Patents

Literature

46results about How to "Affect strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

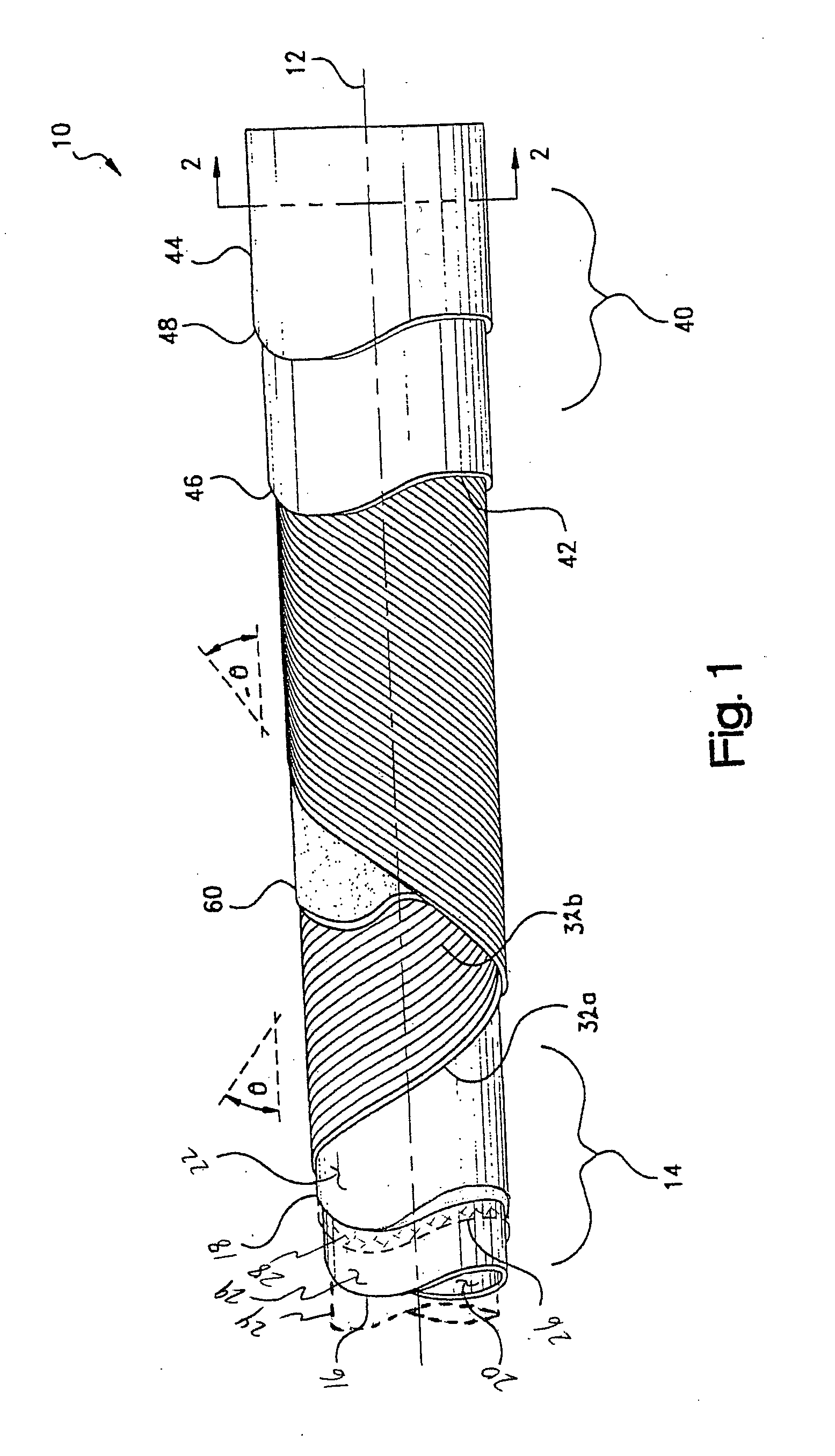

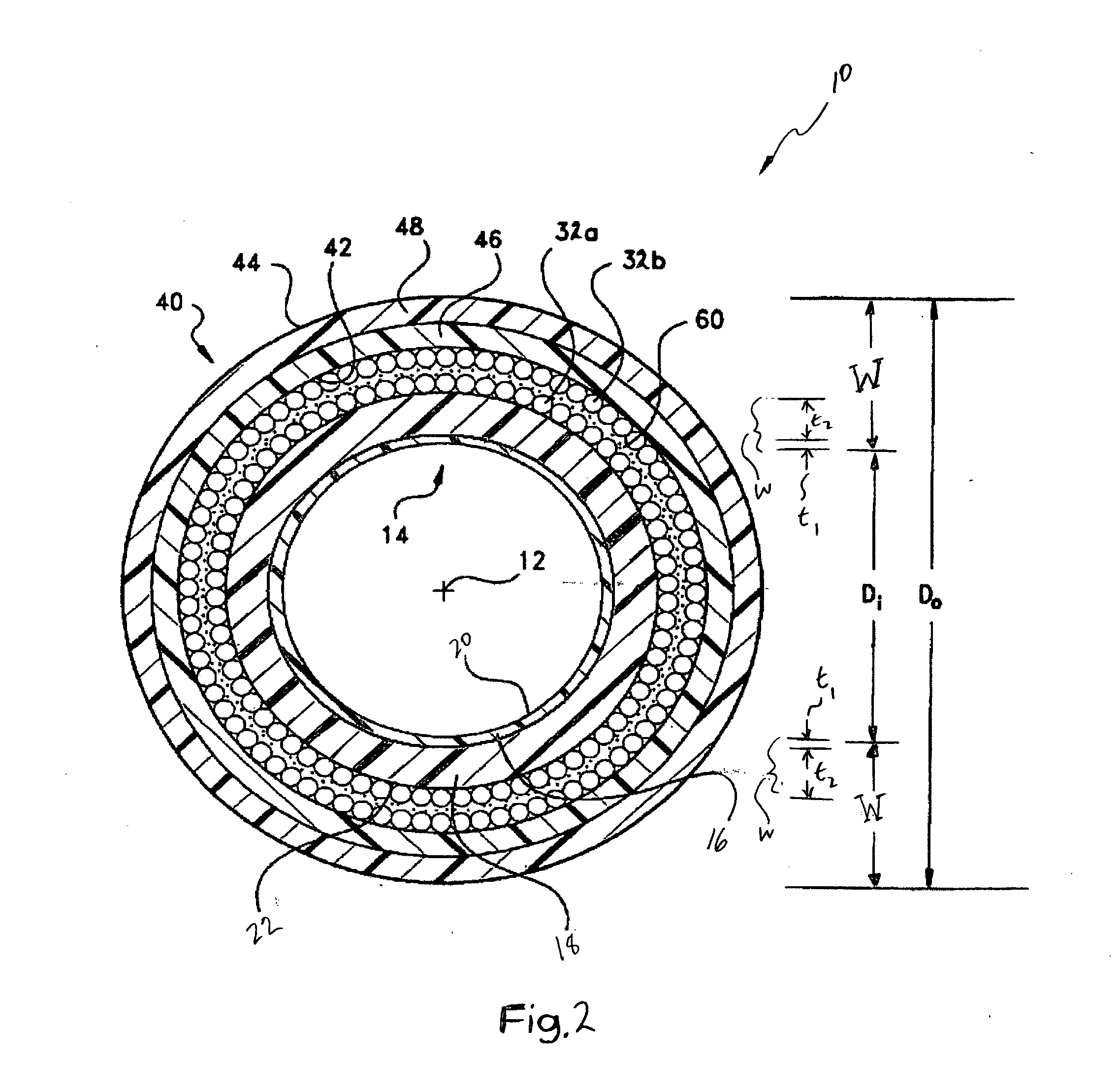

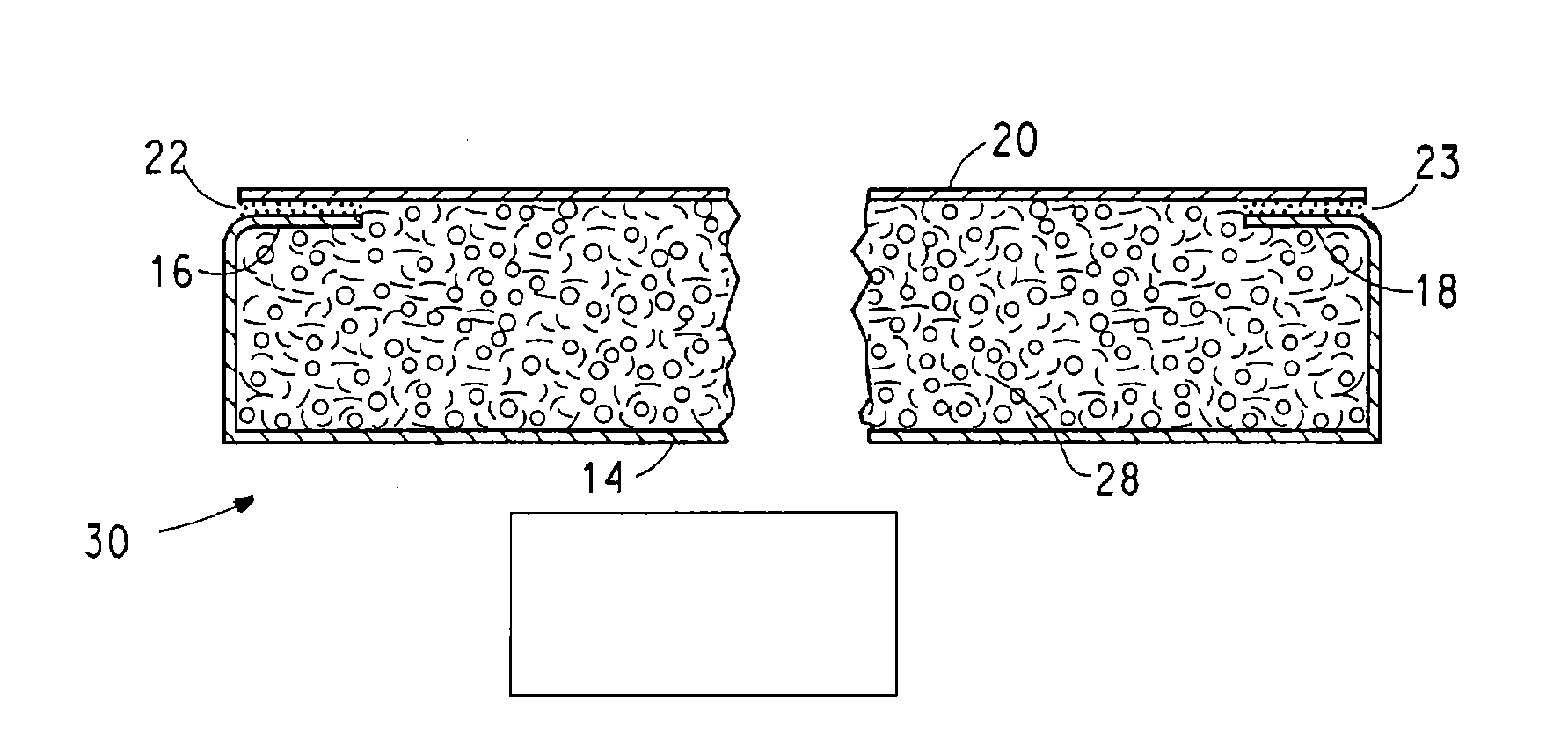

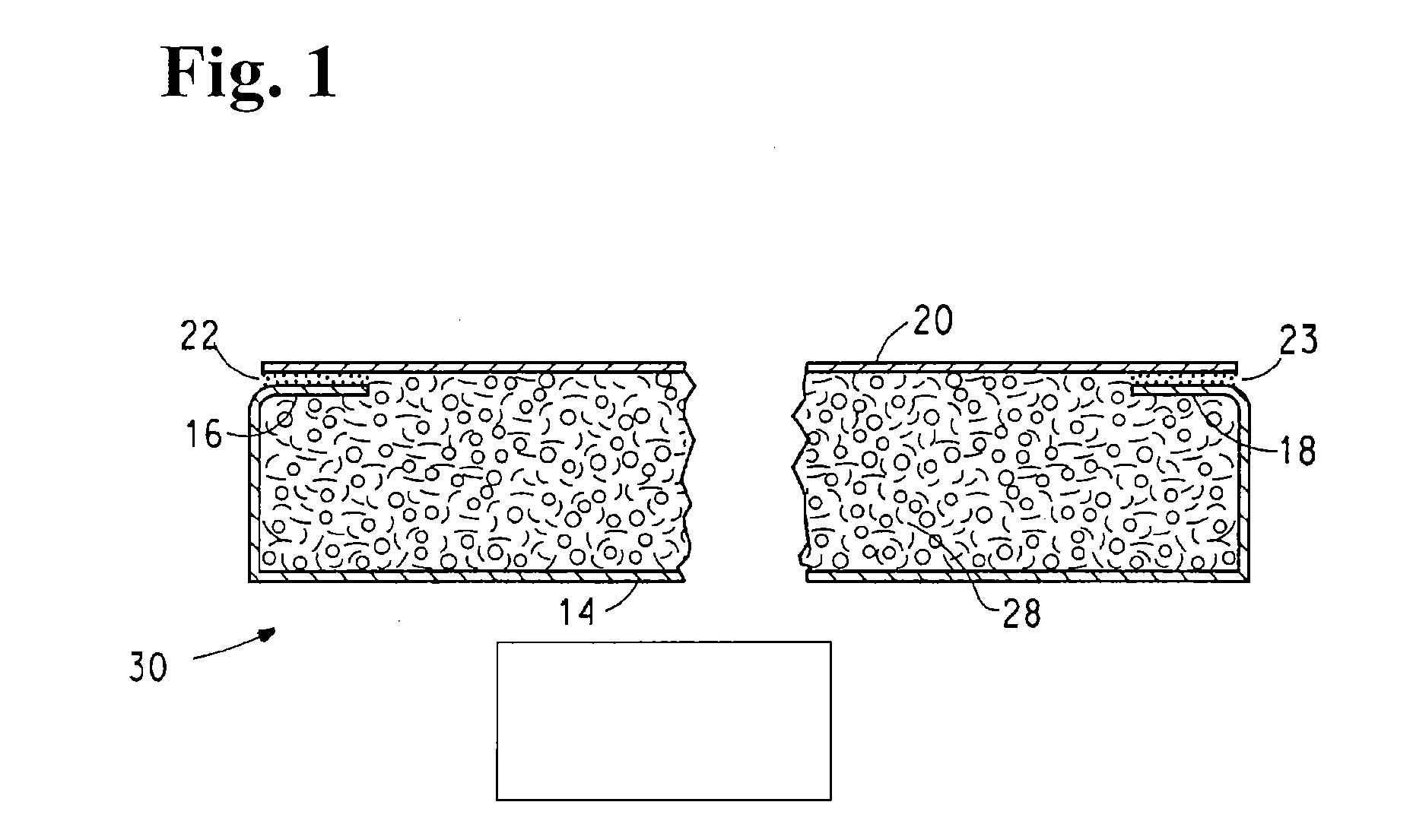

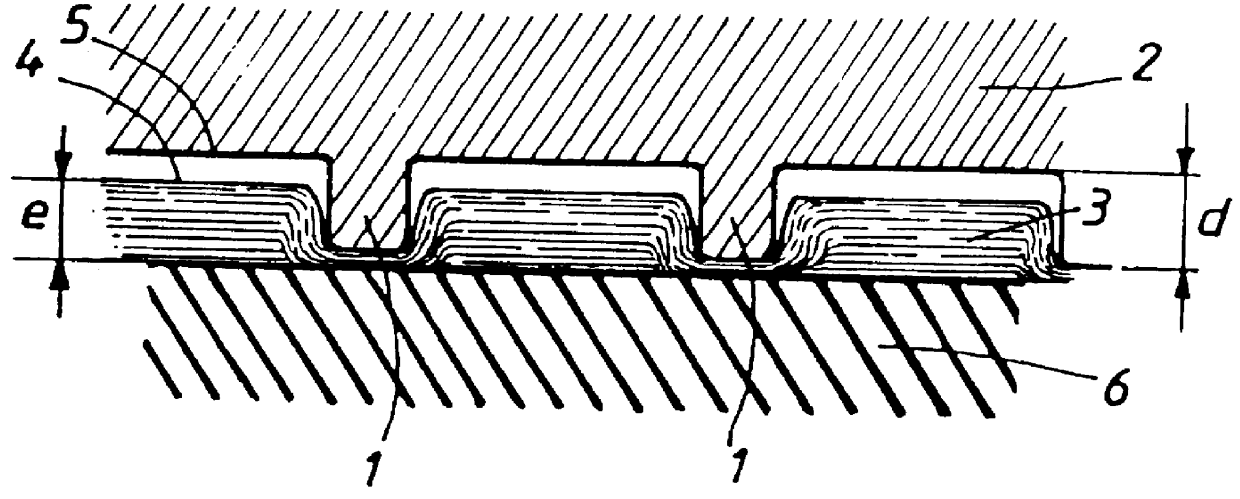

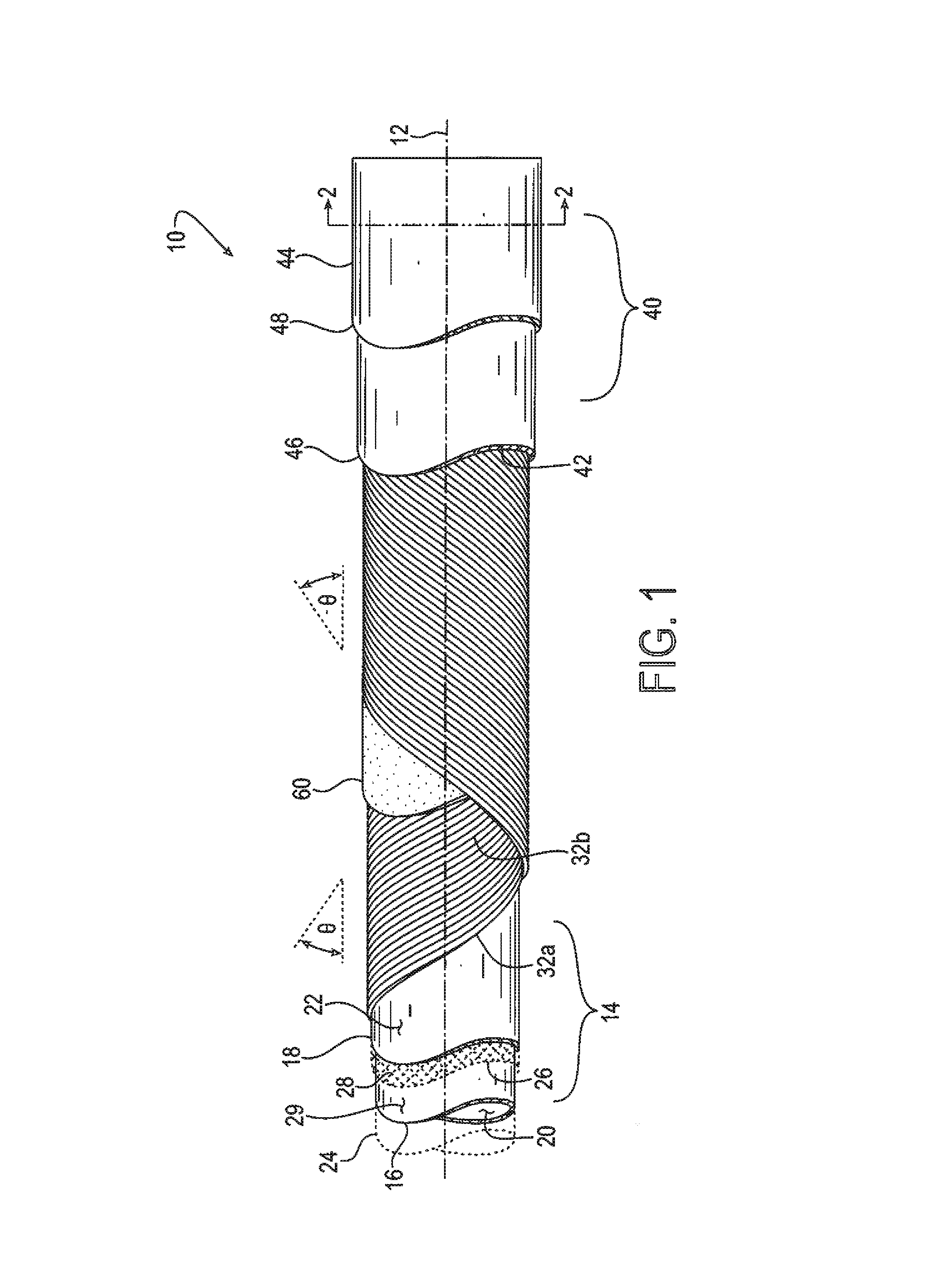

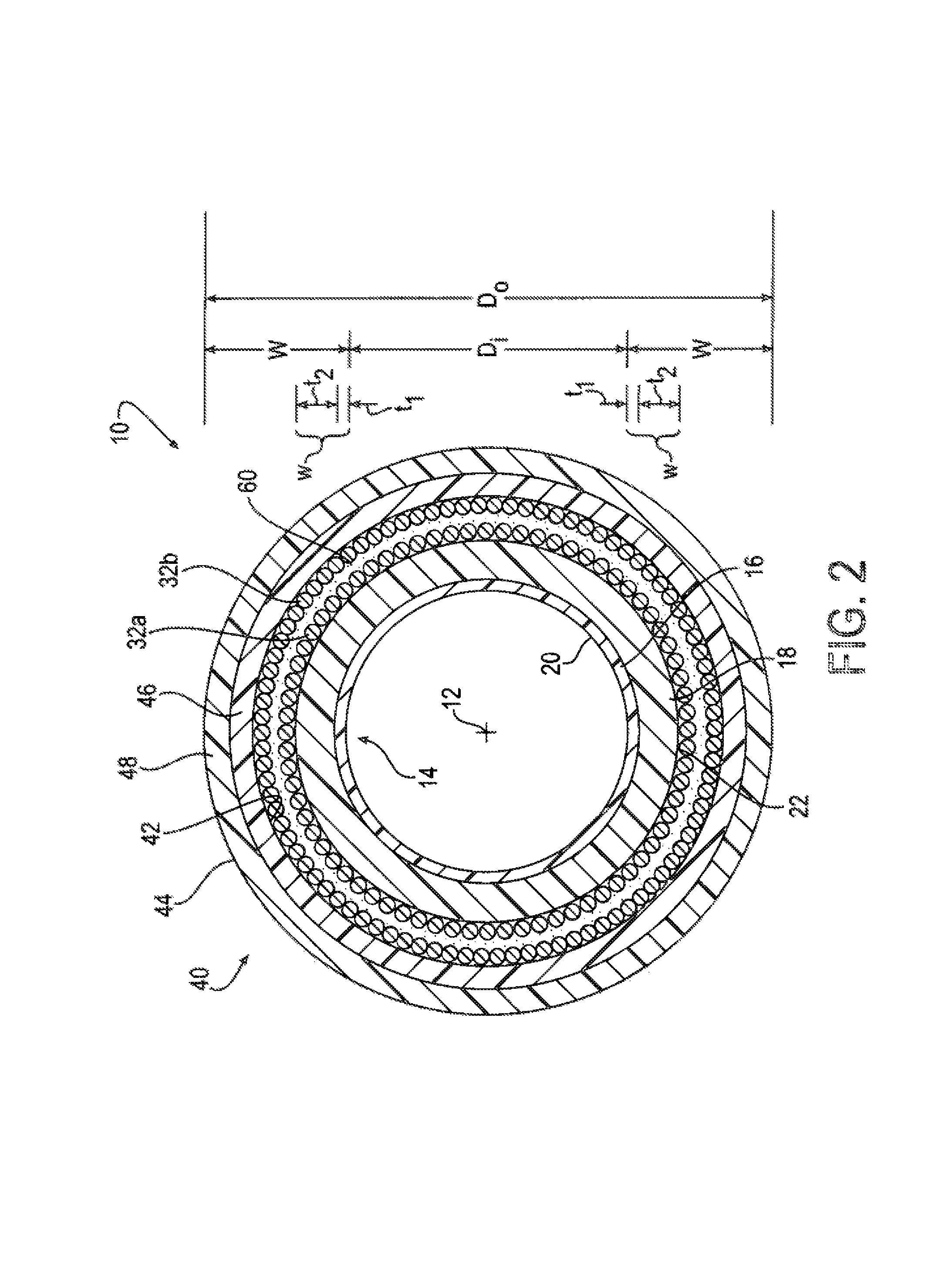

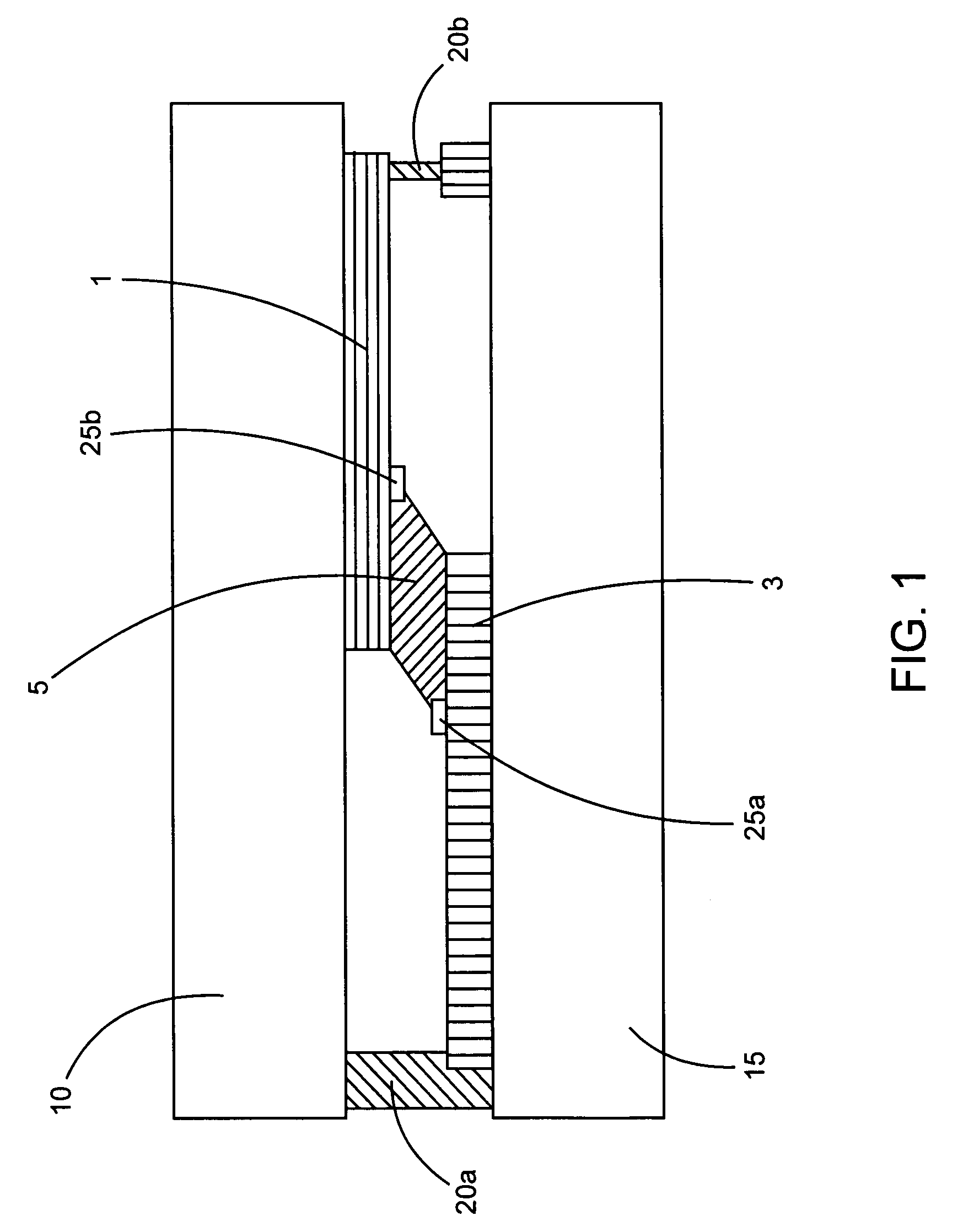

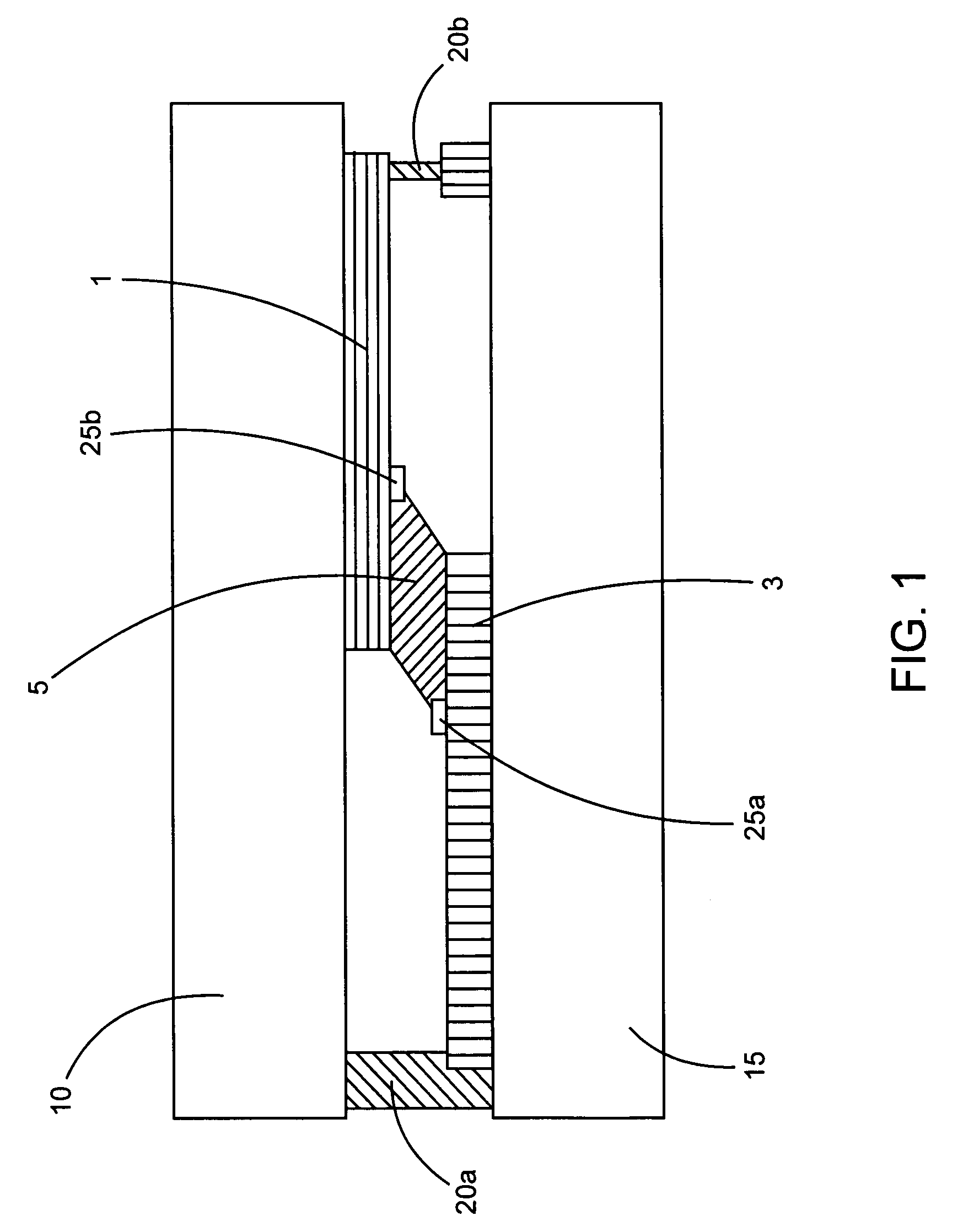

Electrically-conductive hose

InactiveUS20060127620A1Affect strengthAffect flexibilitySynthetic resin layered productsFlexible pipesPolyesterParticulates

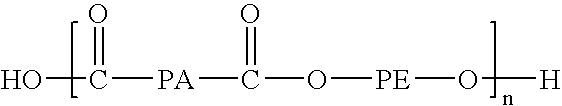

Tubular polymeric composite for articles such as tubing and hoses. The composite is formed of a tubular first layer of a thermoplastic block polyether amide resin (PEBA) filled with a more structured carbon black particulate filler to render it electrically-conductive, and a tubular second layer of a thermoplastic polyamide, polyester, polyolefins, or other thermoplastic resin compatible with the PEBA resin of the first material, and which second material optionally may be filled with a less structured carbon black particulate filler to render it electrically-conductive.

Owner:PARKER HANNIFIN CORP

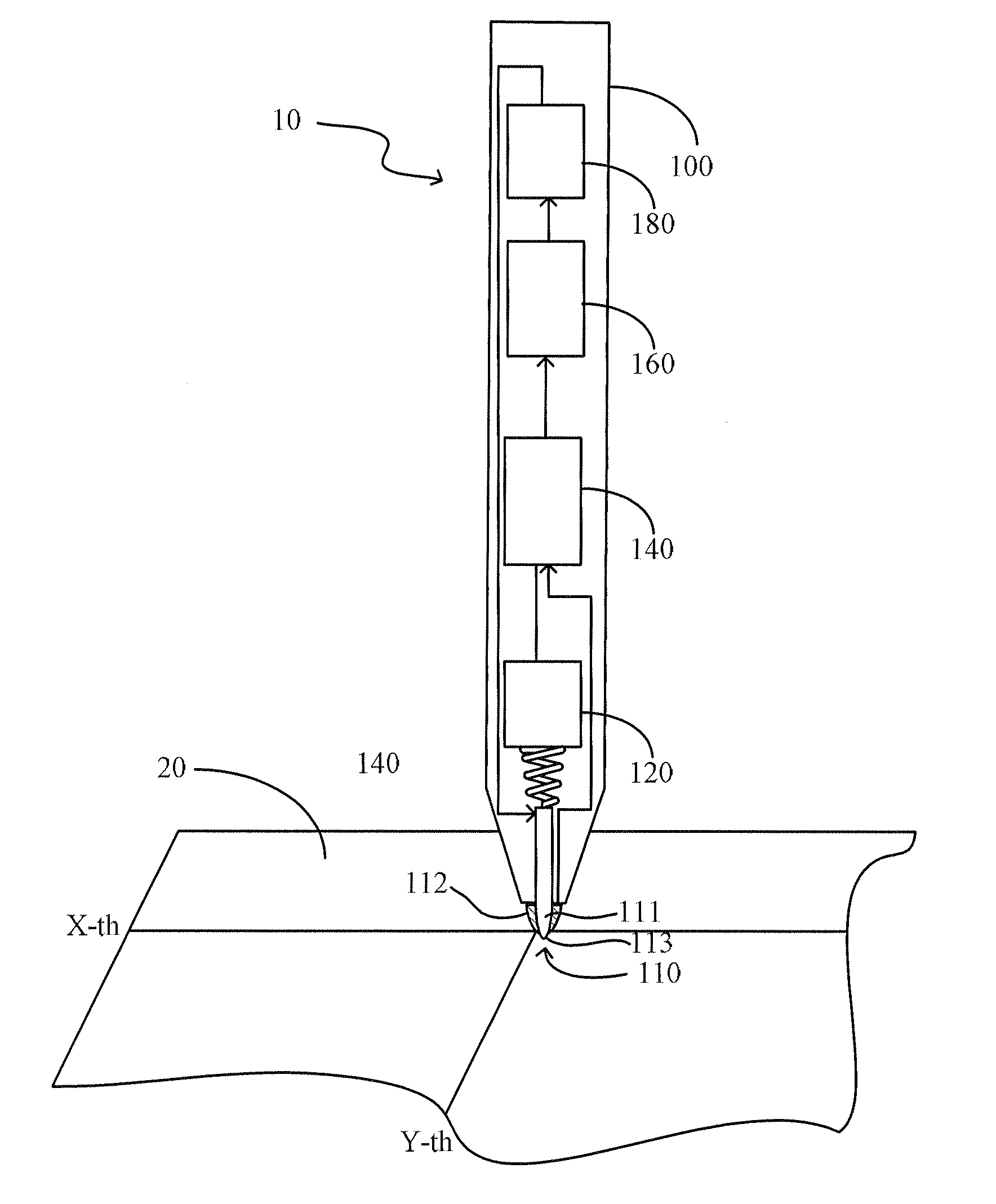

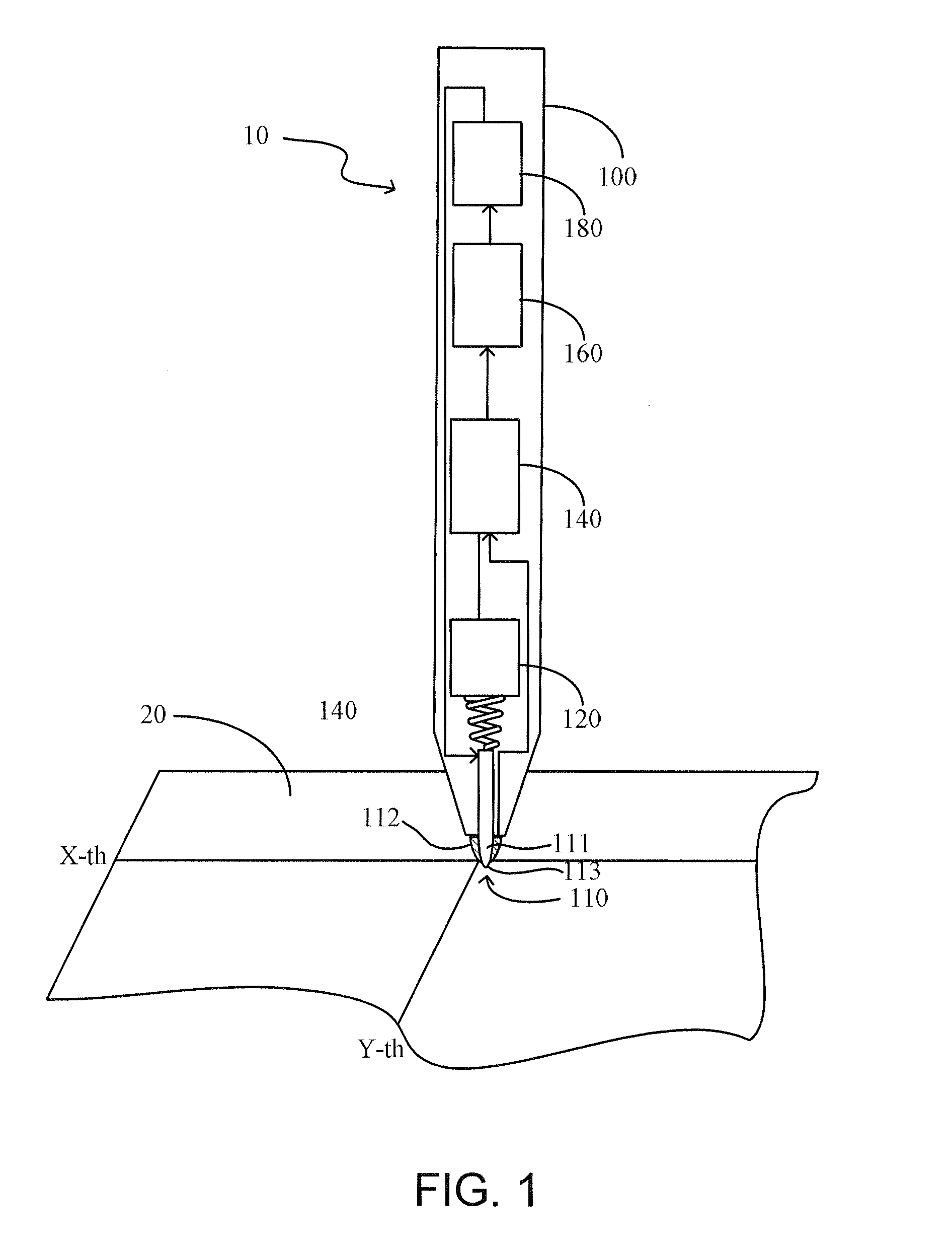

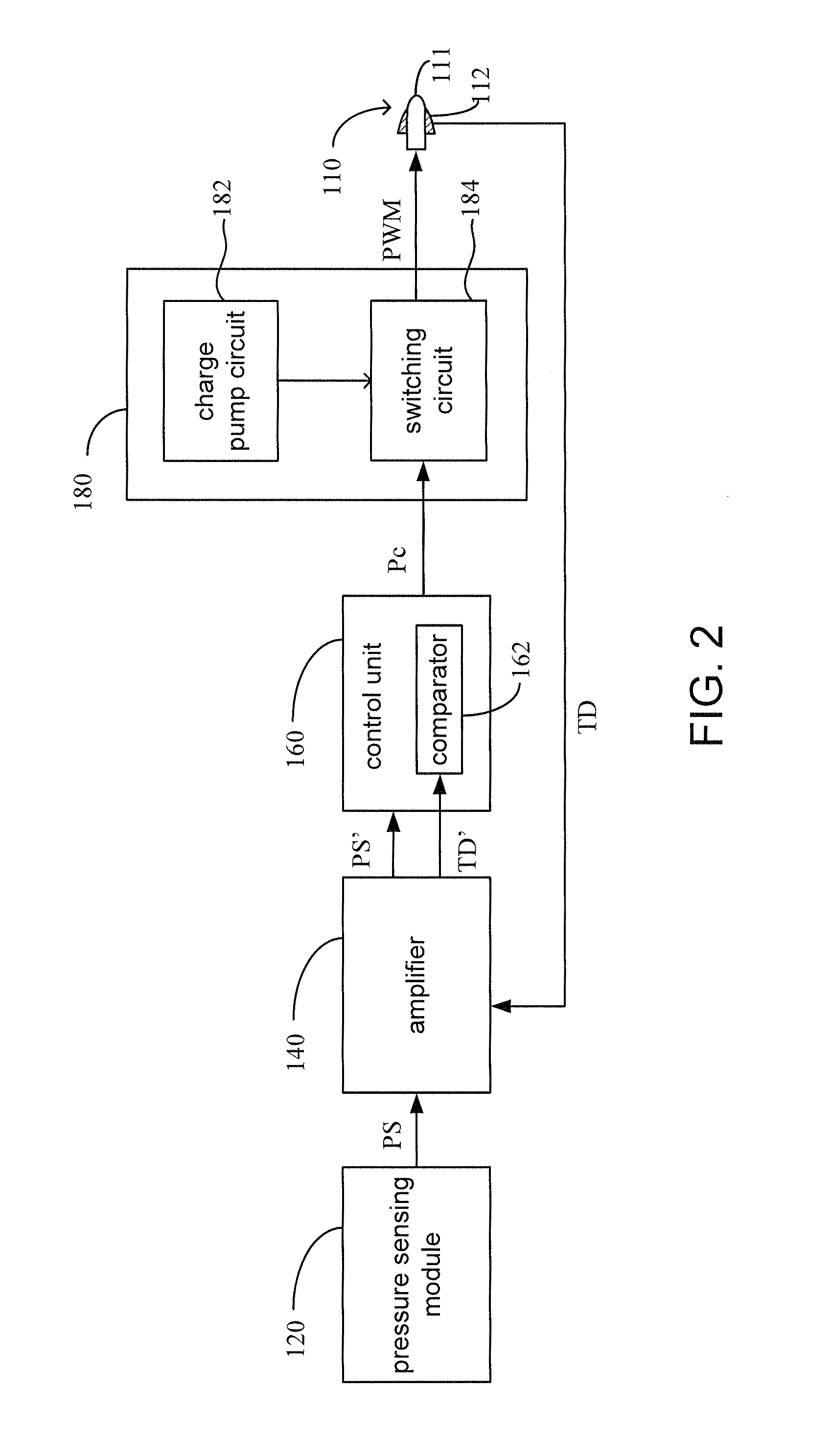

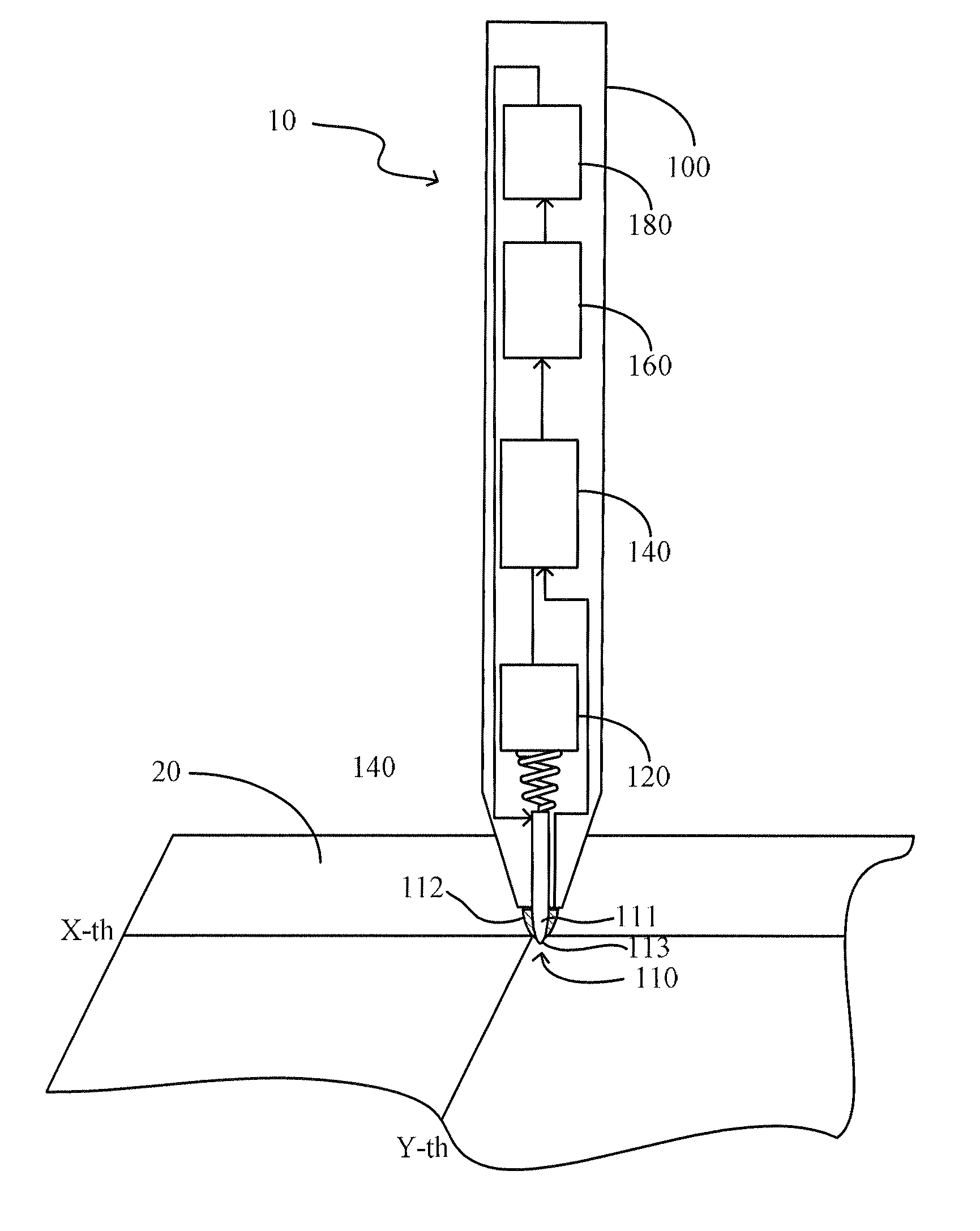

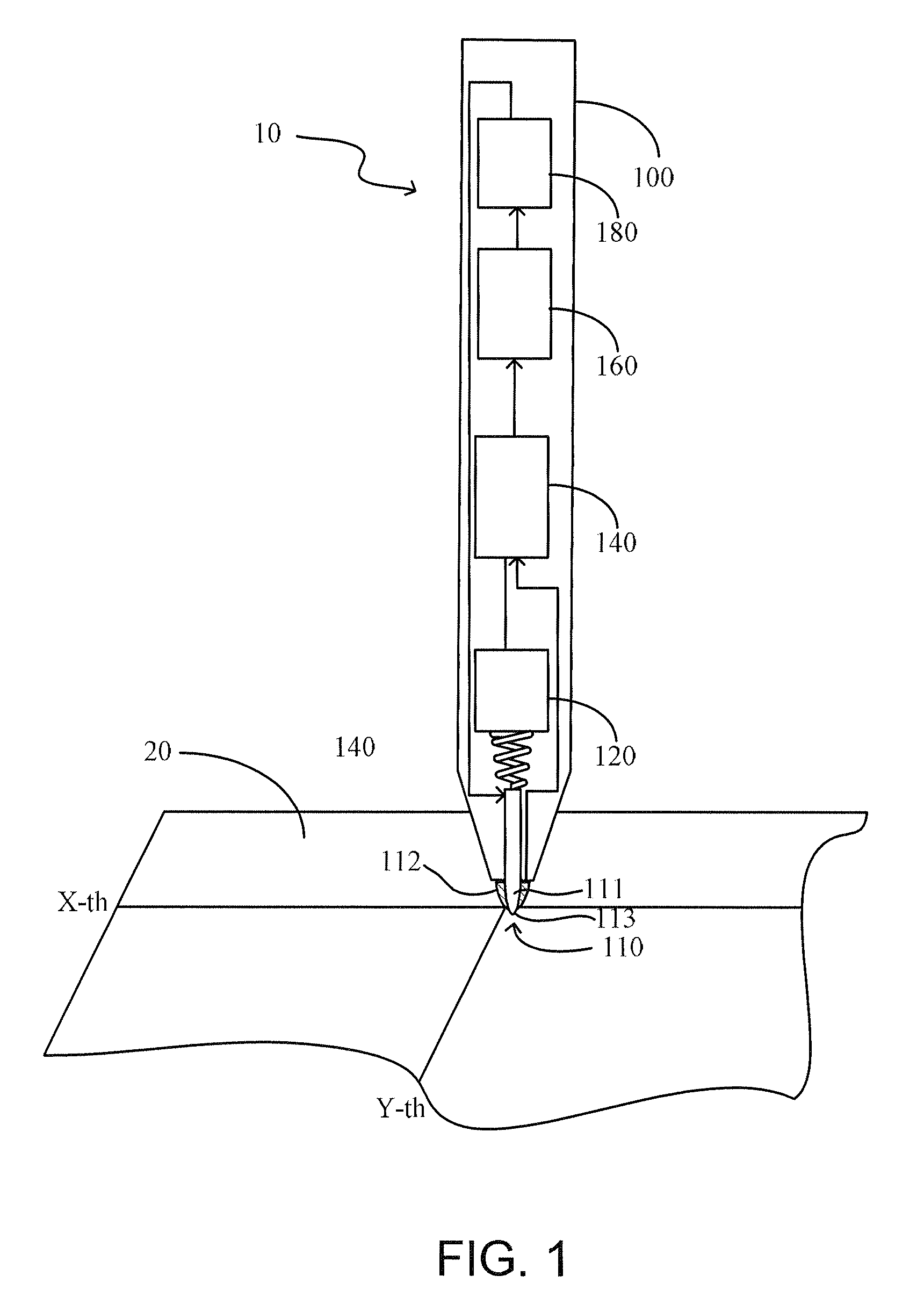

Touch Input Device and System Thereof

ActiveUS20150070293A1Affect strengthInput/output processes for data processingControl signalPressure sense

A touch input device provided in the present invention includes a pen tip, a pressure sensing module, a control unit and a PWM generator. The pen tip is utilized to touch a capacitive touchscreen and conduct a touchscreen driving signal. The pressure sensing module is utilized to generate a pressure sensing signal which corresponds to a pressure of the pen tip on the capacitive touchscreen. The control unit is utilized to receive the touchscreen driving signal and the pressure sensing signal, and then to generate a PWM control signal according to the pressure sensing signal. Further, a pulse width of the PWM control signal is proportional to the pressure. The PWM generator is utilized to provide a PWM signal to the pen tip according to the PWM control signal. A touch input system is further provided in the present invention.

Owner:SILICON INTEGRATED SYSTEMS

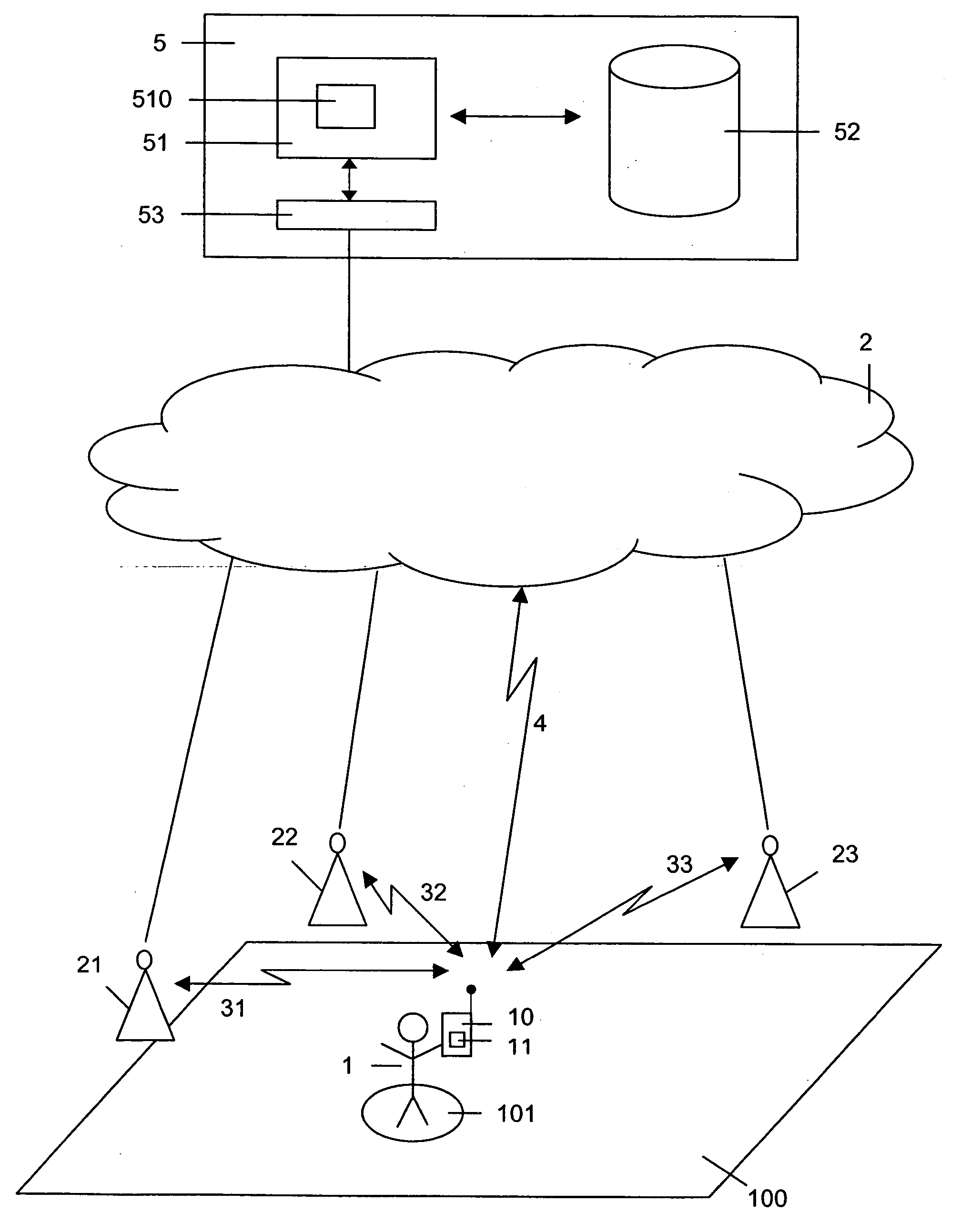

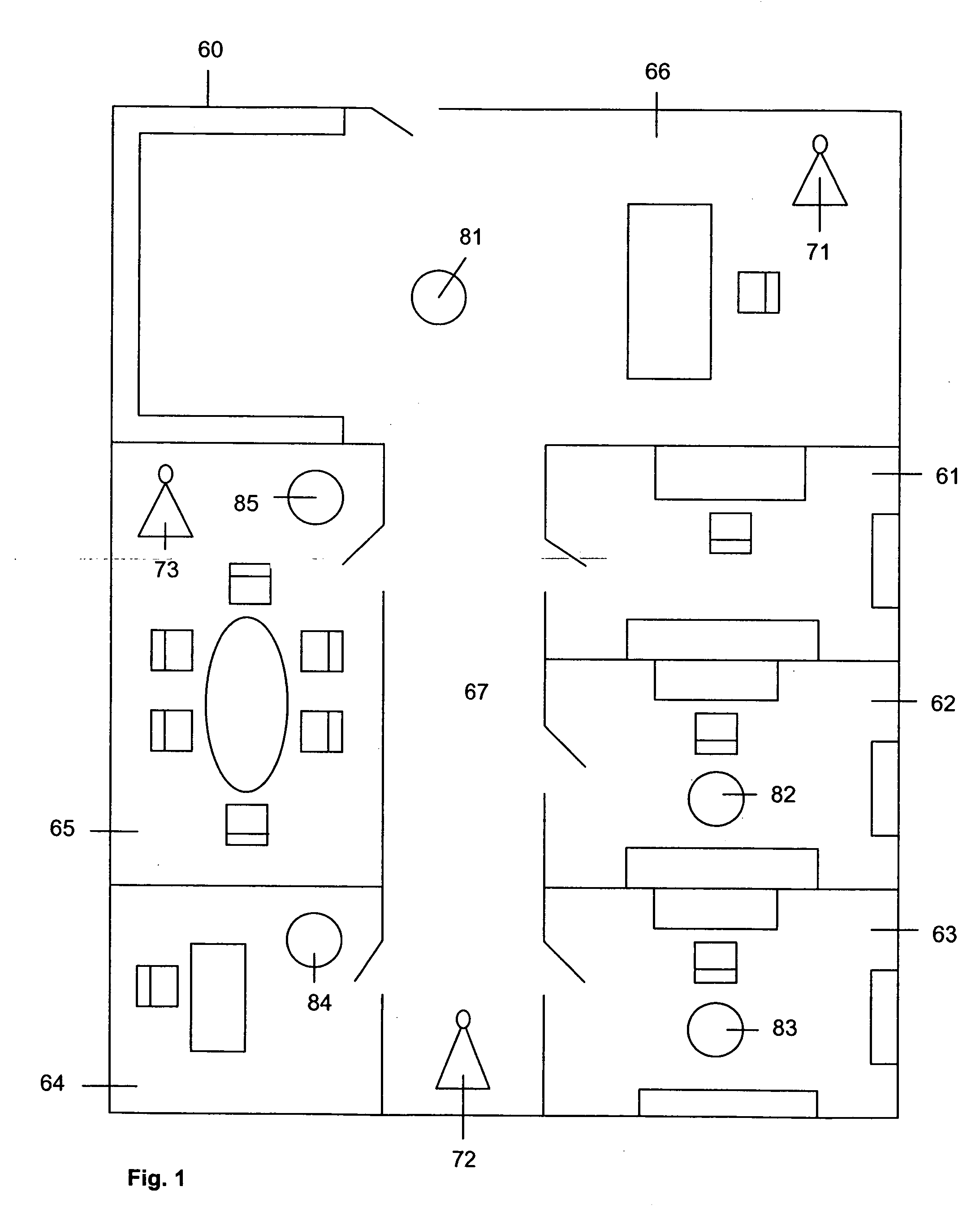

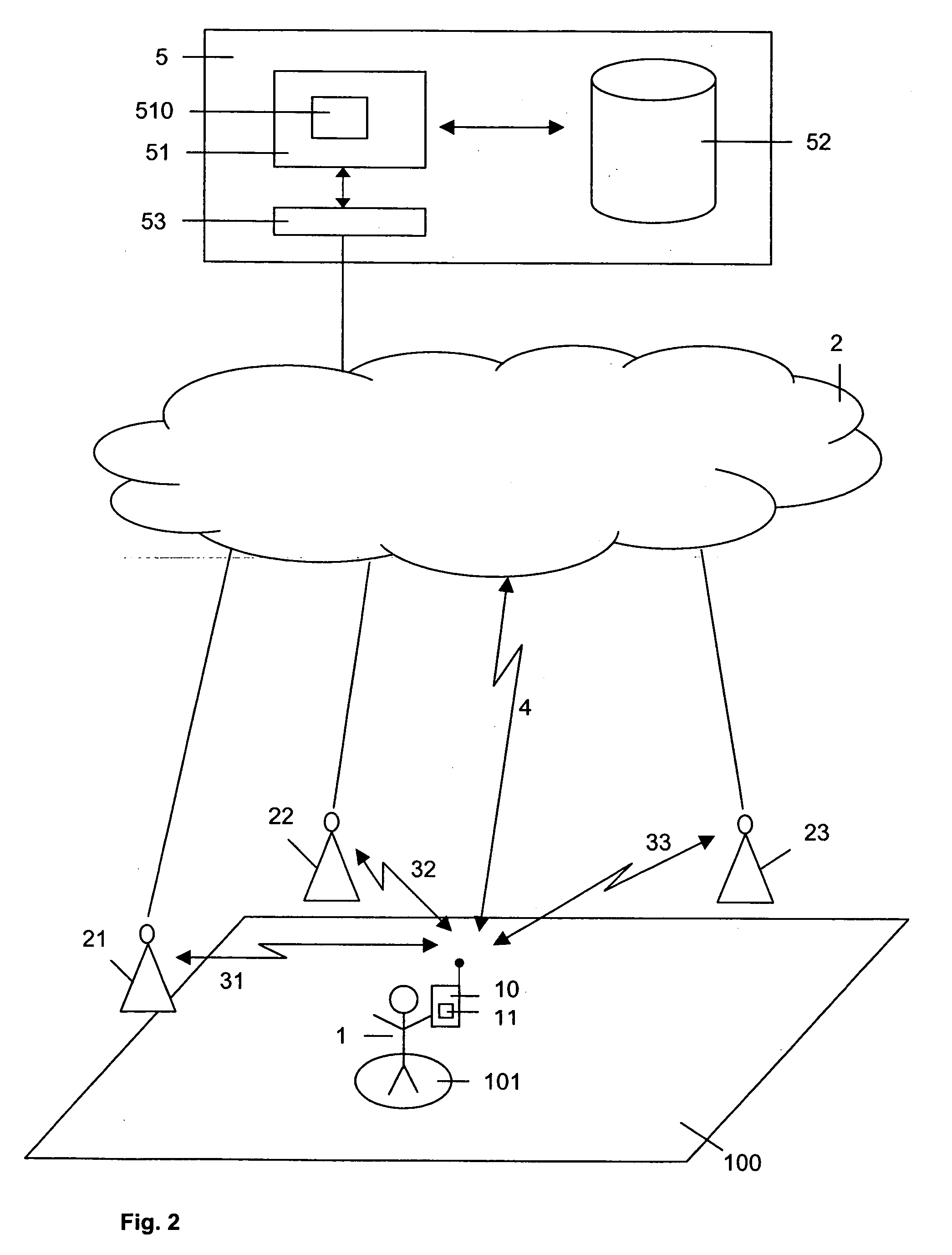

Geographical localisation service

InactiveUS20060176849A1Improvement in provisioningSatisfied with the resultNetwork topologiesRadio/inductive link selection arrangementsLocal area networkGeolocation

The invention concerns a method of providing a geographical localisation service within a wireless local area network having two or more wireless network access points. The terminal of a user is located at a location of a plurality of locations. The terminal measures at least two times the strength of signals received from two or more wireless network access points. It chooses the strongest signals of the several measurements as valid signal strengths and triggers a localisation server to compare the valid signal strengths to an intensity map stored in a data base. The location from the intensity map which best matches the valid signal strengths is provided as location of the terminal.

Owner:ALCATEL LUCENT SAS

Hydrophobically modified clay polymer nanocomposites

InactiveUS7211613B2Good physical propertiesImprove propertiesMaterial nanotechnologyLayered productsColloidSolution polymerization

The present invention is directed, in part, to improved nanocomposite compositions and processes for preparing same. Specifically, in one embodiment, there is provided a process for preparing an aqueous nanocomposite dispersion, wherein the process comprises: polymerizing via suspension polymerization a suspension comprising at least one ethylenically unsaturated monomer and a hydrophobically modified clay to form the nanocomposite dispersion after polymerization, wherein the hydrophobically modified clay is dispersed in the monomer. Other embodiments include processes for preparing aqueous nanocomposite particles, colloids, and dispersions using hydrophobically modified clays in aqueous systems and compositions comprising same.

Owner:ROHM & HAAS CO

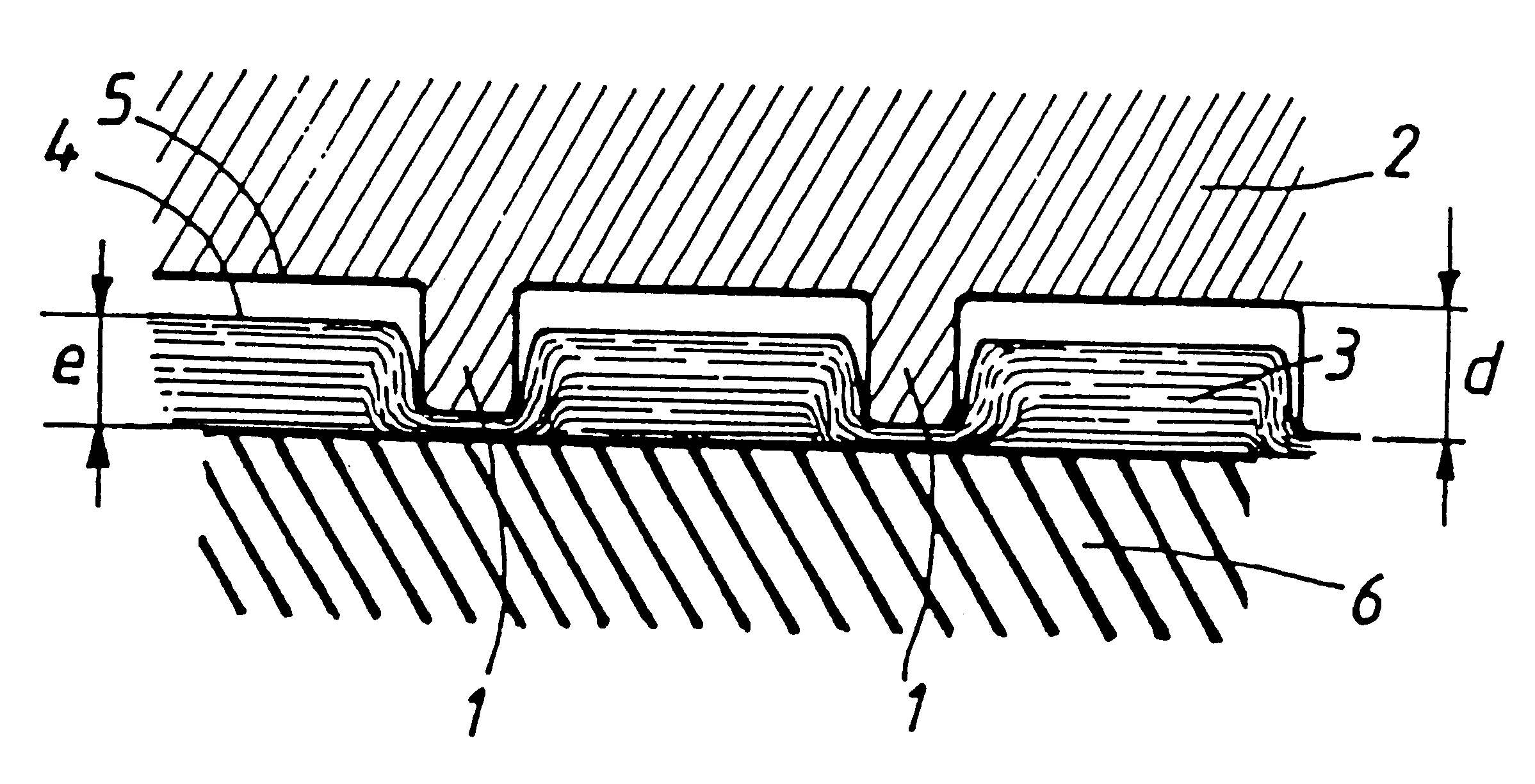

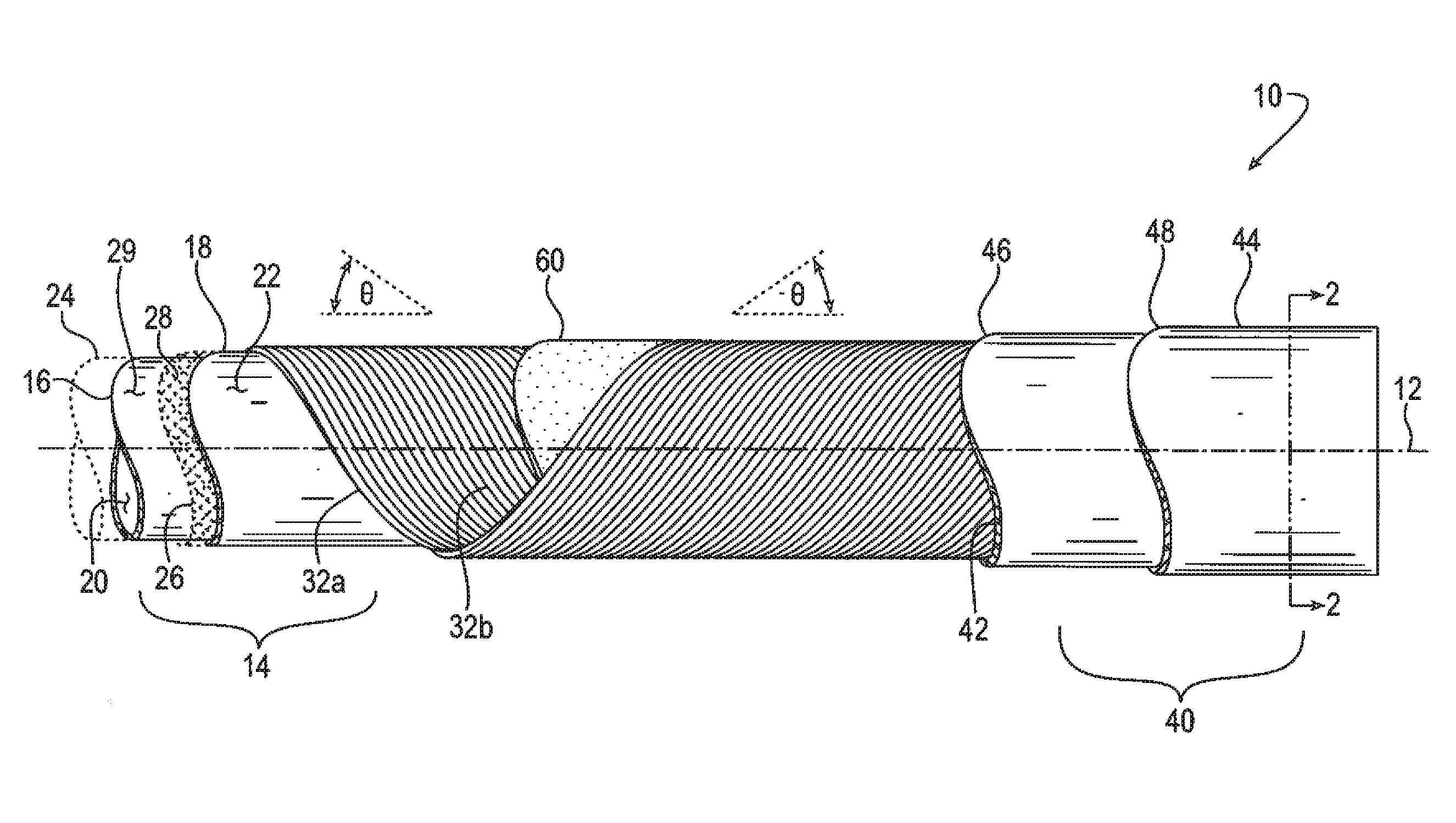

Process of finishing an air-laid web and web obtained thereby

InactiveUS6332996B1Simple economicSimple processMechanical working/deformationRotary pressesHardnessEngineering

The general application of the invention is a finishing process for an air-laid nonwoven web composed of short cellulosic fibers, bound by a thermoplastic binder and having a less than perfect homogeneous fiber distribution. In the invention, the process includes deforming under hot stress the web between an undeforming hard engraved cylinder and a slave cylinder having a hardness between about 60 and 90 degrees shore hardness D. The slave cylinder is resilient and deformable at the pressure applied to it by the engraved cylinder. In particular, the invention applies to the manufacture of webs and of disposable, decorative napkins.

Owner:GEORGIA PACIFIC FRANCE SAS

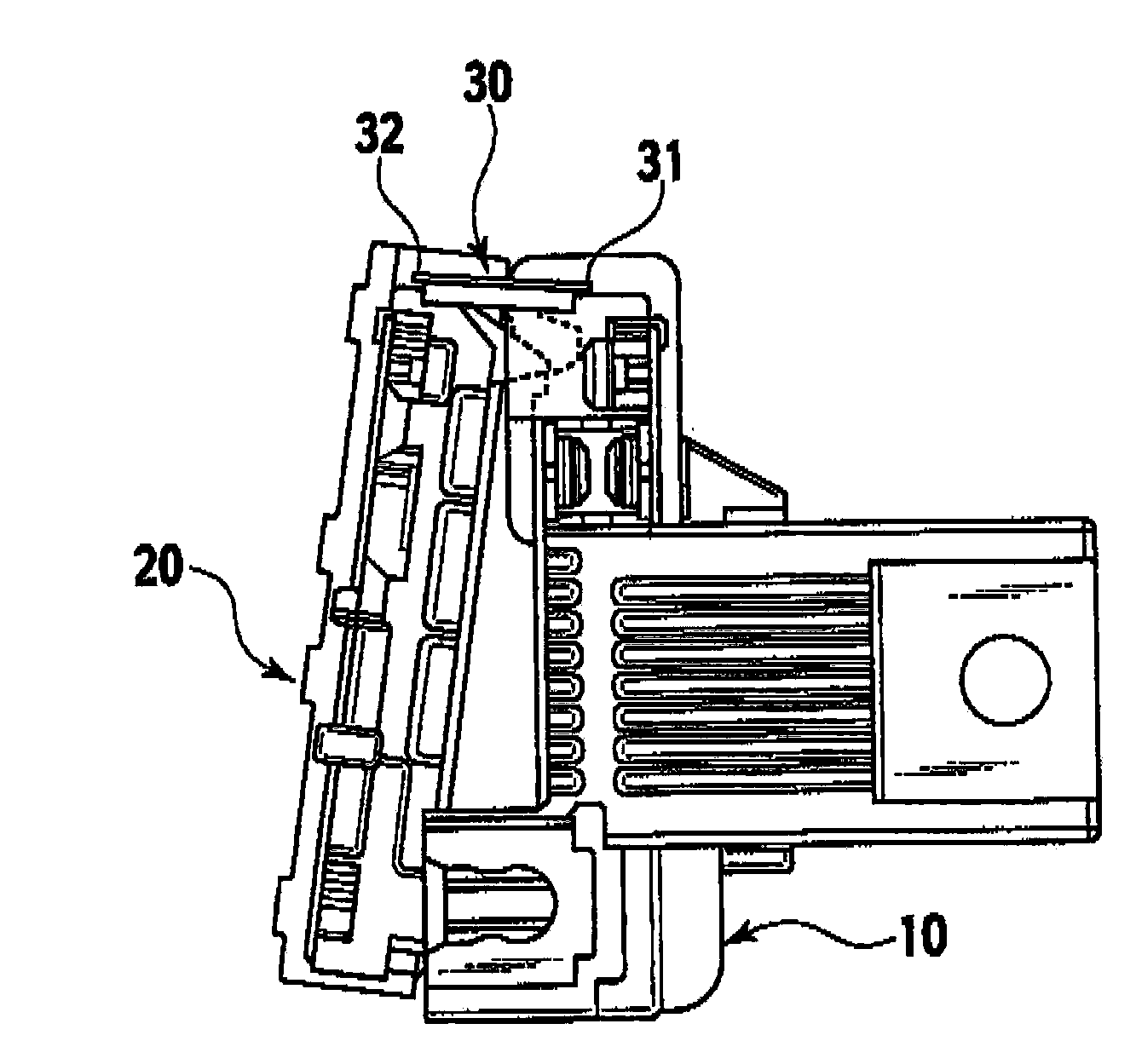

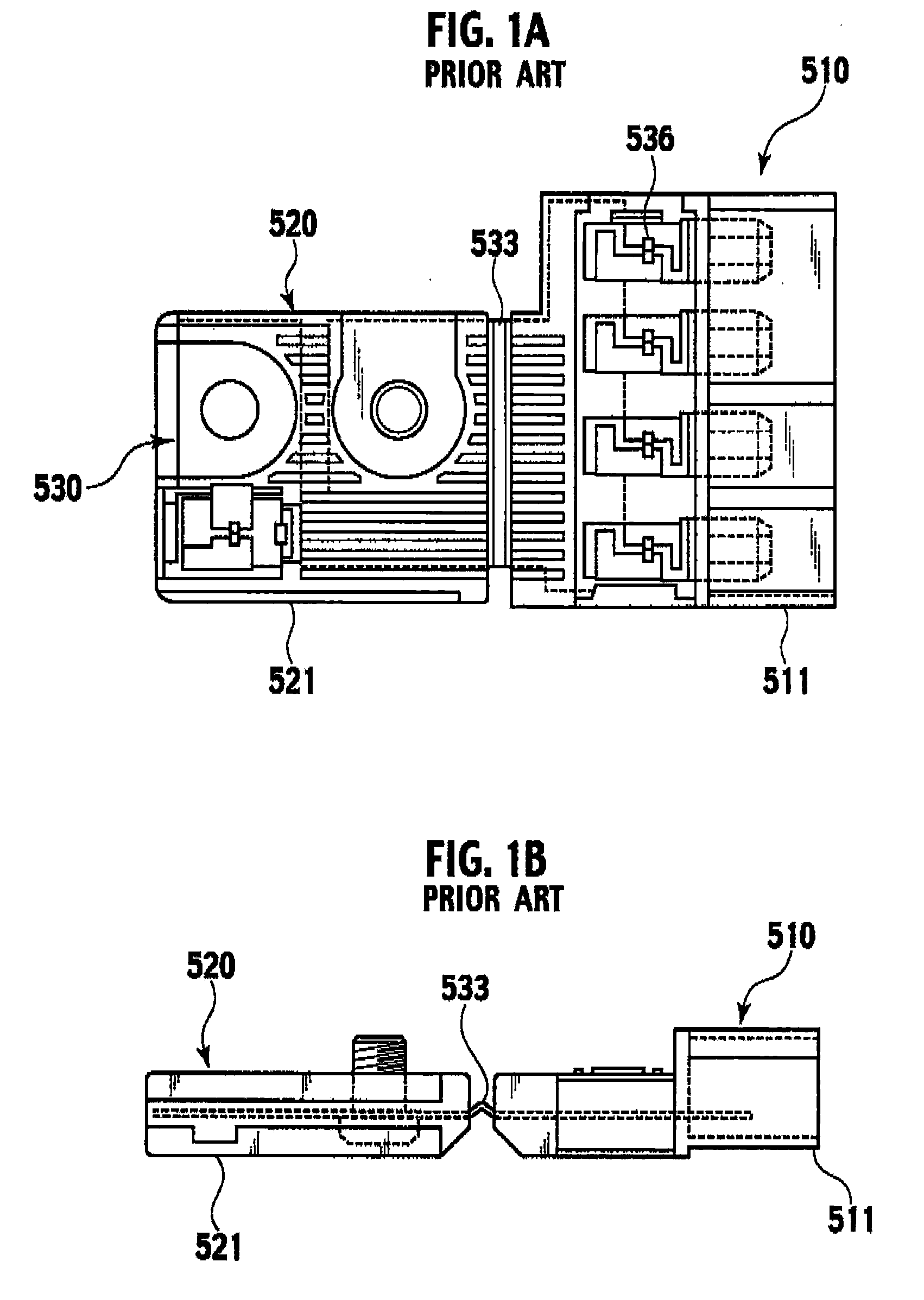

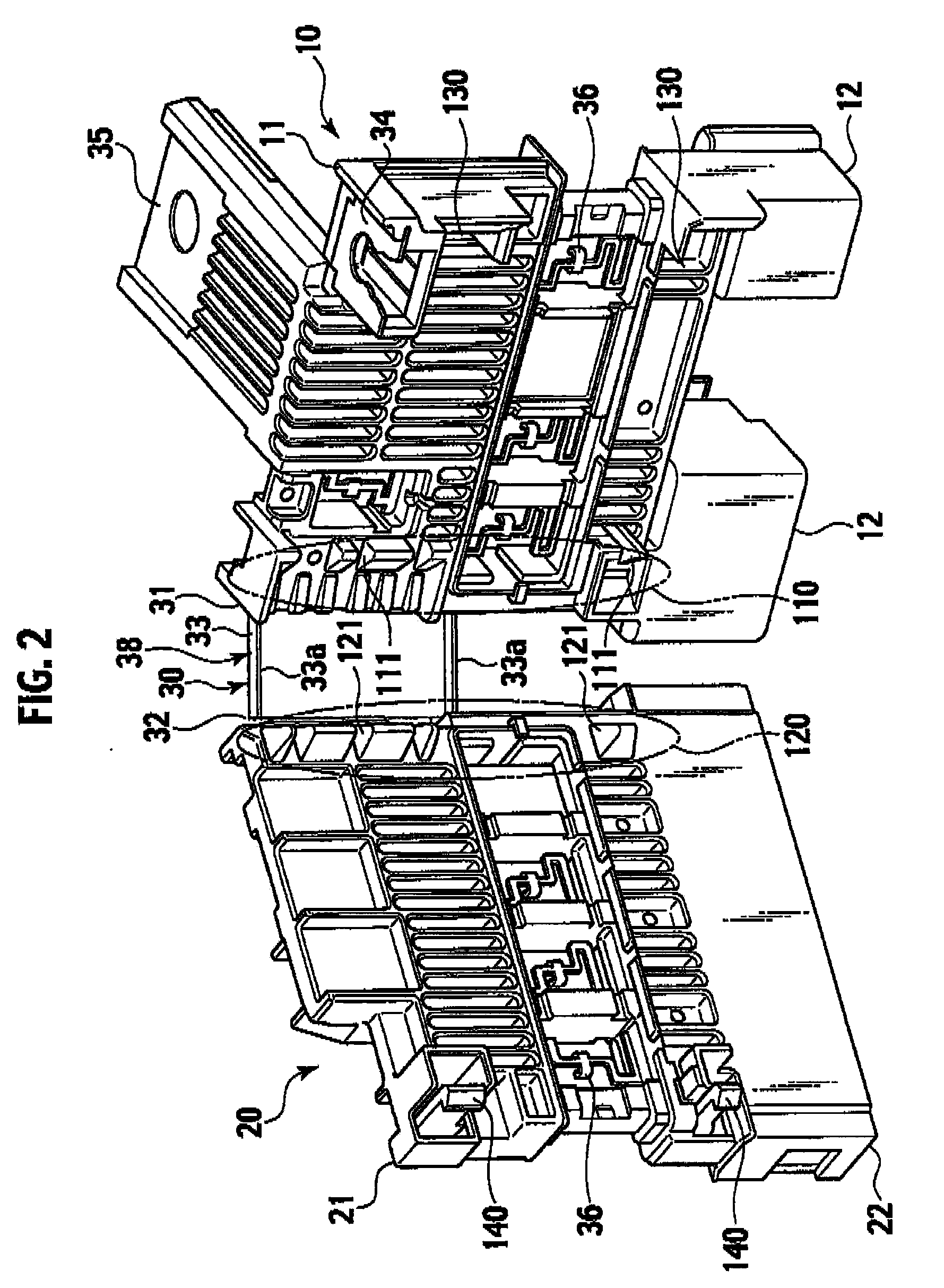

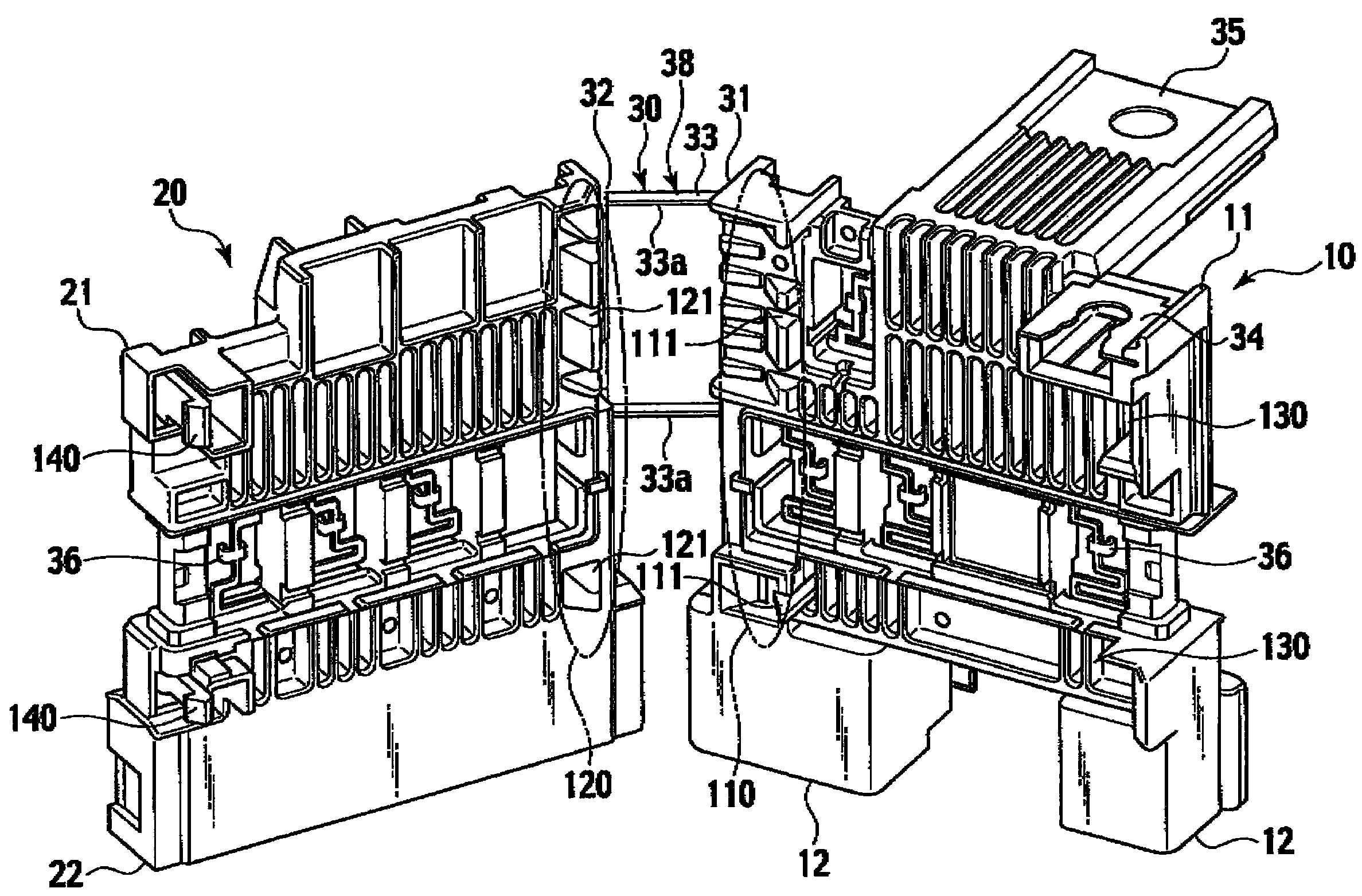

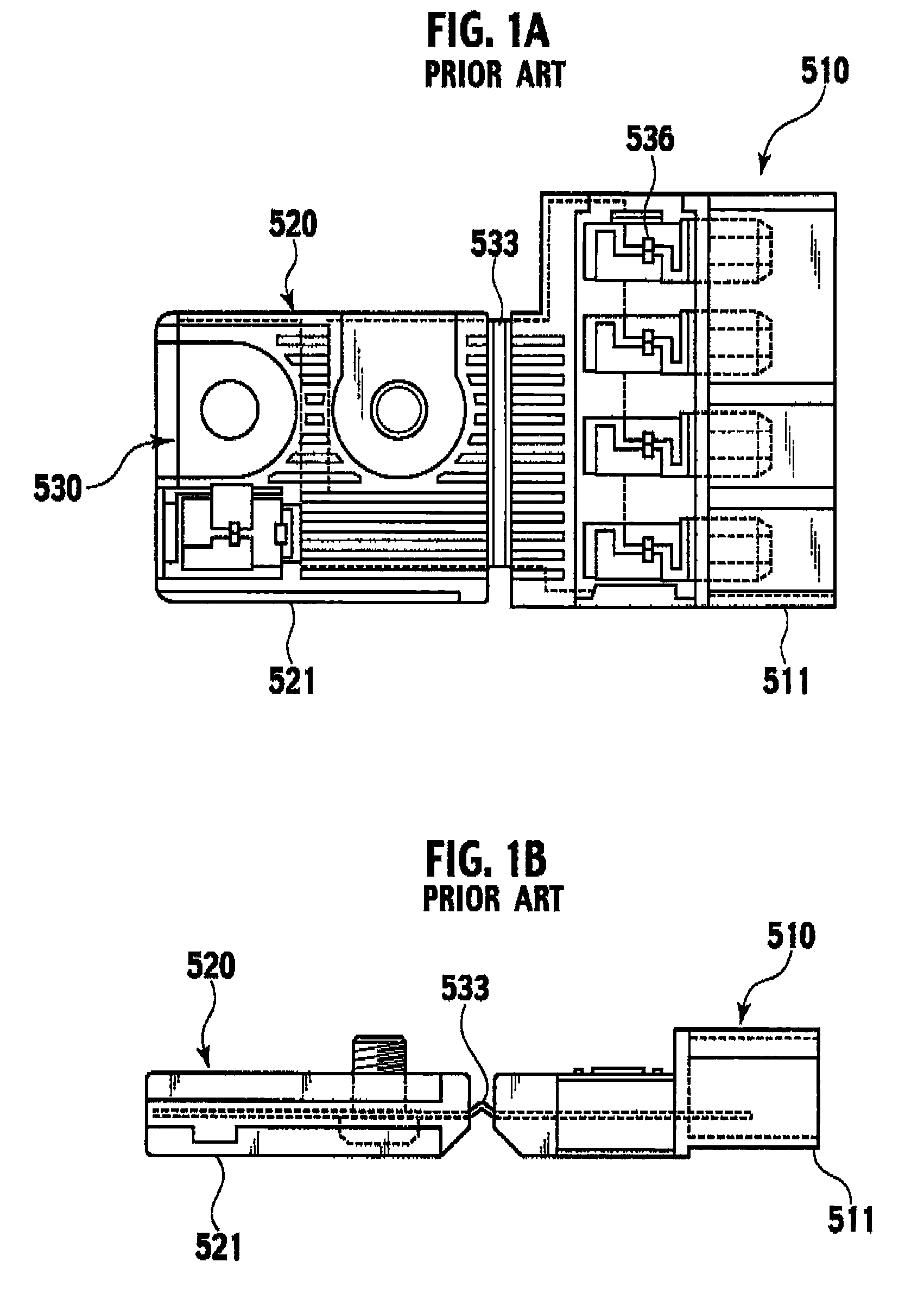

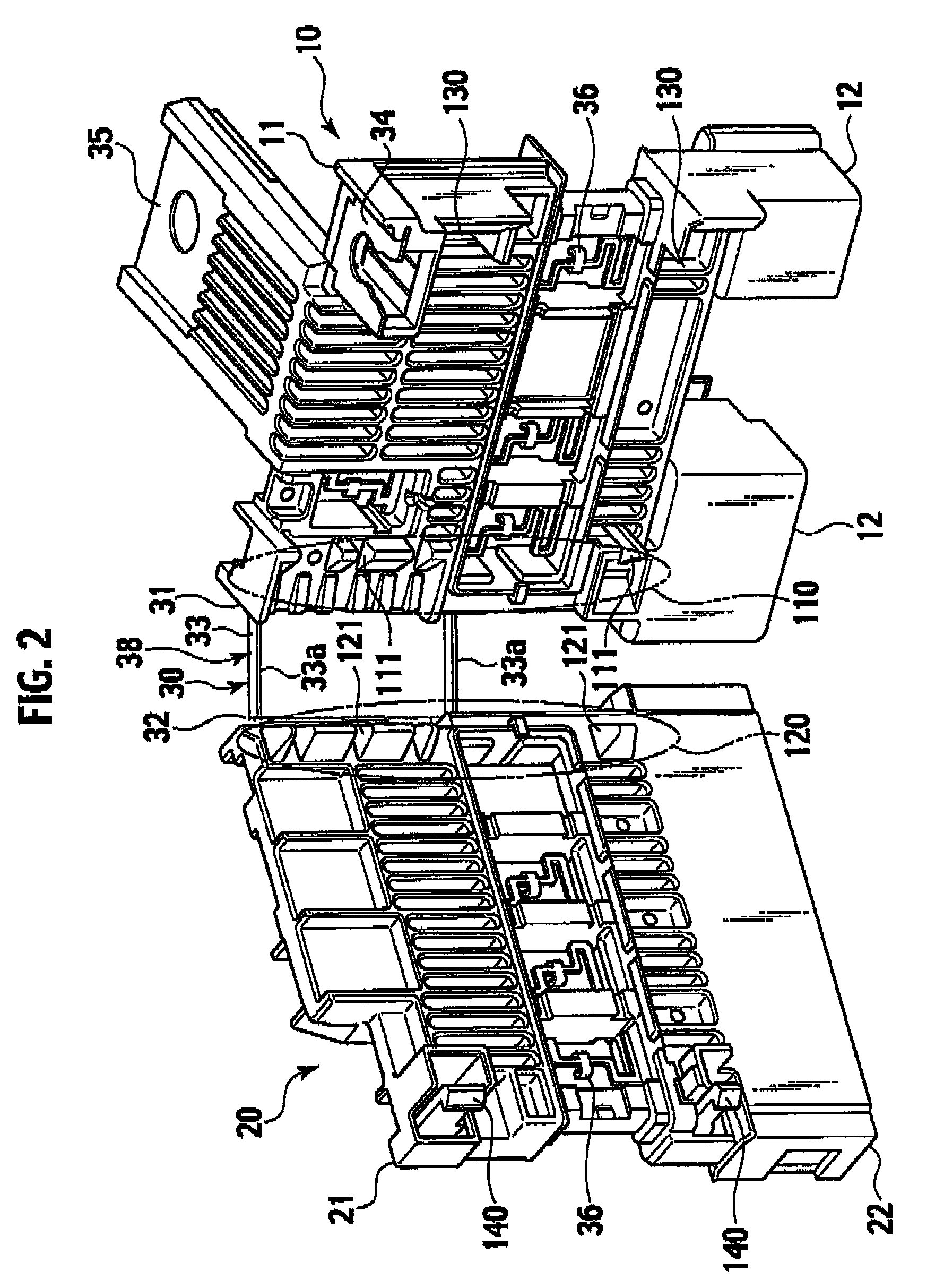

Fusible Link Unit with Hinge Section

ActiveUS20090111316A1Improve vibration resistanceAvoid noiseIncorrect coupling preventionEmergency protective devicesBusbarEngineering

A hinge section including bending sections at both side edges of a band plate section is provided in center of a busbar. On both sides of the hinge section, two fuse circuit constituting plate sections are integrally formed to be linked thereto. Two resin housings are assembled by insert molding to the respective fuse circuit constituting plate sections, thus forming two bodies. The two bodies are pivoted in the same direction at the bending sections, and engagement units are locked, thus constituting a fusible link unit having a U-shaped plan view. The two bodies are engaged with each other in vicinity areas of the hinge section in the opposed surfaces of the opposed resin housing when the two bodies are pivoted. The fusible link unit also includes recessed and projected guides guiding the two resin housings to proper positions.

Owner:YAZAKI CORP

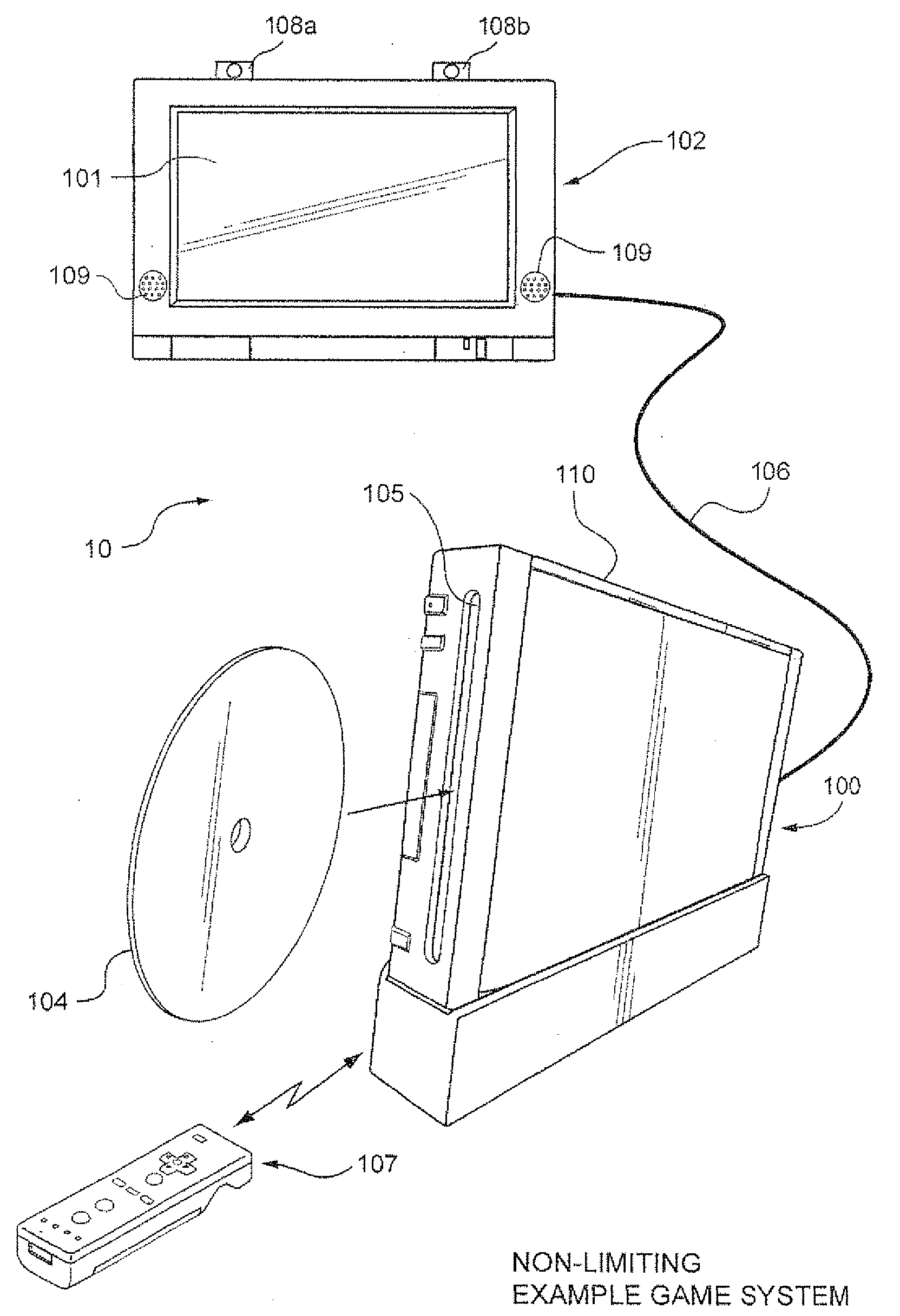

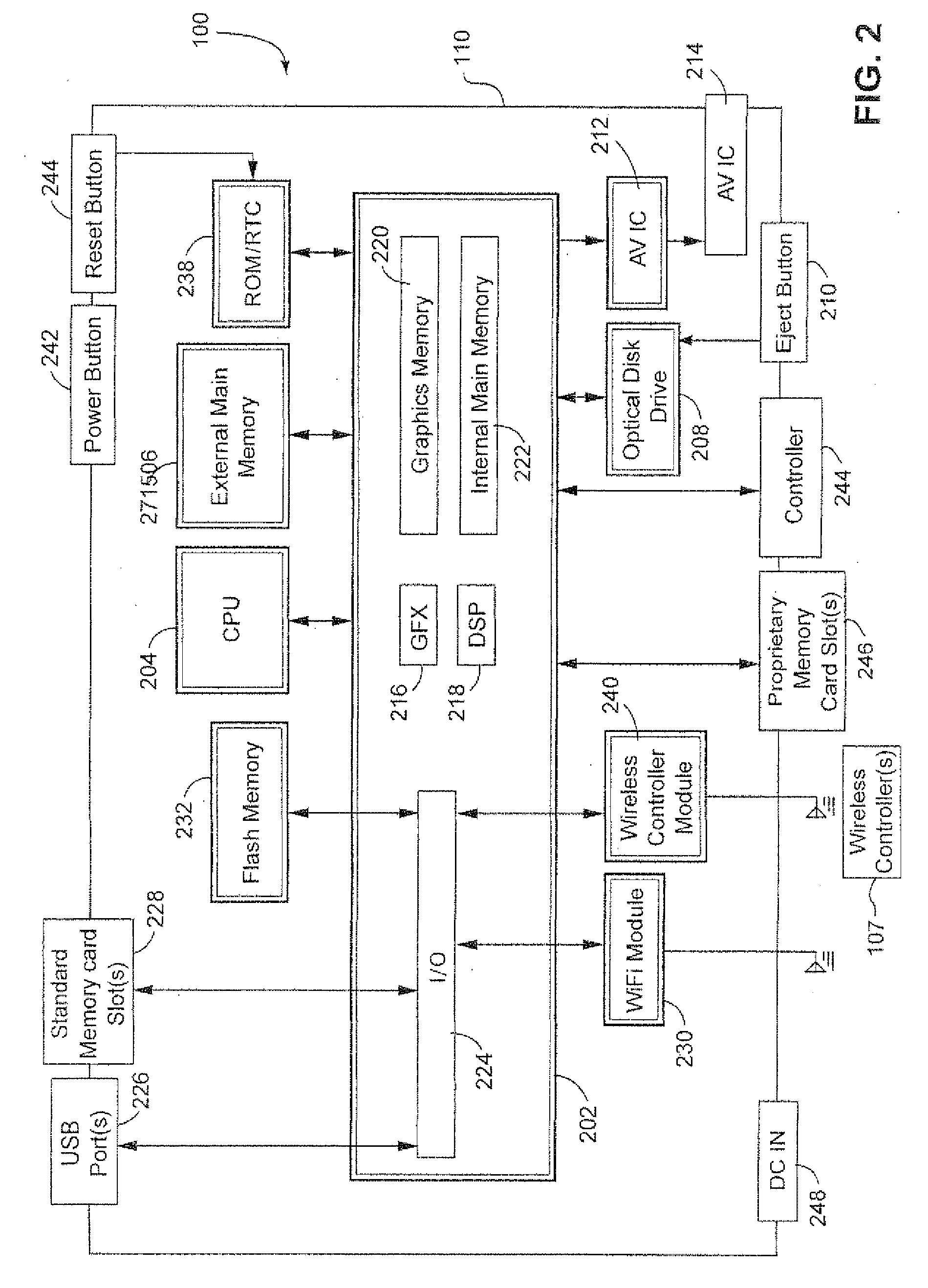

Sports video game with enhanced control features

ActiveUS20090048009A1Improve gaming experienceControl freedomVideo gamesSpecial data processing applicationsRelevant featureHuman–computer interaction

Owner:NINTENDO CO LTD

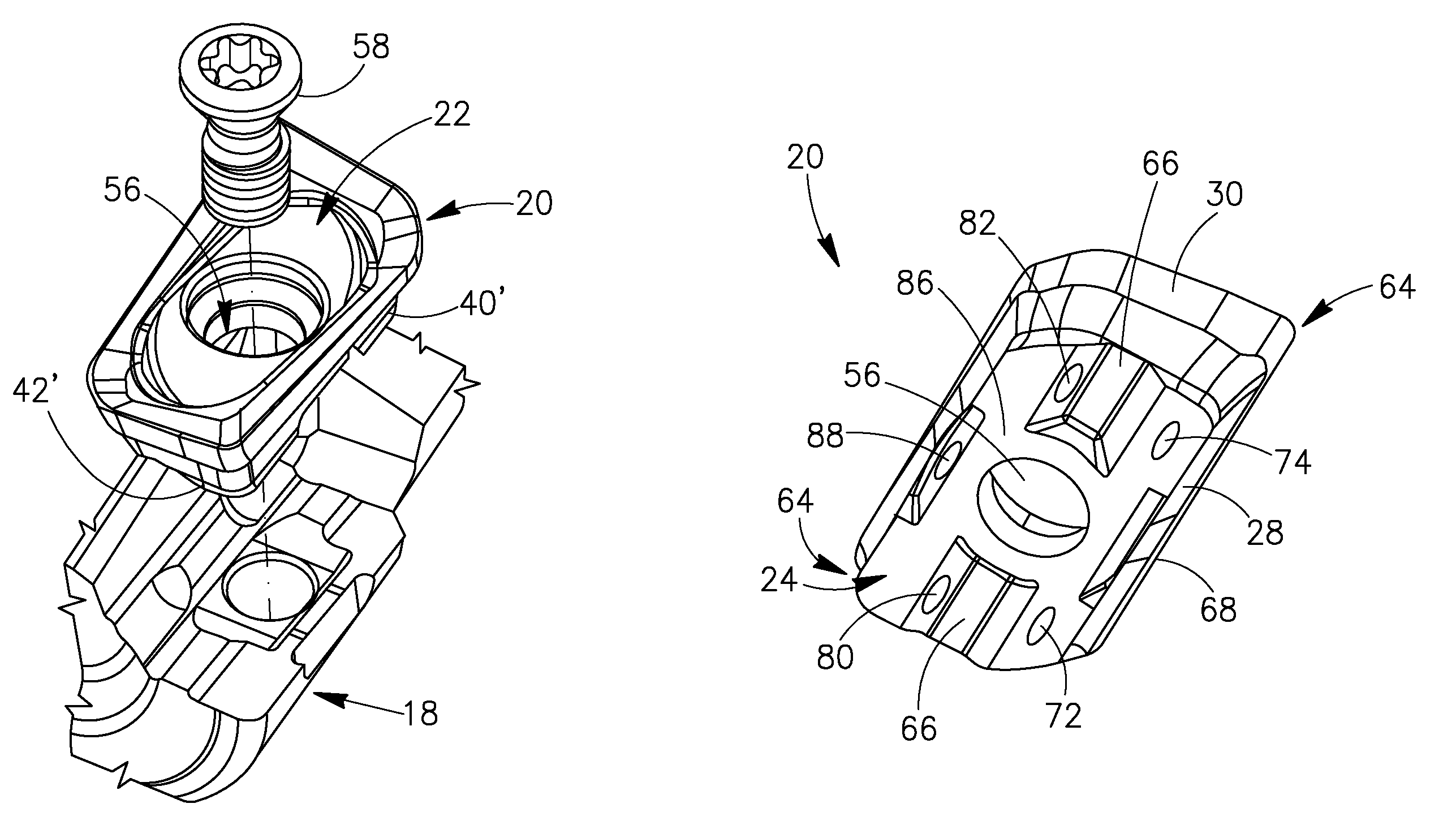

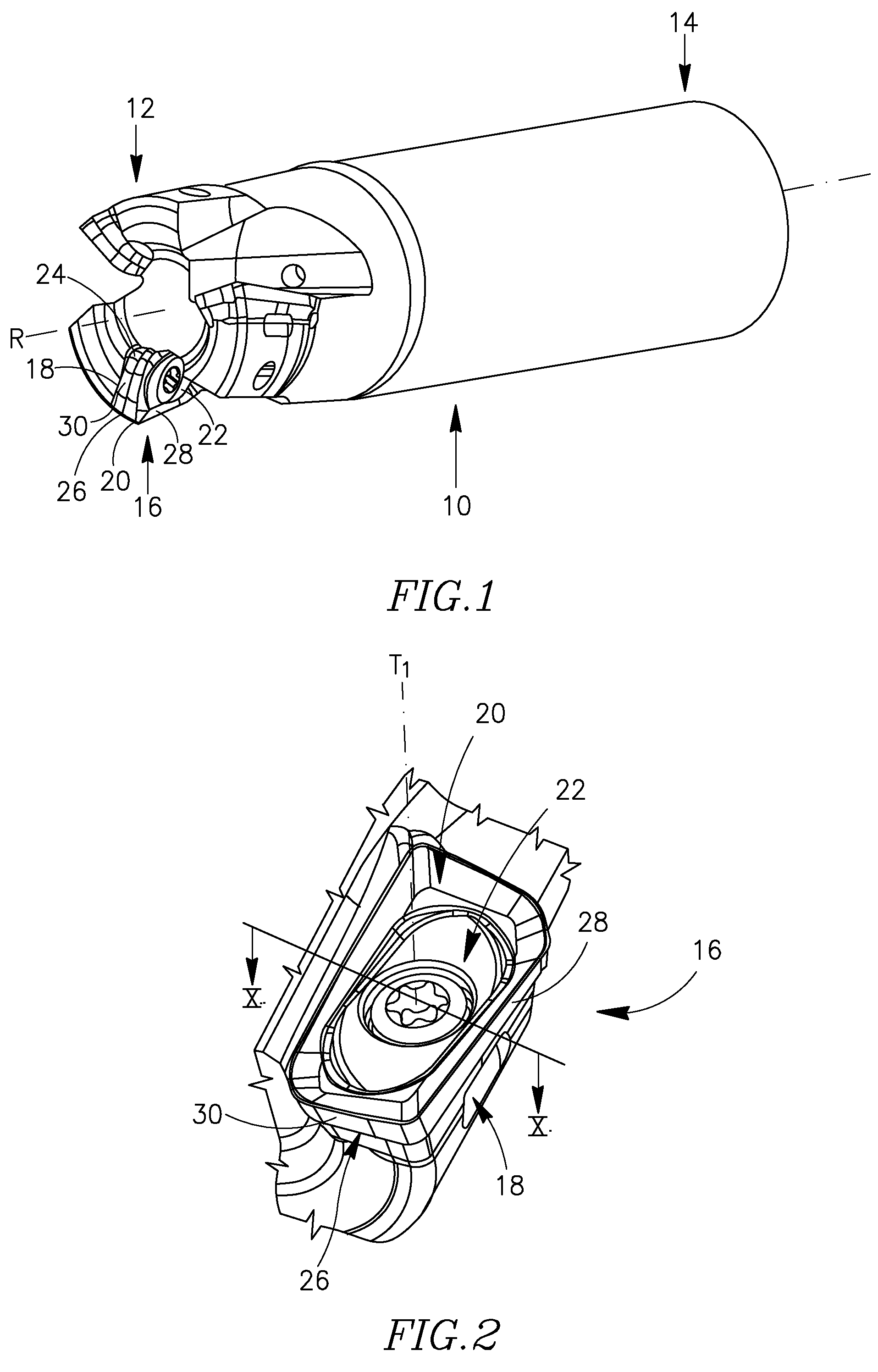

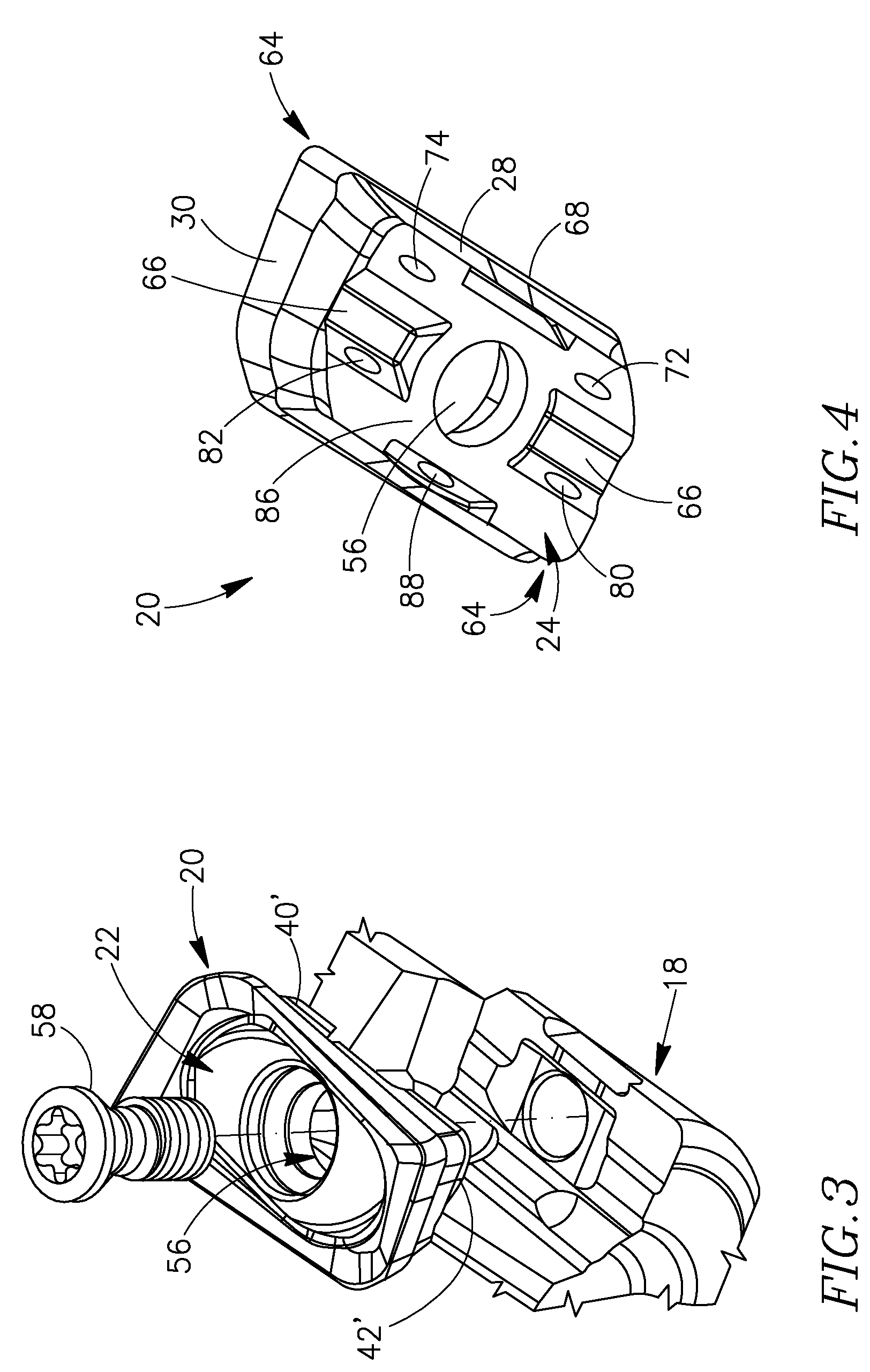

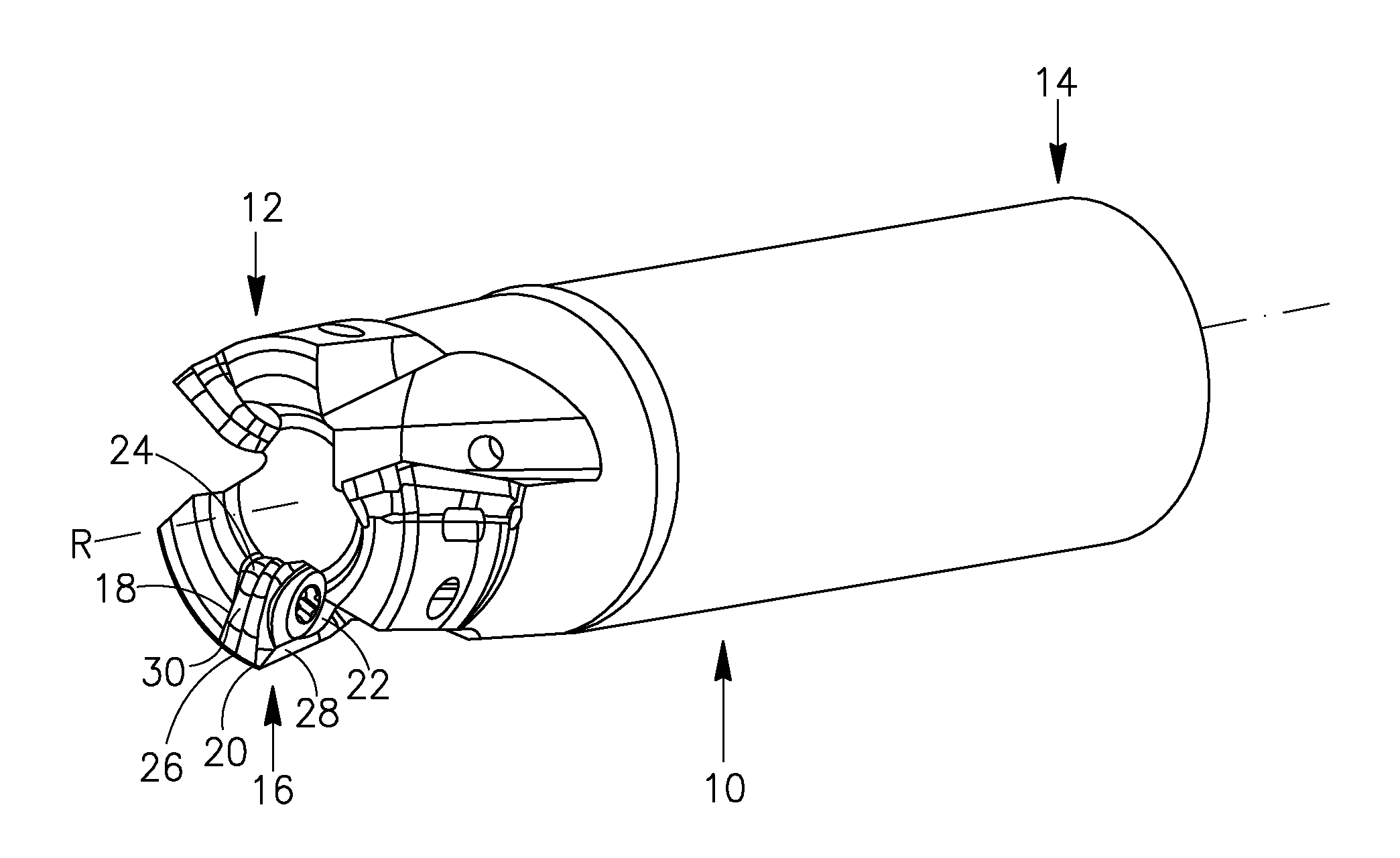

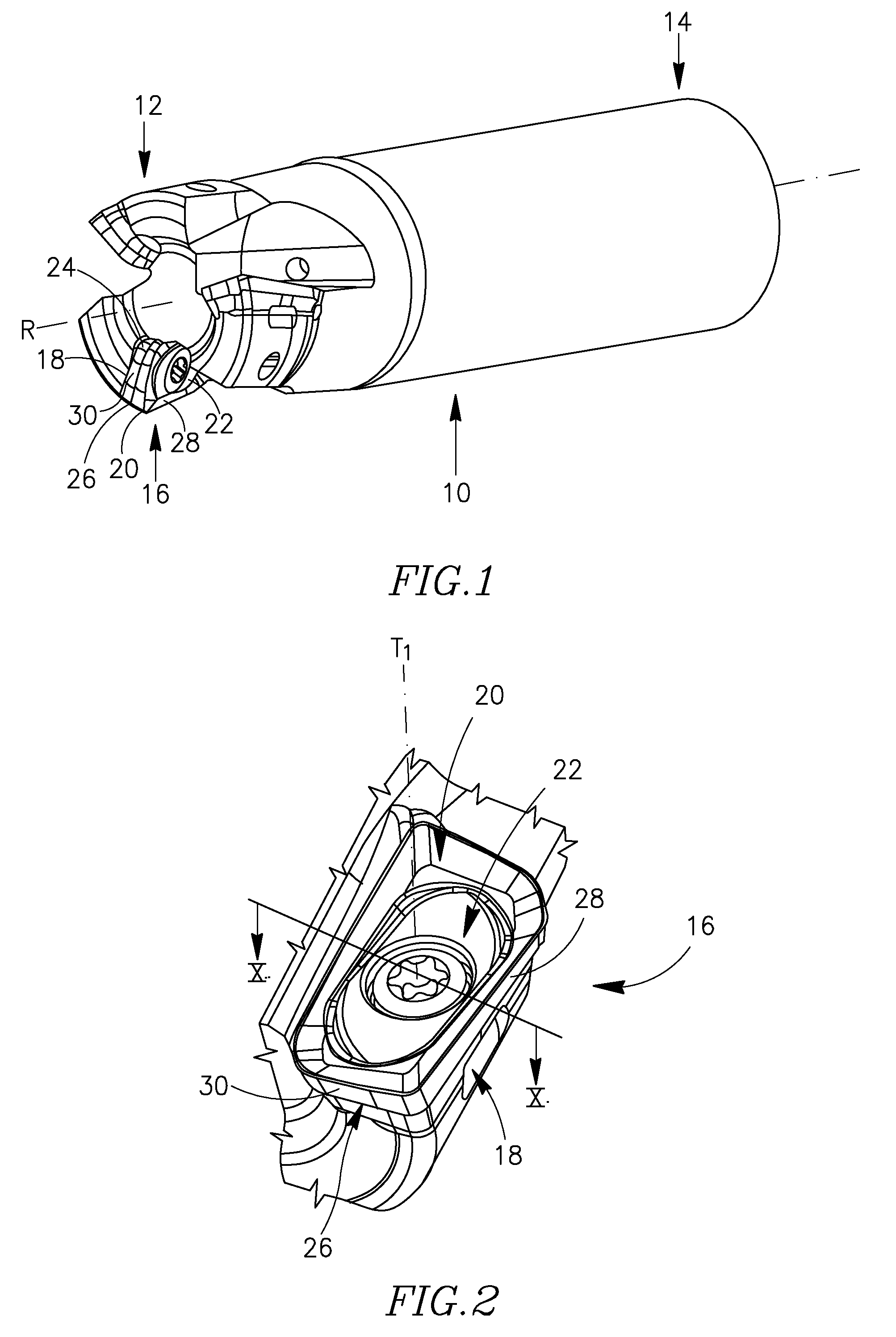

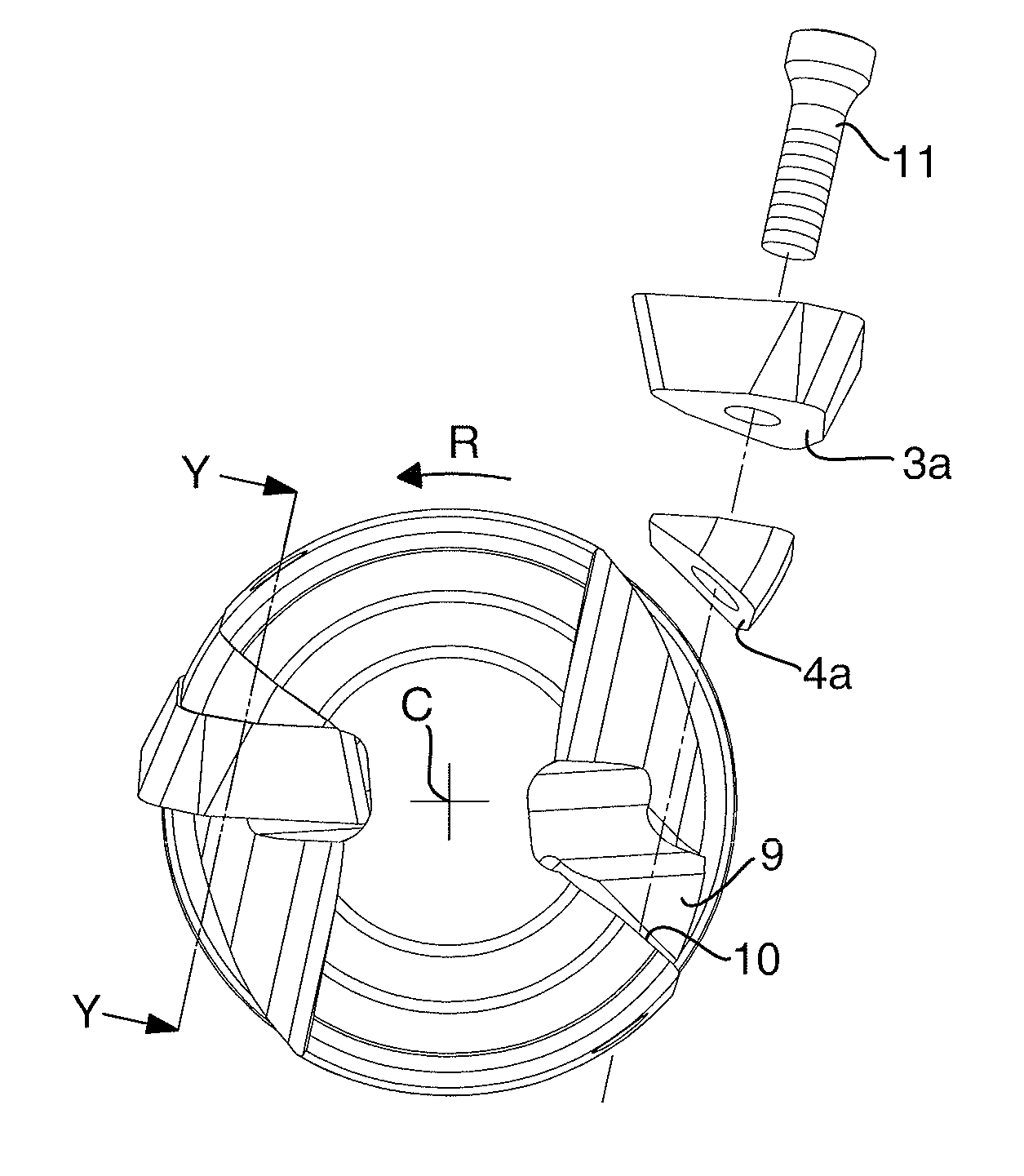

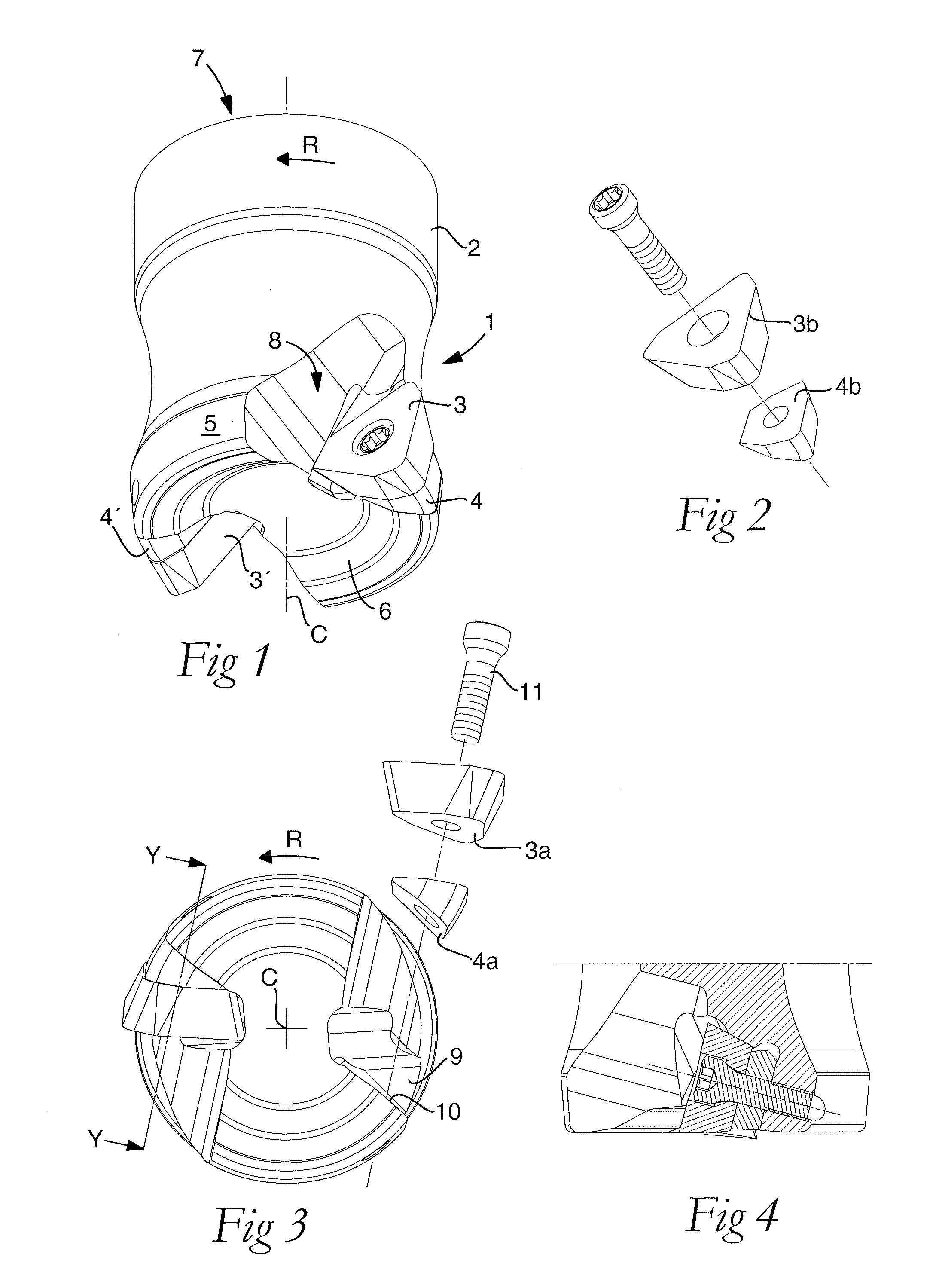

Cutting tool and cutting insert therefor

ActiveUS8313270B2Increase resistanceFixed and accurateMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting tool includes one or more cutting portions, each including an insert pocket having a cutting insert releasably retained therein. The cutting insert has a bottom surface, including a plurality of surfaces, engaging a plurality of walls of the insert pocket in a plurality of sloping and non-sloping engagement regions. These engagement means provide secure and stable clamping of the cutting insert, and prevent displacement of the cutting insert during intensive cutting operations, such as high speed milling, e.g., by significantly decreasing the force exerted on the screw that fastens the cutting insert in the insert pocket.

Owner:ISCAR LTD

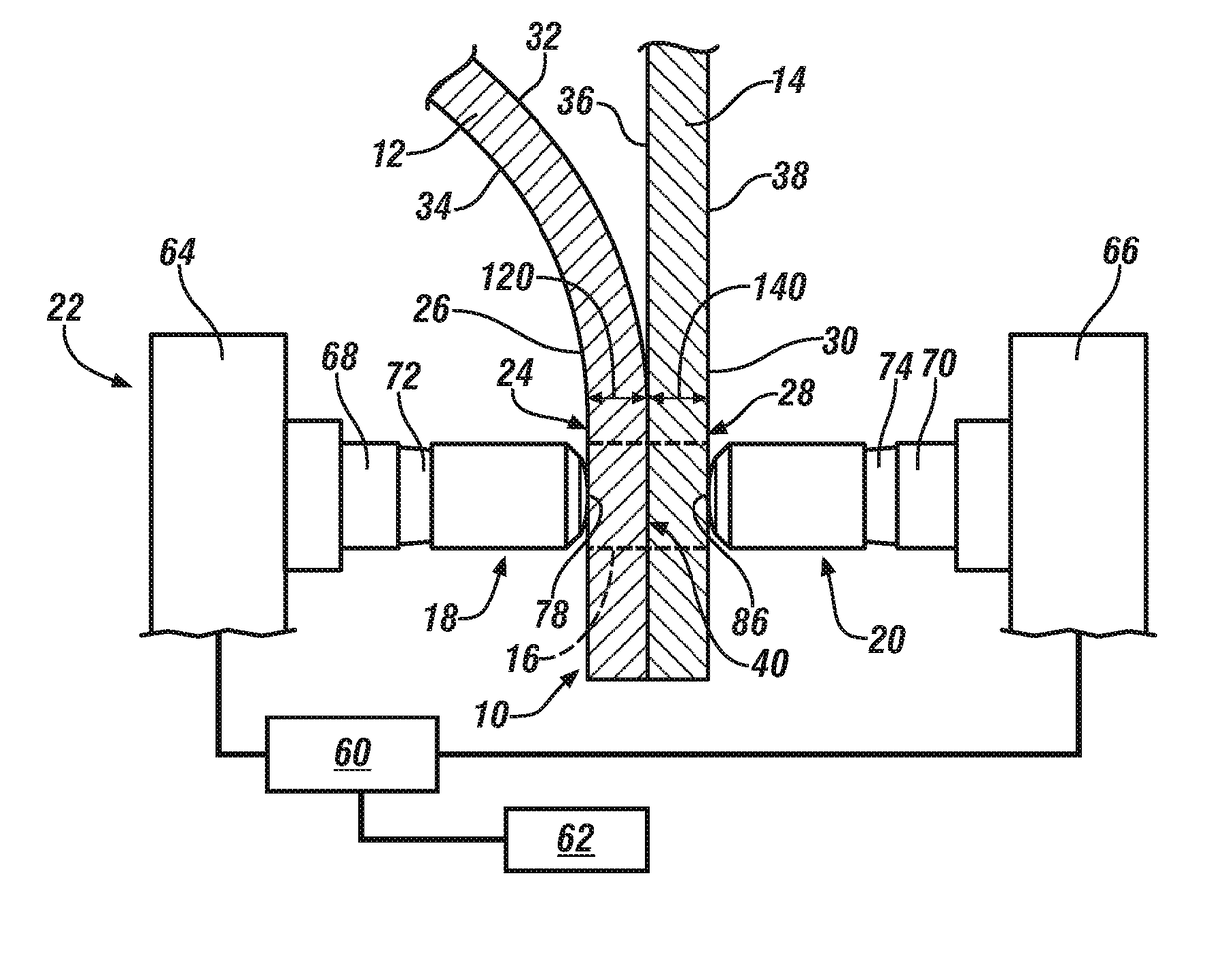

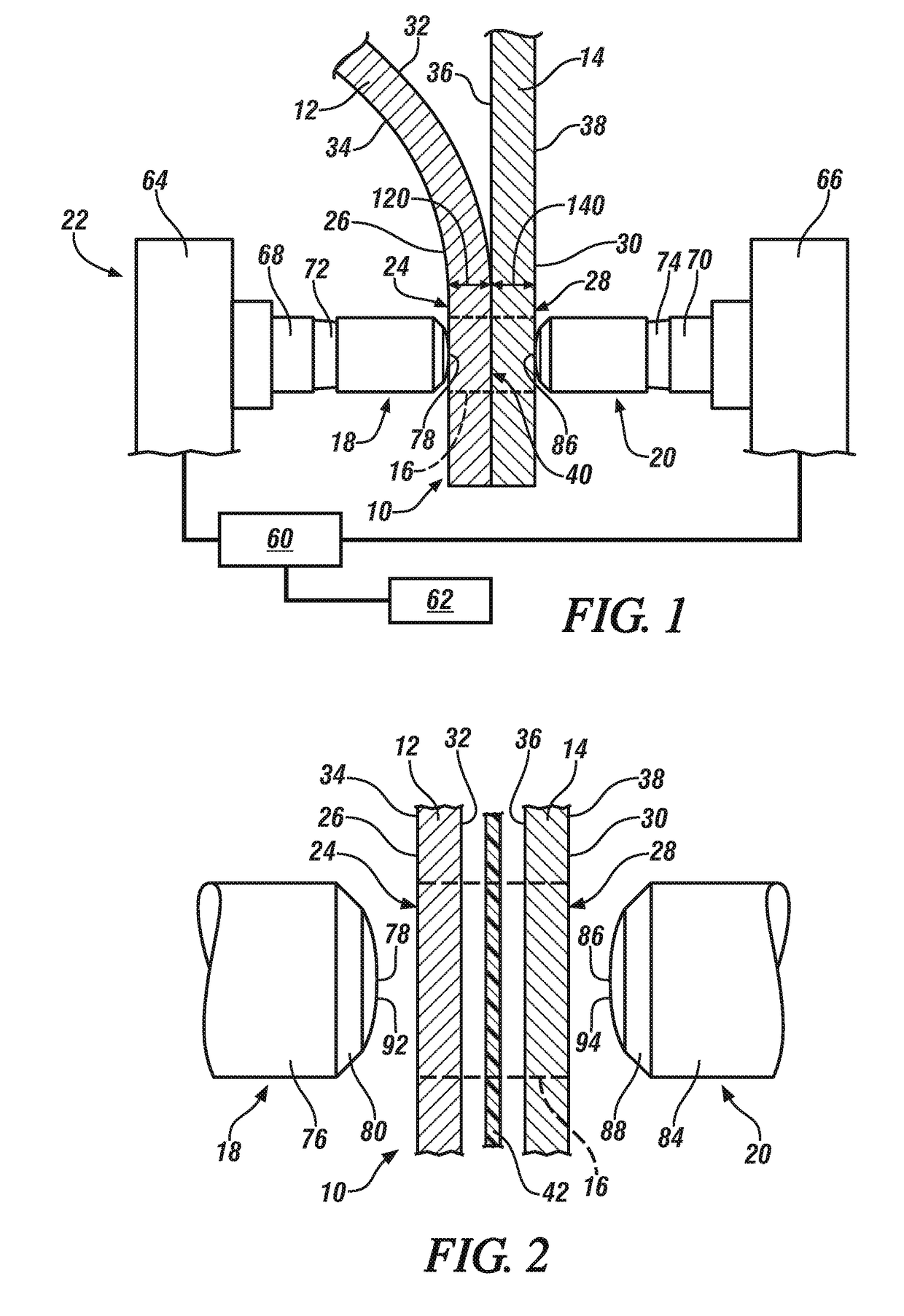

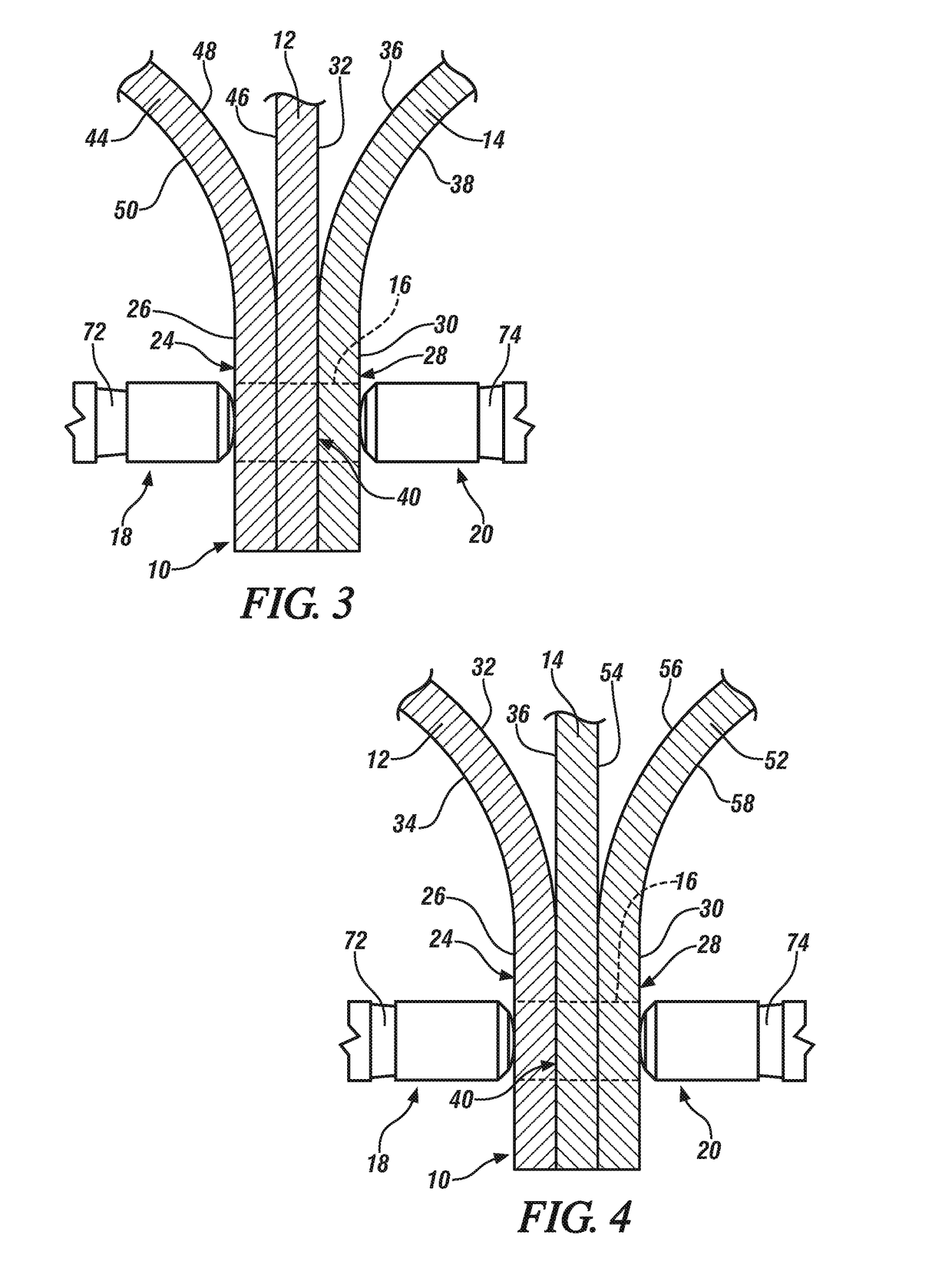

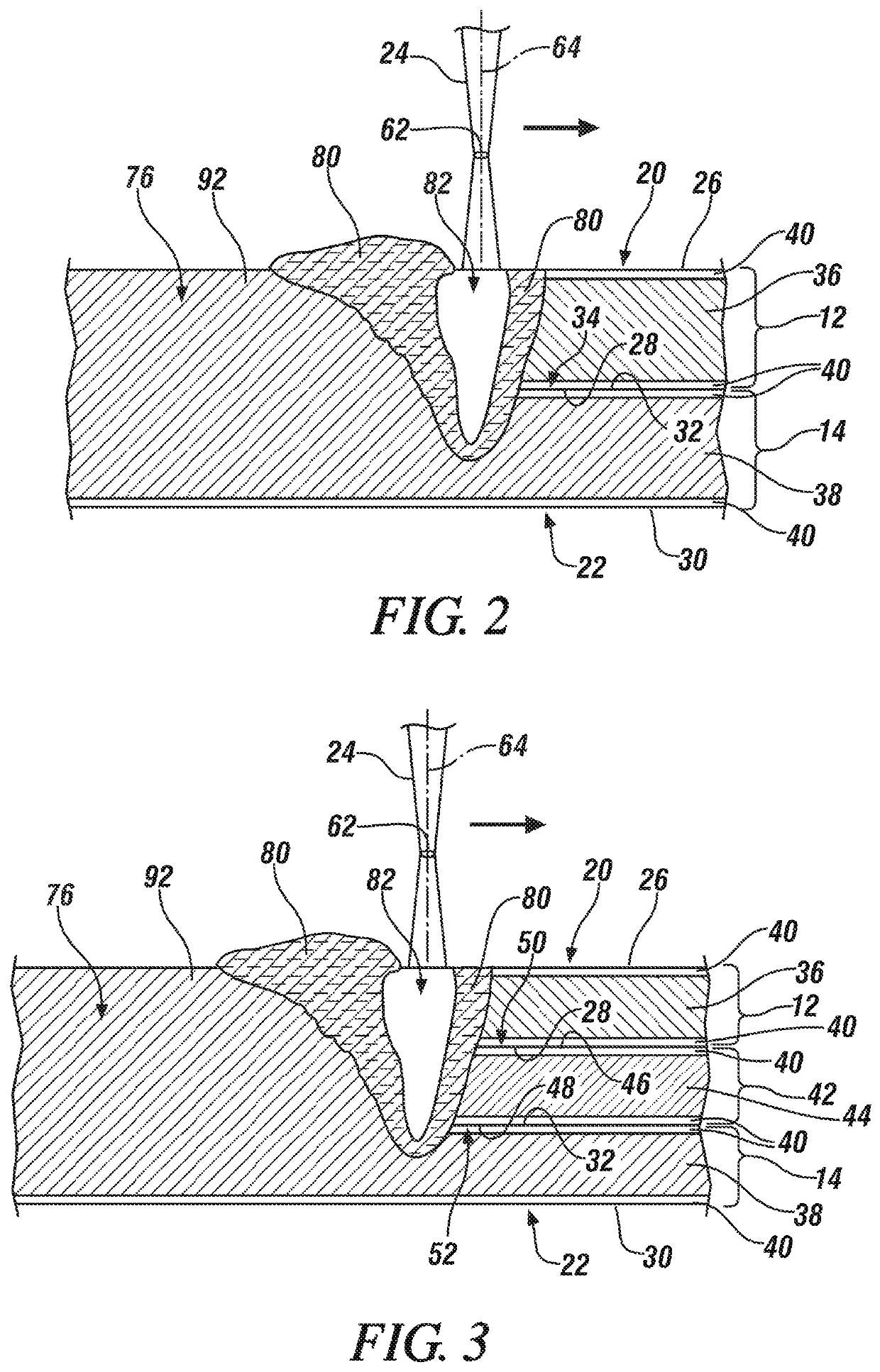

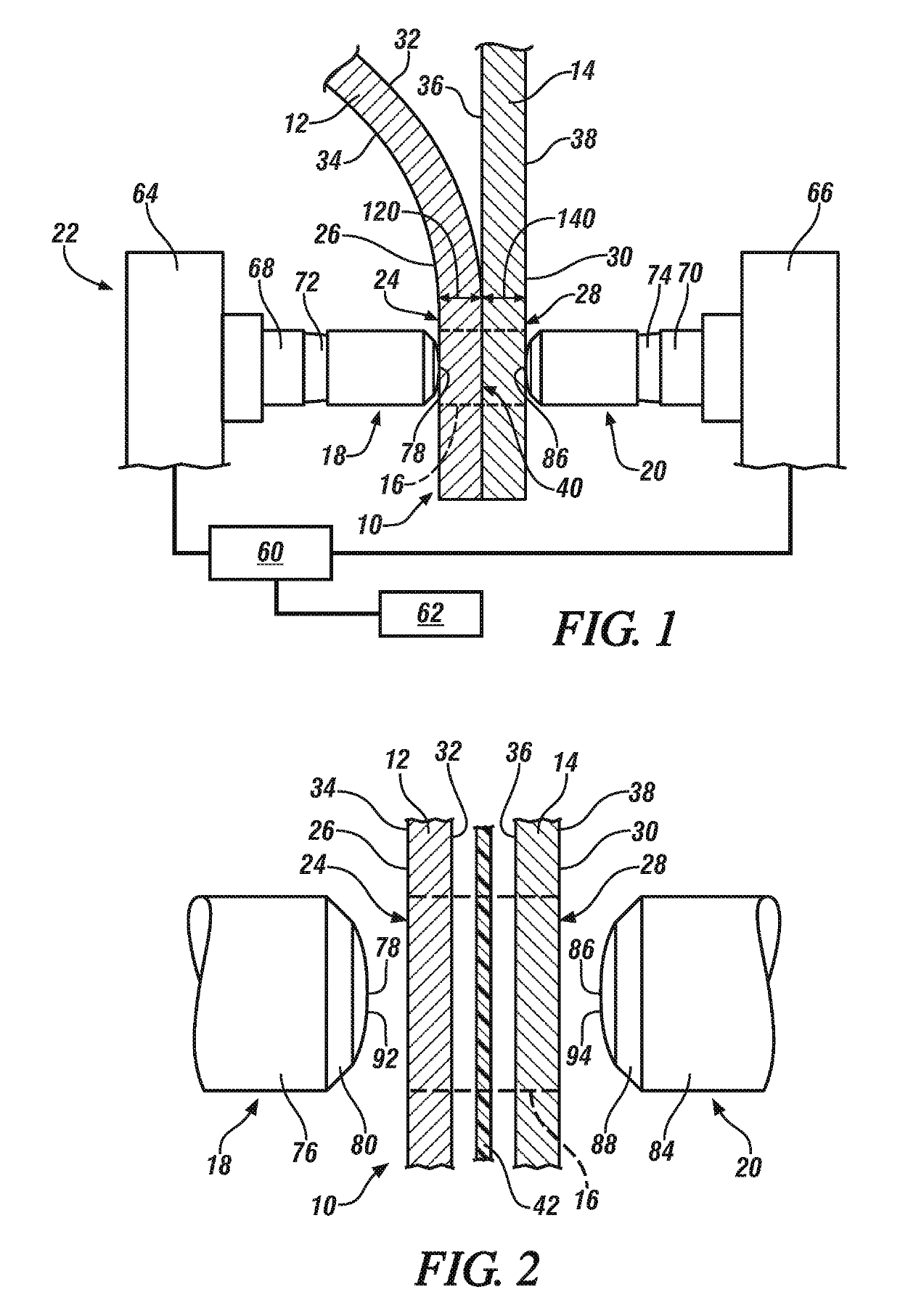

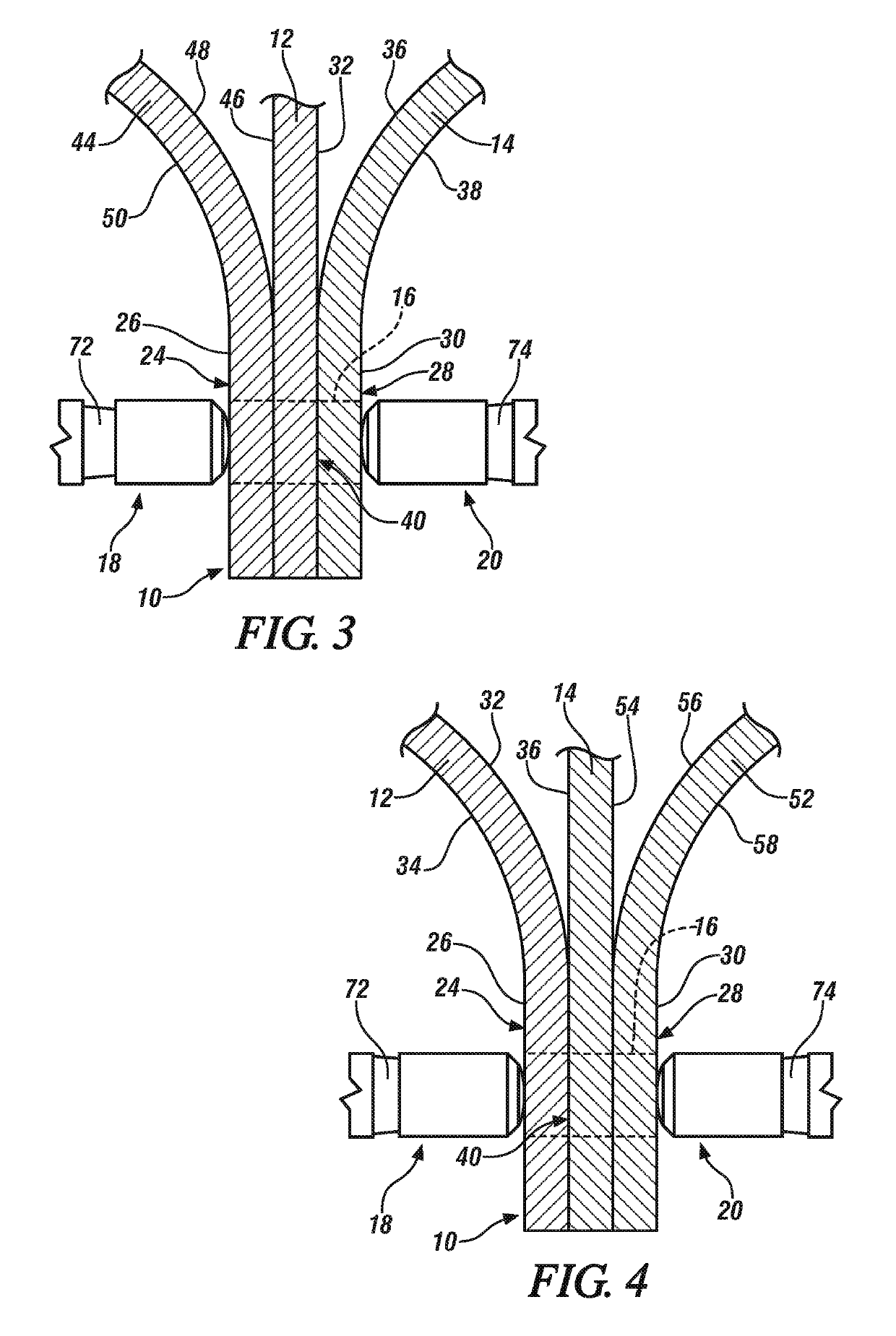

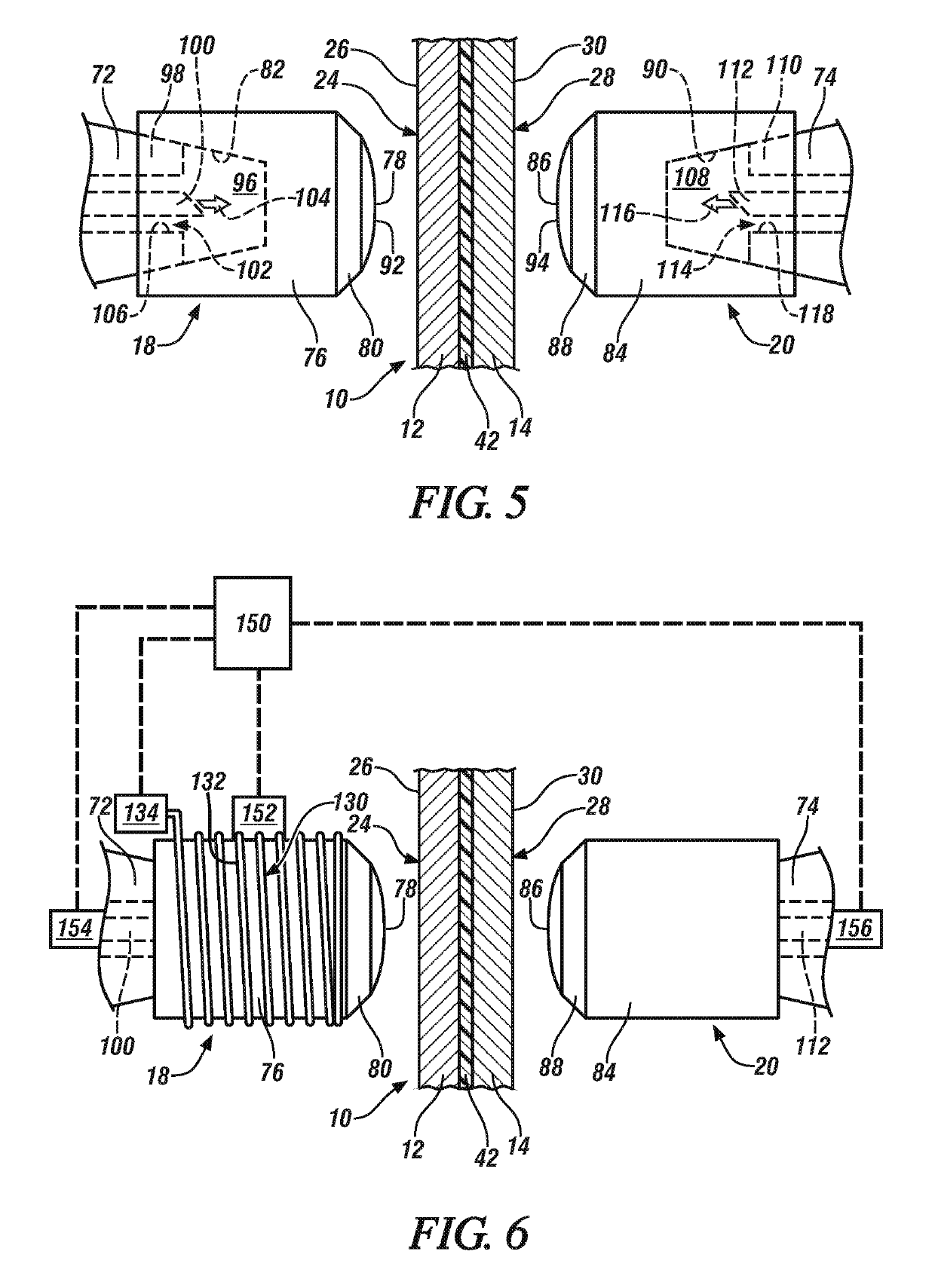

External heat assisted welding of dissimilar metal workpieces

ActiveUS20170304925A1Enhance strength-mostReduce heatWelding/soldering/cutting articlesResistance welding apparatusEngineeringSpot welding

A method of resistance spot welding a workpiece stack-up that includes an aluminum workpiece and an adjacent overlapping steel workpiece is disclosed. The method uses a first welding electrode positioned proximate the aluminum workpiece and a second welding electrode positioned proximate the steel workpiece to effectuate the spot welding process. In an effort to positively affect the strength of the ultimately-formed weld joint, external heat may be supplied to the first welding electrode by an external heating source disposed in heat transfer relation with the first welding electrode either before or after, or both before or after, an electrical current is passed between the first and second welding electrodes to create a molten aluminum weld pool within the aluminum workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Process for producing grain-oriented electrical steel strip and grain-oriented electrical steel strip obtained according to said process

InactiveUS20160108488A1Affect strengthHigh chemical proportions of copperInorganic material magnetismSolid state diffusion coatingWater vaporGrain growth

With a process for producing grain-oriented electrical steel strip by means of thin slab continuous casting, comprising the following process steps: a) smelting a steel with a smelt which, in addition to iron (Fe) and unavoidable impurities, contains Si: 2.00-4.00 wt %, C: 0.025-0.100 wt %, Mn: 0.060-0.500 wt %, Cu: 0.200-0.550 wt %, Alsl: 0.010-0.030 wt %, S: <100 ppm, N: 80-120 ppm, and one or more elements from the group comprising Cr, V, Ni and Mo, each <0.100 wt %, b) continuously casting the smelt by thin slab continuous casting to form a strand having a thickness of 50-120 mm, and dividing the strand into thin slabs, c) heating up the thin slabs, preferably in a linear furnace, to a temperature above 1050° C. and subjecting the slabs to homogenization annealing at a maximum temperature of 1250° C., d) immediately prior to the first hot rolling pass of a subsequent hot rolling process, passing the slabs through an induction heating device, in particular, a high frequency induction heating device, and heating the thin slabs to a maximum temperature of 1350° C., which is above the respective homogenization temperature of process step c), e) continuously hot rolling the thin slabs to form a hot strip having a thickness of 1.8 mm-3.0 mm, f) cooling and reeling the hot-rolled strip at a reeling temperature of less than 650° C. to form a coil, g) pickling the hot-rolled strip after reeling and prior to a subsequent cold rolling step, h) cold rolling the hot strip in a first cold rolling stage to an (intermediate) thickness of 0.50 mm-0.80 mm, i) subjecting the resulting cold-rolled strip to recrystallization and decarburization annealing at a strip temperature ranging from 820° C.-890° C. for a period of 300-600 seconds in a gaseous annealing atmosphere which acts on the cold-rolled strip and contains nitrogen (N2) and hydrogen (H2), and which has a water vapor / hydrogen partial pressure ratio pH2O / pH2 of 0.30 to 0.60, j) in a second cold rolling stage, cold rolling the cold strip which has been subjected to recrystallization and decarburization annealing to its (final) thickness or its nominal usable thickness of 0.15 mm-0.40 mm, k) applying an annealing separator (non-stick layer) containing MgO to the strip surface of the cold-rolled strip which has been rolled to its final thickness or usable thickness, l) subjecting the cold-rolled strip which has been coated with the annealing separator to secondary recrystallization annealing by high-temperature annealing in a bell-type furnace at a temperature of >1150° C., forming a finished steel strip having a pronounced Goss texture, and m) coating the finished steel strip which has undergone secondary recrystallization annealing with an electrically insulating layer and then stress-free annealing or stress-relief annealing the coated finished steel strip, an improved process for producing grain-oriented electrical steel strip by means of thin slab continuous casting is provided, by which it is possible to introduce an inhibitor into the steel strip, which controls secondary grain growth during secondary recrystallization annealing in a high-temperature bell-type annealing furnace.

Owner:SMS GRP GMBH

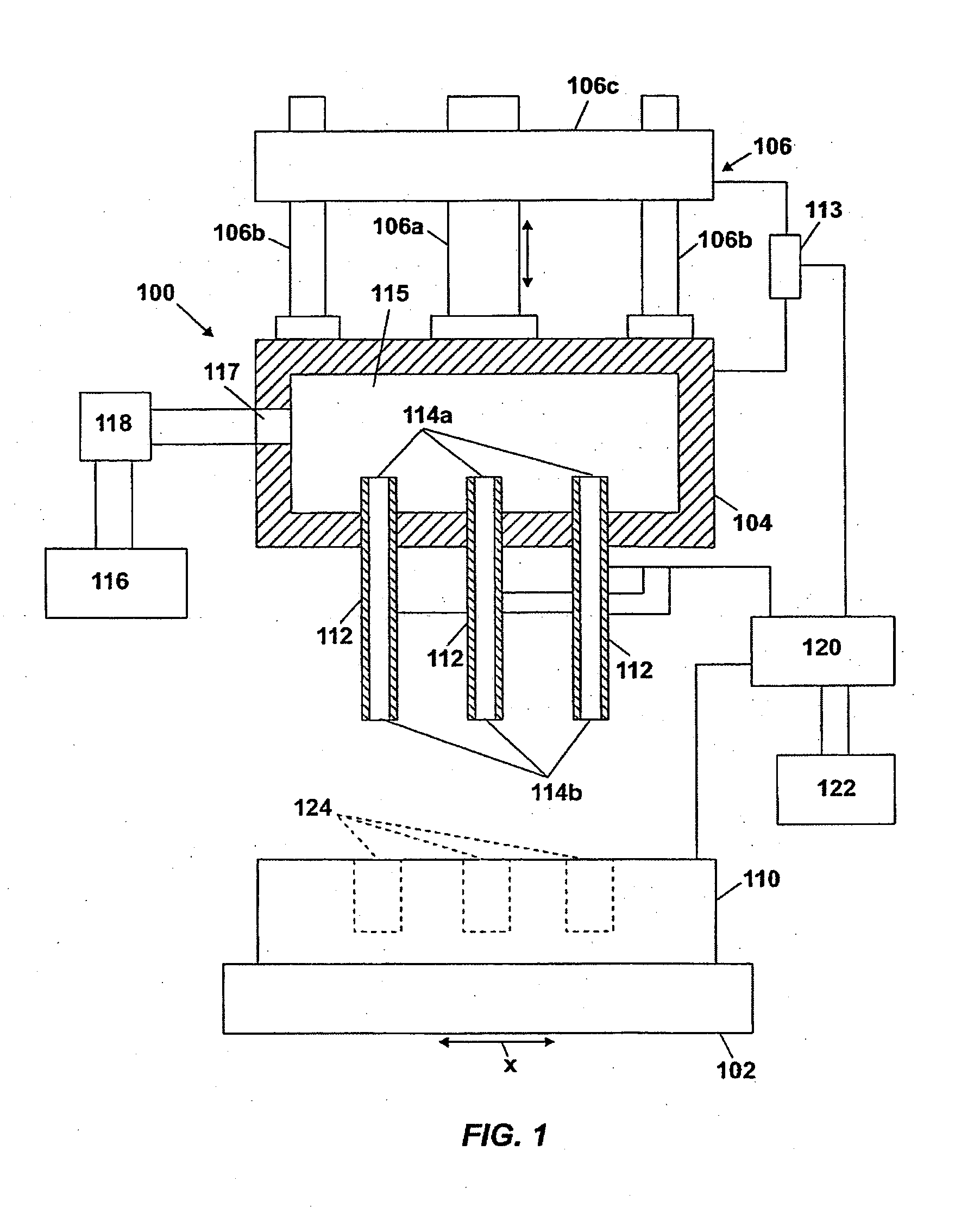

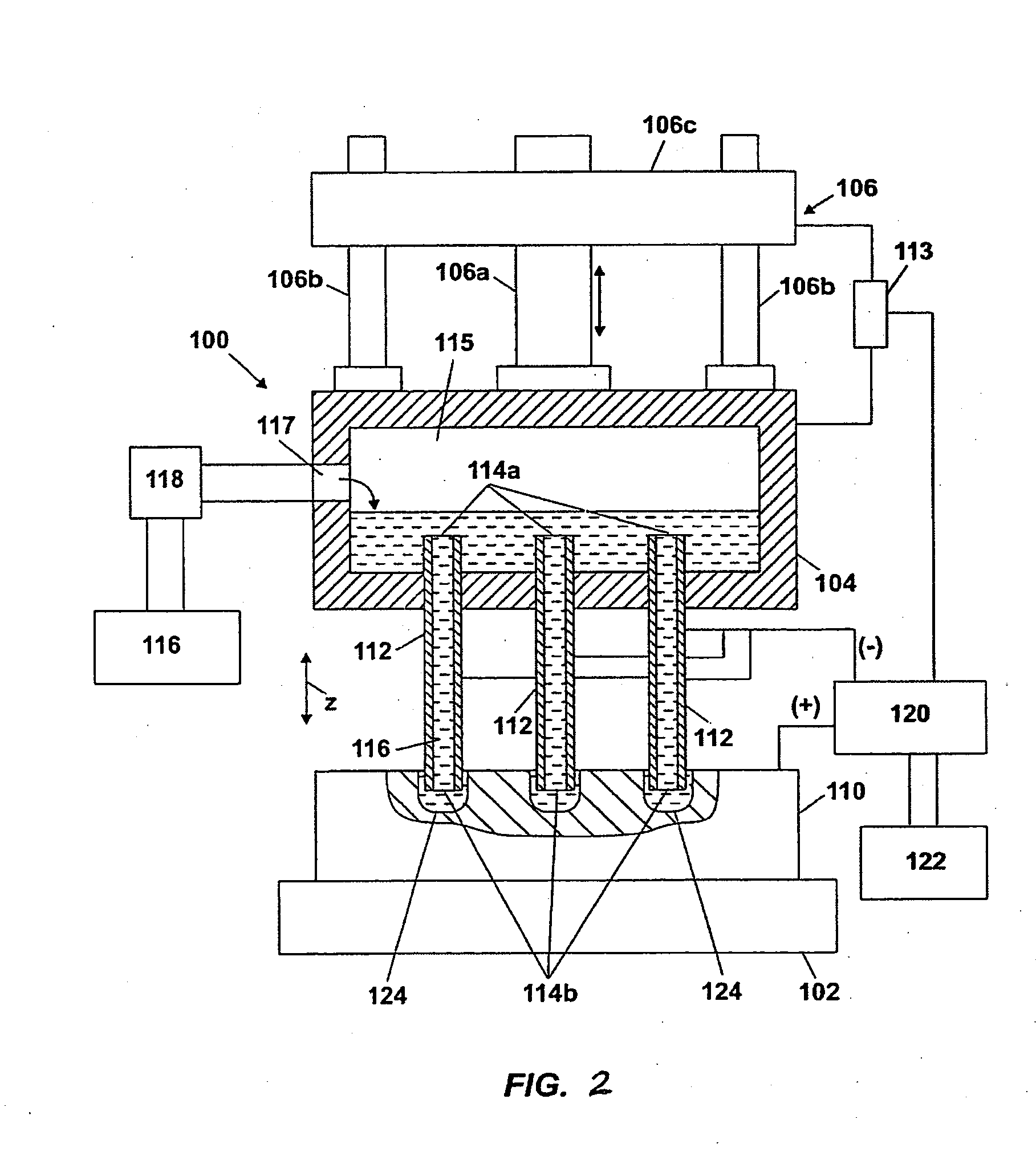

Electrochemical machining method and apparatus

InactiveUS20080099343A1Reduce conductivityAffect performanceElectrolysis componentsMachining electric circuitsReverse currentElectrochemistry

An electrochemical machining system and method includes at least one tube arranged in a first fixture, a second fixture arranged adjacent to the first fixture, the second fixture adapted for supporting a workpiece relative to the tube, a translation mechanism which causes relative movement between the first fixture and the second fixture, a power supply which supplies a current to the workpiece and the tube, and a control unit which controls the power supply to alternately apply a forward current and a zero current (C0) to the workpiece and the tube for a total time interval (tt) wherein deplation of the workpiece occurs and bubbles are separated from the tube. This may be followed by a reverse current (CR) or voltage to the workpiece and the tube for a second time interval (tR), wherein deplation of the workpiece occurs.

Owner:CORNING INC

Non-woven glass fiber mat faced gypsum board and process of manufacture

ActiveUS7829488B2Affect strengthAttains resistance to bleedthroughSpecial paperBuilding componentsHigh resistanceGlass fiber

A gypsum board comprises a set gypsum layer having a first face and a second face. An uncoated fibrous mat is affixed to at least one of the faces. The mat comprises a non-woven web bonded together with a resinous binder. The web comprises glass fiber consisting essentially of a major portion composed of chopped continuous glass fibers having an average fiber diameter ranging from about 8 to 25 μm and optionally a minor portion consisting essentially of at least one of small diameter glass fibers having a fiber diameter of at most about 13 μm and microfibers having an average fiber diameter ranging from about 0.05 to about 6.5 μm. The board is exceedingly durable and has a high resistance to water absorption, rendering it particularly useful for exterior insulation systems.

Owner:JOHNS MANVILLE CORP

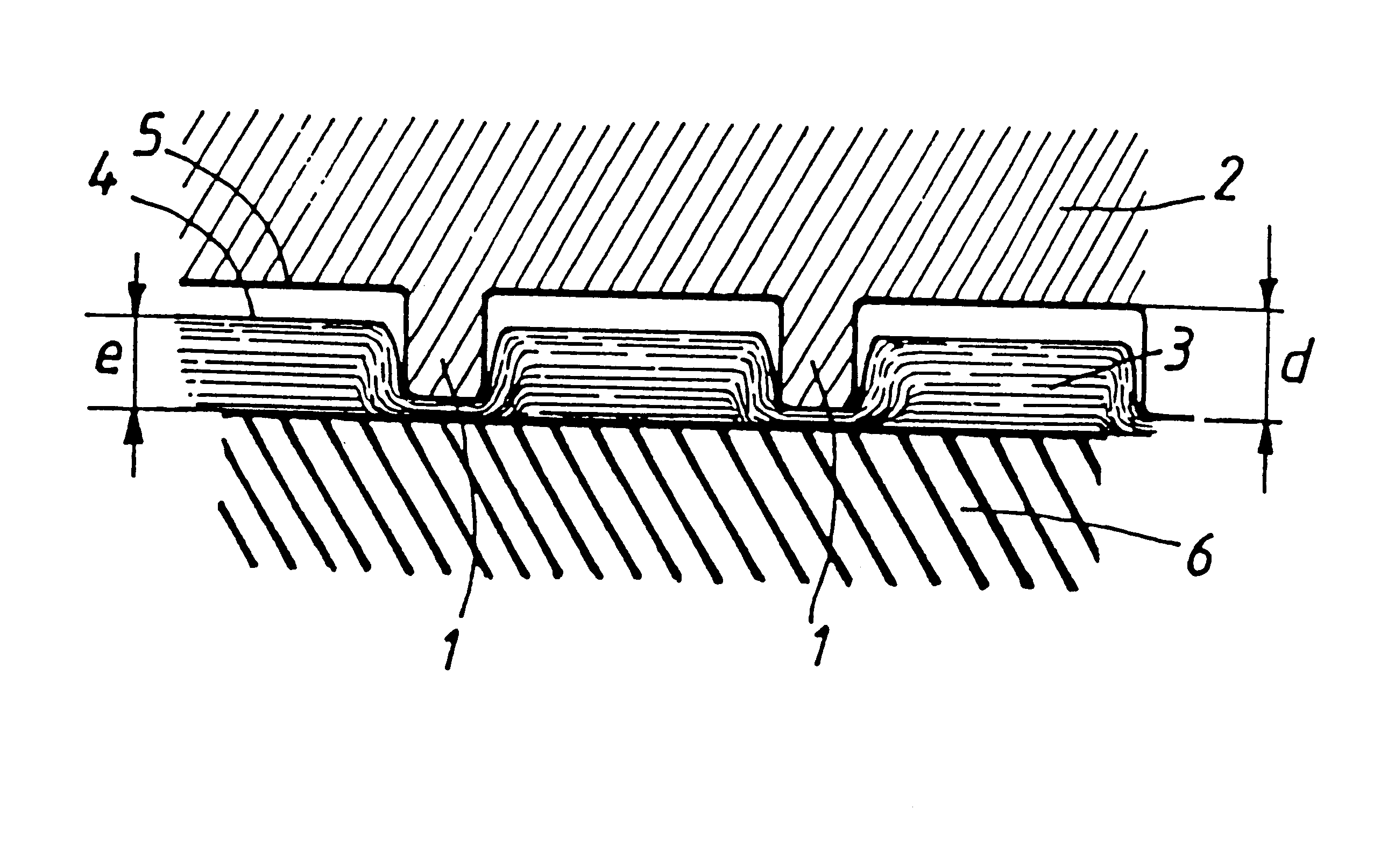

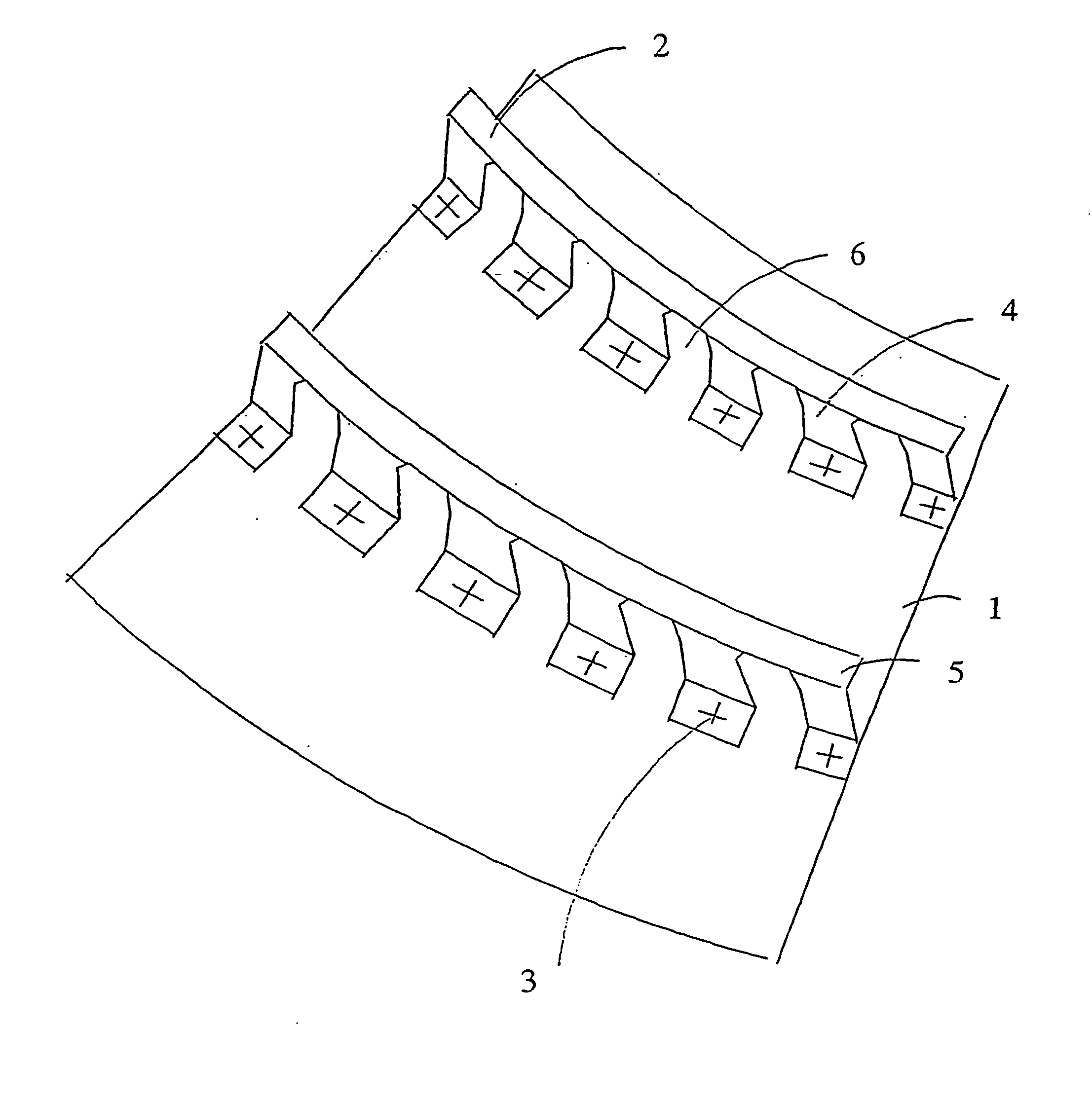

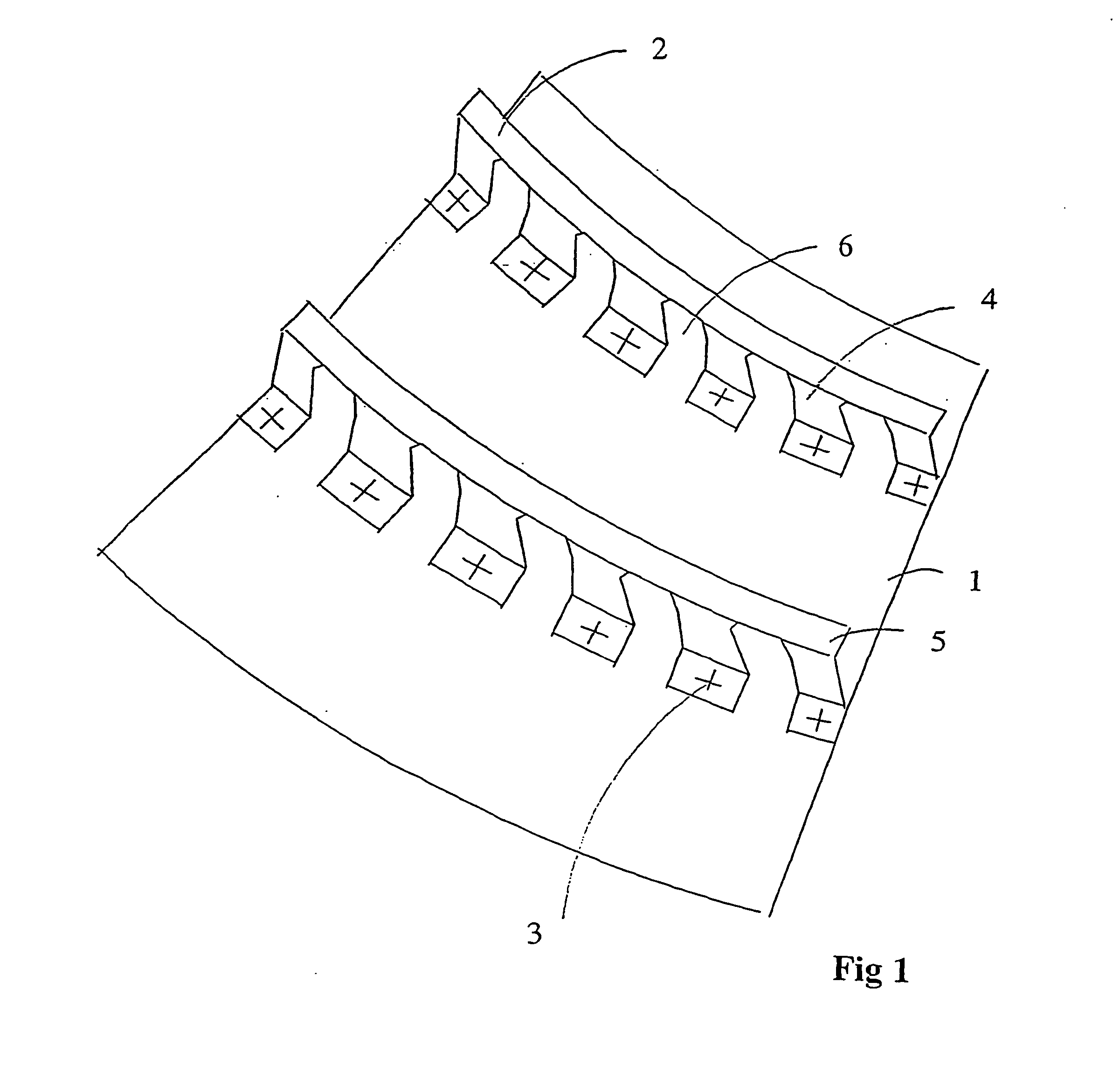

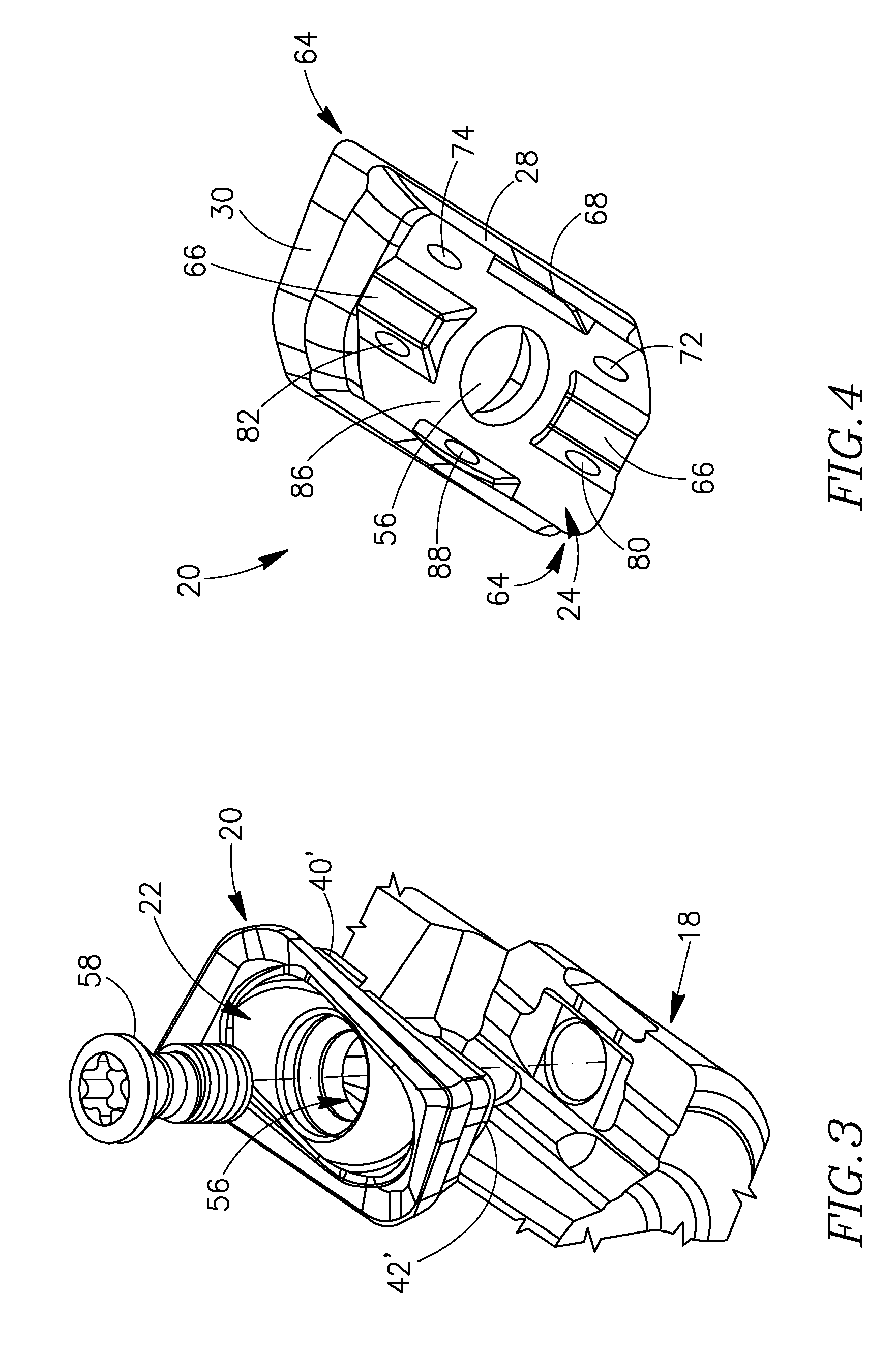

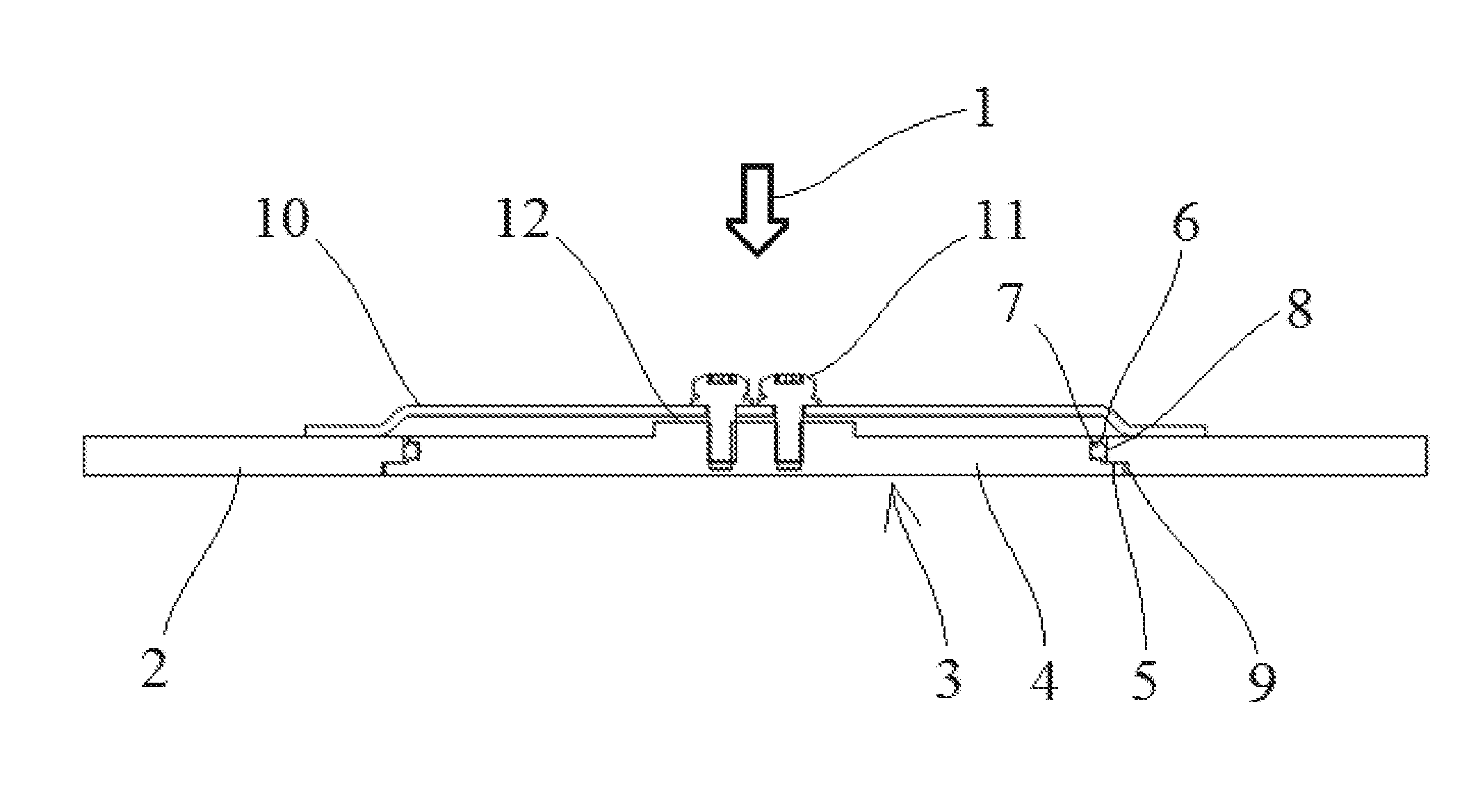

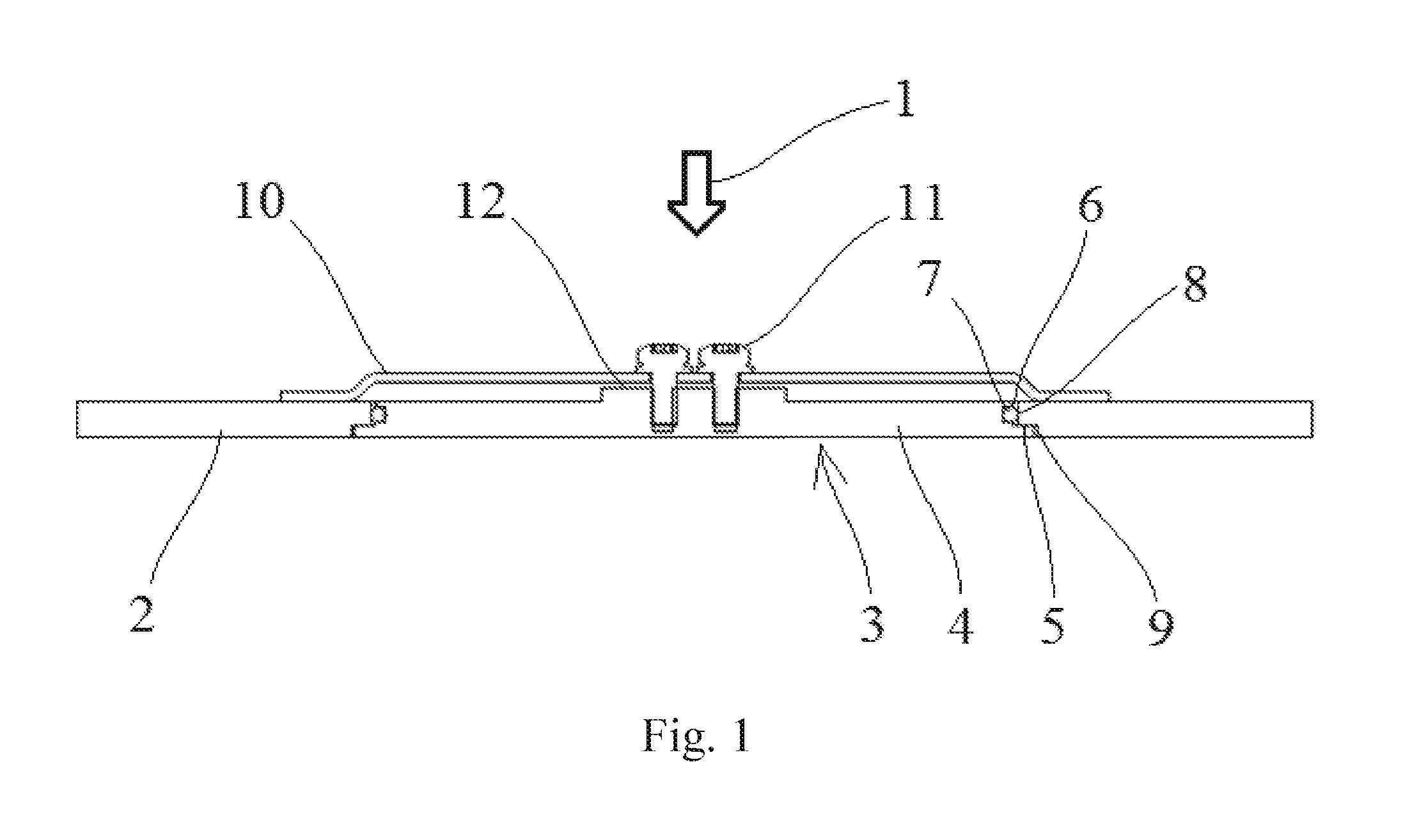

Device for bracing a shell in an aircraft fuselage

InactiveUS20040195452A1Easy to bendAffect durabilityFuselage bulkheadsAircraft floorsFuselageAirplane

A device for bracing a shell surface (1) in an aircraft fuselage against deformations and consisting of a continuous profile that is arranged so as, after conformation, to be mounted against the shell surfaces. Notches (6) are spaced at regular distances apart from each other in at least a portion of the profile. The notches (6) extend through a base surface (3) in the profile, and through an intermediate part (4) perpendicular to the base surface (3). The notches (6) are delimited upwardly by an upper surface (5) that is not encompassed by said notches (6).

Owner:SAAB AB

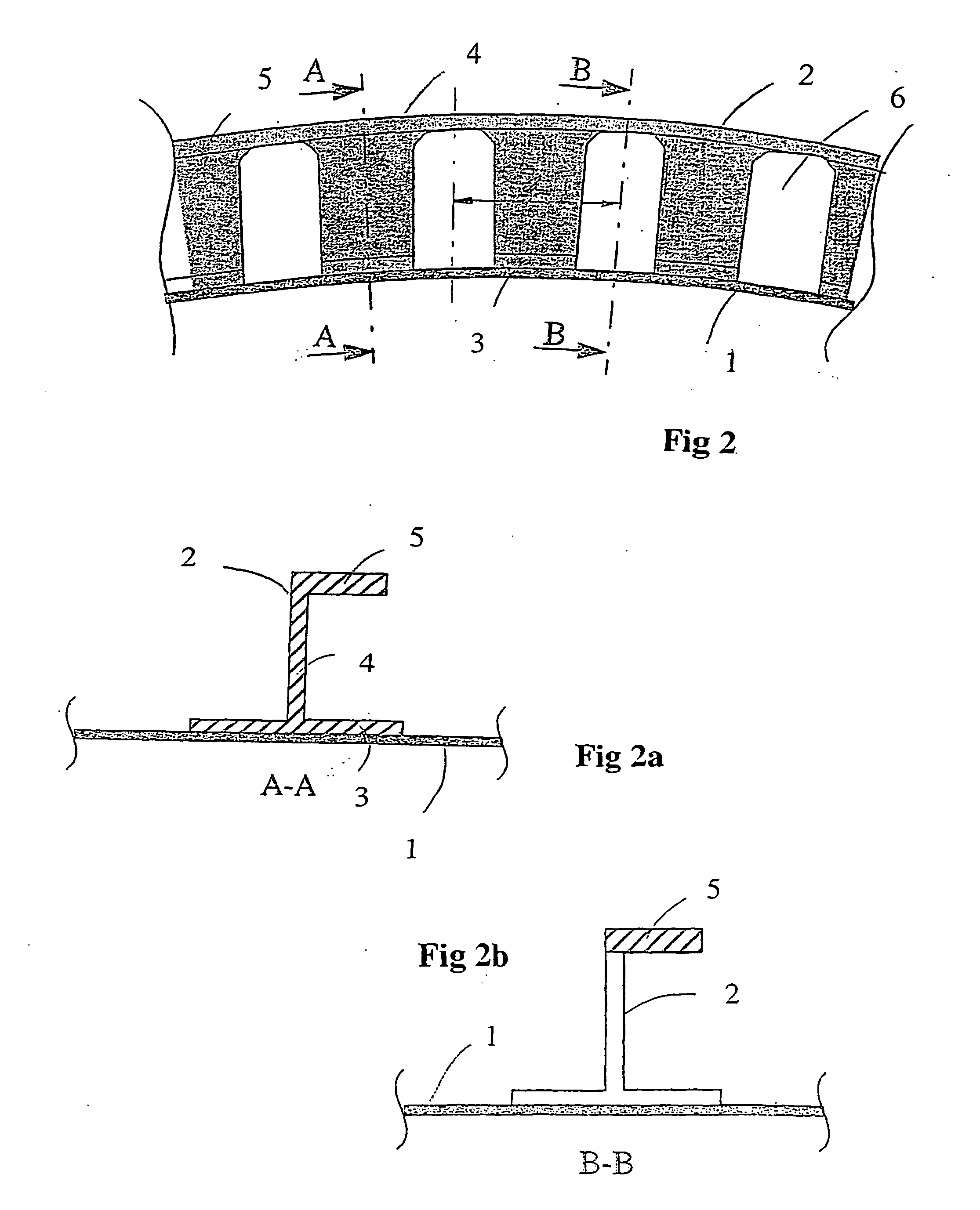

Cutting Tool and Cutting Insert Therefor

ActiveUS20100150670A1Increase resistanceFixed and accurateMilling cuttersShaping cuttersEngineeringMechanical engineering

A cutting tool includes one or more cutting portions, each including an insert pocket having a cutting insert releasably retained therein. The cutting insert has a bottom surface, including a plurality of surfaces, engaging a plurality of walls of the insert pocket in a plurality of sloping and non-sloping engagement regions. These engagement means provide secure and stable clamping of the cutting insert, and prevent displacement of the cutting insert during intensive cutting operations, such as high speed milling, e.g., by significantly decreasing the force exerted on the screw that fastens the cutting insert in the insert pocket.

Owner:ISCAR LTD

Process of finishing an air-laid web and web obtained thereby

InactiveUS6041701ASimple and economic and flexible processingPromote exchangeMechanical working/deformationRotary pressesHardnessEngineering

The general application of the invention is a finishing process for an air-laid nonwoven web composed of short cellulosic fibers, bound by a thermoplastic binder and having a less than perfect homogeneous fiber distribution. In the invention, the process includes deforming under hot stress the web between an undeforming hard engraved cylinder and a slave cylinder having a hardness between about 60 and 90 degrees shore hardness D. The slave cylinder is resilient and deformable at the pressure applied to it by the engraved cylinder. In particular, the invention applies to the manufacture of webs and of disposable, decorative napkins.

Owner:GEORGIA PACIFIC FRANCE SAS

Electrically-conductive hose

InactiveUS8394471B2Affect strengthAffect flexibilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingParticulatesPolyester

Tubular polymeric composite for articles such as tubing and hoses. The composite is formed of a tubular first layer of a thermoplastic block polyether amide resin (PEBA) filled with a more structured carbon black particulate filler to render it electrically-conductive, and a tubular second layer of a thermoplastic polyamide, polyester, polyolefins, or other thermoplastic resin compatible with the PEBA resin of the first material, and which second material optionally may be filled with a less structured carbon black particulate filler to render it electrically-conductive.

Owner:PARKER HANNIFIN CORP

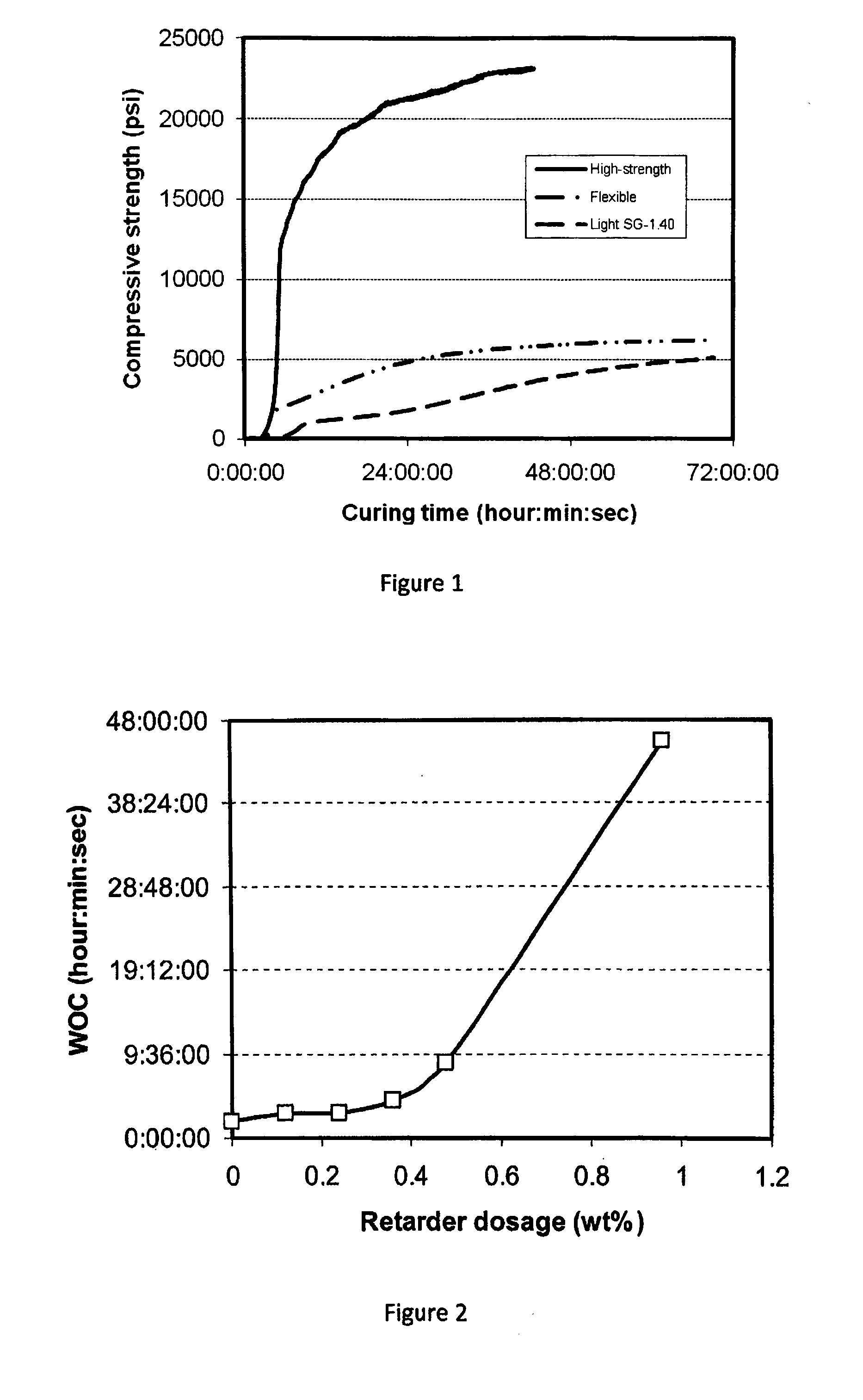

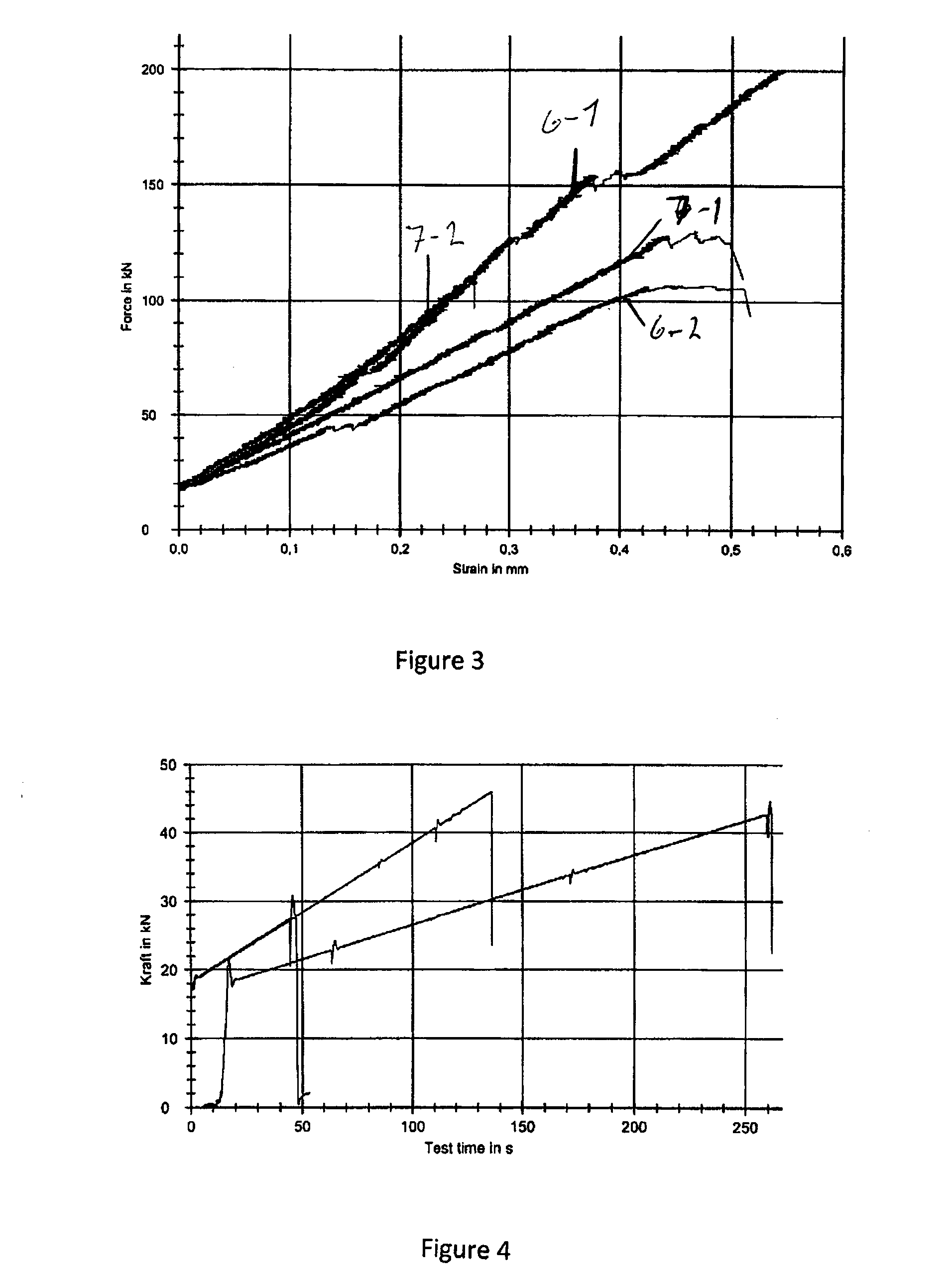

Cement composition based on calcium aluminate cement

InactiveUS20140109799A1Improve acid resistanceHigh compressive strengthSolid waste managementDrilling compositionMineral particlesMaceral

The present invention relates to a current composition for cementing oil or gas wells. The composition comprises calcium aluminate cement in which the proportion of HC203 is at least 50% by weight, dispersant, microsilica, mineral particles, water and optionally a retarder.

Owner:ELKEM

Process for producing grain-oriented electrical steel strip and grain-oriented electrical steel strip obtained according to said process

InactiveUS20160108493A1Affect strengthHigh chemical proportions of copperInorganic material magnetismFurnace typesWater vaporThin slab

With a process for producing grain-oriented electrical steel strip by means of thin slab continuous casting, comprising the following process steps: a) smelting a steel with a smelt which, in addition to iron (Fe) and unavoidable impurities, contains Si: 2.00-4.00 wt %, C: 0.025-0.100 wt %, Mn: 0.060-0.500 wt %, Cu: 0.200-0.550 wt %, Alsl: 0.010-0.030 wt %, S: <100 ppm, N: 80-120 ppm, and one or more elements from the group comprising Cr, V, Ni and Mo, each <0.100 wt %, b) continuously casting the smelt by thin slab continuous casting to form a strand having a thickness of 50-120 mm, and dividing the strand into thin slabs, c) heating up the thin slabs, preferably in a linear furnace, to a temperature above 1,050° C. and subjecting the slabs to homogenization annealing at a maximum temperature of 1,250° C., d) immediately prior to the first hot rolling pass of a subsequent hot rolling process, passing the slabs through an induction heating device, in particular, a high frequency induction heating device, and heating the thin slabs to a maximum temperature of 1,350° C., which is above the respective homogenization temperature of process step c), e) continuously hot rolling the thin slabs to form a hot strip having a thickness of 1.8 mm-3.0 mm, f) cooling and reeling the hot-rolled strip at a reeling temperature of less than 650° C. to form a coil, g) annealing the hot-rolled strip after reeling and prior to a subsequent cold rolling step at a temperature of between 910° C. and 1,140° C., h) cold rolling the hot strip in a first cold rolling stage to an (intermediate) thickness of 0.50 mm-0.80 mm, i) subjecting the resulting cold-rolled strip to recrystallization and decarburization annealing at a strip temperature ranging from 820° C.-890° C. for a period of 300-600 seconds in a gaseous annealing atmosphere which acts on the cold-rolled strip and contains nitrogen (N2) and hydrogen (H2), and which has a water vapor / hydrogen partial pressure ratio pH2O / pH2 of 0.30 to 0.60, j) in a second cold rolling stage, cold rolling the cold strip which has been subjected to recrystallization and decarburization annealing to its (final) thickness or its nominal usable thickness of 0.15 mm-0.40 mm, k) applying an annealing separator (non-stick layer) containing MgO to the strip surface of the cold-rolled strip which has been rolled to its final thickness or usable thickness, l) subjecting the cold-rolled strip which has been coated with the annealing separator to secondary recrystallization annealing by high-temperature annealing in a bell-type furnace at a temperature of >1,150° C., forming a finished steel strip having a pronounced Goss texture, and m) coating the finished steel strip which has undergone secondary recrystallization annealing with an electrically insulating layer and then stress-free annealing or stress-relief annealing the coated finished steel strip, an improved process for producing grain-oriented electrical steel strip by means of thin slab continuous casting is provided, by which it is possible to introduce an inhibitor into the steel strip, which controls secondary grain growth during secondary recrystallization annealing in a high-temperature bell-type annealing furnace.

Owner:SMS GRP GMBH

Shim plate for tools for cutting machining as well as a tool

InactiveUS20110311326A1Reduce wearAffect strengthTransportation and packagingMilling cuttersRotational axisEngineering

A shim plate for mounting in a cutting tool for rotary chip removing machining, the cutting tool including a basic body having a rotational axis, a peripheral envelope surface concentric with the rotational axis, a front end surface, and at least one insert seat including a seat surface, the basic body being rotatable in a direction of rotation and arranged to, in each insert seat against the seat surface, receive the shim plate and a mountable cutting insert adjacent to the shim plate. The shim plate includes a bottom surface adapted to adjoin to the seat surface of the basic body, a contact surface opposite to the bottom surface and adapted to adjoin to the cutting insert, and at least one side surface that extends between the bottom surface and the contact surface. In a radial cross-section orthogonal to the rotational axis and traversing the shim plate, an imaginary straight line (a) associated with the bottom surface, intersecting a point (a1) of the cross-section where the bottom surface is closest to the envelope surface of the basic body and a point (a2) of the cross-section where the bottom surface is closest to the rotational axis of the basic body, and an imaginary straight line (b) associated with the contact surface, intersecting a point (b1) of the cross-section where the contact surface is closest to the envelope surface of the basic body and a point (b2) of the cross-section where the contact surface is closest to the rotational axis of the basic body, diverge toward the envelope surface of the basic body and form an angle α with each other.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Hot-melt adhesive

InactiveUS7314902B2Reduce internal stressReduce sensitivityOther chemical processesSynthetic resin layered productsPolyolefinHot melt

The present invention provides a hot-melt adhesive composition comprising a blend of: a reactive filler comprising an aluminum compound, a magnesium compound, a calcium compound, a barium compound or a mixture thereof; and, a grafted polyolefin having a functional group for reaction with the reactive filler. Such a hot-melt adhesive is particularly useful for bonding a polyolefin-based substrate to dissimilar materials such as metals, wood, ceramics and thermoset plastics.

Owner:NAT RES COUNCIL OF CANADA

Explosion vent

ActiveUS20160273670A1Easy to manufactureEasy to mountEqualizing valvesFire rescueClosed spaceEngineering

An explosion vent mounted to seal an opening formed on a wall of a closed space comprises a cover being dimensioned to fit on said opening and having a perimeter with an edge adapted to seal the cover against the opening with a sealing element. A spring element is arranged to hold the cover in the opening and the spring element has a direction of spring action. The cover is held by opposite retaining surfaces in the opening and the cover and he retaining surfaces are acting against the spring action of element. The sealing element is positioned against the opening so that the sealing force is directed at least partially crosswise to the direction of the spring action of the spring element.

Owner:ABB (SCHWEIZ) AG

Touch input device and system thereof

ActiveUS9262025B2Affect strengthInput/output processes for data processingControl signalPressure sense

A touch input device provided in the present invention includes a pen tip, a pressure sensing module, a control unit and a PWM generator. The pen tip is utilized to touch a capacitive touchscreen and conduct a touchscreen driving signal. The pressure sensing module is utilized to generate a pressure sensing signal which corresponds to a pressure of the pen tip on the capacitive touchscreen. The control unit is utilized to receive the touchscreen driving signal and the pressure sensing signal, and then to generate a PWM control signal according to the pressure sensing signal. Further, a pulse width of the PWM control signal is proportional to the pressure. The PWM generator is utilized to provide a PWM signal to the pen tip according to the PWM control signal. A touch input system is further provided in the present invention.

Owner:SILICON INTEGRATED SYSTEMS

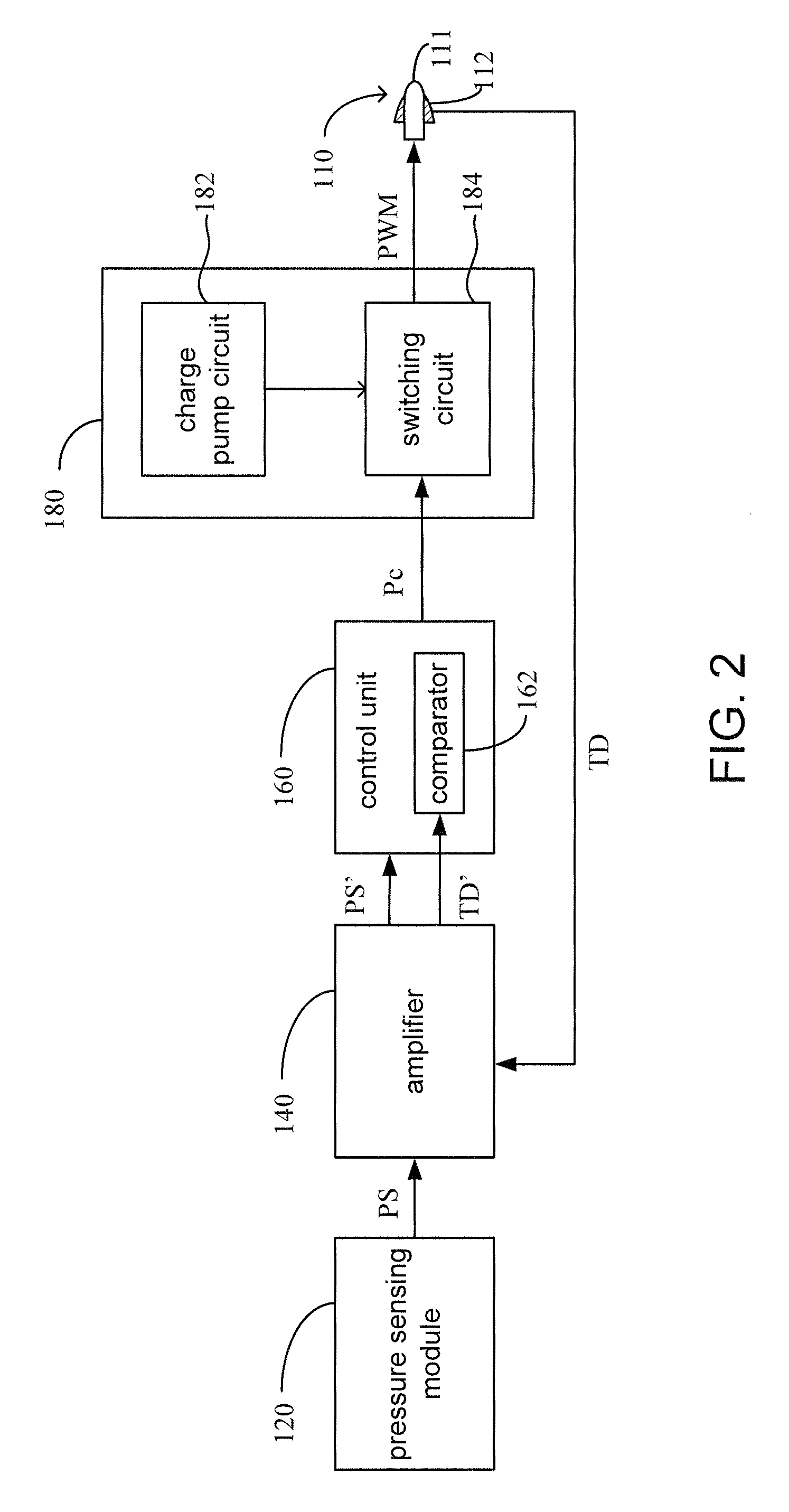

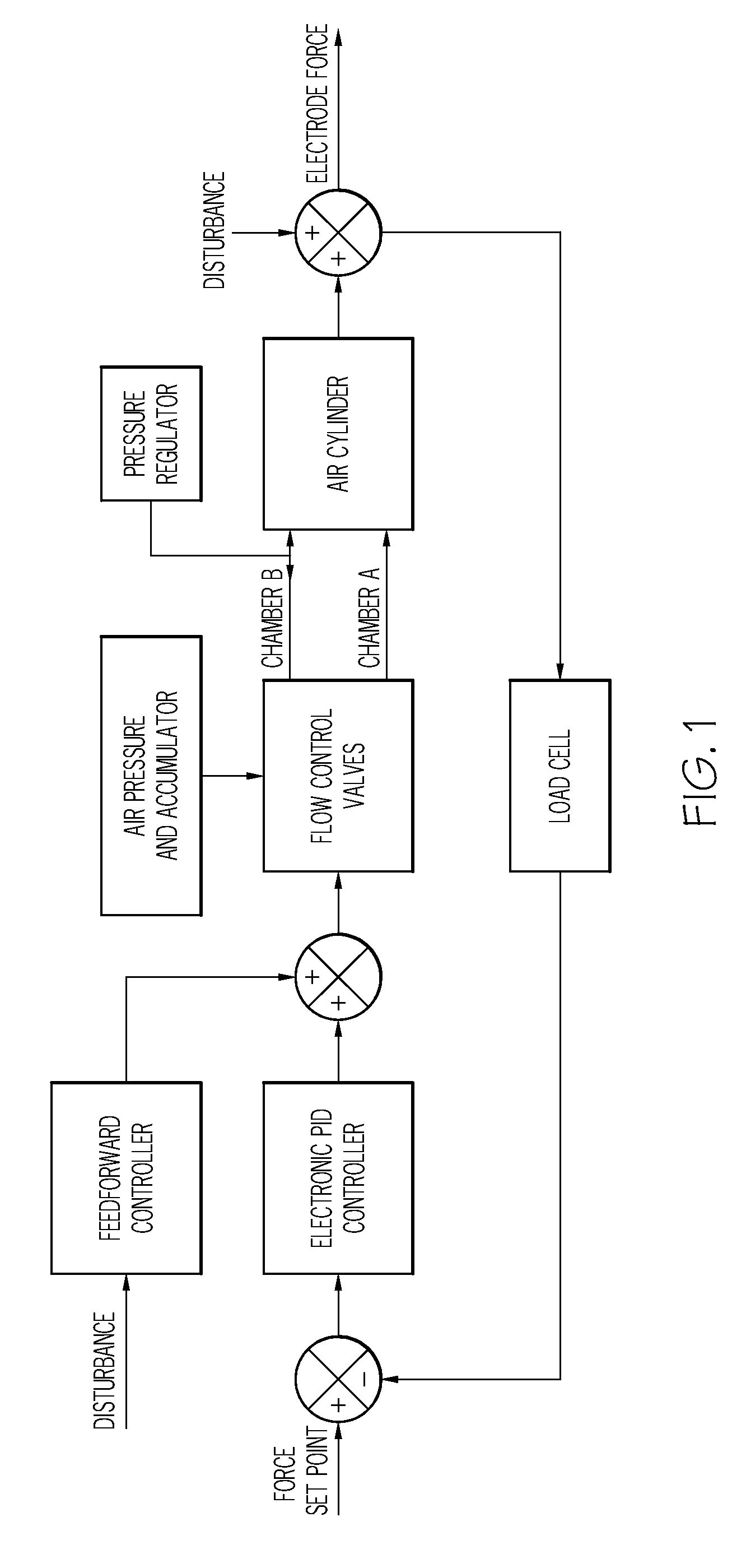

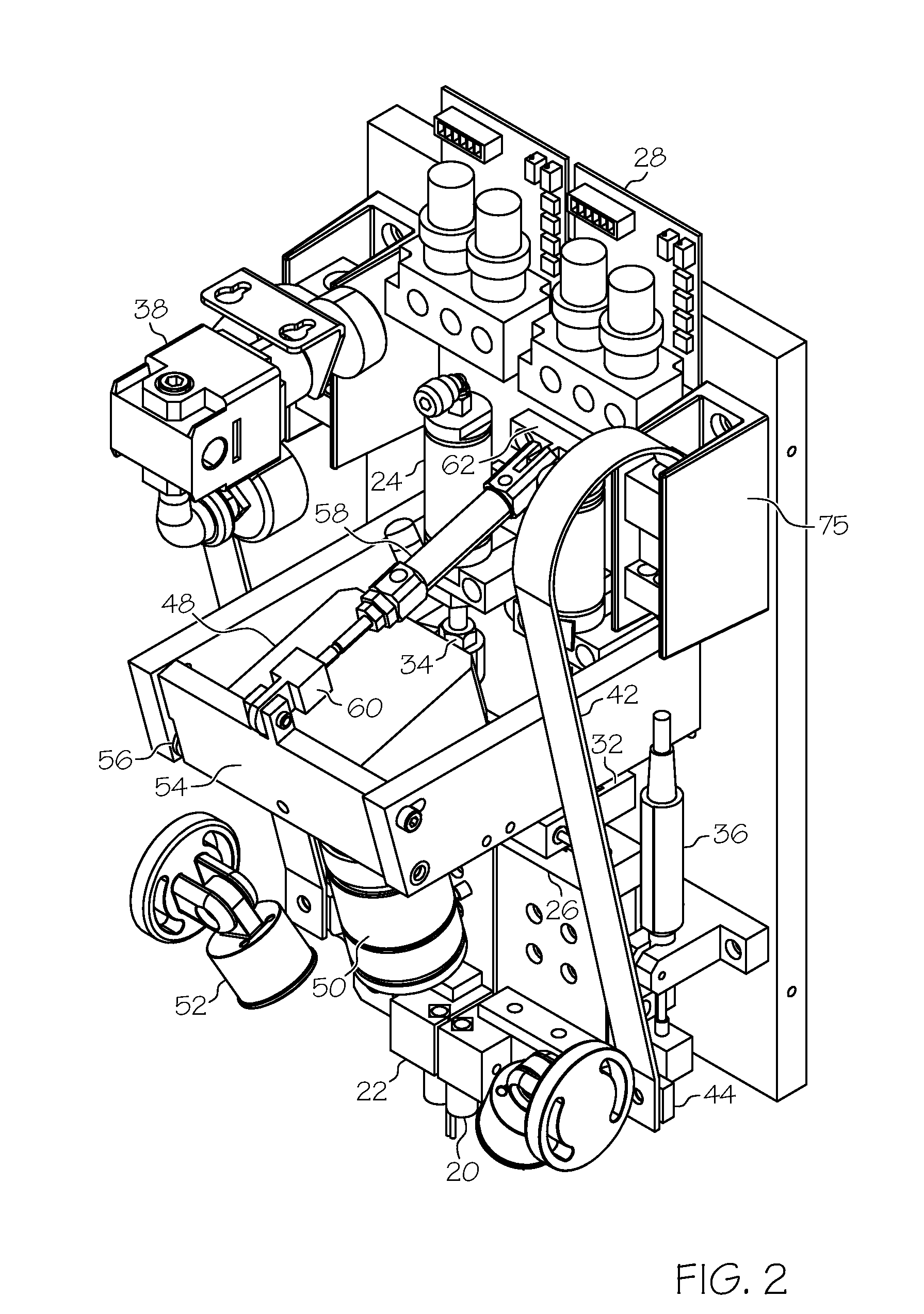

Single Weld Head

InactiveUS20080290073A1Reduce maintenance costsLost productivityWelding monitoring devicesWelding power supplyData acquisition

A welding apparatus includes a single weld head, a weld power supply, a conductive fixture plate, a data acquisition card, and a computer. The single weld head includes one or more electrodes, one or more actuating devices in operative communication with the electrodes, and one or more force control devices in operative communication with the actuating devices. The weld head is in communication with a weld power supply. The weld power supply welds articles in accordance with a computer program running on a computer. The computer is in communication with the weld power supply, the force control device, and the data acquisition card. The computer is capable of receiving, evaluating, and storing welding data received from the data acquisition card. The apparatus further includes a switch in communication with the weld power supply, the electrodes, the conductive fixture plate, and the data acquisition card.

Owner:TECHMATRIX

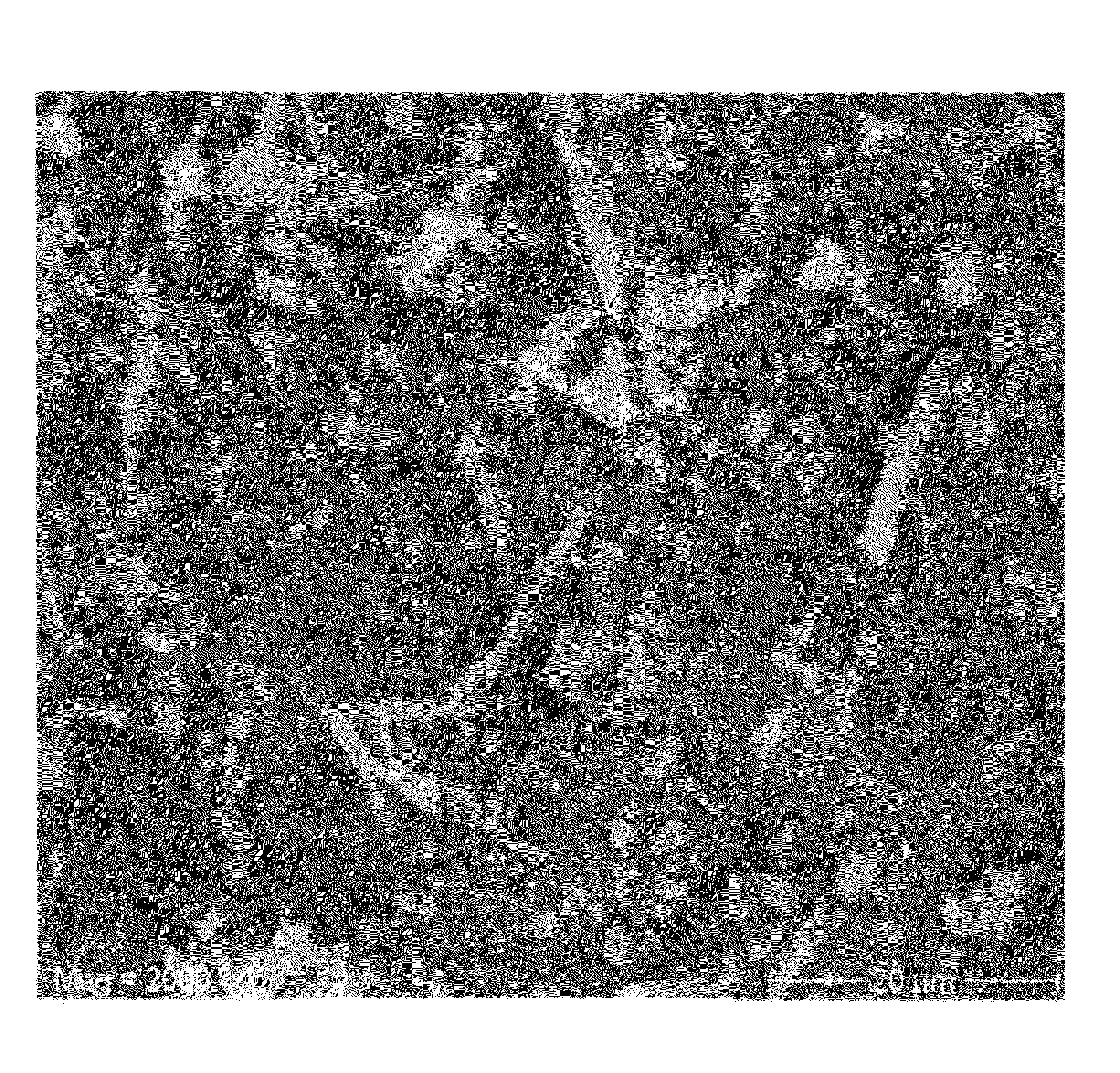

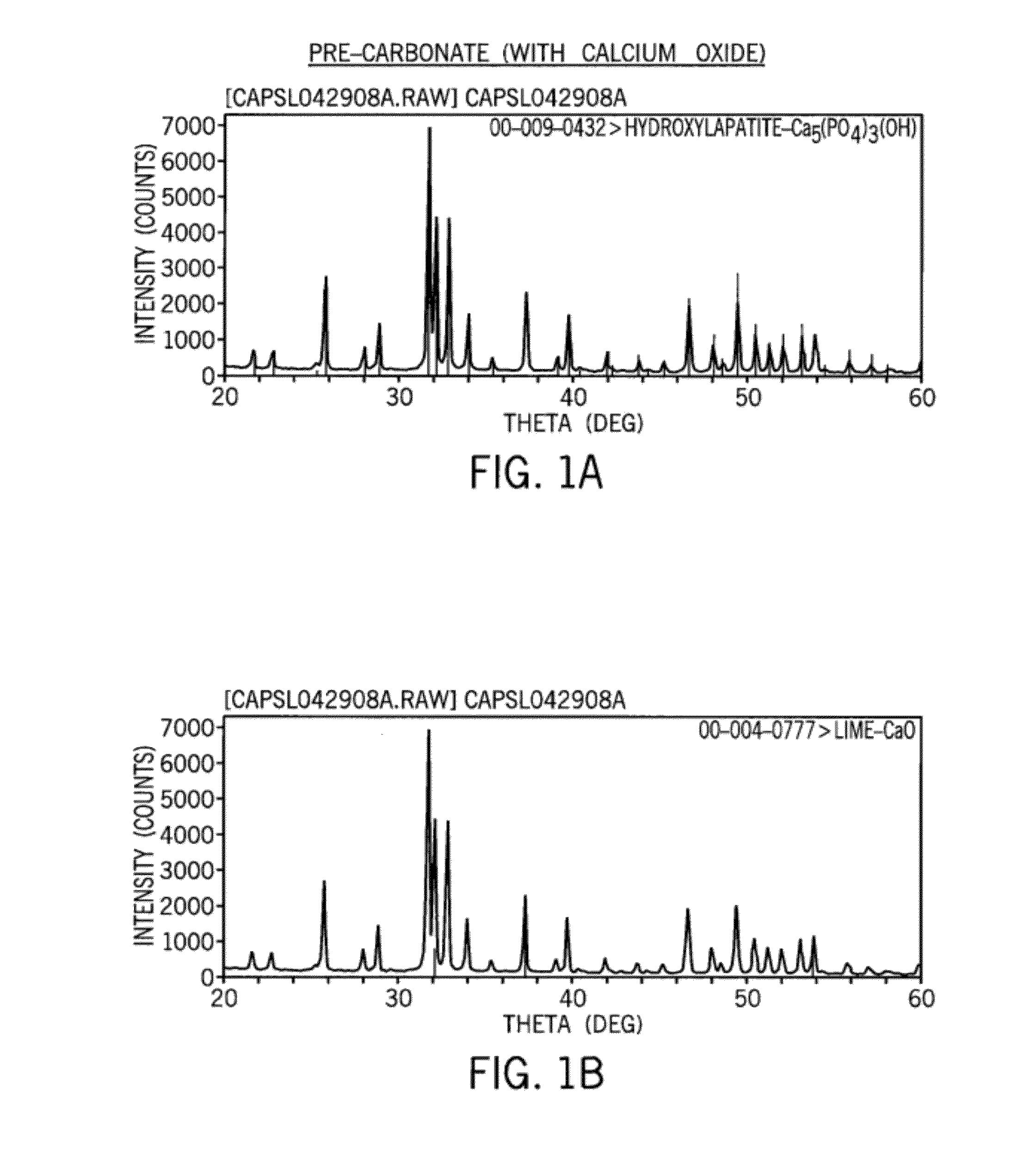

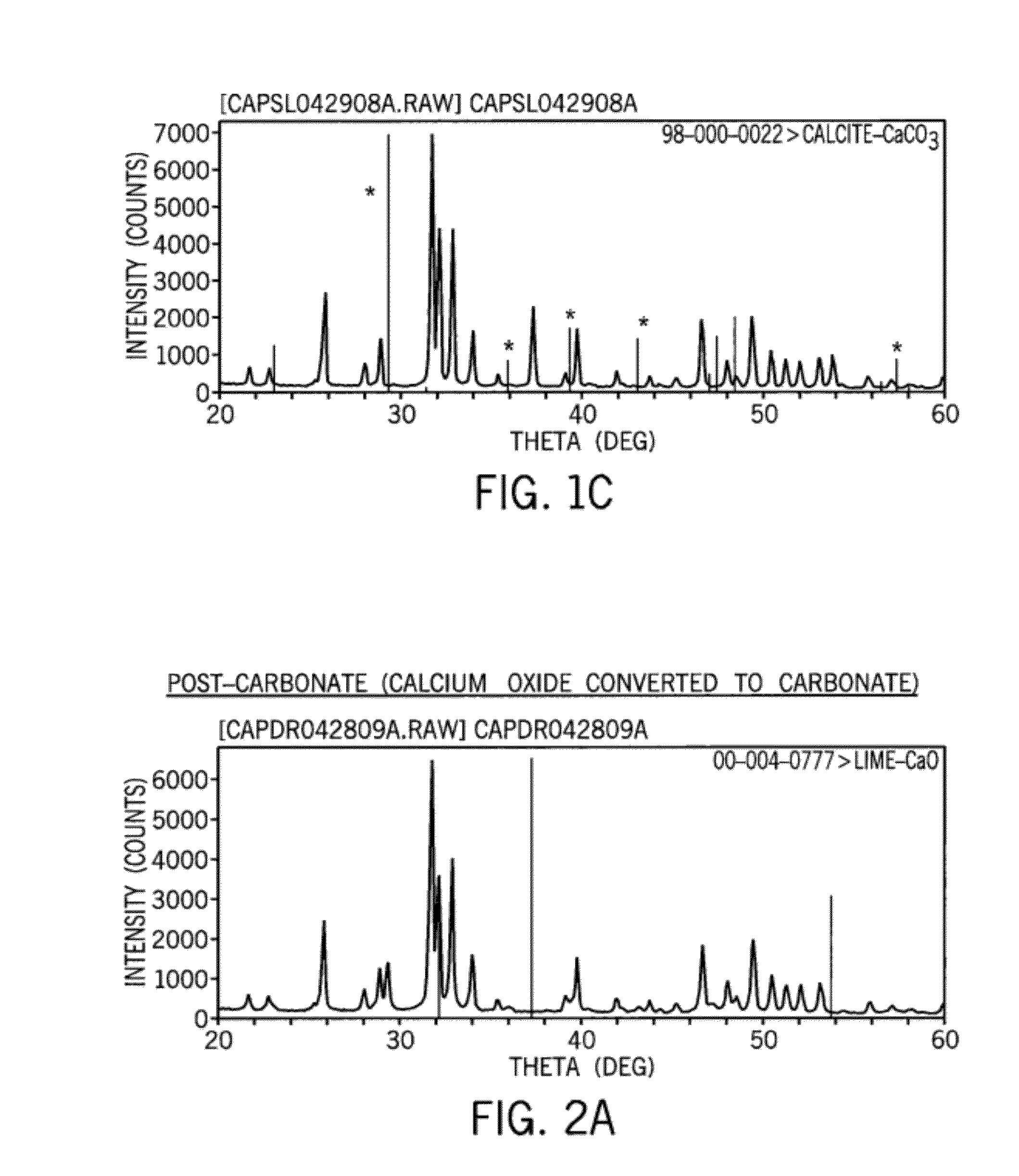

Composites of hydroxyapatite and calcium carbonate and related methods of preparation and use

ActiveUS20120107373A1Affect strengthHigh strengthBiocideInorganic phosphorous active ingredientsHydroxyapatitesCalcium carbonate

Owner:CAP BIOMATERIALS

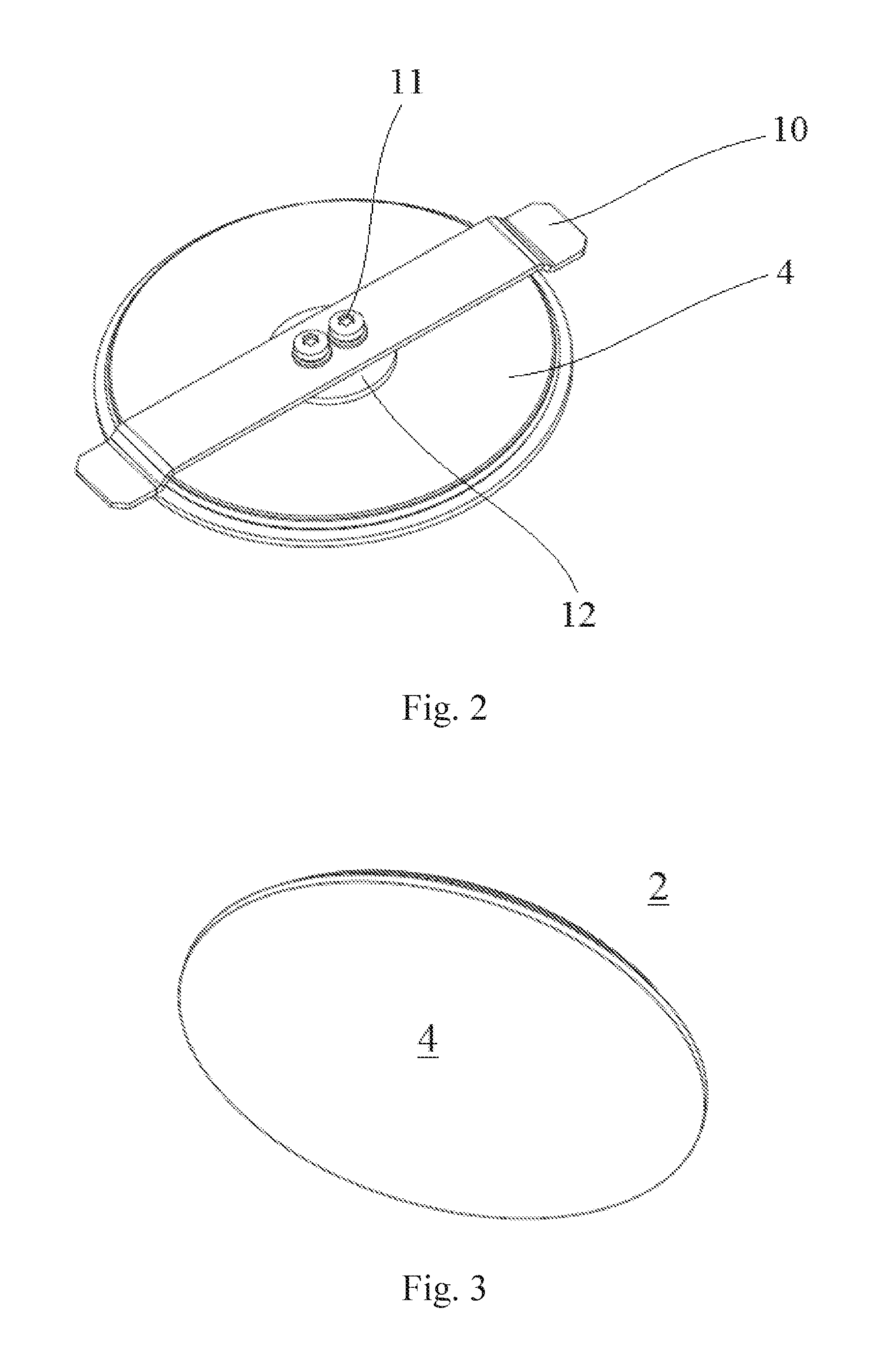

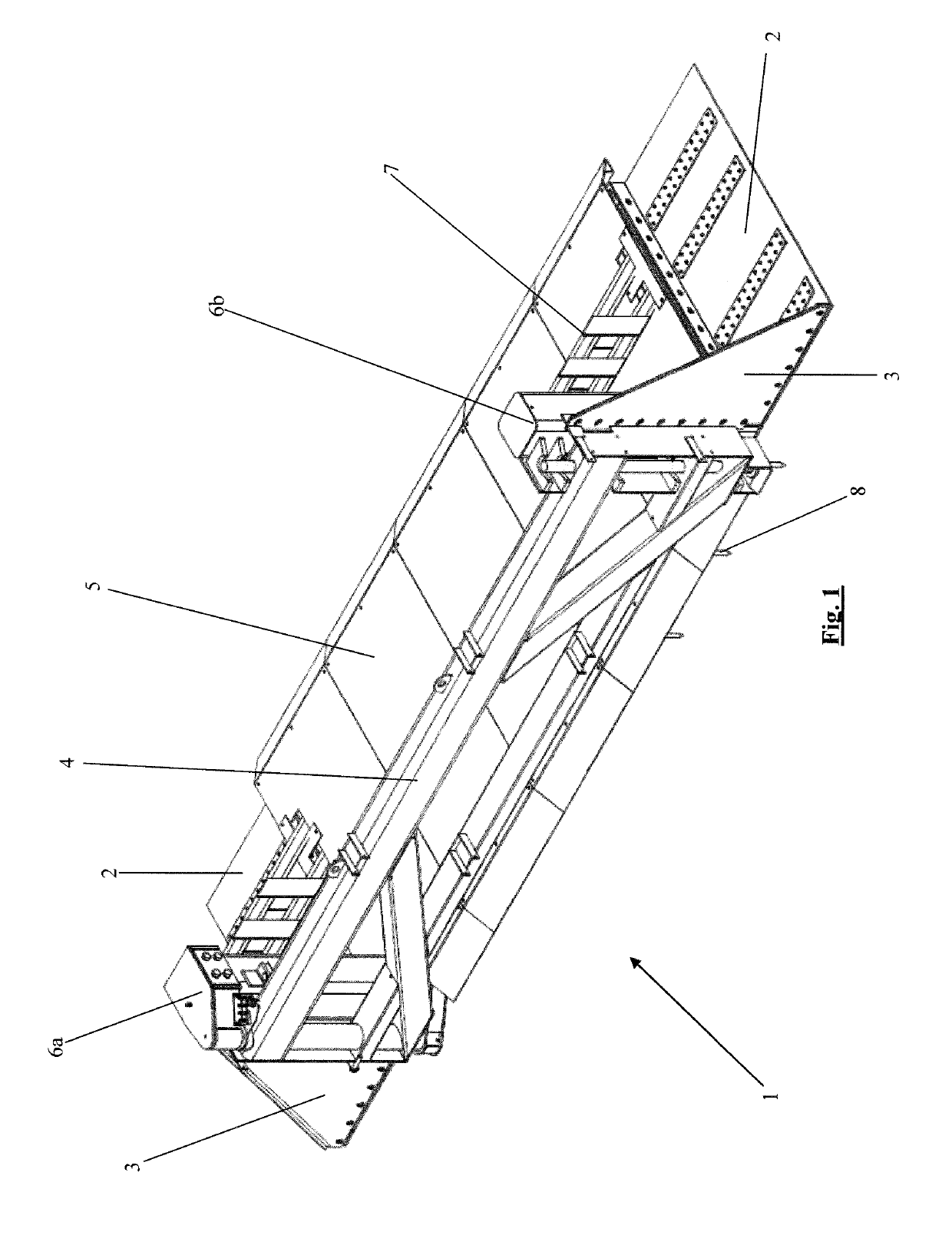

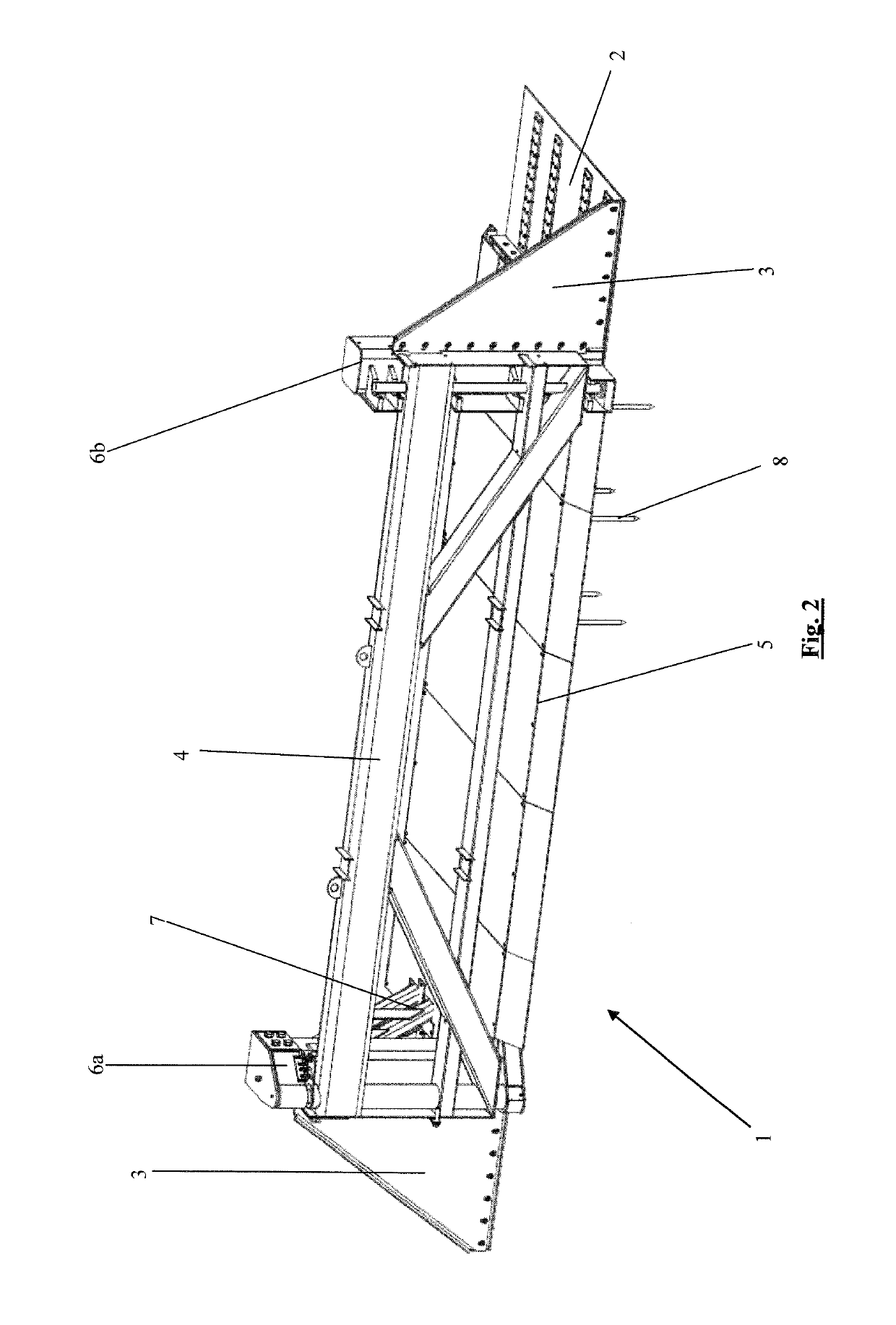

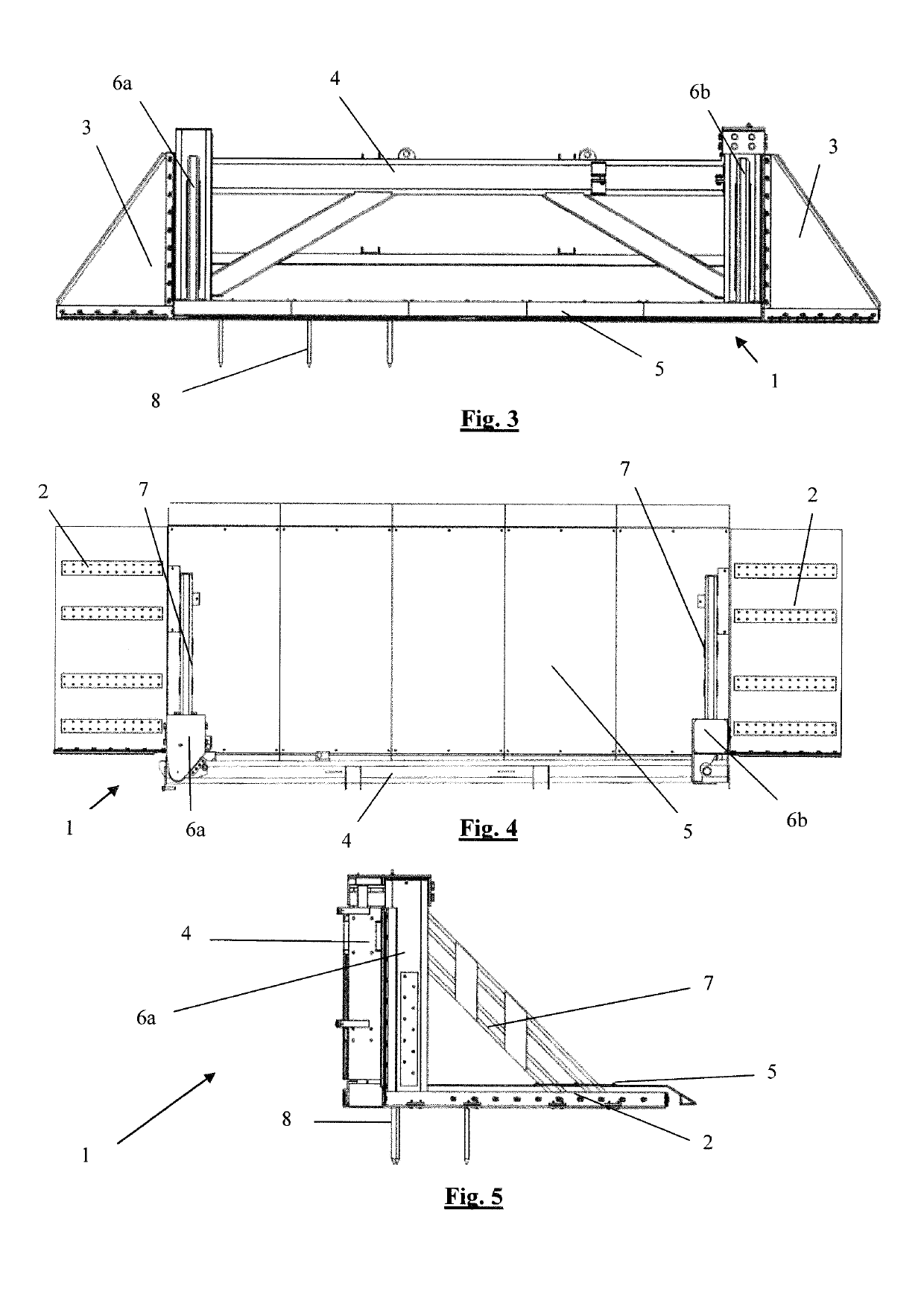

Gate and security barrier comprising a gate

Security barrier comprising at least one barrier structure (10) and at least one gate (1), wherein the barrier structure (10) comprises one or more bottom panels (20) and the gate (1) forms a closable passage through the security barrier and wherein the gate (1) comprises at least one base element (2), wherein in installed state of the security barrier one or more of said one or more bottom panels (20) rest upon the at least one base element (2), such that the gate (1) is at least partly held in place by the barrier structure (10) and gate (1) for a such security barrier.

Owner:GUARDIAR EURO

Hot-melt adhesive

InactiveUS20060009588A1Reduce internal stressReduce sensitivityOther chemical processesSynthetic resin layered productsPolyolefinCeramic

The present invention provides a hot-melt adhesive composition comprising a blend of: a reactive filler comprising an aluminum compound, a magnesium compound, a calcium compound, a barium compound or a mixture thereof; and, a grafted polyolefin having a functional group for reaction with the reactive filler. Such a hot-melt adhesive is particularly useful for bonding a polyolefin-based substrate to dissimilar materials such as metals, wood, ceramics and thermoset plastics.

Owner:NAT RES COUNCIL OF CANADA

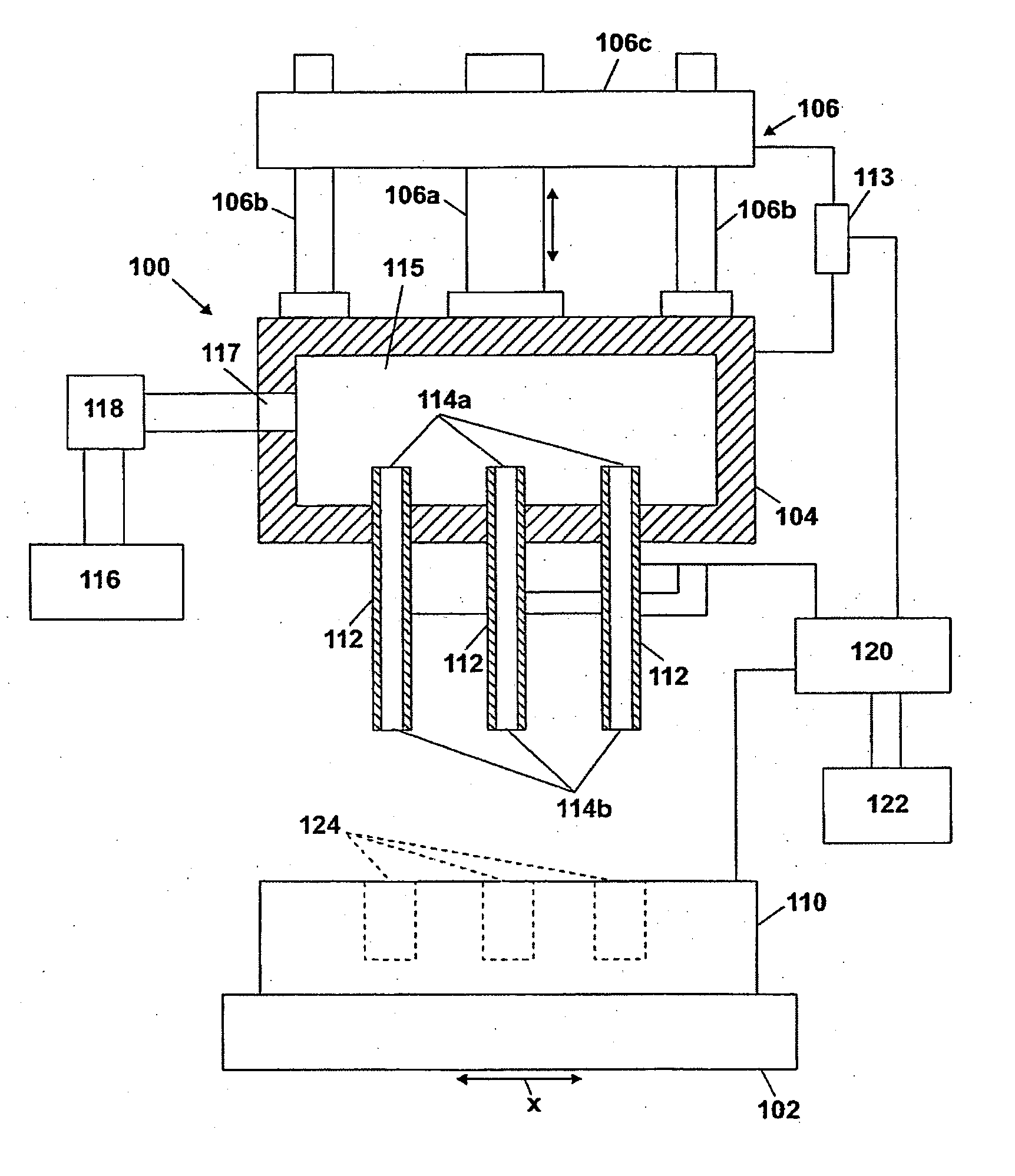

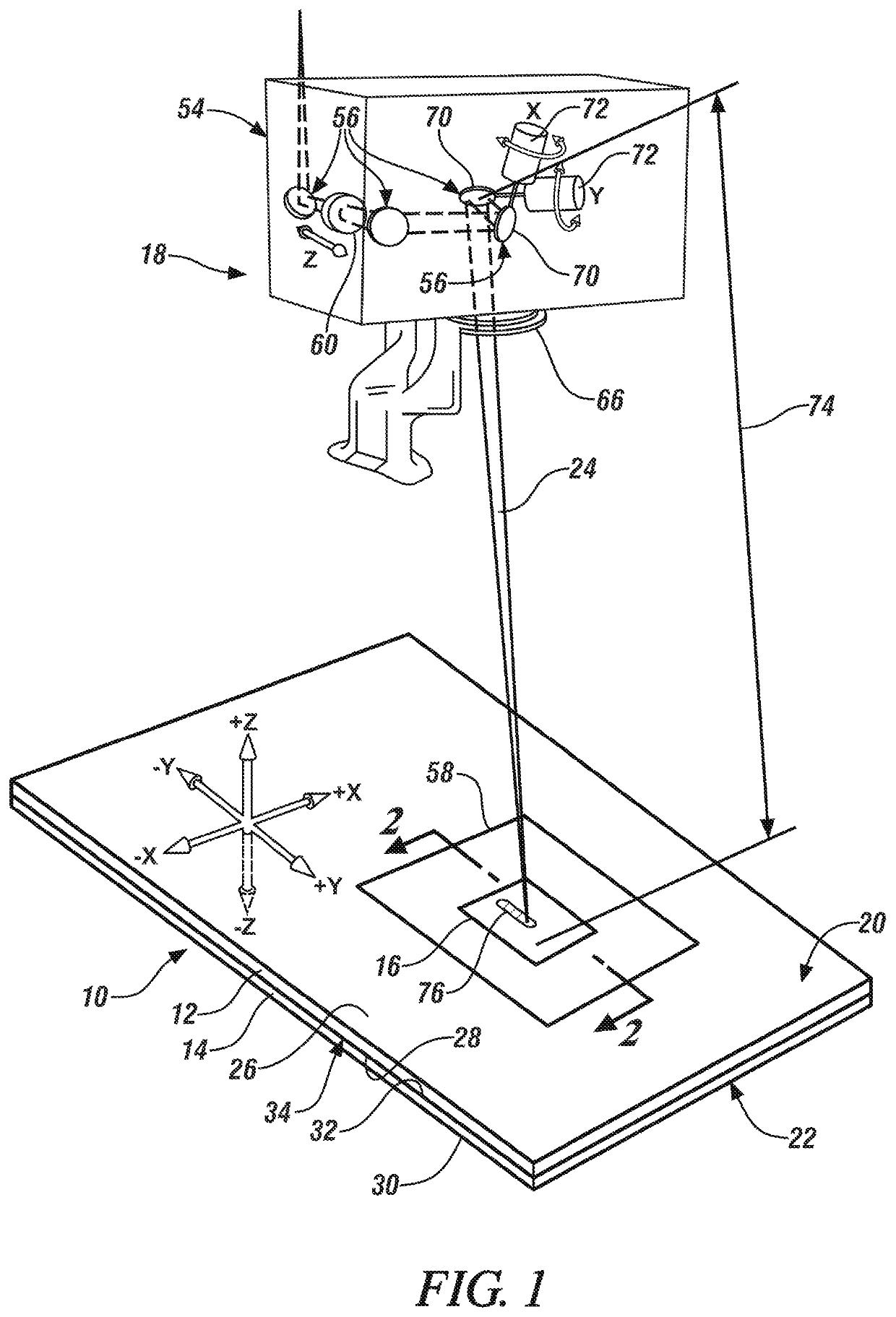

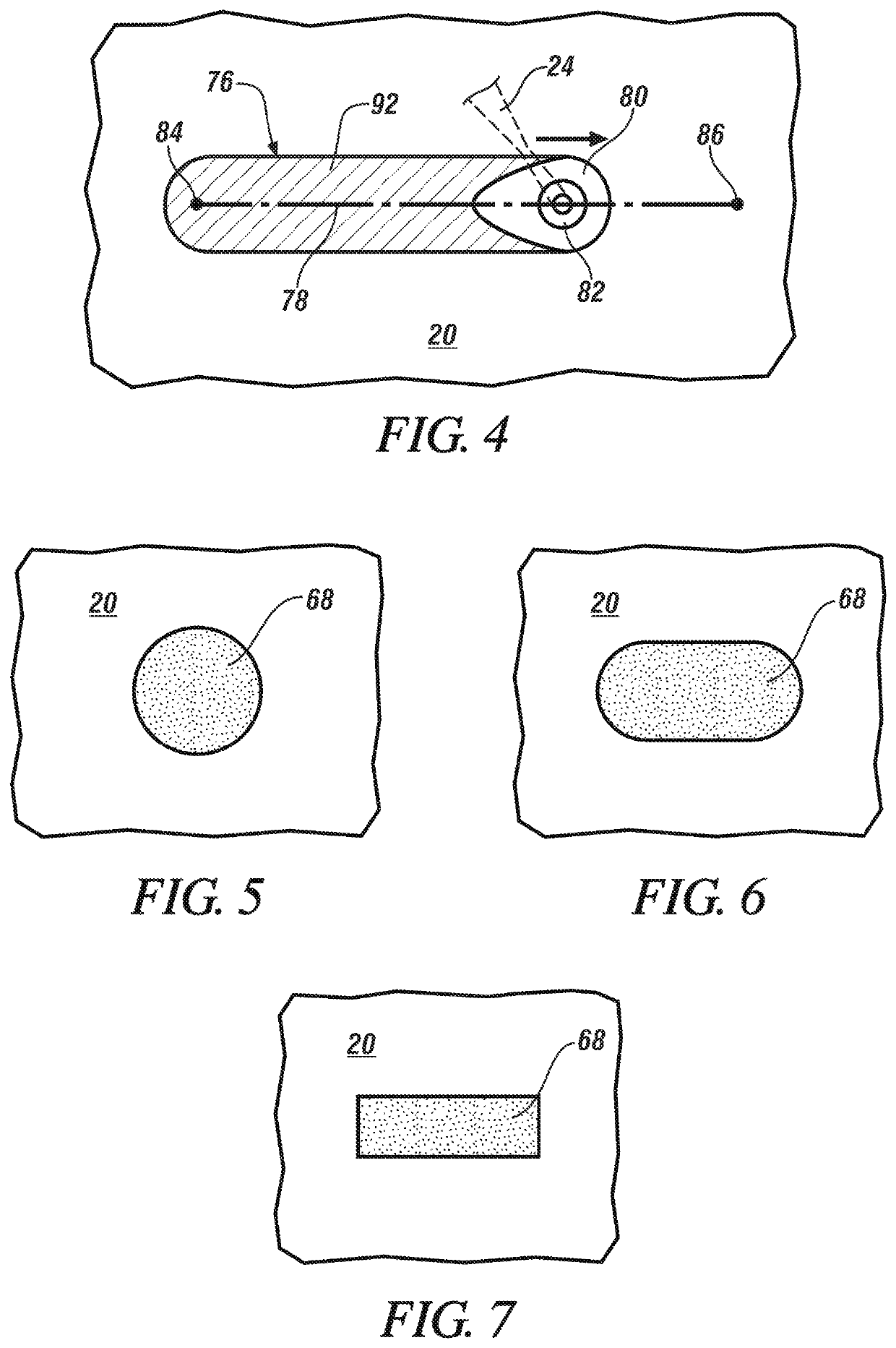

Remote laser welding of overlapping metal workpieces at fast speeds

ActiveUS10953494B2Quick indexHigh strengthVehicle componentsWelding/soldering/cutting articlesEngineeringFusion welding

A method of laser welding a workpiece stack-up (10) that includes at least two overlapping metal workpieces (12, 14) comprises advancing a laser beam (24) relative to a plane of a top surface (20) of the workpiece stack-up (10) from a start point (84) to an end point (86) along a beam travel pattern (78) at a high laser beam travel speed of greater than 8 meters per minute. The two or more overlapping metal workpieces (12, 14) may be steel workpieces or they may be aluminum workpieces, and at least one of the metal workpieces (12, 14) includes a surface coating (40). Advancing the laser beam (24) along the beam travel pattern (78) forms a weld joint (76), which includes resolidified composite workpiece material derived from each of the metal workpieces (12, 14) penetrated by a molten weld pool (80), that fusion welds the metal workpieces (12, 14) together. The relatively high laser beam travel speed contributes to improve strength properties of the weld joint (76).

Owner:GM GLOBAL TECH OPERATIONS LLC

External heat assisted welding of dissimilar metal workpieces

ActiveUS10421148B2Enhance strength-mostReduce heatWelding/soldering/cutting articlesResistance welding apparatusEngineeringSpot welding

A method of resistance spot welding a workpiece stack-up that includes an aluminum workpiece and an adjacent overlapping steel workpiece is disclosed. The method uses a first welding electrode positioned proximate the aluminum workpiece and a second welding electrode positioned proximate the steel workpiece to effectuate the spot welding process. In an effort to positively affect the strength of the ultimately-formed weld joint, external heat may be supplied to the first welding electrode by an external heating source disposed in heat transfer relation with the first welding electrode either before or after, or both before or after, an electrical current is passed between the first and second welding electrodes to create a molten aluminum weld pool within the aluminum workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Particle for lower layer of coating type magnetic recording medium

InactiveUS6171692B1Affect propertyAffect smoothnessMaterial nanotechnologyPigmenting treatmentMetallurgyIron oxyhydroxide

Iron oxyhydroxide particles that are composed of acicular particles having an average major axis of 0.01 to 0.5 mum and containing not less than 0.1 wt. % and not more than 30 wt. % of Al in the iron oxyhydroxide and that release not less than 0.1 wt. % and not more than 2 wt. % of H2O at 100° C. are used as particles of a lower layer of a coating type magnetic recording medium having a multi-layer structure. The acicular particles include ones having two or more branches whose branching direction is skewed toward a two-dimensional orientation.

Owner:DOWA METALS & MINING CO LTD

Fusible link unit with hinge section

ActiveUS7637781B2Easy to engageLow sectionIncorrect coupling preventionEmergency protective devicesBusbarEngineering

A hinge section including bending sections at both side edges of a band plate section is provided in center of a busbar. On both sides of the hinge section, two fuse circuit constituting plate sections are integrally formed to be linked thereto. Two resin housings are assembled by insert molding to the respective fuse circuit constituting plate sections, thus forming two bodies. The two bodies are pivoted in the same direction at the bending sections, and engagement units are locked, thus constituting a fusible link unit having a U-shaped plan view. The two bodies are engaged with each other in vicinity areas of the hinge section in the opposed surfaces of the opposed resin housing when the two bodies are pivoted. The fusible link unit also includes recessed and projected guides guiding the two resin housings to proper positions.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com