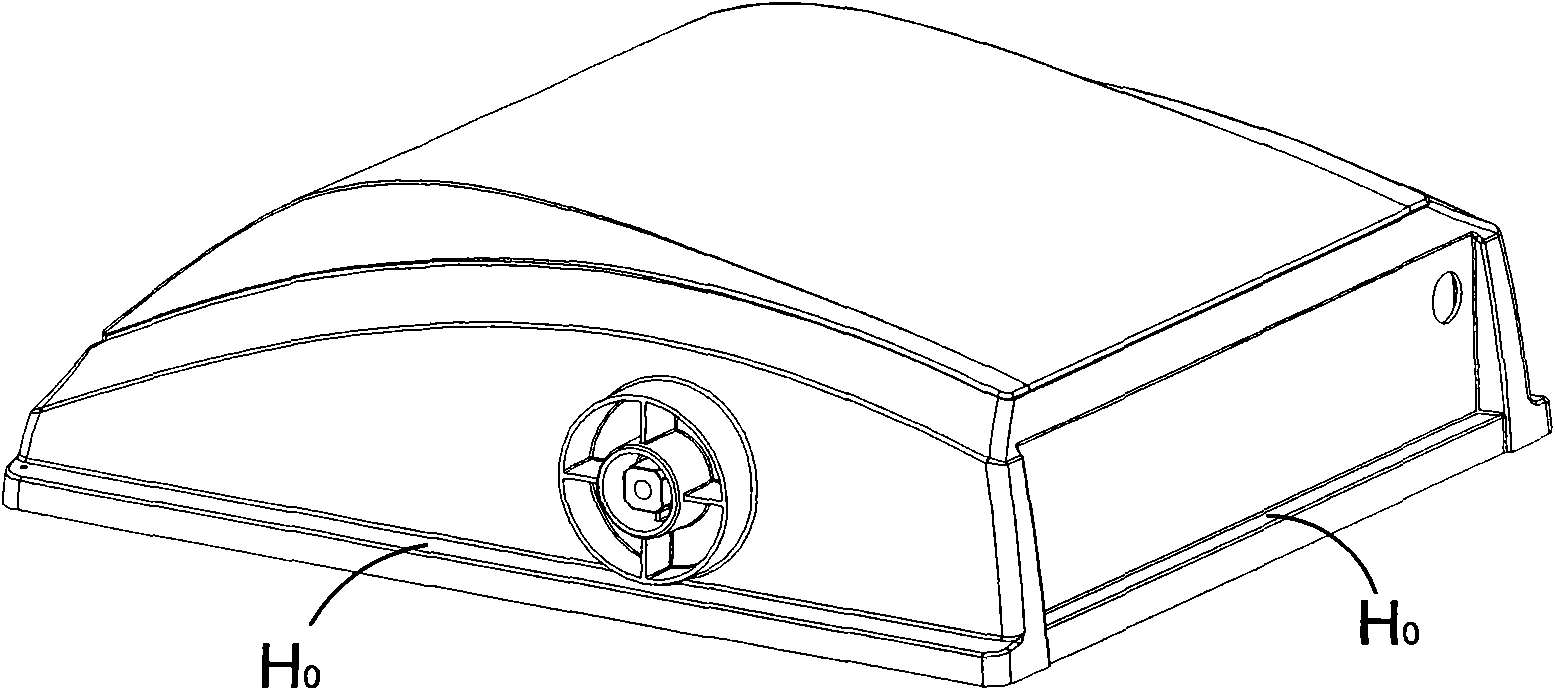

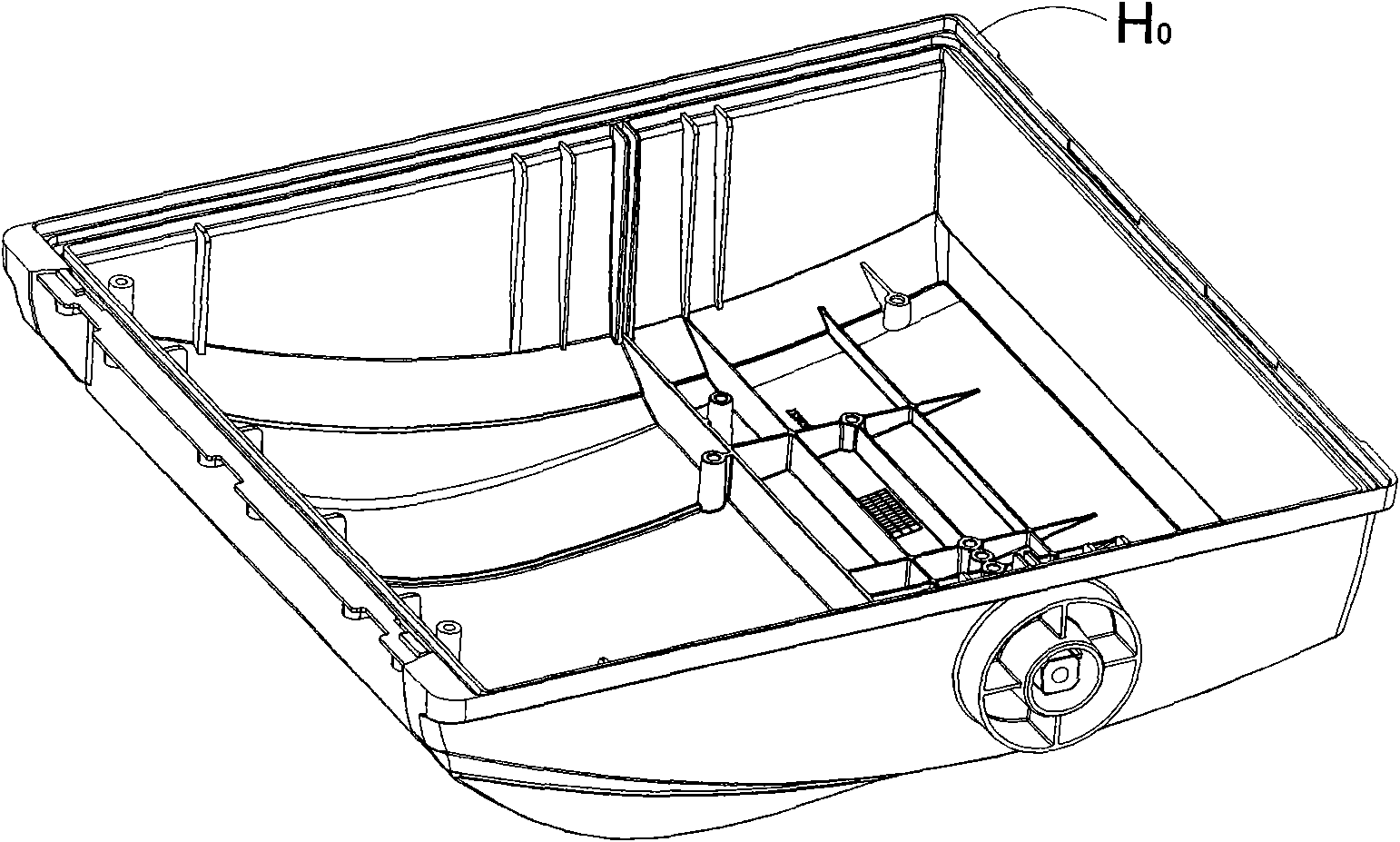

Gating design method for die-casting formation of large thin-wall element with narrow flange

The invention provides a gating design method for die-casting formation of a large thin-wall element with narrow flange. The method comprises the following steps: step 10, calculating the section area of a mater gate, and dividing the section area value to each gate so as to obtain the section area of each gate; step 20, calculating the width of each gate; step 30, calculating cycloid base radiuses of non-edge gate outlines according to the gate widths so as to obtain the cycloid equation of each non-edge gate outline; step 40, calculating cycloid base radiuses of two-edge gate outlines according to the gate widths so as to obtain the cycloid equation of the two-edge gate outlines; and step 50, designing the gate cross dimensions according to the section areas of the gates and the outline sizes. The method changes the conventional straight-line-form gate into a continuous curve form without point of discontinuity, takes advantage of the isochronism of the cycloid to reduce the flowing power loss of a fused mass, causes die-casting fronts to simultaneously reach a destination, and effectively reduces the die-casting defects.

Owner:FUJIAN UNIV OF TECH

Type plate with pipe casting stainless steel water pipe fixed structure

ActiveCN104399942BEliminate the process of milling groove buried pipeShorten the timeMoulding flasksScrew threadWater pipe

The invention discloses a template type pipe casting-containing stainless steel water pipe fixing structure. The structure comprises a sand mold upper box, wherein a rail is arranged at the upper end of the sand mold upper box; slide blocks are arranged in the rail at intervals; a through hole is formed in the middle of each slide block; a connecting rod is connected into each through hole; one end of each connecting rod is connected in the through hole in the corresponding slide block through screw threads and extends into the upper part of the corresponding through hole; the lower end of each connecting rod is positioned at the bottom of the sand mold upper box; a screw hole is formed in the lower end of each connecting rod; a fixing screw with the diameter of 1mm binding wire penetrates through each screw hole; a clearance with the diameter of 3 to 5mm is formed between the end part of each fixing screw and the bottom end of the corresponding connecting rod; the fixing screw is used for connecting a stainless steel water pipe; a binding wire on each fixing screw is used for fixing the stainless steel water pipe; the fixed stainless steel water pipe is in a suspension state; the surrounding of the stainless steel water pipe is not in direction contact with the sand mold upper box and a clearance is reserved, otherwise, the cast steel pipe is exposed on the surface of a casting.

Owner:CHUZHOU JINNUO INDAL

Thermal-bulging forming method of high-temperature alloy rectangular section ring unit

The invention discloses a thermal-bulging forming method of a high-temperature alloy rectangular section ring unit. The method includes the steps that 1, a preheated die sleeve is fixed to a work table of a bulging machine, a heated high-temperature alloy rectangular section ring unit is arranged on the periphery of a preheated bulging block in the bulging machine in a sleeved mode, and the heated high-temperature alloy rectangular section ring unit is located in an annular space formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve; 2, the bulging machine is started, the ring unit can be extruded by the bulging block from the inner circumference surface of the ring unit in the radial direction and extruded into the inner ring face of the die sleeve after the ring unit deforms by 11%-13%, a closed cavity formed by enclosure of the outer circumference face of the bulging block and the inner ring face of the die sleeve is full of the ring unit, and the ring unit becomes the bulged rectangular section ring unit after pressure maintaining. According to the thermal-bulging forming method, bulging forming is achieved by one-shot large deformation, operation is simplified, and the bulged rectangular section ring unit which is high in size accuracy, good in product quality and high in productivity can be obtained. The bulged rectangular section ring unit is mainly applied to revolved body components and parts like cylindrical shells in the fields like aerospace.

Owner:GUIZHOU AVIATION TECHN DEV

Self-centering anti-deviation vibration reduction hole machining tool

The invention belongs to the field of machining, and particularly relates to a self-centering anti-deviation vibration reduction hole machining tool. The self-centering anti-deviation vibration reduction hole machining tool comprises a twist drill, an expanding drill, a center drill, a flat drill, a reamer, a boring cutter and the like, wherein a main cutting edge, an edge belt and an edge back are arranged in structure; on the end face view of the tool, a part of blade back contour lines are wedge-shaped contour lines which are different from the circle center of a machined hole, and the wedge-shaped contour lines and the hole wall of the machined hole form a wedge-shaped space; liquid is dragged into the wedge-shaped space, enters from a large gap, is extruded out from a small gap or is sealed, so that the pressure of the liquid is increased; and the liquid acts on the tool to prevent the tool from deflecting, and the machined hole is used as a process reference to guide the tool to feed. The liquid can convert system vibration energy into liquid pressure energy, so that system vibration is absorbed, the system vibration amplitude is reduced, and the hole machining quality is improved. A substantive improvement scheme is proposed for standard parts such as the twist drill and the like, and the tool has a broad application prospect. The scheme is simple, easy to implement and low in cost, and is a technical breakthrough.

Owner:ZHONGBEI UNIV

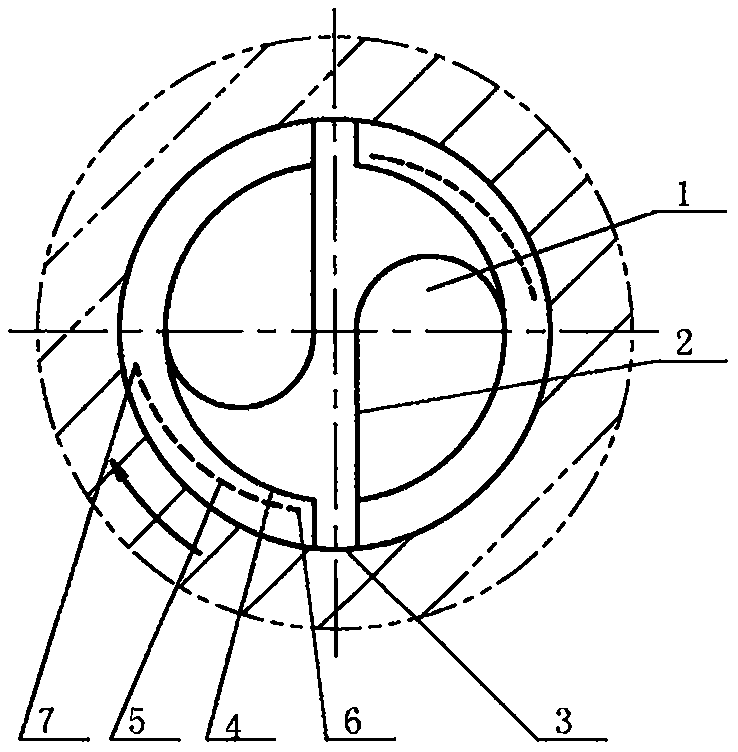

Thermal expansion forming method of rectangular aluminum alloy section ring piece

The invention discloses a thermal expansion forming method of a rectangular aluminum alloy section ring piece. The method comprises the steps that a preheated die sleeve is fixed to a workbench of an expanding machine, the heated rectangular aluminum alloy section ring piece is then arranged on the periphery of a preheated expanding block in the expanding machine in a sleeved mode, and is located in ring space defined by the outer circumferential surface of the expanding block and the inner ring surface of the die sleeve; the expanding machine is started to ensure that the expanding block squeezes the ring piece from the inner circumferential surface of the ring piece in the radial direction, after deforming by 11% to 12%, the ring piece enters the inner ring surface of the die sleeve in a squeezed mode, a sealed cavity defined by the outer circumferential surface of the expanding block and the inner ring surface of the die sleeve is filled with the ring piece, and the ring piece becomes an expanded rectangular section ring piece after pressure holding. Due to the adoption of once large deformation expanding forming, the method simplifies operation and the expanded rectangular section ring piece which is high in size precision, good in quality and high in production rate is acquired. The expanded rectangular section ring piece is mainly used for revolved body parts, like barrel-shaped shells, used in fields like aerospace.

Owner:GUIZHOU AVIATION TECHN DEV

Thermal Expansion Forming Method of Stainless Steel Rectangular Cross-section Ring

The invention discloses a heat bulging forming method for stainless steel rectangular cross section annular elements. The method comprises the following steps that a preheated mold sleeve is fixed on a work table of a bulging machine, then, a heated stainless steel rectangular cross section annular element is sheathed on the periphery of a preheated bulging block in the bulging machine so that the heated stainless steel rectangular cross section annular element is positioned in an annular space surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve, the bulging machine is started so that the bulging block extrudes the annular element from the inner circumference surface of the annular element in the radial direction, deforms 10 percent to 13 percent, and is then extruded into the inner annular surface of the mold sleeve, a sealed die cavity surrounded by the outer circumference surface of the bulging block and the inner annular surface of the mold sleeve is fully filled, and the bulged rectangular cross section annular element is formed after the pressure preservation. The method adopts one-step large-deformation-quantity bulging forming, the operation is simplified, and the bulged rectangular cross section annular element with high dimension precision, high product quality and high productivity is obtained. The bulged rectangular cross section annular element is mainly used for rotating body parts of tubular casings and the like used in the fields of aeronautics and astronautics and the like.

Owner:GUIZHOU AVIATION TECHN DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com