Patents

Literature

33results about How to "Meet the requirements of flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fully-flexible three-dimensional force tactile sensor

ActiveCN103335754AMeet the requirements of flexibilityReduce couplingForce measurement using piezo-resistive materialsElectrical resistance and conductanceEngineering

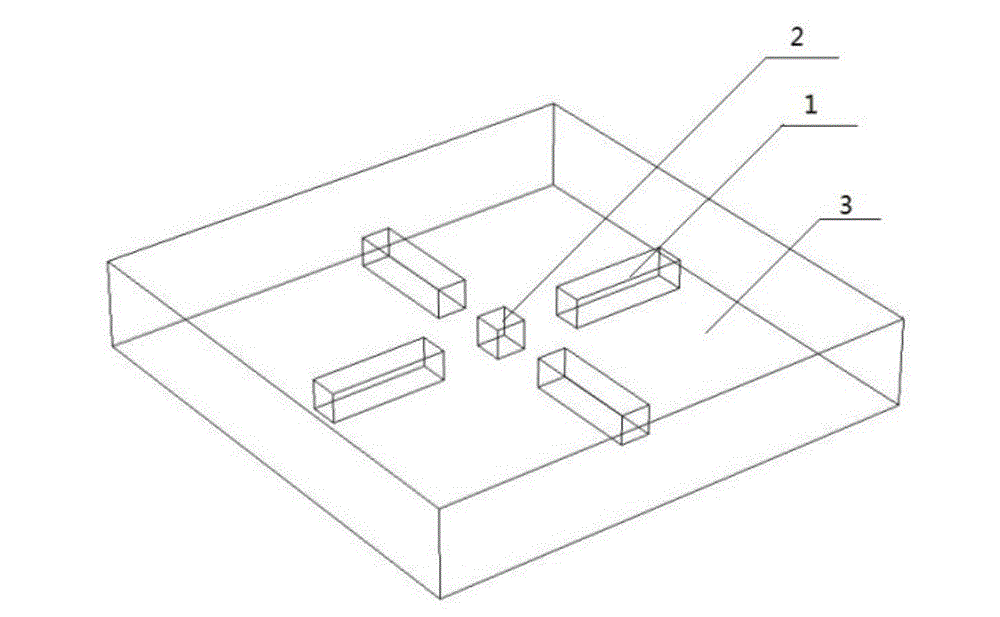

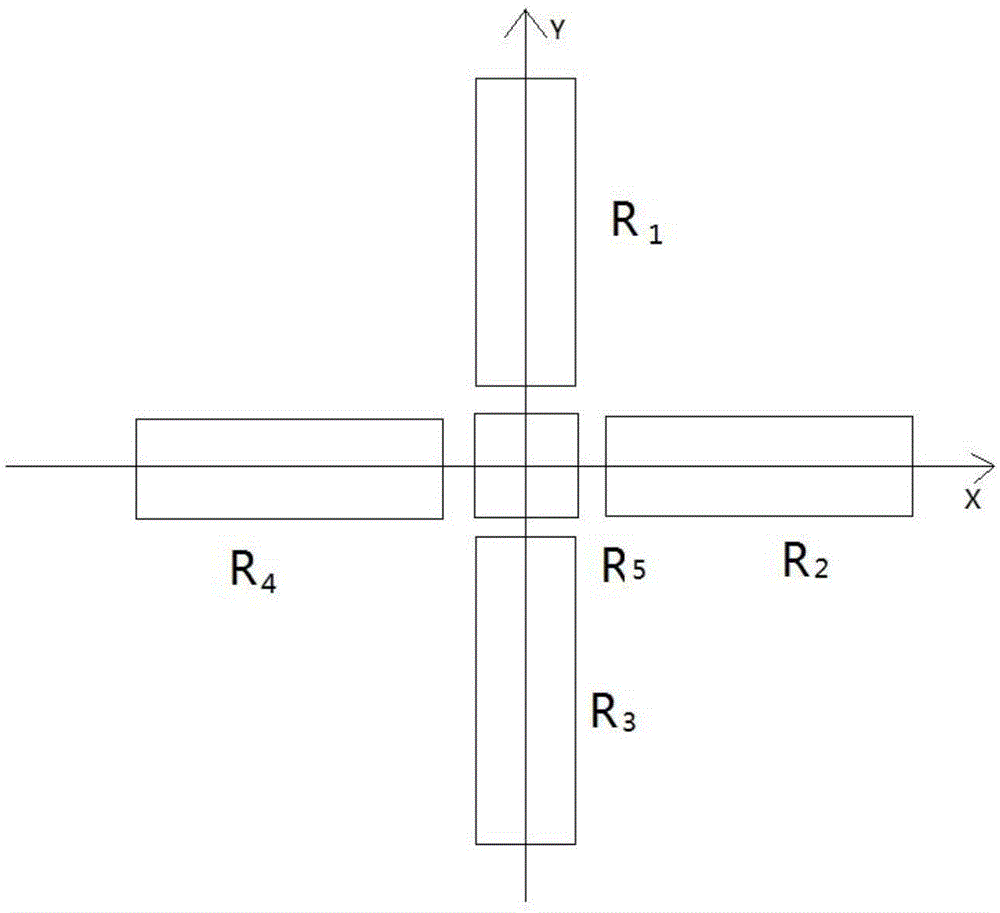

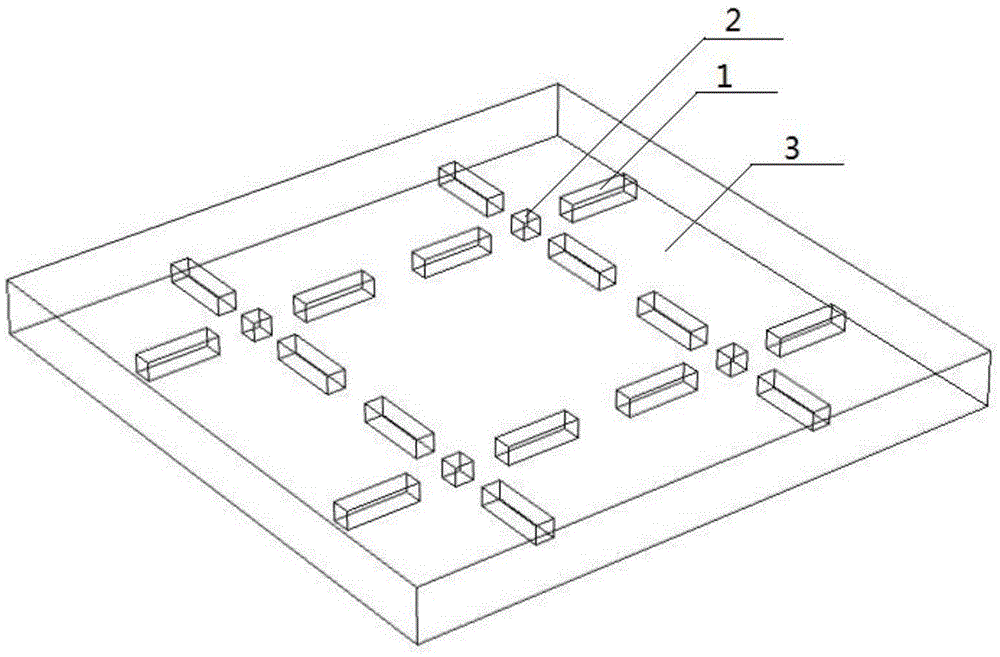

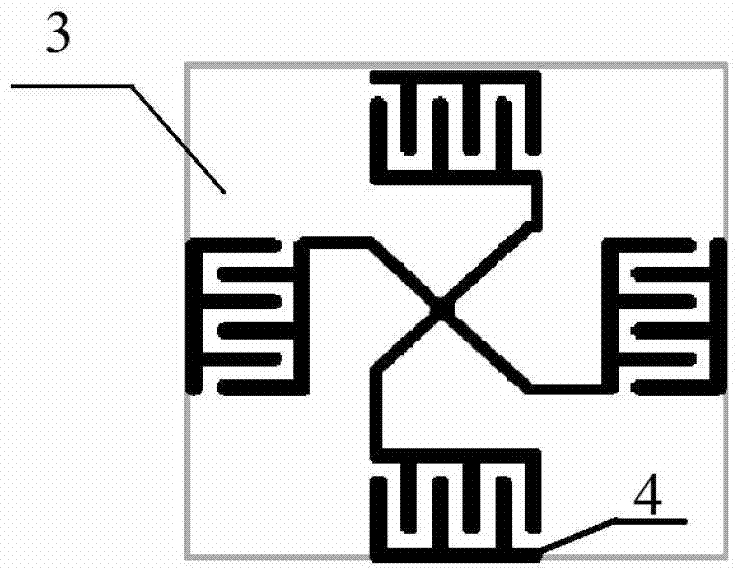

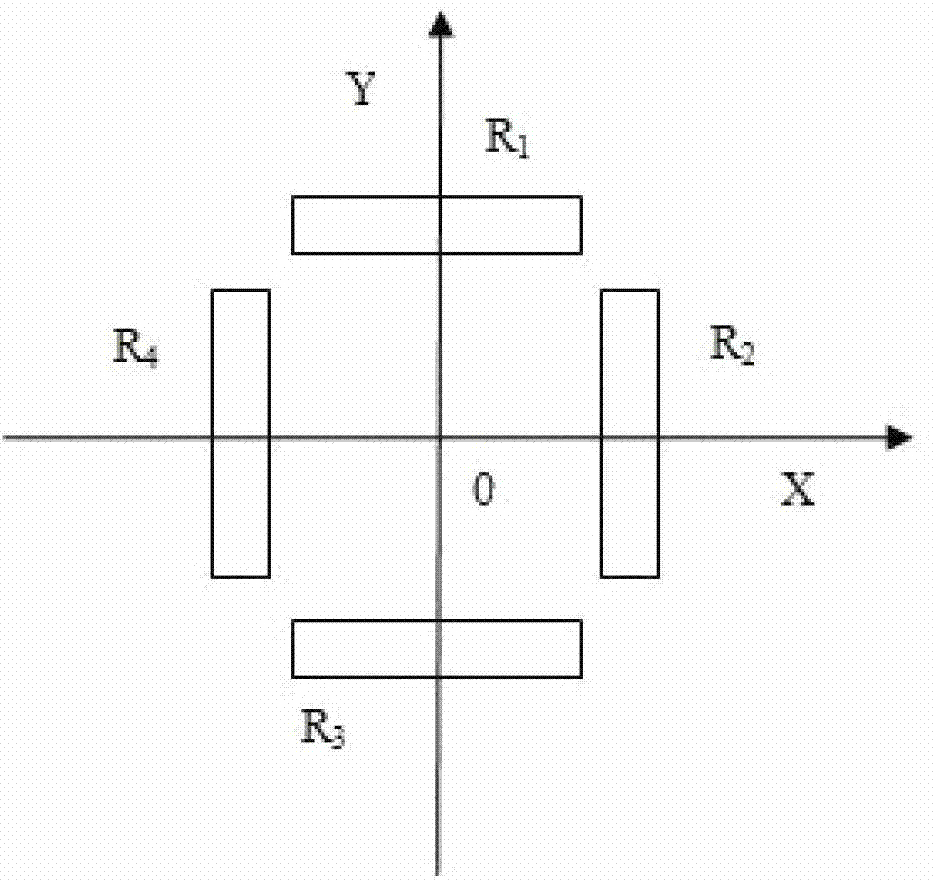

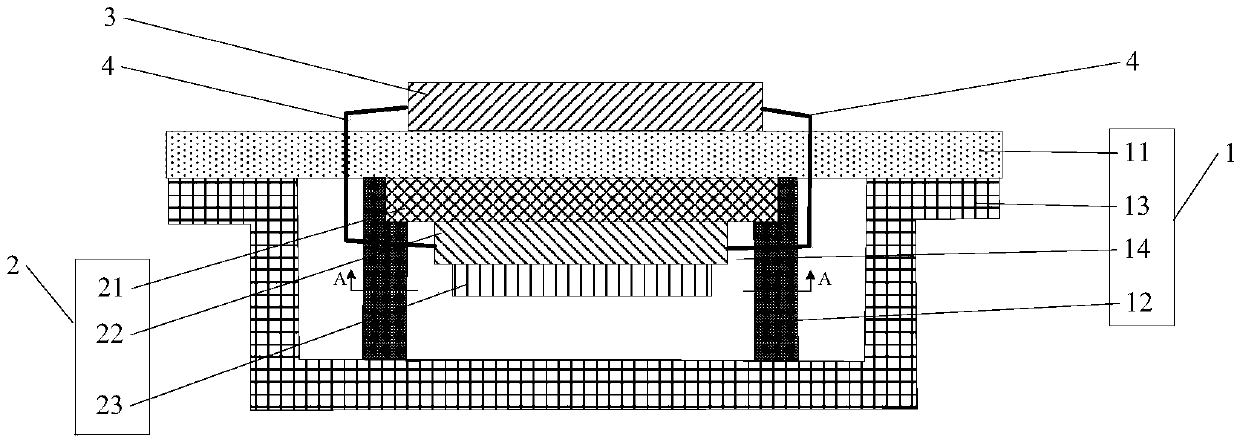

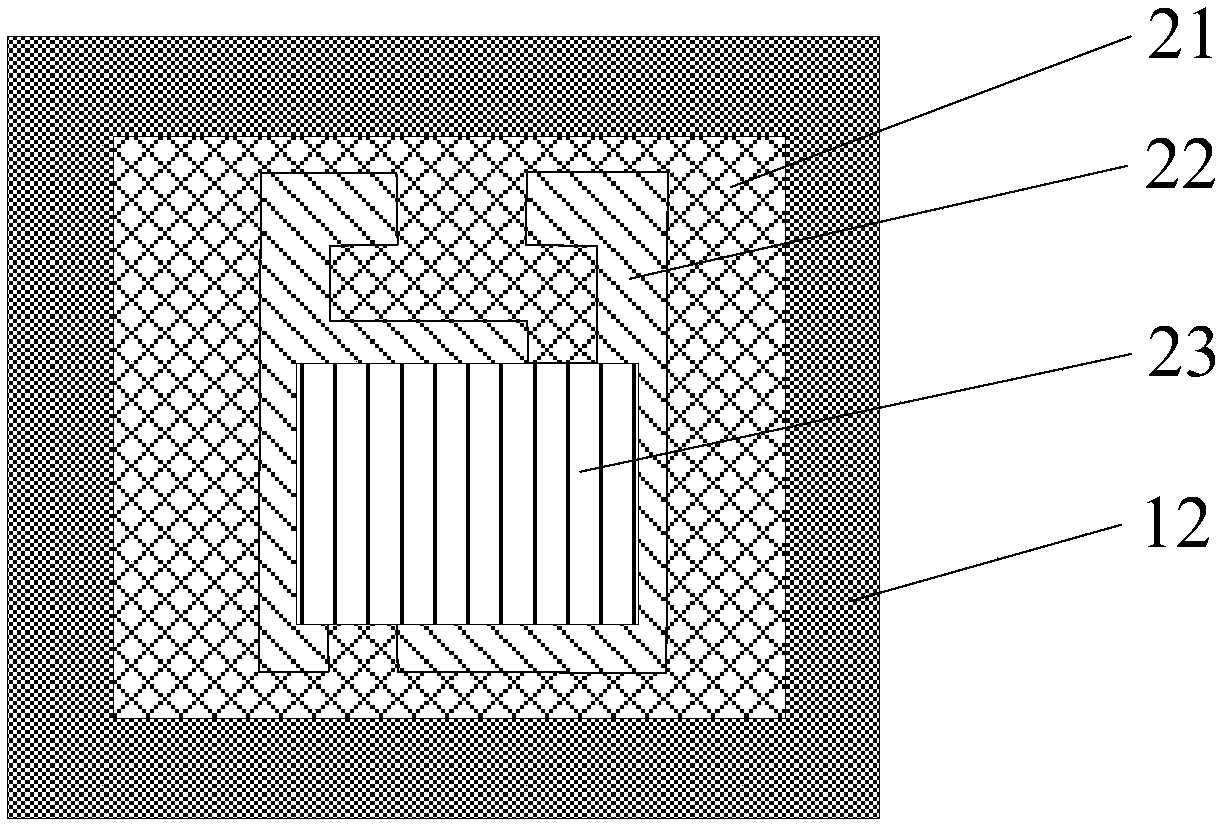

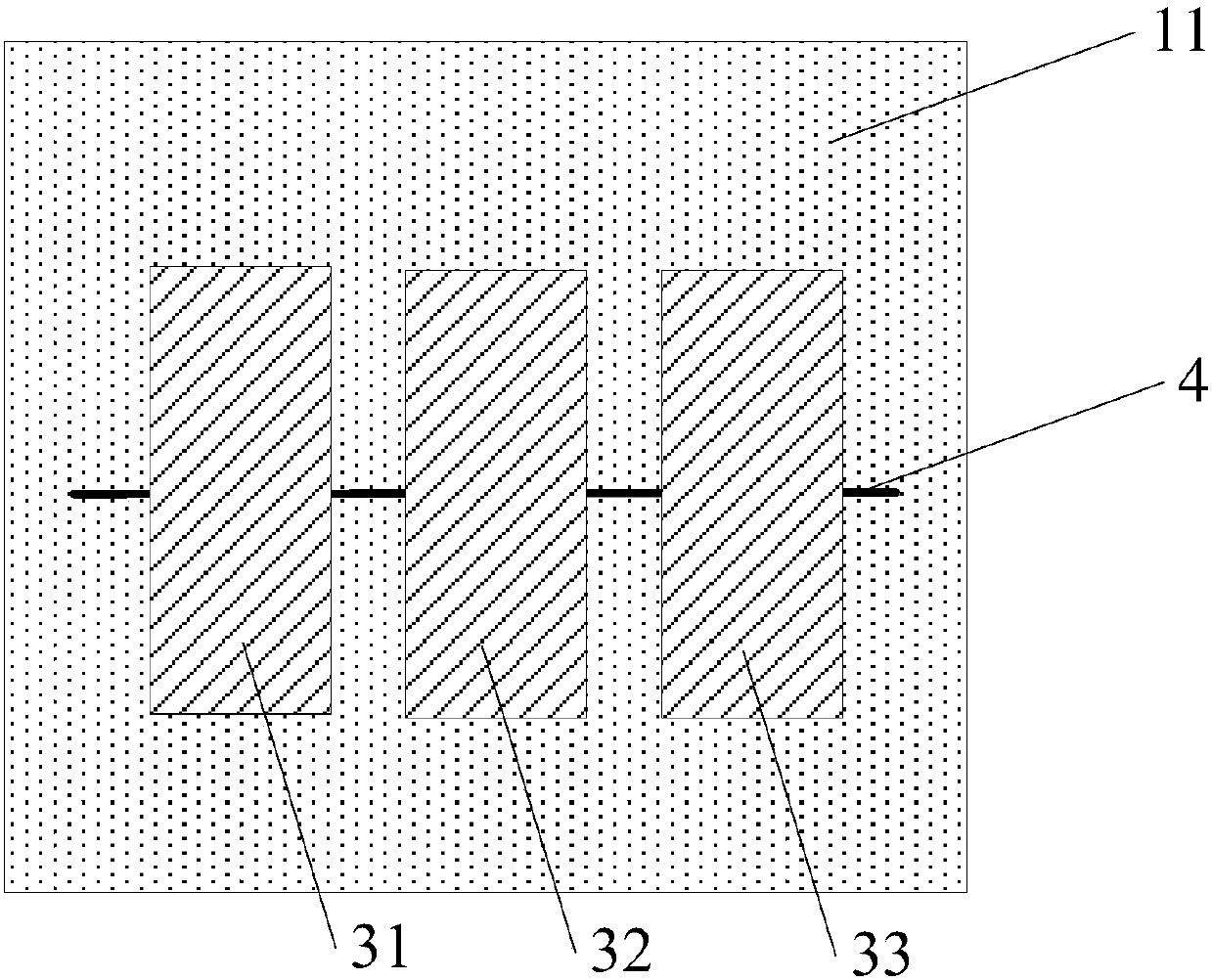

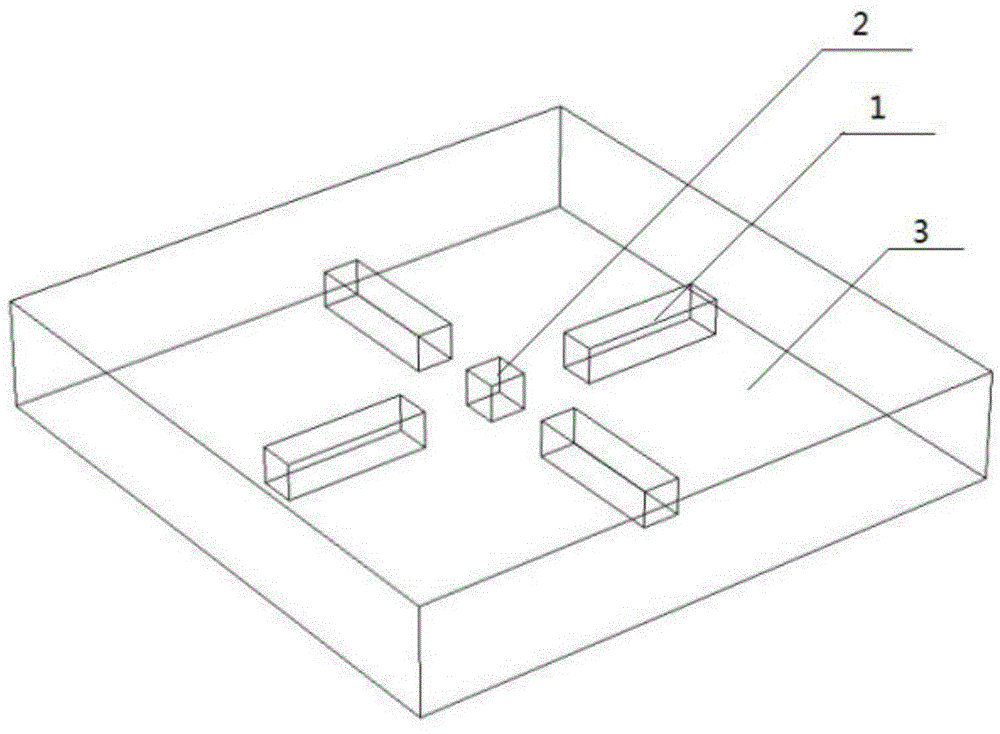

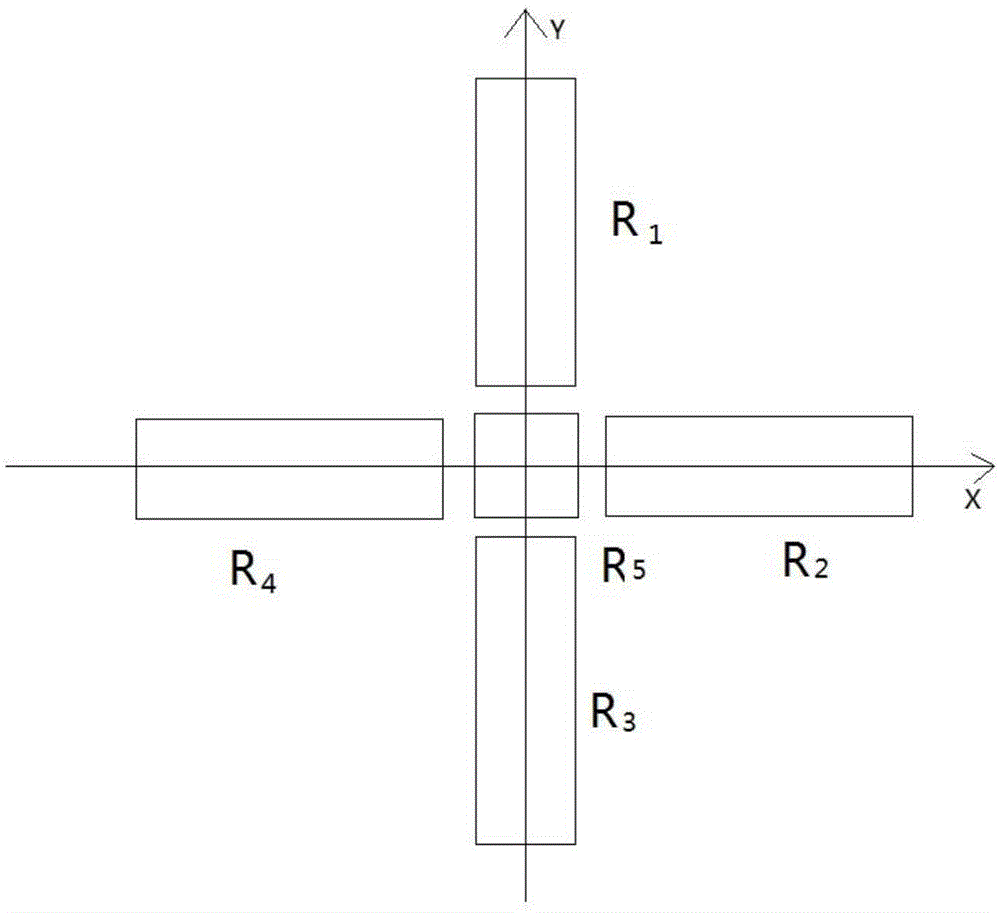

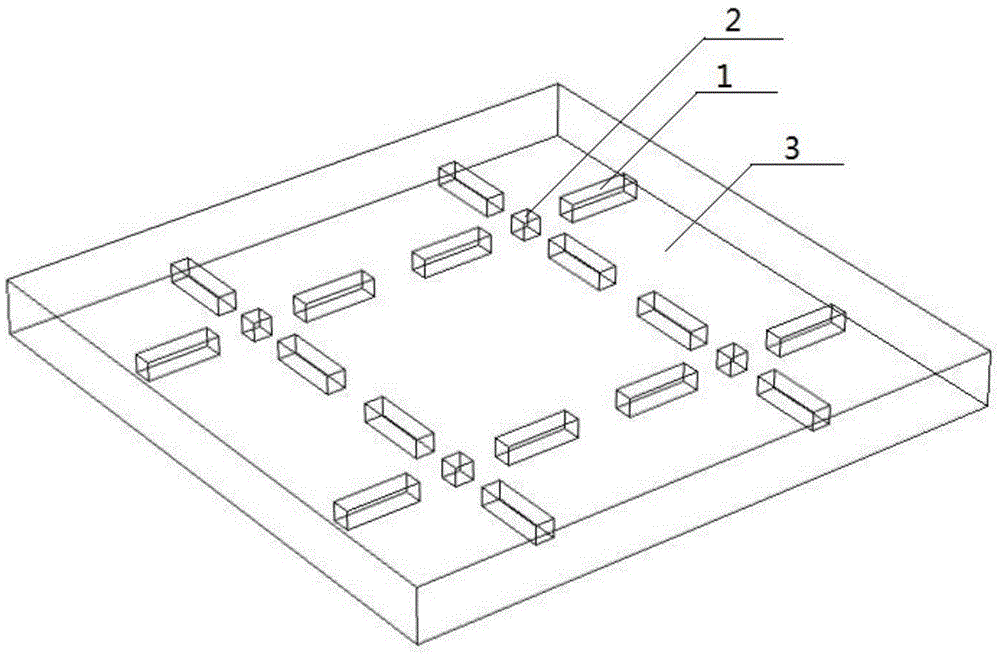

The invention discloses a fully-flexible three-dimensional force tactile sensor. The fully-flexible three-dimensional force tactile sensor is characterized in that in a flexible basal body and on the same plane, a resistor R5 is formed by taking a pressure sensitive element as a center, and four same stretching sensitive elements are respectively arranged in the Y-axis positive direction, the Y-axis negative direction, the X-axis positive direction and the X-axis negative direction respectively, so as to form a resistor R1, a resistor R3, a resistor R2 and a resistor R4; the resistor R1, the resistor R2, the resistor R3, the resistor R4 and the resistor R5 form a three-dimensional force tactile sensing unit which is arranged on the surface of an area to-be-detected. All three-dimensional force tactile sensing units are in an array arrangement on the surface of the area to-be-detected; flexible basal bodies are filled among the three-dimensional force tactile sensing units; the three-dimensional force tactile sensing units and the flexible basal bodies form the three-dimensional force tactile sensor. The three-dimensional force tactile sensor has the advantages of good flexibility, high precision and stable performance.

Owner:合肥庐阳科技创新集团有限公司

Formula and production technology of polyurethane low-speed solid tire

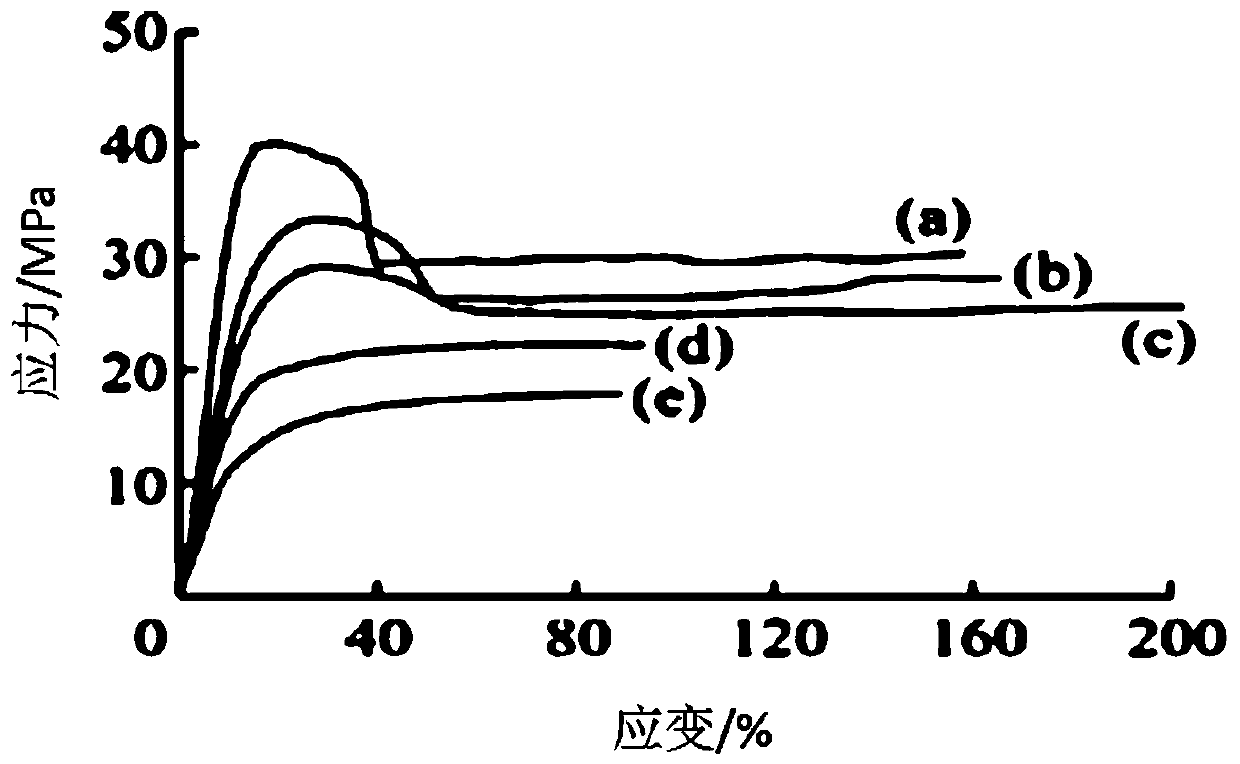

The invention relates to a formula and a production technology of a polyurethane low-speed solid tire and belongs to the technical field of high-polymer material products. The formula is characterized by comprising the following raw materials in parts by weight: 0.8-1.5 parts of polyester polyol, 0.15-0.25 parts of toluene diisocyanate, and 0.1-0.15 parts of curing agent component. The production technology is characterized by specifically comprising the following steps: dehydrating the polyester polyol and adding toluene diisocyanate to firstly obtain a prepolymer; and respectively feeding the prepolymer and the curing agent components into tanks A and B of a casting machine, mixing according to the weight parts and casting into a tire casting die, performing casting forming, and performing secondary vulcanization. The integrated solid tire having completely identical internal material, external material and performances is prepared by virtue of the formula technology and the formula, and the technology can be realized by performing primary cast forming through the tire casting die, and the production technology of the tire can be greatly simplified.

Owner:日照悍马轮胎股份有限公司

Flexible gas sensor based on three-dimensional net structured sensitive film and preparation method of flexible gas sensor

InactiveCN104865293AImprove compatibilityRapid High Sensitivity DetectionMaterial analysis by electric/magnetic meansExtensibilityEngineering

The invention discloses a flexible gas sensing device based on a three-dimensional net sensitive film and a preparation method of the flexible gas sensing device, and belongs to the fields of sensing electronics and flexible electronics. The sensing device comprises a flexible substrate layer, an interdigital electrode layer and a three-dimensional net structured sensitive film layer which are sequentially stacked according to the preparation order. The preparation method mainly comprises steps as follows: preparing a flexible interdigital electrode device, preparing a film material required by the sensing device, and preparing a three-dimensional net structured sensitive film device with a gas injection film forming technology. The flexible gas sensing device based on the three-dimensional net sensitive film and the preparation method of the flexible gas sensing device have the advantages as follows: by means of the extensibility of the flexible substrate on the three-dimensional net structured sensitive film, the response performance of the sensitive film on gas is further improved, meanwhile, the process is simple, the cost is low, and the prepared sensing device can be used in the field of gas detection.

Owner:TSINGHUA UNIV

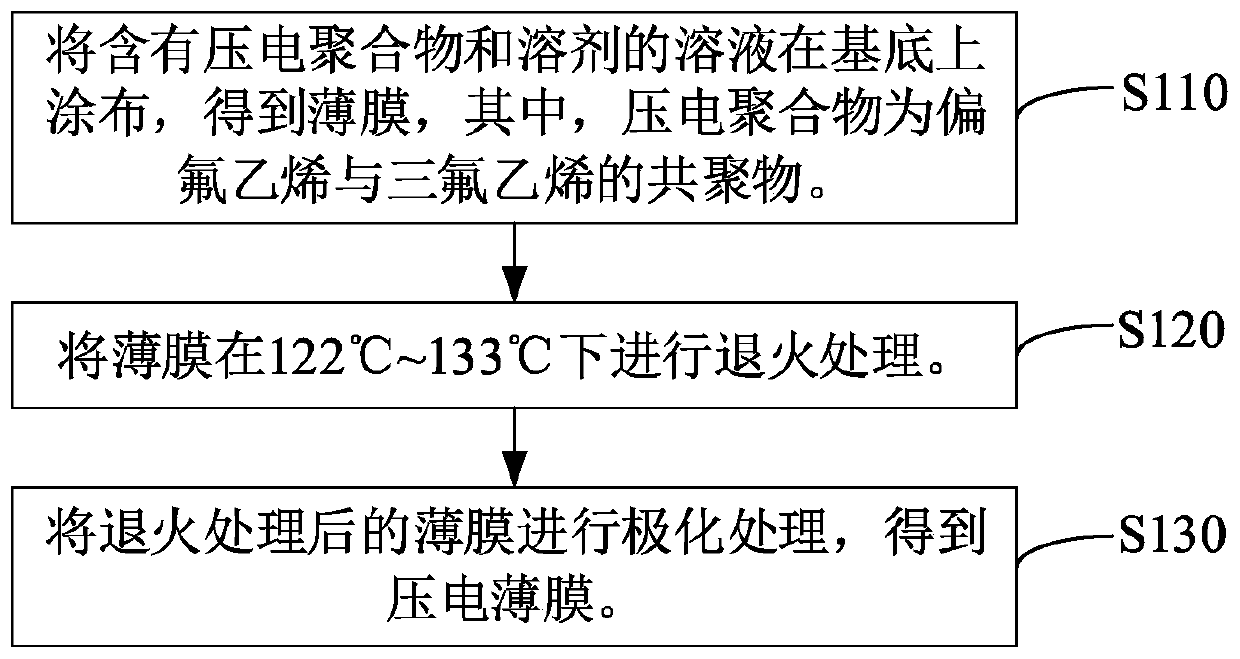

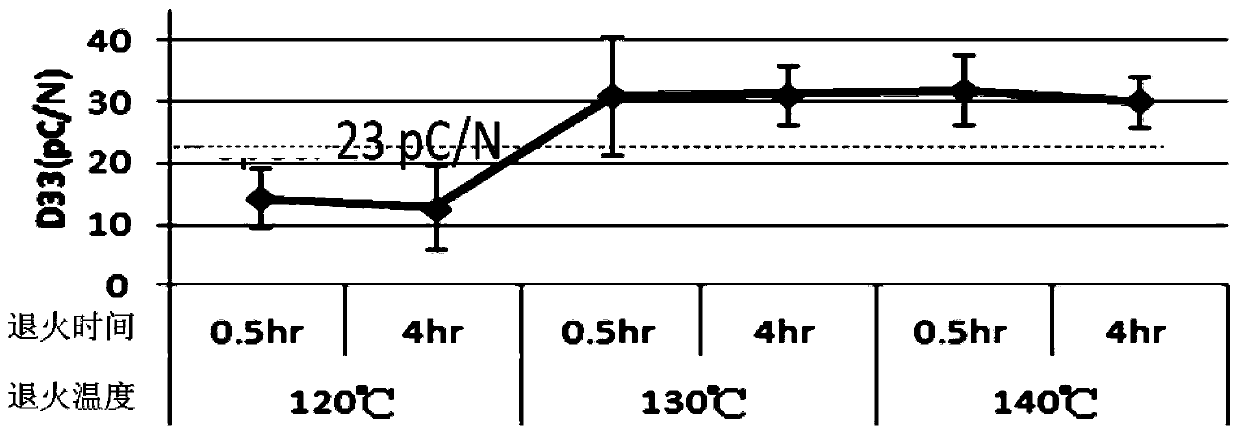

Piezoelectric film, preparation method of piezoelectric film, and piezoelectric film sensor

PendingCN110752286AGood piezoelectric performanceGood flexibilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesThin membraneTrifluoroethene

The invention relates to a piezoelectric film, a preparation method of the piezoelectric film, and a piezoelectric film sensor. The preparation method of the piezoelectric film comprises the steps of:coating solution containing a piezoelectric polymer and a solvent on a substrate, so that a film is obtained, wherein the piezoelectric polymer is a copolymer of vinylidene fluoride and trifluoroethylene; and annealing the film at 122-133 DEG C, so that the piezoelectric film is obtained. By means of the preparation method of the piezoelectric film in the invention, the piezoelectric film havinggood piezoelectric performance and better flexibility can be obtained.

Owner:INTERFACE TECH CHENGDU CO LTD +2

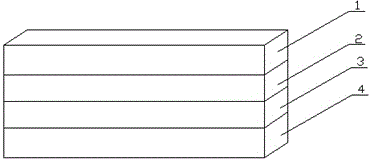

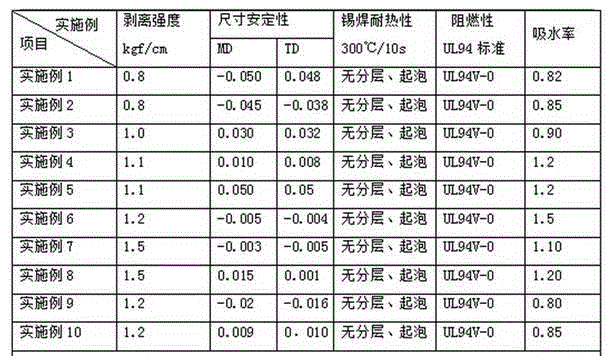

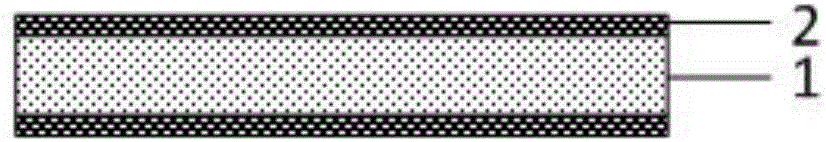

Adhesive-free FCCL (flexible copper-clad laminate) with two medium layers

ActiveCN104859223AGuaranteed performanceReduce thicknessElectrical equipmentCoatingsDownstream processingCopper foil

The invention provides an adhesive-free FCCL (flexible copper-clad laminate) with two medium layers. The FCCL comprises first copper foil, second copper foil and insulating layers arranged between the first copper foil and the second copper foil, wherein the first copper foil, the second copper foil and the insulating layers are arranged in parallel, and the insulating layers comprise a TPI (thermoplastic polyimide) layer and a polyimide structure membrane layer. With the adoption of the FCCL structure, the thickness is reduced, materials are saved, the dimensional stability of the FCCL and the dimensional stability of a PCB (printed circuit board) during downstream processing are guaranteed while manufacturing processes are reduced, the FCCL is excellent in comprehensive performance and thinner, and the requirement for thin electronic products can be met.

Owner:CHENGDU DO ITC NEW MATERIAL

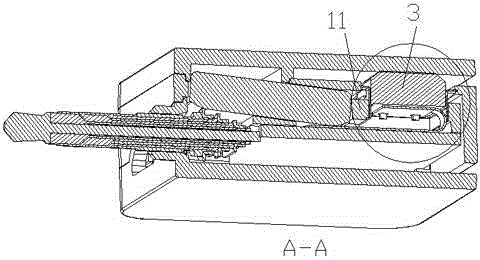

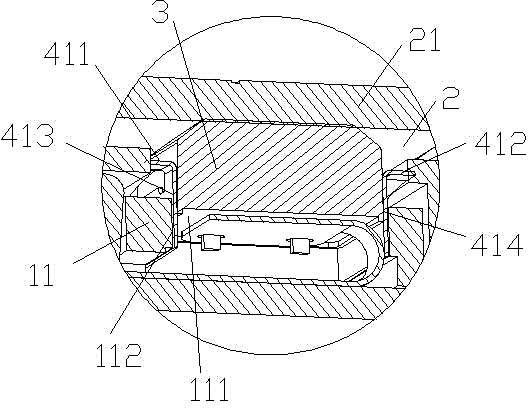

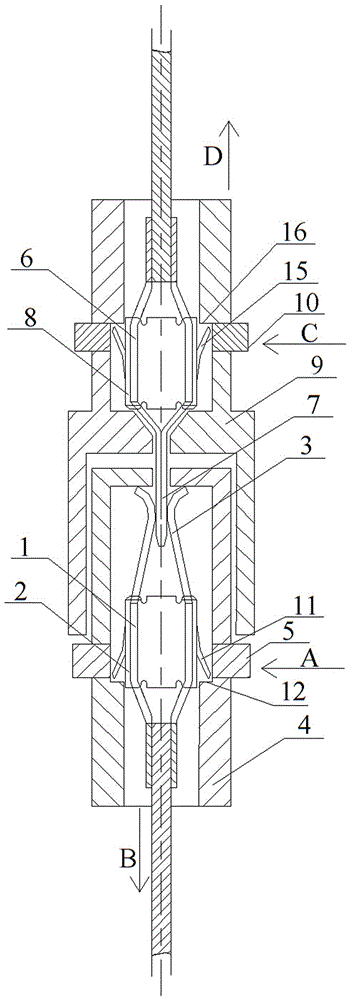

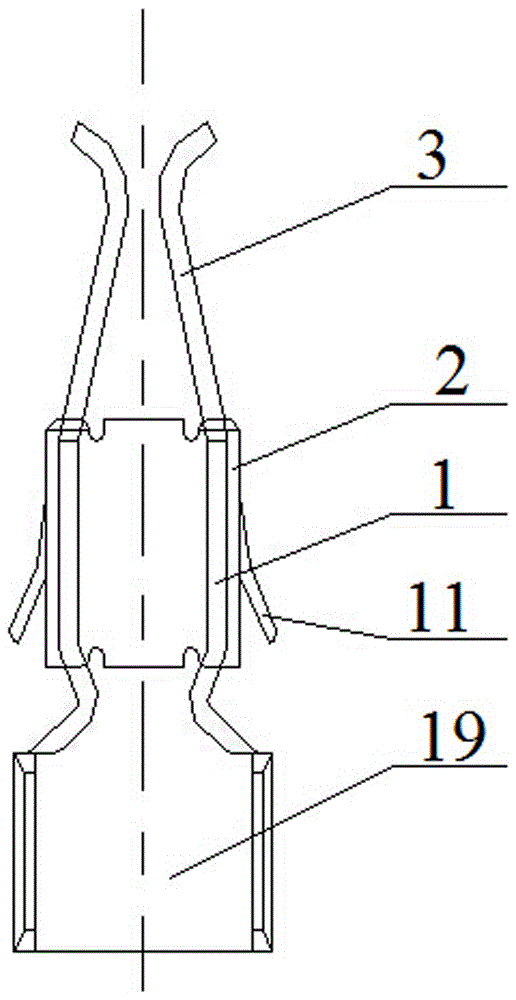

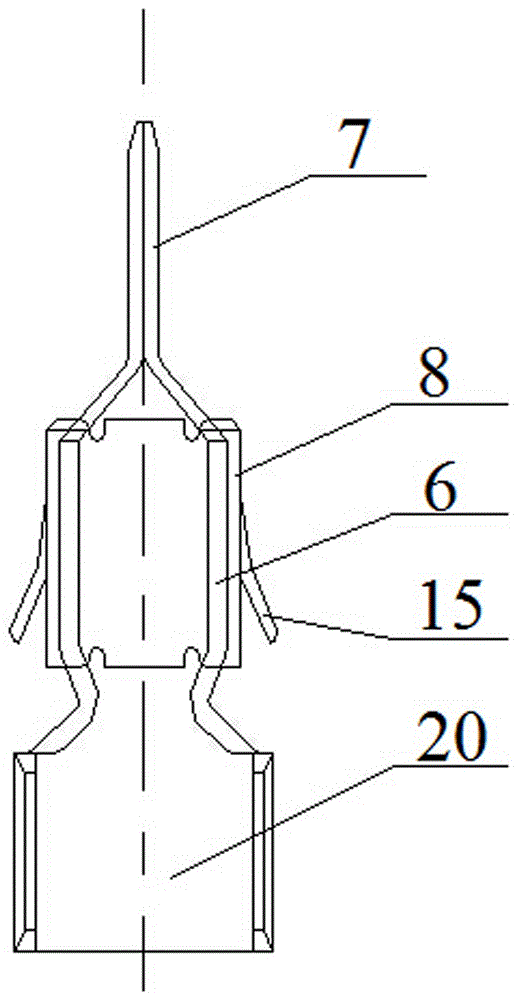

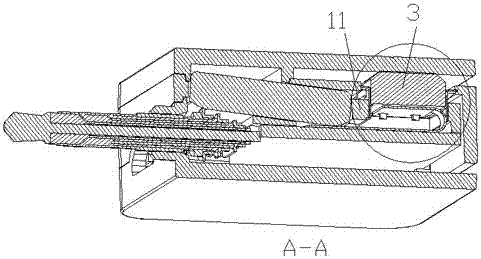

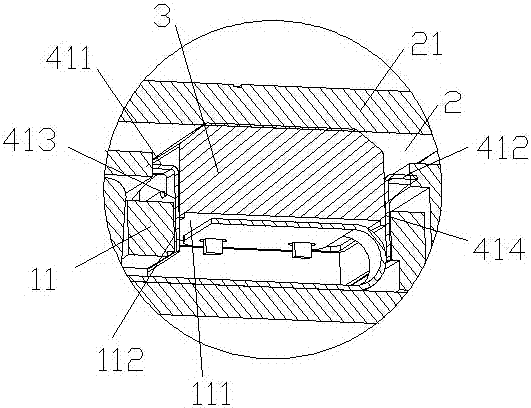

Automobile connector with reinforced elastic terminal structure

ActiveCN104134910AAvoid breakingImprove reliabilitySecuring/insulating coupling contact membersCoupling contact membersElastic componentMetal sheet

The invention discloses an automobile connector with a reinforced elastic terminal structure. The automobile connector comprises a socket terminal, a plug terminal, a socket terminal jacket and a plug terminal jacket, wherein the socket terminal comprises a socket terminal body formed by stamping a metal sheet, the socket terminal body comprises a box part I, the box part I comprises a base wall and two side walls, clamping shrapnels upwards extend from the two side walls of the box part I, a box part II is arranged at the periphery of the box part I and formed by stamping the metal sheet, first elastic parts downwards extend from the two side walls of the box part II, the socket terminal is arranged in the socket terminal jacket, and a socket terminal press element is arranged on the outer wall of the socket terminal jacket and opposite to the first elastic parts. The automobile connector has the advantages that the terminals are designed into two box structures, the elastic parts made of stainless steel are arranged on the box part at the outer layer, so that the elastic parts have good restoration performance after the terminals are arranged in the jackets.

Owner:HENAN THB ELECTRIC

Flexible generation device through adoption of industrial waste heat and manufacturing method thereof

InactiveCN106384781AIncrease the rate of temperature changeImprove heat-to-electricity conversion efficiencyThermoelectric device with dielectric constant thermal changeCapacitor collector combinationsCopper conductorChemical reaction

The present invention provides a flexible generation device through adoption of industrial waste heat and a manufacturing method thereof. Layers of membrane electrodes are made on the upper and lower surfaces of a pyroelectricity thin film, copper conductors are fixed on the upper and lower membrane electrodes through electric conduction silver paste to obtain a flexible heat collection device; a supercapacitor and the flexible heat collection device are connected in parallel, positive and negative electrodes are led out through the copper conductors to obtain a flexible generation unit; the PDMS is dripped on the flexible generation unit to allow the flexible generation unit to be completed wrapped by the PDMS thin film and only expose the copper conductors to obtain the flexible generation device through heating and solidification; at usage, the flexible generation device is pasted at the outer side of a beaker, an ampere meter is connected with the positive and negative electrodes through the copper conductors, different solutions are prepared in the beaker for chemical reaction to realize the different thermal electricity conversion efficiency through controlling the concentration of the chemical reagent and the stirring rate. According to the invention, the flexible generation device through adoption of industrial waste heat and the manufacturing method thereof can allow the waste heat generated in the industrial chemical reaction to perform direct collection and convert into electric energy.

Owner:XI AN JIAOTONG UNIV

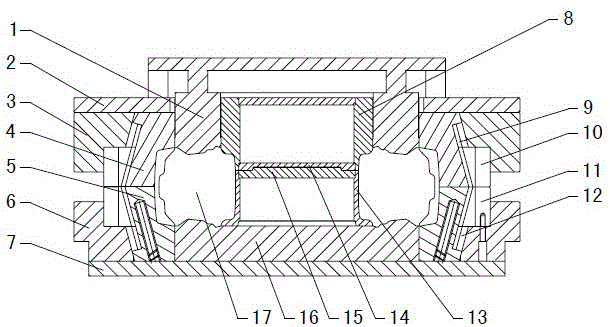

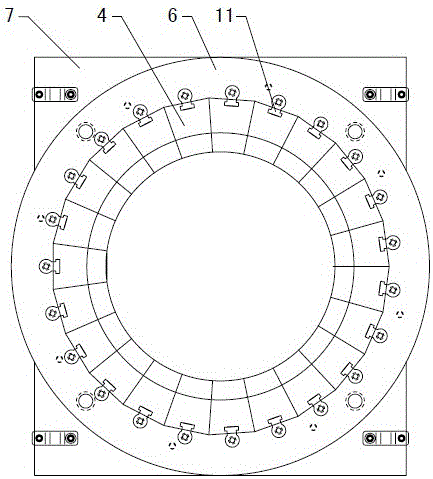

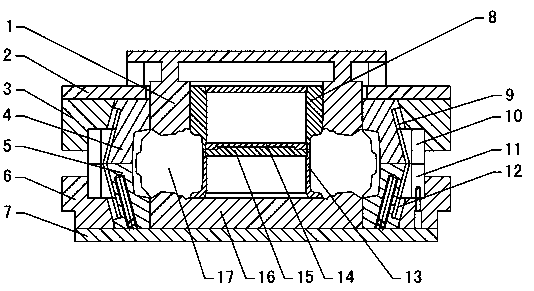

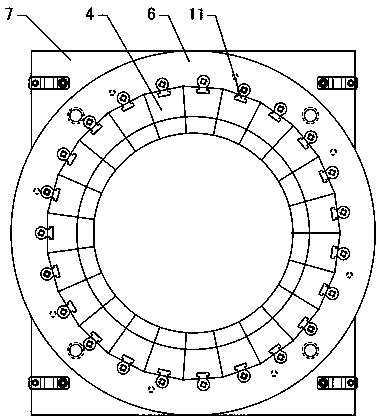

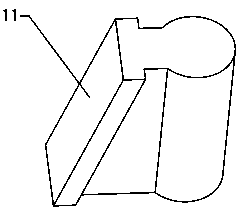

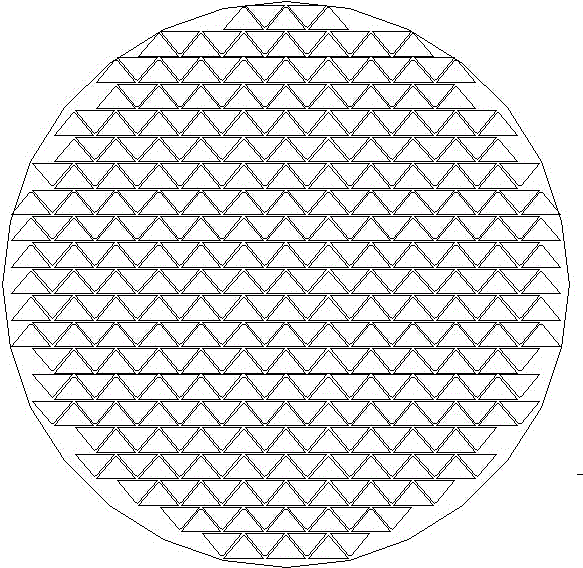

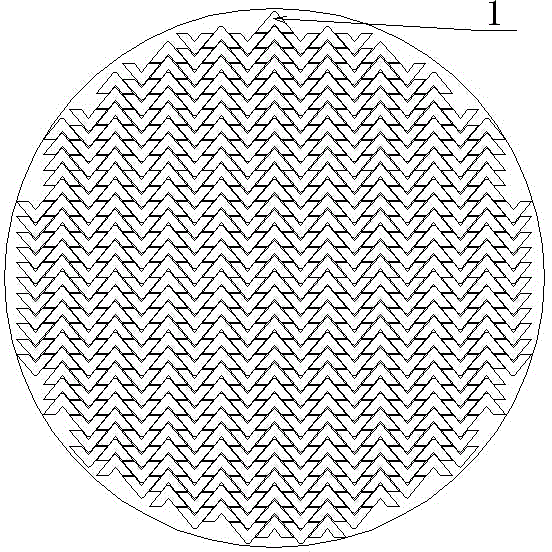

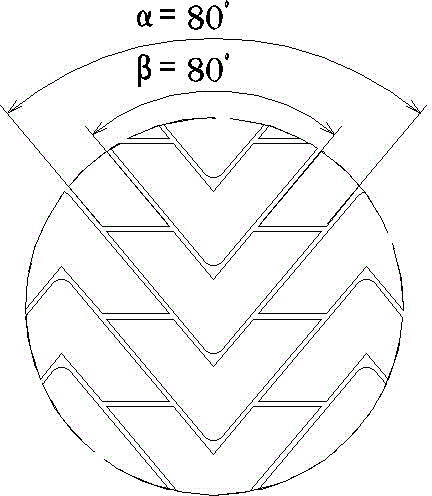

Polyurethane solid tire mold and its processing method

A polyurethane solid tire mold and a processing method thereof belong to the technical field of solid tire processing. The lower pattern module is composed of a plurality of lower pattern blocks (5) spliced along the circumferential direction, and the lower pattern blocks (5) are slidably arranged in the lower fixing seat (6) through the lower pattern block guide mechanism, and the lower pattern block guide mechanism makes the lower pattern block (5) Displacement radially outward occurs while sliding upward. When the mold is opened, the lower pattern block slides upwards and produces a radially outward displacement, so that the lower pattern blocks are separated from each other and separated from the tire, which is convenient for taking the tire out of the tire mold cavity. The processing method of polyurethane solid tire can be The air bubbles in the raw materials are extruded and vulcanized twice to produce polyurethane low-speed solid tires with wear resistance 5 to 10 times that of ordinary rubber. The load capacity is large, which solves the common problems of falling blocks and cracks in rubber solid tires, and can achieve no traces of running brakes, which is environmentally friendly and clean.

Owner:ZIBO SAITONG POLYURETHANE

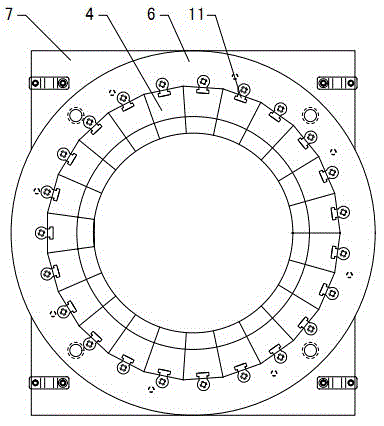

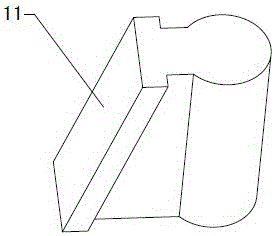

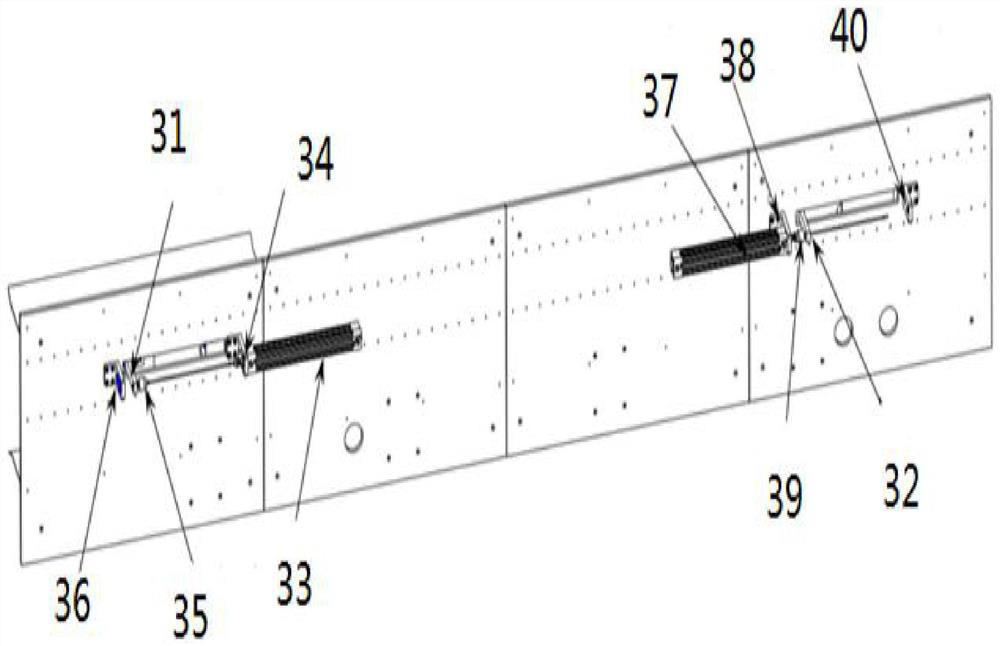

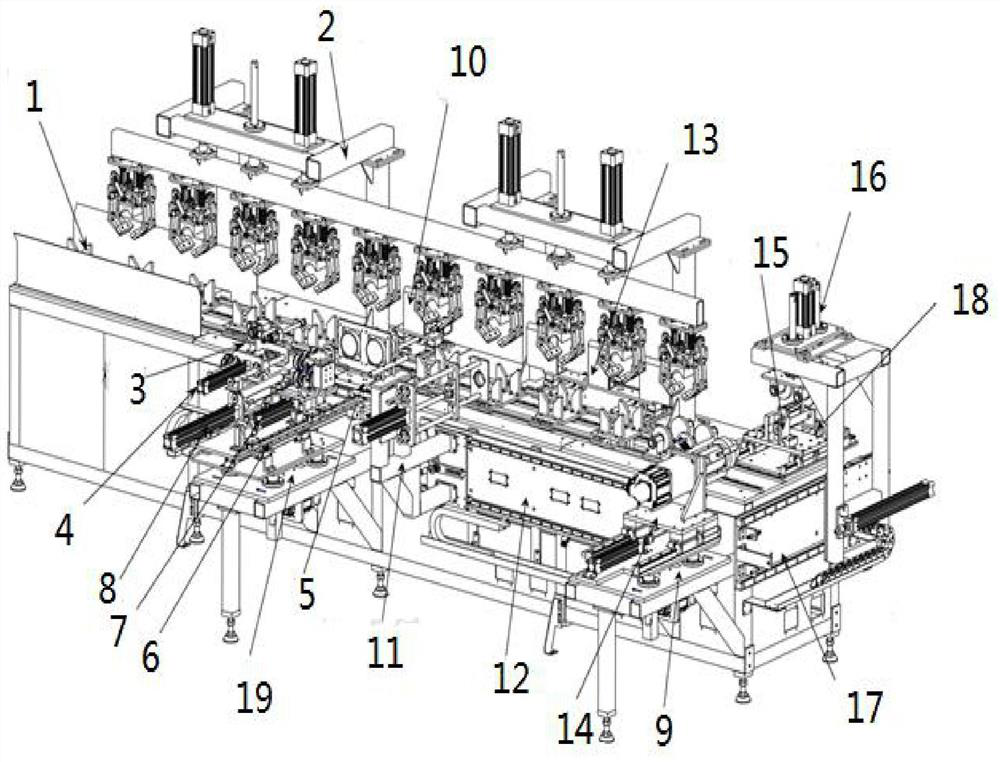

Flexible automatic assembly production line for oil cylinders

ActiveCN112222818AHigh degree of automationStable cleanlinessSpraying apparatusAssembly machinesProduction lineEngineering

The invention discloses a flexible automatic assembly production line for oil cylinders. The flexible automatic assembly production line for oil cylinders comprises a transfer mechanism, a lifting mechanism, an oil injection mechanism, a push rod mechanism, a guide mechanism, a sleeve feeding mechanism, a sleeve replacing mechanism, a first servo jacking mechanism, a first limiting mechanism, an auxiliary power assisting mechanism, a first moving mechanism, a second limiting mechanism, a guide sleeve screwing mechanism, a second servo jacking mechanism, a rotation stopping mechanism, a pressing mechanism, a rotation stopping adjusting mechanism and a second moving mechanism. The transfer mechanism enables a cylinder body to enter from the left end of the production line, the cylinder bodysequentially passes through various structures and then is output from the right end, the transfer mechanism transfers the cylinder body to the lifting mechanism, the lifting mechanism lifts the cylinder body, the transfer mechanism automatically withdraws, and the lifting mechanism transfers the cylinder body to a next positioning tool. The flexible automatic assembly production line for the oilcylinders is reasonable in design; and the production line is high in automation degree, stable in assembly process, standard in operation, reliable in assembly quality, high in production efficiencyand low in labor intensity, and workpieces are continuously and automatically transferred and assembled.

Owner:SHANDONG ATAW IND ROBOT TECH

Special-type flexible and washable electronic tag for military use

InactiveCN104050498AStrong linkGuaranteed stabilityRecord carriers used with machinesEpoxyEngineering

The invention belongs to the technical field of electronic tags, and provides a special-type flexible and washable electronic tag for military use. The special-type flexible and washable electronic tag for military use comprises a base material, an antenna arranged on the base material and an electronic tag chip connected with the antenna. The special-type flexible and washable electronic tag for military use is characterized by being provided with a metal wire; the antenna is connected with the electronic tag chip in a conductive mode through the metal wire; the electronic tag chip is covered with an epoxy resin layer. The special-type flexible and washable electronic tag for military use can meet the requirement of the military that an electronic tag can still operate normally and stably after being washed, ironed and impacted at high / low temperature repeatedly, and also meets the requirement for flexibility of electronic tags.

Owner:陶福平

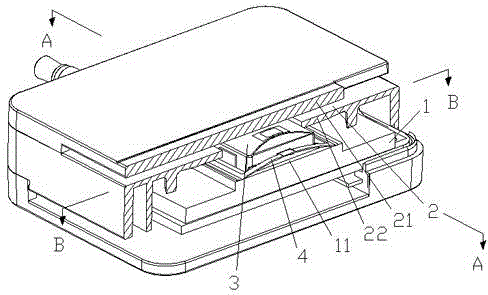

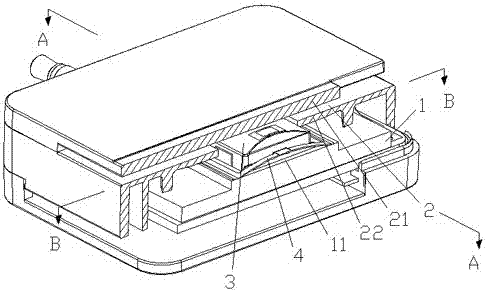

Mini card swiping device

Owner:FUJIAN NEWLAND PAYMENT TECH

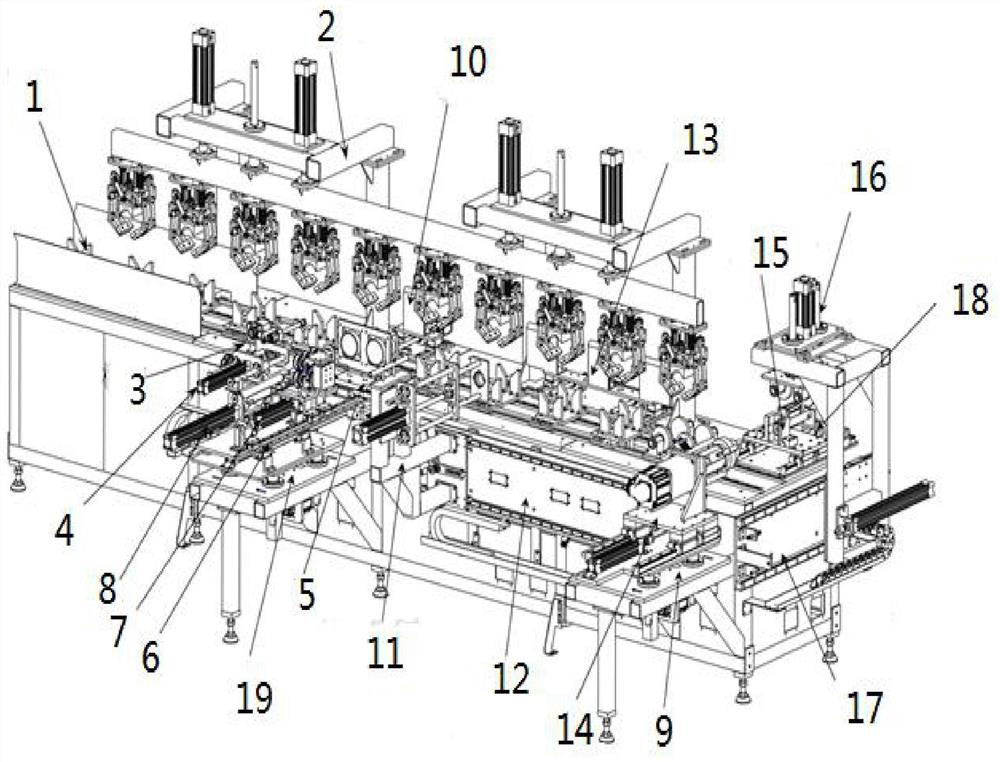

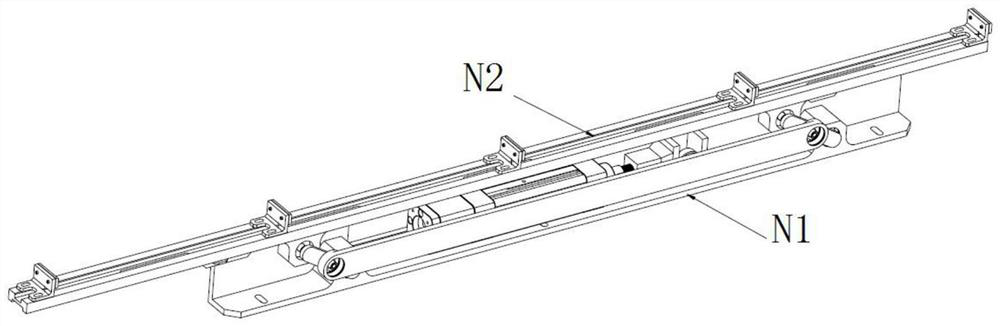

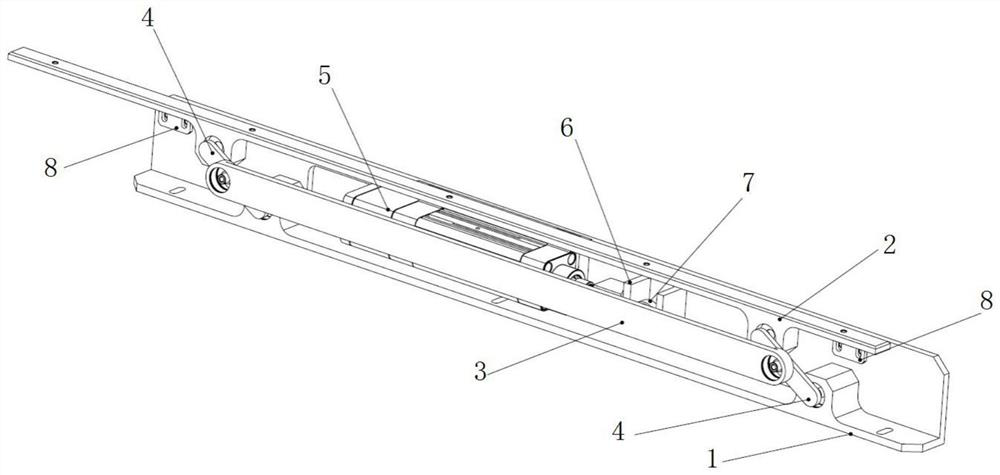

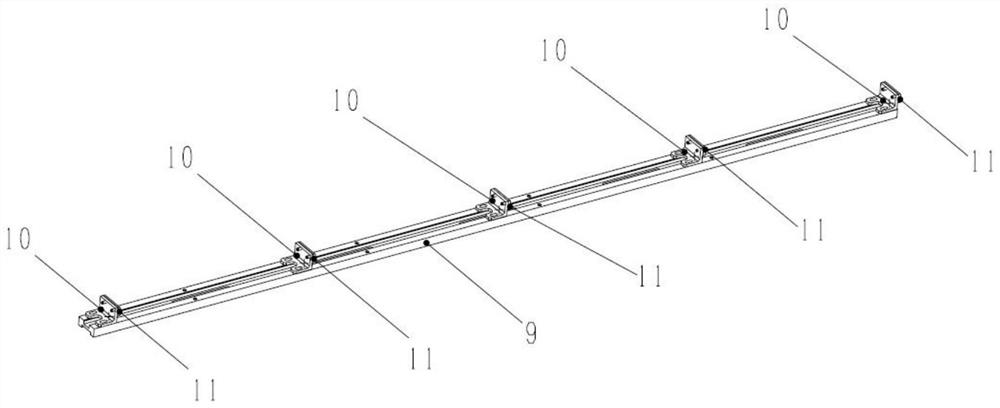

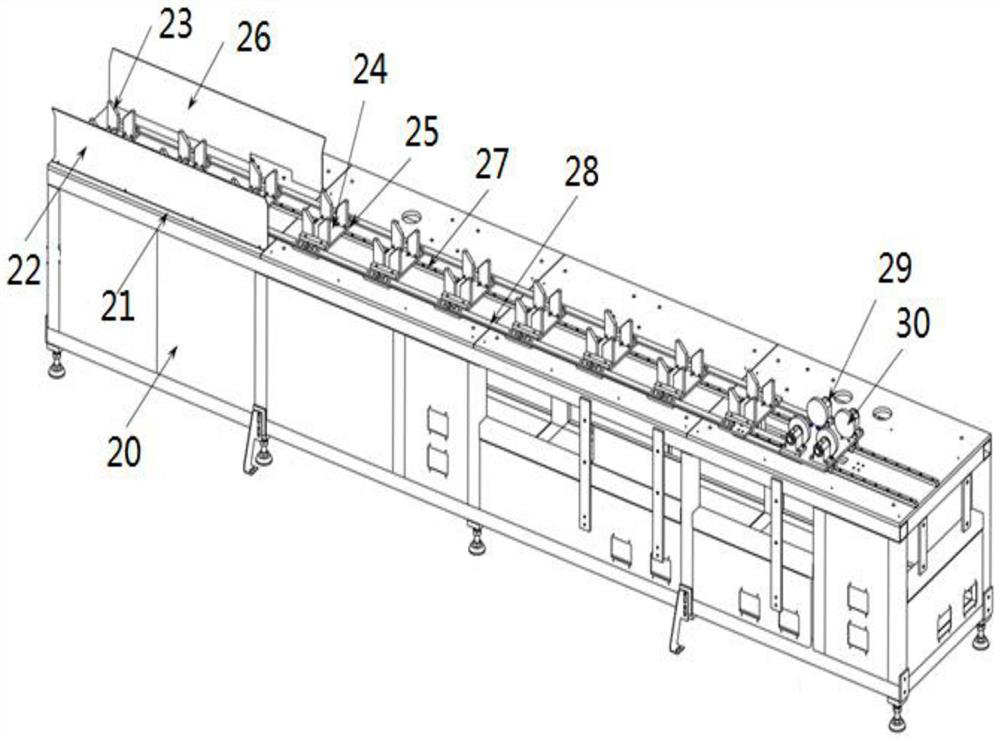

Flexible multi-station continuous clamping device and method

InactiveCN114394272ASolve the problem of stoppingShorten cycle timePackaging cigaretteControl engineeringClamping Activity

The invention discloses a flexible multi-station continuous clamping device. The flexible multi-station continuous clamping device comprises a four-connecting-rod base assembly (N1) and a movable clamping assembly (N2). The movable clamping assembly (N2) is located on the four-connecting-rod base assembly (N1), and the four-connecting-rod base assembly (N1) drives the movable clamping assembly (N2) to move along an arc track so as to generate displacement in the vertical direction and the horizontal direction at the same time. The movable clamping assembly (N2) comprises a plurality of clamping movable plates (10). Different station intervals can be rapidly achieved, clamping of different product specifications and sizes can be met, the requirement for continuity of product production is met while the flexible production requirement is met, the structure is simple and compact, the clamping device can be installed in a conveying channel, operation of other installation stations is not affected, application of a four-connecting-rod mechanism is not affected, and the production efficiency is improved. The working stroke of the electric cylinder is reduced, space is saved, and the working stability of the clamping device is improved.

Owner:云南烟草机械有限责任公司

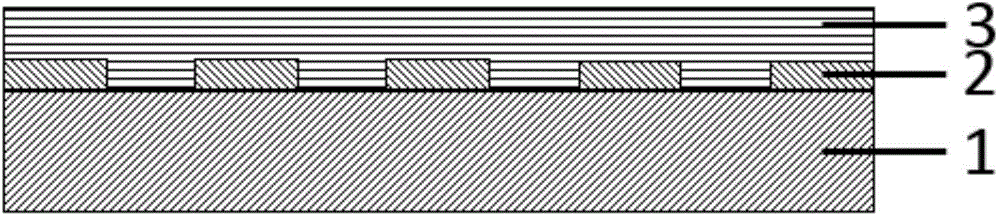

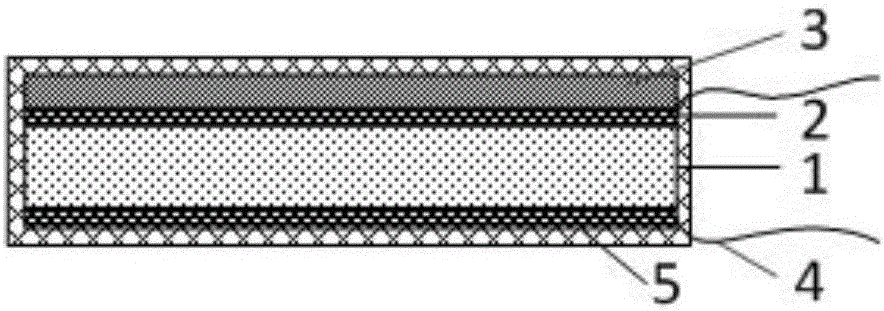

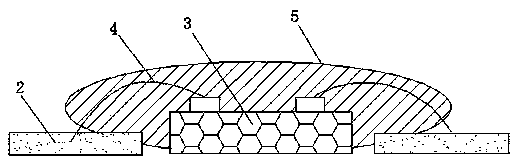

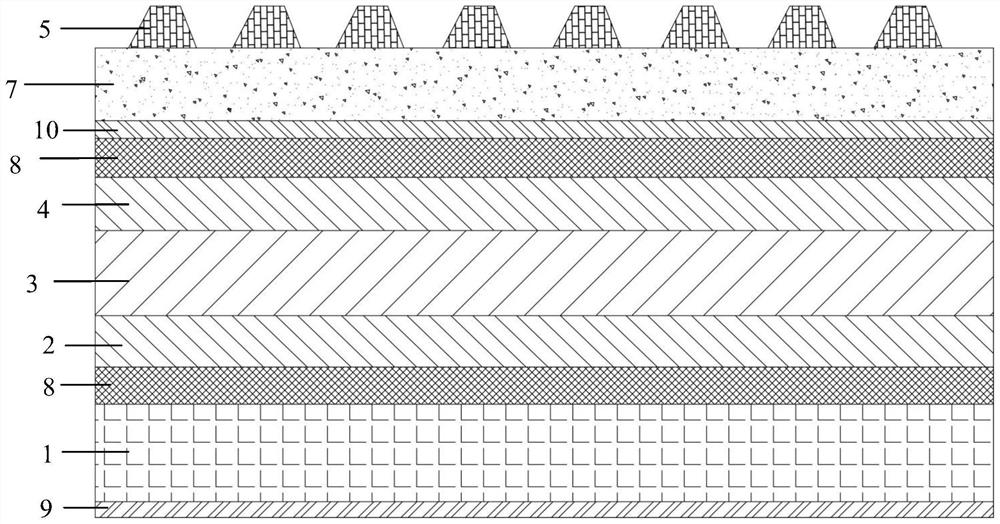

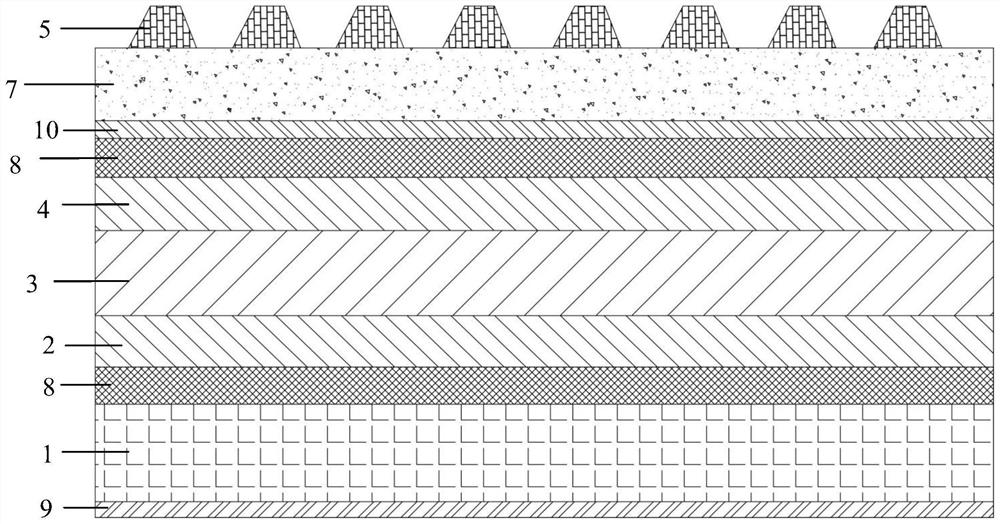

Tactile sensor based on pvdf piezoelectric film

ActiveCN111780659AMeet the requirements of flexibilityUnrestricted structure sizeElectrical/magnetic solid deformation measurementThin membraneContact layer

The invention discloses a tactile sensor based on a pvdf piezoelectric film. The tactile sensor comprises a substrate, a lower conducting layer, the pvdf piezoelectric film, an upper conducting layerand a tactile contact layer, and the lower conducting layer, the pvdf piezoelectric film, the upper conducting layer and the tactile contact layer sequentially cover the top end of the substrate frombottom to top; the left and right sides of the lower conducting layer are provided with linear electrodes, and the front and rear ends of the upper conducting layer are provided with linear electrodes. The sensor can cover the body surface of the robot in a large area, the structural size is not limited, the detection precision is high, and the speed is high.

Owner:山西工程职业学院

A kind of polyurethane low-speed solid tire and its production process

ActiveCN104693401BSimple production processLarge adjustable range of hardnessSpecial tyresPolyesterPolyol

The invention relates to a formula and a production technology of a polyurethane low-speed solid tire and belongs to the technical field of high-polymer material products. The formula is characterized by comprising the following raw materials in parts by weight: 0.8-1.5 parts of polyester polyol, 0.15-0.25 parts of toluene diisocyanate, and 0.1-0.15 parts of curing agent component. The production technology is characterized by specifically comprising the following steps: dehydrating the polyester polyol and adding toluene diisocyanate to firstly obtain a prepolymer; and respectively feeding the prepolymer and the curing agent components into tanks A and B of a casting machine, mixing according to the weight parts and casting into a tire casting die, performing casting forming, and performing secondary vulcanization. The integrated solid tire having completely identical internal material, external material and performances is prepared by virtue of the formula technology and the formula, and the technology can be realized by performing primary cast forming through the tire casting die, and the production technology of the tire can be greatly simplified.

Owner:日照悍马轮胎股份有限公司

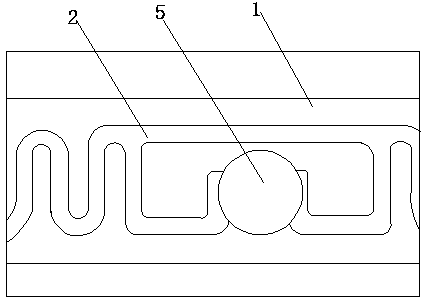

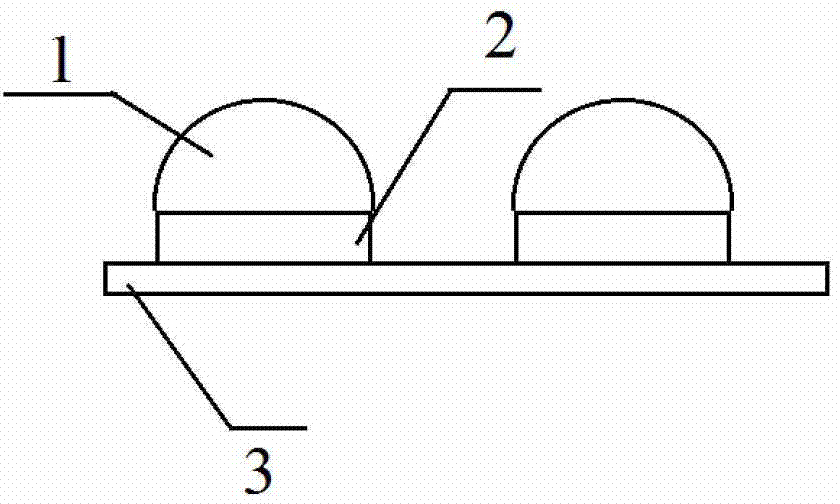

Four-interdigital-electrode type three-dimensional force contact sensor for artificial skin

InactiveCN102928137BMeet the requirements of flexibilityImprove stability and sensitivityForce measurementTactile sensorContact sensor

The invention discloses a four-interdigital-electrode type three-dimensional force contact sensor for artificial skin. The four-interdigital-electrode type three-dimensional force contact sensor is characterized in that four same interdigital electrodes are symmetrically arranged on the same one plane and mutually form 90 degrees; pressure sensitive material layers cover the interdigital electrodes to form resistors R1, R2, R3 and R4 respectively; and the upper surface of the pressure sensitive material is covered with a hemispherical contact to form a three-dimensional force contact sensing unit arranged on the surface of a detected zone.

Owner:HEFEI UNIV OF TECH

Surface-mounted gas sensor device for detecting formaldehyde in food packaging container as well as preparation method and application of surface-mounted gas sensor device

PendingCN107643328AAvoid food contaminationEasy to prepareMaterial resistanceFood packagingEngineering

The invention discloses a surface-mounted gas sensor device for detecting formaldehyde in a food packaging container. The surface-mounted gas sensor device comprises an air chamber, a formaldehyde sensor element, a signal processing module and a connecting line, wherein the air chamber comprises a first connecting piece, a second connecting piece, a connecting wall positioned between the first connecting piece and the second connecting piece as well as an inner cavity formed by surrounding the first connecting piece, the second connecting piece and the connecting wall; the formaldehyde sensorelement is positioned in the inner cavity; the top surface of the formaldehyde sensor element is combined and fixed with the bottom surface of the first connecting piece; the signal processing moduleis positioned on the first connecting piece; the bottom surface of the signal processing module is combined and fixed with the top surface of the first connecting piece; the connecting line penetratesthrough the top surface and the bottom surface of the first connecting piece; one end of the connecting line is connected with the signal processing module; the other end of the connecting line is connected with the formaldehyde sensor element; the top end of the connecting wall comprises a groove which is formed by inward concaving the side face of the top end of the connecting wall and is matched with the top end of the formaldehyde sensor element. According to the device, the formaldehyde in food package can be detected in real time.

Owner:AGRI INFORMATION INST OF CAS

Fully-flexible three-dimensional force tactile sensor

ActiveCN103335754BMeet the requirements of flexibilityReduce couplingForce measurement using piezo-resistive materialsElectrical resistance and conductanceEngineering

The invention discloses a fully-flexible three-dimensional force tactile sensor. The fully-flexible three-dimensional force tactile sensor is characterized in that in a flexible basal body and on the same plane, a resistor R5 is formed by taking a pressure sensitive element as a center, and four same stretching sensitive elements are respectively arranged in the Y-axis positive direction, the Y-axis negative direction, the X-axis positive direction and the X-axis negative direction respectively, so as to form a resistor R1, a resistor R3, a resistor R2 and a resistor R4; the resistor R1, the resistor R2, the resistor R3, the resistor R4 and the resistor R5 form a three-dimensional force tactile sensing unit which is arranged on the surface of an area to-be-detected. All three-dimensional force tactile sensing units are in an array arrangement on the surface of the area to-be-detected; flexible basal bodies are filled among the three-dimensional force tactile sensing units; the three-dimensional force tactile sensing units and the flexible basal bodies form the three-dimensional force tactile sensor. The three-dimensional force tactile sensor has the advantages of good flexibility, high precision and stable performance.

Owner:合肥庐阳科技创新集团有限公司

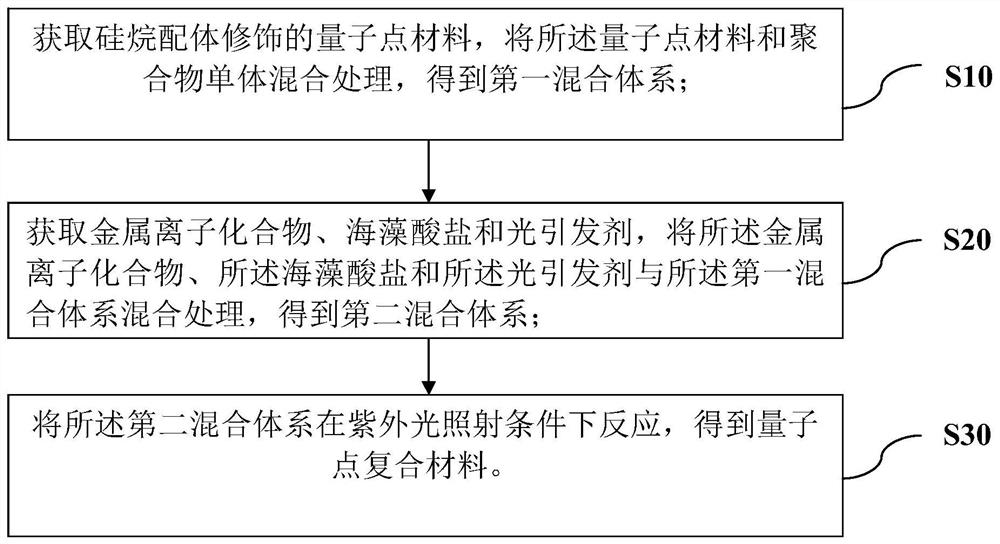

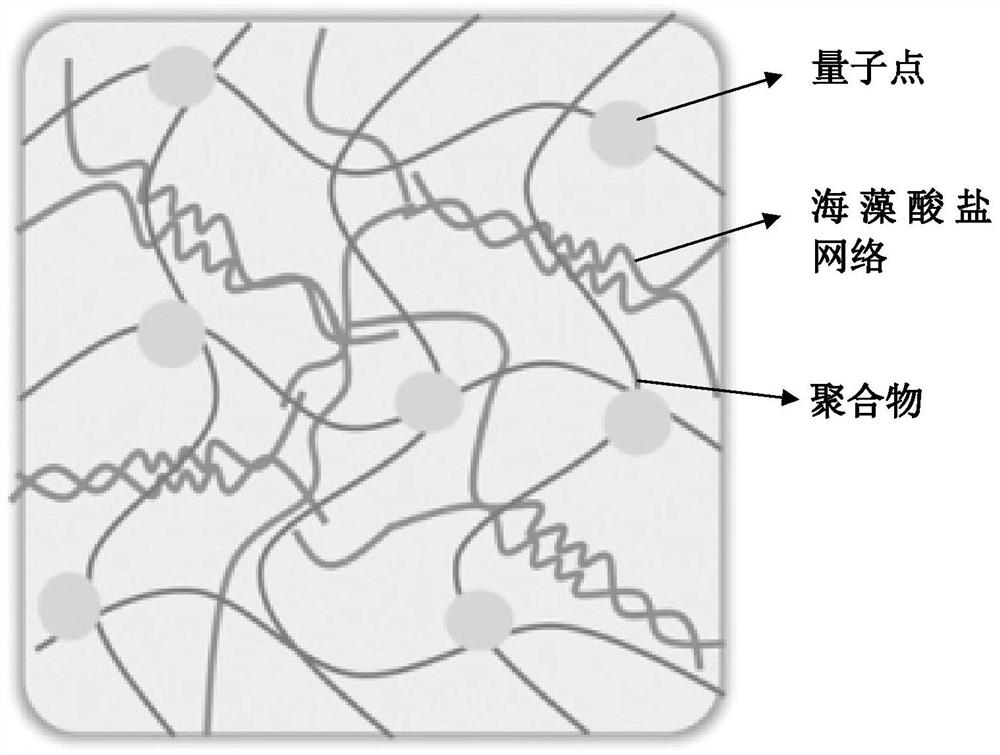

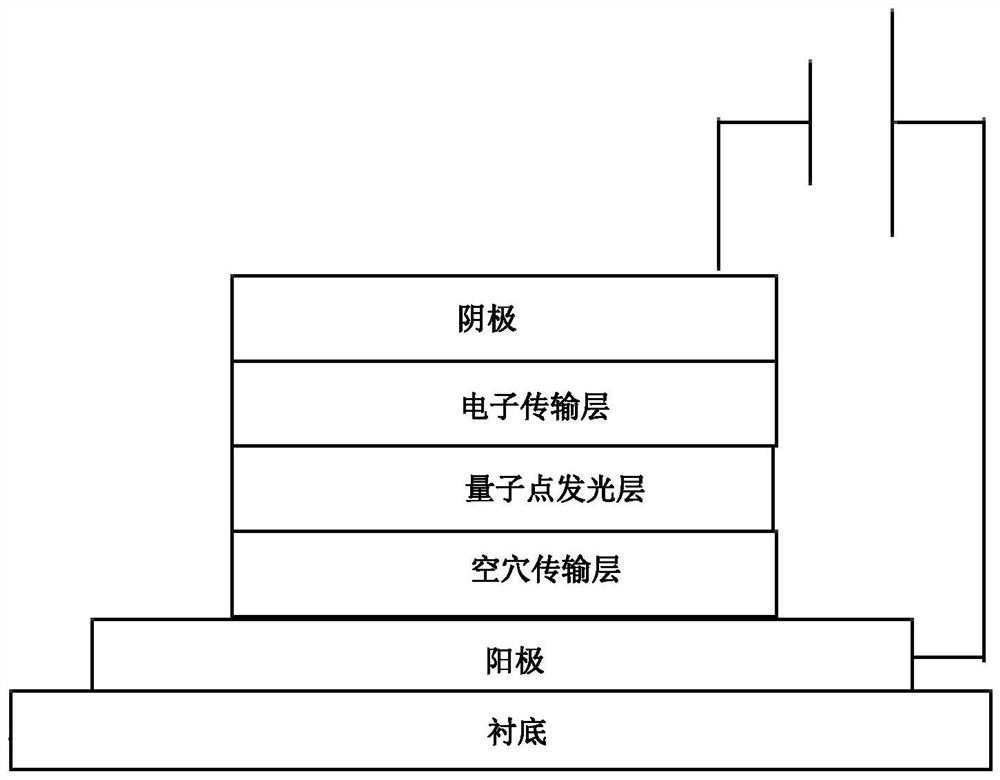

Quantum dot composite material, preparation method thereof and quantum dot light-emitting device

ActiveCN113754978AGood dispersionFlexible enoughMaterial nanotechnologySolid-state devicesPhoto irradiationSilanes

The invention belongs to the technical field of quantum dots, and particularly relates to a preparation method of a quantum dot composite material, the preparation method comprises the following steps: obtaining a silane ligand modified quantum dot material, and mixing the quantum dot material with a polymer monomer to obtain a first mixed system; obtaining a metal ion compound, alginate and a photoinitiator, and mixing the metal ion compound, the alginate and the photoinitiator with the first mixed system to obtain a second mixed system; enabling the second mixed system to react under the ultraviolet irradiation condition, and obtaining the quantum dot composite material. According to the preparation method of the quantum dot composite material, the prepared quantum dot composite material has a double-layer network structure of the alginate and the polymer, and the quantum dots are protected by two flexible network matrixes of the alginate and the polymer at the same time, so that the quantum dot composite material has more stable optical performance and stronger tensile property and mechanical property, and the method is especially suitable for flexible photoelectric devices.

Owner:TCL CORPORATION

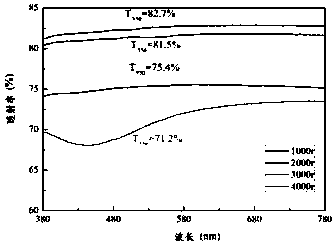

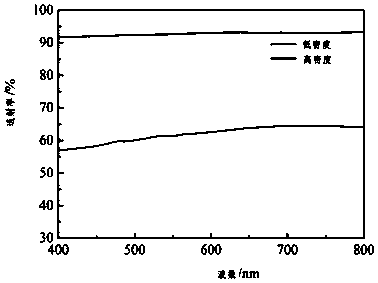

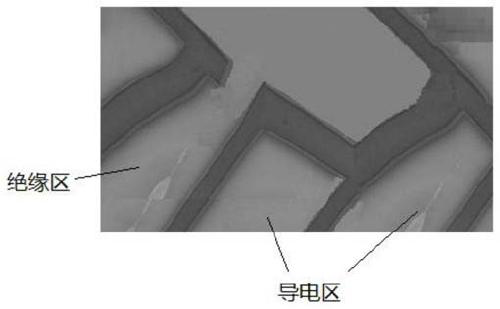

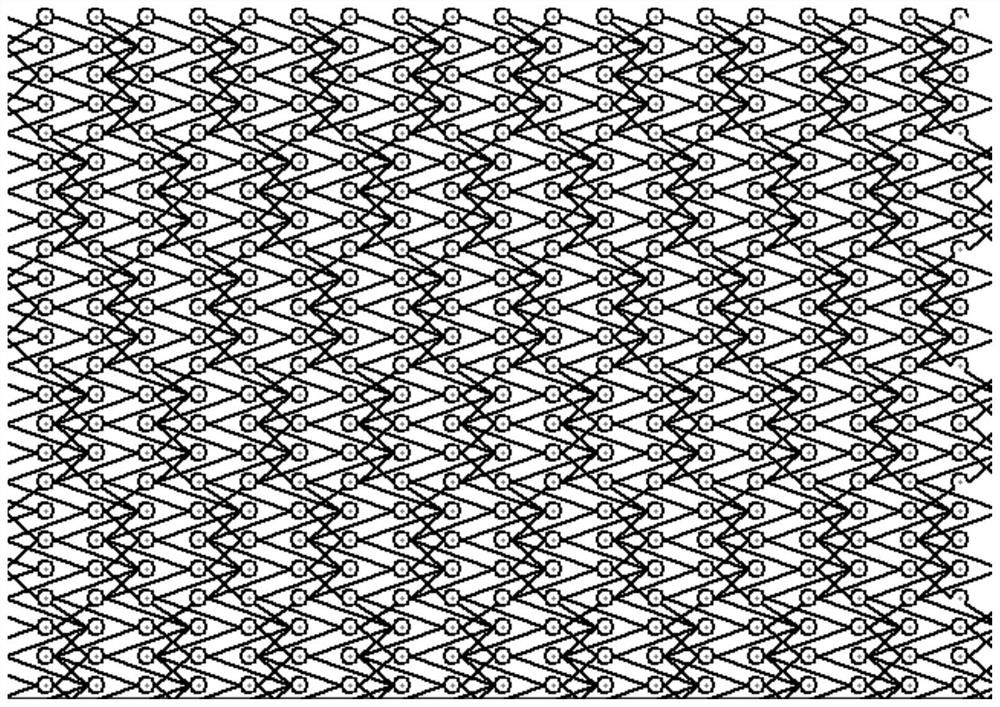

A kind of transparent conductive silver mesh film and preparation method thereof

ActiveCN109872834BEliminate seepageEliminate dense distributionConductive layers on insulating-supportsCable/conductor manufactureSilver inkAcrylic resin

The present invention relates to the technical field of thin film materials, and in particular to a transparent conductive silver grid thin film and a preparation method thereof. The transparent conductive grid film is prepared from particle-free silver ink, and includes an irregular grid woven by silver grid lines extending in the plane direction, including a conductive area and an insulating area, and the conductive area is woven from silver grid lines. Irregularly shaped grid frame, the insulating area is a blank area surrounded by silver grid lines, the transparent conductive silver grid film thickness is 2-20μm, the transmittance is 60~92%, and the sheet resistance is 1-50Ω / sq, the present invention applies particle-free silver ink to a cracked plate made of acrylic resin CA-600 emulsion, and obtains the transparent conductive silver grid film after drying and cleaning. The grid structure in the present invention has good flexibility and conductivity, and can withstand multiple bends and flexions. By setting the spin coating process parameters, different grid morphologies can be obtained, thereby obtaining different transmittances and different A conductive film of sheet resistor.

Owner:NORTHEASTERN UNIV LIAONING

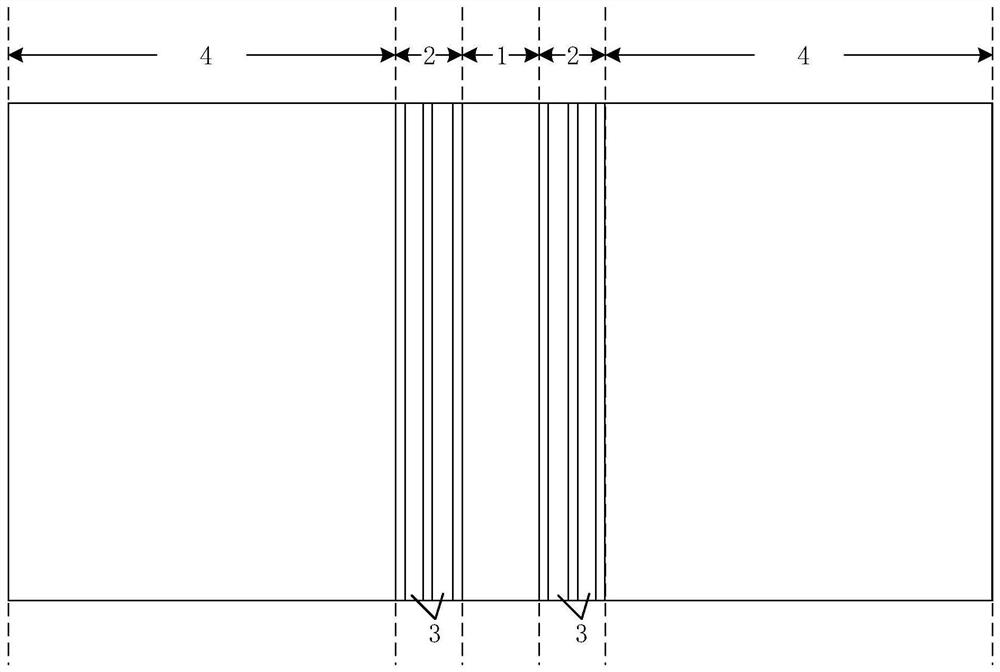

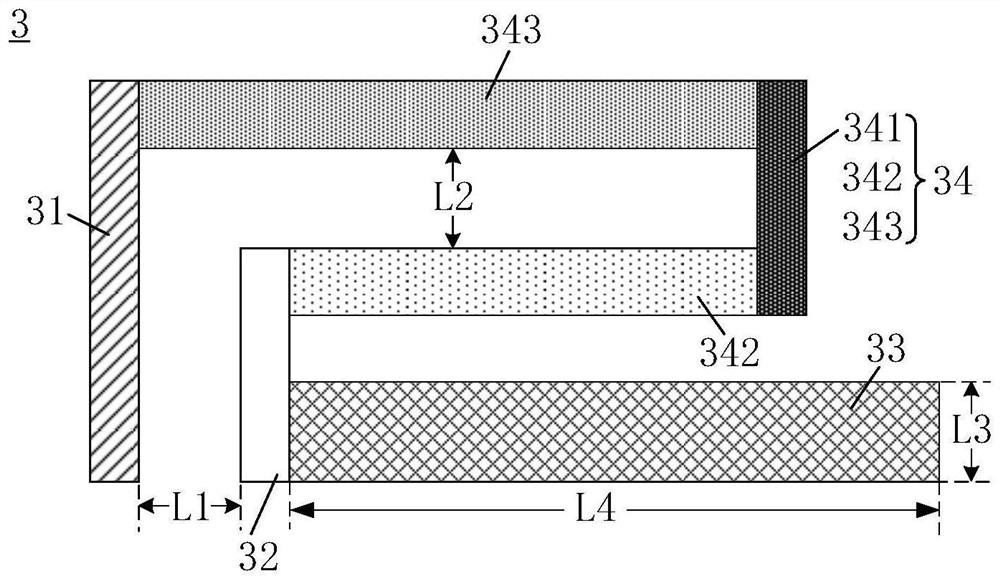

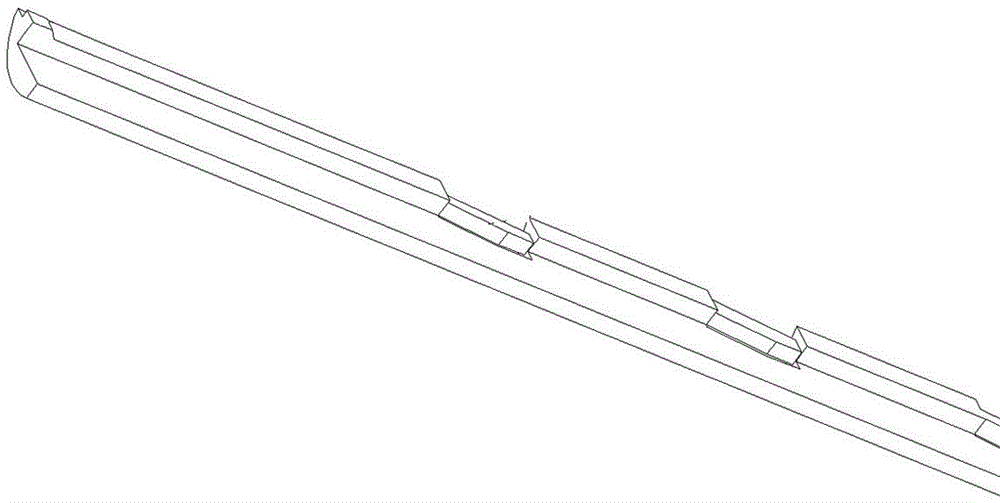

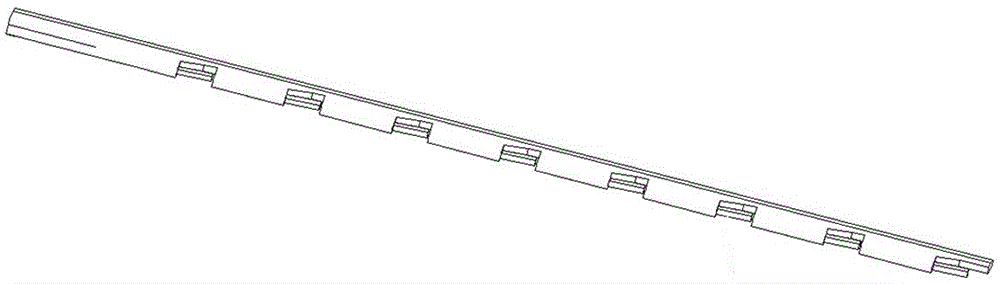

Supporting structure, preparation method thereof and display device

PendingCN113763819AAvoid cracksImprove yield rateIdentification meansPhotovoltaic energy generationEngineeringStructural engineering

The embodiment of the invention provides a supporting structure, a preparation method thereof and a display device. The supporting structure comprises a bending area and first areas located on the two sides of the bending area; one side of the supporting structure is used for arranging a flexible display panel; the supporting structure located in the first area comprises a plurality of adjusting structures, and each adjusting structure comprises a first sub-adjusting structure, a second sub-adjusting structure and a corresponding first connecting structure which are arranged at intervals; the two ends of the first connecting structure of one adjusting structure are connected with the second sub-adjusting structure of one adjusting structure and the first sub-adjusting structure of the other adjacent adjusting structure correspondingly; in the bending state, the first distance between the first sub-adjusting structure and the second sub-adjusting structure is matched with the bending curvature of the flexible display panel at the corresponding position. According to the embodiment of the invention, the stress generated when the flexible display panel is bent is released, the damage of the flexible display panel caused by stress concentration is avoided, and the yield of a product with a supporting structure is further improved.

Owner:BOE TECH GRP CO LTD +1

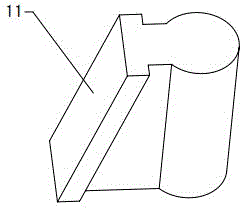

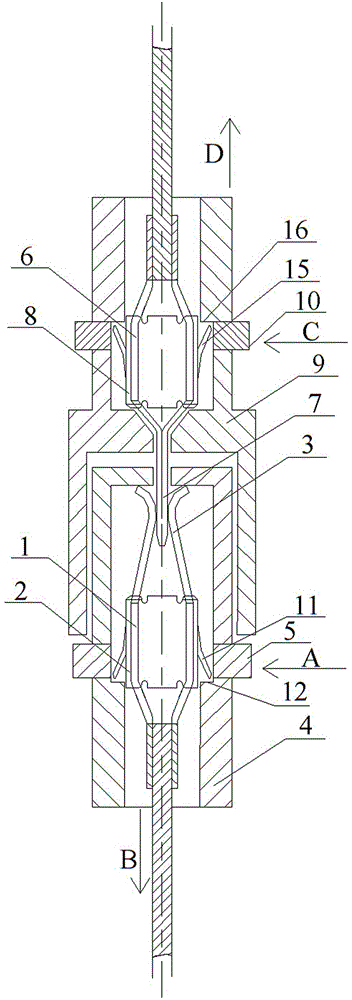

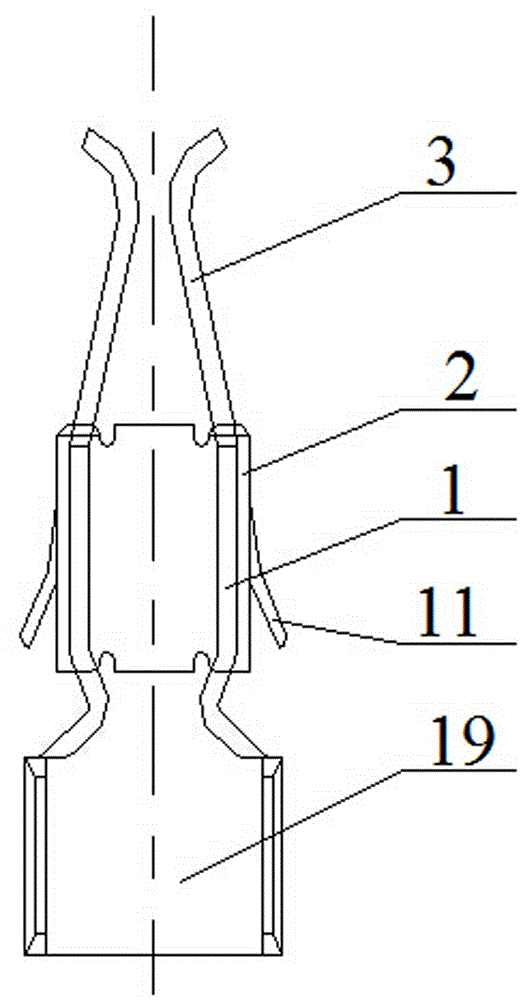

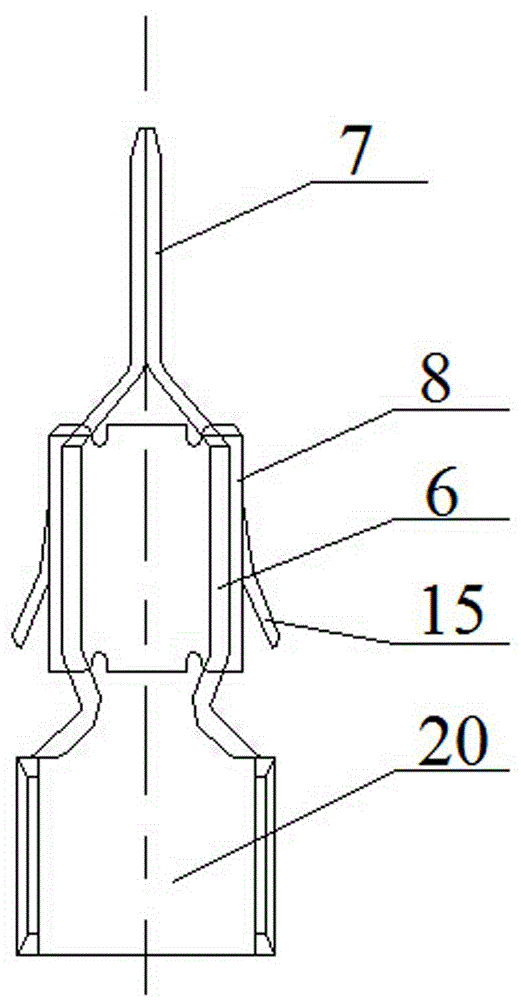

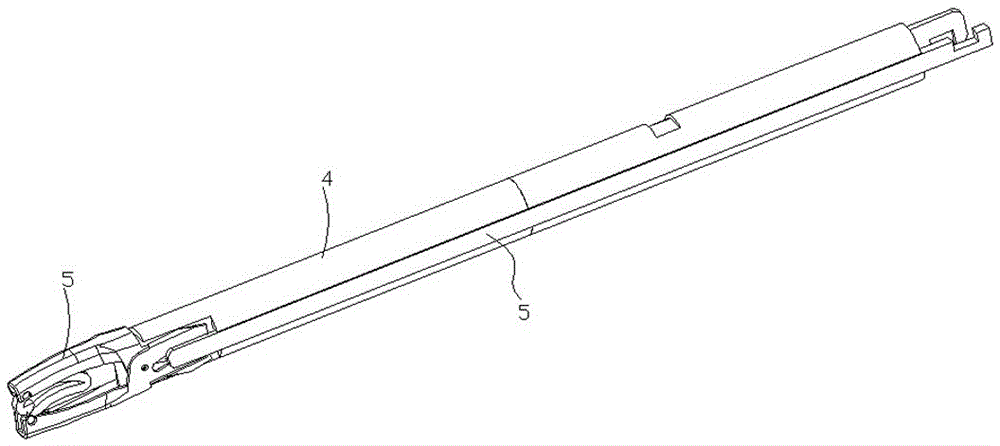

Hemostasis clip holder and clip applier comprising same

The invention discloses a hemostasis clip holder and a clip applier comprising the same. The hemostasis clip holder comprises a hemostasis clip holder body (101), and the hemostasis clip holder body (101) is provided with a linkage part cooperating with a power unit. The hemostasis clip holder also comprises a clip pushing part (102), and the clip pushing part (102) is fixedly connected to the hemostasis clip holder body (101) in a non-integrated manner. The clip applier can fully improve the propulsive force and stability.

Owner:CHENGDU IDING IND PROD DESIGN

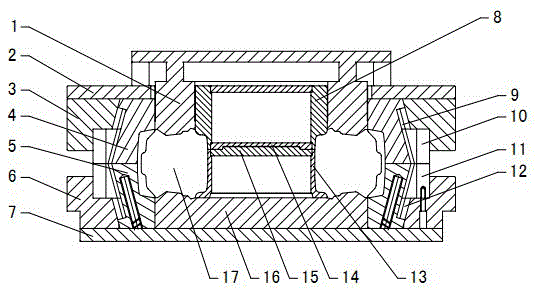

Automotive connector with reinforced terminal elastic structure

ActiveCN104134910BAvoid breakingImprove reliabilitySecuring/insulating coupling contact membersCoupling contact membersEngineeringMetal sheet

The invention discloses an automobile connector with a reinforced terminal elastic structure, which comprises a socket terminal, a plug terminal, a socket terminal sheath and a plug terminal sheath, the socket terminal includes a socket terminal main body formed by punching a metal plate, the The main body of the socket terminal includes a box body I, and the box body I includes a bottom wall and two side walls, and a clamping shrapnel extends upward from the two side walls of the box body I; The box part II formed by punching the metal sheet has a first elastic member extending downward from the two side walls of the box part II, the socket terminal is located in the socket terminal sheath, and on the outer wall of the socket terminal sheath The position corresponding to the first elastic part is provided with a socket terminal pressing part; the present invention has the following advantages: the terminal is designed as a structure of two boxes, and an elastic part made of stainless steel is arranged on the outer box part, so that After the terminal is put into the sheath, the elastic part has good reset performance.

Owner:HENAN THB ELECTRIC

A micro card swiping device

Owner:FUJIAN NEWLAND PAYMENT TECH

A Tactile Sensor Based on PVDF Piezoelectric Film

ActiveCN111780659BMeet the requirements of flexibilityUnrestricted structure sizeElectrical/magnetic solid deformation measurementThin membraneEngineering

The invention discloses a tactile sensor based on a PVDF piezoelectric film, comprising a base, a lower conductive layer, a PVDF piezoelectric film, an upper conductive layer and a tactile contact layer, a lower conductive layer, a PVDF piezoelectric film, an upper conductive layer, and a tactile contact The layers are sequentially covered on the top of the substrate from bottom to top; the left and right sides of the lower conductive layer are provided with linear electrodes, and the front and rear ends of the upper conductive layer are provided with linear electrodes. The invention can cover a large area on the body surface of the robot, has unlimited structural size, and has high detection accuracy and high speed.

Owner:山西工程职业学院

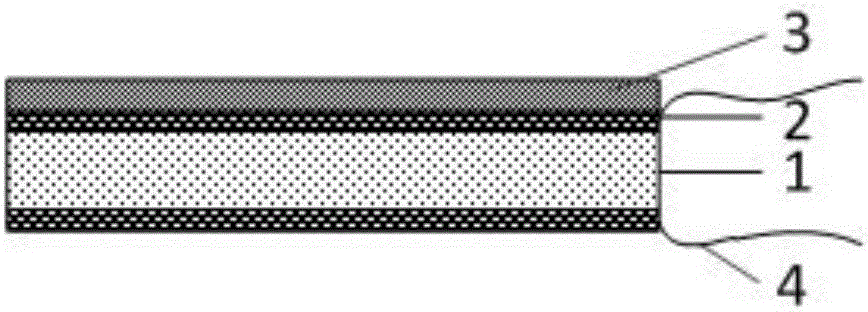

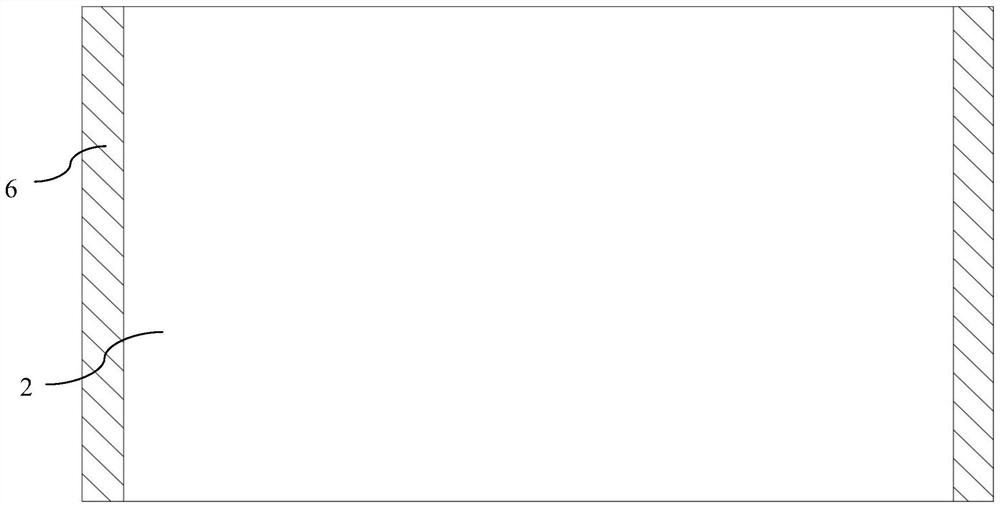

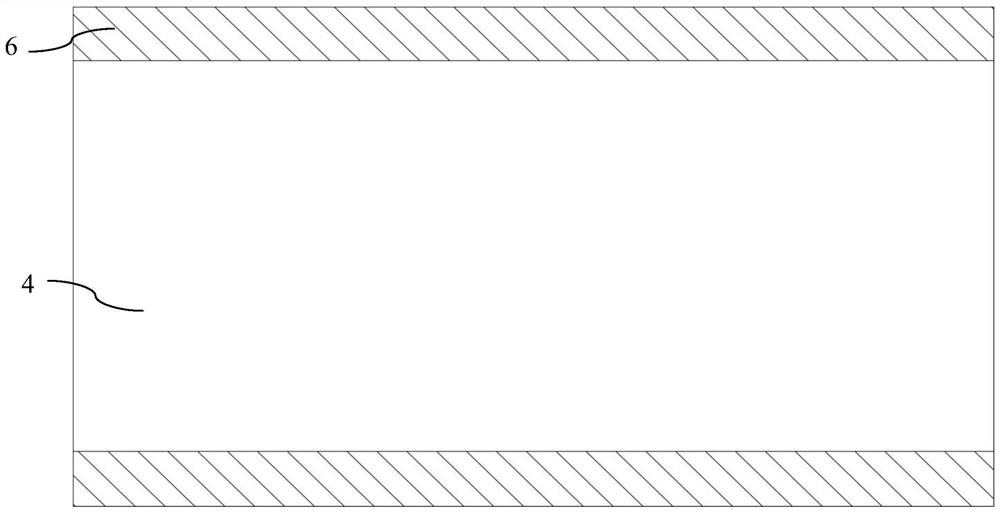

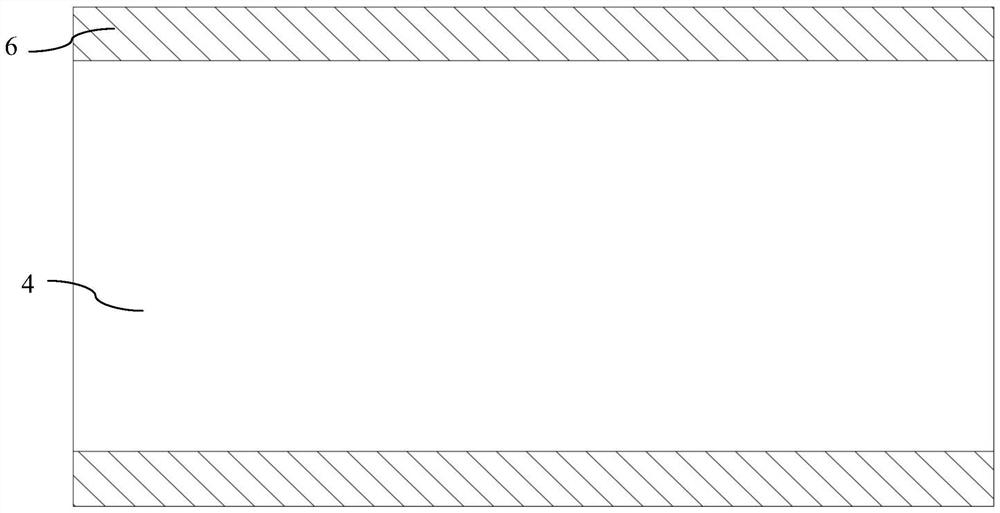

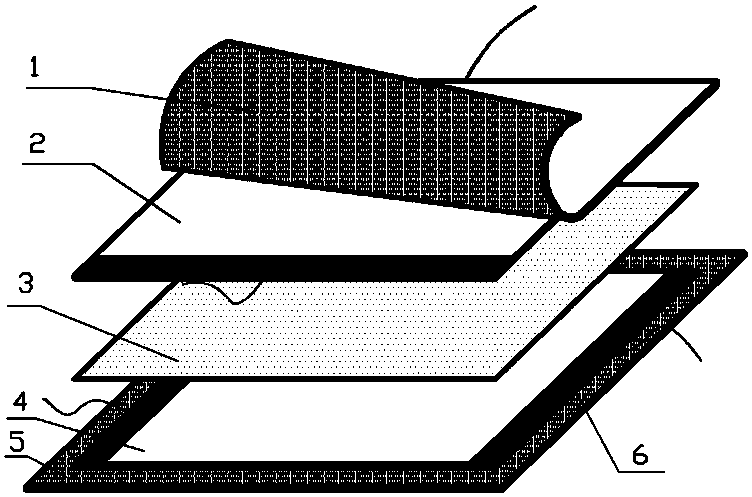

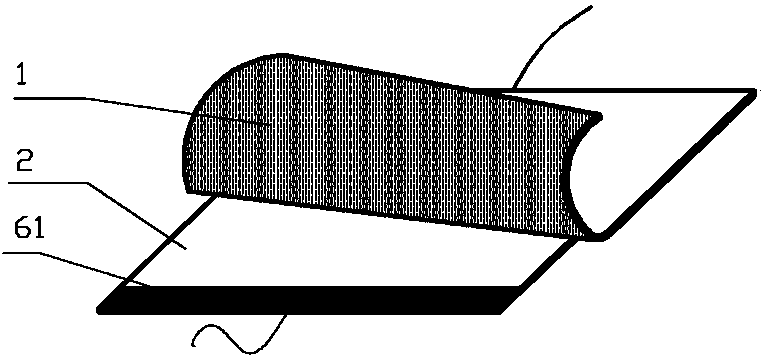

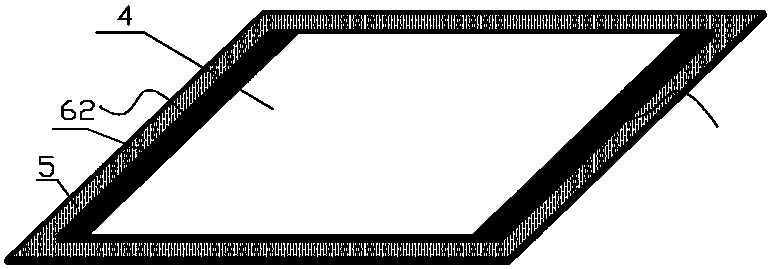

Uniform electric field type robot tactile sensor and detection method thereof

ActiveCN105067161BMeet the requirements of flexibilityReduce computing timeForce measurement using piezo-electric devicesManipulatorEngineeringContact position

The invention relates to a uniform electric field type robot tactile sensor and a detection method thereof. The tactile sensor comprises an upper flexible layer, a mesh-shaped separating layer and a lower flexible layer. The upper flexible layer and the lower flexible layer is respectively composed of a conductive surface and an insulating surface through fitting, and the conductive surface acts as the internal surface of the upper flexible layer and the lower flexible layer. The conductive surfaces of the upper flexible layer and the lower flexible layer are directly adhered on the upper and lower surfaces of the mesh-shaped separating layer respectively. The two opposite sides of the conductive surface of the upper flexible layer and the other two opposite sides of the conductive surface of the lower flexible layer are respectively provided with parallel line electrodes, and a dimensionally enclosed rectangle is formed by the parallel line electrodes of the upper flexible layer and the parallel line electrodes of the lower flexible layer through splicing. The line electrodes of the upper flexible layer and the line electrodes of the lower flexible layer are arranged in a mutually perpendicular way. The adopted material has flexibility, and a collision and touch position can be effectively detected so that the uniform electric field type robot tactile sensor has characteristics of being small in size, simple in structure, simple in technology manufacturing, low in cost and relatively high in flexibility.

Owner:FUZHOU UNIV

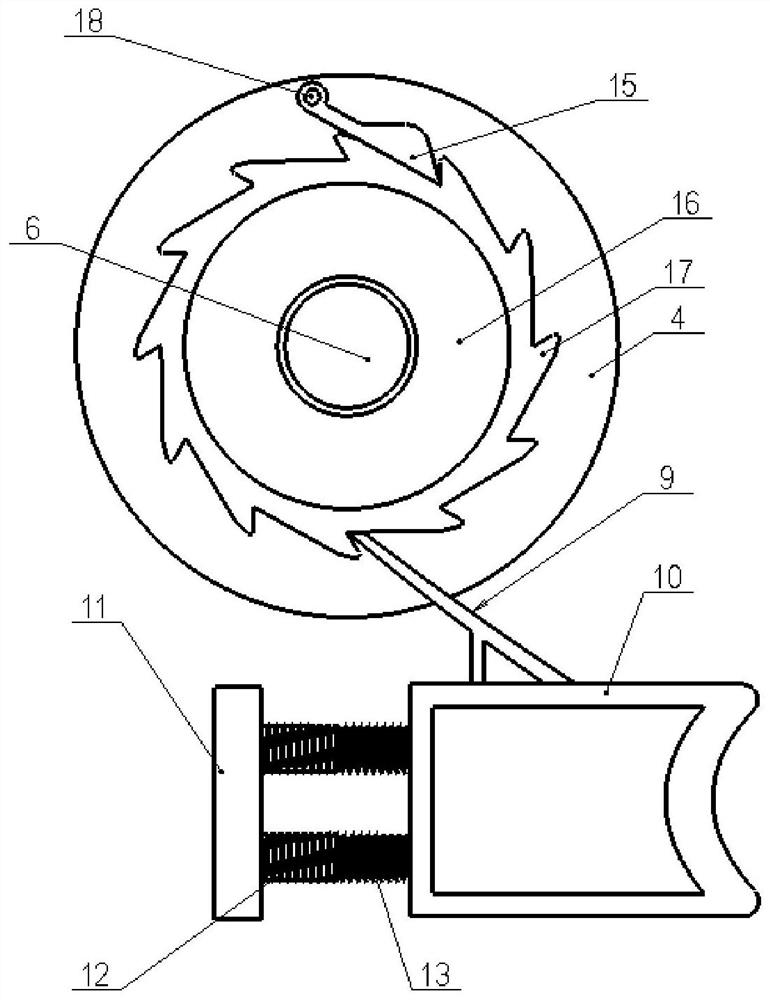

Numerical control turning ultra-hard blade with V-shaped cubic boron nitride cutting units

InactiveCN104439340AReduce wasted areaReduce manufacturing costCutting insertsWorkpiecesNumerical controlAcute angle

The invention provides a numerical control turning ultra-hard blade with V-shaped cubic boron nitride cutting units, and belongs to the technical field of metal cutting tools. The numerical control turning ultra-hard blade is formed by welding the cubic boron nitride cutting units to a hard alloy base body. The cubic boron nitride cutting units are the V-shaped cubic boron nitride cutting units, the upper end face and the lower end face of the hard alloy base body are each provided with two acute angles, each acute angle is provided with one V-shaped cubic boron nitride cutting unit, V-shaped protrusions are arranged on the hard alloy base body, the V-shaped cubic boron nitride cutting units stretch across the V-shaped protrusions, and the inner walls of the V-shaped cubic boron nitride cutting units are attached to the V-shaped protrusions. By the adoption of the V-shaped cubic boron nitride cutting units, the section welding area is increased, welding strength is improved, and the cutting toughness and impact force resistance of the blade are improved. The area of the upper end faces of the cubic boron nitride cutting units is reduced, a round cubic boron nitride composite sheet blank can be cut into more V-shaped cubic boron nitride cutting units under the condition of the certain area, resources are saved, and waste is reduced.

Owner:江苏切剀刀具有限公司

Breathable shading soft fabric and production method thereof

ActiveCN114808262AImprove breathabilityGood shading effectWarp knittingTextile/flexible product manufactureYarnEngineering

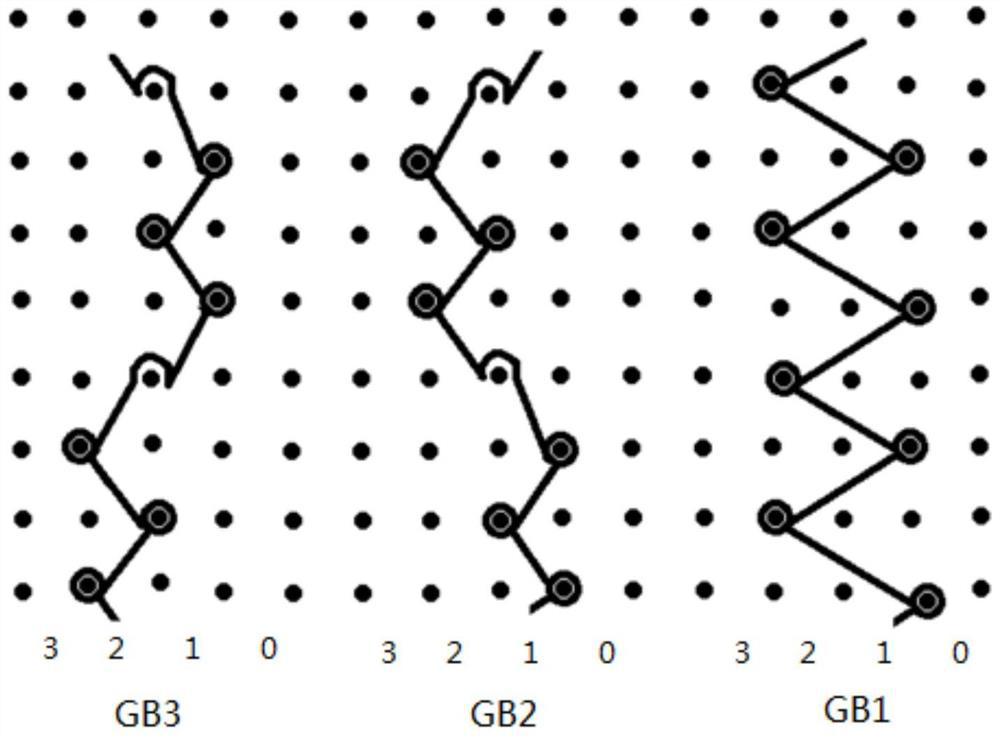

The invention discloses a breathable shading soft fabric and a production method thereof. The fabric is woven by three guide bars; the yarn threading mode of the first guide bar GB1 is full threading, and the yarn laying number of the first guide bar GB1 is 1-0 / 2-3 / / ; the yarn threading mode of the second guide bar GB2 is one threading one empty, and the yarn laying number of the second guide bar GB2 is 10 / 12 / 10 / 12 / 23 / 21 / 23 / 21 / / ; the yarn threading mode of the third guide bar GB3 is one-empty one-threading, and the yarn laying number of the third guide bar GB3 is 23 / 21 / 23 / 21 / 10 / 12 / 10 / 12 / / ; the GB2 and the GB3 are woven into hollowed-out meshes of the fabric, and the hollowed-out meshes are locally shielded by the structure woven by the GB1. The fabric has good air permeability, shading performance and elasticity at the same time, and is fine and smooth in texture, soft in hand feeling, high in sweat and water absorption and good in size stability.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

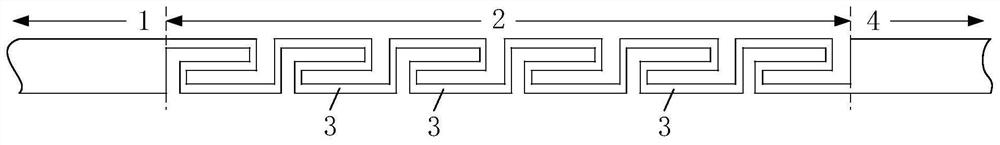

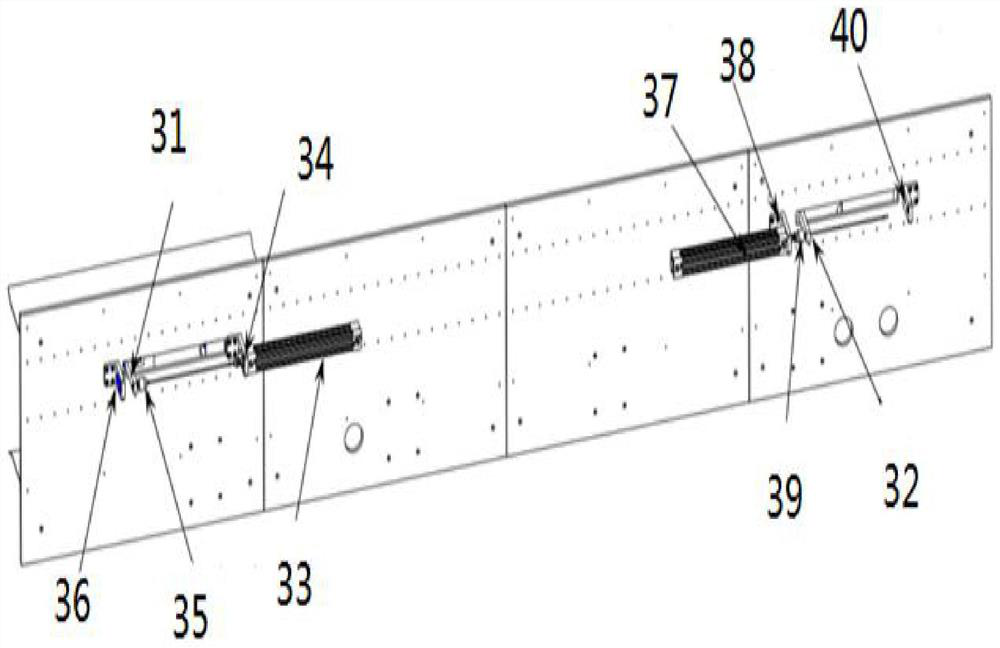

Machining method for metal guide wire

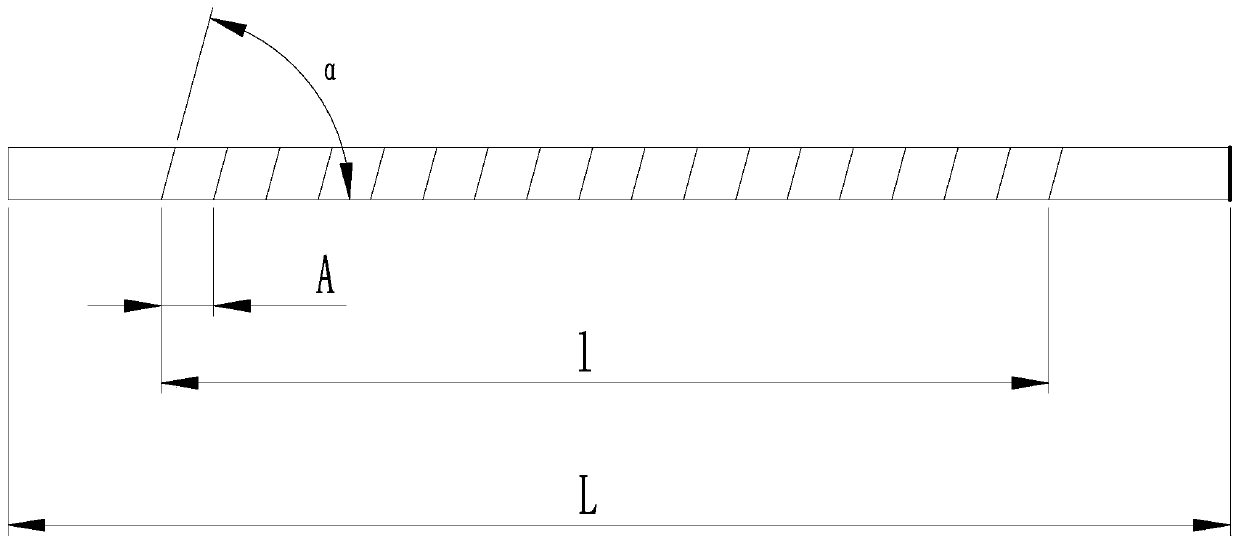

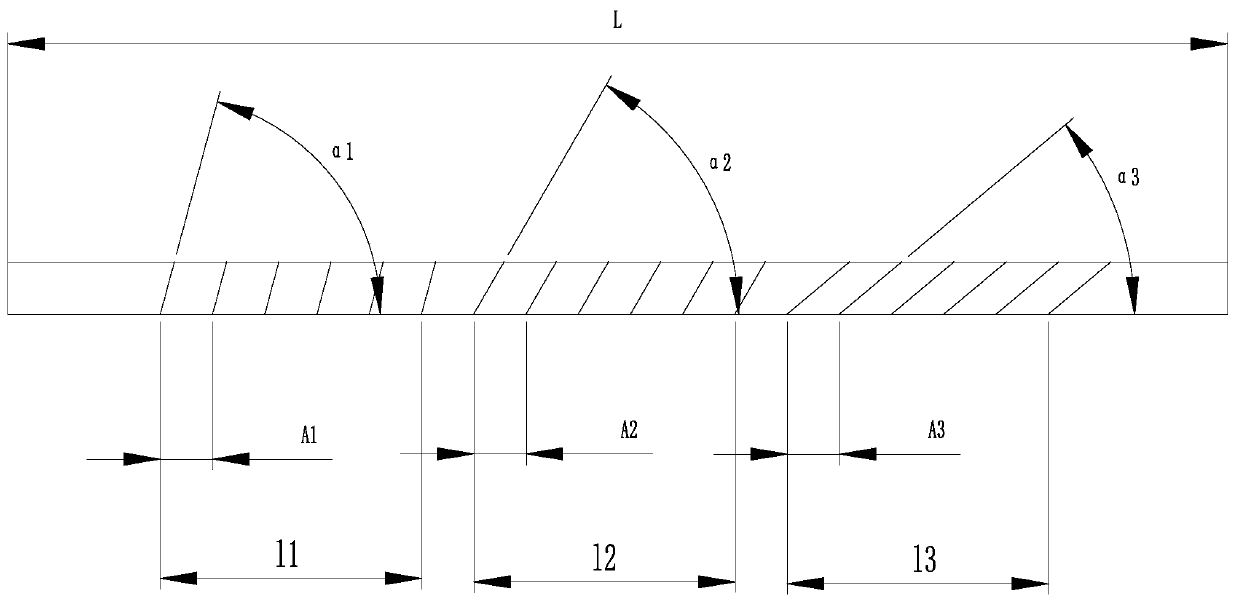

The invention discloses a machining method for a metal guide wire. The machining method for the metal guide wire comprises the following steps: a. the requirements of an effective length L and a diameter D of the metal guide wire are determined according to the use requirements of a metal wire, and the metal wire meeting the requirements of the length L and the diameter D is selected; b. the metalwire is corrected by virtue of automatic straightening equipment; c. the two ends of the metal wire are grinded into shapes meeting the use requirements; d. cutting is carried out around the metal wire through a laser cutting machine, a cutting depth is h, a cutting section length is l, an included angle between each cutting line and the axis of the metal wire is alpha, and a distance between theadjacent cutting lines is A; and e. the cut metal wire is cleaned. According to the machining method for the metal guide wire, the cutting is carried out around the surface of the metal wire by virtue of the laser cutting machine, the machining process is simple to operate, and one metal wire is adopted, so that material straightening is facilitated, difficult bending or breaking of the metal guide wire is avoided, and meanwhile, over-winding for the metal wire is avoided, the flexibility of the metal guide wire is ensured, and the metal guide wire is enabled to be stable and controllable inperformance.

Owner:YUNYI BEIJING MEDICAL INSTR CO LTD

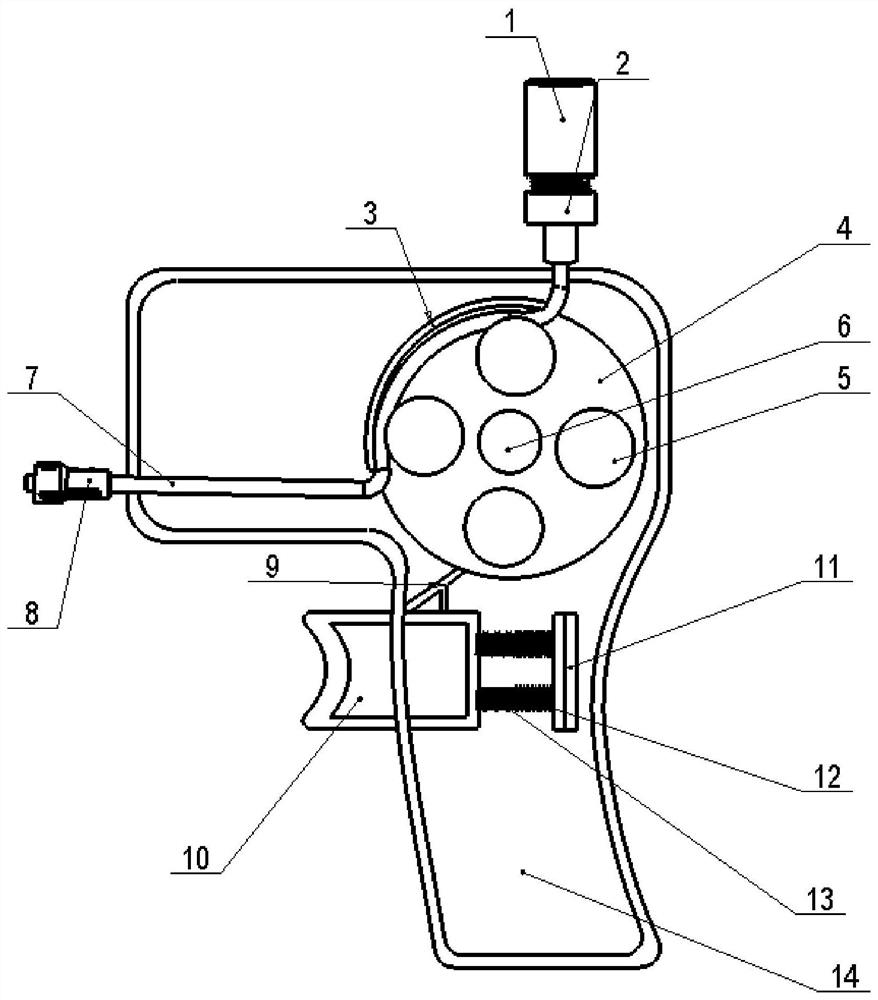

Handheld liquid quantitative distribution device

PendingCN114652383AQuantitative distribution is reliable and convenientReliable deliveryIntravenous devicesOcculdersPeristaltic pumpHand held

The invention relates to a handheld liquid quantitative distribution device which comprises a handheld peristaltic pump and a container for distributed liquid, the handheld peristaltic pump comprises a manual driving part, a pump head and a distribution pipe, one end of the distribution pipe is connected with the container, and the other end of the distribution pipe penetrates through the pump head; the pump head comprises a rotating part used for extruding the distribution pipe, and the manual driving part is in driving connection with the rotating part and used for driving the rotating part to rotate so as to quantitatively send out liquid in the container through the distribution pipe.

Owner:SUZHOU HENRUI DISHENG MEDICAL CO LTD

A flexible automatic assembly line for oil cylinders

ActiveCN112222818BHigh degree of automationStable cleanlinessSpraying apparatusAssembly machinesProduction lineControl engineering

The invention discloses a flexible automatic assembly production line for oil cylinders, which includes a transfer mechanism, a lifting mechanism, an oil injection mechanism, a push rod mechanism, a guide mechanism, an upper sleeve mechanism, a sleeve changing mechanism, a first servo jacking mechanism, a first limit position Mechanism, auxiliary booster mechanism, first moving mechanism, second limit mechanism, guide sleeve tightening mechanism, second servo jacking mechanism, anti-rotation mechanism, downward pressure mechanism, anti-rotation adjustment mechanism, second moving mechanism, the The transfer mechanism enters the cylinder body from the left end of the production line, passes through various structures in turn, and then outputs from the right end. The transfer mechanism transfers the cylinder body to the lifting mechanism. Transfer the cylinder to the next positioning tool. The invention has reasonable design, high production line automation degree, stable assembly process, standardized operation, reliable assembly quality, continuous automatic transfer and automatic assembly of workpieces, high production efficiency and low labor intensity.

Owner:SHANDONG ATAW IND ROBOT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com