Patents

Literature

48 results about "Protein kinase A" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In cell biology, protein kinase A (PKA) is a family of enzymes whose activity is dependent on cellular levels of cyclic AMP (cAMP). PKA is also known as cAMP-dependent protein kinase (EC 2.7.11.11). Protein kinase A has several functions in the cell, including regulation of glycogen, sugar, and lipid metabolism.

Methods for suppressing the induction of nitric oxide synthase in a cell

InactiveUS7049058B2Increase ratingsIncrease volumeBiocideMicrobiological testing/measurementAntioxidantSuppressor

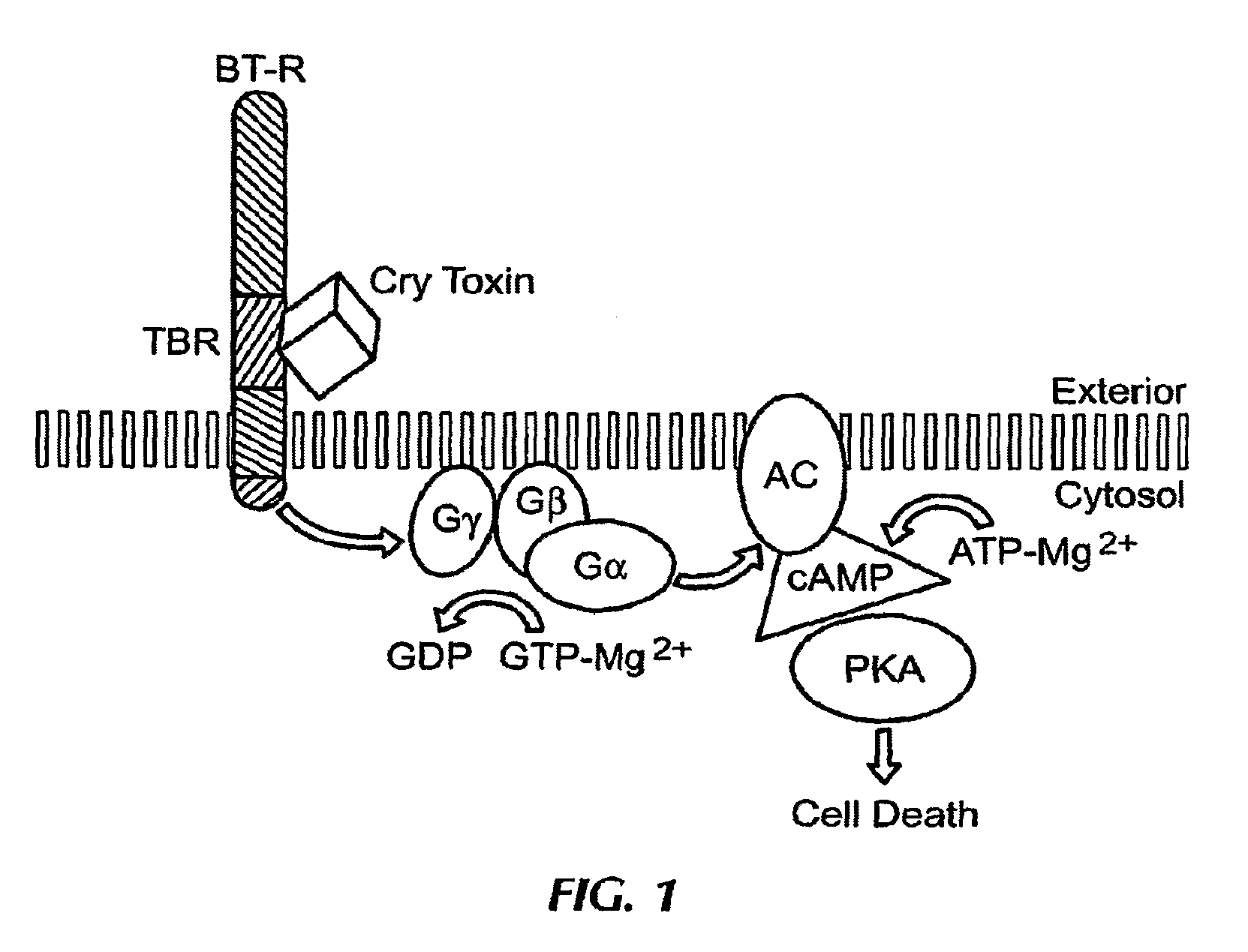

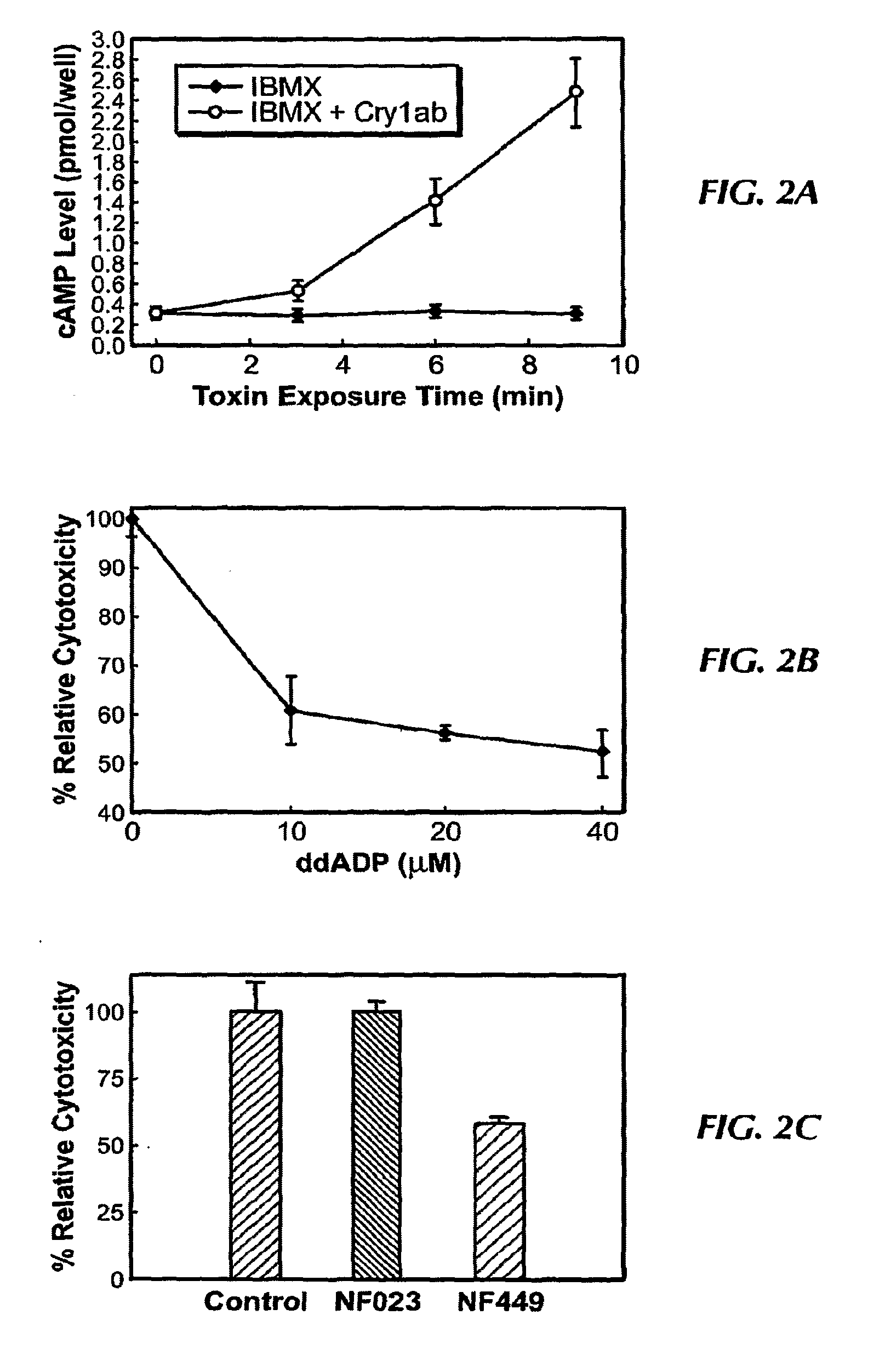

Disclosed are methods for suppressing the induction of inducible nitric oxide synthase in a cell comprising contacting said cell with an effective amount of at least one induction suppressor of inducible nitric oxide synthase or a cytokine are disclosed. The induction suppressor can be an inhibitor of mevalonate synthesis, an inhibitor of the farnesylation of Ras, an antioxidant, an enhancer of intracellular cAMP, an enhancer of protein kinase A (PKA), an inhibitor of NF-kβ activation, an inhibitor of Ras / Raf / MAP kinase pathway, an inhibitor of mevalonate pyrophosphate decarboxylase or an inhibitor of farnesyl pyrophosphate.

Owner:MUSC FOUND FOR RES DEV

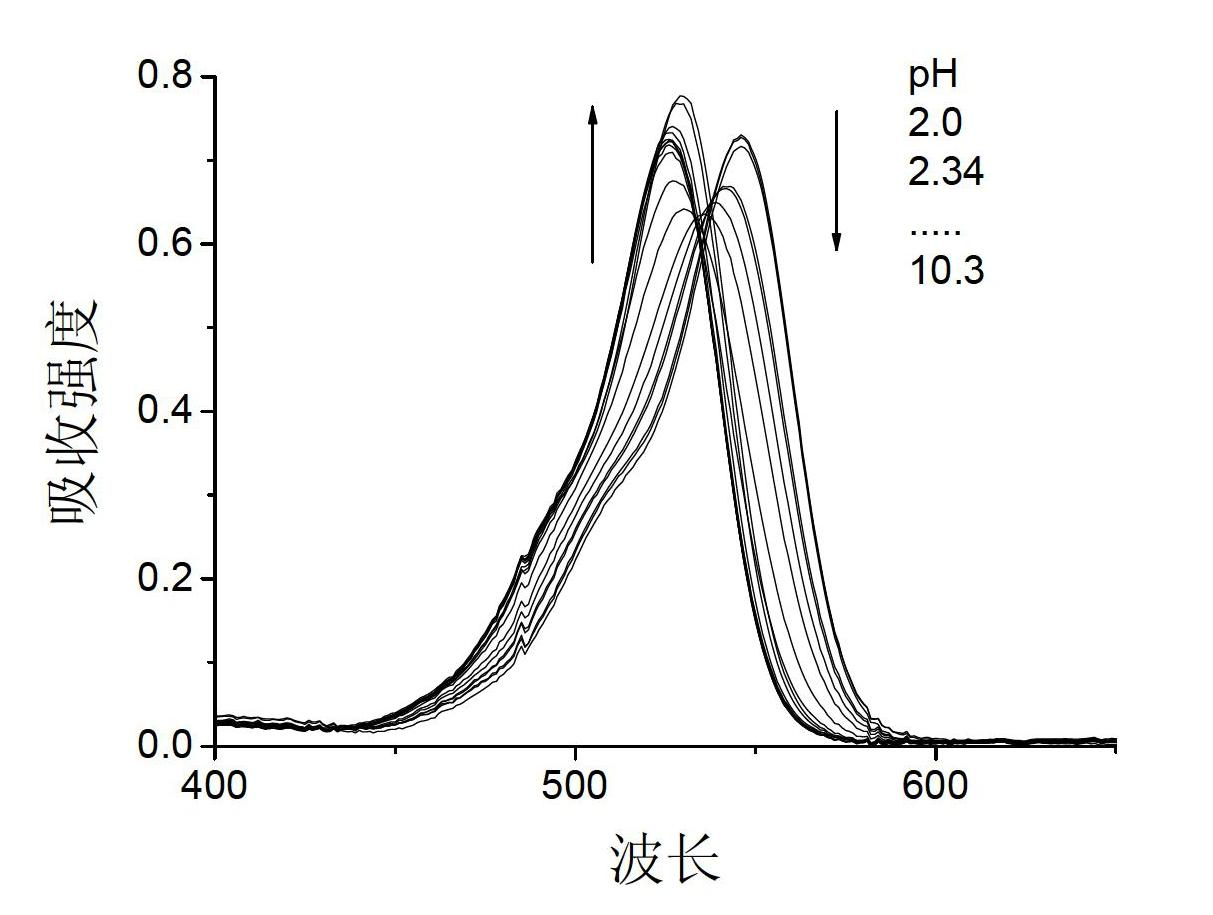

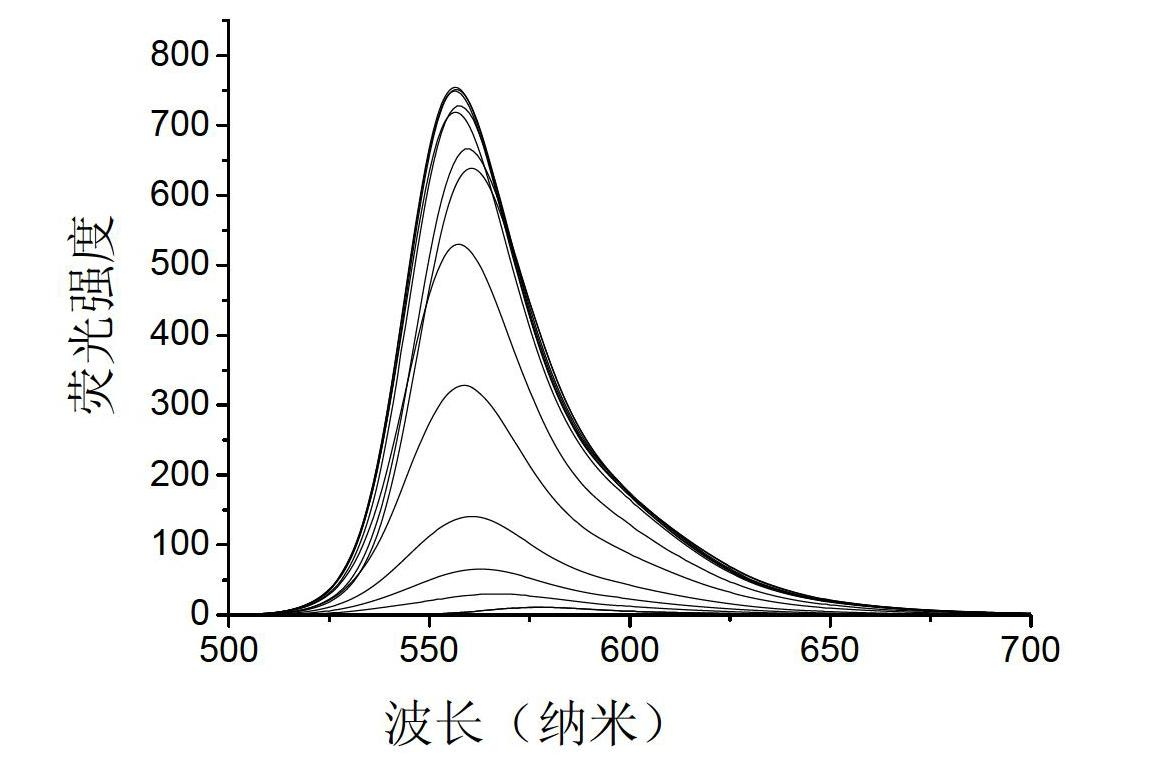

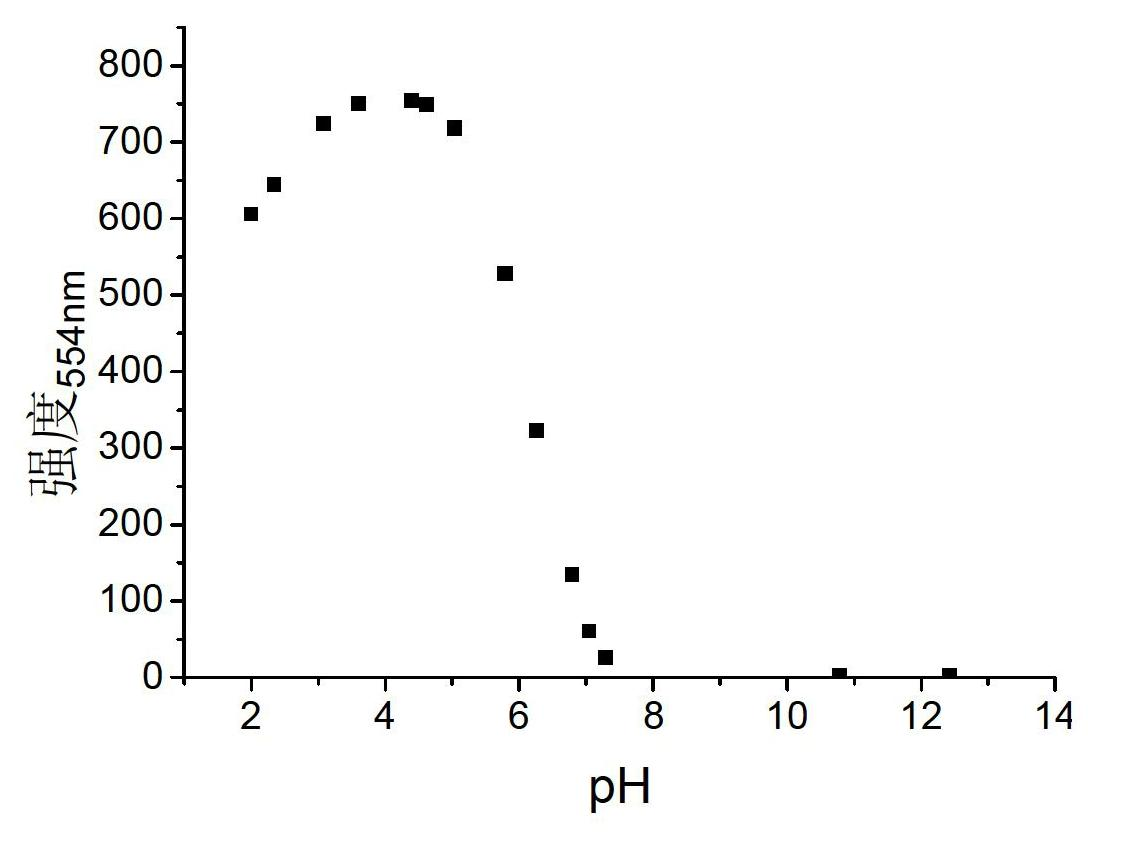

Rhodamine fluorescent probe sensitive to pH change, synthetic method and application

InactiveCN102659744AEasy to synthesizeHigh sensitivityOrganic chemistryMaterial analysis by observing effect on chemical indicatorCellular MicroenvironmentSolubility

The invention relates to a class of rhodamine fluorescent probe sensitive to pH change. The fluorescent probe has the following structural general formula, the molecules of the fluorescent probe have a simple synthetic process and better chemical and light stability, fluorescence is sensitive to pH change, and the fluorescent probe has different protein kinase A (pKa) values by introducing different amine groups. Meanwhile, the rhodamine fluorescent probe sensitive to the pH change has very good water solubility and biological compatibility and higher fluorescent quantum yield and has the function of cellular localization. Meanwhile, the pH value of a cellular microenvironment can be detected.

Owner:DALIAN UNIV OF TECH

Process for preparing human serum albumin

ActiveCN103394076ANon-deterministicHigh yieldPeptide/protein ingredientsSerum albuminUltrafiltrationFiltration

The invention discloses a process for preparing human serum albumin. According to the process, a low-temperature ethanol separation method is adopted, and the human serum albumin is prepared from human plasma. The process comprises the steps of dissolving plasma; preparing an ingredient I; preparing an ingredient II and an ingredient III; preparing an ingredient IV; preparing an ingredient V; refining the ingredient V; carrying out ultrafiltration; diluting; carrying out pasteurization; sterilizing and packaging albumen; incubating products; and packaging finished products. The process has the advantages that solid-liquid separation is carried out by adopting a pressure filtration technology, so that the albumin yield which is higher than 29 g / L plasma is increased remarkably, the purity is higher than 98%, and the stability of the products is improved remarkably; Zetaplus deep filter-core filtration is combined with the prolongation of pasteurization time, so that the PKA (Protein Kinase A) level of the products is effectively controlled to be lower than 20IU / ml, and the risks of excessive heat source and virus infection in the products are reduced; and during the process, sodium chloride solutions of two gradient concentrations are used for carrying out ultrafiltration, so that not only can the ethanol residual quantity of the products be controlled to be lower than 0.025%, but also the aluminum residual quantity can be effectively minimized to be lower than 50 micrograms / L.

Owner:华润博雅生物制药集团股份有限公司

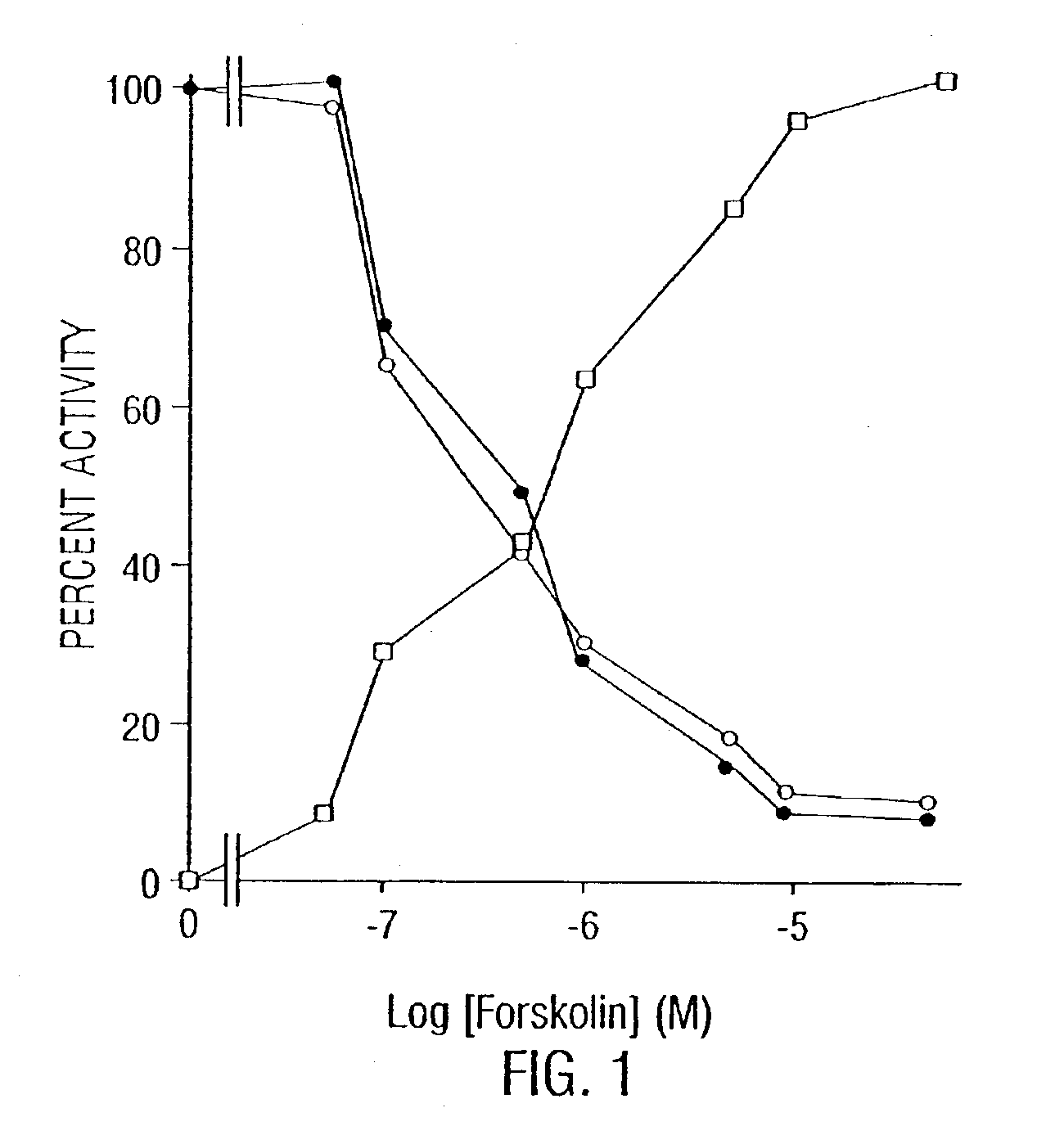

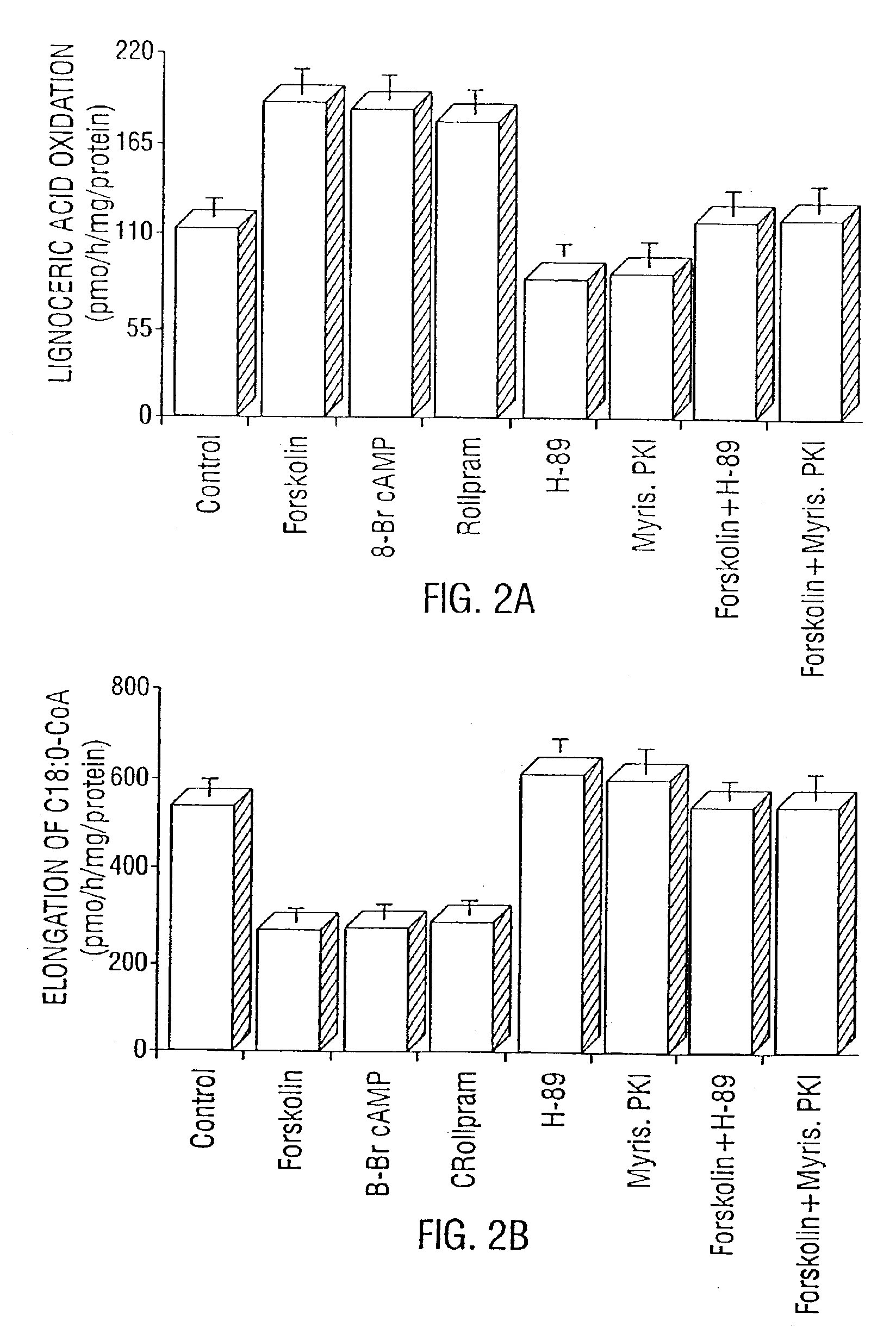

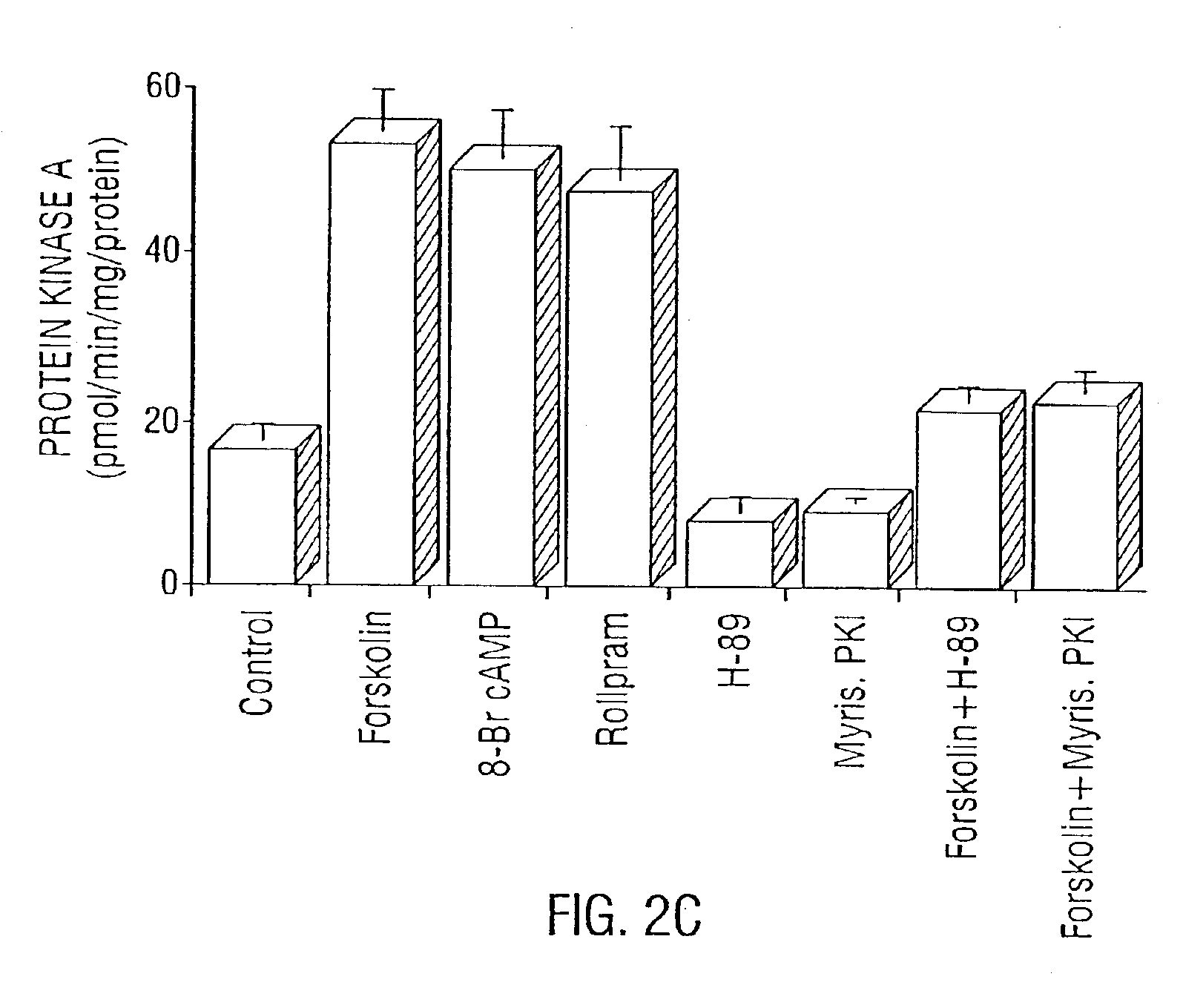

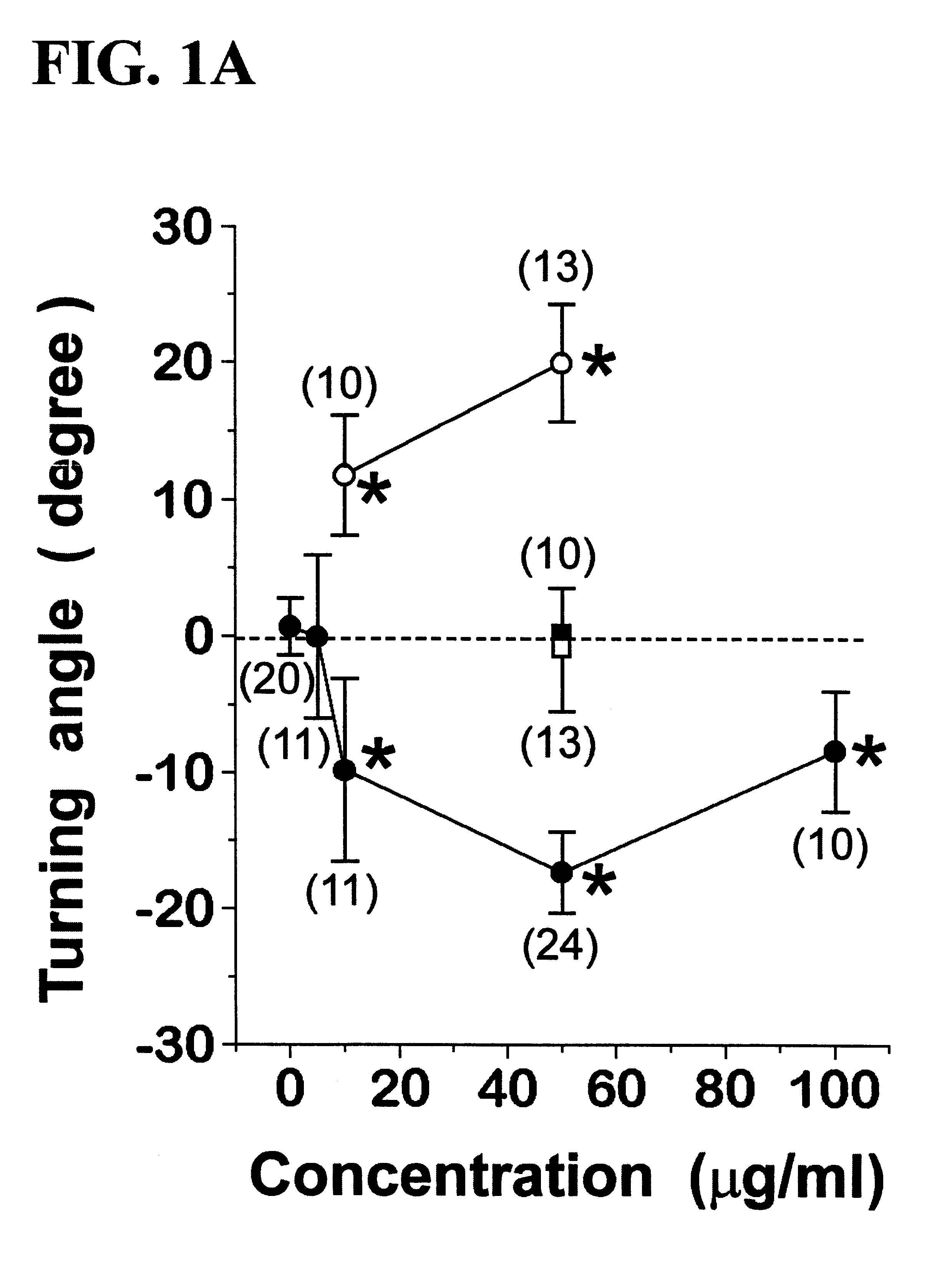

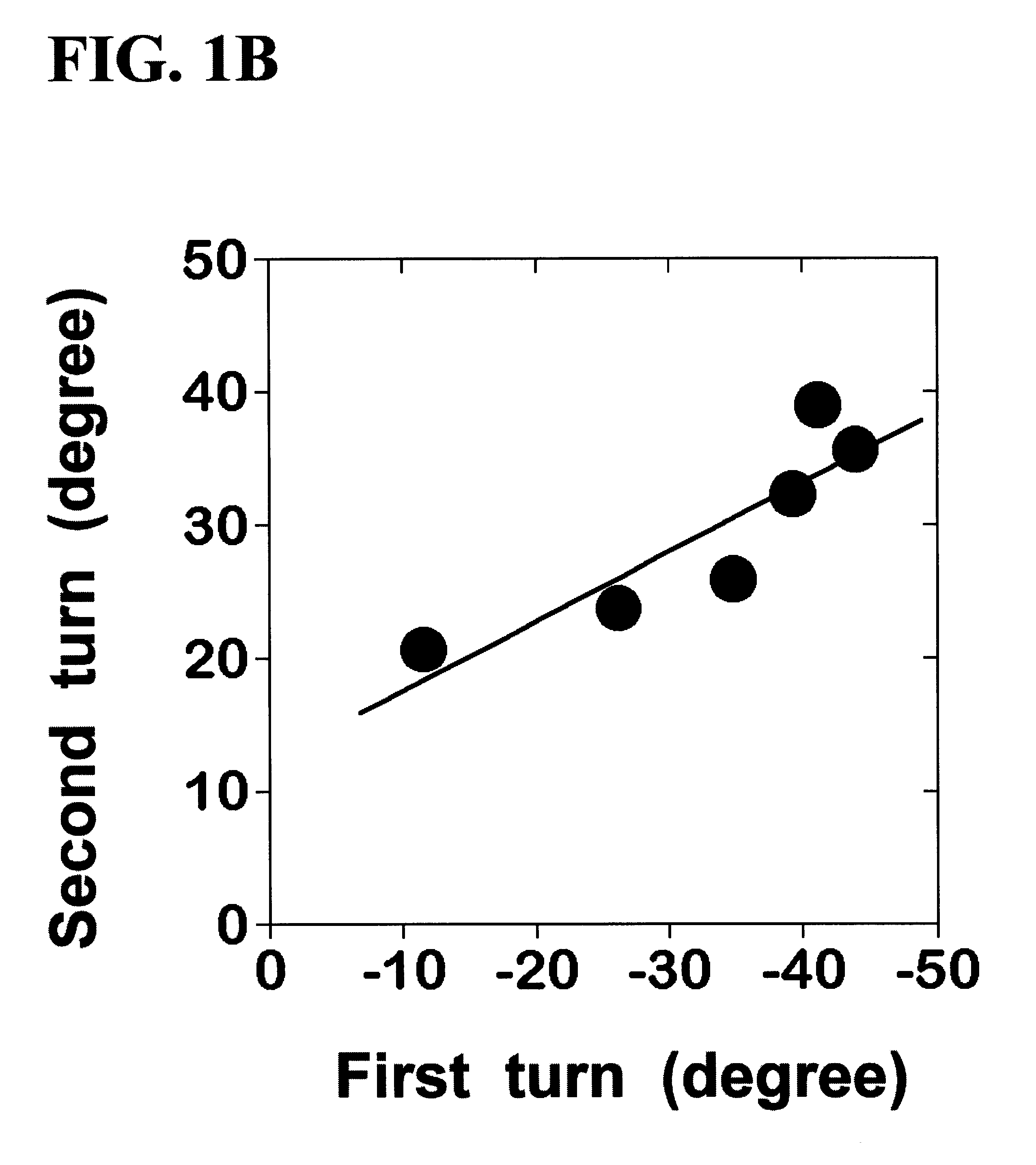

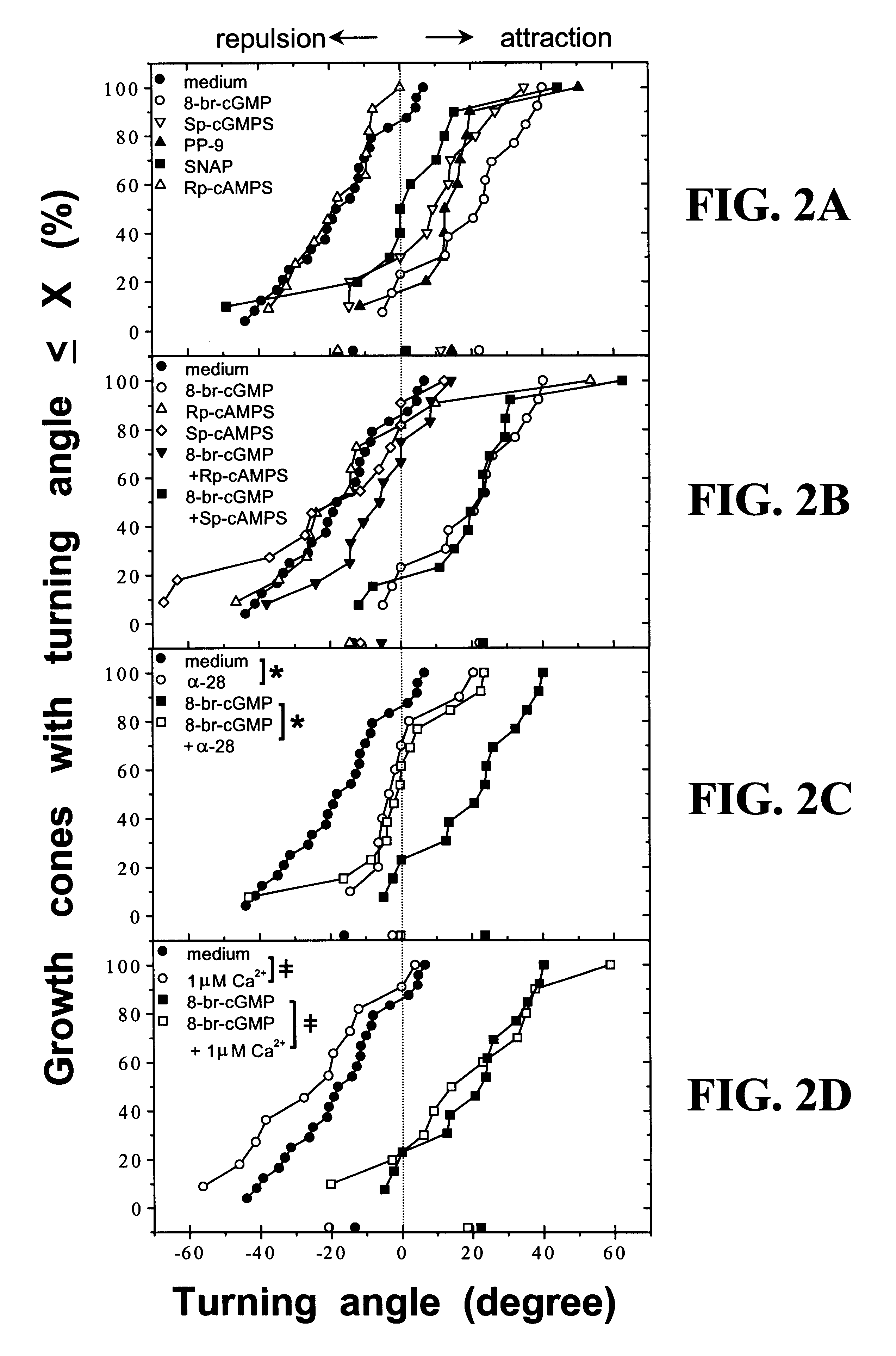

Promoters of neural regeneration

InactiveUS6268352B1Promote nerve growthImprove the level ofBiocideNervous disorderProtein kinase ABiophysics

The invention provides methods and compositions for promoting neural cell growth and / or regeneration. The general methods involve contacting with an activator of a cyclic nucleotide dependent protein kinase a neural cell subject to growth repulsion mediated by a neural cell growth repulsion factor. The activator may comprise a direct or an indirect activator of the protein kinase; the repulsion factor typically comprises one or more natural, endogenous proteins mediating localized repulsion or inhibition of neural cell growth; and the target cells are generally vertebrate neurons, typically injured mammalian neurons. The subject compositions include mixtures comprising a neural cell, an activator of a cyclic nucleotide dependent protein kinase and a neural cell growth repulsion factor.

Owner:RGT UNIV OF CALIFORNIA

Methods and kits for detecting protein kinases

Owner:LONZA GRP

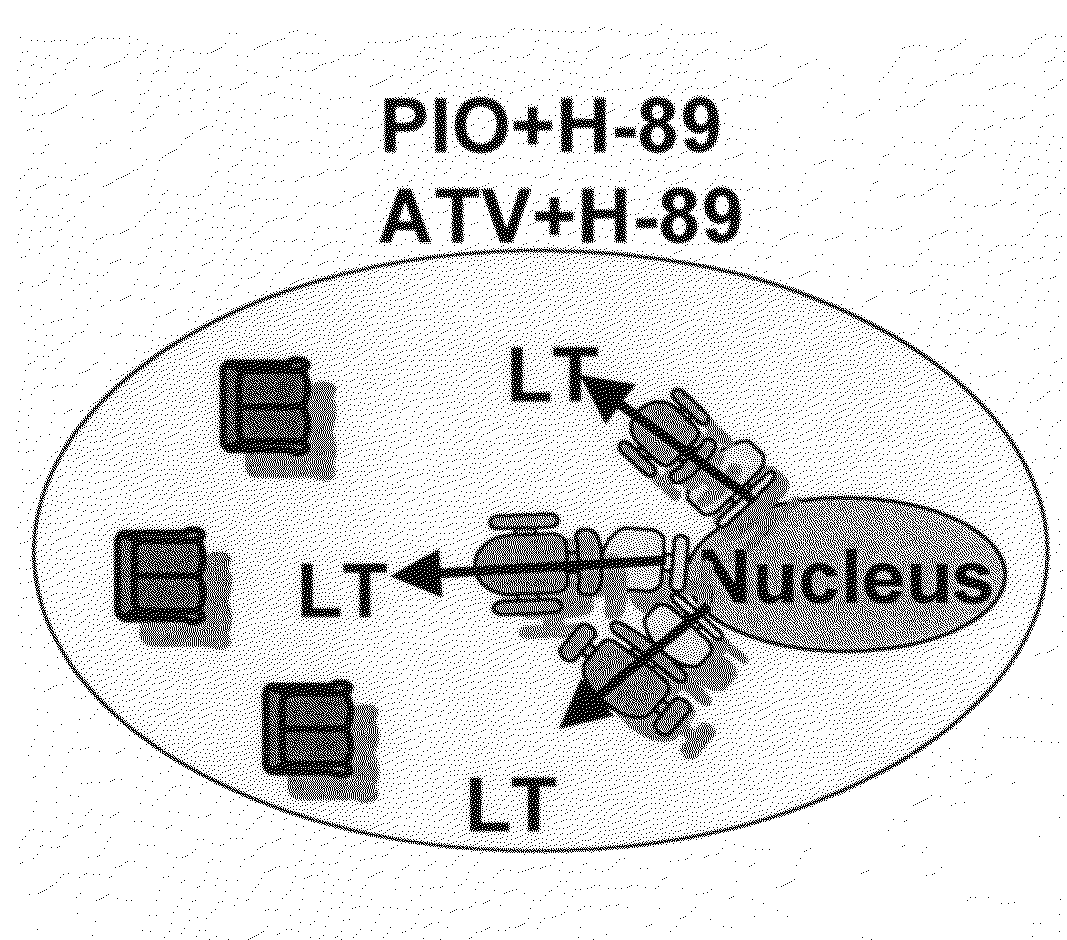

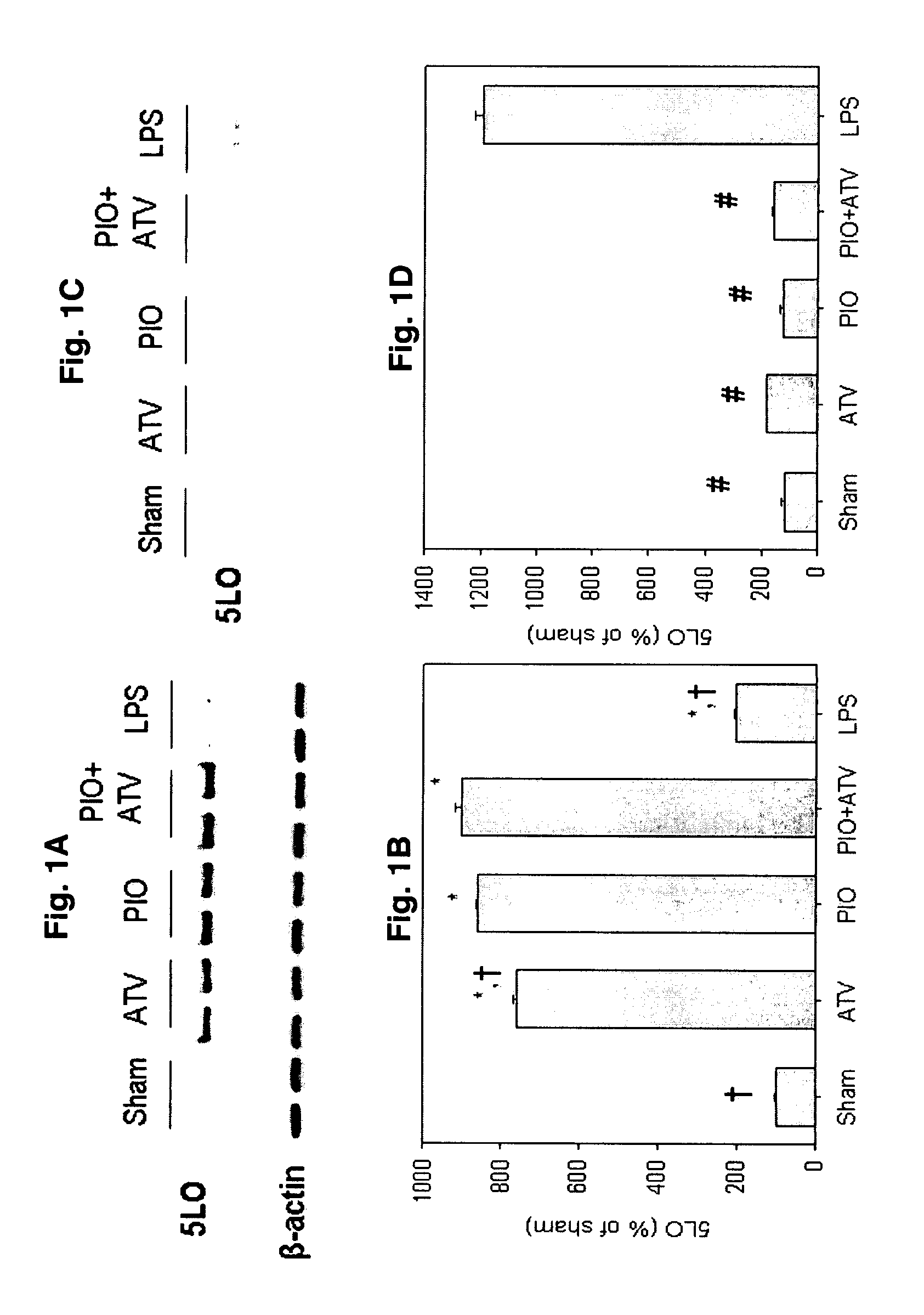

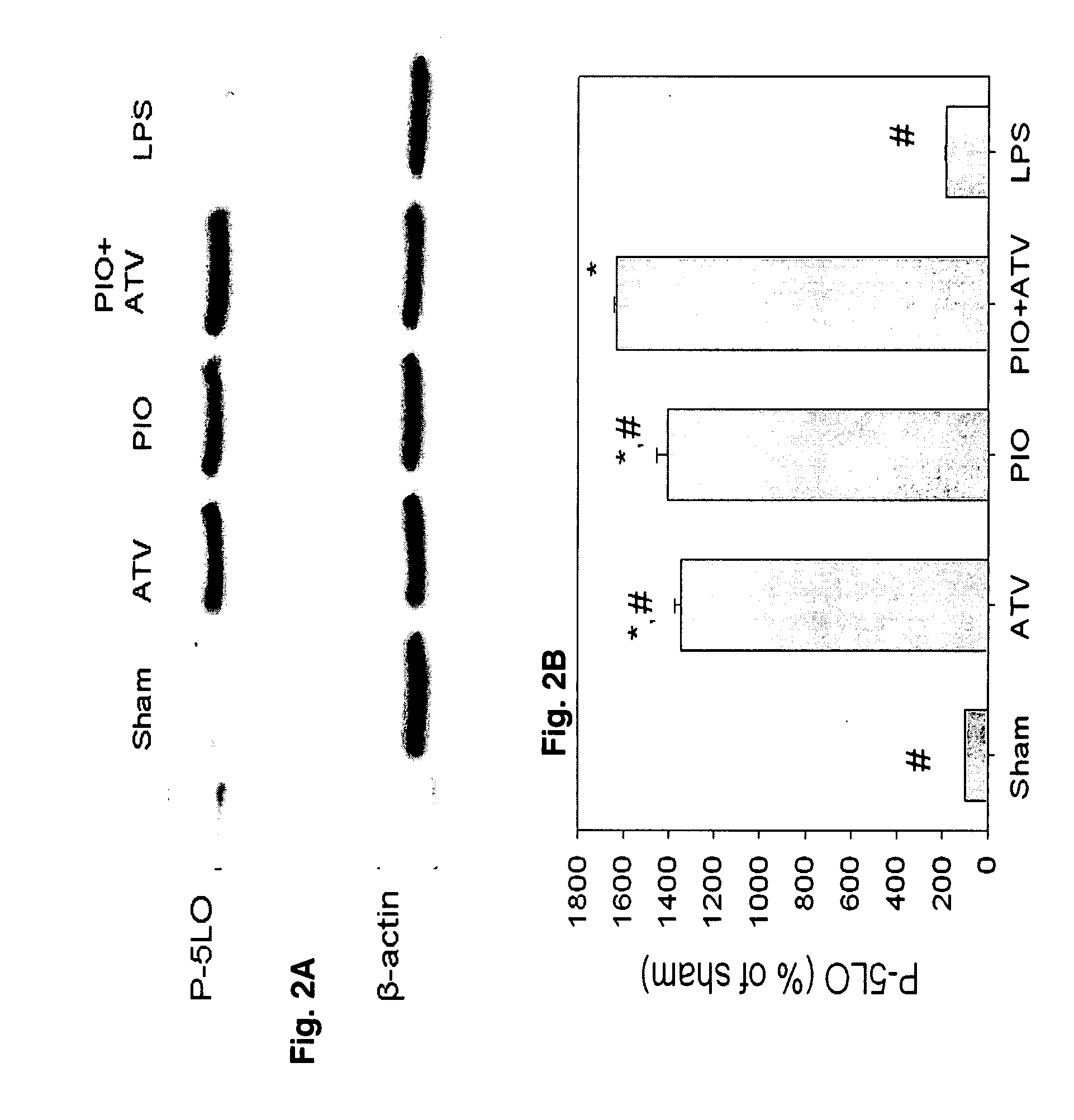

Phosphorylation of 5-lipoxygenase at ser523 and uses thereof

InactiveUS20090042849A1Reduce infarct sizeGood effectBiocideMicrobiological testing/measurementPhosphorylationProtein kinase A

The present invention provides novel mechanisms that regulate the production of anti-inflammatory and pro-inflammatory mediators generated by 5-lipoxygenase. In this regard, the present invention establishes that phosphorylation of 5-Lipoxygenase by protein kinase A, has a crucial role in determining the end products of 5-Lipoxygenase. With translocation to the nucleus, potent proinflammatory leukotrienes are produced, whereas following phosphorylation by protein kinase A, anti-inflammatory mediators are produced. The present invention also discloses compounds that regulate these pro- and anti-inflammatory mediators.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

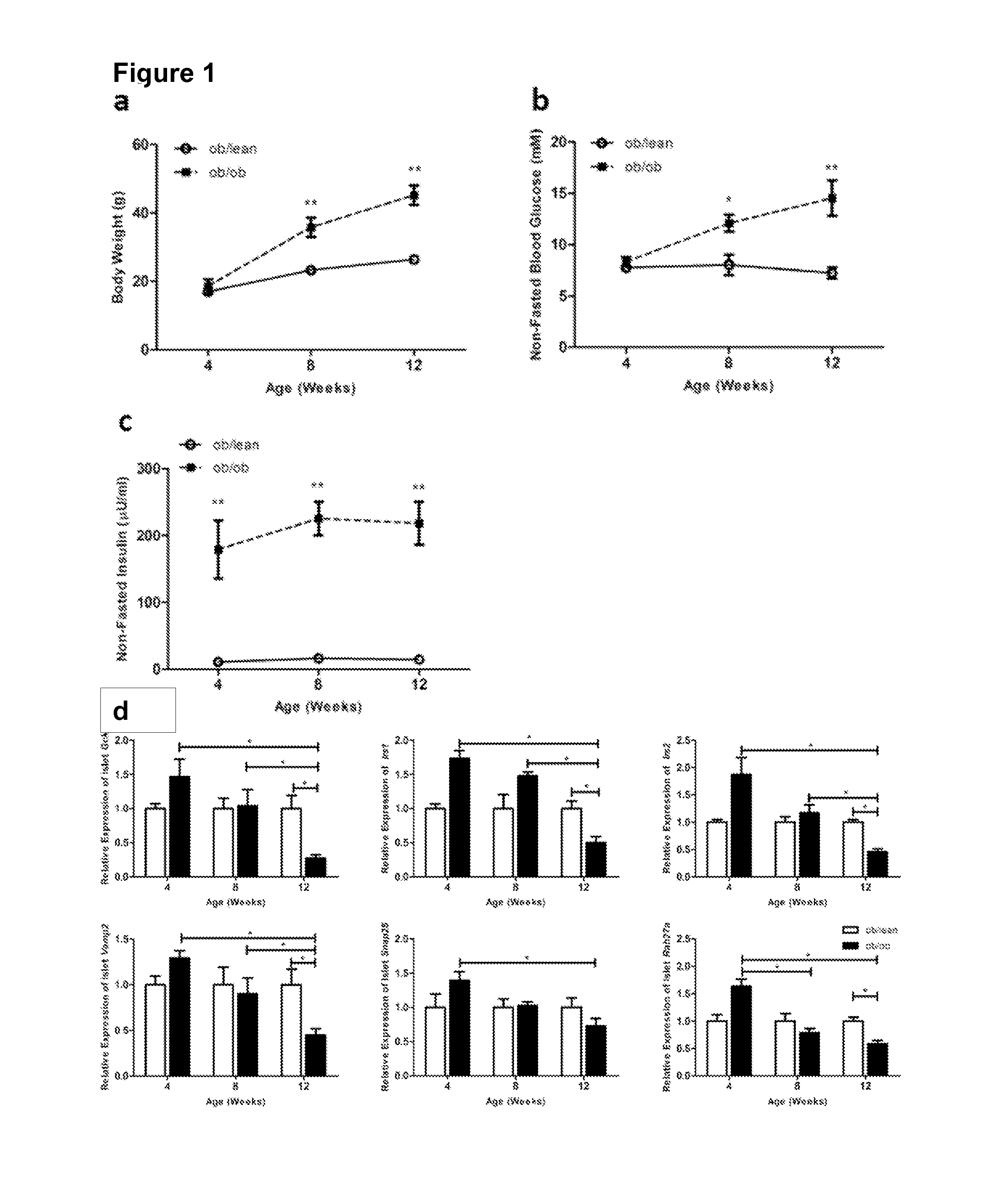

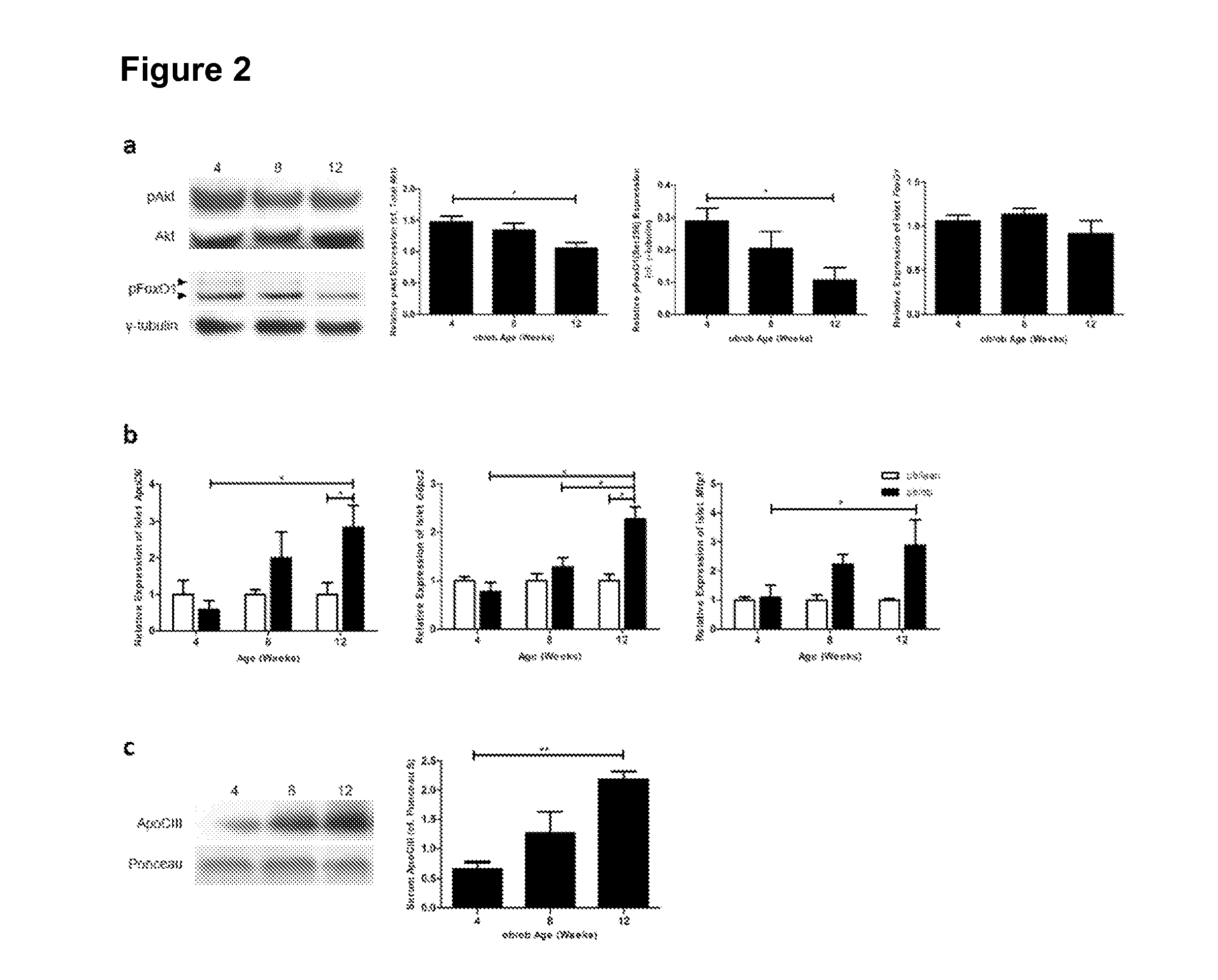

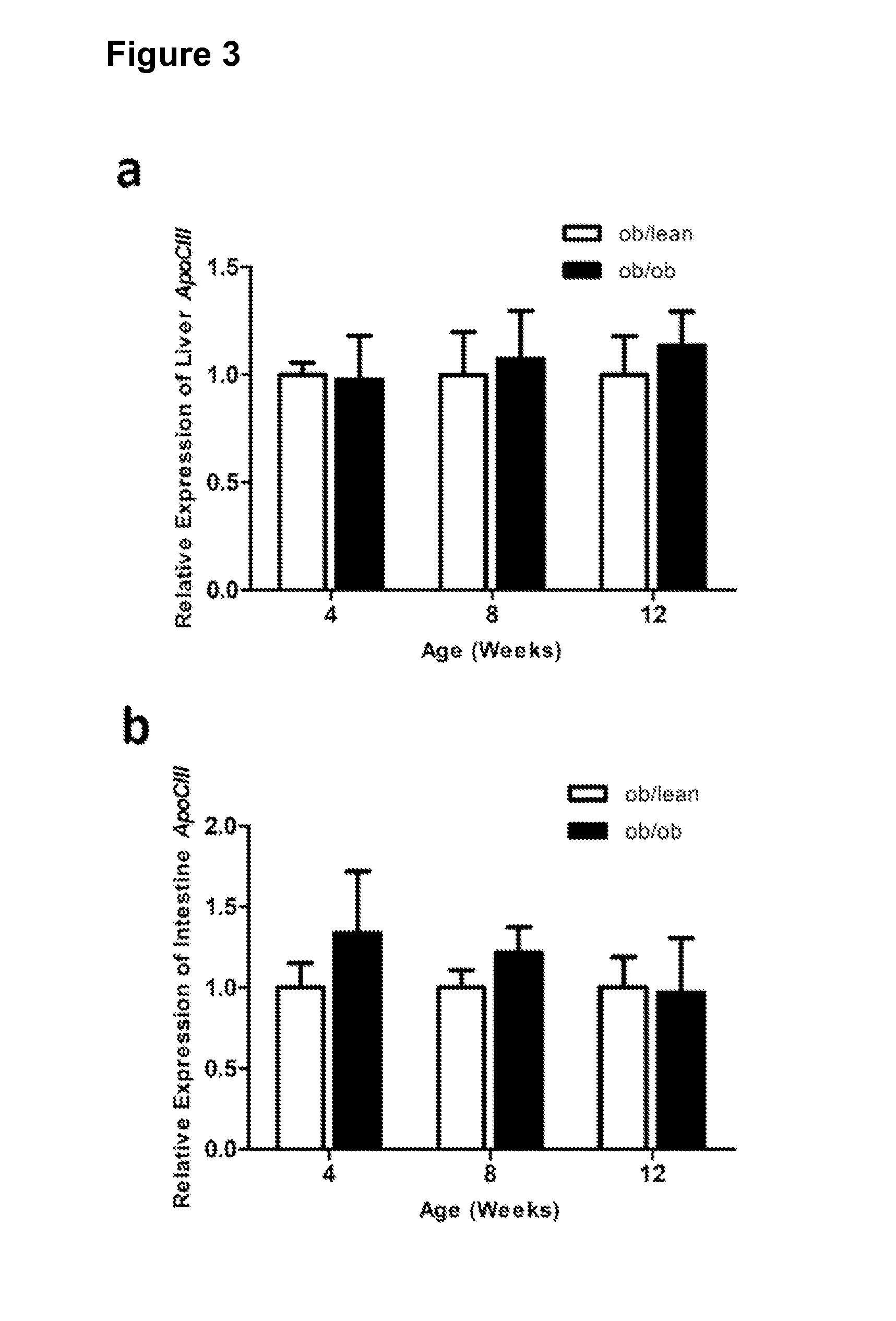

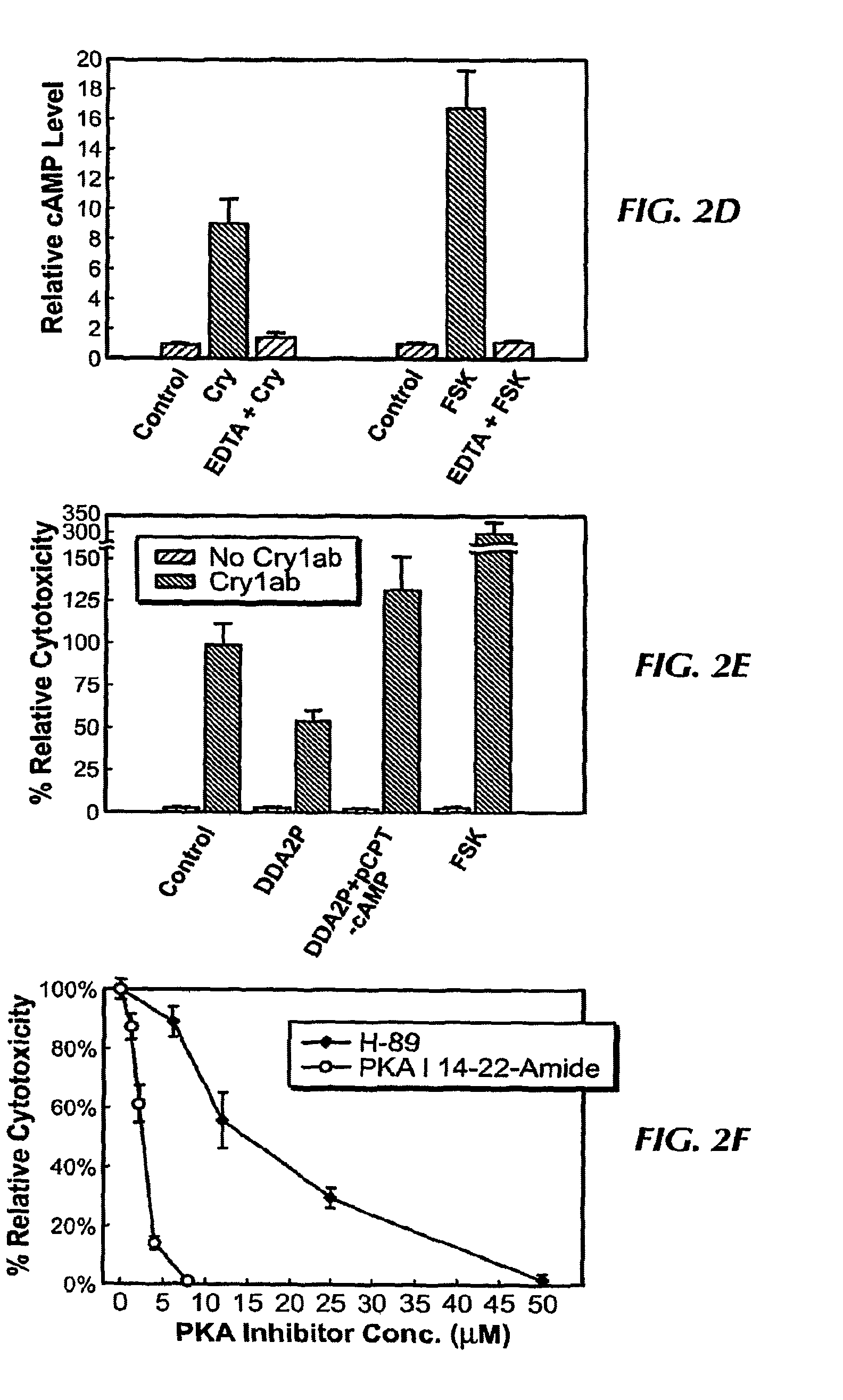

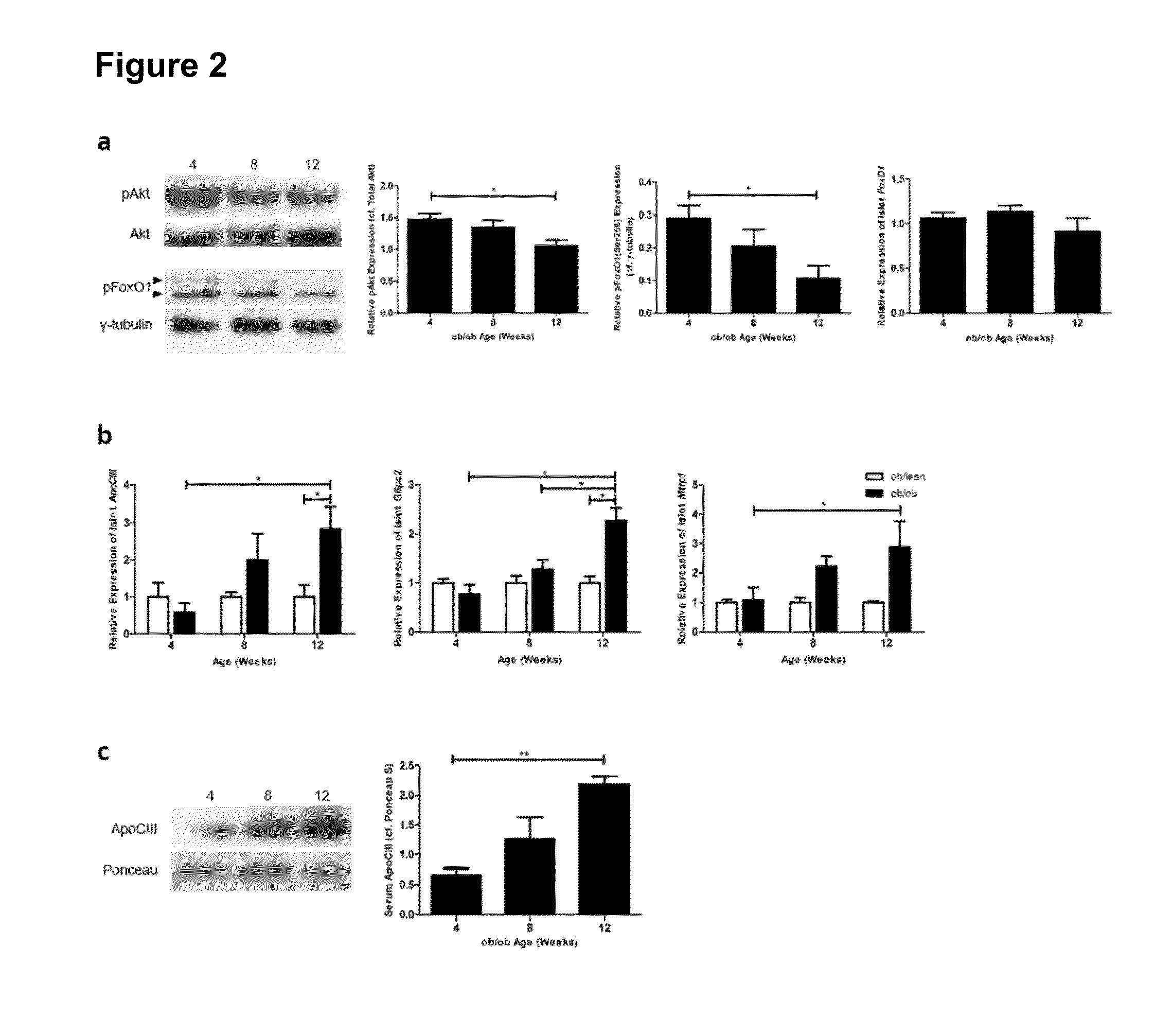

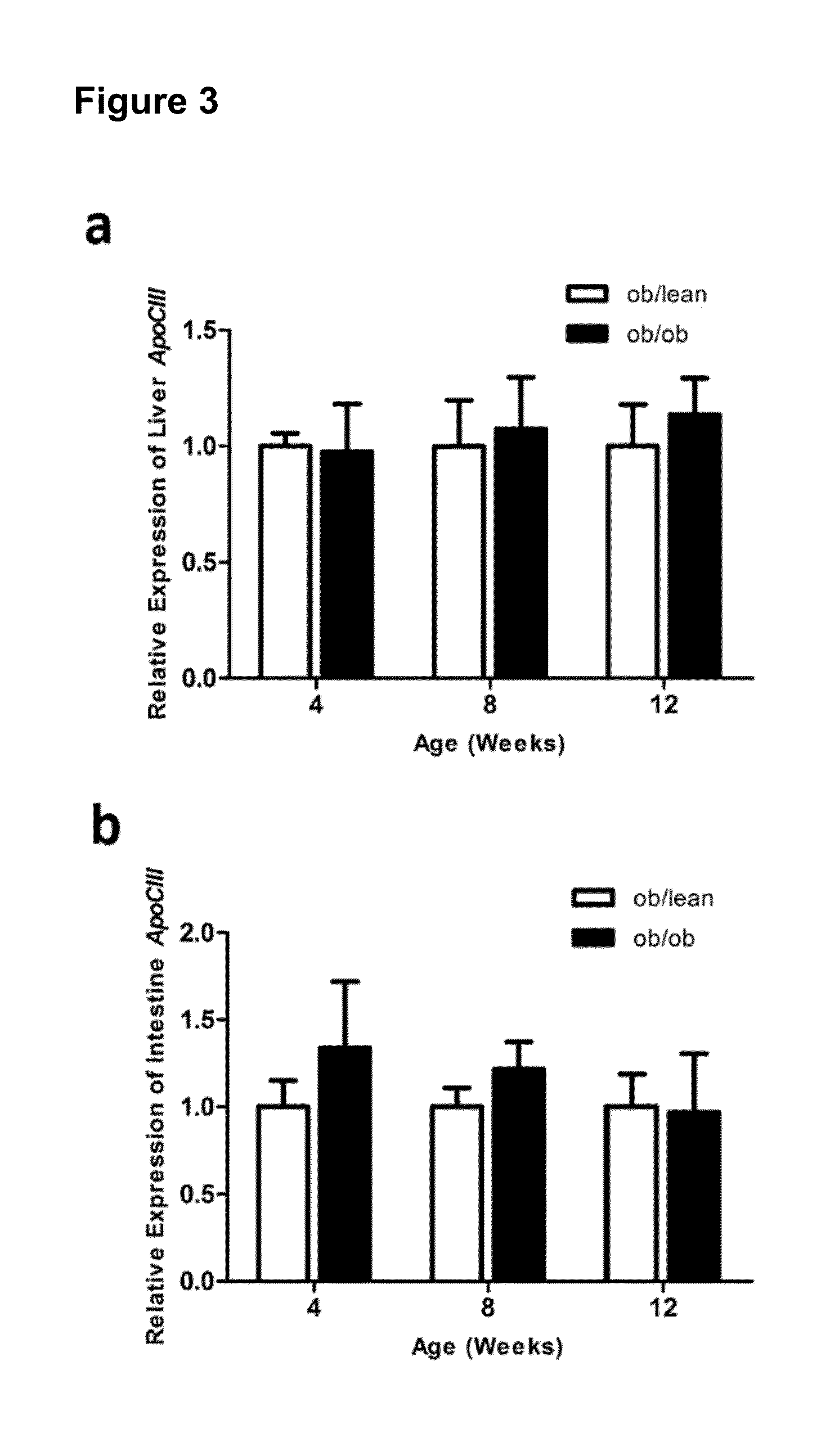

Methods for treating and/or limiting development of diabetes

InactiveUS20170037118A1Antibody mimetics/scaffoldsImmunoglobulins against animals/humansDiabetes mellitusApolipoprotein CIII

Provided herein are methods and compositions for limiting development of and / or treating diabetes, involving compounds of formula A-B, wherein A is a pancreatic β cell targeting moiety, and B is an inhibitor of expression and / or activity of Apolipoprotein CIII (apoCIII), protein kinase A (PKA), Src kinase, and / or β1 integrin.

Owner:BIOCRINE

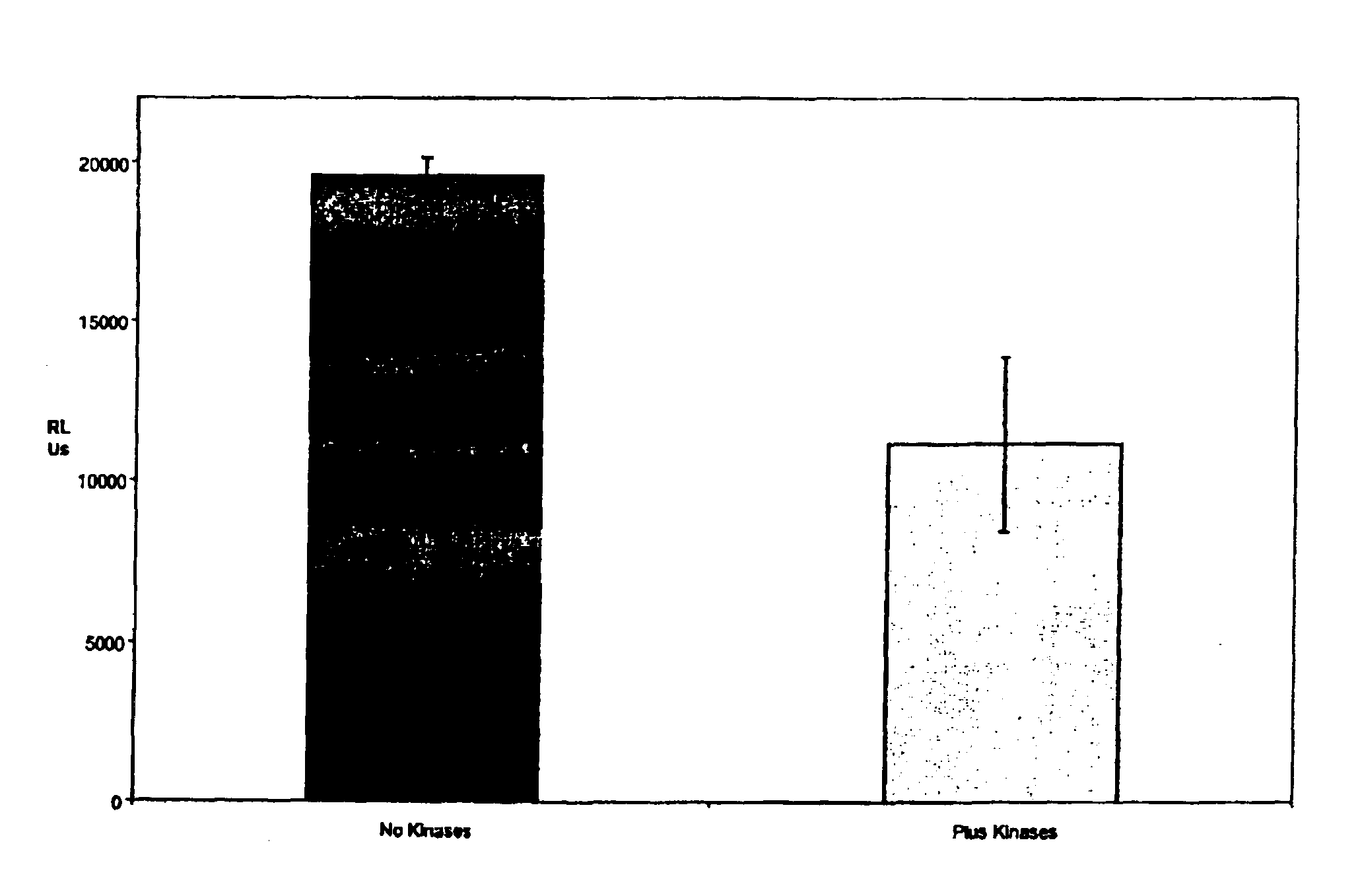

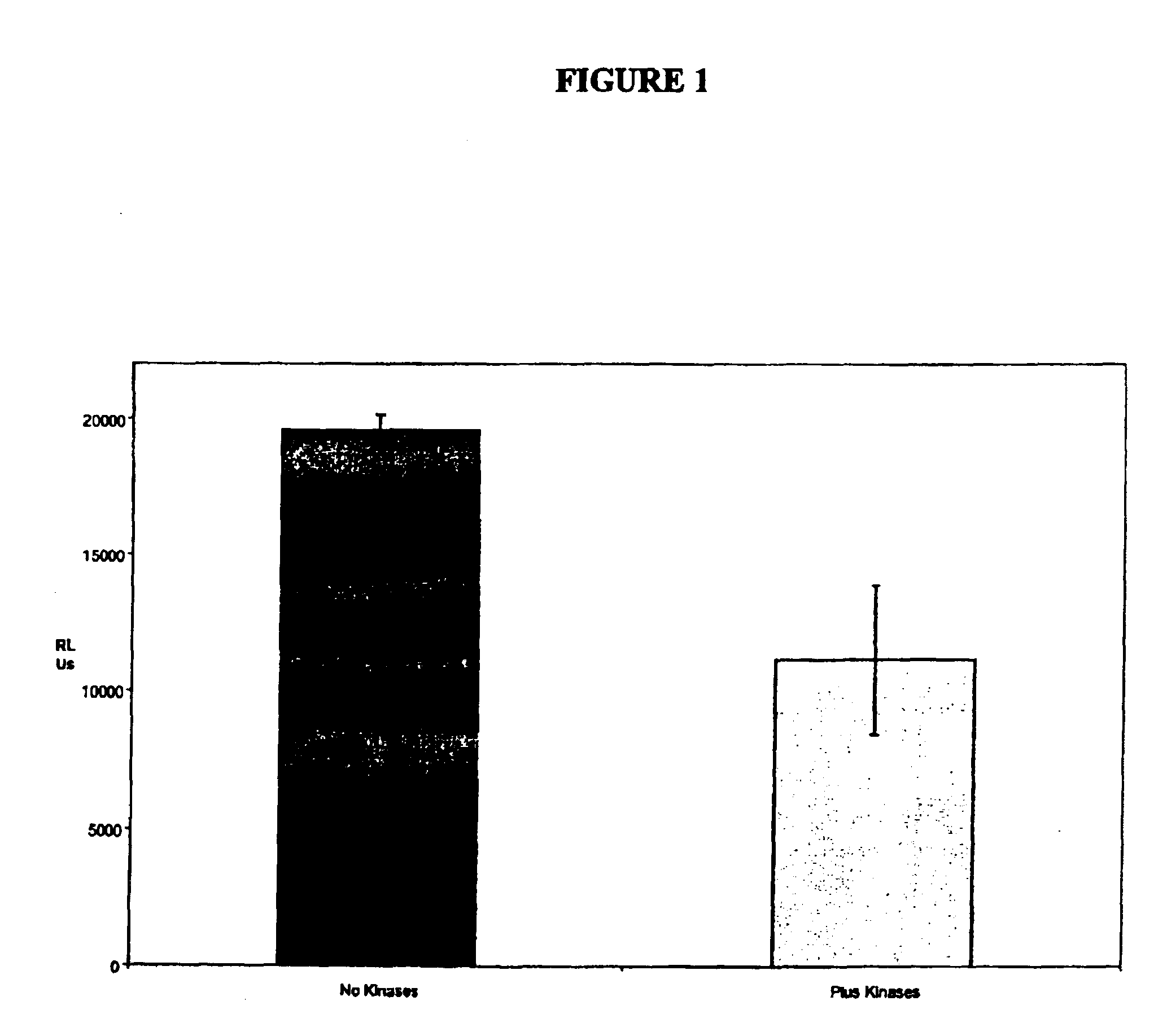

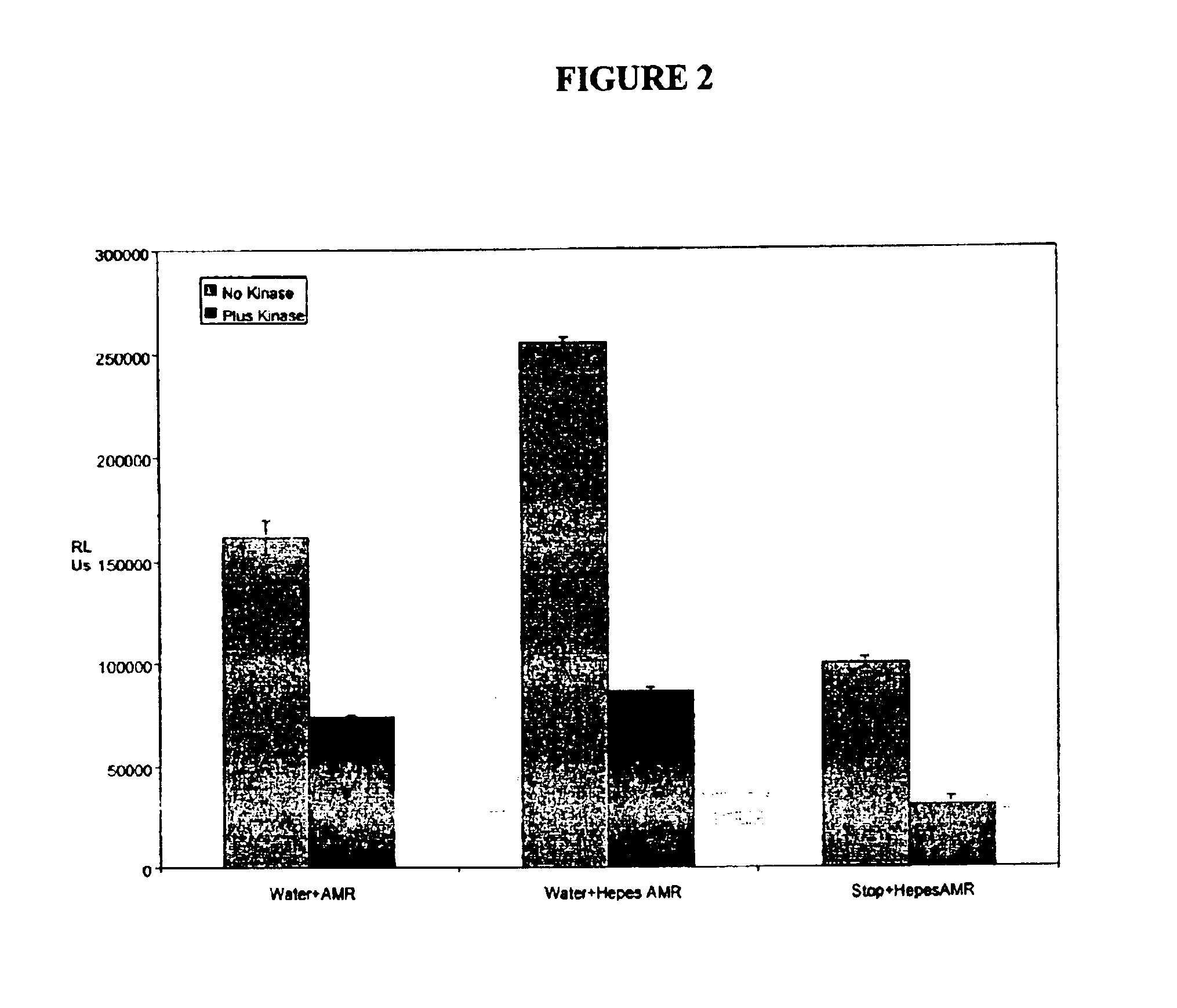

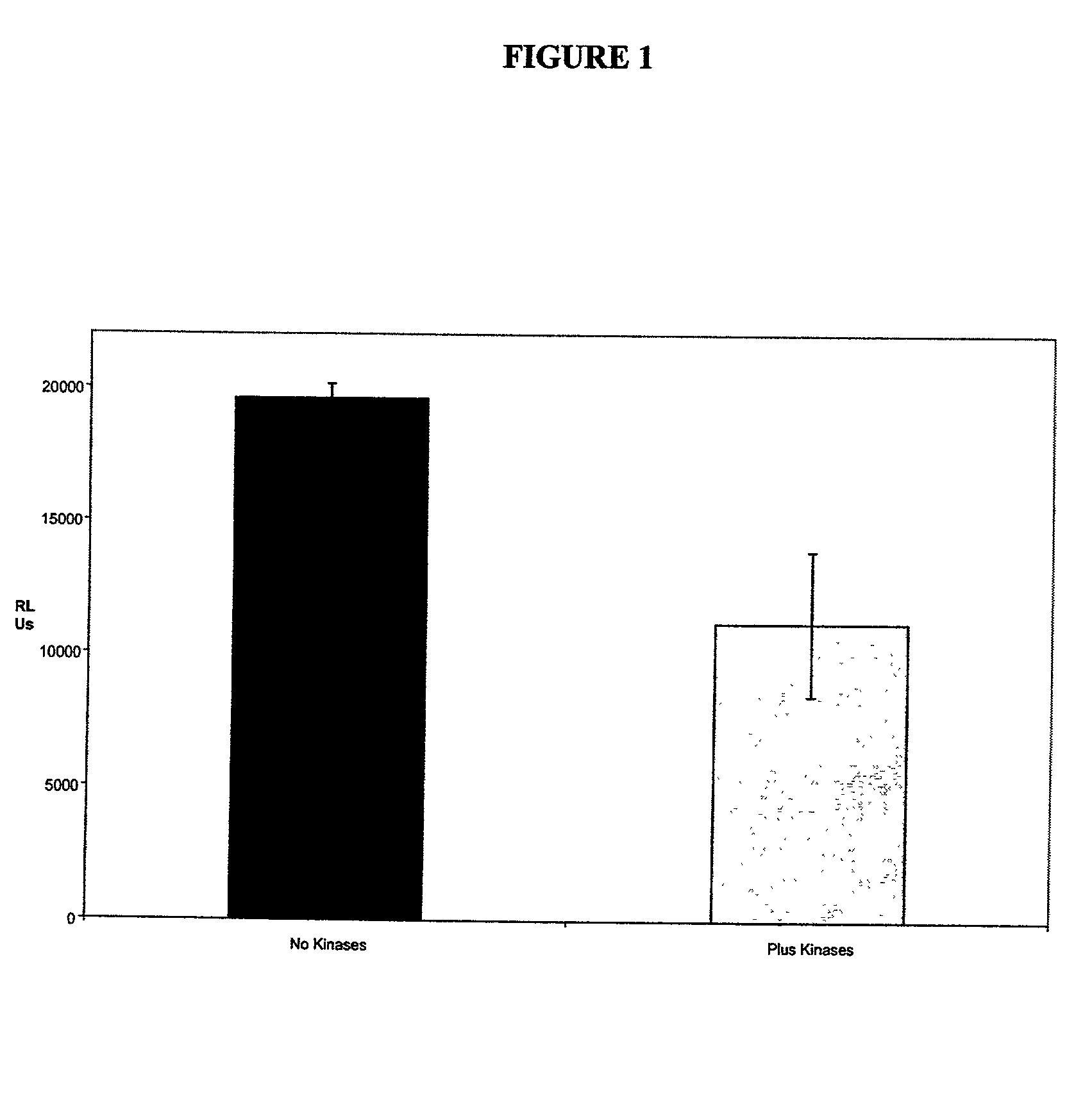

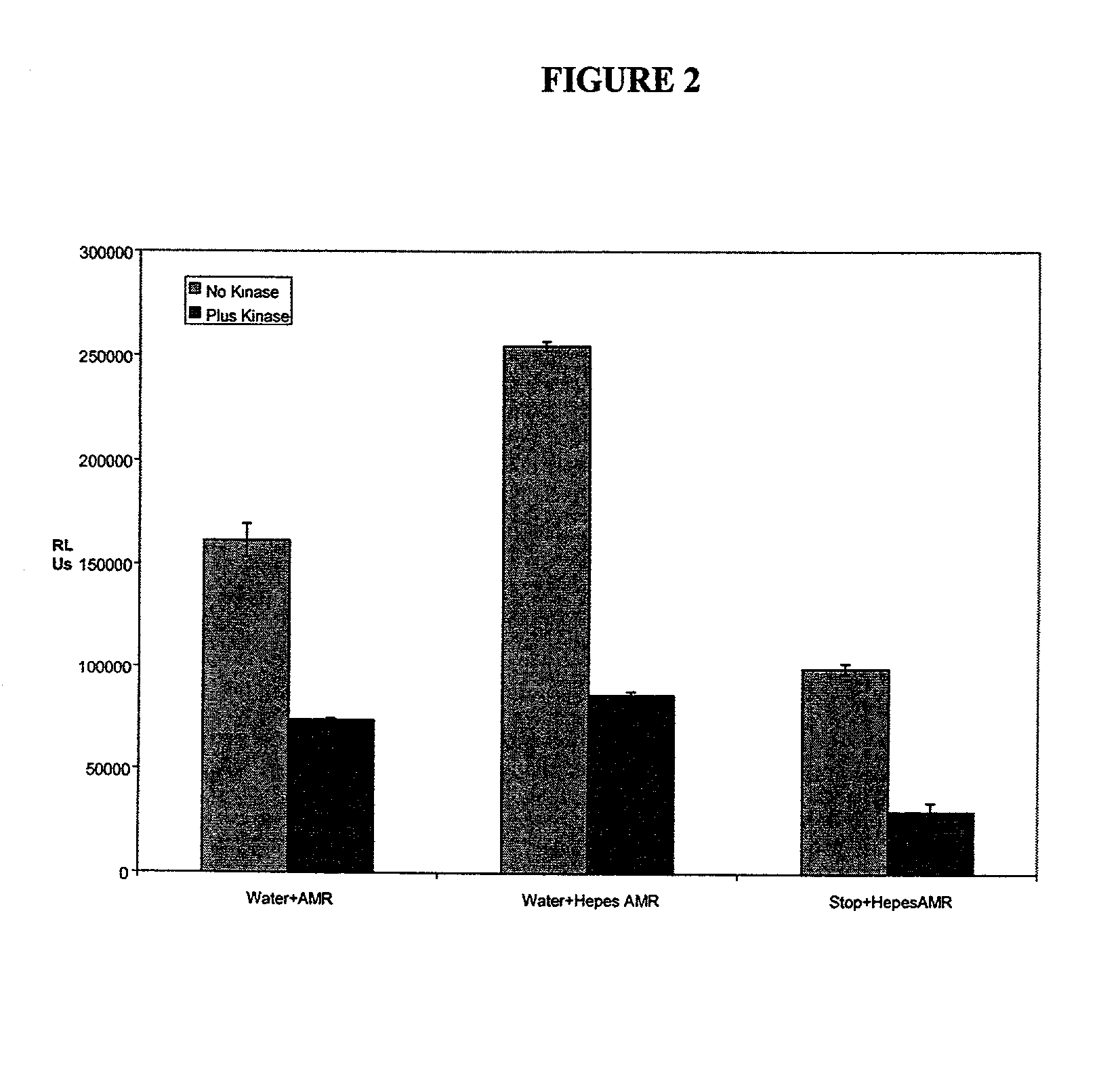

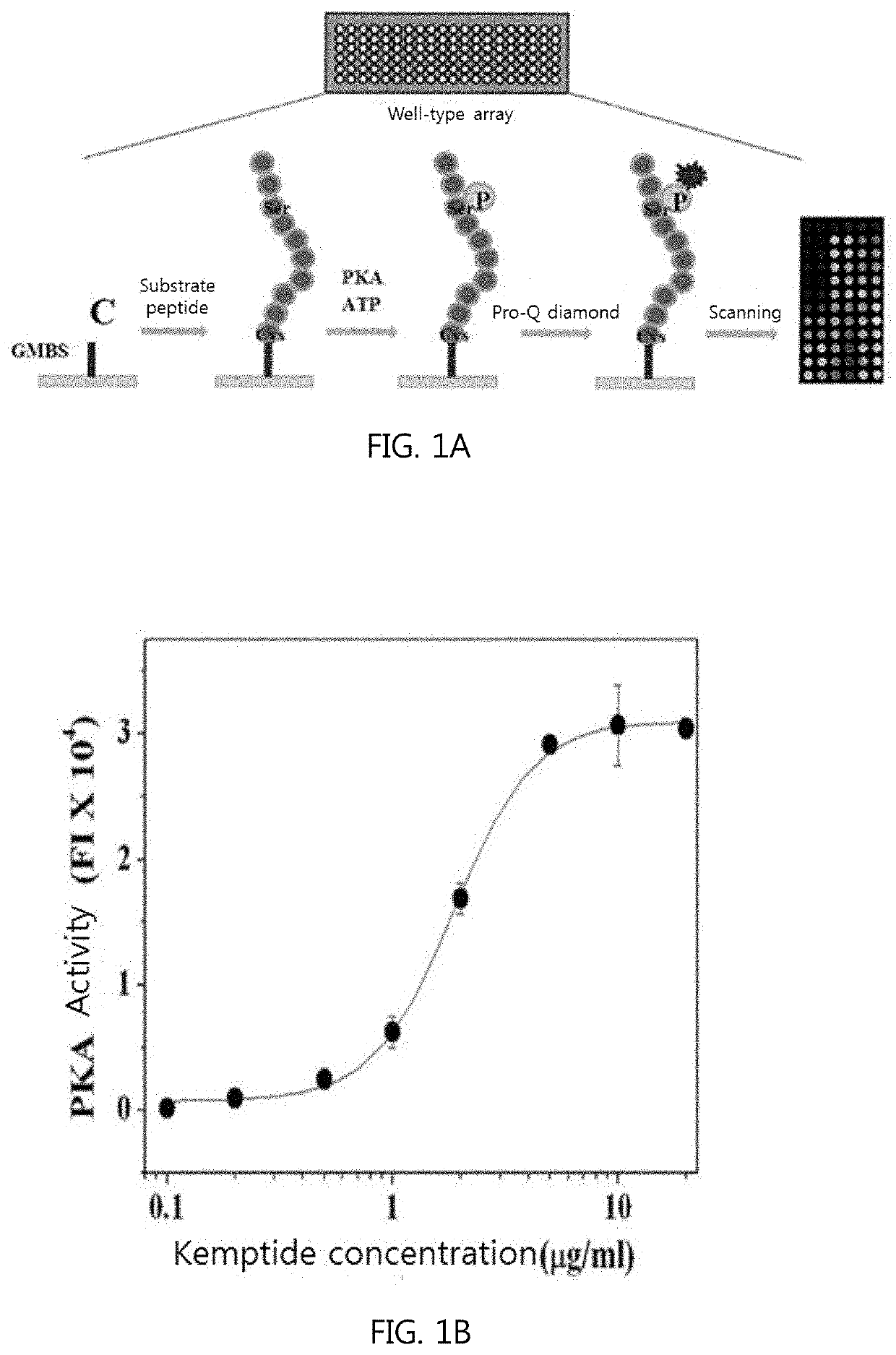

Methods and kits for detecting protein kinases

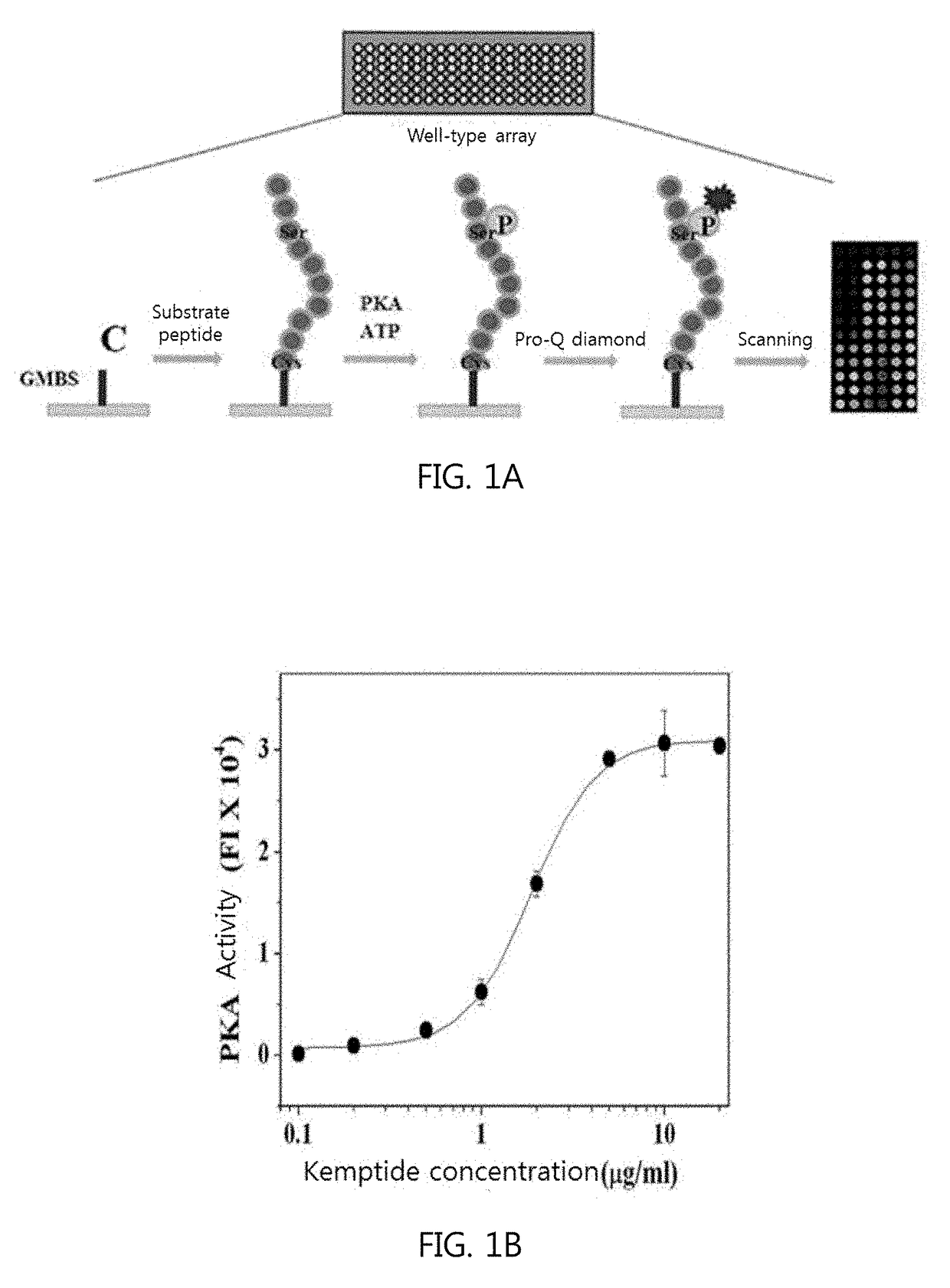

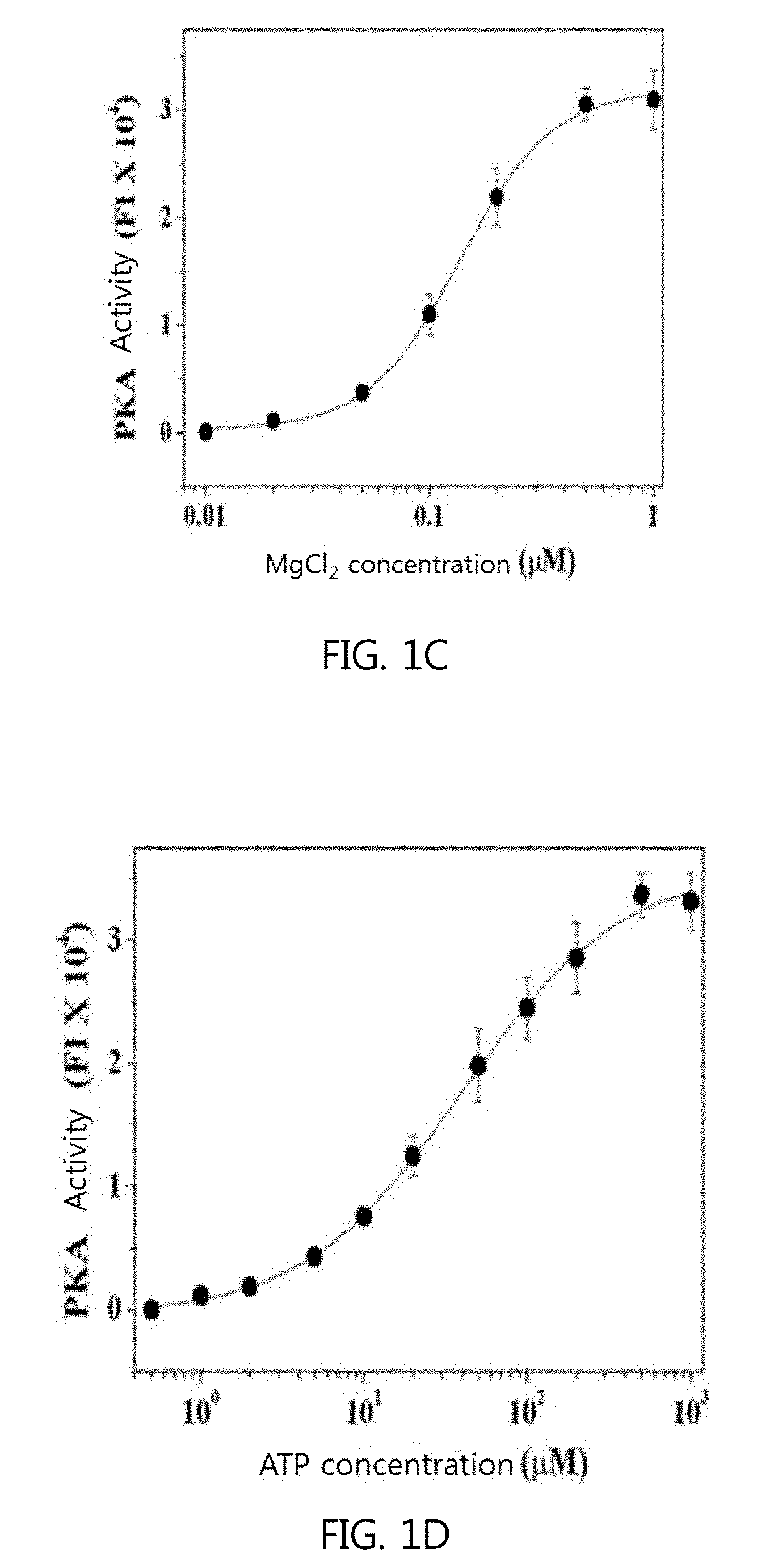

InactiveUS20020172991A1Increase ratingsDecrease kinase activityCompound screeningApoptosis detectionKinase activityProtein kinase A

A method for measuring protein kinase activity comprising: (a) providing a first solution comprising ATP and a protein kinase to be tested, and a second solution comprising ATP in the absence of said kinase to be tested; (b) adding a substrate capable of being phosphorylated by the protein kinase to be tested to the first and second solutions of step (a); (c) measuring the concentration of ATP and / or ADP, or the rate of change thereof with respect to time, in each of the reaction mixtures formed in step (b) using a bioluminescence reaction; and (d) using the information about the concentration of ATP and / or ADP to determine the activity of the protein kinase to be tested.

Owner:LONZA GRP

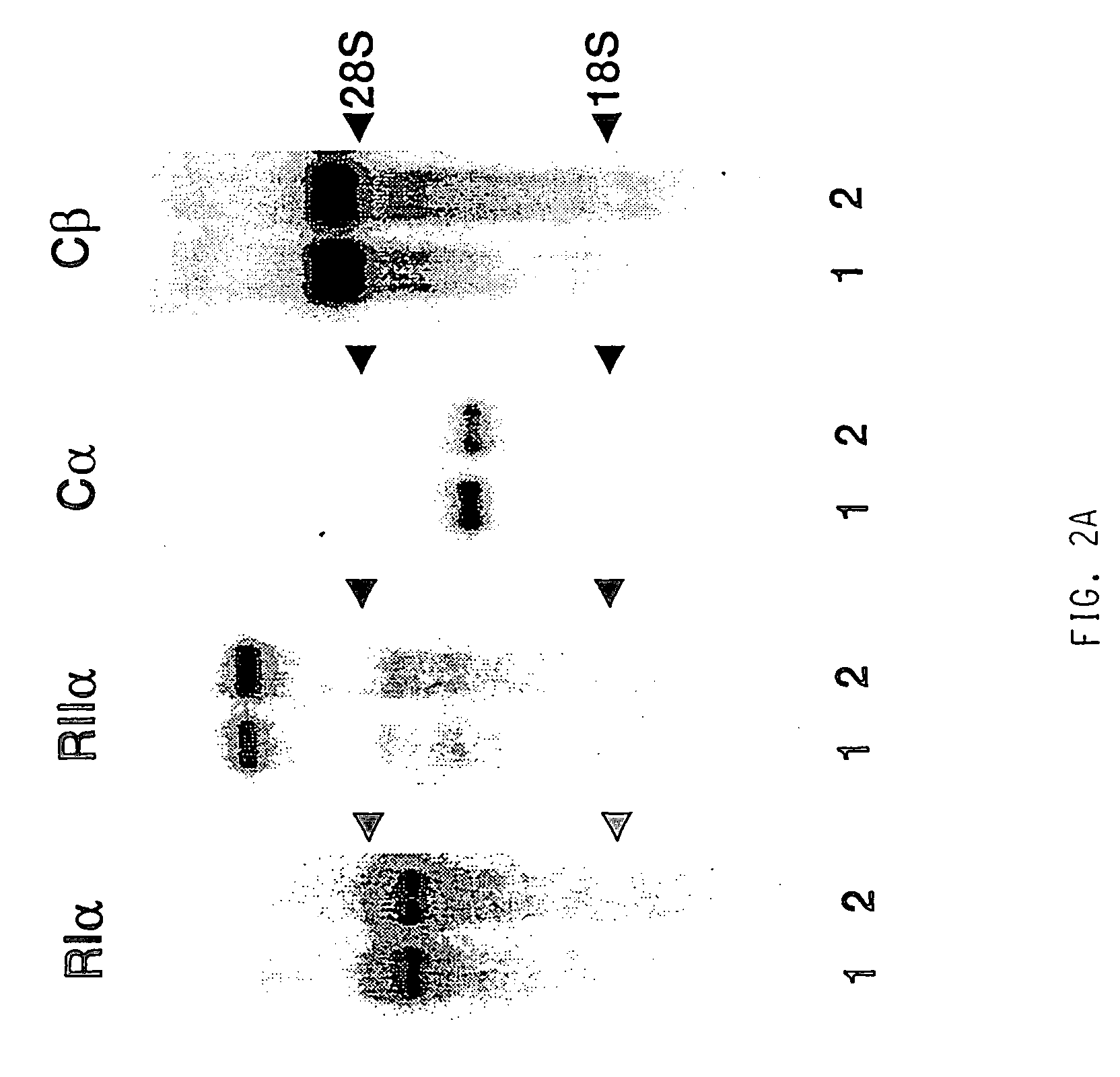

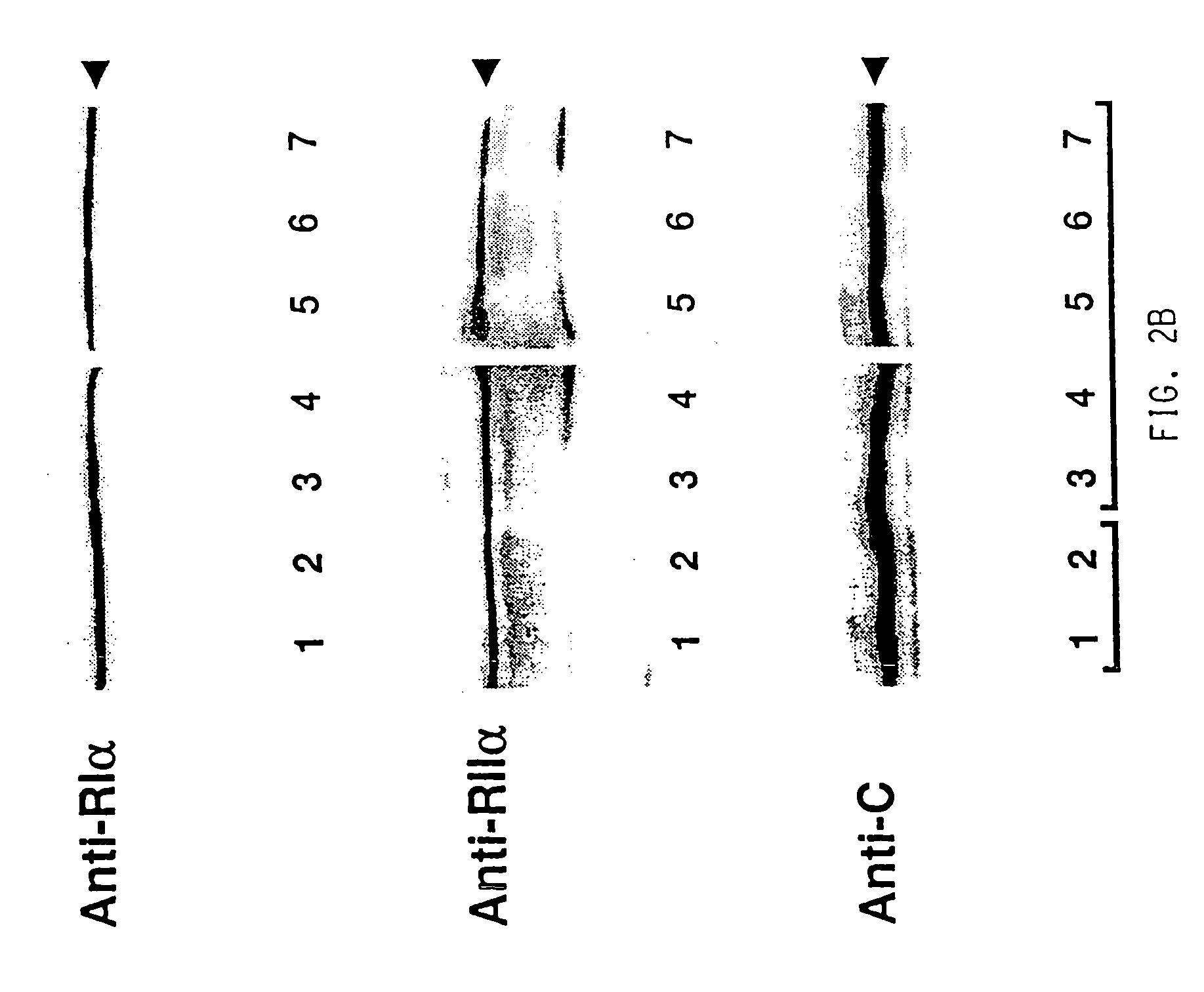

Modified protein kinase A-specific oligonucleotides and methods of their use

InactiveUS7074768B2Less side effectsReduced mitogenicityBiocideSugar derivativesProtein kinase AOligonucleotide

Disclosed are synthetic, modified oligonucleotides complementary to, and capable of down-regulating the expression of, nucleic acid encoding protein kinase A subunit RIα. The modified oligonucleotides have from about 15 to about 30 nucleotides and are hybrid, inverted hybrid, or inverted chimeric oligonucleotides. Also disclosed are therapeutic compositions containing such oligonucleotides and methods of using the same. In addition, therapeutic compositions and methods of their use are described which are directed to a synergistic effect resulting from the combination of oligonucleotides of the invention and other therapeutic compositions and methods.

Owner:IDERA PHARMA INC

Methods for treating and/or limiting development of diabetes

InactiveUS20150259416A1Organic active ingredientsPeptide/protein ingredientsDiabetes mellitusApolipoprotein CIII

Provided herein are methods and compositions for limiting development of and / or treating diabetes, involving compounds of formula A-B, wherein A is a pancreatic β cell targeting moiety, and B is an inhibitor of expression and / or activity of Apolipoprotein CIII (apoCIII), protein kinase A (PKA), Src kinase, and / or β1 integrin.

Owner:BIOCRINE

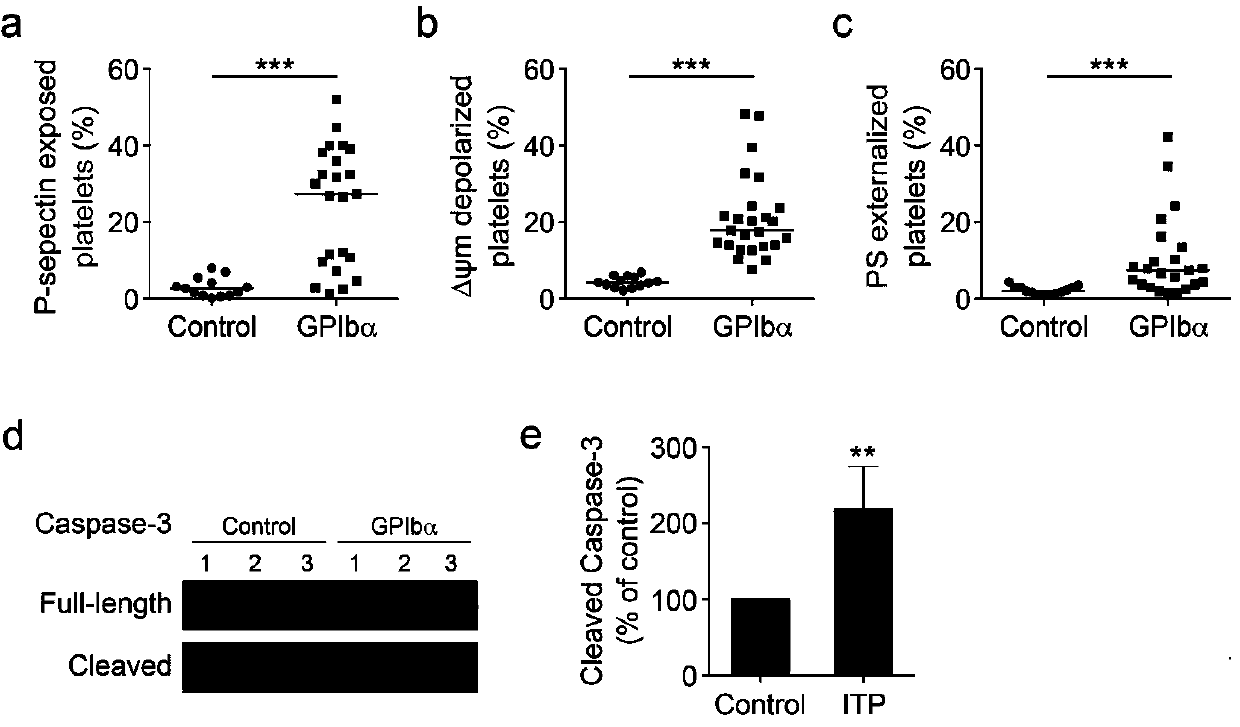

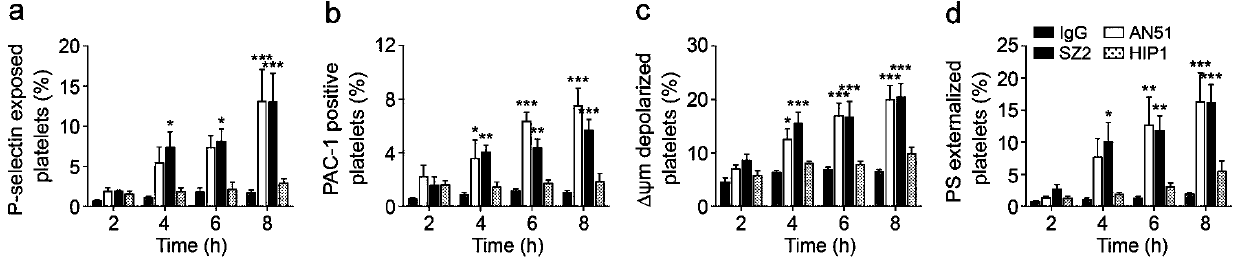

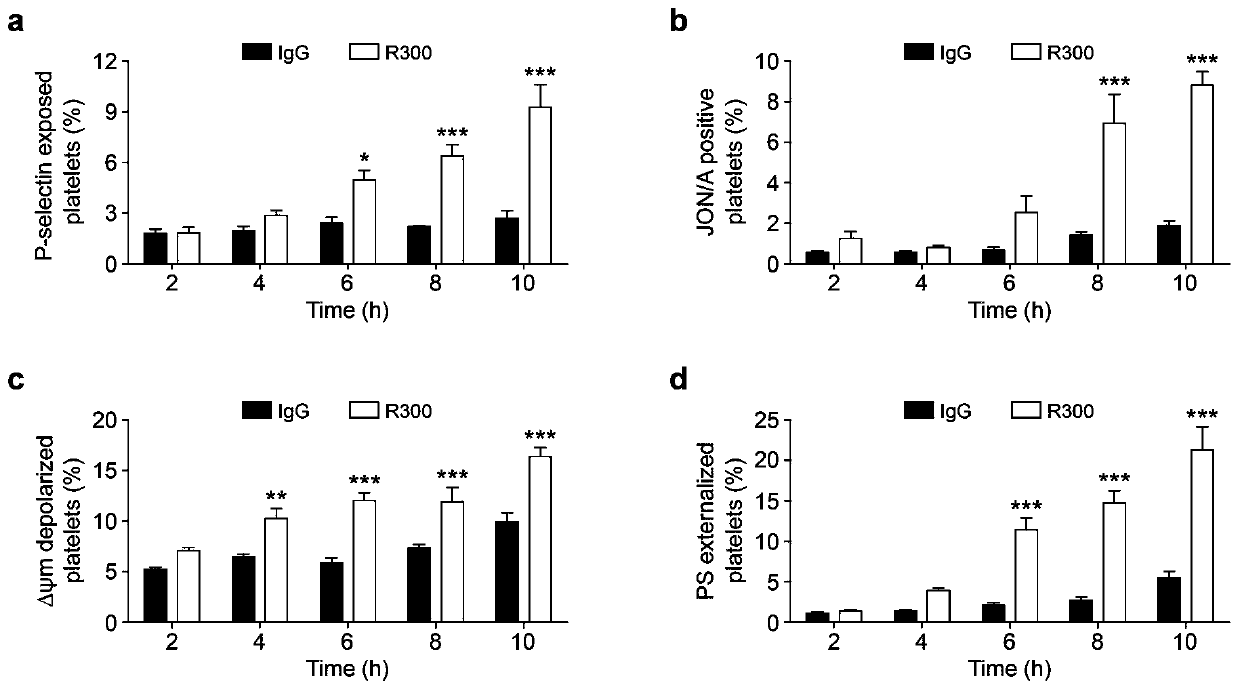

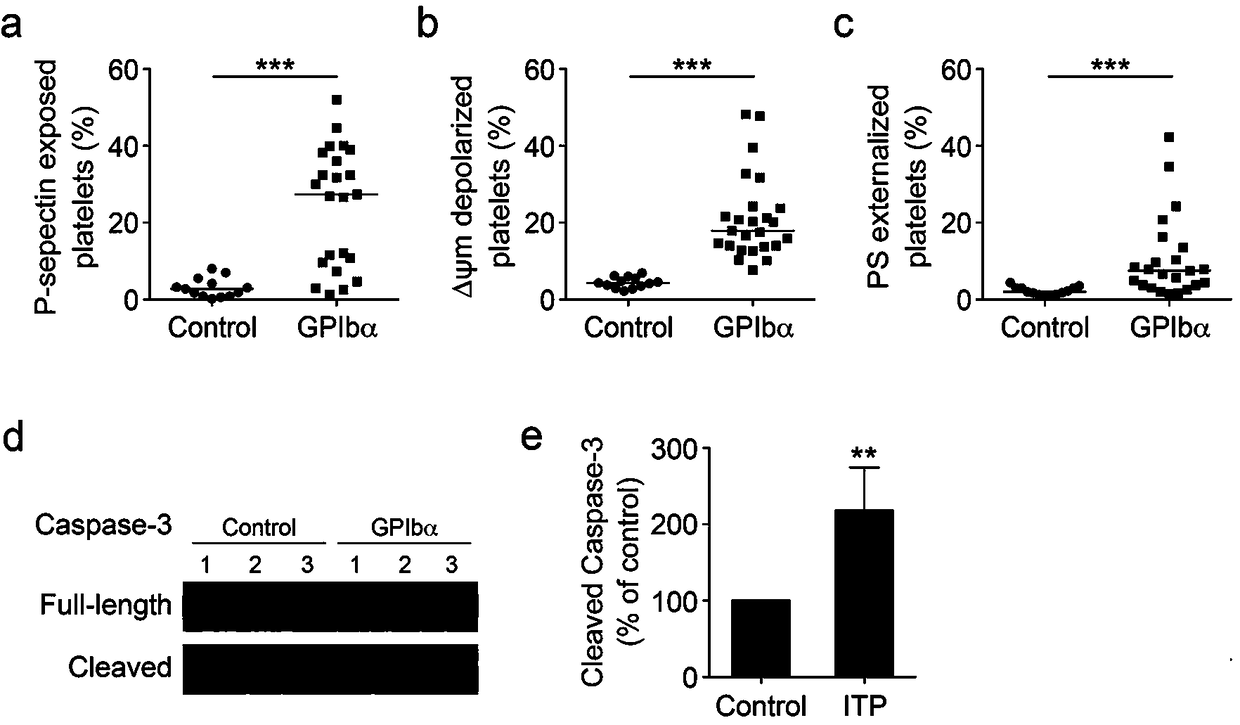

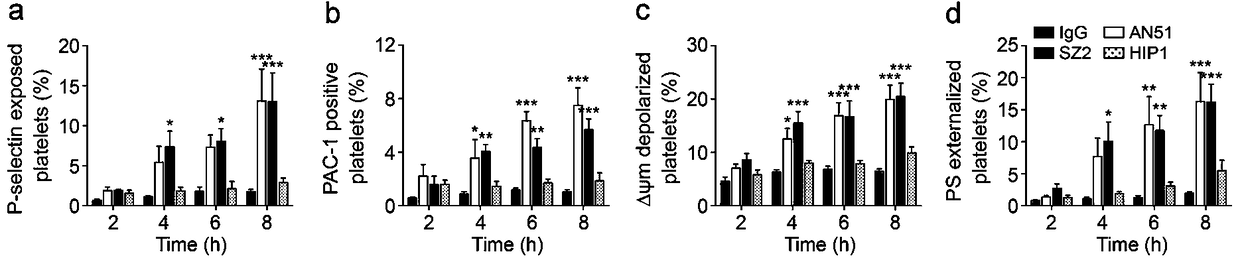

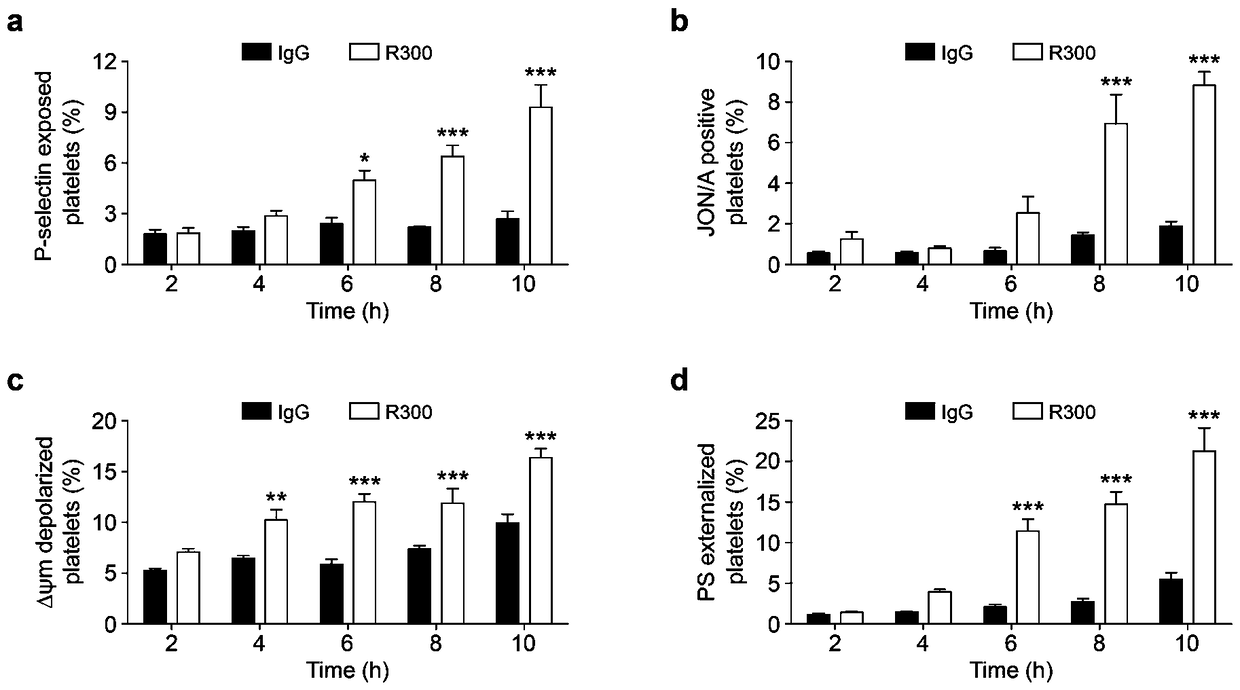

Application of Akt inhibitor in preparation of drug for treating platelet number decrease related diseases

ActiveCN108187052AReduce total usagePrevent clearingBlood disorderPharmaceutical active ingredientsPhosphodiesteraseGlycoprotein Ib

The invention discloses an application of an Akt inhibitor in preparation of a drug for treating platelet number decrease related diseases. Experiments prove that Akt regulates apoptosis and activation of platelet by activating cyclic adenosine monophosphate dependent phosphodiesterase and phosphodiesterase medicated PKA (protein kinase A), the apoptotic and activated platelet exposes phosphatidylserine, so that the phosphatidylserine is swallowed by macrophages. Inhibition or gene knockout of Akt or Akt medicated platelet activation and apoptosis or blocking of phosphatidylserine ectropion can stop clearance of antibody-bound platelet. Research indicates that the Akt inhibitor can be used for an anti-platelet membrane glycoprotein Ib alpha antibody to induce the treatment process of platelet number change related diseases and inhibit decrease of the number of platelets in peripheral circulation blood, so that the Akt inhibitor has the potential of being developed into novel platelet protection drugs and novel drugs for treating thrombocytopenic diseases and has great scientific research and economic value.

Owner:SUZHOU UNIV

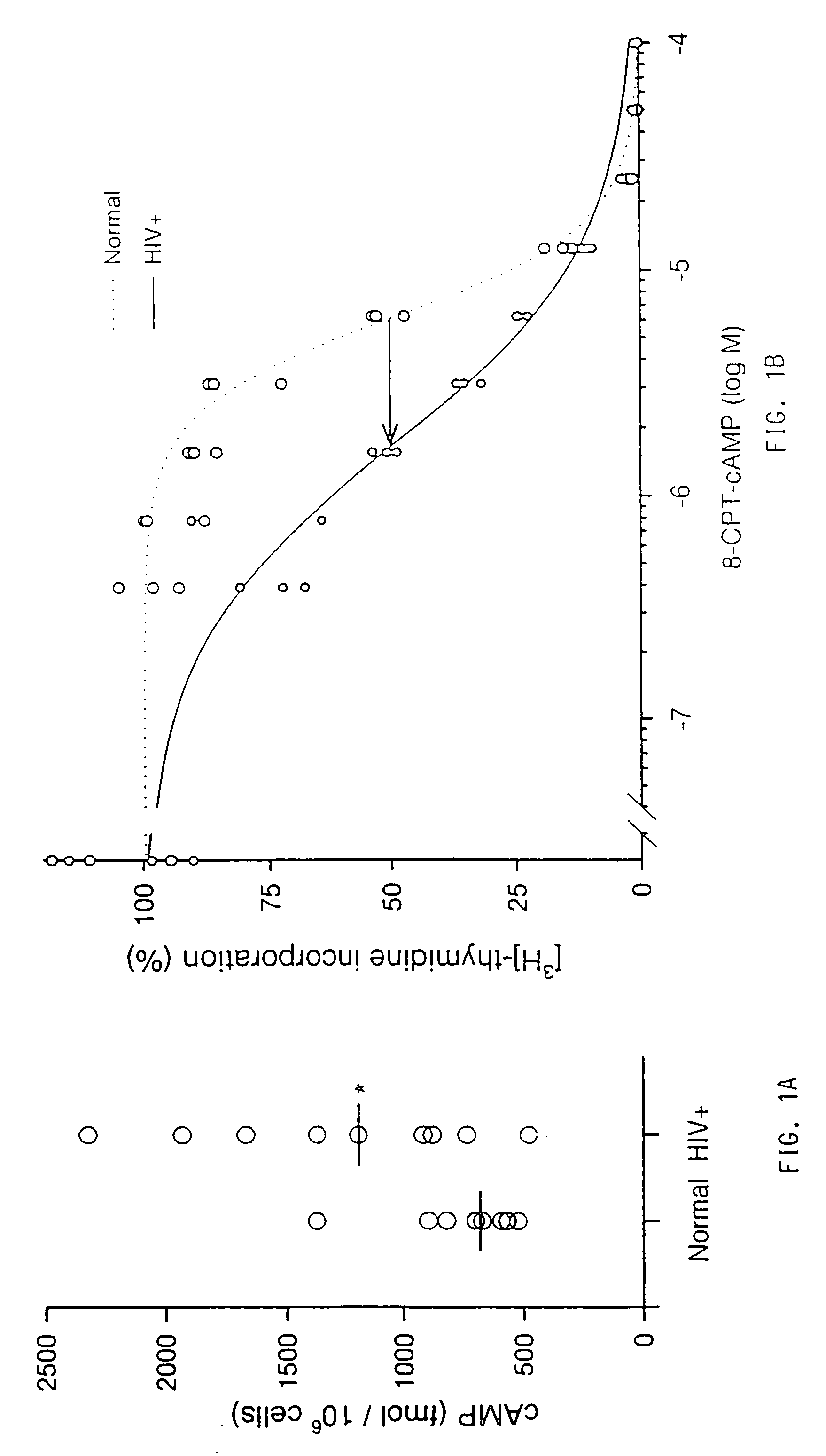

Use of immunomodulating agents

InactiveUS7192932B1Good effectImprove permeabilityBiocideSugar derivativesDiseaseImmunomodulating Agent

Owner:LAURAS AS

Method for improving dyeing performance of wool fiber product through enzymatic modification

ActiveCN107022912AImprove catalytic reaction efficiencyImprove reaction efficiencyDyeing processPhosphorylationProtein kinase A

The invention discloses a method for improving the dyeing performance of a wool fiber product through enzymatic modification, and belongs to the technical field of textile biology. Wool pretreatment is performed through hydrogen peroxide; protein kinase A is combined for catalyzing serine and threonine residues phosphorylation in the wool, so that more electronegative groups are generated on the fiber surface; the dyeing of cationic dye on the wool fiber is realized; the dyeing performance of the wool fiber product is improved. The method comprises the following concrete steps of (1) wool hydrogen peroxide pretreatment; (2) wool phosphorylation catalyzed by protein kinase A; (3) cationic dye dyeing; (4) water washing and drying aftertreatment. Compared with a method that the electronegative groups are introduced onto the wool through a chemical method, and realizing the cationic dye wool dyeing, the method disclosed by the invention has the advantages that the enzymic catalytic reaction efficiency is high; the wool phosphorylation reaction conditions are mild; the dyeing performance of the wool fiber product is obviously improved.

Owner:JIANGNAN UNIV

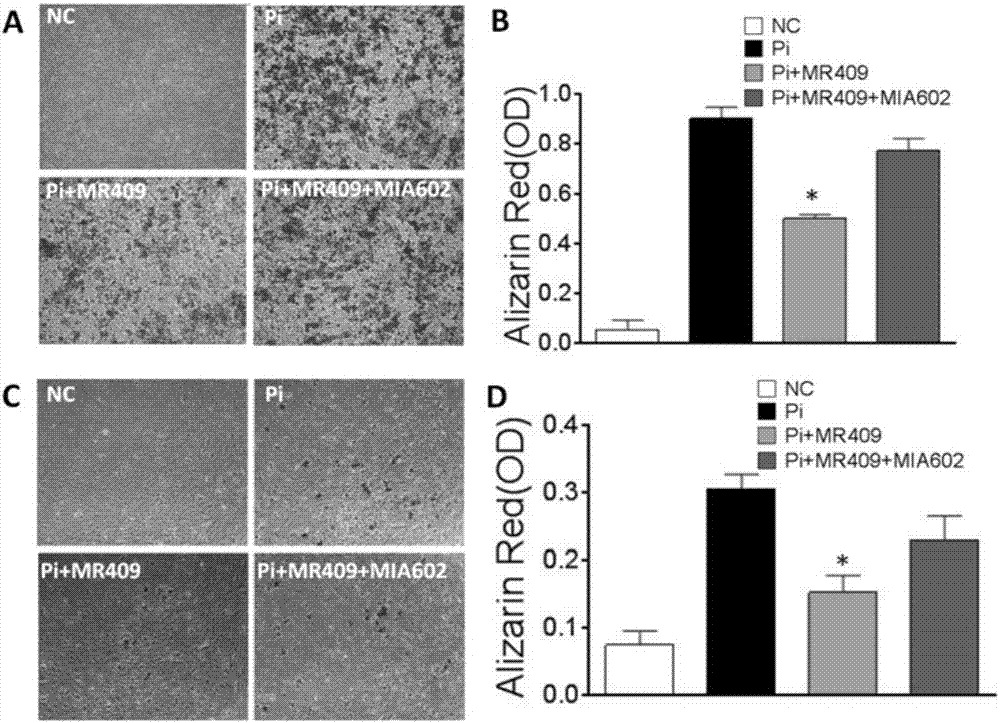

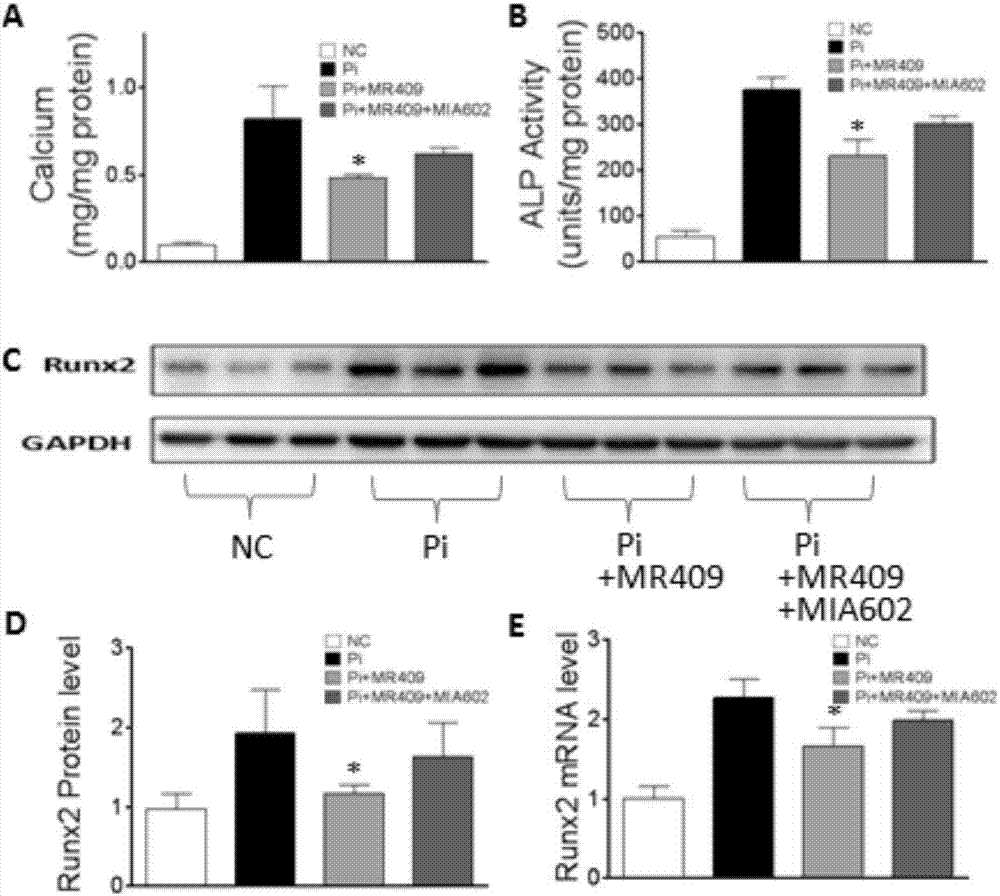

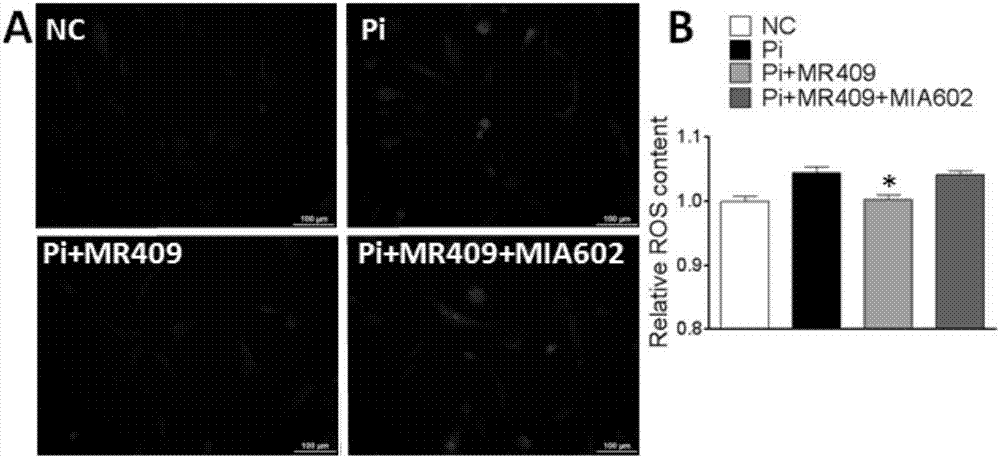

Applications of growth hormone release hormone agonist in preparation of anti-vascular calcification drugs

ActiveCN107320718APeptide/protein ingredientsCardiovascular disorderVascular calcificationGrowth hormone–releasing hormone

The present invention discloses a new medical use of a growth hormone release hormone (GHRH) agonist, particularly applications of a growth hormone release hormone agonist in preparation of anti-vascular calcification drugs. According to the present invention, GHRH-A can increase the cAMP level and the protein kinase A (PKA) activity in smooth muscle cells, can decrease the expression and the activity of NAPDH oxidase in smooth muscle cells, can decrease the ROS level in smooth muscle cells, can decrease the expression and the activity of Runx2 in smooth muscle cells, can decrease the expression and the activity of alkaline phosphatase (ALP) in cells, and can decrease the inorganic phosphorus content in blood so as to reduce the calcium deposition and the phosphorus deposition in aorta, reduce the activity of ALP in aorta, and achieve the purposes of treatment or prevention of vascular calcification and arteriosclerosis.

Owner:余红

Application of PI3K (Phosphatidylinositol 3-Kinase) inhibitor to preparation of medicine for treating related diseases of thrombocytopenia

ActiveCN108310384AInhibition clearanceReduce in quantityBlood disorderPharmaceutical active ingredientsProtein kinase AAntibody

The invention discloses application of PI3K (Phosphatidylinositol 3-Kinase) inhibitor to preparation of a medicine for treating related diseases of thrombocytopenia. Firstly, an experiment explores the effect of PI3K in a process of clearing platelets and proves that activation and apoptosis of the platelets of patients with the thrombocytopenia occur. An anti-Ibalpha antibody induces PI3K activation and Akt is activated after the PI3K is activated; the Akt is used for mediating the activation and apoptosis of the platelets. The Akt is used for regulating and controlling the apoptosis of the platelets through phosphodiesterase mediated protein kinase A. PS (Phosphatidylserine) is exposed after the apoptosis and activation of the platelets and is phagocytized by macrophages of liver. The activation of the PI3K is inhibited, the activation and apoptosis of the platelets are inhibited and the clearance of the platelets is stopped; the PI3K inhibitor can be used for treating the related diseases of platelet quantity changes and the thrombocytopenia in peripheral circulating blood is inhibited, so that the inhibitor has a potential of being prepared into novel platelet protection medicines and medicines for treating the thrombocytopenia, and extremely good scientific research and economic value.

Owner:SUZHOU UNIV

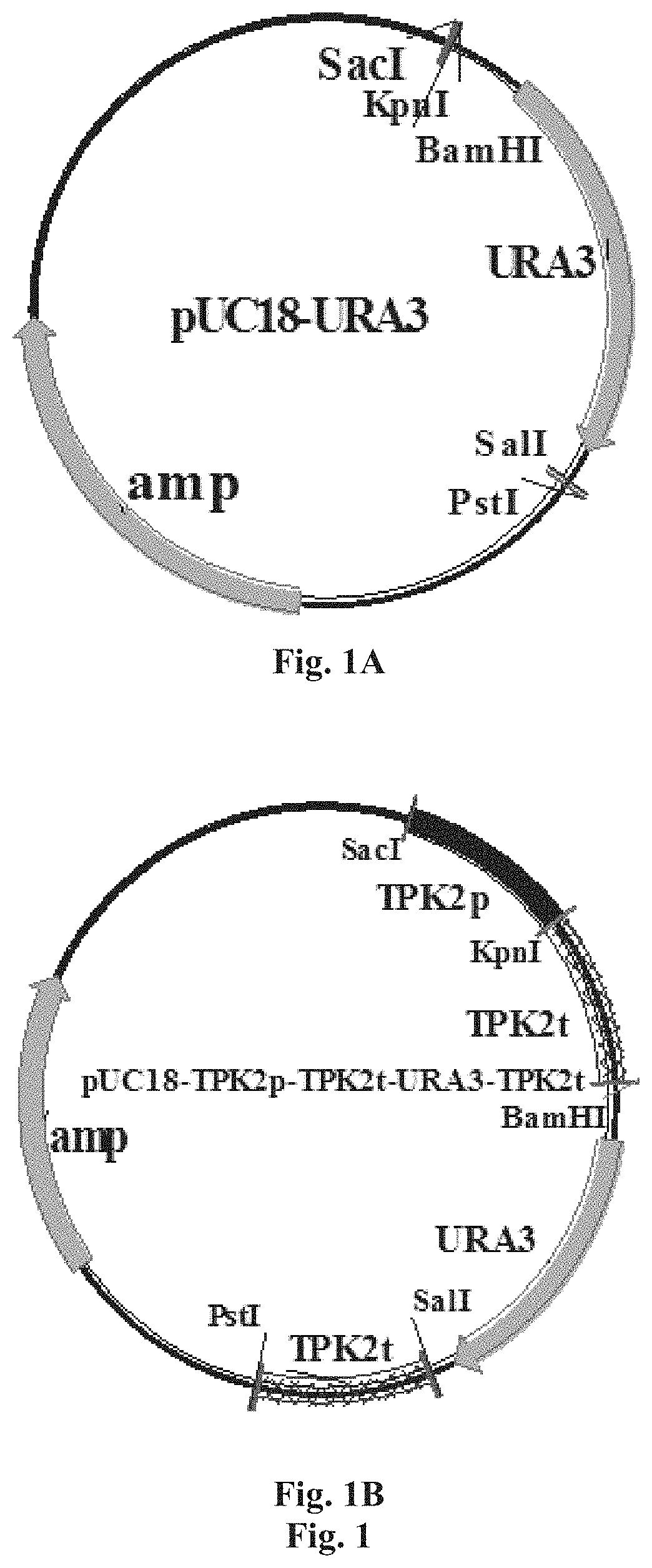

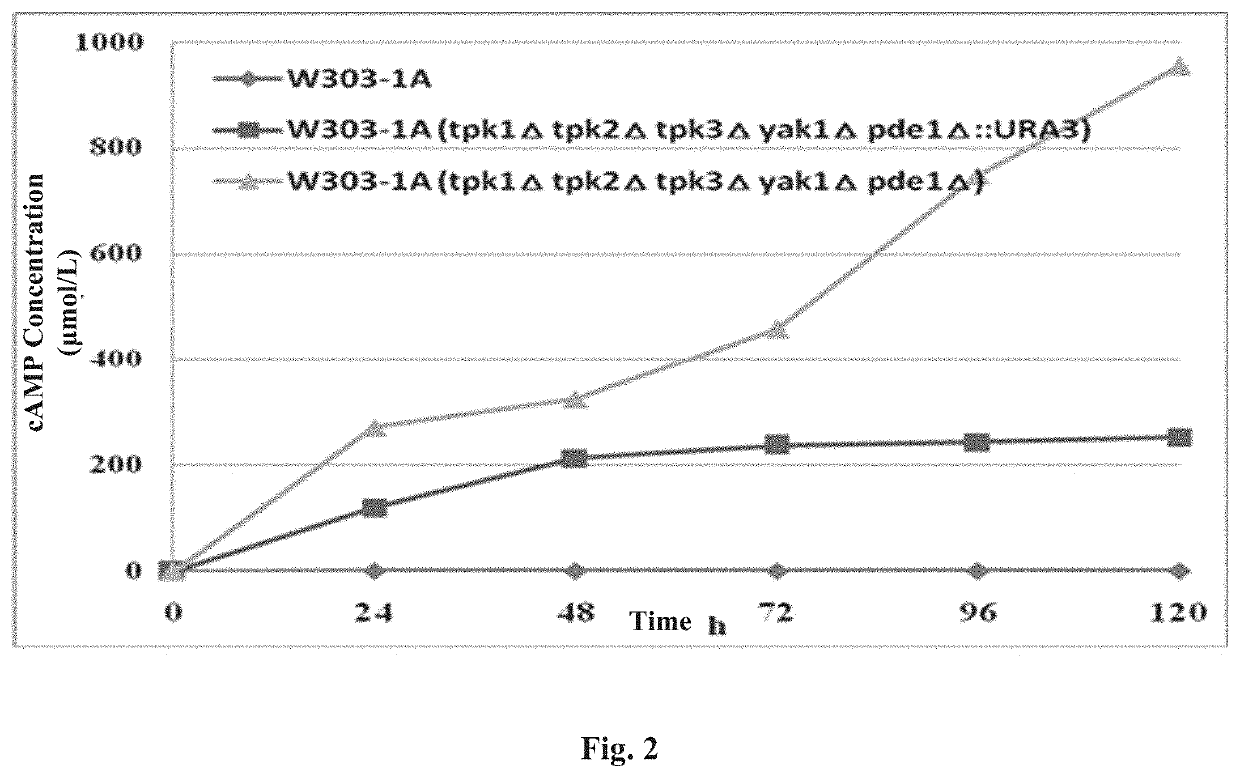

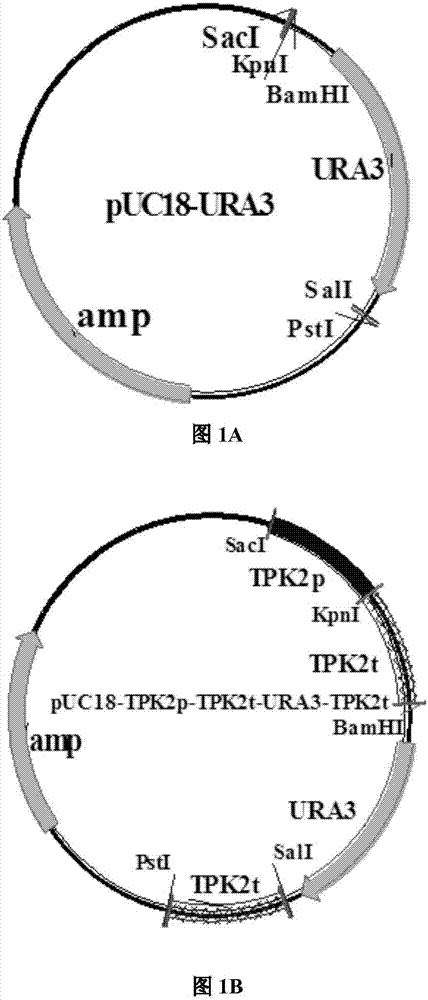

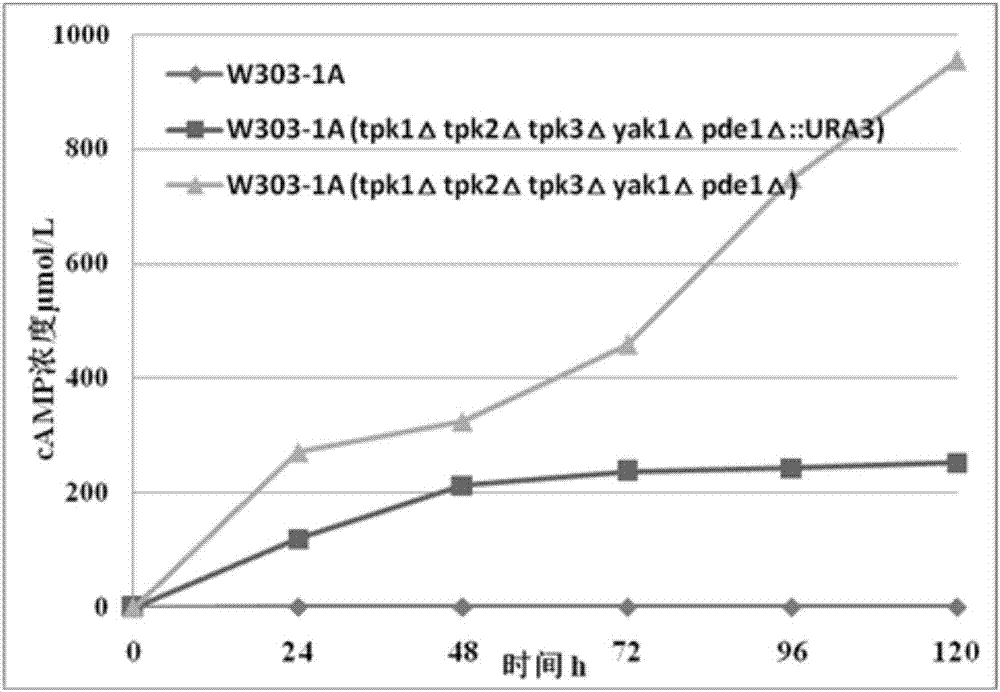

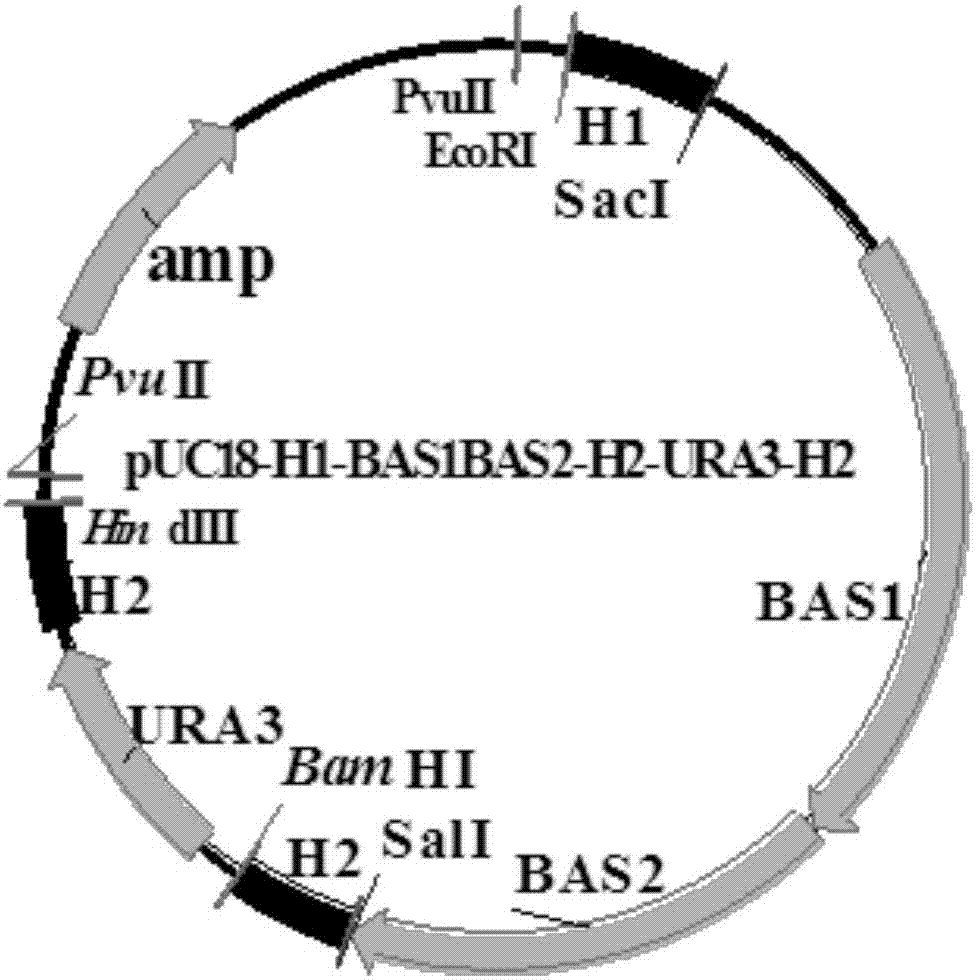

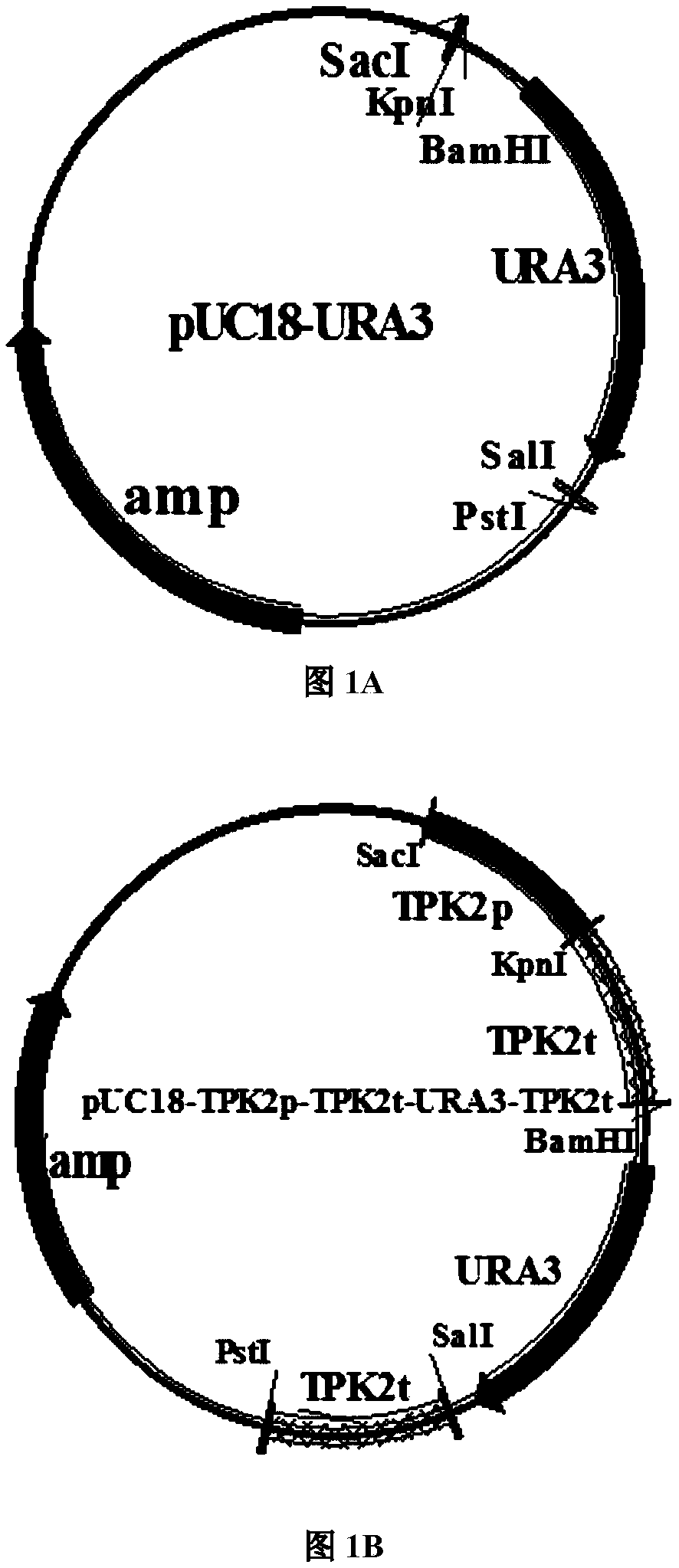

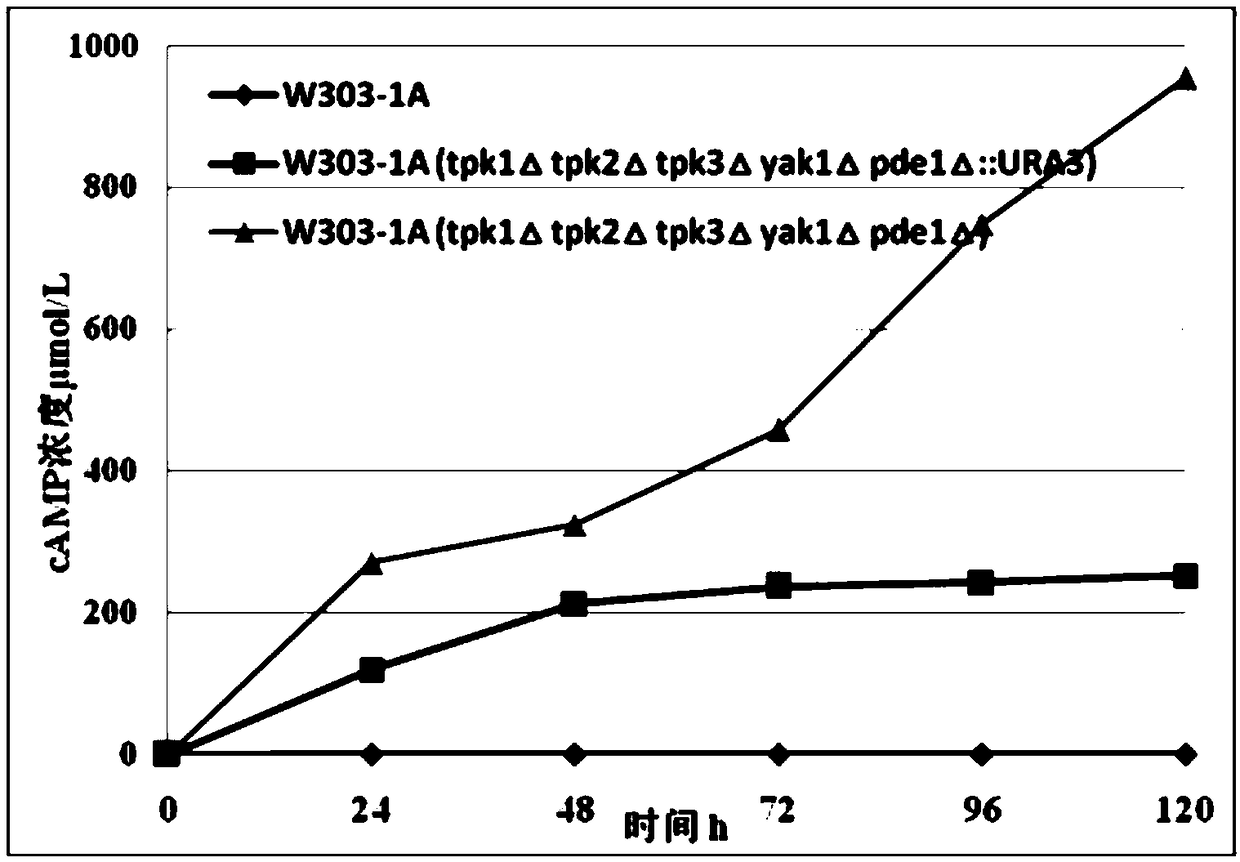

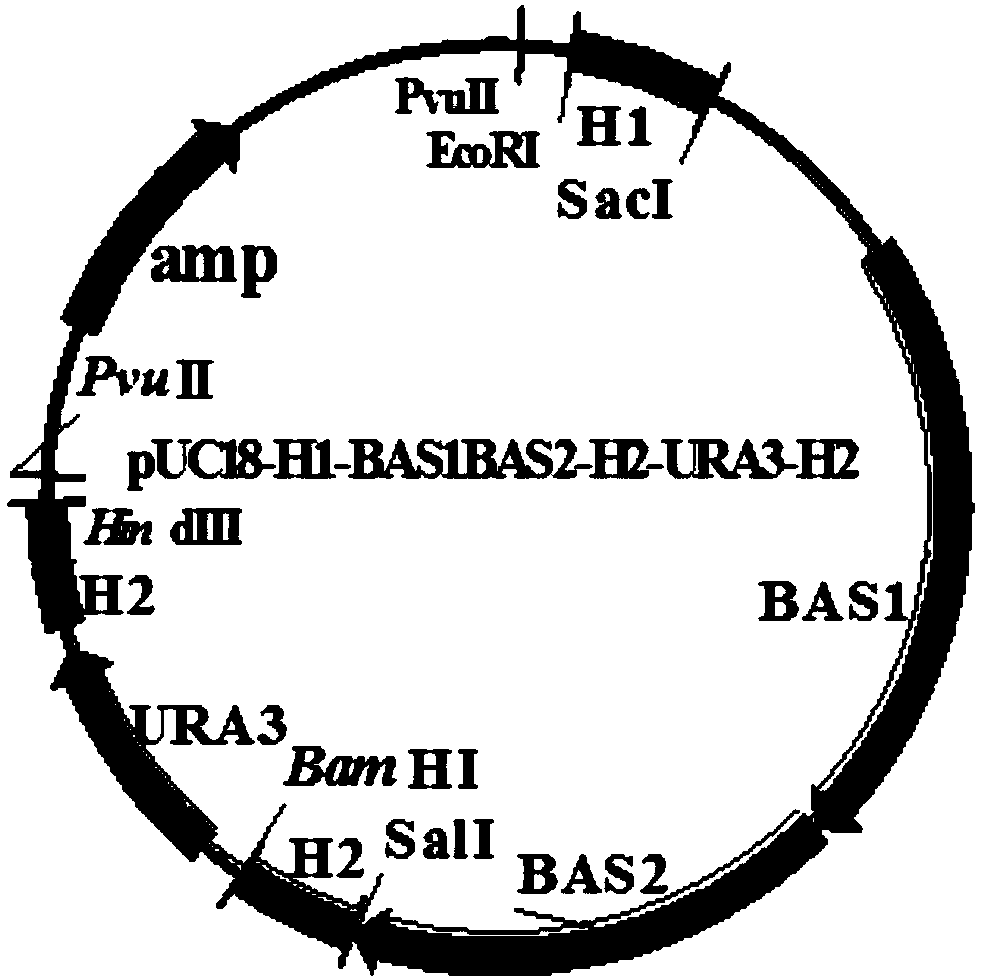

High camp yielding yeast strain and use thereof

Provided is a yeast strain capable of excessively synthesizing cAMP and its construction method and fermentation technique thereof, and application in the field of medicine, animal husbandry, food or chemical industry. The yeast strain includes first and second gene modifications, wherein the first gene includes protein kinase A (PKA) catalytic subunit encoding genes TPK1, TPK2 and TPK3, by modifying the first gene, the activity or expression of PKA is completely inhibited, so that feedback inhibition to cyclic adenosine monophosphate (cAMP) is eliminated, but at the same time, the growth of the yeast is inhibited; and the second gene modification eliminates growth inhibition caused by the first gene modification, so that the yeast grows normally, and the cAMP yield by the yeast is increased, wherein the increase of the cAMP yield is relative to the cAMP yield by an unmodified yeast. The yeast strain further includes third and / or fourth gene modifications. The recombinant yeast strain of the present invention can stably, continuously and efficiently produce extracellular cAMP by up to 9721.6 μmol / L.

Owner:TIANJIN UNIV

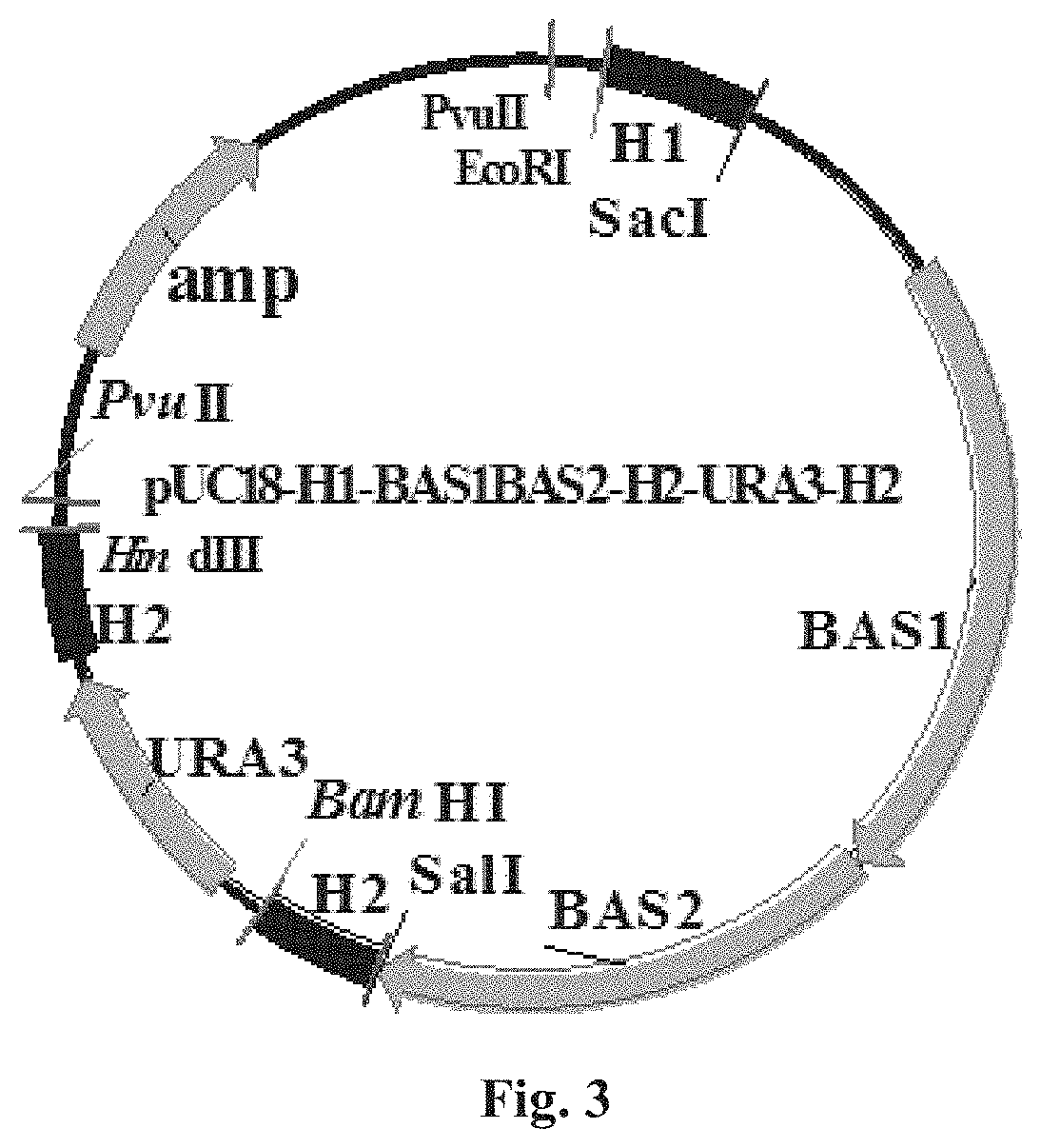

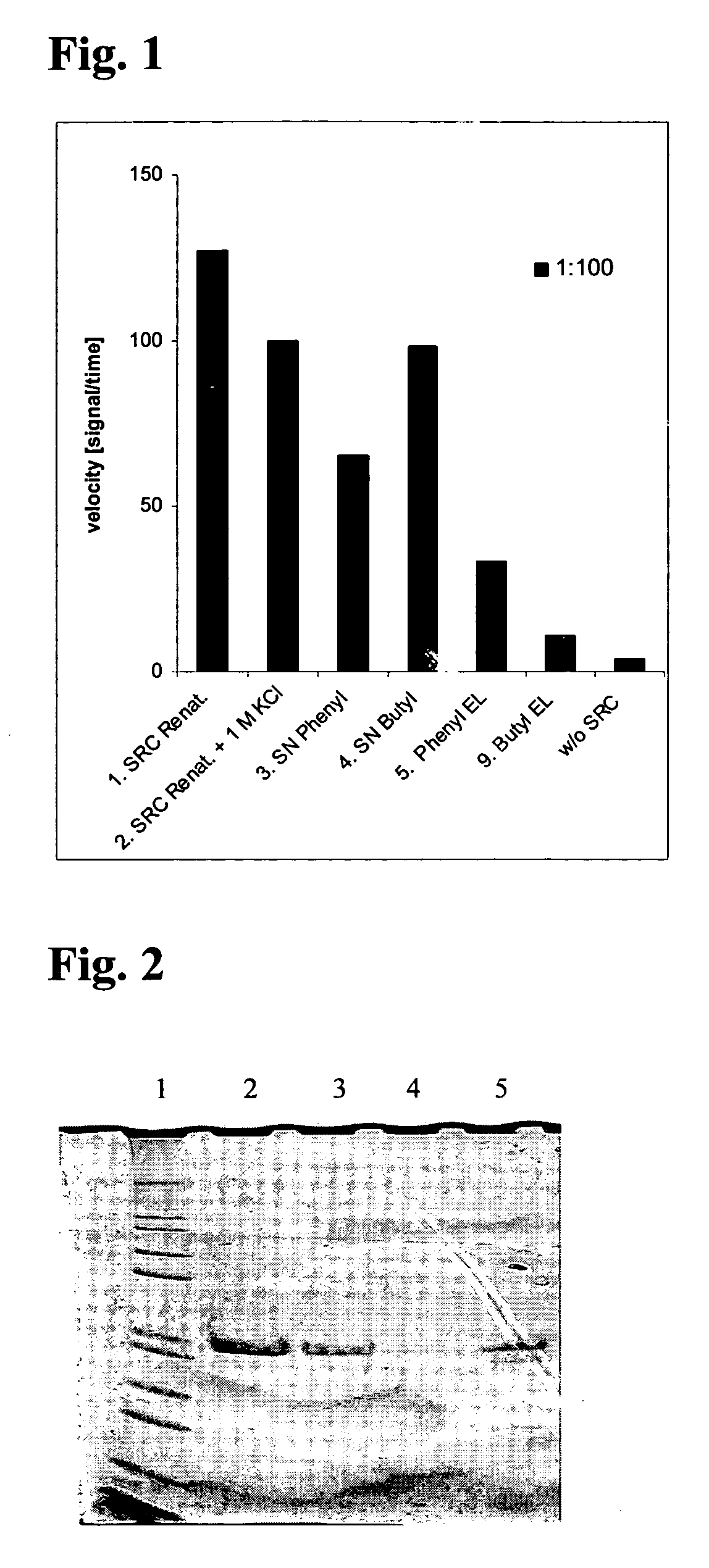

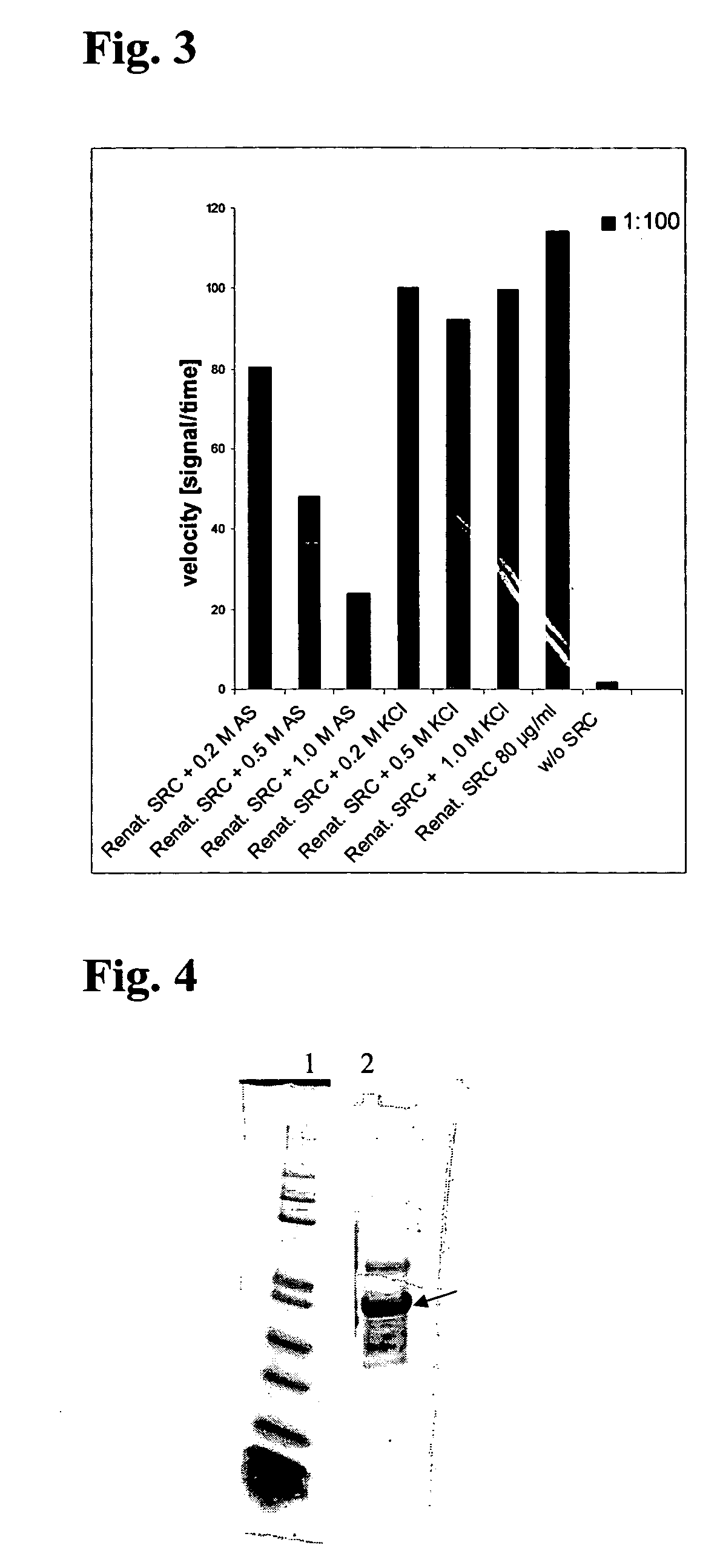

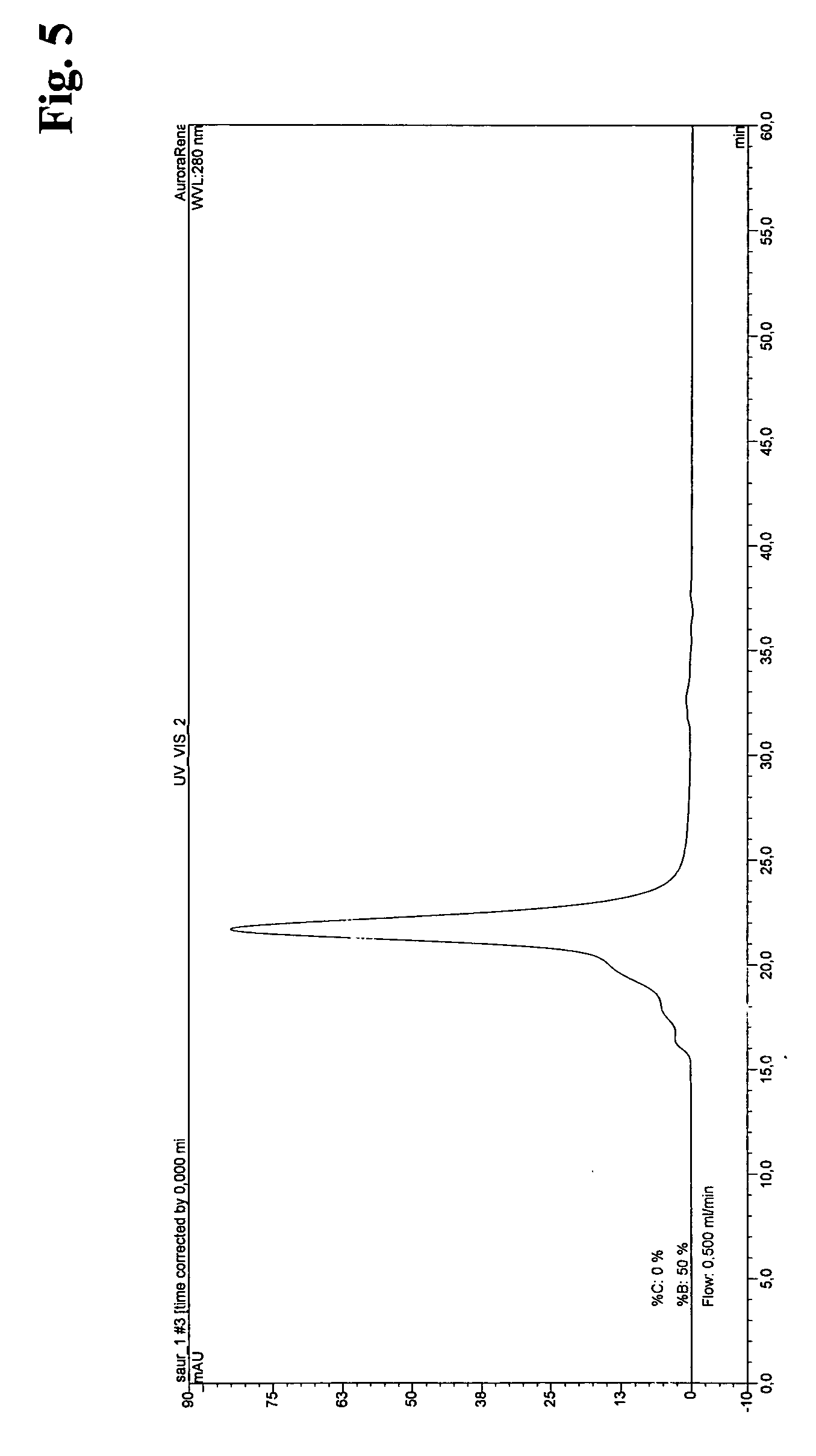

Method for the recombinant production and purification of protein kinases

A method for the recombinant production and purification of a protein kinase selected from the group consisting of tyrosine protein kinases and serine / threonine kinases by expressing a nucleic acid encoding said kinase in a microbial host cell, forming inclusion bodies containing said kinase, isolating, solubilizing, naturing, and purifying said kinase wherein said purification is performed by hydrophobic interaction with an hydrophobic adsorbent under conditions whereby at least 70% of said protein kinase are not bound to said adsorbent and the protein kinase not bound to said adsorbent is recovered.

Owner:F HOFFMANN LA ROCHE & CO AG

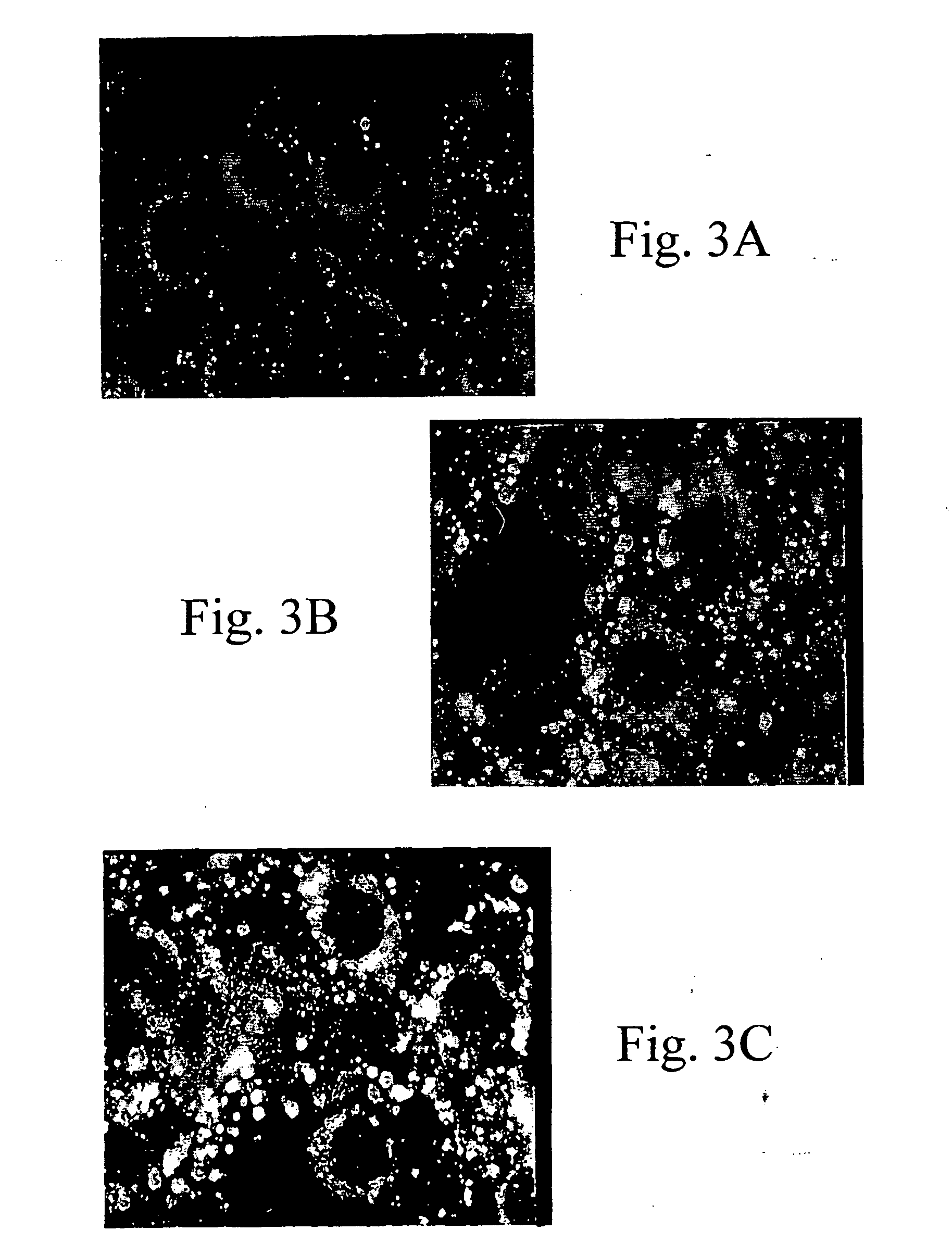

Methods for modulating gap junctions

InactiveUS20050020482A1BiocideCell receptors/surface-antigens/surface-determinantsCell membraneApoptosis

A method for modulating gap junctions is provided. In a first step, the transcription of connexin is enhanced and the gap junction is relocalized at the cell membrane; in a second step, gap junction function is restored by properly gating the channel and / or inducing apoptosis. The method preferably comprises a providing a cell or an animal with a first compound for increasing the activity of protein kinase A (PKA) and in the second step providing the cell or animal with a second compound for specifically inhibiting or activating one or more protein kinase C (PKC) isoforms and / or for specifically inhibiting p38 MAP kinase.

Owner:NAT RES COUNCIL OF CANADA

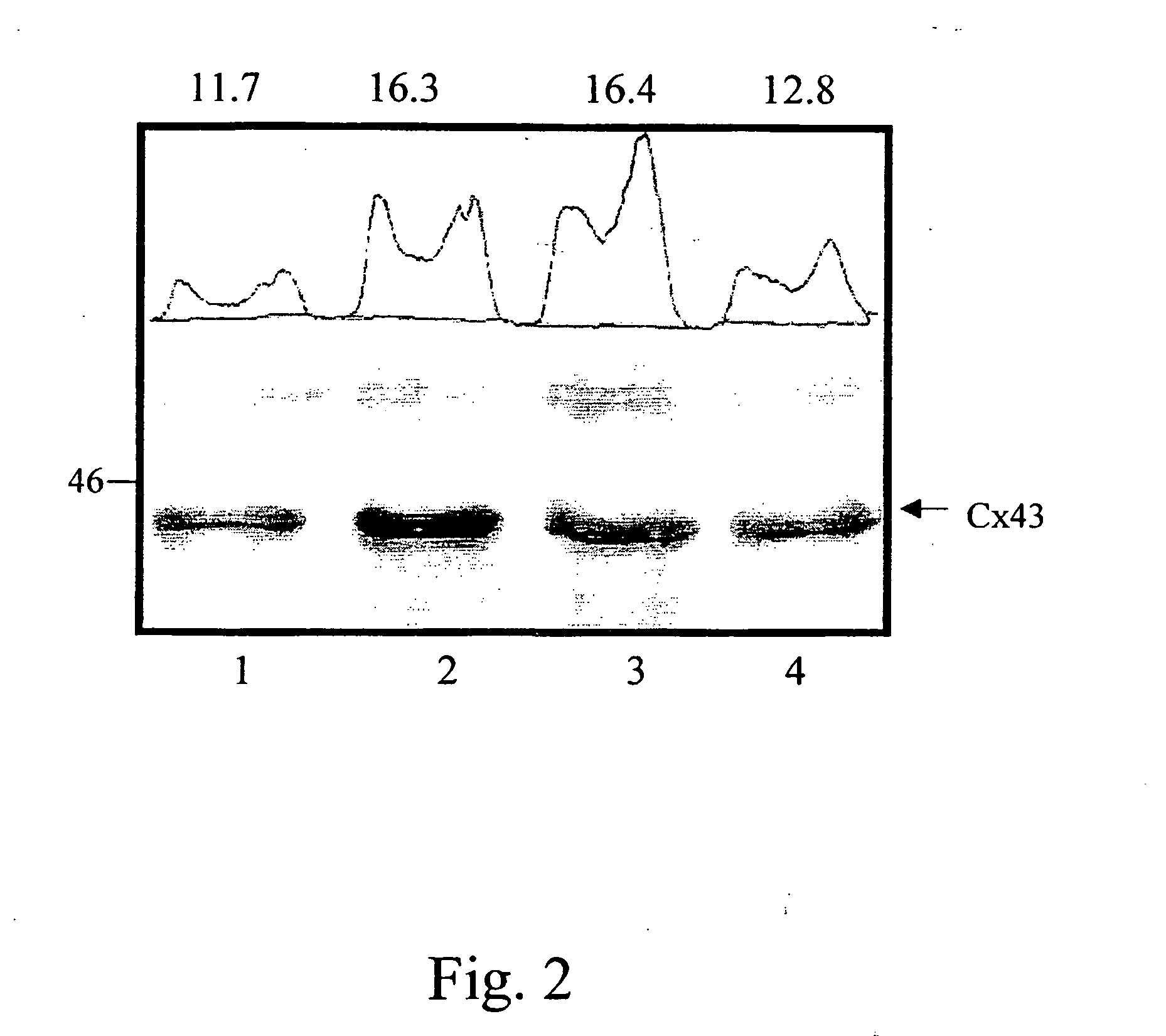

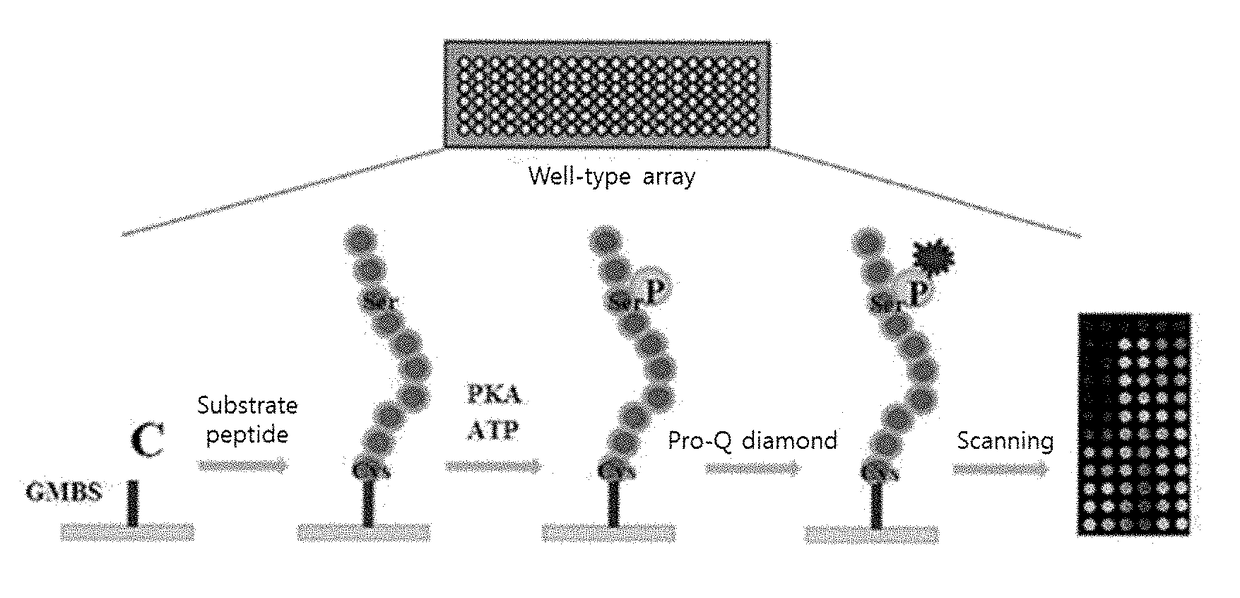

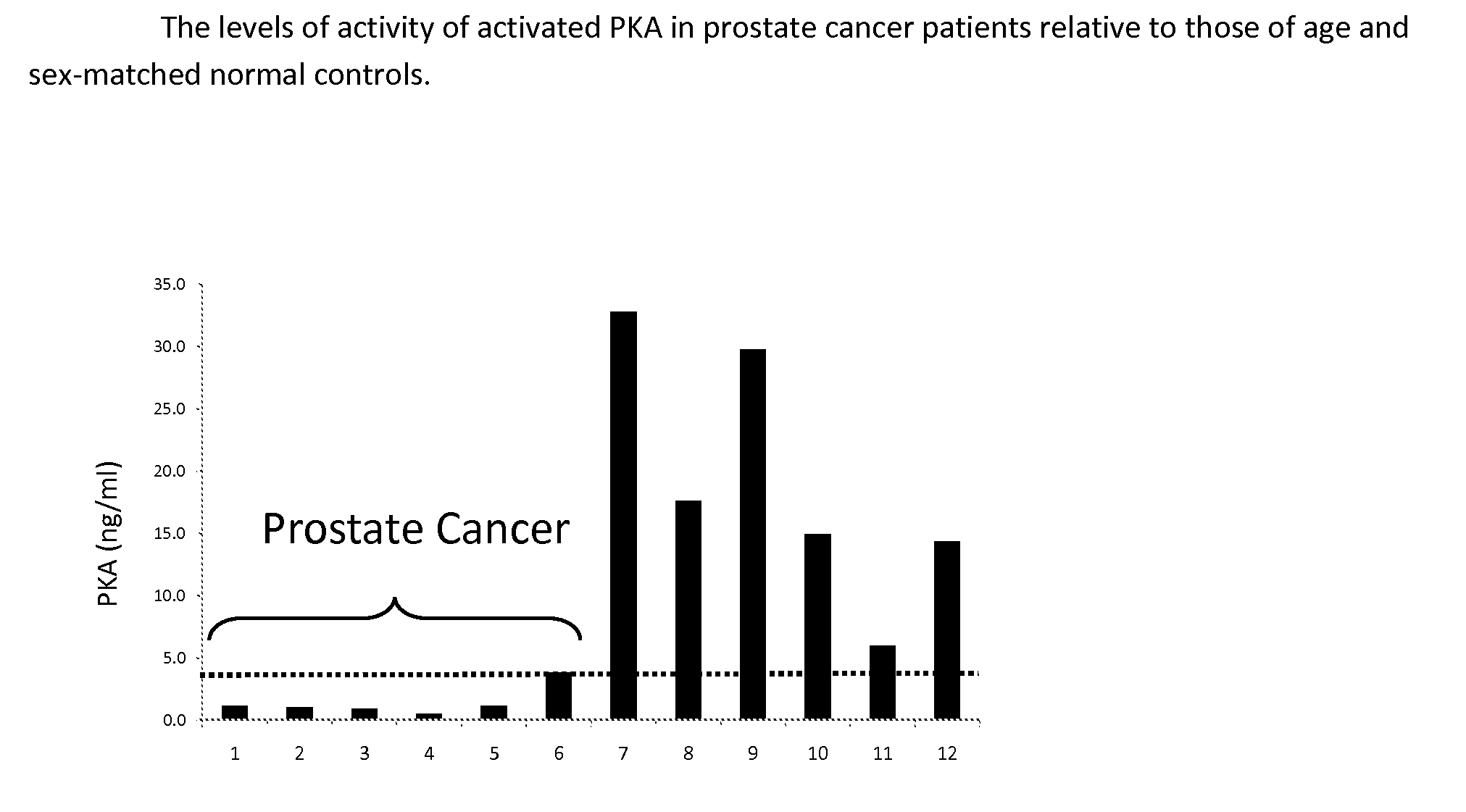

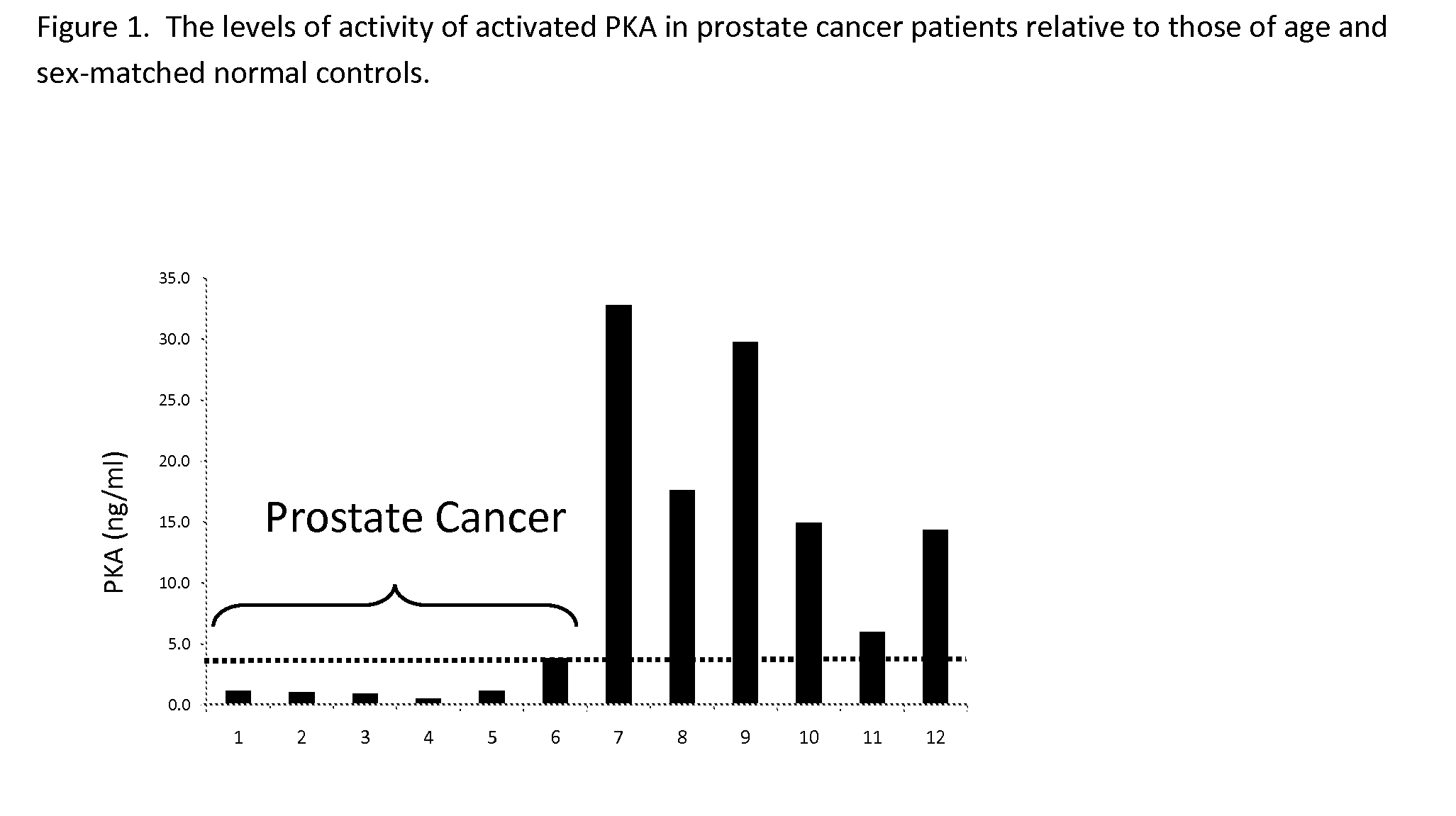

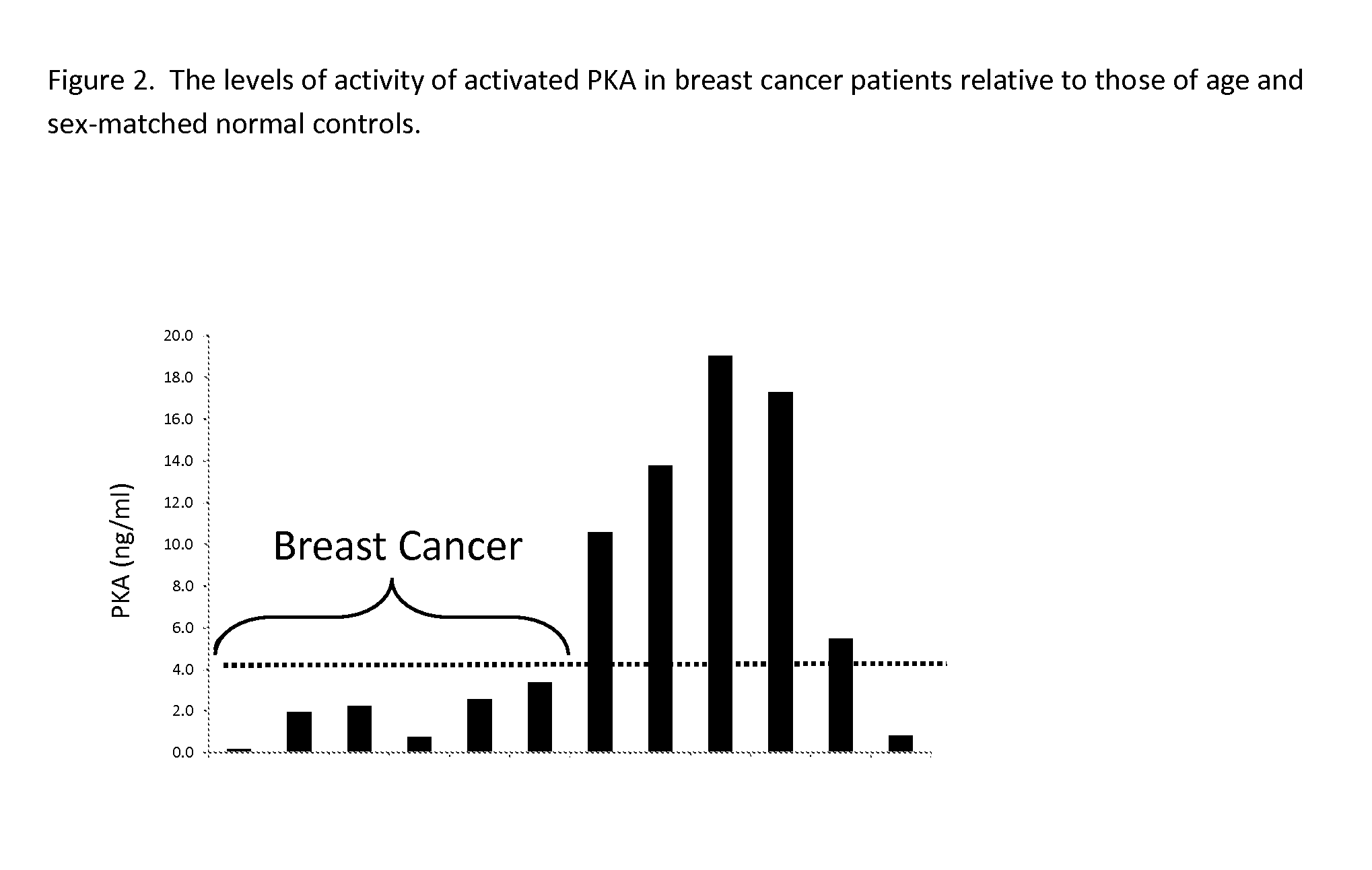

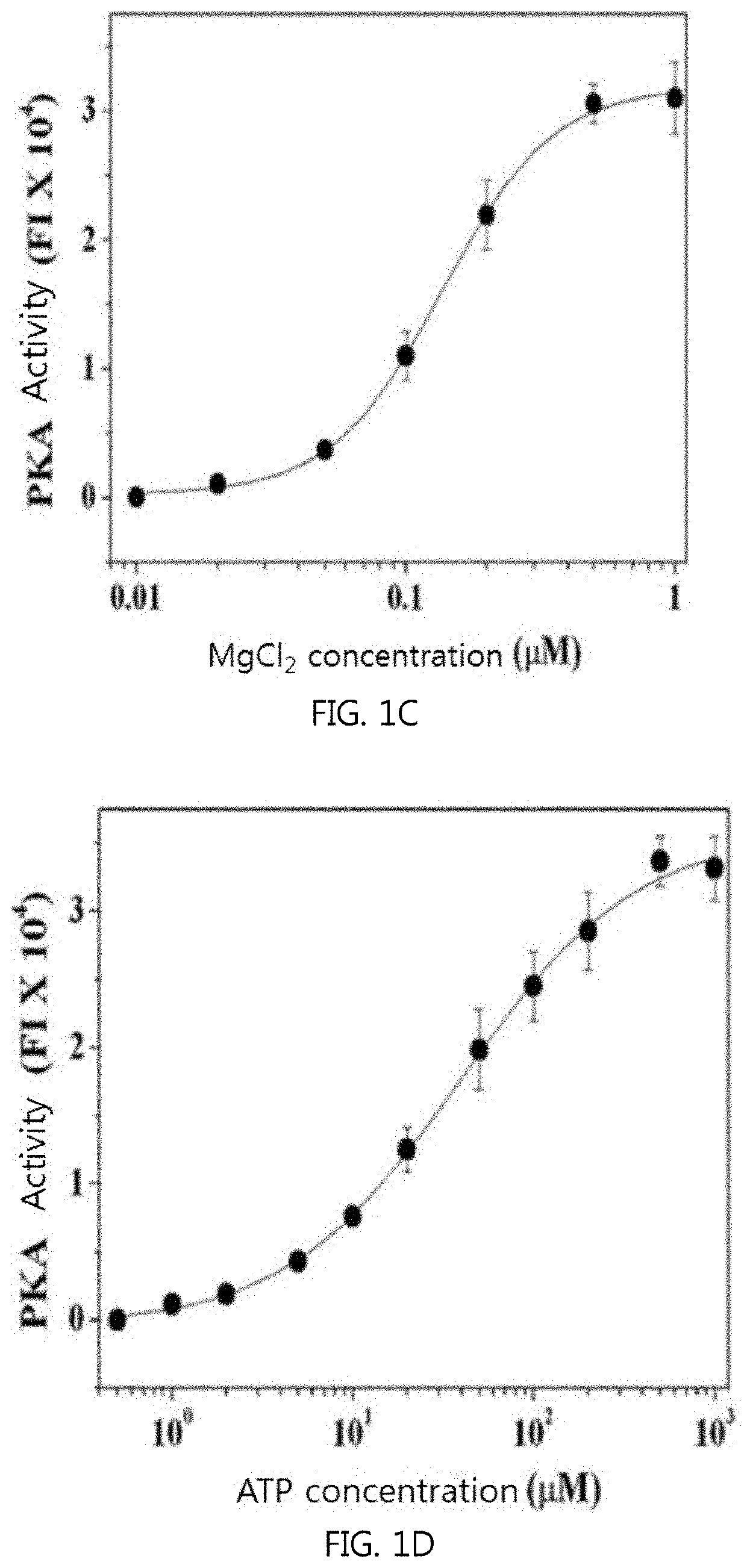

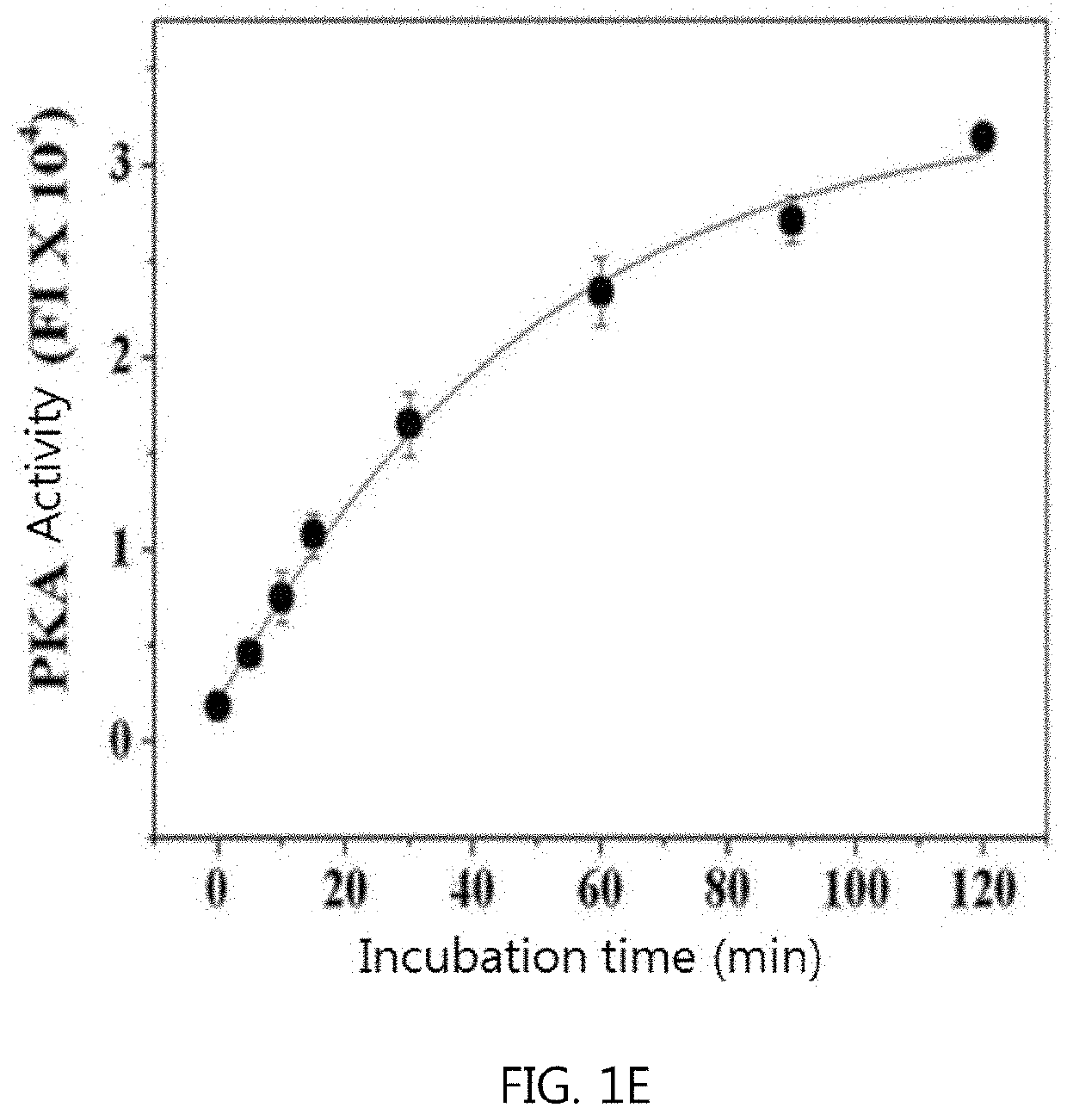

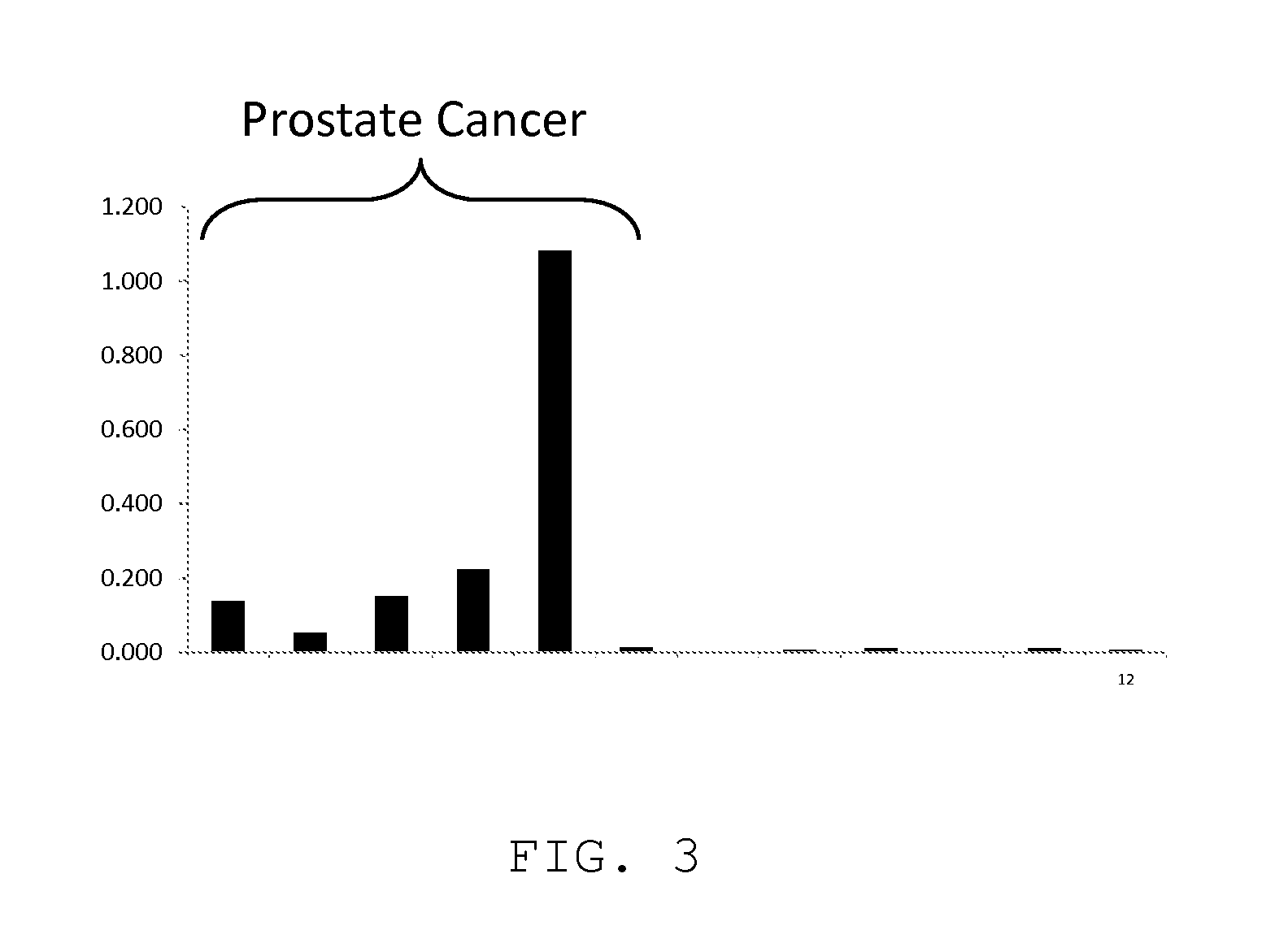

Composition for diagnosing cancer using pka activity and information providing method for diagnosing metastasis

InactiveUS20170175167A1Rapidly and accurately screenedHighly sensitive, easy, and economically feasibleMicrobiological testing/measurementTransferasesLymphatic SpreadProtein kinase A

Owner:AMOLIFESCI CO LTD +1

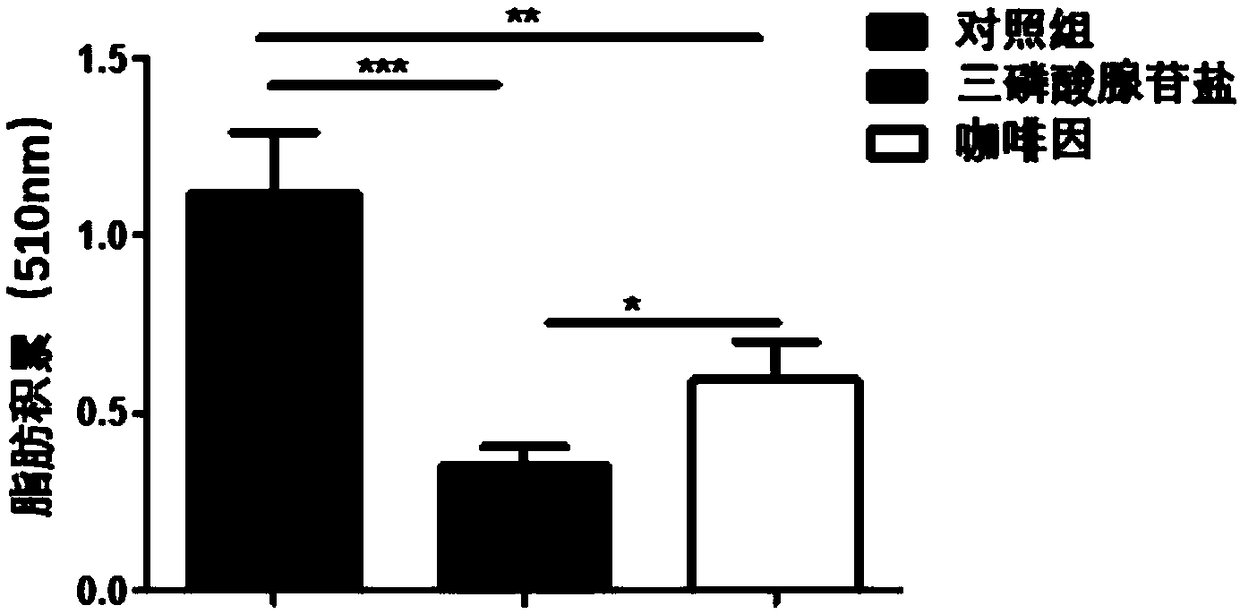

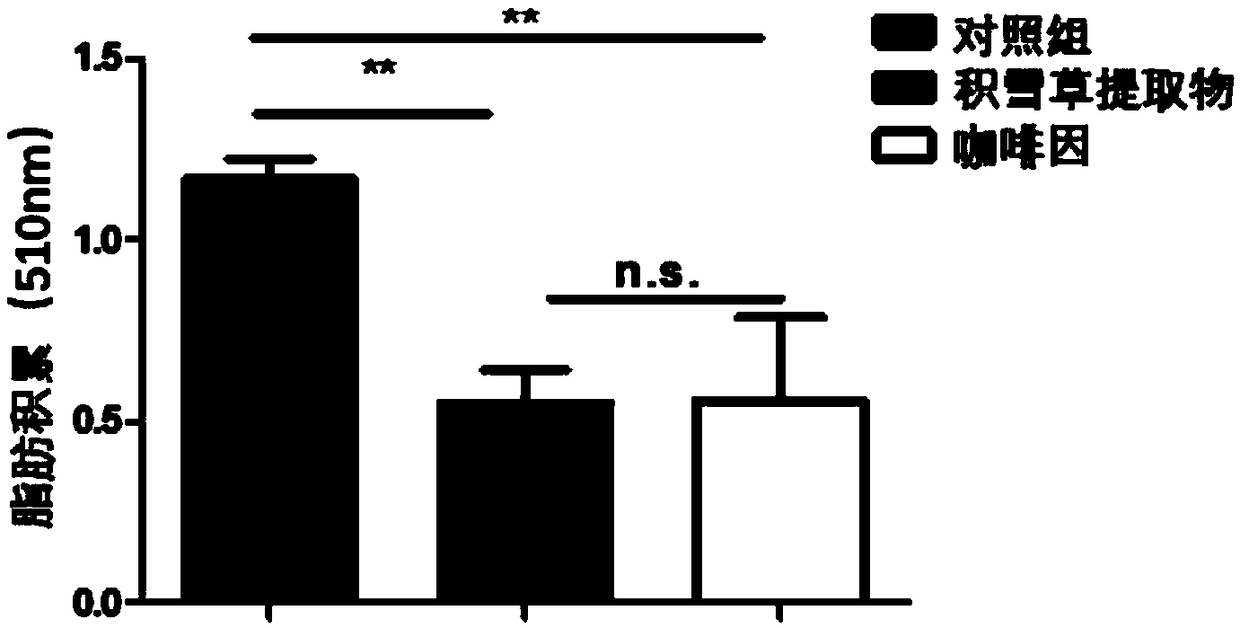

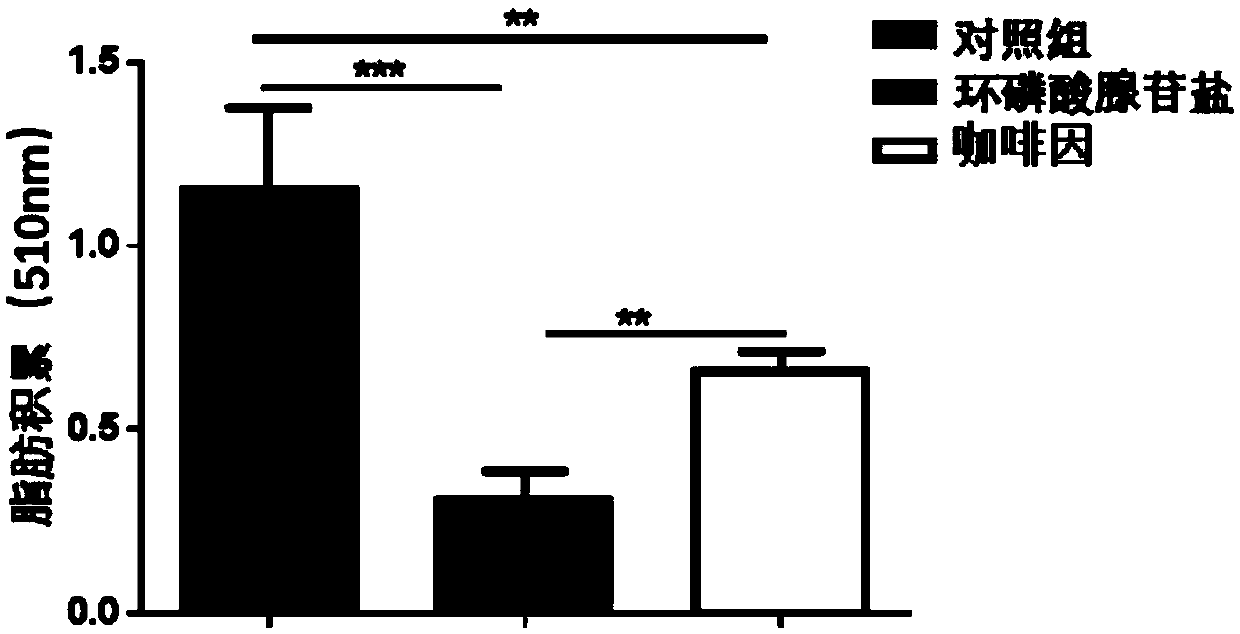

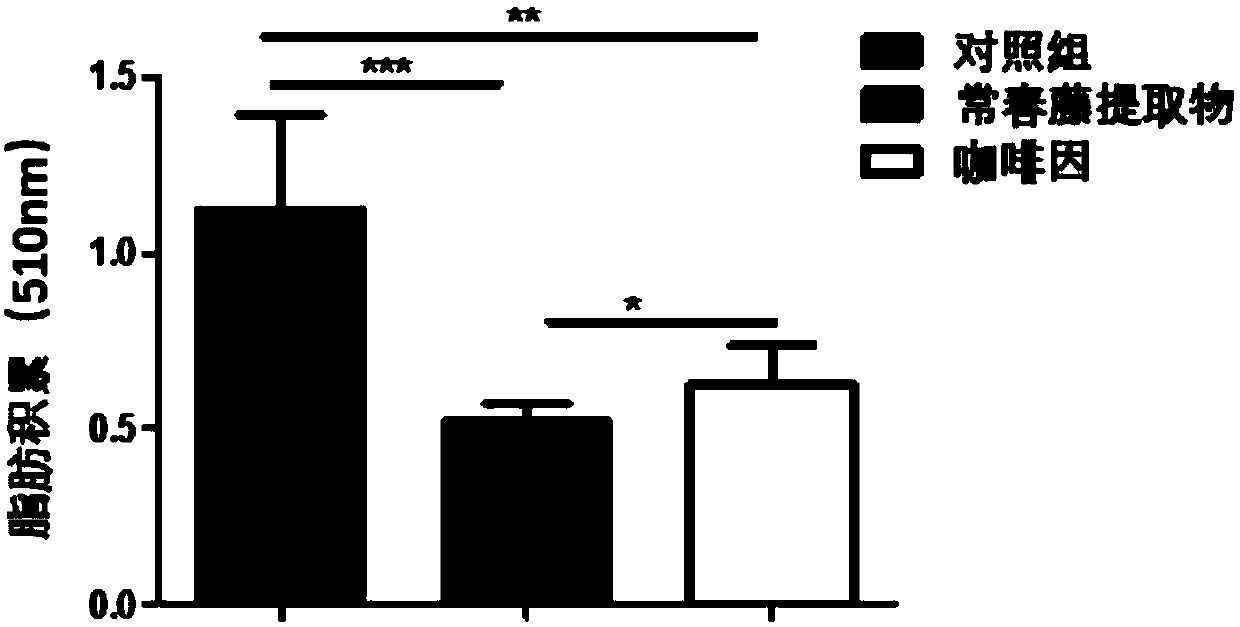

Application of adenosine triphosphate in preparation of slimming product for external use

InactiveCN109464452AReduce fat massTo achieve the purpose of fat lossOrganic active ingredientsCosmetic preparationsAdenosineProtein kinase A

The invention relates to application of adenosine triphosphate in preparation of a slimming product for external use, and belongs to the technical field of medicines. The adenosine triphosphate is converted into cyclic adenosine monophosphate by cyclic adenosine phosphatase in adipose cells, then protein kinase A is activated, the protein kinase can activate lipase and catalyze fat to break up thefat into free fatty acid and glycerinum, and thus, a purpose of eliminating fat is achieved; and by the adenosine triphosphate, the fat mass in the adipose cells can be reduced, and the adenosine triphosphate can be developed into the slimming product for external use.

Owner:广州涵夏基因健康科技有限公司

Yeast strain for highly yielding cAMP, and application thereof

The invention provides a yeast strain capable of excessively synthesizing extracellular cAMP, a constructing method and a fermentation technology thereof, and an application of the yeast strain in the fields of medicines, livestock husbandry, foods, health foods or chemical industry. The yeast strain comprises first gene modification and second gene modification, wherein the first genes are protein kinase A (PKA) catalytic subunit coding genes TPK1, TPK2 and TPK3, the first genes are modified to completely inhibit the activity or expression of the PKA in order to eliminate the feedback inhibition of cyclic adenosine monophosphate (cAMP) and inhibit the growth of yeast, and the second gene modification eliminates the first gene modification induced growth inhibition in order to make yeast grow normally and increase the cAMP yield of the yeast. The yeast strain further includes third gene modification, fourth gene modification, and / or fifth gene modification. The recombinant yeast strain can stably, continuously and highly-efficiently produce the extracellular cAMP.

Owner:TIANJIN UNIV

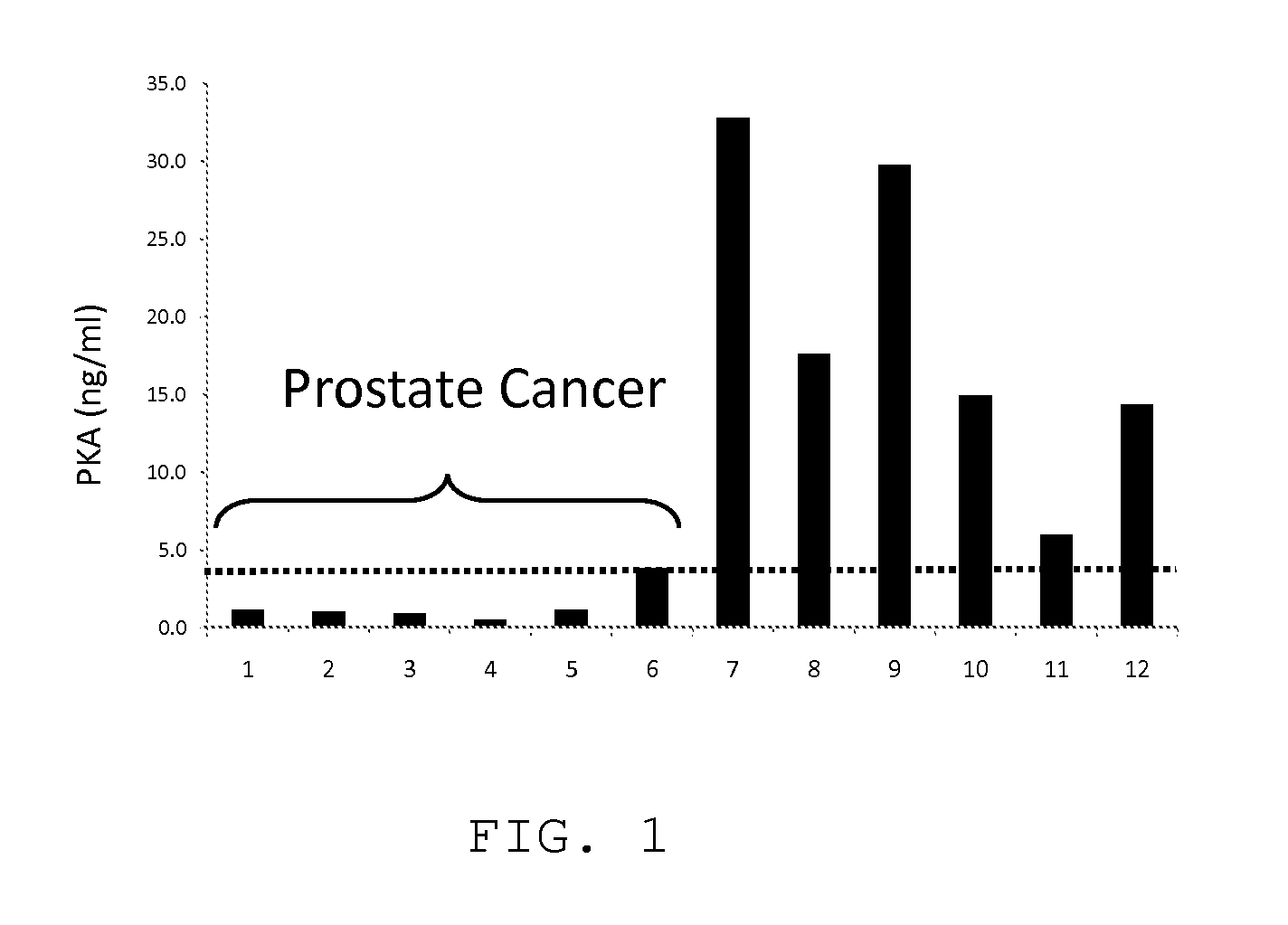

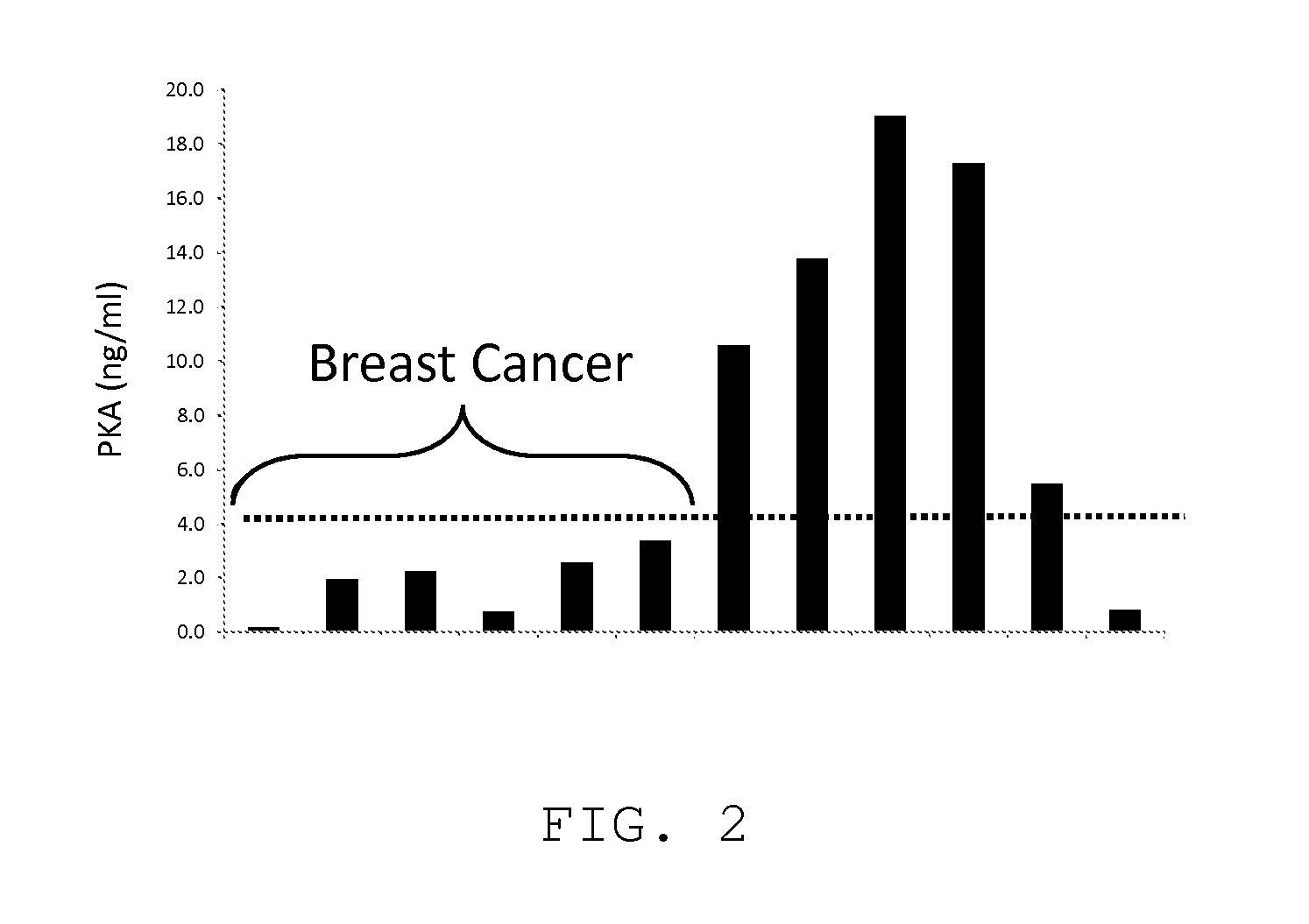

Measurement of PKA for Cancer Detection

ActiveUS20120322080A1Low levelEasy to measurePeptide/protein ingredientsMicrobiological testing/measurementAnalyteMedicine

The present invention relates to a method of detecting the presence of cancer by measuring the level of enzyme activity and autoantibodies in the blood of an individual. In particular the present invention relates to methods for measurement of activated cAMP-dependent protein kinase A (PKA) activity and antibodies to PKA, a kit for activated PKA activity measurement, and the use of the measured levels of these analytes for determining the presence of cancer.

Owner:TRAXXSSON

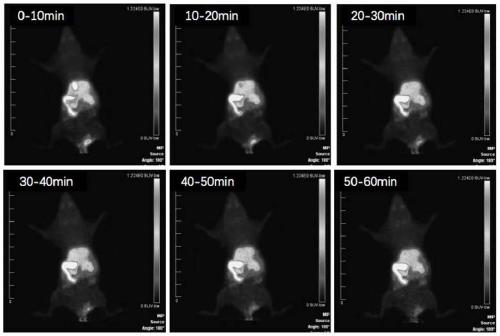

Small-molecule inhibitor of protein kinase A as well as preparation method and application thereof

The invention discloses a small-molecule inhibitor of histone kinase A. The small-molecule inhibitor comprises an H89 isoquinoline precursor structure, the specific molecular formula is CxHyAzNmOnS, and in the molecular formula, x is 20 or 21, y is 20 or 22, A is F, z is 0 or 1, m is 3 or 4, and n is 2 or 4. The invention further provides small-molecule inhibitors HF89, HFC and HN89, and a PET tracer [<11> C] HF<89>. The invention also provides a preparation method and an application of the related small-molecule inhibitor. A new feasible scheme is provided for early diagnosis, treatment, curative effect evaluation and the like of tumors.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

Biomarker assay for use in monitoring autism

The present invention relates to protein kinase A (PKA) for use in diagnosing autism spectrum disorder (ASD) phenotype 1 in an ASD patient wherein PKA levels are measured in a sample of the patient and wherein ASD phenotype 1 is diagnosed if the measured levels are lower than PKA levels in an age and sex-matched control sample. Additionally, the present invention relates to PKA for use in monitoring variation in ASD severity in an ASD patient, wherein PKA levels are measured in a sample of the patient and an increase in ASD severity is characterized by a decrease of PKA levels compared to PKA levels measured in previous samples of the patient. The present invention also relates to PKA for use in monitoring efficacy of an ASD treatment in an ASD phenotype 1 patient, wherein PKA levels are measured in a sample of the patient and wherein a positive response to the ASD treatment is characterized by an increase of PKA levels in comparison to baseline PKA levels of the patient prior to treatment. Furthermore, the present invention is directed to methods of diagnosing ASD phenotype 1 as well as kits comprising means to measure PKA levels.

Owner:STALICLA SA

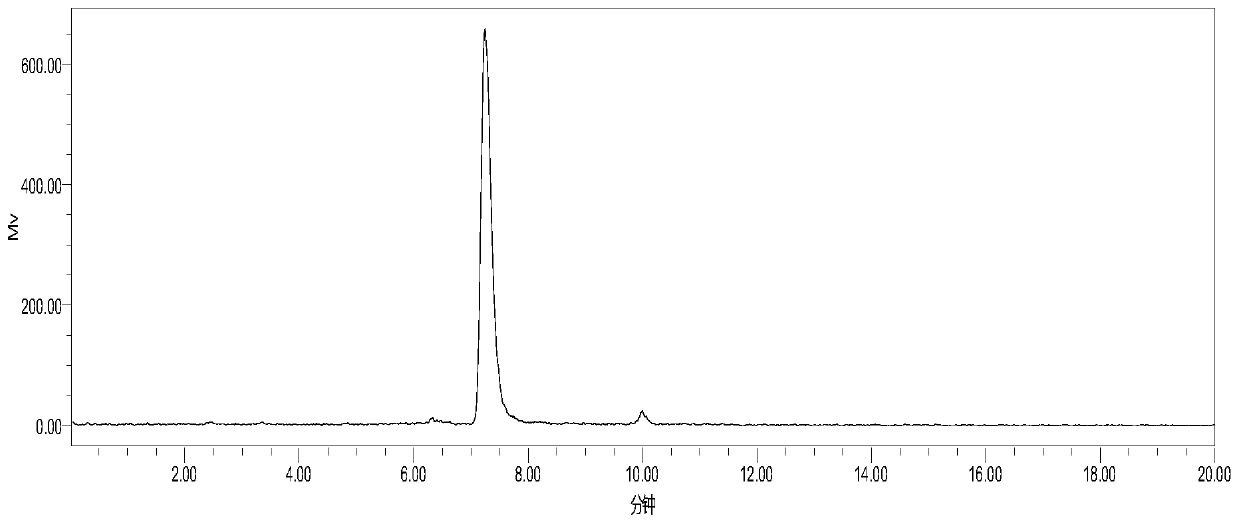

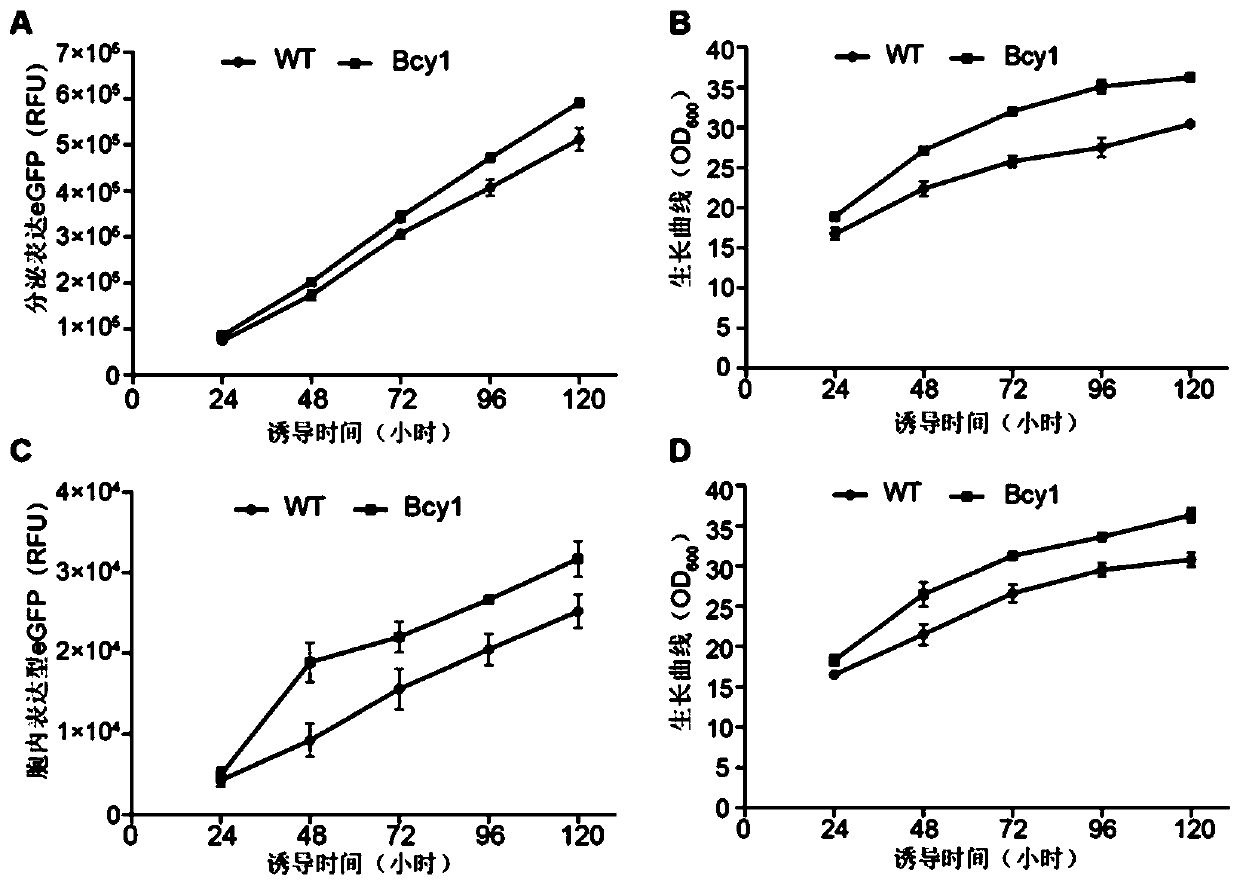

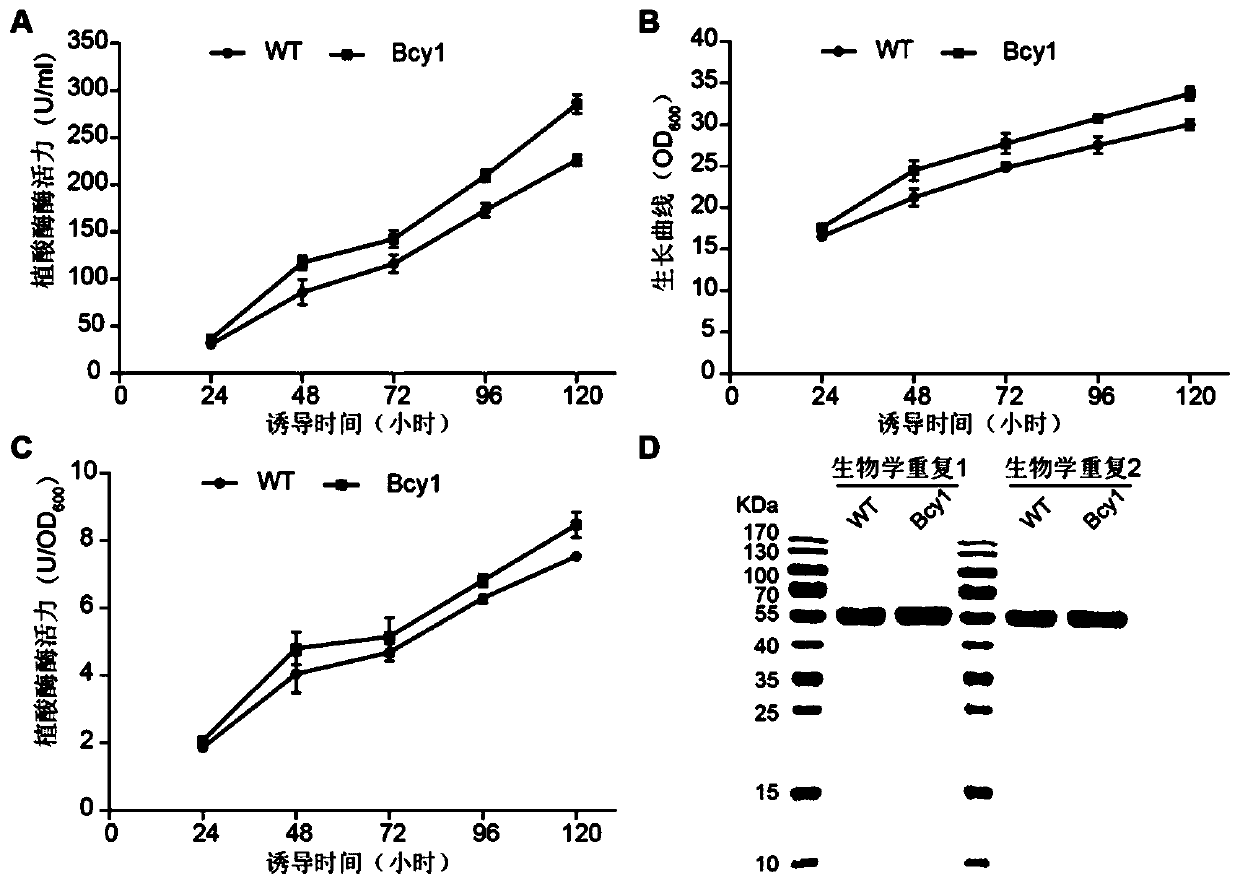

Application of pichia pastoris translation correlation factor Bcy1 to foreign protein expression

The invention discloses application of a pichia pastoris translation correlation factor Bcy1 to foreign protein expression. According to application, it is discovered that the biomass in the cell fermentation process can be significantly improved by the pichia pastoris translation correlation factor Bcy1 (annotation: protein kinase A regulated subunit), the expression quantity of enhanced green fluorescence protein eGFP is improved, the expression quantity of phytase Phy is improved, the cell growth of pichia pastoris during stable fermentation can be promoted, cell biomass accumulation is increased, it is indicated that the pichia pastoris translation related factor Bcy1 has the high universality, and the pichia pastoris translation related factor Bcy1 has good application prospects to aspects of cell biomass accumulation during fermentation and foreign protein yield improvement.

Owner:拜斯特药业(广州)有限公司 +1

Composition for diagnosing cancer using pka activity and information providing method for diagnosing metastasis

InactiveUS20190376117A1Rapidly and accurately screenedHighly sensitive, easy, and economically feasibleMicrobiological testing/measurementTransferasesLymphatic SpreadProtein kinase A

Owner:AMOGREENTECH CO LTD +1

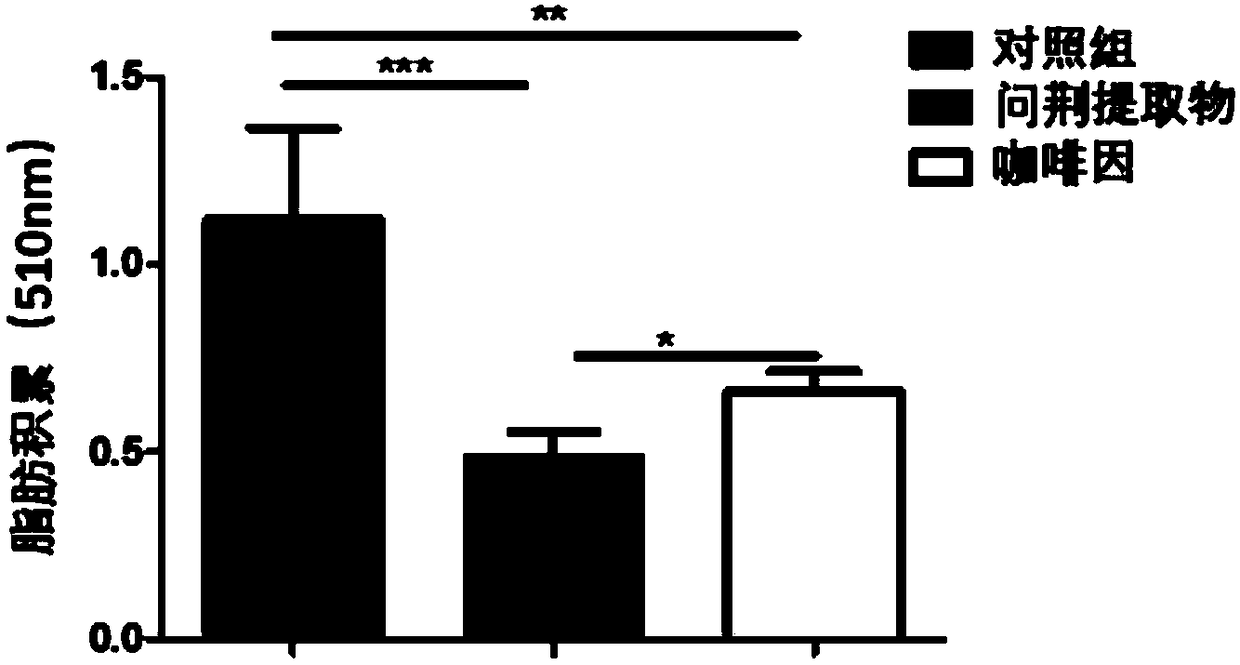

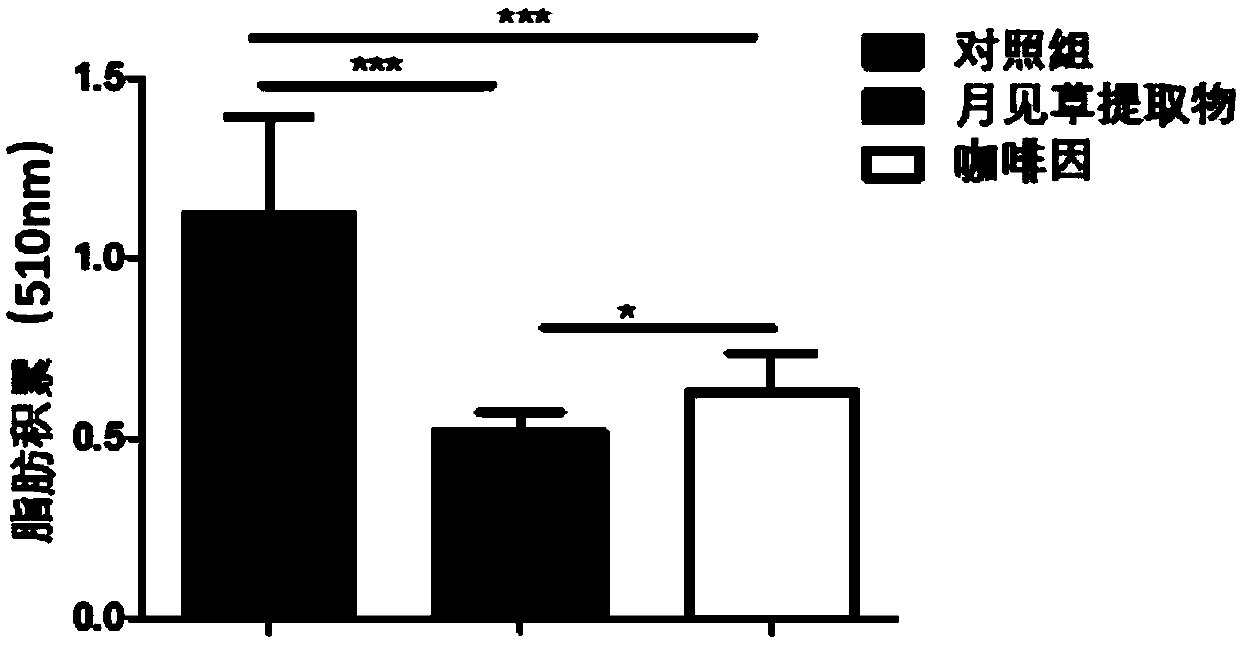

Application of cyclic adenosine monophosphate in preparation of fat reducing and weight losing product for external use

InactiveCN109528748AReduce fat massTo achieve the purpose of fat lossCosmetic preparationsOrganic active ingredientsDecompositionGlycerol

The invention relates to an application of cyclic adenosine monophosphate in preparation of a fat reducing and weight losing product for external use and belongs to the technical field of medicines. Cyclic adenosine monophosphate can directly enter fat cells to activate protein kinase A; then, lipase is activated to catalyze decomposition of fat into free fatty acids and glycerol; and the purposeof fat reducing is achieved. Cyclic adenosine monophosphate can reduce fat mass in the fat cells and be developed into the fat reducing and weight losing product for external use.

Owner:GUANGZHOU YIXIN BIOTECH CO LTD

Measurement of PKA for cancer detection

ActiveUS8455200B2Low levelEasy to measurePeptide/protein ingredientsMicrobiological testing/measurementAnalyteMedicine

Owner:TRAXXSSON

A kind of high-yield camp yeast strain and application thereof

The invention provides a yeast strain capable of excessively synthesizing extracellular cAMP, a constructing method and a fermentation technology thereof, and an application of the yeast strain in the fields of medicines, livestock husbandry, foods, health foods or chemical industry. The yeast strain comprises first gene modification and second gene modification, wherein the first genes are protein kinase A (PKA) catalytic subunit coding genes TPK1, TPK2 and TPK3, the first genes are modified to completely inhibit the activity or expression of the PKA in order to eliminate the feedback inhibition of cyclic adenosine monophosphate (cAMP) and inhibit the growth of yeast, and the second gene modification eliminates the first gene modification induced growth inhibition in order to make yeast grow normally and increase the cAMP yield of the yeast. The yeast strain further includes third gene modification, fourth gene modification, and / or fifth gene modification. The recombinant yeast strain can stably, continuously and highly-efficiently produce the extracellular cAMP.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com