Patents

Literature

40results about How to "Efficiently ground" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

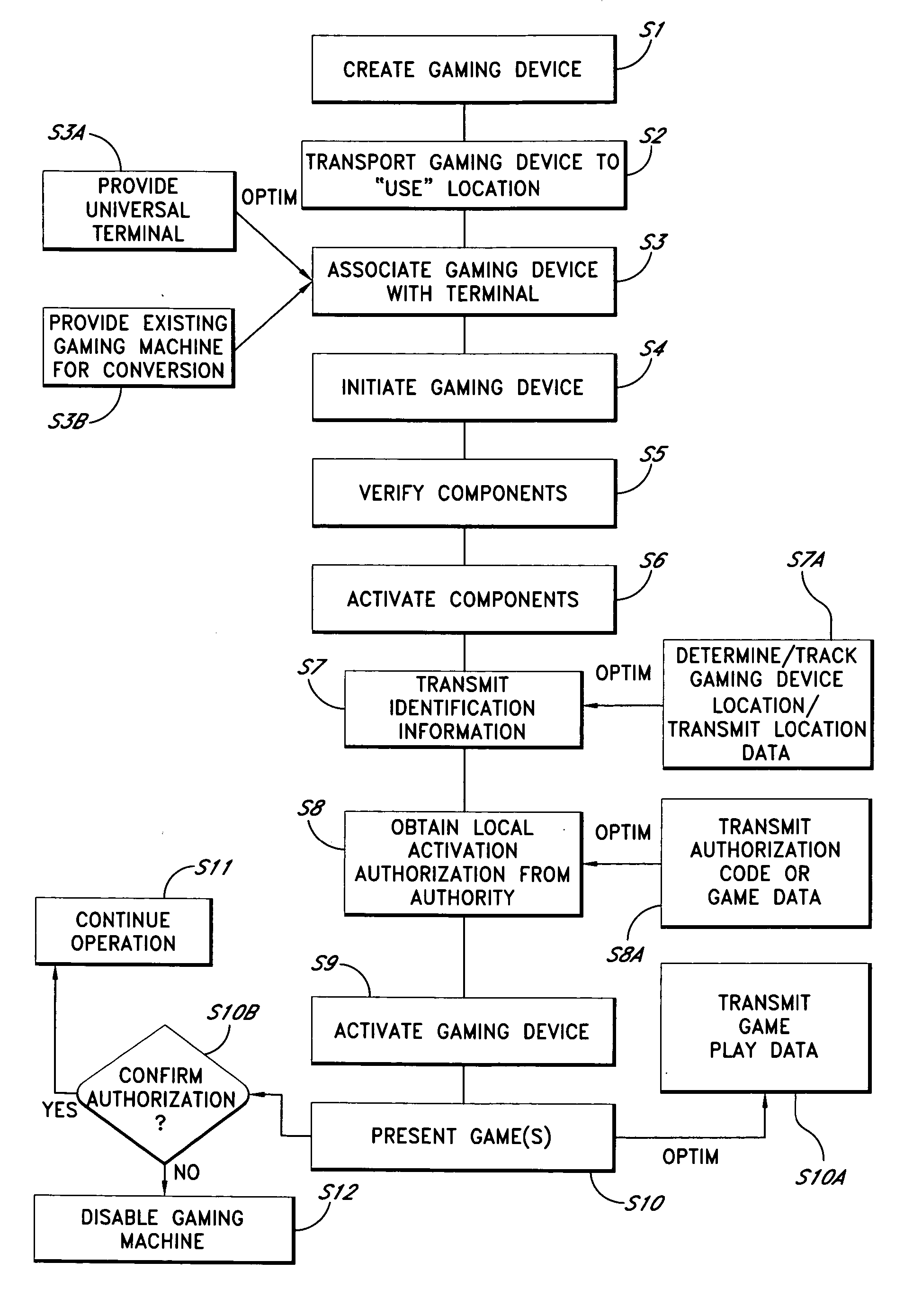

Method and system for localized authentication of gaming machine

InactiveUS20070099698A1Efficiently groundEnsure integrityApparatus for meter-controlled dispensingVideo gamesEngineeringBiological activation

A generic, self-contained gaming device is transportable to various jurisdictions for use. The gaming device when associated with a terminal or gaming machine is configured and authenticated for use in the installed location to present one or more wagering games. The gaming device verifies associated components of the terminal or machine, and contacts a local authority, such as gaming regulator or licensed entity. The local authority provides authorization to operate. The gaming device is then activated to operate in a mode complying with local rules and regulations. In one embodiment, the gaming machine may generate location information and transmit that information to the authority. Authorization to operate may comprise an activation code causing the gaming device to operate in a particular mode, or executable code causing the gaming device to operate as required by governing rules and regulations where the gaming device is located.

Owner:COLE KEPRO INT

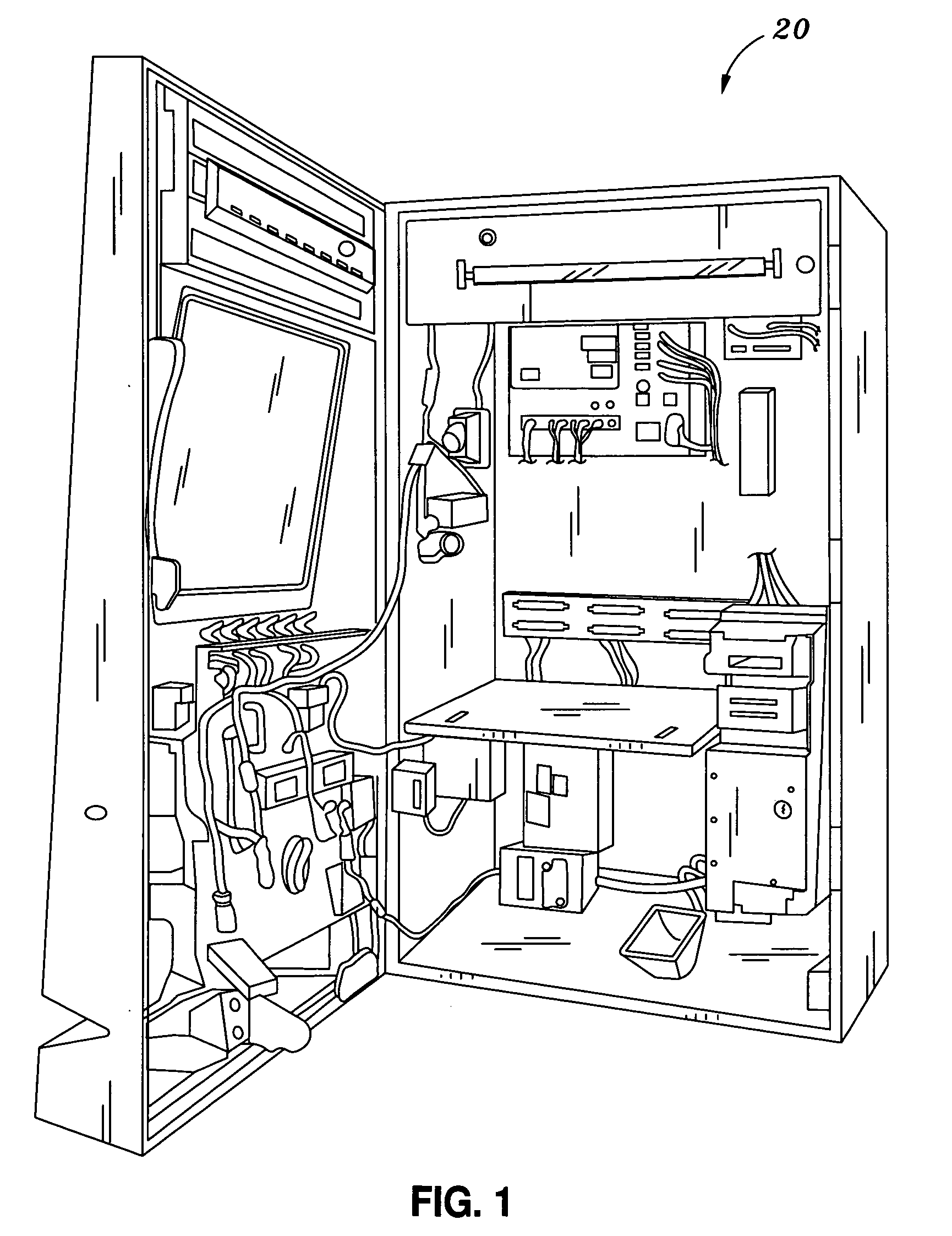

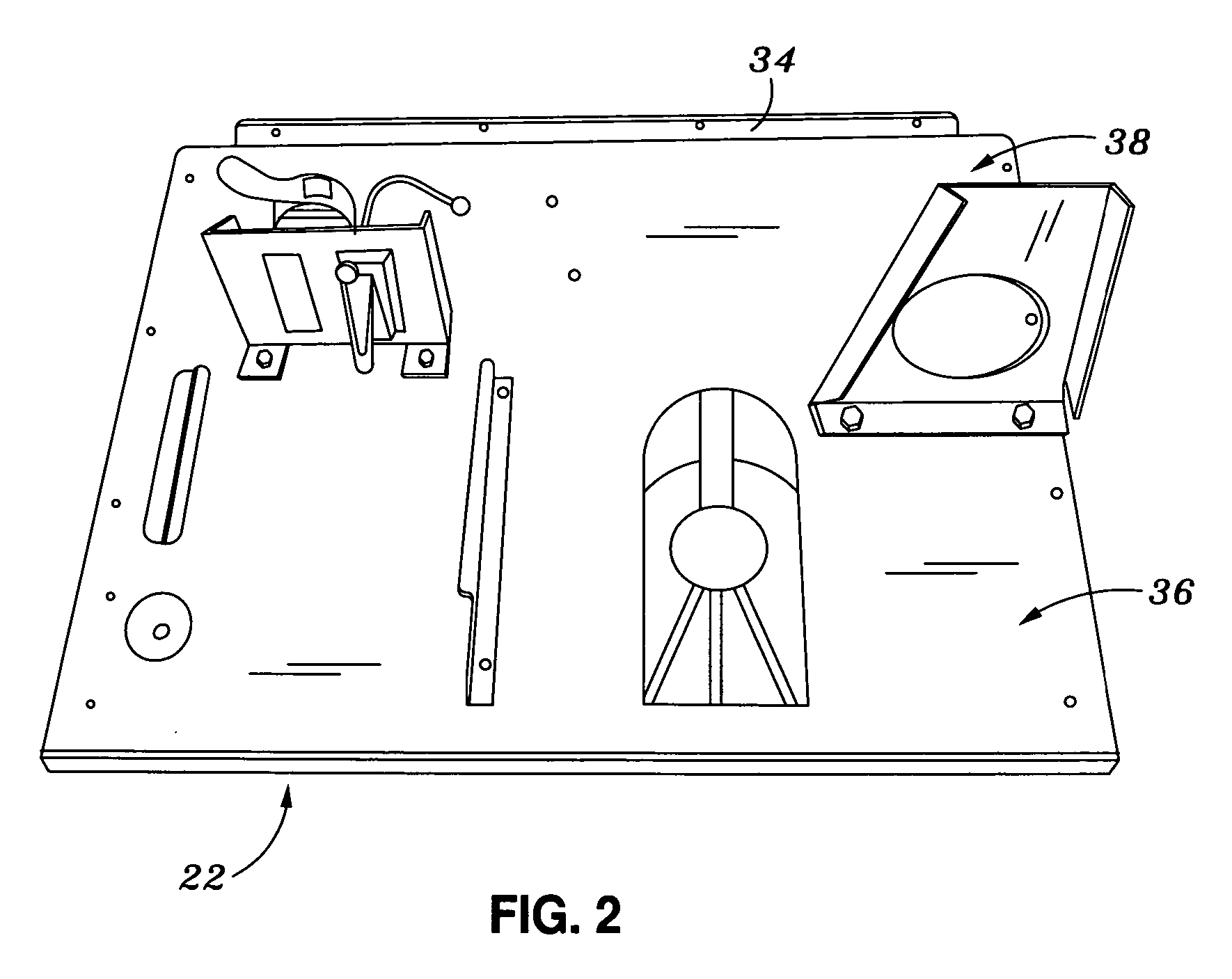

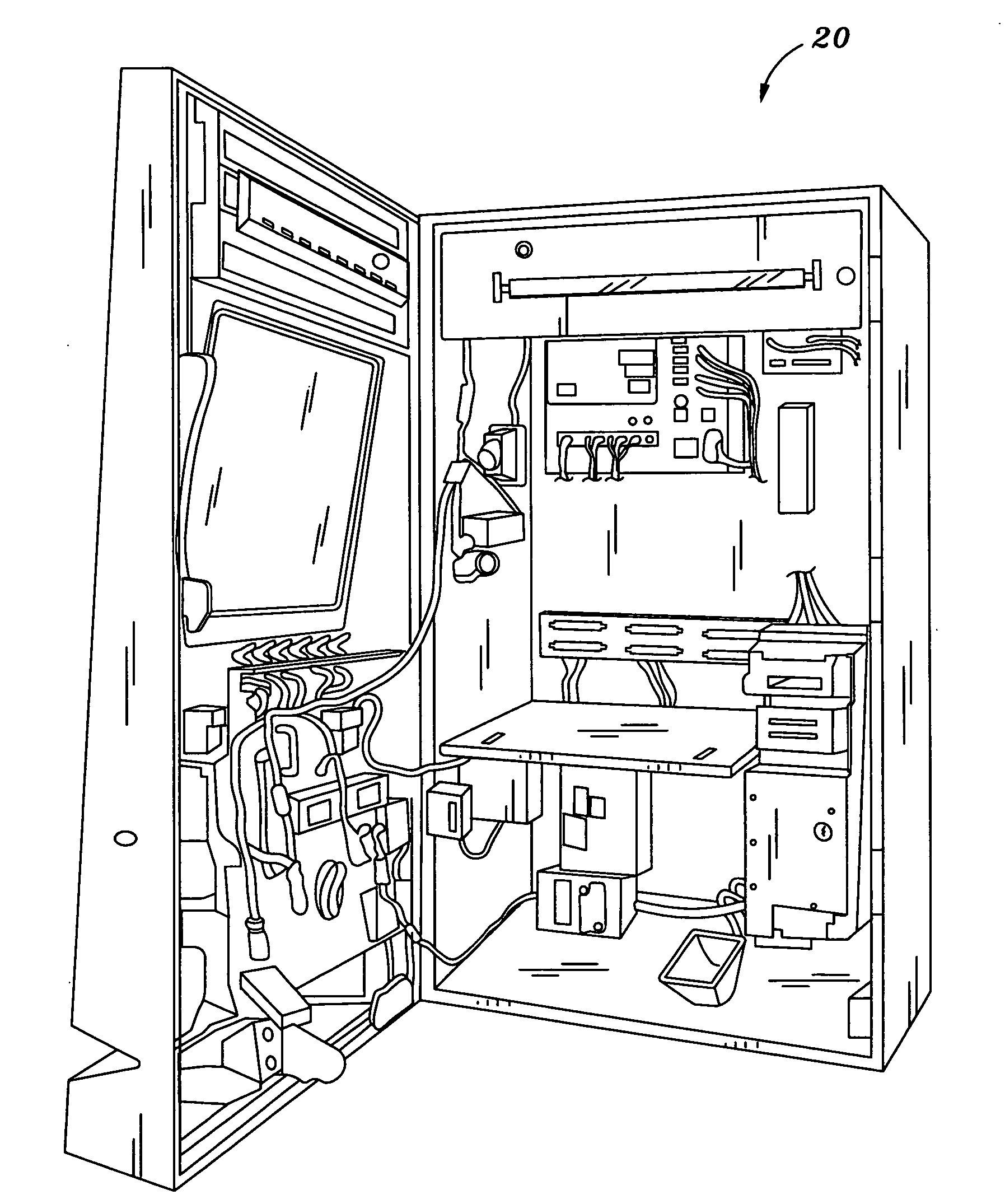

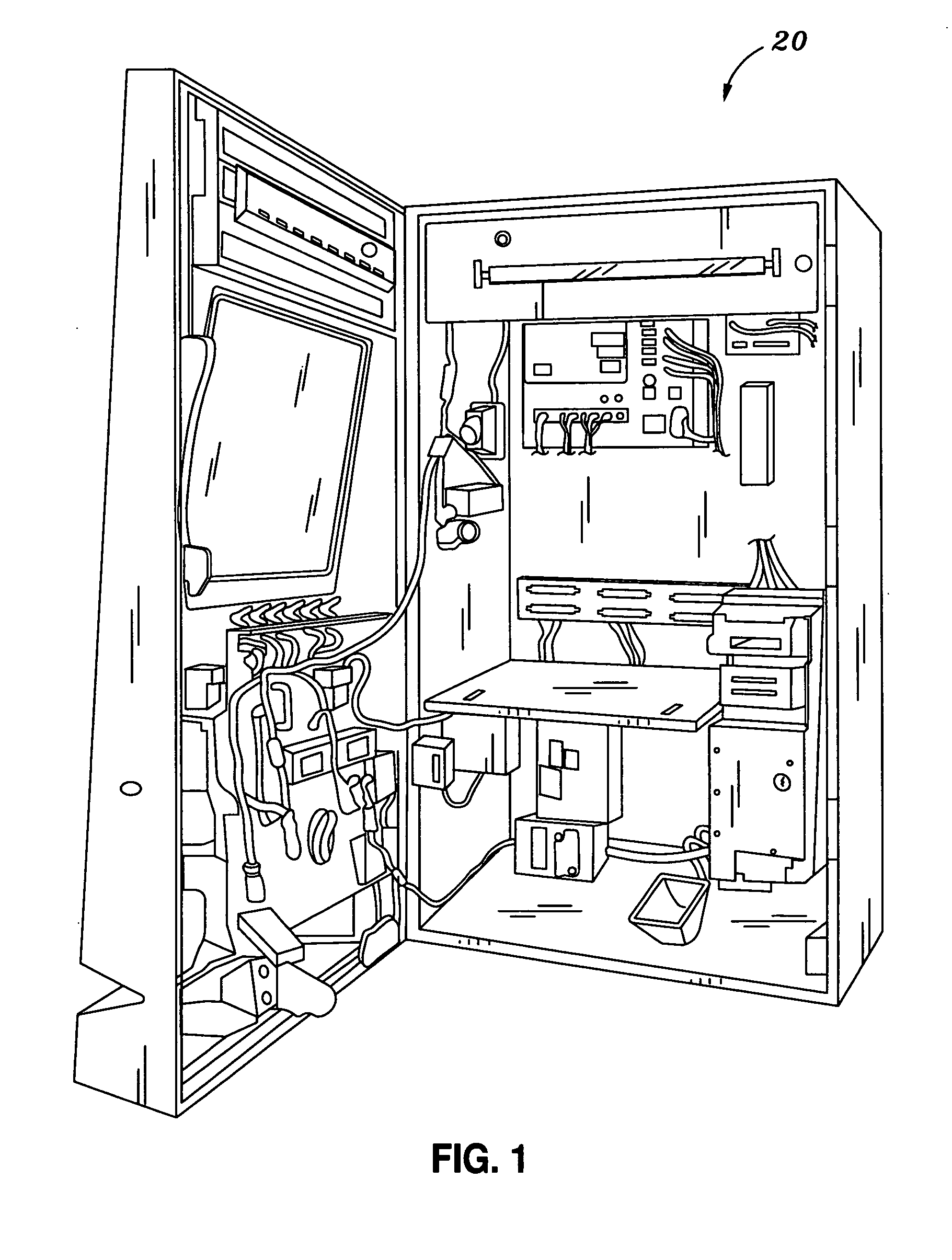

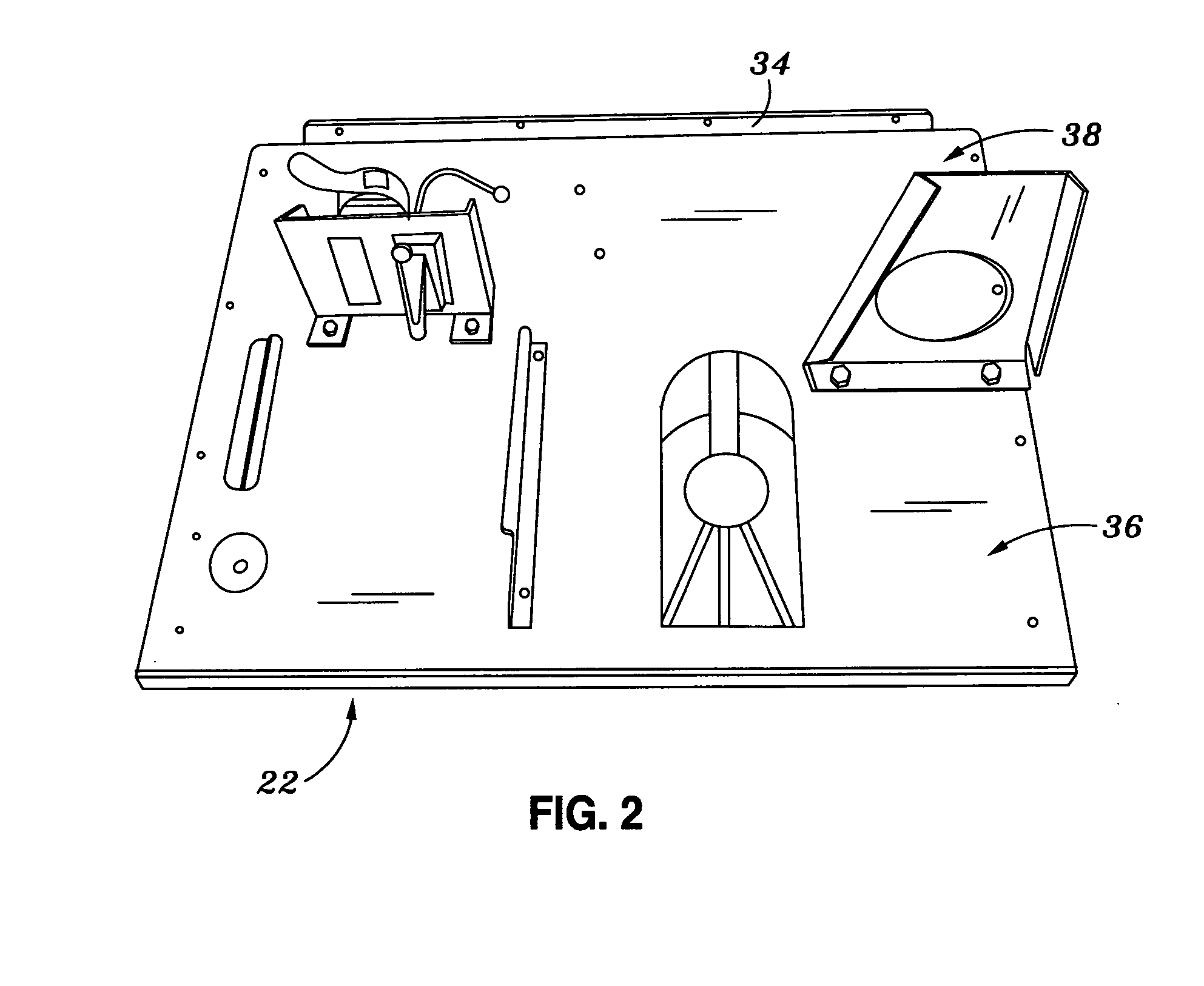

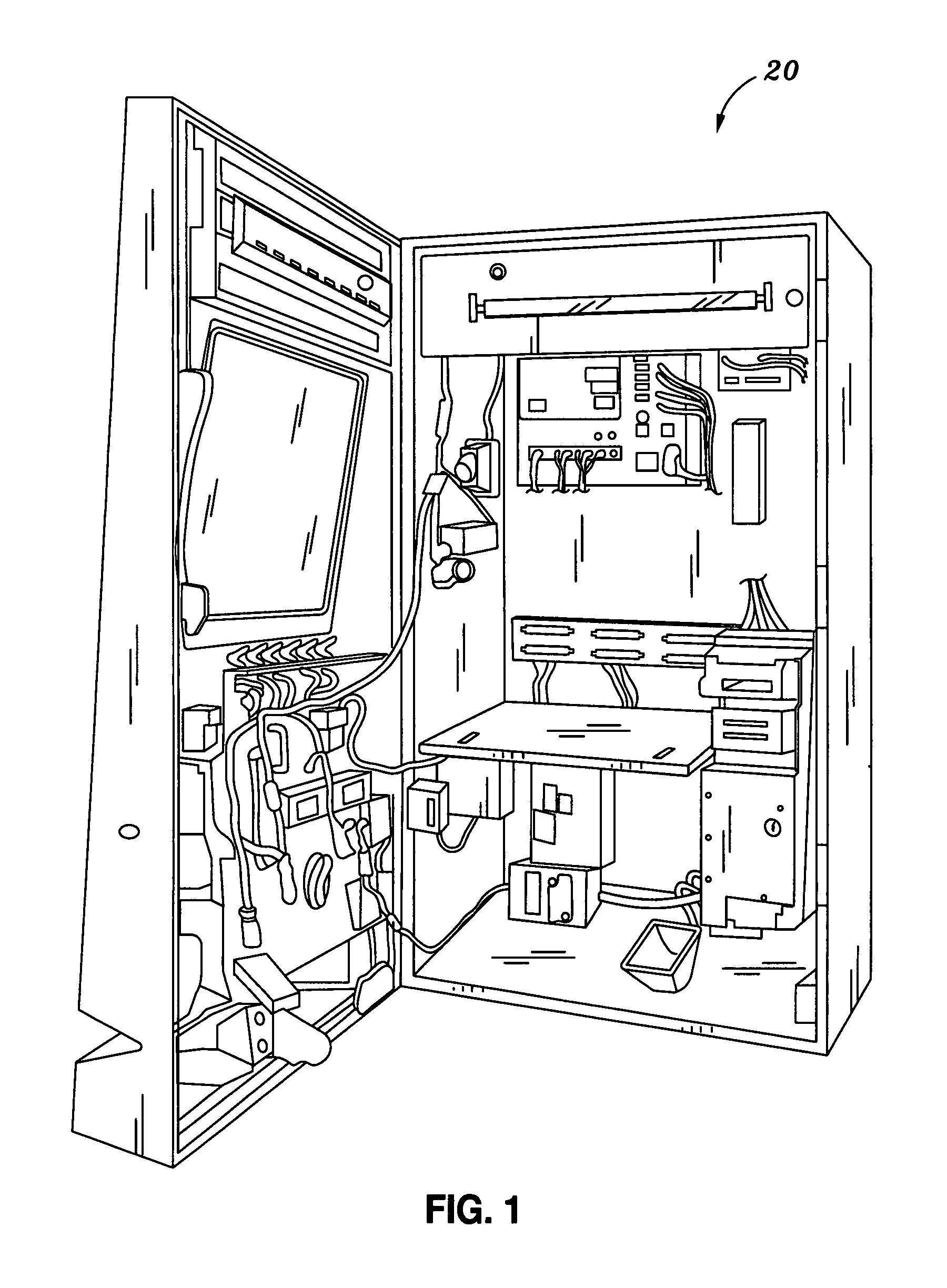

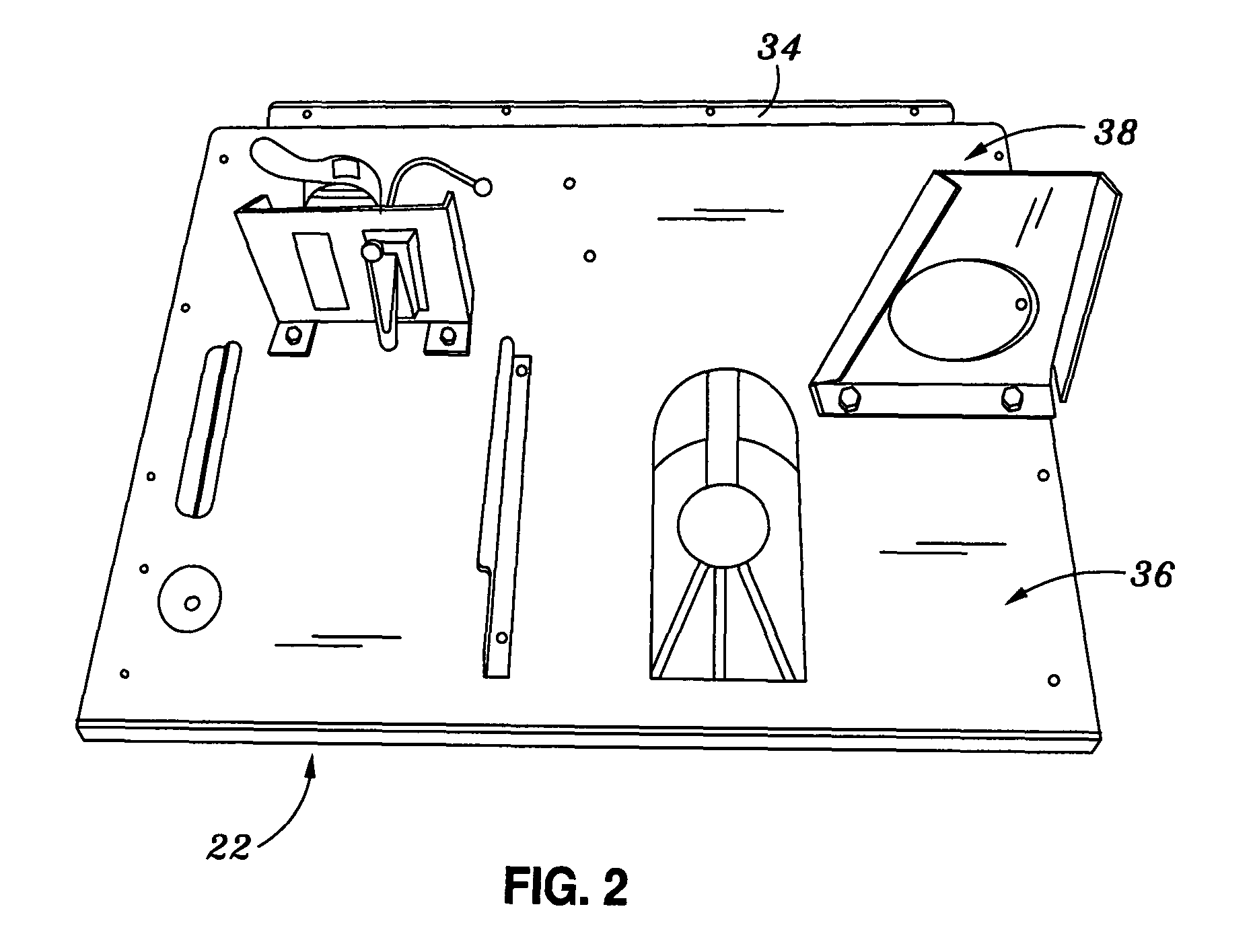

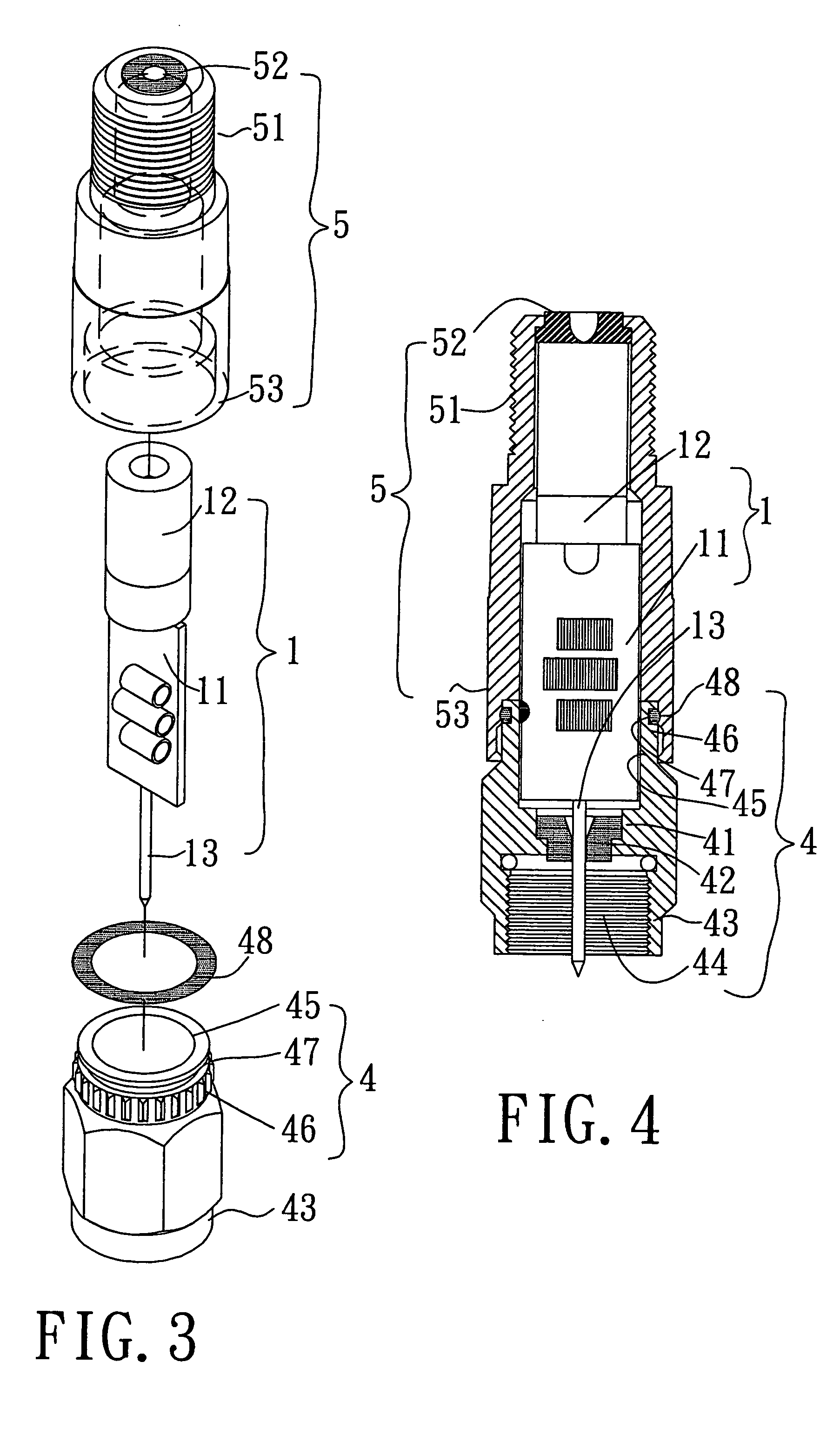

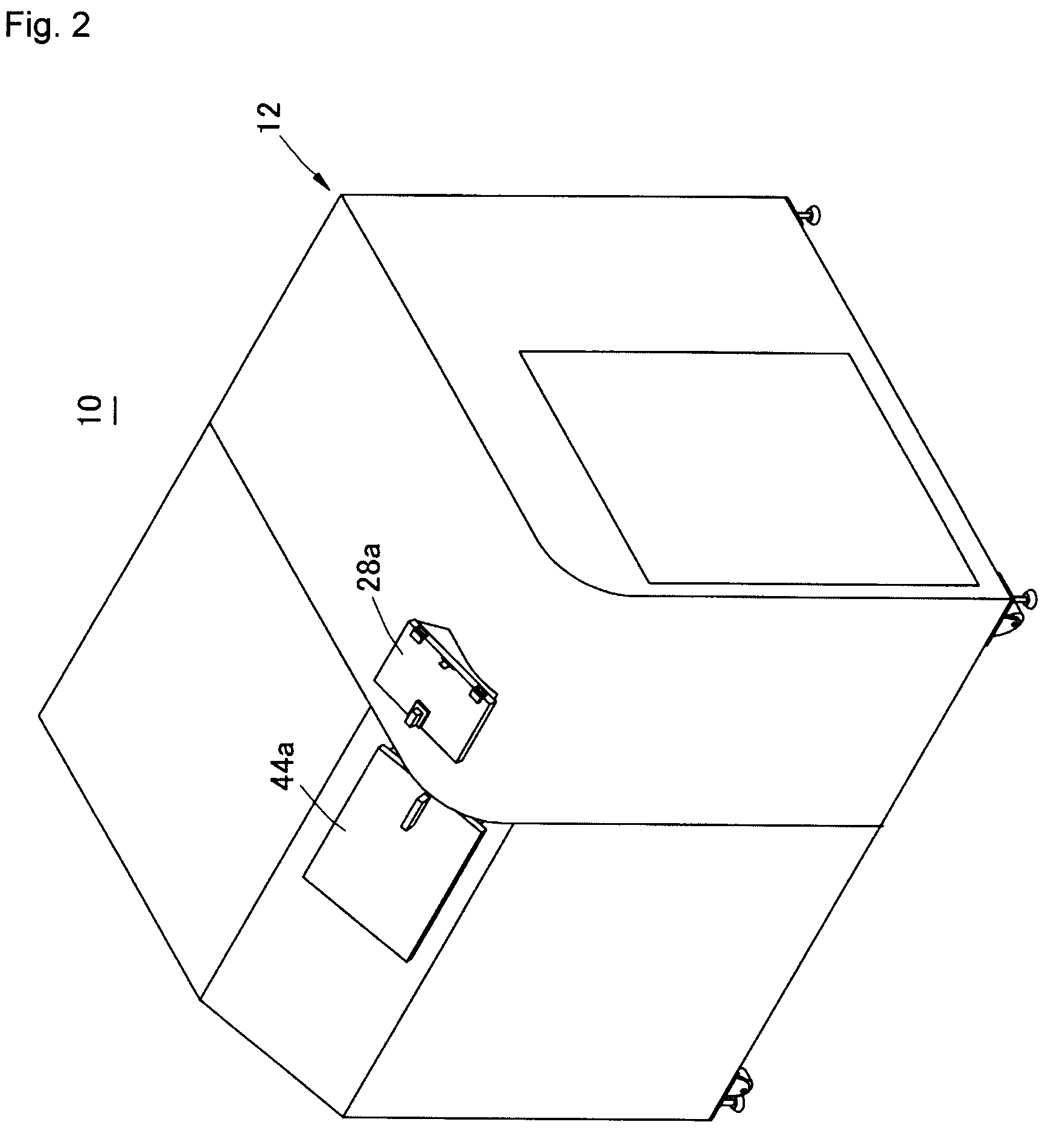

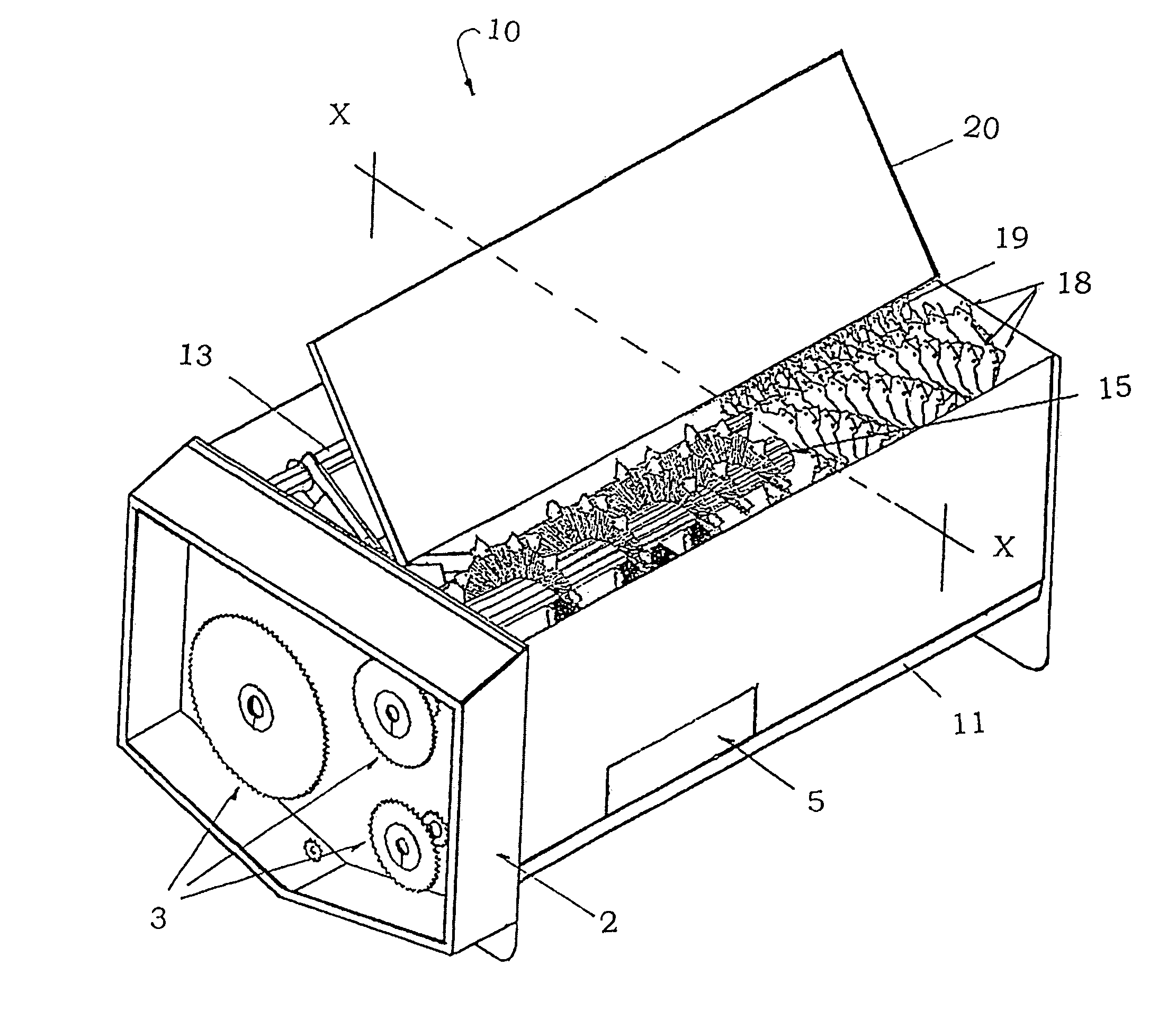

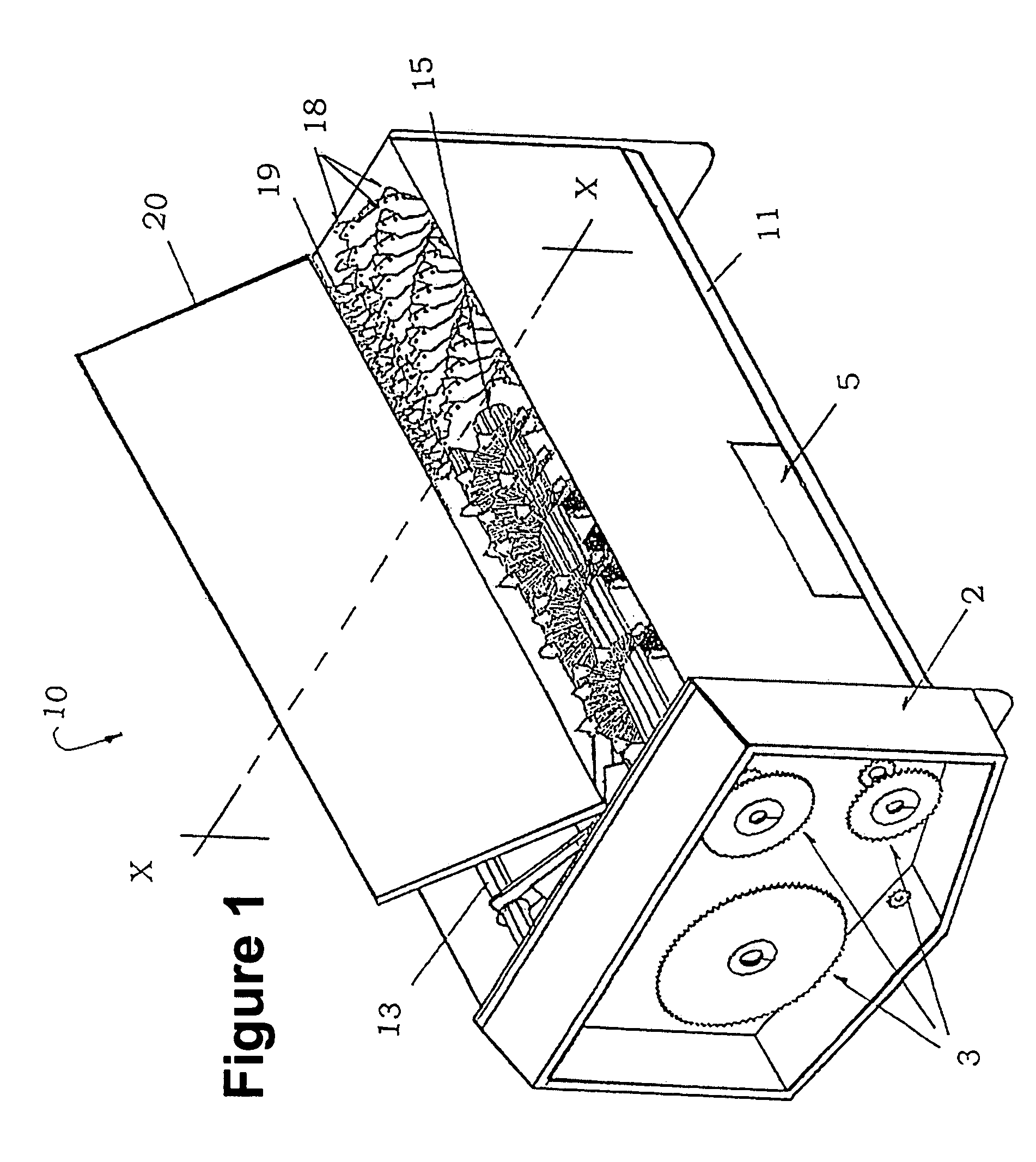

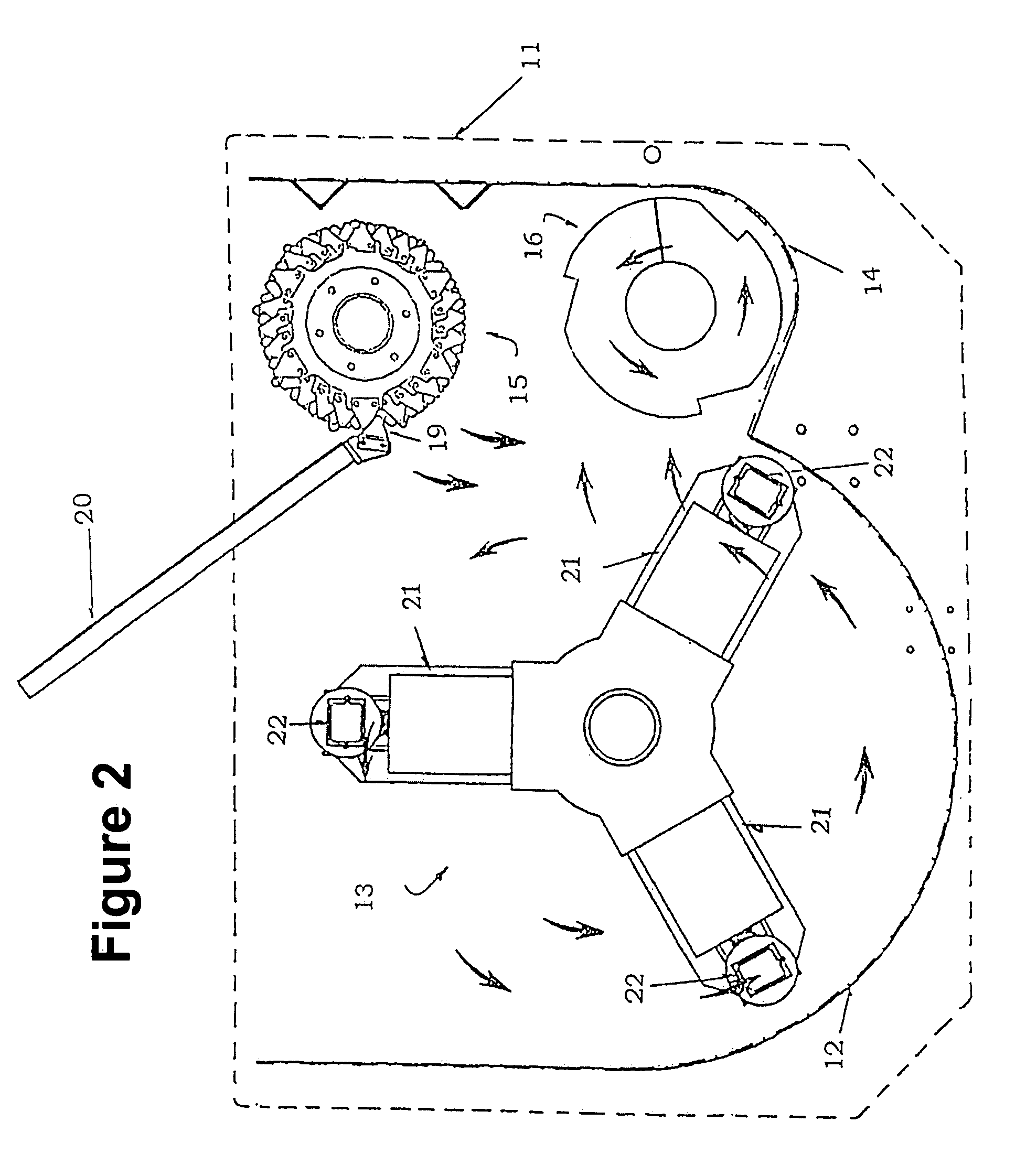

Gaming machine comprising universal presentation platform configured to accept different gaming devices

InactiveUS20080182642A1Efficiently groundEnsure integrityApparatus for meter-controlled dispensingVideo gamesEngineeringElectric equipment

A gaming machine comprises a universal presentation platform configured to accept a variety of gaming devices. The presentation platform comprises a cabinet, a universal gamine device interface and standardized components. In one embodiment, the cabinet is modular and is assembled from base, side, top, back and door components or sections. The gaming device comprises a housing containing a gaming controller and associated electronics. The gaming device is stand-alone, and is capable of use in different gaming machines and is independently verifiable. Other aspects of the invention comprise a grounding configuration for a gaming cabinet and gaming device and gaming machine air flow paths for cooling the machine components, including the gaming device.

Owner:COLE KEPRO INT

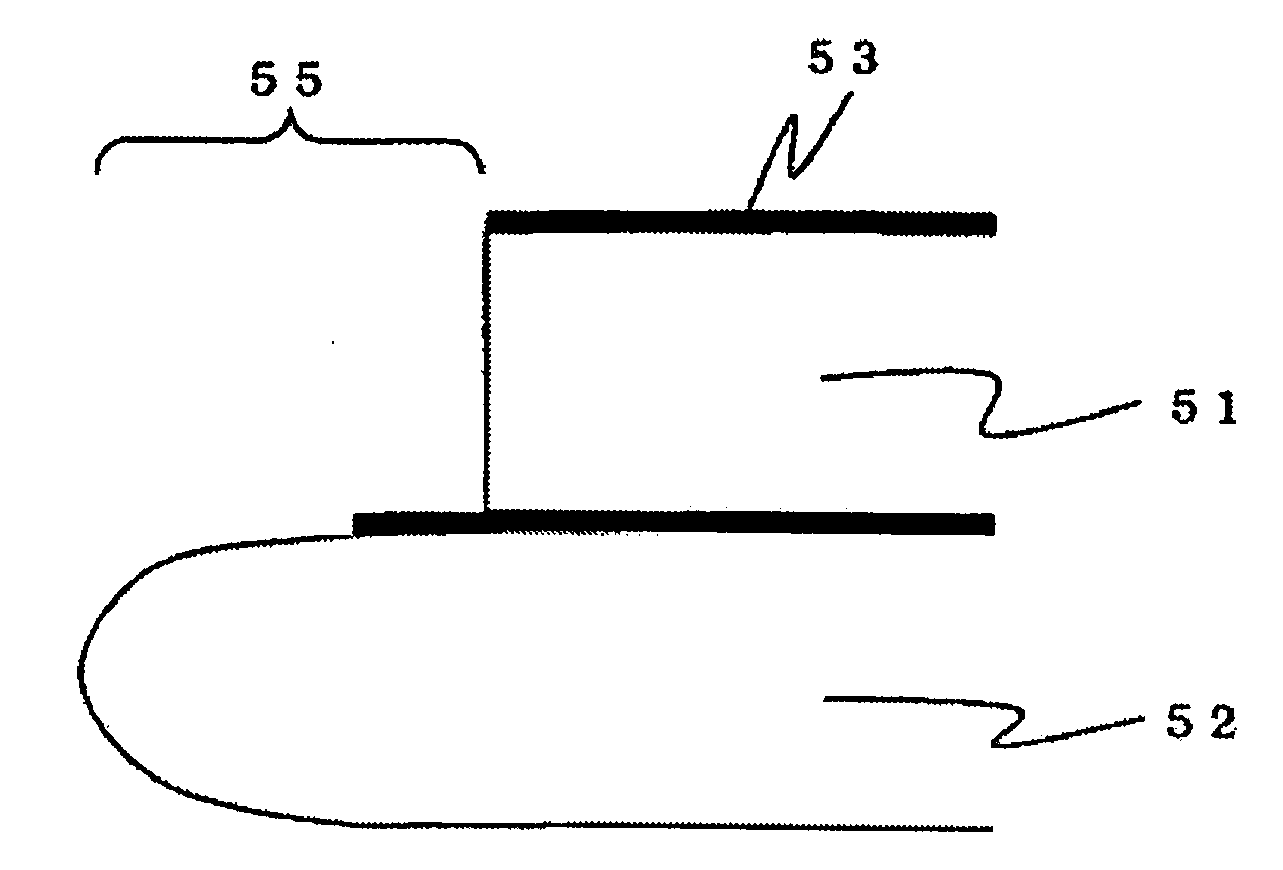

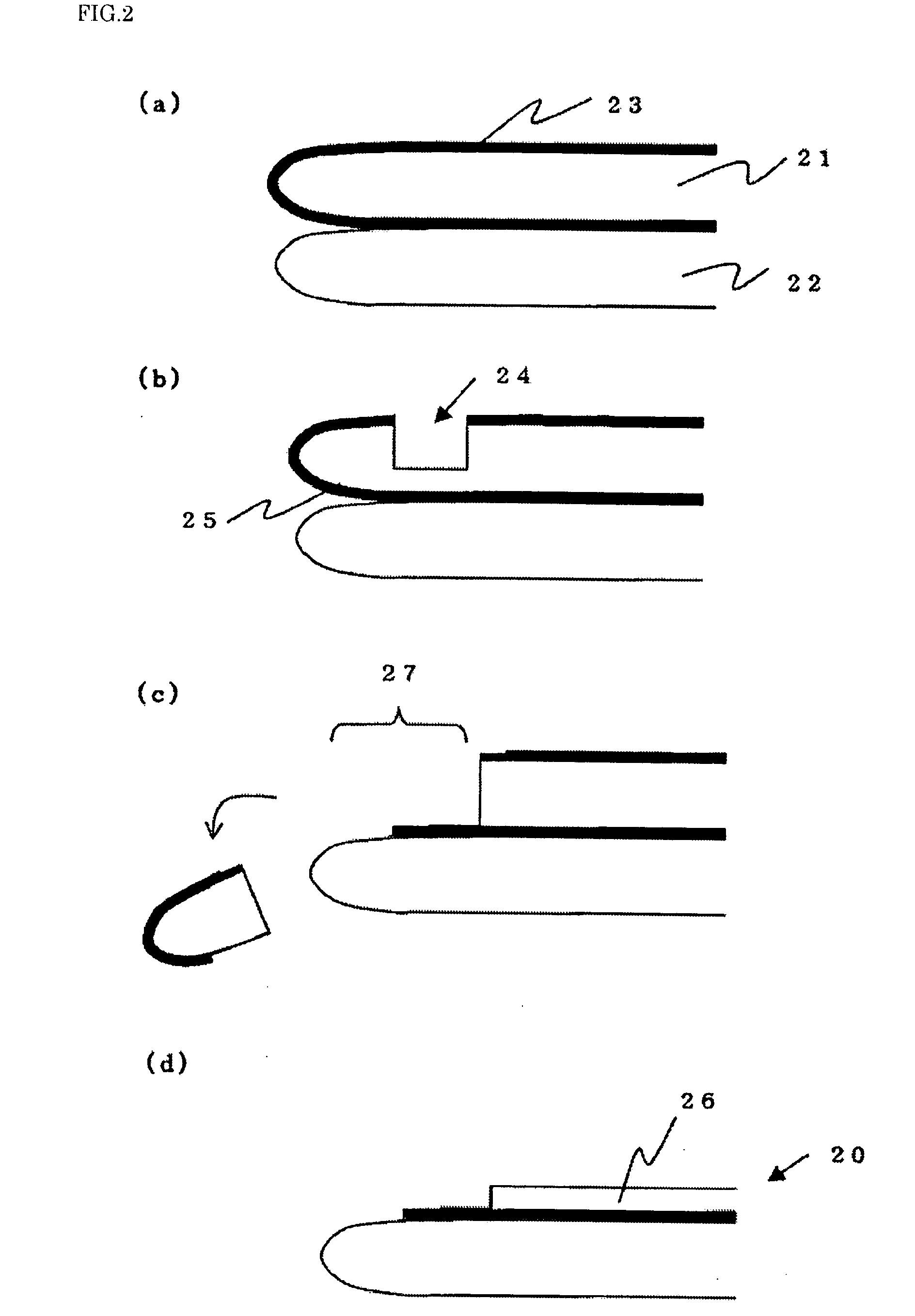

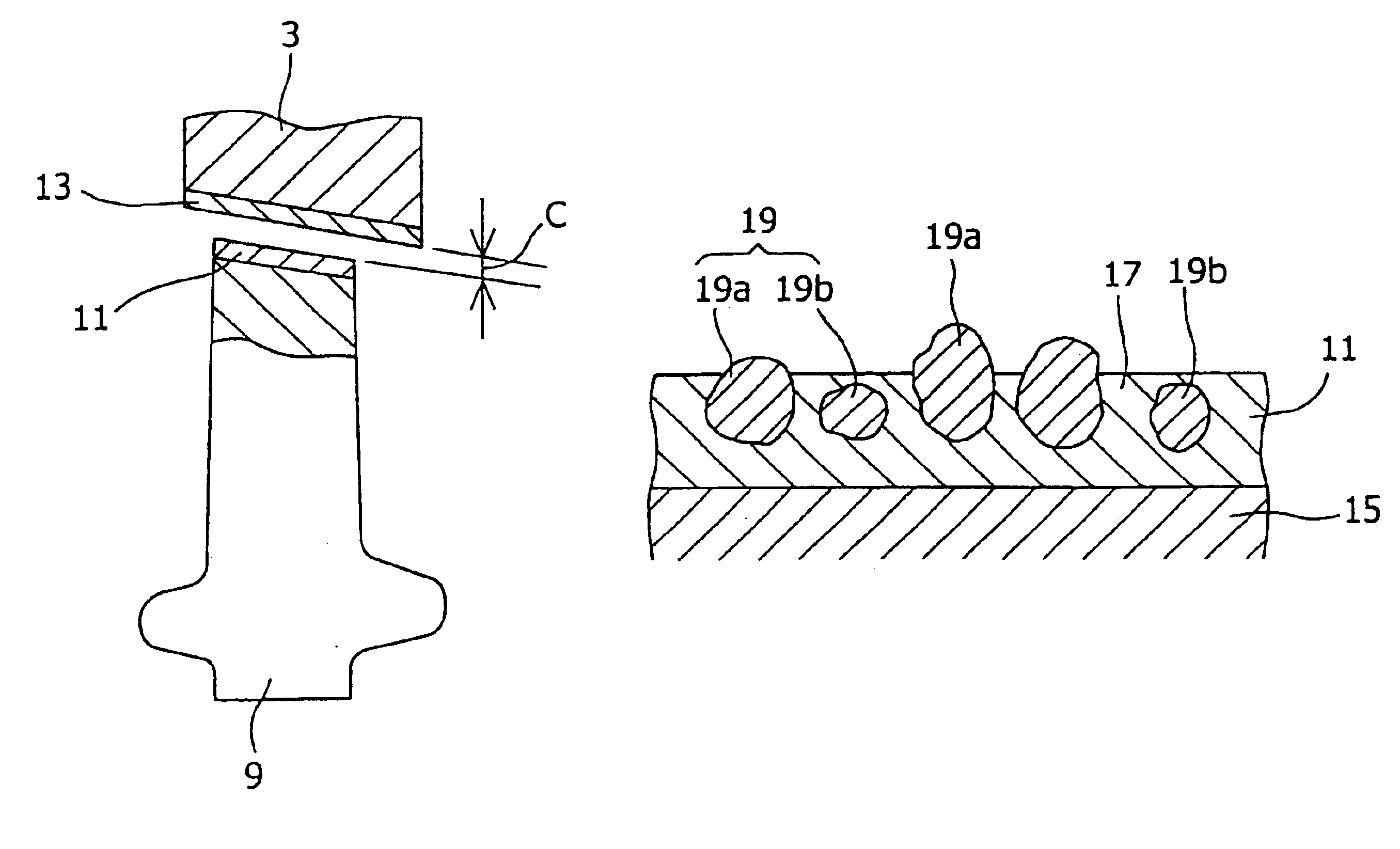

Method for manufacturing bonded wafer and outer-peripheral grinding machine of bonded wafer

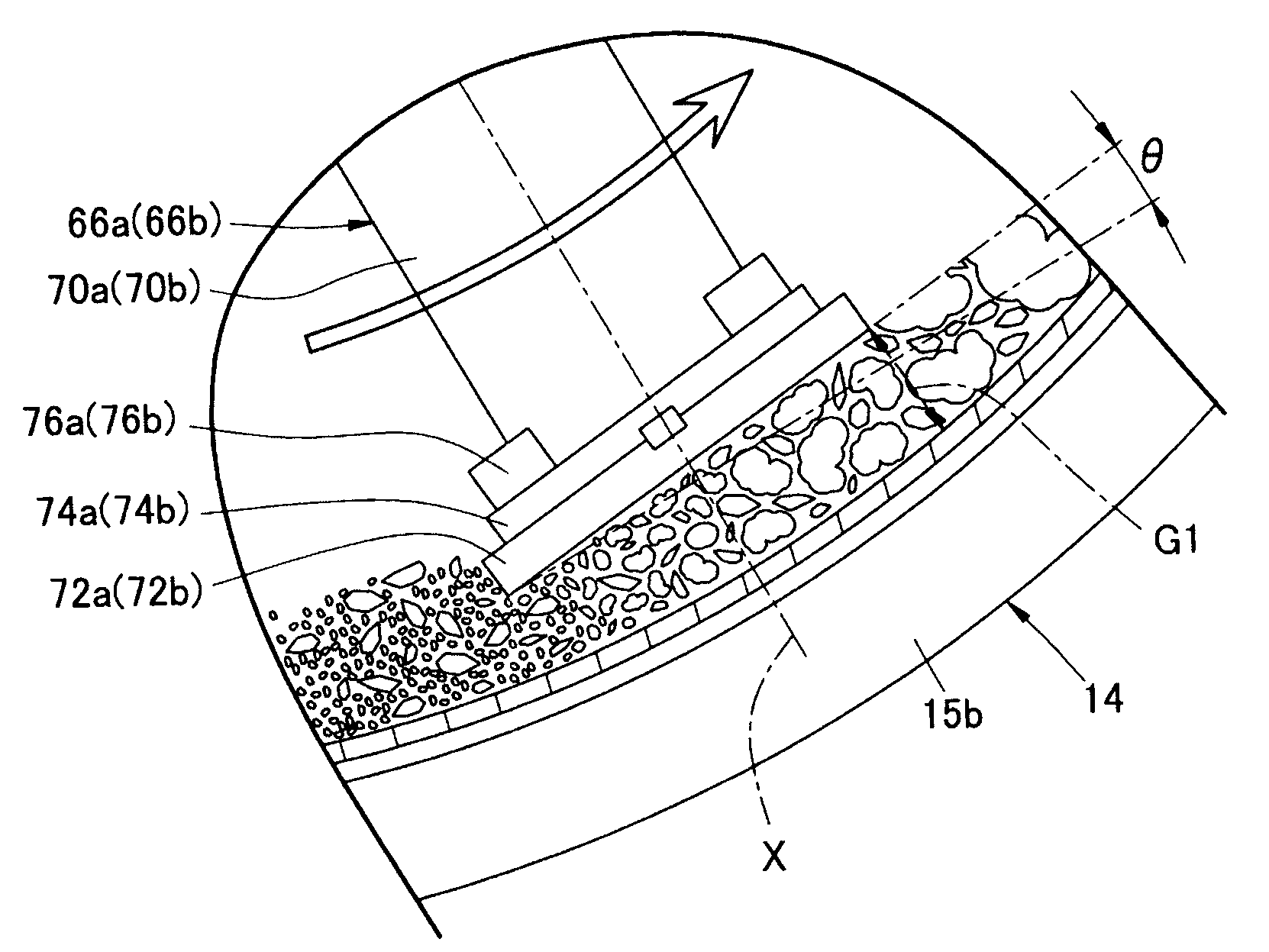

ActiveUS20090042363A1Efficiently groundEnsures enough strengthPolishing machinesRevolution surface grinding machinesEtchingEngineering

The present invention provides a method for manufacturing a bonded wafer, which includes at least the steps of bonding a bond wafer and a base wafer, grinding an outer peripheral portion of the bonded bond wafer, etching off an unbonded portion of the ground bond wafer, and then reducing a thickness of the bond wafer, wherein, in the step of grinding the outer peripheral portion, the bonded bond wafer is ground so as to form a groove along the outer peripheral portion of the bond wafer to form an outer edge portion outside the groove; and in the subsequent step of etching, the outer edge portion is removed together with the groove portion of the bond wafer to form a terrace portion where the base wafer is exposed at the outer peripheral portion of the bonded wafer. Thus, it is possible to provide a method for manufacturing a bonded wafer, which can reduce the number of dimples formed in a terrace portion of a base wafer upon removing an outer peripheral portion of a bonded bond wafer.

Owner:SHIN-ETSU HANDOTAI CO LTD

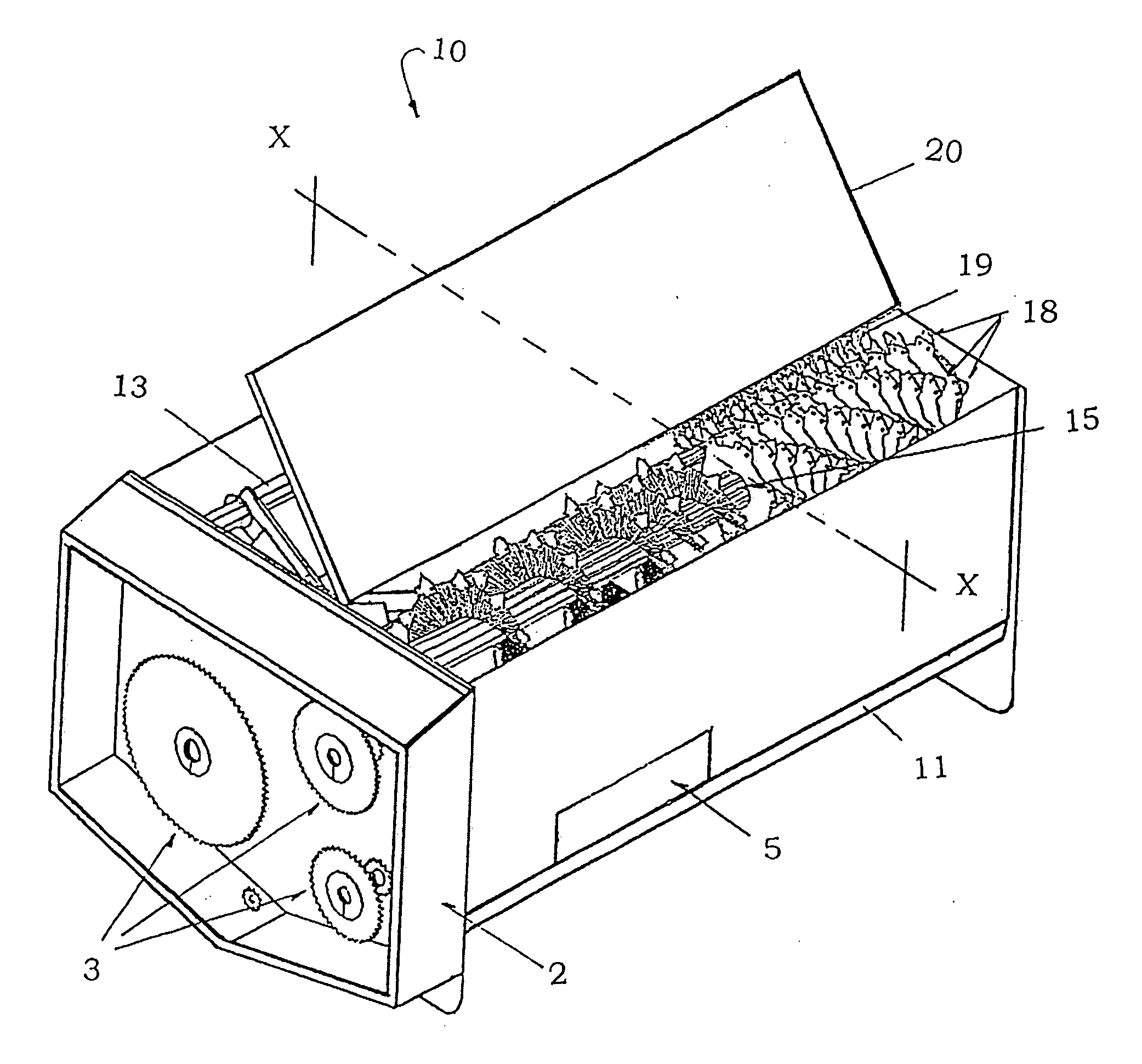

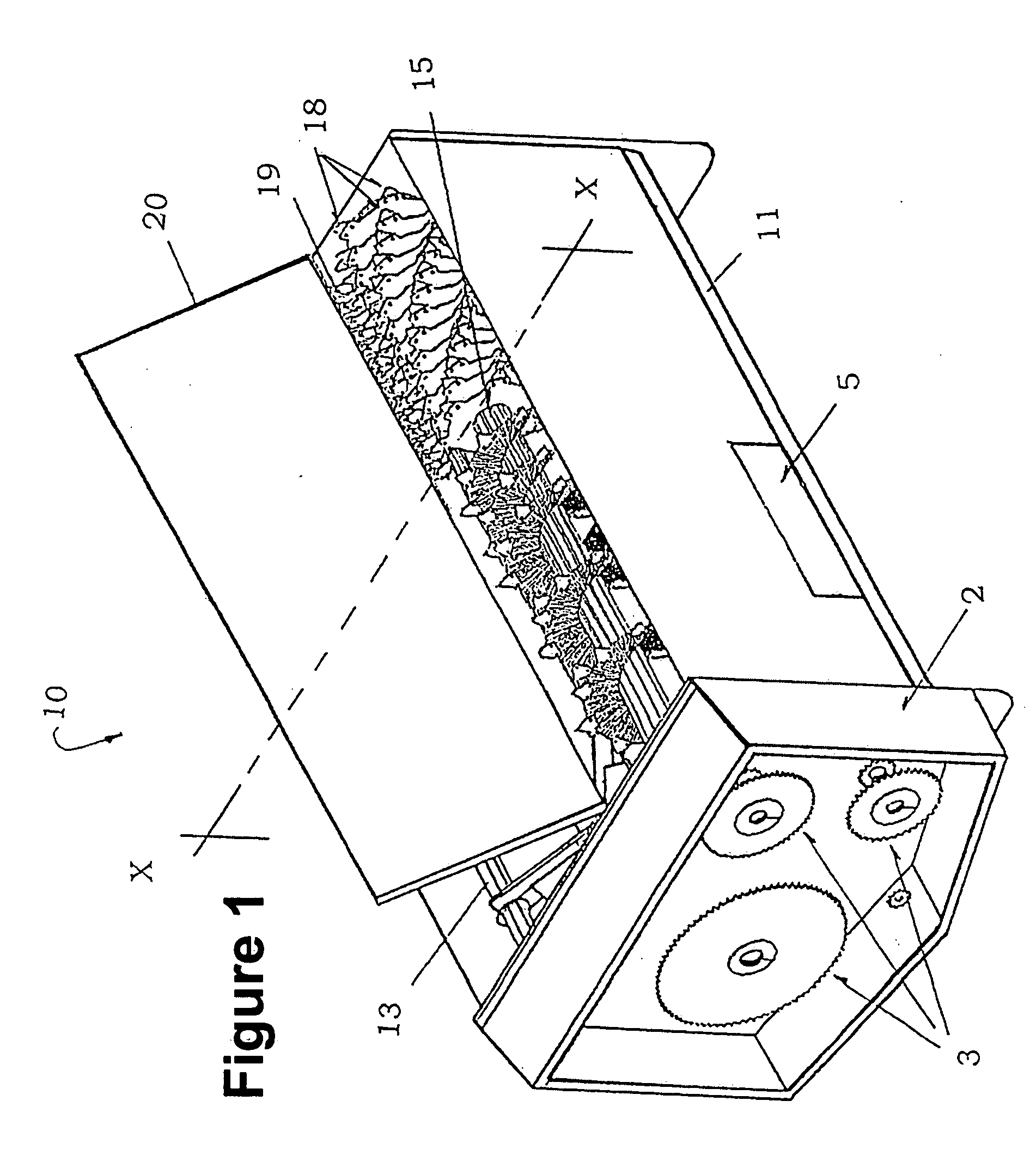

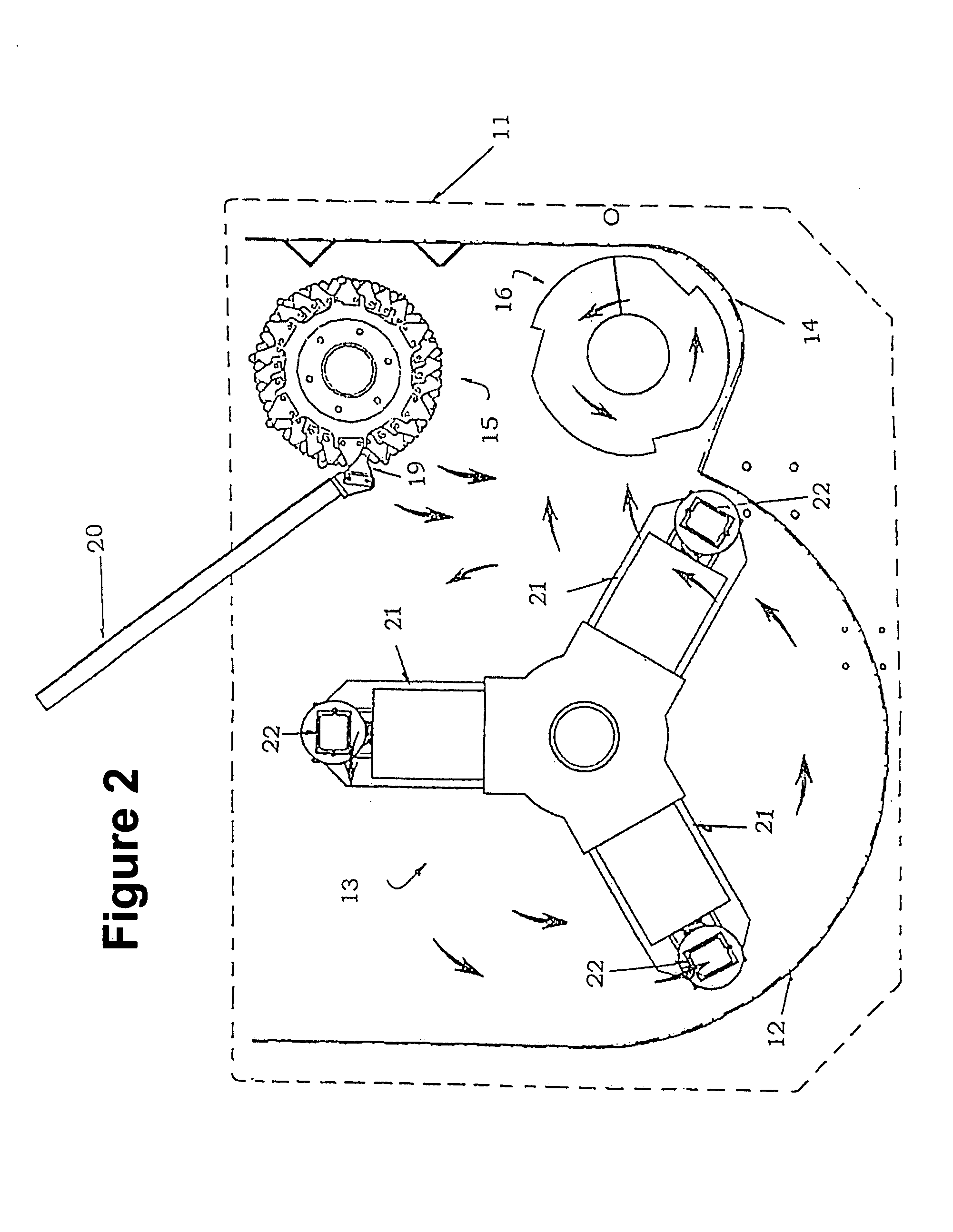

Livestock food processing mixing machine

InactiveUS20050087636A1Quick and efficient mannerCost savingGrain huskingGrain polishingLivestockEngineering

The present invention is related to a mixing machine which basically consists of a hopper, that has a main chamber within its housing, with a rotary member (rotor), where at said rotor ends there are cleaning elements for sweeping the floor and taking up the material, by feeding a secondary chamber, which is located in parallel adjacent to the main chamber, where said secondary chamber has a bottom worm conveying the material from one end of the mixing machine to the other end thereof, until collapsing with a loop found on its front portion and generating a material bubble; an upper worm to remove the material bubble and carrying it up to the middle part of the machine. At the middle part of the machine, the material is forced by a loop system having an upper worm to move towards the rotor area, such that the material is actually moving towards the back portion of the machine, completing a mixing cycle. Said upper worm has from the middle of its axis, a plurality of discs on which peripheral edge of each disc is mounted a series of exchangeable knives placed on a loop arrangement, which are passed through a counterplate, and which shows a series of exchangeable knives placed at the bottom part of the material collector chut, so when the upper worm discs plurality is rotating, it allows both, humid and dry fibers be efficiently crushed and / or ground and besides added to the other several common ingredients a unique and highly qualified mixing is achieved.

Owner:TORMEX IND DE C V

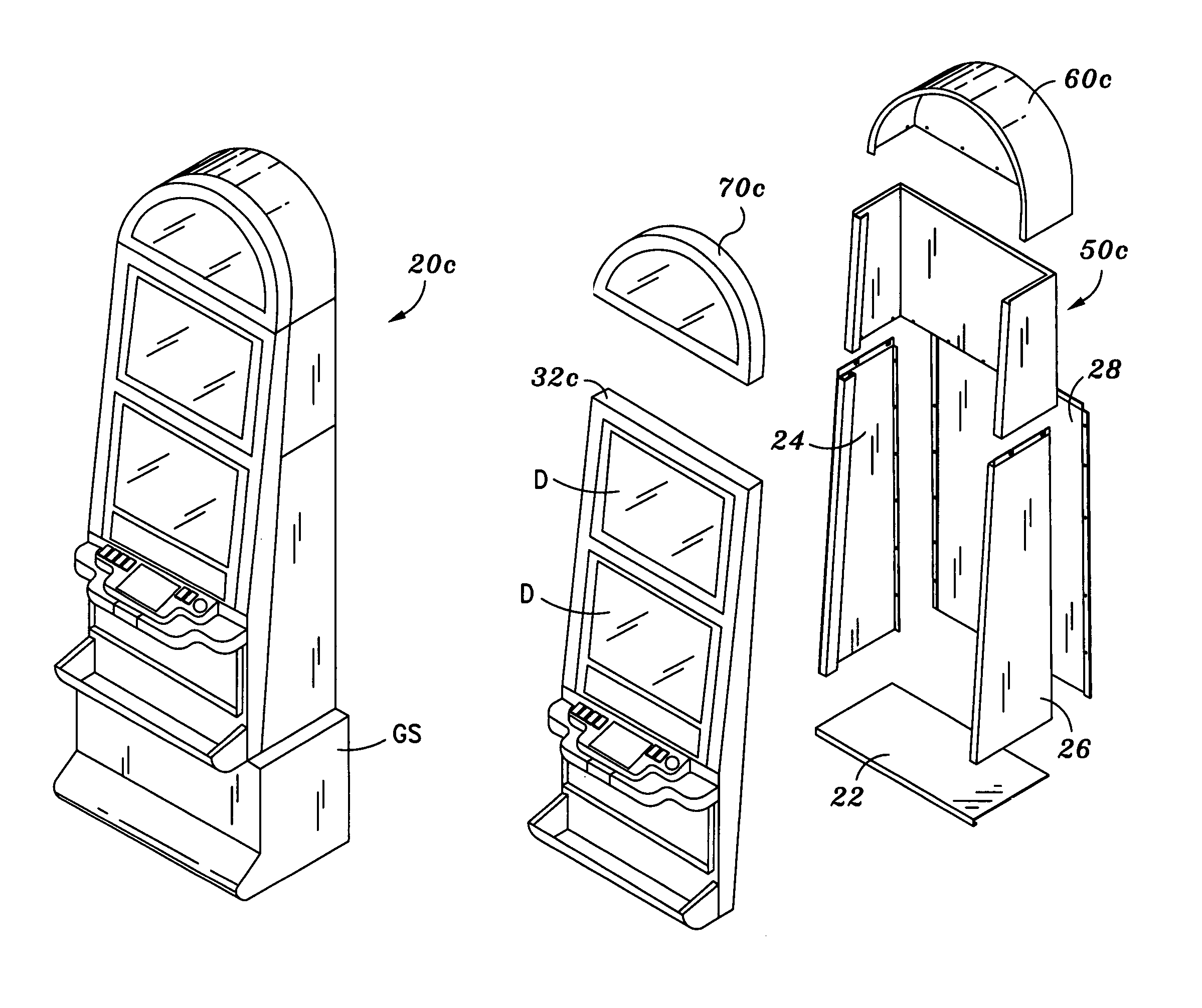

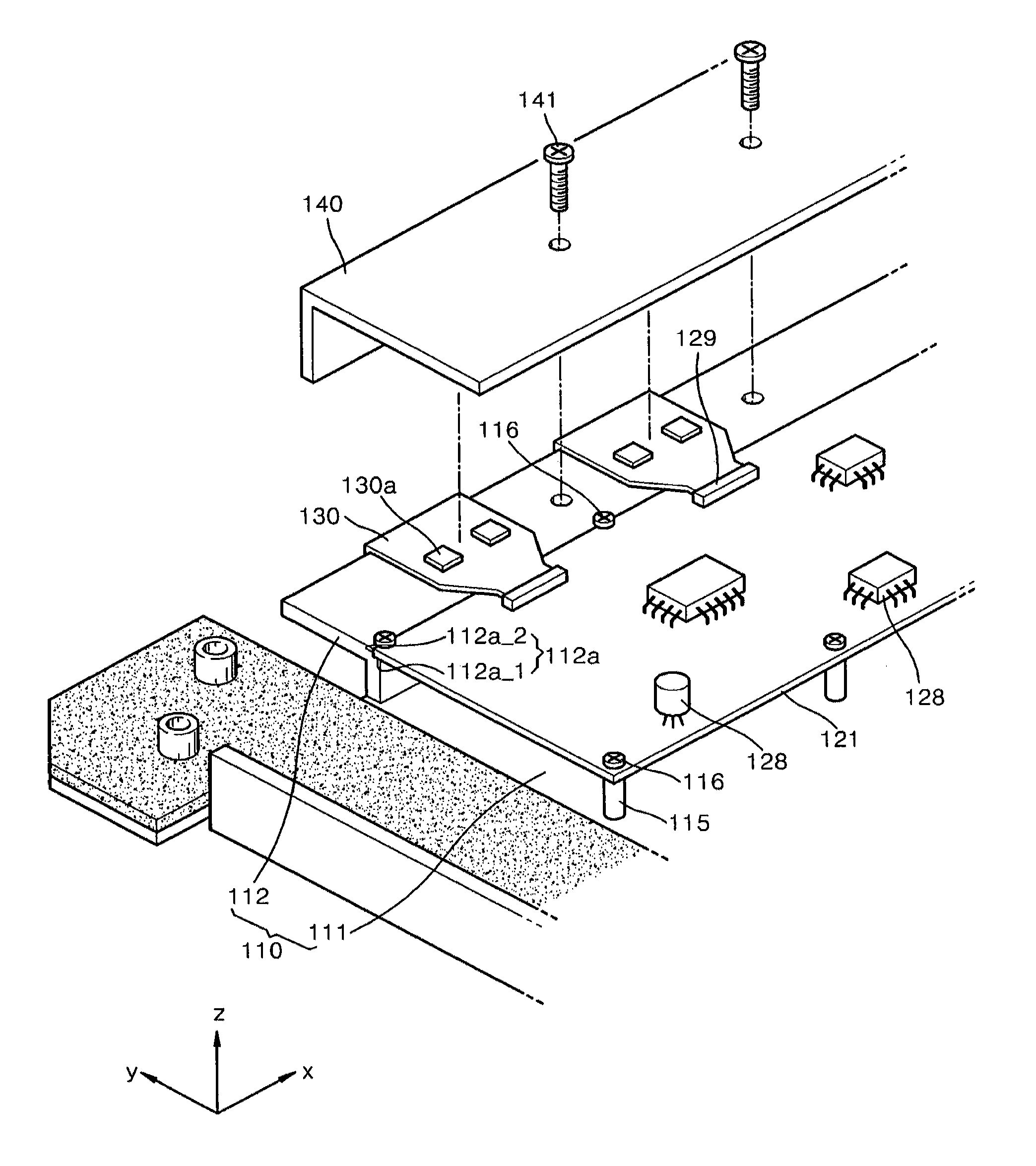

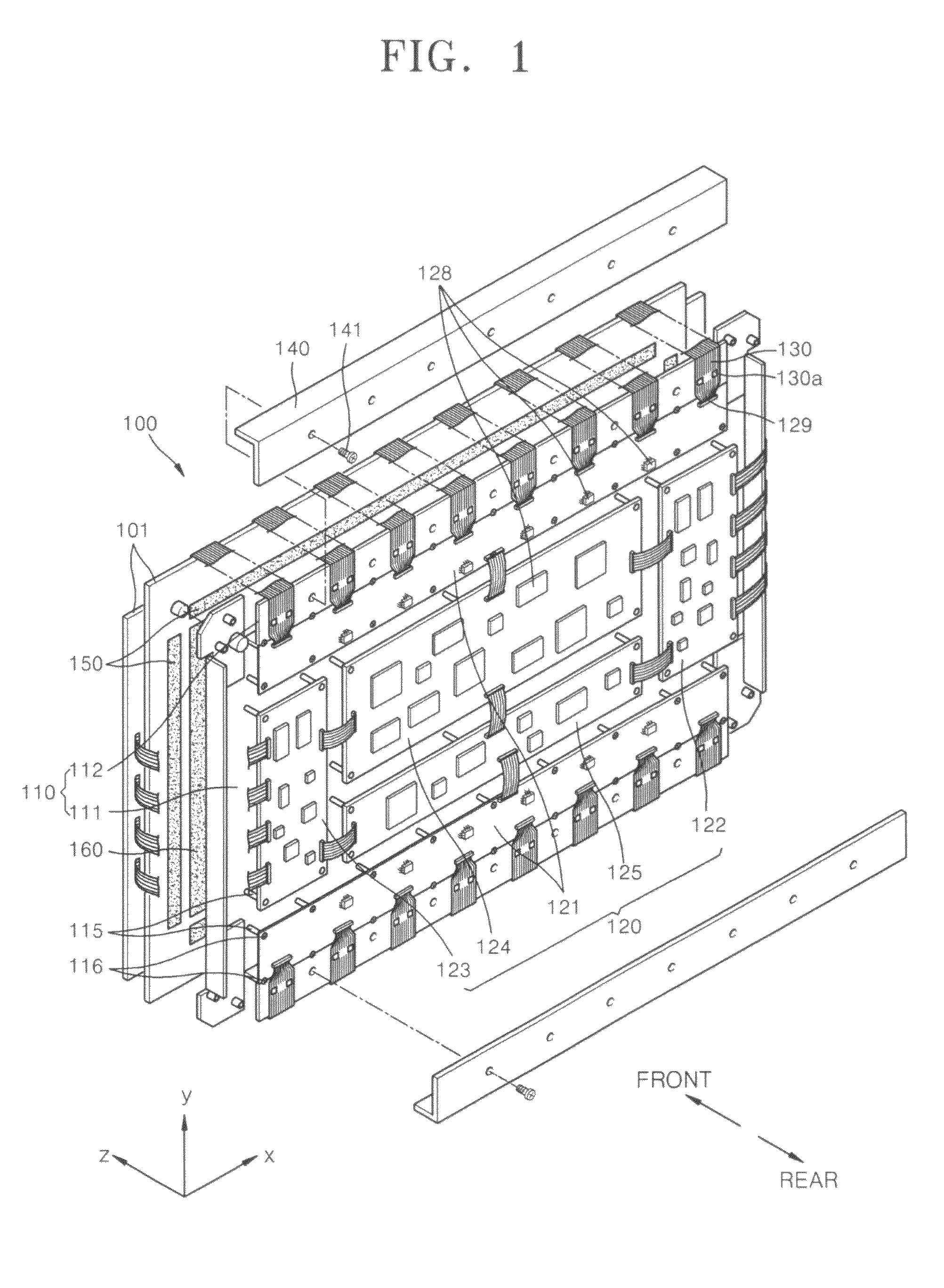

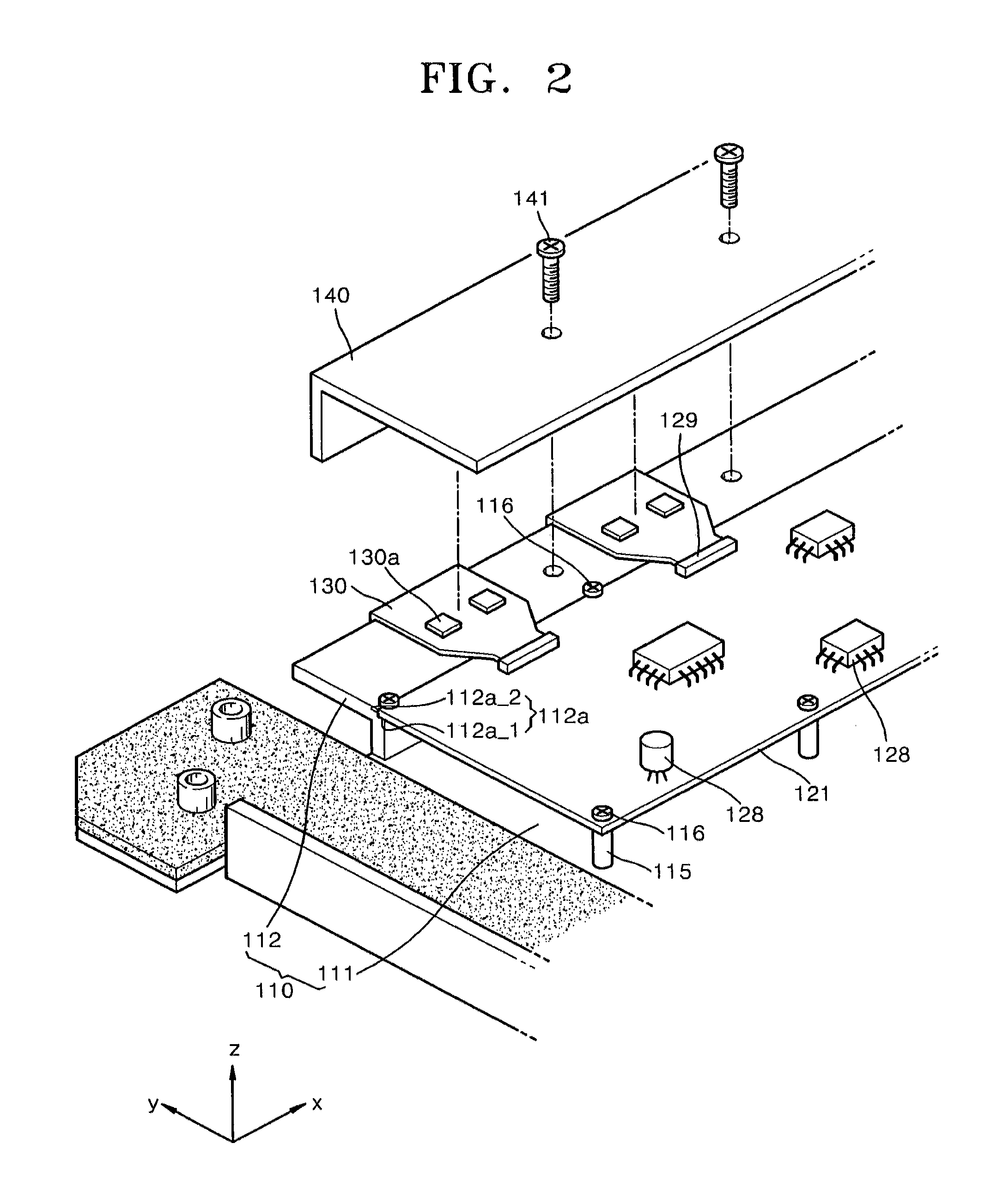

Gaming cabinet constructed from connectable components

InactiveUS8016683B2Efficiently groundEnsure integrityCard gamesApparatus for meter-controlled dispensingMechanical engineeringGame machine

A gaming machine cabinet or housing is constructed from a plurality of connected components. In one embodiment, the cabinet is assembled from base, side, top, back and door components or sections. The housing may have a basis configuration constructed from a base, sides, top, back and a first door. The housing may have a plurality of modified configurations constructed from various of the basic configuration components, such as the base, sides and back, and an extension and modified door. In accordance with the invention, the gaming machine housing may be manufactured in one location and then conveniently shipped in unassembled form to another location for assembly and use. The gaming machine housing may also be constructed in a variety of configurations utilizing a small number of components.

Owner:COLE KEPRO INT

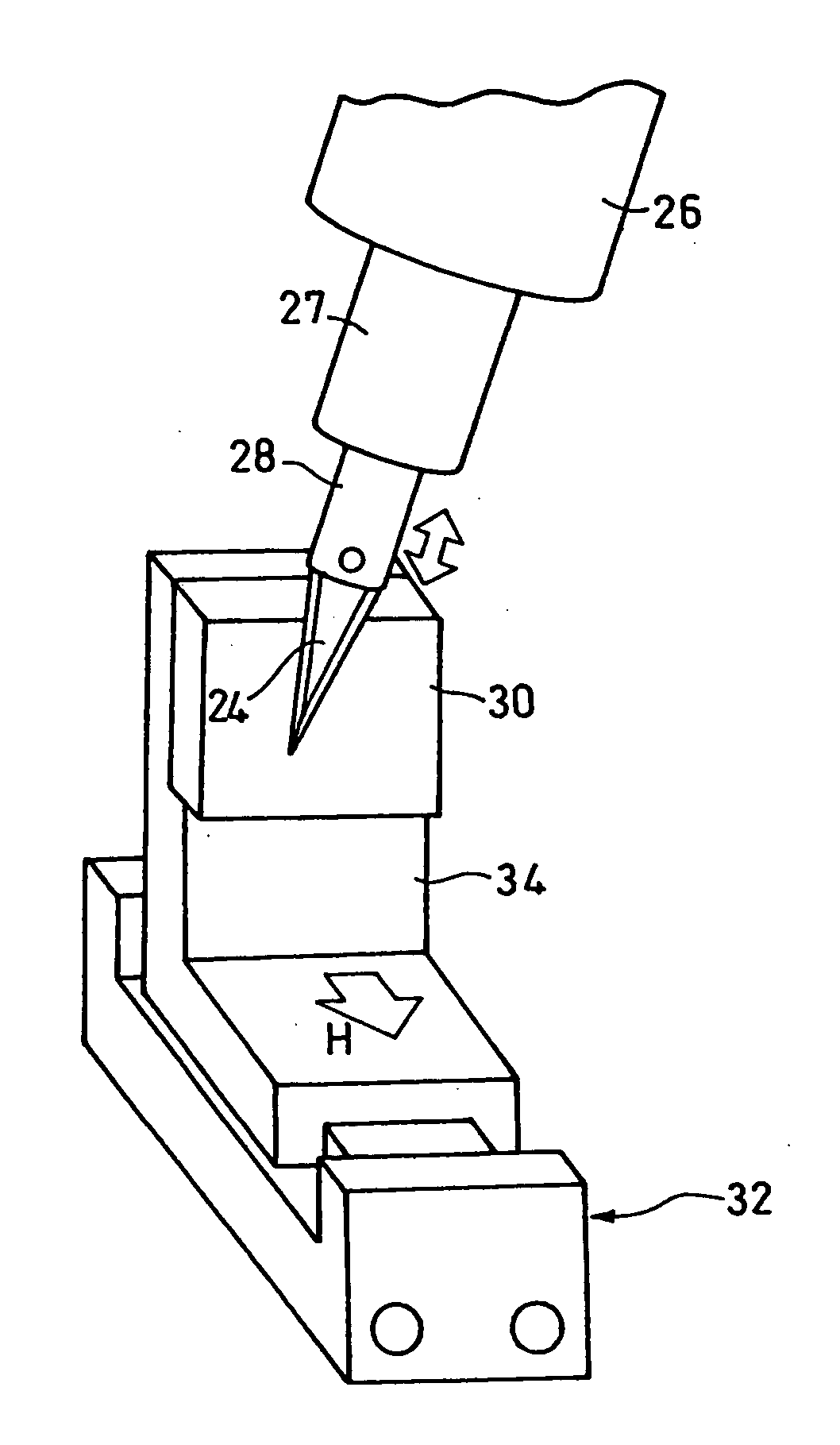

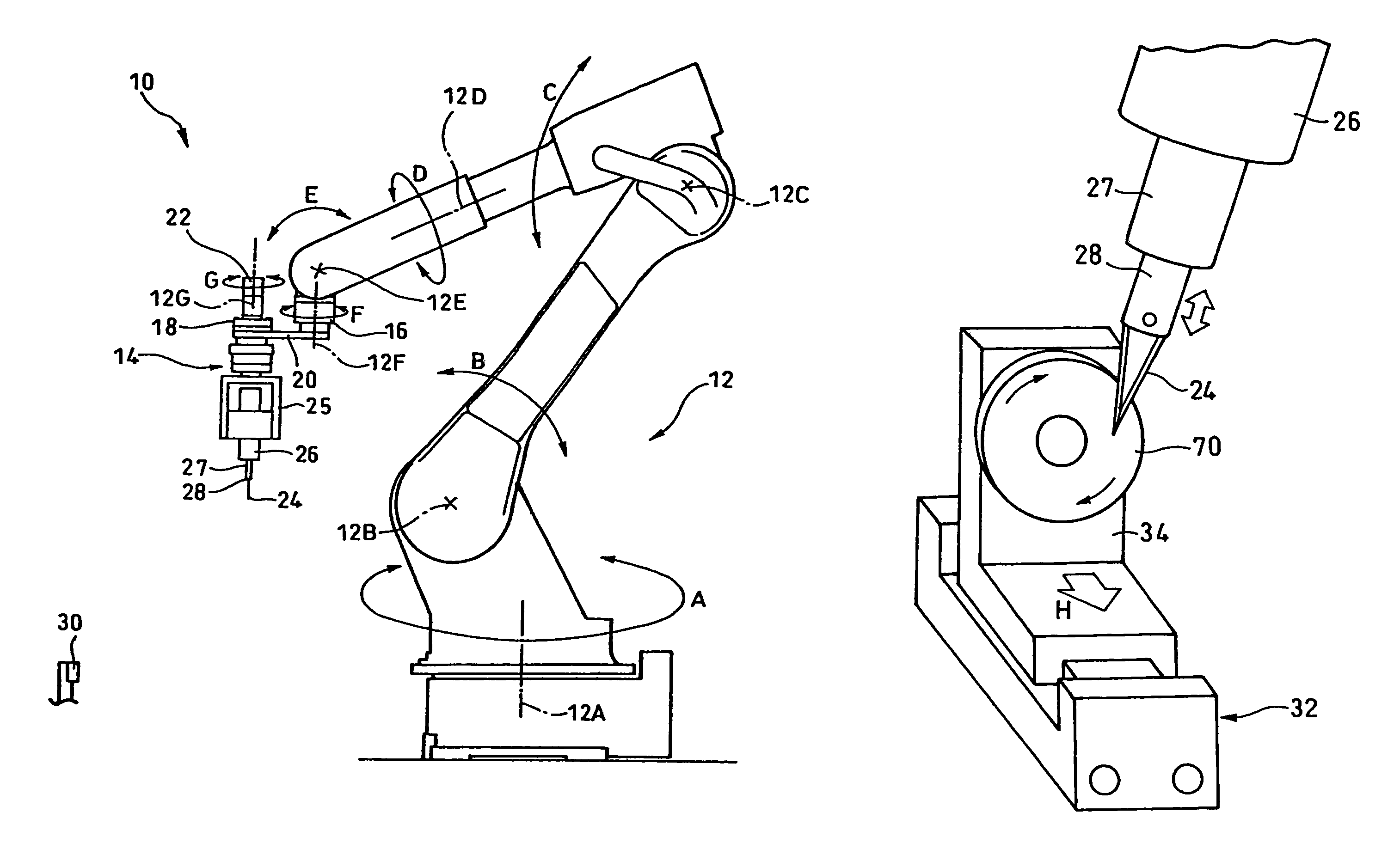

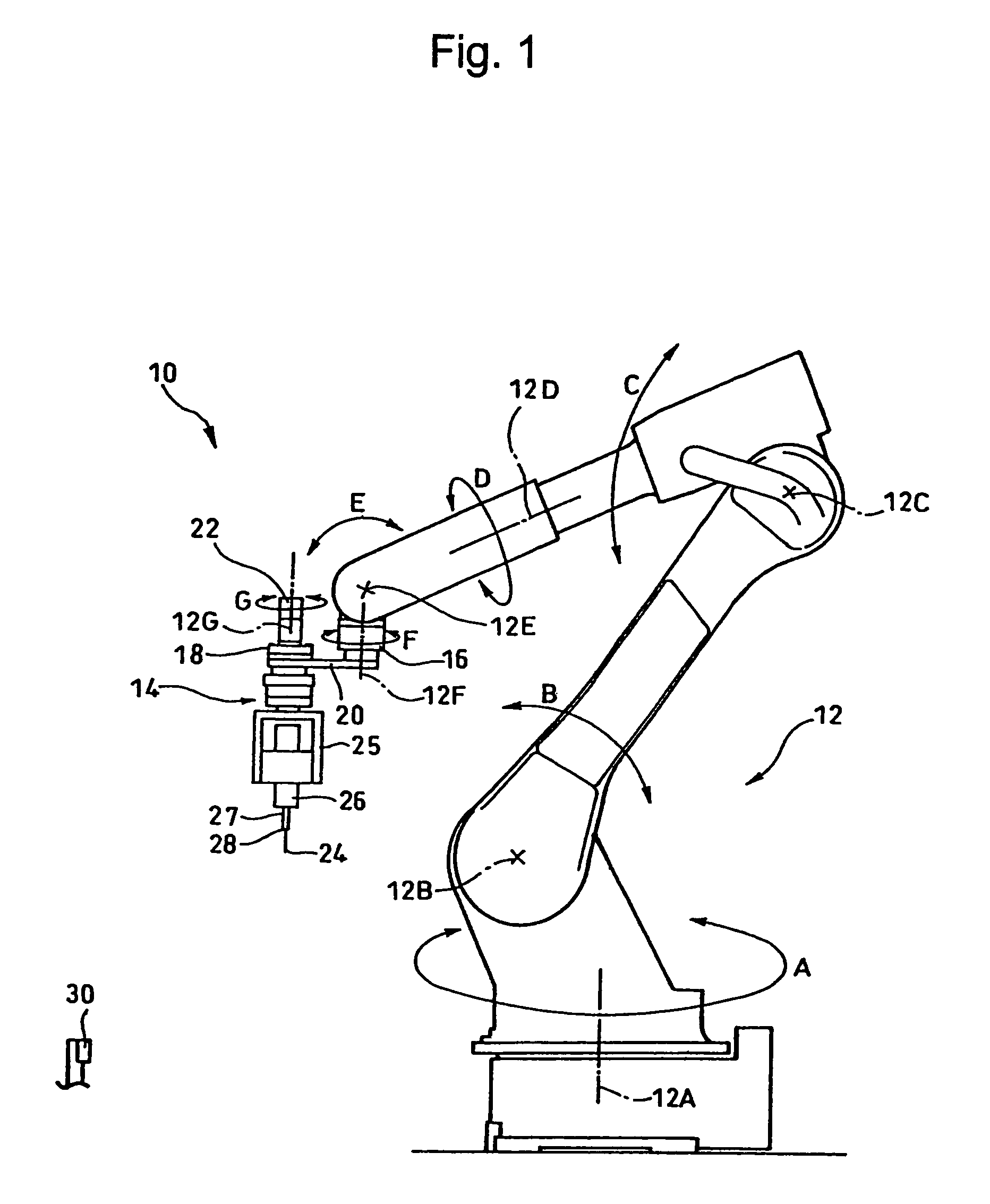

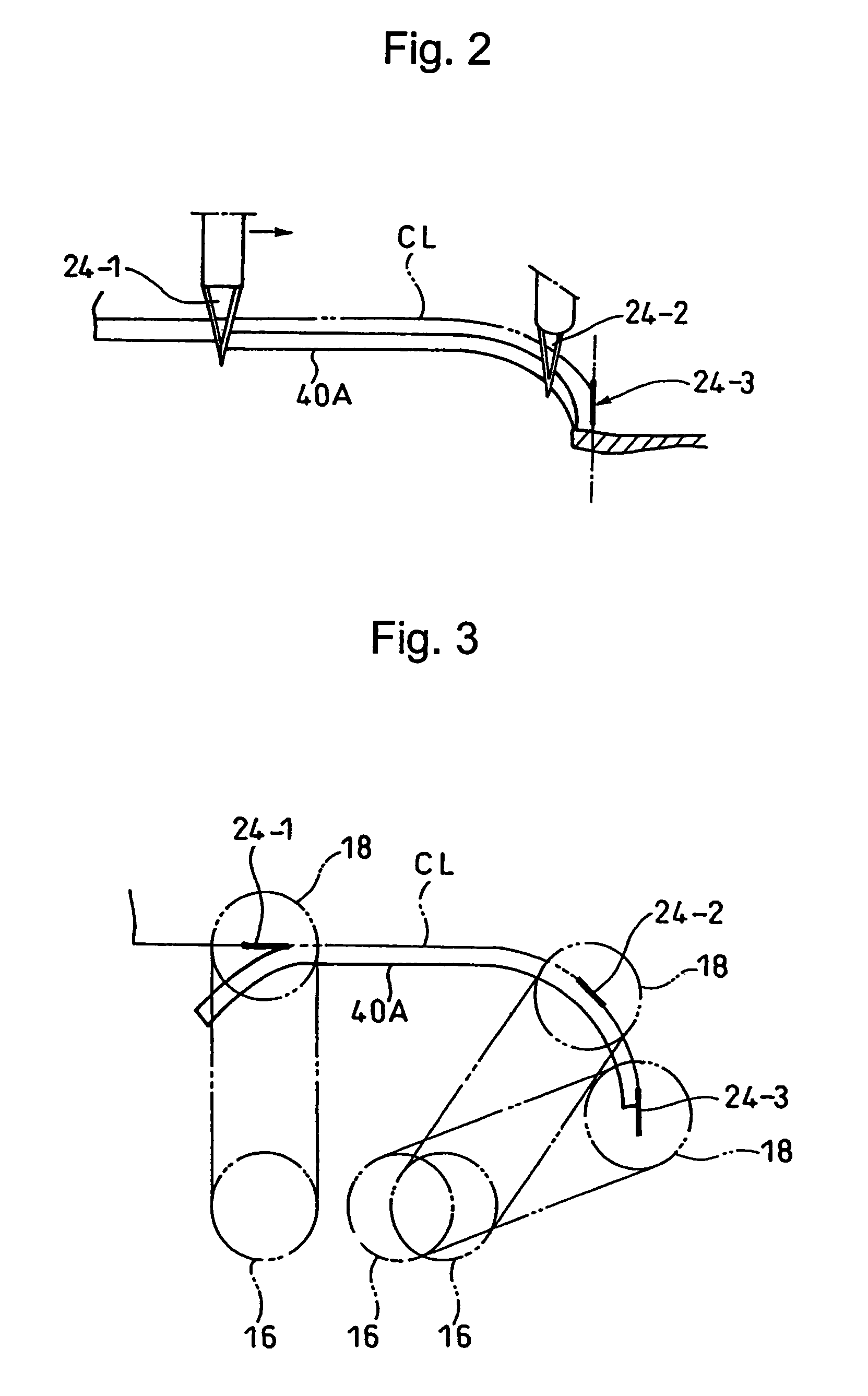

Ultrasonic trimming apparatus and ultrasonic trimming method

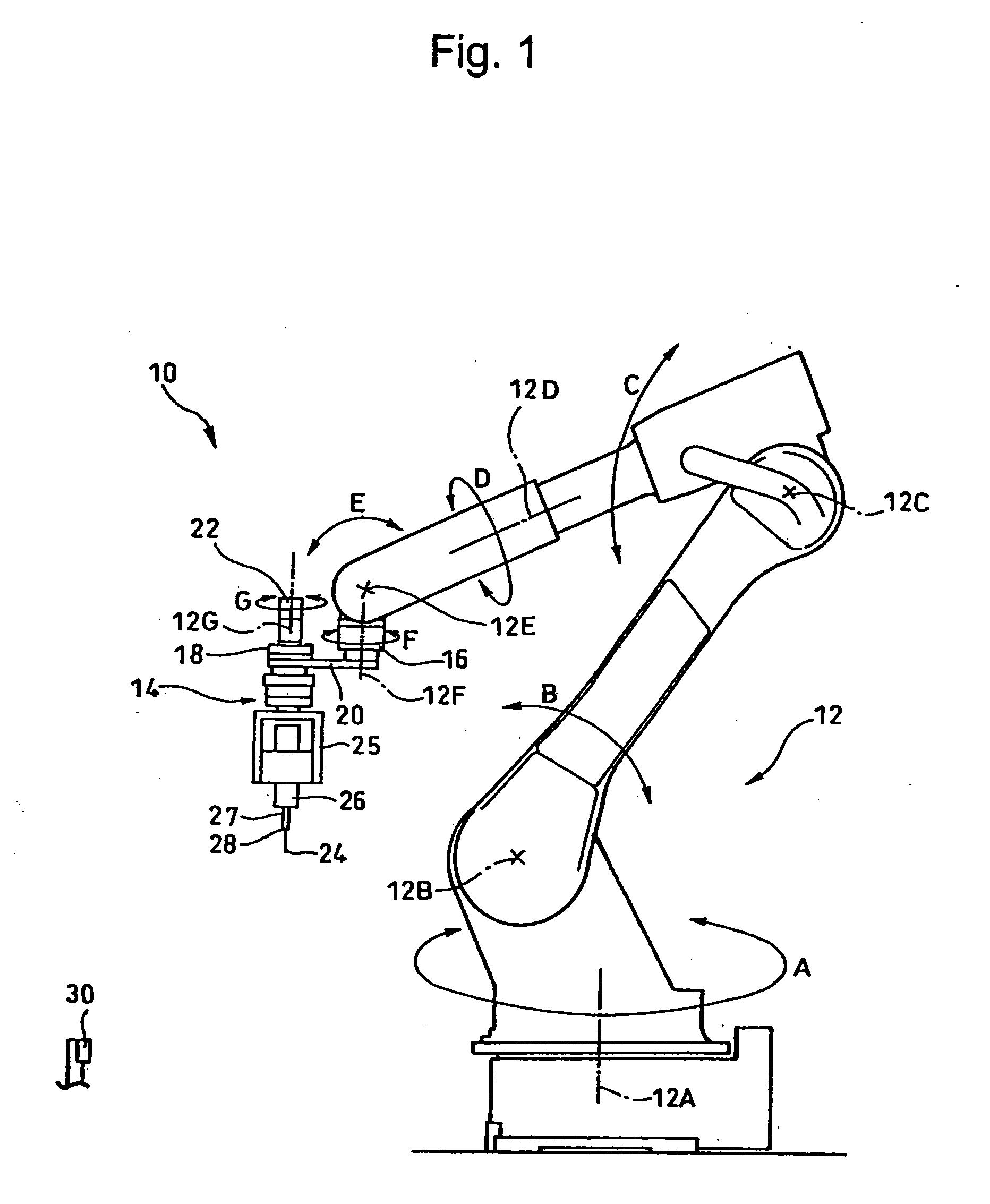

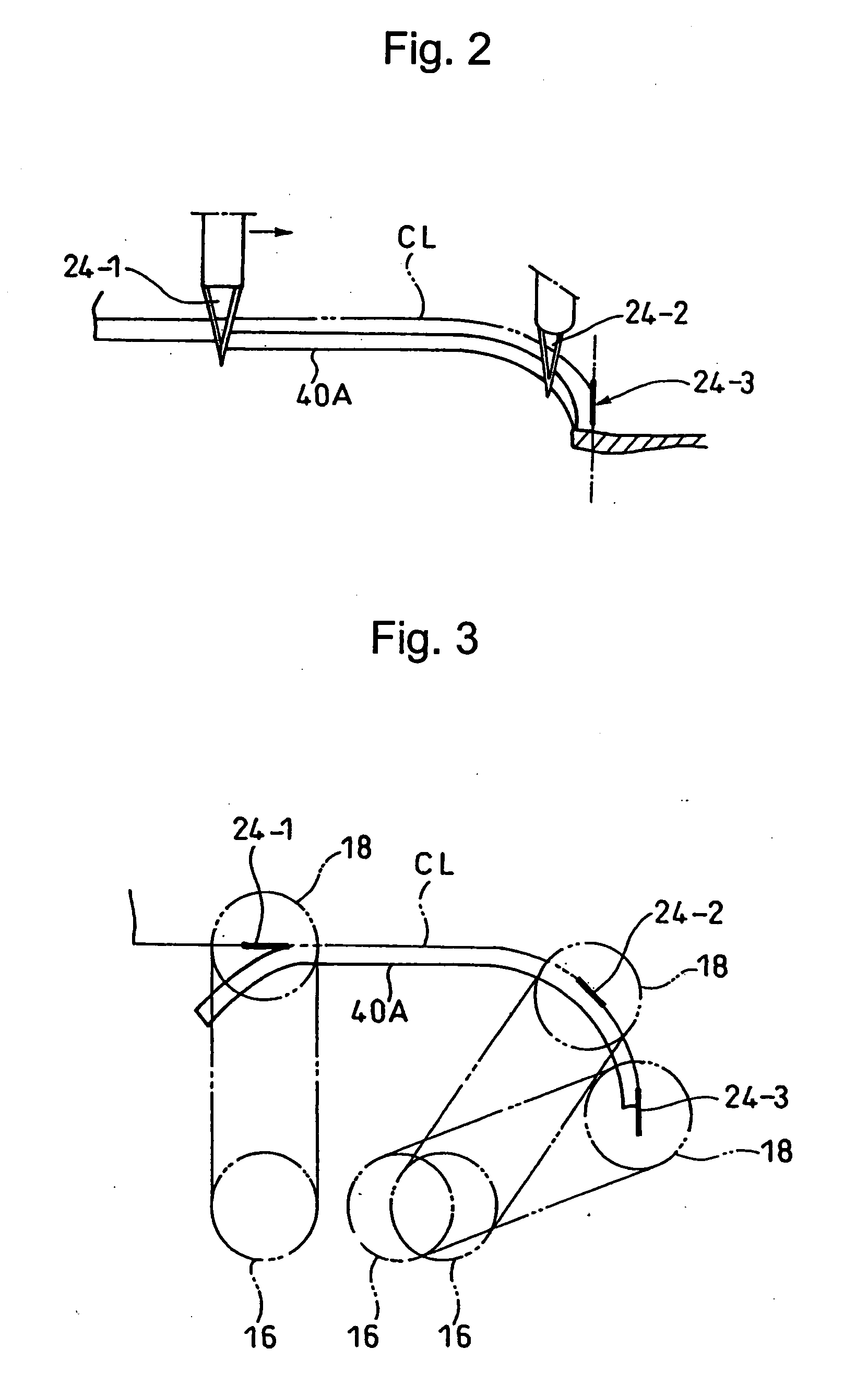

ActiveUS20100043610A1Efficient executionEfficiently grinding a cutter bladeEdge grinding machinesMetal sawing devicesGlass fiberThree dimensional shape

An ultrasonic trimming apparatus is composed of an articulated robot, a cutting apparatus, and a grindstone. The cutting apparatus is composed of an ultrasonic oscillator which is supported by the end portion of the articulated robot, a cutter blade which is supported by the ultrasonic oscillator, and a workpiece securing portion which secures a workpiece. The grindstone serving as a grinding member is disposed within the movable range of the cutter blade driven by the robot and is placed in a position at which the cutter blade can pressure contact the cutter blade. The cutter blade is ultrasonically vibrated by the ultrasonic oscillator and is ground while being pressed against the grindstone by means of the articulated robot. The ultrasonic trimming apparatus efficiently cuts a sheet material composed of soft material such as plastic, fabric, or rubber, a composite material, or a material containing glass fiber by means of an environmentally conscious method even when the material has a three-dimensional shape.

Owner:NIHON SHORYOKU KIKAI

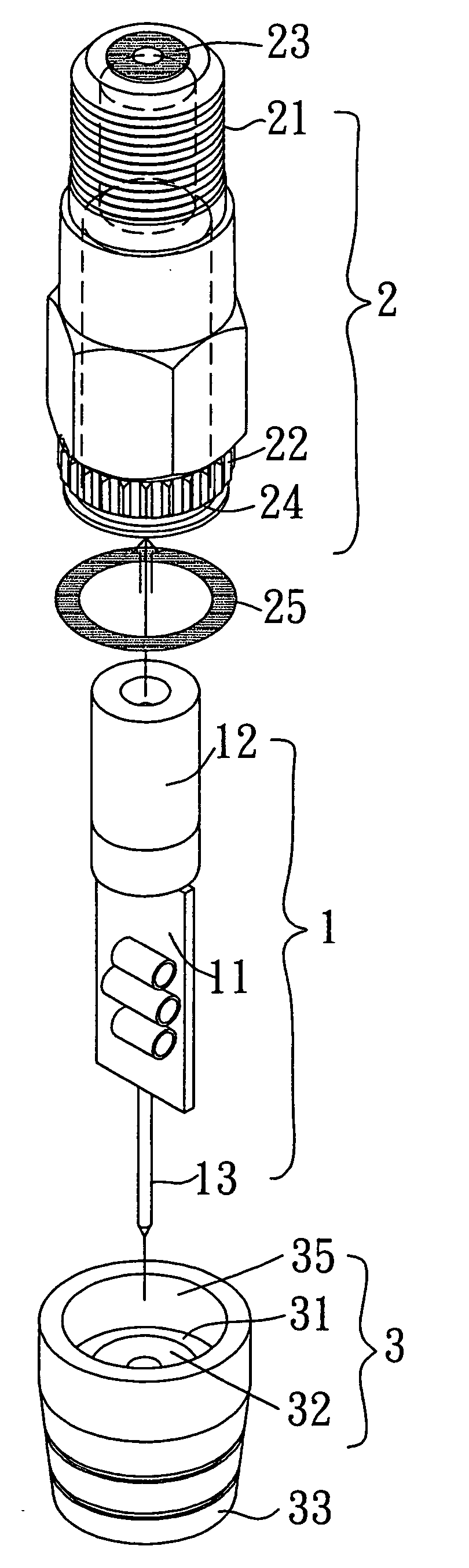

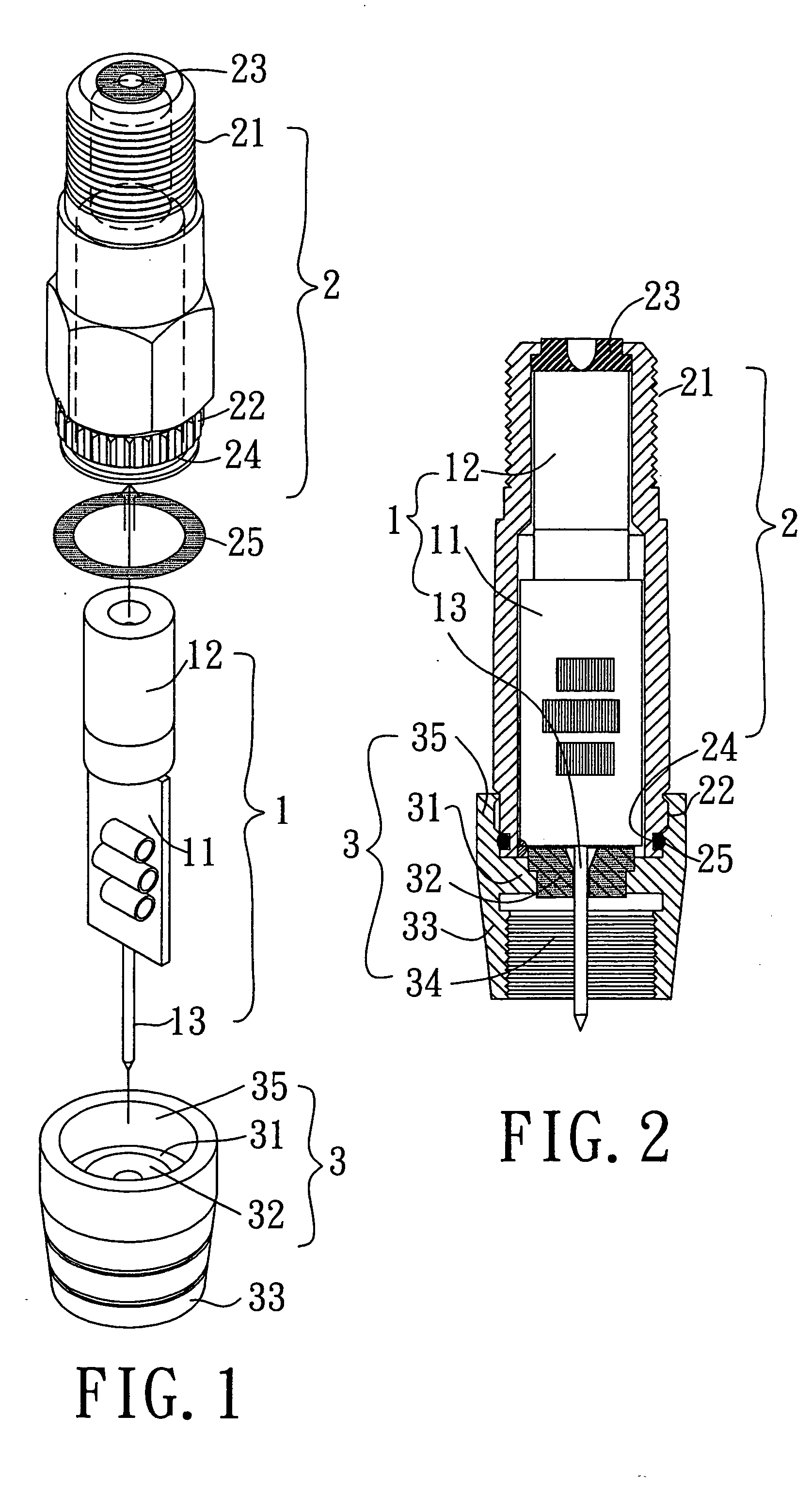

Structure of a wave filter

InactiveUS20050162238A1Efficiently groundEasy to installMultiple-port networksTwo pole connectionsEngineering

Owner:SOONTAI TECH

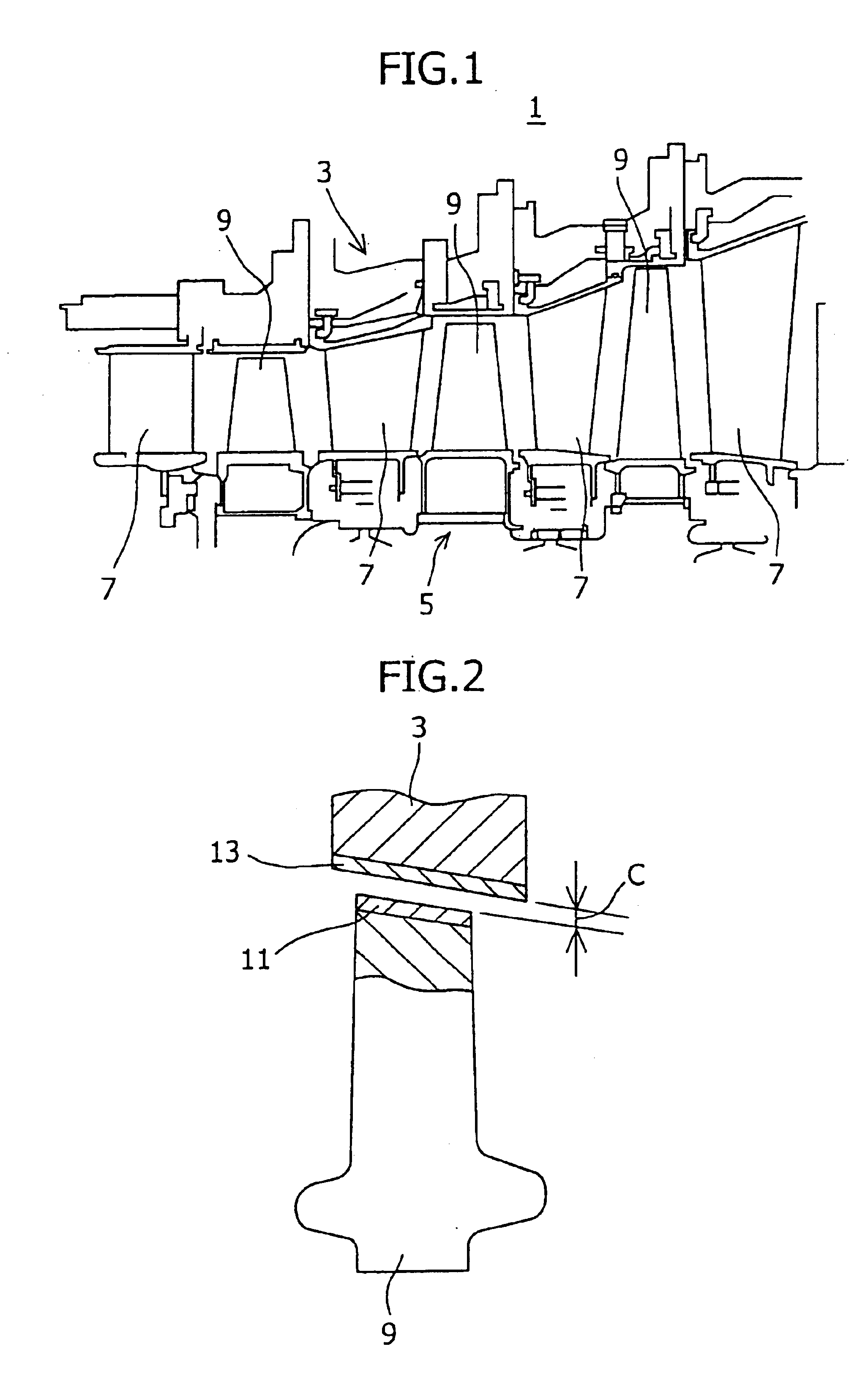

Combustion engine, gas turbine, and polishing layer

The present invention provides a gas turbine in which a proper clearance is kept between a rotor blade and a shroud for a long period of time from the operation start, so that damage to the rotor blade is less liable to occur. In a turbine portion of the gas turbine in accordance with the present invention, the rotor blade and the shroud face each other. At the tip end of the rotor blade is formed an abrasive layer, and on the inner peripheral surface of the shroud is formed a heat insulating layer. The abrasive layer is formed of a matrix and many abrasive particles dispersed in the matrix. The abrasive particles include protruding particles protruding from the matrix and embedded particles embedded in the matrix. In initial sliding of the rotor blade and the shroud at the early stage of operation, the inner peripheral surface of the shroud is ground by the protruding particles. After the protruding particles have disappeared, the inner peripheral surface of the shroud is ground by the embedded particles.

Owner:MITSUBISHI HEAVY IND LTD

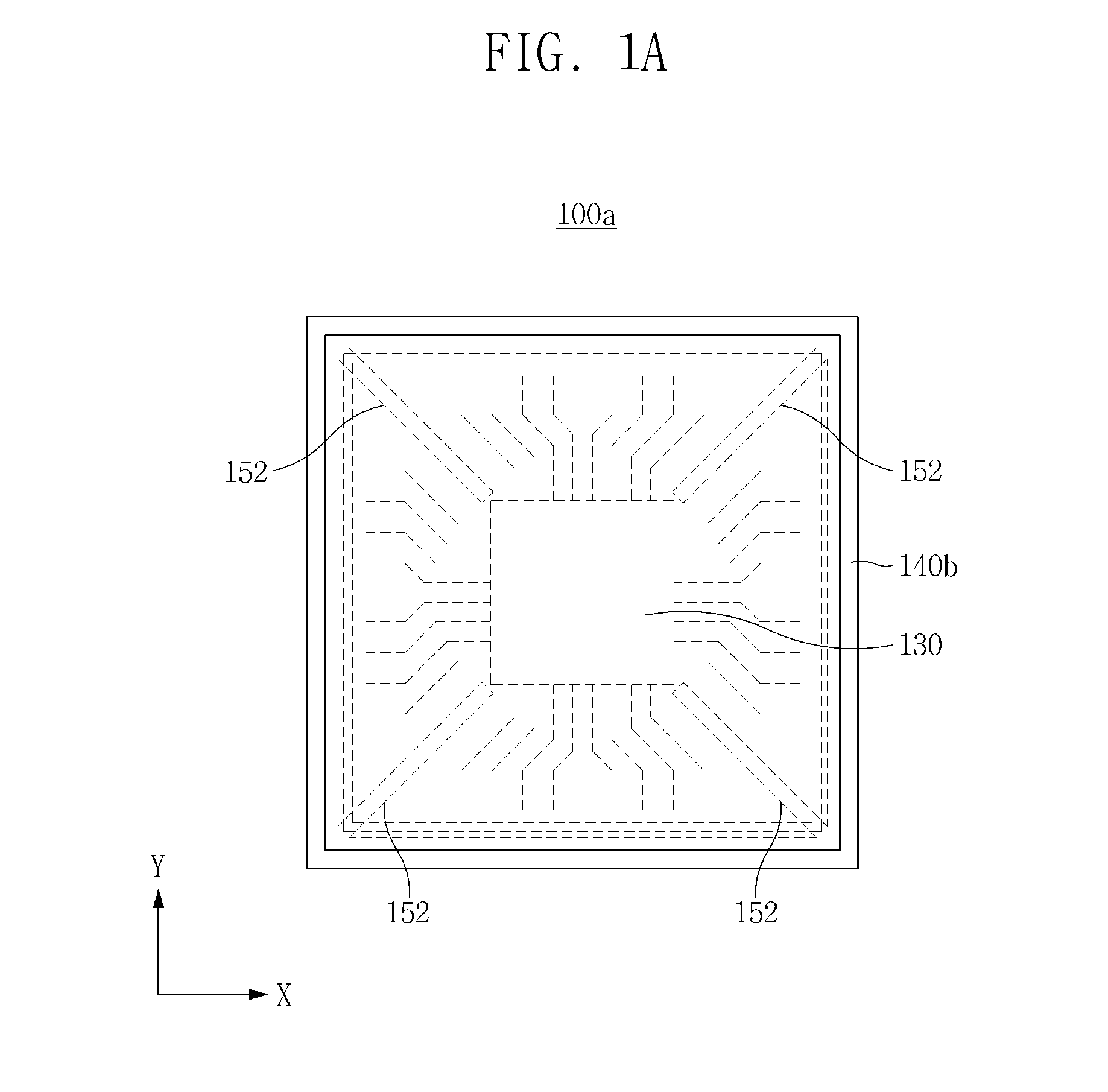

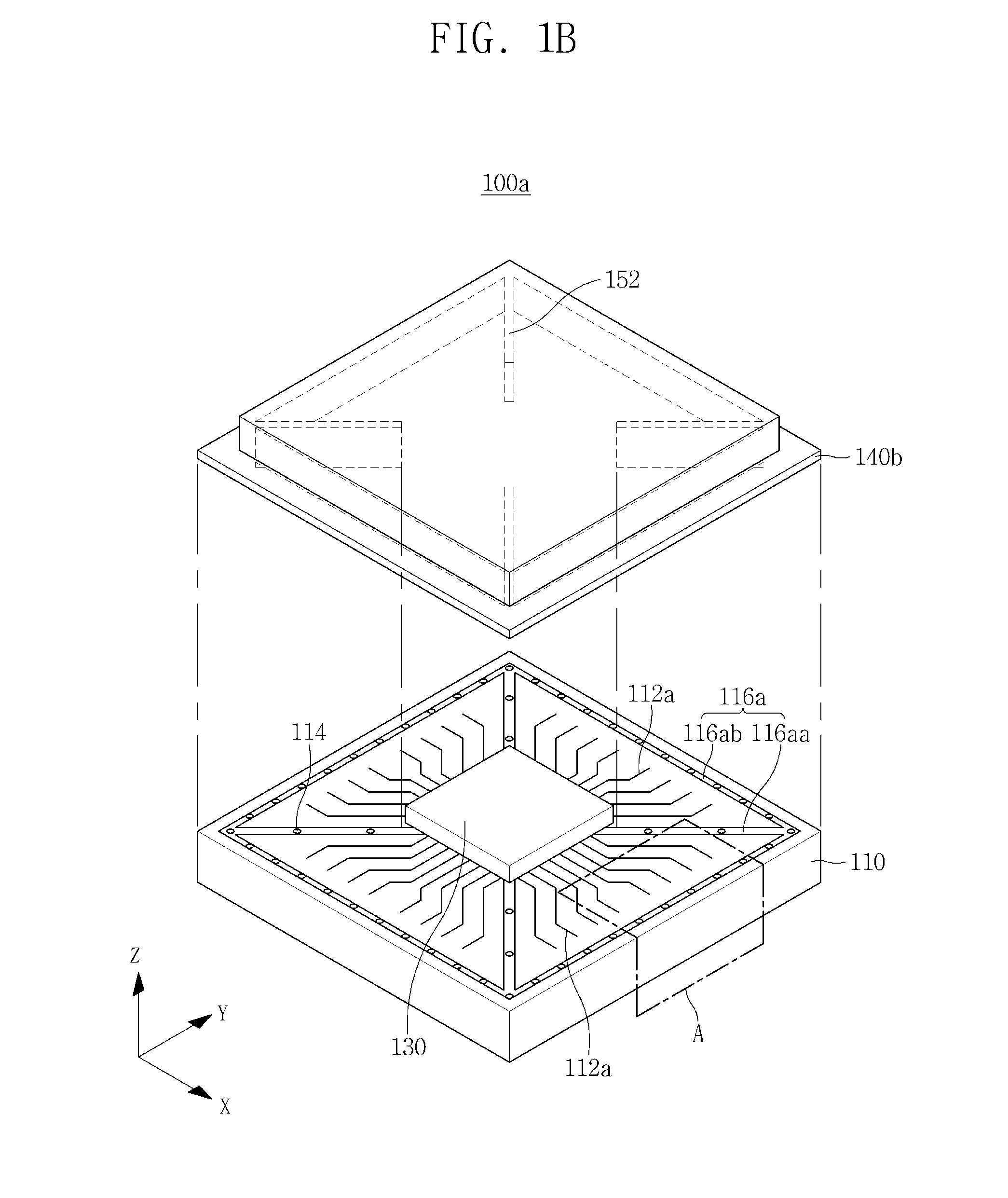

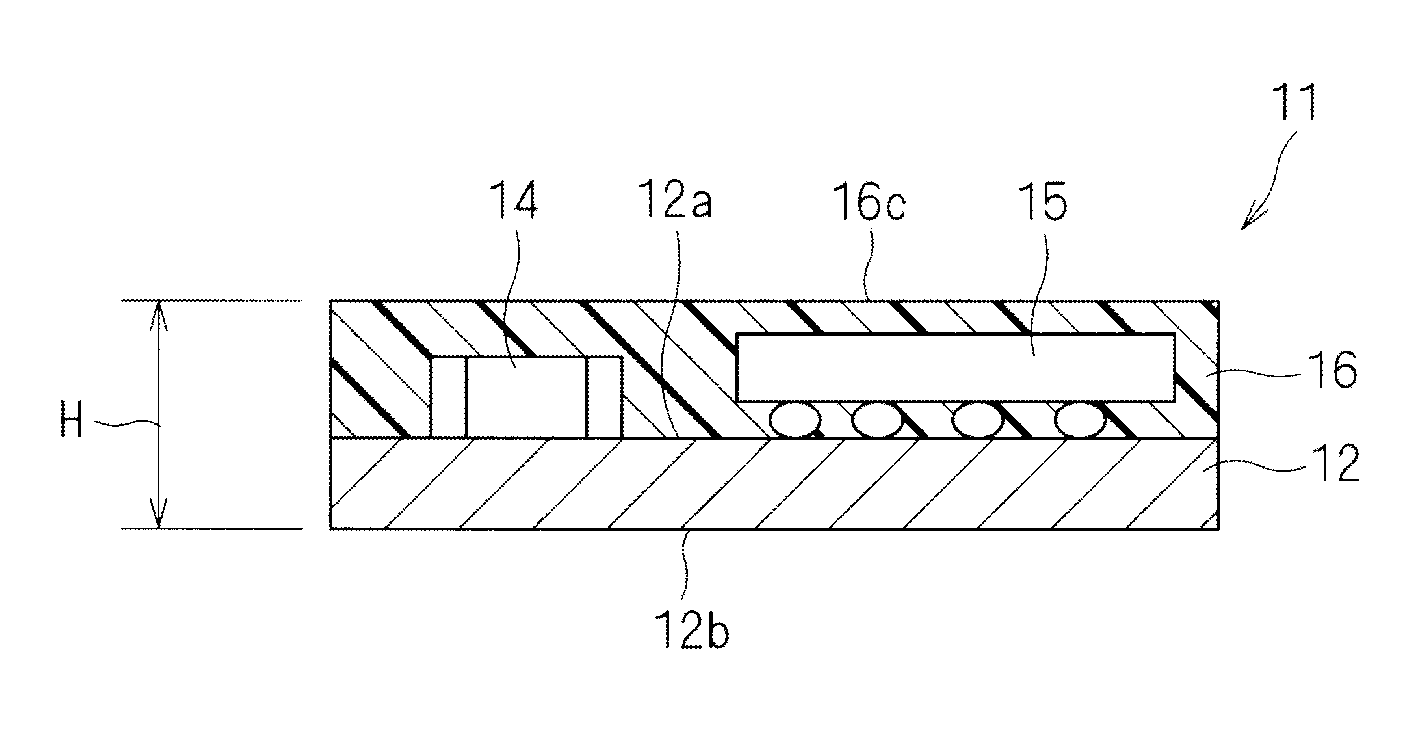

Semiconductor package having EMI shielding function and heat dissipation function

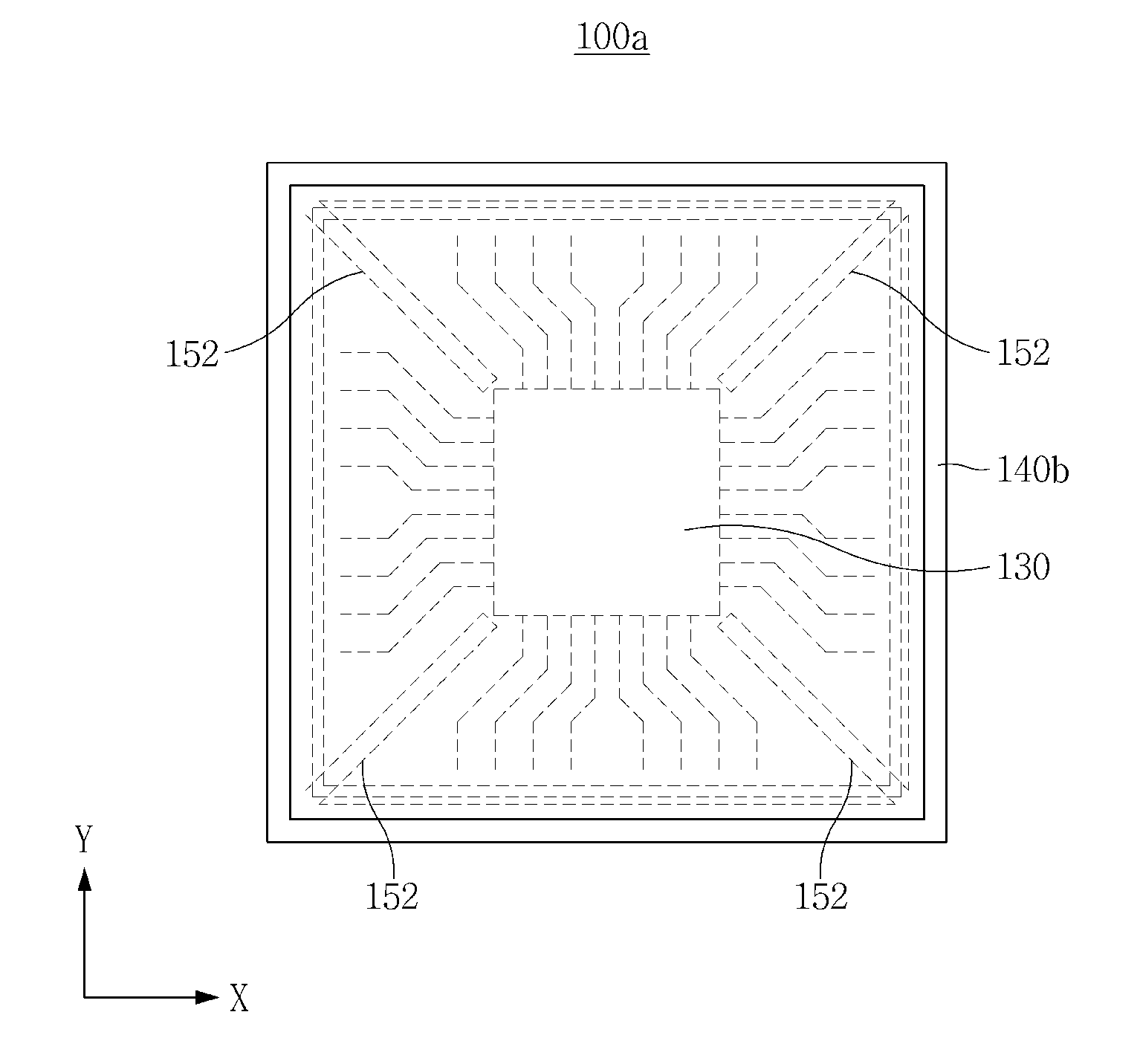

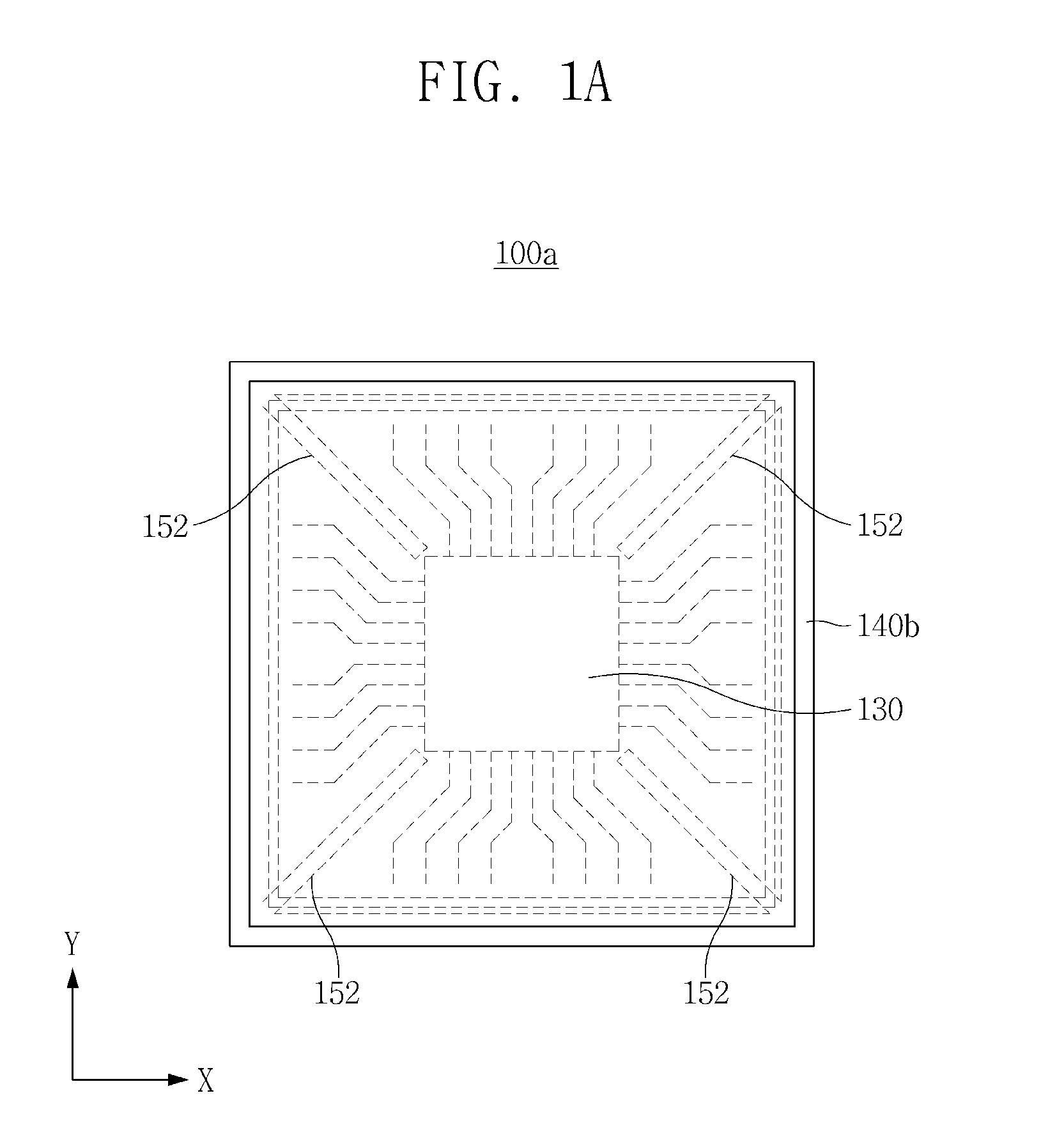

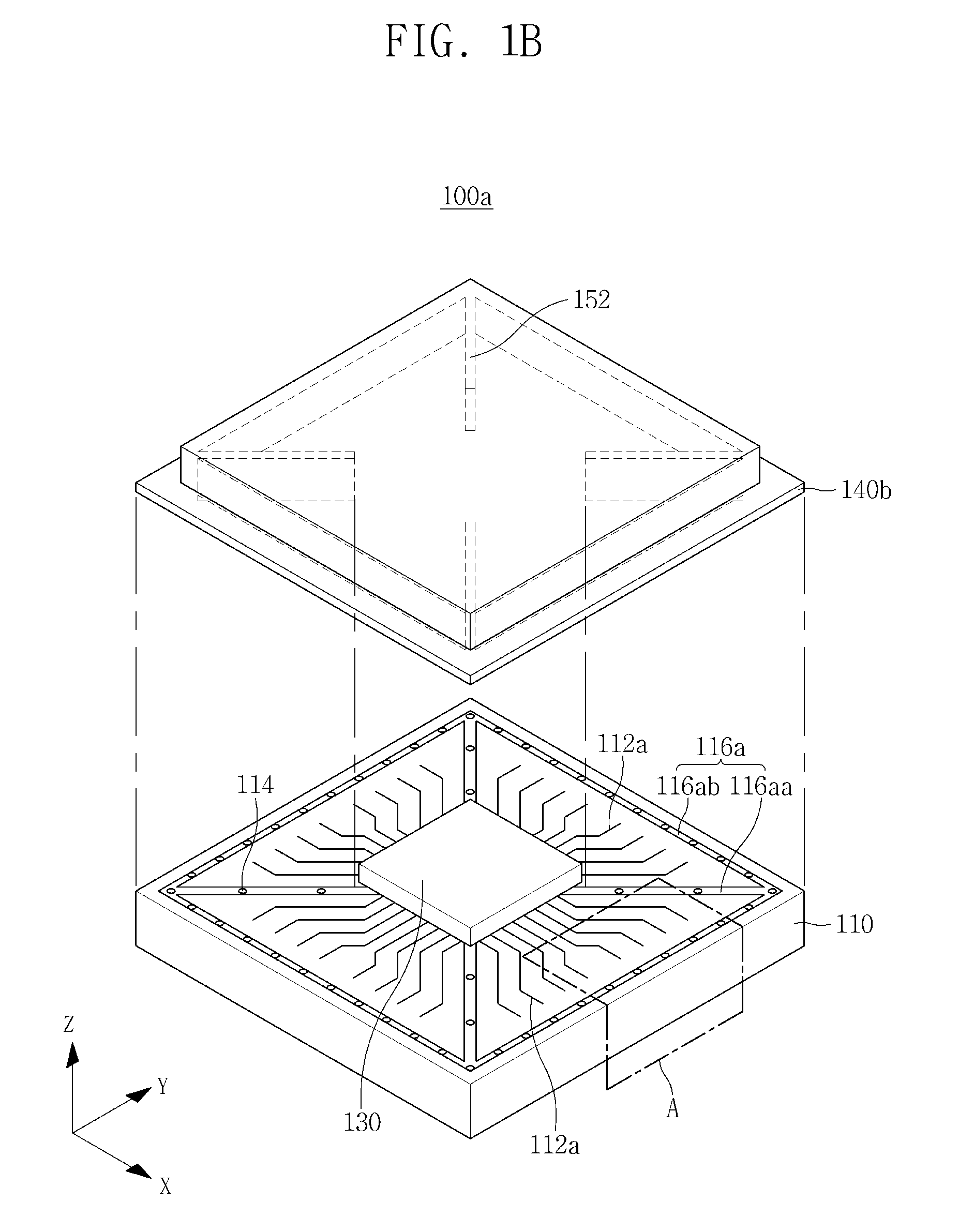

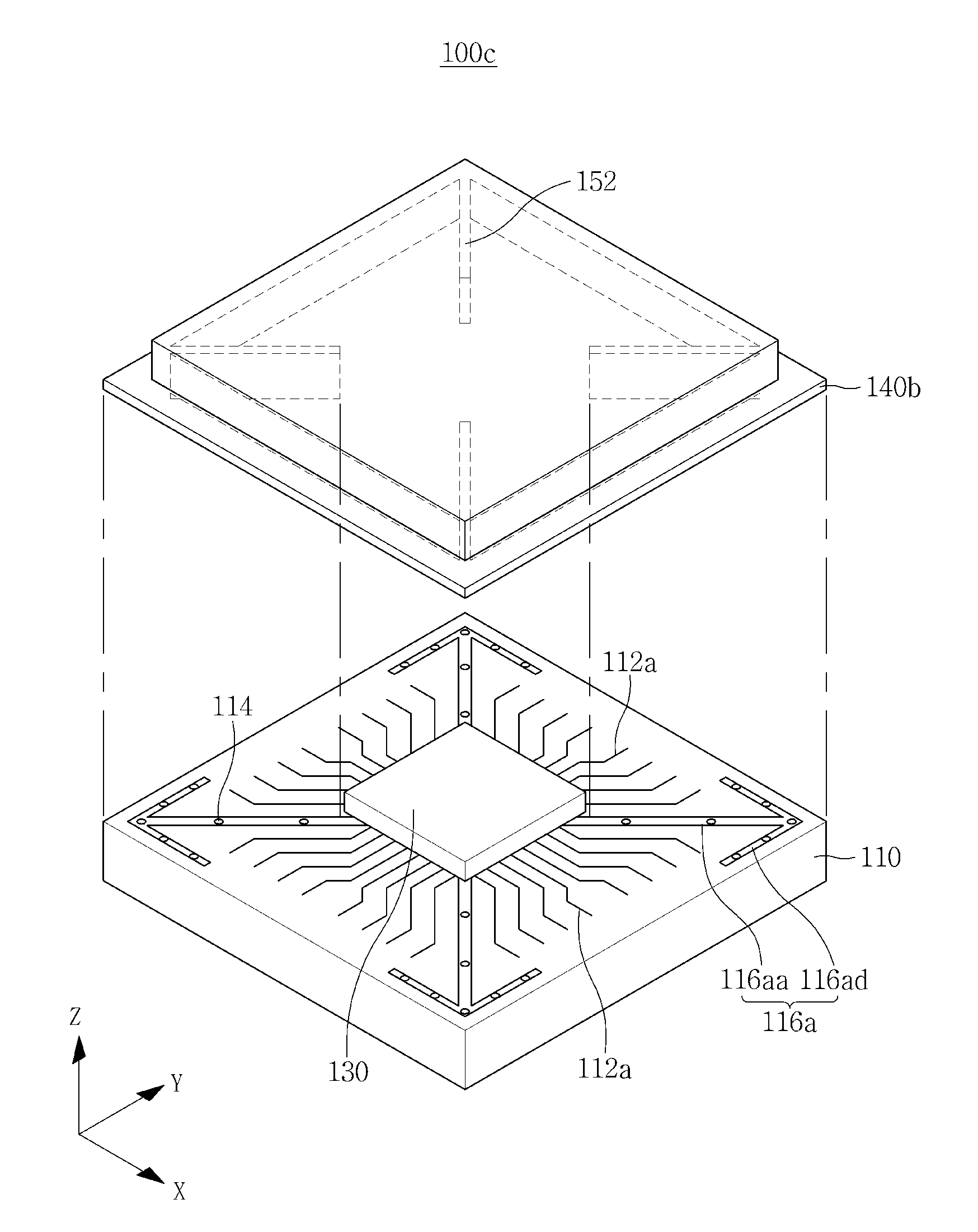

ActiveUS20140328023A1Avoid electromagnetic interferenceAvoid interferenceMagnetic/electric field screeningSemiconductor/solid-state device detailsGround lineEngineering

A semiconductor package includes a substrate, a semiconductor chip located on a top surface of the substrate, signal lines formed on the top surface of the substrate and configured to allow different types of signals to input / output thereto / therefrom, a ground line unit formed on the top surface of the substrate and configured to divide the signal lines into signal lines to / from which the same types of signals are input / output to be isolated from one another, barrier walls configured to contact the ground line unit, and a heat dissipation unit disposed on the semiconductor chip, wherein the ground line unit includes diagonal ground lines located in diagonal directions of the substrate about the semiconductor chip, and the heat dissipation unit includes a thermal interface material (TIM) located on a top surface of the semiconductor chip, and a heat dissipation plate configured to cover the TIM and the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor package having EMI shielding function and heat dissipation function

ActiveUS8921993B2Avoid interferenceEfficiently groundMagnetic/electric field screeningSemiconductor/solid-state device detailsSemiconductor chipSemiconductor package

A semiconductor package includes a substrate, a semiconductor chip located on a top surface of the substrate, signal lines formed on the top surface of the substrate and configured to allow different types of signals to input / output thereto / therefrom, a ground line unit formed on the top surface of the substrate and configured to divide the signal lines into signal lines to / from which the same types of signals are input / output to be isolated from one another, barrier walls configured to contact the ground line unit, and a heat dissipation unit disposed on the semiconductor chip, wherein the ground line unit includes diagonal ground lines located in diagonal directions of the substrate about the semiconductor chip, and the heat dissipation unit includes a thermal interface material (TIM) located on a top surface of the semiconductor chip, and a heat dissipation plate configured to cover the TIM and the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

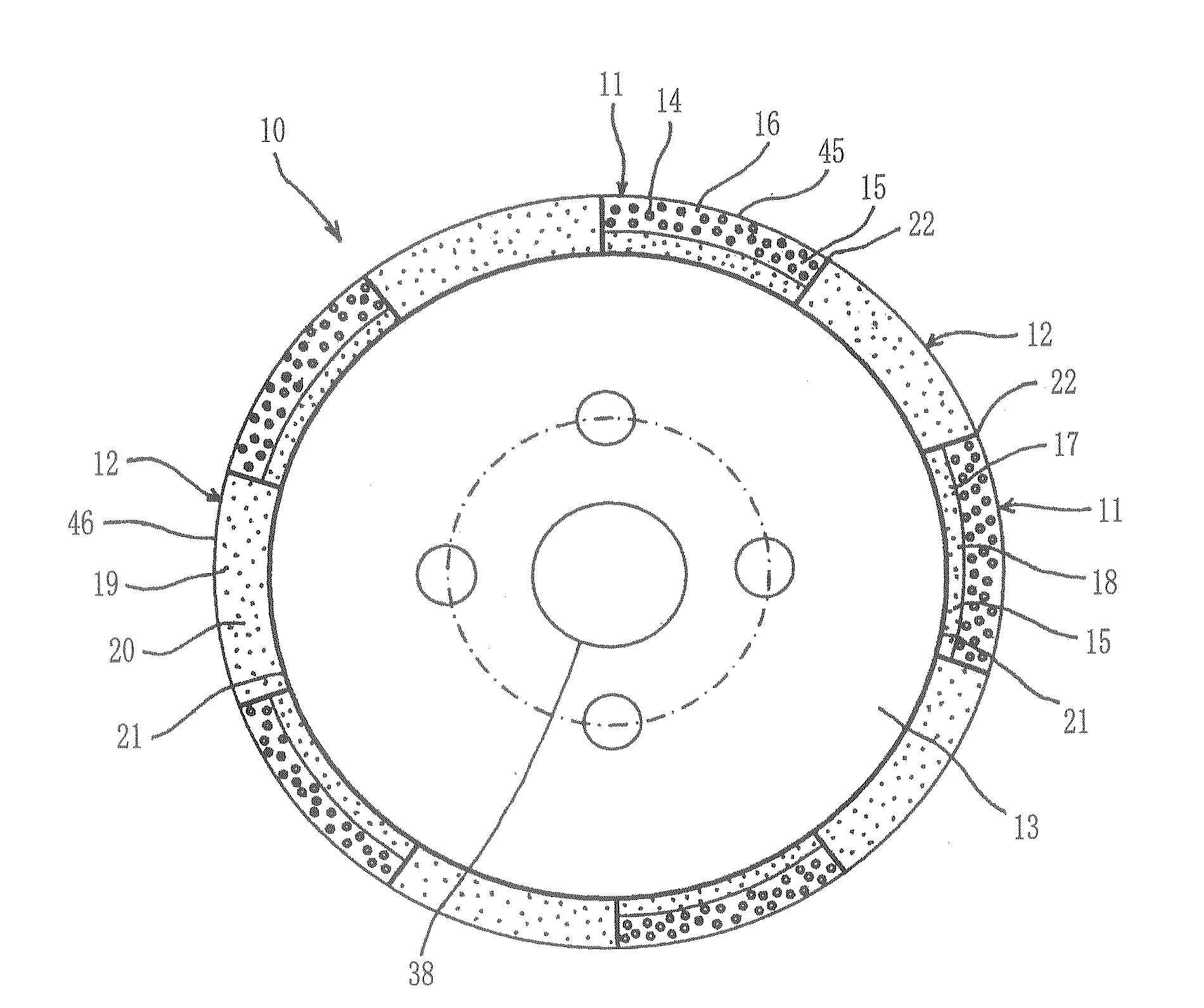

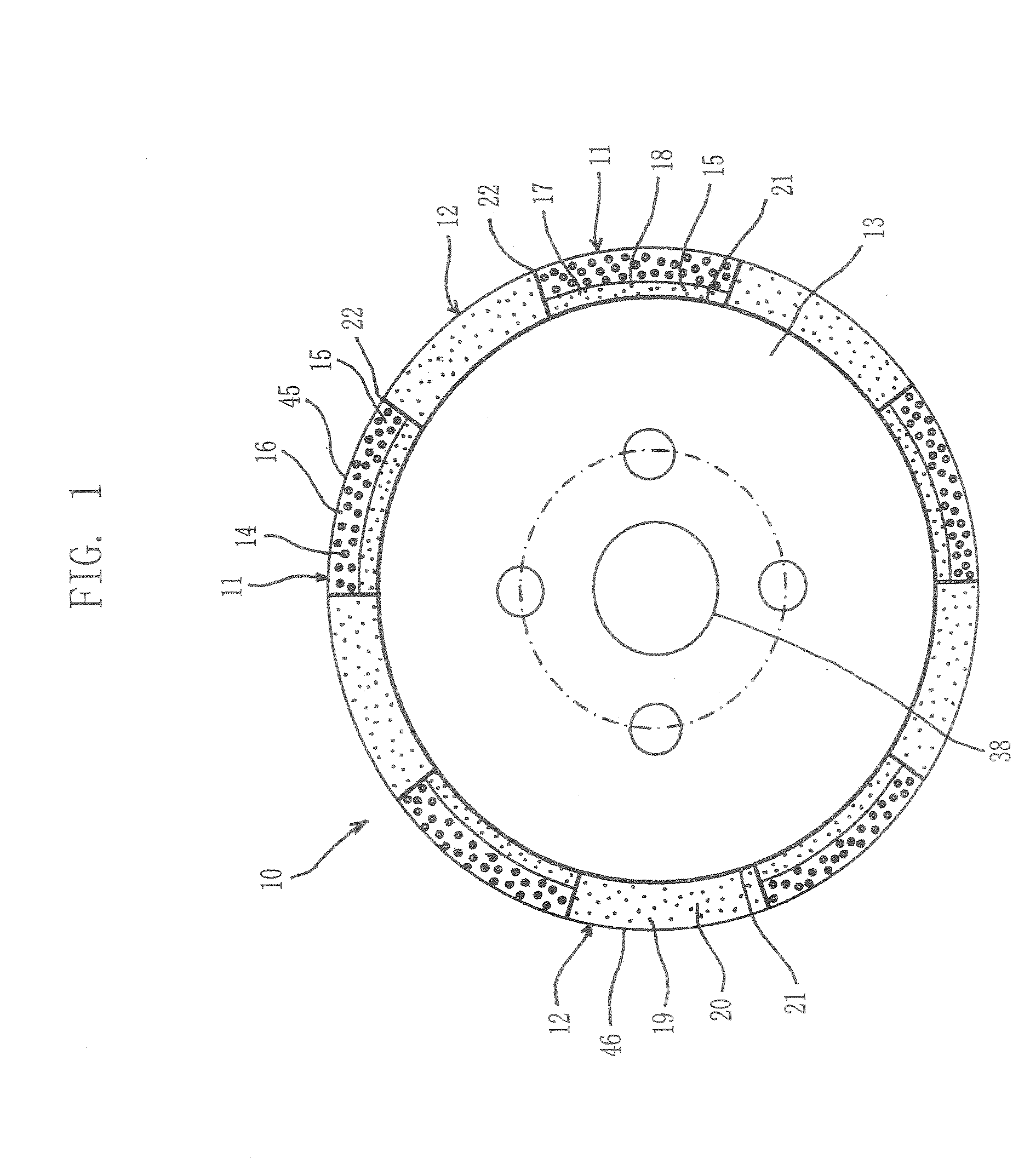

Grinding Wheel

InactiveUS20080299884A1Simple structureAchieve effectRevolution surface grinding machinesPortable grinding machinesRotational axisCircular disc

In a grinding wheel in which abrasive tips for rough grinding and abrasive tips for finish grinding are alternately bonded to a periphery of a disk type base rotating about a rotation axis, each abrasive tip includes the abrasive layer for ed by bonding abrasive grains and a lower layer overlaid and integrally for led with the abrasive layer. The abrasive tip is attached to the periphery of the base at the lower layer. A Young's modulus of the lower layer of the abrasive tip for finish grinding relative to a load acting on the grinding surface of the abrasive tip in an inward direction of the grinding wheel is less than that of the abrasive tip for rough grinding. Thereby, the surface of a workpiece can be both rough-ground and finish-ground with superhigh-precision surface roughness with using one grinding wheel

Owner:TOYODA VAN MOPPES +1

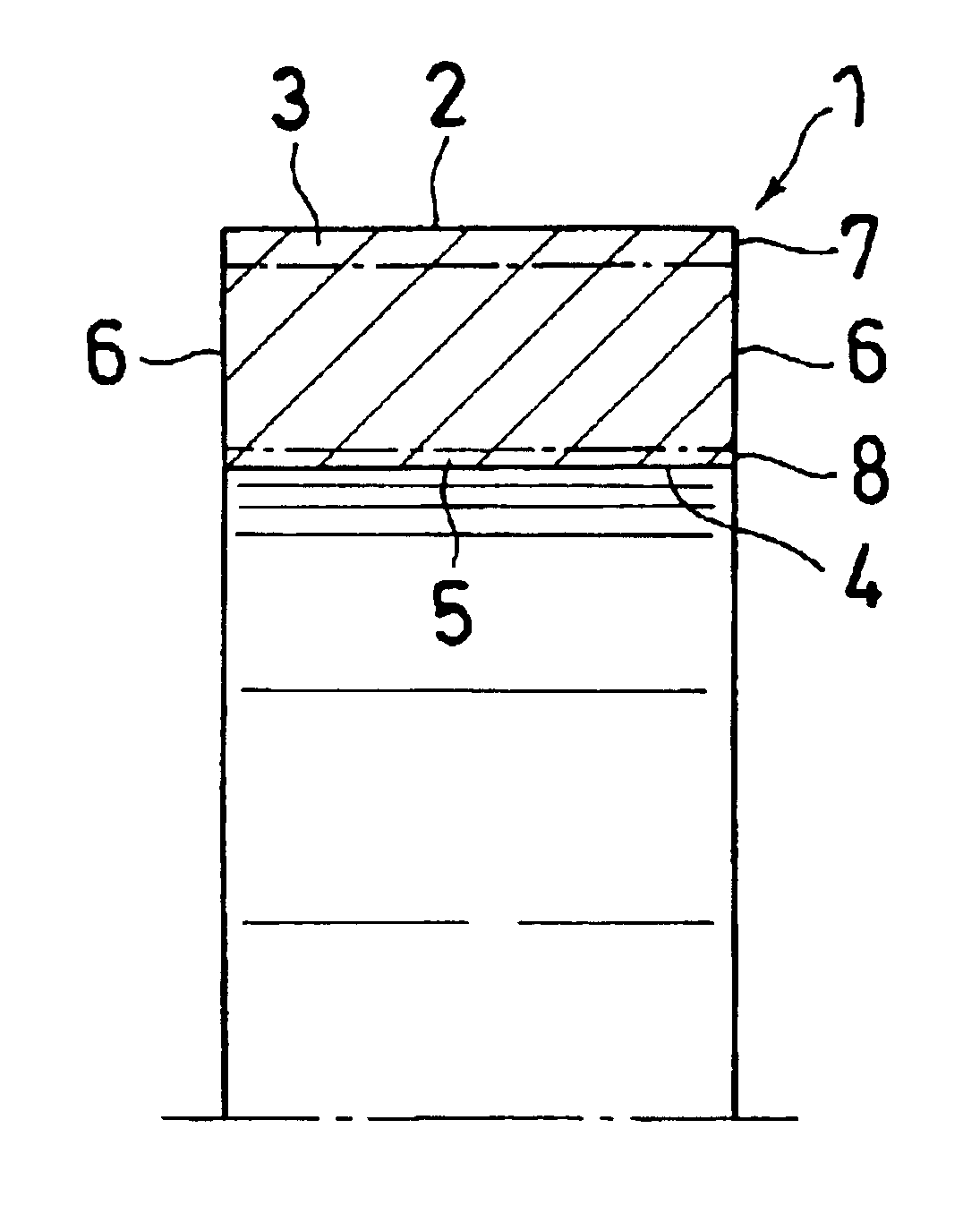

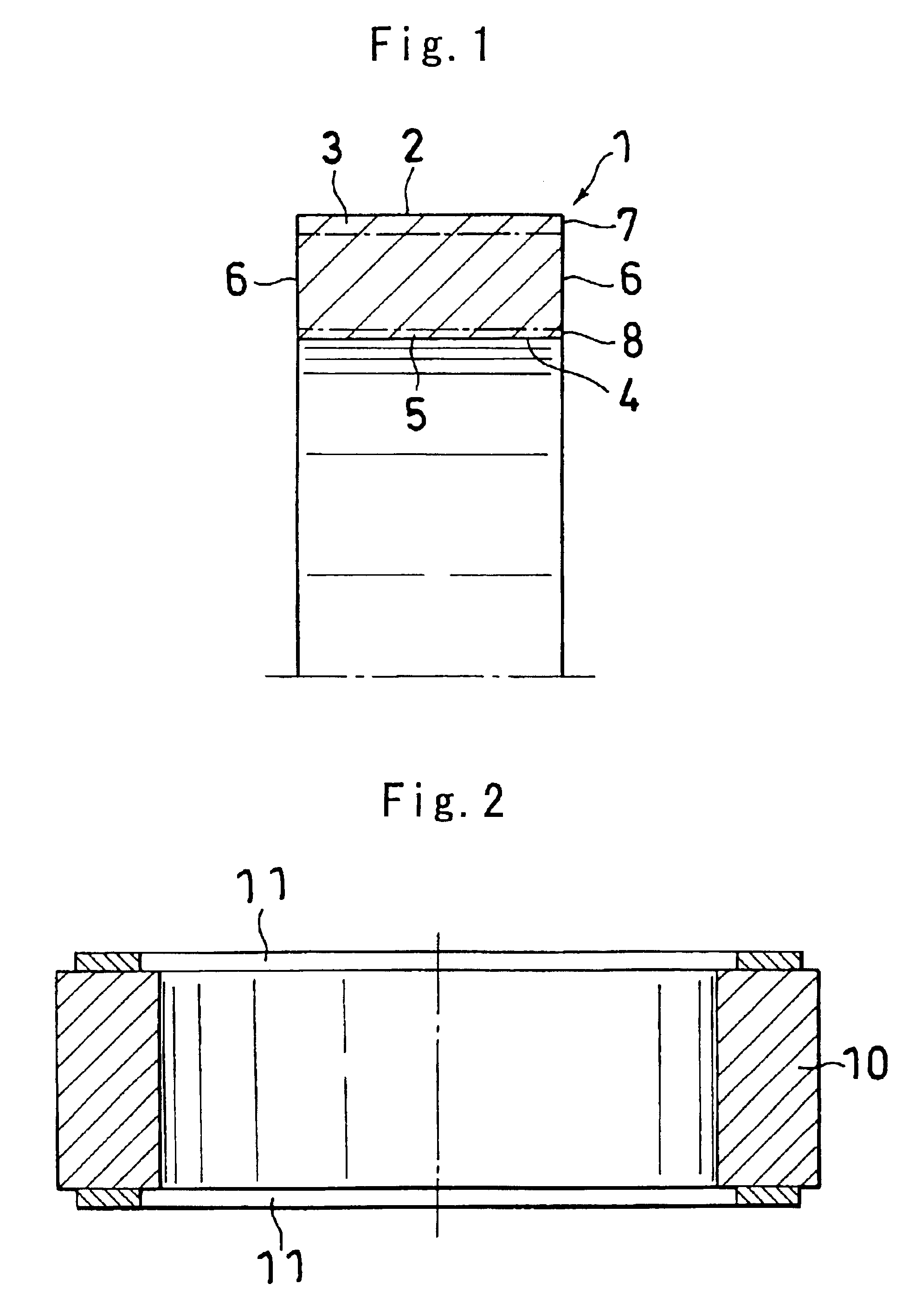

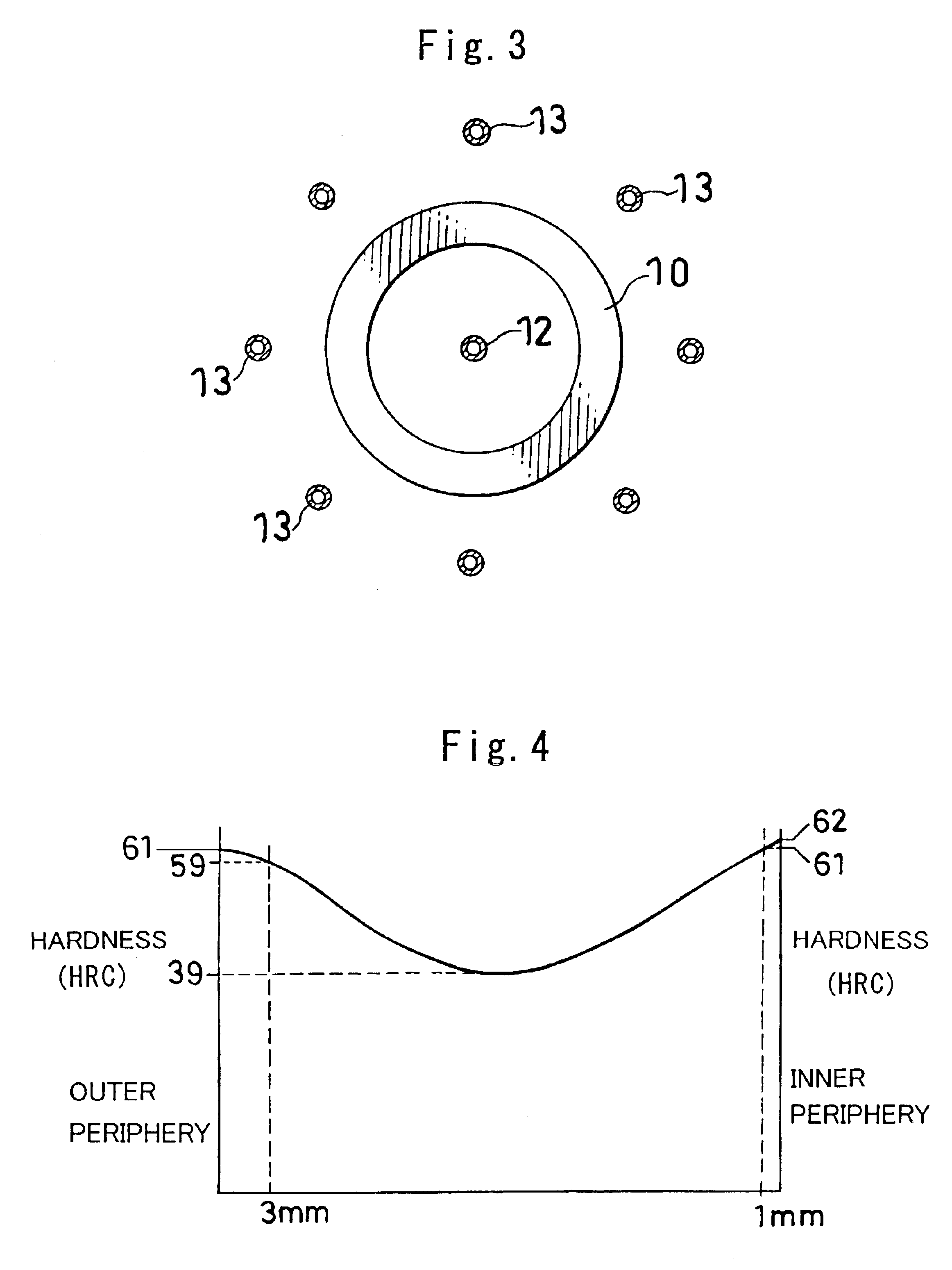

Antifriction bearing and process for producing outer race for use in antifriction bearing

An antifriction bearing comprises an inner race, an outer race having an outer peripheral surface to be brought into contact with other member for use as a roll, and a plurality of rolling elements arranged between the inner and outer races. The portion of the outer race from an outer peripheral surface thereof to a depth of 3 mm has a hardness of 58 to 62 in Rockwell C hardness (hereinafter referred to as “HRC”) and a hardness gradient of up to 1 HRC / 1 mm from the outer peripheral surface inward, and contains 5 to 18 vol. % of retained austenite. The portion of the outer race from an inner peripheral surface thereof to a depth of 1 mm has a hardness of 61 to 64 in HRC and contains 5 to 15 vol. % of retained austenite. The center portion of the thickness of the outer race between the inner and outer peripheral surfaces thereof has a hardness of 35 to 42 in HRC. The outer race can be prevented from cracking or breaking and from undergoing plastic deformation due to use for a short period of time.

Owner:KOYO SEIKO CO LTD

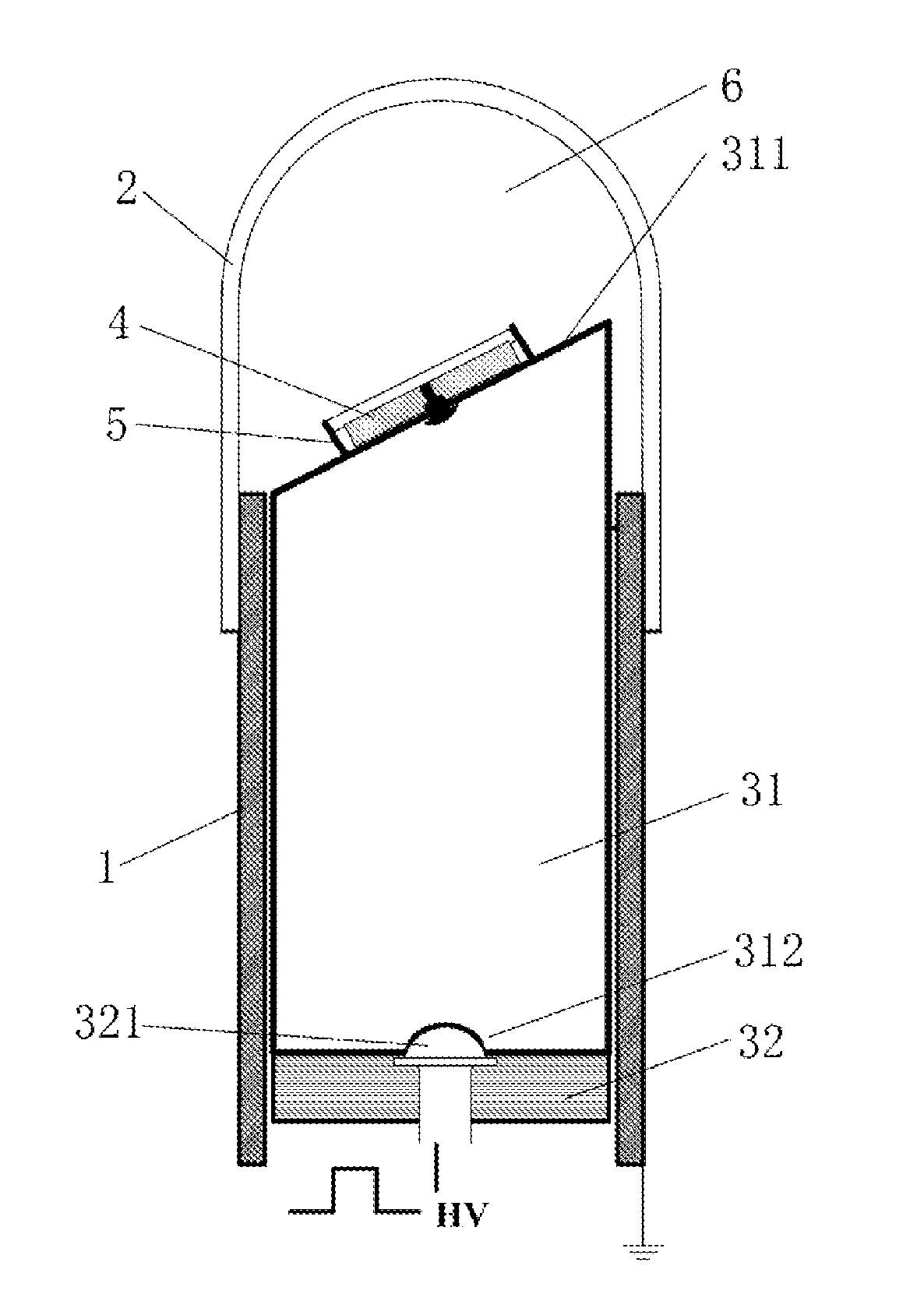

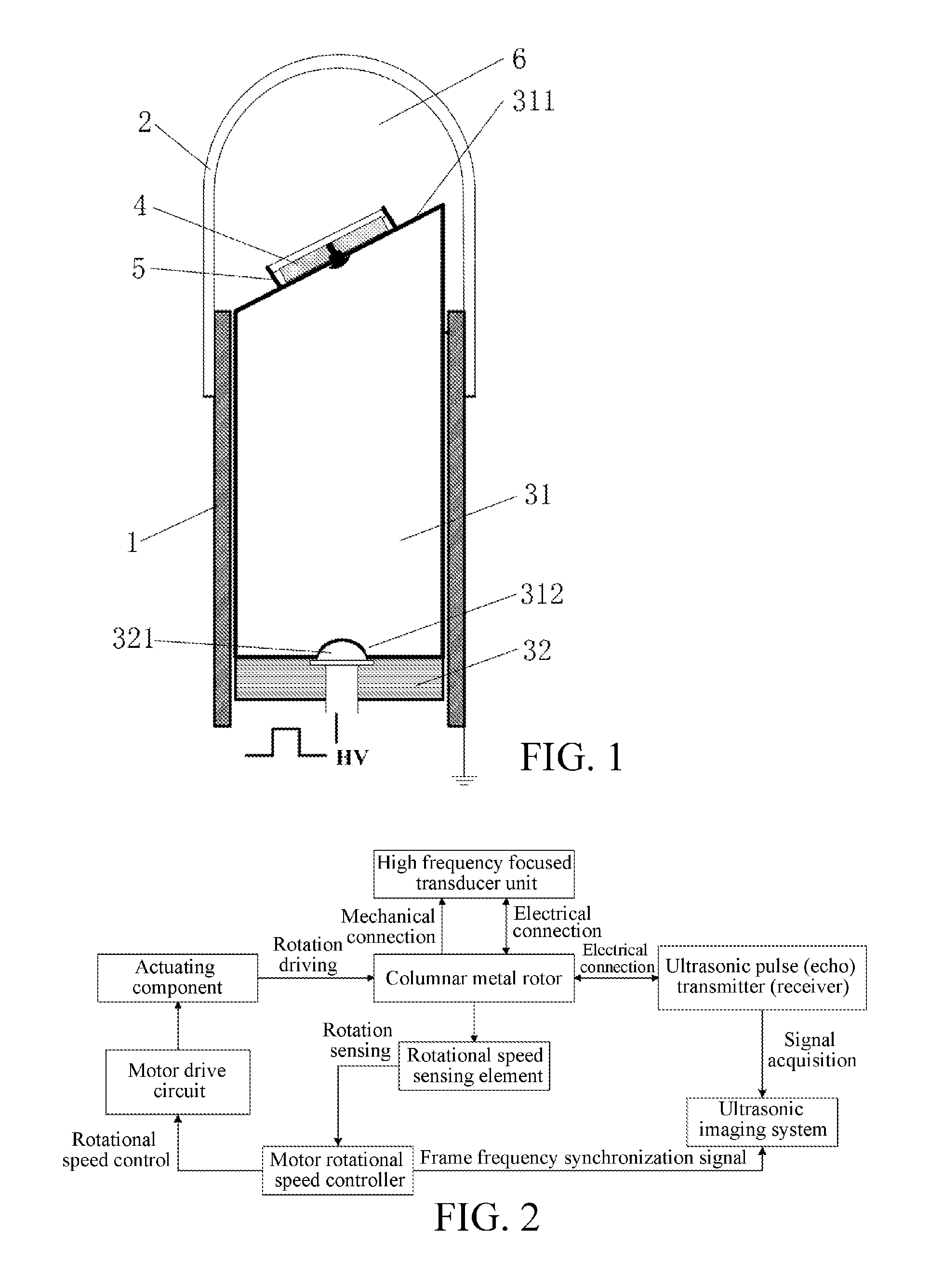

Mechanically rotating intravascular ultrasound probe

ActiveUS20150297182A1Lower the volumeEasy to controlSurgeryCatheterUltrasound angiographyForward looking

A mechanically rotating intravascular ultrasound probe relates to the technical field of medical devices, and aims to provide a forward-looking mechanically rotating intravascular ultrasound probe having a small volume, a high image resolution and good imaging stability. The intravascular ultrasound probe includes a catheter, an ultrasonic transducer disposed at a front end of a cavity of the catheter and a driving apparatus that drives the ultrasonic transducer to rotate mechanically. The driving apparatus is a micro motor disposed in the cavity of the catheter, including a rotor and a stator. The ultrasonic transducer is installed on top of the rotor and electrically connected to the rotor, and the rotor is also electrically connected to the stator; the catheter is a magnetic metal tube, and a front end thereof is enclosed by an acoustic window which has a spherical tip and allows ultrasonic waves of the ultrasonic transducer to pass through; the acoustic window is filled with an ionic liquid having a function of a ultrasonic coupling agent. The ultrasound probe solves a problem of rotation torsion of an image when the catheter passes through a lesion with high-grade stenosis or a curved blood vessel section, and achieves forward scanning imaging and side scanning imaging for a blood vessel wall.

Owner:SHENZHEN UNIV

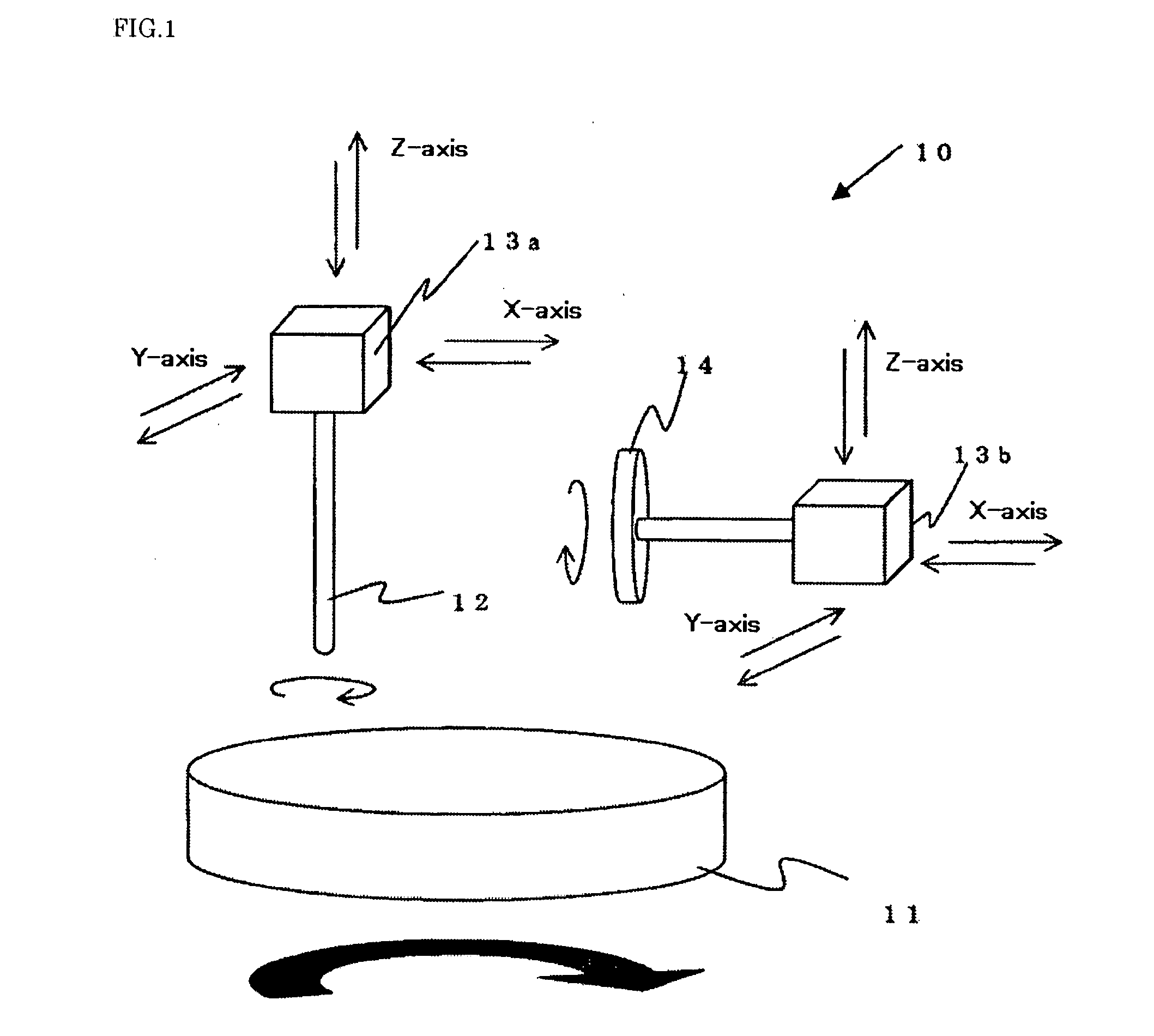

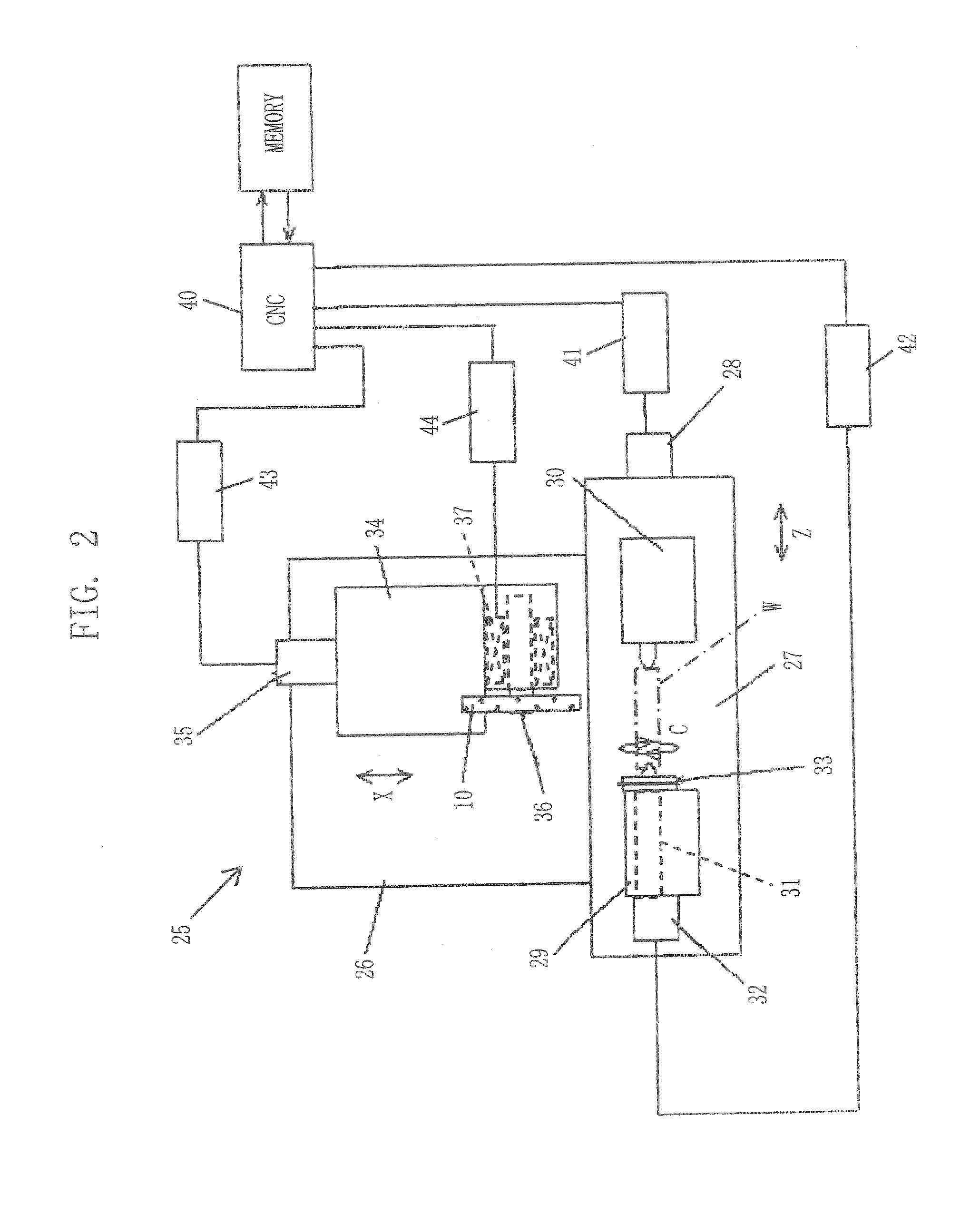

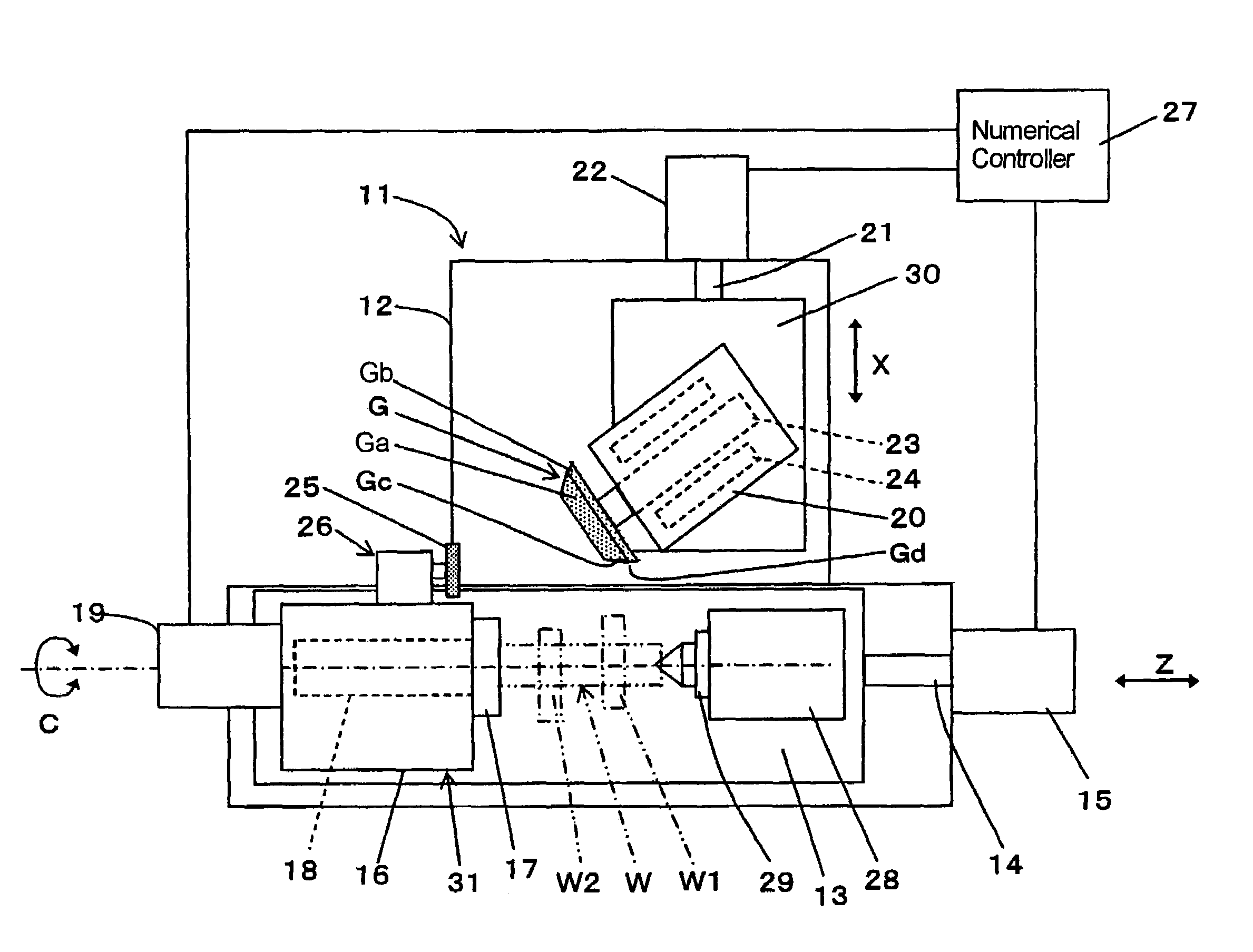

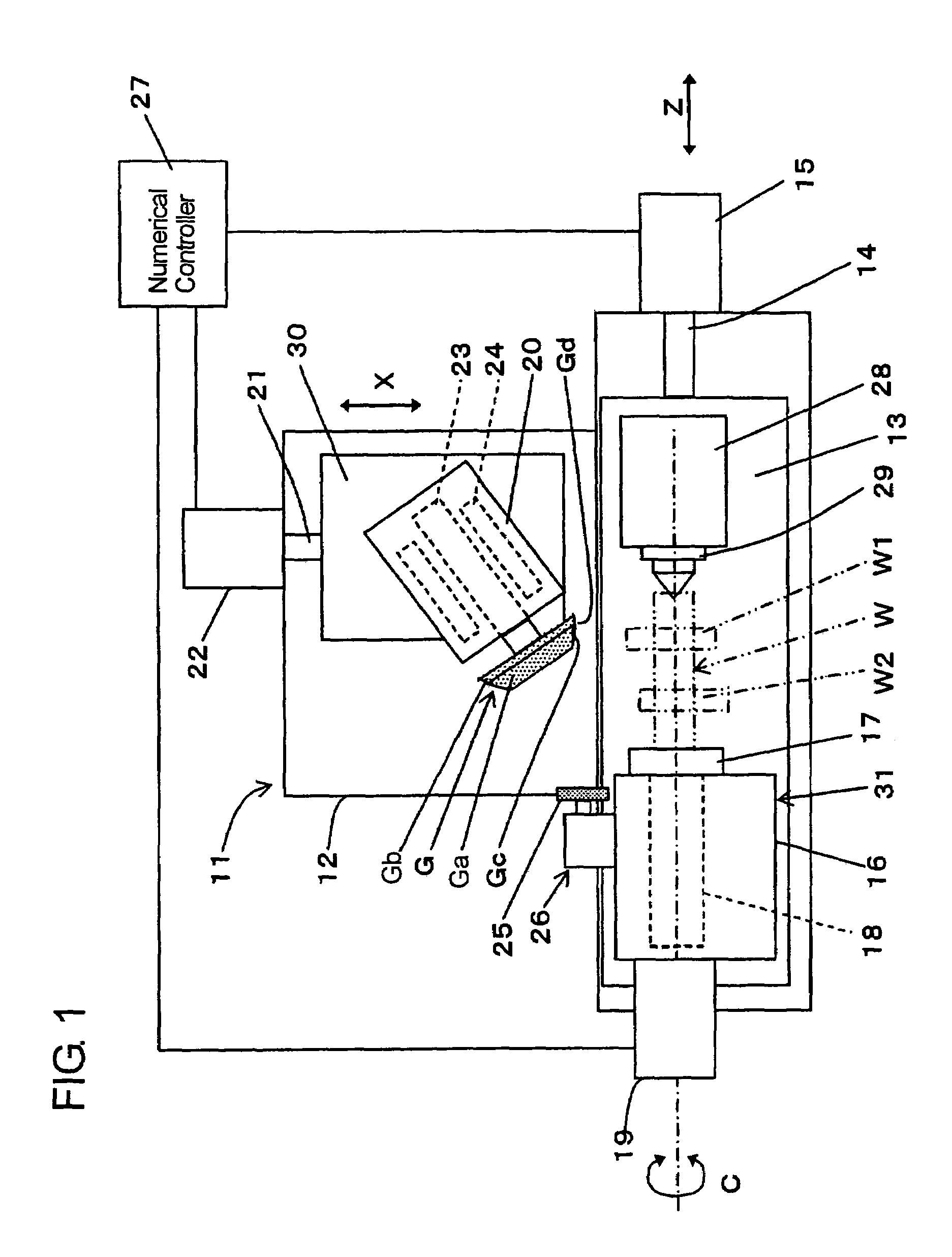

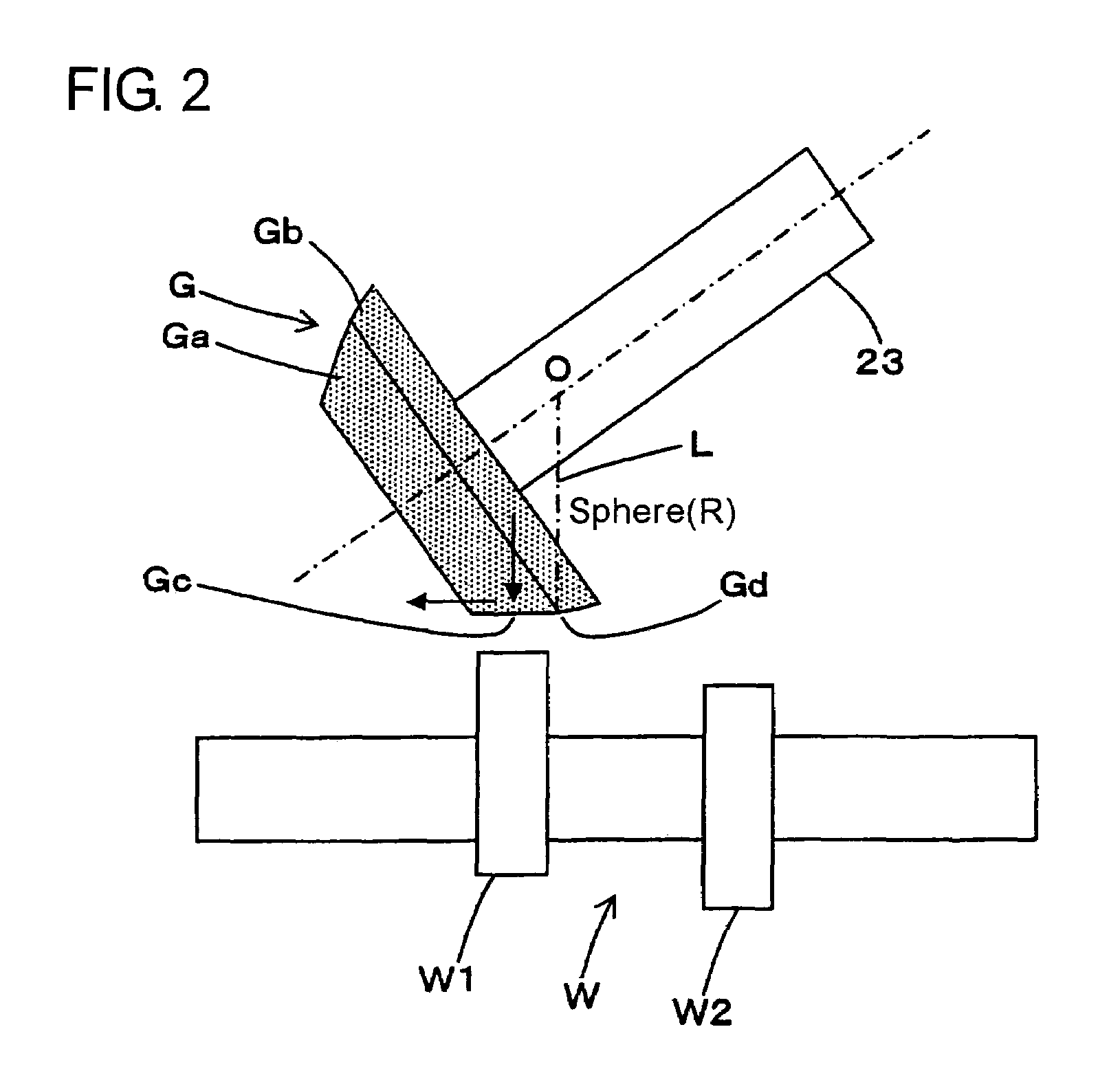

Method and apparatus for grinding cam with re-entrant surface

ActiveUS6979247B1Efficiently groundEfficiency and precisionEdge grinding machinesBelt grinding machinesRotational axisMaximum diameter

A workpiece W and a grinding wheel G are relatively moved in Z and X-axis directions perpendicular to each other, the rotational axis of the grinding wheel is inclined relative to the X-axis, and the grinding wheel is composed of a taper section Ga having a generating line parallel to the Z-axis and a spherical section Gb connecting with the generating line at the maximum diameter portion of the taper section Ga. While performing a cam profile generating motion, the grinding wheel is controlled to perform a plunge grinding feed toward the workpiece in the X-axis direction to effect a plunge grinding on the cam of the workpiece and then, while performing the cam profile generating motion, is controlled to perform a traverse grinding feed in the Z-axis direction to effect a traverse grinding on the cam.

Owner:TOYODA MASCH WORKS LTD

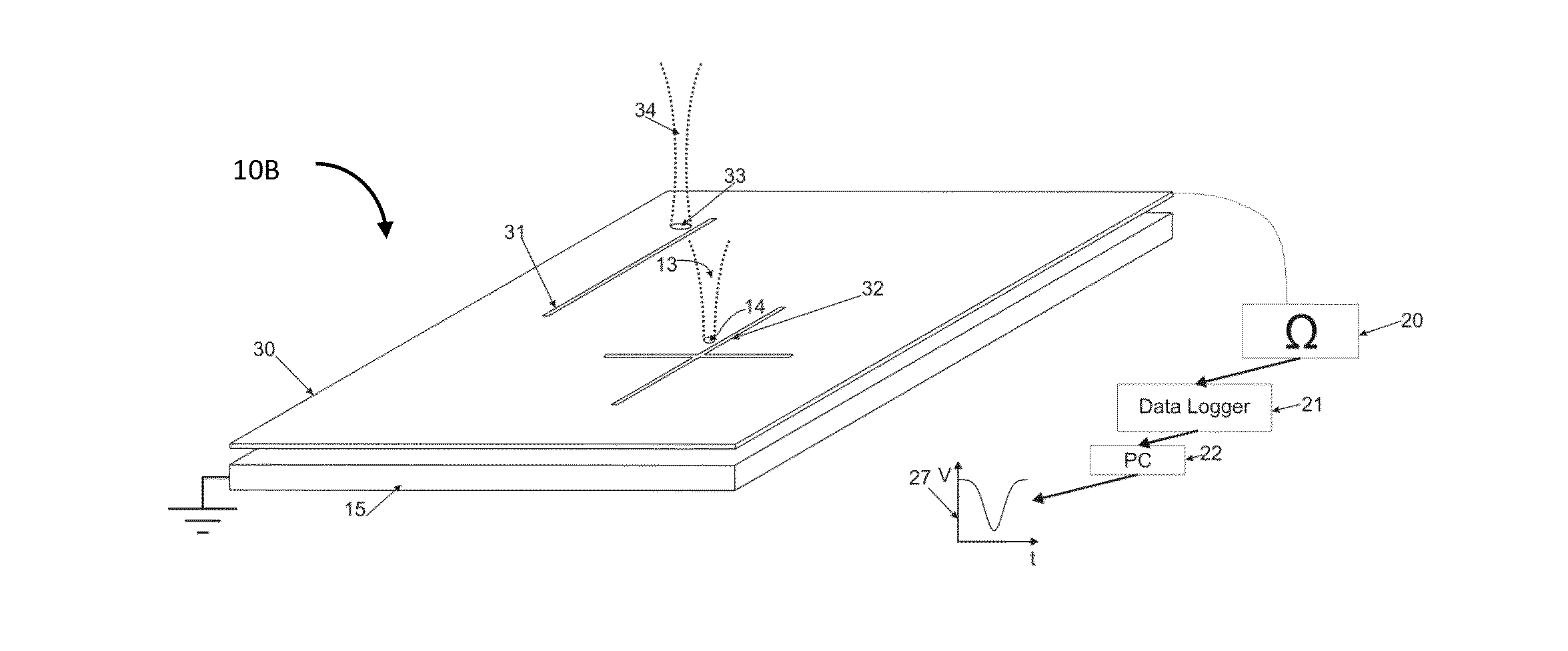

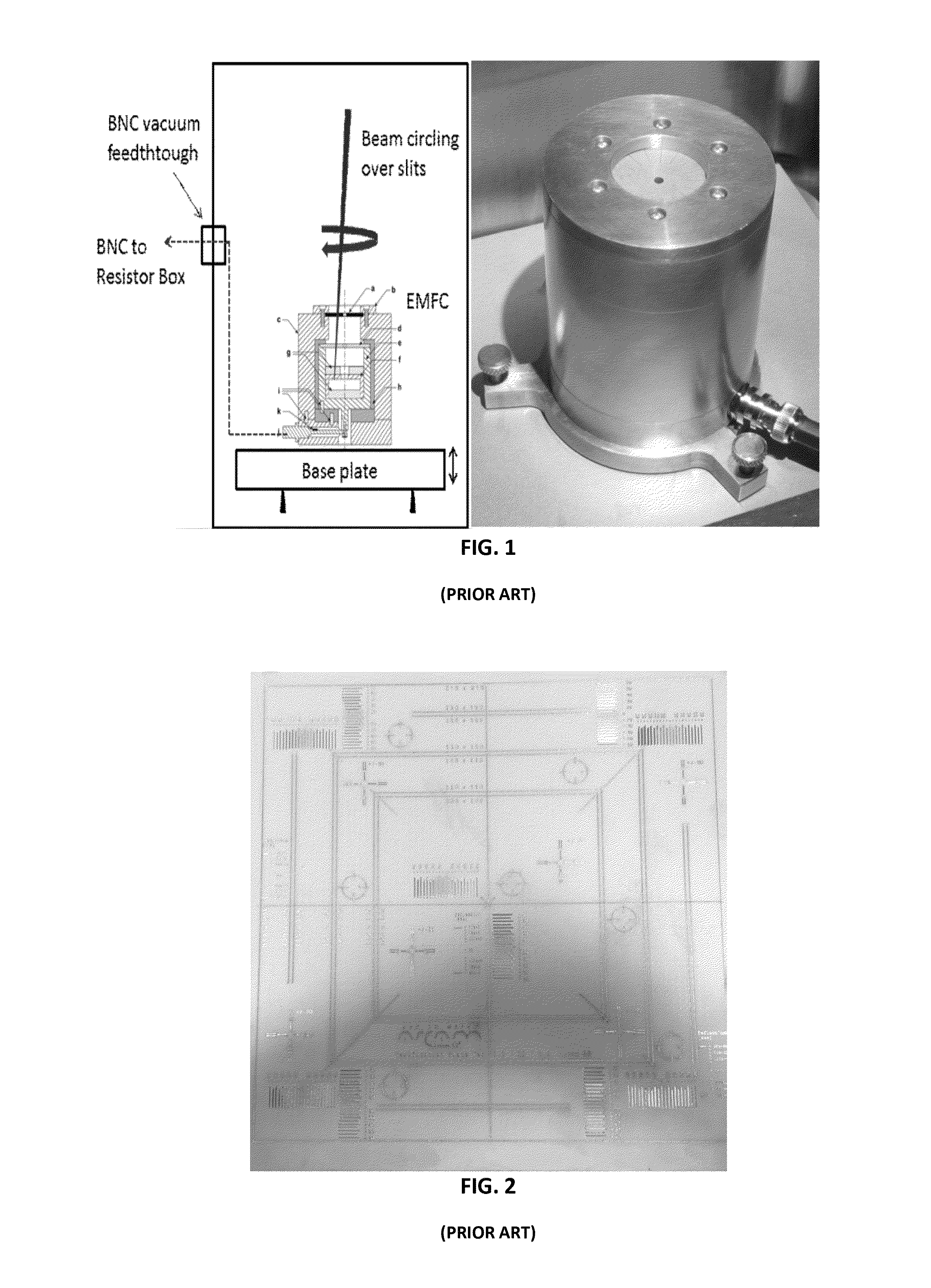

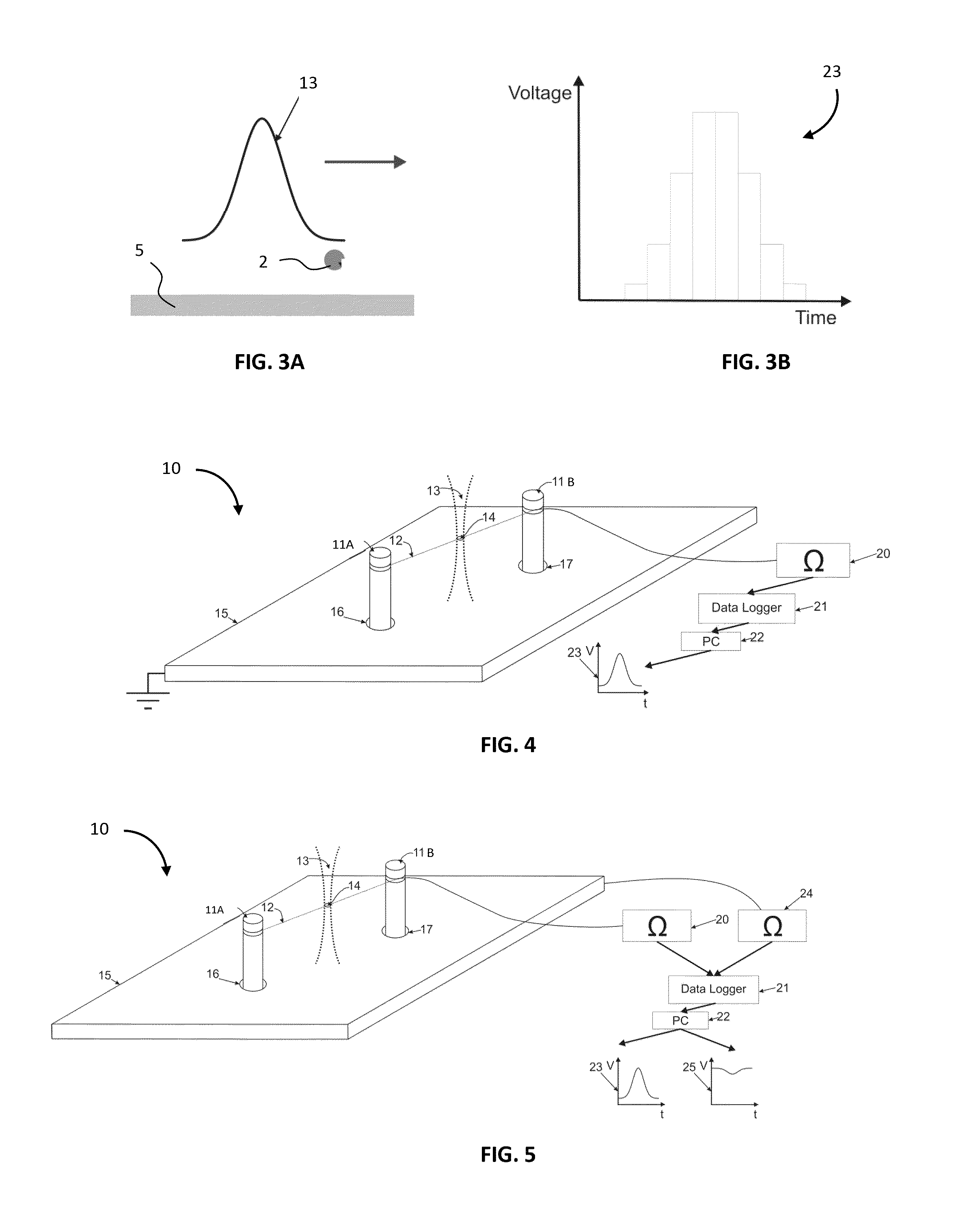

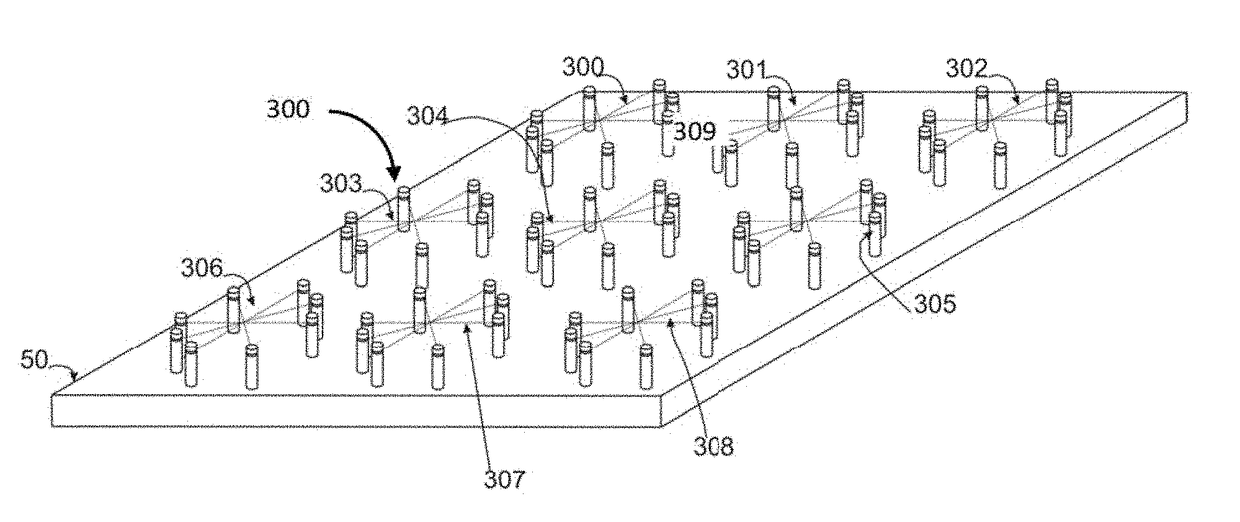

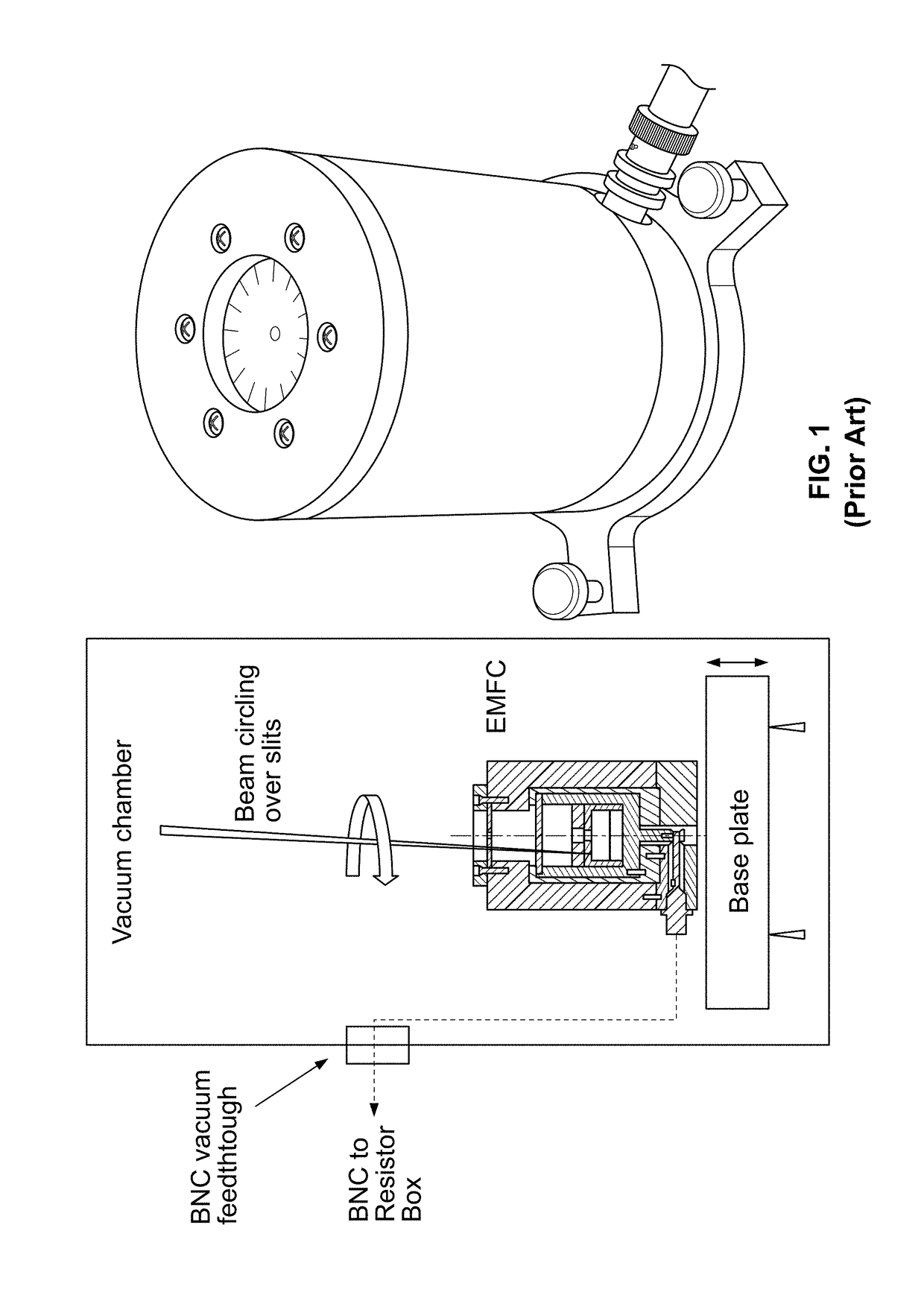

Assessment and calibration of a high energy beam

ActiveUS20160124026A1Measure quickly and accuratelyAccurate measurementElectric discharge tubesCurrent/voltage measurementElectricityElectrical conductor

A high energy beam verification, calibration, and profiling system includes a conductive base plate, supports extending from the base plate, a plurality of conductors, a data logger electrically connected to the conductors, and a computer electrically connected to the data logger. Each conductor is supported by some of the supports such that each conductor is insulated from the conductive base plate. Each conductor has a profile intersecting with profiles of at least some of the other conductors to define a multidirectional and two-dimensional array of conductors. The data logger receives and records data associated with electrical charges flowing through the conductors. The computer is adapted to receive, manipulate, and display the data recorded by the data logger for comparison of beam characteristics at different locations across a high energy beam build area.

Owner:HOWMEDICA OSTEONICS CORP

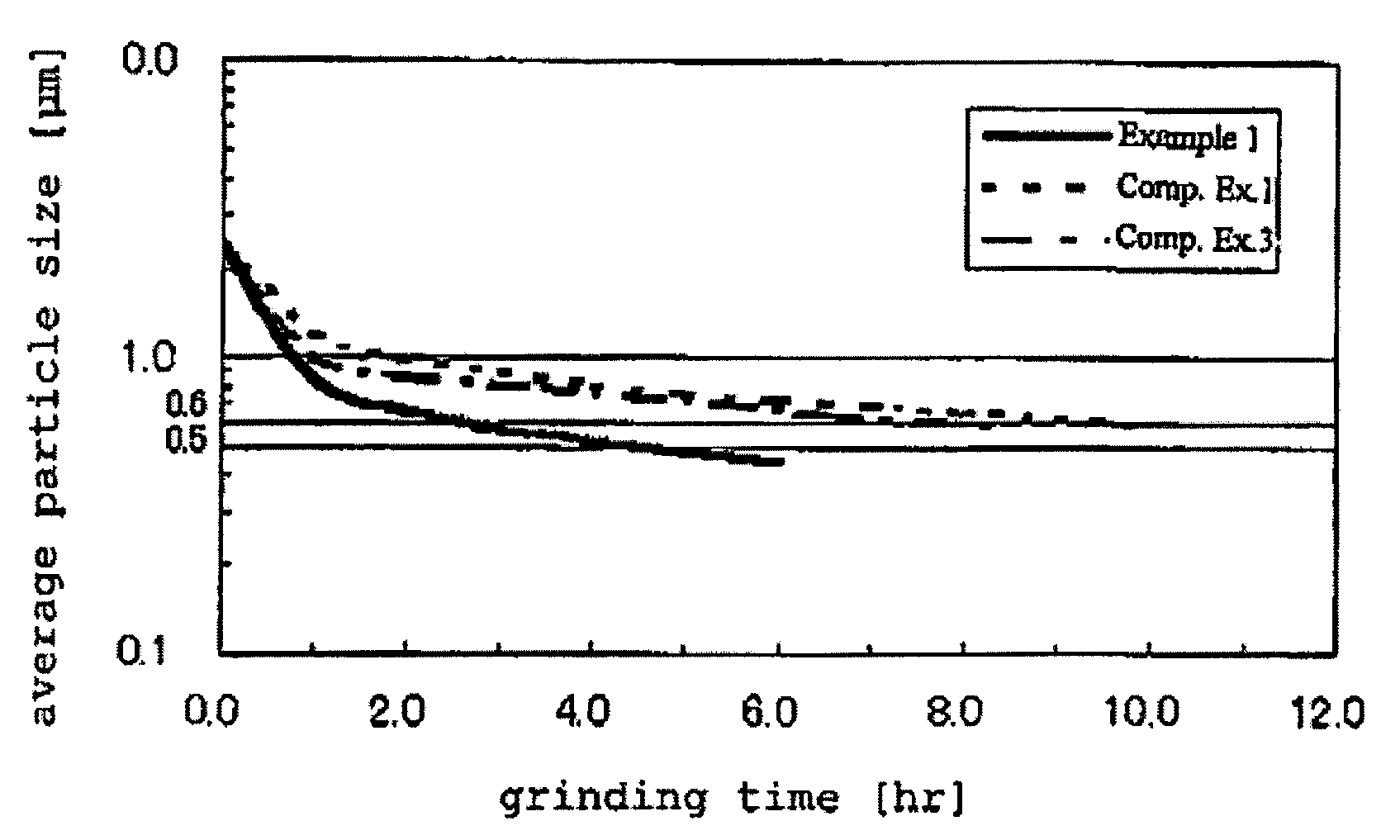

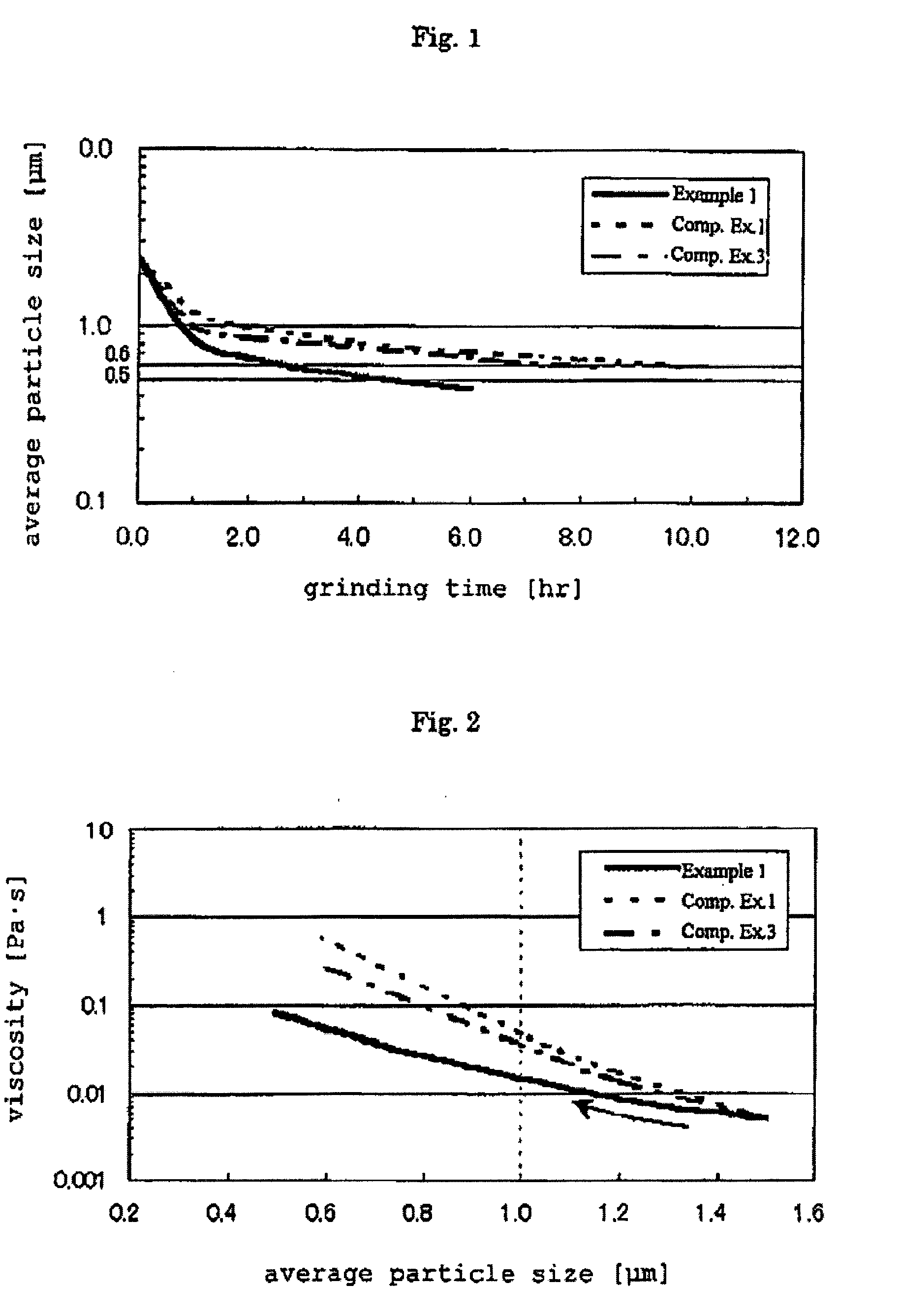

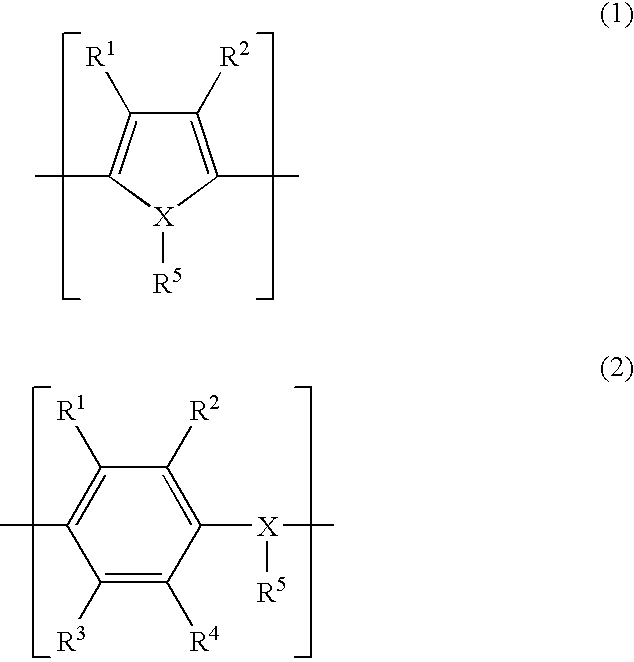

Niobium powder, niobium granulated powder, niobium sintered body, capacitor and production method thereof

InactiveUS20060260437A1Small leakage current valueImprove reliabilityElectrolytic capacitorsTransportation and packagingCapacitanceVolumetric Mass Density

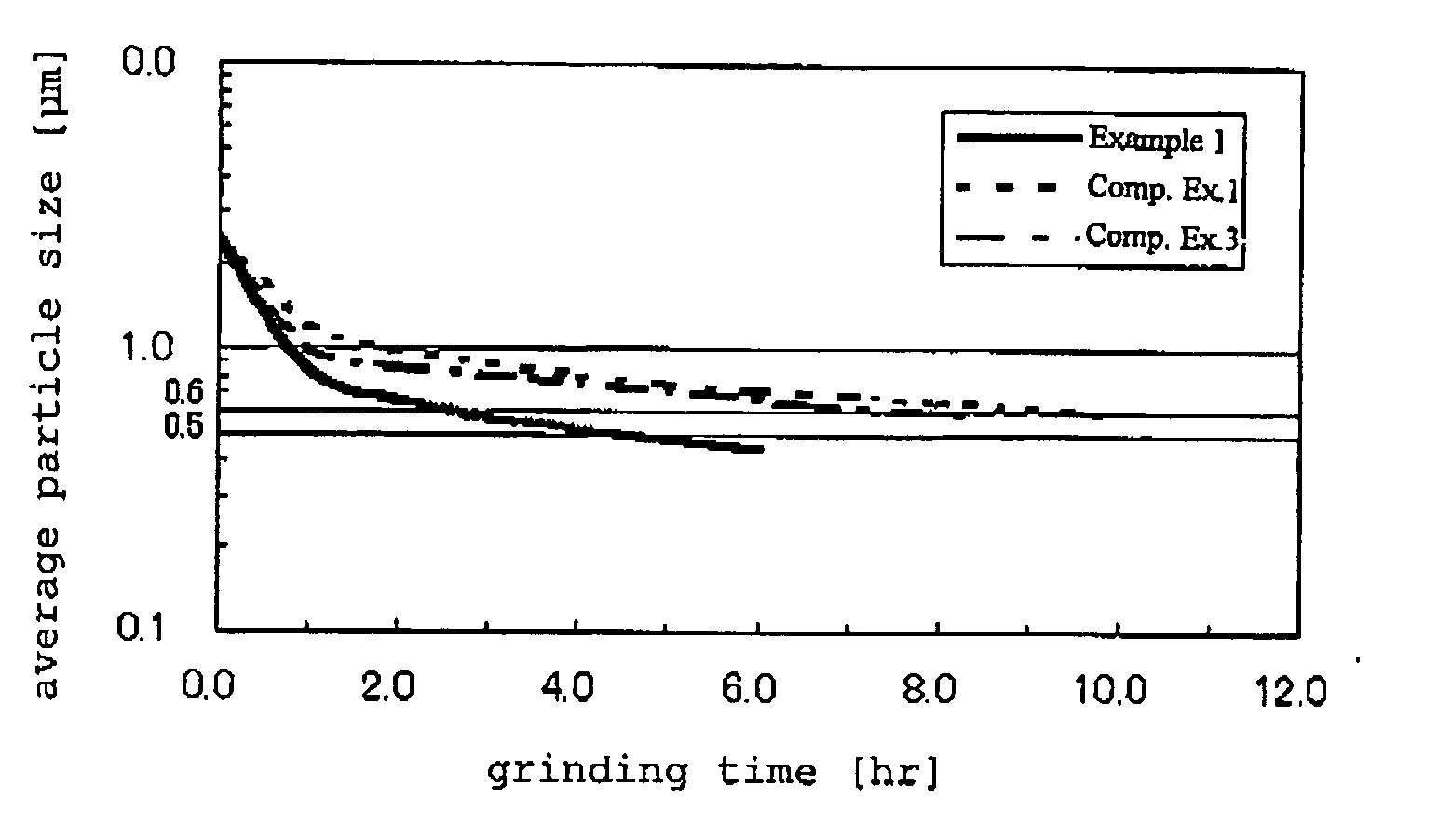

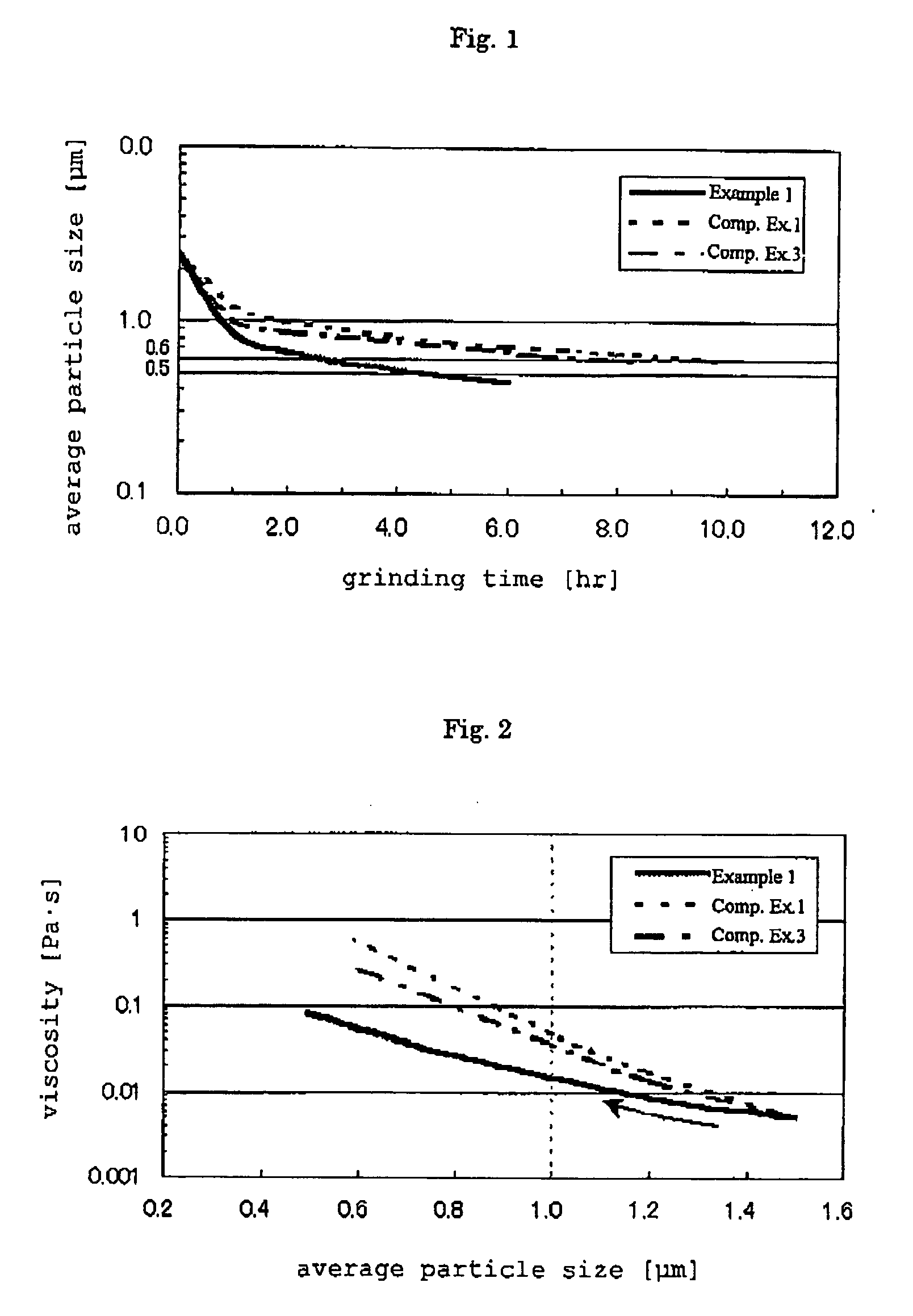

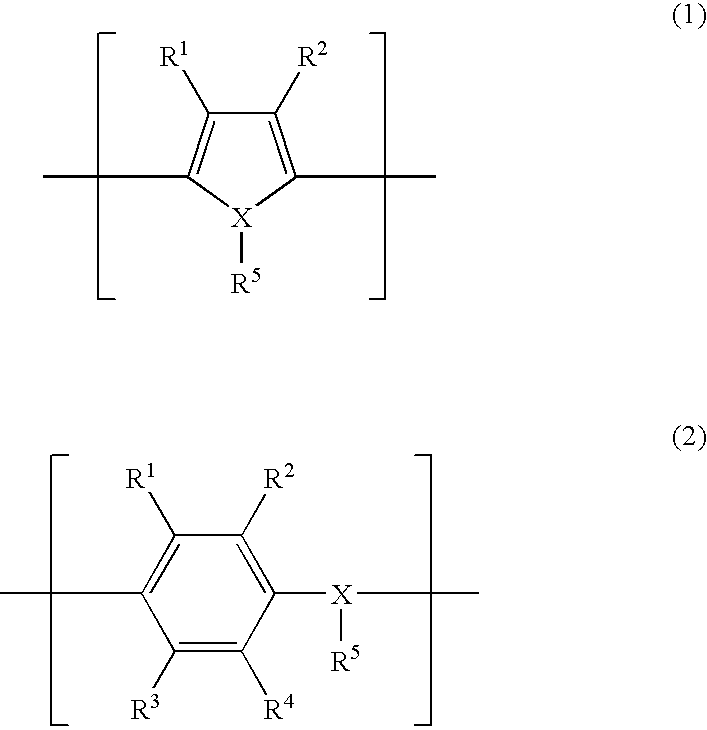

The present invention provides a method of efficiently producing niobium powder, niobium alloy powder, niobium hydride powder or niobium hydride alloy powder for a capacitor, which enables production of capacitor having a high capacitance per unit mass and good leakage current characteristics with narrow variation, and also provides a production method for sintered body and a capacitor using the niobium powder, niobium alloy powder, niobium hydride powder or niobium hydride alloy powder. According to the present invention, by grinding niobium hydride powder or niobium hydride alloy powder with a grinding aid having a density of 2 to 3.6 g / cm3 and a fracture toughness value of 1.5 MPa·m1 / 2 or more, such as beads made of silicon nitride or a compound containing silicon nitride, a niobium powder with high capacitance can be efficiently produced.

Owner:SHOWA DENKO KK

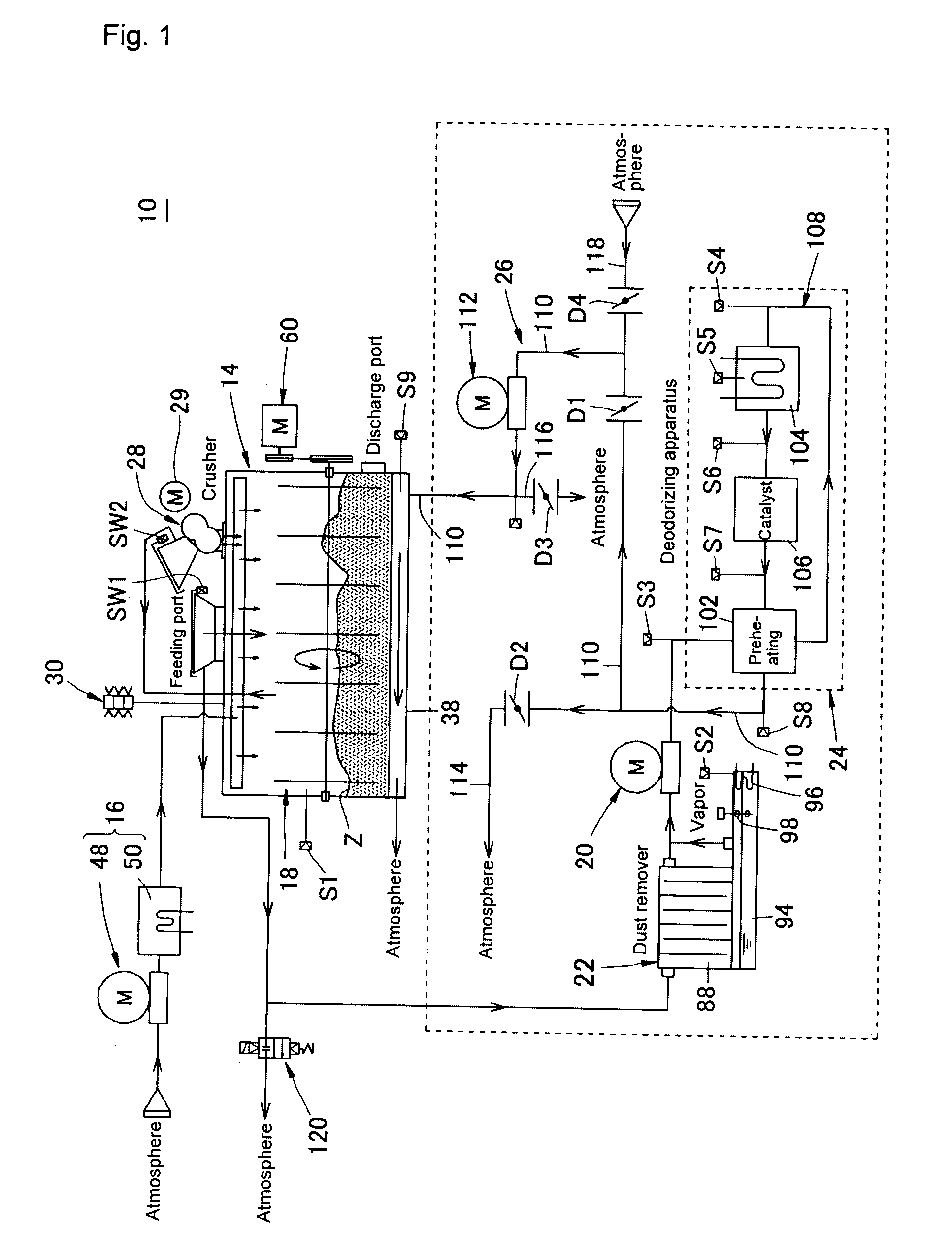

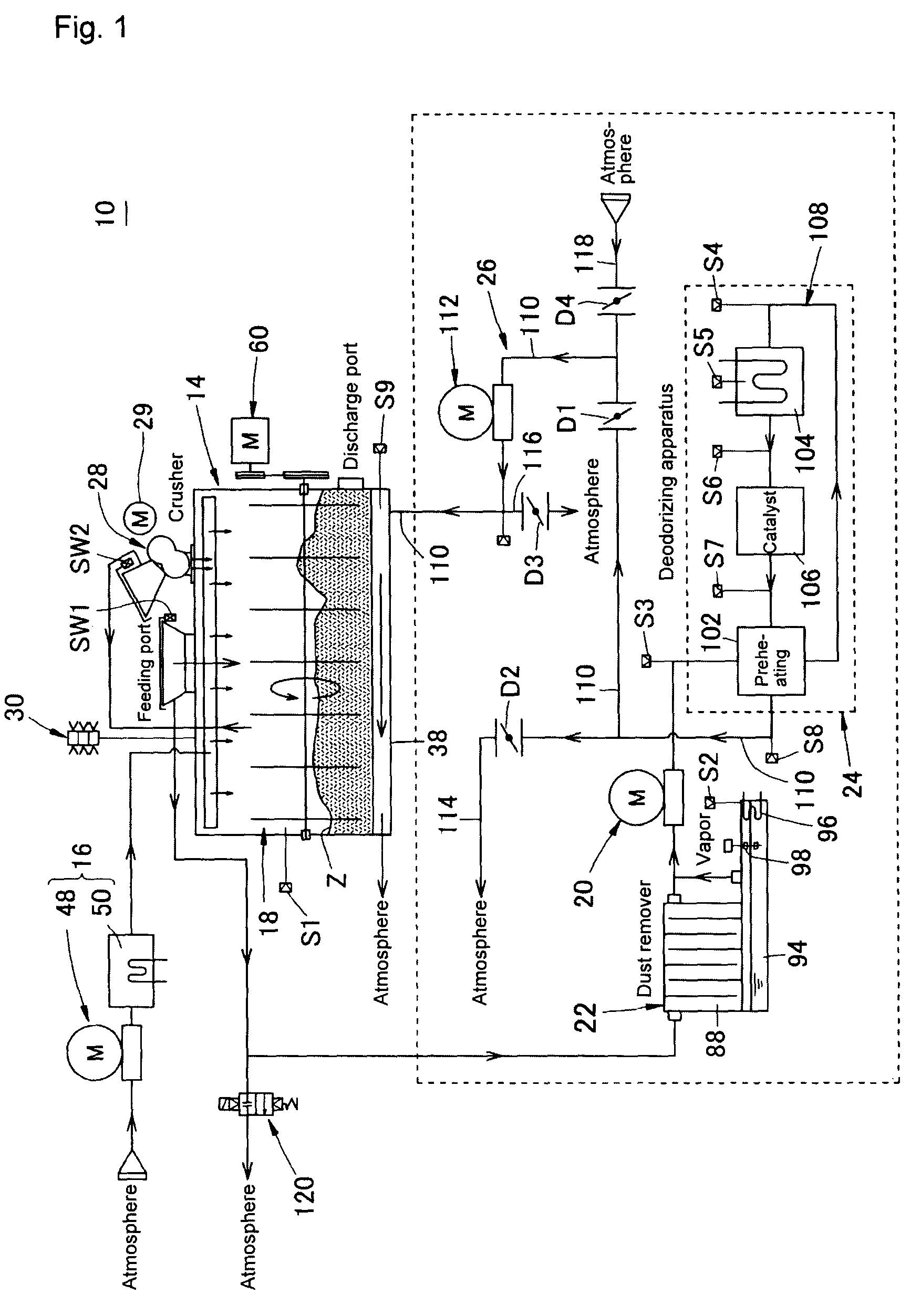

Waste Treatment Apparatus

InactiveUS20070298488A1Efficiently agitatedLittle effortBioreactor/fermenter combinationsBio-organic fraction processingWaste treatmentAnnihilation

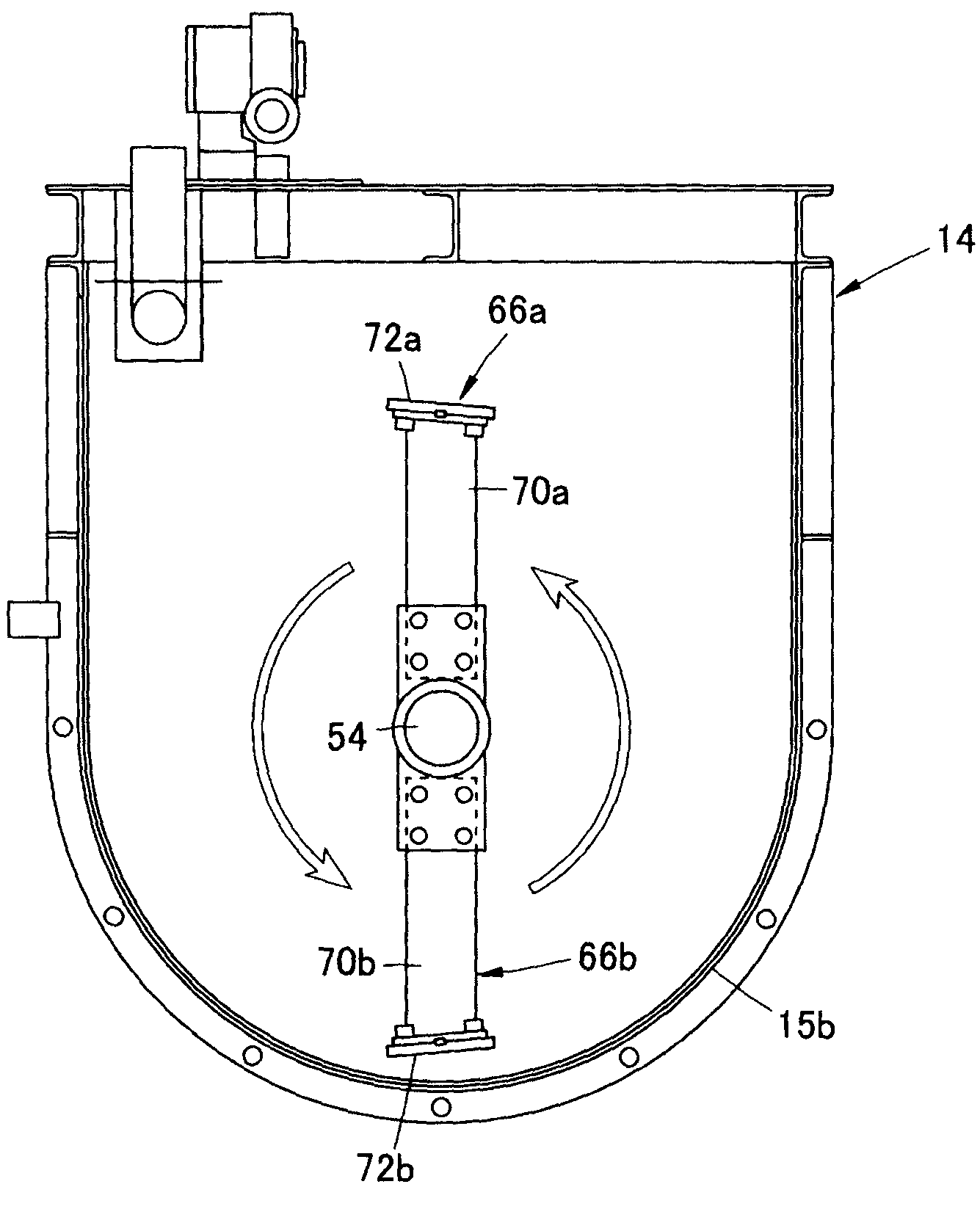

A waste treatment apparatus decomposes waste by the microorganisms to perform annihilation treatment. The waste treatment apparatus includes a treatment tank which accommodates the microorganisms together with the waste, and an agitation device arranged to agitate the microorganisms together with the waste. The agitation device includes a plurality of agitating tools arranged at predetermined intervals in the axial direction of a rotation shaft. The agitating tools have paddle arms, respectively, which are disposed so as to be opposed to each other in a diameter direction of the rotation shaft, and blades, respectively, which are disposed at predetermined distances apart from an inner wall of the treatment tank and are inclined with respect to the axis of the paddle arms. The blade on one side is inclined forward in a direction in which the front side thereof with respect to the rotation direction of the paddle arm approaches the rotation shaft. The blade on the other side is inclined backward in a direction in which the rear side thereof with respect to the rotation direction of the paddle arm 70b approaches the rotation shaft.

Owner:KOAI IND

Waste treatment apparatus

InactiveUS7816127B2Efficient heatingEfficiently agitatedBioreactor/fermenter combinationsBio-organic fraction processingWaste treatmentAnnihilation

A waste treatment apparatus decomposes waste by the microorganisms to perform annihilation treatment. The waste treatment apparatus includes a treatment tank which accommodates the microorganisms together with the waste, and an agitation device arranged to agitate the microorganisms together with the waste. The agitation device includes a plurality of agitating tools arranged at predetermined intervals in the axial direction of a rotation shaft. The agitating tools have paddle arms, respectively, which are disposed so as to be opposed to each other in a diameter direction of the rotation shaft, and blades, respectively, which are disposed at predetermined distances apart from an inner wall of the treatment tank and are inclined with respect to the axis of the paddle arms. The blade on one side is inclined forward in a direction in which the front side thereof with respect to the rotation direction of the paddle arm approaches the rotation shaft. The blade on the other side is inclined backward in a direction in which the rear side thereof with respect to the rotation direction of the paddle arm 70b approaches the rotation shaft.

Owner:KOAI IND

Niobium powder, niobium granulated powder, niobium sintered body, capacitor and production method thererof

InactiveUS20090256014A1Efficiently groundSmall currentElectrolytic capacitorsTransportation and packagingCapacitanceNiobium alloy

The present invention provides a method of efficiently producing niobium powder, niobium alloy powder, niobium hydride powder or niobium hydride alloy powder for a capacitor, which enables production of capacitor having a high capacitance per unit mass and good leakage current characteristics with narrow variation, and also provides a production method for sintered body and a capacitor using the niobium powder, niobium alloy powder, niobium hydride powder or niobium hydride alloy powder. According to the present invention, by grinding niobium hydride powder or niobium hydride alloy powder with a grinding aid having a density of 2 to 3.6 g / cm3 and a fracture toughness value of 1.5 MPa·m1 / 2 or more, such as beads made of silicon nitride or a compound containing silicon nitride, a niobium powder with high capacitance can be efficiently produced.

Owner:SHOWA DENKO KK

Livestock food processing mixing machine

InactiveUS7028933B2Rapid and efficient mannerEfficient crushingGrain huskingGrain polishingFiberAdditive ingredient

A mixing machine consists of a hopper having a main chamber within its housing with a rotary member, a secondary chamber having a bottom worm conveying the material from one end of the mixing machine to the other end thereof, until collapsing with a loop found on its front portion and generating a material bubble; an upper worm to remove the material bubble and carrying it up to the middle part of the machine. At the middle part of the machine, the material is forced by a loop system having an upper worm to move towards the rotor area, such that the material is actually moving towards the back portion of the machine, completing a mixing cycle. The upper worm has from the middle of its axis, a plurality of discs on which peripheral edge of each disc is mounted a series of exchangeable knives placed on a loop arrangement, which are passed through a counterplate, and which shows a series of exchangeable knives placed at the bottom part of the material collector chut, so when the upper worm discs plurality is rotating, it allows both, humid and dry fibers be efficiently crushed and / or ground and besides added to the other several common ingredients a unique and highly qualified mixing is achieved.

Owner:TORMEX IND DE C V

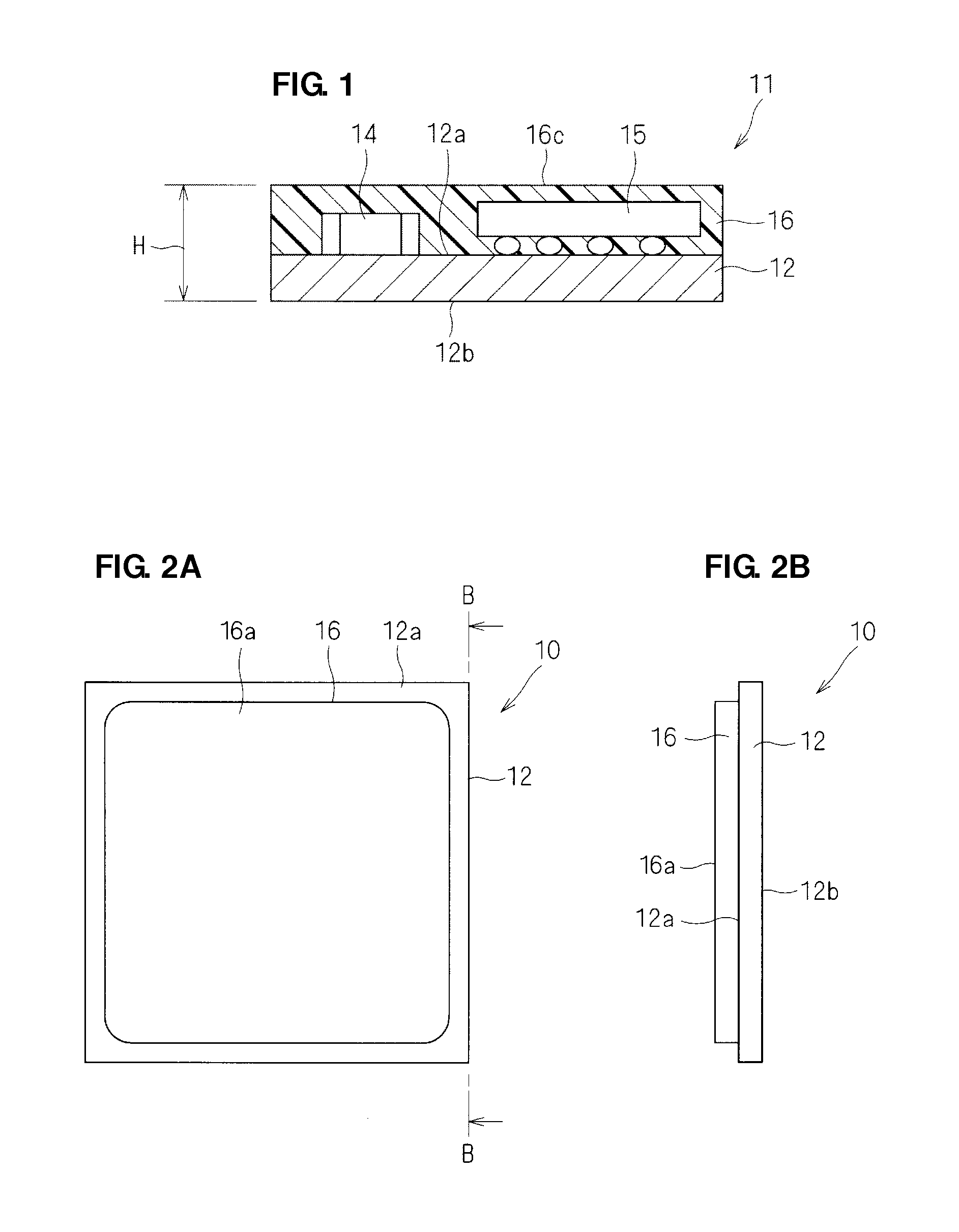

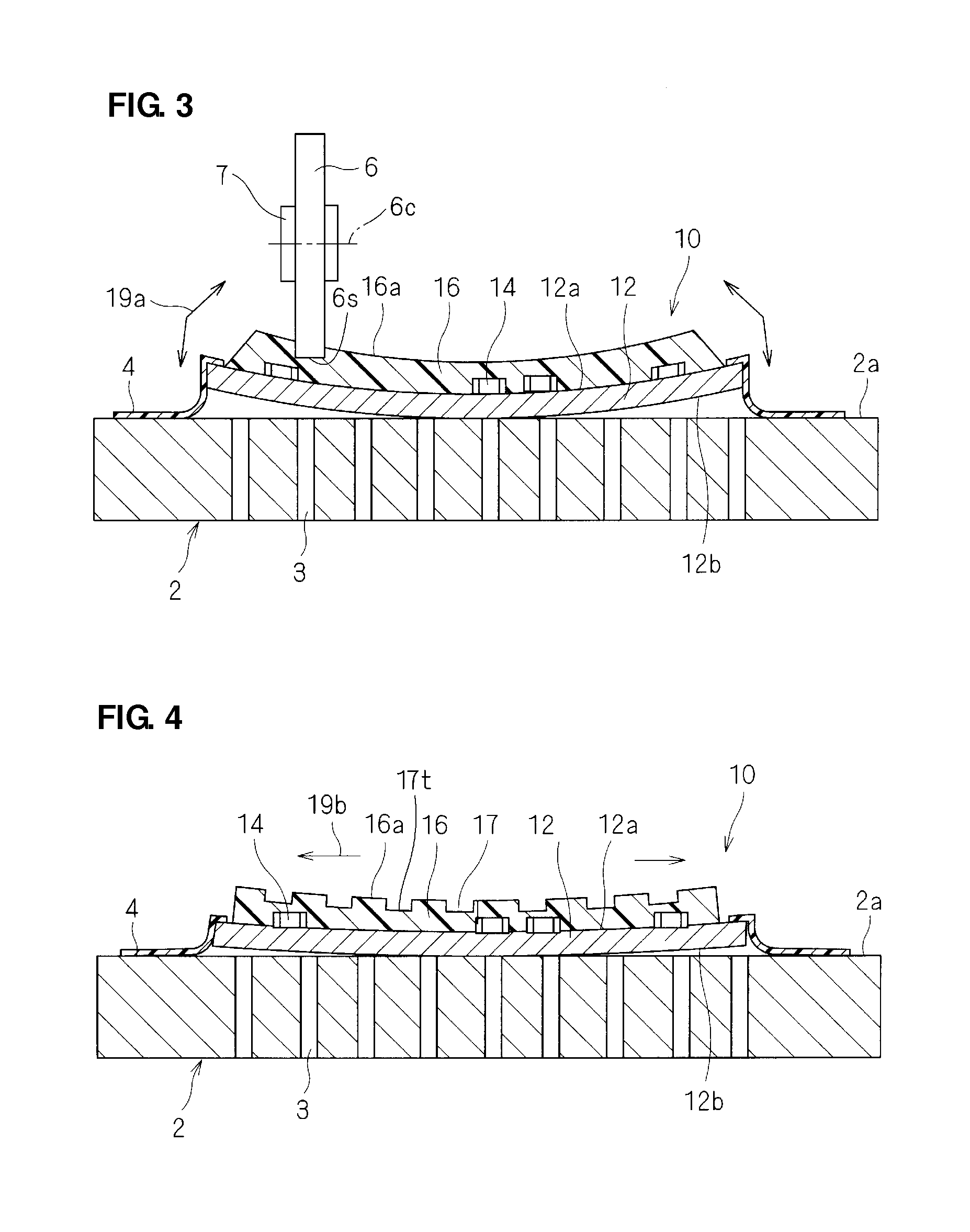

Electronic component manufacturing method

ActiveUS20120251791A1Efficiently groundReduce thicknessLayered productsSemiconductor/solid-state device detailsEngineeringElectronic component

An electronic component manufacturing method that efficiently grinds a cover layer provided on a substrate even when the substrate is warped includes the step of forming first grooves at intervals in a cover layer provided on a substrate by repeating grinding with a rotary blade at a pitch more than a thickness W of the rotary blade. Next, at least portions provided in the cover layer along the first grooves are removed to reduce the thickness of the cover layer by repeating grinding at a pitch equal to or less than the thickness W of the rotary blade.

Owner:MURATA MFG CO LTD

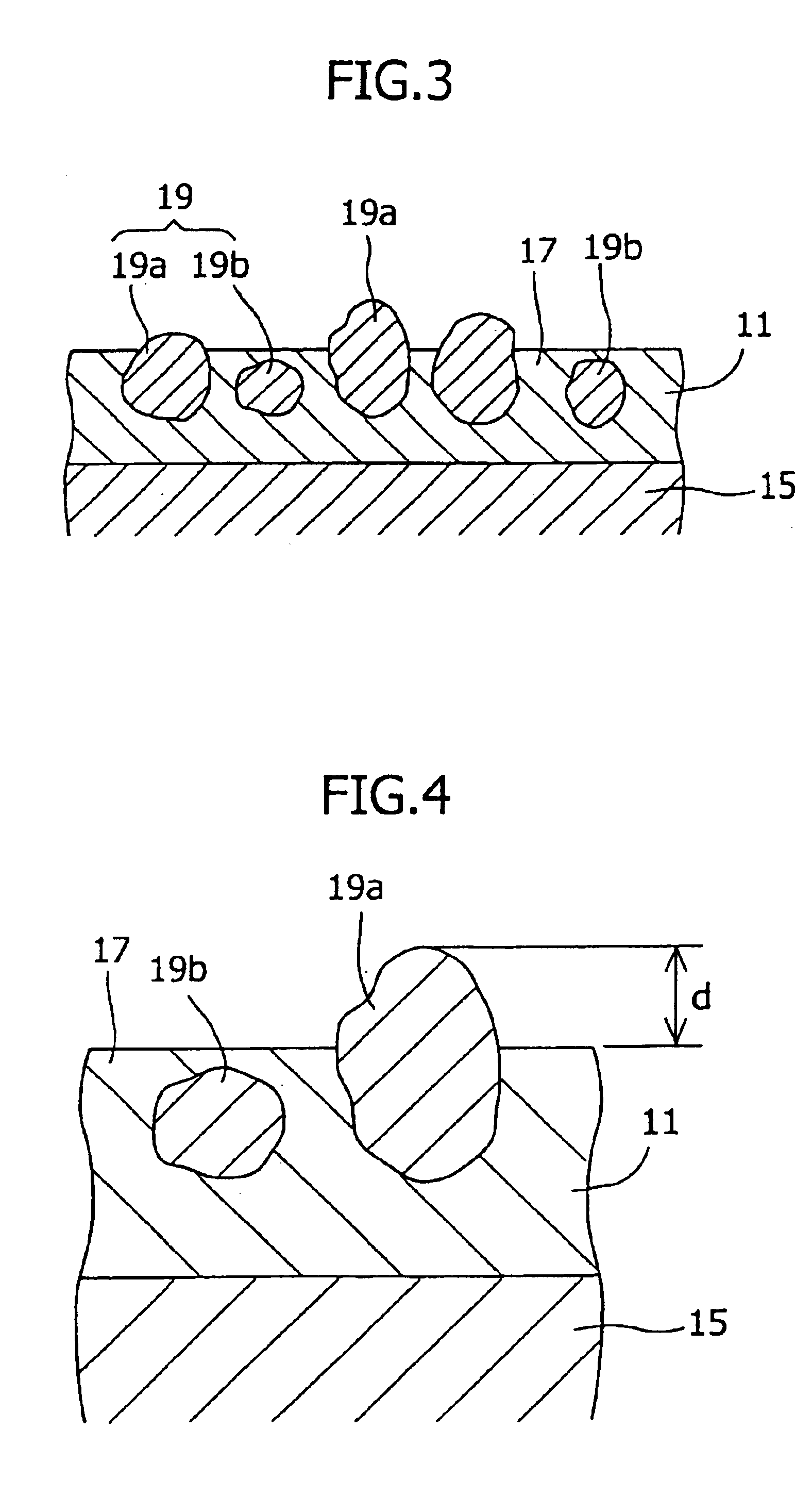

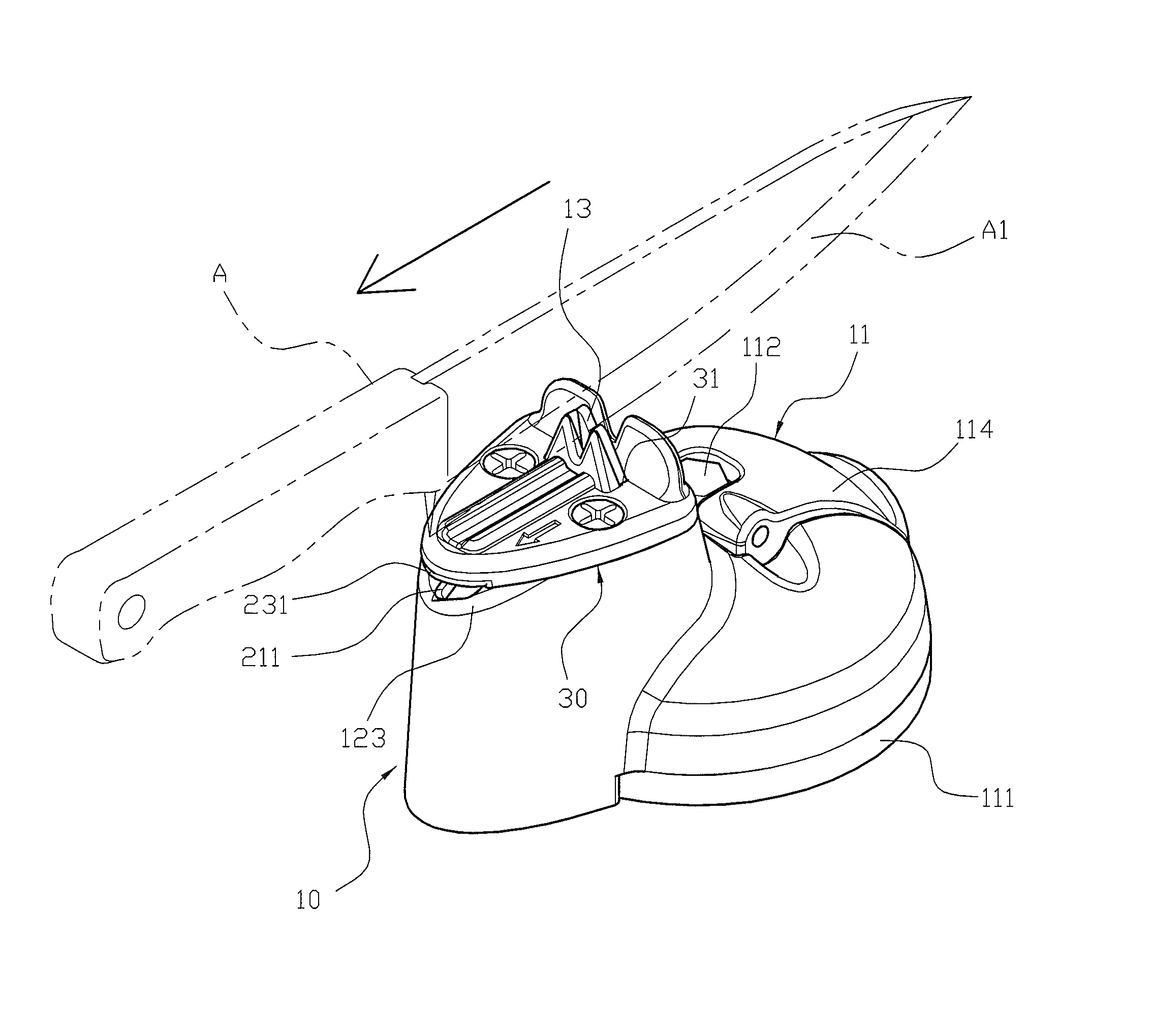

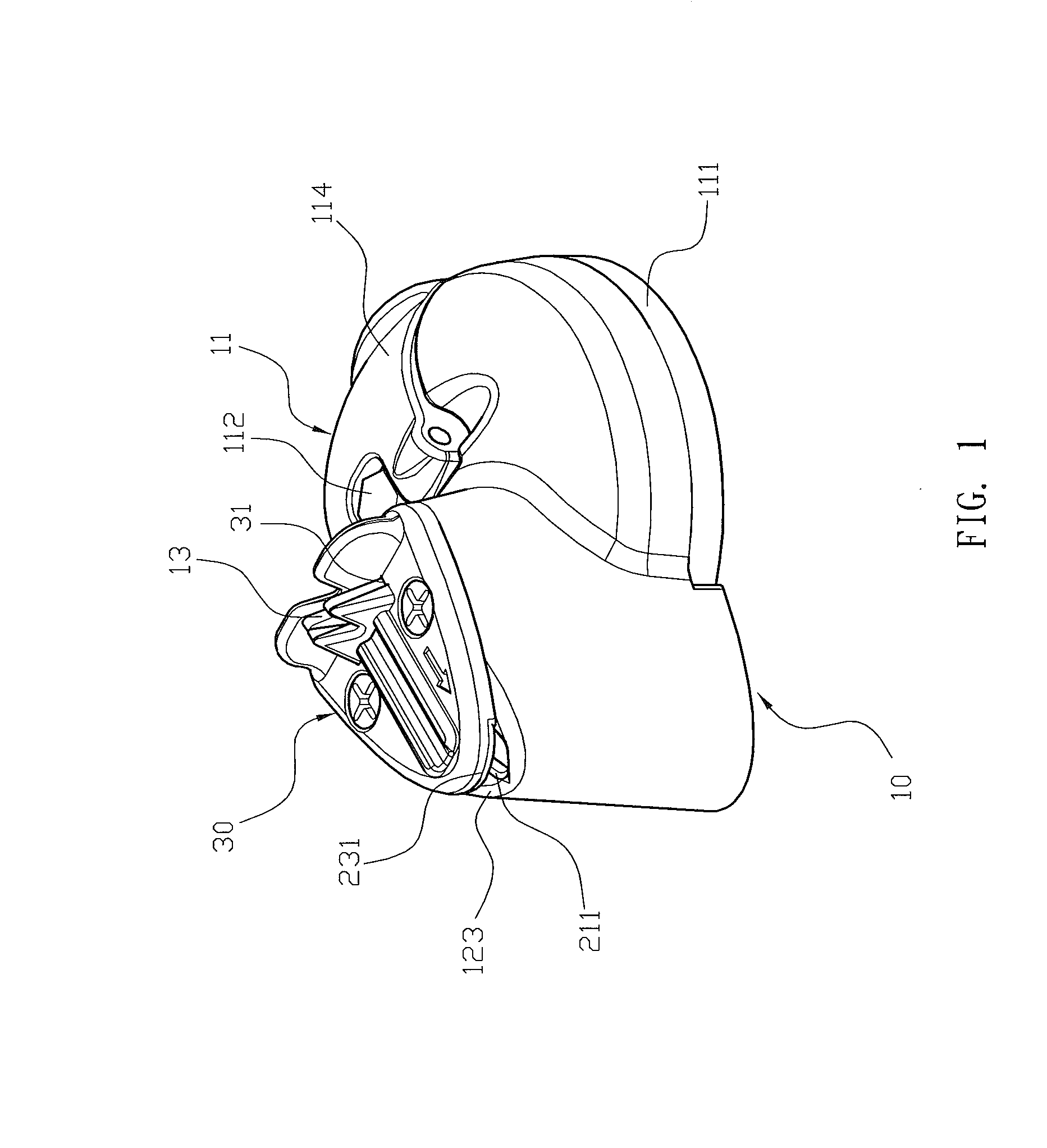

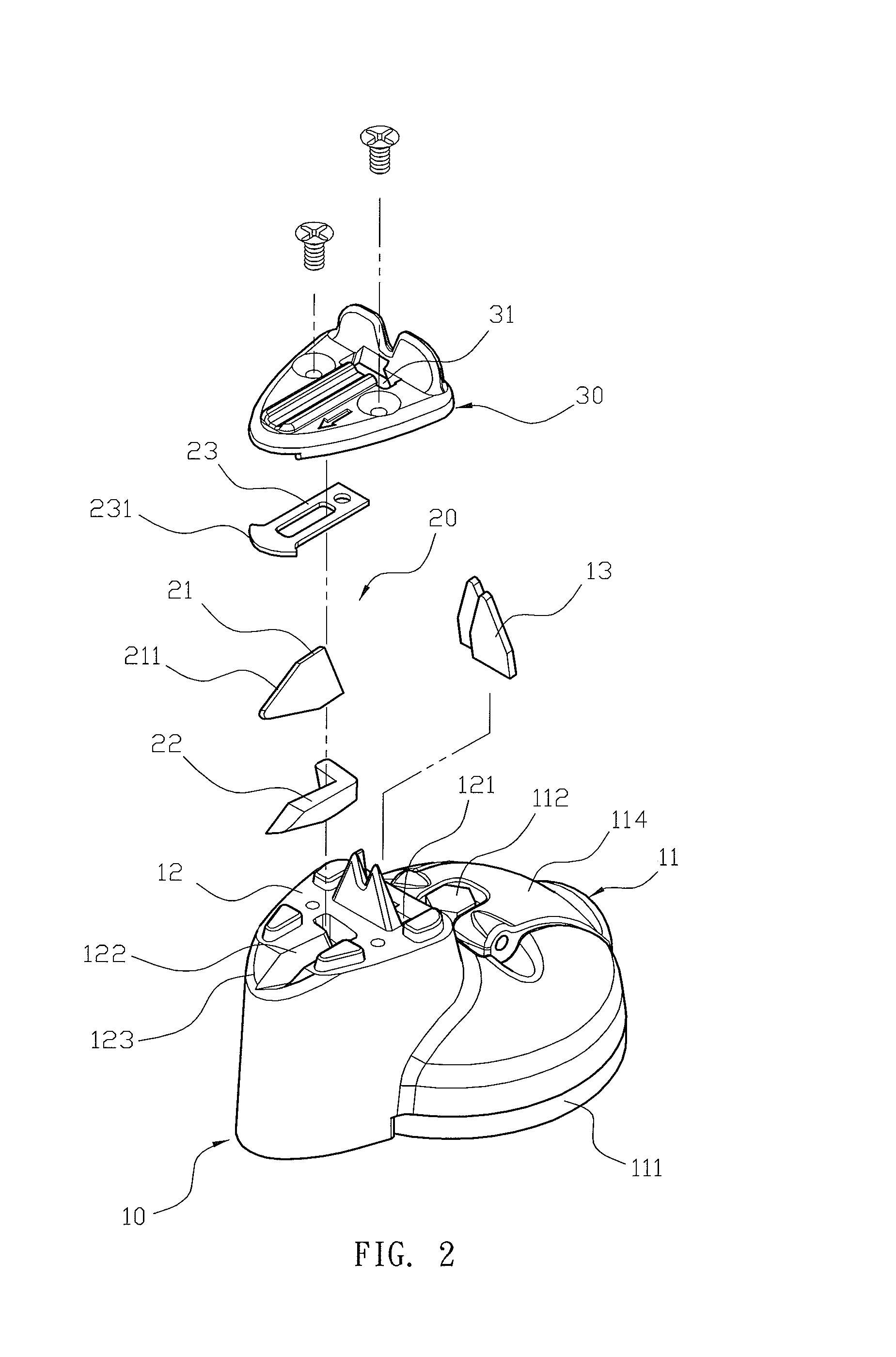

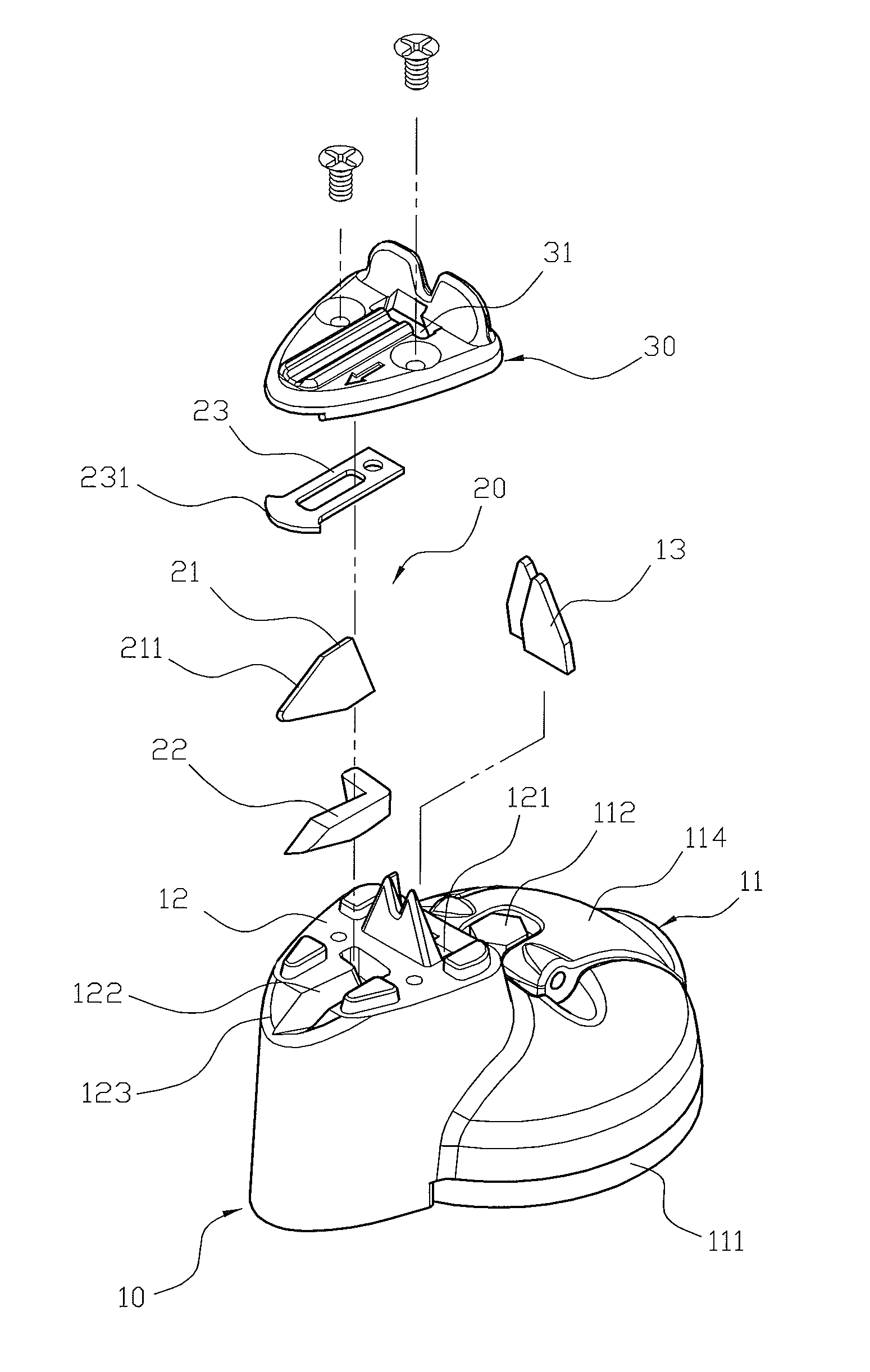

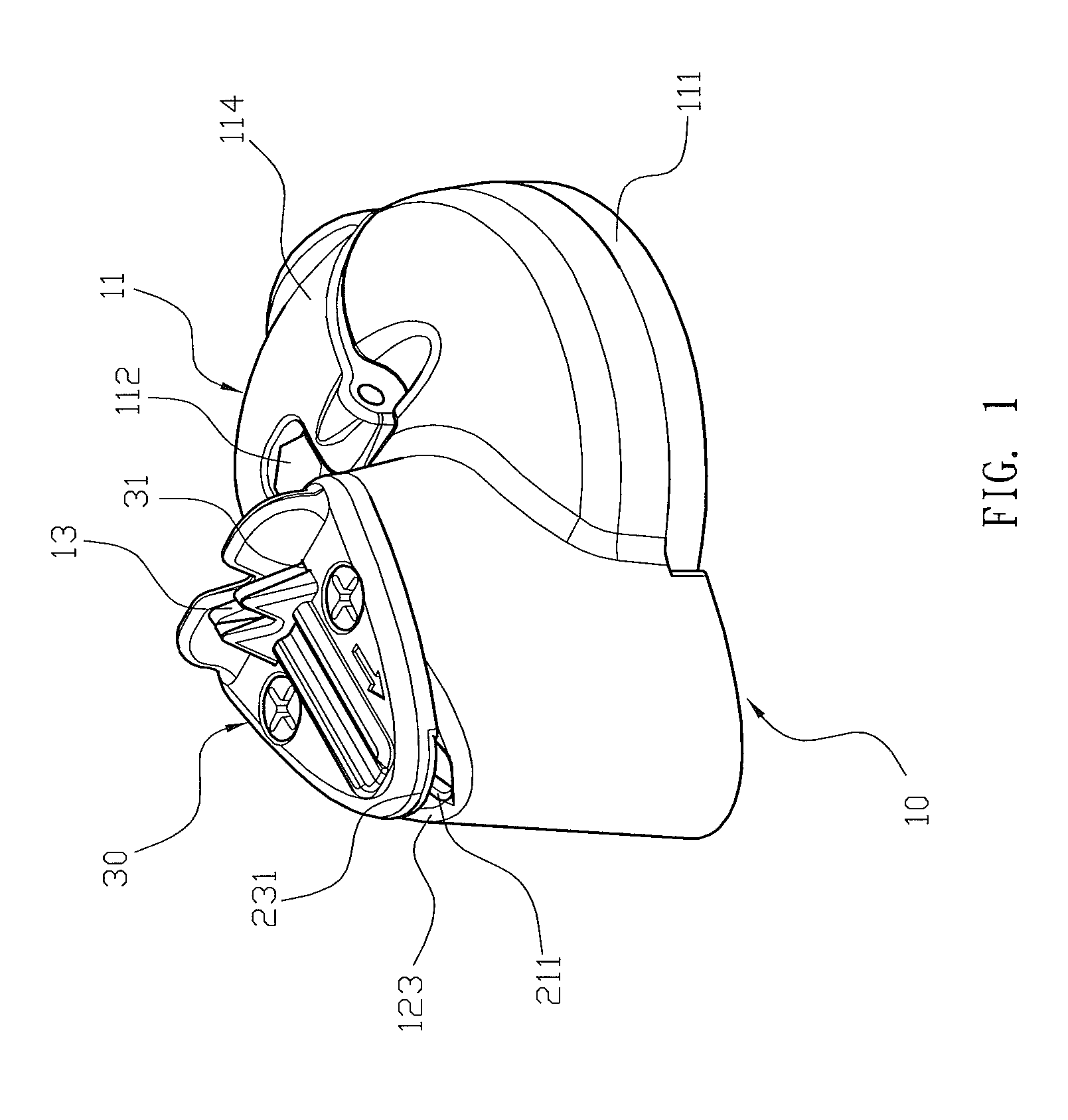

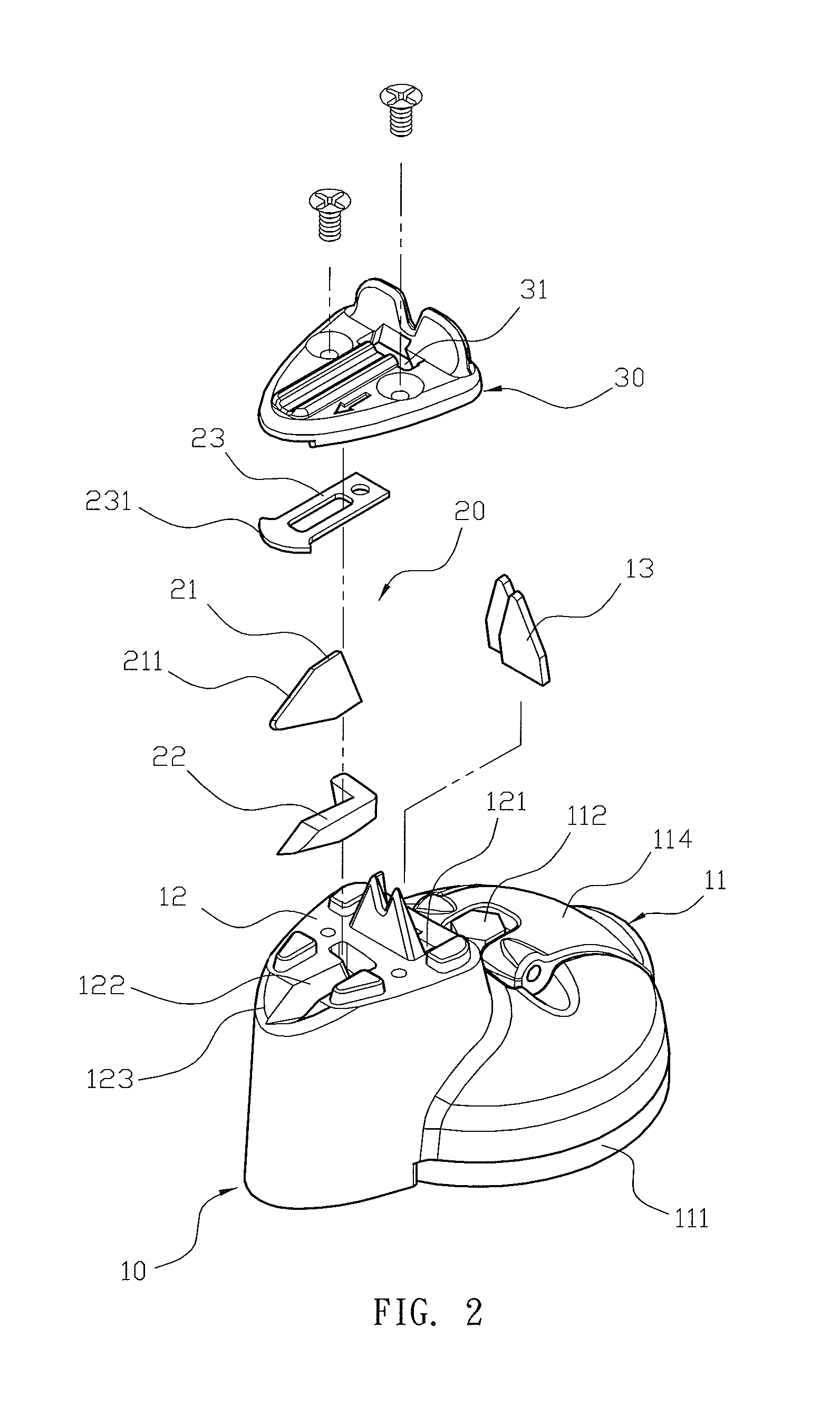

Attachment Type Sharpening Tool

ActiveUS20130231033A1Improve grinding effectImprove versatilityRevolution surface grinding machinesHoning machinesEngineeringSharpening

A sharpening tool includes a main base (10) having a mounting seat (12) provided with a first receiving recess (121) and a second receiving recess (122), two first grinding blades (13) mounted in the first receiving recess, an attachment device (11) mounted on the main base, a grinding unit (20) mounted on the mounting seat, and a cover (30) mounted on the mounting seat. The grinding unit includes a second grinding blade (21) mounted in the second receiving recess and having a grinding face (211), and a catch plate (23) mounted on the second receiving recess and having an abutting portion (231) facing the grinding face of the second grinding blade. The first grinding blades provide a double-side grinding function, and the second grinding blade provides a one-side grinding function.

Owner:JIIN HAUR INDAL

Ultrasonic trimming apparatus and ultrasonic trimming method

ActiveUS8277282B2Efficient executionEfficiently grinding a cutter bladeEdge grinding machinesGrinding feed controlGlass fiberThree dimensional shape

An ultrasonic trimming apparatus is composed of an articulated robot, a cutting apparatus, and a grindstone. The cutting apparatus is composed of an ultrasonic oscillator which is supported by the end portion of the articulated robot, a cutter blade which is supported by the ultrasonic oscillator, and a workpiece securing portion which secures a workpiece. The grindstone serving as a grinding member is disposed within the movable range of the cutter blade driven by the robot and is placed in a position at which the cutter blade can pressure contact the cutter blade. The cutter blade is ultrasonically vibrated by the ultrasonic oscillator and is ground while being pressed against the grindstone by means of the articulated robot. The ultrasonic trimming apparatus efficiently cuts a sheet material composed of soft material such as plastic, fabric, or rubber, a composite material, or a material containing glass fiber by means of an environmentally conscious method even when the material has a three-dimensional shape.

Owner:NIHON SHORYOKU KIKAI

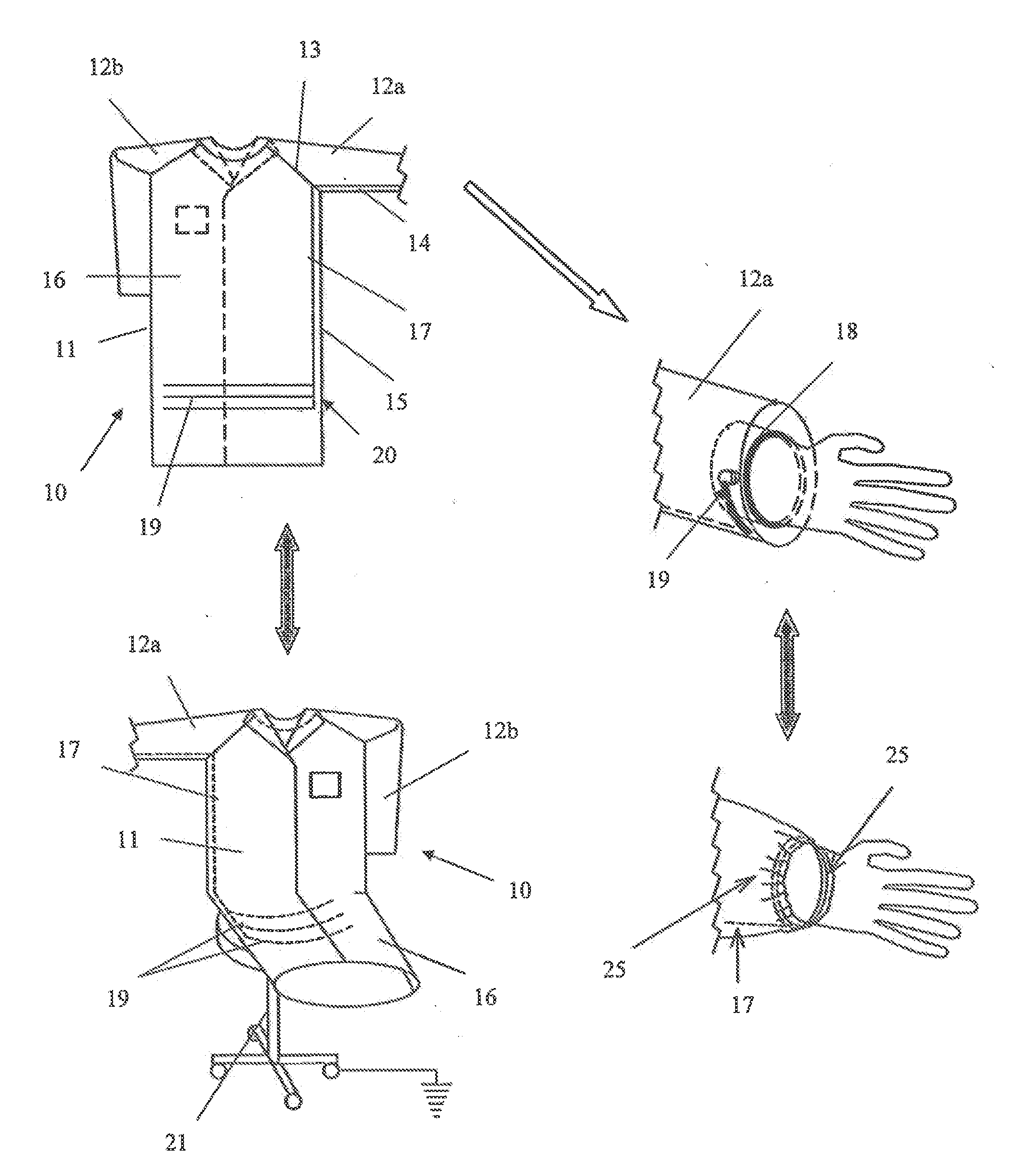

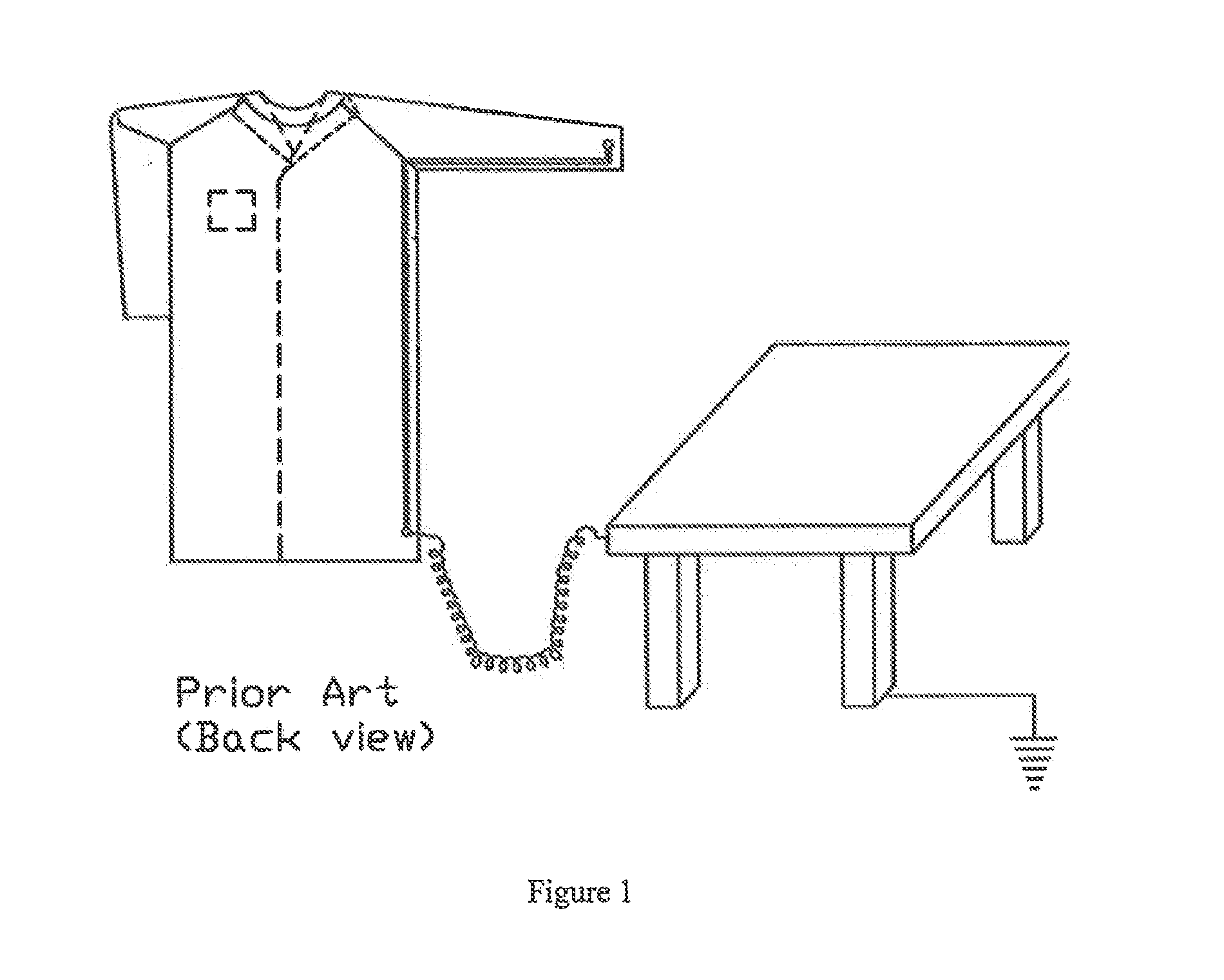

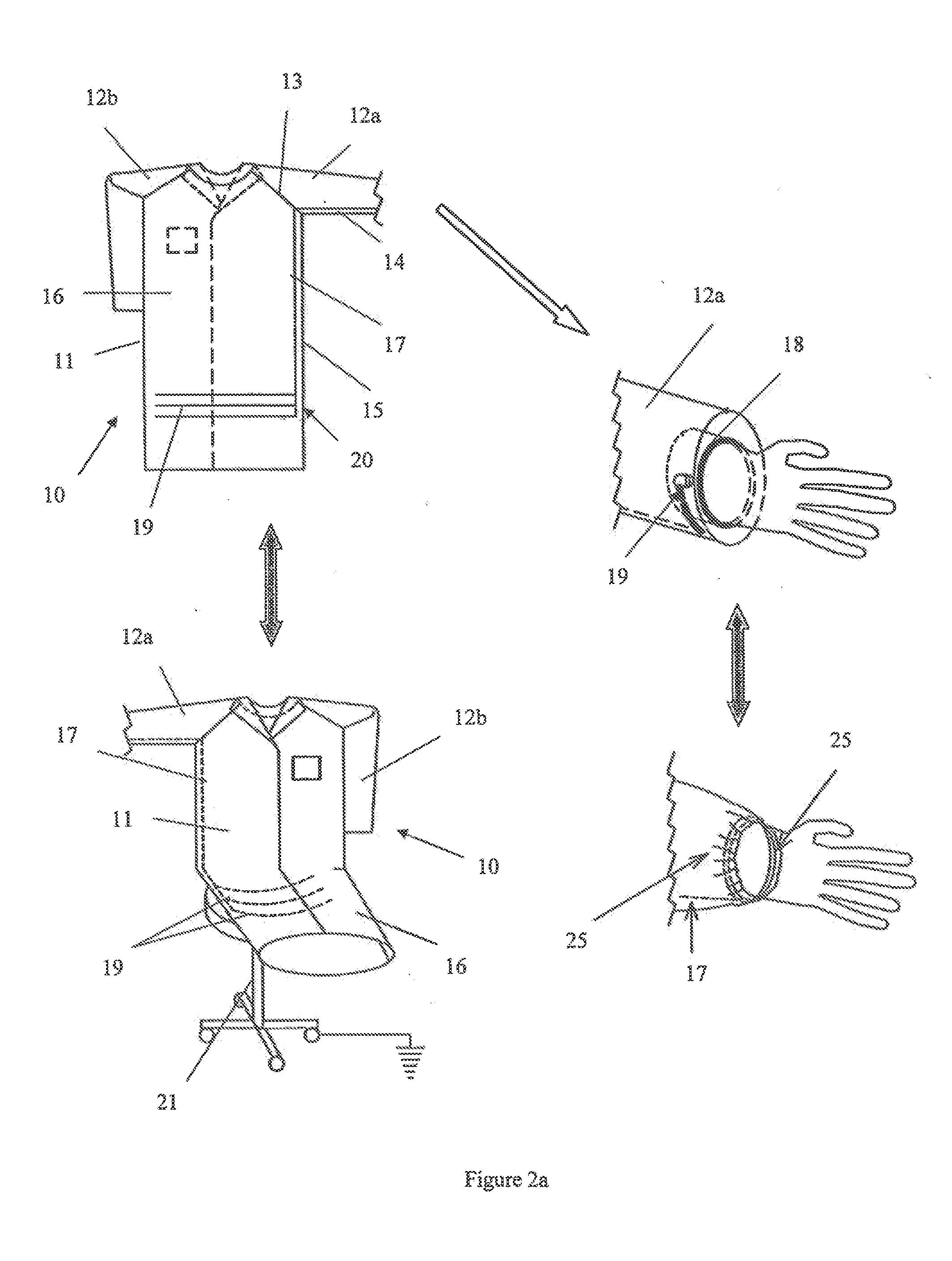

Electrostatic Discharge Garment

InactiveUS20120036621A1Efficiently groundIncrease contactChemical protectionHeat protectionElectrostatic dischargeElectrically conductive

An electrostatic discharge garment (10) having a body (11) and a pair of sleeves (12a, 12b) comprises a continuous electrically conductive path (17) provided along the length of the sleeve (12a) and extended along the substantial length of a corresponding side of said body (11), a conductive means (18) adapted to be in contact with the wrist of said wearer (28) and connected to said electrically conductive path (17) to form an electrical continuity path from said wearer (28) to said garment (10), and a plurality of conductive lines (19) horizontally extended from said electrically conductive path (17) across said body (11) in the vicinity of said wearer's buttock is pressed upon the seat of an electrostatic discharge (ESD) chair (21) when said wearer (28) is in sitting position.

Owner:ESD TECH CONSULTING & LICENSING CO LTD

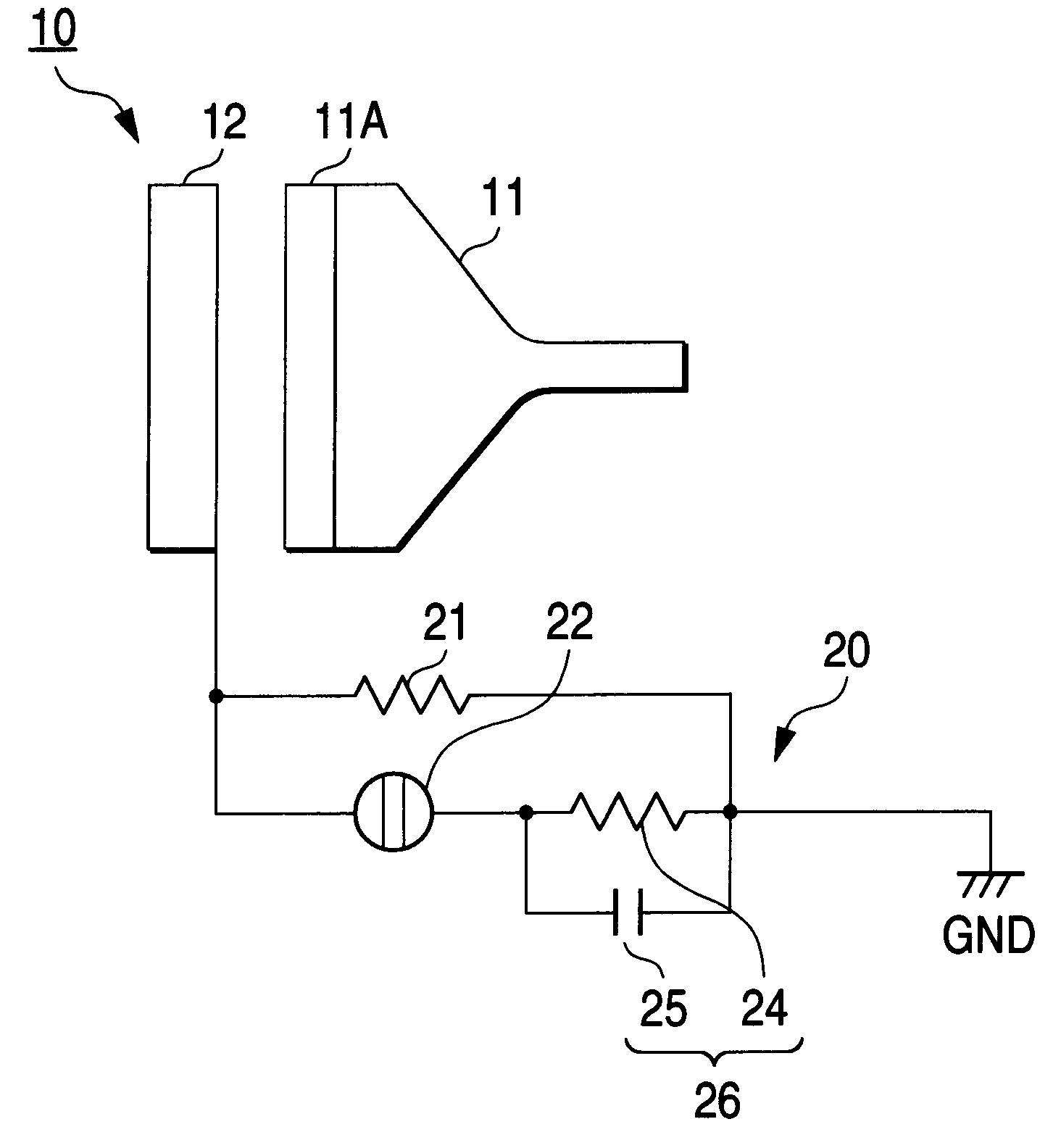

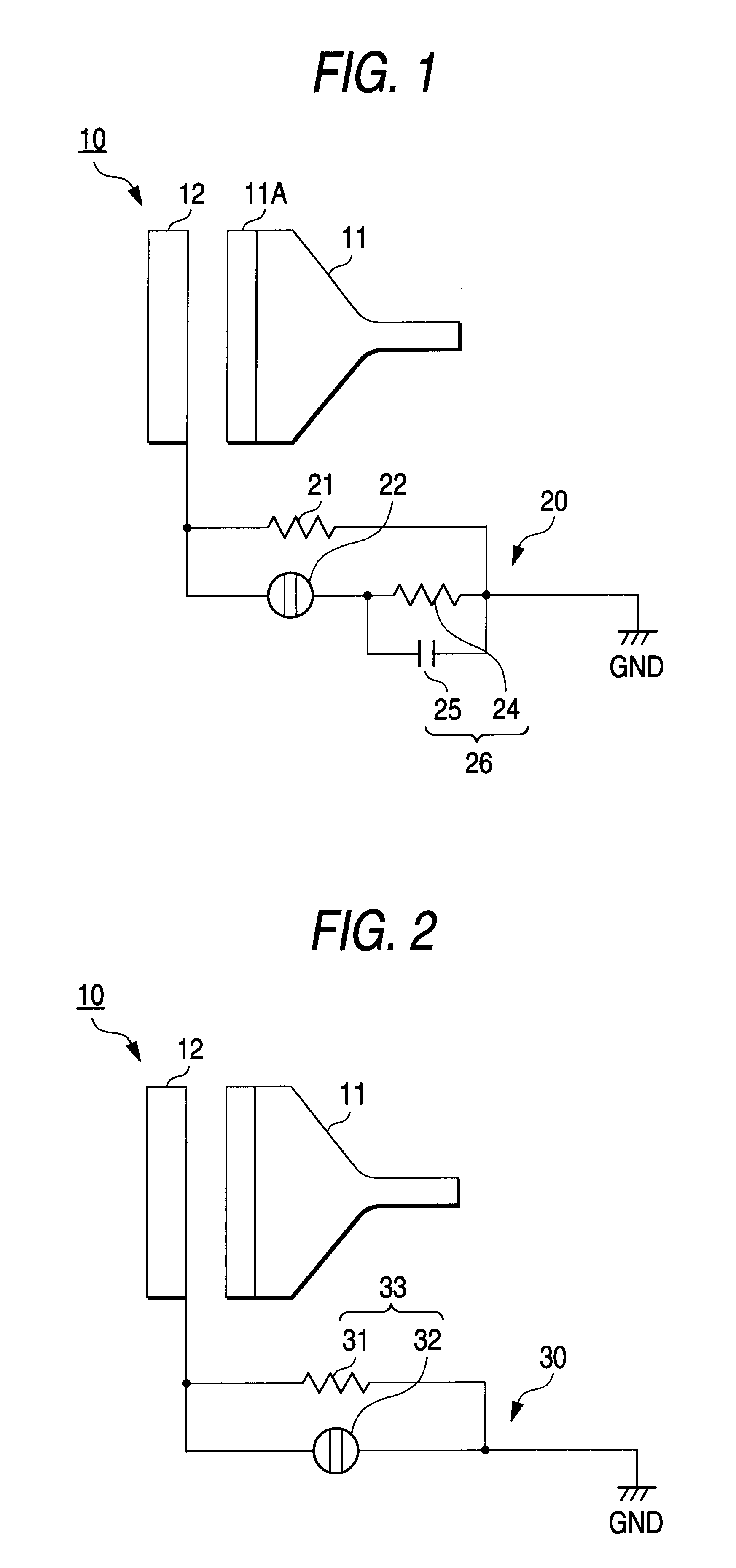

System for dissipating electrical charge from a cabinet of an electronic apparatus

InactiveUS6850287B1Reduce impactAvoid generatingTelevision system detailsCathode-ray/electron-beam tube vessels/containersHigh voltage capacitorsLow voltage

A TV receiver having a metal front cabinet is provided with a discharge path between the front cabinet and a ground portion of the TV receiver. The discharge path includes a series circuit in which a discharge tube is connected in series to a parallel circuit of a first resistor and a high-voltage capacitor and a second resistor that is connected in parallel to the series circuit. The discharge path effectively discharges a voltage occurring at the front cabinet via the second resistor while preventing a sudden flow of current and reducing the influence of static electricity. The series circuit in which the discharge tube is connected in series to the parallel circuit of the first resistor and the high-voltage capacitor has a function of causing high-voltage pulses occurring at the ground portion GND to escape to the front cabinet while converting those into pulses having a low voltage level.

Owner:SONY CORP

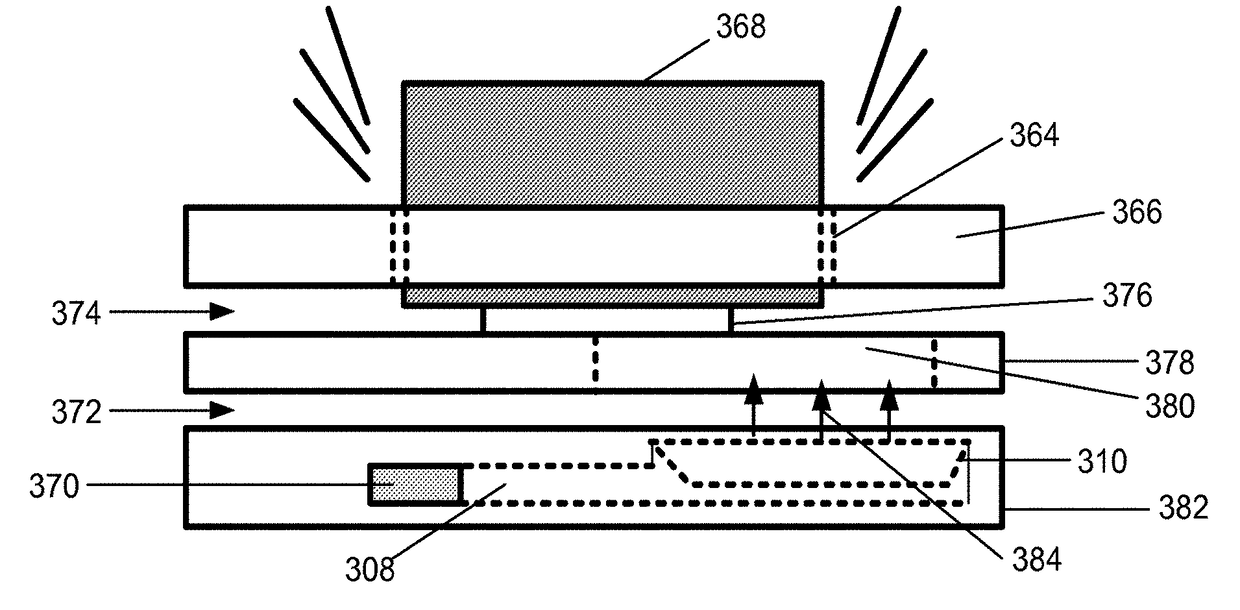

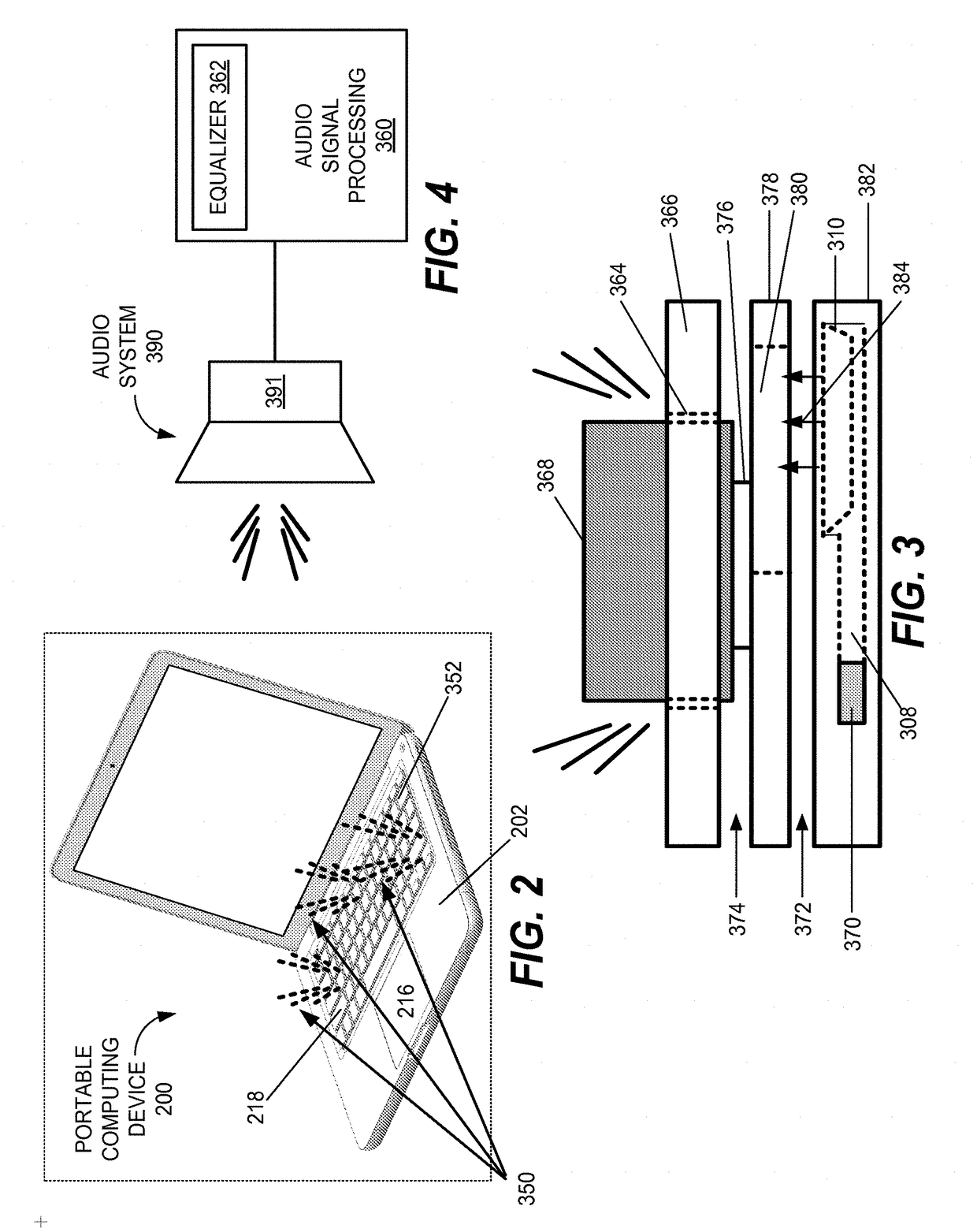

Portable computer electrical grounding and audio system architectures

ActiveUS20180067523A1Maintain performanceReduced ground areaDetails for portable computersSound input/outputAcoustic transmissionElectricity

A portable computing device having a substantially non-conducting outer housing and alternative electrical grounding and audio system architectures is disclosed. The device can be a laptop computer having a main logic board, a keyboard assembly, an audio source positioned below the keyboard assembly, and an equalizer electrically coupled to the audio source, with each of these components being electrically coupled to a universal grounding structure. The audio source emits sound waves that are propagated through the keyboard assembly and between gaps between keyboard keys and the outer housing. Settings for the equalizer can be selected to account for sound absorption and amplification characteristics of the sound waves along these sound transmission paths. The universal grounding structure includes a plurality of separate ground components that are electrically intercoupled, each being substantially smaller than the overall portable computing device, and also includes an electromagnetic interference shield around the main logic board.

Owner:APPLE INC

Attachment type sharpening tool

ActiveUS8715041B2Good effectImprove versatilityRevolution surface grinding machinesPortable grinding machinesEngineeringSharpening

A sharpening tool includes a main base (10) having a mounting seat (12) provided with a first receiving recess (121) and a second receiving recess (122), two first grinding blades (13) mounted in the first receiving recess, an attachment device (11) mounted on the main base, a grinding unit (20) mounted on the mounting seat, and a cover (30) mounted on the mounting seat. The grinding unit includes a second grinding blade (21) mounted in the second receiving recess and having a grinding face (211), and a catch plate (23) mounted on the second receiving recess and having an abutting portion (231) facing the grinding face of the second grinding blade. The first grinding blades provide a double-side grinding function, and the second grinding blade provides a one-side grinding function.

Owner:JIIN HAUR INDAL

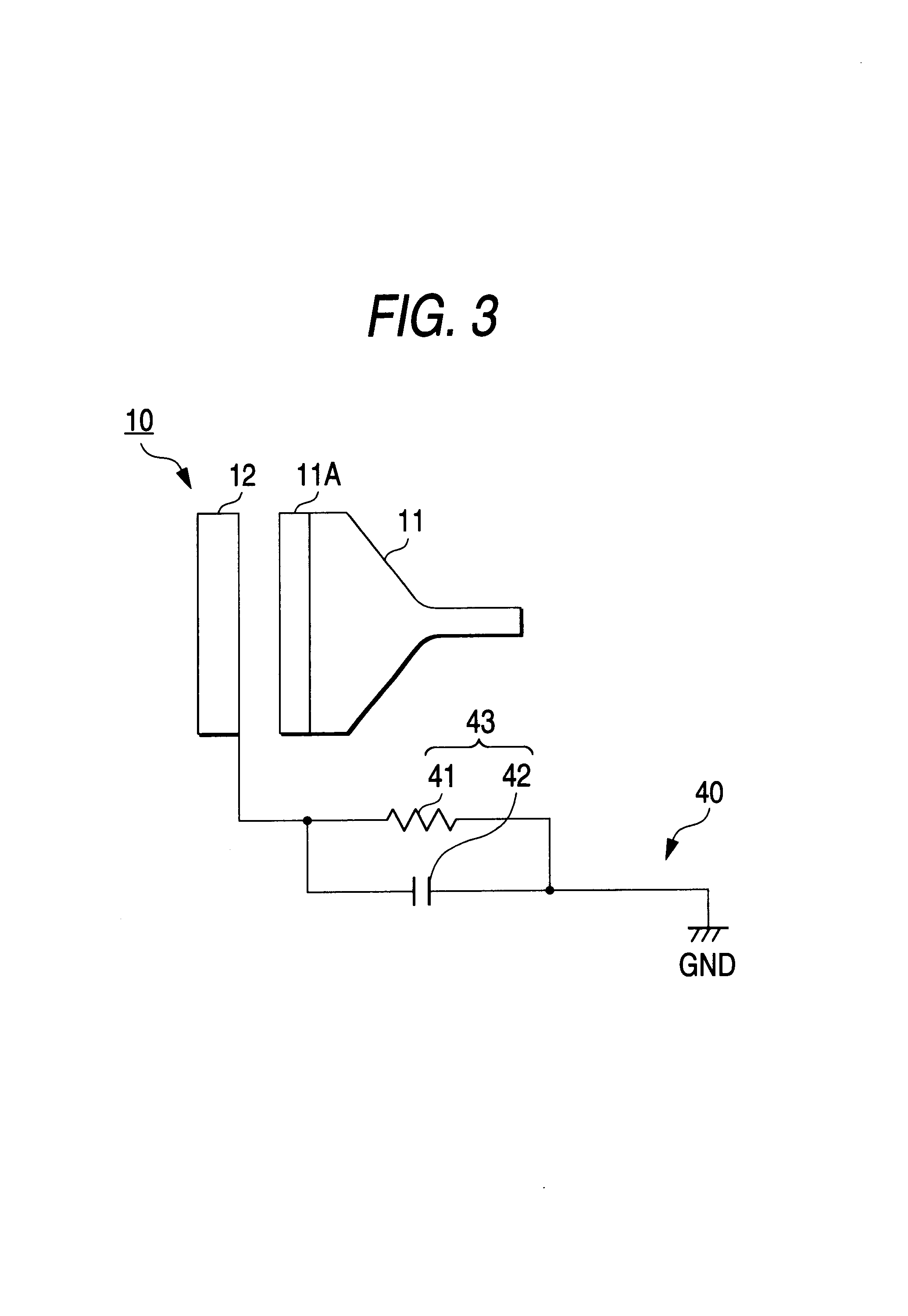

Flat panel display module

InactiveUS8139365B2Efficiently groundEfficient comprehensive utilizationStatic indicating devicesGas discharge vessels/containersEngineeringElectrical and Electronics engineering

A flat panel display module includes a display panel, a chassis configured to support the display panel and having a chassis base and a first extending portion, the first extending portion being parallel to the display panel and extending away from the chassis base, the first extending portion including a seating portion having a predetermined depth, and a circuit board configured to drive the display panel, at least one part of the circuit board being mounted on the seating portion of the first extending portion.

Owner:SAMSUNG SDI CO LTD

Assessment and calibration of a high energy beam

ActiveUS10049852B2Measure quickly and accuratelyAccurate measurementElectric discharge tubesElectrical conductorHigh energy

A high energy beam verification, calibration, and profiling system includes a conductive base plate, supports extending from the base plate, a plurality of conductors, a data logger electrically connected to the conductors, and a computer electrically connected to the data logger. Each conductor is supported by some of the supports such that each conductor is insulated from the conductive base plate. Each conductor has a profile intersecting with profiles of at least some of the other conductors to define a multidirectional and two-dimensional array of conductors. The data logger receives and records data associated with electrical charges flowing through the conductors. The computer is adapted to receive, manipulate, and display the data recorded by the data logger for comparison of beam characteristics at different locations across a high energy beam build area.

Owner:HOWMEDICA OSTEONICS CORP

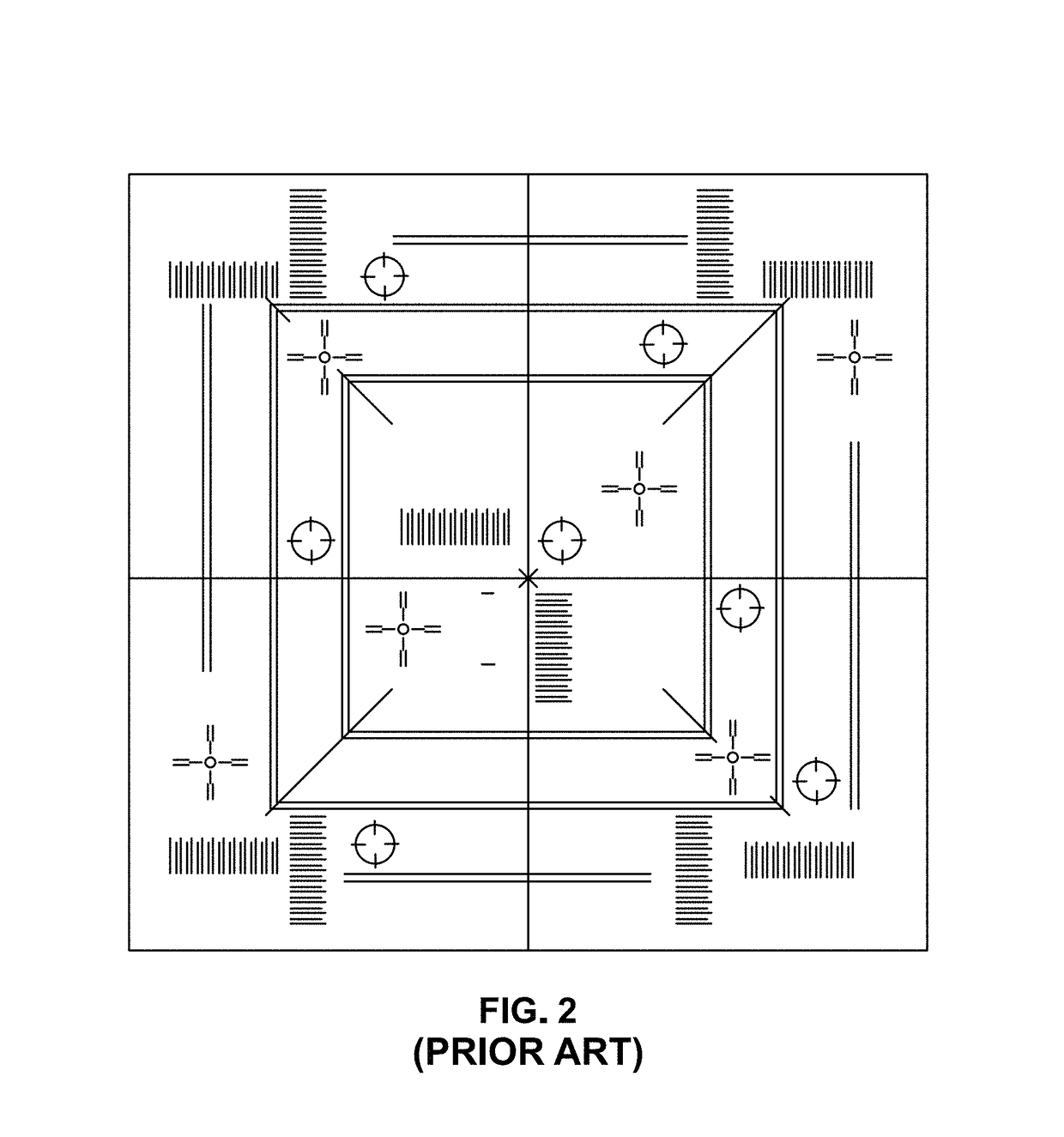

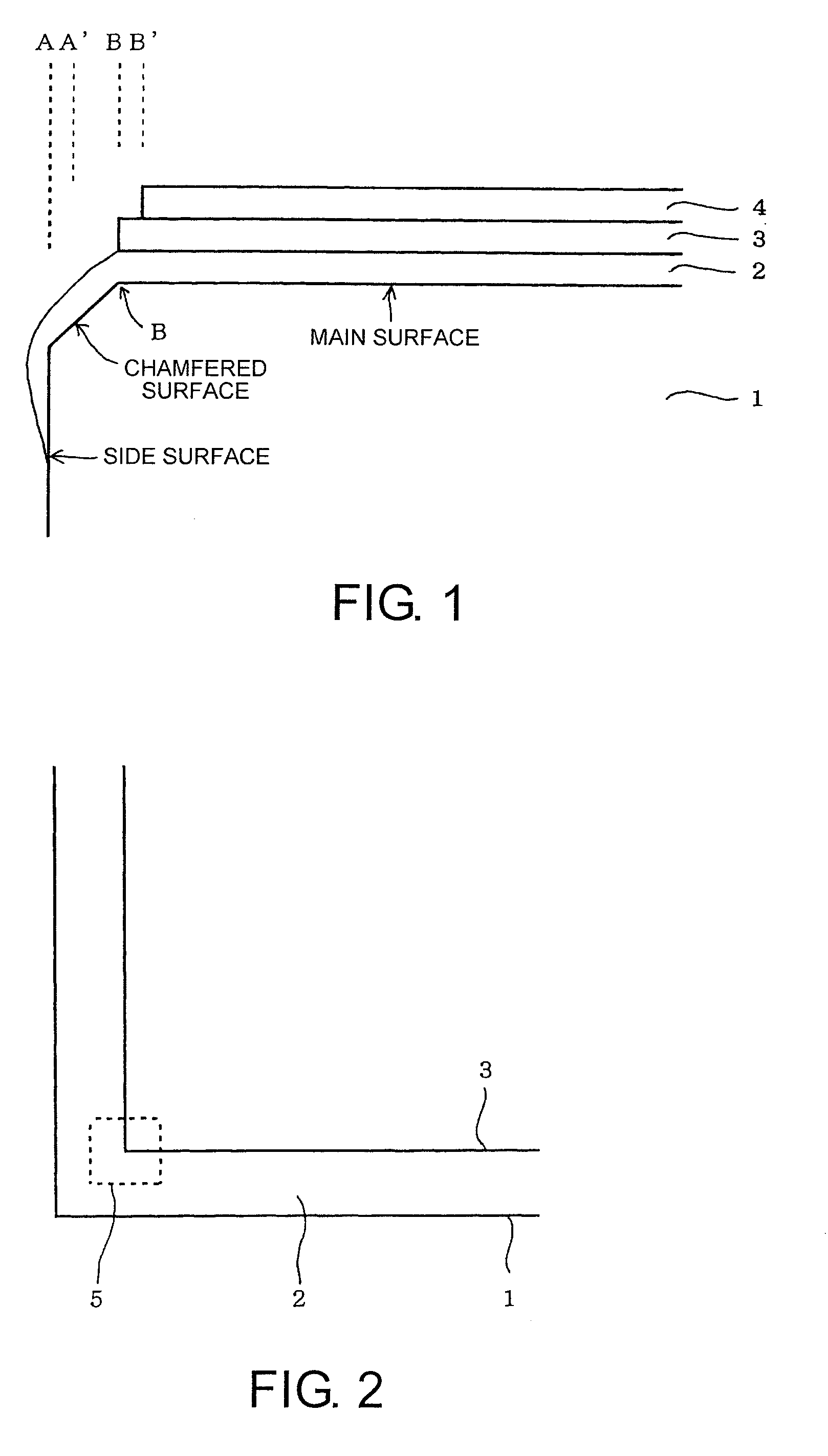

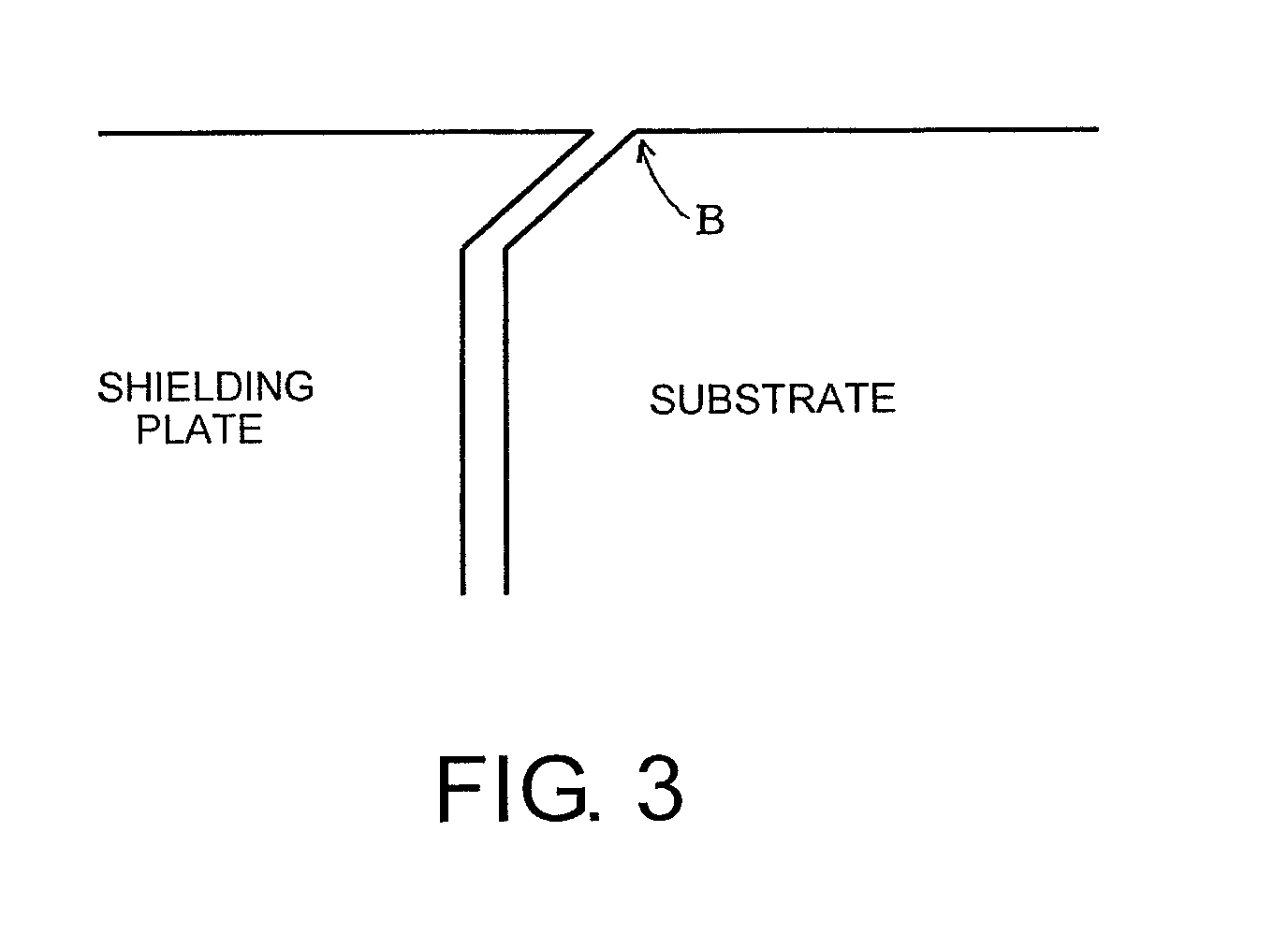

Methods of manufacturing mask blank and transfer mask

ActiveUS7655364B2High resolutionEfficiently groundElectric discharge tubesRadiation applicationsResist

In a method of manufacturing a mask blank adapted to be formed with a resist pattern by electron beam writing and having a light-shielding film and an etching mask film of an inorganic-based material resistant to etching of the light-shielding film which are formed in this order on a transparent substrate, when forming the etching mask film, shielding is performed using a shielding plate so as to prevent the etching mask film from being formed at least at a side surface of the substrate.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com