Patents

Literature

45results about How to "Unified efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

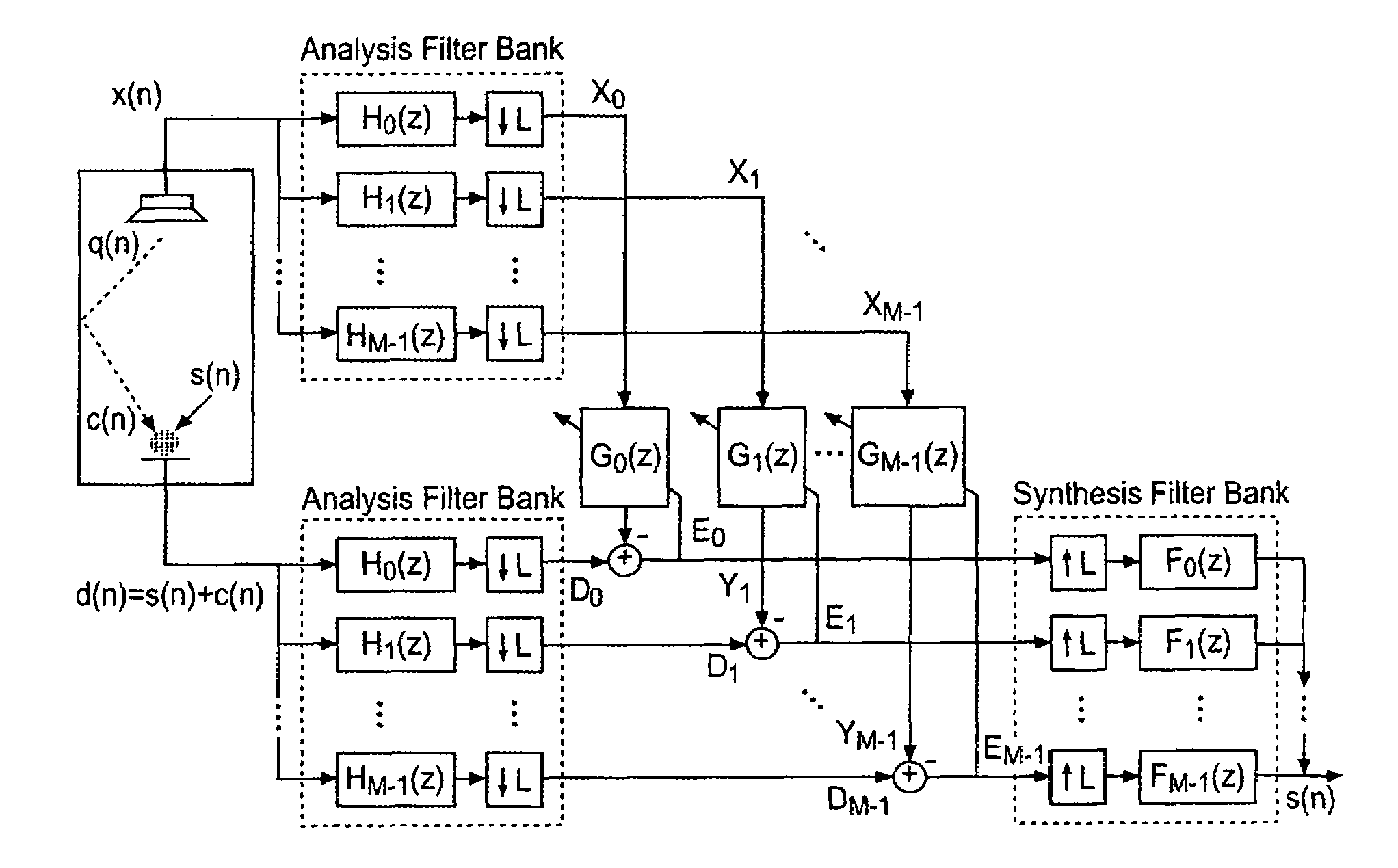

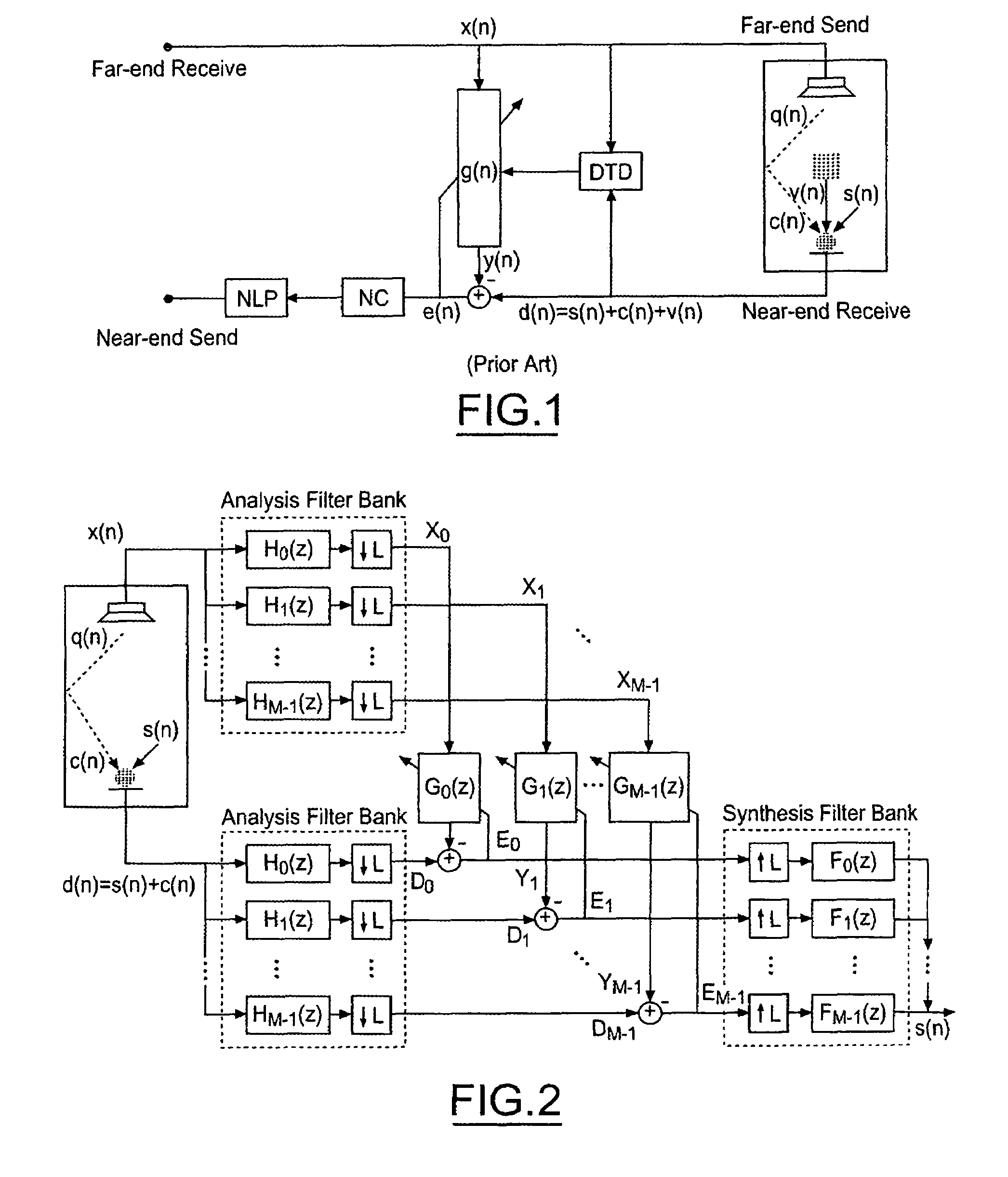

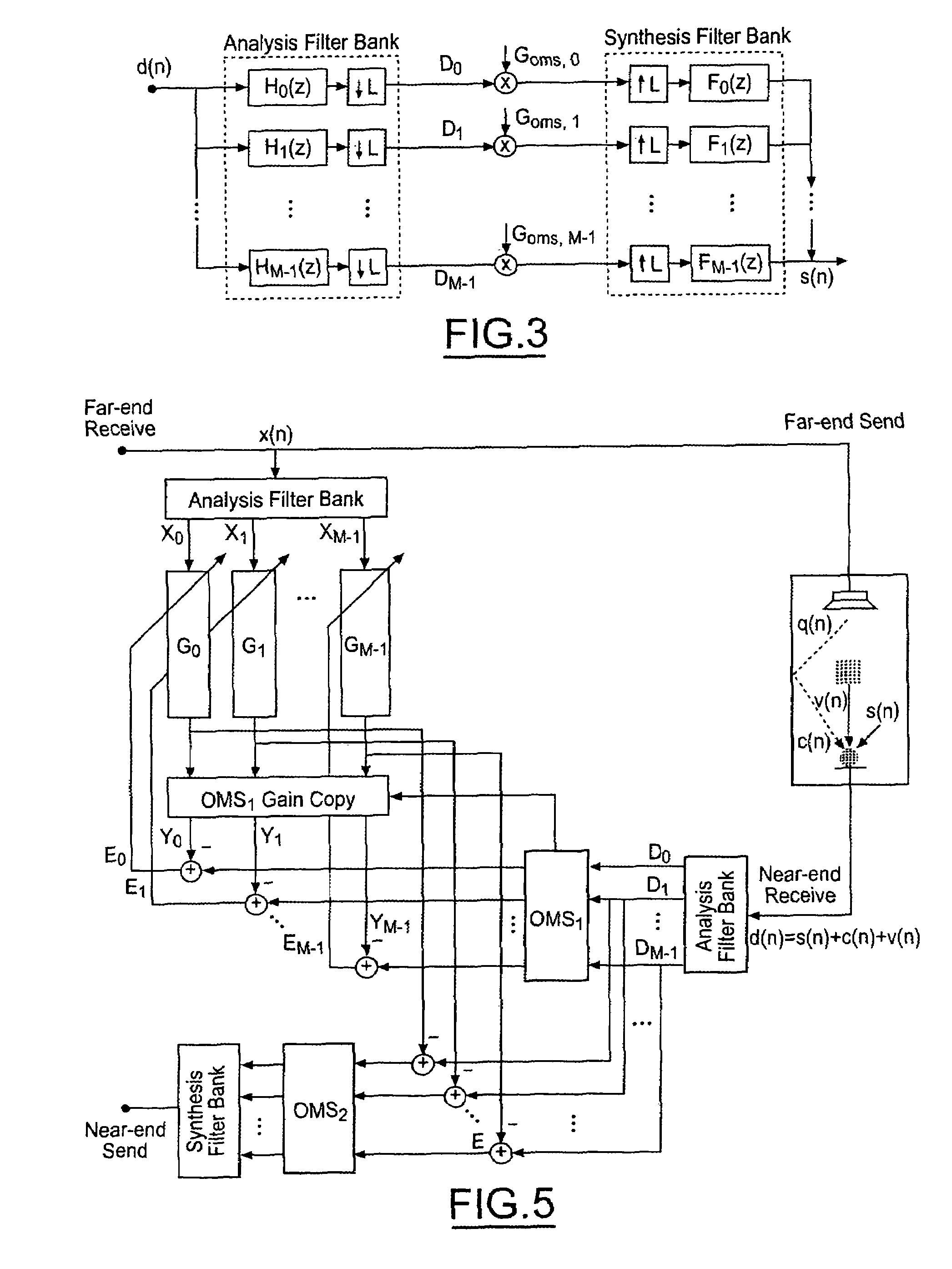

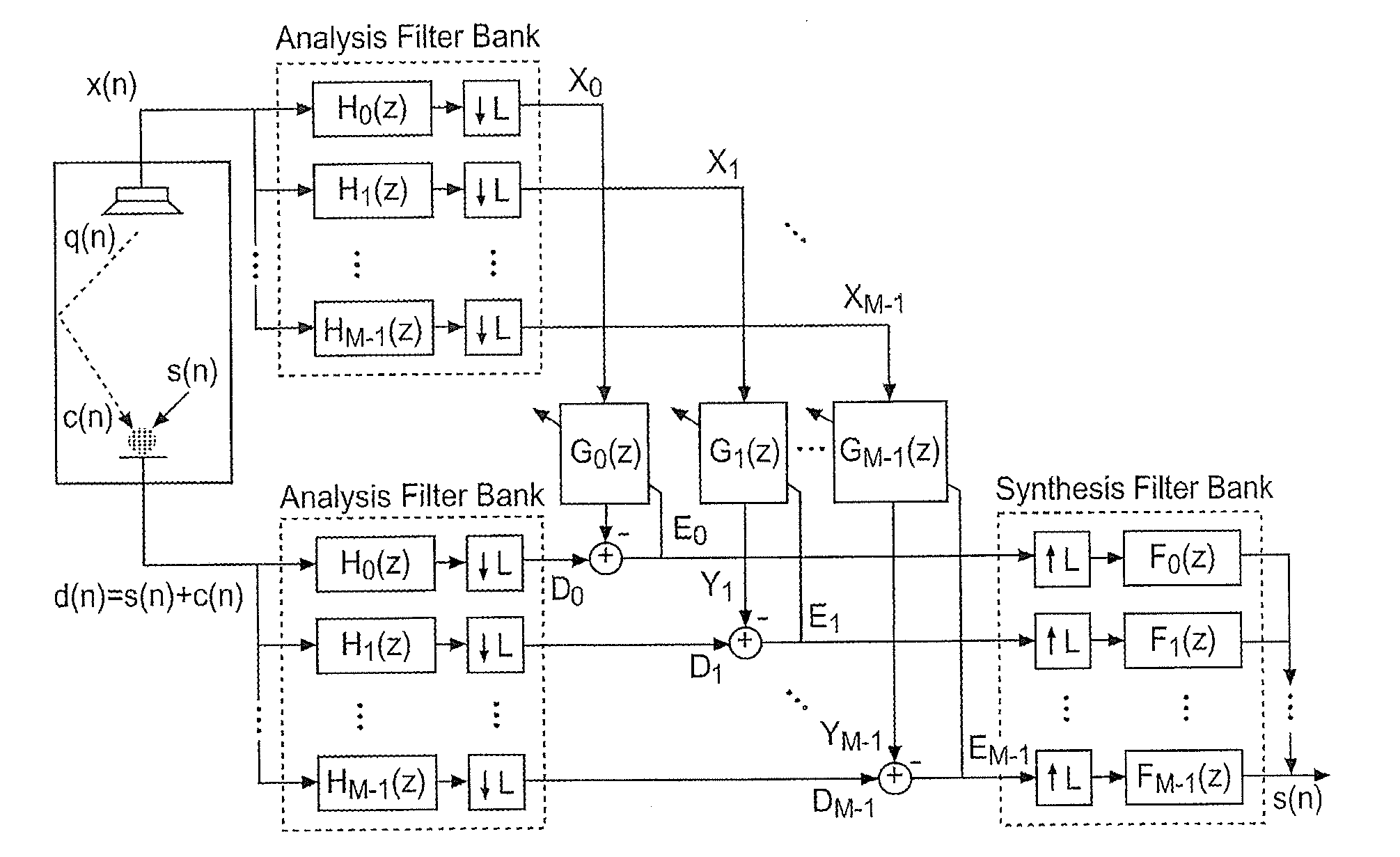

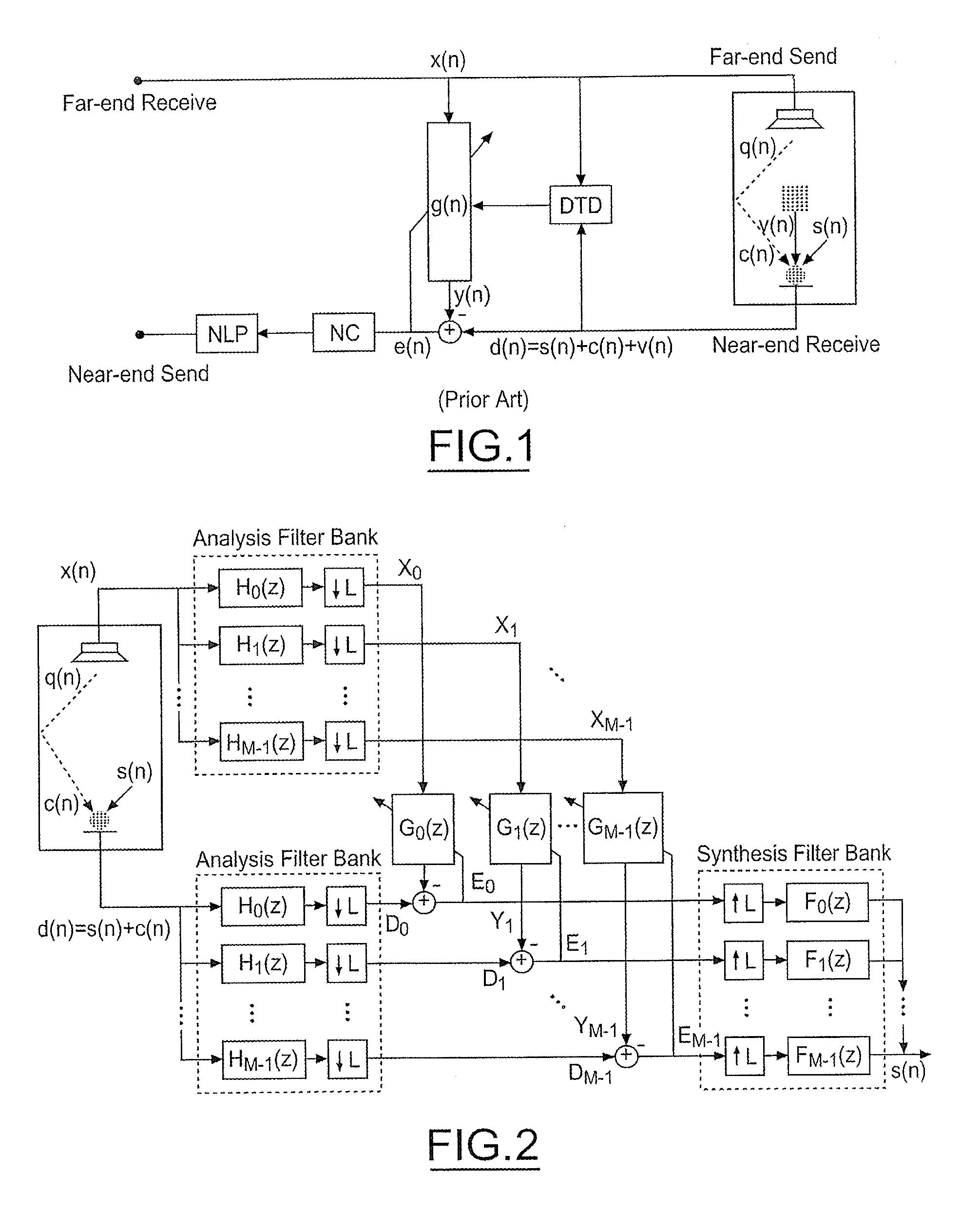

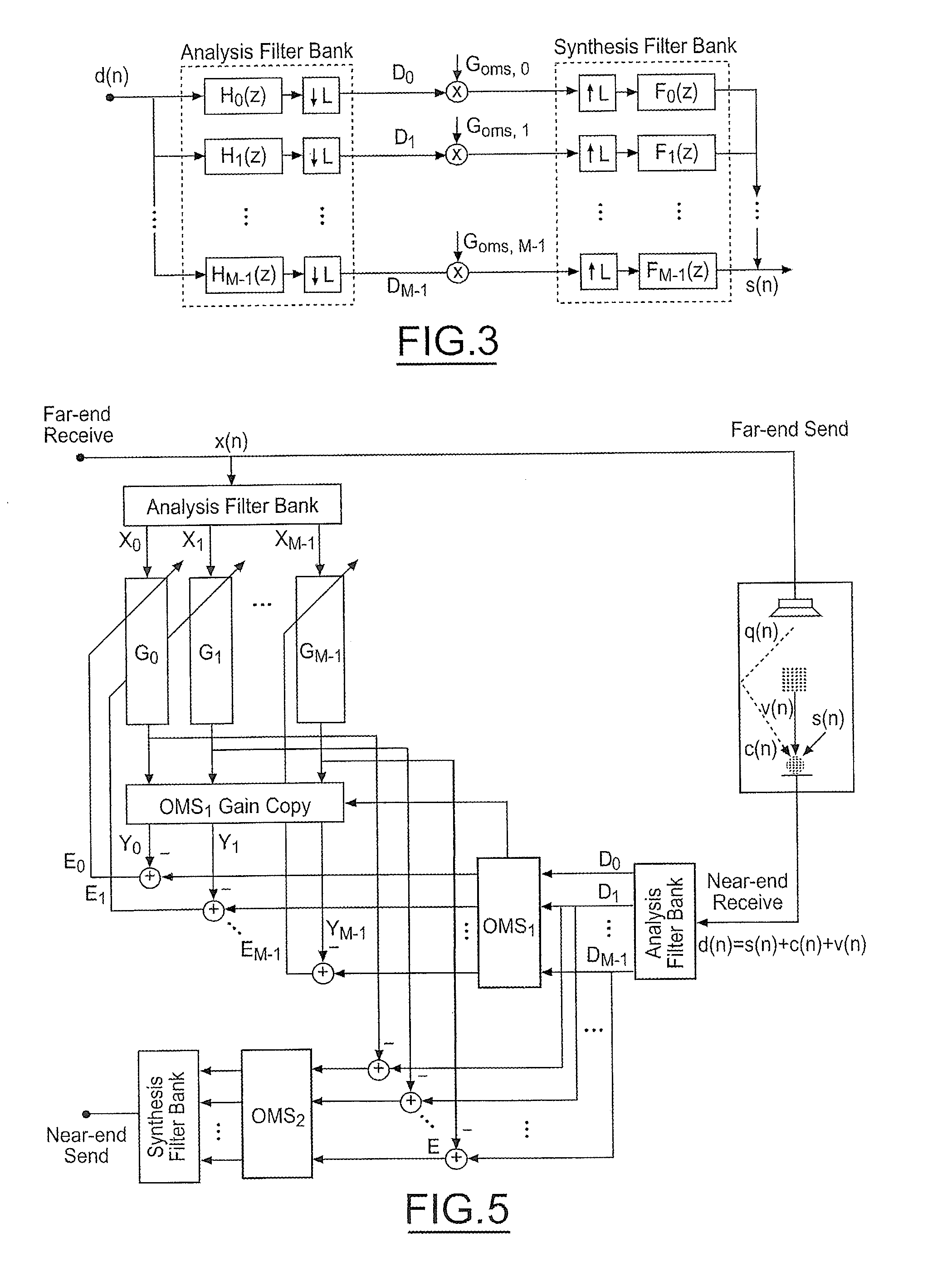

Echo cancellation and noise reduction method

InactiveUS7433463B2Better model the echo pathReduce generationTwo-way loud-speaking telephone systemsSpeech analysisHands freeEngineering

A method and system for clear signal capture comprehend several individual aspects that address specific problems in improved ways. In addition, the method and system also comprehend a hands-free implementation that is a practical solution to a very complex problem. Individual aspects comprehended related to echo and noise reduction, and divergence control.

Owner:CSR TECH INC

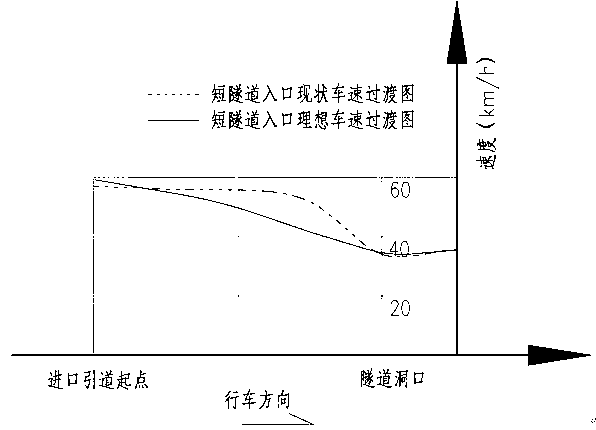

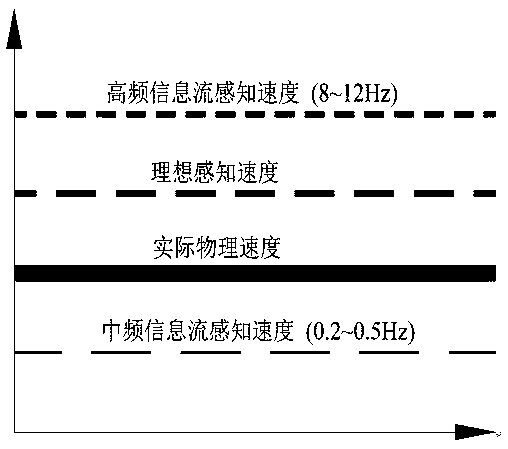

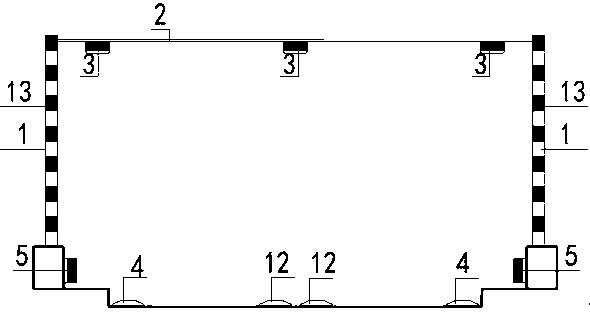

Retroreflection information based method for improving lighting system in urban under-crossing short tunnel

InactiveCN103062688AModerate illuminationEasing space transitionOutdoor lightingTraffic signalsStructural engineeringRoad surface

The invention provides a retroreflection information based method for improving lighting system in urban under-crossing short tunnel. A wall lamp pole at an approach end of the short tunnel is provided with a variable-height transverse suspension cable, three rows of lamps are transversely arranged on the suspension cable, the longitudinal direction of the lamps is in accordance with the tunnel line shape and the arranging direction of the inside tunnel lamps, facade mark lines are arranged at the lower edge of the lamp pole, side walls of the approach are provided with vertical markings and multiple layers of delineators, transverse optical illusion decelerated markings are arranged on the road surface, and accordingly mid-frequency retroreflection information flow of the tunnel approach is composed. A mid-frequency retroreflection information flow of the under-crossing section of the tunnel is composed by the multiple layers of delineators of the side walls, transverse optical illusion decelerated markings on the road surface, and side wall vertical markings which are arranged on an under-crossing section of the tunnel and extend to a roof. The facade mark lines are arranged on the inner side walls of the tunnel and side walls of the approach at intervals of 1 to 2 meters in the longitudinal direction, while protruding road signs are arranged on road surfaces and road sides, and accordingly the high-frequency retroreflection information flow is composed. By the retroreflection information based method for improving lighting system in urban under-crossing short tunnel, light transition in the exit and entrance of the tunnel can be eased, and smooth transition of vehicle speeds in the exit and entrance of the tunnel is realized through arrangement of multiple retroreflection visual information.

Owner:WUHAN UNIV OF TECH

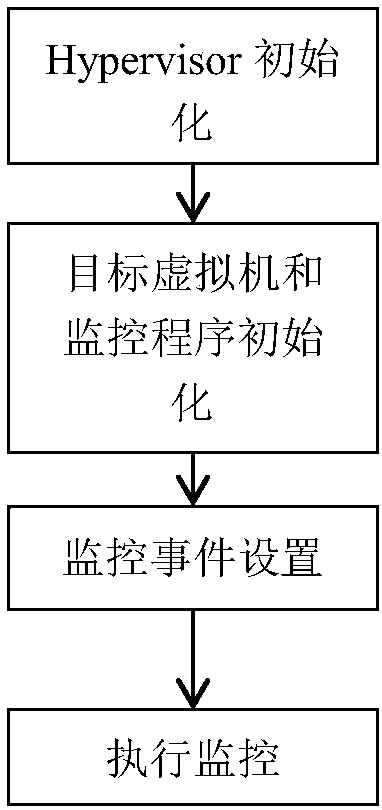

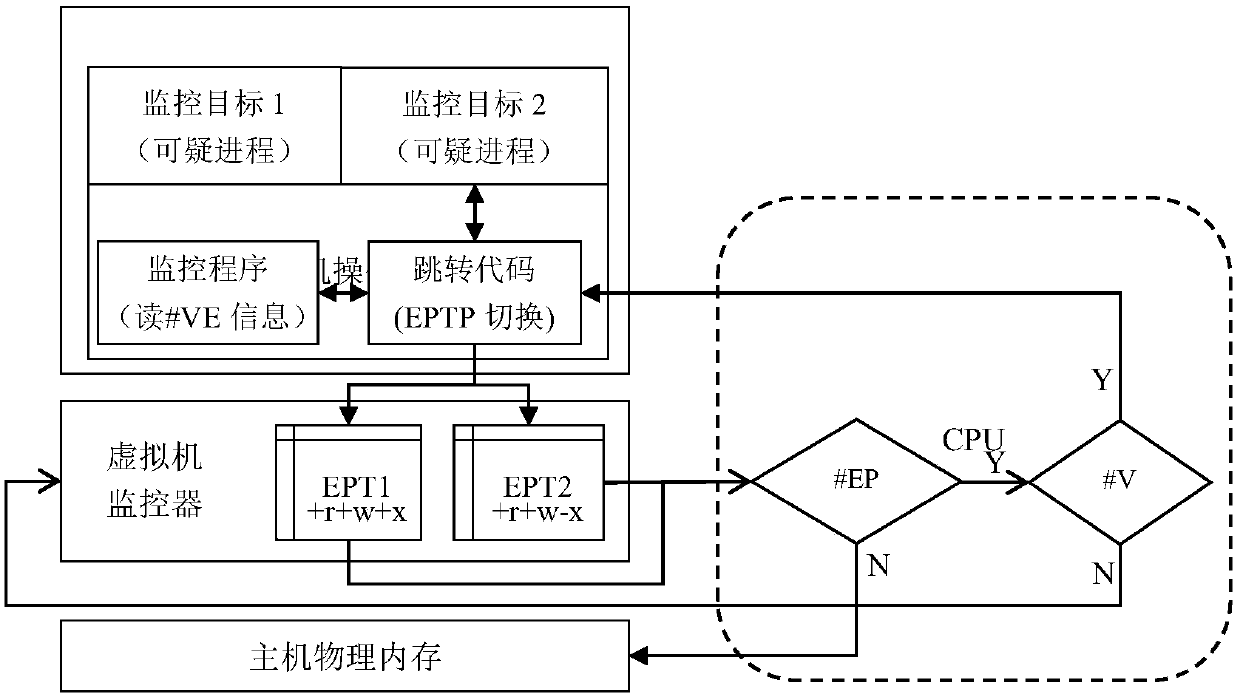

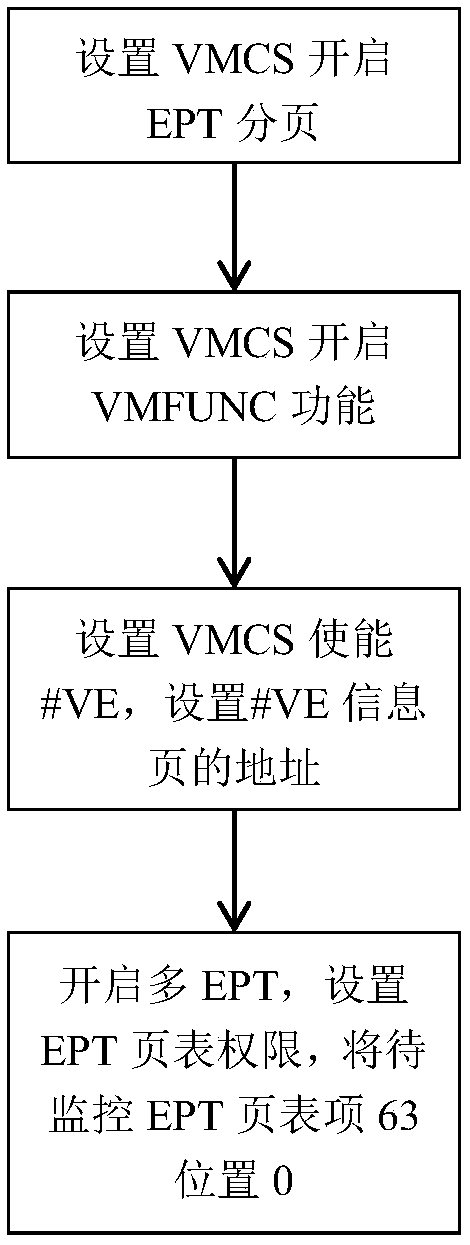

Virtual machine security monitoring method and system

InactiveCN107797895AExpand available memoryRealize security monitoringHardware monitoringSoftware simulation/interpretation/emulationVirtualizationOperational system

The invention discloses a virtual machine security monitoring method and system. A virtualization abnormal function (#VE) is utilized to realize monitoring of application program execution. Meanwhile,through isolation of EPT page tables, isolation of application programs from an operating system and memory isolation of different application programs can be realized. During execution of a CPU, through a VMFUNC function provided by CPU hardware, switching of different EPT page tables is realized, and therefore switching of execution streams is realized. According to the virtual machine securitymonitoring method and system, an in-band mode is adopted to realize virtual machine security monitoring, meanwhile secure isolation of a monitoring program from a monitoring target is supported and guaranteed based on new hardware characteristics, and finally unity of security and efficiency is achieved.

Owner:NAT UNIV OF DEFENSE TECH

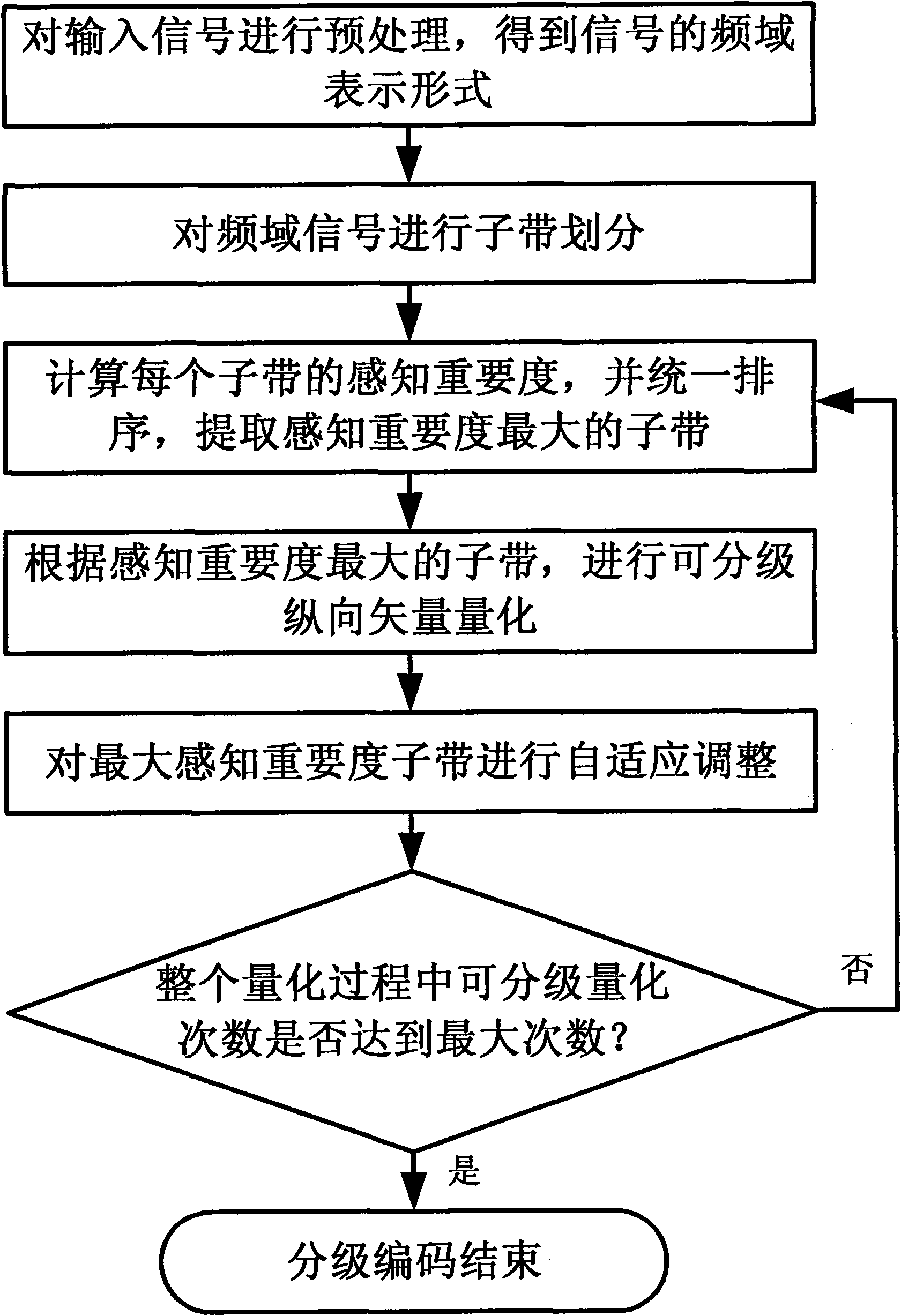

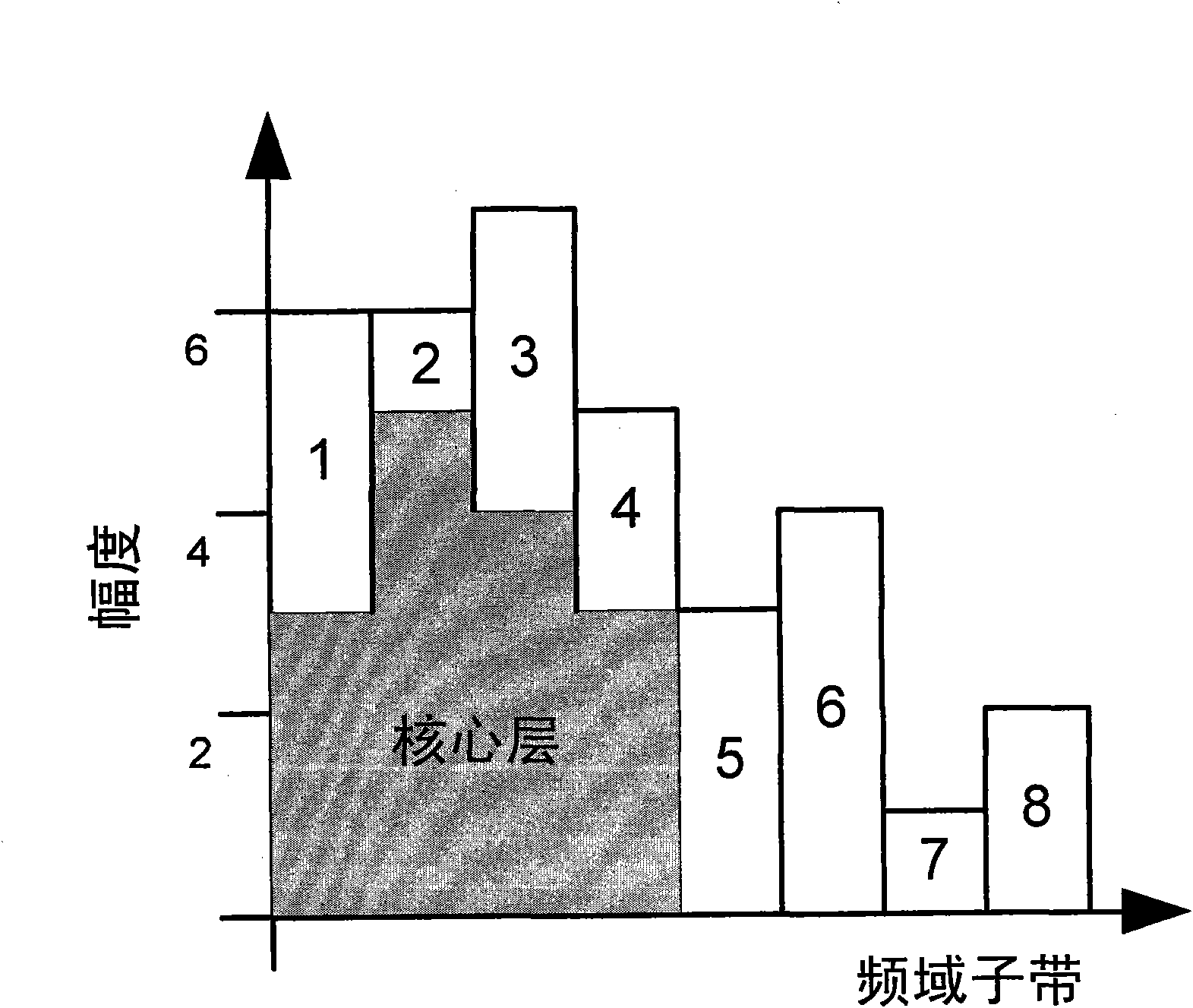

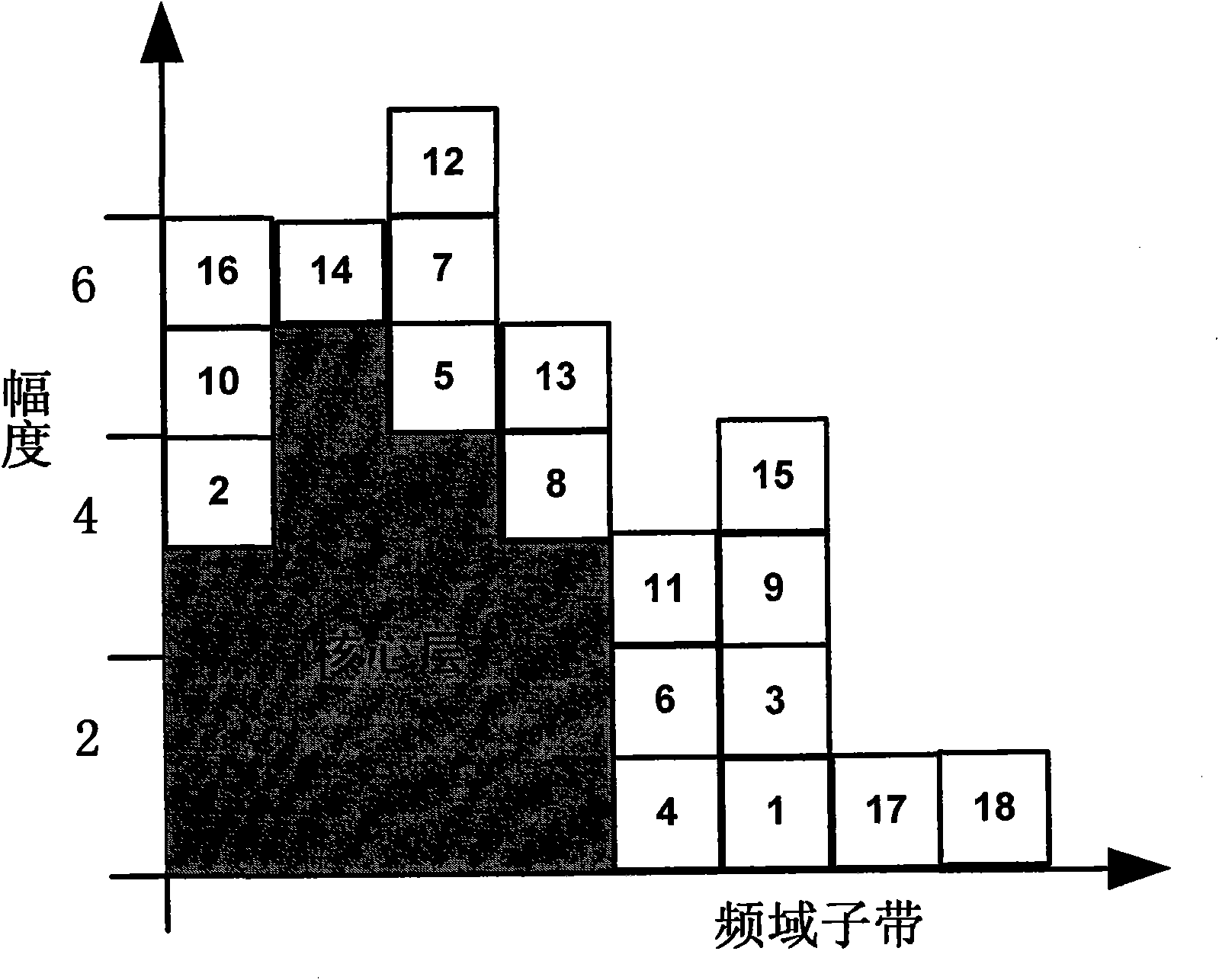

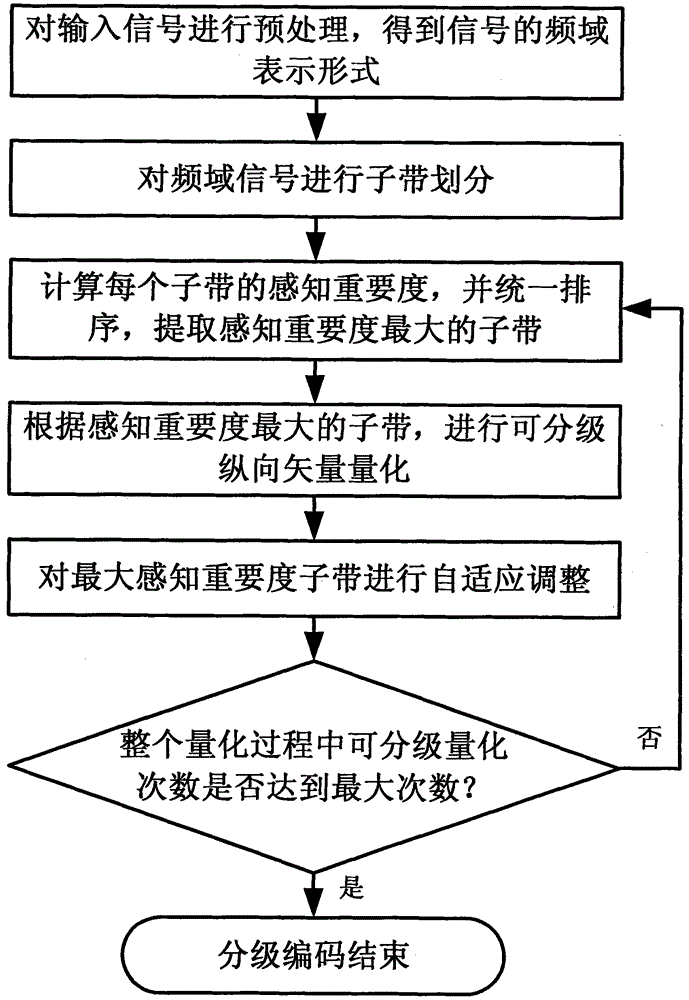

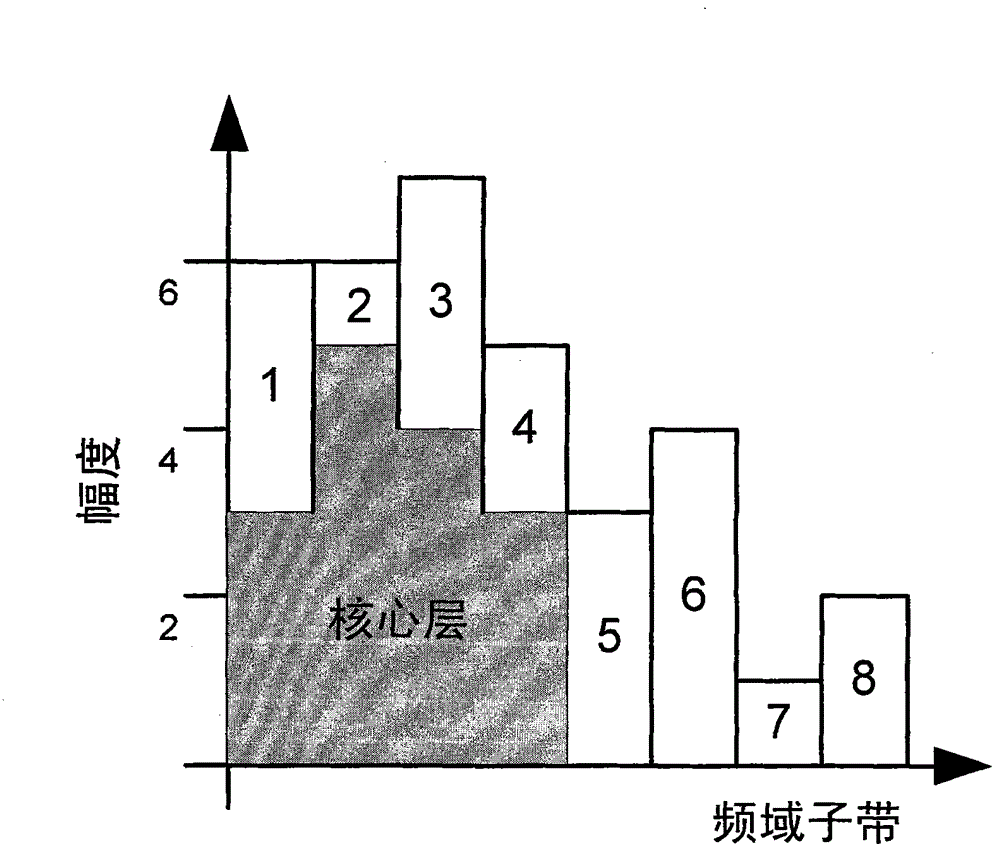

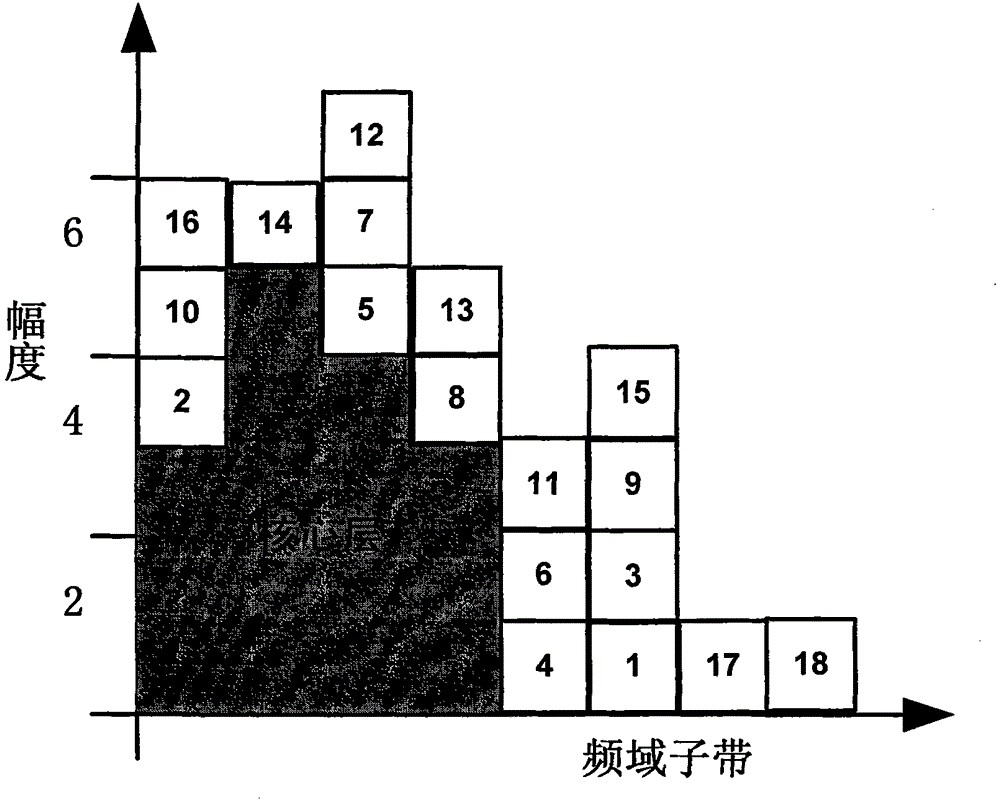

Audio fine scalable coding method and system based on perception self-adaption bit allocation

InactiveCN101800050AUnified efficiencyImprove classification accuracySpeech analysisCode moduleBit allocation

The invention relates to the technical field of audio coding, in particular to audio fine scalable coding method and system based on perception self-adaption bit allocation. The method comprises the following steps of: preprocessing input signals; carrying out subband division on frequency-domain signals; calculating the perception importance of each subband; uniformly sequencing the subband from small to large according to the perception importance; extracting the subband with the largest perception importance for scalable longitudinal vector quantization; and then carrying out self-adaption adjustment on the vector-quantized subband with the largest perception importance. The system comprises a preprocessing module, a subband division module, a perception importance calculating, sequencing and extracting module, a scalable quantizing and coding module, a self-adaption adjusting module and a scalable coding finish judging module. The invention realizes high-efficient fine scalable audio coding, preferably realizes the unification of quantization precision and quantization efficiency and also satisfies the requirement of high tone quality when improving coding efficiency.

Owner:WUHAN UNIV

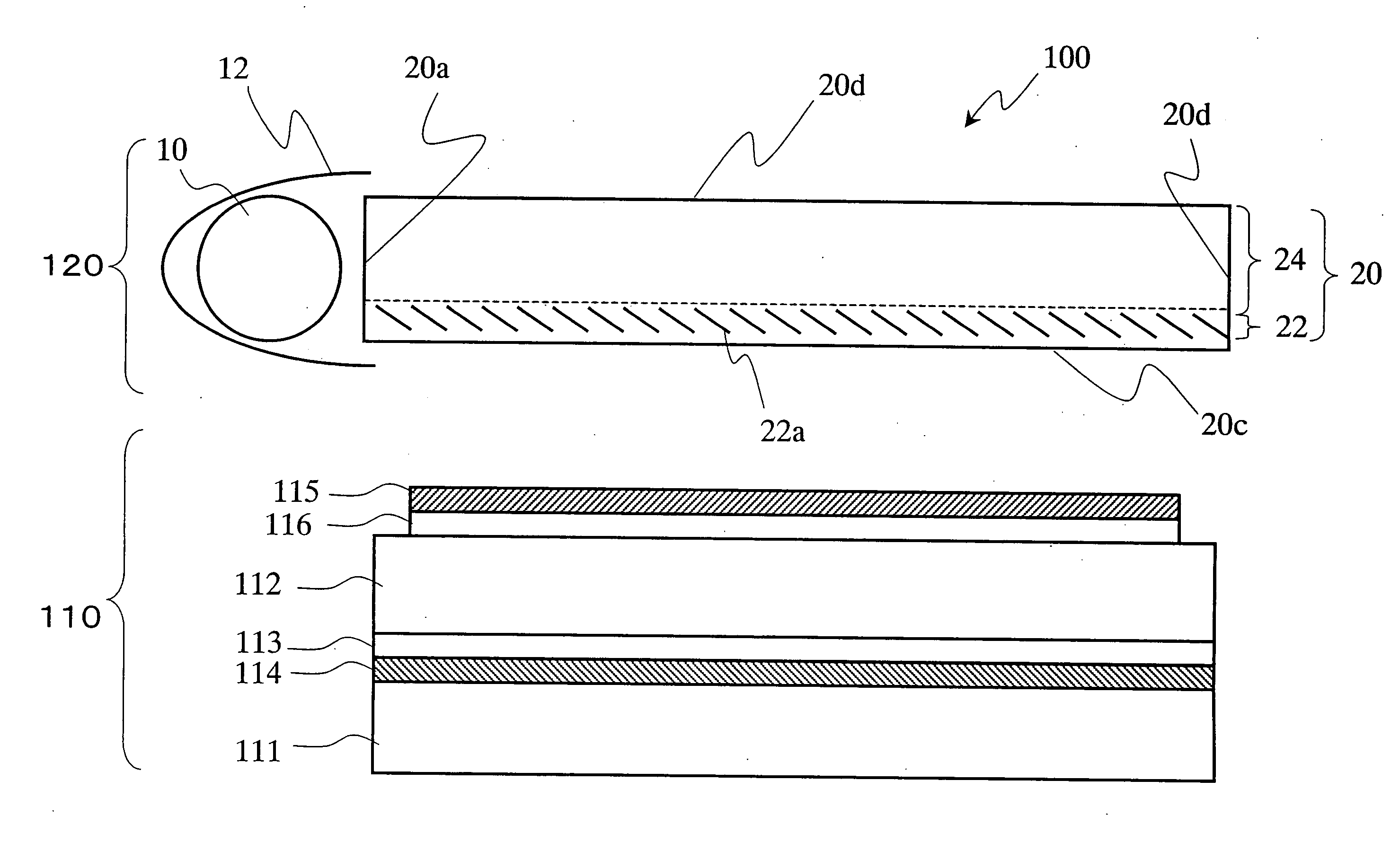

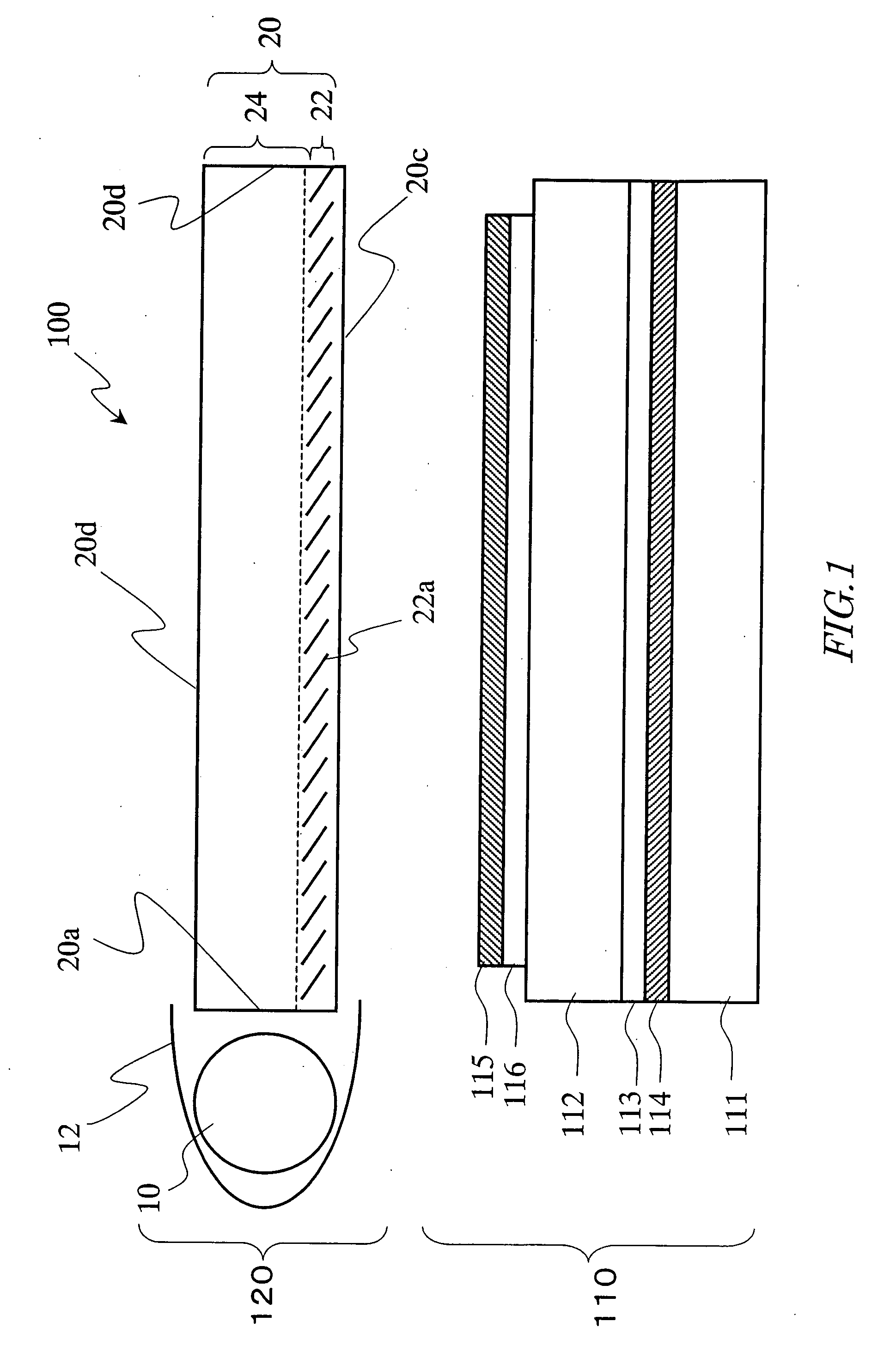

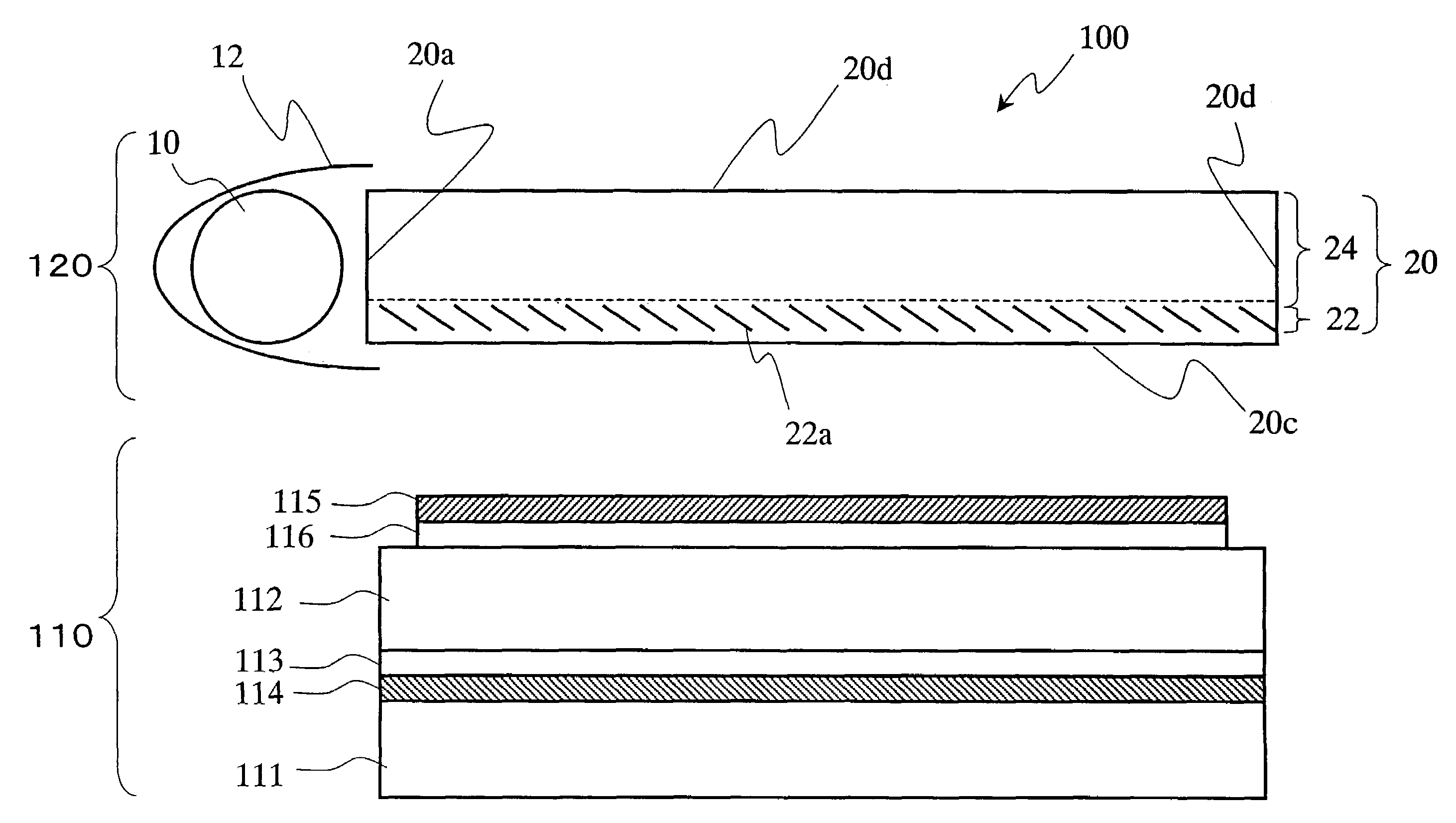

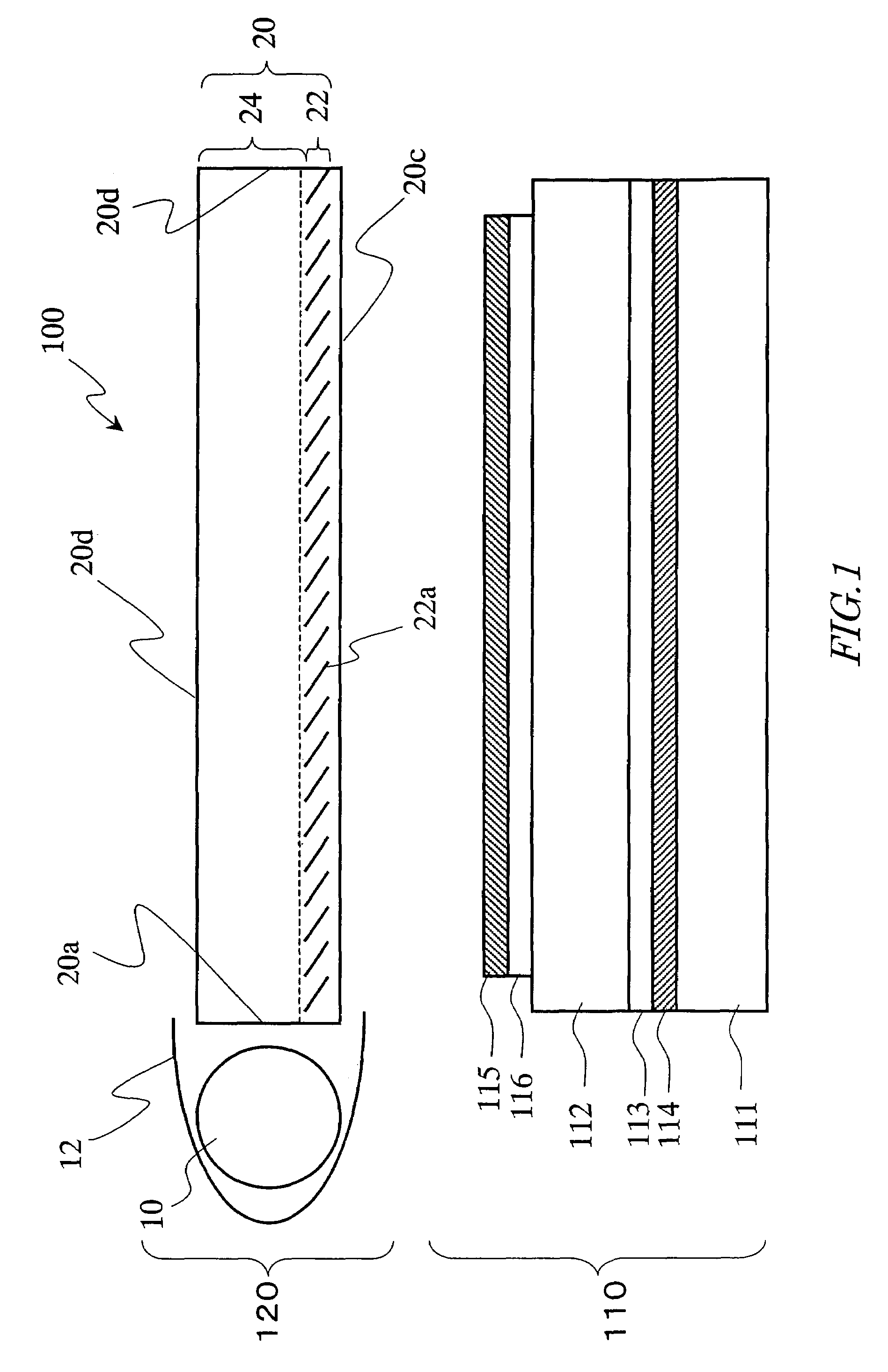

Lighting device and image display unit and light guide provided with it

InactiveUS20060056196A1Reduce lightLight utilization efficiencyMechanical apparatusPolarising elementsLight guideOptoelectronics

An illumination device according to the present invention includes a light source; and a lightguide element including an incidence surface for receiving light emitted from the light source and an outgoing surface from which the light incident from the incidence surface goes out. The lightguide element includes a polarization selection layer for causing light of a specific polarization direction (first polarized light), among the light incident from the incidence surface, to selectively go out from the outgoing surface, and a polarization conversion layer for converting second polarized light, polarized in a different direction from that of the first polarized light, into the first polarized light. The polarization selection layer reflects the first polarized light substantially only toward the outgoing surface.

Owner:SHARP KK

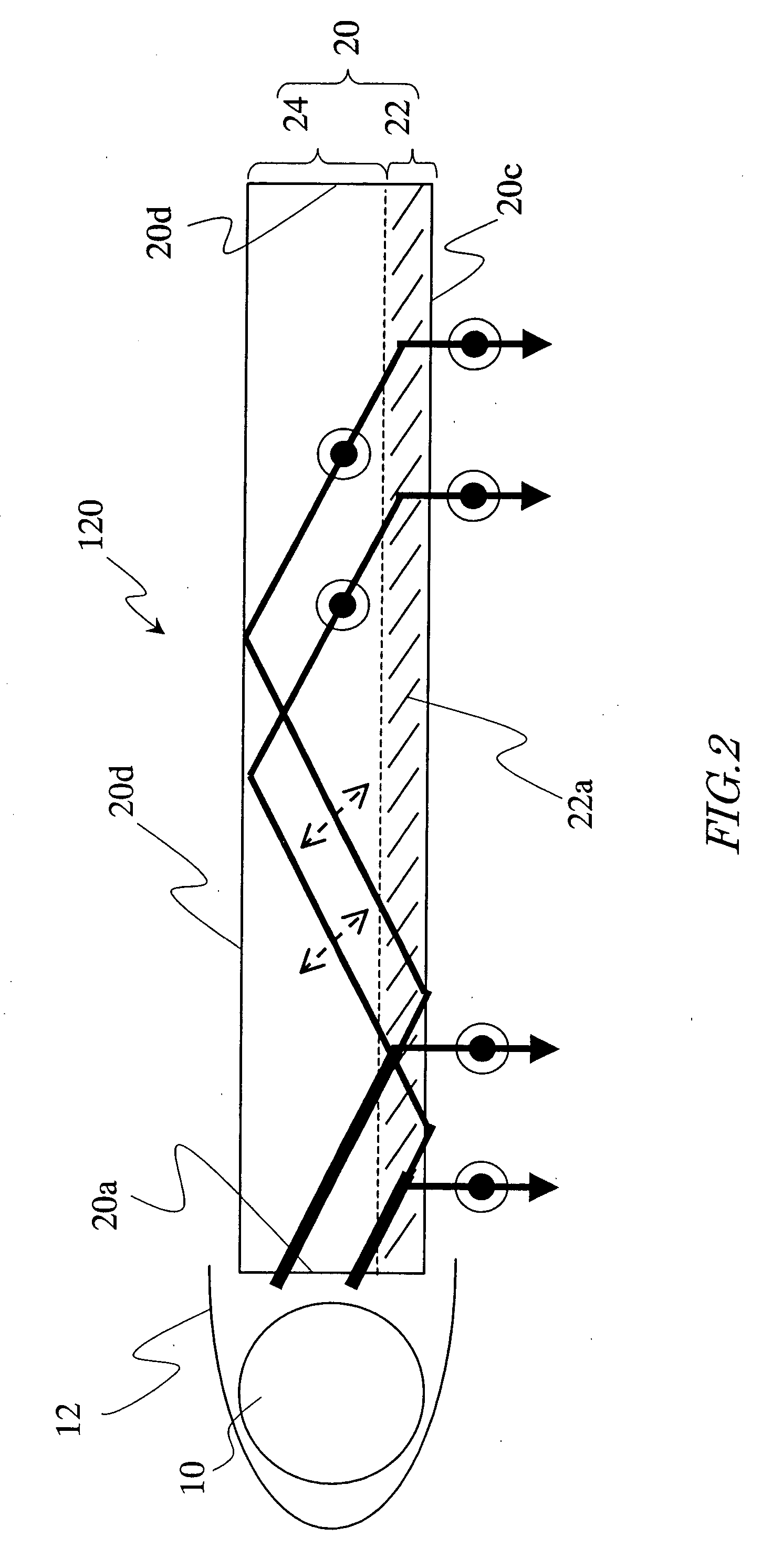

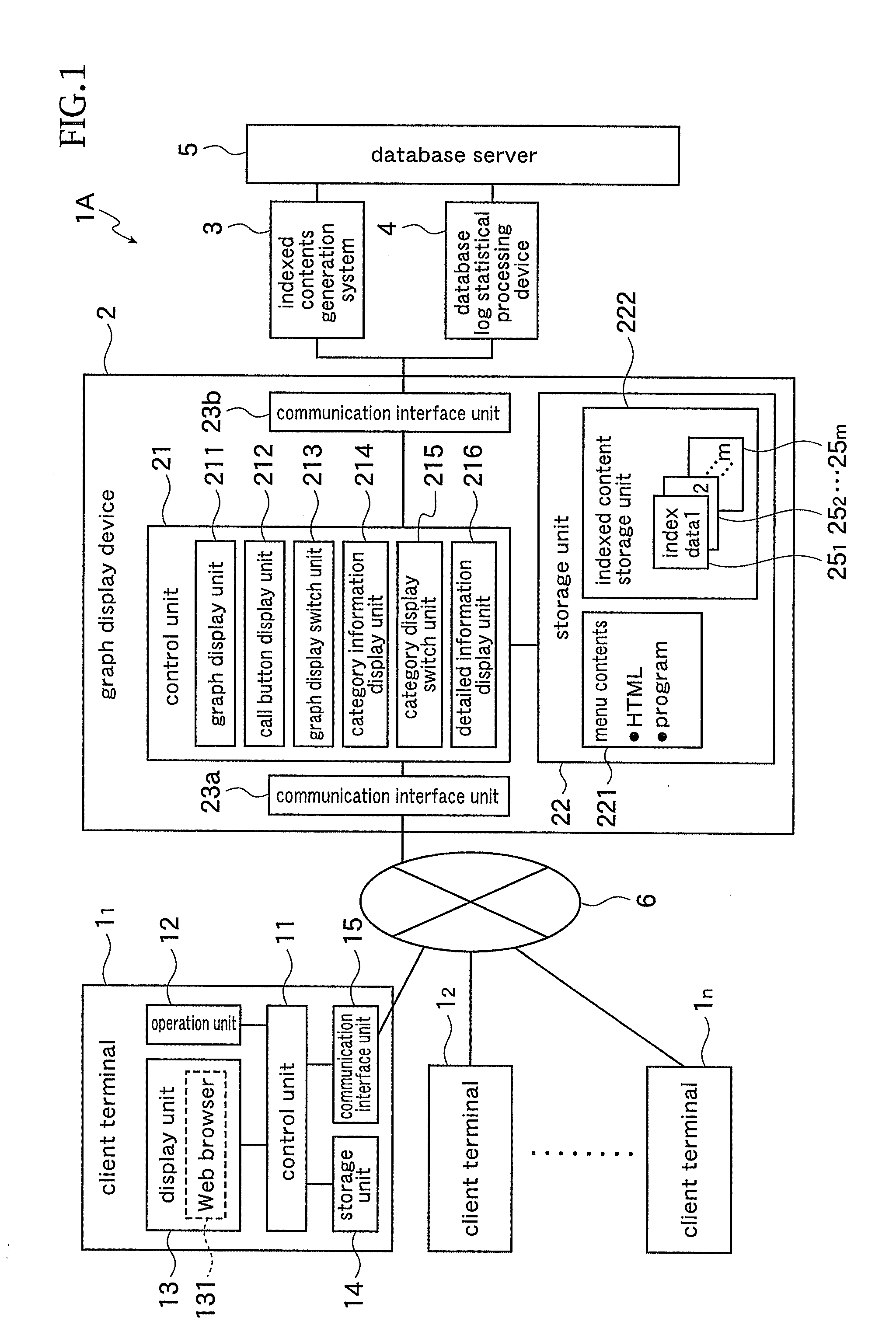

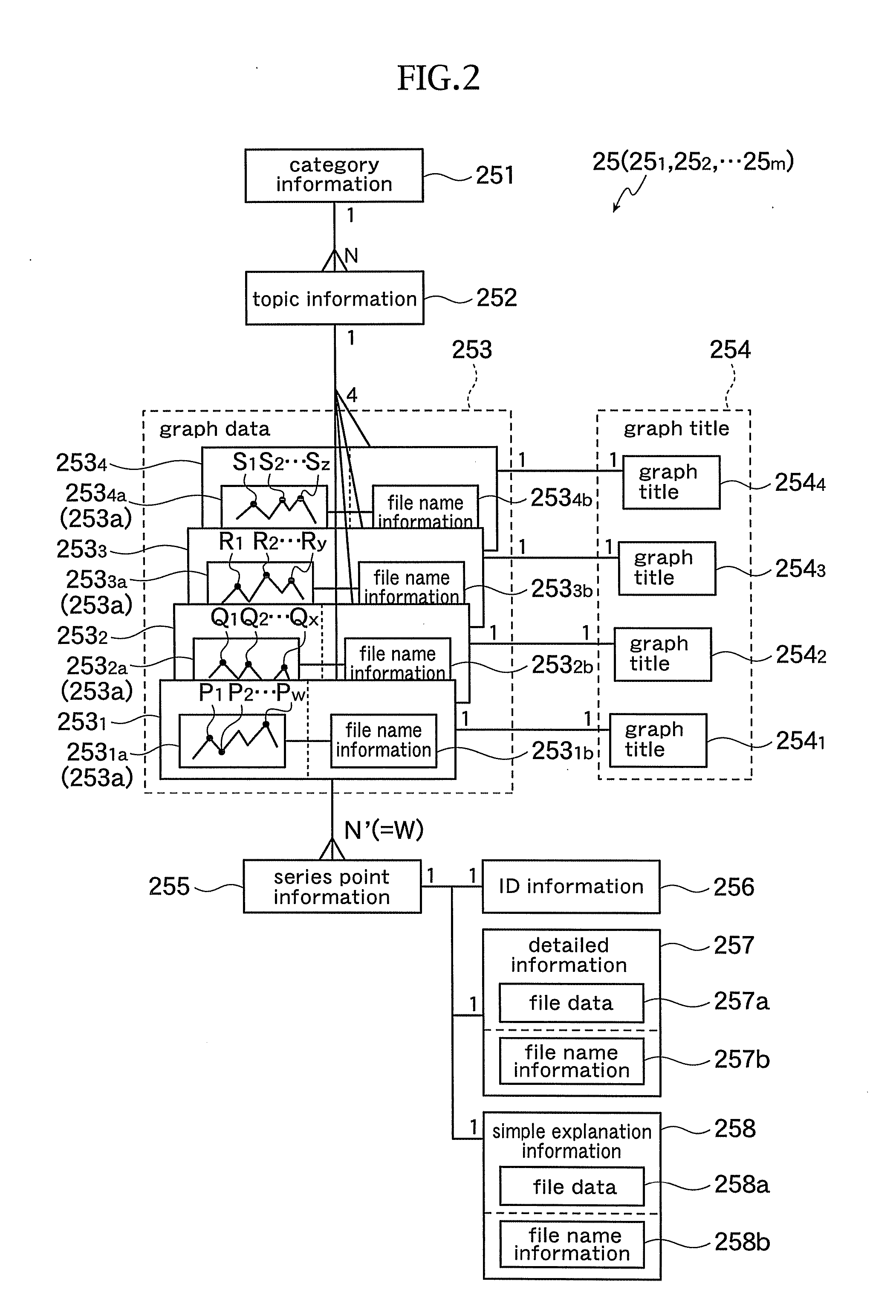

Graph display system and program

InactiveUS20100103177A1Easy to understandEasy to compareDrawing from basic elementsFinanceGraphicsWeb browser

Graphs drawn by using economic statistics data are easily and quickly displayed on a display in the form enabling easy recognition and appropriate mutual comparison. Index data 251 . . . including graphs drawn by using economic statistics data and attribute information are recorded in a content-by-index storage section (222) of a graph display (2) serving as a Web server. The graph display (2) has a graph display section (211) for allowing a Web browser (131) of a client terminal (1) to display a graph, a call button display section (212) for allowing the Web browser (131) to display an array of graph call buttons associated with the respective displayable graphs, and a graph display change section (213) for changing the graph to the graph associated with the call button according to the command from the client terminal (1).

Owner:I N INFORMATION SYST

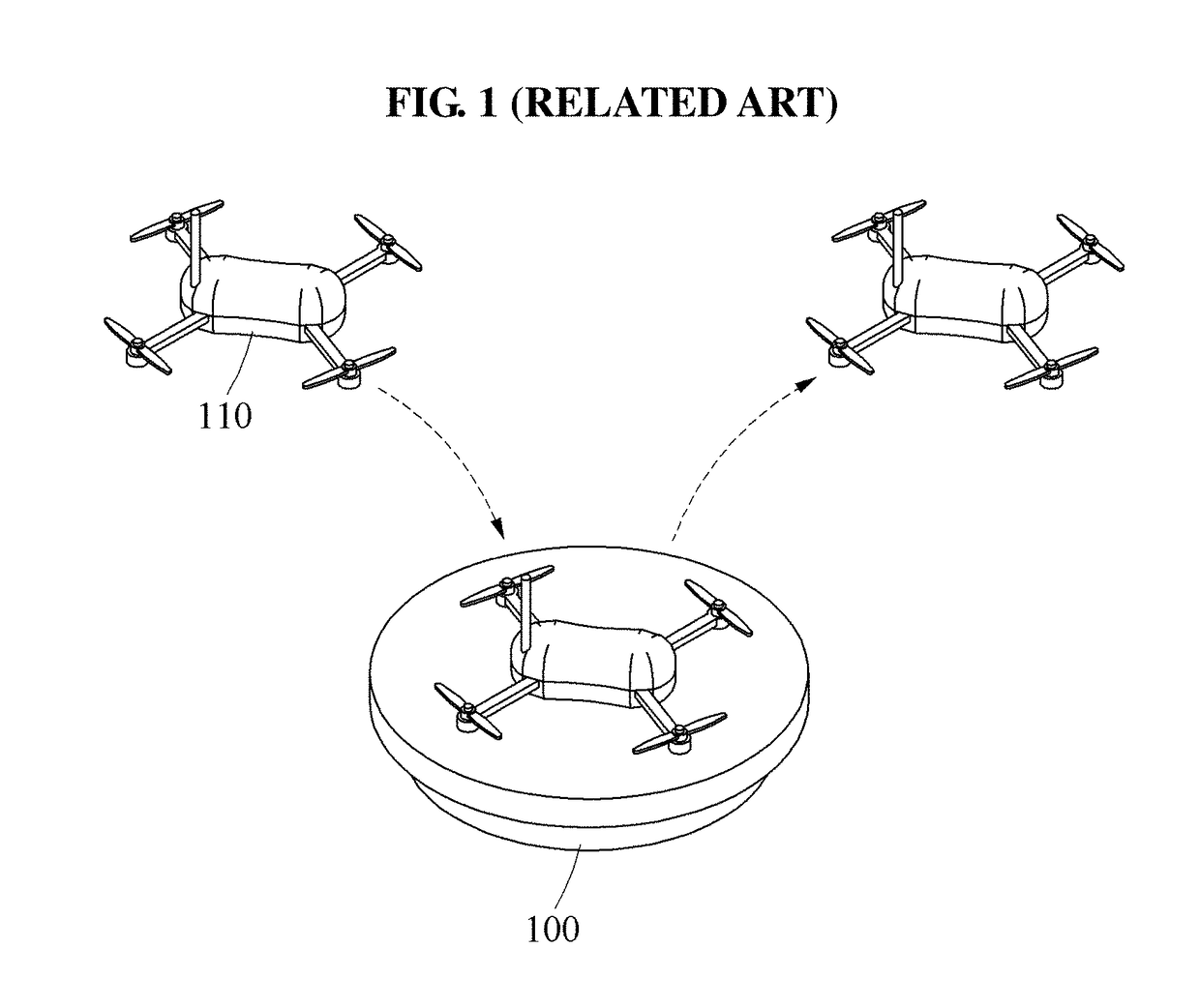

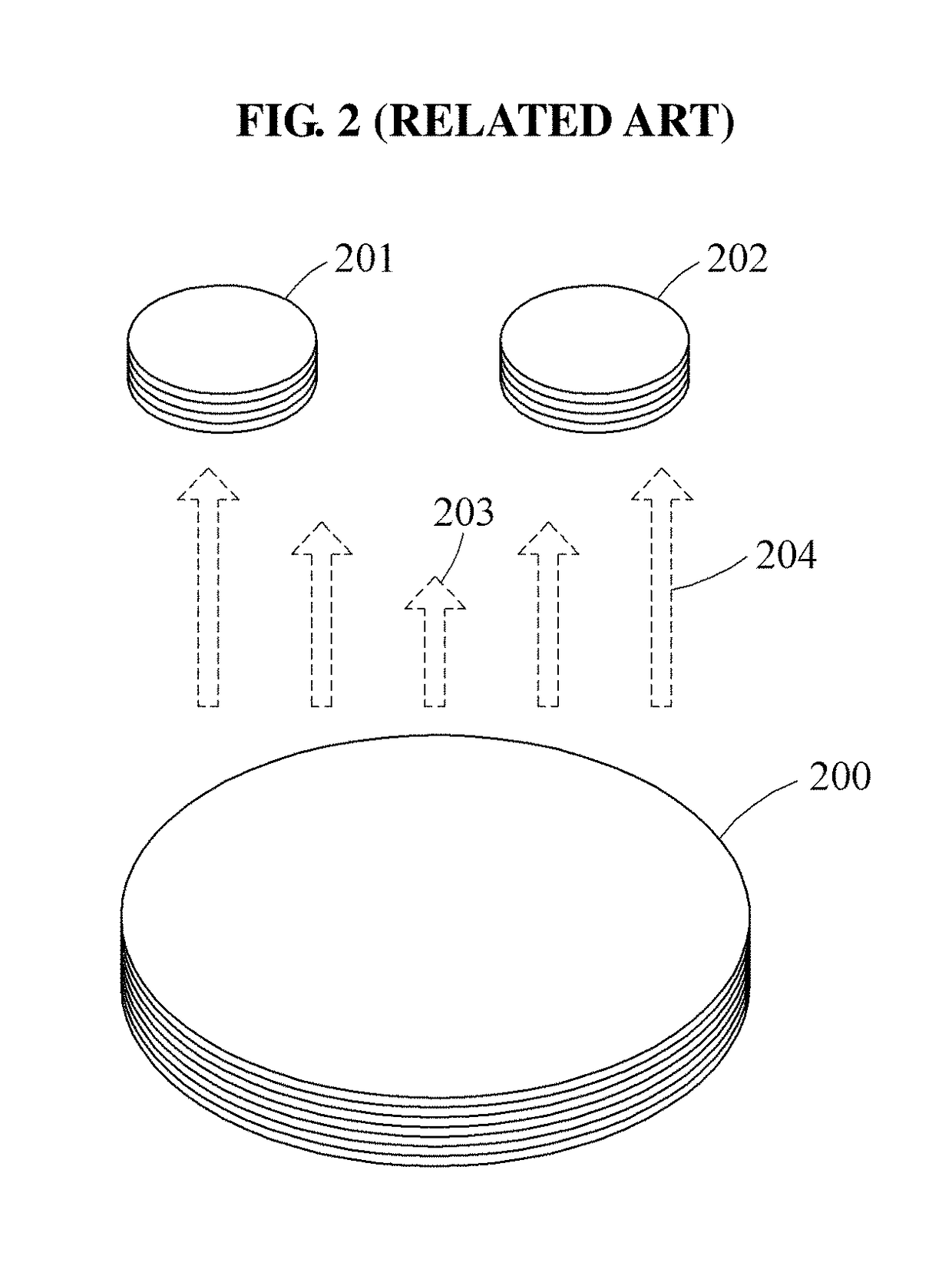

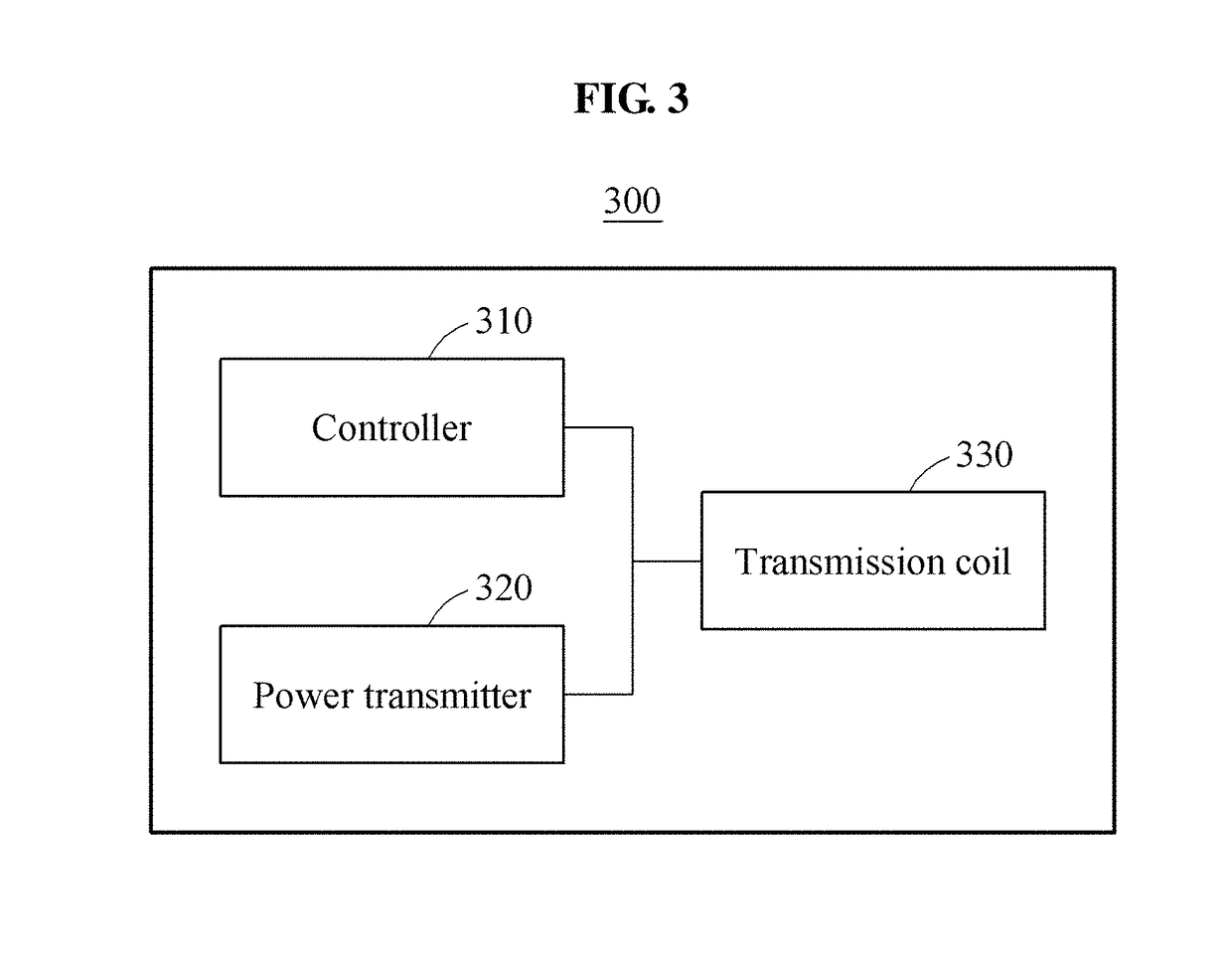

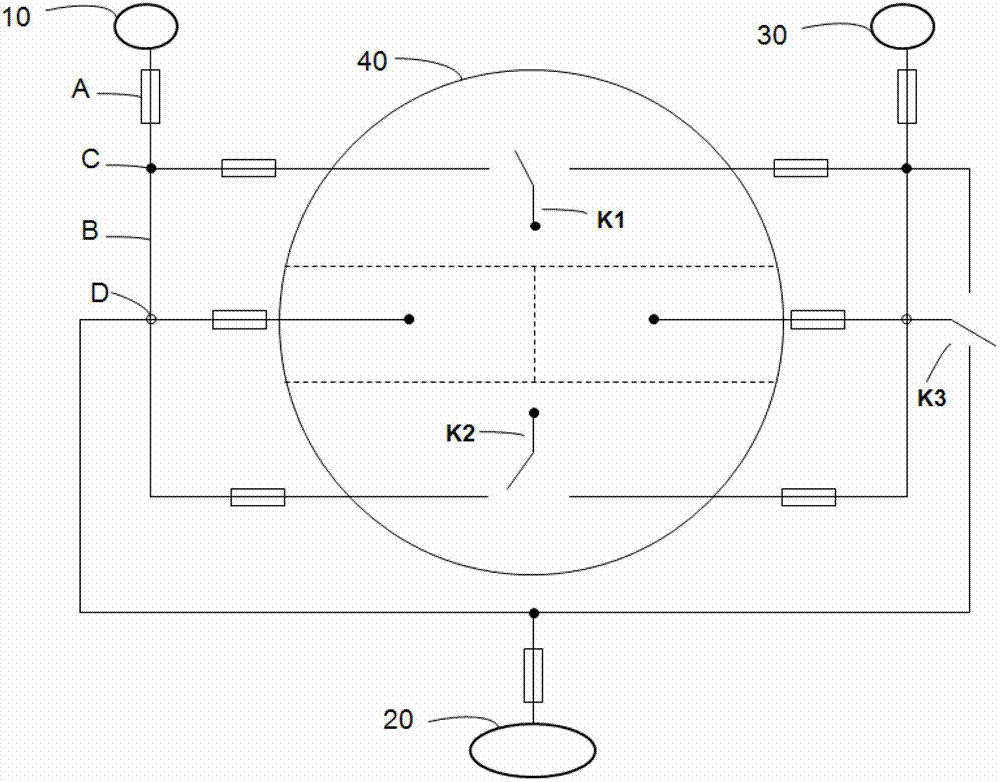

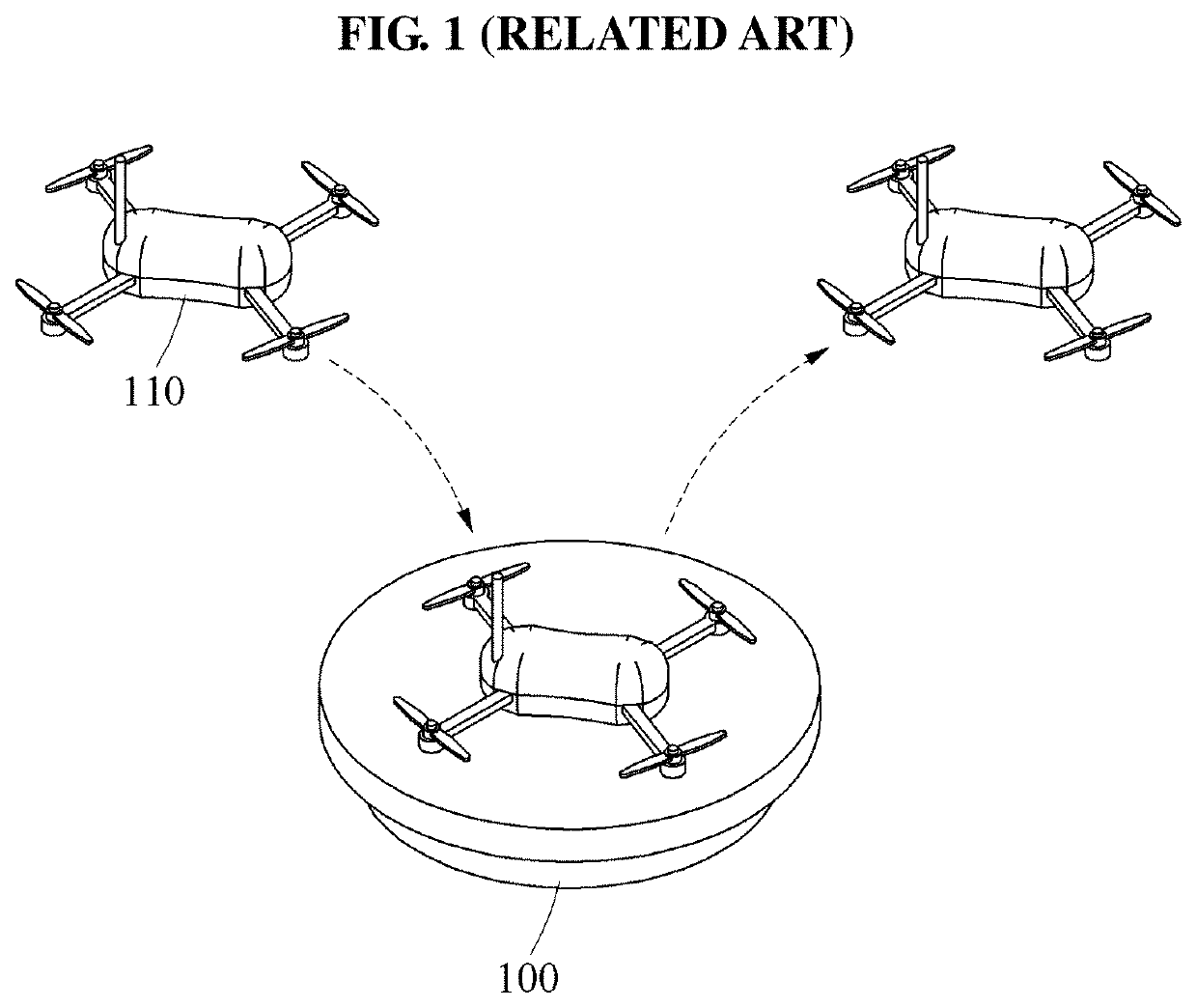

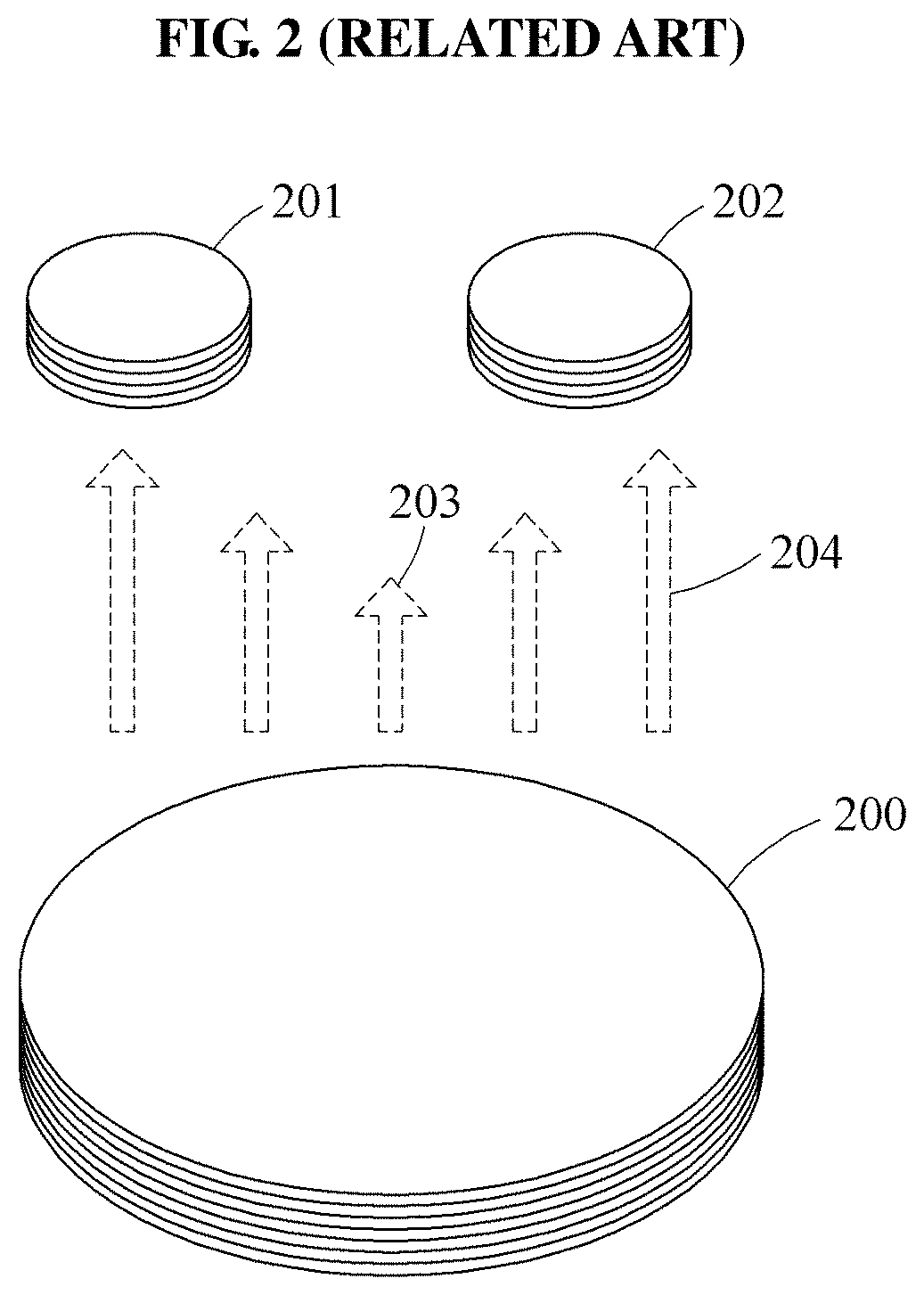

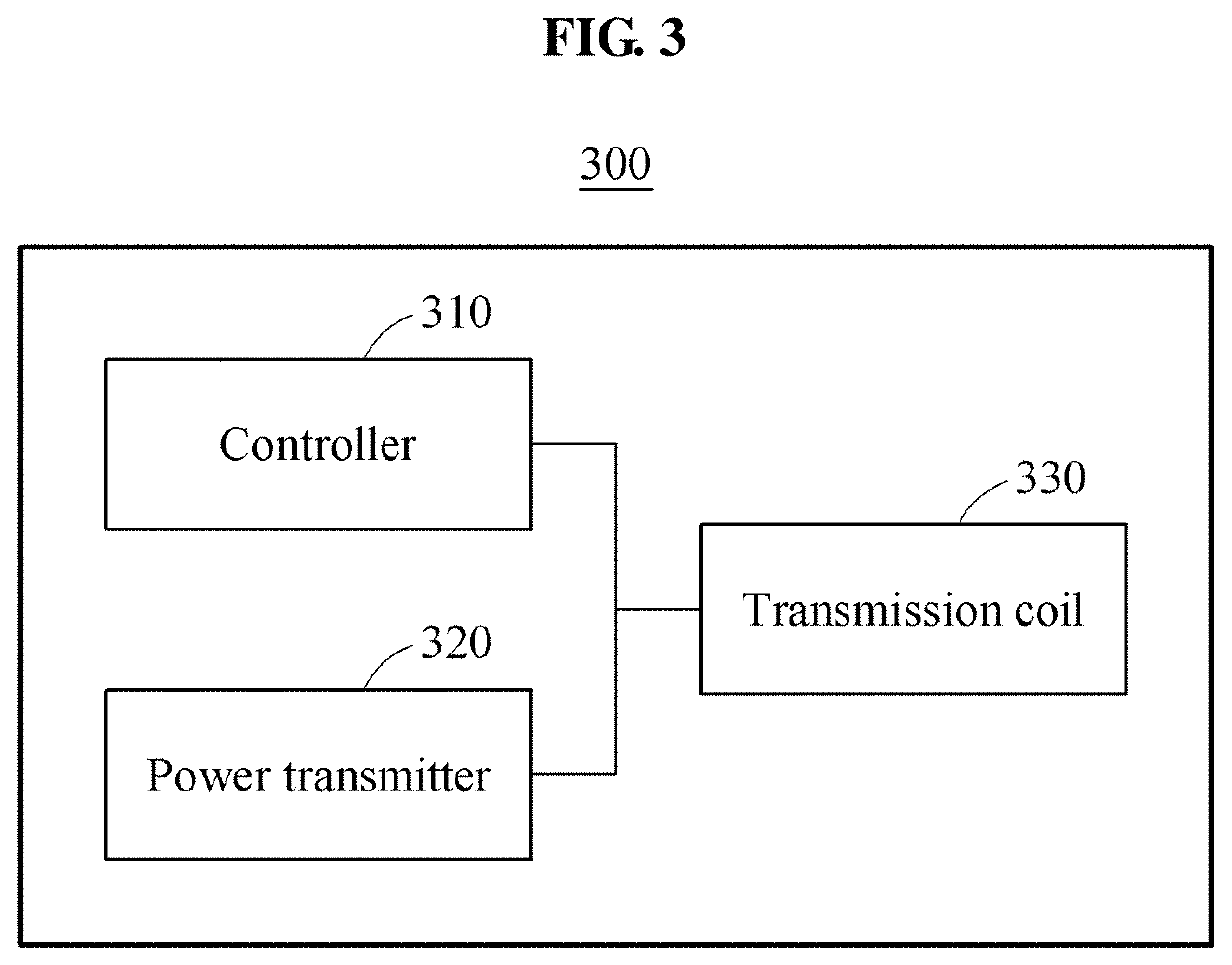

Wireless power transmitting device and method

ActiveUS20190058349A1Expand coverageUniform charging efficiencyNear-field transmissionBatteries circuit arrangementsElectric power transmissionEngineering

Disclosed is a wireless power transmitting device and method, the wireless power transmitting device including, in response to detection of a power receiver within a predetermined separation distance from a charging pad, a controller configured to generate a magnetic field through a transmission coil with a multilayer structure in which a plurality of coil layers of different sizes are stacked, and a power transmitter configured to wirelessly transmit, to a reception coil of the power receiver, a power signal generated using magnetic fields generated by the plurality of coil layers.

Owner:ELECTRONICS & TELECOMM RES INST

Lighting device and image display unit and light guide provided with it

InactiveUS7425089B2Reduce lightLight utilization efficiencyMechanical apparatusPolarising elementsLight guideOptoelectronics

An illumination device according to the present invention includes a light source; and a lightguide element including an incidence surface for receiving light emitted from the light source and an outgoing surface from which the light incident from the incidence surface goes out. The lightguide element includes a polarization selection layer for causing light of a specific polarization direction (first polarized light), among the light incident from the incidence surface, to selectively go out from the outgoing surface, and a polarization conversion layer for converting second polarized light, polarized in a different direction from that of the first polarized light, into the first polarized light. The polarization selection layer reflects the first polarized light substantially only toward the outgoing surface.

Owner:SHARP KK

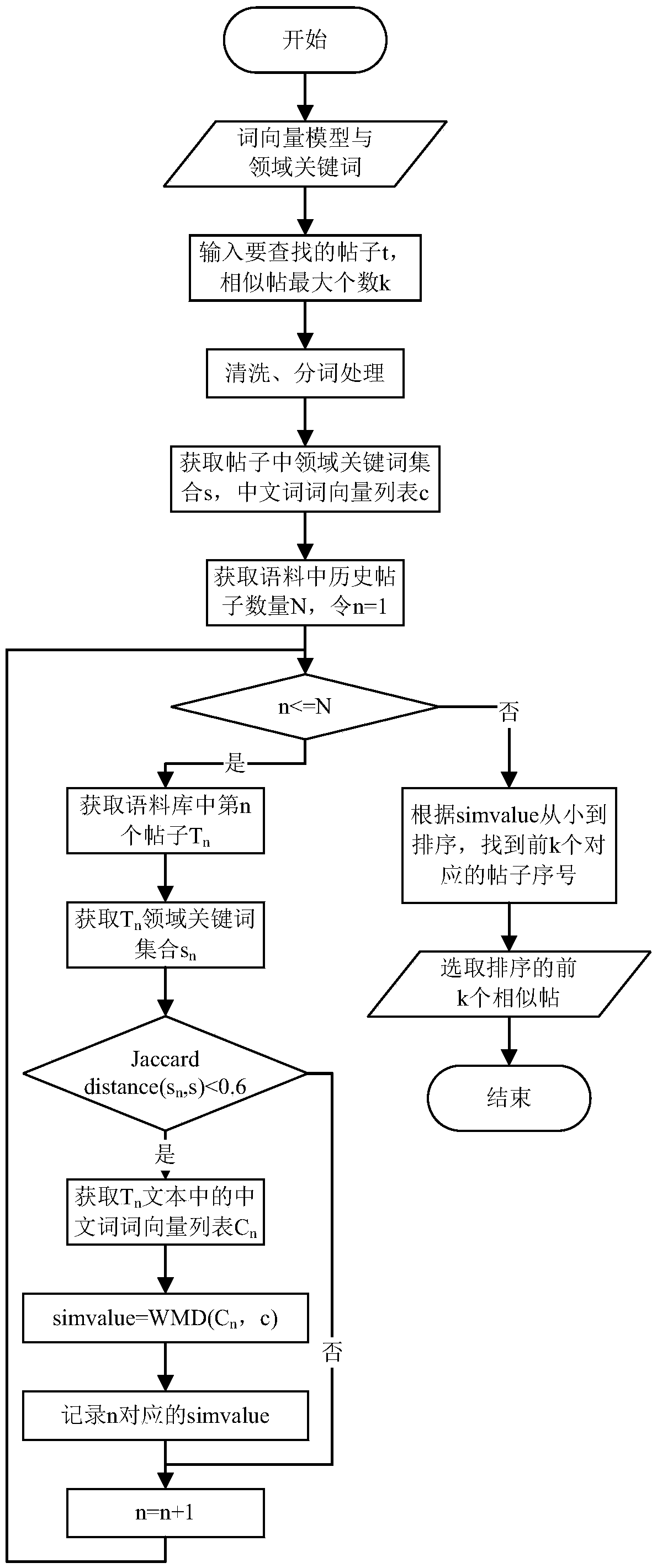

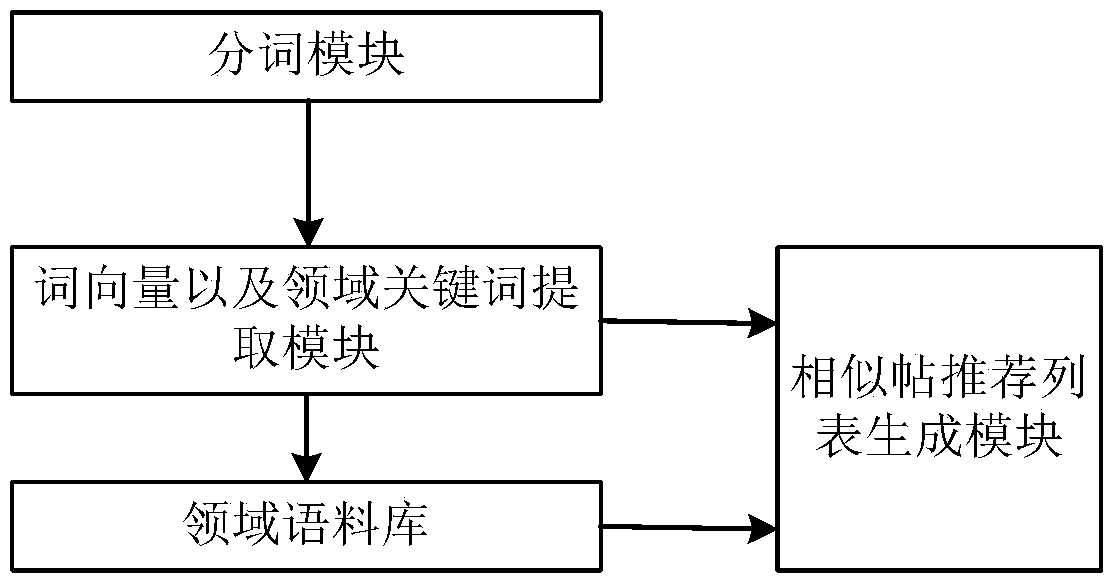

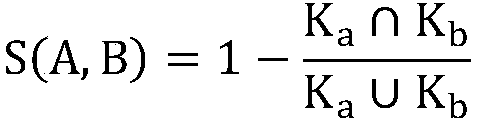

Method and system for recommending content of online course forum based on text similarity

InactiveCN109063147ARich contentIncrease profitData processing applicationsSpecial data processing applicationsText corpusKeyword extraction

The invention provides an online course forum content recommendation method and system based on text similarity, which is applicable to the application field of online education. The system includes word segmentation module, word vector and domain keyword extraction module, domain corpus and similar post recommendation list generation module. This method will discuss the text content of the post for word segmentation, extraction of word vectors and domain keywords; Using Historical Discussion Posts to Construct Domain Corpus; Generate a list of similar posts from the corpus for the discussionposts the user is browsing. The invention improves the utilization rate of historical discussion content, Using text similarity analysis, It can compare the semantic similarity of the two discussion posts more accurately from the course content level, recommend more needed similar posts for students, and use Jaccard distance for preliminary screening in advance, and then use WMD distance measurement to discuss the similarity between the posts, which improves the efficiency of the recommendation system and reduces the computational load.

Owner:BEIHANG UNIV

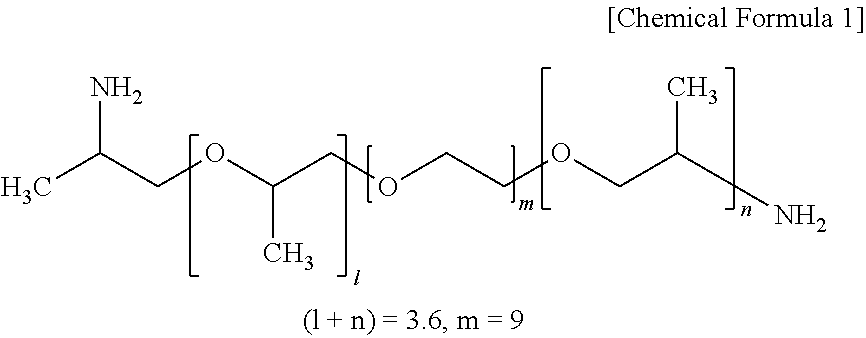

Method for manufacturing carbonaceous luminescent material

ActiveUS20180022994A1High quantum yieldImprove featuresGrapheneLuminescent compositionsCarboxylic acidSolvent

Provided is a method for manufacturing a carbonaceous luminescent material in which a polycarboxylic-acid-containing starting material, an acid catalyst, and a solvent are mixed together and heated.

Owner:NISSAN CHEM IND LTD

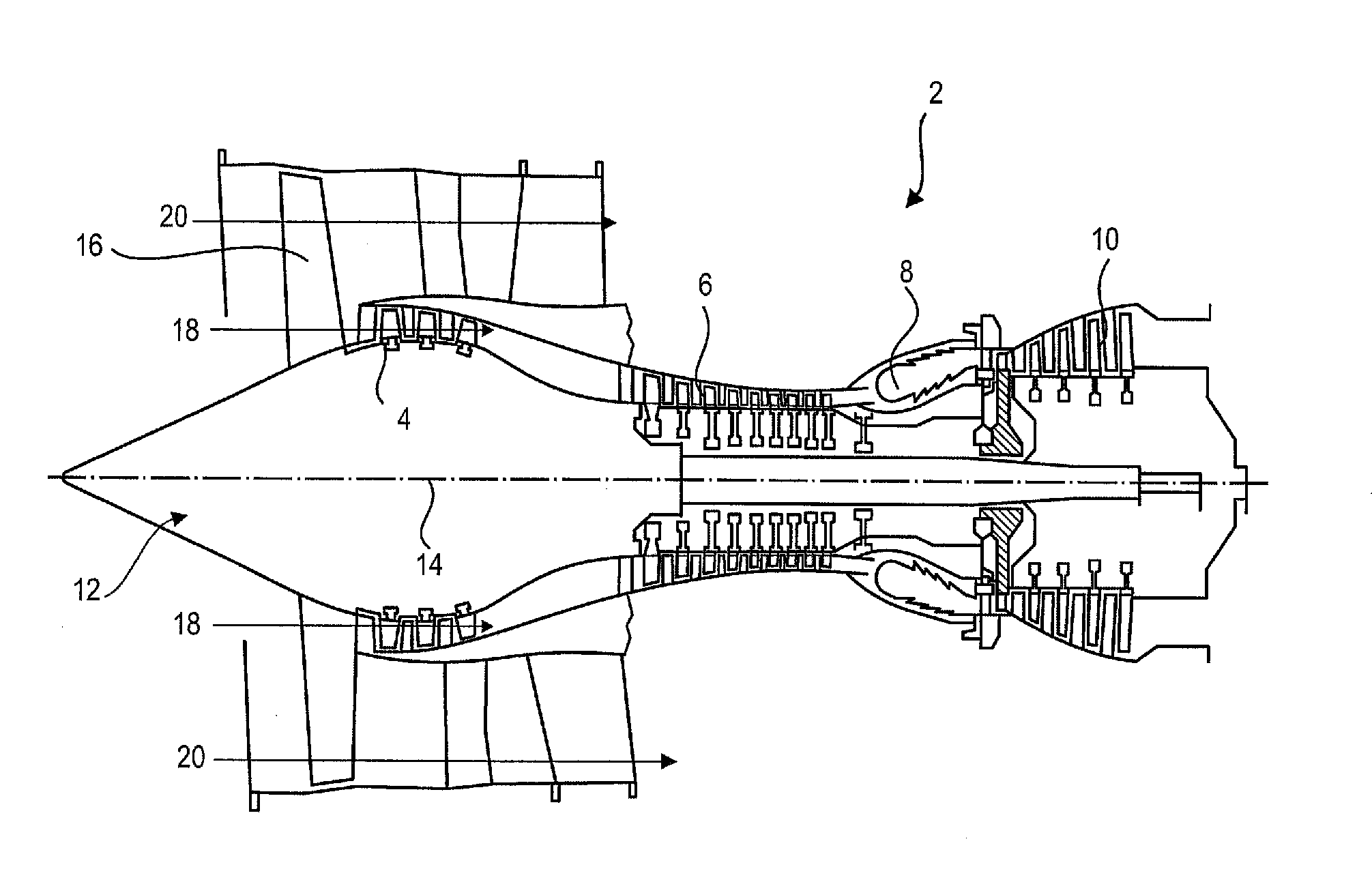

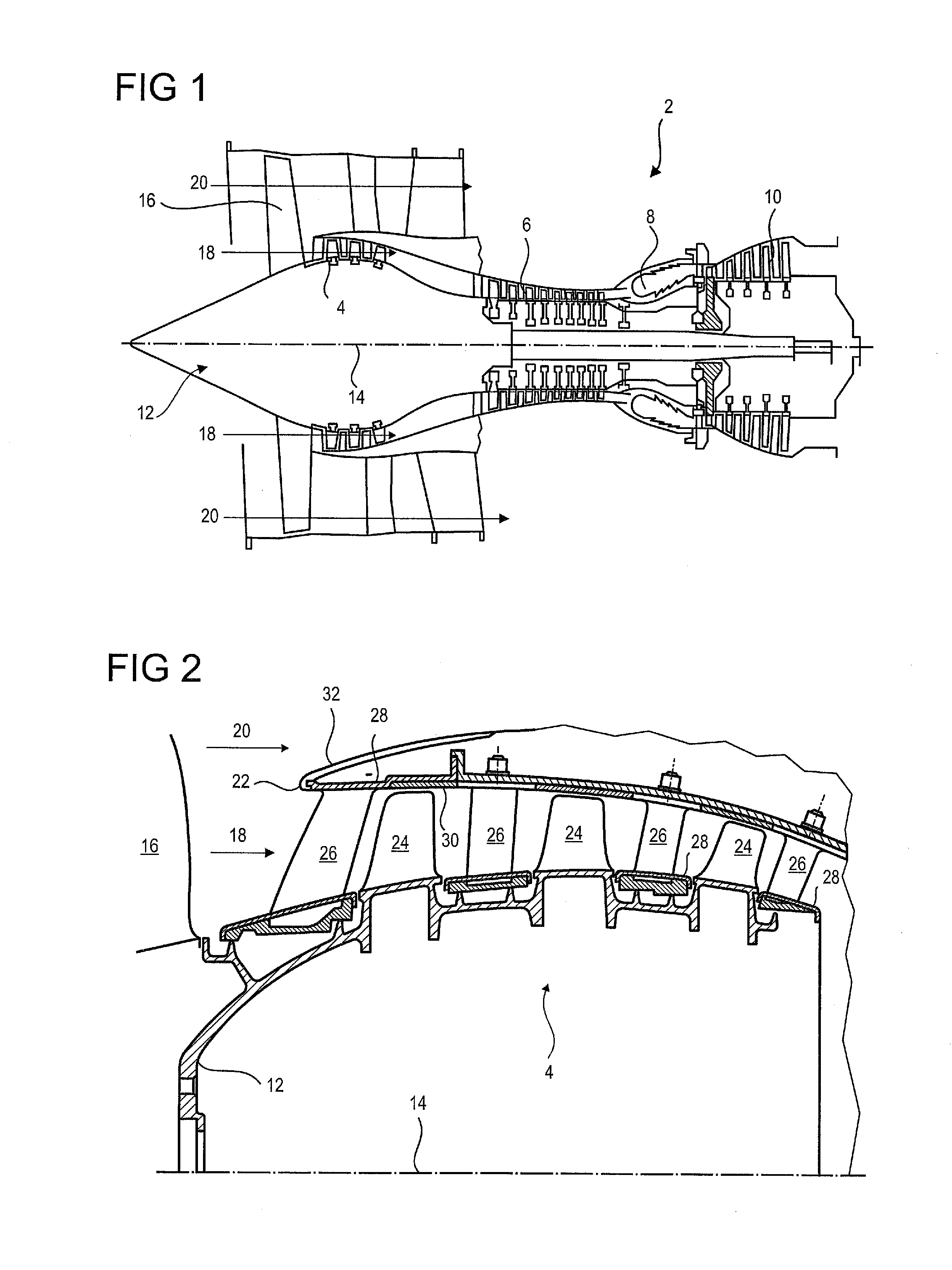

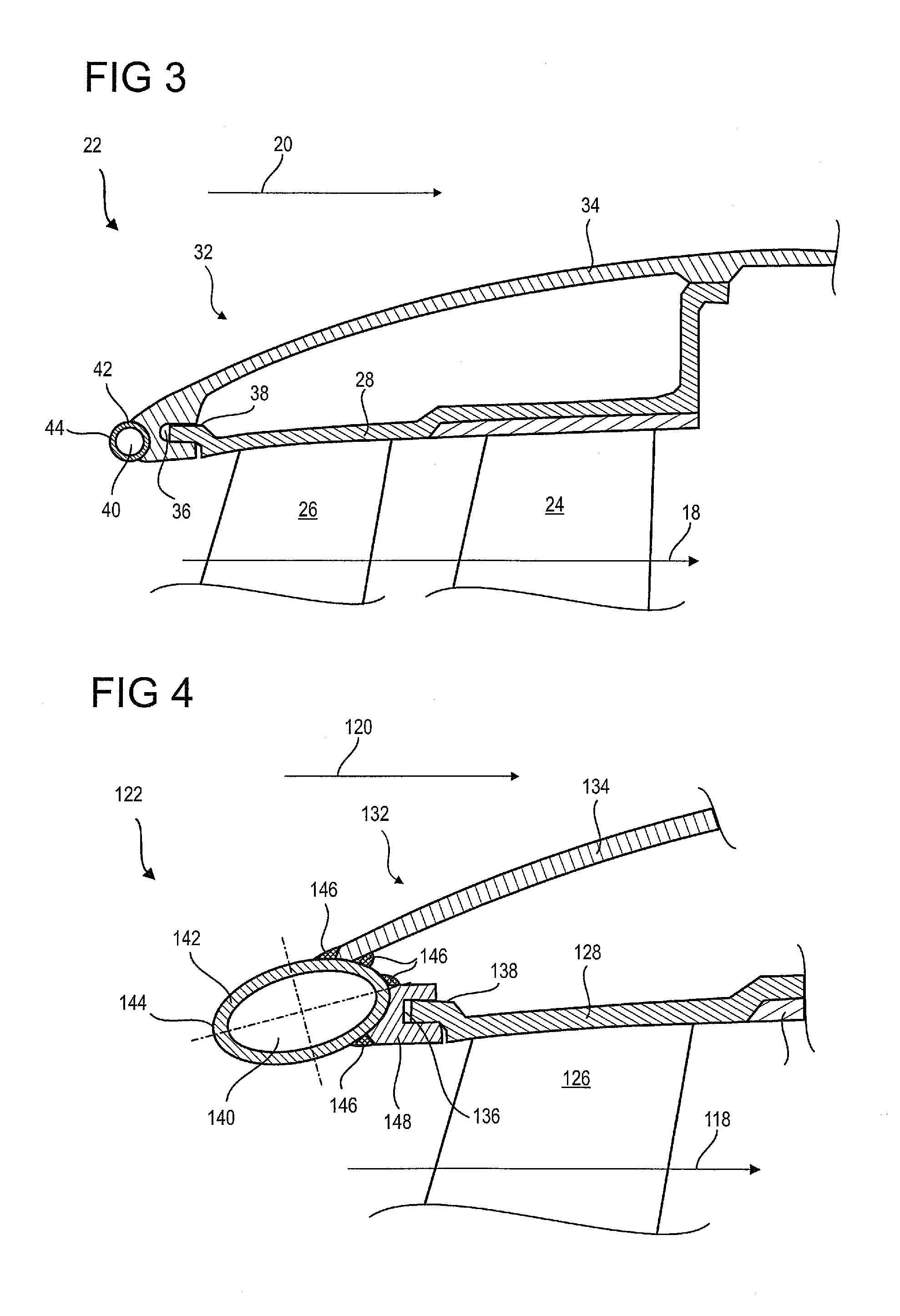

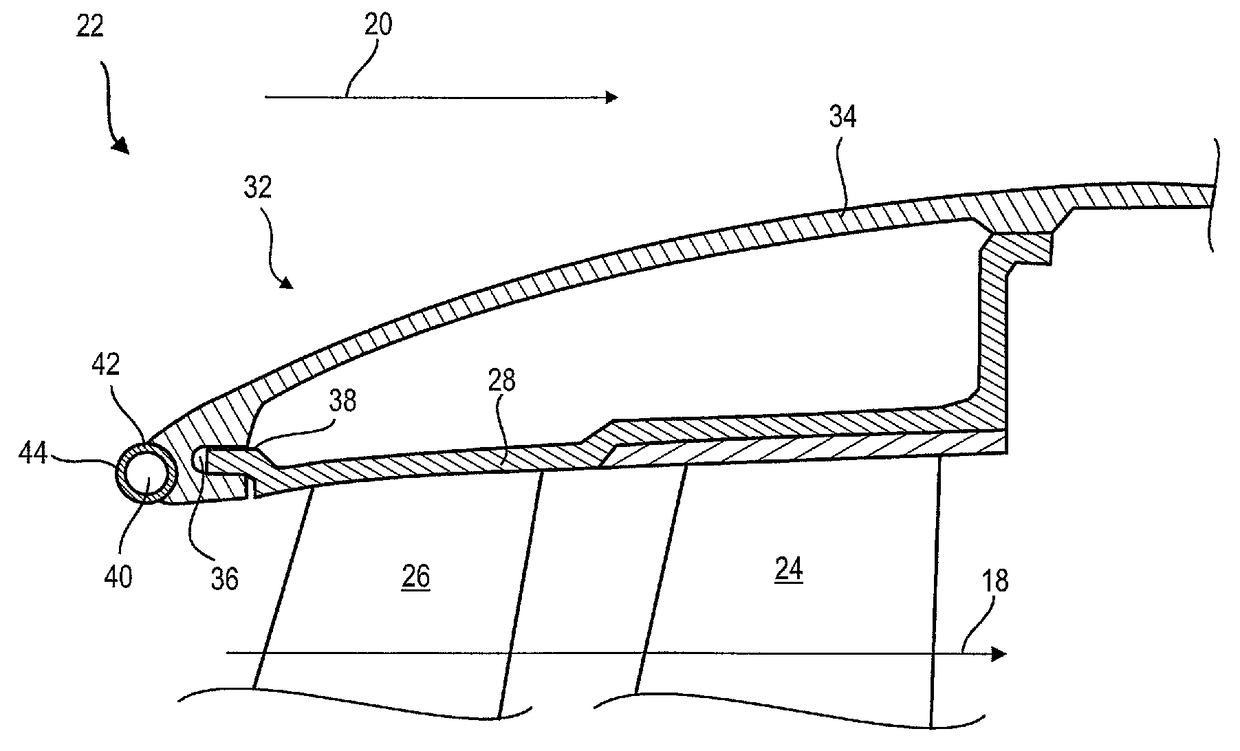

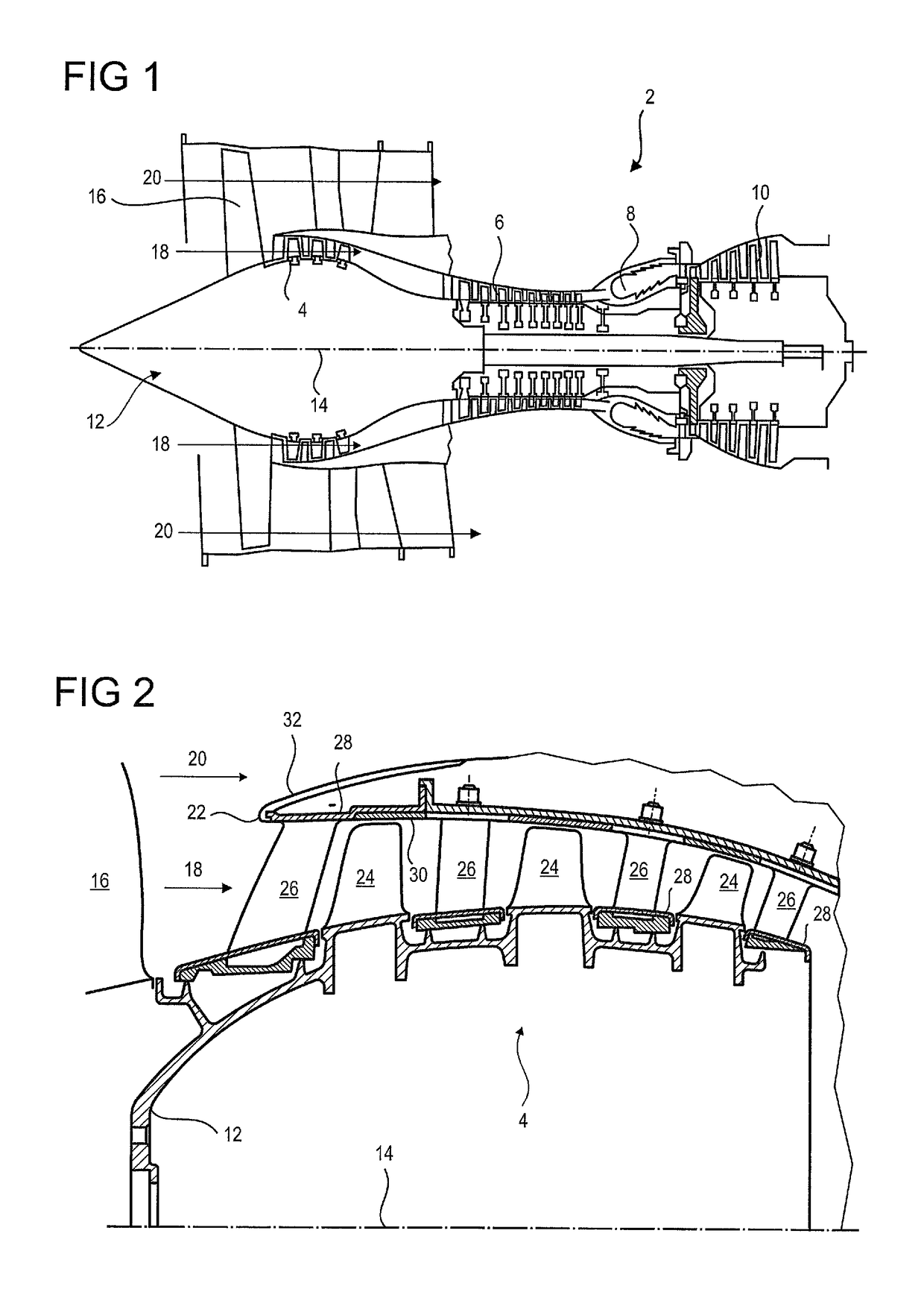

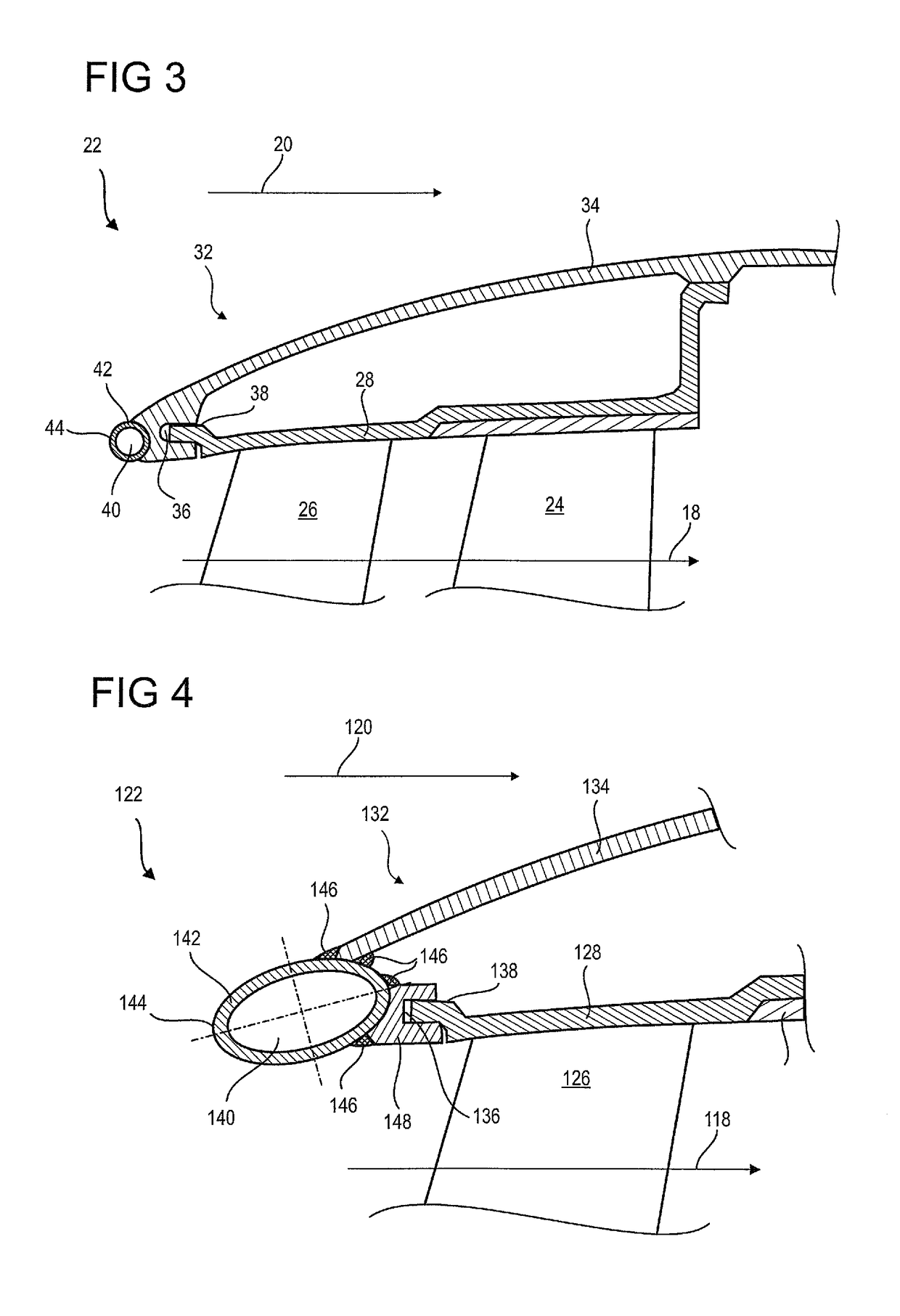

Axial turbomachine blade with platforms having an angular profile

InactiveUS20140161597A1Improve thermal efficiencyReduce material thicknessPump componentsBlade accessoriesLeading edgeThermodynamic cycle

The present application relates to a splitter nose of an axial turbomachine designed to separate an annular flow into the turbomachine into a primary flow and a secondary flow for undergoing a thermodynamic cycle. The nose includes a de-icing device with a wall defining, at least partially, an annular channel. A hot oil stream created by the turbomachine circulates in this latter. The oil runs through the circular nose and de-ices it while itself getting cooled. The wall is located so as to form the leading edge of the said splitter nose. The wall is an open or closed strip such as a tube which can be fixed by bonding, welding or recessing. The present application also relates to a multi-flow turbomachine with splitter noses fitted with de-icing devices.

Owner:TECHSPACE AERO

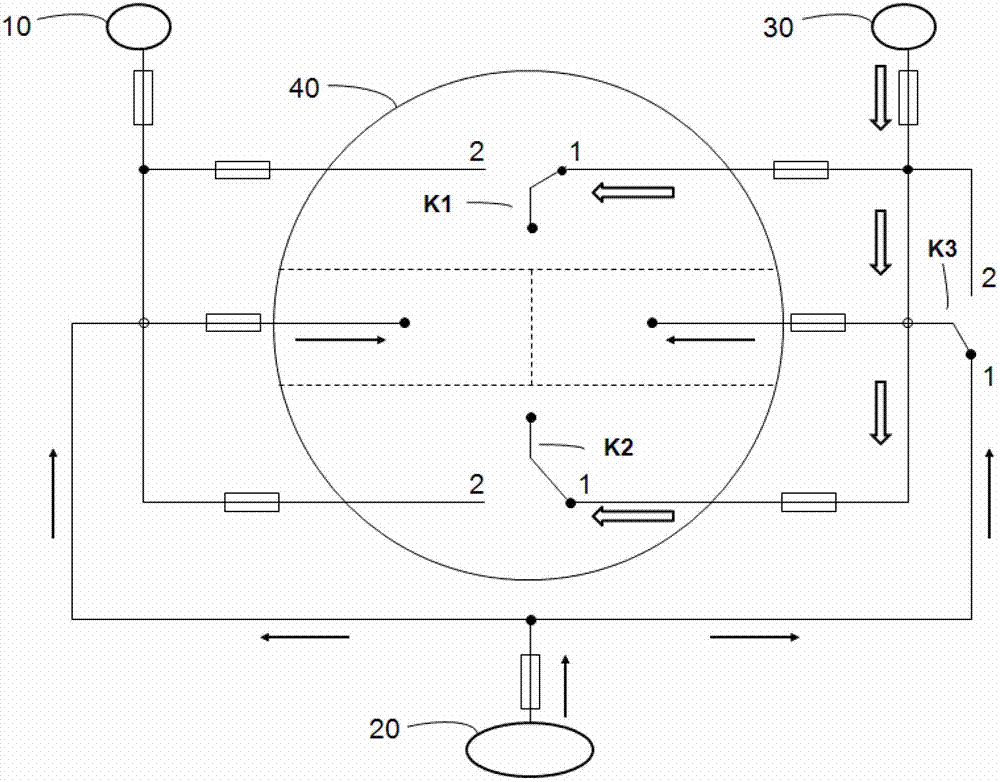

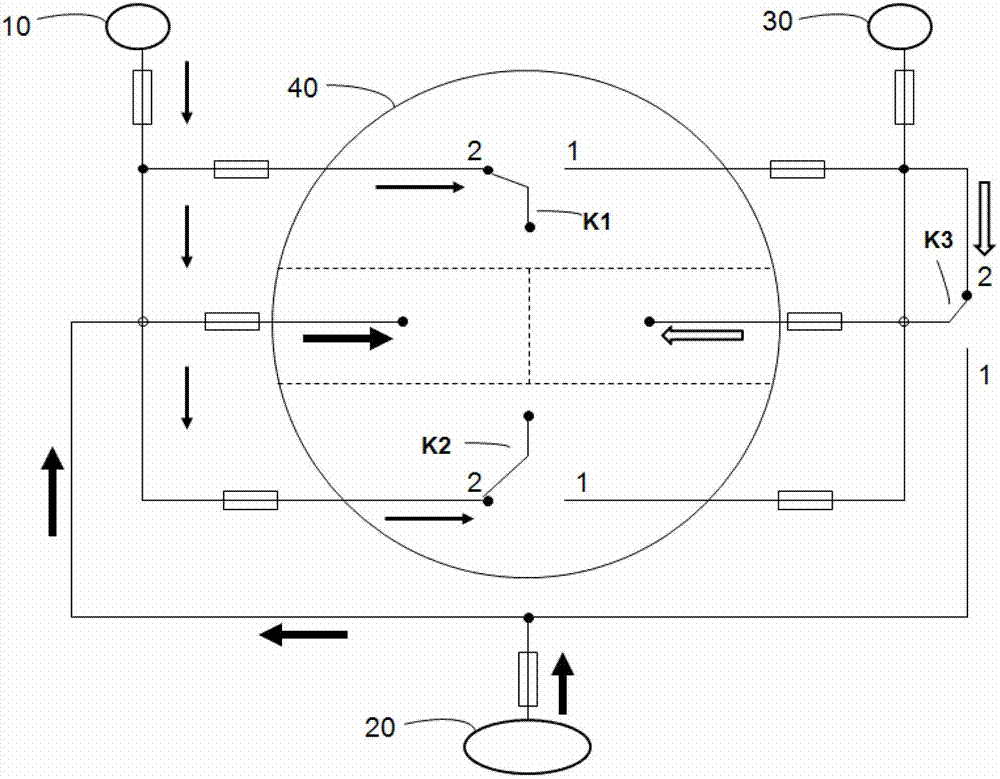

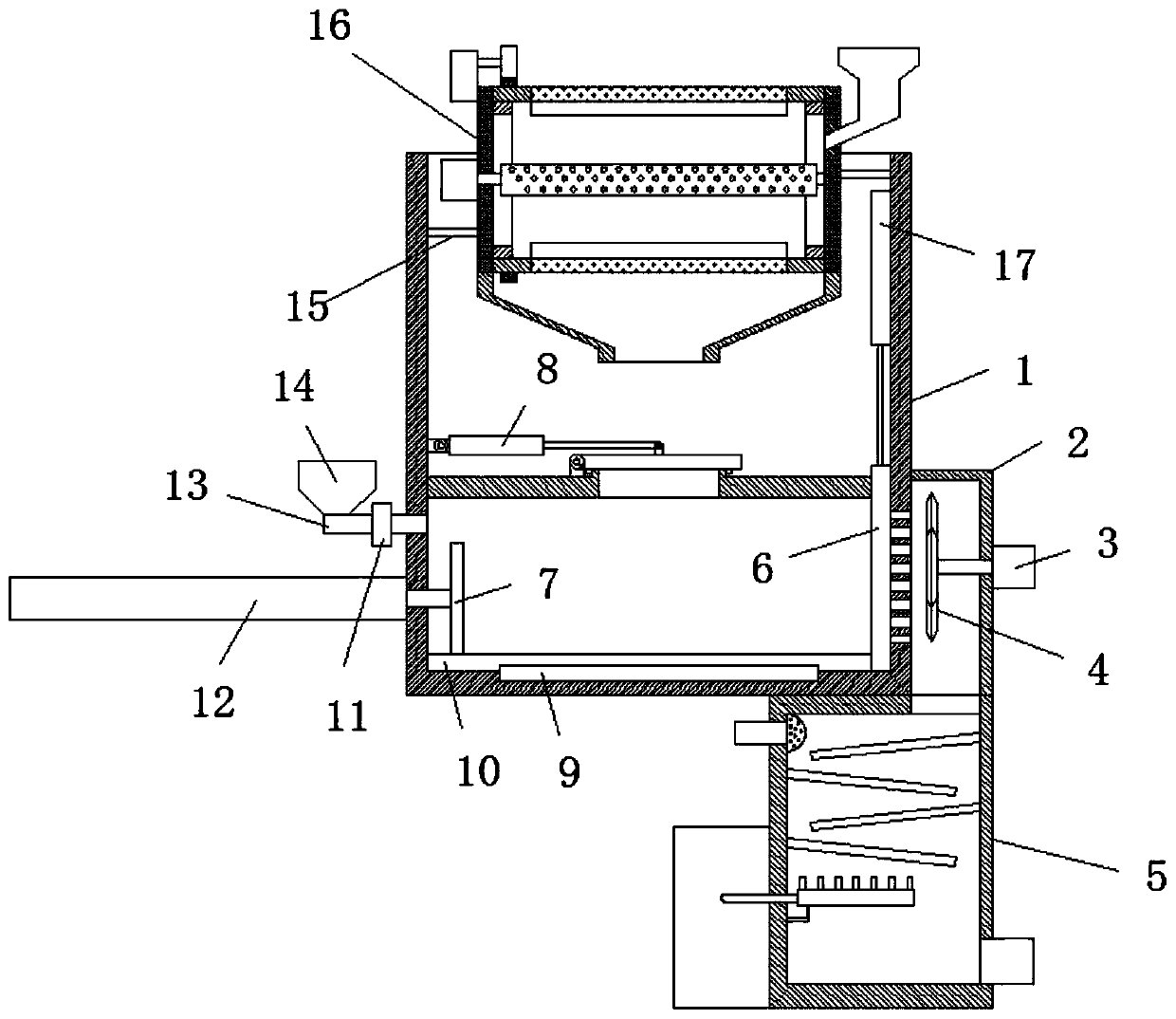

Dual-mode system used for film growth and control method of dual-mode system

ActiveCN102925875AUnified efficiencyUniform qualityPolycrystalline material growthFrom chemically reactive gasesQuality optimizationDual mode

The invention discloses a dual-mode system used for film growth and a control method of the dual-mode system. The dual-mode system comprises a non-reaction gas source, a first reaction source, a second reaction source, a reaction chamber with a rotary carrying platform, and a control device, wherein the control device controls mutual conversion of the system between two reaction modes; in the first reaction mode, the control device only provides two reaction sources to communicate with a fluid in the reaction chamber; in the second reaction mode, the control device controls the non-reaction gas source and the two reaction sources to communicate with the fluid in the reaction chamber; the two reaction sources form mutually spaced and sequentially arranged independent regions on the surface of the rotary carrying platform along the rotating direction of the rotary carrying platform through the isolation function of the non-reaction resource; and independent growth reaction occurs in the independent region formed by each reaction source. The dual-mode system disclosed by the invention has the advantage of realizing in-situ conversion of OCVD (Oxidative Chemical Vapor Deposition) and ALD (Atomic Layer Deposition) reaction modes, thereby eliminating contradiction between the maximum efficiency of raw materials used for deposition and the quality optimization of a deposited film.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

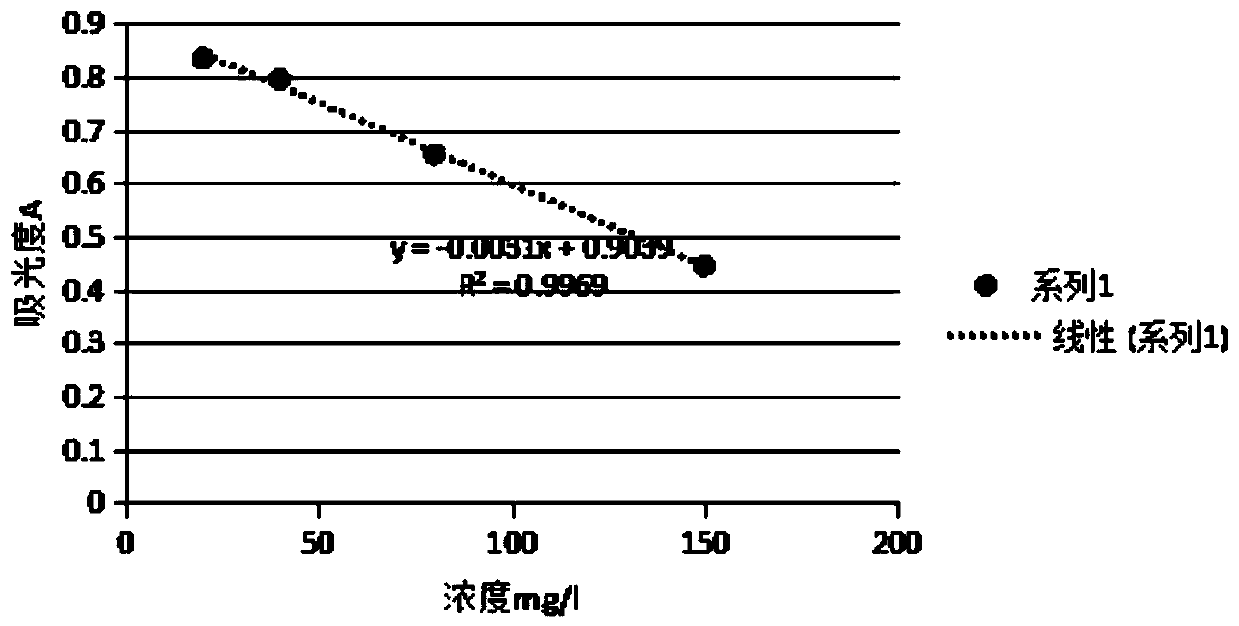

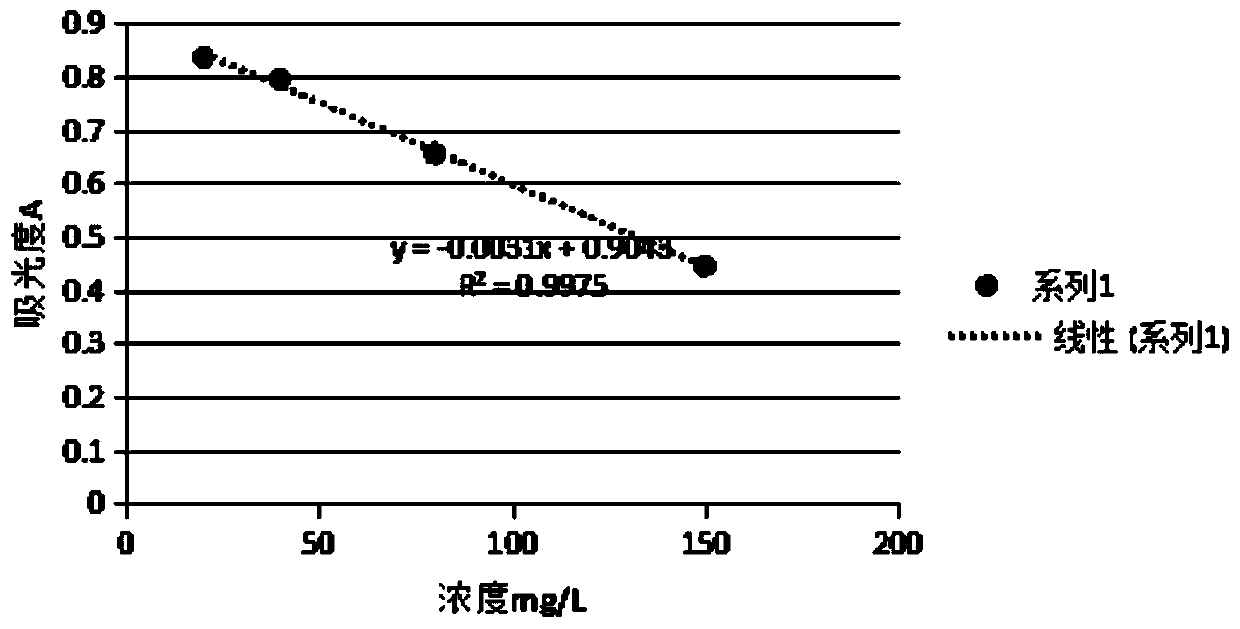

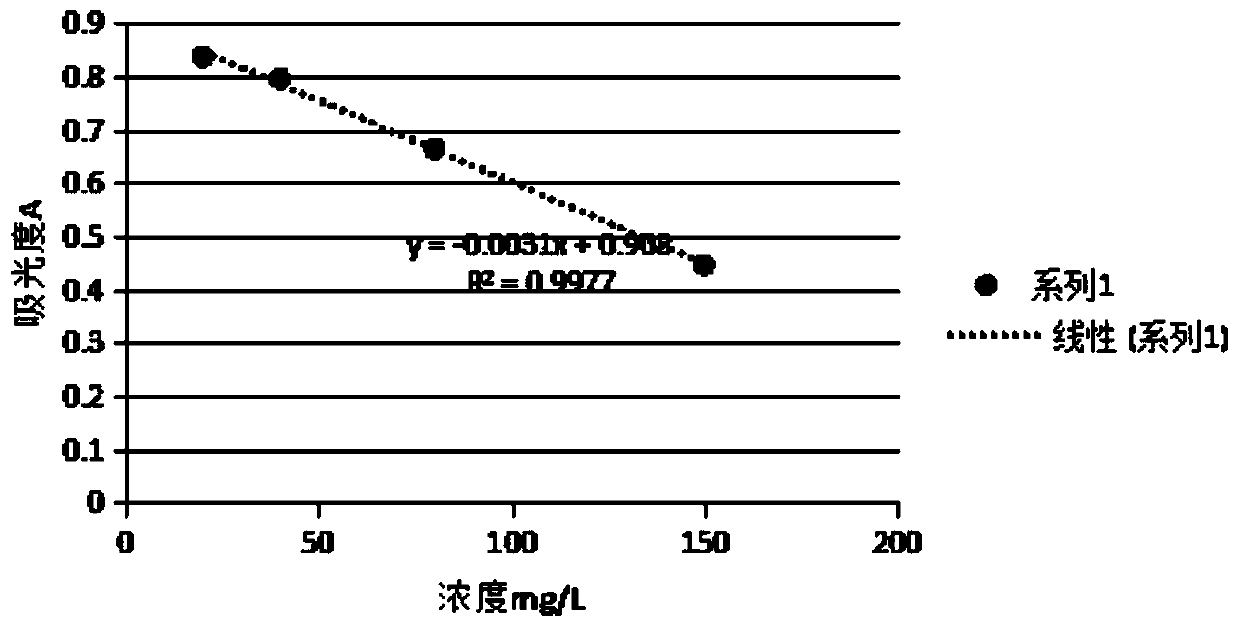

Sewage COD rapid detection method

InactiveCN109781644AHigh precisionImprove accuracyPreparing sample for investigationColor/spectral properties measurementsAnalytical chemistry

The invention discloses a sewage COD rapid detection method. The sewage COD rapid detection method specifically comprises the following steps: S1, preparing a COD rapid digestion solution; S2, preparing COD standard solutions of 20ppm, 40ppm, 80ppm and 150ppm, respectively adding 2.00 ml of the COD standard solution into a colorimetric tube containing 3.00 ml of the COD rapid digestion solution, heating, cooling, and making a standard curve by using an absorbance method; S3, diluting a certain amount of to-be-tested sample to a certain concentration, and performing a blank experiment by usingpurified water; S4, adding 2.00 ml of the diluted to-be-detected solution into a colorimetric tube containing 3.00 ml of a COD rapid digestion solution, carrying out a blank experiment by using purified water, heating and cooling, and standing; and S5, measuring the to-be-measured sewage by adopting a Hash ultraviolet visible light spectrophotometer, combining the standard curve in the step S2 tomeasure the CDO of the to-be-measured sewage, and further calculating the actual sewage COD. The method has the beneficial effects of simplicity and convenience in measurement, short time consumptionand high precision and accuracy.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

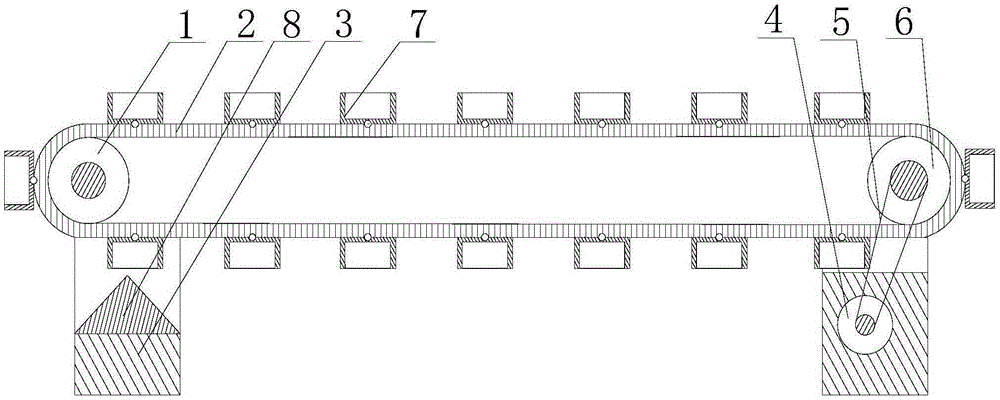

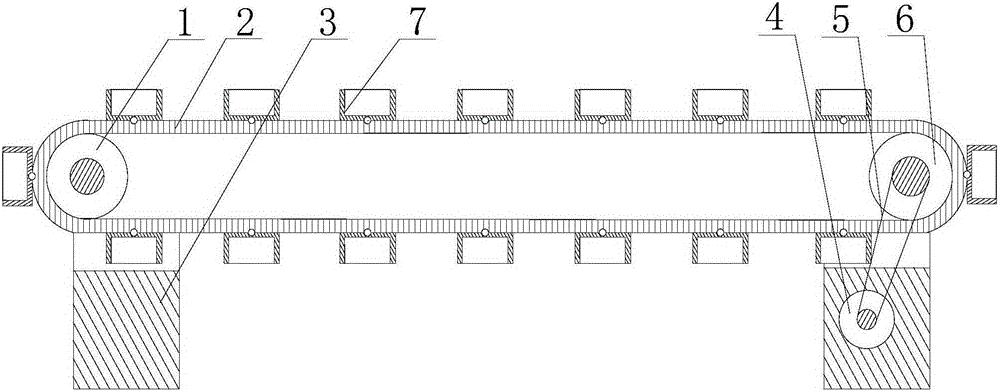

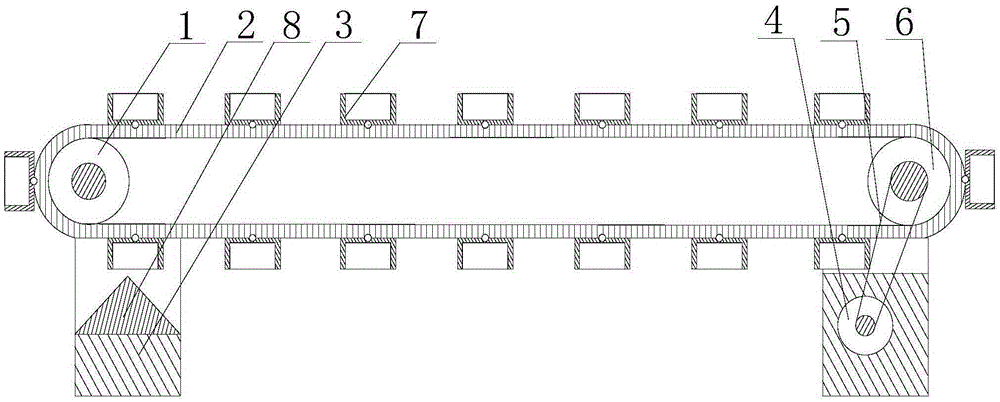

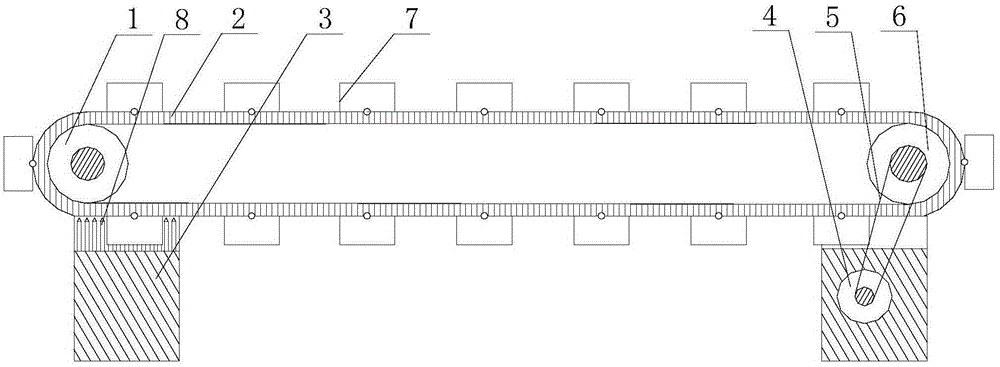

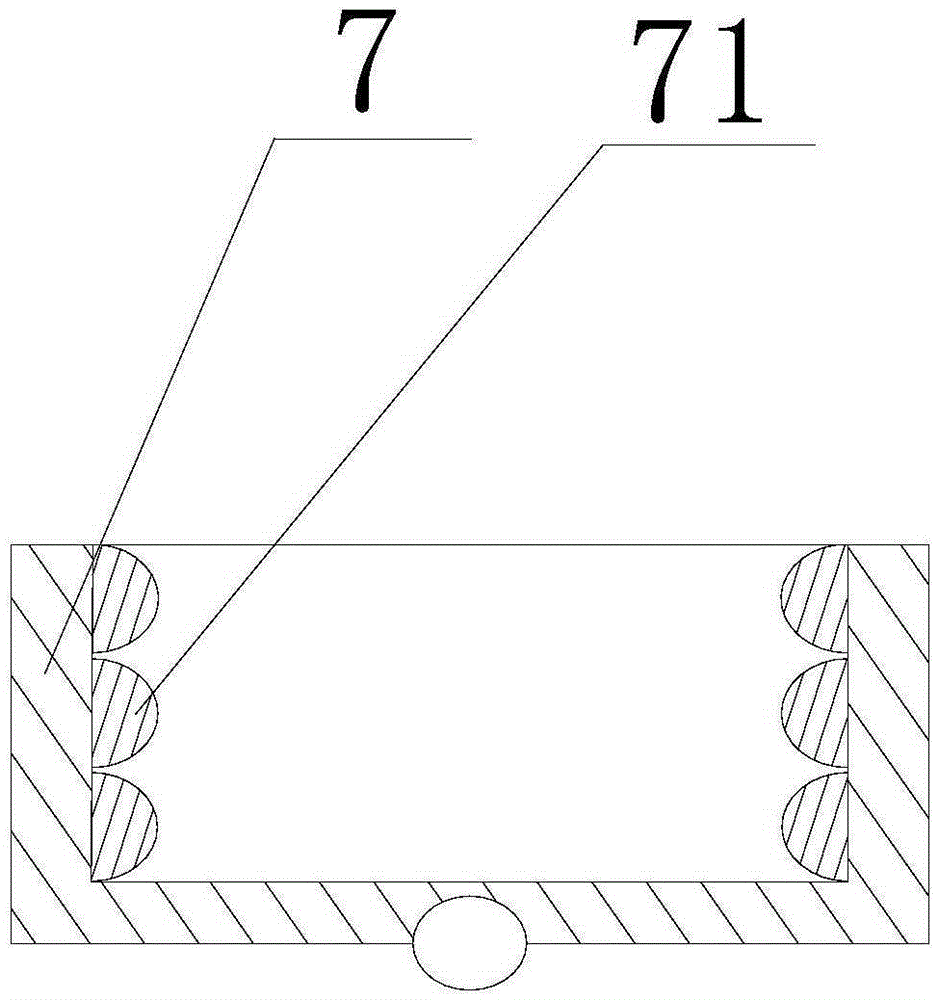

Feeding device for metal machining

InactiveCN106697732AAvoid scattered distributionFeed effectiveConveyorsConveyor partsTransfer procedureMetal machining

The invention discloses a feeding device for metal machining. The feeding device comprises two supporting bases and a conveying chain plate. A main roller and an auxiliary roller are rotationally arranged on the two supporting bases correspondingly. The two ends of the conveying chain plate are arranged in U-shaped areas of the supporting bases and matched with the main roller and the auxiliary roller. Multiple hoppers with the interiors matched with the outlines of aluminum ingots are hinged to the conveying chain plate. A motor is arranged at the bottom of one supporting base, and the output end of the motor is connected and matched with a rotating shaft of the main roller through a belt. A collection block is installed at the bottom of the U-shaped area of the supporting base corresponding to the auxiliary roller. The upper end of the collection block is composed of two connected inclined faces. The connected point of the two inclined faces is right opposite to the conveying chain plate. In the conveying process, the aluminum ingots are in one-to-one correspondence with the hoppers, the traditional problem that aluminum ingots are distributed on a conveying belt in a scattered mode when conveyed is avoided, the step that manual picking is carried out again during feeding is omitted, and feeding of the aluminum ingots is effectively carried out.

Owner:重庆龙之火科技有限公司

Axial turbomachine blade with platforms having an angular profile

InactiveUS9869203B2Improve thermal efficiencyReduce material thicknessEfficient propulsion technologiesGas turbine plantsLeading edgeFlow splitter

The present application relates to a splitter nose of an axial turbomachine designed to separate an annular flow into the turbomachine into a primary flow and a secondary flow for undergoing a thermodynamic cycle. The nose includes a de-icing device with a wall defining, at least partially, an annular channel. A hot oil stream created by the turbomachine circulates in this latter. The oil runs through the circular nose and de-ices it while itself getting cooled. The wall is located so as to form the leading edge of the said splitter nose. The wall is an open or closed strip such as a tube which can be fixed by bonding, welding or recessing. The present application also relates to a multi-flow turbomachine with splitter noses fitted with de-icing devices.

Owner:TECHSPACE AERO

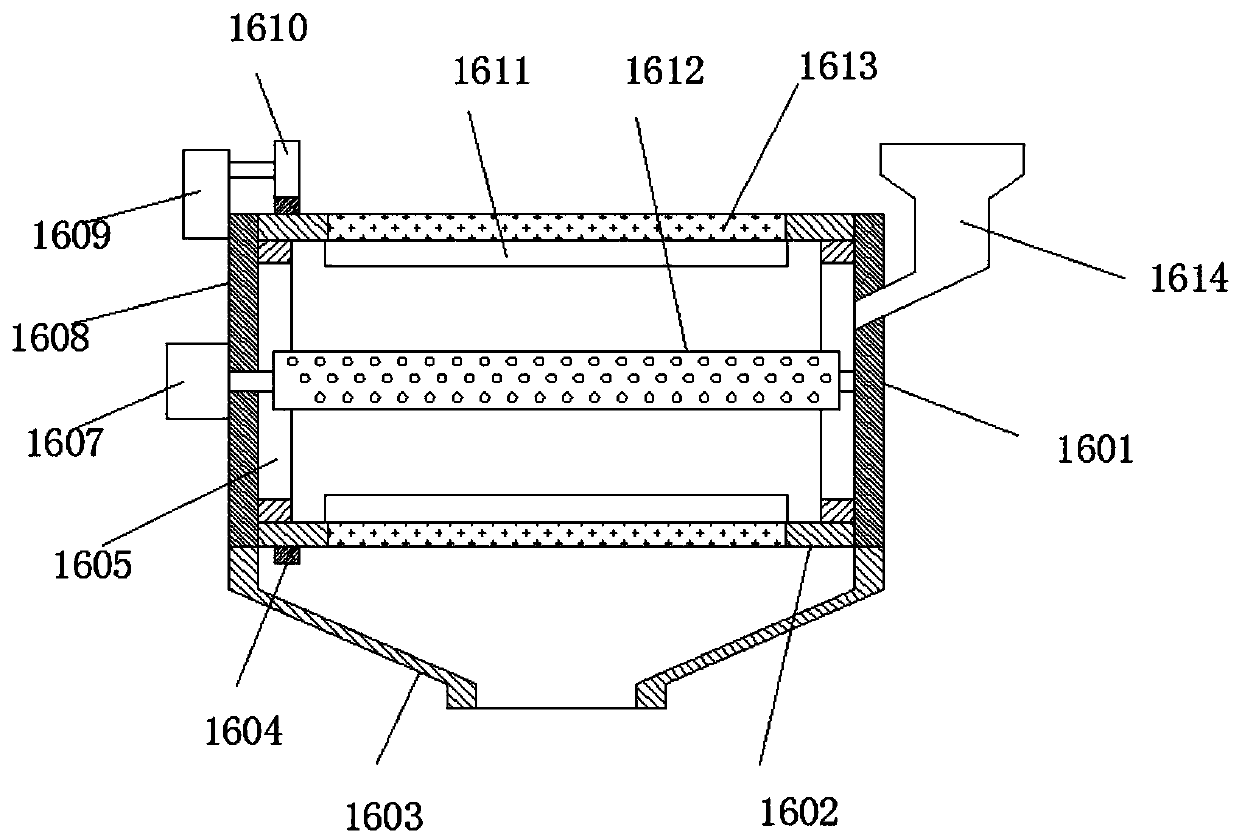

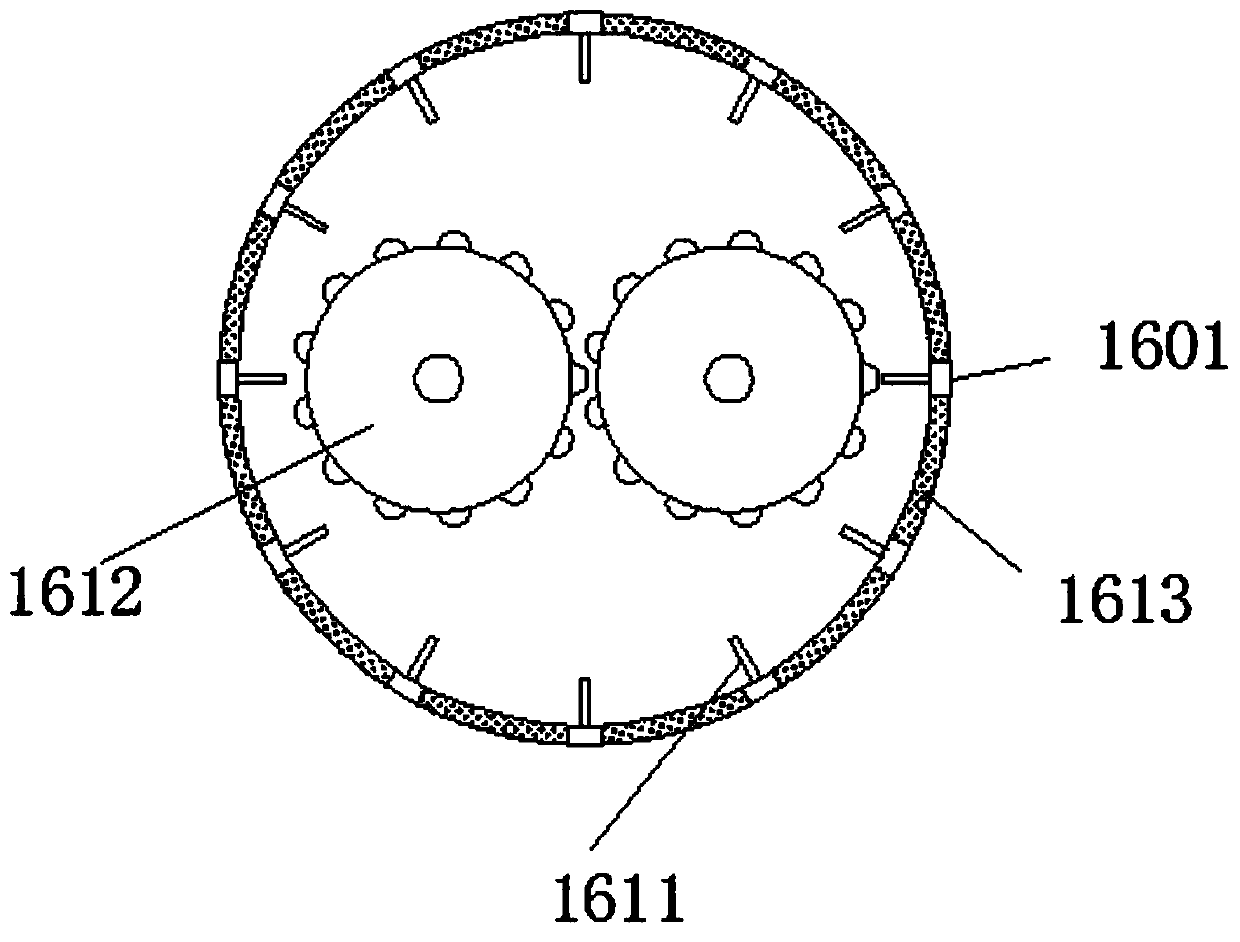

Composite fertilizer production device

InactiveCN110357694ARealize grinding and crushingRealize the drying operationFertilizer mixturesHydraulic cylinderHeat conducting

The invention discloses a composite fertilizer production device. The composite fertilizer production device comprises a first casing; a pulverizing device is arranged in the first casing; a sealing cover device is arranged in the first casing and positioned below the pulverizing device; a heating plate is fixed at the bottom of the first casing; a heat-conducting plate is fixed at the top of theheating plate; a third hydraulic cylinder is arranged on the inner wall of the first casing; a first baffle is fixed on a piston rod of the third hydraulic cylinder; a second hydraulic cylinder is arranged on the side of the first casing; a piston rod of the second hydraulic cylinder is inserted into the first casing and fixed with a pressing plate; the side of the first casing is communicated with a water adding pipe; the tail end of the water adding pipe is communicated with a first funnel; and a shut-off valve is arranged on a pipe section of the water adding pipe. The efficient pulverizing, curing, extrusion pelleting and drying process of materials can be realized; processing continuity and high efficiency are unified; and the composite fertilizer production device is convenient to operate and suitable for promotion.

Owner:扬州市耕地质量保护站

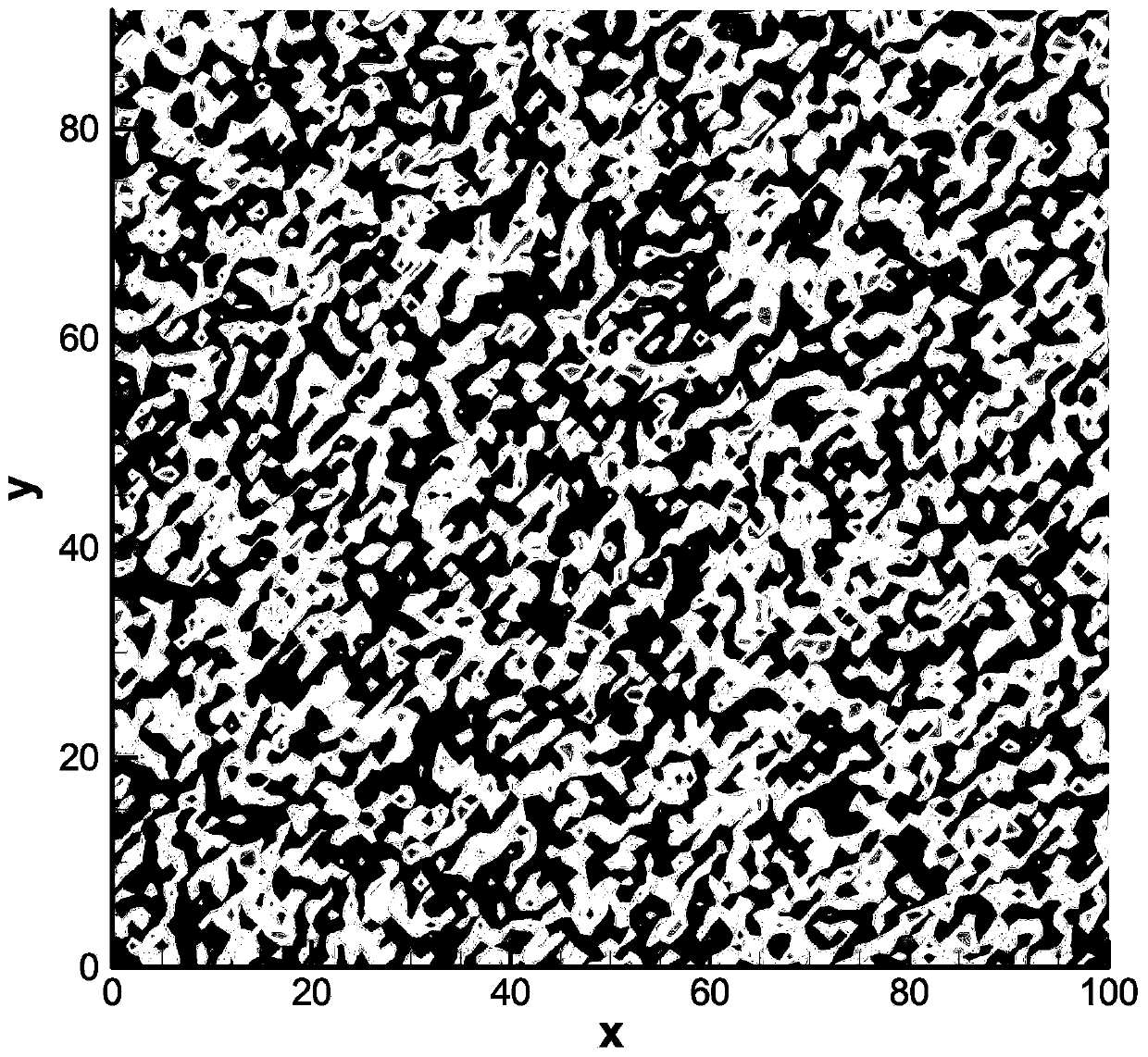

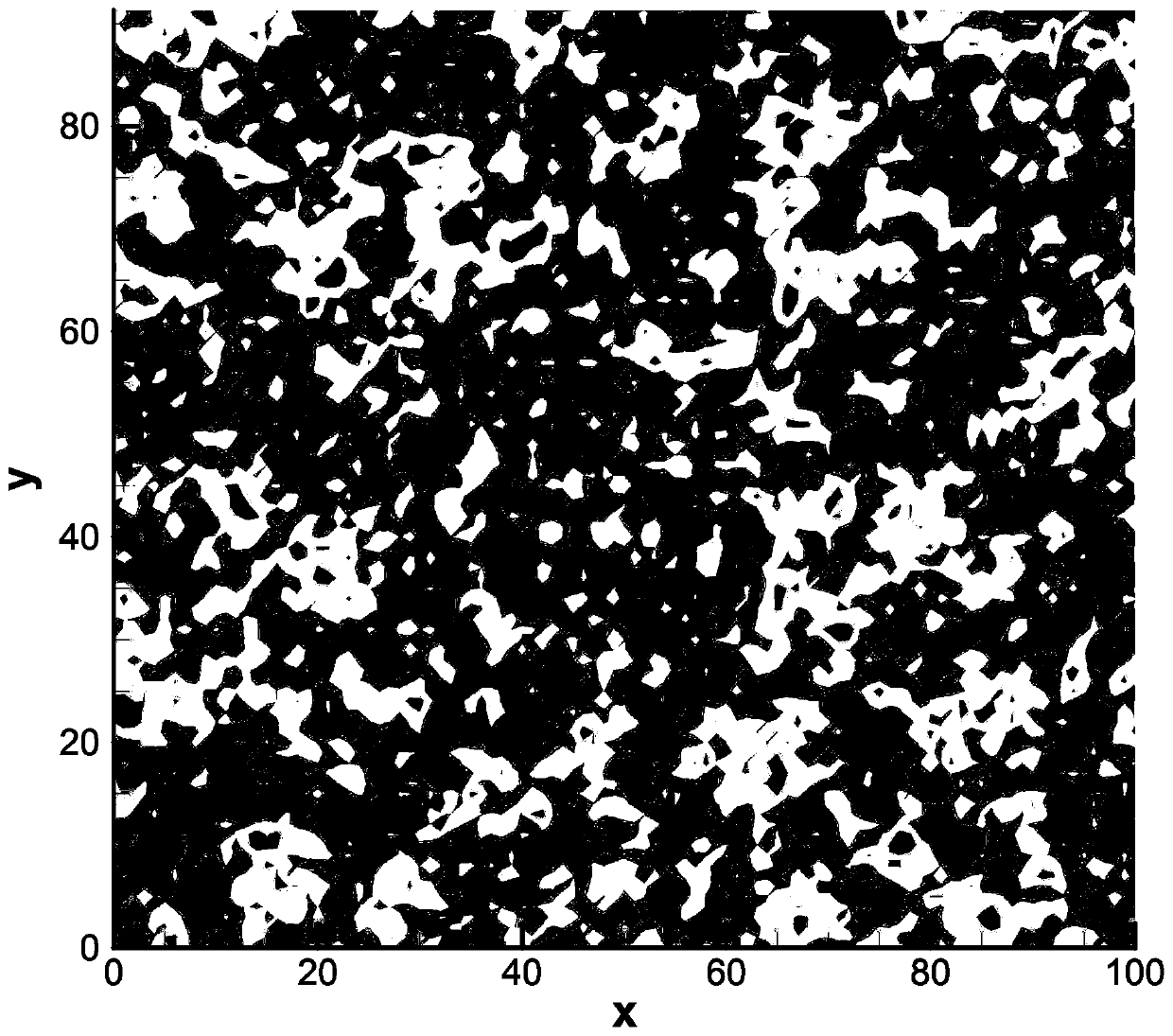

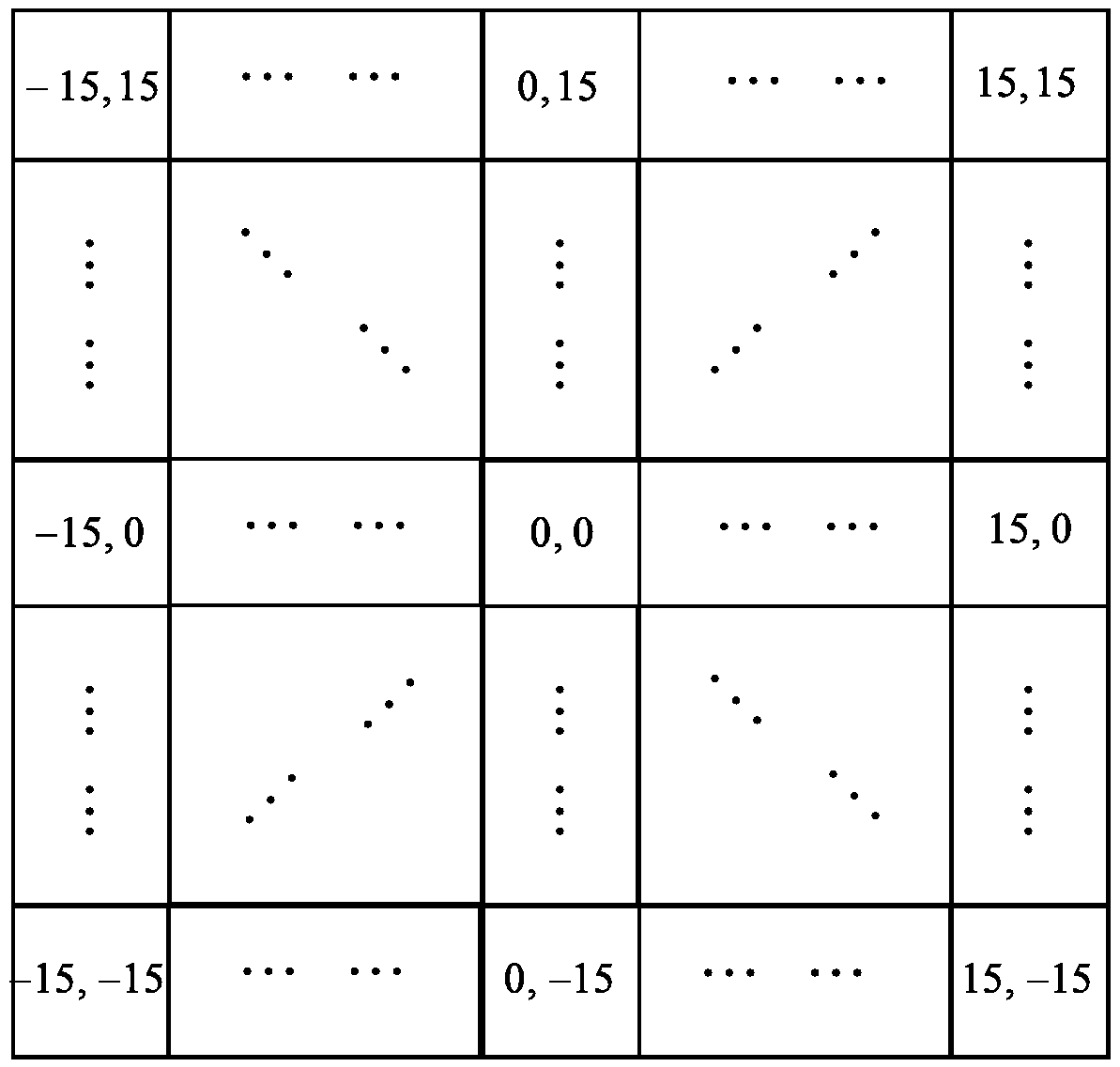

Rock-soil parameter random field inversion method

ActiveCN110069851AUniform precisionUnified efficiencyGeometric CADSpecial data processing applicationsSpatial correlationCorrelation function

The invention discloses a rock-soil parameter random field inversion method. The method comprises the following steps: analyzing conventional statistical characteristics, spatial correlation structures and spatial correlation functions of rock-soil parameters; according to the precision requirement of geotechnical engineering reliability analysis, determining the calculation range of the spatial correlation of the geotechnical parameters; constructing a spatial correlation matrix B according to the calculation range of the spatial correlation and the grid size of the engineering analysis numerical model; solving a coefficient vector c according to the spatial correlation matrix B; utilizing a pseudo-random program to assign an initial random value to each grid of the engineering analysis numerical model, and generating an initial random field; depending on basic inversion equations, performing cyclic operation on each grid in sequence; generating parametric random fields, wherein the basic inversion equation is shown in the specification; wherein x (p, q) = m (p, q) + sigma(p, q) cTu, in the formula, x (p, q) is a parameter random value of any grid (p, q), m (p, q) is a mean valueat the grid (p, q), sigma(p, q) is a standard deviation at the grid (p, q), c is a coefficient vector, and u is an initial random vector which is generated based on an initial random field and influences parameter value at (p,q).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

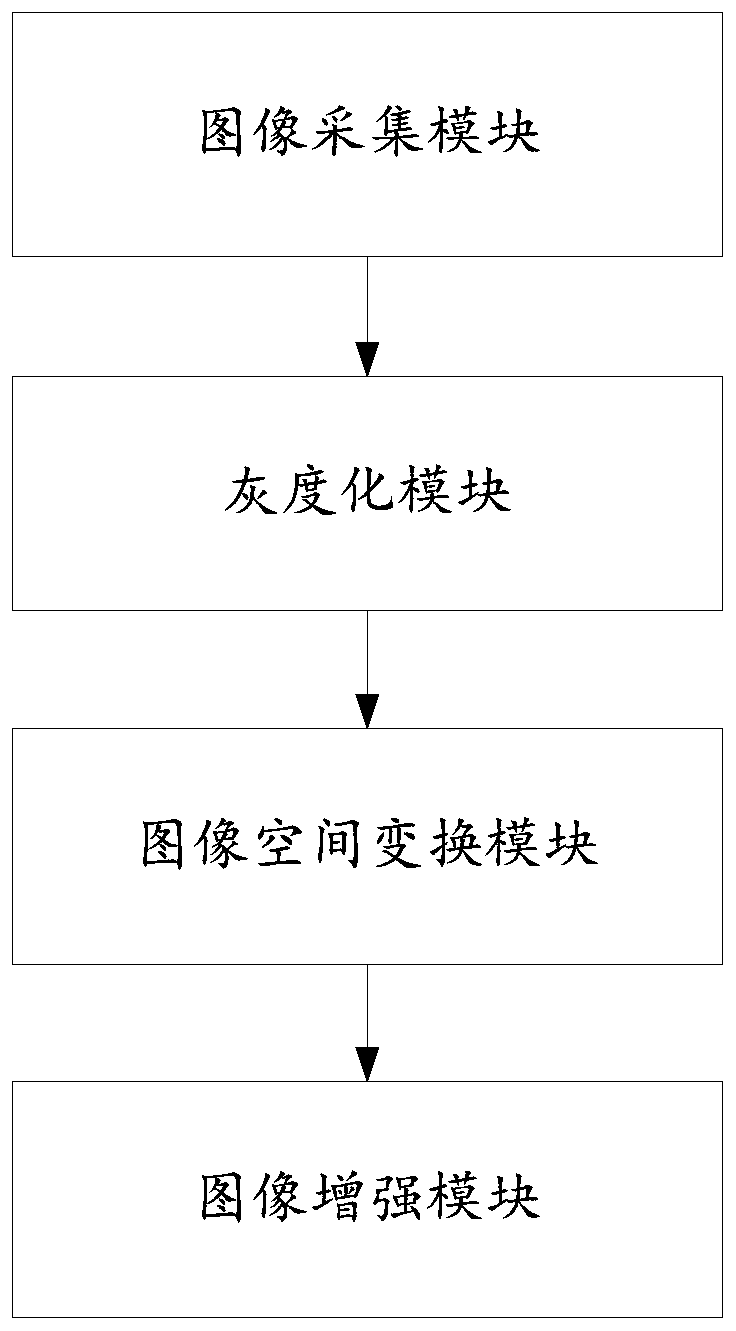

Data preprocessing system for cervical cancer laser image

PendingCN110752013AEasy to detectImproved Feature ExtractionImage enhancementImage analysisHuman bodyRadiology

The invention discloses a data preprocessing system for a cervical cancer laser image. The system comprises an image collection module, which is used for collecting a cervical laser image; a graying module, which is used for carrying out graying processing on the cervical laser image by adopting a human physiology weighted average method; an image space transformation module, which is used for carrying out space transformation on the image subjected to the graying processing by adopting a bicubic interpolation method; and an image enhancement module, which is used for enhancing the transformedimage by adopting a spatial domain and frequency domain combined method.

Owner:SHANDONG UNIV

Use method of feed transmission mechanism for semi-finished aluminum ingots

InactiveCN106697891AAvoid scattered distributionFeed effectiveConveyorsConveyor partsMetallurgyWork in process

The invention discloses a use method of a feed transmission mechanism for semi-finished aluminum ingots. The use method comprises the steps: the produced semi-finished aluminum ingots are put into hoppers, the surroundings of each aluminum ingot directly contacts with the inner wall of a containing chamber, the aluminum ingot extrudes the inner wall of the containing chamber by gravity, and therefore the aluminum ingot is stably placed; a main roller is driven by a starting motor to run, and a slave roller is matched with the main roller; a transmission chain plate starts continuous motion from the main roller to the slave roller, and the hoppers correspond to the aluminum ingots one to one; when the hopper move to the transmission chain plate directly facing to the slave roller, the hoppers tip over, and therefore the feed transmission of the aluminum ingots is realized.

Owner:重庆龙之火科技有限公司

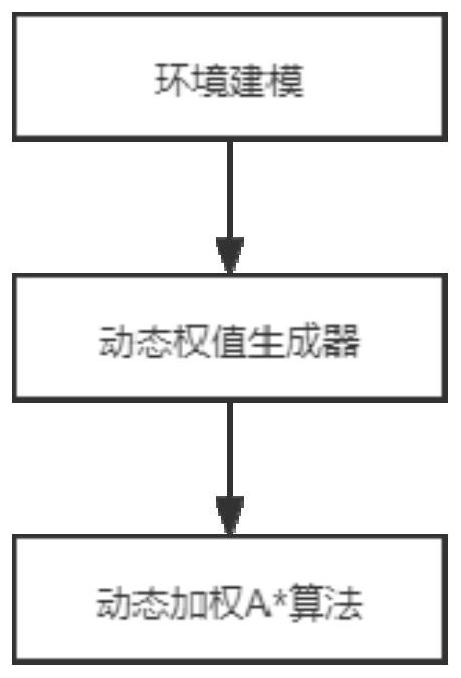

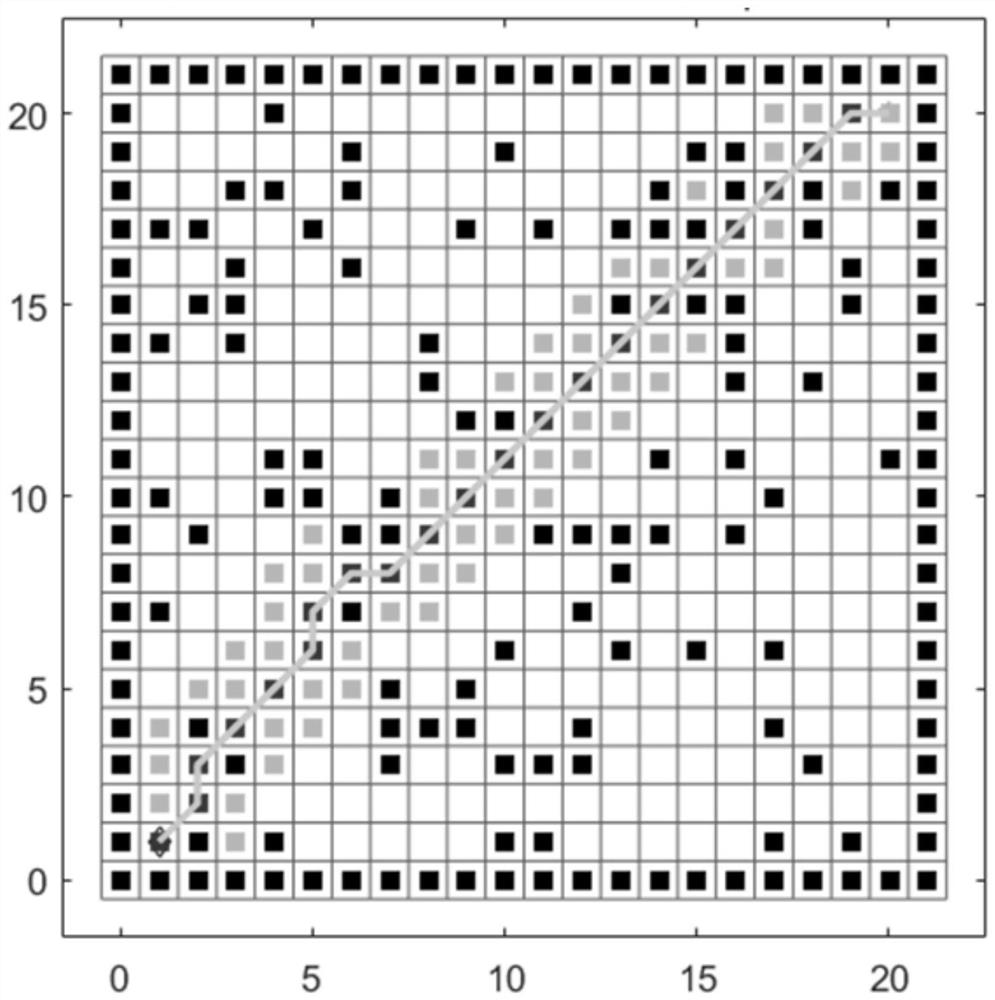

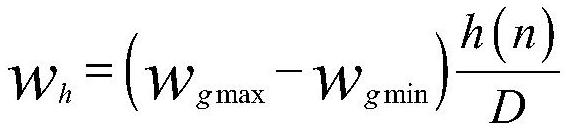

A star algorithm improvement method, system and device based on dynamic weight and medium

PendingCN114527788AUniform precisionUnified efficiencyInternal combustion piston enginesPosition/course control in three dimensionsAlgorithmUncrewed vehicle

The invention discloses a dynamic weight-based A star algorithm improvement method, system and device, and a medium. The method comprises the steps of obtaining environment information collected in a flight process of an unmanned aerial vehicle; improving an evaluation function of an A star algorithm; designing a dynamic weight generator, and generating a heuristic weight of the current node in real time according to the environment information; when the unmanned aerial vehicle is close to the starting point, the proportion of h (n) is large; when the unmanned aerial vehicle continuously approaches the target, the weight of g (n) is gradually increased; wherein h (n) is the estimated cost of moving from the specified position to the terminal point, and g (n) is the moving cost of moving from the starting point to the specified grid. According to the method, in the process that the unmanned aerial vehicle carries out path finding on the target point, the dynamic heuristic weight adjusted in real time is added into the path evaluation function of the A star algorithm, and unification of path finding accuracy and efficiency is achieved. The method can be widely applied to the technical field of unmanned aerial vehicle obstacle avoidance and path planning.

Owner:SOUTH CHINA UNIV OF TECH

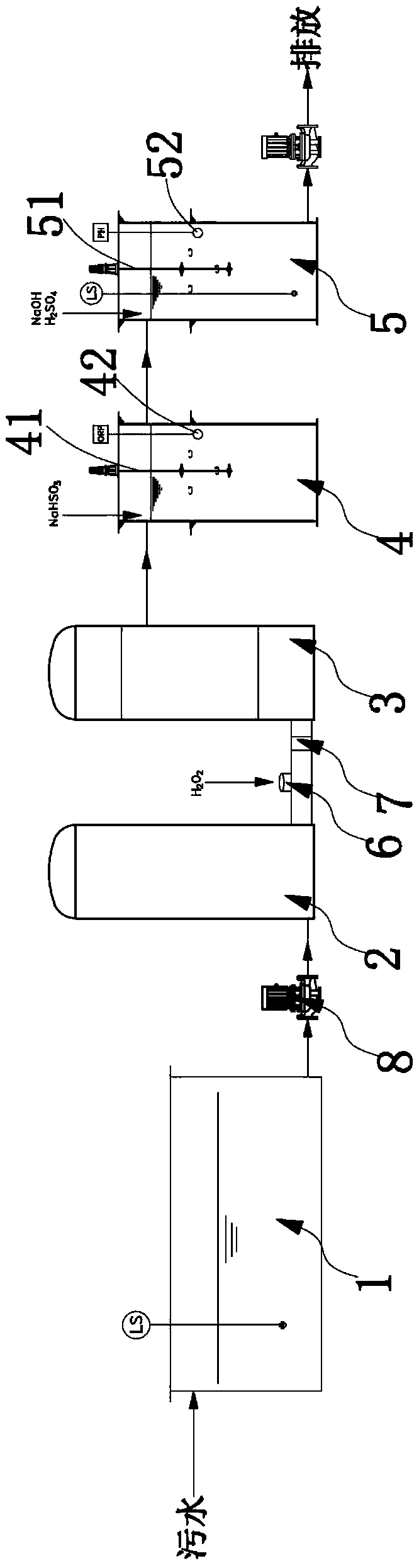

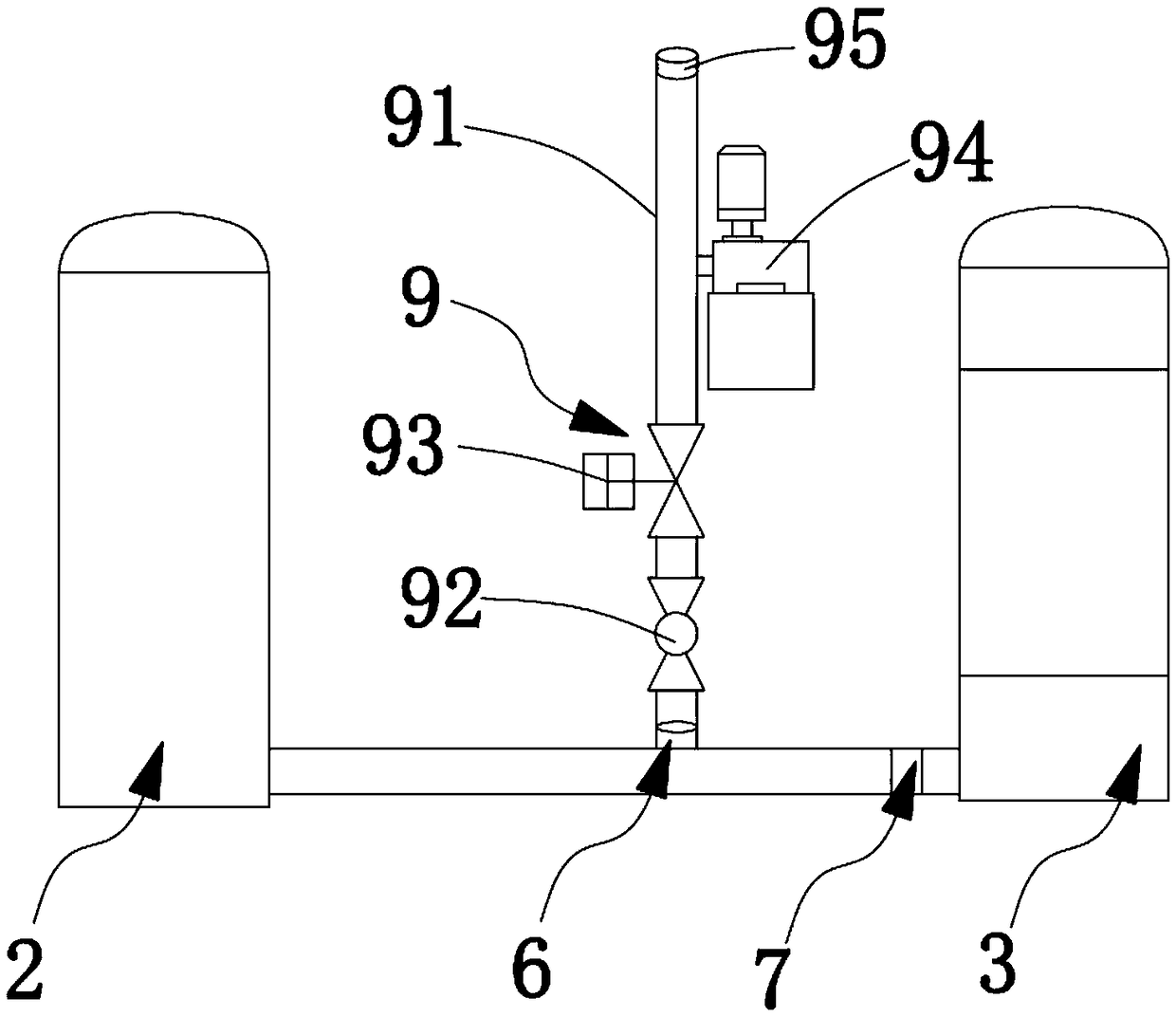

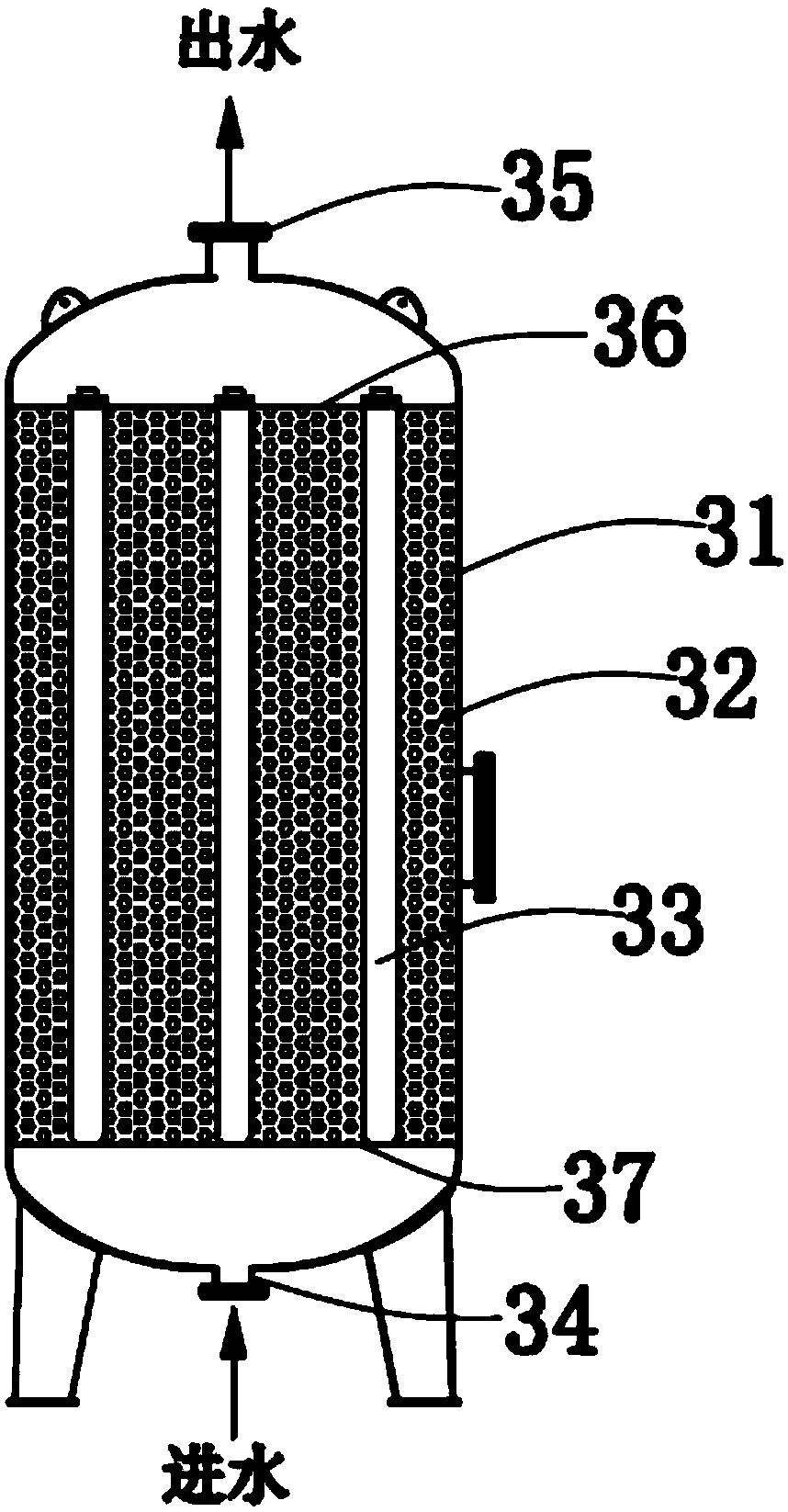

Fenton technology based sewage treatment system and treatment method thereof

PendingCN109110990AReduce contentReduce outputWater/sewage treatment by irradiationWater treatment compoundsSorbentOperating cost

The invention discloses a Fenton technology based sewage treatment system and a treatment method thereof. The treatment system comprises a sand filtering tank, a Fenton reactor, a reaction tank and aclean water tank which are sequentially connected, wherein the sand filtering tank has a structure for trapping pollutants from sewage; the Fenton reactor is used for producing hydroxyl free radicalsin a manner that activated charcoal serves as a catalyst and reacts with hydrogen peroxide; the reaction tank is used for removing superfluous hydrogen peroxide from the Fenton reactor; the clean water tank is used for adjusting a pH value of the sewage in the clean water tank. According to the Fenton technology based sewage treatment system and the treatment method thereof, the design is ingenious, activated charcoal serves as an adsorbent and also serves as a catalyst; on one hand, pollutants can be enriched through an adsorptive action, and the content of the pollutants is lowered; meanwhile, the activated charcoal catalyzes H2O2 to form .OH free radicals, the .OH free radicals fully react with and degrade the pollutants, and the reaction efficiency is greatly increased; furthermore, the activated charcoal does not participate in a reaction as a reactant during reaction, and the amount of the activated charcoal cannot be reduced along with the reaction, so that the consumption of agents is greatly lowered, tedious operations of repeatedly adding the agents are saved; meanwhile, the yield of sludge is reduced, and the operating cost is reduced.

Owner:苏州新工环境工程技术有限公司

Method and system for clear signal capture

InactiveUS20080304654A1Better model the echo pathReduce generationTwo-way loud-speaking telephone systemsSpeech analysisAlgorithmHands free

A method and system for clear signal capture comprehend several individual aspects that address specific problems in improved ways. In addition, the method and system also comprehend a hands-free implementation that is a practical solution to a very complex problem. Individual aspects comprehended related to echo and noise reduction, and divergence control.

Owner:CSR TECH INC

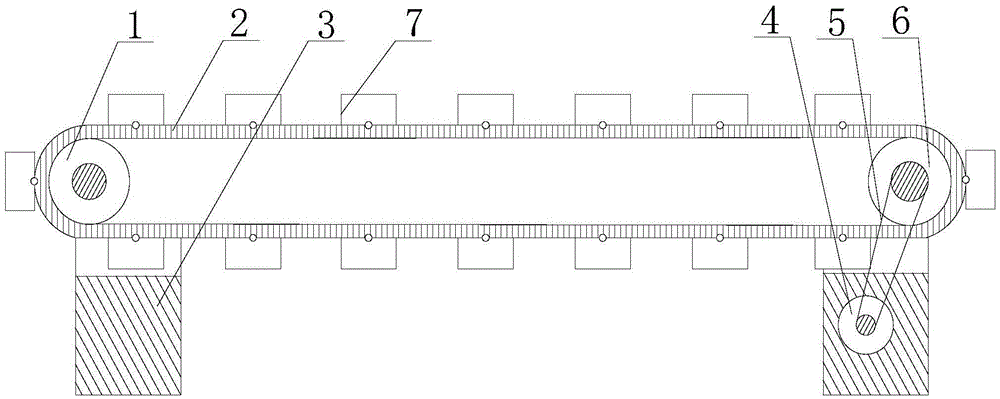

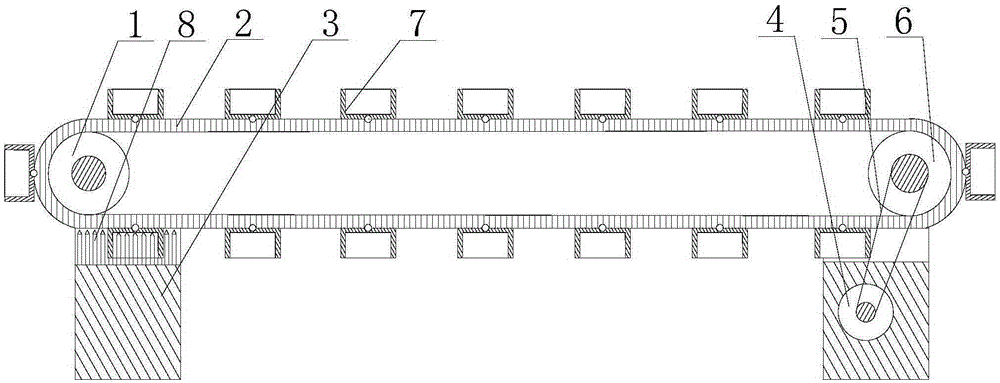

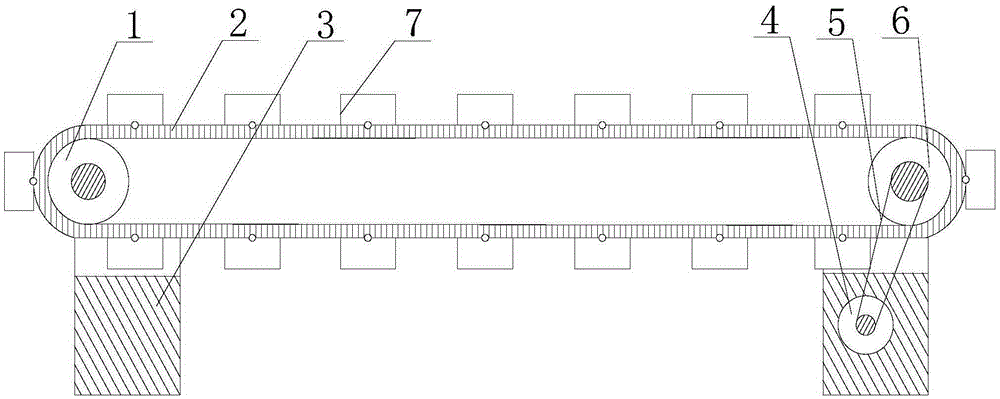

Automatic aluminium ingot conveying structure

InactiveCN106697731AAvoid scattered distributionFeed effectiveConveyorsTransfer procedureEngineering

The invention discloses an automatic aluminium ingot conveying structure. The automatic aluminium ingot conveying structure comprises two U-shaped supporting seats which are arranged at an interval and a conveying chain plate; a master roller and a slave roller are respectively and rotatably arranged on the two supporting seats; the two ends of the conveying chain plate are placed in U-shaped areas of the supporting seats and are matched with the master roller and the slave roller; a plurality of material hoppers of which the interiors are matched with the appearance of aluminium ingots are hinged to the conveying chain plate; the automatic aluminium ingot conveying structure also comprises a motor; the motor is placed at the bottom of a supporting seat, and an output end of the motor is connected and matched with a rotating shaft of the master roller through a belt. During a conveying process, the aluminium ingots are in one-to-one correspondence with the material hoppers, so that the aluminium ingots are prevented from being dispersedly distributed on a conveying belt in conventional conveying; the step of manual picking when the aluminium ingots are fed is omitted, and the aluminium ingots are fed effectively.

Owner:重庆龙之火科技有限公司

Audio fine scalable coding method and system based on perception self-adaption bit allocation

InactiveCN101800050BUnified efficiencyImprove classification accuracySpeech analysisCode moduleComputer architecture

The invention relates to the technical field of audio coding, in particular to audio fine scalable coding method and system based on perception self-adaption bit allocation. The method comprises the following steps of: preprocessing input signals; carrying out subband division on frequency-domain signals; calculating the perception importance of each subband; uniformly sequencing the subband fromsmall to large according to the perception importance; extracting the subband with the largest perception importance for scalable longitudinal vector quantization; and then carrying out self-adaptionadjustment on the vector-quantized subband with the largest perception importance. The system comprises a preprocessing module, a subband division module, a perception importance calculating, sequencing and extracting module, a scalable quantizing and coding module, a self-adaption adjusting module and a scalable coding finish judging module. The invention realizes high-efficient fine scalable audio coding, preferably realizes the unification of quantization precision and quantization efficiency and also satisfies the requirement of high tone quality when improving coding efficiency.

Owner:WUHAN UNIV

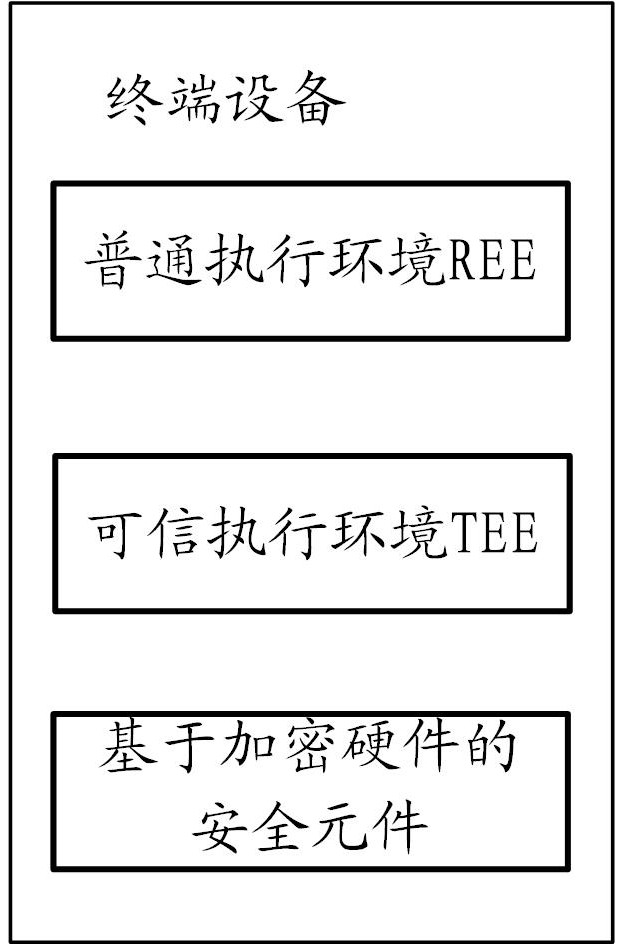

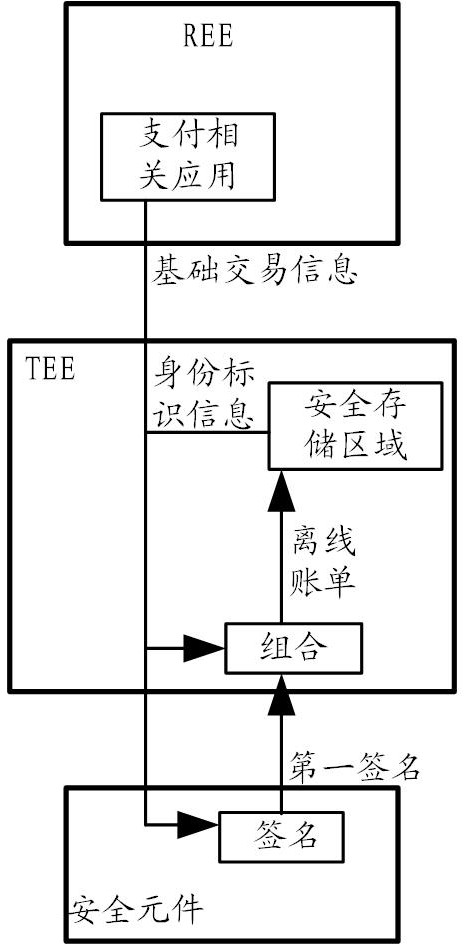

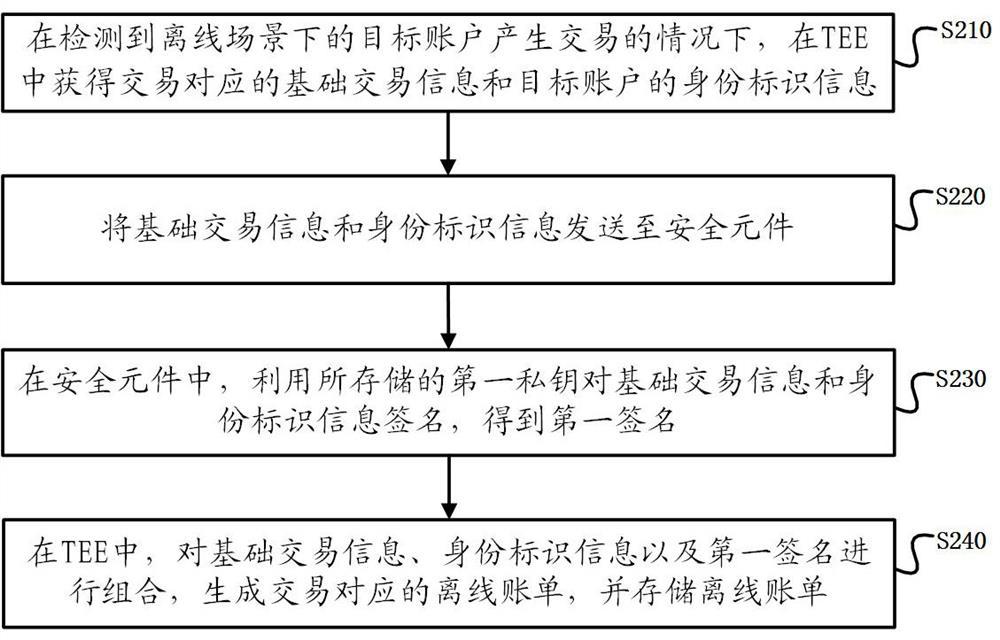

Offline bill generation method and device

ActiveCN113298526AEfficient storageEfficient managementPayment protocolsTerminal equipmentFinancial transaction

The embodiment of the invention provides an offline bill generation method and device, and the method comprises the steps that a terminal device comprises a trusted execution environment (TEE) and a security element based on encryption hardware, and the terminal device obtains basic transaction information corresponding to the transaction and identity identification information of the target account in the TEE under the condition that the terminal device detects that a target account generates a transaction in an offline scene; the basic transaction information and the identity identification information are sent to a secure element; in the secure element, the basic transaction information and the identity information are signed by using a stored first private key to obtain a first signature; and in the TEE, the basic transaction information, the identity identification information and the first signature are combined, an offline bill corresponding to the transaction is generated, and the offline bill is stored.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

Feeding mechanism for machine tool

InactiveCN106697742AAvoid scattered distributionFeed effectiveConveyorsTransfer procedureEngineering

The invention discloses a feeding mechanism for a machine tool. The feeding mechanism comprises two supporting seats and a transfer chain plate. A driving roller and a driven roller are rotatably arranged on the two supporting seats separately; the two ends of the transfer chain plate are placed in the U-shaped regions of the supporting seats and the transfer chain plate is matched with the driving roller and the driven roller; and a plurality of hoppers matched with aluminum ingots in shape inside are hinged to the transfer chain plate. The motor is placed in the bottom of one of the supporting seats and the output end of the motor is connected to and matched with a rotary shaft of the driving roller; and a collecting block is mounted in the bottom of the U-shaped region of the supporting seat corresponding to the driven roller, the upper end of the collecting block is formed by two inclined surfaces which are connected to each other, and the connecting points of the two inclined surfaces is aligned to the transfer chain plate. In the transfer process, the aluminum ingots are in one-to-one correspondence to the hoppers, the aluminum ingots are prevented from being scattered and distributed to a conveyor belt during conventional conveyance, and the step of manually sorting the aluminum ingots during feeding is cancelled, so that the aluminum ingots are effectively fed.

Owner:重庆龙之火科技有限公司

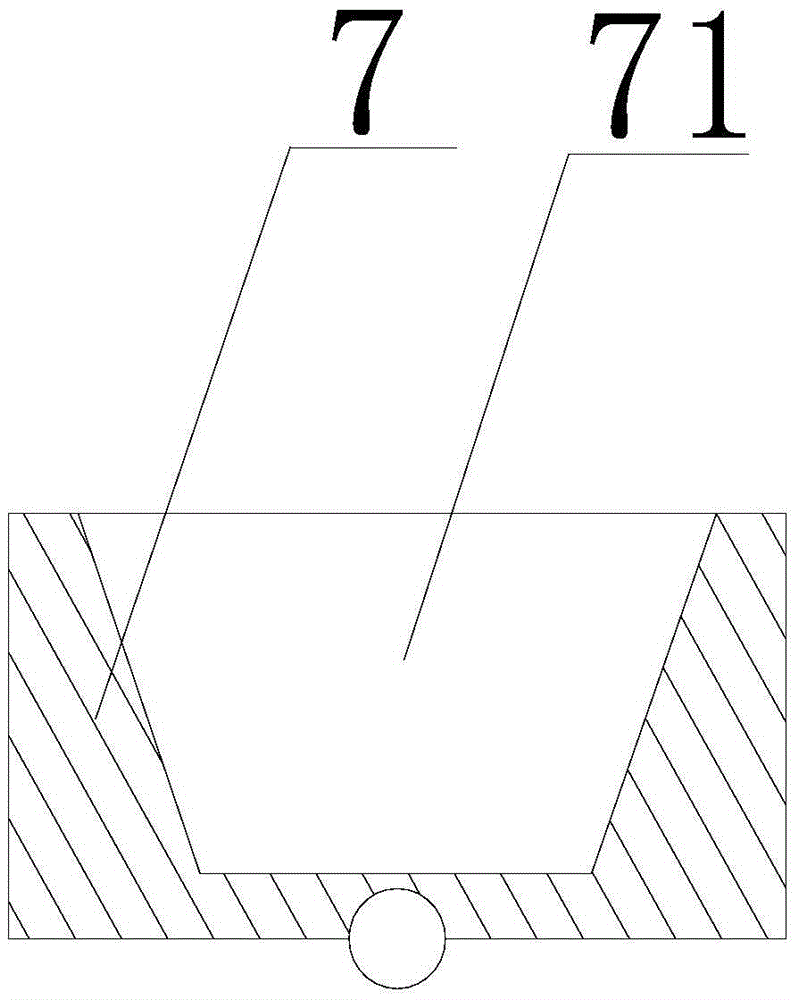

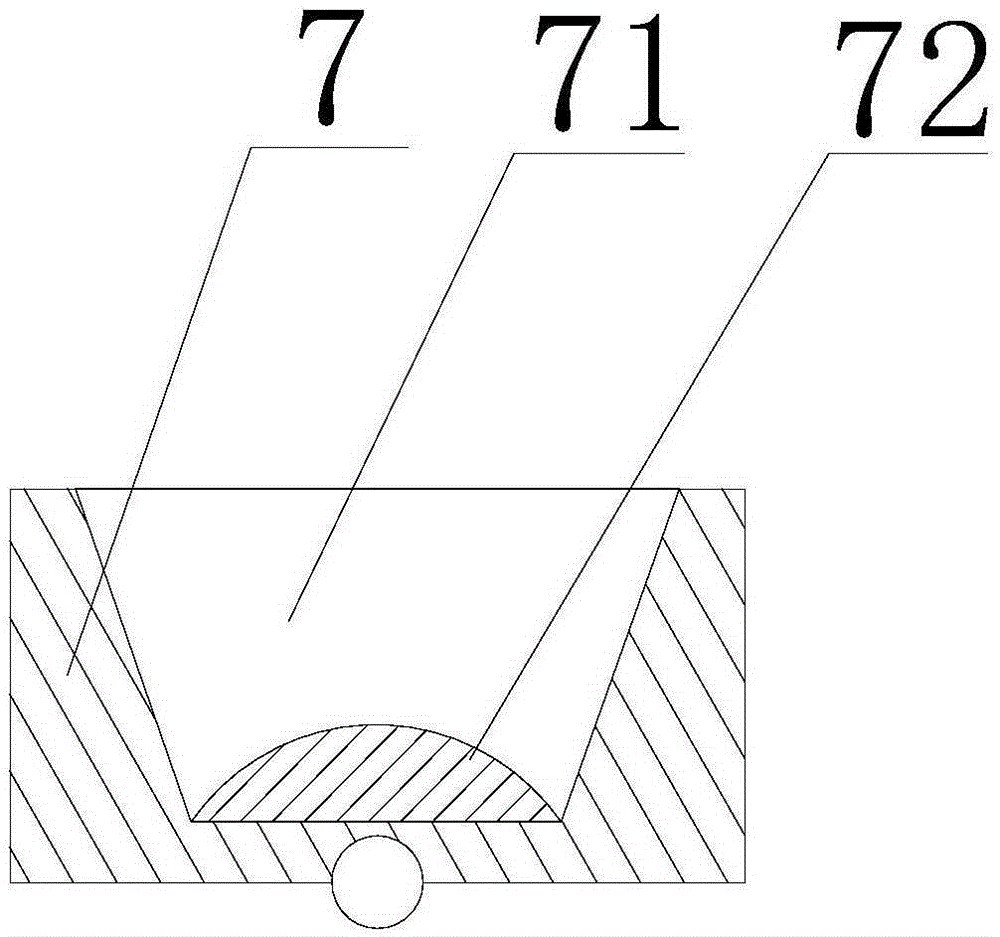

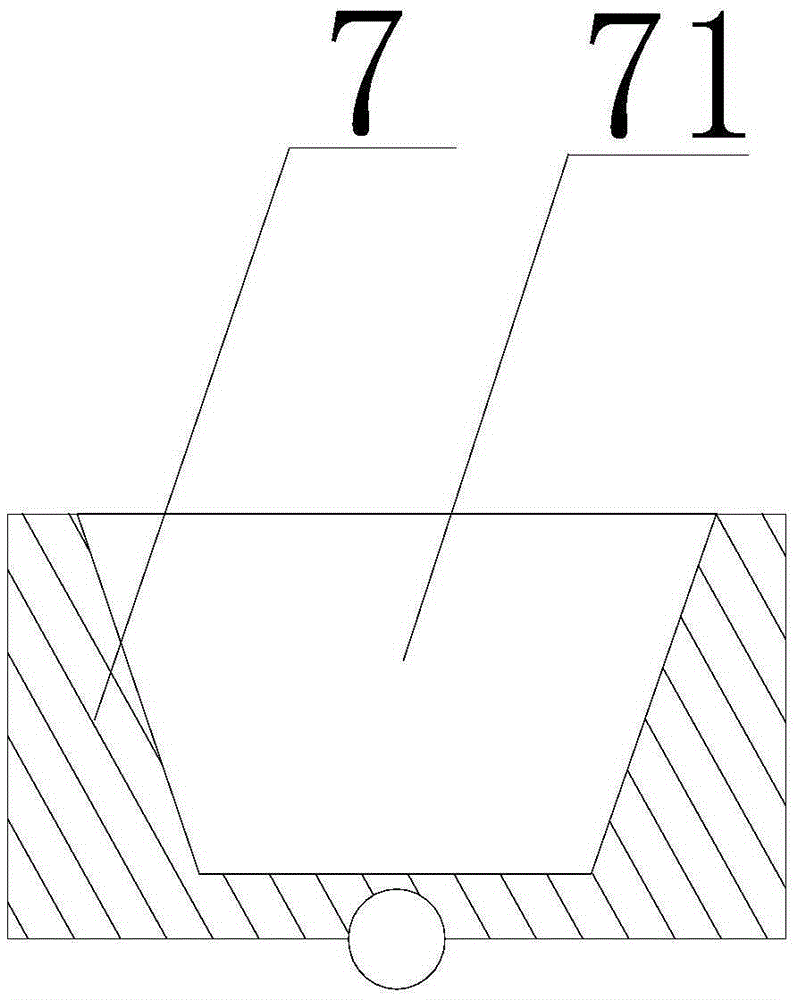

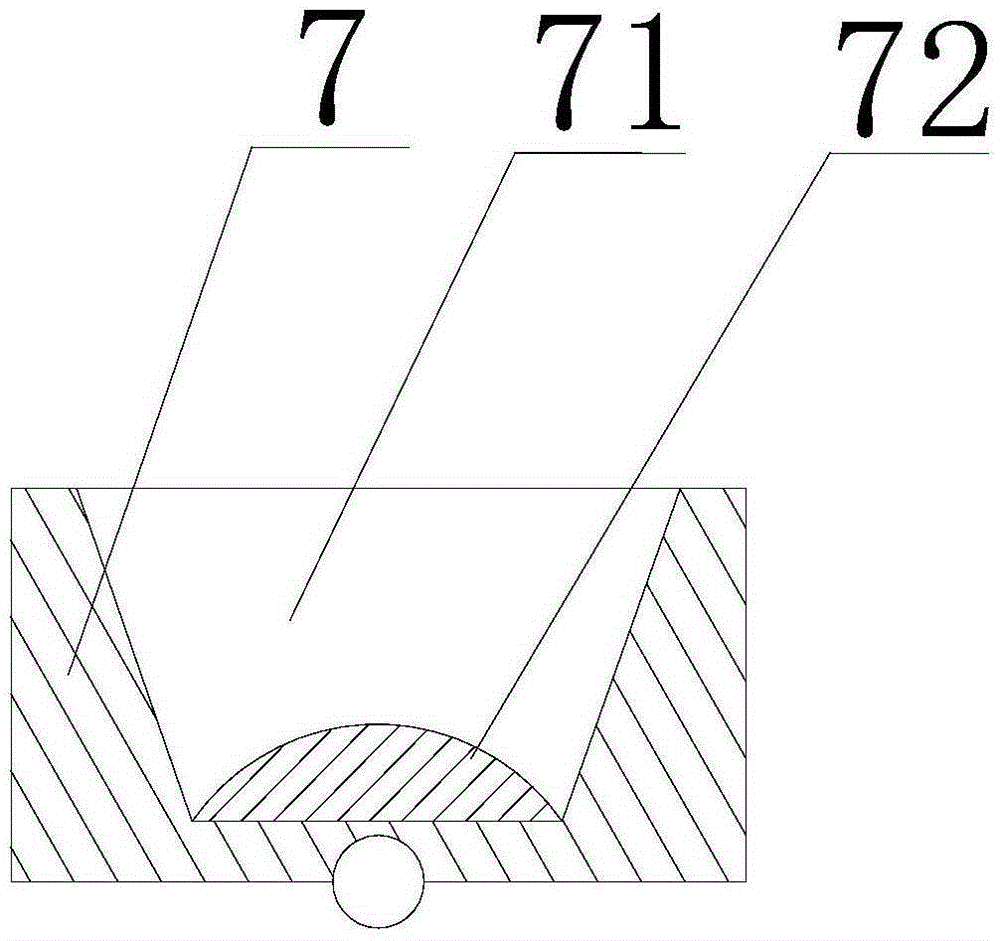

Conveying transfer structure

InactiveCN106697745AAvoid scattered distributionLarge carrying capacityConveyorsCleaningBristleTransfer procedure

The invention discloses a conveying transfer mechanism which comprises two supporting bases and a conveying chain plate. A main roller and an auxiliary roller are rotationally arranged on the two supporting bases correspondingly. The two ends of the conveying chain plate are arranged in U-shaped areas of the supporting bases and matched with the main roller and the auxiliary roller. Multiple hoppers with the interiors matched with the outlines of aluminum ingots are hinged to the conveying chain plate. A bristle brush is installed at the bottom of the U-shaped area of the supporting base corresponding to the auxiliary roller. A containing cavity is formed in the middle of each hopper. The longitudinal section of each containing cavity is in a trapezoid shape, and the width of each containing cavity is gradually decreased in the direction vertically from the upper end to the lower end of the corresponding hopper. In the conveying process, the aluminum ingots are in one-to-one correspondence with the hoppers, the traditional problem that aluminum ingots are distributed on a conveying belt in a scattered mode when conveyed is avoided, the step that manual picking is carried out again during feeding is omitted, and feeding of the aluminum ingots is effectively carried out.

Owner:重庆龙之火科技有限公司

Wireless power transmitting device and method

ActiveUS10910864B2Uniform chargeExpand coverageNear-field transmissionBatteries circuit arrangementsReceiver coilMagnetic field

Disclosed is a wireless power transmitting device and method, the wireless power transmitting device including, in response to detection of a power receiver within a predetermined separation distance from a charging pad, a controller configured to generate a magnetic field through a transmission coil with a multilayer structure in which a plurality of coil layers of different sizes are stacked, and a power transmitter configured to wirelessly transmit, to a reception coil of the power receiver, a power signal generated using magnetic fields generated by the plurality of coil layers.

Owner:ELECTRONICS & TELECOMM RES INST

Using method of metal aluminum product transporting mechanism

The invention discloses a using method of a metal aluminum product transporting mechanism. The using method comprises the following steps that produced aluminum ingot semi-finished products are placed in hoppers, the peripheries of the aluminum ingots make direct contact with the inner walls of cavities, the aluminum ingots form extrusion for the inner walls of the cavities through the self gravity, elastic protrusions are arranged at the bottoms of the cavities, accordingly, the bottoms of the aluminum ingots make contact with the tops of the elastic protrusions when the aluminum ingots are placed in the hoppers, and then it is ensured that the aluminum ingots are stably placed; a motor is started to drive a main roller to operate, and an auxiliary roller is used in cooperation with the main roller; a conveying chain plate starts to continuously move in the direction from the main roller to the auxiliary roller, the hoppers are turned over when moving to the conveying chain plate part right opposite to the auxiliary roller, and then conveying feeding of the aluminum ingots is achieved; and when each hopper enters the bottom of the conveying chain plate after finishing dumping, a bristle brush is bent to enter the hopper through the self elasticity, meanwhile, relative movement occurs between the hopper and the bristle brush, and therefore the bristle brush starts to remove scraps in the hopper.

Owner:重庆龙之火科技有限公司

Aluminum ingot conveyor

The invention discloses an aluminum ingot conveyor. The aluminum ingot conveyor comprises two supporting bases and a conveying chain plate. A drive roller and a driven roller are rotationally arranged on the two supporting bases correspondingly. A plurality of hoppers are hinged to the conveying chain plate. A motor is arranged at the bottom of one supporting base, and the output end of the motor is connected and matched with a rotating shaft of the drive roller through a belt. Containing cavities are formed in the middle portions of the hoppers, the longitudinal sections of the containing cavities are in a trapezoid shape, and the widths of the containing cavities are gradually reduced in the direction that the upper ends of the hoppers vertically point at the lower ends of the hoppers. Elastic protrusions are arranged at the bottoms of the containing cavities, the longitudinal sections of the elastic protrusions are in an arc shape, the vertical distance between the highest point of the elastic protrusions and the bottoms of the containing cavities is h, and the height of the containing cavities is H, wherein h<=1 / 2H. In the transmission process, aluminum ingots correspond to the hoppers in a one-to-one manner, the traditional manner that during conveying, the aluminum ingots are distributed on a conveying belt in a scattered manner is avoided, the step of conducting manual sorting again during feeding is omitted, and aluminum ingot feeding is effectively conducted.

Owner:重庆龙之火科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com