Patents

Literature

35results about How to "Suitable physical property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

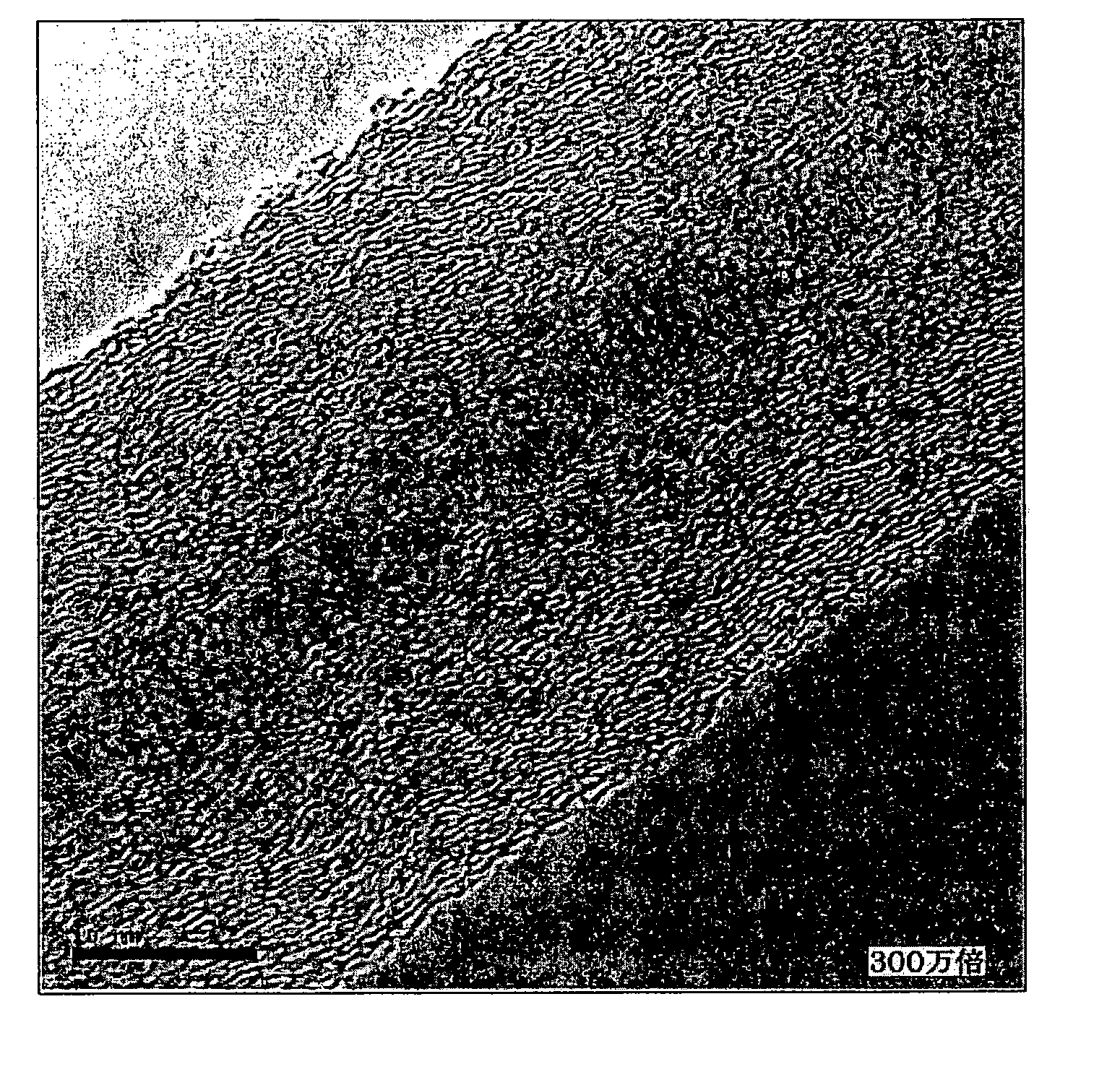

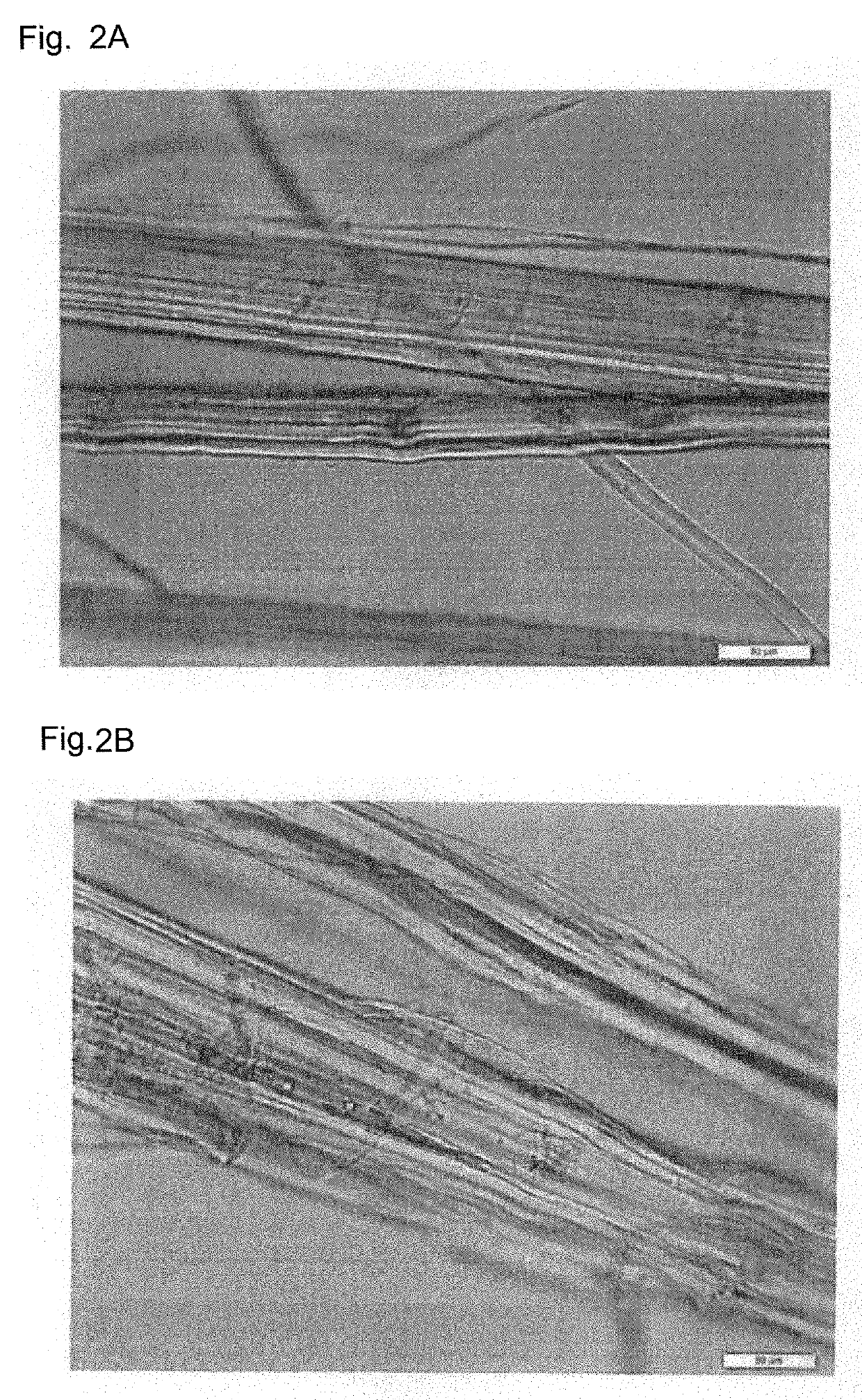

Ultrathin carbon fibers

InactiveUS20060062715A1Increased bending stiffnessSolving the Insufficiency of ElasticityMaterial nanotechnologyCarbon compoundsAspect ratioRaman spectroscopy

An ultrathin carbon fiber having two or more tubular graphene sheets layered is disclosed. The tubular graphene sheets has a polygonal cross section in a direction substantially orthogonal to the axis of the ultrathin carbon fibers, a diameter of the fiber is 15 to 100 nm, an aspect ratio of the carbon fiber is not more than 105, and ID / IG of the carbon fiber as determined by Raman spectroscopy is not more than 0.2.

Owner:HODOGAYA KAGAKU IND

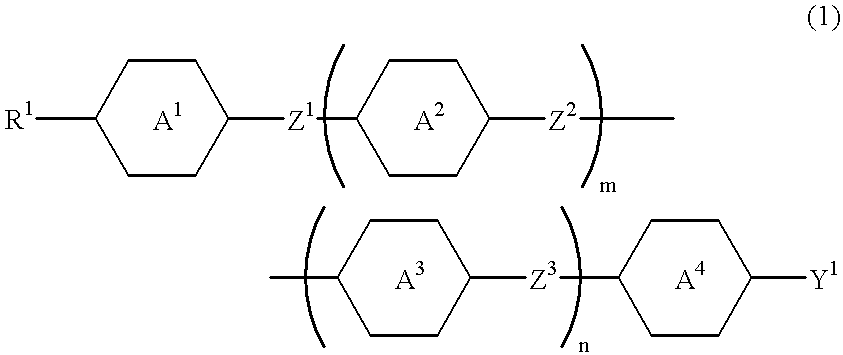

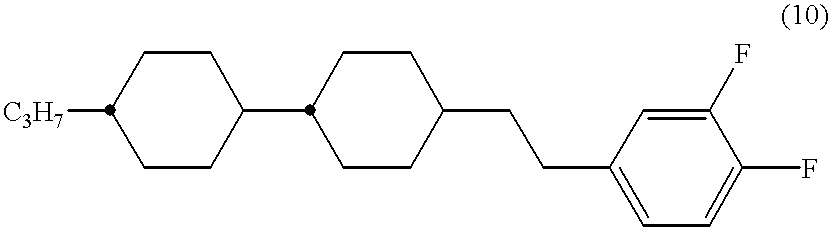

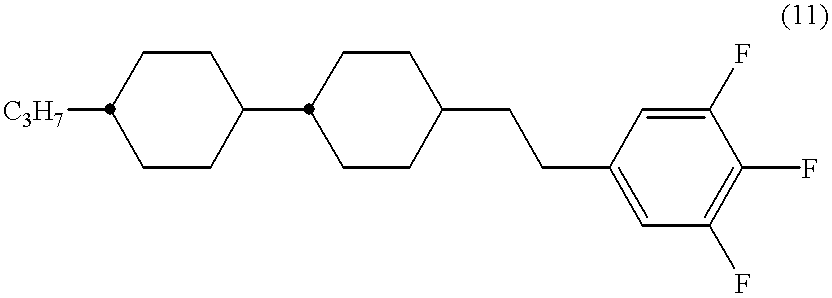

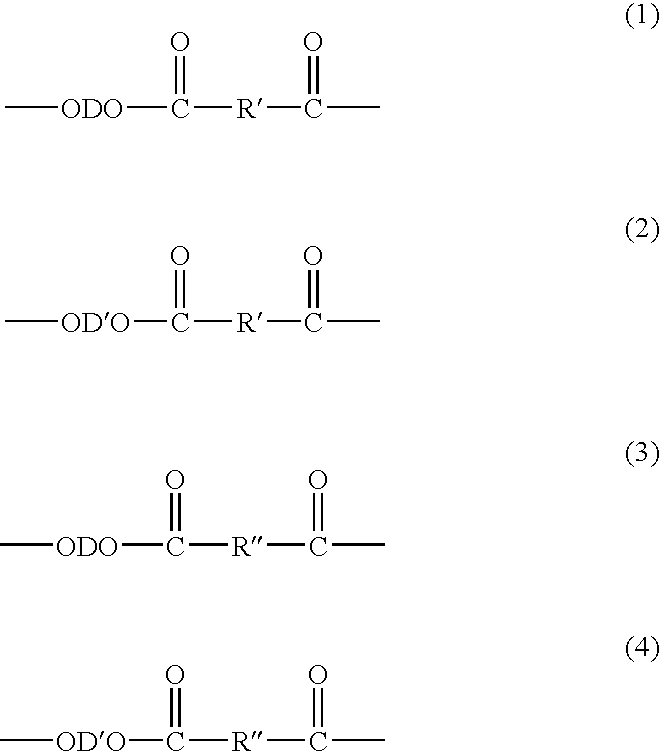

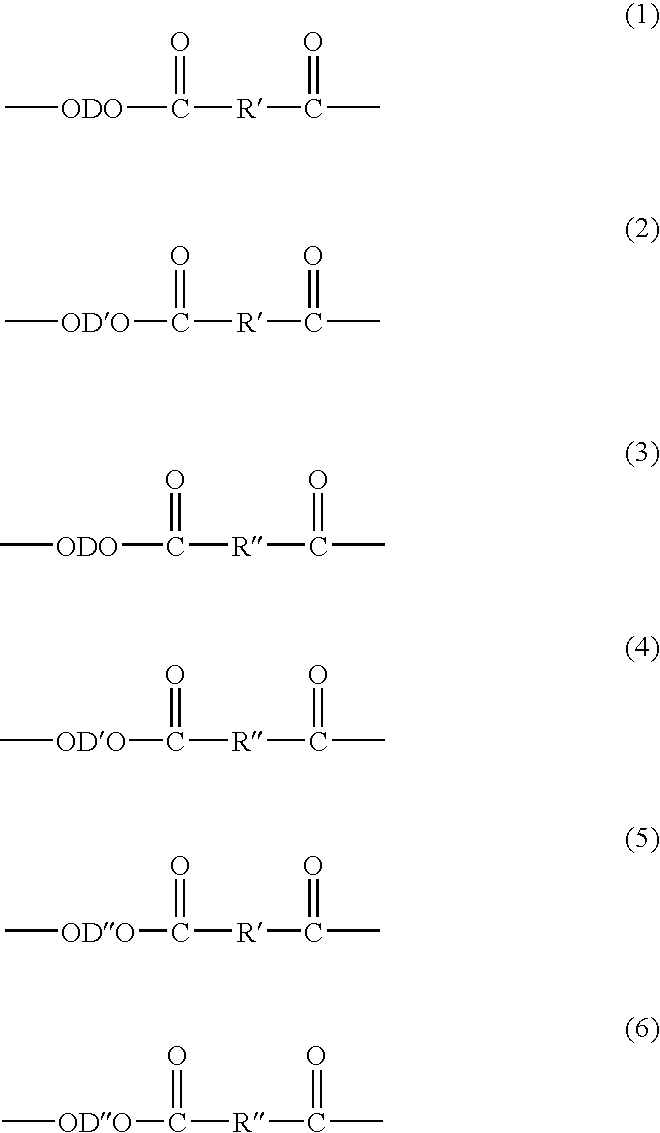

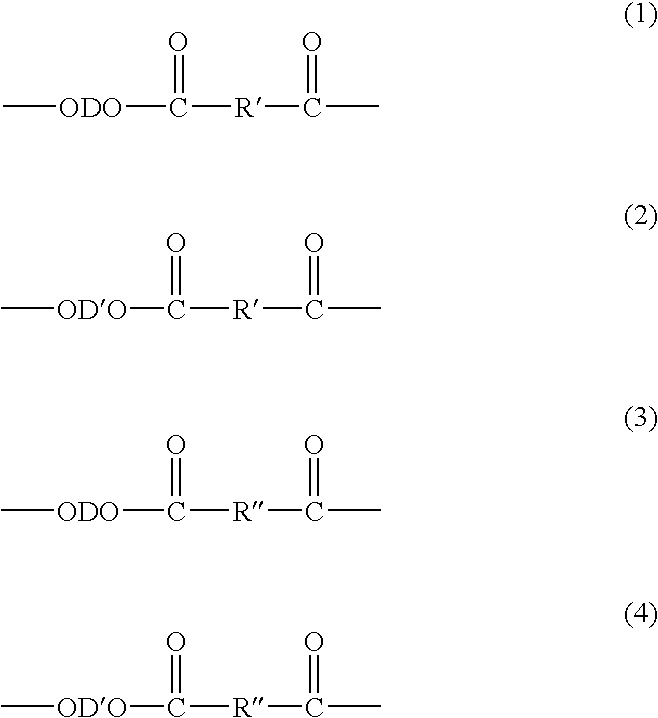

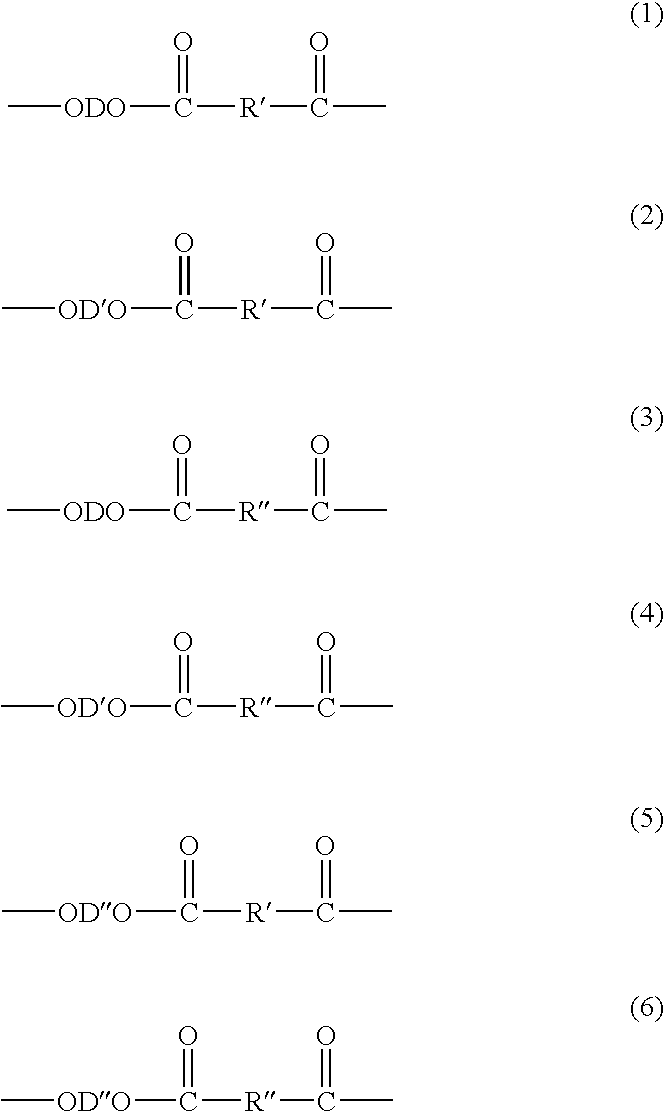

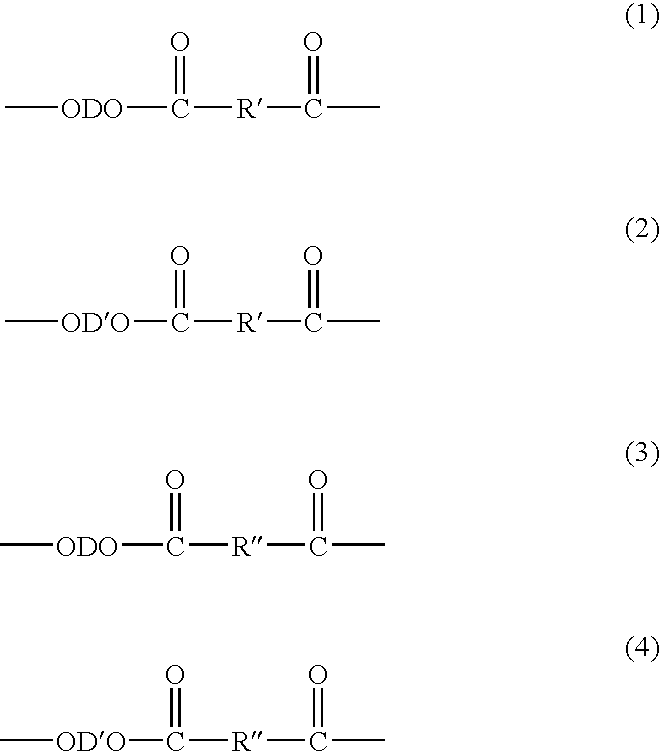

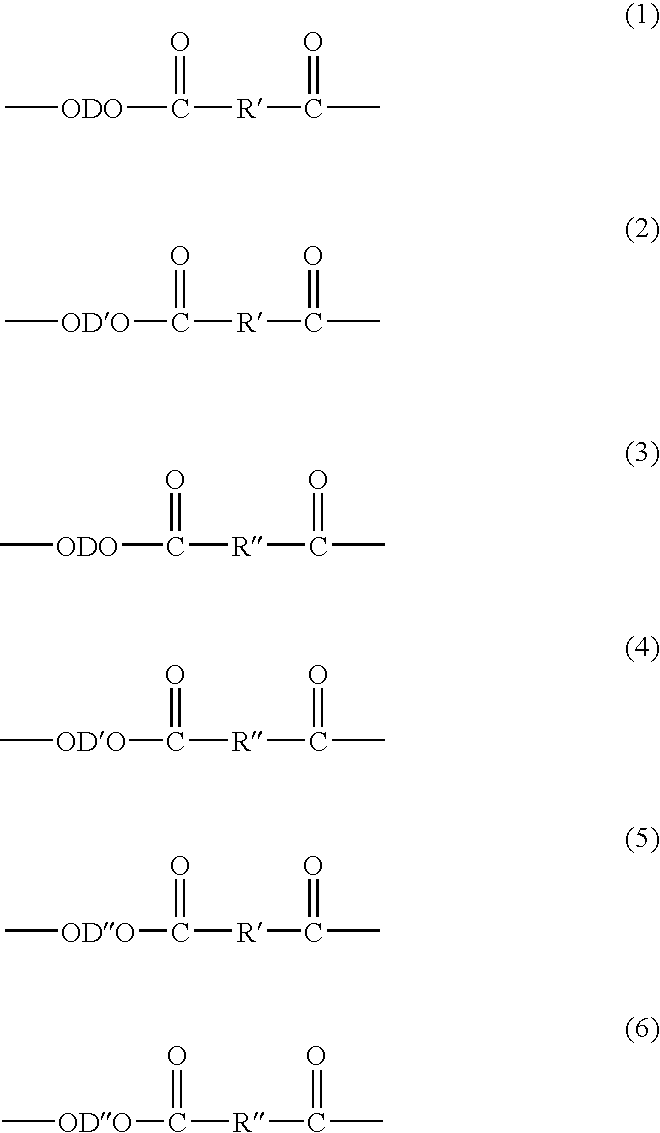

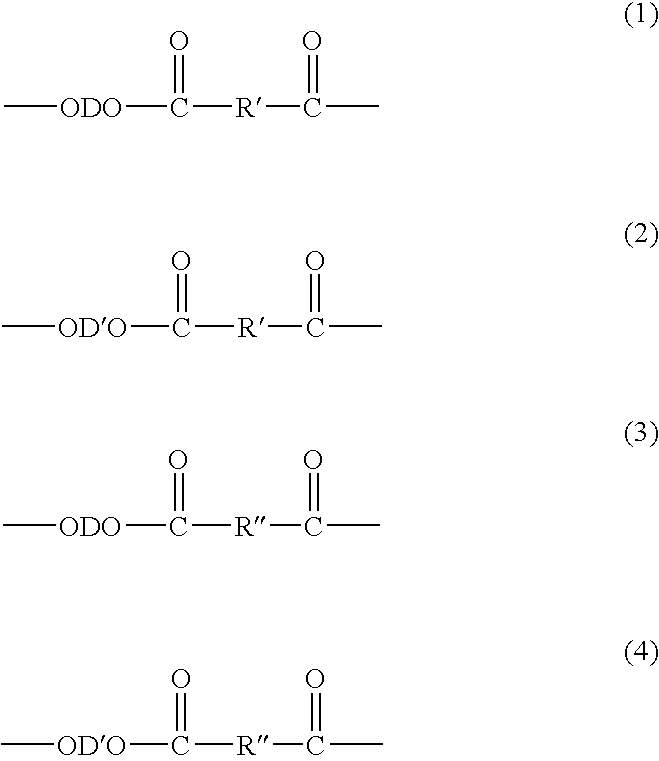

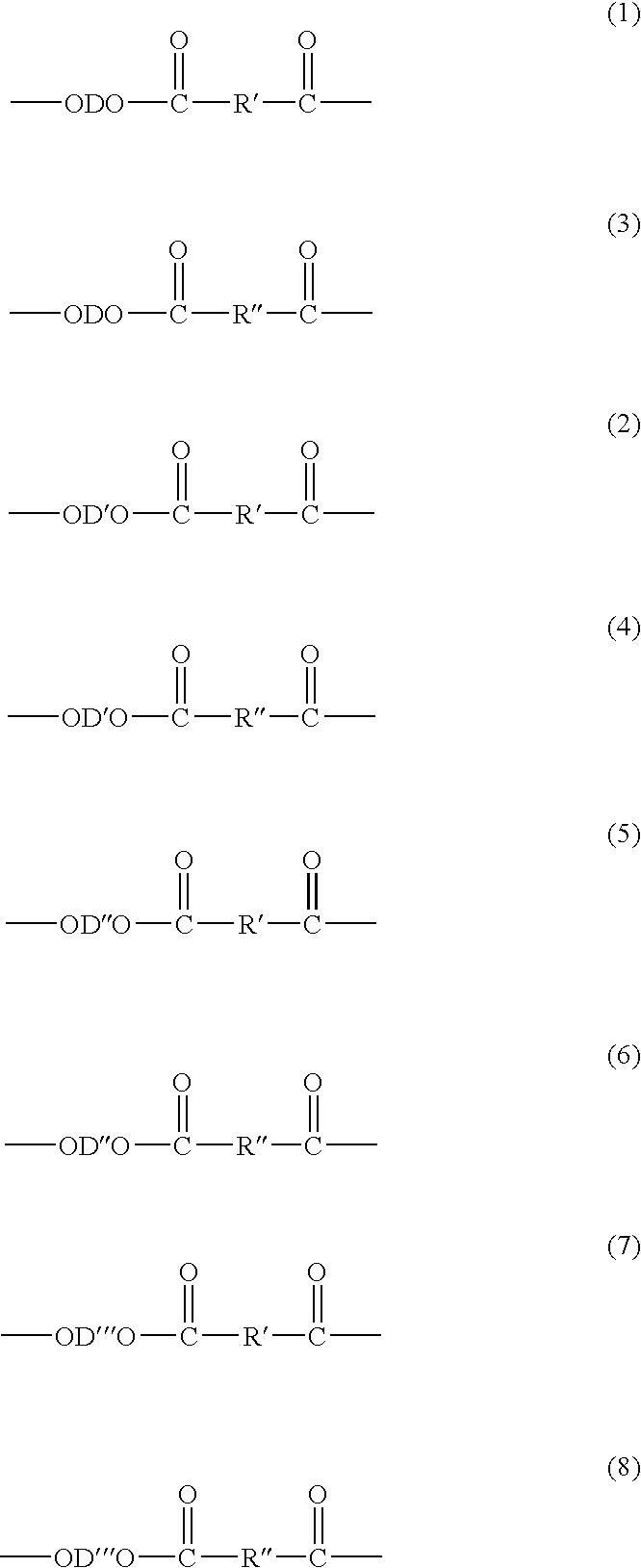

Polyhaloalkyl ether derivatives as well as liquid crystal compositions and liquid crystal display elements containing them

InactiveUS6187223B1High DELTAImprove compatibilityLiquid crystal compositionsOrganic chemistryOxygenPhotochemistry

A compound expressed by the general formula (1):wherein R1 denotes an alkyl group having from 1 to 20 carbon atoms in which one or more methylene groups in said group may be replaced by oxygen atoms or -CH=CH- and one or more hydrogen atoms in said group may be replaced by flourine or chlorine atoms, with the proviso that two or more methylene groups may not be continuously replaced by oxygen atoms,Y1 denotes an alkoxy group having 1 to 5 carbon atoms, in which at least one hydrogen atom is replaced by a fluorine atom and one or more hydrogen atoms may be further replaced by chlorine atoms,Z1, Z2 and Z3 each independently denote a covalent bond, -CH2CH2-, -CH=CH-, -COO- or -CF2)-, with the proviso that at least one of Z1, Z2 and Z3 is -COO- or -CF2O-,rings A1, A2, A3 and A4 each independently denote trans-1,4-cyclohexylene, 3-cyclohexen-1,4-ylene, 3-fluoro-3-cyclohexen-1,4-ylene, pyrimidine-2,5-diyl, 1,3-dioxan-2,5-diyl, trans-1-sila-1,4-cyclohexylene, trans-4-sila-1,4-cyclohexylene, or 1,4-phenylene in which one or more hydrogen atoms may be replaced by fluorine atoms or chlorine atoms,andm and n denote 0 or 1,with the proviso that when Z1, Z2 or Z3 is -CF2O-, then at least two groups selected from rings A1, A2, A3 and A4 directly bonded to -CF2O- are both 1,4-phenylene in which one or more hydrogen atoms may be replaced by fluorine atoms or chlorine atoms, and any of the rings A1, A2 and A3 bonded with the carbon atoms of -CF2O- is 1,4-phenylene in which at least one hydrogen atom is replaced by fluorine or chlorine atoms.

Owner:JNC CORP

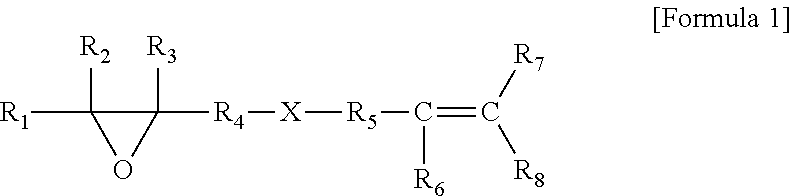

Energy ray-curable ink composition

ActiveUS20110015294A1Low viscositySuitable physical propertyDuplicating/marking methodsInksDouble bondPolydimethylsiloxane

The present invention provides an energy ray-curable ink composition excellent in the continuous discharge property, and excellent in curability and adherability. The present invention relates to an energy ray-curable ink composition which contains a coloring agent, contains only a monofunctional monomer having an acrylic equivalent of 300 or less, and having one ethylenic double bond in one molecule, and a polyfunctional monomer having an acrylic equivalent of 150 or less, and having two or more ethylenic double bonds in one molecule as a polymerizable compound, contains an α-aminoalkylphenone compound and a thioxanthone compound as a photopolymerization initiator, and contains a silicone compound having a polydimethylsiloxane structure as a surface conditioner.

Owner:MAXELL HLDG LTD

Polysiloxane film and process for producing the same

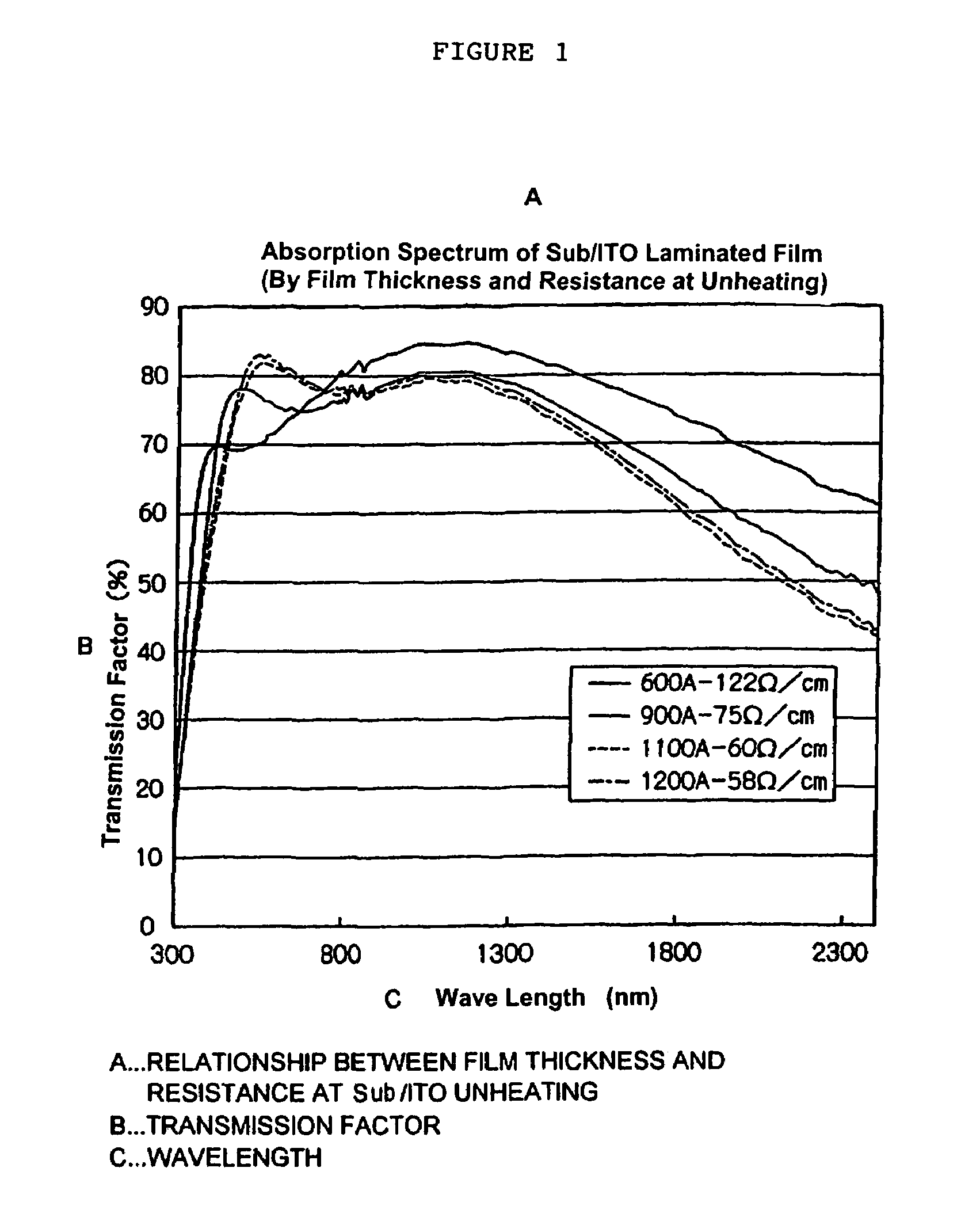

InactiveUS7381470B2Improve breathabilityLow birefringencePretreated surfacesMetallic material coating processesPolymer sciencePtru catalyst

The present invention relates to a film made from a cross-linked polysiloxane obtained by subjecting a polysiloxane that has a specific chemical structure and contains at least two unsaturated aliphatic hydrocarbon groups in one molecule and an organosilicon compound with at least two hydrogen atoms directly bonded to silicon atoms in one molecule to cross-linking reaction in the presence of a platinum-type catalyst.The film provided by the invention possesses superior heat-resistant properties, has excellent permeability for light in the visible wavelength range, is characterized by low birefringence, and demonstrates physical properties suitable for practical application. By forming an inorganic substance layer on the aforementioned polysiloxane, it is possible to use the laminated film of the invention, e.g., as a transparent electrode film.

Owner:DOW CORNING TORAY CO LTD

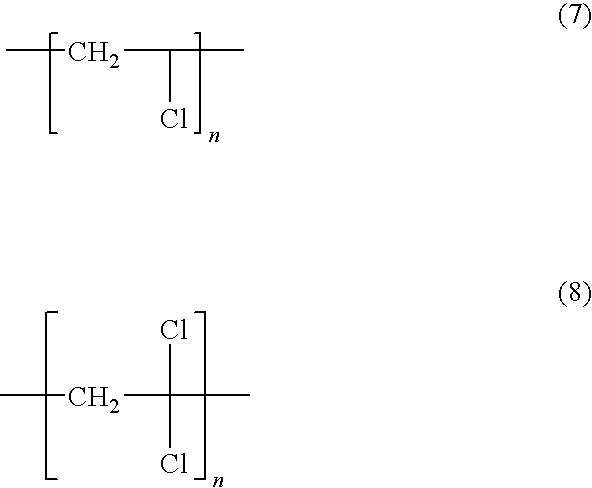

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS20100168336A1Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolymer recoveryPolytetramethylene terephthalatePolymer science

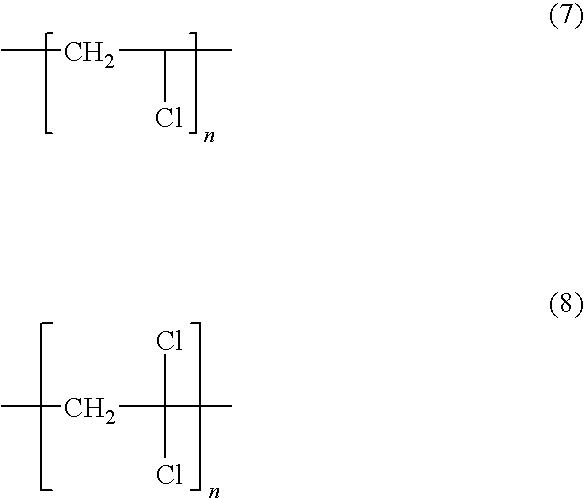

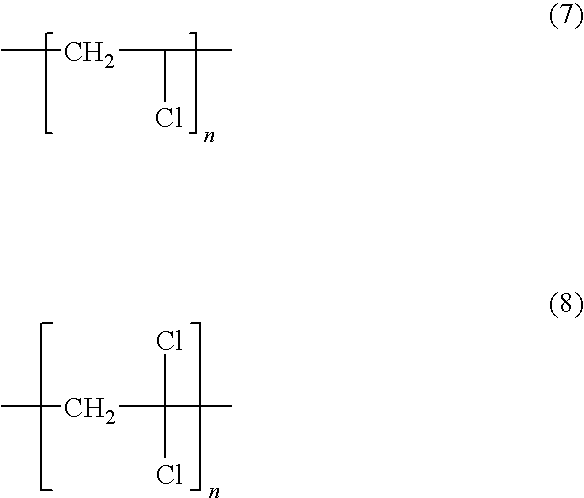

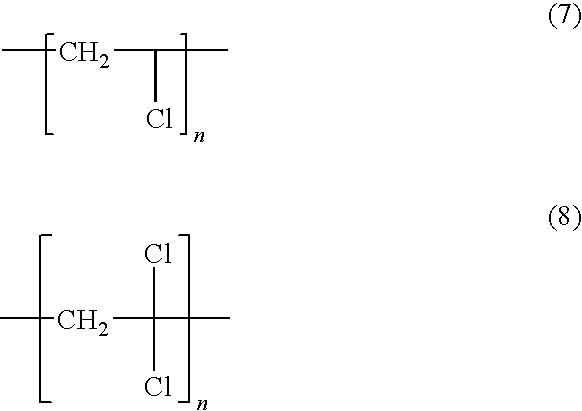

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Tooth Whitener

InactiveUS20120134936A1Promote disseminationEfficient deliveryCosmetic preparationsToilet preparationsPolyolSolvent

A tooth whitener is provided, including a water-in-oil (W / O) emulsion phase including: a discontinuous phase comprising a peroxide, a hydrophilic solvent, and a polyol, and a continuous phase comprising a glycerol monooleate, a polymer and a polyol, wherein the tooth whitener is flowable upon being applied to teeth and is solidified by the action of moisture after being applied to teeth, and then is adhered and fixed to teeth, and wherein the glycerol monooleate is in an amount of 15% to 95% by weight, based on total weight of the tooth whitener composition.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

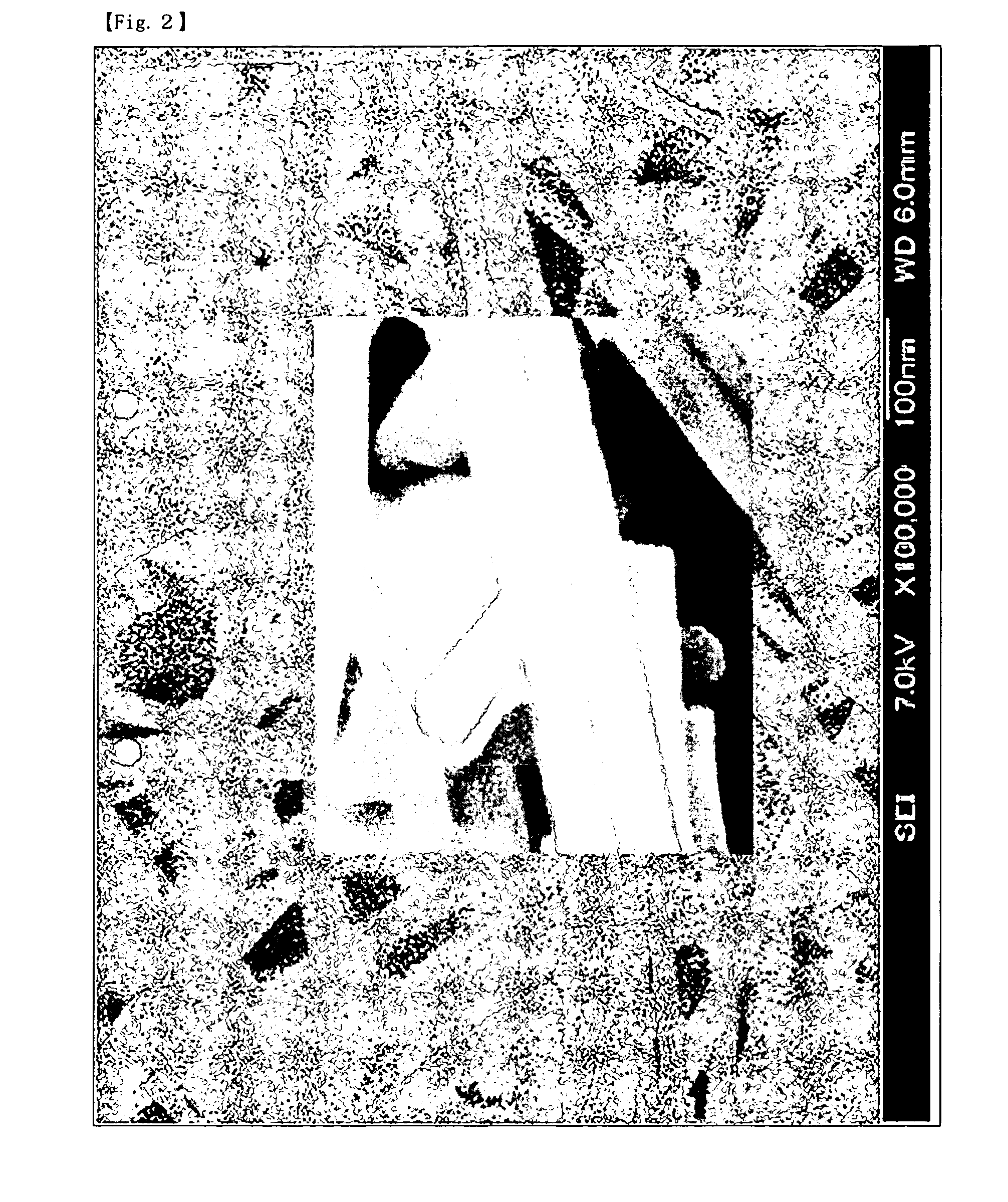

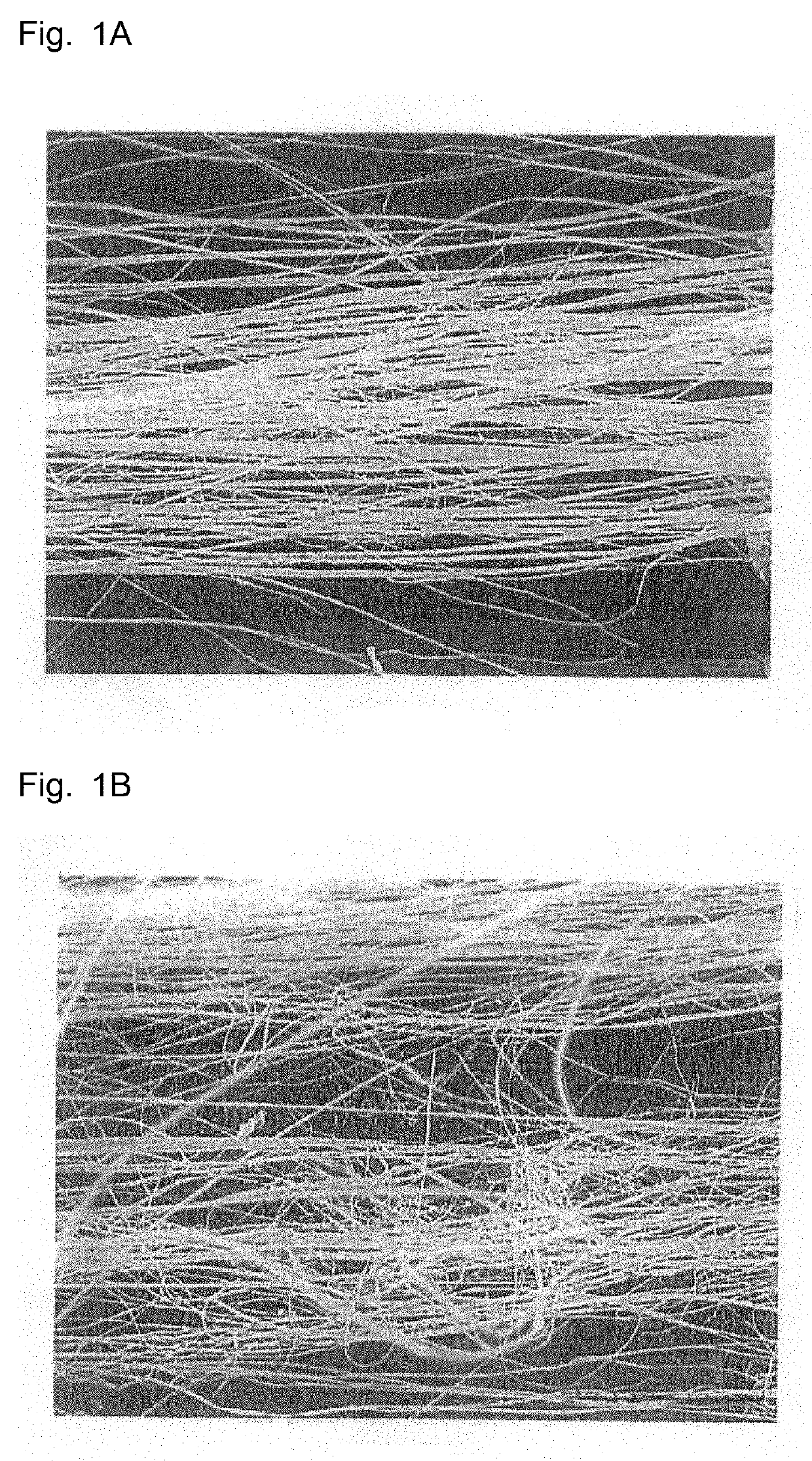

Composite material

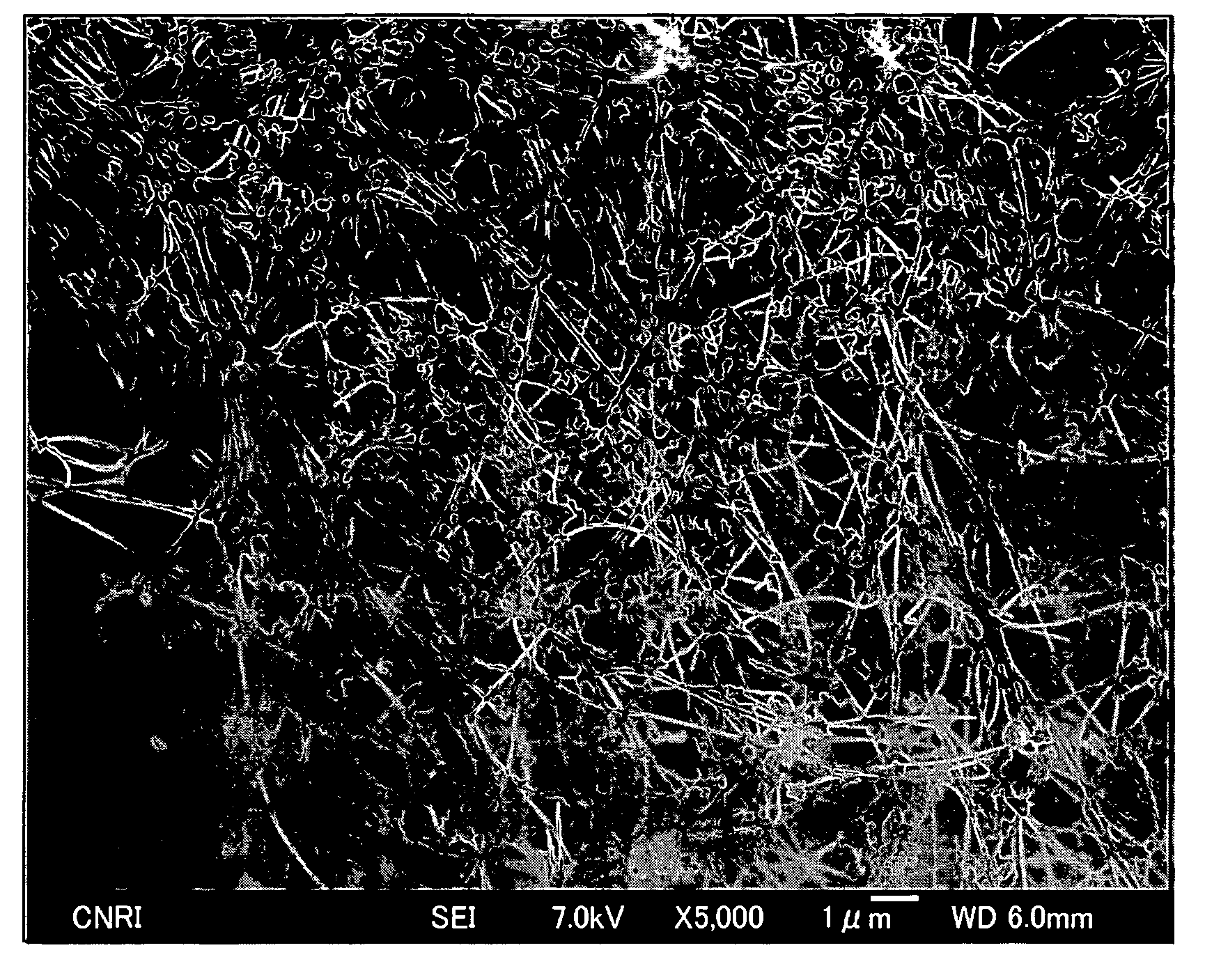

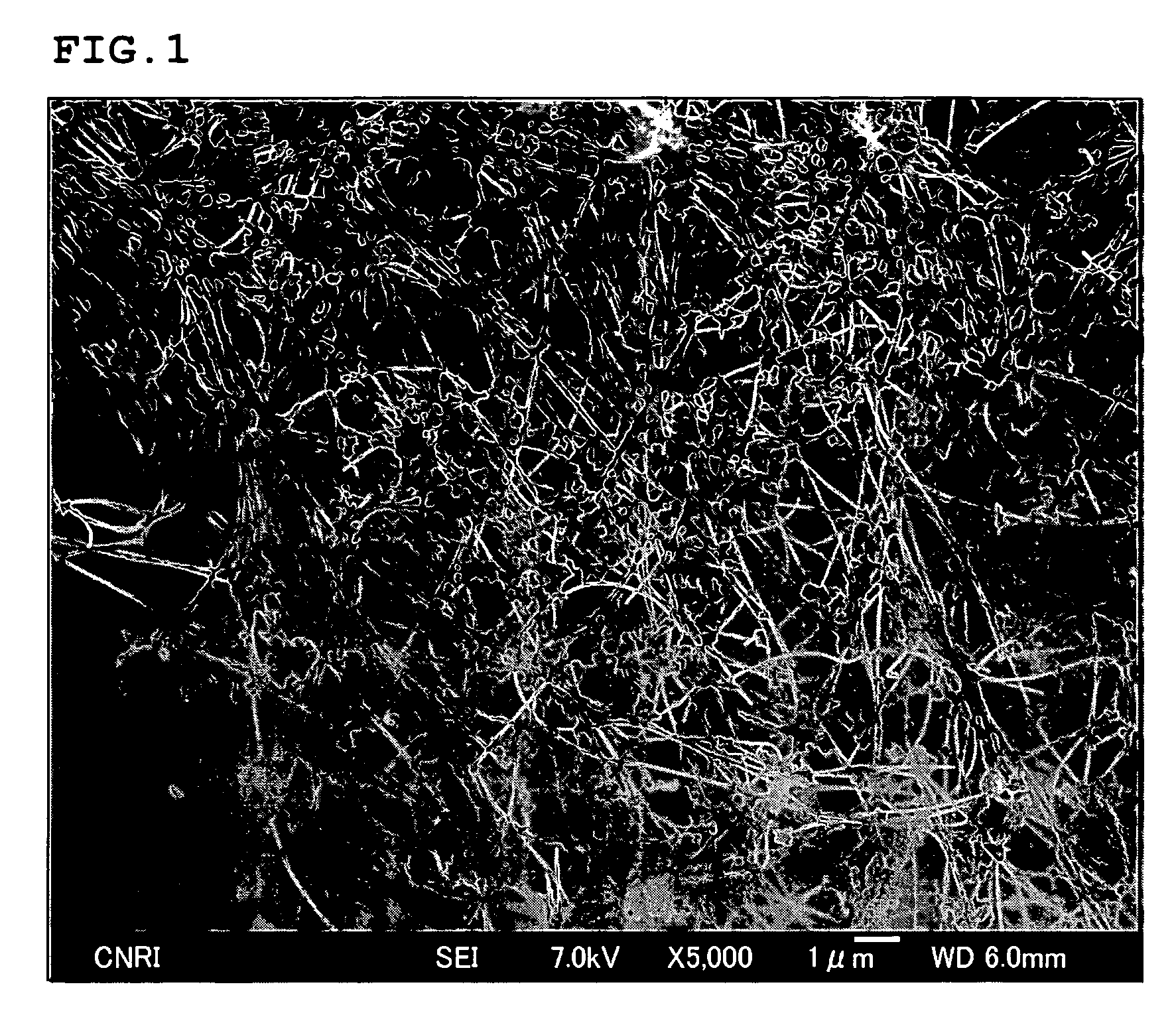

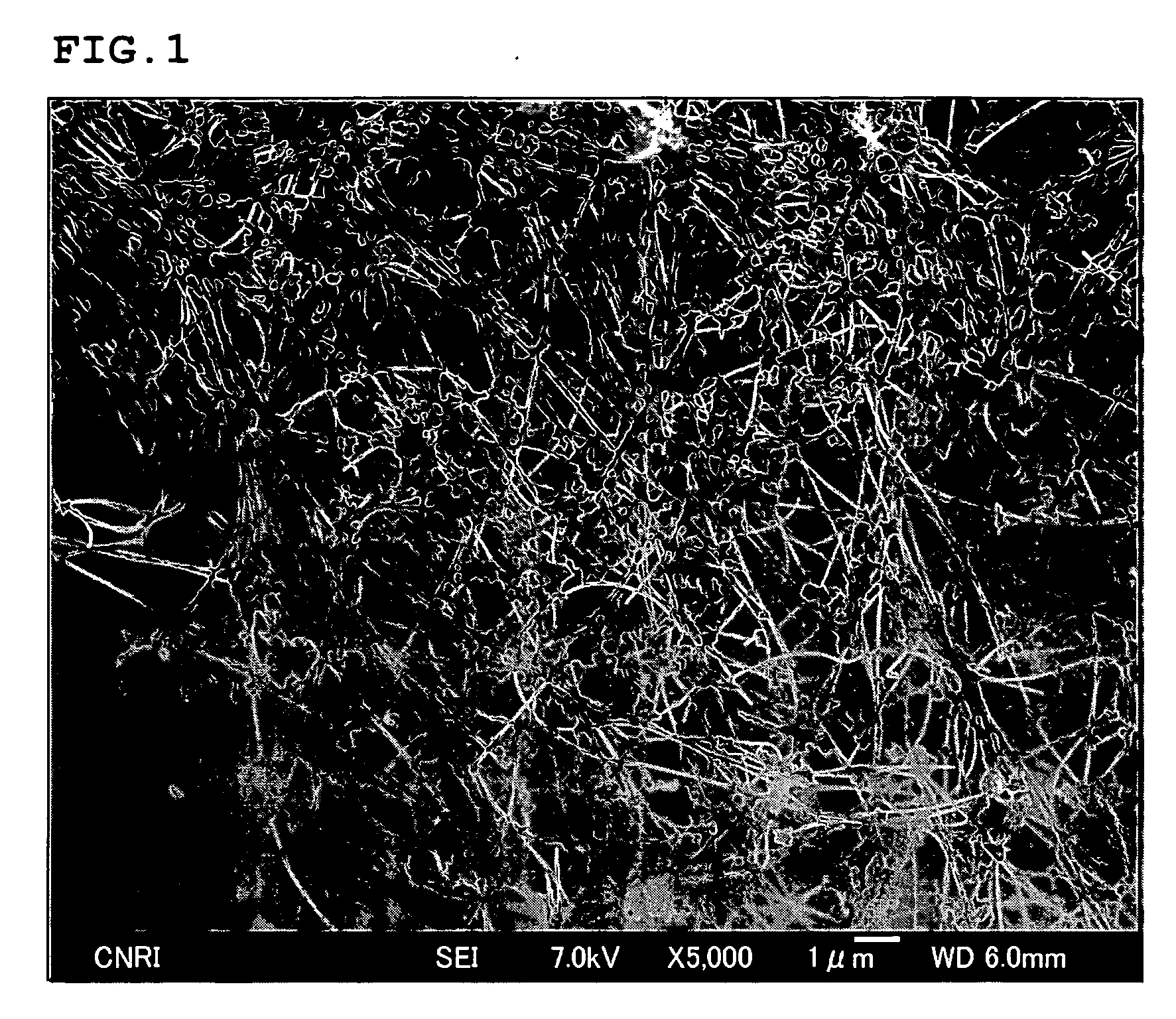

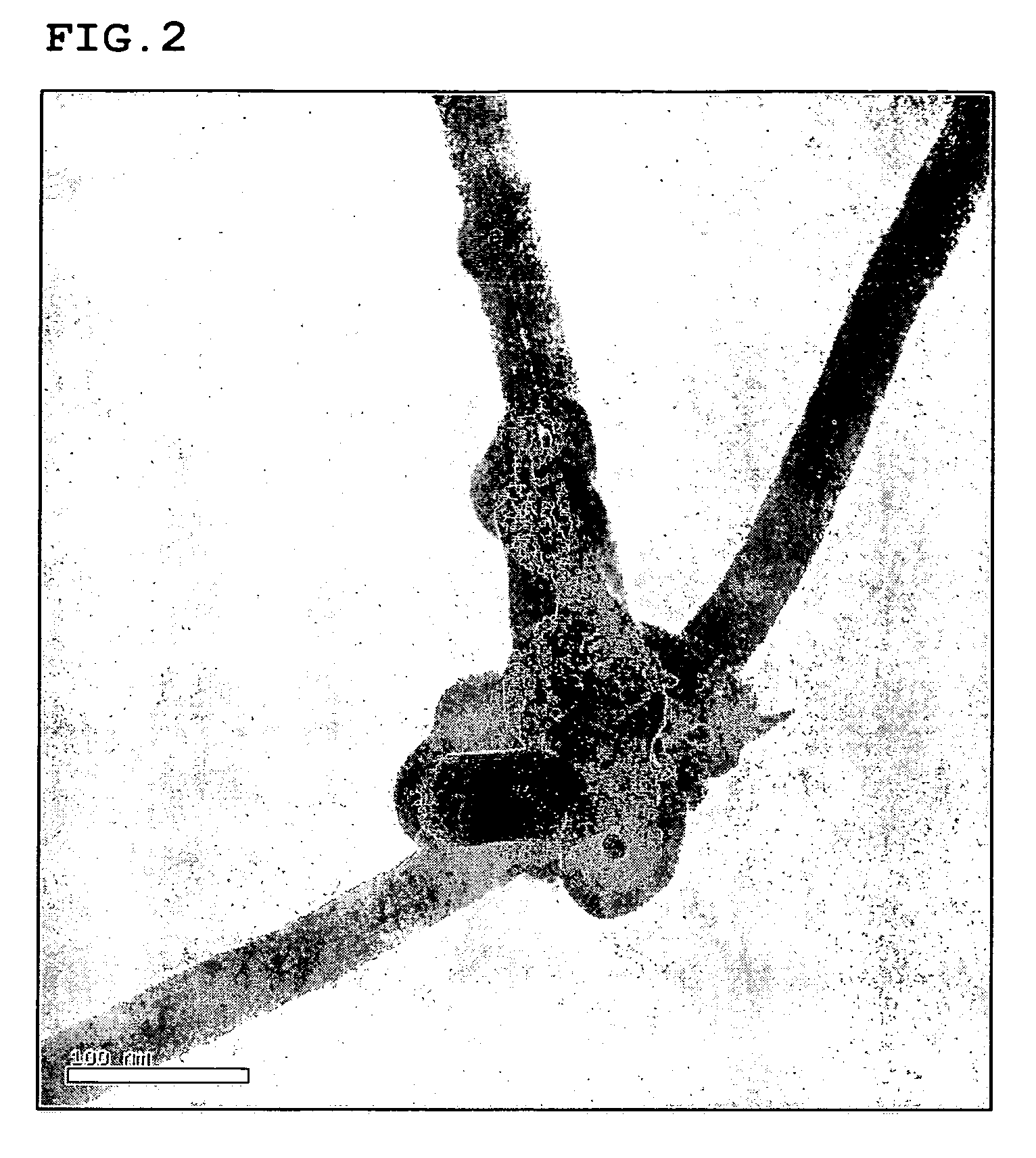

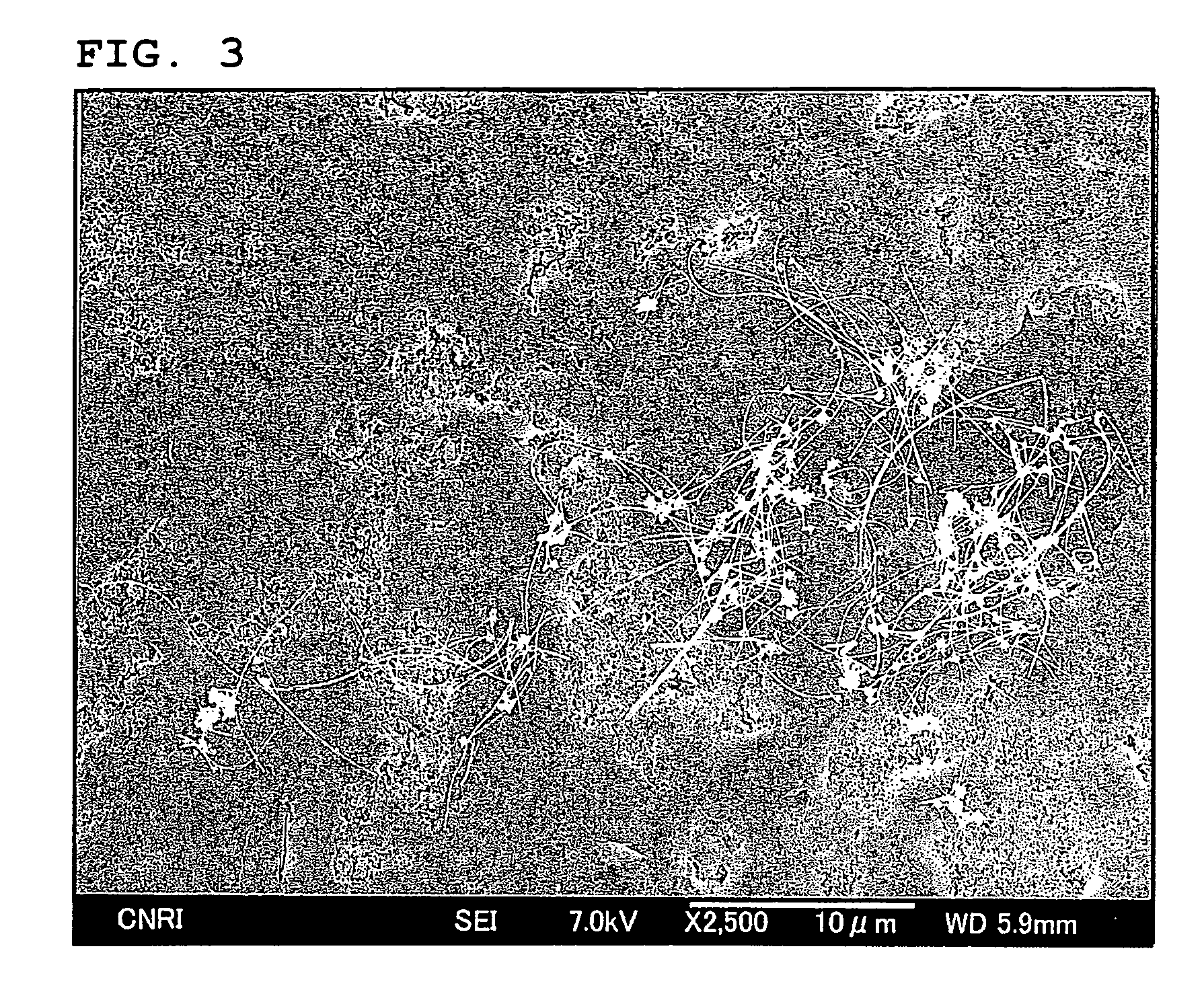

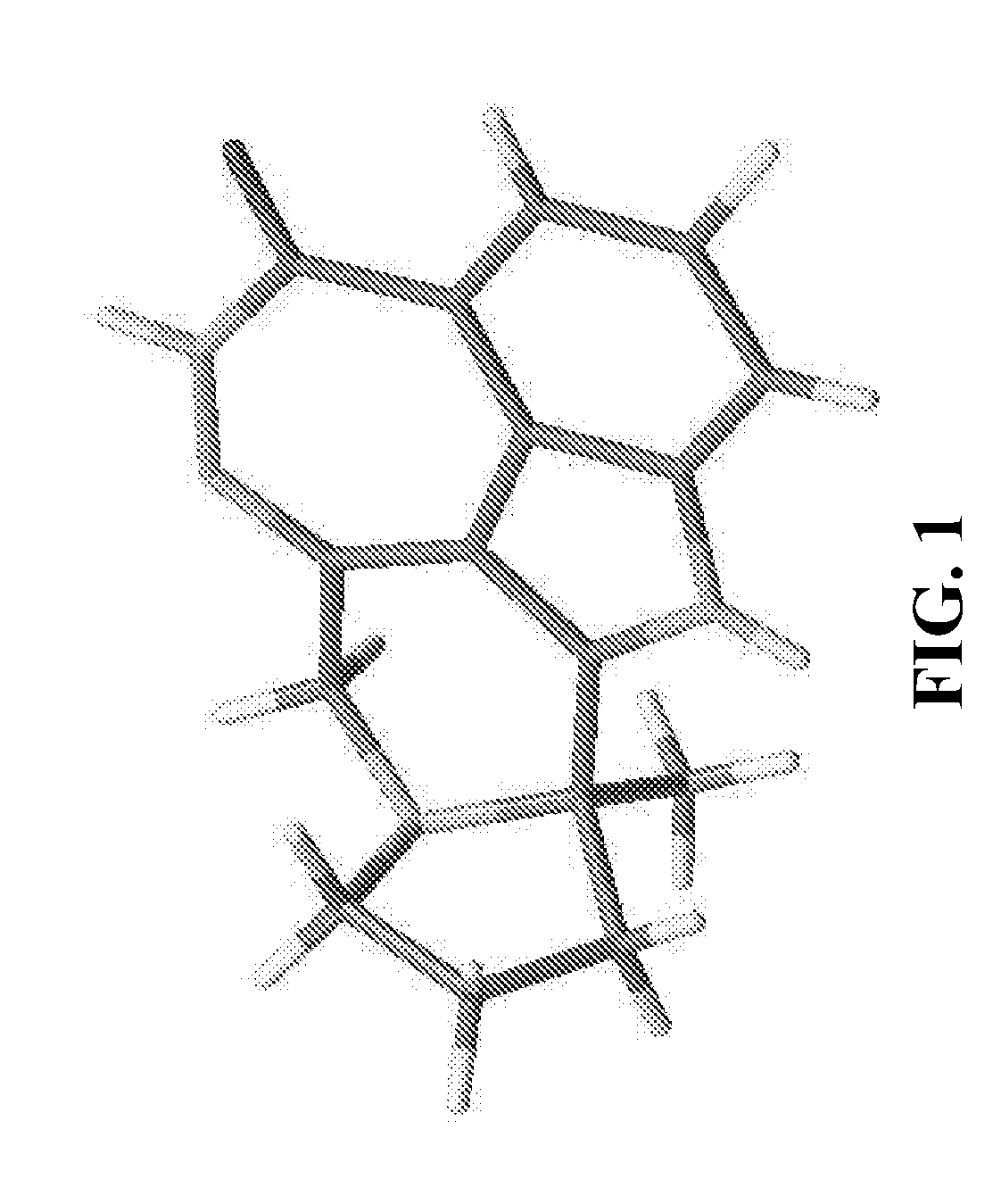

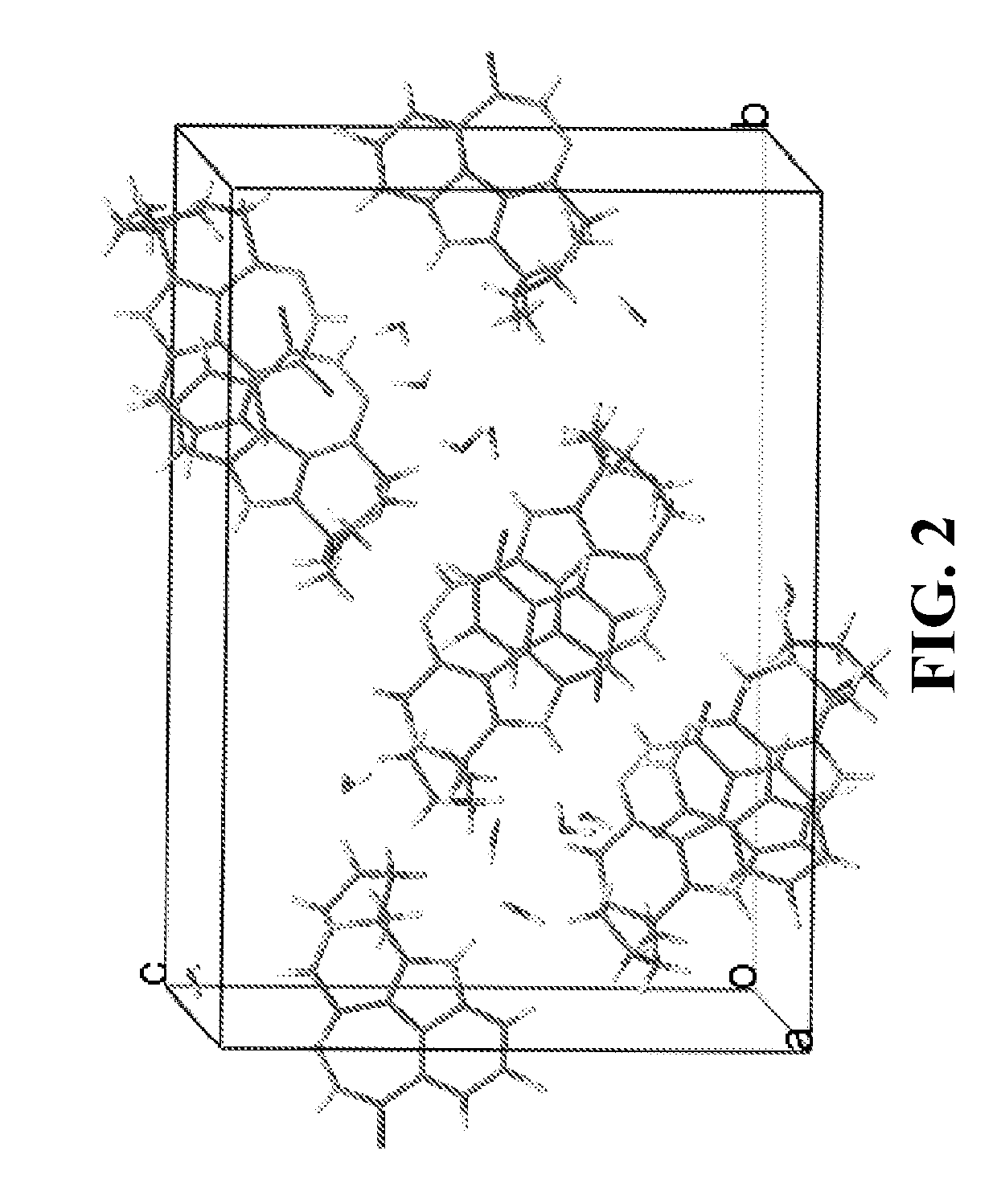

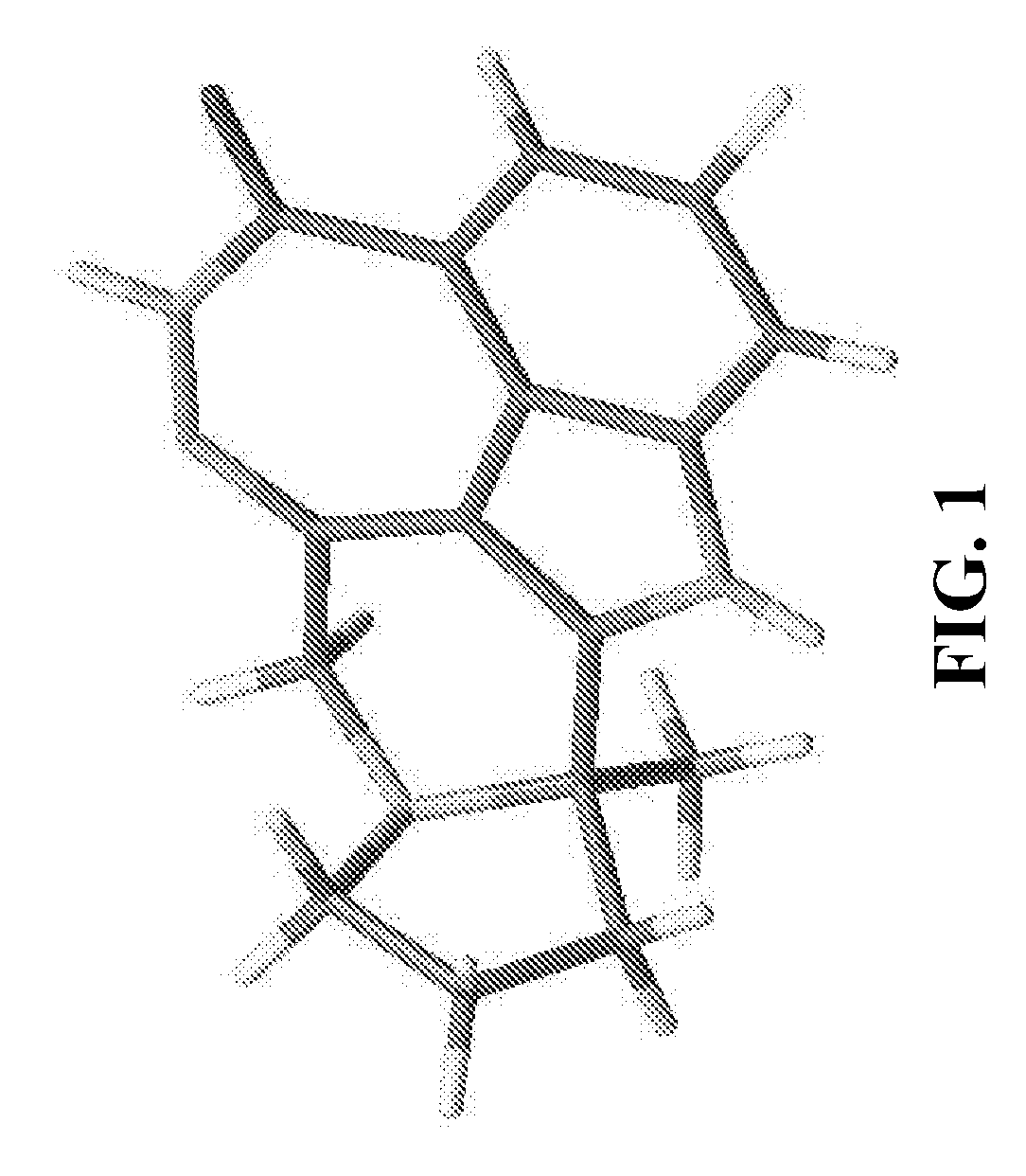

InactiveUS7214430B2Good physical propertiesSuitable physical propertyMaterial nanotechnologyNon-aqueous electrolyte accumulatorsFiberCarbon fibers

A composite material includes a matrix and carbon fibrous structures. The carbon fibrous structure has a three dimensional network of carbon fibers, each having an outside diameter of 15–100 nm, and has a granular part with which carbon fibers are bound in a state such that the carbon fibers extend outwardly from the granular part, and the granular part being produced in a growth process of the carbon fibers. The additive amount of the carbon fibers is in the range of 0.1 to 30% by weight of total weight of the composite material.

Owner:HODOGOYA CHEMICAL CO LTD

Poly(butylene terephthalate) compositions, methods of manufacture, and articles thereof

InactiveUS20100168317A1Improved flow and mechanical propertyImprove protectionPolyethylene terephthalatePolyamide

A composition comprises, from 5 to 90 wt. % of a modified poly(butylene terephthalate) copolymer, wherein (i) the modified poly(butylene terephthalate) copolymer is derived from a first polymer comprising a poly(ethylene terephthalate) component selected from the group consisting of poly(ethylene terephthalate) homopolymers, poly(ethylene terephthalate) copolymers, and combinations thereof, in the presence of a second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof, and wherein (ii) the modified poly(butylene terephthalate) copolymer comprises at least one poly(ethylene terephthalate) component residue and a member selected from the group consisting of a second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof at least one residue derived from the second polymer, and combinations thereof; from 5 to 90 wt. % of a polycarbonate component; at least 1 wt. % of an impact modifier component.

Owner:SABIC INNOVATIVE PLASTICS IP BV

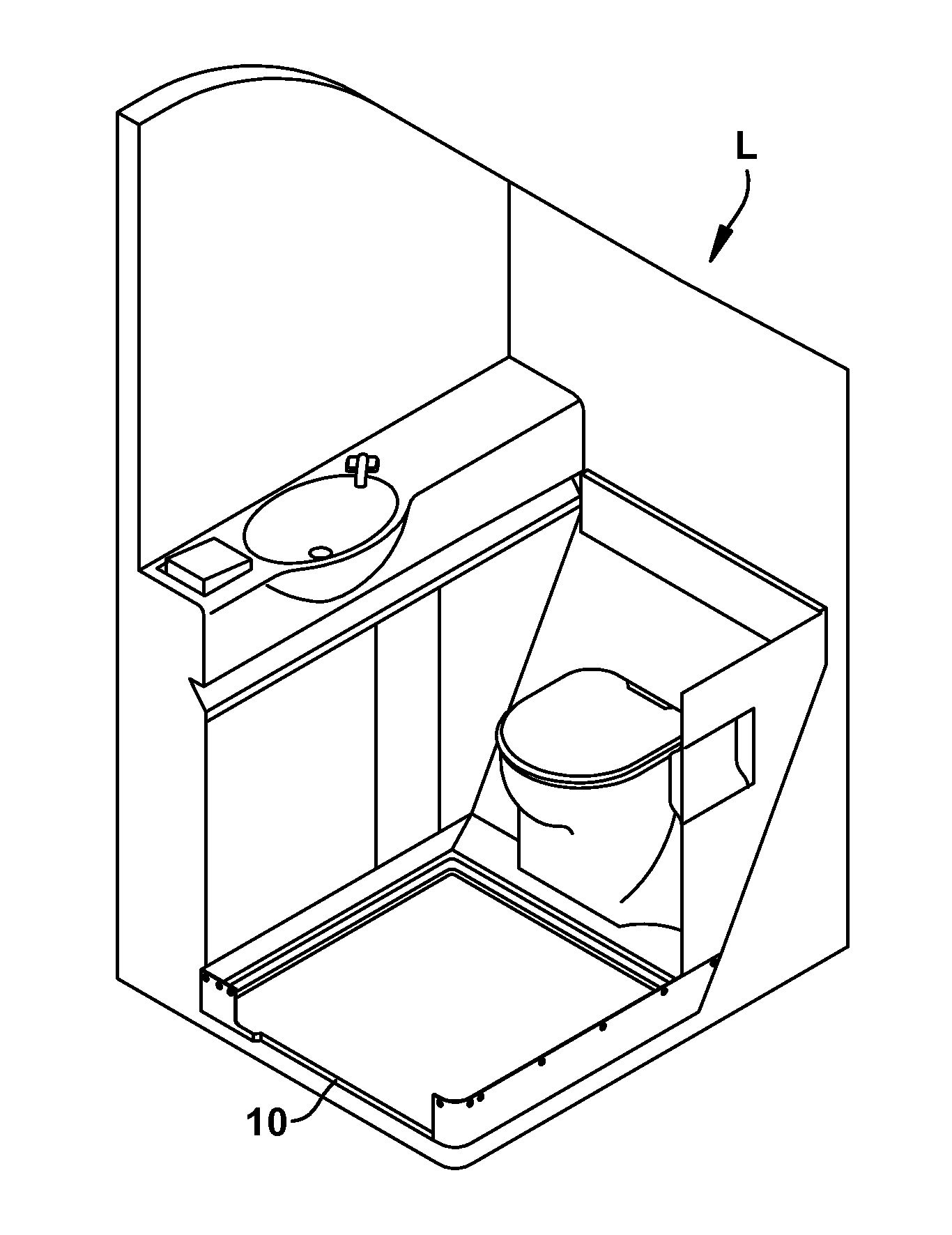

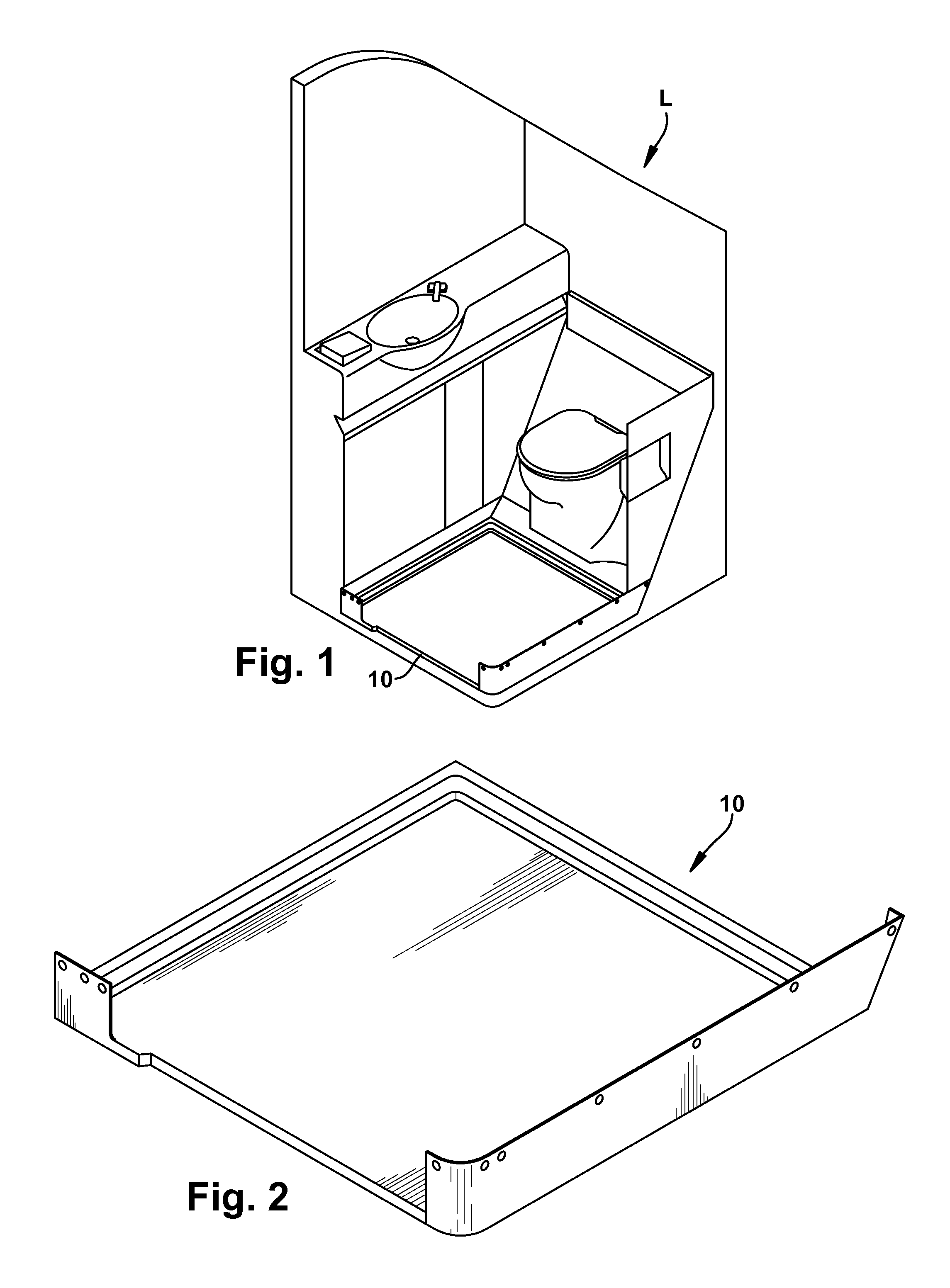

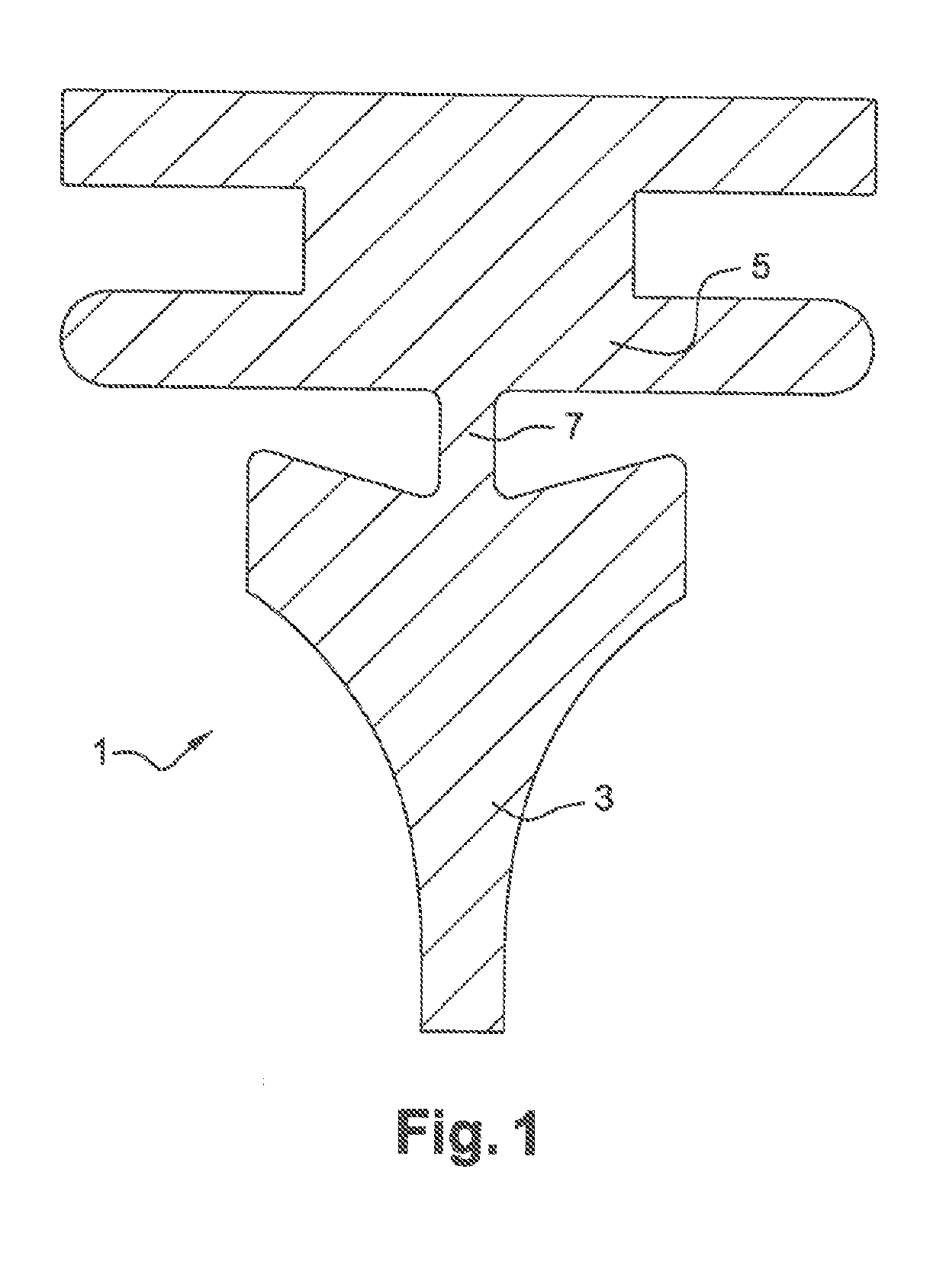

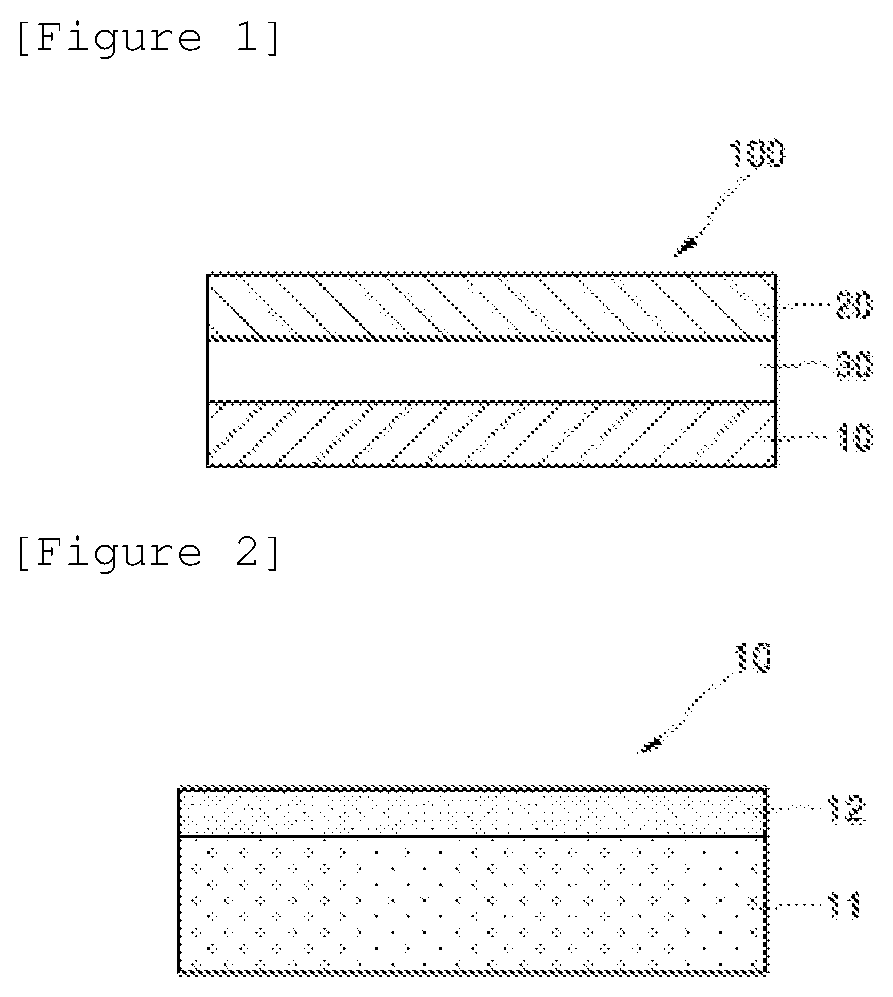

Integrated lavatory pan for commercial aircraft

InactiveUS20130099055A1Low combustionLow toxicityAir-treatment apparatus arrangementsFuselagesCombustionWear resistance

Aircraft flooring construction wherein the floor covering (e.g. over the floor structure of the aircraft) is an integrated single construction of material or materials with suitable physical properties including moisture impermeability, wear resistance and low combustion and toxicity, for long term and safe use in aircraft and particularly for aircraft lavatory.

Owner:SCHNELLER

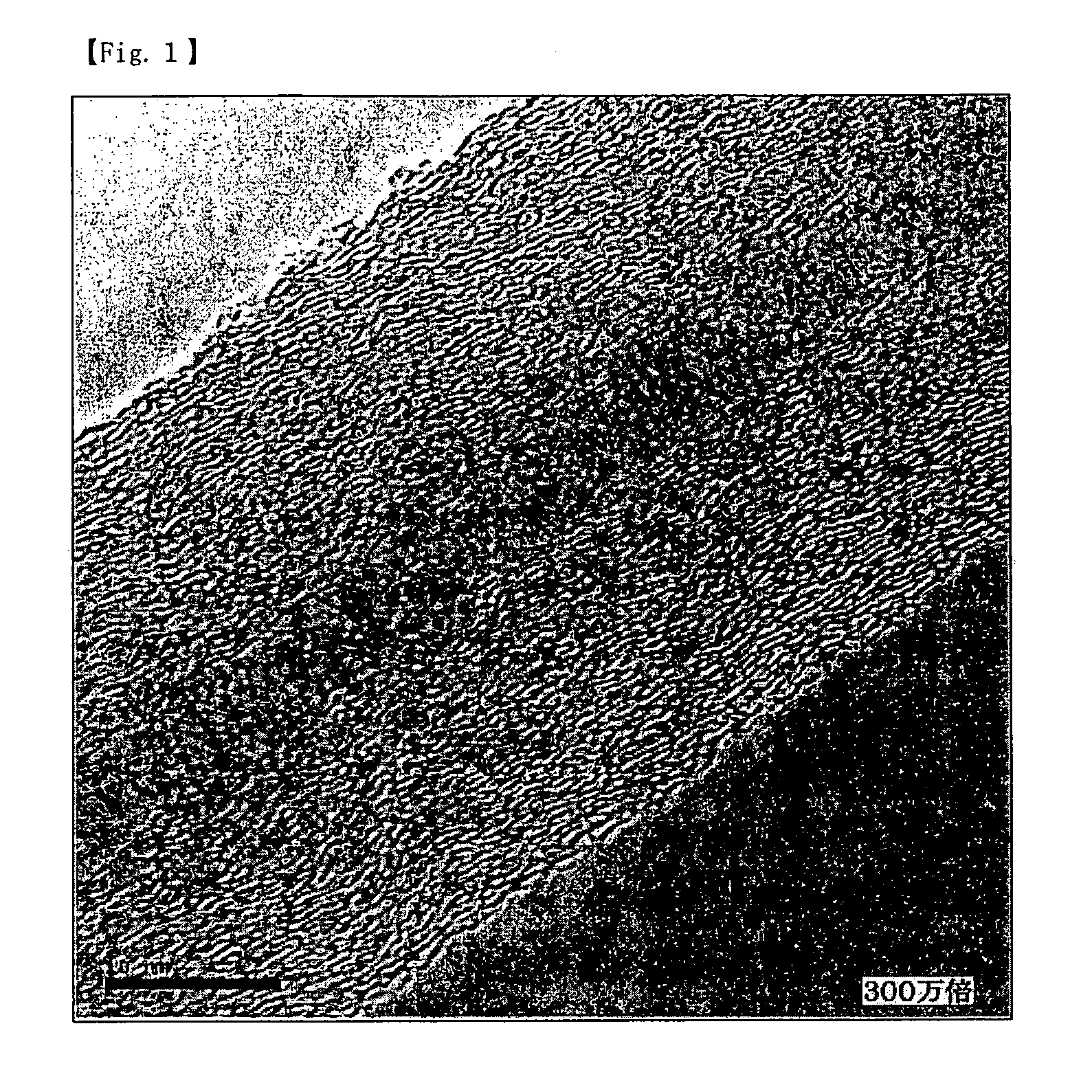

Composite material

InactiveUS20060216517A1Good physical propertiesSuitable physical propertyMaterial nanotechnologyNon-aqueous electrolyte accumulatorsFiberCarbon fibers

A composite material includes a matrix and carbon fibrous structures. The carbon fibrous structure has a three dimensional network of carbon fibers, each having an outside diameter of 15-100 nm, and has a granular part with which carbon fibers are bound in a state such that the carbon fibers extend outwardly from the granular part, and the granular part being produced in a growth process of the carbon fibers. The additive amount of the carbon fibers is in the range of 0.1 to 30% by weight of total weight of the composite material.

Owner:HODOGOYA CHEMICAL CO LTD

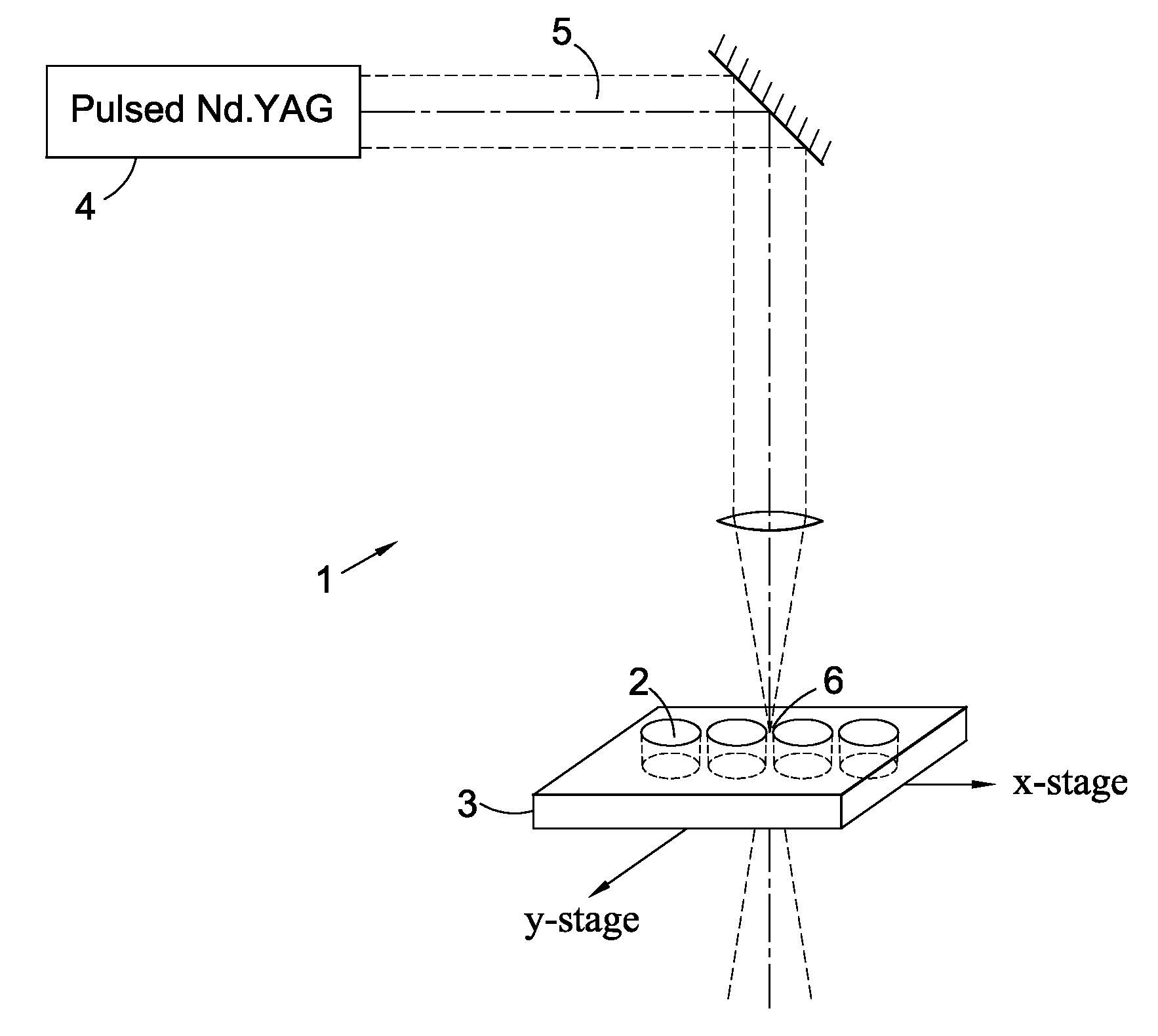

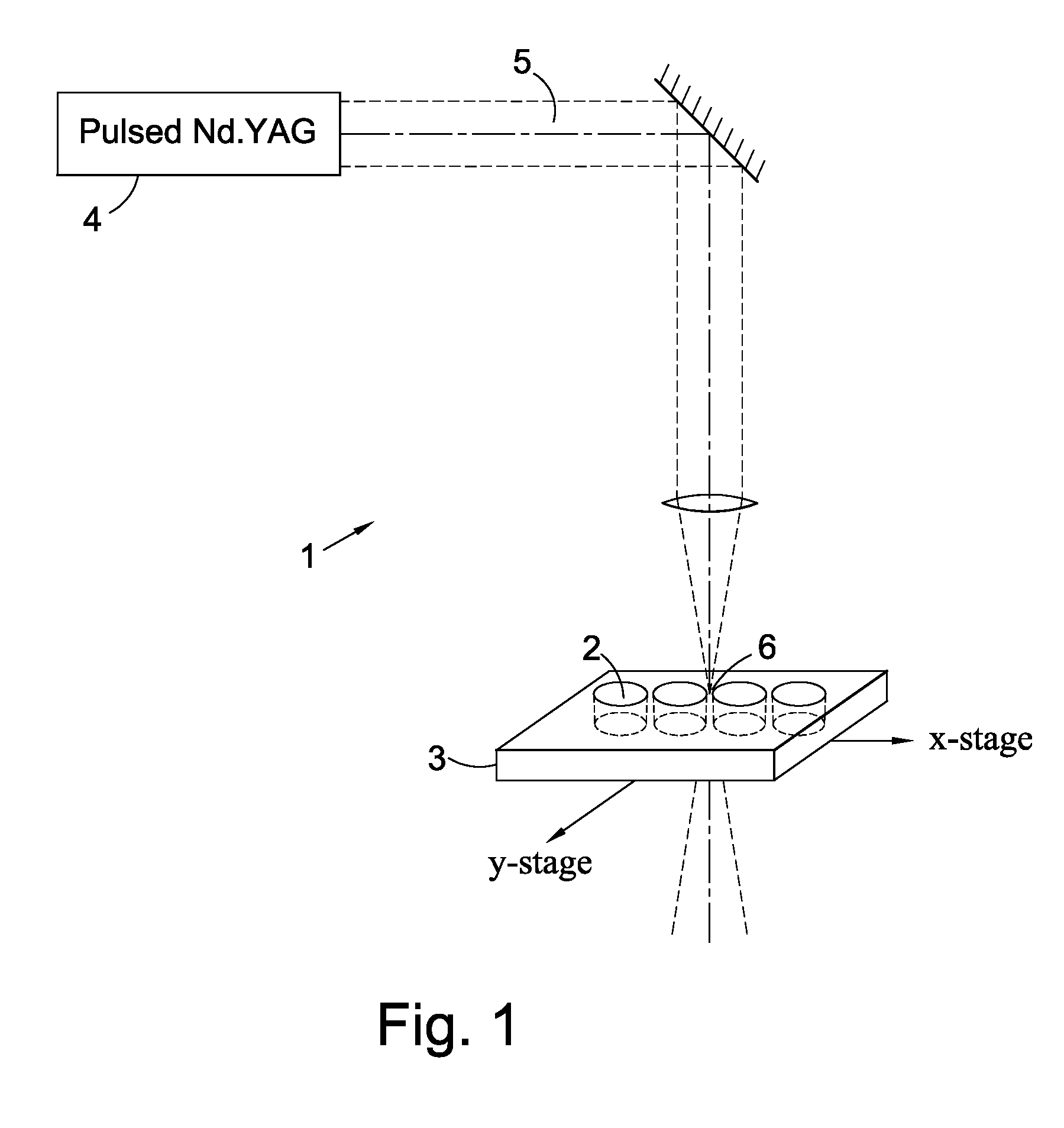

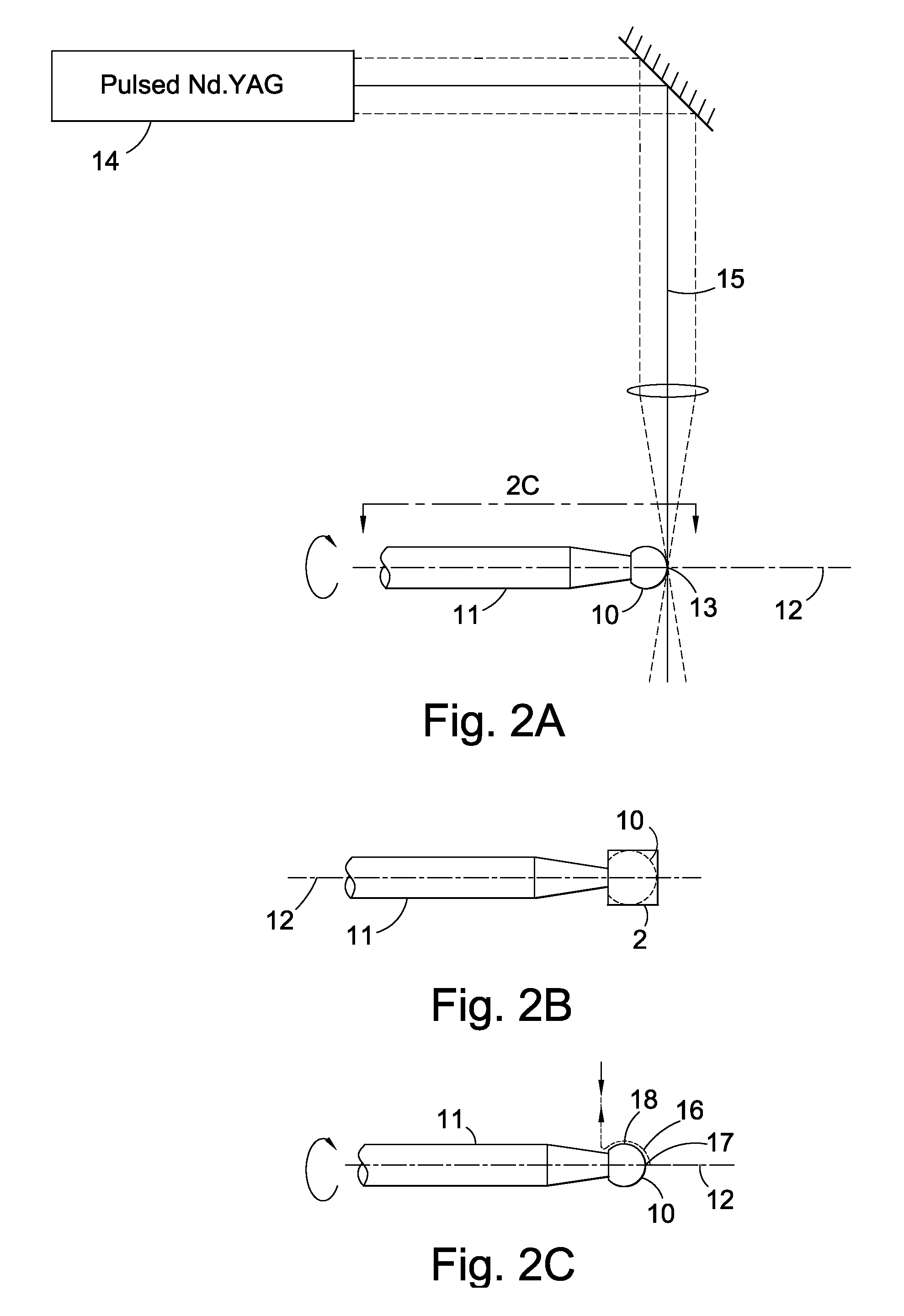

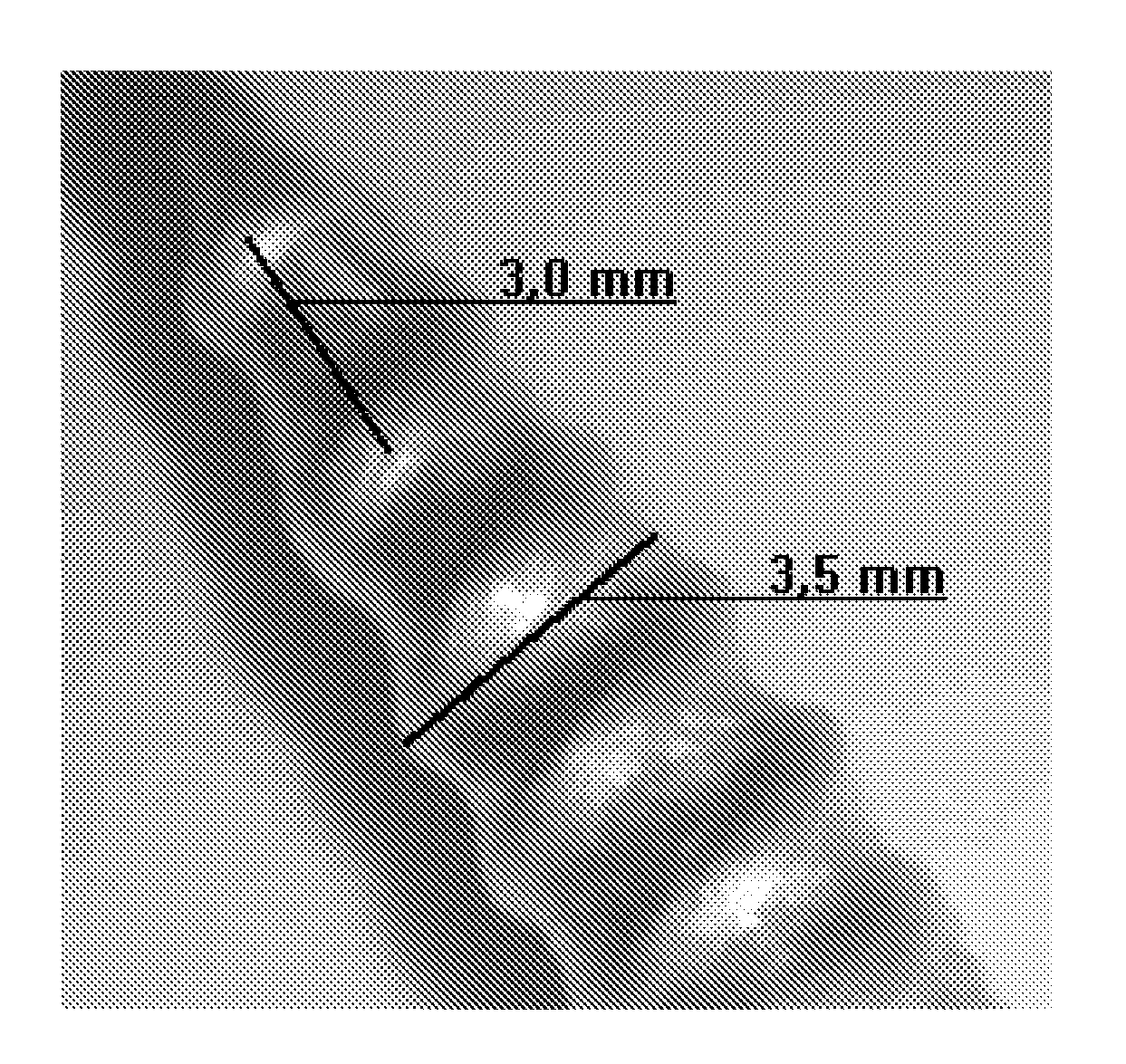

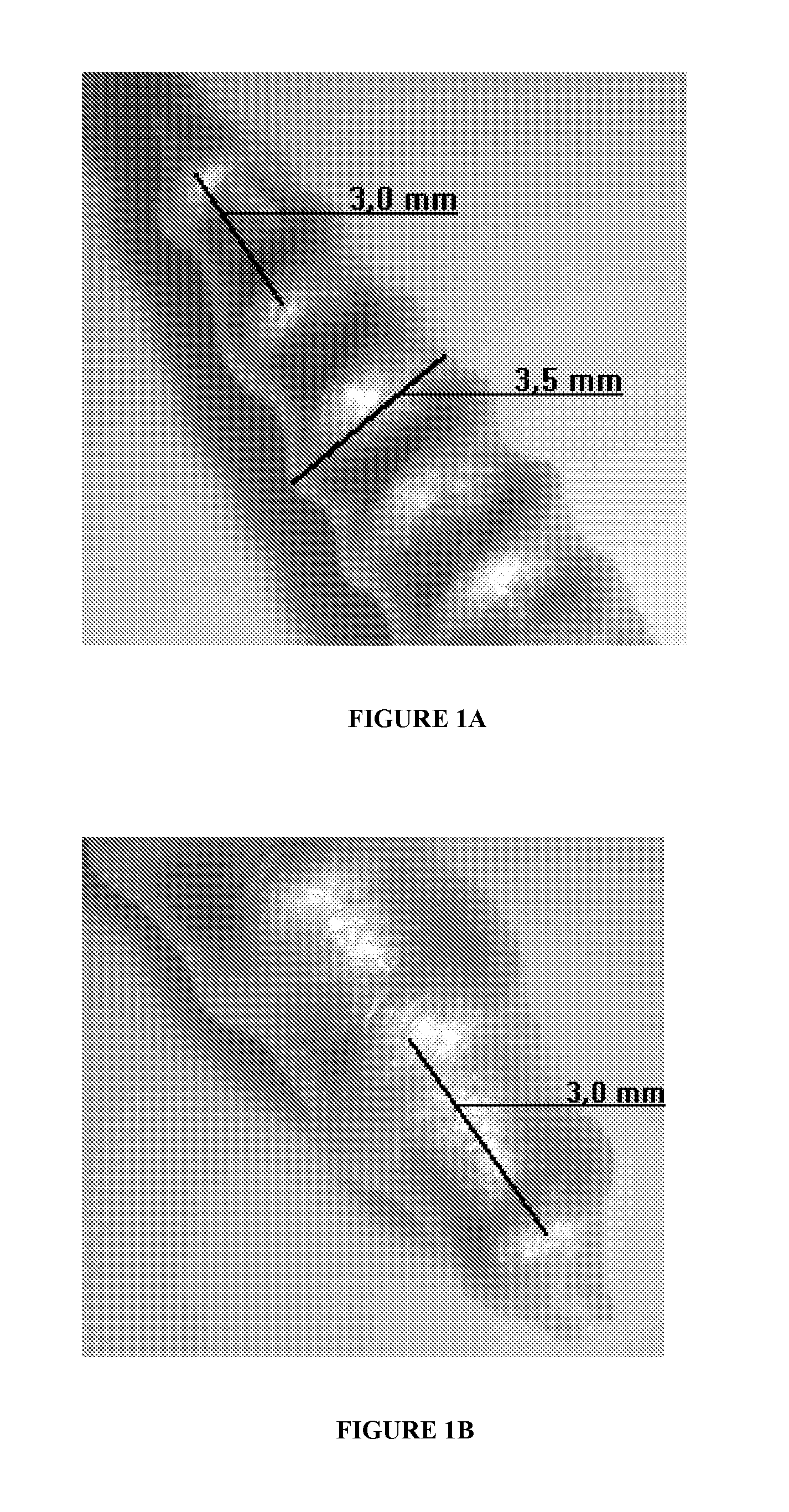

Single crystal diamond elements having convex surfaces and methods of its fabrication

ActiveUS20090022951A1Quality improvementLow radius of curvatureLayered productsRecord information storageCircular coneConvex side

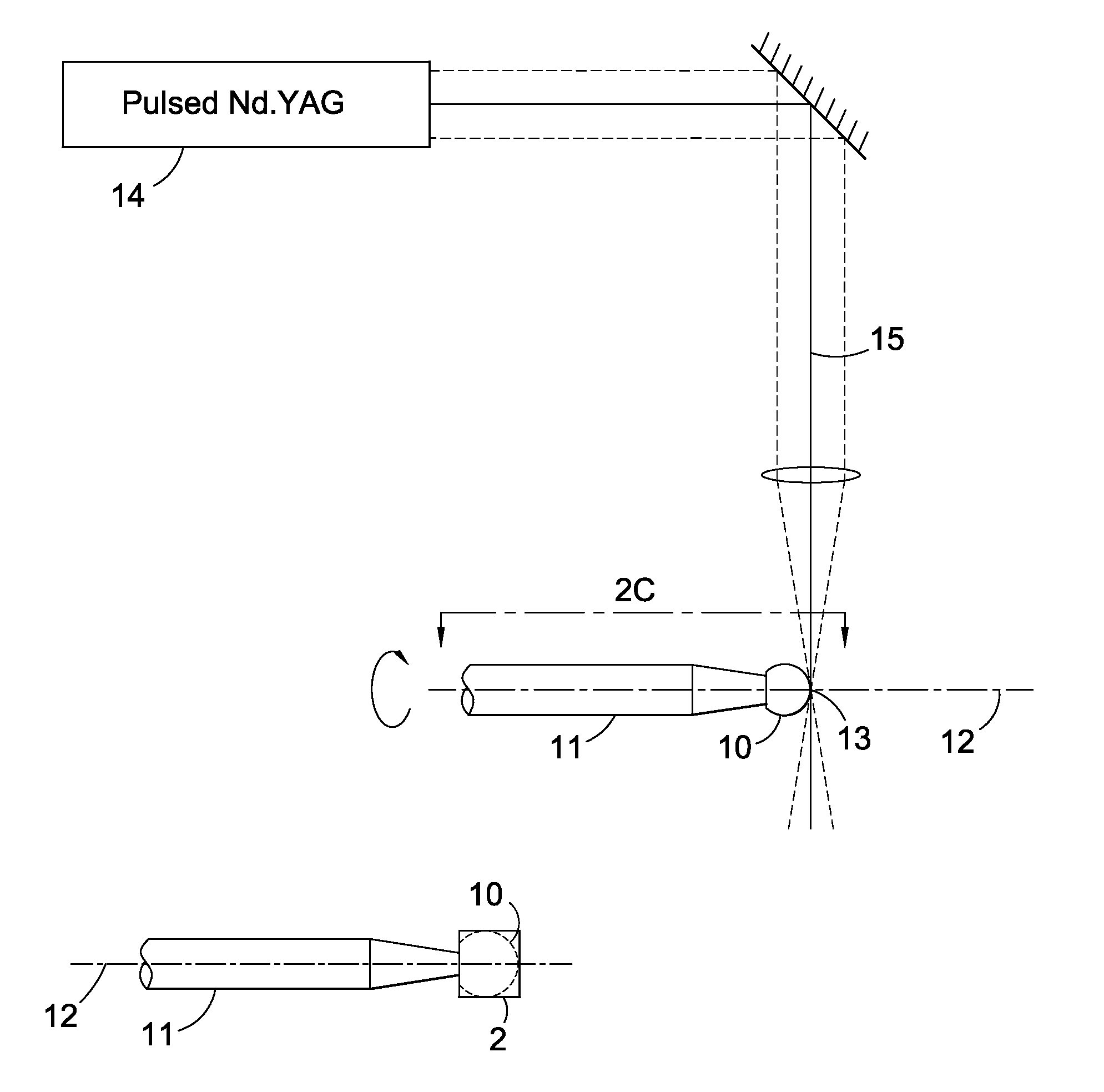

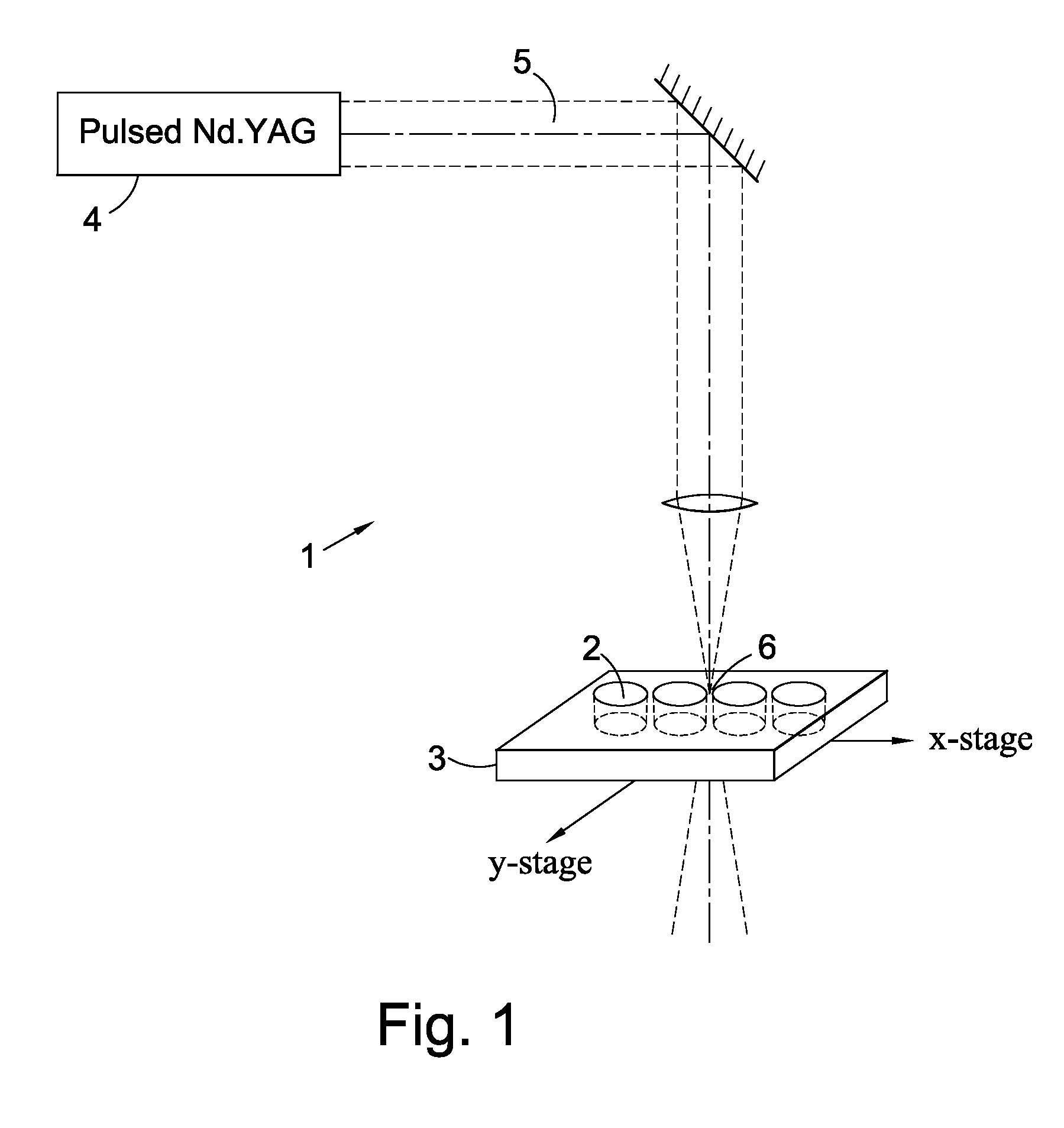

A single crystal diamond element having a convex surface is disclosed, the convex surface including a spherical segment for which the maximum peak to valley deviation from a perfect spherical surface is less than about 5 μm. Alternatively or in addition, the RMS deviation from a perfect spherical surface may be less than about 500 nm, or the RMS roughness less than about 30 nm. A single crystal diamond element with a radius of curvature less than about 20 mm is also disclosed. In one aspect a single crystal diamond element having a conical half-angle greater than about 10° is described. The invention also provides a method for forming a rotationally symmetrical surface on a single crystal diamond element, comprising rotating the element about a first axis, applying a laser beam to the element in a direction perpendicular to the first axis, and translating the laser beam in two dimensions in a plane perpendicular to the direction of the beam. If the two-dimensional path follows the arc of a circle a spherical surface may be formed. The invention also provides improving a spherical surface on a single crystal diamond element by pressing a rapidly rotating cup onto a slowly rotating element. The element may be a lens, in particular a solid immersion lens.

Owner:ELEMENT SIX LTD

Implantable Degradable Biopolymer Fiber Devices

InactiveUS20100178313A1Eliminating additional cost and potential complicationReduce the possibilityPeptide/protein ingredientsSurgeryFiberBiopolymer

Degradable fibers that include biopolymers, as well as implantable devices including one or more fibers made from degradable biopolymers, e.g., alginate, chitosan, hyaluronans or their derivatives. The devices provide a combination of degradability and biocompatibility with physical properties suitable for use of the devices as implants. Exemplary devices are fastening devices including one or more biopolymer fibers. The use of such degradable biopolymers minimizes or eliminates the need for a second surgery to remove the implant, thereby eliminating the additional cost and potential complications of such a second surgery and should reduce the likelihood of secondary fractures resulting from the stress-shielding effect or the presence of screws holes that serve as stress concentrators. Methods for the fabrication of the degradable biopolymer fibers of the present invention are also provided, as well as methods for the fabrication of implantable degradable devices of the present invention which contain one or more degradable biopolymer fibers.

Owner:FMC CORP

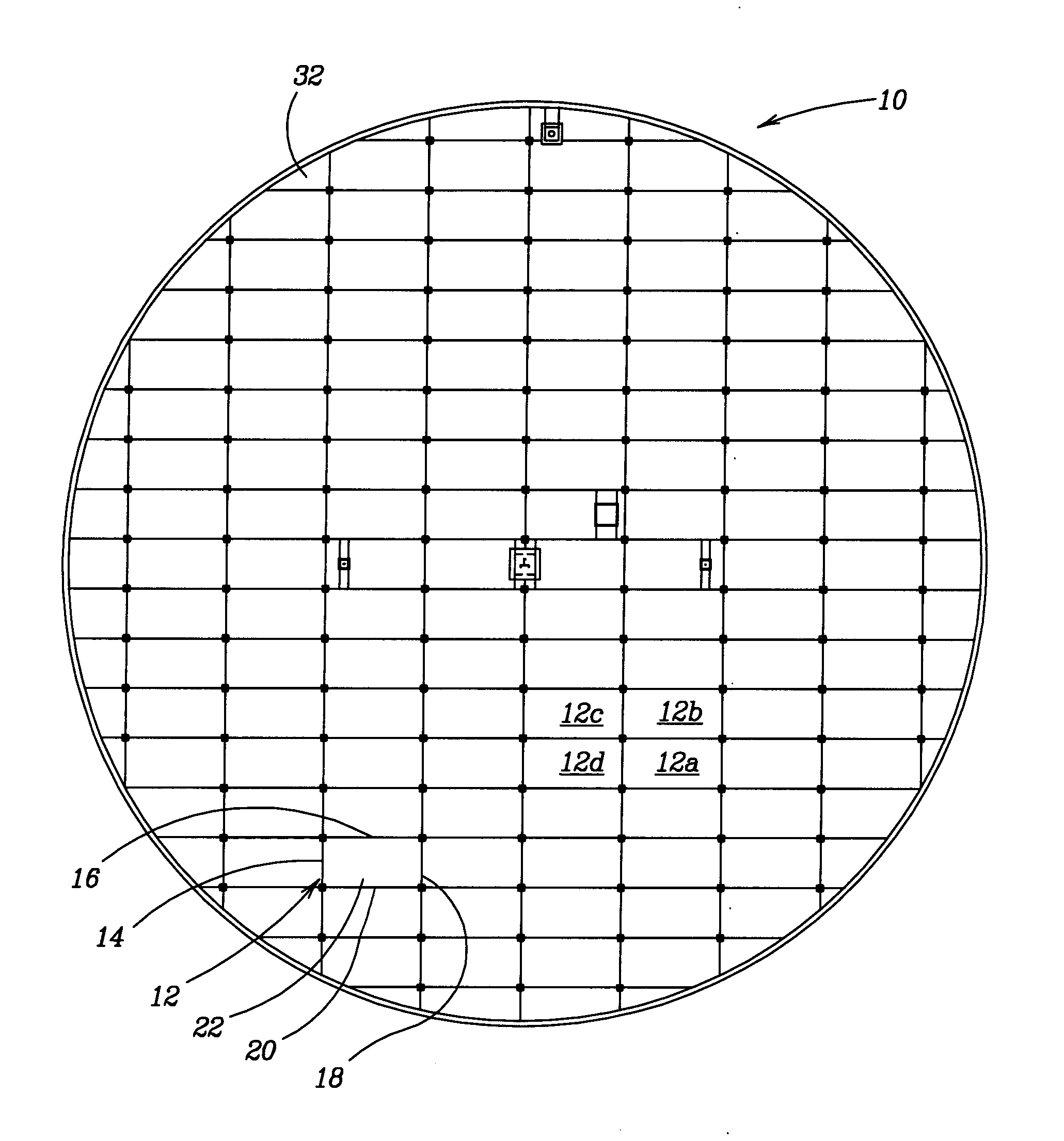

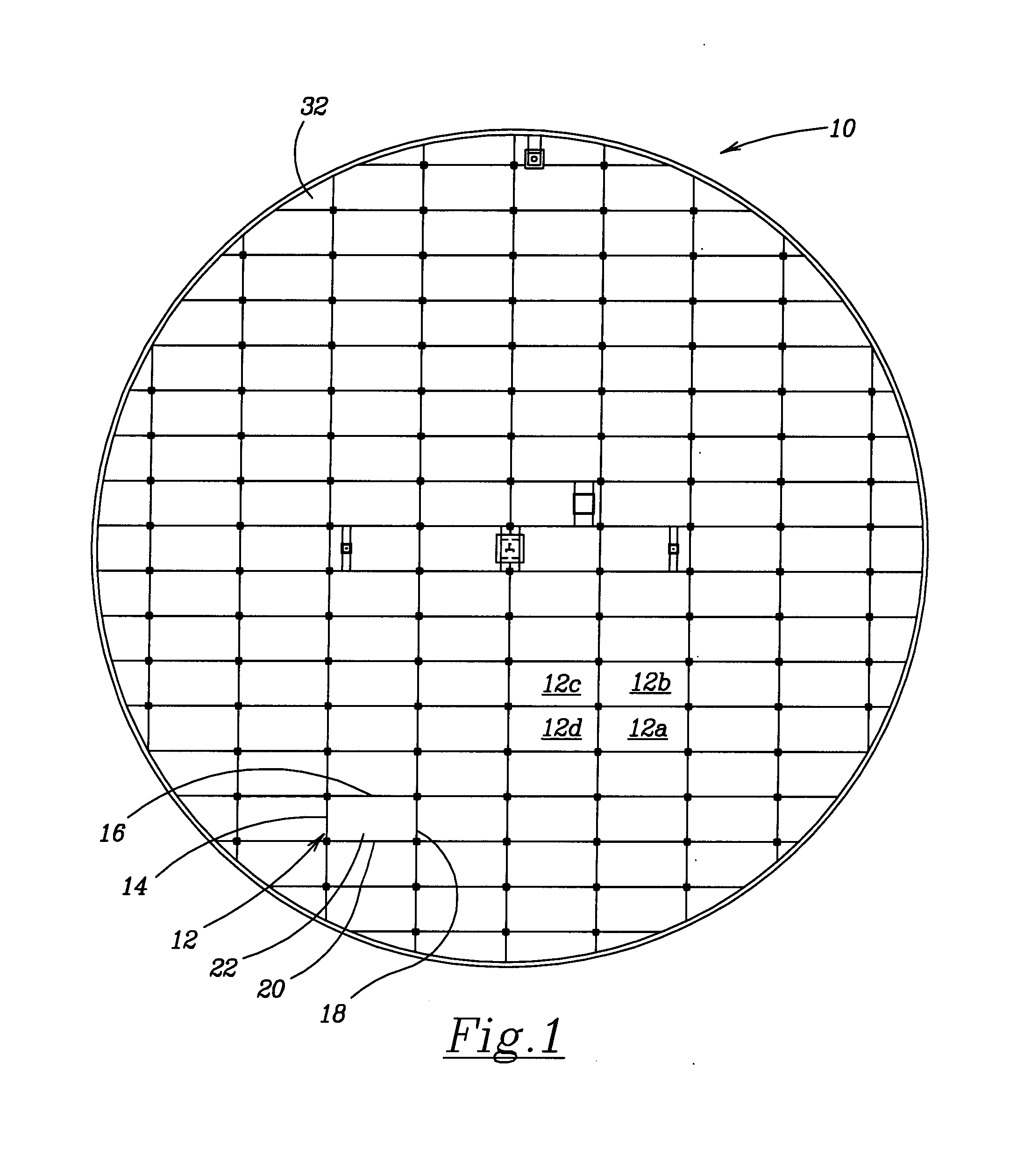

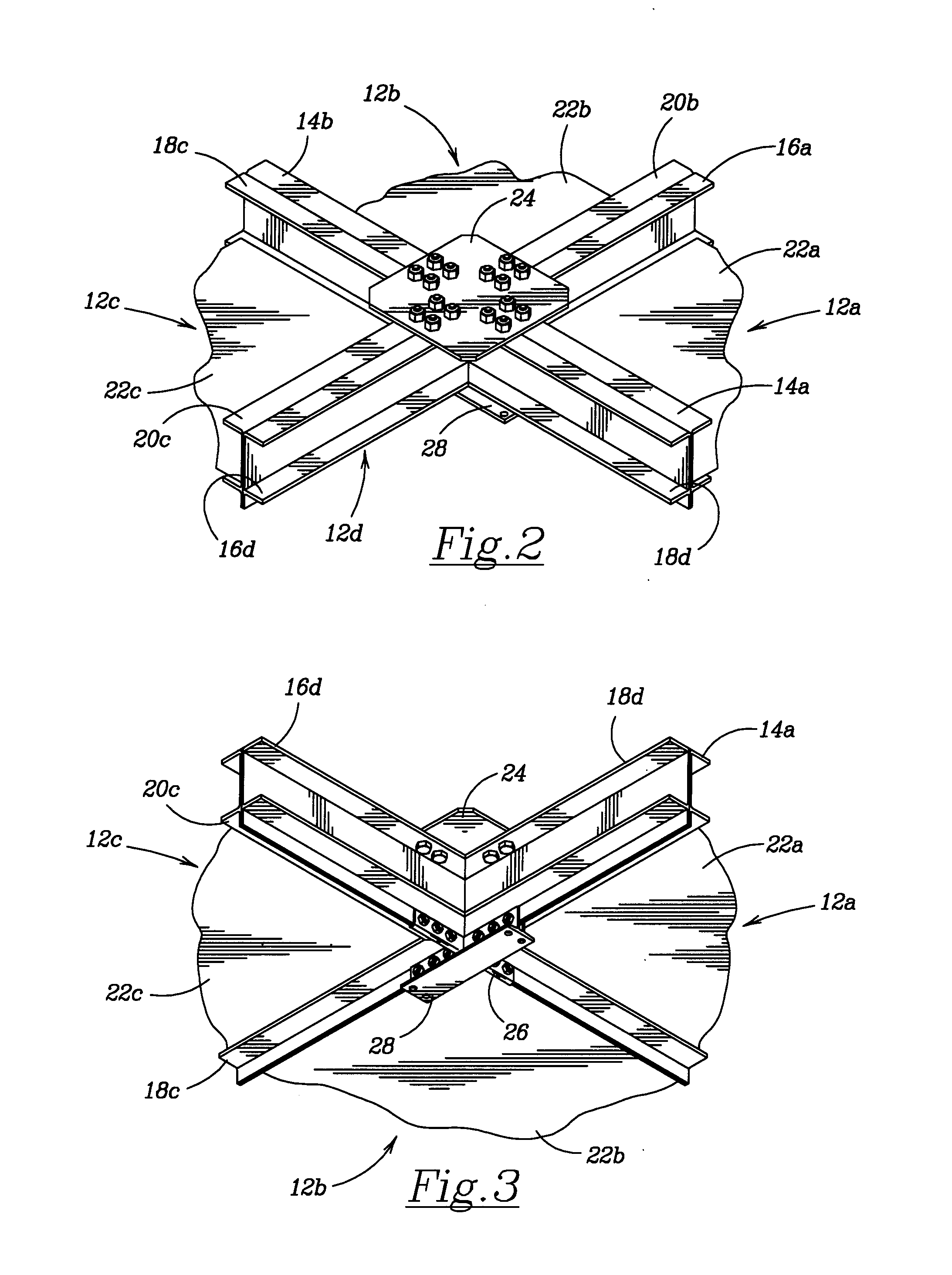

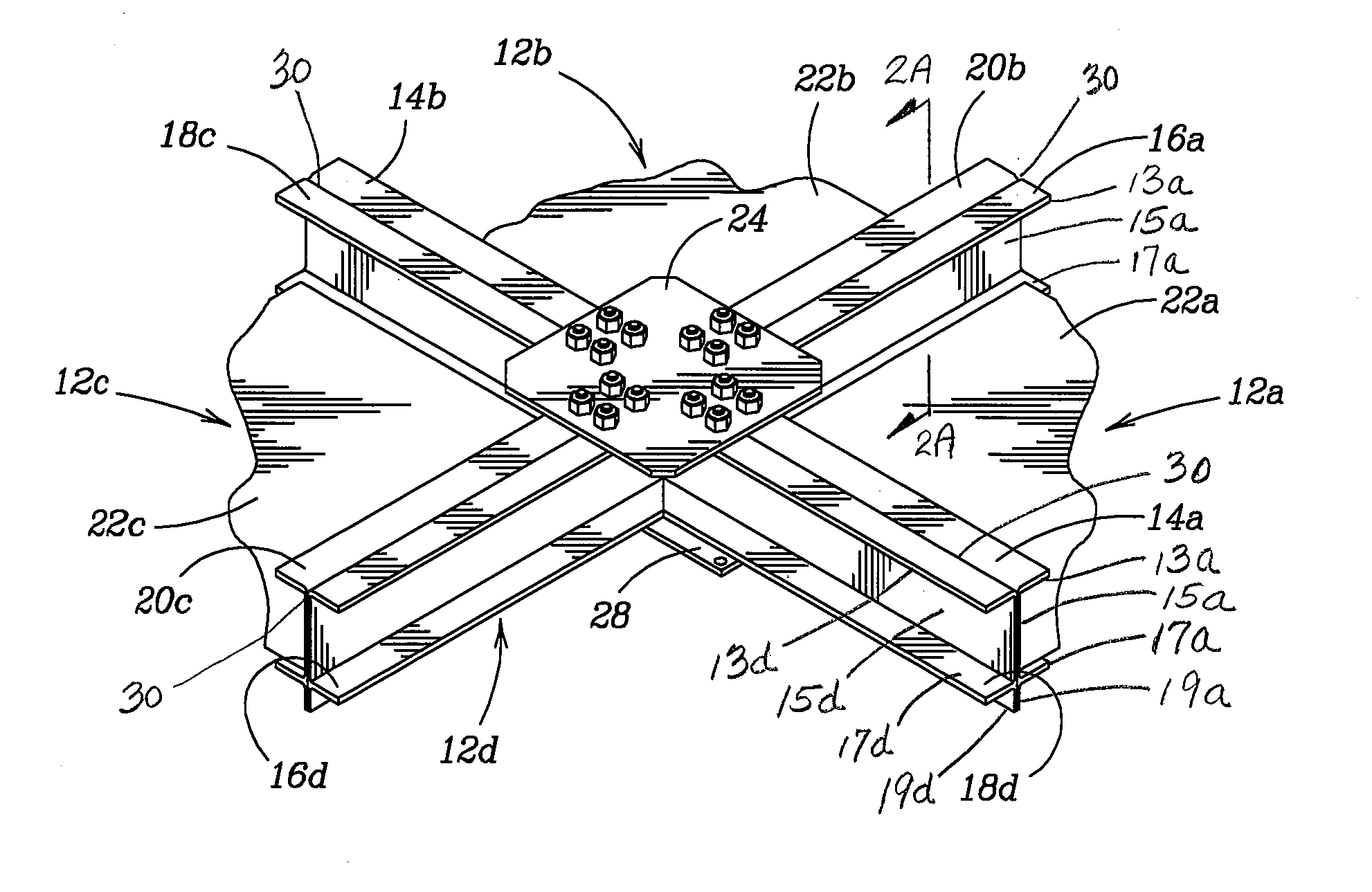

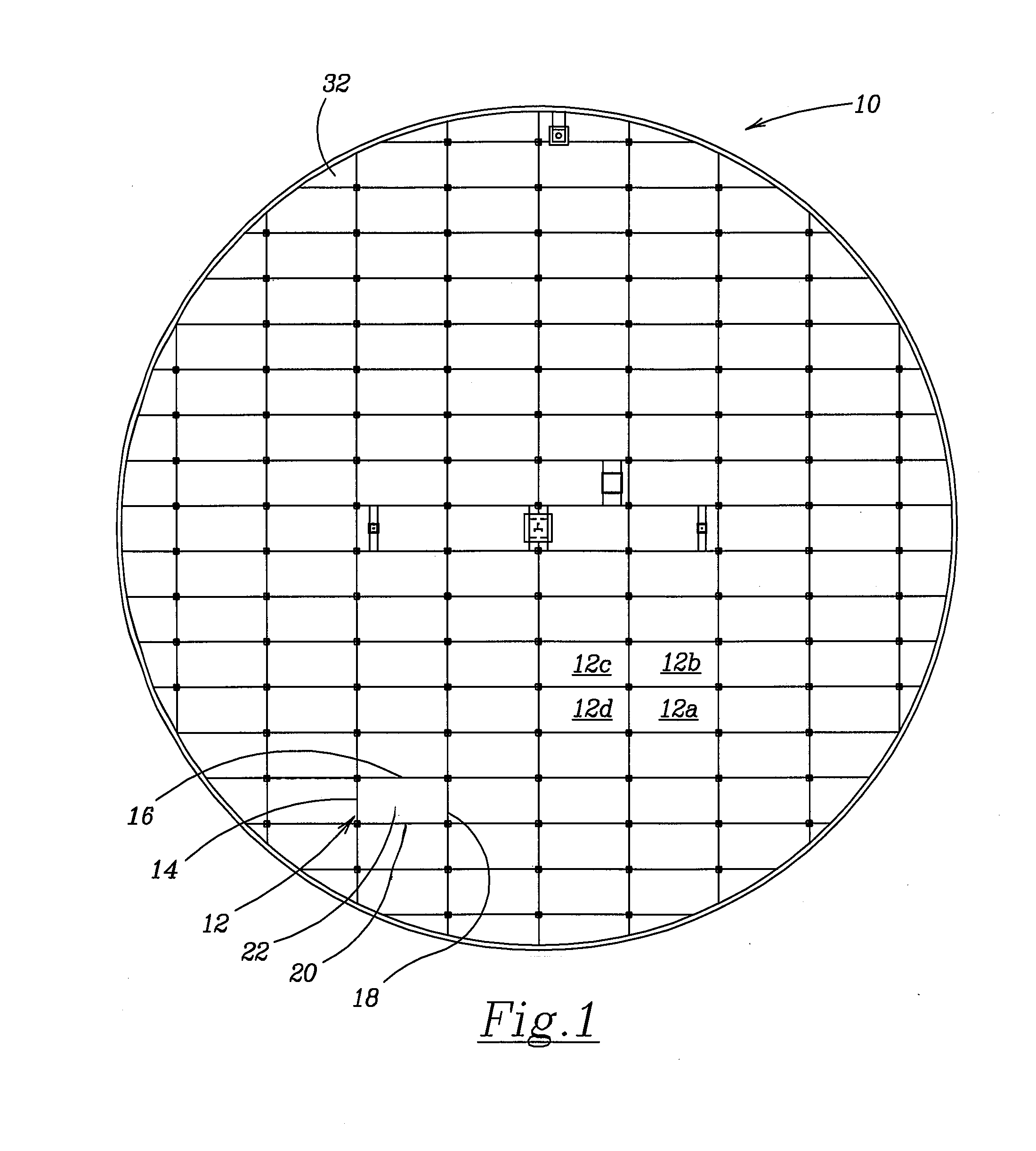

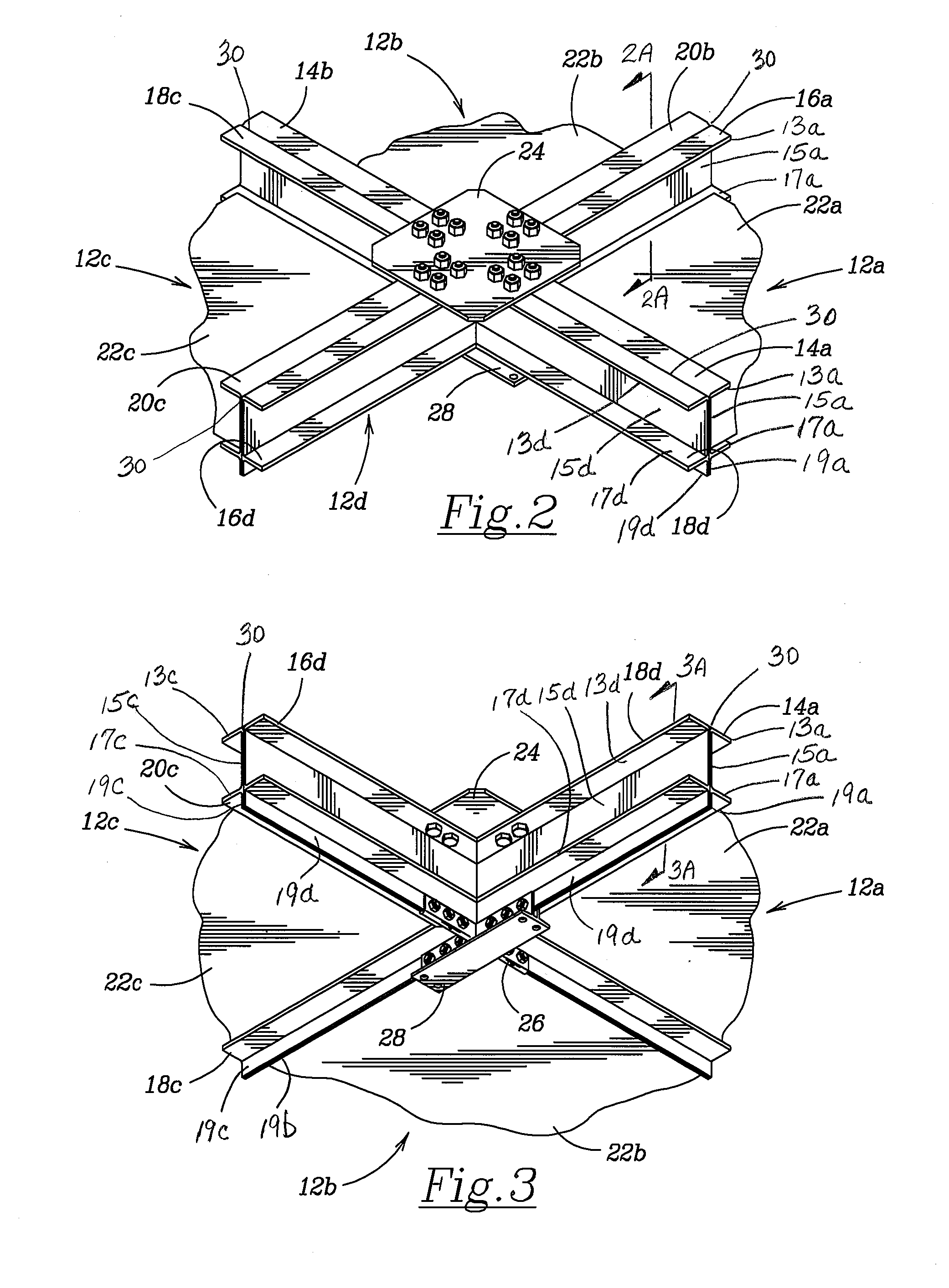

Internal Floating Roof for Covering Fluid Bodies in Storage Tanks

InactiveUS20130327773A1Lower potentialSuitable physical propertyLarge containersLiquid storage tankEngineering

An internal floating roof for use in large volatile or hazardous liquid storage tanks constructed of a plurality of open-top panel systems including C-shaped sidewalls having flanges extending inward along the top and bottom of the sidewall and another flange extending downward from the bottom. The panel systems are secured together using top and bottom bracket means to construct a rigid, non-flexing roof structure to contain the hazardous gases and vapors beneath the floating roof.

Owner:ROSENKRANTZ DAVID JON

Internal Floating Roof for Covering Fluid Bodies in Storage Tanks

ActiveUS20140231431A1Eliminate any potentialSuitable physical propertyLarge containersLiquid storage tankEngineering

An internal floating roof for use in large volatile or hazardous liquid storage tanks constructed of a plurality of open-top panel systems including C-shaped beams each having a vertical sidewall and flanges extending inward along the top and bottom of the beams with a bottom flange extending the vertical wall downward beyond the bottom. The panel systems are secured together using top and bottom brackets to construct a rigid, non-flexing roof structure to contain the hazardous gases and vapors beneath the floating roof without creating alternative escape pathways along the respective joints or seams between the panel systems. An additional seal in the form of a weld or resilient sealing member may be used along the joint between adjacent beams to further secure against leaking.

Owner:ROSENKRANTZ DAVID JON

Process for the manufacture of polybutylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

ActiveUS7910657B2Improved flow and mechanical propertyEfficient recyclingPlastic recyclingPolytetramethylene terephthalatePolyethylene terephthalate glycol

A process comprises depolymerizing, with 1,4-butane diol, a first polymer comprising a polyethylene terephthalate component in the presence of at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof to produce a molten mixture; and polymerizing the molten mixture under conditions sufficient to form a modified polybutylene terephthalate copolymer. The modified PBT comprises (a) at least one polyethylene terephthalate component residue, and (b) a member selected from the group consisting of (i) the at least one second polymer selected from the group consisting of polyvinyl chlorides, polyvinylidene chlorides, polyamides, polylactic acid, and combinations thereof; (ii) the at least one residue derived from the second polymer; and (iii) combinations thereof.

Owner:SHPP GLOBAL TECH BV

Single crystal diamond elements having convex surfaces and methods of its fabrication

ActiveUS8309205B2Quality improvementLow radius of curvatureLayered productsRecord information storageConvex sideCircular cone

A single crystal diamond element having a convex surface is disclosed, the convex surface including a spherical segment for which the maximum peak to valley deviation from a perfect spherical surface is less than about 5 μm. Alternatively or in addition, the RMS deviation from a perfect spherical surface may be less than about 500 nm, or the RMS roughness less than about 30 nm. A single crystal diamond element with a radius of curvature less than about 20 mm is also disclosed. In one aspect a single crystal diamond element having a conical half-angle greater than about 10° is described. The invention also provides a method for forming a rotationally symmetrical surface on a single crystal diamond element, comprising rotating the element about a first axis, applying a laser beam to the element in a direction perpendicular to the first axis, and translating the laser beam in two dimensions in a plane perpendicular to the direction of the beam. If the two-dimensional path follows the arc of a circle a spherical surface may be formed. The invention also provides improving a spherical surface on a single crystal diamond element by pressing a rapidly rotating cup onto a slowly rotating element. The element may be a lens, in particular a solid immersion lens.

Owner:ELEMENT SIX LTD

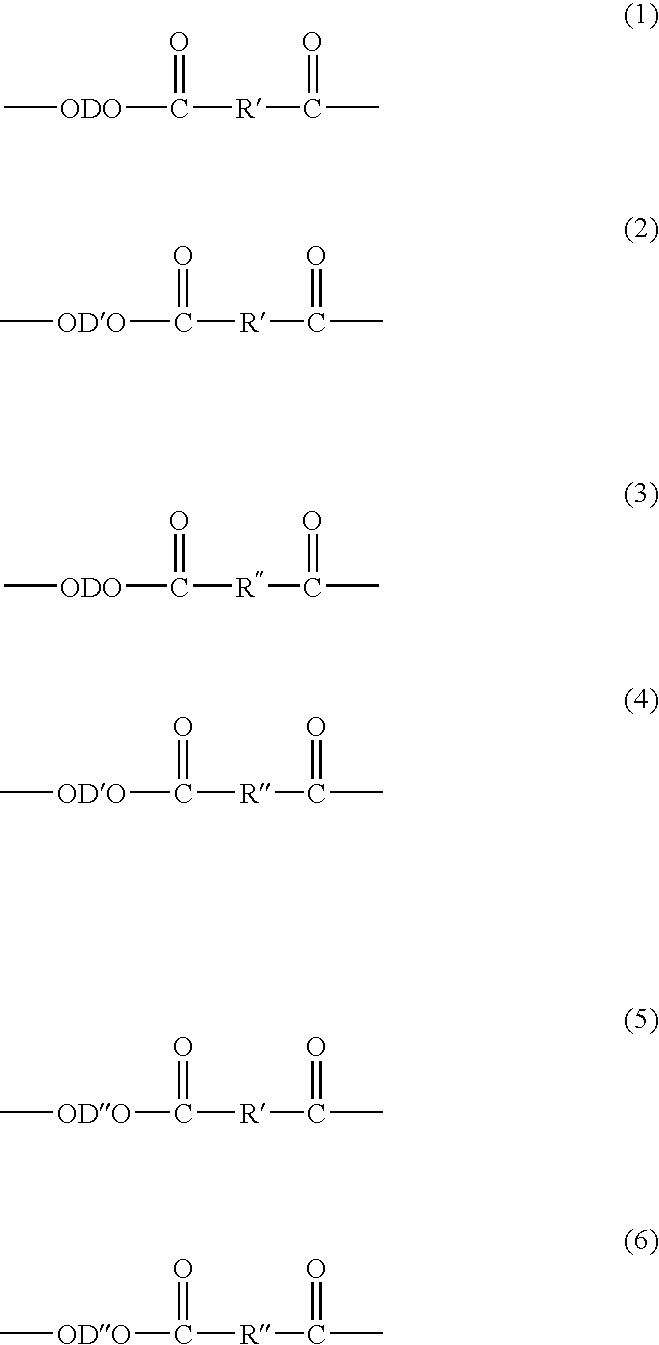

Catalyst for synthesizing polyester resin and method of manufacturing polyester resin using the same

InactiveUS20140288261A1Not to damageSuitable physical propertyOrganic-compounds/hydrides/coordination-complexes catalystsAbsorbent padsPolyester resinTitanium

A catalyst used to manufacture a biodegradable polyester resin, in particular, an organic titanium catalyst which does not contain a heavy-metal component, and a method of manufacturing a polyester resin using the same. Accordingly, the method of manufacturing a polyester resin can be useful in attaining desired physical properties without using a catalyst harmful to environments and a human body. The biodegradable resin, which can be safely used in the field of applications in which the use of harmful components is a sensitive issue without using the components harmful to environments and a human body during the manufacture of a resin, can be prepared.

Owner:S ENPOL +1

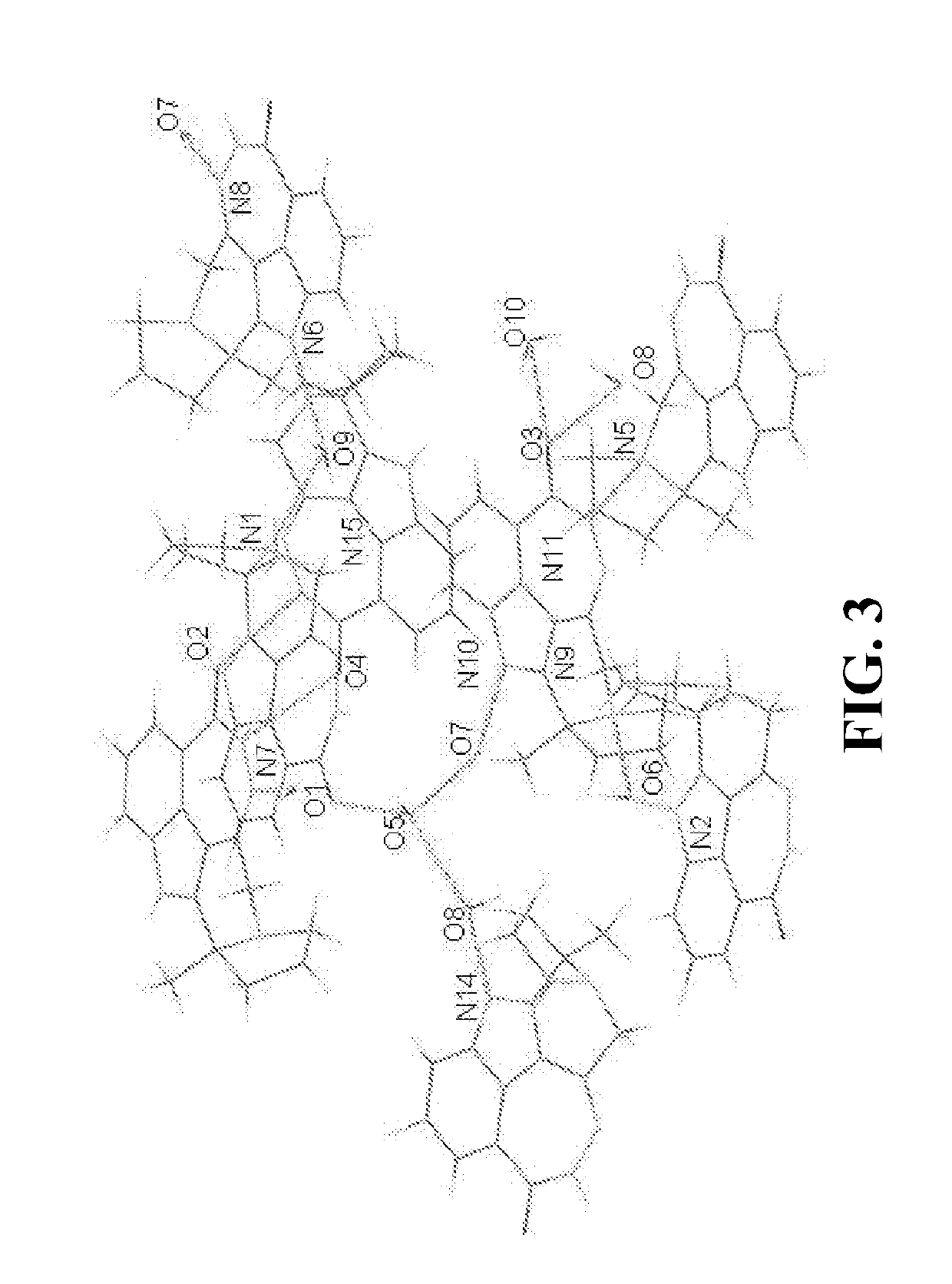

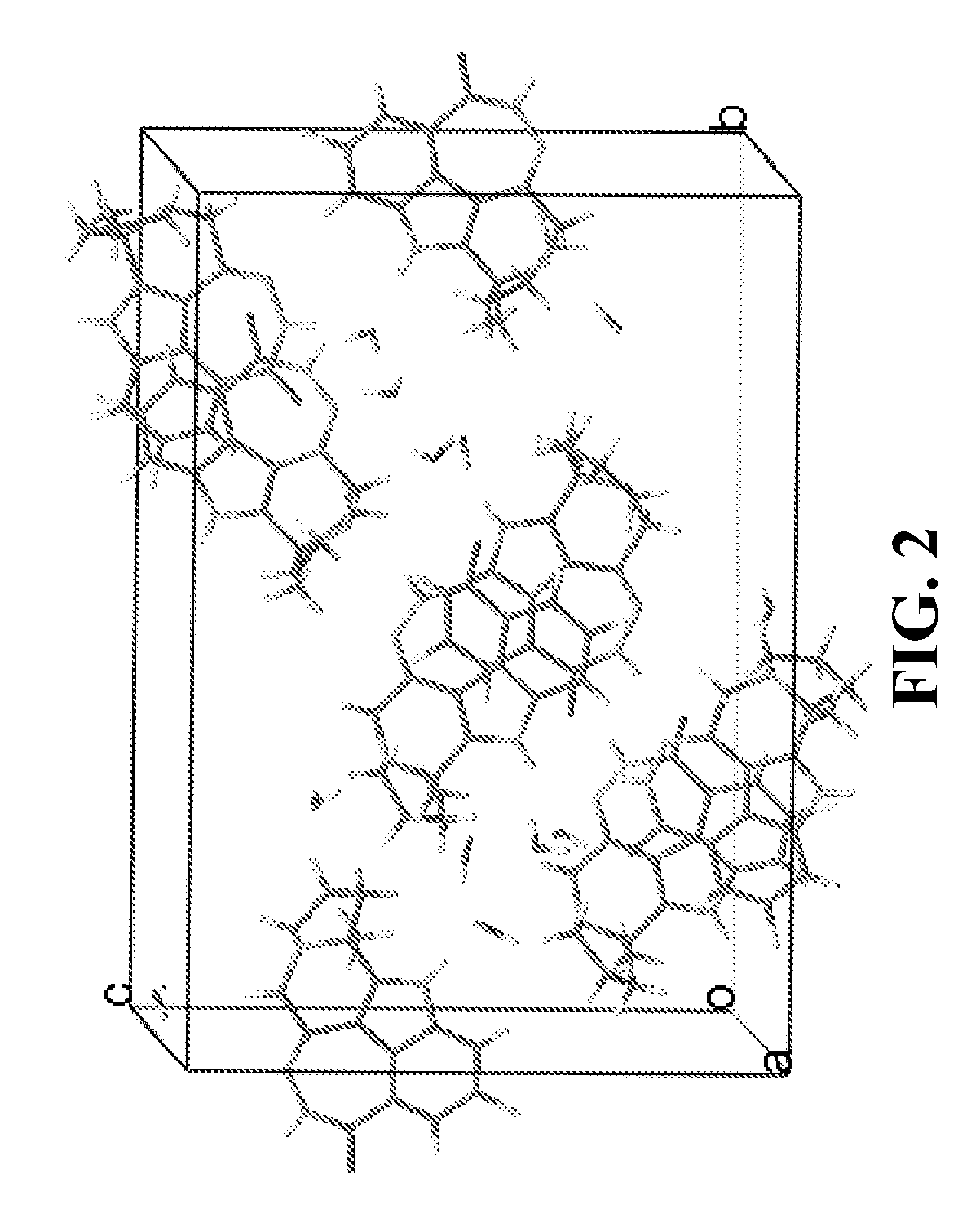

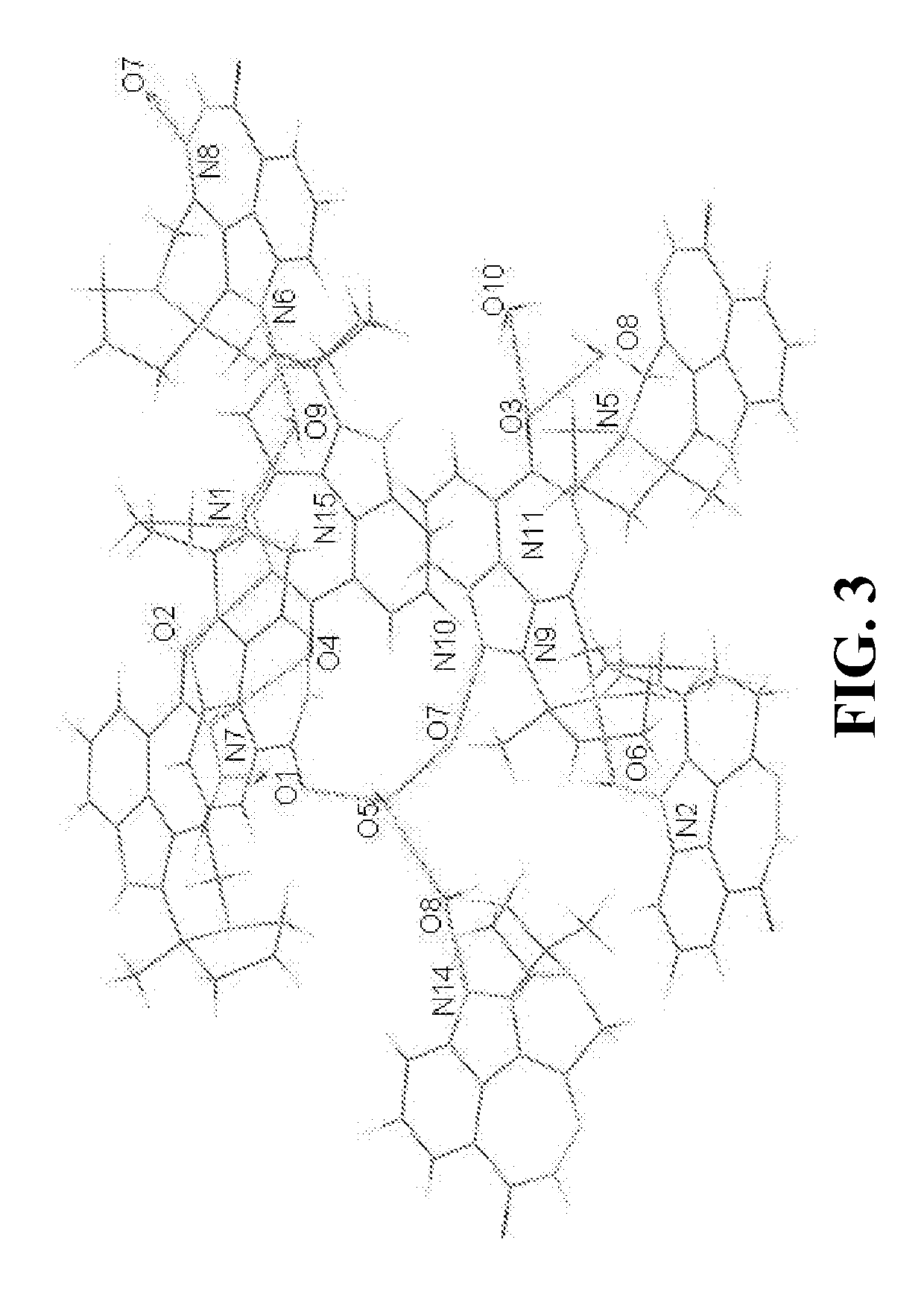

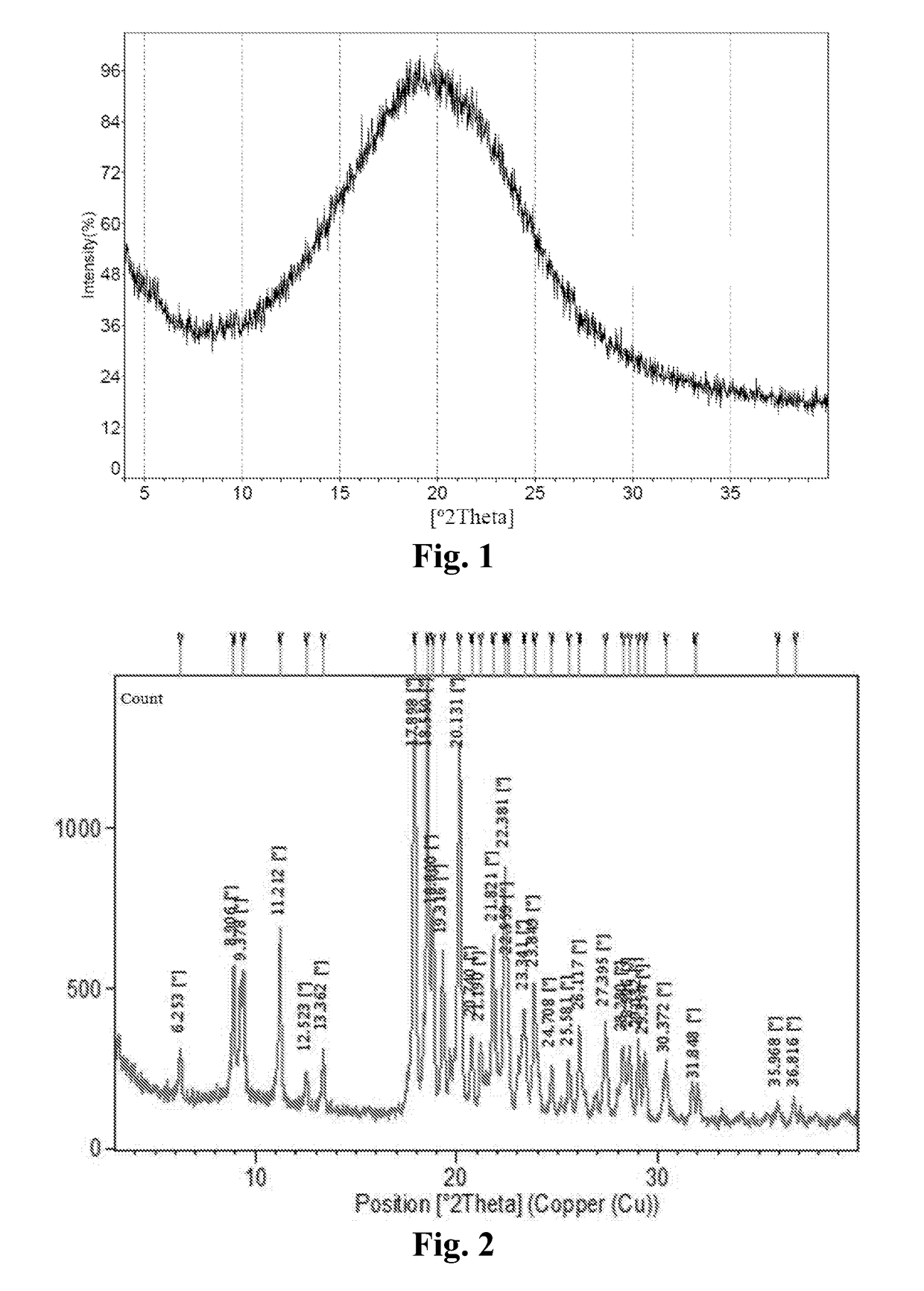

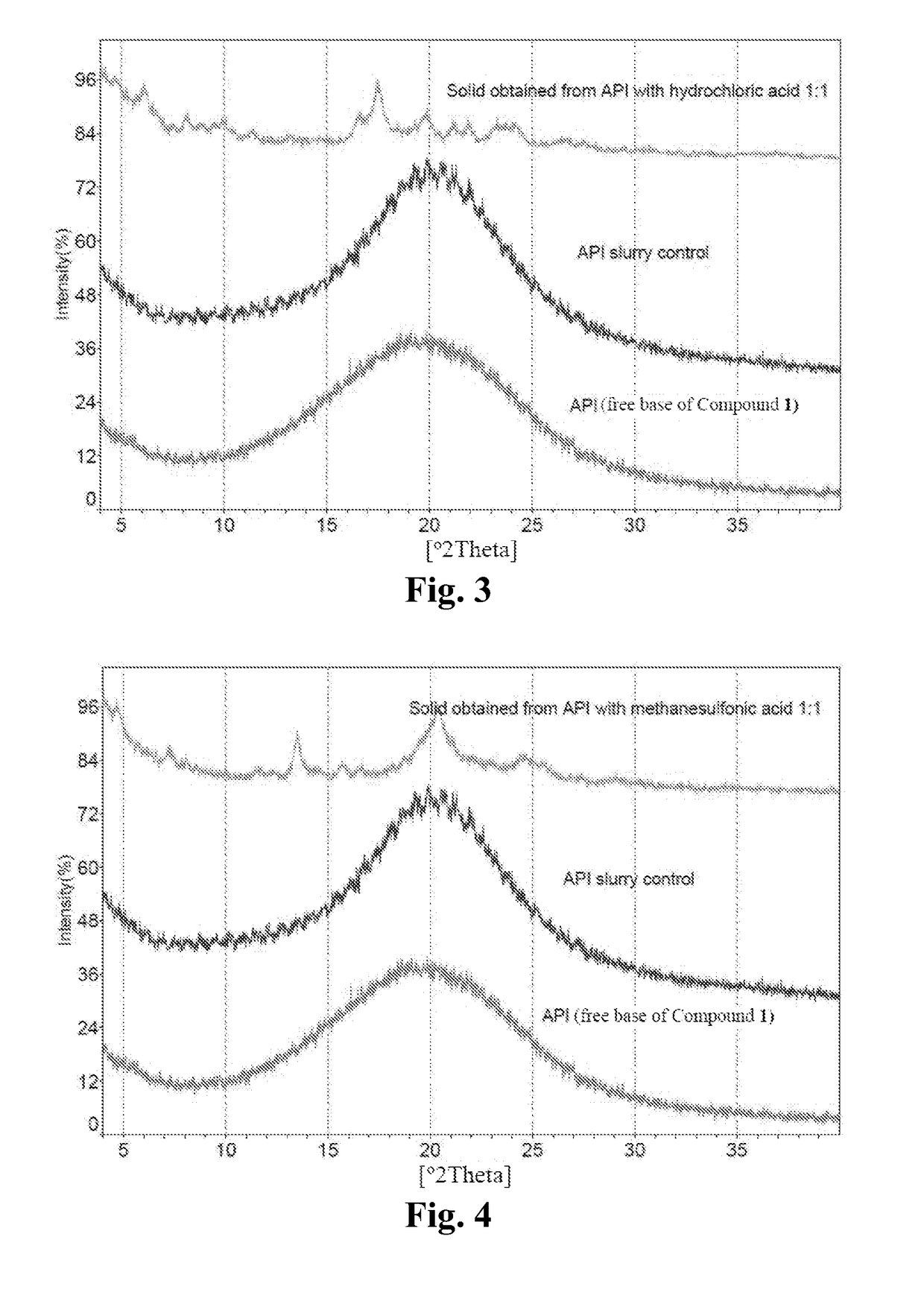

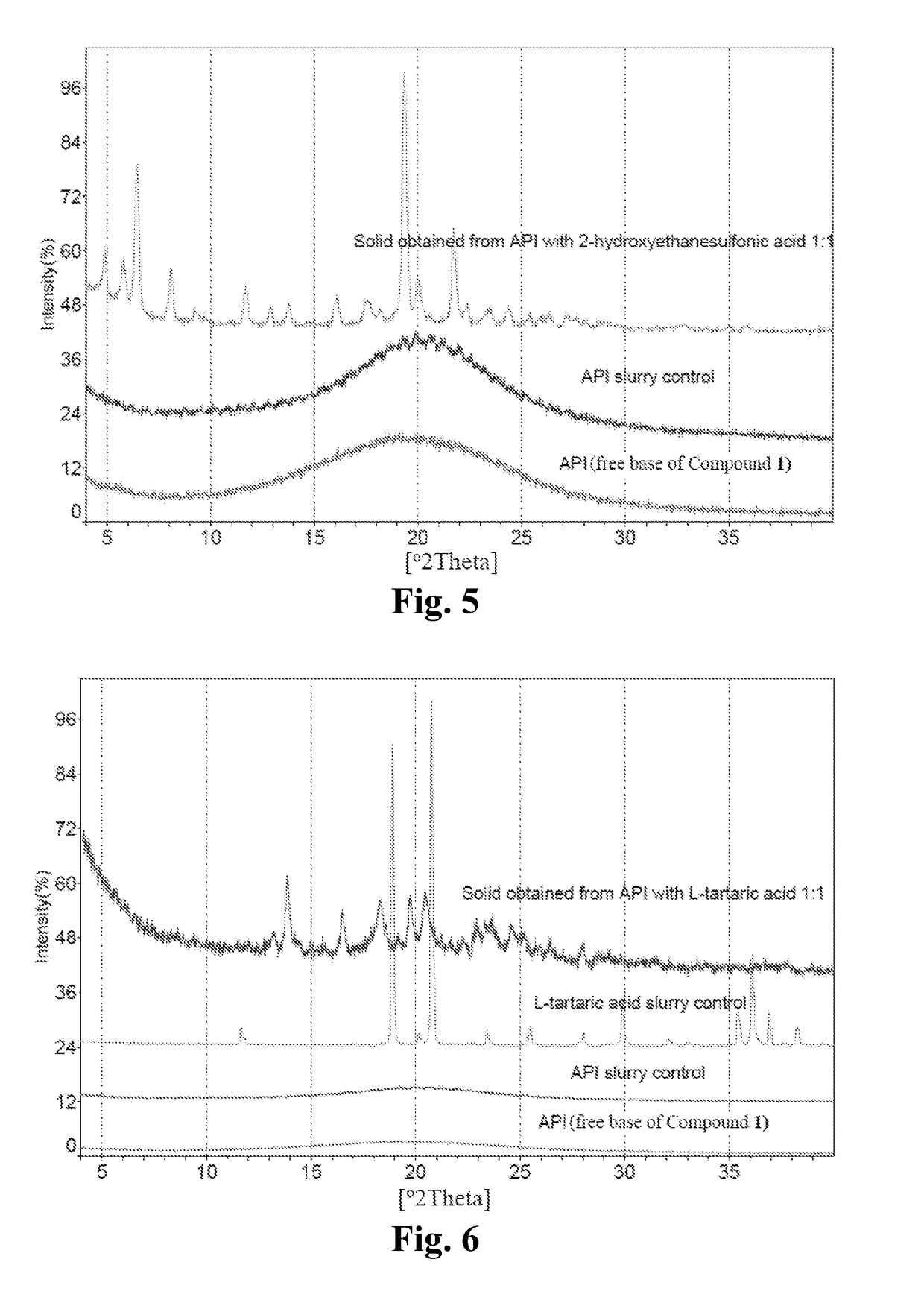

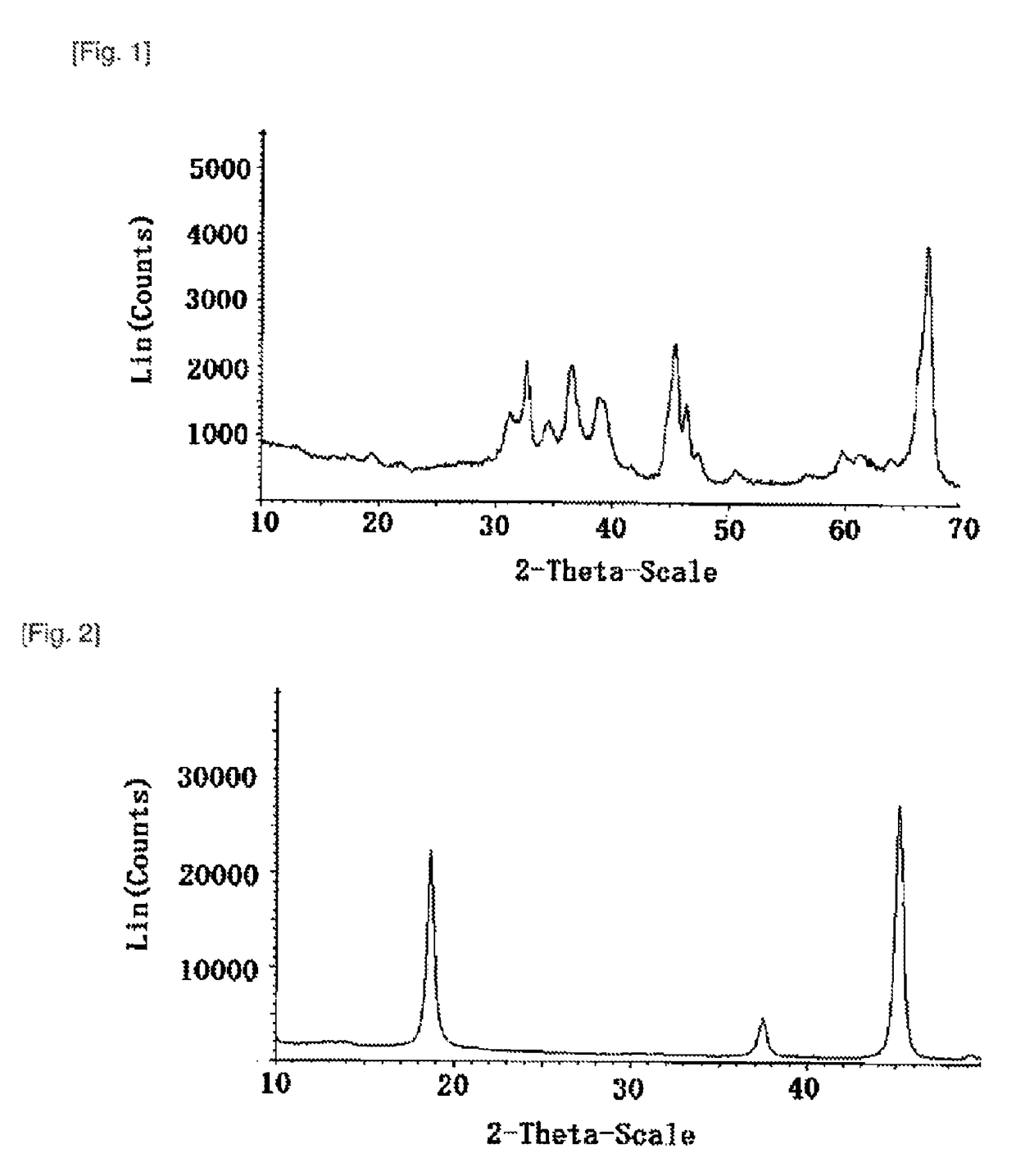

Process for preparing a parp inhibitor, crystalline forms, and uses thereof

ActiveUS20190177325A1Cost-effective and of commercial benefitReduce usageOrganic active ingredientsOrganic chemistry methodsCompound aPARP inhibitor

Provided are a process for preparing a Parp1 / 2 inhibitor, i.e., (R)-2-fluoro-10a-methyl-7,8,9,10,10a,11-hexahydro-5,6,7a,11-tetraazacyclohepta[def]cyclopenta[a]fluoren-4(5H)-one (hereinafter referred to as Compound A), crystalline forms (poly-morphs) of Compound A or hydrate or solvate thereof, methods for preparing the crystalline forms, and the use thereof.

Owner:BEIGENE SWITZERLAND GMBH

Process for preparing a PARP inhibitor, crystalline forms, and uses thereof

ActiveUS10457680B2Cost-effective and of commercial benefitReduce usageOrganic active ingredientsOrganic chemistry methodsCrystallographyCompound a

Provided are a process for preparing a Parp1 / 2 inhibitor, i.e., (R)-2-fluoro-10a-methyl-7,8,9,10,10a,11-hexahydro-5,6,7a,11-tetraazacyclohepta[def]cyclopenta[a]fluoren-4(5H)-one (hereinafter referred to as Compound A), crystalline forms (poly-morphs) of Compound A or hydrate or solvate thereof, methods for preparing the crystalline forms, and the use thereof.

Owner:BEIGENE SWITZERLAND GMBH

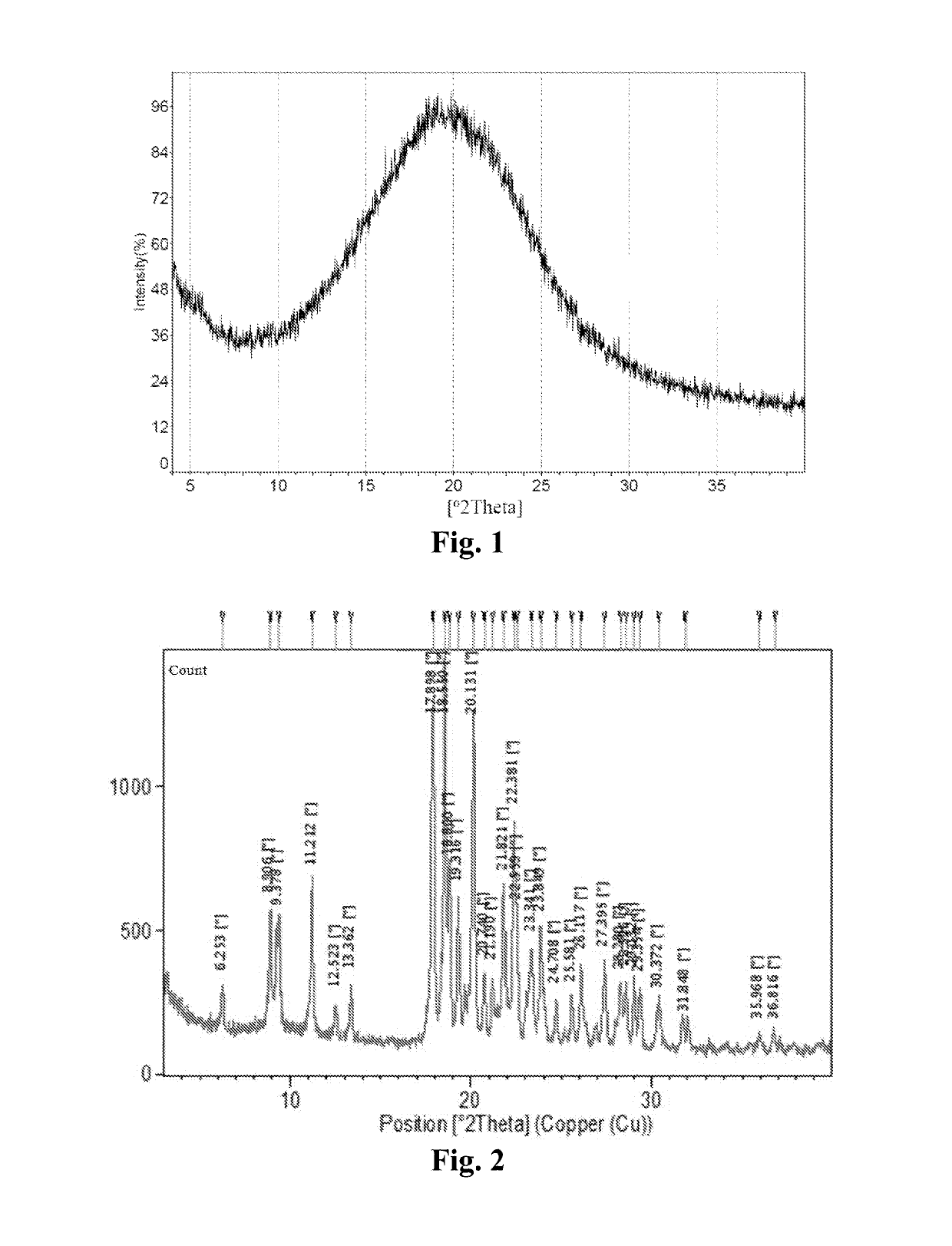

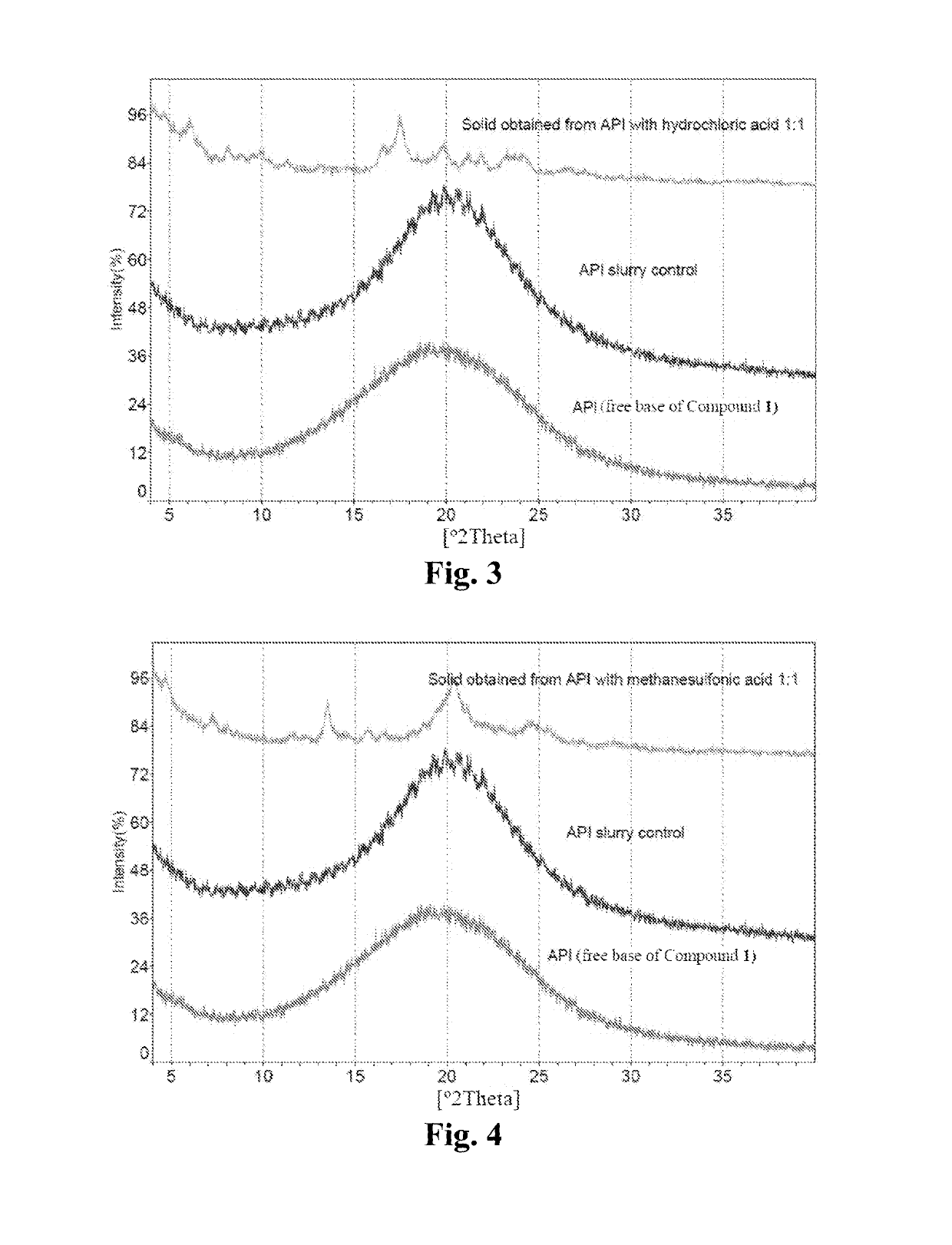

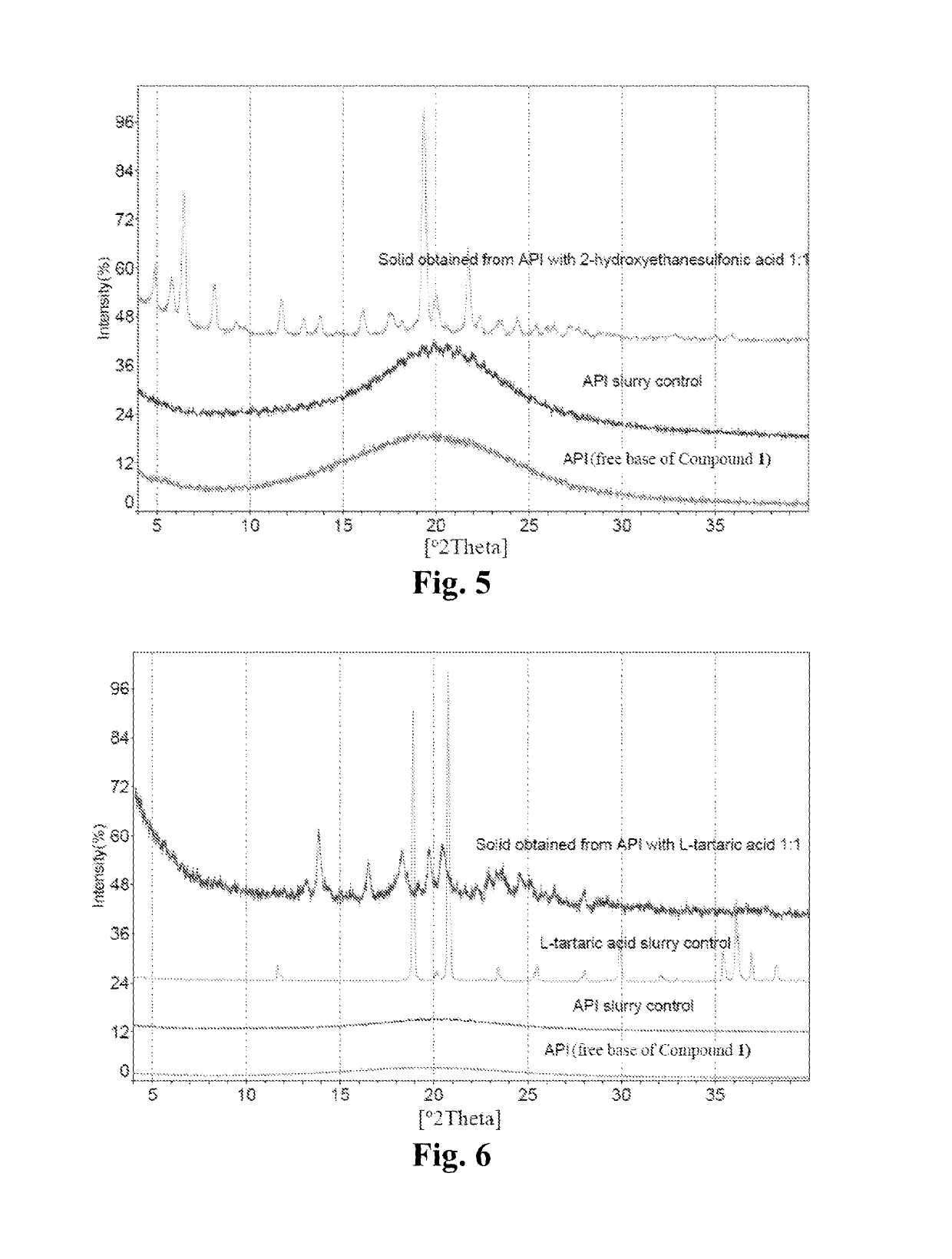

Maleate salts of a b-raf kinase inhibitor, crystalline forms, methods of preparation, and uses therefore

ActiveUS20180127412A1Good physical propertiesLarge scaleOrganic active ingredientsOrganic chemistry methodsDiseaseRaf Kinase Inhibitor

The invention relates to 5-(((1R,1aS,6bR)-1-(6-(trifluoromethyl)-1H-benzo [d] imidazol-2-yl)-1a,6b-dihydro-1H-cyclopropa [b] benzofuran-5-yl) oxy)-3,4-dihydro-1,8-naphthyridin-2 (1H)-one (Compound 1) maleate salts, in particular the sesqui-maleate salt and its crystalline forms, methods of preparation, pharmaceutical compositions, and therapeutic uses for treatment of diseases or disorders mediated by BRAF or other kinases.

Owner:BEIGENE

Maleate salts of a B-RAF kinase inhibitor, crystalline forms, methods of preparation, and uses therefore

ActiveUS10351559B2Good physical propertiesLarge scaleOrganic active ingredientsOrganic chemistry methodsRaf Kinase InhibitorDisease

The invention relates to 5-(((1R,1aS,6bR)-1-(6-(trifluoromethyl)-1H-benzo [d] imidazol-2-yl)-1a,6b-dihydro-1H-cyclopropa [b] benzofuran-5-yl) oxy)-3,4-dihydro-1, 8-naphthyridin-2 (1H)-one (Compound 1) maleate salts, in particular the sesqui-maleate salt and its crystalline forms, methods of preparation, pharmaceutical compositions, and therapeutic uses for treatment of diseases or disorders mediated by BRAF or other kinases.

Owner:BEIGENE

Wiper blade for a windscreen wiper frame

InactiveUS20190176765A1Easy to manufactureProcess environmental protectionVehicle cleaningEngineeringWindshield

The invention concerns a wiper blade (1) for a windscreen wiper frame, at feast a portion of said blade (1) comprising a material made from natural rubber and at least one additive, characterised in that said additive is at least a bio-sourced plasticiser and in that said blade comprises, as the only rubber, said natural rubber in the vulcanised state, said vulcanised rubber being obtained by vulcanising a non-functionalised natural rubber. The invention also concerns a windscreen wiper frame comprising such a wiper blade and a wiper system comprising such a windscreen wiper frame.

Owner:VALEO SYST DESSUYAGE

Production method of hemp fiber for spinning and hemp fiber for spinning

ActiveUS10415155B2Improve breathabilityImprove solubilityBiochemical treatment with enzymes/microorganismsYarnCelluloseCellulose degradation

A production method of hemp fiber for spinning, the method including: an immersion treatment process of immersing raw hemp fiber in a treatment liquid including an alkali, water, and at least one type of enzyme selected from the group consisting of cellulose-degrading enzymes and glycosidic bond hydrolyzing enzymes for an immersion time of from 30 minutes to 60 minutes under conditions of a temperature of from 60° C. to 100° C.; a water-washing process of washing the immersion treated hemp fiber with water; and a drying process of drying the water-washed hemp fiber.

Owner:AVEX GROUP +1

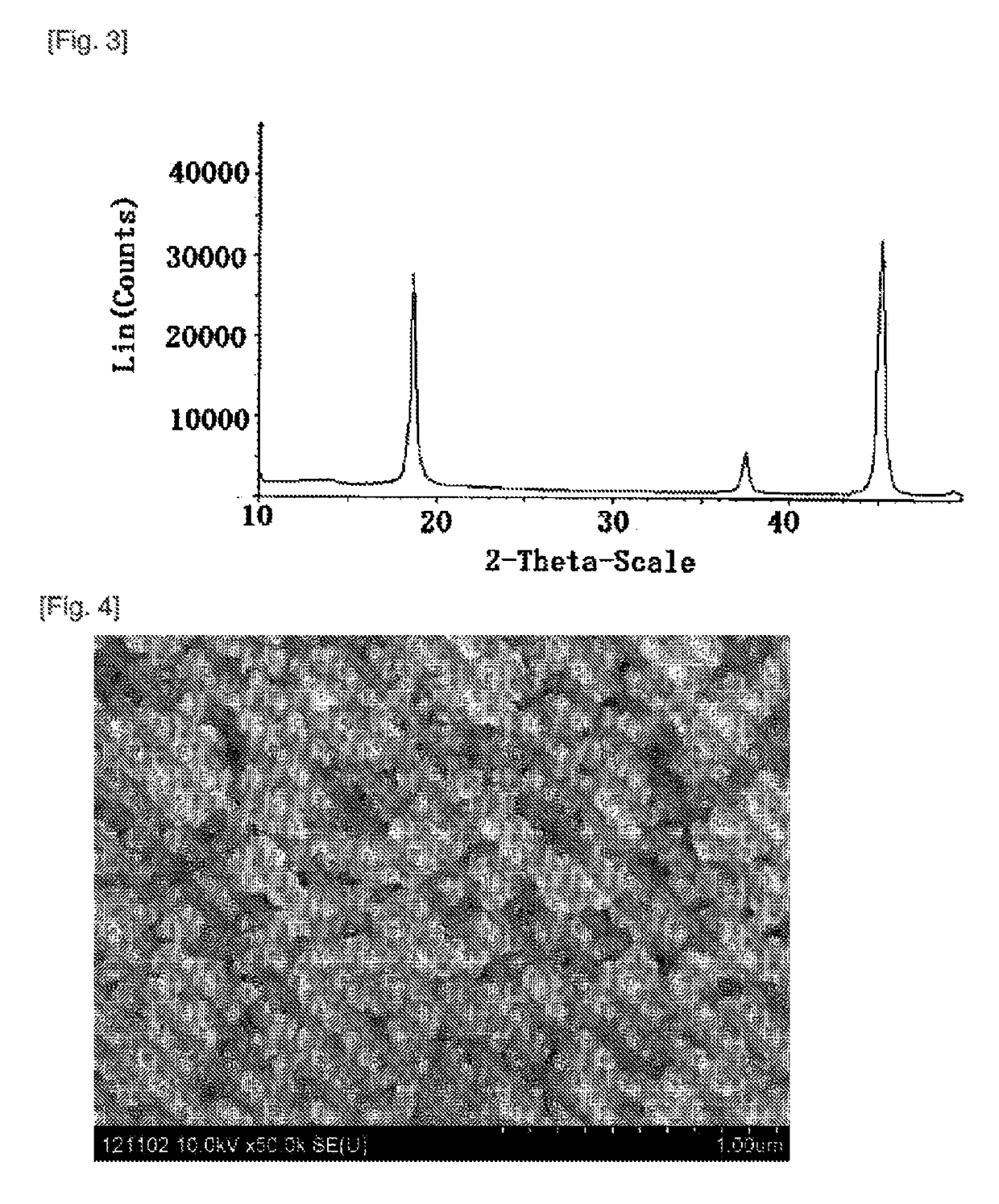

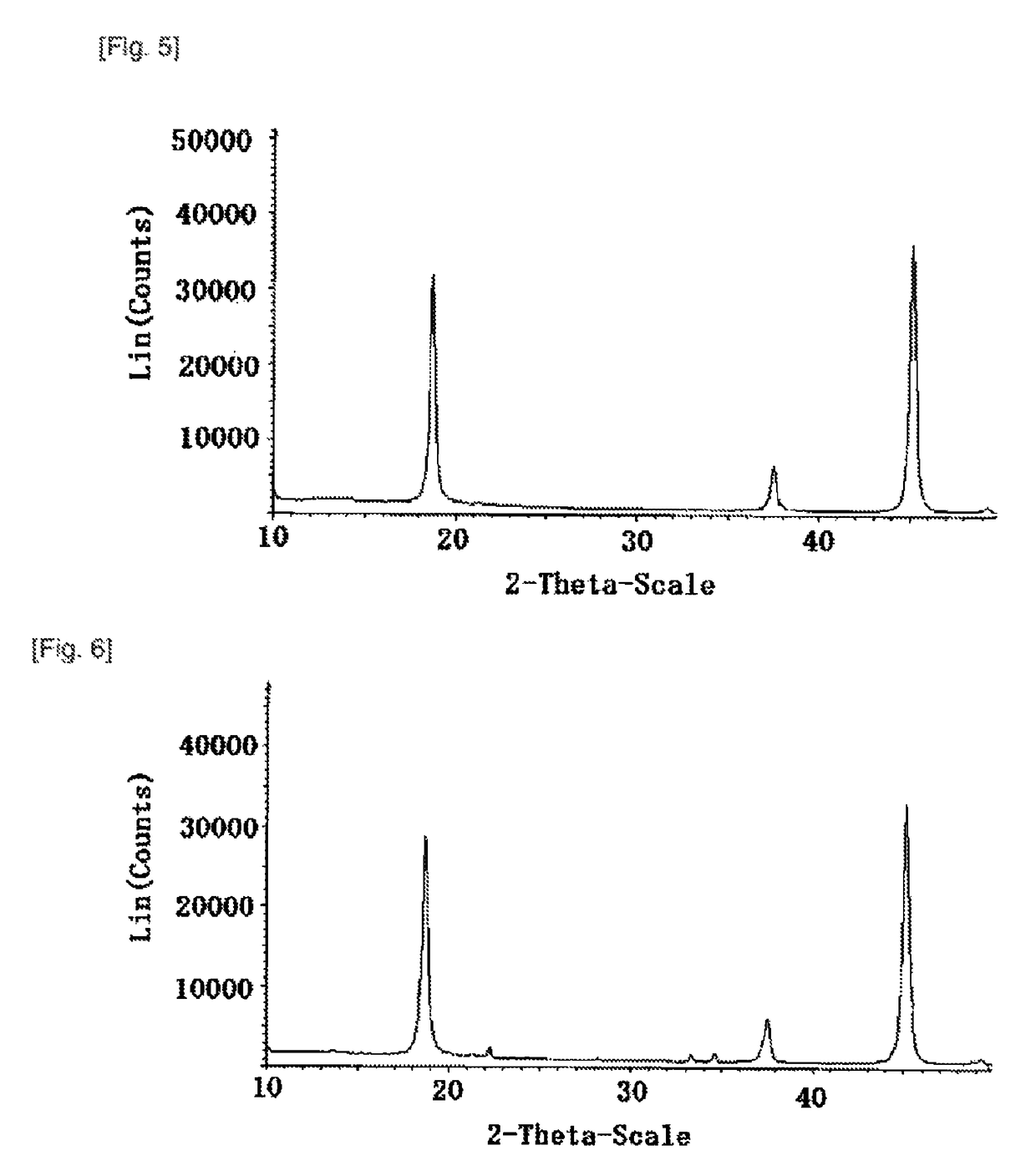

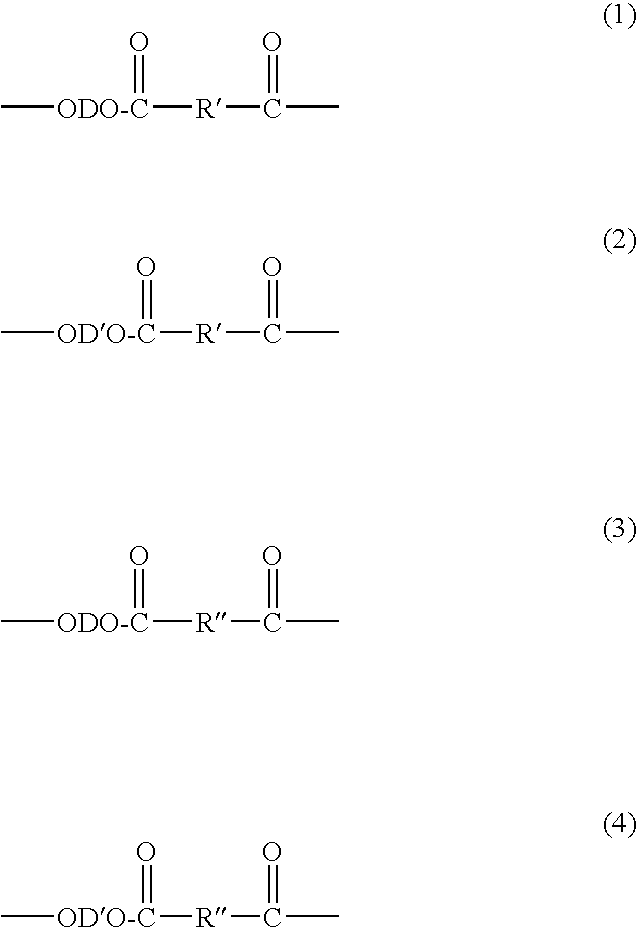

Method for producing α-lithium aluminate

InactiveUS9731977B2Improve thermal stabilitySuitable physical propertyElectrolyte holding meansFused electrolyte fuel cellsLithium carbonateLithium aluminate

The purpose of the present invention is to provide an industrially advantageous method for producing α-lithium aluminate which has physical properties that are suitable for use as an electrolyte holding plate of a MCFC having excellent thermal stability, even if the α-lithium aluminate is a fine material having a BET specific surface area of 10 m2 / g or higher in particular. Provided is a method for producing α-lithium aluminate characterized by subjecting a mixture (a), which is obtained by mixing transitional alumina and lithium carbonate at an Al / Li molar ratio of 0.95-1.01, to a first firing reaction so as to obtain a fired product, and subjecting a mixture (b), which is obtained by adding an aluminum compound to the obtained fired product at quantities whereby the molar ratio of aluminum atoms in the aluminum compound relative to lithium atoms in the fired product (Al / Li) is 0.001-0.05, to a second firing reaction.

Owner:NIPPON CHECMICAL IND CO LTD

Poly(butylene terephthalate) compositions, methods of manufacture, and articles thereof

InactiveUS20100168321A1Improved flow and mechanical propertyImprove protectionEmulsion paintsPolyethylene terephthalatePolyvinyl chloride

A composition comprises, based on the total weight of the composition:from 5 to 90 wt. % of a modified poly(butylene terephthalate) copolymer, wherein(i) the modified poly(butylene terephthalate) copolymer is derived from a first polymer comprising a poly(ethylene terephthalate) component that is a poly(ethylene terephthalate) homopolymer, poly(ethylene terephthalate) copolymer, or combination thereof, in the presence of a second polymer that is a polyvinyl chloride, polyvinylidene chloride, polyamide, polylactic acid, or combination thereof, and(ii) the modified poly(butylene terephthalate) copolymer comprises (a) at least one poly(ethylene terephthalate) component residue, and (b) a member selected from the group consisting of(a) at least one second polymer that is a polyvinyl chloride, polyvinylidene chloride, polyamide, polylactic acid, or combination thereof,(b) at least one residue derived from the second polymer, and(c) combinations thereof;optionally, more than 0 wt. % of a filler component; andoptionally, from 0 to 5 wt. % of at least one additive.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Process for the manufacture of polycyclohexane dimethylene terephthalate copolymers from polyethylene terephthalate, and compositions and articles thereof

InactiveUS20100168328A1Improved flow and mechanical propertyEfficient recyclingCyclohexanedimethanolPolymer science

A process comprises heating at a first temperature under an inert atmosphere and at a first pressure of at least 101 kPa a cyclohexanedimethanol, and a polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers, to form a molten mixture; and heating the molten mixture with agitation at a second temperature higher than the first temperature and a second, subatmospheric pressure for a time and under conditions effective to form a modified polycyclohexane dimethylene terephthalate copolymer comprising at least one residue derived from the polyethylene terephthalate component.

Owner:SABIC INNOVATIVE PLASTICS IP BV

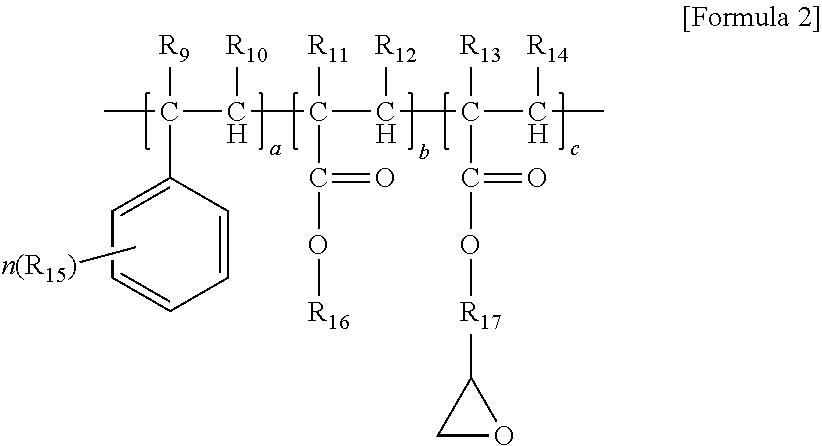

Thermoplastic resin composition, method of preparing the same, and molded part manufactured using the same

ActiveUS10647847B2Improve mechanical propertiesHigh suppression characteristicsCyanide compoundPolymer science

The present invention relates to a thermoplastic resin composition, a method of preparing the same, and a molded part manufactured using the same. More specifically, the present invention provides a thermoplastic resin composition having excellent mechanical properties, such as tensile strength and impact strength, and weather resistance while having low gloss characteristics, a method of preparing the same, and a molded part manufactured using the same. According to the present invention, the thermoplastic resin composition includes an ASA graft copolymer having a core-shell structure having an average particle diameter of 0.05 to 1 μm, an aromatic vinyl compound-vinyl cyanide compound copolymer, and an epoxy group-containing copolymer having a weight average molecular weight of 2,000 to 8,000 g / mol in specific amounts.

Owner:LG CHEM LTD

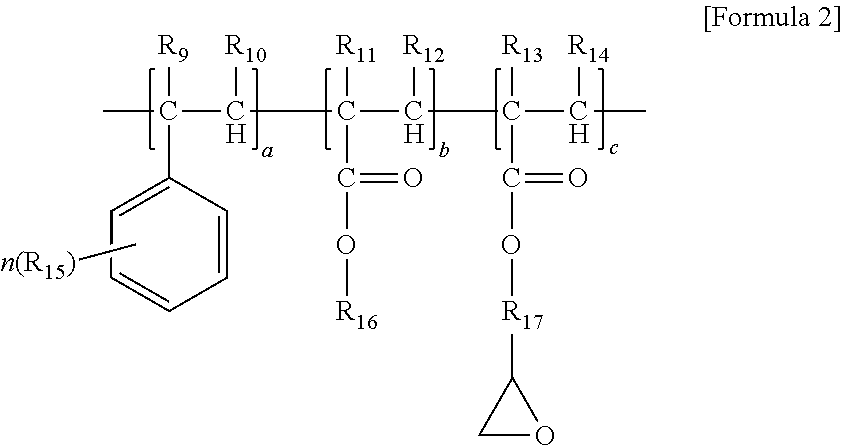

Method for measuring peeling stability of release film and release film laminate

ActiveUS10562265B2Easy to peelEfficiency may be securedFilm/foil adhesivesAdhesive articlesPolymer scienceUltimate tensile strength

Owner:LG CHEM LTD

Method for manufacturing polyimide-based film and polyimide-based film manufactured thereby

ActiveUS20200353668A1Excellent bending characteristicExcellent surface hardness and scratch resistancePhotovoltaic energy generationFlexible electronicsThin membrane

The present invention relates to a method for manufacturing a polyimide-based film and a polyimide-based film manufactured thereby and, particularly, to a method for manufacturing a polyimide-based film and a polyimide-based film manufactured thereby, wherein the polyimide-based film is useful as a cover substrate for a flexible electronic device since flexure characteristics thereof, represented by yield elongation, are excellent.

Owner:KOLON IND INC

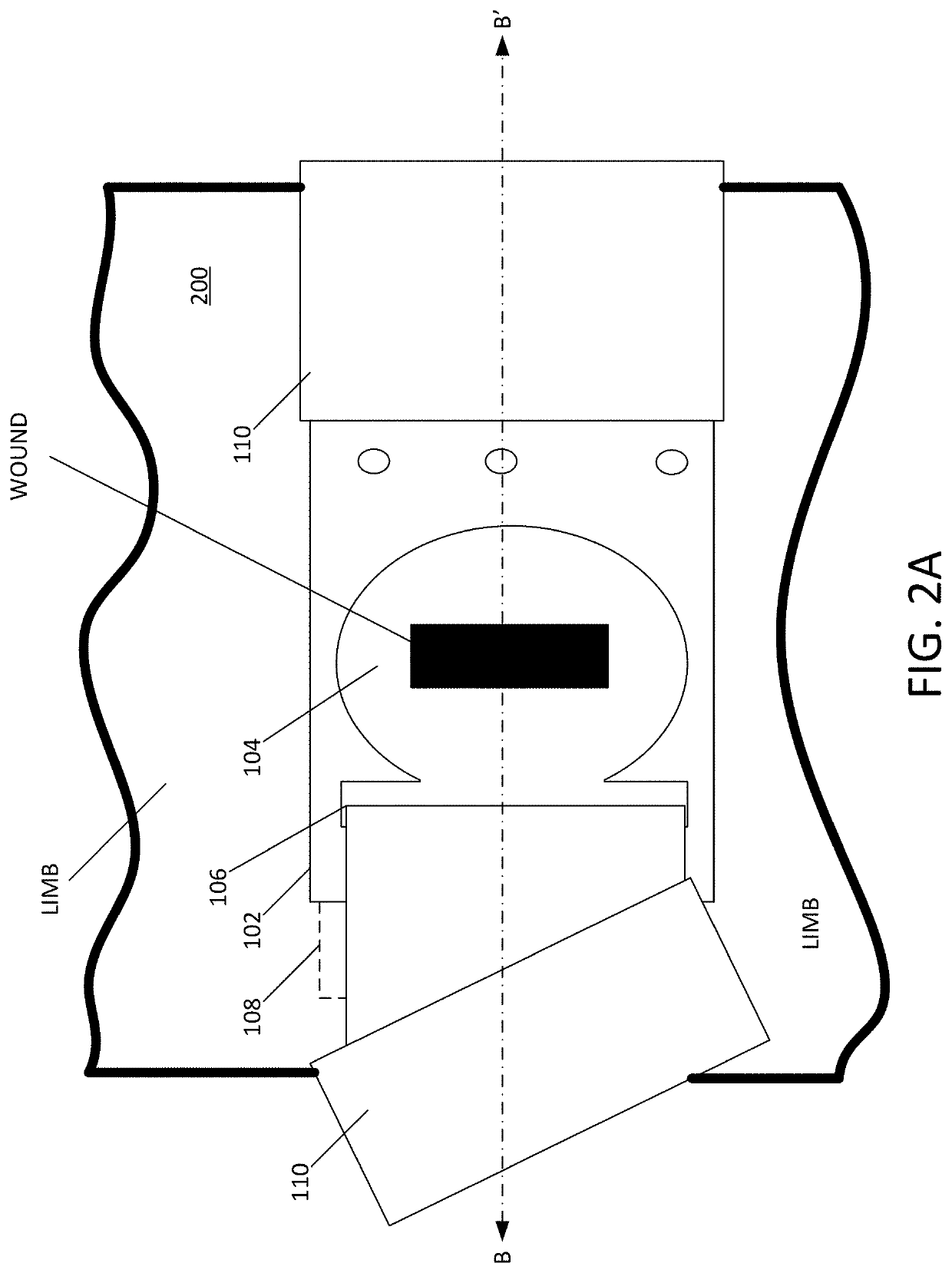

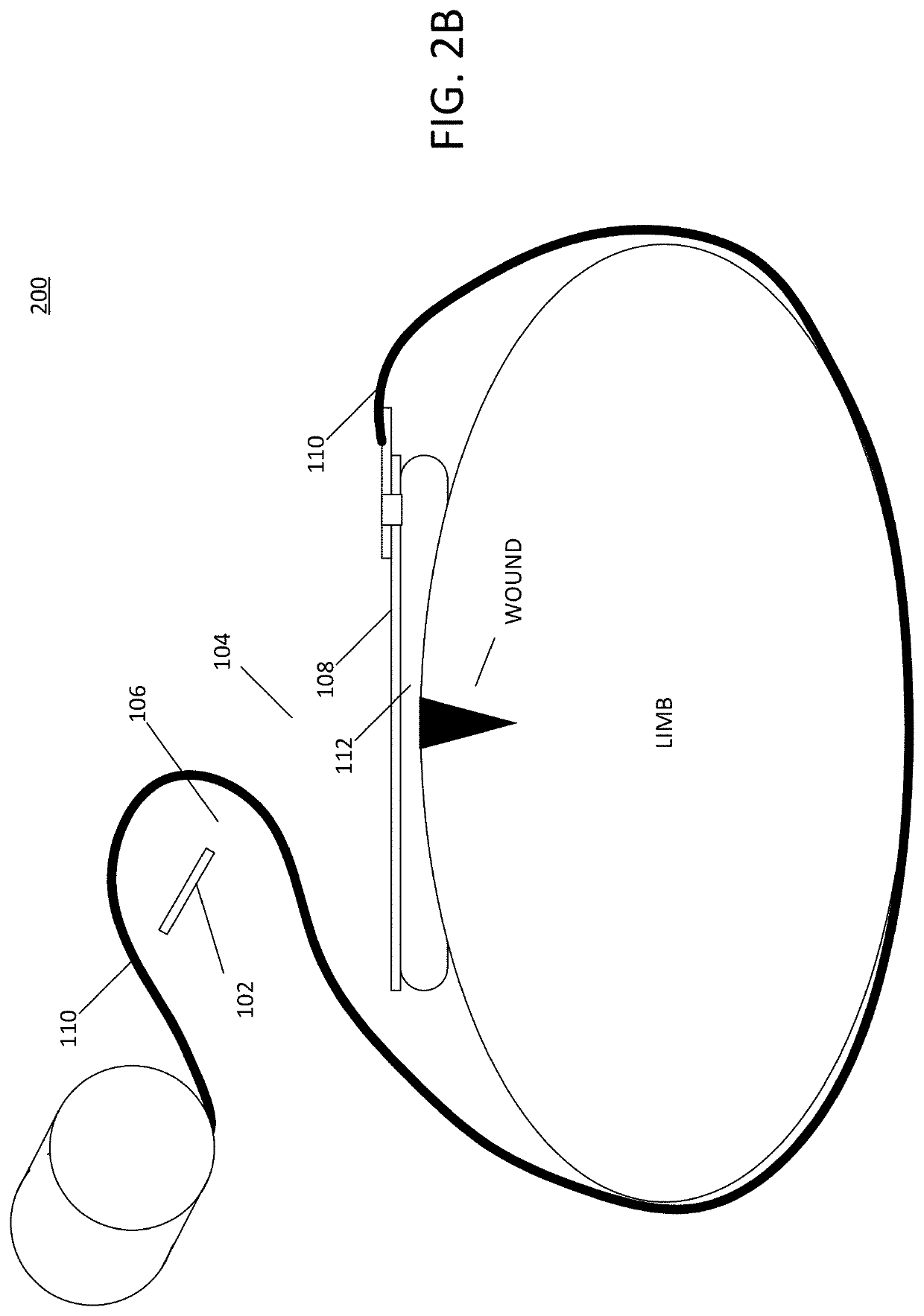

Enhanced trauma bandage

InactiveUS20220110798A1Avoid strainHigh bonding strengthAdhesive dressingsEngineeringElastic bandage

Disclosed is an enhanced trauma bandage suitable for use as a compression dressing, the structure including an elastic bandage roll, a pass-through structure attached to one end of the elastic bandage roll, a pass-through structure having both an opening and a bandage guide structure at one edge of the opening; a support surface on a lower surface of the pass-through structure; and an absorbent pad removably attached to the lower surface of the pass-through structure.

Owner:OWEN JONATHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com