Patents

Literature

30 results about "PBR322" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PBR322 is a plasmid and was one of the first widely used E. coli cloning vectors. Created in 1977 in the laboratory of Herbert Boyer at the University of California, San Francisco, it was named after Francisco Bolivar Zapata, the postdoctoral researcher who constructed it. The p stands for "plasmid," and BR for "Bolivar" and "Rodriguez."

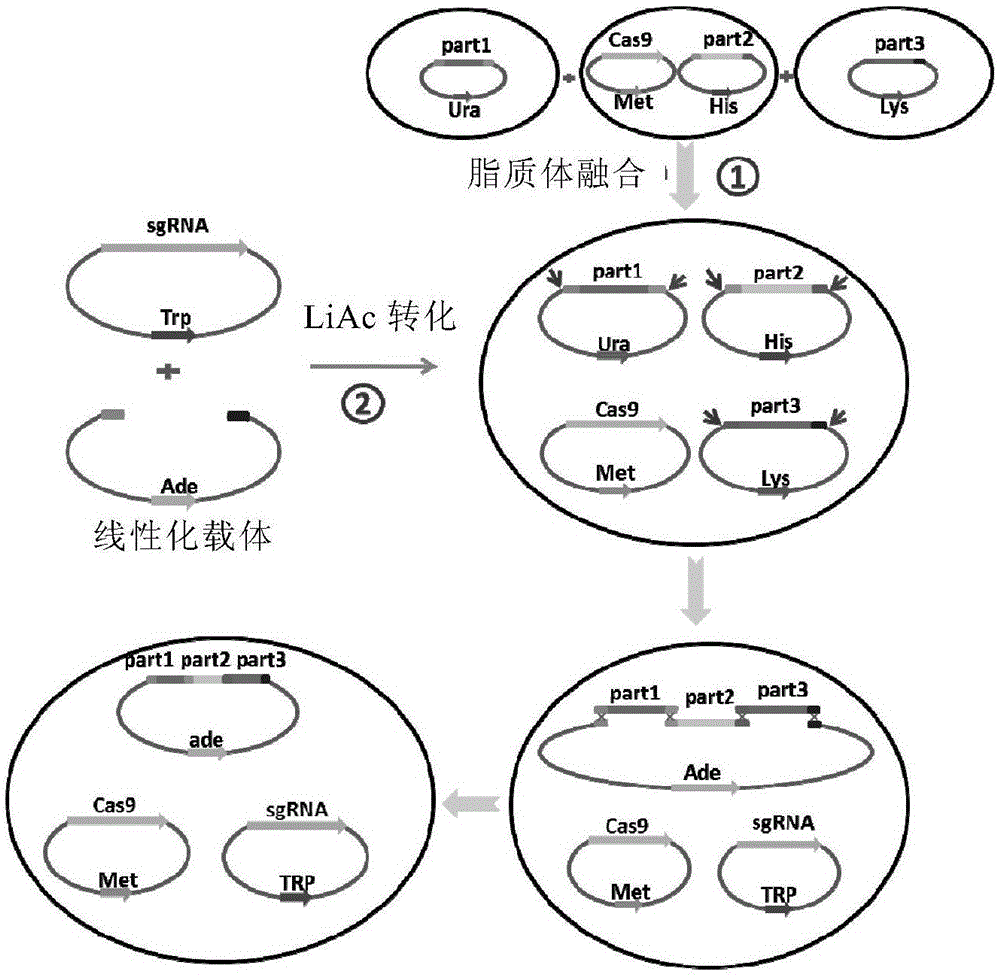

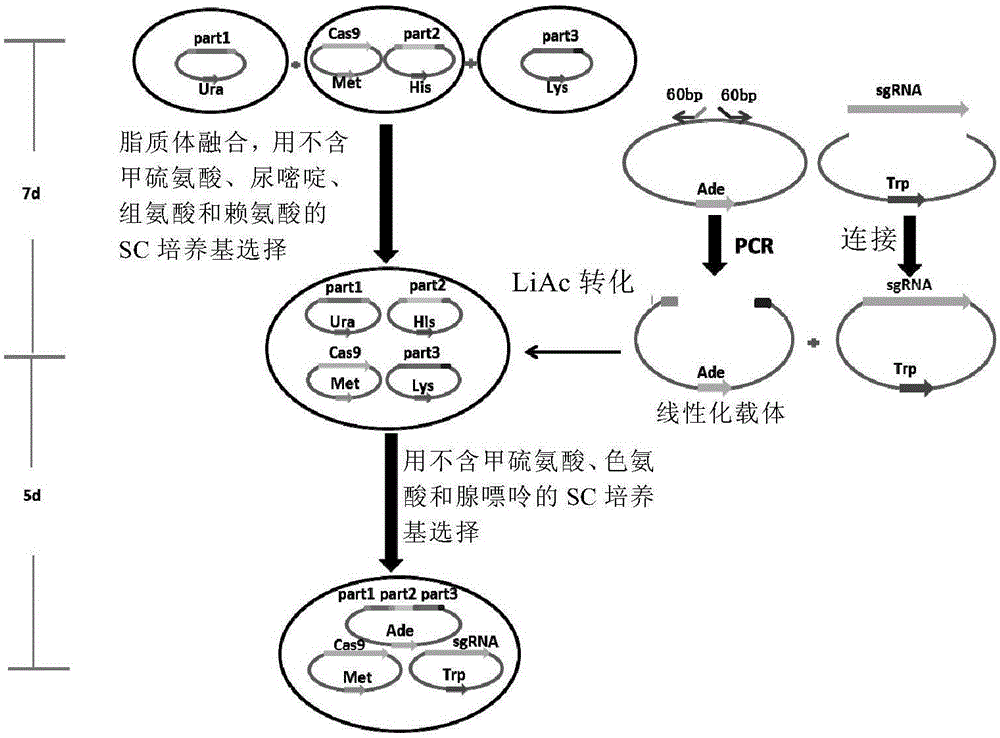

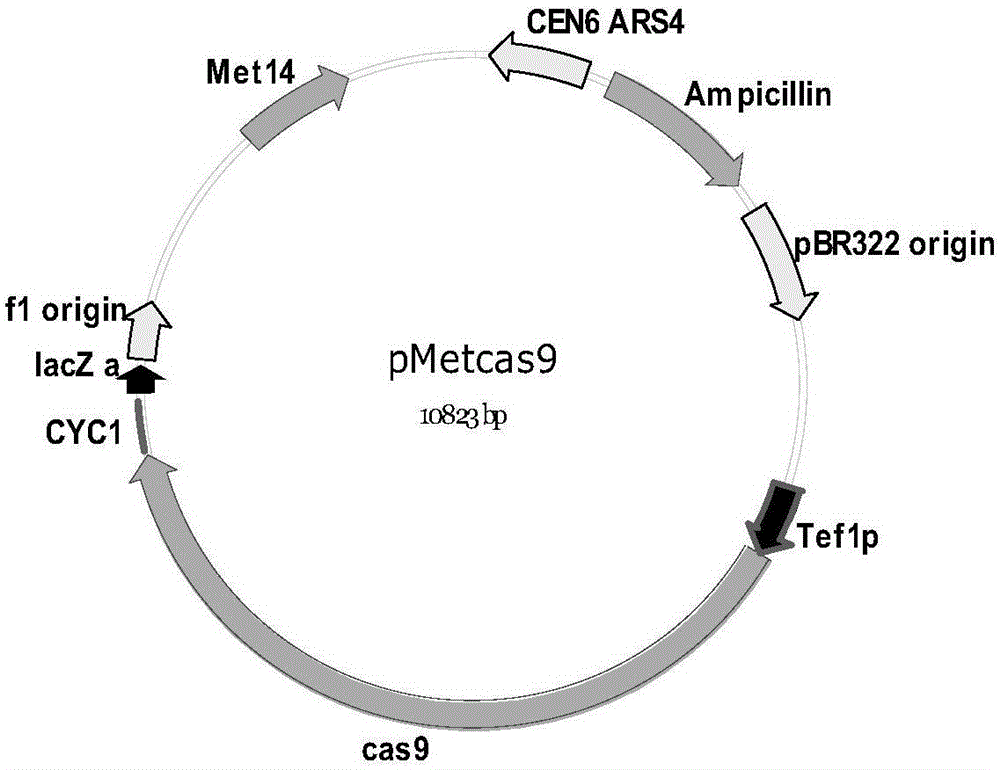

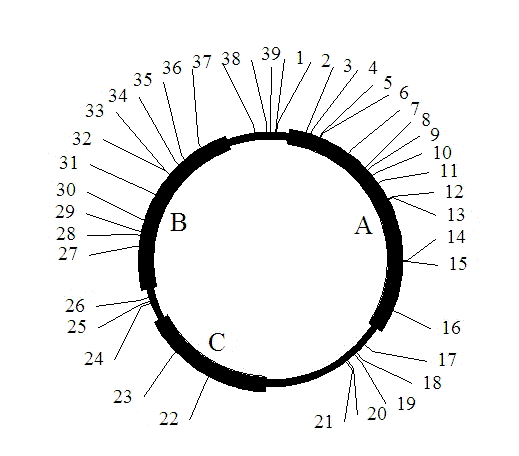

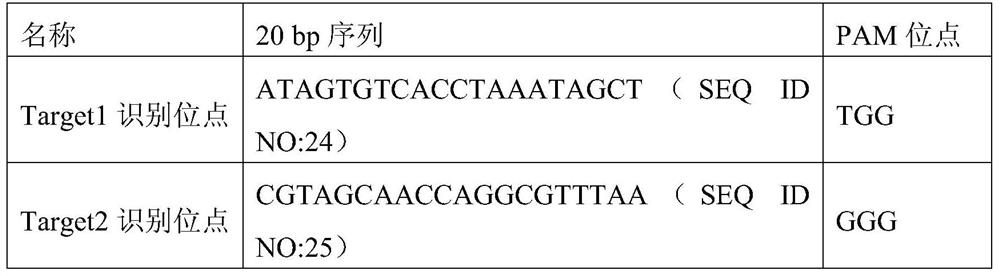

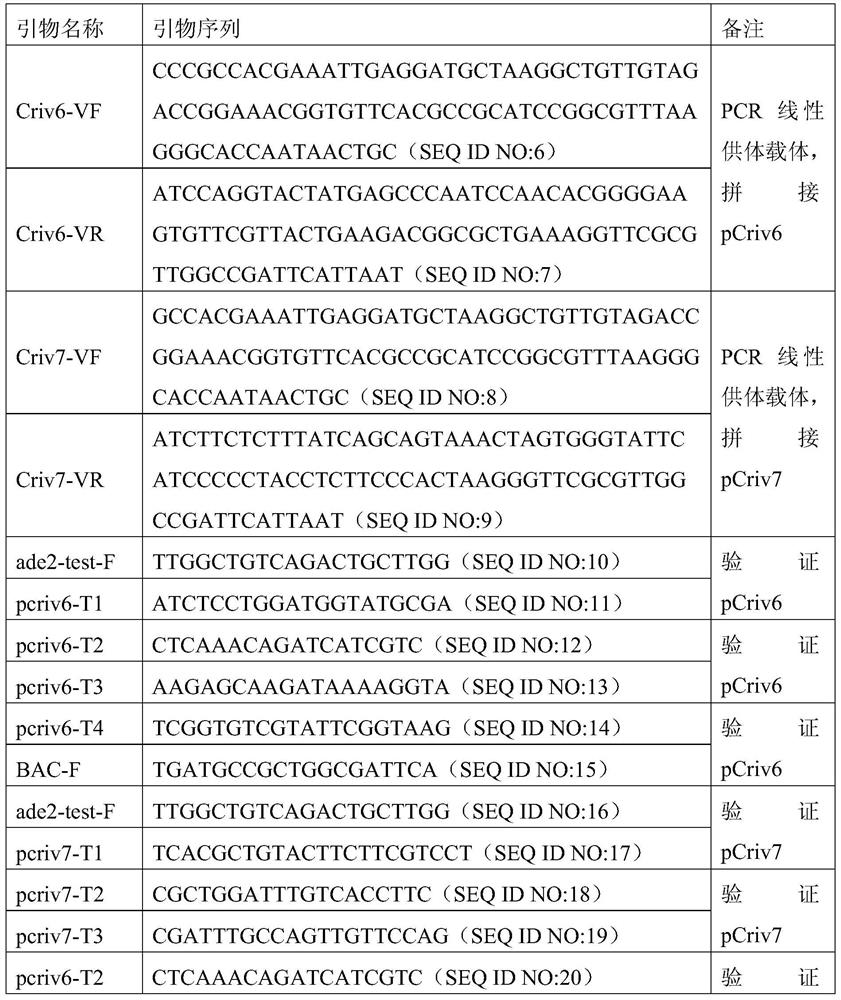

CRISPR/Cas9-mediated large DNA fragment assembling method

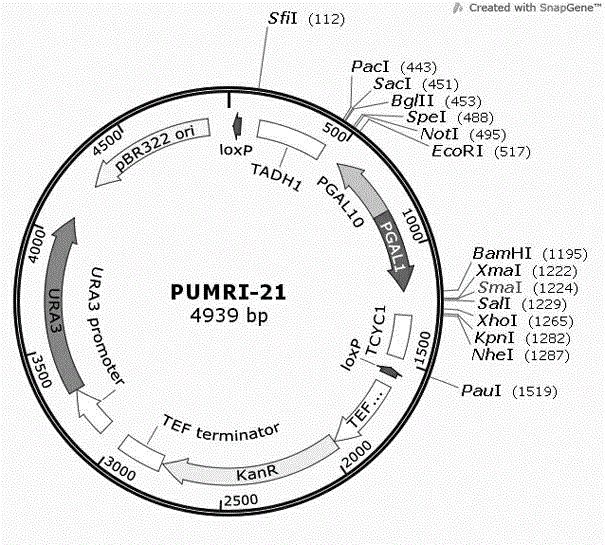

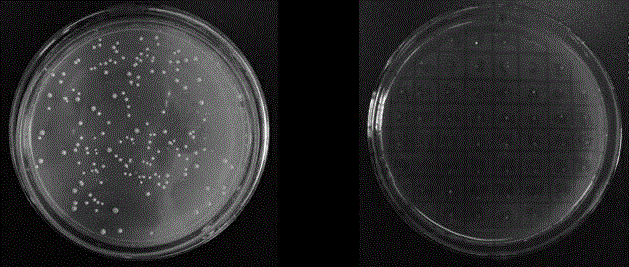

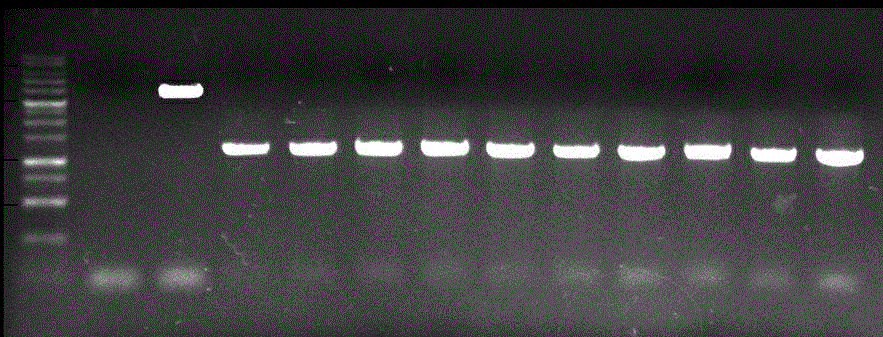

The invention discloses a CRISPR / Cas9-mediated large DNA fragment assembling method. Specifically, the invention provides a nucleic acid construct capable of carrying out constitutive expression of Cas9 in yeast; the nucleic acid construct contains a yeast Tef1 promoter operationally connected with a Cas9 gene, a replication origin from pBR322 and a screening mark thereof, and a replication region from CEN6ARS4 and a screening mark thereof; and the nucleic acid construct is in the form of single-copy replication in the yeast and in the form of high-copy replication in Escherichia coli. The invention also provides a nucleic acid construct capable of carrying out constitutive expression of sgRNA in yeast, a nucleic acid construct used as a receptor vector and a DNA assembling method. According to the invention, two or more to-be-assembled large DNA fragments are successfully assembled in microzyme to form a large plasmid in one shot; so low-efficiency in-vitro digestion recovery, genetic transformation and the like of large DNA fragments are avoided, and the method provided by the invention is more convenient and efficient compared with traditional methods.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

Newcastle disease virus heat resistant live vaccine vector system and application thereof

ActiveCN104059942AHeat resistantHigh heat resistanceSsRNA viruses negative-senseMicroorganism based processesDiseasePBR322

The invention belongs to the field of virus genetic operation, and in particular to a Newcastle disease virus (NDV) heat resistant live vaccine vector system and application thereof. The Newcastle disease virus (NDV) heat resistant live vaccine vector system comprises a) a transcription plasmid, b) three auxiliary plasmids and c) host cells. The transcription plasmid is obtained by cloning genomic full-length cDNA of a NDV heat resistant vaccine strain to pBR322 vector; and the three auxiliary plasmids are obtained by cloning nucleoprotein, phosphoprotein and large polymerase protein gene of the NDV heat resistant vaccine strain to pcDNA3.1 vector. The artificial recombinant Newcastle disease virus has the characteristic of heat resistance, and the Newcastle disease virus (NDV) heat resistant live vaccine vector system is established for the first time. The artificial recombinant Newcastle disease virus has great application prospect in the aspects of research and development of multiple (multivalent) heat resistant genetic engineering live vaccines of the NDV, avian influenza and other major diseases of poultry, research on virus heat-resistant mechanism, and the like.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

Candida utilis expression vector and construction method thereof

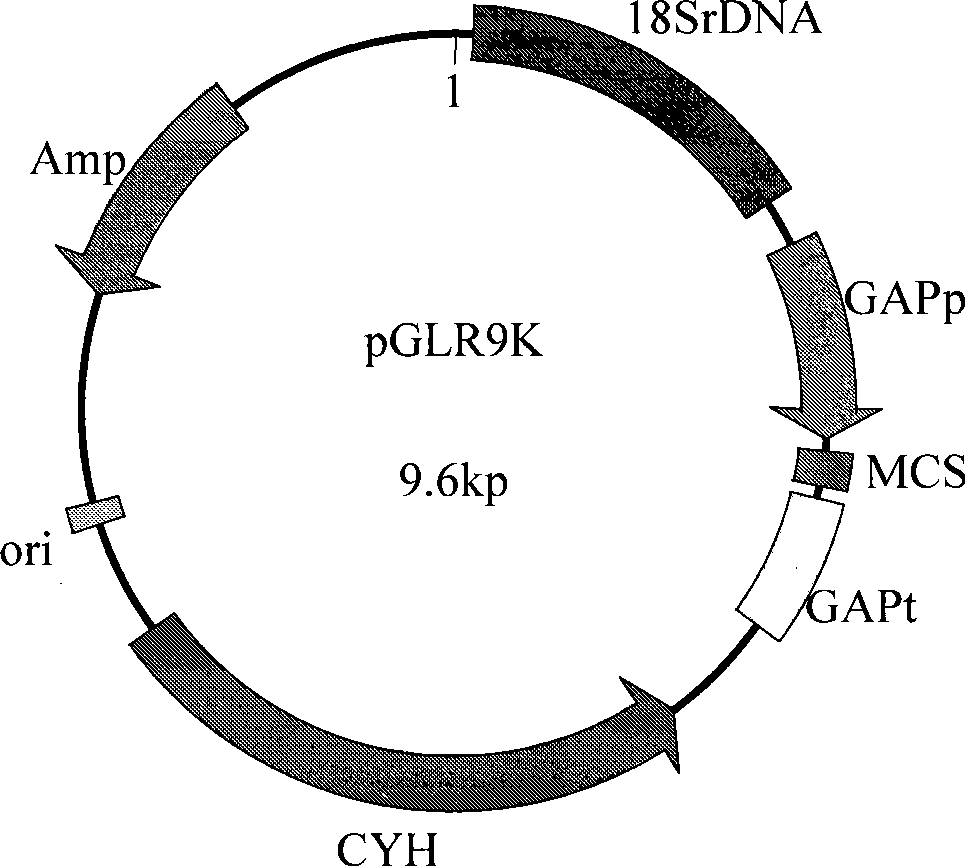

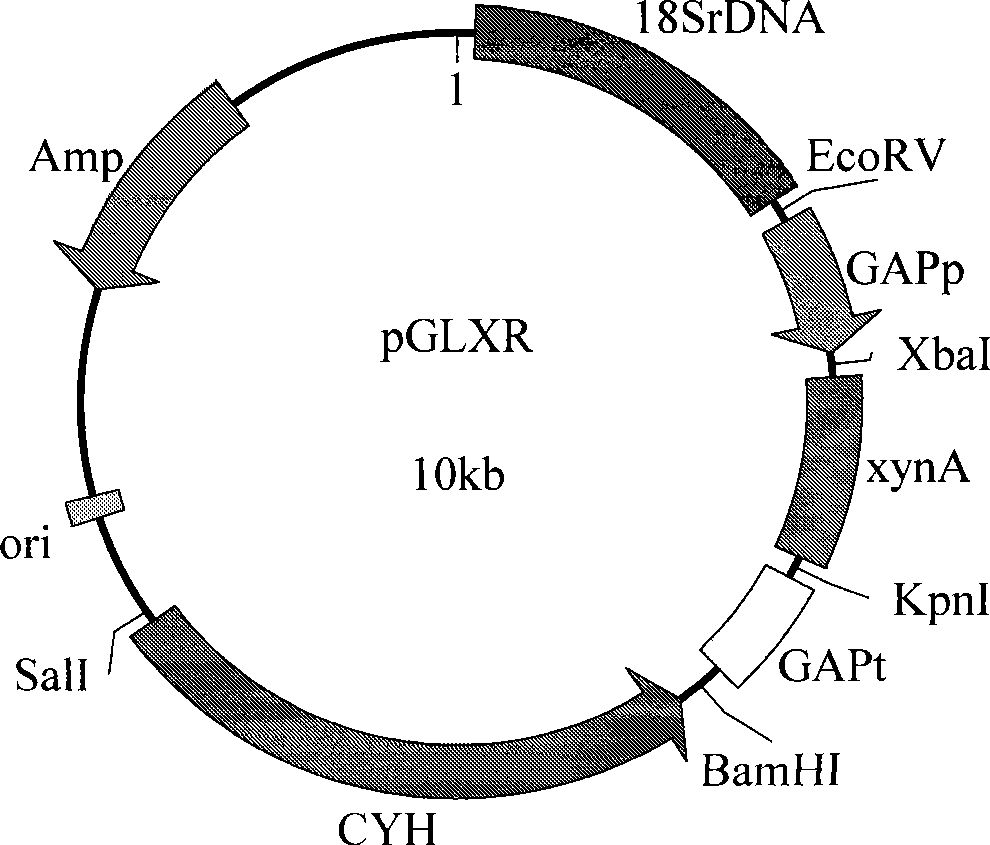

InactiveCN101487019ASave manpower, material and financial resourcesFermentationVector-based foreign material introductionGenomic DNAPBR322

The invention discloses an expression carrier of an industrial microorganism that is candida utili and simultaneously provides a construction method of the candida utili expression carrier. The invention uses a basic skeleton of a pBR322 carrier and a template of candida utili genomic DNA, obtains a cycloheximide resistance gene with the site-directed mutagenesis method, obtains a rDNA segment and a GAP promoter-terminator segment of the candida utili genomic DNA by adopting the PCR method and the template of the candida utili genomic DNA, and constructs the integrated candida utili expression carrier that is mediated by 18S rDNA and has cycloheximide resistance. The integrated candida utili expression carrier can be used for preparing a foreign candida utili expression protein and can be widely applied into the fields of feedstuff addition agents, food industry, and pharmacy, and the like.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

Brewing yeast integrated expression vector with recyclable selective marker and construction method thereof

InactiveCN104561080ARealize repeated useAchieve integrationMicroorganism based processesVector-based foreign material introductionBiotechnologyEscherichia coli

The invention provides a brewing yeast integrated expression vector with a recyclable selective marker as well as a construction method and application thereof. The Brewing yeast integrated expression vector with the recyclable selective marker comprises a loxp-KanMX-URA-PBR322 replicon-Loxp (SEQ ID NO:1), a yeast primary expression cassette and a homologous arm insertable section, wherein the yeast primary expression cassette is any one of a yeast promoter, a multiple cloning site and a transcription terminator. According to the brewing yeast integrated plasmid, replacement of an expression cassette element, cloning of a foreign gene in escherichia coli, integration and screening of the gene in yeast, rapid, simple and convenient removal of the selective marker and recycling of the tool can be realized. According to the invention, removal of the selective marker is represented and verified; the brewing yeast integrated expression vector can be widely applied to long-way multi-gene integration of brewing yeast.

Owner:ZHEJIANG UNIV

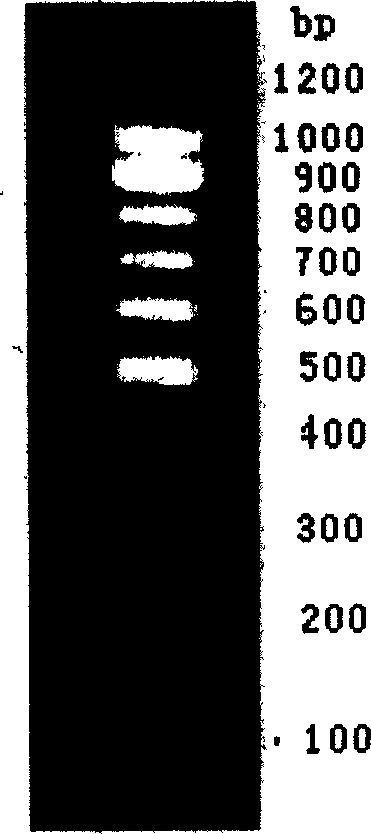

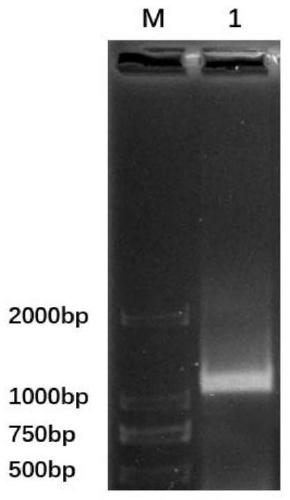

100bp gradient ribonucleic acid molecular weight marker and its preparation

InactiveCN1654650AVector-based foreign material introductionDNA/RNA fragmentationDNA fragmentationDNA

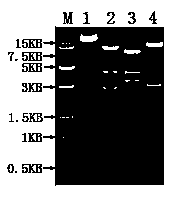

The 100 bp gradient DNA molecular weight marker and its preparation belongs to the field of molecular biology reagent preparing technology. The molecular weight marker is one kind of mixture comprising 11 DNA stripes with the lengths of 100 bp, 200 bp, 300 bp, 400 bp, 500 bp, 600 bp, 700 bp, 800 bp, 900 bp,1000 bp, and 1200 bp separately and the concentration of 4 ng / microliter. The preparation process includes simultaneous synthesis of the 11 DNA stripes through PCR with 11 pairs of specific primers and plasmid PBR322 as template DNA in the presence of Taq DNA polymerase, Taq DNA polymerase buffering liquid and 4 kinds of ribotides (dTTP, dATP, dCTP and dGTP), in the same amplification condition in a PCR instrument; and the subsequent purification and mixing. The present invention features the fast, precise and mass preparation of DNA molecular weight markers of different lengths in the set target.

Owner:JIANGSU INST OF PARASITIC DISEASES

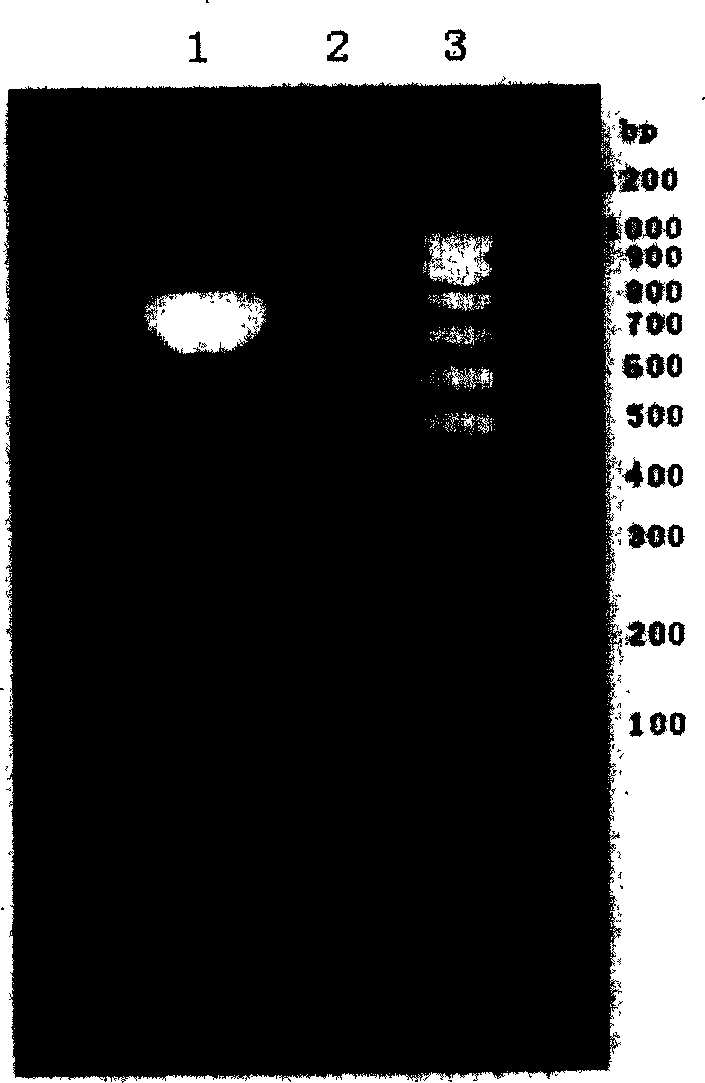

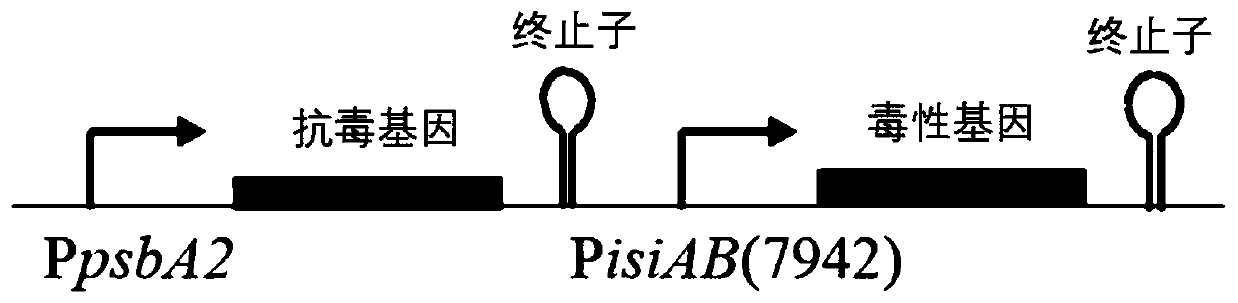

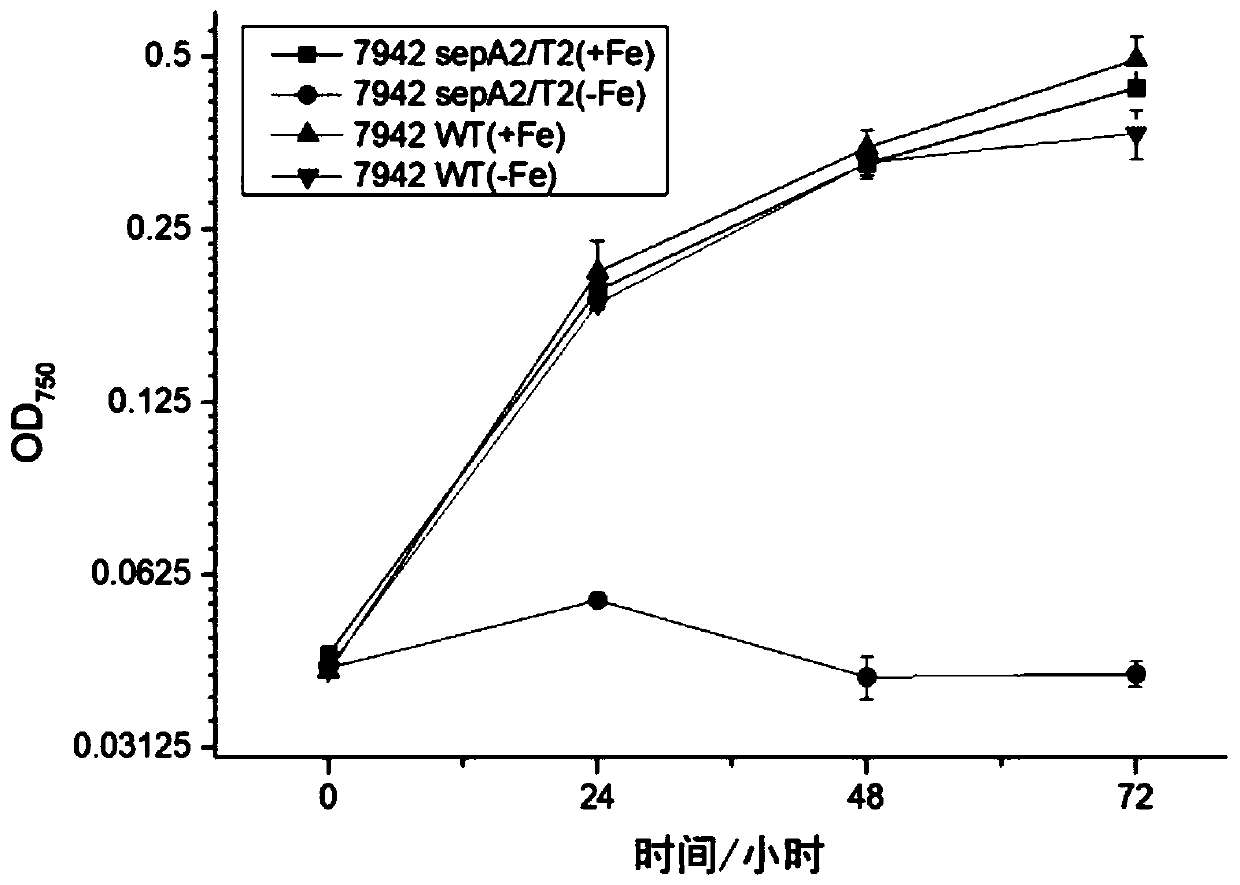

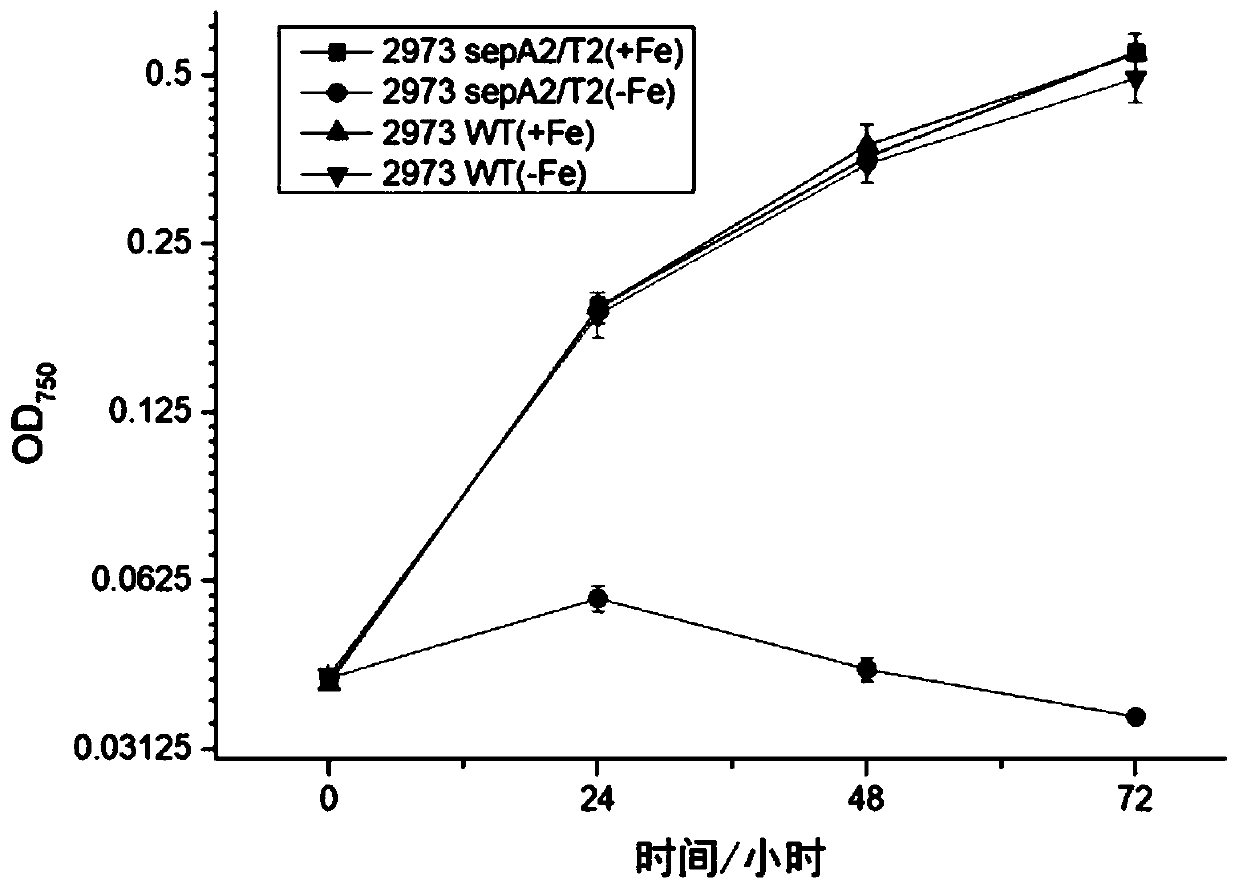

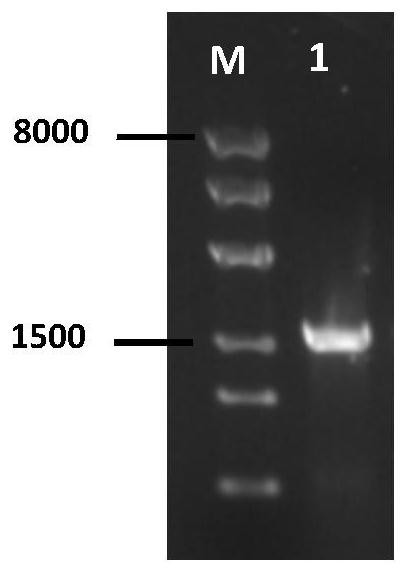

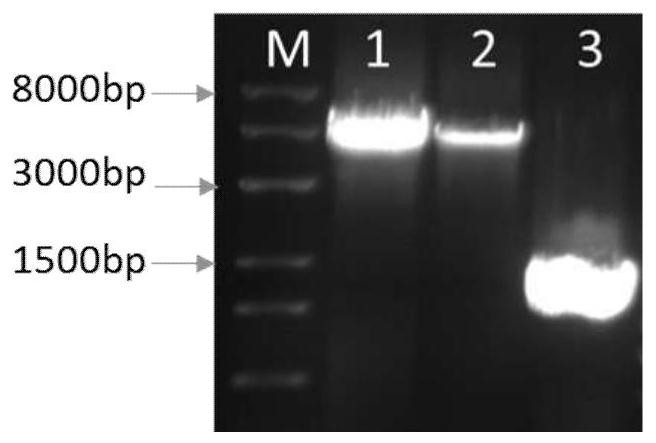

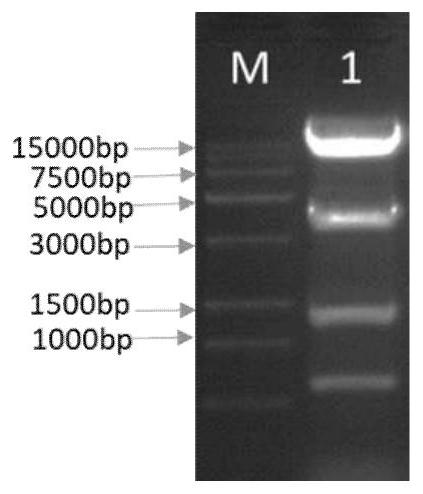

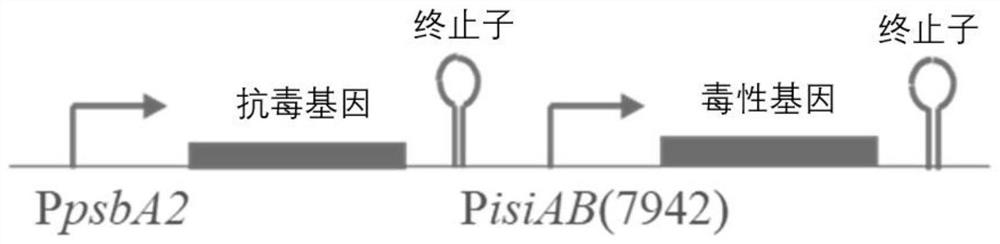

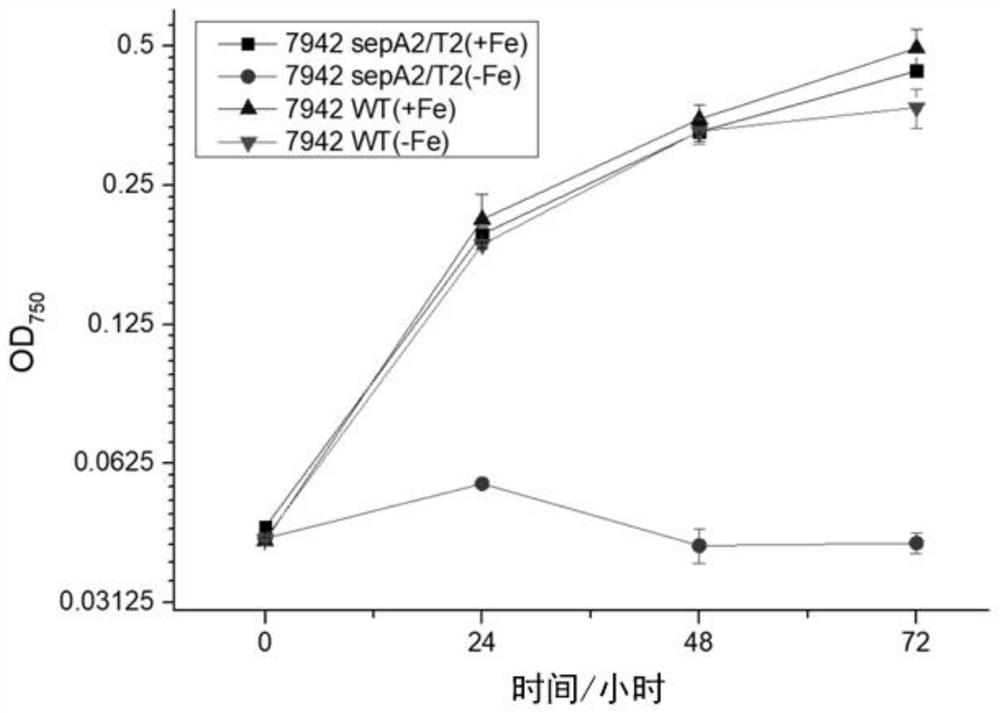

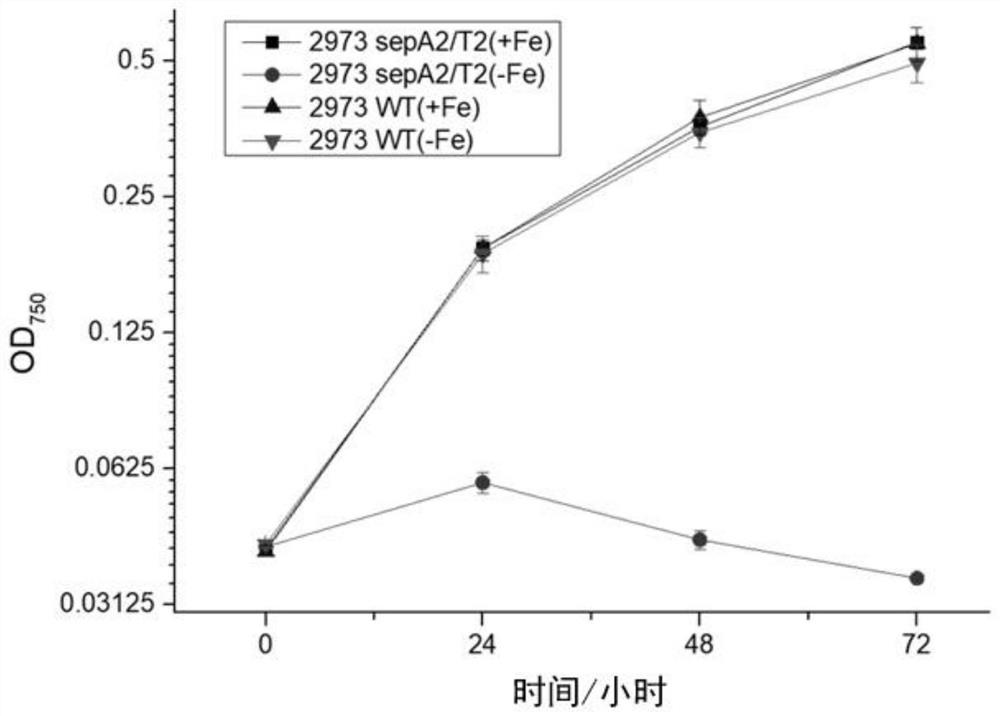

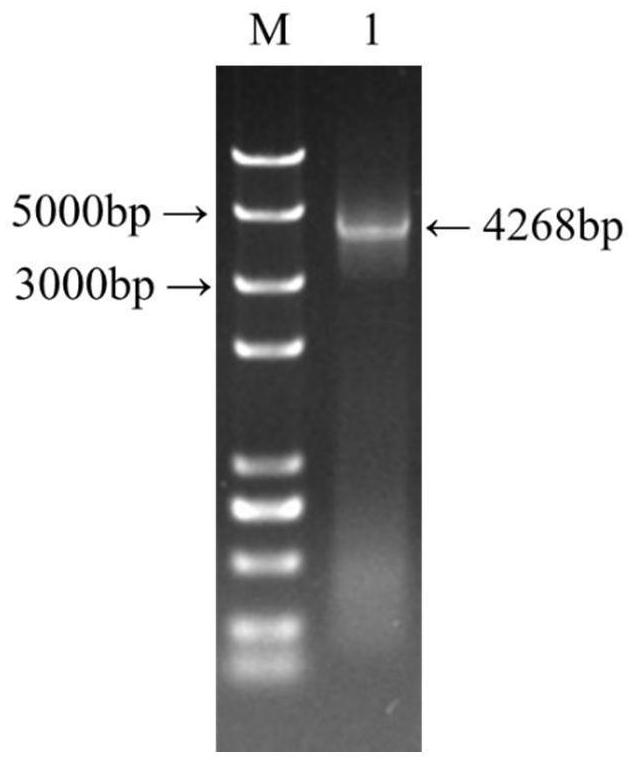

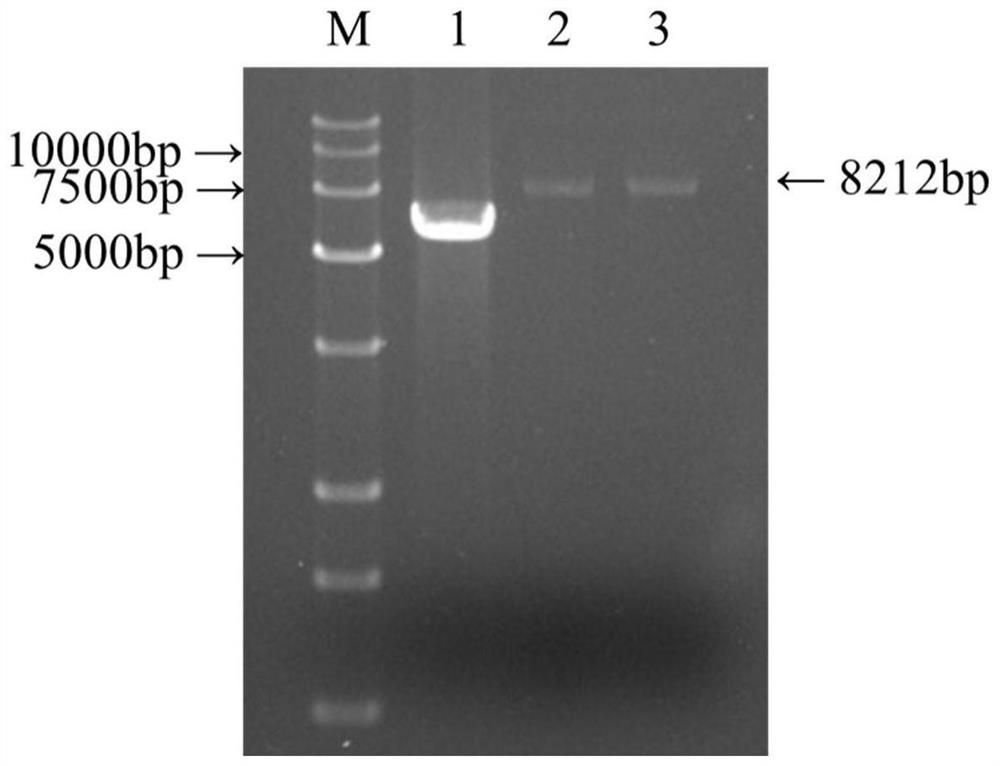

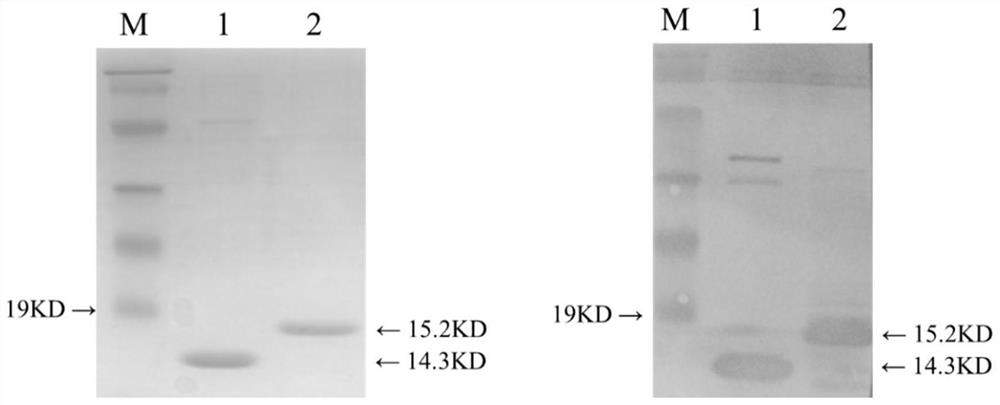

Biological mothballing system suitable for synechococcus elongatus, and construction method and application of biological mothballing system

ActiveCN110438053AAvoid Biosafety ConcernsBacteriaMicroorganism based processesPhylum CyanobacteriaSynechococcus elongatus

The invention discloses a biological mothballing system suitable for synechococcus elongatus, and a construction method and application of the biological mothballing system. The construction method comprises the steps that a virulent gene sepT2, an antitoxic gene sepA2 and an iron-deficiency inducible promoter PisiAB are obtained from the synechococcus elongatus 7942, and a promoter PpsbA2 is obtained from synechocystis 6803; a terminator Trbcl is obtained from integrative plasmid pBA3031 through amplification; pBR322 is taken as a carrier, the virulent gene sepT2 is expressed with the iron-deficiency inducible promoter PisiAB, and the terminator Trbcl is used for terminating transcription; and the antitoxic gene sepA2 is expressed with the promoter PpsbA2, and plasmid is constructed and transferred into the synechococcus elongatus. According to the system, the synechococcus elongatus grows normally under the non-inducing situation and rapidly dies after being induced. The important theoretical and practical significance for development and optimization of the biological mothballing system of the synechococcus elongatus is achieved, and reference is also provided for solving the bio-safety problem of other cyanobacteria.

Owner:TIANJIN UNIV

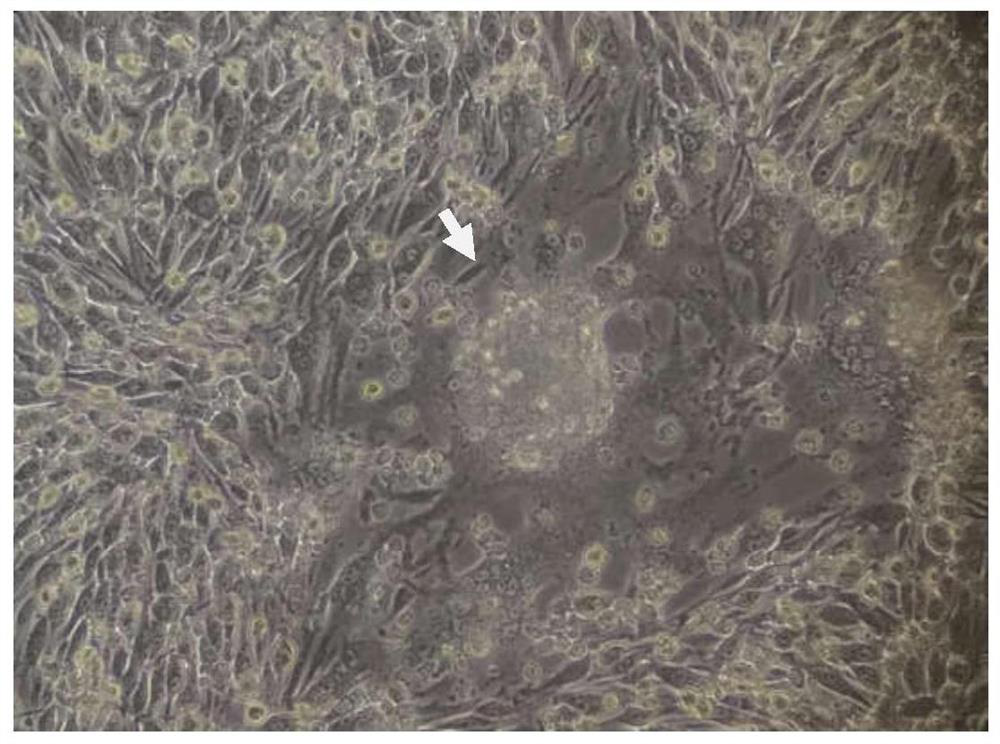

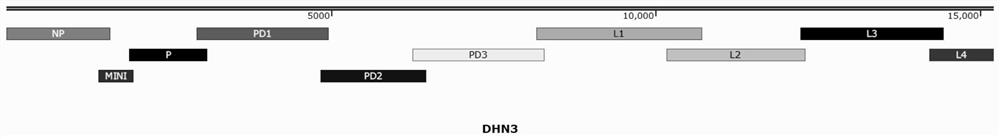

Recombinant plasmid, recombinant gene VII type Newcastle disease virus and culture method thereof

PendingCN112626123AMeet the immunogenicitySsRNA viruses negative-senseCell dissociation methodsNewcastle disease virus NDVPBR322

The invention belongs to the field of biology, and discloses a recombinant plasmid pBR322-FDHN3-S1. The sequence of the recombinant plasmid pBR322-FDHN3-S1 is shown as a sequence table SEQ ID NO: 1. The recombinant plasmid is based on a VII subtype NDV strain DHN3 strain with strong toxicity, an F gene of a Lasota attenuated strain is used for replacing an F gene of the DHN3 strain, an S1 gene is inserted, and the recombinant plasmid has immunogenicity for II-type and VII-type Newcastle diseases and IBV. Meanwhile, the invention also discloses a recombinant virus and a high-titer culture method for the virus.

Owner:ZHAOQING INST OF BIOTECHNOLOGY CO LTD

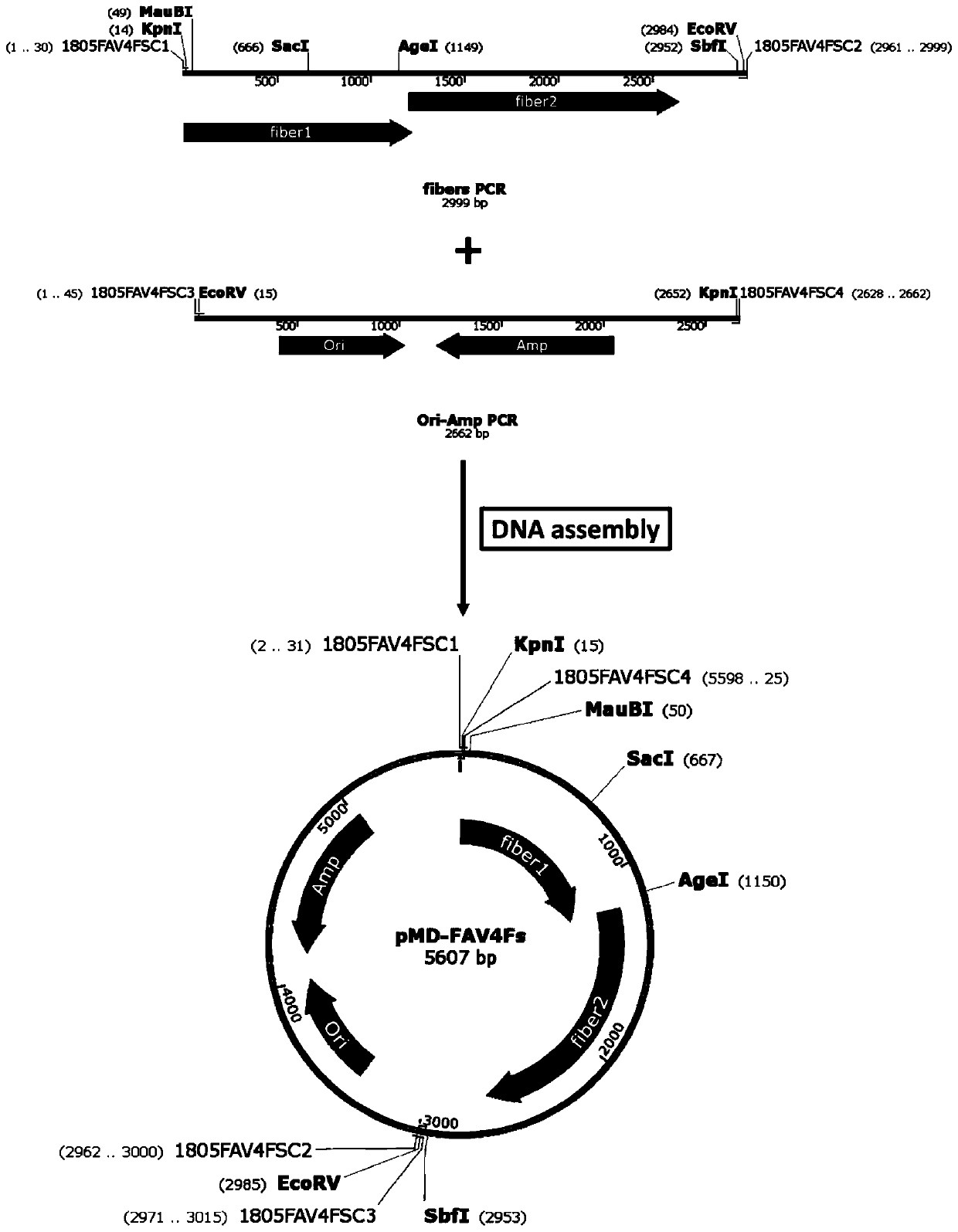

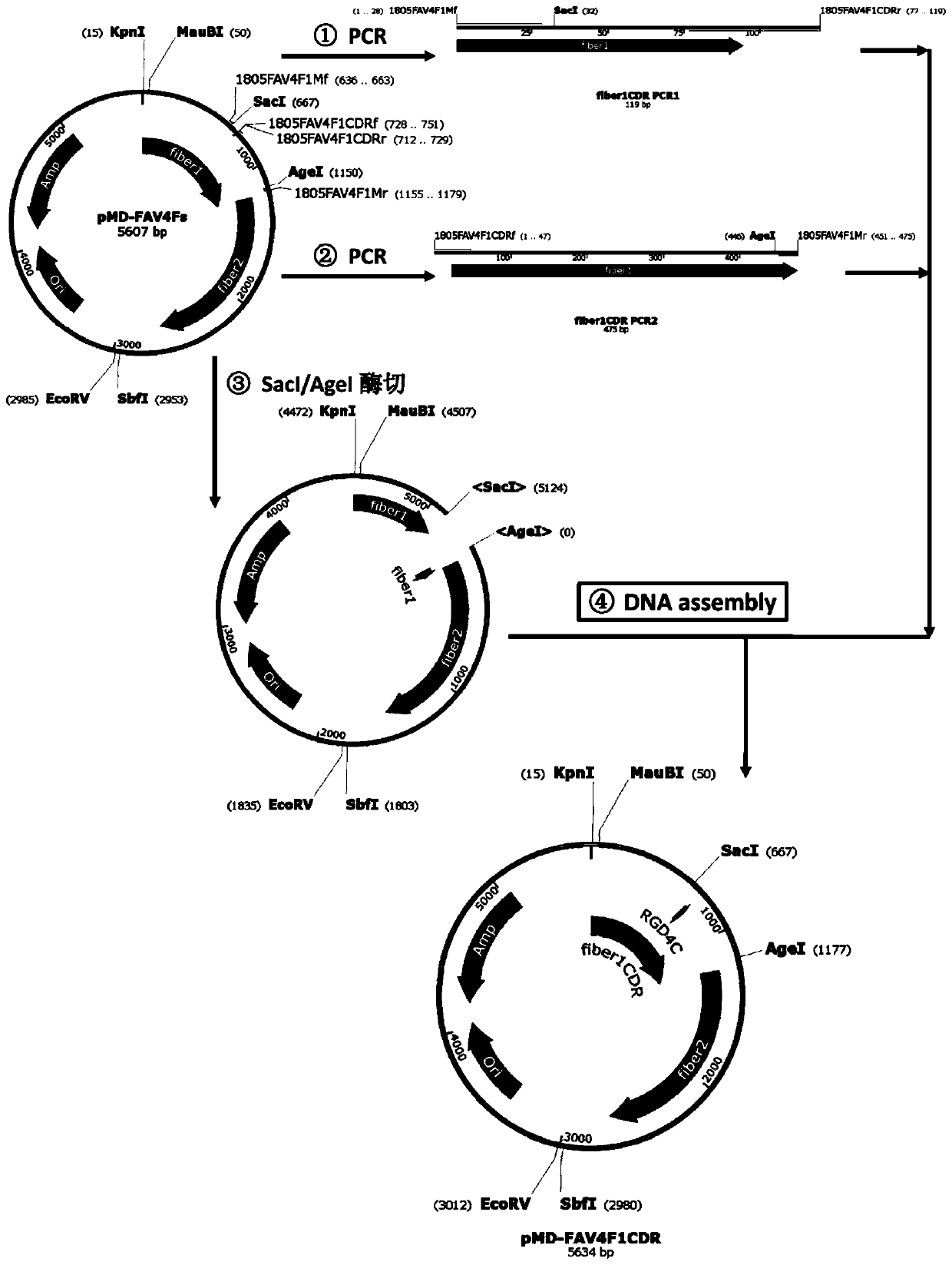

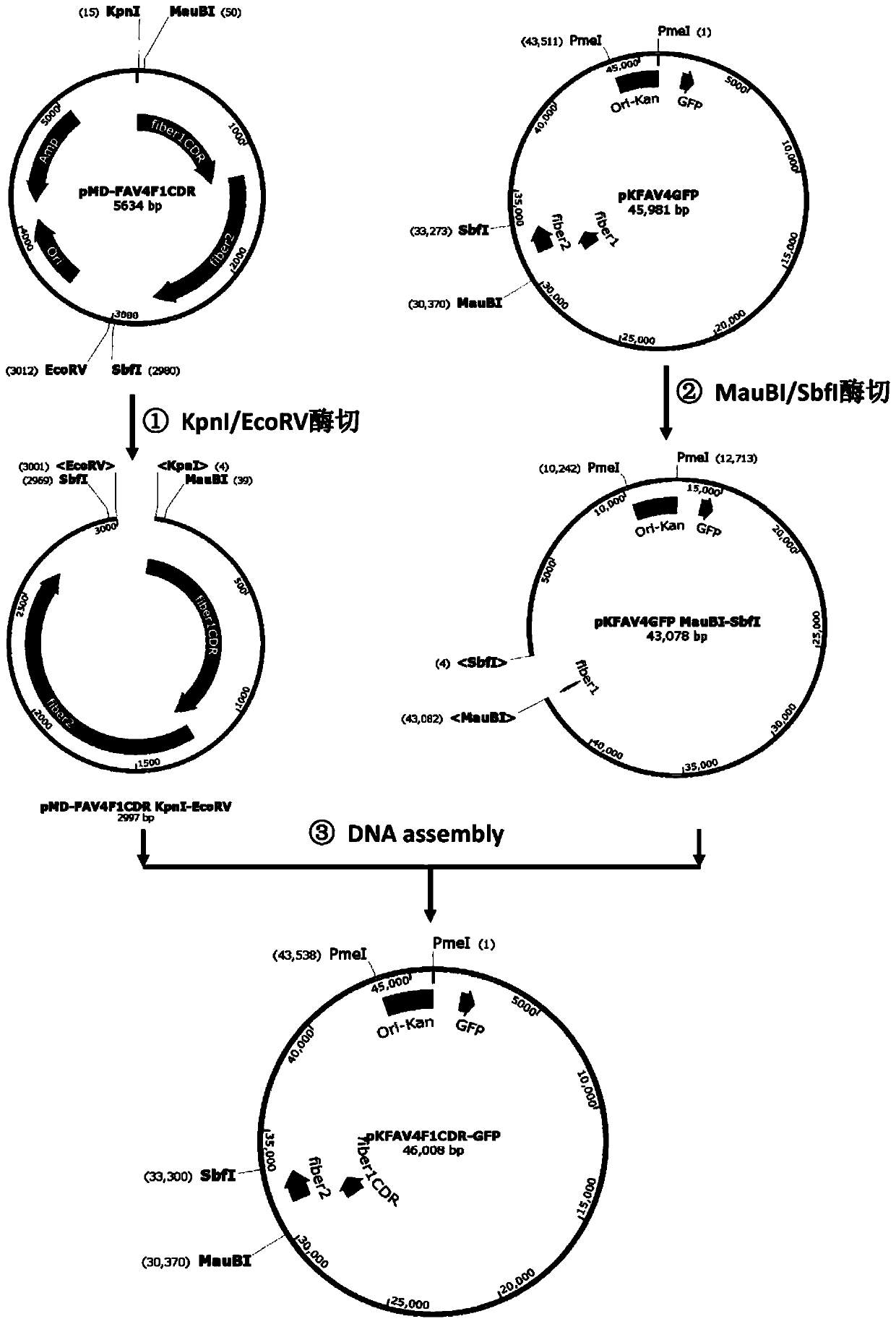

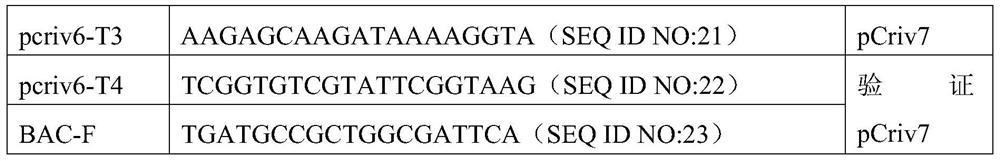

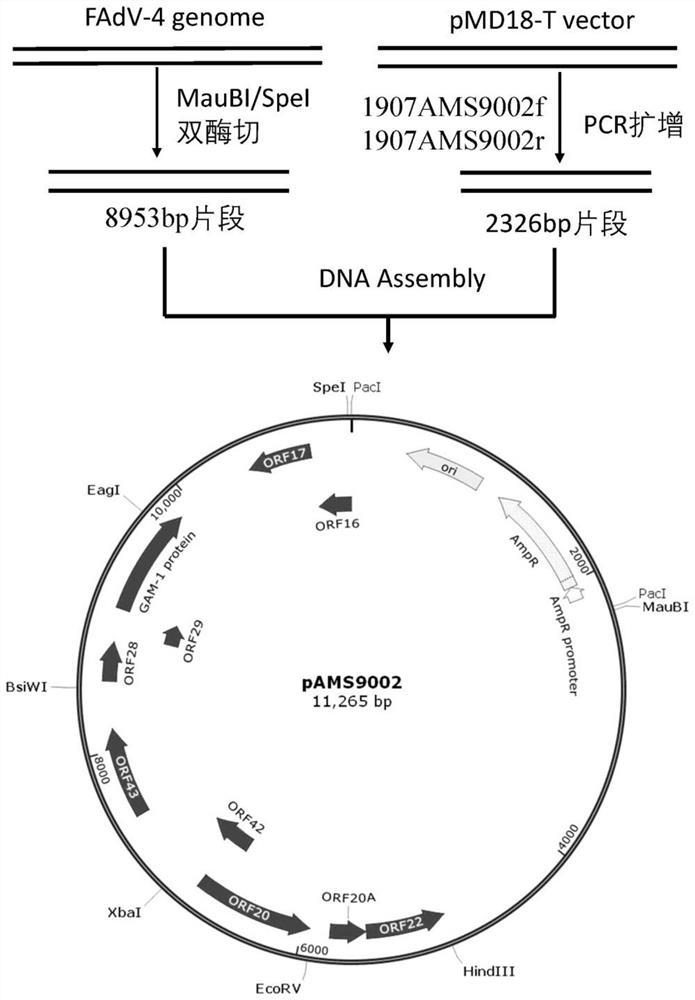

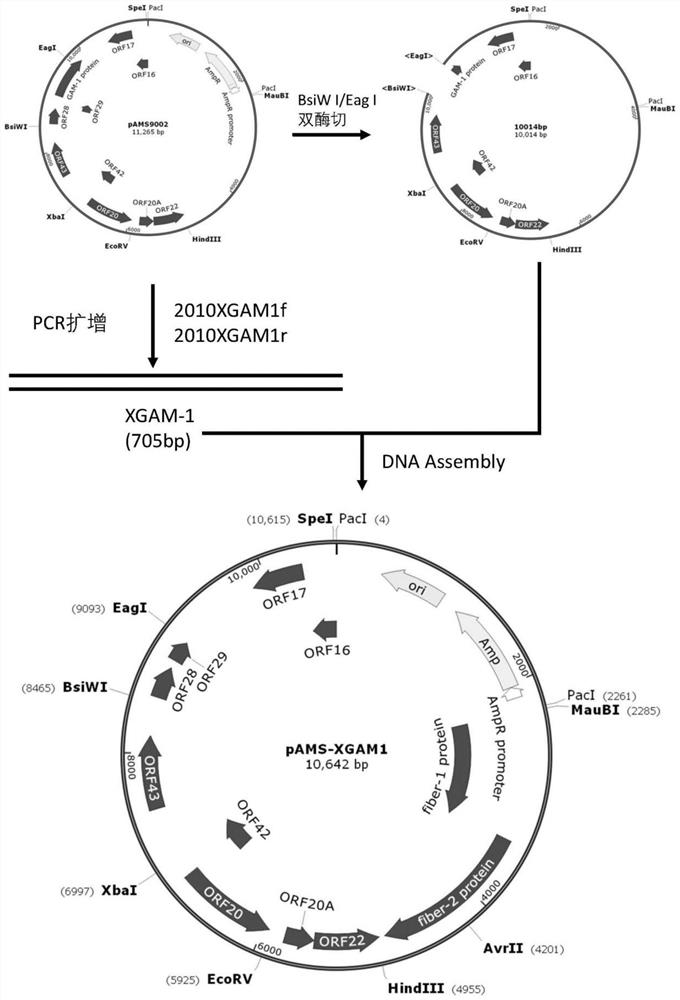

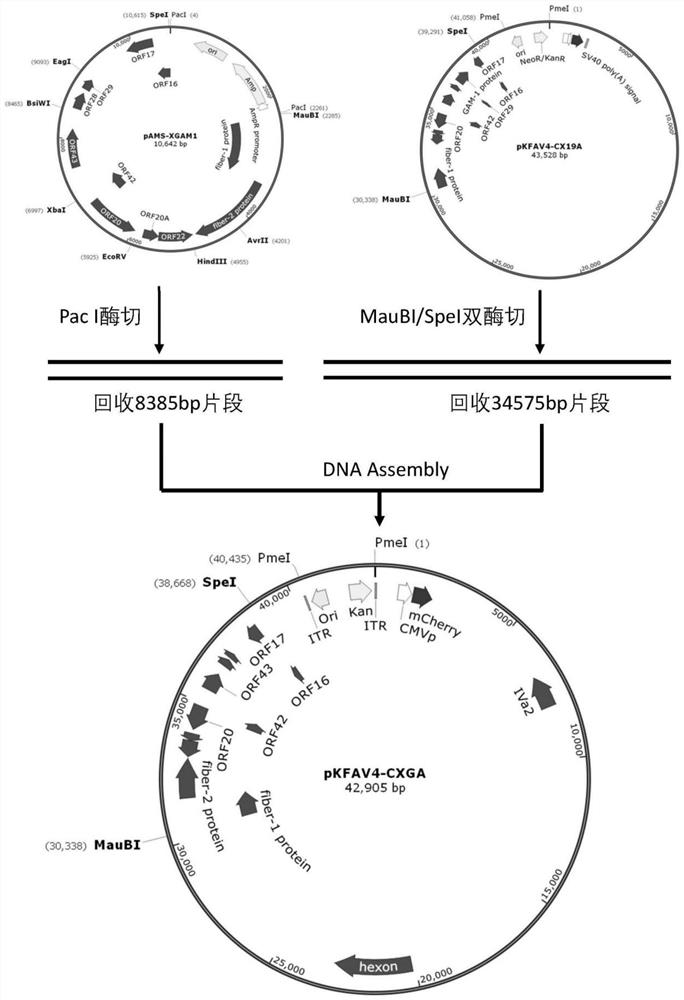

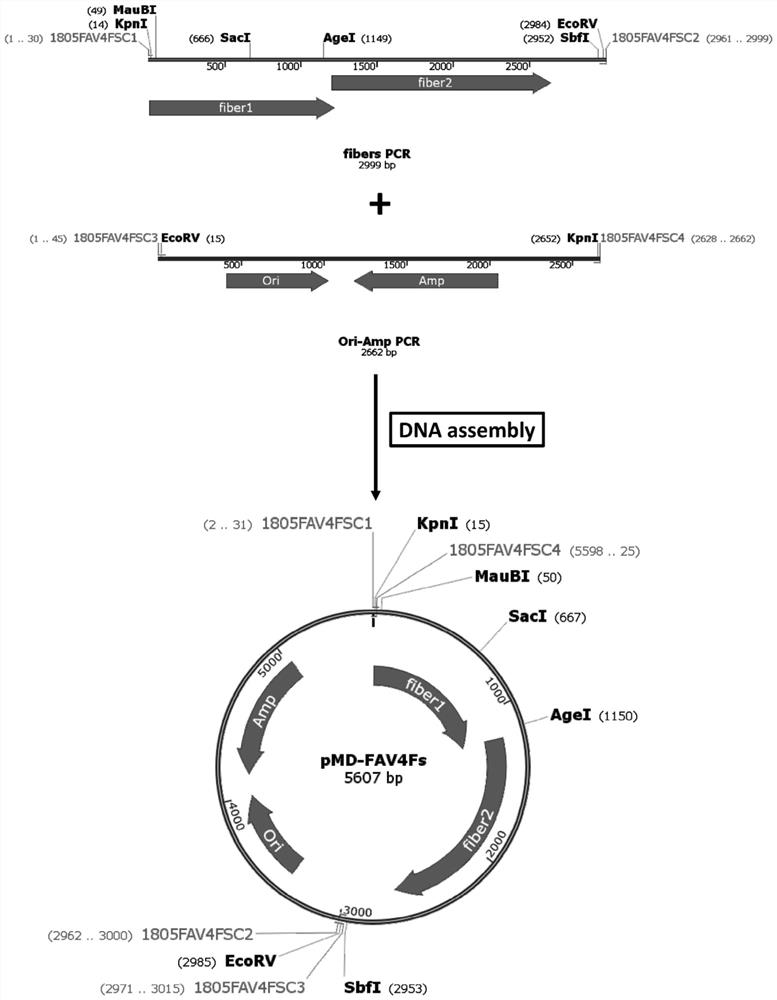

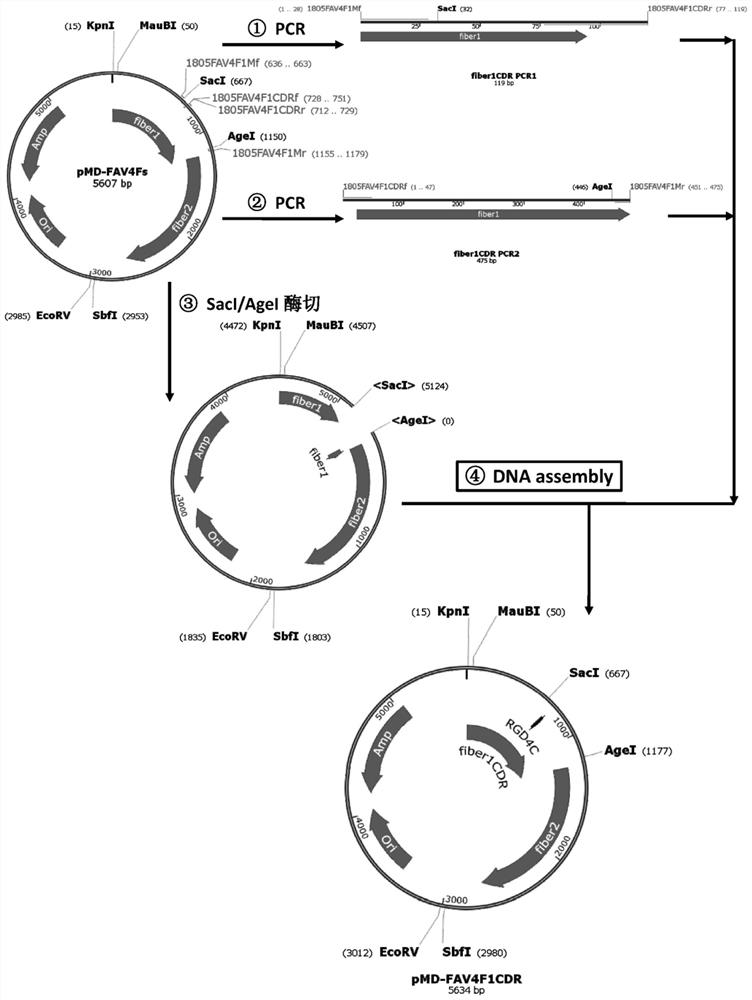

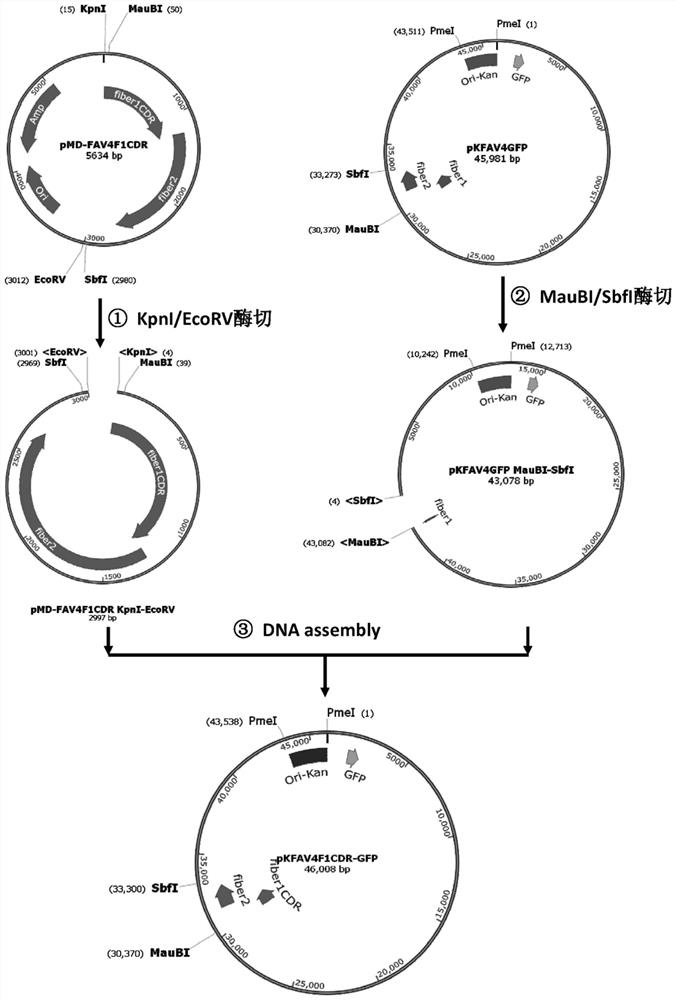

Fowl type-4 adenovirus vector for target infection on mammalian cells and application of fowl type-4 adenovirus vector

ActiveCN111218477AHigh infection efficiencyWhole-cell/virus/DNA/RNA ingredientsNon-active genetic ingredientsOrigin of replicationRecombinant vaccines

The invention discloses a fowl type-4 adenovirus vector for target infection on mammalian cells and application of the fowl type-4 adenovirus vector. The vector comprises a genome sequence of a fowl type-4 adenovirus, a replication origin nucleotide sequence of pBR322 and a kanamycin resistance nucleotide sequence, wherein a fiber nucleotide sequence in the genome sequence is artificially transformed, including inserting an RGD4C short peptide nucleotide sequence into a Knob region of a fiber gene, and / or the Knob region of the fiber gene is replaced by a nucleotide sequence of human type-35 adenovirus fiber Knob. The transformed fowl type-4 adenovirus vector disclosed by the invention is capable of improving the infection efficiency on the mammalian cells, and can be adopted to prepare recombinant vaccines or gene treatment kits of mammals.

Owner:中国疾病预防控制中心病毒病预防控制所

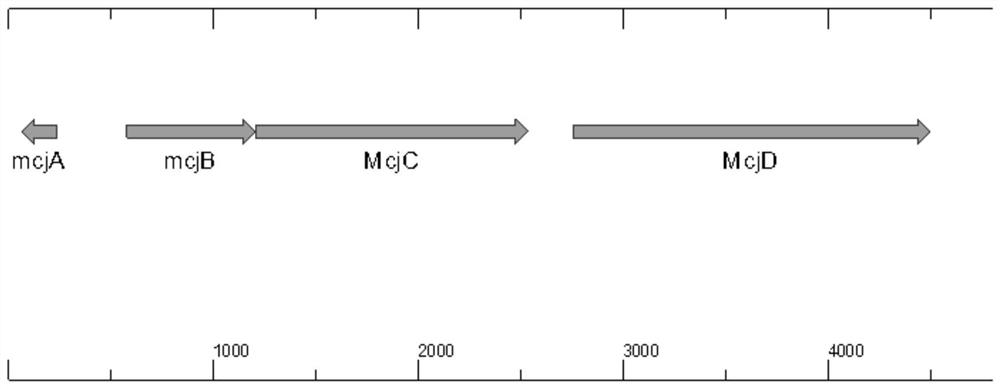

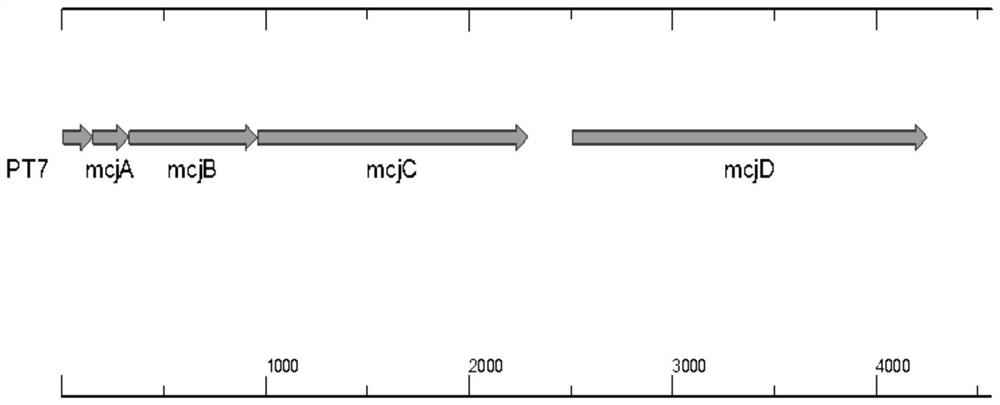

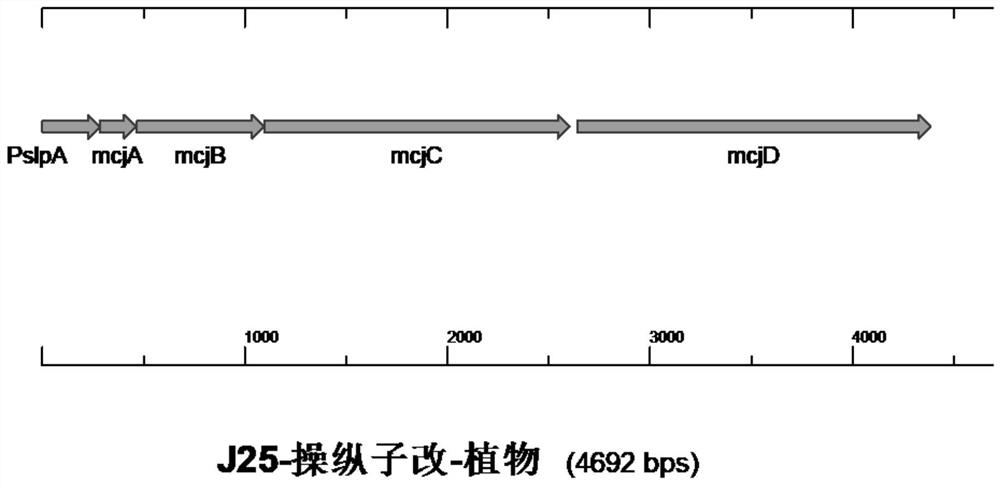

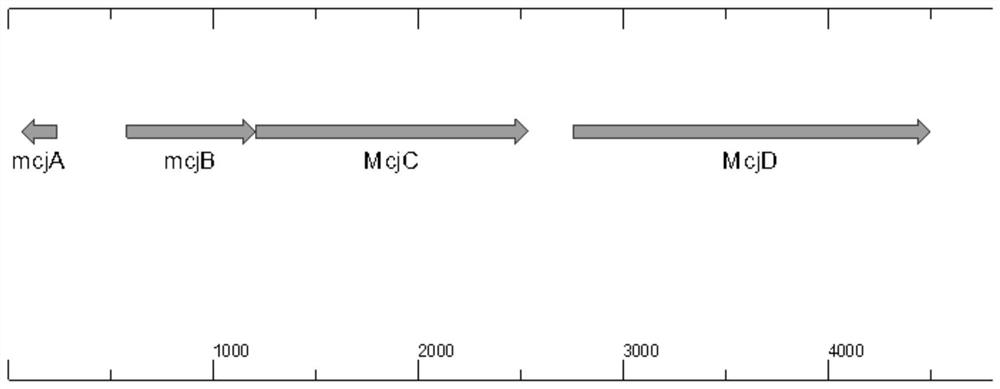

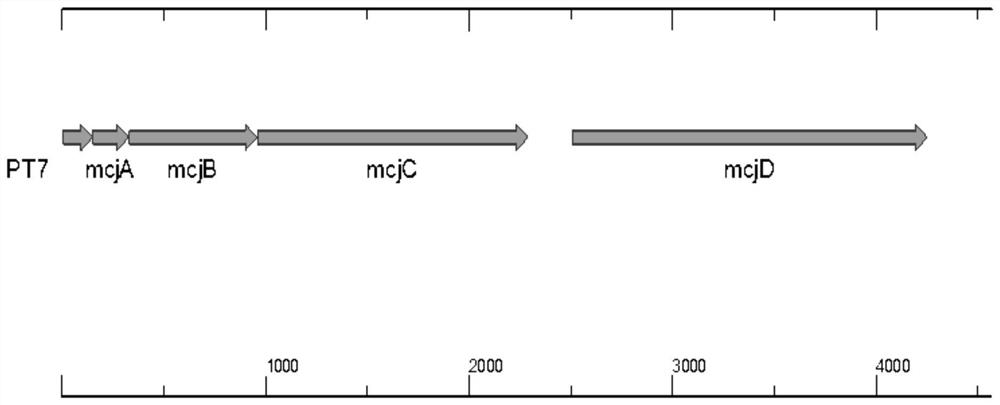

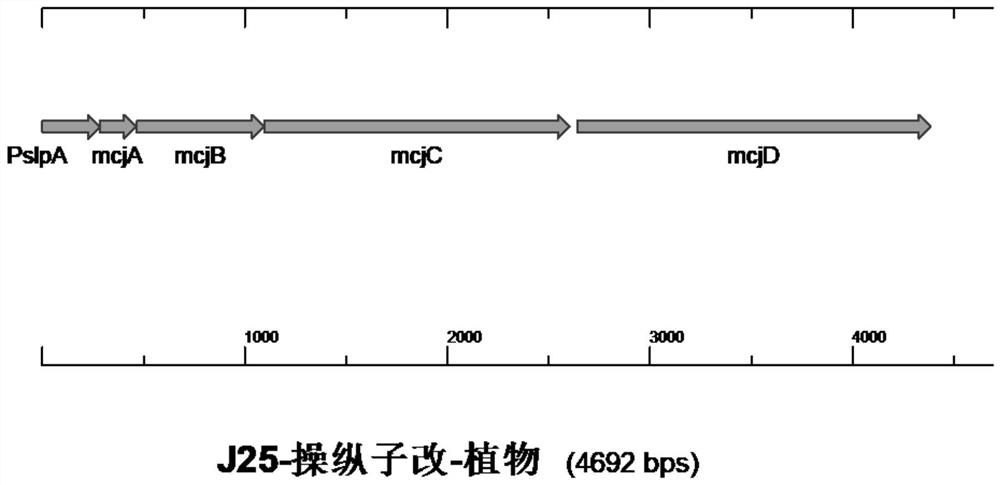

Engineering strain for efficiently expressing MccJ25 and fermentation process of engineering strain

ActiveCN113774006AEfficient expressionThe post-processing purification process is simpleBacteriaMicroorganism based processesBiotechnologyEscherichia coli

The invention provides an engineering strain for efficiently expressing MccJ25. The engineering strain is used for solving the problem of low expression level of Microcin J25 in the prior art. The engineering strain is constructed by the following method: genetic operation is separately carried out on mcjABCD to become a direction, a promoter T7 is shared in Escherichia coli and is cloned on a vector pBR322, high-efficiency expression in the Escherichia coli is realized, and the expression level is 2.4 g / L. According to the scheme, new expression vectors are constructed, an Escherichia coli expression vector and a lactobacillus plantarum expression vector are separately constructed to efficiently express the MccJ25, meanwhile, a directed evolution technology is adopted, molecular evolution is performed on an MccJ25 gene cluster, and efficient expression of the MccJ25 is realized. Extracellular expression is carried out on the Escherichia coli, intracellular expression is carried out on lactobacillus plantarum, the expression levels reach 4.1g / L and 2.3g / L separately, an industrialization level is achieved, and a foundation is laid for further application of biological veterinary drugs and feed additives.

Owner:安杰利(重庆)生物科技有限公司

Heat-resistant newcastle disease virus live vaccine vector system and use thereof

ActiveUS20140287496A1Improve featuresReduce shipping costsSsRNA viruses negative-senseAnimal cellsVector systemHeat resistance

A heat-resistant NDV live vaccine vector system includes a transcription plasmid, three helper plasmids, and host cells. The transcription plasmid is constructed by through cloning complete genomic cDNA of a heat-resistant NDV vaccine strain to a pBR322 vector. The three helper plasmids are constructed by cloning sequences coding nucleoprotein (NP), phosphoprotein, large polymerase protein of a heat-resistant NDV vaccine strain respectively to pcDNA3.1 vectors. A recombinant NDV artificially obtained by cotransfacting host cells with the transcription plasmid and the three helper plasmids shows heat-resistance.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

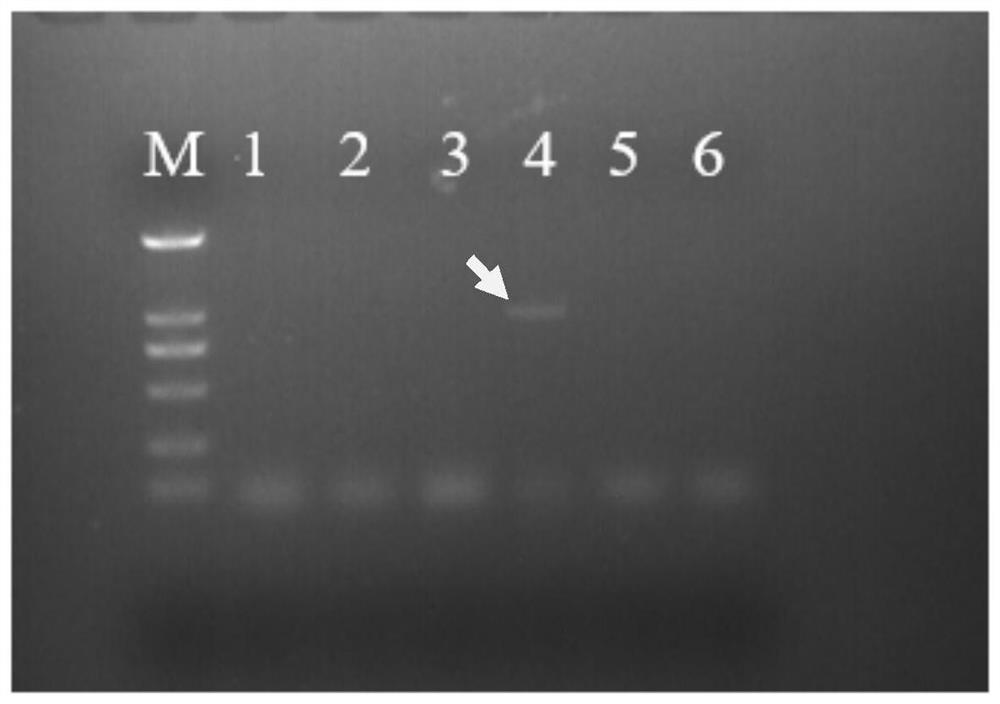

Rescuing method of gene VII type Newcastle disease virus subjected to codon replacement

ActiveCN111926025AStable expressionReduce the possibilitySsRNA viruses negative-senseVirus peptidesT7 RNA polymeraseNewcastle disease virus NDV

The invention relates to the technical field of reverse genetic manipulation, and discloses a rescuing method of a gene VII type Newcastle disease virus subjected to codon replacement. The method comprises the steps: respectively cloning the NP, P and L genes of the Newcastle disease virus and the DE3 gene for expressing the T7 RNA polymerase into a pXJ40 vector to obtain plasmids pXJ40-NP, pXJ40-P, pXJ40-L and pXJ40-DE3; cloning the whole genome cDNA of the Newcastle disease virus into a pBR322 plasmid to obtain pBR322-DHN3; replacing part of codons in an NP gene coding region with codons with the highest use frequency in a unified manner, and replacing the codons with pBR322-DHN3 plasmids to form new plasmids pBR322-mNPDHN3; and co-transfecting bHK-21 cells by adopting the five plasmidsso that the rescued virus rDHN3-mNP is obtained. The method provided by the invention is more beneficial to virus rescue and virus pathogenic mechanism research.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing rebaudioside M through fermentation catalysis of bacillus subtilis

PendingCN114214378AReduce stepsLow costBacteriaMicroorganism based processesBiotechnologyUltrafiltration

The invention relates to a method for preparing rebaudioside M by fermentation catalysis of bacillus subtilis, which is characterized by comprising the following steps: (1) connecting glycosyl transferase UGT76G1 and UGT11 genes to a PBR322 plasmid vector, guiding into the bacillus subtilis, inoculating into an LB culture medium, and culturing for 20-24 hours at the temperature of 30-37 DEG C and the speed of 100-250 rpm; (2) inoculating into a seed tank according to the inoculum size of 1%-10%, and culturing for 20-24 hours at the temperature of 30-37 DEG C at the speed of 200-400 rpm and the ventilation ratio of 0.1-1 V / V.min; (3) inoculating into a fermentation tank according to the ratio of 1%-10%, and culturing for 48-72 hours at the temperature of 30-37 DEG C and the pH value of 6-8 at the speed of 200-1000 rpm and the ventilation ratio of 0.1-2 V / V.min; (4) carrying out ceramic membrane ultrafiltration on the fermentation liquor, carrying out resuspension and high-pressure homogenization on the thallus, and carrying out ceramic membrane ultrafiltration on the thallus crushing liquor to obtain crude enzyme liquor; and (5) mixing stevioside, uridine diphosphate glucose, a phosphate buffer and the crude enzyme according to a mass ratio of (5-10): (1-5): (40-60): (5-20), and reacting at 25-40 DEG C for 12-48 hours. The method has the advantages that two crude enzyme solutions are obtained through one-time fermentation, the operation is simple, the cost is low, and the conversion rate is 88.4% or above.

Owner:ANHUI JINGHE IND

Avian pathogenicity escherichia coli type VI secretion system clpV gene deleted strain as well as construction method and application thereof

The invention relates to the technical field of biology, and discloses an avian pathogenicity escherichia coli type VI secretion system clpV gene deleted strain as well as a construction method and anapplication thereof, which are used for researching, preventing and controlling pathogenesis of avian pathogenicity escherichia coli. And successfully a clpV gene deleted strain of the APEC TW-XM strain is constructed by using a Red homologous recombination system to obtain the deleted strain TW-XM clpV. And the clpV gene is cloned into an expression vector pBR322, and transformed into a deletedstrain TW-XM delta clpV to obtain a corresponding gene complementary strain TW-XMC delta clpV. A mouse infected animal model is constructed by intraperitoneal injection of escherichia coli, and it isfound through detection that the bacterial load of brain, blood and lung tissue and the expression of meningitis related inflammatory factor mRNA in the brain tissue are obviously reduced. It demonstrates that clpV is closely related to APEC pathogenicity.

Owner:YANGZHOU UNIV

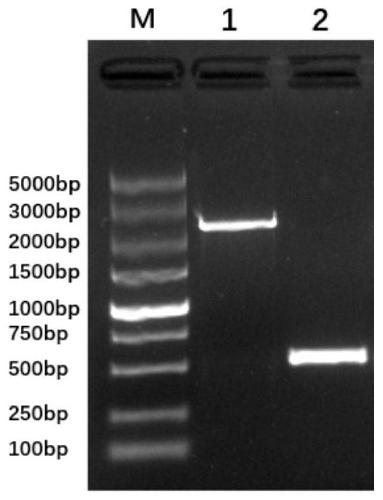

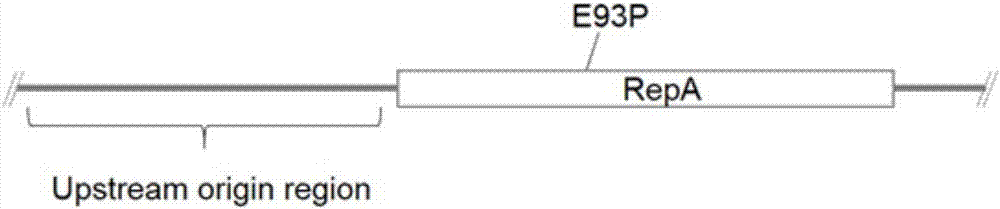

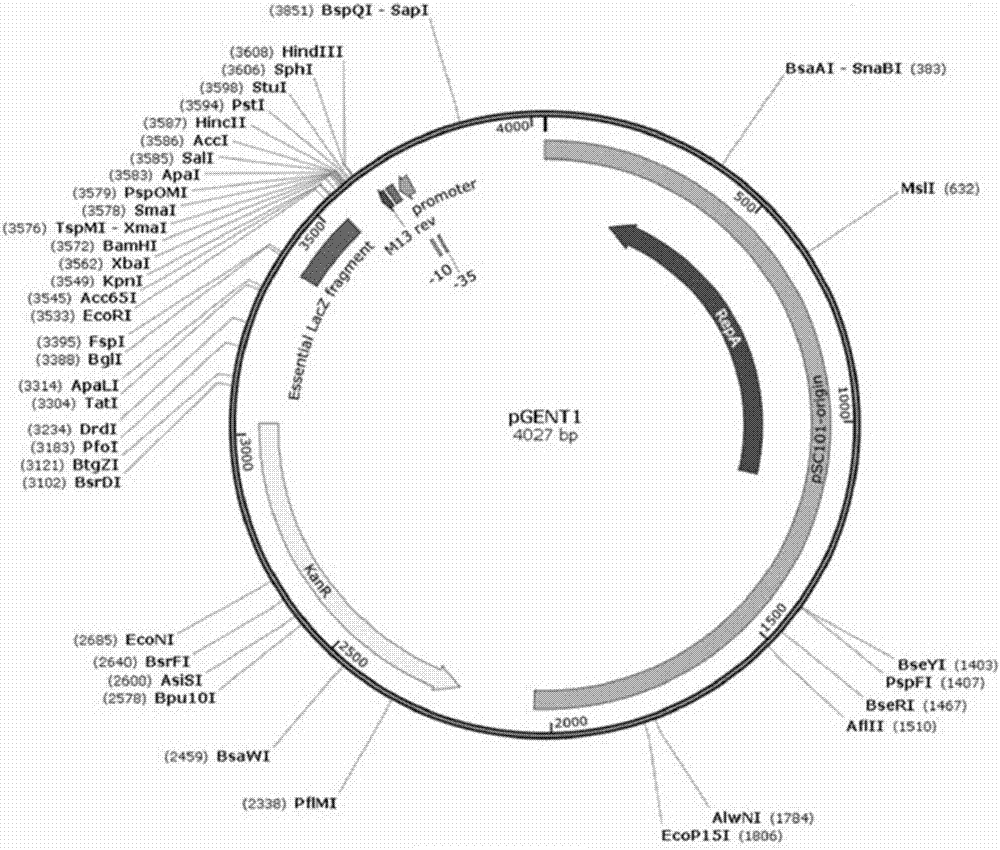

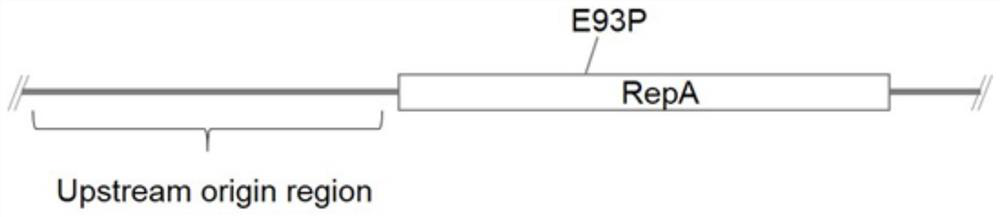

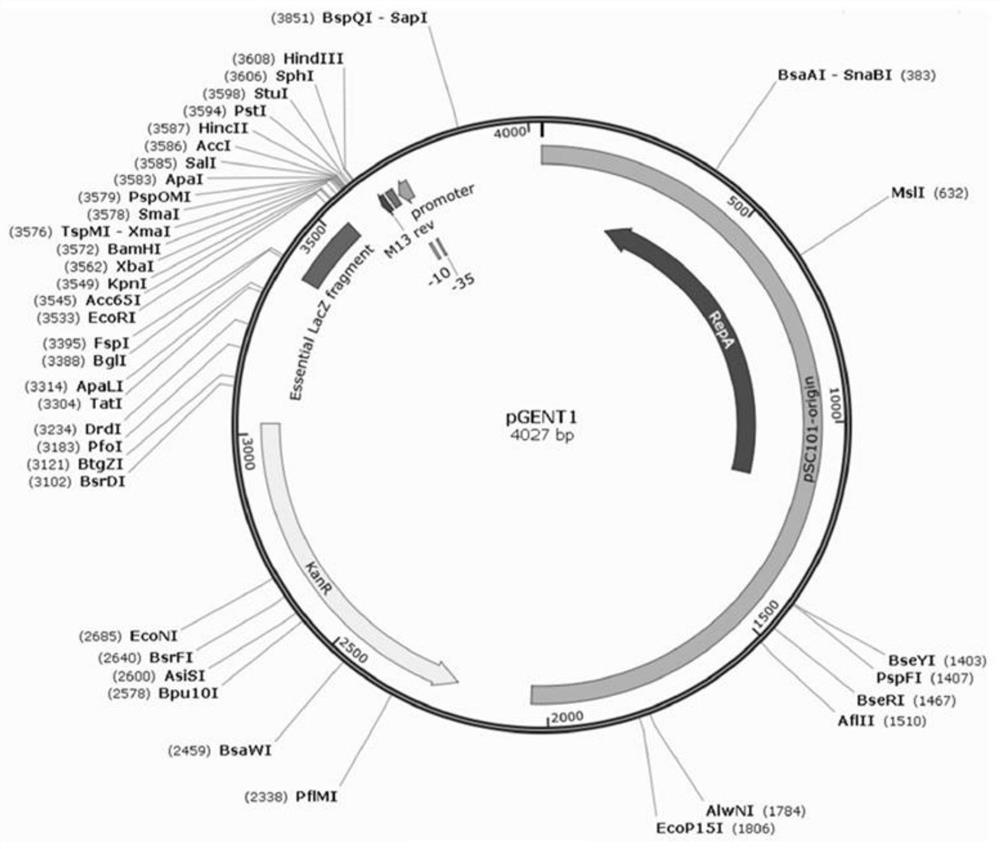

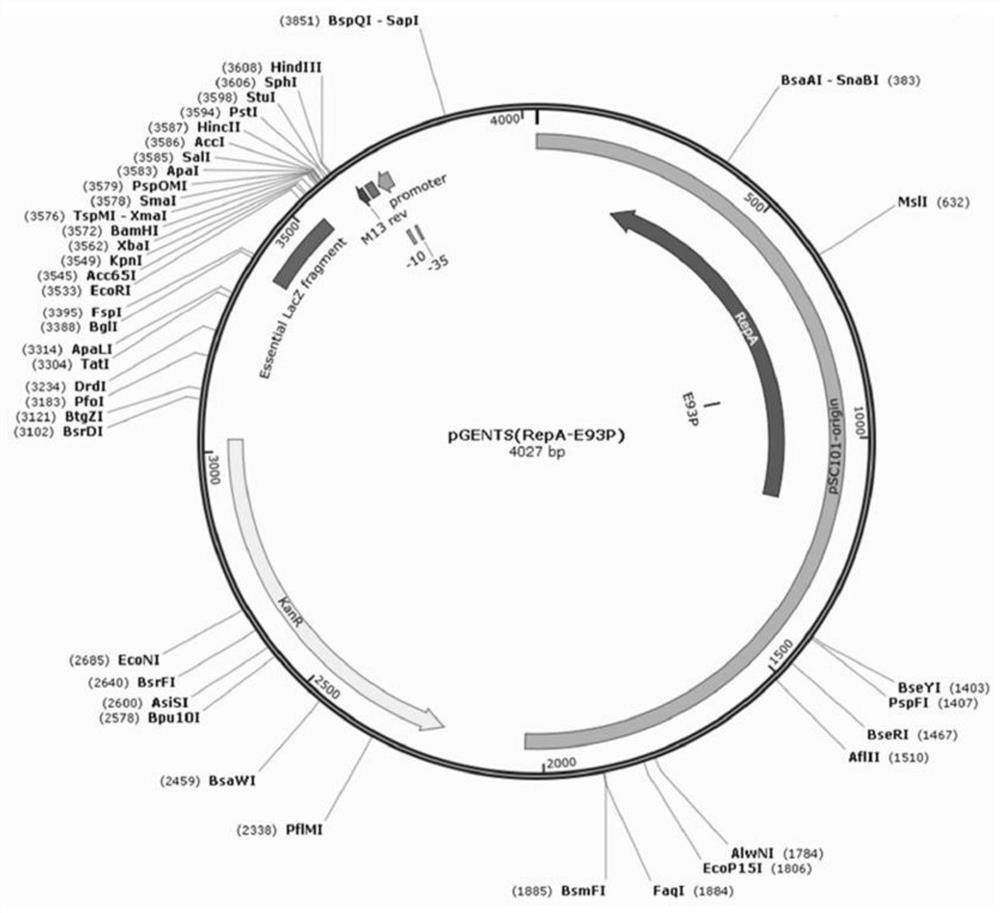

Modified plasmid replicon and application thereof

ActiveCN107142269AImprove applicabilityFix incompatibilitiesMicroorganism based processesPeptidesEscherichia coliWild type

The invention discloses a modified plasmid replicon and application thereof. The modified plasmid replicon is a mutant of a classic low-copy replicon pSC101 with the 93rd glutamic acid of RepA protein mutating into proline, and the codon encoding the proline is CCG. Plasmids carrying the artificially-modified plasmid replicon (pSC101-RepA-E93P), after being replicated in escherichia coli, can achieve an in-vitro extraction yield, which is about 12 times of that of plasmids carrying a wild type replicon of pSC101 and about twice of that of plasmids of pUC57 carrying CorEI / pMB1 / pBR322-type high-copy replicons. Meanwhile, in the Escherichia coli, the plasmids carrying the modified plasmid replicon can achieve replication almost at the same proportion with the plasmids carrying the CorEI / pMB1 / pBR322-type high-copy replicons.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

Method for preparing rebaudioside A by fermentation and catalysis of bacillus subtilis

PendingCN111593062AIncrease productionSolve the problems of low enzyme activity, complicated operation and high production costTransferasesMicroorganism based processesBiotechnologyPhosphate

The invention relates to a method for preparing rebaudioside A by fermentation and catalysis of bacillus subtilis. The method is characterized by comprising the following steps of: 1, connecting a glycosyltransferase UGT76G1 gene onto a PBR322 plasmid vector, transferring the plasmid vector to a competent state of bacillus subtilis, inoculating the bacillus subtilis into an LB culture medium, andculturing at 30-37 DEG C for 20-24 h; 2, inoculating into a seed tank according to an inoculation amount of 1-10% volume ratio, culturing, introducing air, and culturing at 30-37 DEG C for 20-24 h; 3,inoculating into a fermentation tank according to an inoculation amount of 1-10% volume ratio, culturing, introducing air, controlling the pH to be 6-8, and culturing at 30-37 DEG C for 48-72 h; 4, carrying out filter pressing to obtain bacillus subtilis thalli, re-suspending, carrying out high-pressure homogeneous crushing, and carrying out filter pressing to obtain crude enzyme solution; and 5,mixing stevioside, uridine diphosphate glucose, phosphate buffer solution and the crude enzyme solution according to a mass ratio of (5-10): (1-5): (40-60): (5-20), and carrying out a reaction at 25-40 DEG C for 12-48 h. The method in the invention has the advantages that: the yield of the rebaudioside A is increased, and can reach 85.3 g / L; and the method is few in operation step, low in production cost and easy for industrial production.

Owner:ANHUI JINGHE IND

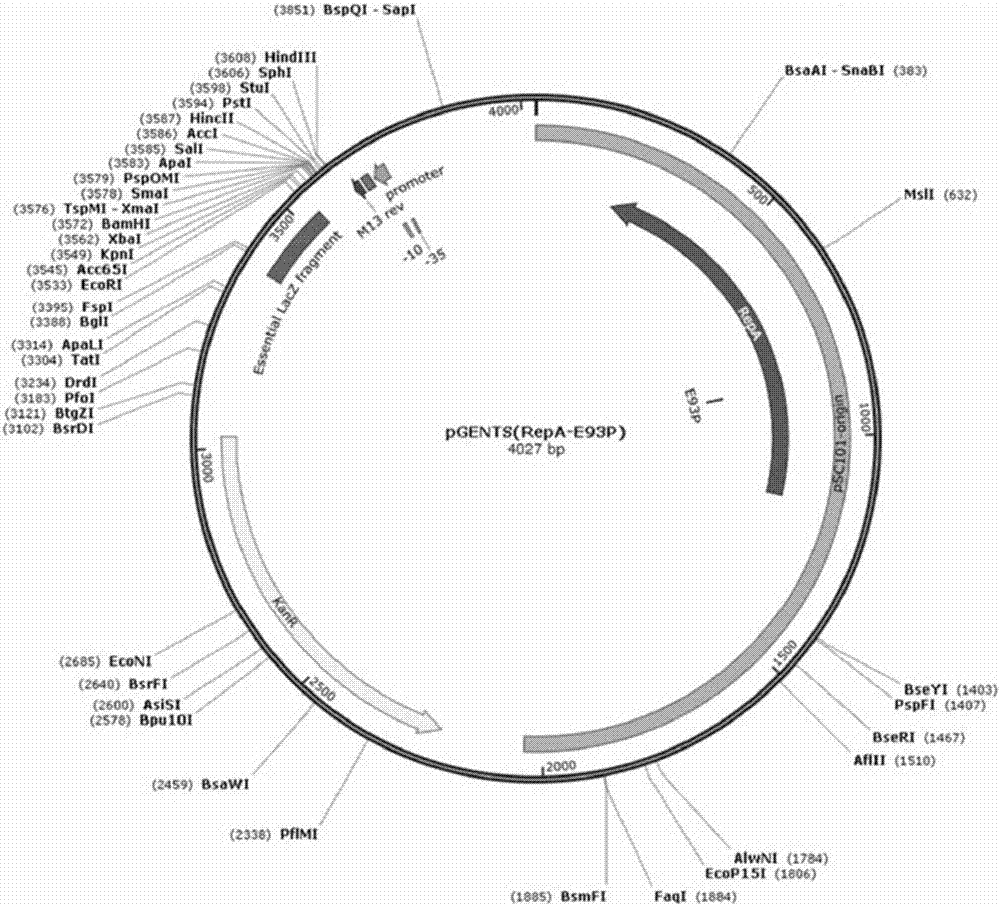

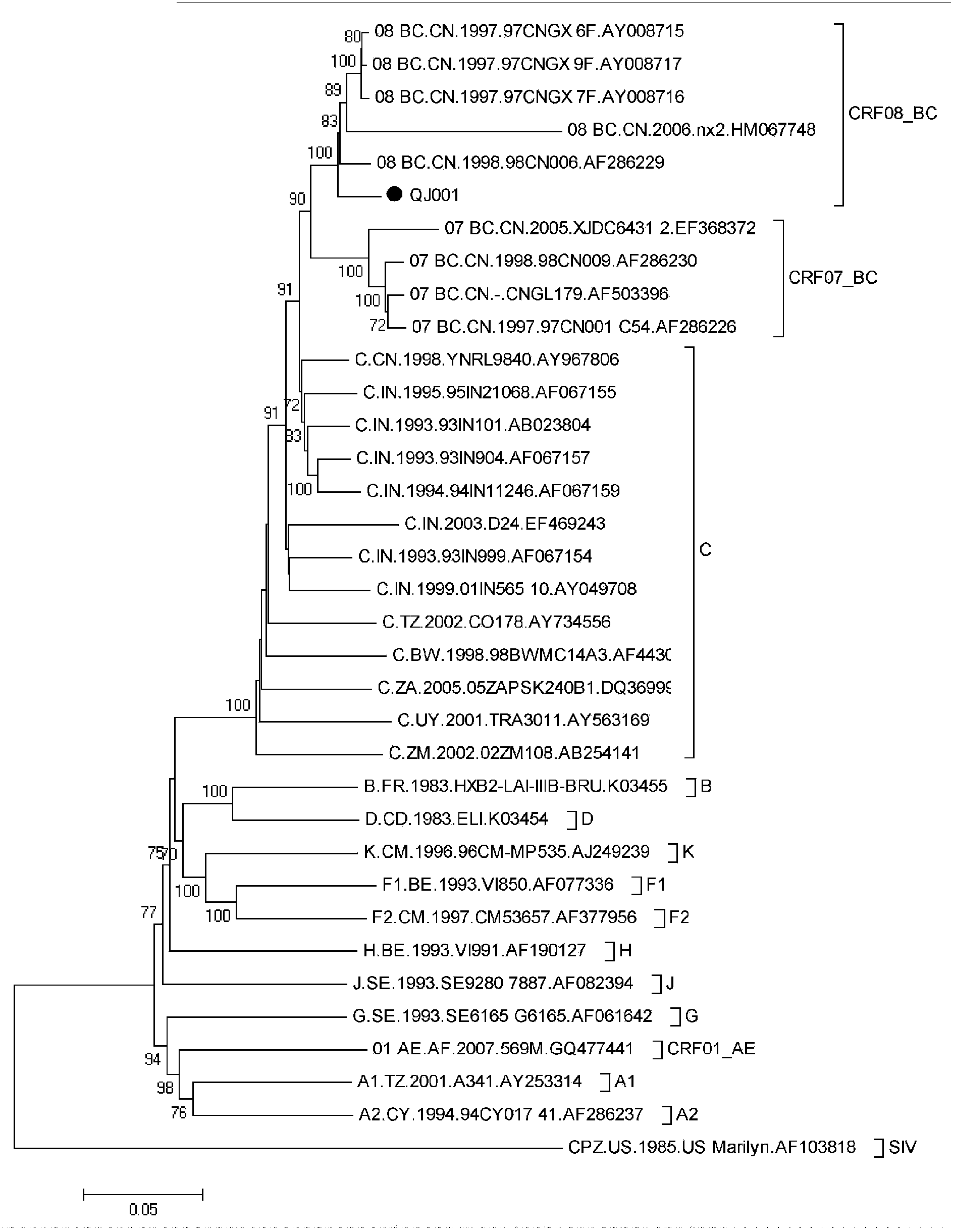

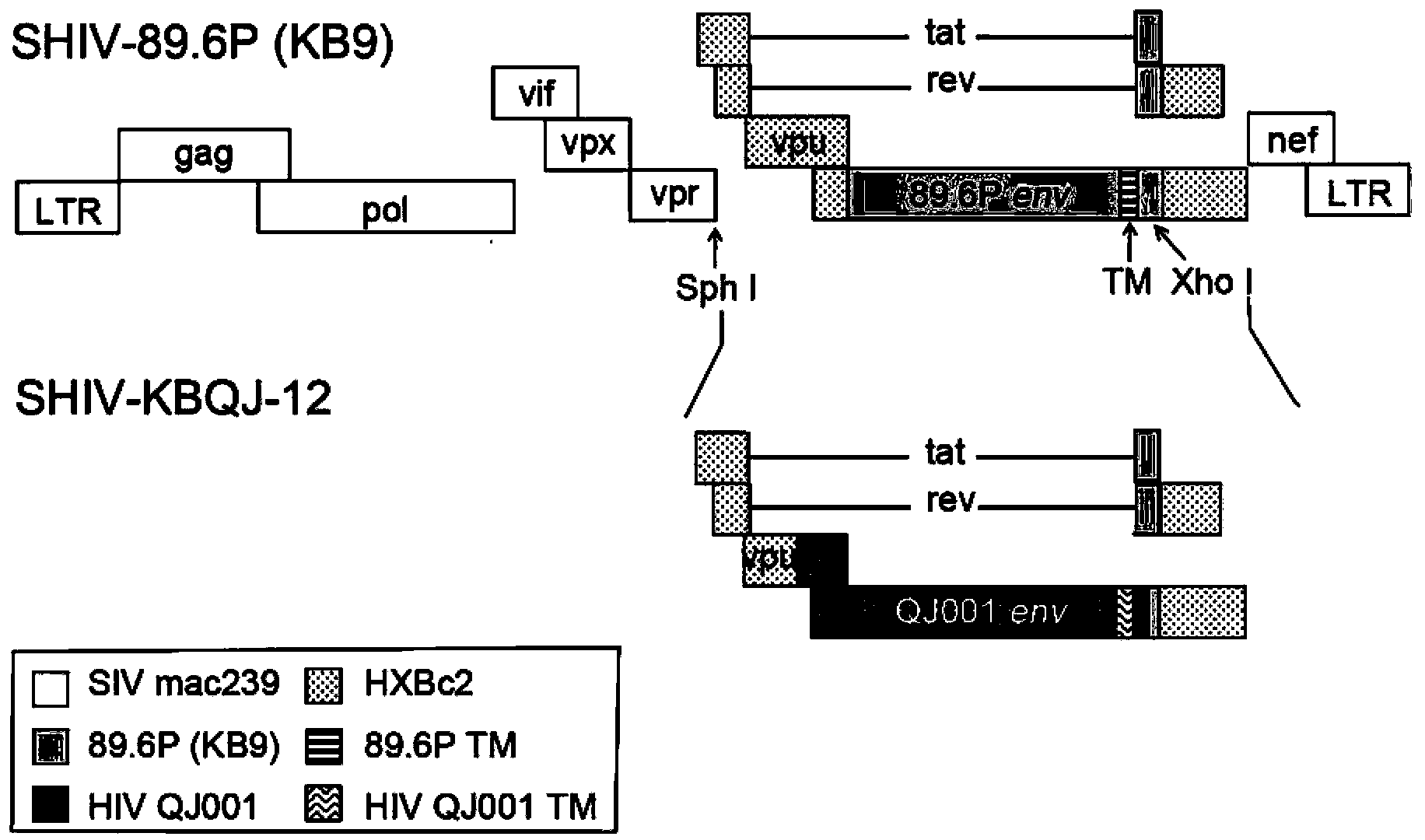

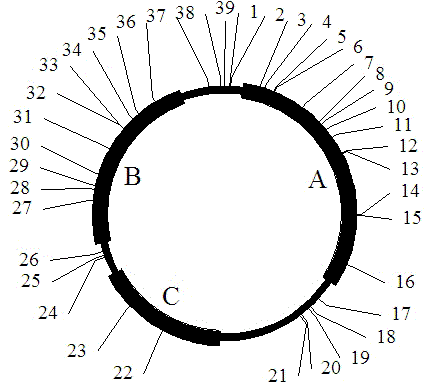

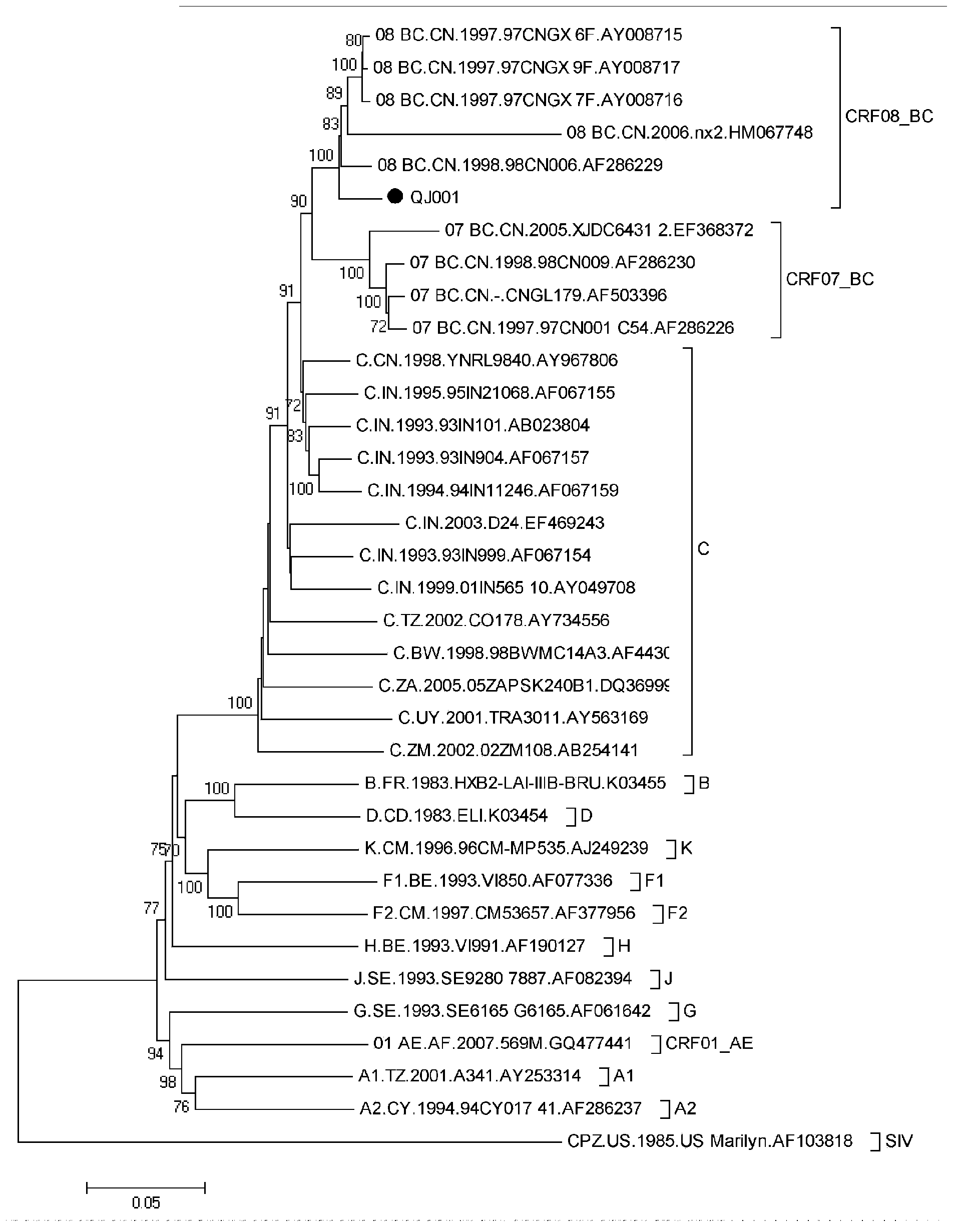

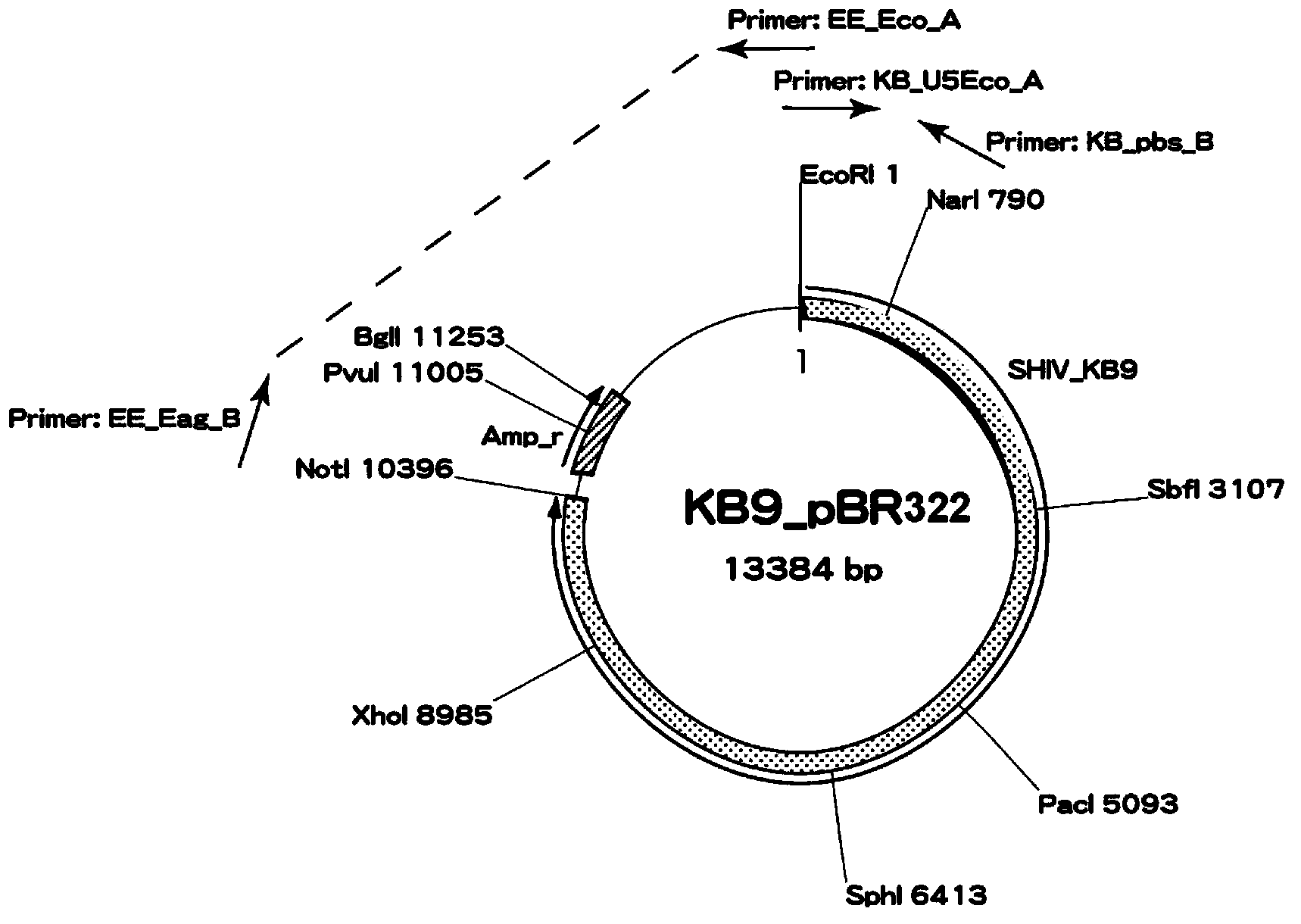

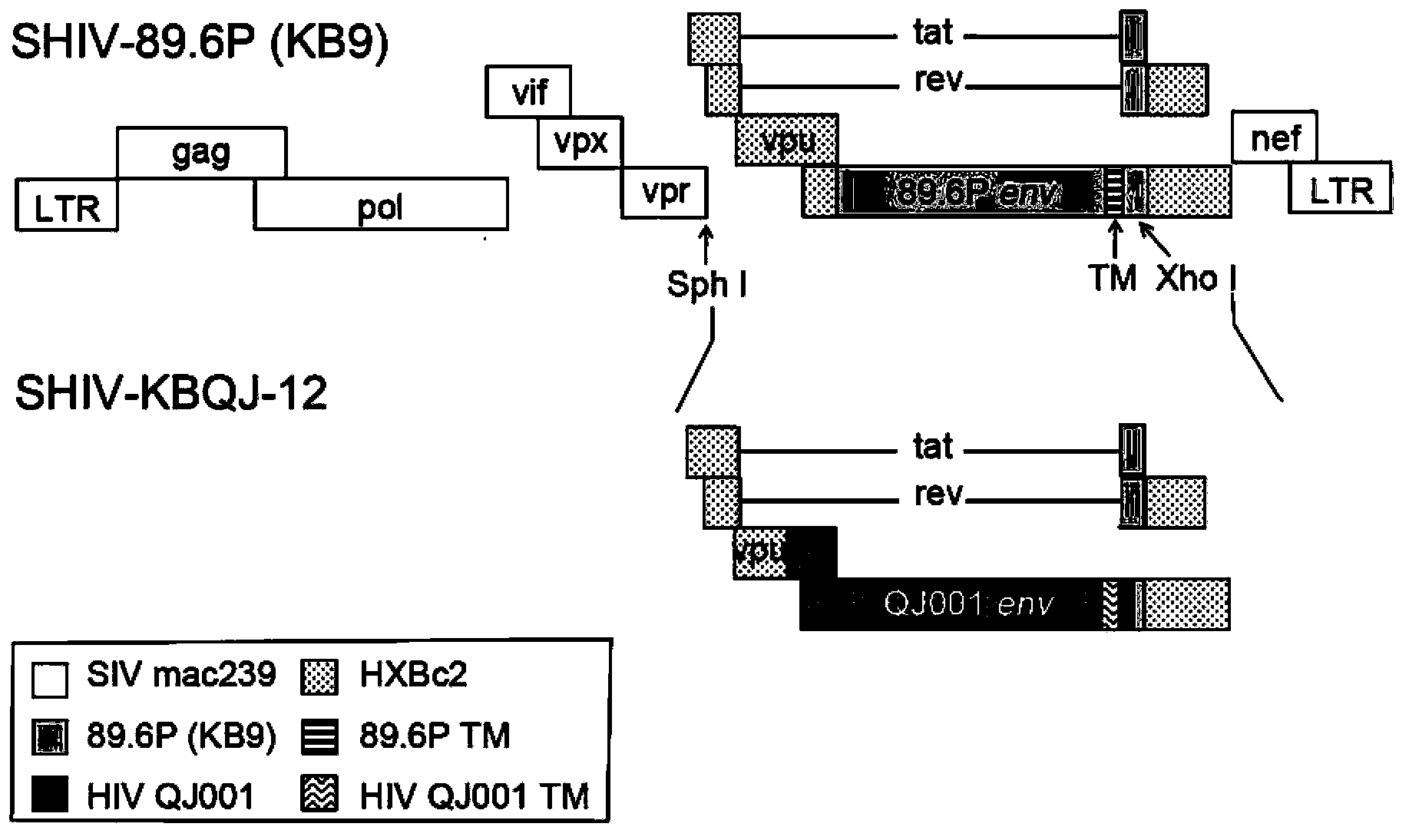

Construction and application of SHIV (simian/human immunodeficiency virus) infectious clone

InactiveCN103374550AGood replicationStable productive infectionMicroorganism based processesViruses/bacteriophagesNucleotideEnvelope Gene

The invention relates to construction and application of SHIV (simian / human immunodeficiency virus) infectious clone. Firstly, the overall length genome of a virulent strain SHIV-KB9 embedded with a B subtype env gene is cloned to a low copy number carrier pBR322, the obtained plasmid SHIV-KB9 / pBR322 is taken as a genome skeleton, the env gene of Chinese main prevalent strain CRF08_BC of HIV-1 is used for substituting for corresponding gene segments so as to obtain the infectious clone SHIV-KBQJ-12, the replacing env gene is from the infectious clone strain QJ001 of HIV-1CRF08_BC and comprises the whole intracellular region, a transmembrane region and part of an extracellular region of gp120 and gp41, and the position of the replacing env gene, corresponding to the position of the nucleotide of a standard reference strain HXB2, is 6103-8249. The construction is simple and convenient to operate, has high success rate, can obtain the infectious clone in a short time, and can be used for establishing an SHIV / Chinese rhesus infection model.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

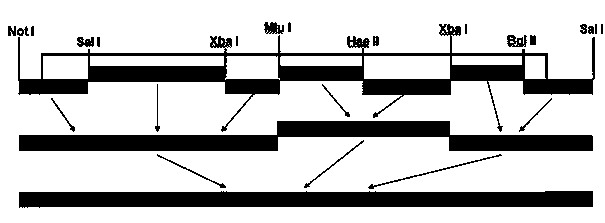

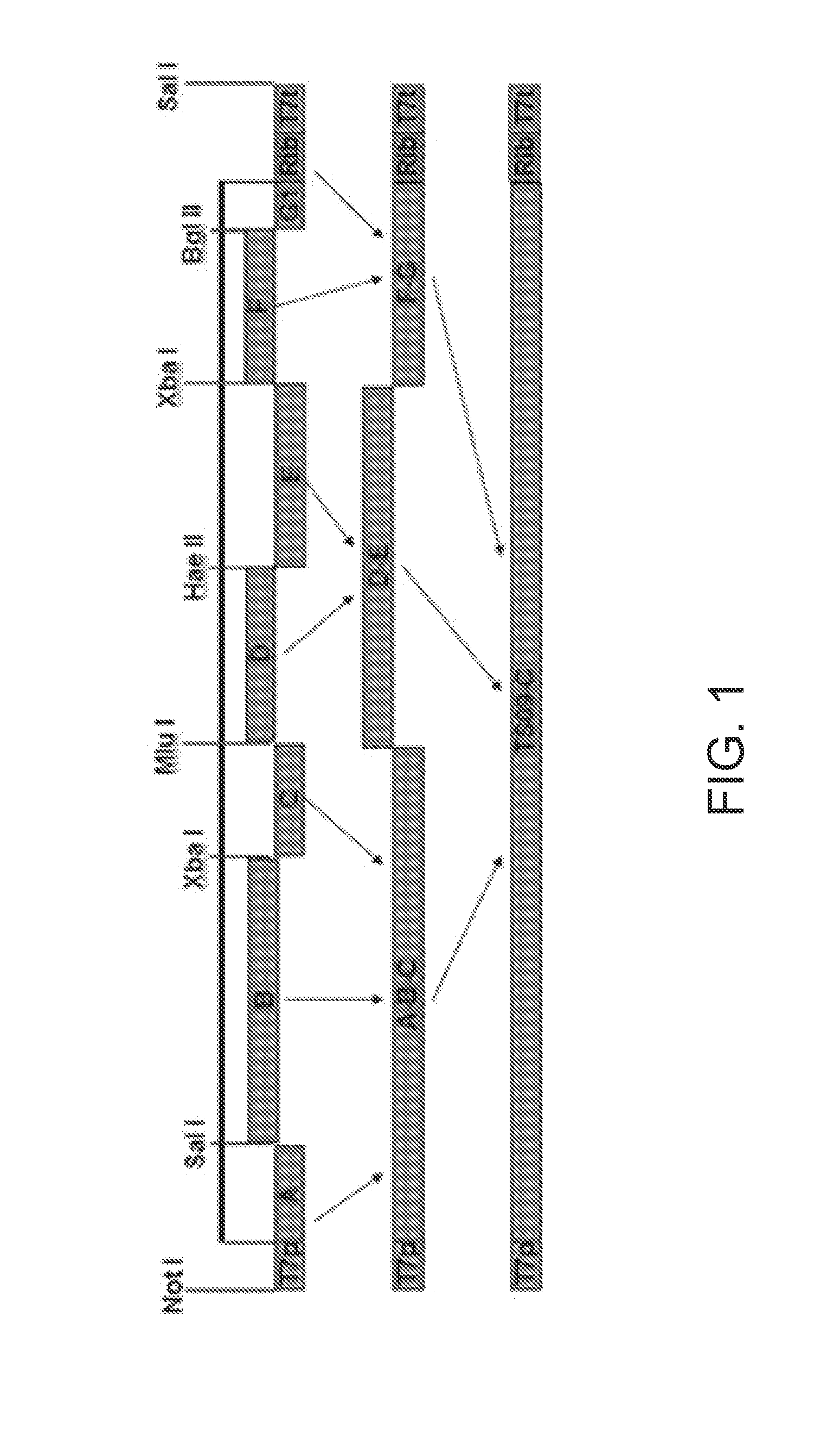

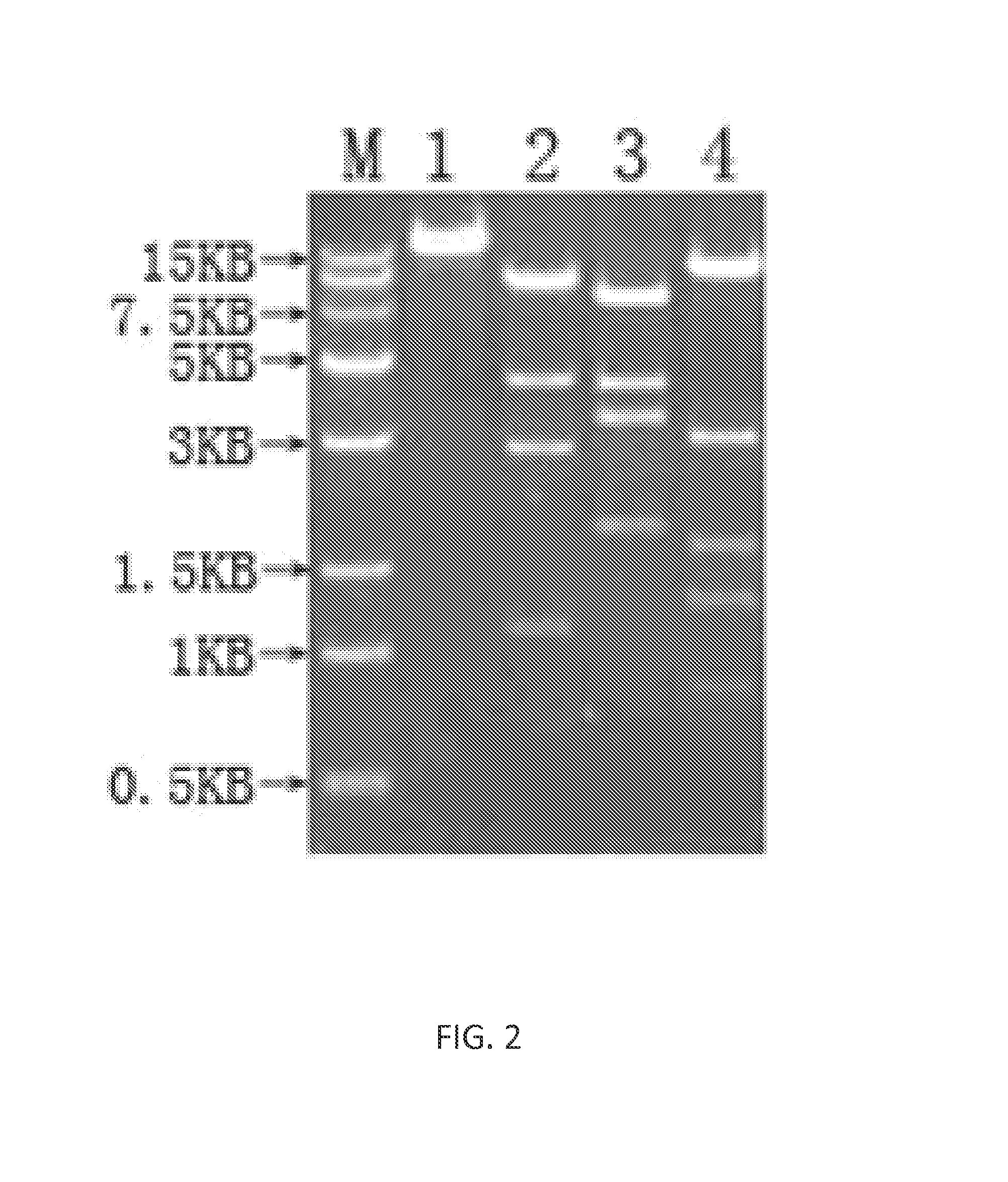

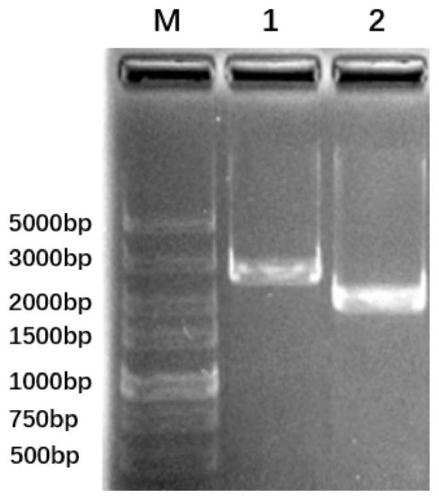

Novel cloning vector pATC4185

InactiveCN103602698ASmall molecular weightIncrease plasmid copy numberVector-based foreign material introductionAmpicillinResistant genes

The invention relates to an insertional inactivation type cloning vector pATC 4185 with ampicillin and tetracycline resistant genes. The vector is obtained by the following steps: removing the Rop gene on pBR322 by double digestion method, filling in the end and looping internally. pATC4185 not only preserves the insertional inactivation screening mark of pBR322, but also has smaller molecular weight and higher stability, and the plasmid copy number increases more than three times, and the product is convenient for gene clone operation with higher operating efficiency. The product can replace pBR322 plasmid which is widely used at present, and is used as a general high efficiency cloning vector.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

CRISPR/Cas9-mediated method for splicing large fragments of DNA

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

A new cloning vector patc4185

InactiveCN103602698BSmall molecular weightIncrease productionVector-based foreign material introductionAmpicillinResistant genes

The invention relates to an insertional inactivation type cloning vector pATC 4185 with ampicillin and tetracycline resistant genes. The vector is obtained by the following steps: removing the Rop gene on pBR322 by double digestion method, filling in the end and looping internally. pATC4185 not only preserves the insertional inactivation screening mark of pBR322, but also has smaller molecular weight and higher stability, and the plasmid copy number increases more than three times, and the product is convenient for gene clone operation with higher operating efficiency. The product can replace pBR322 plasmid which is widely used at present, and is used as a general high efficiency cloning vector.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

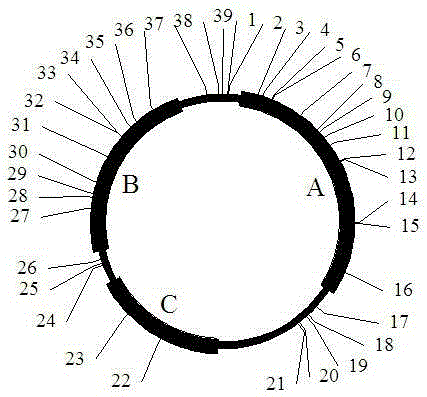

Avian 4-type adenovirus vector, construction method and attenuated live vaccine and application of avian 4-type adenovirus vector

ActiveCN113388641AImproving immunogenicityGood immune effectViral antigen ingredientsDigestive systemOrigin of replicationPBR322

The invention discloses an avian 4-type adenovirus vector, a construction method and an attenuated live vaccine and application of the avian 4-type adenovirus vector. The avian 4-type adenovirus vector comprises a replication origin nucleic acid sequence of pBR322 plasmid, a nucleic acid sequence of a kanamycin resistance gene and a genomic sequence of avian 4-type adenovirus; and in the genomic sequence of the avian 4-type adenovirus, genes ORF1, ORF1B, ORF2, ORF19A and GAM-1 are all inactivated. The avian 4-type adenovirus obtained by rescuing after the linearized avian 4-type adenovirus vector transfects cells is used as the attenuated live vaccine, and the attenuated live vaccine has the advantages of no pathogenicity, high safety and good immune protection effect, and can be used for preparing drugs for preventing diseases caused by avian adenovirus infection.

Owner:中国疾病预防控制中心病毒病预防控制所 +1

An engineering strain and its fermentation process for highly expressing mccj25

ActiveCN113774006BEfficient expressionThe post-processing purification process is simpleBacteriaMicroorganism based processesBiotechnologyEscherichia coli

Owner:安杰利(重庆)生物科技有限公司

Avian type 4 adenovirus vector targeting mammalian cells and its application

ActiveCN111218477BHigh infection efficiencyWhole-cell/virus/DNA/RNA ingredientsNon-active genetic ingredientsOrigin of replicationRecombinant vaccines

The invention discloses an avian type 4 adenovirus vector targeted to infect mammalian cells and its application. The vector includes the genome sequence of the avian type 4 adenovirus, the replication origin nucleic acid sequence of pBR322 and the kanamycin resistance nucleic acid sequence; The fiber nucleic acid sequence in the genome sequence has been artificially modified, including: inserting the RGD4C short peptide nucleic acid sequence into the Knob region of the fiber gene, and / or replacing the Knob region of the fiber gene with the nucleic acid sequence of the human adenovirus type 35 fiber Knob. The transformed avian type 4 adenovirus vector of the invention can improve the infection efficiency of mammalian cells, and can be used to prepare mammalian recombinant vaccines or gene therapy kits.

Owner:STATION OF VIRUS PREVENTION & CONTROL CHINA DISEASES PREVENTION & CONTROL CENT

A new cloning vector pat3733

InactiveCN103602694BSmall molecular weightIncrease productionVector-based foreign material introductionResistant genesAmpicillin

The invention relates to an insertional inactivation type cloning vector pAT 3733 with ampicillin and tetracycline resistant genes. The vector is obtained by the following steps: removing the Rop gene on pBR322 by double digestion method, filling in the end and looping internally. pAT3733 not only preserves the insertional inactivation screening mark of pBR322, but also has smaller molecular weight and higher stability, and the plasmid copy number increases more than three times, and the product is convenient for gene clone operation with higher operating efficiency. The product can replace pBR322 plasmid which is widely used at present, and is used as a general high efficiency cloning vector.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

A modified plasmid replicator and its application

ActiveCN107142269BImprove applicabilityFix incompatibilitiesMicroorganism based processesPeptidesEscherichia coliWild type

The invention discloses a modified plasmid replicon and application thereof. The modified plasmid replicon is a mutant of a classic low-copy replicon pSC101 with the 93rd glutamic acid of RepA protein mutating into proline, and the codon encoding the proline is CCG. Plasmids carrying the artificially-modified plasmid replicon (pSC101-RepA-E93P), after being replicated in escherichia coli, can achieve an in-vitro extraction yield, which is about 12 times of that of plasmids carrying a wild type replicon of pSC101 and about twice of that of plasmids of pUC57 carrying CorEI / pMB1 / pBR322-type high-copy replicons. Meanwhile, in the Escherichia coli, the plasmids carrying the modified plasmid replicon can achieve replication almost at the same proportion with the plasmids carrying the CorEI / pMB1 / pBR322-type high-copy replicons.

Owner:NANJING GENSCRIPT BIOTECH CO LTD

Method for preparing rebaudioside D through fermentation catalysis of bacillus subtilis

PendingCN114150031ASolve the problems of low enzyme activity, complicated operation and high production costReduce stepsBacteriaMicroorganism based processesBiotechnologyUltrafiltration

The invention relates to a method for preparing rebaudioside D by fermentation catalysis of bacillus subtilis, which is characterized by comprising the following steps: (1) inoculating glycosyl transferase UGT76G1 and AtSUSY genes to a PBR322 plasmid vector, guiding into the bacillus subtilis, inoculating into an LB culture medium, and culturing for 20-24 hours at the temperature of 30-37 DEG C and the speed of 100-250 rpm; (2) inoculating into a seed tank according to the inoculation amount of 1%-10%, and culturing for 20-24 hours at the temperature of 30-37 DEG C at the speed of 200-400 rpm and the ventilation ratio of 0.1-1 V / V.min; (3) inoculating into a fermentation tank according to the volume ratio of 1%-10%, and culturing for 48-72 hours under the conditions that the speed is 200-1000 rpm, the ventilation ratio is 0.1-2 V / V.min, the temperature is 30-37 DEG C and the pH value is 6-8; (4) carrying out ultrafiltration on the fermentation liquor by adopting a ceramic membrane, resuspending bacteria, carrying out high-pressure homogeneous crushing, and carrying out ultrafiltration on the crushed liquor by adopting the ceramic membrane to obtain crude enzyme liquor; and (5) mixing stevioside, uridine diphosphate glucose, a Tris-HCl buffer solution and the crude enzyme solution according to a mass ratio of (5-10): (1-5): (40-60): (5-20), and reacting at 25-40 DEG C for 12-48 hours. The method has the advantages that two crude enzymes are obtained through one-time fermentation, the cost is low, and the conversion rate of rebaudioside D reaches 88-90 g / L.

Owner:ANHUI JINGHE IND

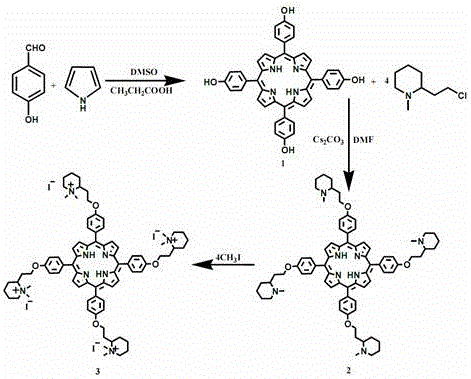

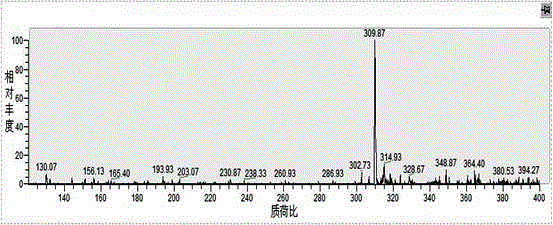

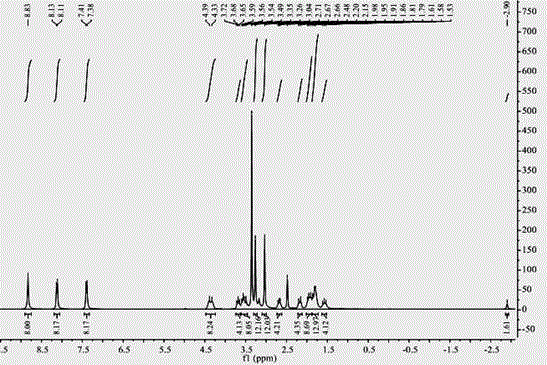

A kind of synthetic method of water-soluble porphyrin and its photocatalytic application

InactiveCN104513250BHigh purityGood water solubilityOrganic chemistryMicrobiological testing/measurementPorphyrin synthesisPBR322

The invention discloses a synthesis method for water-soluble porphyrin. The chemical compound is named as tetraiodide 5,10,15,20-tetra{4-[2-(N,N-dimethyl-2-piperidine) ethyoxyl]phenyl}porphyrin. The synthesis method comprises the following steps: 1) synthesizing 5,10,15,20-tetra(4-hydroxy phenyl) porphyrin; 2) synthesizing 5,10,15,20-tetra{4-[2-(N-methyl-2-piperidine) ethyoxyl] phenyl}porphyrin; 3) synthesizing the water-soluble porphyrin target object. The prepared water-soluble porphyrin is used for studying the influences of porphyrin in different concentrations on cutting pBR322 plasmid DNA under the acidity and neutrality conditions, as well as the lighting and dark conditions, through the photocatalytic DNA cutting experiments. The synthesis method has the advantages of being simple and easy in synthesis process and relatively high in product purity; chemicals used in the whole process are less in toxicity; the product is good in water solubility, and has good pH selectivity.

Owner:NANKAI UNIV

A biostorage system, construction method and application suitable for Synechococcus

ActiveCN110438053BAvoid Biosafety ConcernsBacteriaMicroorganism based processesBiological storageSynechococcus sp.

The invention discloses a biological storage system suitable for Synechococcus 7942, a construction method and an application. The promoter PpsbA2 was obtained from algae 6803; the terminator Trbcl was amplified from the integrated plasmid pBA3031; the toxic gene sepT2 was expressed with the iron deficiency inducible promoter PisiAB using pBR322 as the vector, and the transcription was terminated with the terminator Trbcl; the expression was expressed with the promoter PpsbA2 The antiviral gene sepA2 was constructed and transformed into Synechococcus sp. The system of the present invention grows normally without induction, and dies rapidly after induction. This has important theoretical and practical significance for the development and optimization of the biostorage system of Synechococcus, and also provides a reference for solving the biosafety problems of other cyanobacteria.

Owner:TIANJIN UNIV

A kind of recombinant bacteria expressing sef14 functional pili and its application

ActiveCN112481287BHas agglutinationSpecific and fastBacteriaMicrobiological testing/measurementPBR322Salmonella diarizonae

The invention discloses a recombinant plasmid, which is the sef14 The operon gene is inserted into the expression vector pBR322. The invention also discloses a recombinant bacterial strain, which is obtained by introducing the recombinant plasmid into the inert carrier strain S9. The invention also discloses the preparation method and application of the recombinant bacterial strain. In the present invention, for the first time, SEF14 is displayed on the surface of an inert carrier strain S9 to express a single pili SEF14, which can avoid background non-specific reactions and at the same time specifically detect Salmonella Enteritidis infection, and has the advantages of rapidity, specificity, sensitivity, simplicity and low price. , while meeting the requirements of on-site and large-scale testing. The SEF14 functional pili of the present invention can be used to detect and monitor Salmonella Enteritidis infected chicken flocks after displaying and expressing a single pili SEF14 on the surface of an inert carrier. Plate agglutination reaction, by visually observing the reaction results on site and accurately judging whether the animal is infected by Salmonella Enteritidis.

Owner:YANGZHOU UNIV

Novel cloning vector pAT 3733

InactiveCN103602694ASmall molecular weightIncrease plasmid copy numberVector-based foreign material introductionResistant genesAmpicillin

The invention relates to an insertional inactivation type cloning vector pAT 3733 with ampicillin and tetracycline resistant genes. The vector is obtained by the following steps: removing the Rop gene on pBR322 by double digestion method, filling in the end and looping internally. pAT3733 not only preserves the insertional inactivation screening mark of pBR322, but also has smaller molecular weight and higher stability, and the plasmid copy number increases more than three times, and the product is convenient for gene clone operation with higher operating efficiency. The product can replace pBR322 plasmid which is widely used at present, and is used as a general high efficiency cloning vector.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Construction and application of SHIV (simian/human immunodeficiency virus) infectious clone

InactiveCN103374550BGood replicationStable productive infectionMicroorganism based processesViruses/bacteriophagesEnvelope GenePBR322

The invention relates to construction and application of SHIV (simian / human immunodeficiency virus) infectious clone. Firstly, the overall length genome of a virulent strain SHIV-KB9 embedded with a B subtype env gene is cloned to a low copy number carrier pBR322, the obtained plasmid SHIV-KB9 / pBR322 is taken as a genome skeleton, the env gene of Chinese main prevalent strain CRF08_BC of HIV-1 is used for substituting for corresponding gene segments so as to obtain the infectious clone SHIV-KBQJ-12, the replacing env gene is from the infectious clone strain QJ001 of HIV-1CRF08_BC and comprises the whole intracellular region, a transmembrane region and part of an extracellular region of gp120 and gp41, and the position of the replacing env gene, corresponding to the position of the nucleotide of a standard reference strain HXB2, is 6103-8249. The construction is simple and convenient to operate, has high success rate, can obtain the infectious clone in a short time, and can be used for establishing an SHIV / Chinese rhesus infection model.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com