Patents

Literature

43 results about "Neutron pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

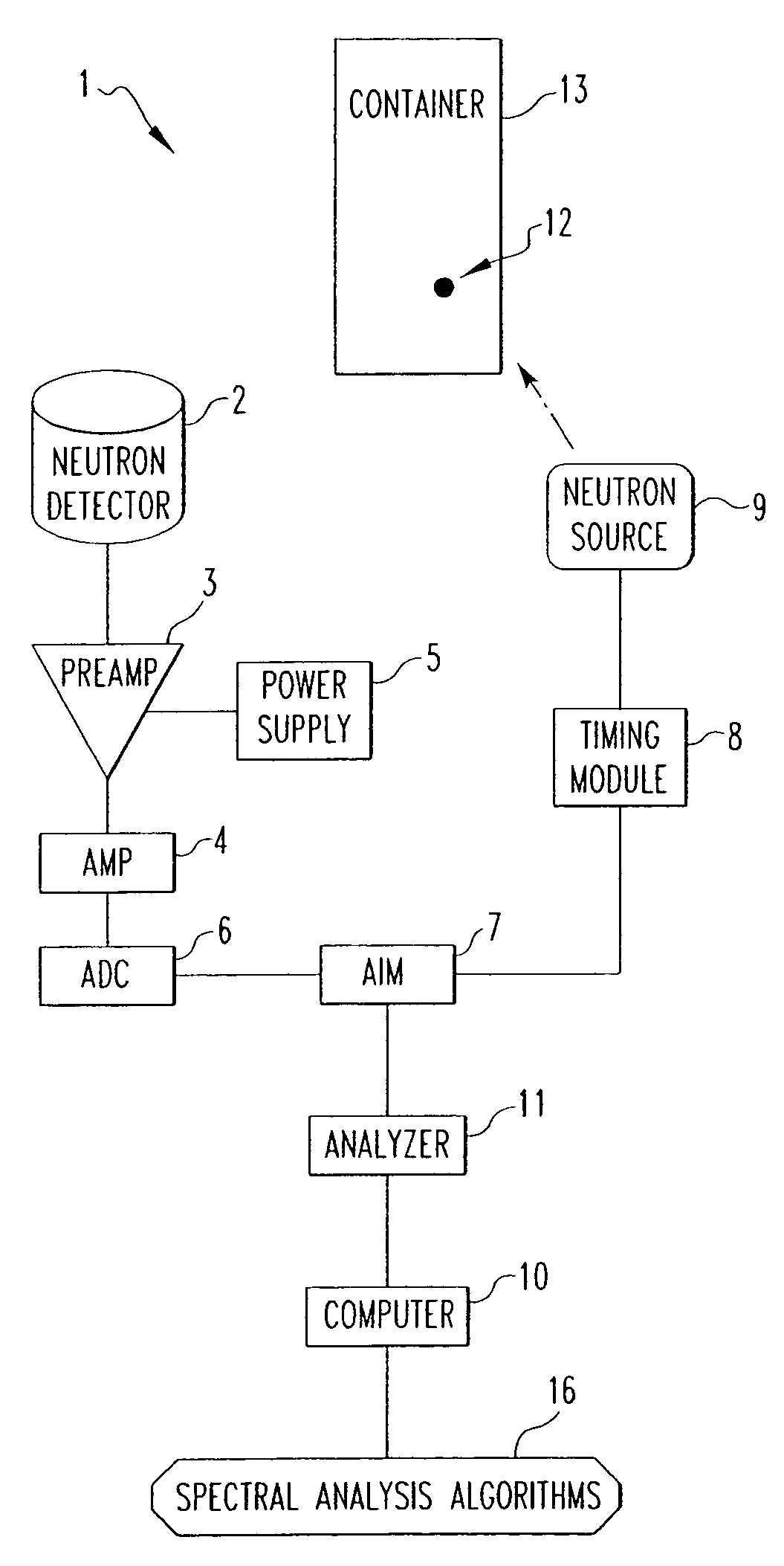

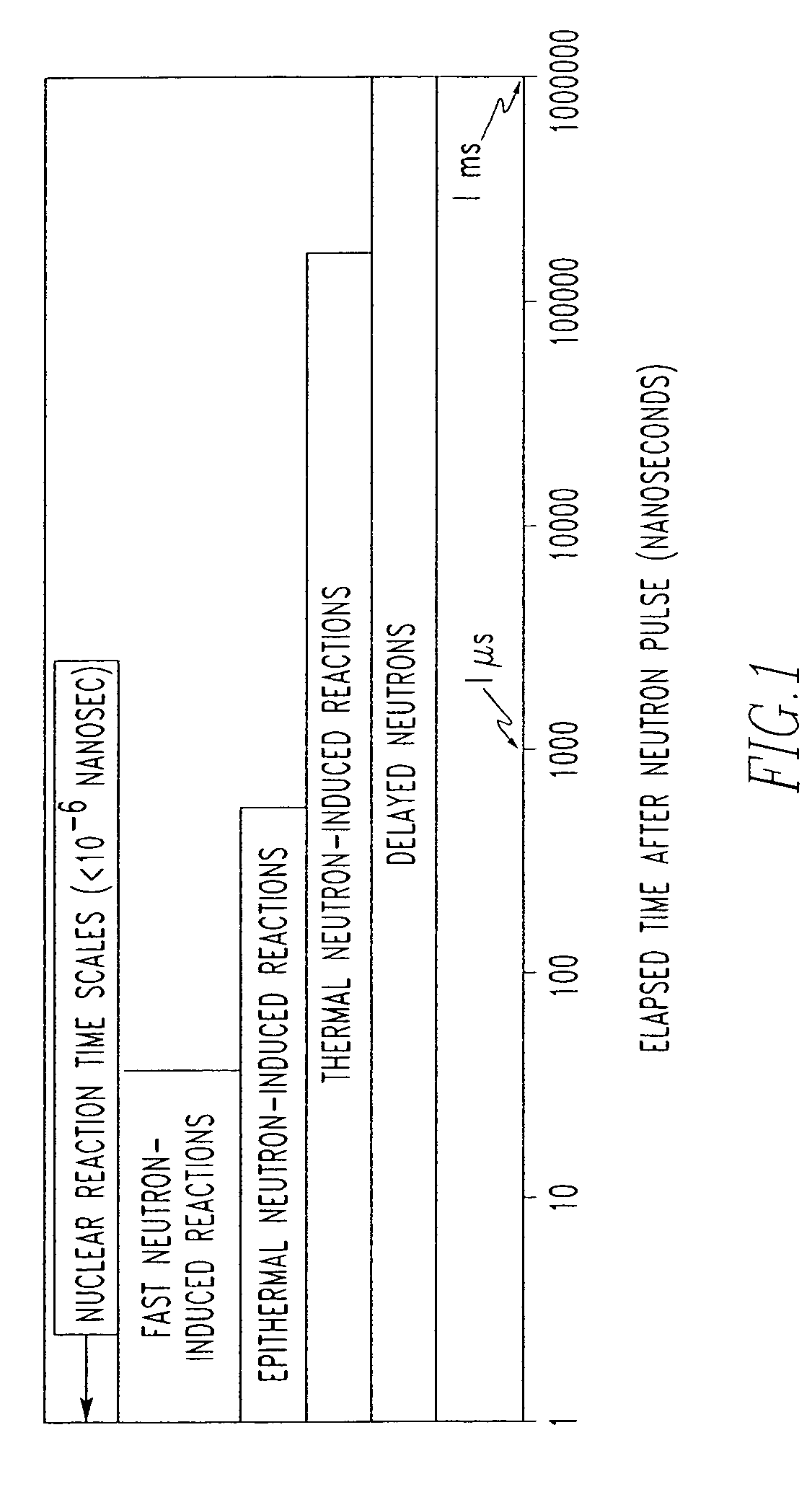

Nonintrusive method for the detection of concealed special nuclear material

ActiveUS20050220247A1Overcome problemsConversion outside reactor/acceleratorsNuclear monitoringNeutron pulseRadiation damage

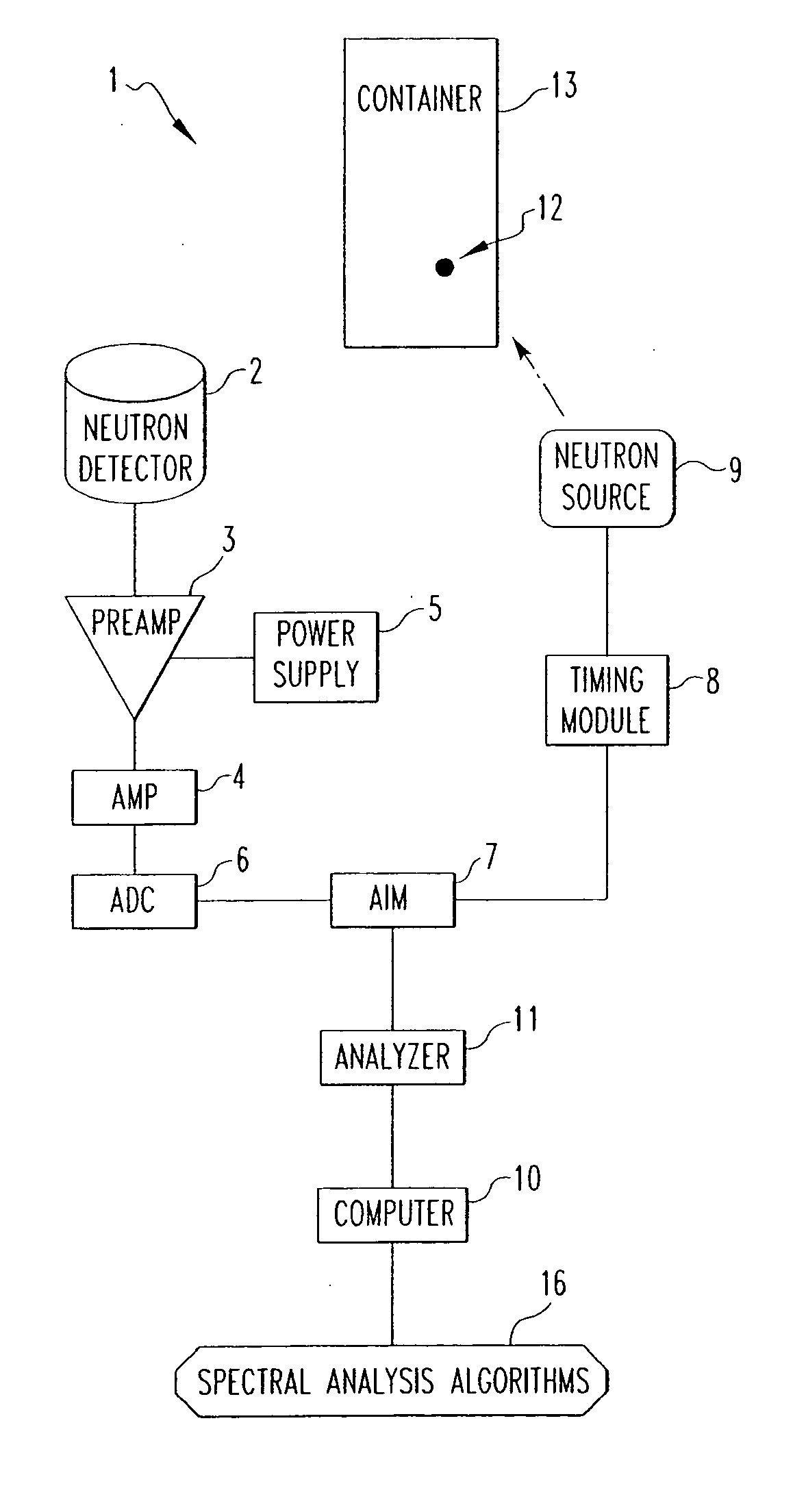

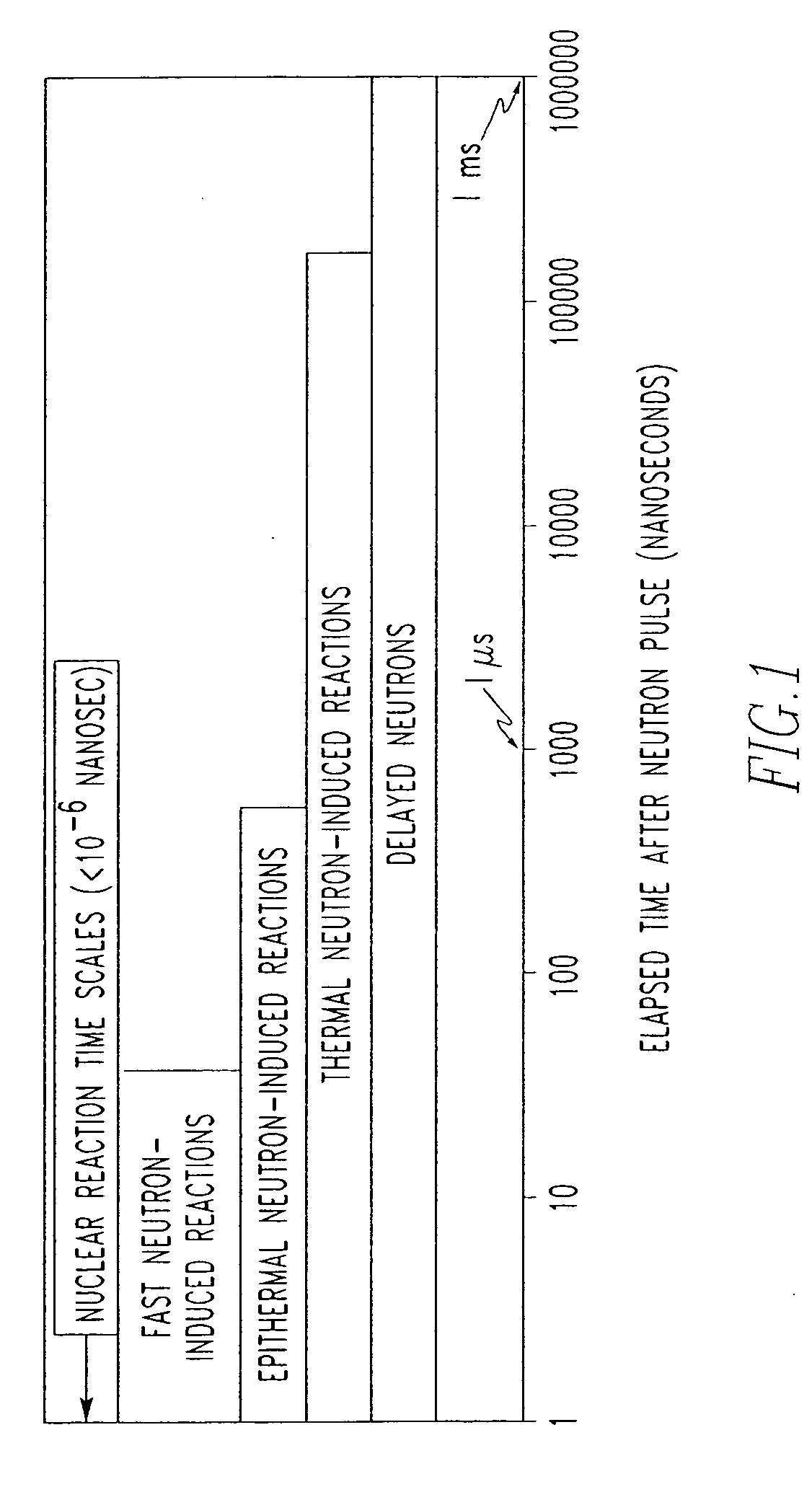

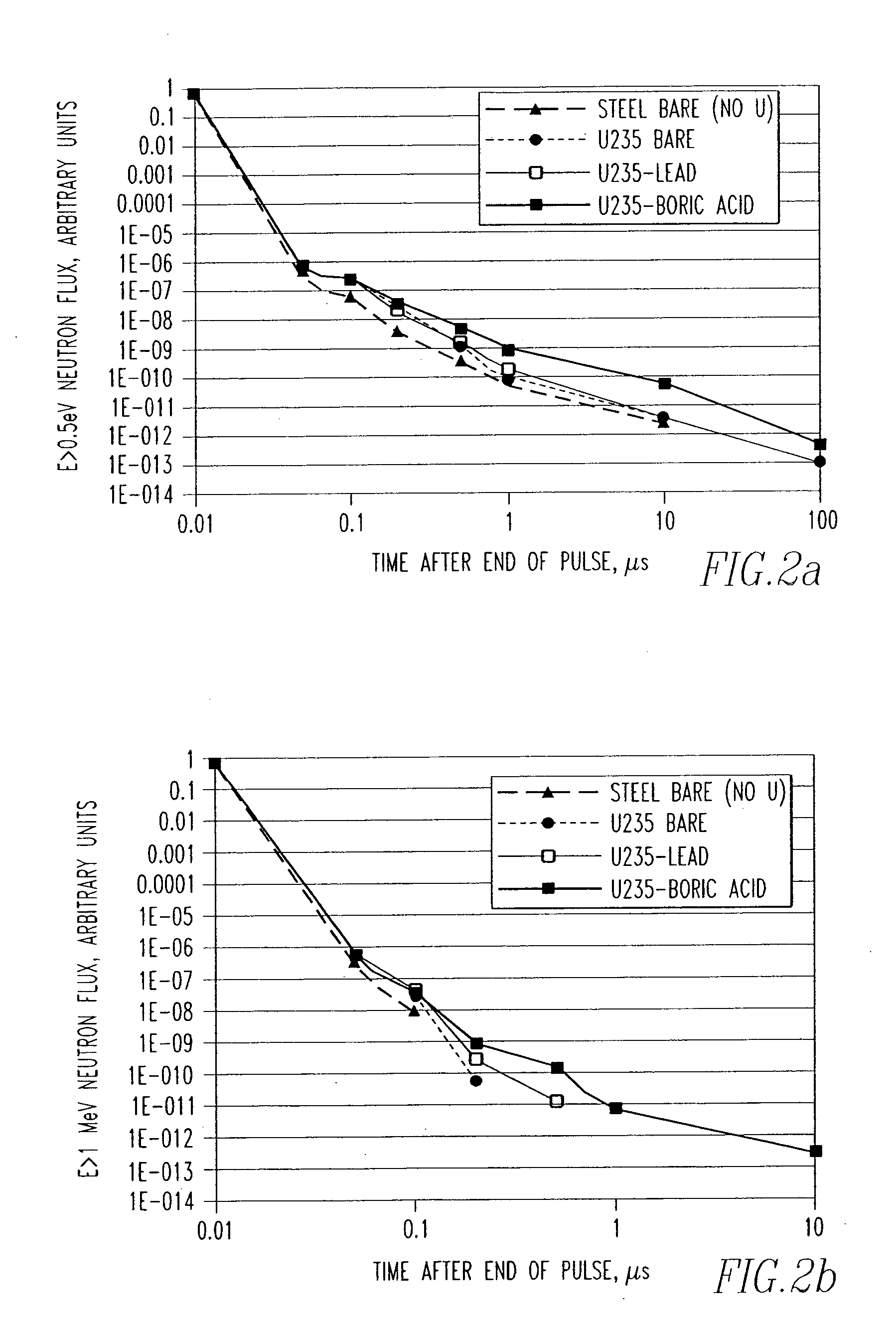

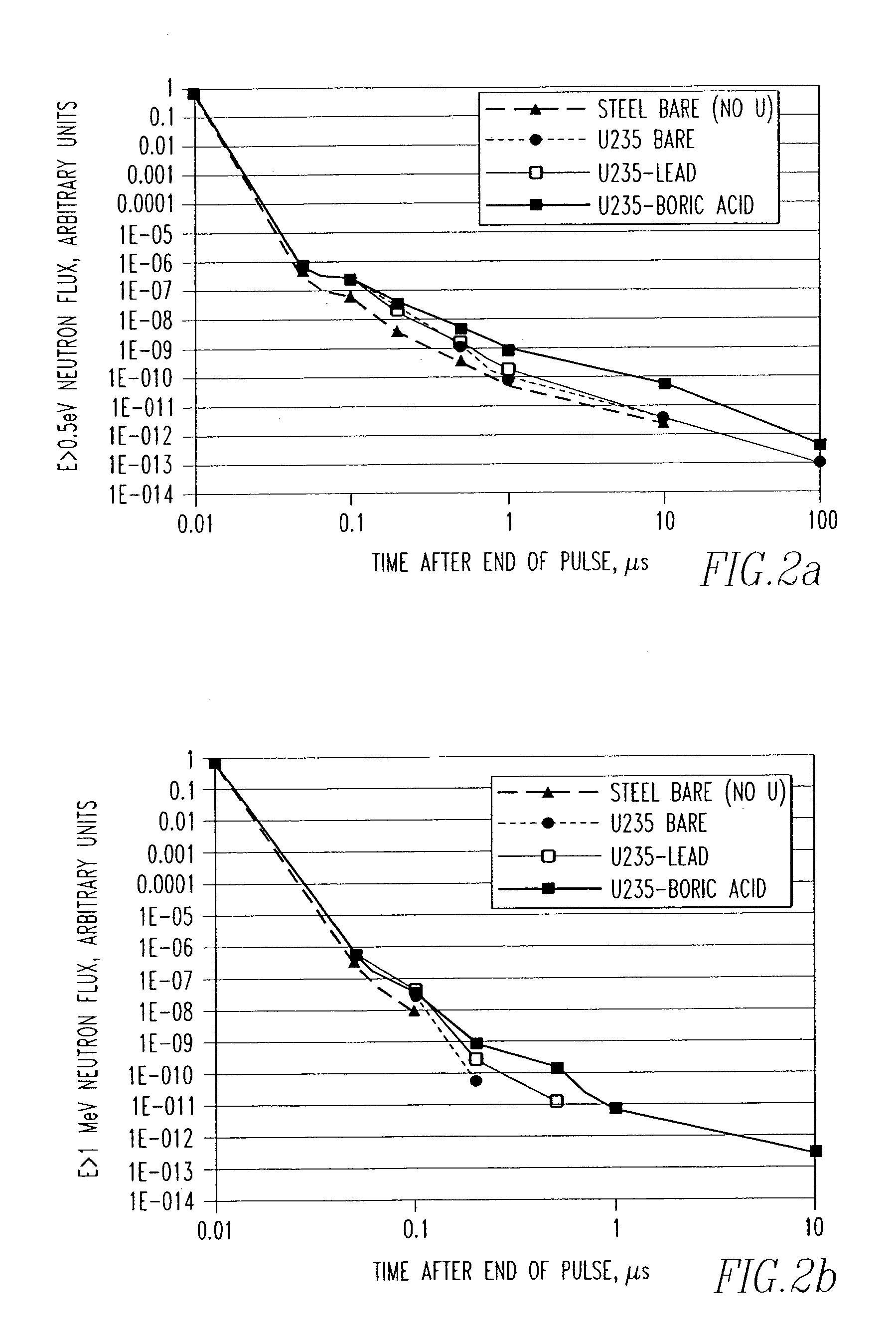

A method and associated apparatus for detecting concealed fissile, fissionable or special nuclear material in an article, such as a shipping container, is provided. The article is irradiated with a source of fast neutrons, and fast neutrons released by the fissile or fissionable material, if present, are detected between source neutron pulses. The method uses a neutron detector that can detect and discriminate fast neutrons in the presence of thermal neutrons and gamma radiation. The detector is able to process high count rates and is resistant to radiation damage, and is preferably a solid state neutron detector comprised of silicon carbide.

Owner:WESTINGHOUSE ELECTRIC CORP

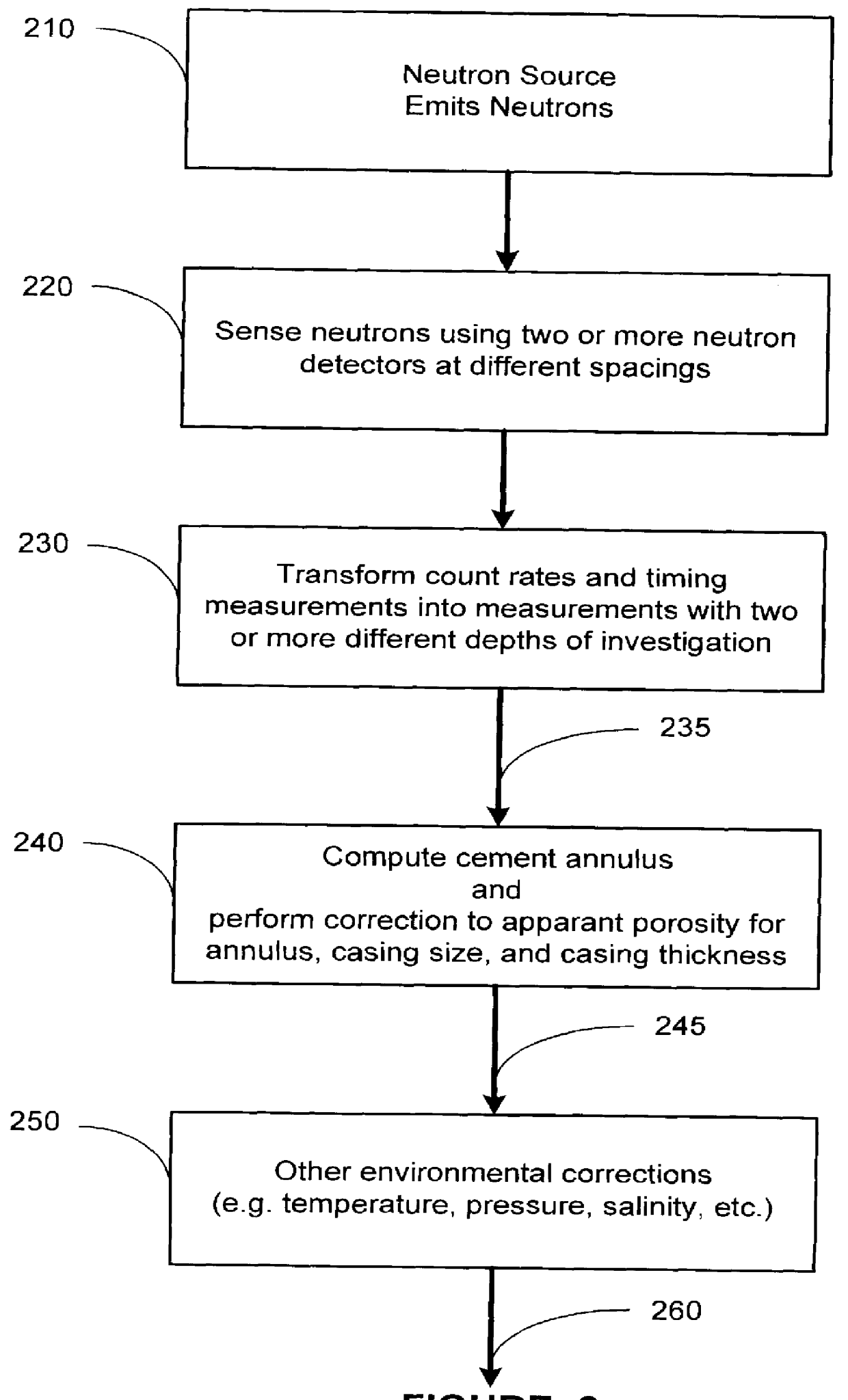

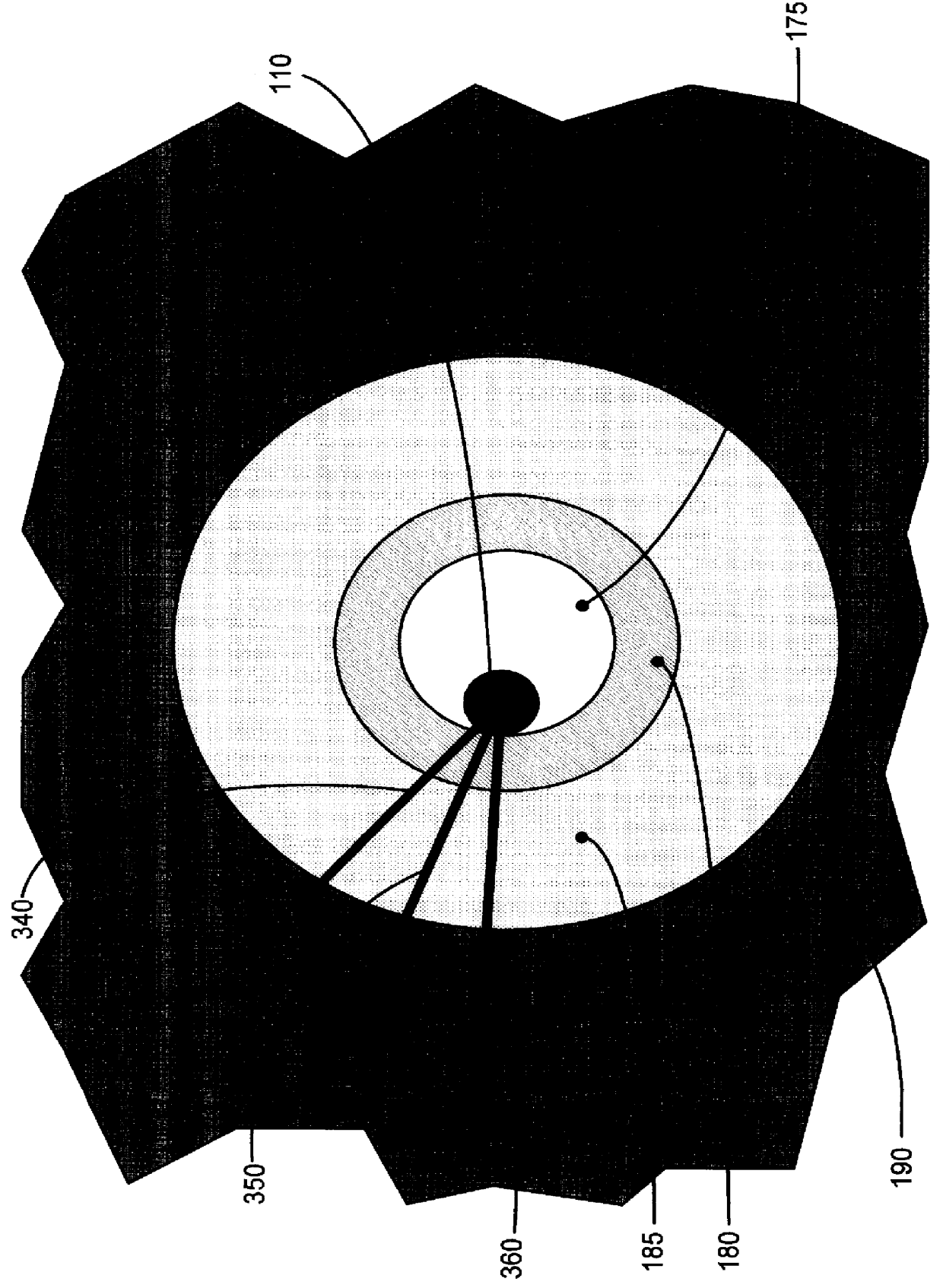

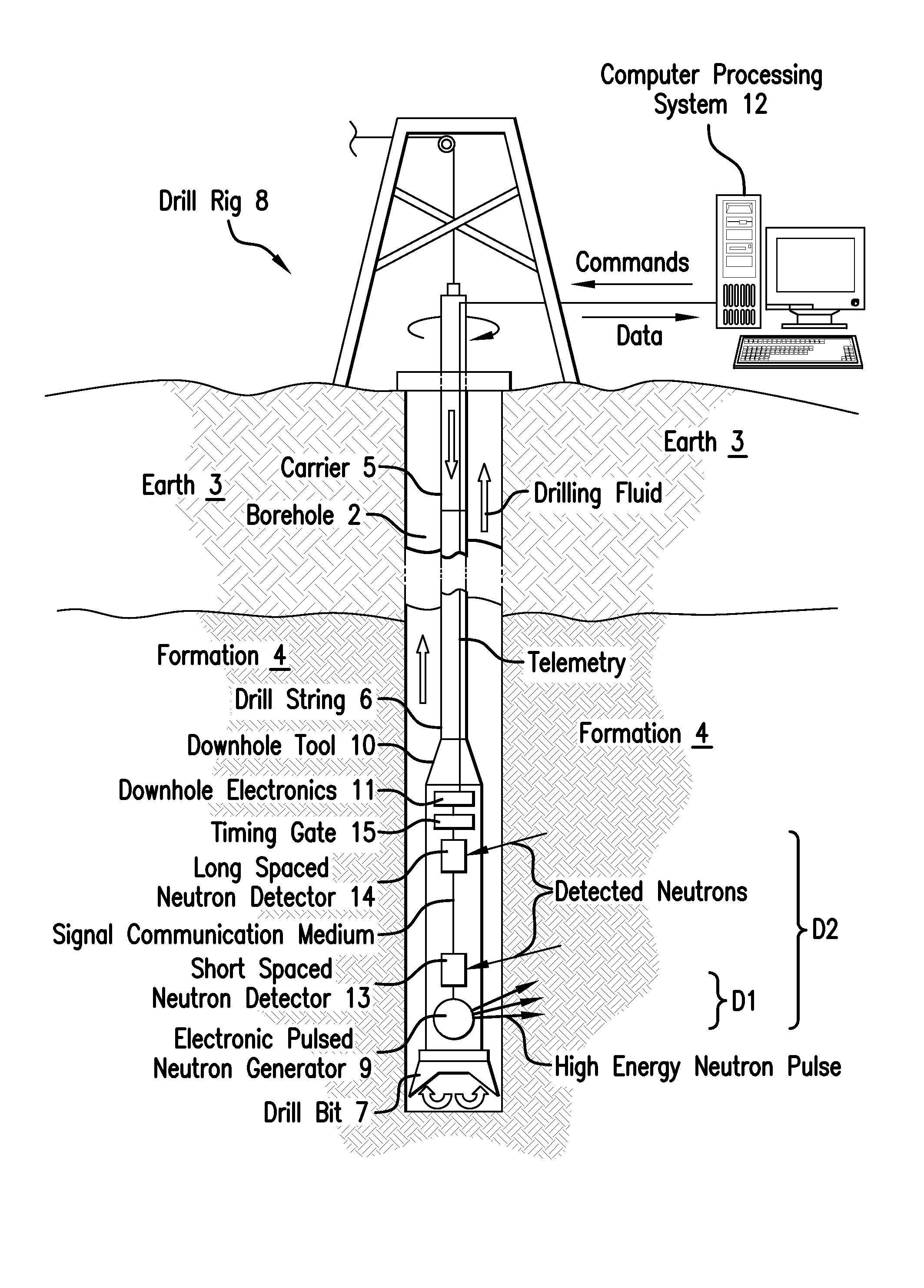

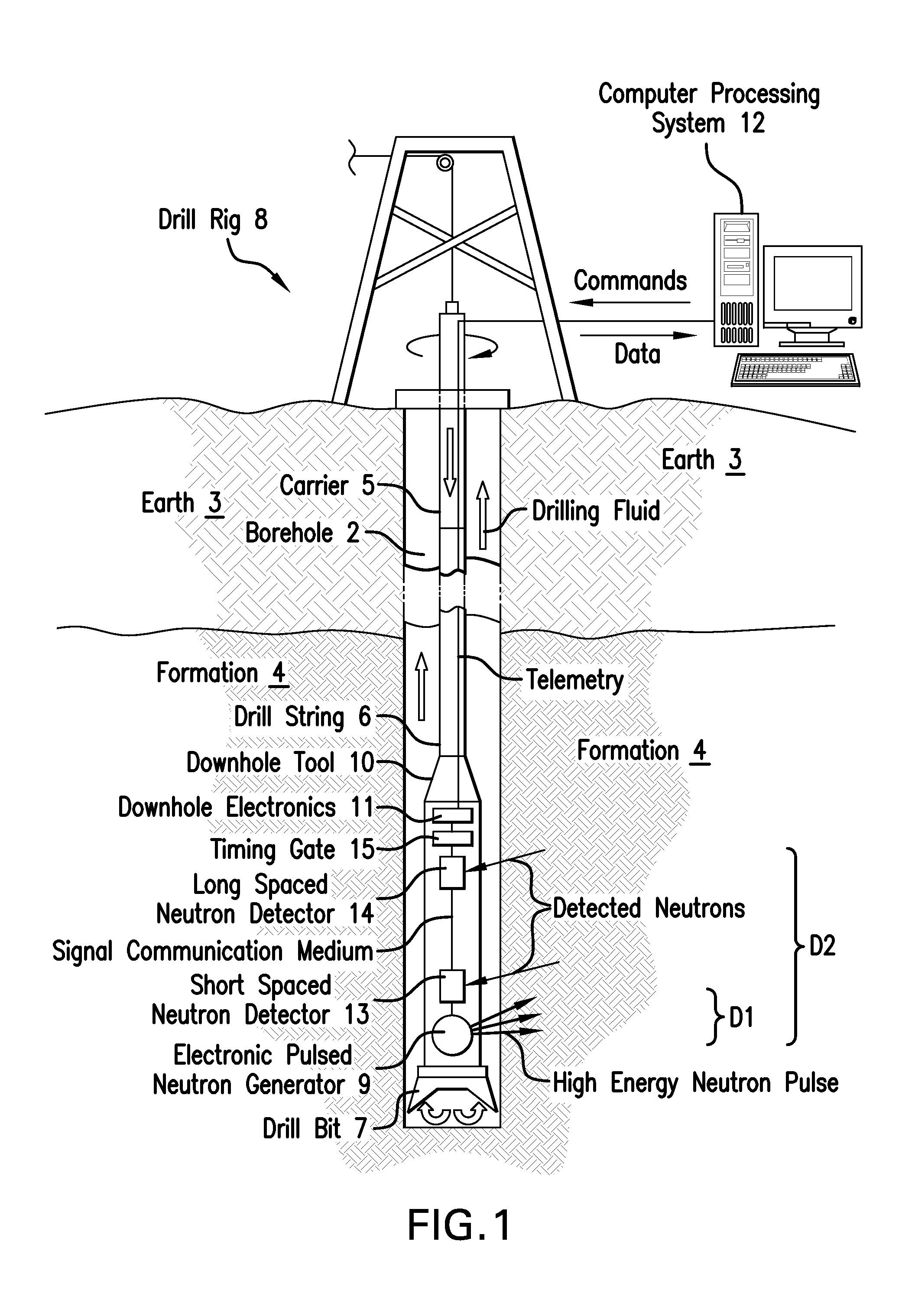

Method and apparatus for measuring well characteristics and formation properties

InactiveUS6032102AElectric/magnetic detection for well-loggingSeismology for water-loggingCounting ratePorosity

The present invention provides for method and an apparatus for determining the porosity of a geological formation surrounding a cased well. The method further comprises of generating neutron pulses that release neutrons into an area adjacent the well, from a neutron source. Neutrons are sensed and a plurality of neutron detector count rates is acquired using at least two neutron source to neutron detector spacings. A timing measurement is acquired at one of the spacings to measure a first depth of investigation. A ratio of the neutron detector count rates is acquired to measure a second depth of investigation. An apparent porosity is calculated using the timing measurements and the ratios of neutron count rates. The effect of a well casing on the calculated apparent porosity is determined in response to at least one of the ratio of neutron detector count rates and the timing measurement. A cement annulus is computed based on the ratios of neutron count rates and the timing measurement. A formation porosity is calculated by performing a correction to the apparent porosity for the casing and the cement annulus.

Owner:SCHLUMBERGER TECH CORP

Nonintrusive method for the detection of concealed special nuclear material

ActiveUS7151815B2Conversion outside reactor/acceleratorsNuclear monitoringNeutron pulseRadiation damage

Owner:WESTINGHOUSE ELECTRIC CORP

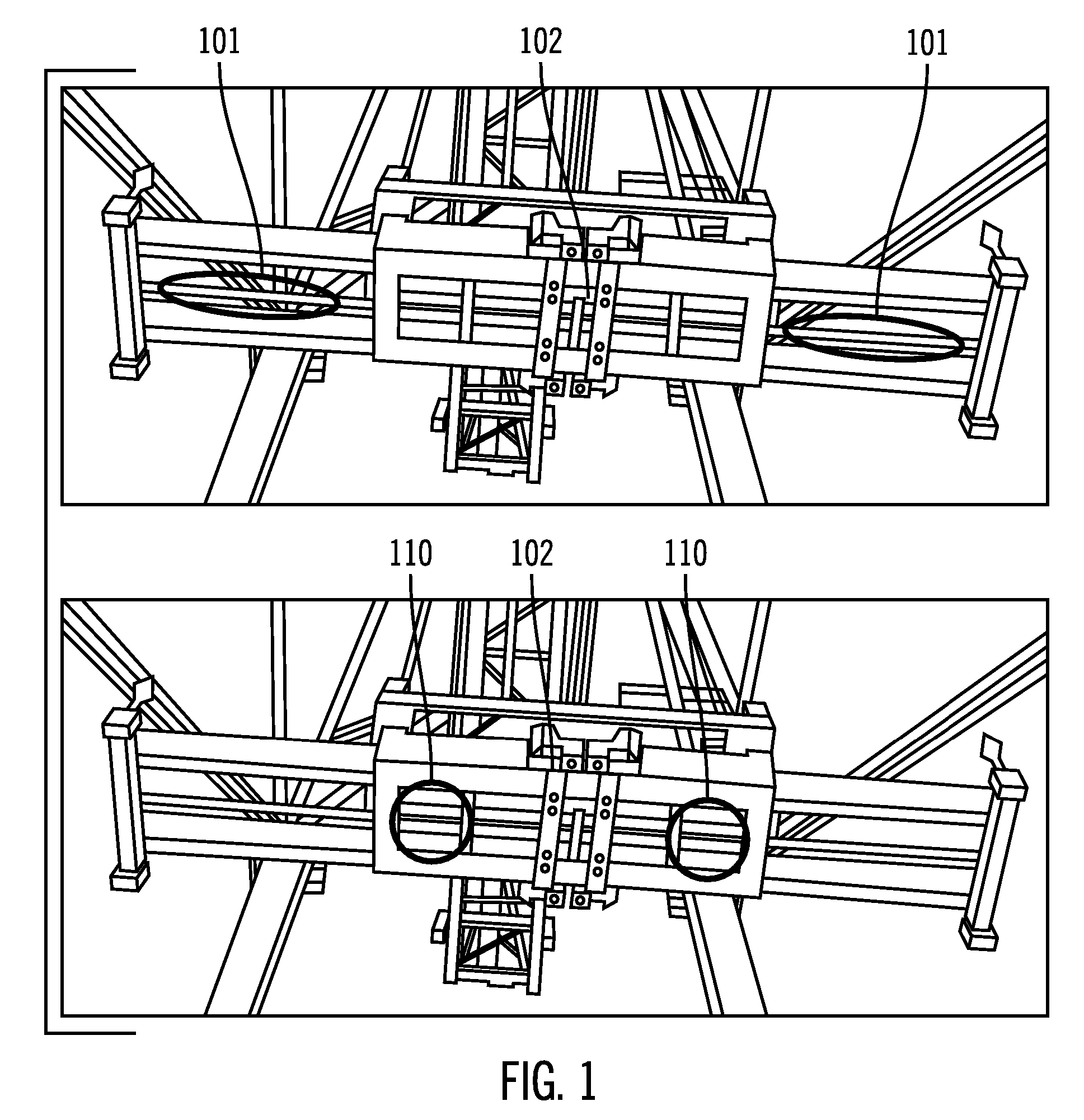

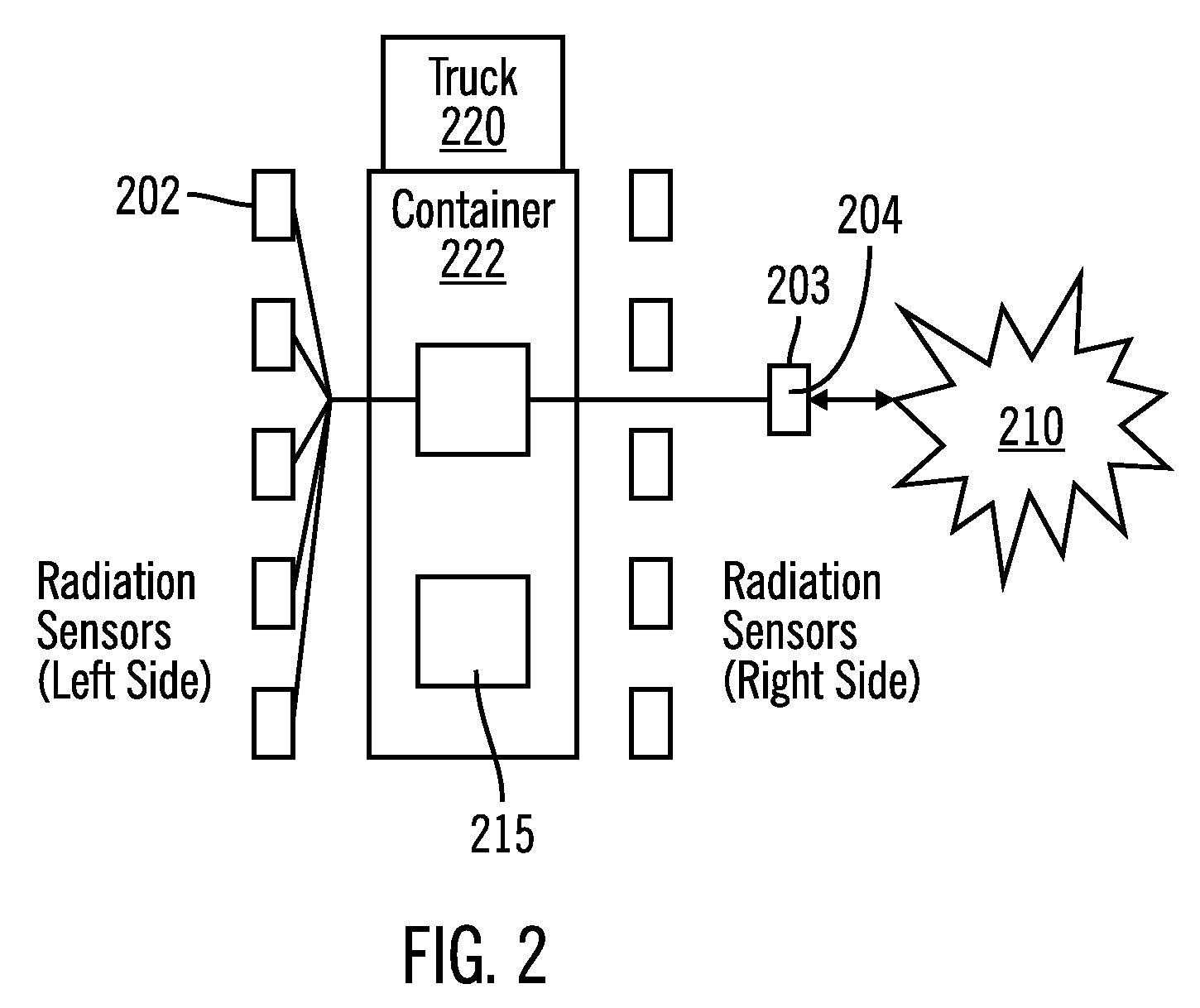

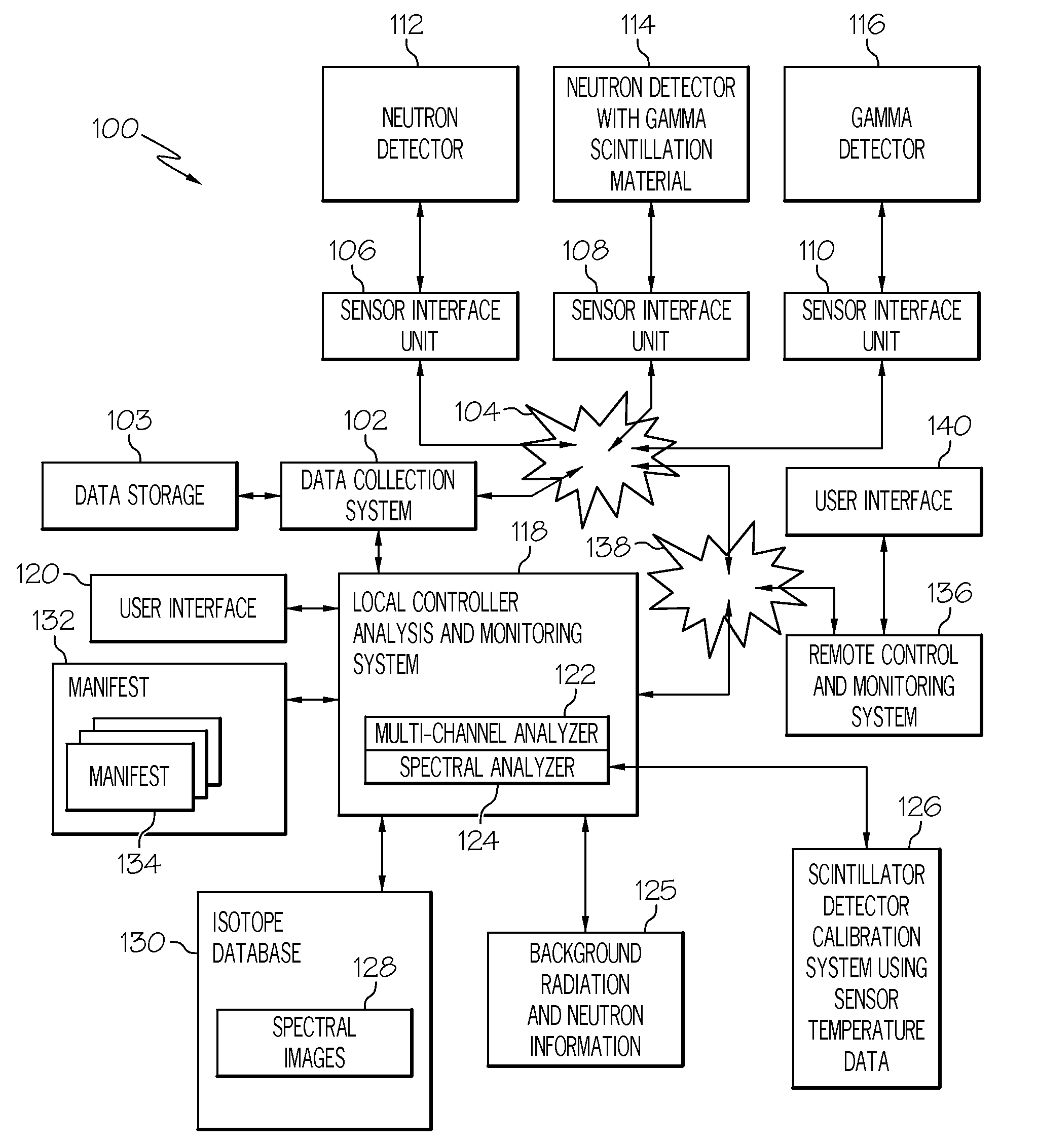

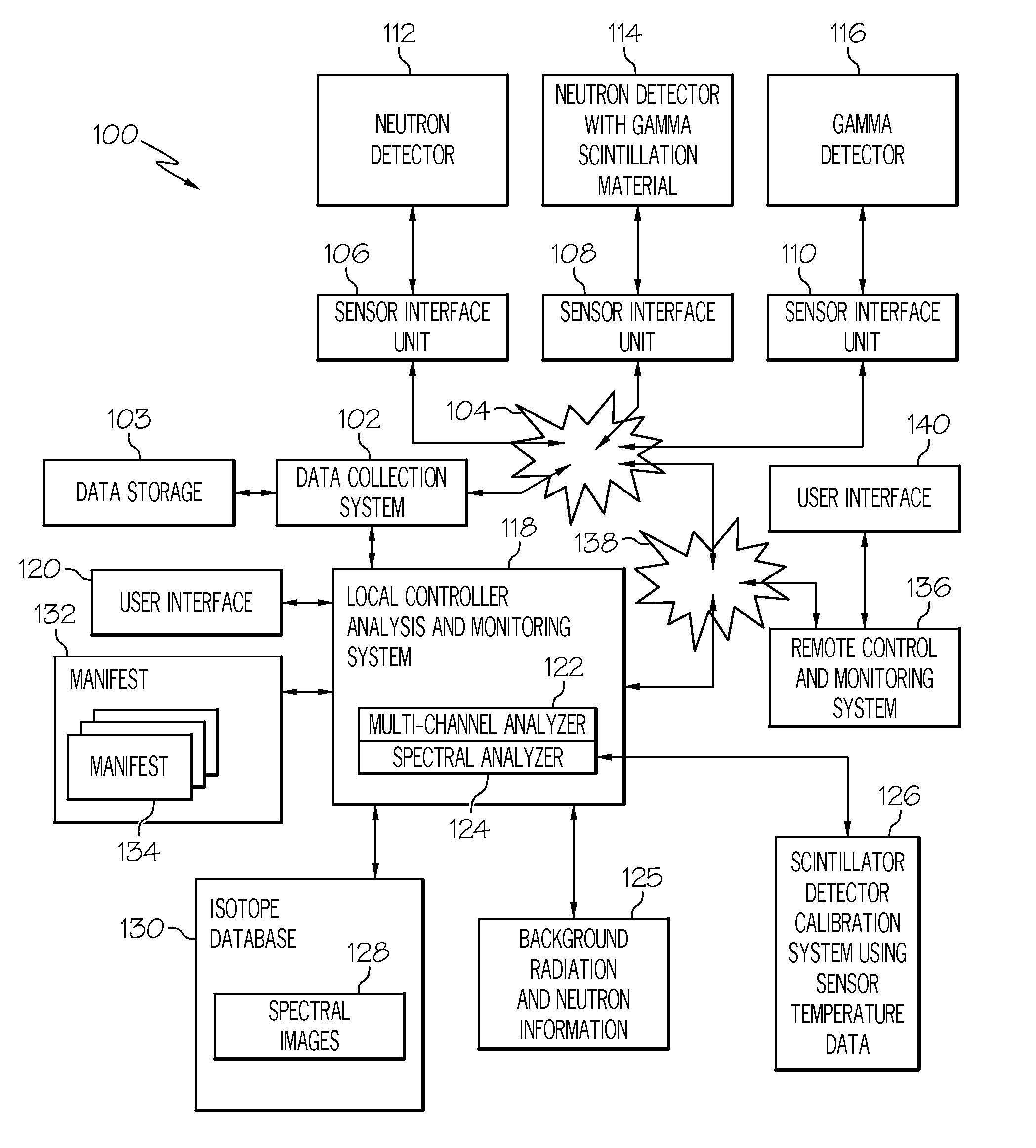

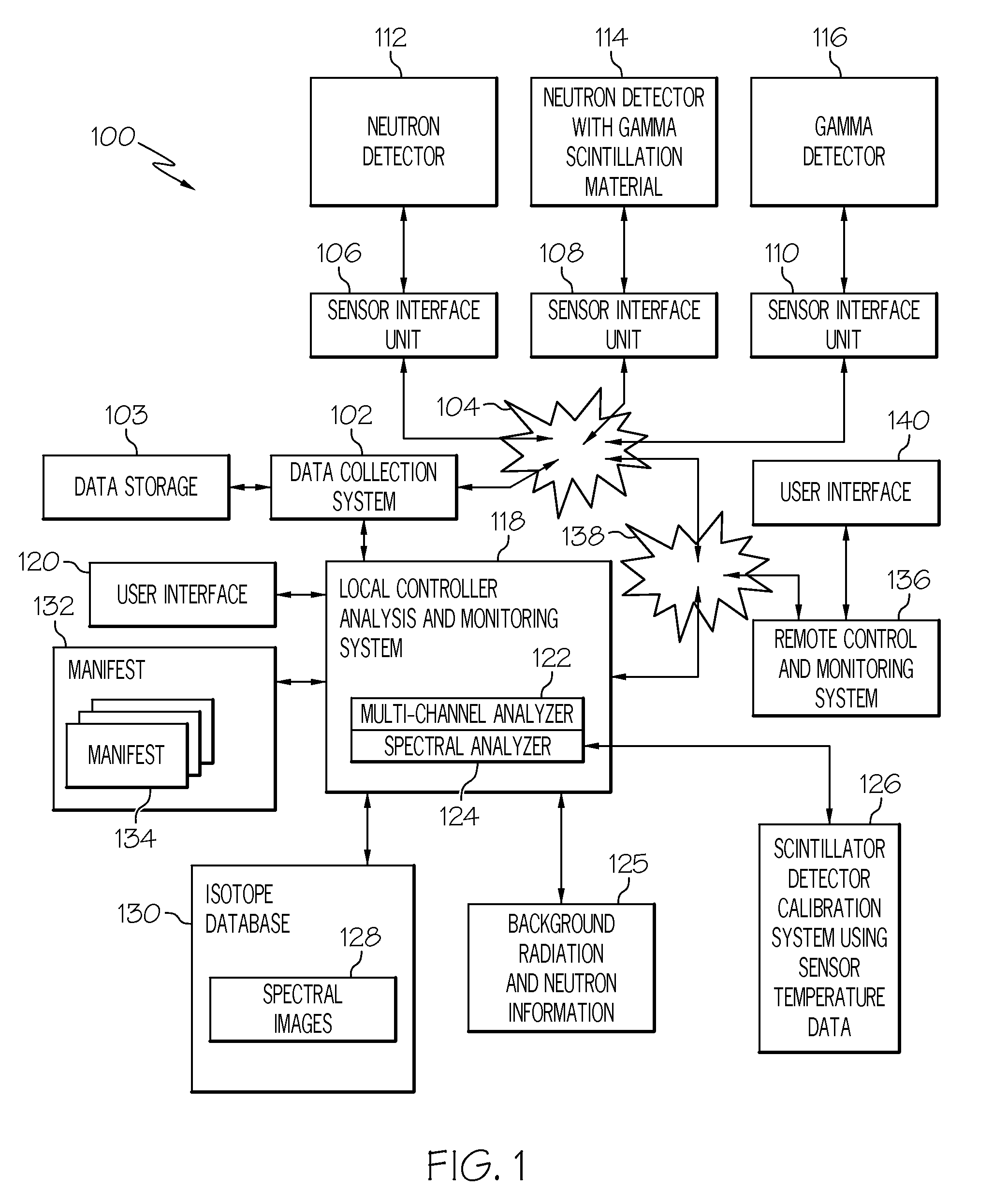

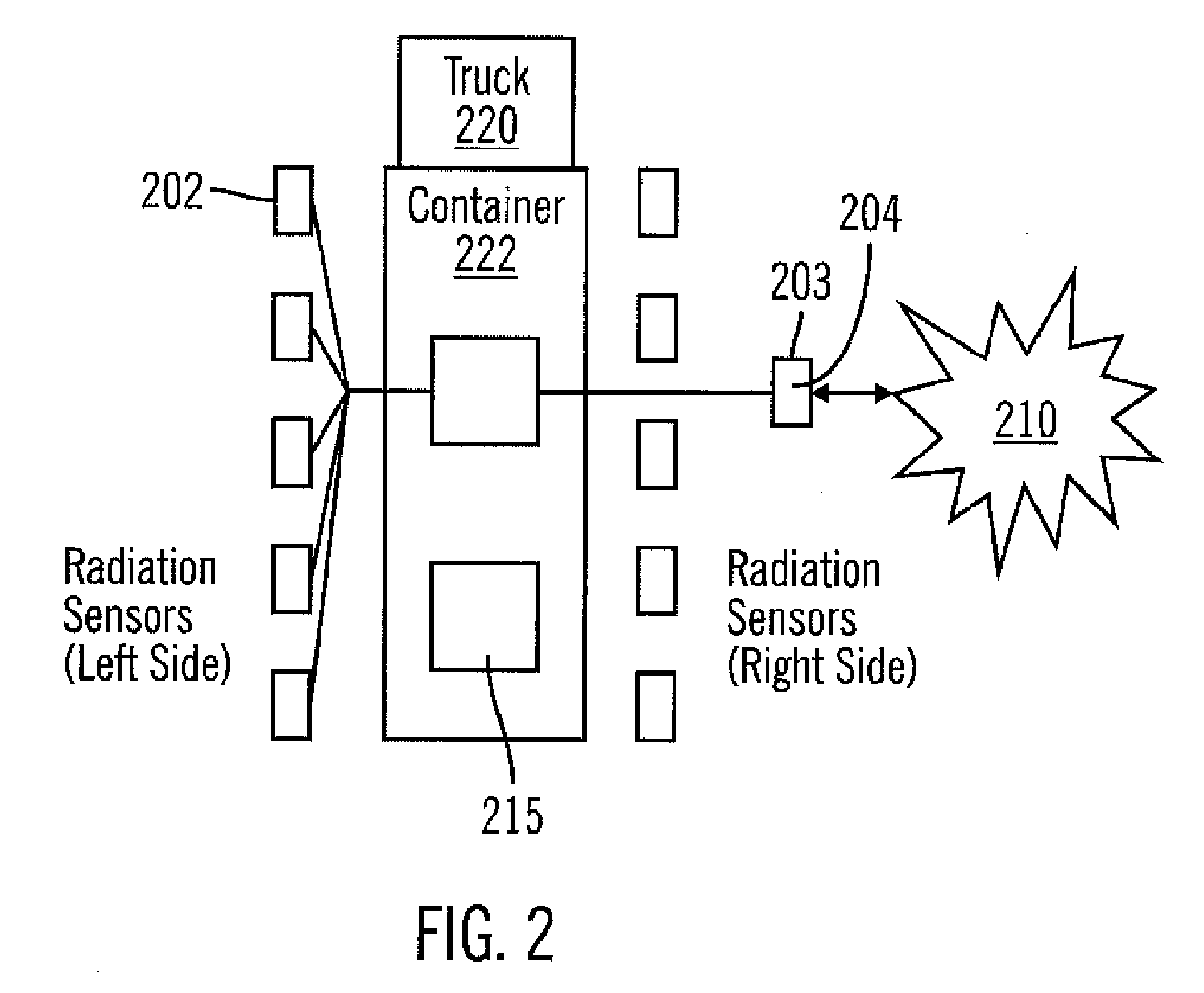

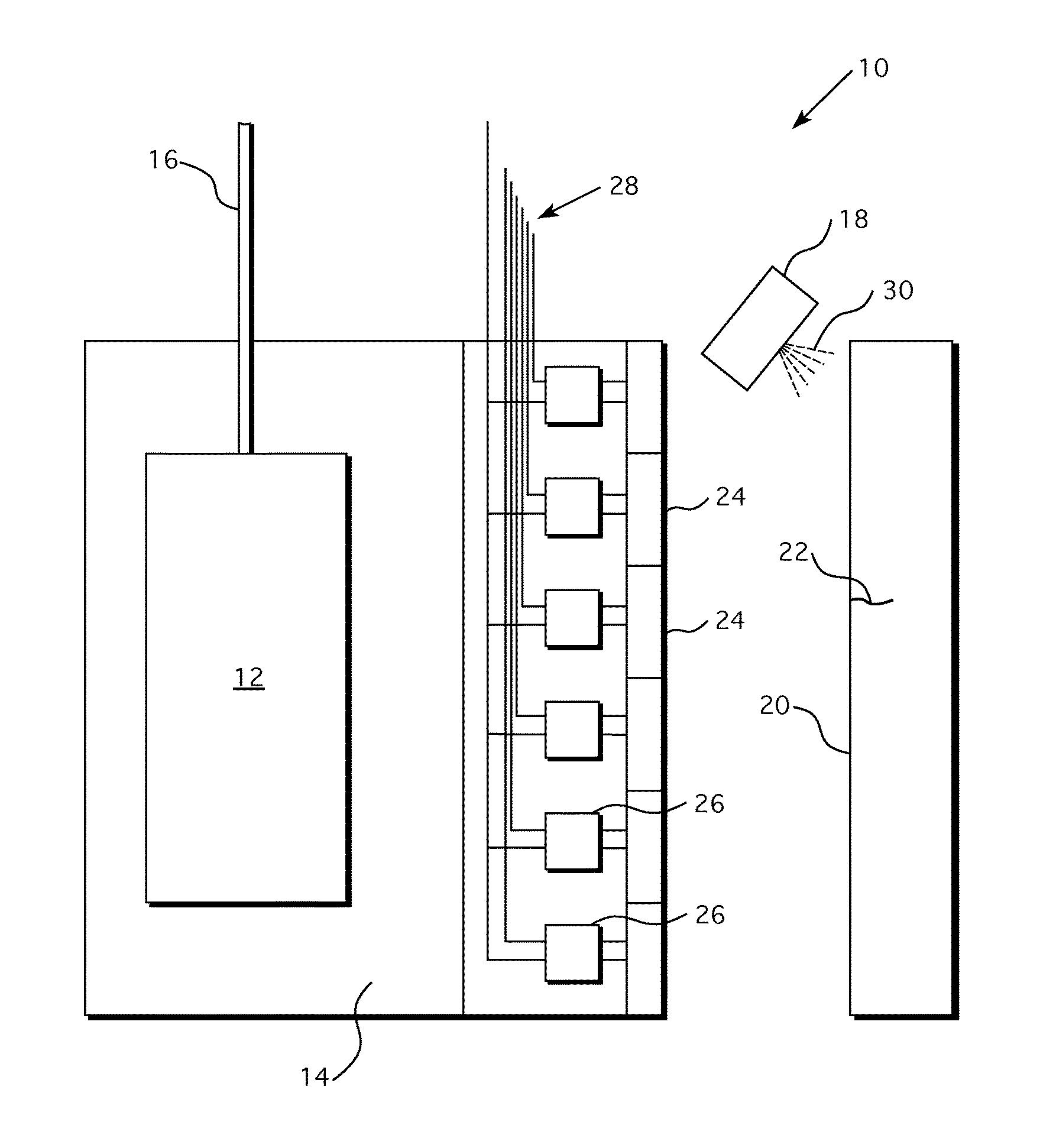

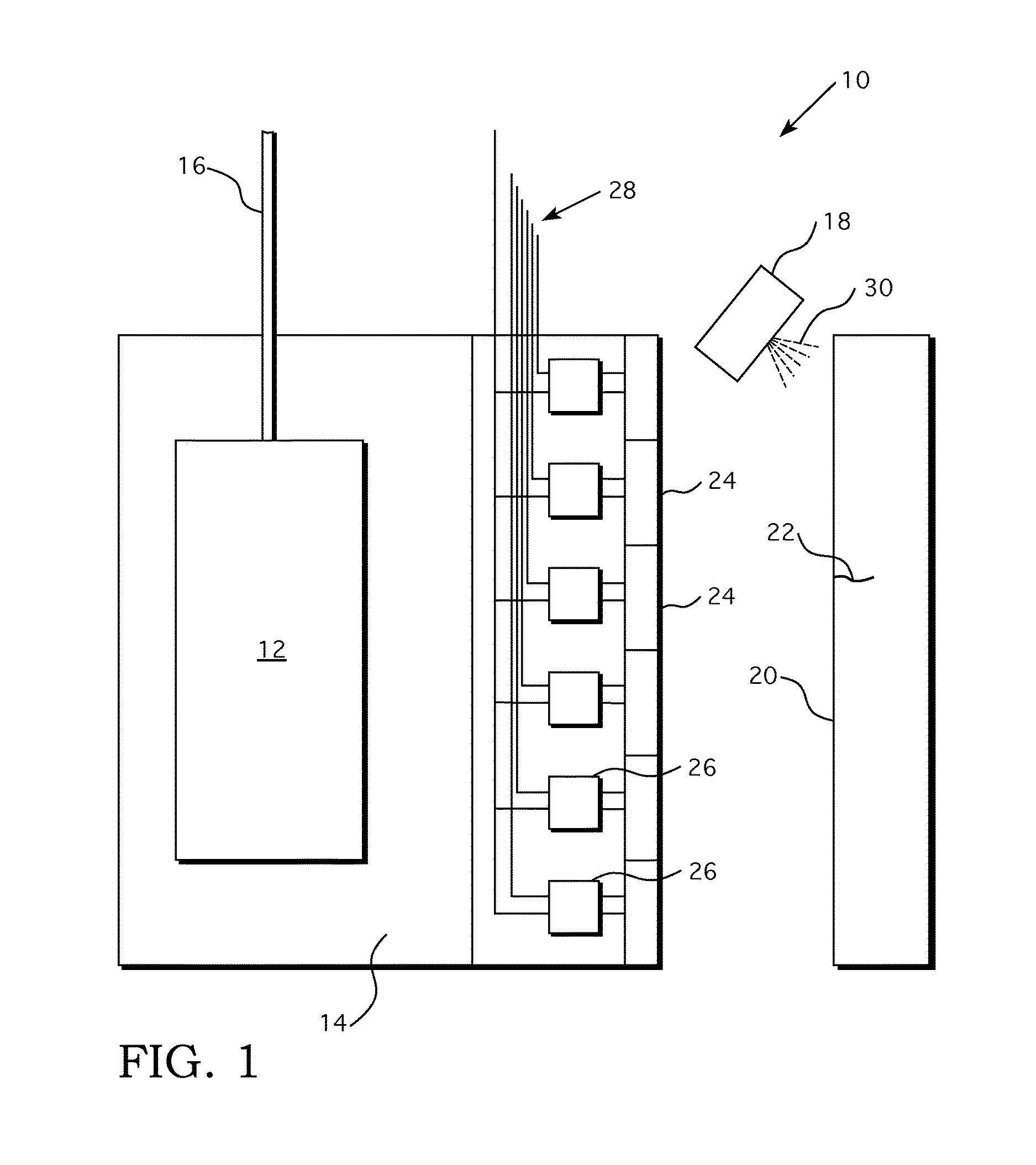

Multi-stage system for verification of container contents

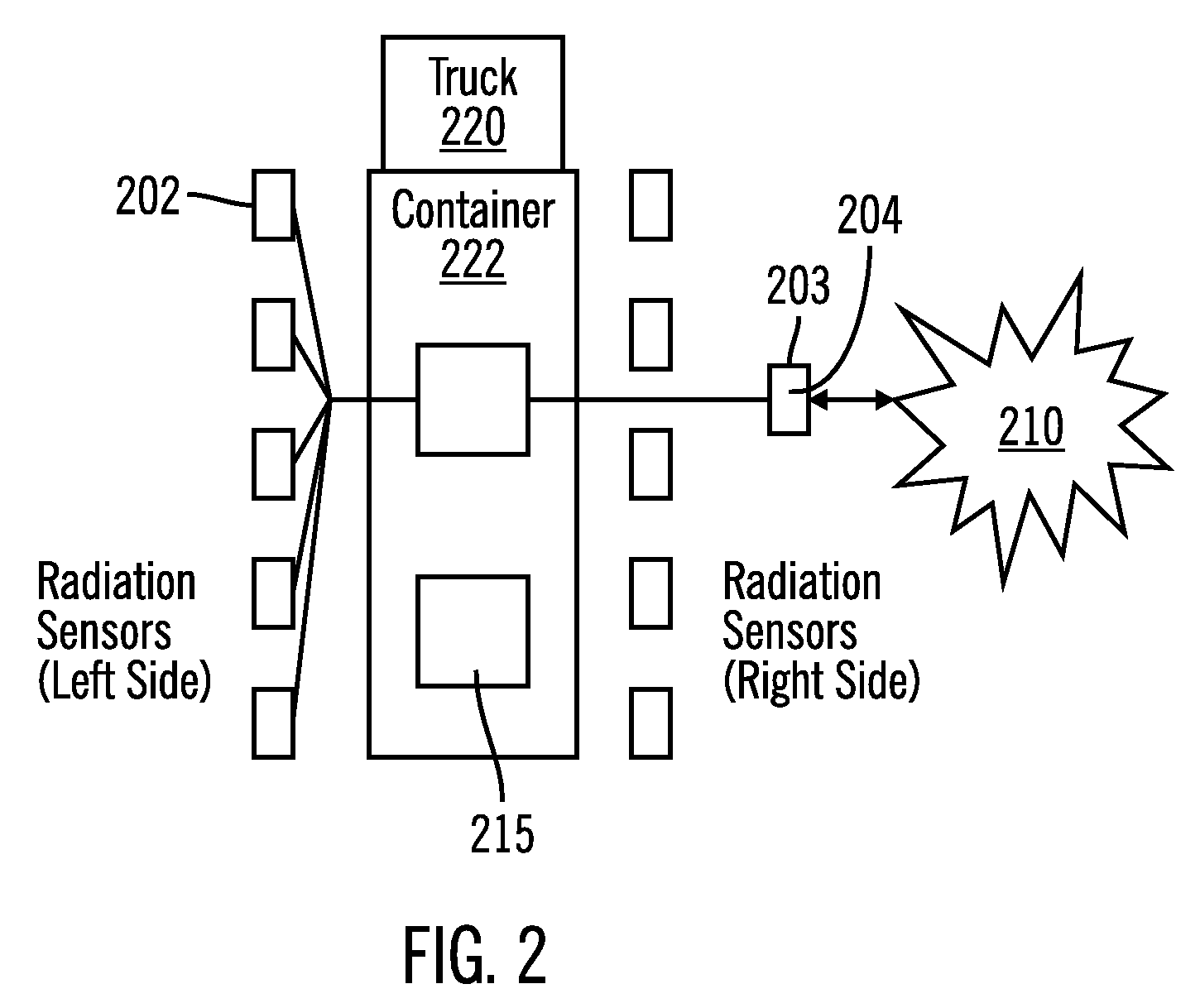

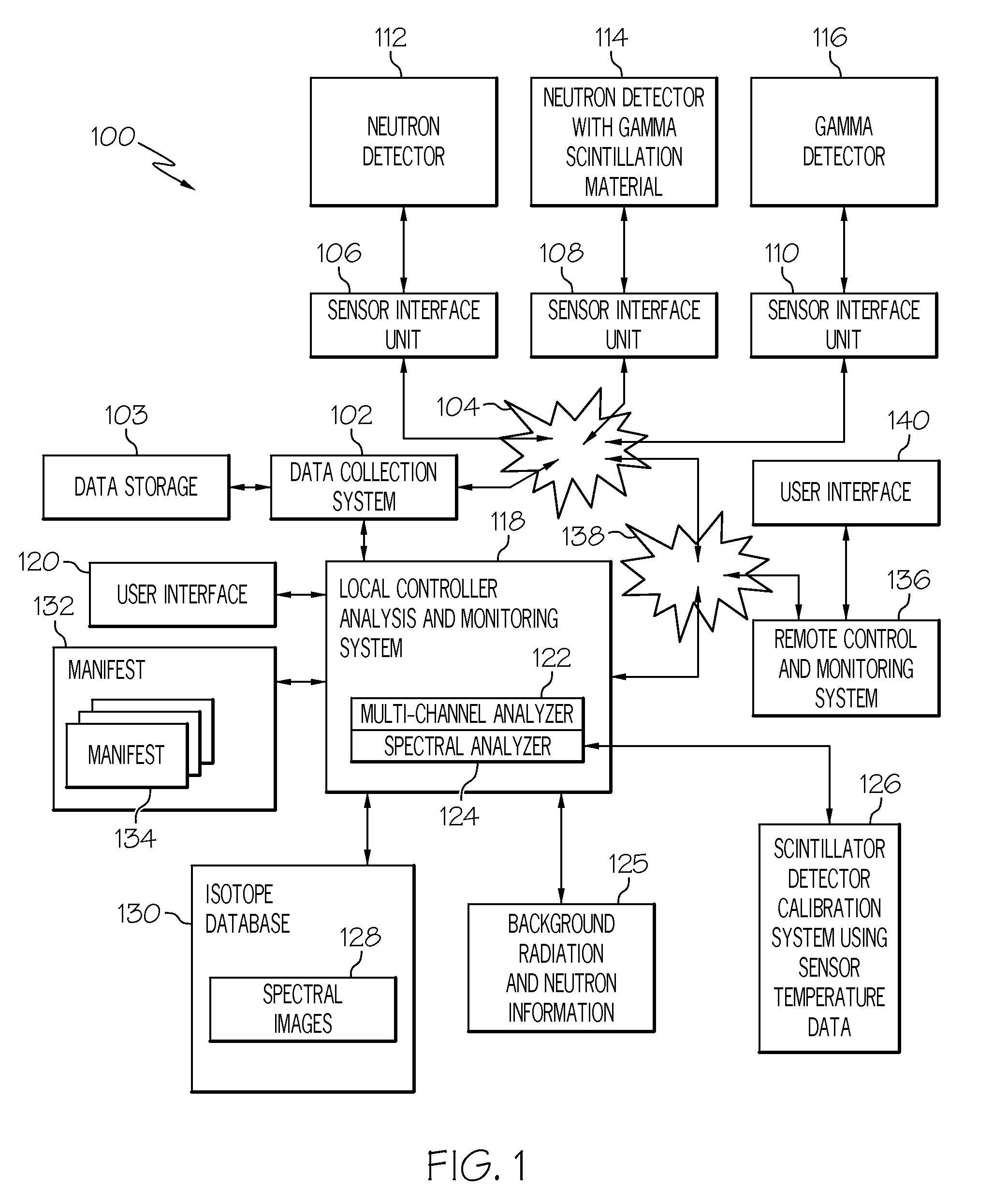

InactiveUS7760103B2Further analysisWithout negative impact to the flow of commerceMeasurement with semiconductor devicesMaterial analysis by optical meansNeutron pulseIsotope

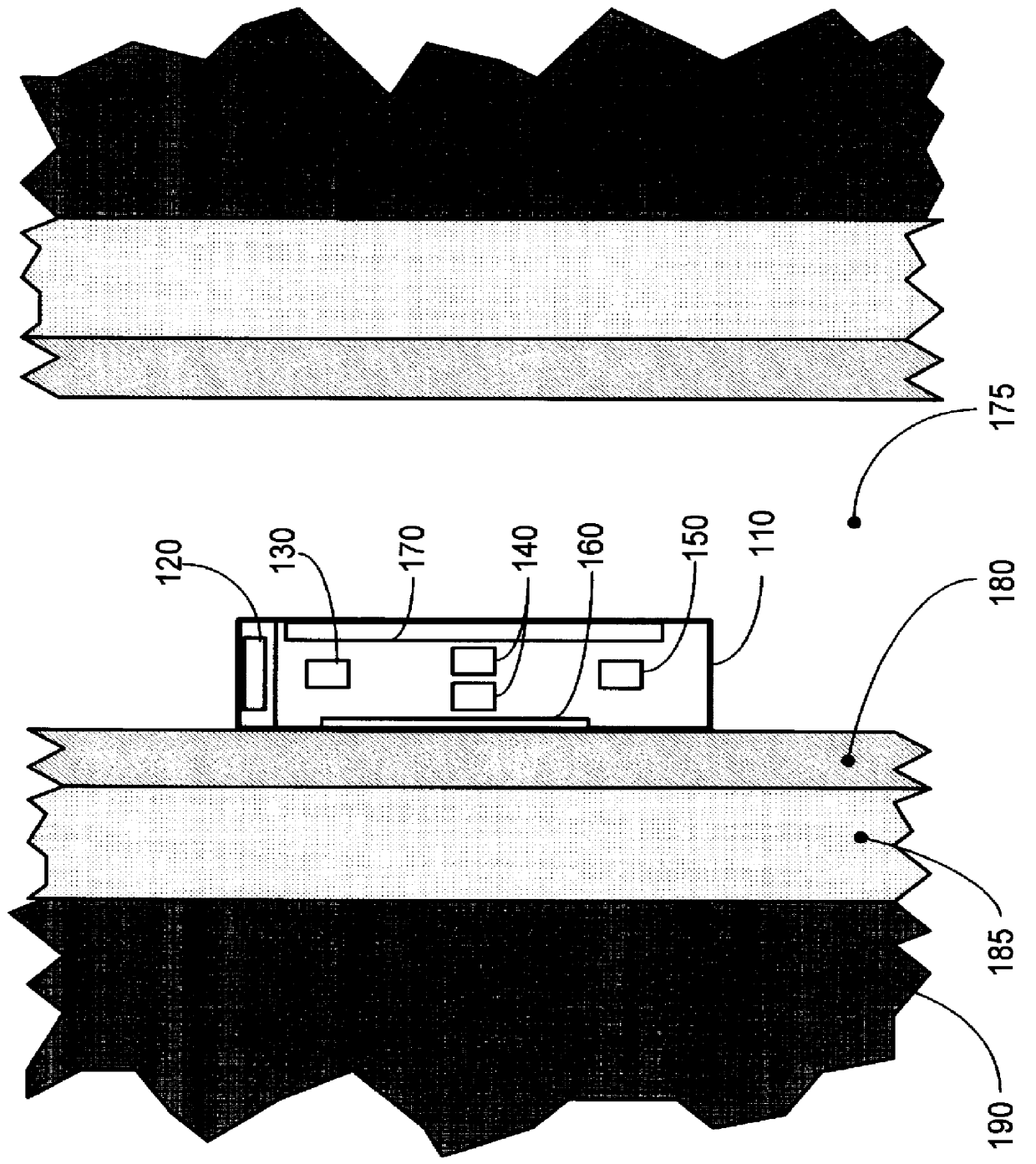

A multi-stage process utilizing one or more radiation sensors on a distributed network for the detection and identification of radiation, explosives, and special materials within a shipping container. The sensors are configured as nodes on the network. The system collects radiation data from one or more nodes and compares the collected data to one or more stored spectral images representing one or more isotopes to identify one or more isotopes present. The identified one or more isotopes present are corresponded to possible materials or goods that they represent. The possible materials or goods are compared with the manifest relating to the container to confirm the identity of materials or goods contained in the container or to detect and / or identify unauthorized materials or goods in the container. For shielded materials, explosives and other types of material detection, a neutron pulse device could be incorporated into the system.

Owner:S2 PHOTONICS LLC +1

Multi-stage system for verification of container contents

InactiveUS20080048872A1Measurement with semiconductor devicesX/gamma/cosmic radiation measurmentNeutron pulseIsotope

Owner:S2 PHOTONICS LLC +1

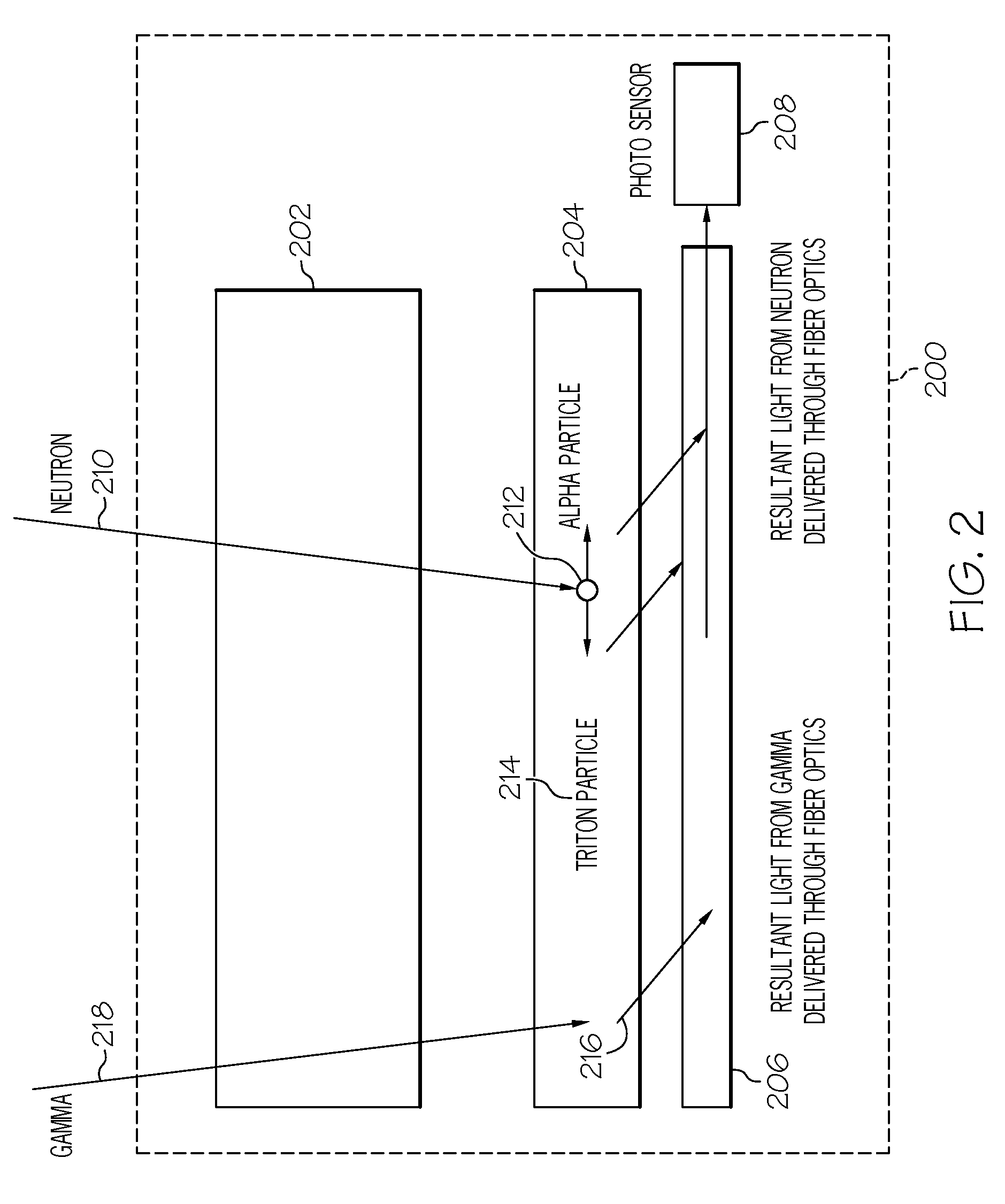

High performance neutron detector with near zero gamma cross talk

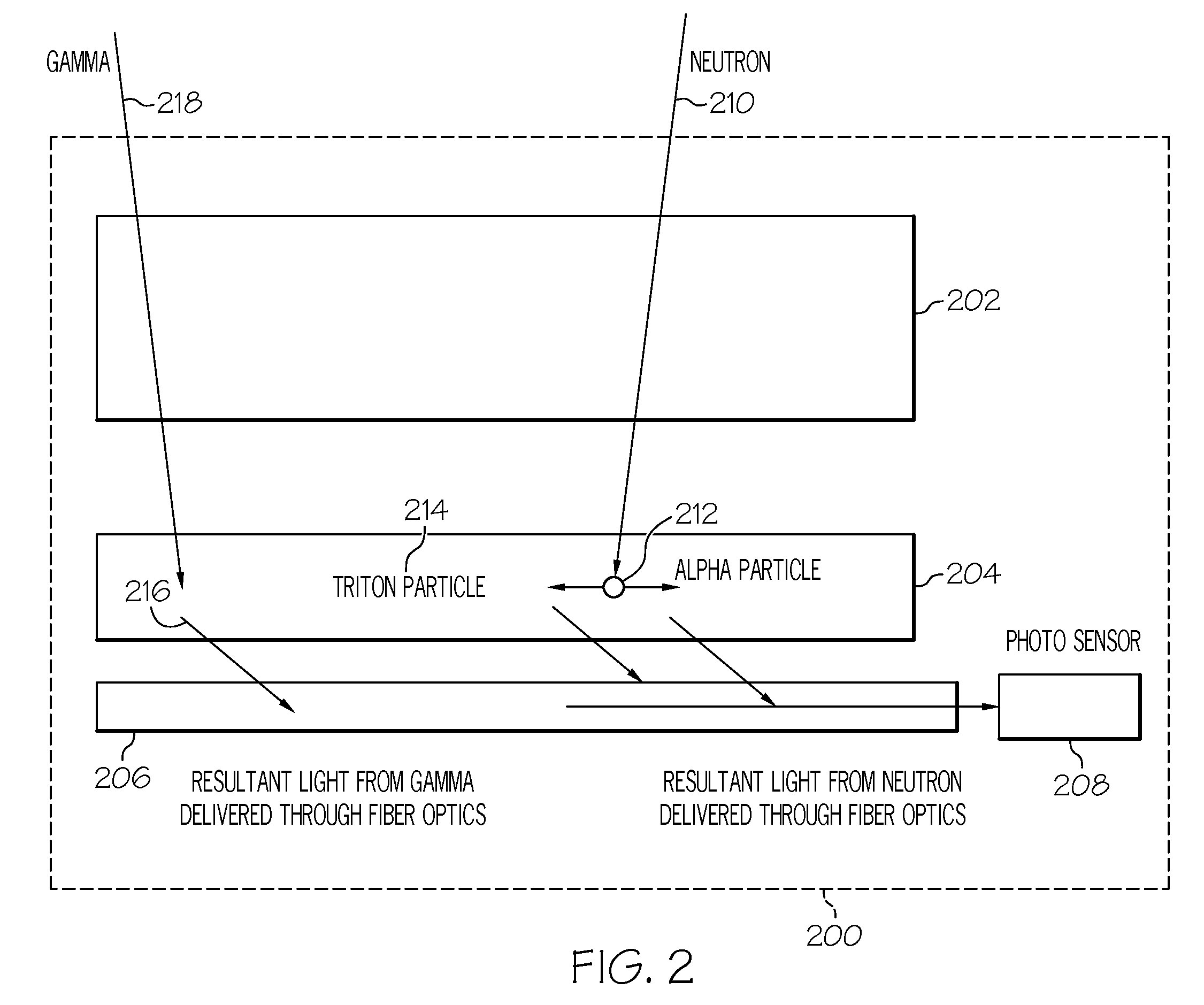

InactiveUS20100294943A1Light transmissionReduce manufacturing costMeasurement with scintillation detectorsPhotometryFiberRadioactive agent

A scintillator system is provided to detect the presence of fissile material and radioactive material. One or more neutron detectors include scintillator material, and are optically coupled to one or more wavelength shifting fiber optic light guide media that extend from the scintillator material to guide light from the scintillator material to a photosensor. An electrical output of the photosensor is connected to an input of a pre-amp circuit designed to provide an optimum pulse shape for each of neutron pulses and gamma pulses in the detector signals. Scintillator material as neutron detector elements can be spatially distributed with interposed moderator material. Individual neutron detectors can be spatially distributed with interposed moderator material. Detectors and moderators can be arranged in a V-shape or a corrugated configuration.

Owner:EMR RESOURCES +2

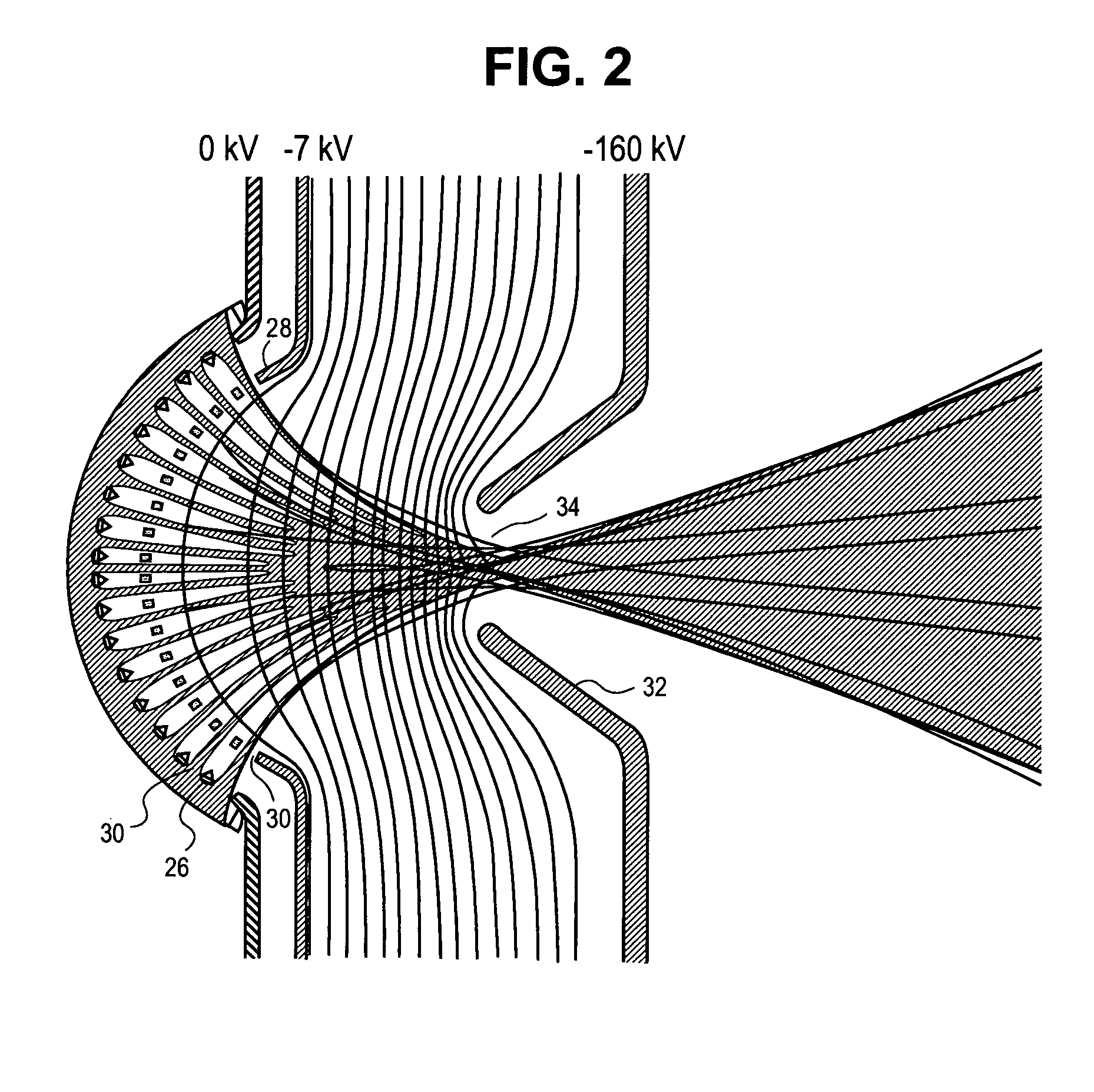

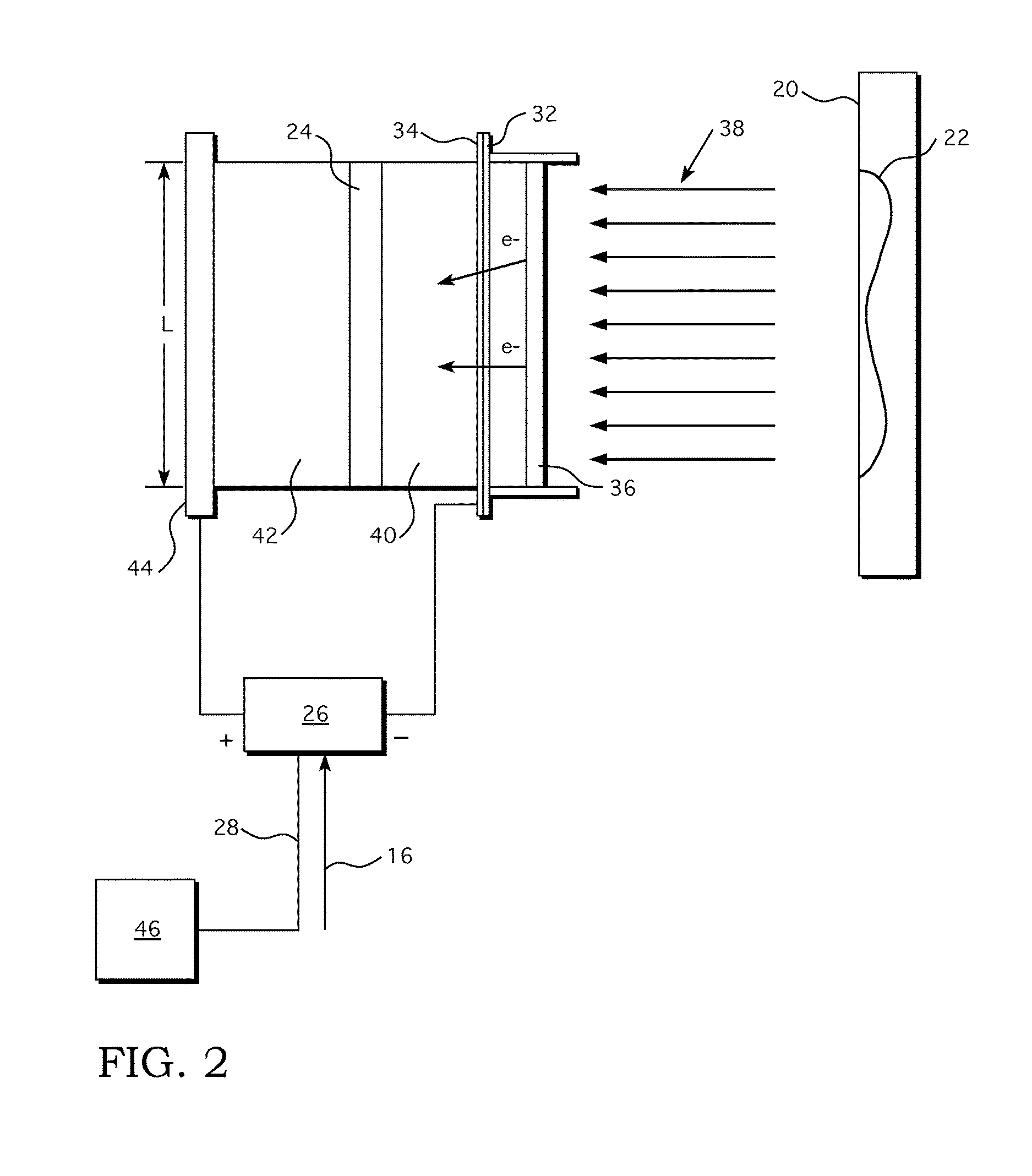

Ultra-short ion and neutron pulse production

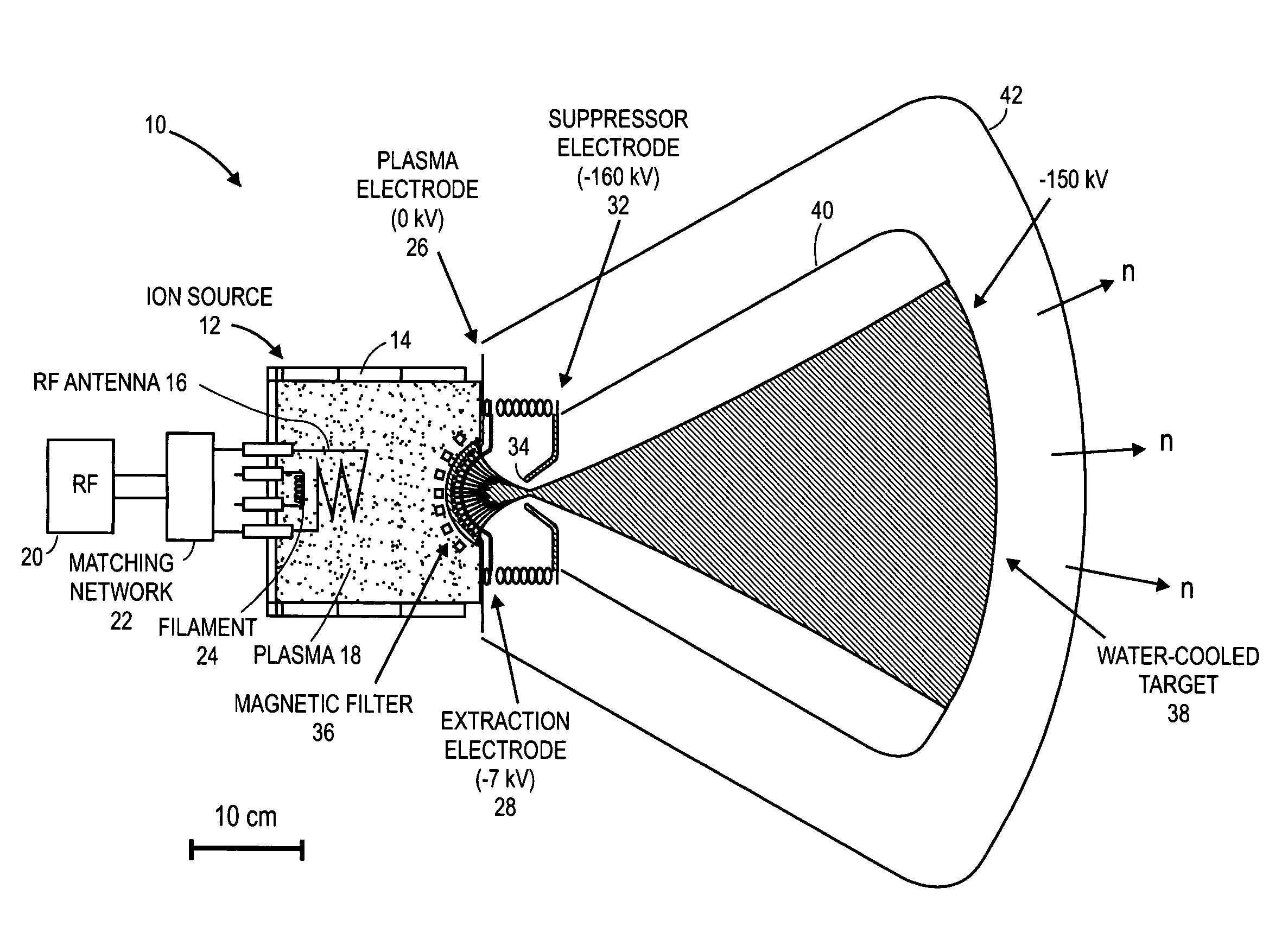

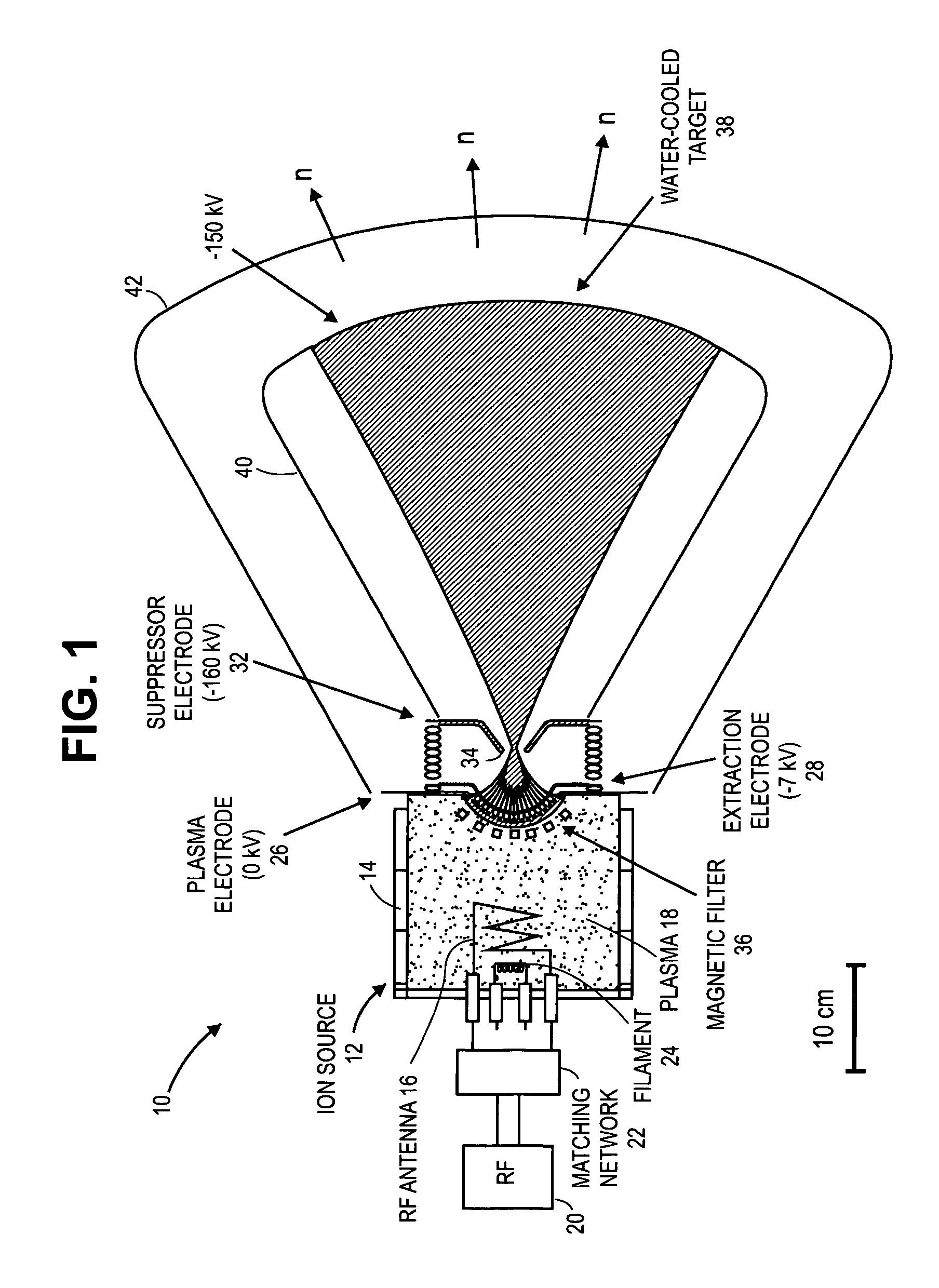

InactiveUS6985553B2Prevent leakageConversion outside reactor/acceleratorsIon beam tubesVoltage pulseNeutron pulse

An ion source has an extraction system configured to produce ultra-short ion pulses, i.e. pulses with pulse width of about 1 μs or less, and a neutron source based on the ion source produces correspondingly ultra-short neutron pulses. To form a neutron source, a neutron generating target is positioned to receive an accelerated extracted ion beam from the ion source. To produce the ultra-short ion or neutron pulses, the apertures in the extraction system of the ion source are suitably sized to prevent ion leakage, the electrodes are suitably spaced, and the extraction voltage is controlled. The ion beam current leaving the source is regulated by applying ultra-short voltage pulses of a suitable voltage on the extraction electrode.

Owner:RGT UNIV OF CALIFORNIA

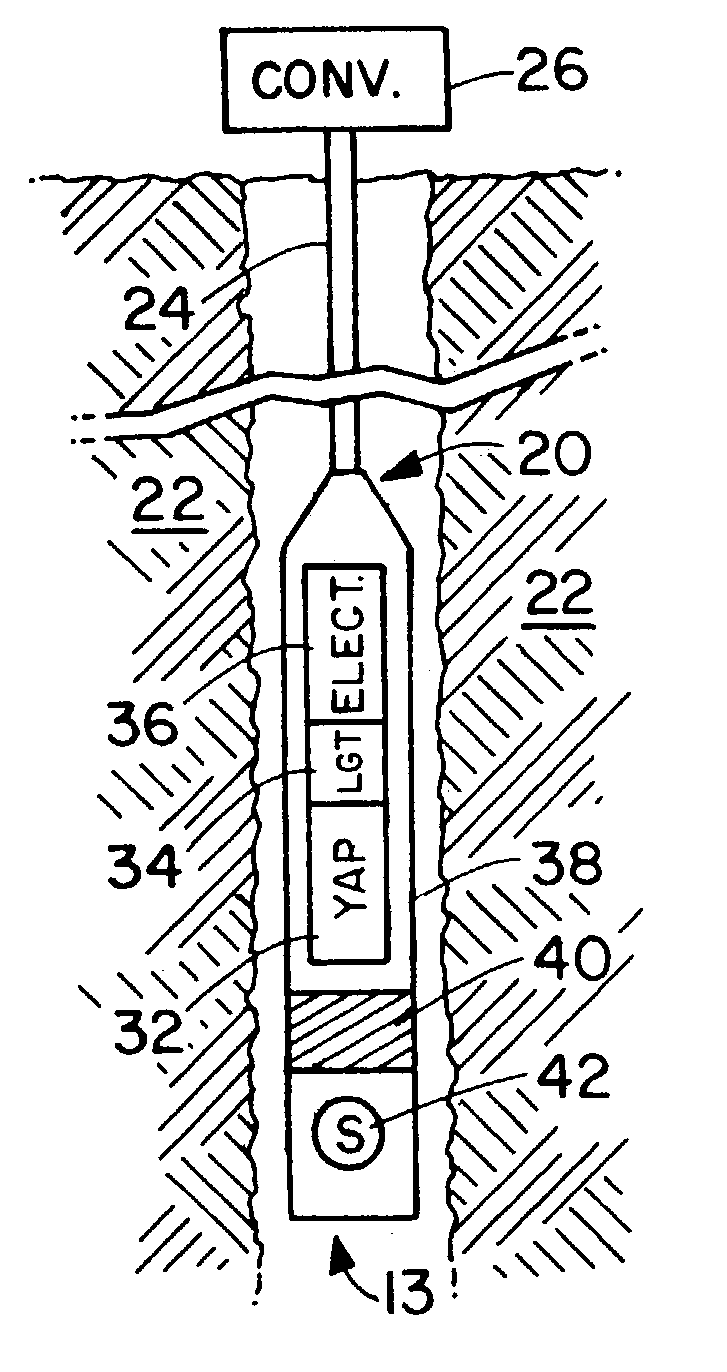

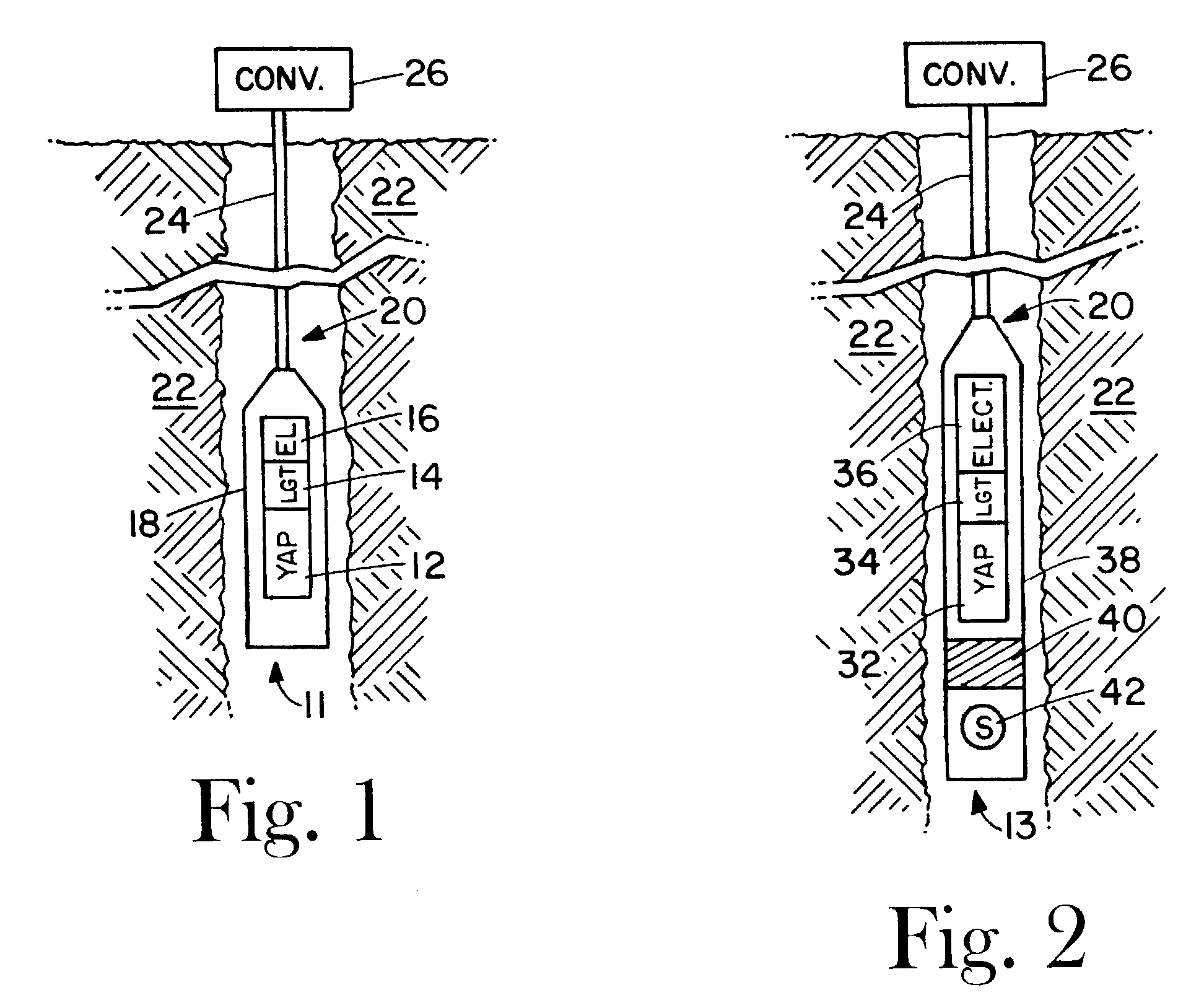

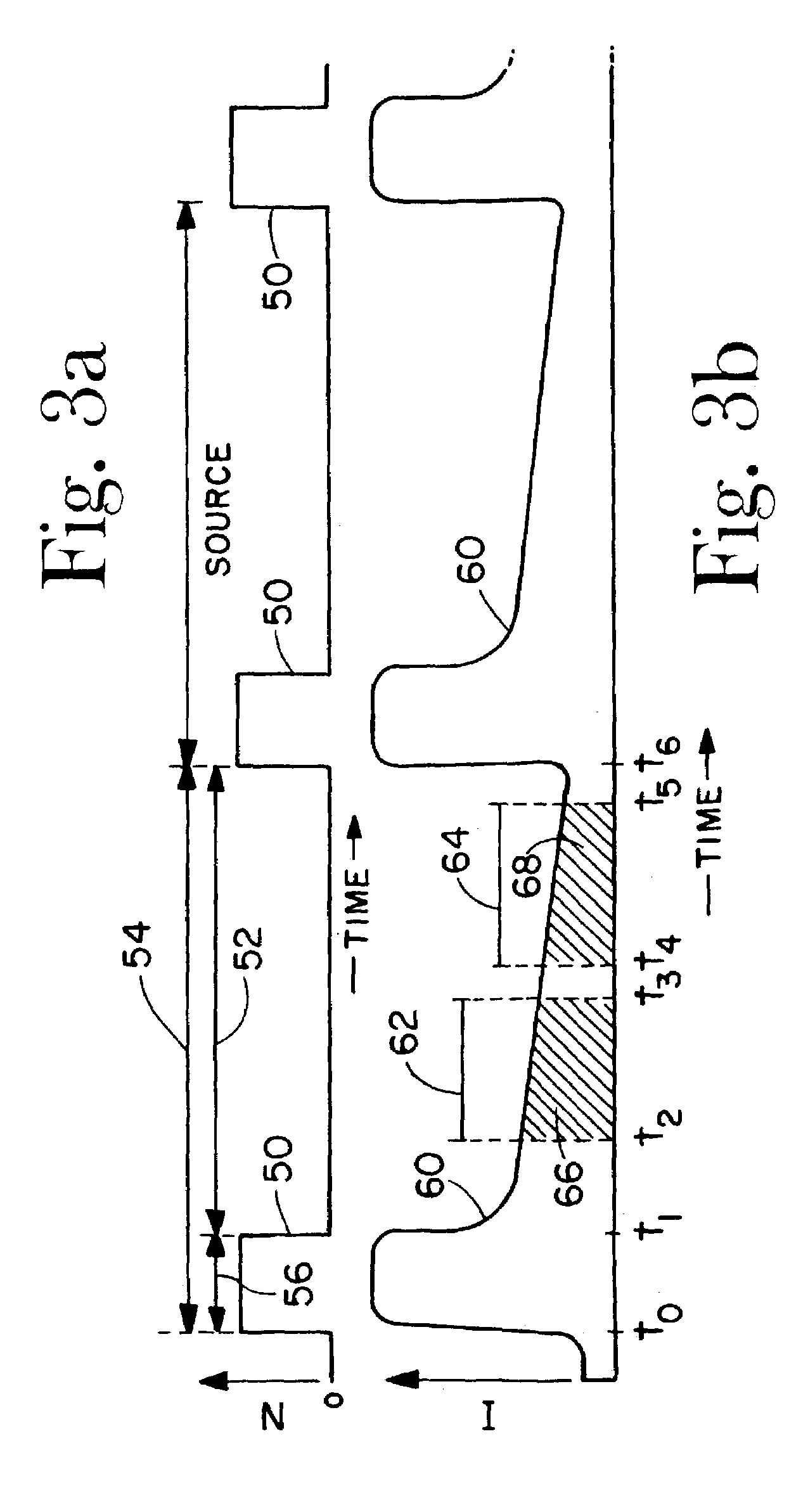

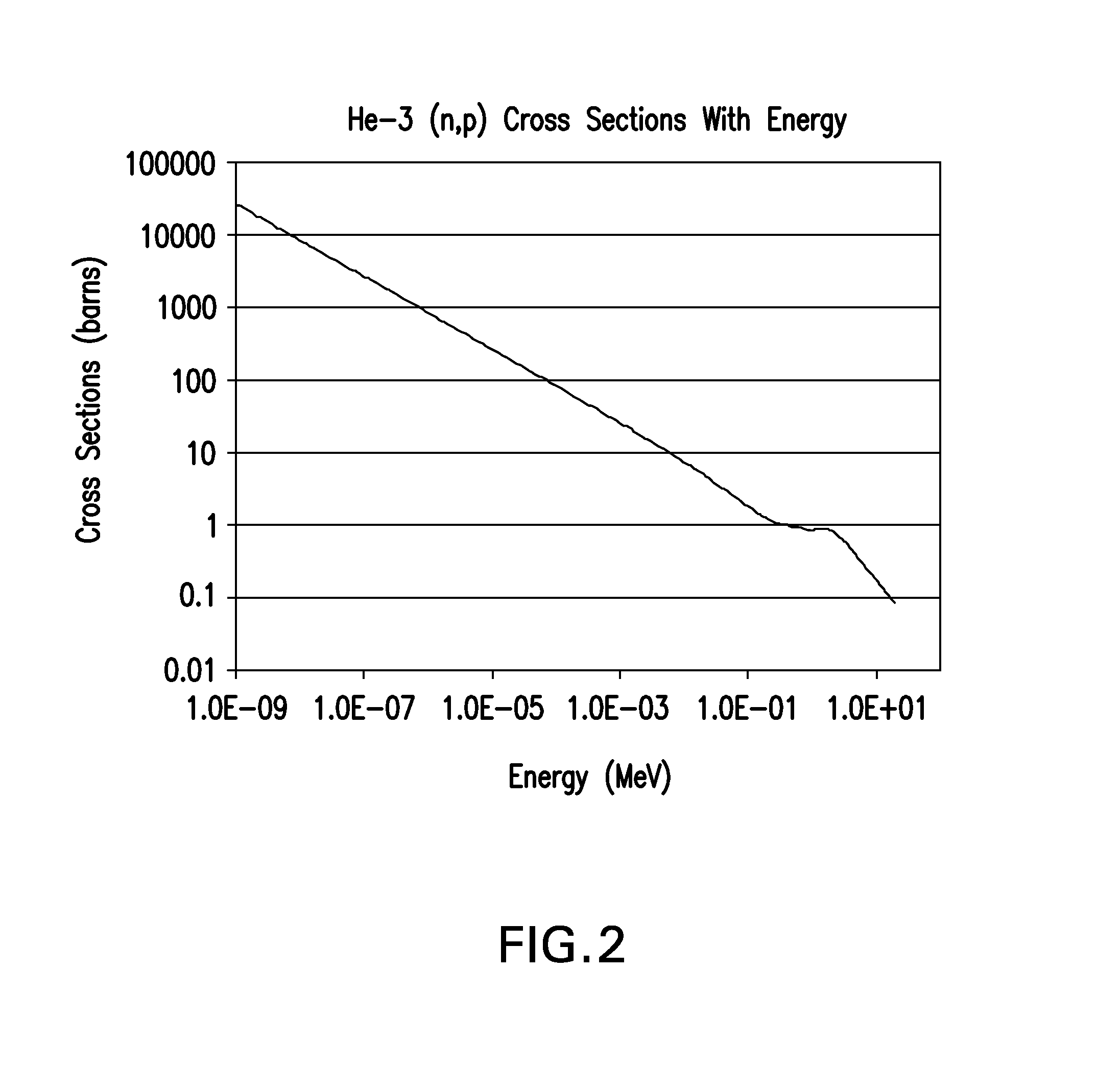

Method and apparatus for measuring radiation in a borehole

InactiveUS7139350B2Subject to damageImprove design flexibilityConversion outside reactor/acceleratorsNuclear radiation detectionLight sensingScintillation crystals

Apparatus and methods for measuring radiation in a borehole environment using a YAlO3:Ce (YAP) scintillation crystal. Borehole instruments are disclosed which employ a gamma ray detector comprising a YAP scintillator coupled to a light sensing means such as a photomultiplier tube. One instrument embodiment combines a YAP scintillation detector and a source of pulsed neutrons. Borehole environs are irradiated with neutrons, and induced gamma radiation is measured using a YAP scintillation detector. Response of the detector is used to determine characteristics of the borehole environs. Mechanical and physical properties of YAP are utilized to obtain improved measurements. The relatively short light decay constant of YAP minimized pulse pile-up in the detector when measurements require that the detector be operated during a neutron pulse.

Owner:WEATHERFORD TECH HLDG LLC

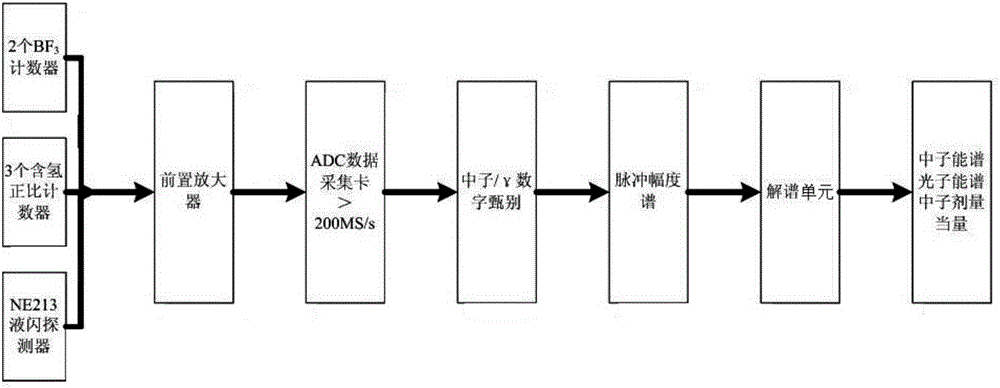

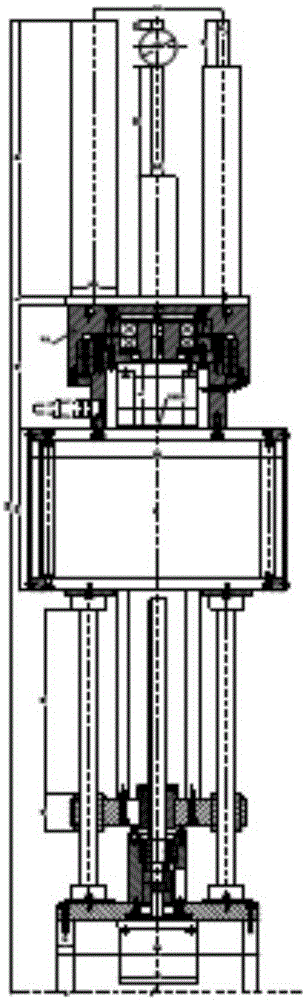

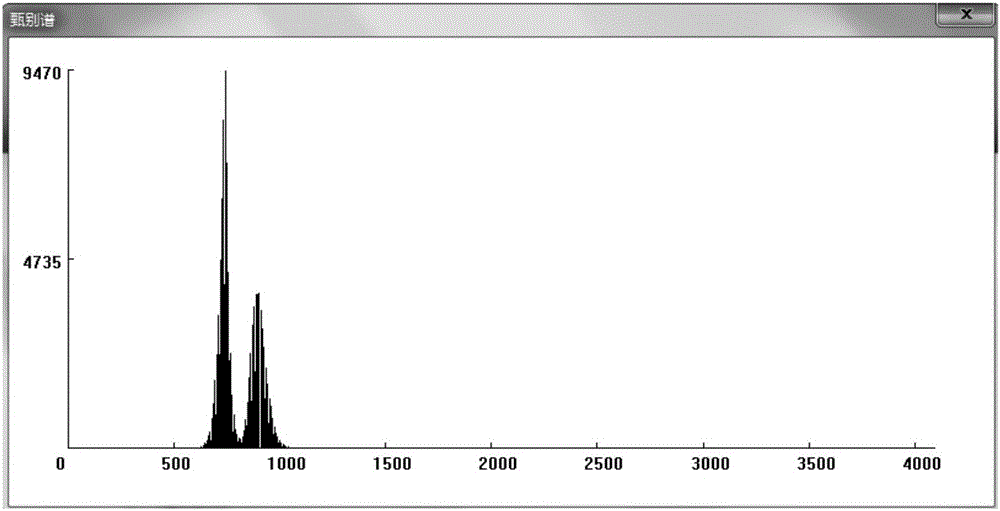

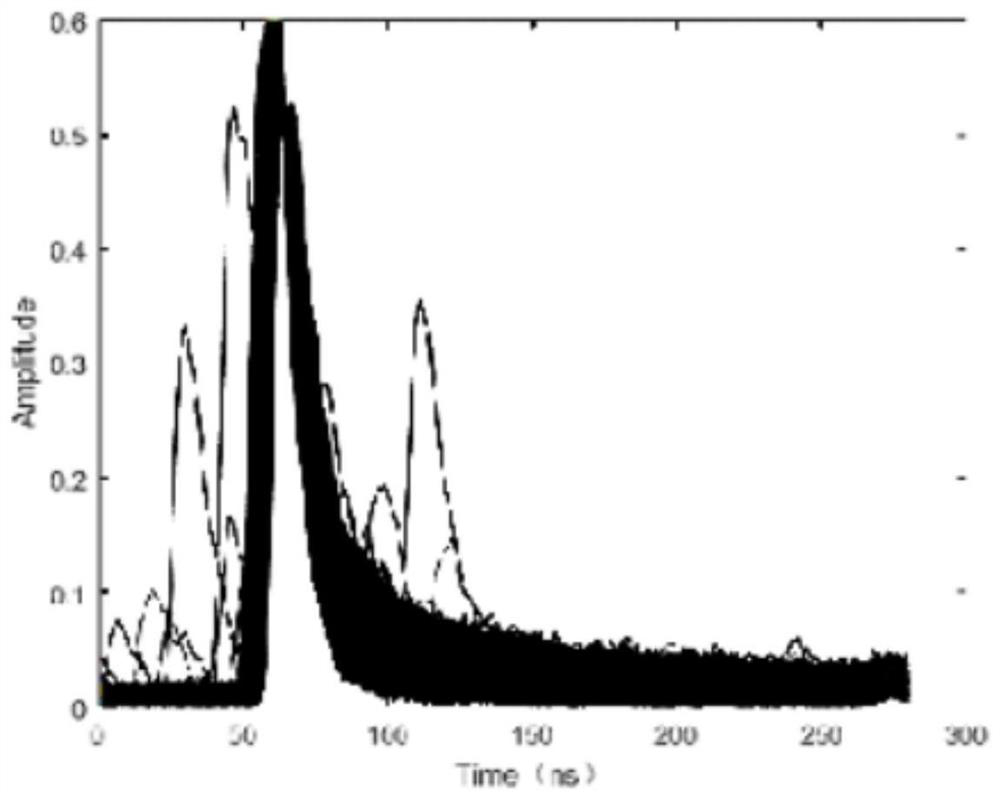

Digital neutron spectrometer

ActiveCN105022084AReduce Interscattering EffectsGood real-time discrimination abilityMeasurement with scintillation detectorsTime discriminationGamma energy

The invention relates to a digital neutron spectrometer, which comprises a detector unit, a mechanical control unit, a digital acquisition unit and a discrimination unit, wherein the detector unit is used for detecting neutron information of a radiation field to be detected; the mechanical control unit is used for controlling rotation and lifting of the detector unit; the digital acquisition unit is used for converting analog signals generated by the detector unit into digital signals; and the discrimination unit is used for analyzing the shape of pulses of the detector unit, and judging whether the pulses belong to neutron pulse signals or Gamma-ray pulse signals in real time. The neutron spectrometer provided by the invention is wide in neutron energy measurement range, can effectively determine an effective central position of detector measurement, reduce mutual scattering influences of detectors, has a good neutron and photon real-time discrimination ability, and respectively gives neutron and Gamma energy spectrum information in a neutron-Gamma mixed filed in real time.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

High performance neutron detector with near zero gamma cross talk

InactiveUS8330115B2Increase the number ofImprove efficiencyMeasurement with scintillation detectorsPhotometryFiberRadioactive agent

Owner:EMR RESOURCES +2

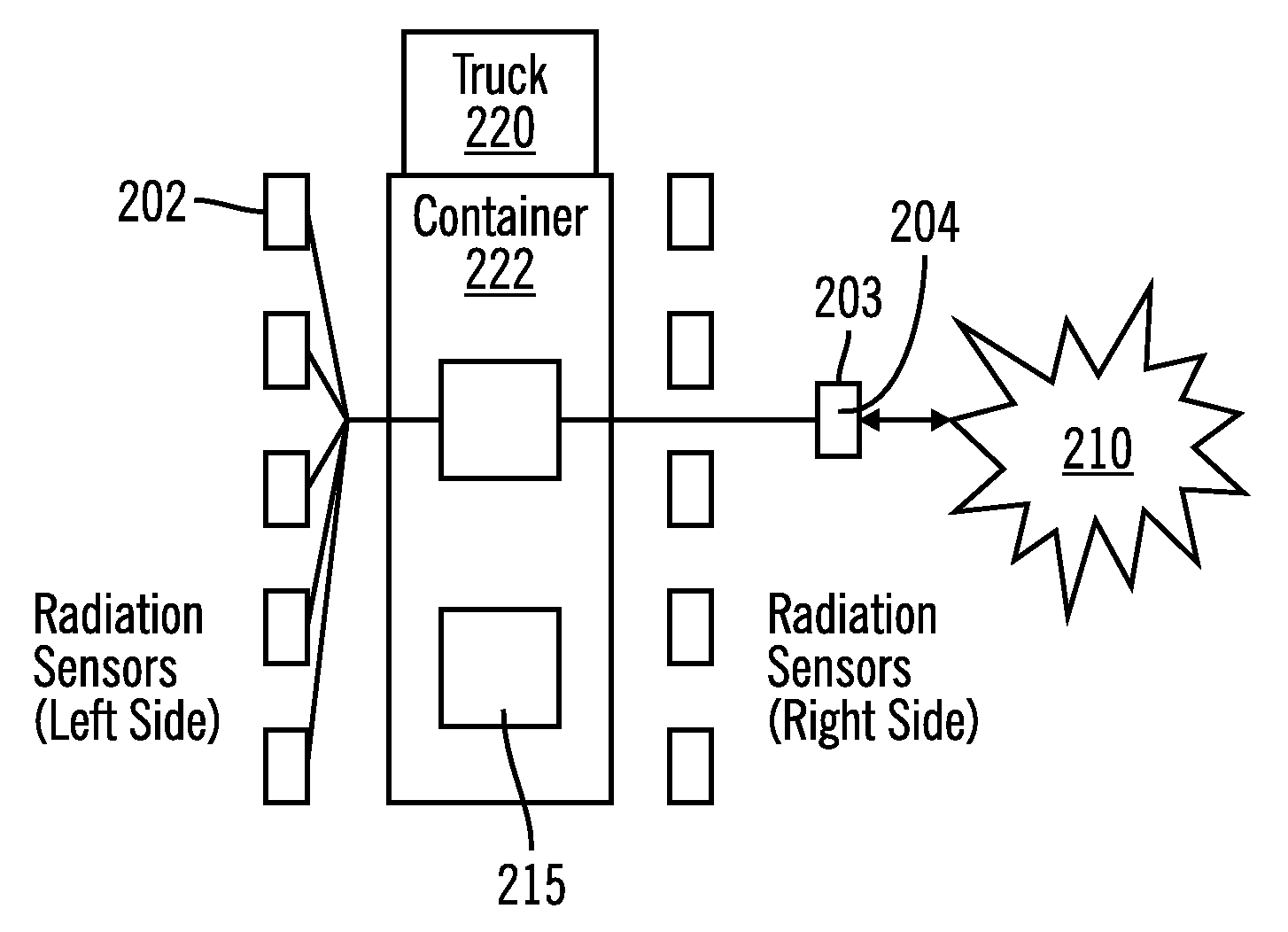

Multi-stage system for verification of container contents

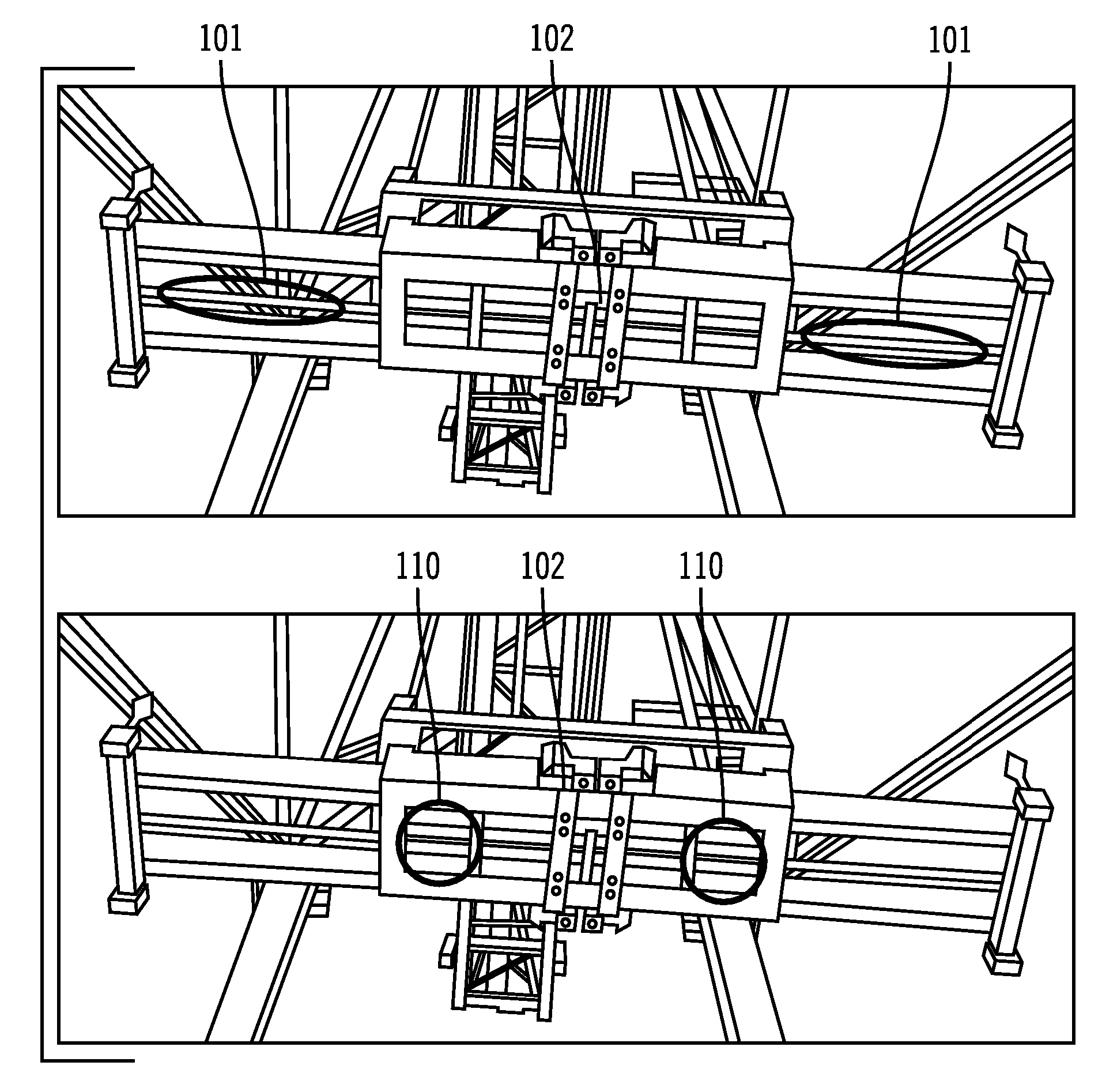

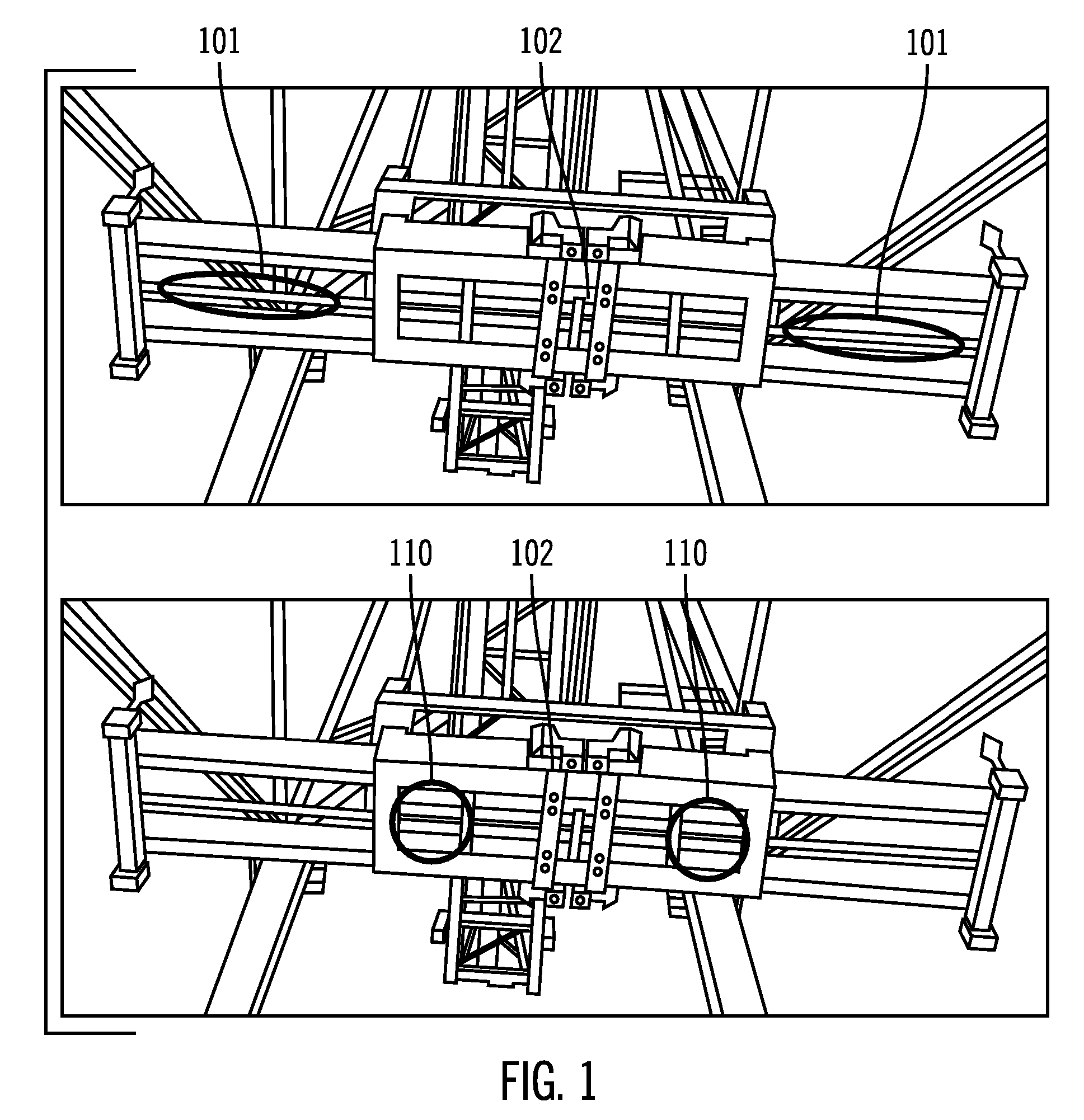

InactiveUS20090101826A1Further analysisMeasurement with semiconductor devicesDigital computer detailsData acquisitionNeutron pulse

A multi-stage process utilizing one or more radiation sensors on a distributed network for the detection and identification of radiation, explosives, and special materials within a shipping container. The sensors are configured as nodes on the network. The system supports extended time options at each node and the ability to combine data from multiple nodes for the data acquisition and analysis of shipping containers. The system collects radiation data from one or more nodes and compares the collected data to one or more stored spectral images representing one or more isotopes to identify one or more isotopes present. The identified one or more isotopes present are corresponded to possible materials or goods that they represent. The possible materials or goods are compared with the manifest relating to the container to confirm the identity of materials or goods contained in the container or to detect and / or identify unauthorized materials or goods in the container. The containers are monitored and tracked as they are moved between the nodes. A central monitoring station monitors the radiological sensors, the information from the nodes and the tracking of the shipping containers. For shielded materials, explosives and other types of material detection, a neutron pulse device could be incorporated into the spreader bar position, the secondary position or both.

Owner:S2 PHOTONICS LLC +1

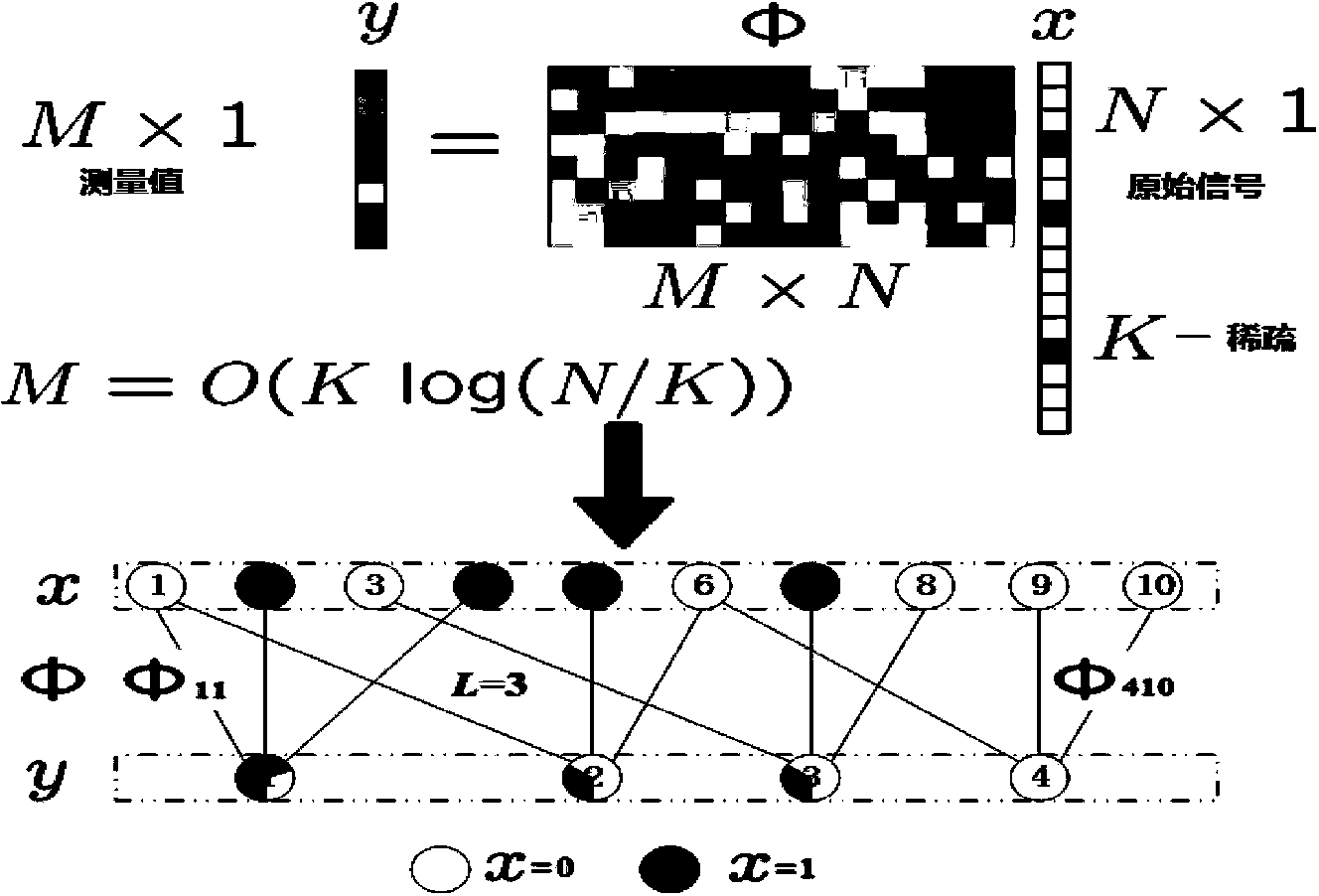

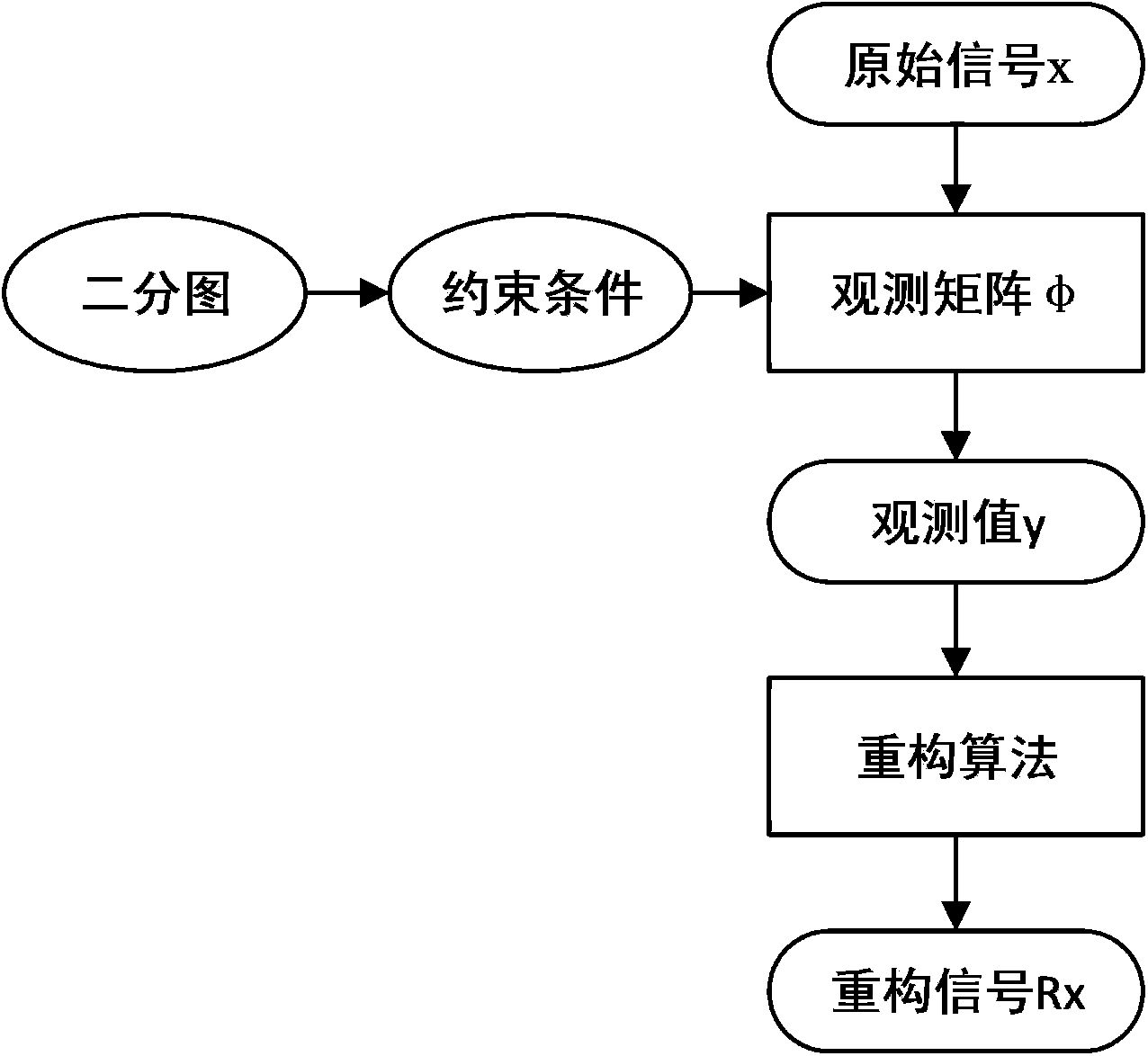

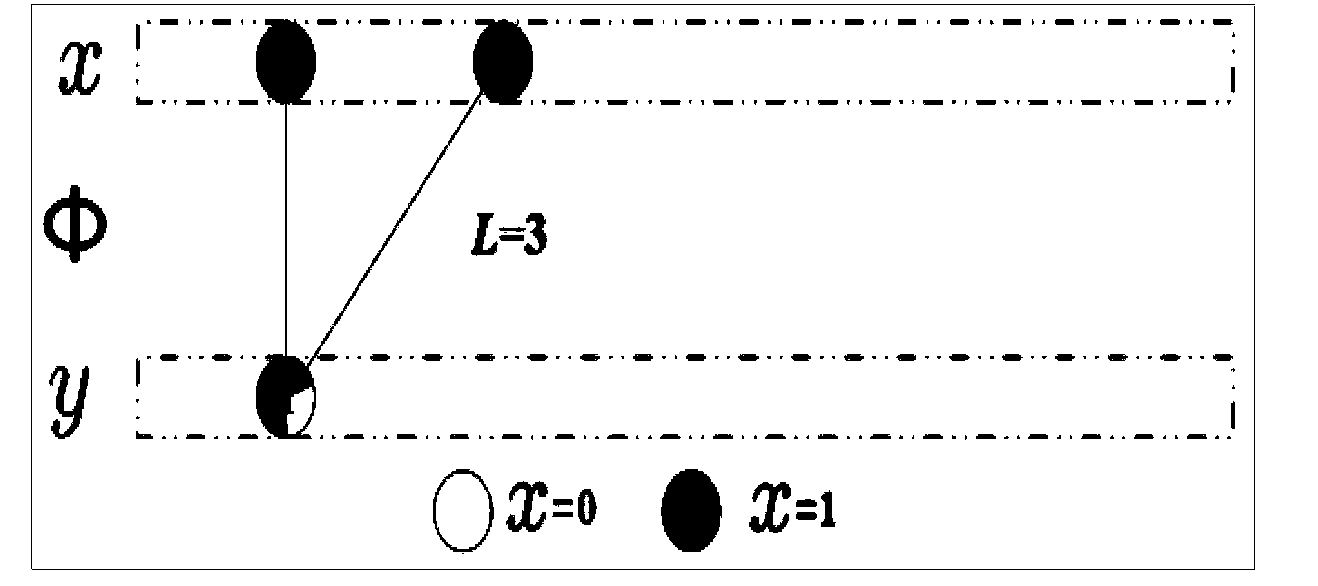

Effective '0,1' sparse signal compressed sensing reconstruction method

ActiveCN103825621AImplement refactoringNo reconstruction errorsCode conversionReconstruction methodReconstruction algorithm

The invention discloses an effective '0,1' sparse signal compressed sensing reconstruction method. The method mainly comprises a sparse and uniform measurement matrix construction part and an iteration reconstruction order part based on a bipartite graph. According to the method, a bipartite graph model in a graph theory is ingeniously introduced, the minimum cover characteristic of the bipartite graph is closely combined, a constraint condition is appropriately added, and the sparse, uniform and minimally-covered measurement matrix is constructed. Based on the special structure that the '0,1' sparse signals are fully utilized in an iteration reconstruction algorithm based on the bipartite, the connecting line phi ij of the bipartite graph is deleted and a measurement value y is updated through an iteration method, and an original signal reconstruction method is achieved finally. According to the method, the bipartite graph model in the graph theory is introduced in compressed sensing sampling and reconstruction, compared with an l1 norm minimization method, reconstruction errors do not exist, the method can be applied to compressive sampling of neutron pulse sequences, earthquake signals, wireless sensor networks, binary images and the like.

Owner:CHONGQING UNIV

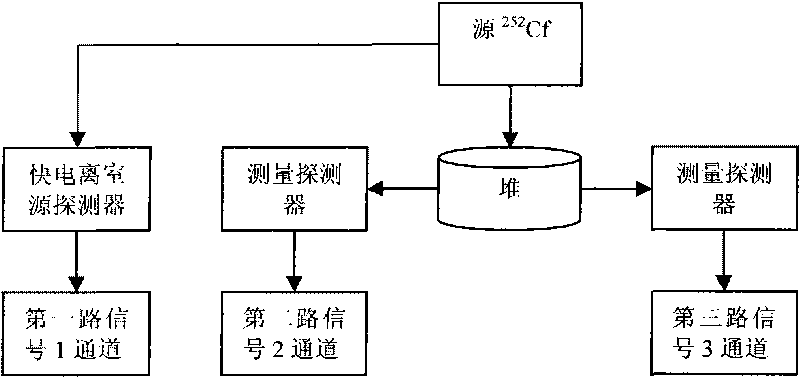

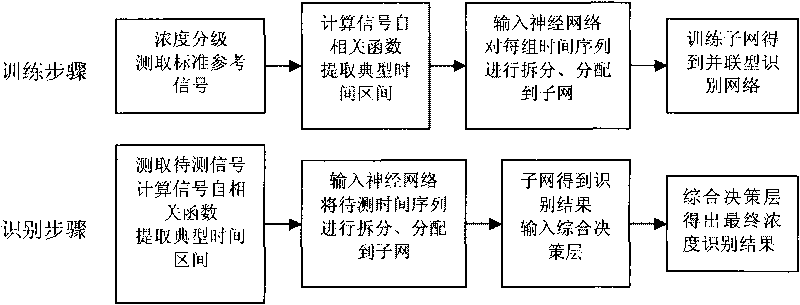

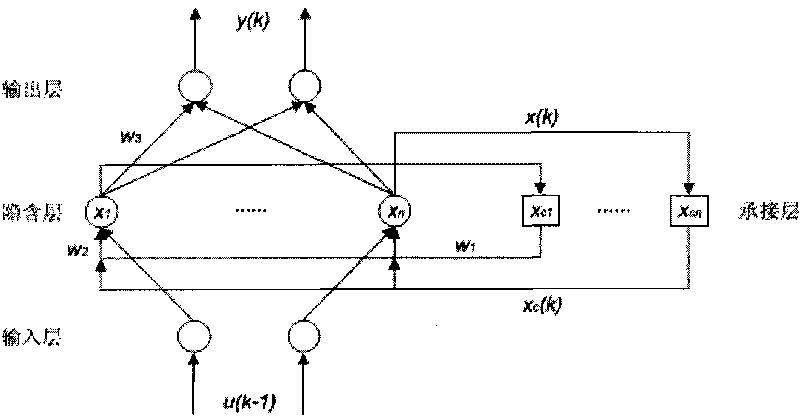

Parallel type genetic Elman neural network-based source driving 235U concentration recognition method

InactiveCN101718769AReduce adverse effectsPlay a role in processing optimizationGenetic modelsNeural learning methodsPattern recognitionNerve network

The invention discloses a parallel type genetic Elman neural network-based source driving 235U concentration recognition method, which mainly comprises the following steps: establishing a neural network model, wherein the neural network model is structurally divided into three layers which are a data allocation layer, a sub-network layer and a comprehensive decision-making layer respectively; preprocessing an acquired neutron pulse signal auto-correlation function; inputting a processed signal auto-correlation function sample into the data allocation layer of a parallel type genetic Elman network and adopting a cyclic random multi-point sampling method to allocate the data of the sample; inputting the allocated data into each genetic Elman sub-network in the sub-network layer respectivelyfor recognition and giving recognition results; and performing comprehensive processing on the recognition results of the plurality of sub-networks by the comprehensive decision-making layer to obtain a final 235U concentration recognition result. Through the method, relatively better 235U concentration recognition effect is obtained due to relatively higher data utilization ratio and a novel network structure.

Owner:CHONGQING UNIV

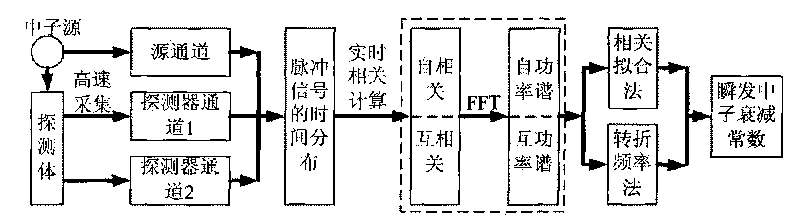

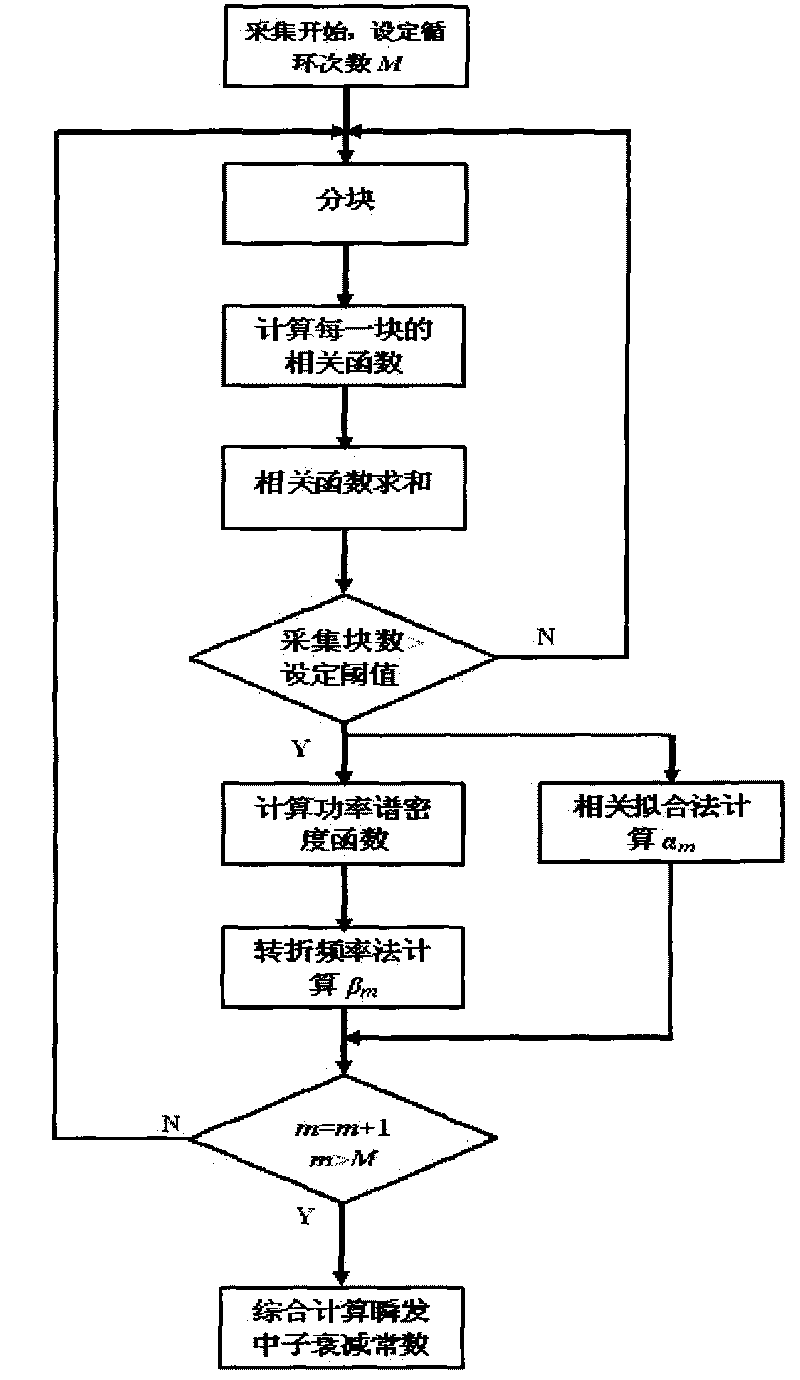

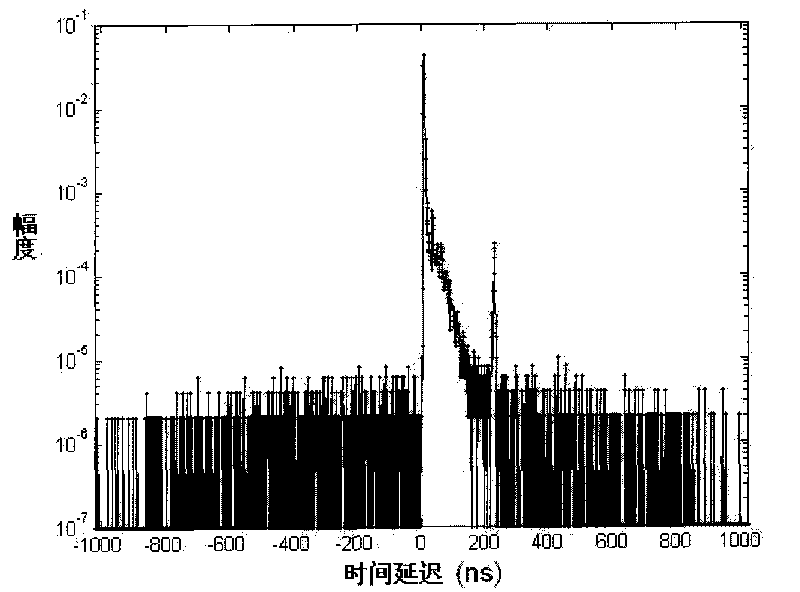

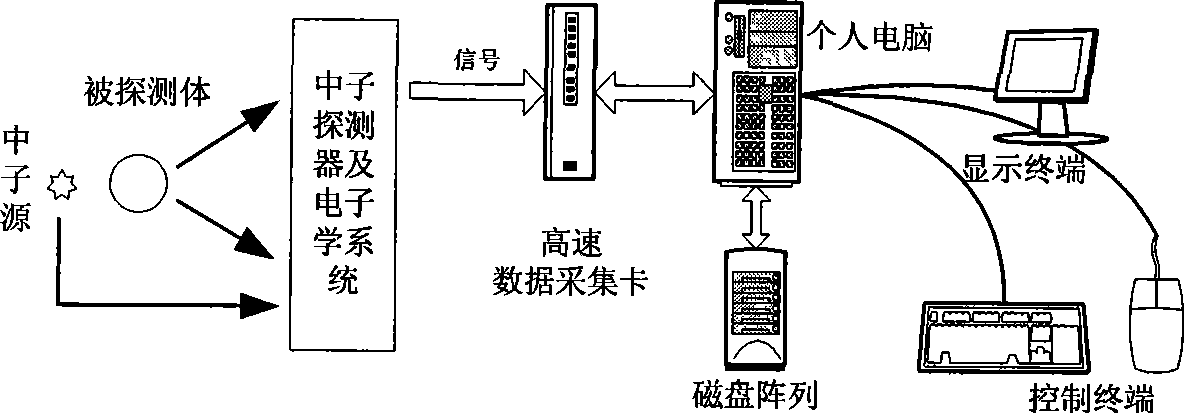

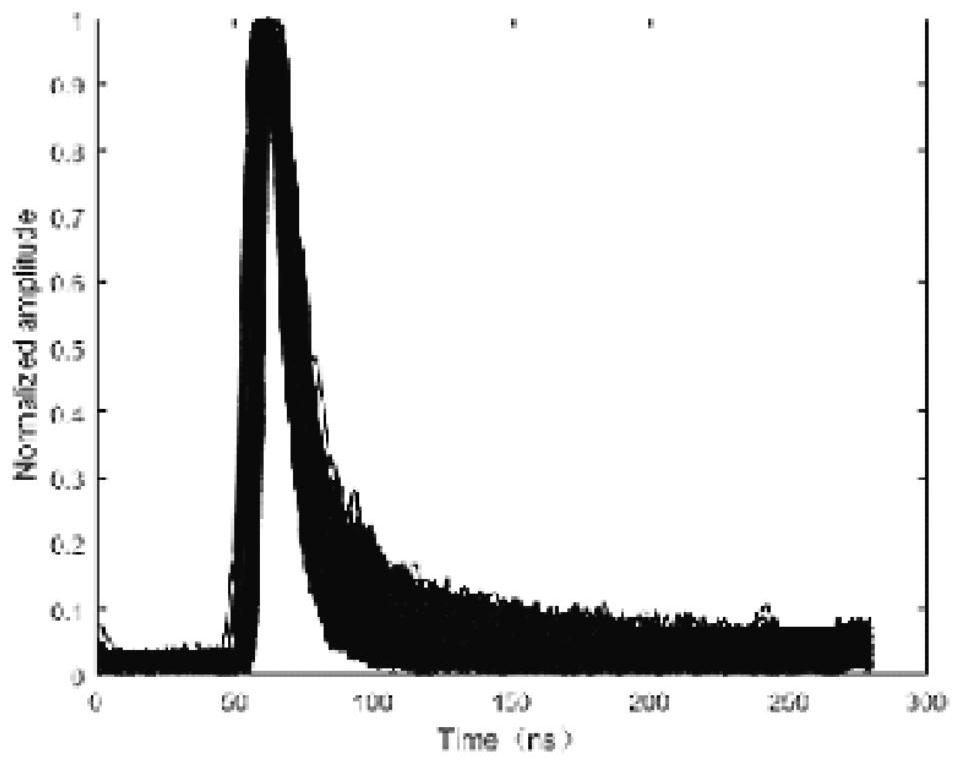

Comprehensive on-line measuring method of prompt neutron attenuation constant

InactiveCN101713830AIncrease credibilityImprove measurement efficiencyNeutron radiation measurementUltrasound attenuationTime domain

The invention discloses a comprehensive on-line measuring method of prompt neutron attenuation constant. The method mainly comprises the following stages: 1) collecting neutron pulse to obtain the time distribution of neutron pulse generated by neutron source and detecting body excited by the neutron source; 2) partitioning the collected data pack according to a given length, calculating the correlation function and power spectrum density of each block of neutron signal; 3) adopting the correlated fitting method to treat the correlation function so as to calculate the prompt neutron attenuation constant, adopting the break frequency method to treat the power spectrum density so as to calculate the prompt neutron attenuation constant; and 4) performing a comprehensive treatment to the results of the two different methods to obtain the final measuring result. The method can be used to estimate the prompt neutron attenuation constant both in time domain and frequency domain and perform measurement at the same time, thus as the operating precision of measurement increases gradually, the aim of on-line measurement is finally realized.

Owner:CHONGQING UNIV

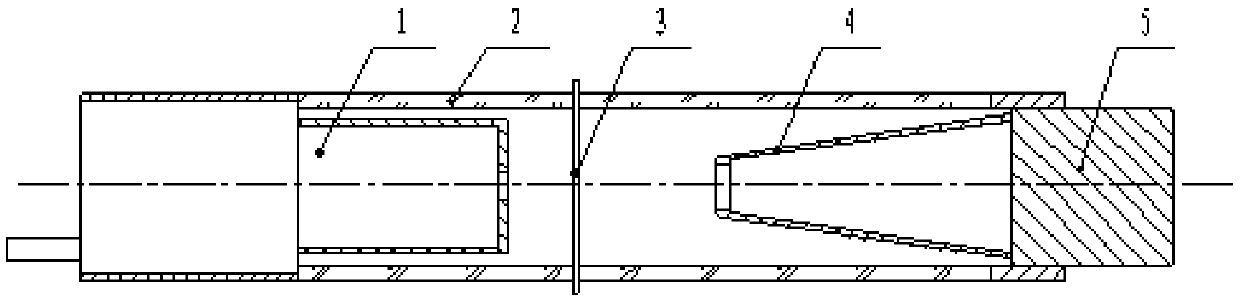

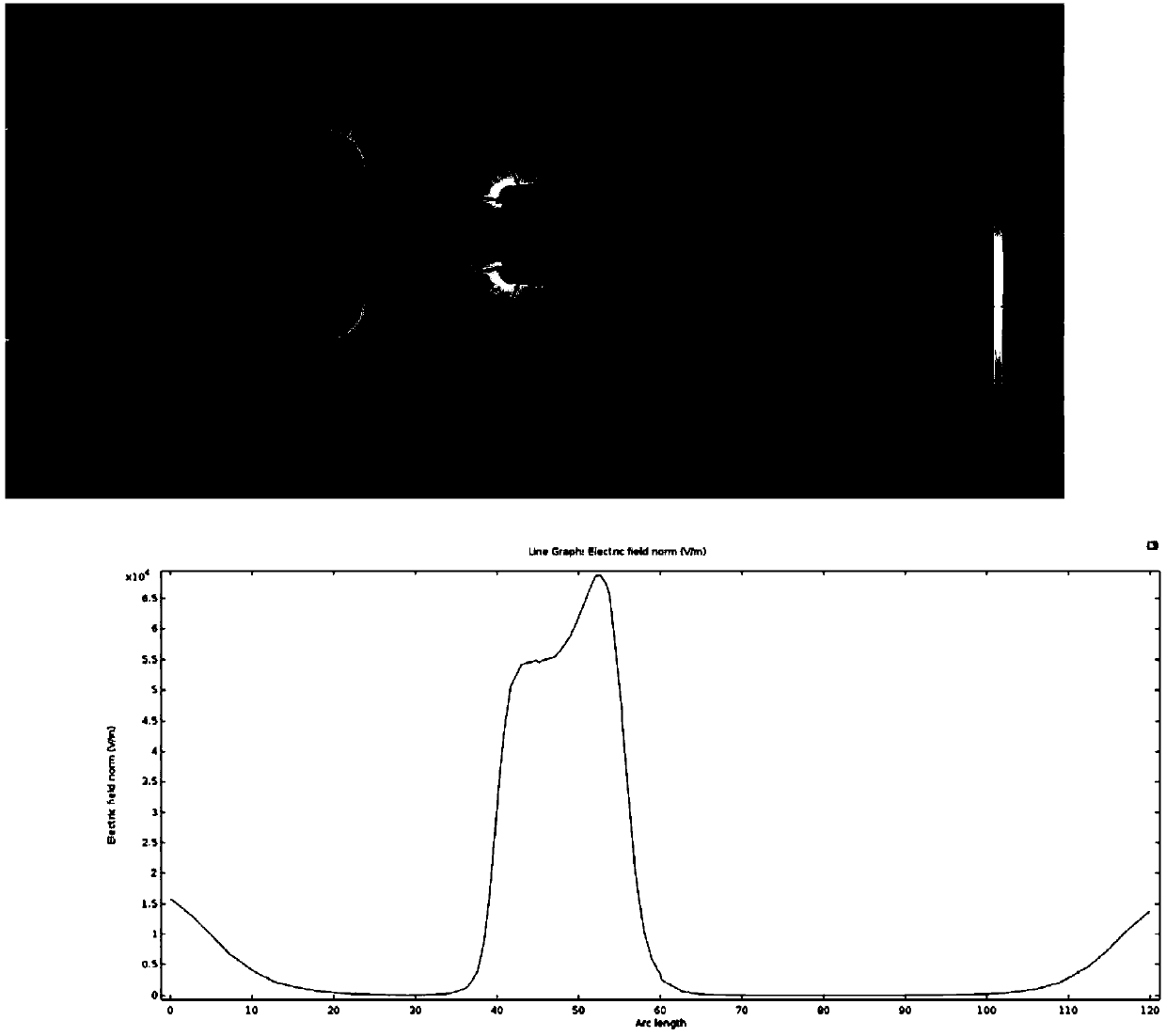

Neutron generator tube

InactiveCN107567174AReduce disturbanceGuaranteed bombardmentDirect voltage acceleratorsTarget surfaceNeutron pulse

The invention relates to the technical field of neutron source equipment, specifically to a neutron generator tube, and aims to overcome the problem that waveform of the pulse neutrons generated by bombardment of a target has delay of several or dozens of microseconds and cannot realize sharp cut-off in the prior art. According to a provided technical scheme, the neutron generator tube comprises an ion source, a shell, a gate, an accelerated pole and a target; in a vacuum cavity in the shell, the sheet-like gate is arranged between the ion source and the accelerated pole; the gate is preparedfrom a metal molybdenum material and net-shaped grids are arranged on the gate; the gate is equivalent to ''door'' for controlling an ion beam; in a started state, the ion beam is led from the ion source and is accelerated to bomb the target surface to generate neutrons; and in a closed state, the ion beam is not led from the ion source, and the neutron tube does not generate neutrons. The waveform delay of the neutron pulse generated by the neutron generator tube can be shortened to be within 5[mu]s, so that sharp cut-off can be realized.

Owner:XIAN TECH UNIV

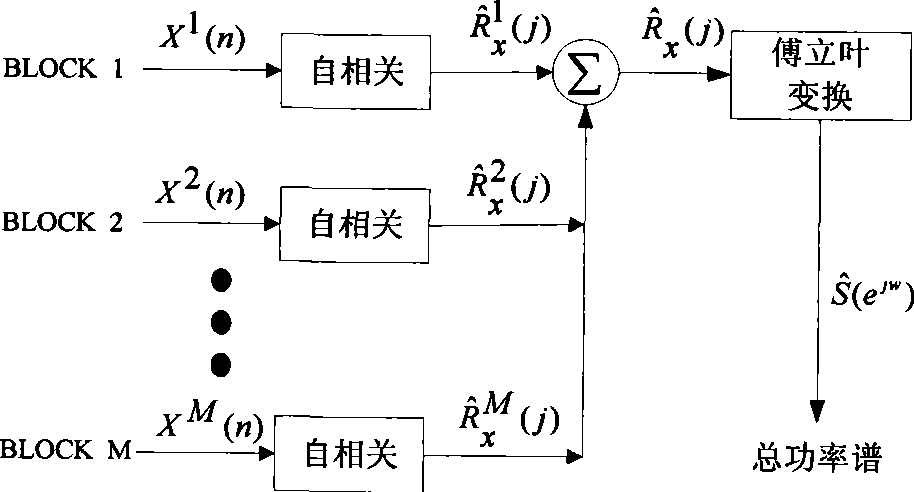

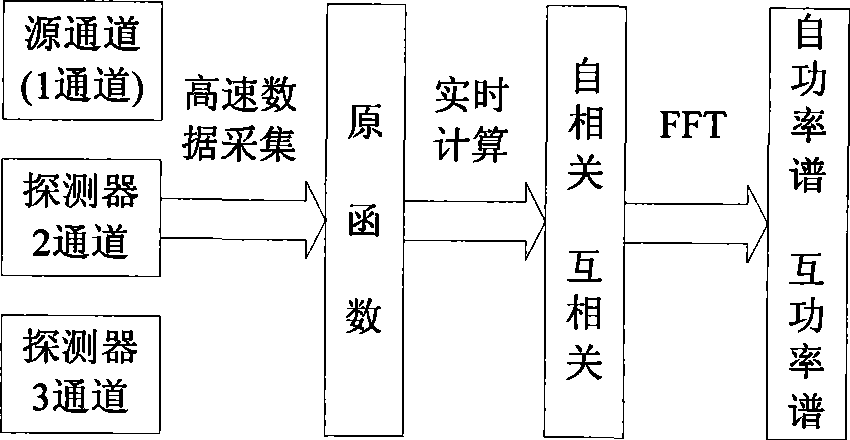

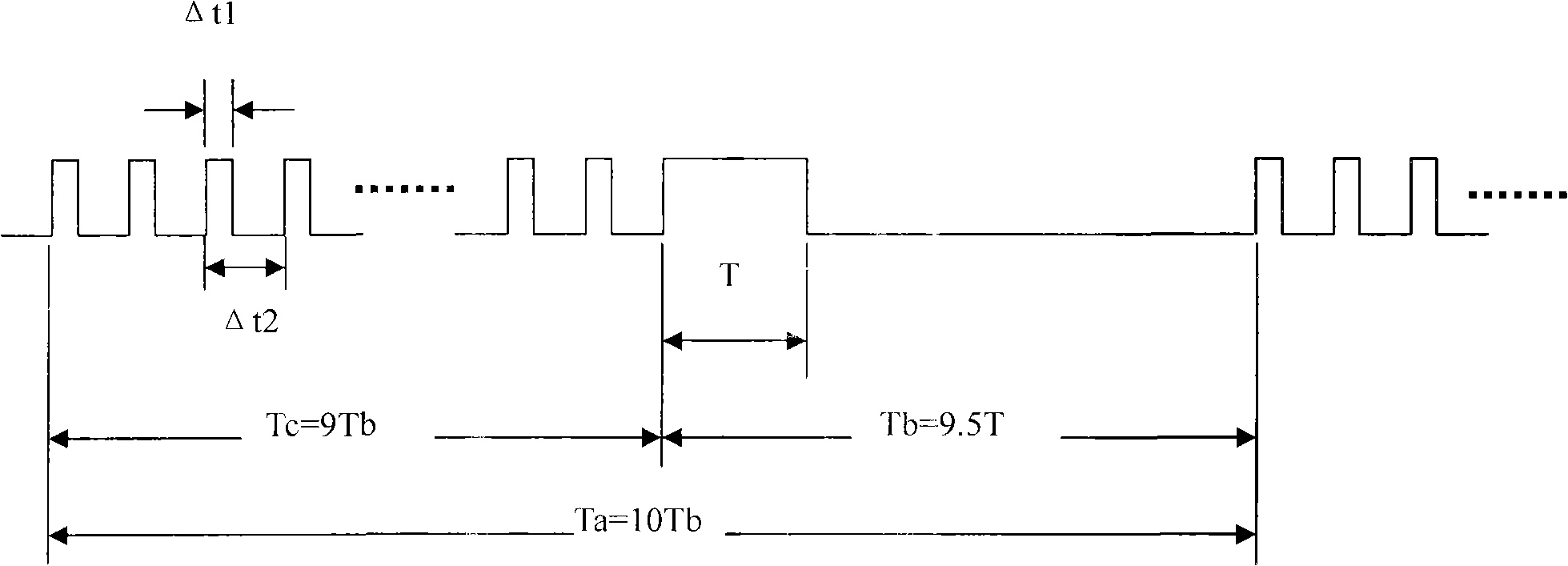

Spectral analysis method for neutron pulse sequences

InactiveCN101533045AReal-time analysisImprove computing efficiencySpectral/fourier analysisNeutron radiation measurementFrequency spectrumNetwork packet

The invention relates to a spectral analysis method for neutron pulse sequences. The method comprises the following steps: (1) acquiring neutron pulse data to obtain a neutron source and the time distribution of the neutron detection counting produced by a detected body which is excitated by the neutron source; (2) partitioning the acquired data package into blocks which are continuous without intervals according to a certain length to obtain neutron pulse original sequences in the blocks; (3) carrying out relevant calculation on the data in the data blocks to obtain correlation sequences of the data blocks or among the data blocks; and (4) further calculating correlation sequences on the data blocks or among the data blocks to obtain a power spectrum. The method is characterized in that: a quick deviation method is used in the relevant calculation of the data in the data blocks in the step (3). The spectral analysis method can realize the real-time spectral analysis of the neutron pulse sequences through real time computation quick deviation algorithm and the optimization of the power spectrum calculation procedures.

Owner:CHONGQING UNIV

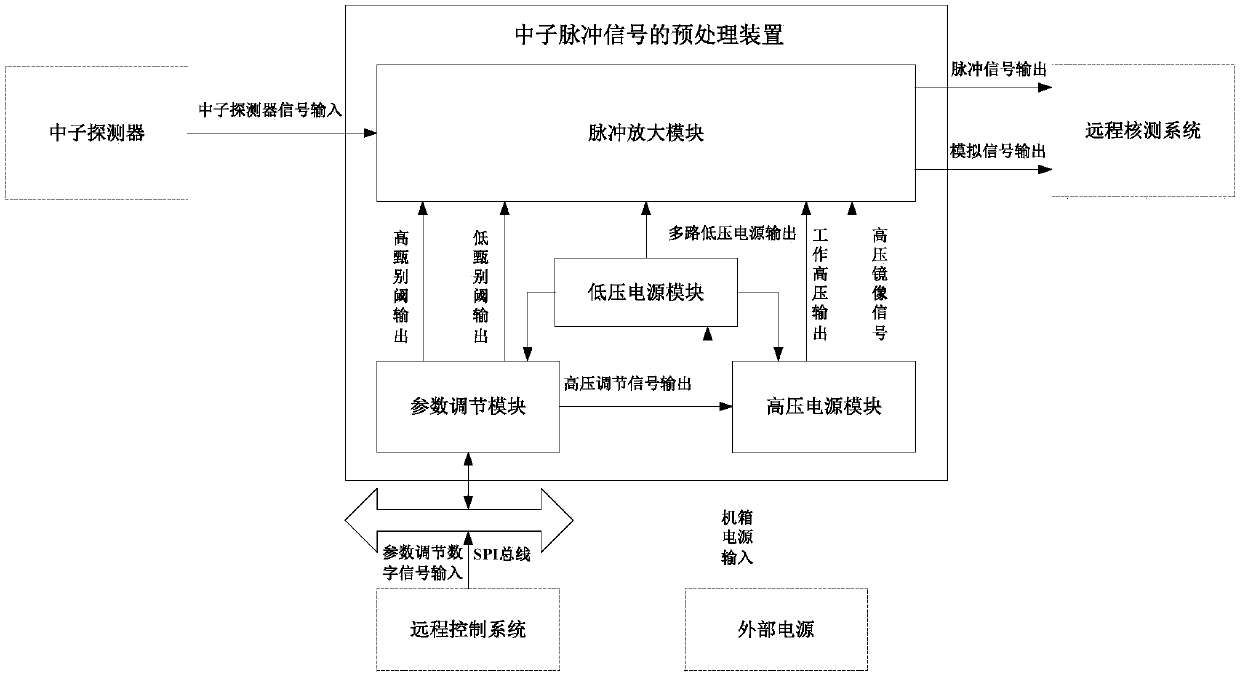

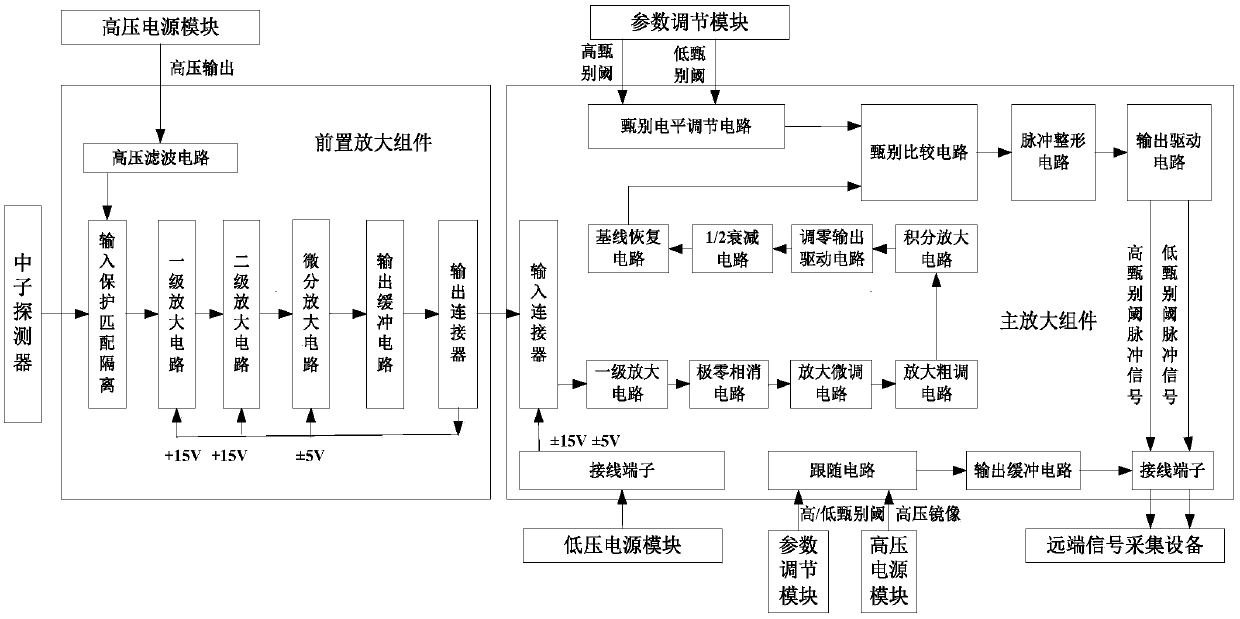

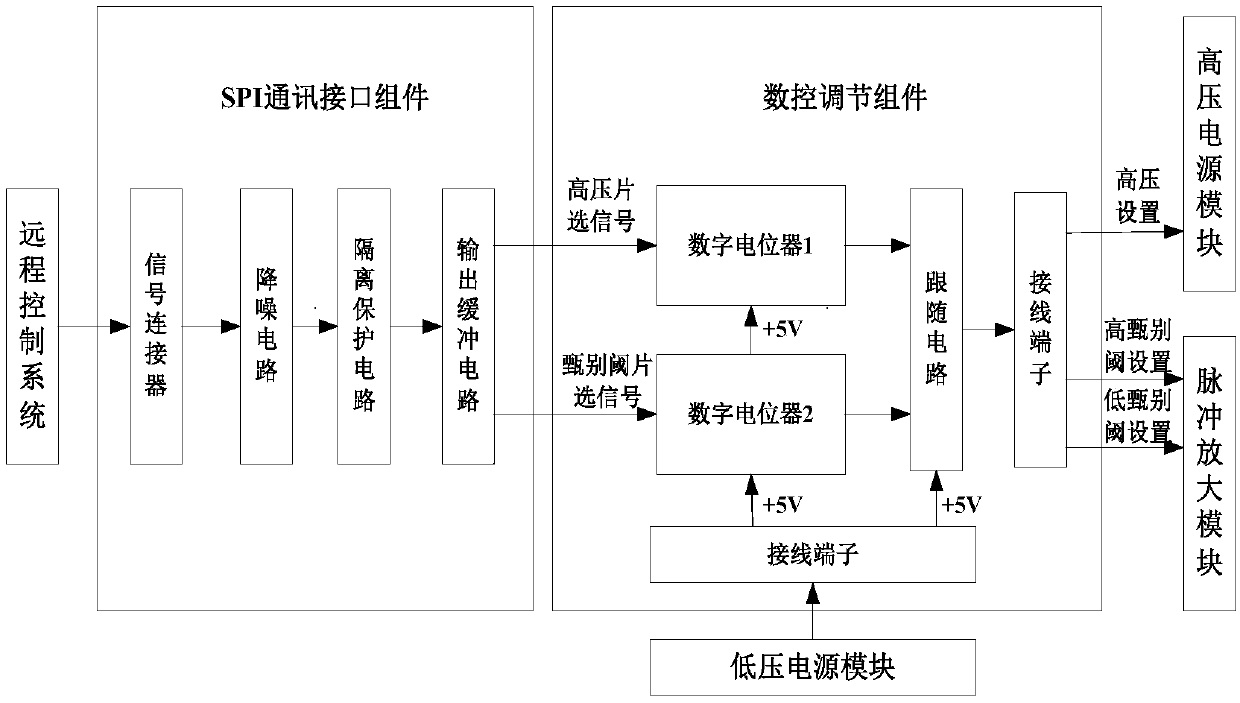

Preprocessing device for neutron pulse signals in reactor

ActiveCN109581922AAchieving a modular designEnables integrated preprocessingProgramme controlComputer controlLow voltageControl system

The invention discloses a preprocessing device for neutron pulse signals in a reactor. The preprocessing device comprises a pulse amplifying module, a parameter adjusting module, a low-voltage power supply module and a high-voltage power supply module. The pulse amplifying module performs preprocessing such as discriminating, shaping, and amplifying on the pulse signals output by a neutron detector and then inputs the pulse signals to a remote pulse signal acquiring device; the parameter adjusting module outputs control parameters to the pulse amplifying module and the high-voltage power supply module respectively, and the parameter adjusting module is connected to a remote control system; remote setting and adjusting of the control parameters are realized by the remote control system; thelow-voltage power supply module provides the power supply by an external power supply, and provides a working power supply for the pulse amplifying module, the high-voltage power supply module and the parameter adjusting module respectively; the high-voltage power supply module provides a high-voltage power supply signal and a high-voltage mirror signal for the pulse amplifying module. The preprocessing device has the advantages of integration and intelligence, and solves the problems that signal transmitting interference in a existing system is large and the stability for parameter adjustingis low.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Pulsed neutron generated prompt gamma emission measurement system for surface defect detection and analysis

ActiveUS9528952B1Material analysis using wave/particle radiationNeutron radiation measurementNeutron pulseGamma ray

A method of determining structural defects in a component that utilizes neutron activation of a solution having the ability to penetrate small cracks on the surface of a material via capillary absorption that produces a discernable prompt gamma release of a defined energy when exposed to a neutron pulse. The intensity of the gamma rays produced at the desired energy at a user controlled position on the surface is used to determine the crack location, length and depth.

Owner:WESTINGHOUSE ELECTRIC CORP

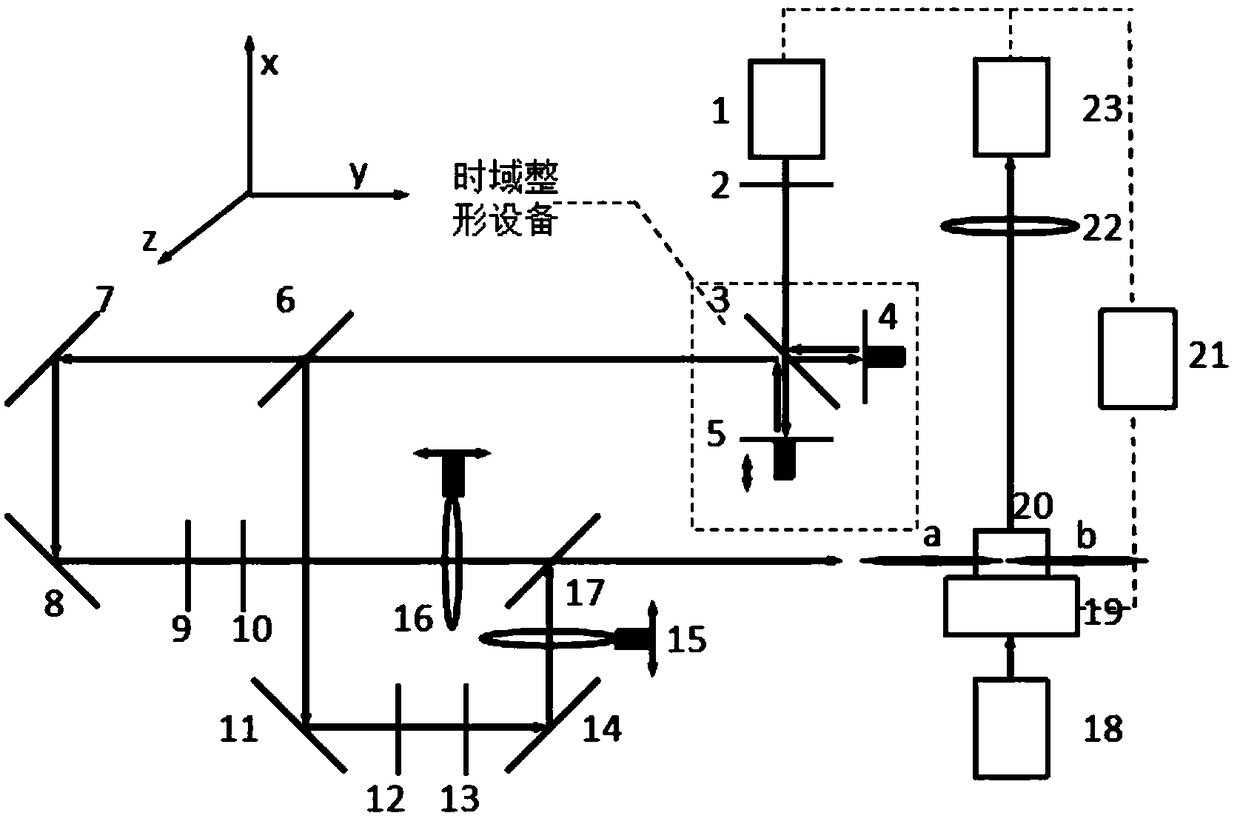

Device for preparing high-quality high-depth-diameter-ratio micro hole by using light ray obtained through femtosecond laser time domain/space shaping

ActiveCN108747059AQuality improvementHigh precisionLaser beam welding apparatusMaximum depthOptoelectronics

The invention relates to a device for preparing a high-quality high-depth-diameter-ratio micro hole by using a light ray obtained through femtosecond laser time domain / space shaping, and belongs to the field of transparent material micro-machining. According to the technical scheme, pulse time domain shaping equipment is used for generating a femtosecond laser pulse sequence; the position of a to-be-machined sample is adjusted to enable the light rays to generate micro holes with the maximum depths in the sample; the neutron pulse time delay of the pulse sequence is optimized so as to improvethe micro hole quality; a half-wave plate and a polarizing plate are combined for use to adjust the energy of lasers focused by two lenses correspondingly so as to enable the diameters of the micro holes formed by the lasers after being focused by the two lenses in the to-be-machined sample to be equal; the two focusing lenses are adjusted to enable the two independent light rays to be collinear in space and to be overlapped in an end-to-end mode to form an extended uniform light ray; and the position of the sample is moved to enable the light ray which is overlapped in the end-to-end mode togenerate a micro hole with the maximum depth-diameter ratio on the sample. According to the device, the quality and the depth-diameter ratio of the machined micro hole can be remarkably improved, themicro hole diameter adjusting range is wide, the machining environment is free of special requirements, the machining efficiency is high, and the machining cost is low.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

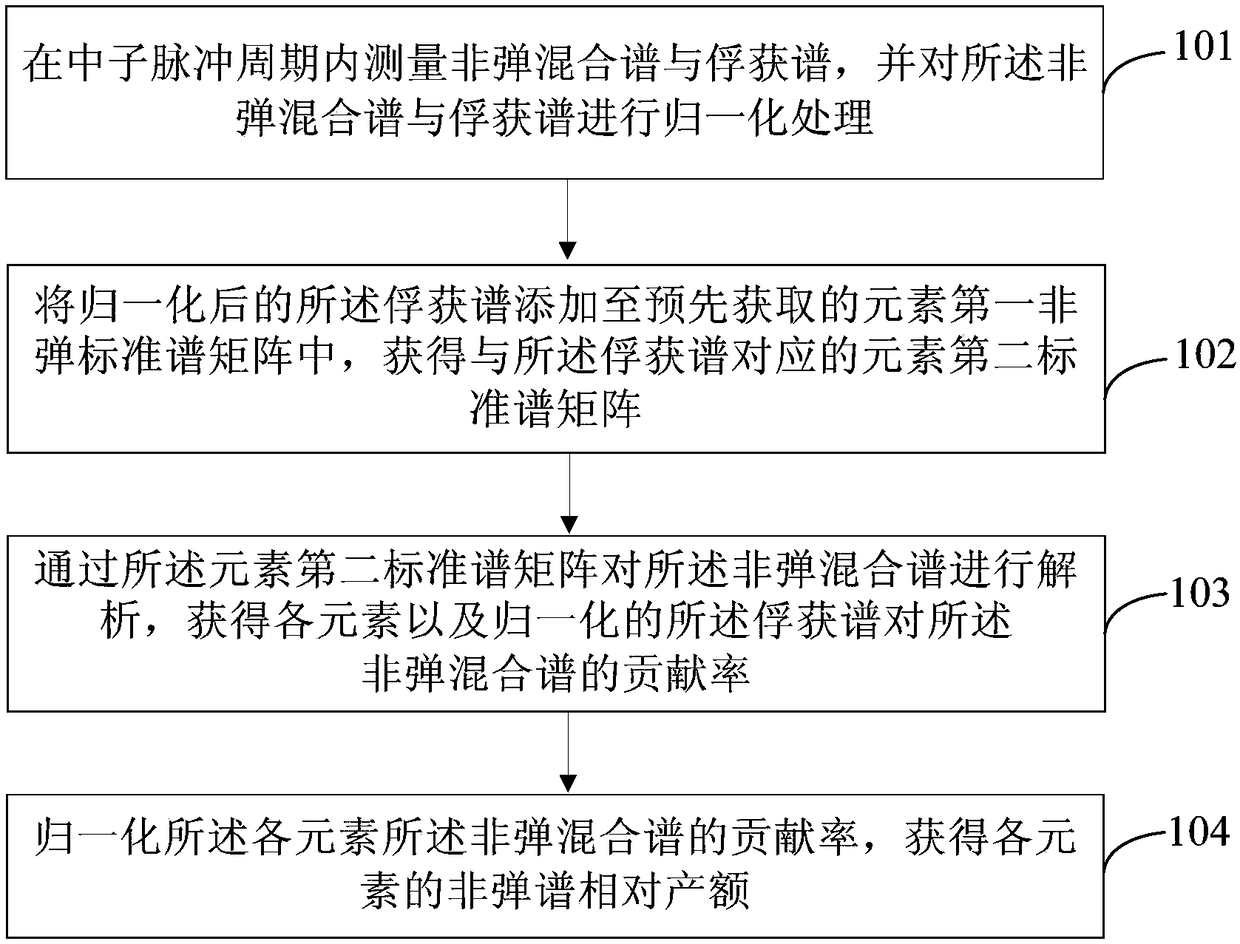

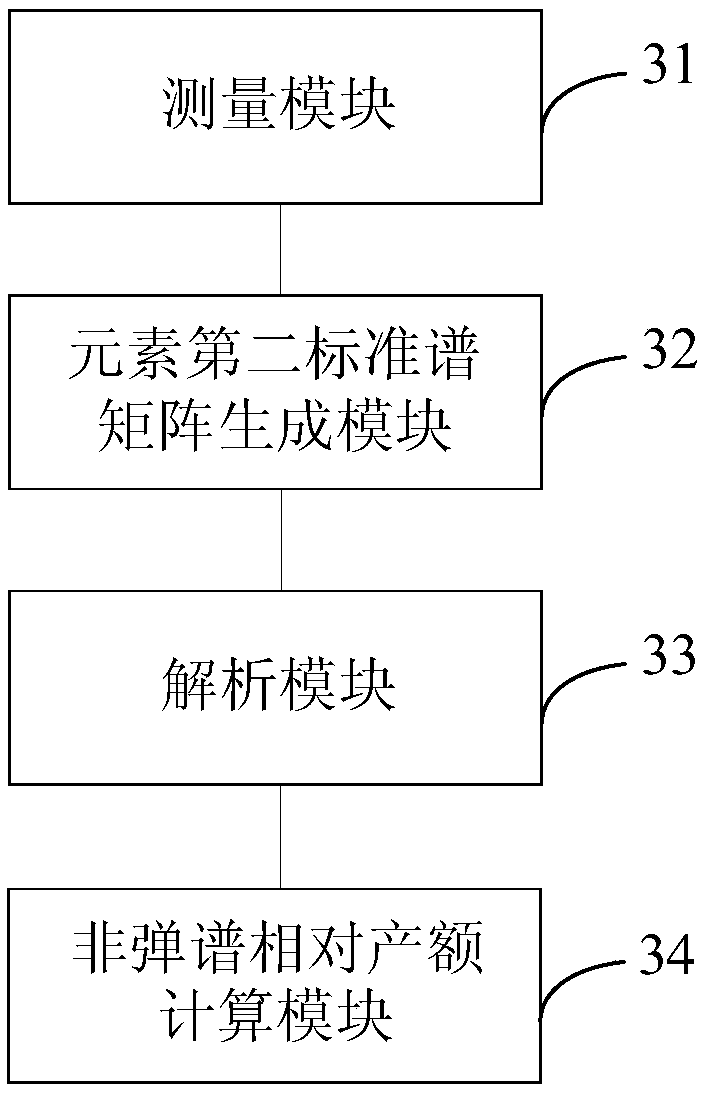

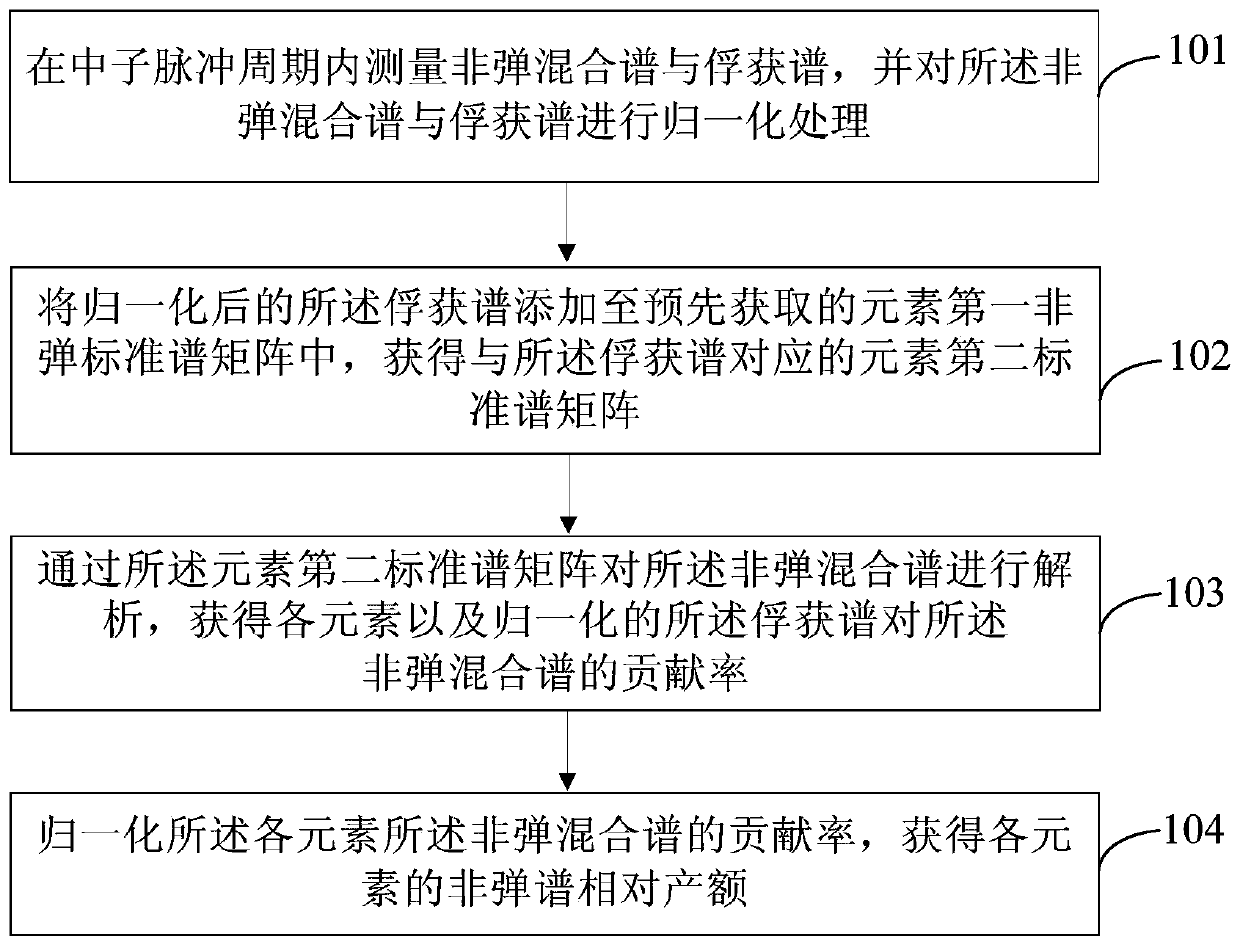

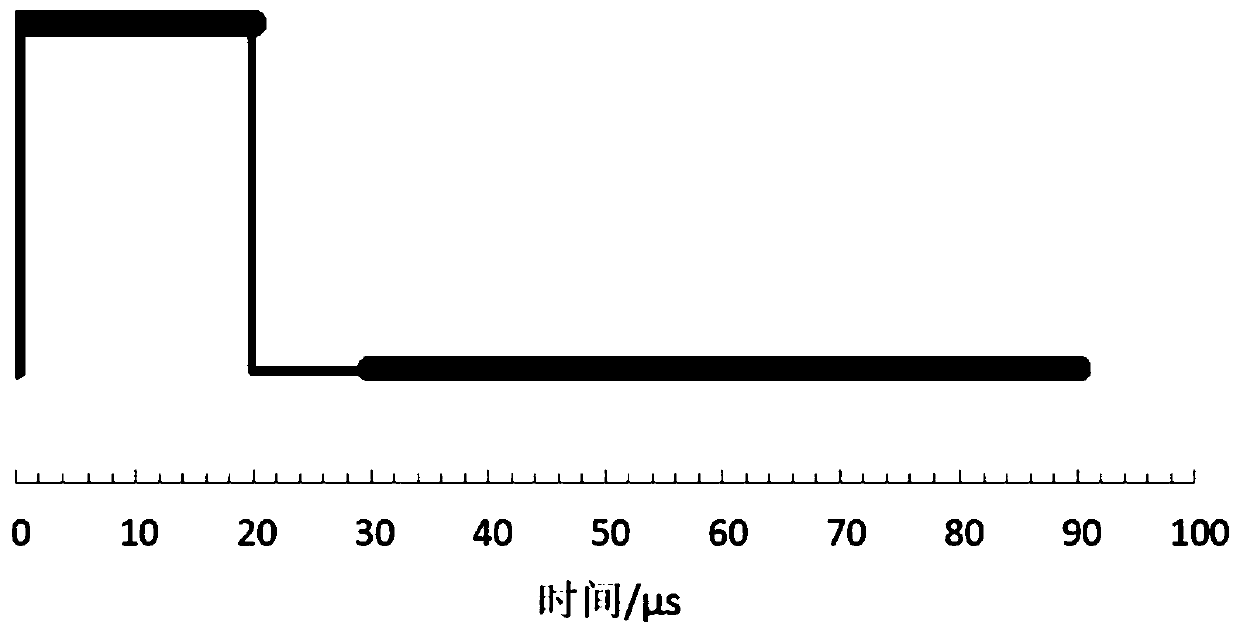

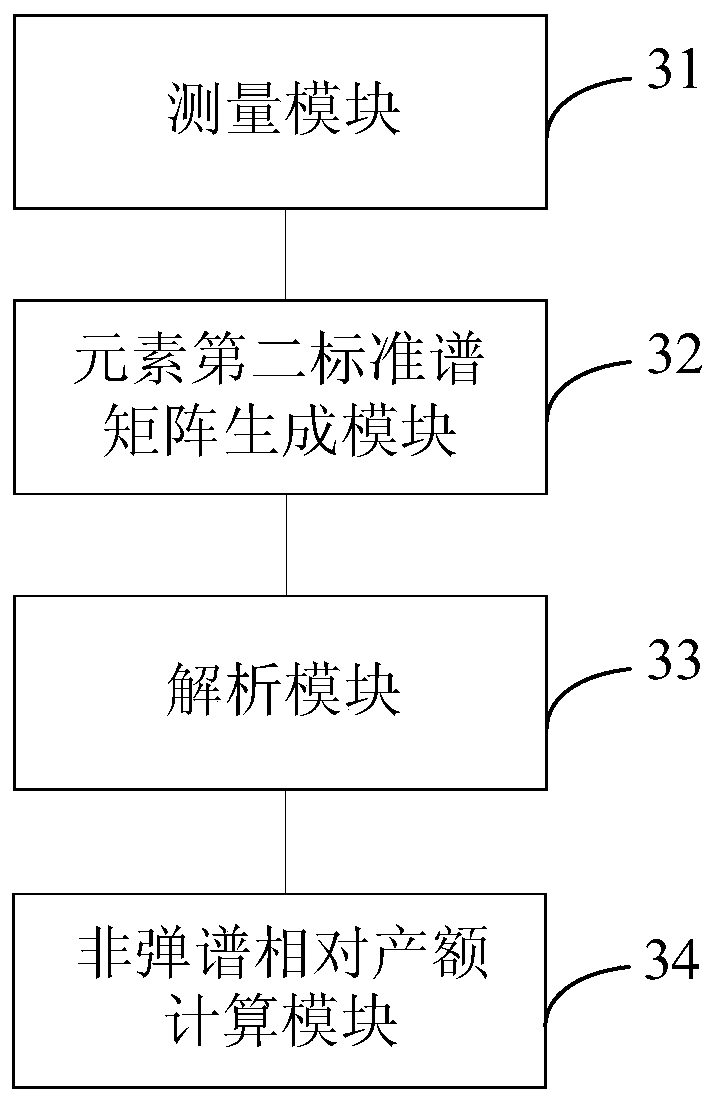

Inelastic scattering gamma-ray spectrometry analysis method and device

ActiveCN108535786AAvoid oilyAvoid accuracyNuclear radiation detectionInelastic scatteringMixed spectrum

The invention provides an inelastic scattering gamma-ray spectrometry analysis method and device. The method comprises the steps as follows: inelastic mixed spectrum and capture spectrum are measuredin a neutron pulse cycle and subjected to normalization processing; the normalized capture spectrum is added to an element first inelastic standard spectrum matrix obtained in advance, and an elementsecond standard spectrum matrix corresponding to the capture spectrum is obtained; the inelastic mixed spectrum is analyzed through the element second standard spectrum matrix, and contribution ratesof elements and the normalized capture spectrum for the inelastic mixed spectrum are obtained; the contribution rates of all the elements for the inelastic mixed spectrum are normalized, and inelasticspectrum relative yields of all the elements are obtained. Pure inelastic spectrum is not required to be obtained firstly during measurement of inelastic spectrum relative yields of all the elements,so that the defect of inaccurate underground stratum oil saturation due to defects of a fixed pure spectrum coefficient method which is mainly adopted at present can be overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

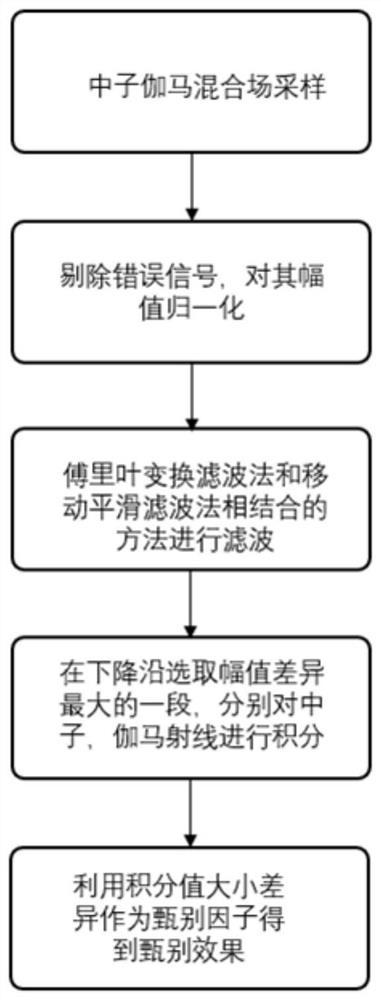

Digital n-gamma discrimination method based on falling edge integration

ActiveCN112505742AReduce discrimination errorsEasy to operateNuclear energy generationMeasurement with scintillation detectorsNuclear engineeringNeutron pulse

The invention relates to the technical field of radiation detection, and particularly relates to a digital n-gamma discrimination method based on falling edge integration. The method comprises the steps of measuring a neutron gamma mixed field by a detector and a card collector, taking 280 points for each signal, and eliminating double-peak, flat-peak and stacked-peak signals in pulse signals; carrying out amplitude normalization processing on the eliminated pulse signals; carrying out filtering processing on the normalized pulse signals; setting two optimal B-type threshold lines on the section with the most obvious difference between the falling edges of the neutrons and the gamma pulse signals, and limiting two optimal B-type threshold line segments at 11 points in width; respectively integrating neutrons and gamma pulse signals in the two optimal B-type threshold line segments by using a differential method; summing the amplitudes of the points between the sections with the most obvious difference to respectively obtain neutron pulse falling edge integral values; taking the difference between the falling edge integral values of the neutrons and the gamma pulse signals as a discrimination factor to obtain a discrimination effect distribution curve of the neutrons and the gamma pulse signals; and enabling the discrimination effect to be better.

Owner:THE ENG & TECHN COLLEGE OF CHENGDU UNIV OF TECH +1

Measuring total, epithermal and thermal neutron formation porosities with one single set of neutron detectors and a pulsed neutron generator

Owner:BAKER HUGHES INC

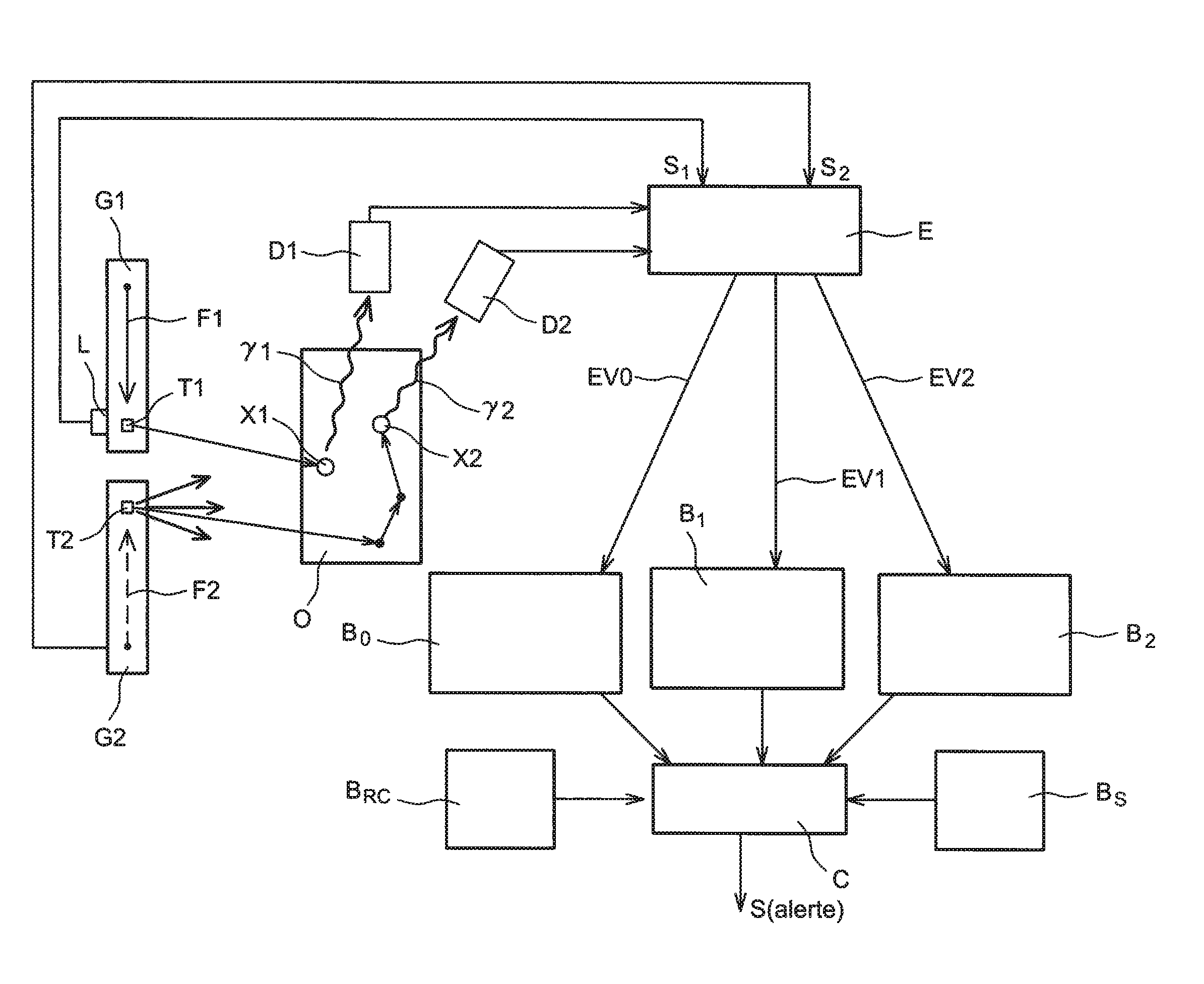

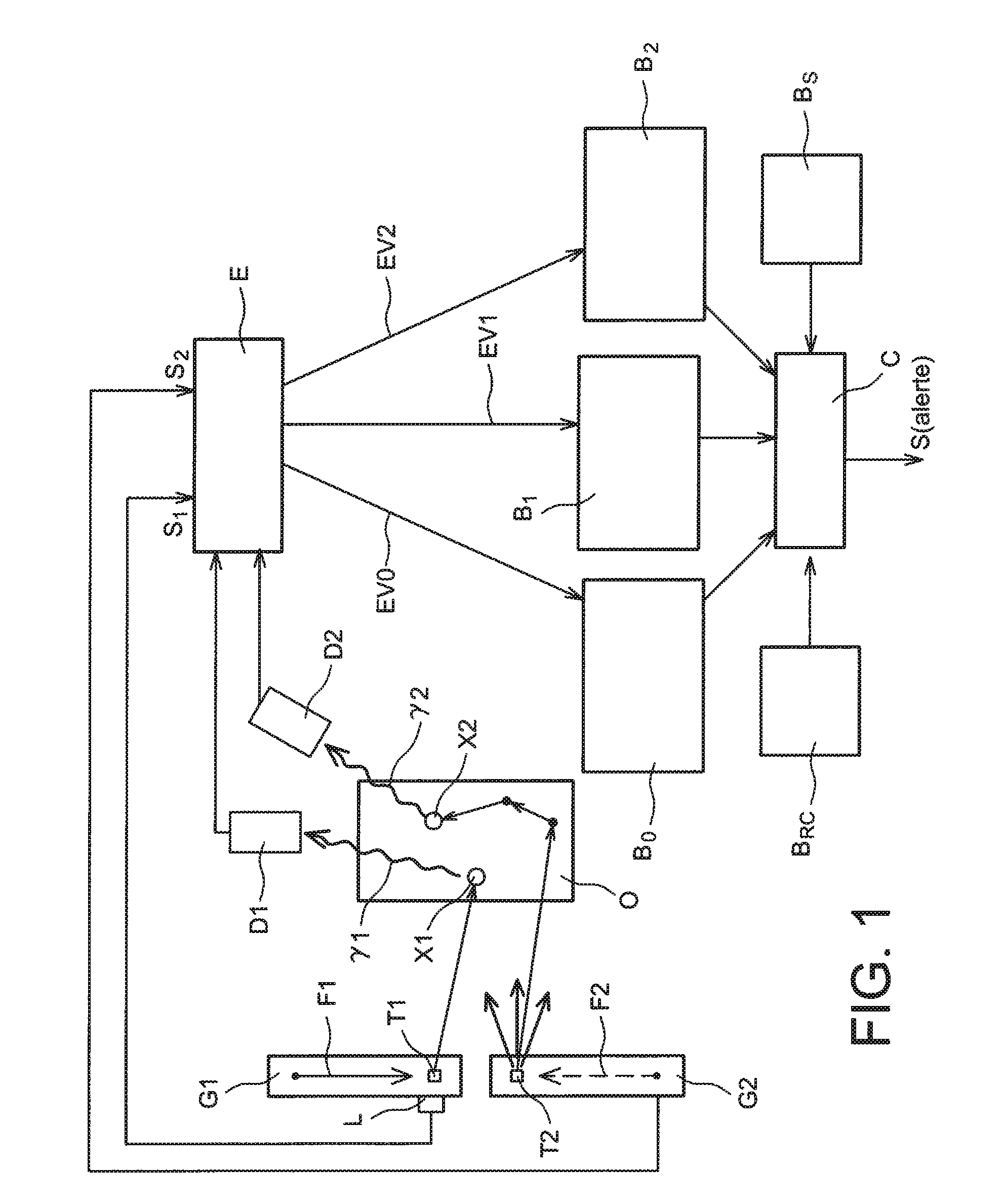

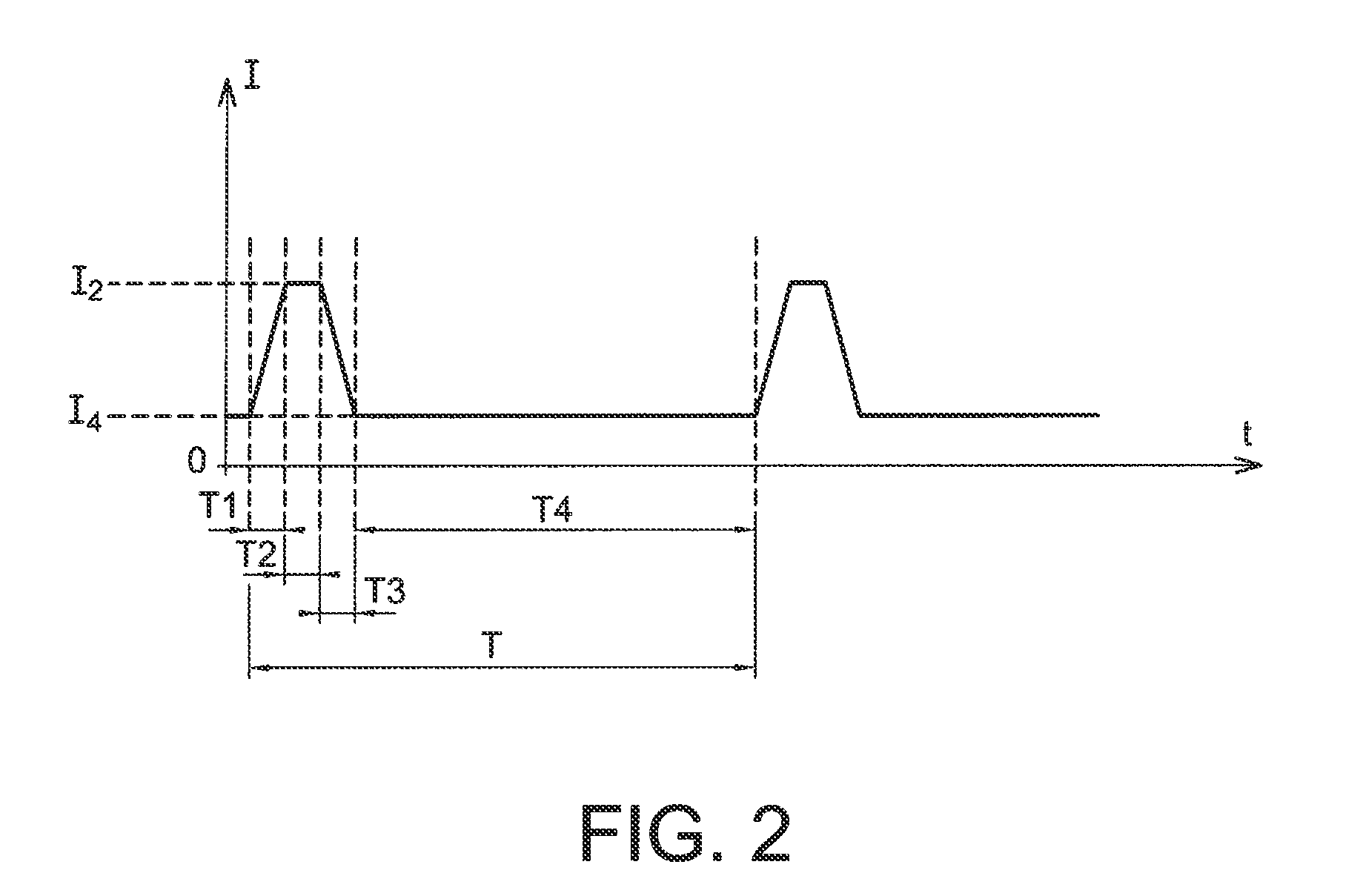

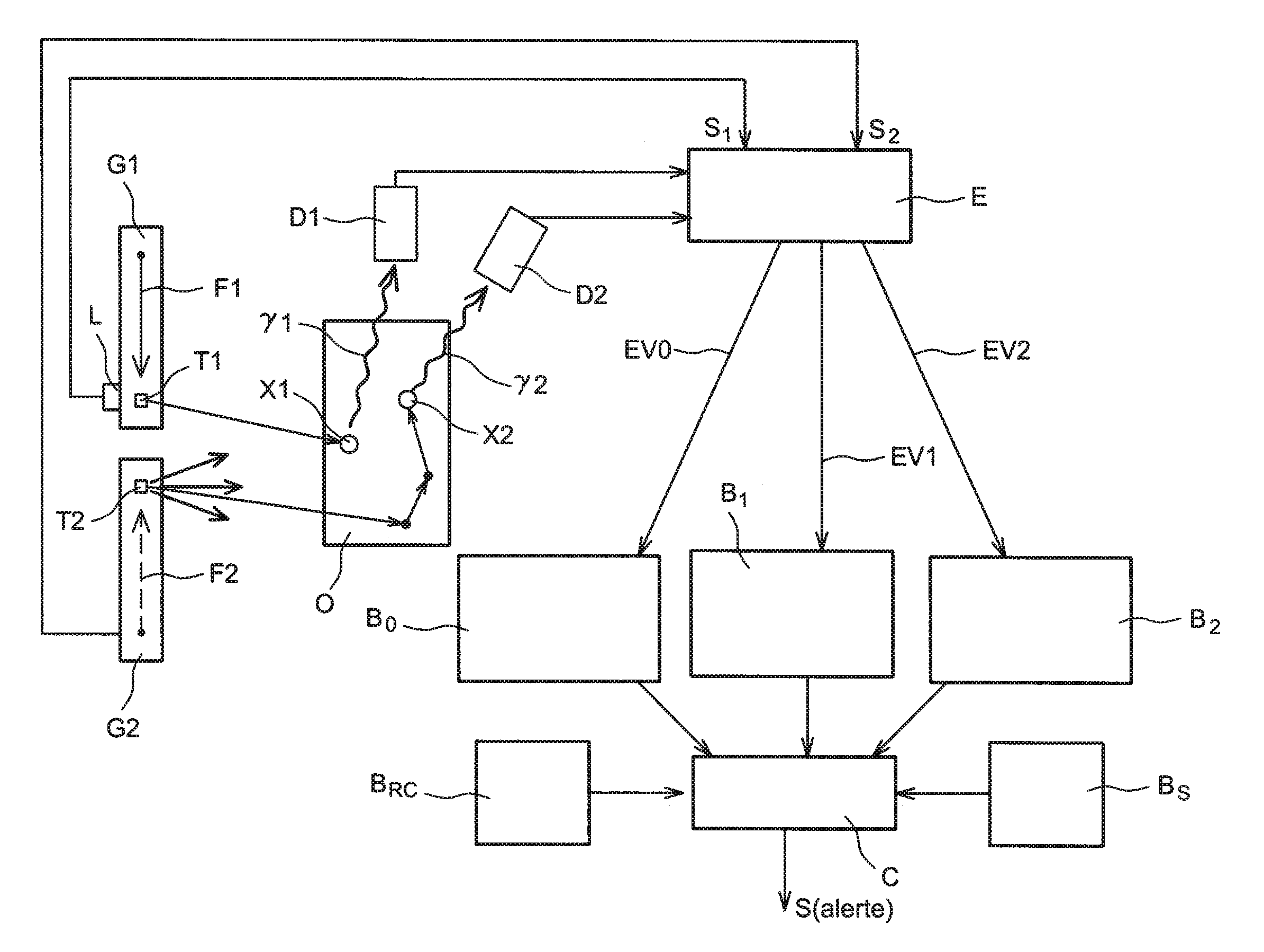

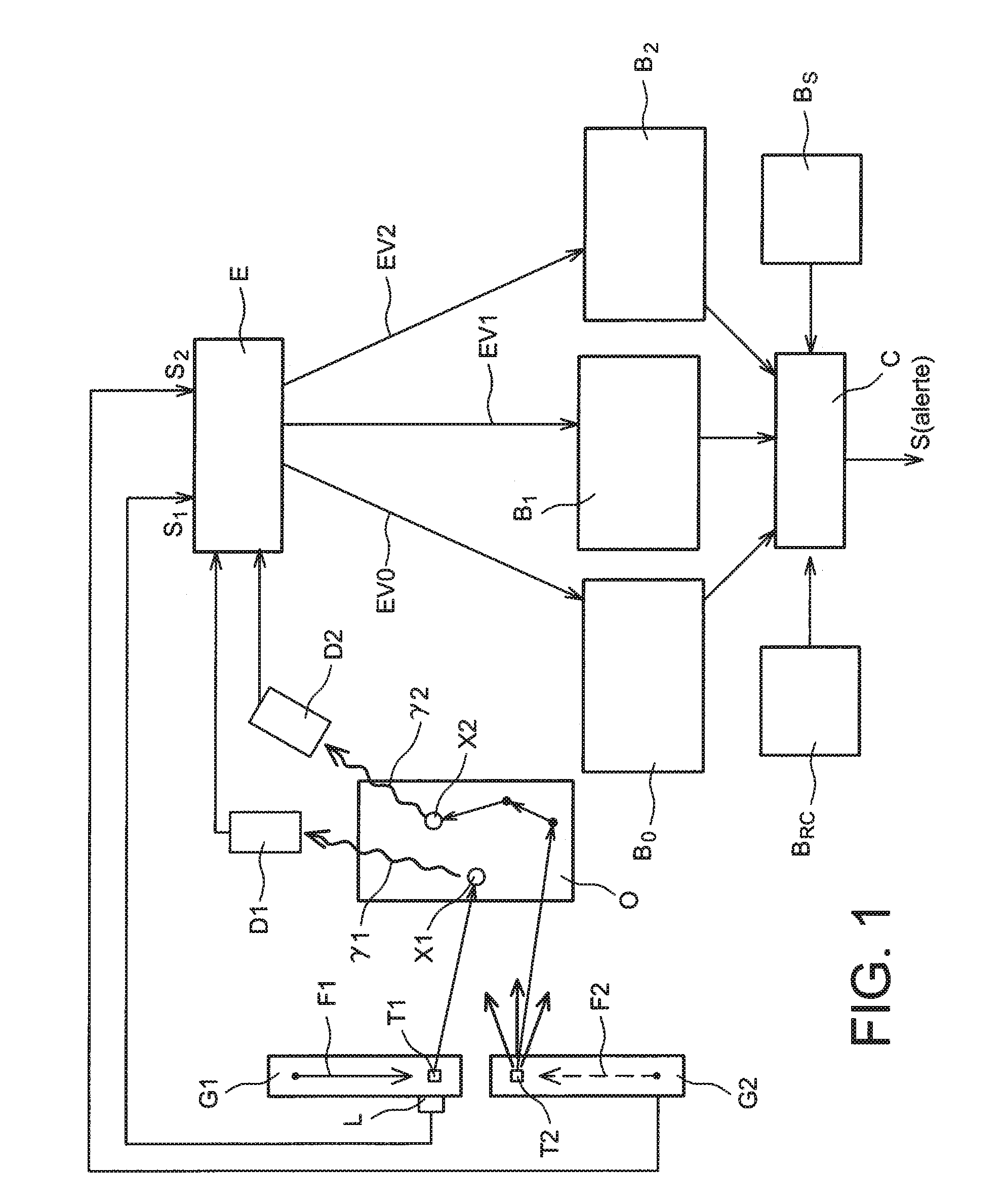

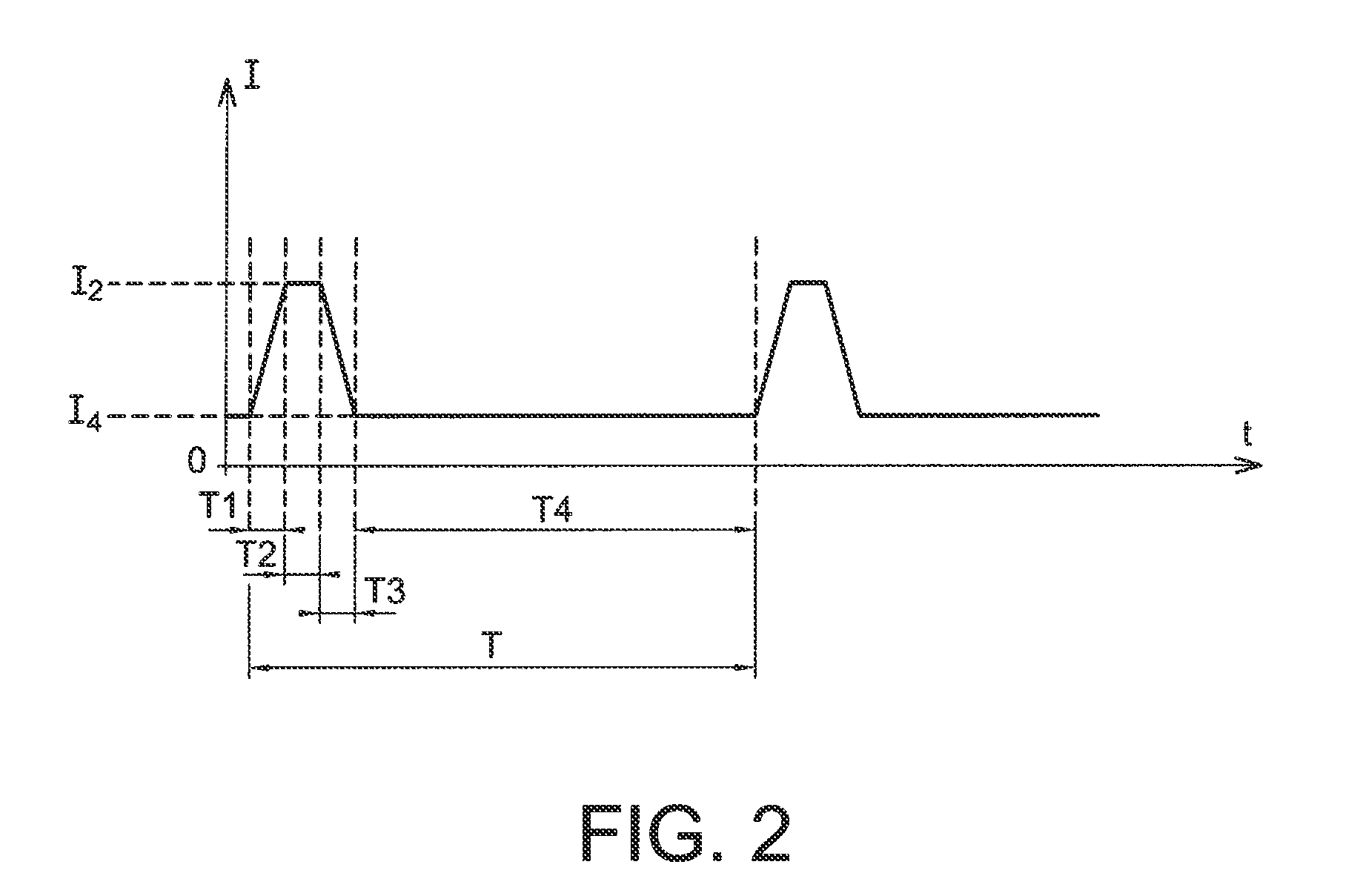

Non-intrusive method for detection of chemical elements

InactiveUS8748837B2Material analysis using wave/particle radiationElectric discharge tubesNeutron emissionChemical element

A method for detecting the presence of a chemical element in an object by emission of neutrons onto the object, characterized in that the emission of neutrons onto the object is constituted, firstly, by a continuous emission of neutrons originating from an associated particle neutron generator (G1) and, secondly, by an emission of neutron pulses which are superimposed on the continuous emission of neutrons, where the neutron pulses originate from a pulsed neutron generator (G2) which generates neutron pulses of pulse duration T2, where two successive neutron pulses are separated by a duration T4, and where the continuous and pulsed emissions of neutrons on to the object produce a gamma capture radiation and an inelastic gamma radiation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

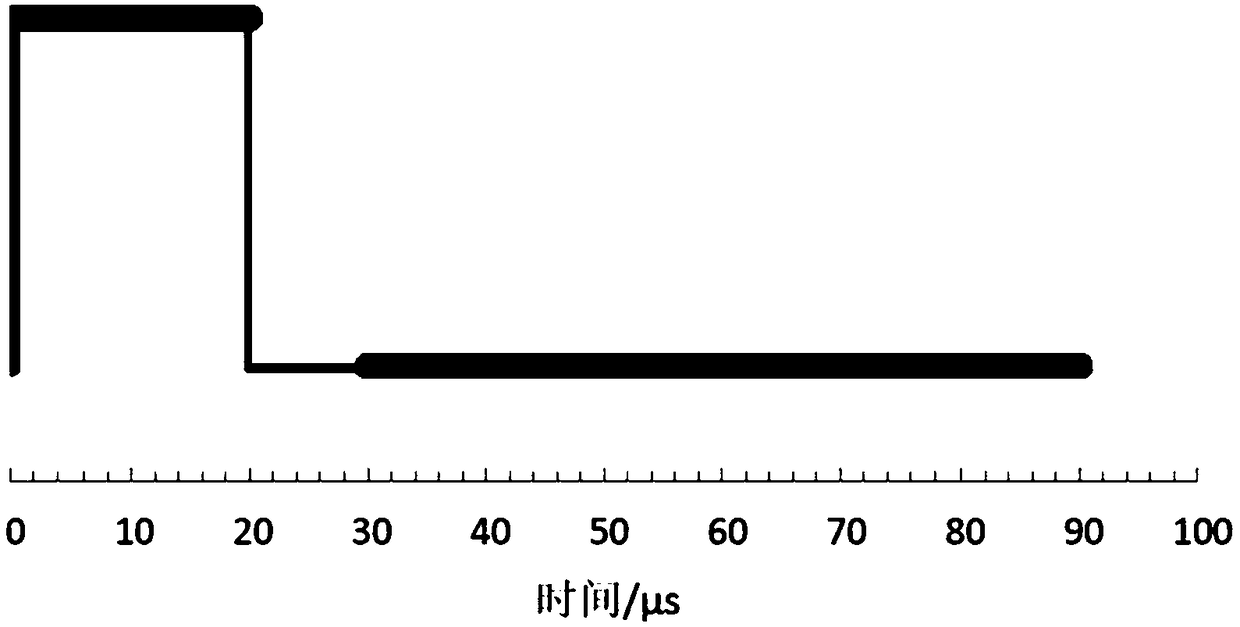

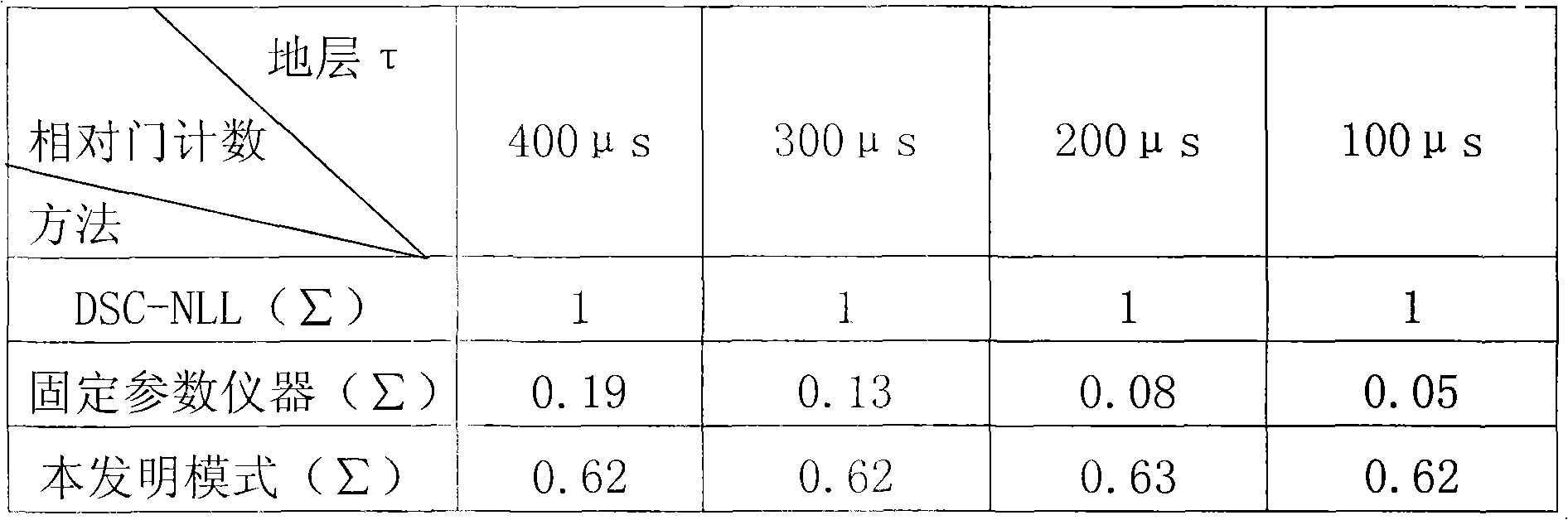

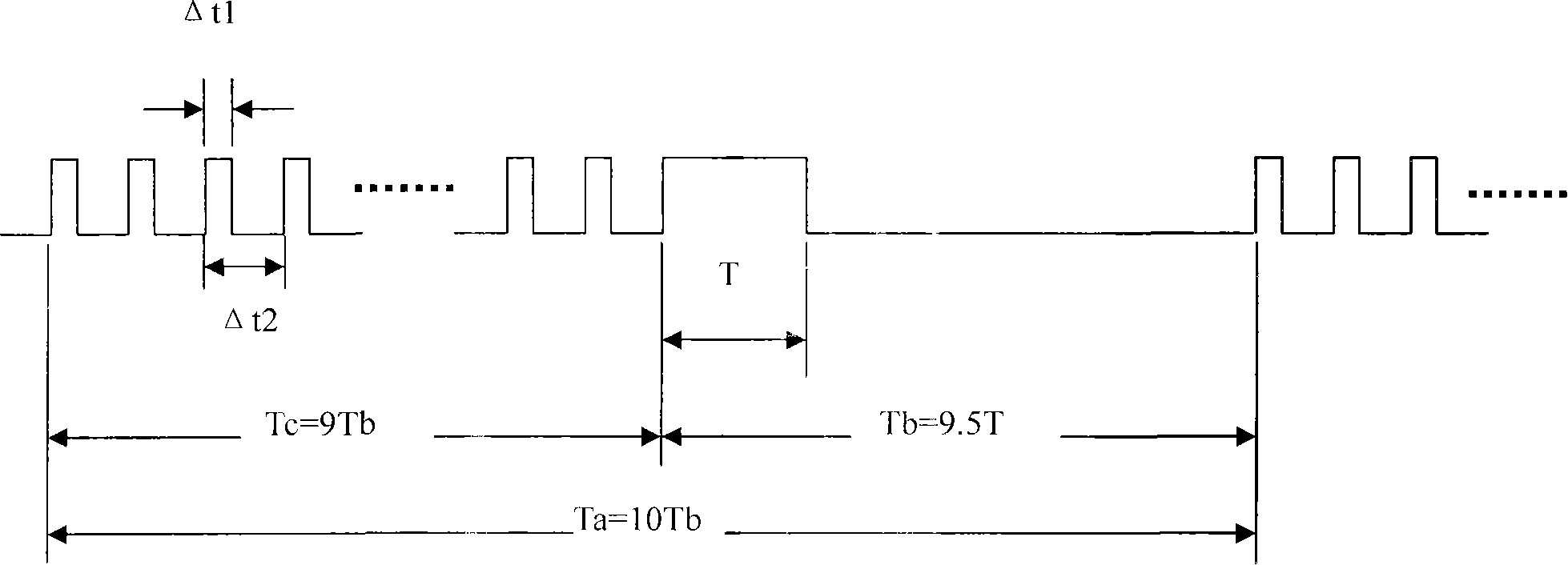

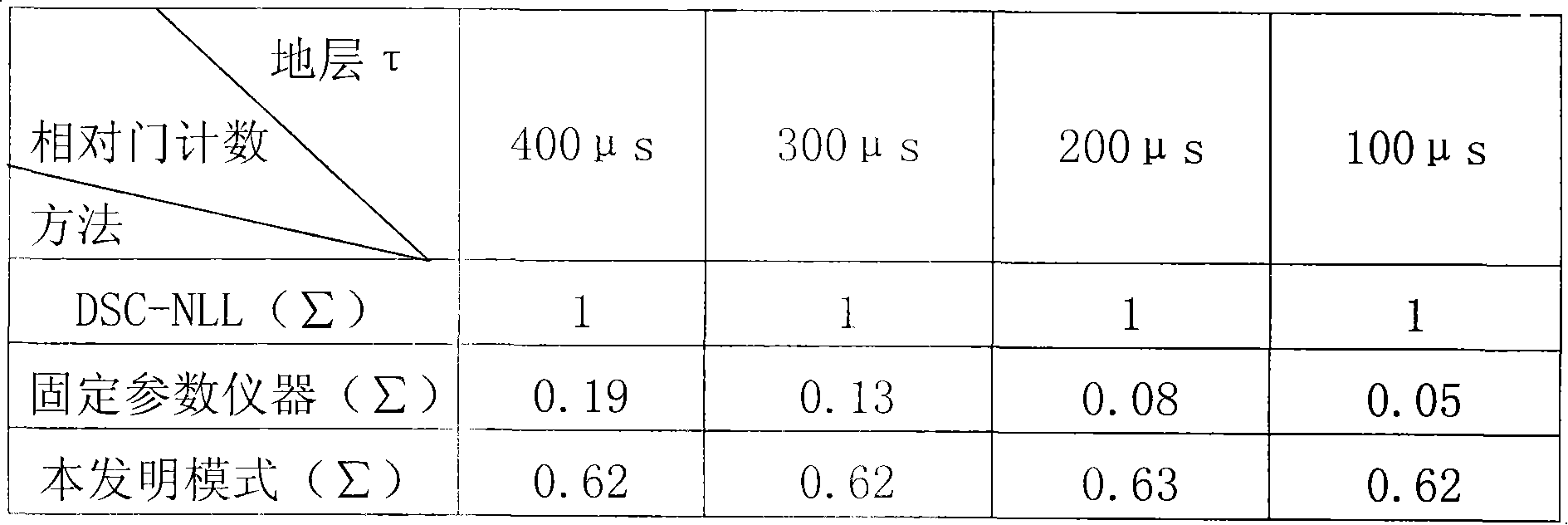

Impulse neutron complete spectrum saturability logging instrument variable parameter neutron pulse timing mode

ActiveCN101255793AOvercoming the defect of low gate count rateIncreased gate count rateBorehole/well accessoriesNuclear radiation detectionCounting rateNeutron emission

The present invention relates to a neutron pulse timing mode for pulse neutron whole spectrum saturation logging tool, emitting rapid neutron continuously by broad pulse design, and adding the neutron emitting time corresponding, resolves technique problem that great fluctuation error of Sigma parameter in present neutron pulse timing mode cause Sigma detecting well data can't be used, enhances the gate counting rate of monitoring Sigma and reduces the fluctuation error of Sigma parameter, reaches the similar effect near to result by special Sigma measuring apparatus.

Owner:XIAN AOHUA ELECTRONICS INSTR +1

Non-intrusive method for detection of chemical elements

InactiveUS20110243306A1Material analysis using wave/particle radiationNuclear radiation detectionNuclear engineeringChemical element

A method for detecting the presence of a chemical element in an object by emission of neutrons onto the object, characterized in that the emission of neutrons onto the object is constituted, firstly, by a continuous emission of neutrons originating from an associated particle neutron generator (G1) and, secondly, by an emission of neutron pulses which are superimposed on the continuous emission of neutrons, where the neutron pulses originate from a pulsed neutron generator (G2) which generates neutron pulses of pulse duration T2, where two successive neutron pulses are separated by a duration T4, and where the continuous and pulsed emissions of neutrons on to the object produce a gamma capture radiation and an inelastic gamma radiation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

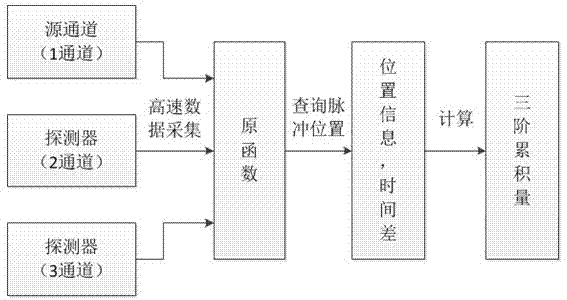

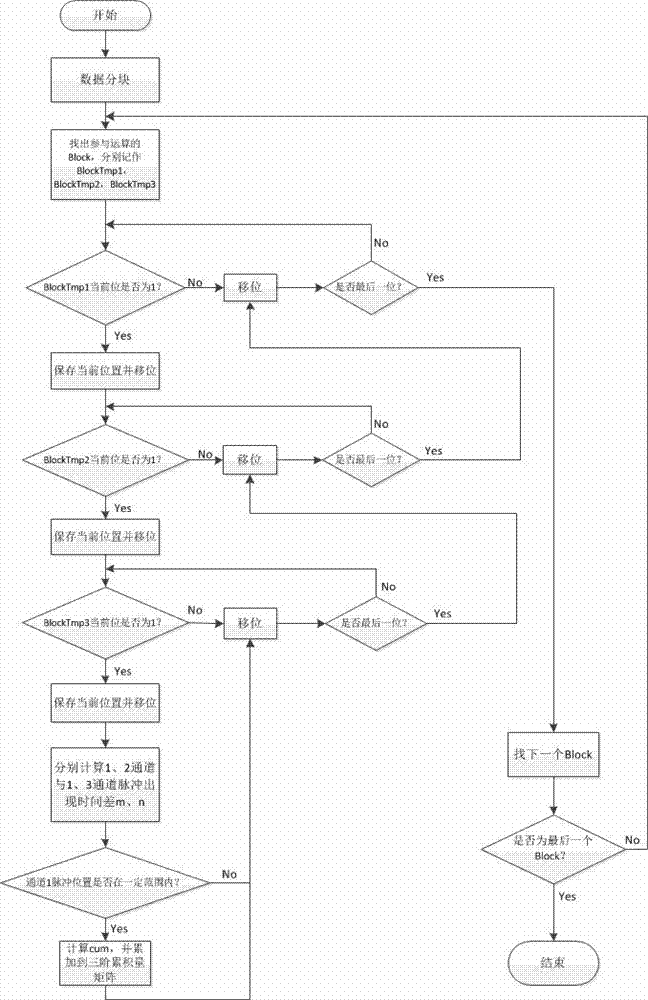

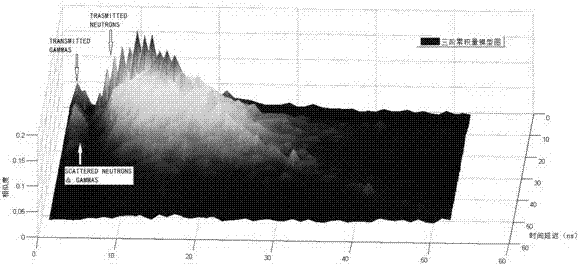

Quick analysis method of neutron pulse sequence three-order cumulant model

InactiveCN102769446AReduce computing timeImprove computing efficiencyPulse train pattern monitoringData packReal time analysis

The invention provides a quick analysis method of a neutron pulse sequence three-order cumulant model. The method includes the following steps: 1) collecting neutron pulse data to obtain a neutron source and time distribution of neutron detection counting stimulated by the neutron source and generated by two detection bodies at different positions; 2) blocking a neutron pulse data package collected in the step 1) according to certain length, conducting reduction to obtain neutron pulse sequences in each data block in each channel under the condition that the data blocks are continuously arranged without gaps; 3) conducting three-order cumulant calculation on data of each obtained data block to obtain the neutron pulse sequence three-order cumulant model. Counting of three-order cumulant in each data block in the step 3) adopts quick search algorithm. The model quick analysis method effectively reduces calculation time consumption, improves calculation efficiency and has important meaning on real time analysis of the three-order cumulant of materials to be measured.

Owner:CHONGQING UNIV

Detection system of neutron generator

InactiveCN107356981AImprove work performanceAccurate identificationNuclear radiation detectionSurveillance cameraNeutron pulse

The invention relates to a detection system of a neutron generator, comprising a neutron generator body mechanism, a guiding device, a monitoring camera and an automatic diagnosis device, the neutron generator mechanism is used to generate fast neutron pulses, and the guiding device is coupled to The main mechanism of the neutron generator is used to emit fast neutron pulses to the formation, the monitoring camera is used to shoot towards the neutron generator mechanism to obtain images of the neutron generator, the automatic diagnosis equipment and the The neutron generator mechanism is connected, and is used to analyze the state of each parameter of the neutron generator mechanism, wherein the automatic diagnosis equipment outputs relevant information of parameters whose state is abnormal. Through the present invention, the detection structure of the neutron generator can be optimized.

Owner:秦佑胜

Impulse neutron complete spectrum saturability logging instrument variable parameter neutron pulse timing mode

ActiveCN101255793BOvercoming the defect of low gate count rateIncreased gate count rateBorehole/well accessoriesNuclear radiation detectionCounting rateNeutron emission

Owner:XIAN AOHUA ELECTRONICS INSTR +1

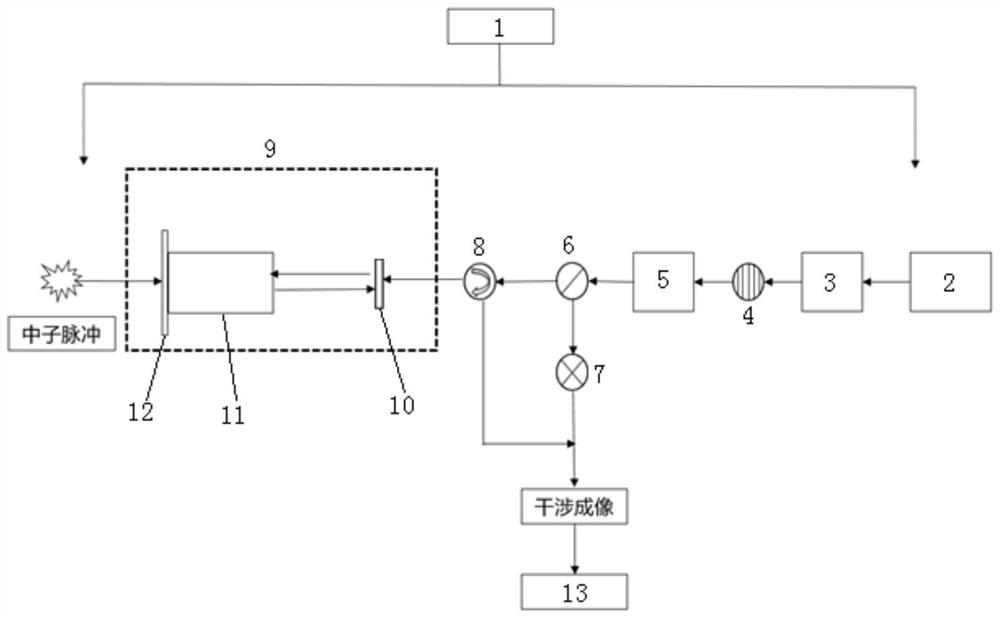

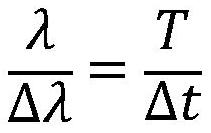

Ultra-fast neutron pulse energy spectrum detection system and method

ActiveCN113552611AImprove signal-to-noise ratioNuclear energy generationNeutron radiation measurementBeam splitterSpectrograph

The invention relates to an ultrafast neutron pulse energy spectrum detection system and method, and aims to solve the problem that an existing neutron energy spectrometer cannot meet the energy spectrum detection of ultrafast neutron pulse picosecond-level time resolution. The system comprises a synchronous trigger unit, a linearly polarized light generation unit, a delay module, a beam splitter, a reference light unit, a detection light unit and a spectrograph. The synchronous trigger unit synchronously triggers the neutron pulse source and the linearly polarized light generation unit; the linearly polarized light generation unit generates linearly polarized light L, and the linearly polarized light L is divided into first reference light L1 and first detection light L2 after sequentially passing through the delay module and the beam splitter; the first reference light L1 is subjected to phase delay pi through the reference light unit to form second reference light L1'; and the detection light unit comprises an optical fiber circulator, a Pockels crystal and a reflector, the Pockels crystal and the reflector are arranged in the DIM cavity, the first detection light L2 enters the Pockels crystal to form second detection light L2'with a changed polarization state, the second detection light L2' and the second reference light L1' interfere with each other, and the spectrometer receives an interference image.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Inelastic scattering gamma spectrum analysis method and device

The invention provides an inelastic scattering gamma-ray spectrometry analysis method and device. The method comprises the steps as follows: inelastic mixed spectrum and capture spectrum are measuredin a neutron pulse cycle and subjected to normalization processing; the normalized capture spectrum is added to an element first inelastic standard spectrum matrix obtained in advance, and an elementsecond standard spectrum matrix corresponding to the capture spectrum is obtained; the inelastic mixed spectrum is analyzed through the element second standard spectrum matrix, and contribution ratesof elements and the normalized capture spectrum for the inelastic mixed spectrum are obtained; the contribution rates of all the elements for the inelastic mixed spectrum are normalized, and inelasticspectrum relative yields of all the elements are obtained. Pure inelastic spectrum is not required to be obtained firstly during measurement of inelastic spectrum relative yields of all the elements,so that the defect of inaccurate underground stratum oil saturation due to defects of a fixed pure spectrum coefficient method which is mainly adopted at present can be overcome.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com