Patents

Literature

86results about "Discharge tube liquid electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

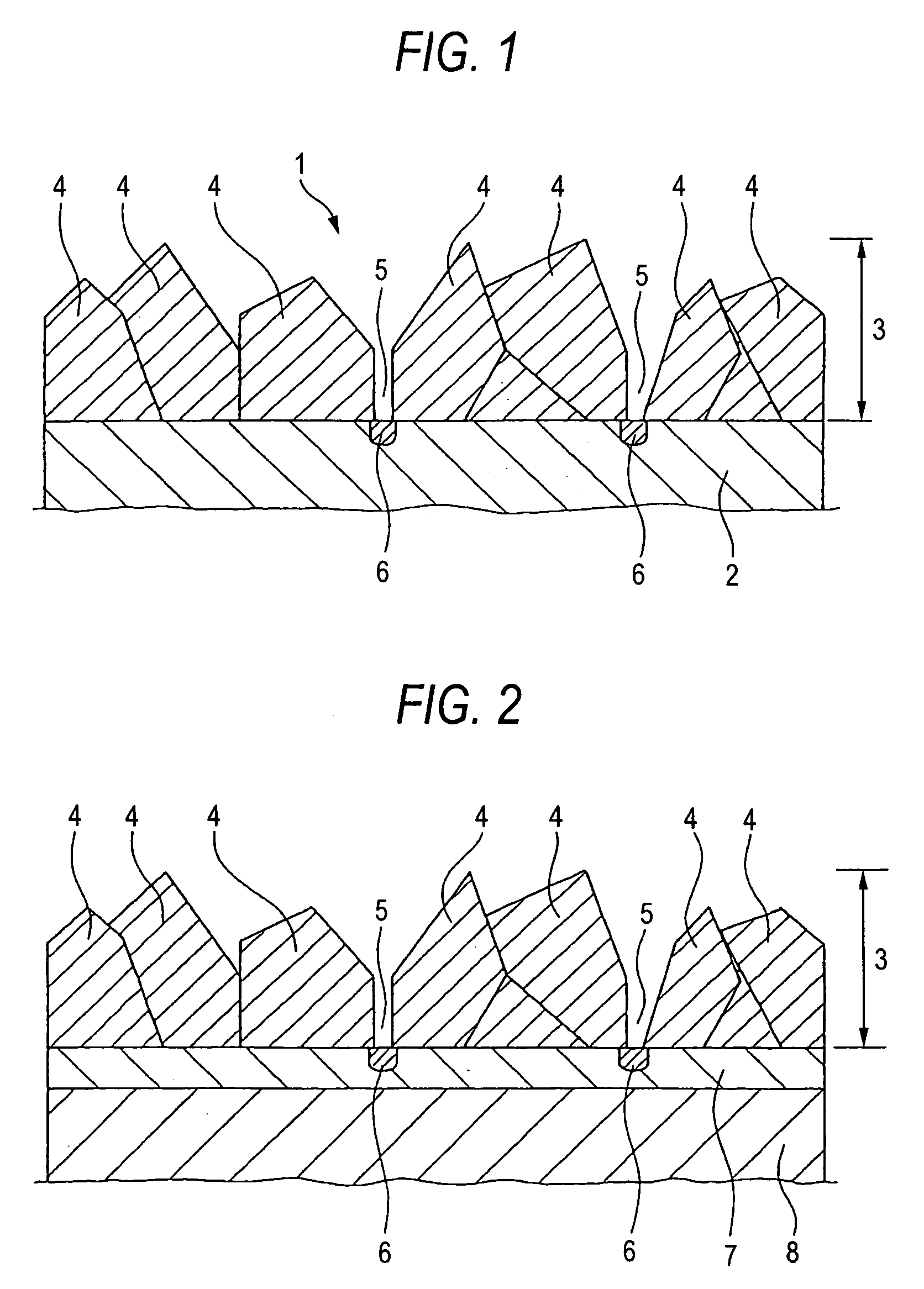

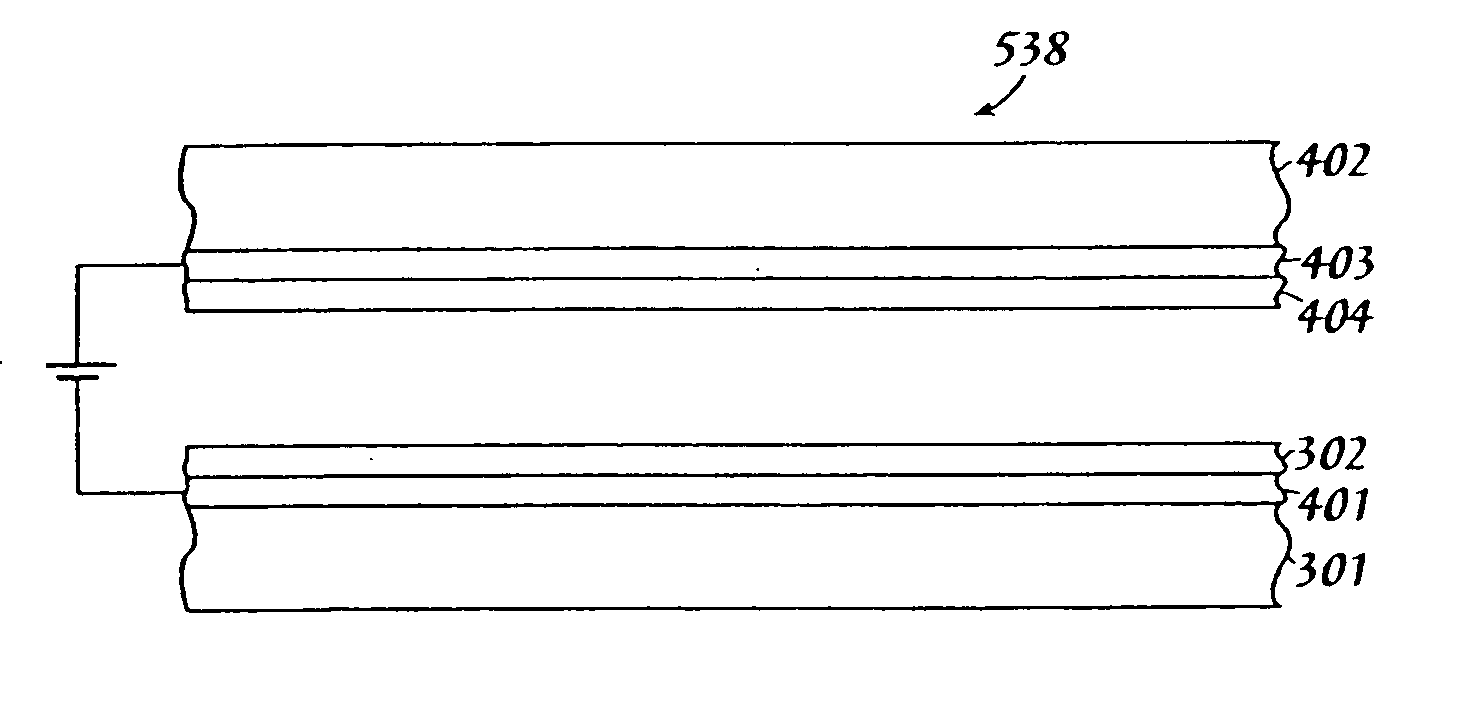

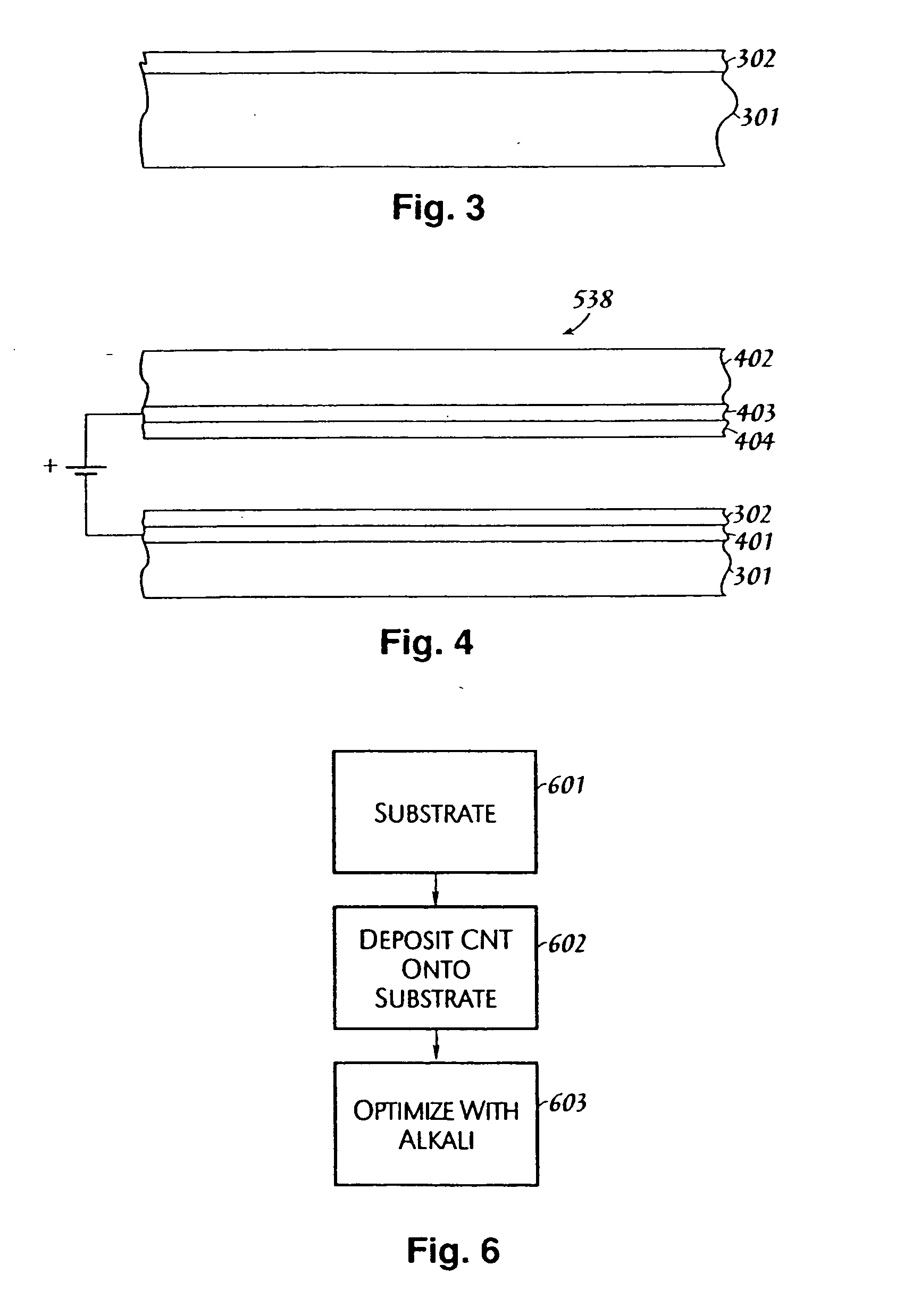

Field emission devices using modified carbon nanotubes

InactiveUS20030090190A1Accelerate emissionsReduce voltageNanostructure manufactureNanoinformaticsField emission deviceModified carbon

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes nanotubes which have been subjected to energy, plasma, chemical, or mechanical treatment. The present invention also relates to a field emission cathode comprising carbon nanotubes which have been subject to such treatment. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been subject to such treatment is further disclosed.

Owner:HYPERION CATALYSIS INT

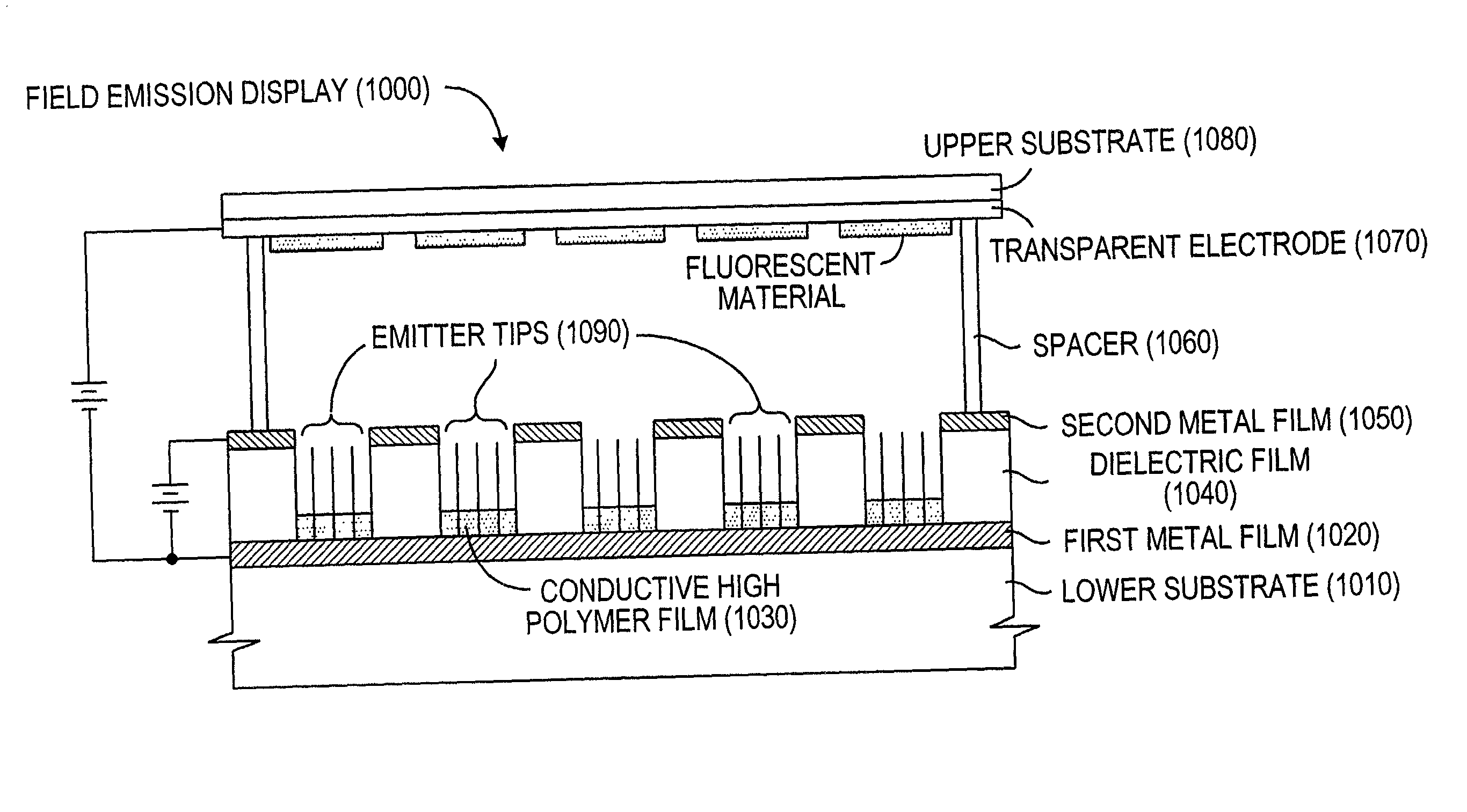

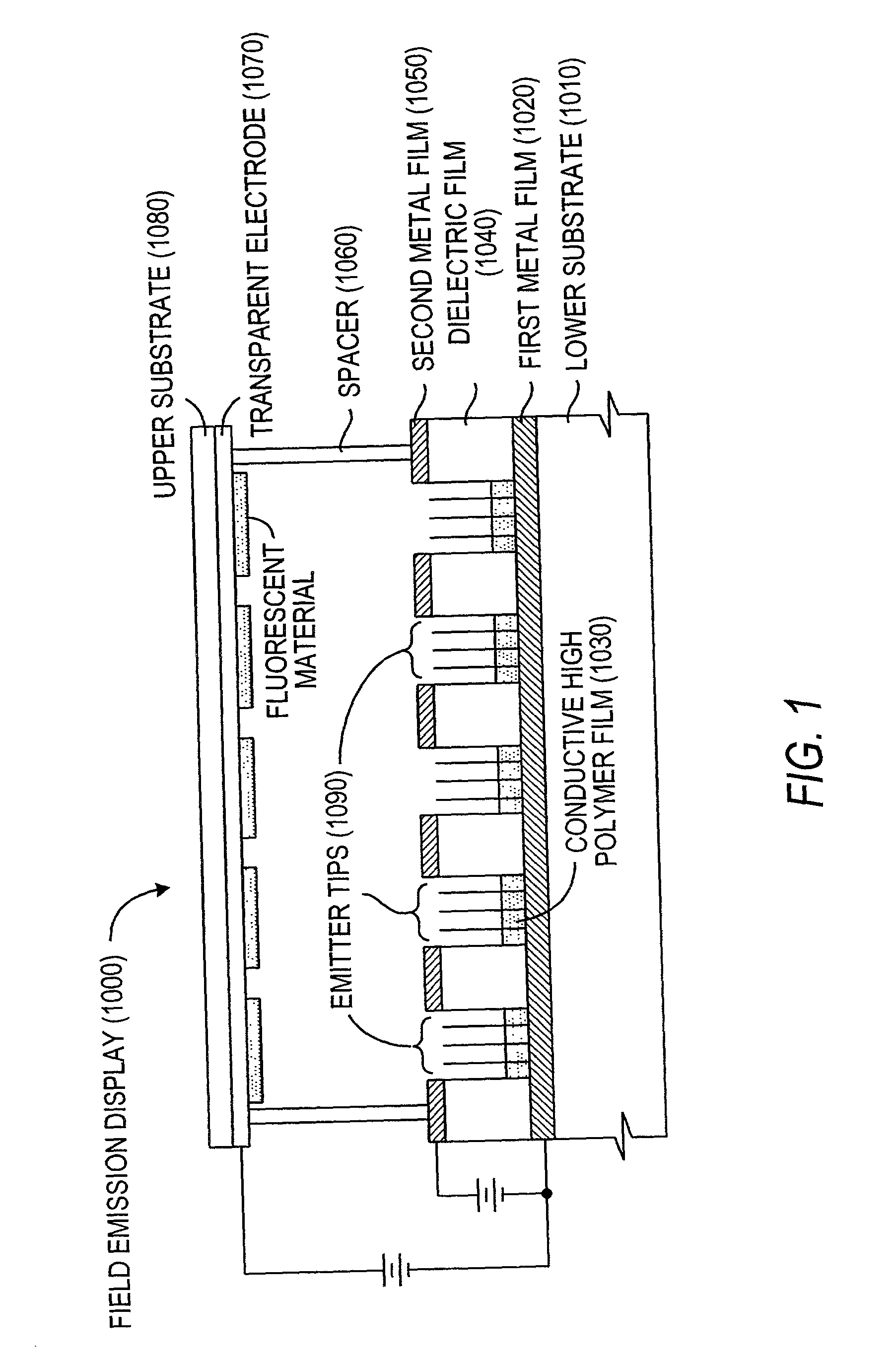

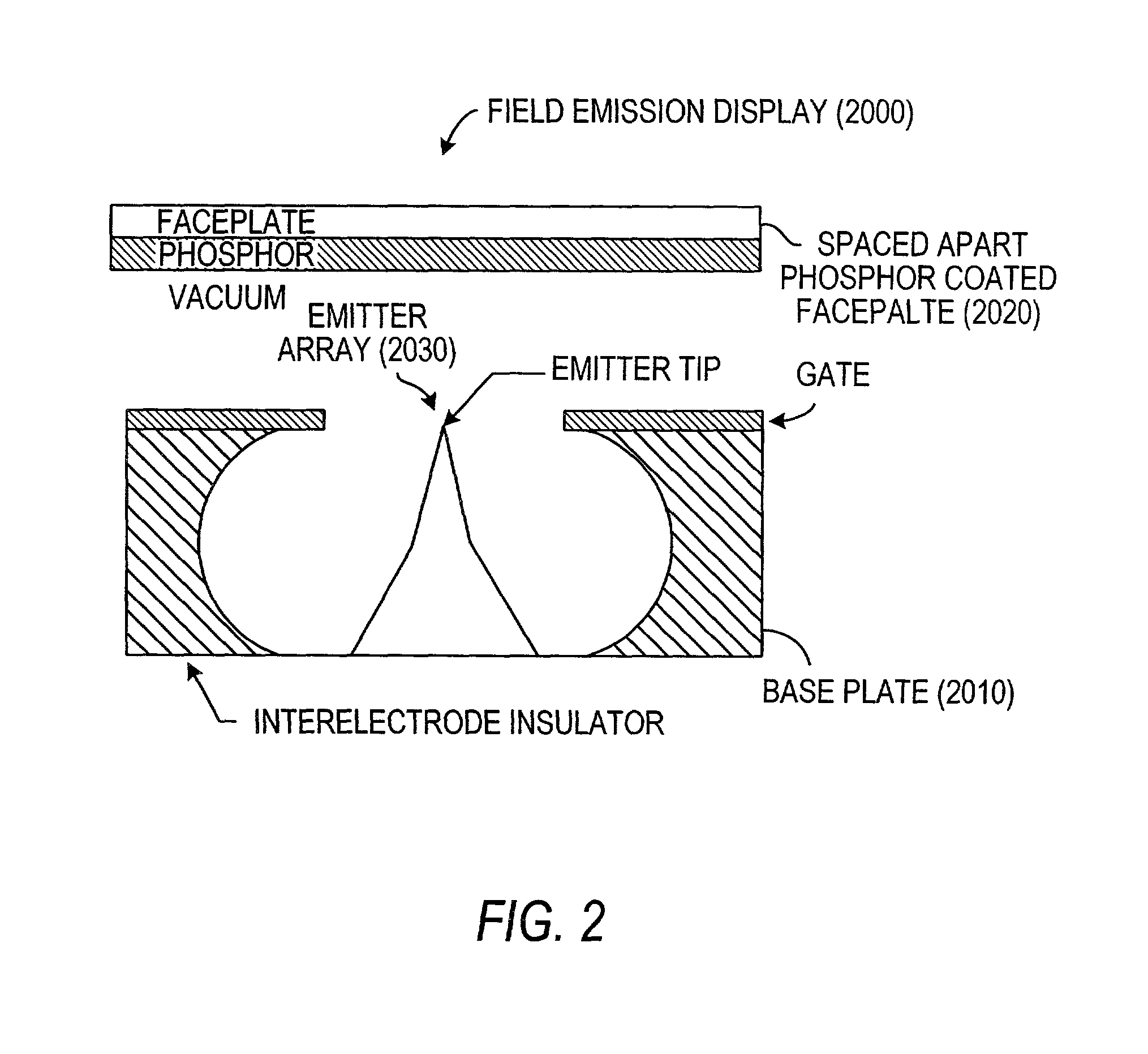

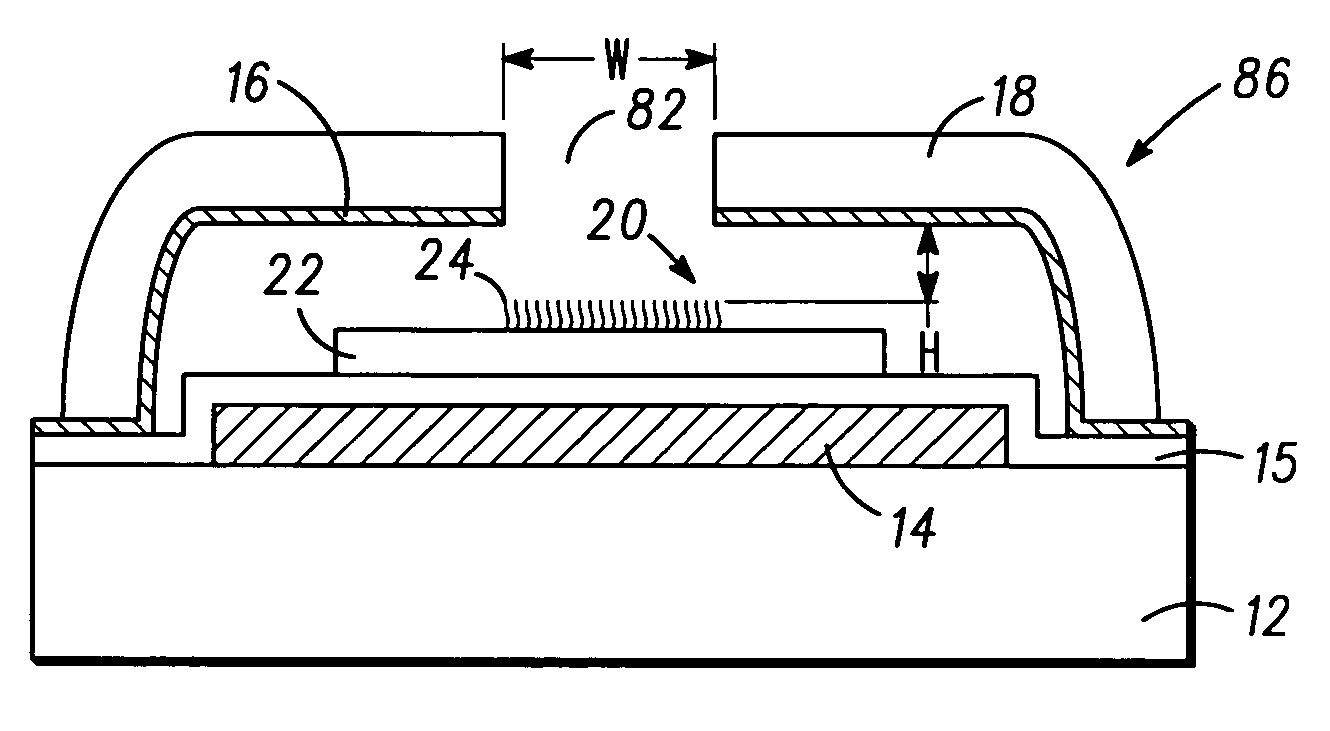

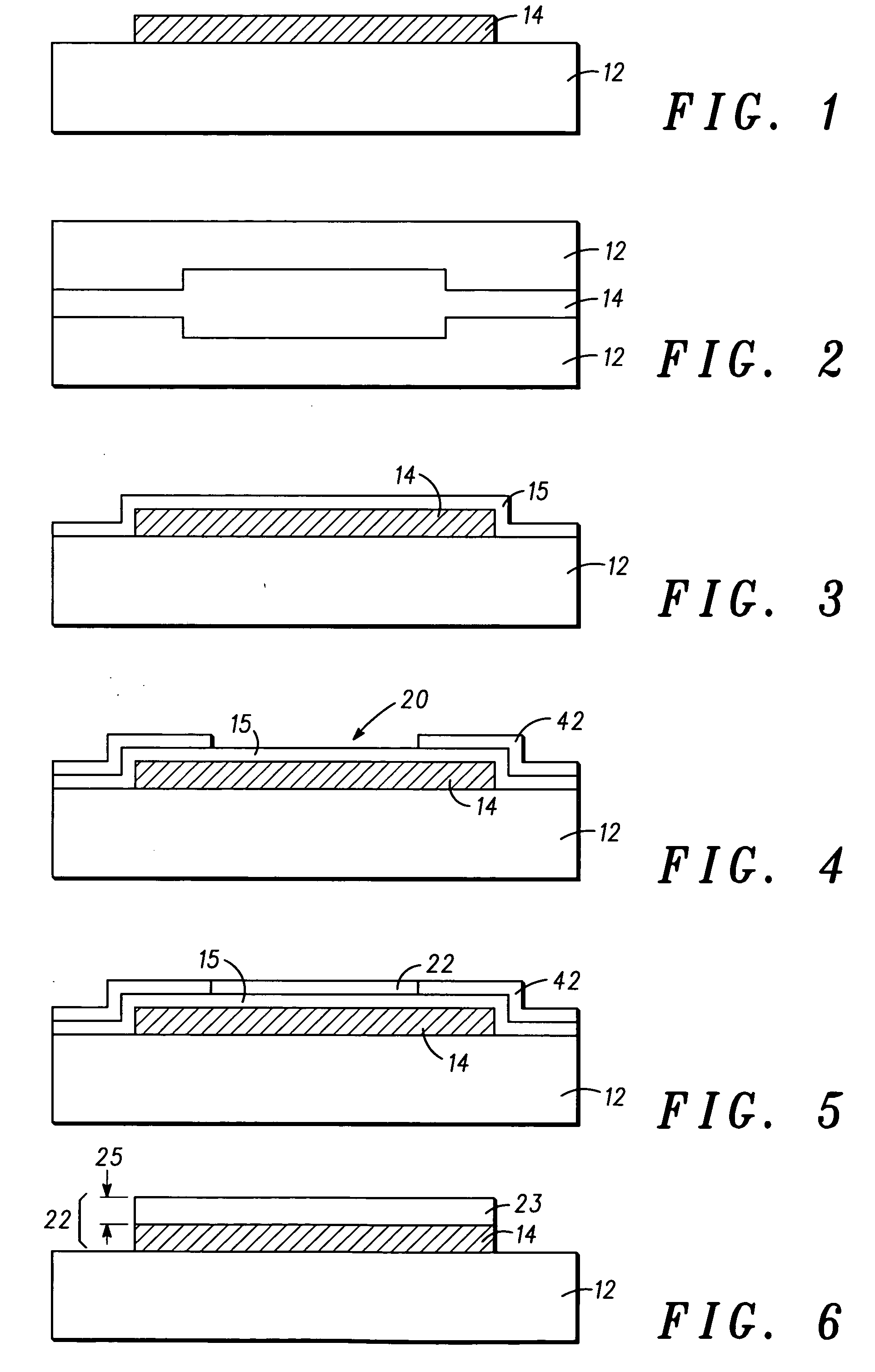

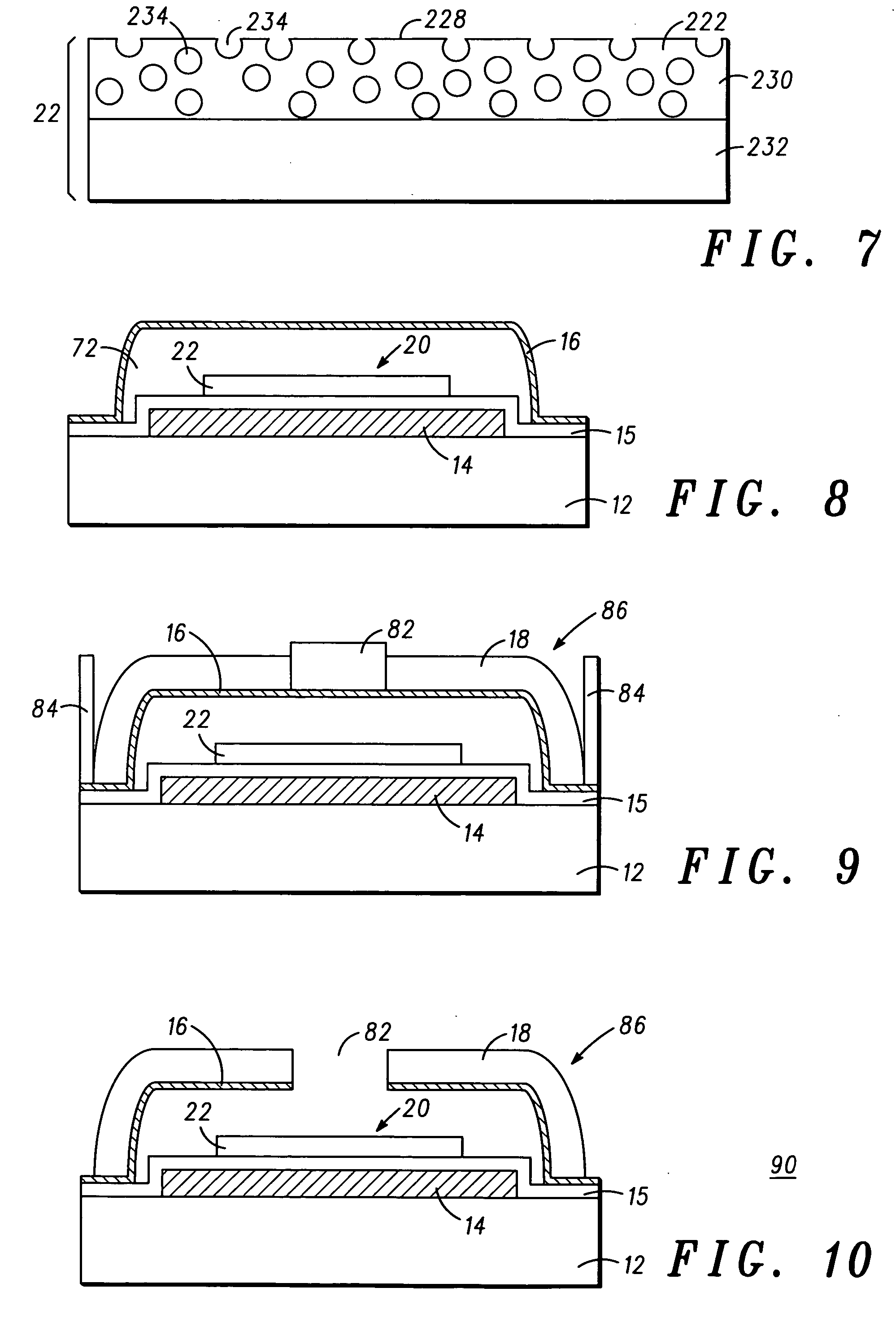

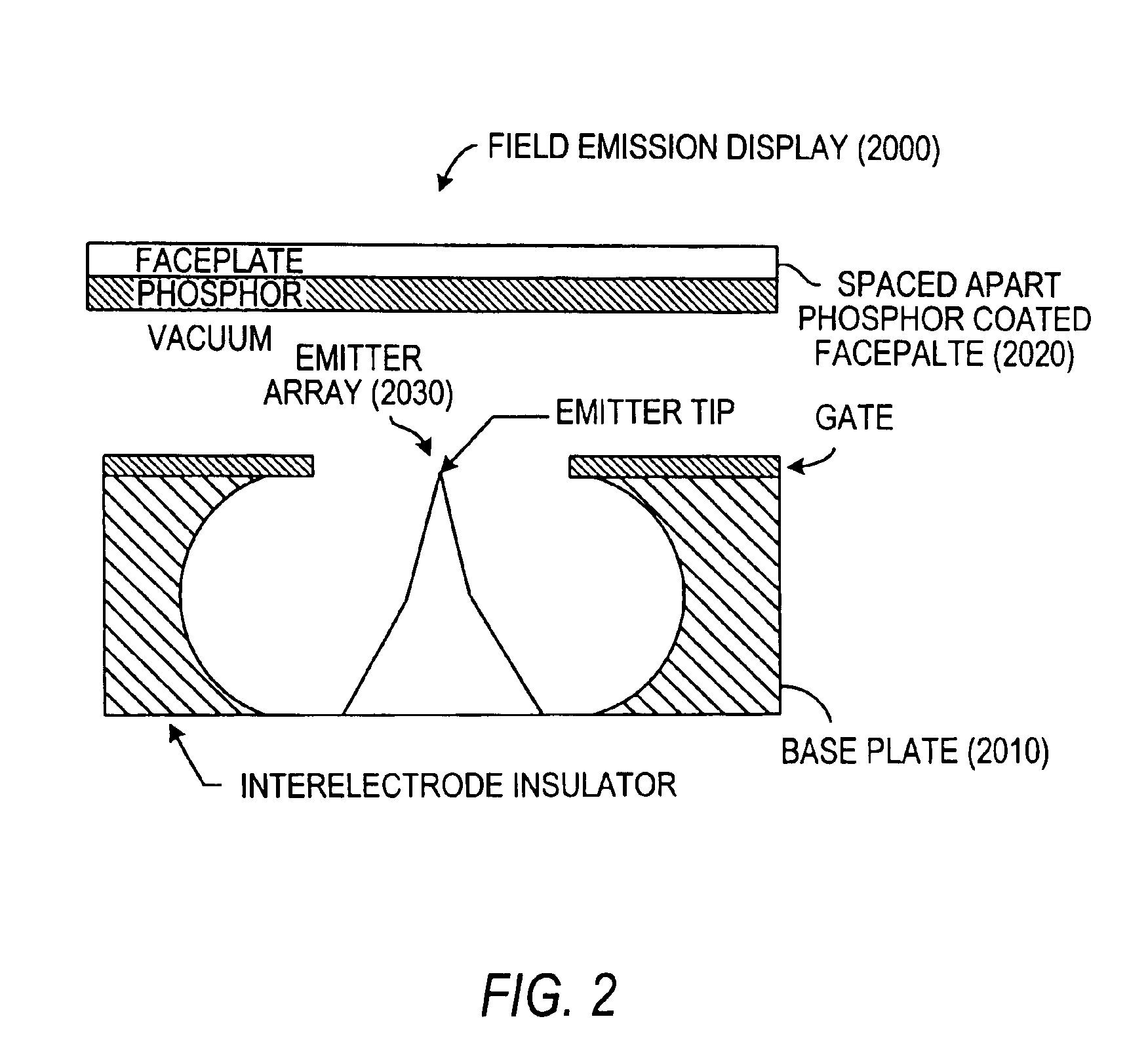

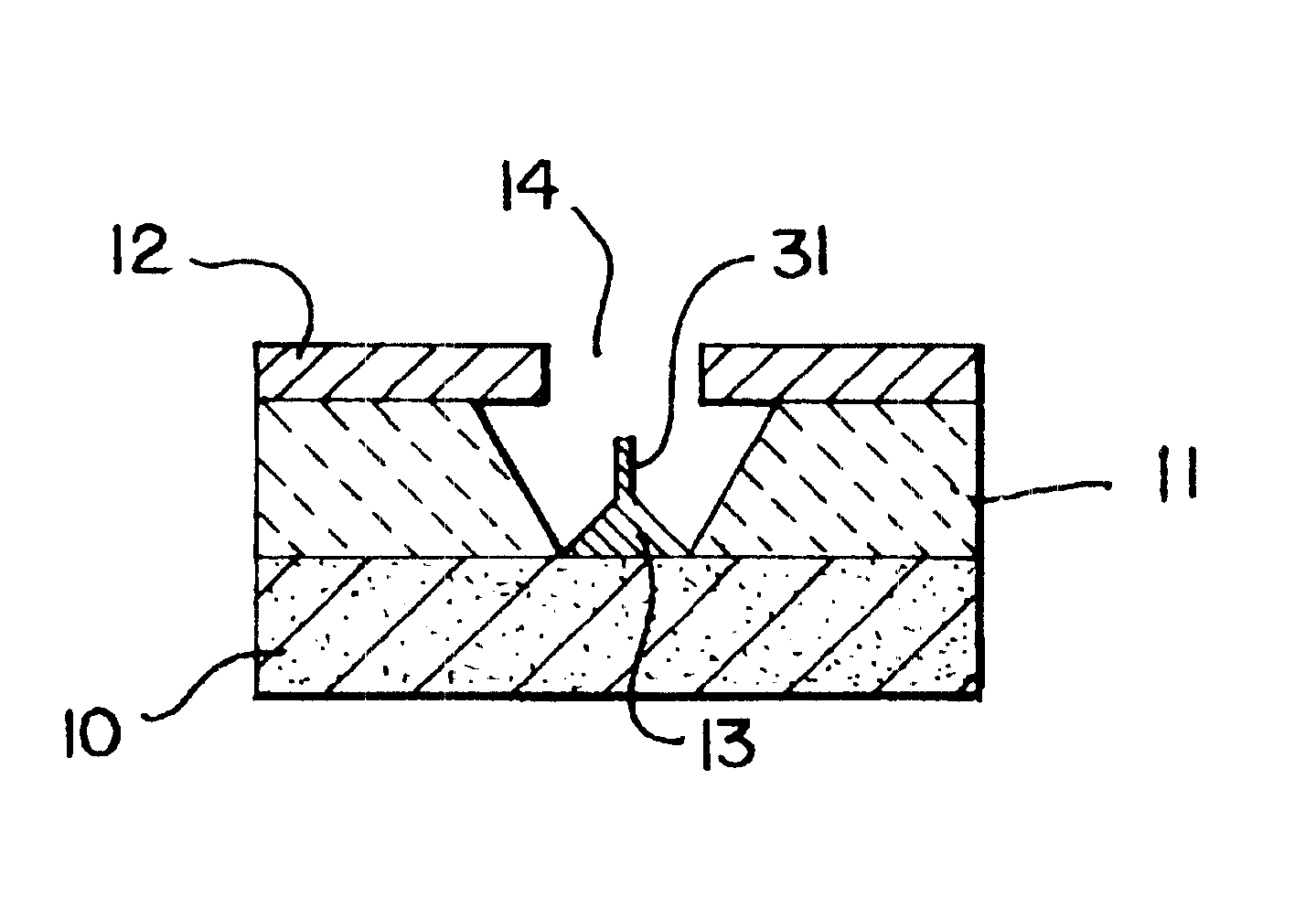

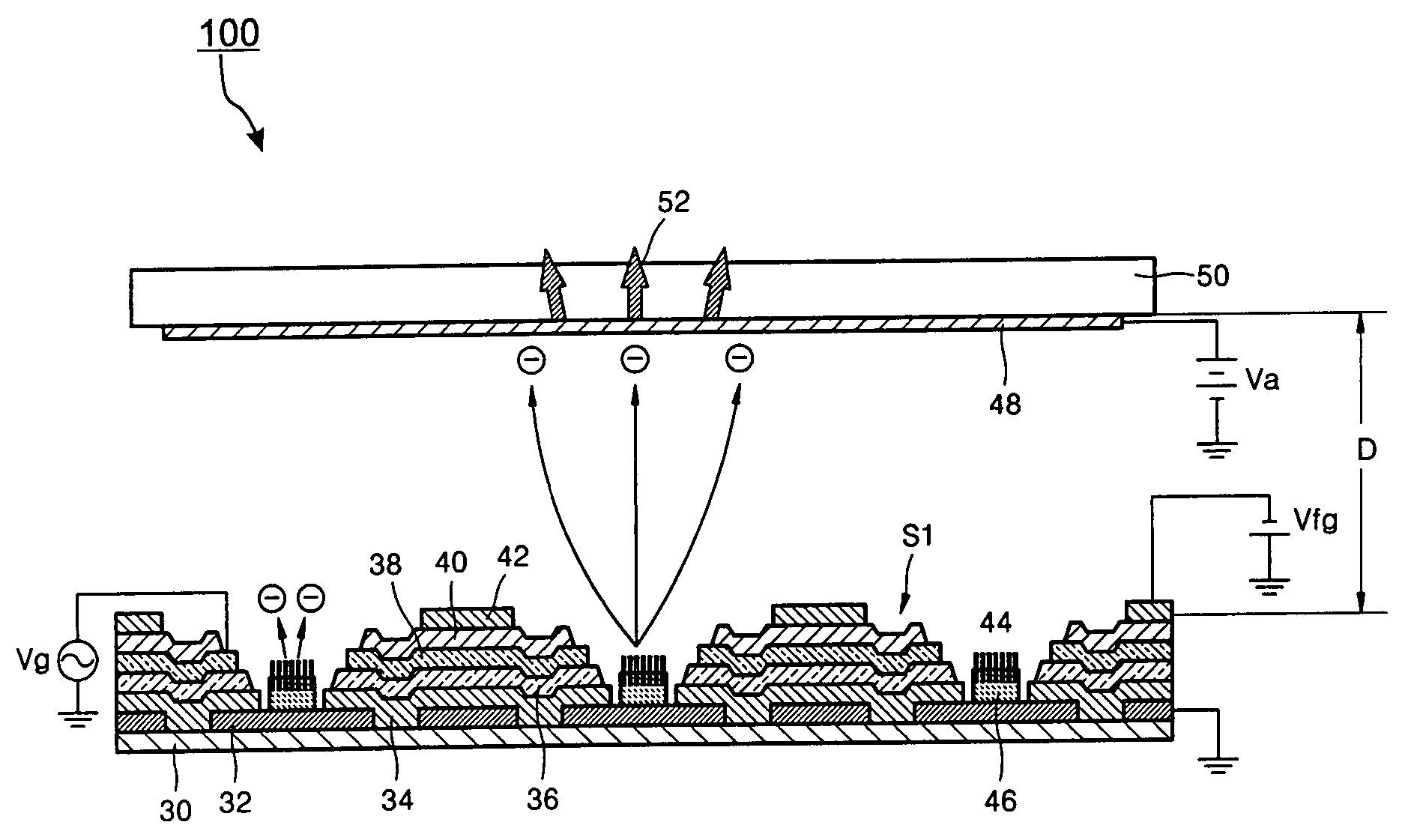

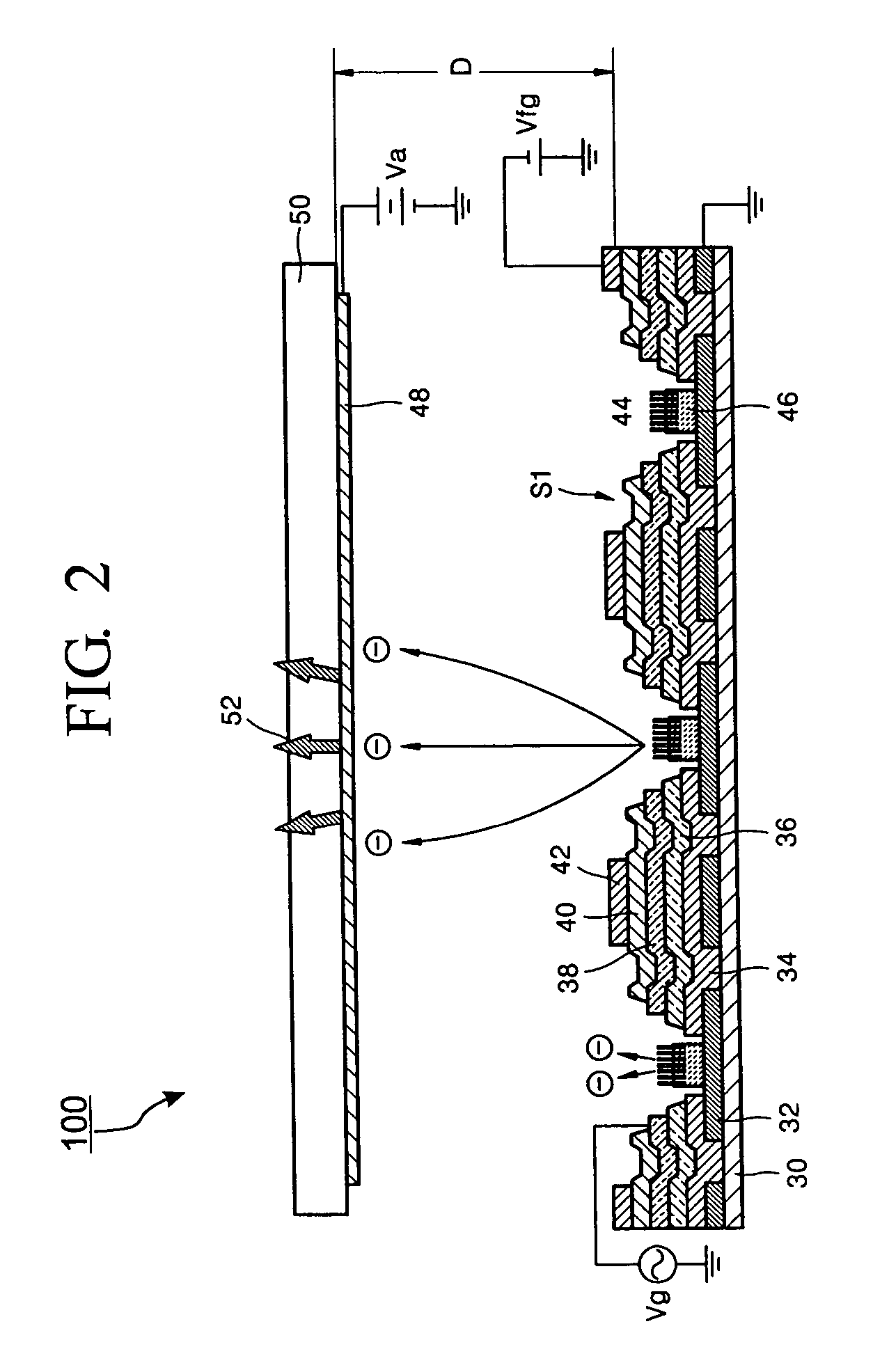

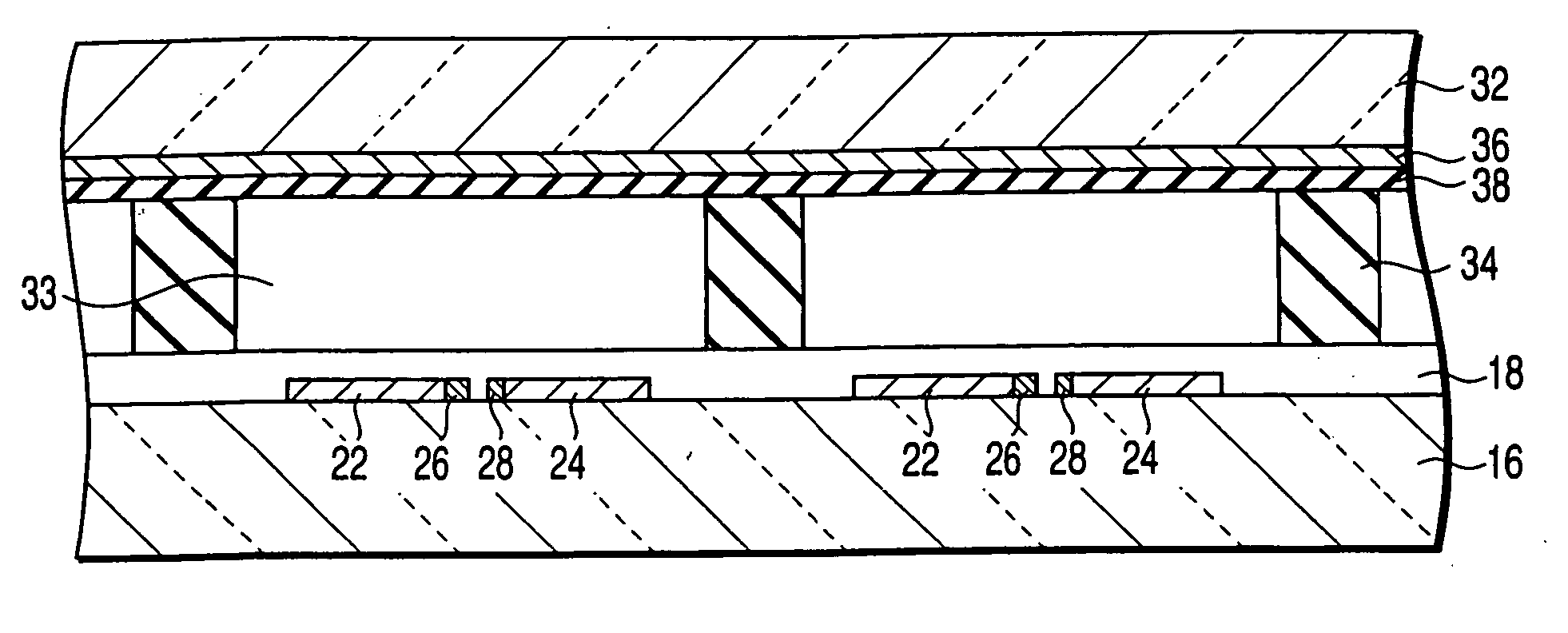

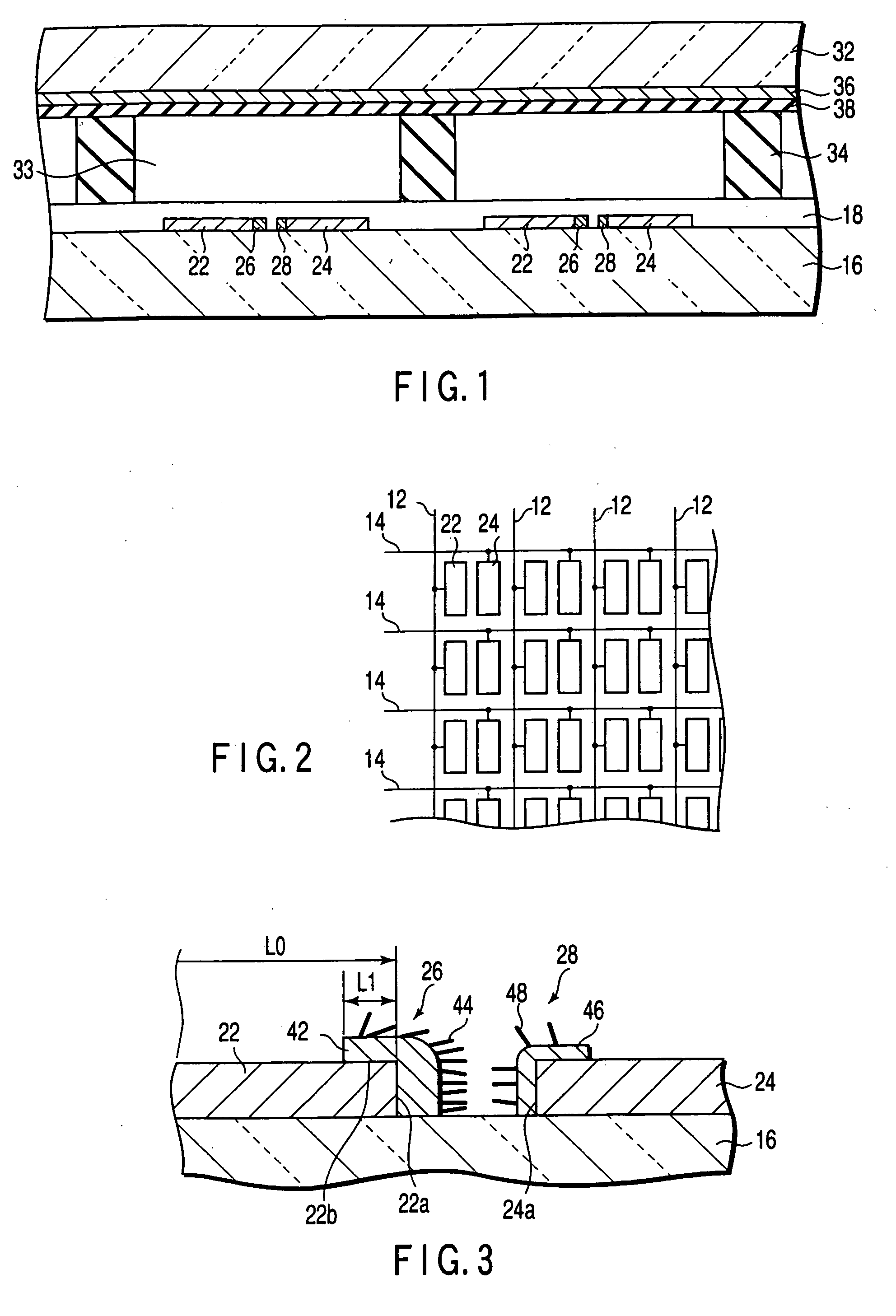

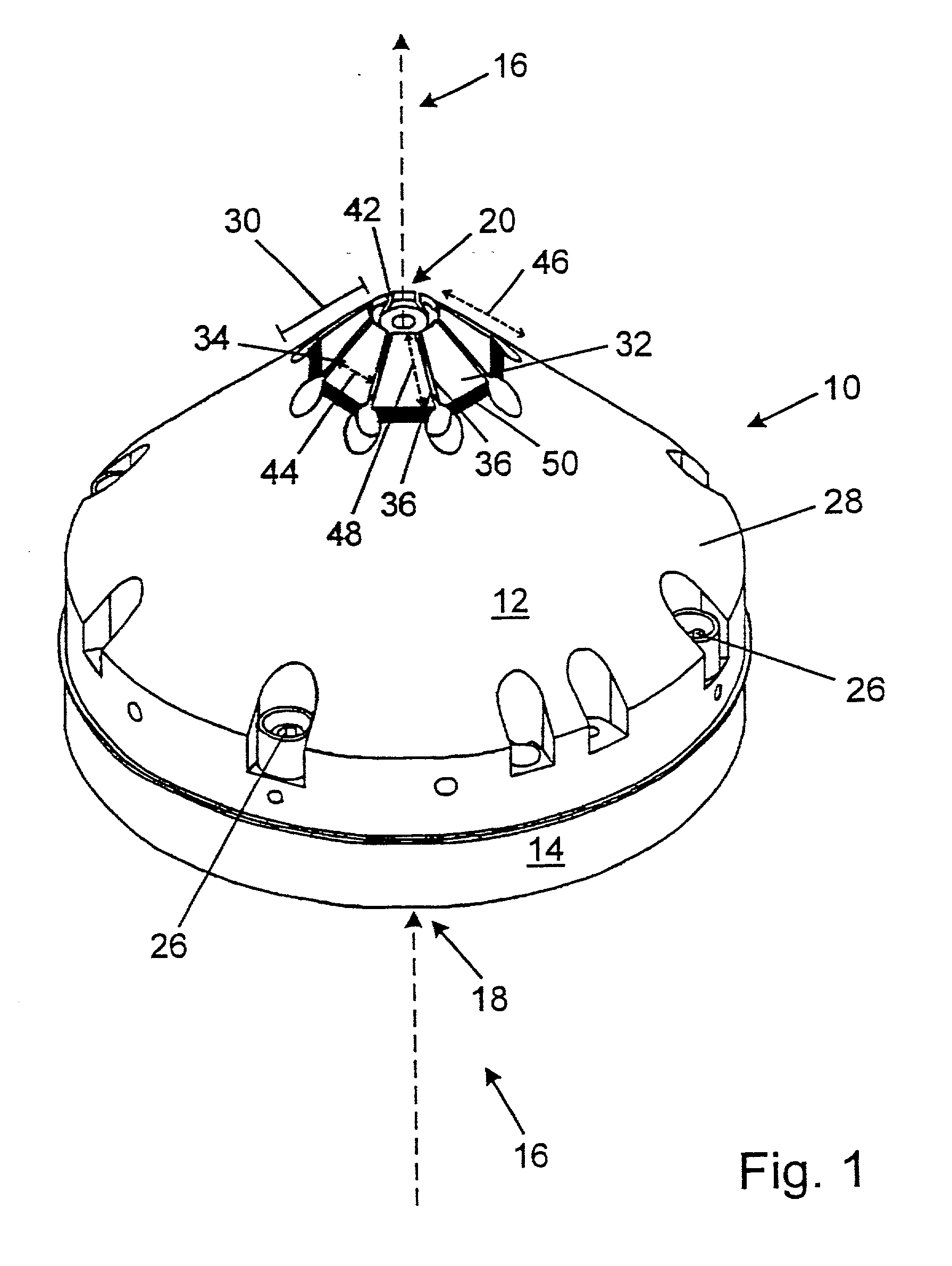

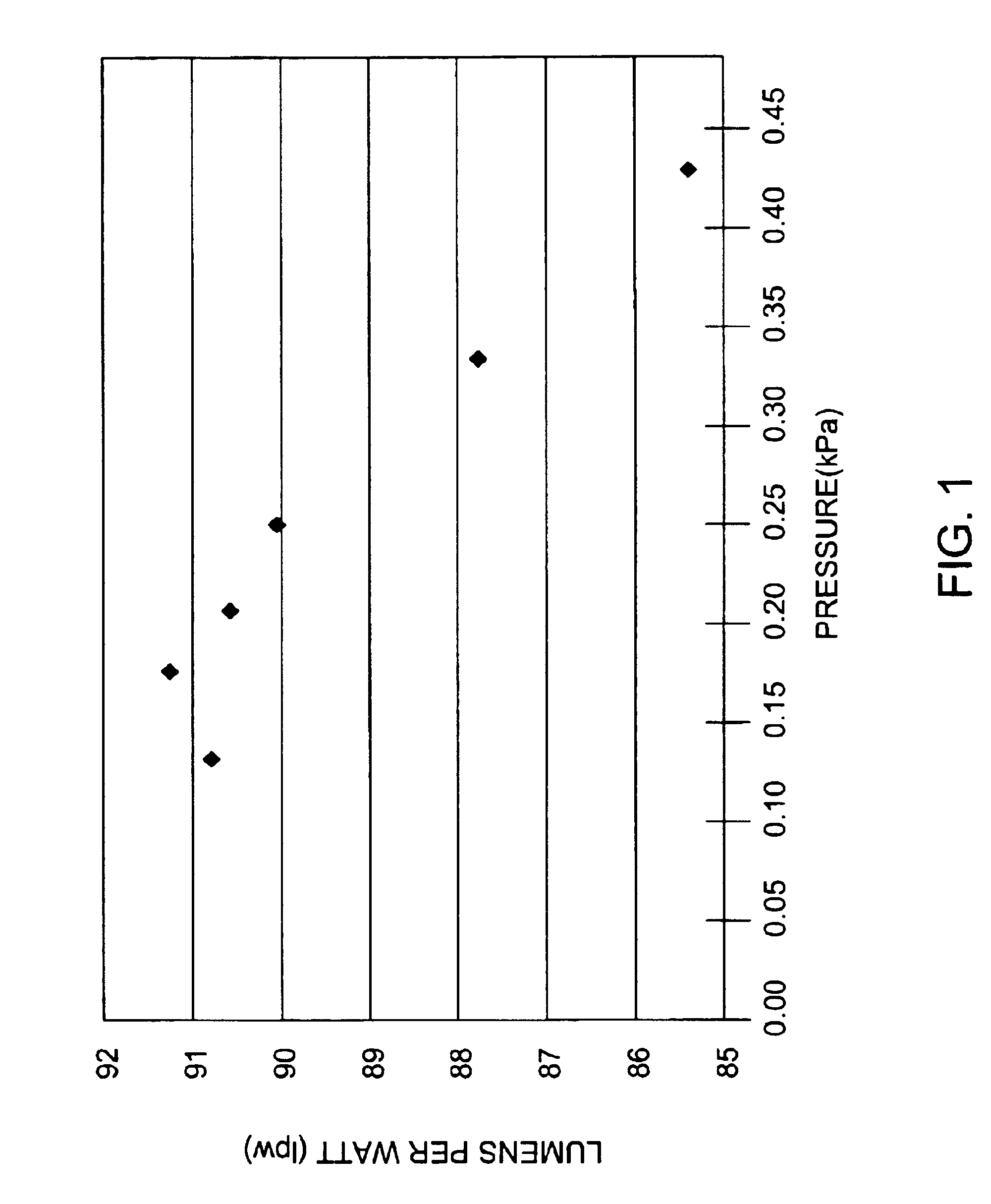

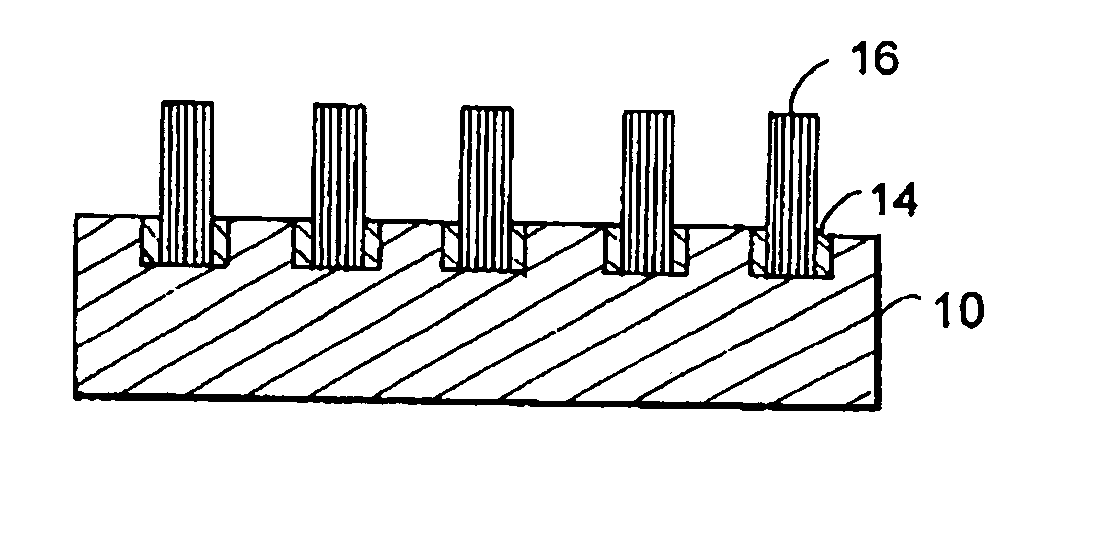

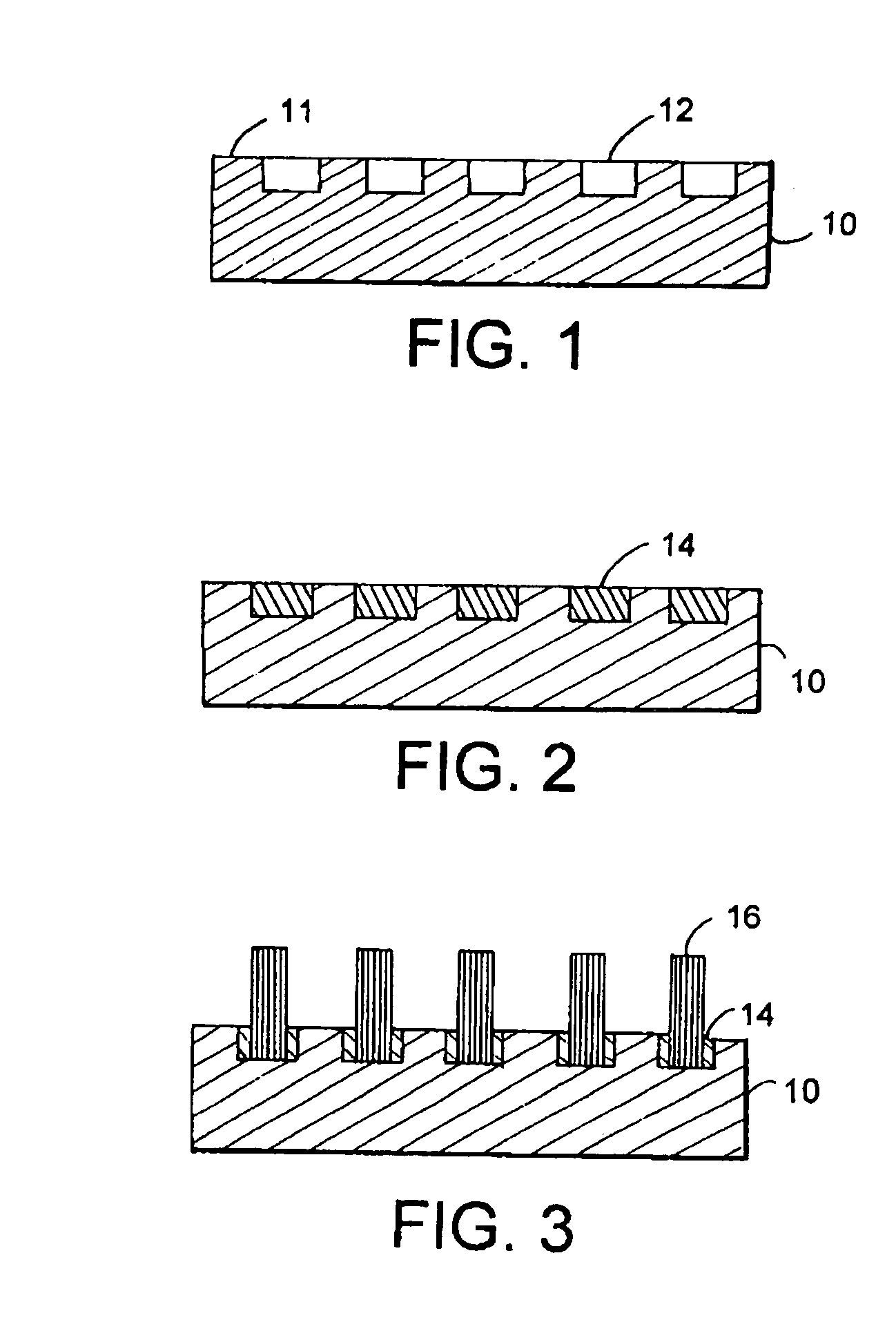

Field emission display and methods of forming a field emission display

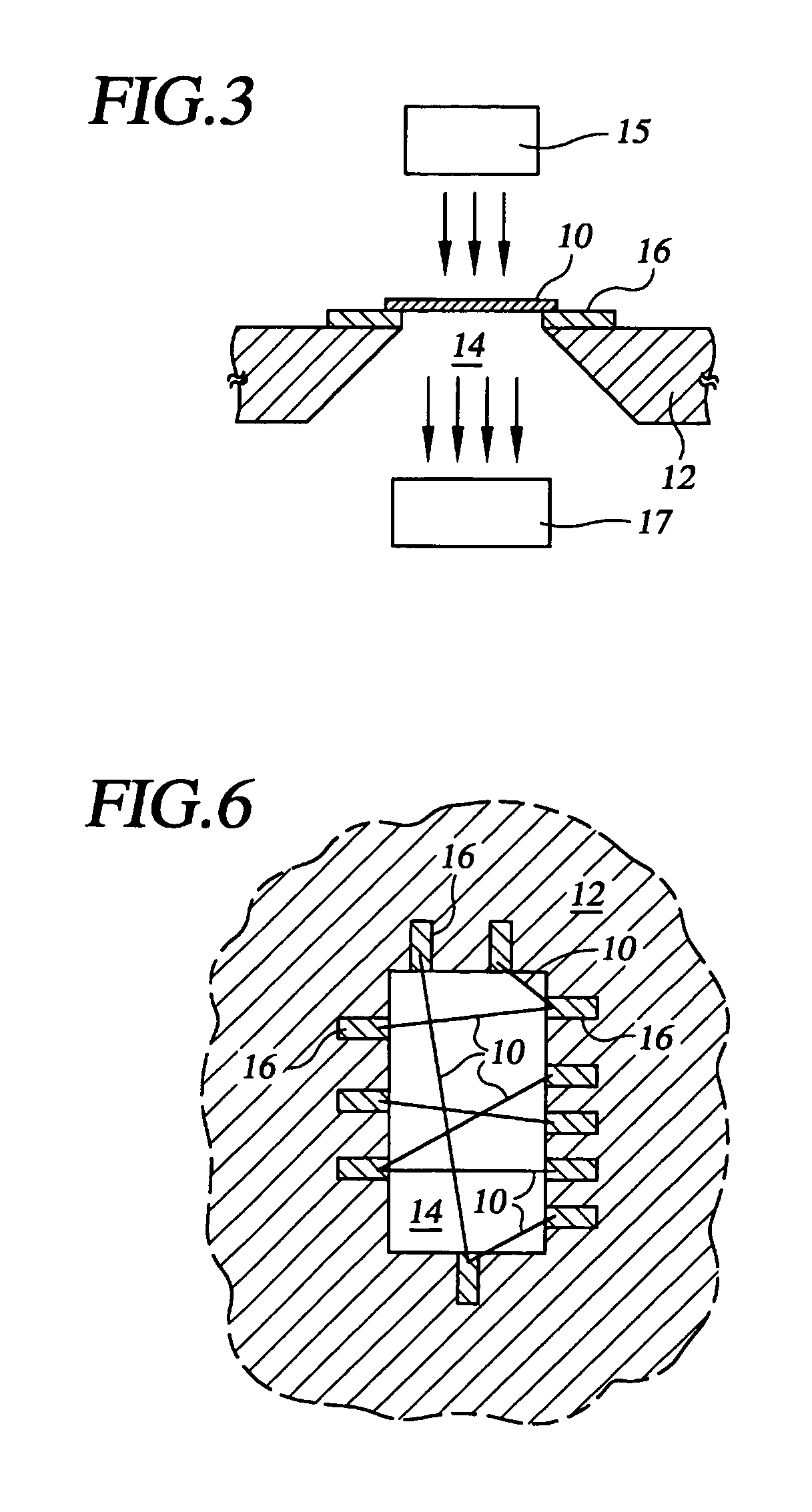

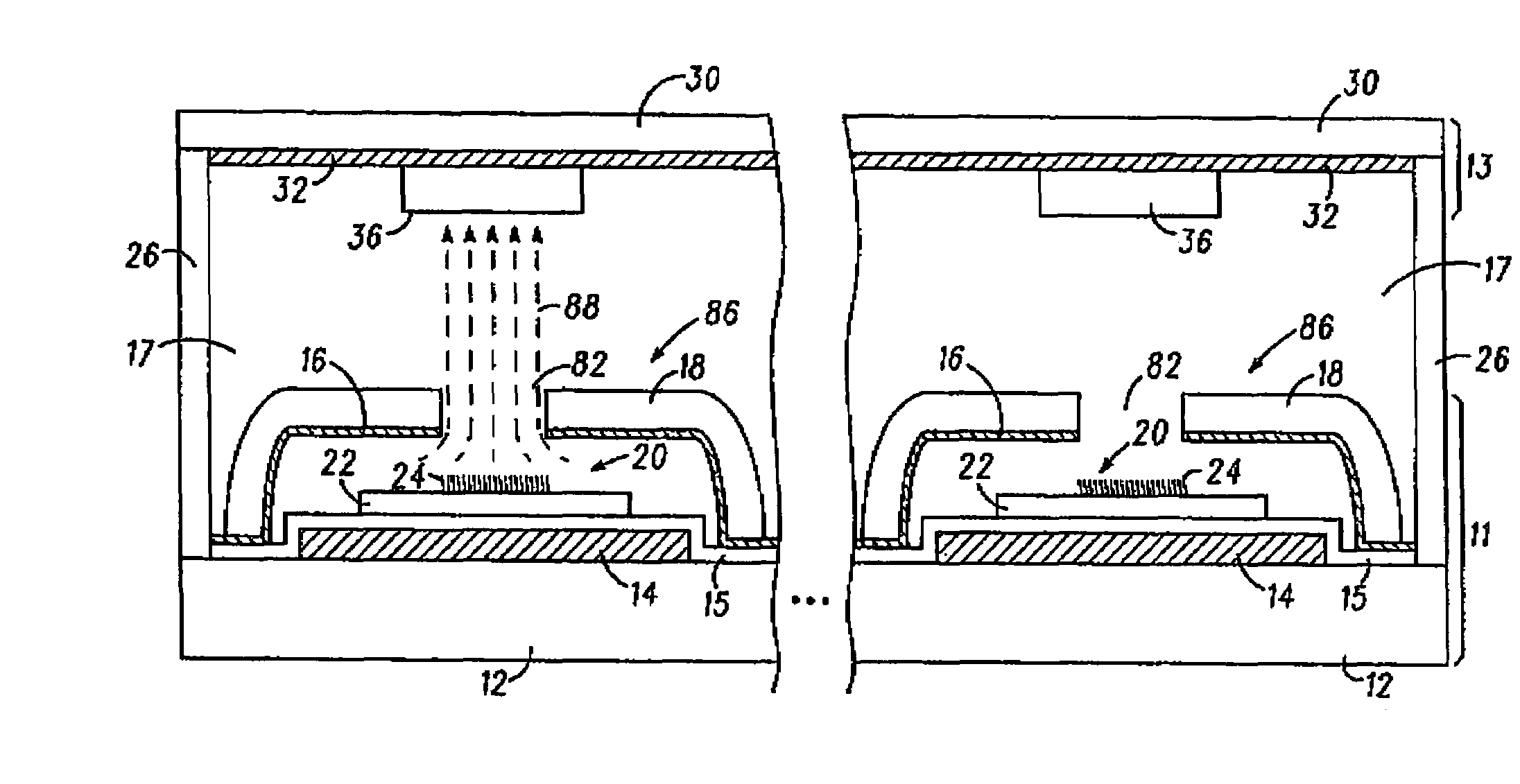

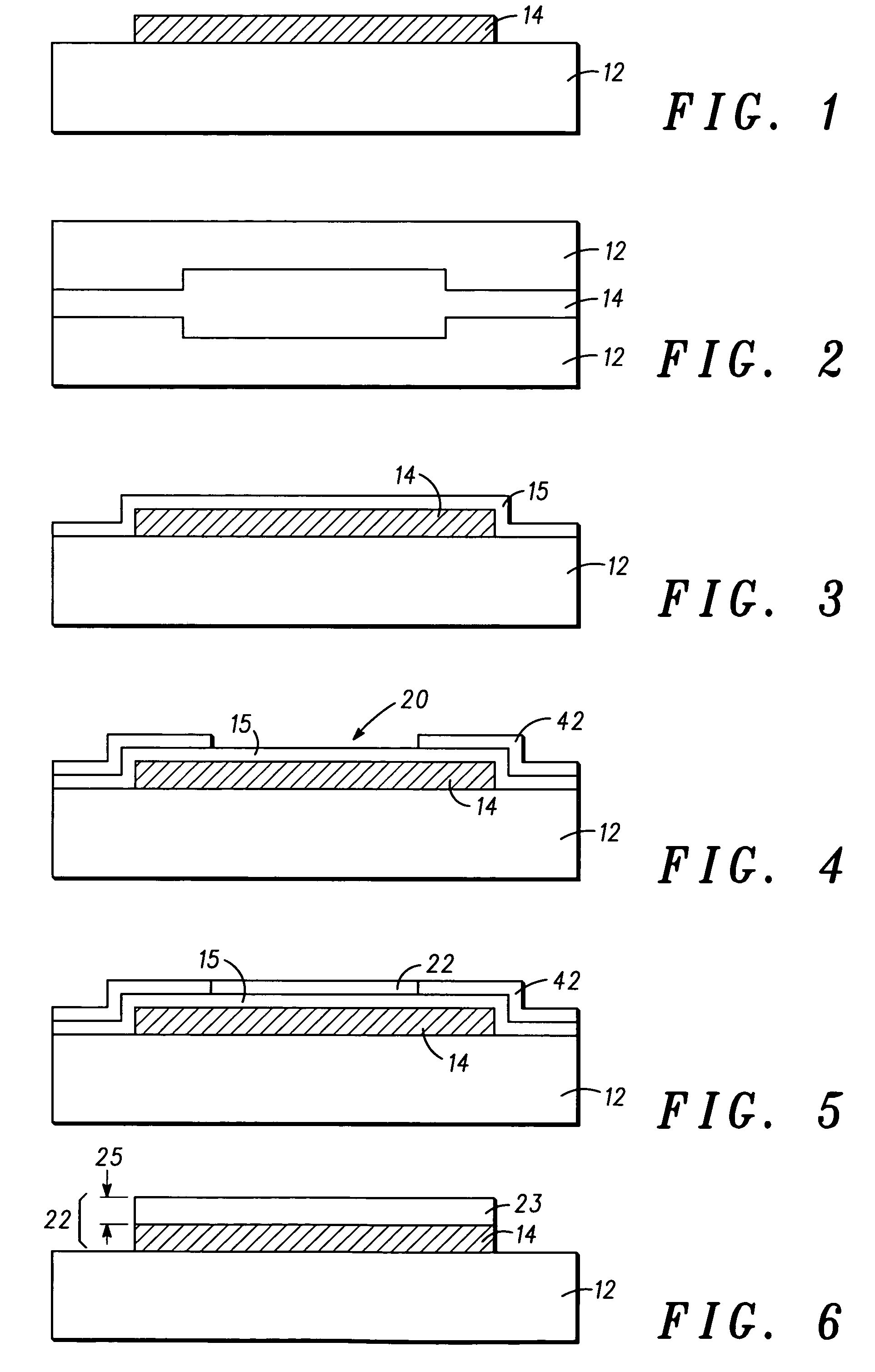

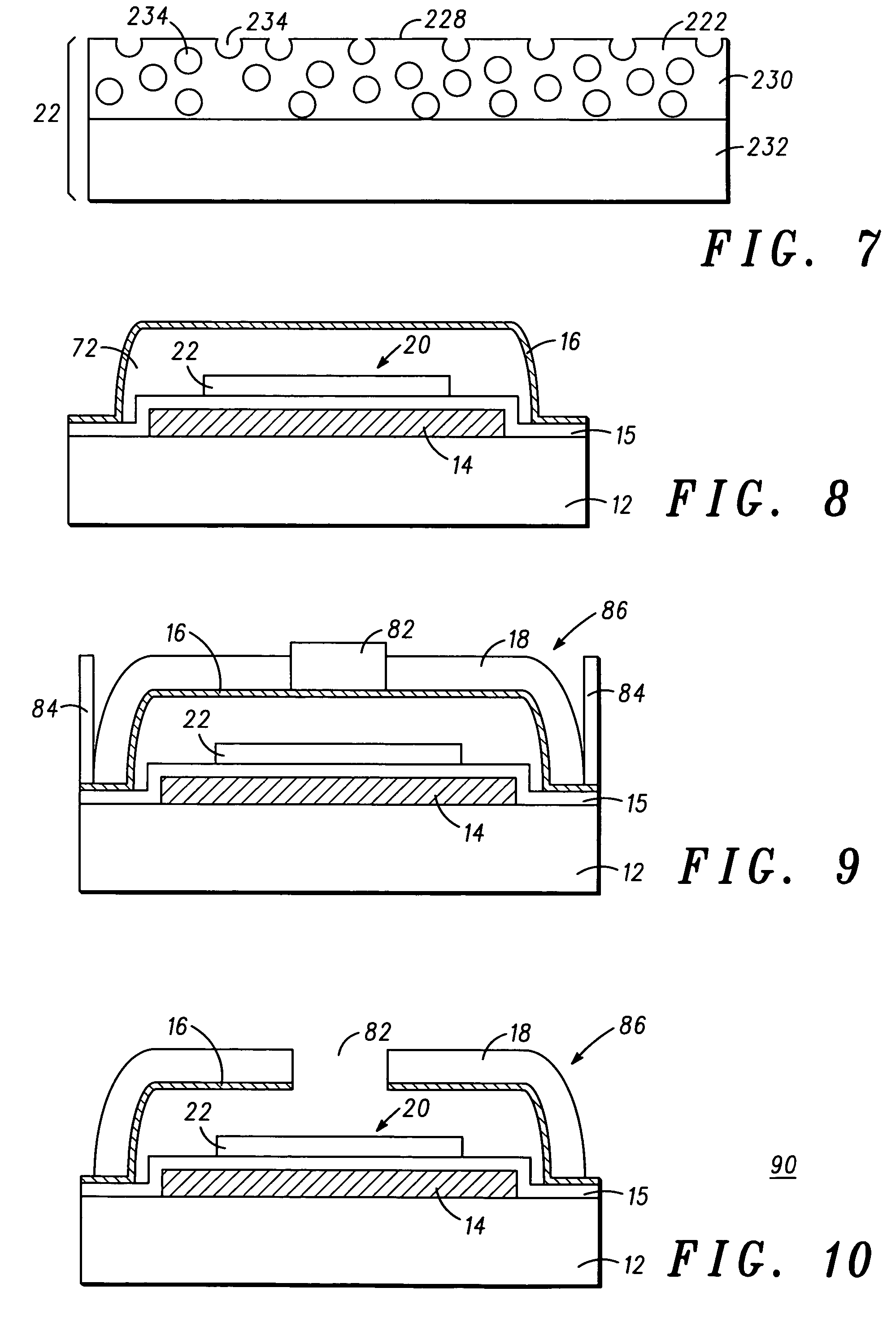

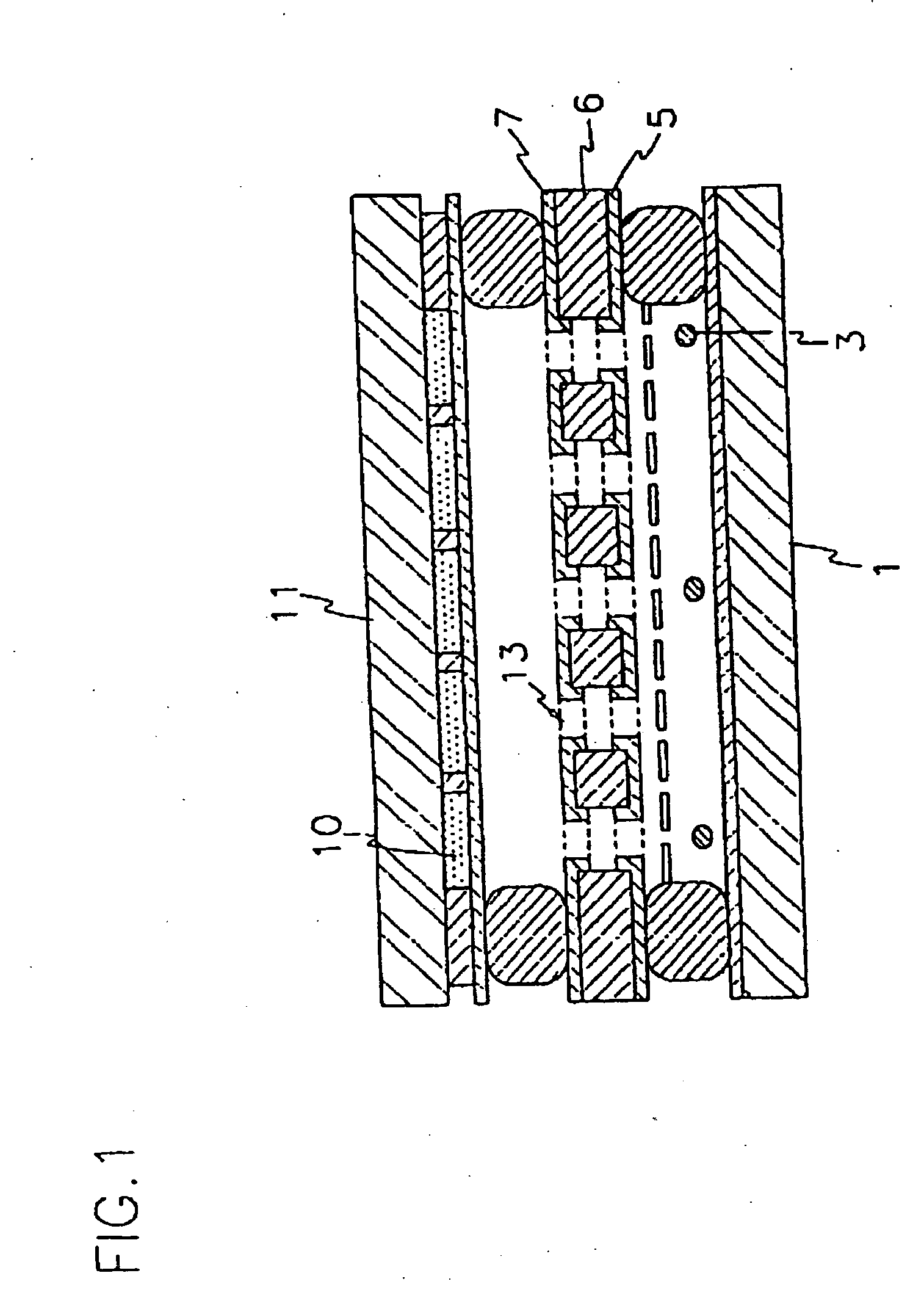

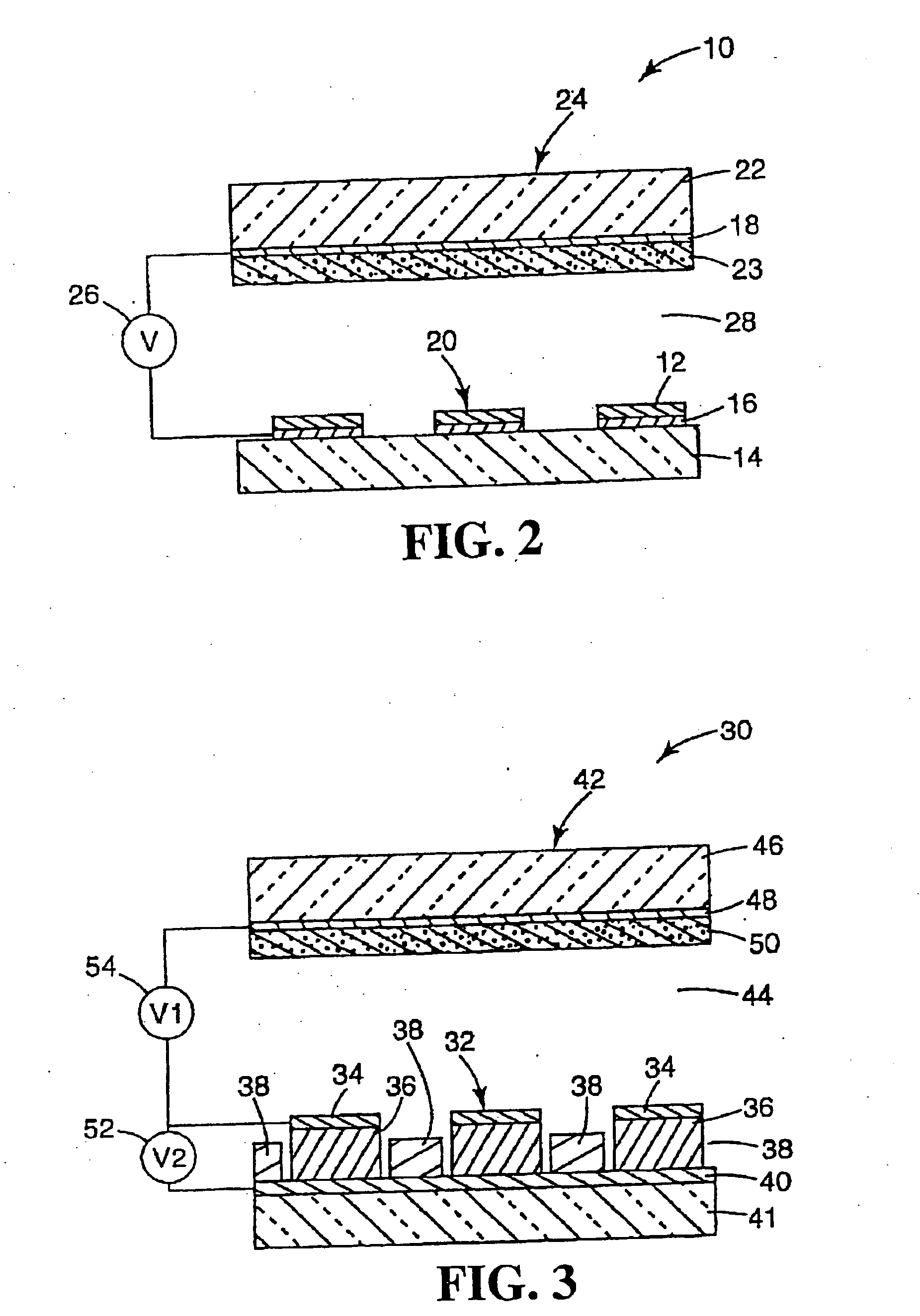

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

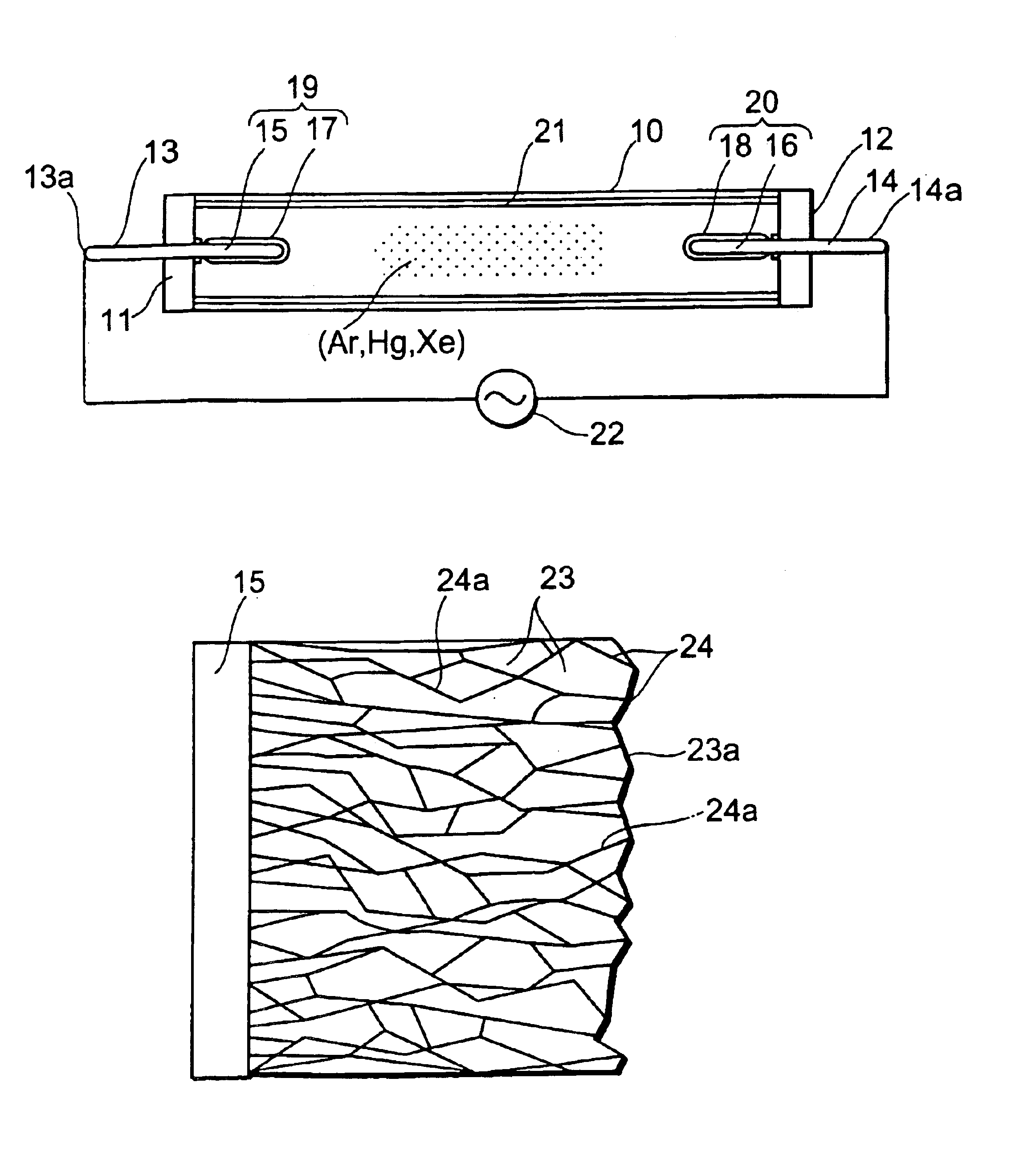

Field emission devices using ion bombarded carbon nanotubes

InactiveUS6911767B2Reduce voltageAccelerate emissionsCathode ray tubes/electron beam tubesNanoinformaticsField emission deviceOxygen

The present invention relates to a field emission device comprising an anode and a cathode, wherein said cathode includes carbon nanotubes which have been treated with an ion beam. The ion beam may be any ions, including gallium, hydrogen, helium, argon, carbon, oxygen, and xenon ions. The present invention also relates to a field emission cathode comprising carbon nanotubes, wherein the nanotubes have been treated with an ion beam. A method for treating the carbon nanotubes and for creating a field emission cathode is also disclosed. A field emission display device containing carbon nanotube which have been treated with an ion beam is further disclosed.

Owner:HYPERION CATALYSIS INT

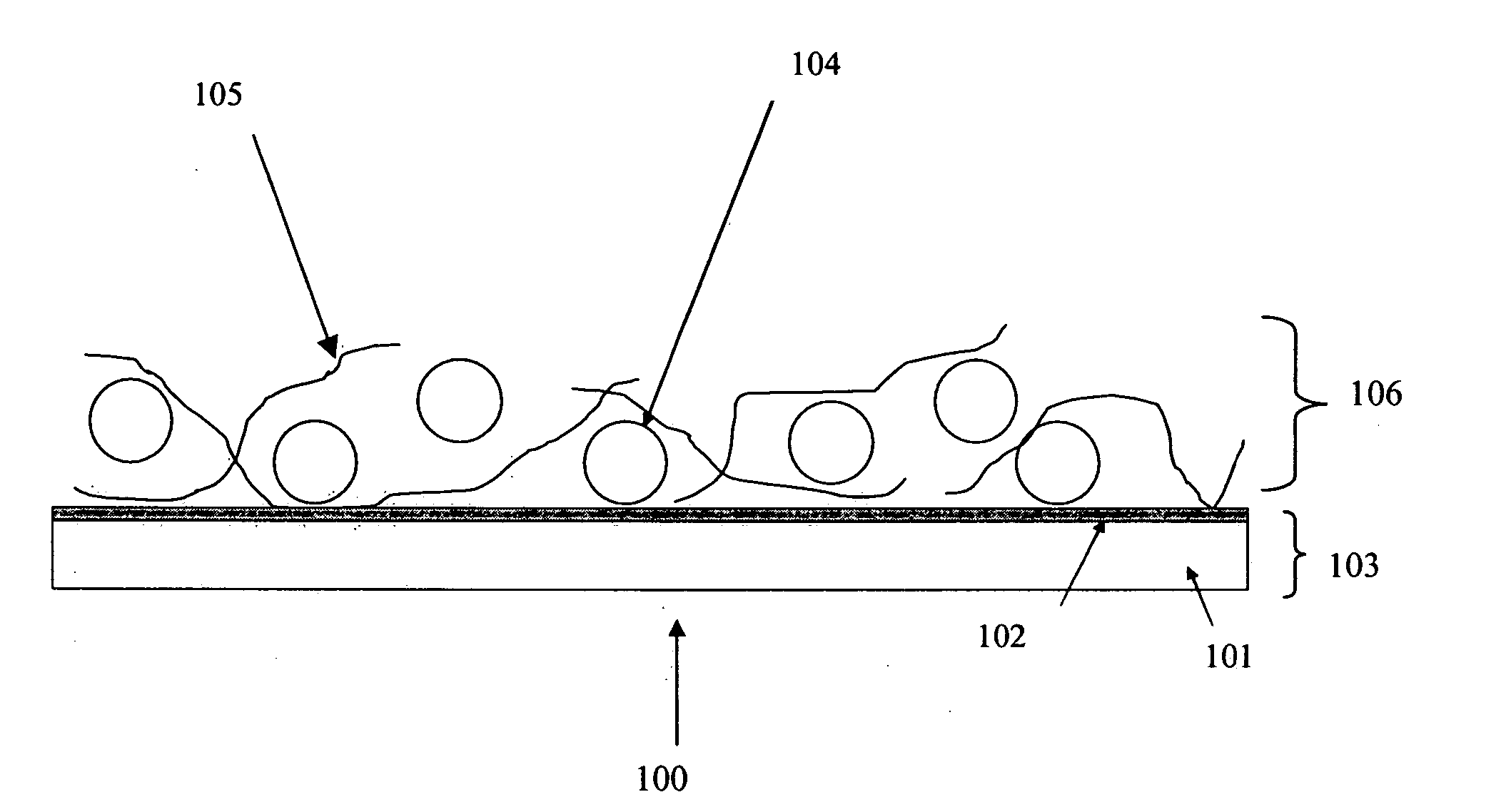

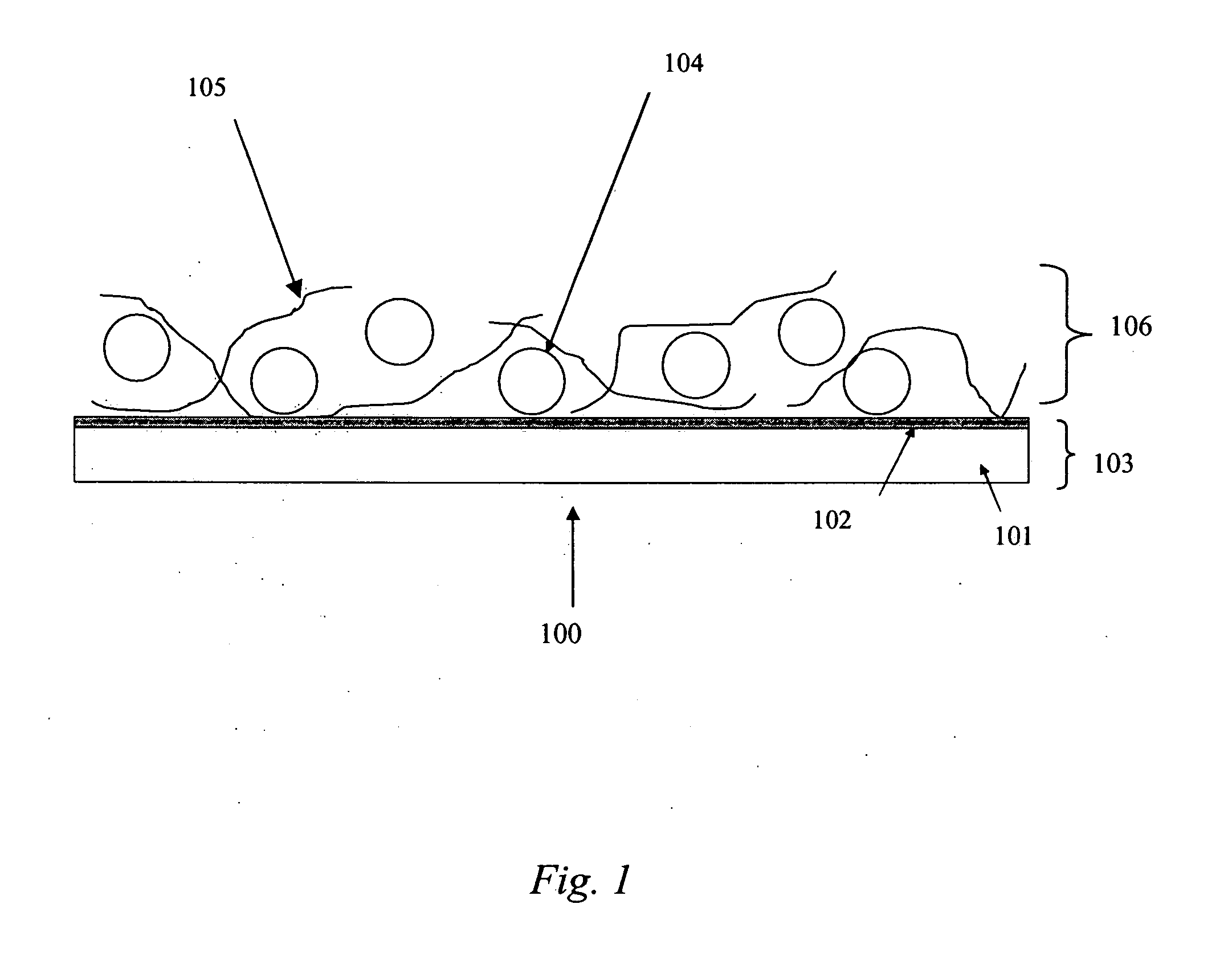

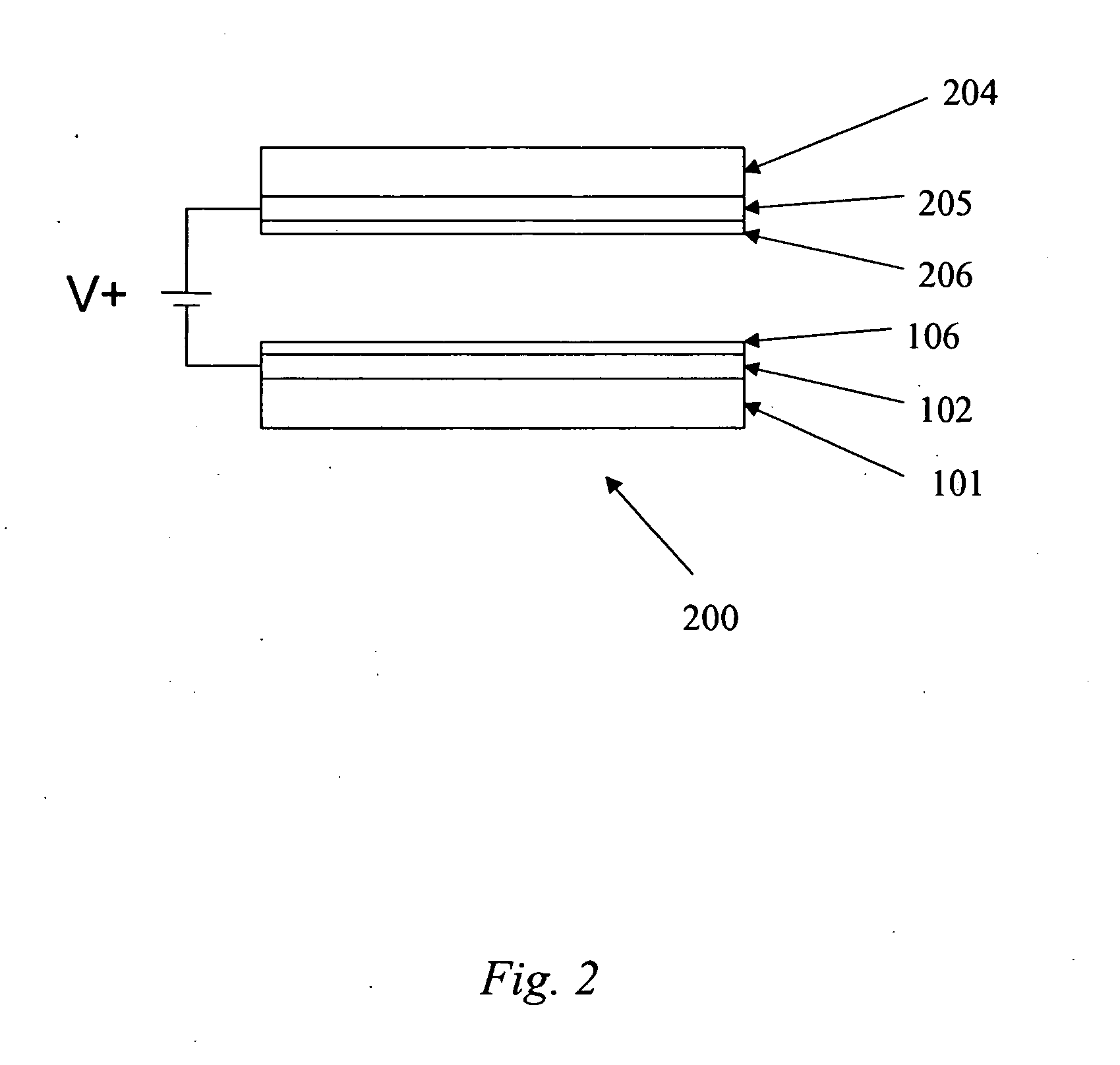

Enhanced field emission from carbon nanotubes mixed with particles

ActiveUS20050001528A1Optimizing electron field emission performanceEmission reductionDischarge tube luminescnet screensNanoinformaticsField emission deviceCarbon nanotube

The present invention is directed toward cathodes and cathode materials comprising carbon nanotubes (CNTs) and particles. The present invention is also directed toward field emission devices comprising a cathode of the present invention, as well as methods for making these cathodes. In some embodiments, the cathode of the present invention is used in a field emission display. The invention also comprises a method of depositing a layer of CNTs and particles onto a substrate to form a cathode of the present invention, as well as a method of controlling the density of CNTs used in this mixed layer in an effort to optimize the field emission properties of the resulting layer for field emission display applications.

Owner:SAMSUNG ELECTRONICS CO LTD

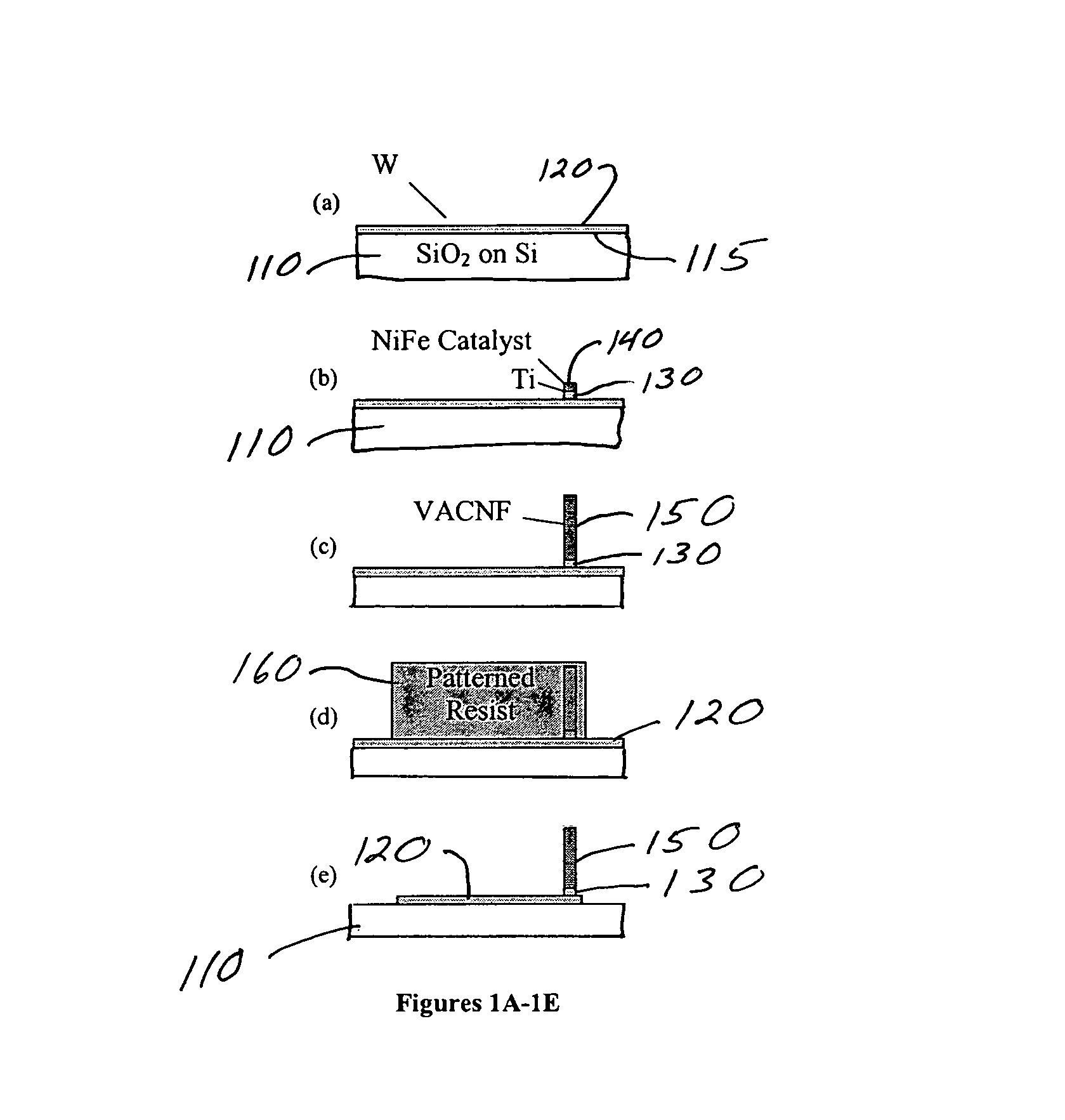

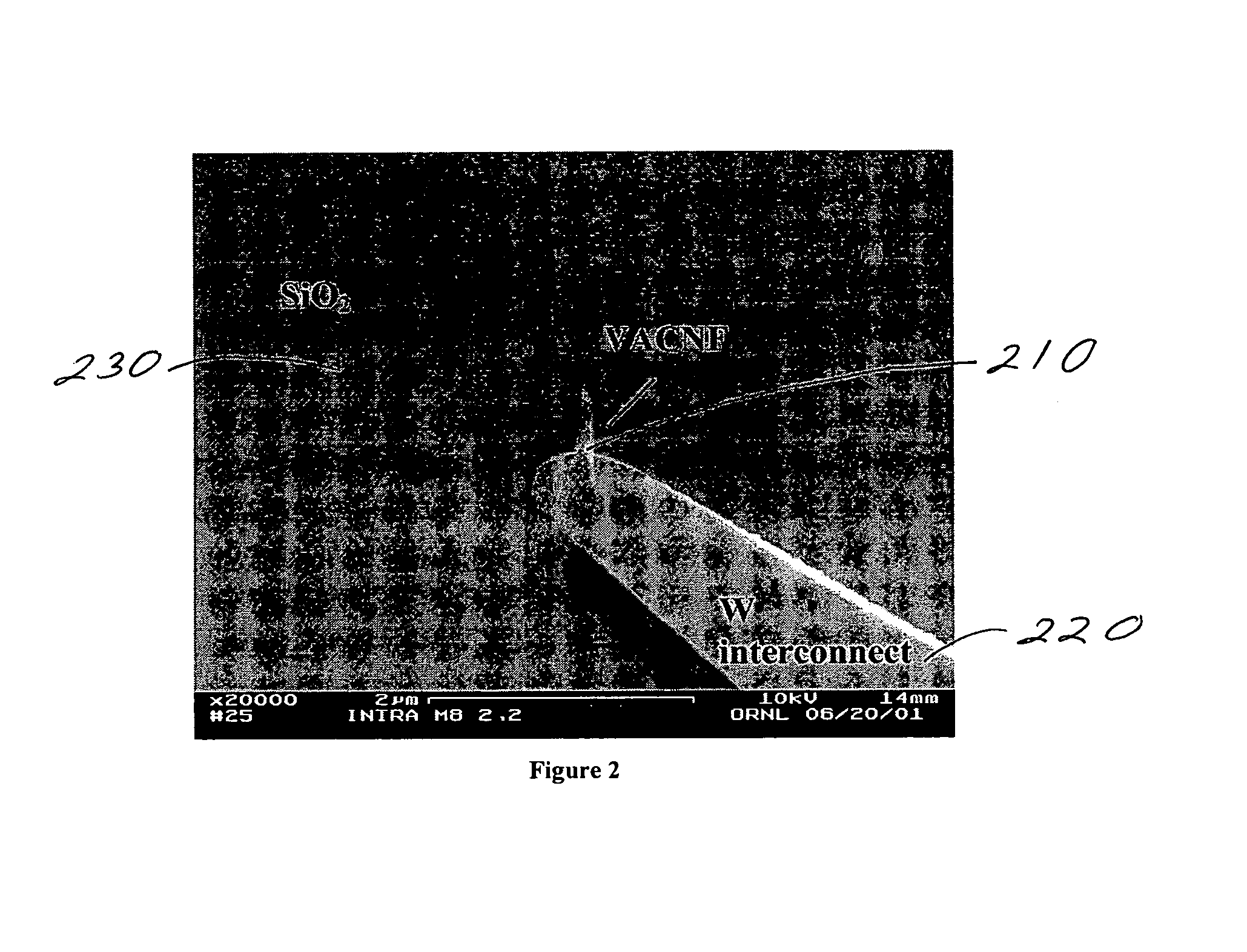

Individually electrically addressable vertically aligned carbon nanofibers on insulating substrates

Systems and methods are described for individually electrically addressable carbon nanofibers on insulating substrates. An apparatus includes an electrically conductive interconnect formed on at least a part of an insulating surface on a substrate; and at least one vertically aligned carbon nanofiber coupled to the electrically conductive interconnect. A kit includes a substrate having an insulating surface; an electrically conductive interconnect formed on at least a part of the insulating surface; and at least one vertically aligned carbon nanofiber coupled to the electrically conductive interconnect.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

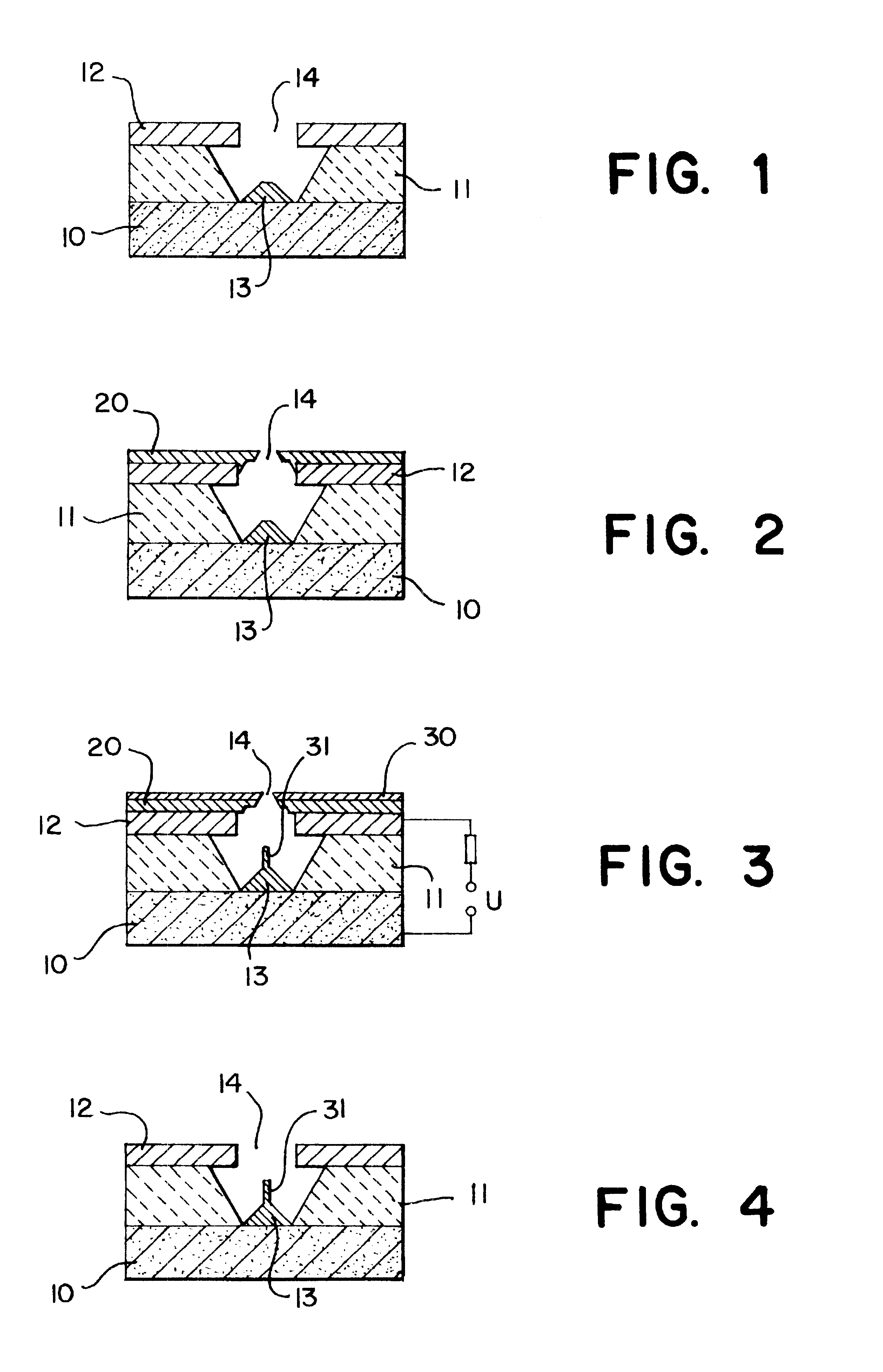

Field emission cathode having an electrically conducting material shaped of a narrow rod or knife edge

InactiveUSRE38223E1Improve emission qualityLong lastingNanoinformaticsThermionic cathodesConfocalConductive materials

A field emission cathode device consisting of an electrically conducting material and with a narrow, rod-shaped geometry or a knife edge, to achieve a high amplification of the electric field strength is characterized in that the electron-emitting part of the field emission cathode at least partly has preferred cylindrical host molecules and / or compounds with host compounds and / or cylindrical atomic networks, possibly with end caps with diameters measuring in the nanometer range.

Owner:KEESMANN TILL

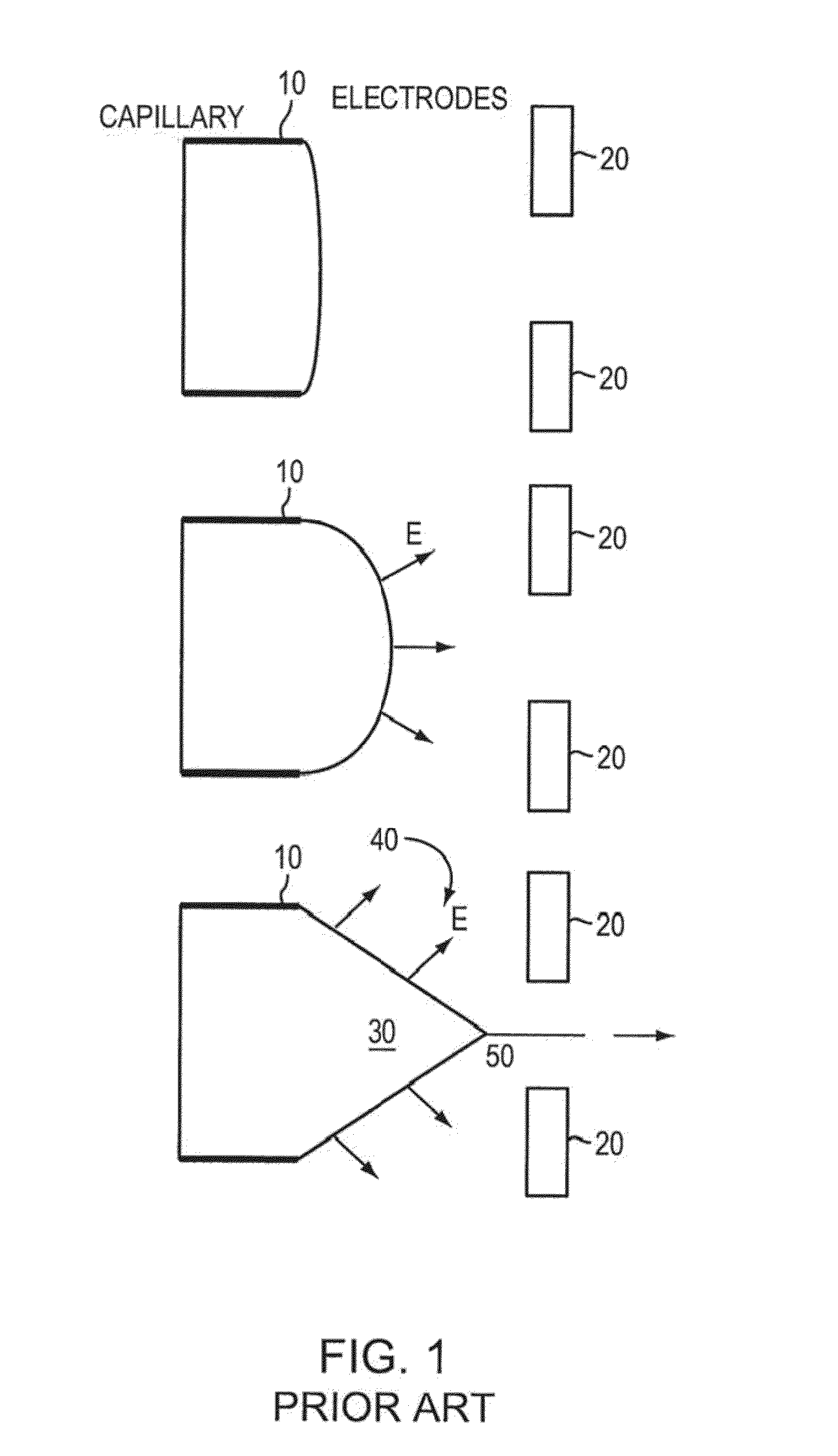

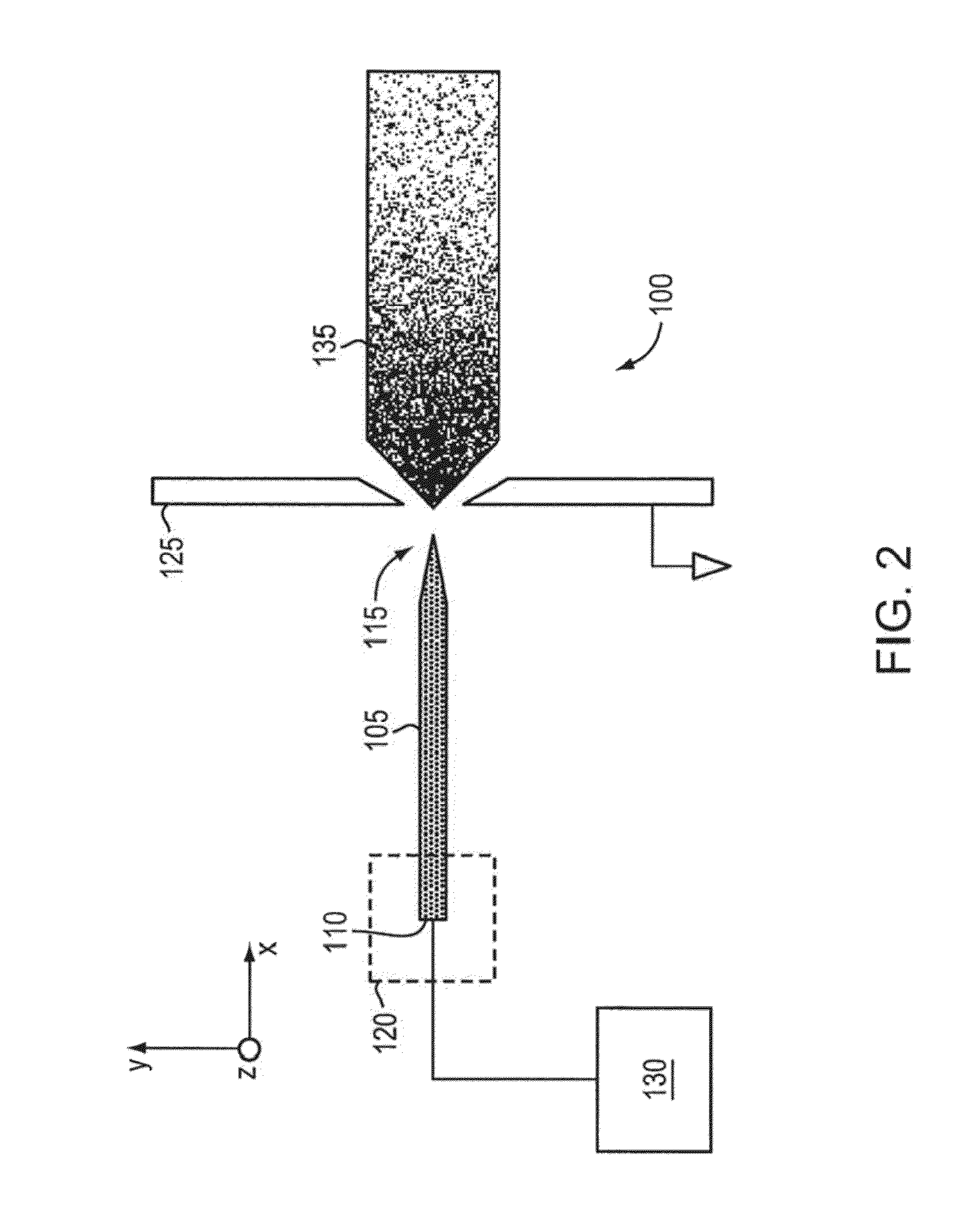

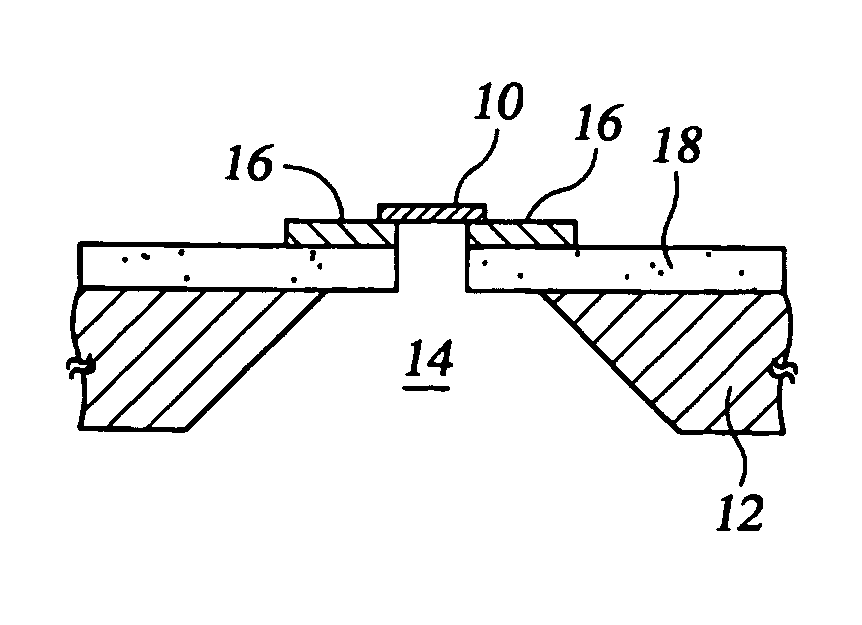

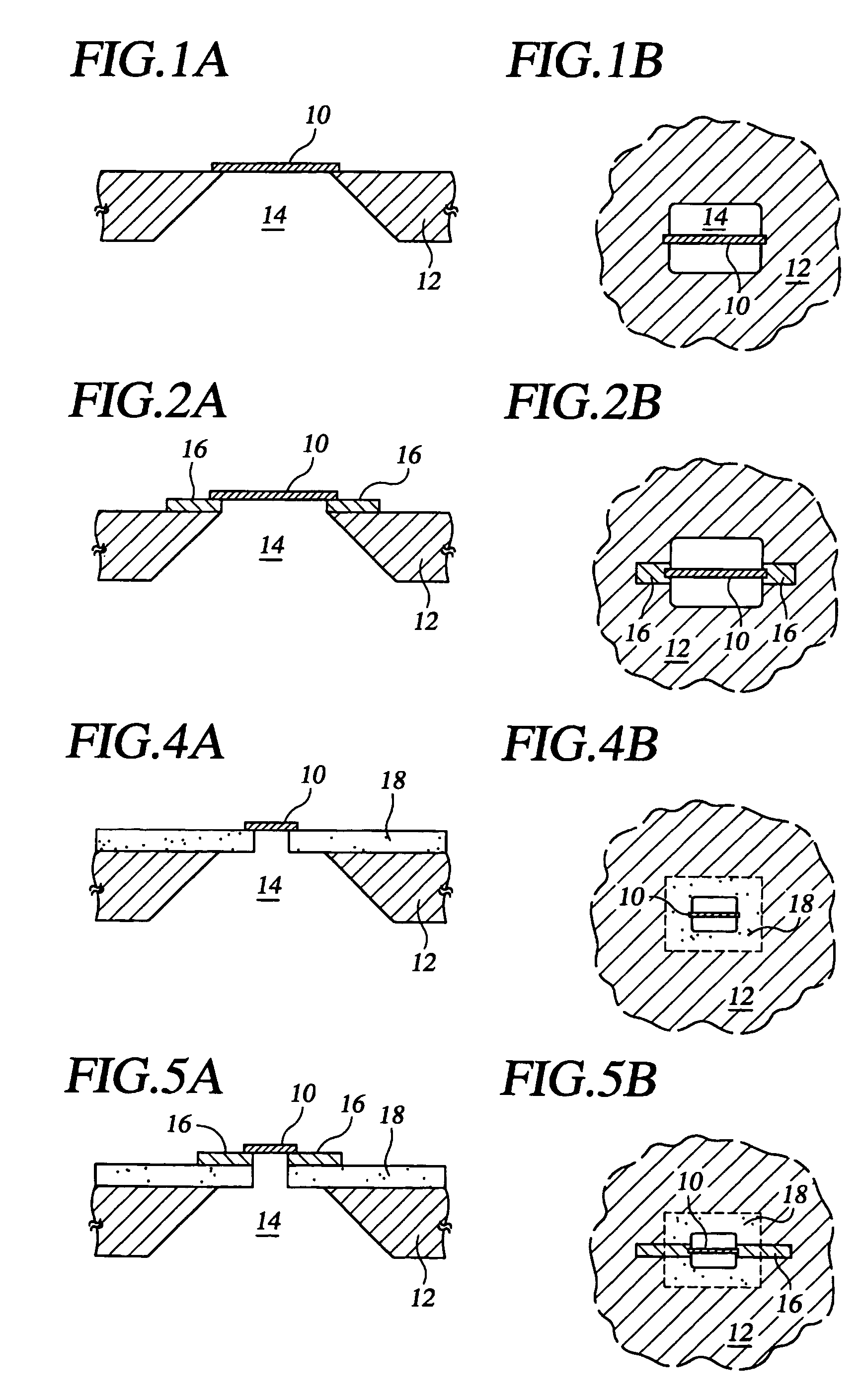

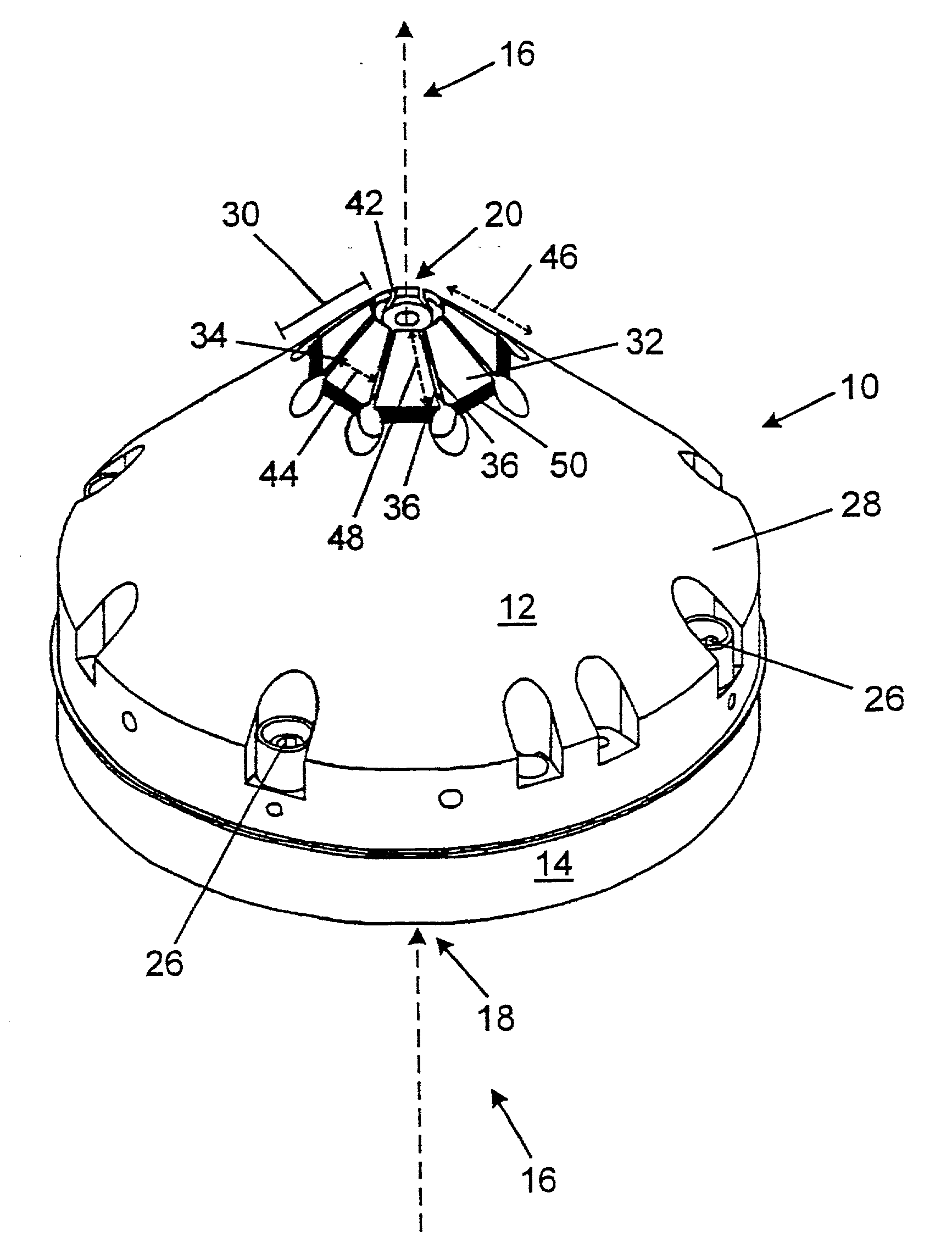

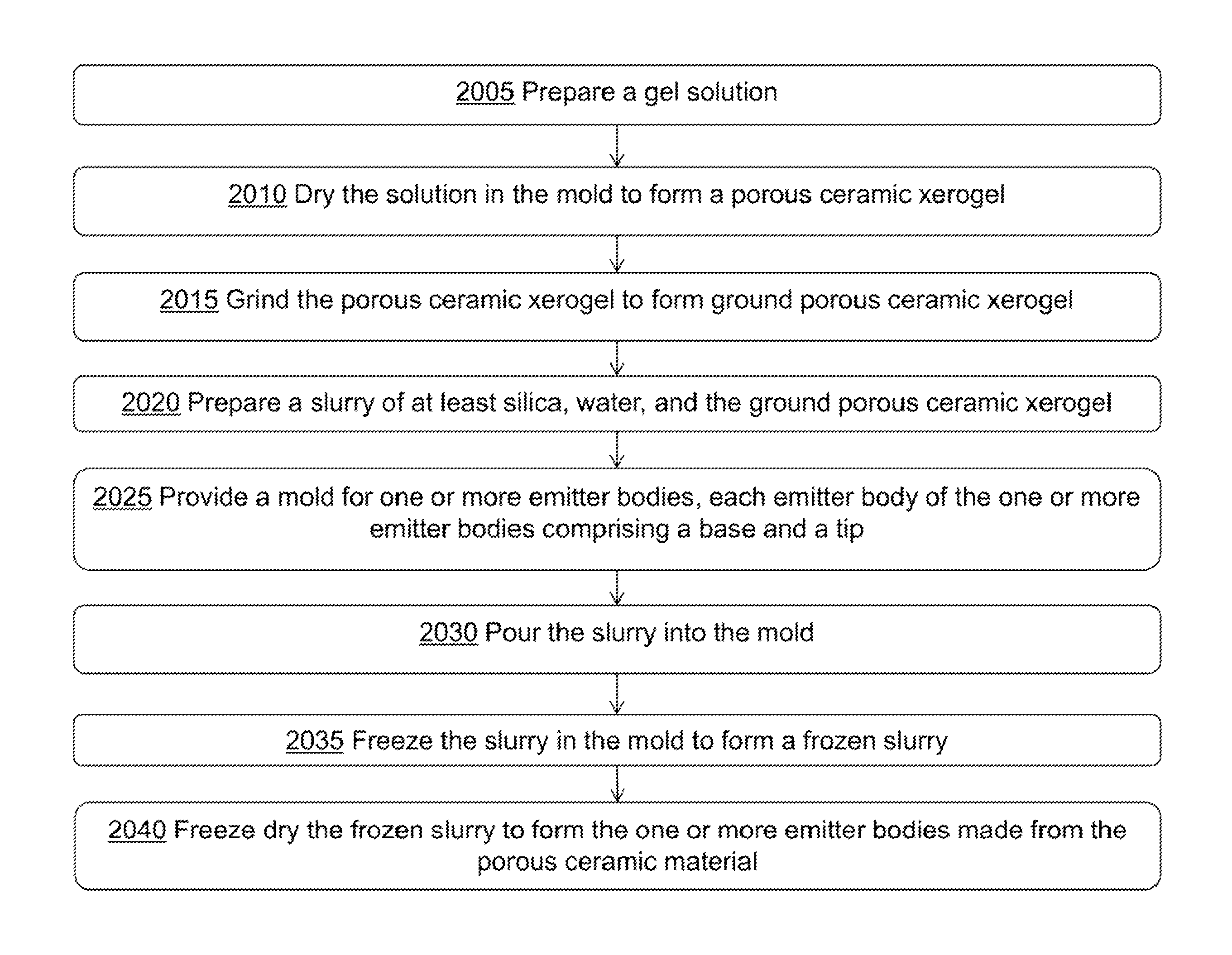

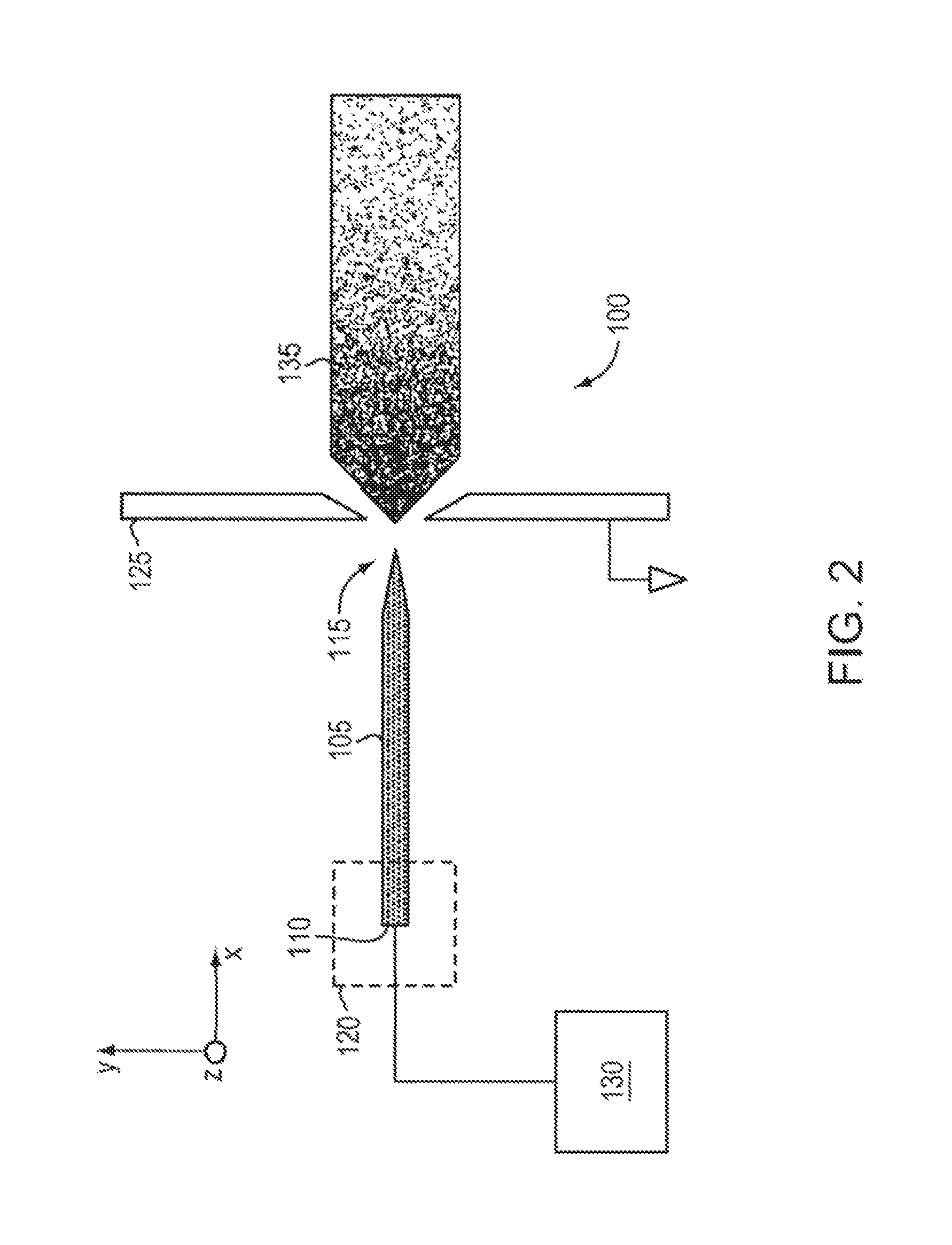

Method and apparatus for a porous electrospray emitter

ActiveUS20140054809A1Increased capillary flow capacityReduce complexityParticle separator tubesMovable spraying apparatusRoom temperatureMolten salt

An ionic liquid ion source can include a microfabricated body including a base and a tip. The body can be formed of a porous material compatible with at least one of an ionic liquid or room-temperature molten salt. The body can have a pore size gradient that decreases from the base of the body to the tip of the body, such that the at least one of an ionic liquid or room-temperature molten salt is capable of being transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

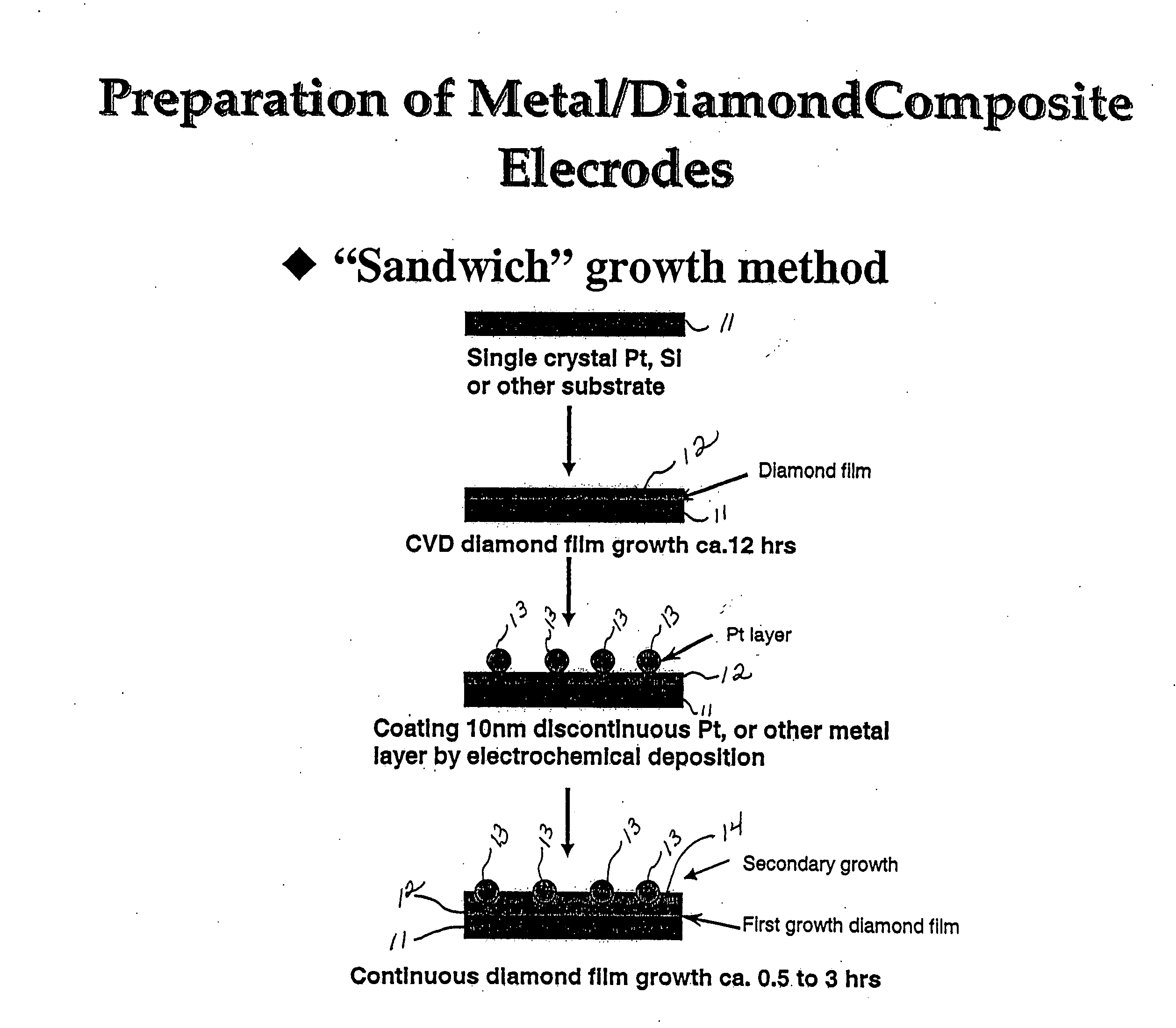

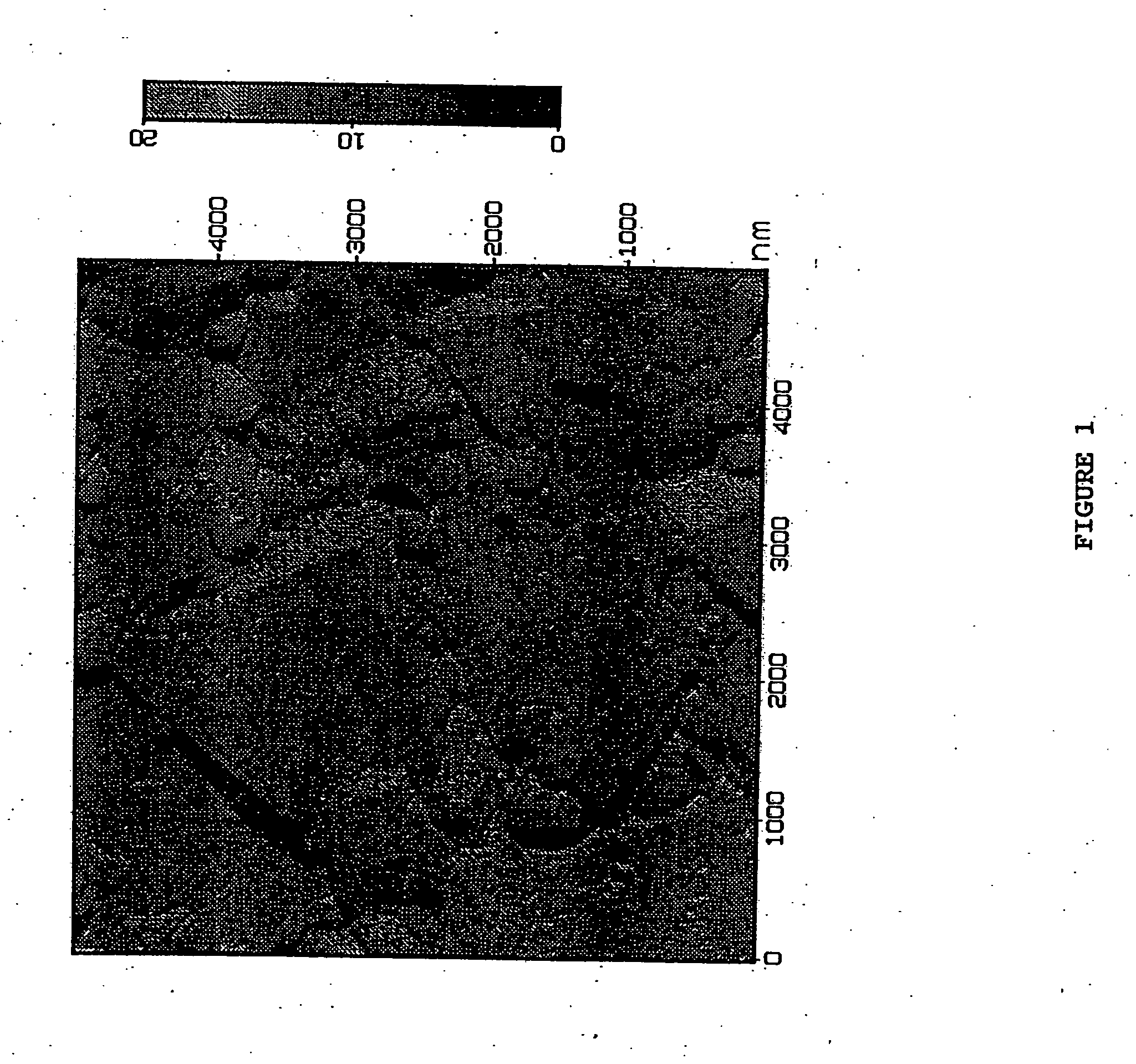

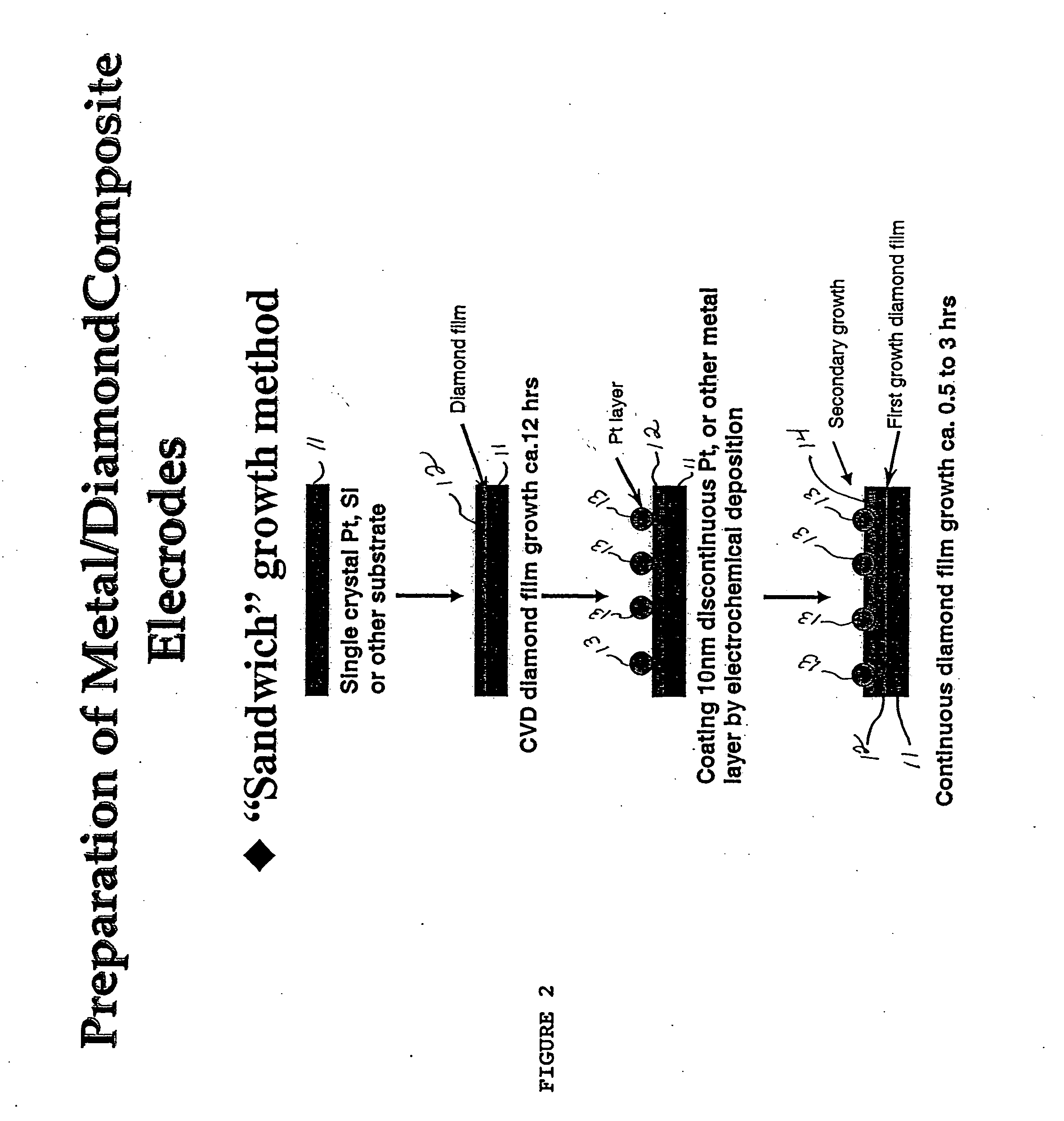

Electrically conductive diamond electrodes

InactiveUS20060175953A1From normal temperature solutionsUltra-high pressure processesHydrogenDiamond electrodes

An electrically conductive diamond electrode and process for preparation thereof is described. The electrode comprises diamond particles coated with electrically conductive doped diamond preferably by chemical vapor deposition which are held together with a binder. The electrodes are useful for oxidation reduction in gas, such as hydrogen generation by electrolysis.

Owner:MICHIGAN STATE UNIV

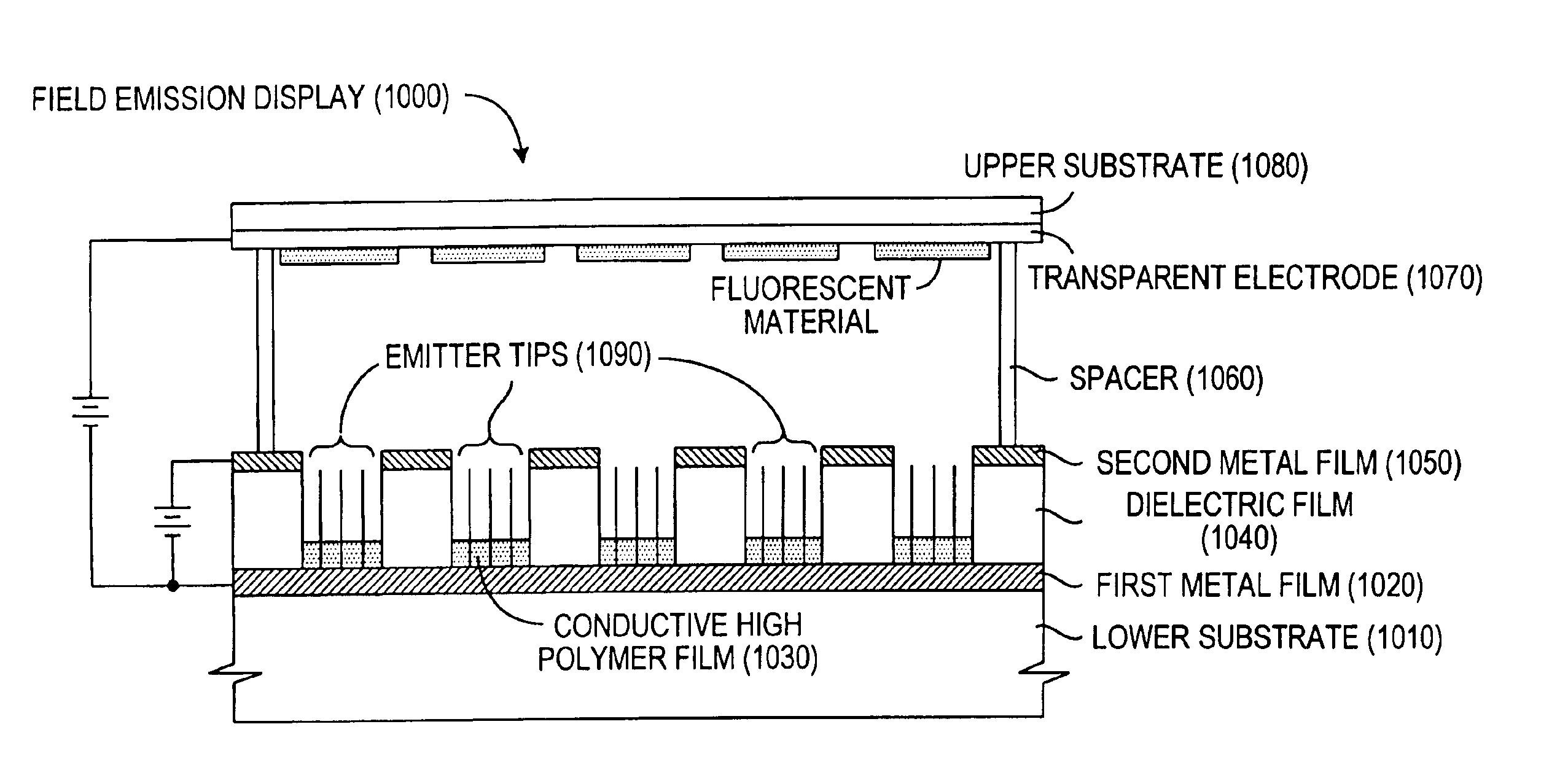

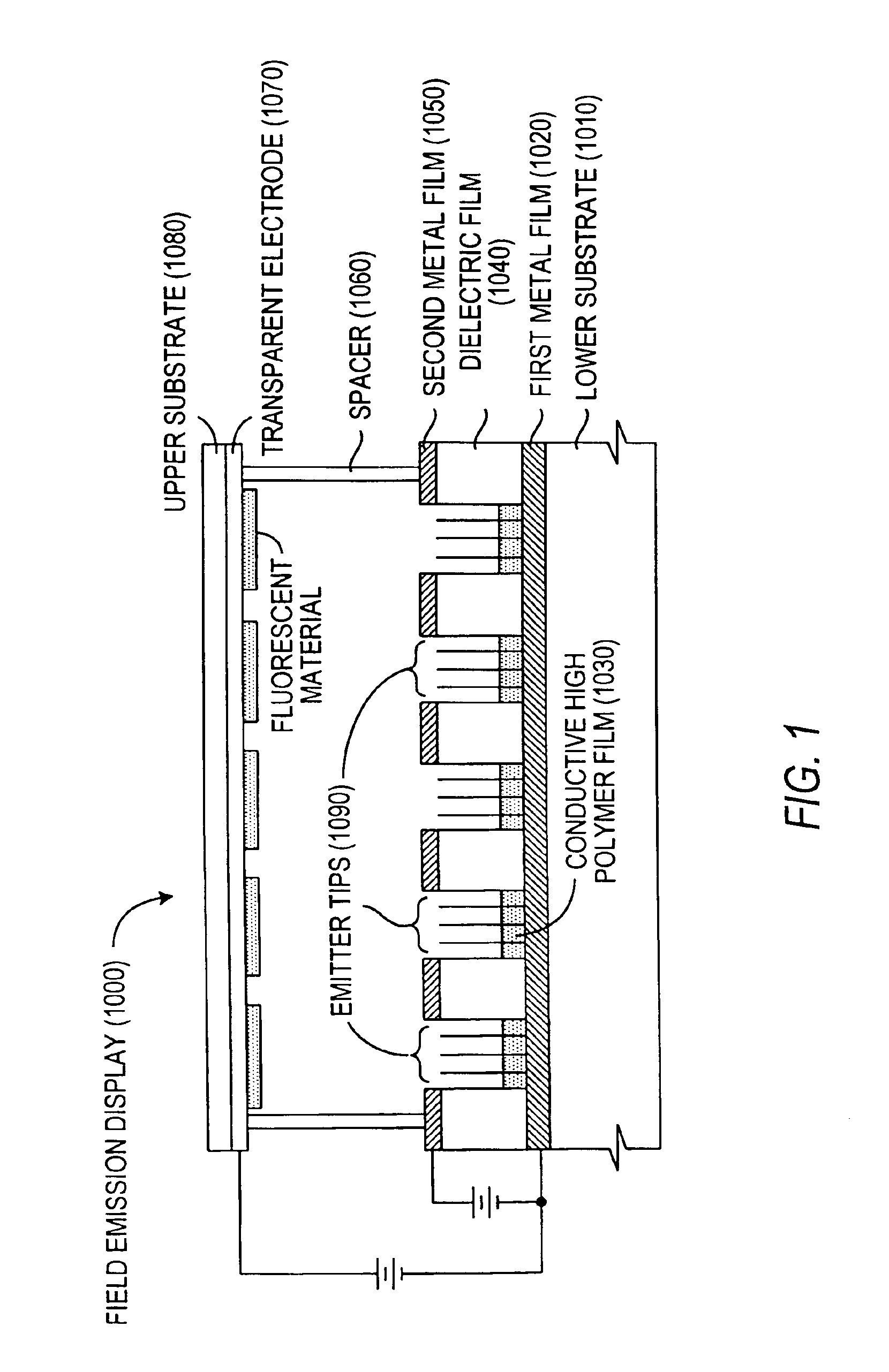

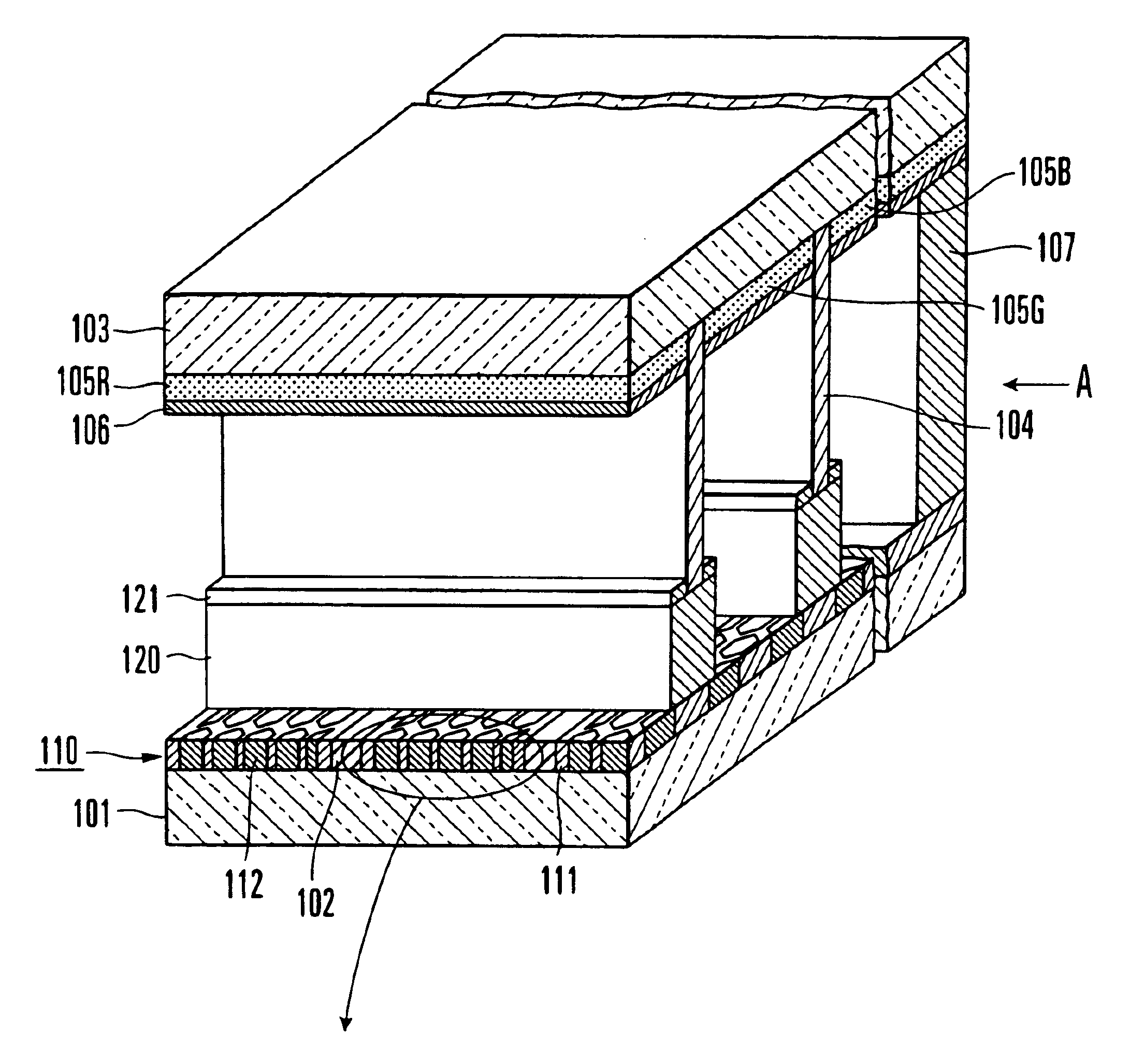

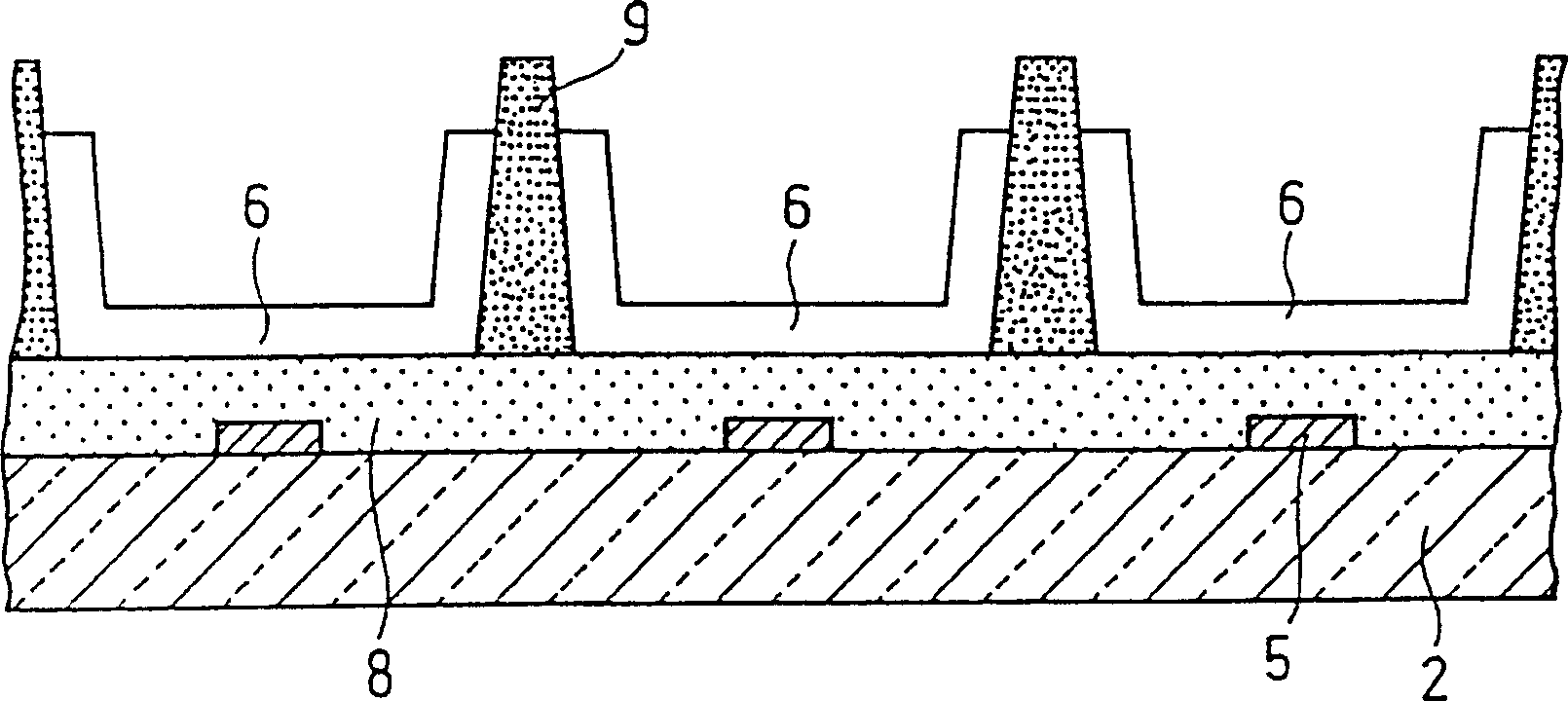

Field emission display having carbon nanotube emitter and method of manufacturing the same

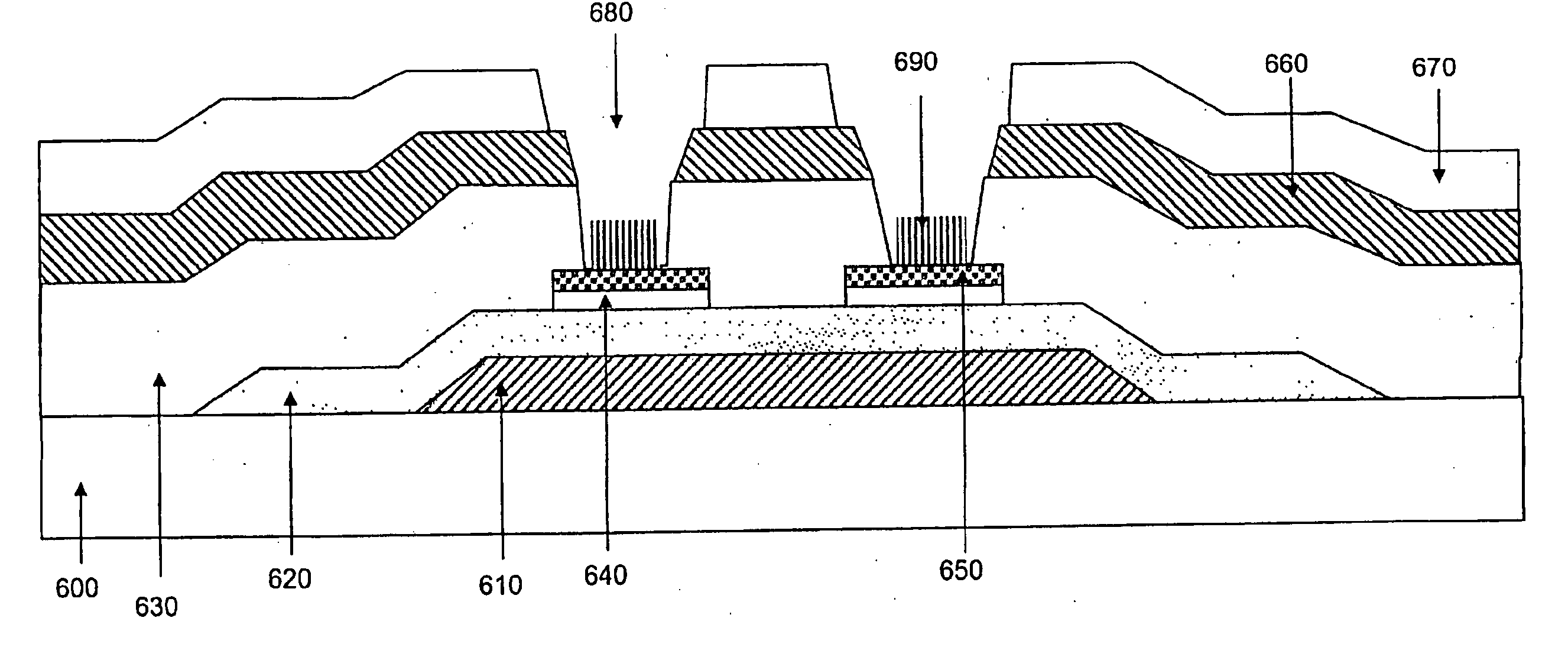

InactiveUS20050035701A1Good step coverageReduce leakage currentNanoinformaticsElectrode and associated part arrangementsSilanesCarbon nanotube

Provided is a field emission display (FED) with a carbon nanotube emitter and a method of manufacturing the same. A gate stack that surrounds the CNT emitter has a mask layer that covers an emitter electrode adjacent to the CNT emitter, and a gate insulating film, a gate electrode, a focus gate insulating film (SiOx, X<2), and a focus gate electrode formed on the mask layer. The focus gate insulating film has a thickness 2 μm or more, and preferably 3˜15 μm and is preferably made using PECVD. A flow rate of silane and nitric acid for forming the focus gate insulating film and / or the gate insulating film are maintained at 50˜700 sccm and 700˜4,500 sccm, respectively. By doing so and by making the oxide thick, the oxide is less apt to crack and thus less apt to generate a leakage current.

Owner:SAMSUNG SDI CO LTD

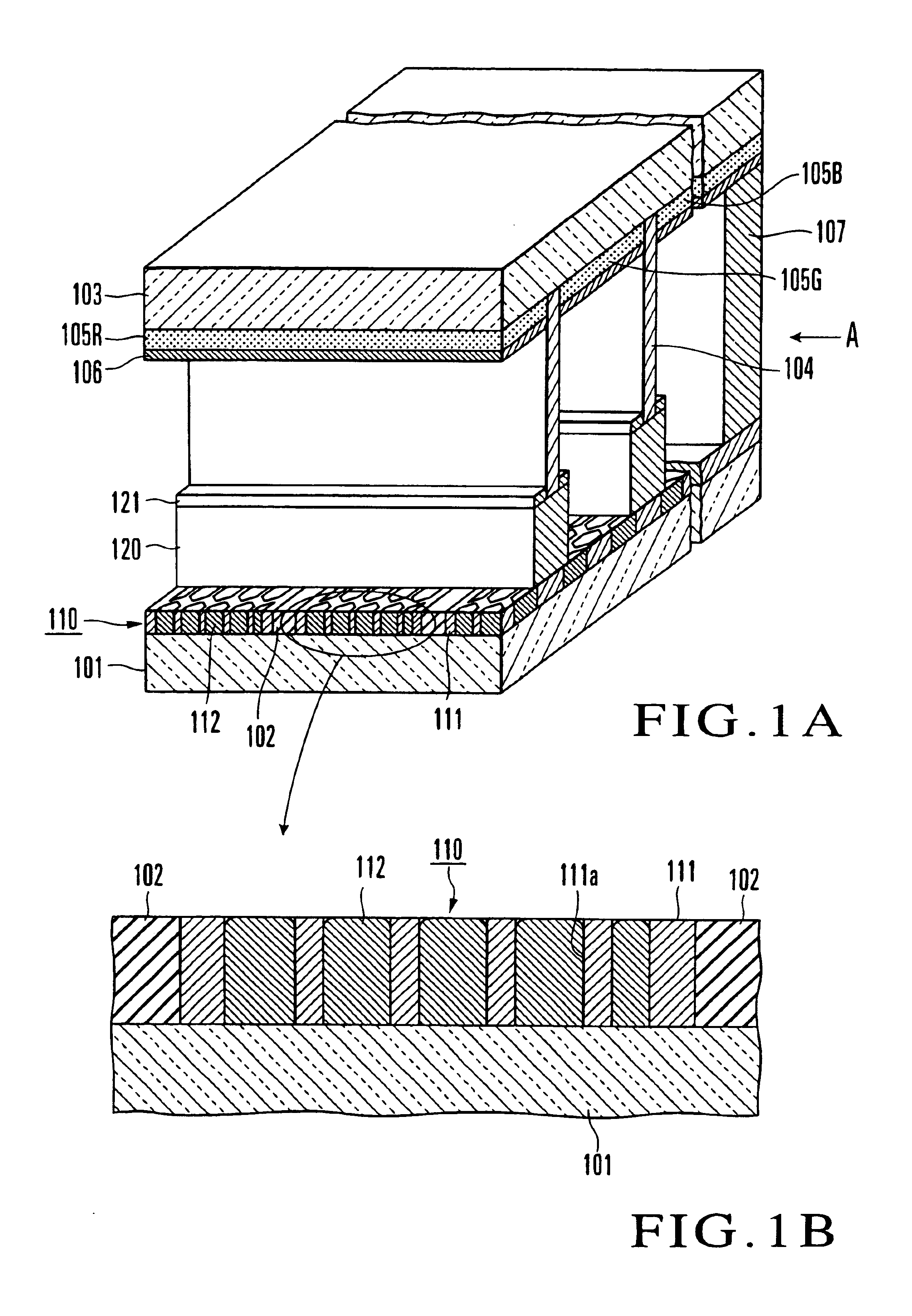

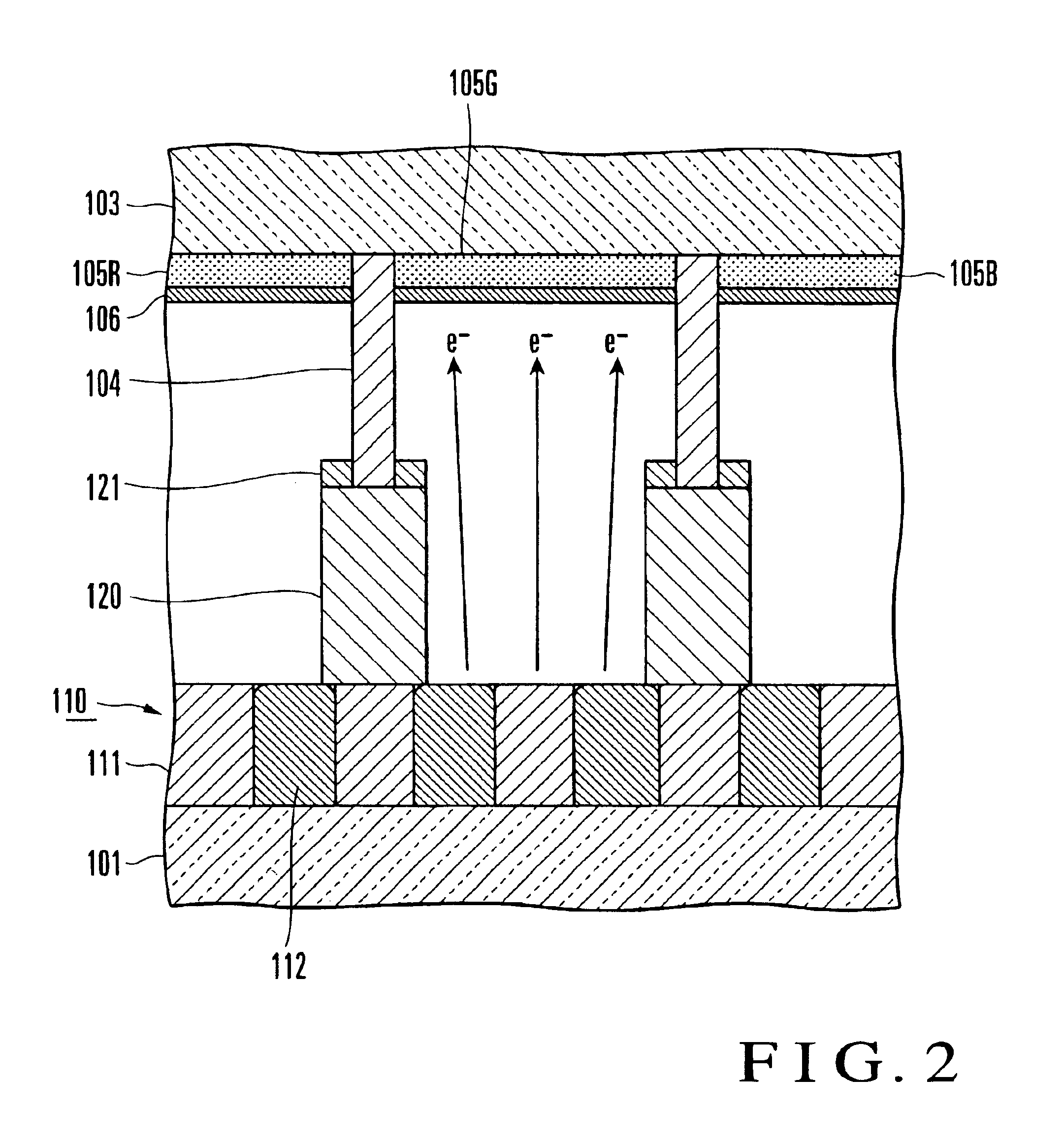

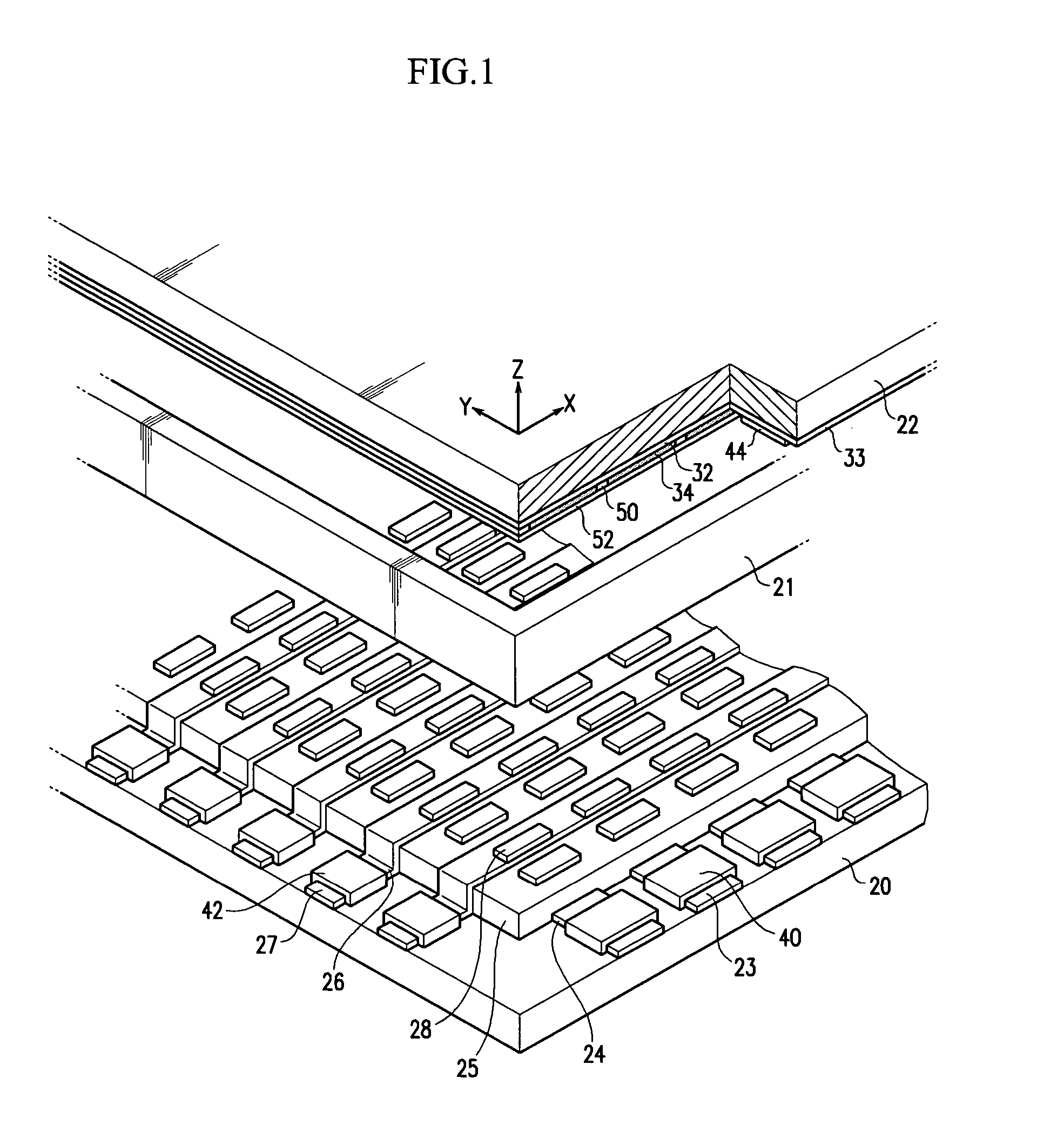

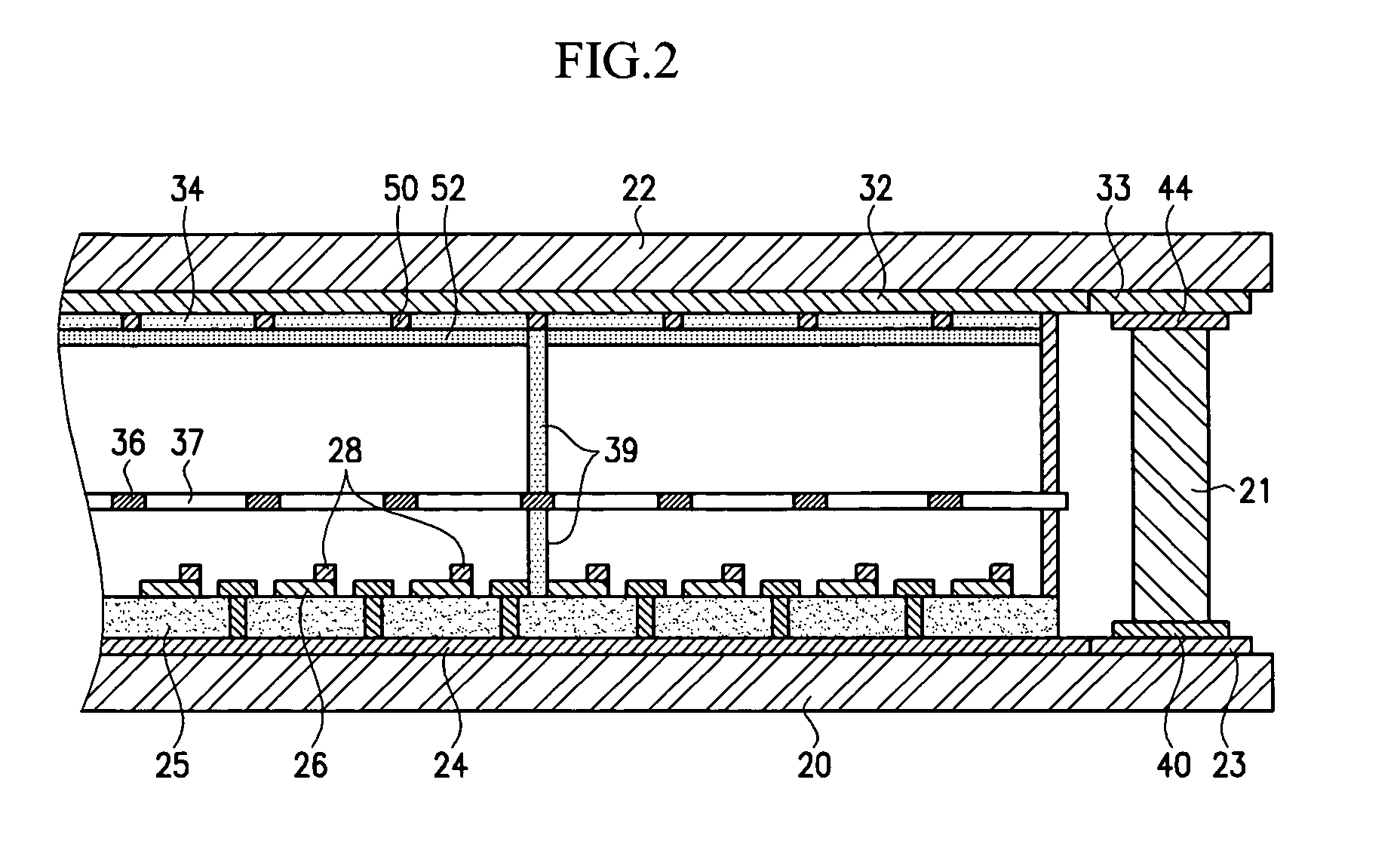

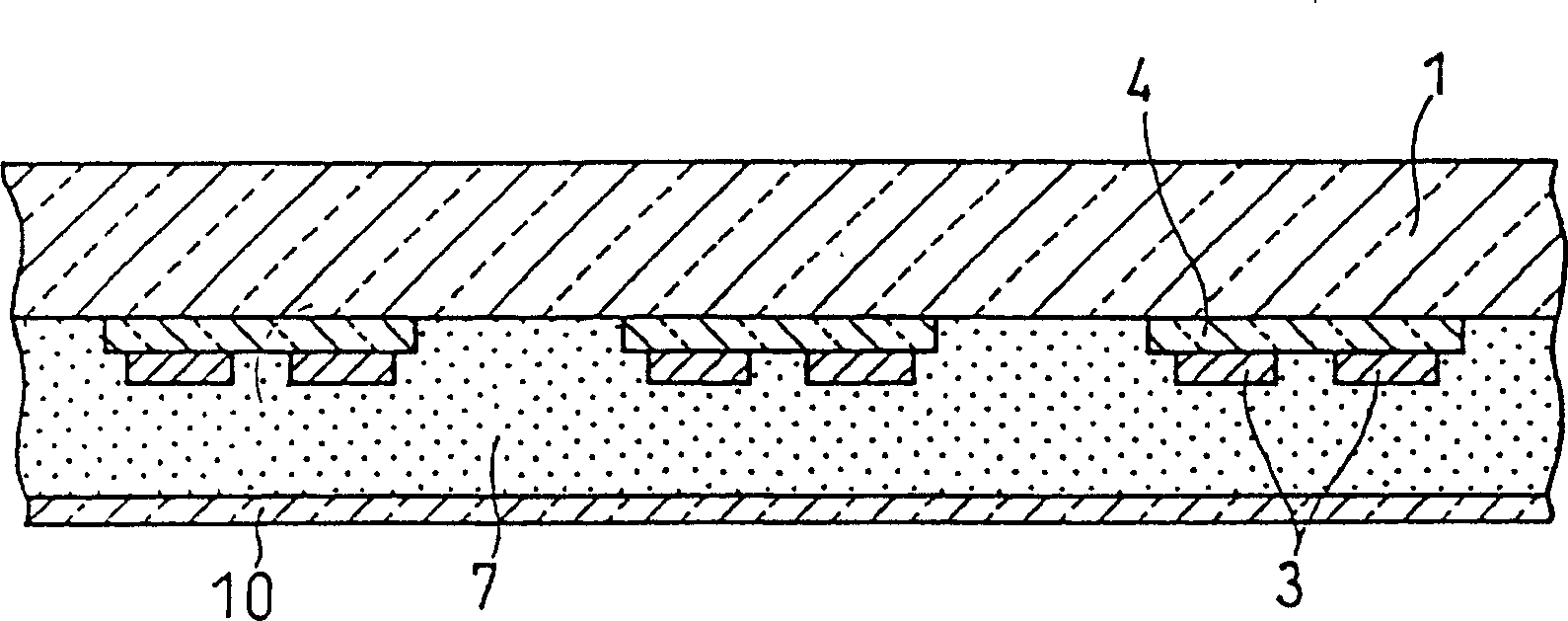

Flat-panel display and flat panel display cathode manufacturing method

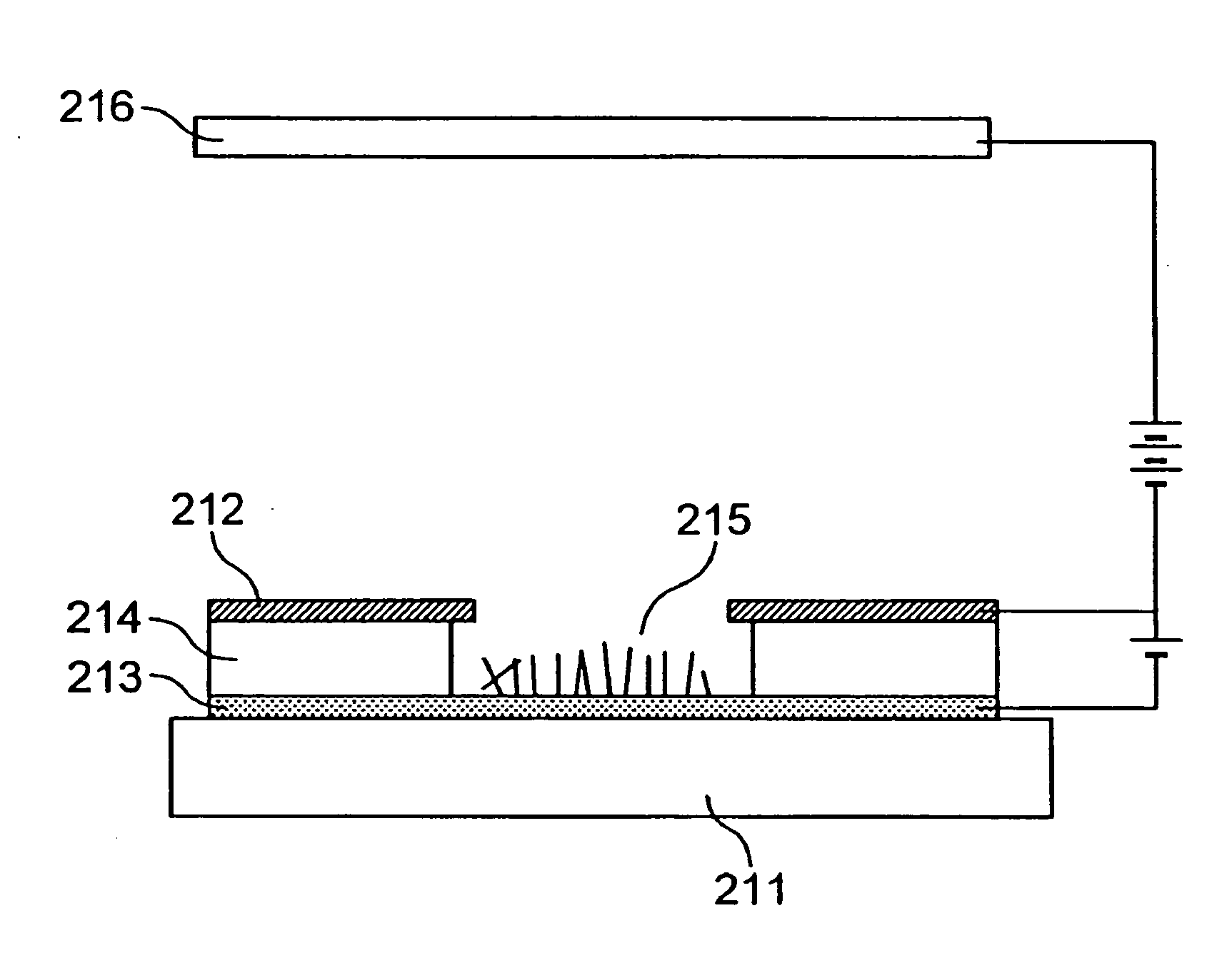

InactiveUS6943493B2Free from luminance irregularityNanoinformaticsElectrode and associated part arrangementsPhosphorFluorescence

A flat-panel display includes a front glass, glass substrate, cathodes, gate electrodes, phosphor films, and anodes. The front glass has translucency at least partly. The substrate is placed to oppose the front glass through a vacuum space. The cathodes are formed on the substrate. The gate electrodes are placed in the vacuum space and spaced apart from the cathodes. The phosphor layers and anodes are formed on a surface of the front glass which opposes the substrate. Each cathode includes a metal member having many opening portions which is mounted on the substrate, and a conductive material containing carbon nanotubes filled in the mesh-like opening portions. A method of manufacturing a flat-panel display is also disclosed.

Owner:NORITAKE CO LTD

Carbon nanotube device fabrication

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

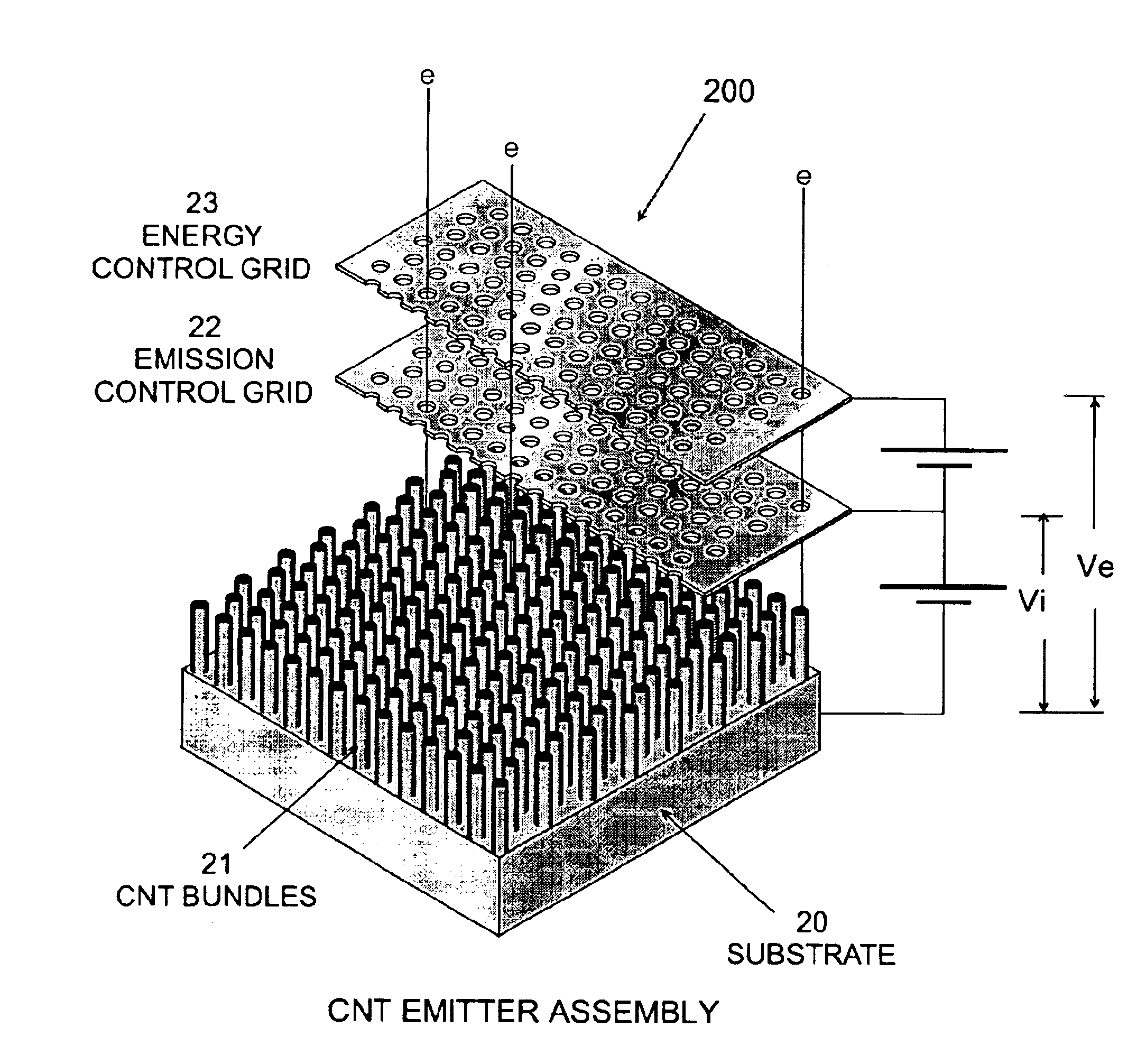

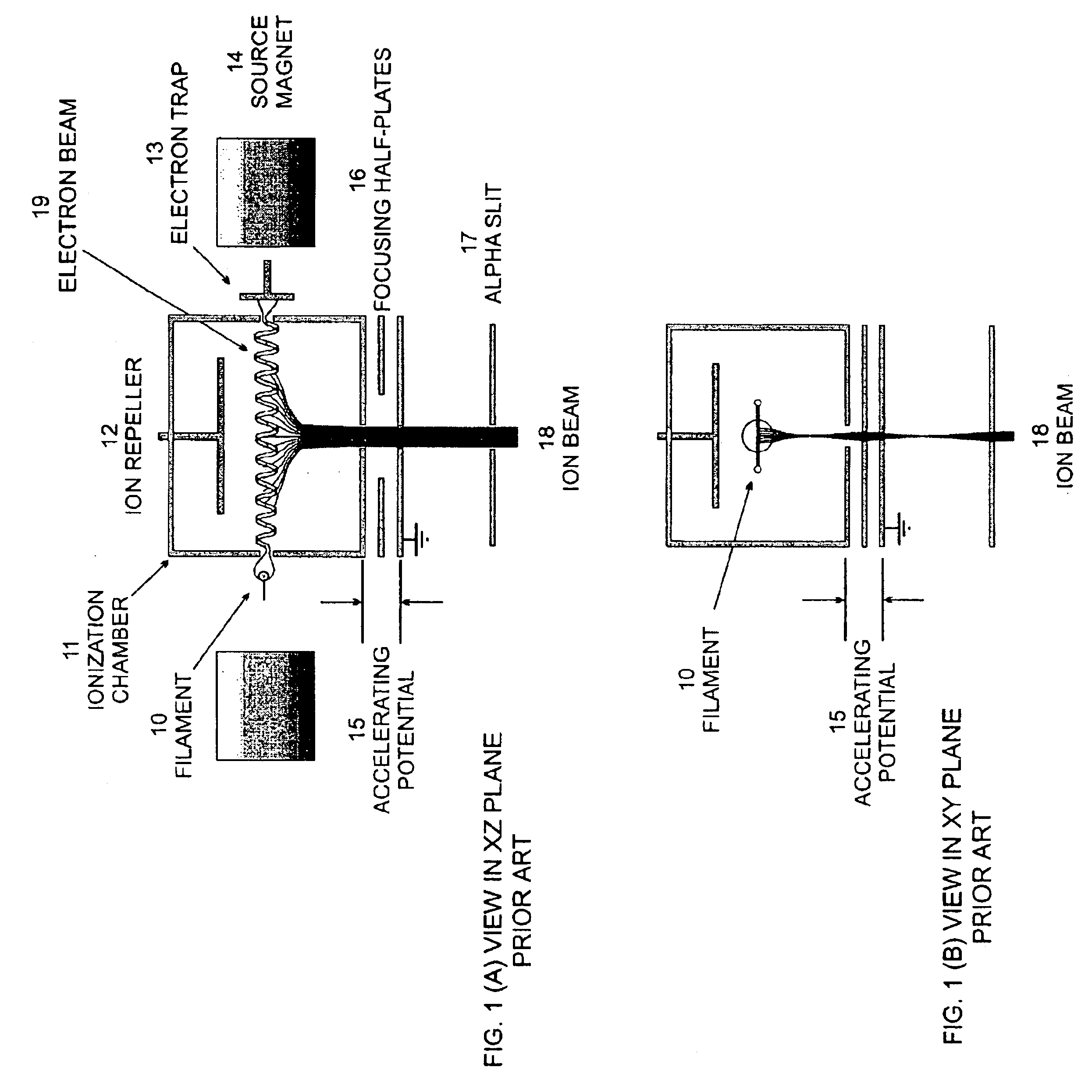

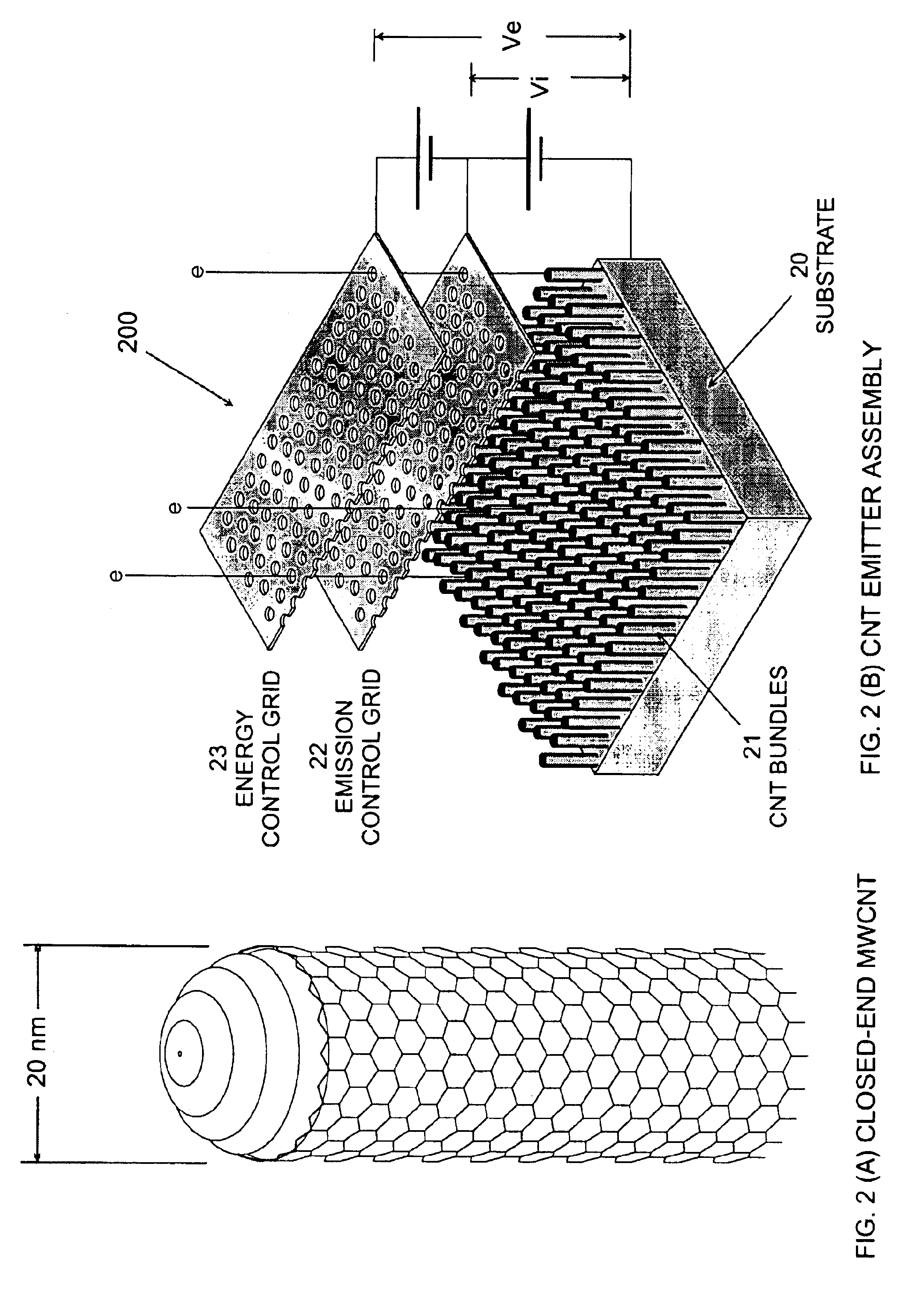

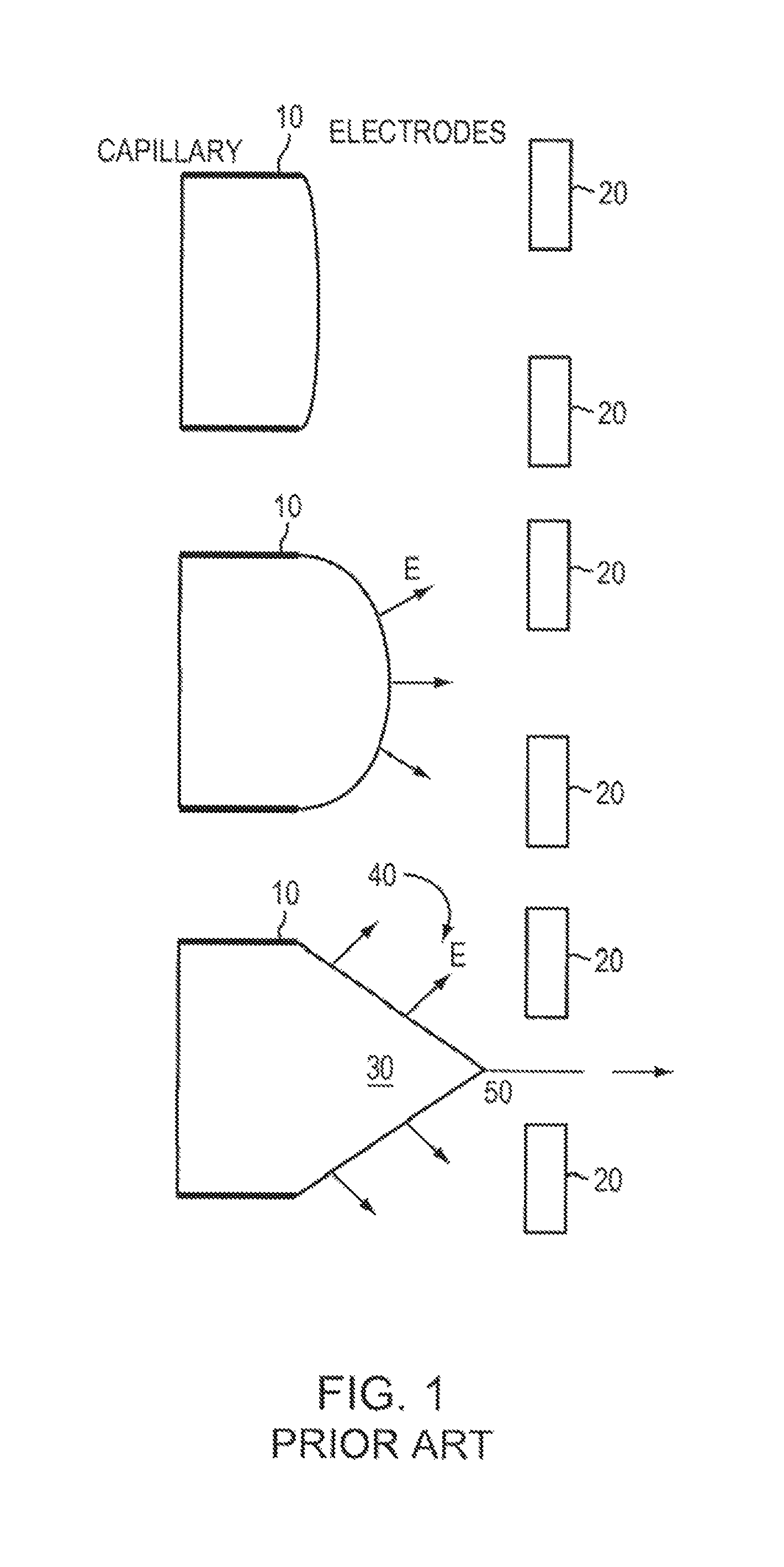

Carbon nanotube electron ionization sources

ActiveUS6885010B1Reduce in quantityEasy CalibrationMaterial nanotechnologyLamp incadescent bodiesLight beamIonization chamber

An ion source for use in a mass spectrometer includes an electron emitter assembly configured to emit electron beams, wherein the electron emitter assembly comprises carbon nanotube bundles fixed to a substrate for emitting the electron beams, a first control grid configured to control emission of the electron beams, and a second control grid configured to control energies of the electron beams; an ionization chamber having an electron-beam inlet to allow the electron beams to enter the ionization chamber, a sample inlet for sample introduction, and an ion-beam outlet to provide an exit for ionized sample molecules; an electron lens disposed between the electron emitter assembly and the ionization chamber to focus the electron beams; and at least one electrode disposed proximate the ion-beam outlet to focus the ionized sample molecules exiting the ionization chamber.

Owner:THERMO ELECTRON A DE

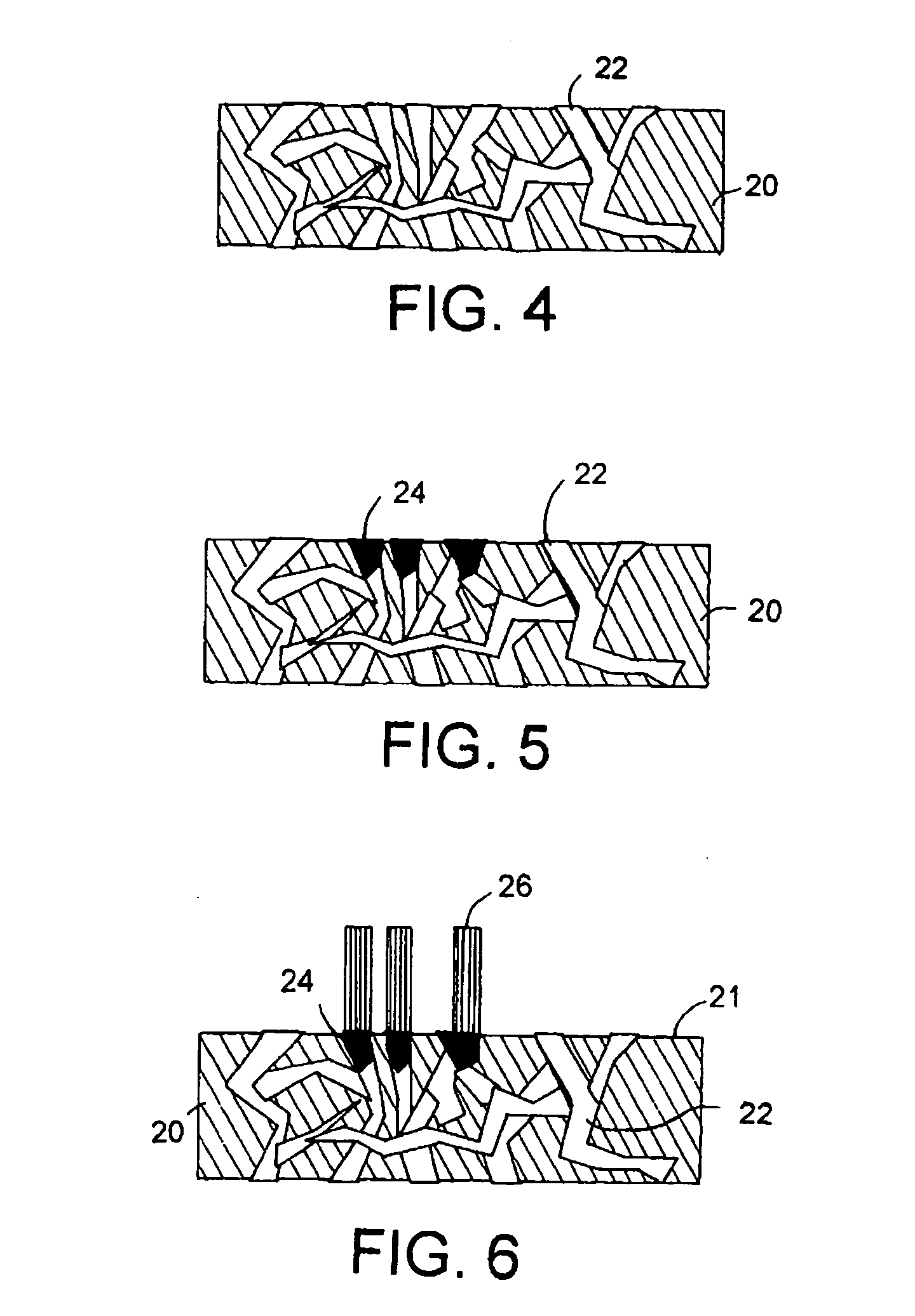

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

Method of manufacturing an electron emitting device with carbon nanotubes

InactiveUS7094123B2Easily subject to degradationIntensifies variationNanoinformaticsThermionic cathodesFiberHydrogen

There is provided a method of manufacturing an electron emitting device by disposing a substrate with a catalytic metal film inside a reaction vessel; feeding hydrogen gas and hydrocarbon gas simultaneously into the reaction vessel at a temperature close to room temperature; raising the temperature inside the reaction vessel; and producing carbon fibers by keeping the temperature inside the reaction vessel substantially constant.

Owner:CANON KK

Field emission cold cathode device of lateral type

InactiveUS20060061257A1Material nanotechnologyDischarge tube luminescnet screensCarbon nanotubeCold cathode

A field emission cold cathode device of a lateral type includes a cathode electrode and gate electrode disposed on a major surface of a support substrate laterally side by side. The cathode electrode and gate electrode have side surfaces which oppose each other, and an emitter is disposed on the opposite side surface of the cathode electrode. The emitter includes a metal plating layer formed on the cathode electrode, and a plurality of granular or rod-shaped micro-bodies. The micro-bodies are consisting essentially of a material selected from the group consisting of fullerenes, carbon nanotubes, graphite, a material with a low work function, a material with a negative electron affinity, and a metal material, and are supported in the metal plating layer in a dispersed state.

Owner:KK TOSHIBA

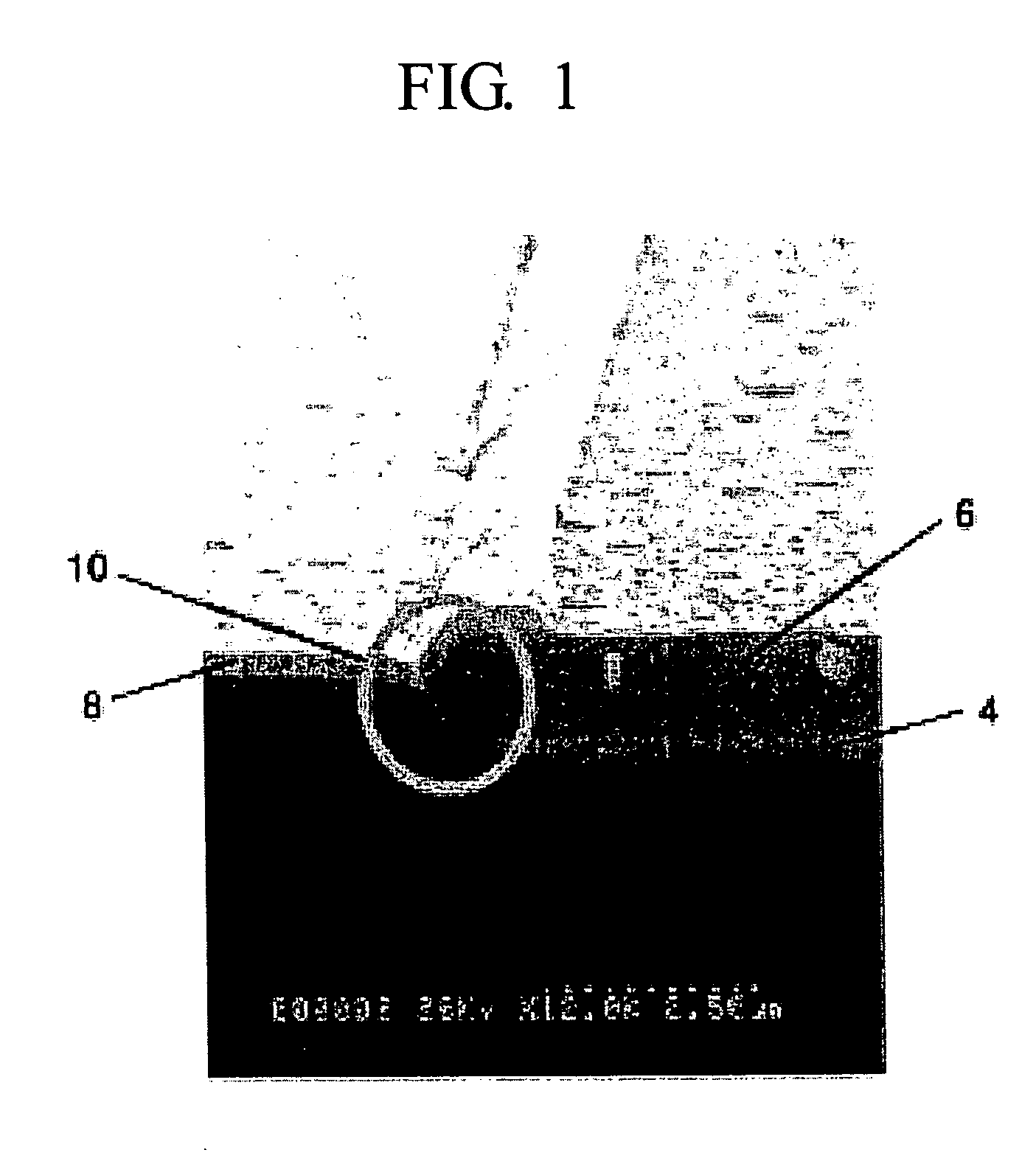

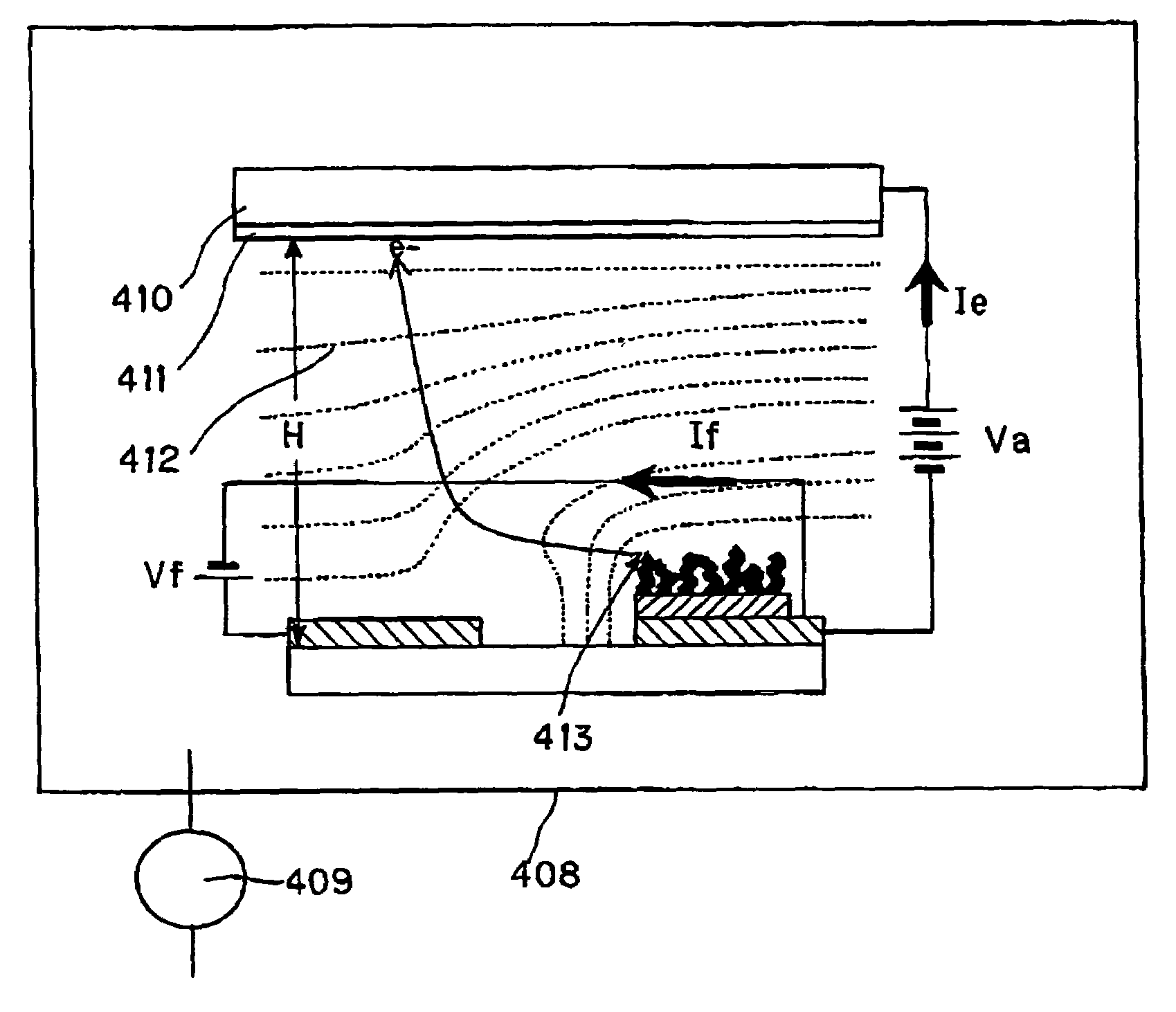

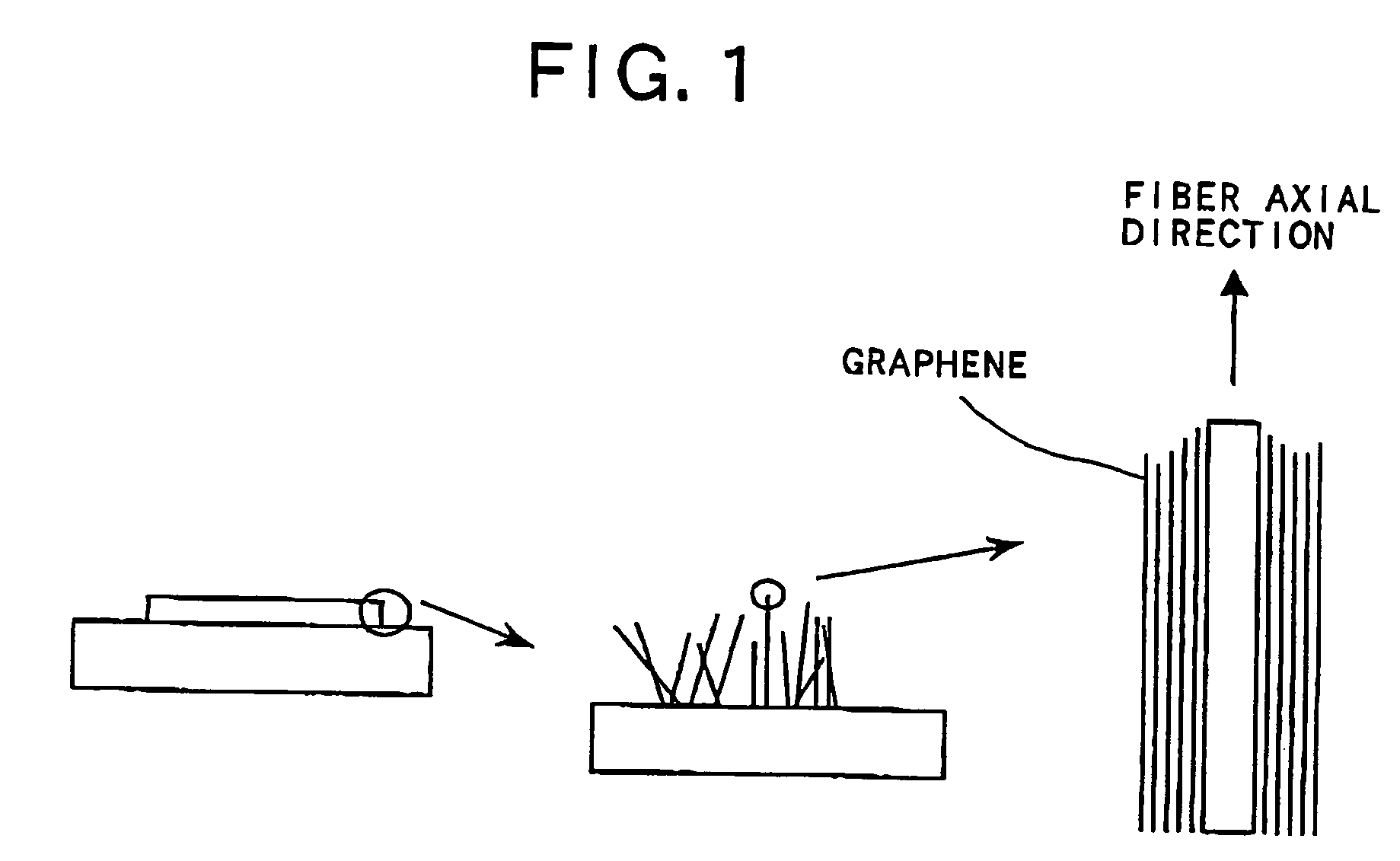

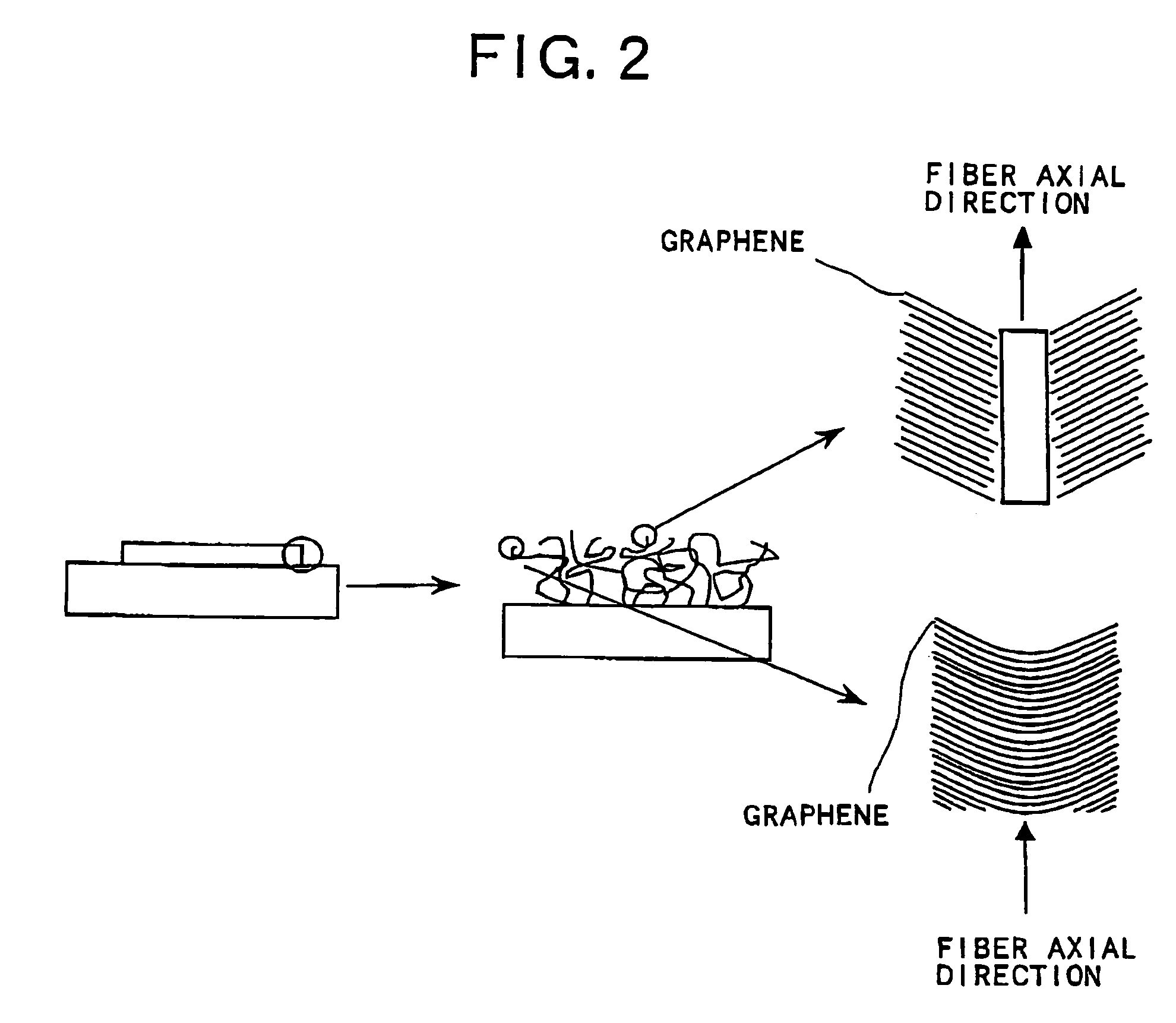

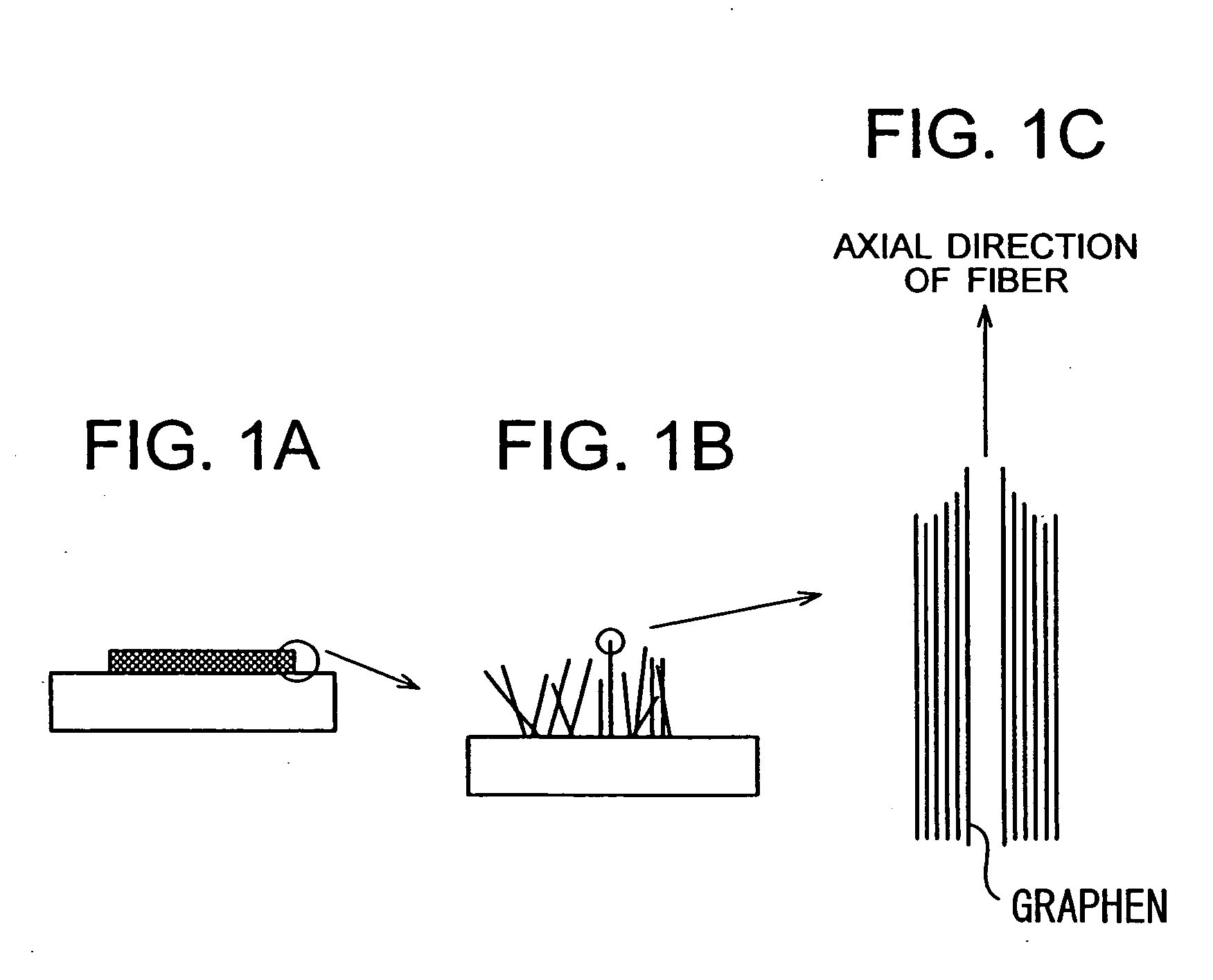

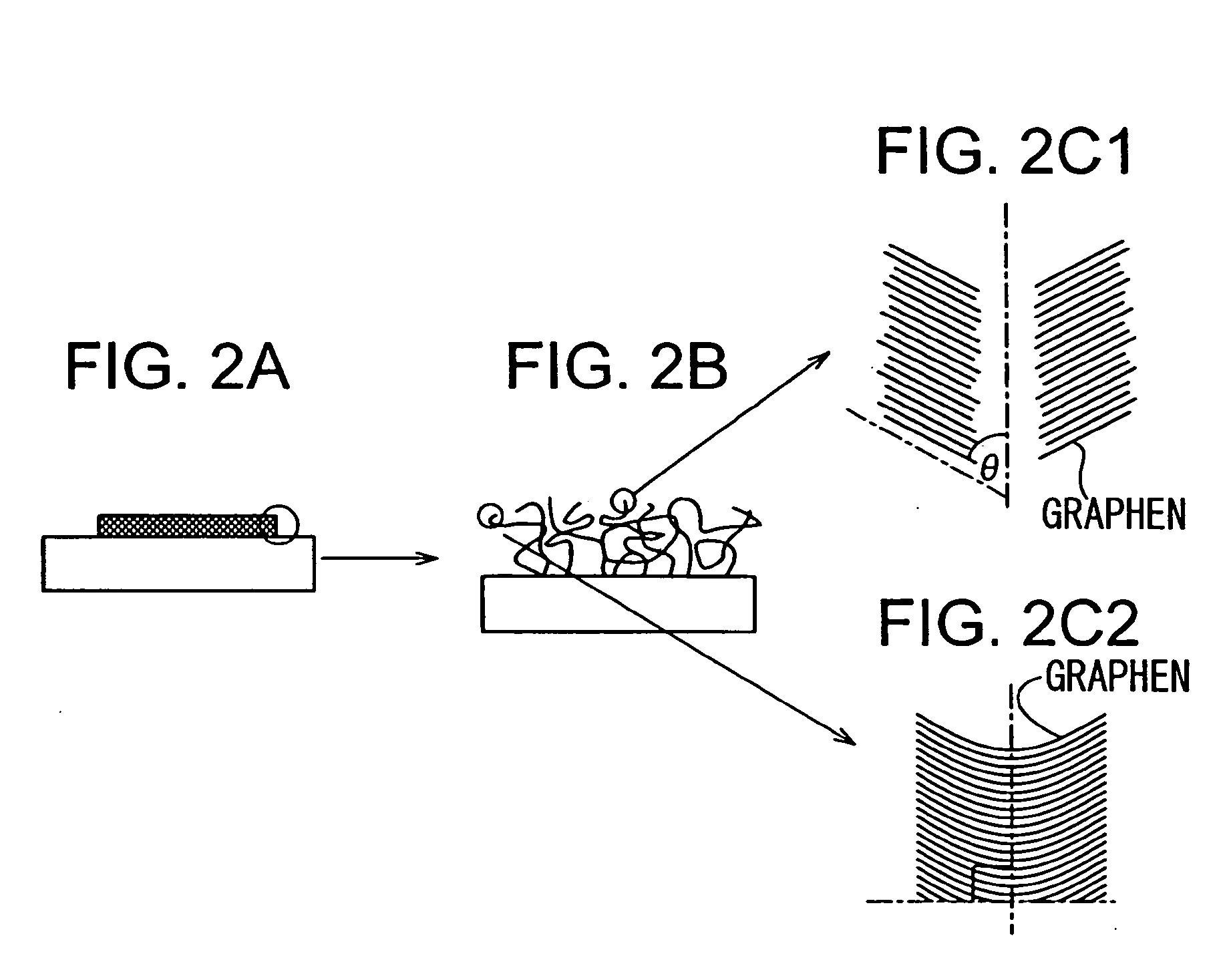

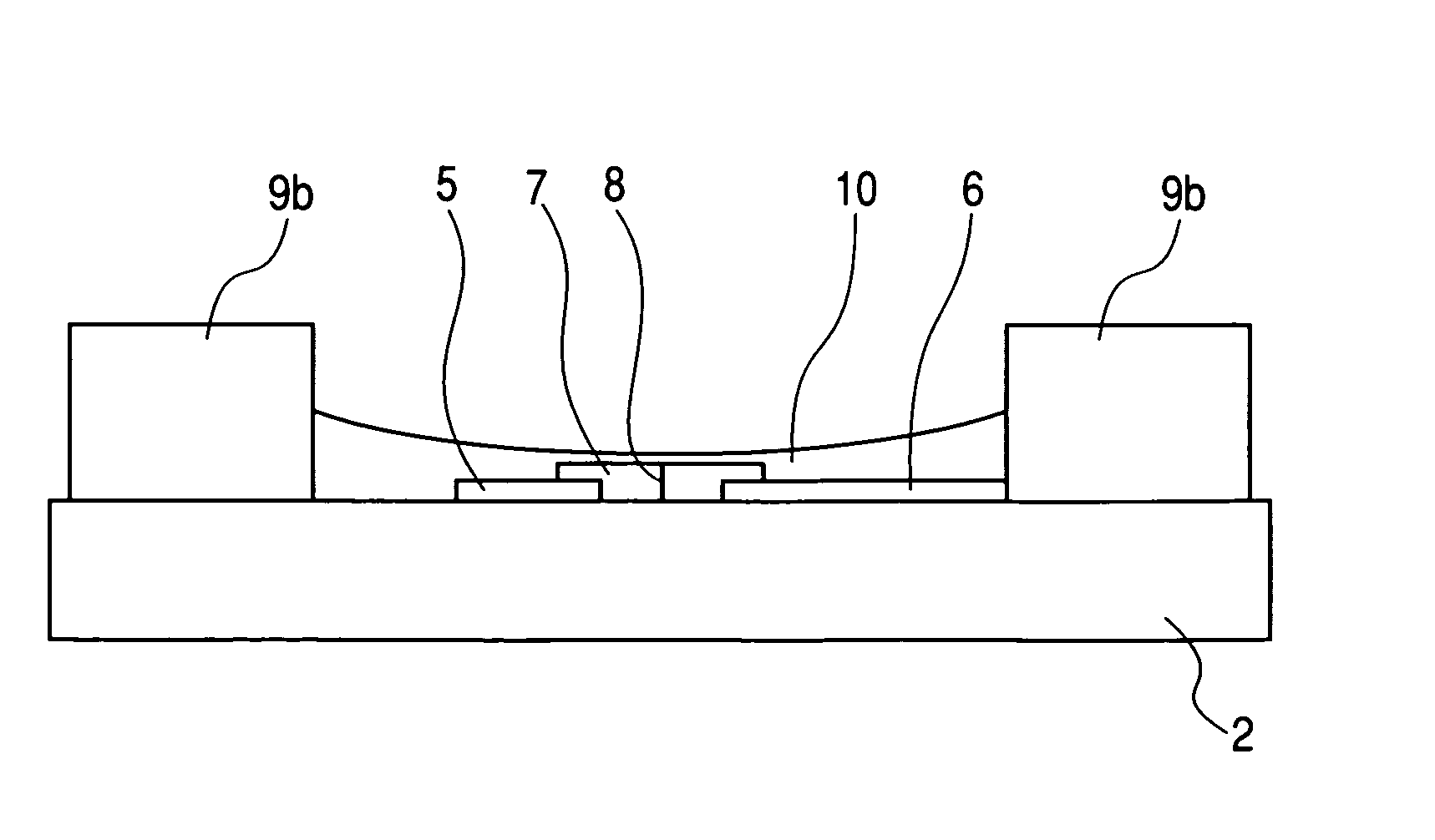

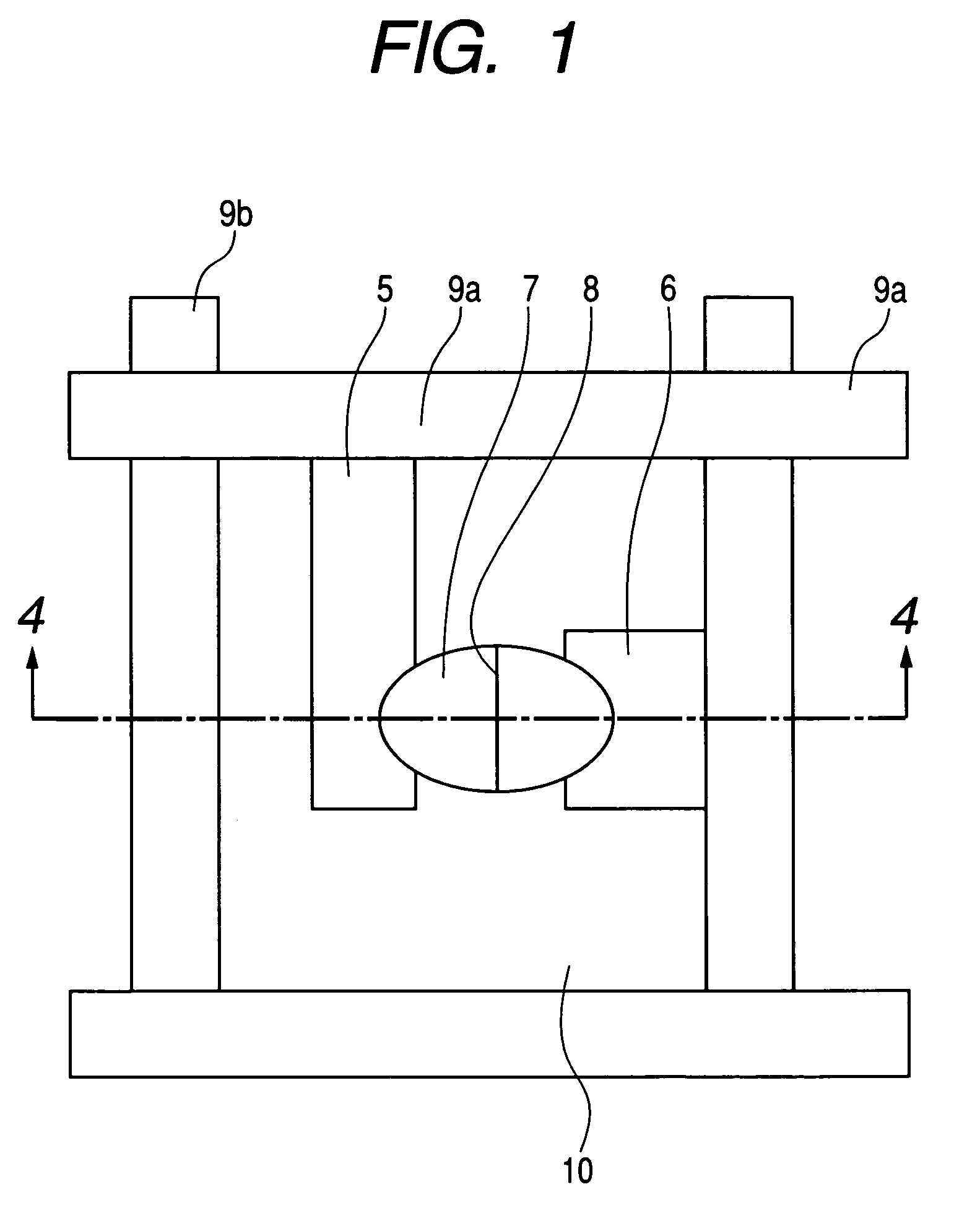

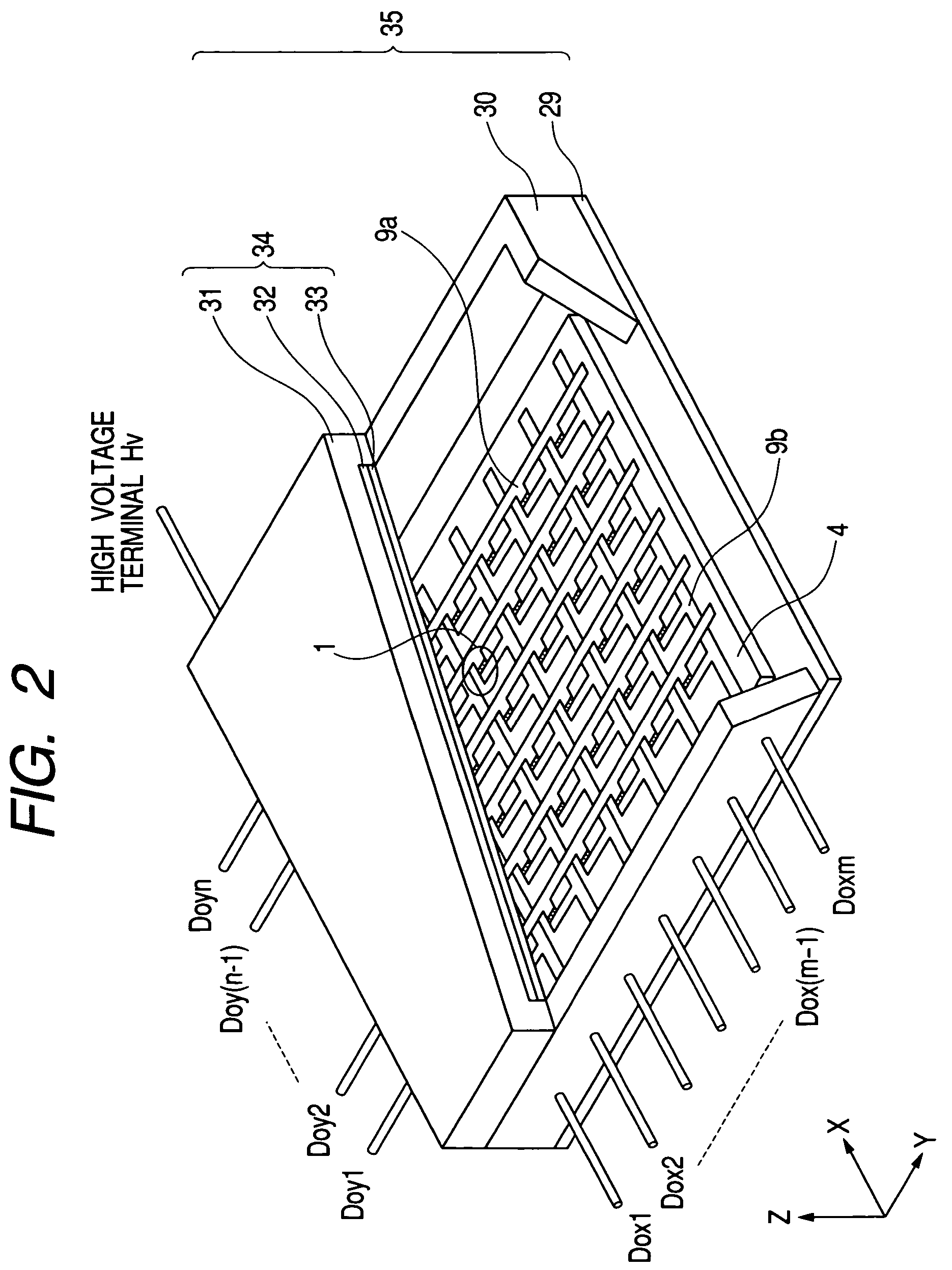

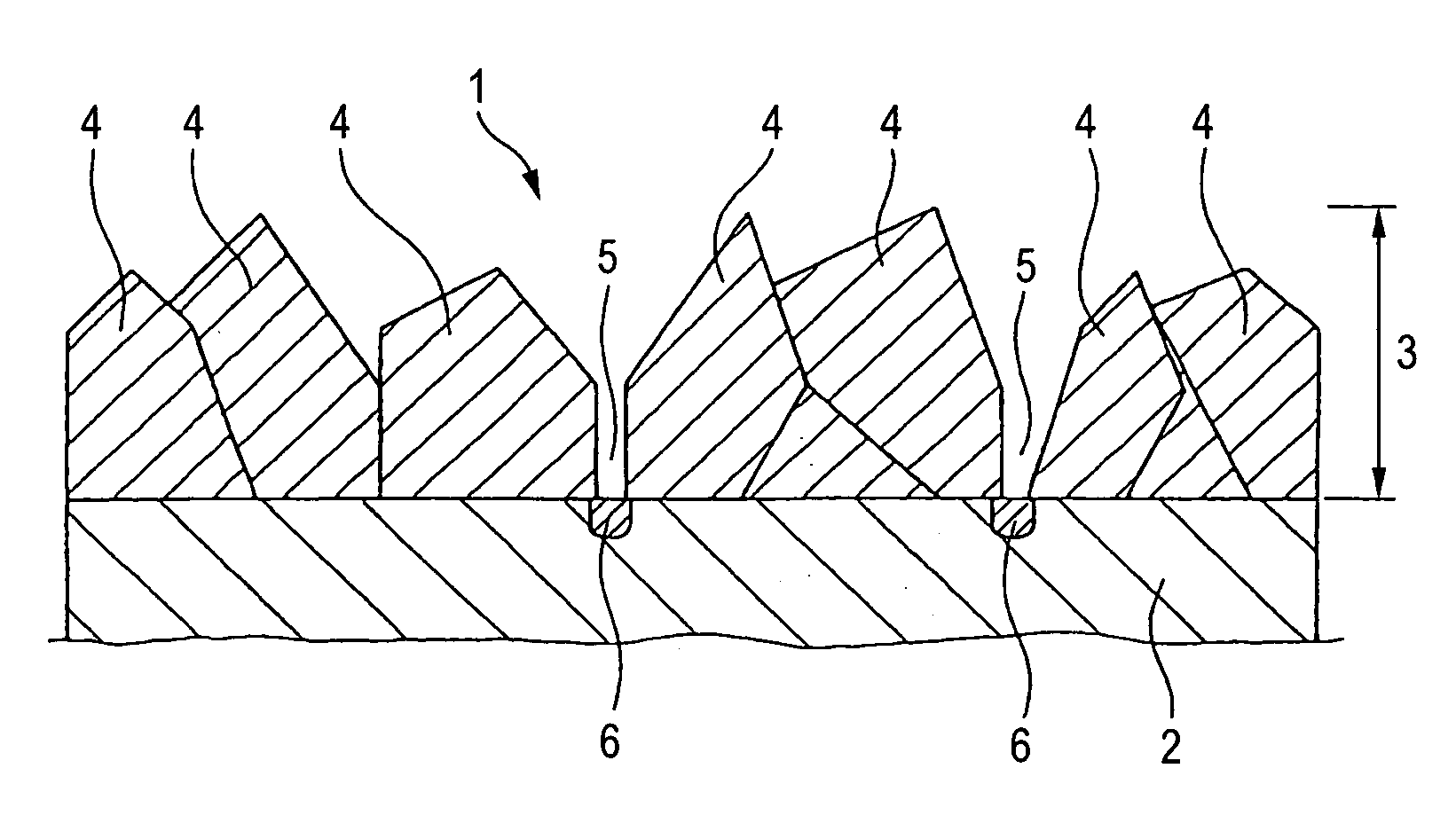

Fiber containing carbon, substrate and electron emission device using fiber containing carbon, electron source using the electron emission device, display panel using the electron source, and information displaying/playing apparatus using the display panel, and a method of manufacturing thereof

InactiveUS20050134161A1Improve evenlyShort timeMaterial nanotechnologyNanostructure manufactureFiberCarbon fibers

The invention provides a fiber containing carbon which is less deteriorated in terms of electron emission characteristic, is excellent in terms of reproducibility, and can in addition be formed at a low cost, a substrate and electron emission device using the fiber containing carbon, an electron source using the electron emission device, a display panel using the electron source, and an information displaying / playing apparatus using the display panel, and a method of manufacturing these. The manufacturing method comprises a first step of preparing a substrate (substrate 1) equipped with a catalyst (catalyst layer 3) on its surface; and a second step of causing the fiber containing carbon (carbon fiber 4) to grow using the catalyst, whereby the second step comprises, in order to decrease, from a midway point of time in this step, the growth rate at which the fiber containing carbon grows, a sub-step of controlling the growth conditions for the fiber containing carbon.

Owner:CANON KK

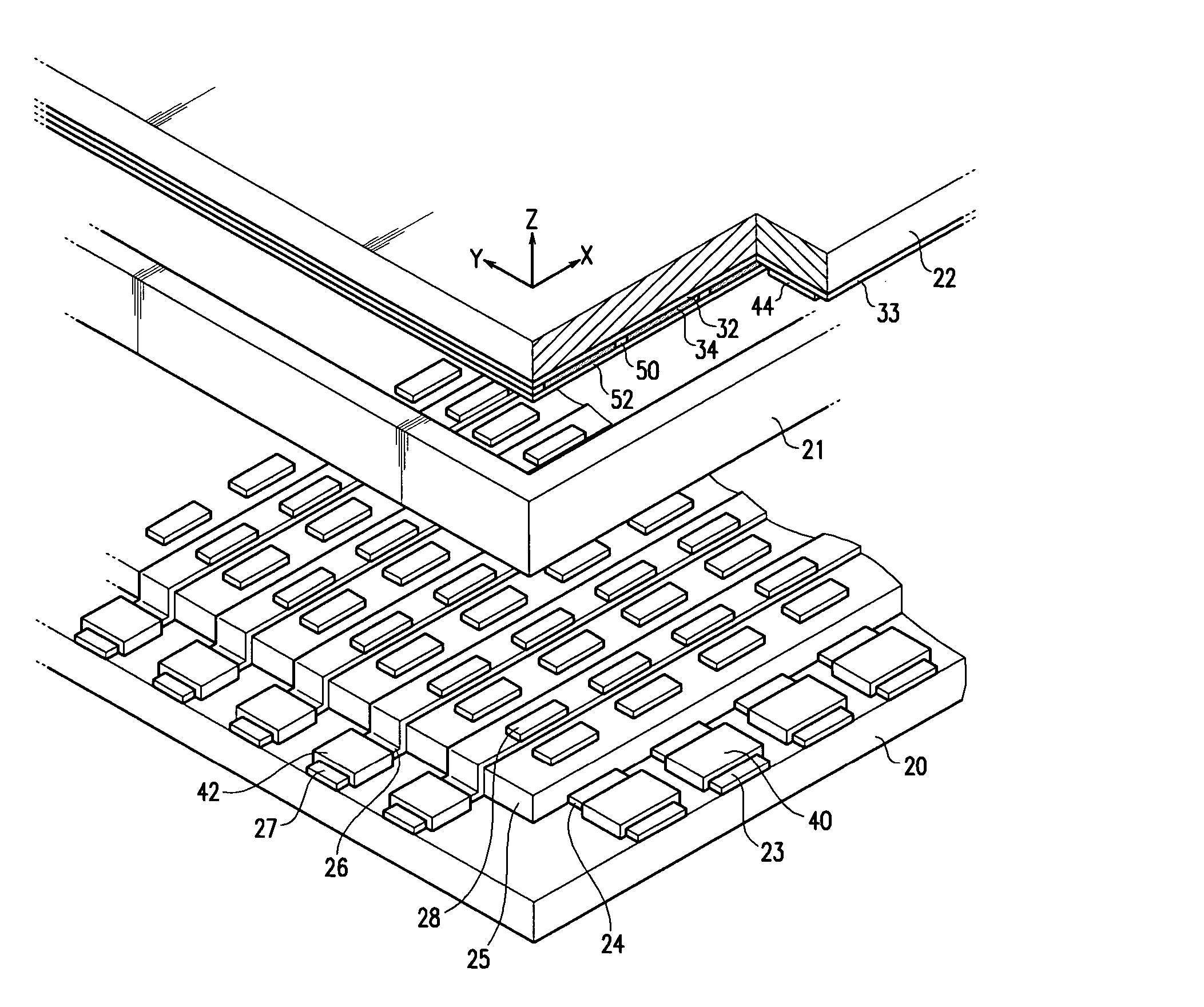

Flat panel display device and method of manufacturing the same

InactiveUS20050168129A1Increase in electrode resistance can be preventedEliminates unnecessary voltage dropCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersEngineeringFlat panel display

A flat panel display device includes a first substrate and a second substrate disposed to oppose each other with a predetermined gap therebetween. An electrode made of a transparent conductive oxide film is formed on at least one of the first substrate and the second substrate. A sealing member is disposed between the first substrate and the second substrate and bonds the first substrate and the second substrate to each other. An electrode protecting layer is formed on a portion of the electrode overlapping with the sealing member and between the sealing member and the electrode.

Owner:SAMSUNG SDI CO LTD

Apparatus and method for applying feedback control to a magnetic lens

InactiveUS20030205678A1Thermometer detailsBeam/ray focussing/reflecting arrangementsControl signalFeedback control

An apparatus configured to control a magnetic field strength of a magnetic lens is provided. The apparatus may include a magnetic sensor configured to generate an output signal responsive to a first magnetic field strength of the magnetic lens. The apparatus may also include a control circuit coupled to the magnetic sensor and the magnetic sensor. The control circuit may be configured to receive the output signal from the magnetic lens and to receive an input signal responsive to a predetermined magnetic field strength. The control circuit may be further configured to generate a control signal responsive to the output signal and the input signal. Additionally, the control circuit may be configured to apply a current to the magnetic lens such that a second magnetic field strength may be generated within the magnetic lens closer to the predetermined magnetic field strength than the first magnetic strength.

Owner:KLA TENCOR TECH CORP

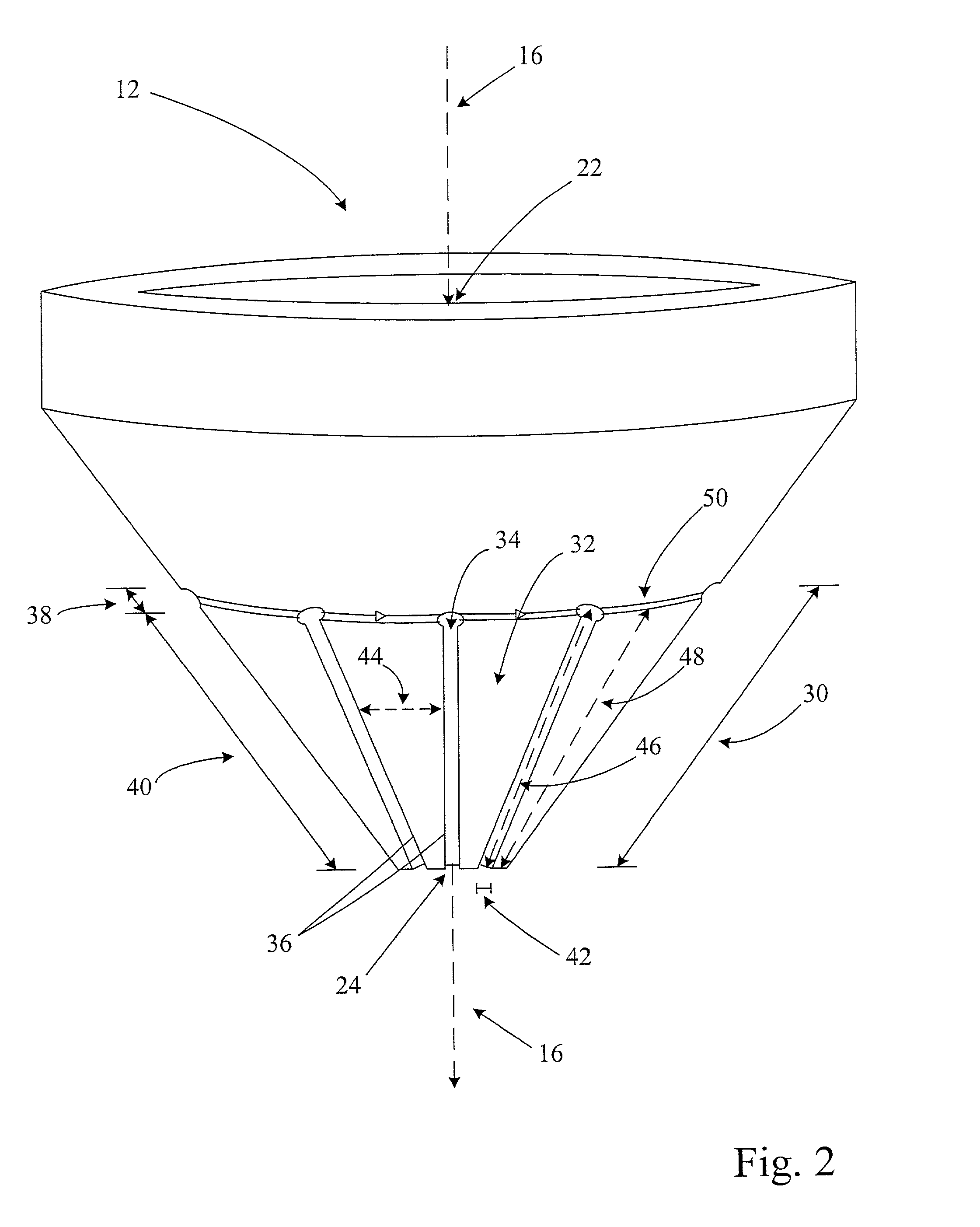

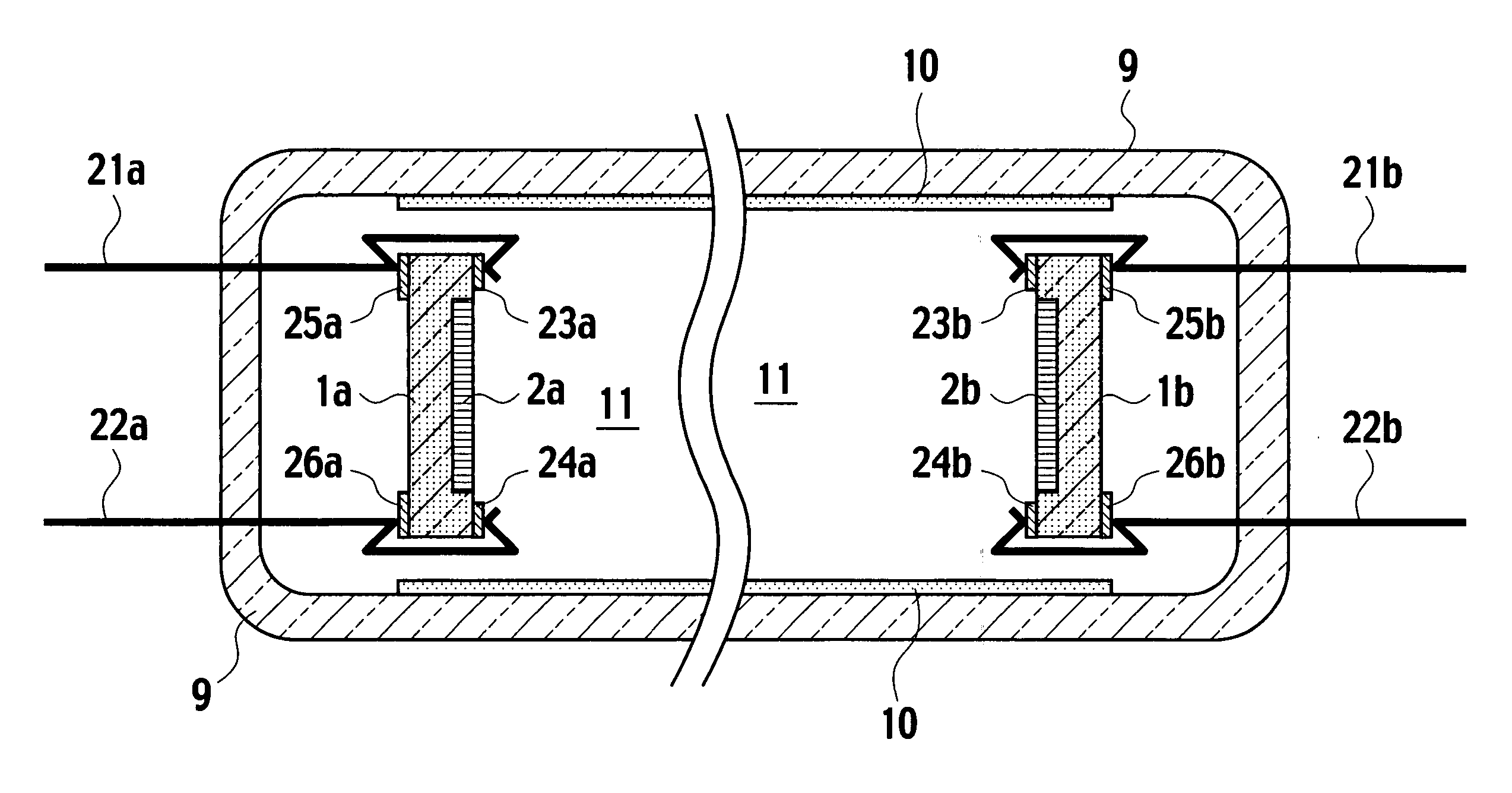

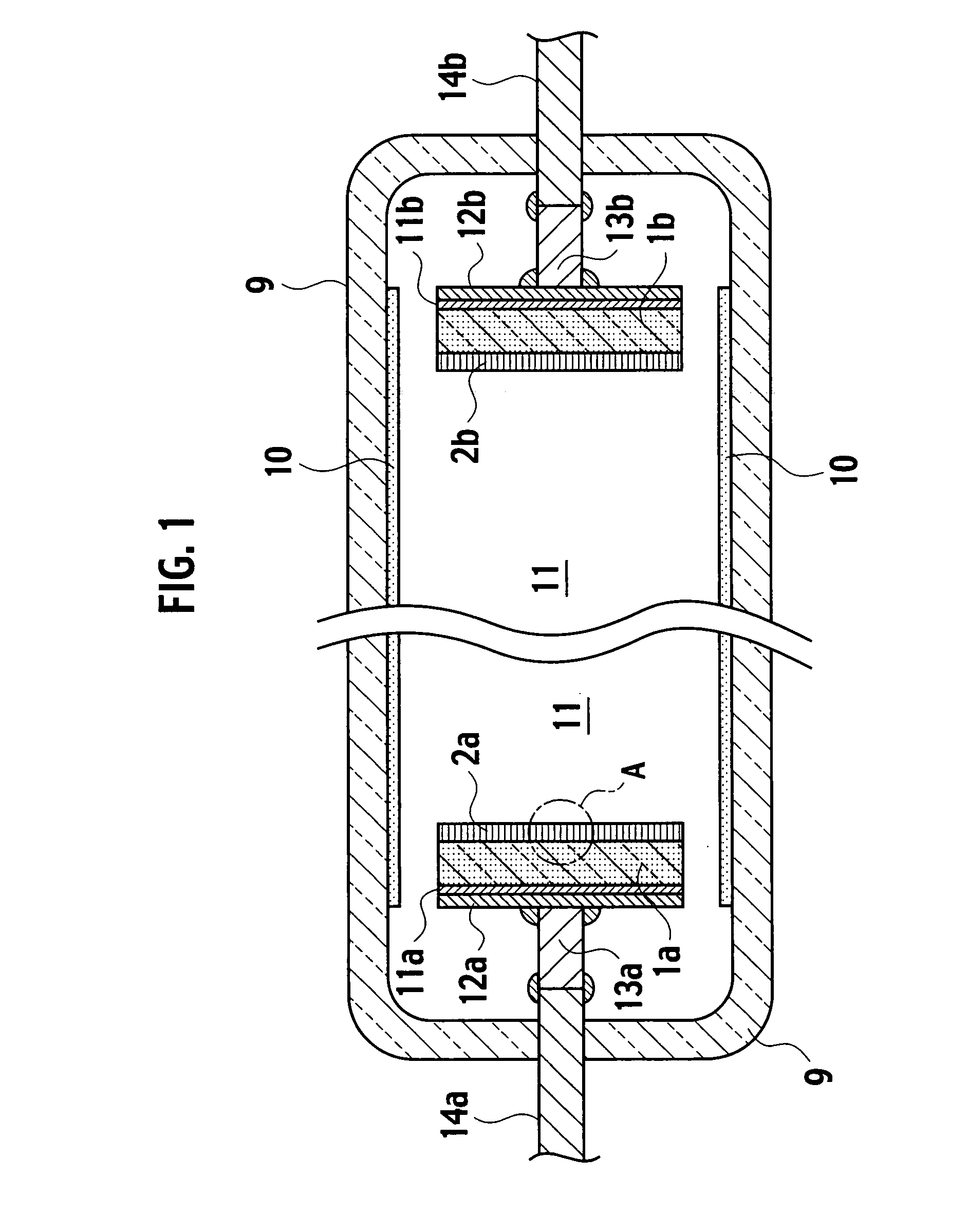

Electron emitter including carbon nanotubes and its application in gas discharge devices

InactiveUS6949877B2Reduce the amount requiredReduction in background gas pressureDischarge tube luminescnet screensLamp incadescent bodiesCarbon nanotubeAlkaline earth oxides

Owner:GENERAL ELECTRIC CO

Discharge electrode and discharge lamp

InactiveUS20050264157A1Efficient emissionsLong lastingLamp incadescent bodiesThermionic cathodesHydrogen atomEngineering

A discharge lamp encompassing a sealed-off tube filled with a discharge gas and a discharge electrode provided in the sealed-off tube. The discharge electrode embraces a supporting base and an electron-emitting layer formed of a wide bandgap semiconductor and provided on the supporting base, implemented by a plurality of protrusions, at least part of surfaces of the protrusions are unseen from a perpendicular direction to thereof above a top surface of the electron-emitting layer, dangling bonds of the wide bandgap semiconductor at the surfaces are terminated with hydrogen atoms.

Owner:KK TOSHIBA

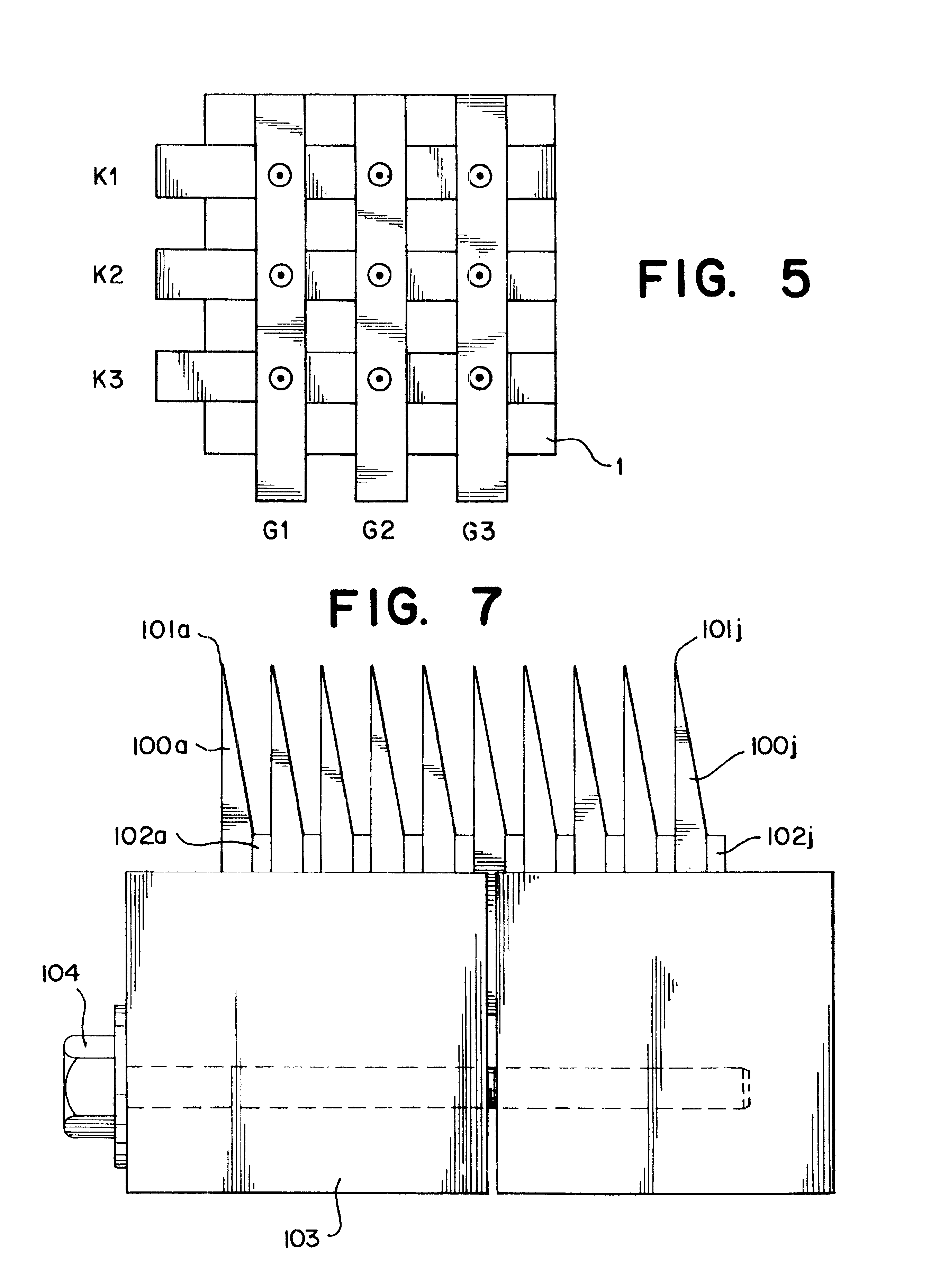

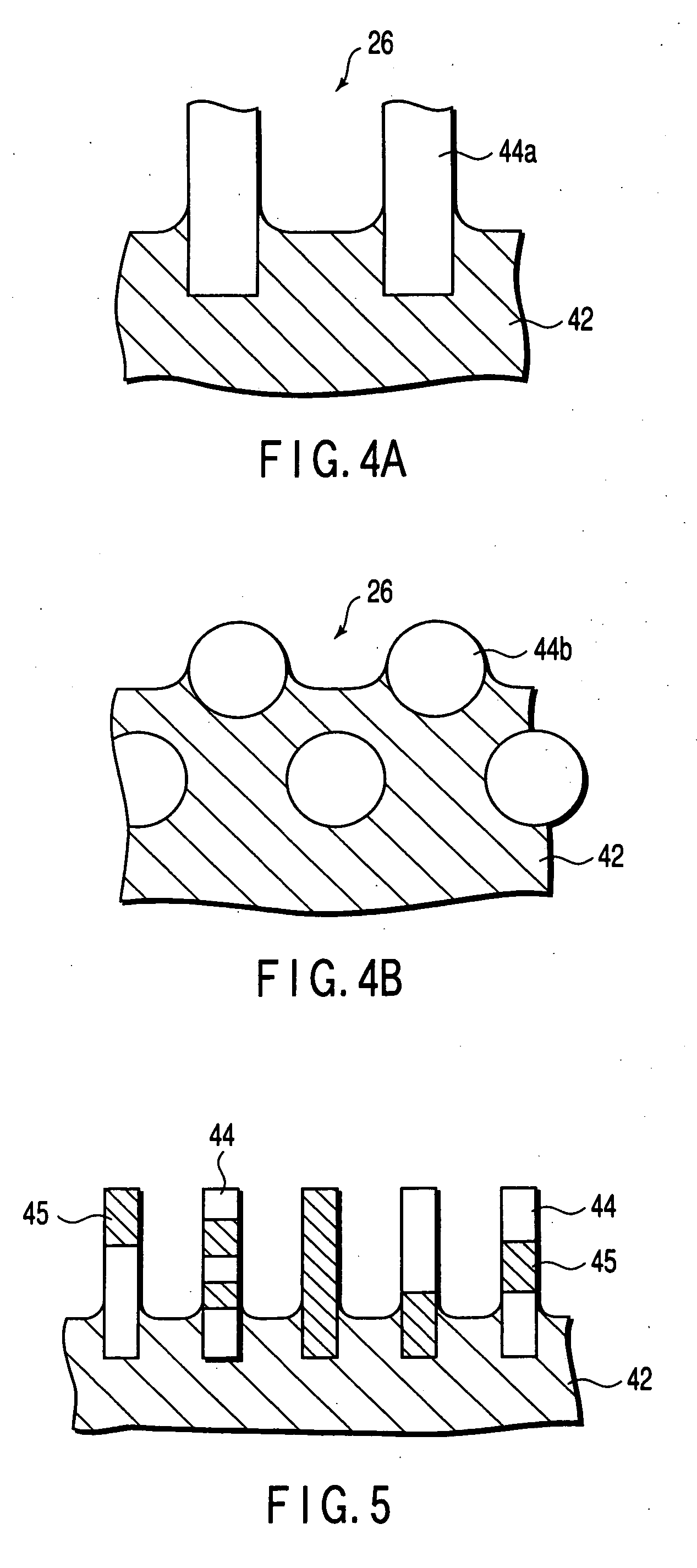

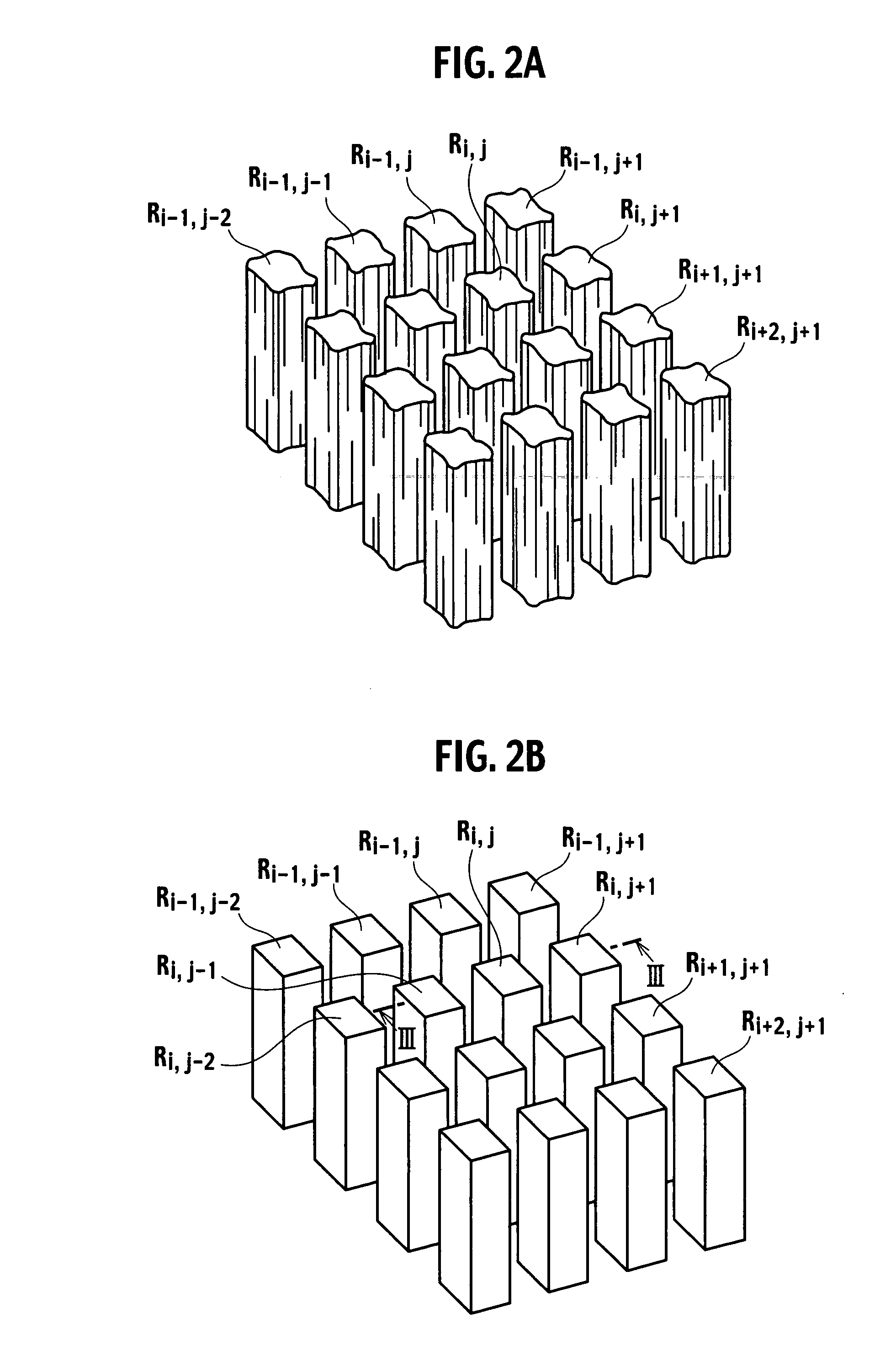

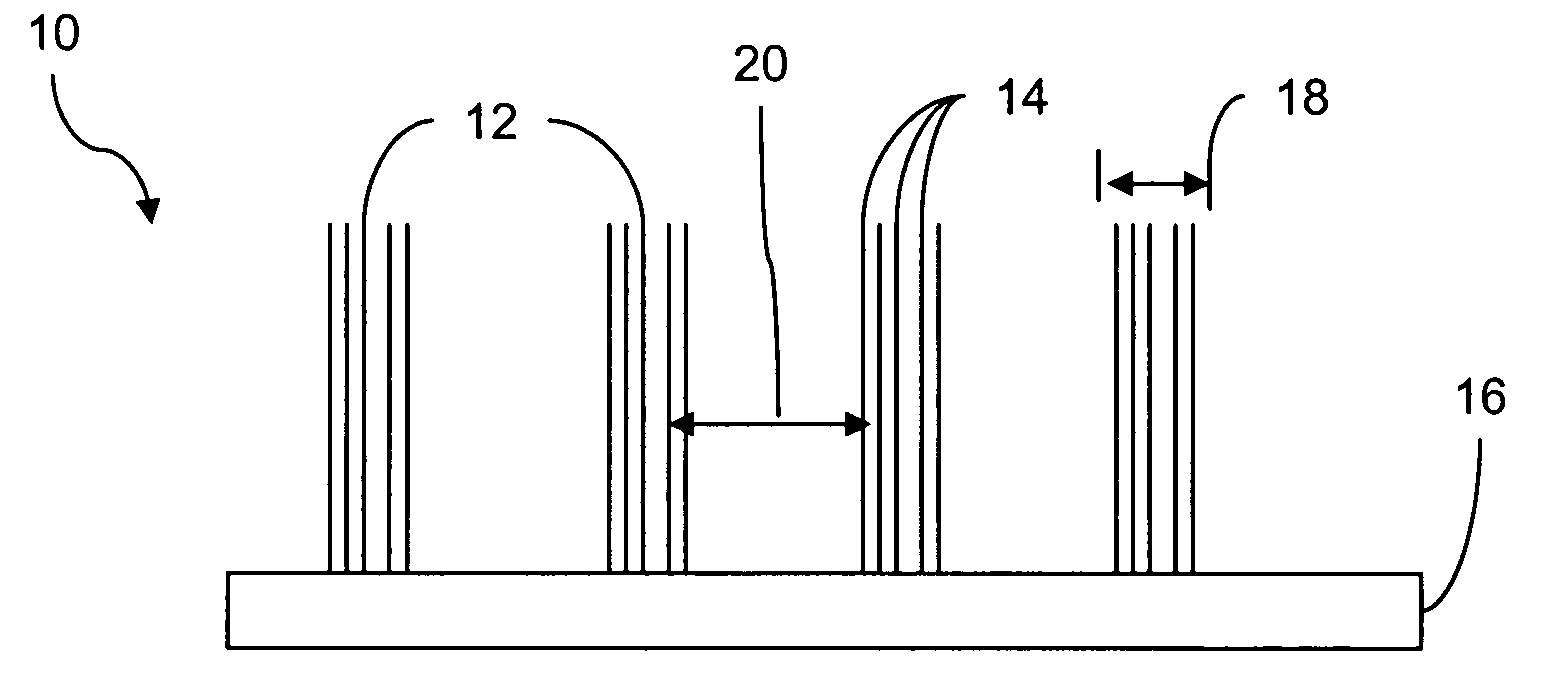

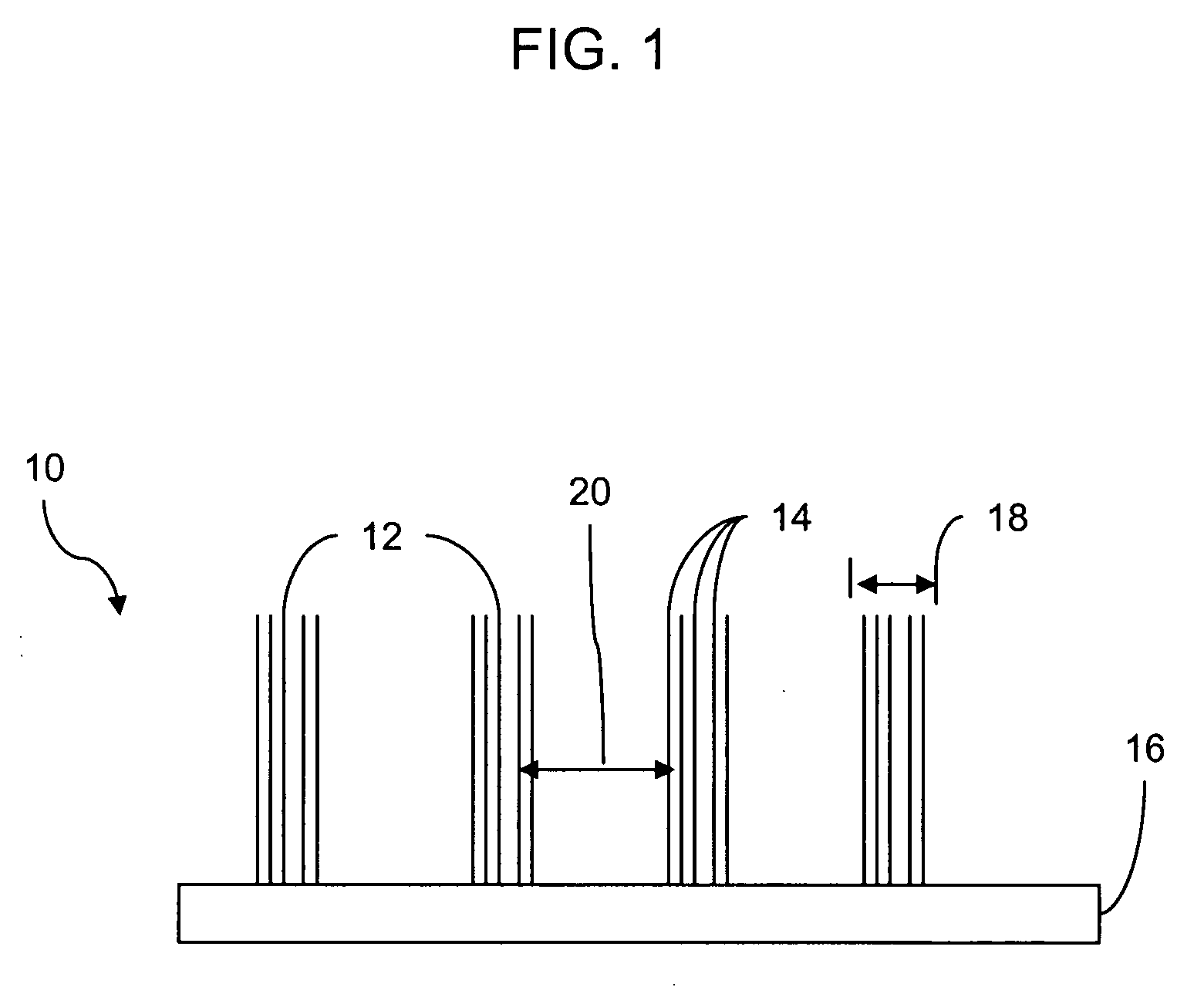

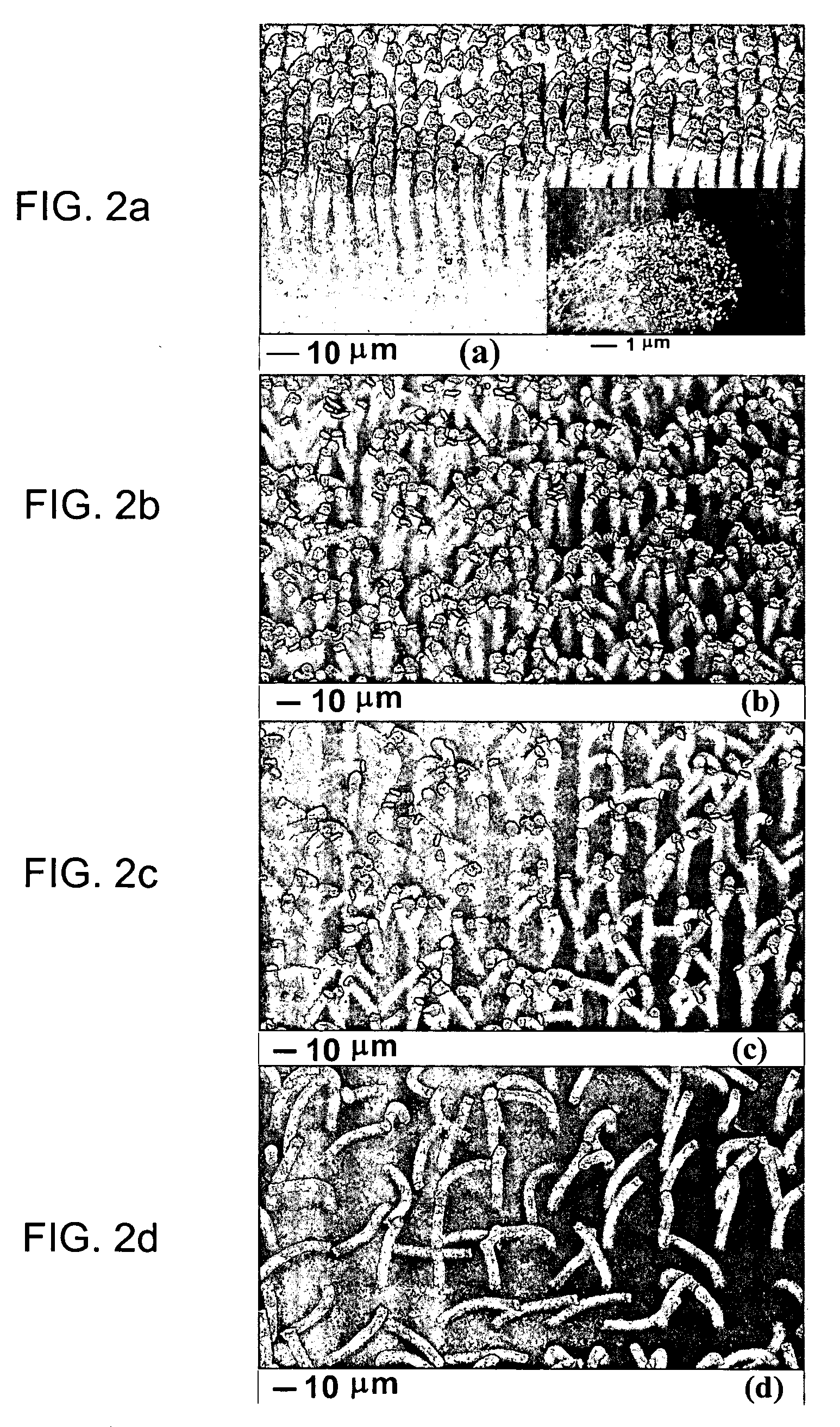

Carbon nanotube high-current-density field emitters

High-current density field emission sources using arrays of nanofeatures bundles and methods of manufacturing such field emission sources are provided. Variable field emission performance is provided with the variance in the bundle diameter and the inter-bundle spacing, and optimal geometries for the lithographically patterned arrays were determined. Arrays of 1-μm and 2-μm diameter multi-walled carbon nanotube bundles spaced 5 μm apart (edge-to-edge spacing) were identified as the most optimum combination, routinely producing 1.5 to 1.8 A / cm2 at low electric fields of approximately 4 V / μm, rising to >6 A / cm2 at 20 V / μm over a ˜100-μm-diameter area.

Owner:CALIFORNIA INST OF TECH

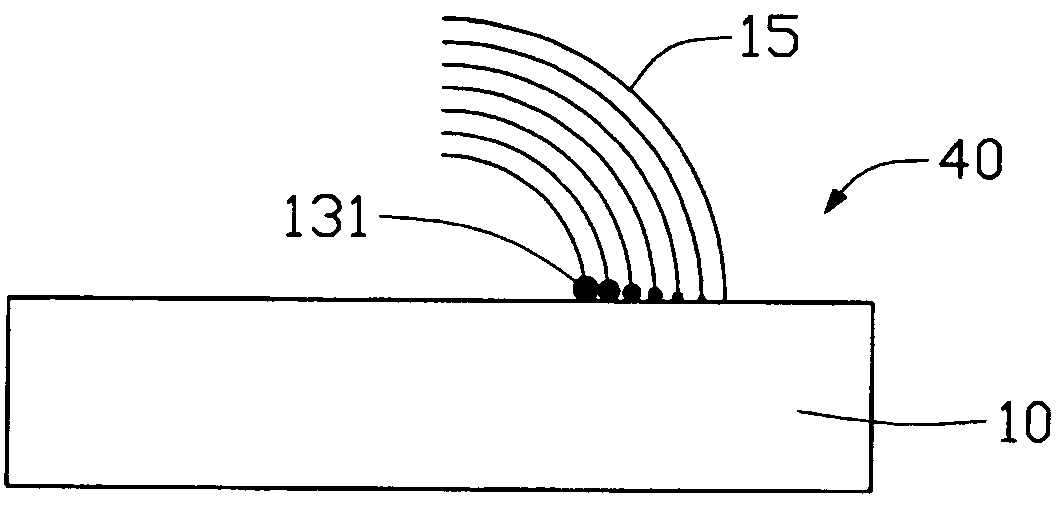

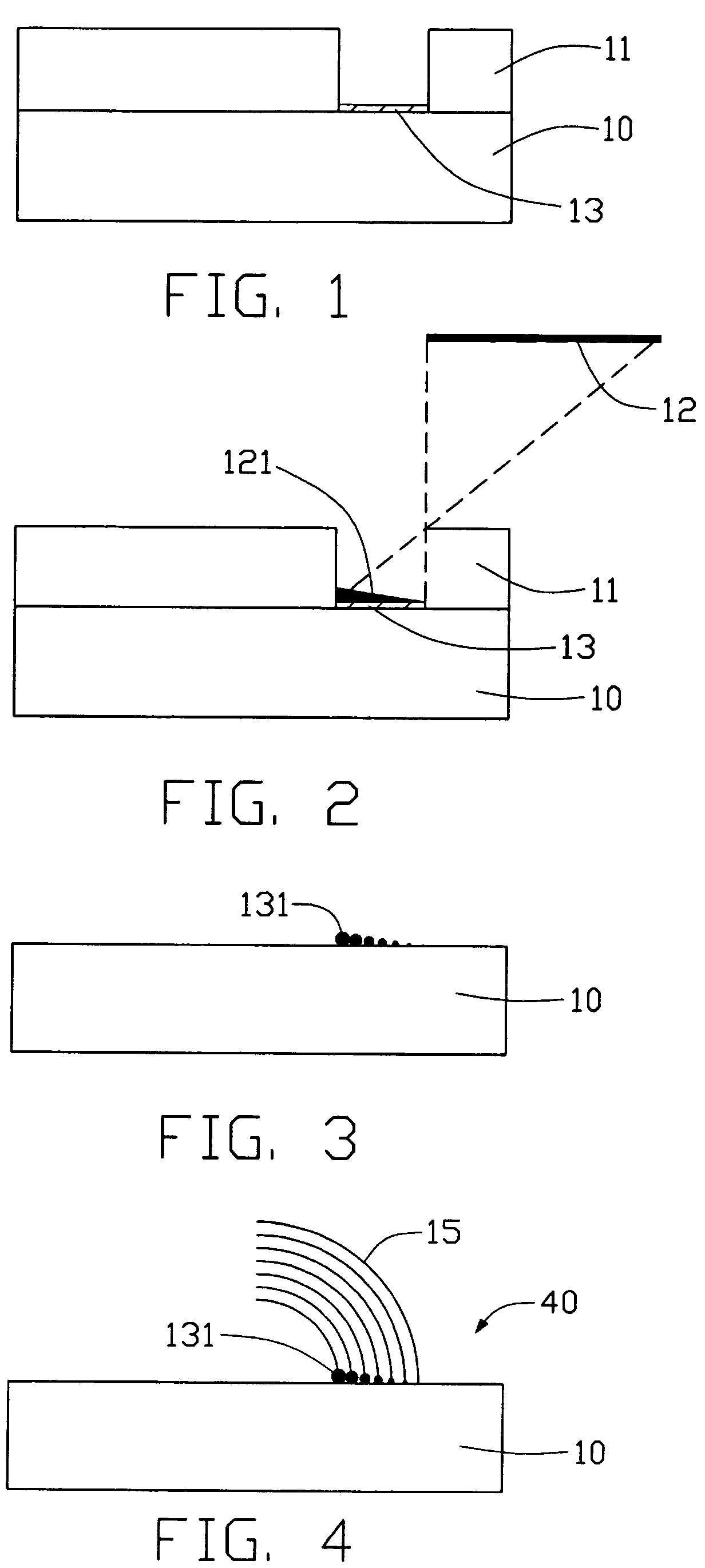

Carbon nanotube array and method for making same

A carbon nanotube-based device (40) includes a substrate (10), a number of catalytic nano-sized particles (131) formed on the substrate, and an aligned carbon nanotube array (15) extending from the alloy catalytic nano-sized particles. The aligned carbon nanotube array progressively bends in a predetermined direction. A method for making the carbon nanotube-based device includes the steps of: providing a substrate; depositing a layer of catalyst on the substrate; depositing a layer of catalyst dopant material on the catalyst layer, for varying a reaction rate of synthesis of the aligned carbon nanotube array; annealing the catalyst and the catalyst dopant material in an oxygen-containing gas at a low temperature; and exposing the nano-sized particles and catalyst dopant material to a carbon-containing source gas at a predetermined temperature such that the aligned carbon nanotube array grows from the substrate.

Owner:TSINGHUA UNIV +1

Electron source structure covered with resistance film

InactiveUS7064475B2Novel structureLarge thicknessThermionic cathodesPhoto-emissive cathodes manufactureElectrical conductorElectron source

To provide an antistatic film that requires low power consumption and provides satisfactory electric contact, as a measure for preventing an insulating substrate surface having an electronic device formed thereon from being charged. The electronic device includes: an insulating substrate; a conductor; and a resistance film connected with the conductor, the conductor and the resistance film being formed on the insulating substrate, characterized in that the resistance film has a larger thickness in a connection region with the conductor than a thickness in portions other than the connection region.

Owner:CANON KK

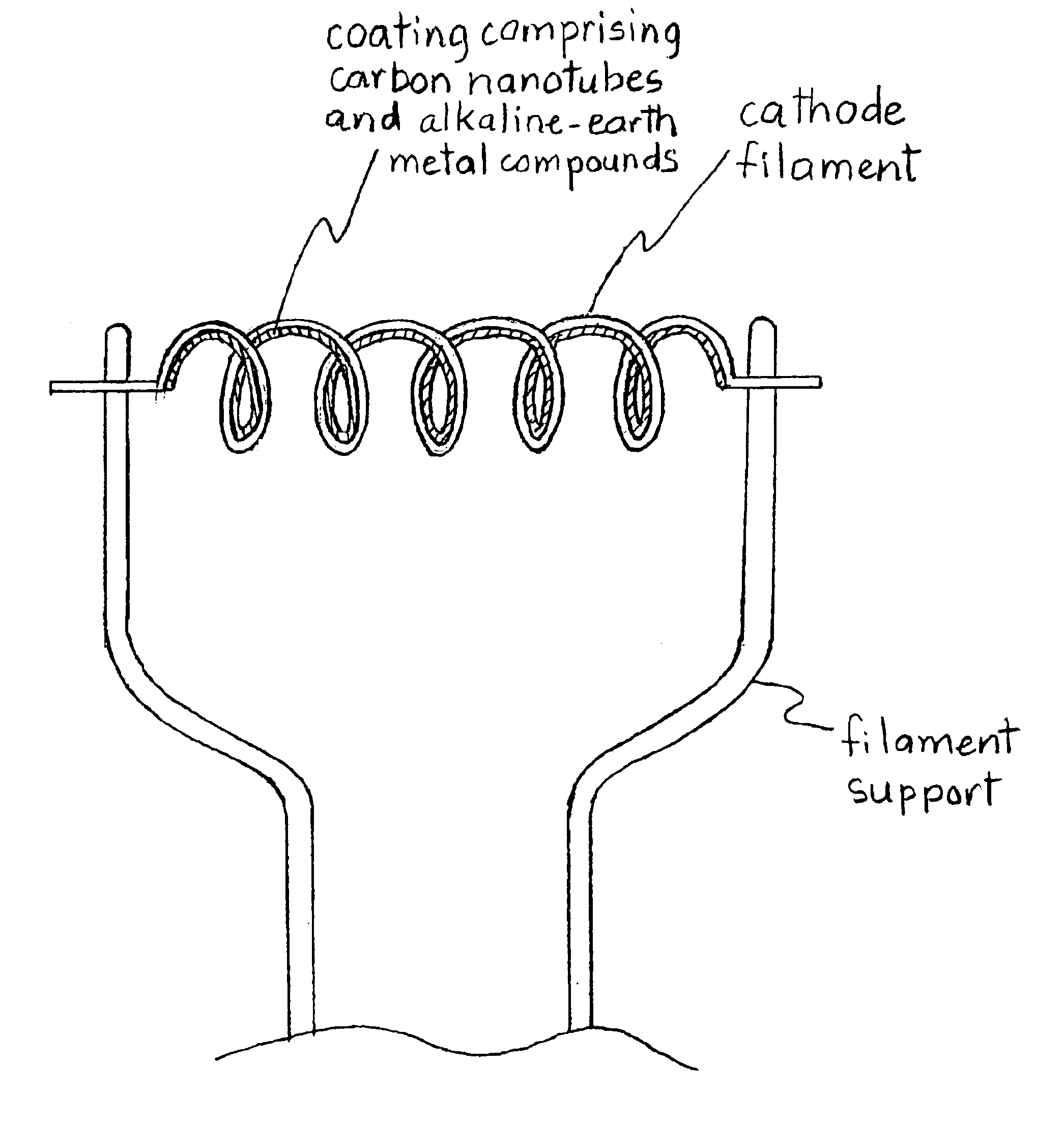

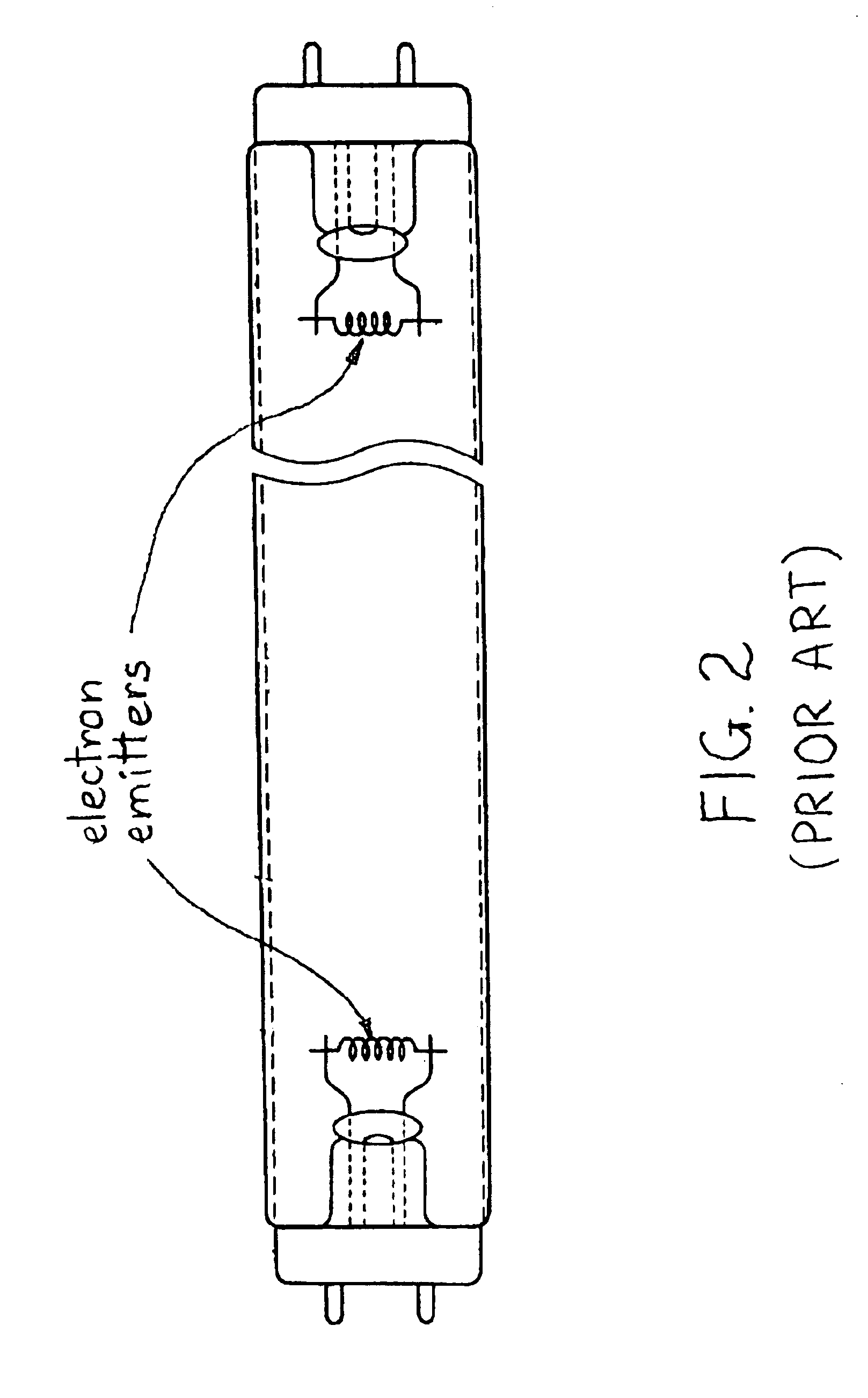

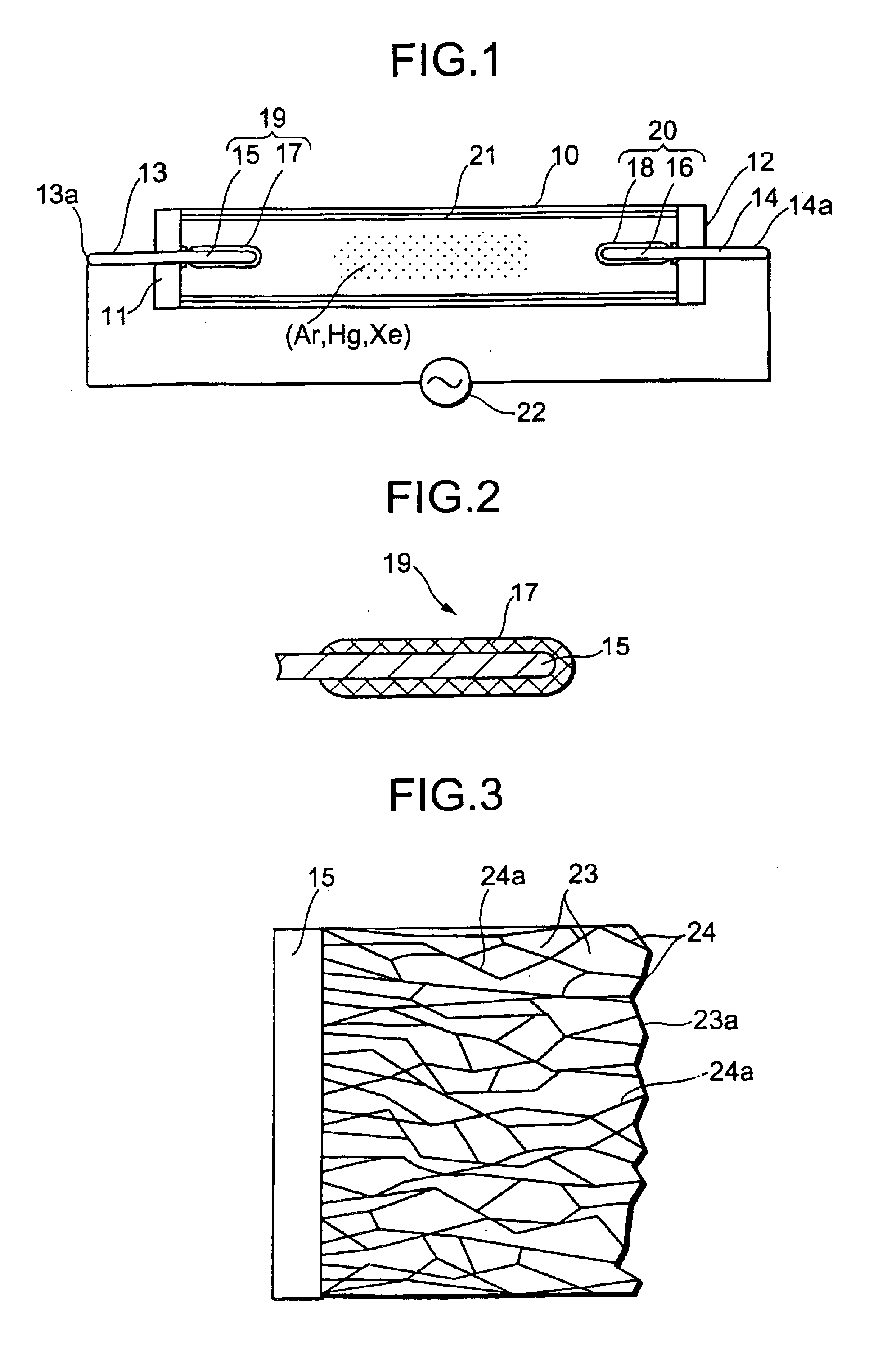

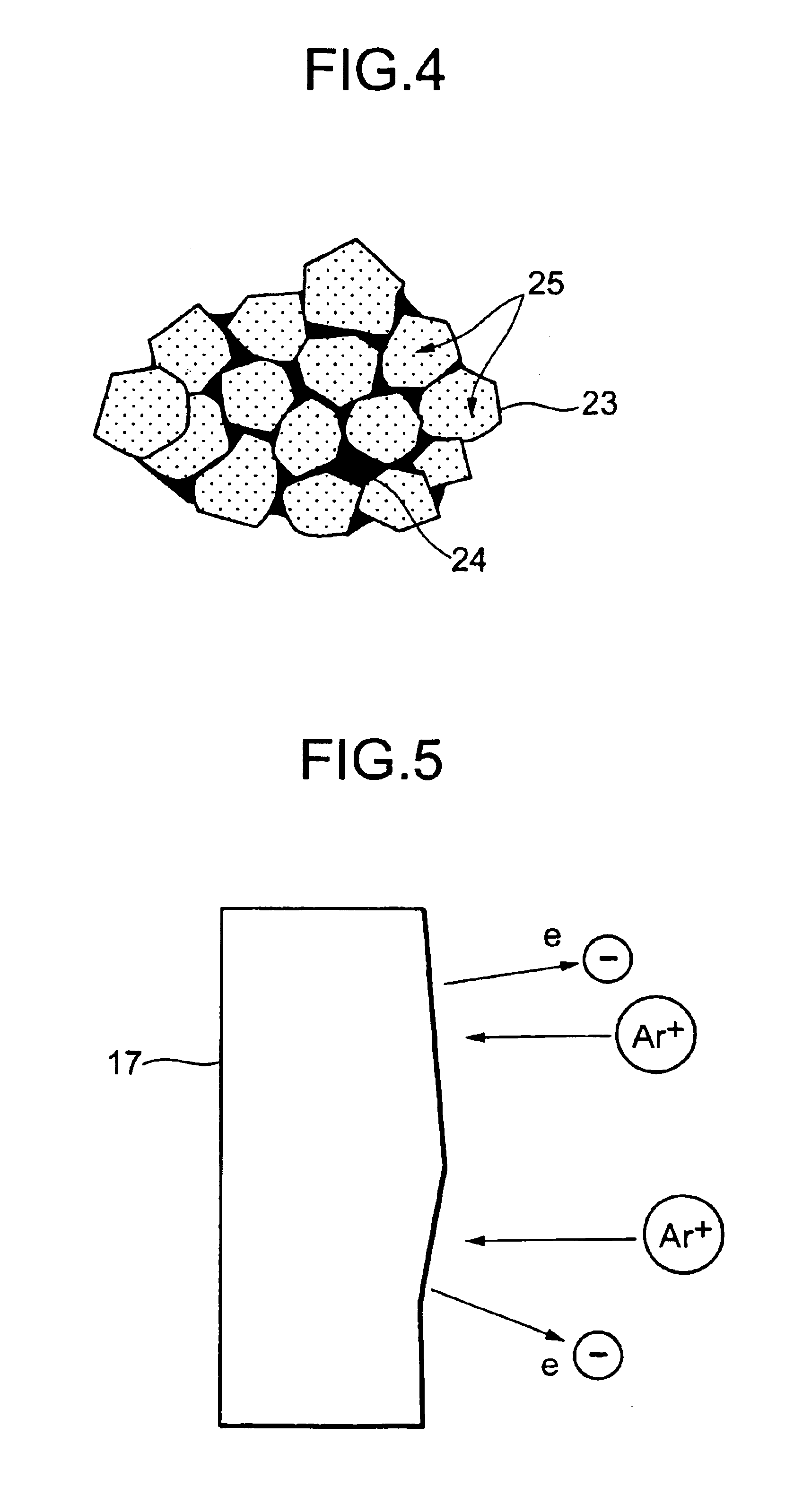

Cold cathode and cold cathode discharge device

InactiveUS6952075B2Improve efficiencySolution to short lifeDischarge tube luminescnet screensLamp incadescent bodiesCold cathodeGraphite

A cold cathode discharge device with high efficiency of light emission and long life is prepared by a cold cathode having both high secondary electron emission and anti-spattering property.Using carbon system cold cathodes constituted of a mixed phase of diamond and graphite, a cold cathode discharge device with high efficiency of light emission and long life is realized. It is desirable that an element having a wavelength of light emission equal to or shorter than 200 nanometers should be mixed in the discharge gas.

Owner:KK TOSHIBA

Conductive diamond electrode and process for producing the same

ActiveUS20060066203A1Avoid corrosionIncreased durabilityMachining electrodesCell electrodesElectrolytic agentDiamond electrodes

A conductive diamond electrode including a conductive substrate comprising a carbonaceous material, a conductive diamond catalyst layer formed on a surface of the conductive substrate, and a carbon fluoride formed on an exposed portion present on the surface of the conductive substrate. The formed carbon fluoride prevents the conductive substrate from contacting with an electrolytic solution, thereby suppressing corrosion of the substrate. A long life of the electrode can be attained.

Owner:DE NORA PERMELEC LTD

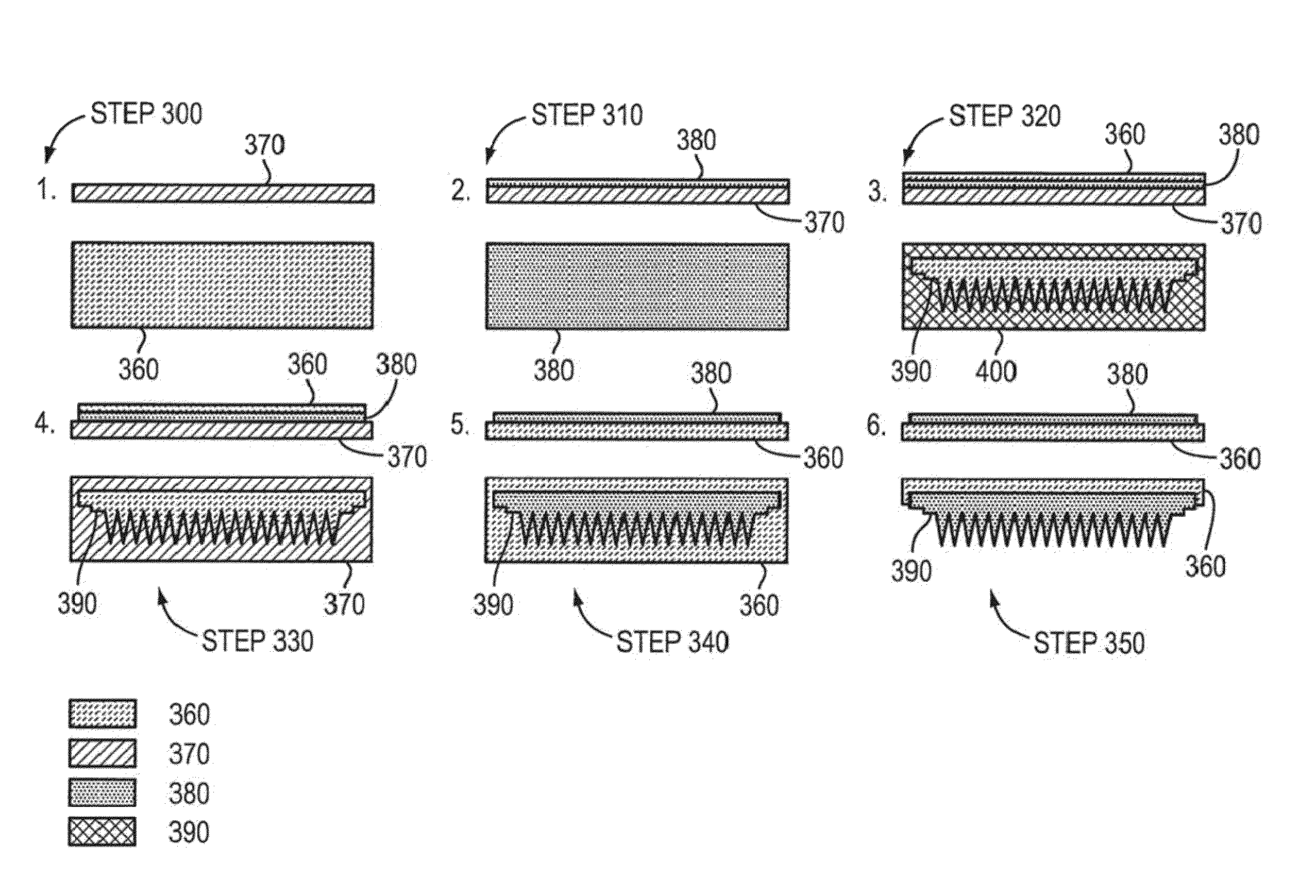

Method and apparatus for a porous electrospray emitter

ActiveUS8785881B2High currentImprove liquidityParticle separator tubesMaterial analysis by optical meansMolten saltRoom temperature

An ionic liquid ion source can include a microfabricated body including a base and a tip. The body can be formed of a porous material compatible with at least one of an ionic liquid or room-temperature molten salt. The body can have a pore size gradient that decreases from the base of the body to the tip of the body, such that the at least one of an ionic liquid or room-temperature molten salt is capable of being transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

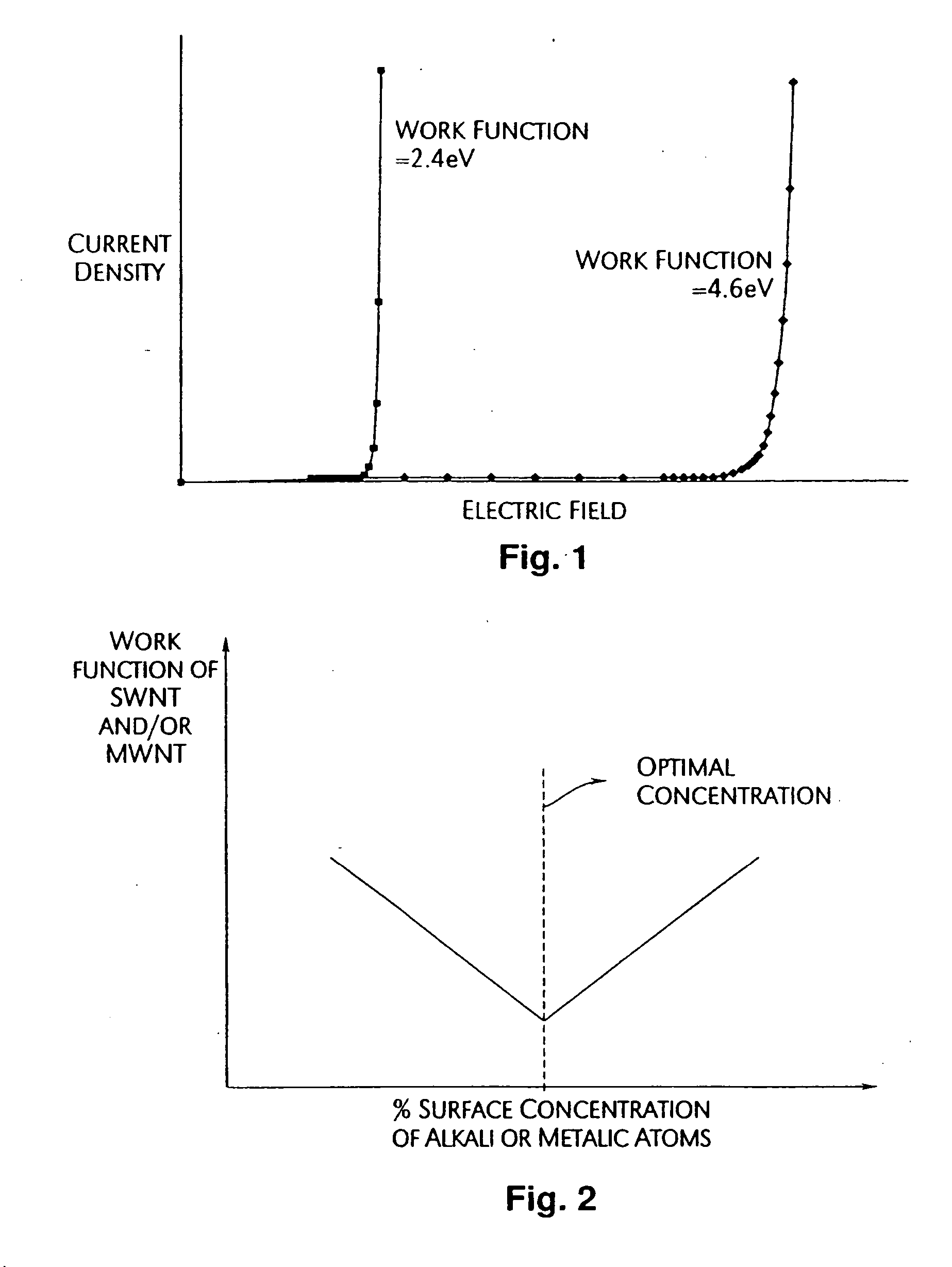

Low work function cathode

InactiveUS20050200261A1High protection levelLower work functionNanoinformaticsThermionic cathodesHigh current densityVolumetric Mass Density

Field emission properties may also be improved by coating the carbon materials with metal oxides. These metal oxides contribute to lowering the work function of the carbon material as well as improve the life of the field emission properties of the carbon materials, especially under high current density operation.

Owner:APPLIED NANOTECH HLDG

Electrode material, dielectric material and plasma display front panel

InactiveCN1424738ADischarge tube luminescnet screensGas discharge electrodesImaging qualityDielectric layer

A material usable for the electrodes and the dielectric layer plasma display panels and capable of reducing the occurrence of yellowing and a high-image-quality plasma display panel using the material are provided. Using glass powder containing 25 to 50 wt % of Bi2O3, 5 to 35 wt % of B2O3, 10 to 20 wt % of ZnO, 5 to 20 wt % of BaO, 0 to 15 wt % of SiO2 and 0 to 10 wt % of Al2O3, the electrodes and the dielectric layer of a plasma display panel are formed.

Owner:PANASONIC CORP

Porous glass substrate for field emission device

InactiveUS20060043861A1Improve adhesionUniform diameterLamp incadescent bodiesNanoinformaticsField emission deviceCarbon nanotube

An improved process for growing carbon nanotubes includes steps of providing a glass substrate that has a porous surface, depositing a catalyst into the pores on the porous surface, and growing carbon nanotubes on the substrate. Desirably, the carbon nanotubes are grown using a chemical vapor deposition technique in which the direction of flow of a carbon precursor gas (and any optional diluent gases) is aligned with the desired direction of growth propagation. The techniques of the invention provide a field emission device having more uniformly aligned carbon nanotubes and / or more uniformly sized carbon nanotubes.

Owner:CORNING INC

Barrier metal layer for a carbon nanotube flat panel display

InactiveUS20050001529A1Reduce in quantityEliminate needLamp incadescent bodiesNanoinformaticsCarbon nanotubeDisplay device

An electron-emitting device, for example as used in a field emissive display device, includes a barrier layer between an emitter electrode structure and a catalyst layer, upon which microstructures of carbon nanotubes are formed. The barrier layer may act as an anti diffusion layer between the catalyst layer and, for example, a resistive layer of the emitter electrode structure. In this way, the catalyst layer may be prevented from diffusing into the resistive layer during the growing of the carbon nanotubes or other electron-emissive elements. The barrier layer may also enhance the adhesion characteristics of the catalyst layer to improve the uniformity of growth of the electron-emissive elements with the catalyst layer.

Owner:ARROW CAPITAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com