Patents

Literature

34results about How to "Mass productivity can be improved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

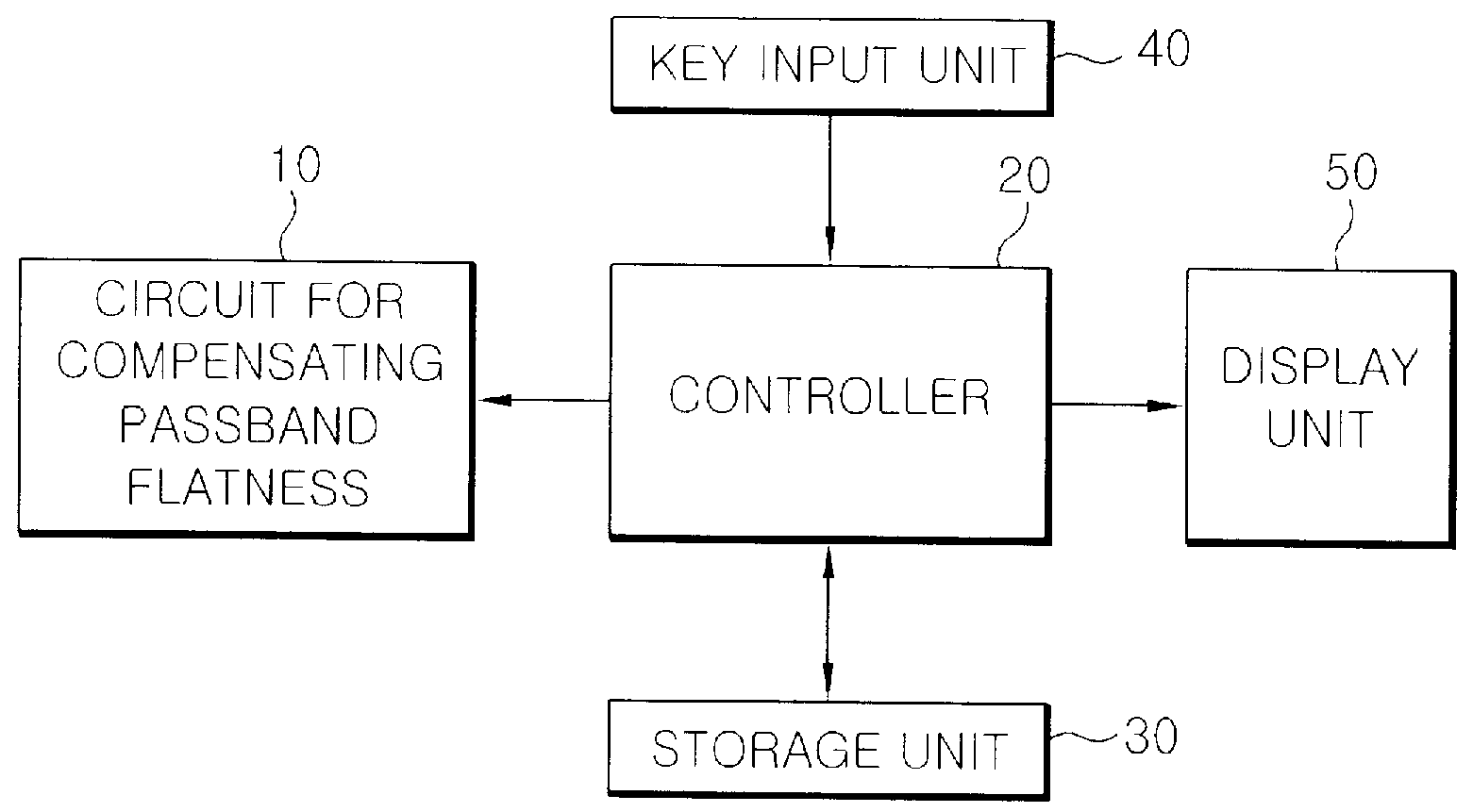

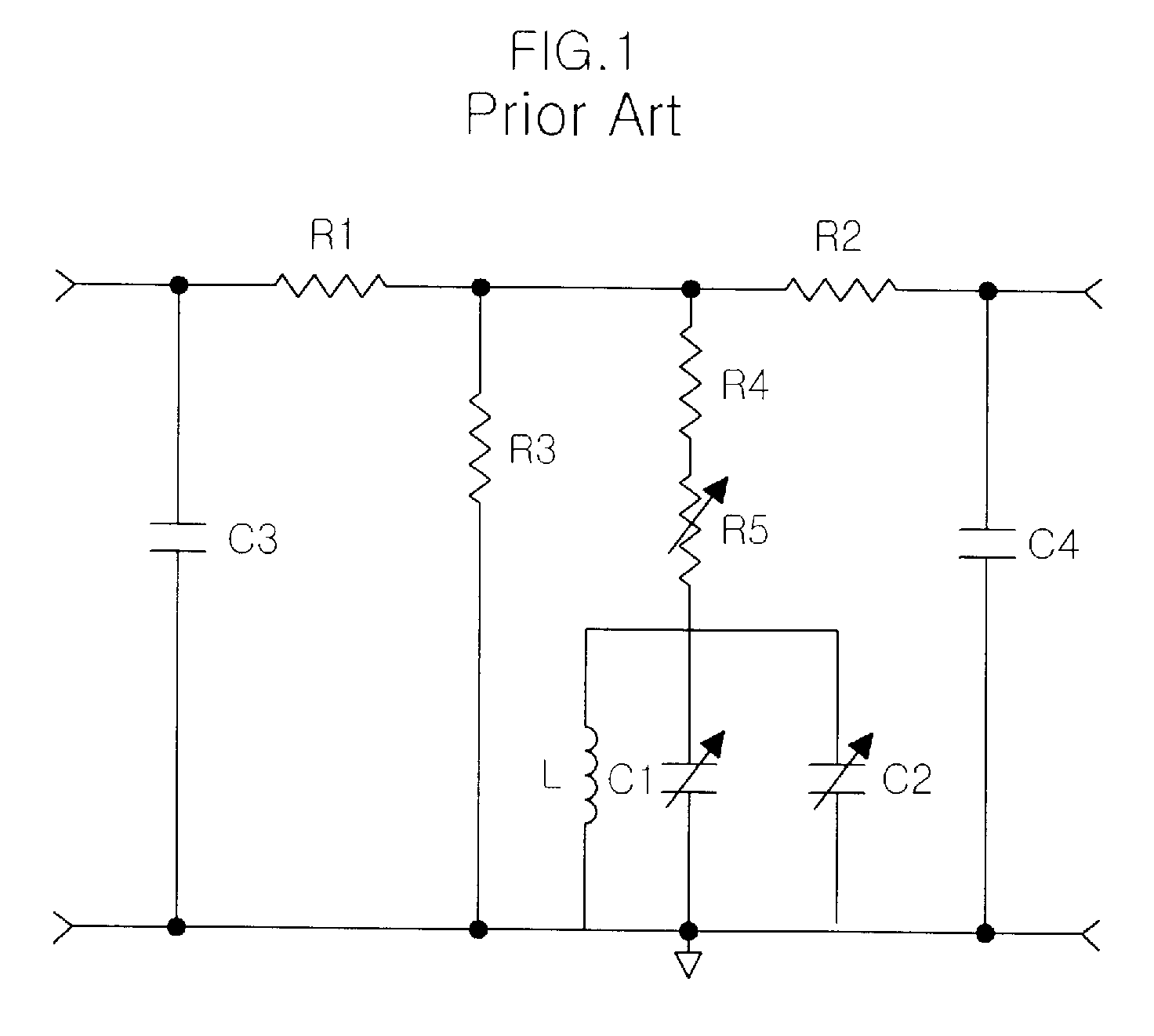

Circuit for compensating passband flatness, apparatus and method for compensating passband flatness

InactiveUS20090264065A1Flatness defectReduce inconvenienceRepeater circuitsRadio relay systemsFrequency bandVaricap

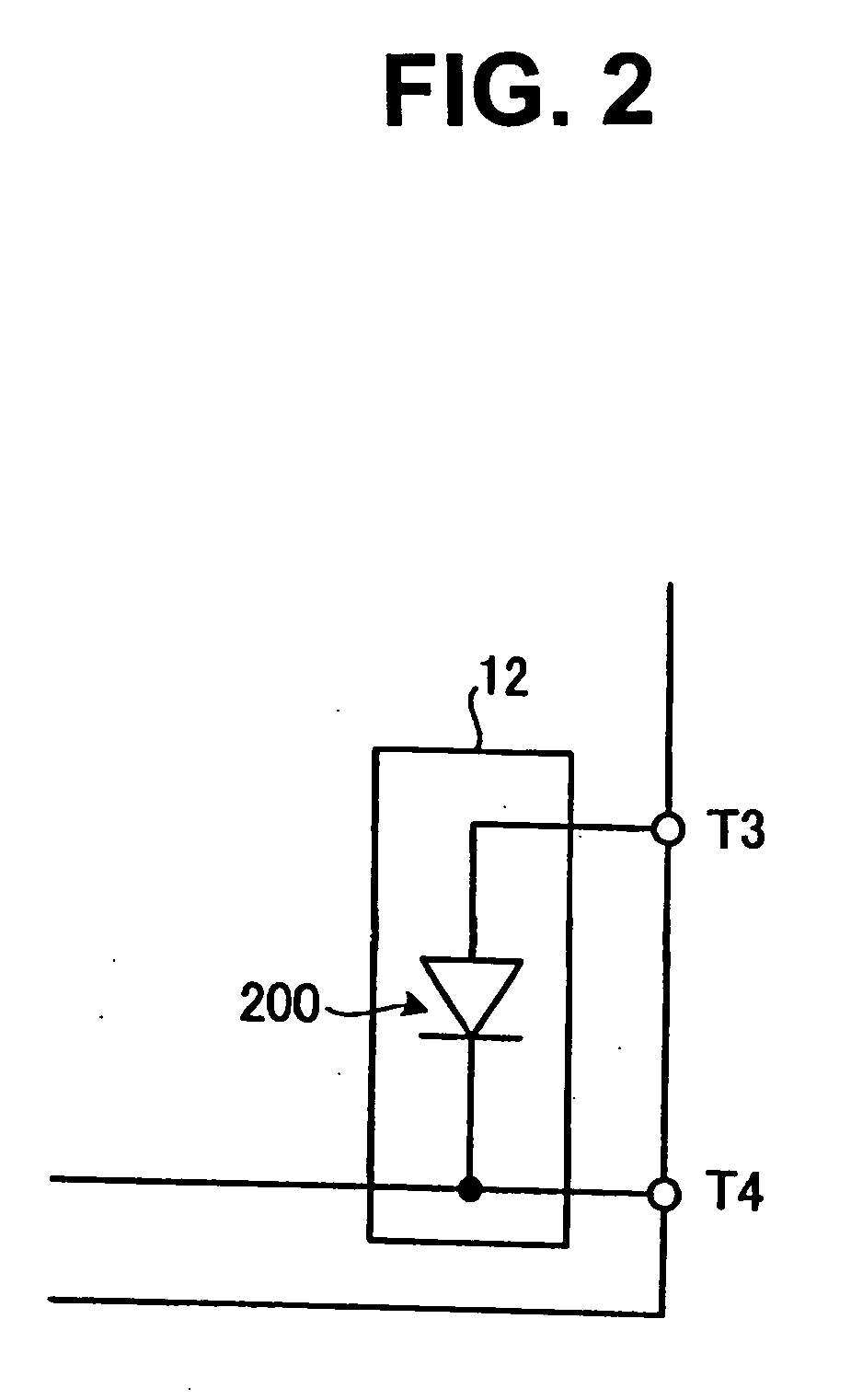

Disclosed is an apparatus for compensating passband flatness according to the present invention. The apparatus for compensating passband flatness for a mobile communication repeater to compensate passband flatness of band passed input signals comprises: a circuit for compensating passband flatness that includes a varactor diode formed to be connected to an inductance element to correct micro resonance frequencies for passbands of input signals according to voltages applied from the outside; and a controller that controls voltages input to the circuit for compensating passband flatness and varies the voltages applied to the varactor diode of the circuit for compensating passband flatness based on preset voltage values applied to the varactor diode so that passband flatness characteristics are compensated according to the corresponding frequency bands.

Owner:ECTELECOM

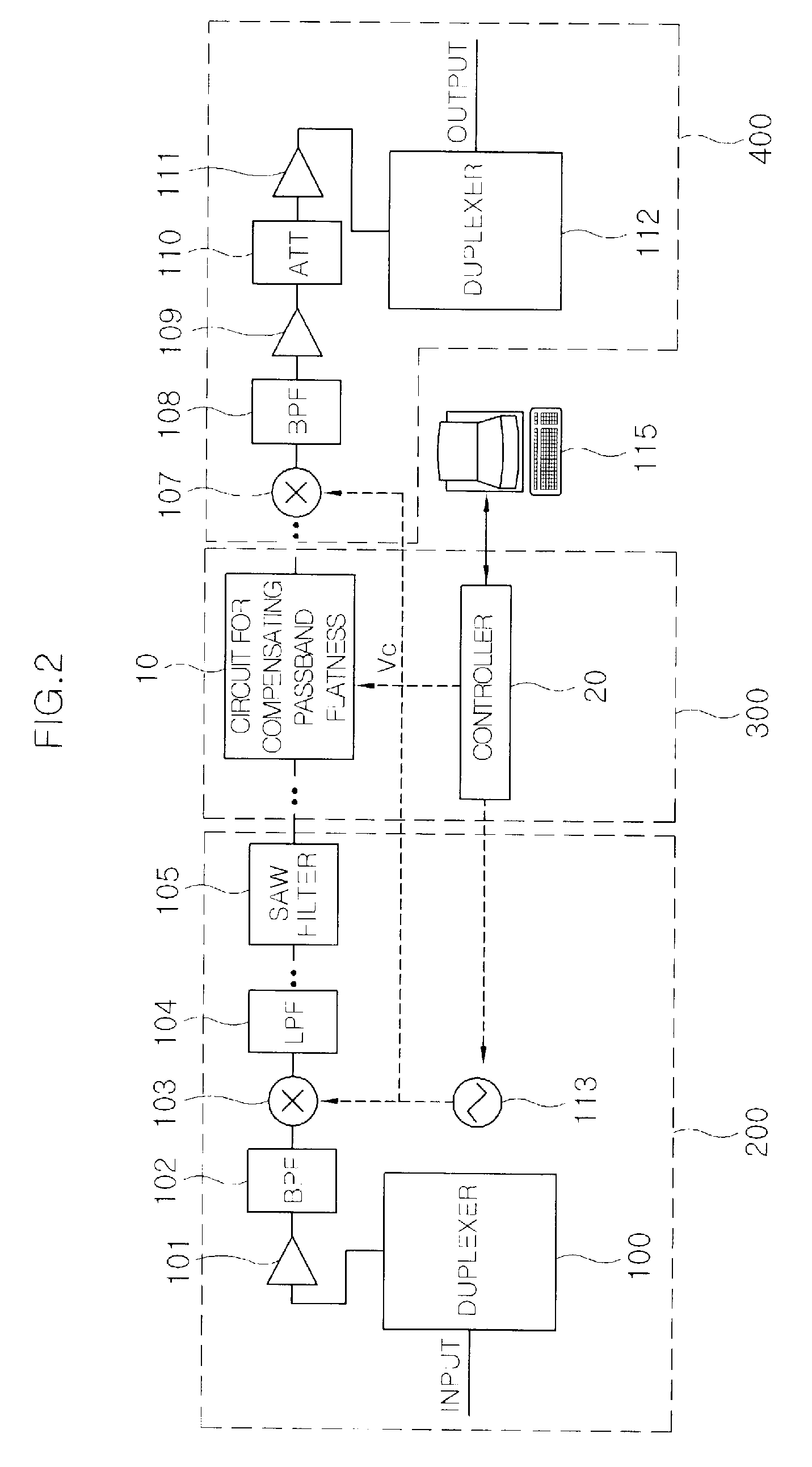

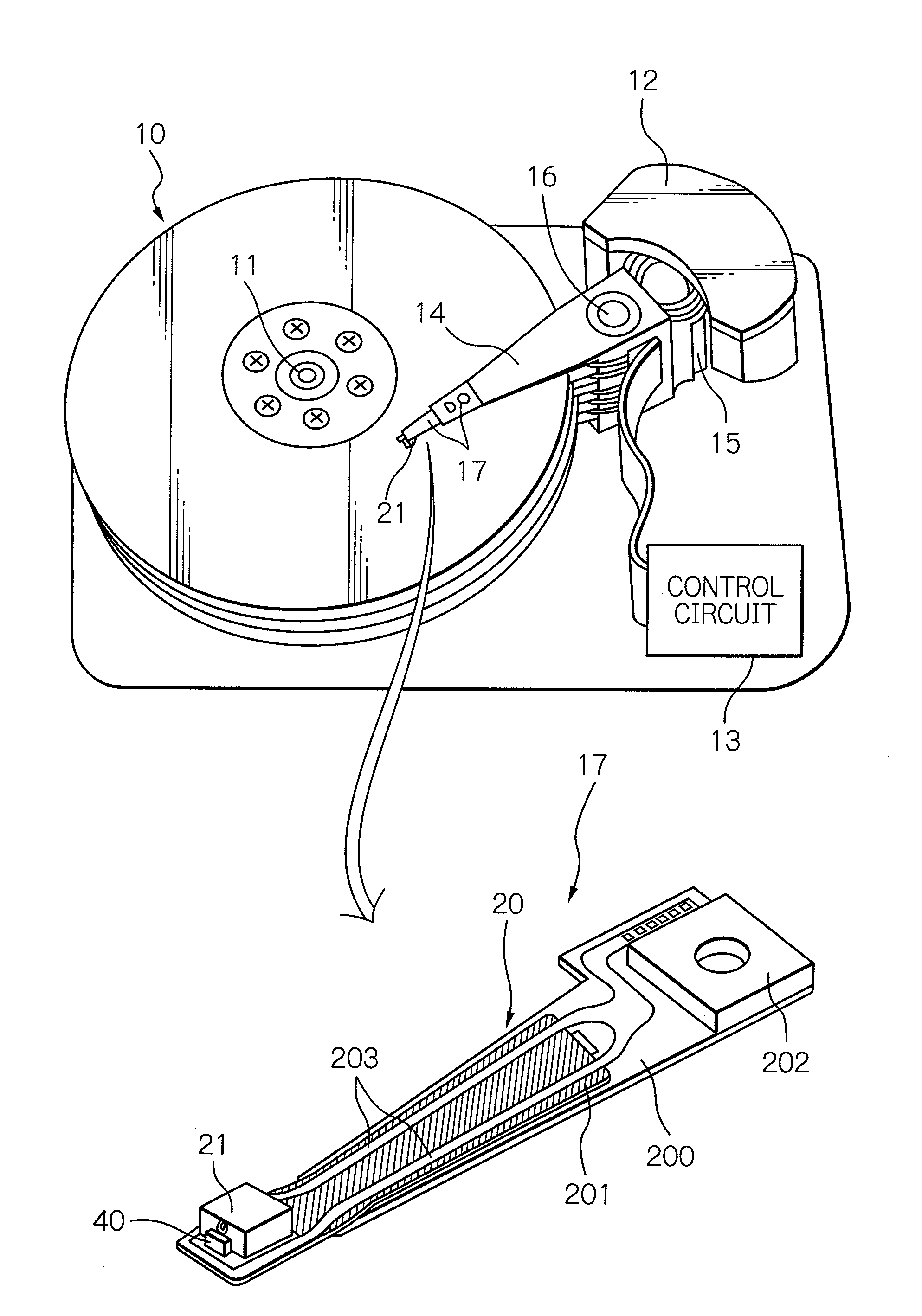

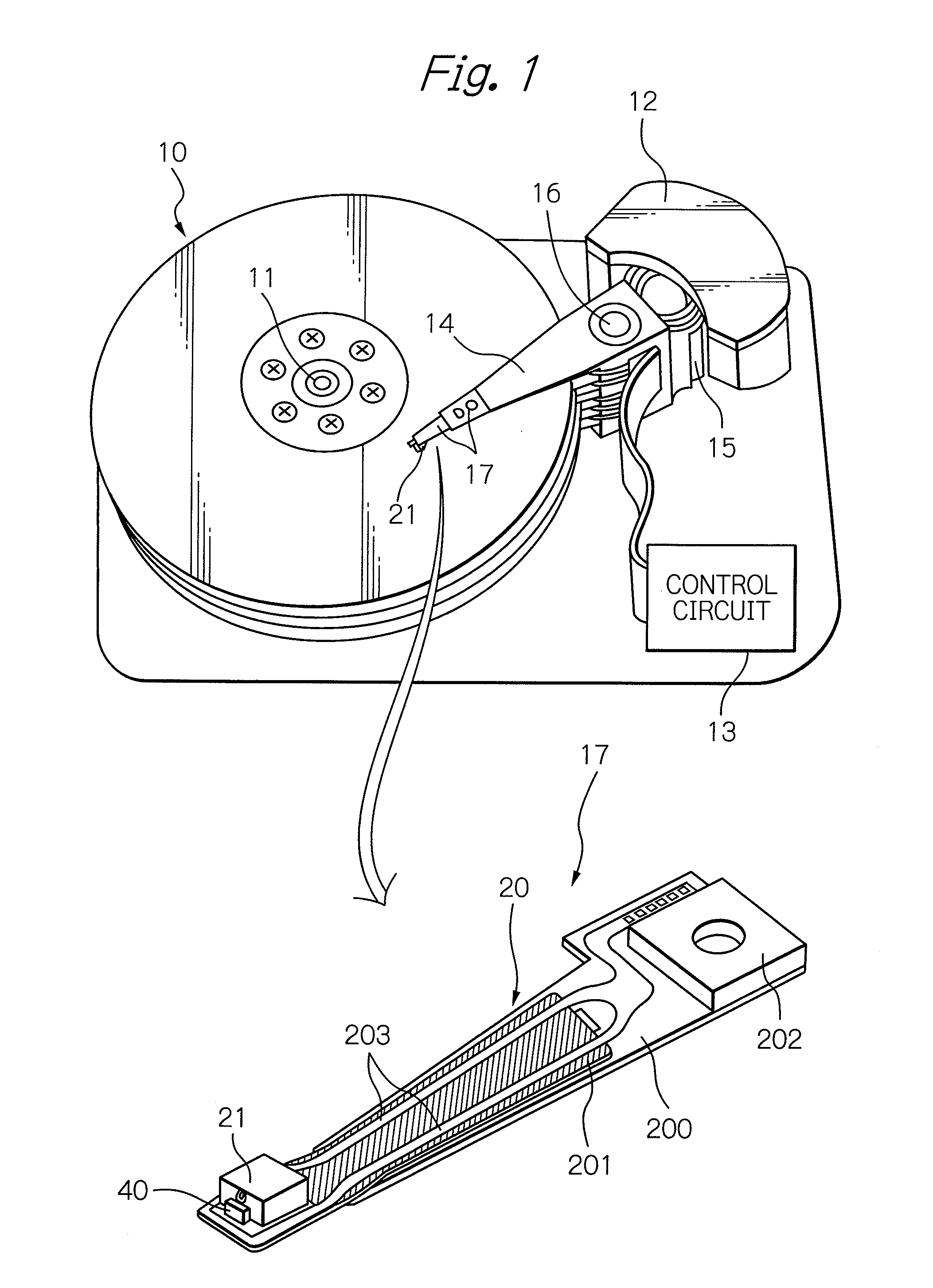

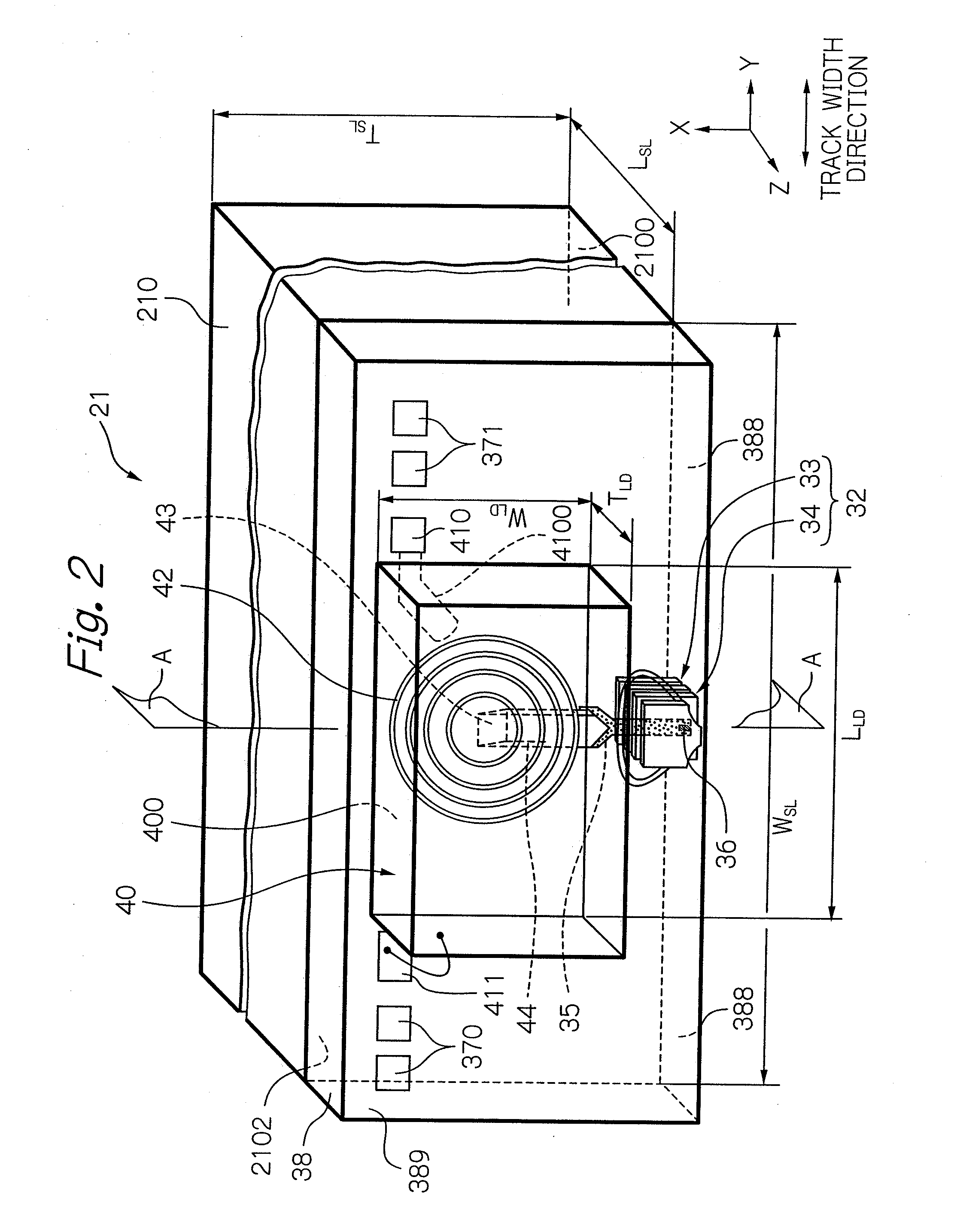

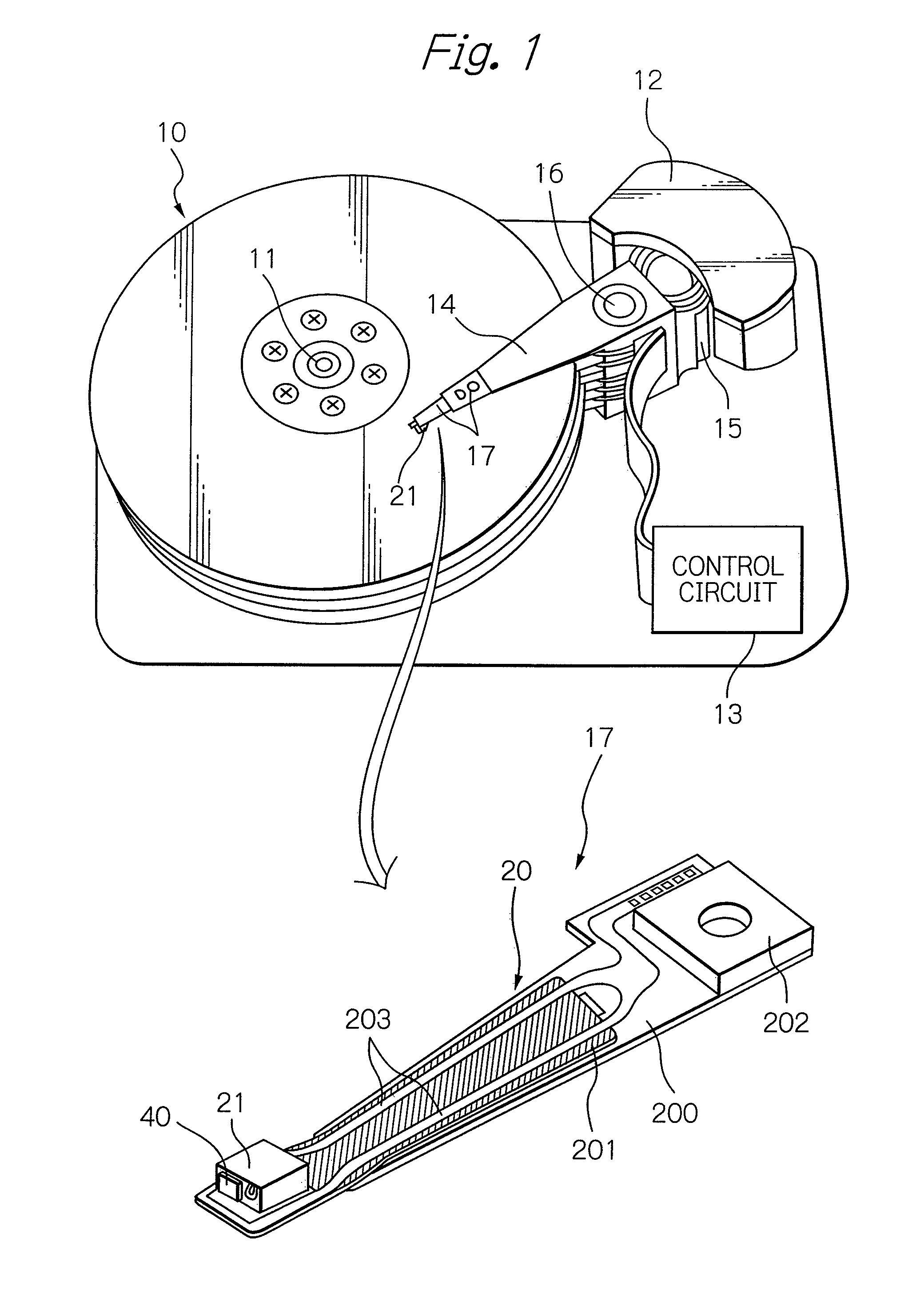

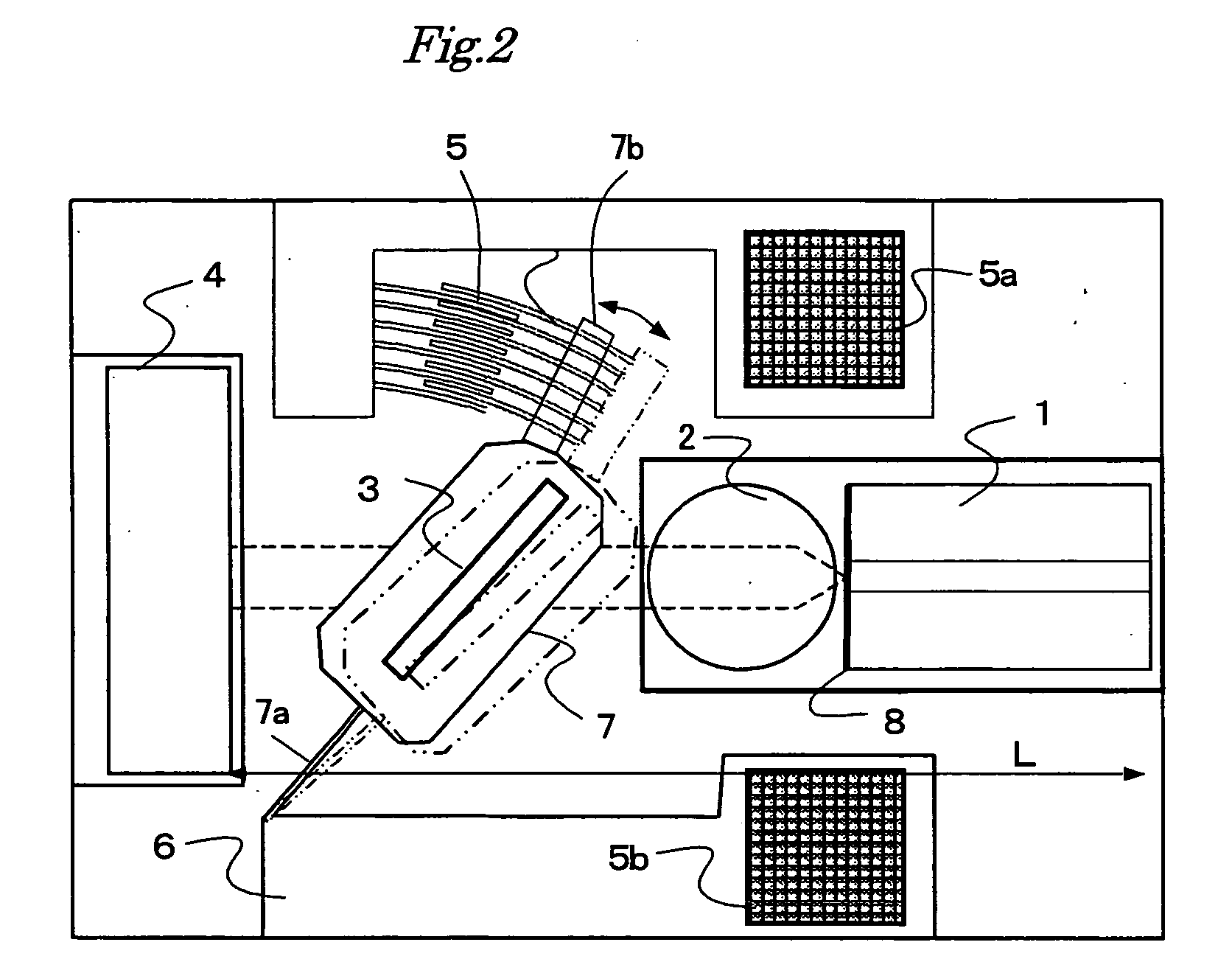

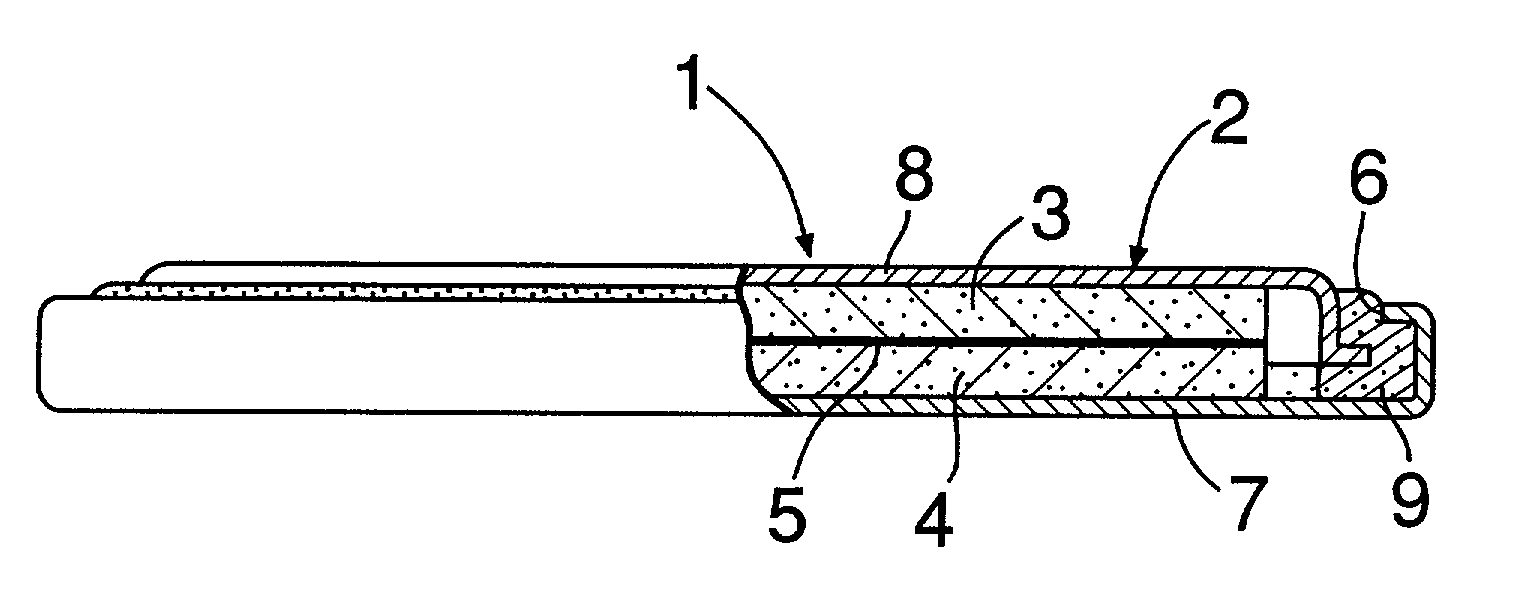

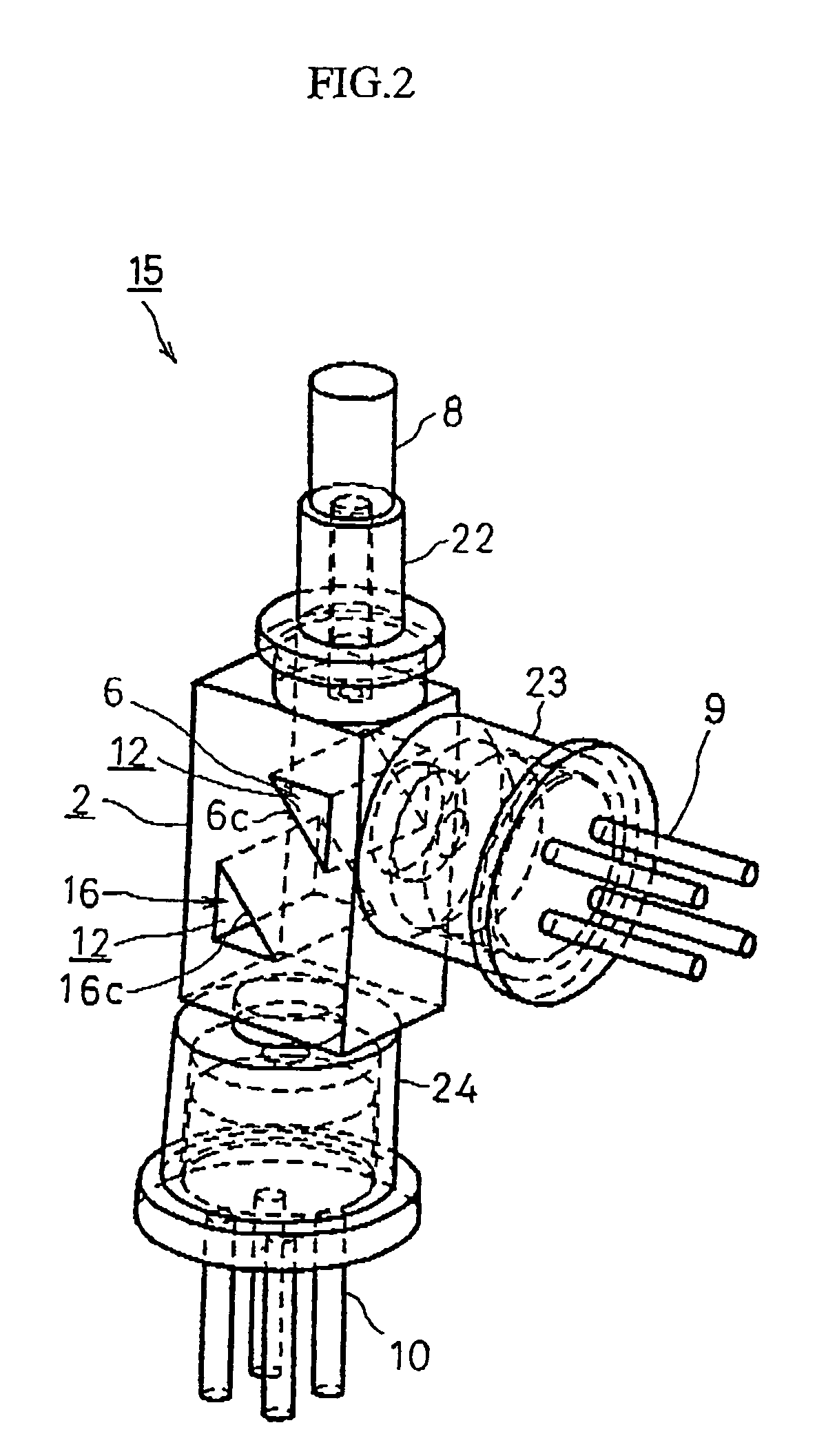

Thermally-Assisted Magnetic Recording Head Comprising Light Source with Photonic-Band Layer

ActiveUS20110026377A1Increase output powerMass productivity can be improvedCombination recordingRecord information storageProduction rateHeat-assisted magnetic recording

A thermally-assisted magnetic recording head is provided, in which a light source having sufficiently high output power for performing thermal-assist is disposed in the element-integration surface of the substrate to achieve improved mass-productivity. The head includes: a light source having a multilayered structure including a photonic-band layer and having a light-emitting surface opposed to the element-integration surface; a diffraction optical element that converges the emitted light; a light-path changer that changes the direction of the converged light; a waveguide that propagates the direction-changed light toward the opposed-to-medium surface; and a magnetic pole that generates write field. The surface-emitting type light source includes a photonic-band layer having a periodic structure in which a light from an active region resonates, and thus emits laser light on a quite different principle from a VCSEL. Therefore, the light source can be disposed in the element-integration surface, even though having sufficiently high output power.

Owner:TDK CORPARATION

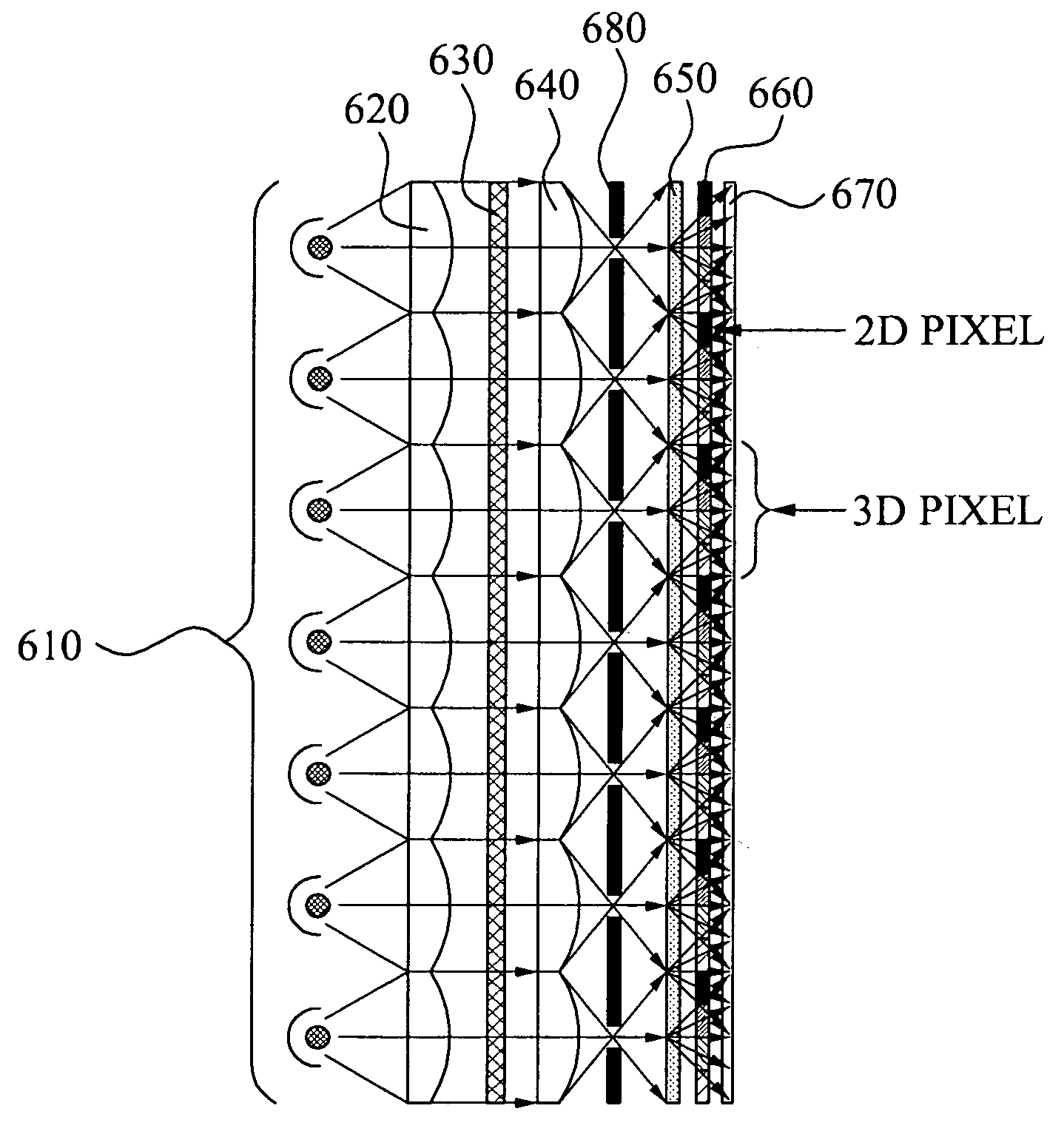

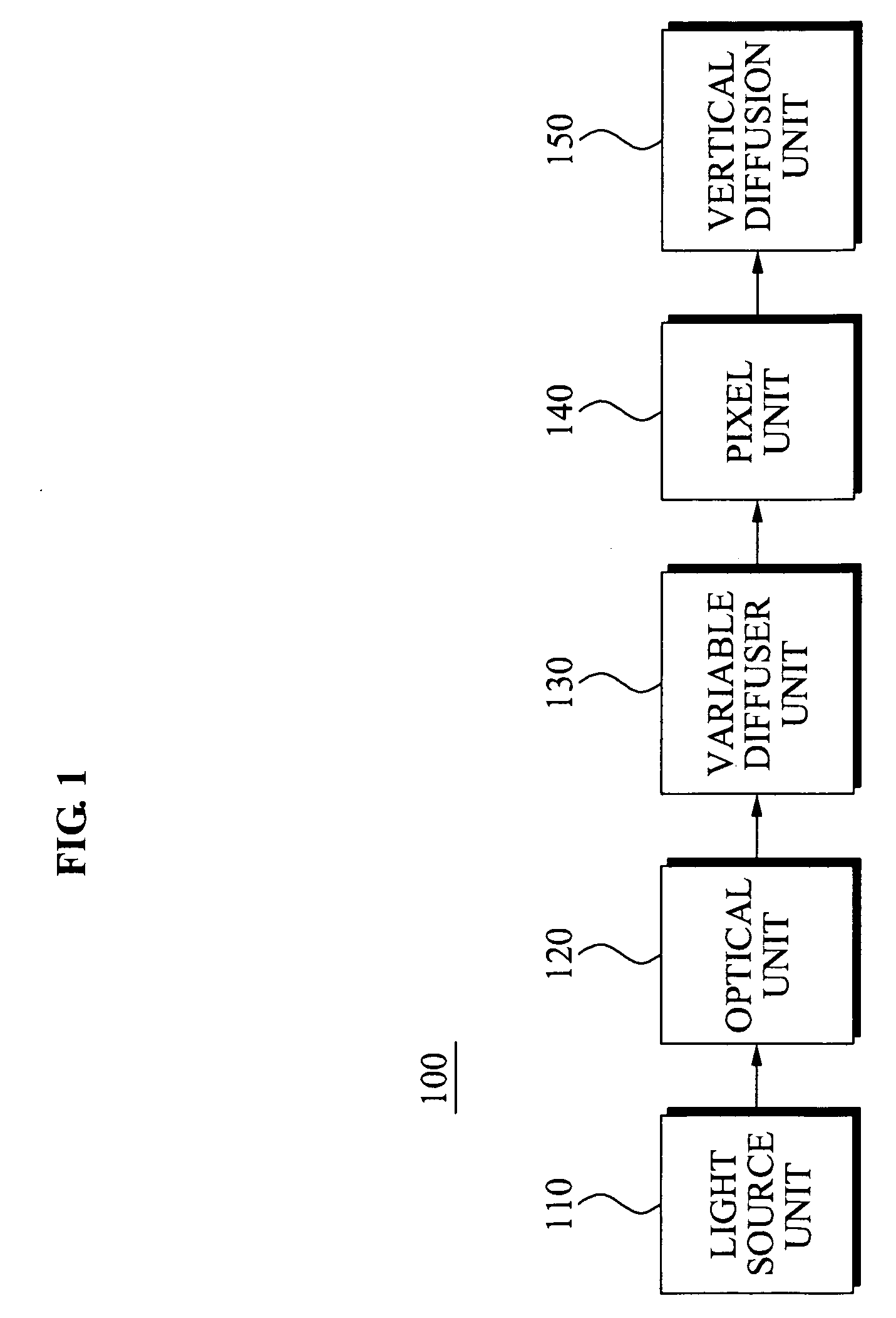

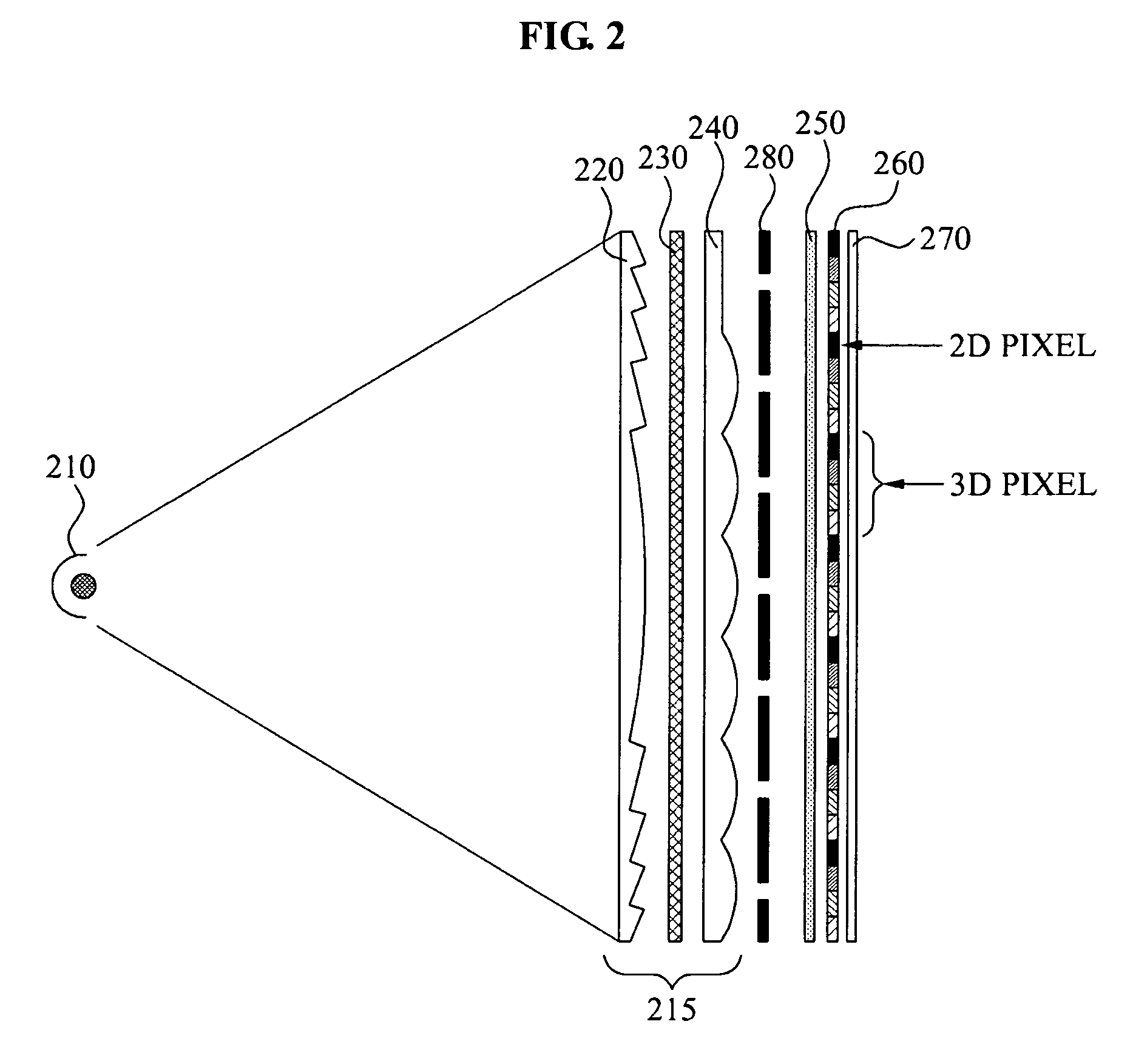

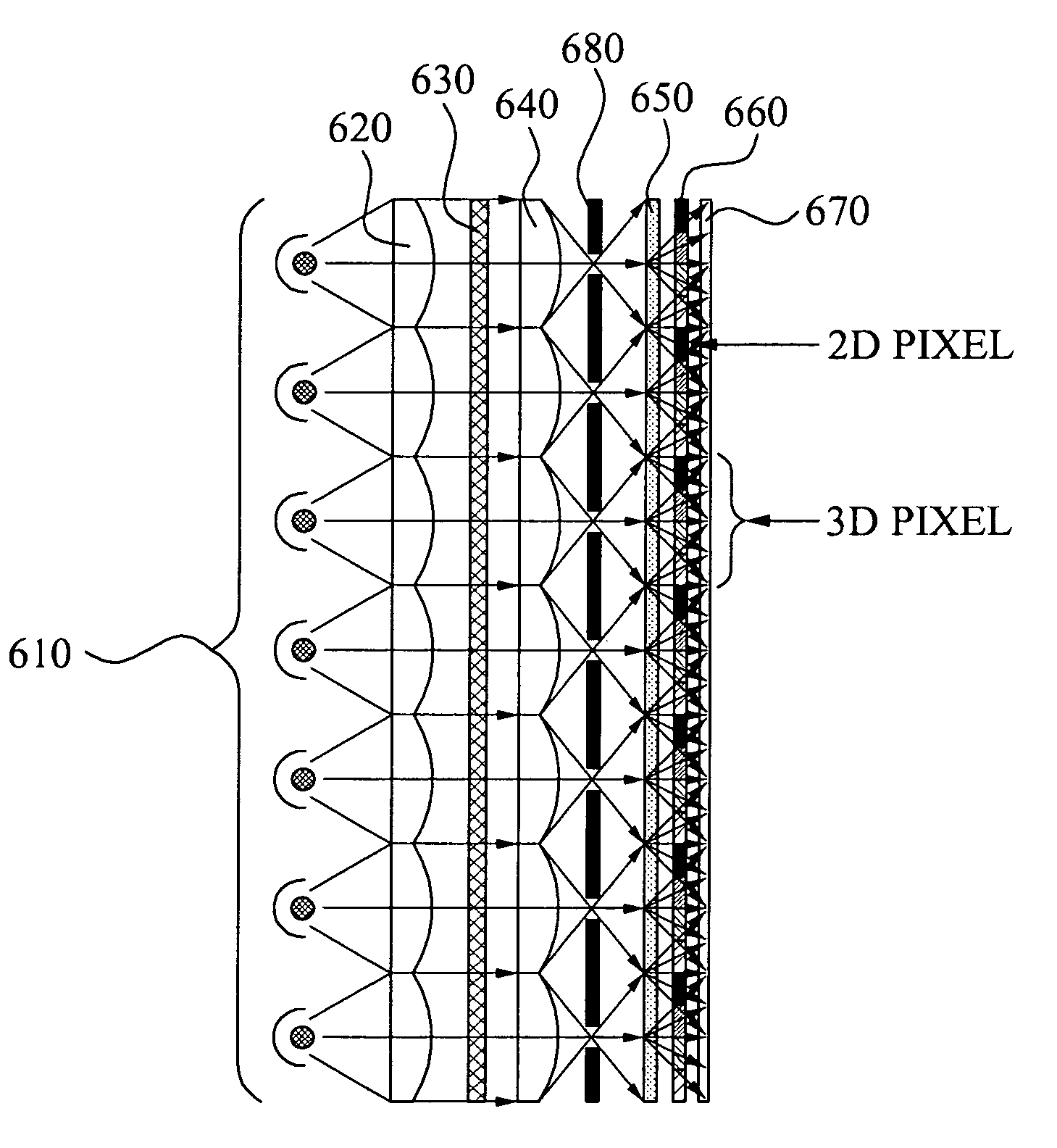

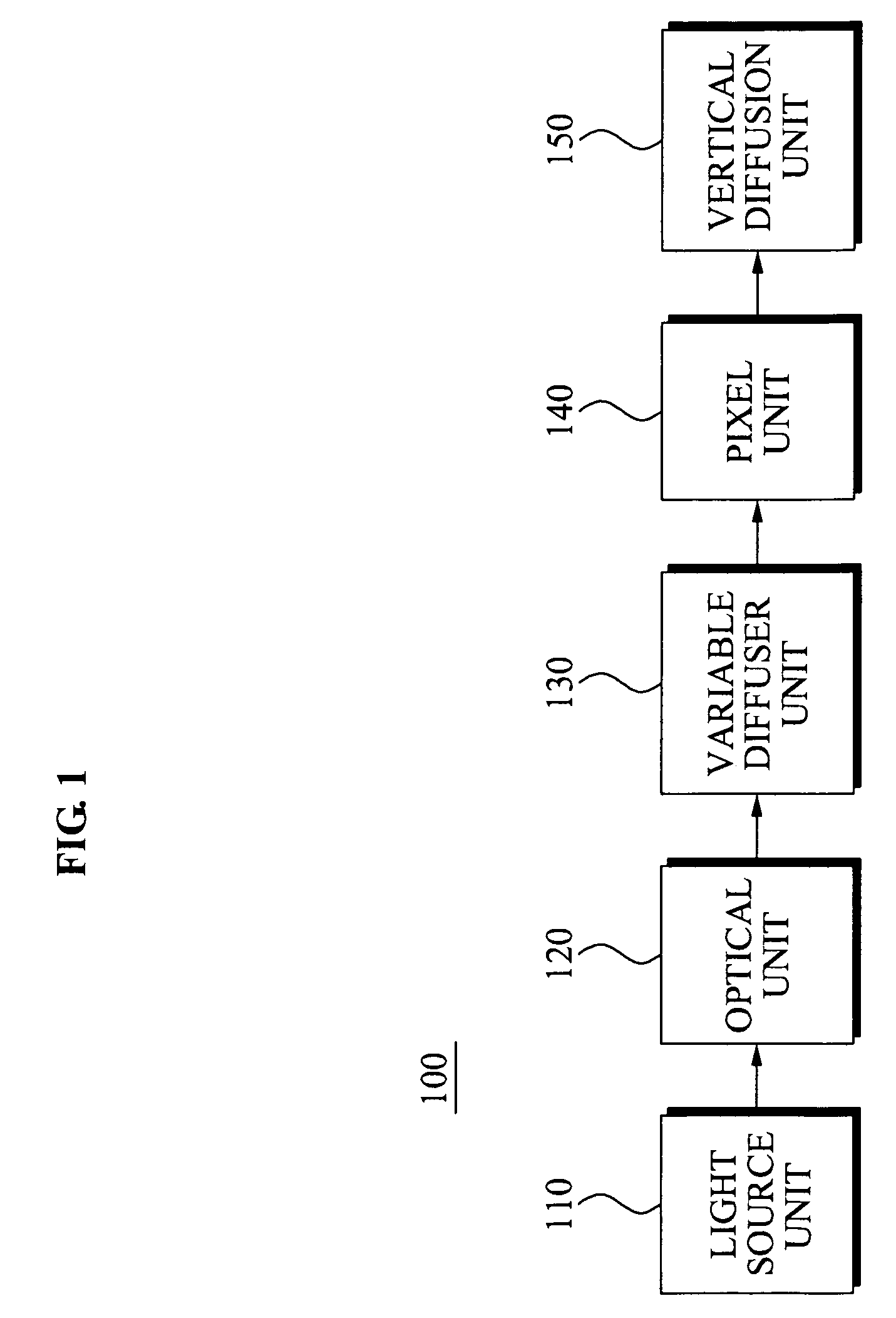

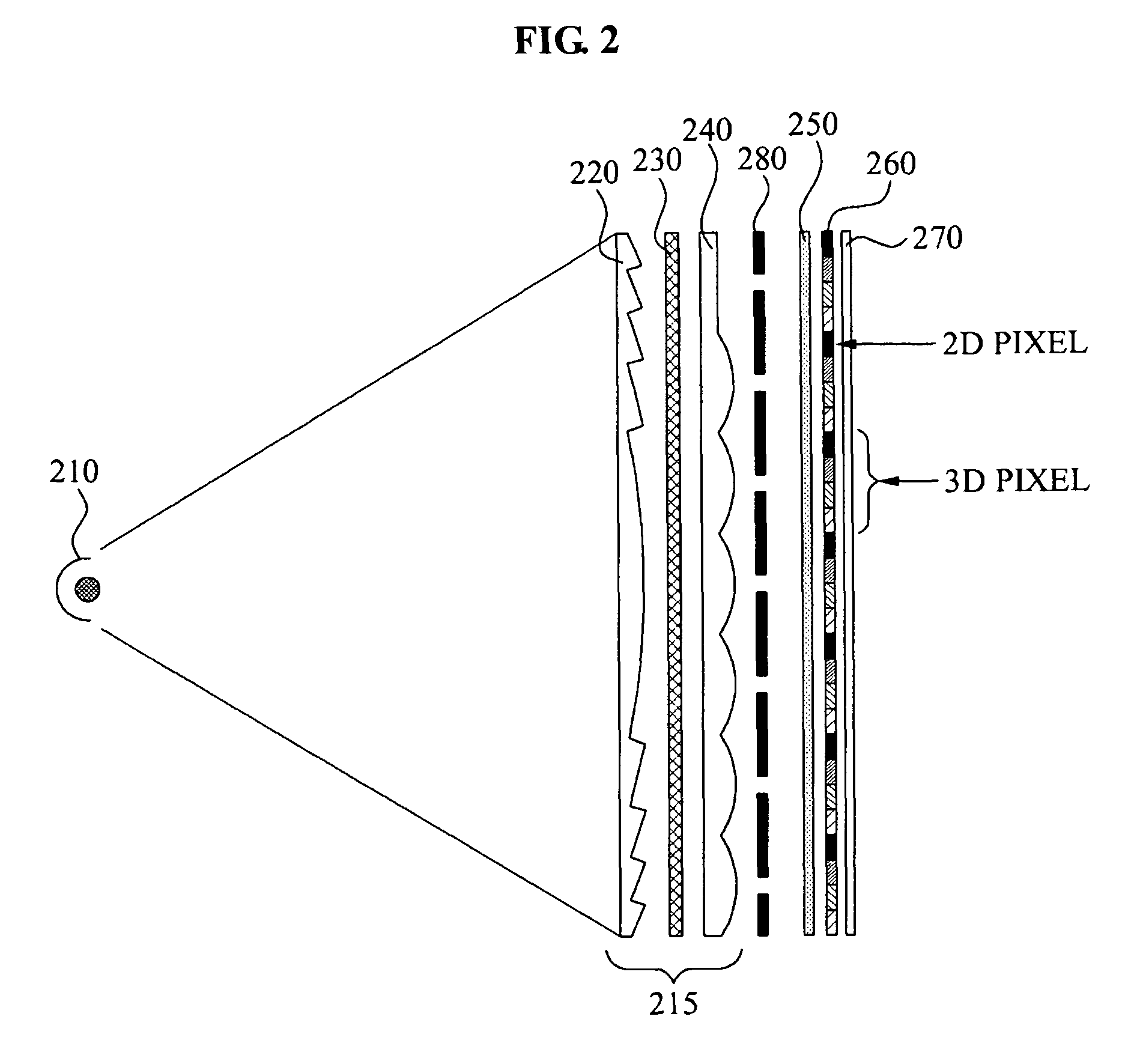

Apparatus and method for 2D and 3D image switchable display

InactiveUS20100091354A1Reduce deteriorationHigh quality imagingSteroscopic systemsNon-linear opticsComputer graphics (images)3d image

An image display apparatus and method are disclosed. The image display apparatus includes a light source unit to include at least one light source, an optical unit to generate a directional light using a light projected from the light source unit, a variable diffuser unit to control diffusion of the directional light, a pixel unit to selectively generate one of two-dimensional (2D) images and three-dimensional (3D) images to correspond to the control of the variable diffuser unit, and a vertical diffusion unit to diffuse the 3D images in a vertical direction

Owner:SAMSUNG ELECTRONICS CO LTD

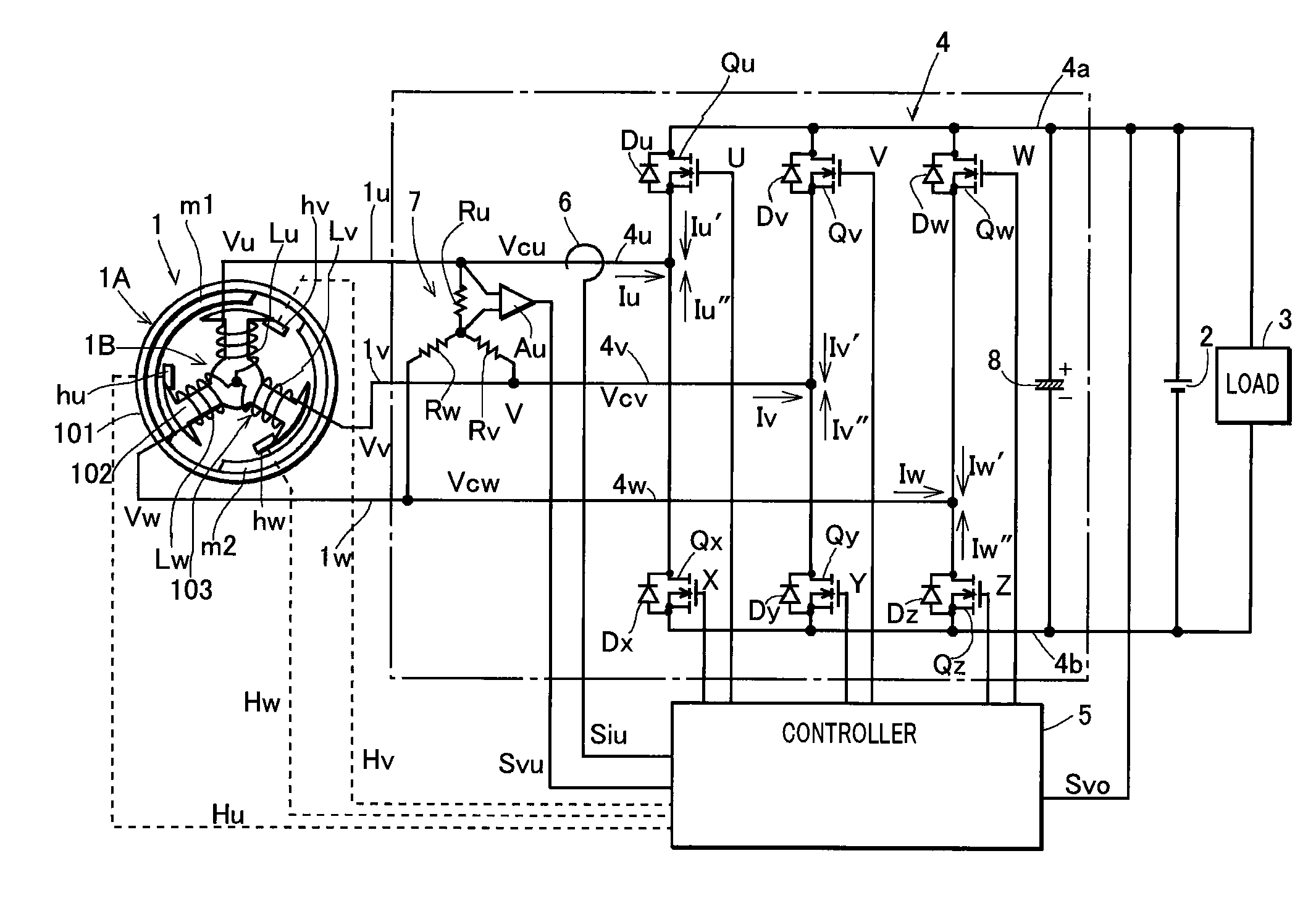

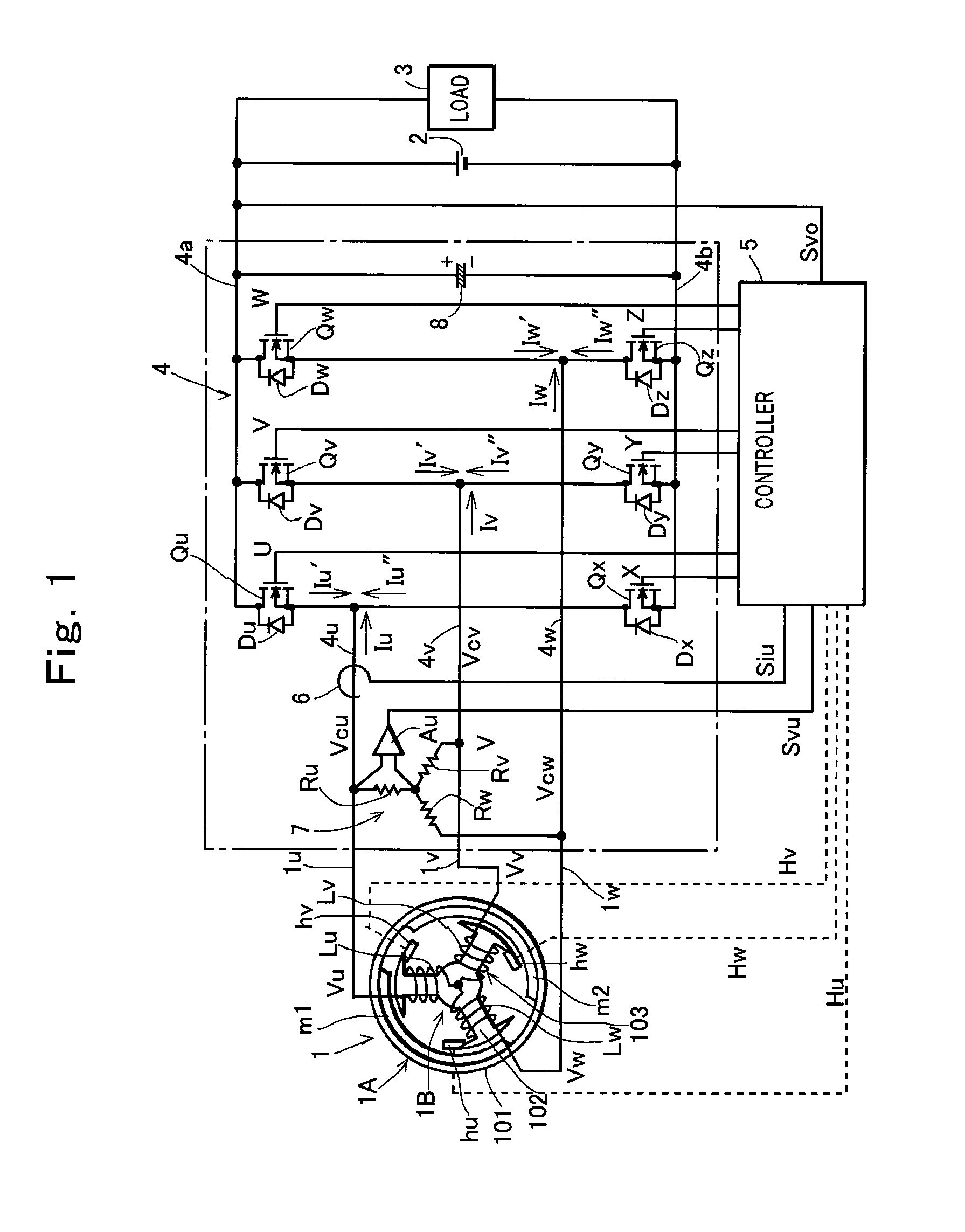

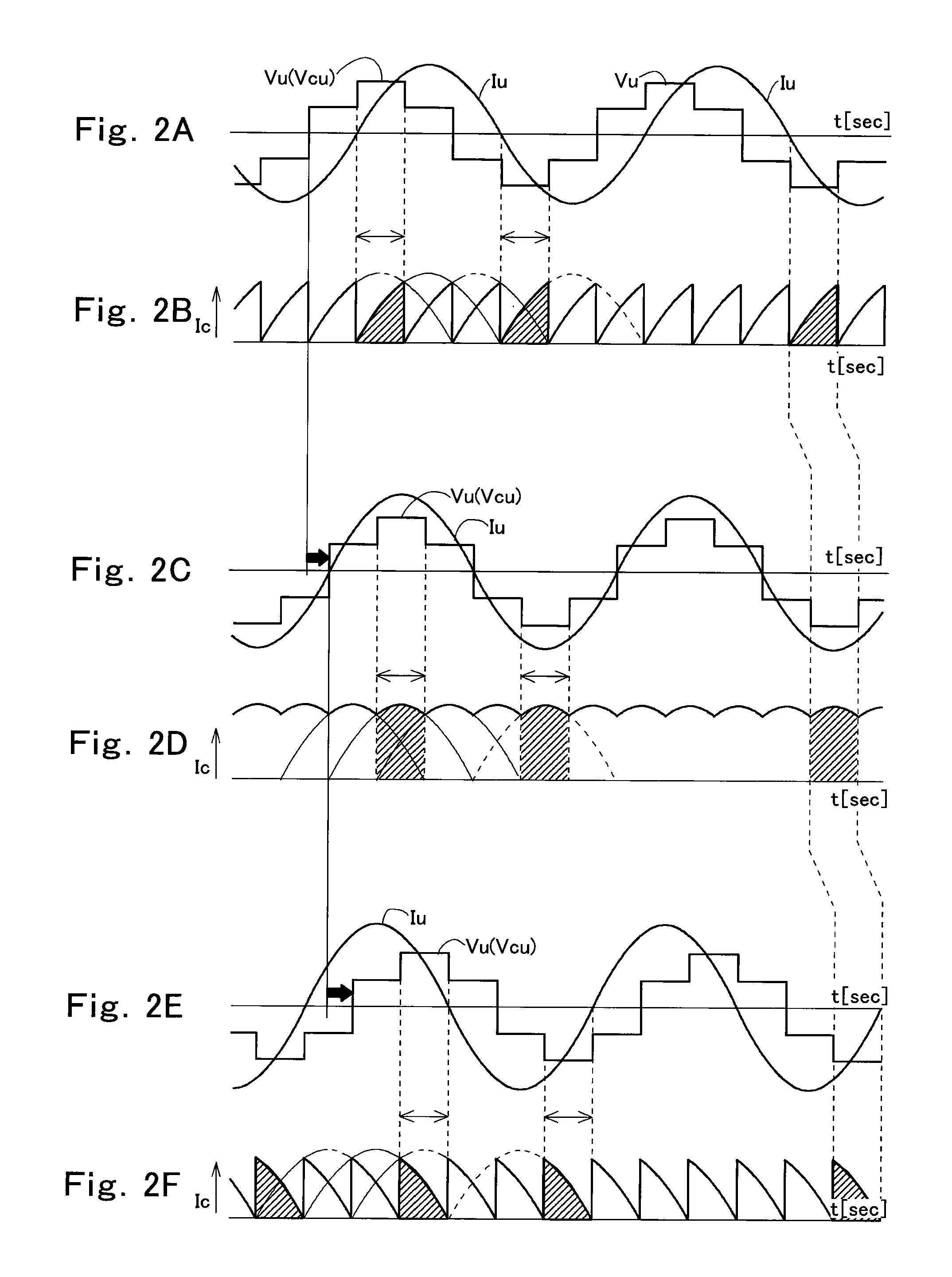

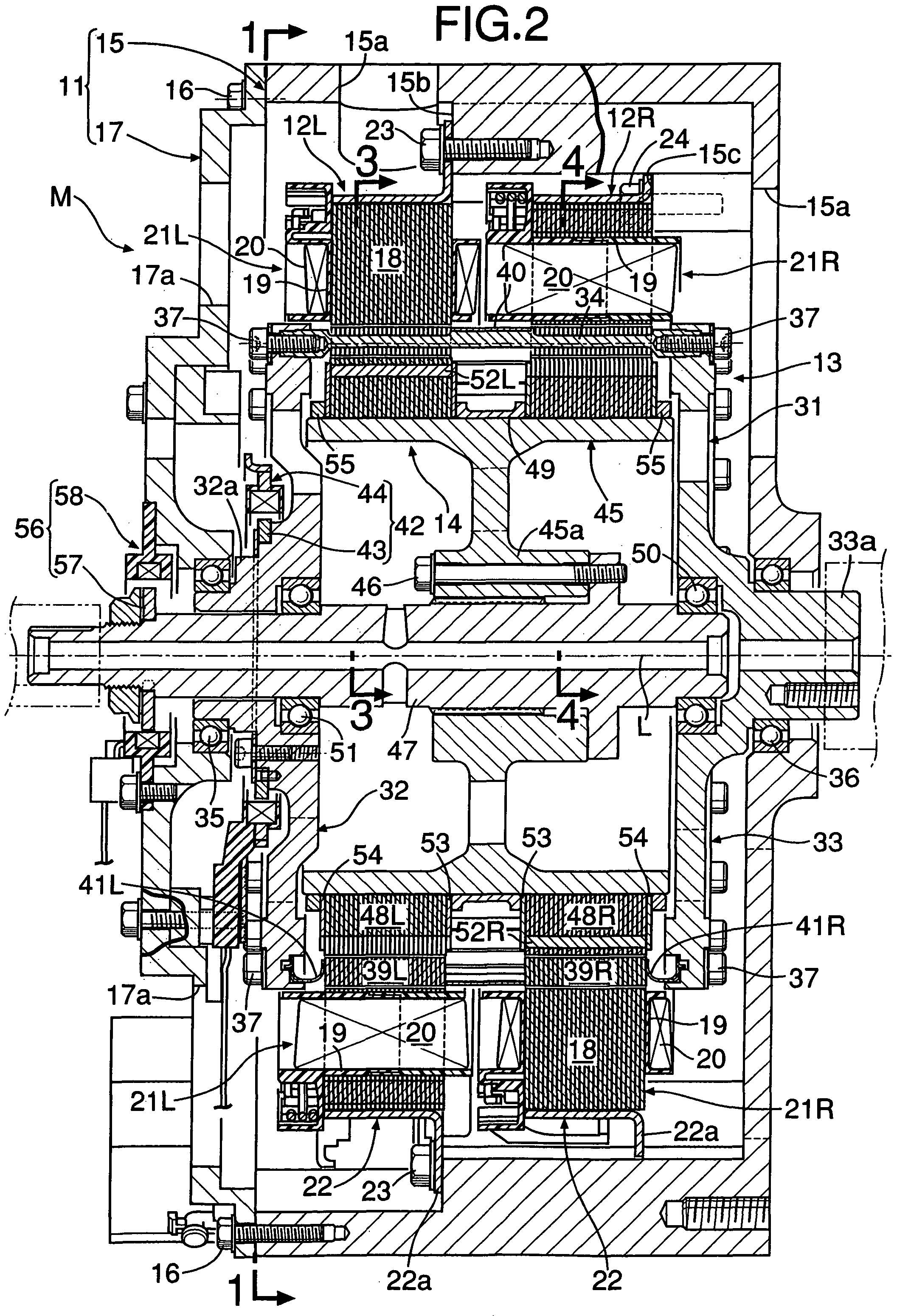

Power generating apparatus

ActiveUS20090102437A1Easy to controlReduce arithmetical processing amountConversion with intermediate conversion to dcDc-dc conversionPhase currentsEngineering

A power generating apparatus including an AC generator that supplies electric power to a load including a voltage accumulating means, an inverter that applies AC control voltage to armature winding of the generator from the voltage accumulating means, and a controller that controls a phase of control voltage applied to the armature winding by the inverter to keep load voltage at a target value, wherein the phase of the control voltage is controlled so as to advance when the load voltage is higher than the target value, hold the present phase when the load voltage is equal to the target value, advance when the load voltage is lower than the target value and a phase of phase voltage of the generator is delayed behind a phase of a phase current of the same phase, and delay when the load voltage is lower than the target value and the phase of the phase voltage of the generator is advanced ahead of a phase of a phase current of the same phase.

Owner:MAHLE INT GMBH

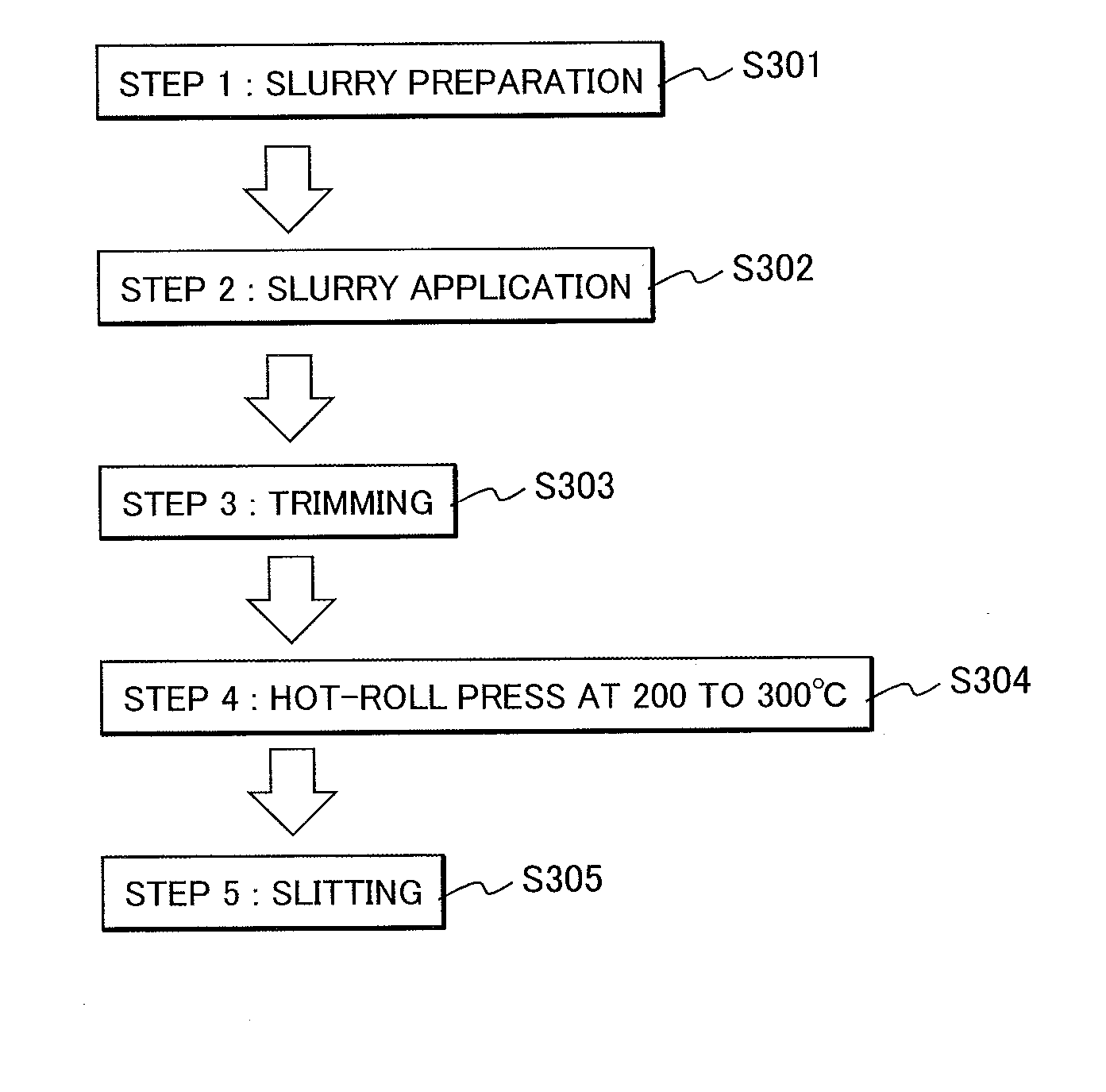

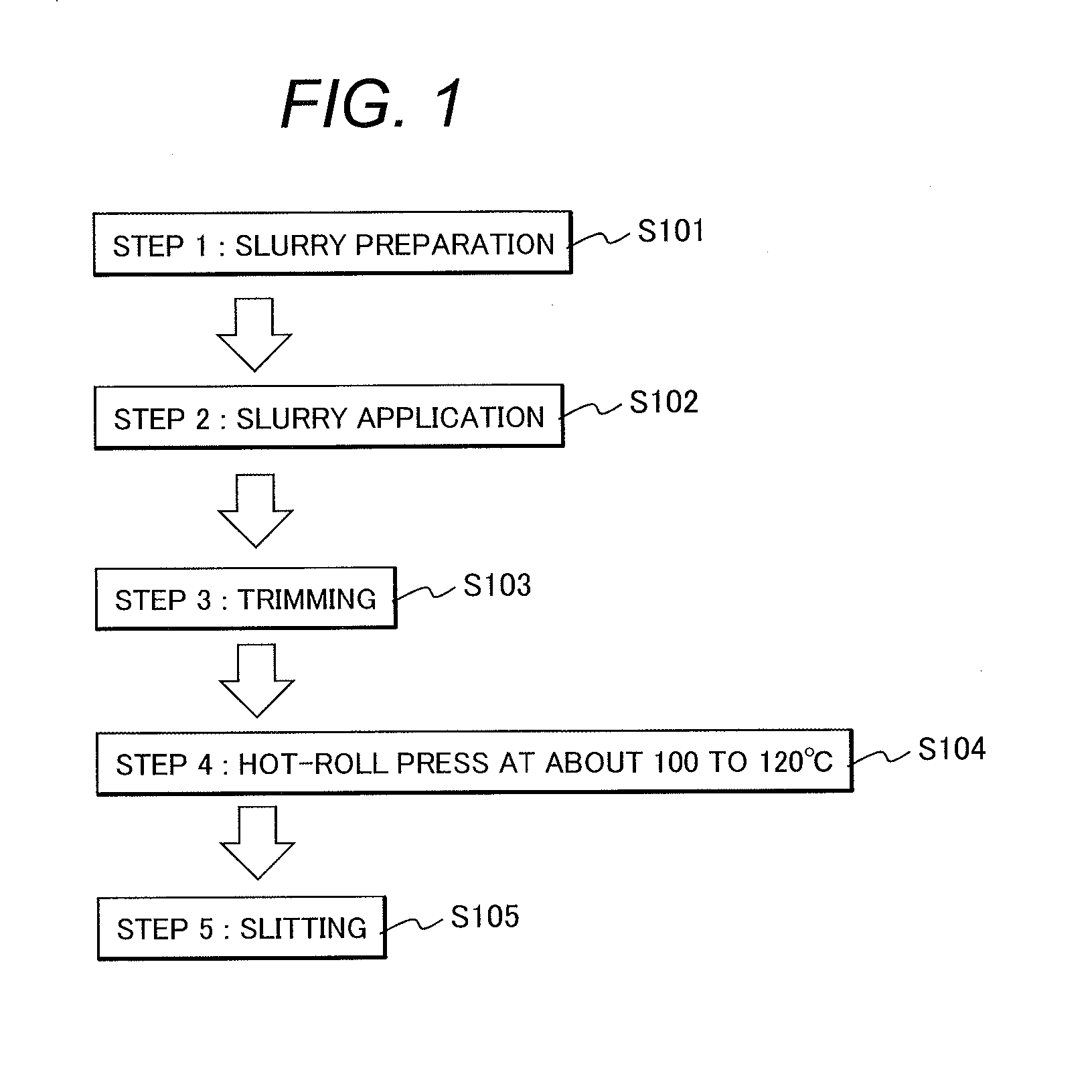

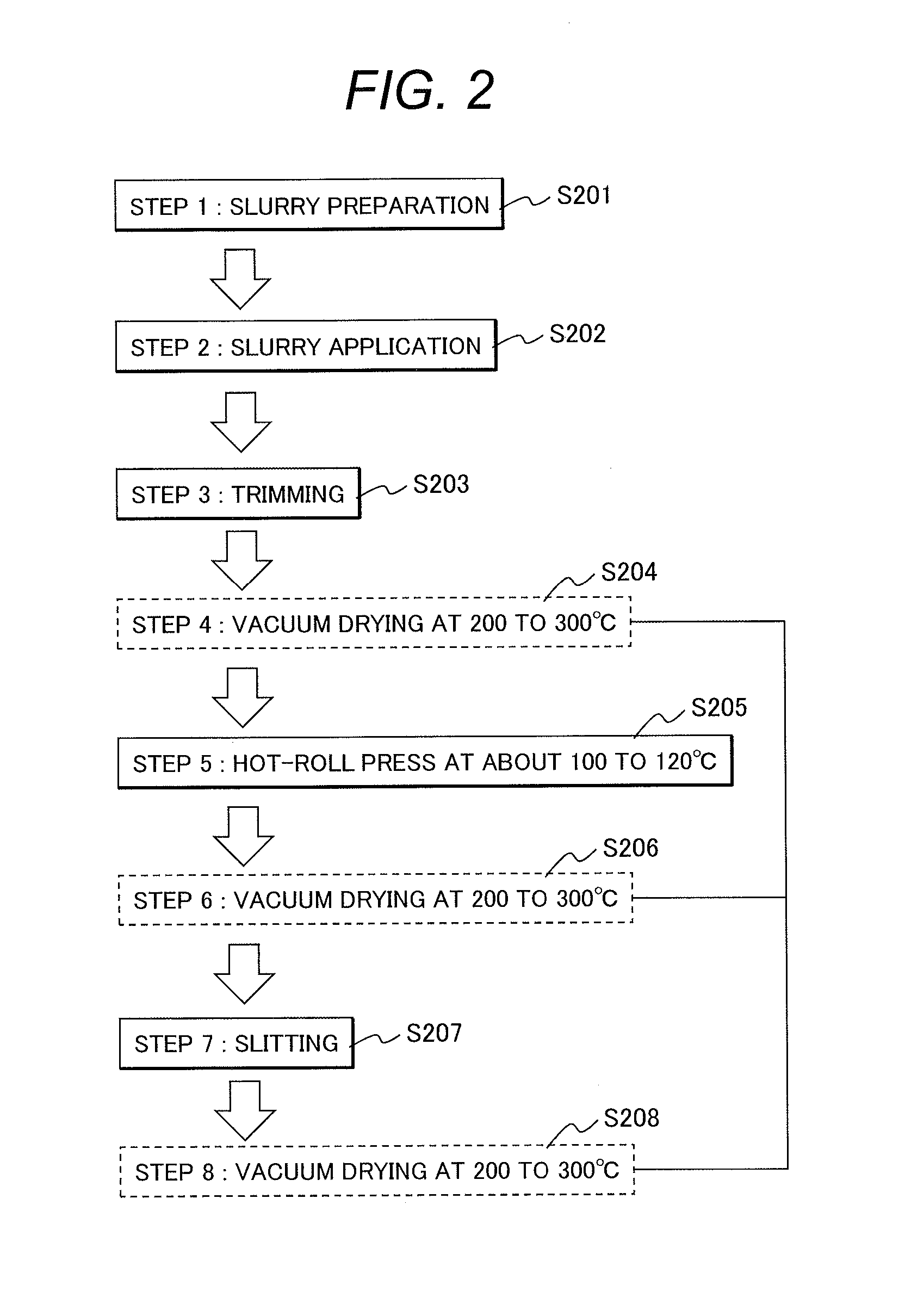

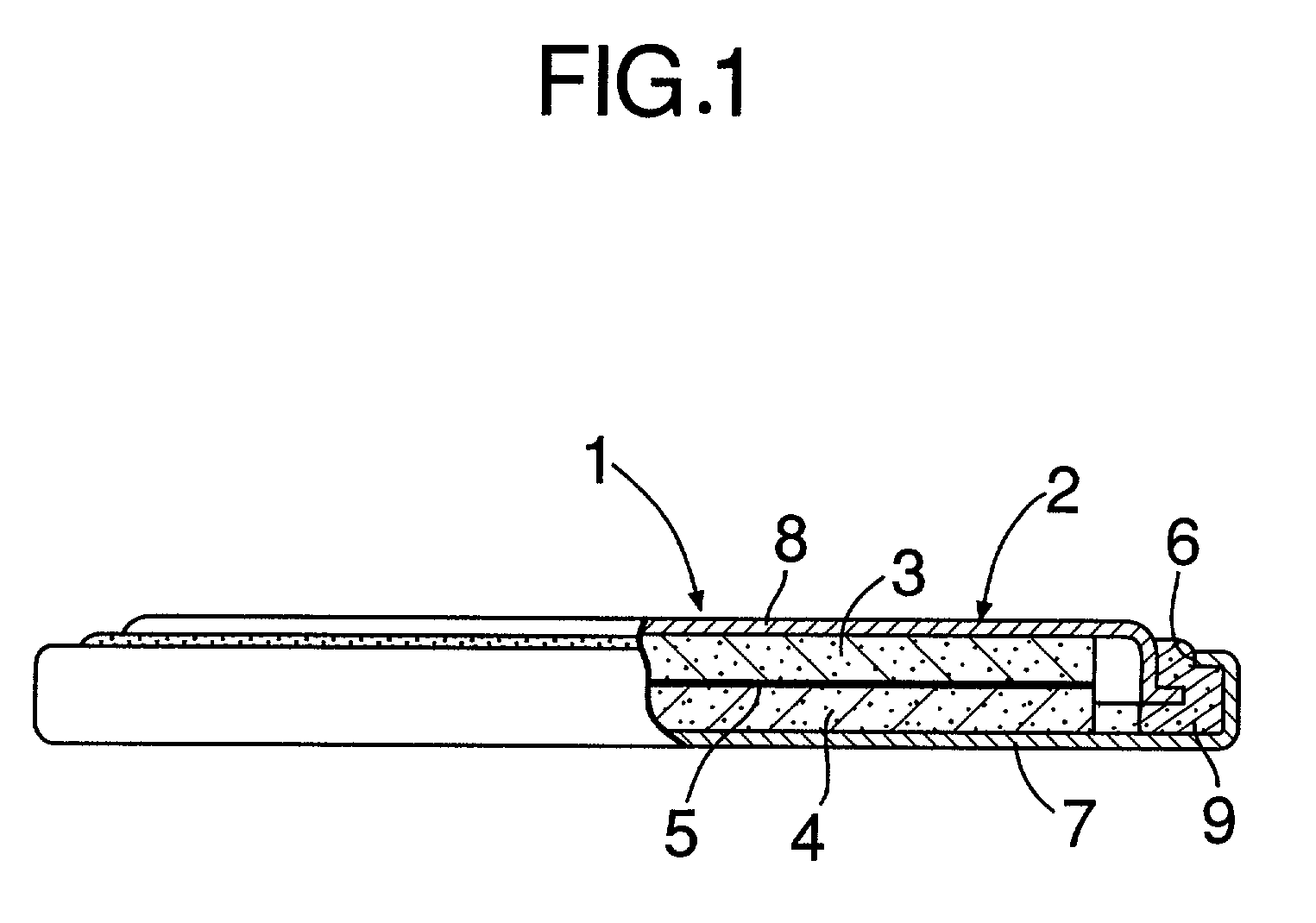

Method and apparatus for manufacturing negative electrode for lithium-ion secondary battery, negative electrode for lithium-ion secondary battery, and lithium-ion secondary battery

InactiveUS20150280208A1Reduced areaManufacturing facility can be simplifiedElectrode rolling/calenderingElectrode thermal treatmentLithiumPolyamide-imide

In manufacturing a negative electrode for a lithium-ion secondary battery, the negative electrode including a negative-electrode mixture layer including a negative-electrode active material and a binder containing at least one selected from a group consisting of a polyimide, a polyamide-imide and a polyamide, and a negative-electrode collector, the negative-electrode collector coated with a negative-electrode mixture slurry containing the binder is pressed by a hot-press roller which is heated to perform thermal curing and press together, such that the negative-electrode collector with the negative-electrode mixture slurry has a temperature of 200 to 400° C. Thus, mass-productivity of the negative electrode for the lithium-ion secondary battery is improved, and reduction in each of adhesiveness and adhesion uniformity of the binder as a component of the negative electrode is suppressed, and thereby direct-current resistance (DCR) of the lithium-ion secondary battery is decreased and a cycle life of the battery is improved.

Owner:HITACHI LTD

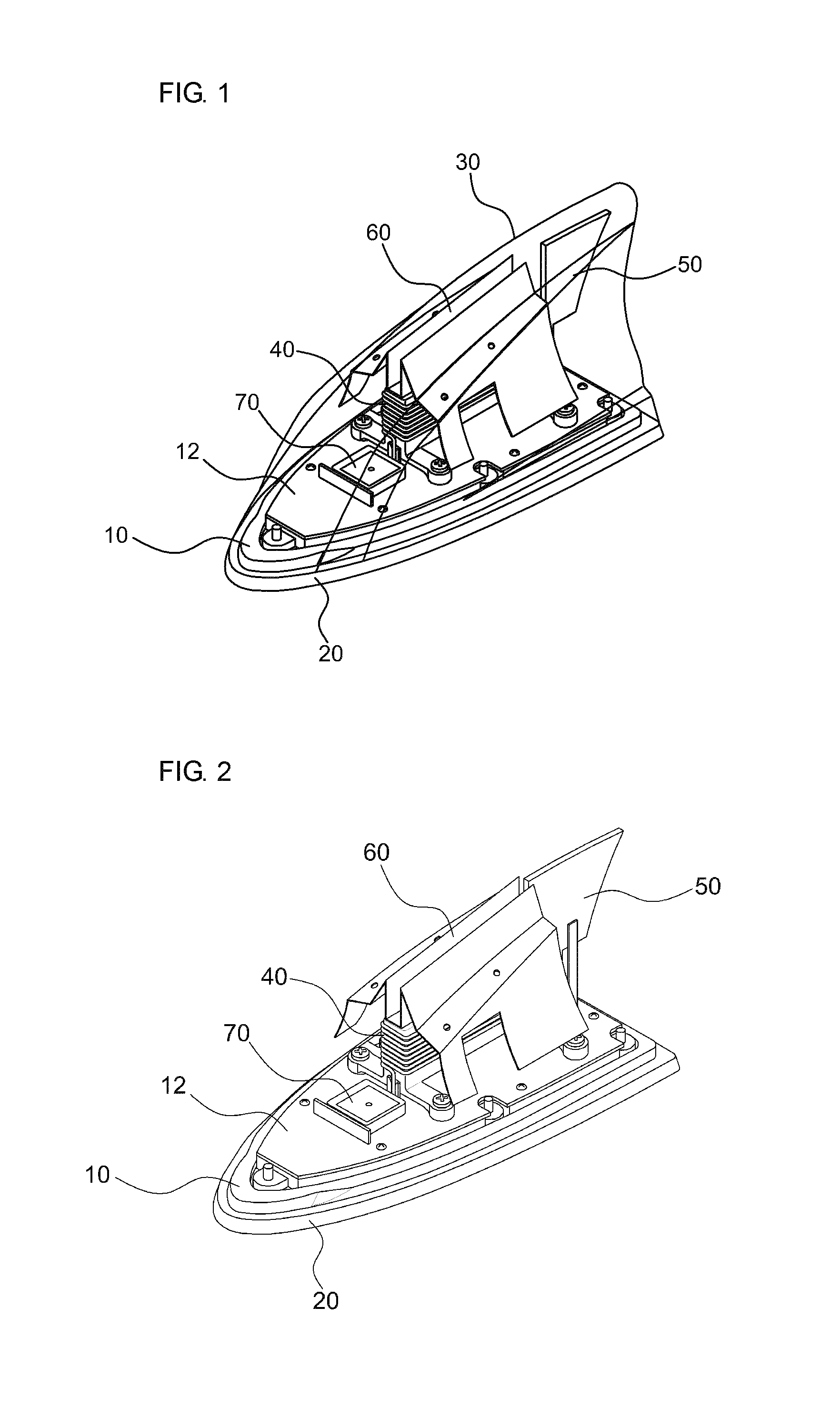

Unified antenna of shark fin type

InactiveUS8836604B2Easy to harvestSmoothly receiving signalAntenna adaptation in movable bodiesRadiating element housingsElectricityGlobal Positioning System

Owner:INFAC ELECS

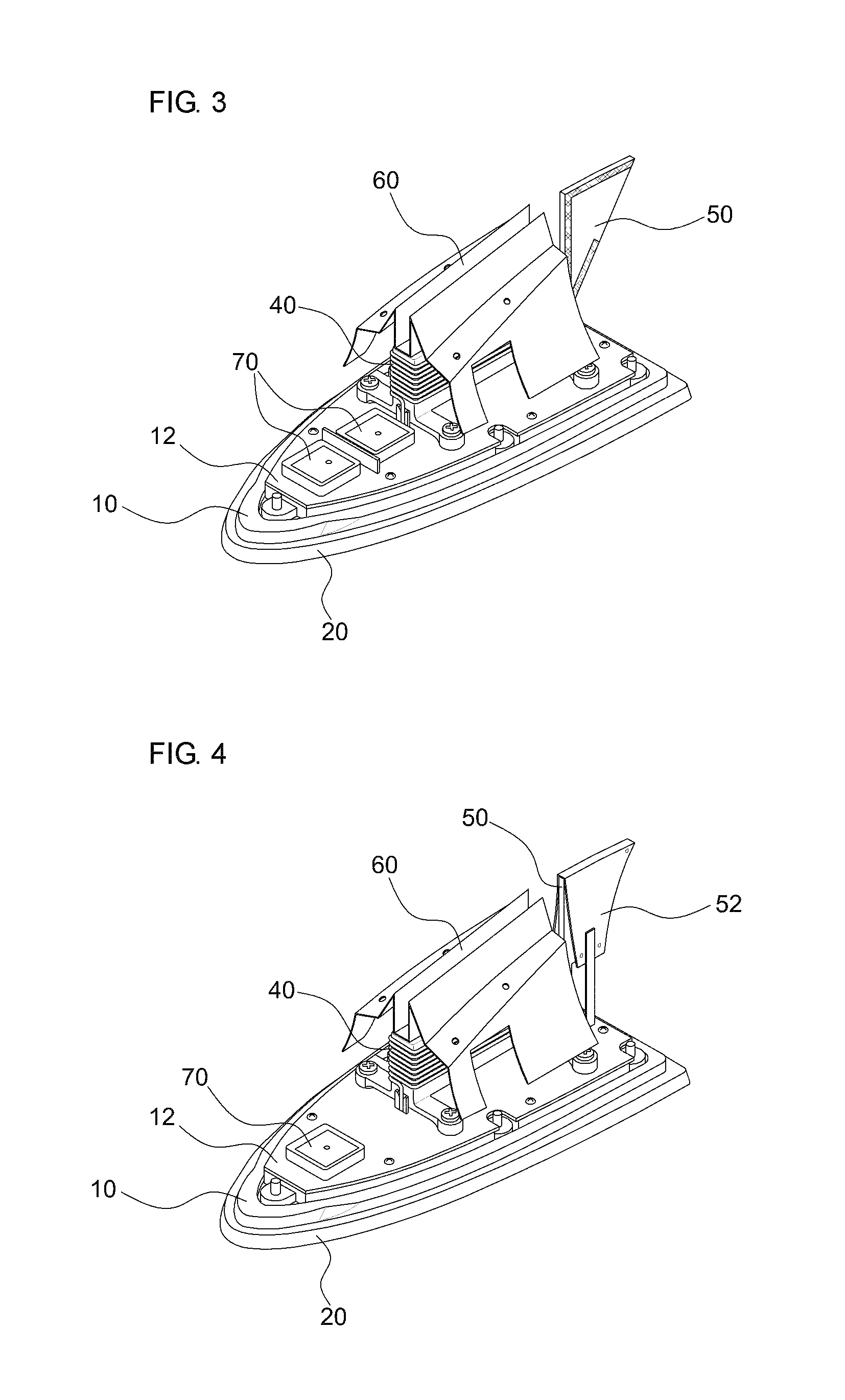

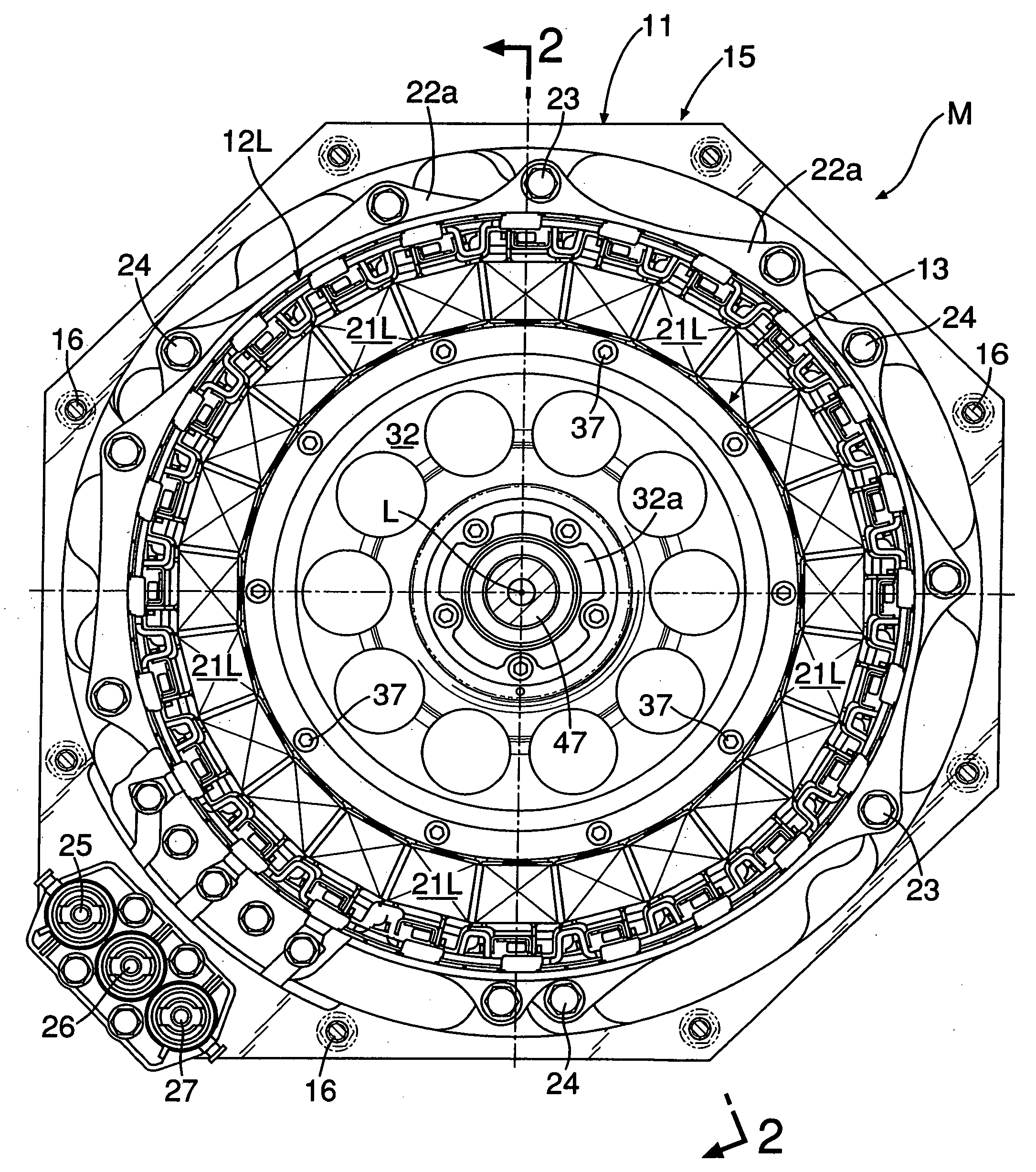

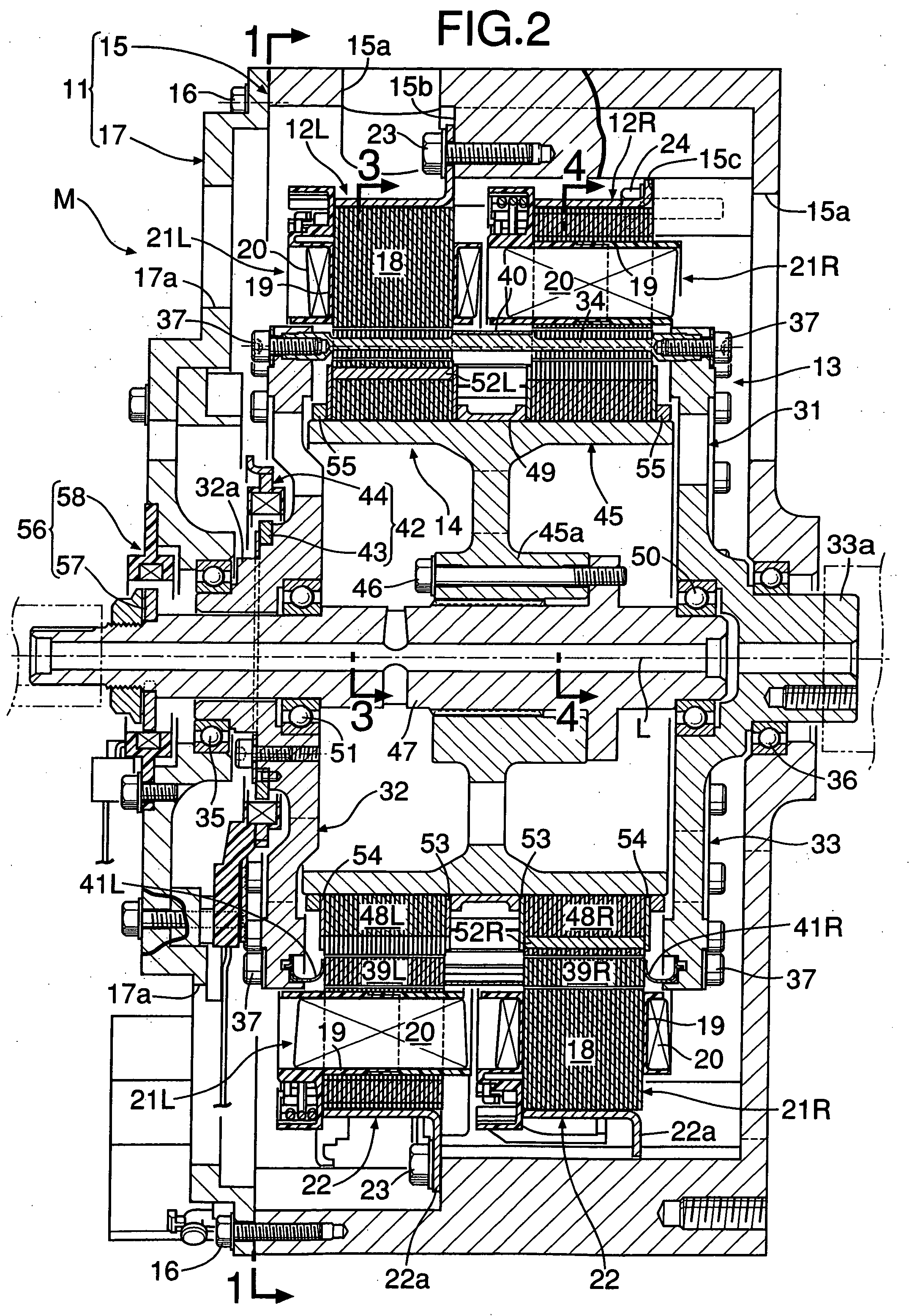

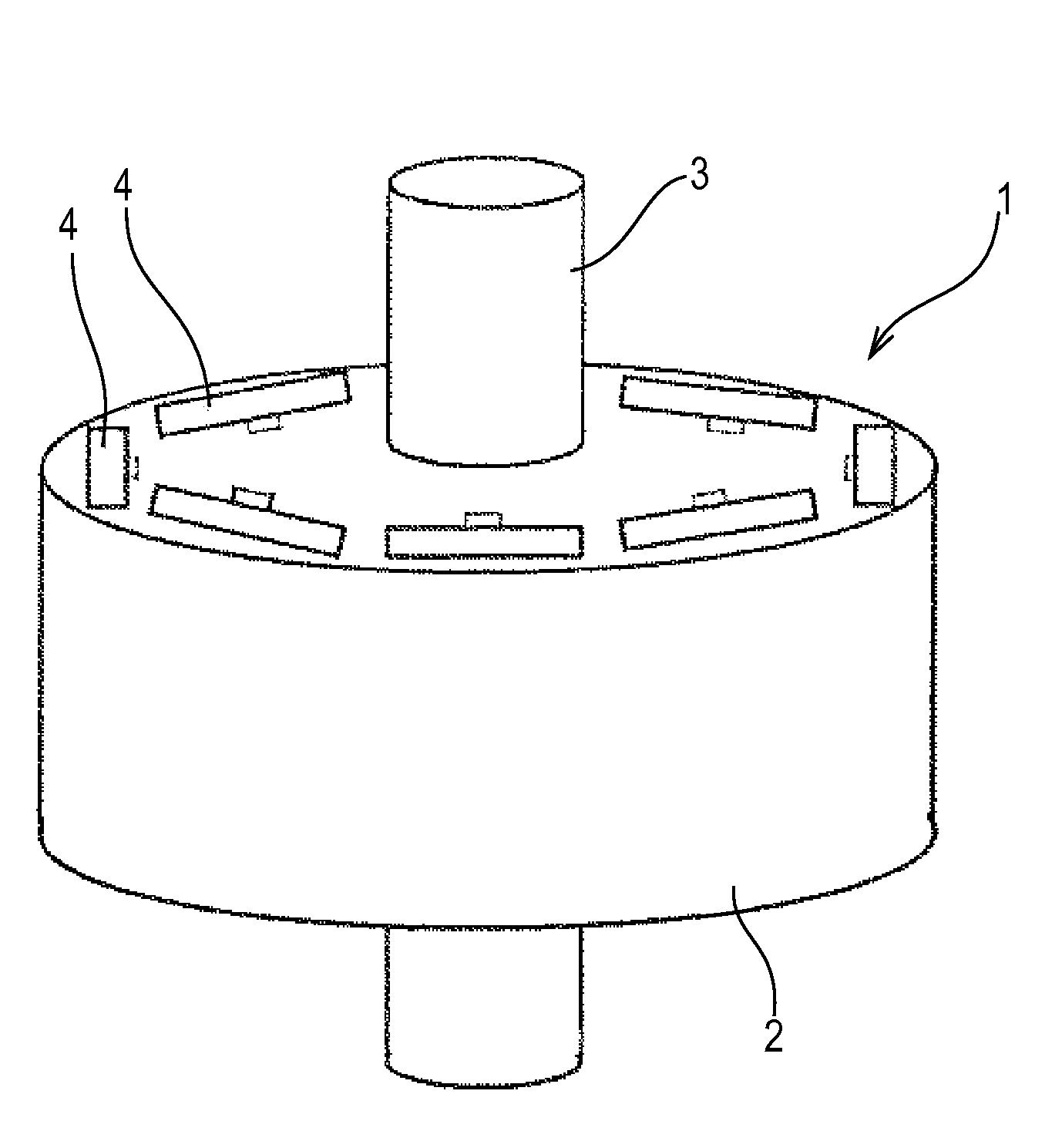

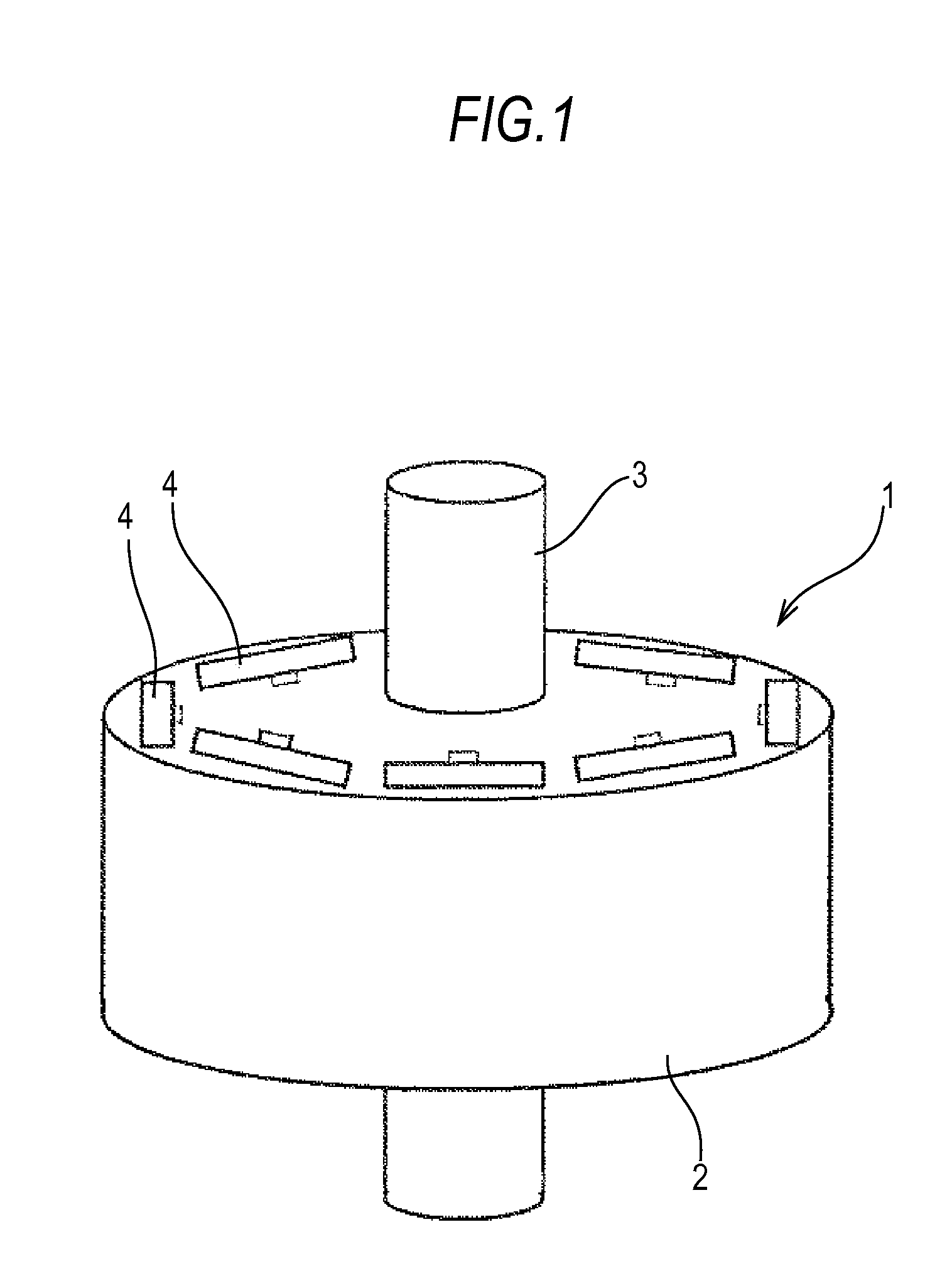

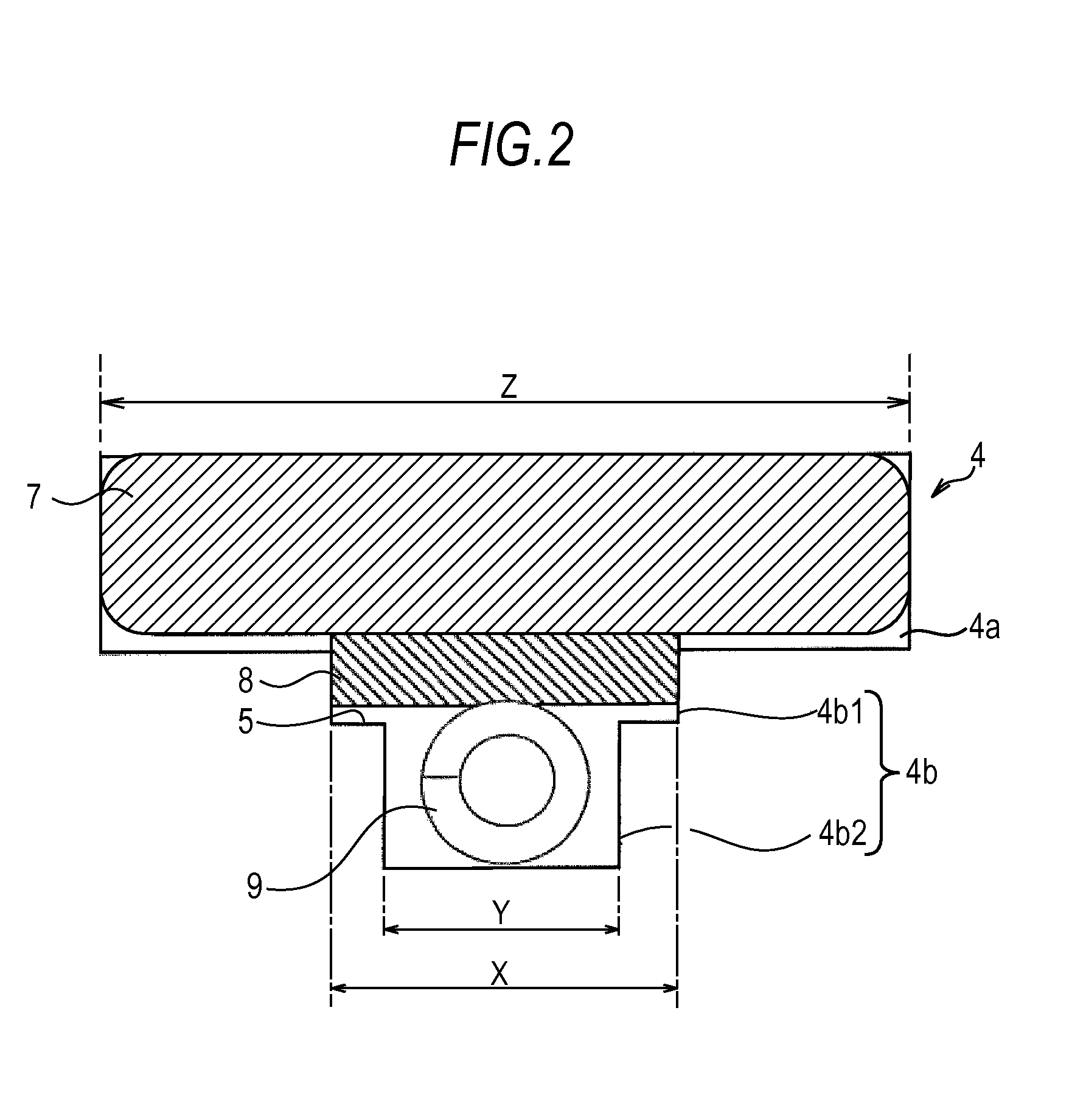

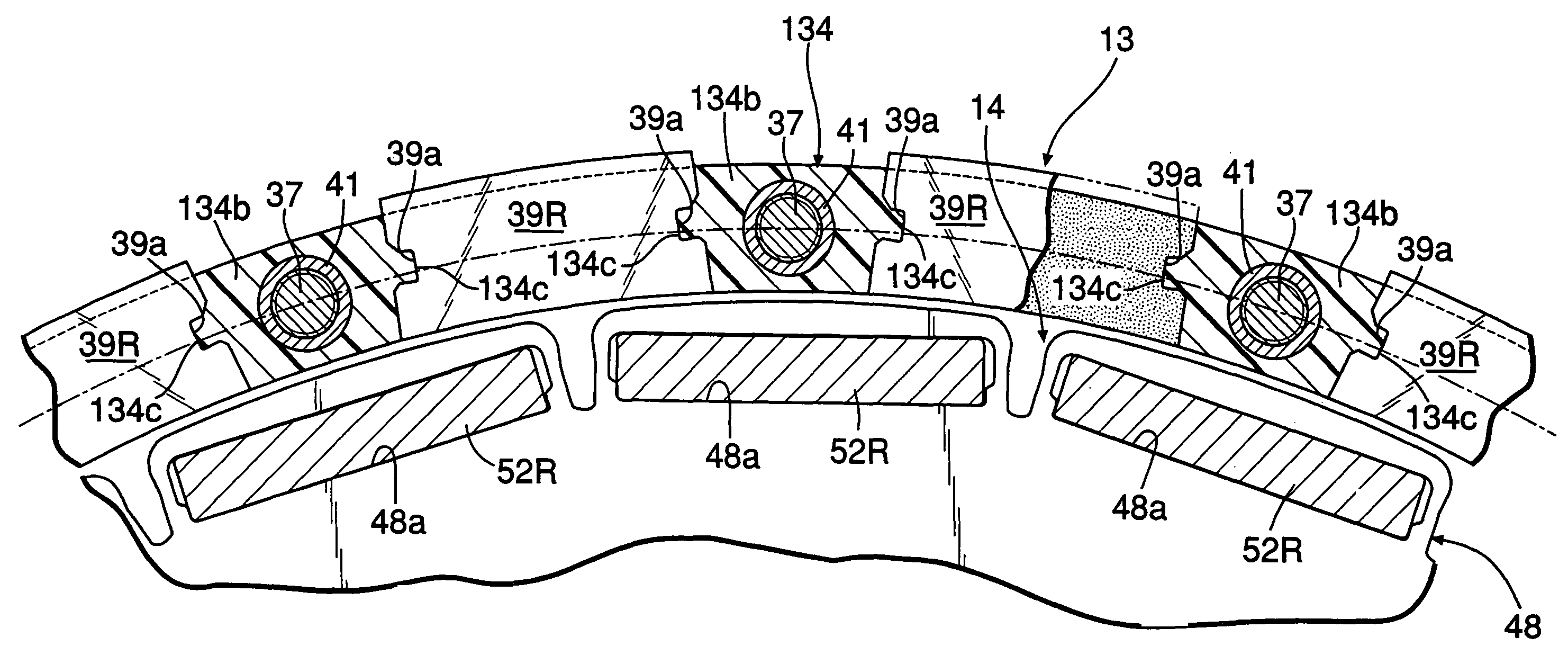

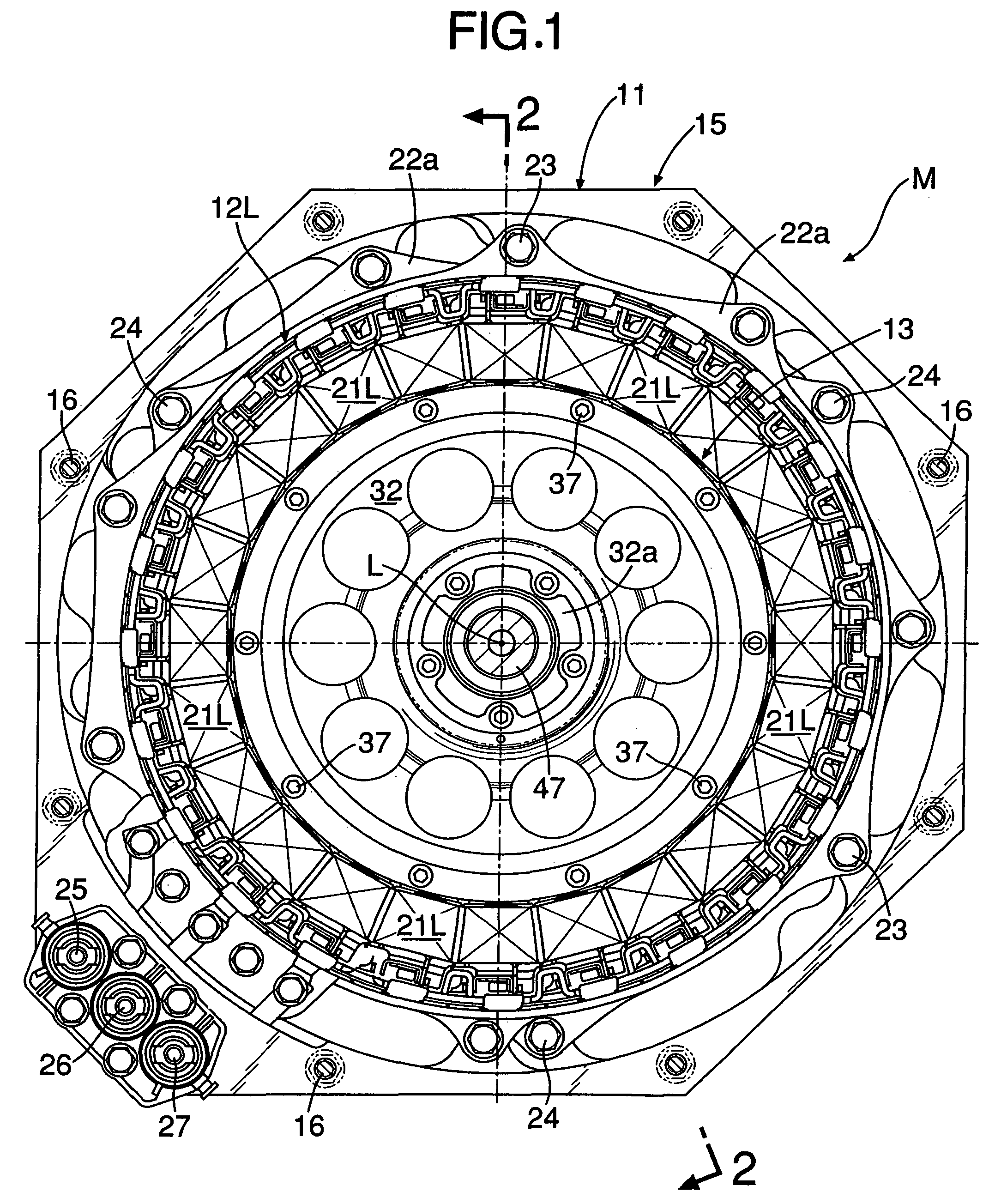

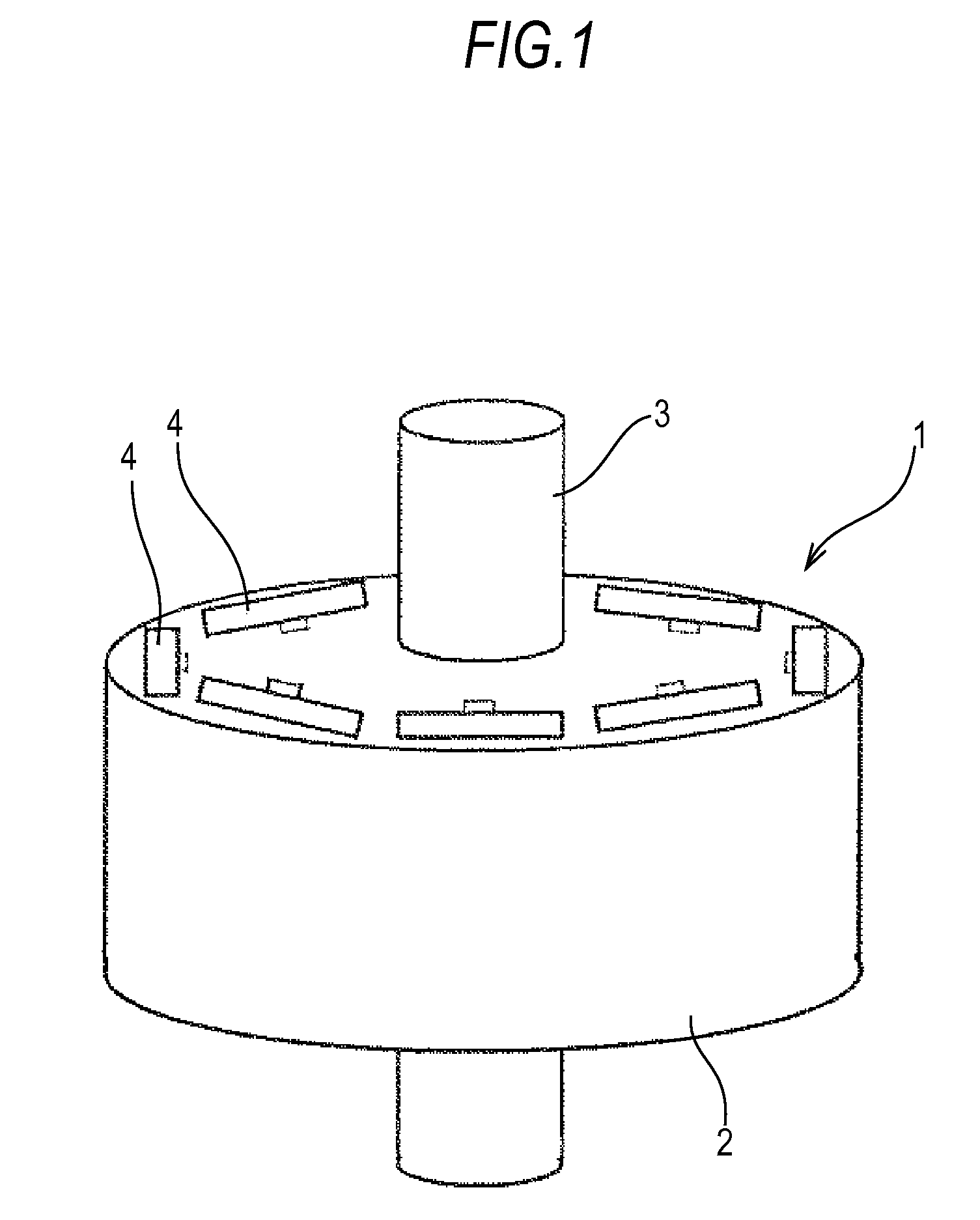

Rotor for rotating electrical machine

ActiveUS20080296997A1Minimize eddy currentReduce energy lossMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesConductive materials

A rotor body for an electric motor is comprised of connecting outer peripheral portions of first and second flange members made of electrically conductive material to the opposite ends of a plurality of connection members made of electrically conductive material of weak magnetic material arranged at predetermined distances therebetween in the circumferential direction with bolts and by supporting induction magnetic poles made of soft magnetic material between the connection members which are adjacent in the circumferential direction. Coupling portions of the first and second flange members and the connection member are electrically insulated by insulation coating so that an eddy current flowing in a closed circuit comprised of the first flange member, the connection member, the second flange member and the other connection member can be reduced and heat dissipation and energy loss accompanied by the eddy current can be minimized at the time of an operation.

Owner:HONDA MOTOR CO LTD

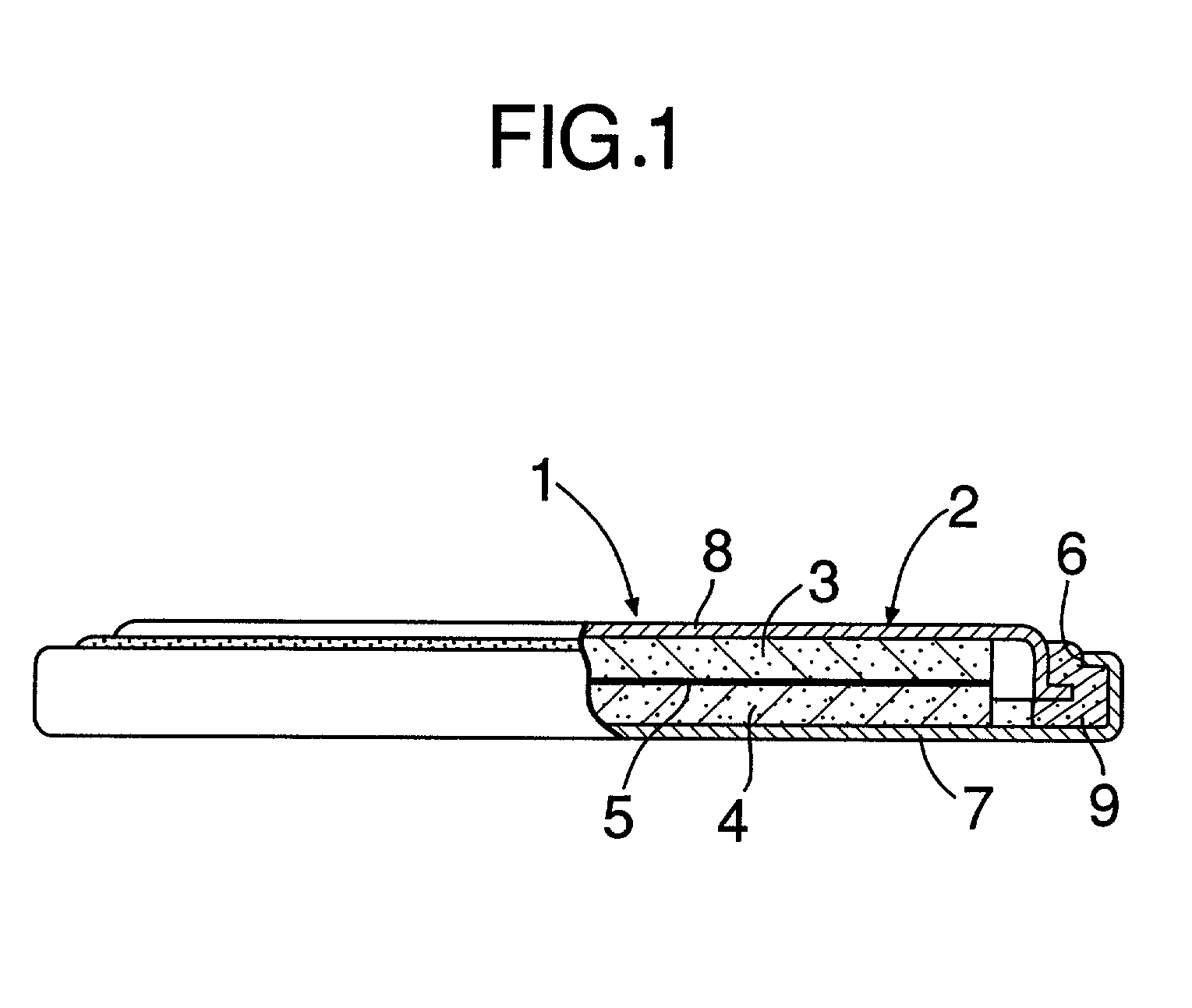

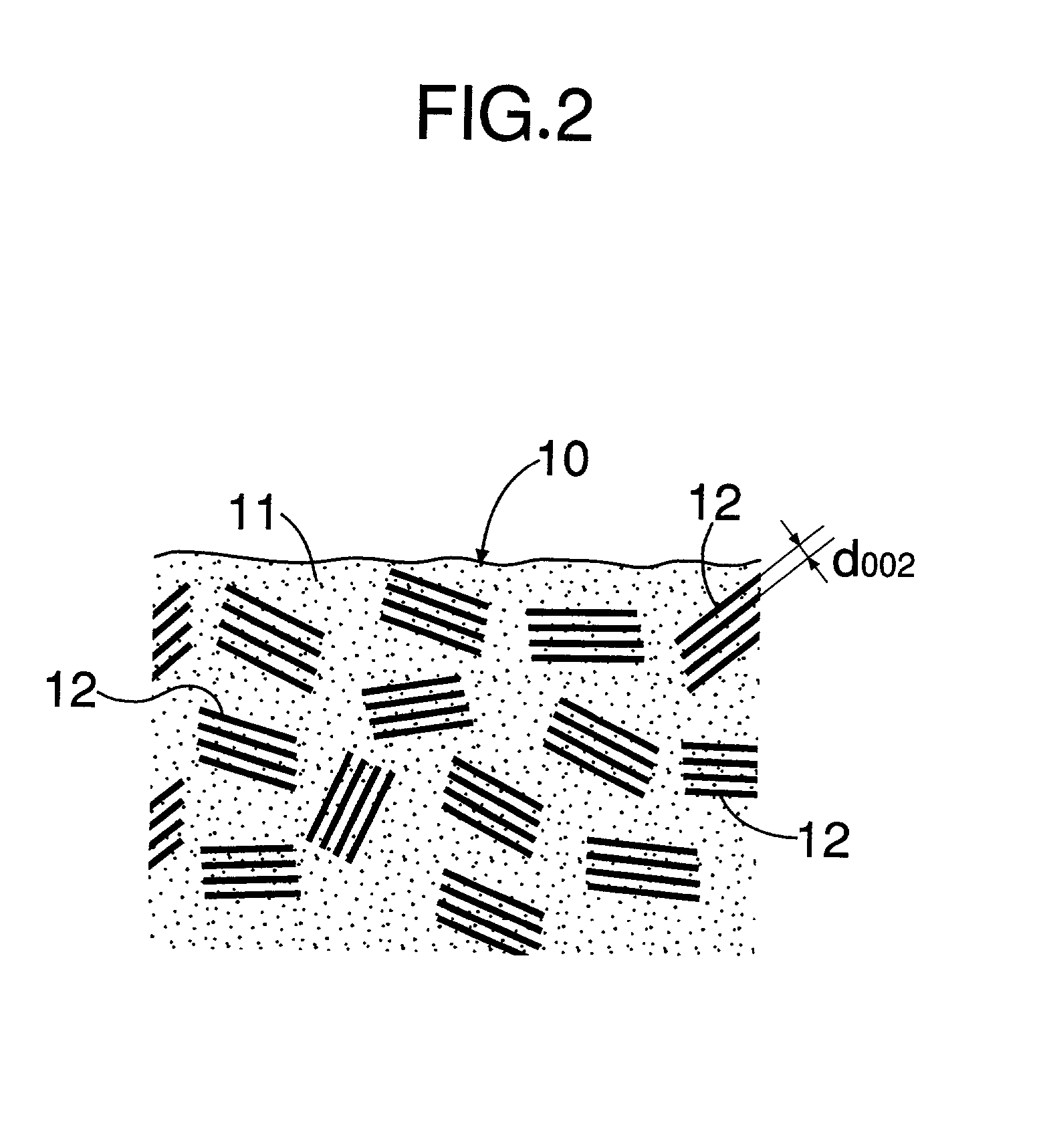

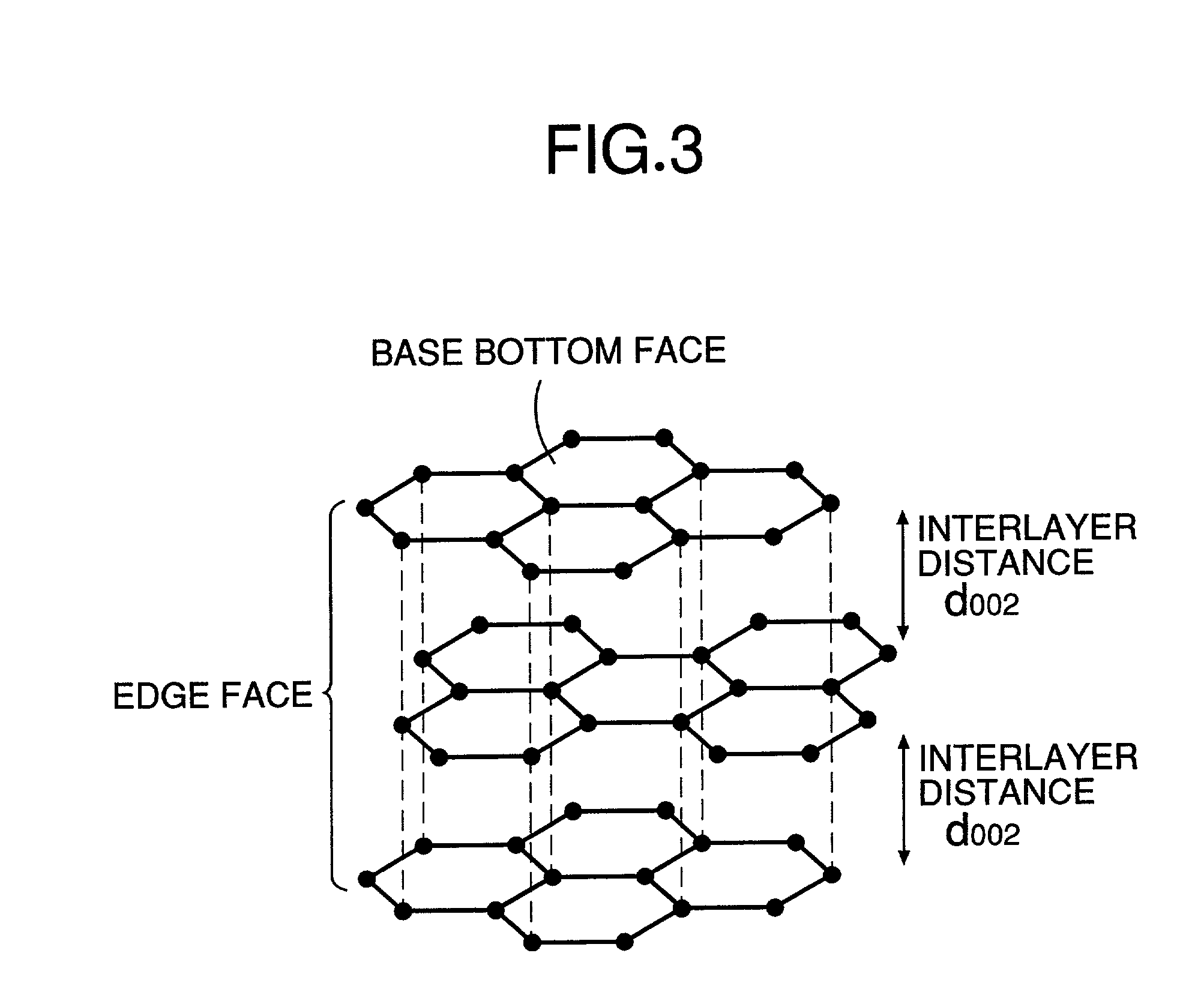

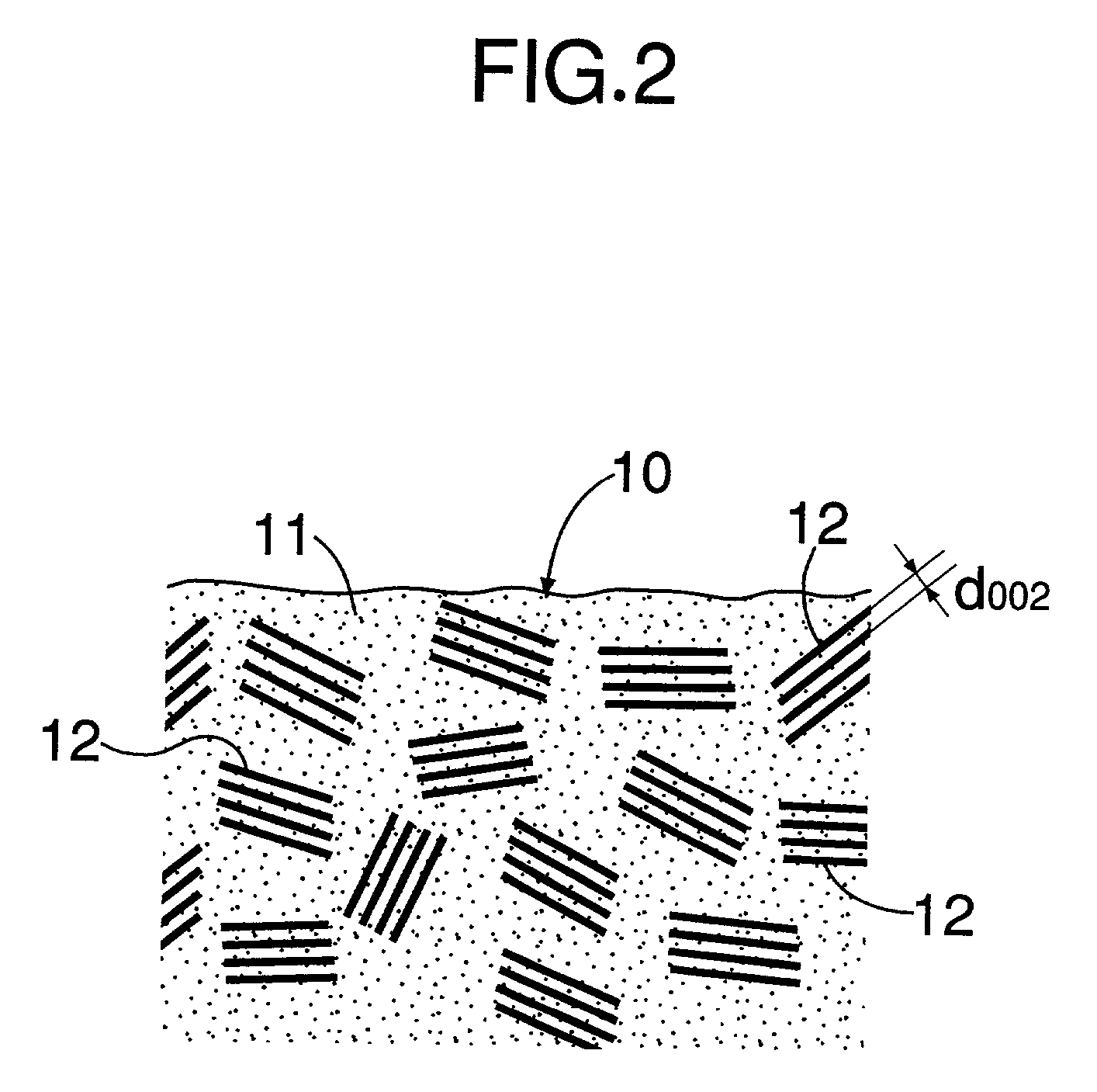

Carbonized product used for production of activated carbon for electrode of electric double-layer capacitor

InactiveUS20030026753A1Improve breathabilityMass-productivity of the activated carbon for the electrode can be improvedHybrid capacitor electrodesConductive materialActivated carbonGraphite

A carbonized product 10 used for production of activated carbon for an electrode of an electric double-layer capacitor, includes a plurality of crystallites 12 each having a graphite structure in an amorphous carbon matrix 11. The interlayer distance d002 of the crystallites 12 is set a value equal to or larger than 0.347 nm. Thus, by using this carbonized product, it is possible to produce activated carbon having a high electrostatic capacity density (F / cc) for an electrode of an electric double-layer capacitor.

Owner:HONDA MOTOR CO LTD

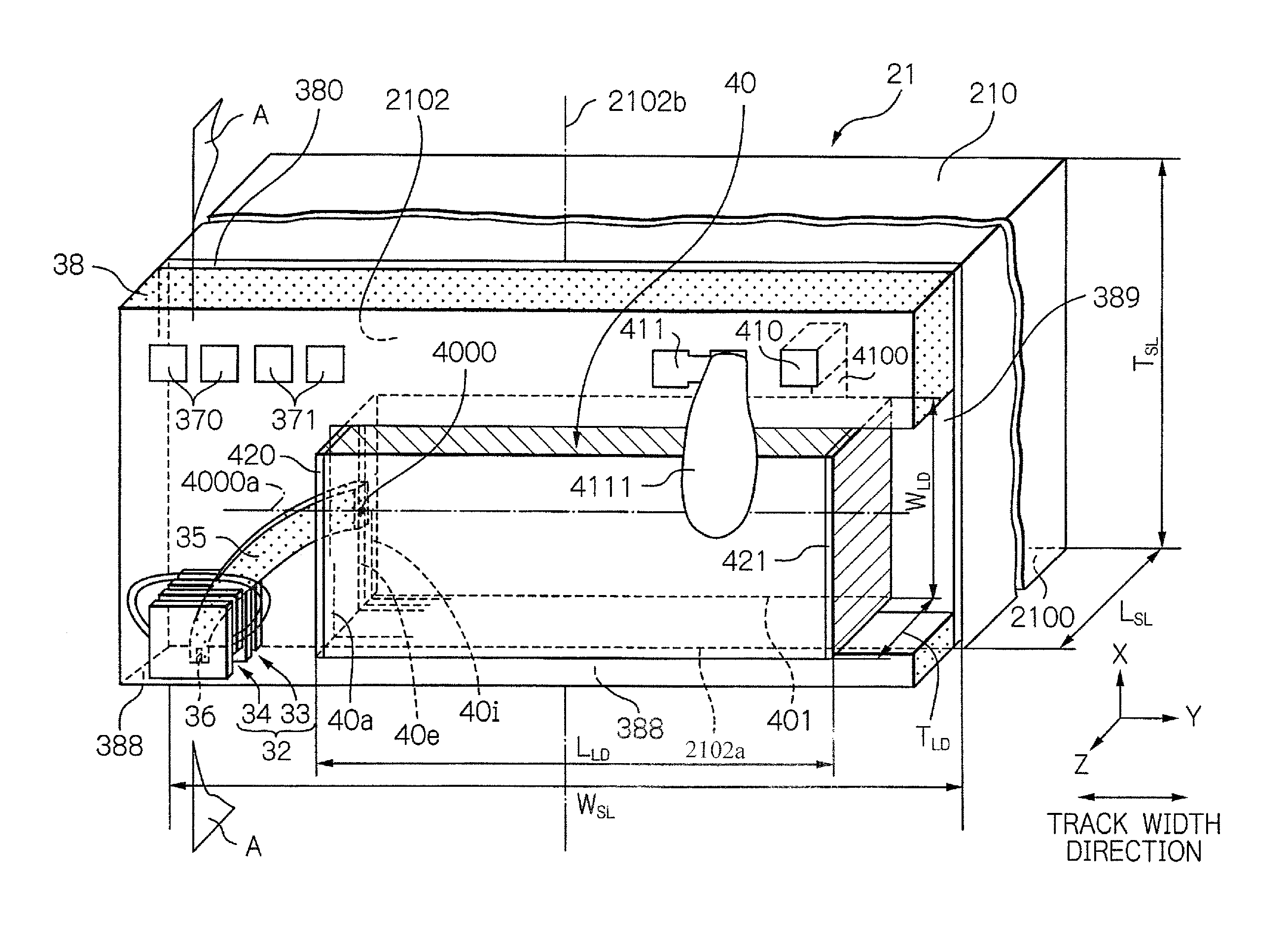

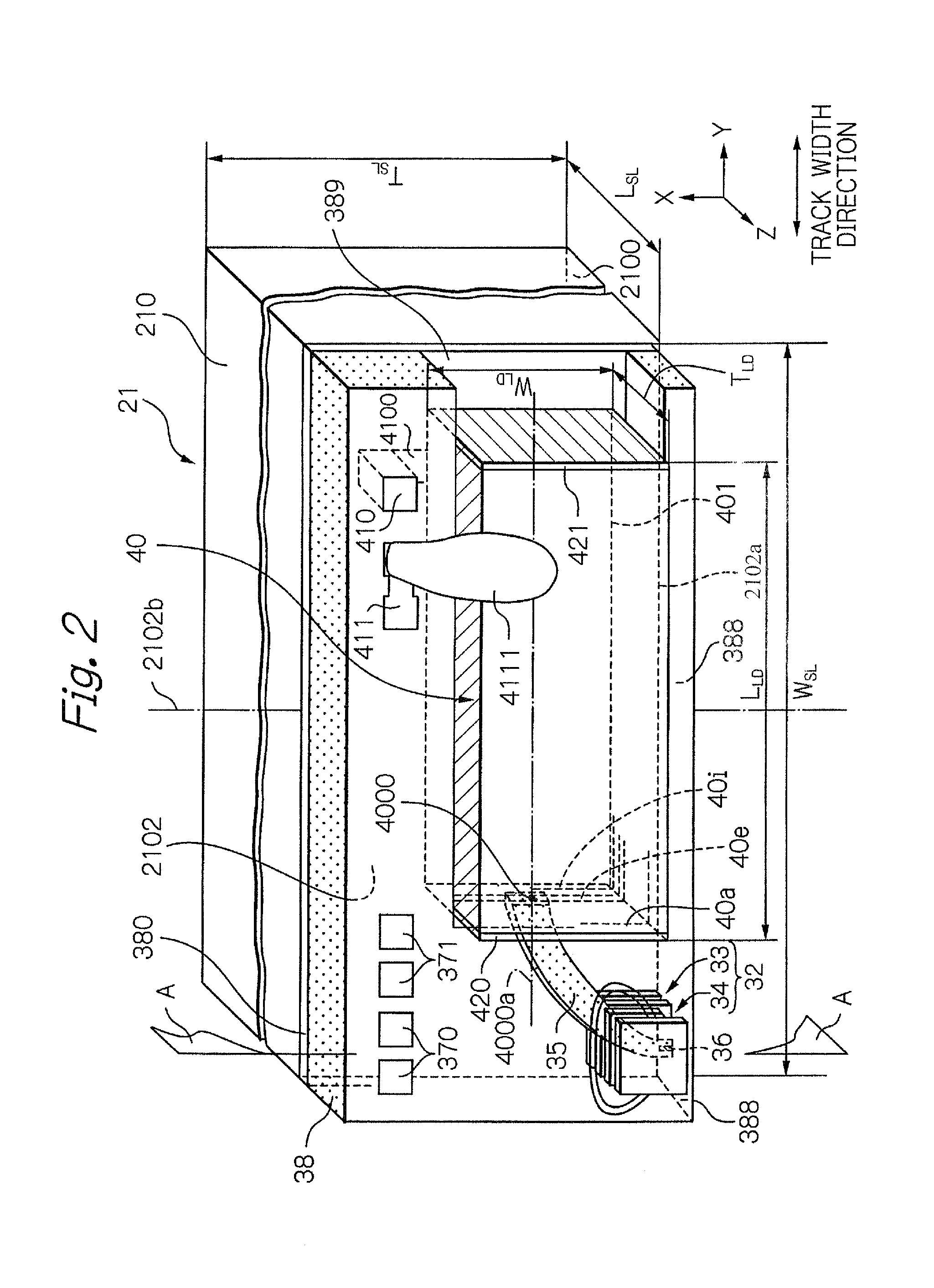

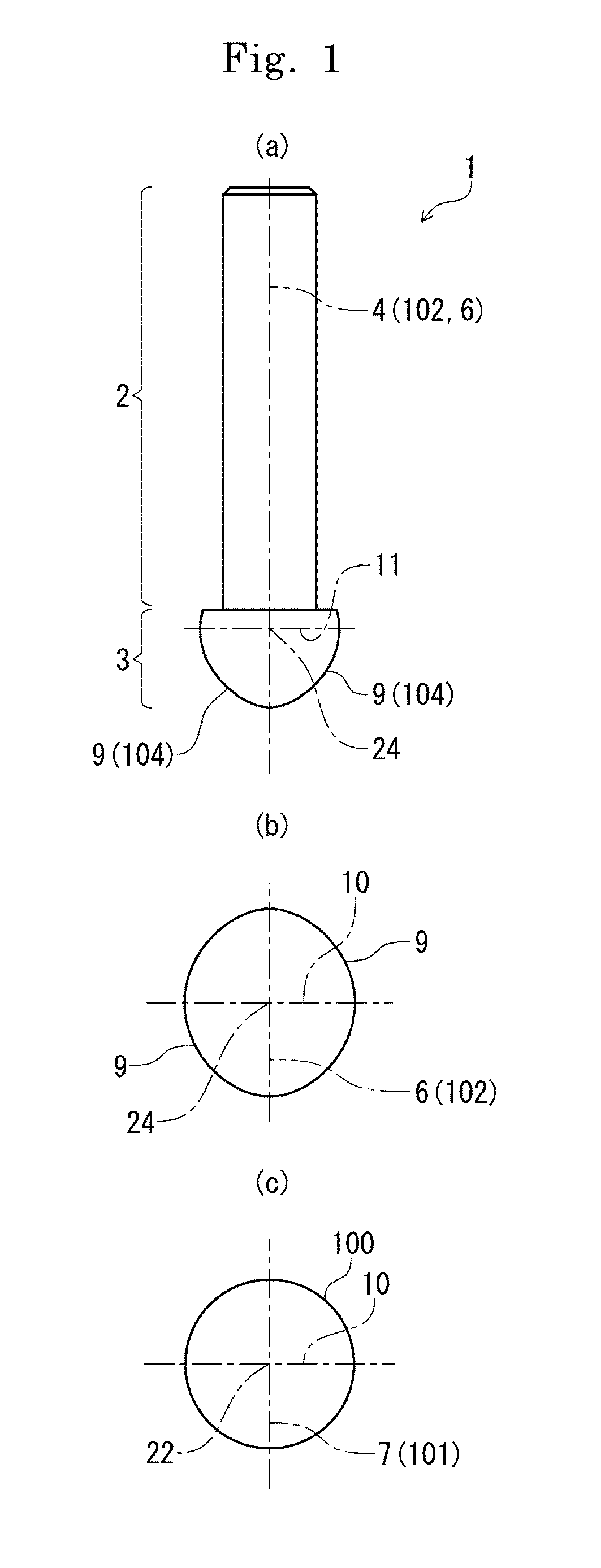

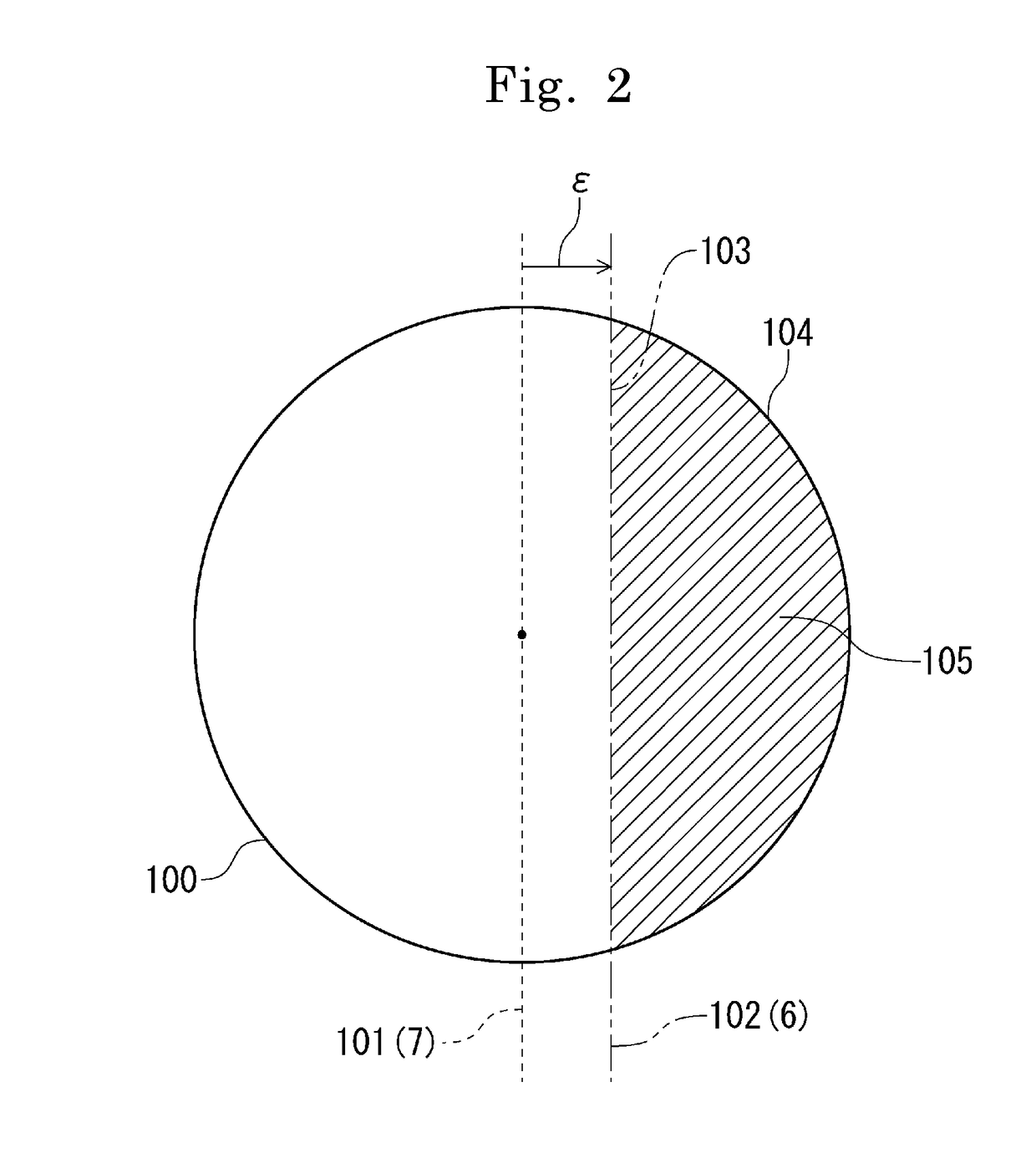

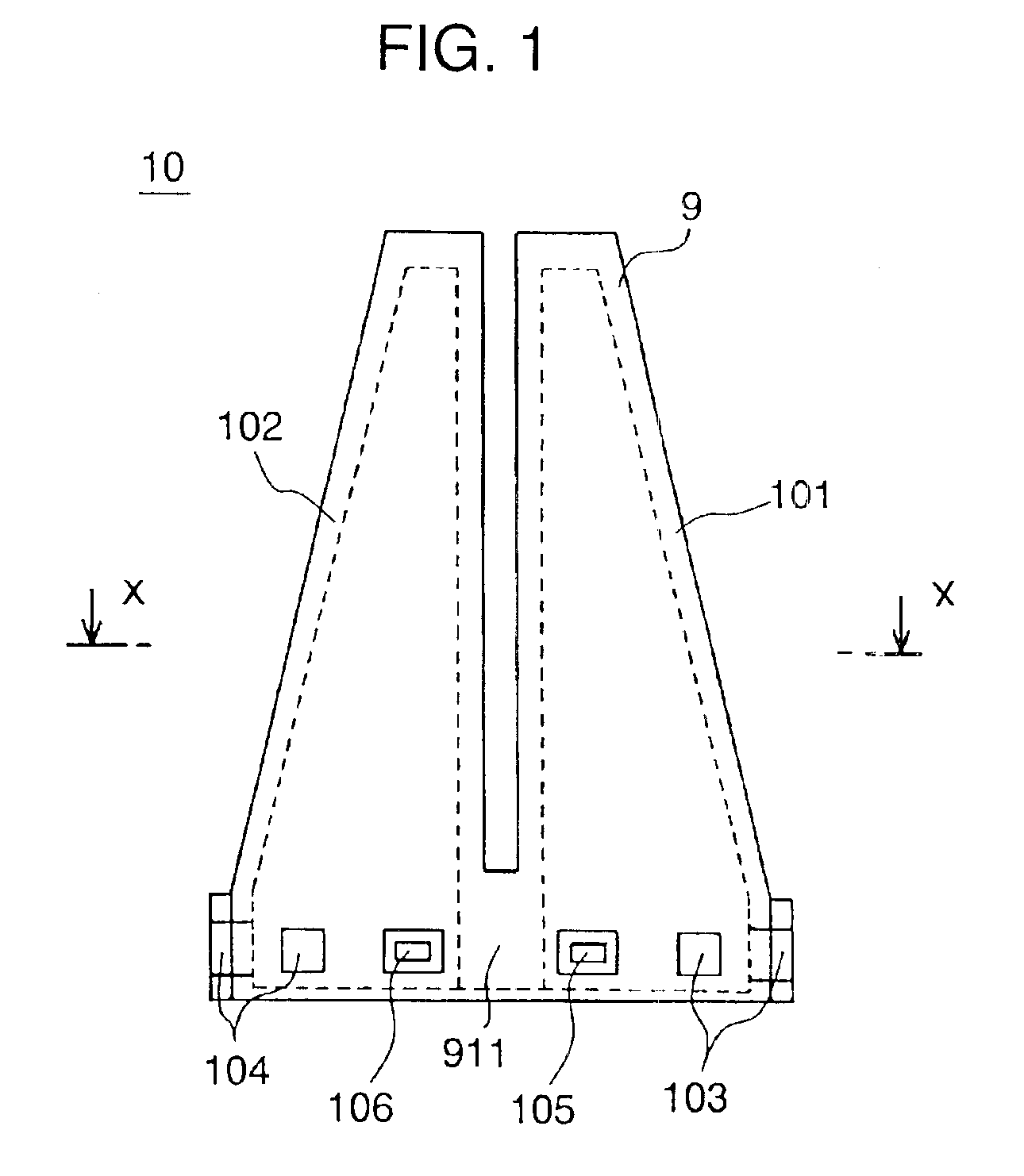

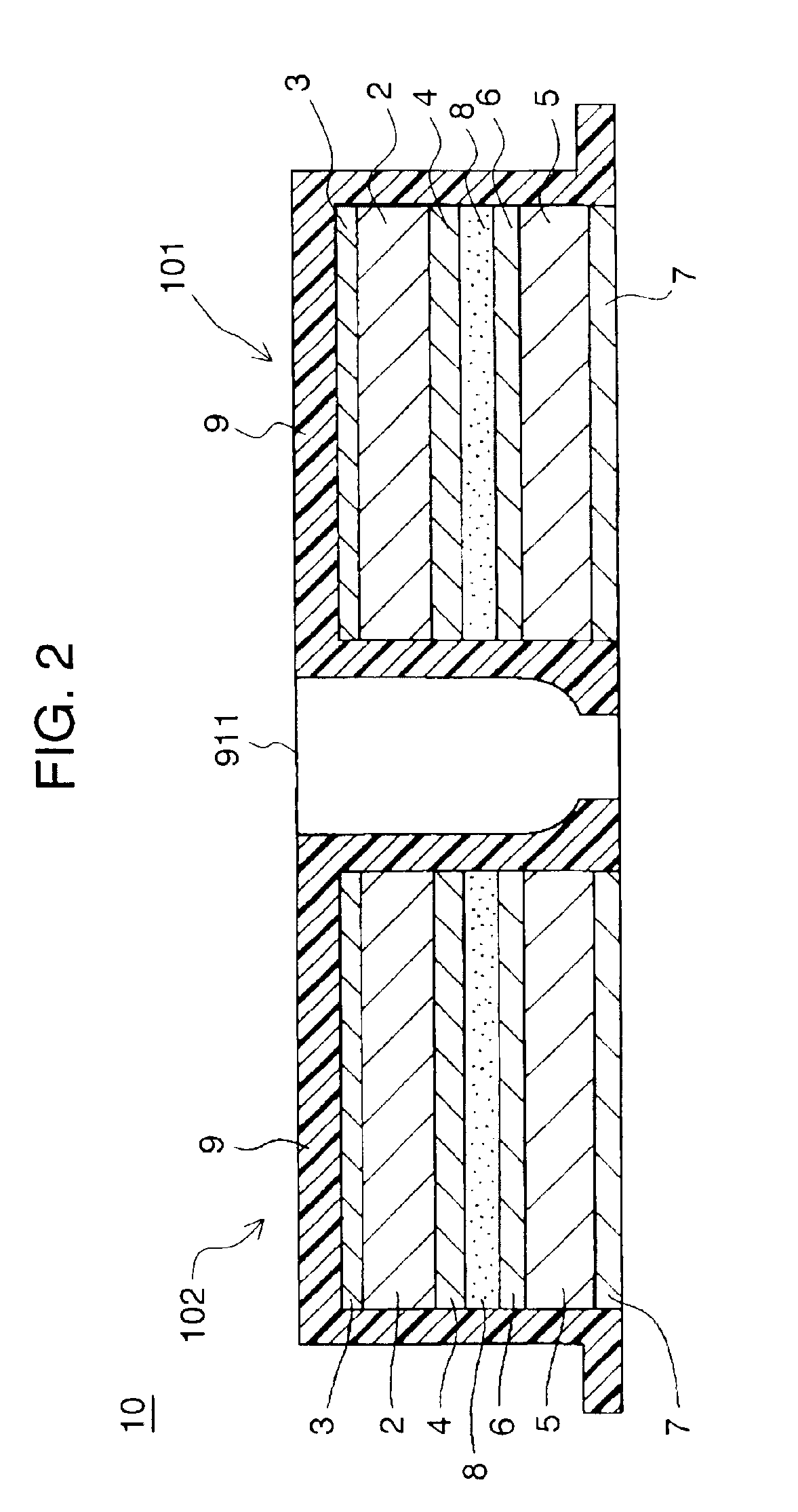

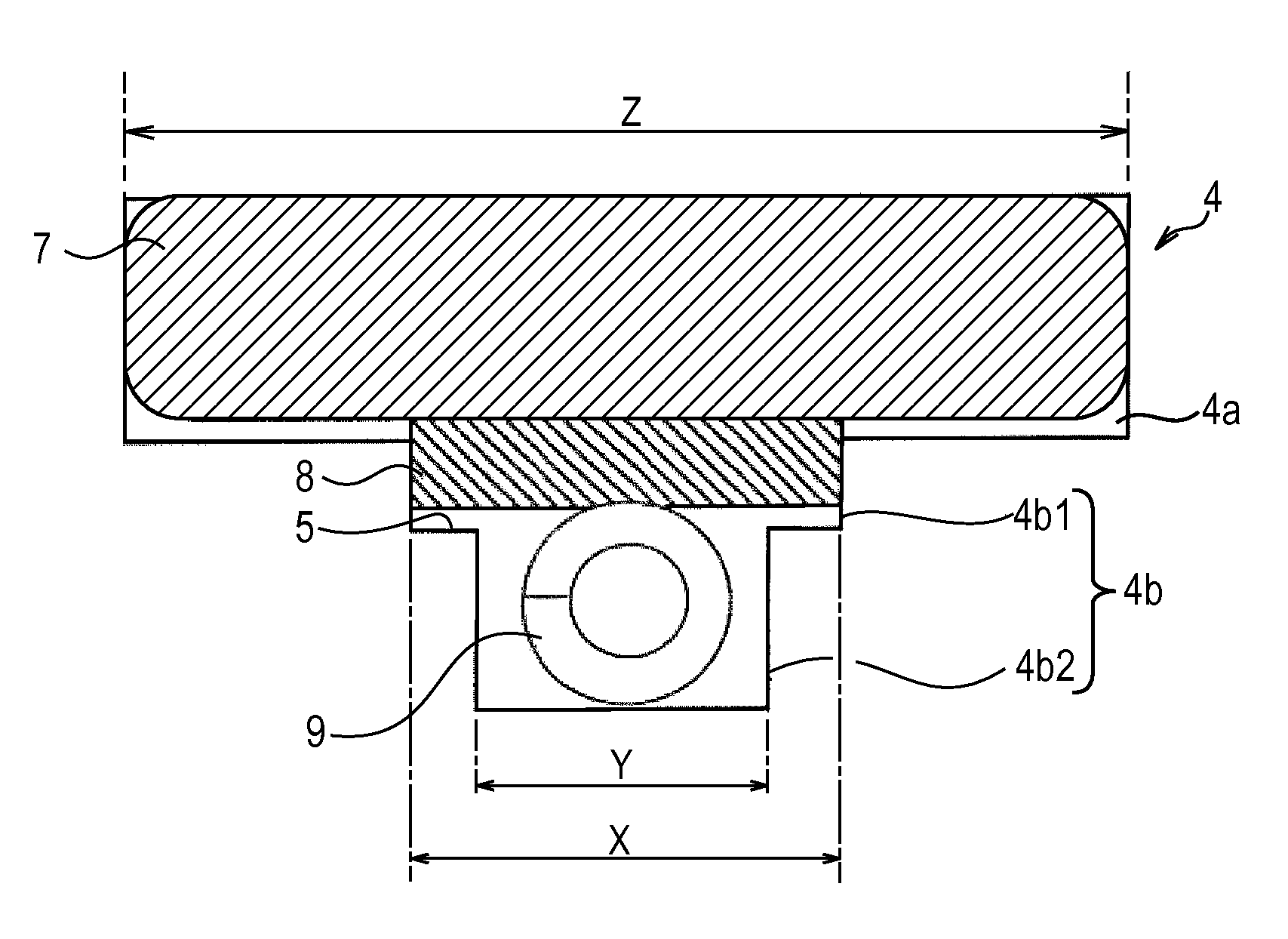

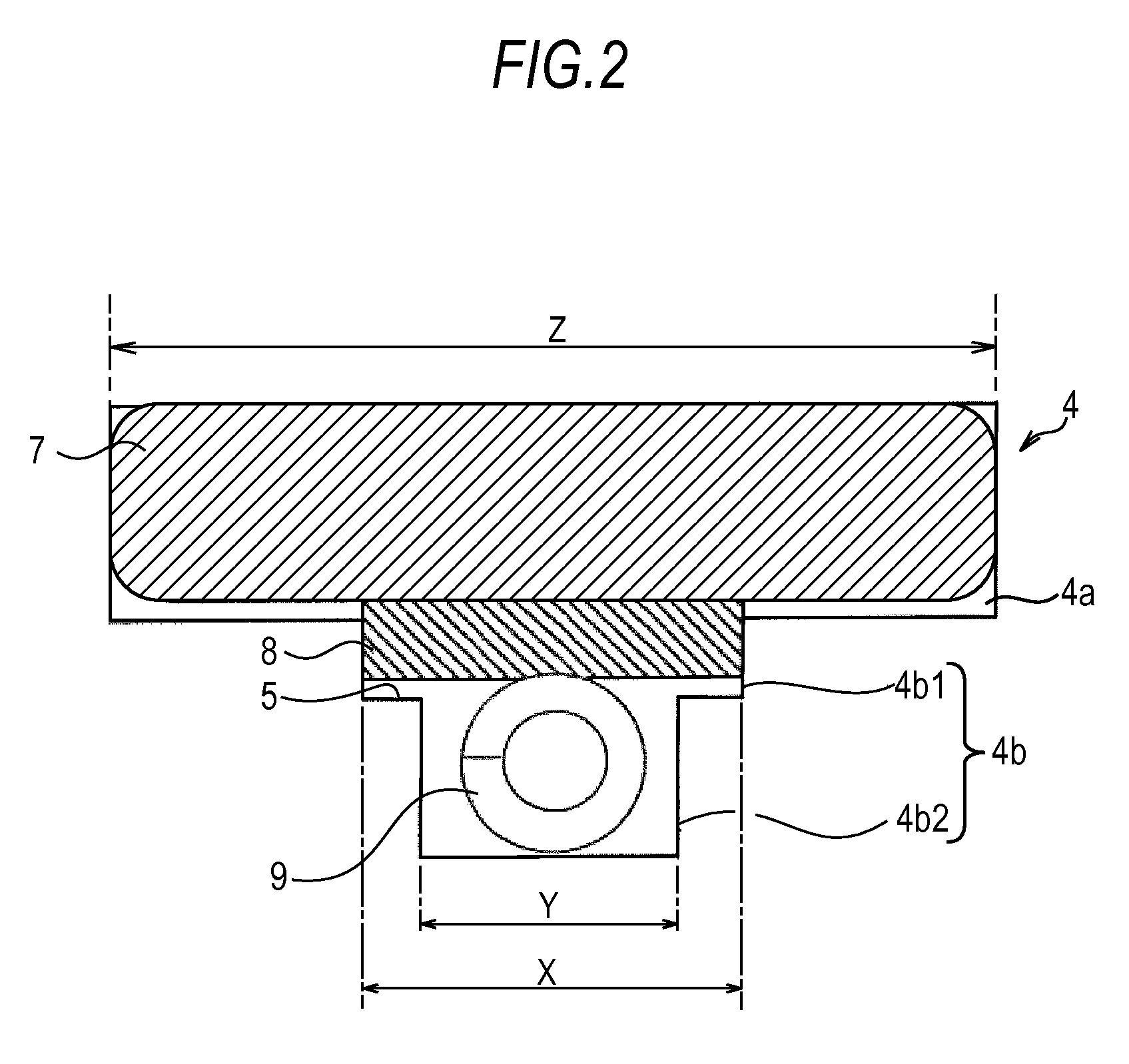

Thermally-assisted magnetic recording head having a light source at least inclined from an opposed-to-medium surface

ActiveUS8325566B2Mass productivity can be improvedIncrease output powerCombination recordingRecord information storageHeat-assisted magnetic recordingWafering

A thermally-assisted magnetic recording head is provided, in which a light source with a sufficient power is disposed in the element-integration surface to improve mass-productivity. The head comprises, in an element-integration surface of a substrate: a light source; a waveguide for propagating light from the light source; and a magnetic pole for generating write field. Further, the edge along optical axis of the light source is set to be parallel with or inclined from the edge on the opposed-to-medium surface side of the element-integration surface. In the head, since the light source is disposed in the element-integration surface, the construction of the optical system can be completed in the stage of a wafer process. This construction can be relatively facilitated and simplified; thus, mass-productivity in the head manufacturing can be improved. Further, a light source with a sufficient power (cavity length) can be disposed in the element-integration surface.

Owner:TDK CORPARATION

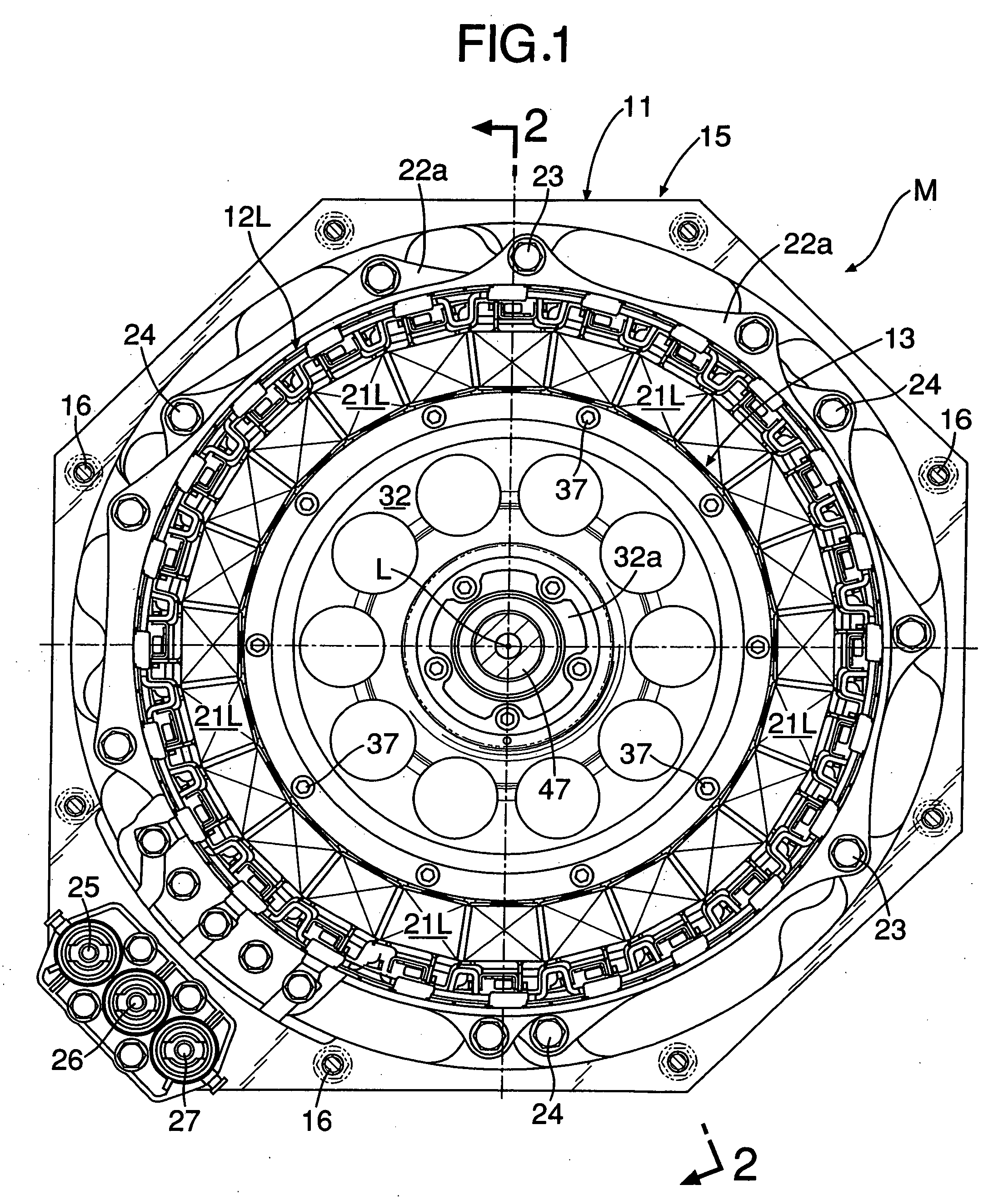

Permanent magnet rotor

ActiveUS20130069468A1Easy to shapeAvoid damageMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorResonance

A permanent magnet rotor includes: a rotor core of a laminated structure about a rotation shaft; a plurality of permanent magnet embedment slots provided to the rotor core at equally spaced positions from the rotation shaft; and permanent magnets inserted into the respective permanent magnet embedment slots. The permanent magnet embedment slots each have a magnet storing portion and a buffer and other members storing portion continuing to the magnet storing portion. One permanent magnet is stored in the magnet storing portion and a buffer member and a pushing member used to fix the permanent magnet are stored in the buffer and other members storing portion. It thus becomes possible to provide a permanent magnet rotor capable of not only preventing damage on a permanent magnet by reducing resonance even when the magnet resonates under a vibration condition, but also enhancing mass-productivity.

Owner:MITSUBISHI ELECTRIC CORP

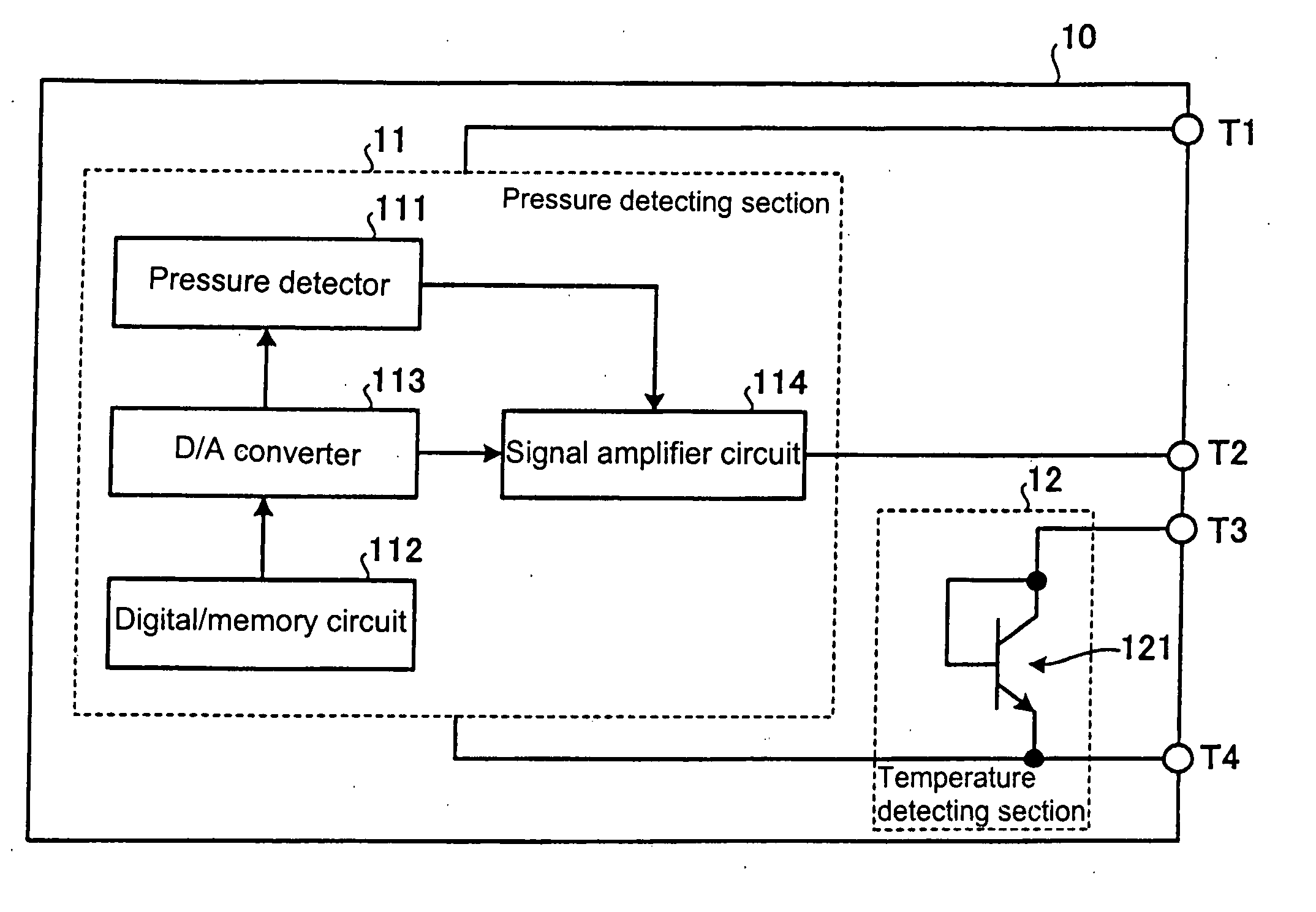

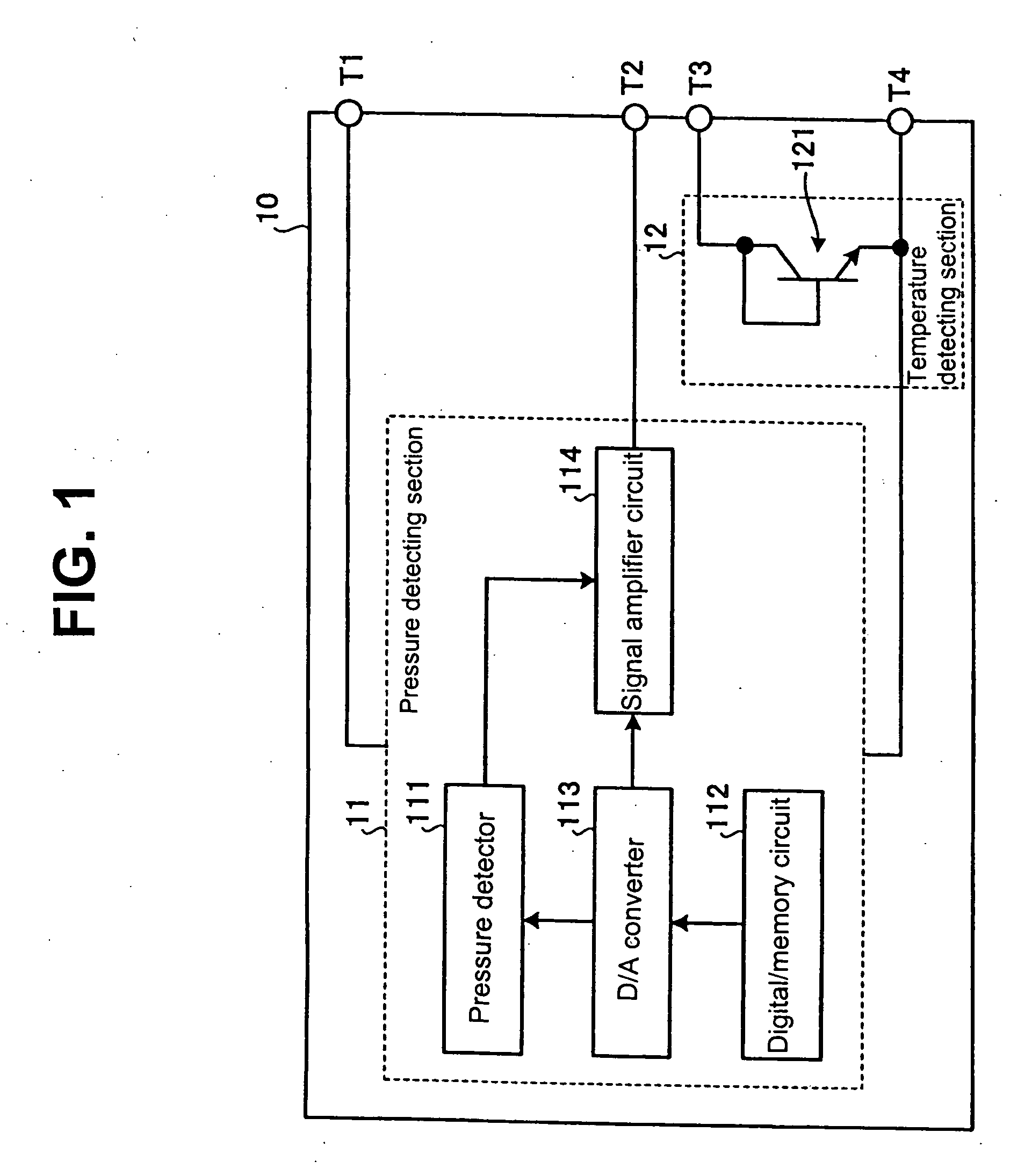

Semiconductor device and temperature detection method using the same

InactiveUS20060238186A1Small sizeMass productivity can be improvedTemperature measurement in motorsThermometers using electric/magnetic elementsDriving currentMeasurement device

A semiconductor apparatus has a temperature detecting section for detecting temperature with a semiconductor device formed in a semiconductor substrate; a temperature detector output terminal formed on the substrate for outputting a detection signal; a current generating device connected to the output terminal for supplying a driving current to the temperature detecting section; and a voltage measuring device connected to the output terminal for measuring the voltage of the output terminal. The apparatus detects temperature based on the voltage measured by the voltage measuring device when the driving current is supplied from the current generating device to the temperature detecting section. The apparatus is small, accurate, and easily manufactured at relatively low cost.

Owner:FUJI ELECTRIC DEVICE TECH CO

Imaging lens and imaging apparatus

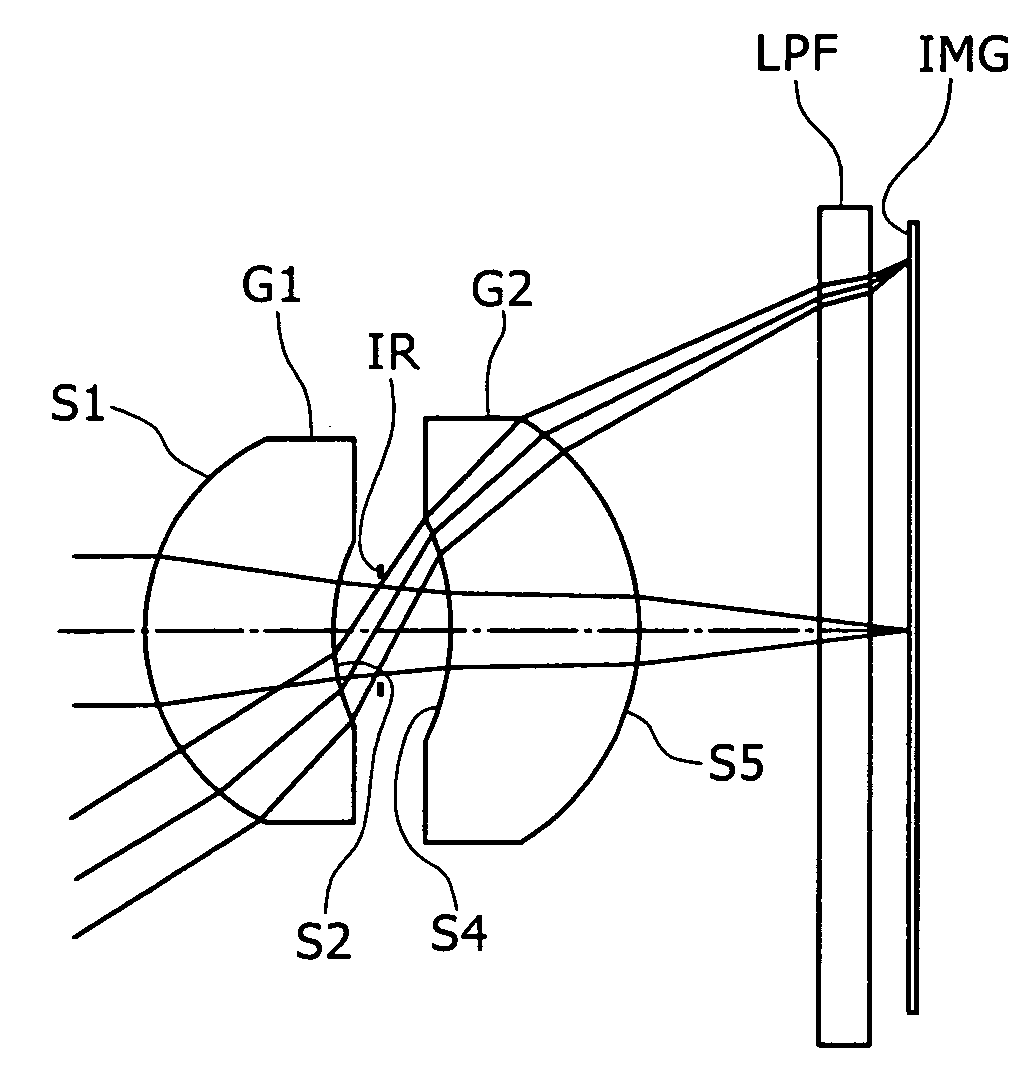

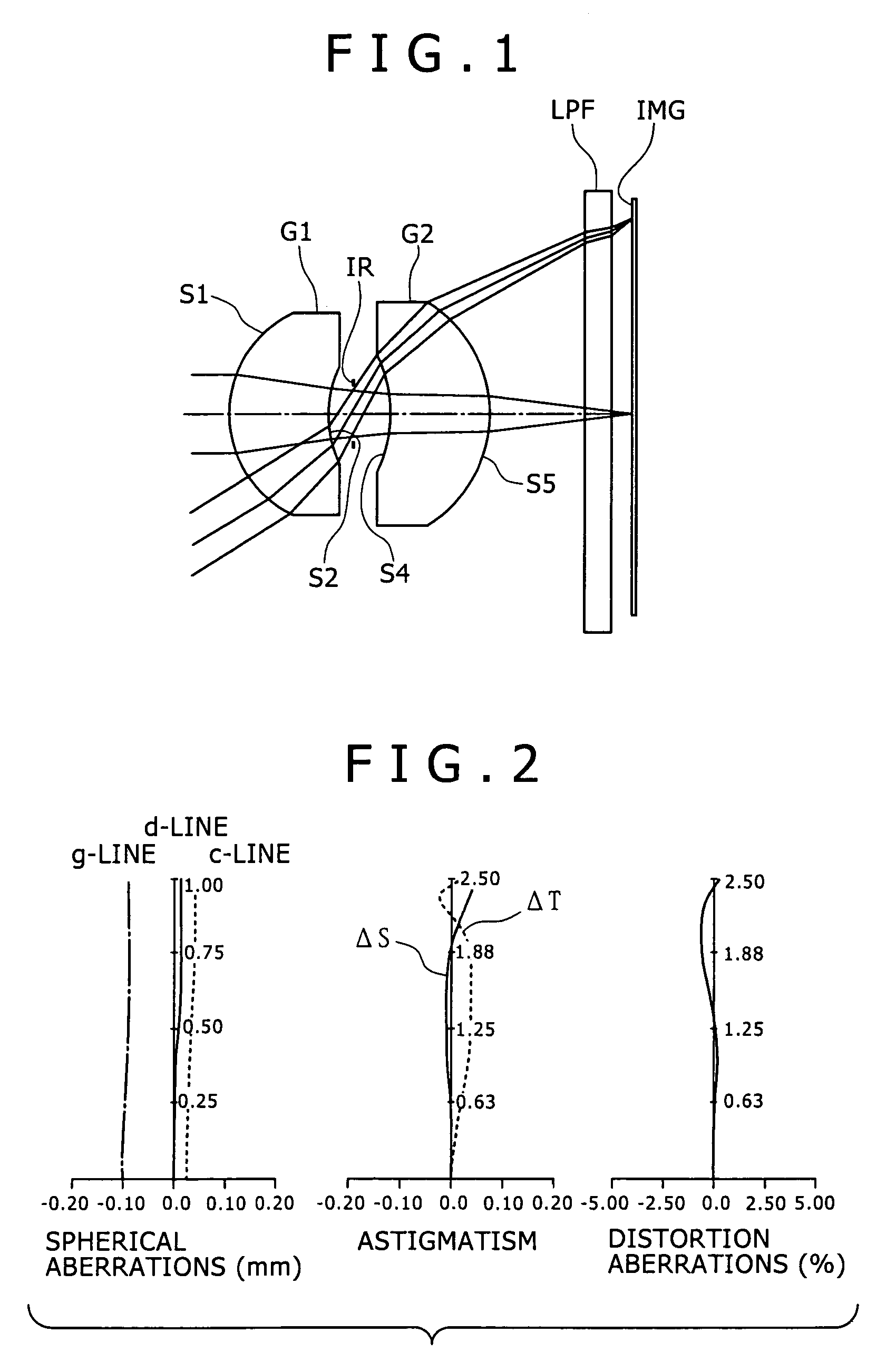

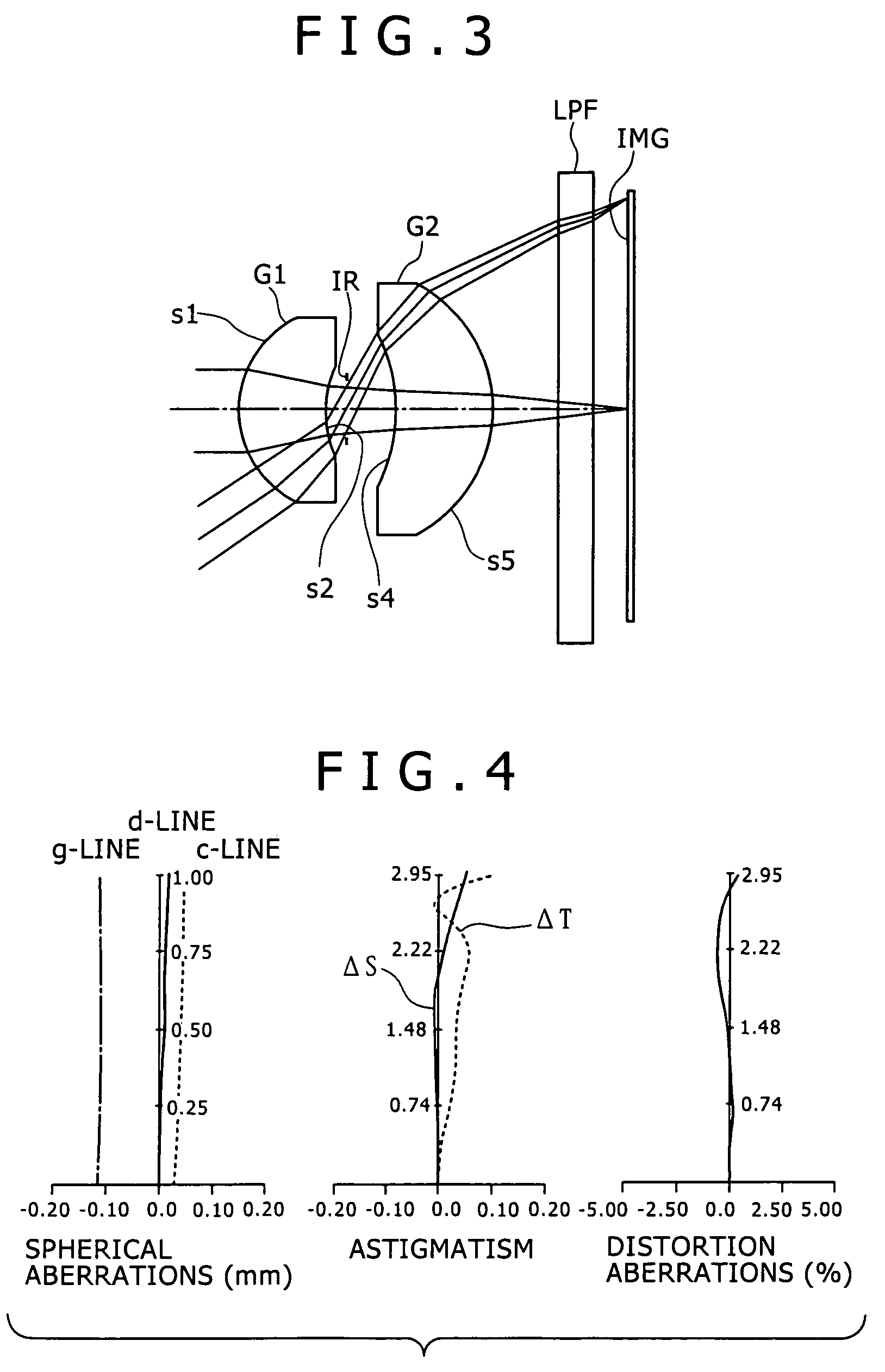

InactiveUS7206144B2Good optical performanceCompact configurationOptical elementsOptical axisRefractive index

An imaging lens system includes a first lens having a meniscus profile with a convex surface facing an object side and having a positive refractive index; an aperture diaphragm; and a second lens having a meniscus profile with a convex surface facing an image side and having a positive refractive index, wherein the first lens, the aperture diaphragm, and the second lens are arranged in this order from the object side. The imaging lens satisfies conditional expressions where f represents a focal distance of a total lens system, f1 represents a focal distance of the first lens, and L represents a distance on the optical axis from the surface on the object side of the first lens to an image plane wherein calculation is done in terms of an air-equivalent thickness for a back insertion glass, and n(ave) represents an average value of refractive indexes at d-lines of the first and second lenses.

Owner:SONY CORP

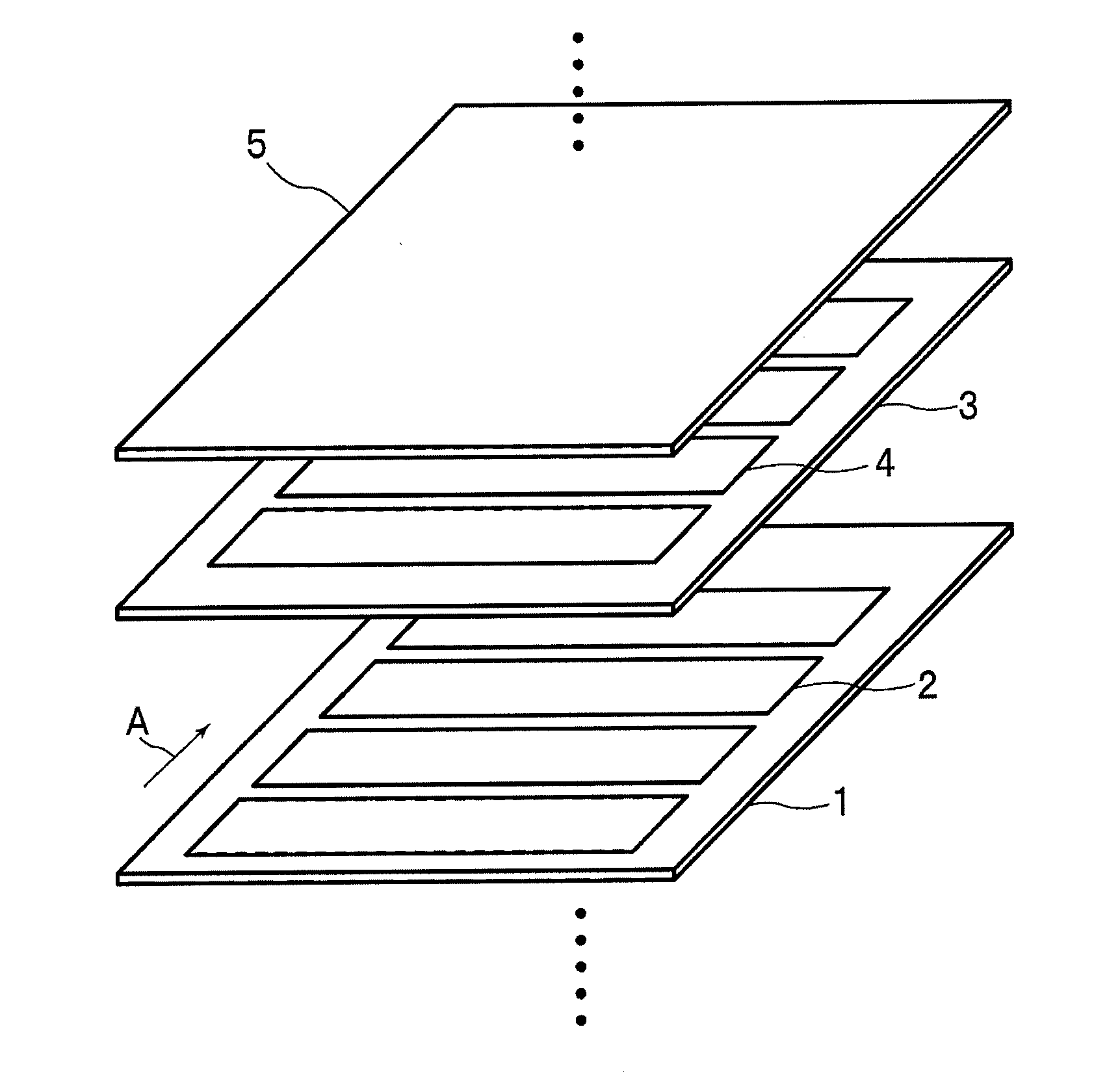

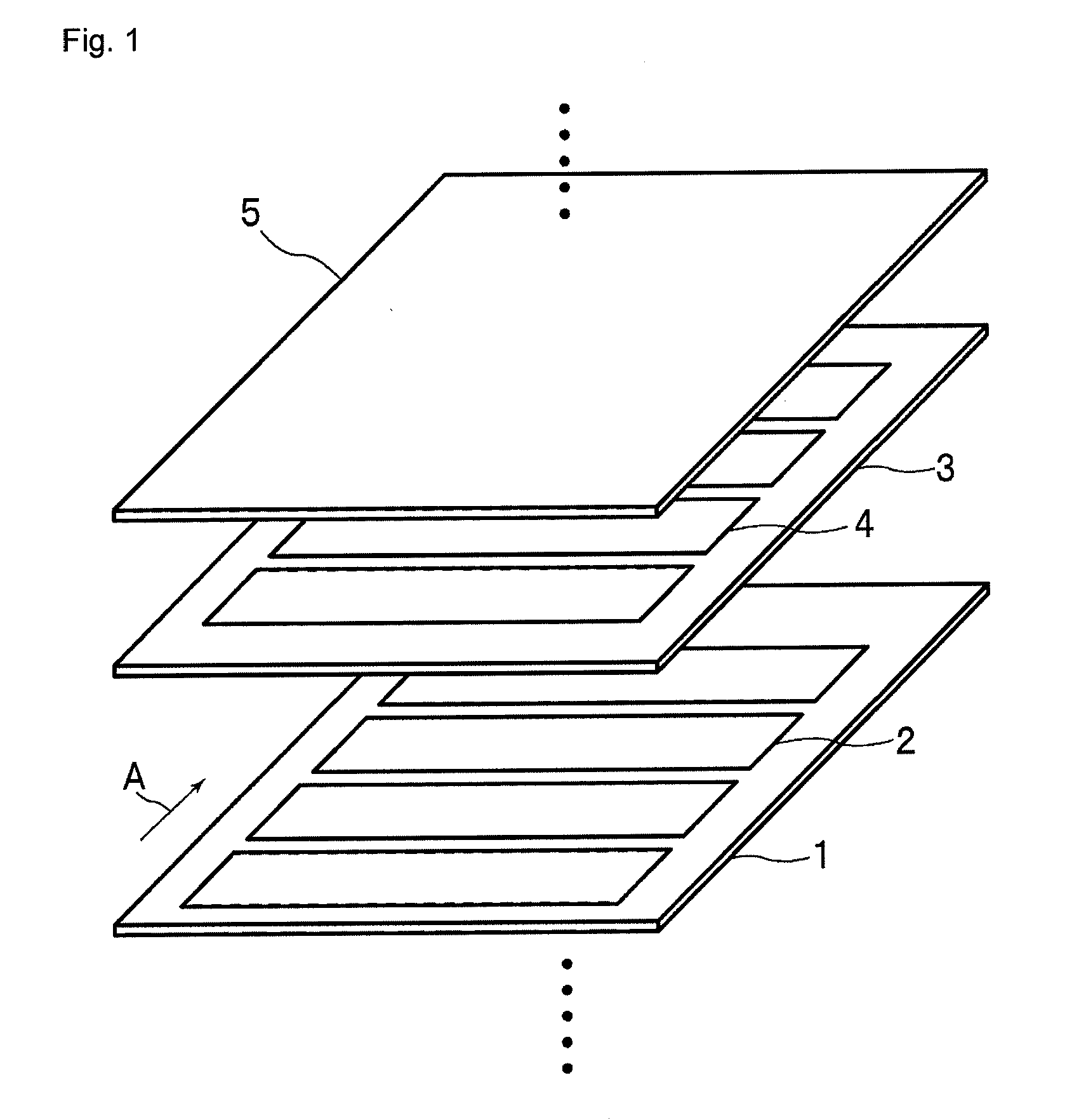

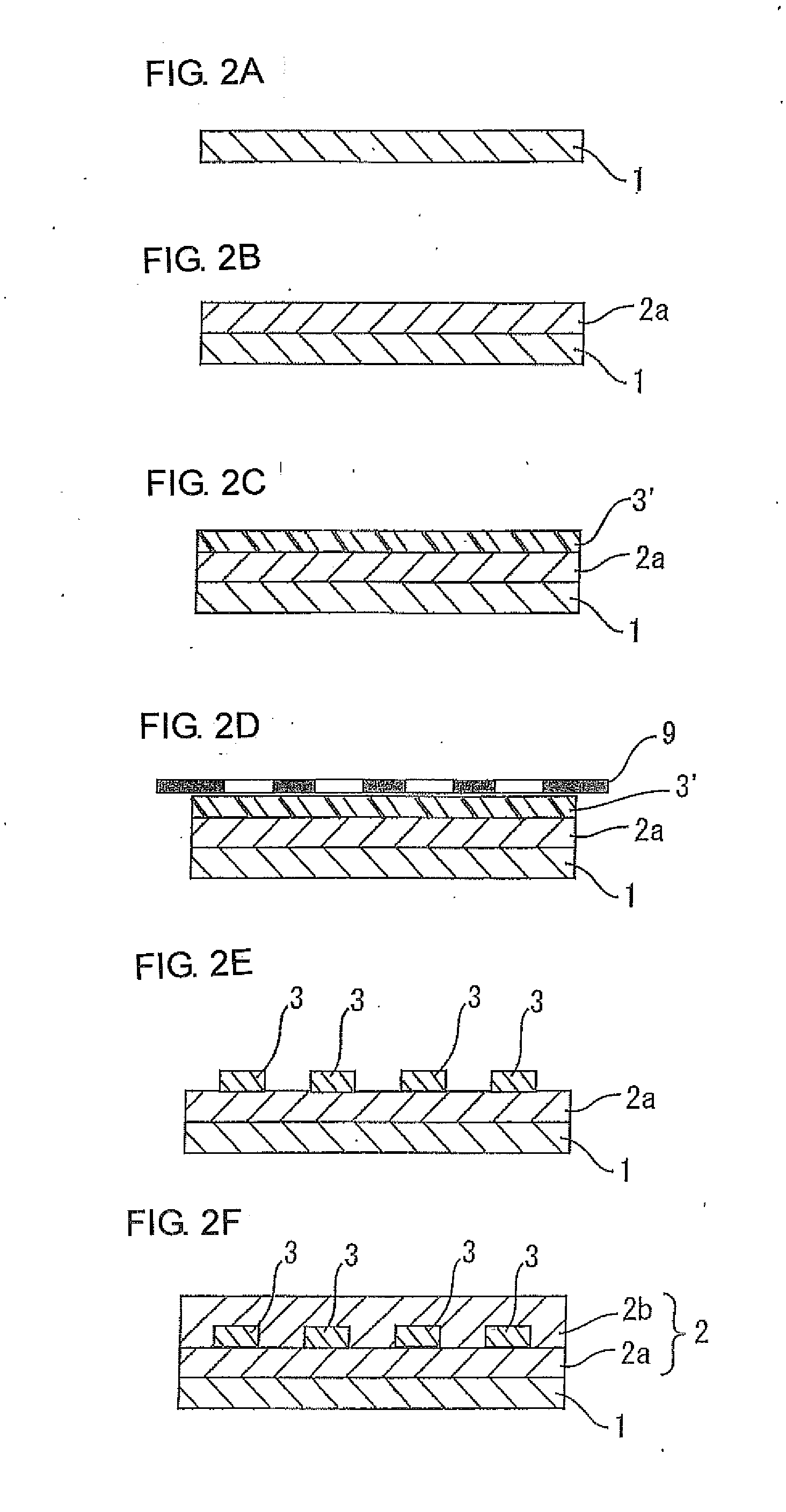

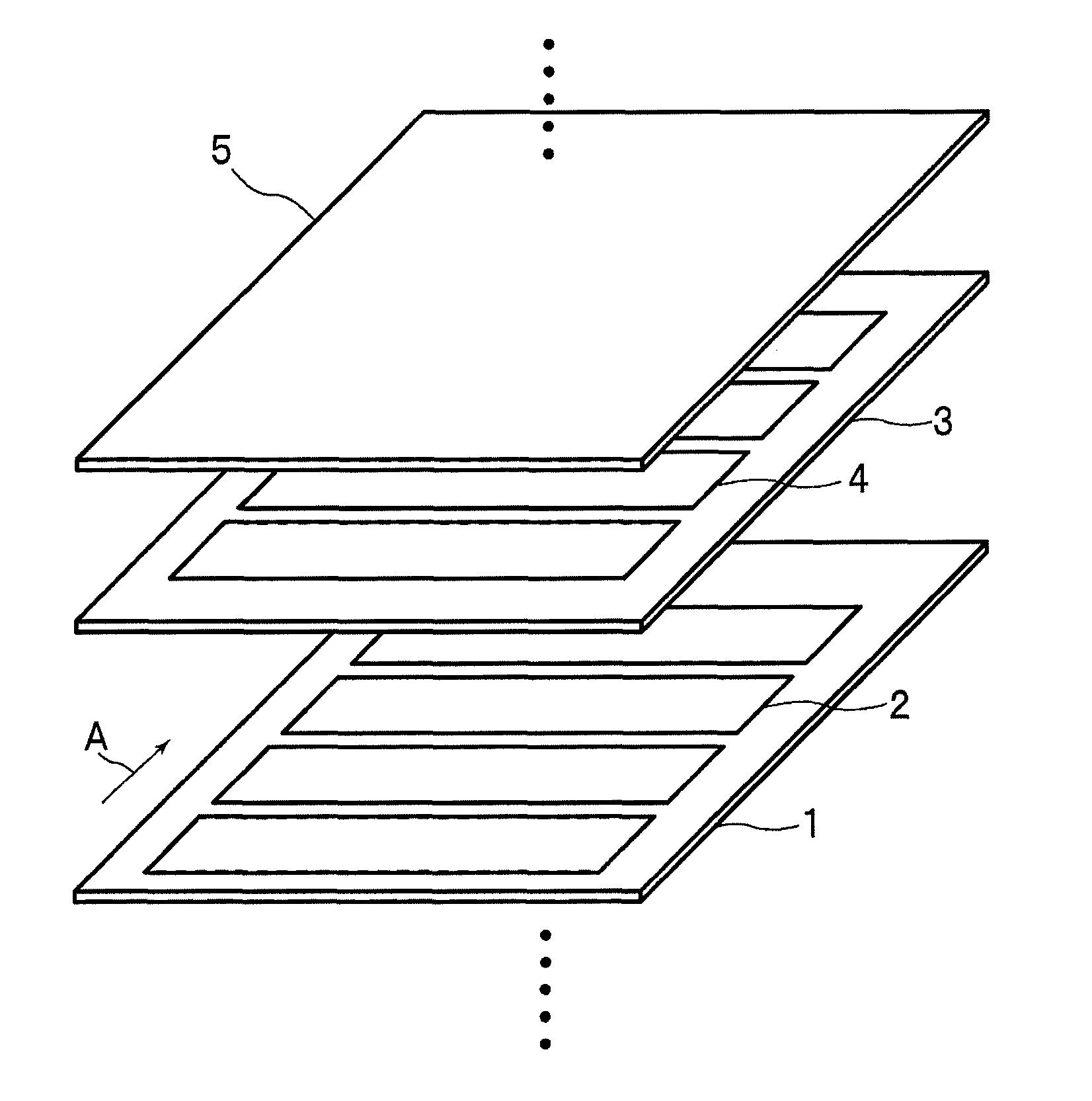

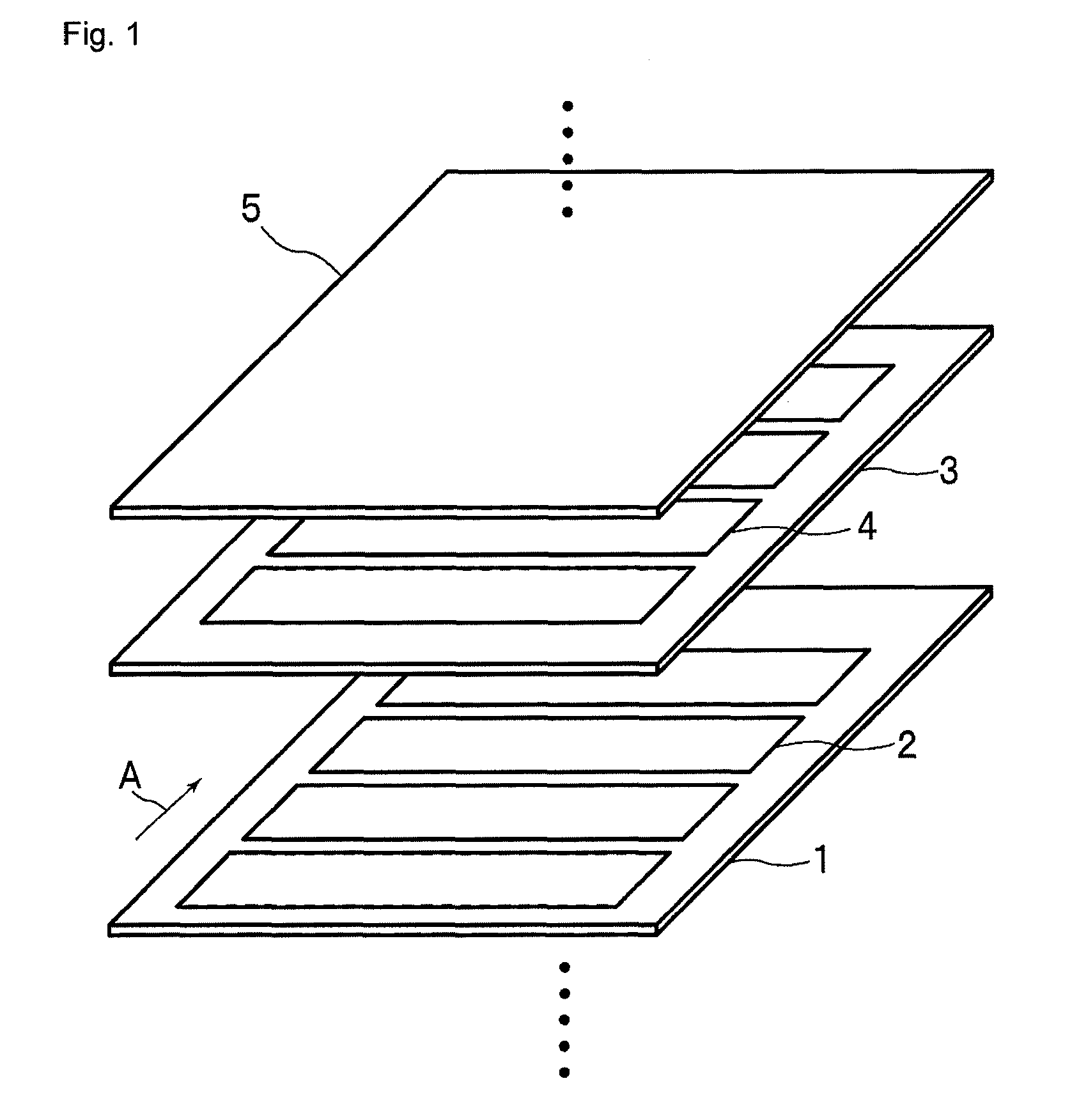

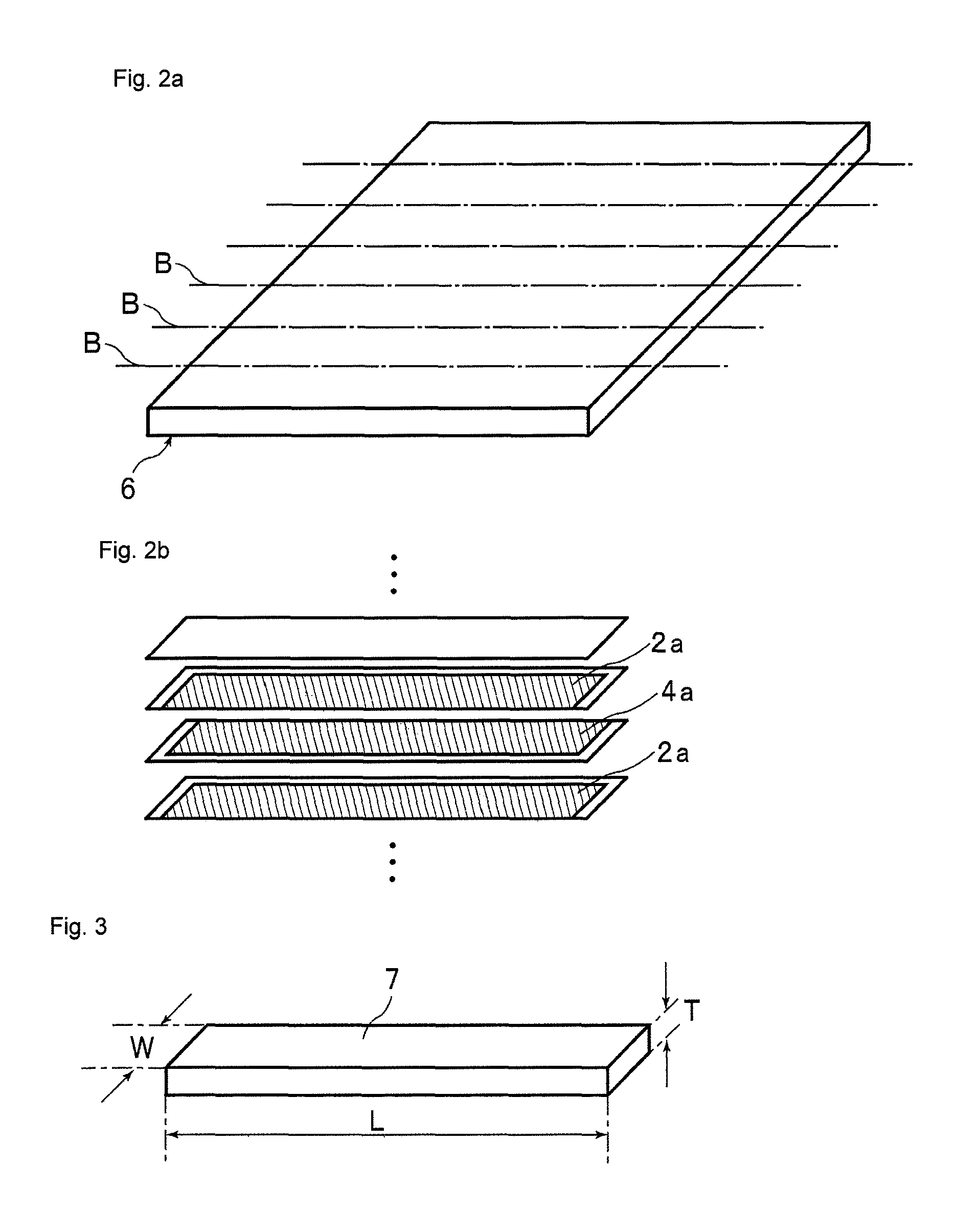

Laminated Pieozelectric Ceramic Element Manufacturing Method

ActiveUS20110024033A1Simplify lamination step stepSimplified cutting stepsPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsMetallurgySecondary layer

There is provided a laminated piezoelectric ceramic element manufacturing method, wherein, even when the number of internal electrode laminations is increased, the lamination and cutting steps can be simplified, to enhance cutting precision and make cutting cost low. A first laminated body having stripe-like internal electrodes is cut into a plurality of second laminated bodies so as to have a width-direction dimension W corresponding to a width dimension of a laminated piezoelectric ceramic element chip to be ultimately obtained. Two or more second laminated bodies are laminated in the laminating direction to obtain a third laminated body, and the third laminated body is cut in the laminating direction and parallel to the width direction W to obtain a laminated piezoelectric body.

Owner:MURATA MFG CO LTD

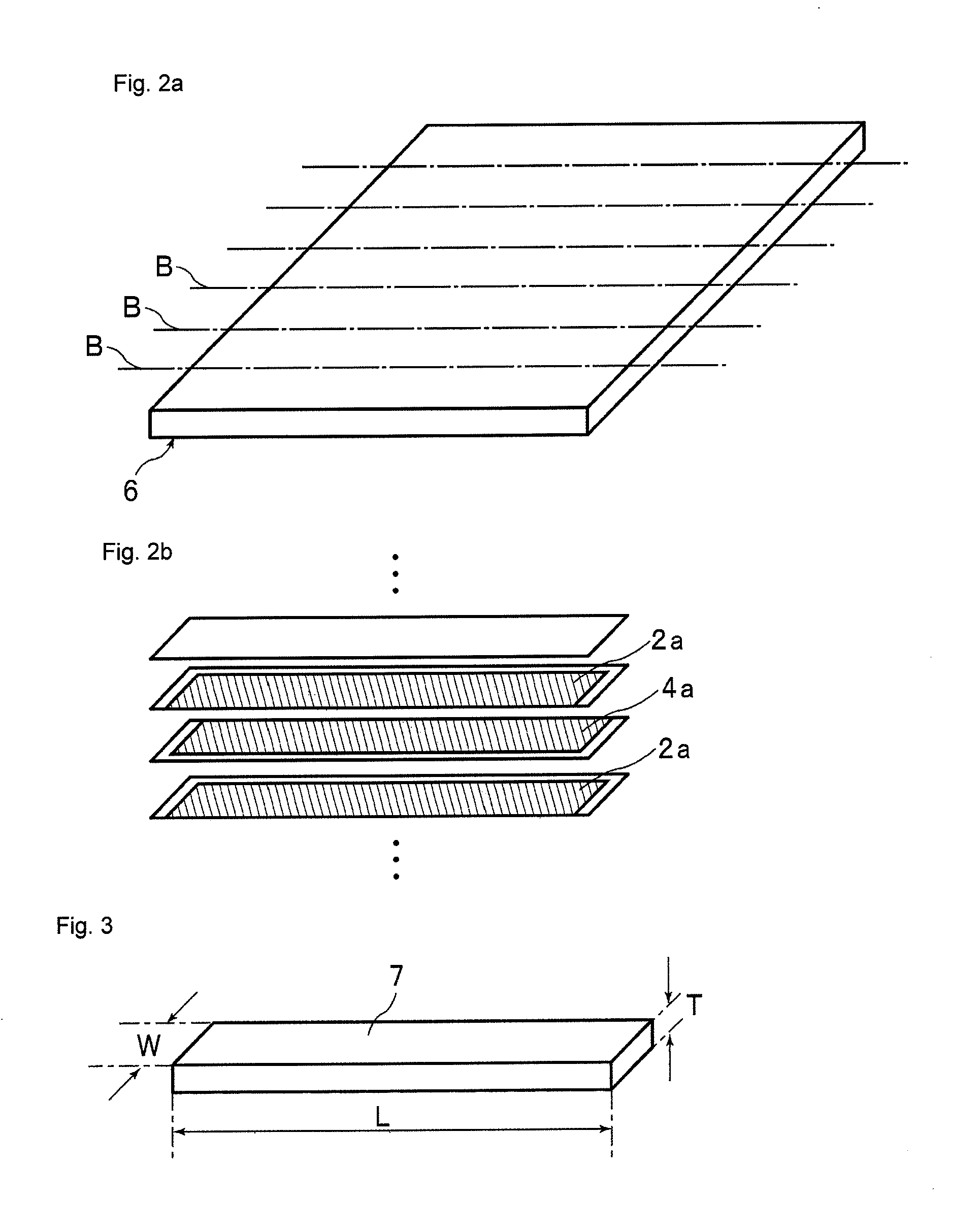

Cross hole deburring tool, cross hole deburring method, and rotary valve machined by using the same

InactiveUS20170282258A1Uniform surface widthSimple structureDrill bitsTransportation and packagingRotary valveEngineering

A cross hole deburring tool which performs rotary cutting on a cross hole burr occurring on a cross ridgeline part between a through path and an inner circumferential surface of a spherically-shaped hollow part. A tool main body includes a tip part and a shank, and the tip part has a shape obtained by setting a diameter axis of a circle, setting an eccentric axis parallel to the diameter axis and away therefrom by a predetermined eccentric distance, setting a closed region in a bow shape formed of a line segment obtained by cutting the eccentric axis by the circle and a minor arc on the circle by defining this line segment as a chord, setting an outer surface shape of a bow-shaped solid of revolution formed by rotating this bow shape about the eccentric axis, and taking this outer surface shape as the shape of the tip part.

Owner:KITZ CORP

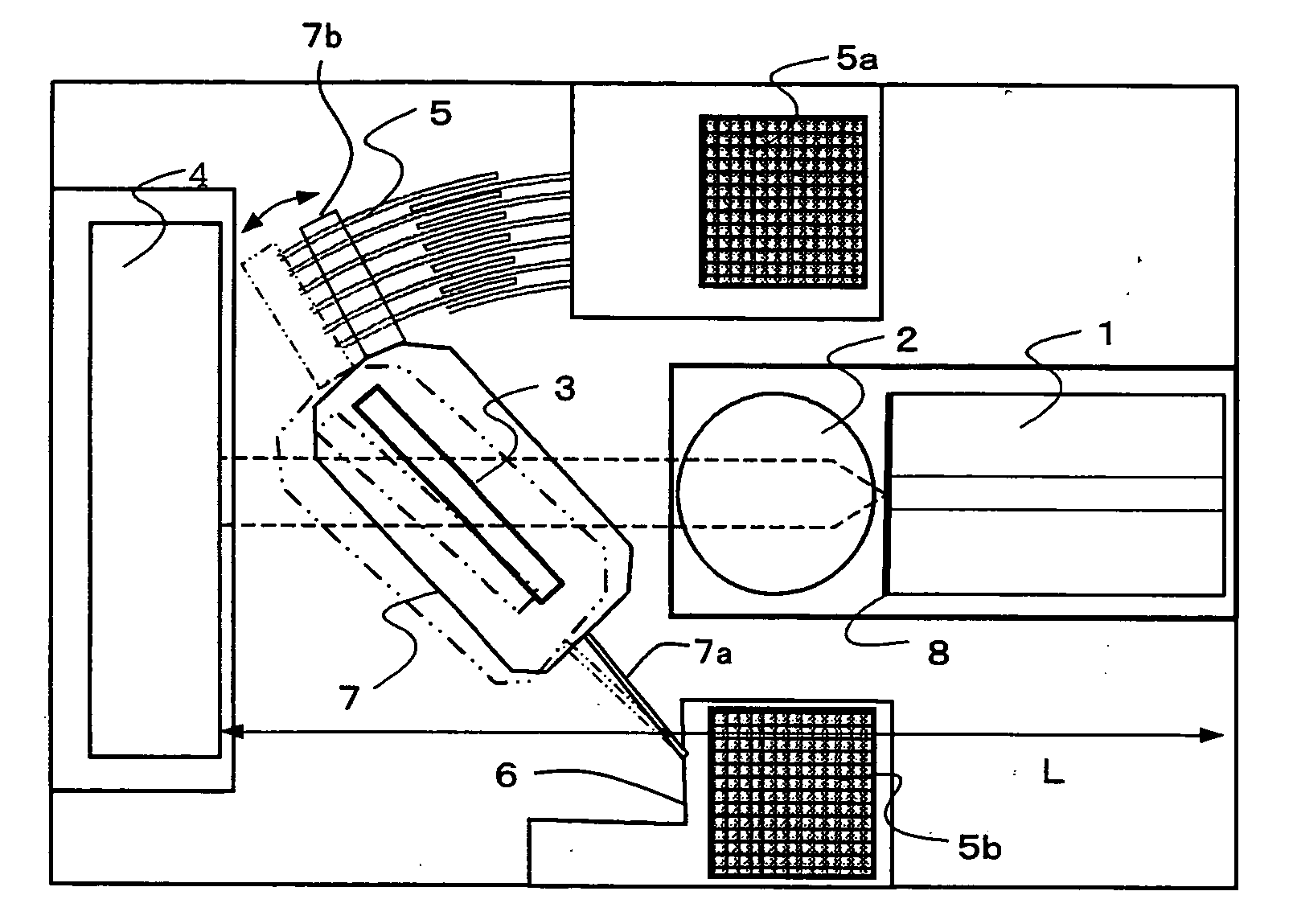

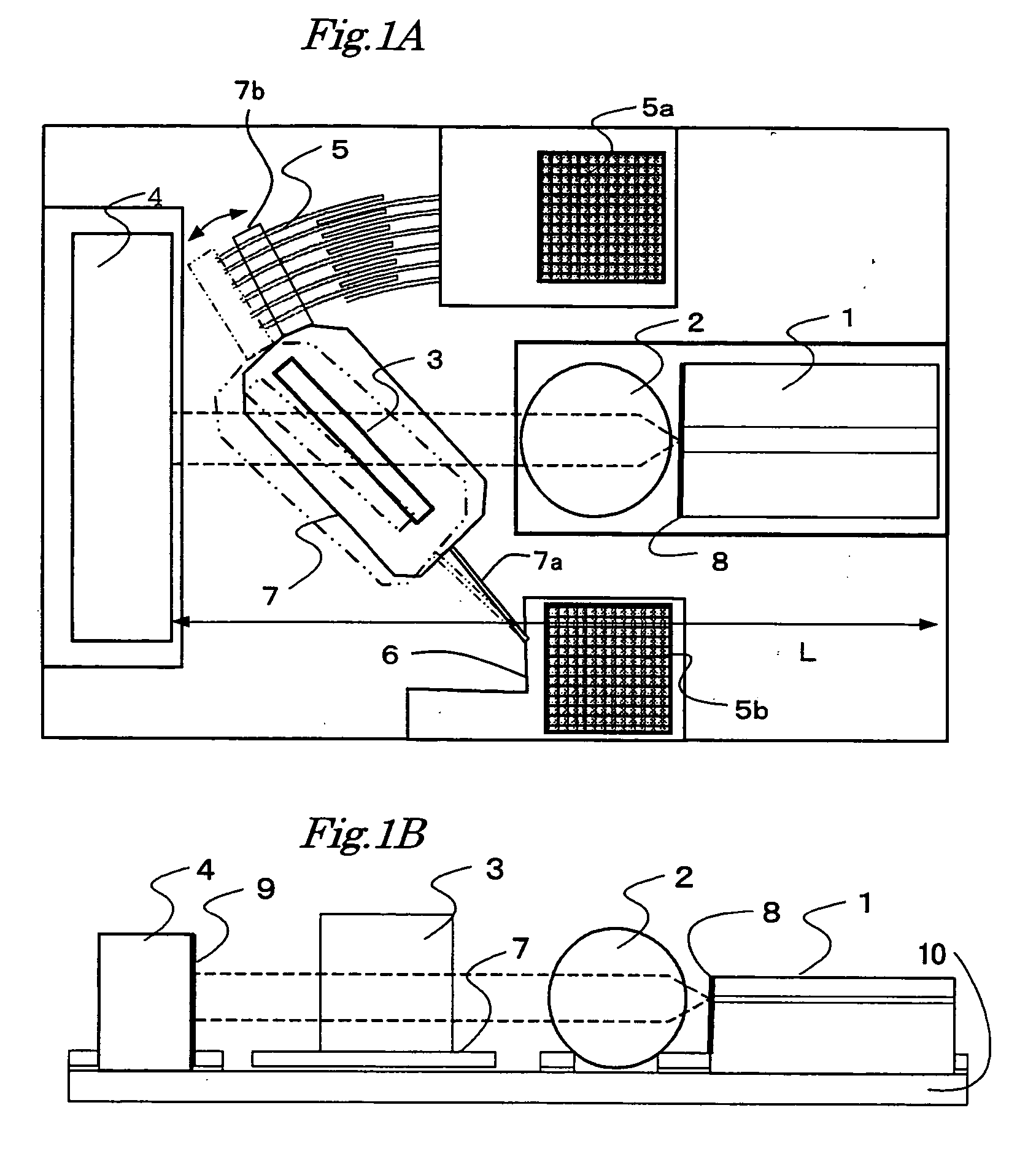

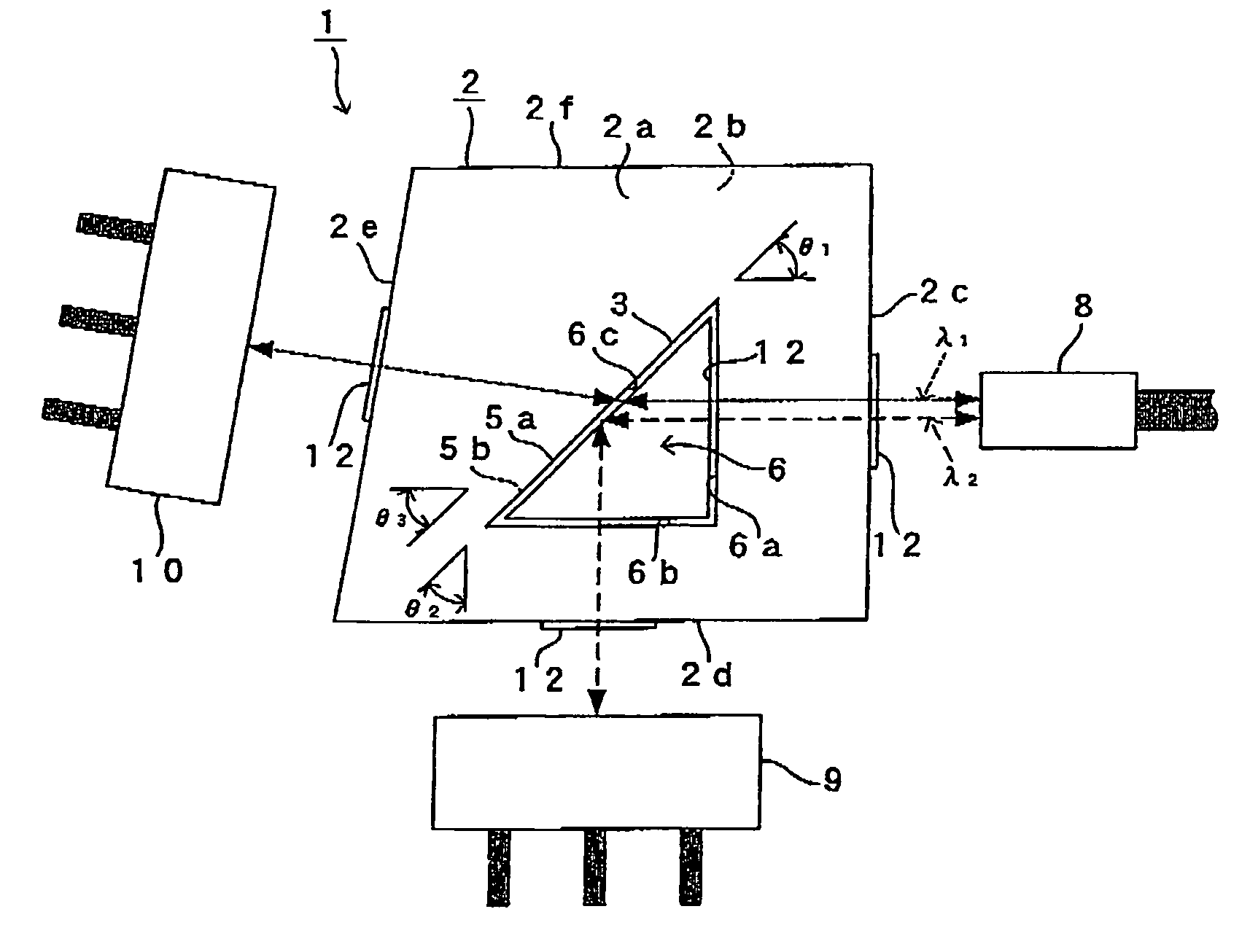

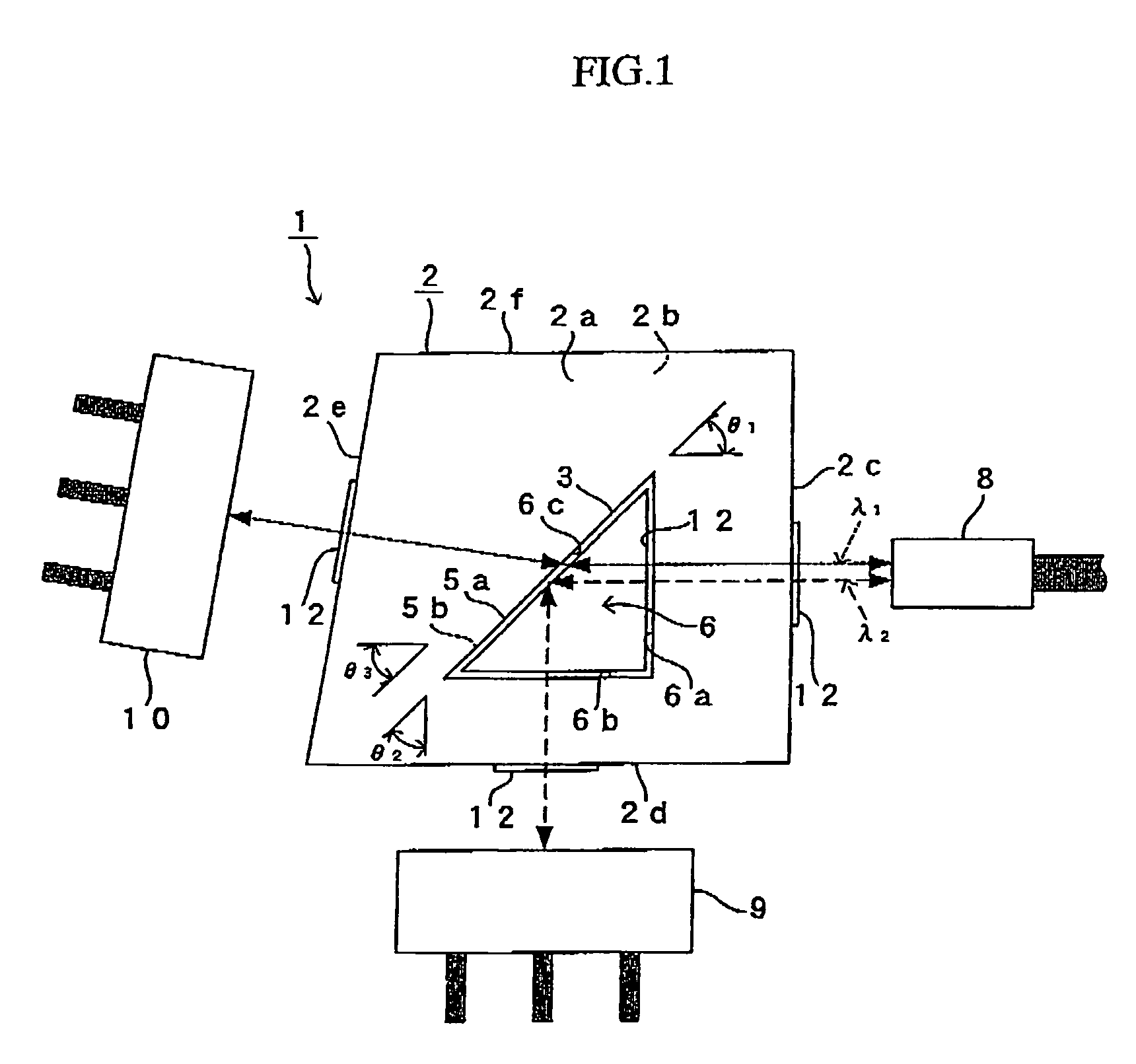

Tunable semiconductor laser apparatus with external resonator

InactiveUS20050185680A1Equipment miniaturizationImprove batch productivityLaser optical resonator constructionSemiconductor laser structural detailsProduction rateActuator

A tunable semiconductor laser apparatus with an external resonator includes: a semiconductor laser device having a first end face and a second end face, the second end face being coated with an antireflection film; an optical device for collimating light emitted from the second end face; a reflecting device for reflecting the collimated light, the reflecting device and the first end face constituting an external resonator; a tunable device located between the optical device and the reflecting device; and a driving mechanism for angularly displacing the tunable device to control incidence angle of light onto the tunable device, wherein the driving mechanism includes a micro-machine actuator, thereby shortening the length of the external resonator, yet providing a wide tunable range, reducing the size of the apparatus while achieving excellent mass-productivity.

Owner:MITSUBISHI ELECTRIC CORP

Apparatus and method for 2D and 3D image switchable display

InactiveUS8144390B2Reduce deteriorationHigh quality imagingSteroscopic systemsNon-linear opticsComputer graphics (images)3d image

An image display apparatus and method are disclosed. The image display apparatus includes a light source unit to include at least one light source, an optical unit to generate a directional light using a light projected from the light source unit, a variable diffuser unit to control diffusion of the directional light, a pixel unit to selectively generate one of two-dimensional (2D) images and three-dimensional (3D) images to correspond to the control of the variable diffuser unit, and a vertical diffusion unit to diffuse the 3D images in a vertical direction.

Owner:SAMSUNG ELECTRONICS CO LTD

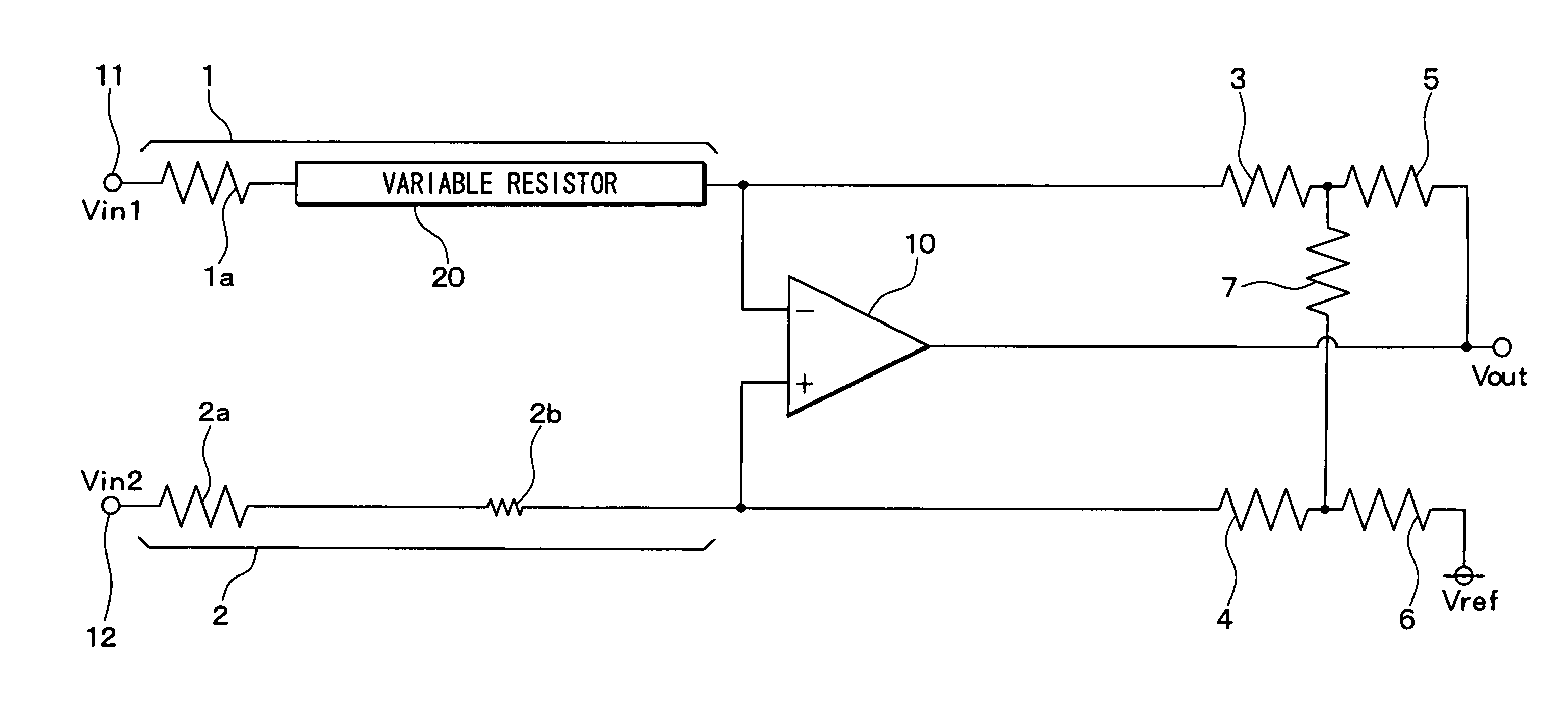

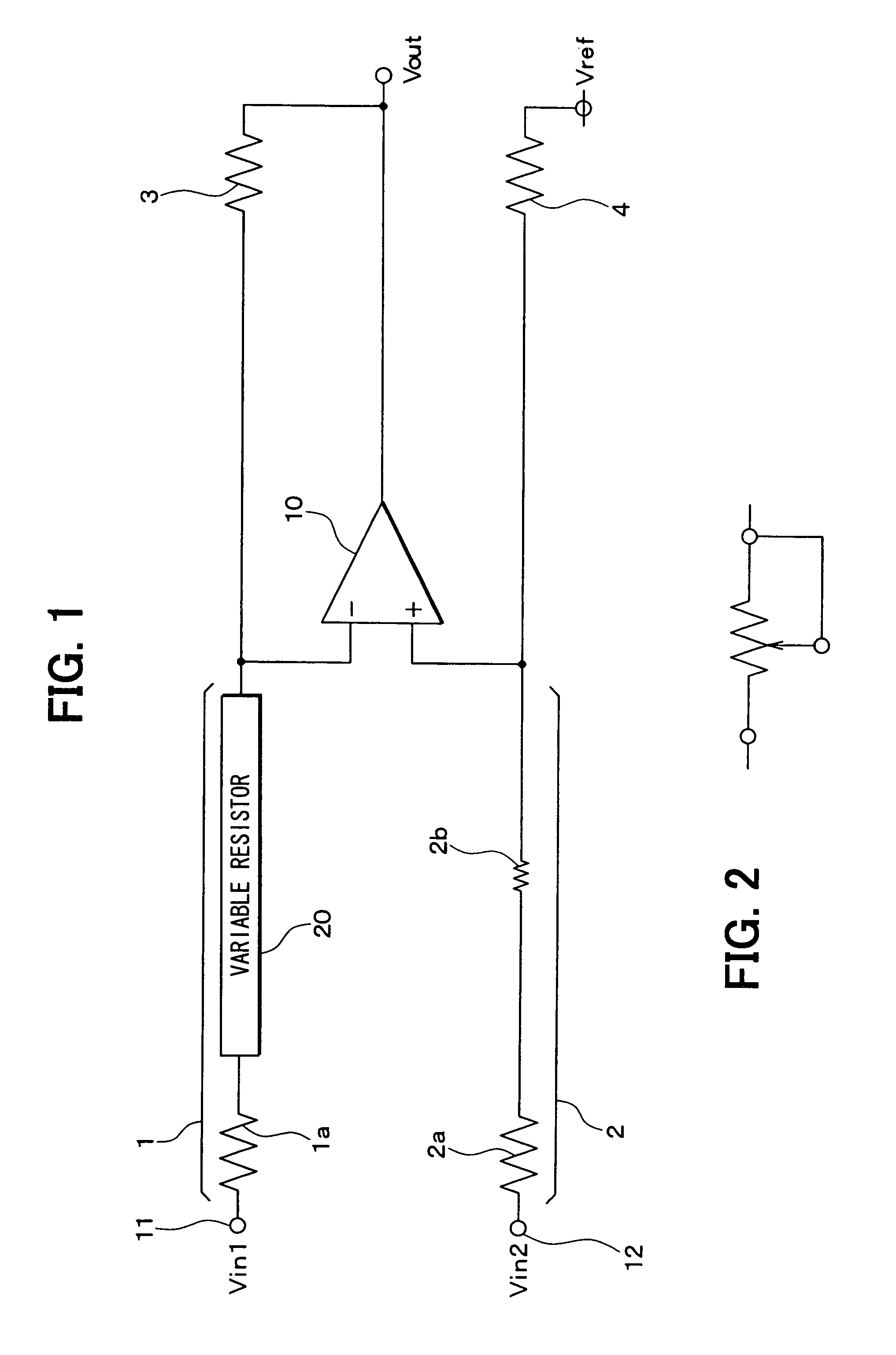

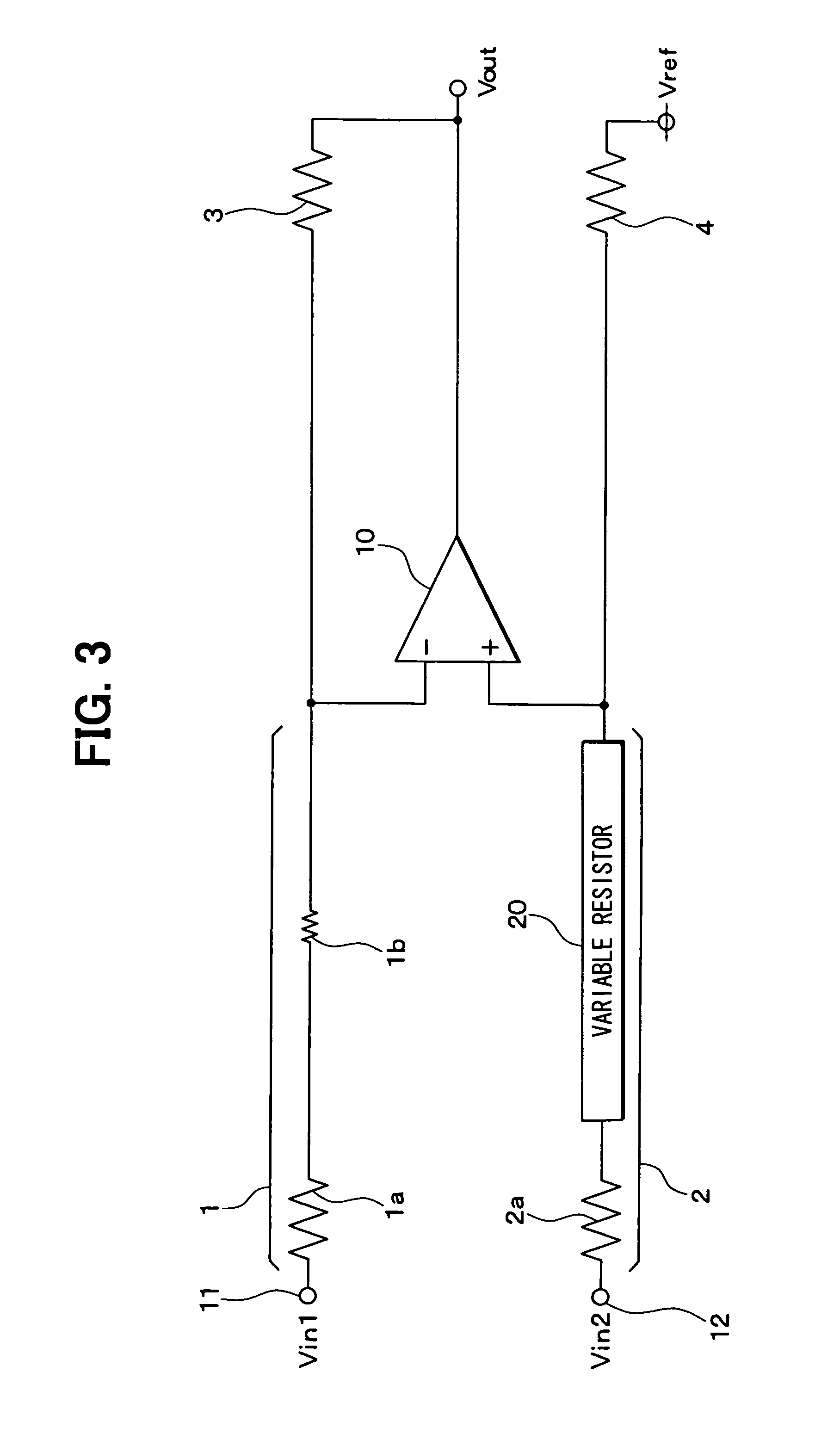

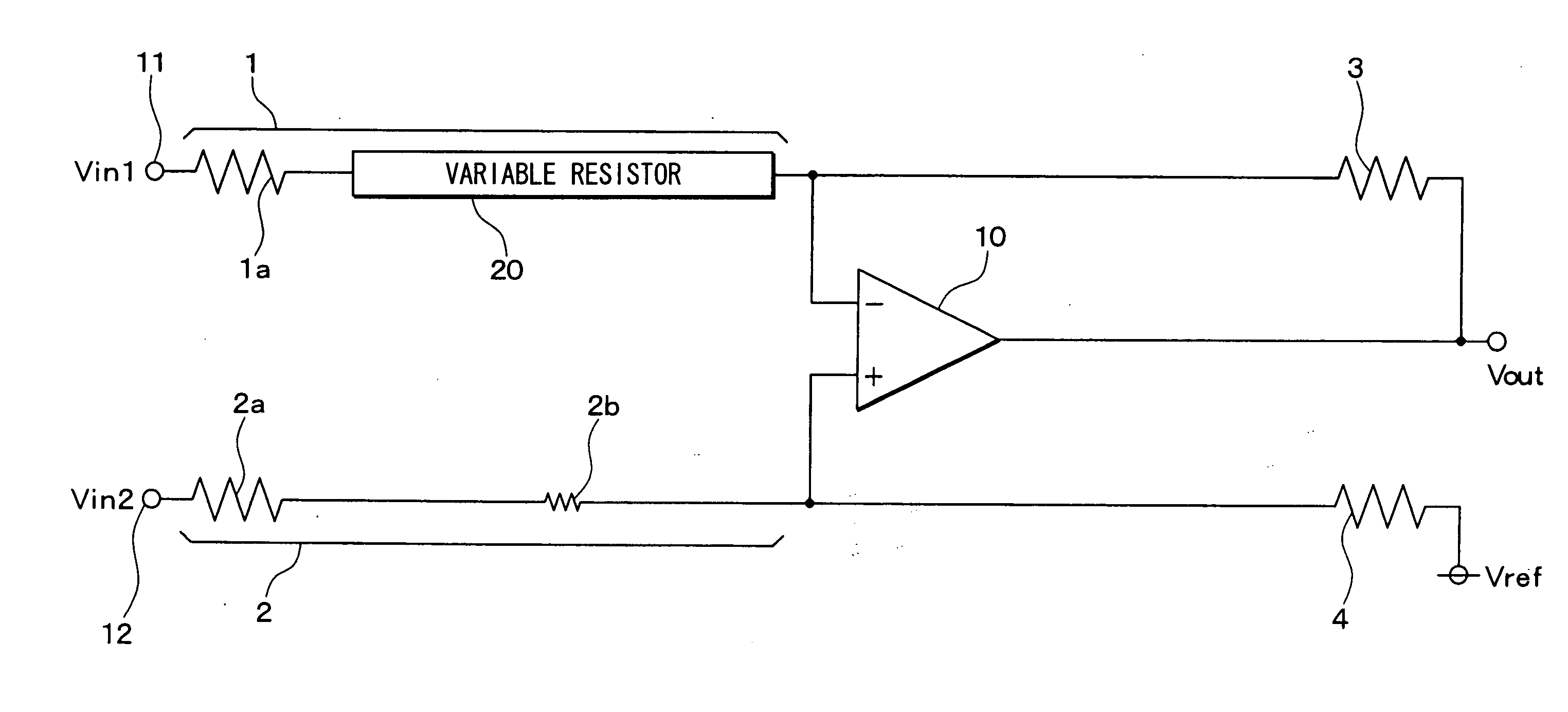

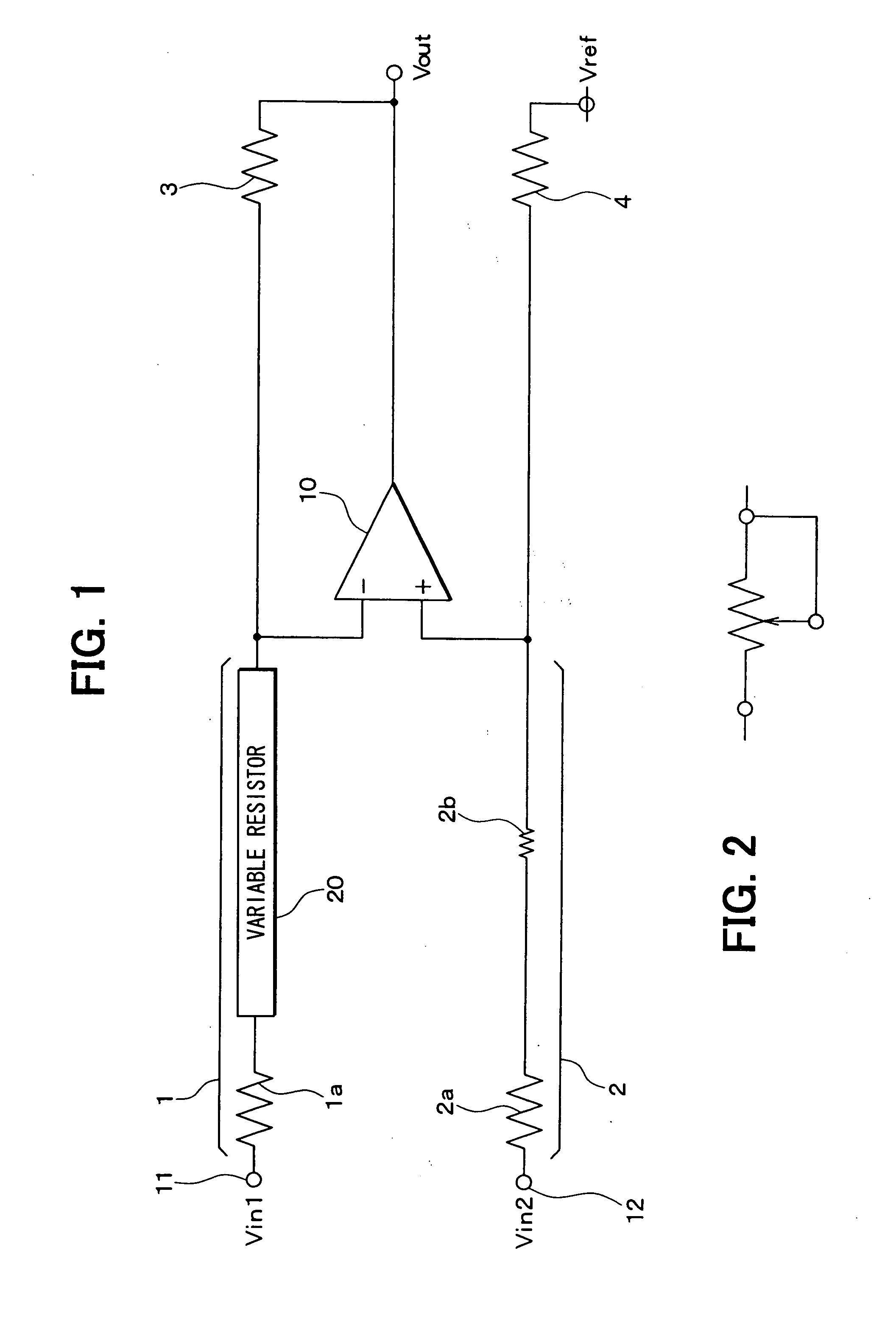

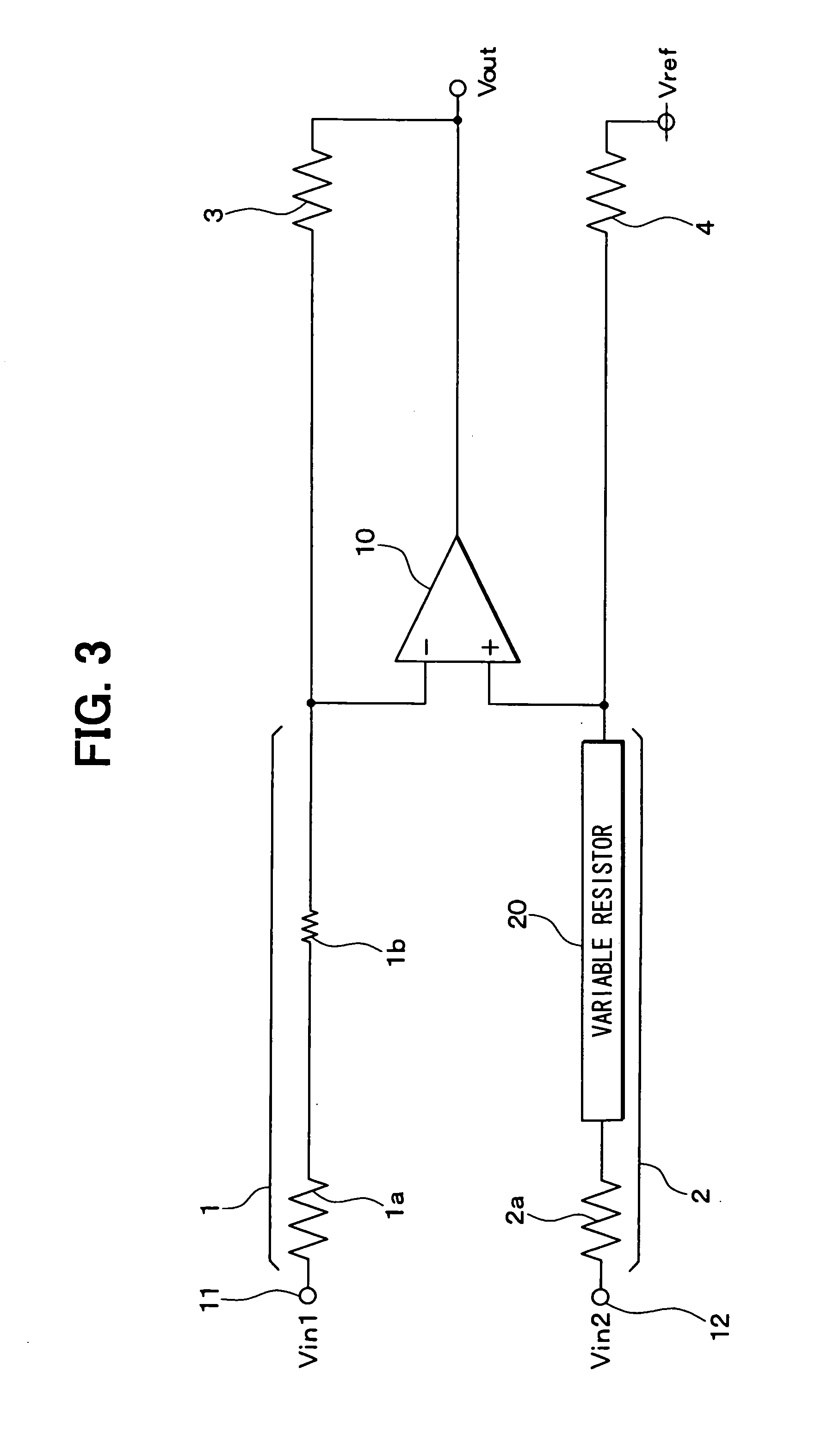

Differential amplification circuit and manufacturing method thereof

InactiveUS7777565B2Avoid it happening againReadily incorporated in ICNegative-feedback-circuit arrangementsElectrical measurement instrument detailsEngineeringResistor

A differential amplification circuit and a method corrects an offset voltage derived from a variance in resistances. With first and second input terminals brought to the same potential and set to a potential different from a reference potential, the resistance value of resistors is adjusted so that an output potential and the reference potential will be substantially equal to each other.

Owner:DENSO CORP

Carbonized product used for production of activated carbon for electrode of electric double-layer capacitor

InactiveUS7088570B2Mass-productivity of the activated carbon for the electrode can be improvedImprove breathabilityHybrid capacitor electrodesConductive materialActivated carbonGraphite

A carbonized product 10 used for production of activated carbon for an electrode of an electric double-layer capacitor, includes a plurality of crystallites 12 each having a graphite structure in an amorphous carbon matrix 11. The interlayer distance d002 of the crystallites 12 is set a value equal to or larger than 0.347 nm. Thus, by using this carbonized product, it is possible to produce activated carbon having a high electrostatic capacity density (F / cc) for an electrode of an electric double-layer capacitor.

Owner:HONDA MOTOR CO LTD

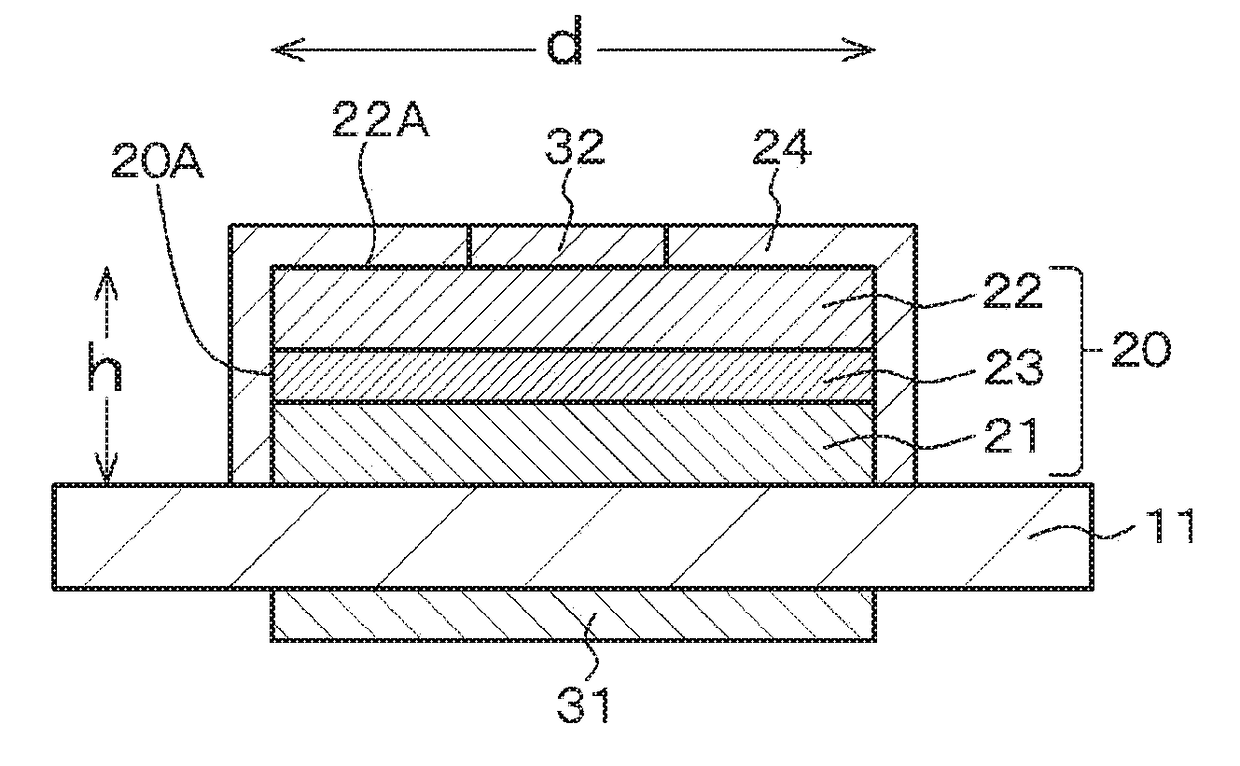

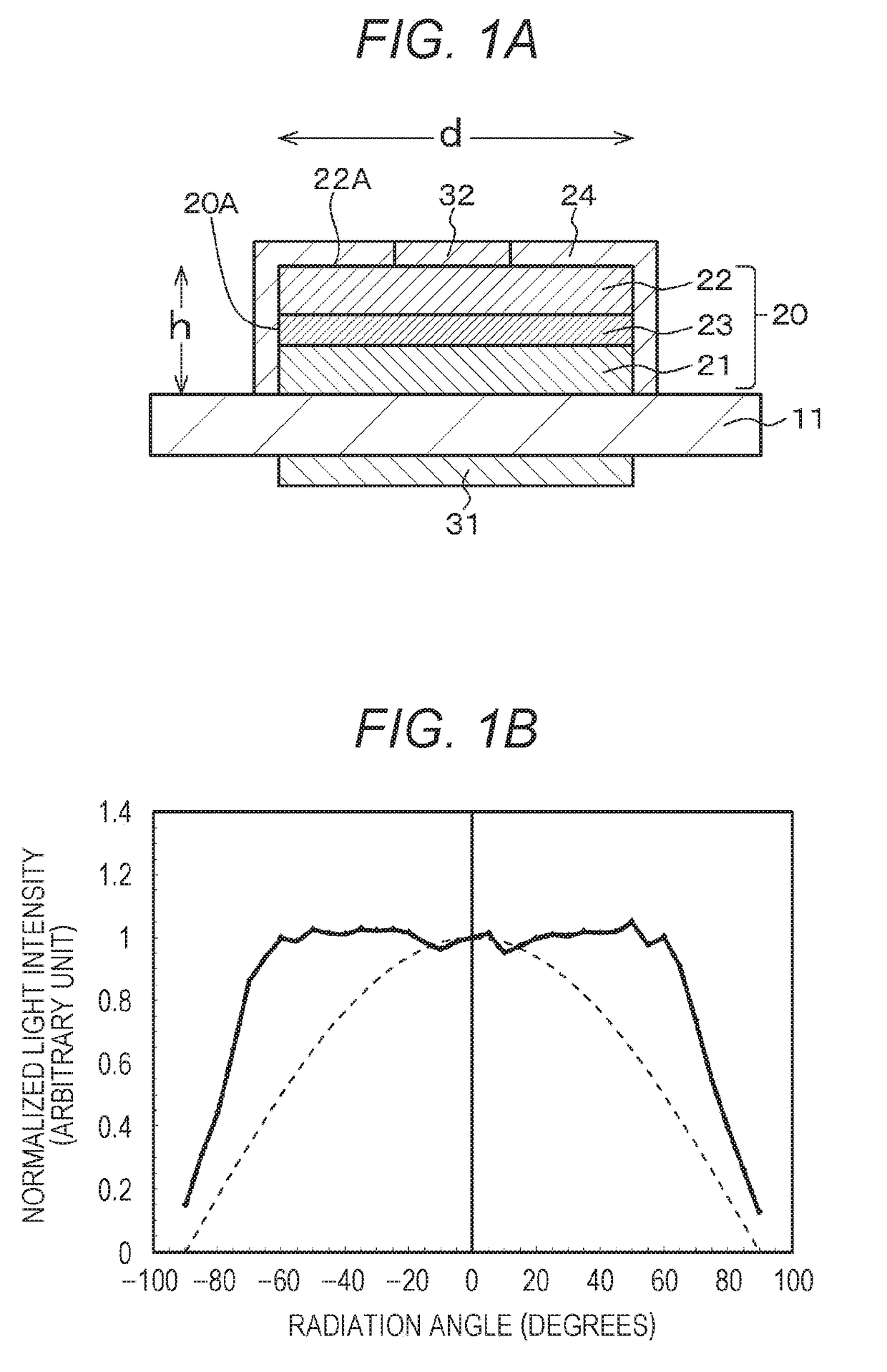

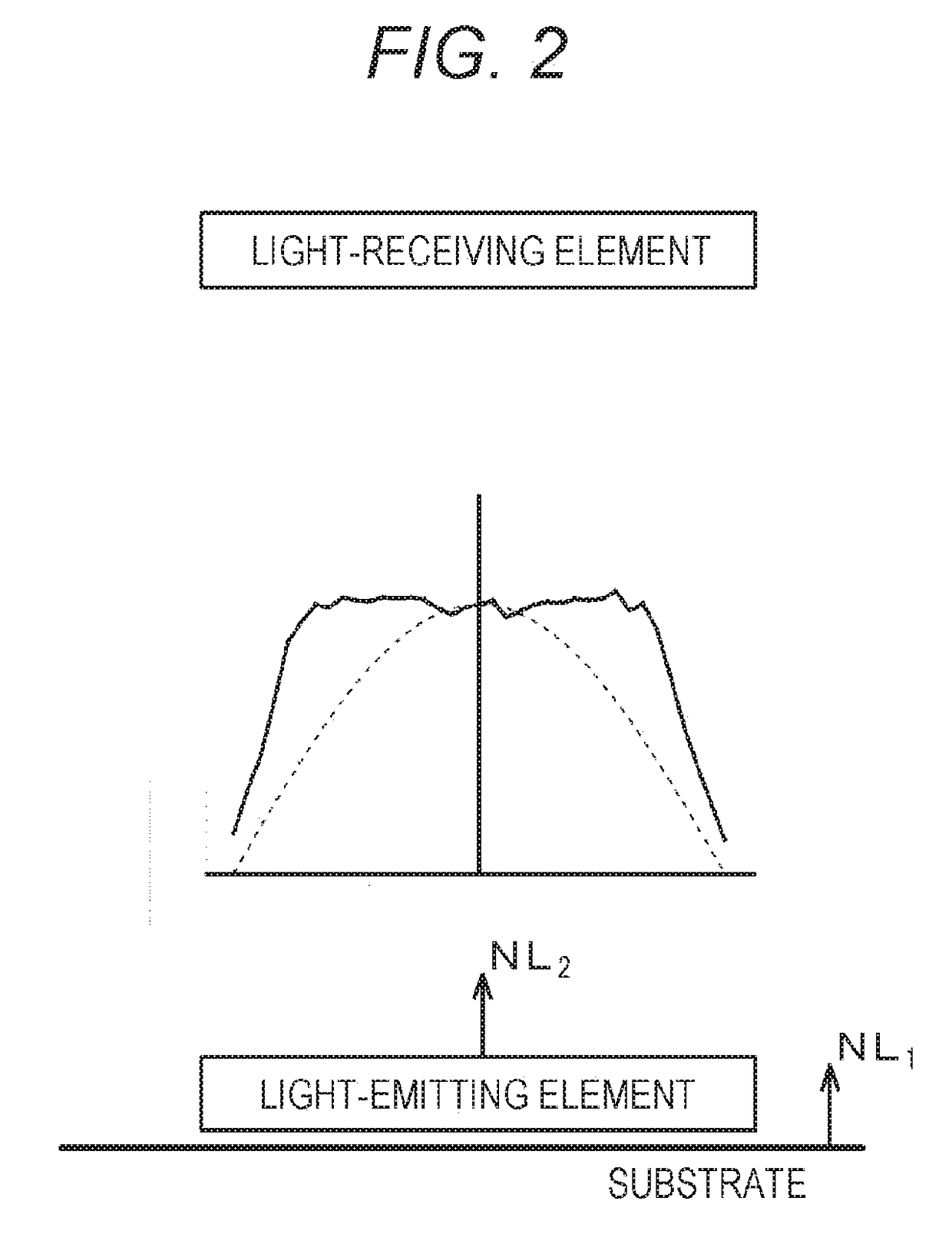

Light-emitting element and light-emitting element assembly

InactiveUS20170162747A1Eliminate needMass productivity can be improvedSemiconductor devicesOptoelectronicsLuminous intensity

The light-emitting element of the present disclosure has a constant light emission intensity over a specific range of emission angle of light emitted from the center of its main light-emitting surface.

Owner:SONY CORP

Differential amplification circuit and manufacturing method thereof

InactiveUS20090096524A1Avoid it happening againReadily incorporated in ICNegative-feedback-circuit arrangementsElectrical measurement instrument detailsElectrical resistance and conductanceResistor

A differential amplification circuit and a method corrects an offset voltage derived from a variance in resistances. With first and second input terminals brought to the same potential and set to a potential different from a reference potential, the resistance value of resistors is adjusted so that an output potential and the reference potential will be substantially equal to each other.

Owner:DENSO CORP

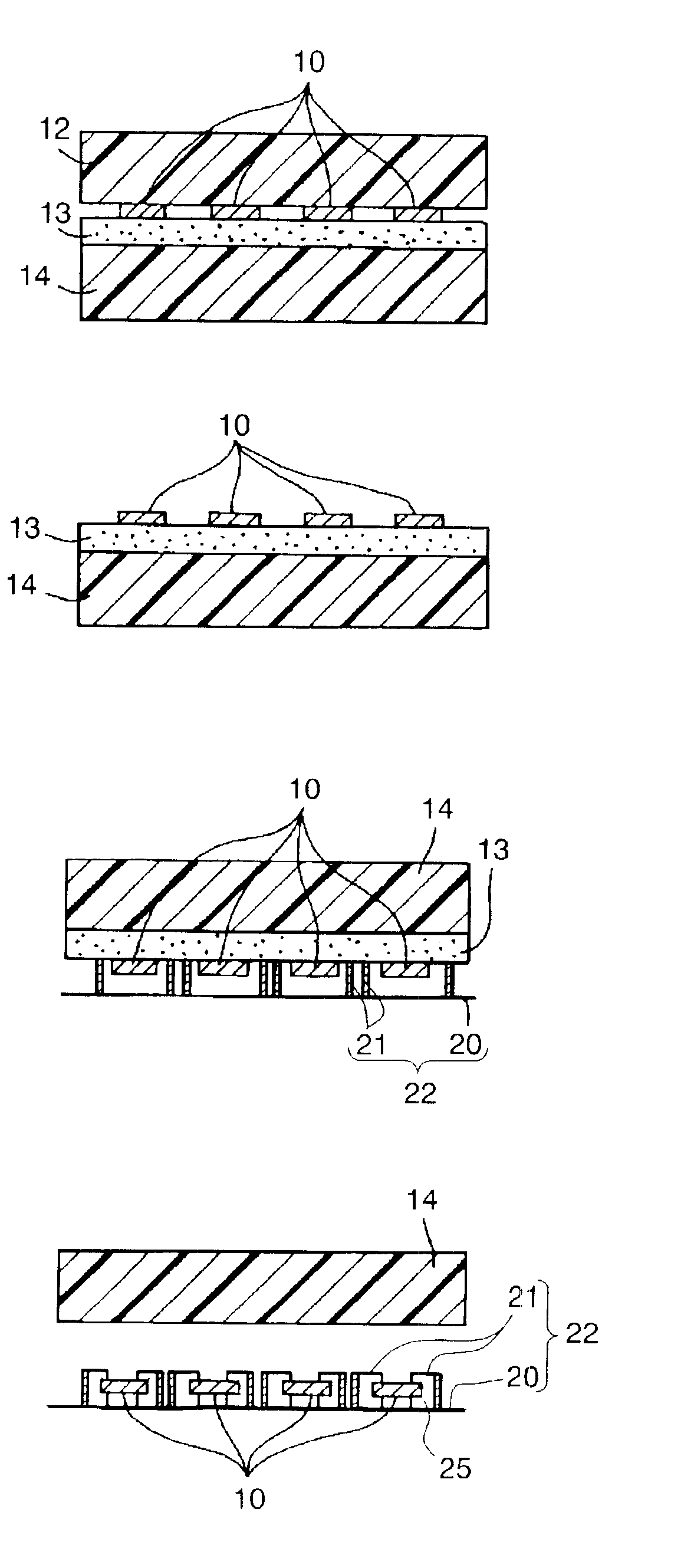

Method of manufacturing thin film piezoelectric element, and element housing jig

ActiveUS6964086B2Good removal effectMass productivity can be improvedPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyEngineeringPellicle membrane

A method comprises: bonding a plurality of thin film piezoelectric elements, formed on a substrate, onto a temporary fixing substrate via an adhesive layer; selectively removing the substrate to expose the thin film piezoelectric elements; fixing an element housing jig having sectional regions for individually isolating the thin film piezoelectric elements in such manner that the thin film piezoelectric elements and the sectional regions correspond to each other; and dissolving and removing the adhesive layer, and housing the thin film piezoelectric elements in the sectional regions of the element housing jig. Accordingly, it is possible to individually isolate and house the thin film piezoelectric elements removed from the substrate.

Owner:TDK CORPARATION

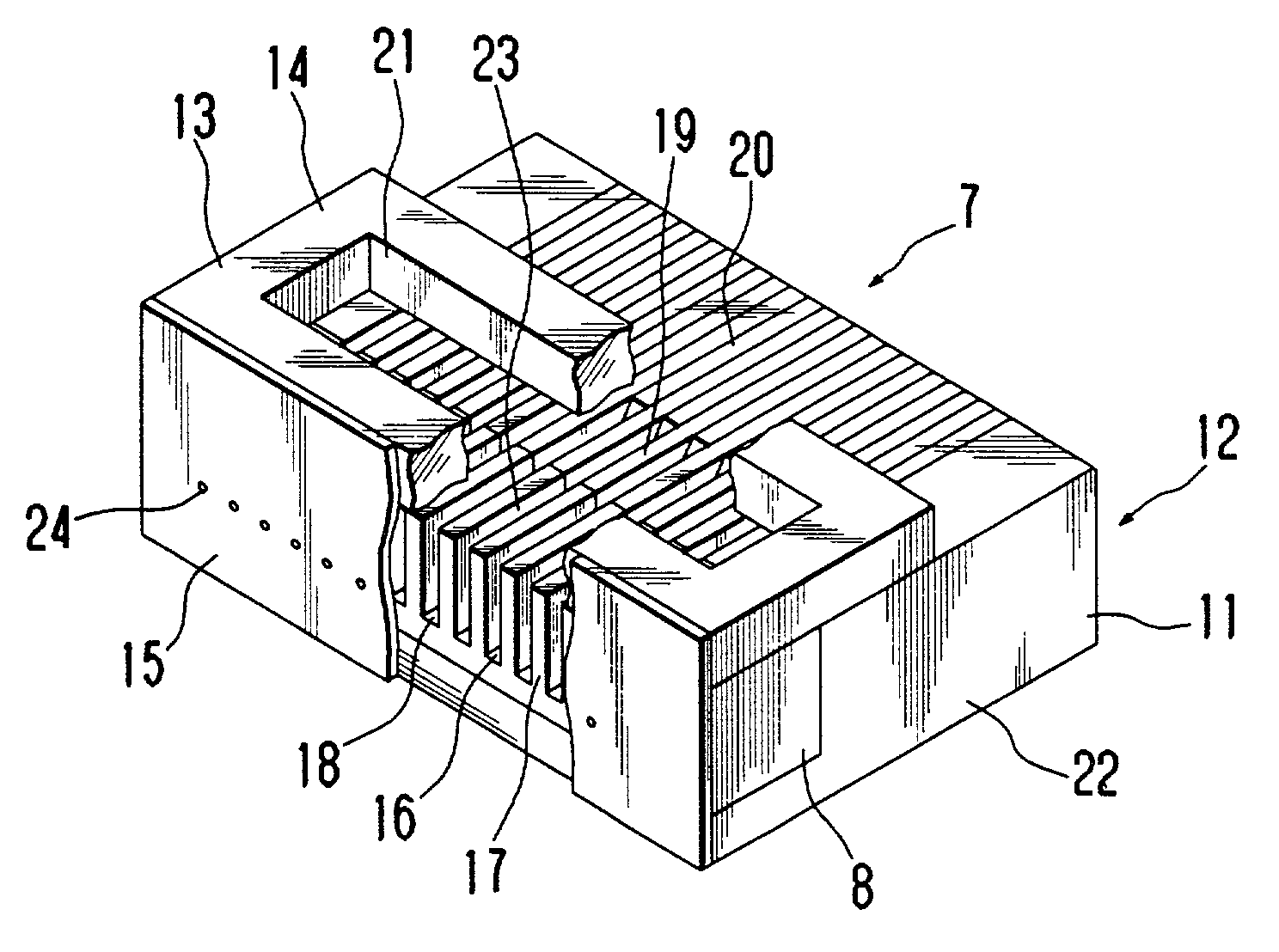

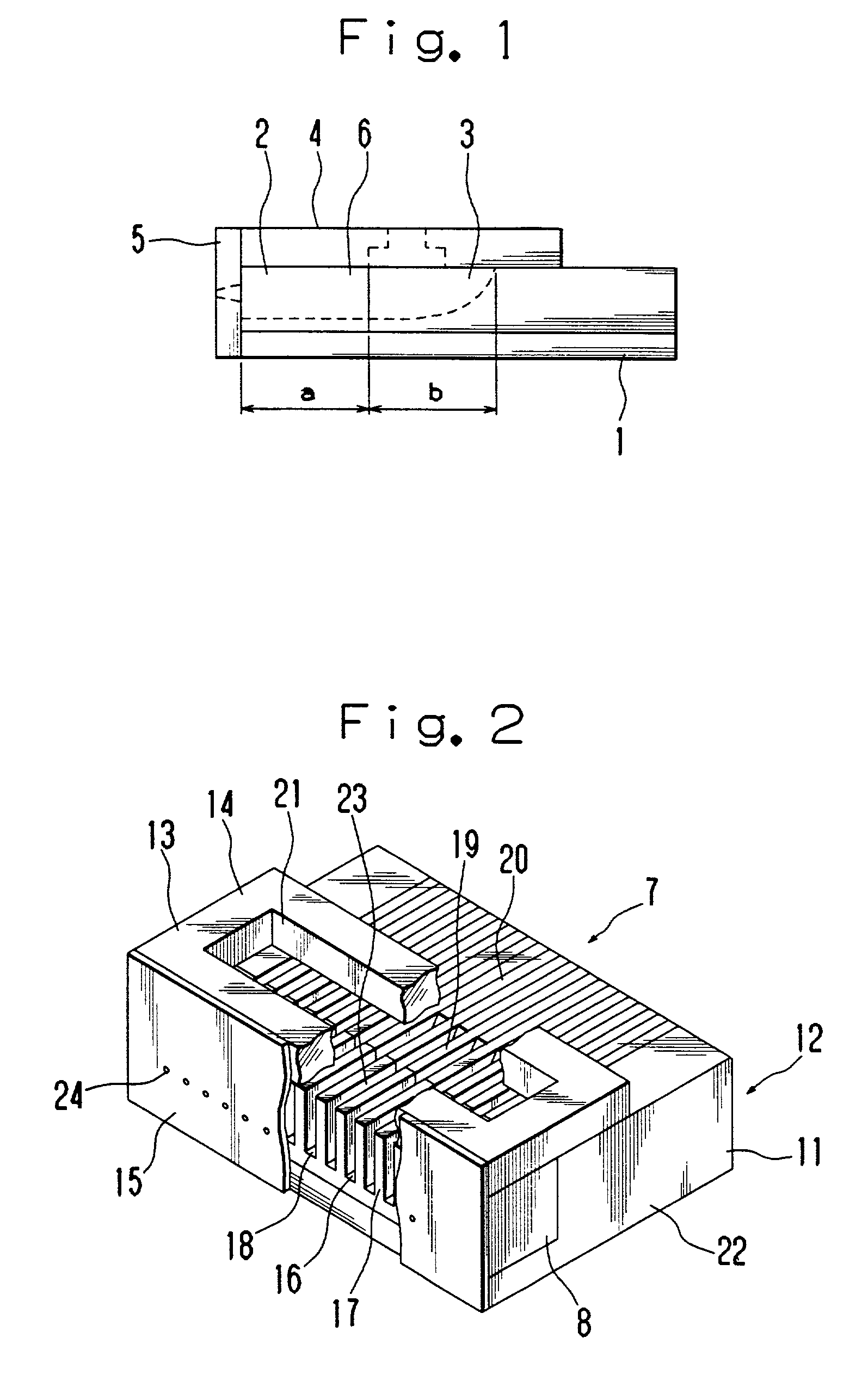

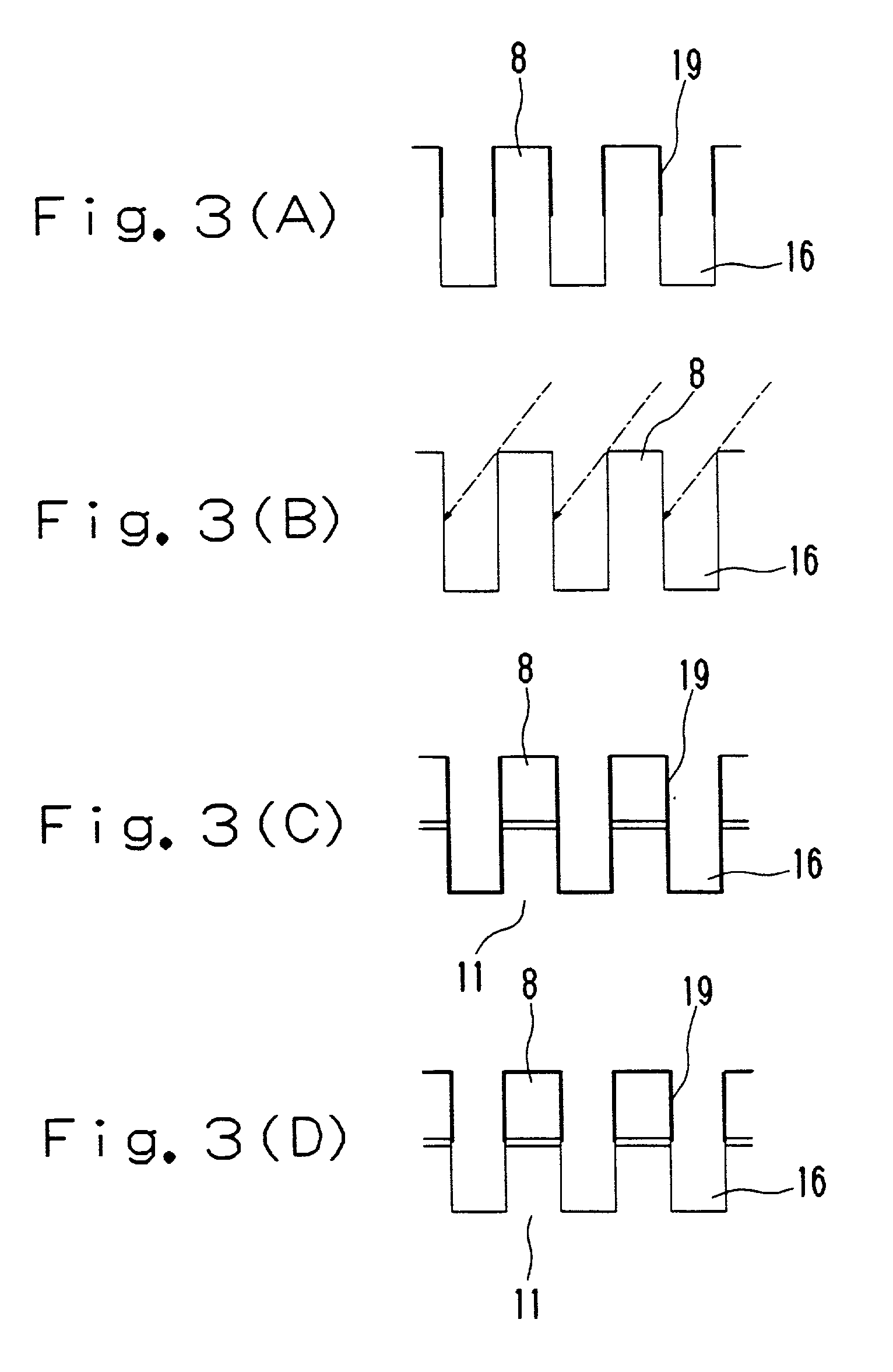

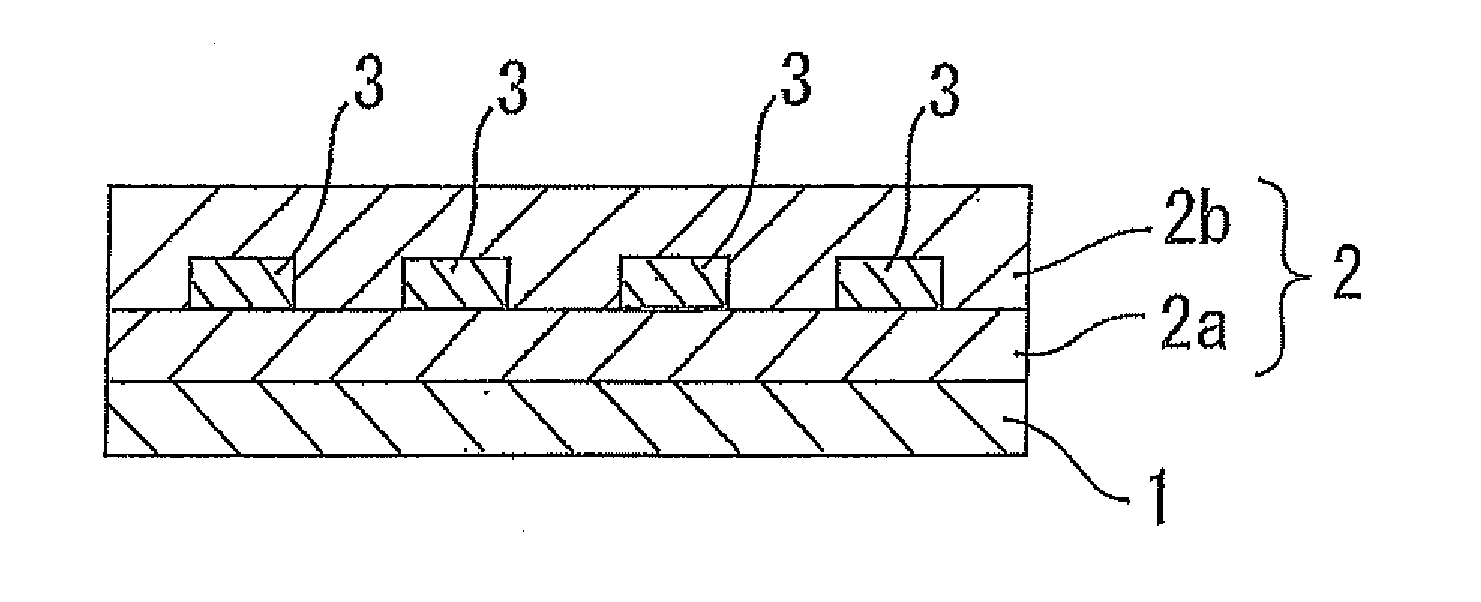

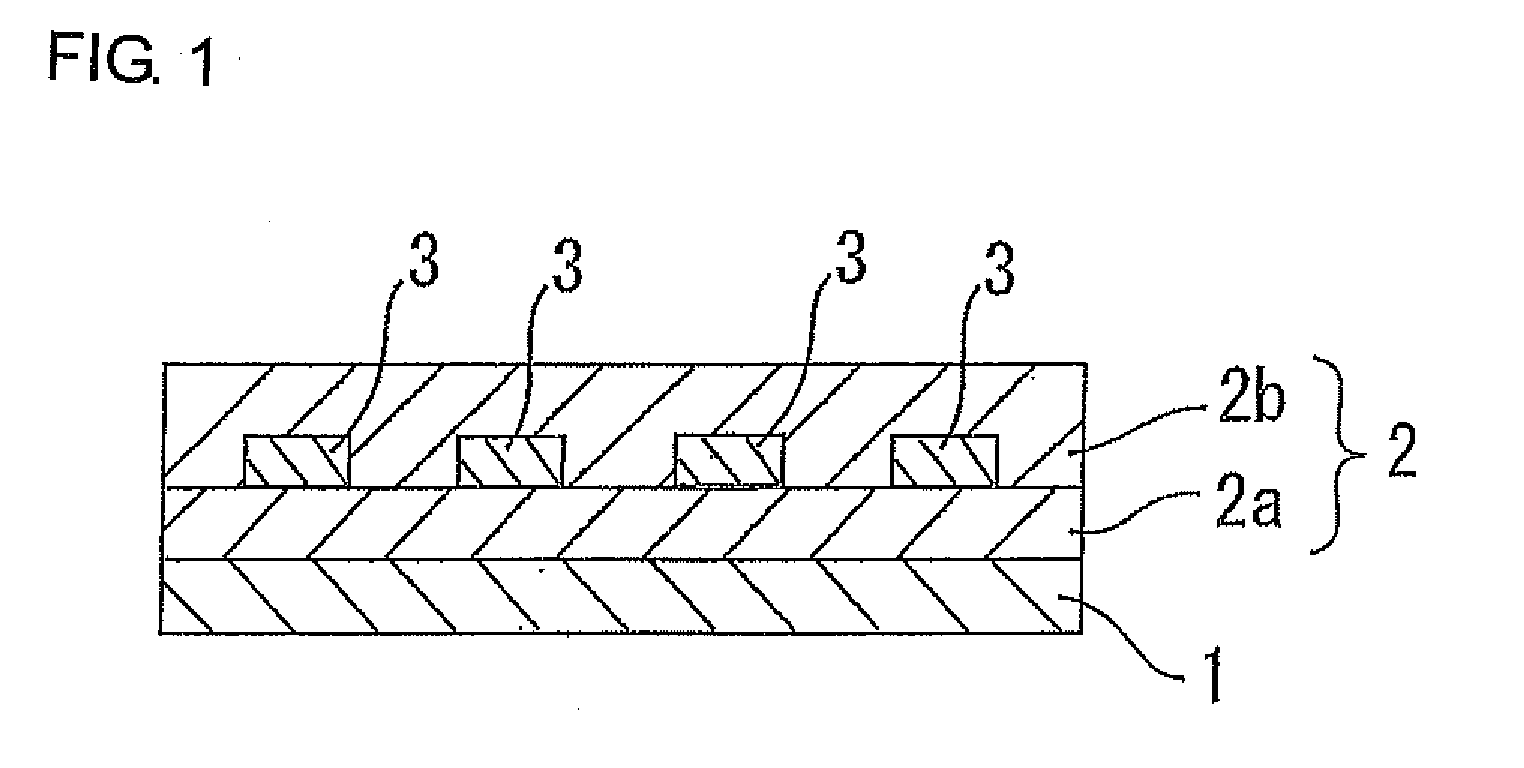

Ink jet printer head and method for fabricating the same

InactiveUS7108359B2Mass productivity can be improvedInhibition formationPiezoelectric/electrostrictive device manufacture/assemblyWriting implementsEngineeringVoltage

A plurality of ink jet printer heads can be obtained from a single substrate through the following steps: a piezoelectric body forming step of cutting a piezoelectric member into a desired width to form a piezoelectirc body, a fitting recess forming step of forming a recess for fitting therein of the piezoelectric body in a base member, a substrate forming step of embedding the piezoelectric body into the recess to form a substrate, a grooving step of forming a plurality of desired grooves in parallel in the substrate, a head substrate forming step of forming an electrically conductive film on inner walls of the grooves to form a head substrate, an electroconductive pattern forming step of making connection to the electrically conductive film for the application of voltage thereto, a top plate joining step of joining a top plate to the head substrate to form a head substrate-top plate composite, a head forming step of cutting the head substrate-top plate composite at a desired position to form a head, and a nozzle plate joining step of joining a nozzle plate to a cut side having groove openings of the head.

Owner:TOSHIBA TEC KK

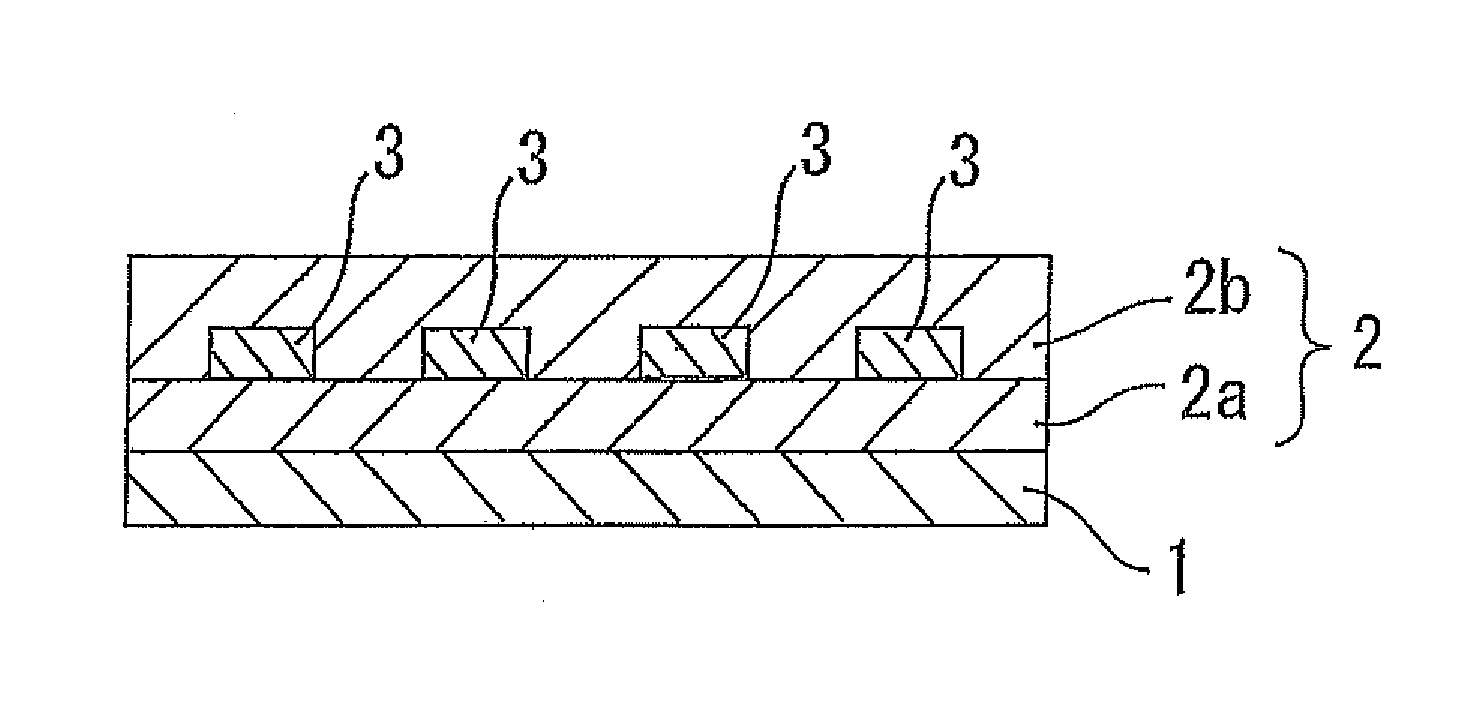

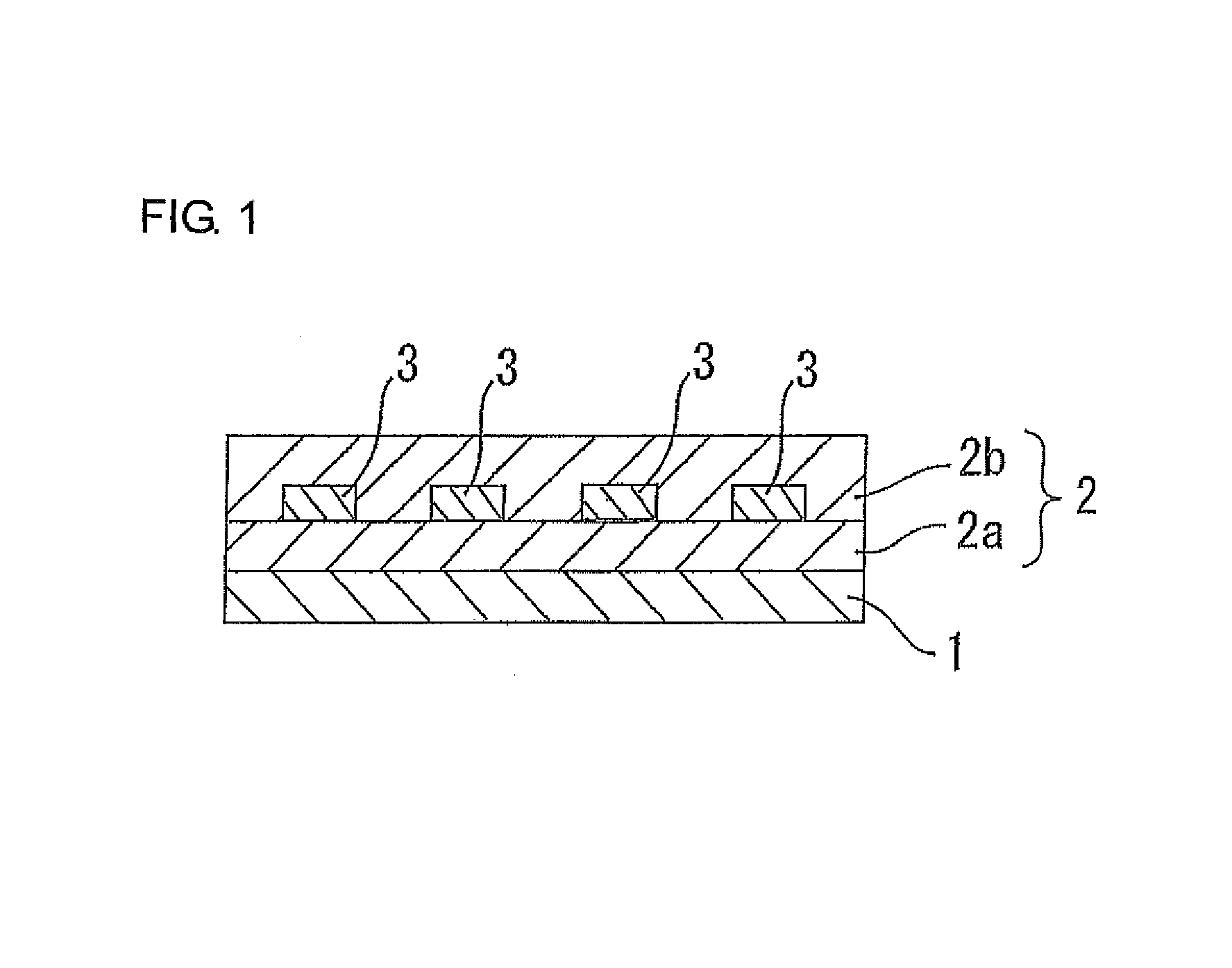

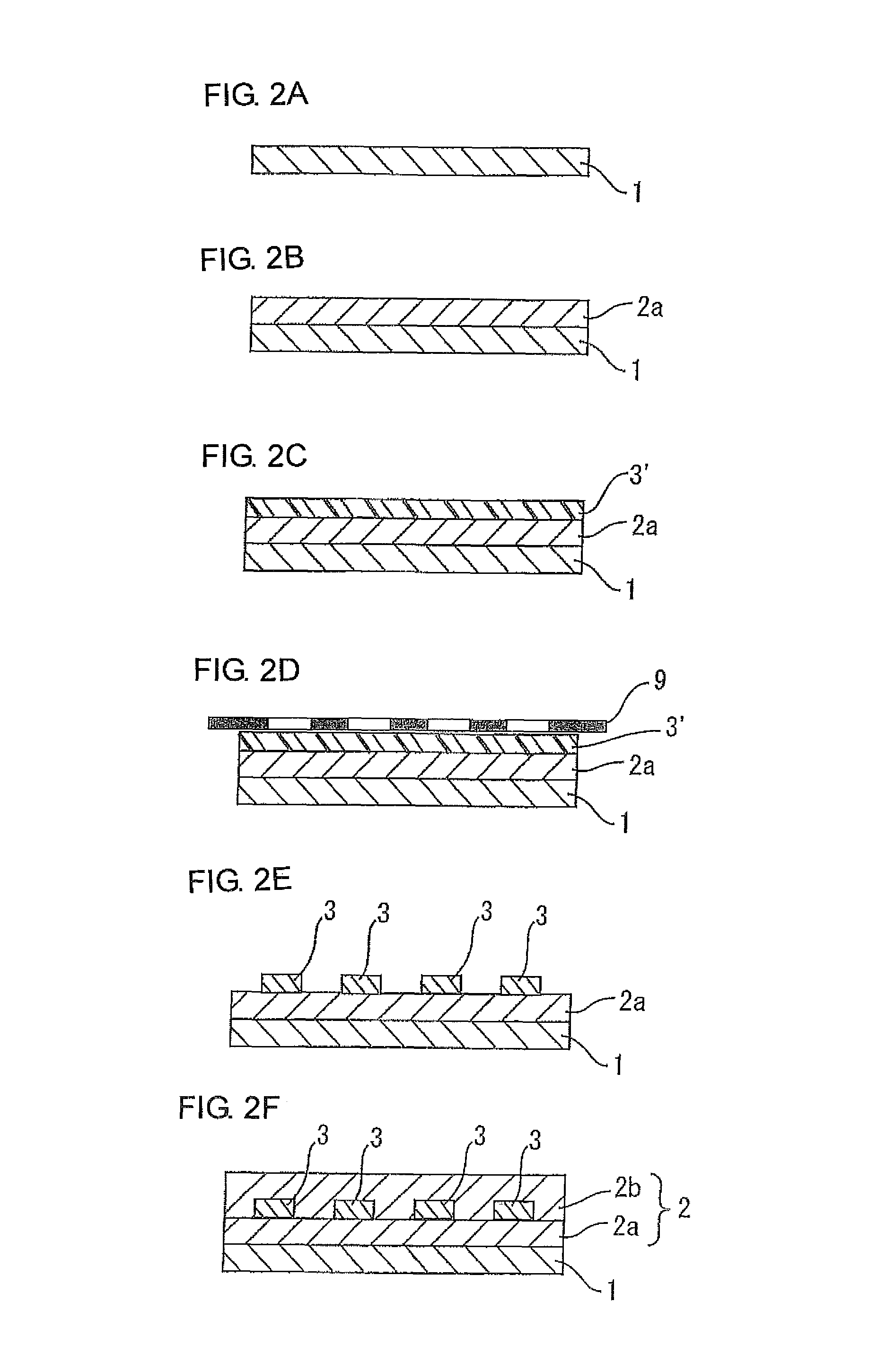

Resin composition for optical waveguide, and optical waveguide produced by using the resin composition

ActiveUS20120114294A1Improve efficiencyMass productivity can be improvedCladded optical fibrePhotosensitive materialsHydrogen atomWaveguide

A resin composition for an optical waveguide is provided, which permits easy formation of a core pattern using an alkali developing liquid and suppresses degradation of the alkali developing liquid. An optical waveguide produced by using the resin composition is provided. The resin composition comprises: (A) an alkali soluble resin, as a major component, having a structural unit represented by formula (1):wherein R1, R2 and R3, which may be the same or different, are each a hydrogen atom or a methyl group; R5 and R6, which may be the same or different, are each a hydrogen atom or a methyl group; R4 isand m+n+p=1, m>0, n>0 and p>0; and (B) a photopolymerization initiator. The optical waveguide includes a substrate, a cladding layer provided thereon, and a core portion provided in the cladding layer for transmitting an optical signal.

Owner:NITTO DENKO CORP

Rotor for rotating electrical machine

ActiveUS7932657B2Minimize eddy currentReduce dissipationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectricityMagnetic poles

A rotor body for an electric motor is comprised of connecting outer peripheral portions of first and second flange members made of electrically conductive material to the opposite ends of a plurality of connection members made of electrically conductive material of weak magnetic material arranged at predetermined distances therebetween in the circumferential direction with bolts and by supporting induction magnetic poles made of soft magnetic material between the connection members which are adjacent in the circumferential direction. Coupling portions of the first and second flange members and the connection member are electrically insulated by insulation coating so that an eddy current flowing in a closed circuit comprised of the first flange member, the connection member, the second flange member and the other connection member can be reduced and heat dissipation and energy loss accompanied by the eddy current can be minimized at the time of an operation.

Owner:HONDA MOTOR CO LTD

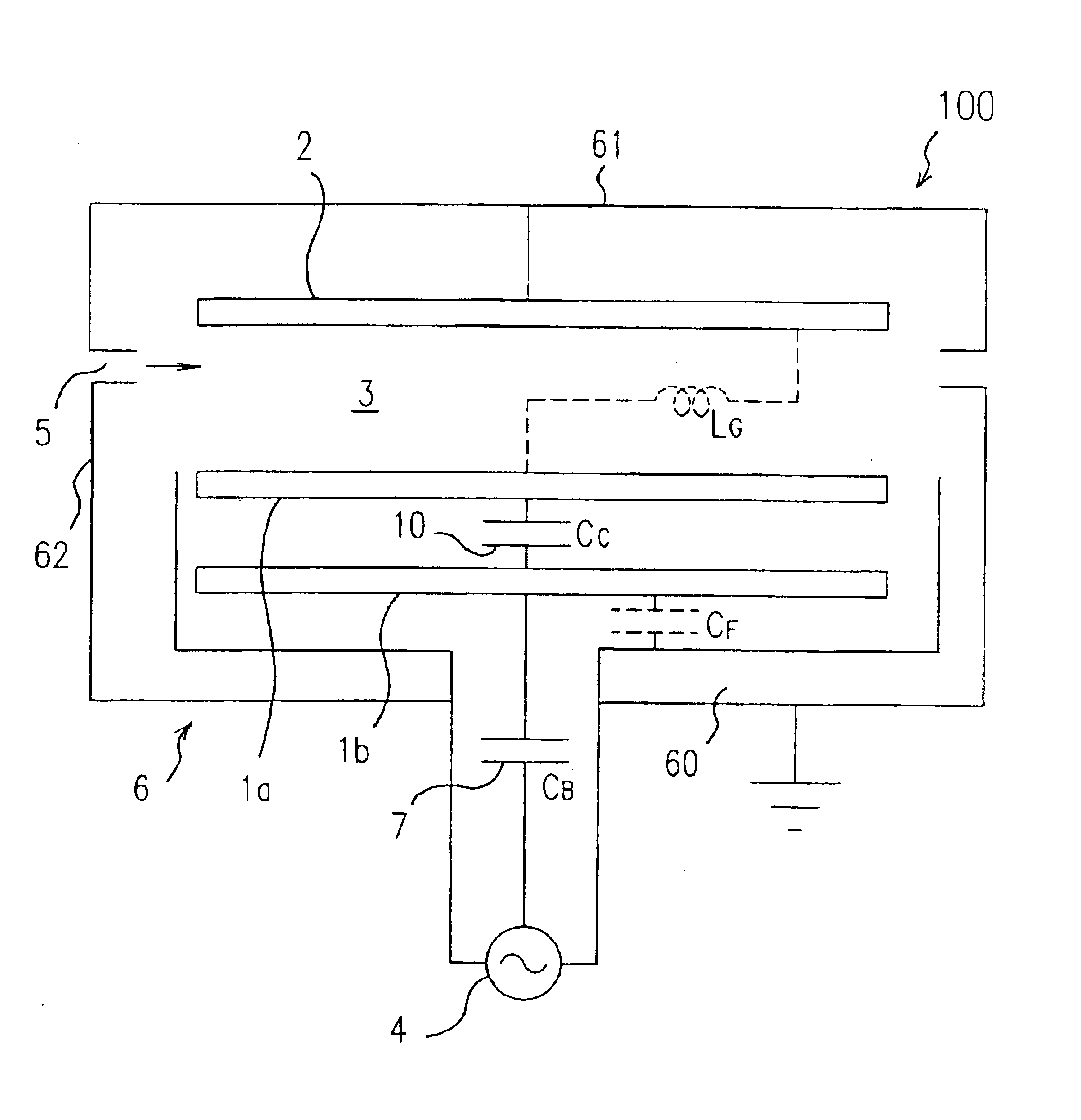

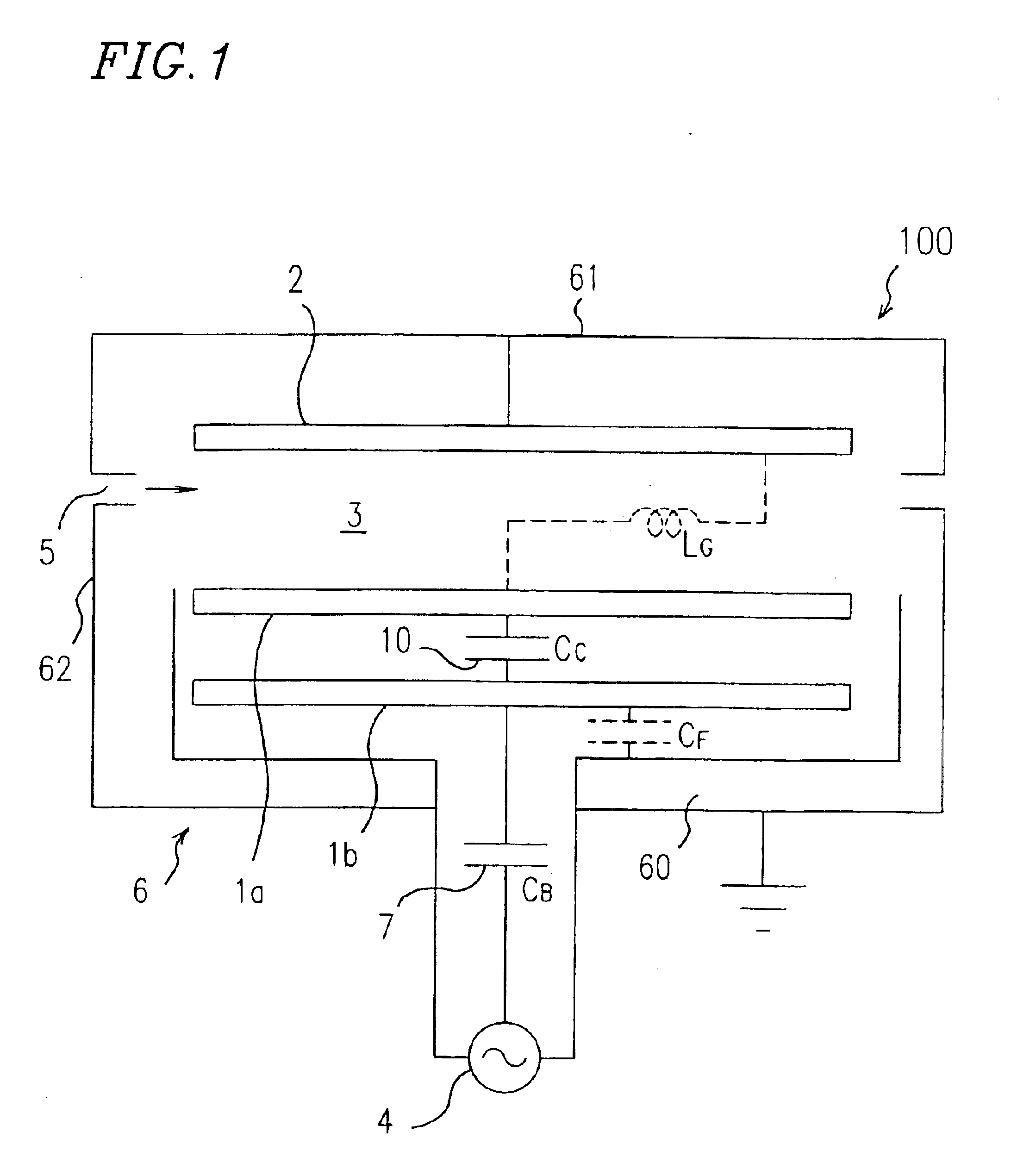

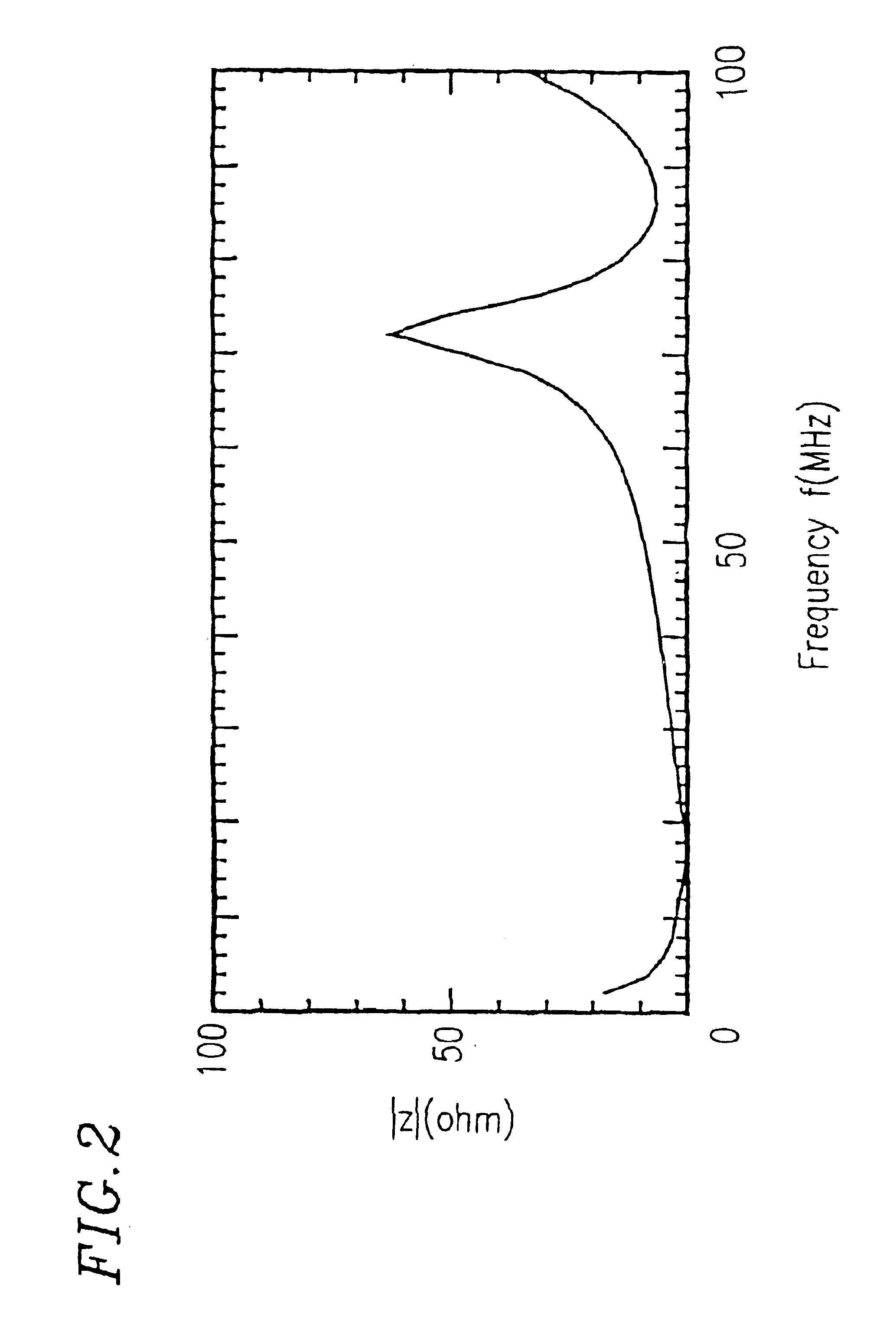

Electronic device manufacturing apparatus and method for manufacturing electronic device

InactiveUSRE39064E1Mass productivity can be improvedQuality improvementElectric discharge tubesDecorative surface effectsCapacitanceHigh frequency power

An electronic device manufacturing apparatus includes: a reaction chamber including a wall having a ground potential level; a reaction gas inlet for introducing a reaction gas into the reaction chamber; a high frequency power generator for generating a high frequency voltage for exciting the reaction gas into plasma state or dissociated state; a cathode electrode connected to the high frequency power generator; and a floating capacitance formed between a potential level of the cathode electrode and the ground potential level. An impedance adjusting capacitor is inserted so as to be in series with the floating capacitance. The impedance adjusting capacitor has a capacitance value less than that of the floating capacitance.

Owner:SHARP KK

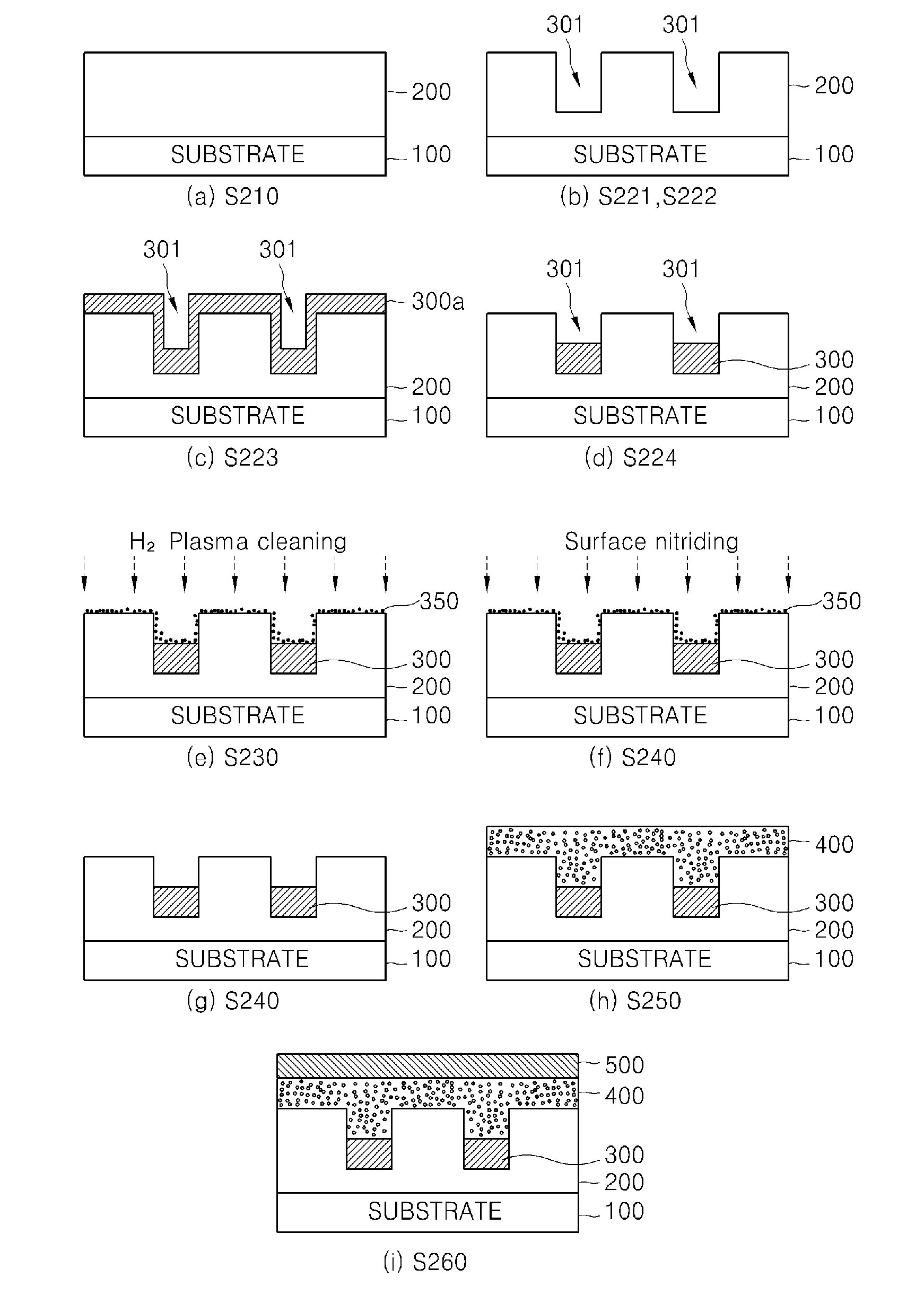

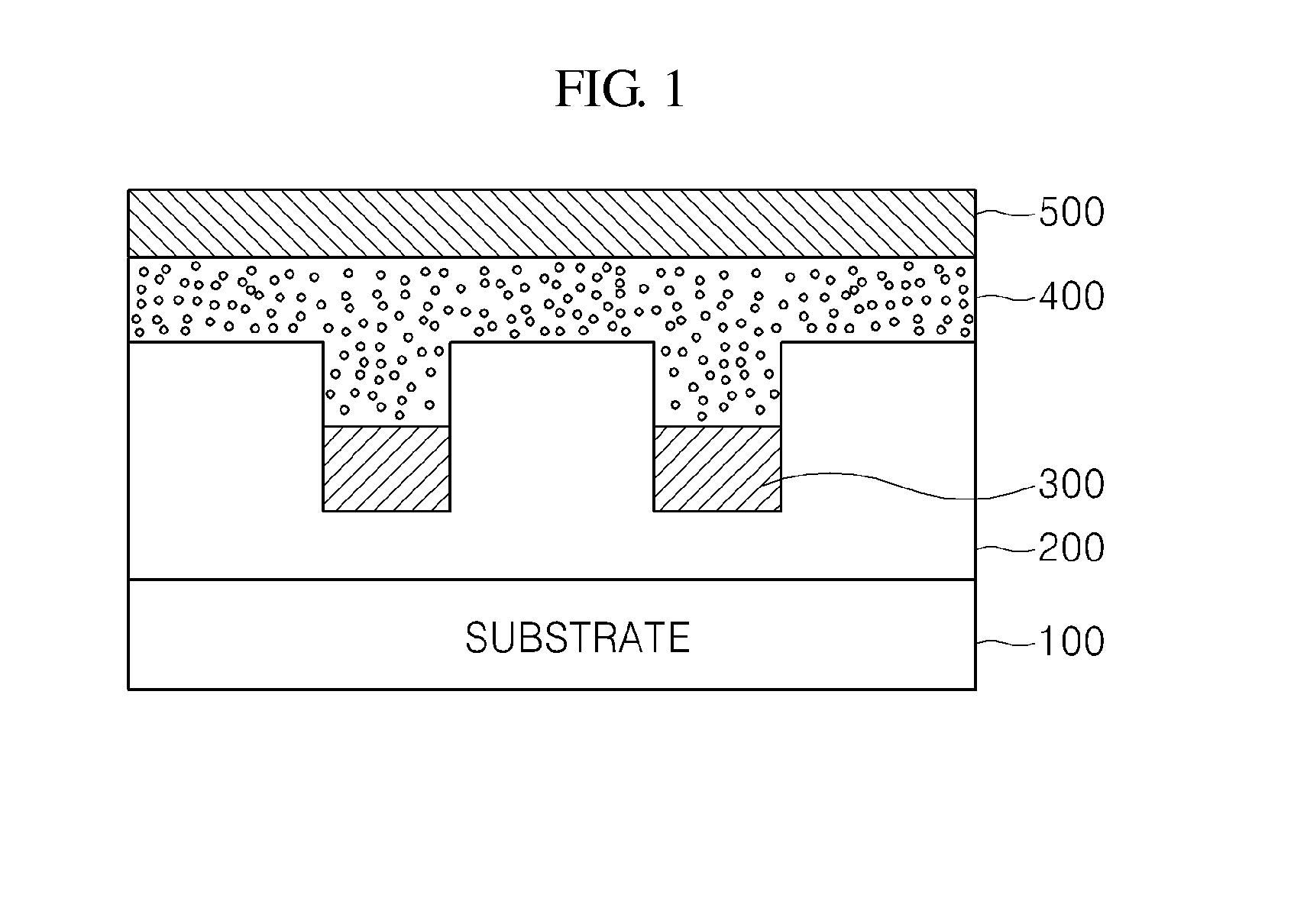

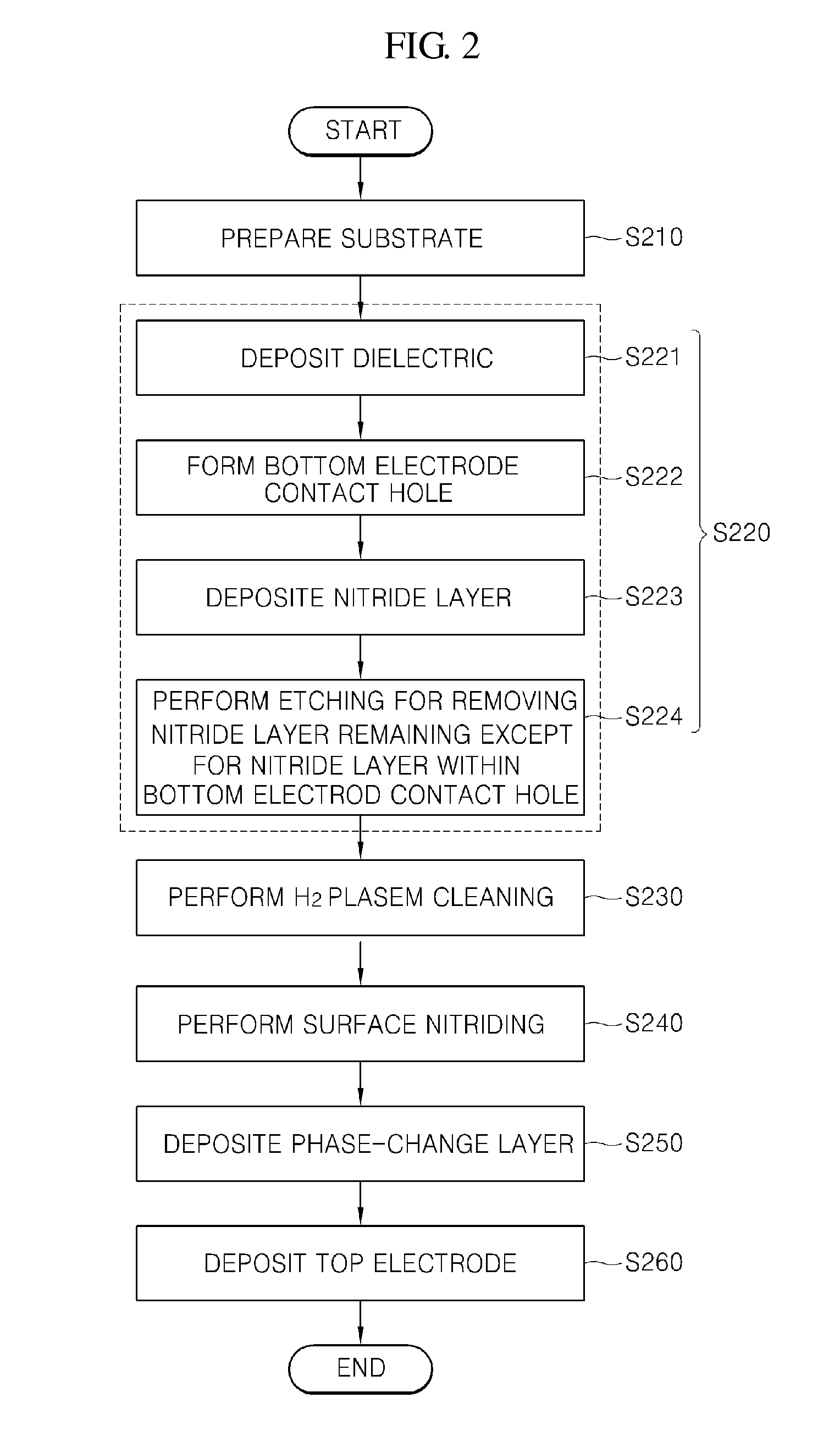

Apparatus and method for treating a substrate

ActiveUS20150037929A1Avoiding characteristicMass productivity can be improvedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPhase-change memoryMetallurgy

Provided are a substrate treating apparatus and method of manufacturing a phase-change layer having superior deposition characteristics. The substrate treating method of manufacturing a phase-change memory includes forming a bottom electrode on a substrate on which a pattern is formed, performing surface treating for removing impurities generated or remaining on a surface of the substrate while the bottom electrode is formed, performing nitriding on the surface of the substrate from which the impurities are removed, and successively depositing a phase-change layer and a top electrode on the bottom electrode. The substrate treating apparatus for manufacturing a phase-change memory includes a load lock chamber into / from which a plurality of substrates are loaded or unloaded, the load lock chamber being converted between an atmosphere state and a vacuum state, a nitriding chamber in which nitriding is performed on a surface of a substrate on which a bottom electrode is disposed, the nitriding chamber being coupled to one side of a plurality of sides of the vacuum transfer chamber, and a process chamber in which a phase-change layer is deposited on the surface of the substrate on which nitriding is performed in the nitriding process chamber, the process chamber being coupled to one of the plurality of sides of the vacuum transfer chamber.

Owner:WONIK IPS CO LTD

Permanent magnet rotor

InactiveUS9166450B2Avoid damageReduce resonanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorEmbedment

A permanent magnet rotor has a rotor core positioned about a rotation shaft. The permanent magnet rotor also has permanent magnet embedment slots located at equally spaced positions from the rotation shaft, with permanent magnets inserted into each of the respective permanent magnet embedment slots. The permanent magnet embedment slots each have both a magnet storing portion, and a buffer and other members storing portion which extends to the magnet storing portion. Once a permanent magnet is stored inside the magnet storing portion, a buffer member, and a pushing member are used to secure the permanent magnet inside the rotor core.

Owner:MITSUBISHI ELECTRIC CORP

Resin composition for optical waveguide, and optical waveguide produced by using the resin composition

ActiveUS8586286B2Improve efficiencyMass productivity can be improvedCladded optical fibrePhotosensitive materialsHydrogen atomMethyl group

A resin composition for an optical waveguide is provided, which permits easy formation of a core pattern using an alkali developing liquid and suppresses degradation of the alkali developing liquid. An optical waveguide produced by using the resin composition is provided. The resin composition comprises: (A) an alkali soluble resin, as a major component, having a structural unit represented by formula (1):wherein R1, R2 and R3, which may be the same or different, are each a hydrogen atom or a methyl group; R5 and R6, which may be the same or different, are each a hydrogen atom or a methyl group; R4 isand m+n+p=1, m>0, n>0 and p>0; and (B) a photopolymerization initiator. The optical waveguide includes a substrate, a cladding layer provided thereon, and a core portion provided in the cladding layer for transmitting an optical signal.

Owner:NITTO DENKO CORP

Optical element

InactiveUS7428102B2Excessive number of componentLow costOptical waveguide light guideLength wavePhysics

An optical element which includes an optical block having a cavity part formed on an optical path and an inclined face formed in an internal face of the cavity part at a prescribed inclining angle with respect to a traveling direction of light. Multilayer films of the same structure are formed at least on the internal face of the cavity part and on an interface between a light incident end and / or emission end of the optical block and outside. The multilayer film formed on the incline face in the internal face of the cavity part has at least a wavelength selecting function for light to be used.

Owner:ENPLAS CORP

Laminated piezoelectric ceramic element manufacturing method

InactiveUS8062460B2Time of lamination complicatedReduce removalPiezoelectric/electrostrictive device manufacture/assemblyLamination ancillary operationsMetallurgyElectrode

There is provided a laminated piezoelectric ceramic element manufacturing method, wherein, even when the number of internal electrode laminations is increased, the lamination and cutting steps can be simplified, to enhance cutting precision and make cutting cost low. A first laminated body having stripe-like internal electrodes is cut into a plurality of second laminated bodies so as to have a width-direction dimension W corresponding to a width dimension of a laminated piezoelectric ceramic element chip to be ultimately obtained. Two or more second laminated bodies are laminated in the laminating direction to obtain a third laminated body, and the third laminated body is cut in the laminating direction and parallel to the width direction W to obtain a laminated piezoelectric body.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com