Patents

Literature

31results about How to "Ensure cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

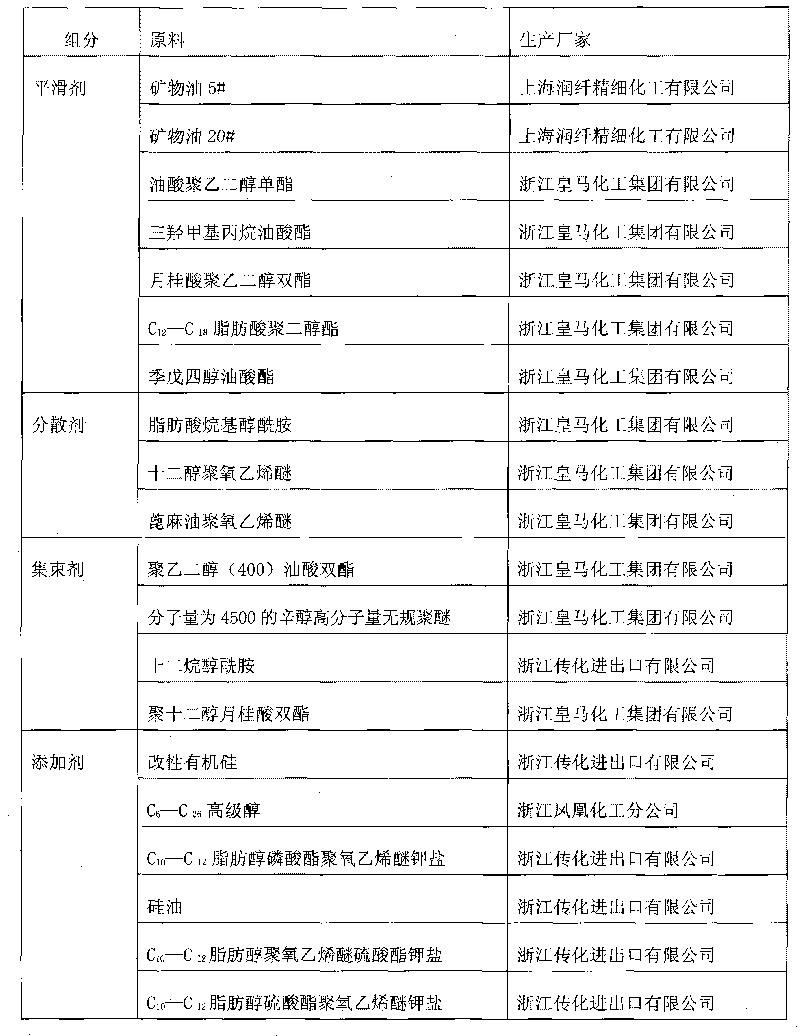

Polypropylene spinning oil agent and manufacturing method thereof

The invention discloses a polypropylene spinning oil agent, which consists of the following formulation raw materials in percentage by weight: 65 to 75 percent of smoothing agent, 2 to 8 percent of dispersant, 15 to 25 percent of bundling agent and 2 to 8 percent of additive. The dispersant is one or a mixture of castor oil polyethenoxy ether and lauryl alcohol polyethenoxy ether; and the dispersant also comprises not less than 20 percent of fatty acid alkylolamide in percentage by weight. A manufacturing method comprises the following steps: firstly pumping the bundling agent and the dispersant into a reaction kettle, heating the mixture to between 40 and 80 DEG C, stirring the mixture evenly, pumping the smoothing agent into the reaction kettle, stirring the mixture for 30 to 50 minutes, then adding the additive into the mixture, stirring the mixture evenly, and cooling, filtering and packing the mixture. Because the fatty acid alkylolamide is added into the dispersant, the polypropylene spinning oil agent avoids adopting alkylphenol polyoxyethylene, the cohesive force of the oil agent is ensured, and the requirement of ecological environment on the oil agent is met.

Owner:ZHEJIANG HUANGMA TECH

Powder for dry refractory material

InactiveUS20120309608A1Improve thermal shock resistanceImprove the immunityFurnace liningsOxideChemical composition

The invention relates to a powder comprising more than 70% of refractory particles, in weight percent relative to the weight of the powder, a particle of said powder being classed in the fraction called “matrix” or in the fraction called “aggregate”, according to whether it is smaller than, or equal to 100 μm, or larger than 100 μm, respectively, said powder comprising, in weight percent relative to the weight of the powder: between 0.1% and 18% of particles of a heat-activatable binder, called “heat-activatable binder particles”; and more than 40% of refractory particles, called “ATZ particles”, having the following chemical composition, in weight percentages on the basis of the oxides of said ATZ particles: 10%≦Al2O3≦55%; 35%≦TiO2≦80%; 1%≦MgO+Cr2O3≦10%; 8%≦ZrO2≦20%; SiO2≦8%.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

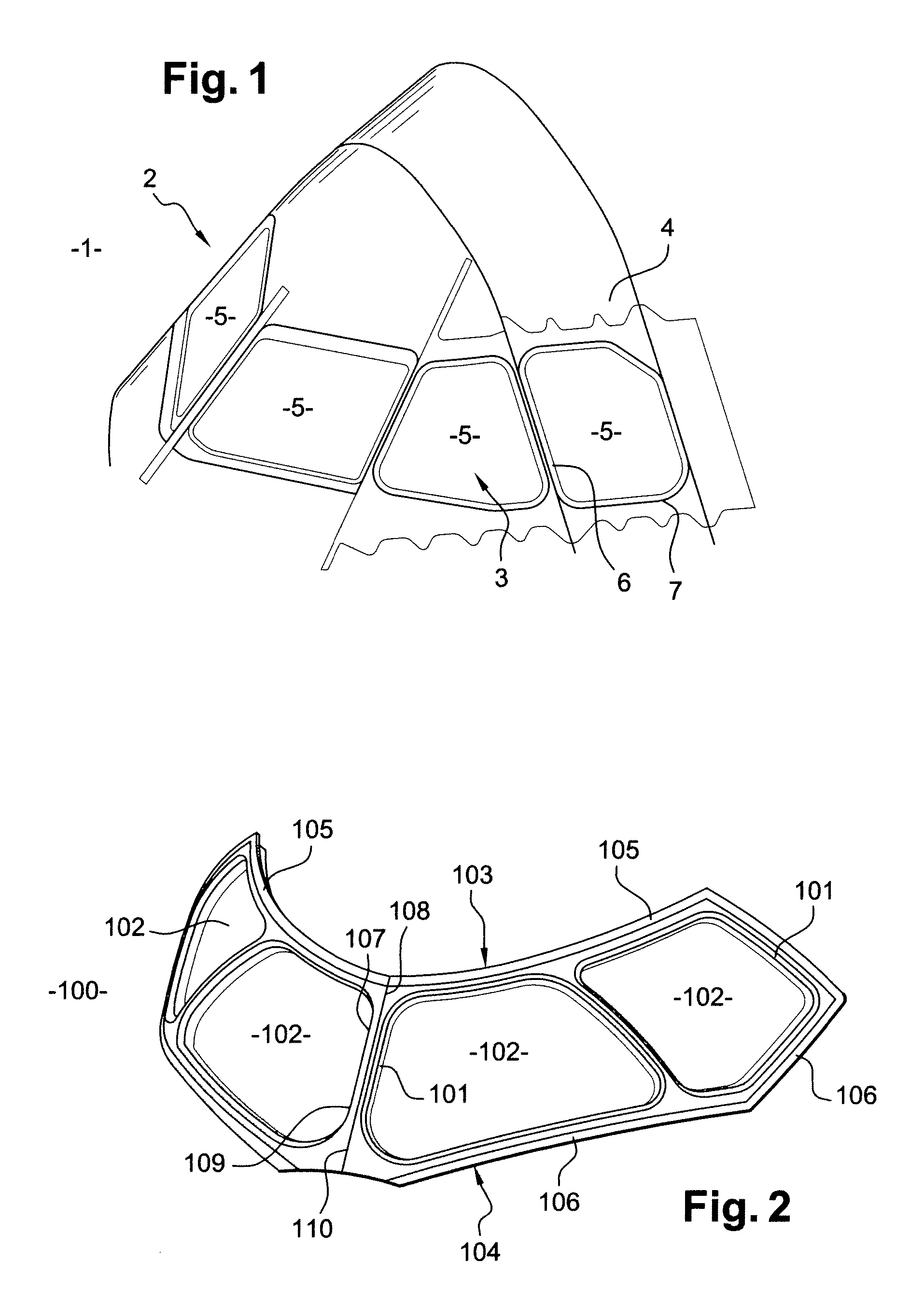

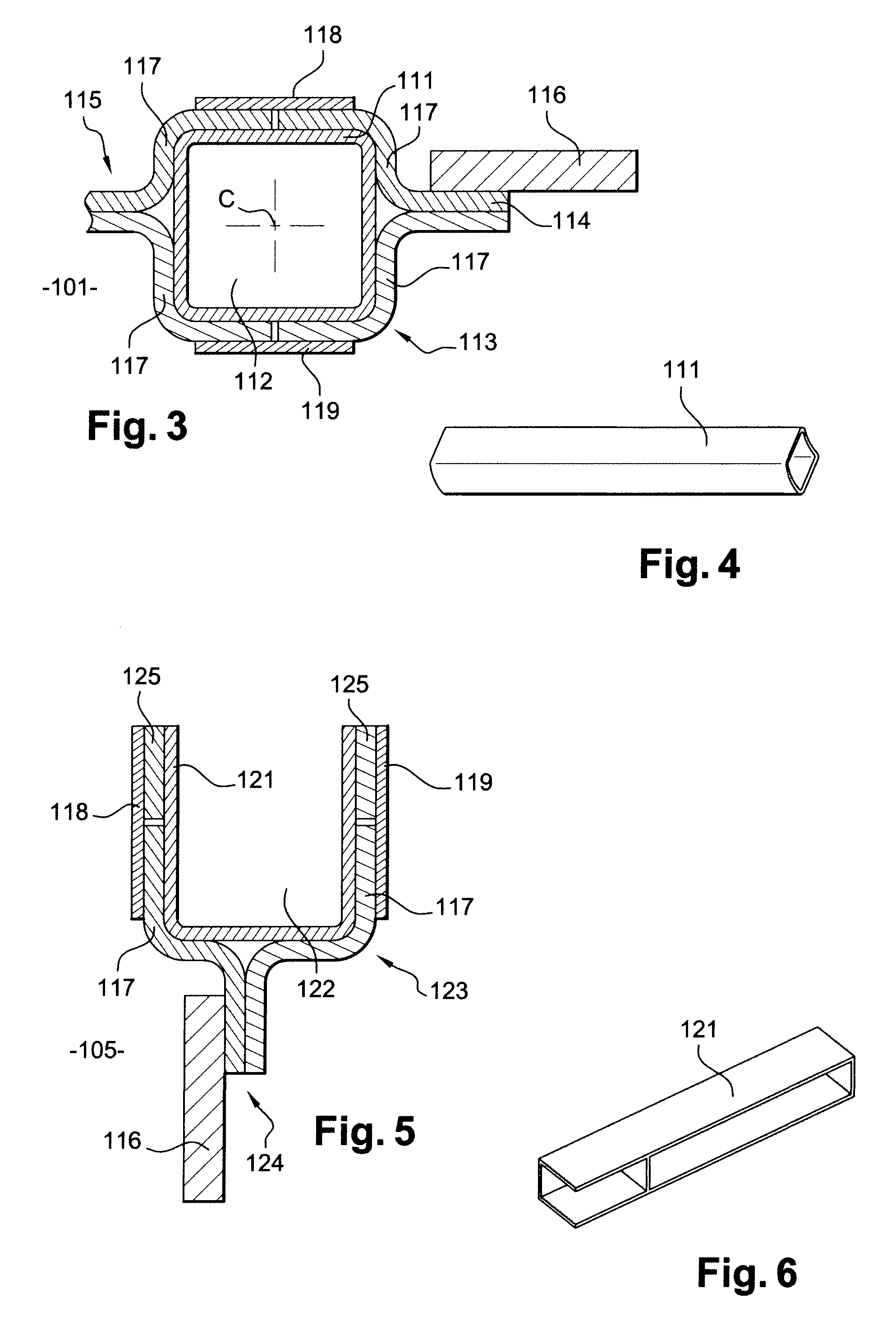

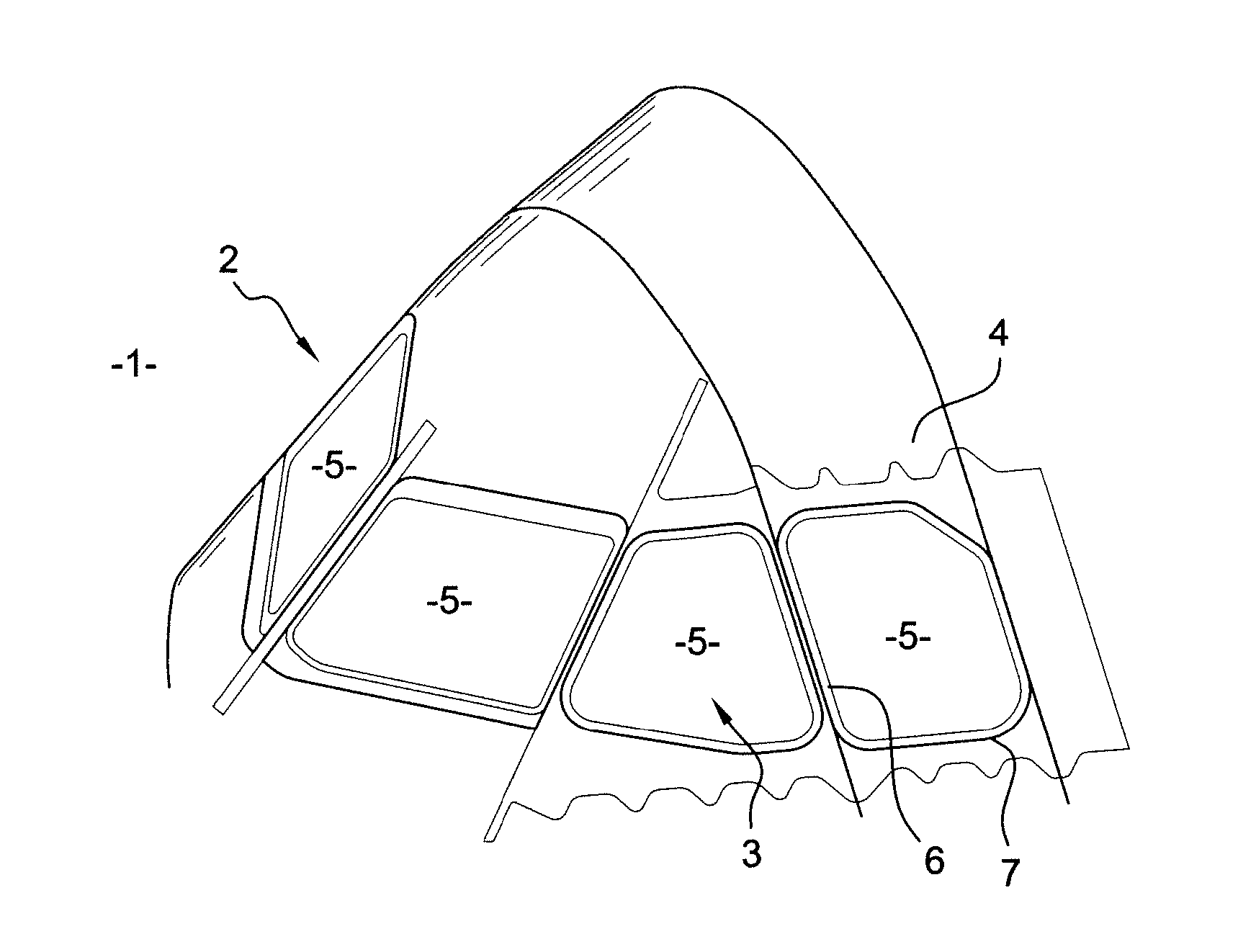

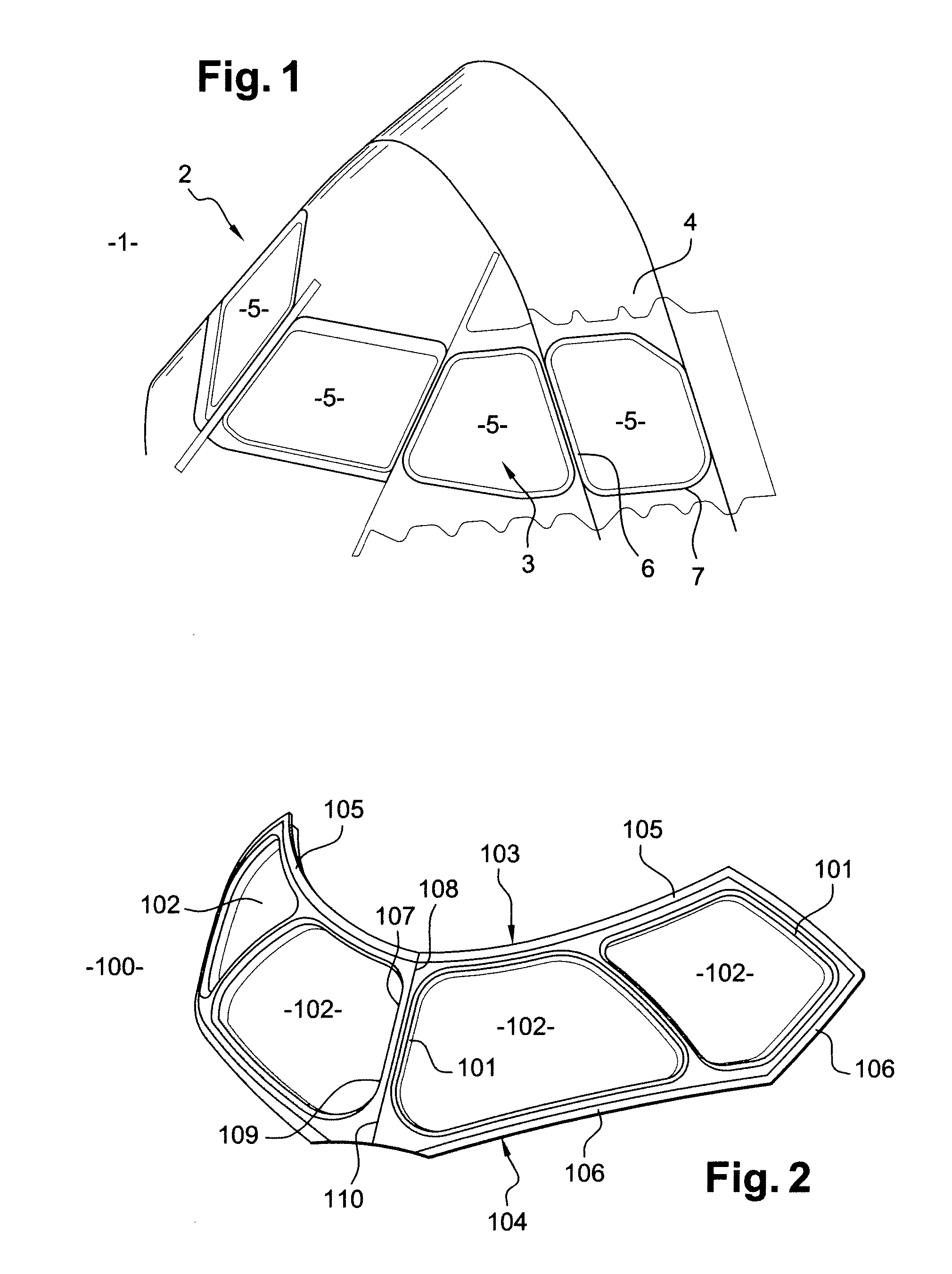

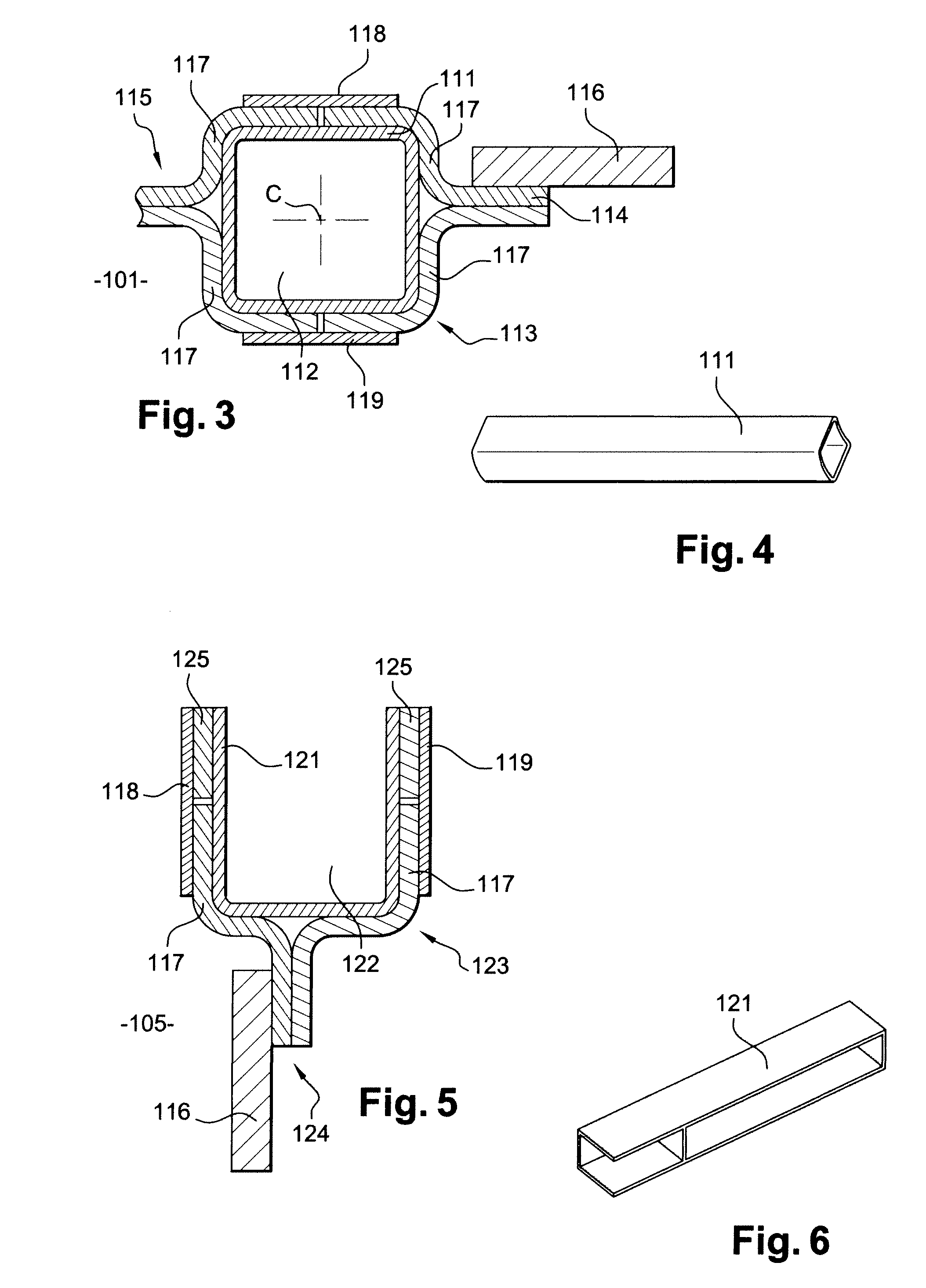

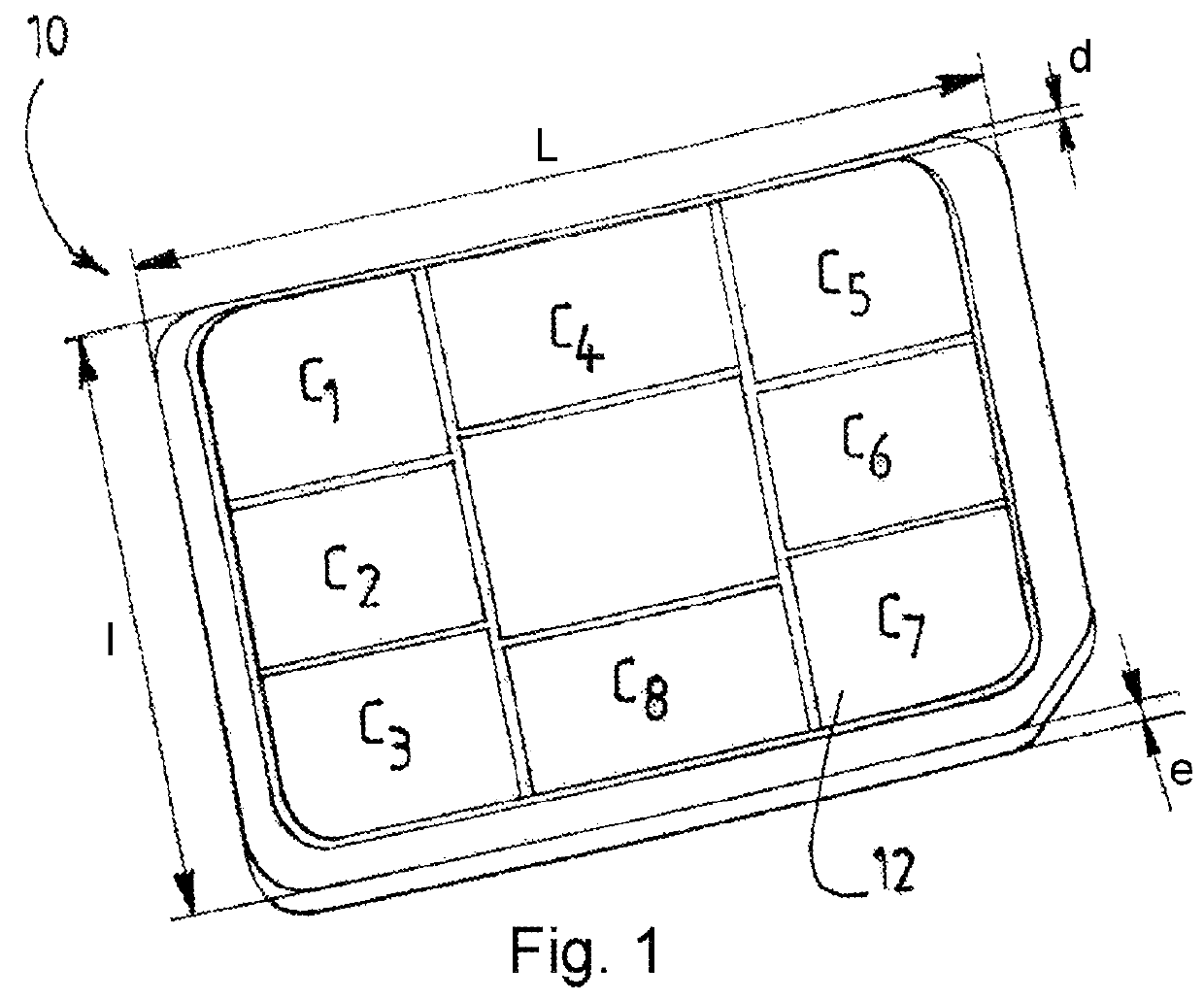

Windscreen frame and a method of production for a windscreen frame

InactiveUS7942369B2Simple conceptEasy to fit into wallWindowsWindscreensEngineeringMethods of production

A windscreen frame, and a method of production for a windscreen frame, designed to hold a windscreen in an opening in a wall, the frame including at least one upper horizontal frame section element, at least one lower horizontal frame section element and at least one vertical mounting, characterized in that it is a single unit in composite material.

Owner:AIRBUS OPERATIONS (SAS)

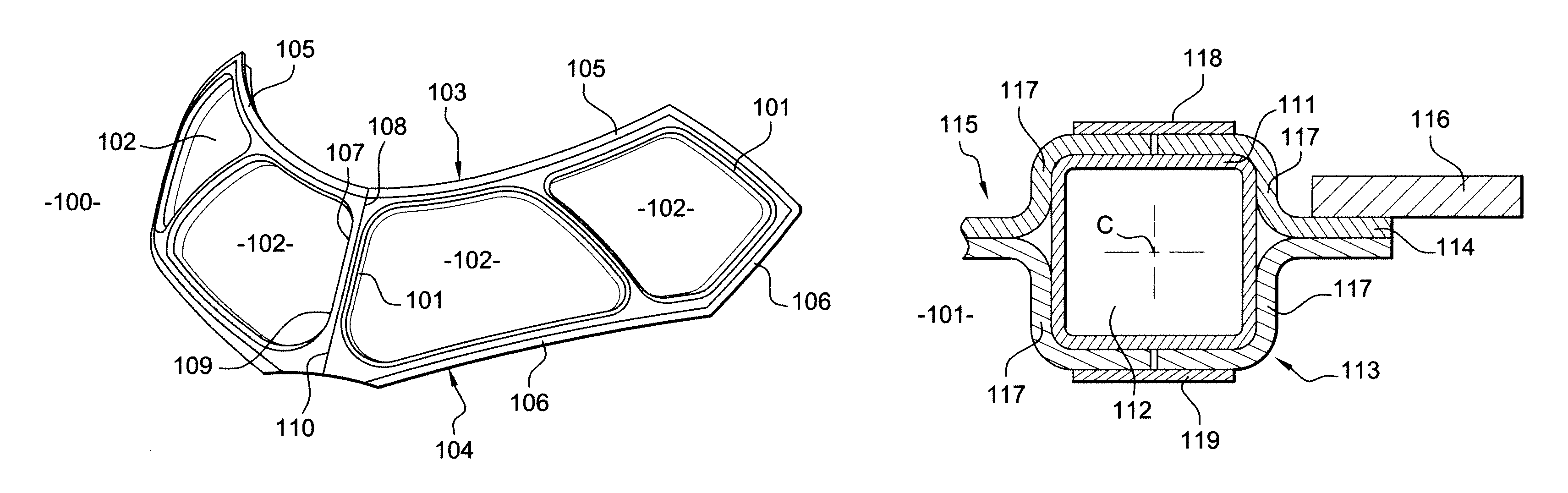

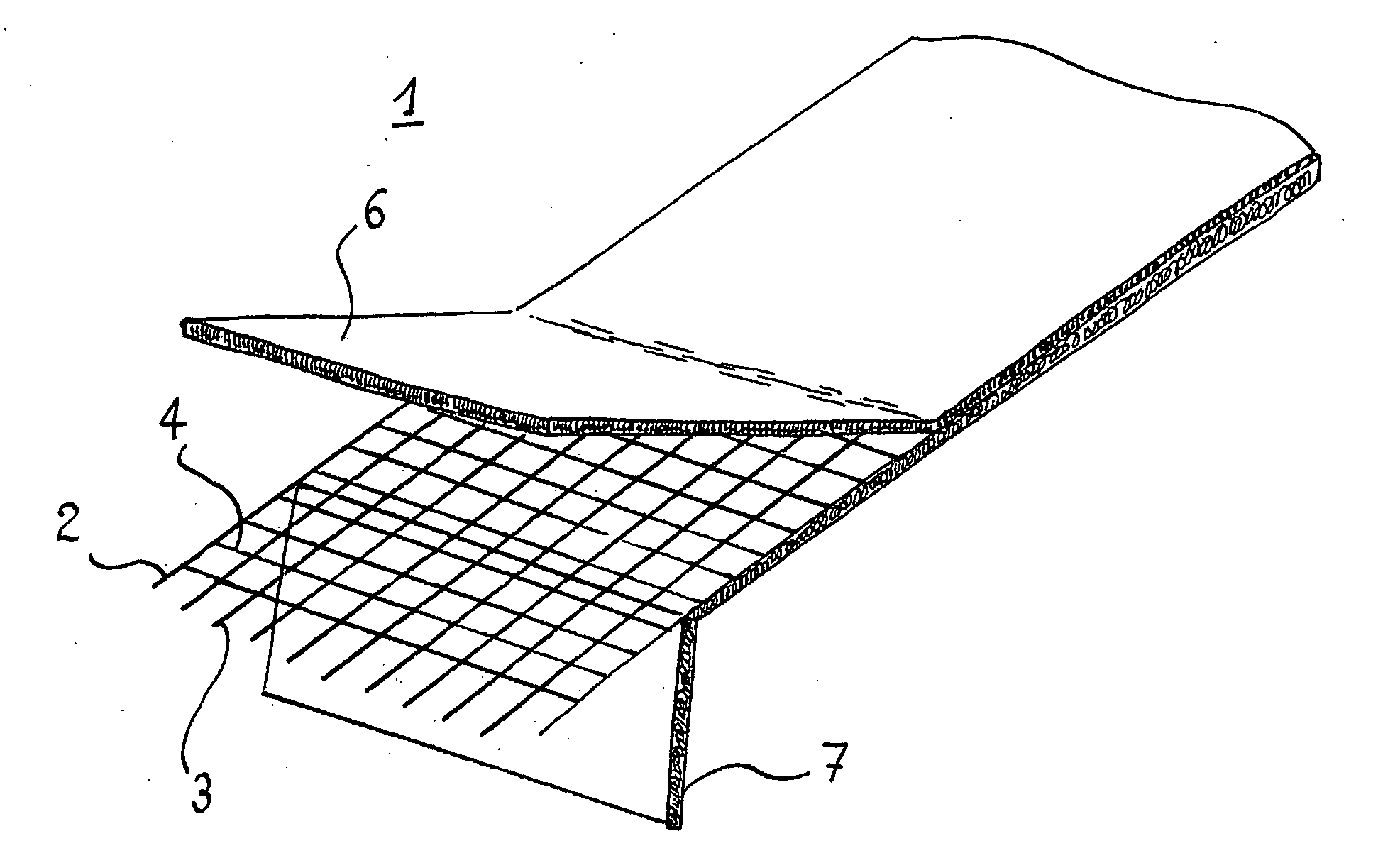

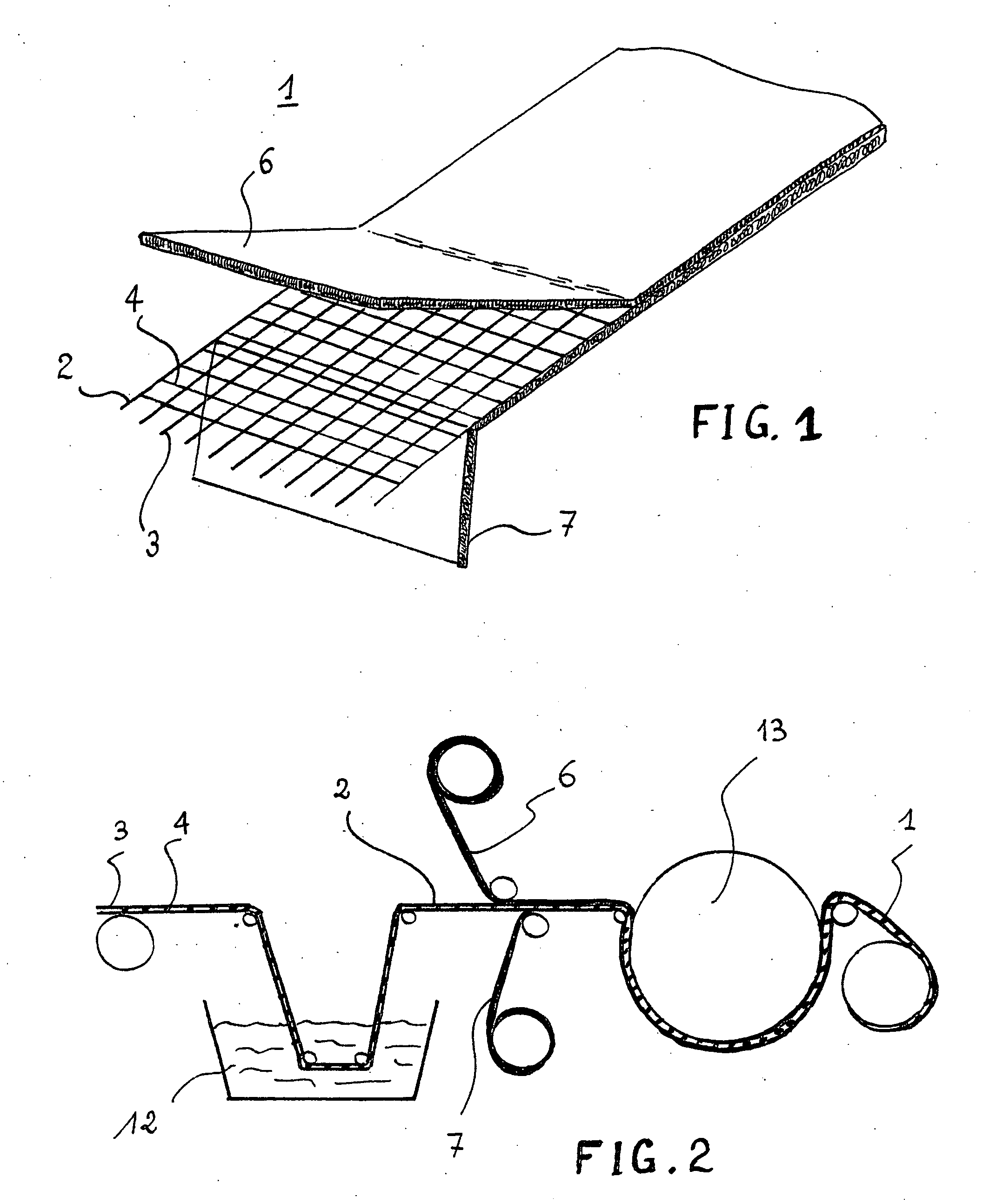

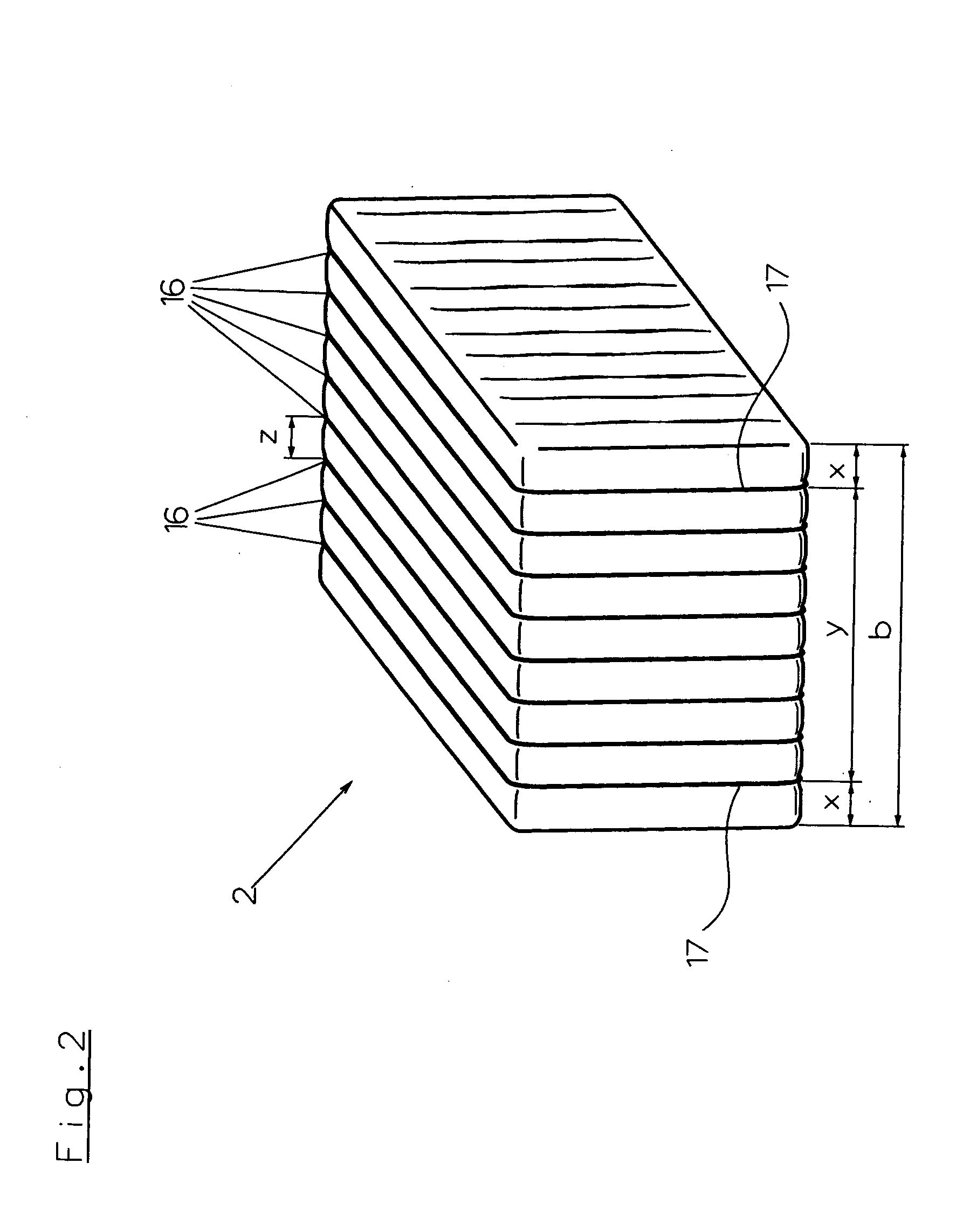

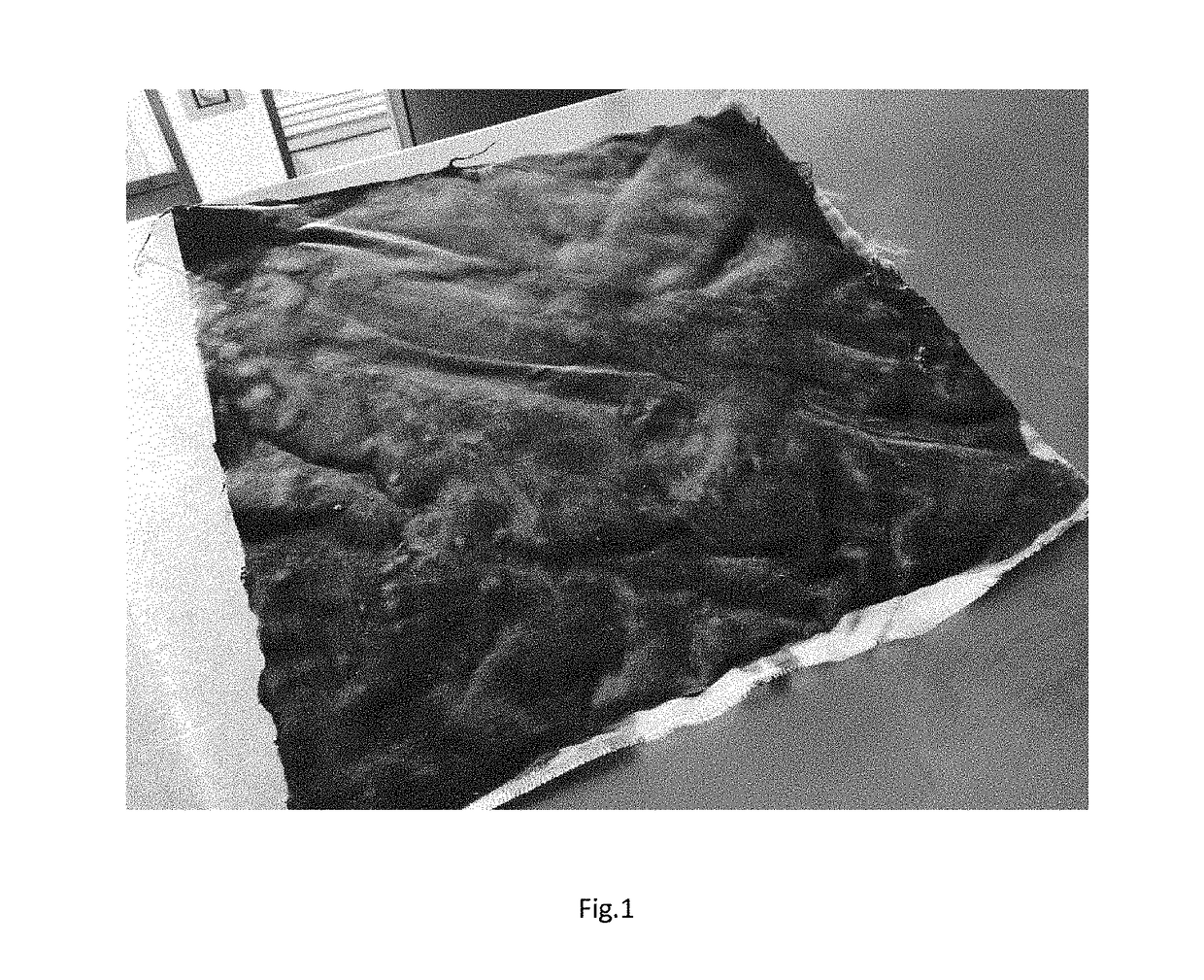

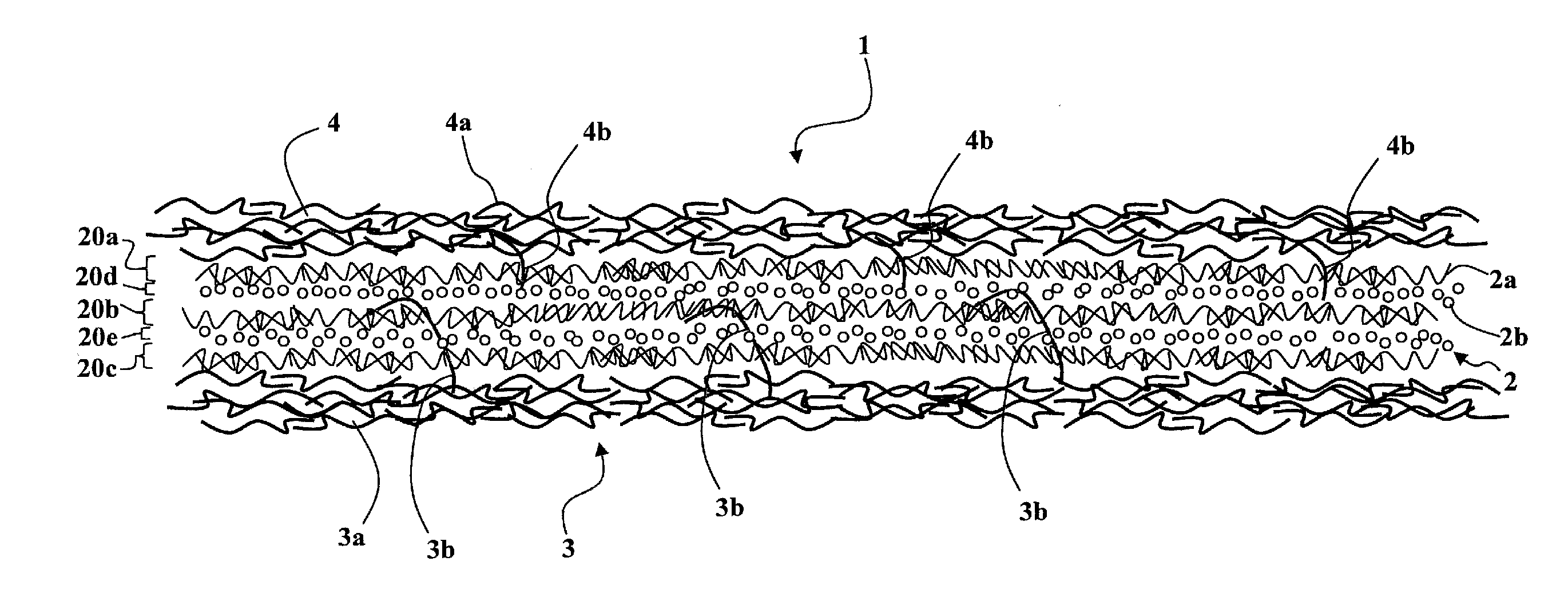

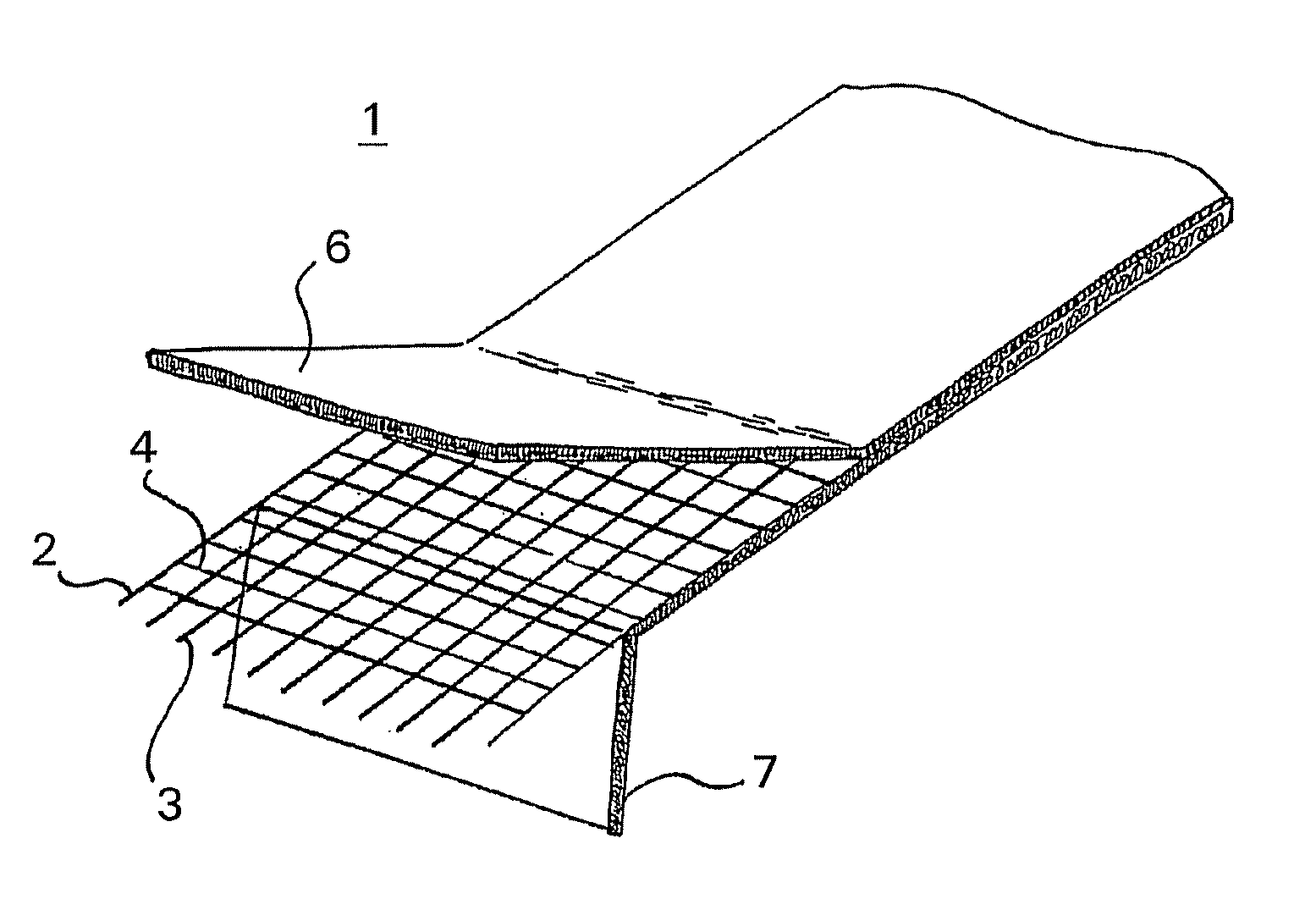

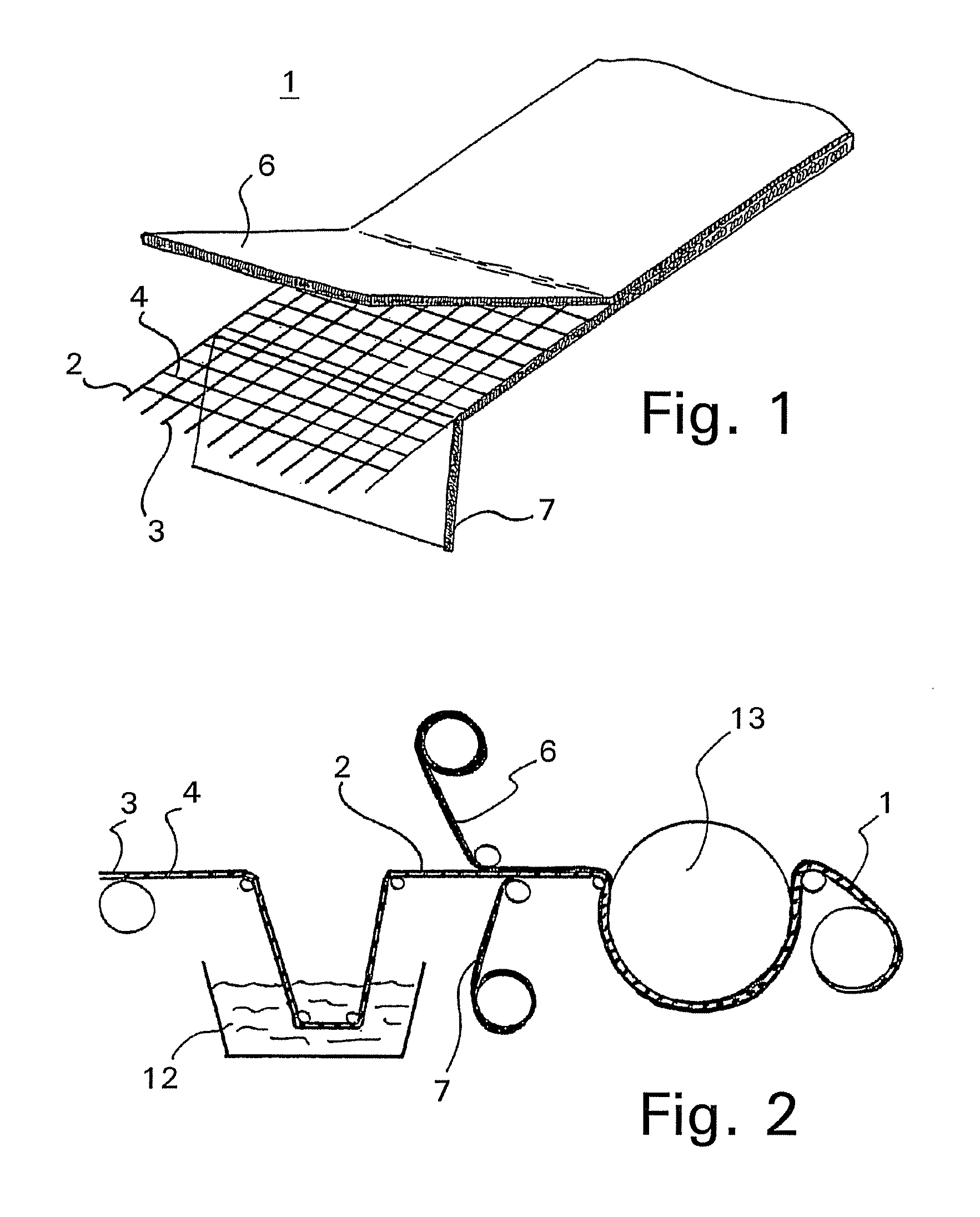

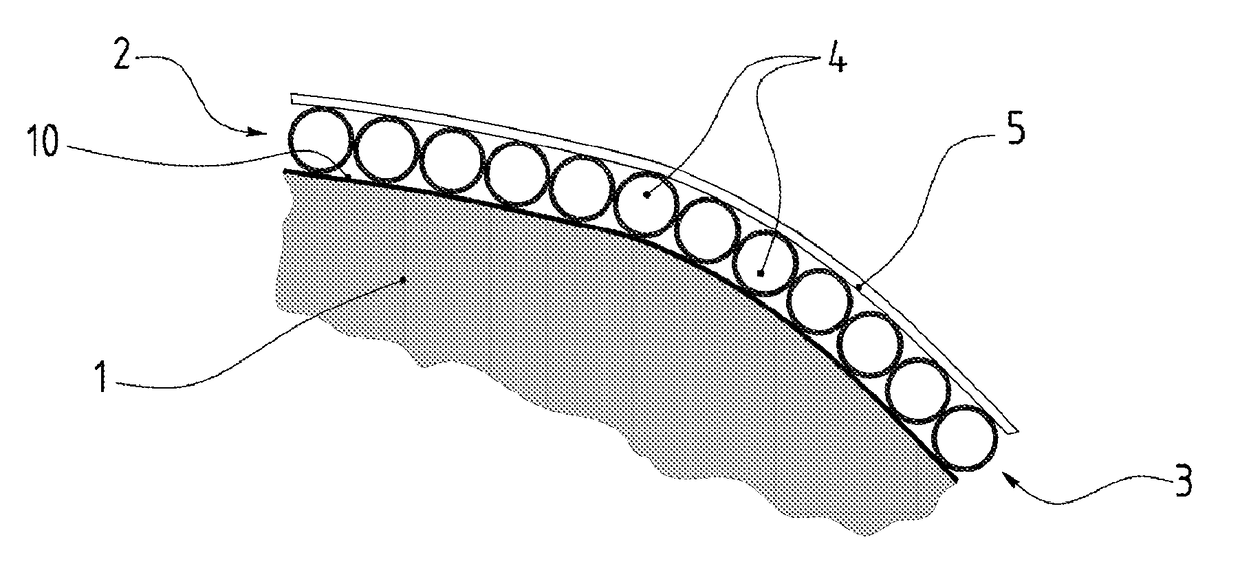

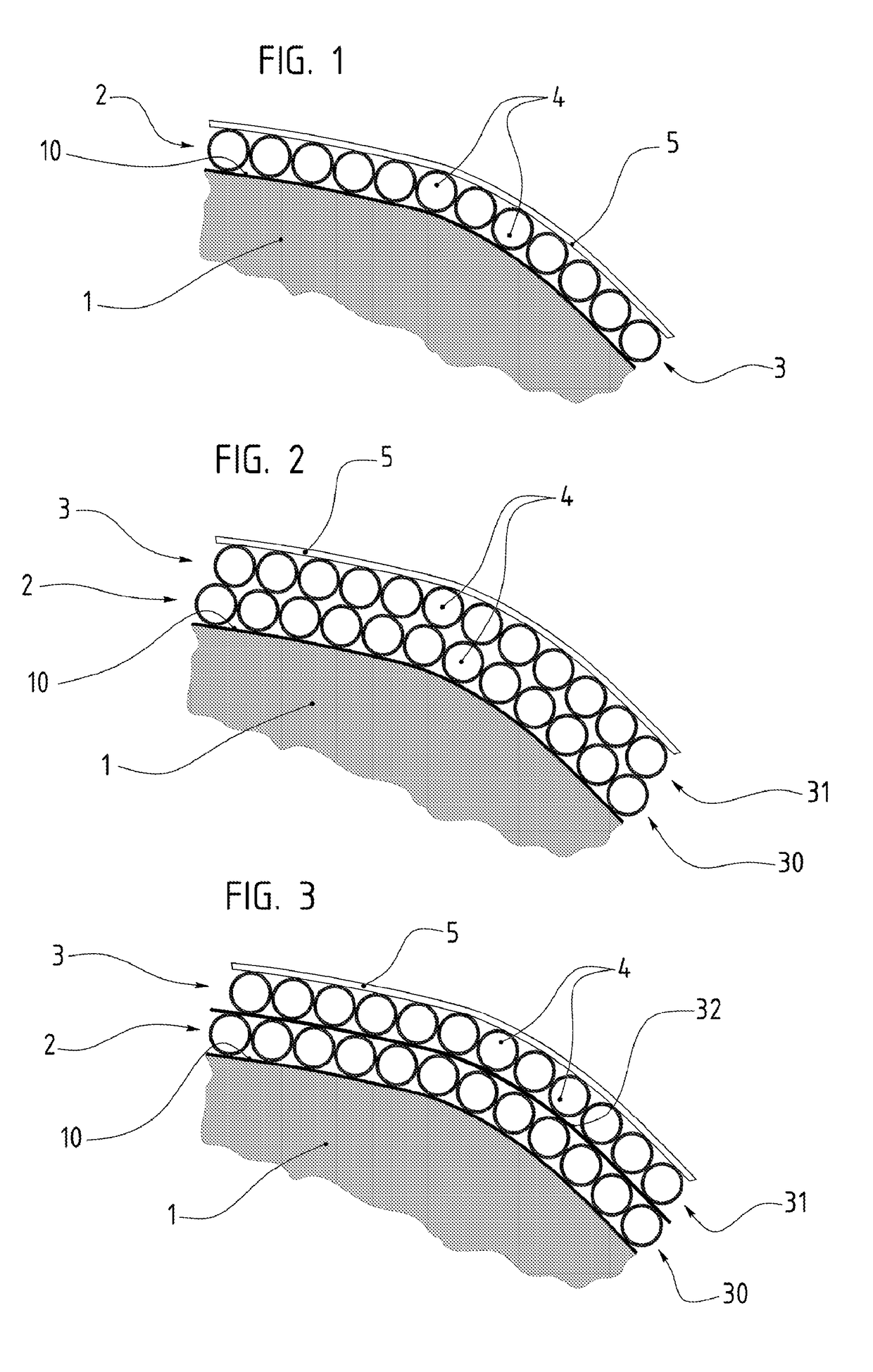

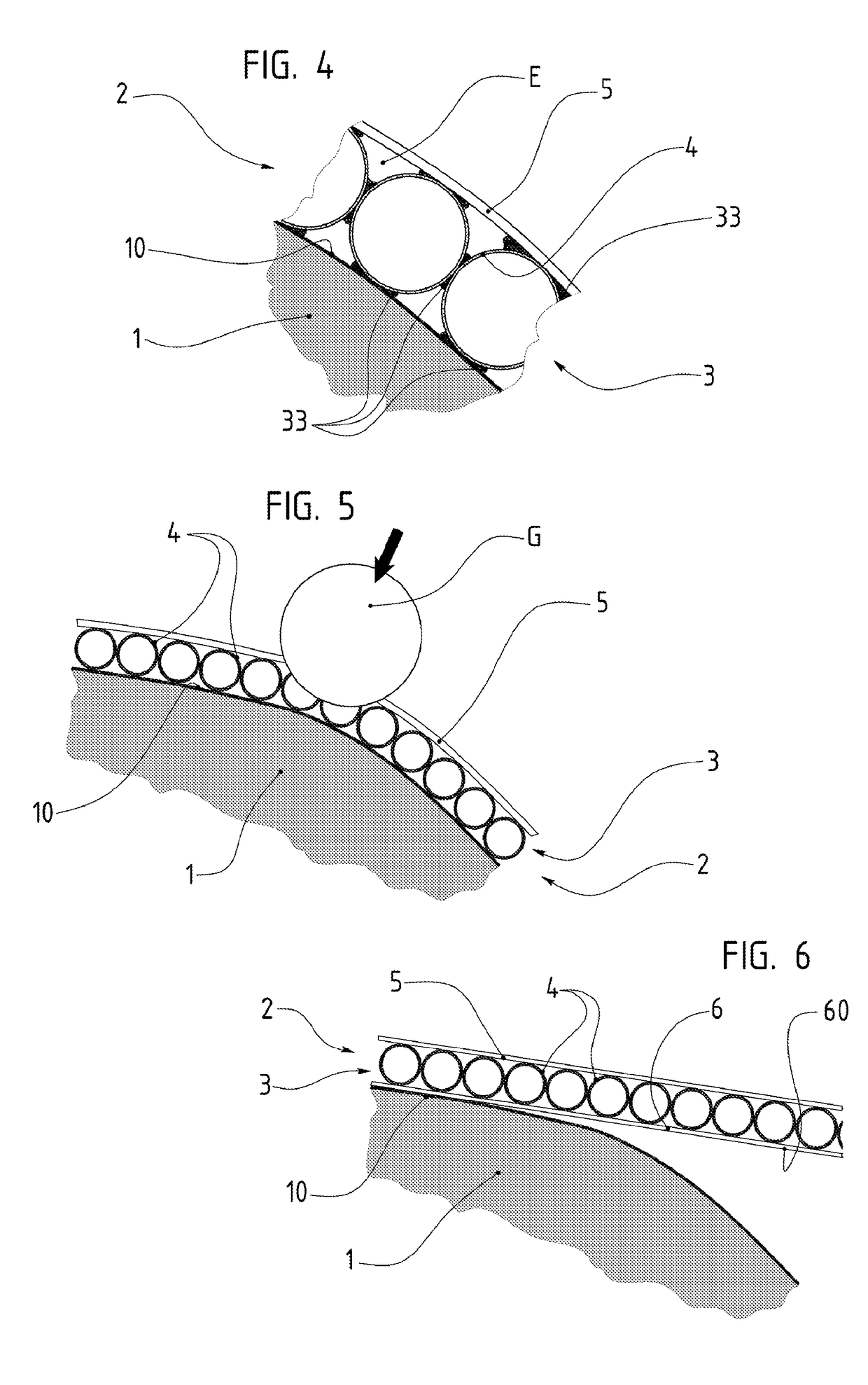

Textile composite intended for mechanical reinforcement of a bitumen-based waterproof coating

InactiveUS20060172638A1Lack of flatnessEnsure cohesionRoof covering using flexible materialsSynthetic resin layered productsSecondary layerSynthetic fiber

A textile composite (1) intended for mechanical reinforcement of a bitumen-based waterproof coating, characterised in that it comprises: a first layer (7) of a non-woven fabric material based on synthetic fibres that is puncture resistant; a second layer (6) of a non-woven fabric material based on mineral or synthetic fibres that is fire resistant; a grid structure (2) placed between the first and second layers (6, 7), the warp yarns (3) and weft yarns (4) of which are connected to each other at the points where they cross by means of an adhesive that also ensures bonding of the first (7) and second (6) layers on the grid (2).

Owner:CHOMARAT COMPOSITES

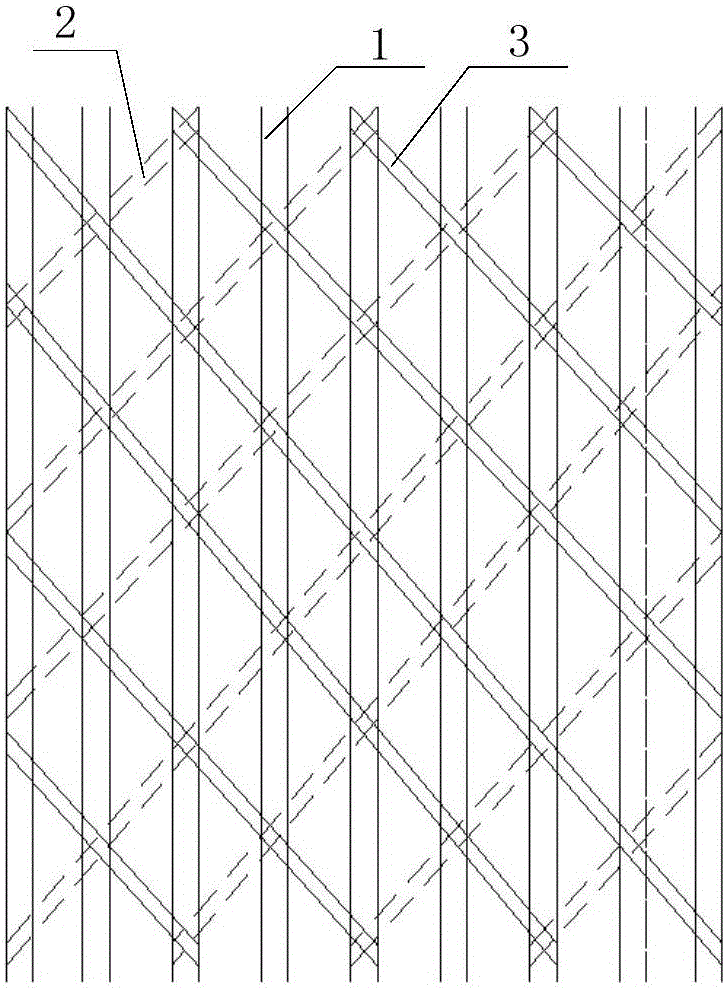

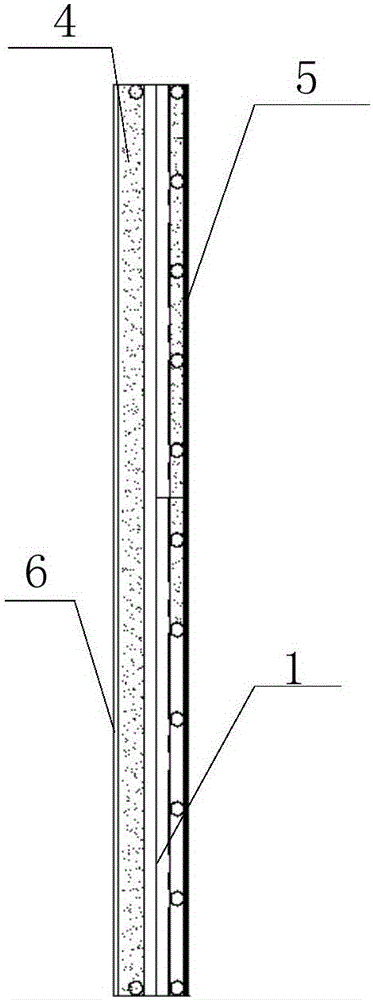

Wall based on raw bamboo framework

The invention discloses a wall based on a raw bamboo framework. The wall based on the raw bamboo framework comprises the raw bamboo framework and a fibred cement board; the raw bamboo framework has a cuboid structure and comprises a plurality of upright columns, a first group of diagonal rods and a second group of diagonal rods; the upright columns are parallel to one another; the first group of diagonal rods are positioned on front side surfaces of the various upright columns; the second group of diagonal rods are positioned on rear side surfaces of the various upright columns; the various diagonal rods in the first group are parallel to one another; the various diagonal rods in the second group are also parallel to one another; the diagonal rods in the first group are intersected with the diagonal rods in the second group, and are connected with the upright columns; the diagonal rods in the second group are connected with the upright columns and side surfaces of the fibered cement board; and a gypsum-based thermal-insulation material wraps the raw bamboo framework. The wall based on the raw bamboo framework is high in strength and long in service life.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Powder for glass-ceramic dry refractory material

InactiveUS8980775B2Promote infiltrationIncrease resistanceMelt-holding vesselsCeramic shaping apparatusThermal energyRefractory

The invention relates to a powder comprising more than 70% of glass-ceramic and / or refractory particles, a particle of said powder being classed in the fraction called “matrix” or in the fraction called “aggregate” according to whether it is smaller than, or equal to 100 μm, or bigger than 100 μm, respectively,the aggregate, representing more than 60% of the powder, comprising:more than 40% of particles of a glass-ceramic material having a crystallization rate of higher than 50% and a thermal expansion value, measured at 700° C., of less than 0.3%, called “glass-ceramic grains”;less than 35% of particles of a refractory material different from a glass-ceramic material, called “refractory grains”, the quantity of refractory grains being higher than 10% if the aggregate comprises more than 40% of glass-ceramic grains having a thermal expansion value, measured at 700° C., of less than or equal to 0.15%;the matrix, representing more than 10% of the powder, comprising:less than 30% of particles of a refractory material different from a glass-ceramic material, called “fine refractory particles”, the quantity of fine refractory particles being higher than 5% and preferably lower than 25%, if the quantity of glass-ceramic grains having a crystallization rate of lower than 75% is higher than 5%;and between 0.1% and 18% of particles of a heat-activatable binder;all of the percentages being weight percentages in relation to the weight of the powder.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Powder for glass-ceramic dry refractory material

InactiveUS20120316053A1Ensure cohesionPromote infiltrationMelt-holding vesselsCeramic shaping apparatusRefractoryThermal expansion

The invention relates to a powder comprising more than 70% of glass-ceramic and / or refractory particles, a particle of said powder being classed in the fraction called “matrix” or in the fraction called “aggregate” according to whether it is smaller than, or equal to 100 μm, or bigger than 100 μm, respectively,the aggregate, representing more than 60% of the powder, comprising:more than 40% of particles of a glass-ceramic material having a crystallization rate of higher than 50% and a thermal expansion value, measured at 700° C., of less than 0.3%, called “glass-ceramic grains”;less than 35% of particles of a refractory material different from a glass-ceramic material, called “refractory grains”, the quantity of refractory grains being higher than 10% if the aggregate comprises more than 40% of glass-ceramic grains having a thermal expansion value, measured at 700° C., of less than or equal to 0.15%;the matrix, representing more than 10% of the powder, comprising:less than 30% of particles of a refractory material different from a glass-ceramic material, called “fine refractory particles”, the quantity of fine refractory particles being higher than 5% and preferably lower than 25%, if the quantity of glass-ceramic grains having a crystallization rate of lower than 75% is higher than 5%;and between 0.1% and 18% of particles of a heat-activatable binder;all of the percentages being weight percentages in relation to the weight of the powder.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Windscreen frame and a method of production for a windscreen frame

A windscreen frame, and a method of production for a windscreen frame, designed to hold a windscreen in an opening in a wall, the frame including at least one upper horizontal frame section element, at least one lower horizontal frame section element and at least one vertical mounting, characterised in that it is a single unit in composite material.

Owner:AIRBUS OPERATIONS SAS

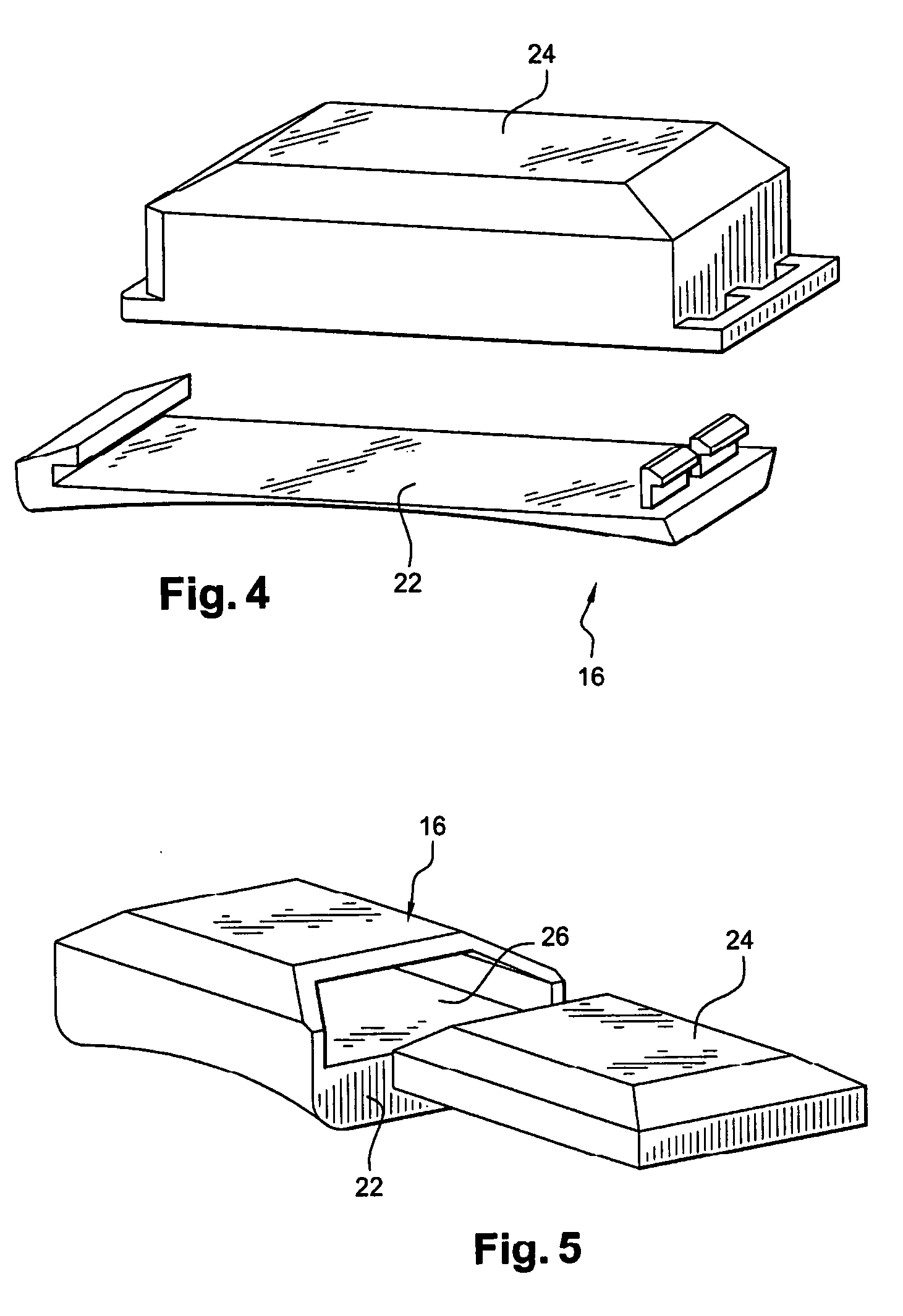

Use of an adhesive for assembling a member and a wheel, a member-and-wheel assembly, a member, and a wheel

InactiveUS20050244605A1Low costSimple and fast and effectiveAdhesive processesLayered productsVitrificationAdhesive

The invention relates to the use of an adhesive for assembling together a member and a wheel, the adhesive presenting the following properties: the breaking stress in traction of the adhesive is greater than 0.5 MPa at 80° C.; the adhesive comprises at least one polymeric component of vitreous transition temperature below -50° C.; and the adhesive comprises at least one other polymeric component of vitreous transition temperature above 100° C.

Owner:MICHELIN RECH & TECH SA +1

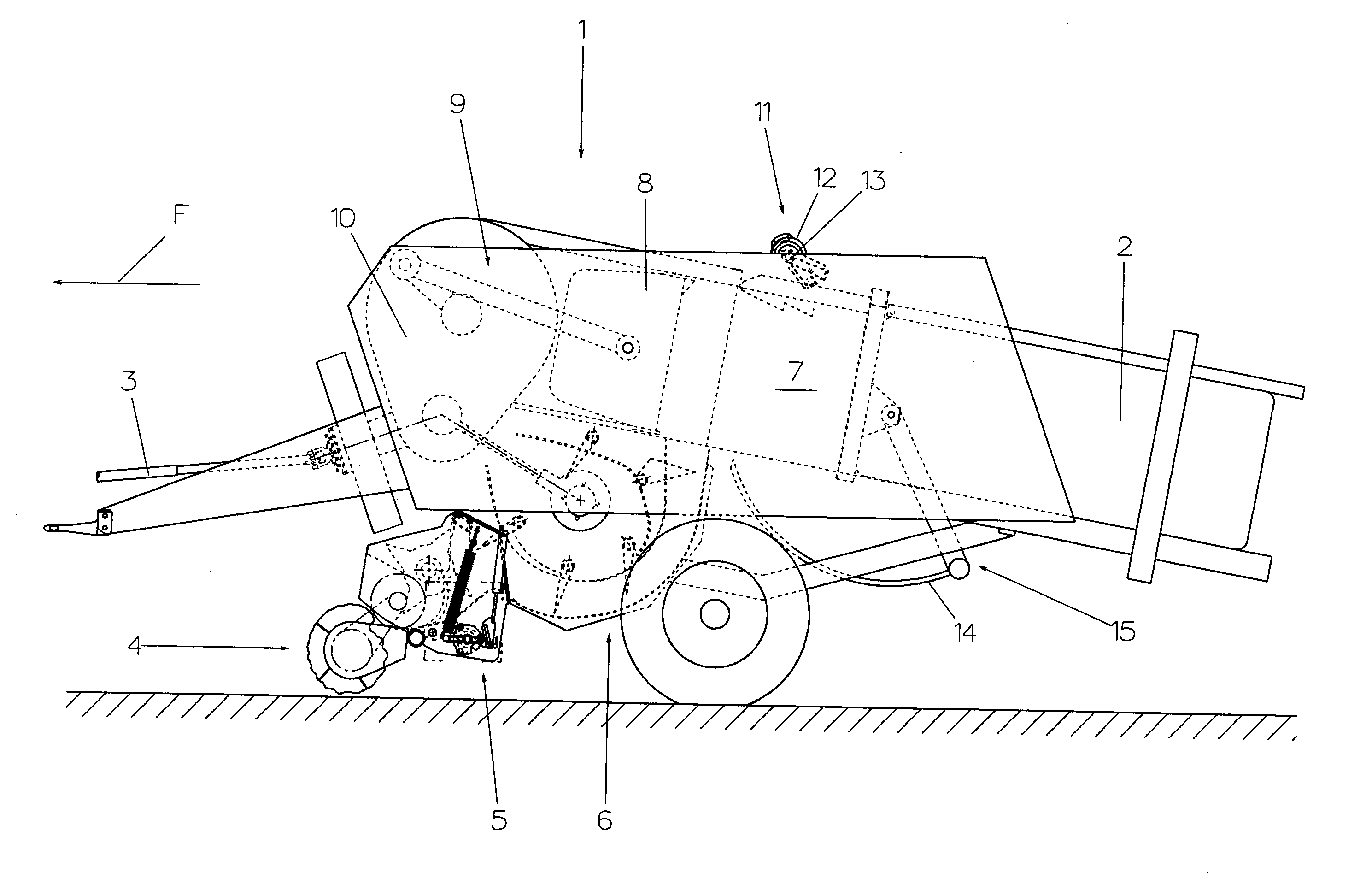

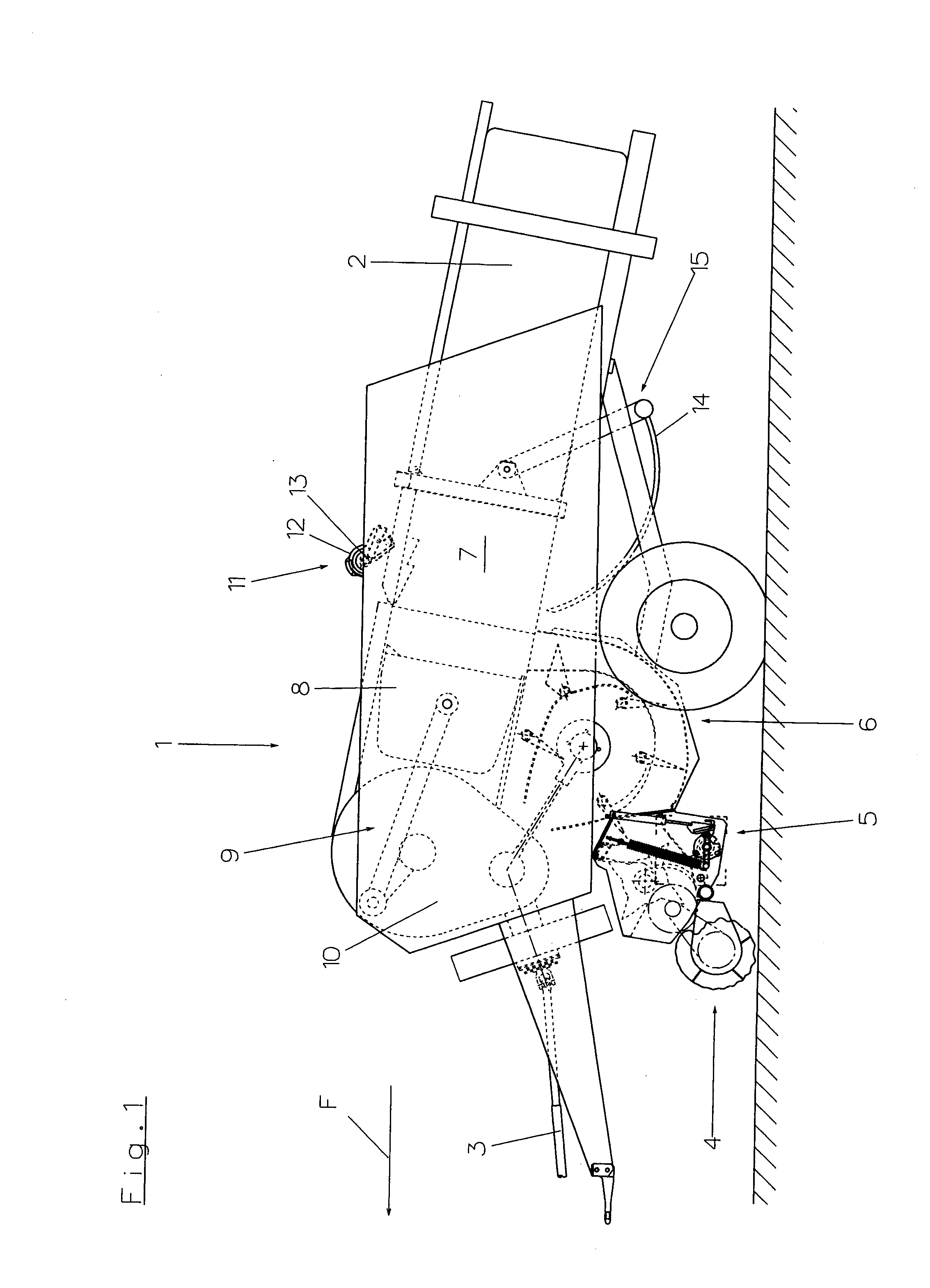

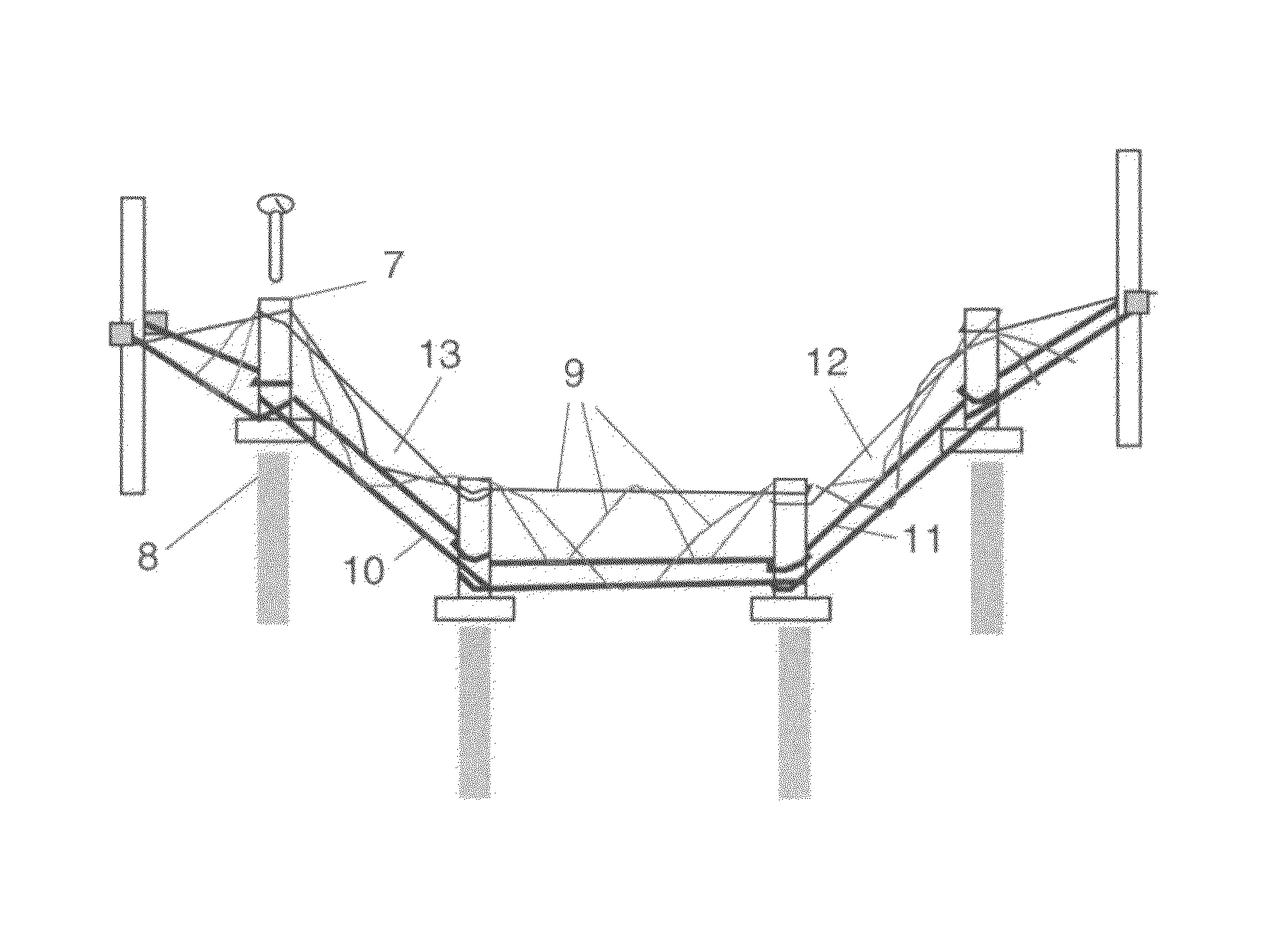

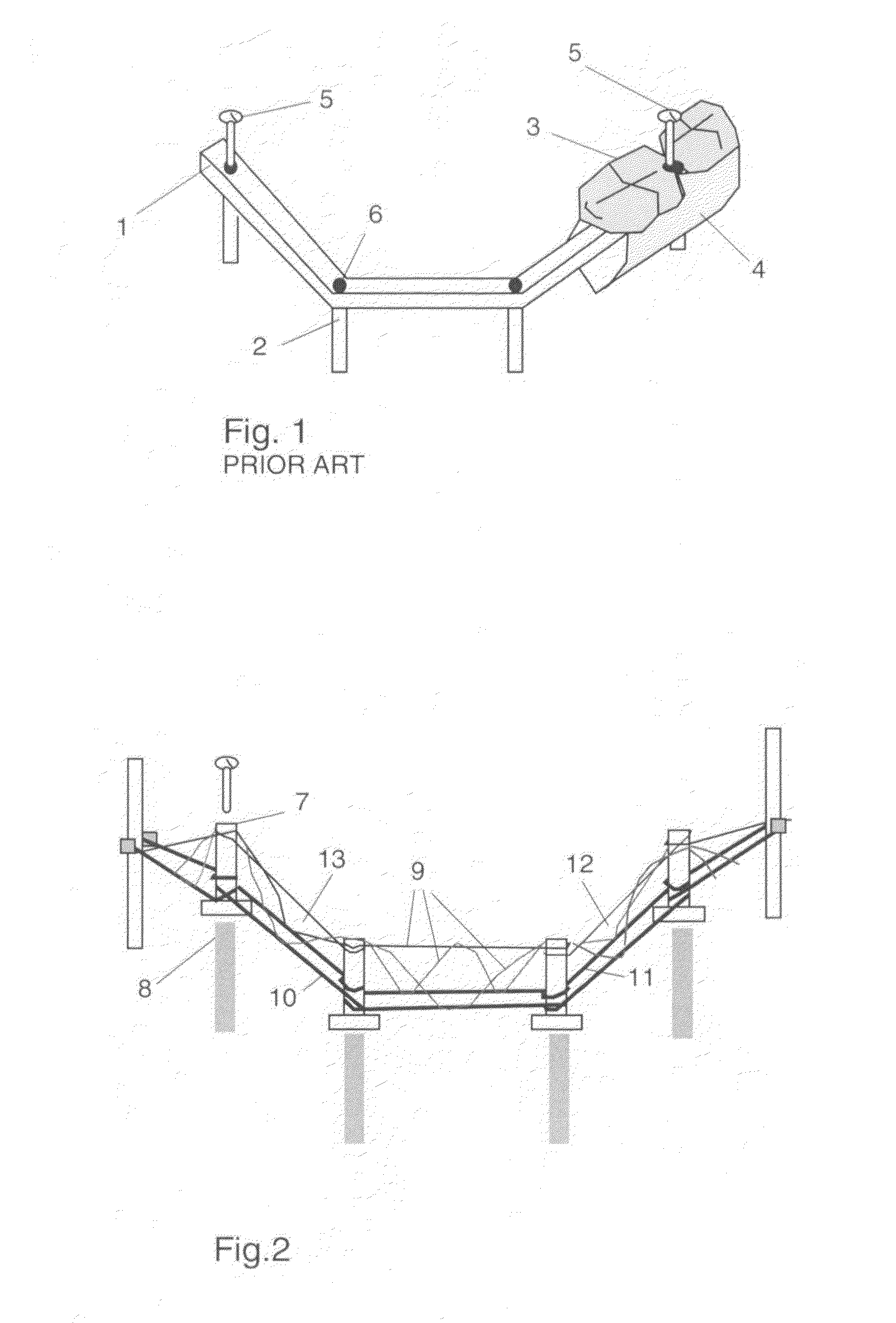

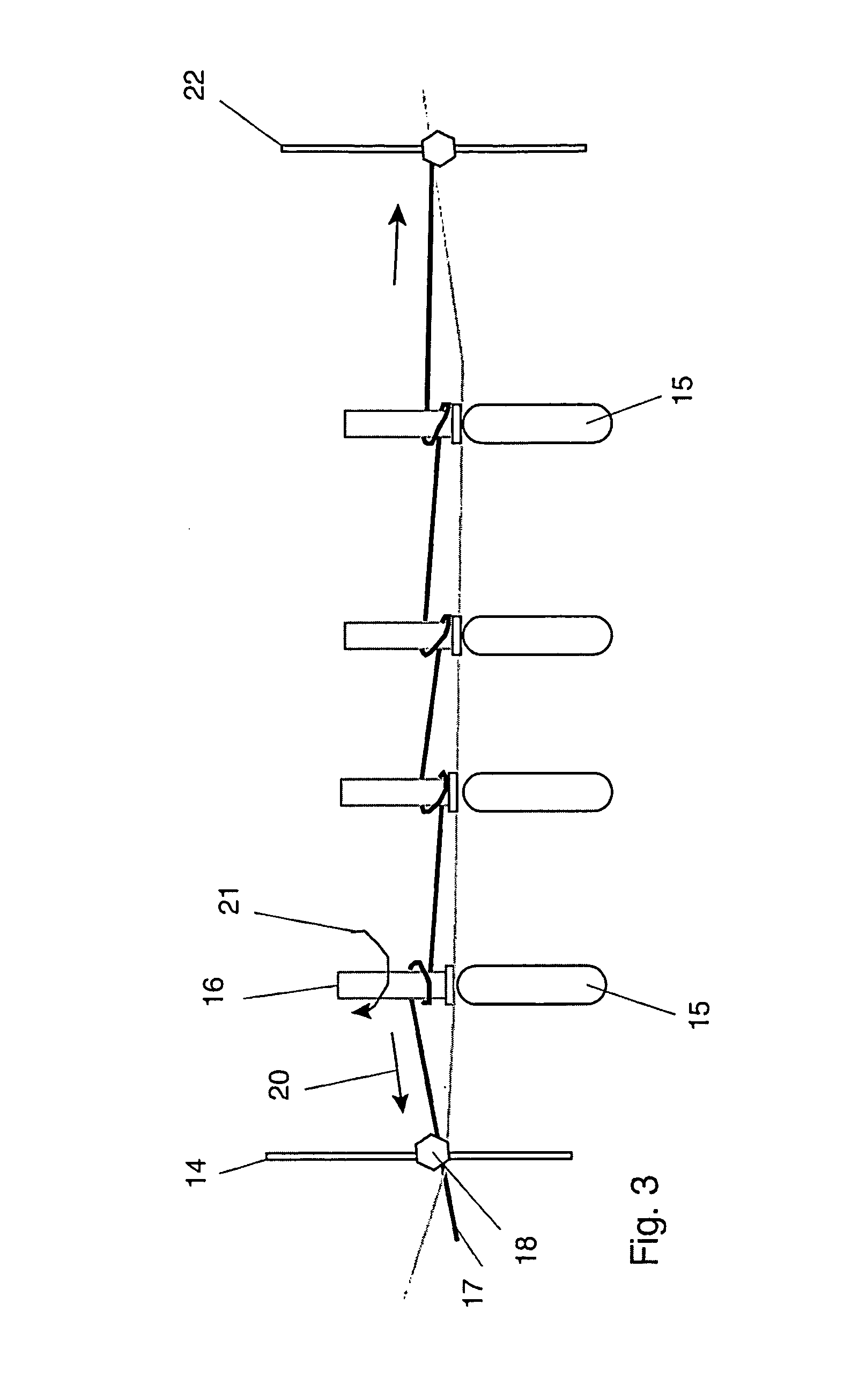

Baling Press for Large Bales

ActiveUS20110005410A1Ensure cohesionMinimal extra expenditureMowersBalingHigh densityMechanical engineering

A baling press for producing large square high-density bales has a pick-up device picking up crop, a cutting device downstream of the pick-up device, a conveying device downstream of the cutting device, and a pressing channel disposed downstream of the conveying device and receiving the crop from the conveying device. The crop is shaped to high-density bales in the pressing channel. A tying device is provided that, for ensuring a permanent cohesion of the bales and completing the bales, ties tying medium strands, connected in endless loops, in longitudinal direction of the bales about the bales. A spacing of outermost tying medium strands, disposed next to outer parallel longitudinal bale edges, relative to the outer parallel longitudinal bale edges, respectively, is at least as large as or greater than an average spacing between neighboring tying medium strands in a transverse direction transverse to the longitudinal bale edges.

Owner:KRONE AGRI SE

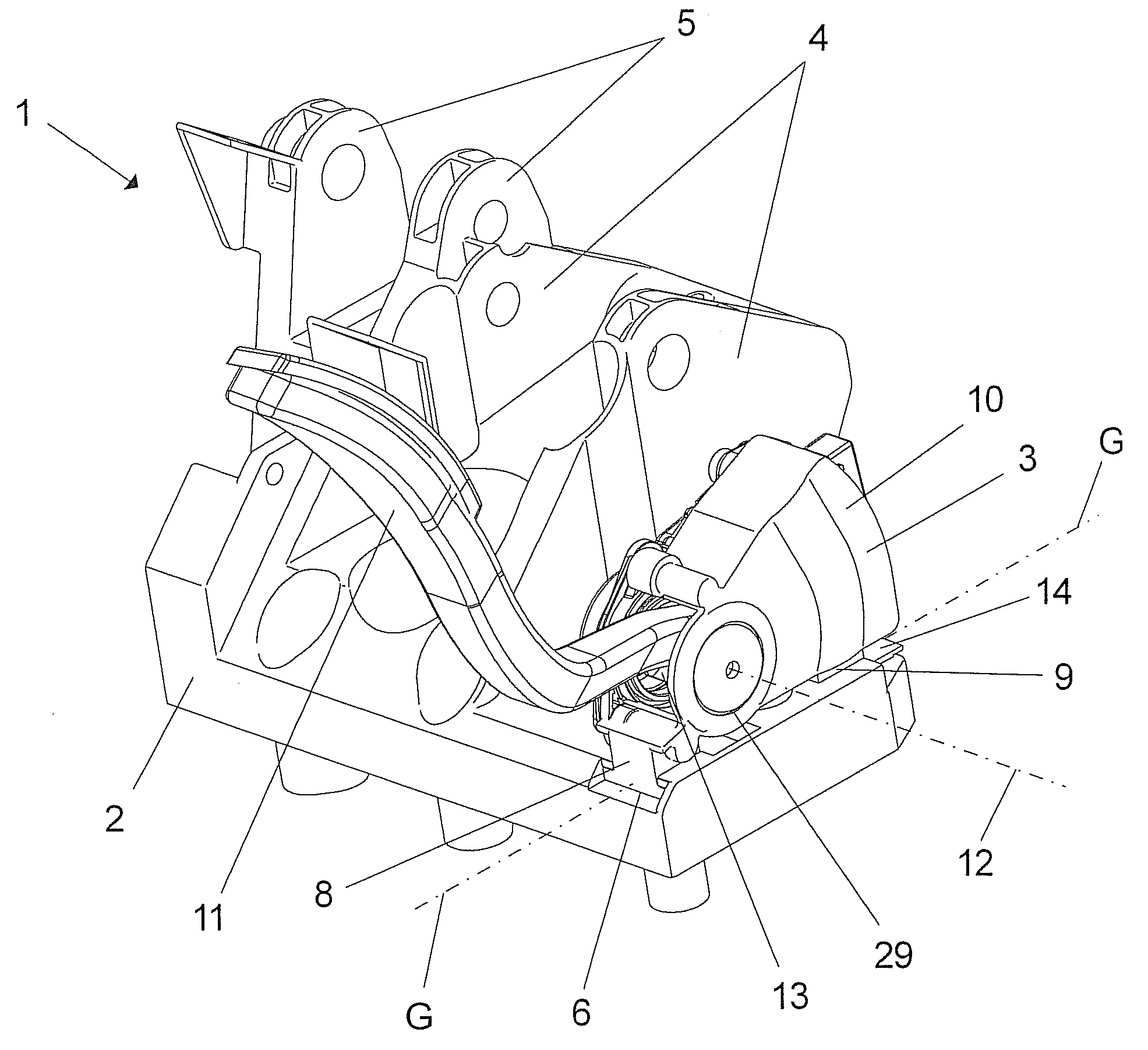

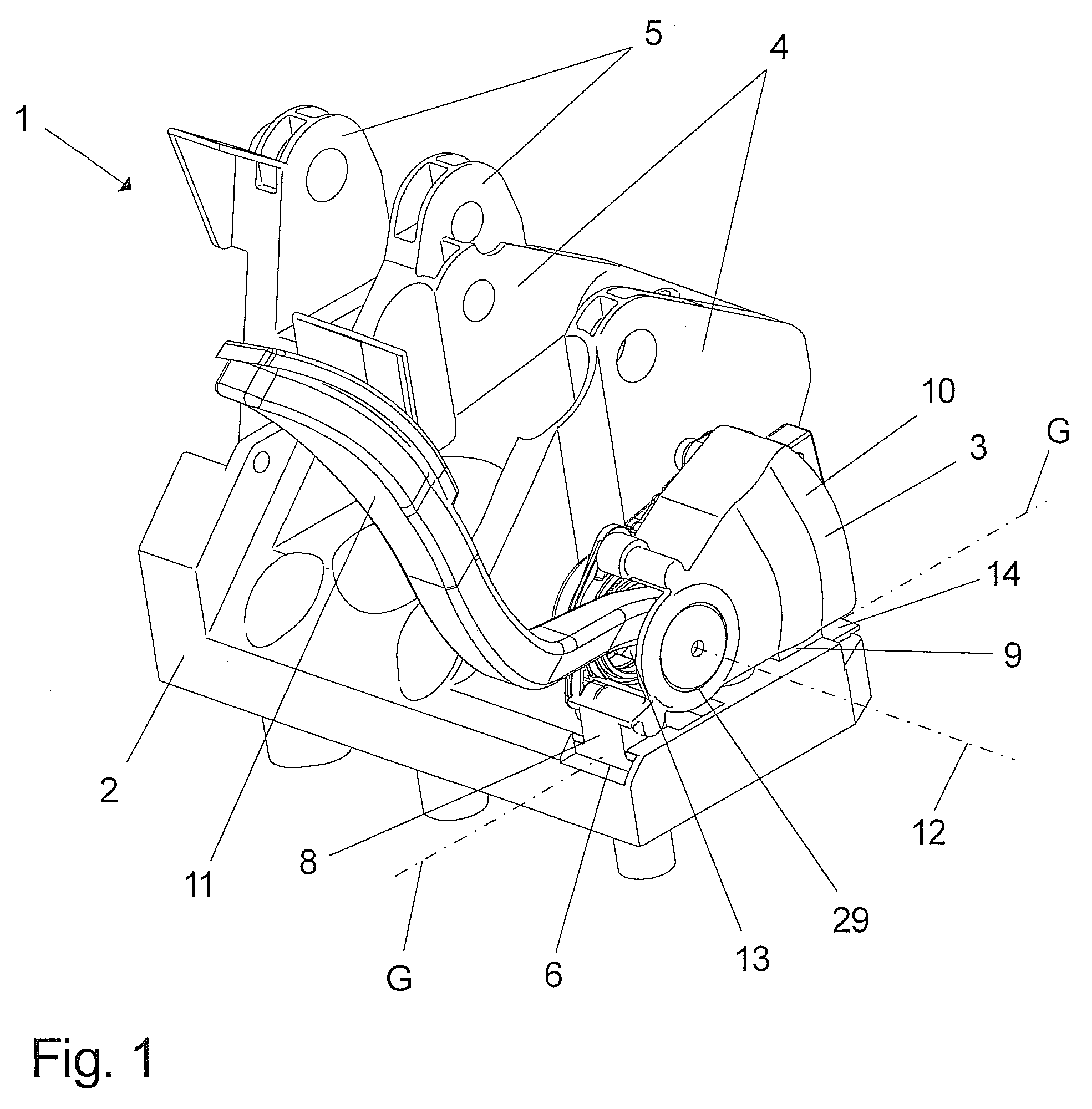

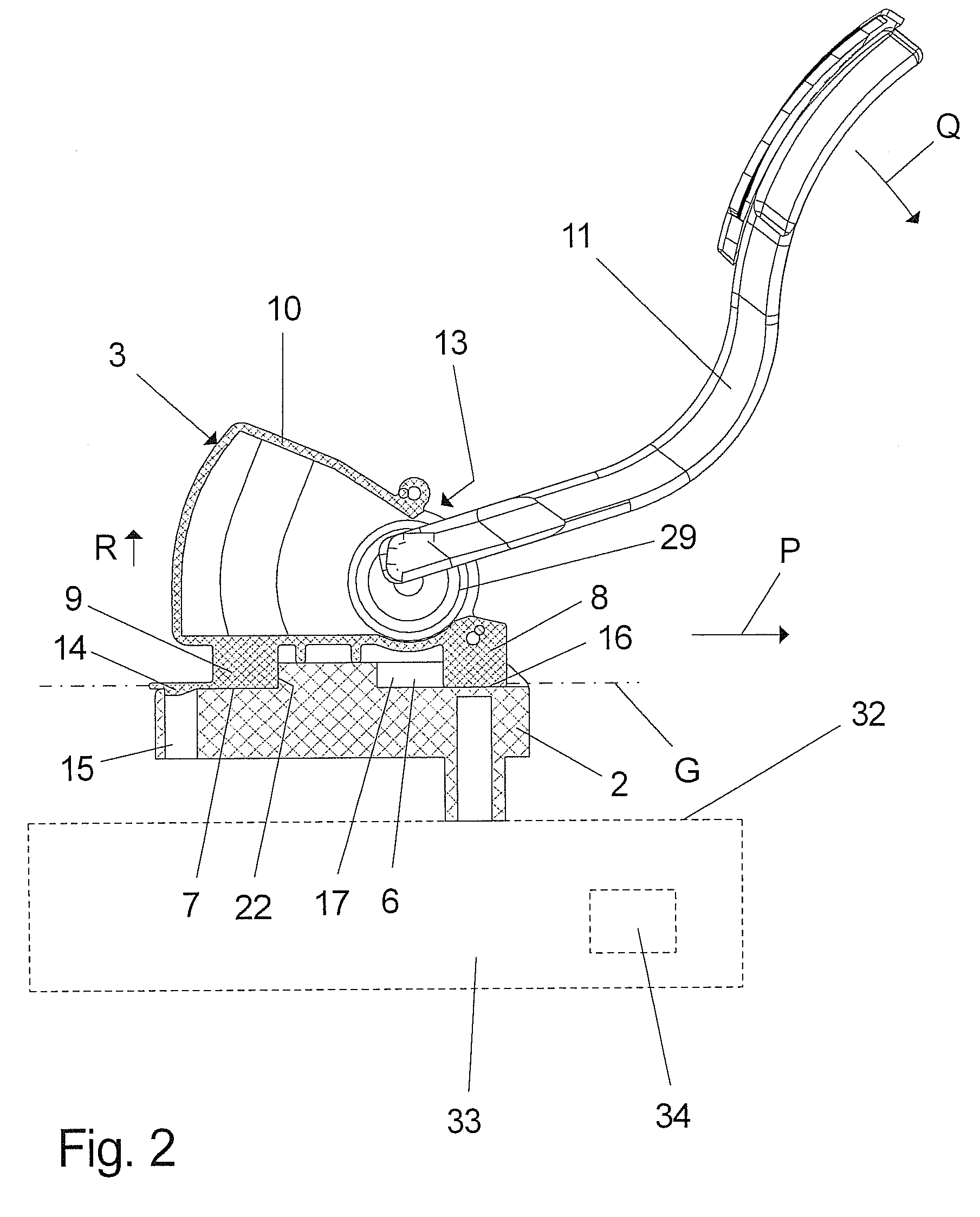

Pedal Arrangement for a Motor Vehilce

InactiveUS20080202279A1Good removal effectAvoid separationControlling membersMechanical apparatusMobile vehicleEngineering

A pedal arrangement is provided for a motor vehicle with a bracket (2) and with an E-gas module (3) fastened thereto via a plug-in connection. The an E-gas module (3) has a pedal bearing (29), on which a gas pedal (11) is mounted pivotably about a pivot axis (12), wherein a structural unit that is independent from the bracket (2) is formed by the E-gas module (3).

Owner:ZF FRIEDRICHSHAFEN AG

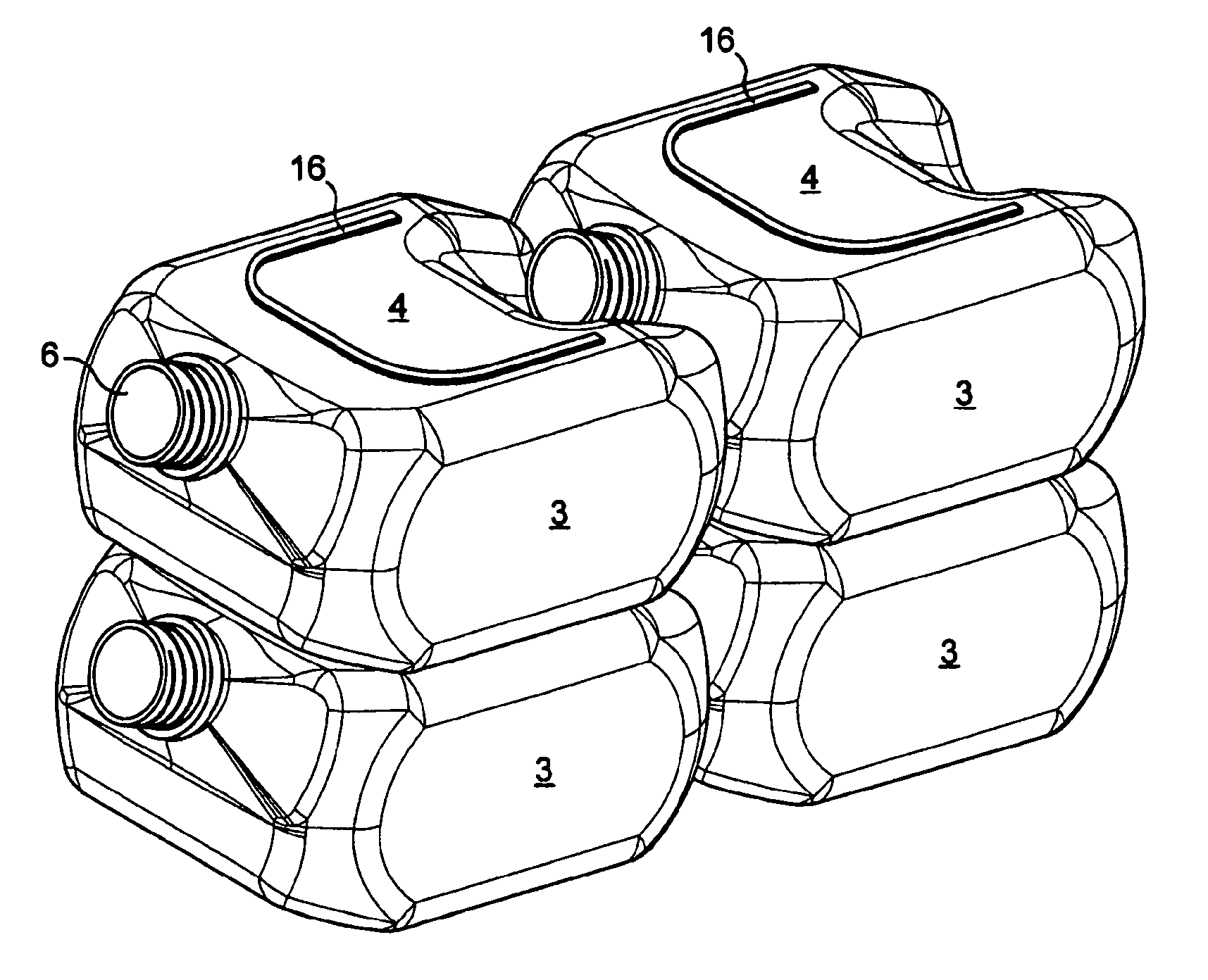

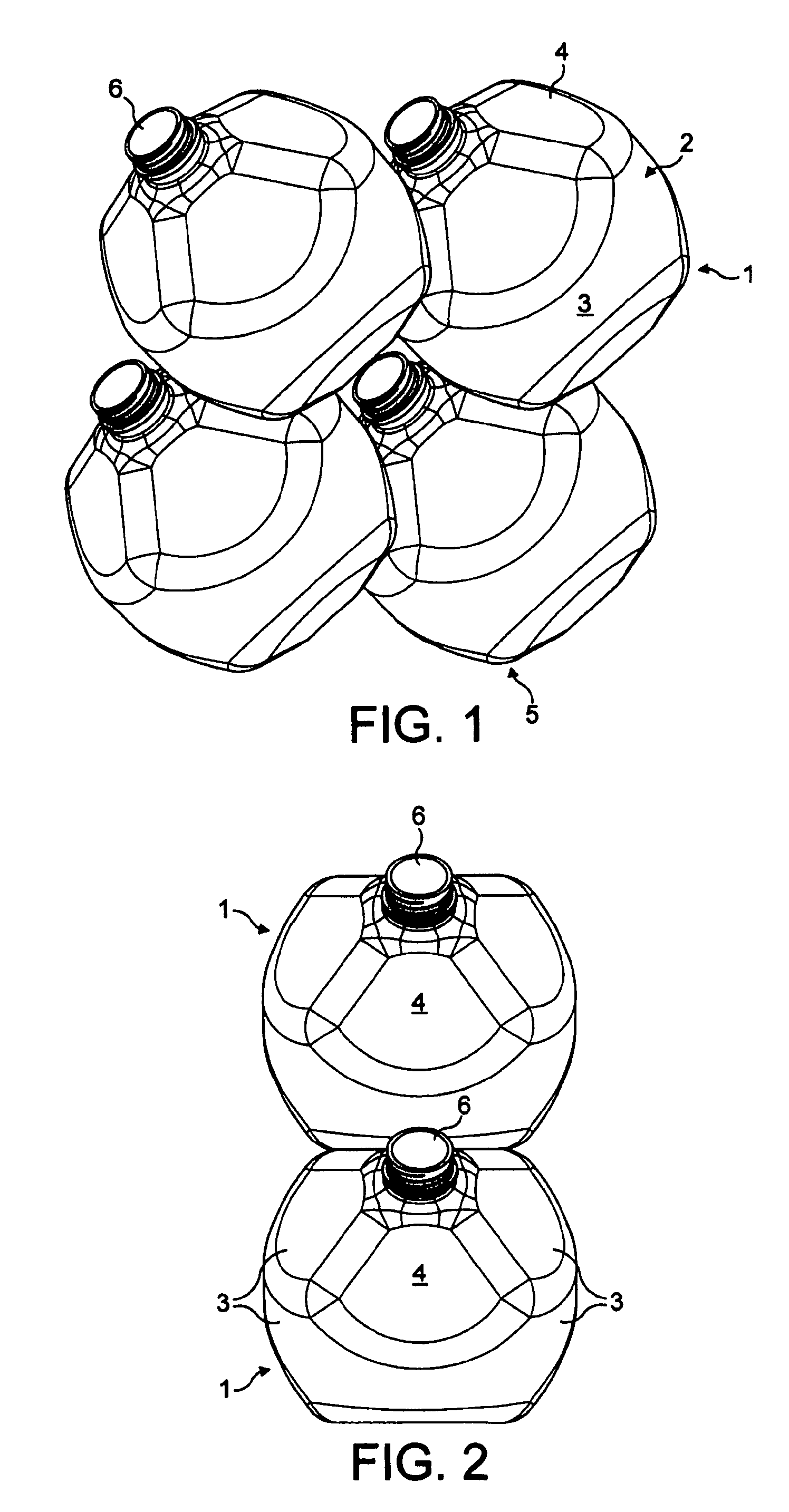

Stackable package and a packaging assembly made therewith

ActiveUS8770407B2Improve the immunityEasy to assembleCans/barrels/drumsTray containersMechanical engineeringVertical axis

The present invention concerns a flexible or semi-flexible stackable package (1) for flowable products, comprising a package body (2) with side (3), top (4) and bottom (5) walls, and a neck (6) adapted to receive closing and / or dispensing means (15) that extends outwardly from one of said walls (3, 4, 5) characterized in that: (i) said neck (6) is off-centered and tilted relative to the vertical axis (V) of said package (1) with an angle (α) comprised between 1° and 179°, preferably comprised between 20° and 60°, more preferably an angle of 45°, and (ii) the package body walls (3, 4, 5) comprise at least one flattened, rounded, or recessed portion (7), such that when stacked in a package assembly (10), the neck (6) of said package (1) fits in between a space (8) defined by similar packages disposed adjacent to said neck (6).

Owner:SOC DES PROD NESTLE SA

Powder for dry refractory material

InactiveUS8901022B2Reduce, or even eliminate, the dustLow wettabilityFurnace liningsChemical compositionPhysical chemistry

The invention relates to a powder comprising more than 70% of refractory particles, in weight percent relative to the weight of the powder, a particle of said powder being classed in the fraction called “matrix” or in the fraction called “aggregate”, according to whether it is smaller than, or equal to 100 μm, or larger than 100 μm, respectively, said powder comprising, in weight percent relative to the weight of the powder: between 0.1% and 18% of particles of a heat-activatable binder, called “heat-activatable binder particles”; and more than 40% of refractory particles, called “ATZ particles”, having the following chemical composition, in weight percentages on the basis of the oxides of said ATZ particles: 10%≦Al2O3≦55%; 35%≦TiO2≦80%; 1%≦MgO+Cr2O3≦10%; 8%≦ZrO2≦20%; SiO2≦8%.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

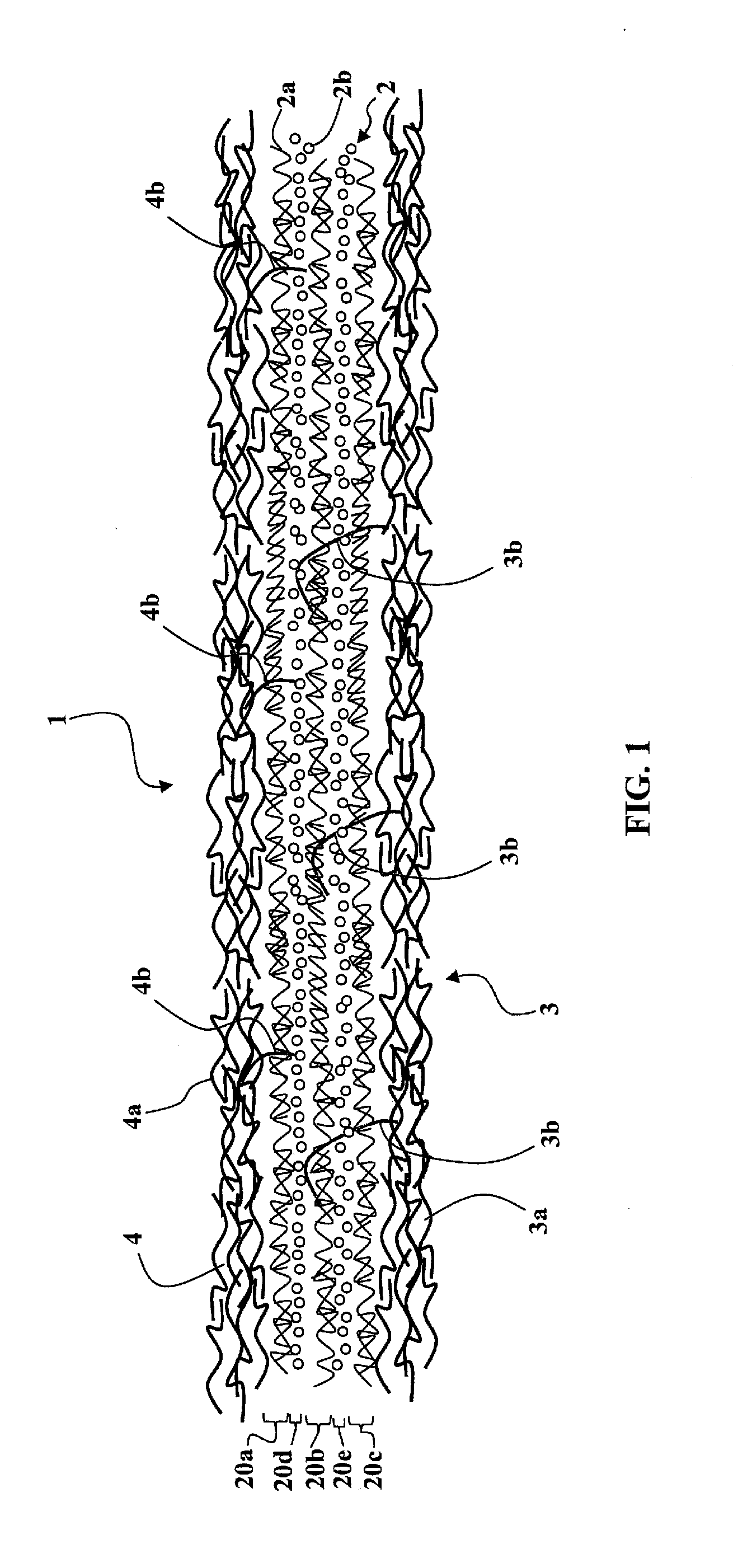

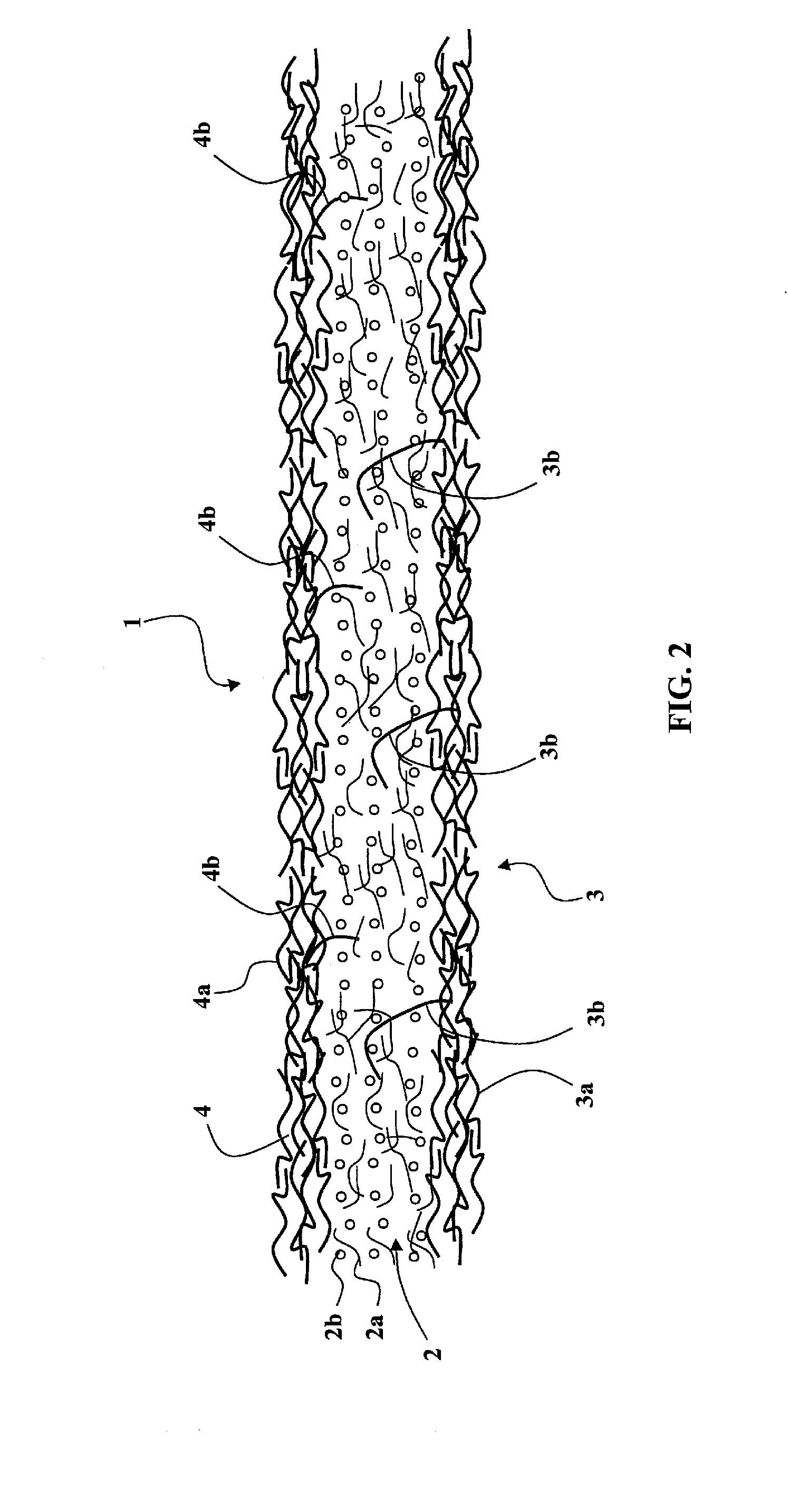

Thermoformable lap having reinforcement fibres

InactiveUS20140147643A1Increase temperatureLow costLayered productsNon-woven fabricsFiberEngineering

A thermoformable lap (1) includes a first web (3) and a second web (4) made of linking fibres (3a, 4a) made of a first thermoreactivatable material having a first reactivation temperature. An intermediate layer (2) is arranged between the first web (3) and the second web (4), and includes reinforcement fibres (2a) and granules (2b) of a second thermoreactivatable material having a second reactivation temperature that is higher than the first reactivation temperature. Certain sections (3b, 4b) of linking fibres of the first and second webs (3, 4) penetrate into the intermediate layer (2) and partially adhere to one another and to the reinforcement fibres (2a) of the intermediate layer (2), ensuring the cohesion of the assembly. Such a lap can be manufactured at a lower cost and at high speed, and can be used for the production of parts by heat moulding.

Owner:CHOMARAT GILBERT

Composite material comprising a fibrous reinforcement and a poly(phospho-sialate) geopolymer matrix and associated manufacturing method

ActiveUS20210230068A1Improve surface reactivityImprove the effect of chemical reactionsCement productionPolymer sciencePhosphoric acid

A composite material containing a matrix and a fibrous reinforcement, in particular a textile embedded in the matrix. The matrix includes a geopolymer of the poly(phospho-sialate) type having the following formula I: (1) (—P—O—Si—O—Al—O—)n in which n is greater than 2. The matrix further includes zirconium covalently bonded to the matrix, especially in the —ZrO form and / or in the —O—Zr—O form. The matrix has a melting temperature greater than 700° C., especially equal to or greater than 1200° C.

Owner:PYROMERAL SYST

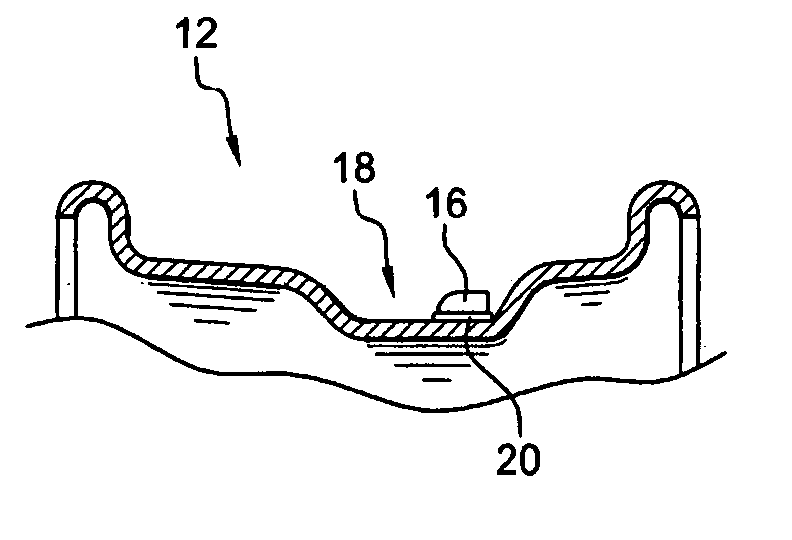

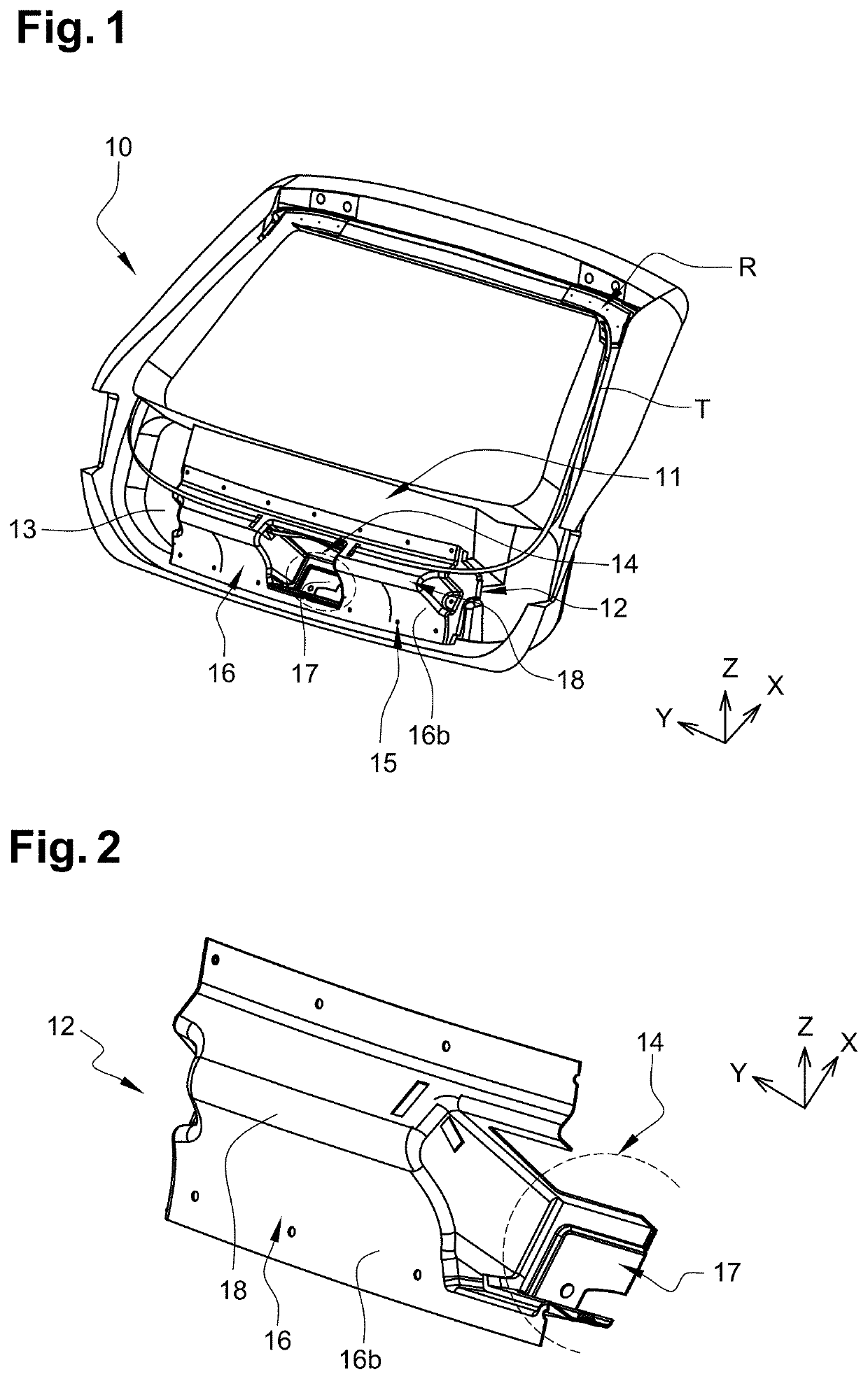

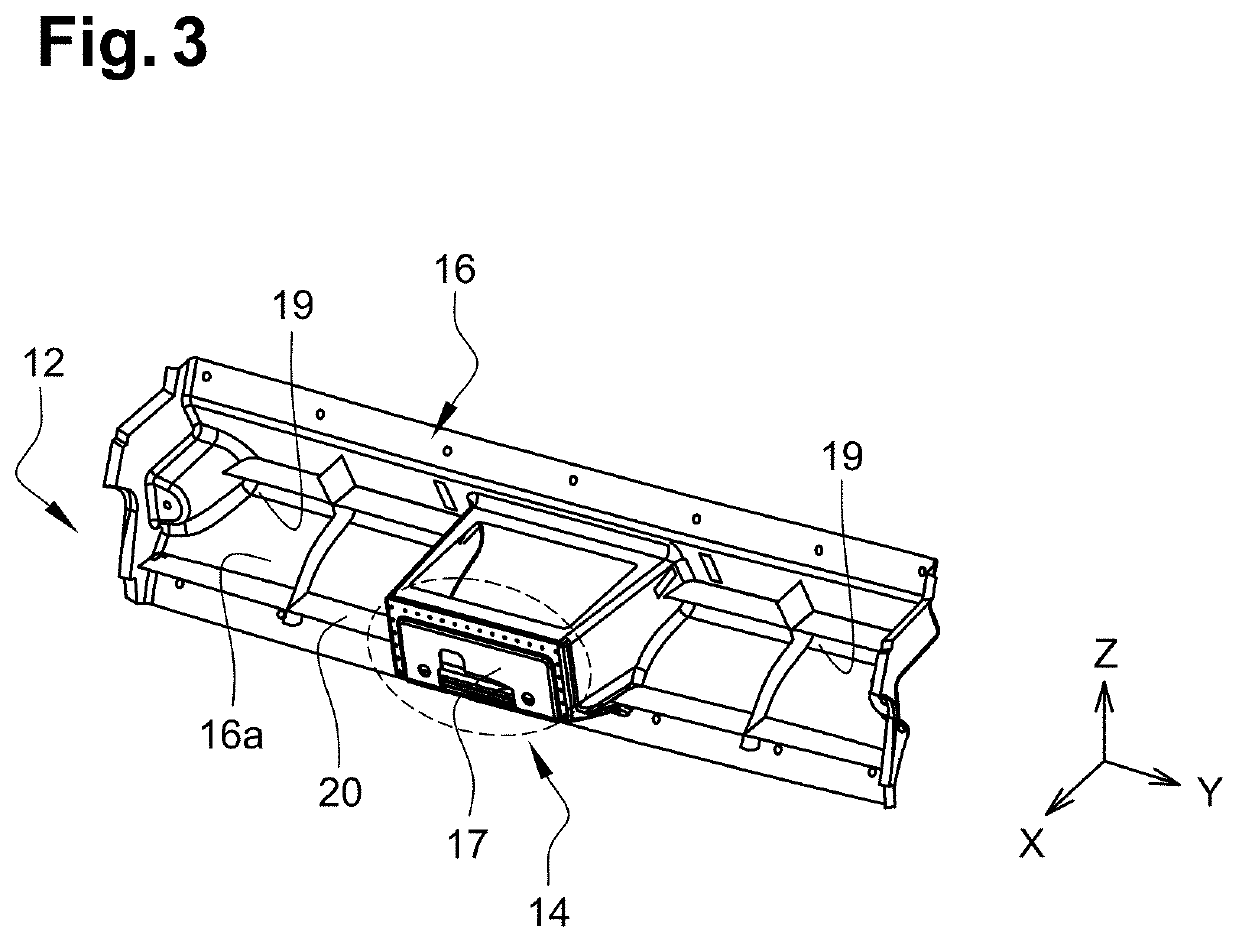

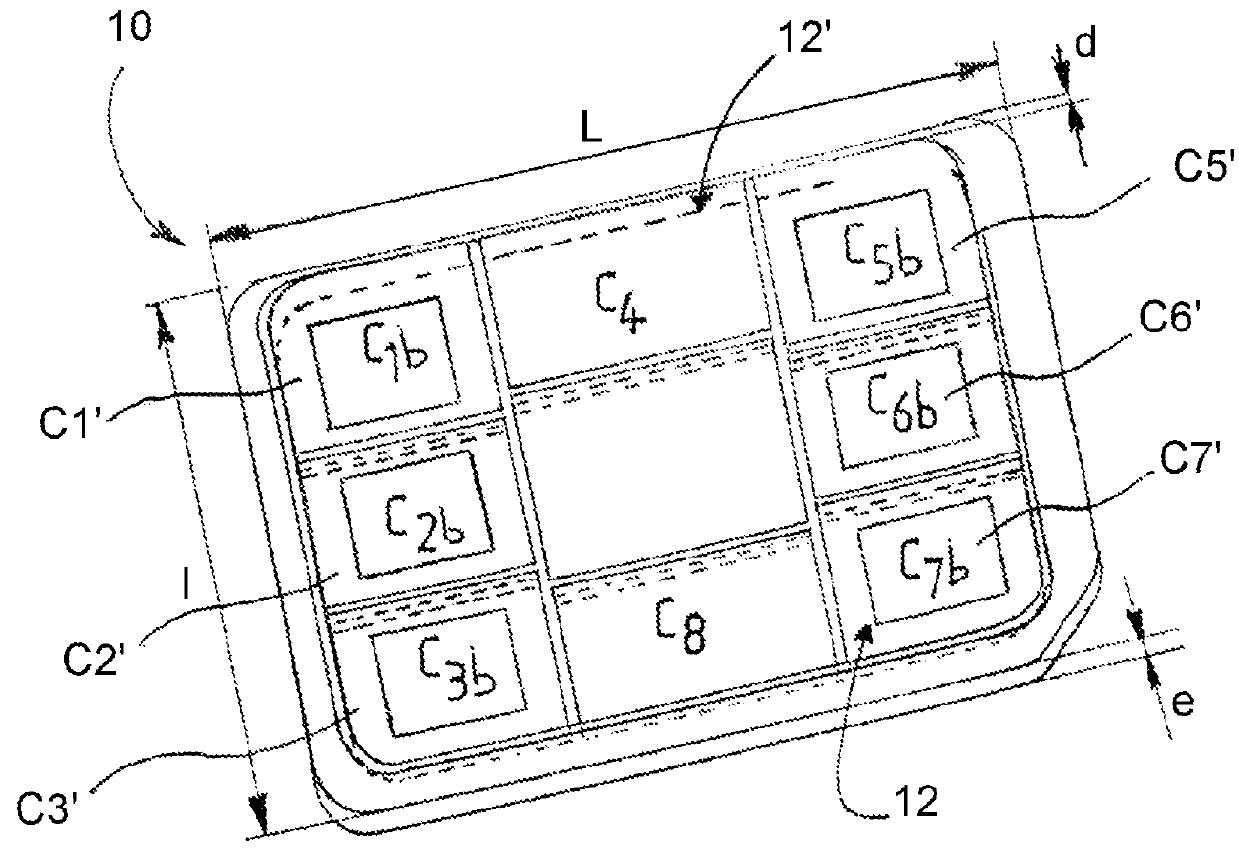

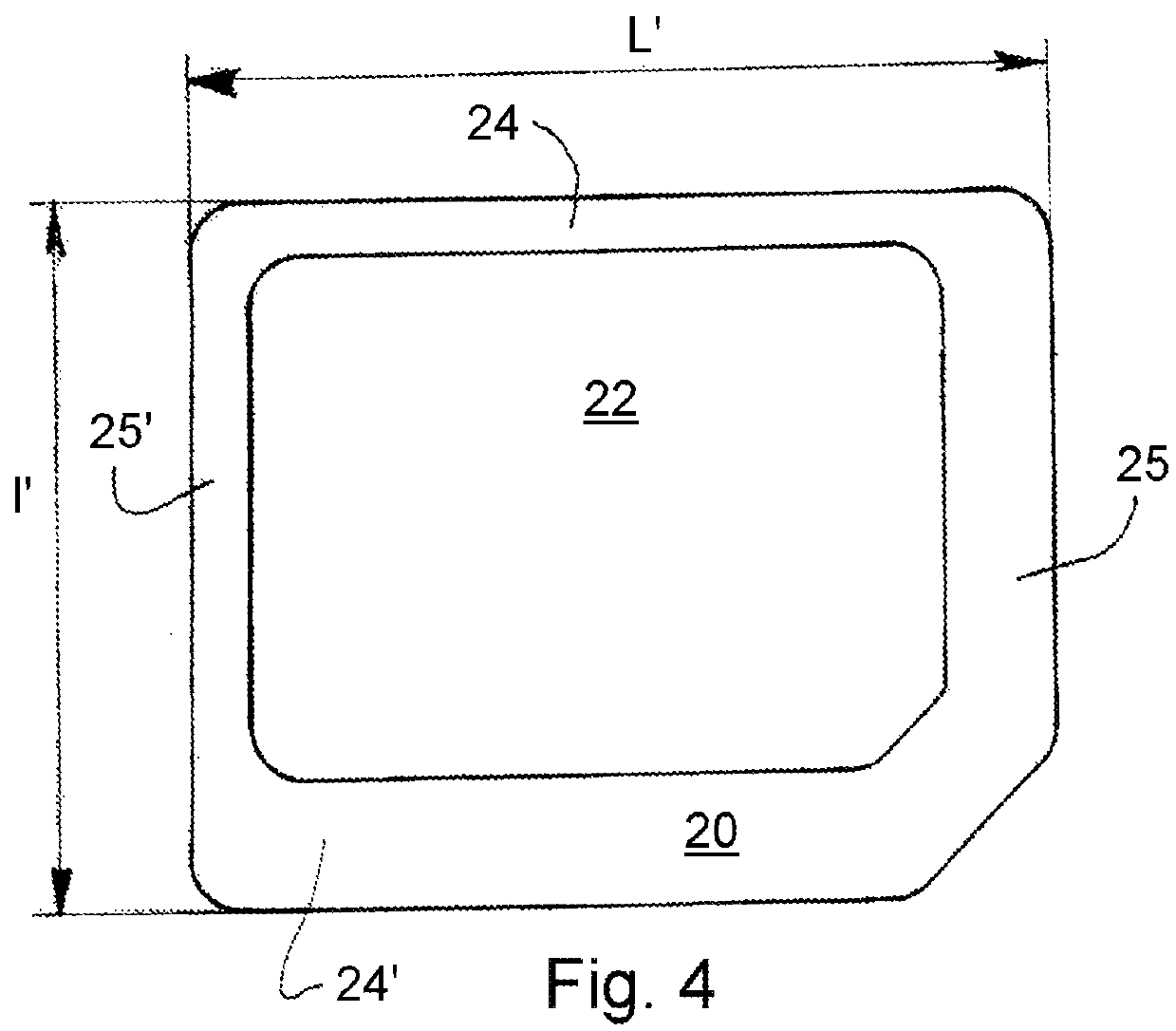

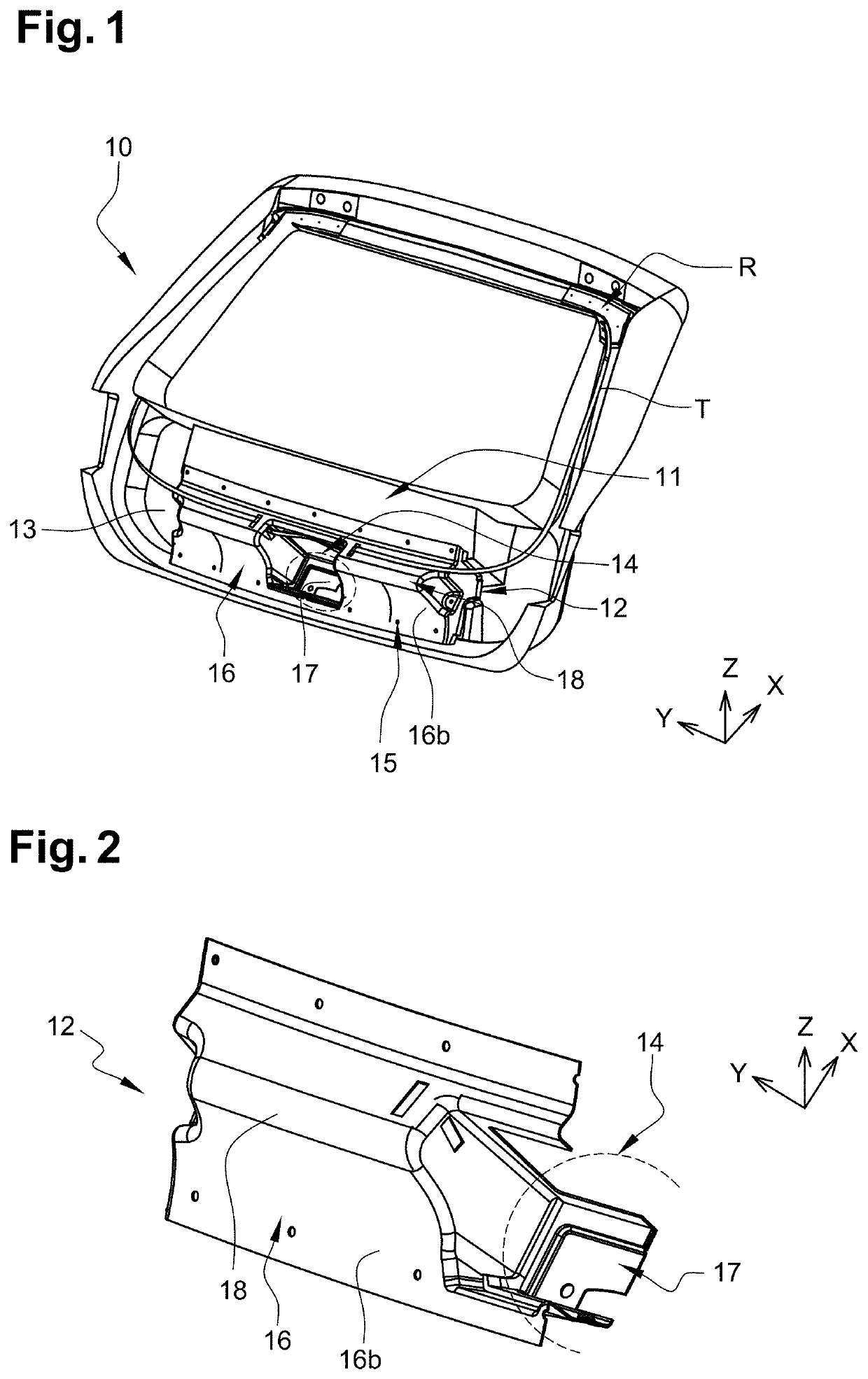

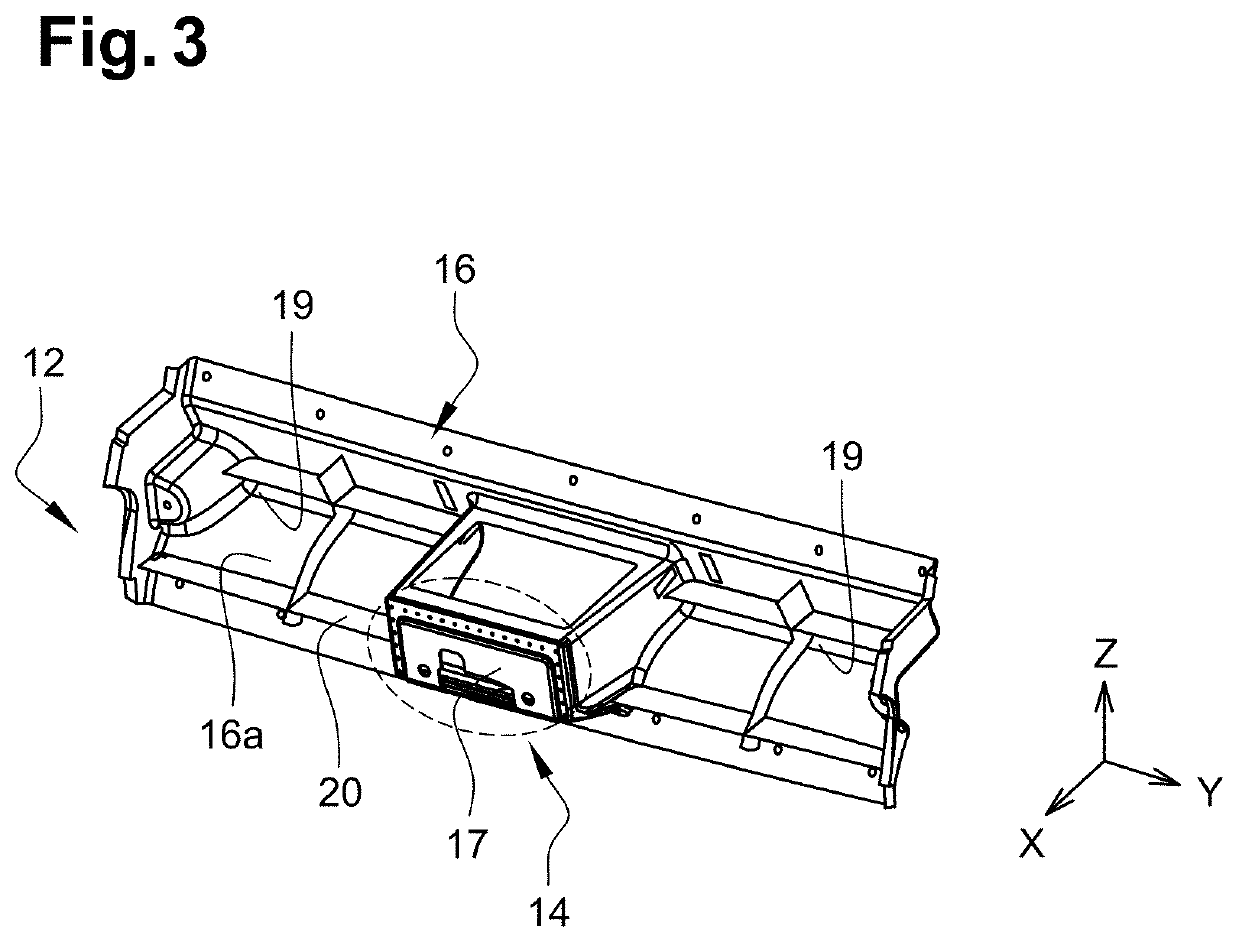

Interfacing element for a lock zone of a motor vehicle door

ActiveUS20200199907A1High tensile strengthEnsure cohesionVehicle locksDoorsPlastic materialsYoung's modulus

The invention relates to an interfacing element (12) of a lock zone (14) of a door of a motor vehicle, and the interfacing element (12) comprises: a support (16) made of plastic material, intended to be attached to a lining (11) of the door, the lining (11) being made of plastic material; and a reinforcing plate (17) of the lock zone (14) onto which a lock is intended to be fastened, the plate (17) being integrated to the support (16) by overmolding. The support (16) is made of a material having a Young's modulus lower than that of the plastic material of the lining (11) of the door, and a coefficient of elongation at break greater than that of the plastic material of the lining (11) of the door. The invention further relates to a sub-assembly (10) of motor vehicle, comprising a lining (11) of tailgate and an interfacing element (12) according to the invention fastened onto an outer face (13) of the lining (11).

Owner:CO PLASTIC OMNIUM

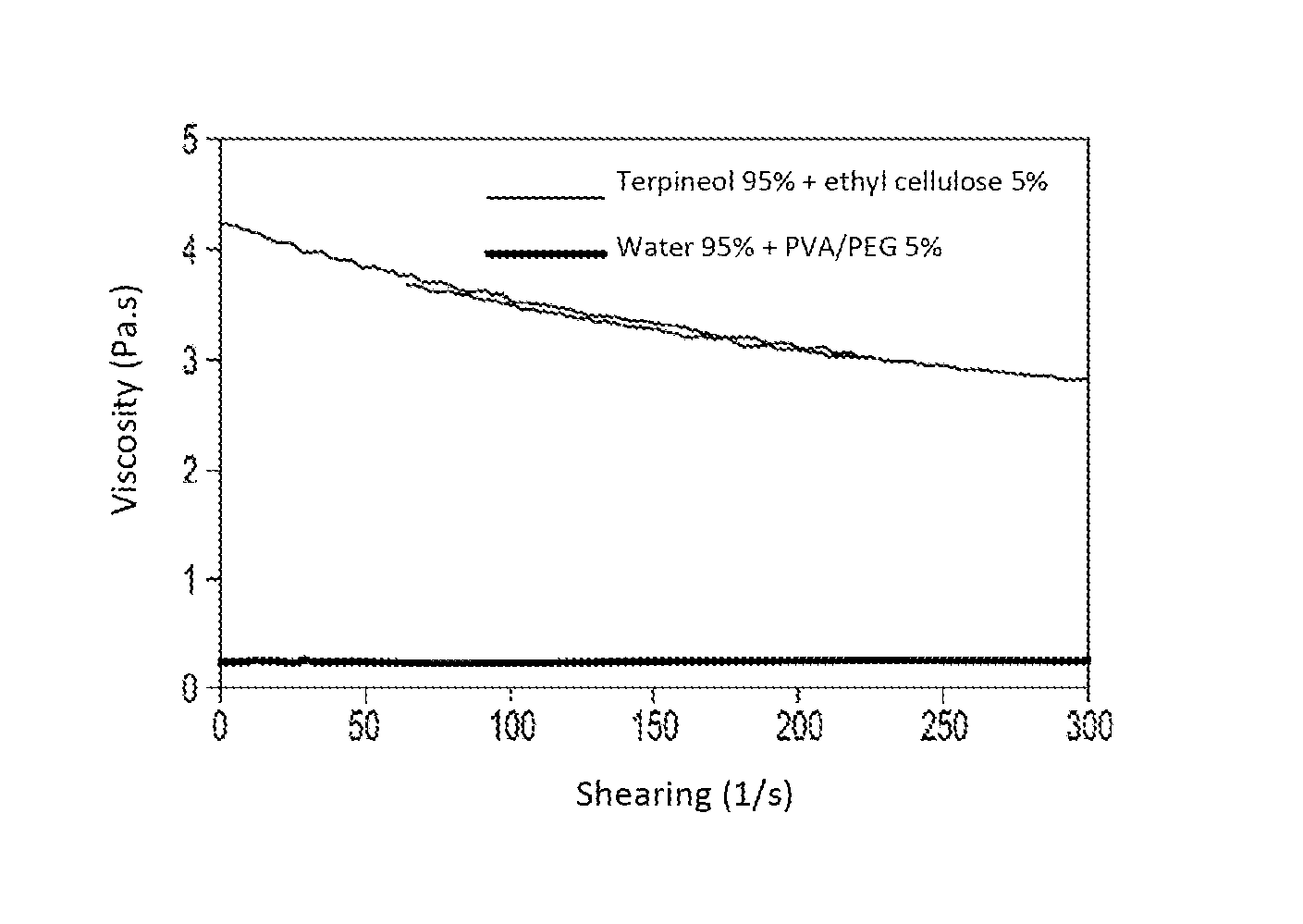

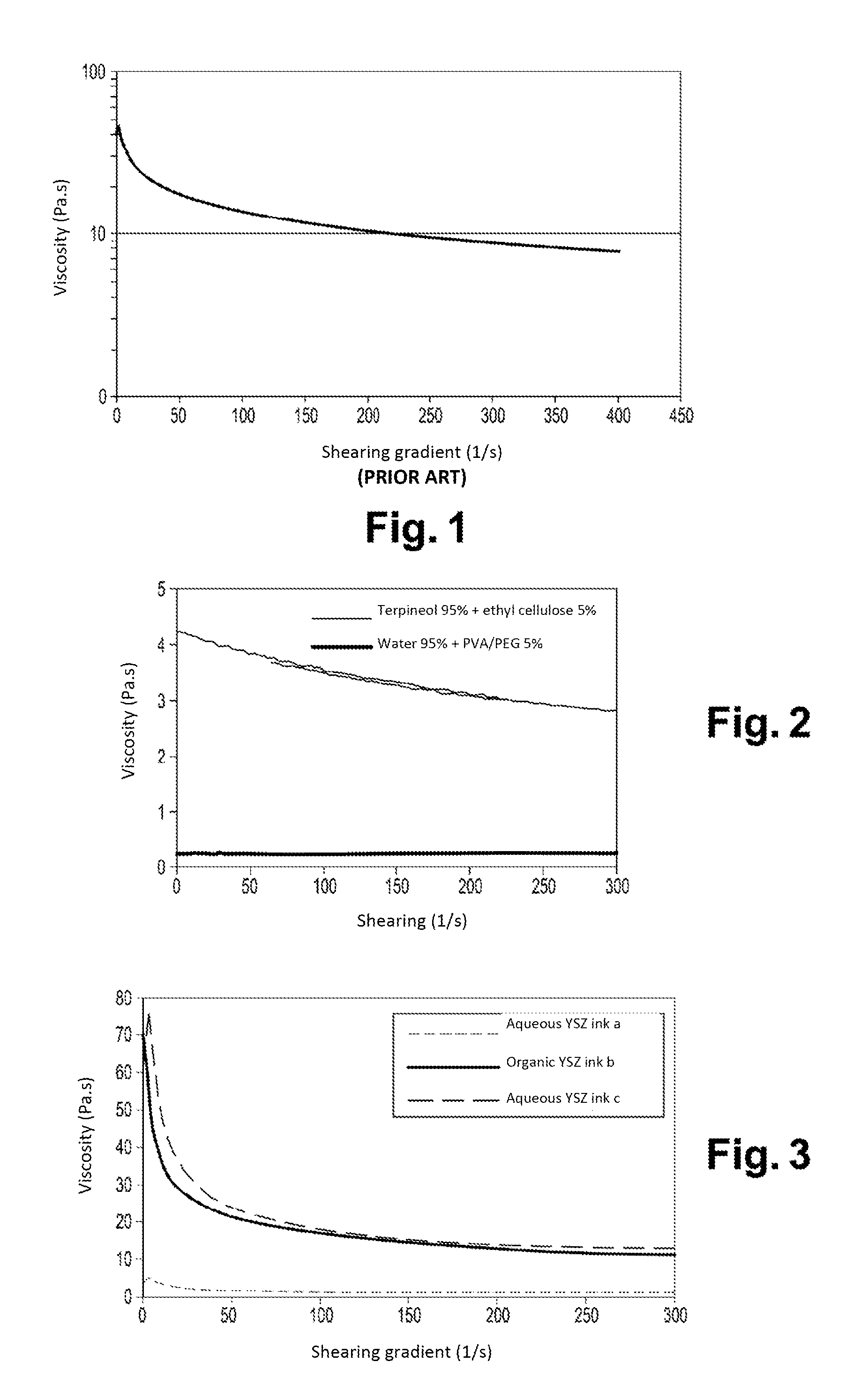

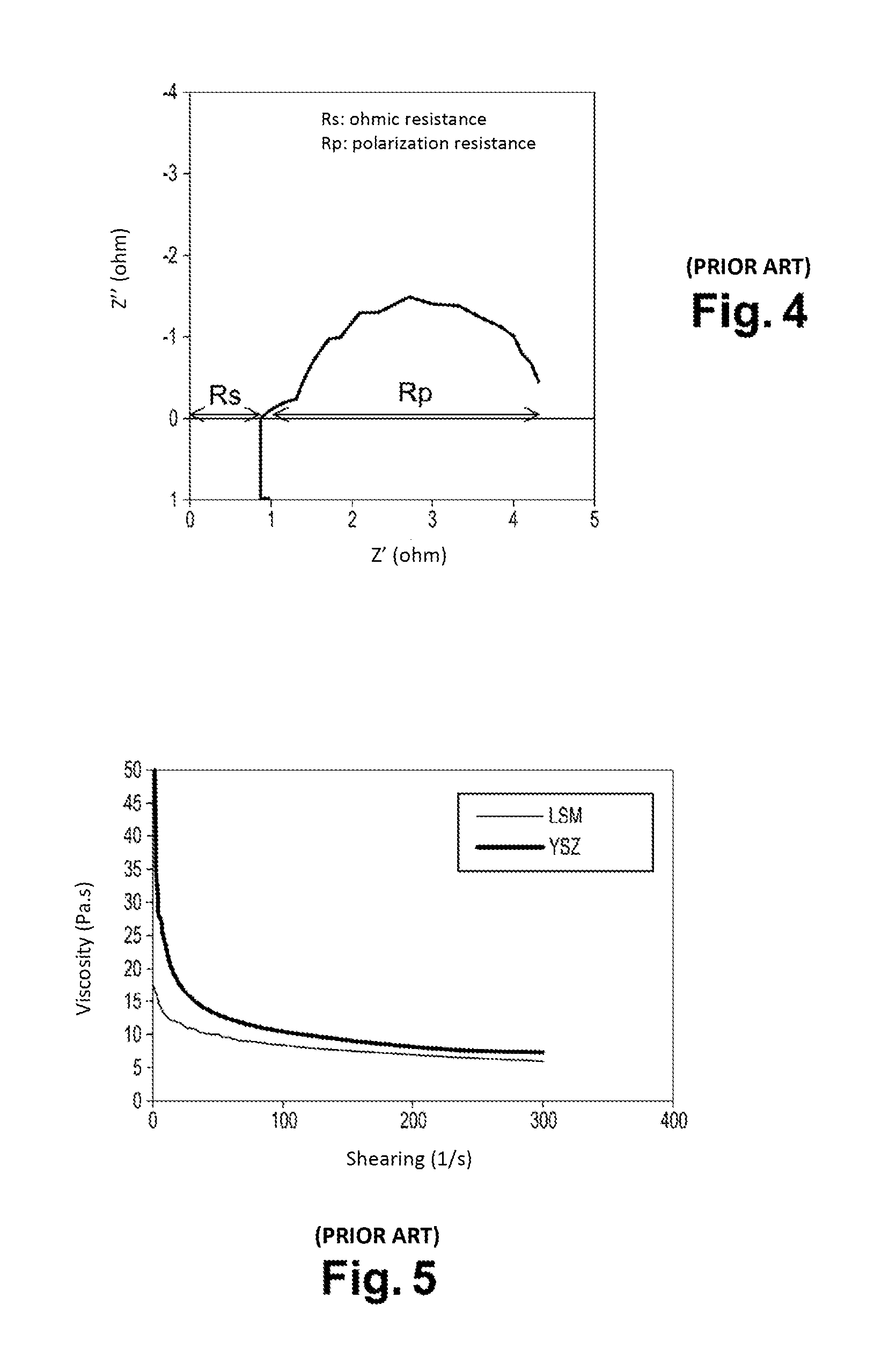

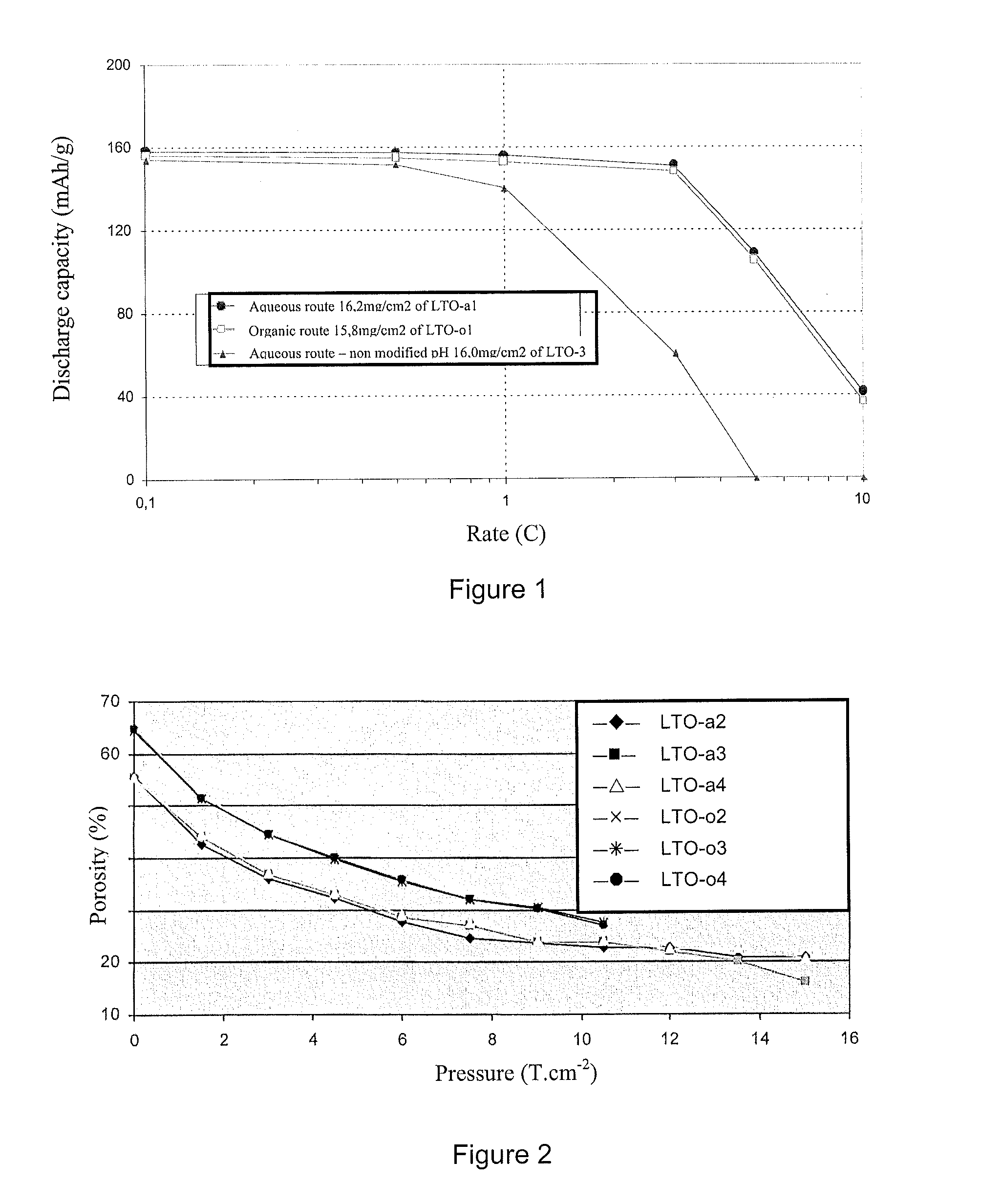

Aqueous ink for producing high-temperature electrochemical cell electrodes

InactiveUS9005488B2Simplify its preparation and its useKeep the thicknessPhotography auxillary processesCell electrodesElectrochemical cellPolymer chemistry

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for manufacturing a textile composite intended for mechanical reinforcement of a bitumen-based waterproof coating

InactiveUS20090133829A1Ensure cohesionRoof covering using flexible materialsLaminationAdhesiveEngineering

A method for manufacturing a textile composite intended for mechanical reinforcement of a bitumen or synthetic-based waterproof coating. The composite comprises a first layer of a non-woven fabric material based on synthetic fibres that is puncture resistant; a second layer of a non-woven fabric material based on mineral or synthetic fibres that is fire resistant; a grid structure placed between the first and second layers, the warp yarns and weft yarns of which are connected to each other at the points where they cross by means of an adhesive that also ensures bonding of the first and second layers on the grid.

Owner:CHOMARAT COMPOSITES

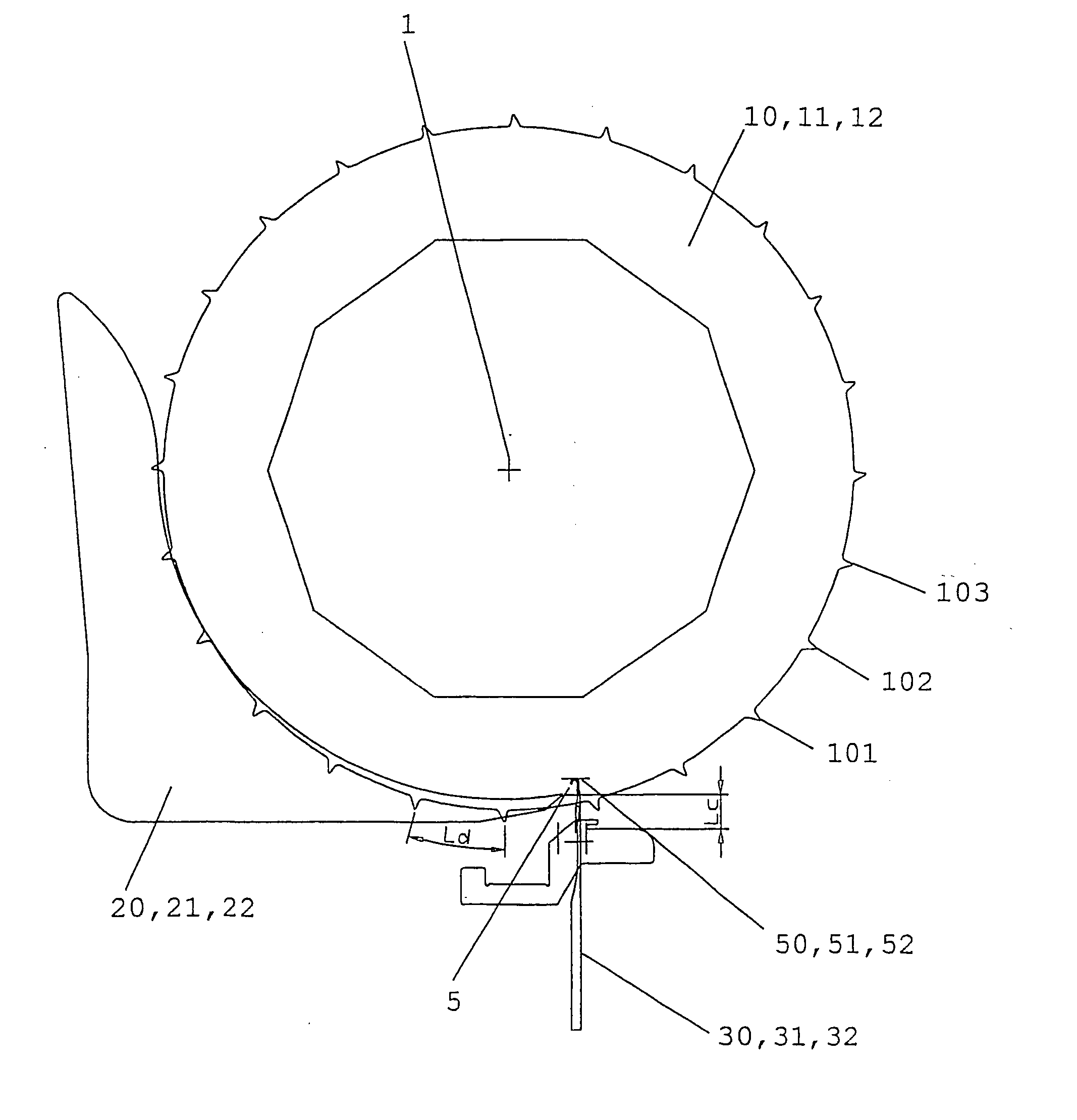

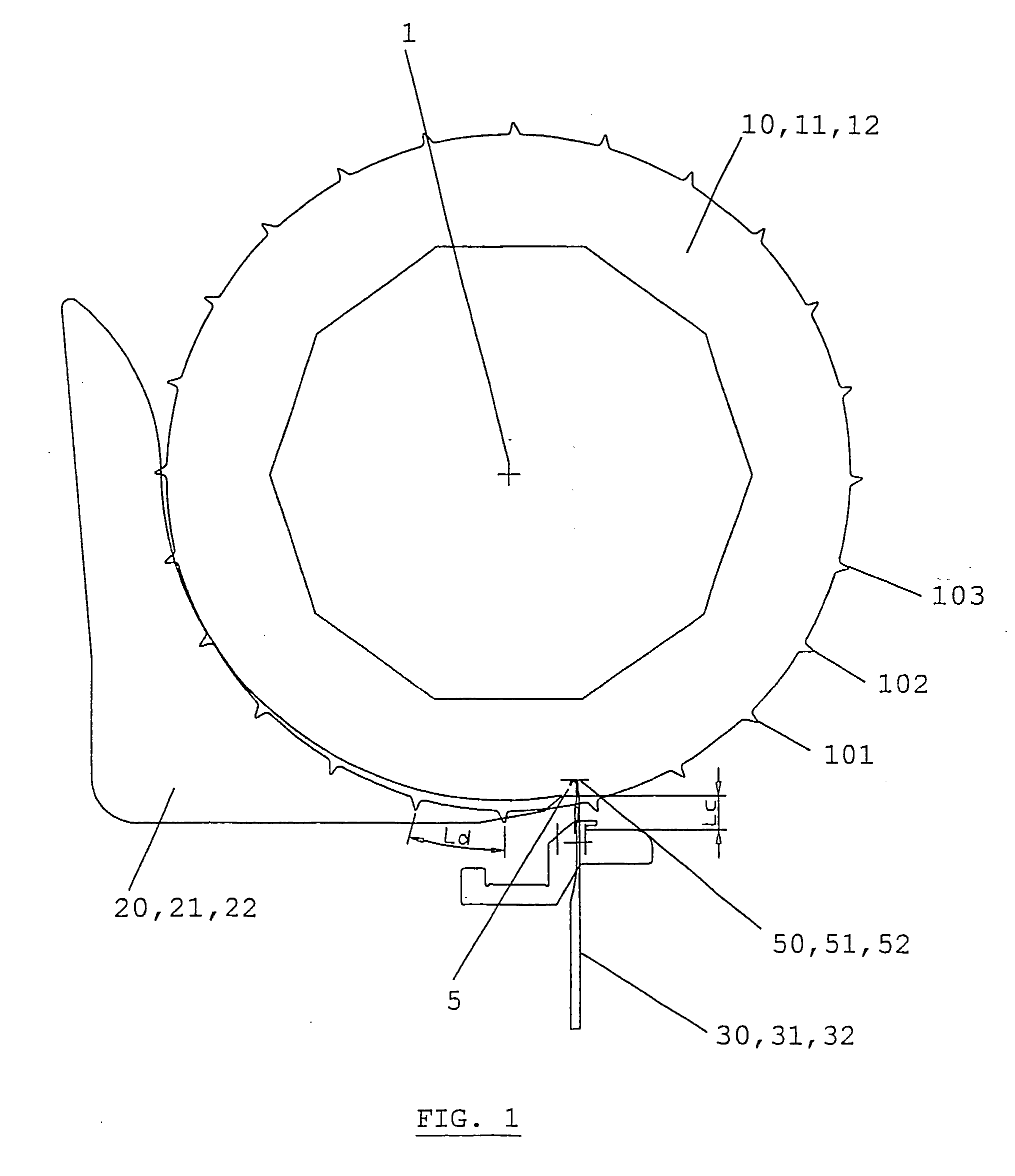

Method and device for making meshed textile products directly from fibres and/or filaments and resulting products

InactiveUS20040231369A1Ensure cohesionMaintain good propertiesWeft knittingLayered productsYarnFiber

The invention concerns a method for making meshed textile products from fibres and / or filaments moving past in the form of a web, which consists in: subjecting the fibres and / or filaments to transverse looping with joint drawing by means of an assembly consisting of a set of interpenetrating identical looping discs spaced apart and located on a common transverse axis with a set of identical looping elements, the looping discs having on their periphery relatively spaced apart teeth; accumulating the fibres and / or filaments in the form of at least a crinkled pseudo-yarn of a certain length wherein the fibres and / or filaments are paralleled, said accumulation of said fibres and / or filaments being carried out against the slope of a tooth opposite the input of the web; transferring into the eye of the set of needles over the entire length of the pseudo-yarn; carrying out in standard manner another fabric course using the pseudo-yarn transferred into the eye of the needles.

Owner:TALKETE ZEUMER

Method for manufacturing an electrode, and ink for an electrode

InactiveUS20140234537A1DenseFlexible can be woundConductive materialNegative electrodesLithium oxideTitanium

The invention relates to a method for fabricating an electrode which includes coating of an aqueous ink over the whole or part of a current collector followed by drying of said ink. The aqueous ink is produced by acidification of an aqueous dispersion including an electrochemically active material having a titanium and lithium oxide base until a pH value comprised between 9.0±0.1 and 10.0±0.1 is obtained. The invention also relates to an aqueous ink for an electrode including an electrochemically active material having a titanium and lithium oxide base and having a pH between 9.0±0.1 and 10.0±0.1, preferably equal to 10±0.1.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Damping skin system for protecting composite parts

InactiveUS20180304579A1Small sensitivityEnsure cohesionProtective equipmentSynthetic resin layered productsEngineering

Damping skin for protecting composite parts includes a composite material having at least two superposed layers, namely a first layer formed from the juxtaposition of hollow spheres, which is intended to be applied and fixed, either directly or indirectly, to the surface of the part to be protected and a second layer covering the first and formed from a wall made of a material having plastic deformation properties.

Owner:SKF AEROSPACE FRANCE SAS

Nonstick treatment for composite molds

InactiveUS20150097104A1Improving easy releaseEnsure cohesionCoatingsCeramic shaping liningsEpoxyHeat resistance

A method for rendering nonstick a mold made of composite material, including the steps of: (i) providing a mold made of a composite material including an epoxy resin; (ii) applying a fluorinated-polymer powder, having a minimum film-forming temperature of less than 300° C. and heat resistance at temperatures higher than 200° C., onto the walls of the mold so as to form a layer; and (iii) heating the resulting layer to a temperature of between 260° C. and 300° C. so as to form a continuous film, whereby a mold made of a composite material is obtained the walls of which are provided with a nonstick coating. The present disclosure also relates to the mold obtainable by said method.

Owner:ASSOC POUR LES TRANSFERTS DE TECH DU MANS

Composite material comprising a fibrous reinforcement and a poly(phospho-sialate) geopolymer matrix and associated manufacturing method

ActiveUS11299425B2Reduces degradation/oxidationImprove mechanical propertiesCement productionPolymer sciencePhosphoric acid

A composite material containing a matrix and a fibrous reinforcement, in particular a textile embedded in the matrix. The matrix includes a geopolymer of the poly(phospho-sialate) type having the following formula I: (1) (—P—O—Si—O—Al—O—)n in which n is greater than 2. The matrix further includes zirconium covalently bonded to the matrix, especially in the —ZrO form and / or in the —O—Zr—O form. The matrix has a melting temperature greater than 700° C., especially equal to or greater than 1200° C.

Owner:PYROMERAL SYST

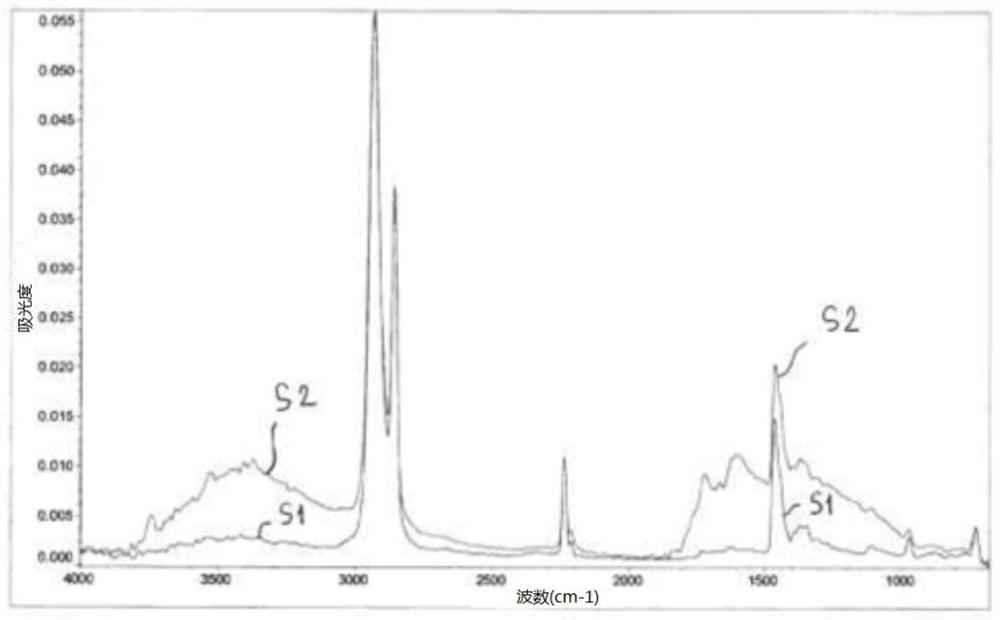

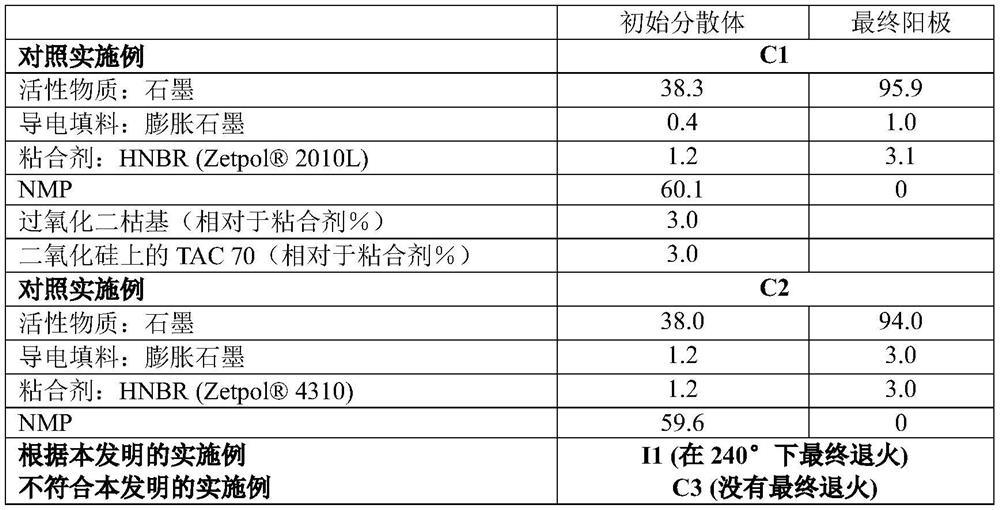

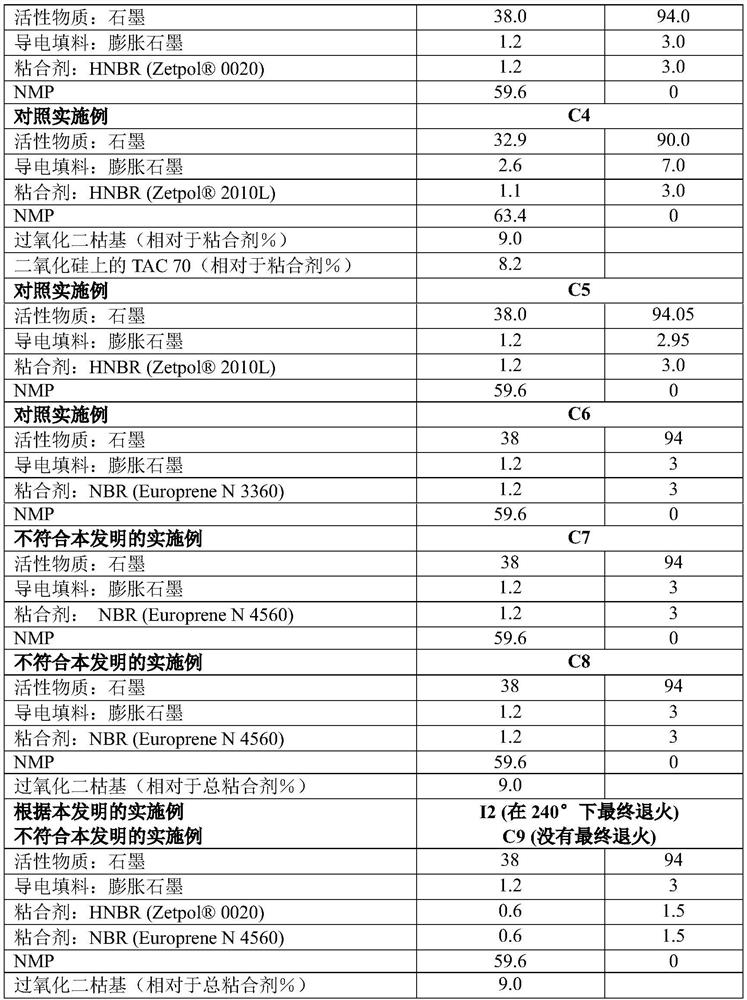

Anodes for lithium-ion battery cells, methods for making anodes, and batteries containing anodes

ActiveCN109496371BEnsure cohesionImprove or optimize manufacturing methodsElectrode thermal treatmentSecondary cellsElastomerAdhesive

The present invention relates to a polymer composition for an electrode, which is suitable for forming an anode of a lithium ion battery, a preparation method thereof, the electrode, and a lithium ion battery comprising the electrode. The composition comprises an active material comprising graphite usable in an anode, conductive fillers and a crosslinked elastomeric binder comprising at least one hydrogenated acrylonitrile-butanediene ethylene copolymer (HNBR). According to the invention, said adhesive comprises at least one non-hydrogenated acrylonitrile-butadiene copolymer (NBR) and / or at least one said hydrogenated acrylonitrile-butadiene copolymer (HNBR), wherein HNBR has Acrylonitrile content greater than or equal to 40% and crosslinked by thermal oxidation. The preparation method comprises successively: a) mixing the ingredients of the composition, the composition comprising the active material, the elastomeric binder in non-crosslinked form and the conductive filler, to obtain a precursor mixture of the composition, b) said mixture deposited on a metal current collector so that the mixture forms a non-crosslinked film, and then c) thermally oxidizing the non-crosslinked film in air containing oxygen at a temperature of 200°C-300°C to obtain the adhesive cross-linked electrodes.

Owner:HUTCHINSON SA

Implant-supported braced dental bridge armature made from composite material, and method for manufacturing the armature

A dental bridge armature designed to be screw-fastened onto dental implants, the dental bridge armature having reinforcing elements formed by long fibers pre-impregnated with photo-polymerizable resin which are either woven or in bundles. The reinforcing elements are in the form of a fibrous framework including a main brace and base reinforcing elements wound around a series of implant abutments screwed onto the implants. Secondary braces are also wound around the main brace and the base reinforcing elements. The braces form an angle between 15° and 85° with the base reinforcing elements. The armature is then included in a PMMA coating resin by a pressing or injection technique.

Owner:CLUNET COSTE BRUNO +3

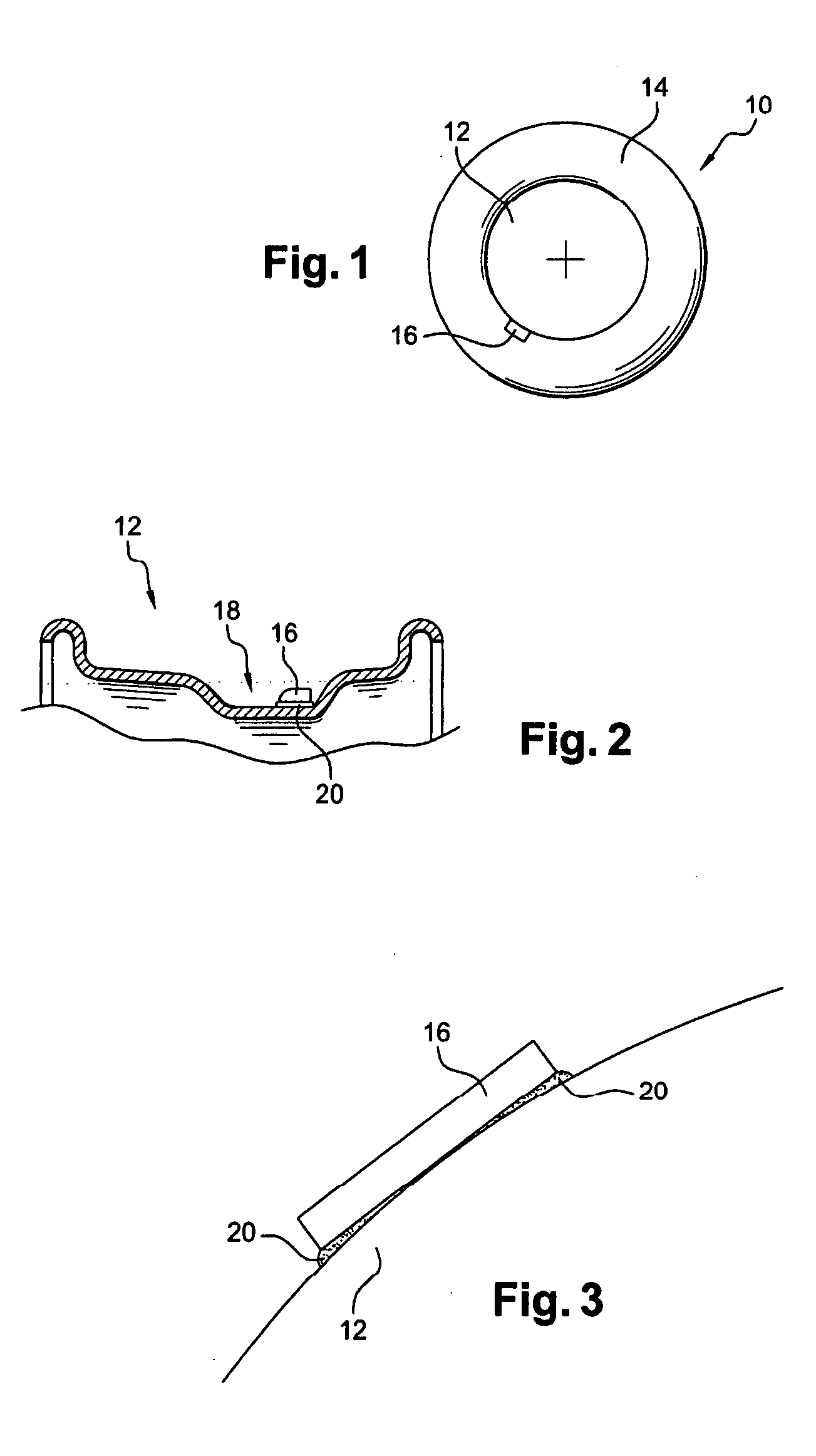

Assembly comprising an adapter and a smart card

ActiveUS9379463B2Resistant to mechanical stressSufficient widthCoupling device connectionsRecord carriers used with machinesMicrometerBiomedical engineering

In an assembly including an adapter and a smart card, the outer dimensions of the adapter are compliant with the 3FF microcircuit card format, the format further defining the positioning and minimum dimensions of contact areas; the smart card includes a plurality of contact surfaces, the dimensions of which are greater than those defined by the 3FF format for the contact areas, the outer dimensions of the card being smaller than those of the 3FF format; and the adapter includes a recess, the outline of which is defined by a plurality of arms that surround the recess, the recess being shaped so as to receive the smart card so the contact areas of the adapter fit inside the contact surfaces of the smart card, each of the contact areas being off-center relative to each of the contact surfaces, so each arm has a width of 700 micrometers, ensuring mechanical stability.

Owner:IDEMIA FRANCE

Interfacing element for a lock zone of a motor vehicle door

An interfacing element of a lock zone of a door of a motor vehicle. The interfacing element comprises: includes a support made of plastic material, intended to be attached to a lining of the door, the lining being made of plastic material and a reinforcing plate of the lock zone onto which a lock is intended to be fastened, the plate being integrated to the support by overmolding. The support is made of a material having a Young's modulus lower than that of the plastic material of the lining of the door, and a coefficient of elongation at break greater than that of the plastic material of the lining of the door. A sub-assembly of motor vehicle includes a lining of tailgate and an interfacing element fastened onto an outer face of the lining.

Owner:CO PLASTIC OMNIUM

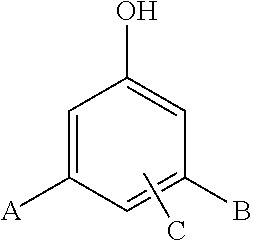

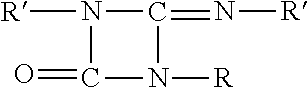

Co-catalysts for polyurethane cold box binders

InactiveUS20170165743A1High mechanical strengthEnsure cohesionFoundry mouldsFoundry coresSubject matterAmidine

The subject matter of the present invention is a binder system containing blocked tertiary amines or amidines as co-catalysts for a polyurethane cold-box application. It also relates to the molding material mixtures produced using such a binder system further comprising volatile tertiary amines, a method for producing the molding material mixtures, and the cores and molds made from the molding material mixtures according to the cold-box process.

Owner:ASK CHEM LP

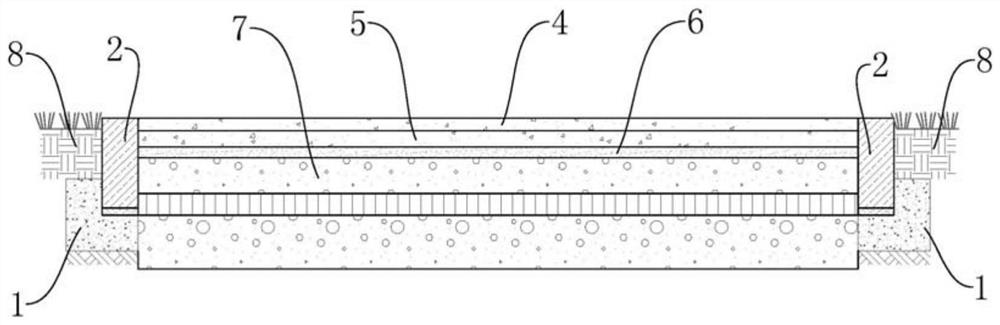

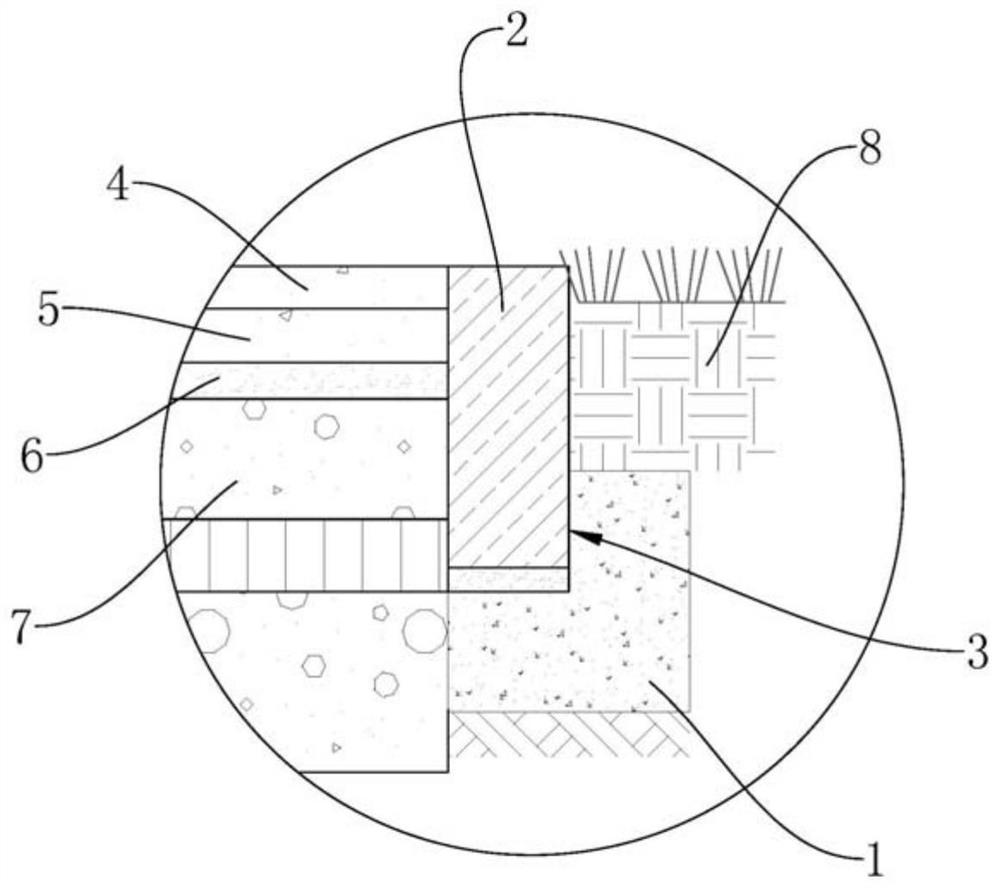

Construction method of permeable pavement

ActiveCN110158396BEnsure cohesionPermeate natureIn situ pavingsPaving gutters/kerbsColor effectPonding

The invention relates to the field of municipal engineering, in particular to a construction method of a permeable pavement, which ensures that the permeable pavement after completion can guide the accumulated water on the pavement to the road through the gap between the sand filter layer and two adjacent roadside stones. At the same time, the water-resisting layer can prevent the accumulated water in the sand filter layer from penetrating into the soil layer below the water-resisting layer and cause the road surface to settle. The paving of the permeable concrete layer and color material is carried out step by step to ensure that After the construction of the permeable concrete layer is completed, the liquid coloring material is spread on the surface of the permeable concrete layer to allow the coloring material to permeate naturally to achieve uniform and bright colors.

Owner:广州市花木有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com