Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29results about How to "Simple discharge method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

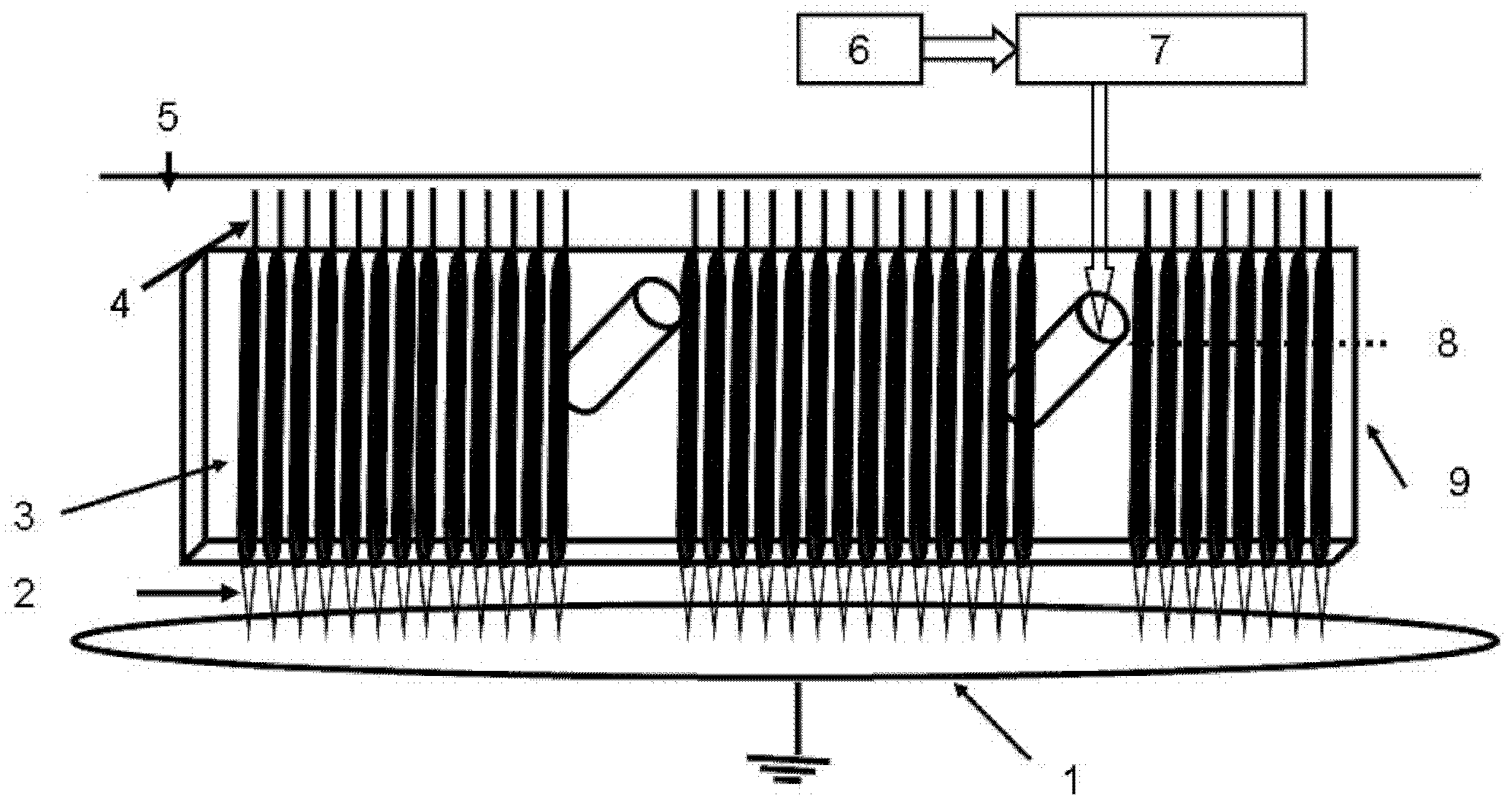

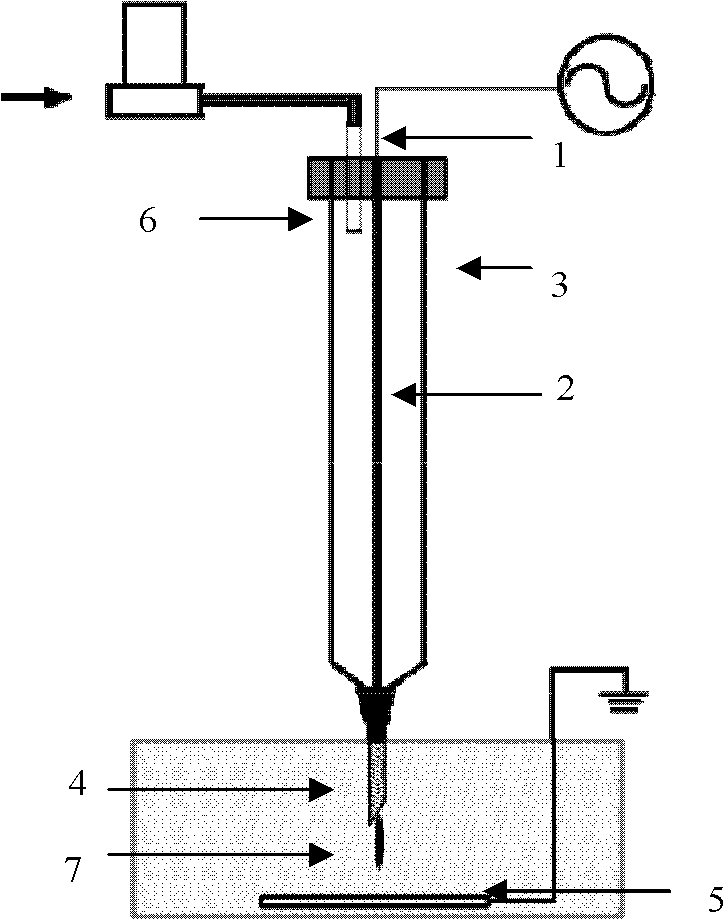

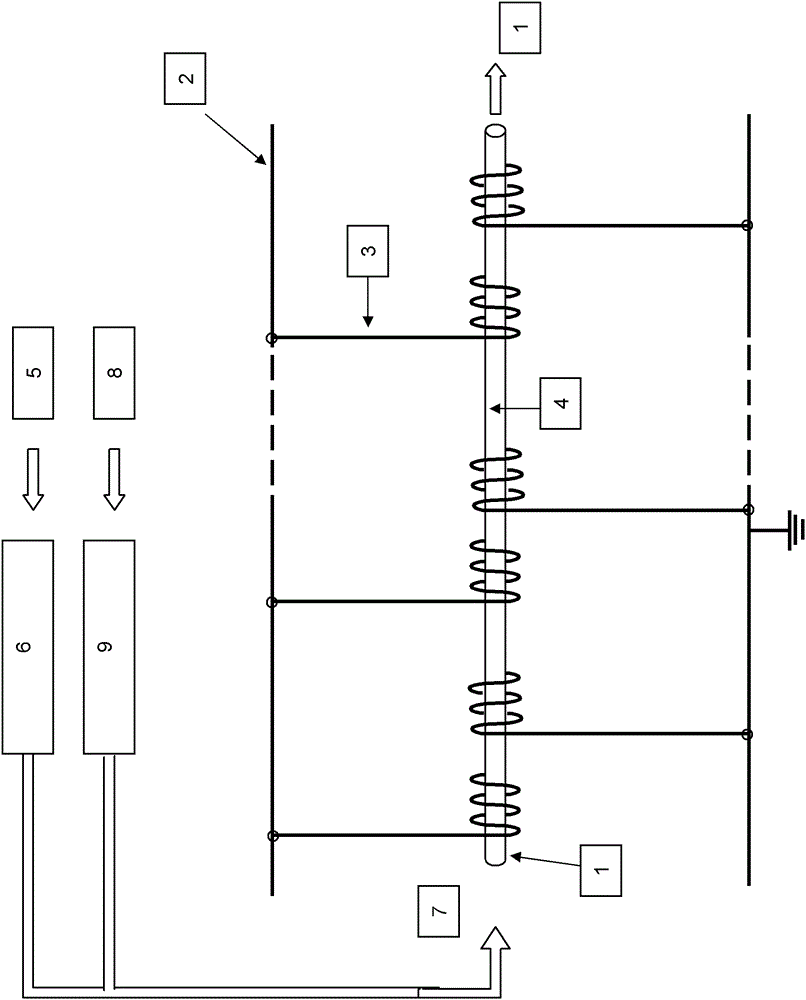

Processing technology and device of optical fiber plasma liquid

InactiveCN102491446AFacilitate contact areaEasy to handleWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsAtmospheric pressure dischargeOptical fiber cable

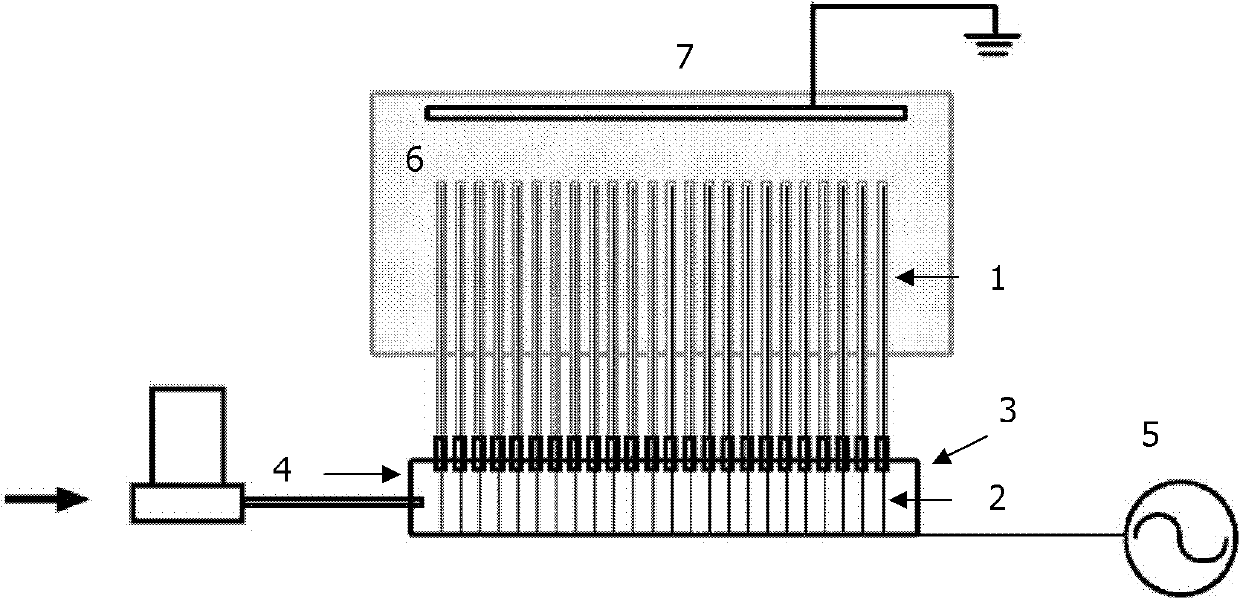

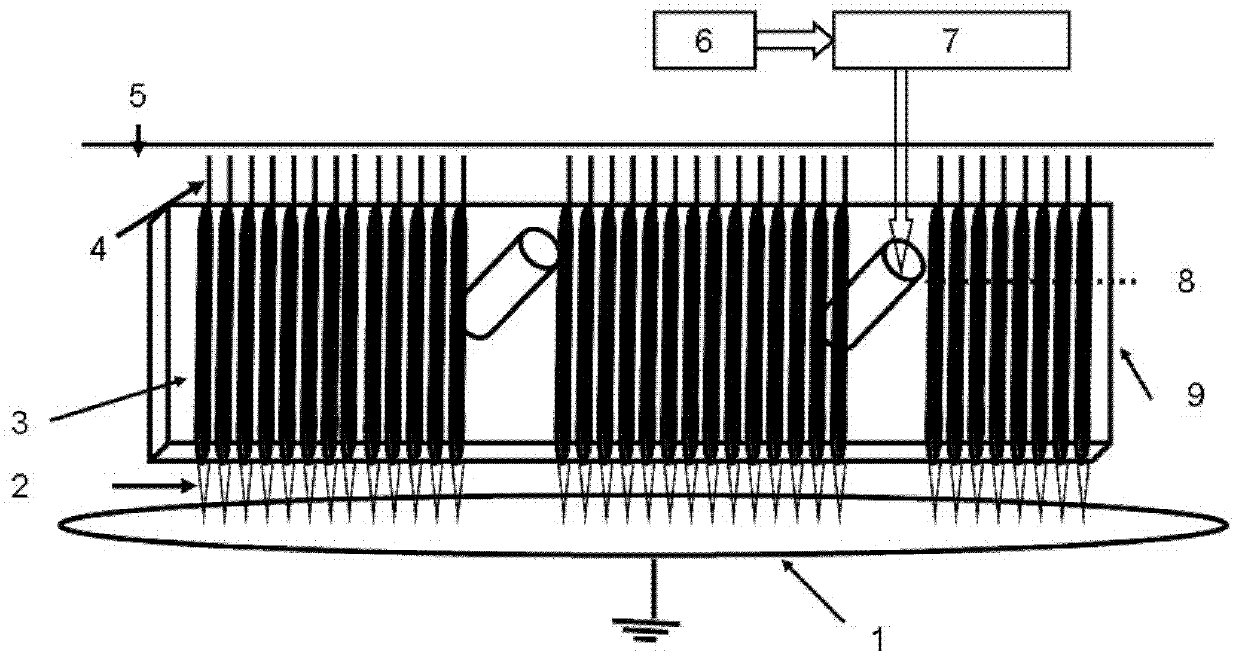

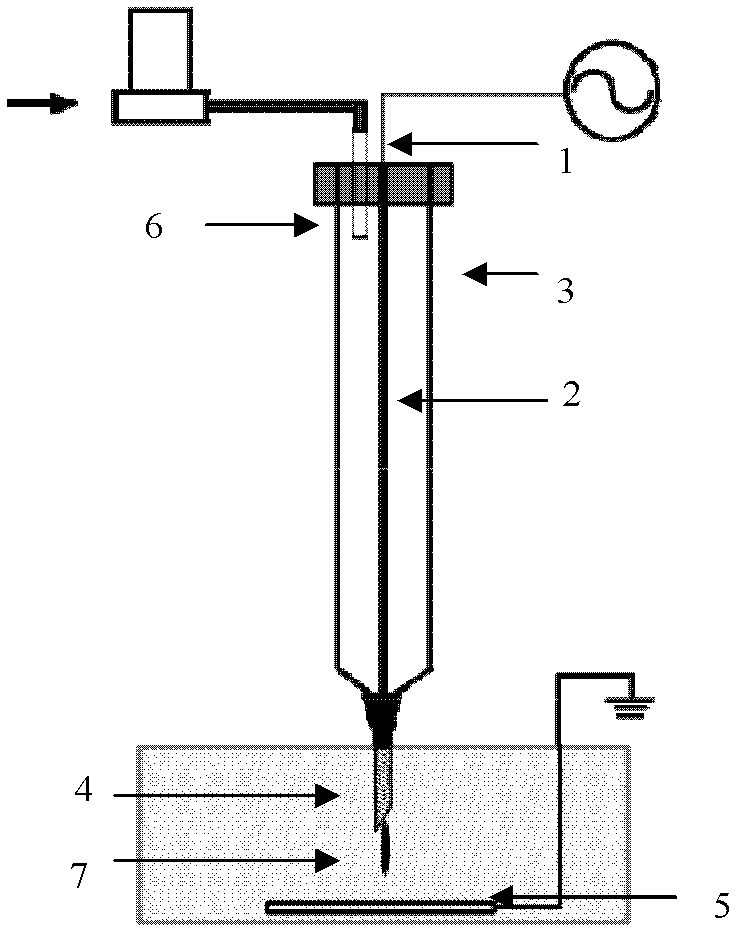

The invention relates to a processing technology and device of an optical fiber plasma liquid. According to the invention, optical fiber pipes are utilized and uniformly ranked, and gas is introduced in the optical fiber pipes; a plasma is generated at a micropore optical fiber pipe orifice or end head by utilizing atmospheric pressure discharge; the area of the plasma is micro-controllable, the contact area of the plasma and a processing material is good, a processing effect can be obviously improved, and the energy utilization rate is greatly improved; and discharge gas is restricted by using optical fiber so as to generate a micro-plasma in a liquid at the atmospheric pressure to process a polluted liquid sample. The processing technology and device have the following specific advantages that gas utilization rate is high, discharge manner is simple, complicated vacuum equipment is not required, equipment cost is low, fungicidal efficiency is high, and energy consumption is low.

Owner:DALIAN NATIONALITIES UNIVERSITY

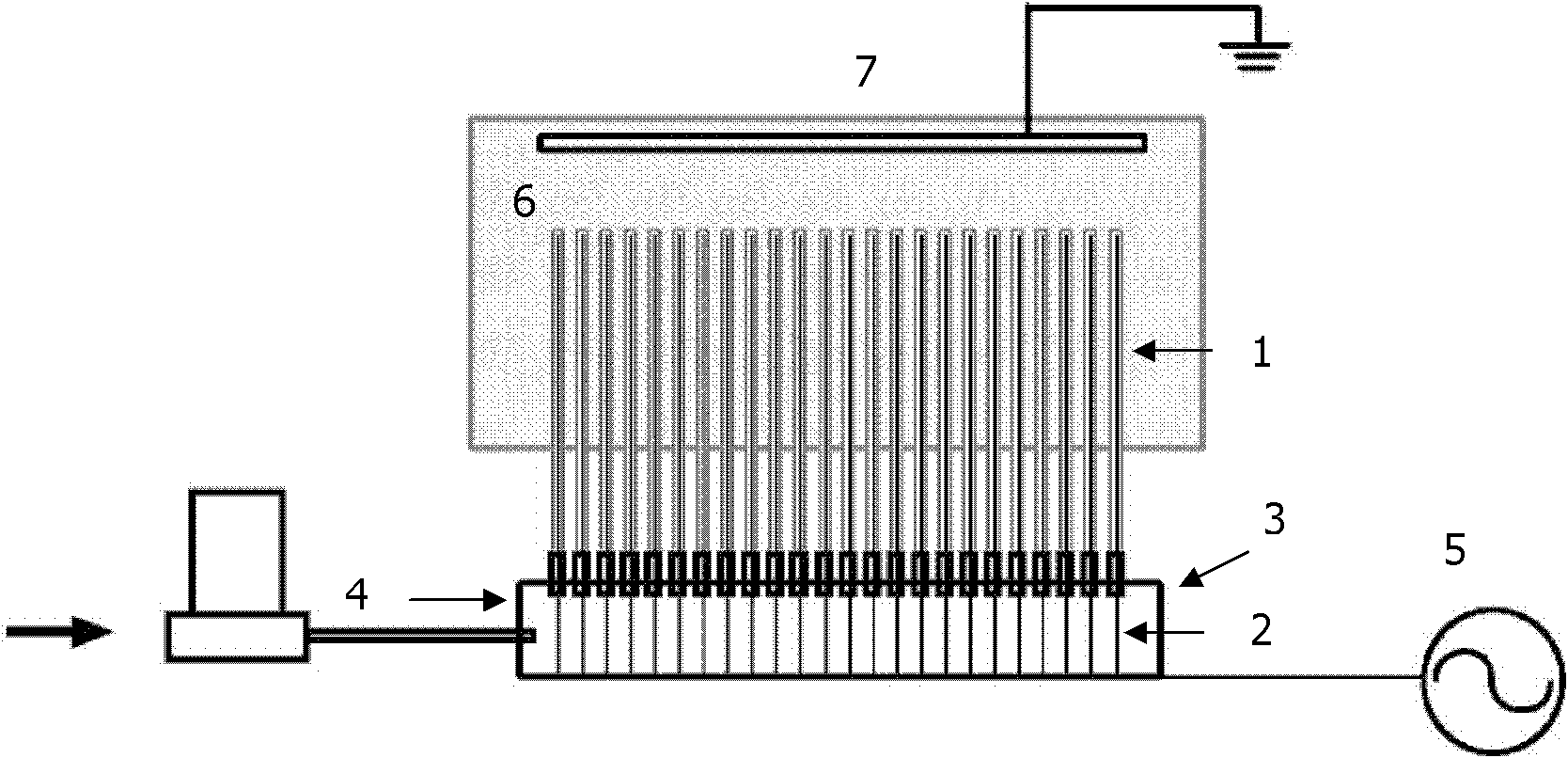

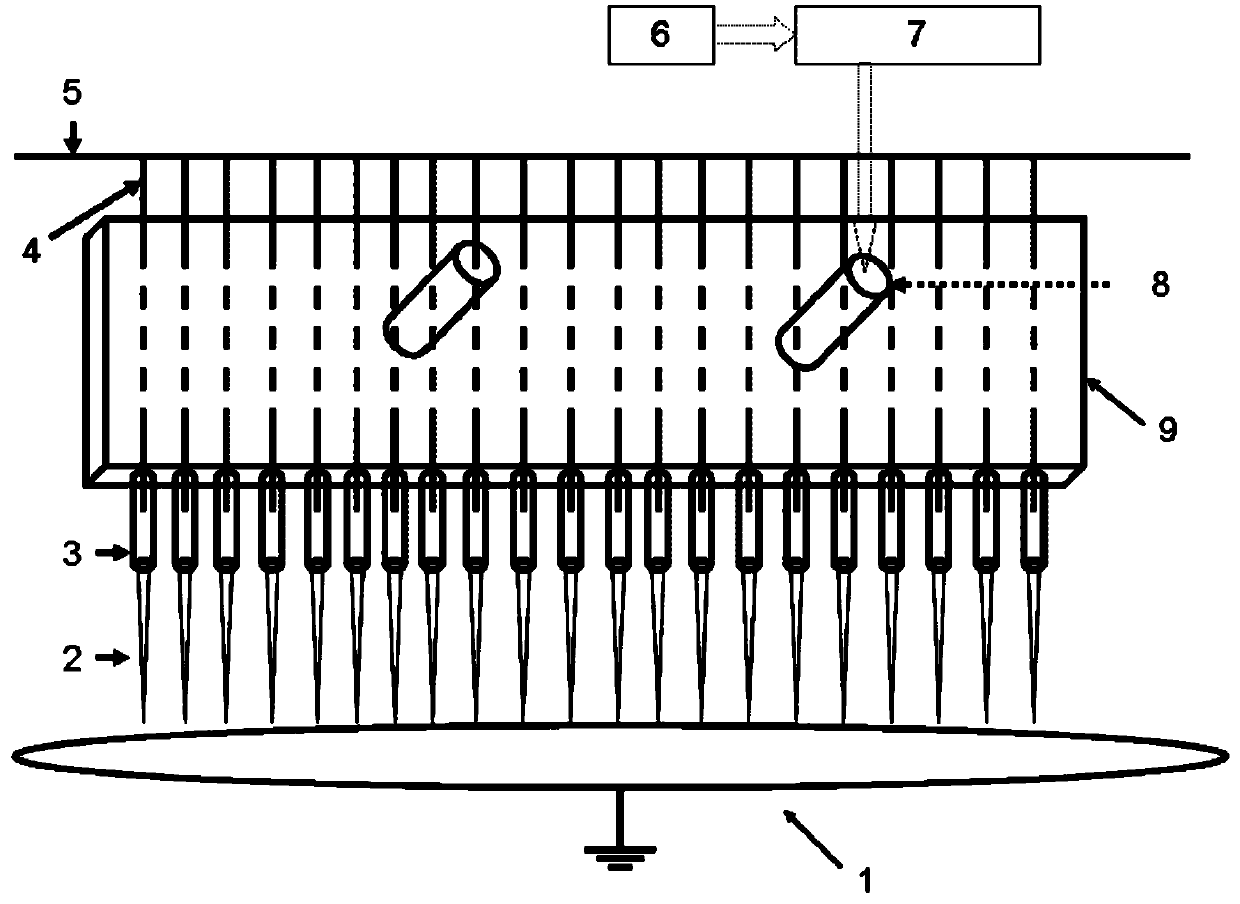

Atmospheric pressure optical plasma brush-type device and electric discharge method thereof

The invention relates an atmospheric pressure optical plasma brush-type device and an electric discharge method thereof. The device comprises an alternating current power supply, an air cavity, microporous optical fibers, high voltage electrodes and a ground electrode, wherein the high voltage electrodes are correspondingly inserted into the microporous optical fibers. According to the invention, the microporous optical fibers are uniformly arranged, the inner parts or the outer parts of the microporous optical fibers are communicated with air, electricity can be discharged under an atmospheric pressure condition, thus plasmas can be generated at electric discharge ends of the microporous optical fibers, and the plasmas can be used for carrying out material surface modification and the processing for materials, cancel cells, bacterium and the like in biomedicine. The atmospheric pressure optical plasma brush-type device disclosed by the invention has the advantages that the cost of an electric discharge device is low, the size is small, the electric discharge mode is simple, a low-voltage vacuum environment is not needed, the energy consumption is low, the electric discharge is stable, uniform and compact, the electric discharge area is controllable, and the electric discharge duration is unlimited.

Owner:东丰科林(天津)医疗科技有限公司

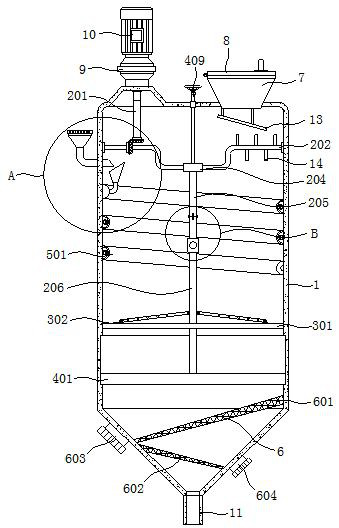

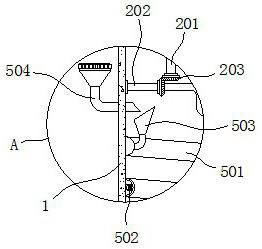

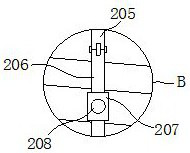

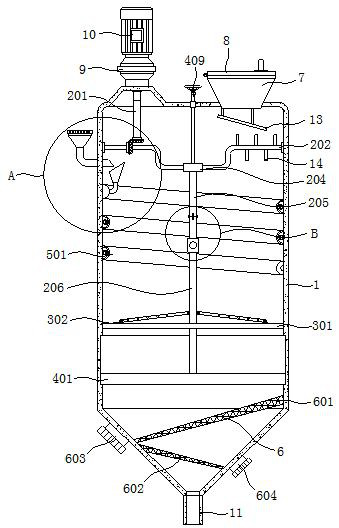

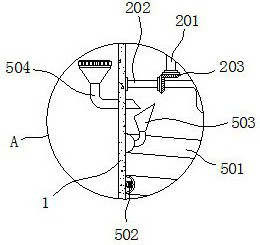

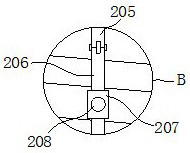

Powder catalyst dipping method

InactiveCN106552677AIncrease productivityImprove impregnation effectCatalyst activation/preparationAluminum silicateEngineering

The invention relates to a powder catalyst dipping method, and mainly solves the problems that in the prior art, the dipping effect is poor, and the production efficiency is low. Mixing of dipping liquid and catalyst powder is accelerated by the powder catalyst dipping method and dipping equipment, the dipping equipment is a closed container, the middle of the body of the dipping equipment is cylindrical while two ends of the body of the dipping equipment are conical, a feeding opening and a discharging opening are respectively formed in two conical tops, the closed container is divided into three layers, a heating medium of a middle jacket is low-pressure steam, an insulating material is aluminum silicate rock wool, a material is fed in an inner layer, a linear shovelling plate is arranged on the inner wall of the closed container, the dipping liquid is added through an intermediate shaft of the equipment, one section is used for adding the material while the other section is vacuumized, and rotary dipping is carried out while the dipping liquid is added; the steam is fed into the outer layer to heat the material and the dipping liquid in the container, and the absorption rate is increased; and according to the technical scheme, ageing is carried out after dipping is finished, the problem is solved well, and the powder catalyst dipping method can be used for dipping a powder catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

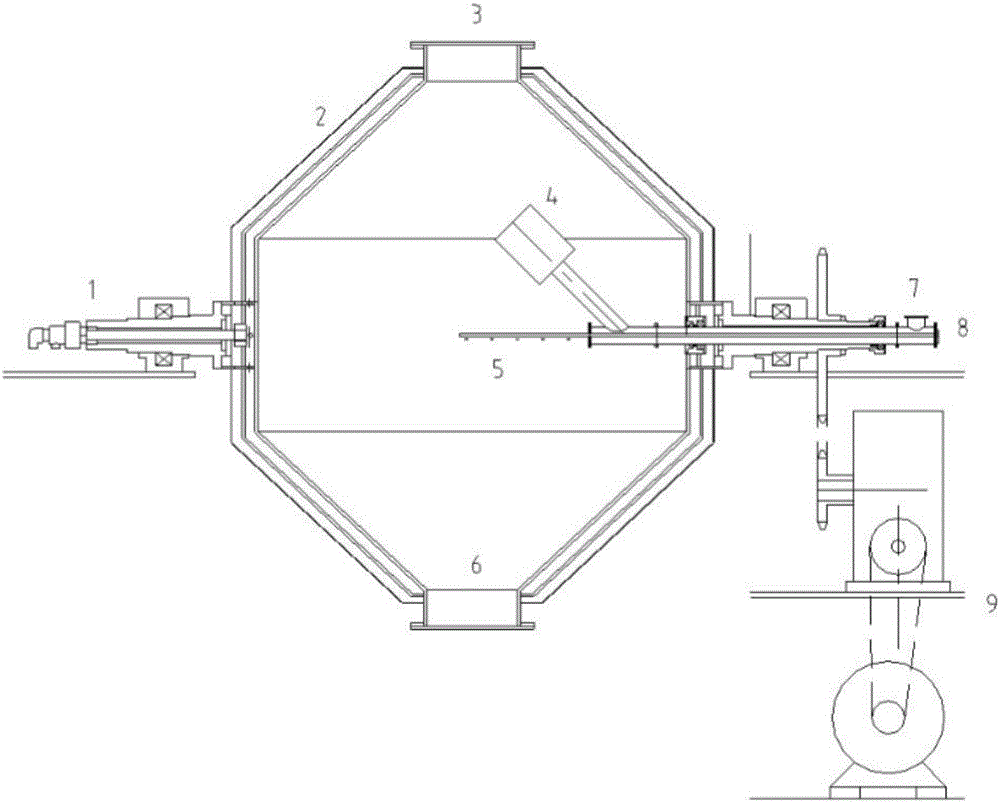

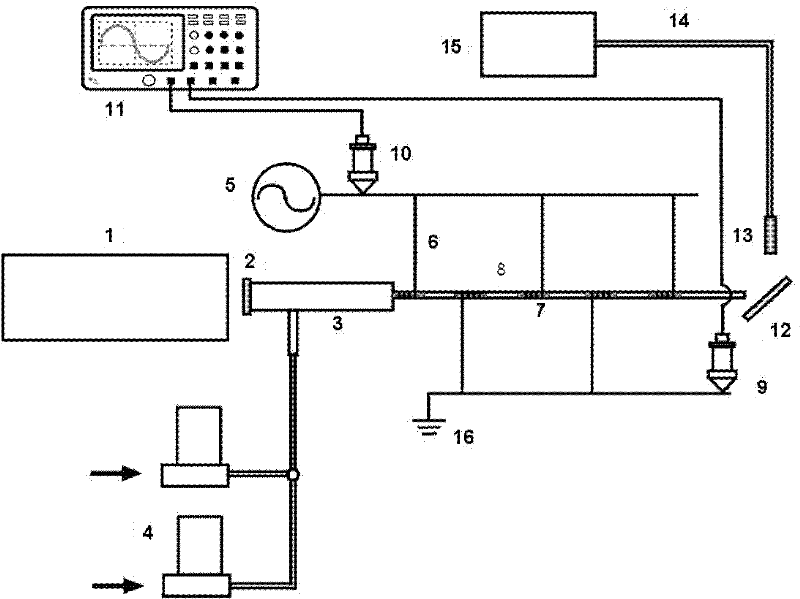

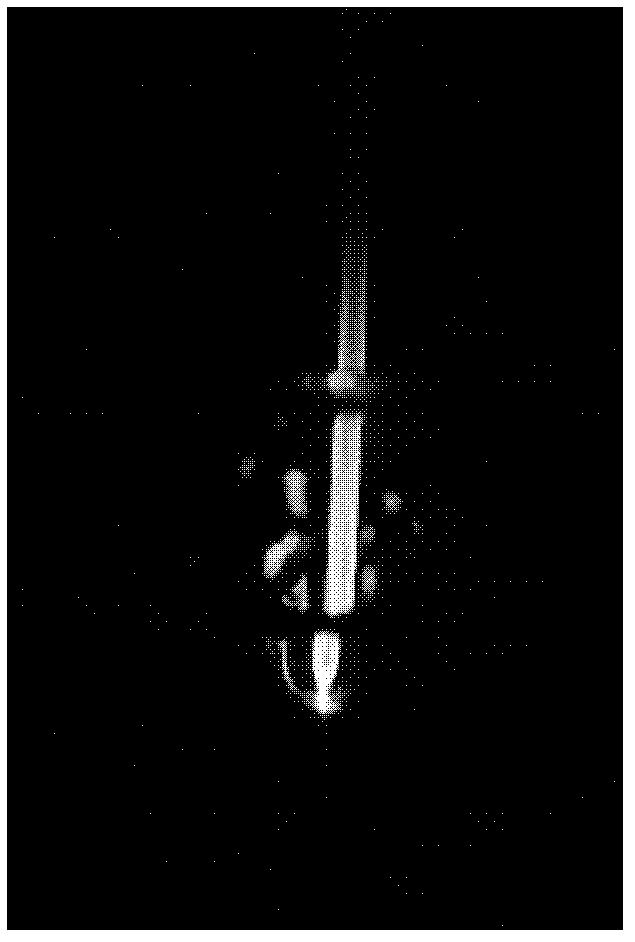

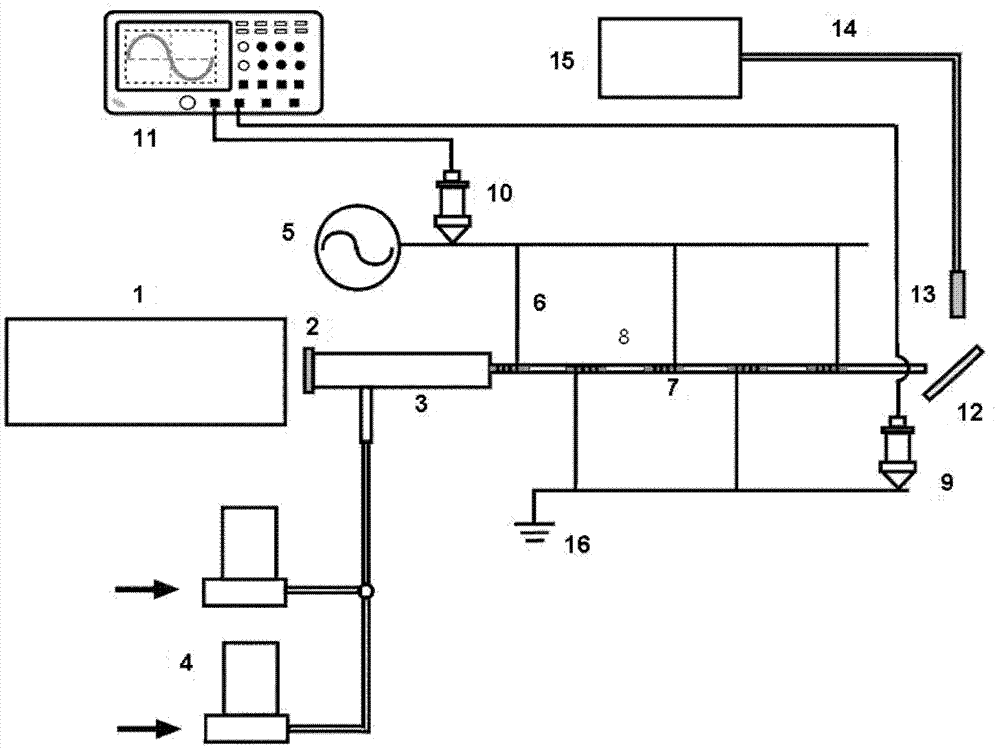

Optical fiber plasma discharge laser amplification device and technology

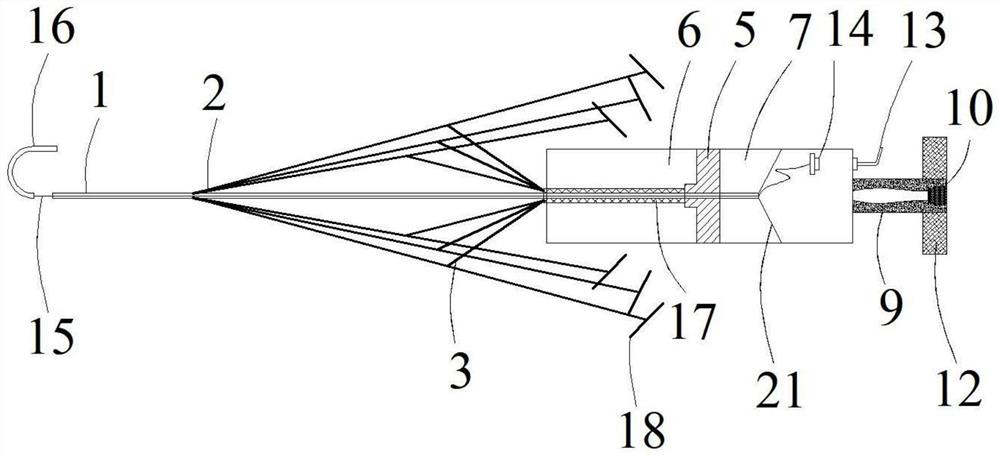

InactiveCN102377097AStable and continuous amplificationSimple discharge methodLaser detailsHigh pressureMetal electrodes

The invention relates to an optical fiber plasma discharge laser amplification device and technology; the device comprises a quartz tube and an optical fiber for electro-discharge, wherein the quartz tube is used for mixing a helium gas and a neon gas; the optical fiber for electro-discharge is communicated at the front end of the quartz tube; and the outer wall of the optical fiber for electro-discharge is used for covering a metal electrode which is sequentially and alternatively connected with a high-voltage power supply and an earth wire. The technology comprises the following steps of: proportions of the helium reactive gas and the neon reactive gas are adjusted by a mass flow controller, the helium reactive gas and the neon reactive gas are fully mixed in a quartz tube, and uniform plasmas are generated at atmospheric pressure by using an inter-electrode alternative discharge structure; and laser beams which are emitted by a helium-neon laser pass through the optical fiber for electro-discharge through a smooth quartz plate at the tail end of the quartz tube to realize population inversion and slave machine irradiation, thereby realizing the amplification of lasers along thelaser transmission direction. The optical fiber plasma discharge laser amplification device has the characteristics that an electro-discharge manner is simple, complicated vacuum equipment is not needed, the equipment cost is low, the volume is small and the energy consumption is low.

Owner:DALIAN NATIONALITIES UNIVERSITY

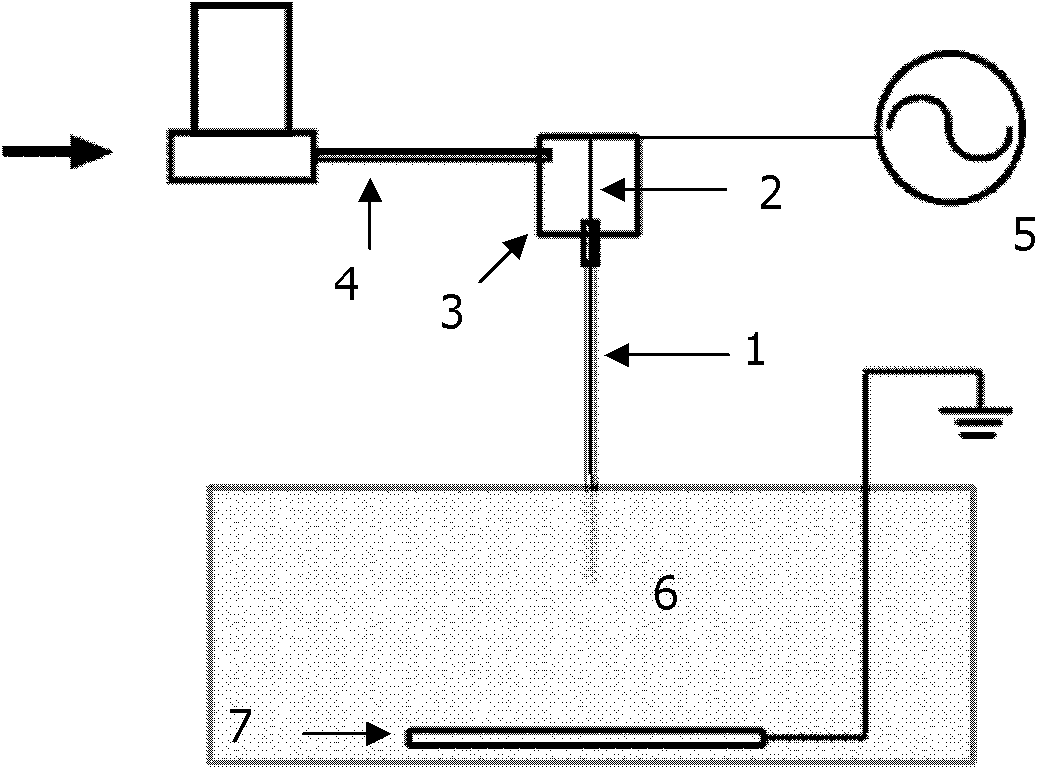

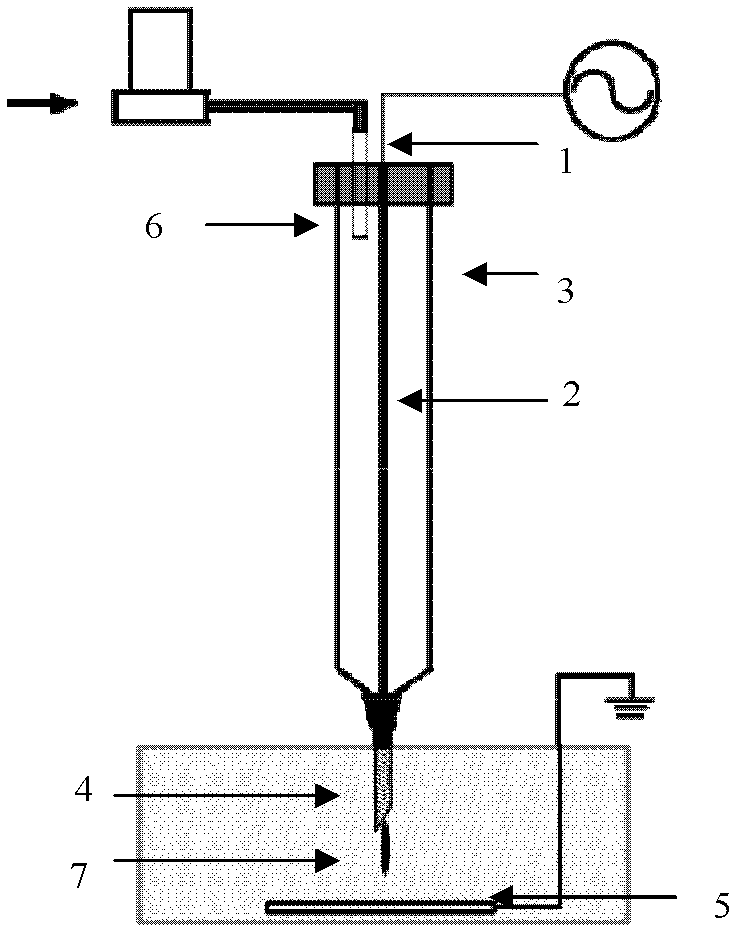

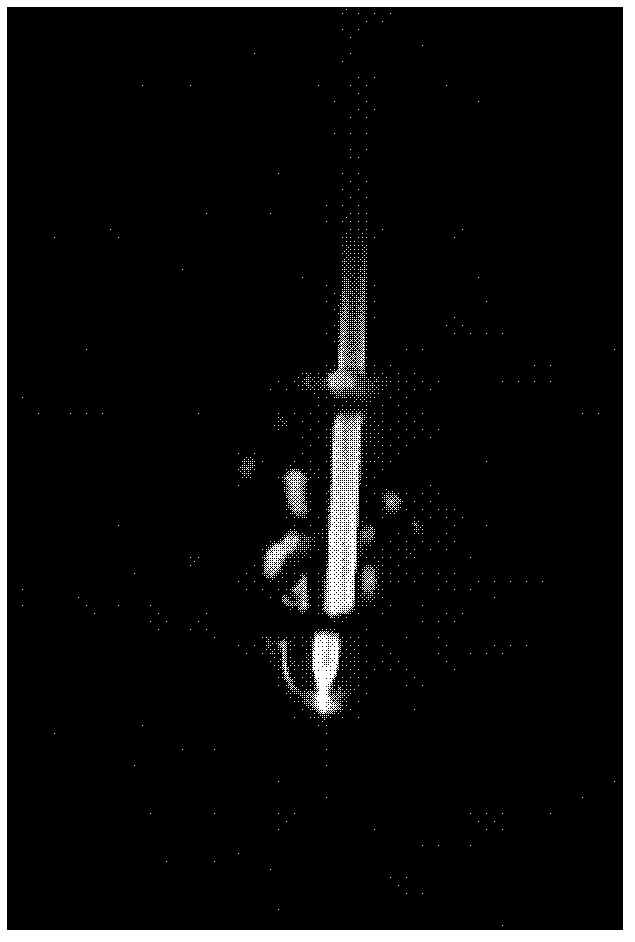

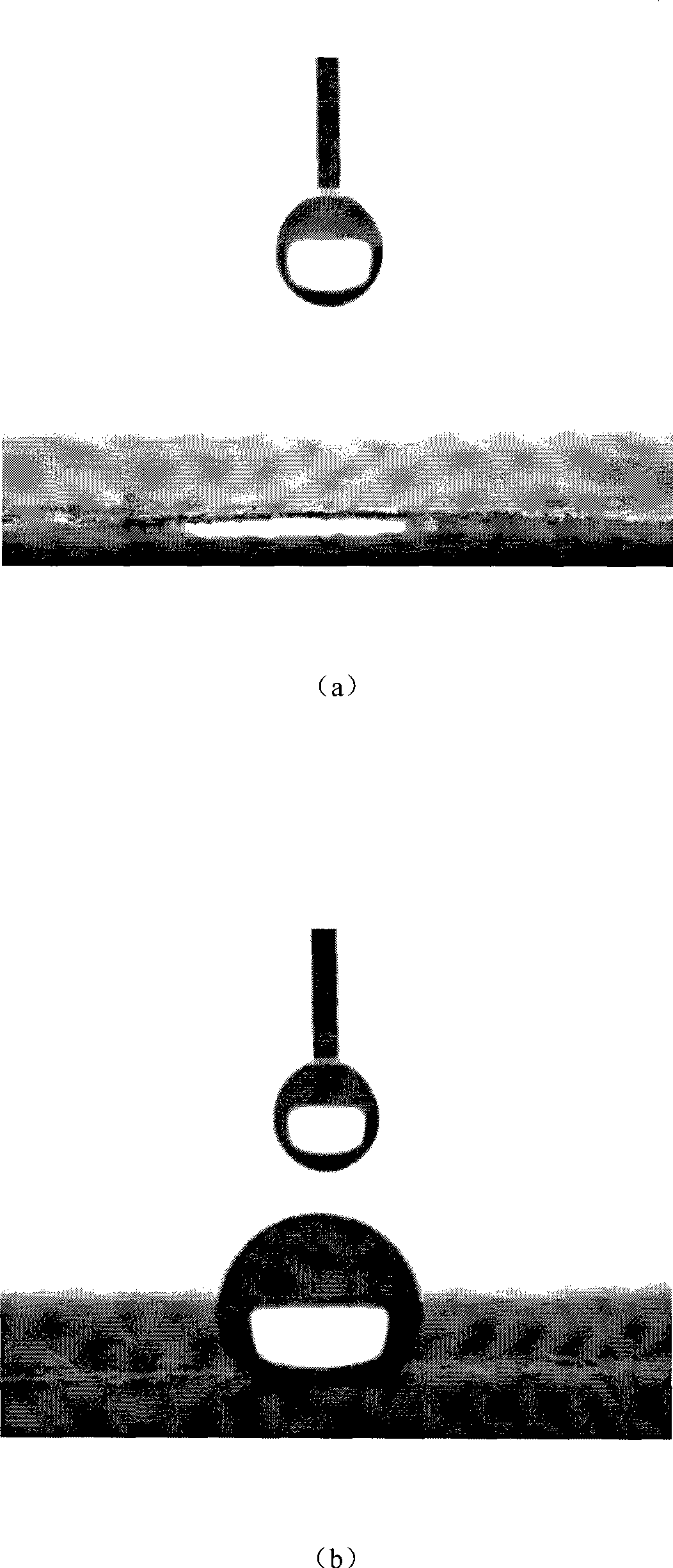

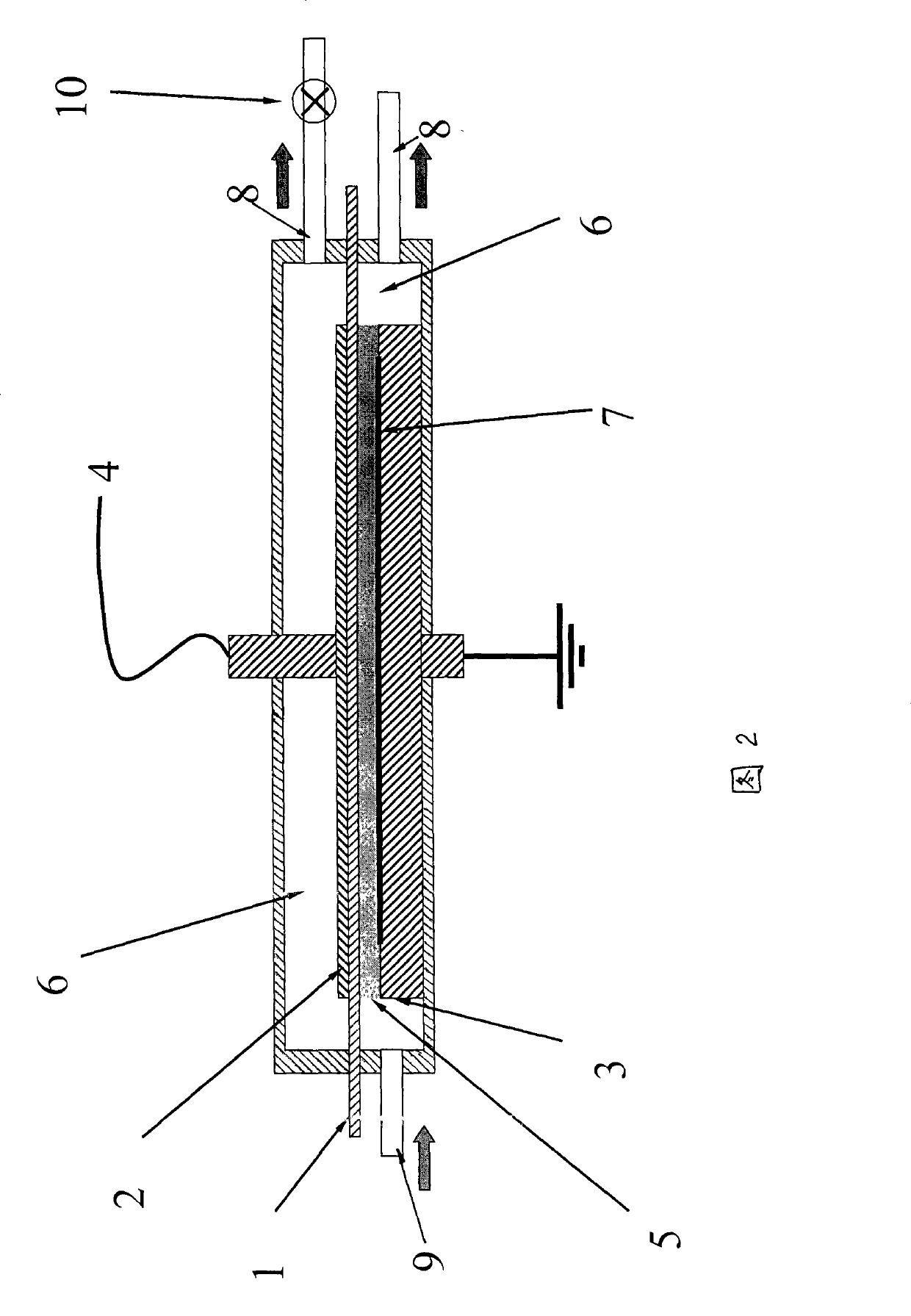

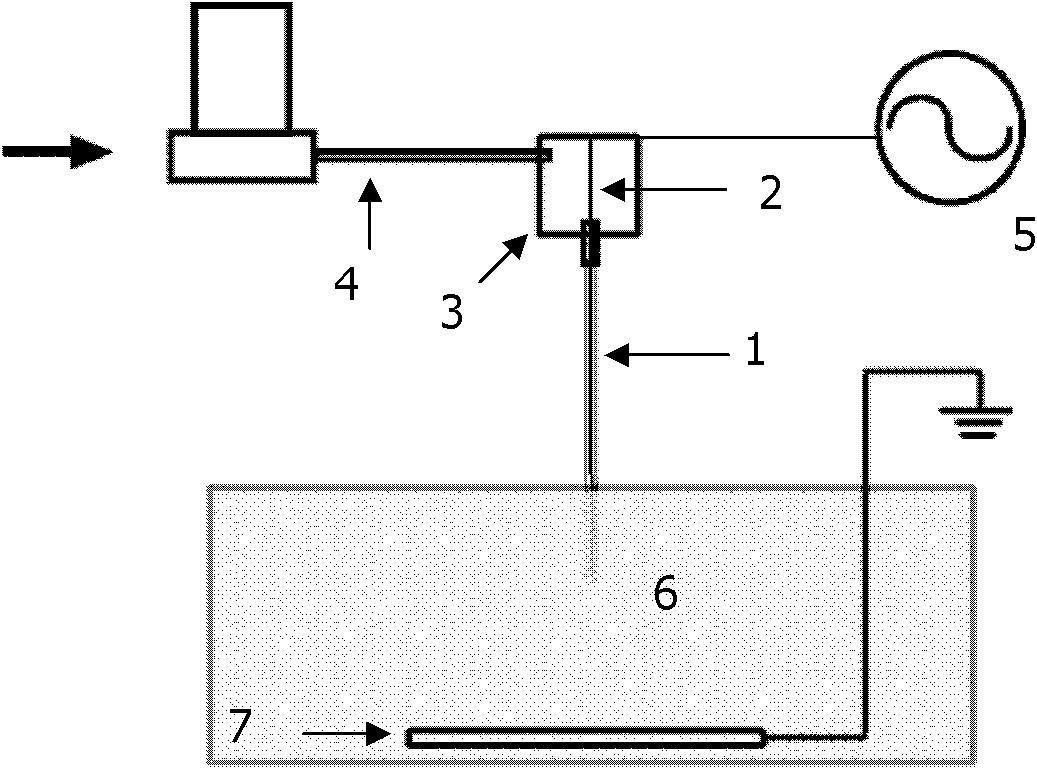

Syringe type atmospheric-pressure micro-plasma generator

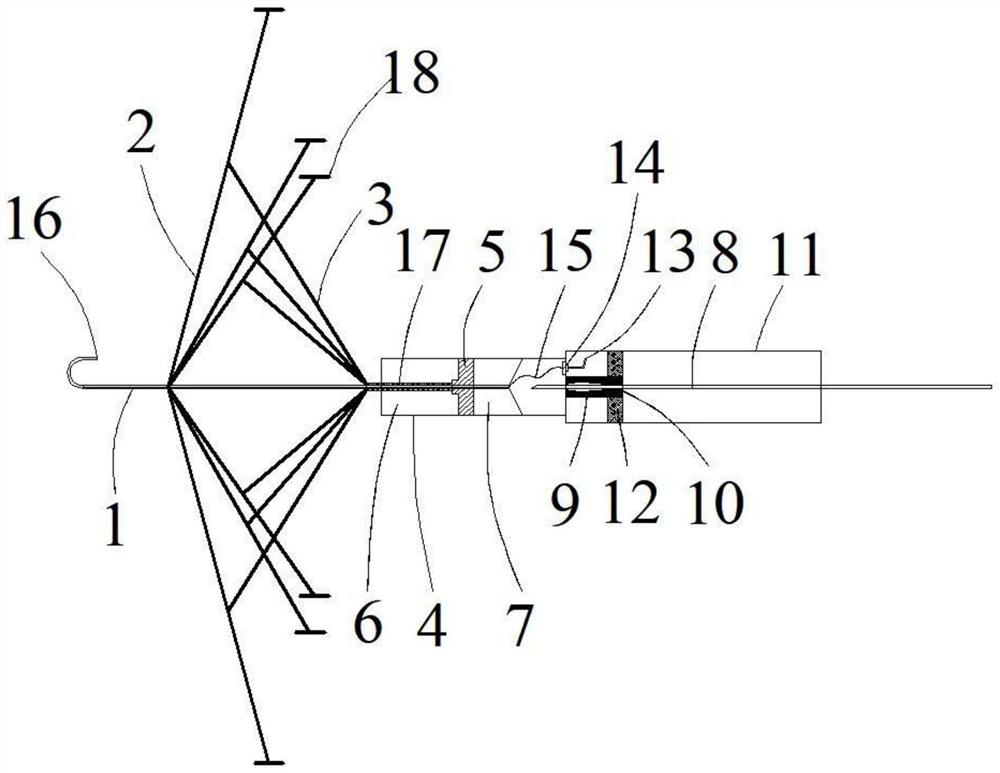

ActiveCN102497719ASimple discharge methodReduce equipment costsPlasma techniqueAir volumeHigh voltage electrode

The invention relates to a syringe type atmospheric-pressure micro-plasma generator which comprises a alternating-current high-voltage power supply, a high-voltage electrode, a ground electrode and a micro-hole optical fiber, wherein the lower end of the micro-hole optical fiber is closed, the high-voltage electrode is inserted in the micro-hole optical fiber, and a needle cylinder is sleeved on the micro-hole optical fiber; the upper end of the needle cylinder is sealed and is connected with an air inlet tube; the lower end of the needle cylinder is connected with a needle head made of insulating material; the lower end of the optical fiber is wrapped in the needle head, and a gap through which air passes is reserved between the optical fiber and the needle head; and the ground electrode is earthed and arranged in a to-be-processed sample. The syringe type atmospheric-pressure micro-plasma generator provided by the invention is simple in electro-discharge mode, low in equipment cost, small in air volume, low in air flow, and low in energy consumption; and the micro-plasma generator can feed gas in a liquid sample so as to obtain plasmas, and is used for processing the insides of materials or processing internal tissues of human bodies.

Owner:DALIAN NATIONALITIES UNIVERSITY

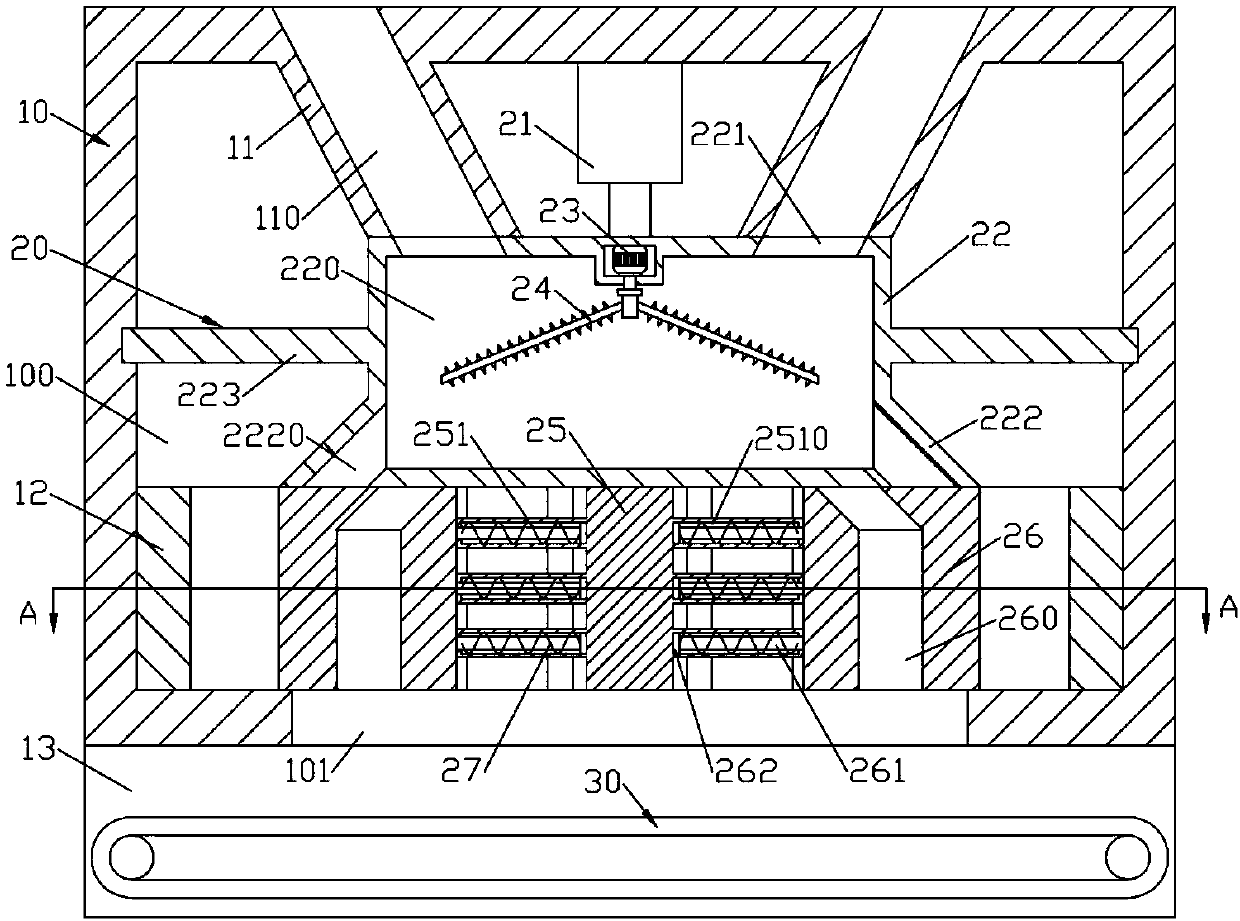

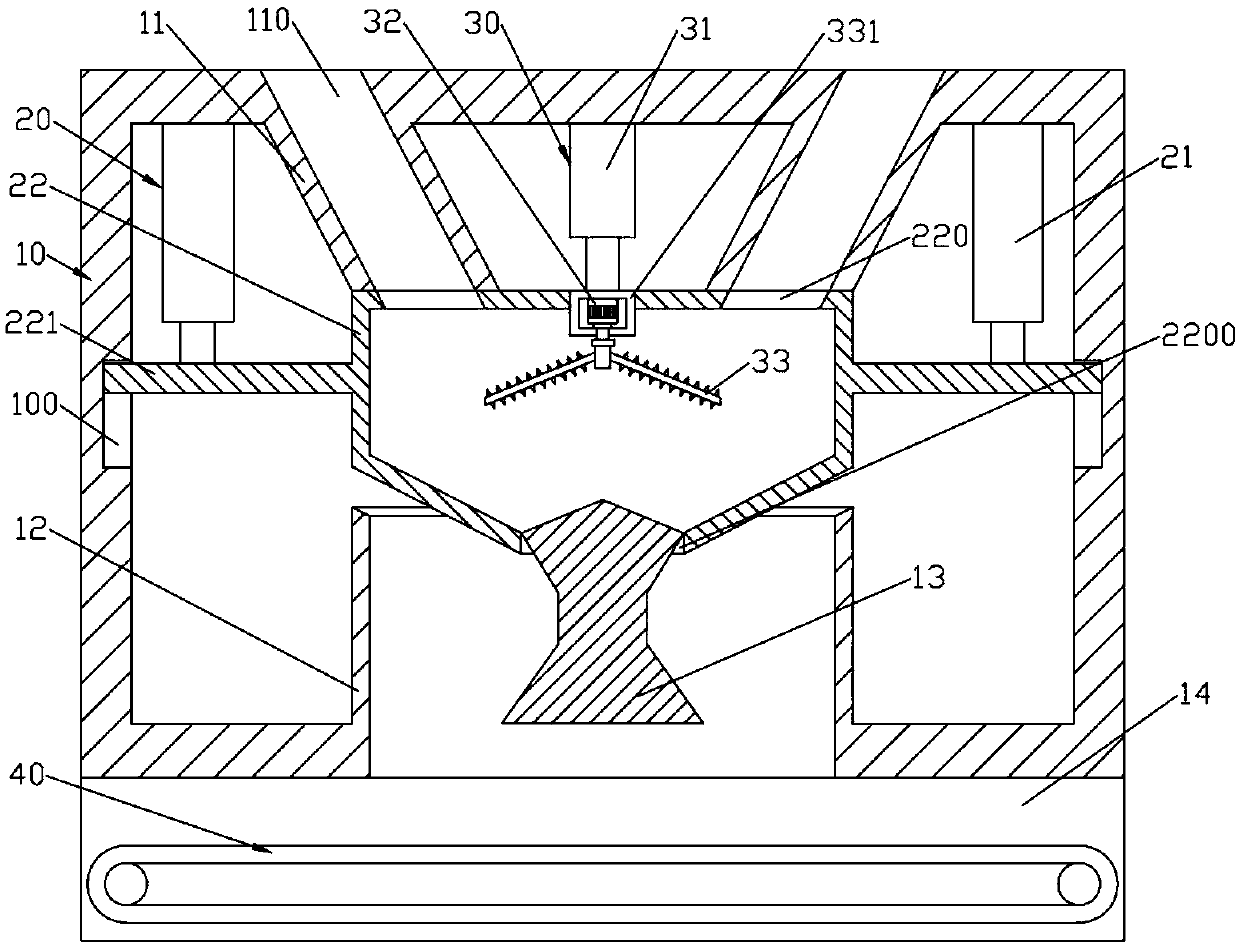

Frying machine for processing special-flavor lima beans

ActiveCN112616866ASolve the problem of deteriorating frying qualityReduce manufacturing costSievingScreeningProcess engineeringLima beans

The invention discloses a frying machine for processing special-flavor lima beans, and relates to the technical field of lima bean processing. The frying machine for processing special-flavor lima beans comprises a frying tank, wherein a transmission mechanism, a dispersing mechanism, a material containing mechanism, a heating mechanism and a material receiving mechanism are arranged on the frying tank; a feeding hopper is fixedly arranged on the top of the frying tank; one end of the feeding hopper extends into the frying tank; and a hopper cover is hinged to a top opening of the feeding hopper. The frying machine for processing special-flavor lima beans has the advantages that the lima beans bonded into balls can be dispersed; the problem of frying quality reduction due to lima bean bonding is solved; meanwhile, the lima beans can be in sufficient contact with oil; the frying efficiency is improved; the energy consumption is reduced; the contact area of the oil and an electric heating wire can also be increased; the preheating efficiency is improved; the preheating waiting time is further shortened; the manufacturing and operation cost of the frying machine is reduced; and the popularization and the use are facilitated.

Owner:重庆芝麻官实业股份有限公司

Self-clean film material and preparation method

InactiveCN101045610BReduce gapAvoid breakingVacuum evaporation coatingPaper coatingHigh resistancePolymer science

Owner:刘东平

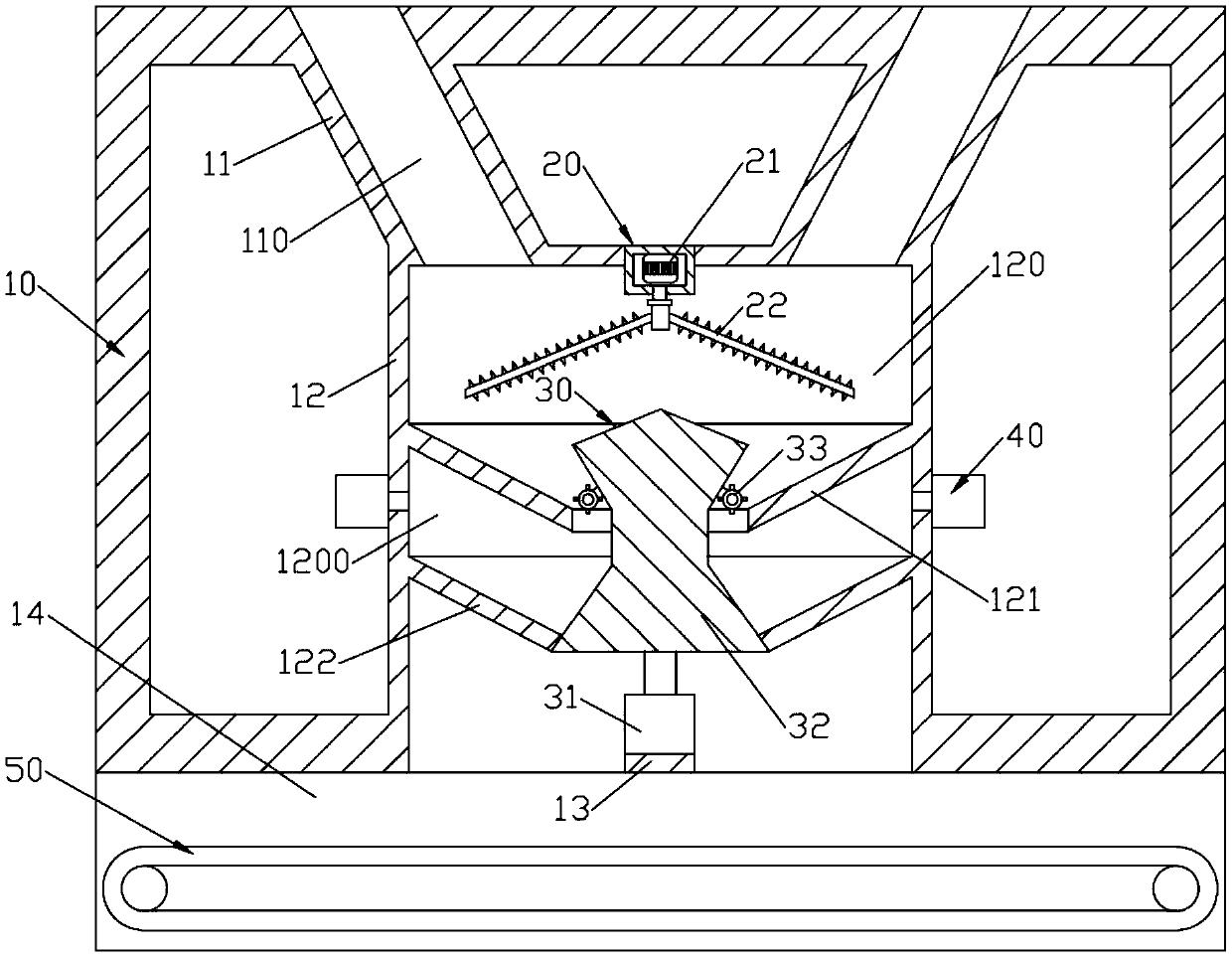

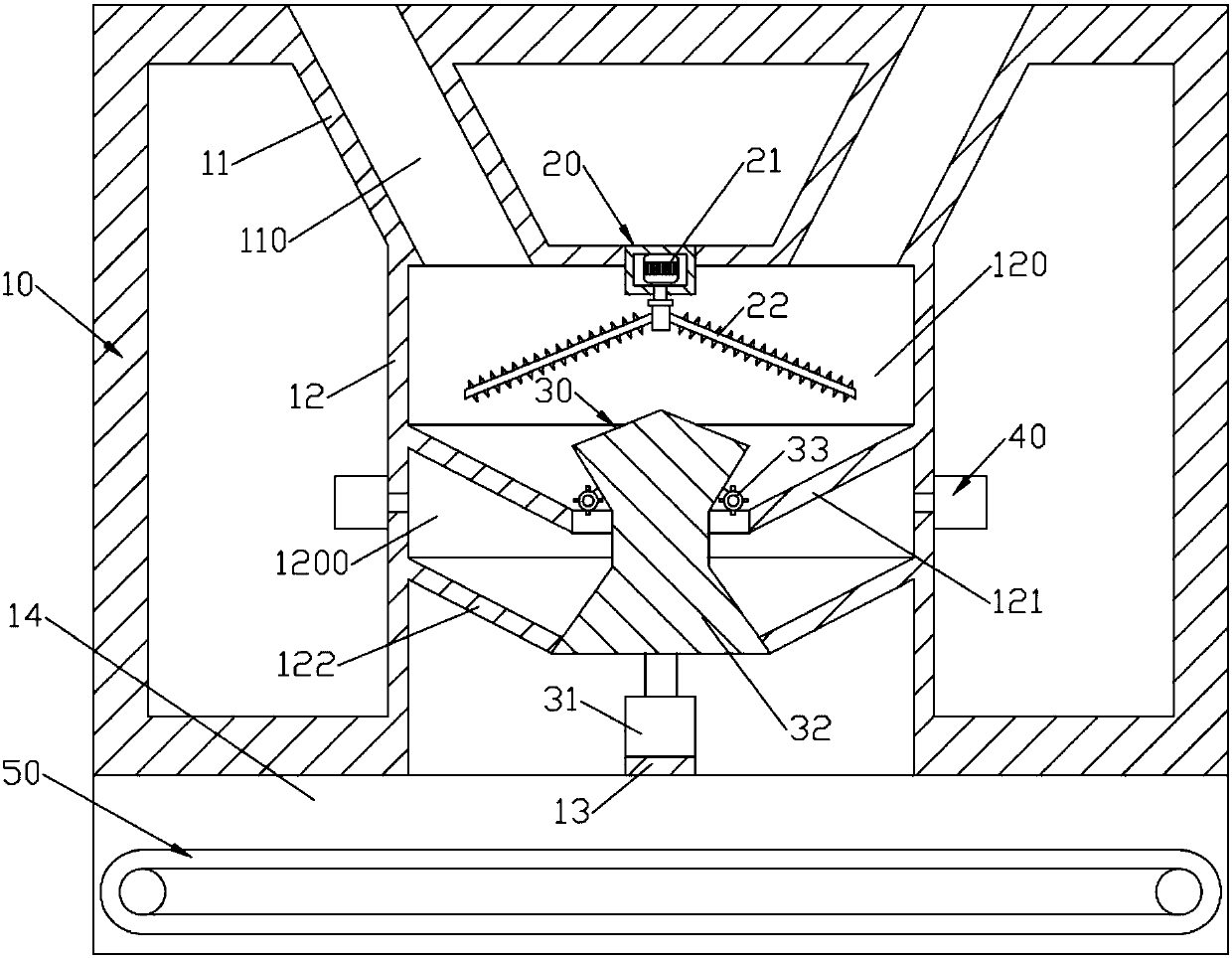

Garbage crushing device with negative pressure feeding

ActiveCN107617470BSimple structureSimple discharge methodGrain treatmentsEngineeringMechanical engineering

Owner:林家豪

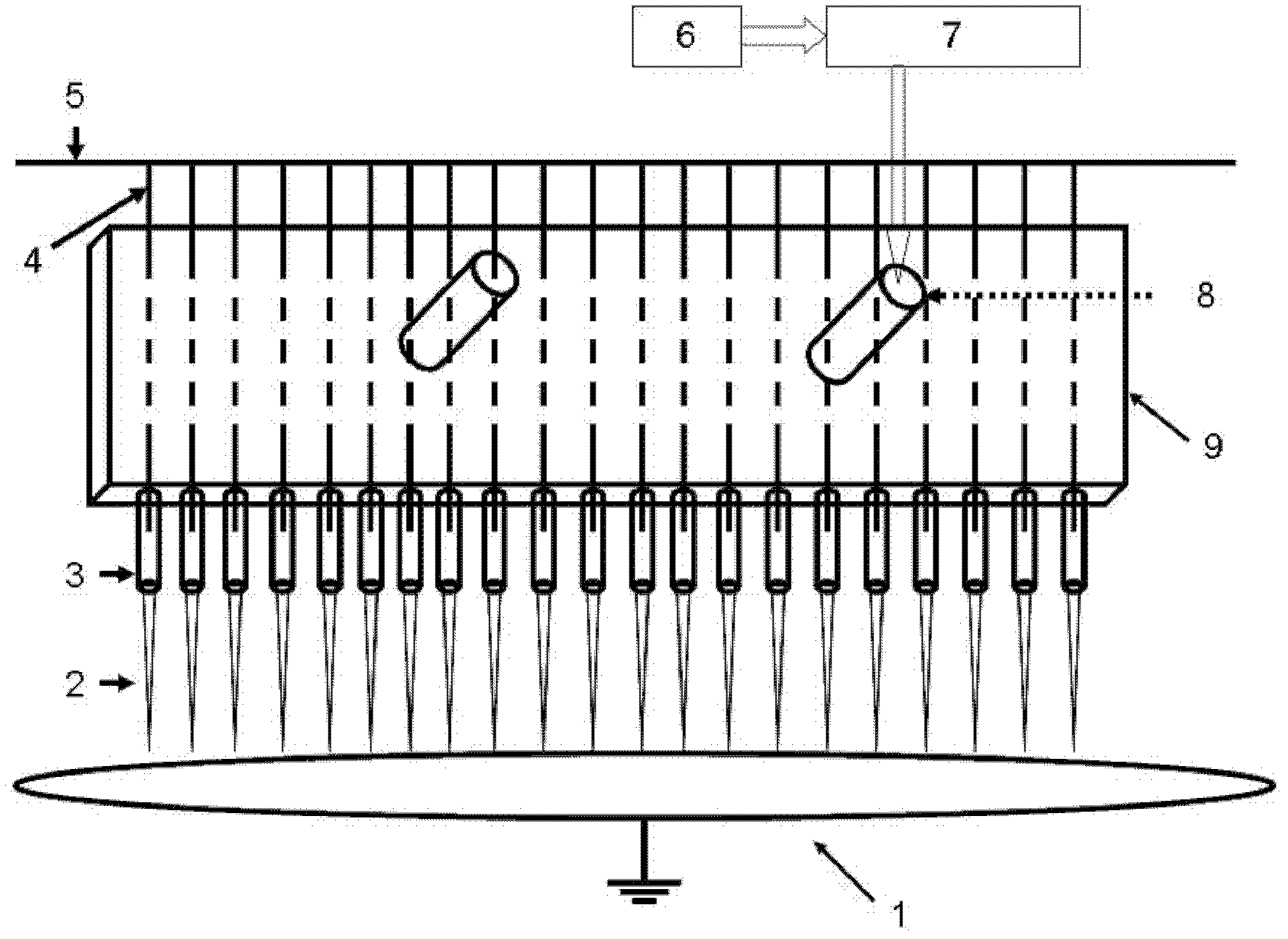

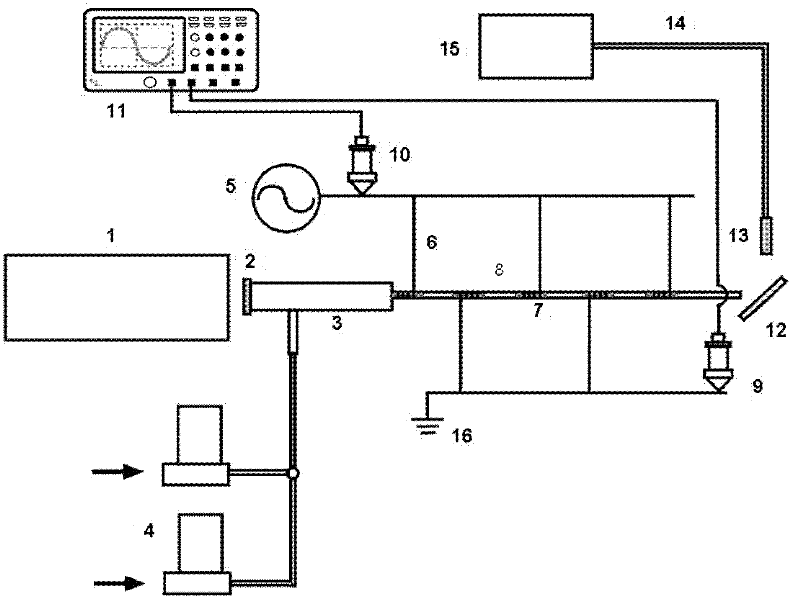

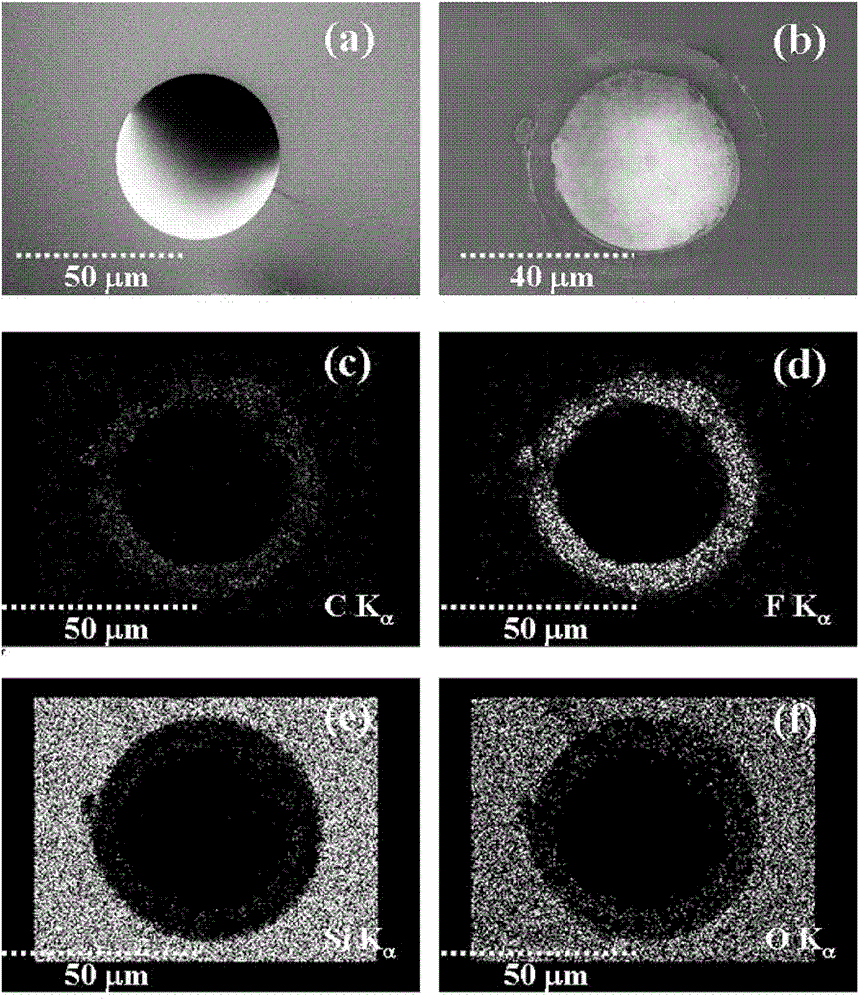

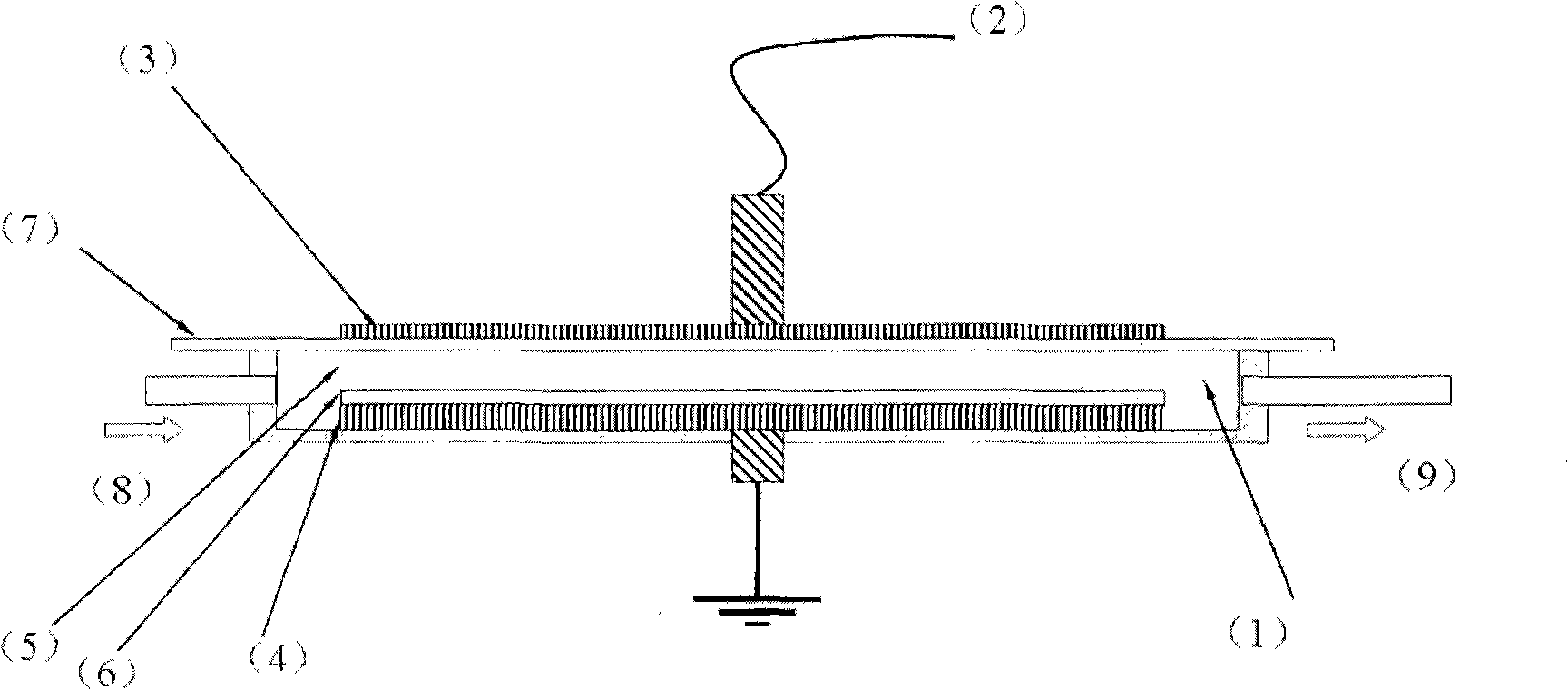

Method and apparatus for depositing film in fiber by using atmospheric pressure glow discharge

The invention relates to a method and apparatus for depositing a film in a fiber by using atmospheric pressure glow discharge. According to the invention, electrodes with alternate high voltage and low voltage are uniformly wound on the outer wall of an optical fiber tube, and, with the inner wall of the optical fiber tube as a deposition substrate, a fluorocarbon film is deposited on the inner wall by using fluorocarbon gas under the condition of atmospheric pressure so as to improve transmission efficiency and anti-oxidation of the fiber. In the invention, dielectric barrier plasma discharge is employed for deposition of the film, so the invention has the following unique advantages: a simple discharge mode, low cost for equipment, small gas volume, low gas flow and low energy consumption.

Owner:DALIAN NATIONALITIES UNIVERSITY

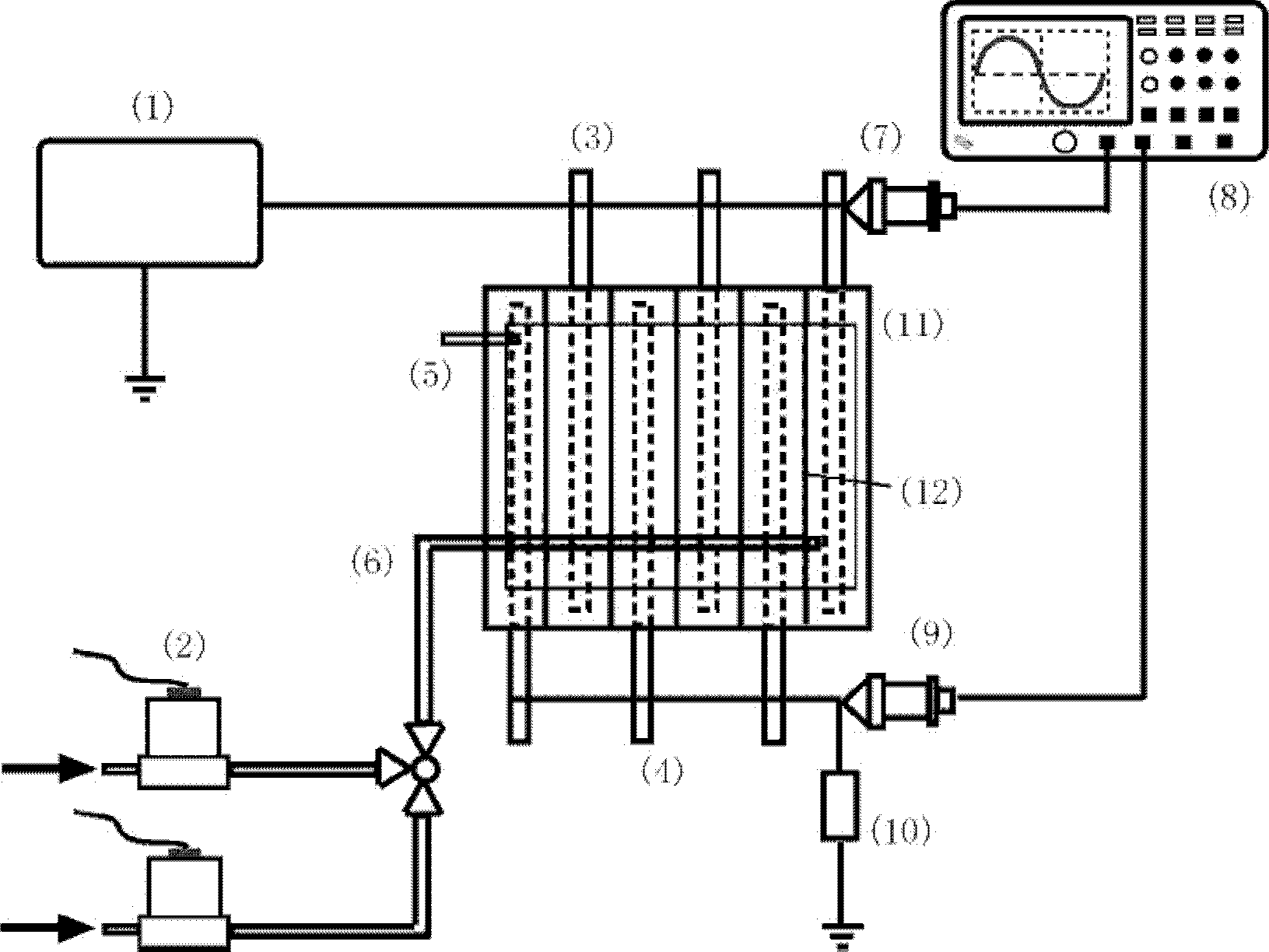

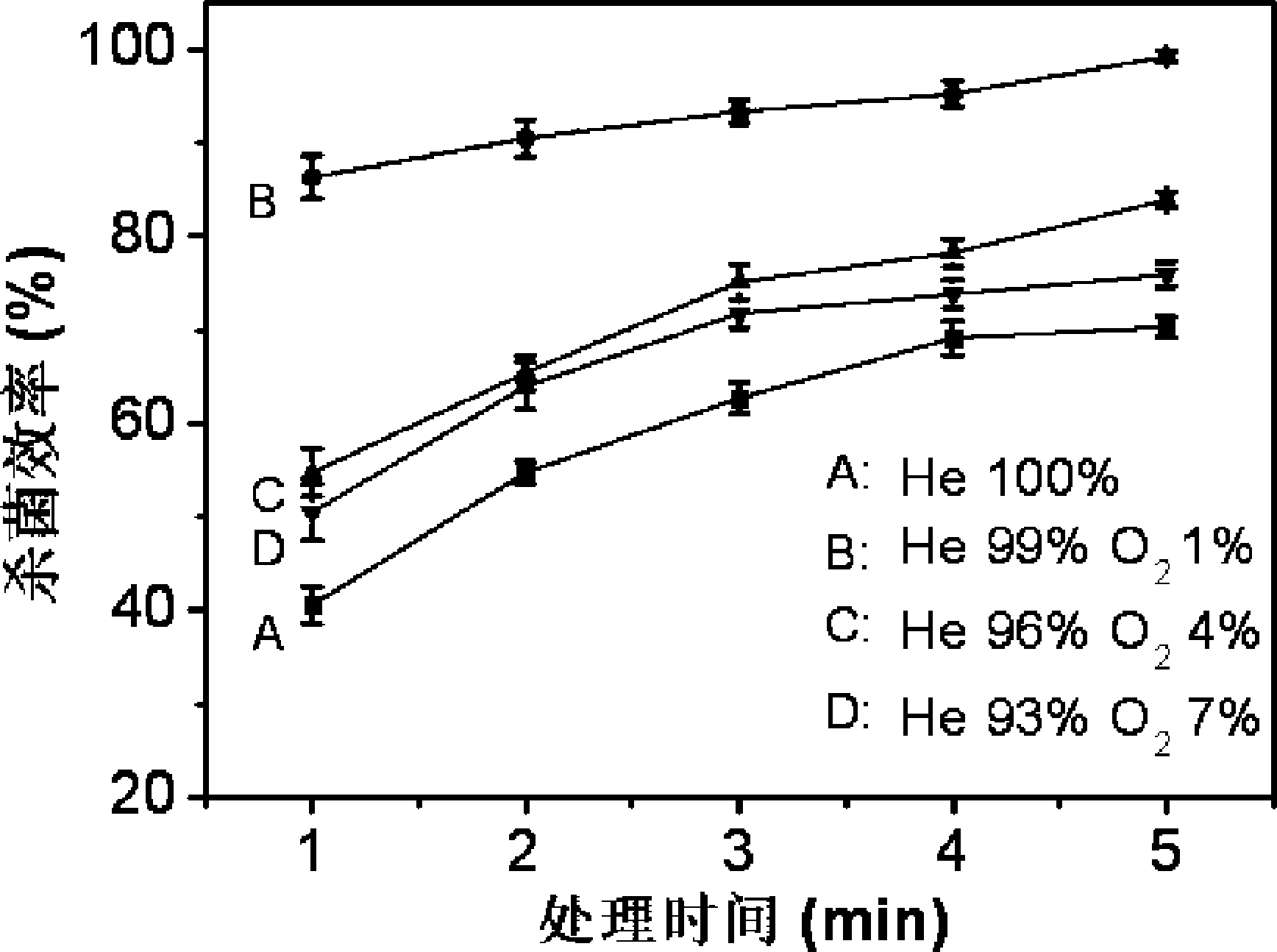

Atmospheric-pressure low-temperature plasma sterilizing device and sterilizing method

ActiveCN102343106BLow costReduce energy consumptionFood preservationLavatory sanitoryEngineeringProduct gas

The invention relates to an atmospheric-pressure low-temperature plasma sterilizing device and a sterilizing method. In the device, the side face of a medium plate is provided with a hole into which a high-voltage grounded tungsten electrode is inserted; an atmospheric-pressure medium blocking discharging way is formed after a high-voltage alternating-current power supply is switched on; and a large area of uniform low-temperature plasmas are produced on the inner surface of a hermetical plastic package filled with reaction gas for sterilizing and disinfecting. The device has a simple structure and low cost, and a complex vacuum system is not required. Harmful fungi are specially killed by using the activity of the produced plasmas. Active substances have very high chemical activity, and undergo a biochemical reaction with fungal cells, so that cell apoptosis is caused in a short period of time. The device and the method have the remarkable characteristics of high sterilizing efficiency and low energy consumption.

Owner:东丰科林(天津)医疗科技有限公司

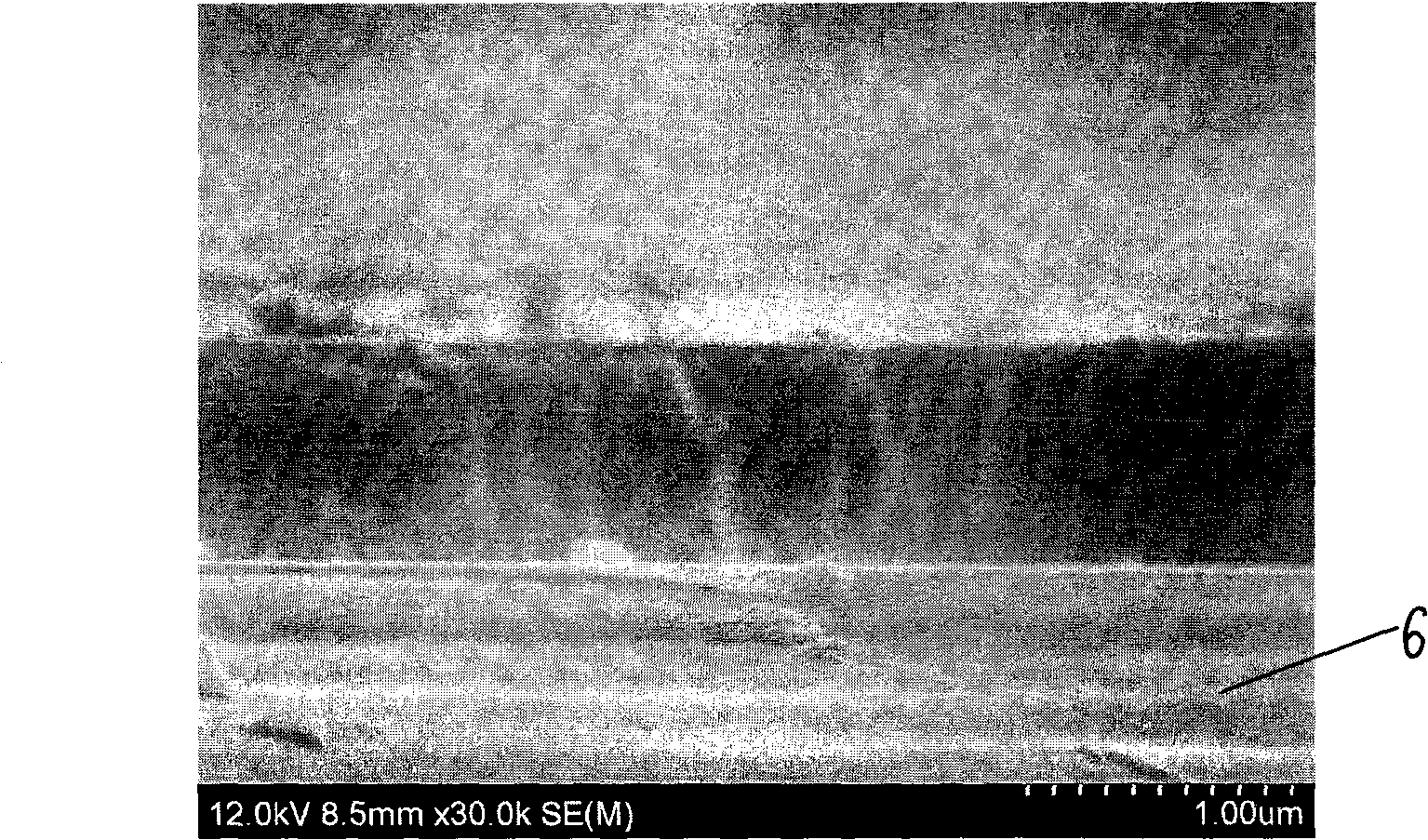

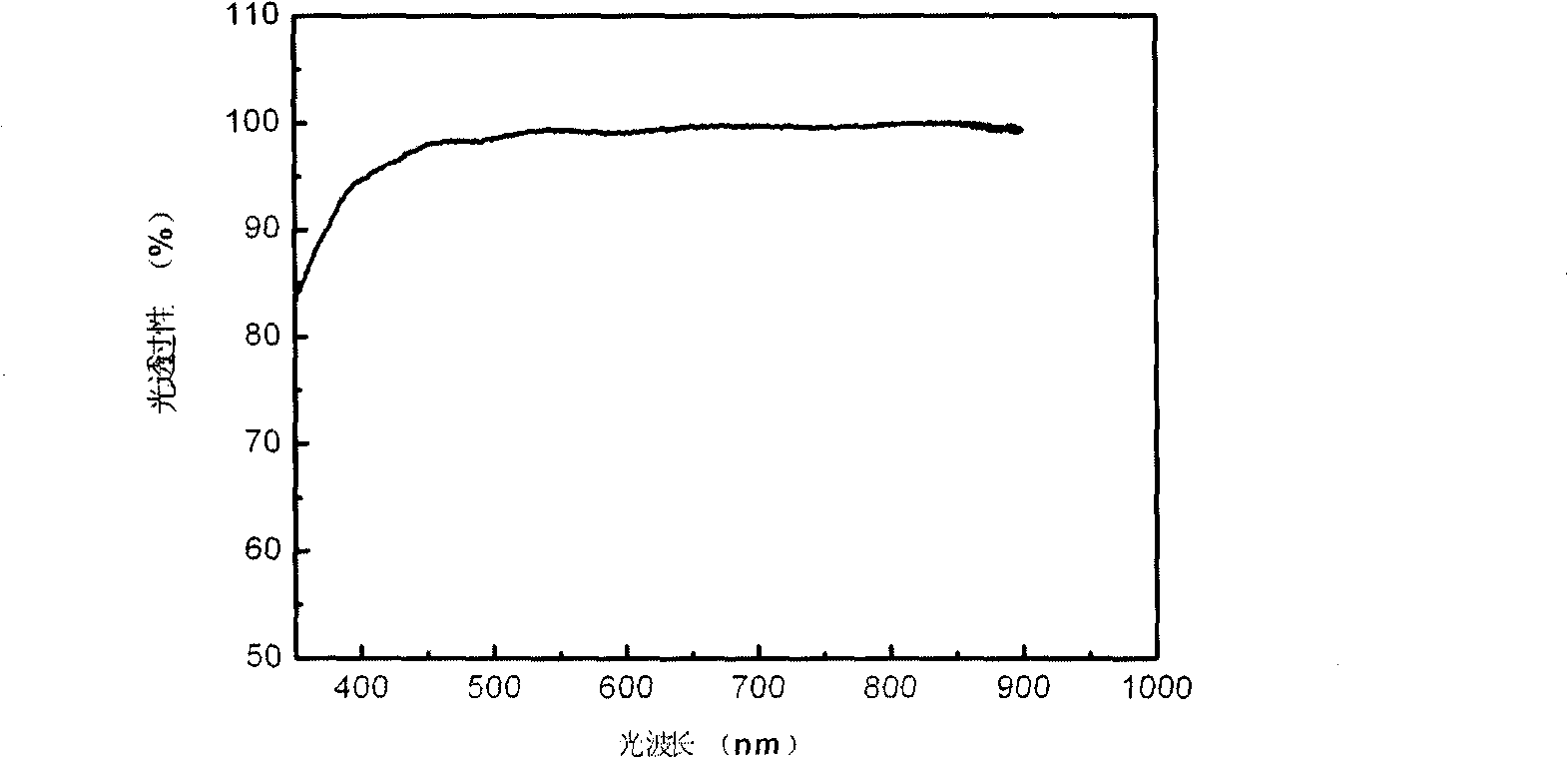

Device and method for depositing acid-resistant and alkaline-resistant diamond film on surface of compact disc

InactiveCN101560648APlay a protective effectSimple discharge methodChemical vapor deposition coatingCD-ROMHigh pressure

The invention relates to a method for coating a film on the surface of a compact disc and a method for depositing an acid-resistant and alkaline-resistant diamond film on the surface of the compact disc. The method comprises the steps of using a low and medium frequency medium to baffle high voltage discharge; using micromolecule hydrocarbon gas; and under the condition of lower air pressure, using the compact disc as a depositing substrate to deposit an ultrahard diamond film on the surface of the compact disc. The invention uses the medium to baffle discharge plasma to deposit the film, has the following unique advantages: simple discharge mode, low power energy and low gas flow, and can realize deposition on an insulating medium. The film has permeability which is more than 90% in blue light and red light for CD-ROM work recording and reading laser wave length. By testing the coated compact disc in a way of recording and reading, the film is proved to have no effect to the normal work of the compact disc. The invention effectively improves the chemical stability and the mechanical property of the surface of the compact disc, therefore, the coated compact disc has good acid-resistant and alkaline-resistant property.

Owner:大连民族学院光电子技术研究所

Processing technology and device of optical fiber plasma liquid

InactiveCN102491446BFacilitate contact areaEasy to handleWater/sewage treatment by irradiationDispersed particle separationAtmospheric pressure dischargeOptical fiber cable

The invention relates to a processing technology and device of an optical fiber plasma liquid. According to the invention, optical fiber pipes are utilized and uniformly ranked, and gas is introduced in the optical fiber pipes; a plasma is generated at a micropore optical fiber pipe orifice or end head by utilizing atmospheric pressure discharge; the area of the plasma is micro-controllable, the contact area of the plasma and a processing material is good, a processing effect can be obviously improved, and the energy utilization rate is greatly improved; and discharge gas is restricted by using optical fiber so as to generate a micro-plasma in a liquid at the atmospheric pressure to process a polluted liquid sample. The processing technology and device have the following specific advantages that gas utilization rate is high, discharge manner is simple, complicated vacuum equipment is not required, equipment cost is low, fungicidal efficiency is high, and energy consumption is low.

Owner:DALIAN NATIONALITIES UNIVERSITY

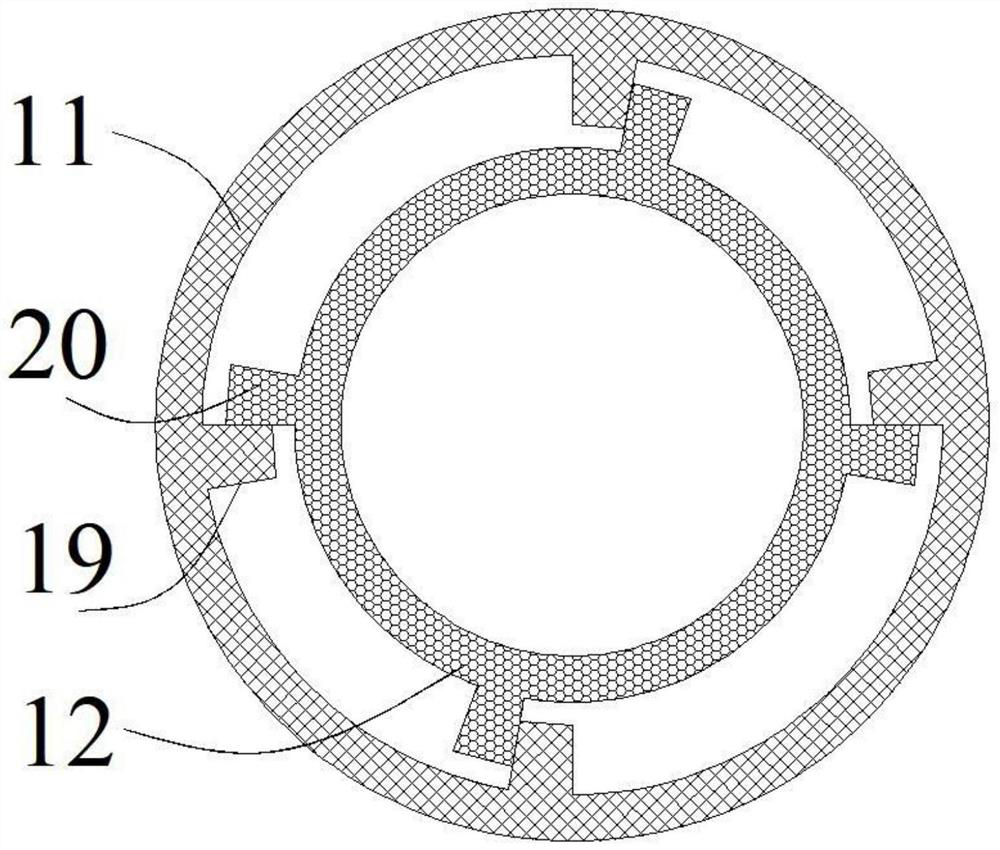

Vena cava filter

The invention relates to the technical field of cardiovascular system medical instrument structures, in particular to a vena cava filter. Comprising a central pipe; the hook part is arranged at the end part of the central pipe and is used for taking out the filter in a matched manner; the umbrella-shaped part comprises a plurality of outer supporting rods, one ends of the outer supporting rods are rotationally connected to the central pipe, and the other ends of the outer supporting rods can be opened and closed to form an umbrella-shaped structure; the supporting part comprises a plurality of inner supporting rods corresponding to the outer supporting rods, and one ends of the inner supporting rods are rotationally connected to the outer supporting rods; the driving part is of a piston type structure and comprises a cylinder body and a piston arranged in the cylinder body; the piston is sleeved on the central pipe, and one axial side of the piston is connected with the other end of the inner supporting rod; the cylinder body is located on one side of the piston to drive the piston to move axially so as to drive the inner supporting rod to adjust the opening angle of the outer supporting rod. The filter is simple in structure, adjustable in opening diameter, capable of adapting to blood vessels of different sizes, better in adaptability, easy to operate and high in safety.

Owner:武汉亚心总医院有限公司

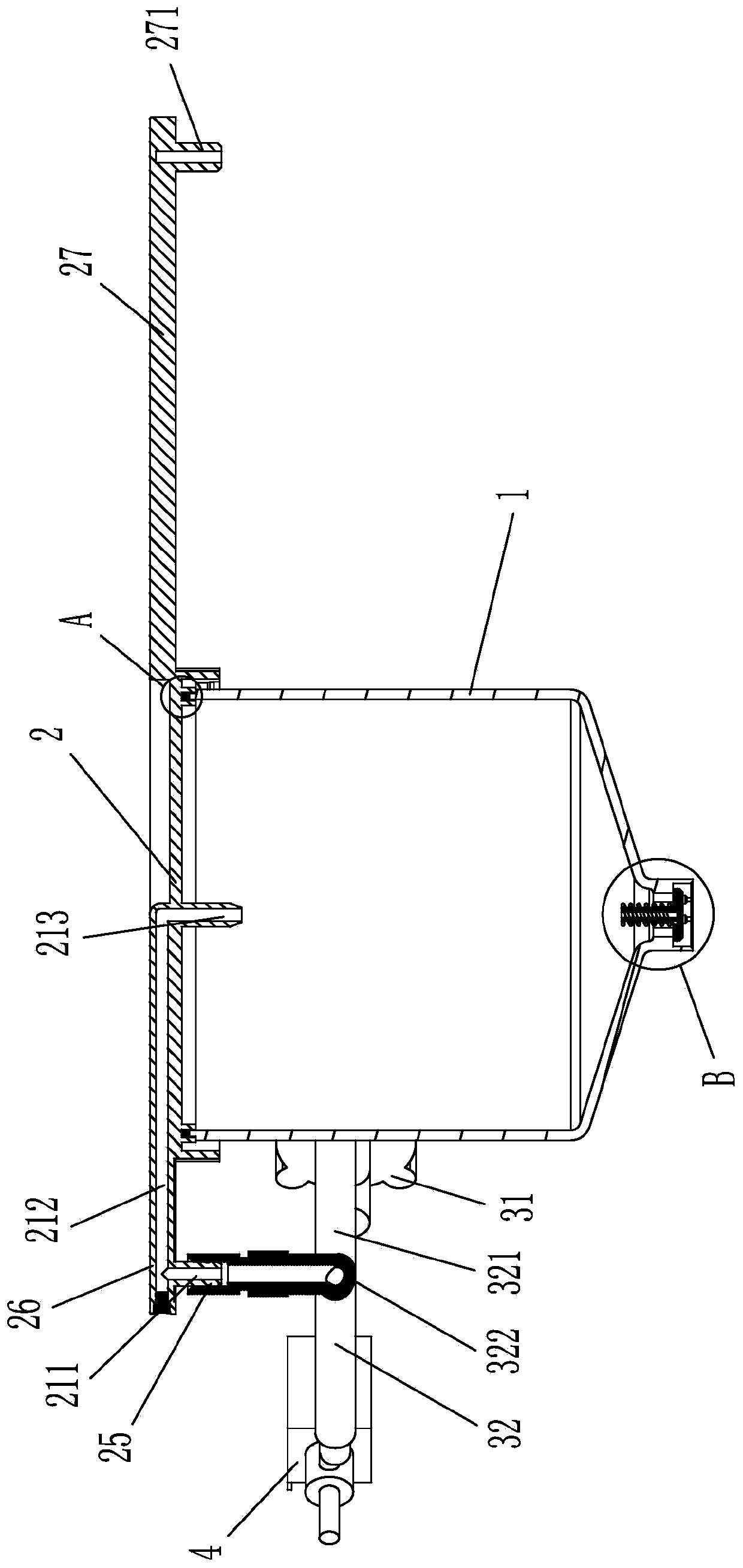

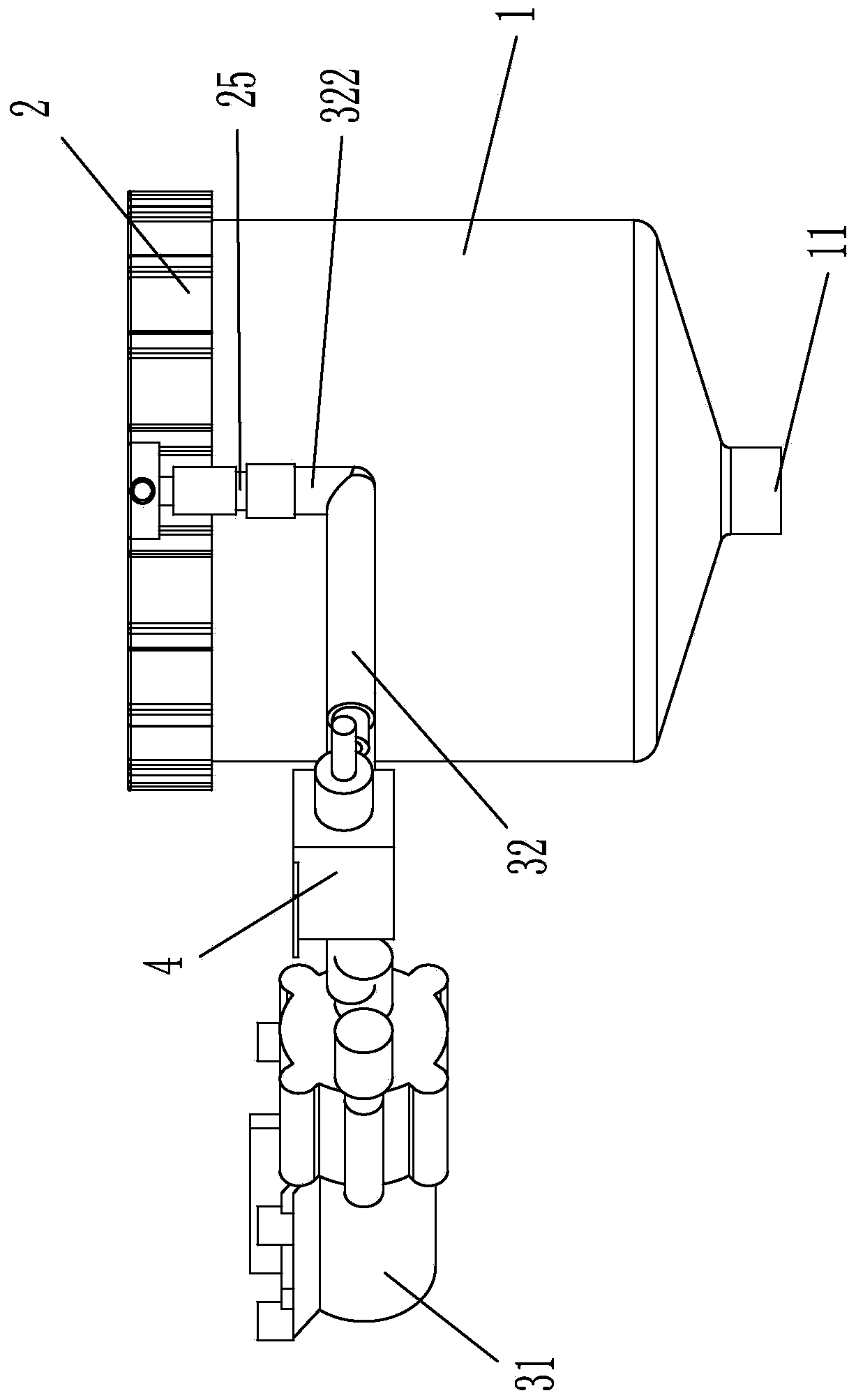

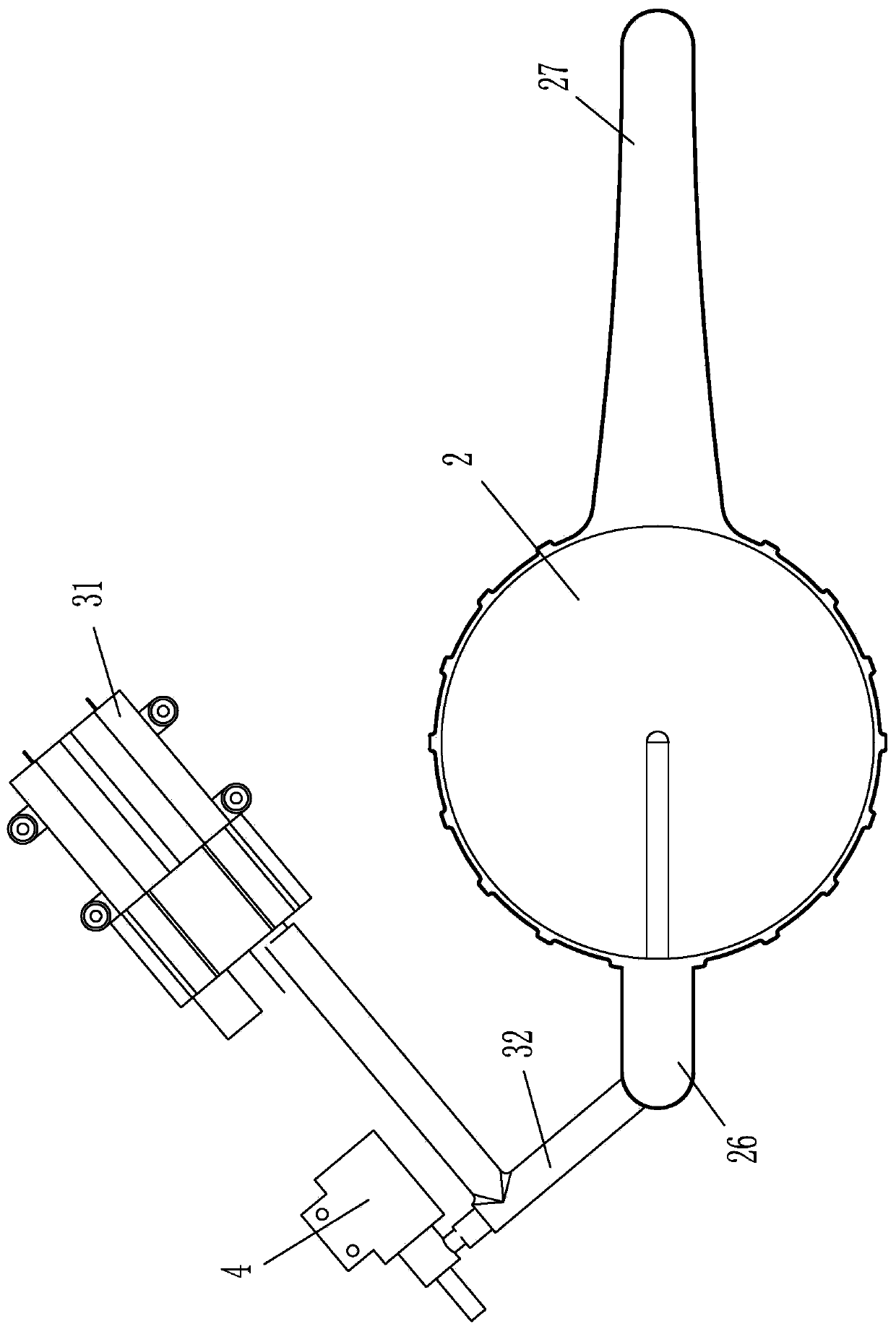

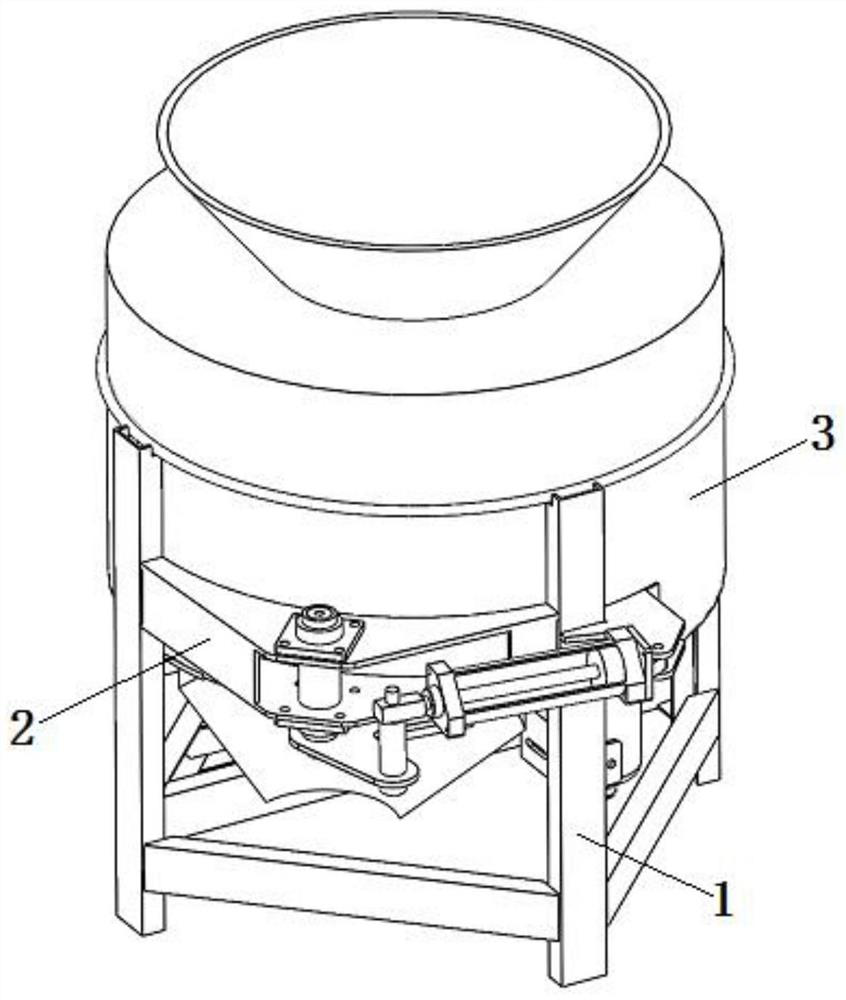

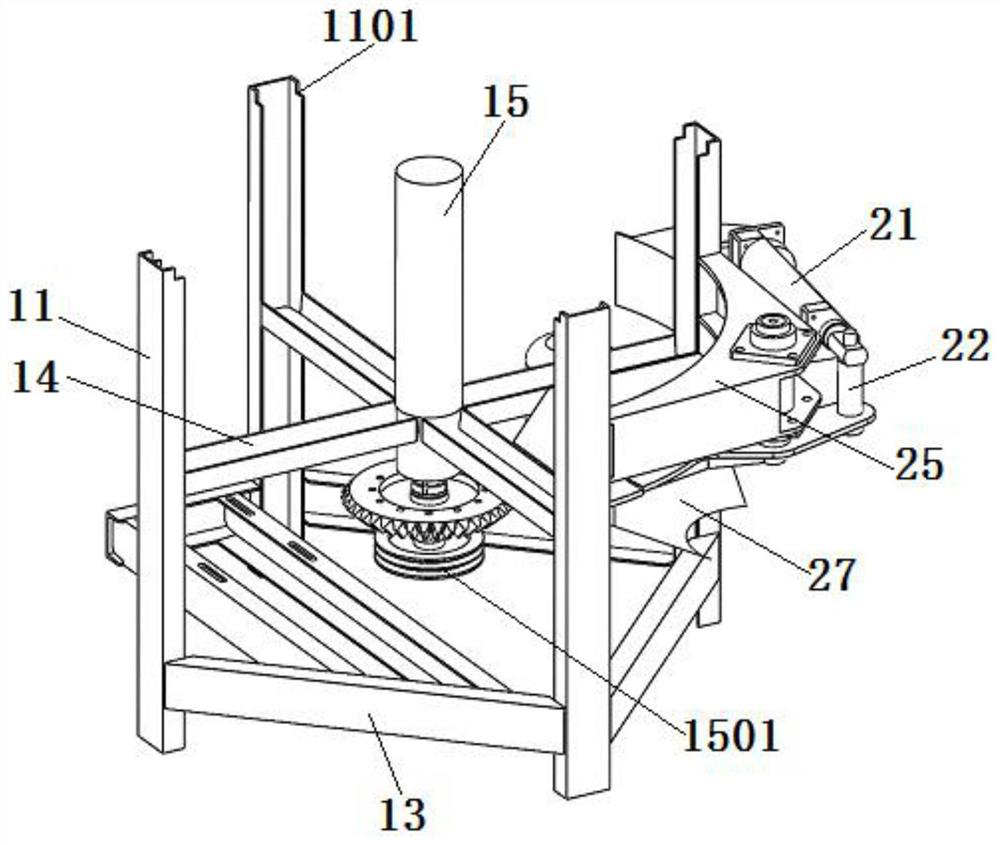

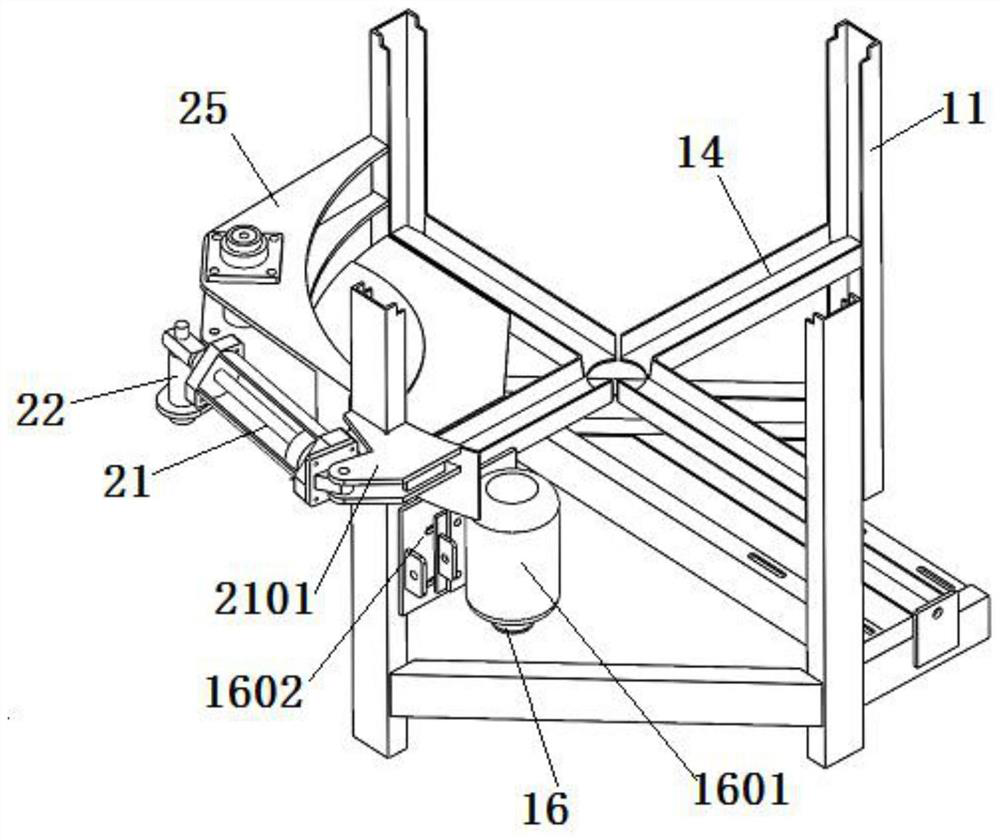

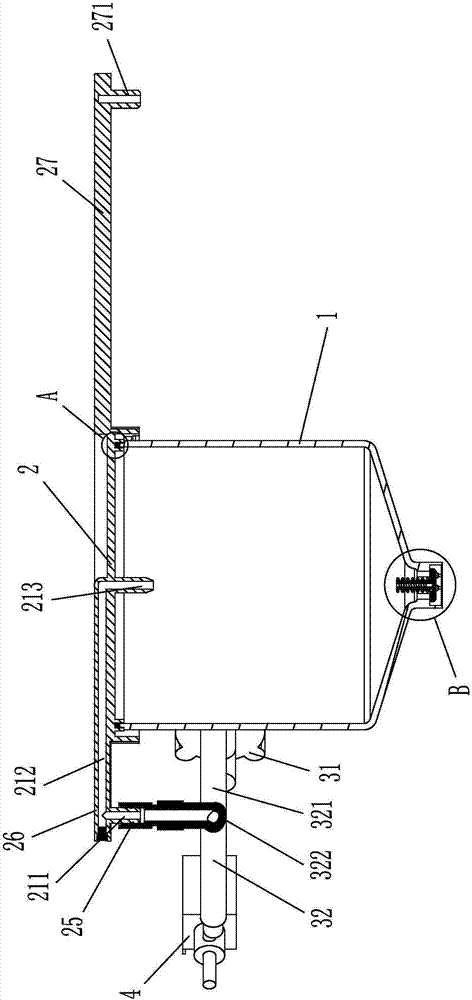

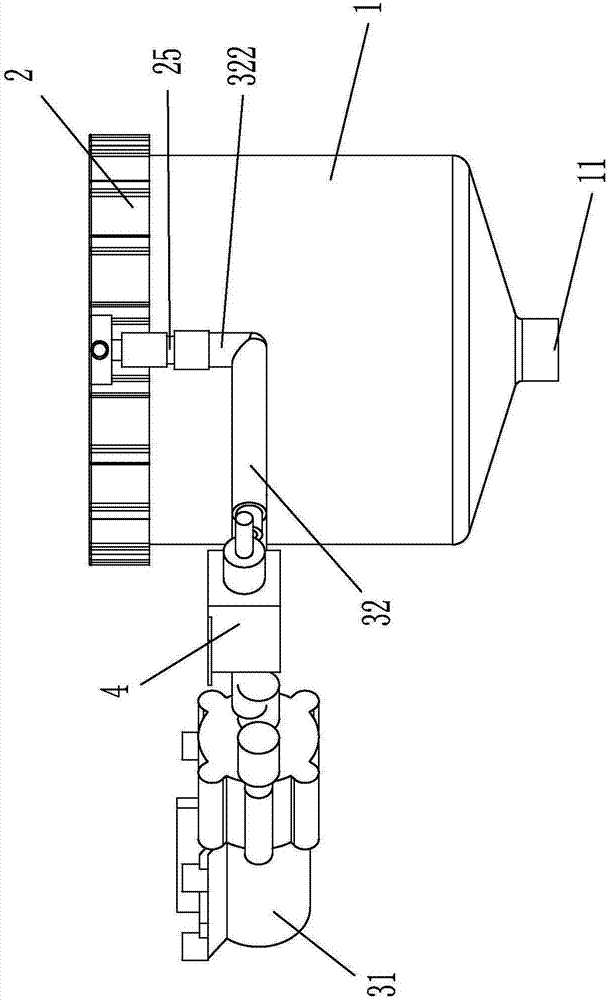

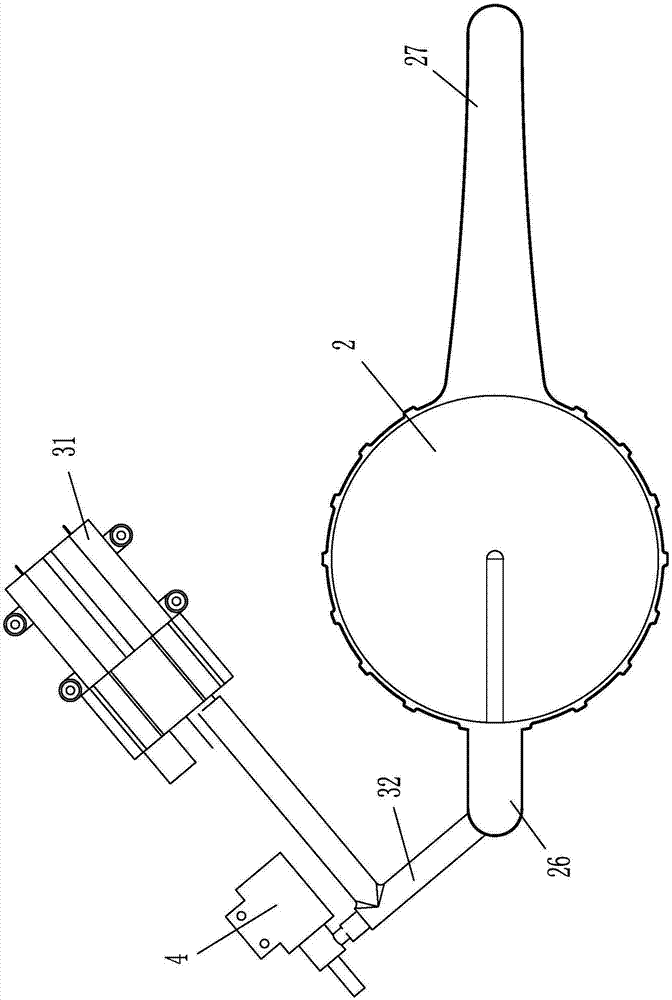

A quantitative blanking system for a household intelligent automatic pancake machine

ActiveCN107049062BSimple discharge methodEasy to implementFrying pansControl engineeringProcess engineering

The invention discloses a quantitative blanking system for a household intelligent automatic pancake making machine. The quantitative blanking system for the household intelligent automatic pancake making machine comprises a pneumatic component, a material storage component and a discharge component which are sequentially installed and connected; the discharge component is a normally closed discharge component arranged on the material storage component; the pneumatic component inflates the material storage component, the normally closed discharge component is opened, and a slurry in the material storage component is discharged from the normally closed discharge component. The quantitative blanking system for the household intelligent automatic pancake making machine is simple in discharge mode, is easy to realize, saves the slurry to the greatest extent, and avoids waste; the pneumatic component, the material storage component and the discharge component can be dismounted and washed, so that the daily maintenance of a user is facilitated.

Owner:UROICA GUANGDONG PRECISION INFORMATION ENG TECH RES INST CO LTD

Traditional Chinese medicinal material rubbing processing device capable of uniformly rubbing medicines and using method thereof

InactiveCN111658678AImprove mixing uniformityImprove the uniformity of forceRotary stirring mixersLarge containersEngineeringStructural engineering

The invention discloses a traditional Chinese medicinal material rubbing processing device capable of uniformly rubbing medicines, which comprises a bearing device, a discharging device and a processing mechanism, and the discharging device and the processing mechanism are both arranged on the bearing device; the bearing device comprises four supporting columns, two second cross beams are fixed tothe middles of the supporting columns, and a first shaft rod is installed in the middles of the two second cross beams in a penetrating mode; the processing mechanism comprises a material barrel, thematerial barrel comprises a barrel bottom plate and a barrel wall, the lower surface of the barrel bottom plate is fixed to the two second cross beams, a circular plate is fixed to the inner surfaceof the peripheral side of the barrel wall, and a discharging opening of a conical feeding opening is right located over the first shaft rod; and a stirring mechanism, a rubbing mechanism and a discharging assisting mechanism are sequentially mounted on the first shaft rod from top to bottom, and the stirring mechanism is located between the circular plate and the conical feeding port. The traditional Chinese medicinal material rubbing processing device is simple in mechanism and easy to operate, can achieve uniform feeding, uniform rubbing and easy discharging, has the advantages of being highin processing efficiency and good in processing effect, and is suitable for rubbing processing of traditional Chinese medicinal materials.

Owner:临泉县朦顺中药材有限公司

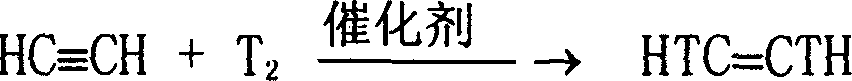

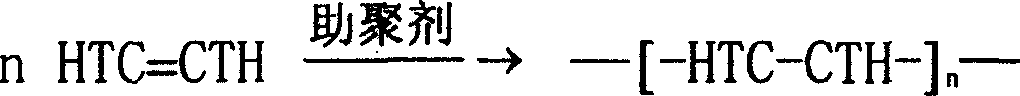

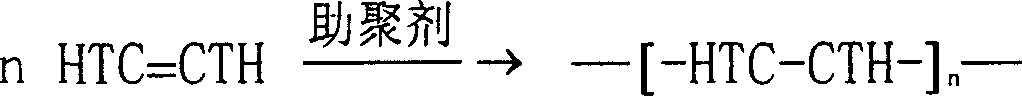

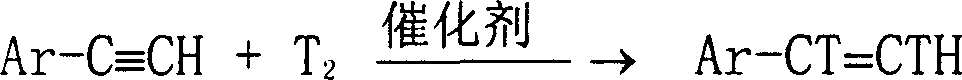

Discharge paint for electronic device and method for making same

The invention belongs to photoelectric source field,concretely relates to a discharge coating of electric equipment and its preparing method. The discharge coating of electric equipment contains alkene polymer with the ratio of 1:104~1:1.5104. The method to prepare the discharge coating includes:firstly,in the effect of carbon catalyst,blow tritium into alkyne for generating alkene tritide,then in the effect of promoter azo compound,through polyreaction to generate polymer of alkene tritide which is finally prepared with alkene polymer. The discharge coating can simplify the discharging made of electric equipment,stabilize the course need short period,as well as prolong the service life of pipe.

Owner:HTA CO LTD

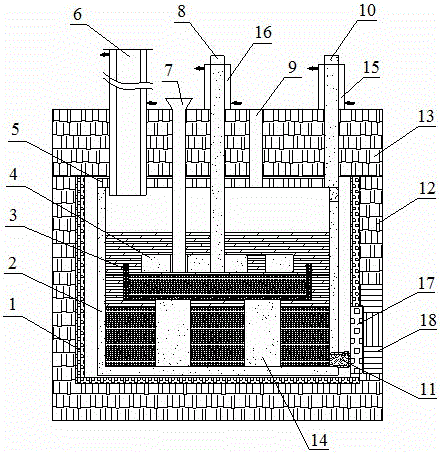

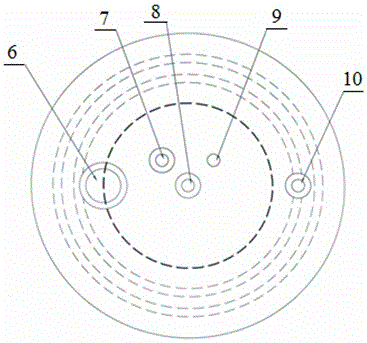

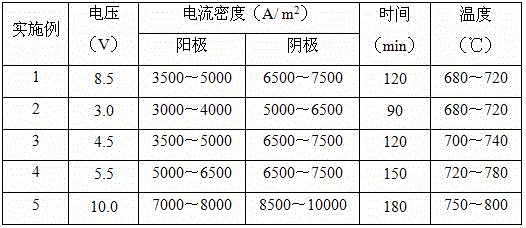

A device and method for separating antimony-containing alloys

The invention discloses a device and method for separating an antimony-containing alloy. The device comprises a heating furnace, a cathode melting bath, an anode melting bath, an anode plate provided with openings, a cathode melting bath cover plate, a return pipe, a feeding hopper, an anode bar, a cathode bar, a cathode slag discharging valve, a heat preserving furnace, a heat preserving furnace cover plate, an anode melting bath supporting seat, a cathode bar cooling jacket, an anode bar cooling jacket, a heating furnace movable door and a heat preserving furnace movable door. The method comprises the following steps: melting the antimony-containing alloy, namely preparing a molten salt, adding into the melting baths gradually, heating, adding the antimony-containing alloy after melting of the molten salt, and melting; and (2) electrolyzing the molten salt, namely performing electrolysis by switching on a direct-current power supply, and discharging cathode residues and anode residues respectively after electrolysis. The anode residues can be further chloridized and subjected to displacement reduction to extract metals. The process disclosed by the invention is environment-friendly, the recovery rate of the separated antimony-containing alloy is more than or equal to 99%, and the direct recovery rate of gold and silver in the antimony-containing alloy reaches 99.9%, so that the device and the method are suitable for separating various antimony-containing alloys.

Owner:锡矿山闪星锑业有限责任公司

Quantitative blanking system for household intelligent automatic pancake making machine

The invention discloses a quantitative blanking system for a household intelligent automatic pancake making machine. The quantitative blanking system for the household intelligent automatic pancake making machine comprises a pneumatic component, a material storage component and a discharge component which are sequentially installed and connected; the discharge component is a normally closed discharge component arranged on the material storage component; the pneumatic component inflates the material storage component, the normally closed discharge component is opened, and a slurry in the material storage component is discharged from the normally closed discharge component. The quantitative blanking system for the household intelligent automatic pancake making machine is simple in discharge mode, is easy to realize, saves the slurry to the greatest extent, and avoids waste; the pneumatic component, the material storage component and the discharge component can be dismounted and washed, so that the daily maintenance of a user is facilitated.

Owner:UROICA GUANGDONG PRECISION INFORMATION ENG TECH RES INST CO LTD

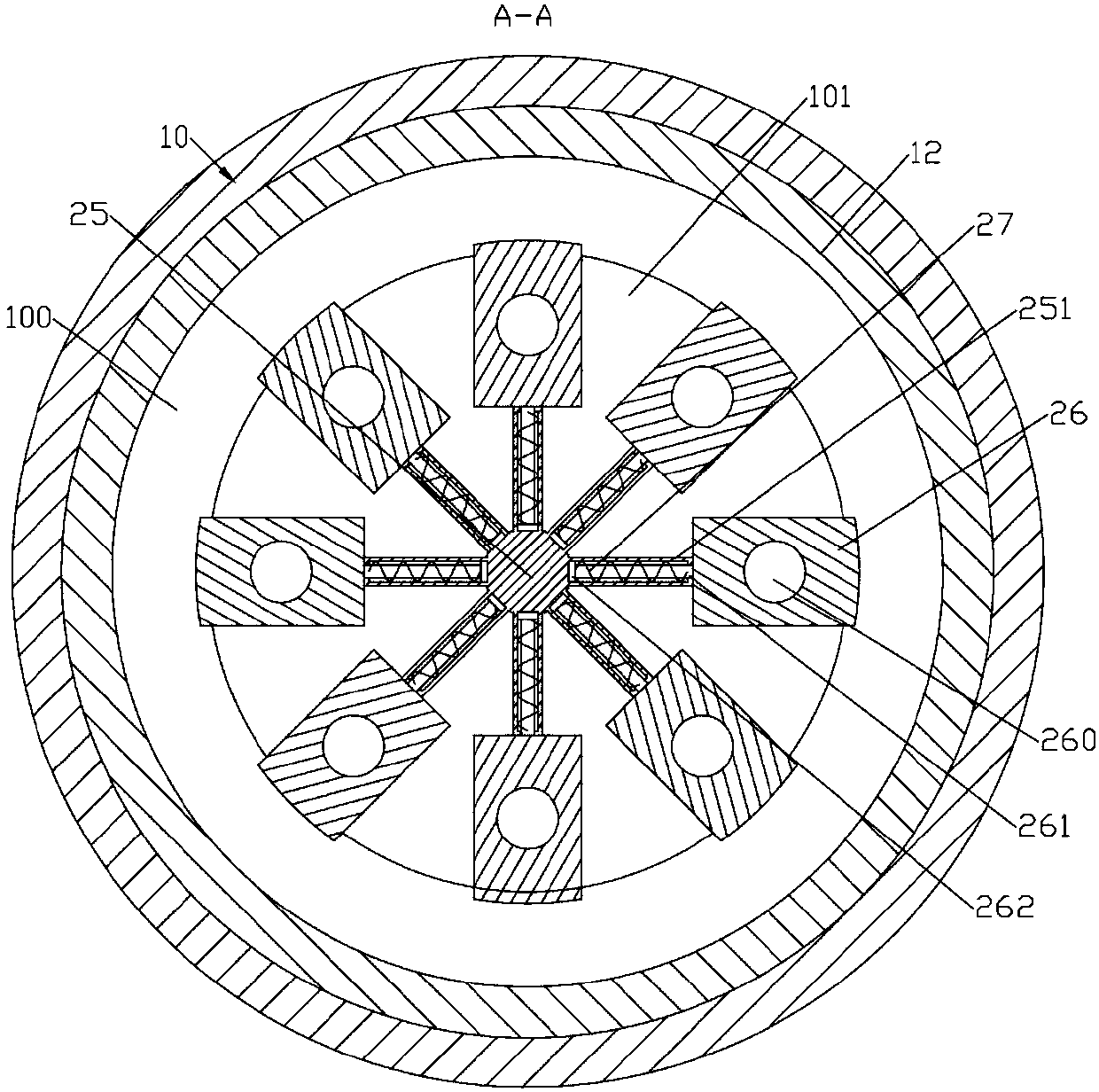

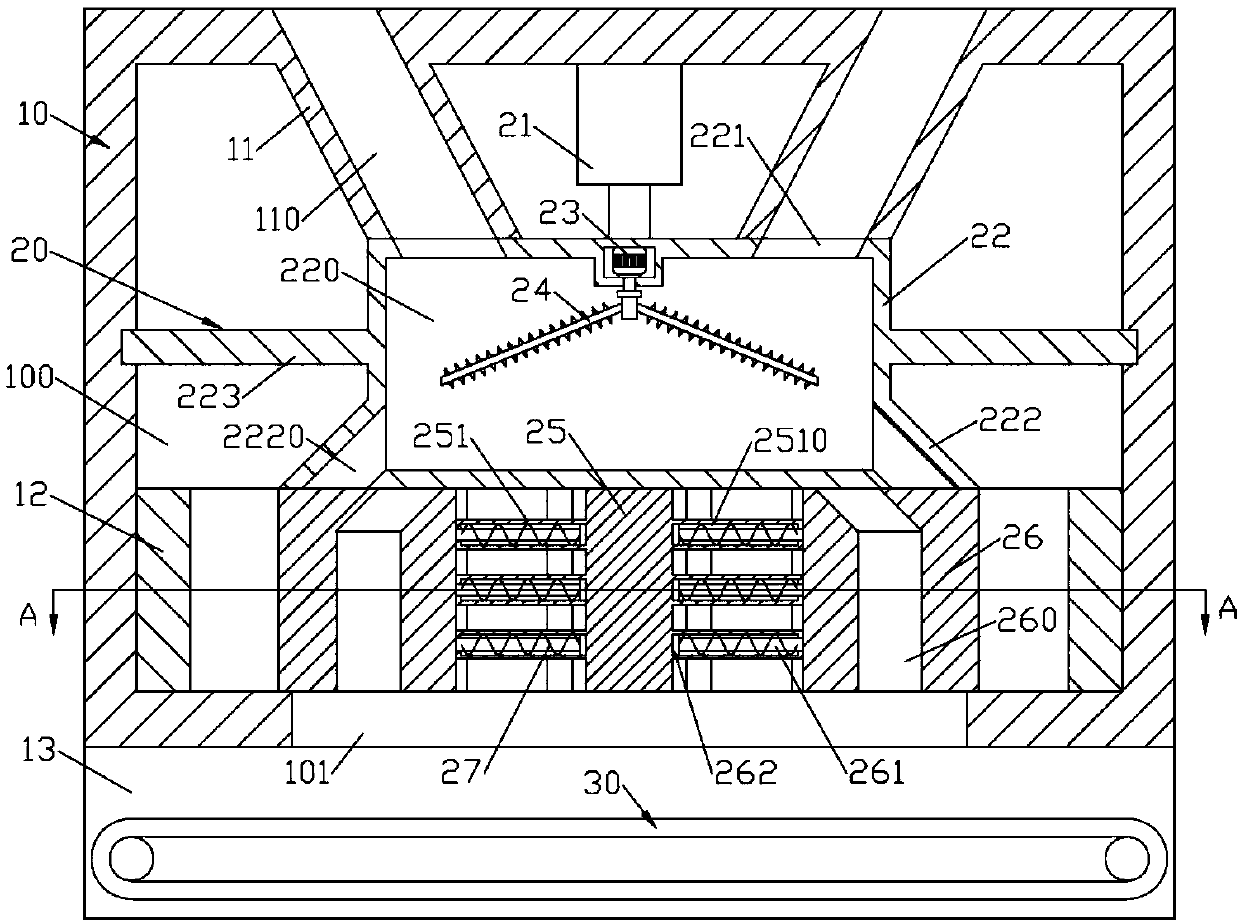

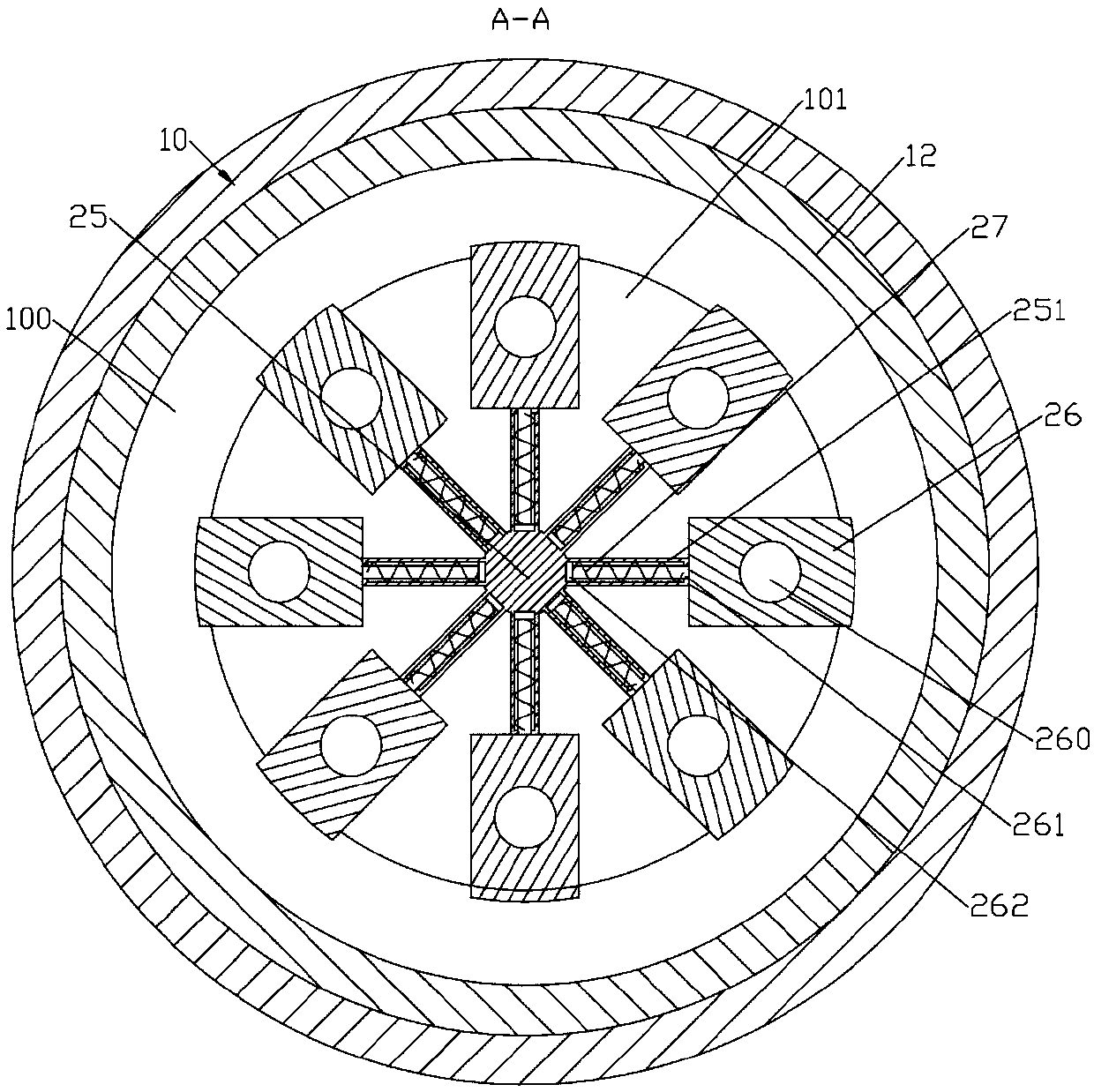

Rotary centrifugal discharge garbage smashing device

ActiveCN107899687ASimple structureSimple discharge methodGrain treatmentsEngineeringMechanical engineering

The invention discloses a rotary centrifugal discharge garbage smashing device which comprises a cylindrical supporting frame, a smashing centrifugal discharge device and a conveying belt device. A holler cavity in a shape of a cylinder groove is molded inside the supporting frame, a discharge groove in a shape of a cylinder groove is molded in the lower side wall of the hollow cavity and is through up and down, the smashing centrifugal discharge device comprises a cylindrical smashing barrel in a rotary manner, a smashing groove in a shape of a cylinder groove is molded inside the smashing groove, and a lower feeding hole which is matched with a feeding guide hole and is through up and down is molded in the upper side wall of the smashing groove; and a plurality of centrifugal discharge pipes which are downwards inclined from inside to outside and are circumferentially and evenly distributed are molded in the lower end of the outer cylinder face of the smashing barrel, a plurality ofradial sliding opening and closing blocks distributed circumferentially are arranged on the lower end face of the smashing barrel, the centrifugal discharge pipes can be opened and closed through theopening and closing blocks, a smashing head is rotationally arranged on the upper side wall of the hollow cavity, and the conveying belt device is arranged at the lower end of the supporting frame. The rotary centrifugal discharge garbage smashing device is simple in discharging manner and high in working efficiency.

Owner:武汉市绿色环保能源有限公司

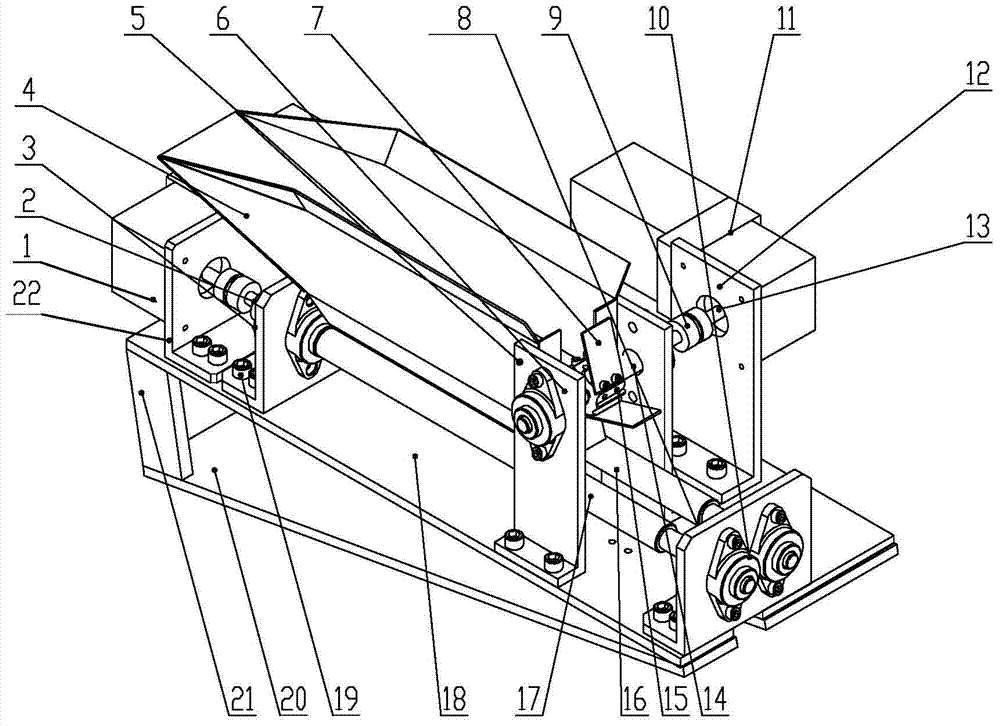

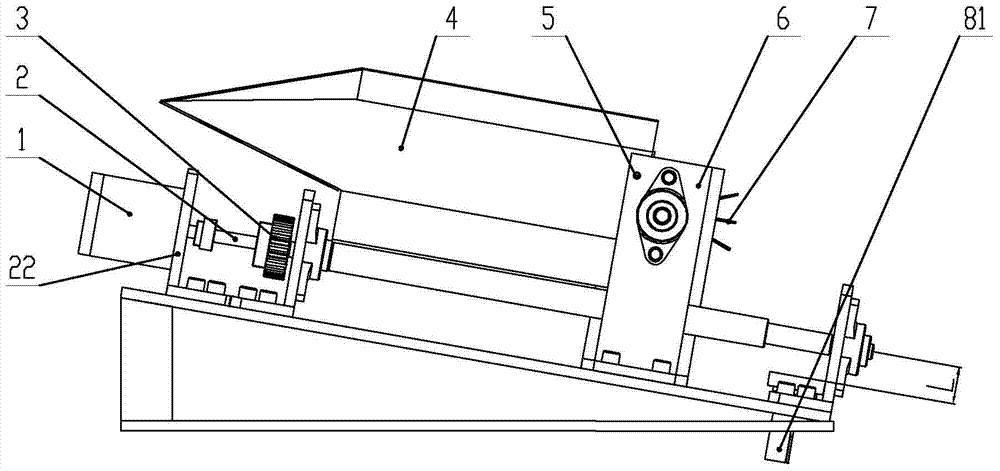

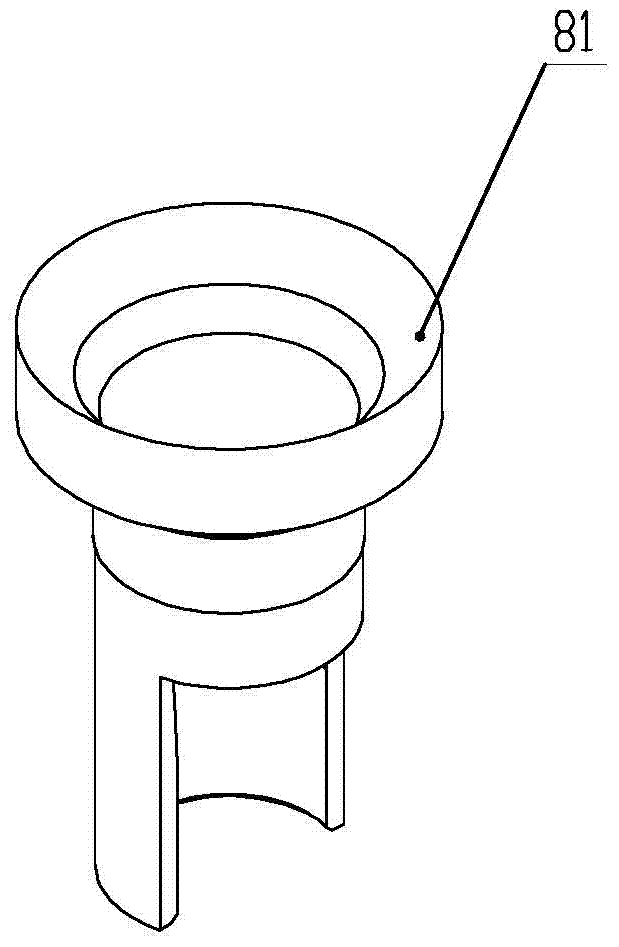

Cone discharge device and method for realizing orderly discharge of cone materials

ActiveCN105501917BReduce working noiseOrderly rowsLoading/unloadingConveyor partsEngineeringMechanical engineering

A cone discharging device comprises a horizontal base, a base plate, a box body used for containing cones to be discharged, pushing sheets used for conveying the cones, a rolling shaft I, a rolling shaft II, a motor I driving the rolling shaft I and the rolling shaft II, a motor II driving the pushing sheets and a falling hopper used for receiving cone materials; the box body is installed on the base plate through a box body supporting seat; the motor I and the motor II are installed at the two ends of the base plate respectively; the rolling shaft II is connected with a motor I rotating shaft through a clamp spring, the rolling shaft I is connected with the rolling shaft II through gear engagement, the rolling shaft I and the rolling shaft II are parallel to each other, the heights of the lowest points are the same, and the included angle between the rolling shaft I and the rolling shaft II and the horizontal base ranges from 13 degrees to 18 degrees; a ratchet wheel rolling shaft used for installing a ratchet wheel is connected with a motor II rotating shaft through a shaft sleeve and a bearing seat, and the ratchet wheel rolling shaft and the motor rotating shaft are coaxial; the pushing sheets are installed on the ratchet wheel, and the installation position of the ratchet wheel is in the middles of the rolling shaft I and the rolling shaft II. By means of the cone discharging device, cone parts which enter a feed box of the device irregularly can be sequentially discharged one by one according to a certain sorting order in a big-end-up or small-end-up mode.

Owner:LIUZHOU OVM MASCH CO LTD

Atmospheric pressure optical plasma brush-type device and electric discharge method thereof

The invention relates an atmospheric pressure optical plasma brush-type device and an electric discharge method thereof. The device comprises an alternating current power supply, an air cavity, microporous optical fibers, high voltage electrodes and a ground electrode, wherein the high voltage electrodes are correspondingly inserted into the microporous optical fibers. According to the invention, the microporous optical fibers are uniformly arranged, the inner parts or the outer parts of the microporous optical fibers are communicated with air, electricity can be discharged under an atmospheric pressure condition, thus plasmas can be generated at electric discharge ends of the microporous optical fibers, and the plasmas can be used for carrying out material surface modification and the processing for materials, cancel cells, bacterium and the like in biomedicine. The atmospheric pressure optical plasma brush-type device disclosed by the invention has the advantages that the cost of an electric discharge device is low, the size is small, the electric discharge mode is simple, a low-voltage vacuum environment is not needed, the energy consumption is low, the electric discharge is stable, uniform and compact, the electric discharge area is controllable, and the electric discharge duration is unlimited.

Owner:东丰科林(天津)医疗科技有限公司

A lifting type garbage crushing device

The invention discloses a lifting type garbage crushing device. The lifting type garbage crushing device comprises a support frame, a lifting feeding and discharging device, a lifting crushing unit and a conveyor belt device, wherein the support frame adopts a rectangular solid structure and in which a rectangular cavity is formed; a pair of bilaterally symmetrical feeding guide blocks is formed on the upper side wall of the support frame; a feeding guide hole tilting inwards and downwards is formed in each of the feeding guide blocks; the lifting feeding and discharging device comprises a lifting storage box arranged in a lifting manner; connecting guide holes matched with the feeding guide holes are formed in the upper side wall of the lifting storage box; the lifting crushing unit comprises a crushing head rotatably arranged; the crushing head is arranged in the lifting storage box in a lifting manner; a square discharging frame is formed on the lower side wall of the support frame;the lower end of the discharging frame is opened, and an opening and closing sealing block is formed between the front and rear side walls; a discharging hole is formed in the lower side wall of thelifting storage box; and the discharging hole sleeves the opening and closing sealing block. The lifting type garbage crushing device has the benefits as follows: the garbage can be crushed continuously, the discharging method is simple, and the working efficiency is high.

Owner:湖南省爱华环保科技股份有限公司

Syringe type atmospheric-pressure micro-plasma generator

ActiveCN102497719BReduce volumeWidely applicable processingPlasma techniqueAir volumePlasma generator

The invention relates to a syringe type atmospheric-pressure micro-plasma generator which comprises a alternating-current high-voltage power supply, a high-voltage electrode, a ground electrode and a micro-hole optical fiber, wherein the lower end of the micro-hole optical fiber is closed, the high-voltage electrode is inserted in the micro-hole optical fiber, and a needle cylinder is sleeved on the micro-hole optical fiber; the upper end of the needle cylinder is sealed and is connected with an air inlet tube; the lower end of the needle cylinder is connected with a needle head made of insulating material; the lower end of the optical fiber is wrapped in the needle head, and a gap through which air passes is reserved between the optical fiber and the needle head; and the ground electrode is earthed and arranged in a to-be-processed sample. The syringe type atmospheric-pressure micro-plasma generator provided by the invention is simple in electro-discharge mode, low in equipment cost, small in air volume, low in air flow, and low in energy consumption; and the micro-plasma generator can feed gas in a liquid sample so as to obtain plasmas, and is used for processing the insides of materials or processing internal tissues of human bodies.

Owner:DALIAN NATIONALITIES UNIVERSITY

A garbage crushing device with rotary centrifugal discharge

The invention discloses a rotary centrifugal discharge garbage smashing device which comprises a cylindrical supporting frame, a smashing centrifugal discharge device and a conveying belt device. A holler cavity in a shape of a cylinder groove is molded inside the supporting frame, a discharge groove in a shape of a cylinder groove is molded in the lower side wall of the hollow cavity and is through up and down, the smashing centrifugal discharge device comprises a cylindrical smashing barrel in a rotary manner, a smashing groove in a shape of a cylinder groove is molded inside the smashing groove, and a lower feeding hole which is matched with a feeding guide hole and is through up and down is molded in the upper side wall of the smashing groove; and a plurality of centrifugal discharge pipes which are downwards inclined from inside to outside and are circumferentially and evenly distributed are molded in the lower end of the outer cylinder face of the smashing barrel, a plurality ofradial sliding opening and closing blocks distributed circumferentially are arranged on the lower end face of the smashing barrel, the centrifugal discharge pipes can be opened and closed through theopening and closing blocks, a smashing head is rotationally arranged on the upper side wall of the hollow cavity, and the conveying belt device is arranged at the lower end of the supporting frame. The rotary centrifugal discharge garbage smashing device is simple in discharging manner and high in working efficiency.

Owner:武汉市绿色环保能源有限公司

Optical fiber plasma discharge laser amplification device and technology

InactiveCN102377097BStable and continuous amplificationSimple discharge methodLaser detailsHigh pressureMetal electrodes

The invention relates to an optical fiber plasma discharge laser amplification device and technology; the device comprises a quartz tube and an optical fiber for electro-discharge, wherein the quartz tube is used for mixing a helium gas and a neon gas; the optical fiber for electro-discharge is communicated at the front end of the quartz tube; and the outer wall of the optical fiber for electro-discharge is used for covering a metal electrode which is sequentially and alternatively connected with a high-voltage power supply and an earth wire. The technology comprises the following steps of: proportions of the helium reactive gas and the neon reactive gas are adjusted by a mass flow controller, the helium reactive gas and the neon reactive gas are fully mixed in a quartz tube, and uniform plasmas are generated at atmospheric pressure by using an inter-electrode alternative discharge structure; and laser beams which are emitted by a helium-neon laser pass through the optical fiber for electro-discharge through a smooth quartz plate at the tail end of the quartz tube to realize population inversion and slave machine irradiation, thereby realizing the amplification of lasers along thelaser transmission direction. The optical fiber plasma discharge laser amplification device has the characteristics that an electro-discharge manner is simple, complicated vacuum equipment is not needed, the equipment cost is low, the volume is small and the energy consumption is low.

Owner:DALIAN NATIONALITIES UNIVERSITY

Discharge paint for electronic device and method for making same

Owner:HTA CO LTD

Garbage crushing device capable of feeding materials under negative pressure

ActiveCN107617470ASimple structureSimple discharge methodGrain treatmentsEngineeringMechanical engineering

The invention discloses a garbage crushing device capable of feeding materials under negative pressure. The garbage crushing device capable of feeding materials under negative pressure comprises a support frame, a crushing unit, a lifting opening and closing device and a conveying belt device, wherein the support frame is a cuboid; a rectangular accommodating cavity is formed in the cuboid; a pairof feeding guide blocks is formed on the upper side wall of the support frame; a cylindrical crushing and discharging barrel of a device with the unsealed bottom is formed on the lower side wall of the support frame; the lower ends of the feeding guide blocks are fixed on the crushing and discharging barrel; a downward feeding guide hole which is inwards inclined is formed in each feeding guide block; the feeding guide holes communicate with a cavity of the crushing and discharging barrel; an annular crushing and isolating ring and a closed isolating ring are formed on the inner side wall ofthe crushing and discharging barrel from top to bottom; upper end surfaces and lower end surfaces of the crushing and isolating ring and the closed isolating ring are conical tables which are projected downwards; the crushing unit is arranged on the upper side wall of the crushing and discharging barrel; and an opening and closing sealing block is arranged in the crushing and discharging barrel ina lifting manner. The garbage crushing device can continuously crush garbage, a discharging mode is simple, and the working efficiency is high.

Owner:林家豪

A frying machine for processing strange-flavored soybeans

ActiveCN112616866BSolve the problem of deteriorating frying qualityReduce manufacturing costSievingScreeningProcess engineeringIndustrial engineering

Owner:重庆芝麻官实业股份有限公司

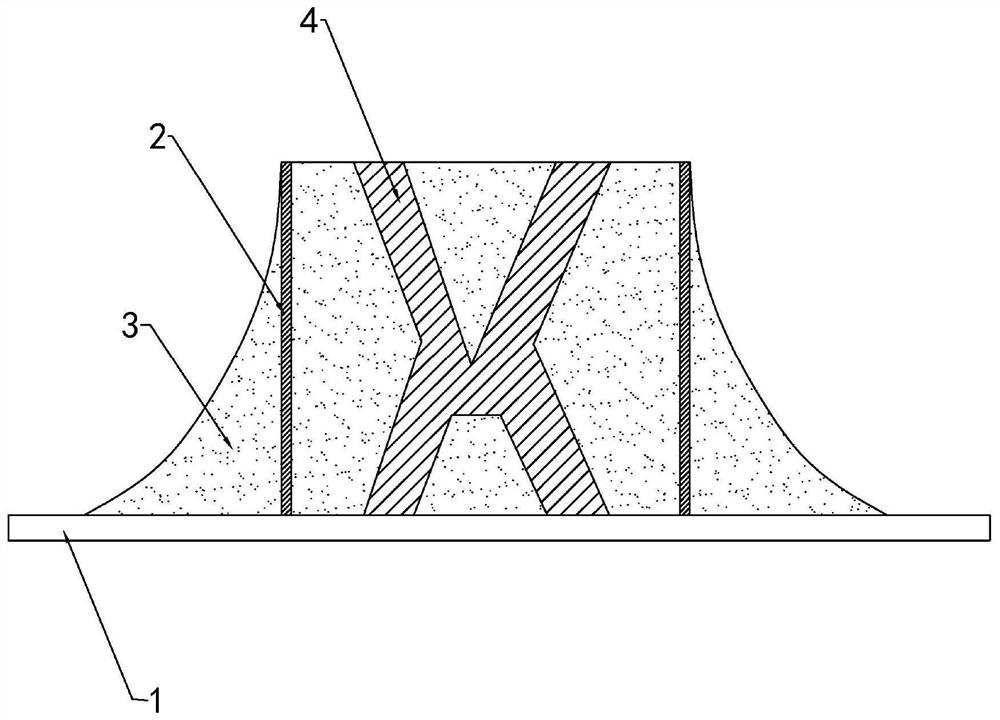

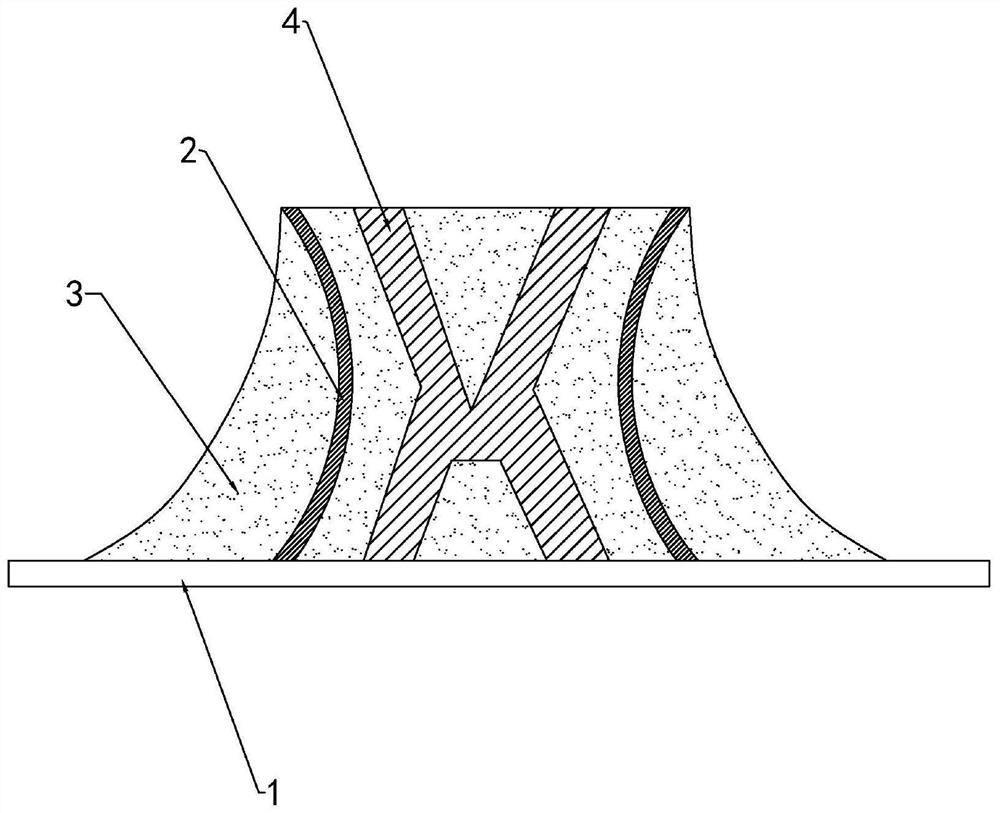

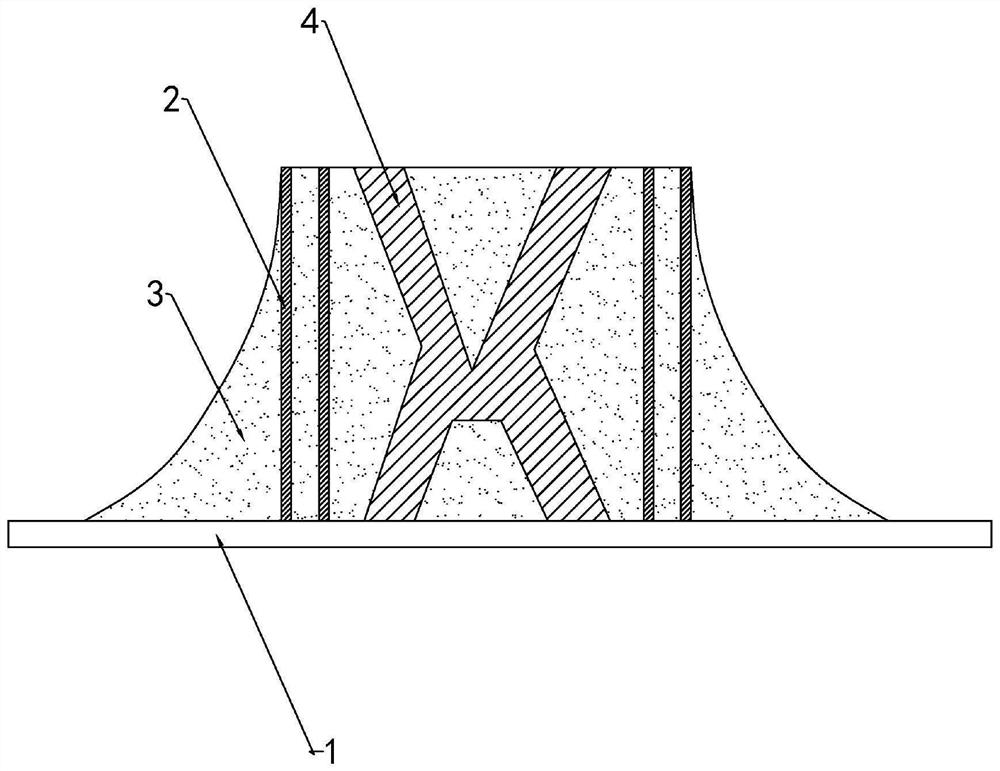

Variable-size large-breadth 3D printing method and printing structure

ActiveCN113619115ASimple discharge methodAvoid damageManufacturing enclosuresIncreasing energy efficiencyGraphicsLarge format

The invention provides a variable-size large-breadth 3D printing method and a variable-size large-breadth 3D printing structure. The printing method comprises the steps that firstly, printing powder is laid, and then a preset pattern and a closed boundary are printed on the surface of the laid powder, so that the printed pattern and the closed boundary form an integrated structure and have certain mechanical strength; then laying and printing are repeatedly conducted on the upper portion of the last-time-laid printing powder till printing of the workpiece is completed, in the laying and printing process, all the positions of the closed boundaries of every two adjacent layers of printing powder are continuous, and 3D printing is completed after a frame shell formed by combining the closed boundaries is removed and the printing powder on the surface of the workpiece is removed; the printing structure comprises a bottom plate, printing powder laid on the bottom plate, a frame shell and a printing workpiece, wherein the frame shell and the printing workpiece are formed by curing the printing powder, and the printing workpiece is located on the inner side of the frame shell. The problems that a large workpiece cannot be manufactured through conventional 3D printing and a large printing working cylinder leaks sand can be solved.

Owner:武汉阿尔法激光有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com