Patents

Literature

34results about How to "Point defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

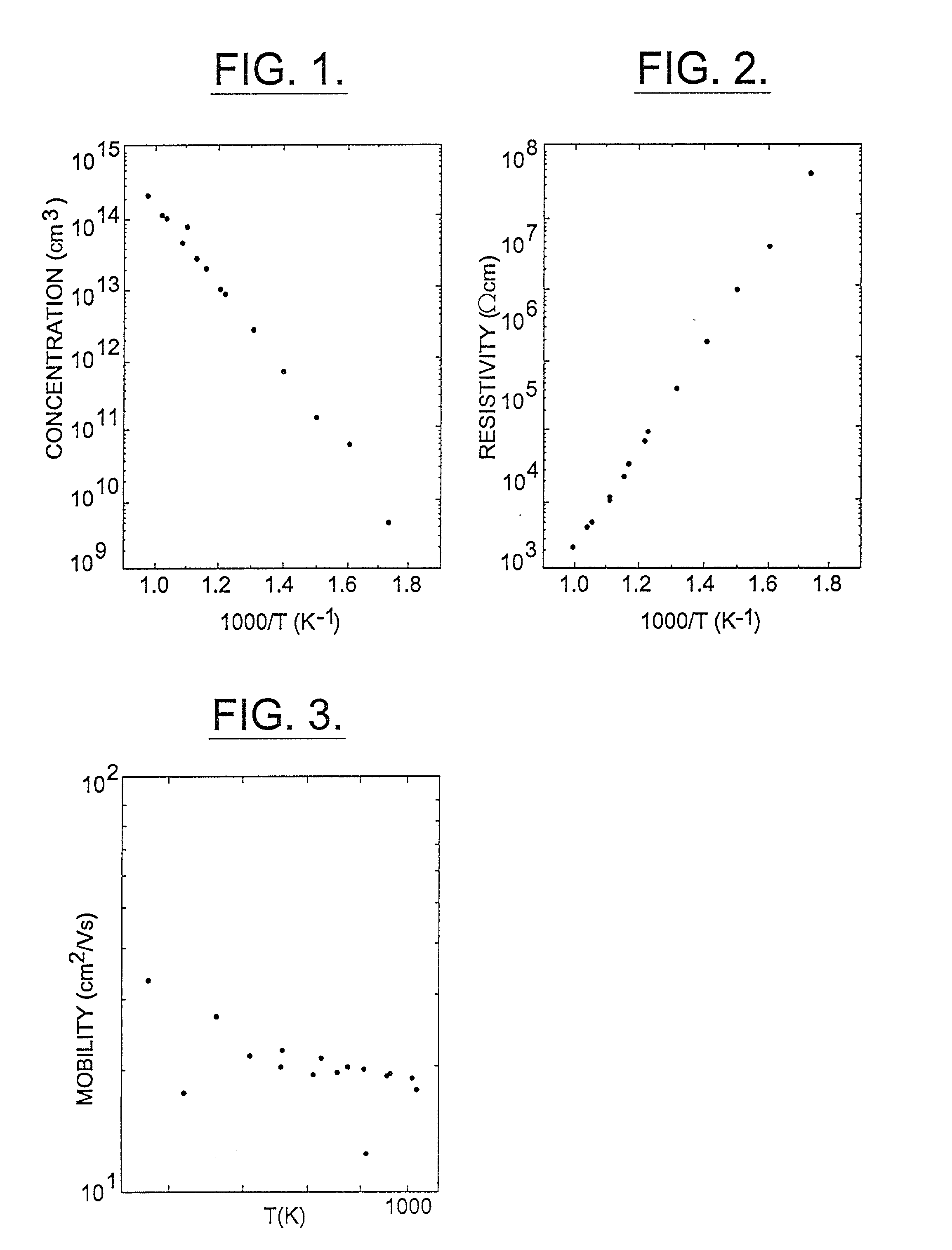

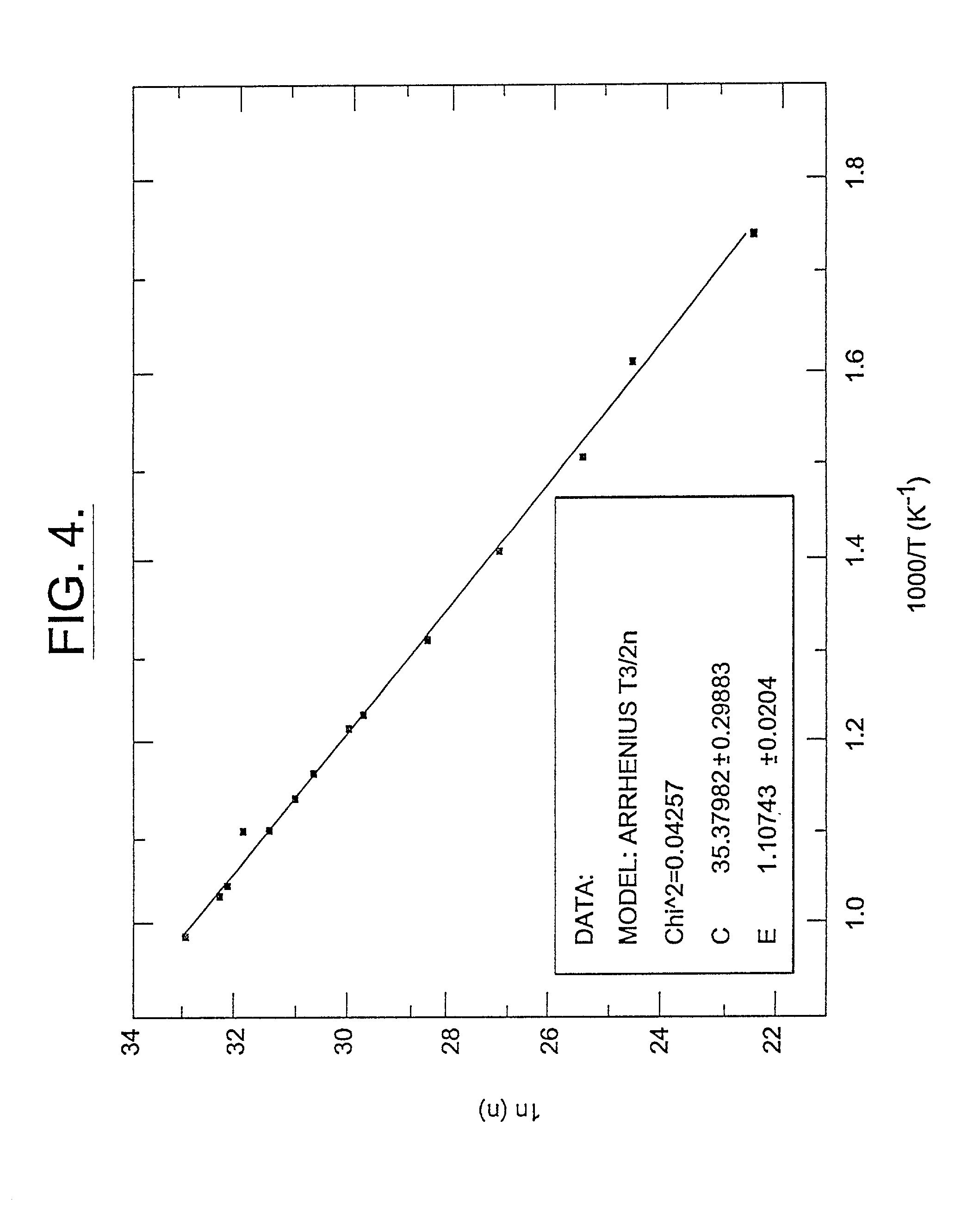

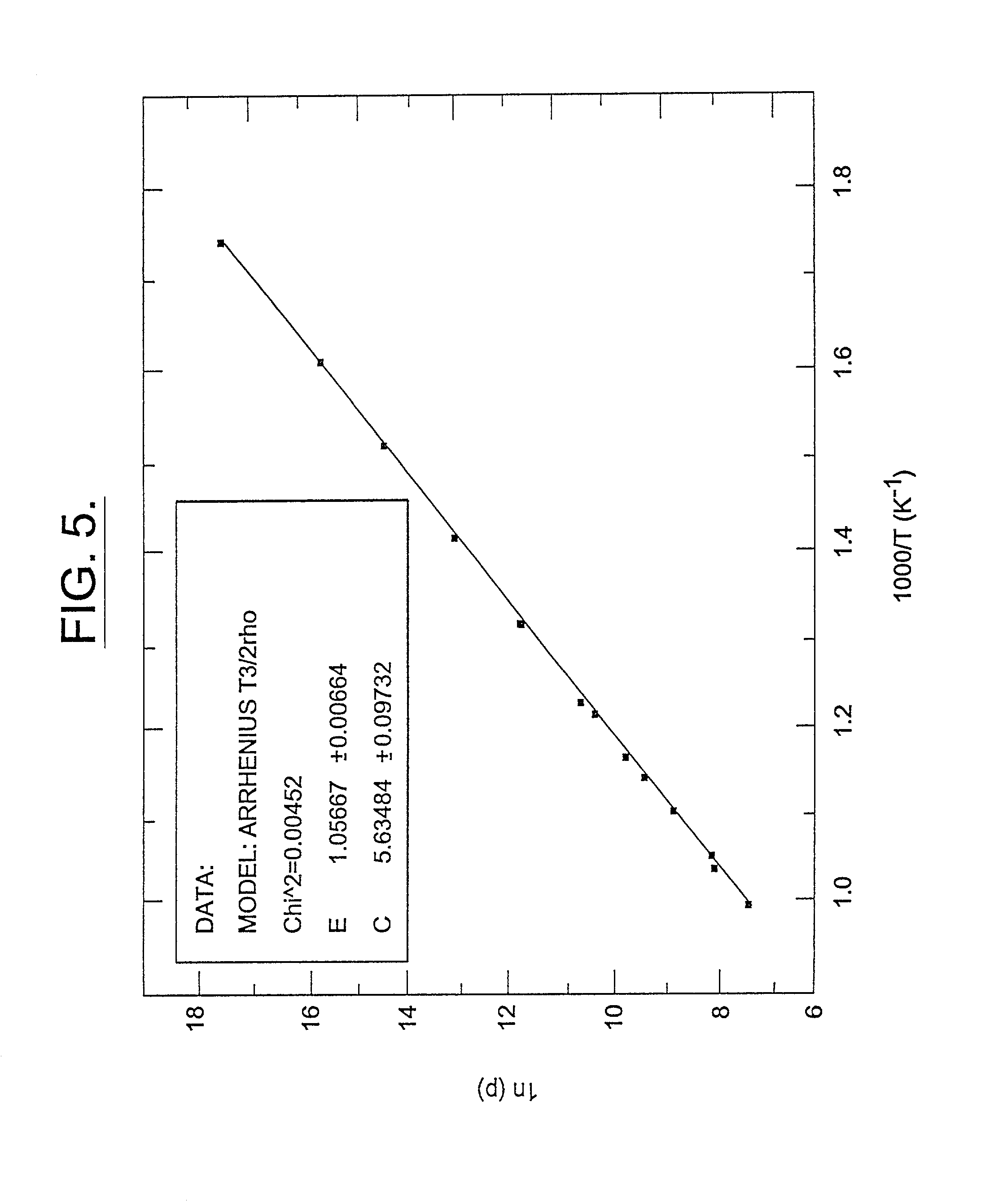

Semi-insulating silicon carbide without vanadium domination

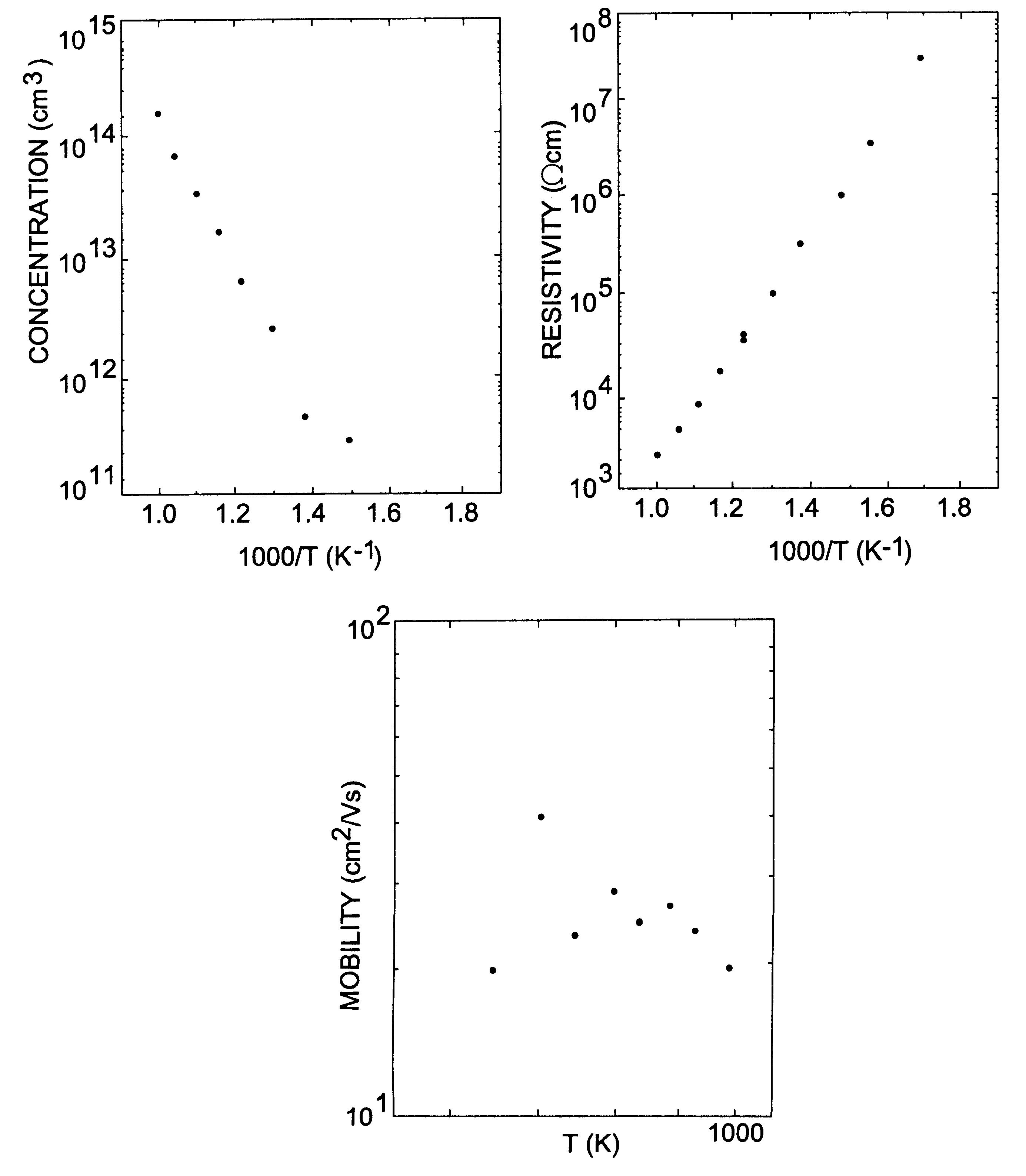

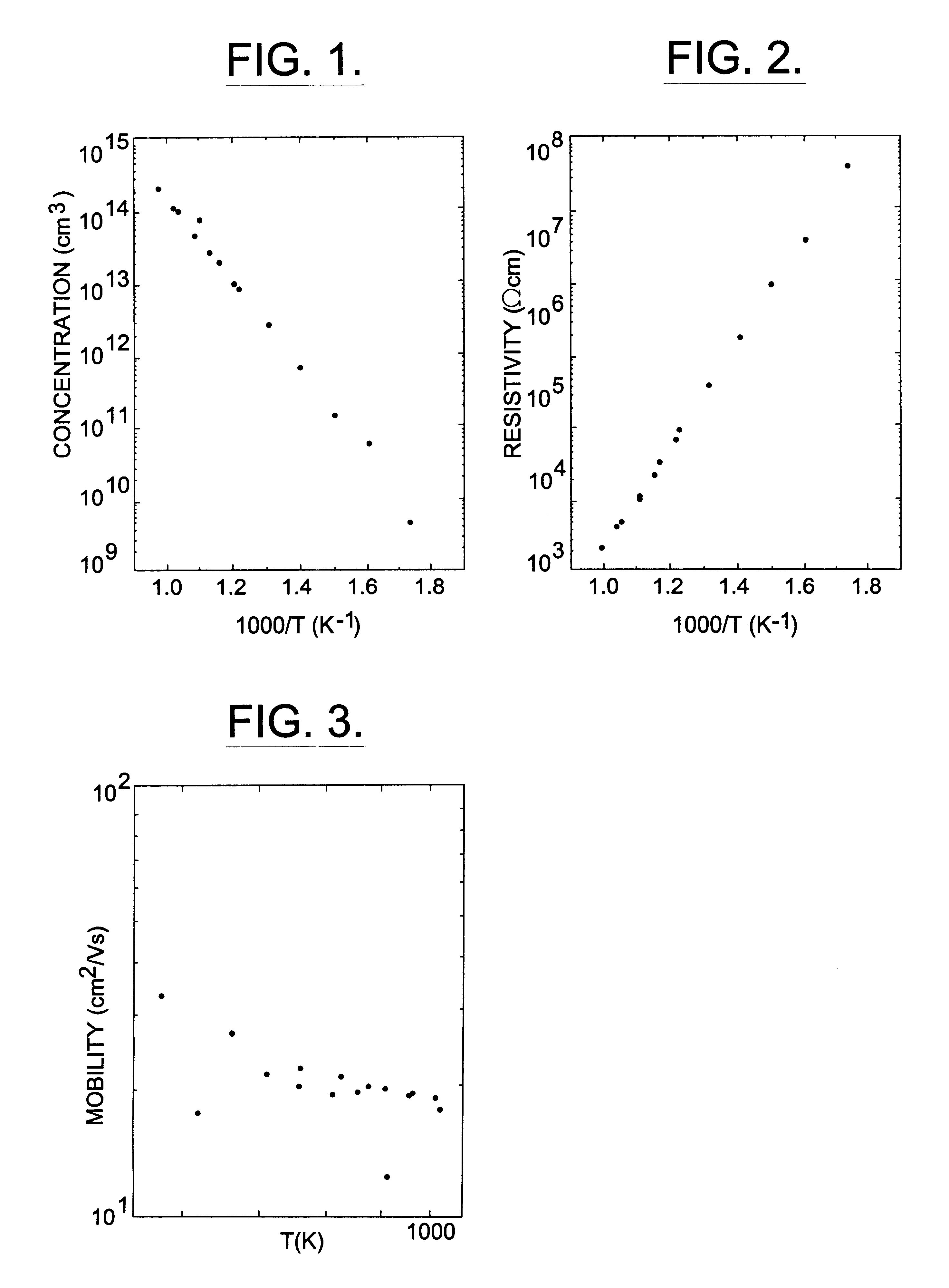

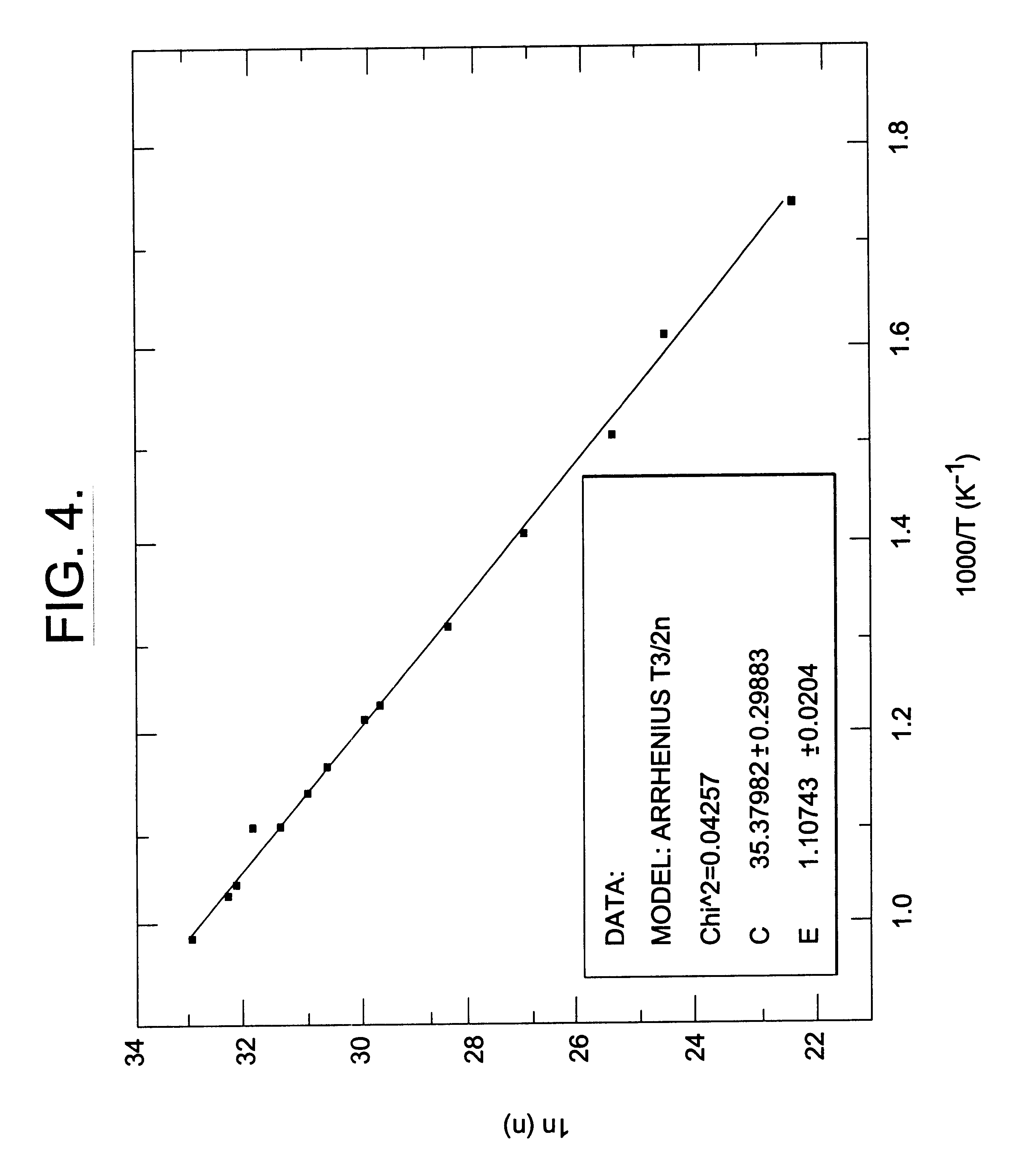

InactiveUS6218680B1Reduce the amount requiredIncrease the number ofPolycrystalline material growthAfter-treatment detailsDevice formTrapping

Owner:CREE INC

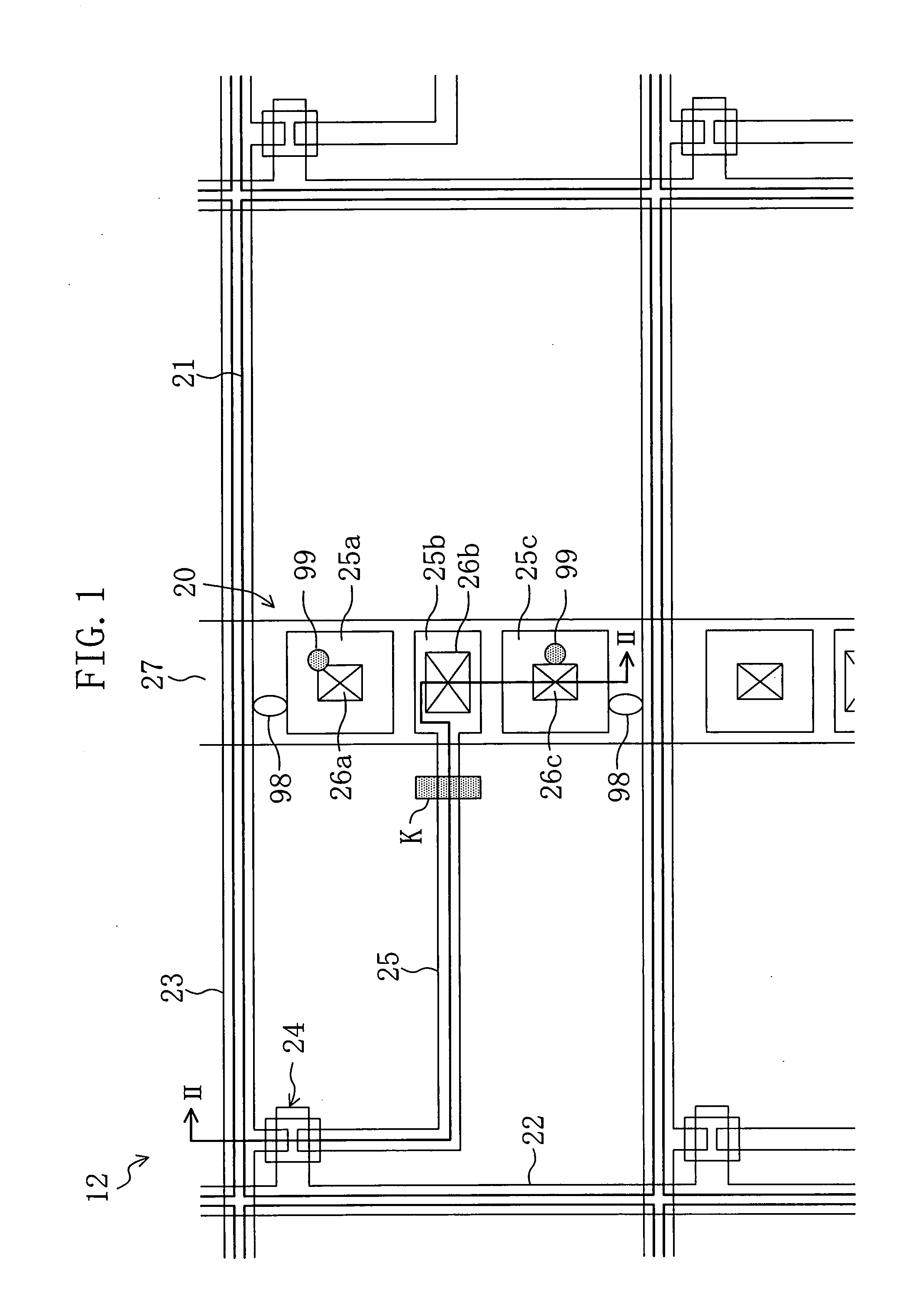

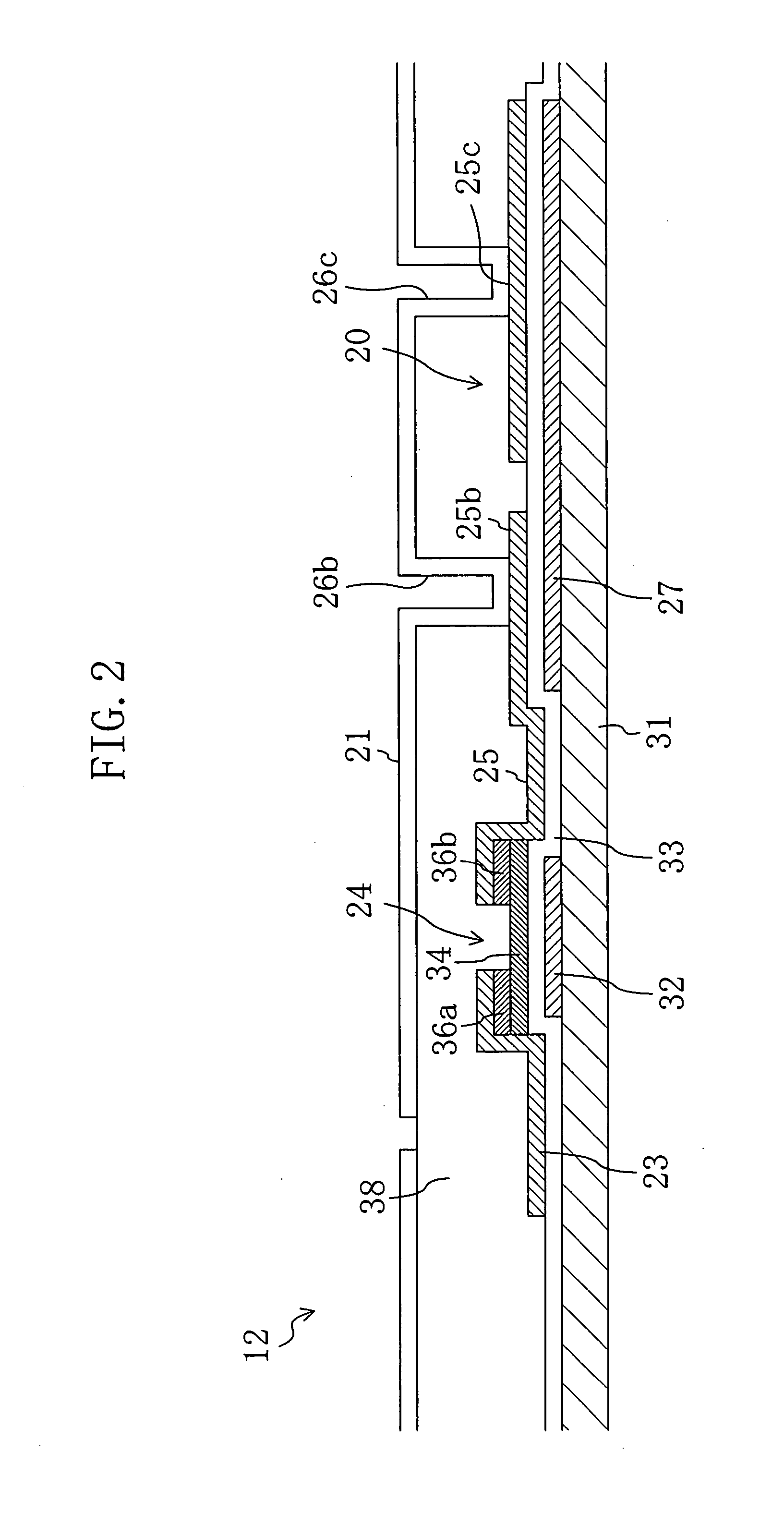

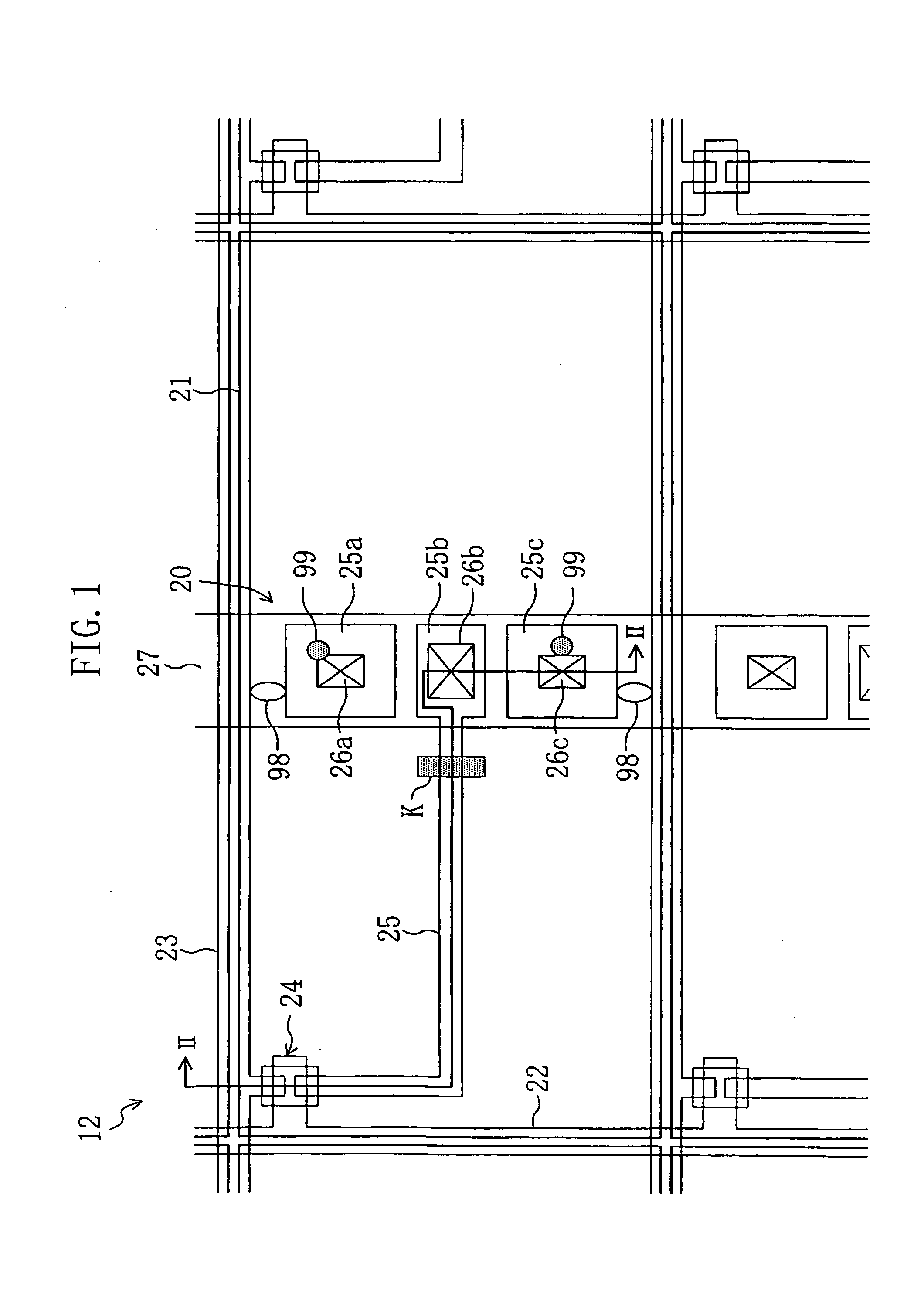

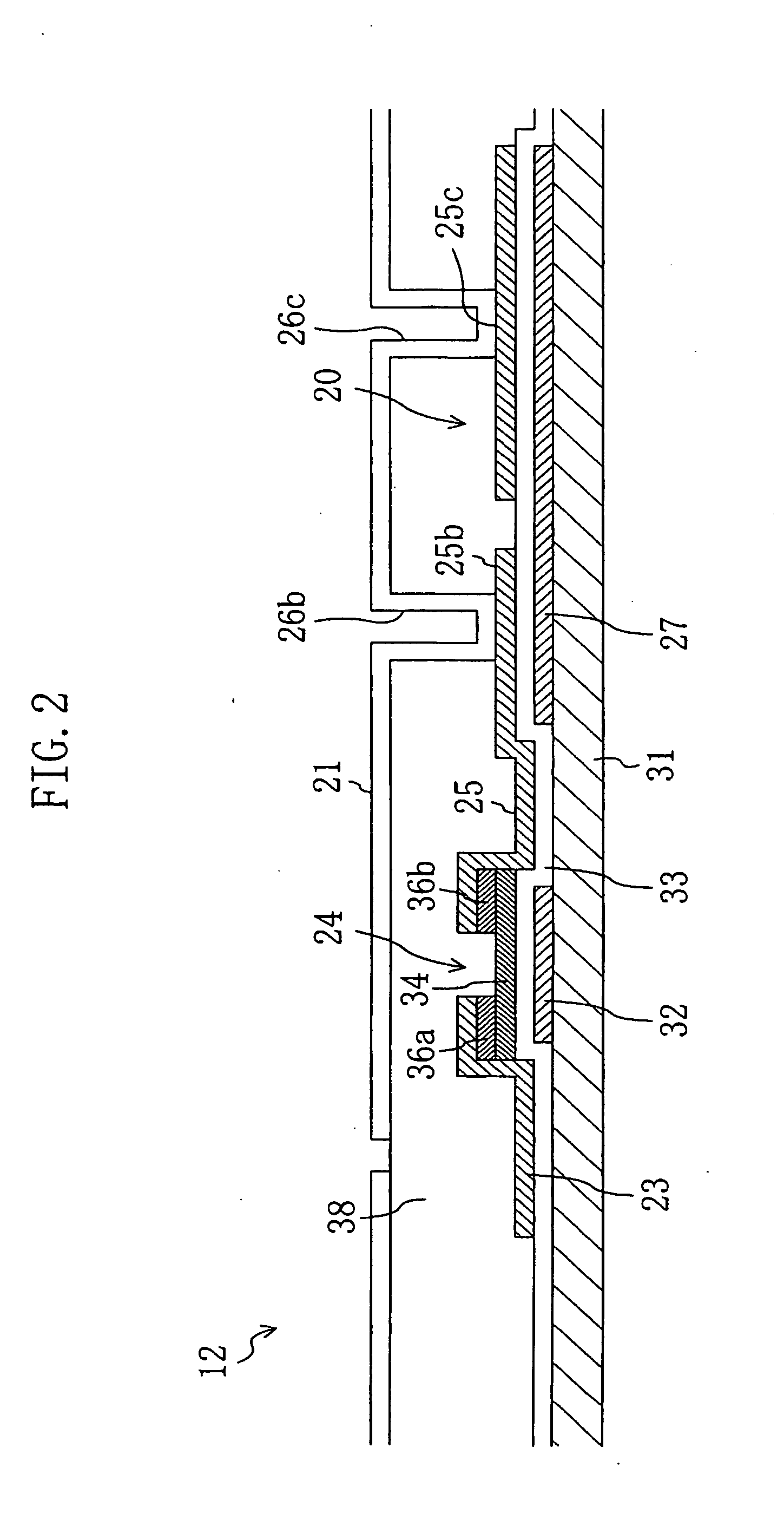

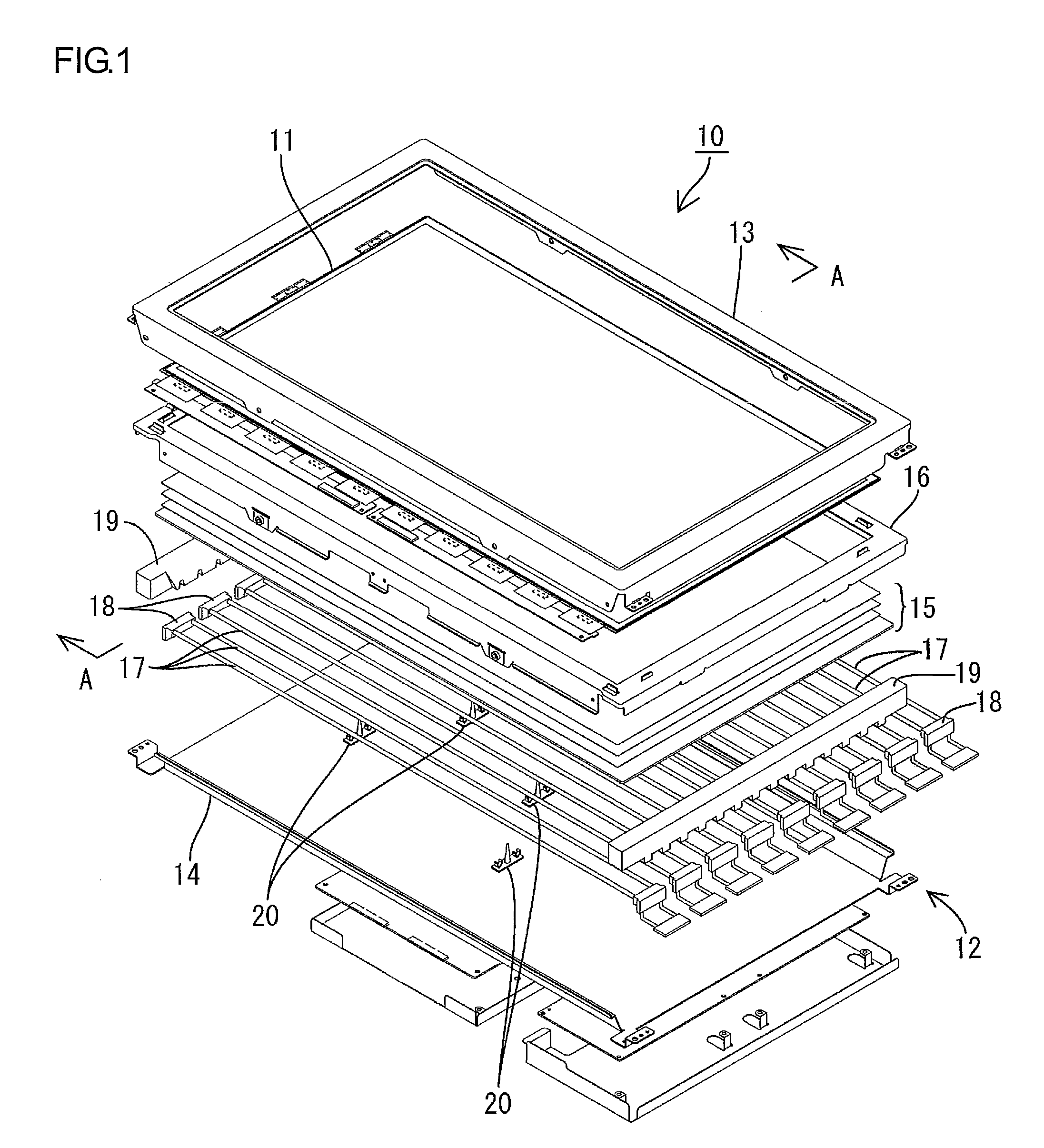

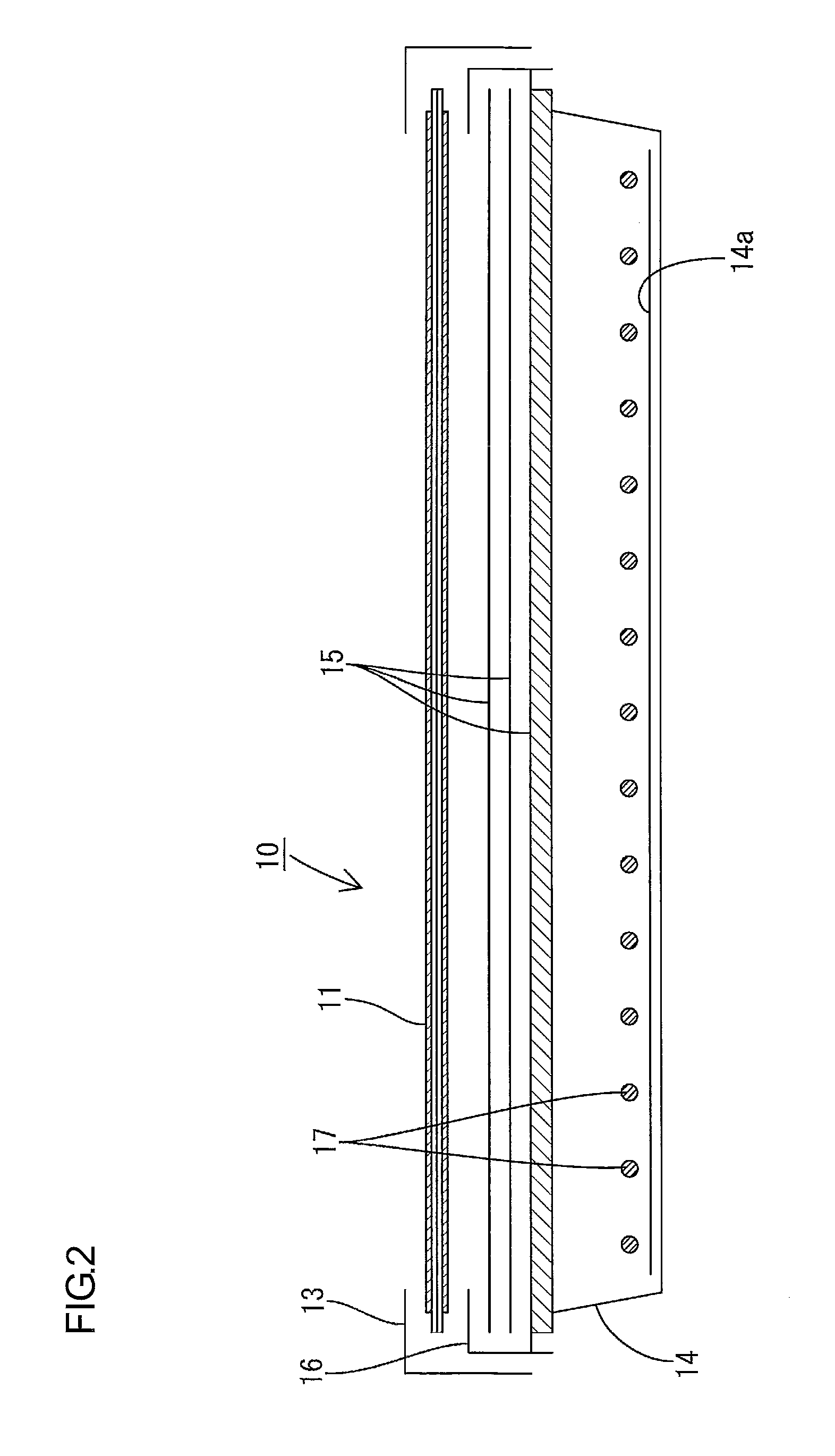

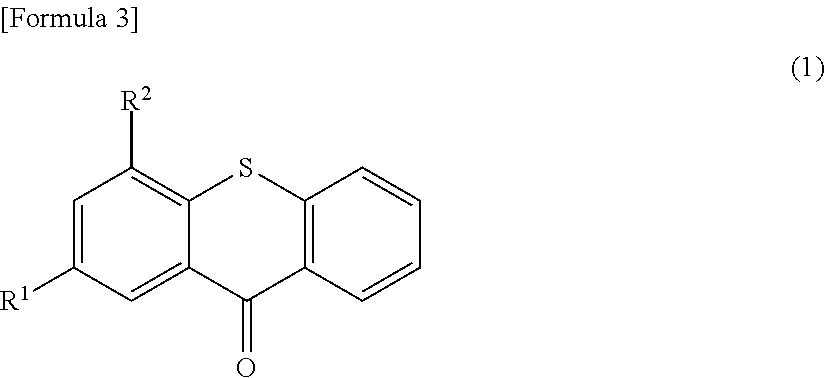

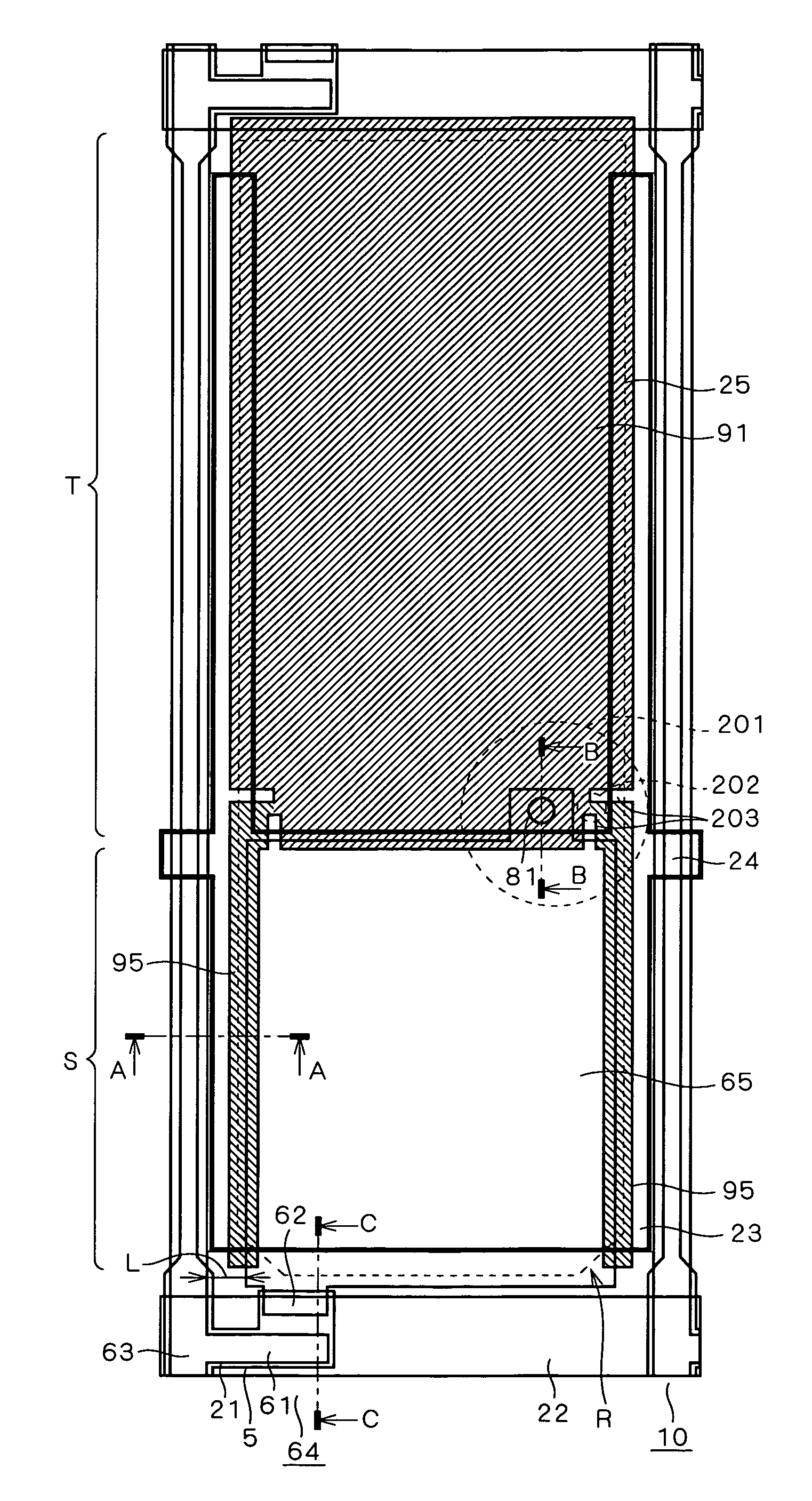

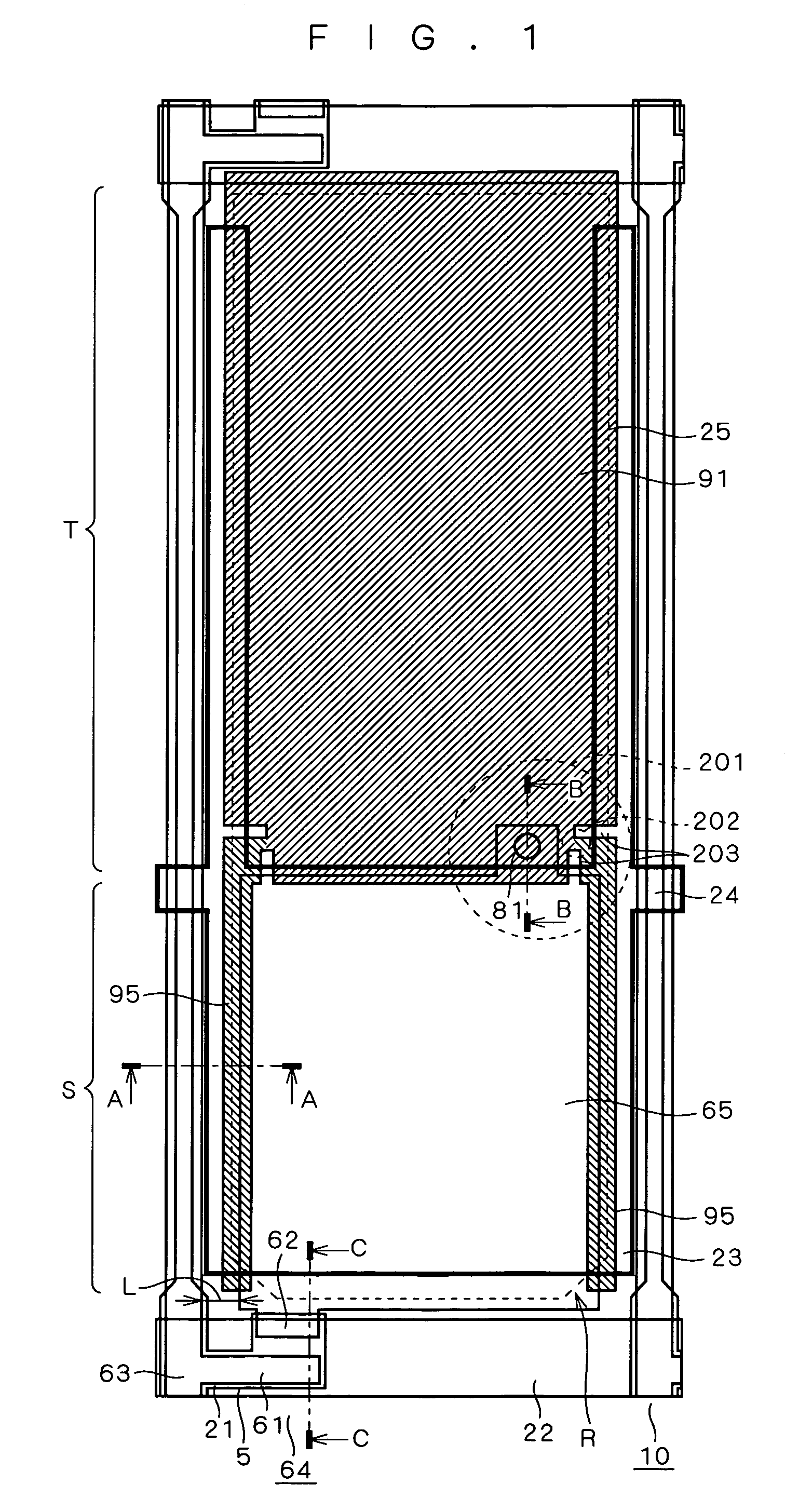

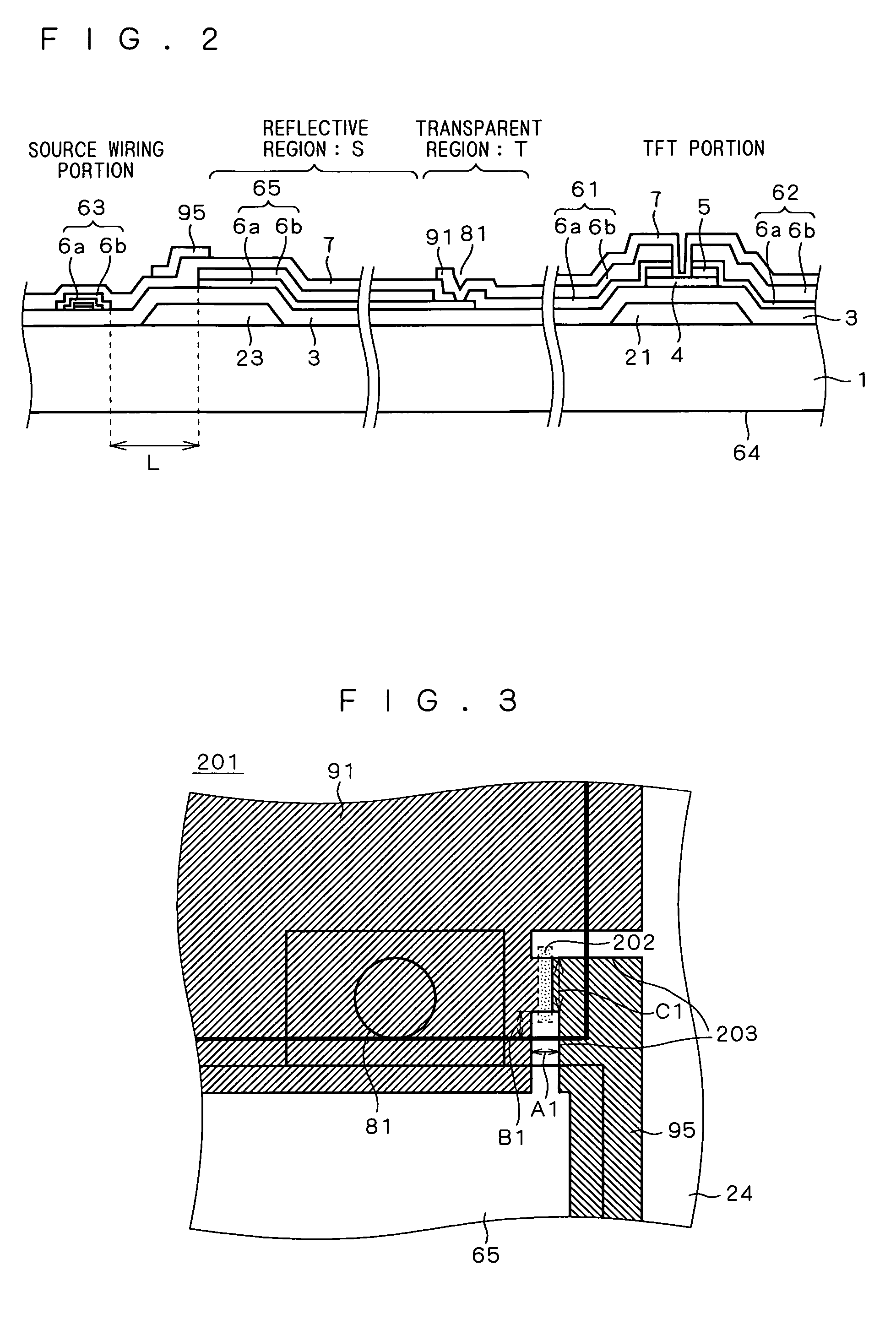

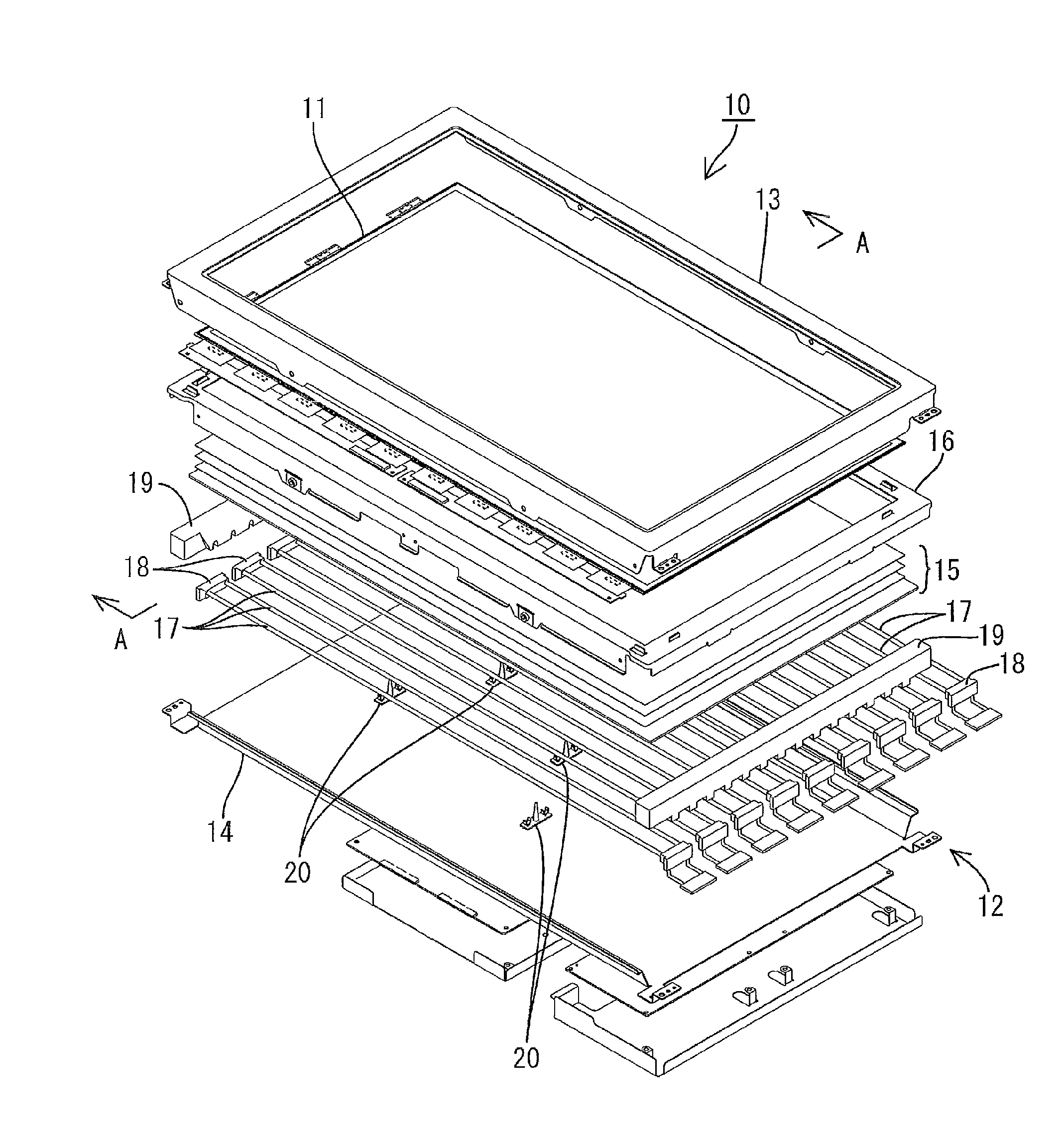

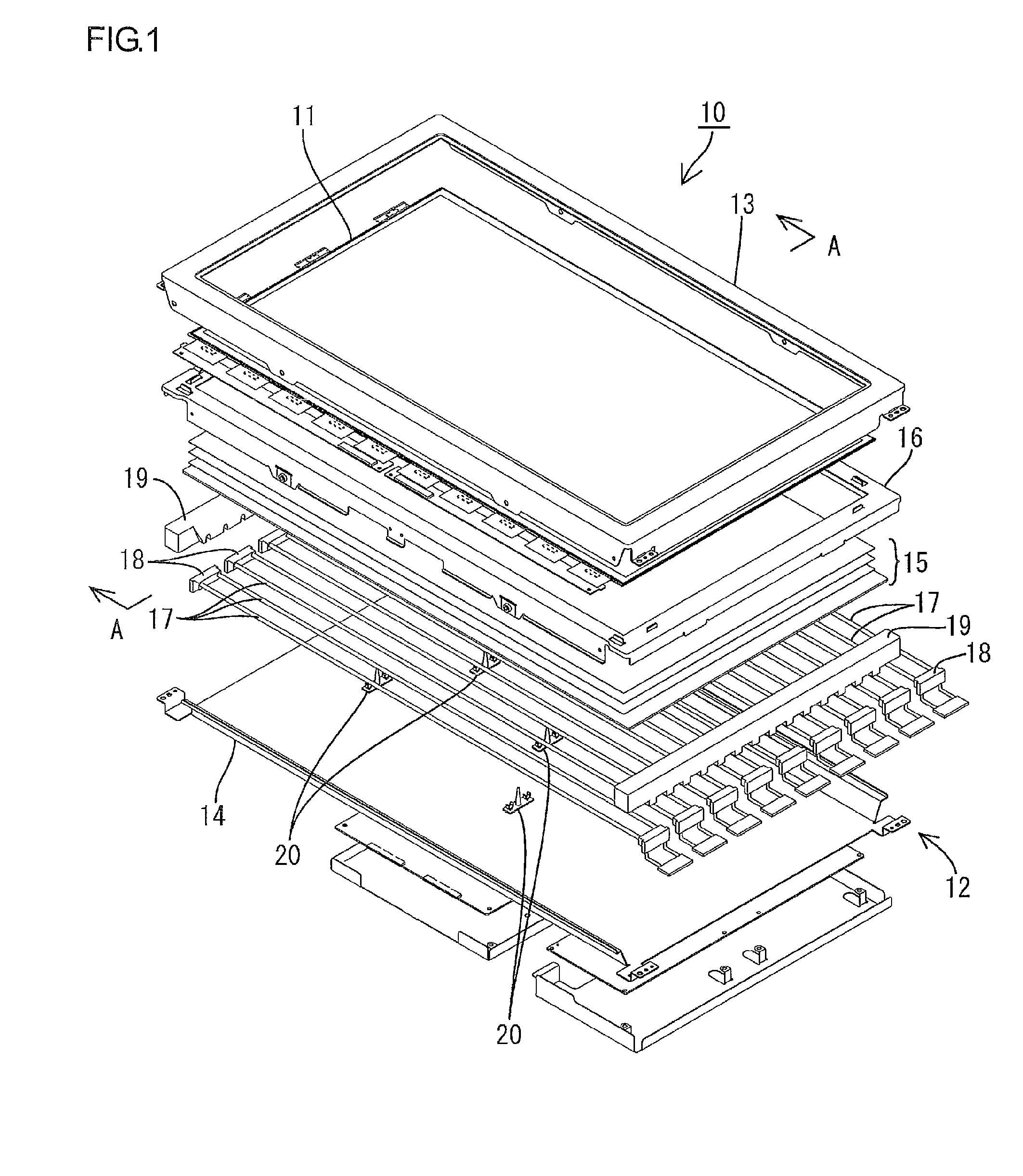

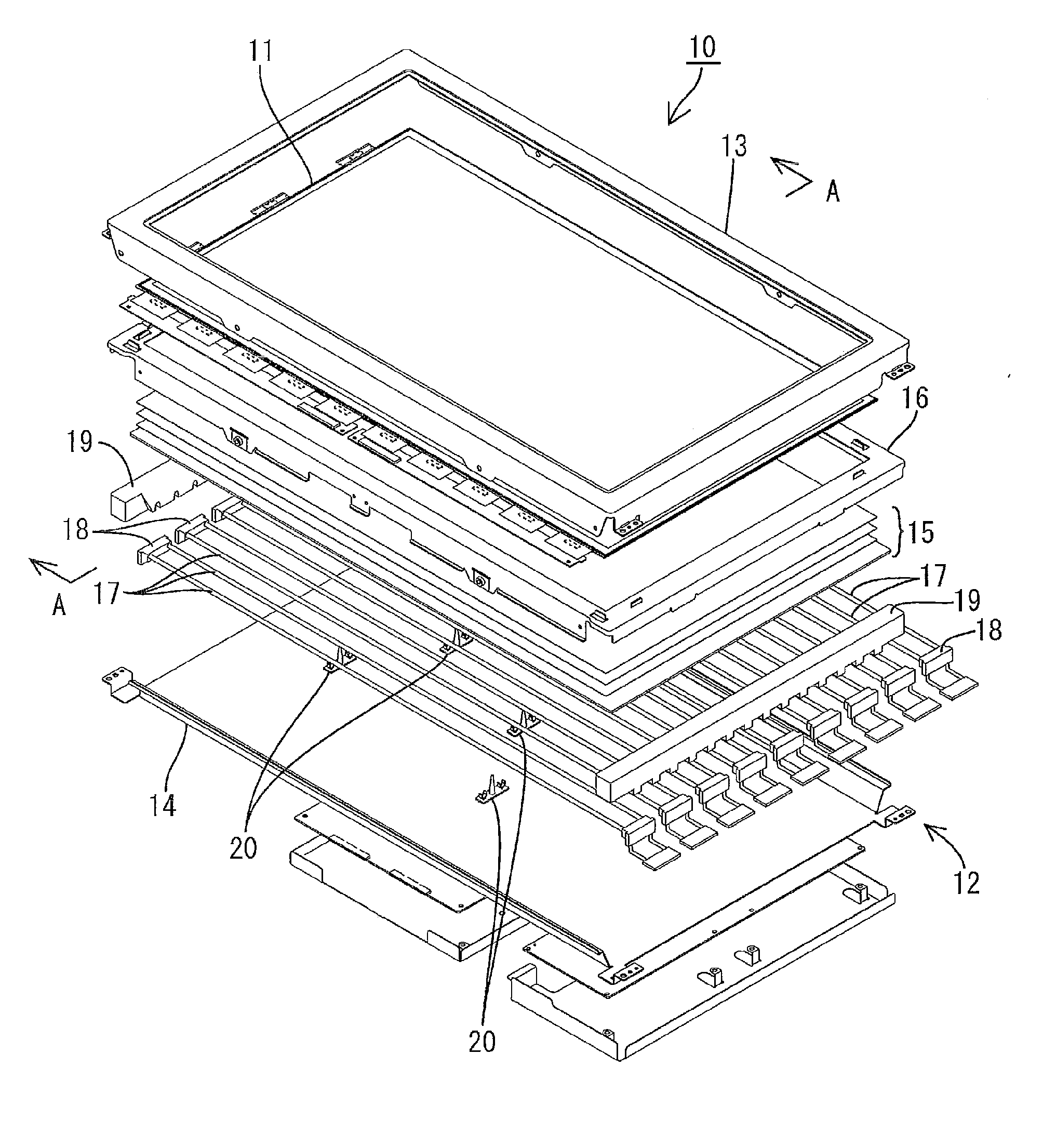

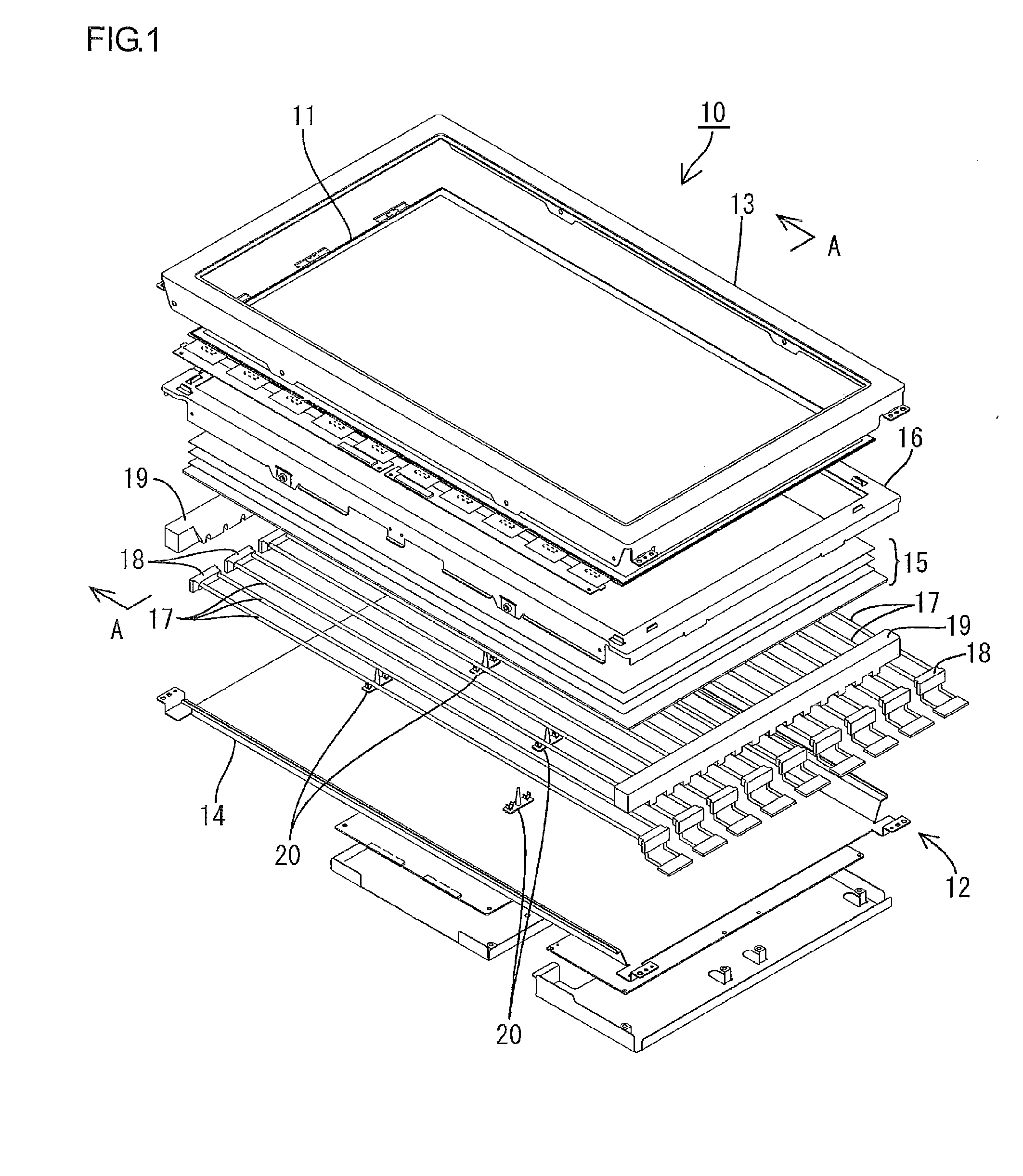

Active Matrix Substrate, Method for Fabricating Active Matrix Substrate, Display Device, Liquid Crystal Display Device, and Television Device

ActiveUS20080002076A1Improve production yieldPoint defectSemiconductor/solid-state device manufacturingNon-linear opticsCapacitanceLiquid-crystal display

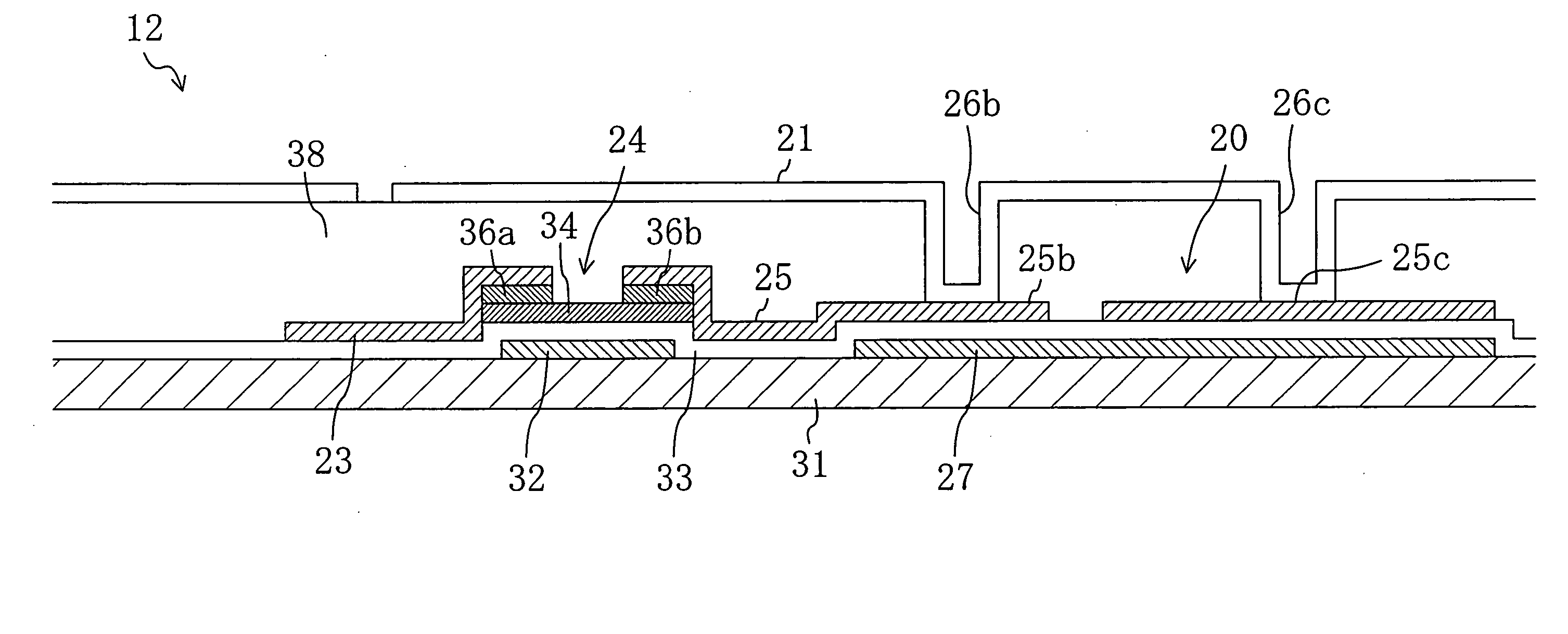

An active matrix substrate includes a substrate, a TFT formed on the substrate, a storage capacitor element formed on the substrate, an interlayer insulating film covering the storage capacitor element, and a pixel electrode formed on the interlayer insulating film. The storage capacitor element includes a storage capacitor line, an insulating film formed on the storage capacitor line, and two or more storage capacitor electrodes opposed to the storage capacitor line with the insulating film interposed therebetween. The two or more storage capacitor electrodes are electrically connected via associated contact holes formed in the interlayer insulating film to the pixel electrode and electrically continuous with a drain electrode of the TFT.

Owner:SHARP KK

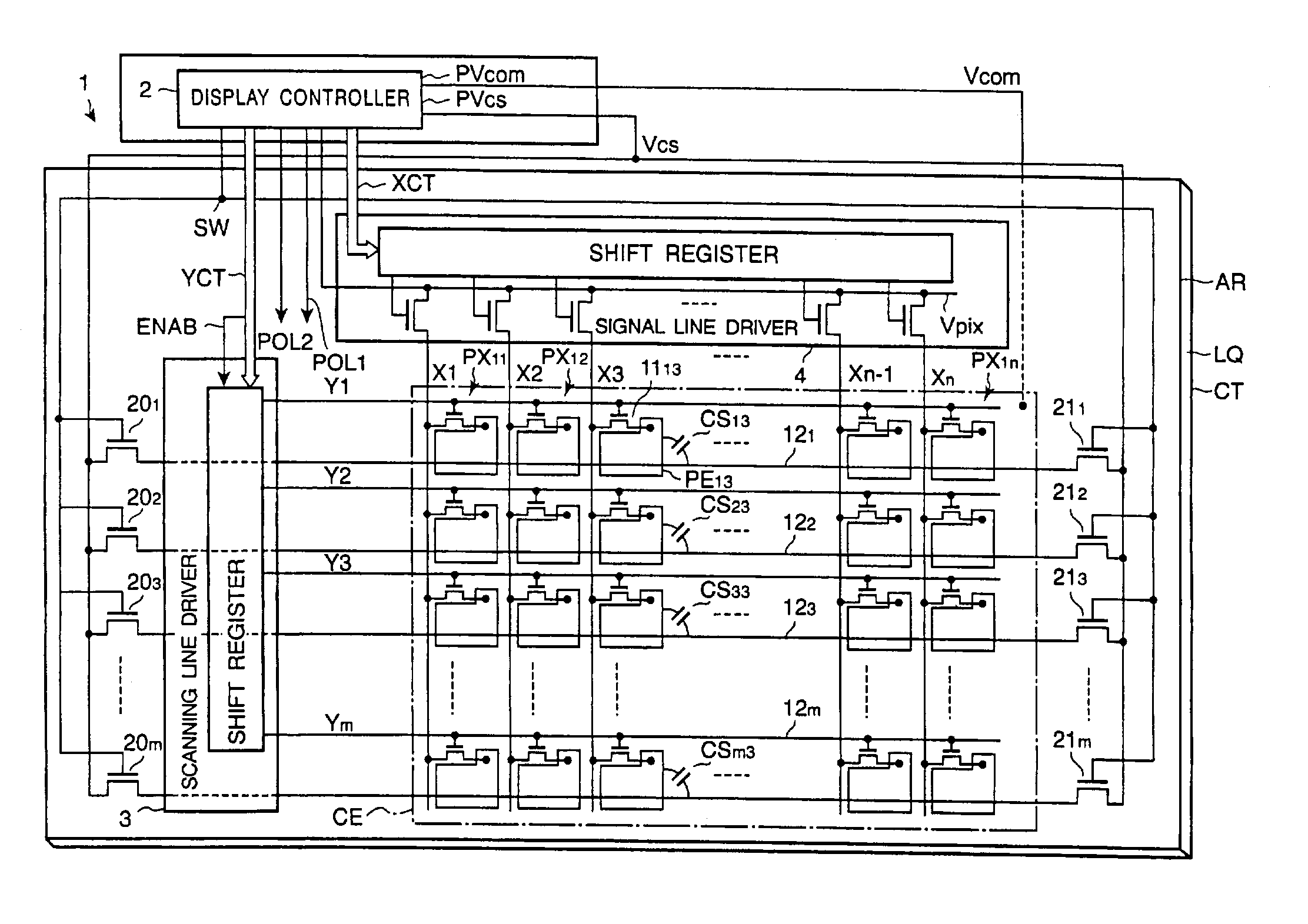

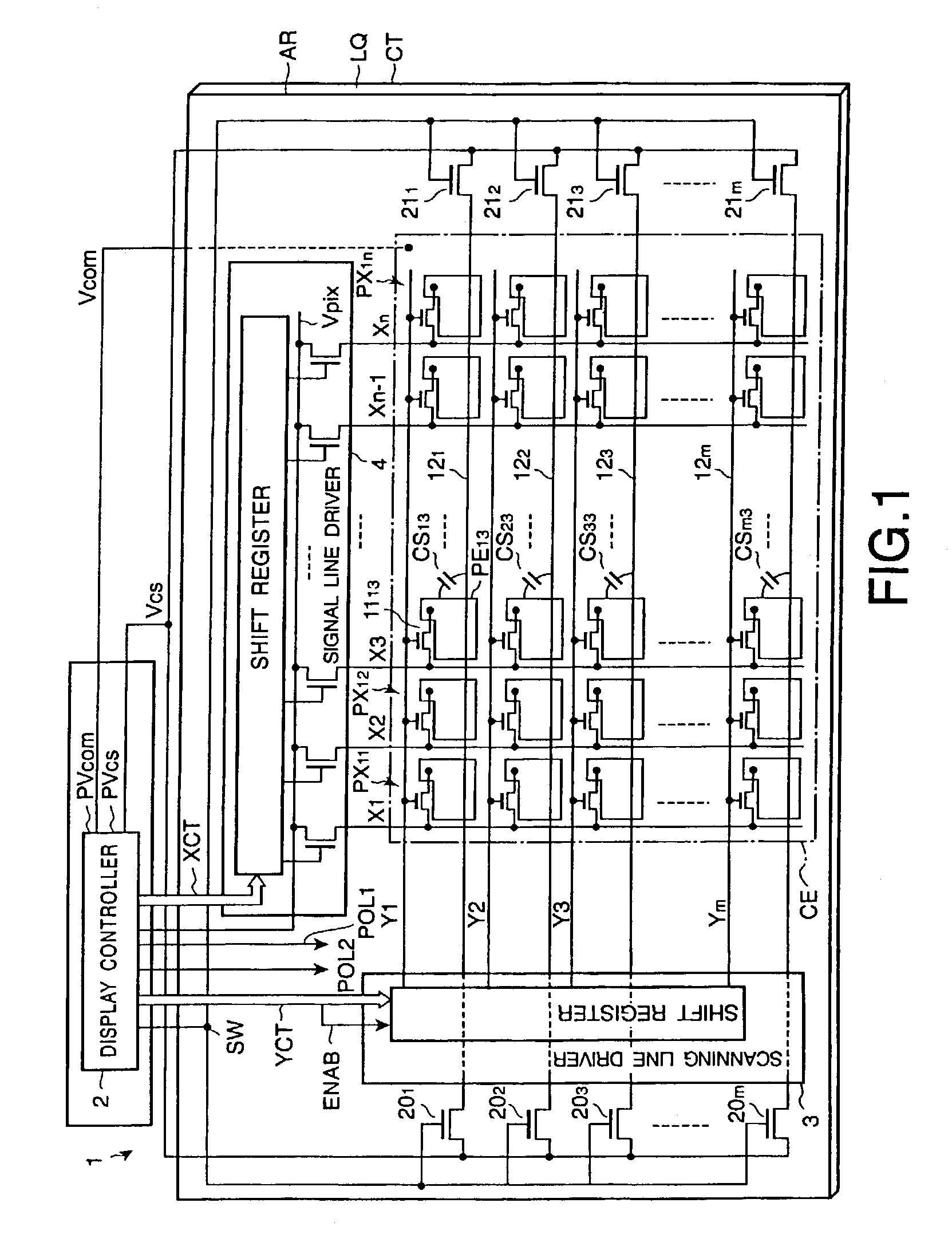

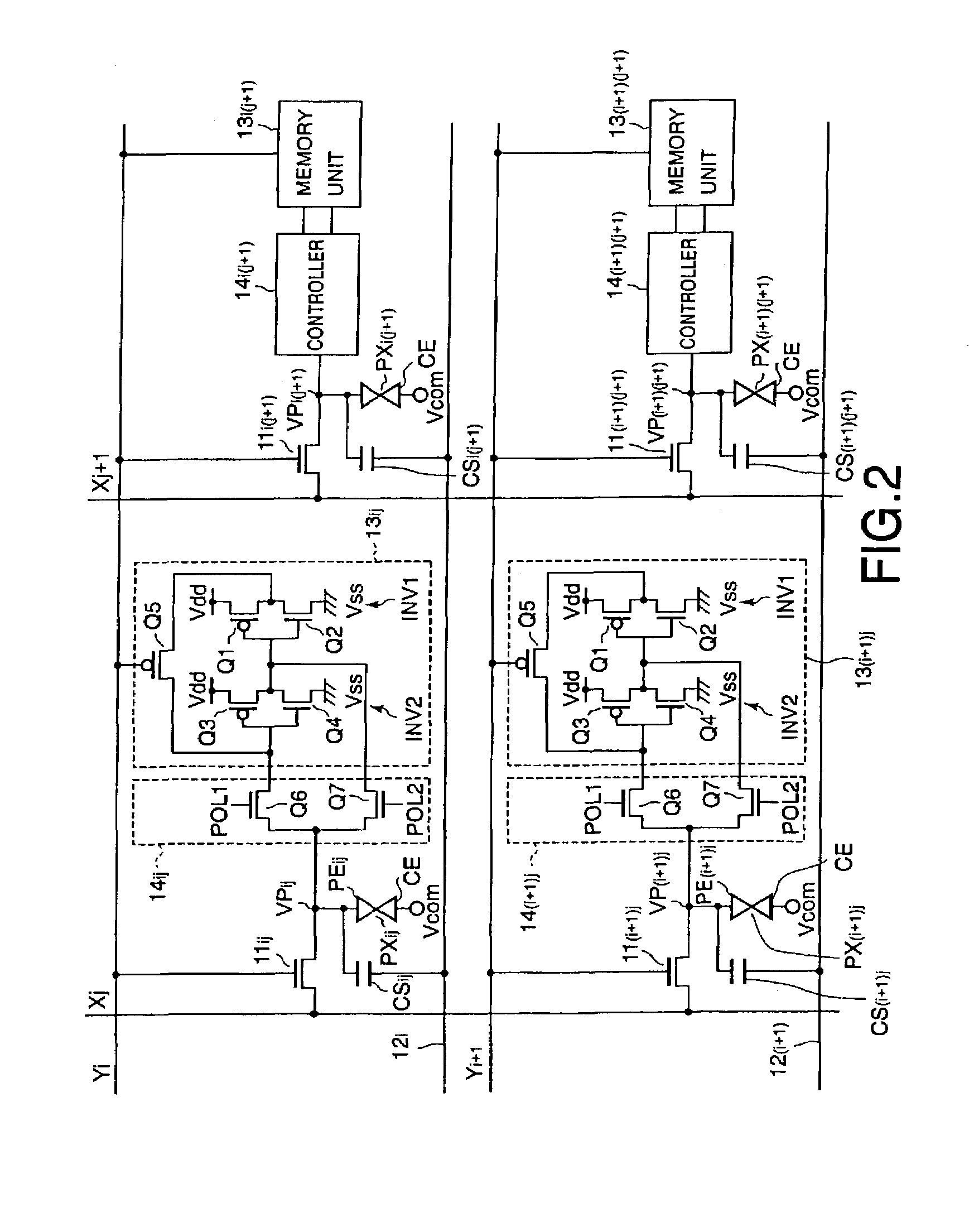

Liquid crystal display device

InactiveUS6958744B2Reduce pointsPoint defectStatic indicating devicesNon-linear opticsElectricityCapacitance

A liquid crystal display device includes pixels having pixel electrodes and a common electrode. A liquid crystal material is held between the pixel electrodes and common electrode. Pixel switches are provided to supply video signals to the pixel electrodes. A plurality of memories are provided to store the video signals in a digital form supplied from the switches to the pixel electrodes. Connection controllers connect the memories to the pixel electrodes and periodically reverse polarities of the video signals output from the memories to the pixel electrodes with respect to potential of the common electrode. A potential setting terminal is provided and auxiliary capacitor lines connected to the potential setting terminal constitute capacitive coupling with the pixel electrodes. Separation circuits are provided to keep the auxiliary capacitor lines in an electrically floating state by electrically disconnecting the auxiliary capacitor lines from the potential setting terminal while the connection controllers connect the memories to the pixels.

Owner:KK TOSHIBA

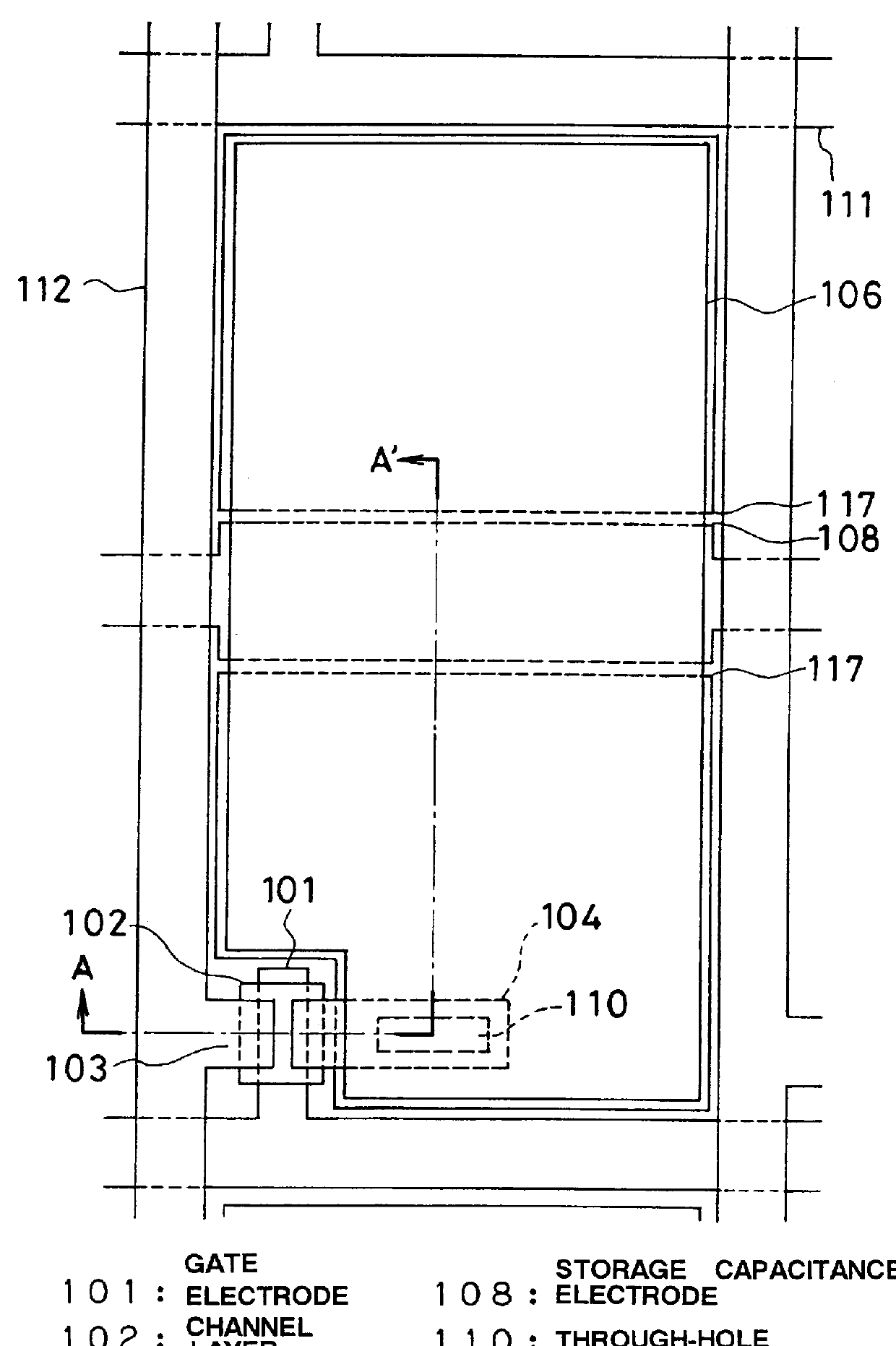

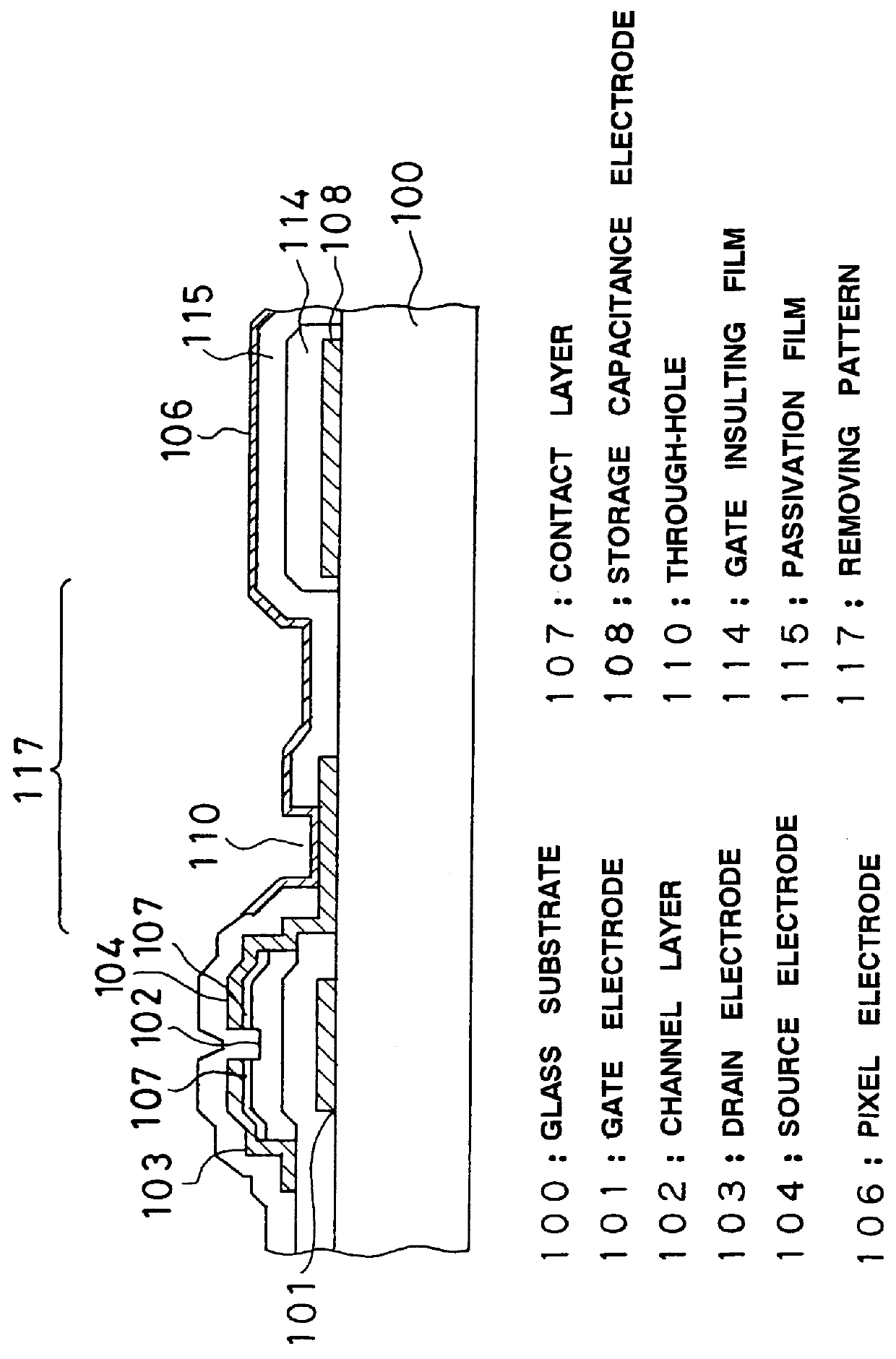

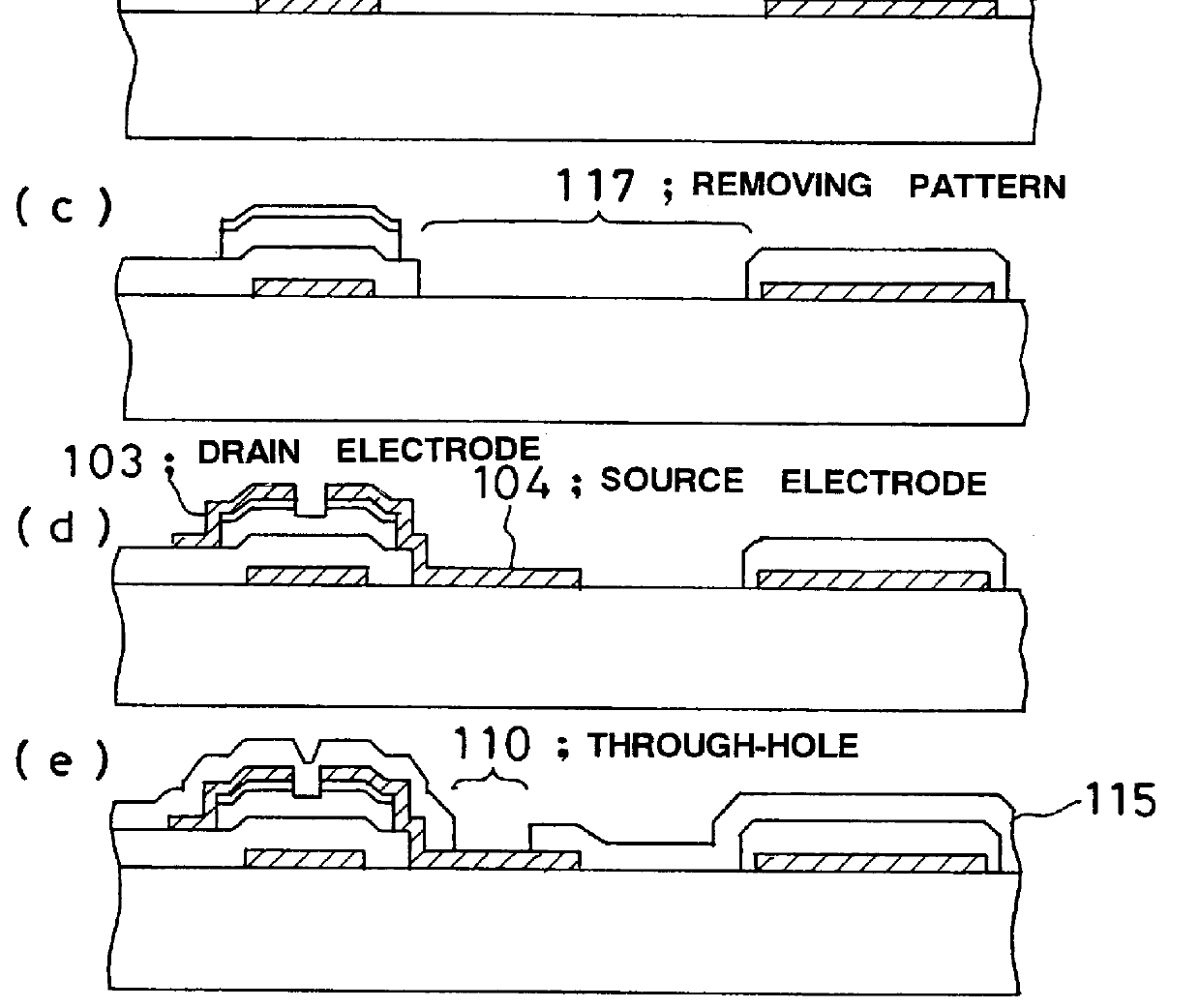

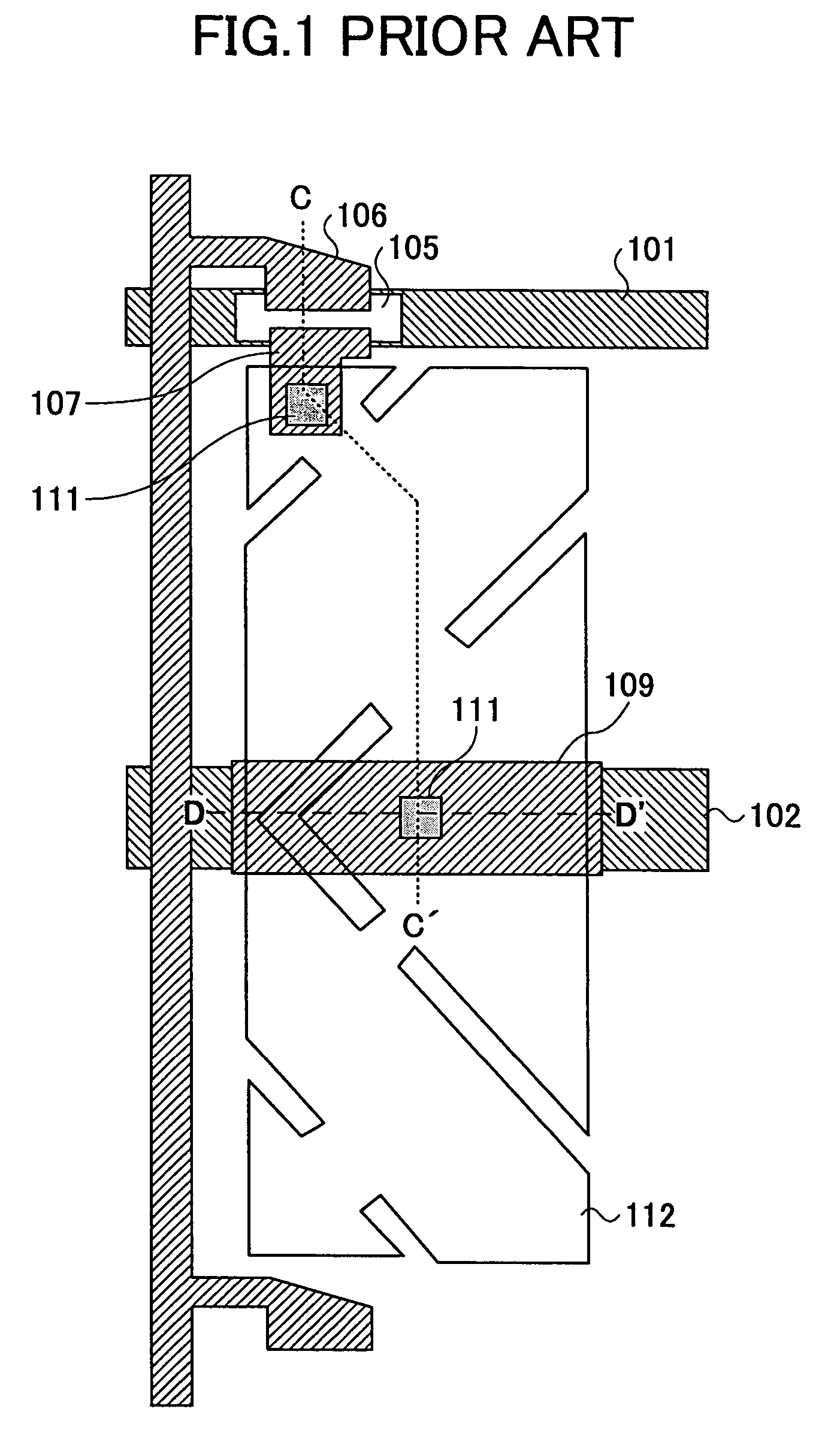

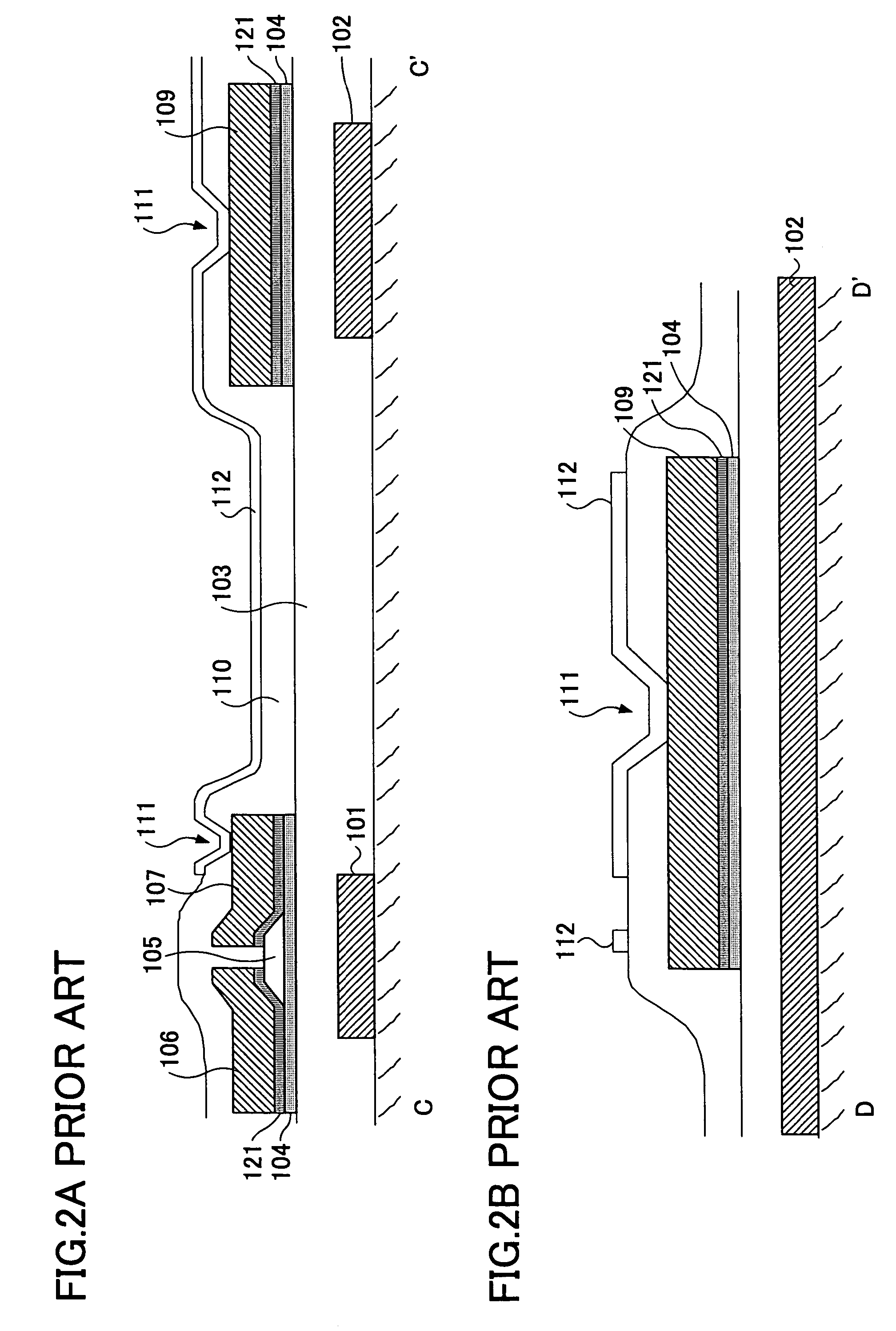

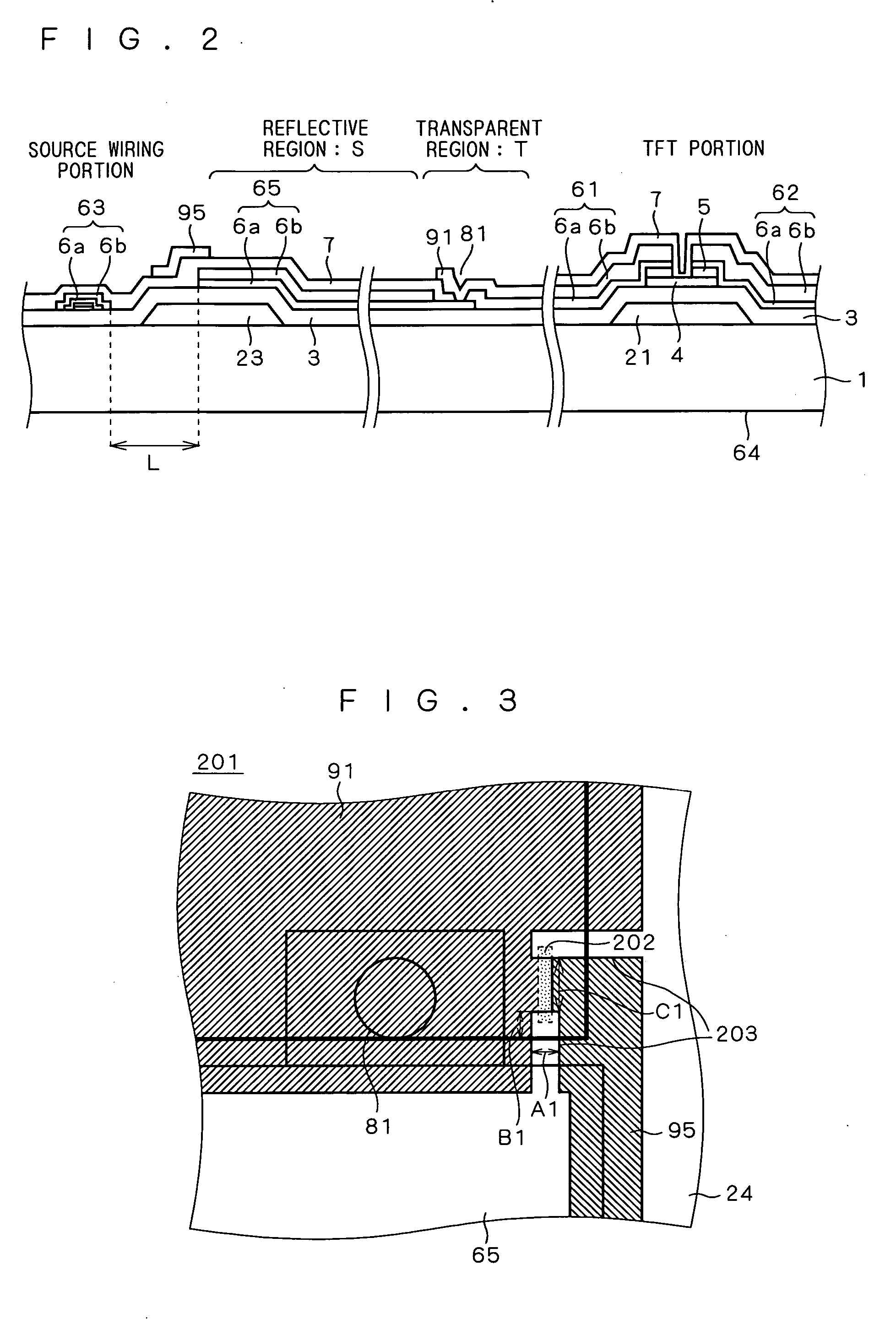

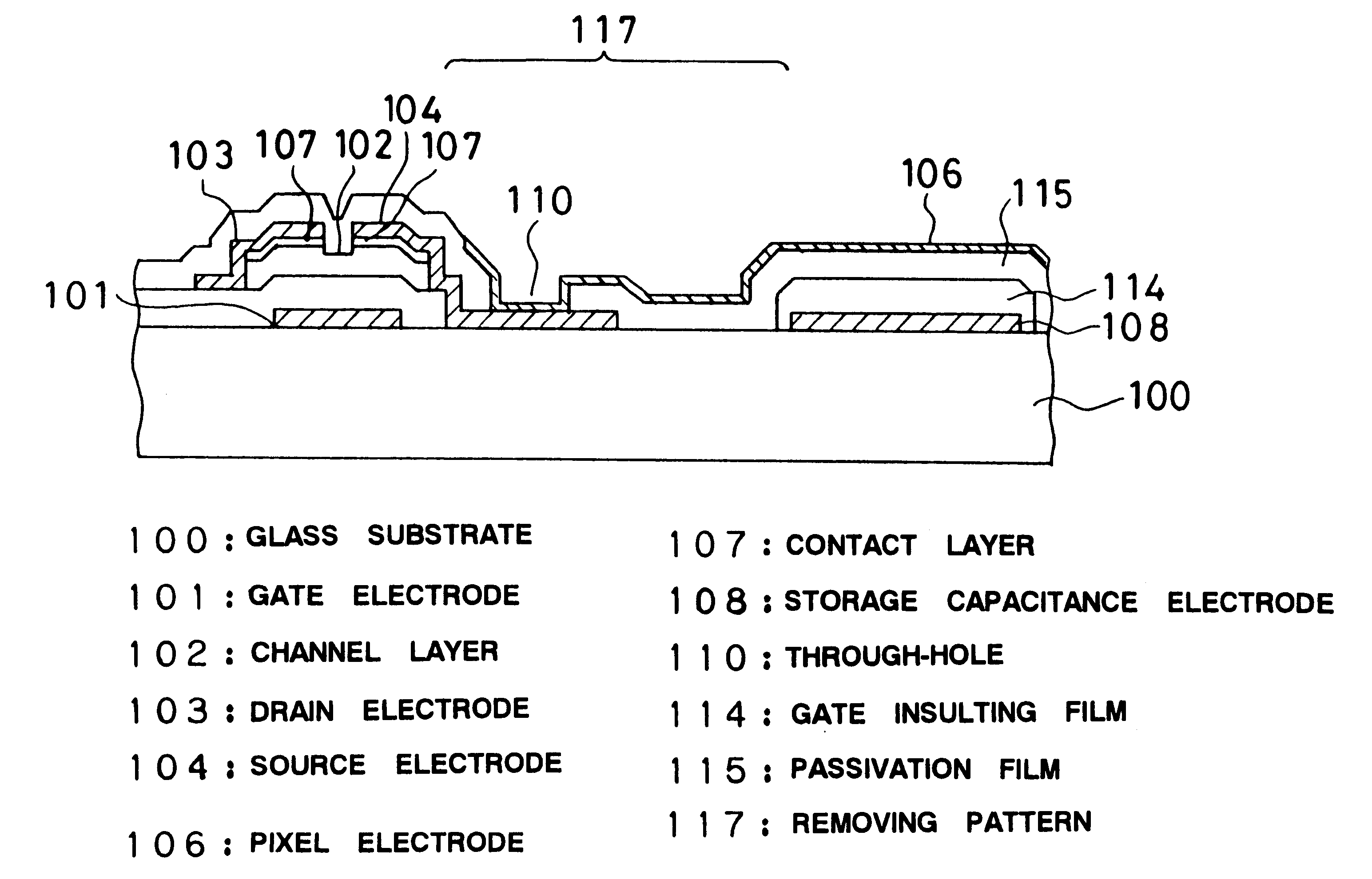

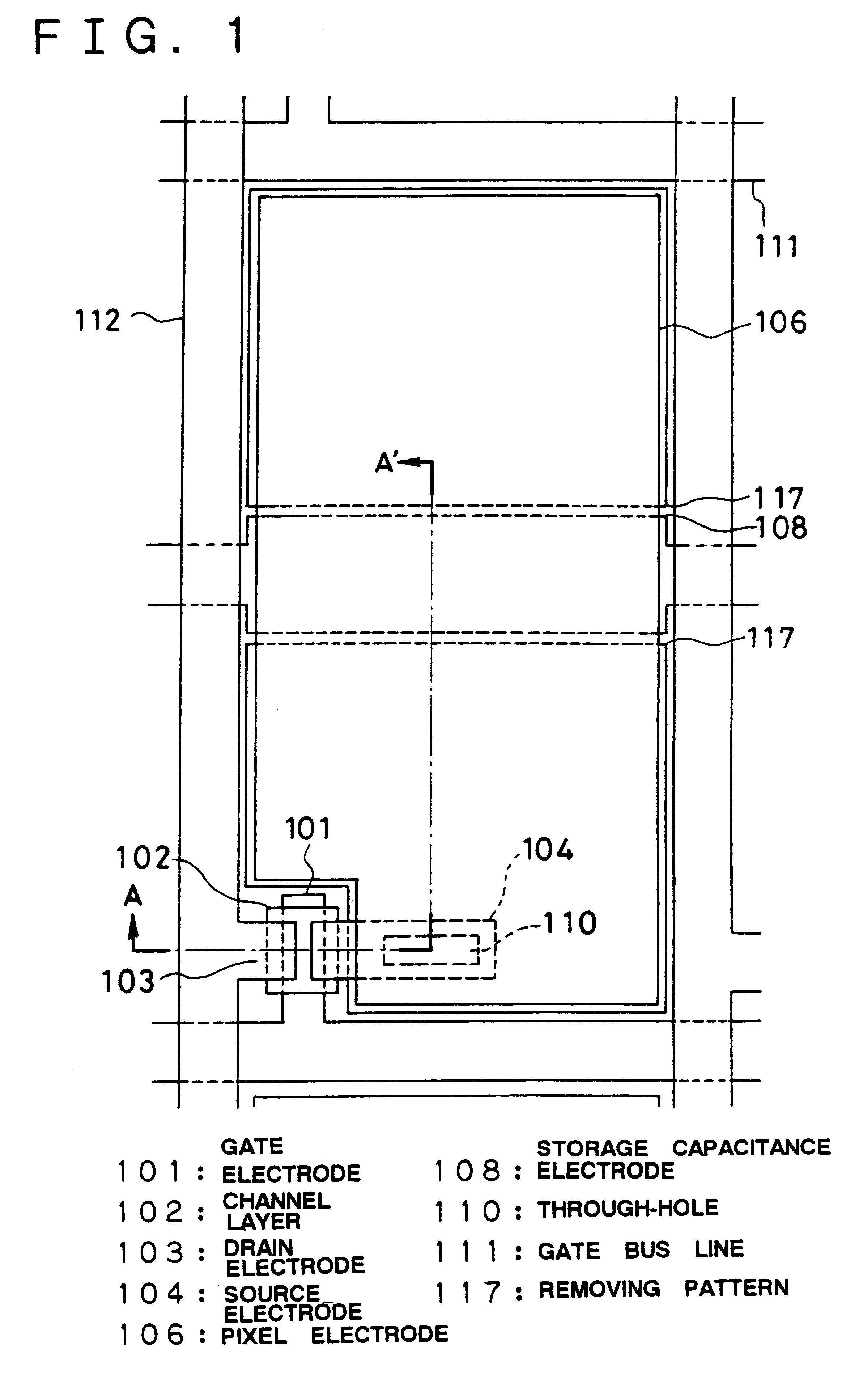

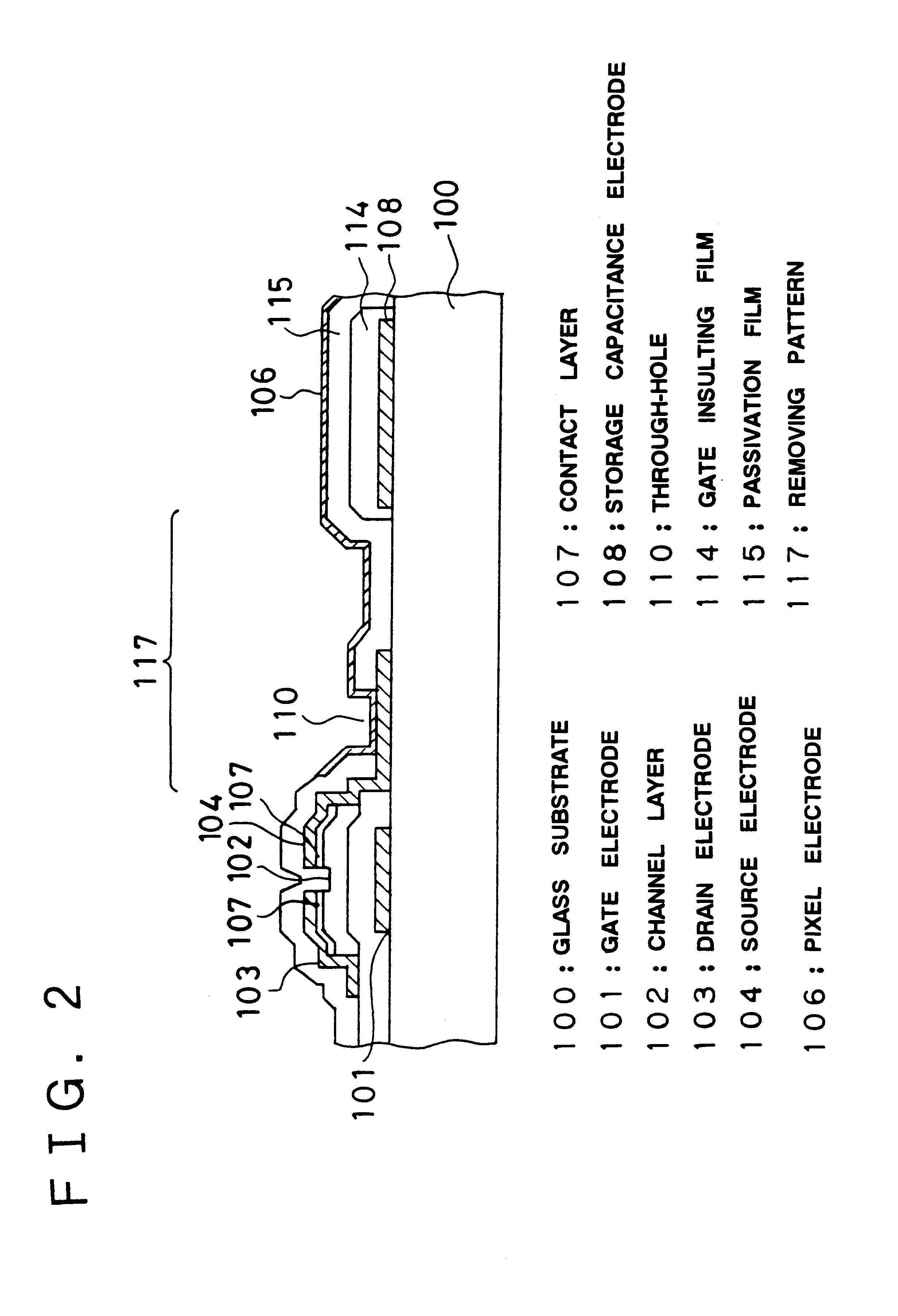

Thin-film transistor array and method for manufacturing same

InactiveUS6121632AEvading complication of manufacturing processIncrease the areaTransistorSemiconductor/solid-state device detailsCapacitanceCapacitive coupling

A high-quality thin-film transistor array. The gate insulating film below the pixel electrode is etched off in its entirely or along a slit extending along a drain bus line in order to simultaneously remove the residual a-Si produced due to defective patterning. The insulating film is interposed between a drain bus line and a pixel electrode to form a boundary separating layer therebetween. The reject ratio is suppressed by reducing the occurrence of point defects of semi-bright spots, ascribable to capacitative coupling to the pixel electrodes as a result of interconnection of the residual a-Si produced by defective patterning to the drain bus line.

Owner:NEC LCD TECH CORP

Semi-insulating silicon carbide without vanadium domination

InactiveUS20010019132A1Reduce the amount requiredIncrease the number ofPolycrystalline material growthAfter-treatment detailsDevice formTrapping

A semi-insulating bulk single crystal of silicon carbide is disclosed that has a resistivity of at least 5000 OMEGA-cm at room temperature and a concentration of deep level trapping elements that is below the amounts that will affect the resistivity of the crystal, preferably below detectable levels. A method of forming the crystal is also disclosed, along with some resulting devices that take advantage of the microwave frequency capabilities of devices formed using substrates according to the invention.

Owner:CREE INC

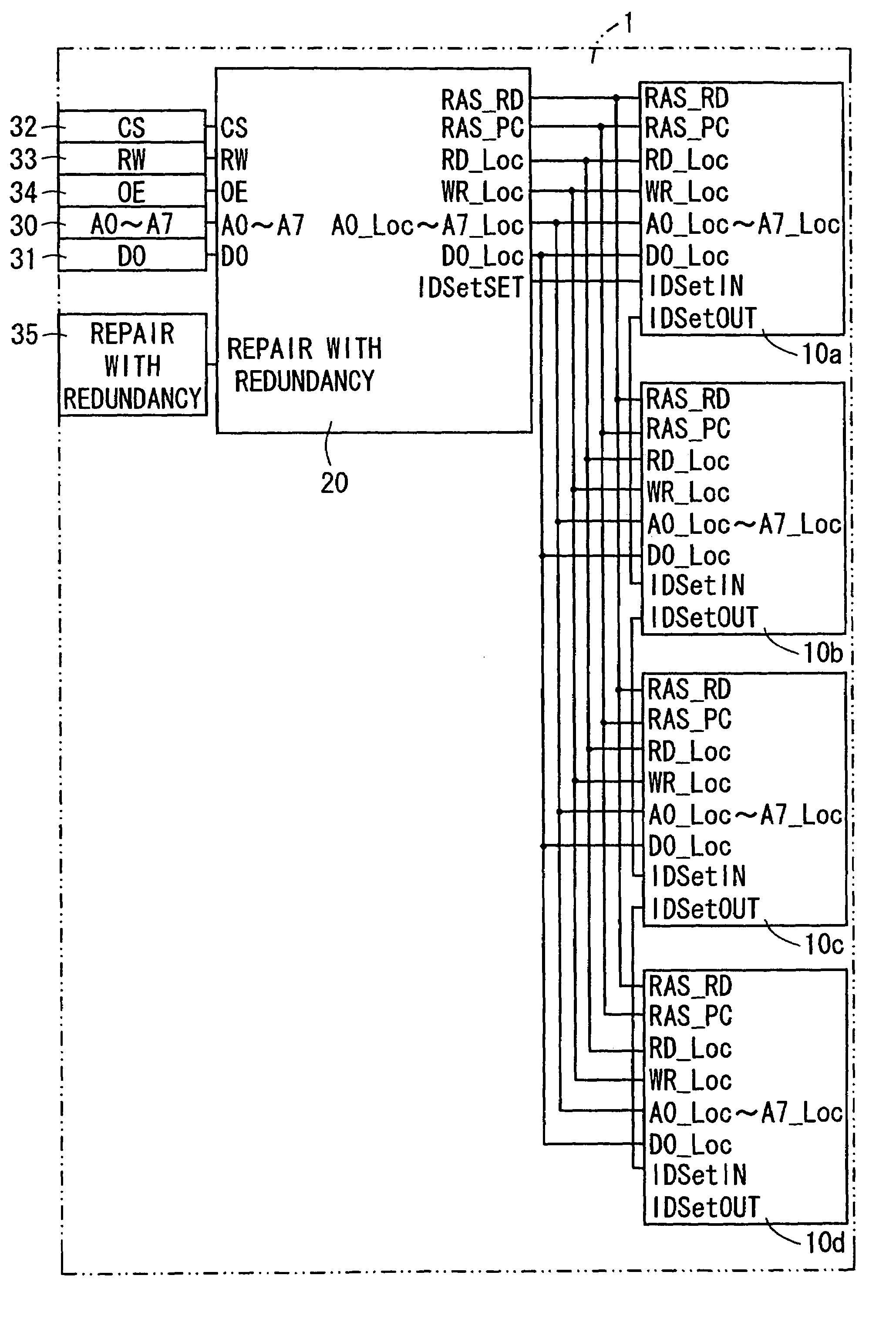

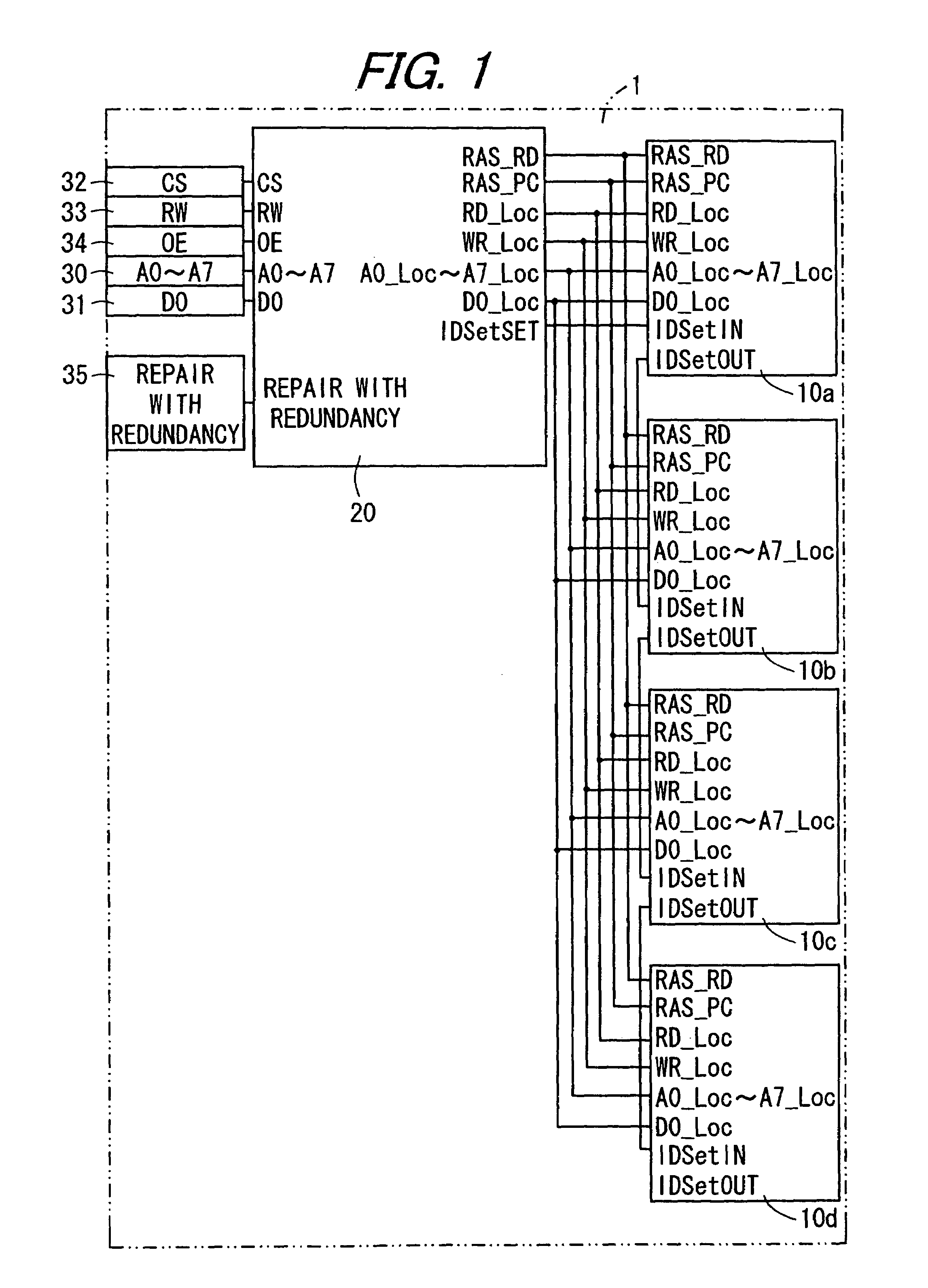

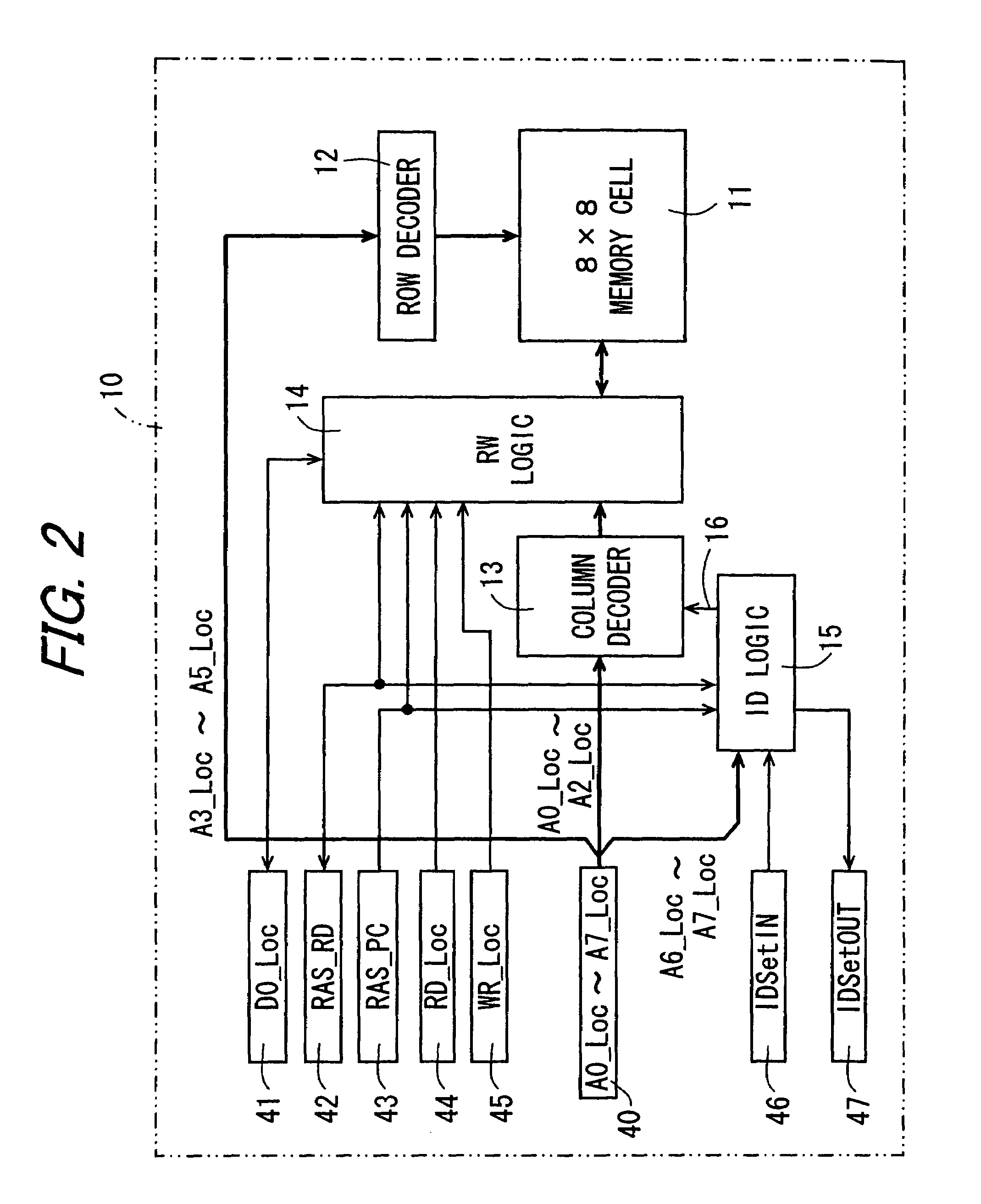

Memory device having redundant memory for repairing defects

First memory chips each have a memory cell as storage means for storing data and do not have a redundant memory cell as redundant storage means for repairing an erroneous bit in the memory cell. Furthermore, a logic minimal in degree is solely provided for operation on a control logic of a second memory chip. The second memory chip has a control logic for effecting memory control of the memory cells, the redundant memory cells, etc. and a redundant memory cell for repairing an error bit of the first memory chips. The memory device is structured by stacking the first and second memory chips.

Owner:SHARP KK

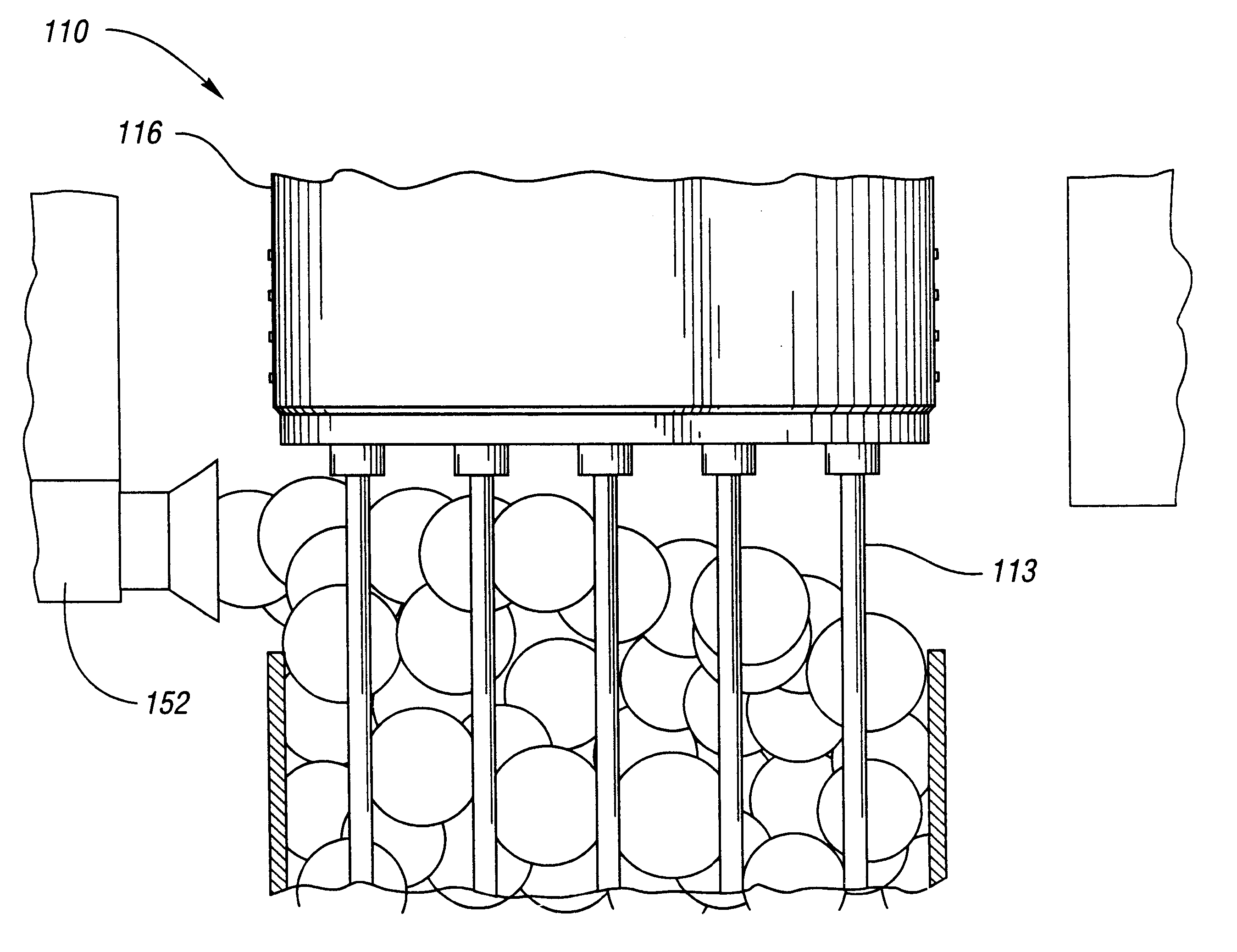

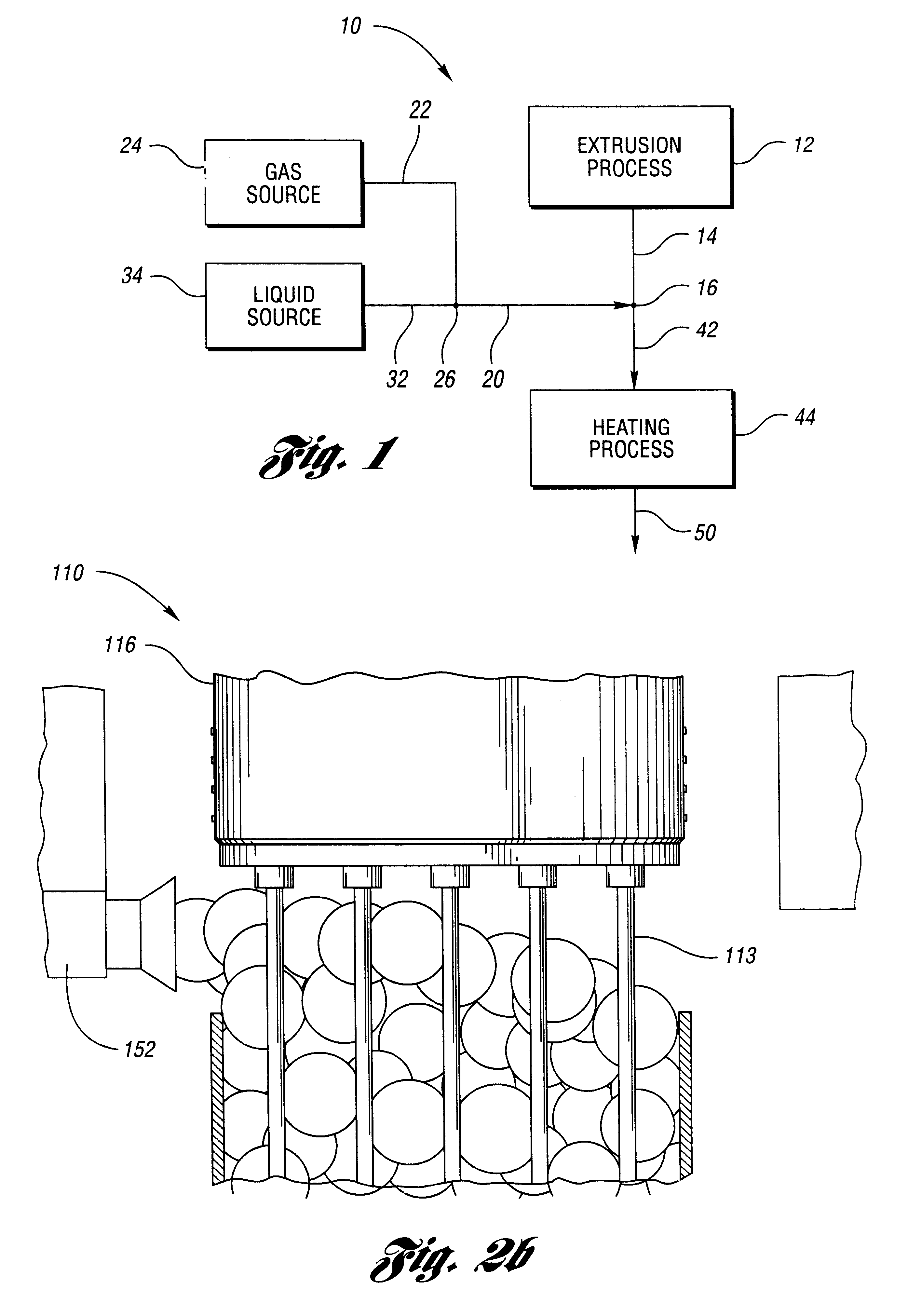

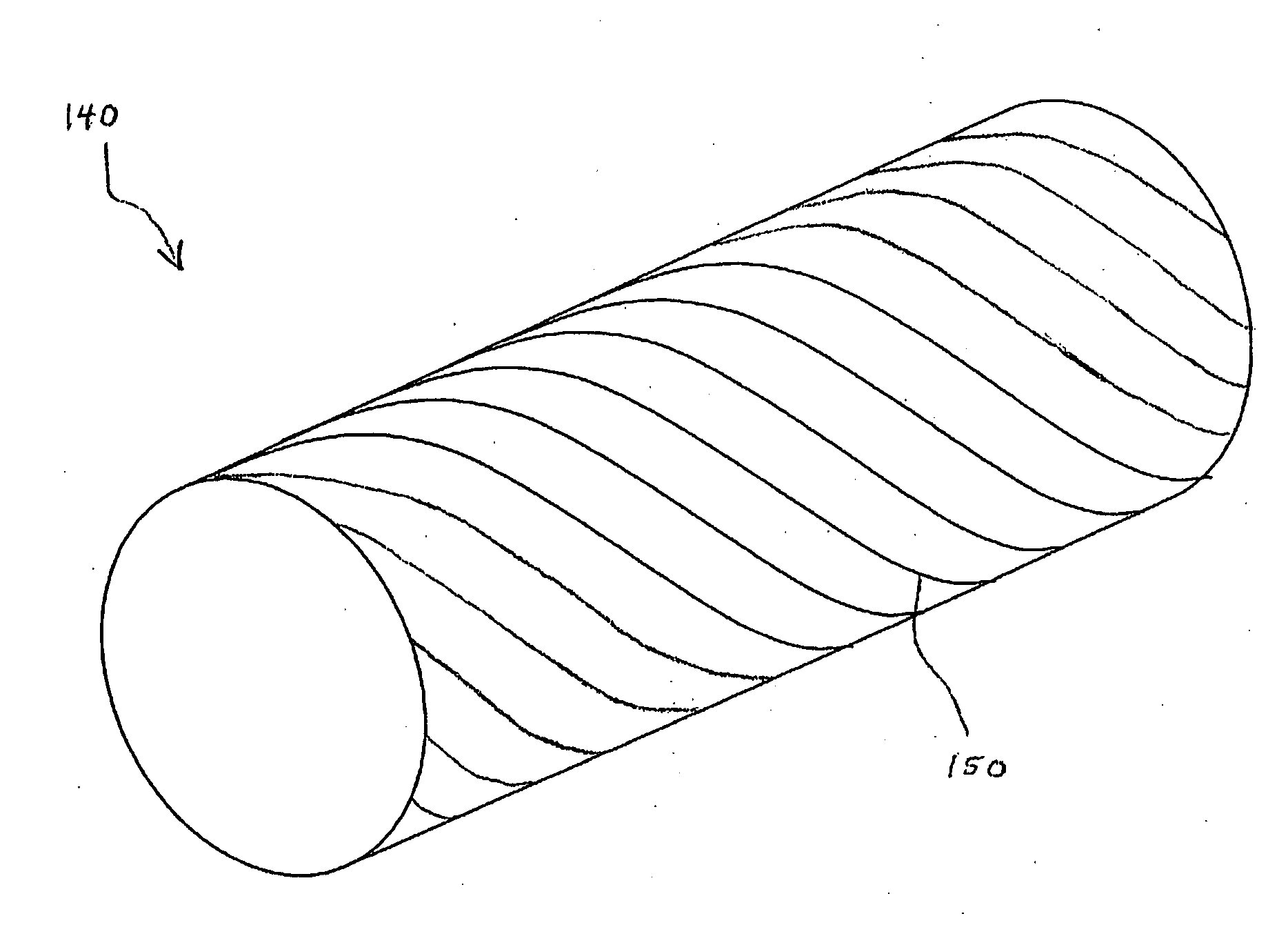

Method of making a supported plurality of electrochemical extruded membranes

InactiveUS6294128B1Add supportImprove cooling effectSolid electrolytesCell electrodesSemi solidHot Temperature

The present invention is a method for the manufature of a membrane structure for use in electrochemical conversions. The method includes providing a first mixture at a first temperature and a second mixture at a second temperature, extruding the first mixture to form a plurality of spaced-apart supportable membranes, cooling the extruded membrane from the first temperature to a third temperature, forming sufficient bubble surfaces of the second mixture between the membranes to facilitate the support of the membranes, cooling the extruded membranes and the formed bubble surfaces to a semi-solid from the second temperature to the third temperature less than the first and second temperatures, heating the cooled extruded membranes and the cooled formed bubble surfaces from the semi-solid at the third temperature to a predetermined elevated temperature sufficient to make the extruded membranes and the formed bubble surfaces into a sintered ceramic, and sufficiently cooling the extruded membranes and the formed bubble surfaces in the sintered ceramic to cause the bubbles to support the membranes.

Owner:FORD GLOBAL TECH LLC

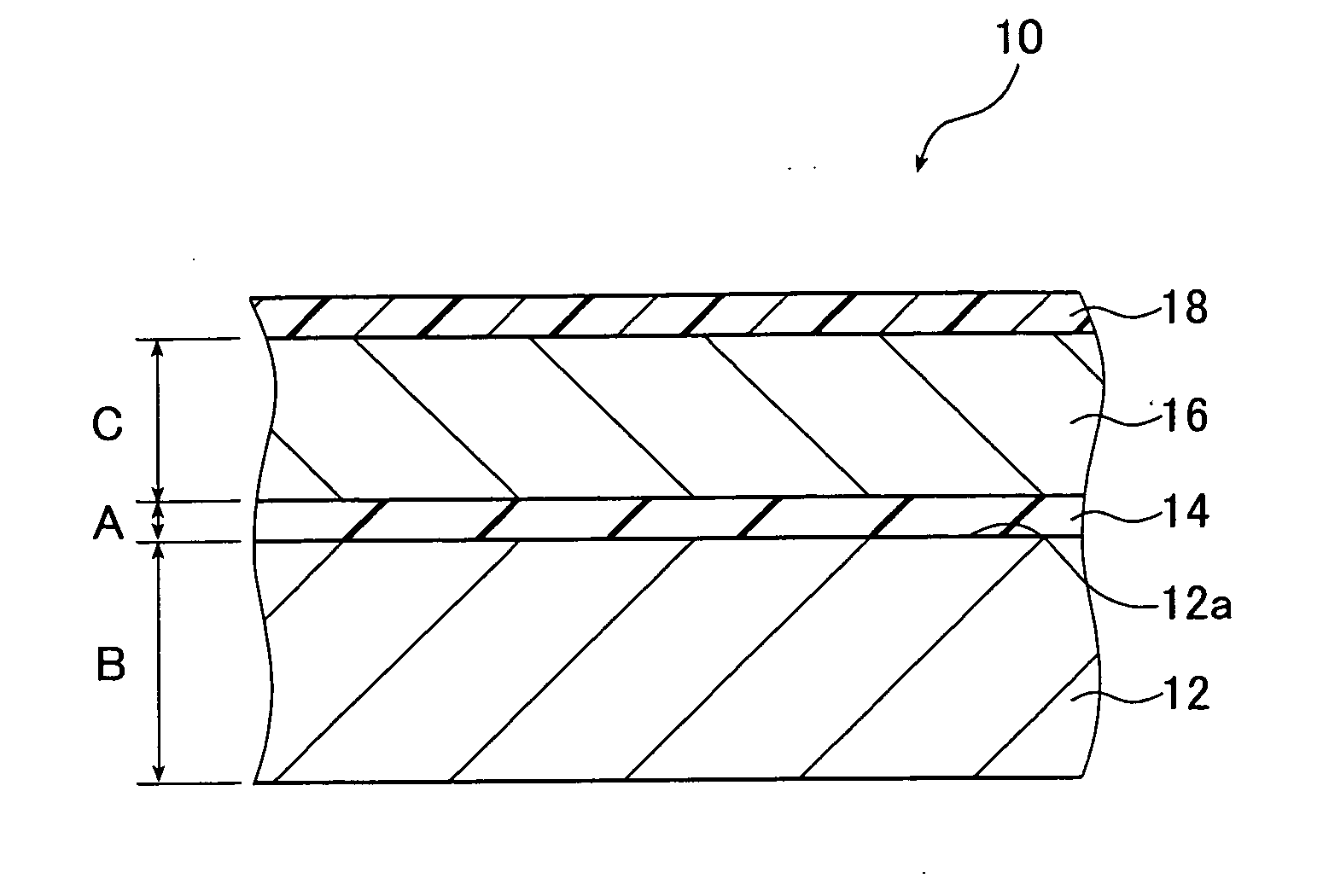

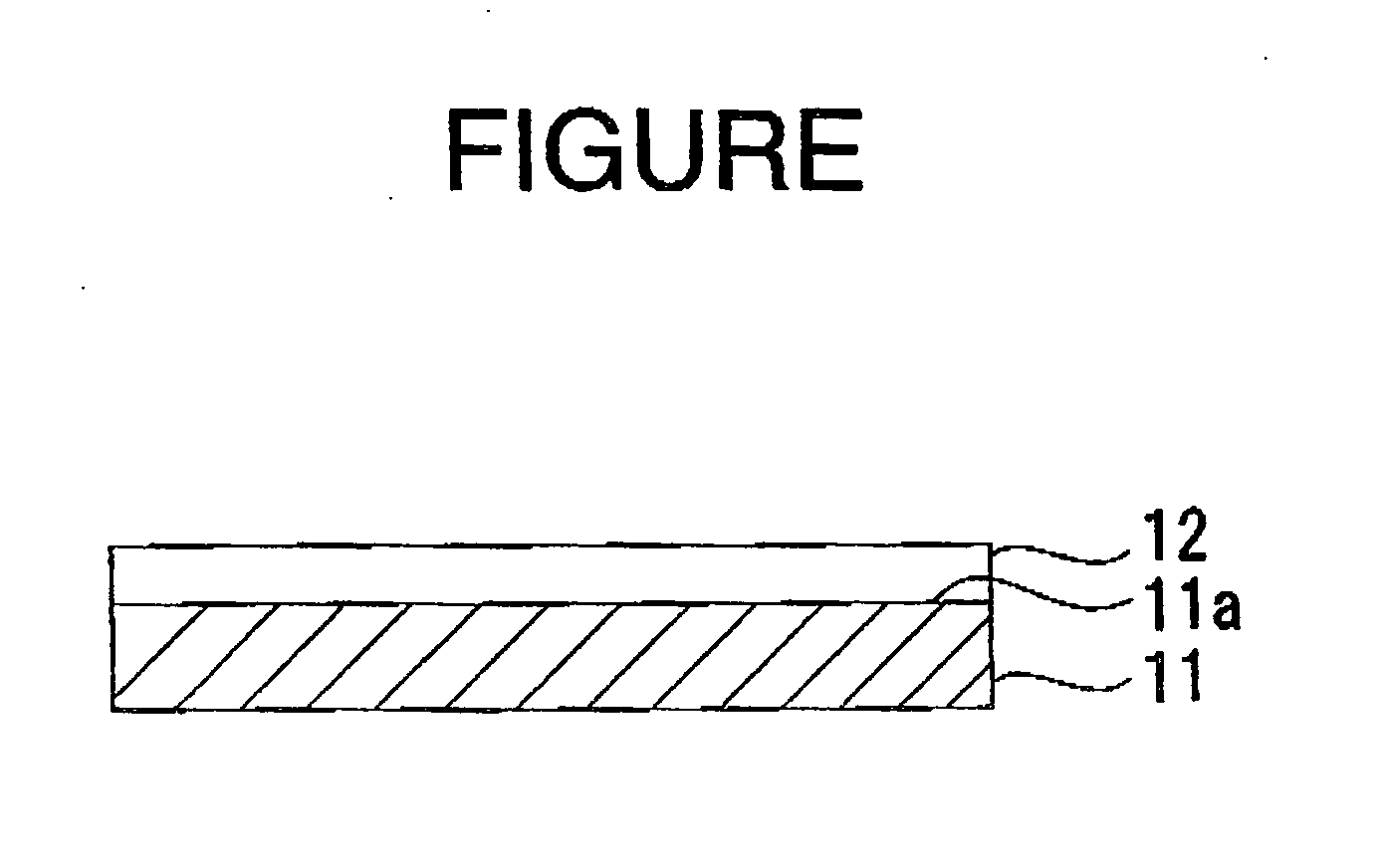

Radiographic image conversion panel and method of manufacturing the same

InactiveUS20060060792A1Highly uniform thicknessWithout deteriorationPhotometryFluorescence/phosphorescenceGas phaseFluorescence

There is provided a radiographic image conversion panel having a substrate made of a metal or an alloy, an oxide layer formed on the substrate by a vapor deposition technique such as sputtering, ion plating or ion beam assisted deposition, and a phosphor layer formed on the oxide layer by the vapor deposition technique. A method of manufacturing the radiographic image conversion panel is also provided. The radiographic image conversion panel is capable of suppressing for a long time corrosion of the surface of the substrate due to a reaction between a stimulable phosphor and the substrate through moisture and also capable of providing a radiographic image without any deterioration of the characteristics.

Owner:FUJIFILM CORP +1

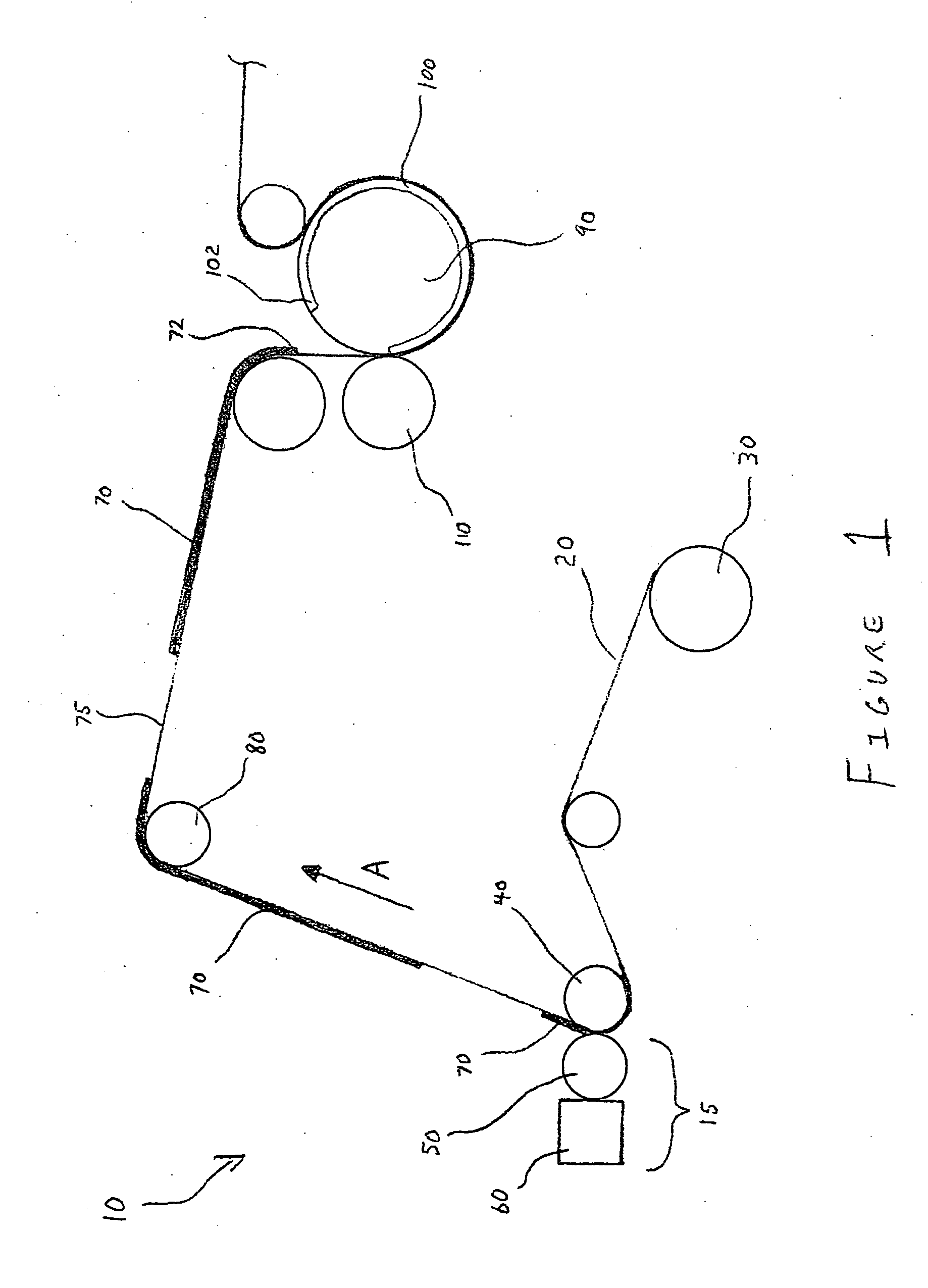

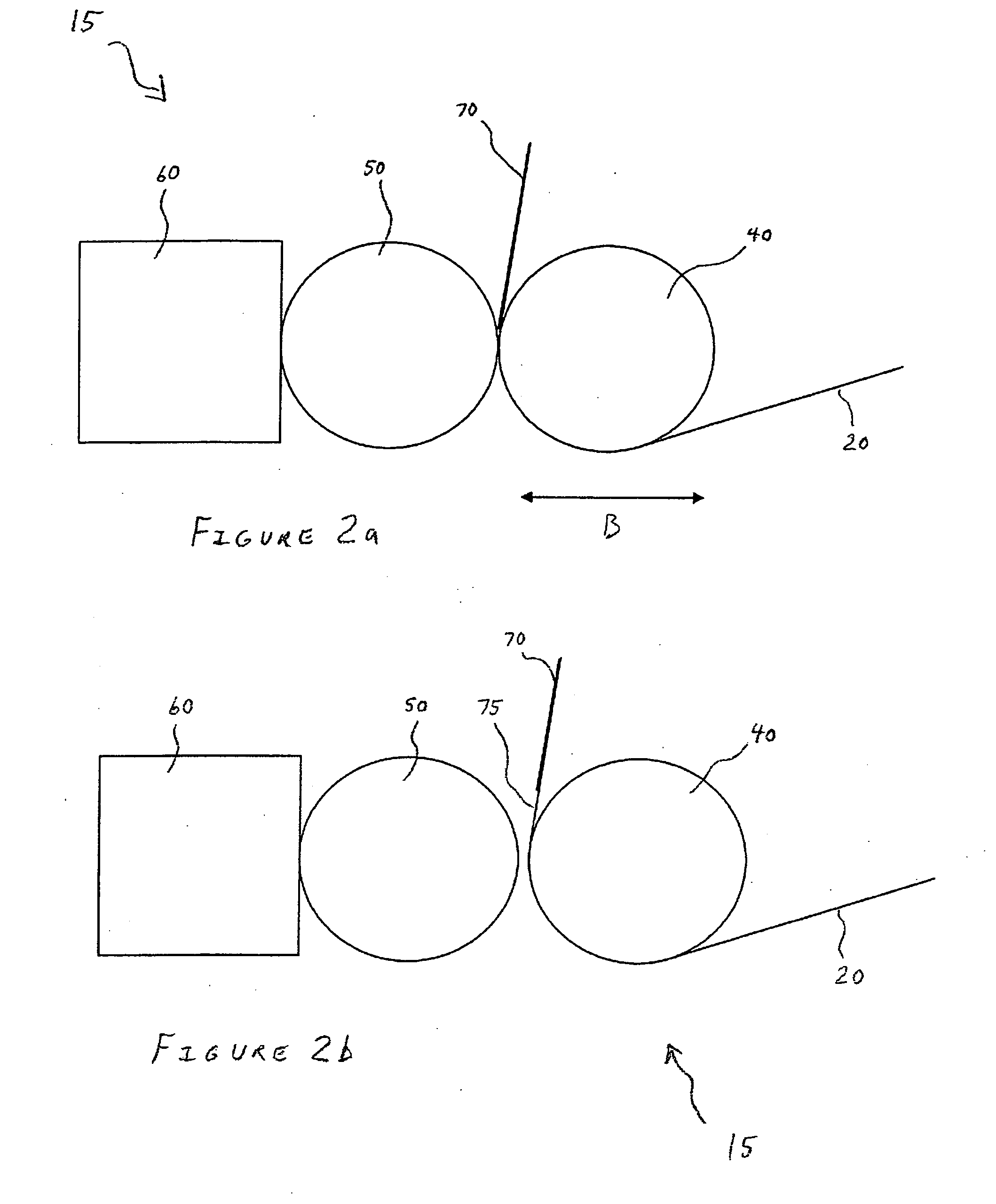

Process for making non-continuous articles with microstructures

InactiveUS20060263530A1Quality improvementGood optical performanceLayered productsOptical articlesDisplay deviceFlat panel display

A system and process for making non-continuous articles with patterned microstructures. The articles are of high quality and may be used in flat panel display applications. The system and process use a casting roll with a pattern on the surface of the casting roll for patterning a non-continuous microstructure on a surface of the substrate, and a coating device that is adapted to apply a coating to the surface of the substrate in a non-continuous manner so that areas of the substrate that are coated by the coating device correspond to the casting roll pattern.

Owner:SABIC INNOVATIVE PLASTICS IP BV

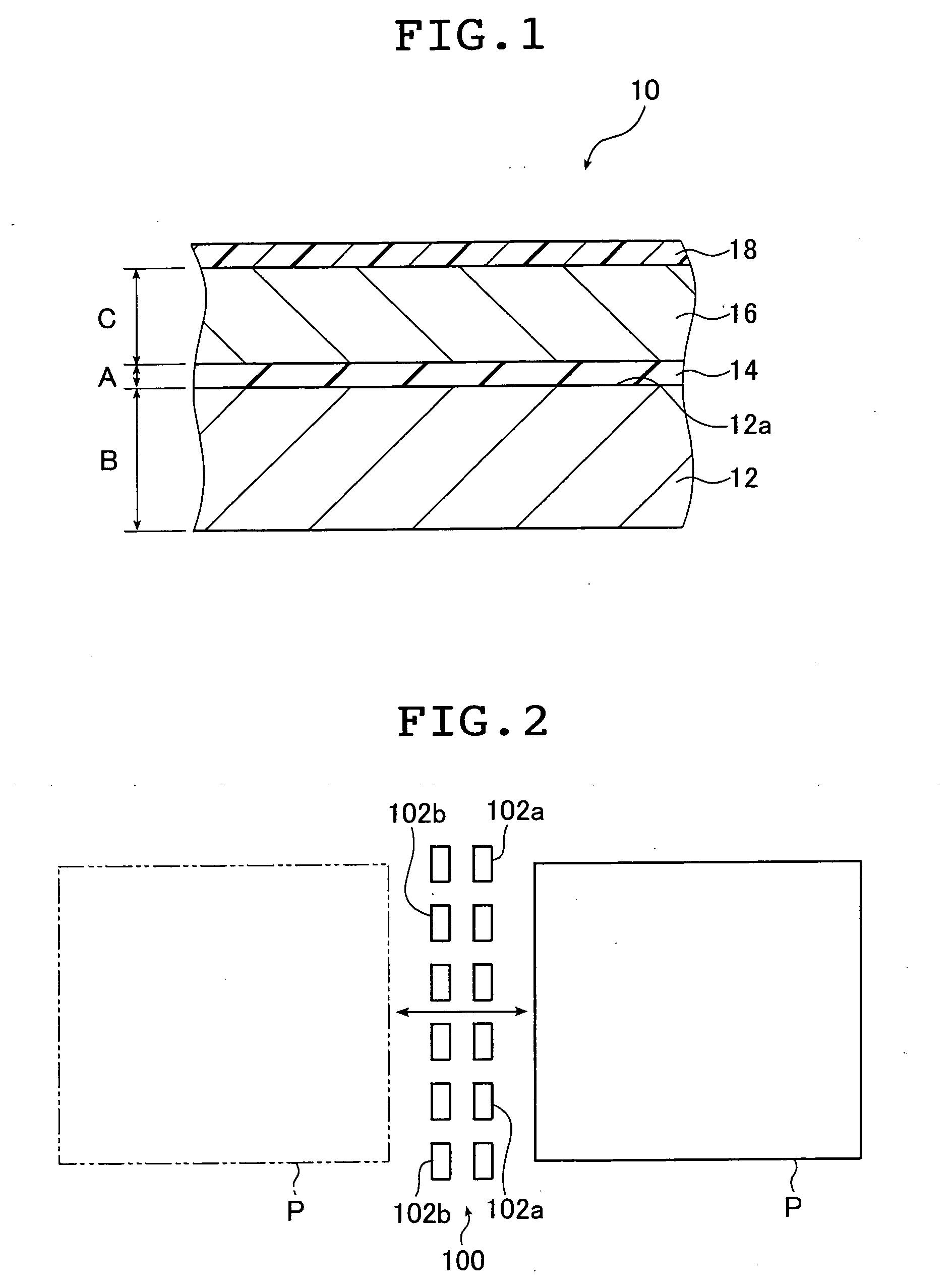

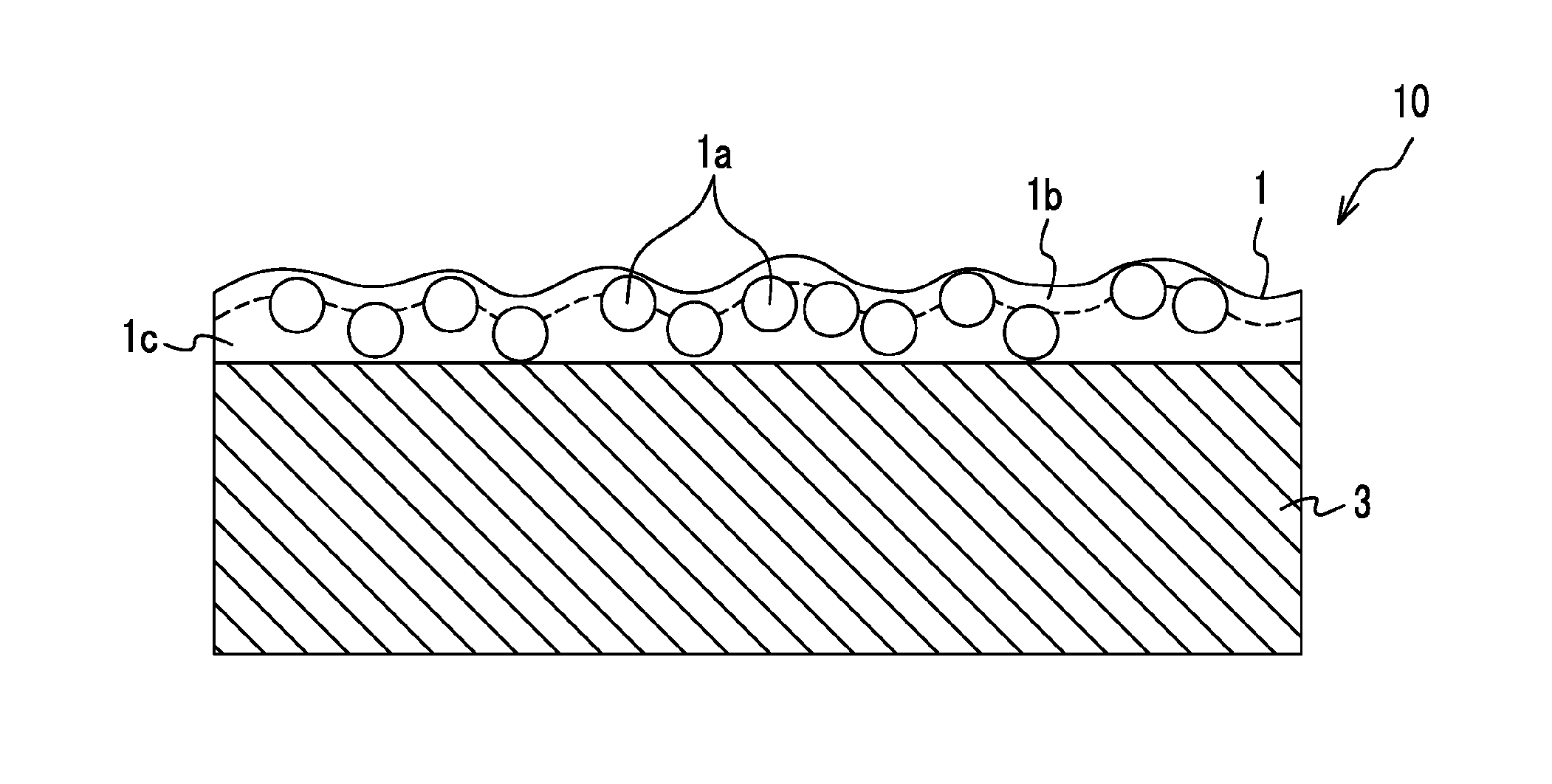

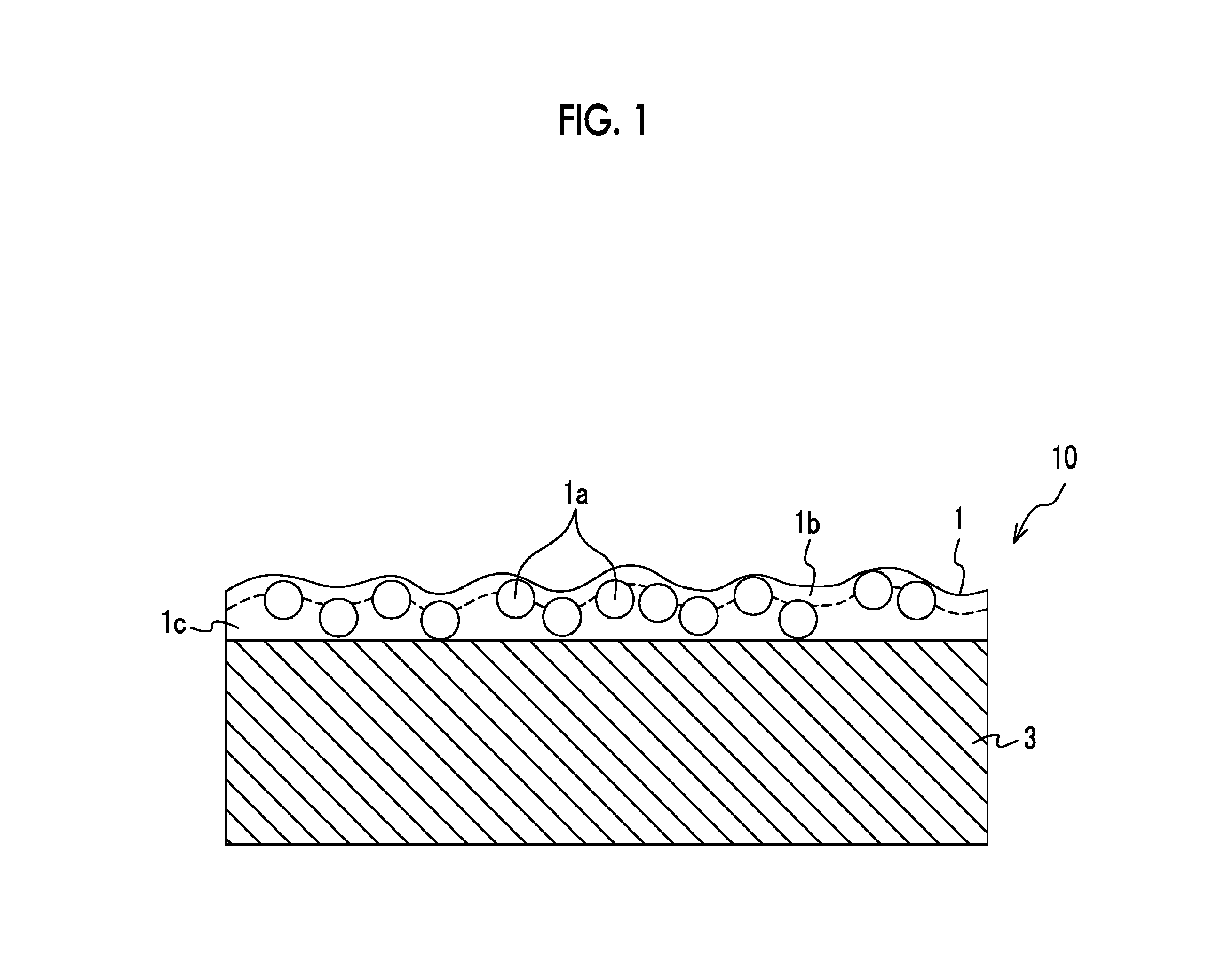

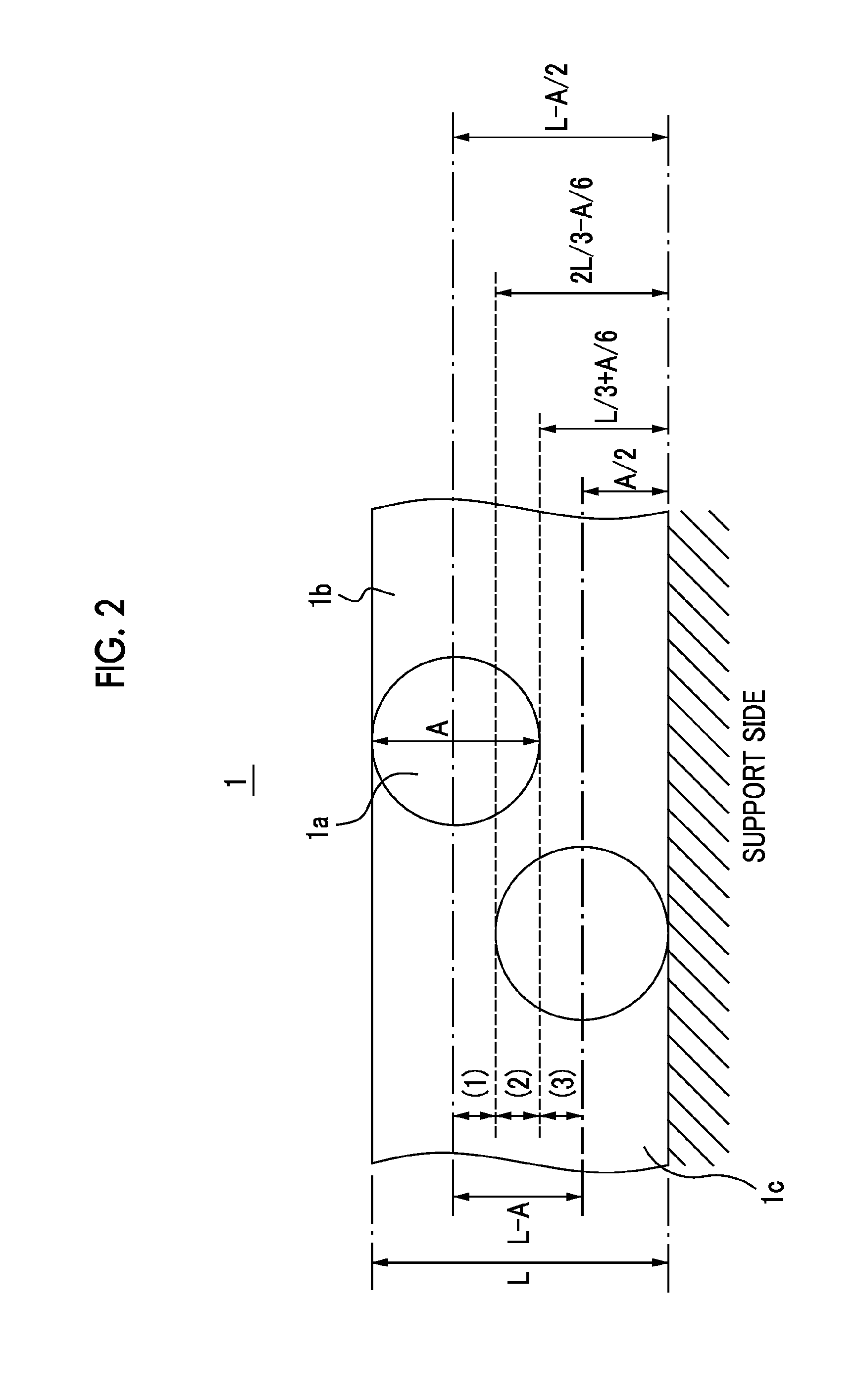

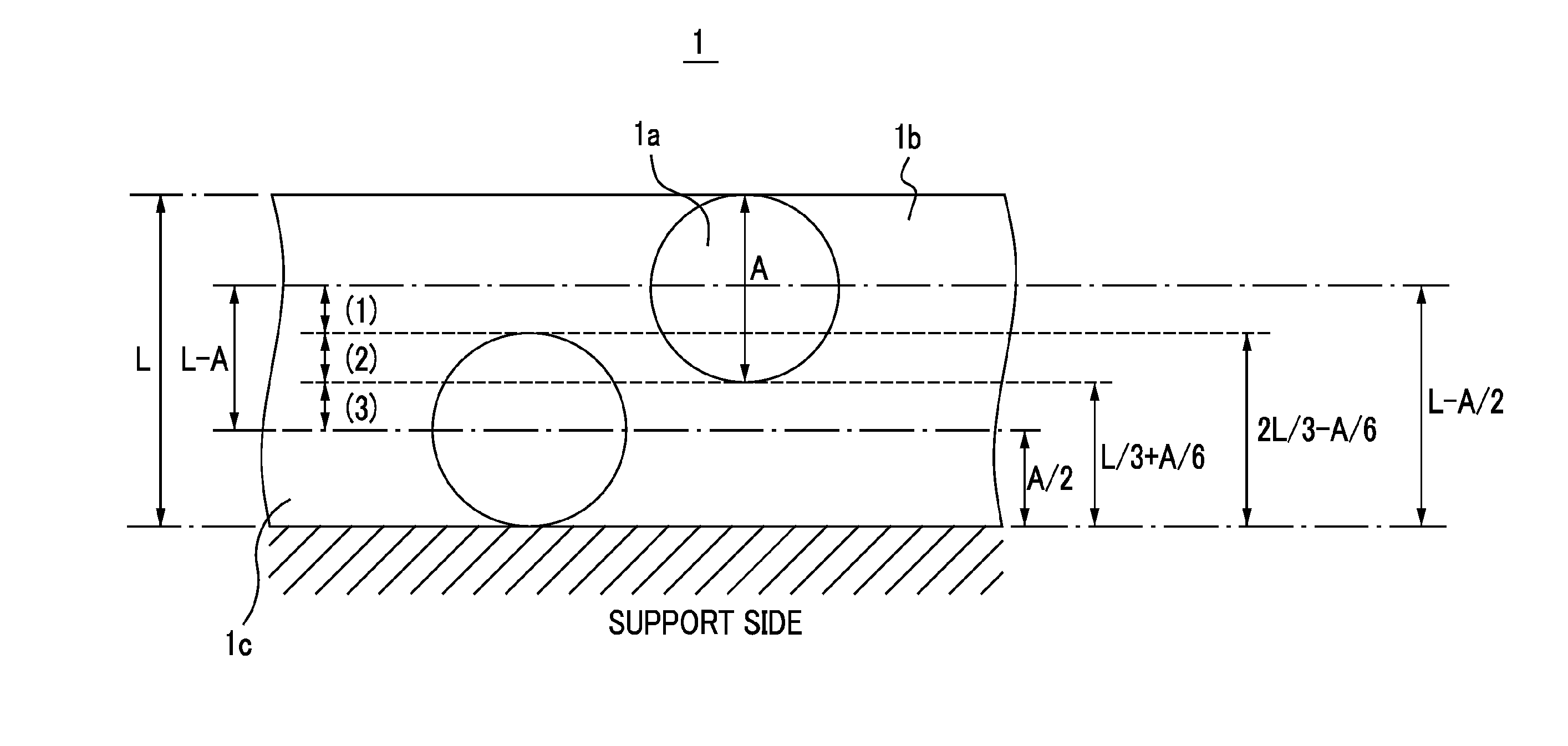

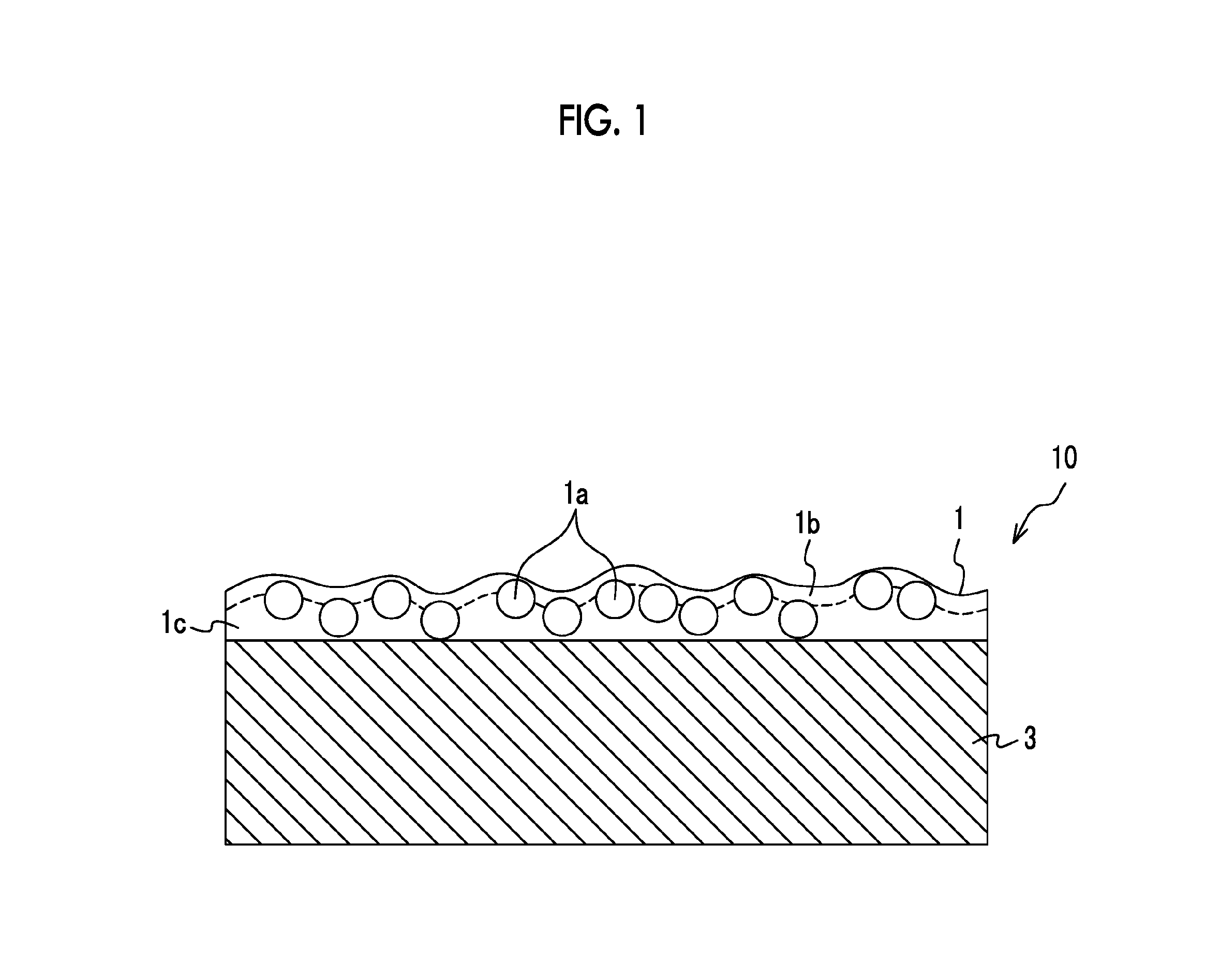

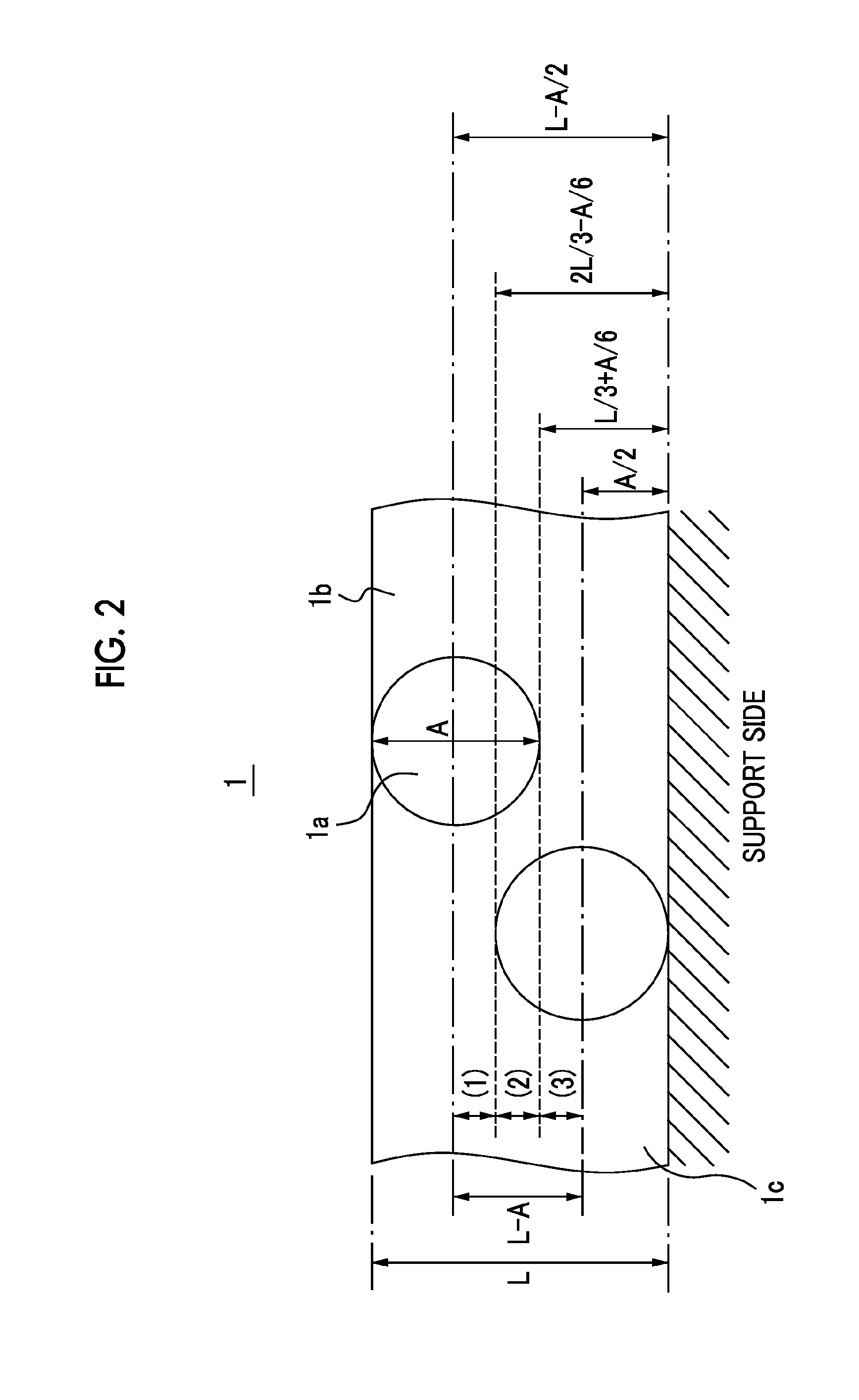

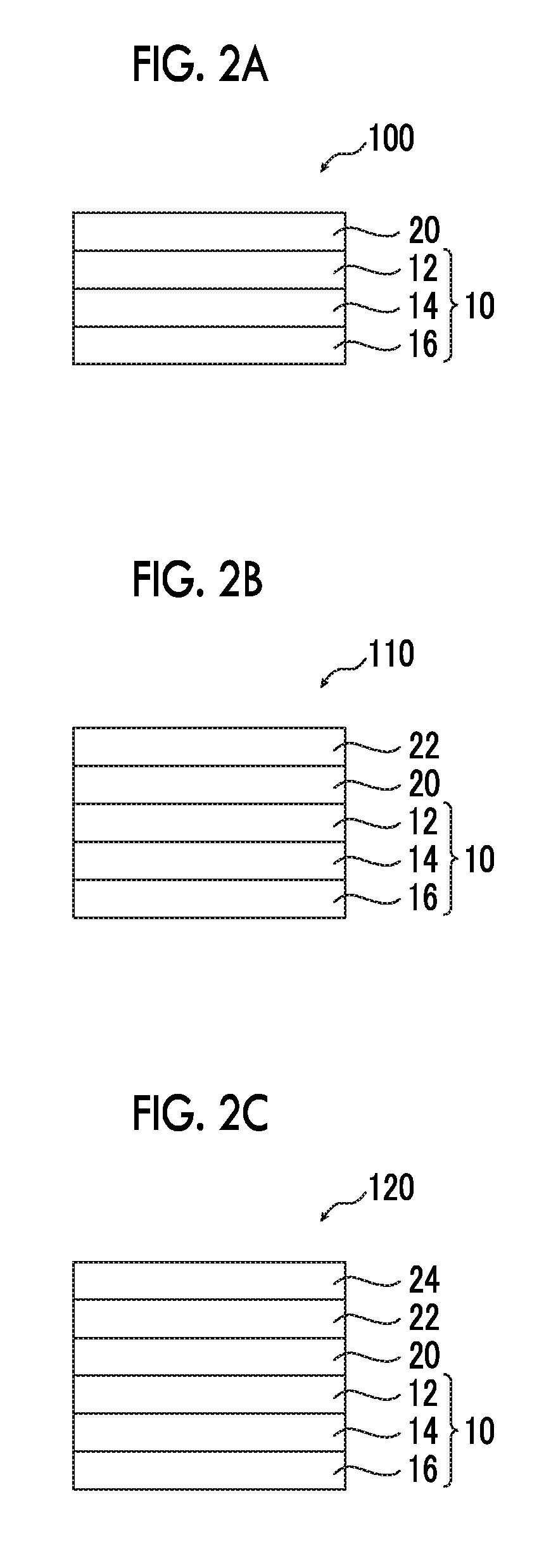

Method for producing optical film

InactiveUS20120237673A1Less point defectHigh product yieldDiffusing elementsPretreated surfacesBand shapeSolvent

The method for producing an optical film includes a step of preparing a first coating liquid containing a certain amount of light-transmitting particles, a resin, and a solvent, a second coating liquid containing an amount less than the certain amount of light-transmitting particles, a resin, and a solvent, or not containing the light-transmitting particles but containing a resin and a solvent; a step of coating the second coating liquid and the first coating liquid in this order from the support side on a traveling band-shaped support in the form of a multilayer to form a second coating film and a first coating film; a step of transferring the light-transmitting particles in the first coating film to the side of the second coating film while drying the first coating film and the second coating film.

Owner:FUJIFILM CORP

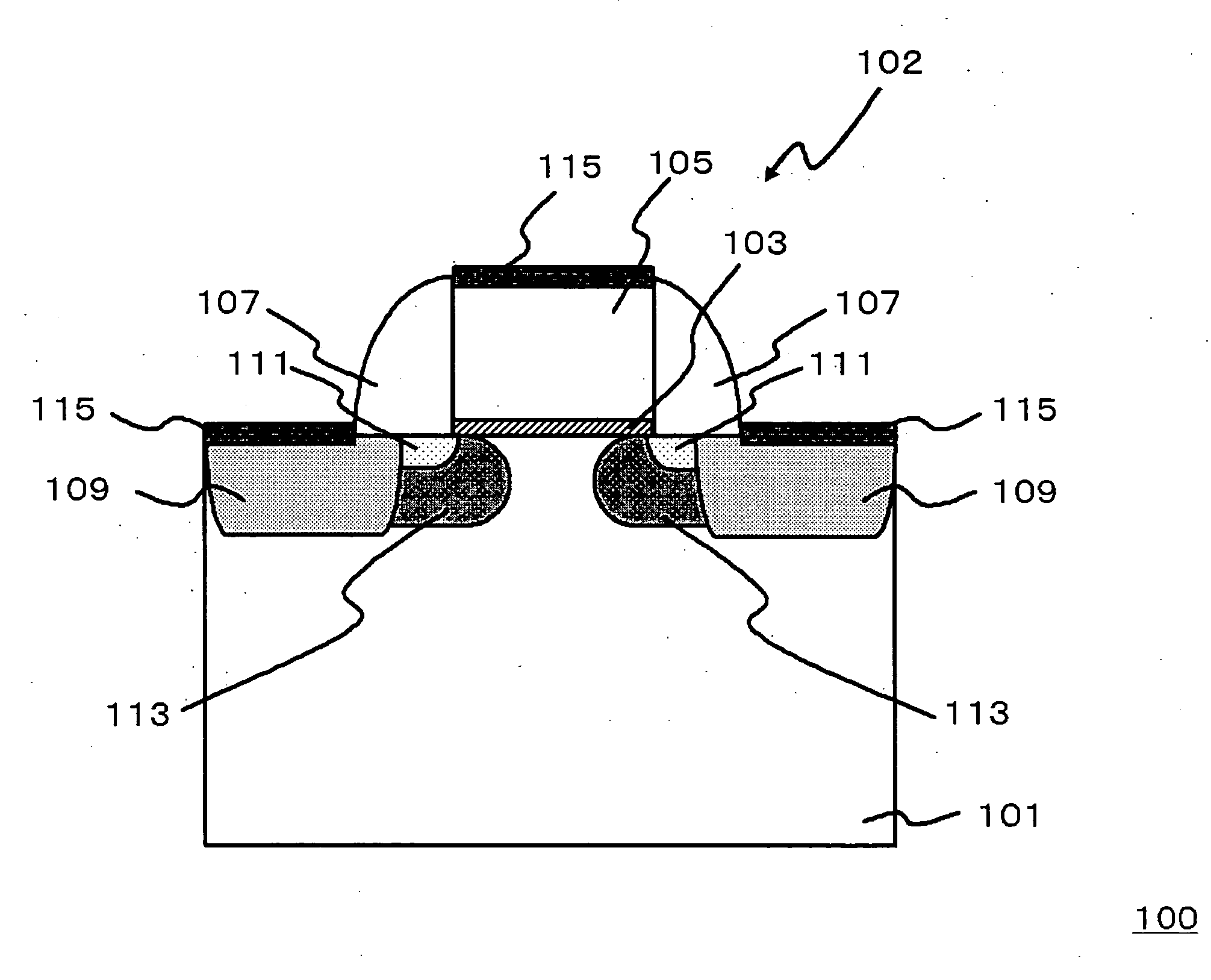

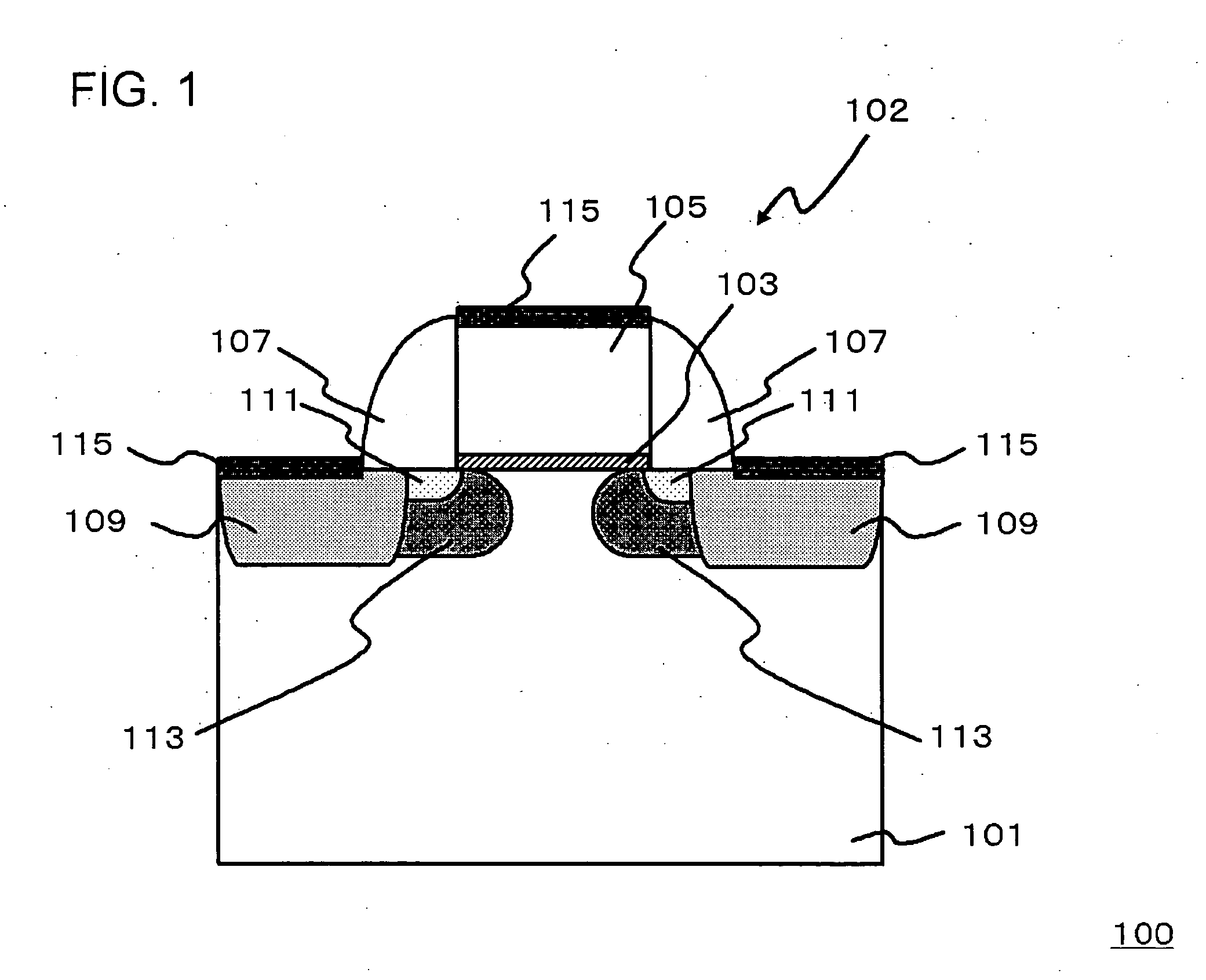

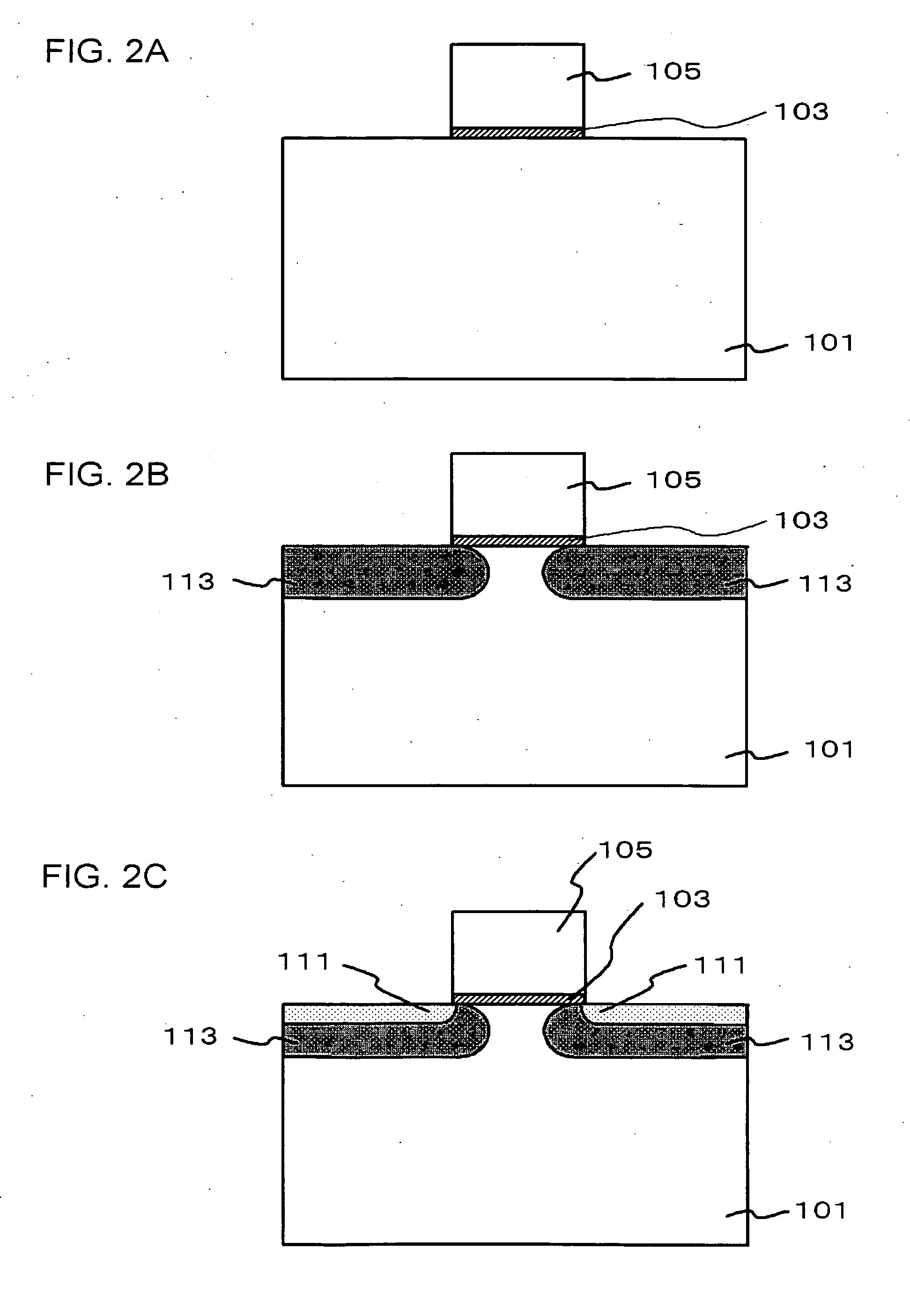

Method for manufacturing field effect transistor

InactiveUS20060199358A1Enhanced diffusion of impurityImprove featuresTransistorSemiconductor/solid-state device manufacturingField-effect transistorLaser beams

The manufacturing stability can be improved while effectively inhibiting the short-channel effect in the transistor according to the present invention. A halo impurity having a conductivity type opposite to a first conductivity type of a first impurity is ion-implanted into the silicon substrate 101, and thereafter, the first impurity having the first conductivity type is ion-implanted, and then a laser beam is irradiated on a region where the first impurity is doped under a condition so that the silicon substrate 101 is not melted to form a p-type halo region 113 and a n-type extension region 111. Then, the second impurity having the first conductivity type is ion-implanted into the silicon substrate 101, and a laser beam is irradiated on a region where the second impurity is doped under a condition so that the silicon substrate 101 is not melted to form a n-type source / drain region 109.

Owner:NEC ELECTRONICS CORP

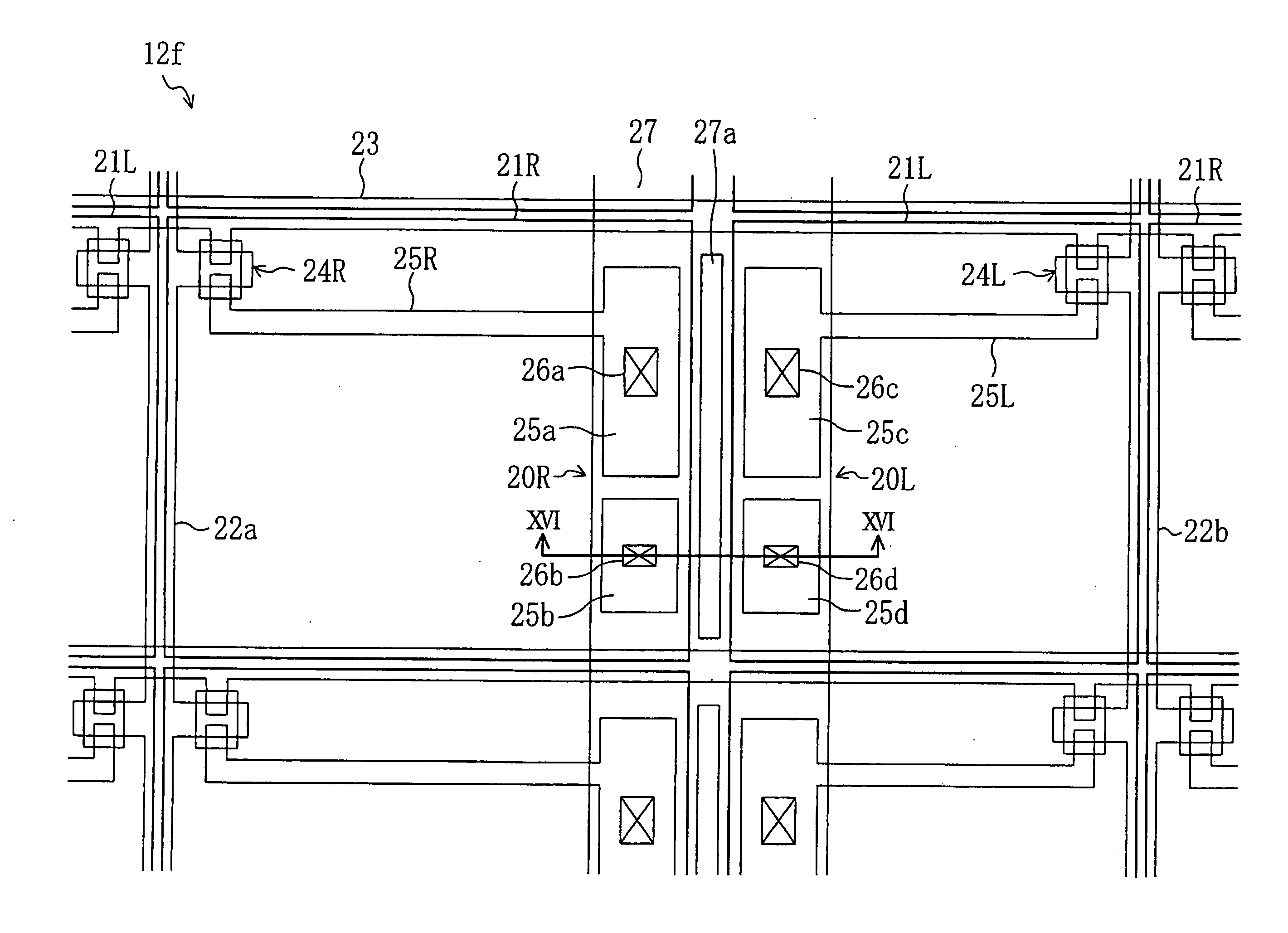

Active matrix substrate, method for fabricating active matrix substrate, display device, liquid crystal display device, and television device

InactiveUS20090225247A1Improve production yieldPoint defectNon-linear opticsLiquid-crystal displayActive matrix

An active matrix substrate includes a substrate, a TFT formed on the substrate, a storage capacitor element formed on the substrate, an interlayer insulating film covering the storage capacitor element, and a pixel electrode formed on the interlayer insulating film. The storage capacitor element includes a storage capacitor line, an insulating film formed on the storage capacitor line, and two or more storage capacitor electrodes opposed to the storage capacitor line with the insulating film interposed therebetween. The two or more storage capacitor electrodes are electrically connected via associated contact holes formed in the interlayer insulating film to the pixel electrode and electrically continuous with a drain electrode of the TFT.

Owner:SHARP KK

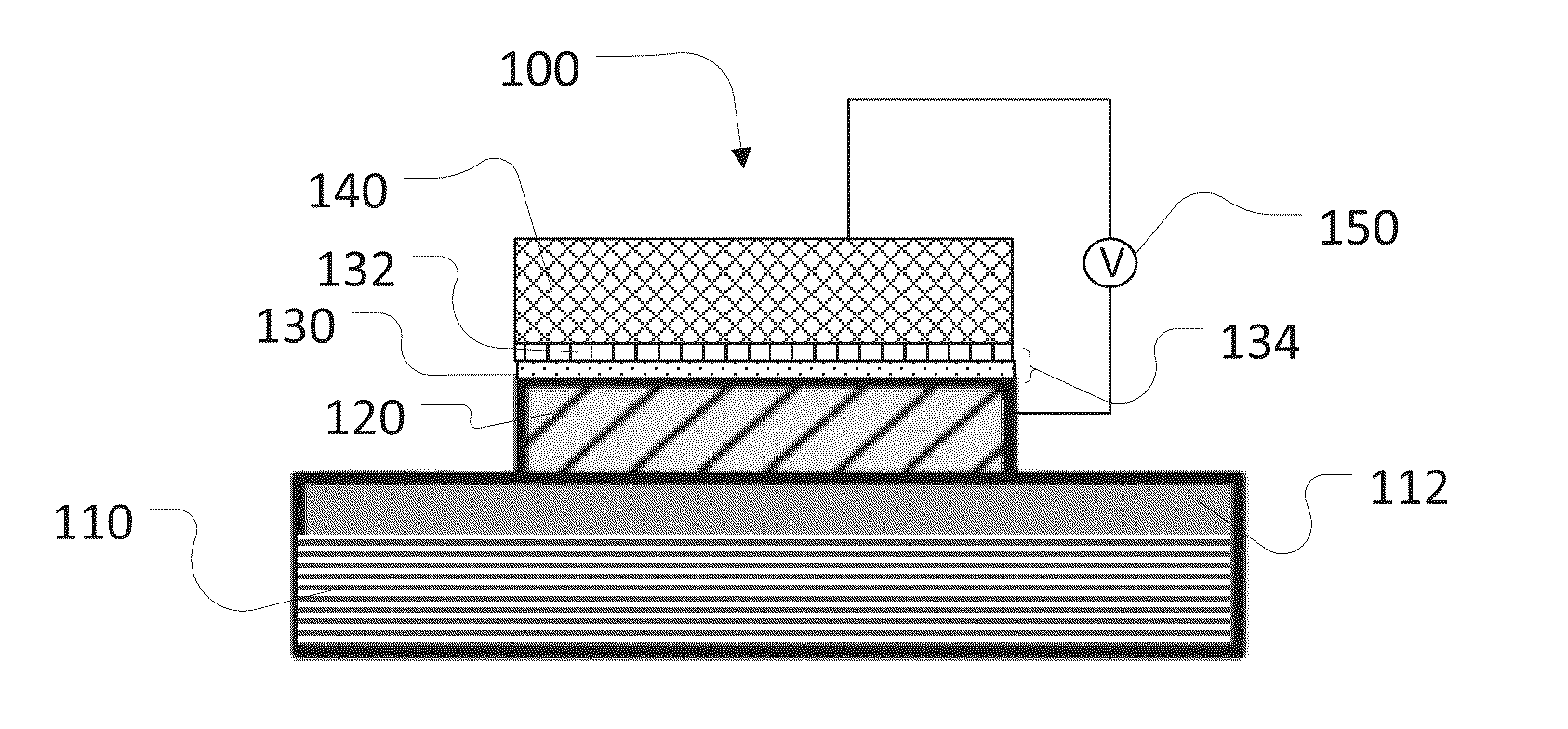

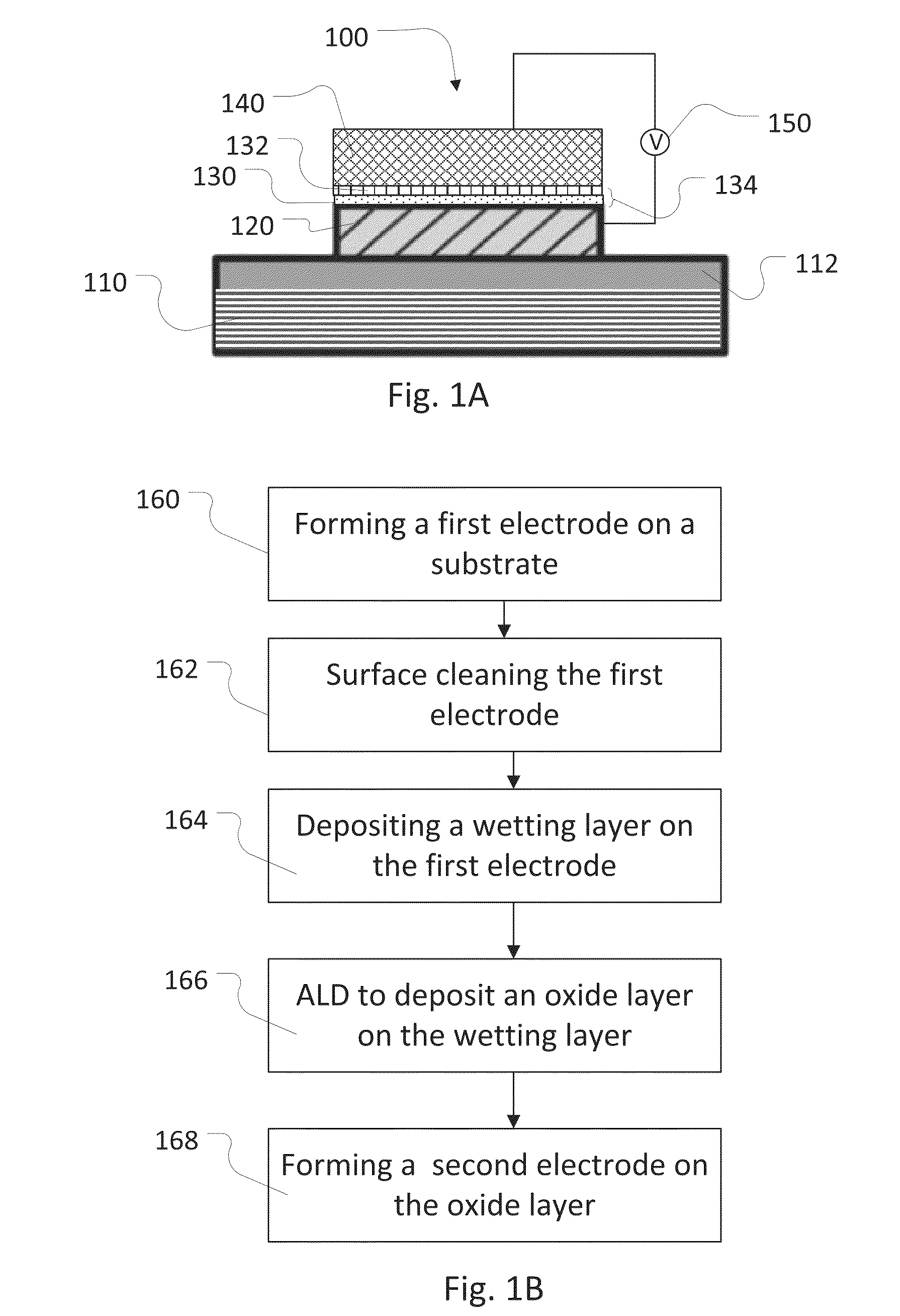

Tunnel junction fabrication

ActiveUS9425377B2Quality improvementImprove performanceQuantum computersThermometers using electric/magnetic elementsOptoelectronicsAtomic layer deposition

A method for fabricating a tunnel junction includes depositing a first electrode on a substrate, depositing a wetting layer having a thickness of less than 2 nm on the first electrode, using atomic layer deposition (ALD) to deposit an oxide layer on the wetting layer, and depositing a second electrode on the oxide layer. The wetting layer and the oxide layer form a tunnel barrier, and the second electrode includes a superconductor.

Owner:RGT UNIV OF CALIFORNIA

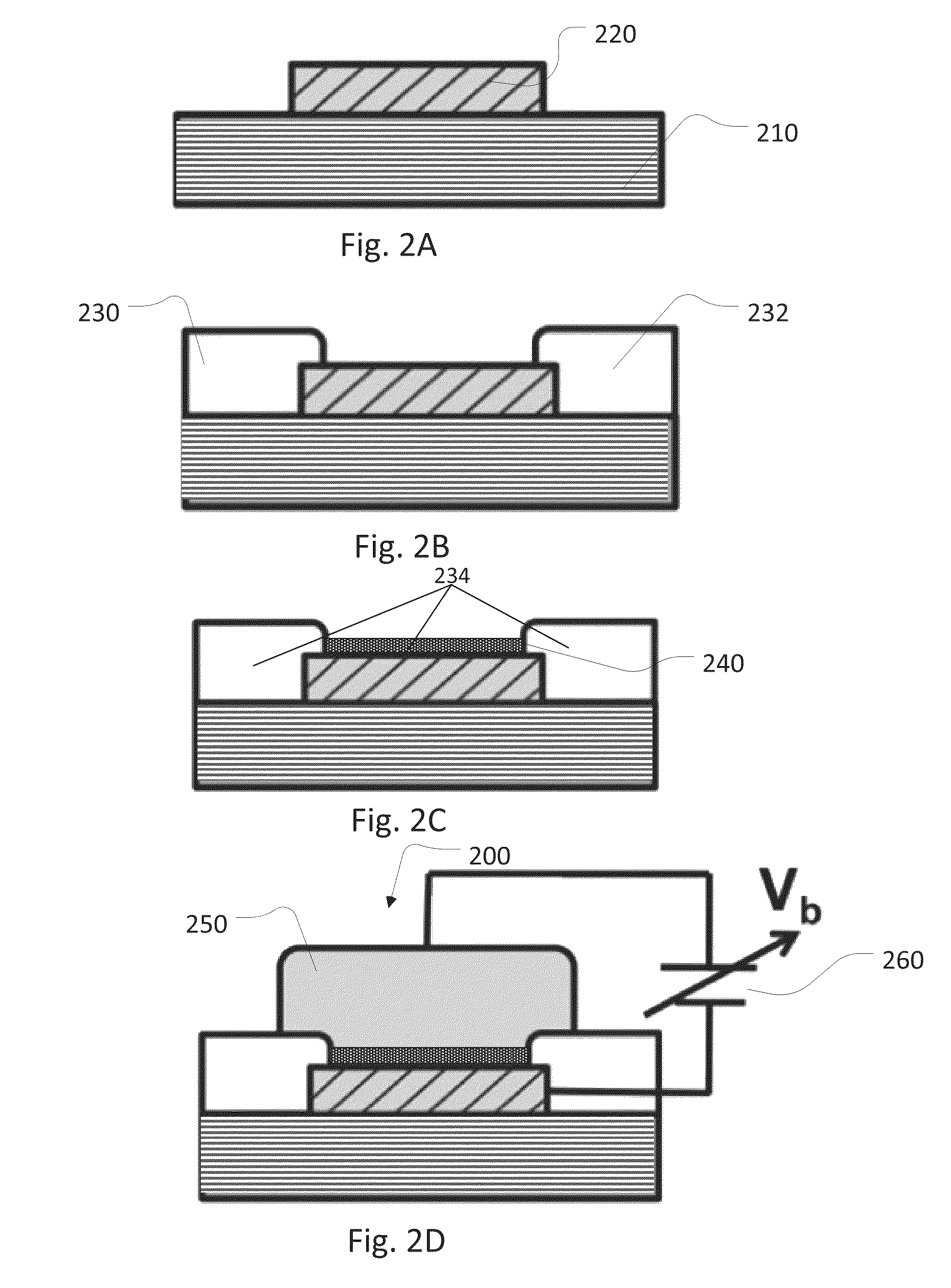

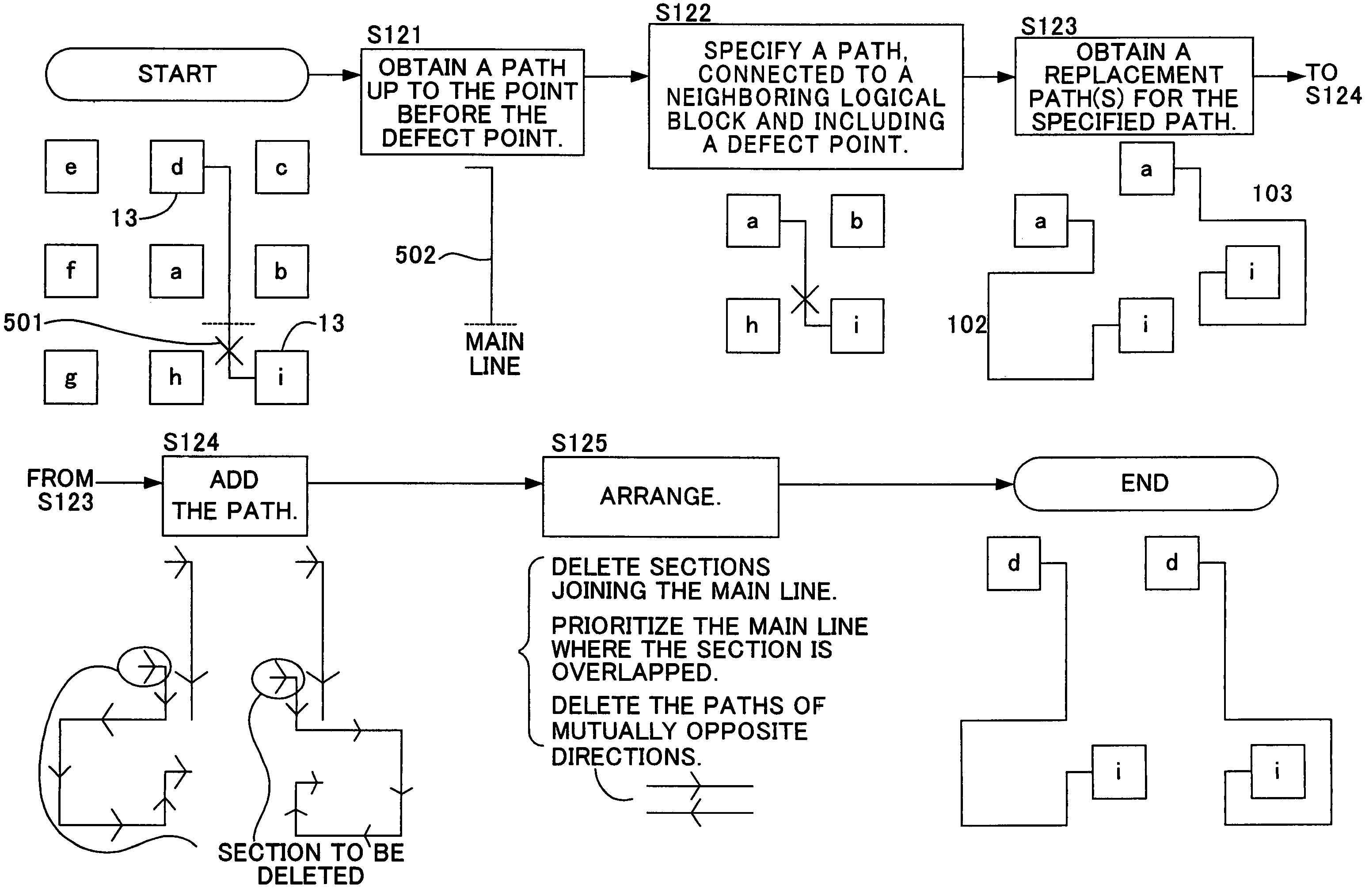

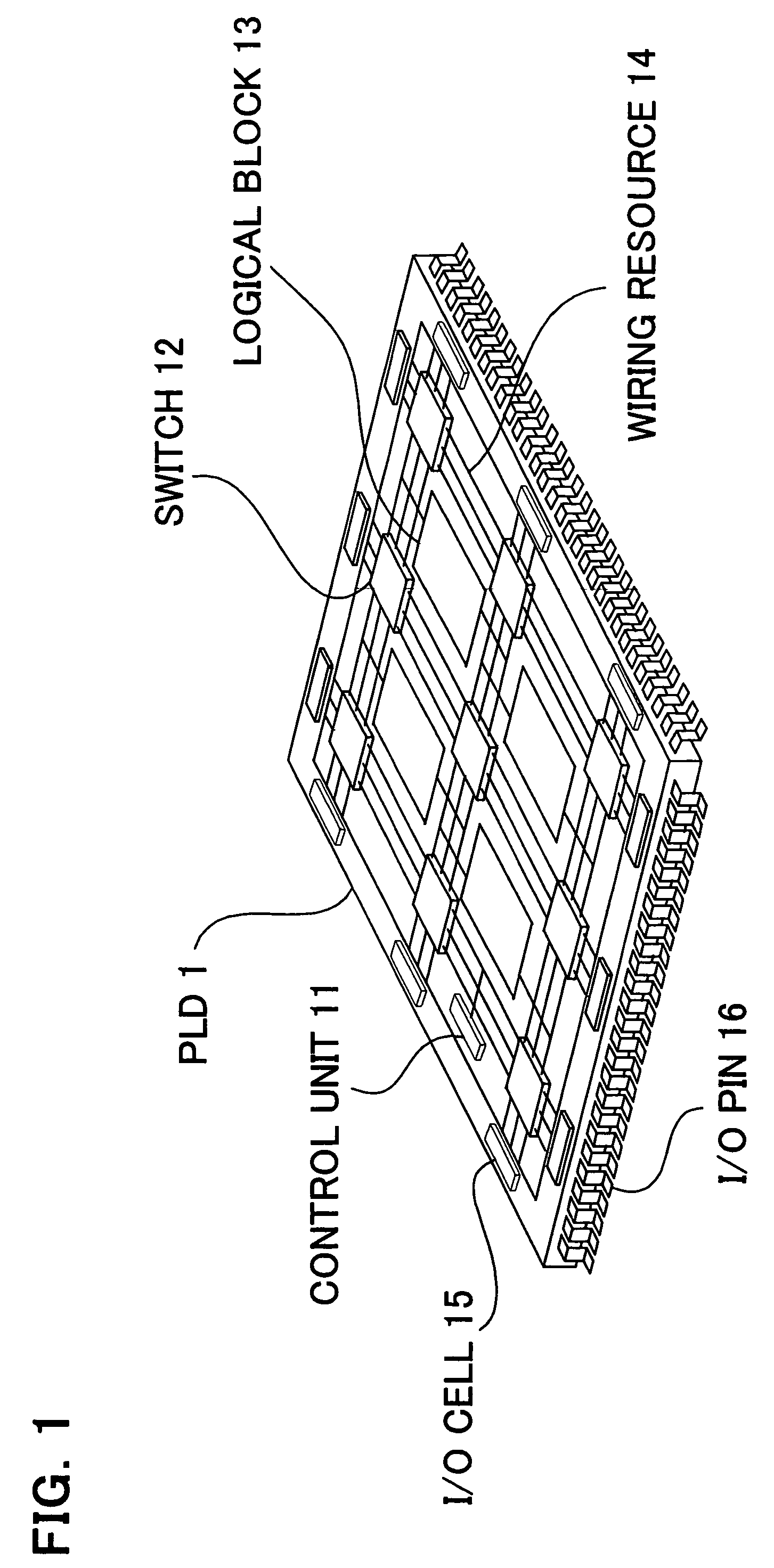

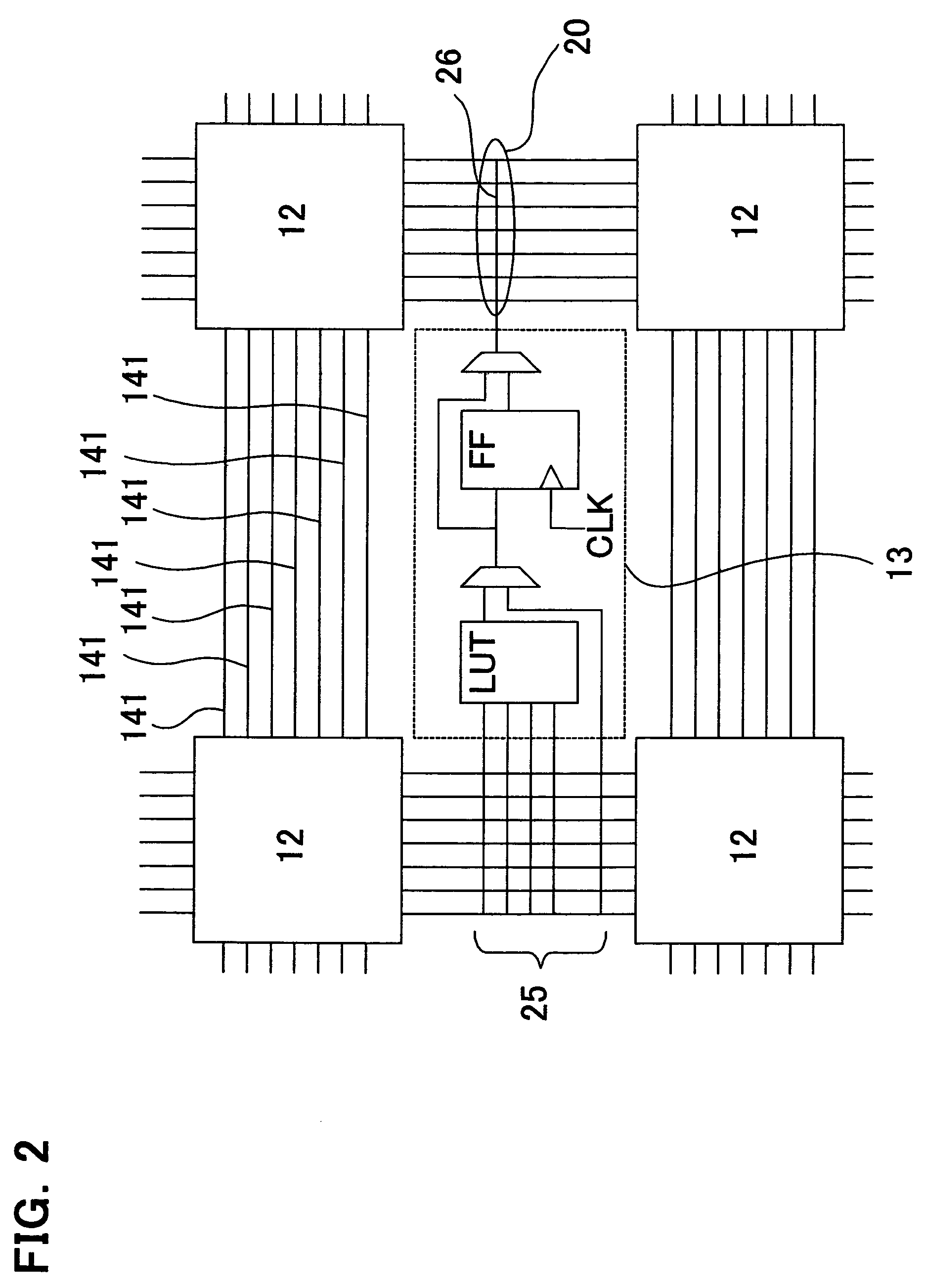

Programmable logic device

InactiveUS7187198B2Improve production yieldAvoiding pointReliability increasing modificationsLogic circuits using elementary logic circuit componentsComputer architectureProgrammable logic device

The present invention aims to provide a programmable logic device (PLD), and a related control program, capable of improving a product yield by avoiding a defect point according to defect point detected after PLD fabrication.The PLD includes a plurality of logical blocks including programmable logic circuits; storage in which both circuit information specifying path connecting the plurality of logical blocks using information specifying resources included in the path and defect point information specifying fault resource are stored in advance; replacement control section which refers to defect point information, decides whether fault resource is included in the path specified by circuit information, and when fault path is included, obtains replacement path, and rewrites circuit information with data identifying resources included in replacement path; and wiring resource section which reads out circuit information stored in storage, and forms a predetermined logic circuit based on readout circuit information.

Owner:FUJITSU LTD

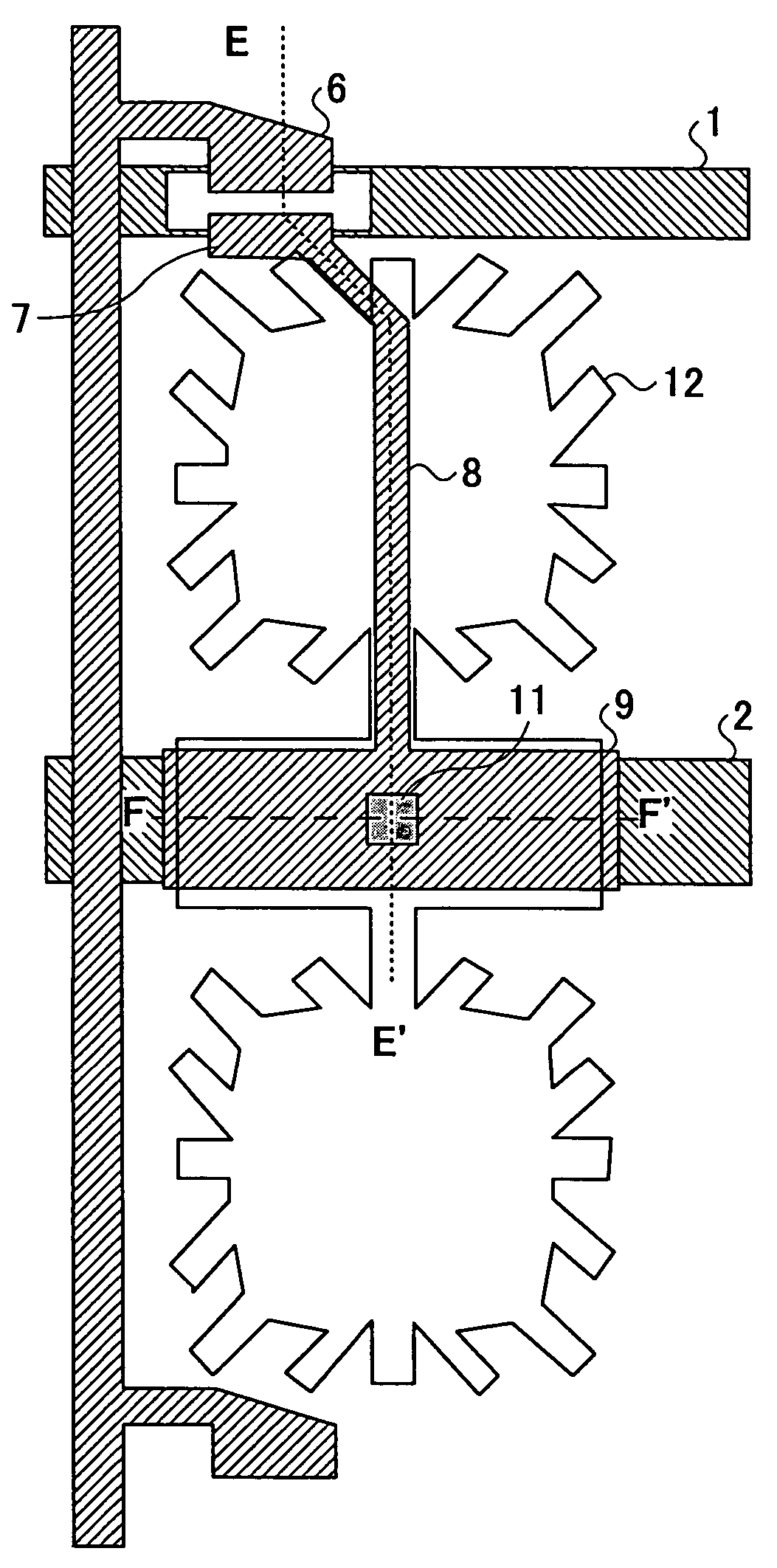

Thin film transistor array substrate and method for repairing the same

ActiveUS7110056B2Increase opening ratioPoint defectSolid-state devicesNon-linear opticsOptoelectronicsCapacitor

A thin film transistor array substrate includes an insulating substrate; a thin film transistor arranged in a part of a pixel area on the insulating substrate; an auxiliary capacitor having an auxiliary capacitor electrode arranged in the pixel area and an opposite electrode facing the auxiliary capacitor electrode via an insulating layer, the opposite electrode being located in the same layer as source and drain electrodes of the thin film transistor; and a pixel electrode formed in the pixel area. The opposite electrode is divided into two or more sections, and each of the sections is electrically connected to the pixel electrode via a contact hole.

Owner:SHARP KK

Radiation image storage panel

InactiveUS20050211916A1Graininess deterioratesImage degradationX-ray/infra-red processesElectrical apparatusPhosphorMetallurgy

A radiation image storage panel is composed of a metal sheet and a phosphor layer formed on one surface of the metal sheet by gas phase-accumulation, in which the metal sheet has a surface having a surface roughness Ra of 0.1 μm or lower.

Owner:FUJIFILM CORP +1

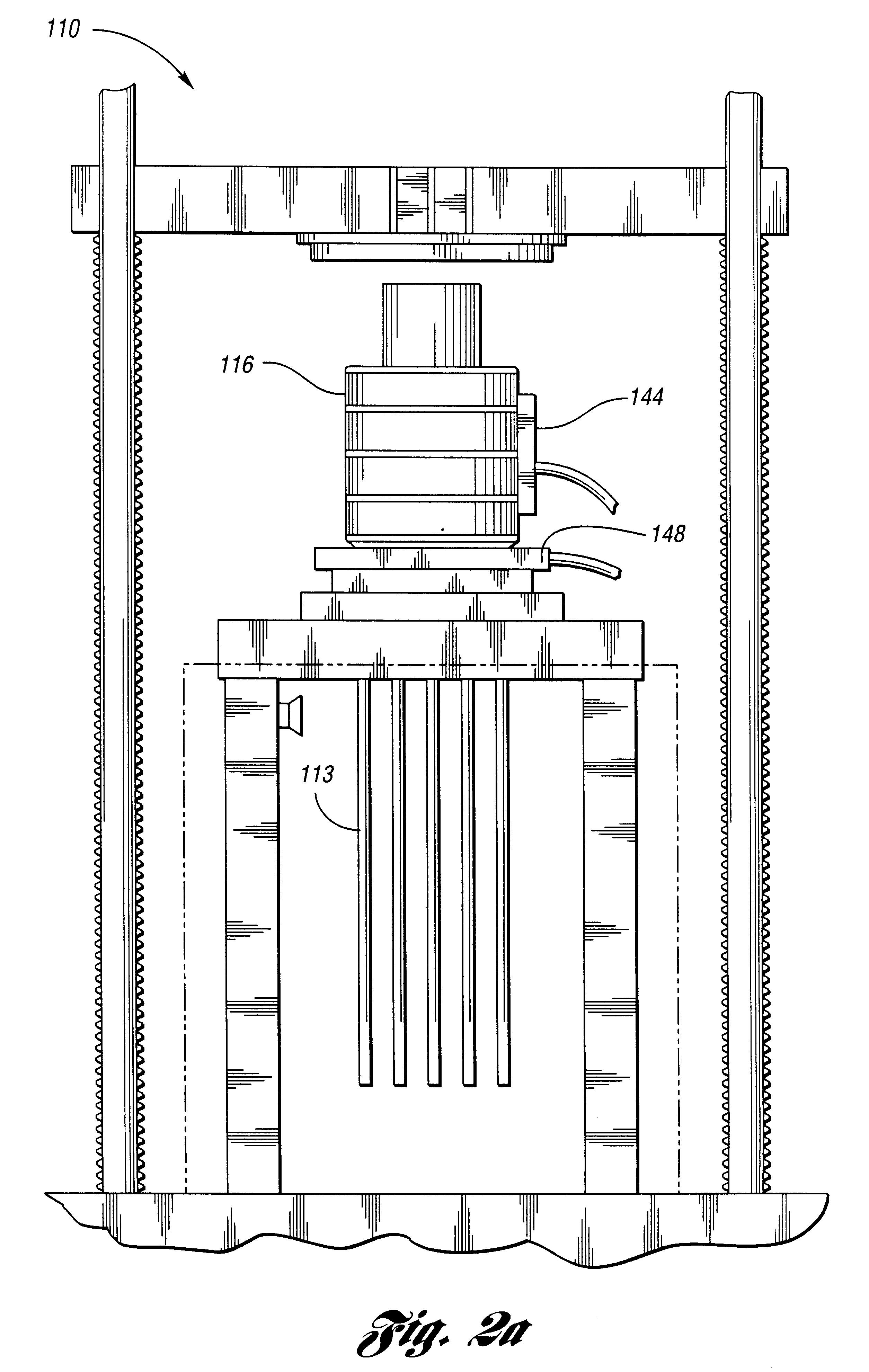

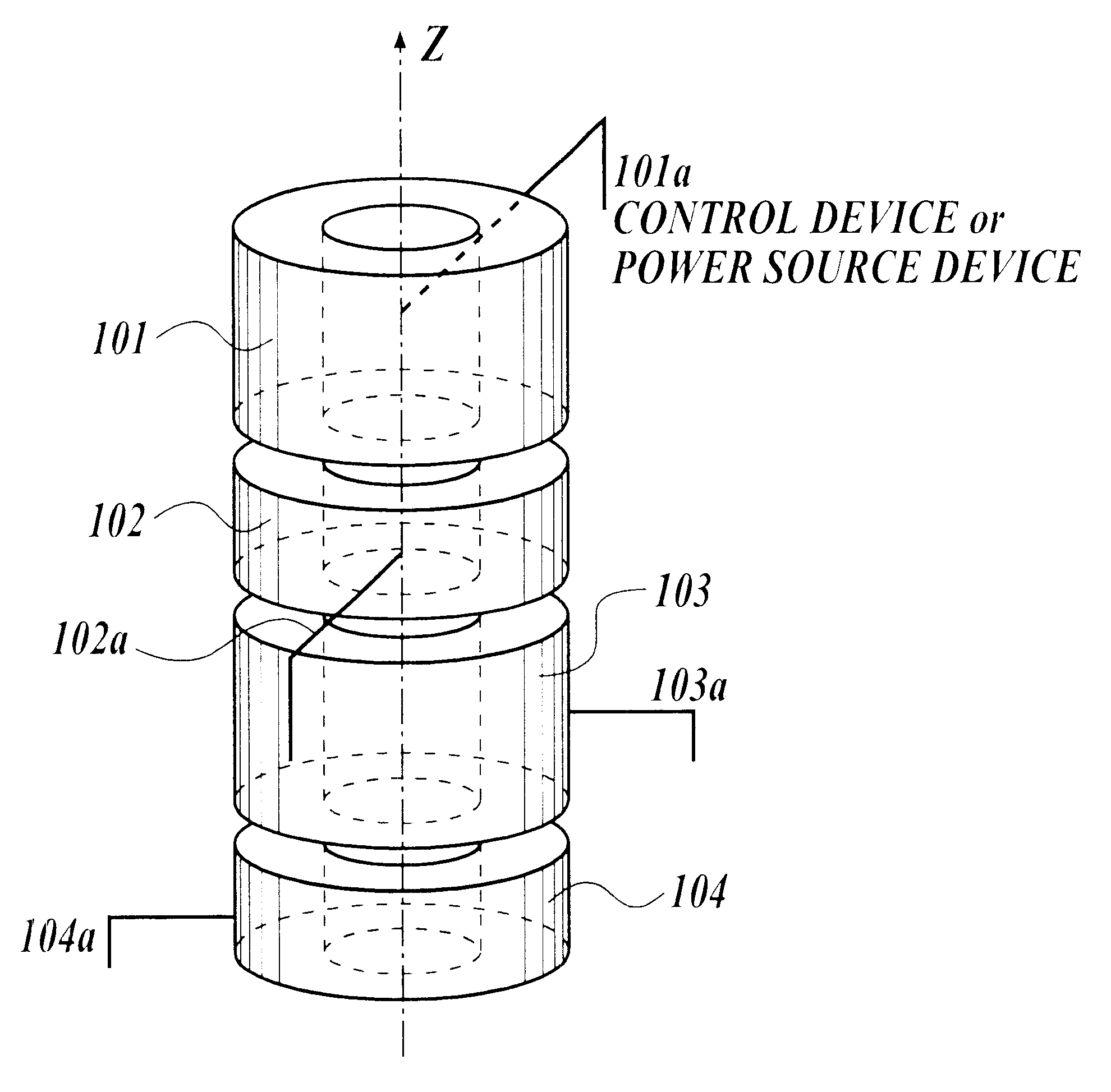

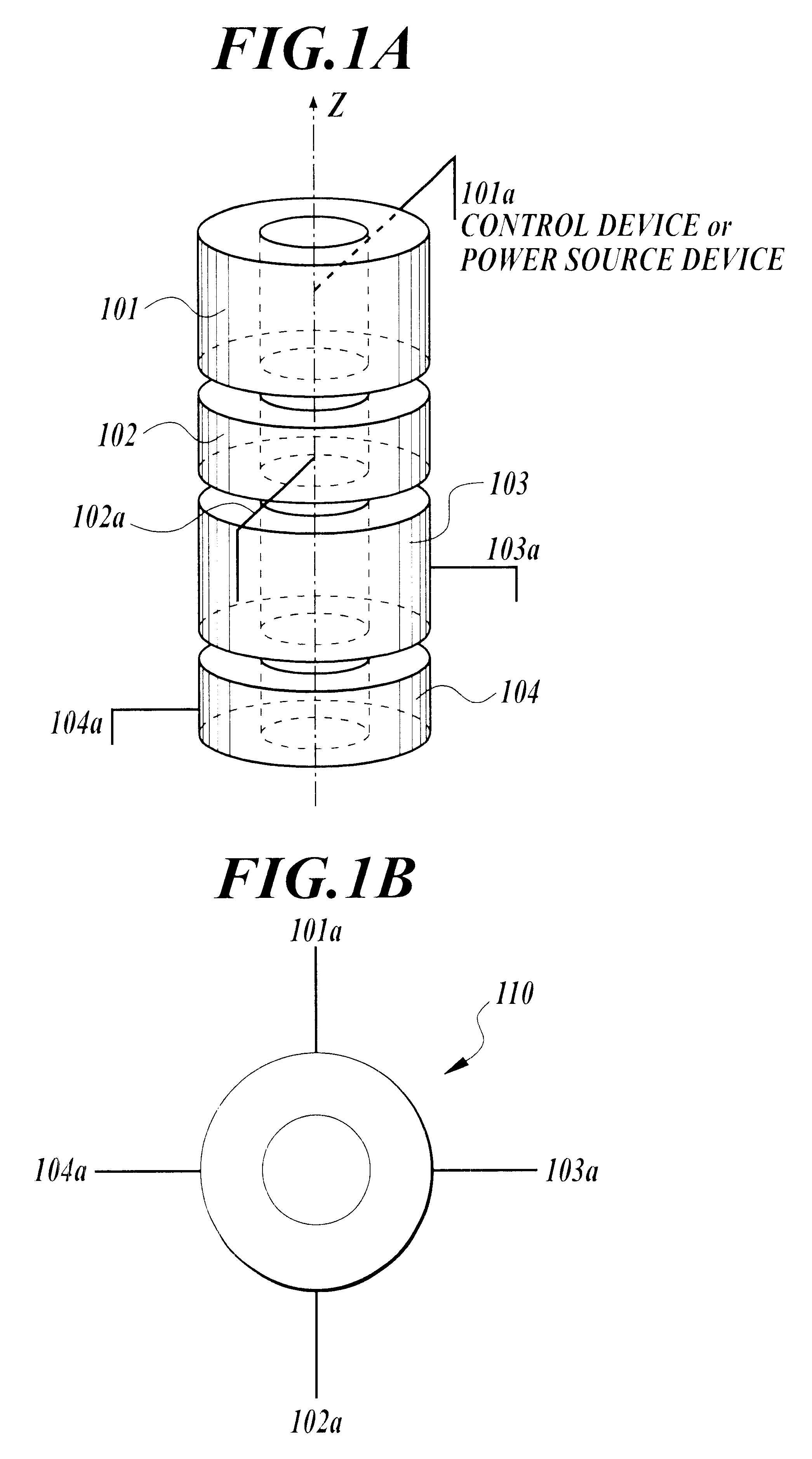

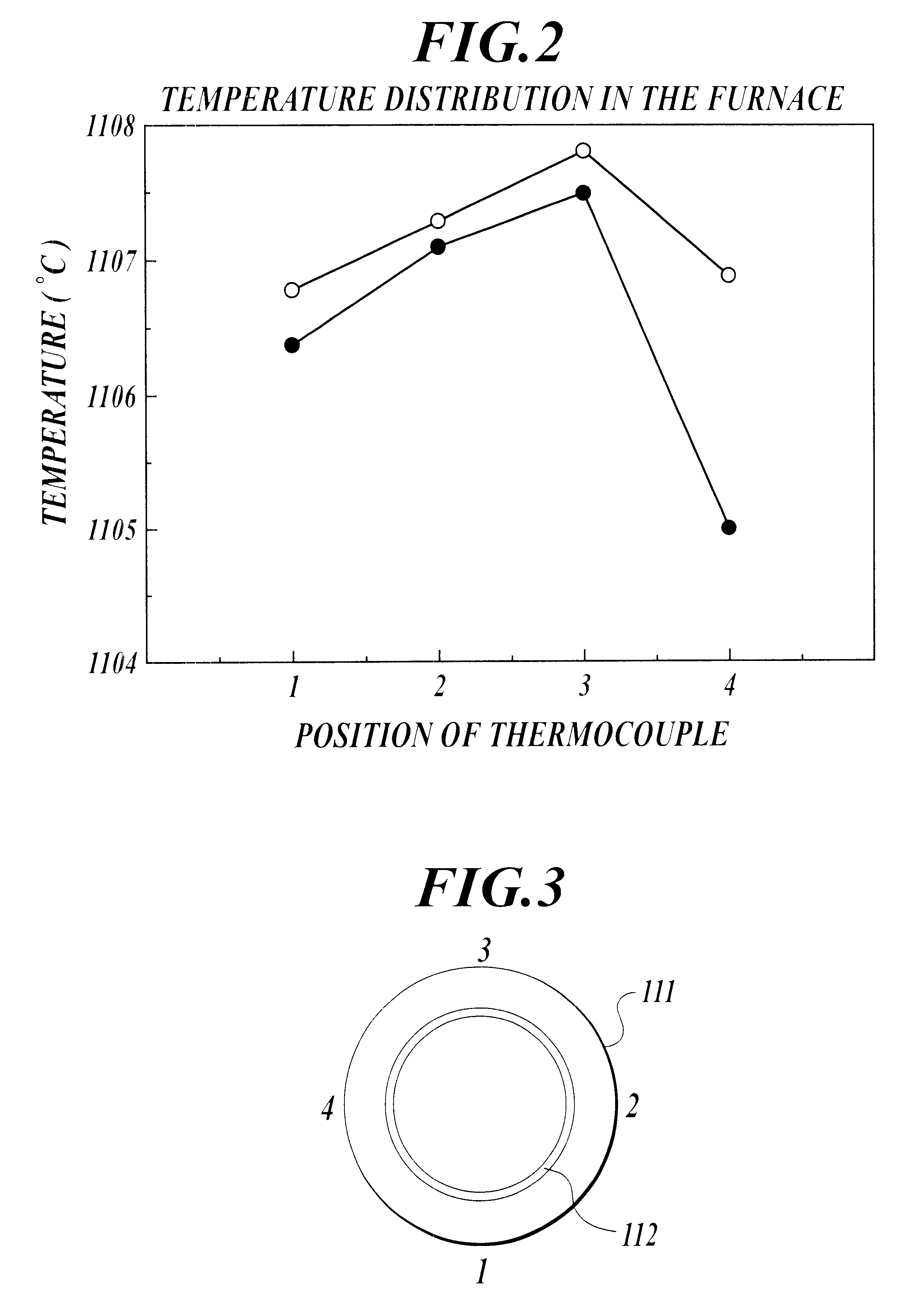

Crystal growing device and method of manufacturing single crystal

InactiveUS6562134B1Uniform distribution of temperatureDecrease in temperatureAfter-treatment apparatusPolycrystalline material growthEngineeringSingle crystal

Owner:JX NIPPON MINING& METALS CORP +1

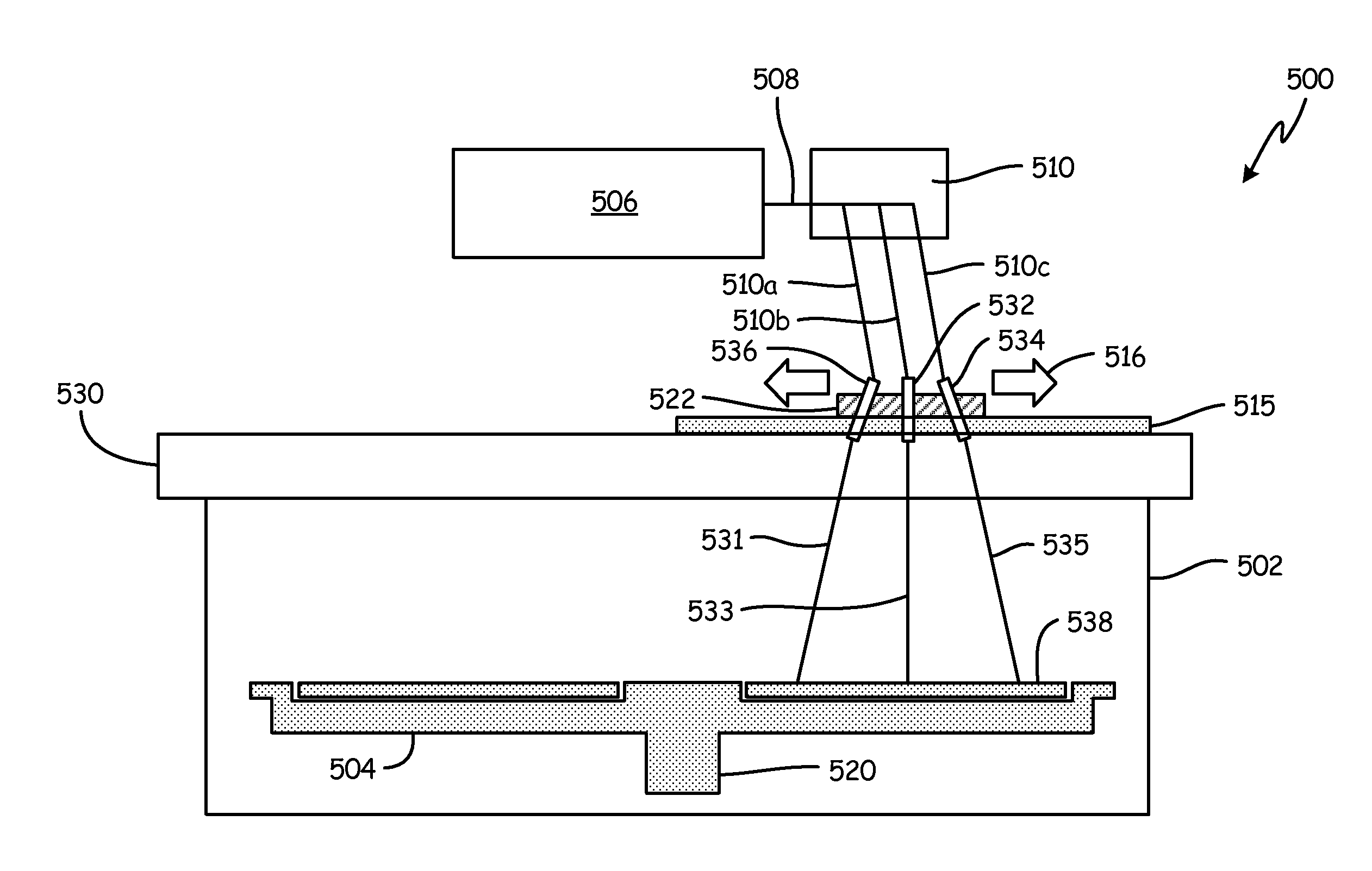

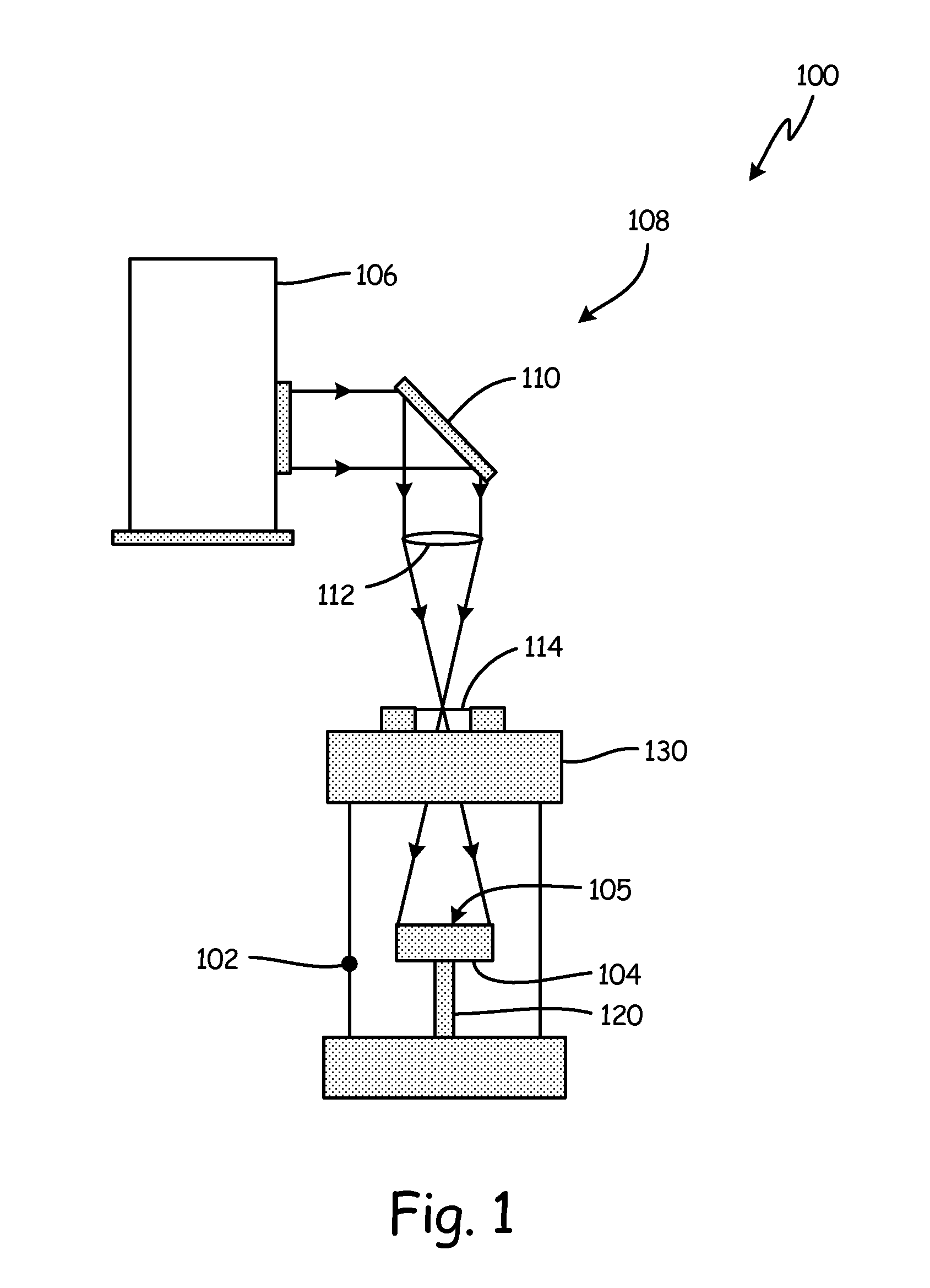

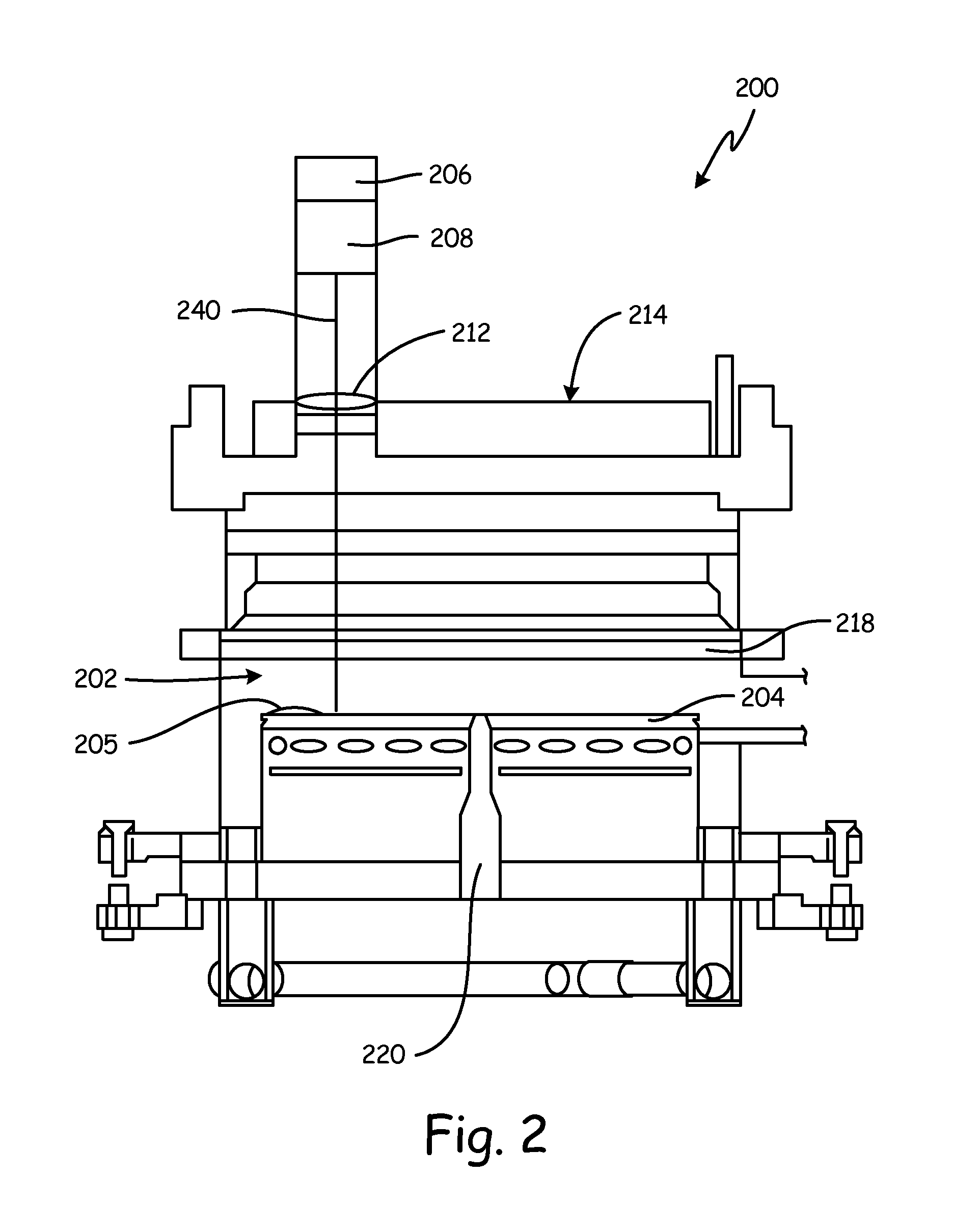

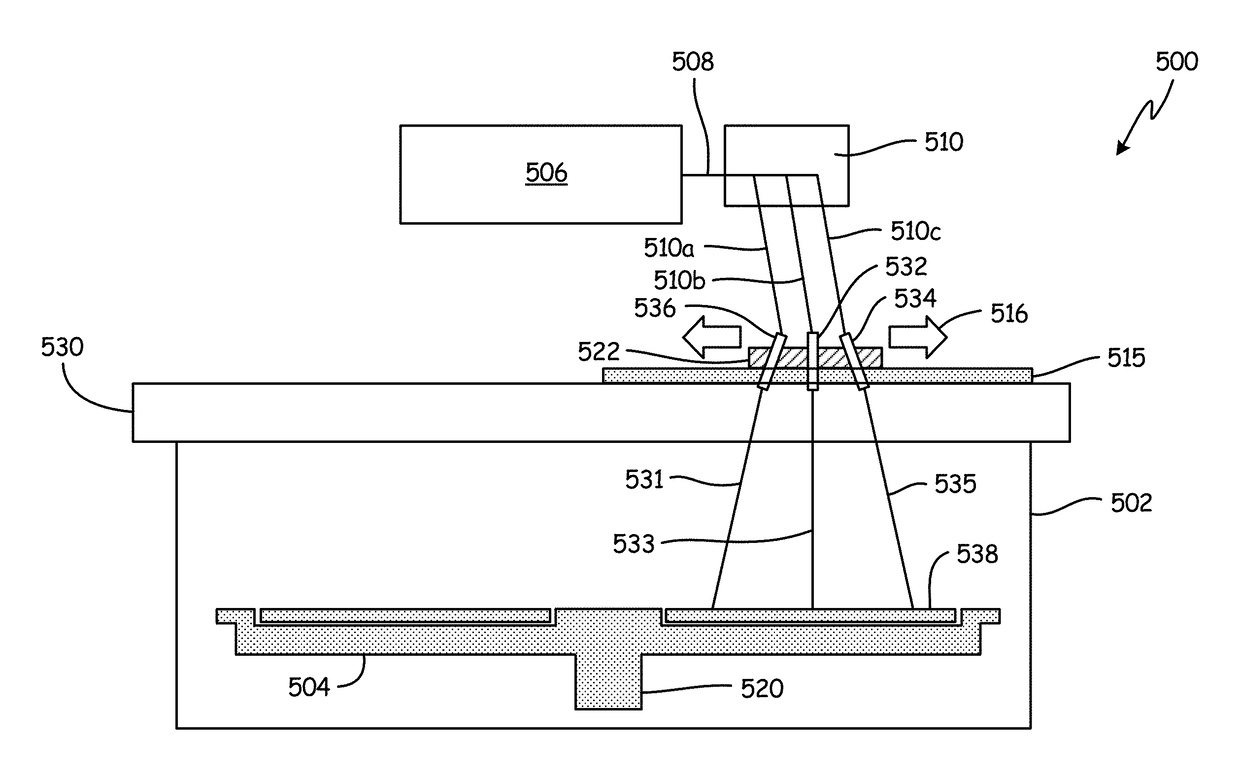

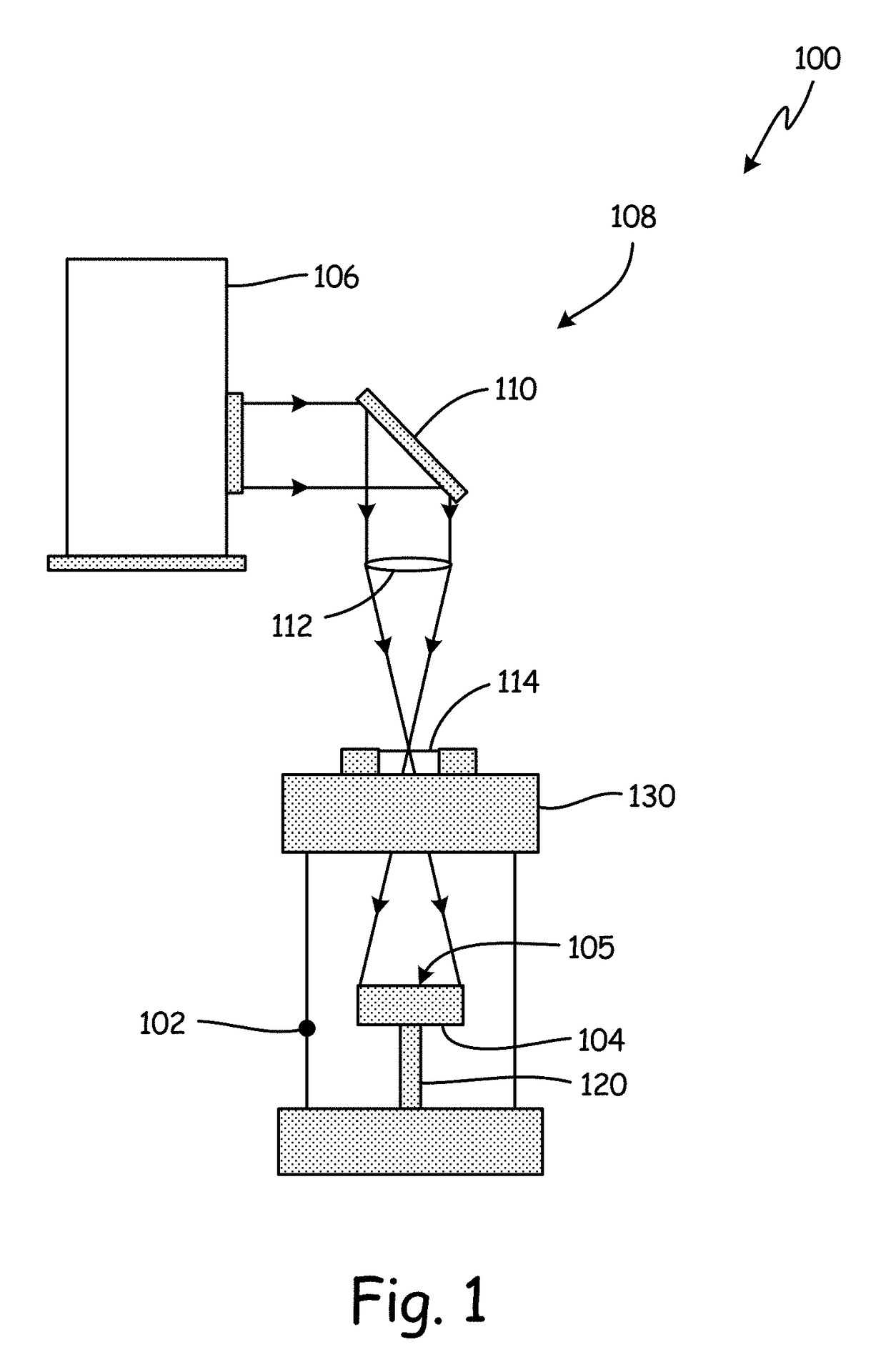

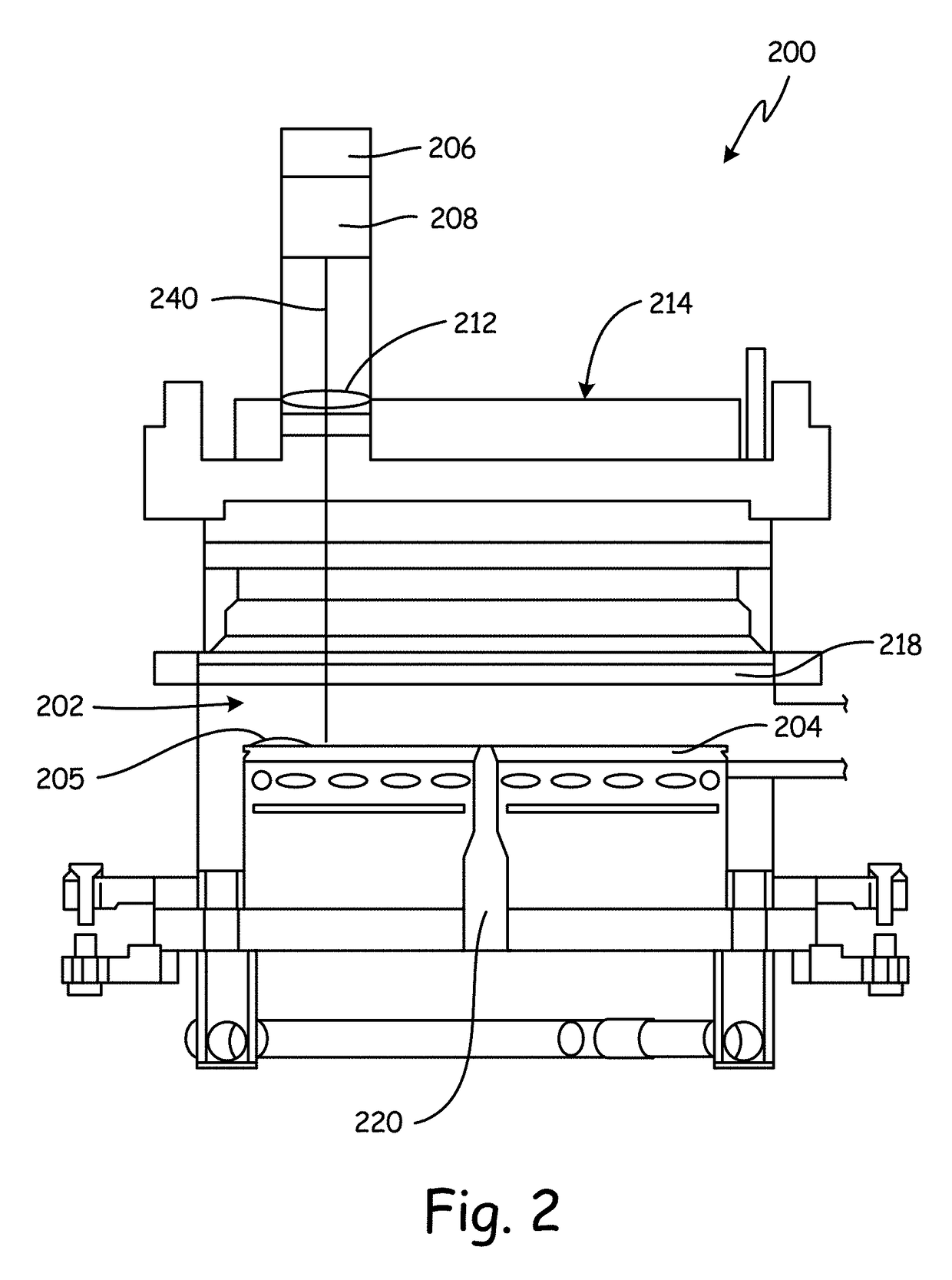

Method and apparatus for controlled dopant incorporation and activation in a chemical vapor deposition system

InactiveUS20170032974A1Point defectReduce in quantitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantGrating

Embodiments include systems and methods for producing semiconductor wafers having reduced quantities of point defects. These systems and methods include a tunable ultraviolet (UV) light source, which is controlled to produce a raster of a UV light beam across a surface of a semiconductor wafer during epitaxial growth to dissociate point defects in the semiconductor wafer. In various embodiments, the tunable UV light source is configured external to a Metal Organic Chemical Vapor Deposition (MOCVD) chamber and controlled such that the UV light beam is directed though a window defined in a wall of the MOCVD chamber.

Owner:VEECO INSTR

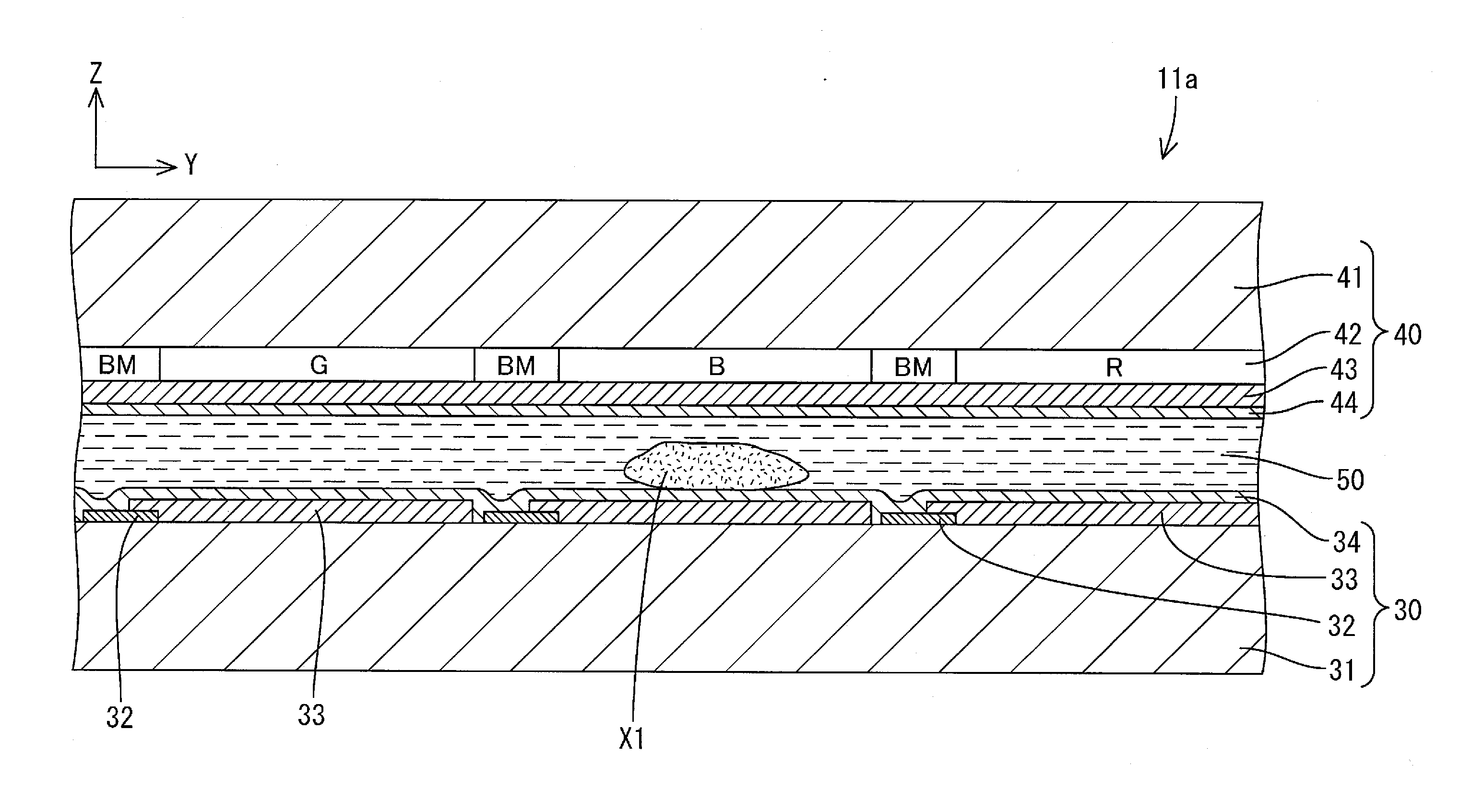

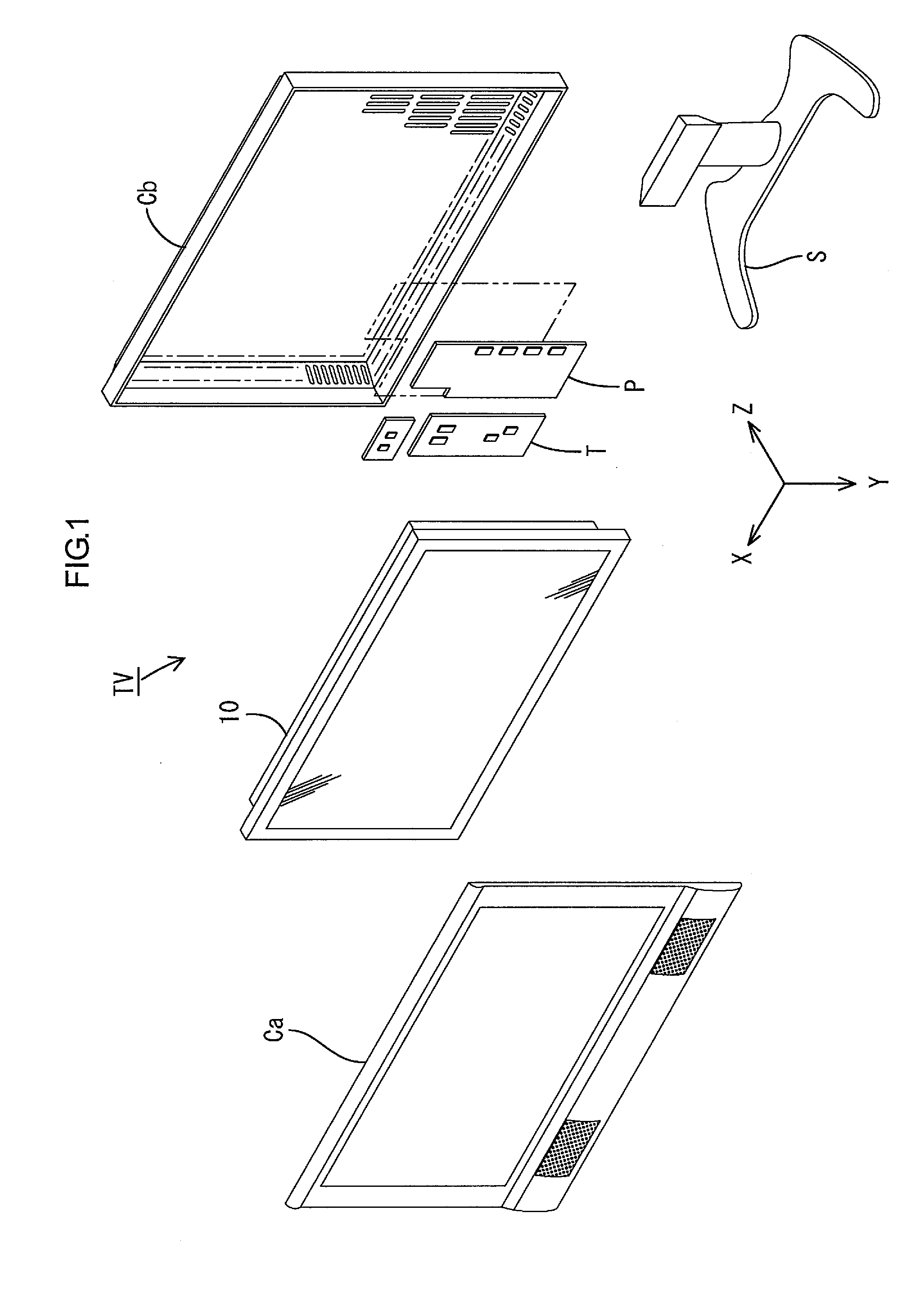

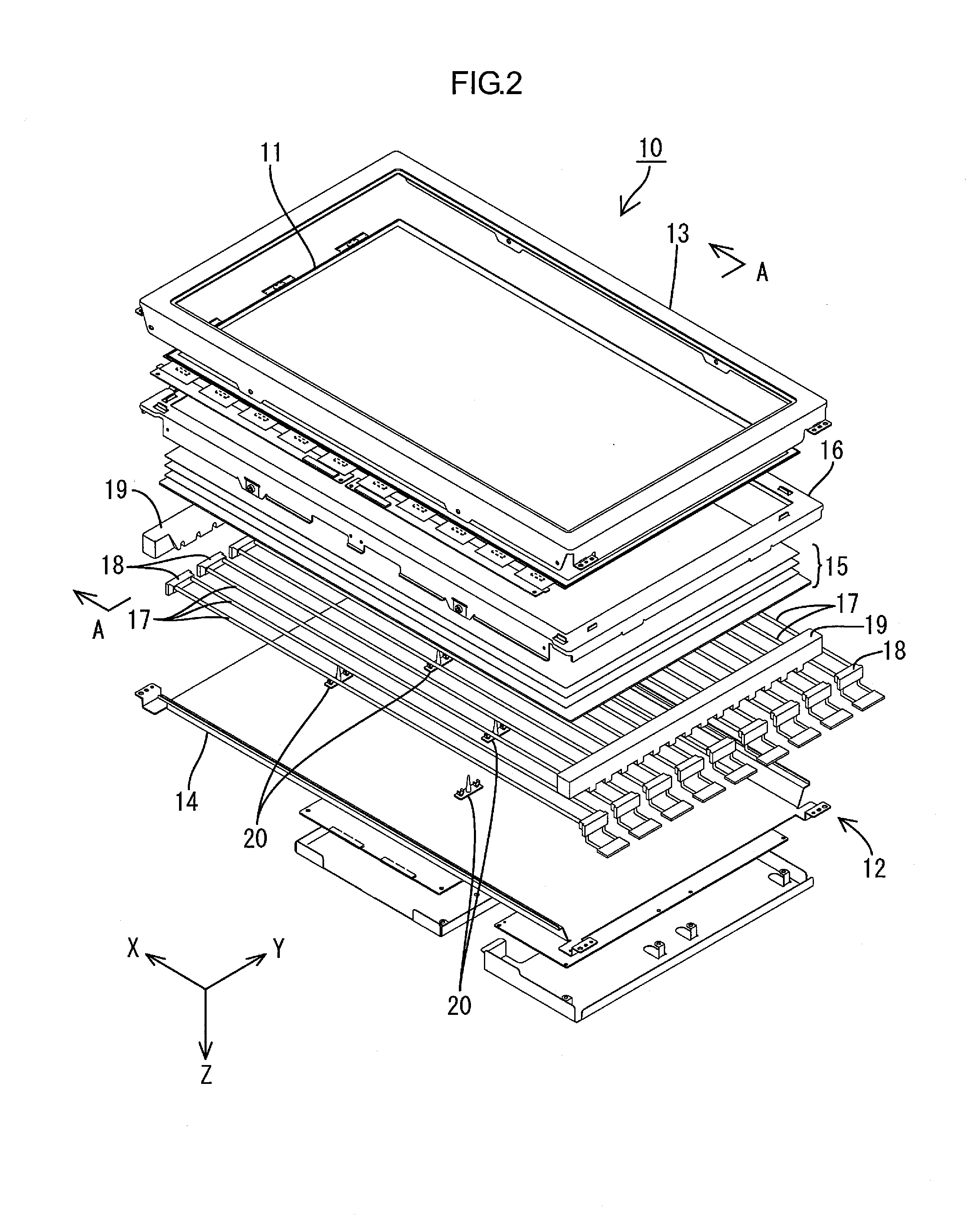

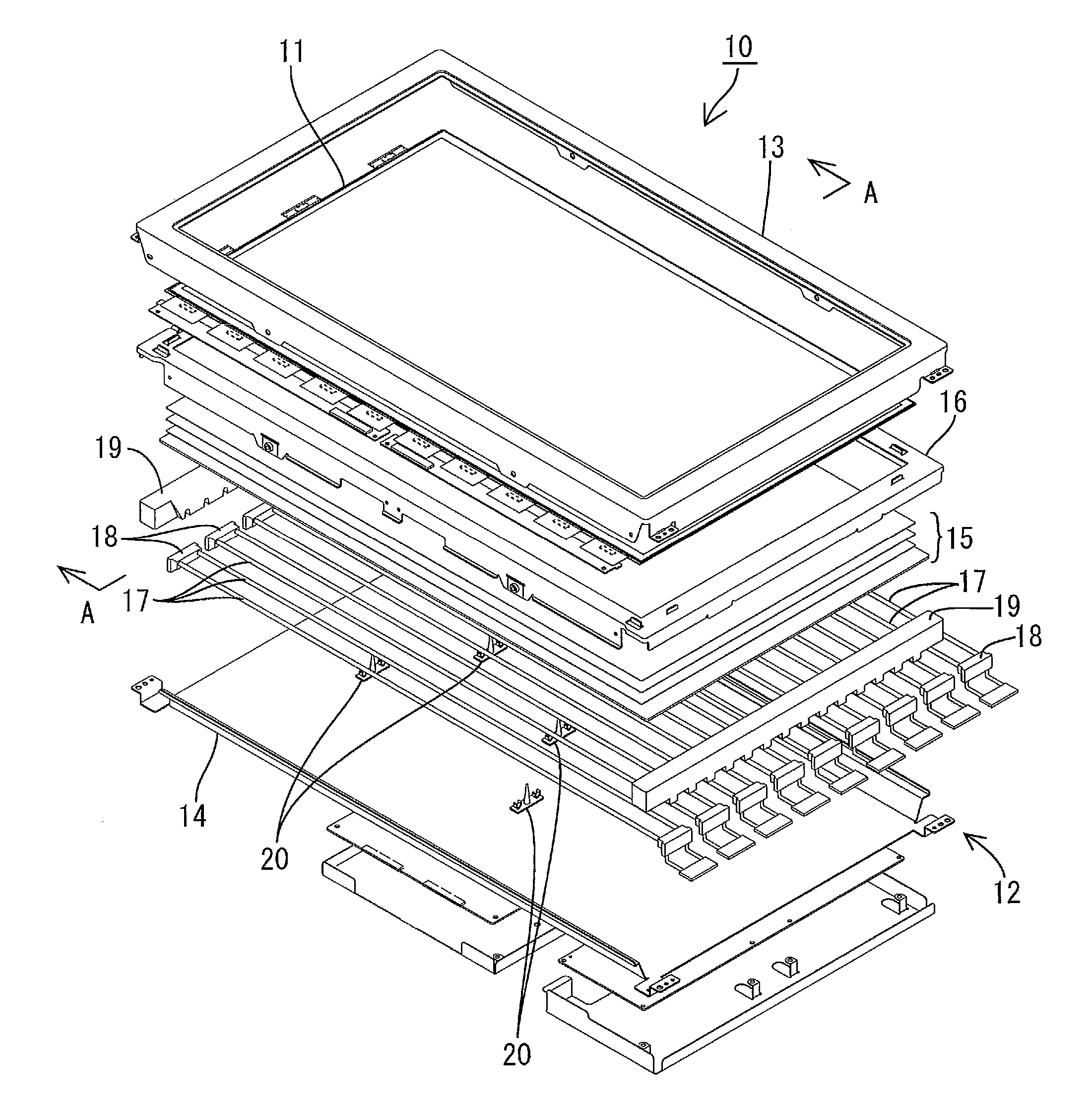

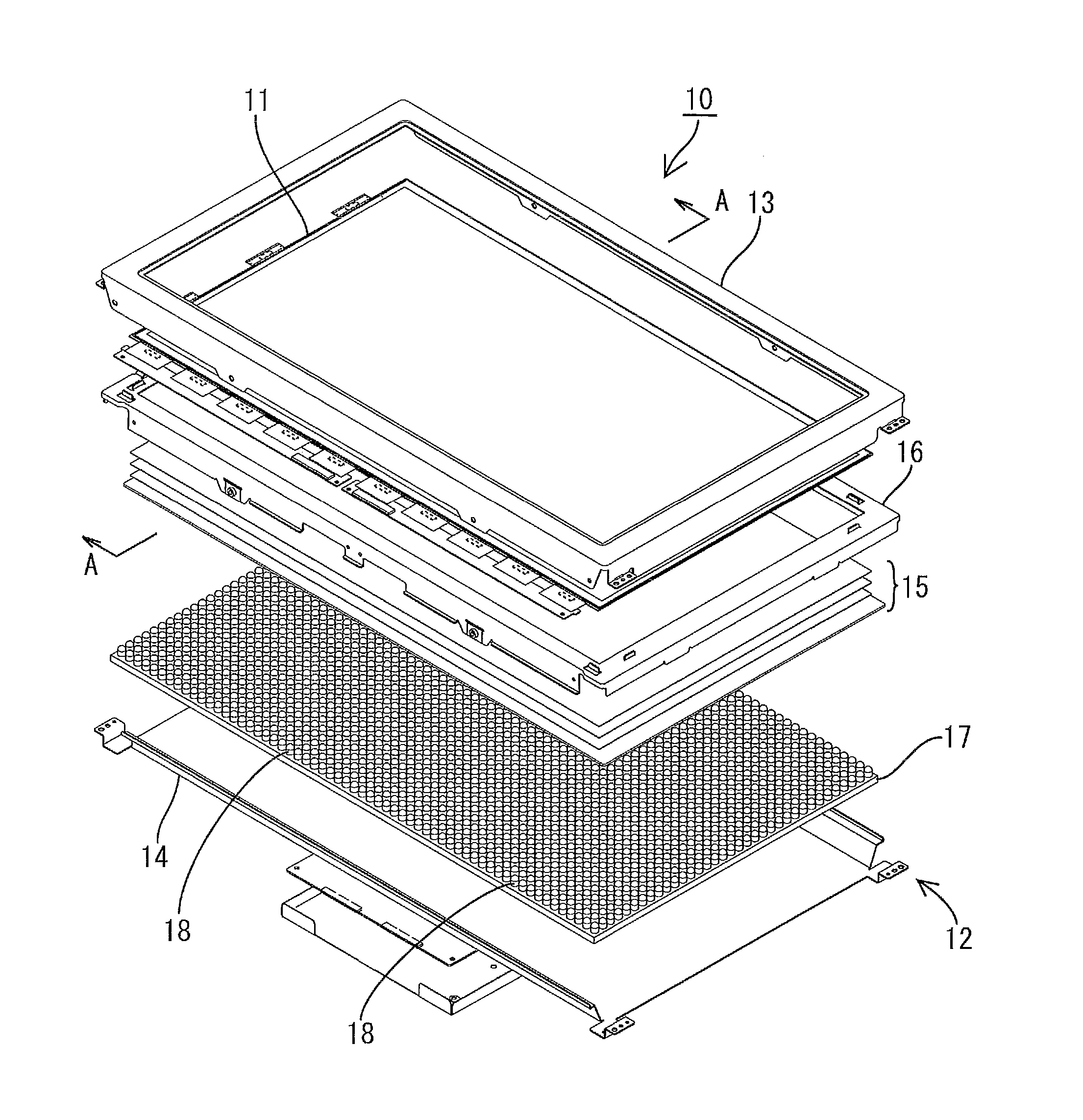

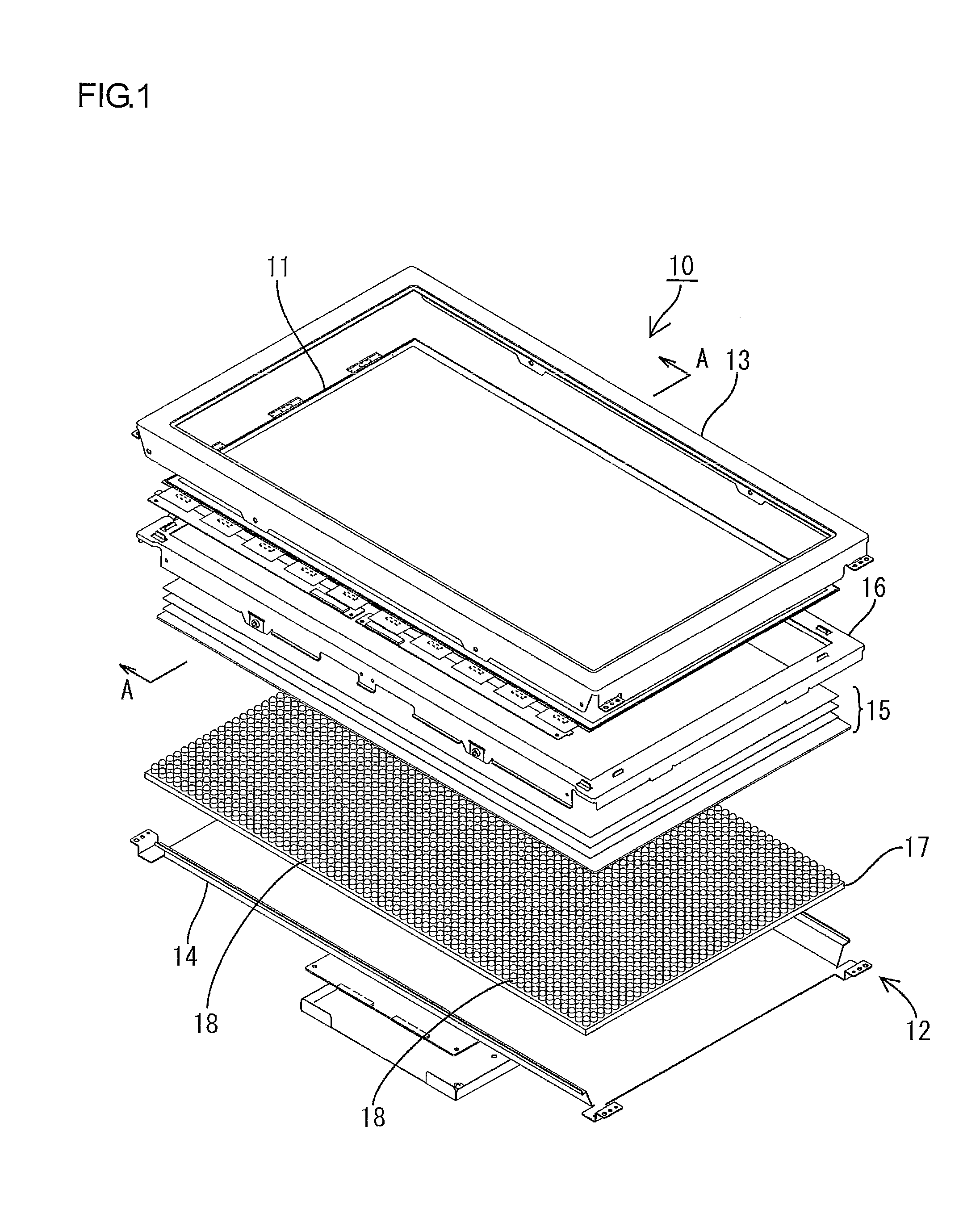

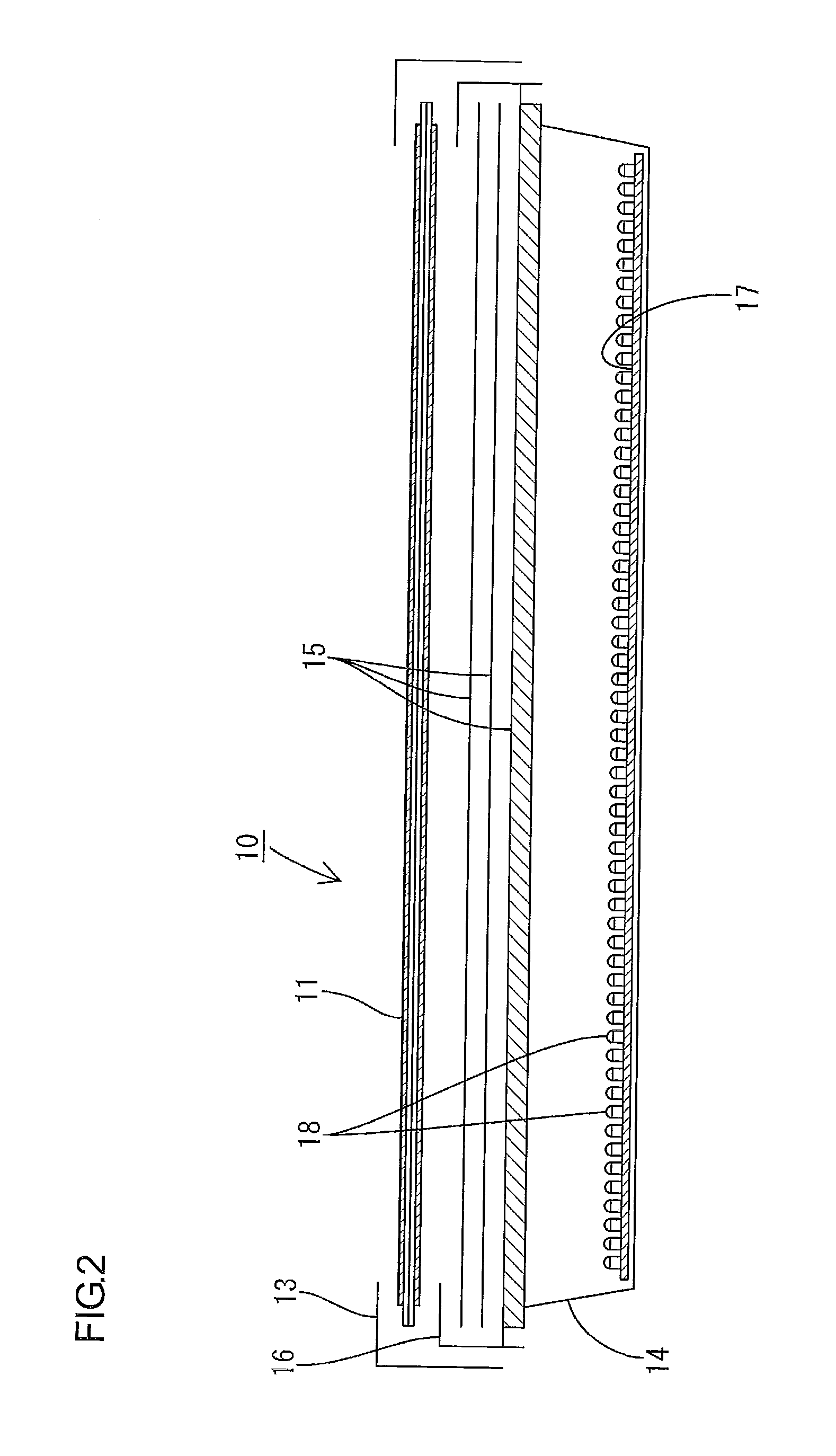

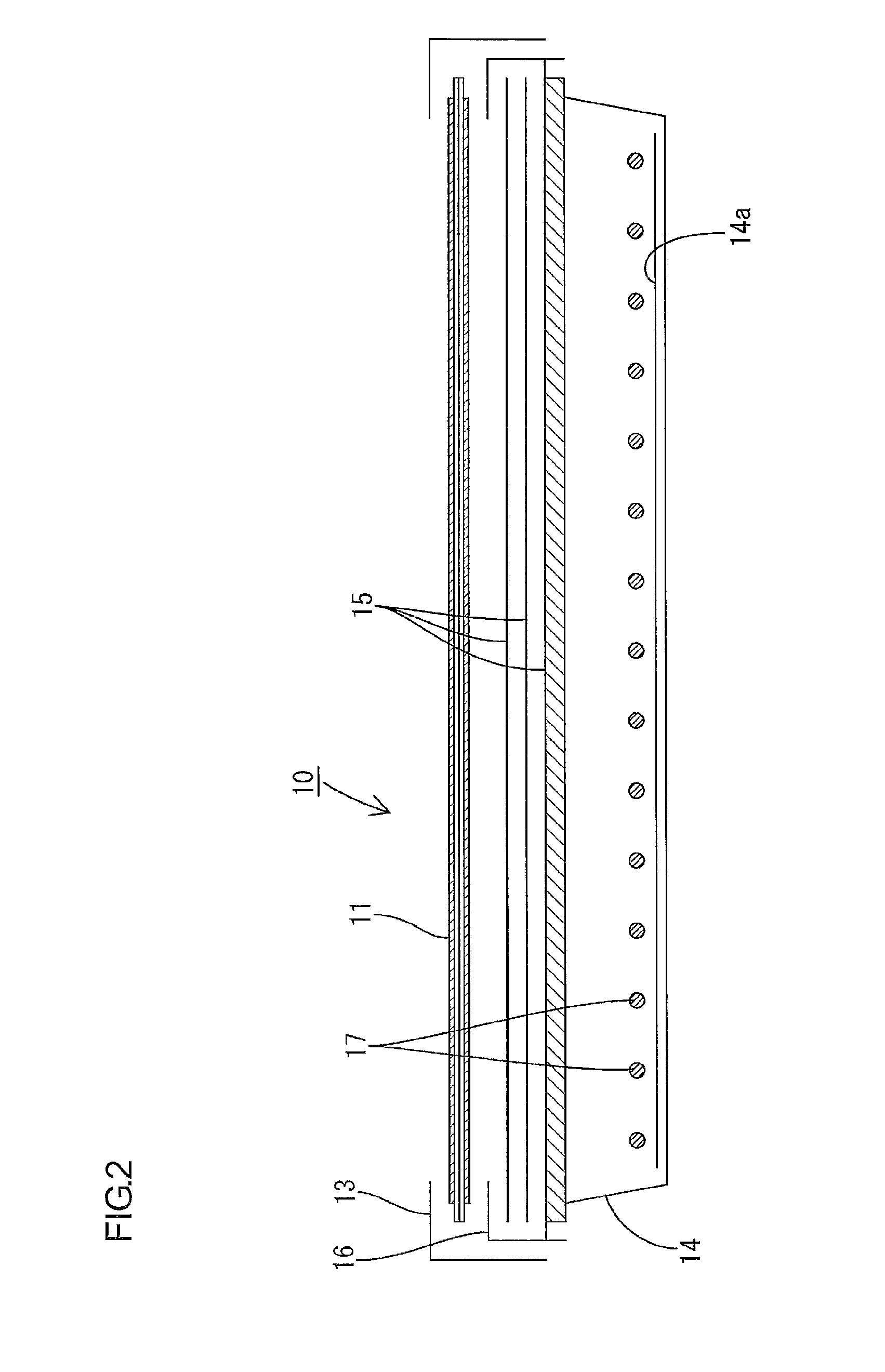

Liquid crystal panel, liquid crystal display device, television device, and method of manufacturing liquid crystal panel

InactiveUS20130235278A1Point defectSparking plugsTelevision system detailsLiquid-crystal displayLiquid crystal

A method of manufacturing a liquid crystal panel in which the bright point defect is effectively corrected is provided. The method of manufacturing a liquid crystal panel 11 including a pair of substrates 40 and 30, and a liquid crystal layer 50 provided between the pair of the substrates 40 and 30 includes detecting a bright point defect in the liquid crystal panel 11; forming a first light blocking portion BL1 in one of the substrates 40 and 30 and in a part of an area that surrounds the bright point defect with a plan view; forming a recess in a portion of one of the substrates 40, 30 that overlaps the bright point defect and on a surface of the one of the substrates 40 and 30 that is opposite from a surface facing the liquid crystal layer; and forming a second light blocking portion BL2 in the recess.

Owner:SHARP KK

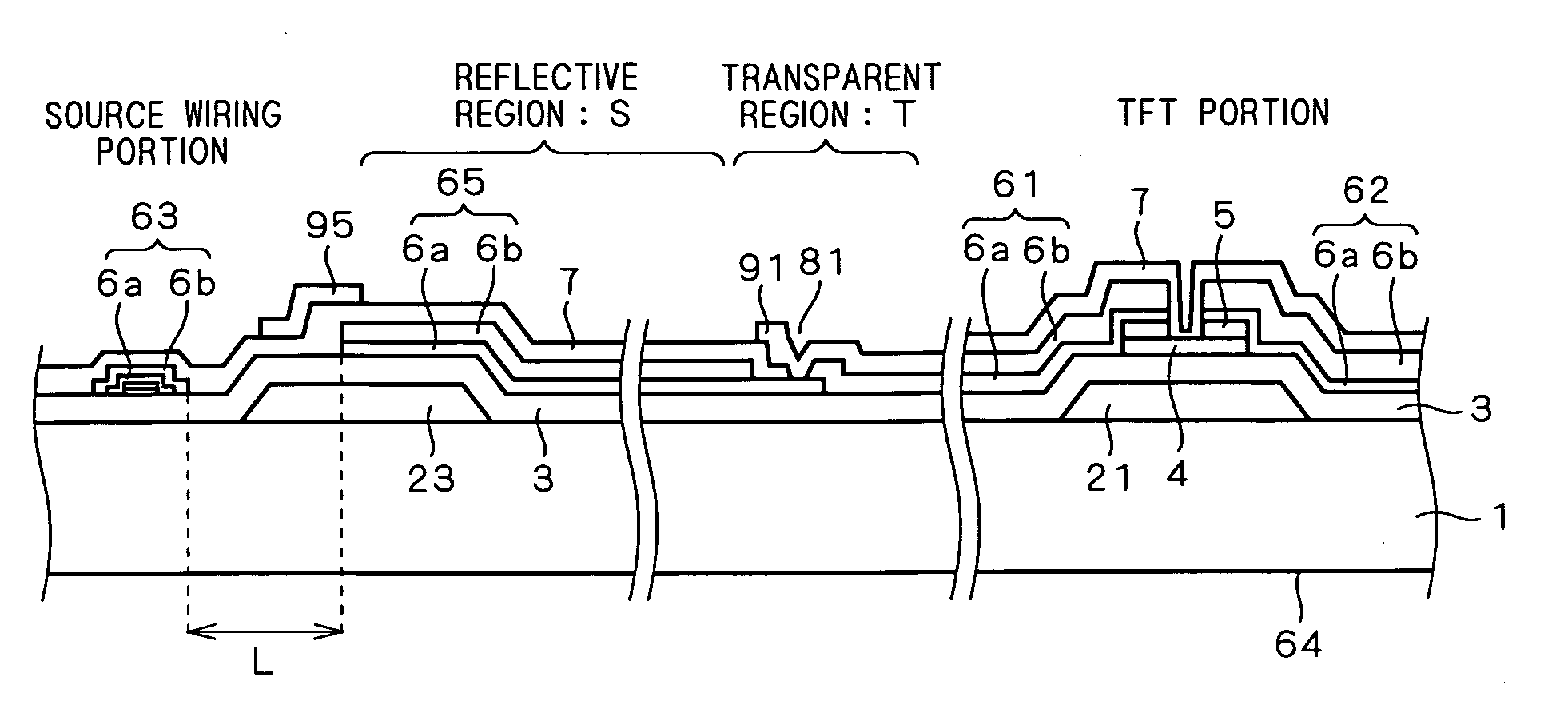

Liquid crystal display device and method of manufacturing same

InactiveUS20100201914A1Improve display qualityPoint defectNon-linear opticsNonbridging oxygenLiquid-crystal display

A liquid crystal display device 10 of the present invention includes a liquid crystal panel 11 and a lighting device 12. The liquid crystal panel 11 has a liquid crystal layer 50 between a pair of glass substrates 31 and 41. The lighting device 12 supplies illumination light to the liquid crystal panel 11. The glass substrate 31 at least has a colored portion including a nonbridging oxygen hole center in an area that can block light to luminance defect area X that is a possible cause of a luminance point defect.

Owner:SHARP KK

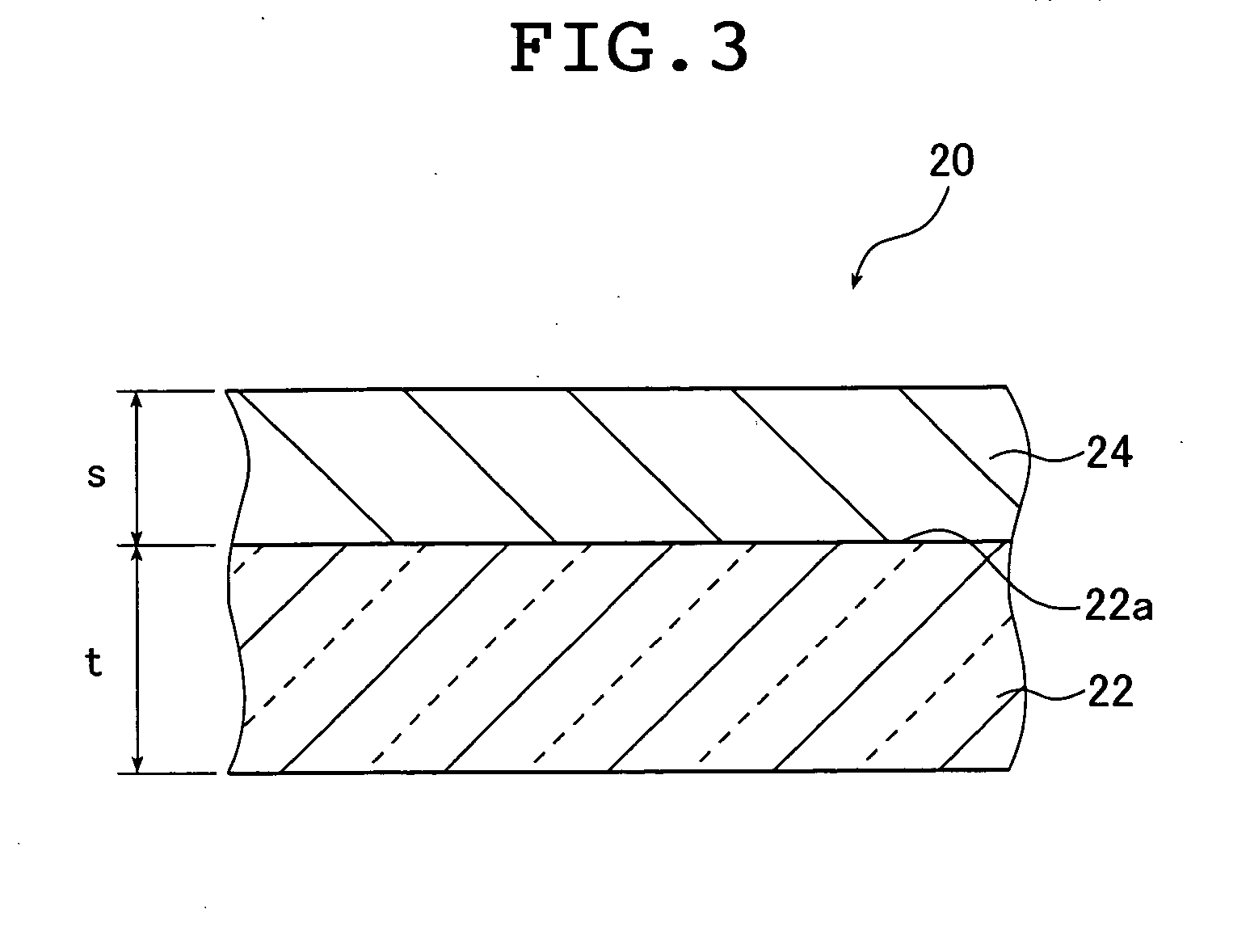

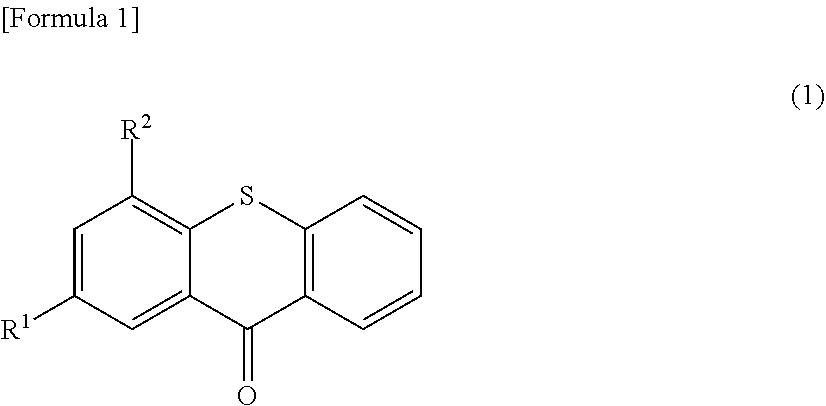

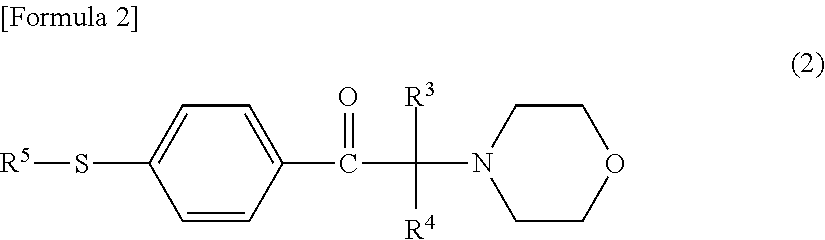

Polarized film, optical film, and image display device

InactiveUS9829605B2Low water vapor permeabilityResists change in resistanceLamination ancillary operationsOptical filtersMoisture permeabilityPolarizer

A polarizing film, comprising a polarizer; transparent protective films with a water-vapor permeability of 150 g / m2 / 24 hours or less provided on both sides of the polarizer; and adhesive layers each interposed between the polarizer and one of the transparent protective films, wherein the adhesive layers are formed by applying an active energy ray to an active energy ray-curable adhesive composition containing a radically polymerizable compound, and the transparent protective films are bonded to the polarizer with the adhesive layers.

Owner:NITTO DENKO CORP

Liquid crystal display apparatus and manufacturing method thereof

InactiveUS20100188603A1Improve display qualityPoint defectNanoopticsNon-linear opticsLiquid-crystal displayPhotonic crystal

A liquid crystal display device 10 in accordance with the present invention includes a liquid crystal panel 11 and a lighting device 12. The liquid crystal panel 11 has a liquid crystal layer 40 provided between a pair of glass substrates 21, 31. The lighting device supplies illumination light to the liquid crystal panel 11. At least a glass substrate 21, which is one of the pair of glass substrates 21, 31 has a photonic crystal 50 formed in a position capable of blocking light toward a luminance point defect occurrence portion X that is a cause of a luminance point defect. The photonic crystal 50 is capable of absorbing light having a color displayable in the luminance point defect occurrence portion X.

Owner:SHARP KK

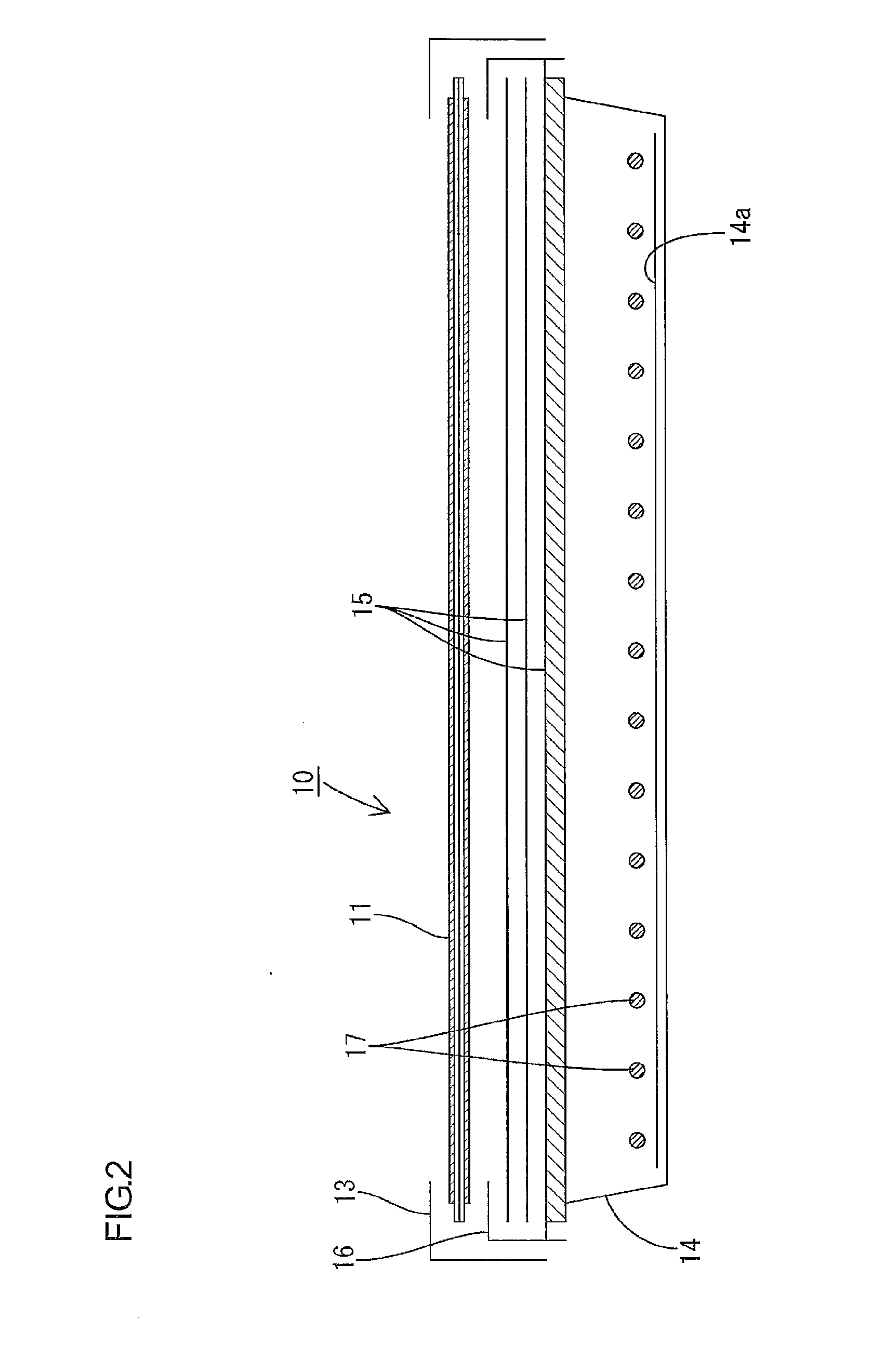

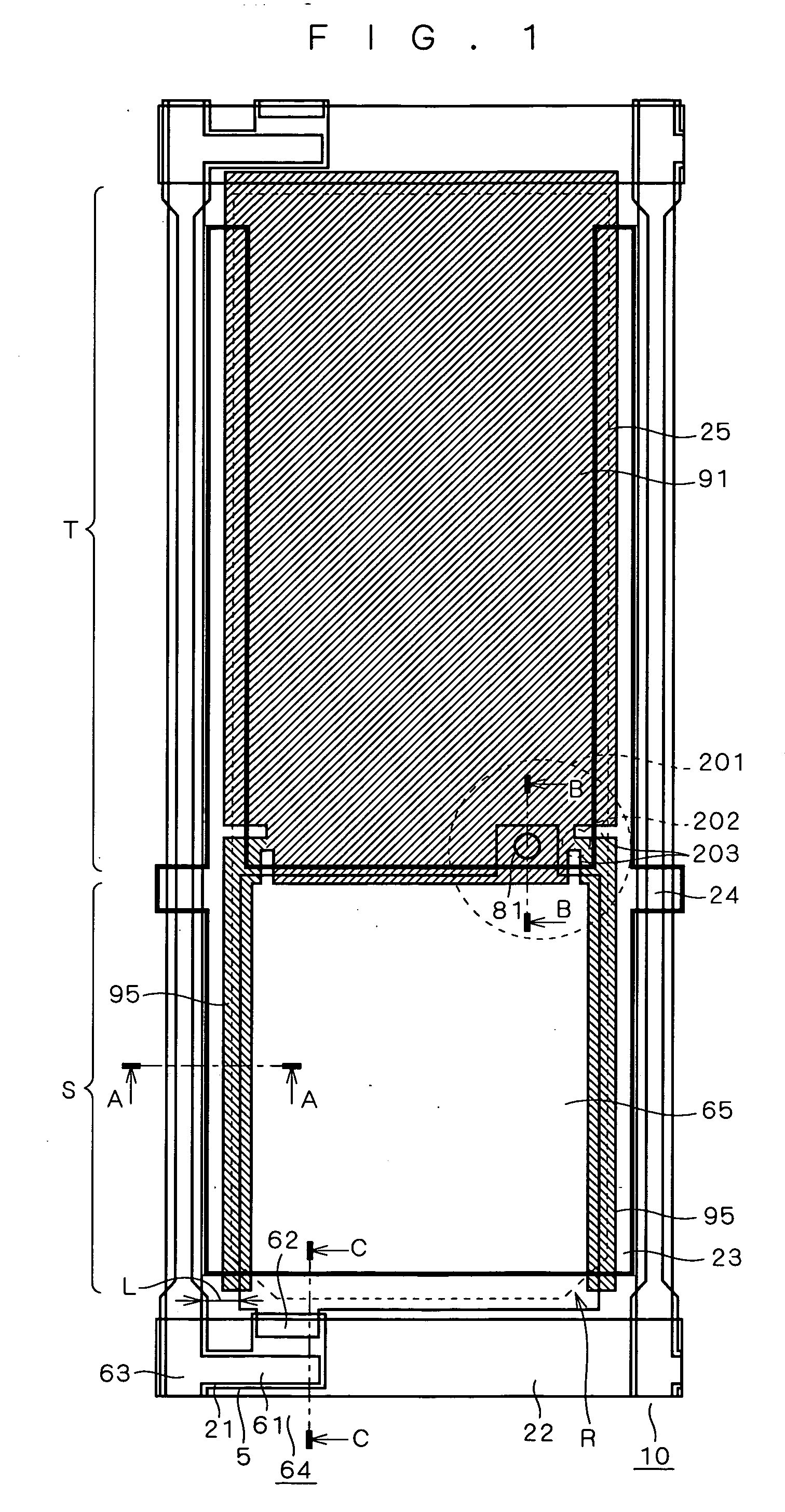

Semi-transparent TFT array substrate, and semi-transparent liquid crystal display with transparent pixel electrode and contrast reduction preventive electrode connected in the same layer

InactiveUS7826014B2Avoid reflective contrastPoint defectSolid-state devicesNon-linear opticsCapacitanceLiquid-crystal display

A semi-transparent TFT array substrate has a TFT including a source electrode, a gate electrode, and a drain electrode. The substrate also has an auxiliary capacitive wiring and a reflective pixel electrode. Further, the substrate has a transparent pixel electrode including an electrode extending from a corner of the rest of the transparent pixel electrode to an edge of the auxiliary capacitive wiring closest to a gate wiring connected to the gate electrode. In addition, the substrate has a source wiring connected to the source electrode. The auxiliary capacitive wiring overlaps a space existing between the reflective pixel electrode and the source wiring. The electrode is disposed between the reflective pixel electrode and the source wiring. A connection which connects the electrode and the rest of the transparent pixel electrode does not overlap the auxiliary capacitive wiring in a plan view. The connection does not overlap the gate wiring.

Owner:MITSUBISHI ELECTRIC CORP

Method for producing optical film

The method for producing an optical film includes a step of preparing a first coating liquid containing a certain amount of light-transmitting particles, a resin, and a solvent, a second coating liquid containing an amount less than the certain amount of light-transmitting particles, a resin, and a solvent, or not containing the light-transmitting particles but containing a resin and a solvent; a step of coating the second coating liquid and the first coating liquid in this order from the support side on a traveling band-shaped support in the form of a multilayer to form a second coating film and a first coating film; a step of transferring the light-transmitting particles in the first coating film to the side of the second coating film while drying the first coating film and the second coating film.

Owner:FUJIFILM CORP

Method and apparatus for controlled dopant incorporation and activation in a chemical vapor deposition system

InactiveUS9748113B2Point defectReduce in quantitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingGratingUltraviolet

Embodiments include systems and methods for producing semiconductor wafers having reduced quantities of point defects. These systems and methods include a tunable ultraviolet (UV) light source, which is controlled to produce a raster of a UV light beam across a surface of a semiconductor wafer during epitaxial growth to dissociate point defects in the semiconductor wafer. In various embodiments, the tunable UV light source is configured external to a Metal Organic Chemical Vapor Deposition (MOCVD) chamber and controlled such that the UV light beam is directed though a window defined in a wall of the MOCVD chamber.

Owner:VEECO INSTR

Liquid crystal display device and manufacturing method thereof

ActiveUS20100201912A1Improve display qualityPoint defectNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device 10 in accordance with the present invention includes a liquid crystal 11 and a lighting device 12, the liquid crystal panel 11 having a liquid crystal layer 50 provided between a pair of glass substrates 31, 41, the lighting device 12 supplying illumination light to the liquid crystal panel 11. The liquid crystal display device 10 is characterized in that a metal-halide containing region 60 is formed in a position in one of the pair of glass substrates 31, 41. The metal-halide containing region 60 contains a crystal of metal halide which exhibits photochromism in the light supplied from the lighting device 12. The position is capable of blocking light toward a luminance point defect occurrence portion X that becomes a cause of a luminance point defect. The one of the pair of glass substrates 31, 41 is disposed on the lighting device 12 side.

Owner:SHARP KK

Semi-transparent TFT array substrate, and semi-transparent liquid crystal display

InactiveUS20060289869A1Avoid reflective contrast reductionPoint defectSolid-state devicesNon-linear opticsCapacitanceLiquid-crystal display

A contrast reduction preventive electrode is formed in a reflective region, and in the same layer as a transparent pixel electrode. A connection for connecting the contrast reduction preventive electrode and the transparent pixel electrode is formed, in such a position that the connection does not overlap an auxiliary capacitive wiring in plan view. When a short circuit is generated between the surfaces of the contrast reduction preventive electrode and an opposed electrode (not shown), the contrast reduction preventive electrode is cut off from the transparent pixel electrode at the connection.

Owner:MITSUBISHI ELECTRIC CORP

Thin-film transistor array and method for manufacturing same

InactiveUS6657226B1Evading complication of manufacturing processIncrease the areaTransistorSolid-state devicesCapacitanceCapacitive coupling

A high-quality thin-film transistor array. The gate insulating film below the pixel electrode is etched off in its entirely or along a slit extending along a drain bus line in order to simultaneously remove the residual a-Si produced due to defective patterning. The insulating film is interposed between a drain bus line and a pixel electrode to form a boundary separating layer therebetween. The reject ratio is suppressed by reducing the occurrence of point defects of semi-bright spots, ascribable to capacitative coupling to the pixel electrodes as a result of interconnection of the residual a-Si produced by defective patterning to the drain bus line.

Owner:NEC LCD TECH CORP

Method of producing optical laminate, optical laminate, polarizing plate and organic el display device

ActiveUS9977165B2Avoid uneven film thicknessPoint defectLiquid crystal compositionsElectroluminescent light sourcesComposition BDisplay device

The present invention provides an optical laminate which is suppressed in film thickness unevenness of an optically anisotropic layer and is free from point defects, a method of producing the same, and a polarizing plate and an organic EL display device using the optical laminate. The method of producing an optical laminate having an optically anisotropic layer A and an optically anisotropic layer B, includes where the layer A and the layer B are provided in direct contact with each other. The method further includes where both a composition a for forming the layer A and a composition b for forming the layer B contain a fluorine compound, and when the layer A is formed using composition a and layer B is formed using composition b, layer A and layer B are formed in this order under the condition that composition a and composition b satisfy predetermined surface tension relationships.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com