Patents

Literature

30 results about "Acetolactic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

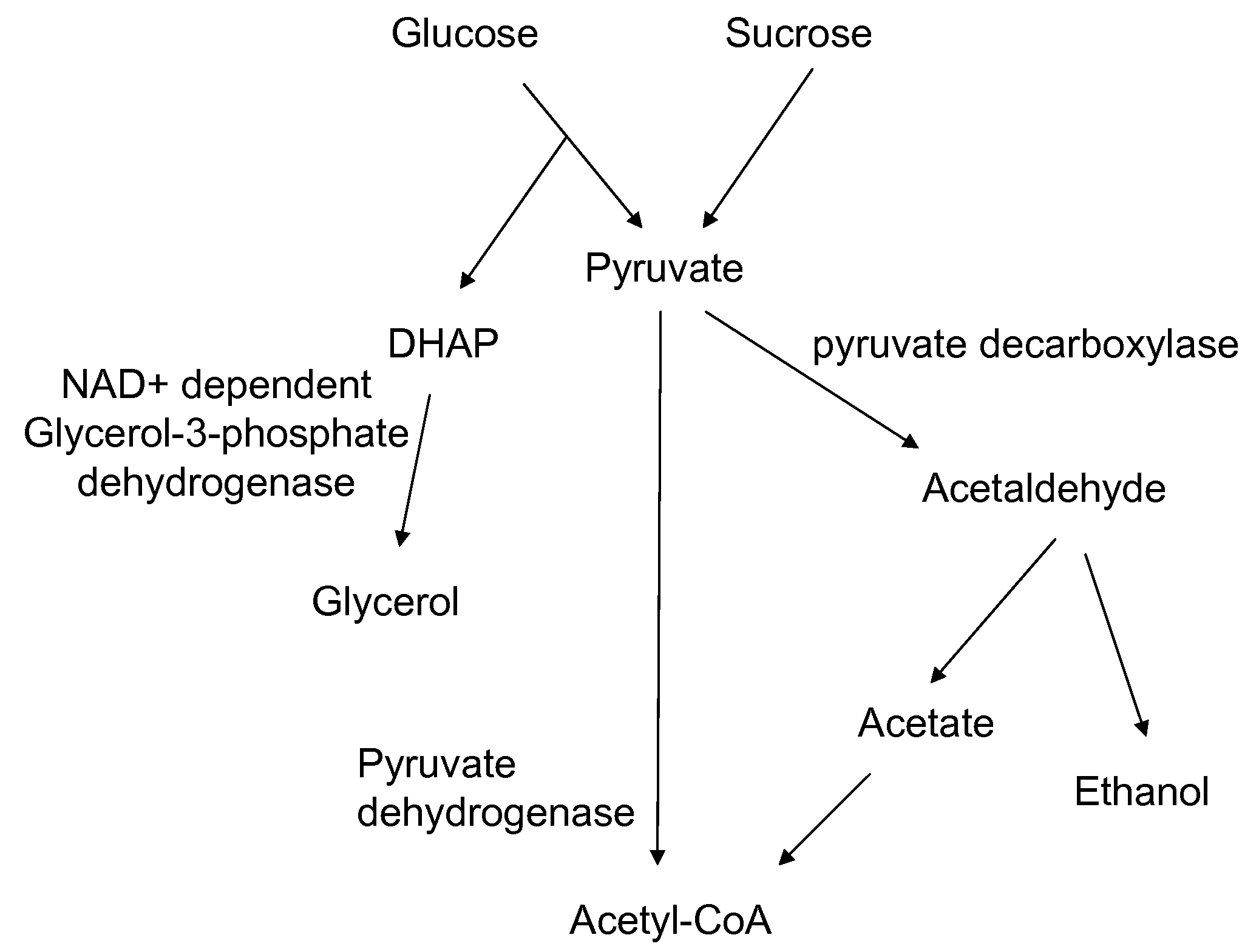

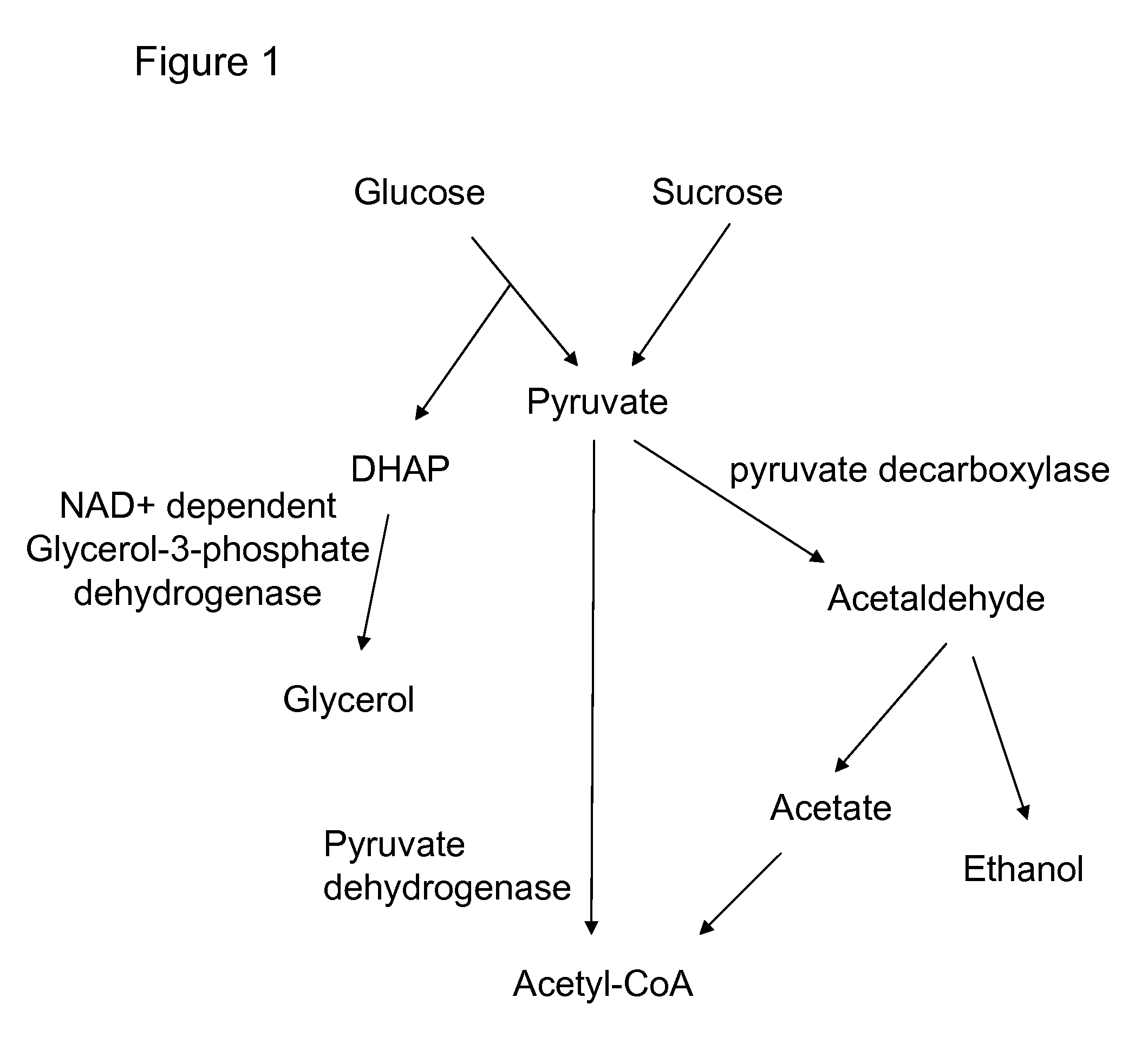

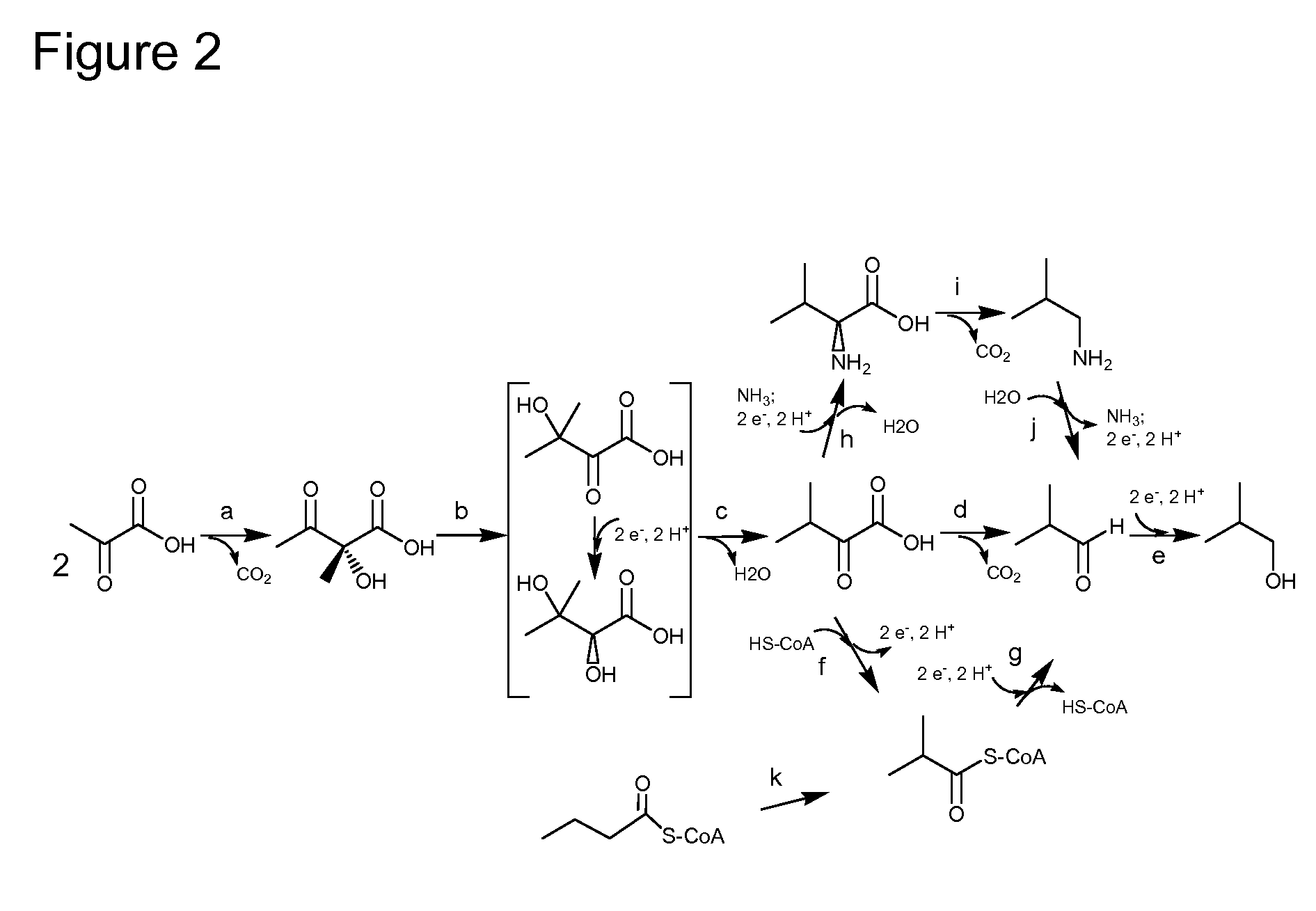

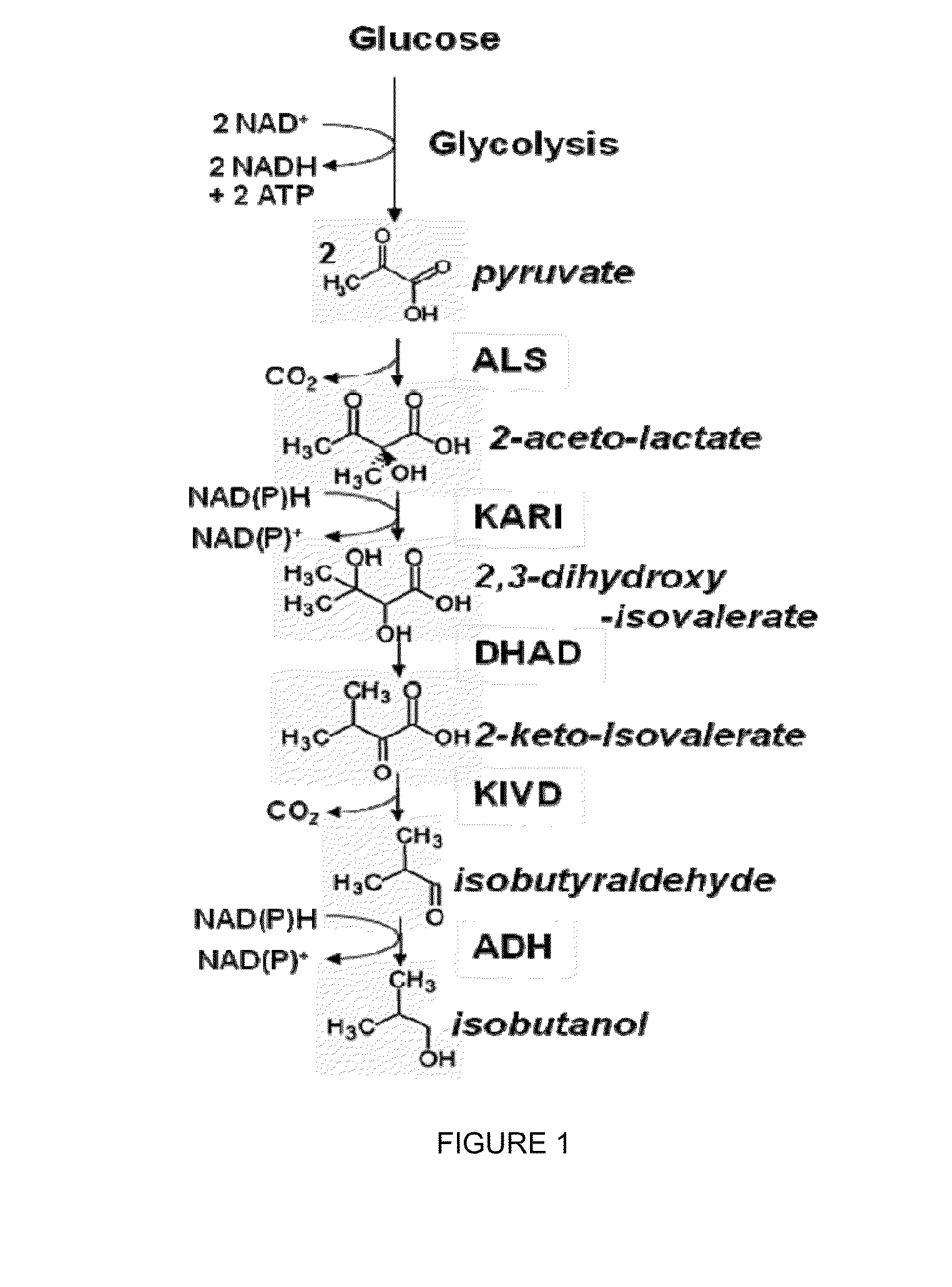

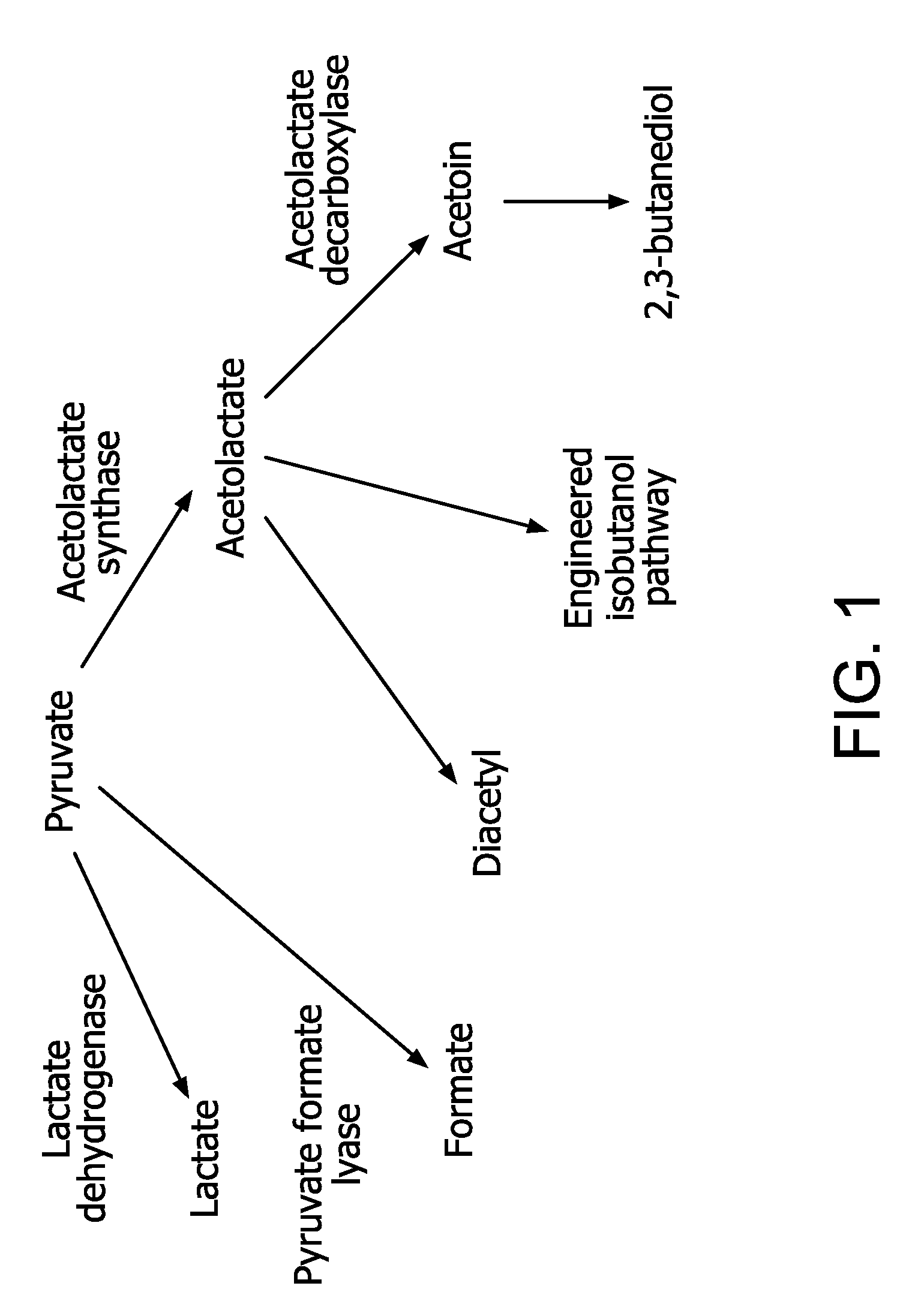

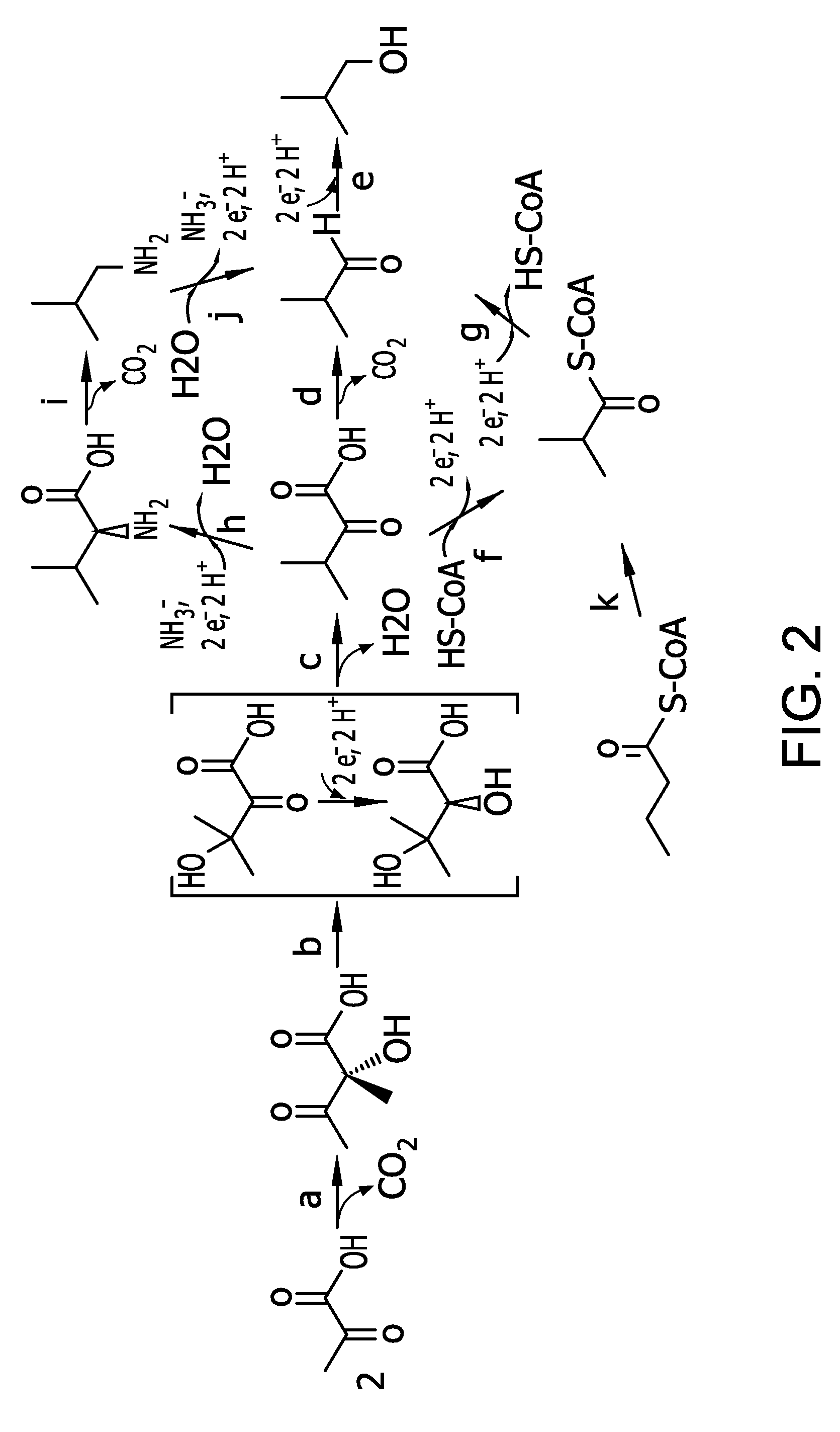

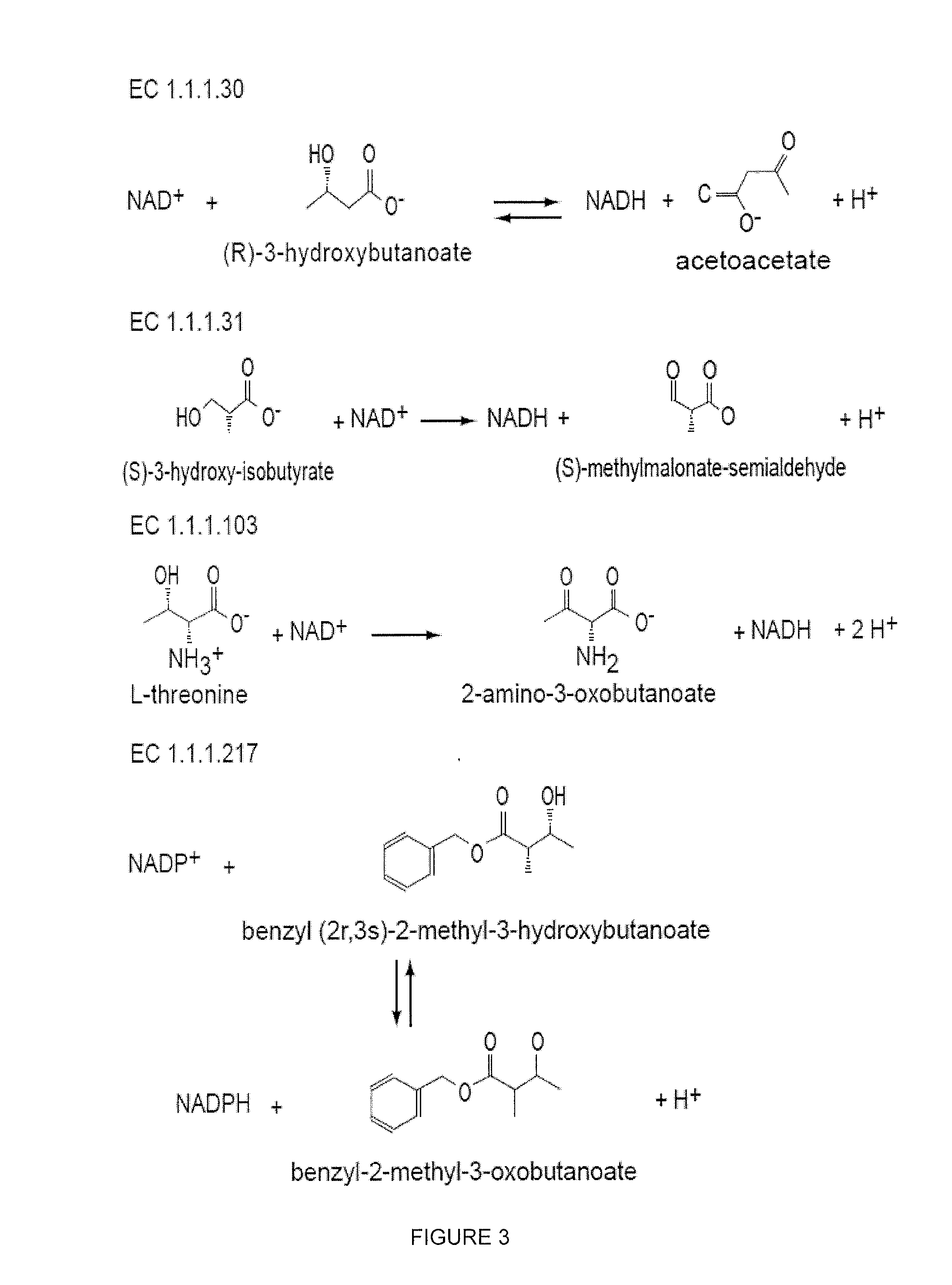

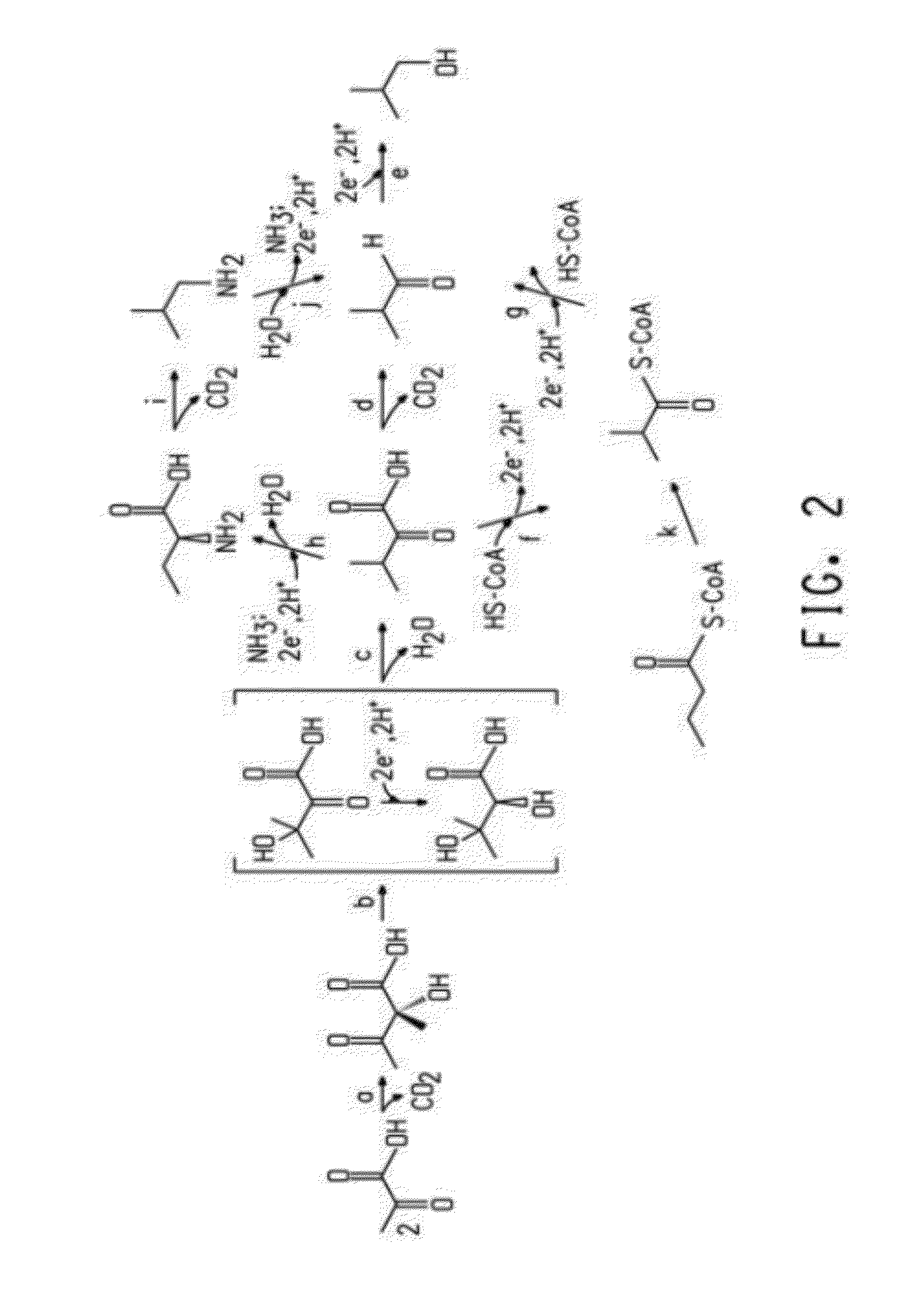

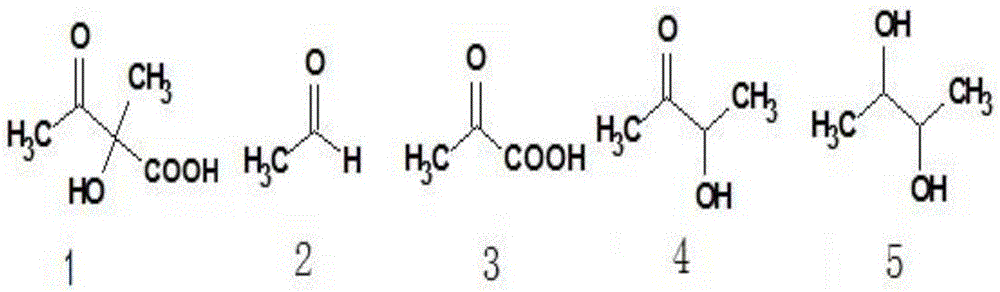

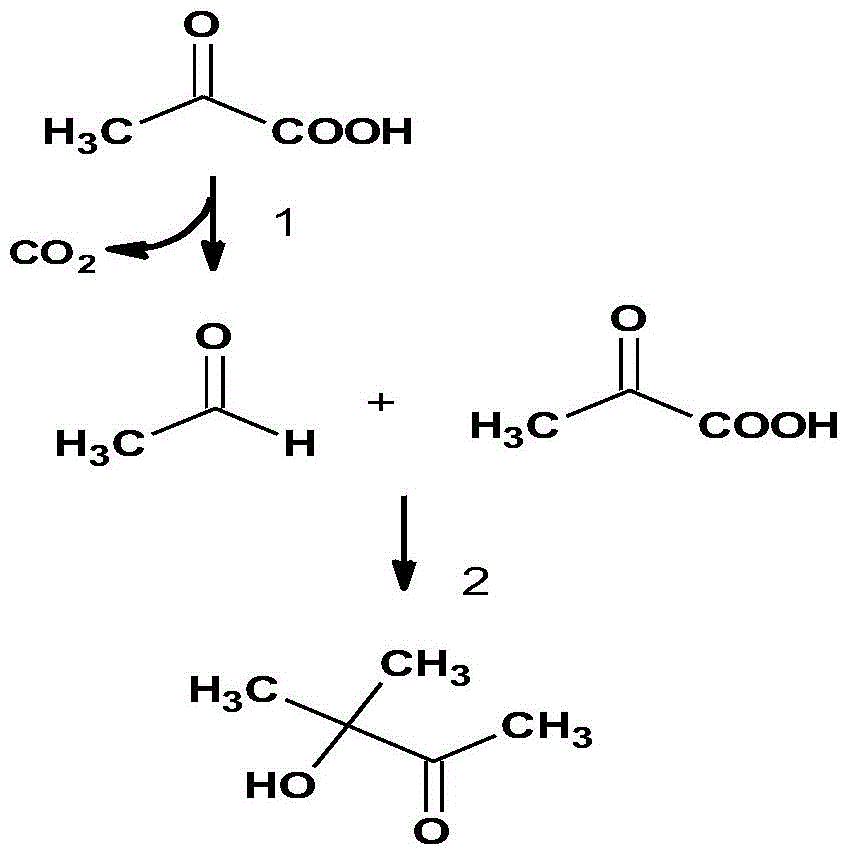

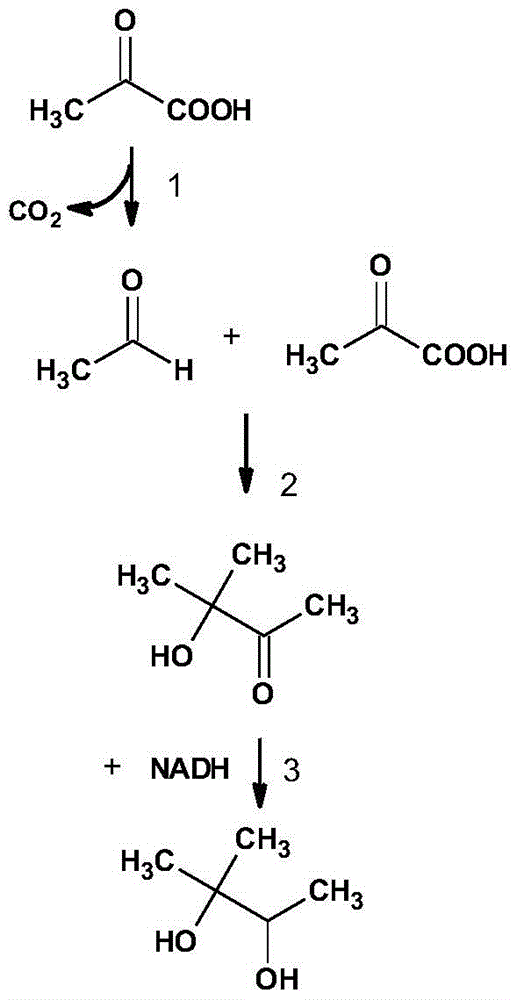

Α-Acetolactic acid (α-acetolactate) is a precursor in the biosynthesis of the branched chain amino acids valine and leucine. α-Acetolactic acid is produced from two molecules of pyruvic acid by acetolactate synthase. α-Acetolactic acid can also be decarboxylated by alpha-acetolactate decarboxylase to produce acetoin.

Enhanced pyruvate to acetolactate conversion in yeast

ActiveUS20090305363A1Improve throughputReduction of pyruvate decarboxylase activityFungiTransferasesYeastCytosol

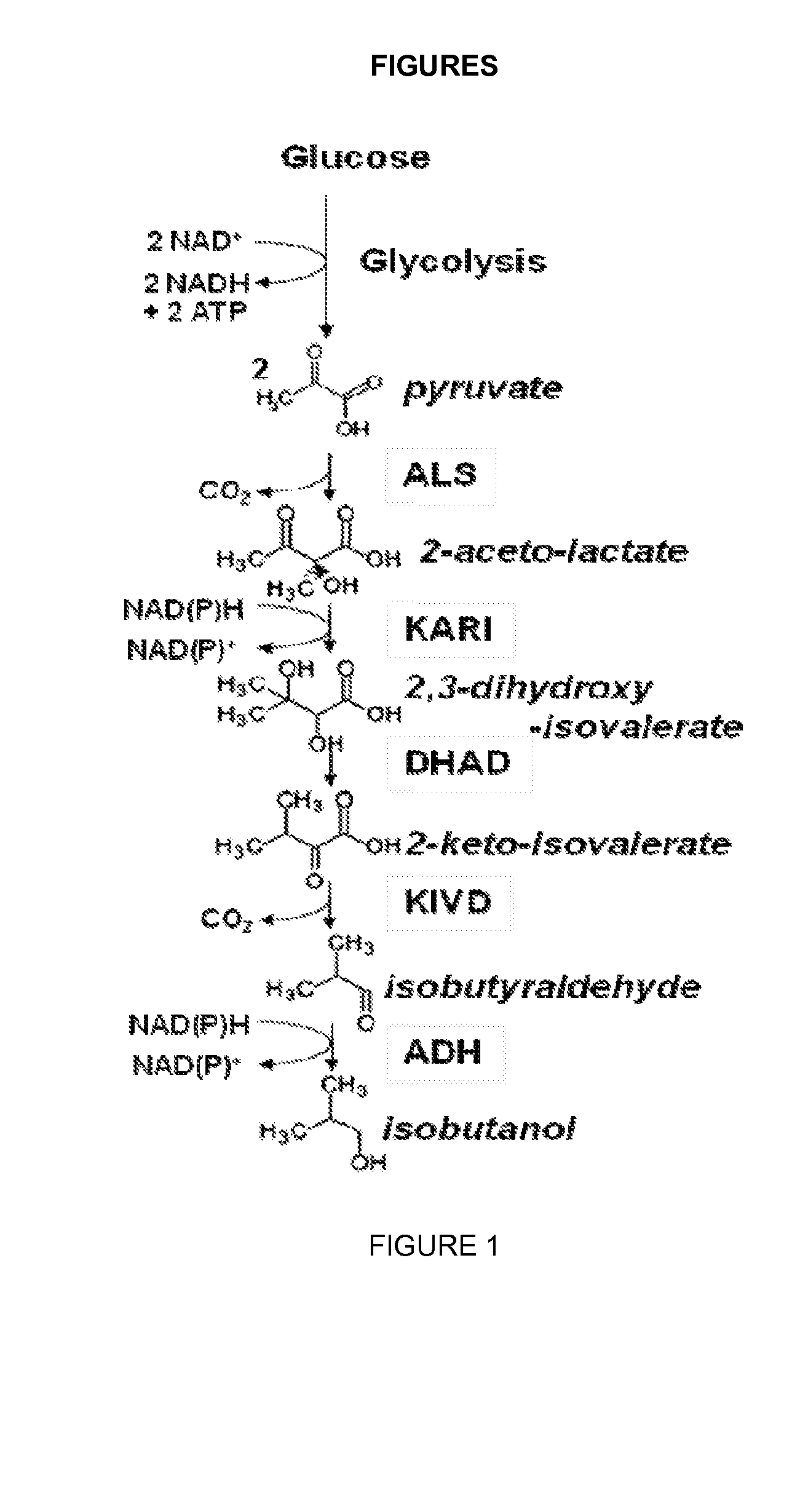

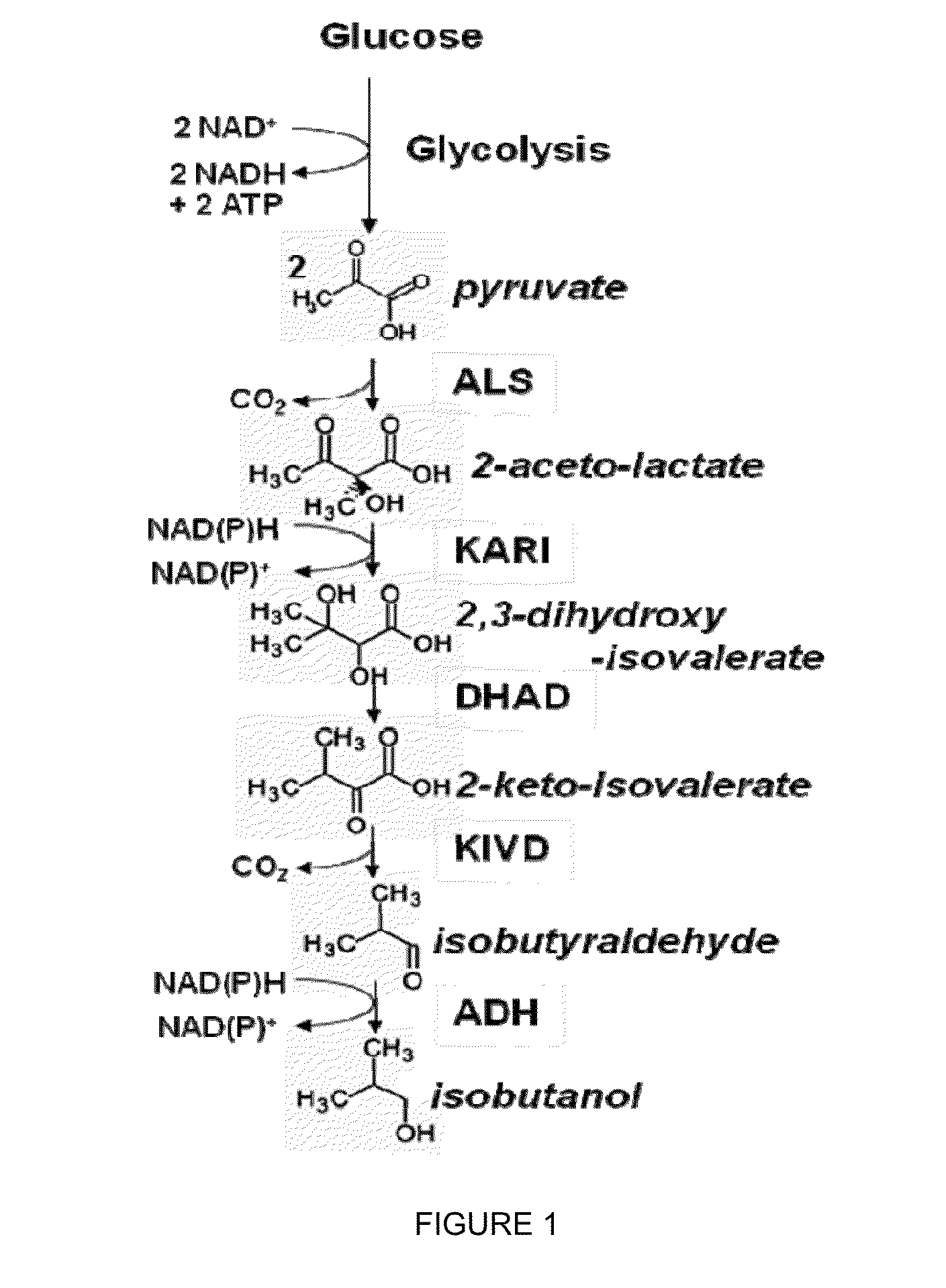

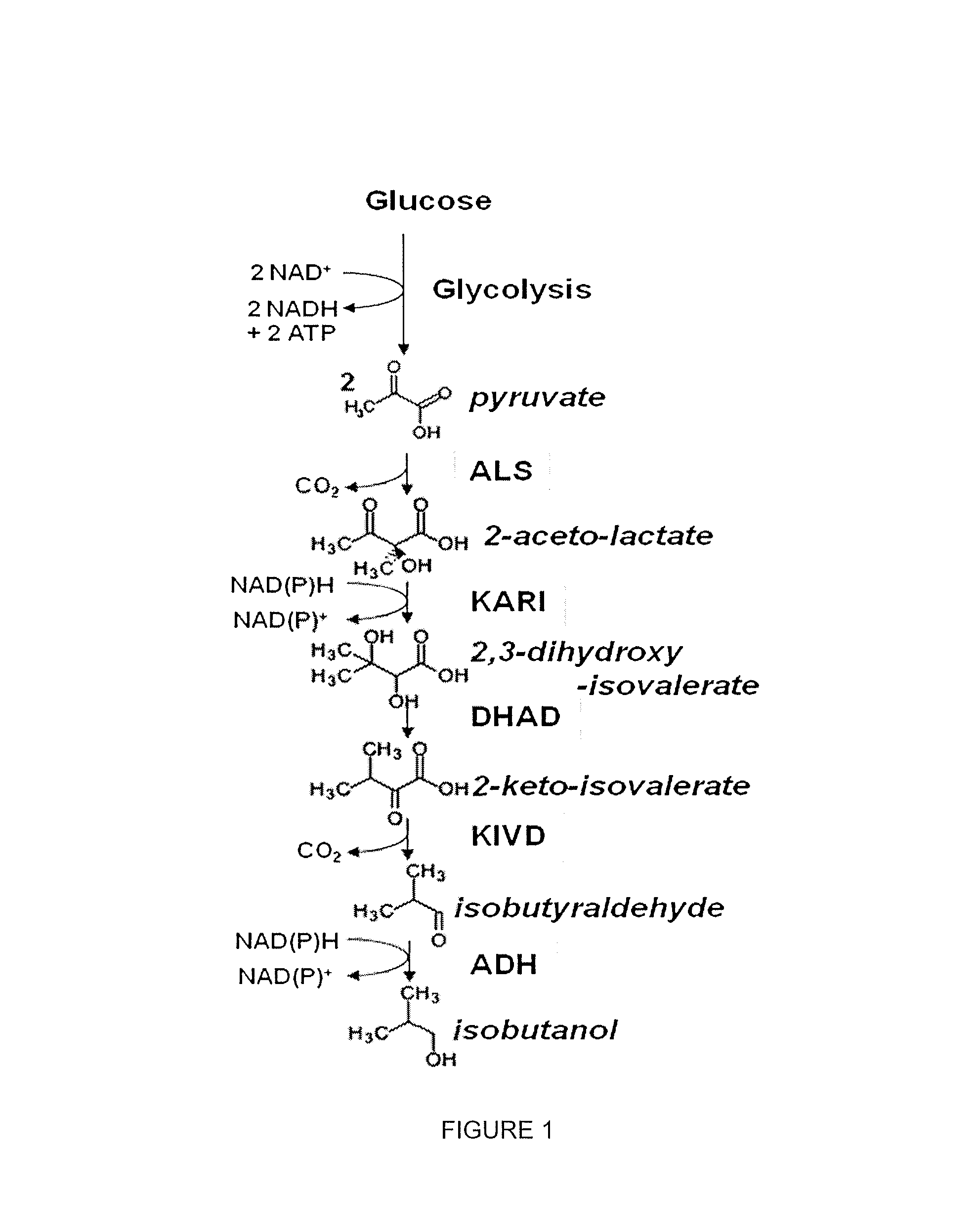

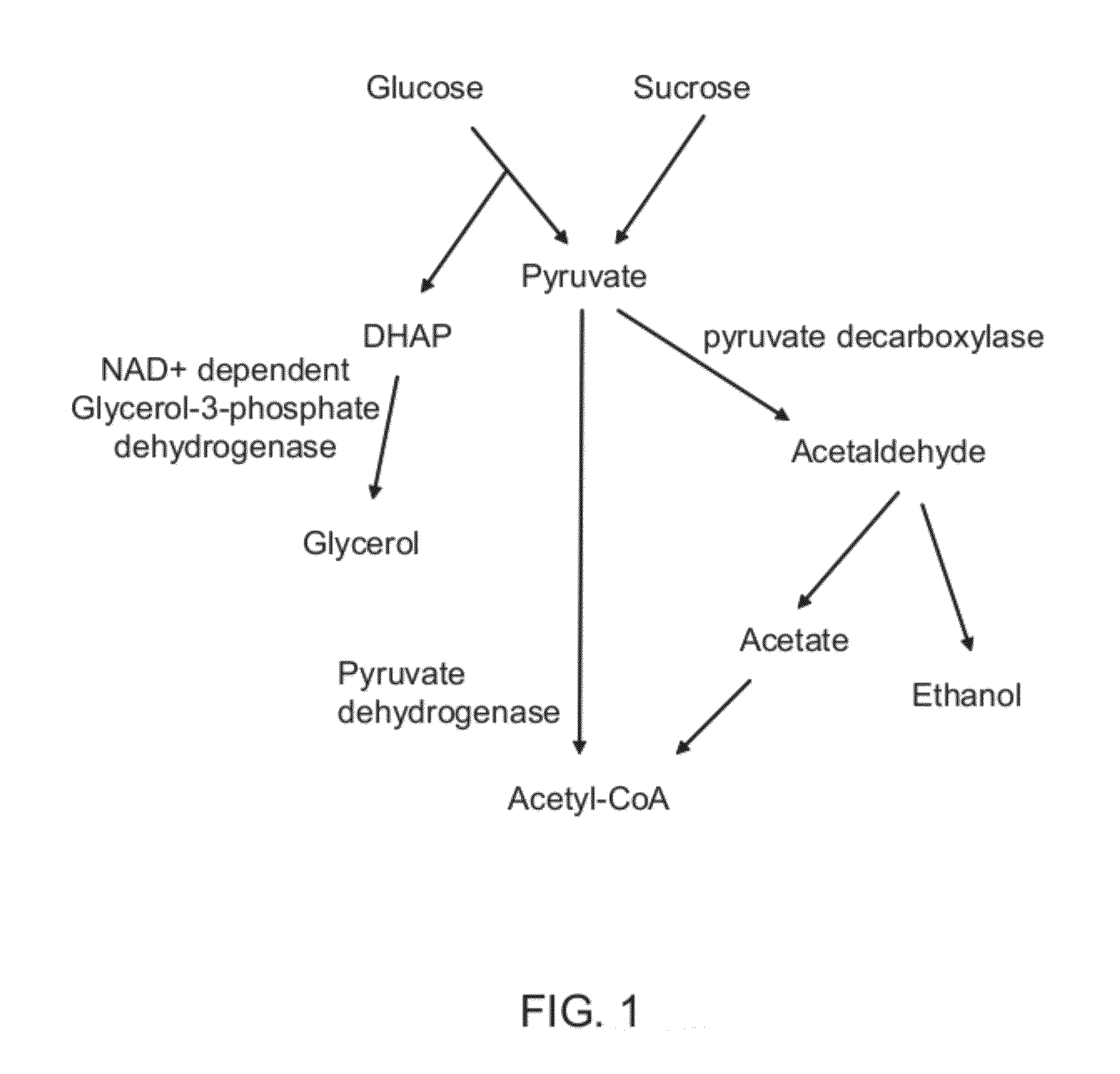

A high flux in conversion of pyruvate to acetolactate was achieved in yeast through expression of acetolactate synthase in the cytosol in conjunction with reduction in pyruvate decarboxylase activity. Additional manipulations to improve flux to acetolactate are reduced pyruvate dehydrogenase activity and reduced glycerol-3-phosphate dehydrogenase activity. Production of compounds having acetolactate as an upstream intermediate benefit from the increased conversion of pruvate to acetolactate in the described strains.

Owner:GEVO INC

Modified alcohol dehydrogenases for the production of fuels and chemicals

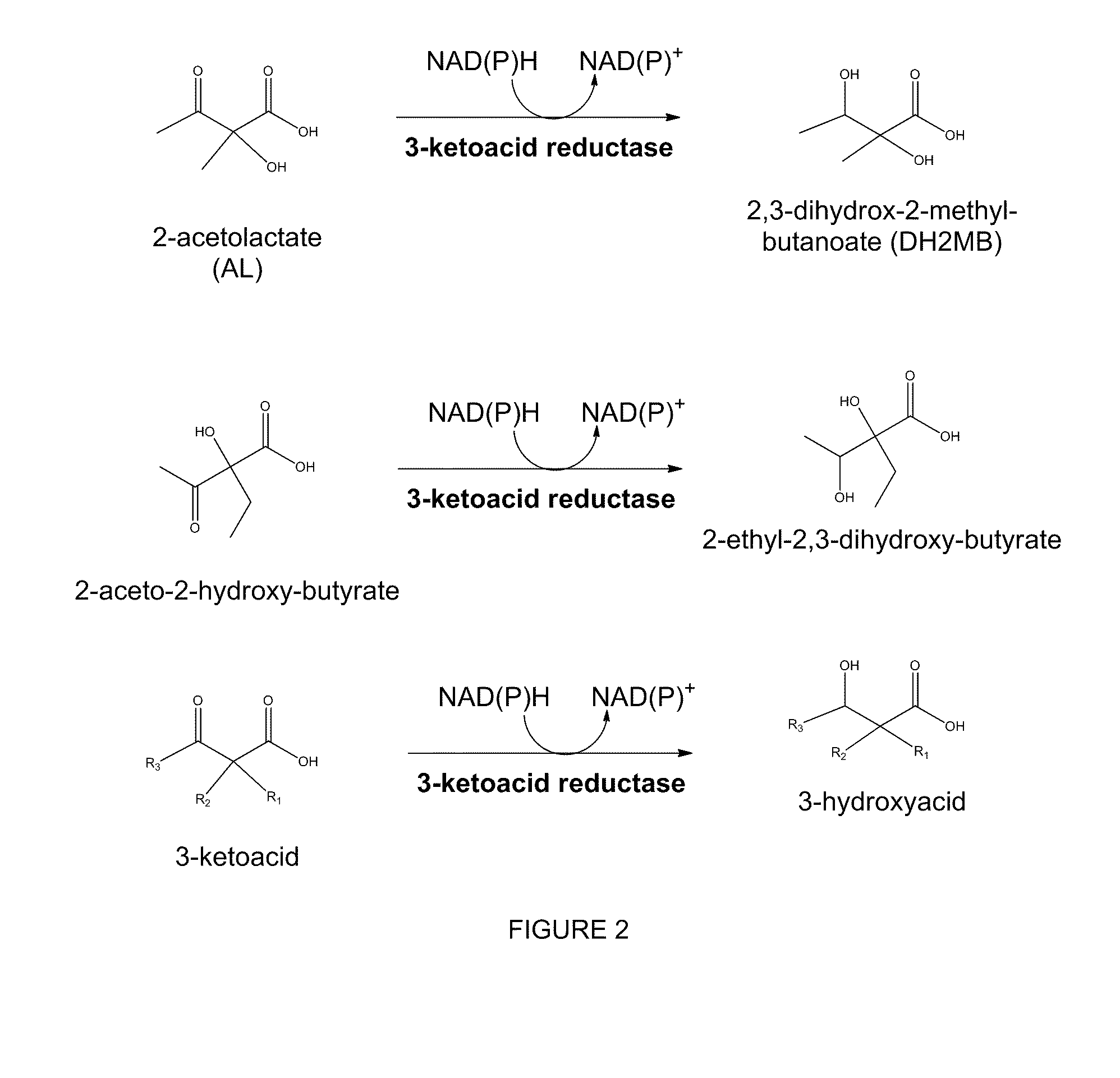

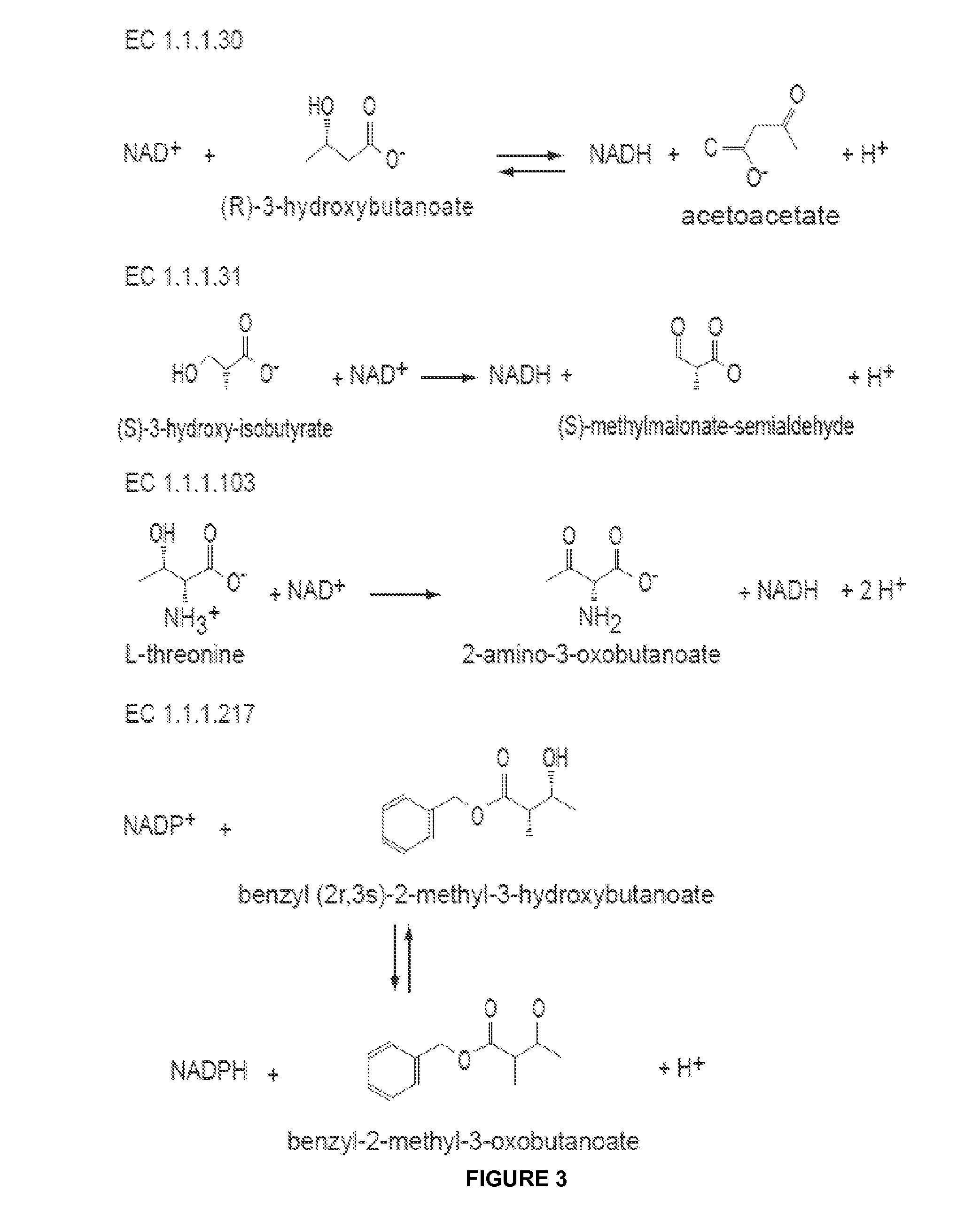

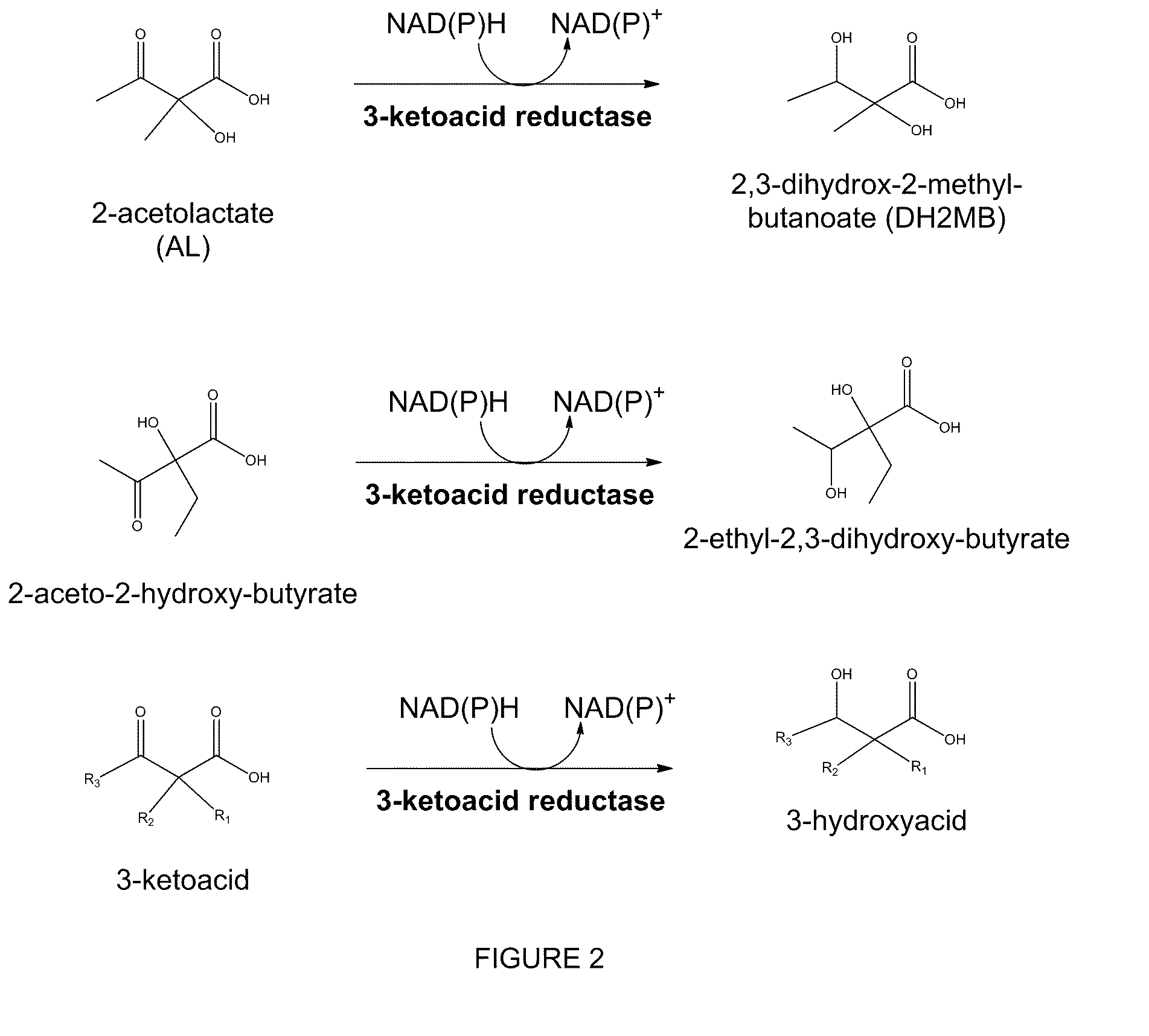

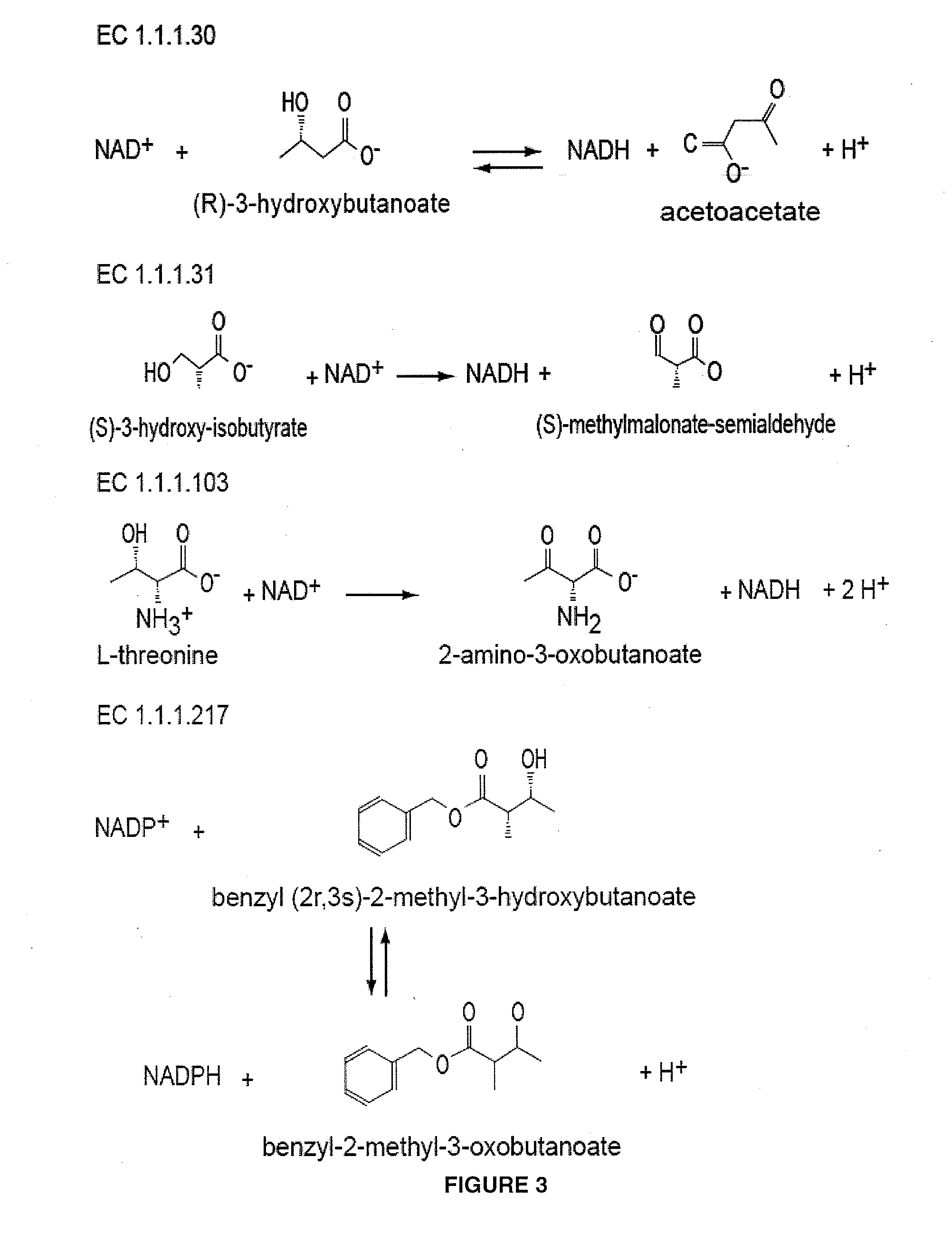

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:CALIFORNIA INST OF TECH +1

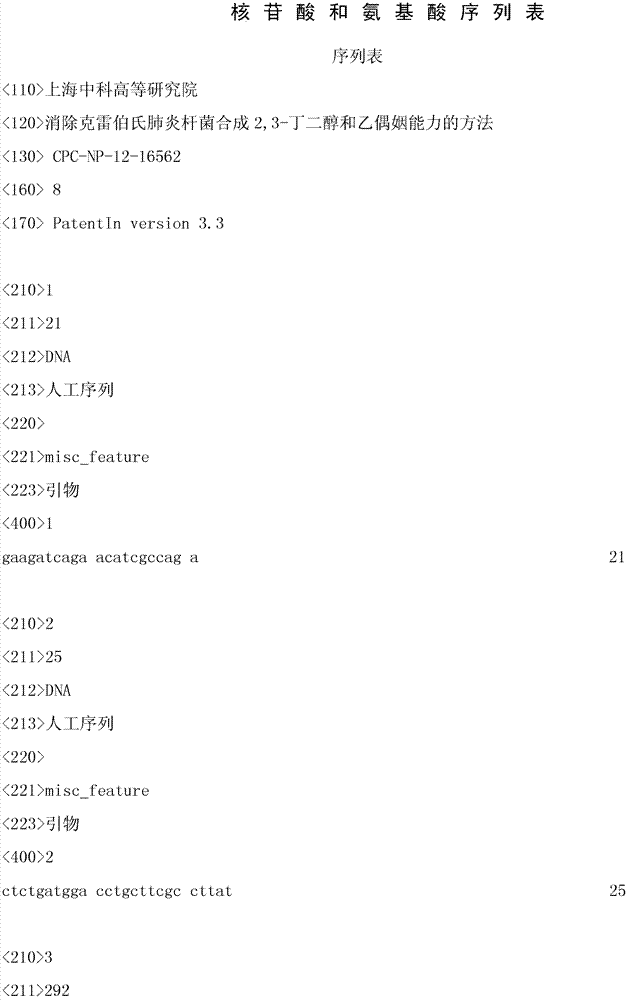

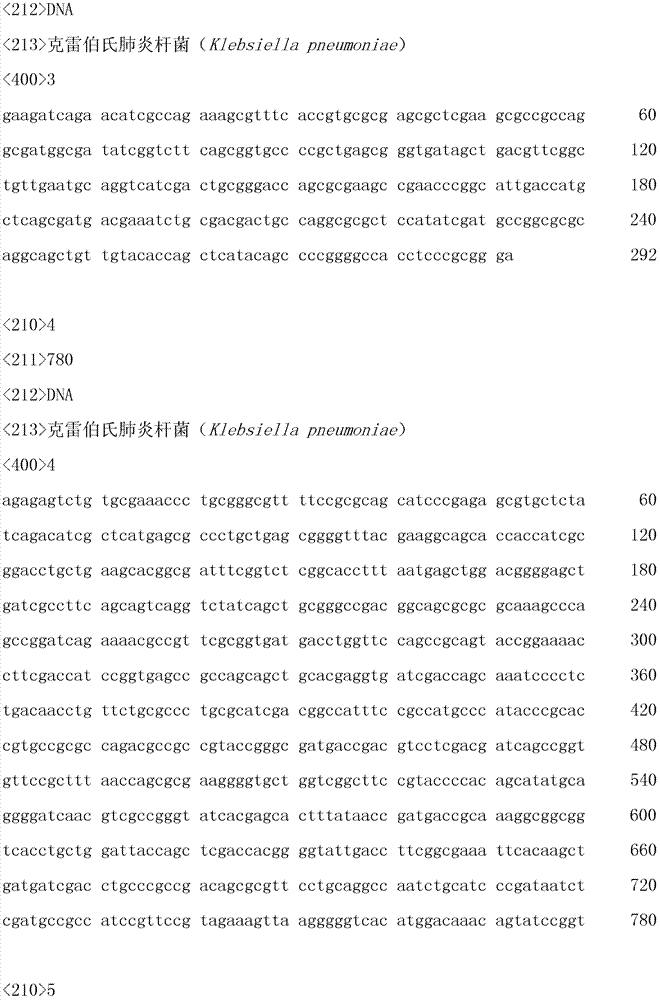

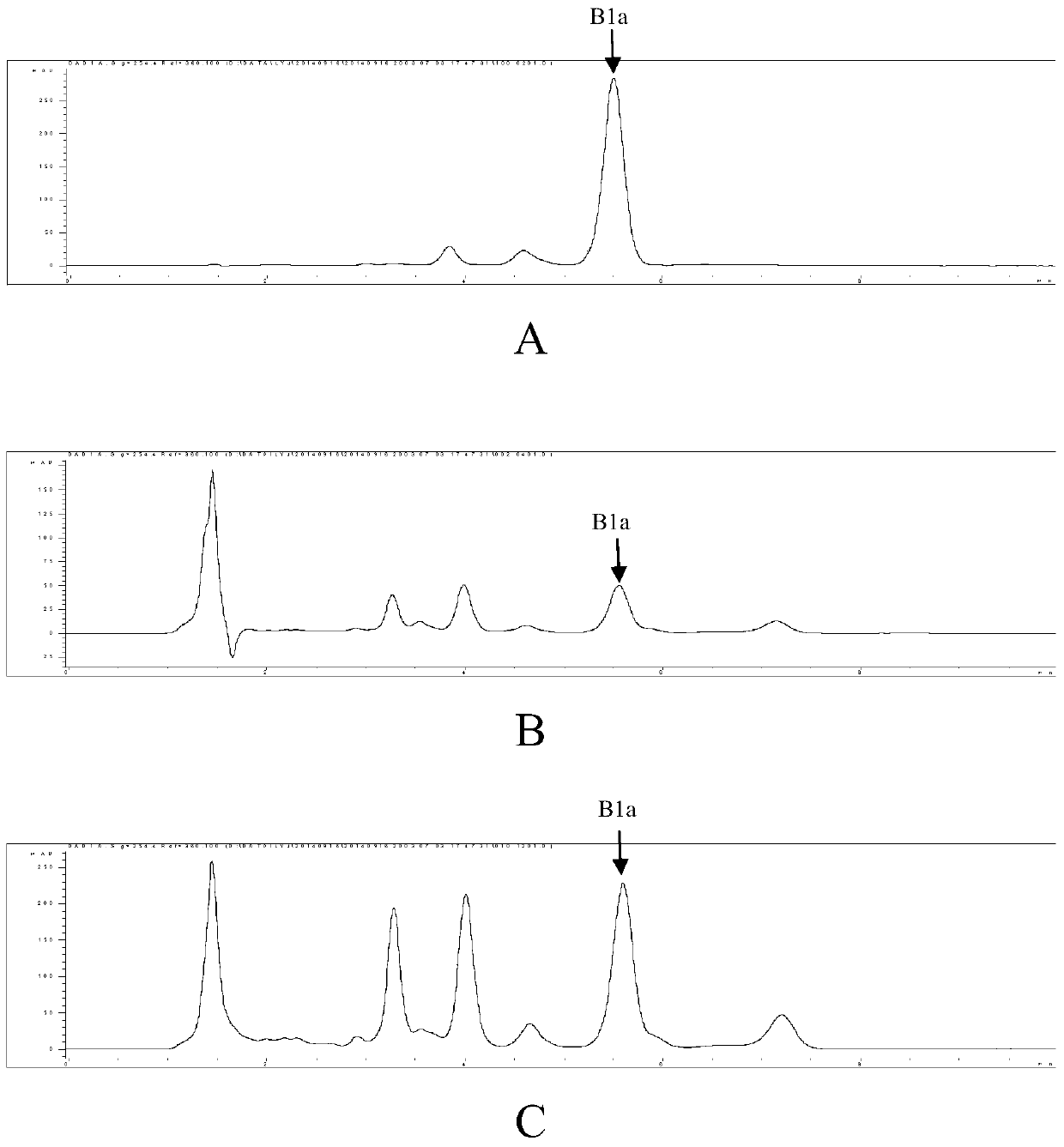

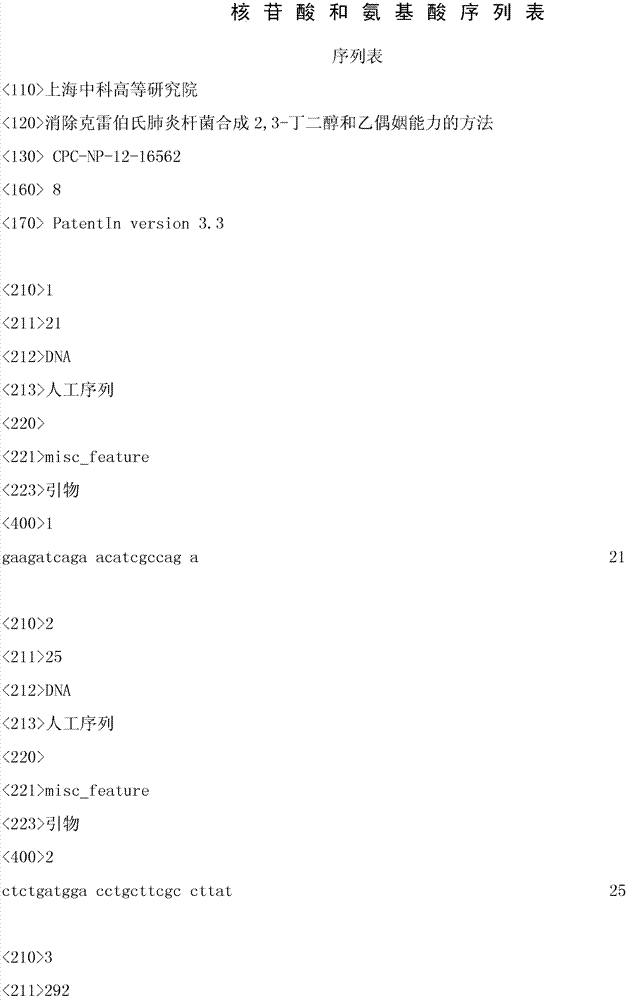

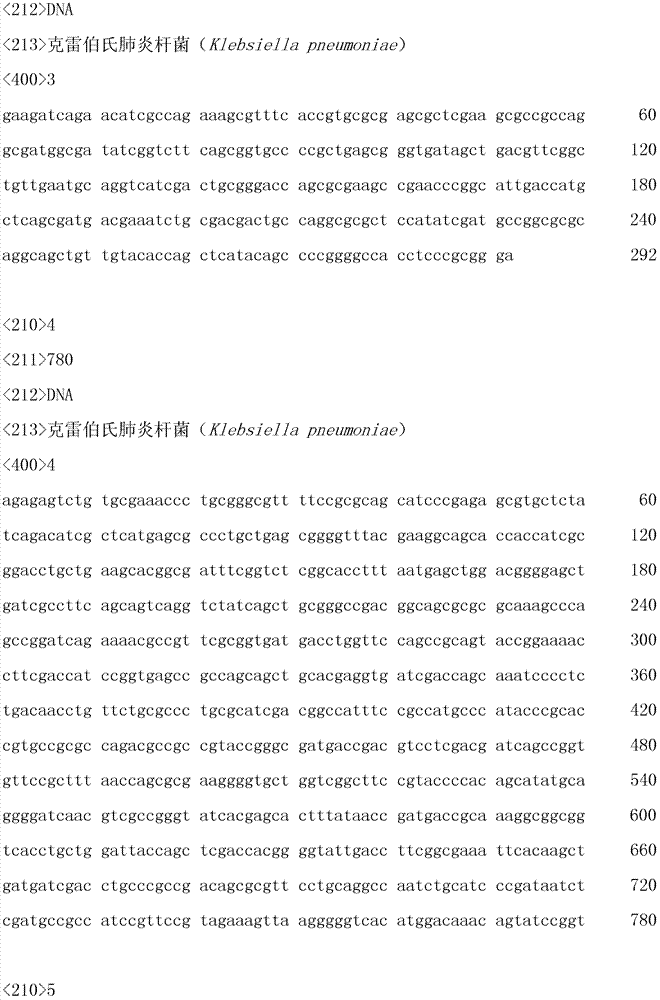

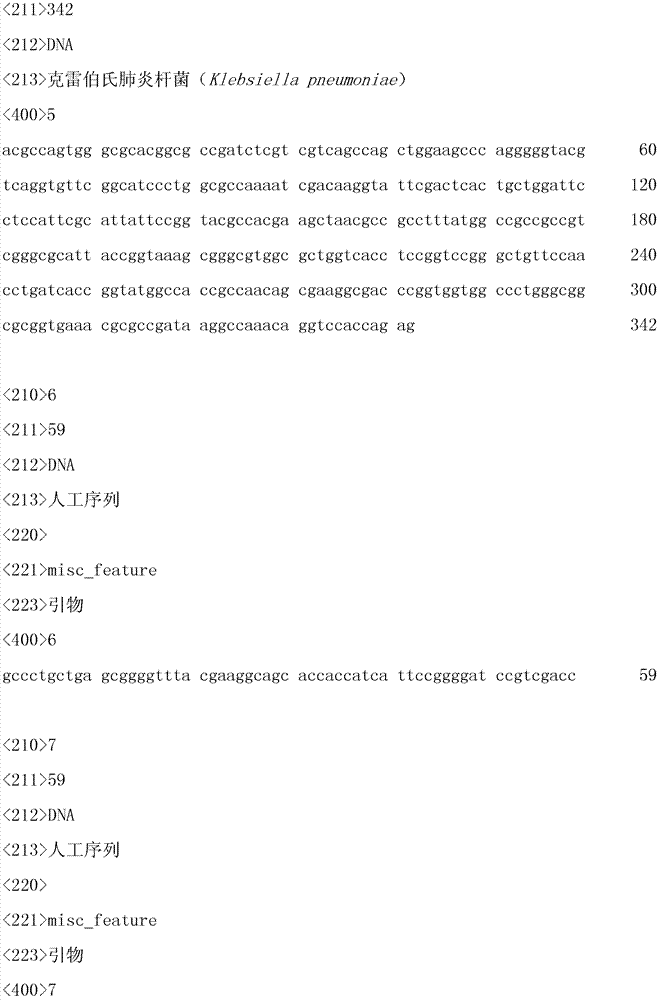

Method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin

ActiveCN102952826AEliminate generationReduce separation and extraction stepsBacteriaStable introduction of DNA2,3-ButanediolGlycerol

The invention discloses a method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin, comprising the following step of inactivating acetolacetate decearboxylase gene in a synthesis route of 2,3-butanediol by lebsiella pneumoniae to cut off the catalytic reaction that acetolactic acid is converted into acetoin. According to the method, when 1,3-propylene glycol is synthesized from glycerol by the klebsiella pneumoniae, the synthesis of byproducts, i.e. 2,3-butanediol and acetoin, can be eliminated, and the conversation rate of glycerol to 1,3-propylene glycol can be improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Reduced by-product accumulation for improved production of isobutanol

ActiveUS20110201073A1Catalytic efficiency be enhanceEnhance abilityFungiBiofuels2-HydroxybutyrateYeast

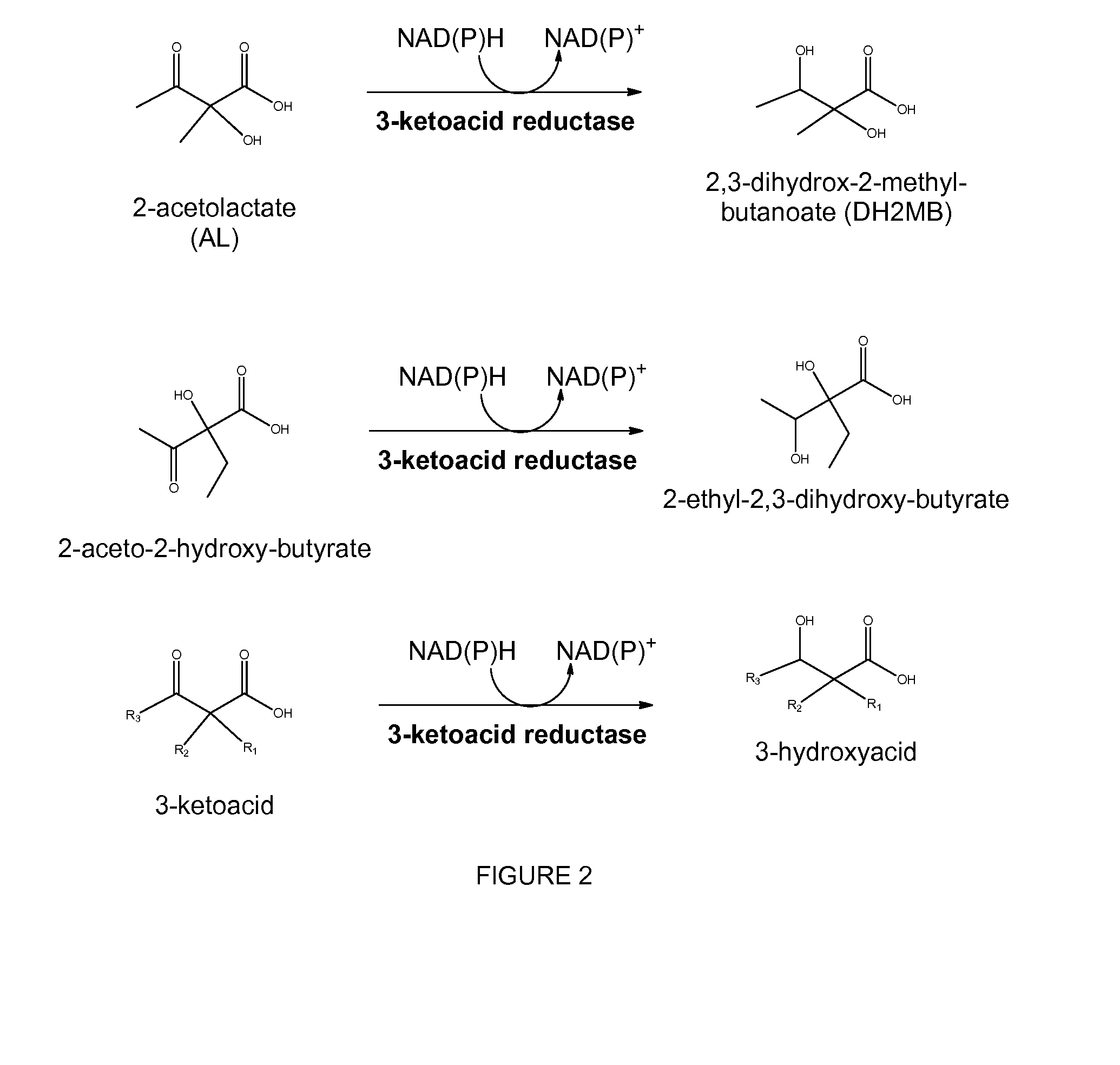

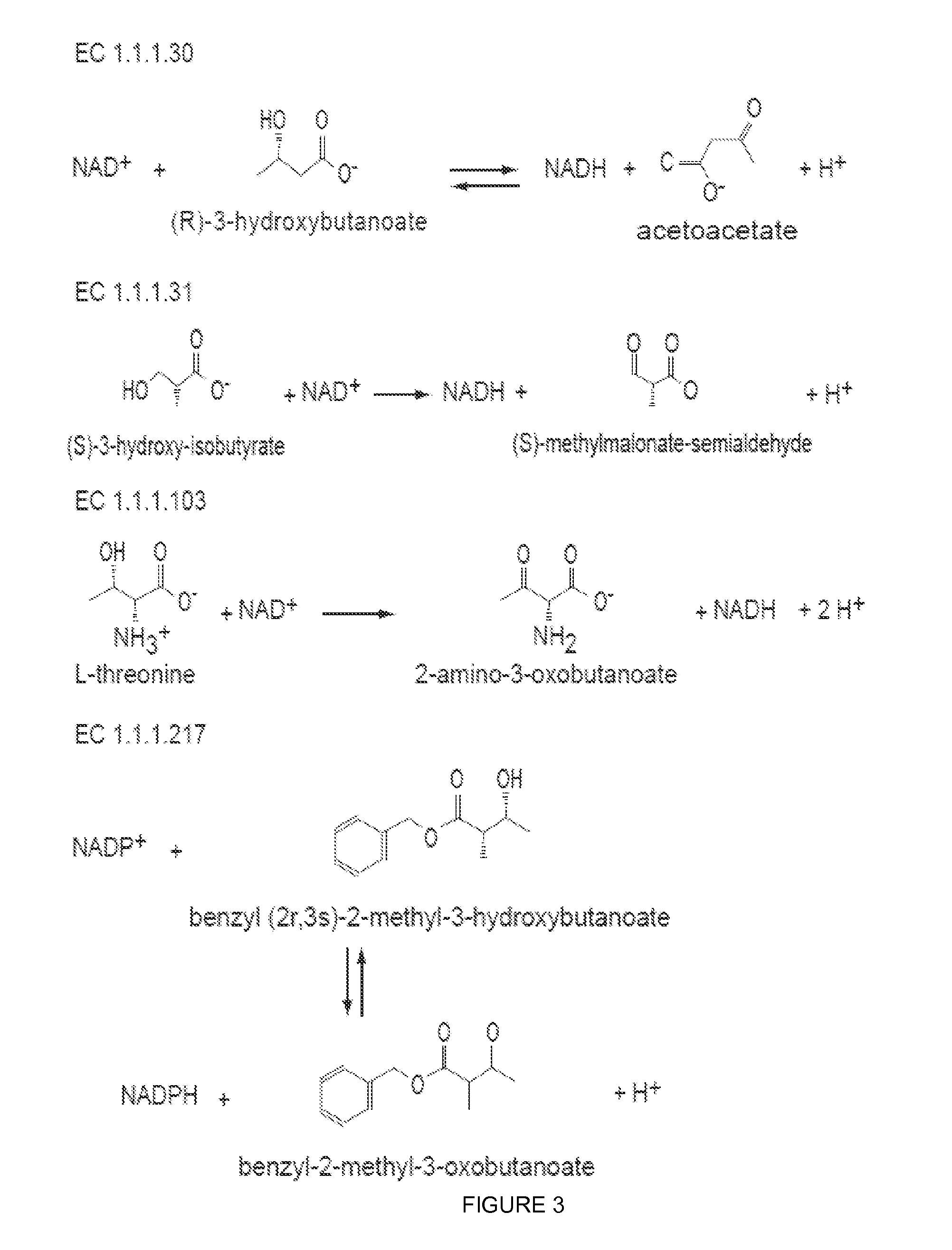

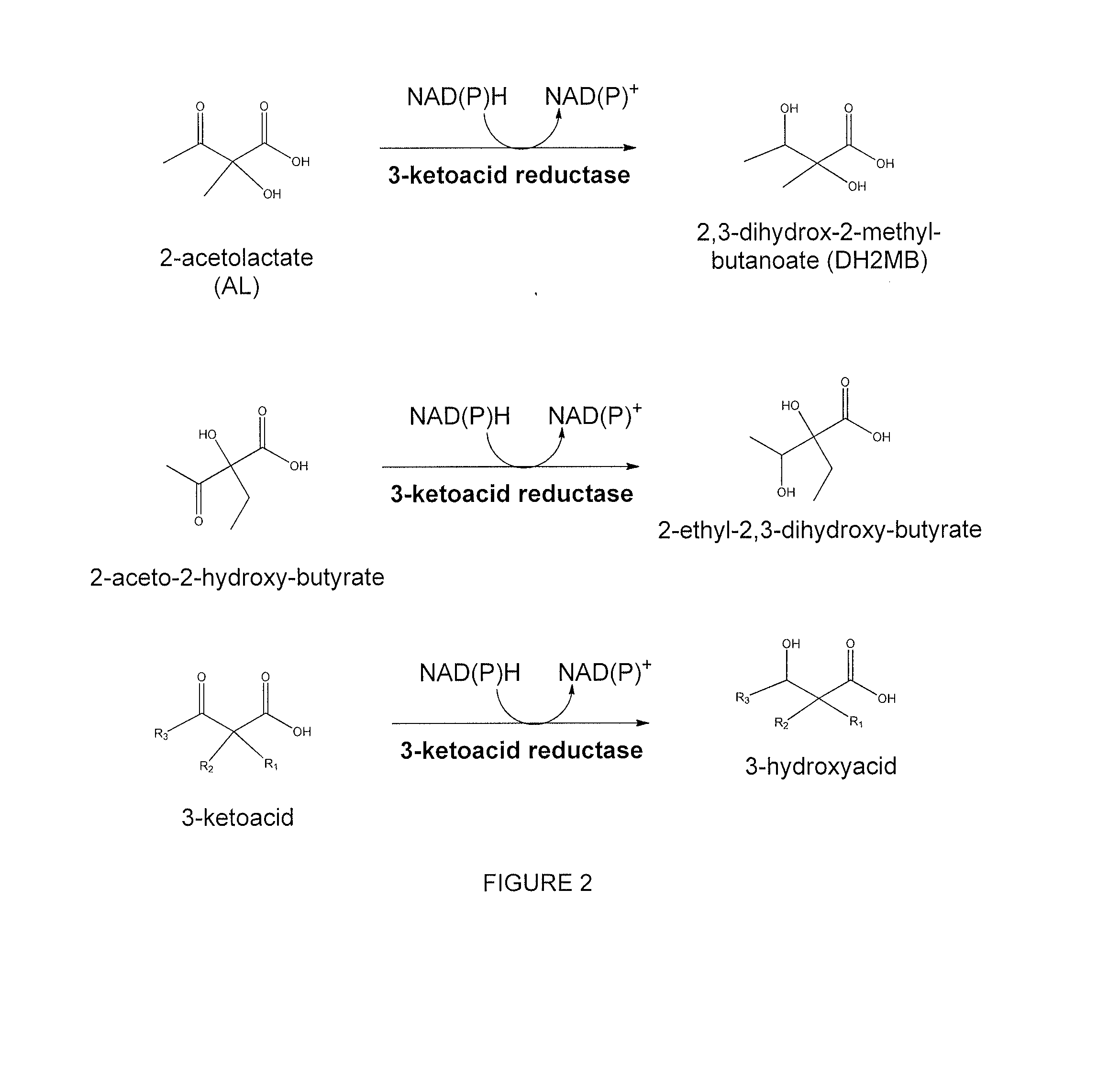

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

Genetic engineering bacteria capable of producing pantothenic acid at high yield without addition of beta-alanine, construction and application of genetic engineering bacteria

ActiveCN109913398AImprove utilizationReduce feedback inhibitionBacteriaStable introduction of DNACell phenotypeEscherichia coli

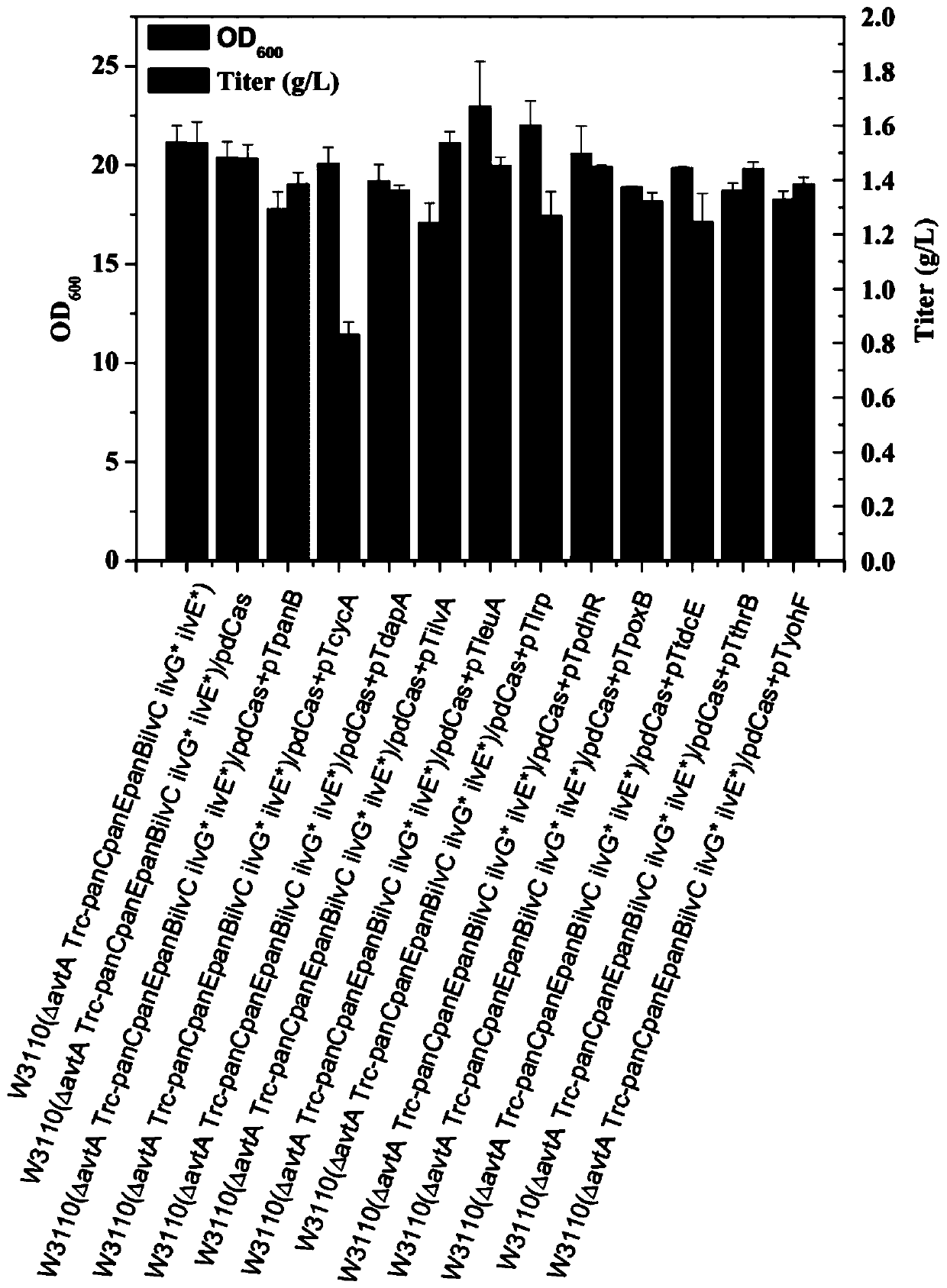

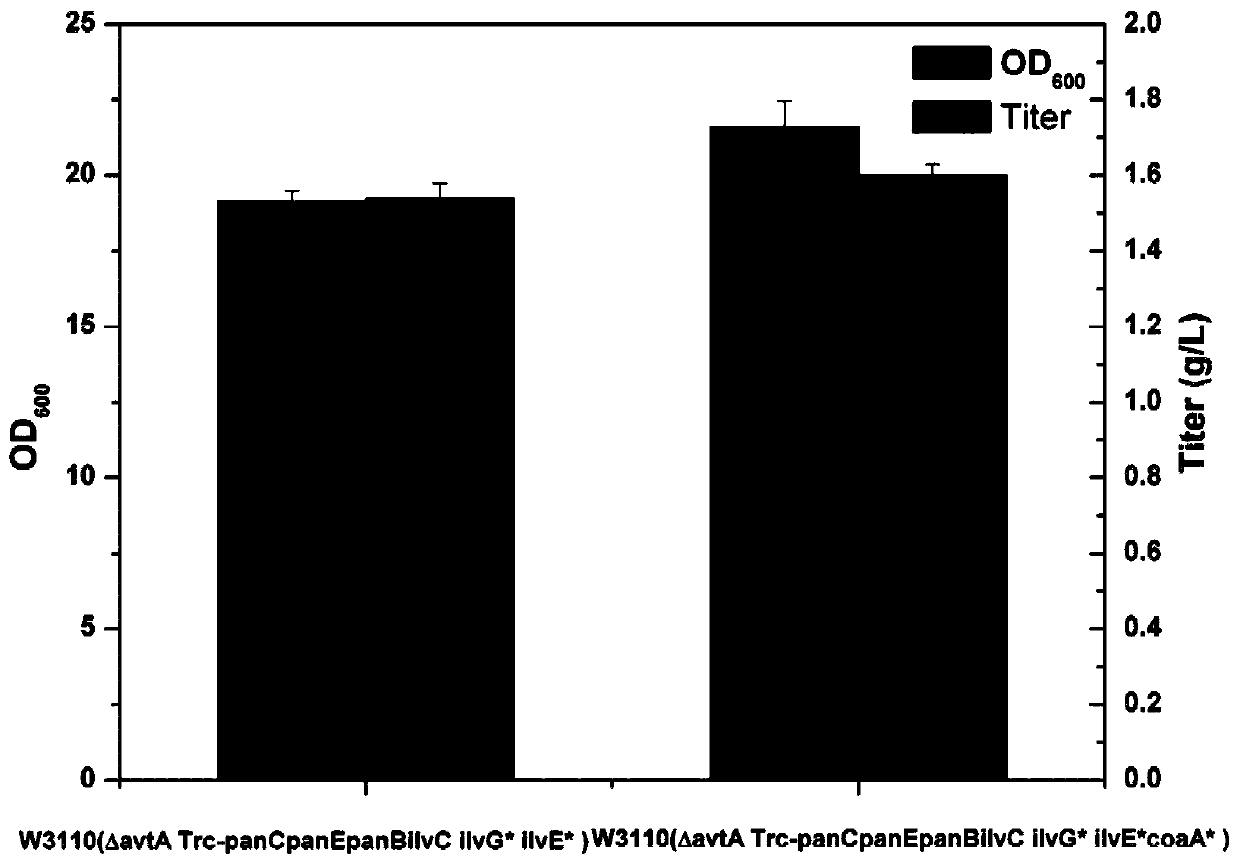

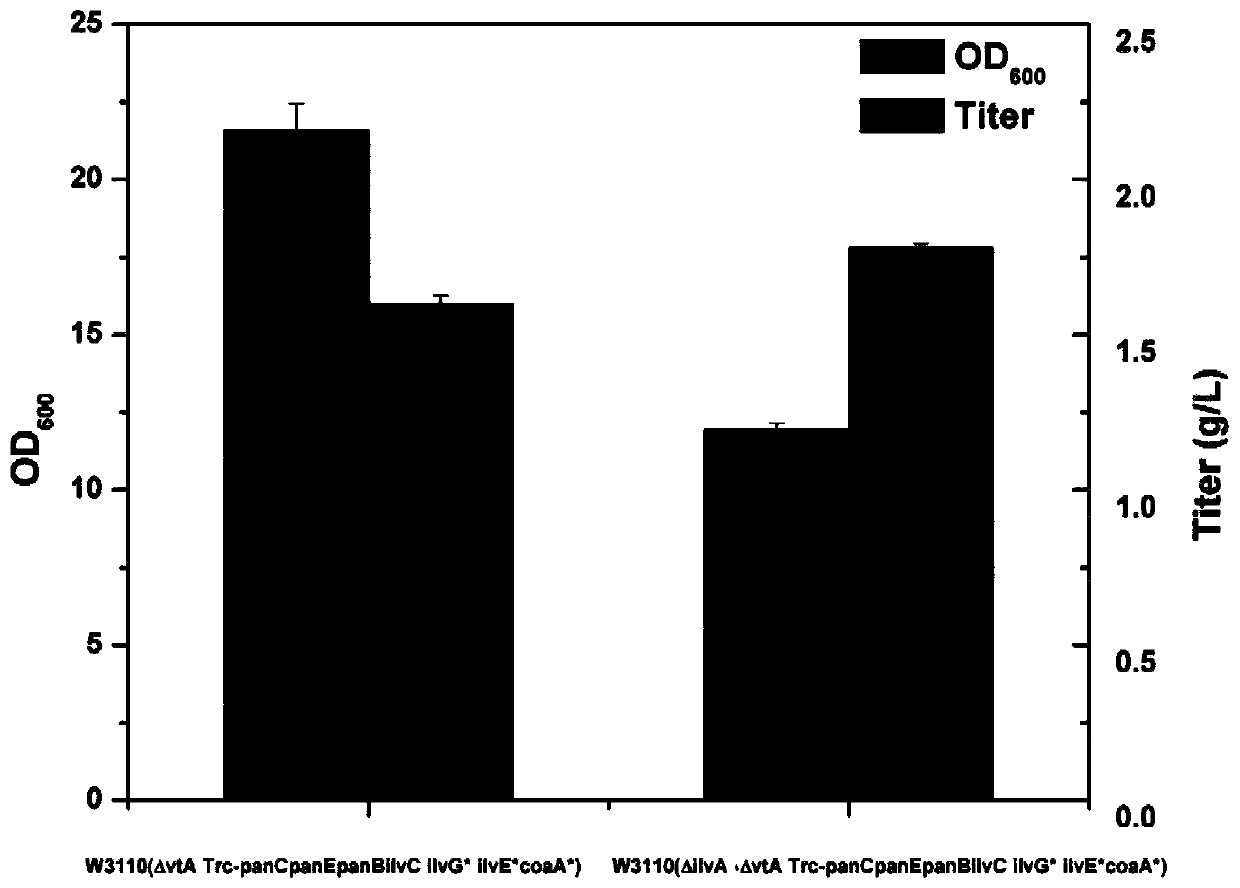

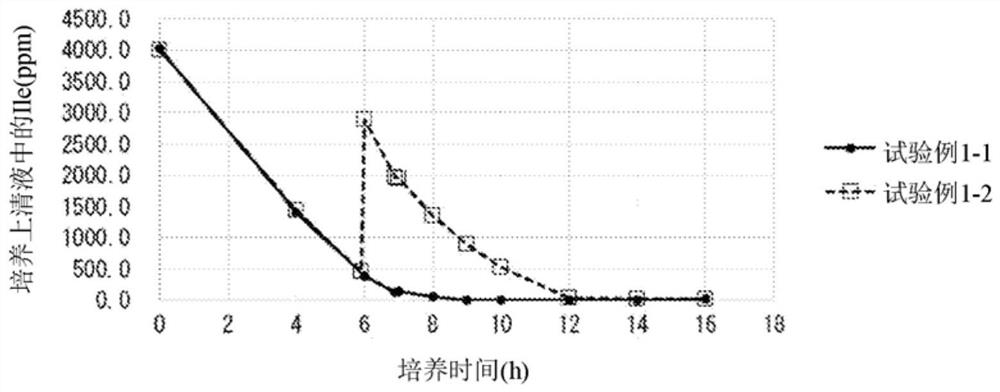

The invention relates to genetic engineering bacteria capable of producing pantothenic acid at high yield without addition of beta-alanine, a construction method of the genetic engineering bacteria, and application of the genetic engineering bacteria in preparation of D-pantothenic acid by microbial fermentation. According to the invention, (1), the final step of an escherichia coli D-pantothenicacid synthesis pathway is enhanced, and the utilizing ability of escherichia coli to extracellular beta-alanine, (2), a pantoic acid synthesis pathway is enhanced, (3), ilvG gene is repaired, and thefeedback inhibition effect of by-products on a pantoic acid synthesis pathway is weakened, (4), according to the change in cell phenotype, flux of a valine synthesis pathway is weakened, (5), a CRISPRi technique is used to screen metabolic modification sites of TCA cycle, a PPP pathway and a by-product metabolic pathway, according to the result, an isoleucine synthesis pathway is blocked, and thecompetition of 2-butanoic acid for reaction of acetolactate synthesized from pyruvic acid under catalysis of acetolactate synthase is relieved, and (6), aspartate decarboxylase from other strains is subjected to heterologous expression to obtain a genetical engineering strain capable of producing the pantothenic acid at high yield without addition of the beta-alanine. By combined expression of panB and panC which are derived from corynebacterium glutamicum and panD derived from bacillus subtilis together on pTrc99A plasmids, 1.2g / L of D- pantothenic acid is obtained without adding the beta-alanine.

Owner:ZHEJIANG UNIV OF TECH

Flux to acetolactate-derived products in lactic acid bacteria

ActiveUS9169499B2Reduces and eliminates enzyme activityReduced activityBacteriaBiofuelsLactobacillusLactate dehydrogenase

Owner:GEVO INC

Yeast microorganisms with reduced by-product accumulation for improved production of fuels, chemicals, and amino acids

InactiveUS20110201090A1Improve abilitiesHigh catalytic efficiencyFungiBiofuelsBiotechnologyMetabolite

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

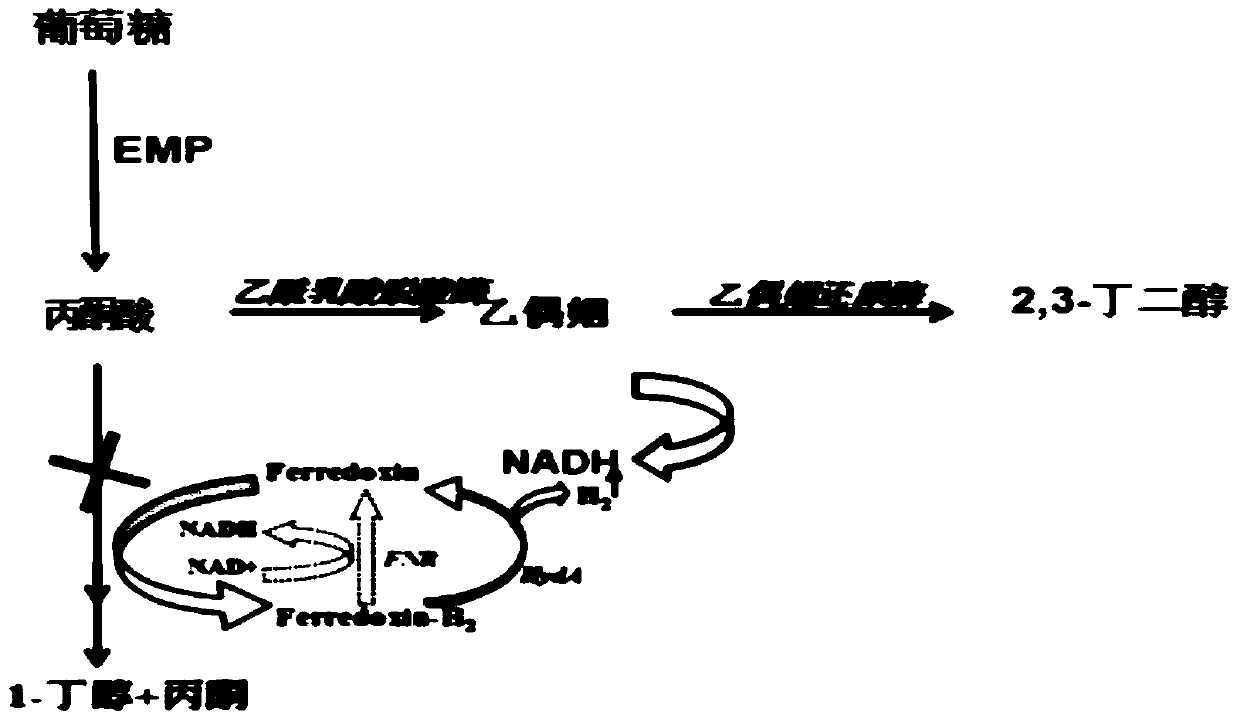

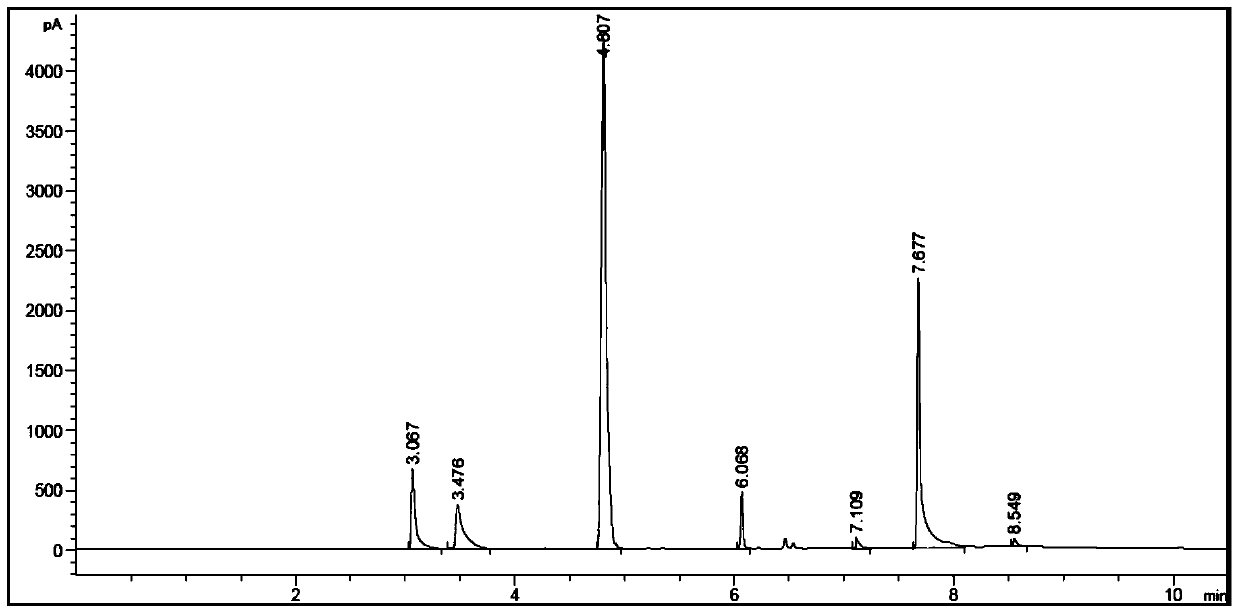

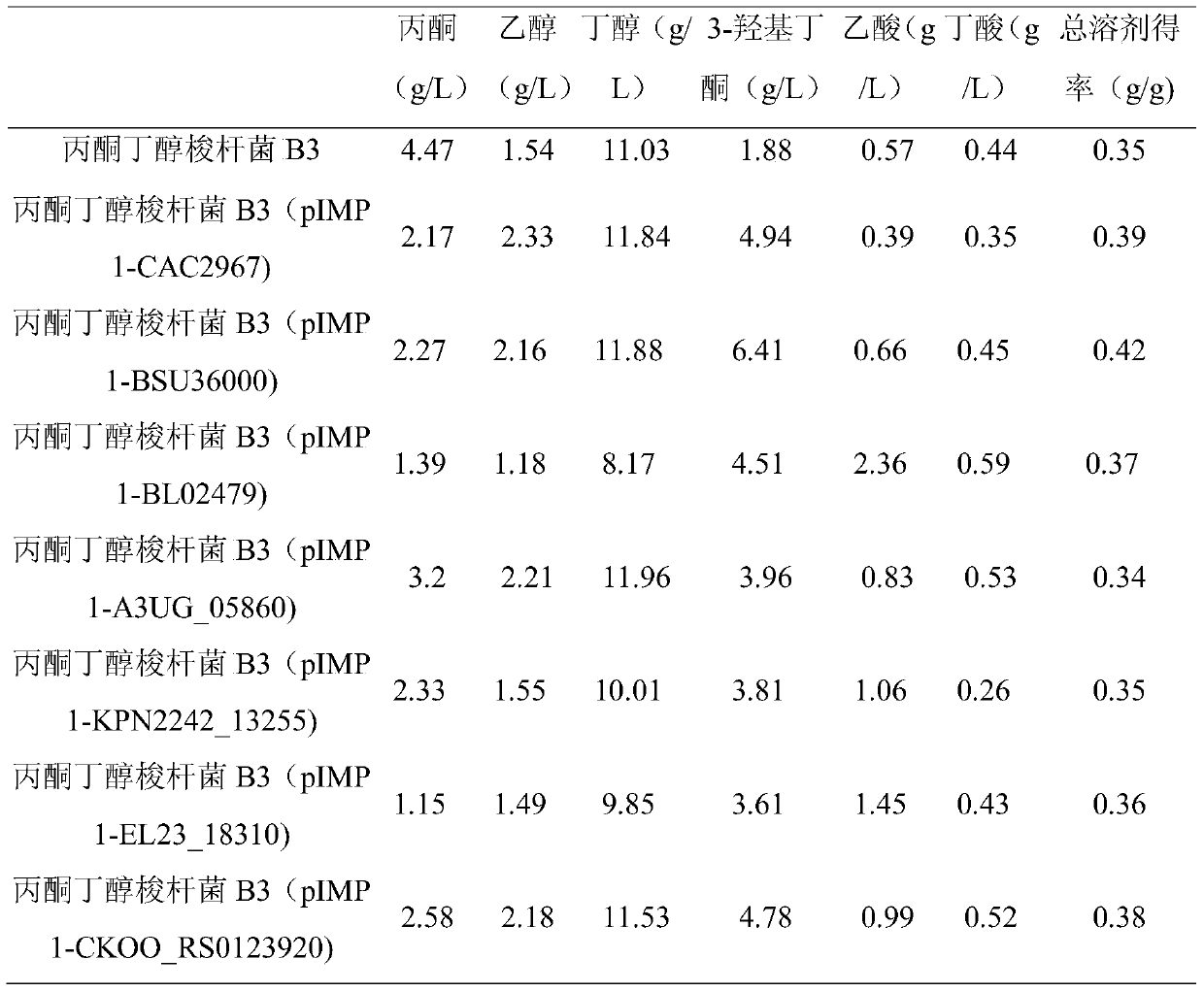

Genetically engineered bacterium for co-generating butanol and 2,3-butanediol and construction method and application thereof

The invention discloses a genetically engineered bacterium for co-generating butanol and 2,3-butanediol. The genetically engineered bacterium is a butanol generating clostridium to which an acetoin reductase gene is introduced or a butanol generating clostridium to which an acetolactic acid decarboxylase gene and the acetoin reductase gene are introduced. The nucleotide sequence of the acetolactic acid decarboxylase gene is any one of nucleotide sequences shown in SEQ ID NO:1-7, and the nucleotide sequence of the acetoin reductase gene is any one of nucleotide sequences shown in SEQ ID NO:8-11. An acetolactic acid decarboxylic reaction is enhanced in a clostridium acetobutylicum, the yield of 3-hydroxy butanone is greatly increased to about 6.4 g / L from initial about 1.8 g / L, and then acetoin is converted into 2,3-butanediol reaching up to 8.05 g / L under the effect of acetoin reductase; acetone is reduced to 2.2 g / L from about 4.5 g / L, and economic benefits of fermentation of the clostridium acetobutylicum are remarkably increased.

Owner:NANJING UNIV OF TECH

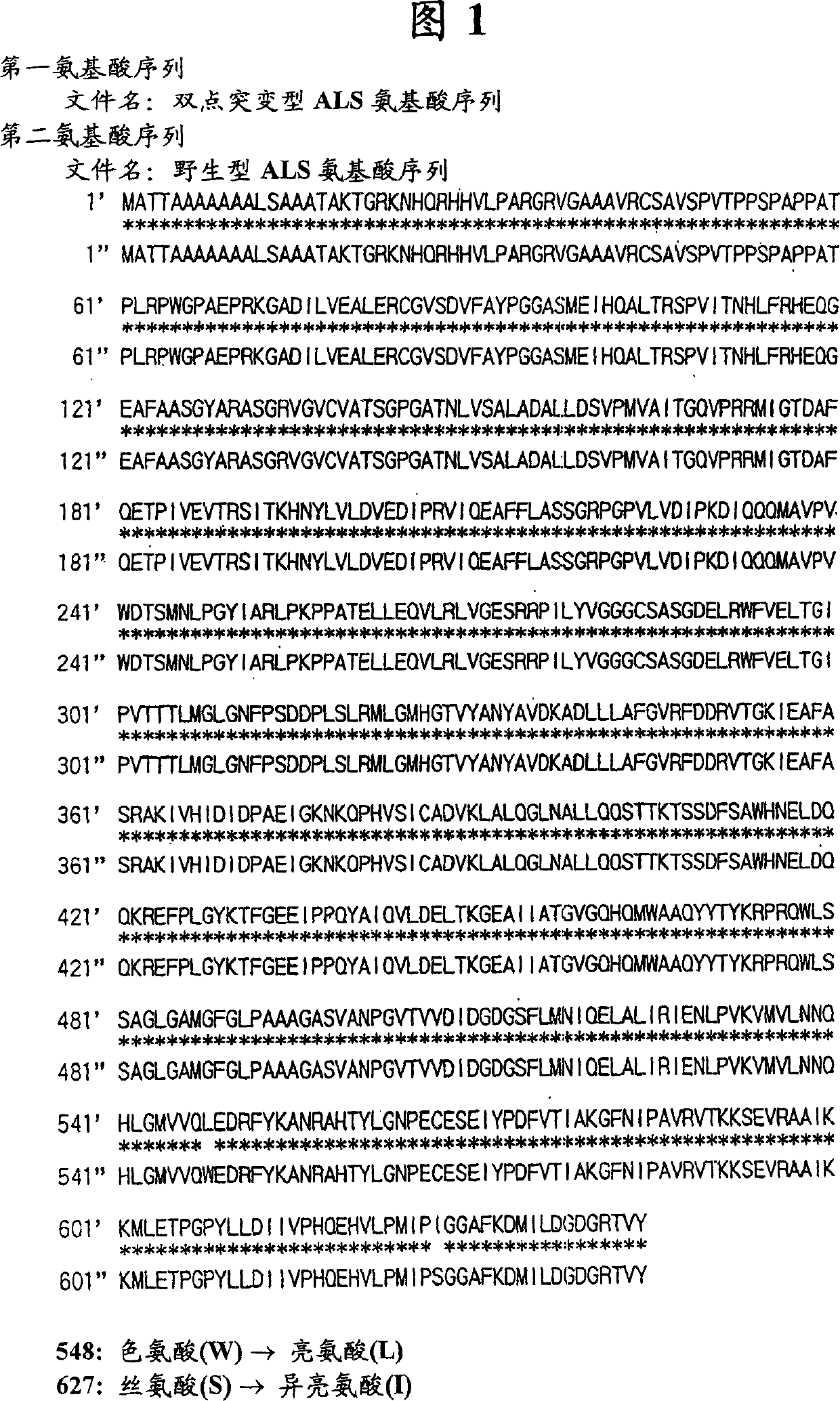

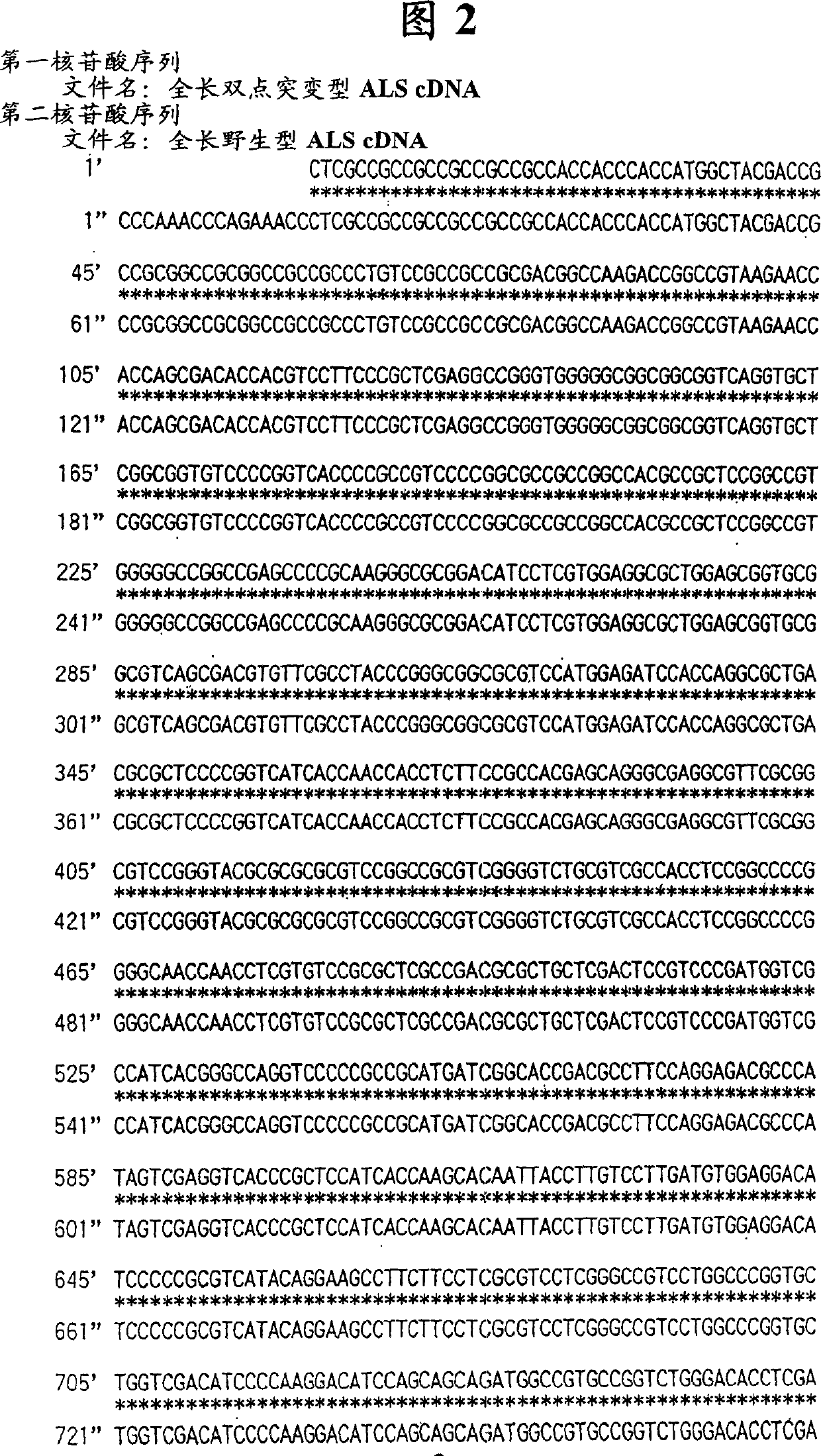

Gene encoding acetolactic acid sy nthase gene

The present invention provides a gene encoding ALS protein which shows extremely high level of resistance to PC herbicides. The gene of the present invention encodes the following protein (a) or (b): (a) a protein which comprises an amino acid sequence of SEQ ID NO: 1; (b) a protein which comprises an amino acid sequence derived from the amino acid sequence of SEQ ID NO: 1 by substitution, deletion or addition of at least one or more amino acids, has resistance to a pyrimidinyl carboxy herbicide and has acetolactate synthase activity.

Owner:KUMIAI CHEM IND CO LTD +1

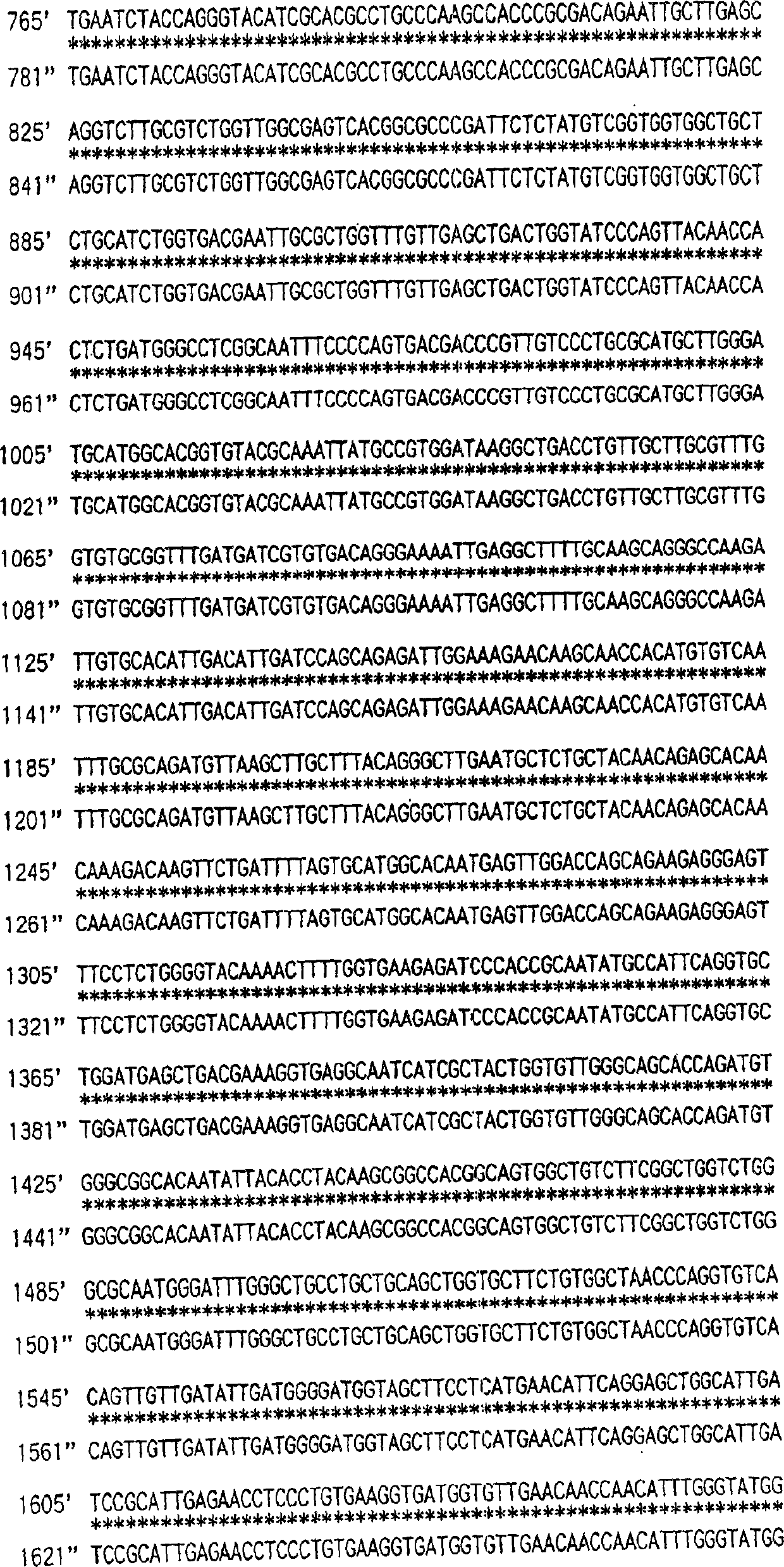

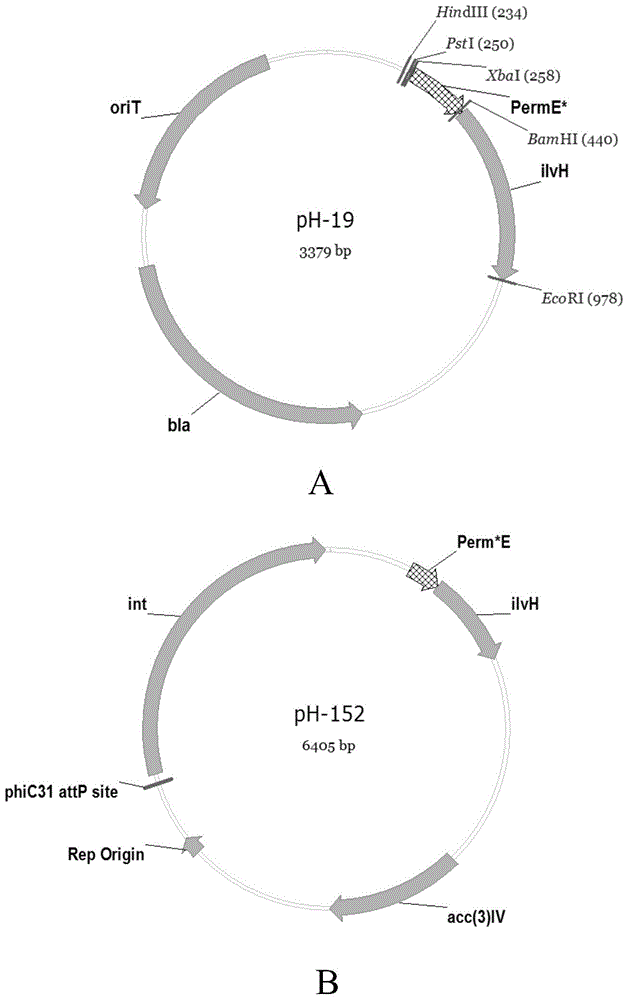

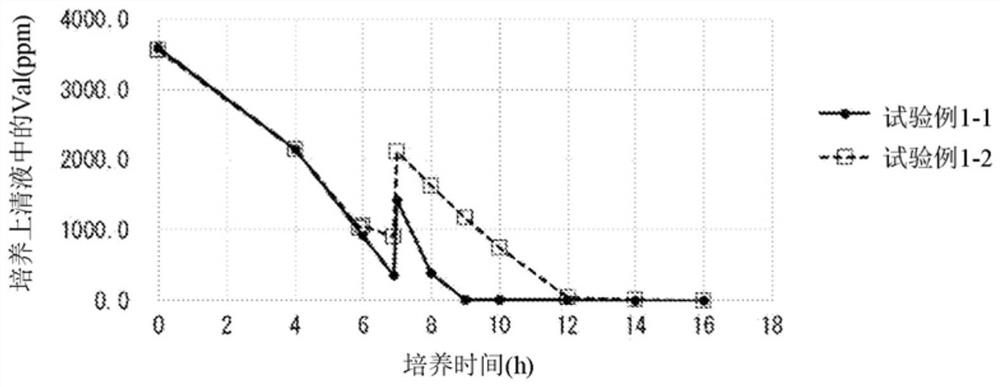

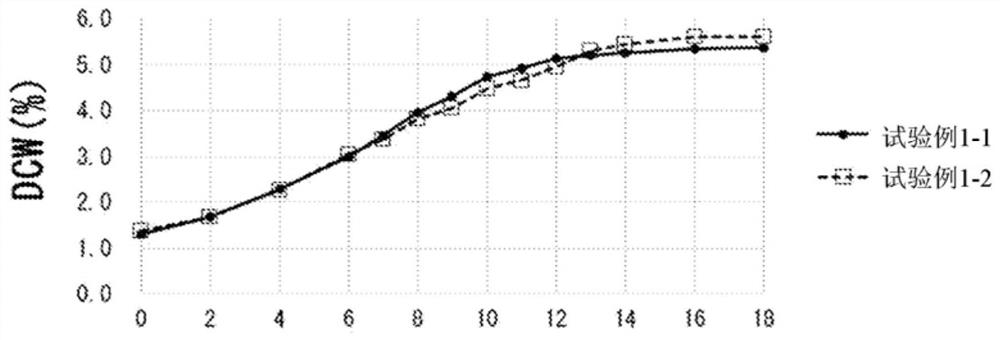

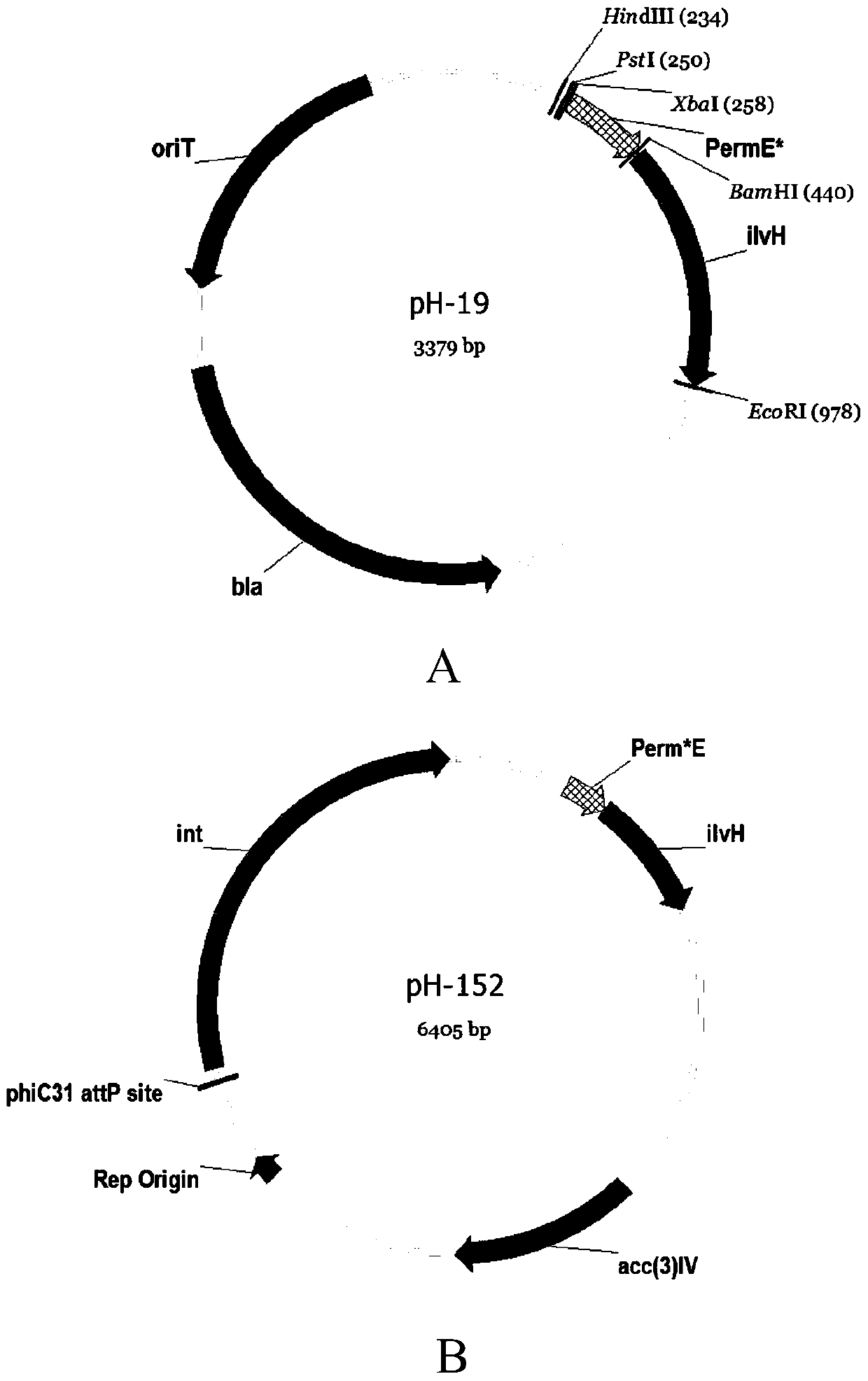

Recombined streptomycete, construction method thereof and method for increasing antibiotic yield

ActiveCN104531598AIncrease productionIncrease the amount of enzymeBacteriaMicroorganism based processesAcetolactic acidAcetolactate synthase

The invention discloses a recombined streptomycete, a construction method of the recombined streptomycete and a method for increasing the antibiotic yield. The recombined streptomycete over-expresses acetolactic acid synthase small subunit ilvH. The recombined streptomycete over-expresses acetolactic acid synthase to adjust subunit genes, and the yield of products such as antibiotics for conducting secondary metabolism with L-isoleucine and / or L-valine and / or L-leucine as precursors / a precursor can be remarkably increased.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

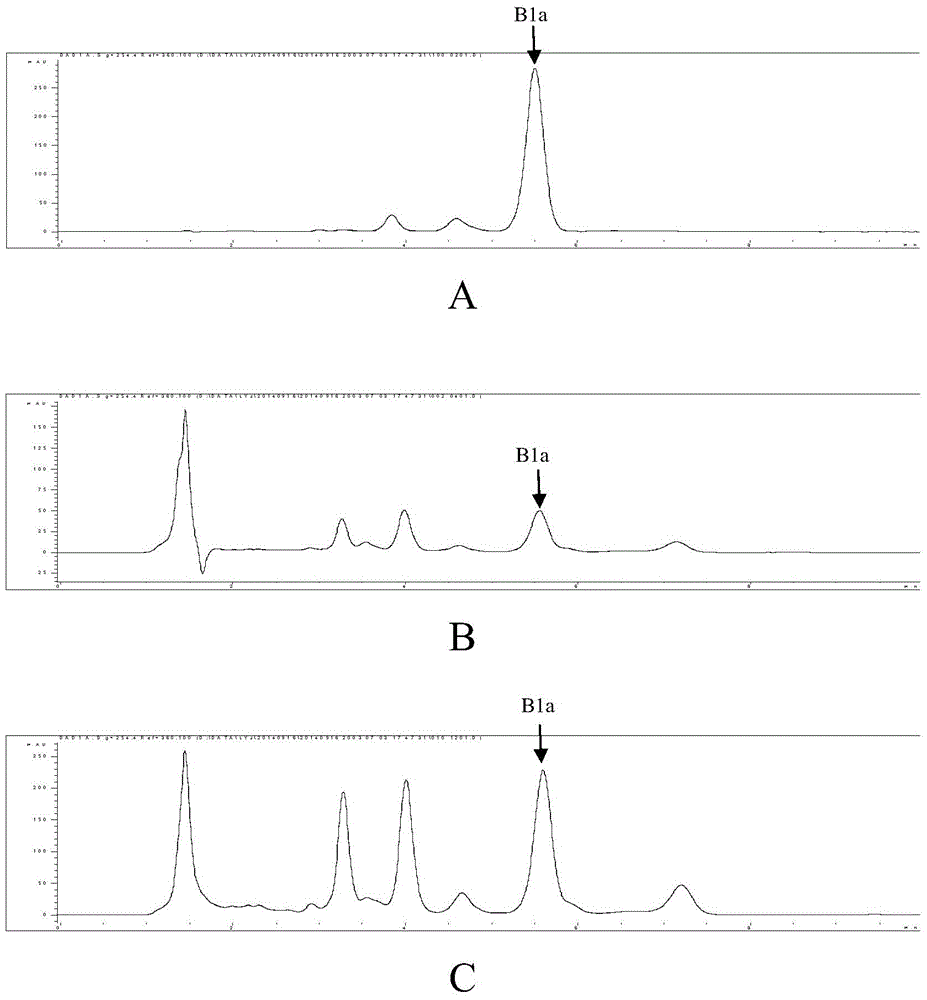

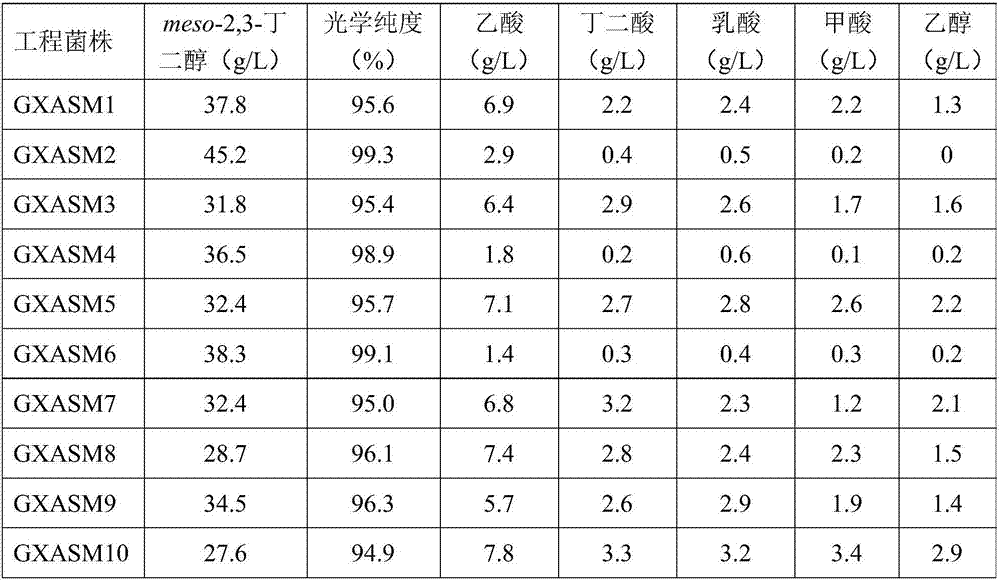

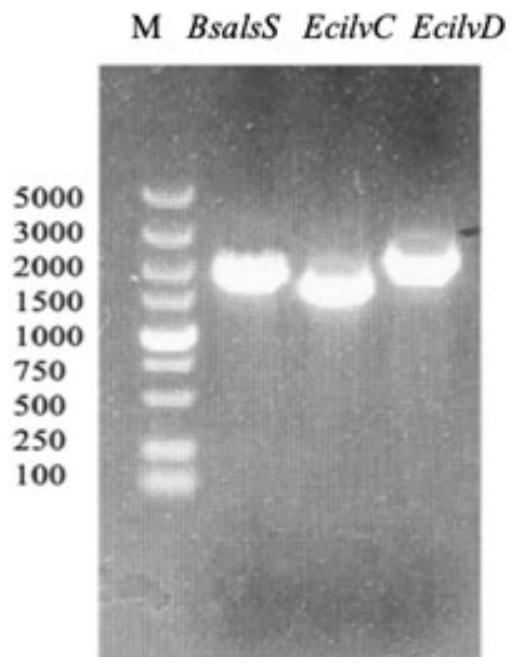

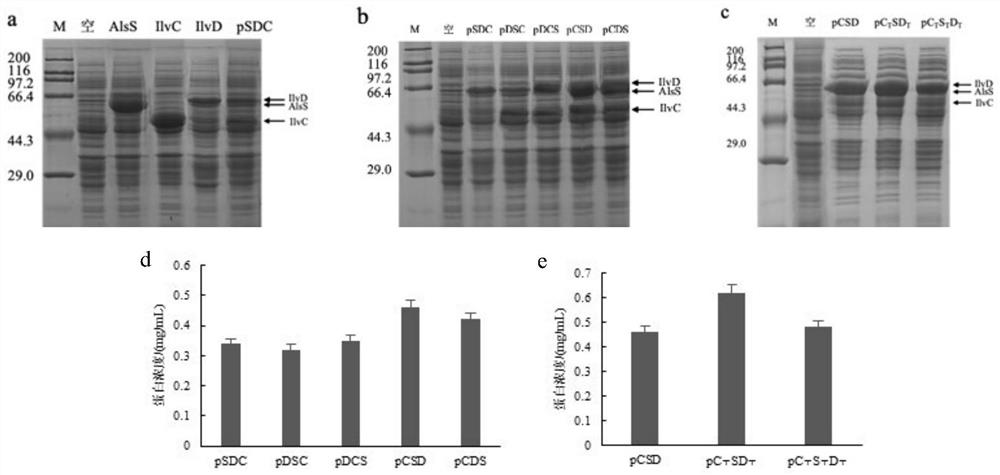

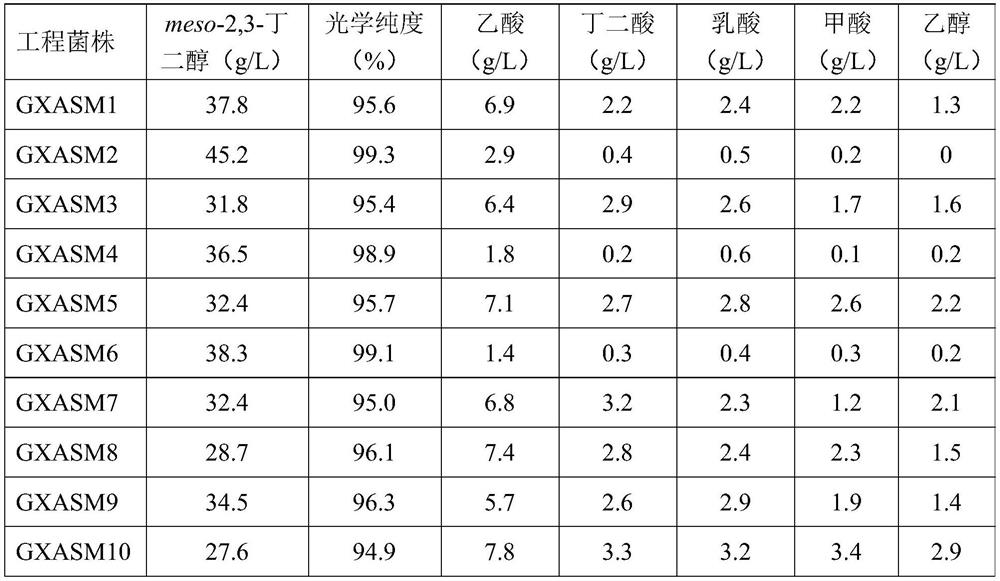

Construction method and application of high-yield engineering strain for optically pure meso-2,3-butanediol

The invention discloses construction of a high-yield engineering strain for optically pure meso-2,3-butanediol. A construction method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and a meso-2,3-butanediol dehydrogenase gene, afterwards, splicing to obtain a gene cluster containing the three genes, then introducing the gene cluster into an expression vector to obtain a polycistronic recombinant plasmid, and finally introducing the recombinant plasmid into a host bacterium E. coli again, so that a high-yield engineering bacterium is obtained. Synthesis raw materials used by the bacterium are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield, high in production efficiency and good in stability, has the highest yield which can reach 91.5g / L and the optical purity which can reach 99 percent or above. The invention discloses application of the high-yield engineering strain to the production of the optically pure meso-2,3-butanediol by utilizing cheap cassava meal as a carbon source and utilizing cottonseed protein powder, soybean pulp powder, soybean cake powder or peanut protein powder as a nitrogen source at the same time. The production cost is lowered.

Owner:GUANGXI ACAD OF SCI

Modified alcohol dehydrogenases for the production of fuels and chemicals

InactiveUS20140017748A1High catalytic efficiencyImprove abilitiesMicroorganismsBiofuelsBiotechnologyMetabolite

The present invention relates to recombinant microorganisms comprising biosynthetic pathways and methods of using said recombinant microorganisms to produce various beneficial metabolites. In various aspects of the invention, the recombinant microorganisms may further comprise one or more modifications resulting in the reduction or elimination of 3 keto-acid (e.g., acetolactate and 2-aceto-2-hydroxybutyrate) and / or aldehyde-derived by-products. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:CALIFORNIA INST OF TECH +1

Enhanced Pyruvate to Acetolactate Conversion in Yeast

Owner:GEVO INC

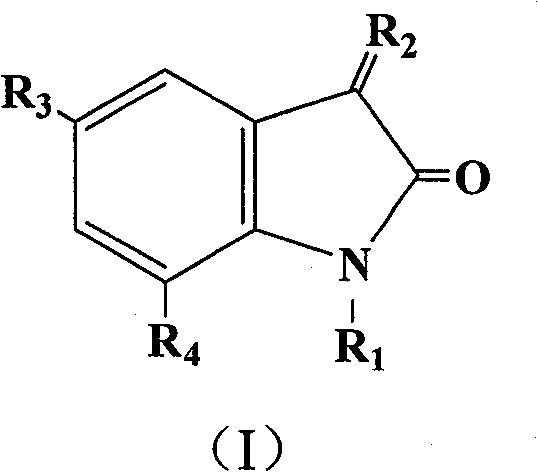

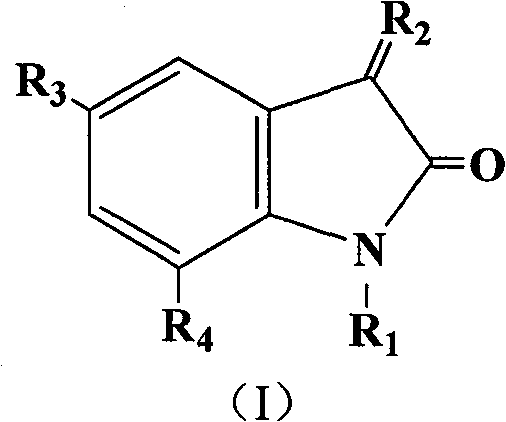

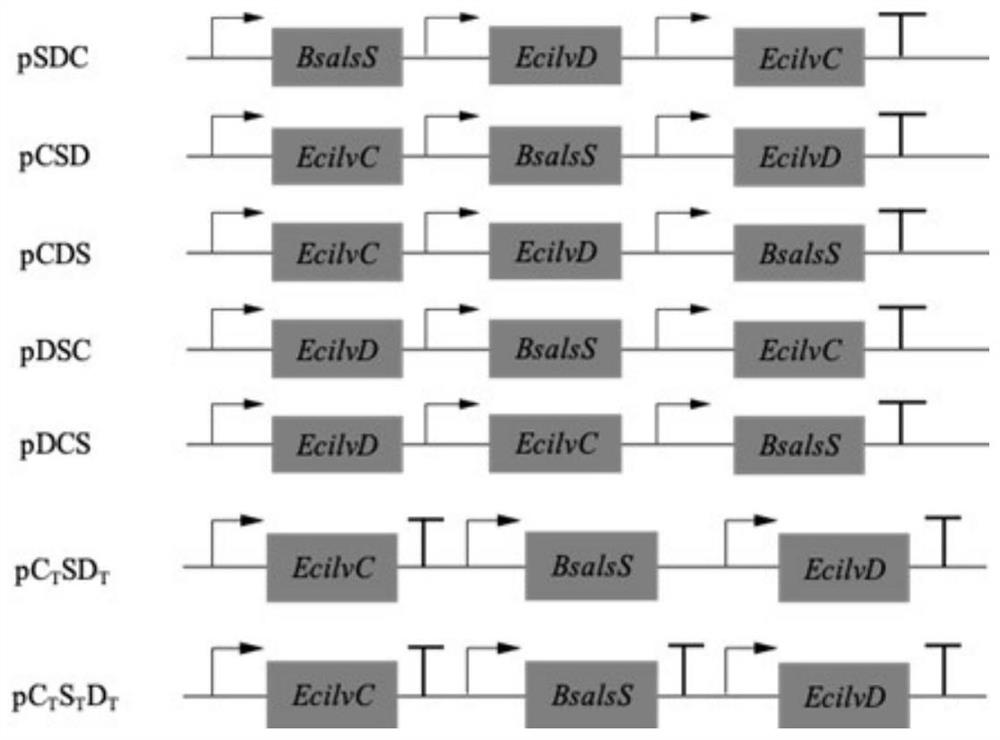

Acetolactate synthetase AHAS restrainer combination

InactiveCN101243793ABreak through structural featuresGrowth inhibitionBiocideAnimal repellantsDiketoneAcetolactic acid

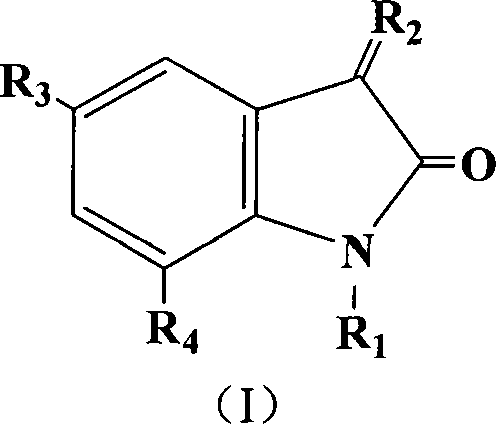

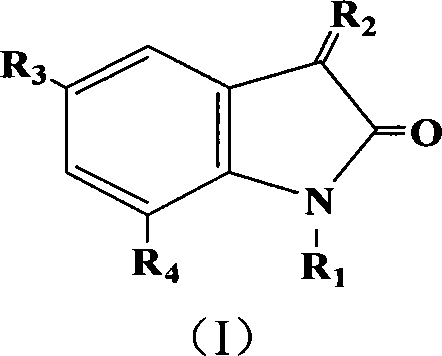

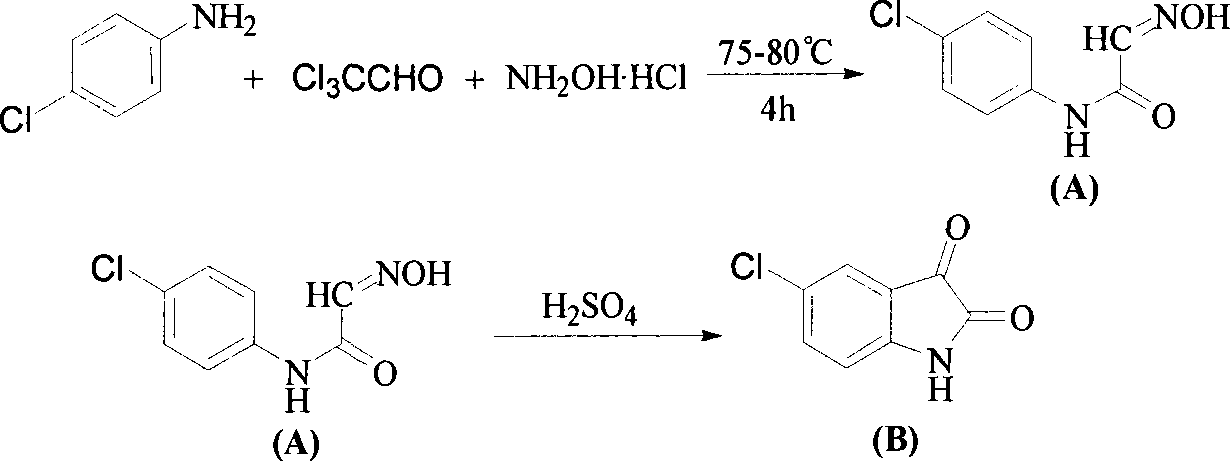

The invention relates to an inhibitor compound for acetolactate synthetase AHAS, which is indoline diketone compound (I); wherein, R1 is H or CH3, R2 is O or N-OH, R3 is F, Cl, Br, I, CH3, OCH3, NO2, SO3H, OCF3 or CF3, R4 is F, Cl, Br, I, CH3 or OCH3. The inhibitor compounds for acetolactate synthetase has the advantages of having herbicidal activity, having inhibiting action upon arabidopis thaliana aceto-lactic acidsynzymeas well as upon growth of rape root and being used for designing new environmentally friendly herbicide molecule.

Owner:NANKAI UNIV

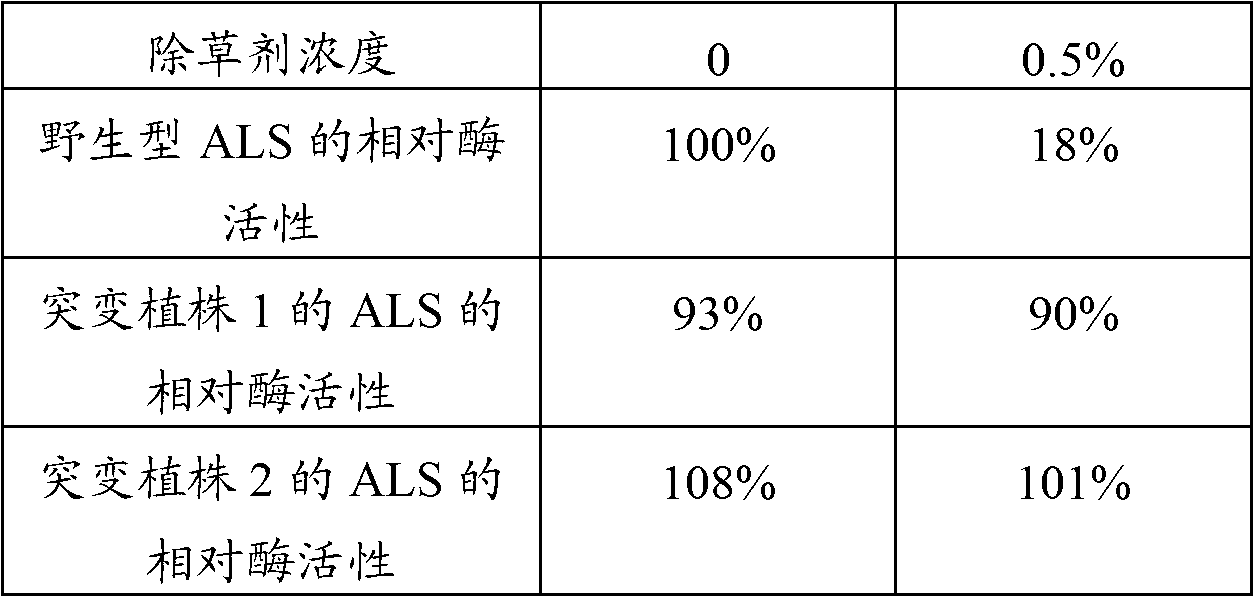

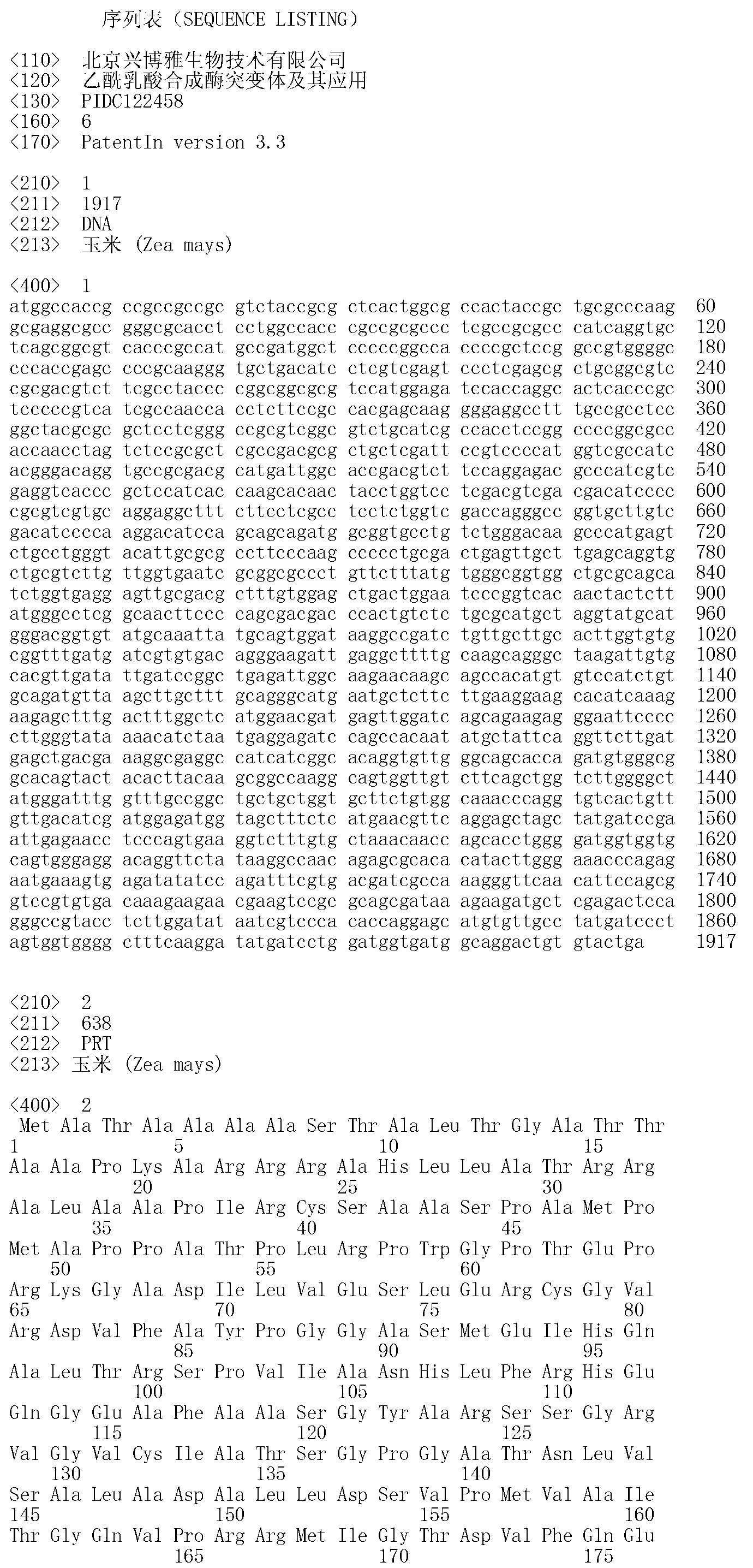

Acetolactic acid synthetase mutants and application thereof

The invention discloses acetolactic acid synthetase mutants and application thereof. Compared with the wild type acetolactic acid synthetase, at least one of the acetolactic acid synthetase mutants Ala173 and Trp542 is mutated. When the acetolactic acid synthetase mutants are expressed in a plant, the plant can have weedicide resistance.

Owner:BEIJING XINGBOYA BIOLOGICAL TECH

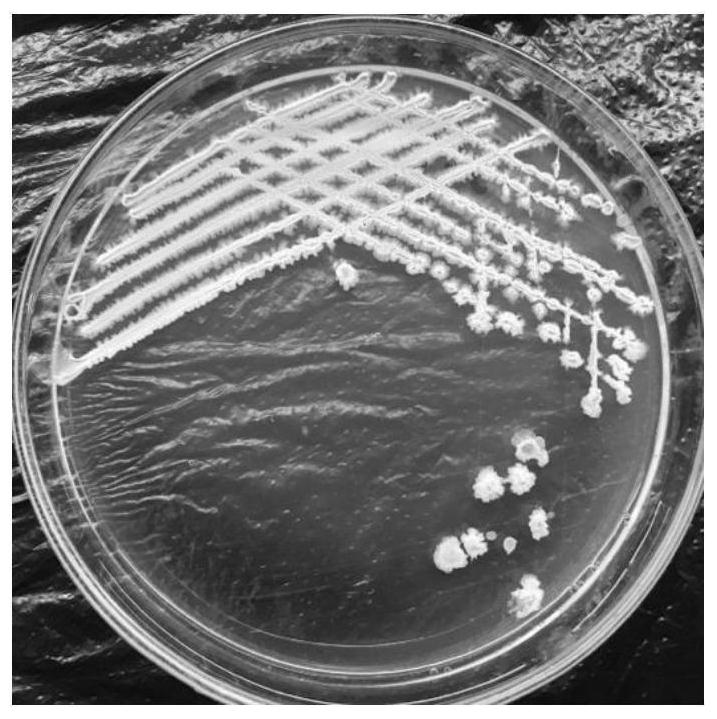

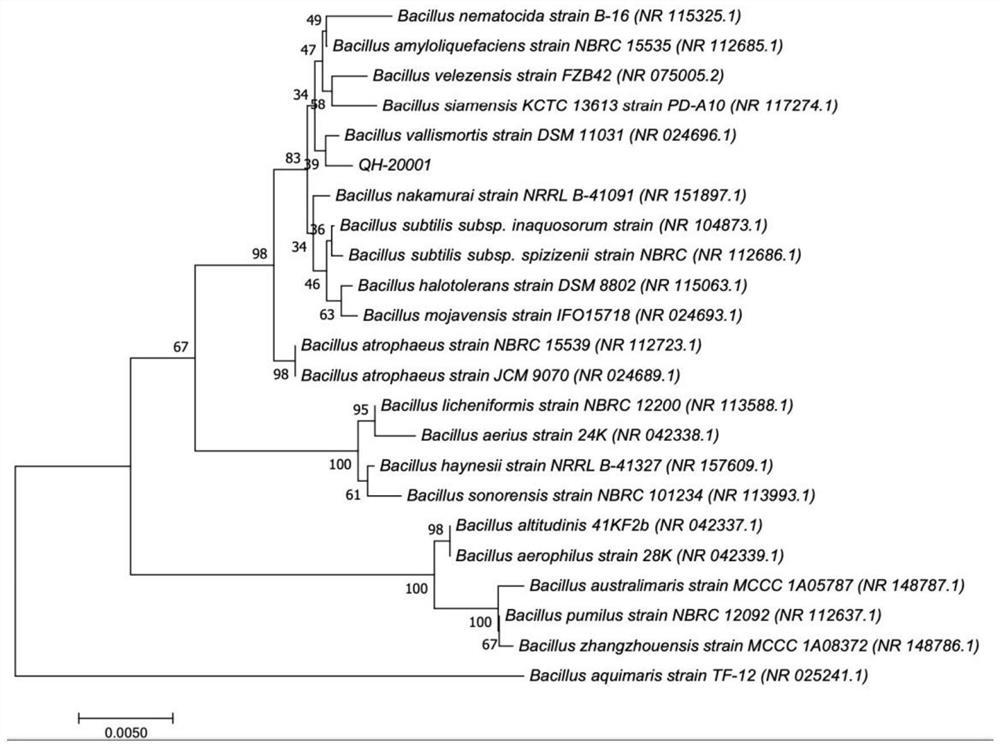

Bacillus vallismortis and application thereof in vinegar brewing

ActiveCN113930368APromote oxidationIncrease contentBacteriaMicroorganism based processesBiotechnologyMicroorganism

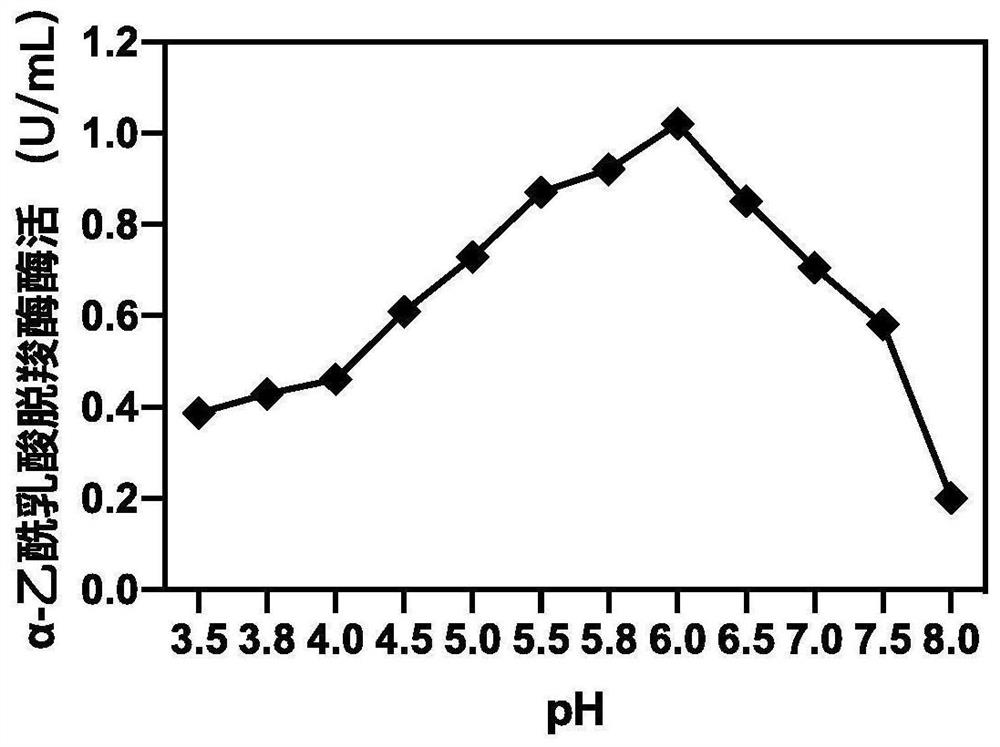

The invention discloses Bacillus vallismortis and application thereof in vinegar brewing. The name of the strain is Bacillus vallismortis QH-20001, the preservation number is CGMCC No.22251, the preservation date is April 27, 2021, the strain is preserved in the China General Microbiological Culture Collection Center, and the preservation address is Institute of Microbiology, Chinese Academy of Sciences, No. 3 , No. 1 Yard, Beichenxi Road, Chaoyang District, Beijing. The Bacillus vallismortis is applied to cellar vinegar brewing, can grow and metabolize under an acidic condition and produce alpha-acetolactate decarboxylase, the step of oxidizing alpha-acetolactate into diacetyl and then reducing the diacetyl to obtain acetoin can be avoided, and the alpha-acetolactate is quickly converted into the acetoin, thus, sufficient premise substances of ligustrazine is provided, the content of the acetoin and the ligustrazine in cellar vinegar can be obviously increased, and the production amount of the diacetyl is balanced.

Owner:QIANHE CONDIMENT & FOOD CO LTD

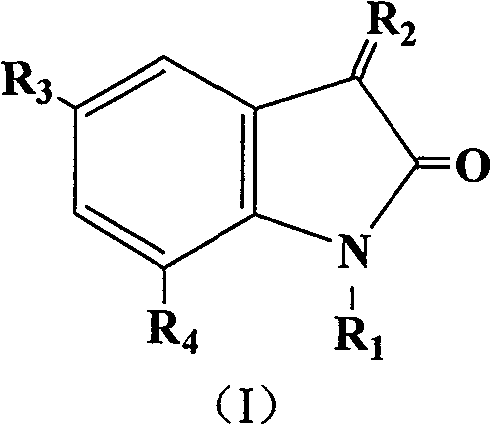

Construction method and application of gene engineering strain for producing (R,R)-2,3-butanediol

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

als mutant gene and its protein and application

The invention discloses an ALS mutation gene. Nucleotide, at site 75 of an ALS gene sequence of rice, of the ALS mutation gene is changed into nucleotide C from G; and / or nucleotide at side 339 is changed into nucleotide C from A; and / or nucleotide at site 710 is mutated into nucleotide T from C. The invention further discloses an ALS protein coded by the ALS mutation gene and an application thereof. The protein is from a rice mutant plant of an anti-ALS inhibitor herbicide; and compared with a rice wild type ALS sequence, the protein sequence of the ALS mutation gene generates mutation at site Gln25, Gln113 or Ala237. A green plant expresses that the protein sequence can resist acetolactic acid to synthesize the enzyme inhibitor herbicide, especially imidazolone and sulfonylurea herbicides.

Owner:JIANGSU ACAD OF AGRI SCI

Acetolactate synthetase AHAS restrainer combination

The invention relates to an inhibitor compound for acetolactate synthetase AHAS, which is indoline diketone compound (I); wherein, R1 is H or CH3, R2 is O or N-OH, R3 is F, Cl, Br, I, CH3, OCH3, NO2, SO3H, OCF3 or CF3, R4 is F, Cl, Br, I, CH3 or OCH3. The inhibitor compounds for acetolactate synthetase has the advantages of having herbicidal activity, having inhibiting action upon arabidopis thaliana aceto-lactic acidsynzymeas well as upon growth of rape root and being used for designing new environmentally friendly herbicide molecule.

Owner:NANKAI UNIV

Construction method and application of genetic engineering strain for producing (r,r)-2,3-butanediol

The invention discloses a construction method and application of a gene engineering strain for producing (R,R)-2,3-butanediol. The method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and an R,R-2,3-butanediol dehydrogenase gene, and obtaining a gene cluster containing the three genes by utilizing an artificial synthesis method; inserting the gene cluster into an expression vector, so as to obtain a polycistronic recombinant plasmid; introducing the polycistronic recombinant plasmid into a host bacterium E. coli, and knocking out a key gene of the synthetic route of a main by-product, so as to obtain the gene engineering strain for producing (R,R)-2,3-butanediol. Raw materials used by the engineering strain provided by the construction method are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield and high in production efficiency for the (R,R)-2,3-butanediol, has the highest yield which can reach 93.5g / L and the optical purity which can reach 99 percent or above. According to the construction method, non-grain cassava meal and a low-cost nitrogen source are also utilized as fermentation raw materials for producing the (R,R)-2,3-butanediol; the production cost is lowered.

Owner:南宁邦尔克生物技术有限责任公司 +1

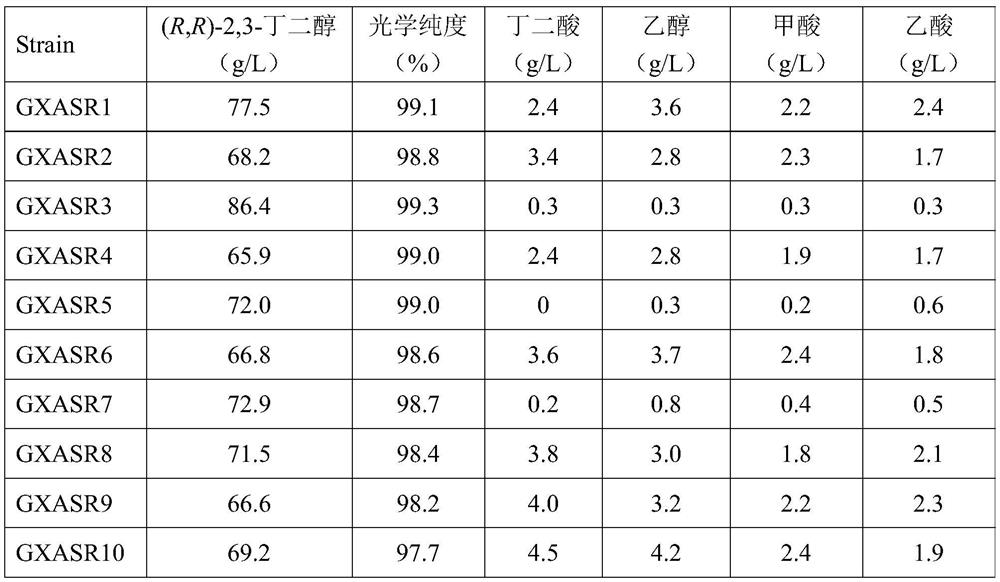

A method for metabolically engineering Escherichia coli to prepare α-ketoisovaleric acid

The invention discloses a method for preparing α-ketoisovaleric acid by transforming Escherichia coli with metabolic engineering, and belongs to the field of bioengineering. The present invention constructs a recombinant bacterial strain coupling expressing acetolactate synthase, acetolactate isomerizing reductase and dihydroxyacid dehydratase, and transforms and optimizes the host strain to obtain efficient production of α-ketoisoamyl by fermentation Acid recombinant bacteria. The recombinant strain can use cheap glucose as a substrate to ferment α-ketoisovaleric acid with higher added value. After 36 hours of fermentation, the yield of α-ketoisovaleric acid can reach 22.91g / L, and the conversion rate of glucose can reach 80%.

Owner:JIANGNAN UNIV

Recombinant bacteria for synthesizing D-lactic acid, construction method of recombinant bacteria and application of recombinant bacteria

ActiveCN108795831AIncrease productionImprove conversion rateBacteriaTransferasesBiotechnologyK pneumoniae

The invention discloses recombinant bacteria for synthesizing D-lactic acid, a construction method of the recombinant bacteria and an application of the recombinant bacteria to production of the D-lactic acid, and belongs to the technical field of gene engineering. Klebsiella pneumoniae serve as original strains, and acetolactic acid synthetase genes budB, alcohol dehydrogenase genes adhE and acetokinase genes ackA in a klebsiella pneumoniae genome are knocked out to obtain the recombinant bacteria. The recombinant bacteria have the advantages that the D-lactic acid is synthesized by glucose,antibiotics are omitted in the fermentation process, production cost is reduced, the yield and the conversion rate of the D-lactic acid produced by the klebsiella pneumoniae through the glucose are effectively increased, 150.1g / L D-lactic acid can be obtained at the level of a 5L fermentation tank, and the conversion rate is 96%. The recombinant bacteria are applicable to industrial production ofthe D-lactic acid.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Construction method and application of optically pure meso-2,3-butanediol high-yield engineering strain

The invention discloses construction of a high-yield engineering strain for optically pure meso-2,3-butanediol. A construction method comprises the following steps of carrying out codon optimization on nucleotide sequences of an alpha-acetolactic acid synthetase gene, an alpha-acetolactic acid decarboxylase gene and a meso-2,3-butanediol dehydrogenase gene, afterwards, splicing to obtain a gene cluster containing the three genes, then introducing the gene cluster into an expression vector to obtain a polycistronic recombinant plasmid, and finally introducing the recombinant plasmid into a host bacterium E. coli again, so that a high-yield engineering bacterium is obtained. Synthesis raw materials used by the bacterium are wide in sources and low in costs; the strain has no pathogenicity; the strain is high in yield, high in production efficiency and good in stability, has the highest yield which can reach 91.5g / L and the optical purity which can reach 99 percent or above. The invention discloses application of the high-yield engineering strain to the production of the optically pure meso-2,3-butanediol by utilizing cheap cassava meal as a carbon source and utilizing cottonseed protein powder, soybean pulp powder, soybean cake powder or peanut protein powder as a nitrogen source at the same time. The production cost is lowered.

Owner:GUANGXI ACAD OF SCI

A method for biologically synthesizing acetoin and its derivatives

The invention discloses a method for synthesizing acetoin and a derivative thereof through a biological method, which belongs to the technical field of the molecular biology. The method comprises the steps of introducing pyruvate decarboxylase genes and genes with acetoin enzyme activity into host bacteria to obtain recombination bacteria, producing the acetoin by fermenting the recombination bacteria, and further producing 2,3-butanediol on the basis of the acetoin. By adopting the method, the acetoin and the 2,3-butanediol are successfully generated by fermenting the recombined bacteria strain, and the problem that the yield of the acetoin and the 2,3-butanediol is influenced by the consumption of an intermediate product acetyl emulsion in the natural production process can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

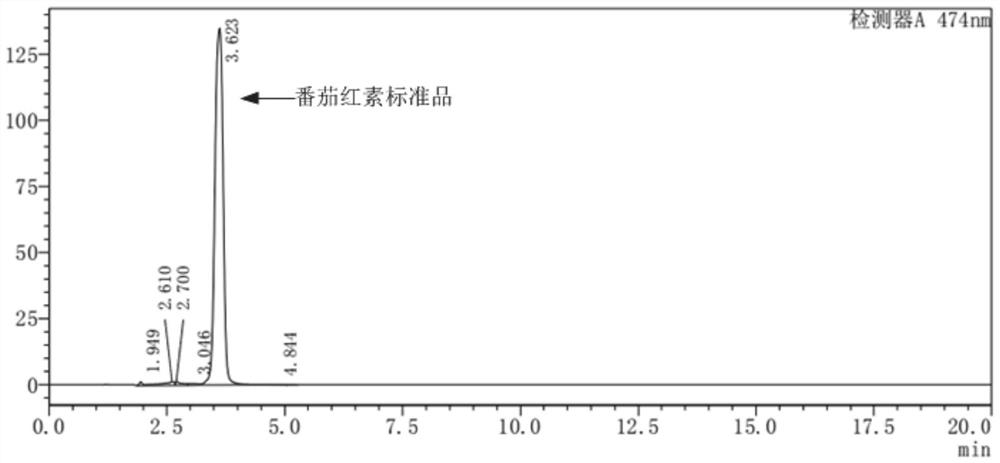

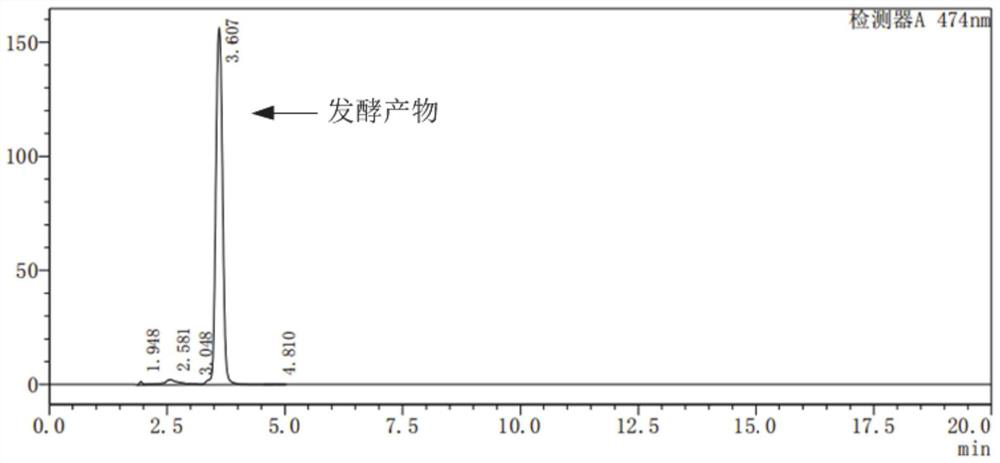

Recombinant lactococcus lactis used for generating lycopene, and application of recombinant lactococcus lactis

ActiveCN112646764AAnti-cancerImprove antioxidant capacityBacteriaTransferasesLycoperseneStaphylococcus lactis

The invention discloses a recombinant lactococcus lactis bacterial strain used for generating lycopene, and a construction method and application of the recombinant lactococcus lacti. The recombinant lactococcus lactis bacterial strain is constructed in a way that parts of nucleotide sequences of two competition approaches, i.e., a lactic dehydrogenase gene and an [alpha]-acetolactic acid synthetase gene, of a lycopene synthesis precursor are eliminated, and then, plasmids are used to introduce a geranyl pyrophosphate synthetase gene (crtE), a phytoene synthetase gene (crtB) and a phytoene dehydrogenase gene (crtI) of a Pantoea ananatis source. Experiments prove that after the recombinant lactococcus lactis disclosed by the invention is subjected to shaking culture, the lycopene can be generated, and the experiments also predict that the recombinant lactococcus lactis has wide application potential in the development field of health care products and biological medicines.

Owner:SHANDONG UNIV

Genetically engineered bacteria co-producing butanol and 2,3-butanediol and its construction method and application

The invention discloses a genetically engineered bacterium for co-generating butanol and 2,3-butanediol. The genetically engineered bacterium is a butanol generating clostridium to which an acetoin reductase gene is introduced or a butanol generating clostridium to which an acetolactic acid decarboxylase gene and the acetoin reductase gene are introduced. The nucleotide sequence of the acetolactic acid decarboxylase gene is any one of nucleotide sequences shown in SEQ ID NO:1-7, and the nucleotide sequence of the acetoin reductase gene is any one of nucleotide sequences shown in SEQ ID NO:8-11. An acetolactic acid decarboxylic reaction is enhanced in a clostridium acetobutylicum, the yield of 3-hydroxy butanone is greatly increased to about 6.4 g / L from initial about 1.8 g / L, and then acetoin is converted into 2,3-butanediol reaching up to 8.05 g / L under the effect of acetoin reductase; acetone is reduced to 2.2 g / L from about 4.5 g / L, and economic benefits of fermentation of the clostridium acetobutylicum are remarkably increased.

Owner:NANJING TECH UNIV

Method for producing yeast containing rich-taste-imparting substance and method for producing yeast extract containing rich-taste-imparting substance

This method for producing yeast containing a rich-taste-imparting substance includes: a step for yeast proliferation, in which yeast is modified such that intracellular acetolactic acid synthase activity is reduced, and isoleucine- and valine-requiring yeast is cultured and proliferated on a medium containing isoleucine and valine; and a step for generating a rich-taste-imparting substance, in which when the isoleucine content in the medium is less than 0.2 mass%, valine is added to the medium to culture the yeast and to generate a rich-taste-imparting substance, wherein the rich-taste-imparting substance is gamma-Glu-Abu and / or gamma-Glu-Abu-Gly.

Owner:ASAHI GRP FOODS LTD

A kind of recombinant streptomyces, its construction method and the method for improving antibiotic production

ActiveCN104531598BIncrease productionIncrease the amount of enzymeBacteriaMicroorganism based processesAcetolactate synthaseValine

The invention discloses a recombined streptomycete, a construction method of the recombined streptomycete and a method for increasing the antibiotic yield. The recombined streptomycete over-expresses acetolactic acid synthase small subunit ilvH. The recombined streptomycete over-expresses acetolactic acid synthase to adjust subunit genes, and the yield of products such as antibiotics for conducting secondary metabolism with L-isoleucine and / or L-valine and / or L-leucine as precursors / a precursor can be remarkably increased.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Method for eliminating capability of klebsiella pneumoniae in synthesizing 2,3-butanediol and acetoin

ActiveCN102952826BEliminate generationReduce separation and extraction stepsBacteriaStable introduction of DNA2,3-ButanediolGlycerol

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

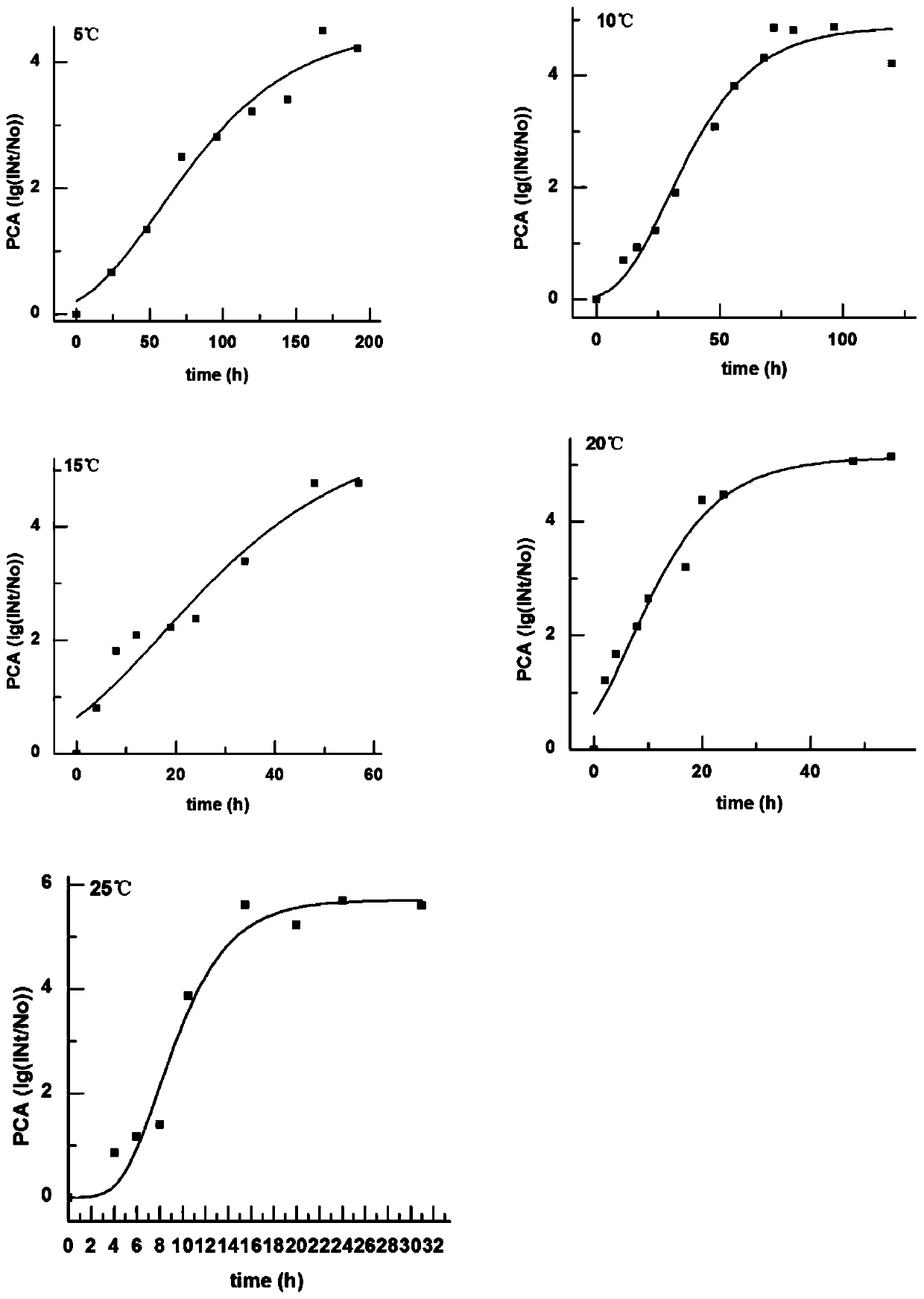

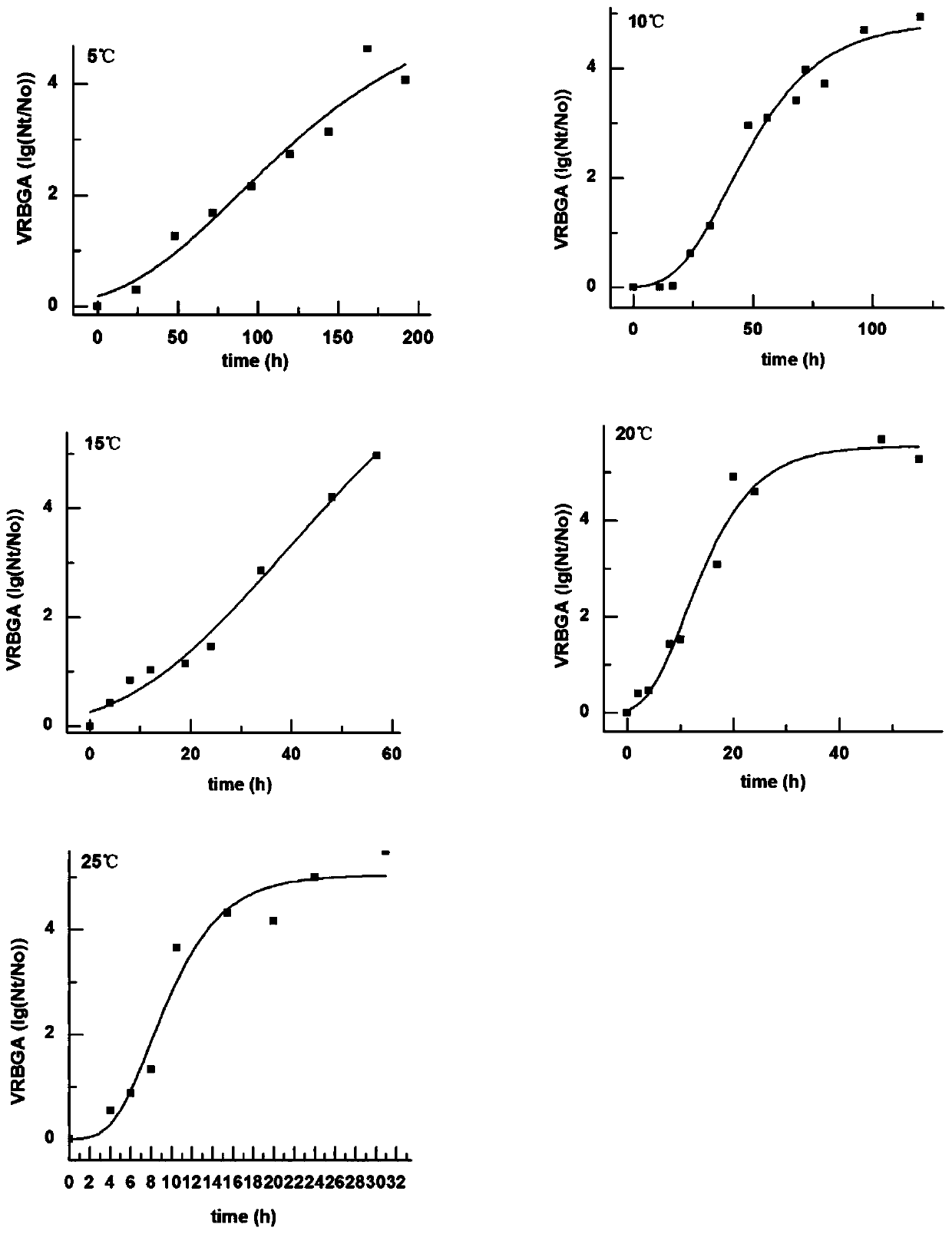

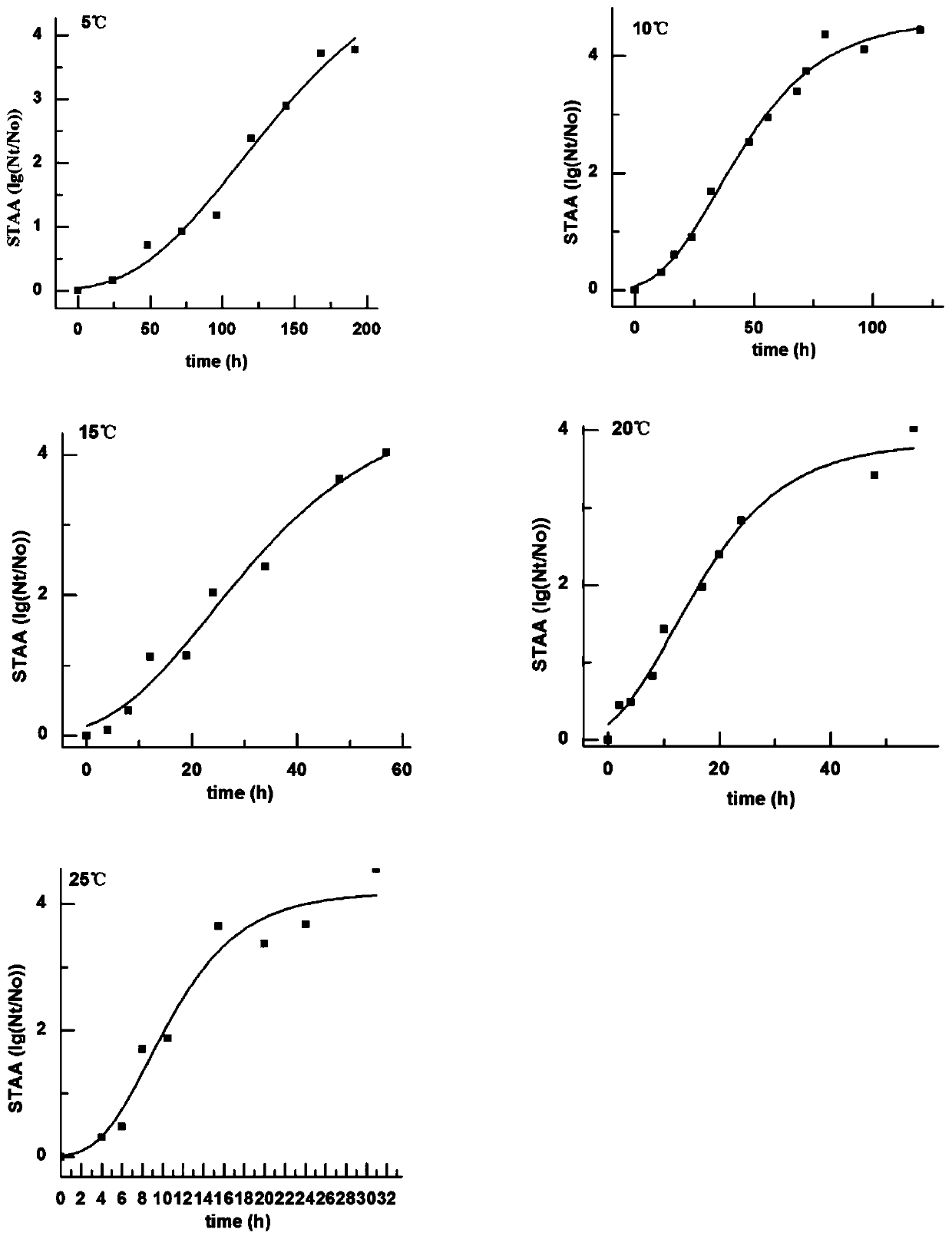

Method for predicting shelf life of chilled chickens

ActiveCN111027784AComprehensive aerobic storageComprehensive Modified Atmosphere Packaging Storage ModeForecastingSystems biologyBiotechnologySpoilage bacteria

The invention discloses a method for predicting the shelf life of chilled chickens. The method comprises the following steps: measuring the total number of bacterial colonies in the chilled chickens at different storage temperatures, and the growth conditions and sensory analysis of enterobacter and thermothecium; establishing a microorganism growth prediction model and a shelf life; evaluating and verifying the shelf life of the chilled chickens; wherein enterobacter sp. And Cyclo thermophilus are main spoilage bacteria in chickens. Enterobacter sp. Can generate alcohol and ketone compounds,and is a main putrefying bacterium causing chicken flavor change. Cyclo thermophilus is dominant putrefying bacteria during low-temperature anaerobic storage of chickens and can generate volatile compounds such as acetone, diacetyl, lactic acid and ethanol to cause deterioration of the flavor of the chickens. The shelf life of the chilled chickens predicted by combining the two dominant spoilage bacteria with the total bacterial count is more accurate than the shelf life of the chilled chickens predicted by using one dominant spoilage bacterium or singly using the total bacterial count, and meanwhile, the aerobic storage mode and the modified atmosphere packaging storage mode of the chilled chickens are covered and considered more comprehensively.

Owner:SHANGHAI ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com