Patents

Literature

84results about "By biological separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

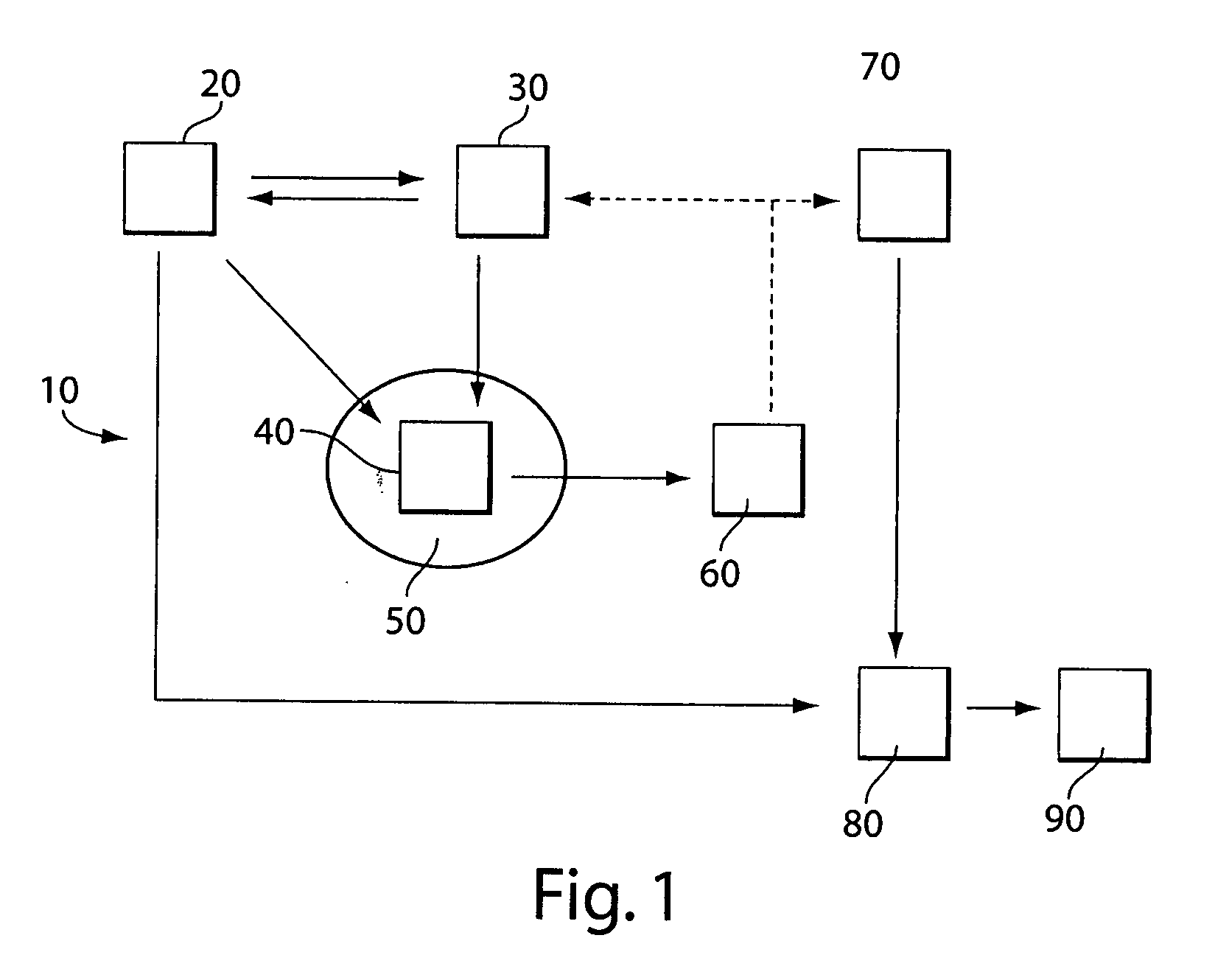

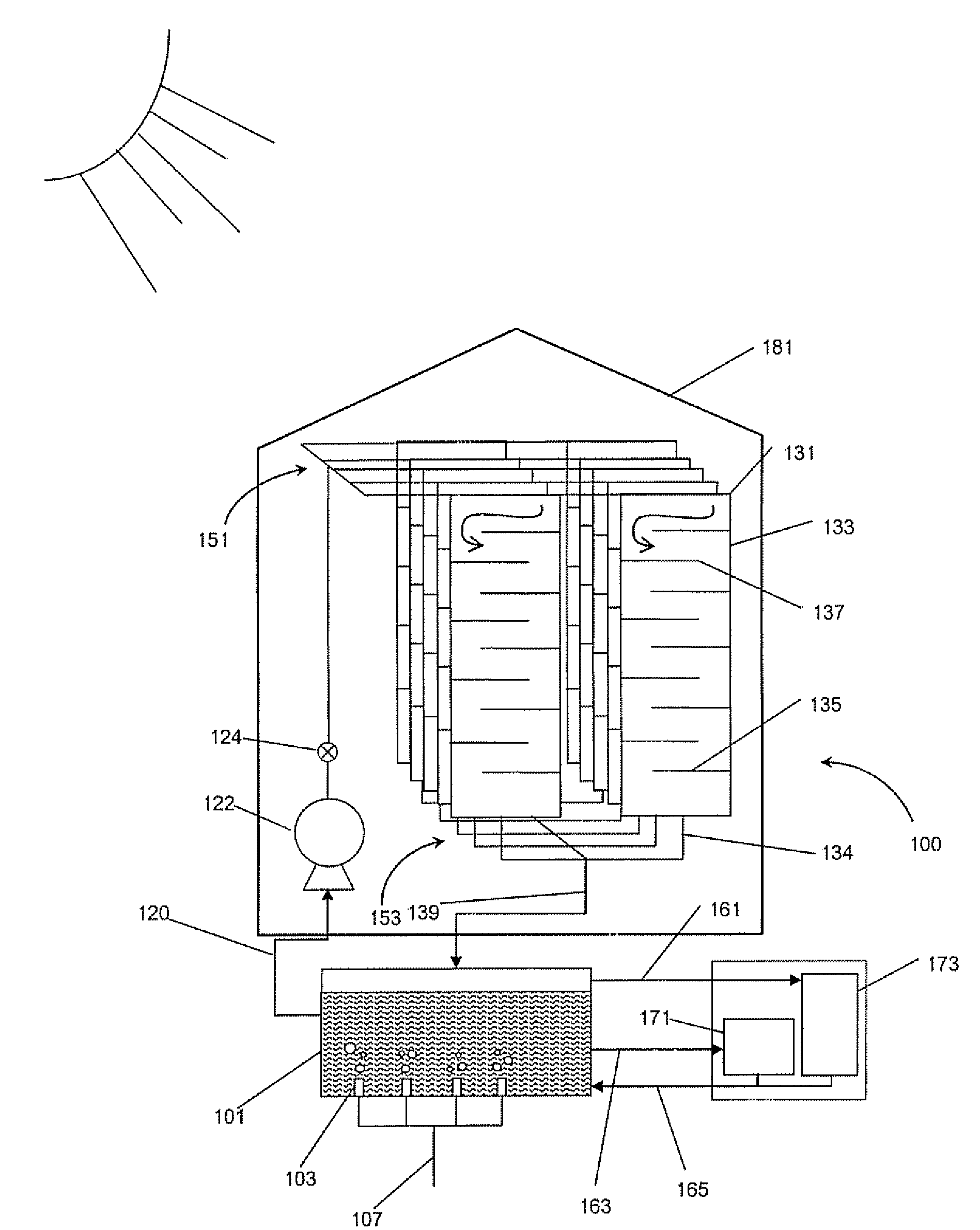

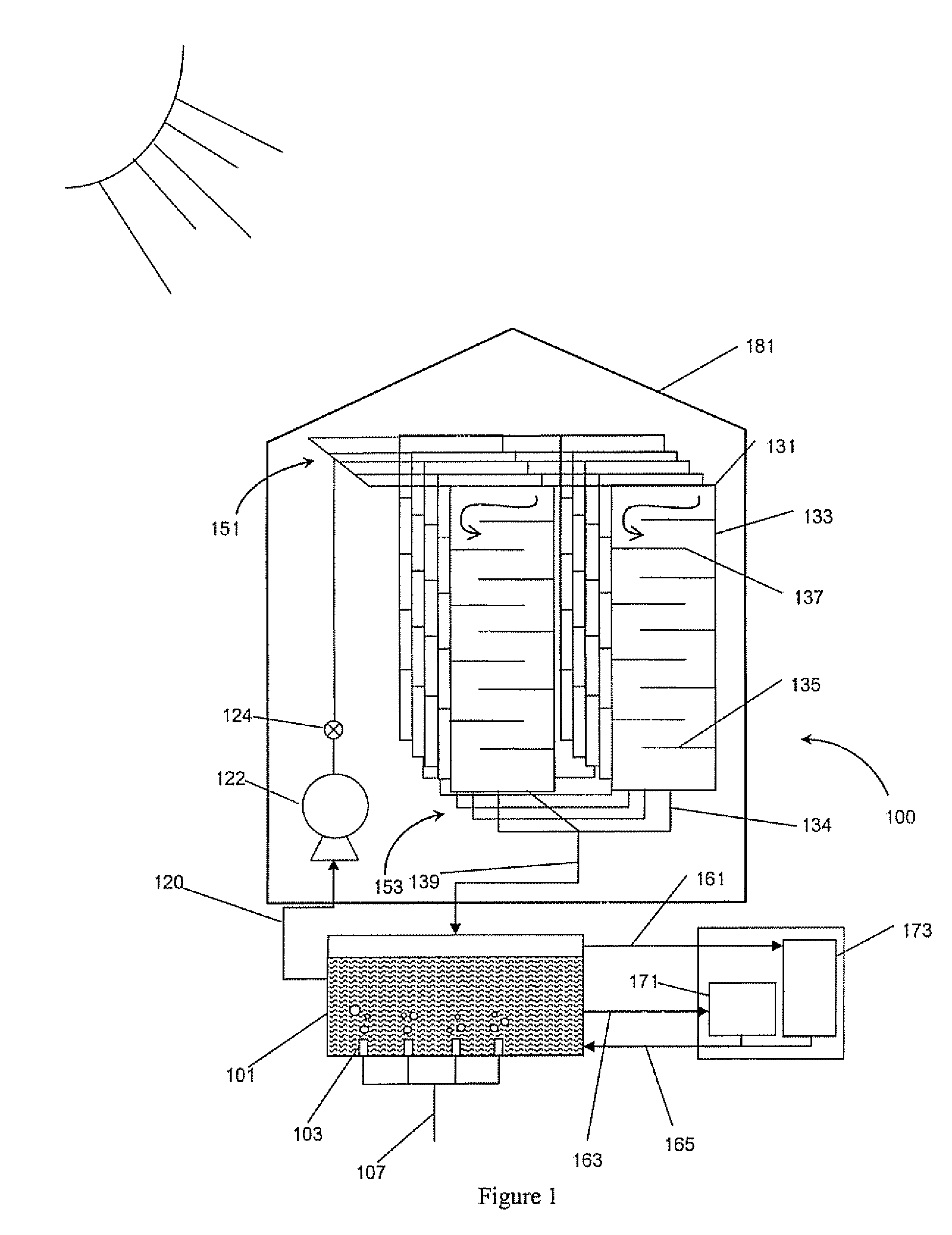

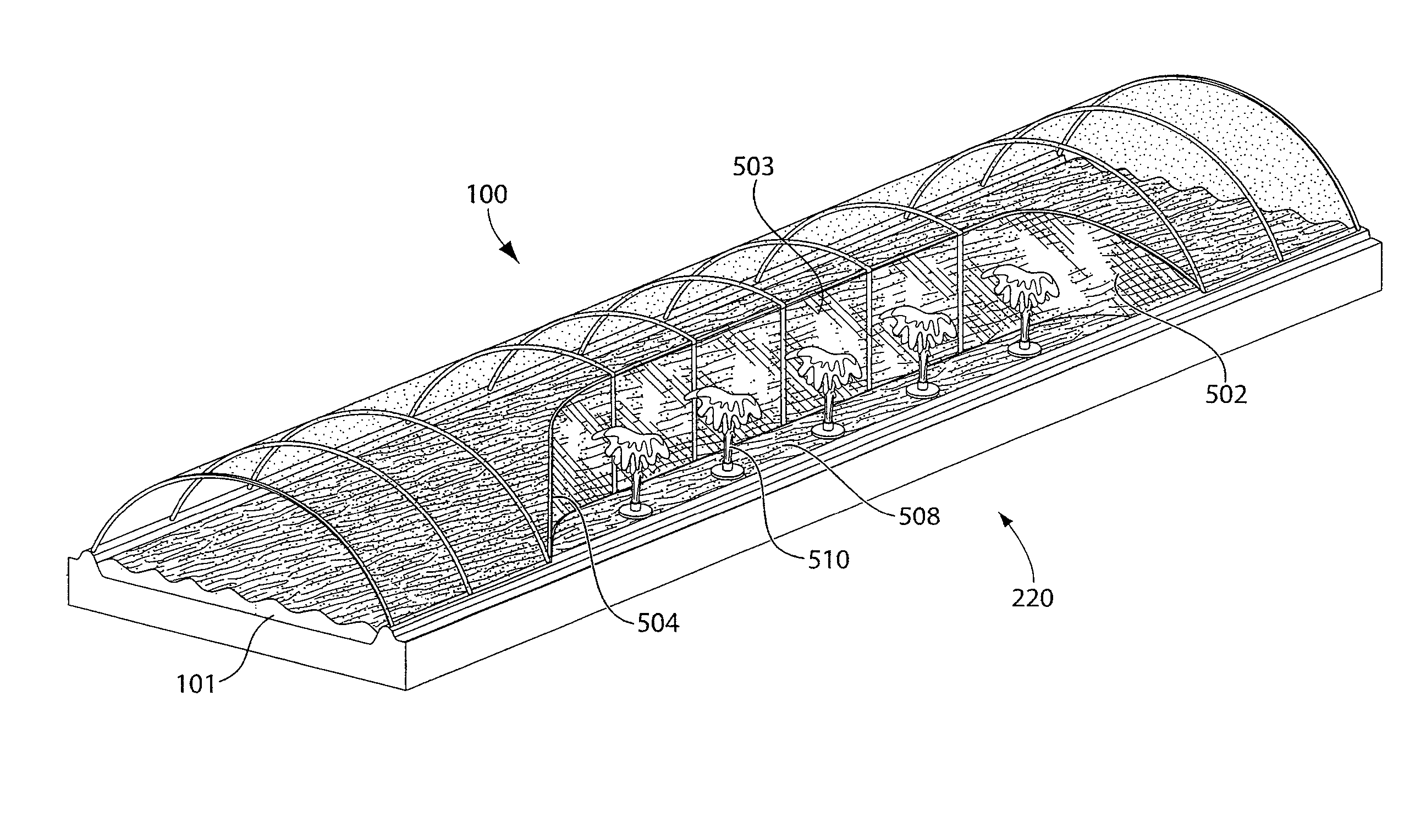

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

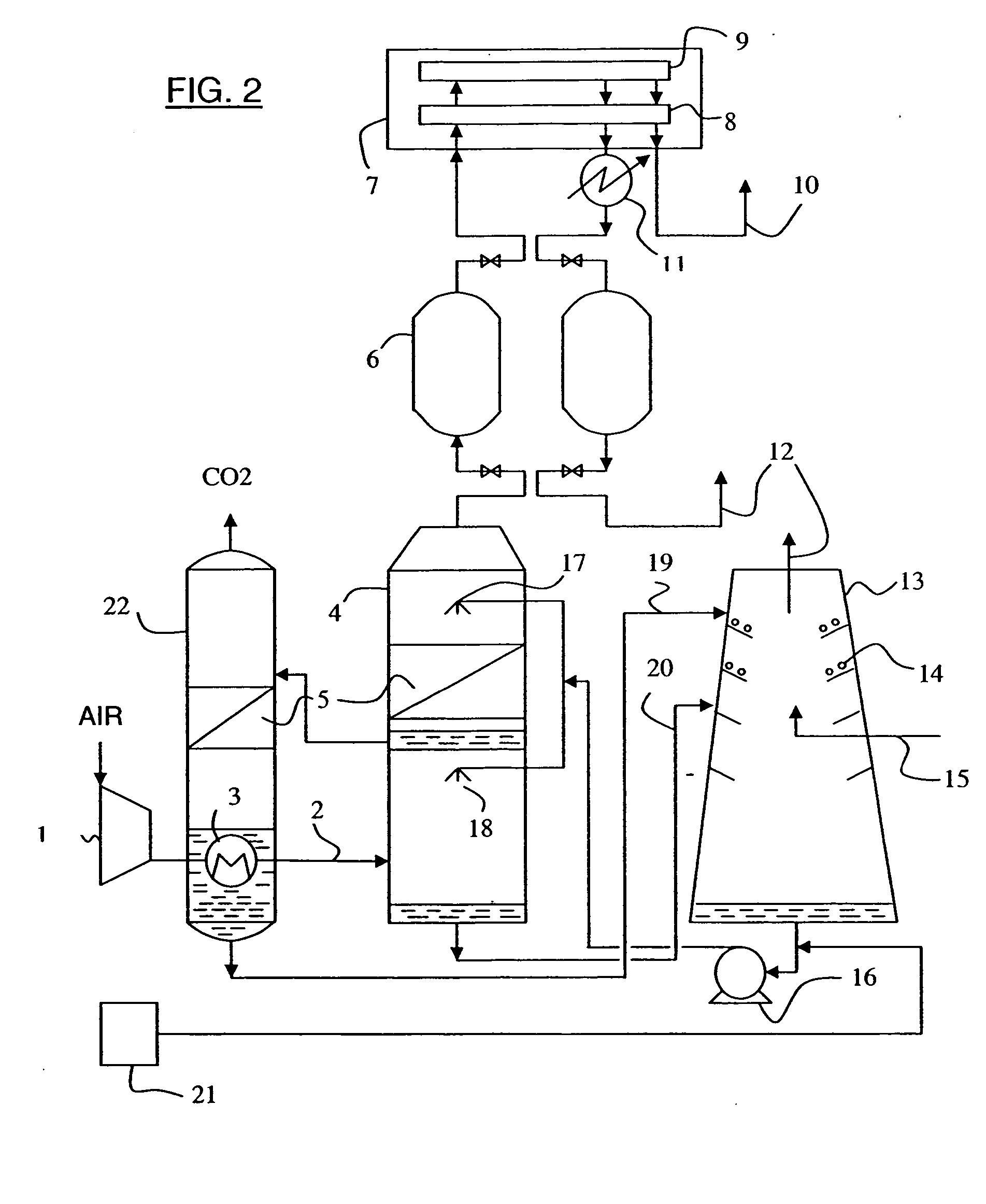

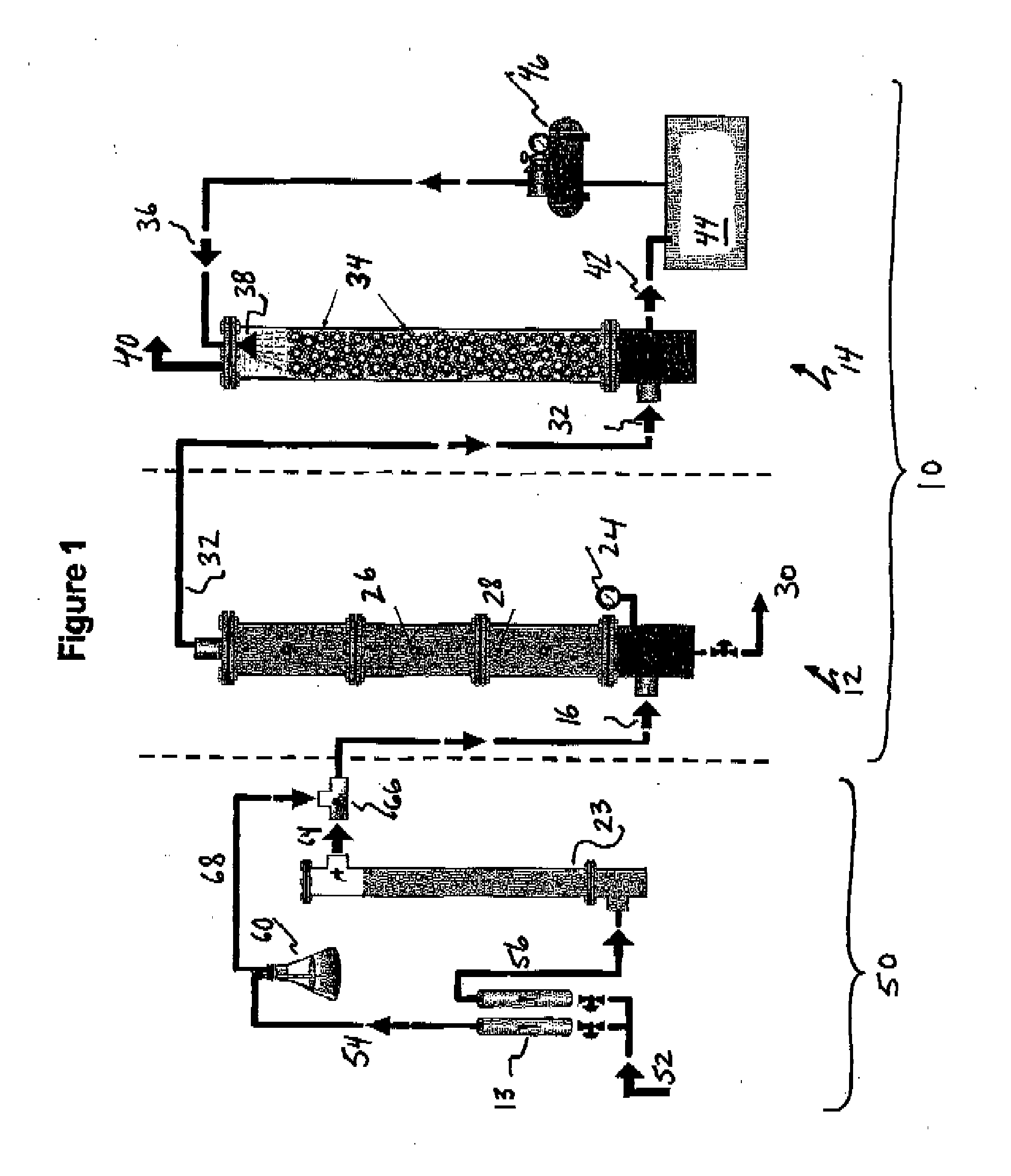

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

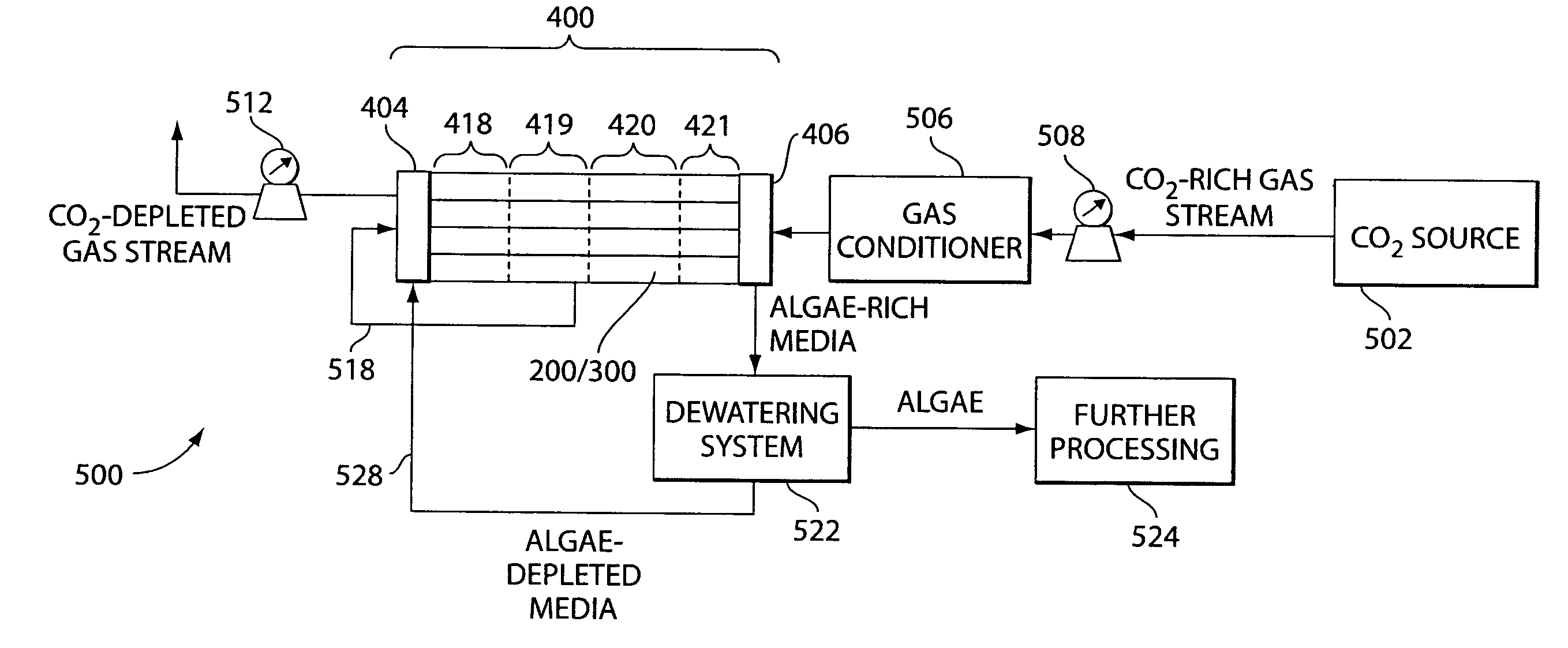

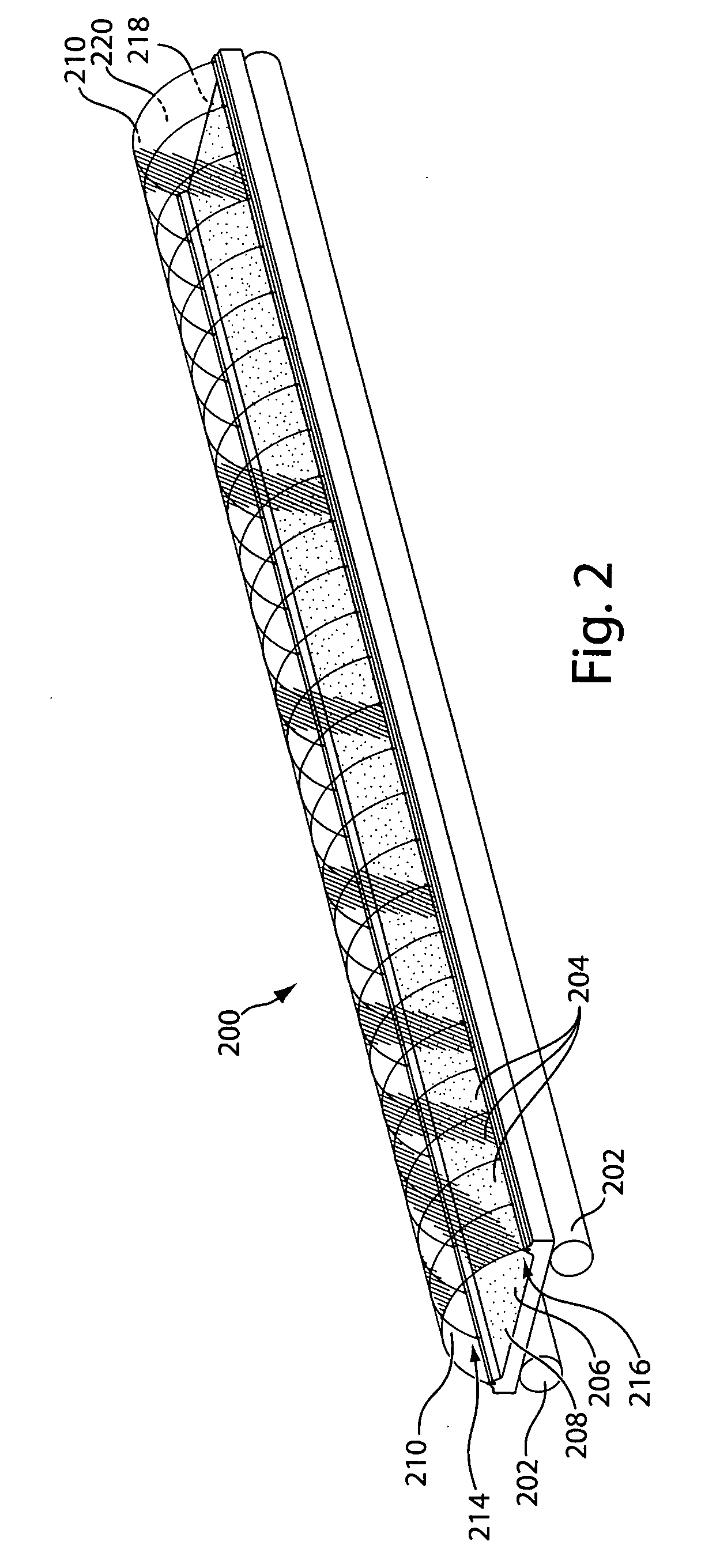

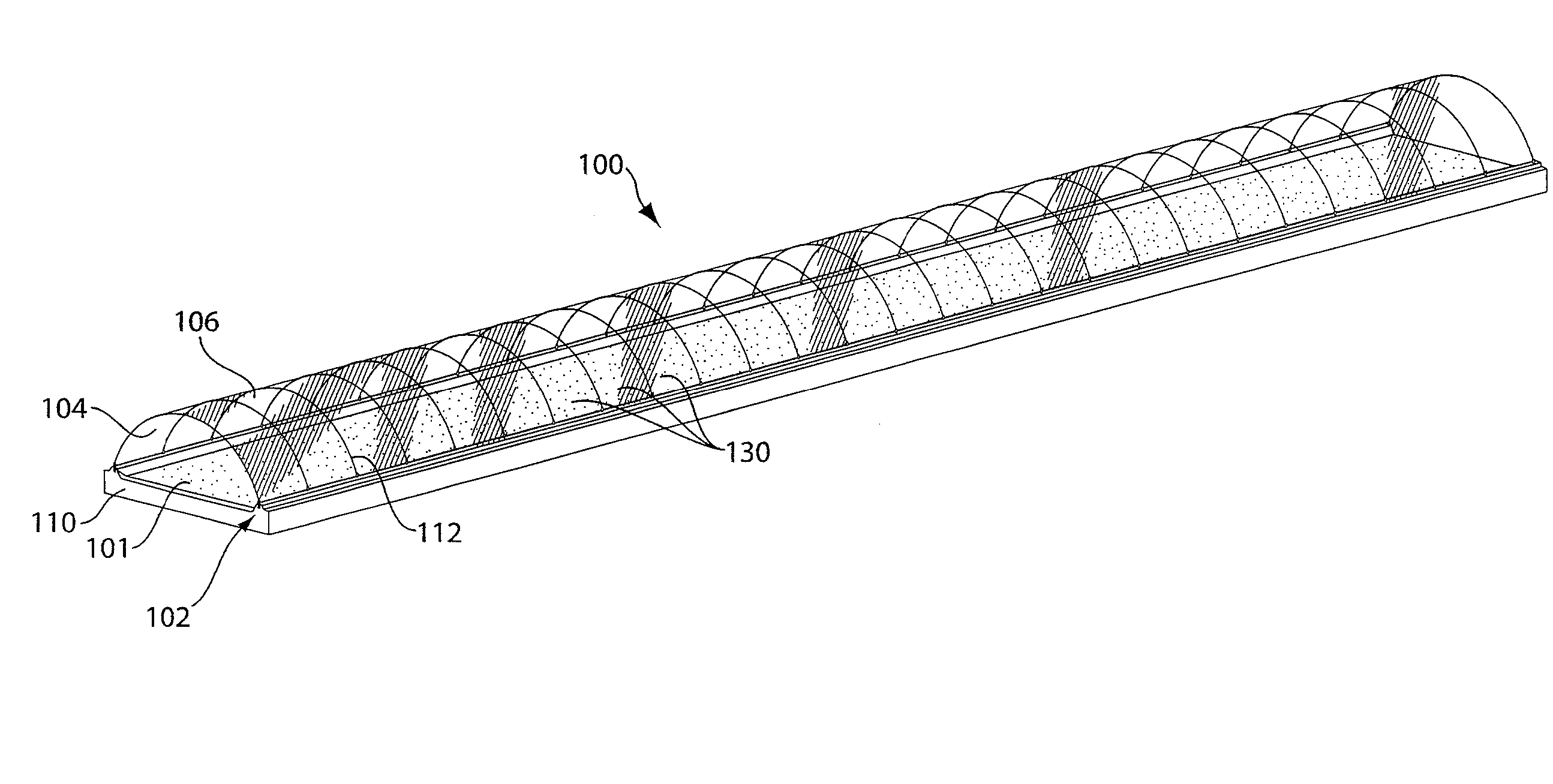

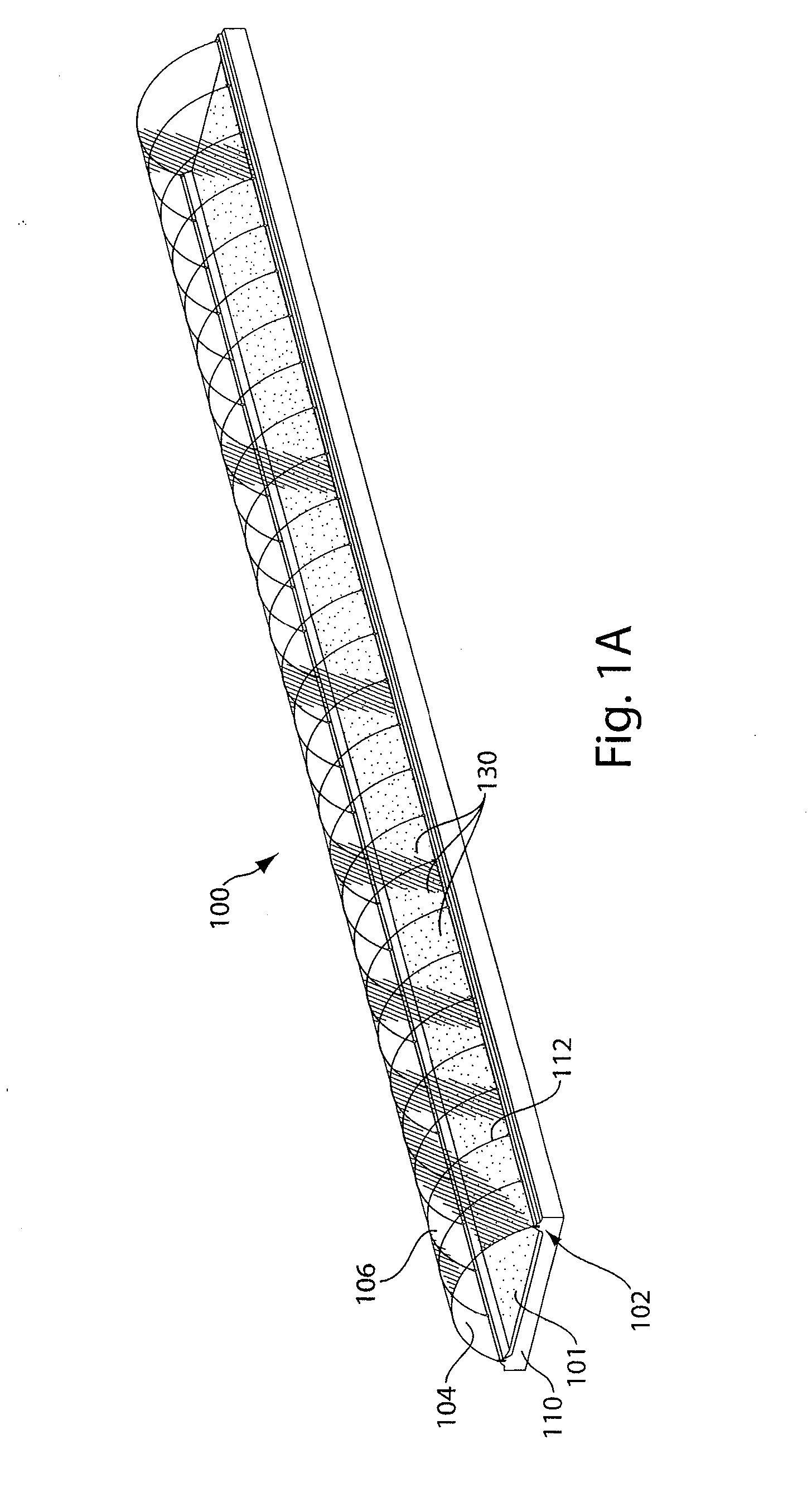

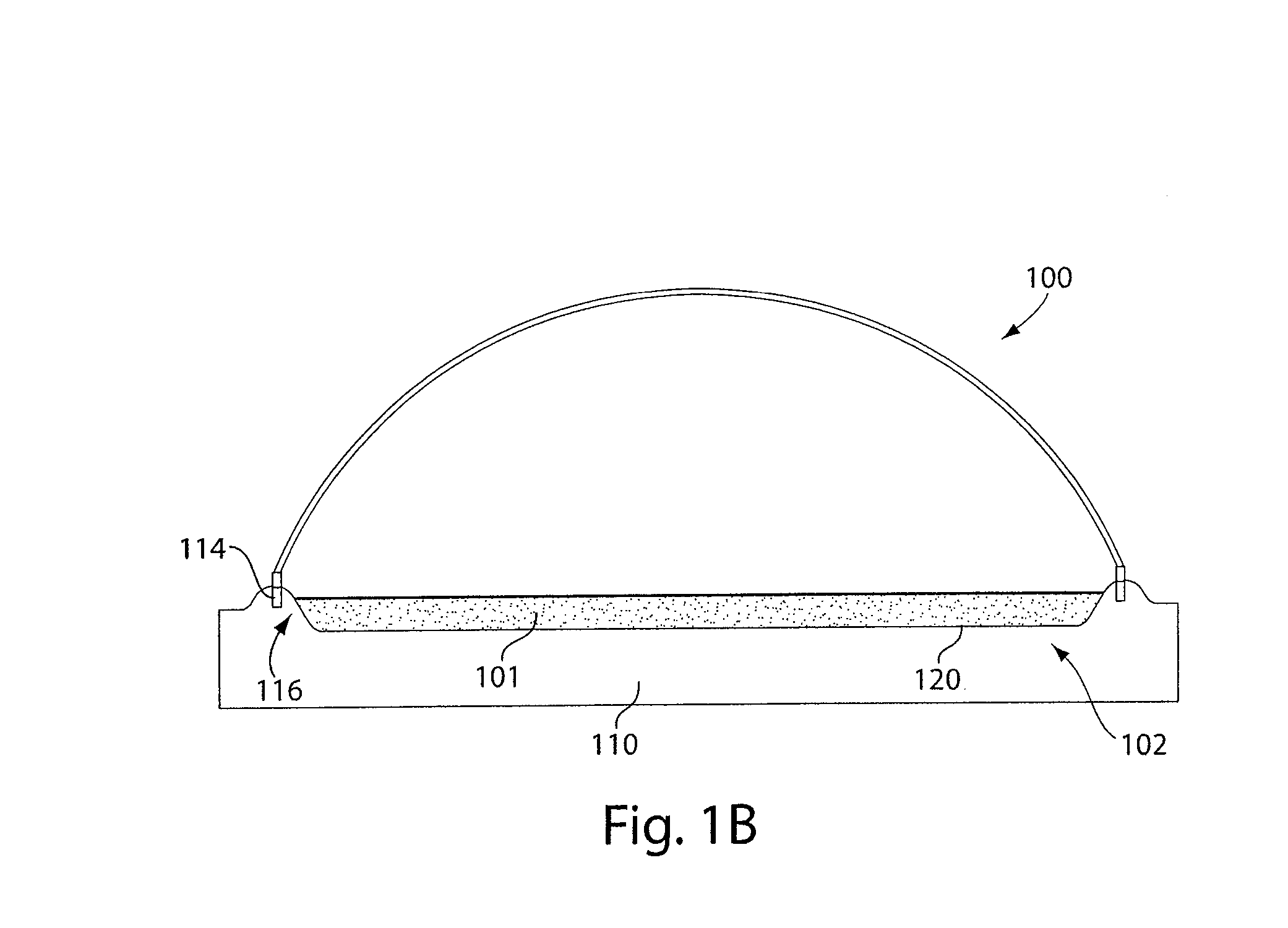

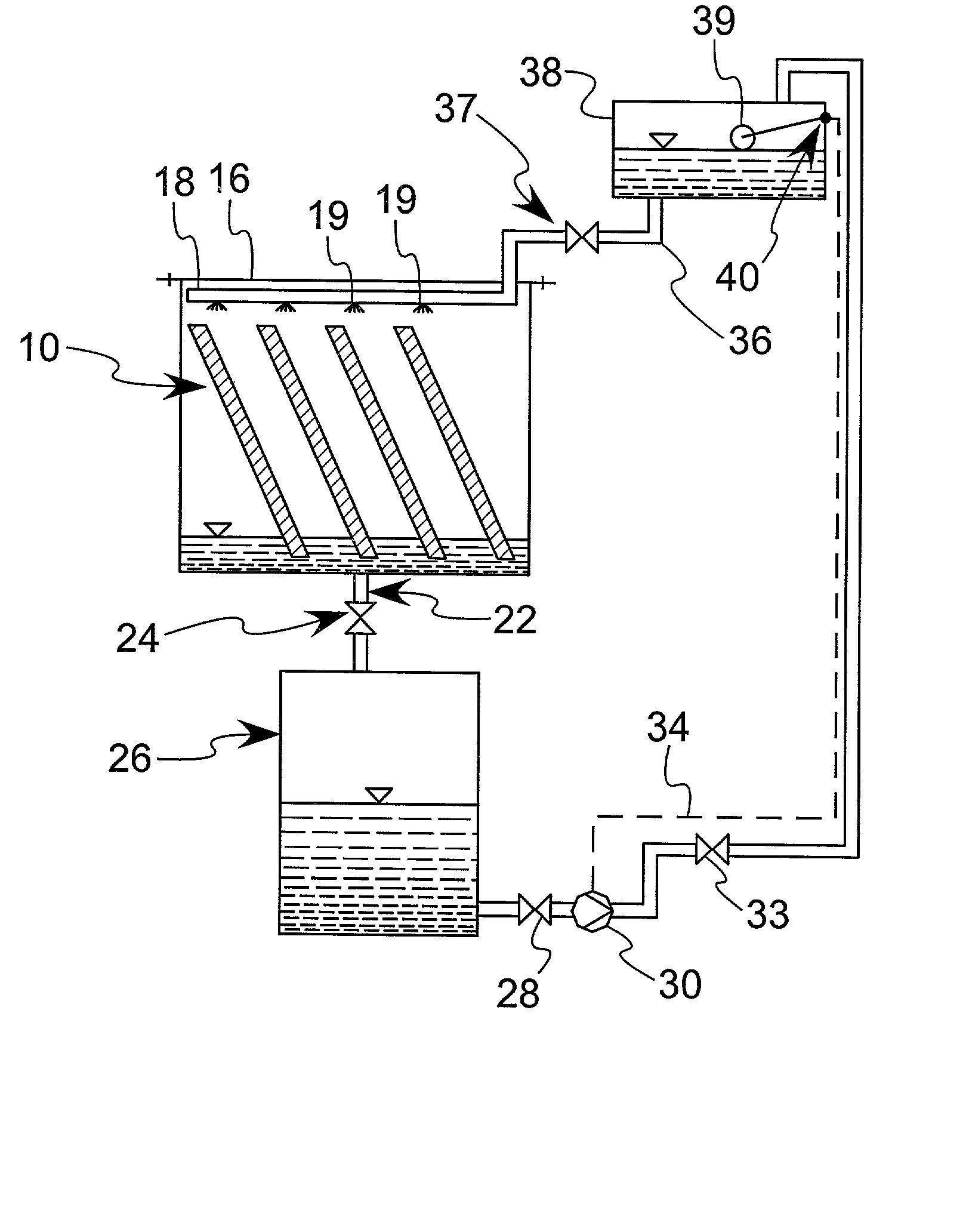

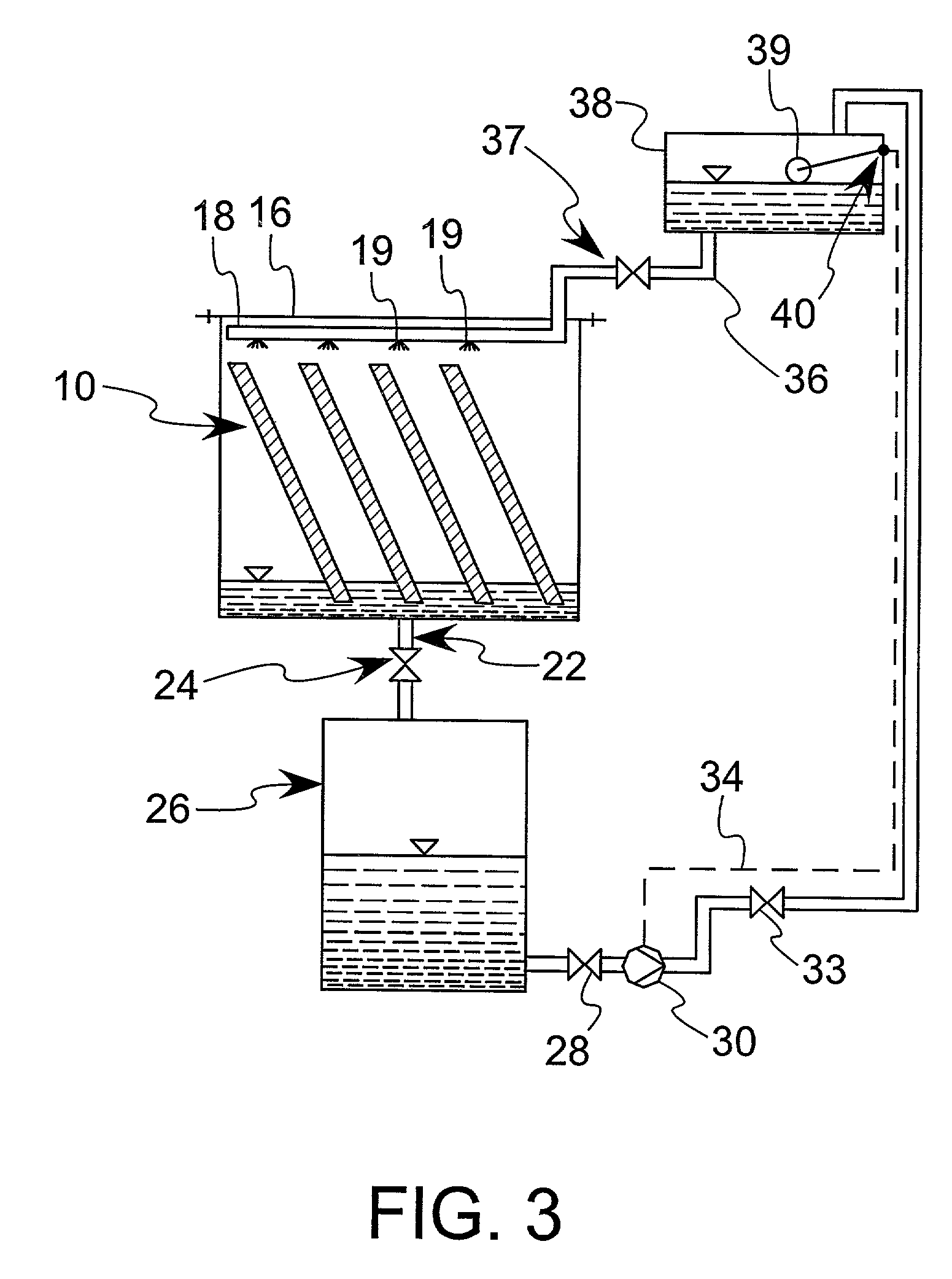

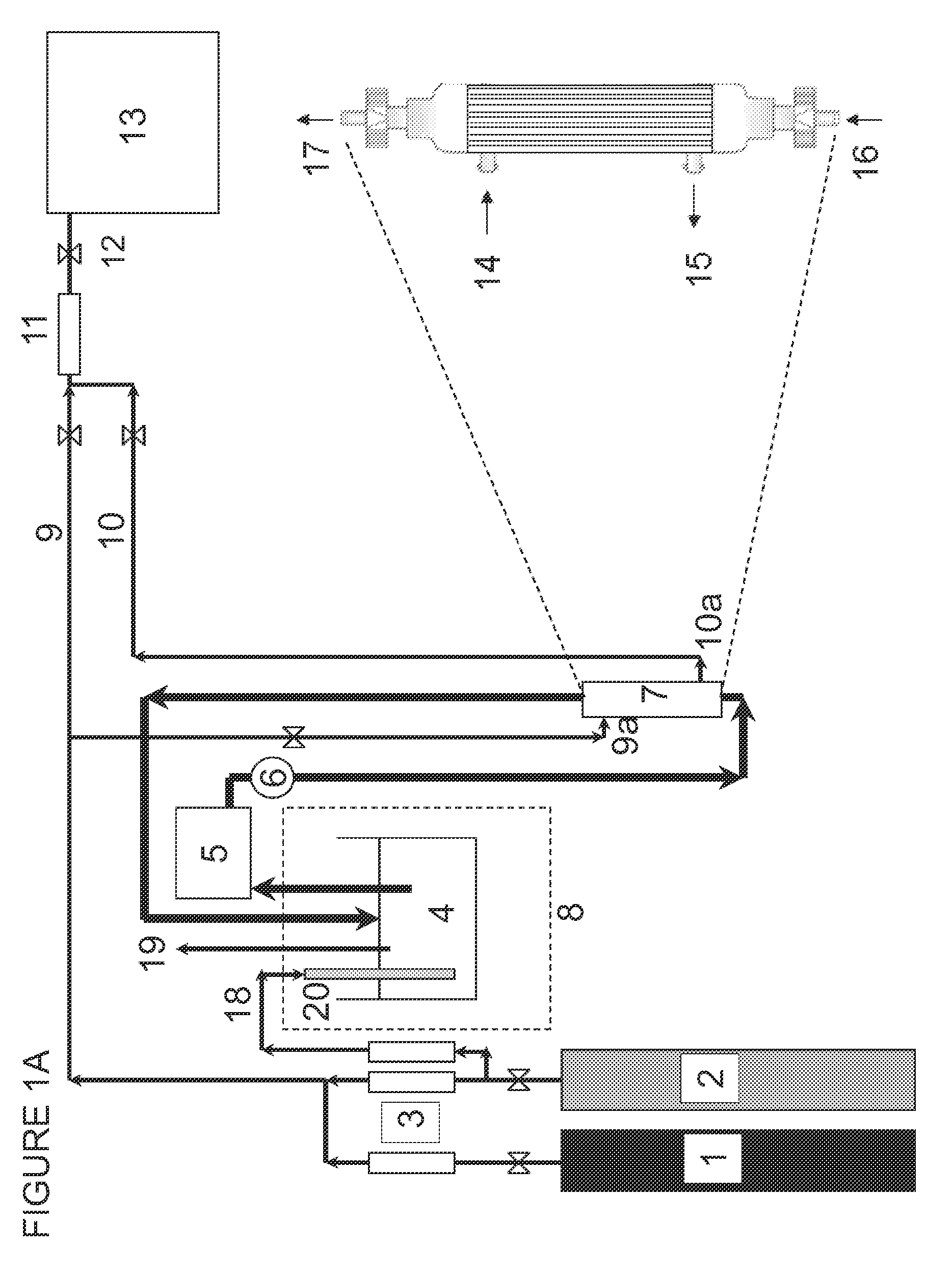

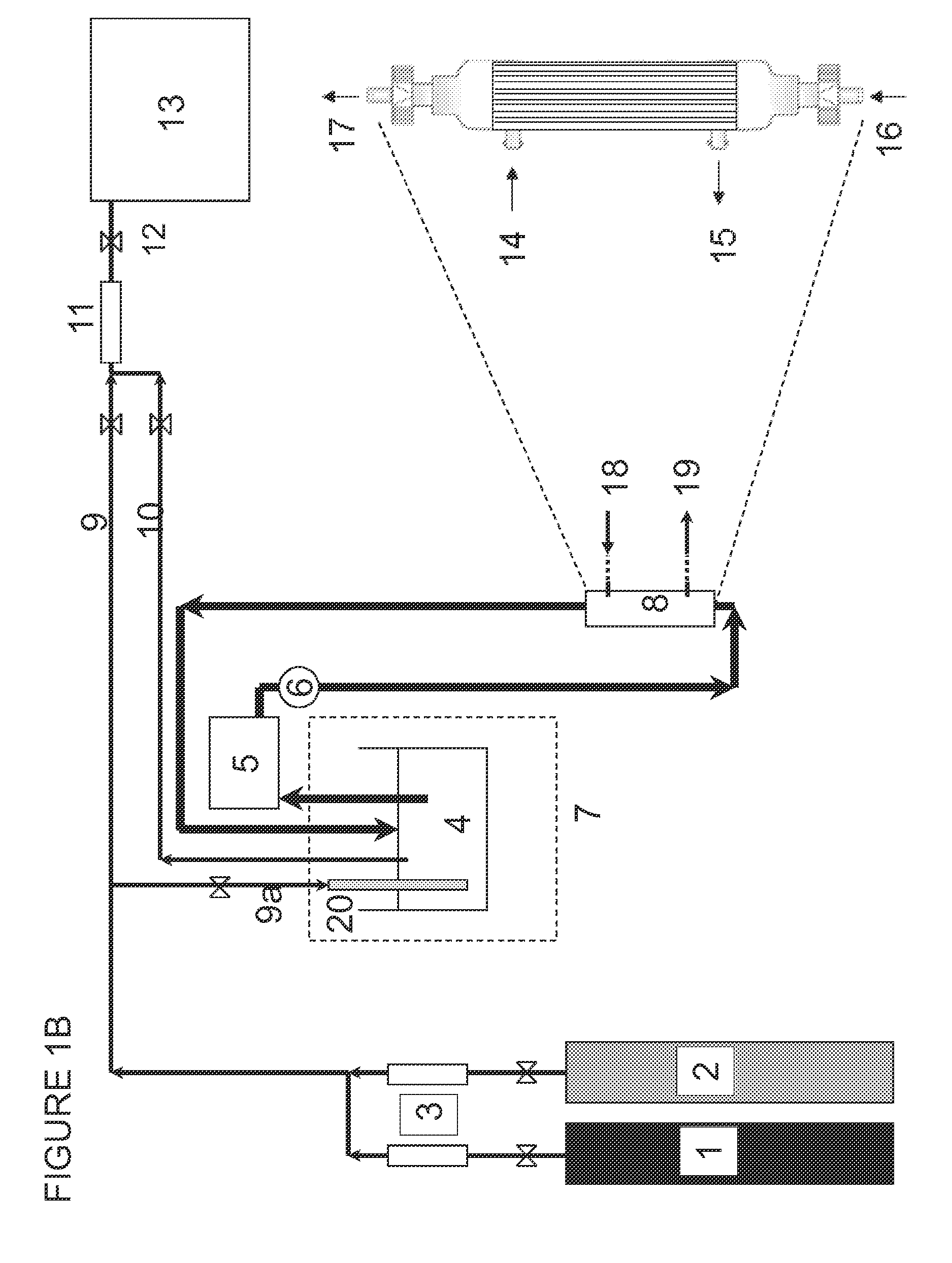

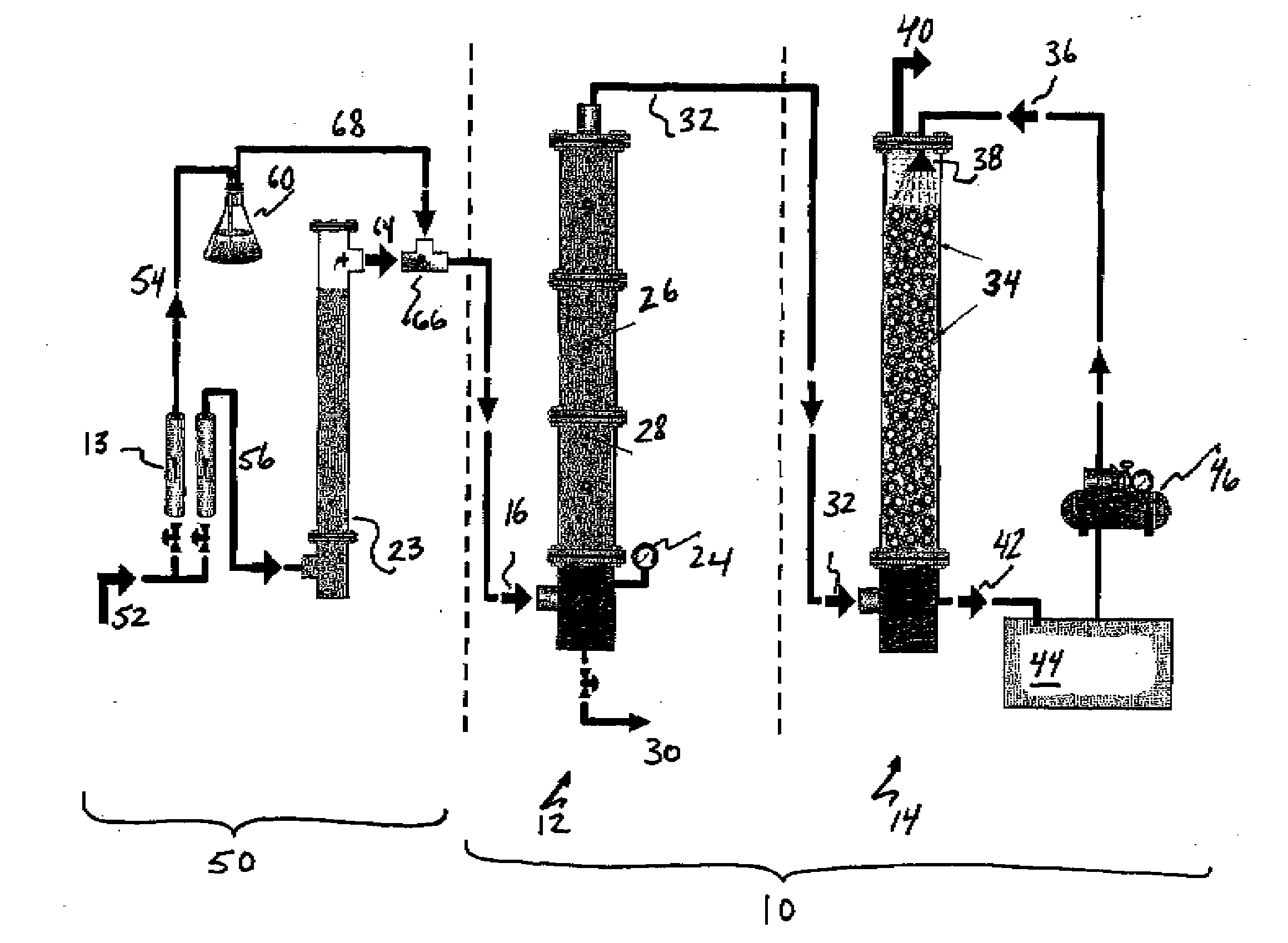

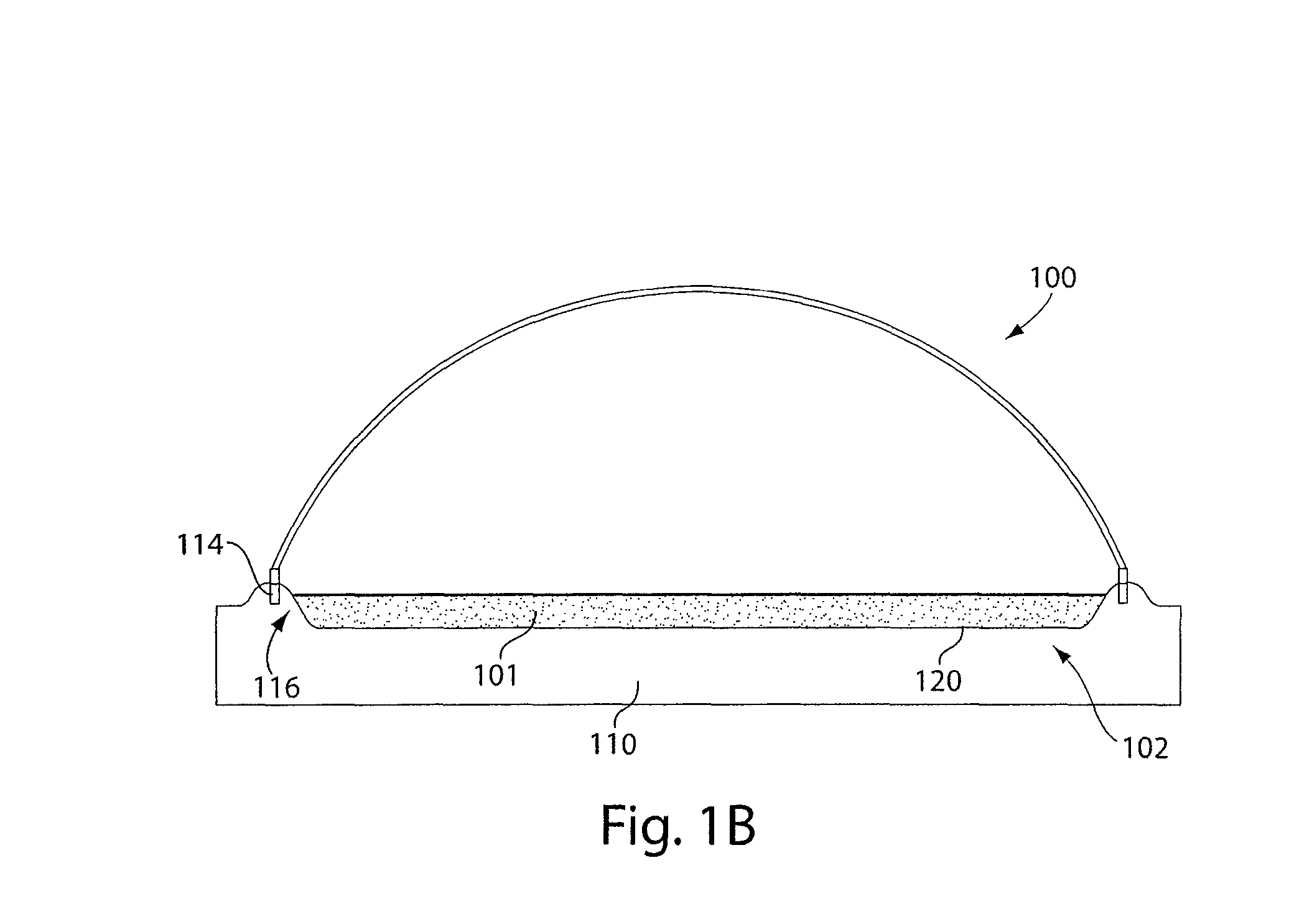

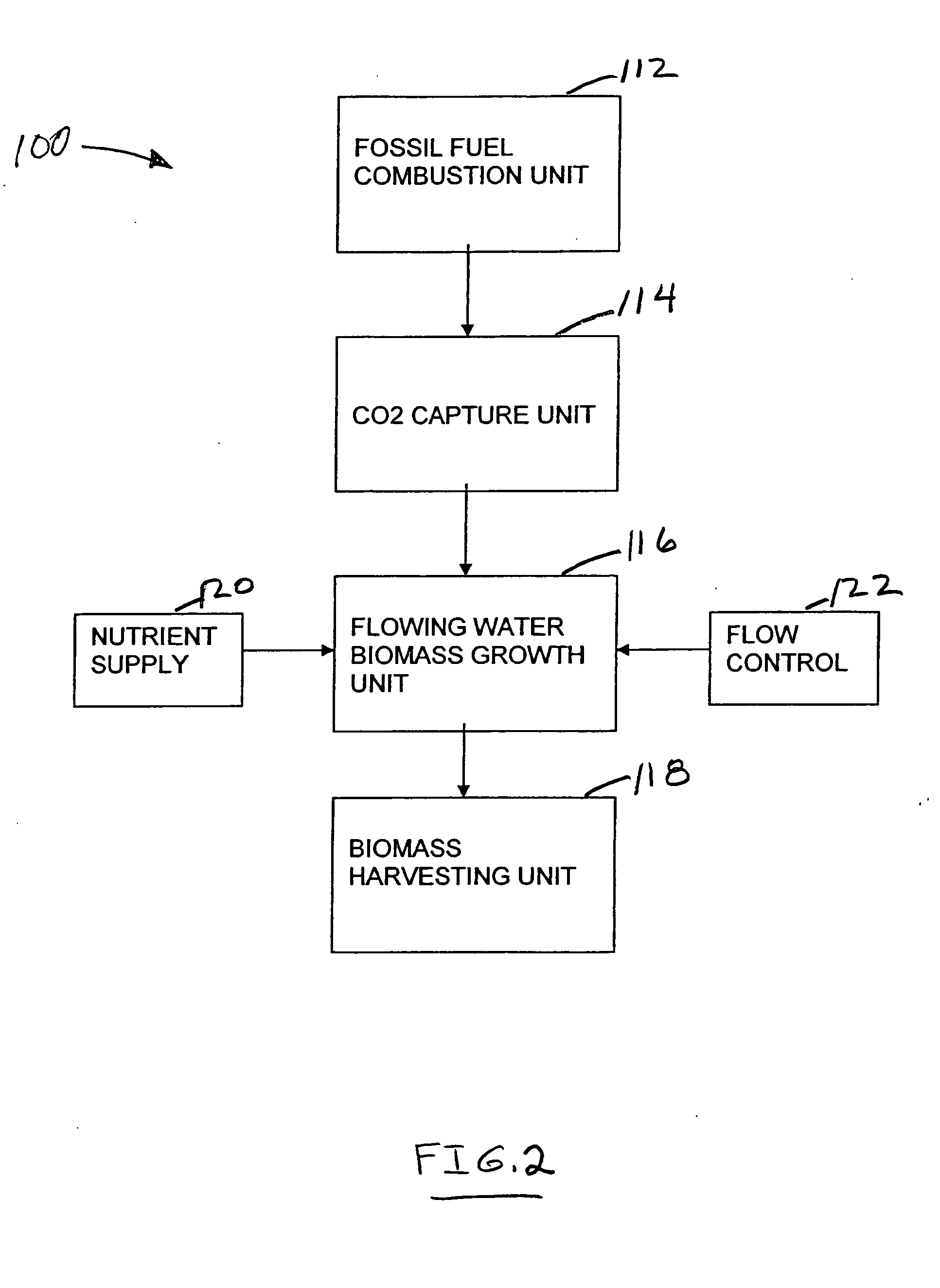

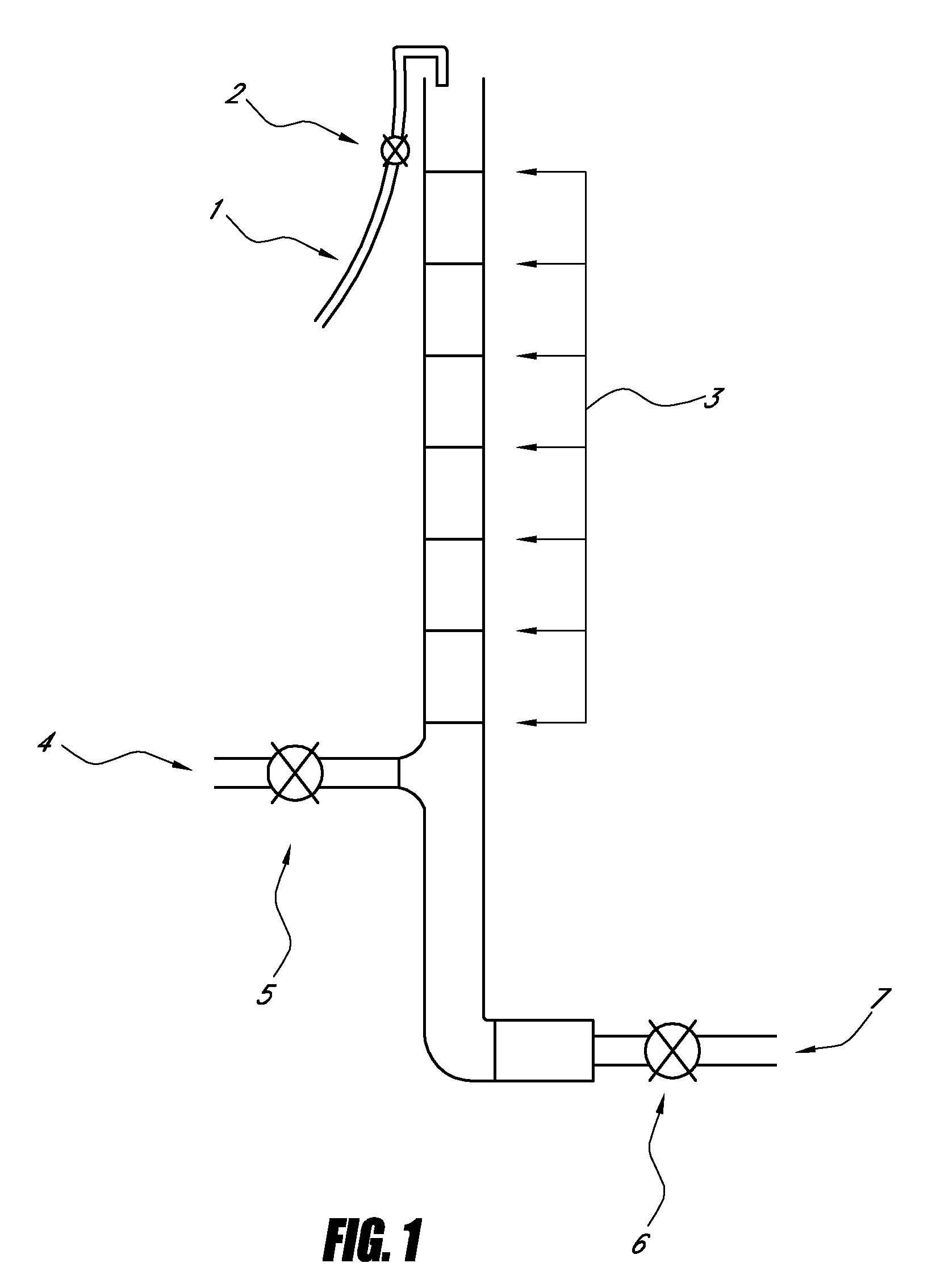

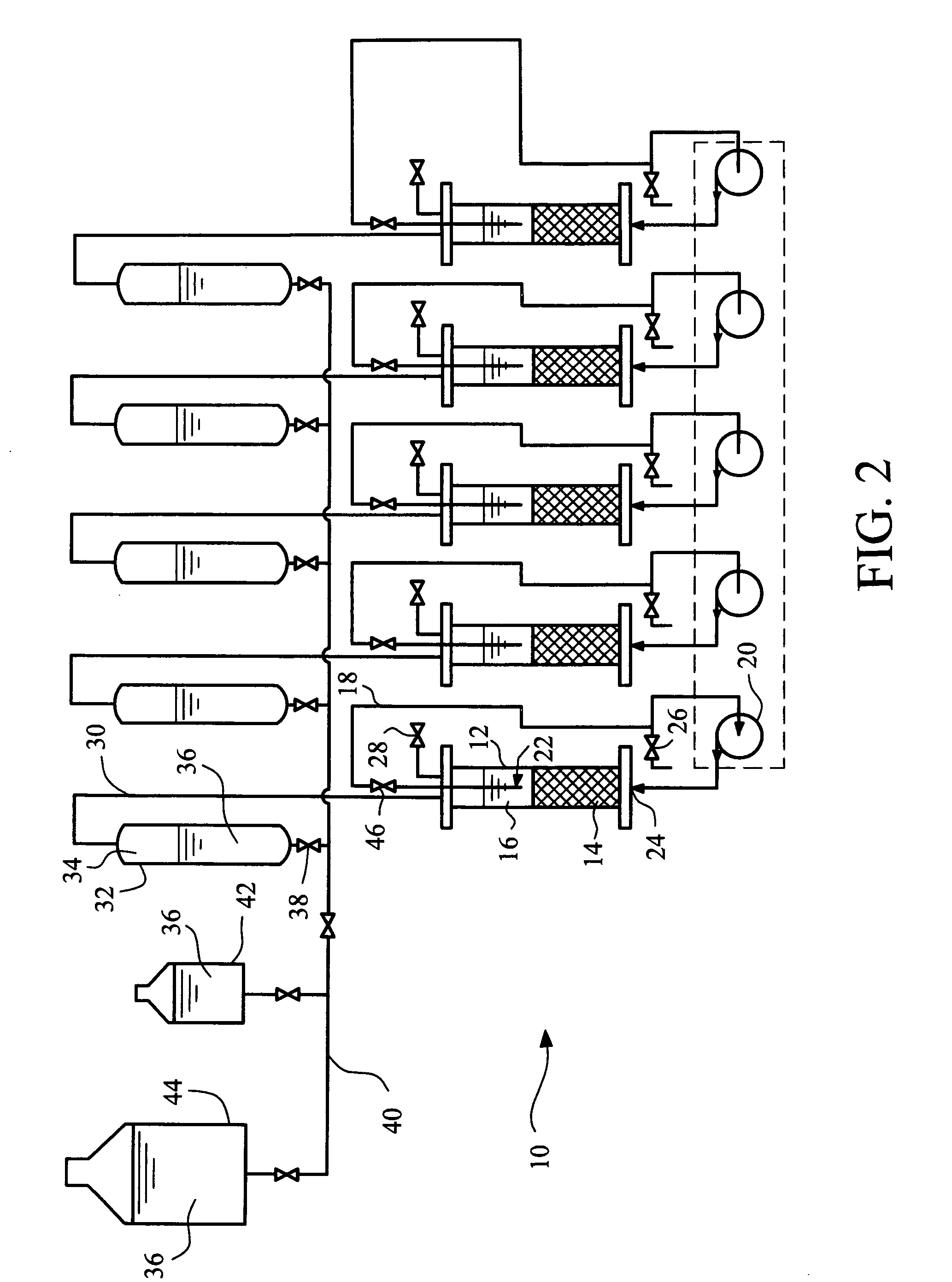

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS20080178739A1Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

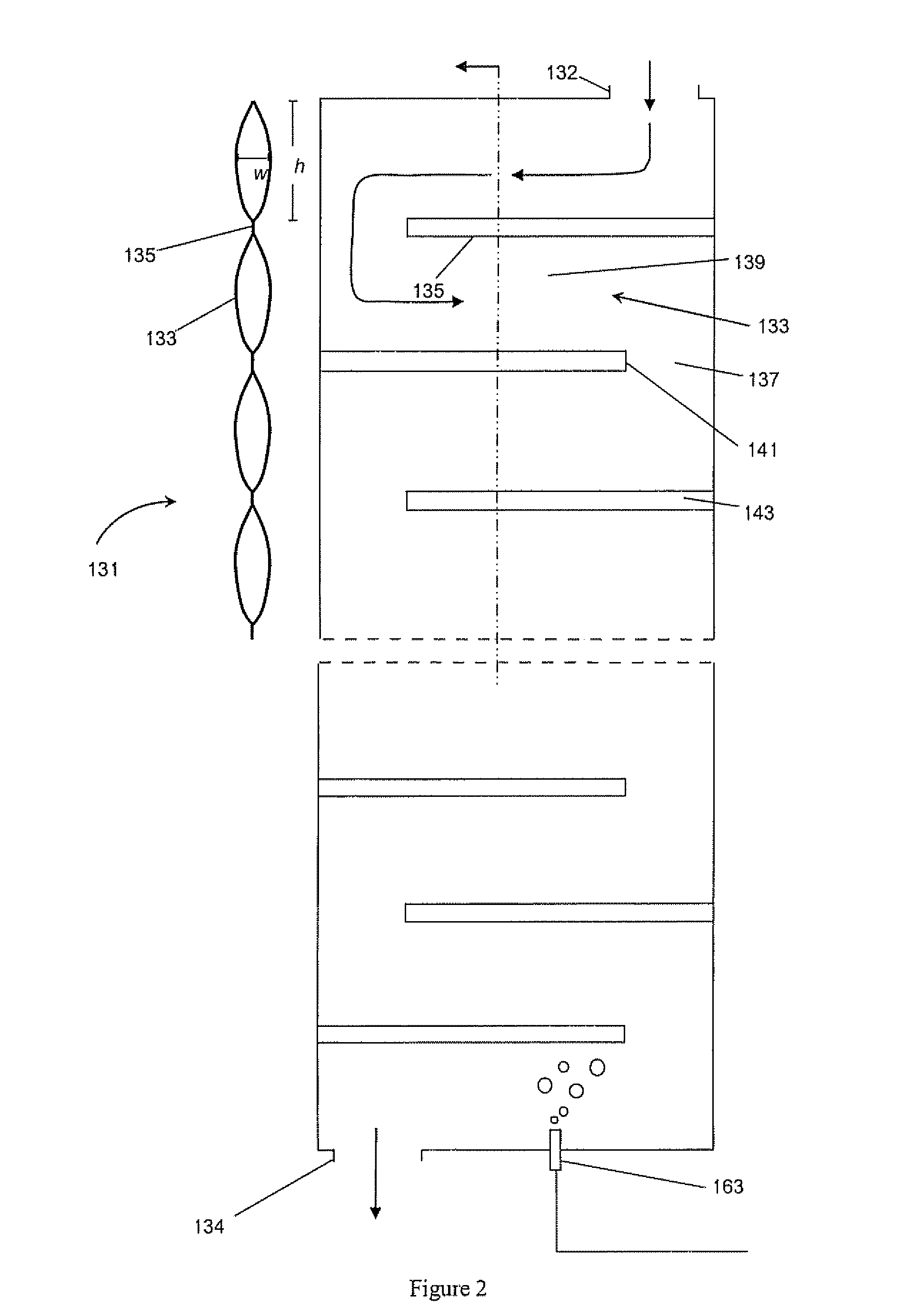

Certain embodiments and aspects of the present invention relate to a photobioreactor including covered photobioreactor units through which a liquid medium stream and a gas stream flow. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, a portion of the liquid medium is diverted from a photobioreactor unit and reintroduced upstream of the diversion position. In certain embodiments, the disclosed photobioreactor system, methods of using such systems, and / or gas treatment apparatus and methods provided herein can be used as part of an integrated combustion method and system, wherein photosynthetic organisms used within the photobioreactor are harvested from the photobioreactor, processed, and used as a fuel source for a combustion system such as an electric power plant.

Owner:THE TRON GRP

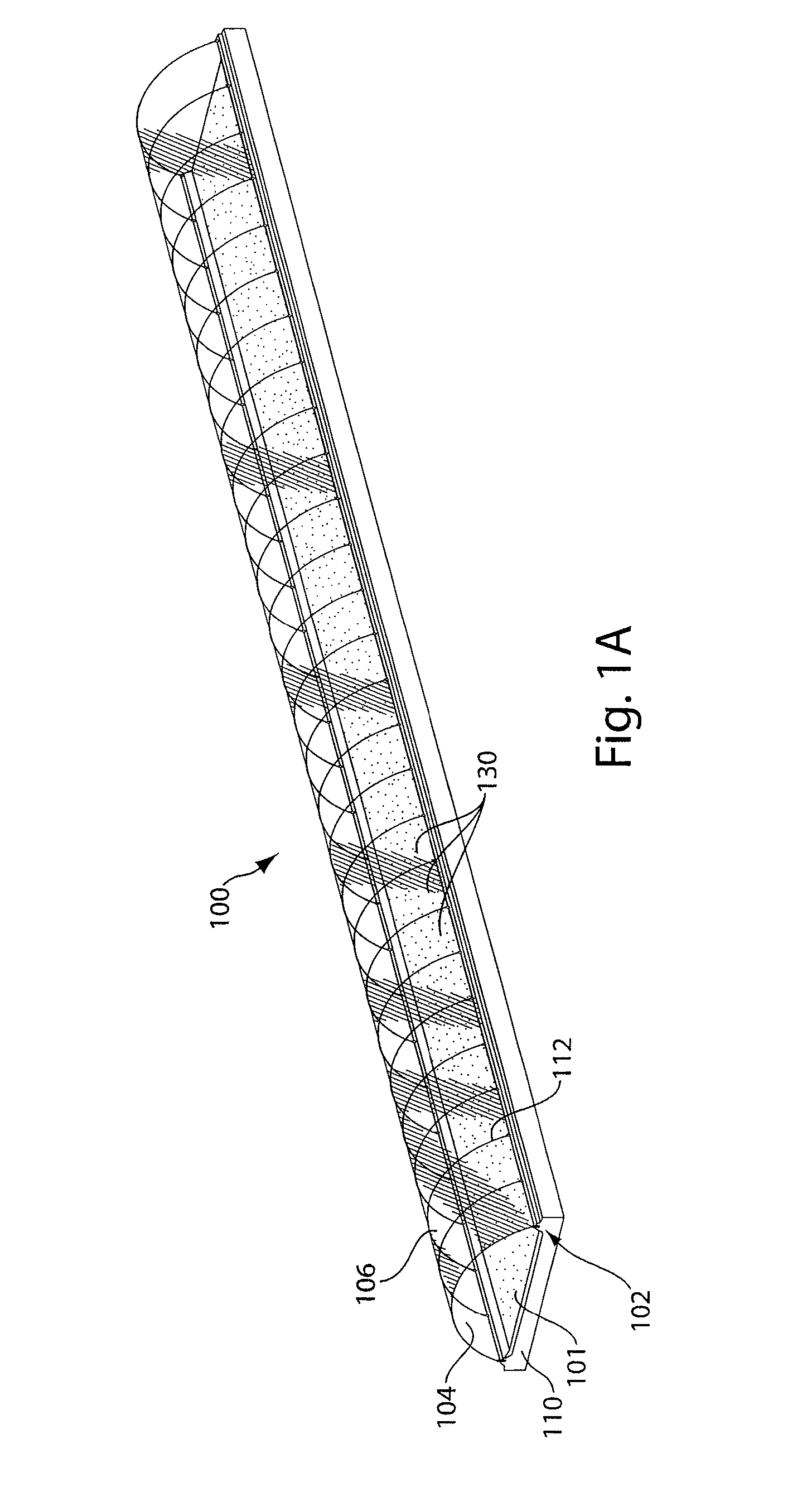

Method and apparatus for co2 sequestration

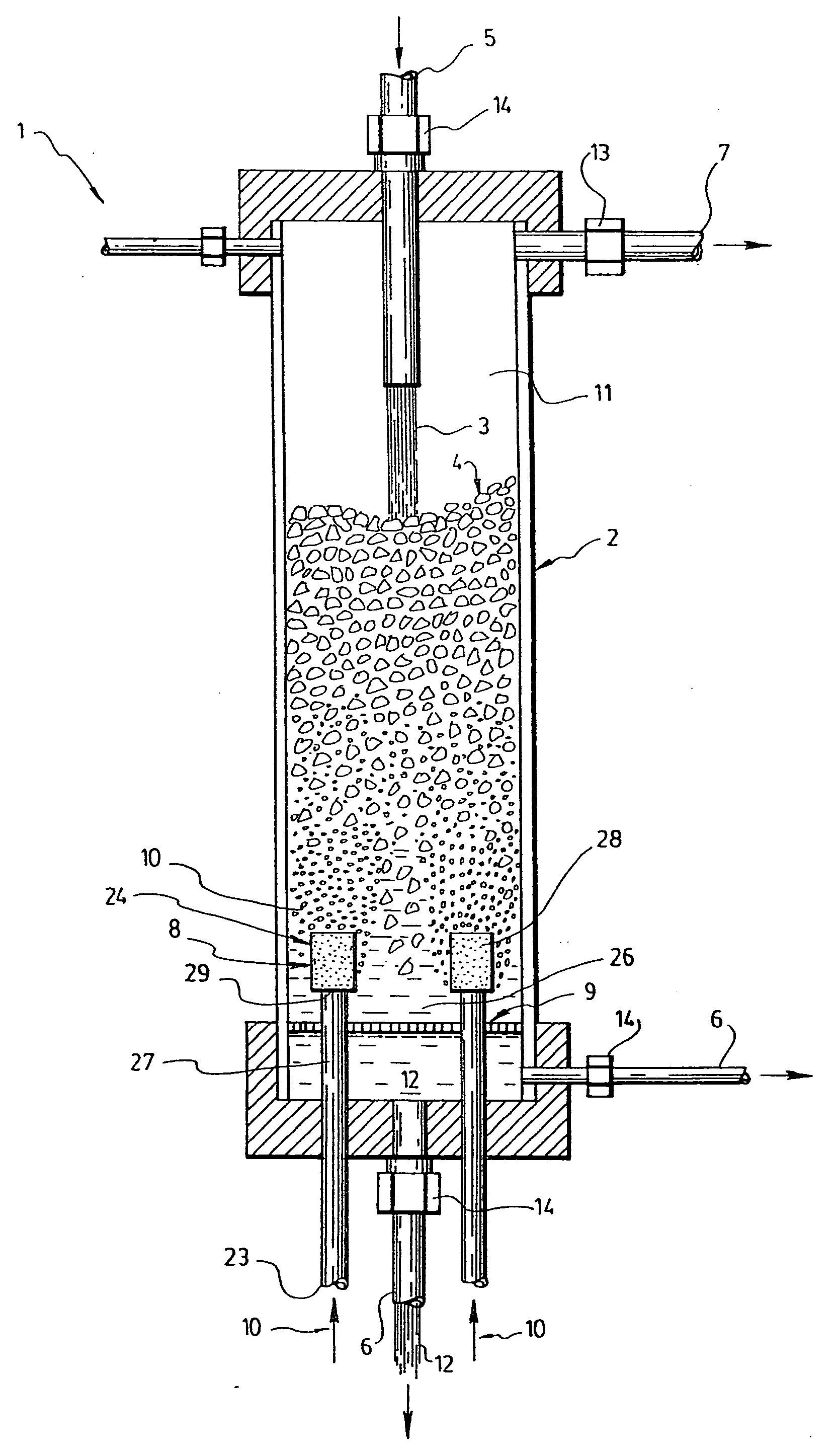

InactiveUS20070289206A1Easy to manufactureIncrease surface areaBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBioreactor

A method and apparatus for sequestering CO2 using algae comprises a plurality of vertically suspended bioreactors, each bioreactor being translucent and including a flow channel formed by a plurality of baffles. A culture tank contains a suspension of water and at least one algae and includes a plurality of gas jets for introducing a CO2-containing gas into the suspension. The culture tank is in fluid communication with an inlet in each channel for flowing the suspension through the channel in the presence of light. A pump pumps the suspension into the channel inlet.

Owner:KERTZ MALCOLM GLEN

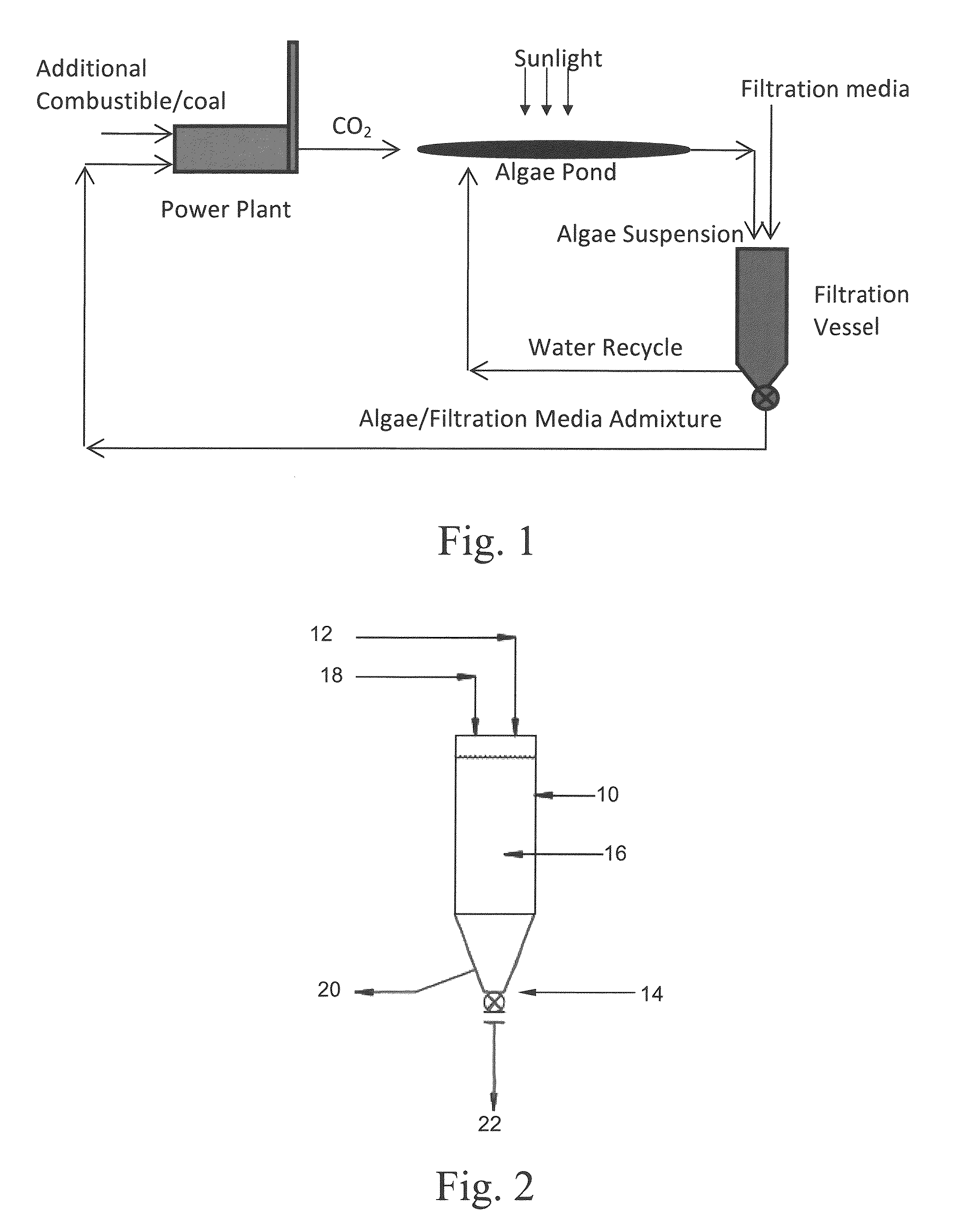

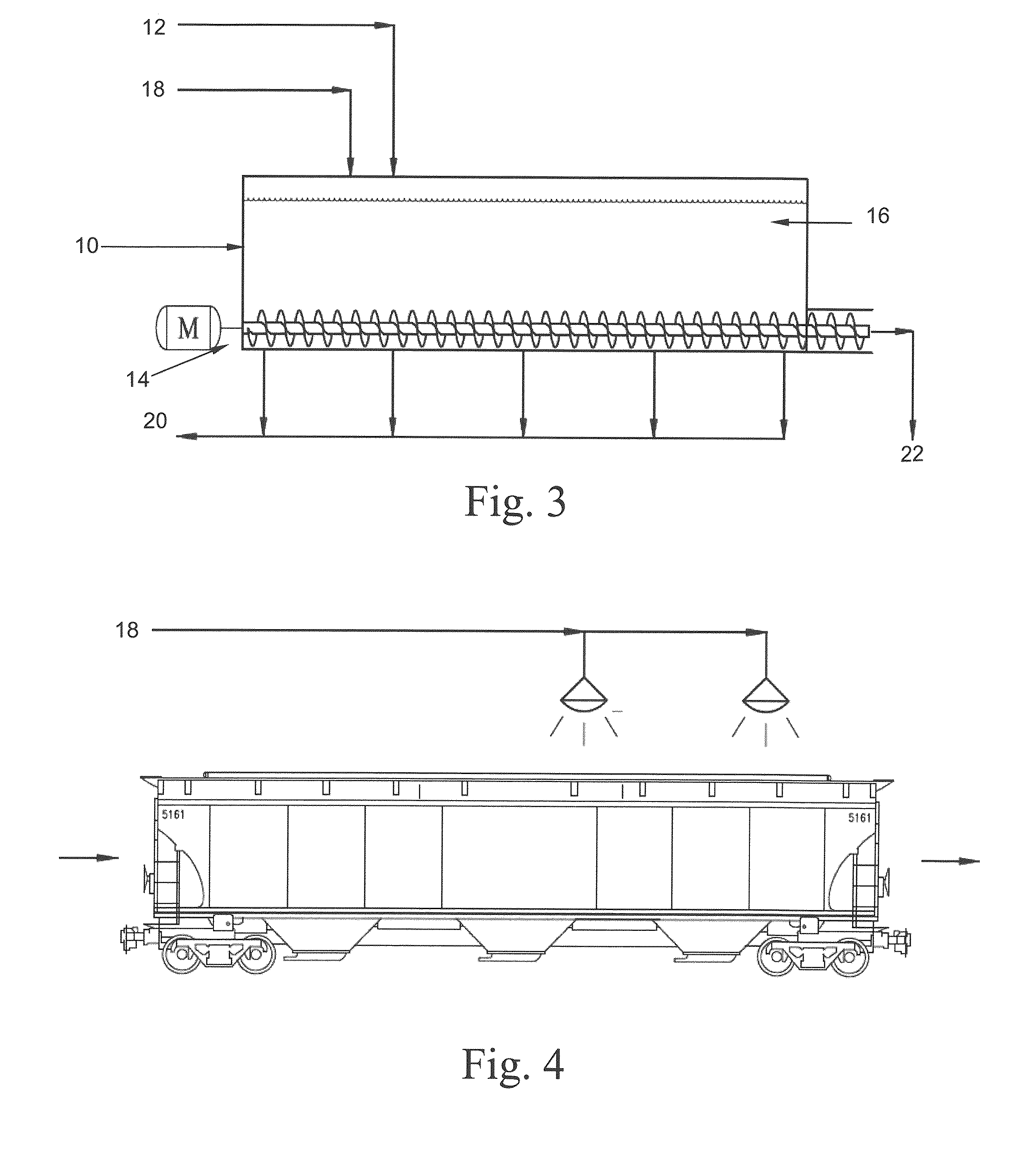

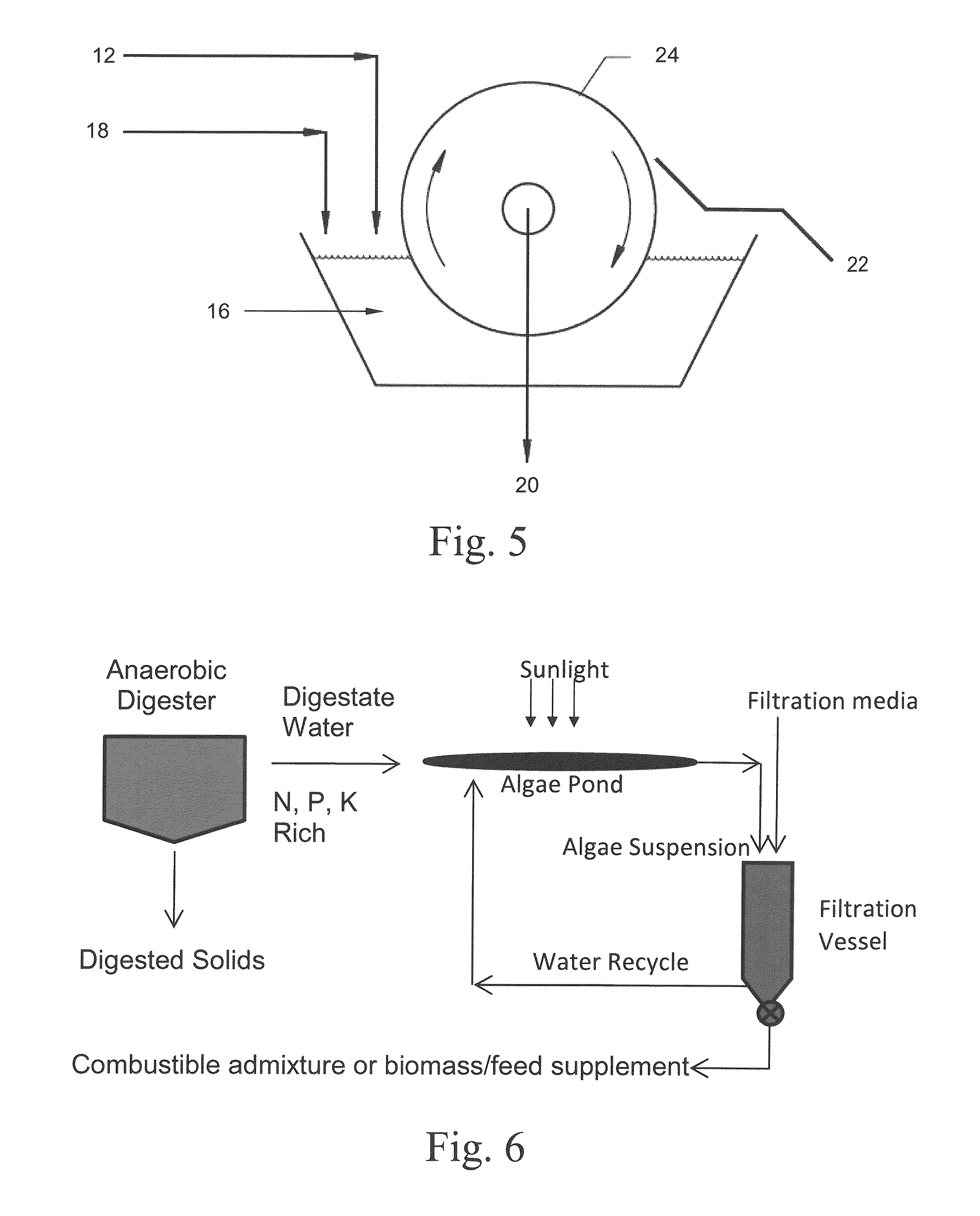

Methods of algae harvesting utilizing a filtering substance and uses therefor

InactiveUS20110143012A1High combustion valueHigh nutritional valueFatty oils/acids recovery from wasteLiquid separation auxillary apparatusFood supplementFiltration

Methods of harvesting algae, and using algae as a biofuel, livestock feed, or food supplement are provided. The methods comprise contacting liquid algae suspensions with a filtration media. Depending upon the filtration media, the resulting algae and filtration media admixture is then utilized as a biofuel, livestock feed, food supplements, or for the extraction of algae oil. Admixtures comprising a combustible filtration media, such as coal, are particularly preferred. The methods are suitable for use with any algae species. Compositions for use as a biofuel, livestock feed, or food supplement are also provided. These compositions comprise an admixture of algae and a filtration media.

Owner:RETTENMAIER ALBERT C

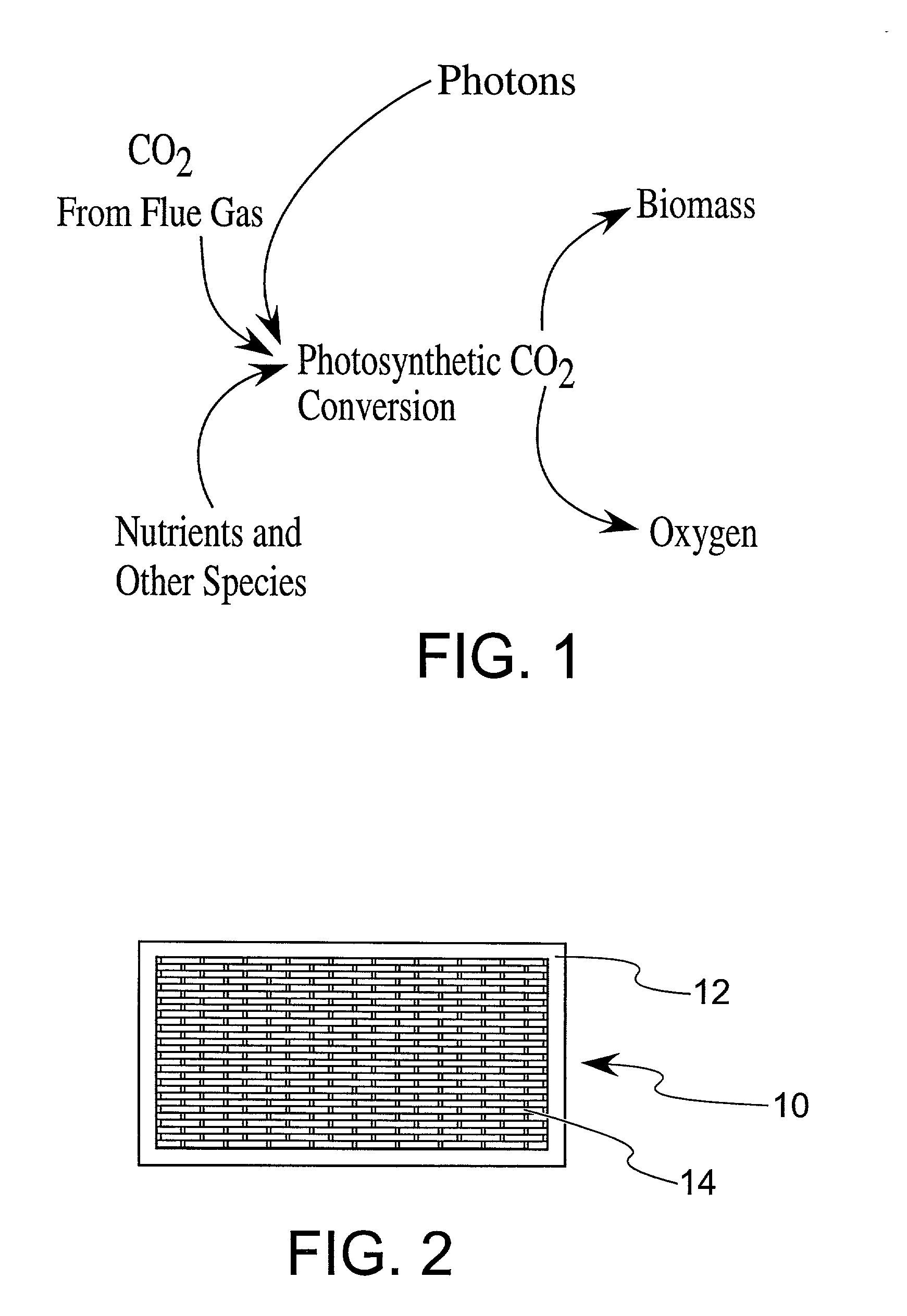

Enhanced practical photosynthetic CO2 mitigation

InactiveUS20020072109A1Increase the amount of waterBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismCyanobacteria

This process is unique in photosynthetic carbon sequestration. An on-site biological sequestration system directly decreases the concentration of carbon-containing compounds in the emissions of fossil generation units. In this process, photosynthetic microbes are attached to a growth surface arranged in a containment chamber that is lit by solar photons. A harvesting system ensures maximum organism growth and rate of CO2 uptake. Soluble carbon and nitrogen concentrations delivered to the cyanobacteria are enhanced, further increasing growth rate and carbon utilization.

Owner:OHIO UNIV

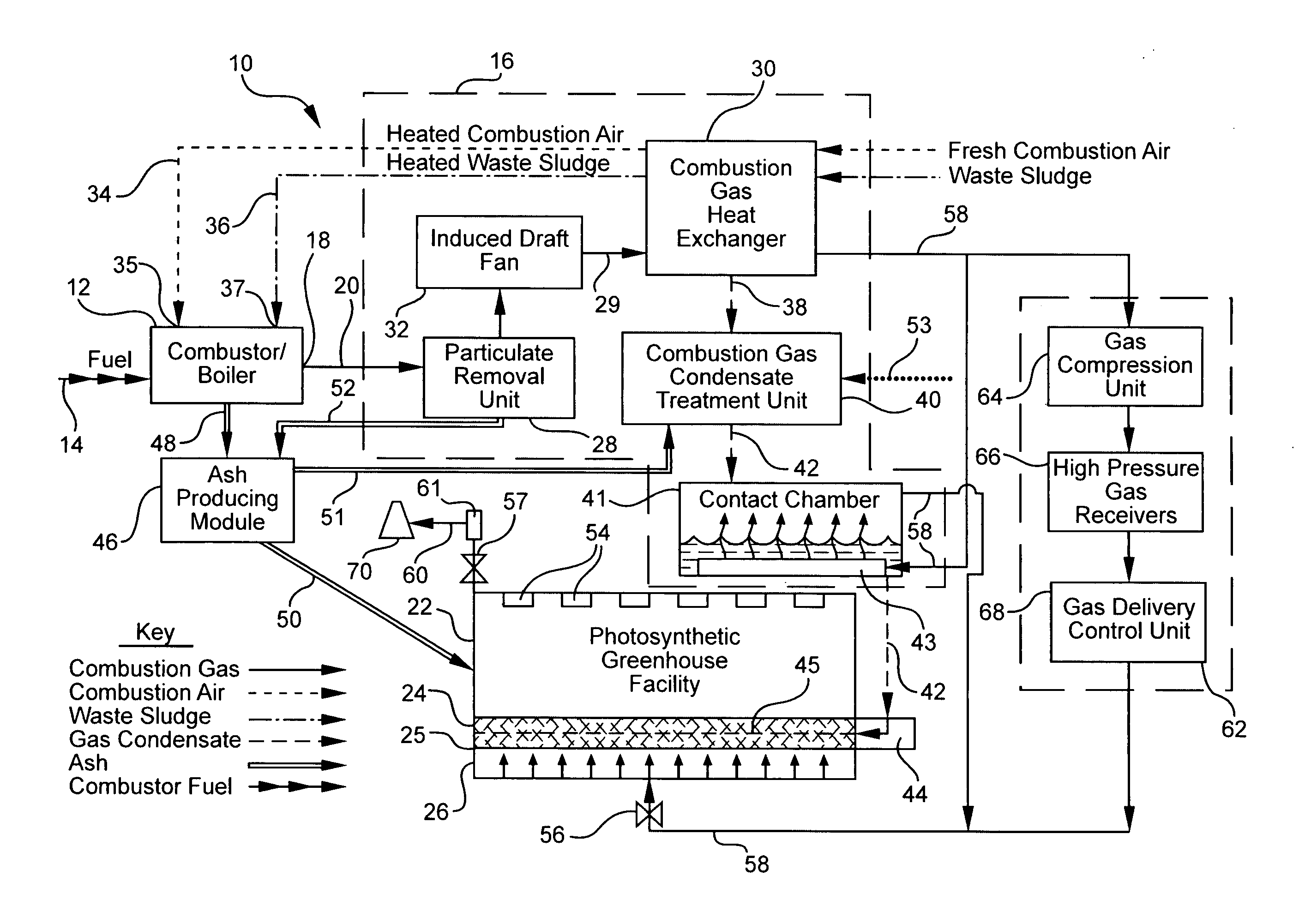

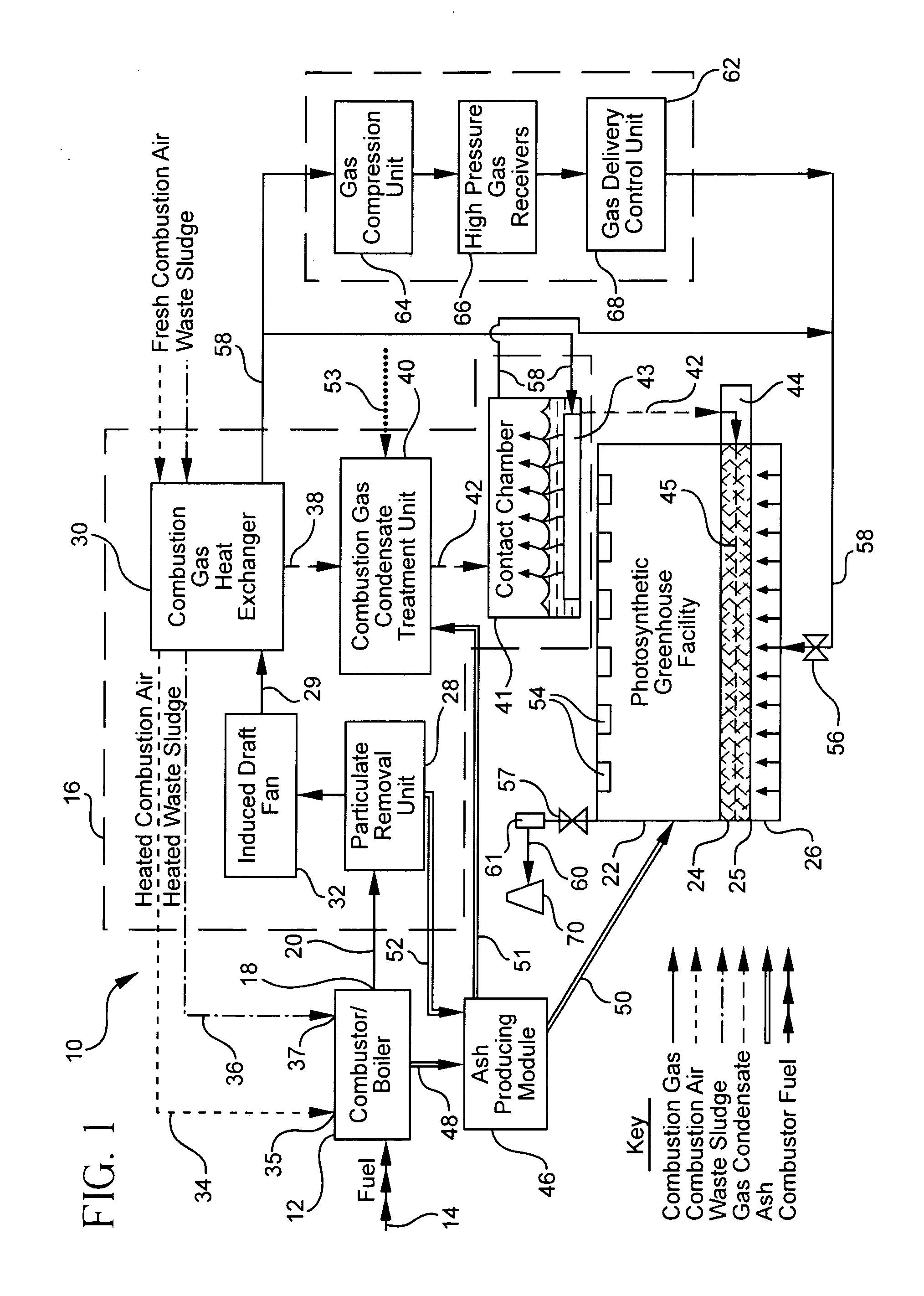

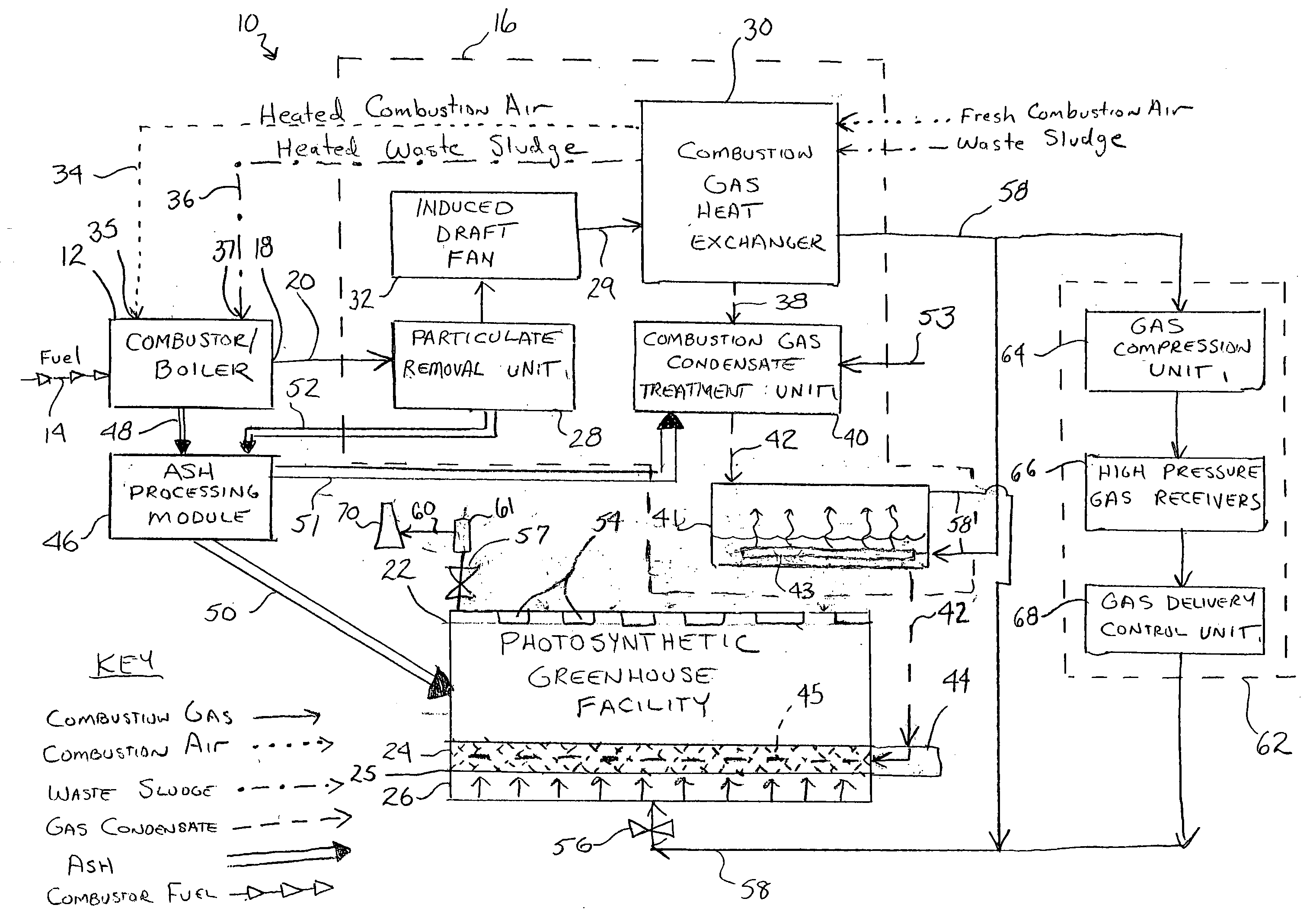

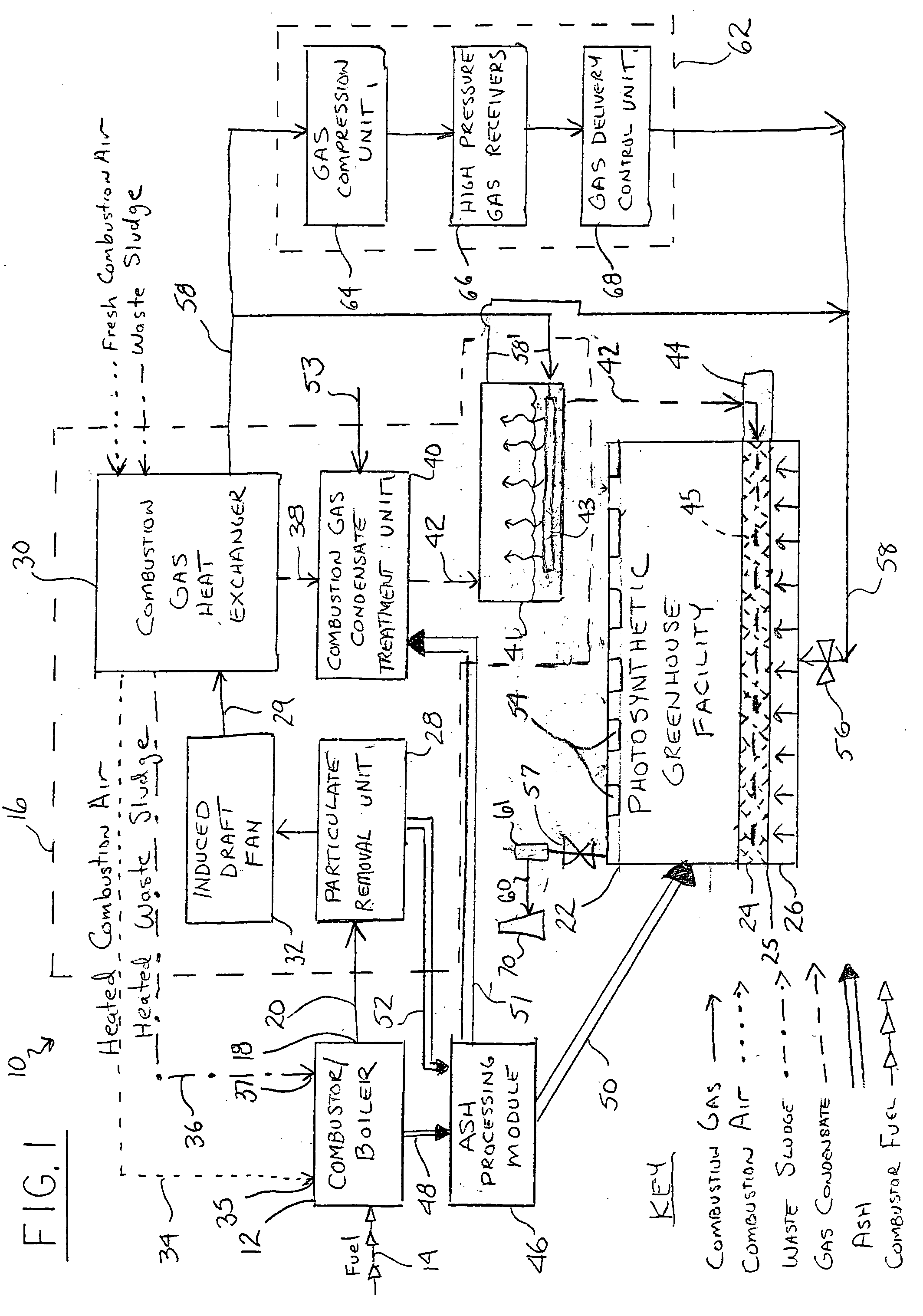

Method and system for sequestering carbon emissions from a combustor/boiler

A system for sequestering carbon emissions from a fuel combustor generally includes a combustion gas extraction module for extracting combustion gas from a fuel combustor and a greenhouse facility for receiving the extracted combustion gas and having at least one vegetation supporting soil bed for absorbing carbon dioxide from the received combustion gas. The extraction module includes a particulate removal unit for removing pollutants from the extracted combustion gas and a heat exchanger in downstream fluid communication with the particulate removal unit for cooling the extracted combustion gas.

Owner:ECO TECH LLC

Method and system for sequestering carbon emissions from a combustor/boiler

A system for sequestering carbon emissions from a fuel combustor generally includes a combustion gas extraction module for extracting combustion gas from a fuel combustor and a greenhouse facility for receiving the extracted combustion gas and having at least one vegetation supporting soil bed for absorbing carbon dioxide from the received combustion gas. The extraction module includes a particulate removal unit for removing pollutants from the extracted combustion gas and a heat exchanger in downstream fluid communication with the particulate removal unit for cooling the extracted combustion gas.

Owner:ECO TECH LLC

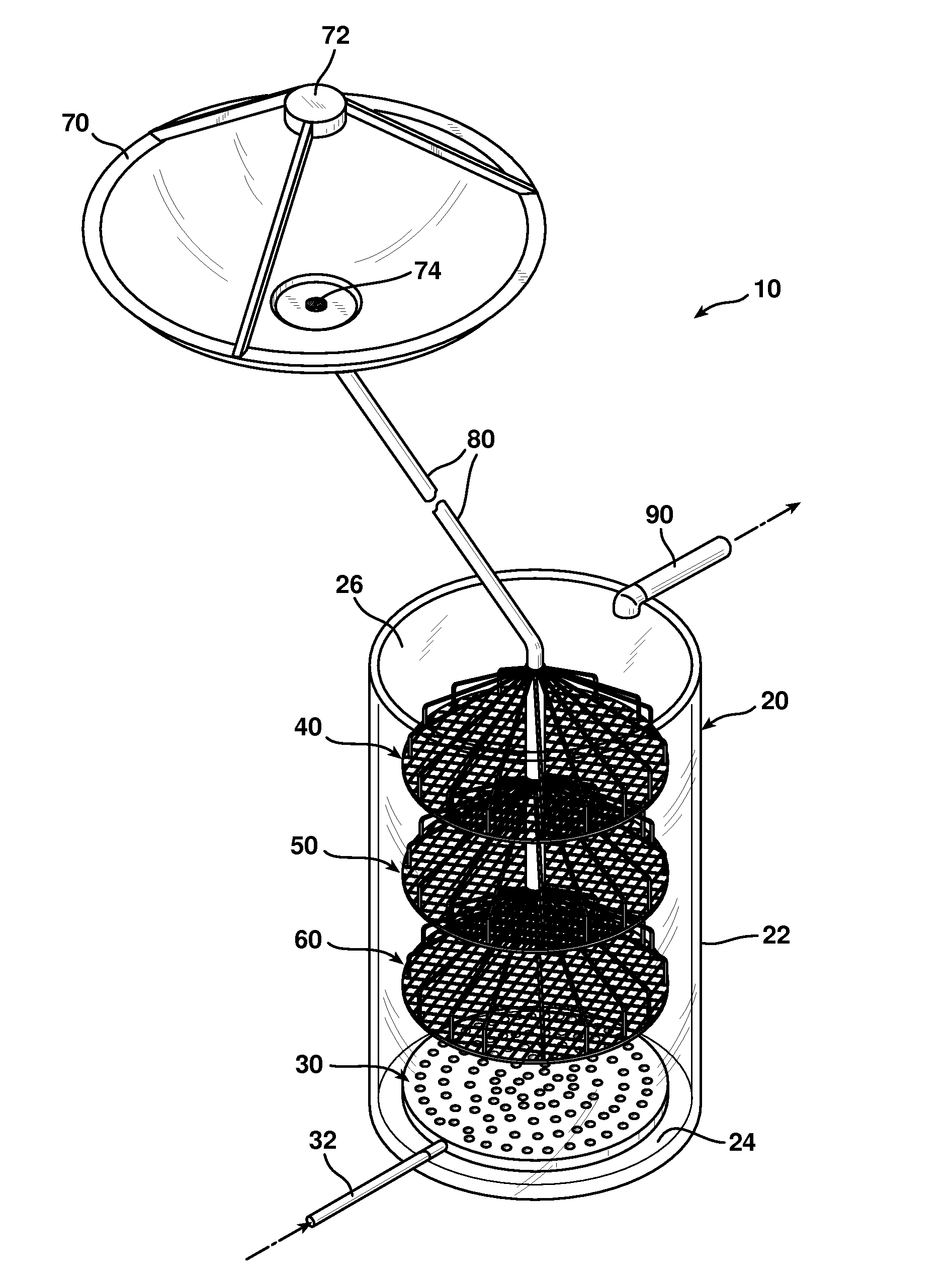

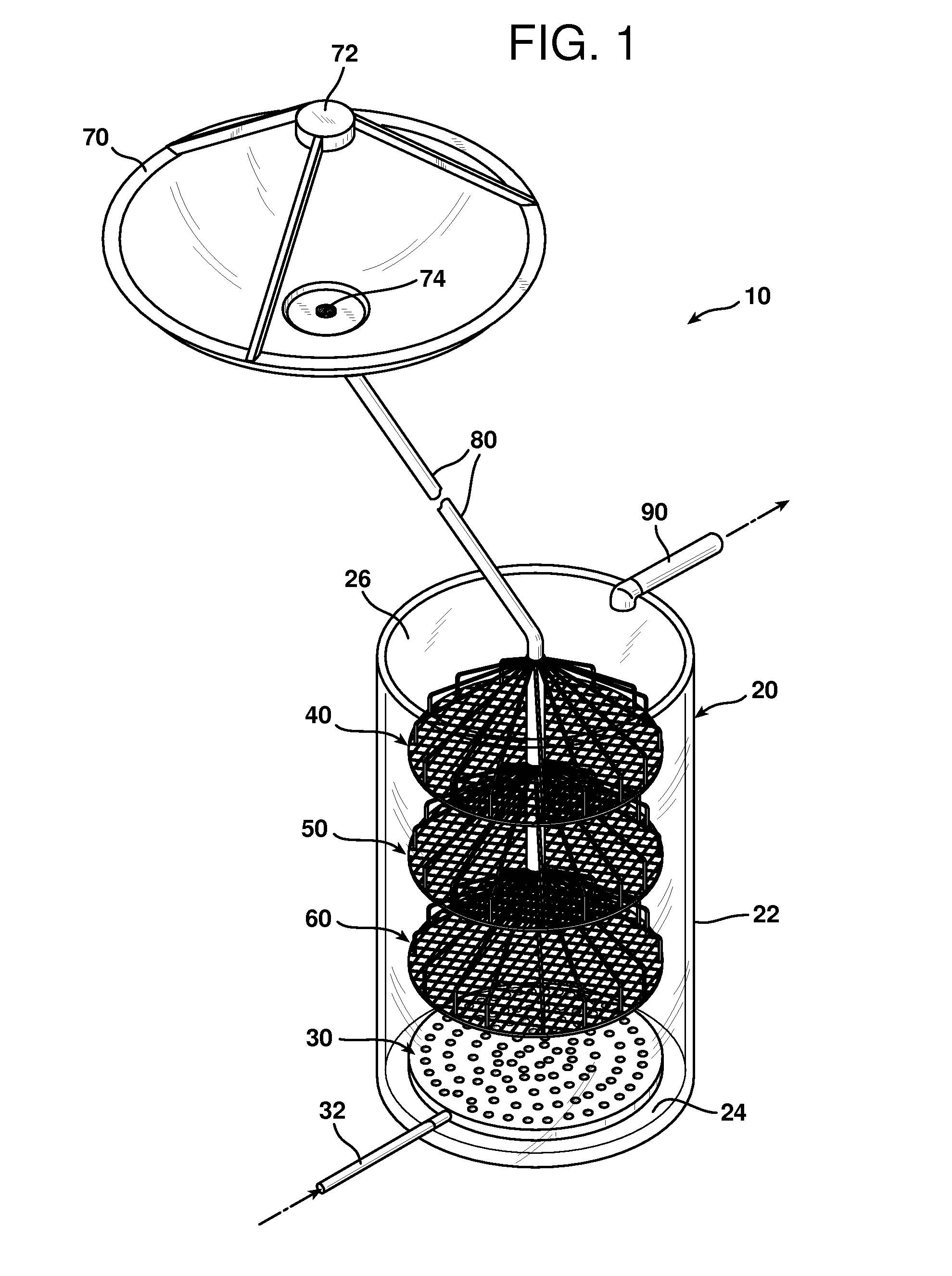

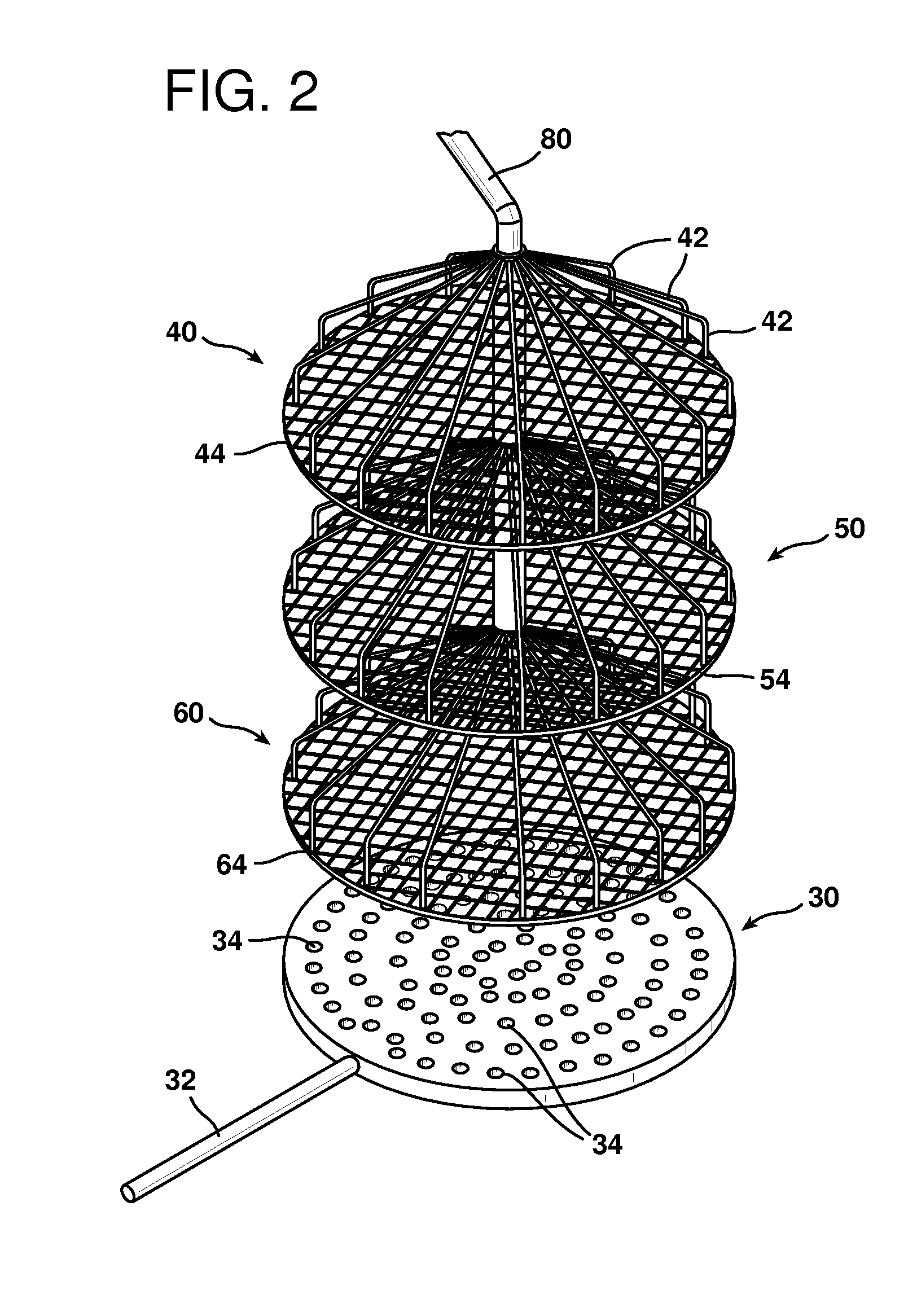

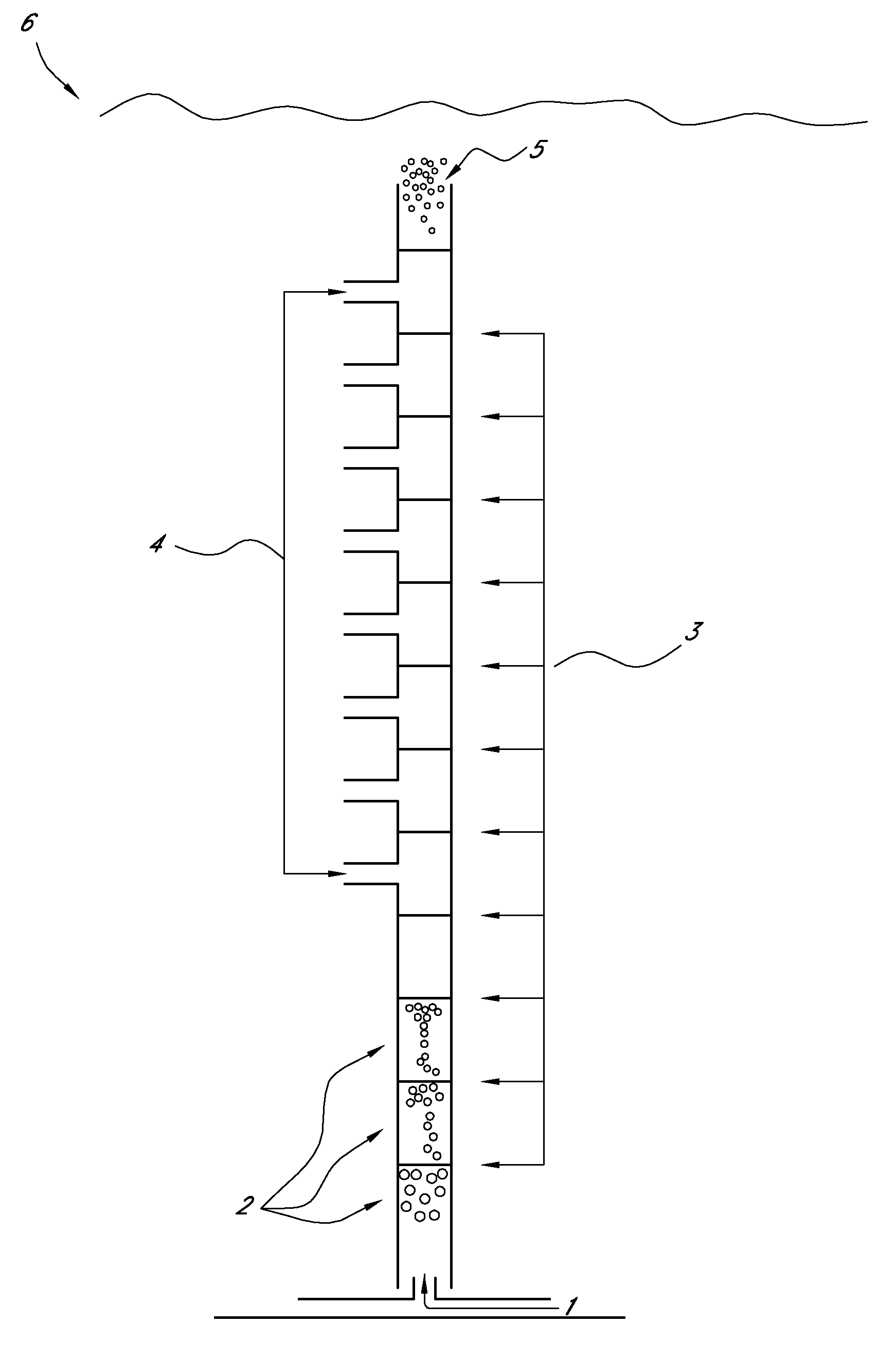

Apparatus and Method for Growing Biological Organisms for Fuel and Other Purposes

ActiveUS20070264708A1Reduce space consumptionImprove productivityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSlurry

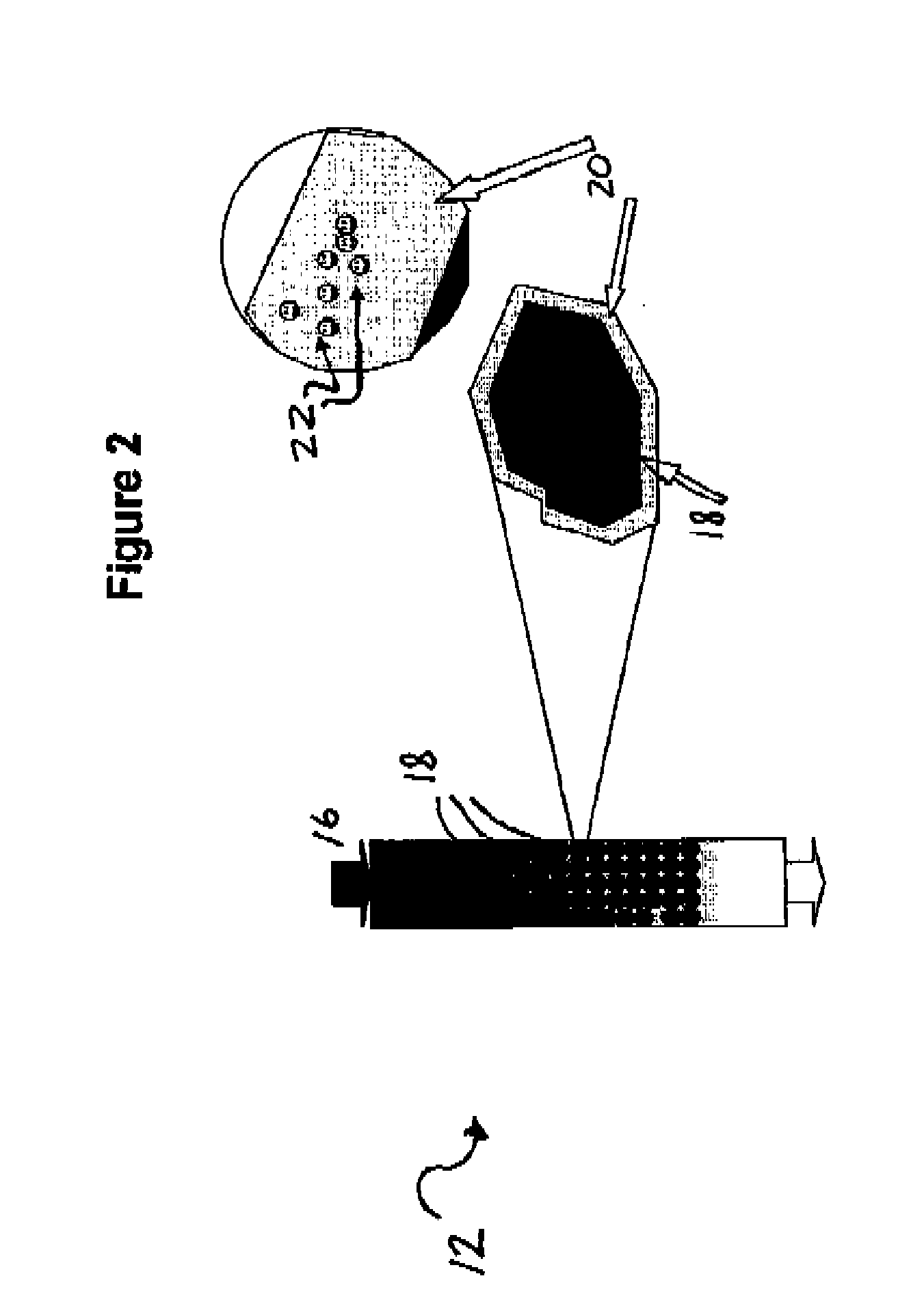

A bioreactor apparatus in which a container has sidewalls, a floor and a ceiling defining a chamber that contains a slurry of water, nutrients and photosynthetic microorganisms. A plurality of optical fibers, each of which has a first end disposed outside the chamber and a second end in the mixture. A light collector spaced from the container has light incident on it and focuses the light onto the first ends of the plurality of optical fibers, thereby permitting the light to be conveyed into the mixture to promote photosynthesis. At least one nozzle is in fluid communication with a source of gas, such as exhaust gas from a fossil-fuel burning power plant containing carbon dioxide. The nozzle is disposed in the mixture beneath the second ends of the optical fibers for injecting the gas into the mixture.

Owner:OHIO UNIV

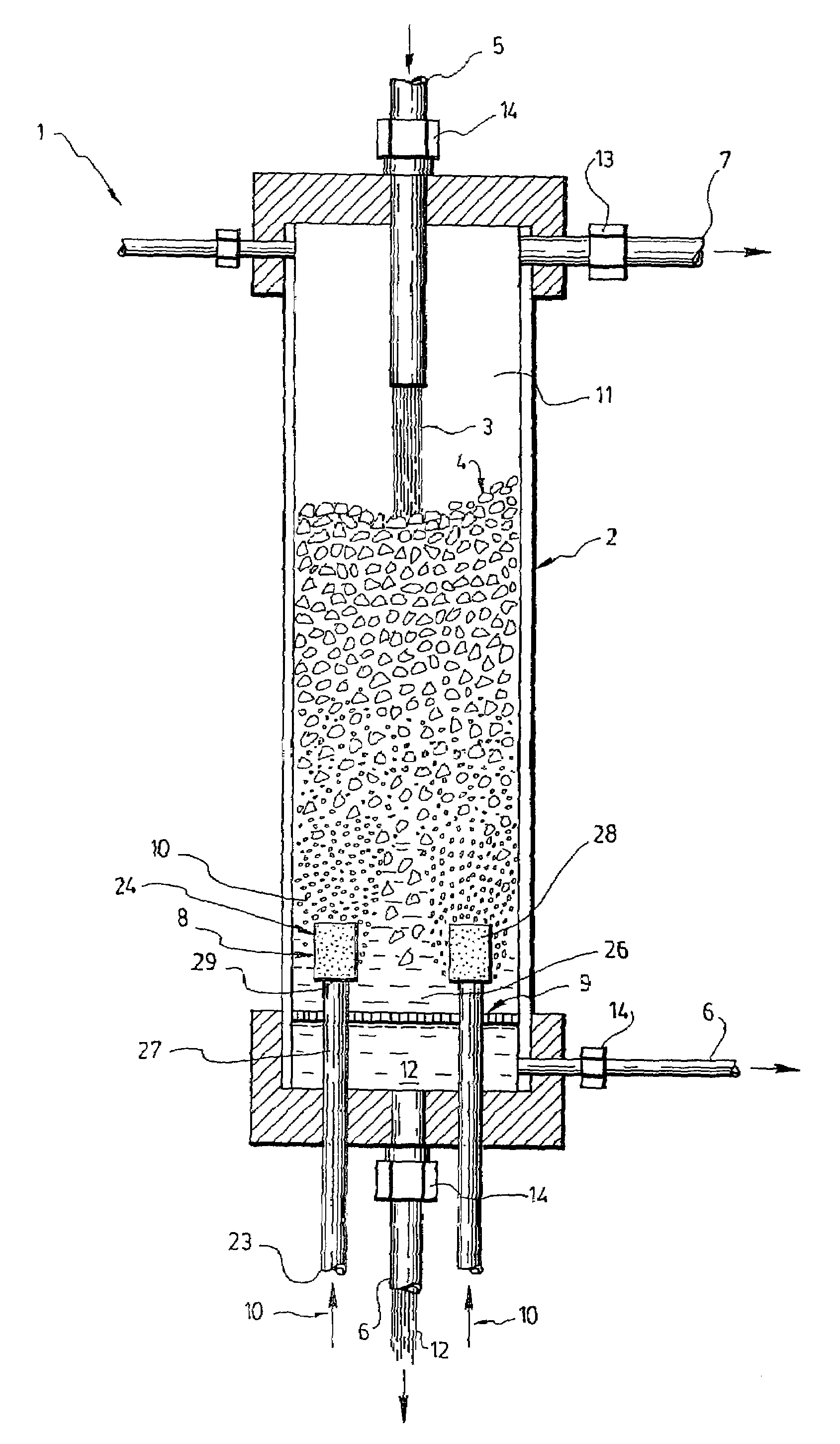

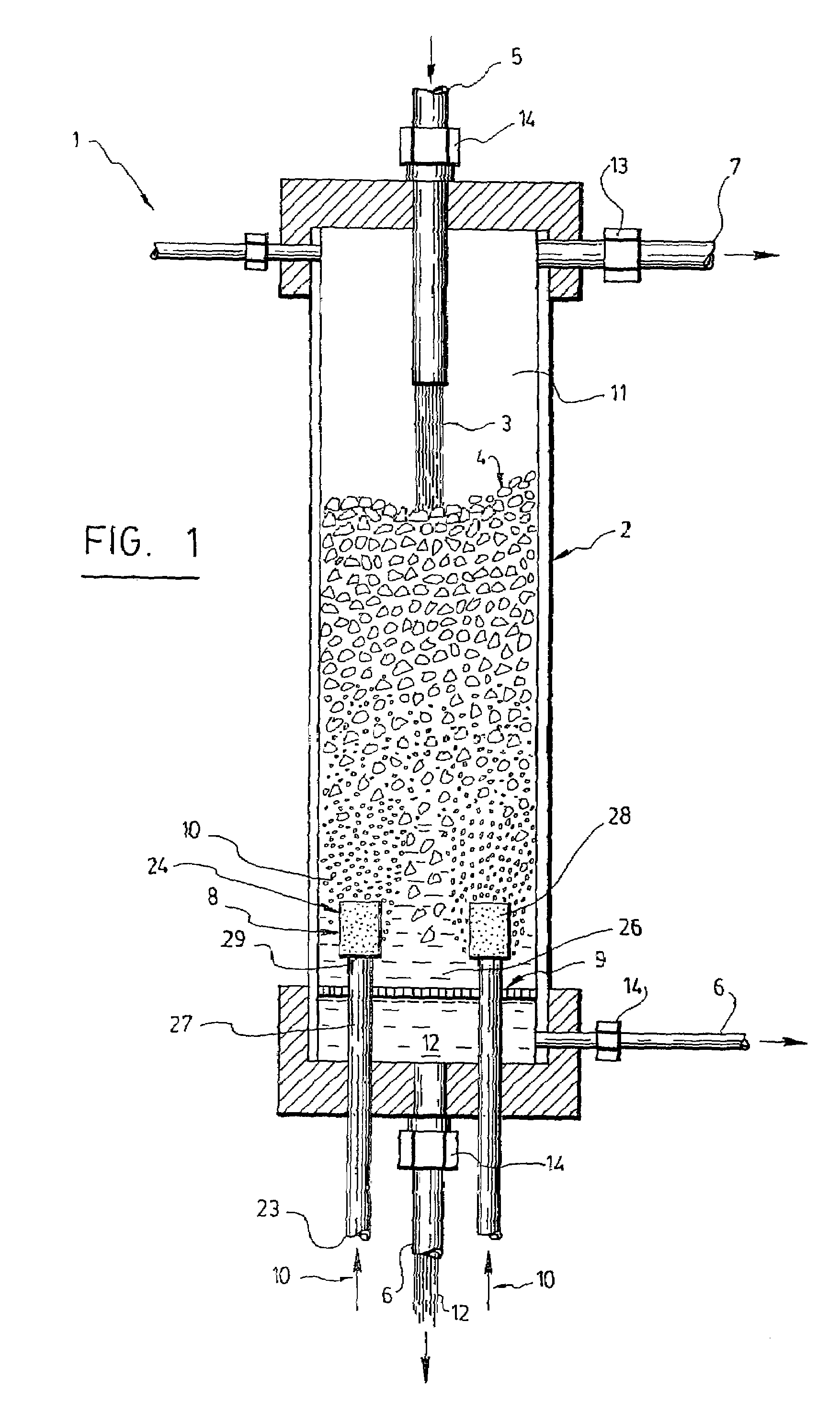

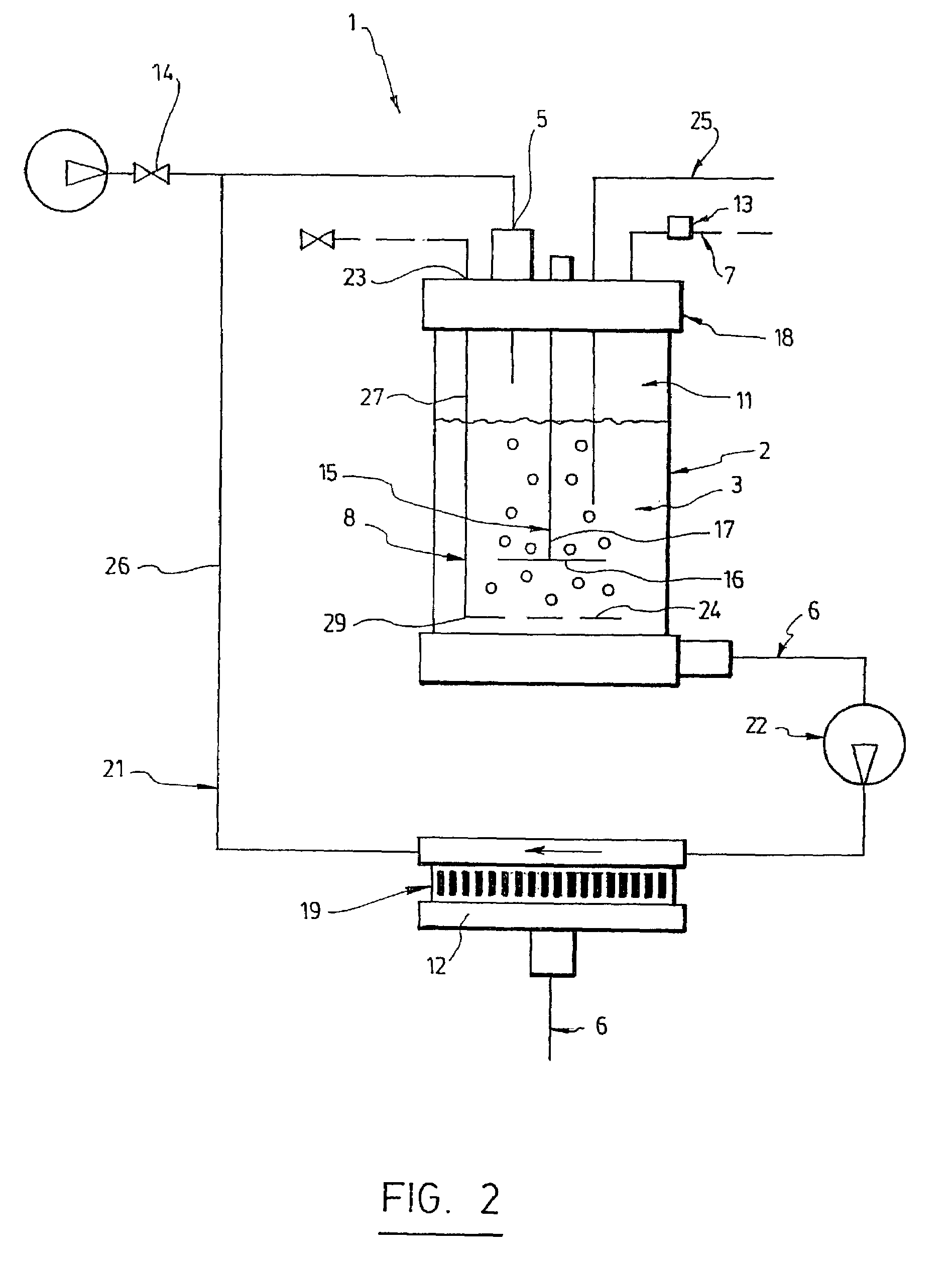

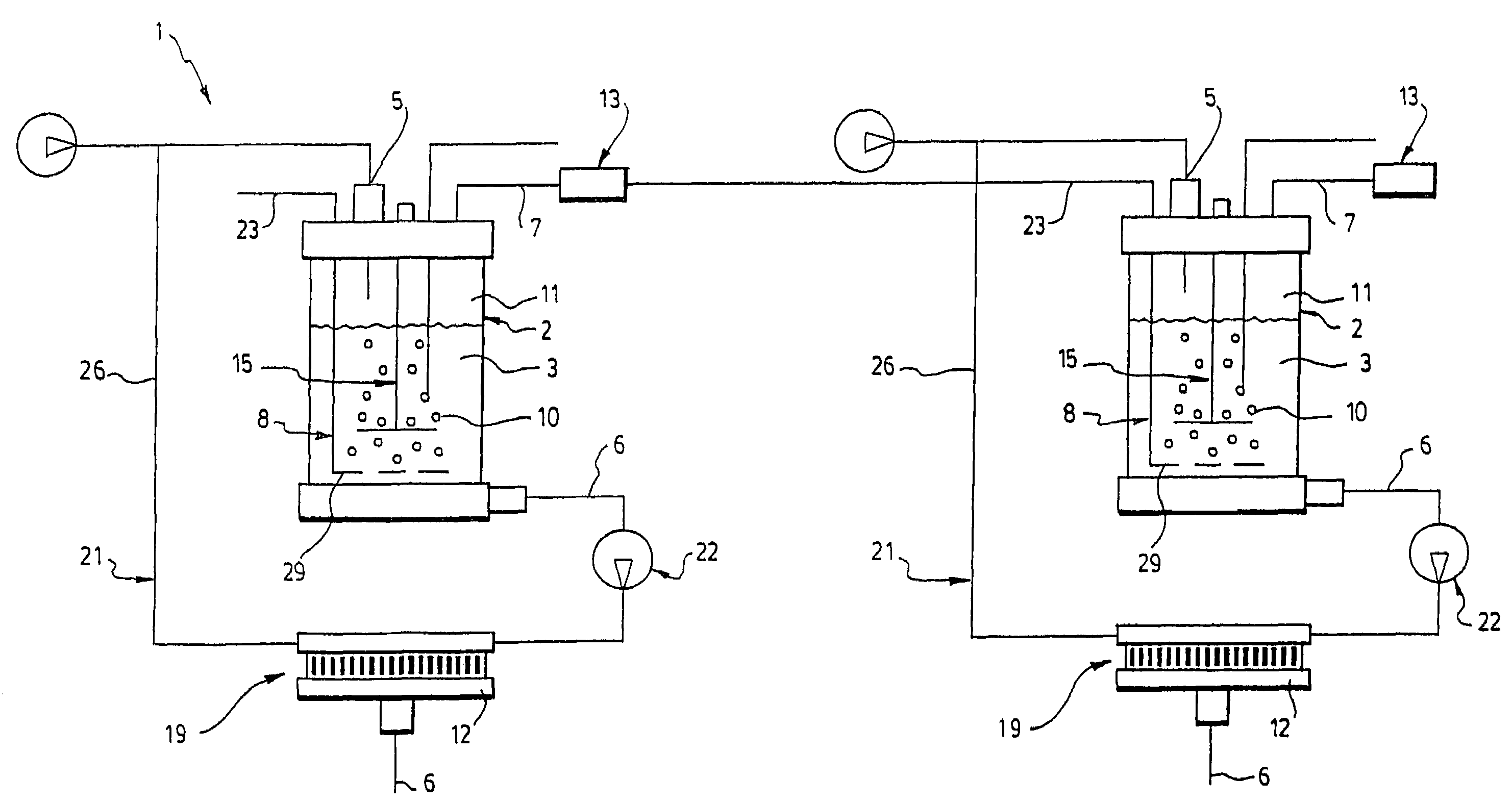

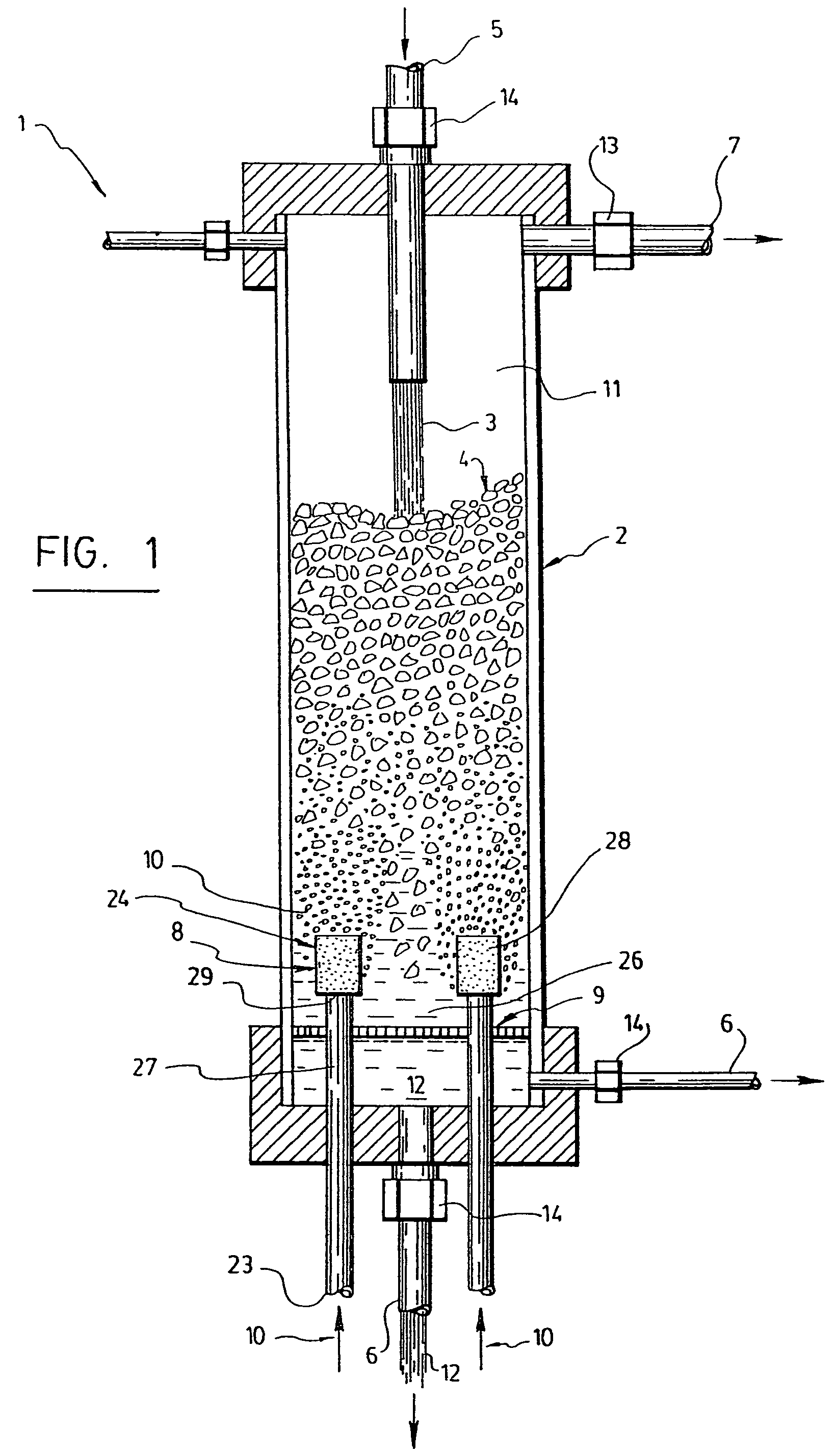

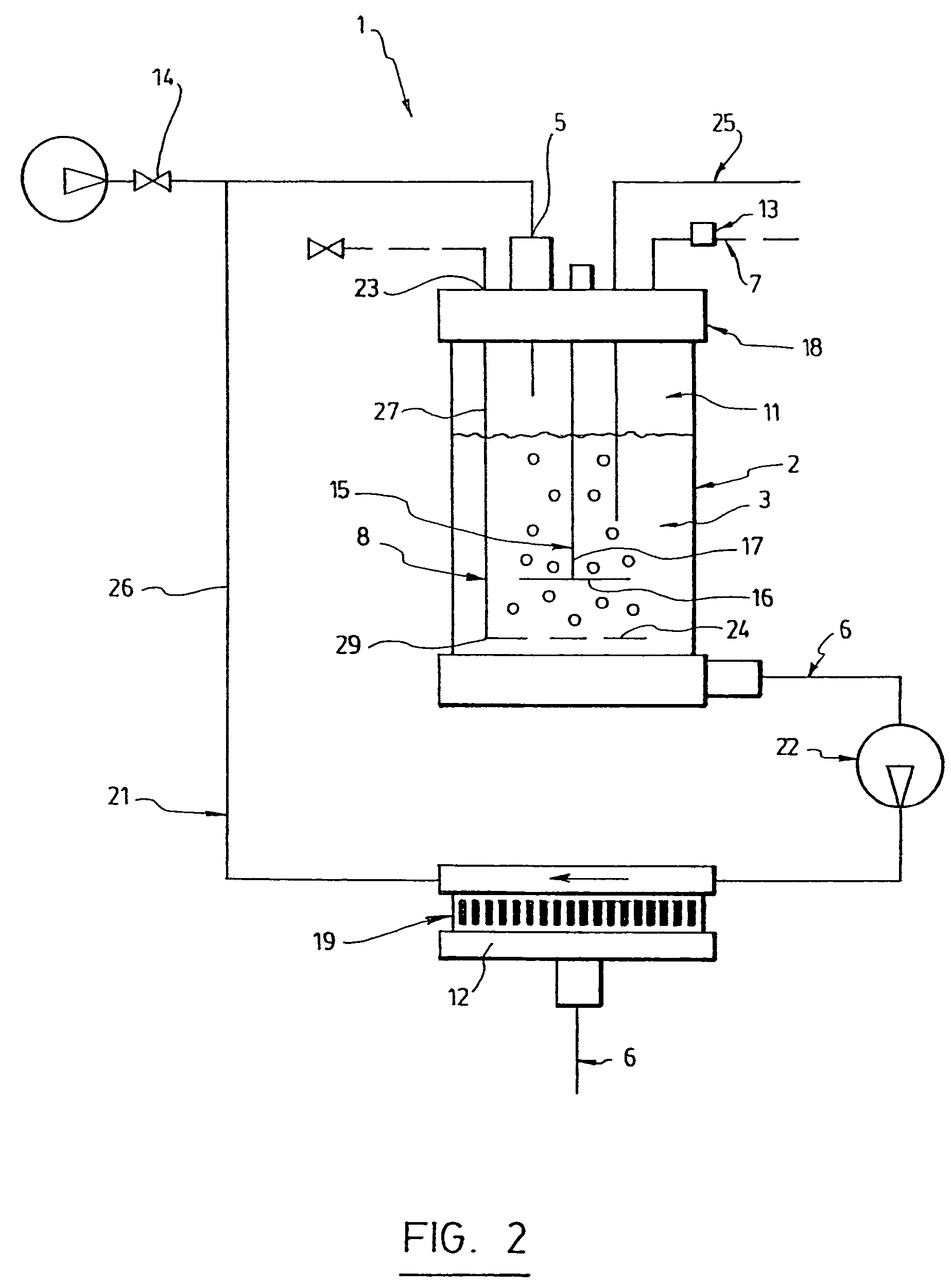

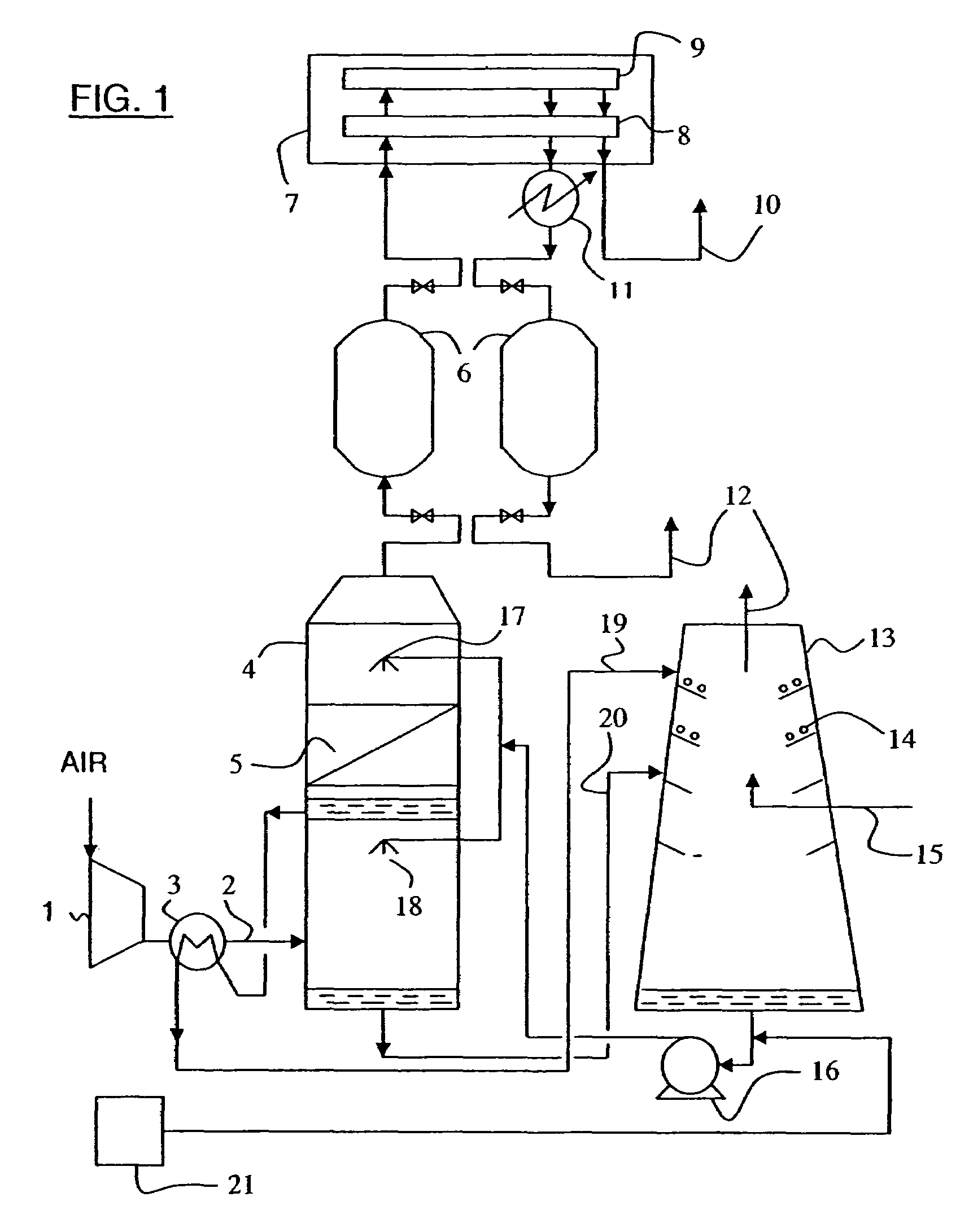

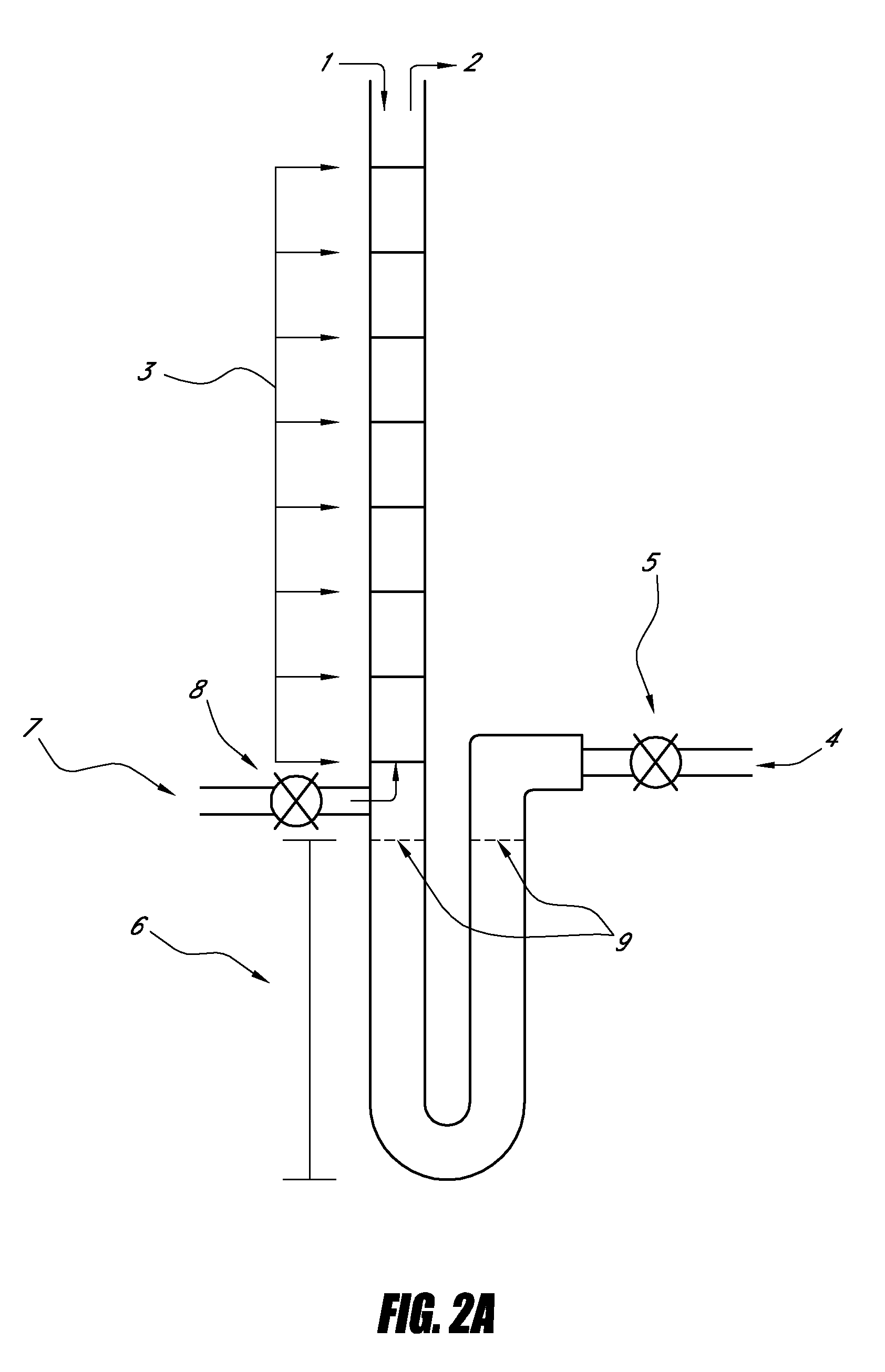

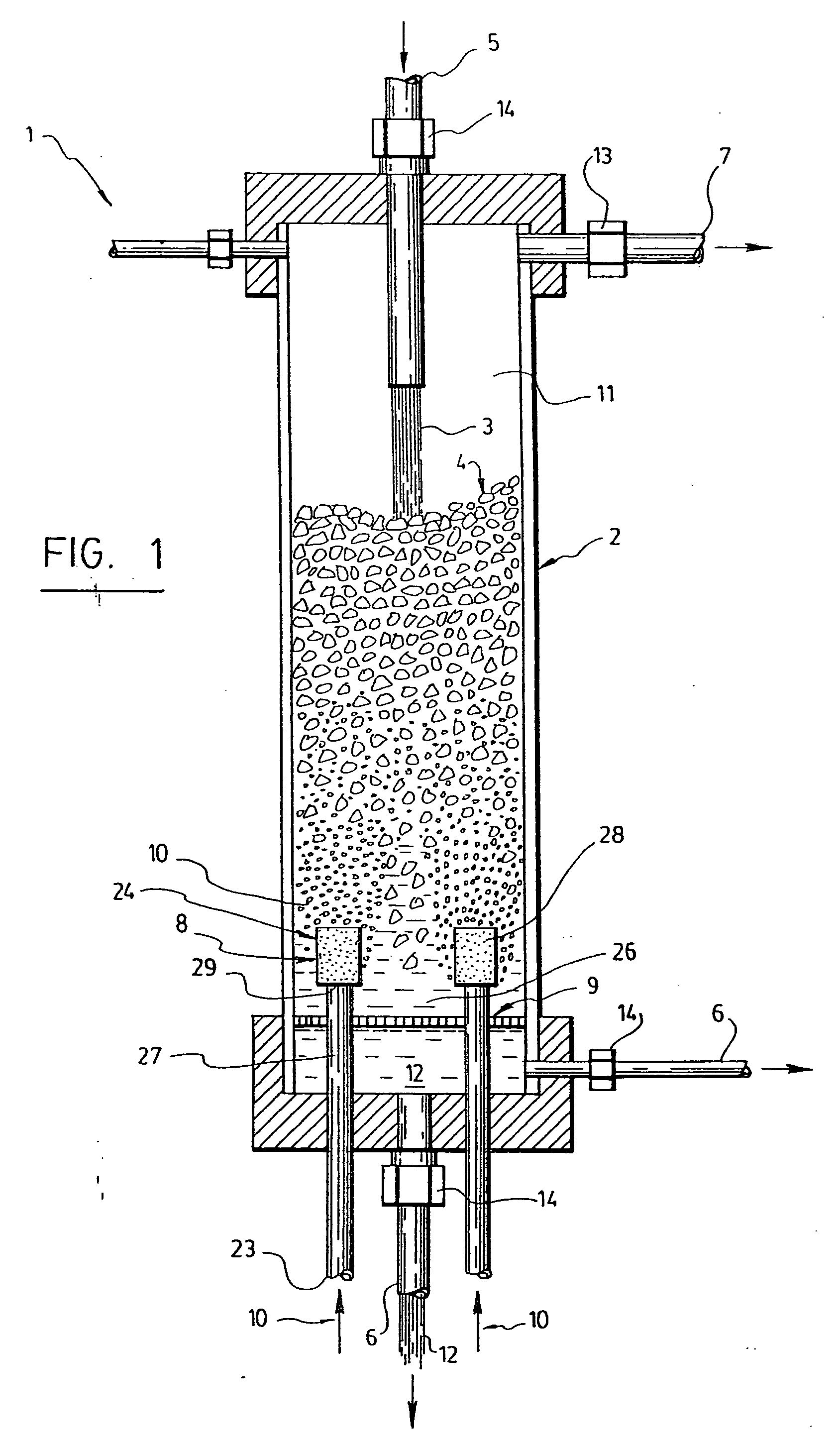

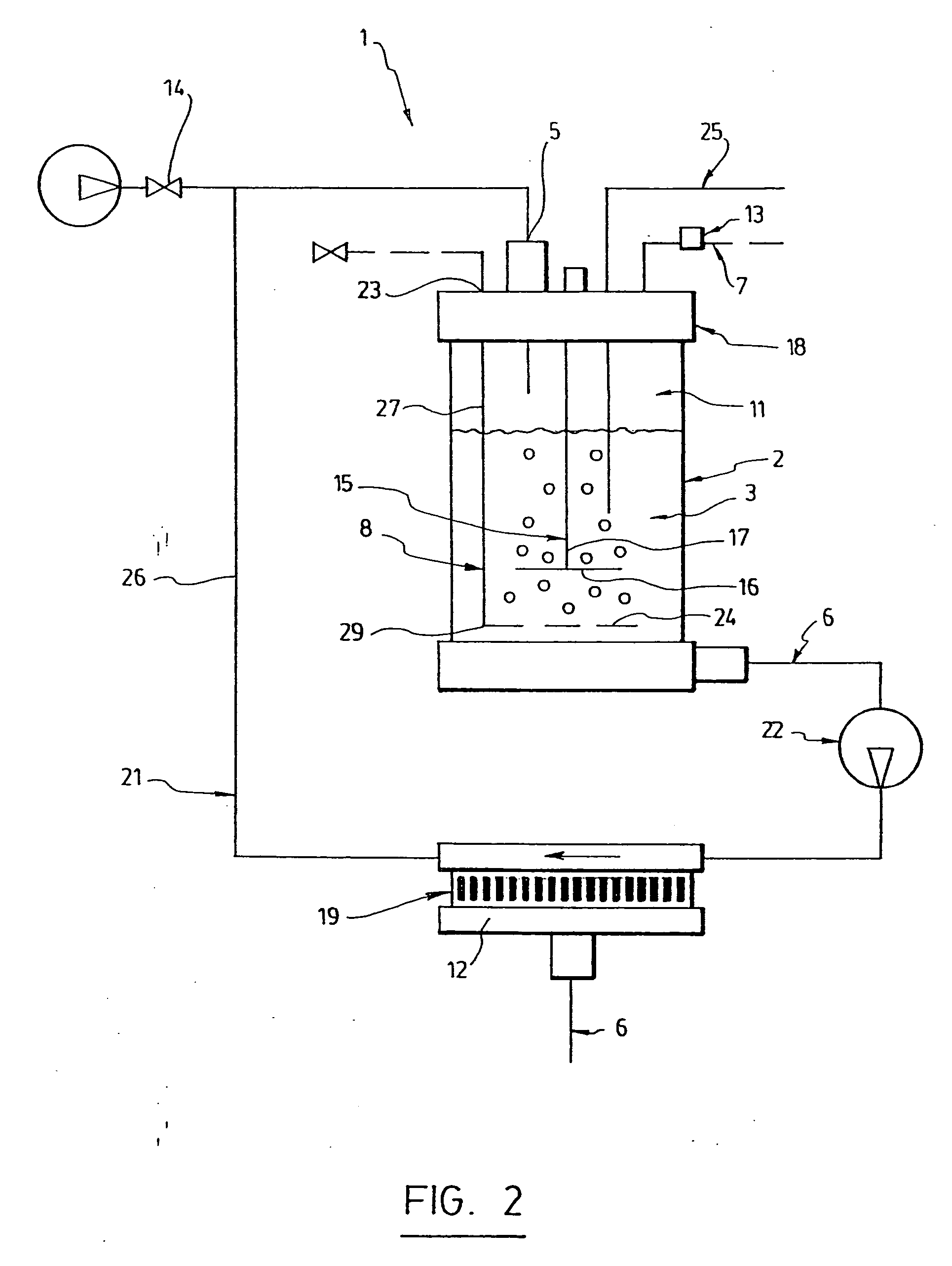

Triphasic bioreactor and process for gas effluent treatment

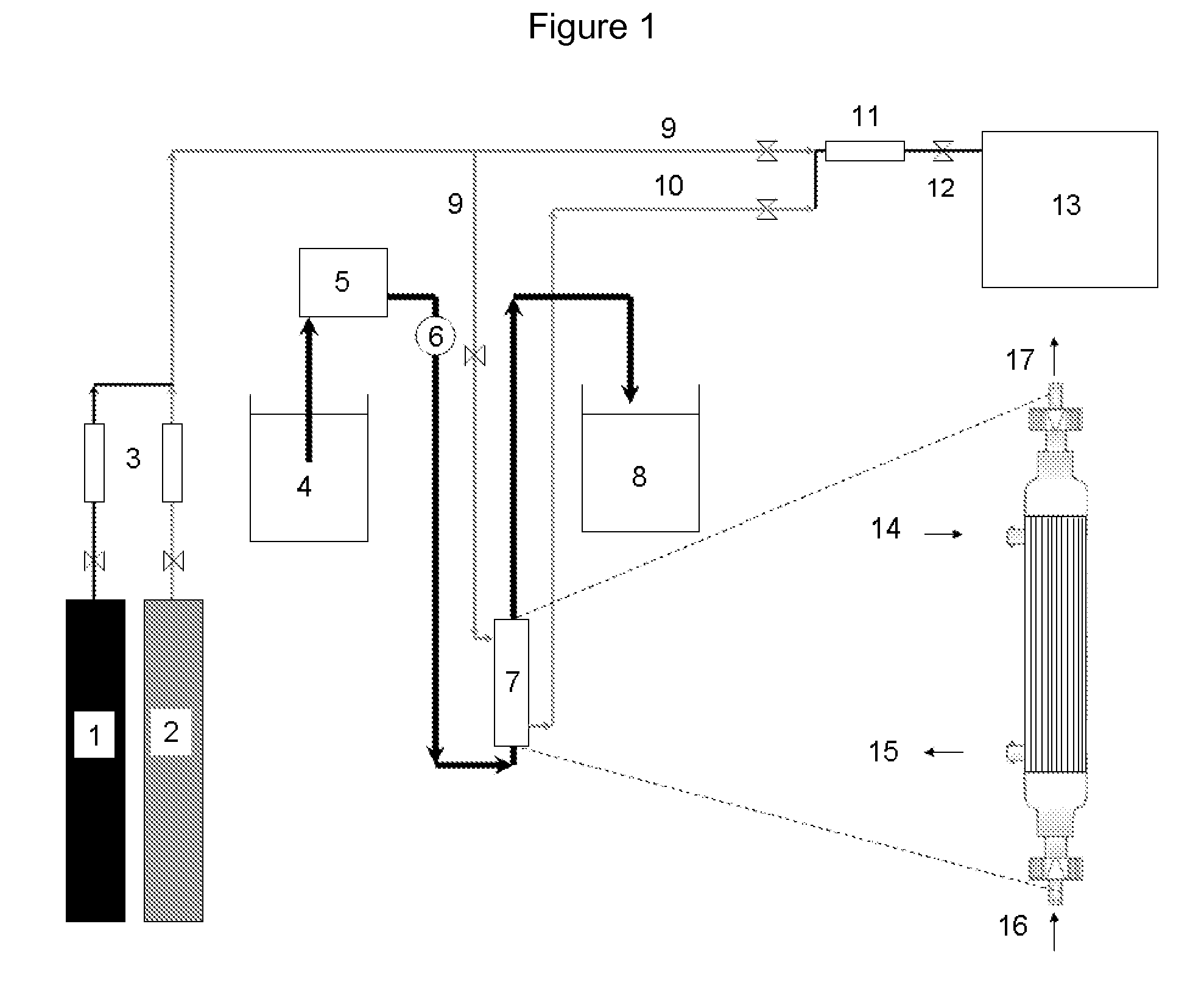

InactiveUS7176017B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorReaction chamber

A triphasic bioreactor for physico-chemically treating a gas is disclosed. The triphasic bioreactor comprises a reaction chamber with a liquid and biocatalysts in suspension in the liquid, for catalyzing a reaction between the gas and the liquid to obtain a treated gas and a solution containing a reaction product. A gas bubbling means is provided in the reaction chamber for bubbling the gas to be treated into the liquid thereby dissolving the gas into the liquid and increasing a pressure inside the reaction chamber. The bioreactor further comprises a liquid inlet in fluid communication with the reaction chamber for receiving the liquid and filling the reaction chamber, a liquid outlet in fluid communication with the reaction chamber for releasing the solution and a gas outlet in fluid communication with the reaction chamber to release the treated gas. The bioreactor further comprises a retention device to retain the biocatalysts in the reaction chamber. The invention also concerns a process using the triphasic bioreactor. The triphasic bioreactor may advantageously be used for removing carbonic dioxide from a CO2-containing gas

Owner:CO2 SOLUTION

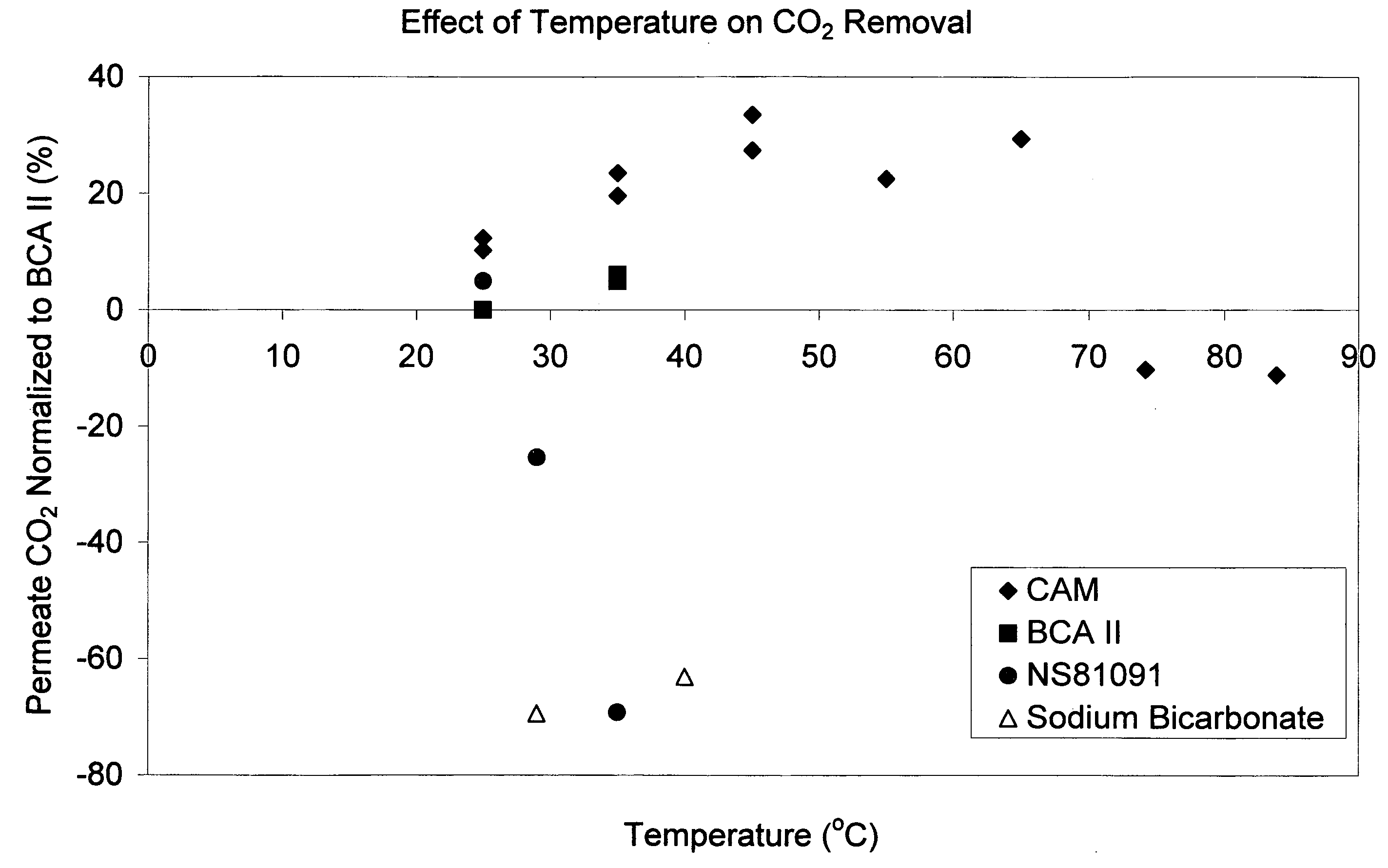

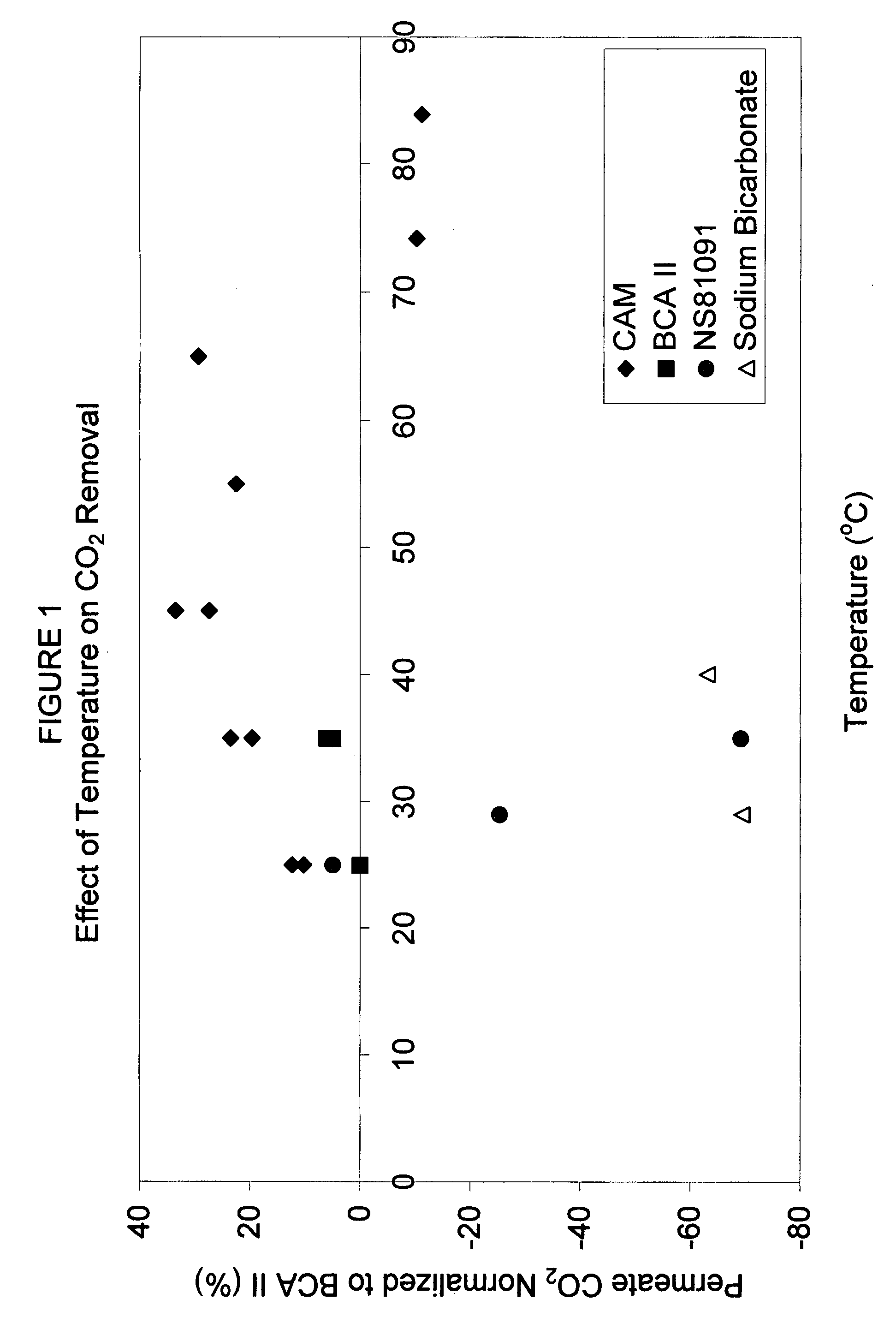

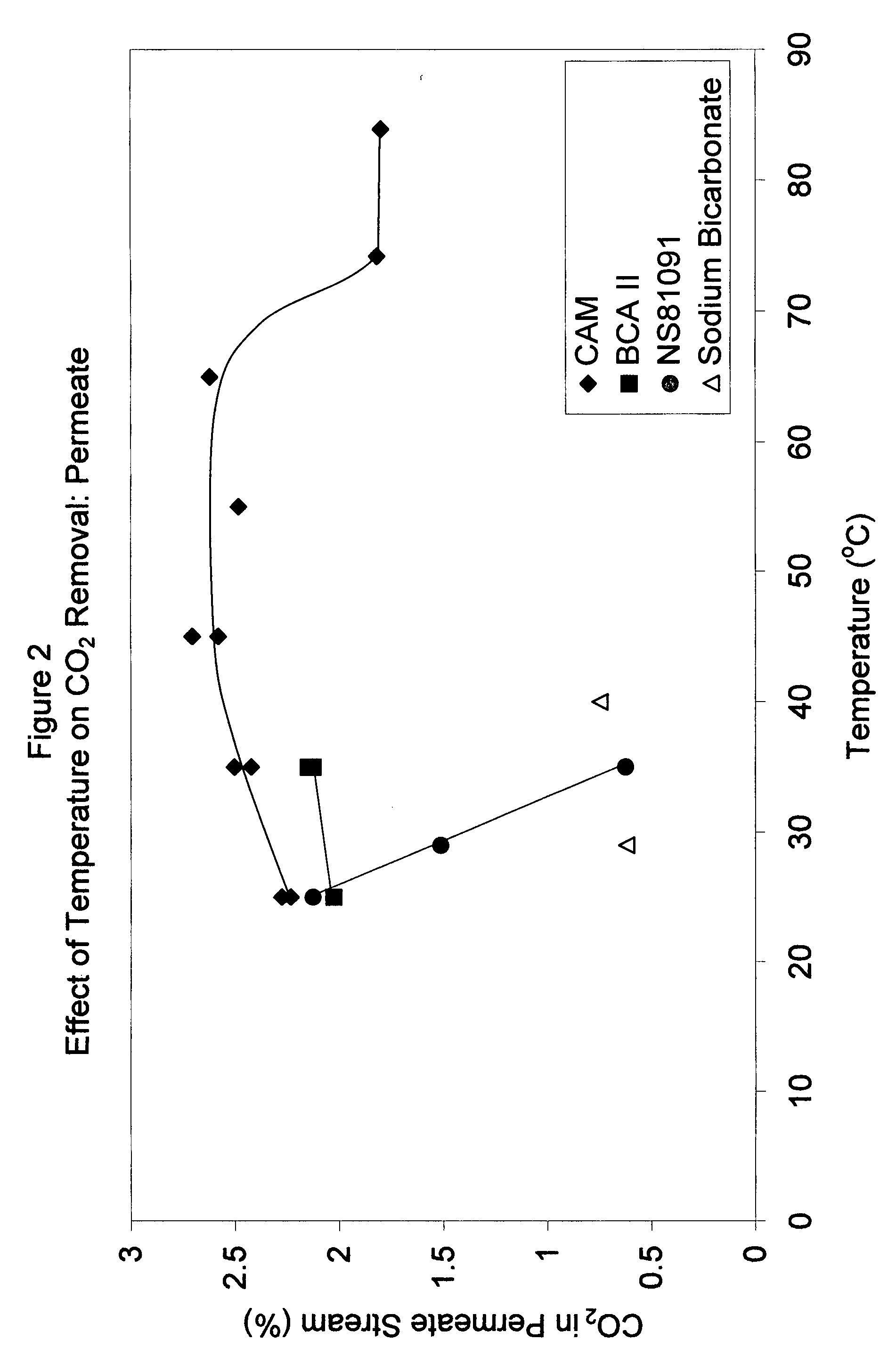

Novel enzyme compositions for removing carbon dioxide from a mixed gas

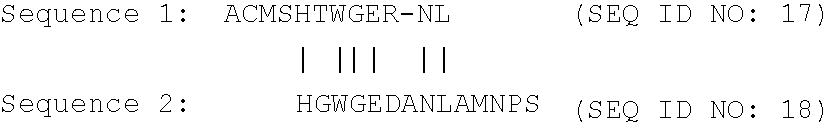

A process is disclosed for gas separation wherein carbon dioxide in a mixed gas stream is converted to bicarbonate by contacting a gamma carbonic anhydrase enzyme designated as CAM in the temperature range of 40 degrees to 85 degrees C. in an enzyme catalyzed carbon dioxide capture system.

Owner:TRACHTENBERG MICHAEL C

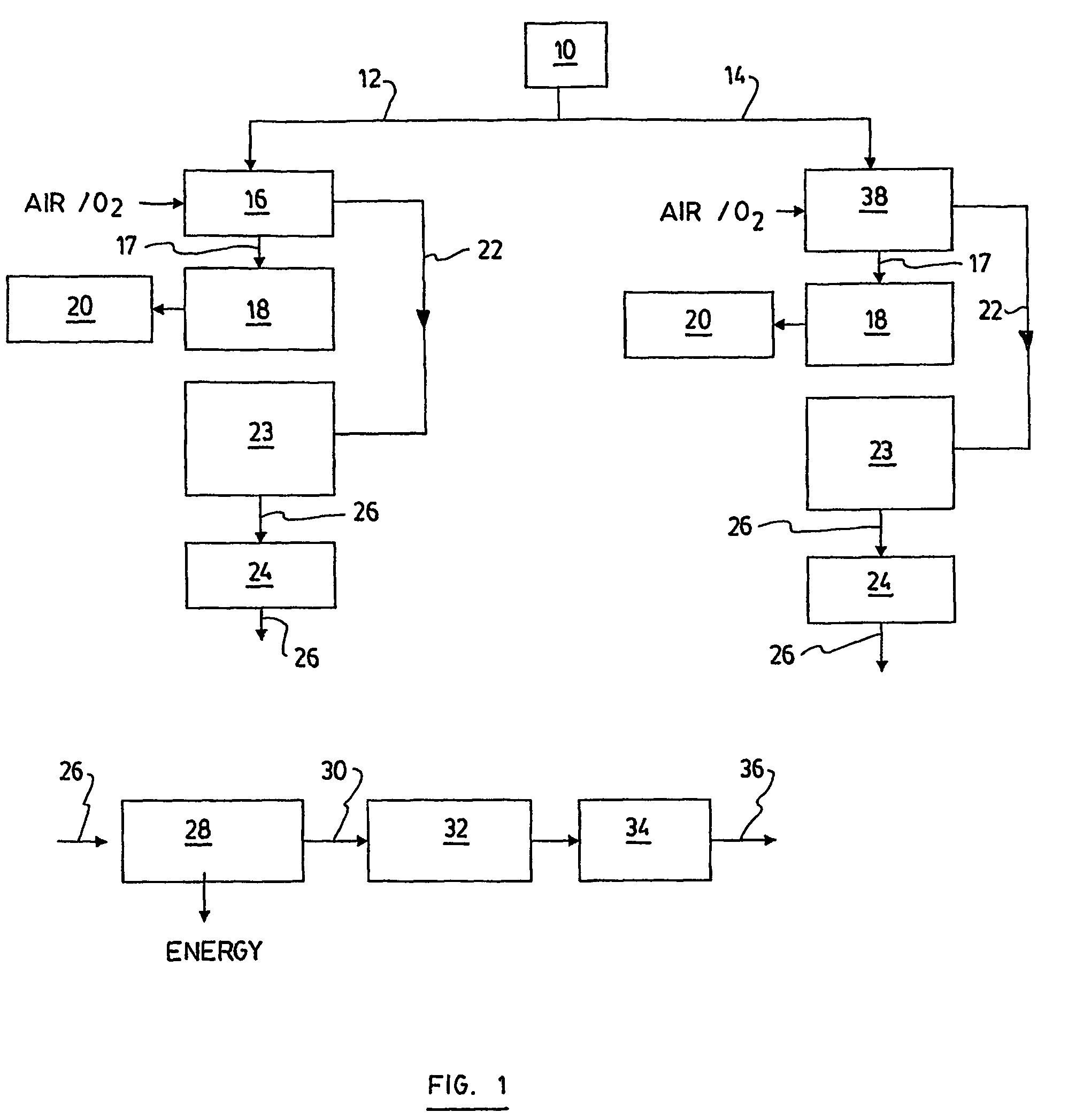

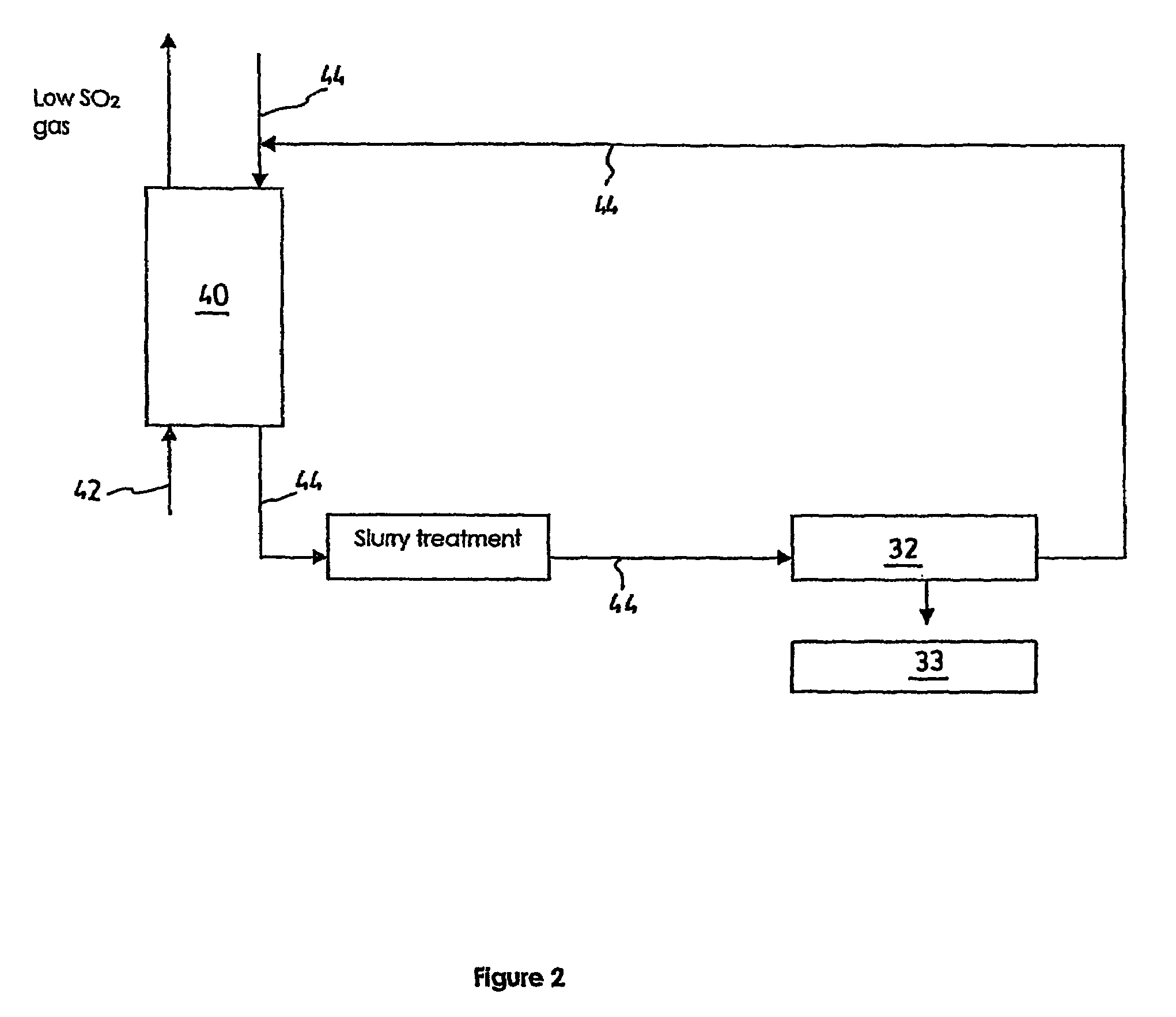

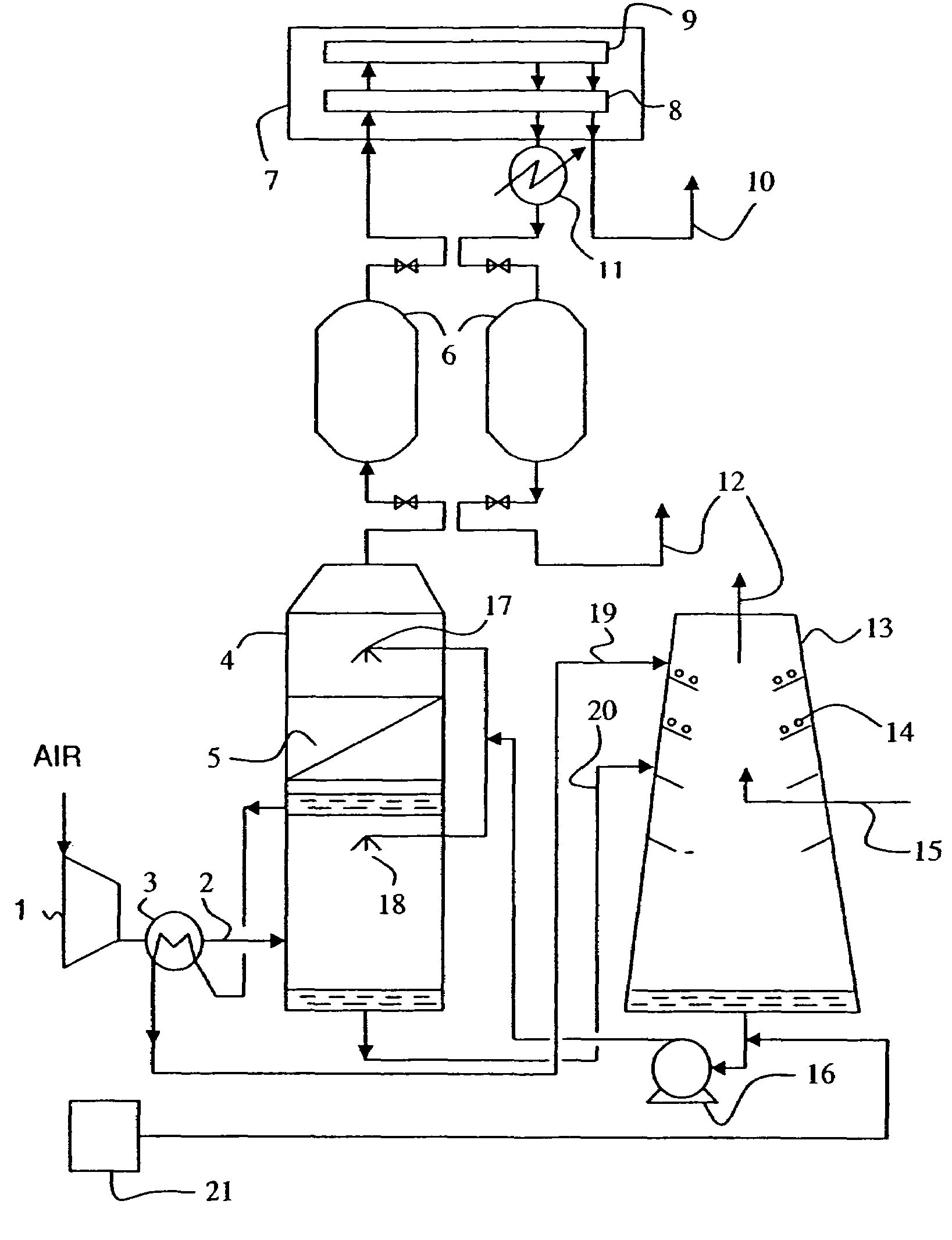

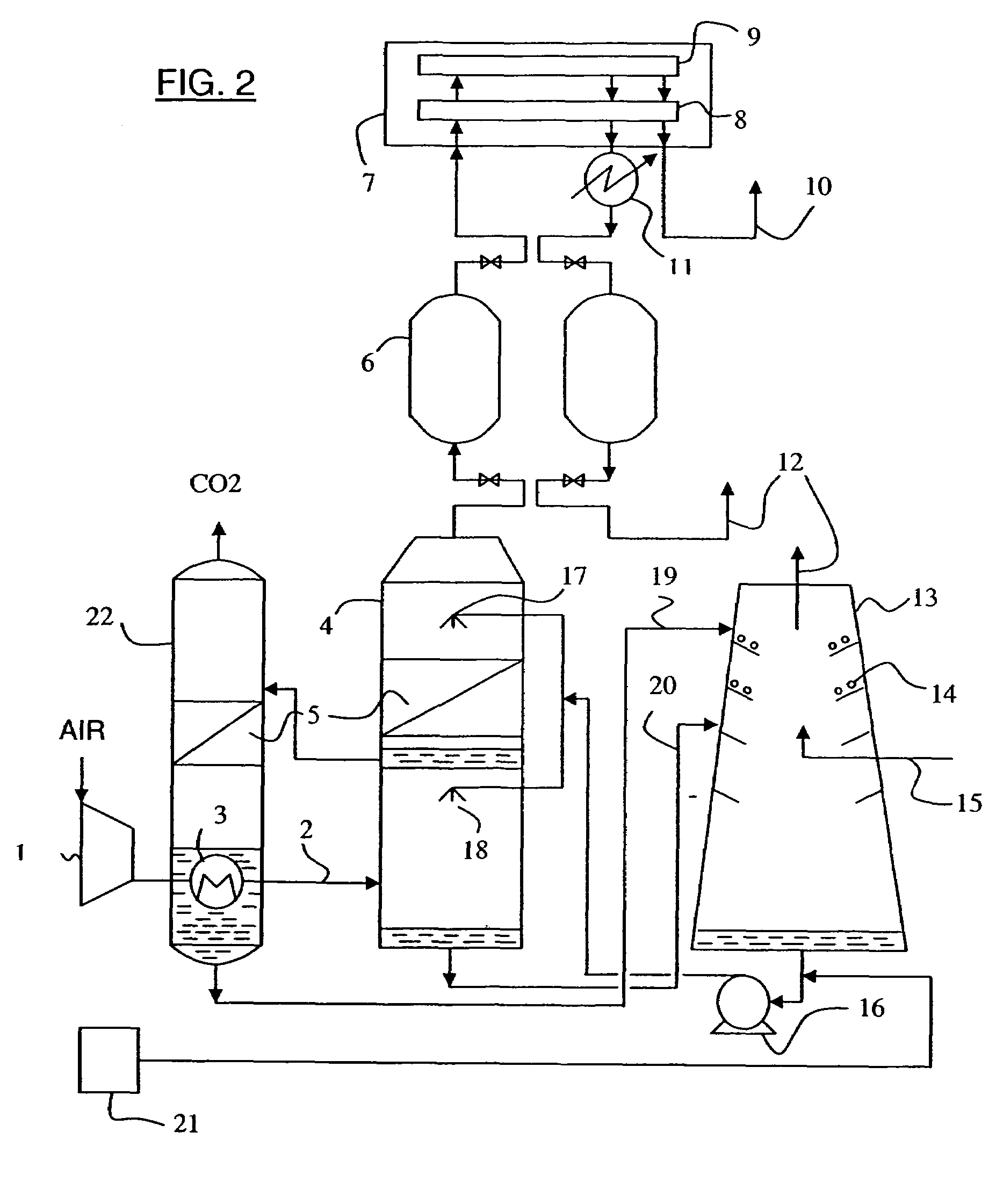

Process and a plant for recycling carbon dioxide emissions from power plants into useful carbonated species

ActiveUS7596952B2Useful carbonated speciesEnvironment safetyCalcium/strontium/barium carbonatesGas turbine plantsAtmospheric airNegative carbon dioxide emission

A process is disclosed for recycling carbon dioxide emissions from a fossil-fuel power plant into useful carbonated species The process primarily comprises the steps of: a) burning the fossil fuel, thereby generating heat and a hot exhaust gas containing CO2; and b) converting the heat into energy. The process is characterized in that it further comprises the steps of: c) cooling the exhaust gas; and d) biologically transforming the CO2 contained in the cooled exhaust gas into carbonated species, thereby obtaining a low CO2 exhaust gas and producing useful carbonated species. The low CO2 exhaust gas obtained in step d) can be released in the atmosphere without increasing the problem of greenhouse effect.

Owner:SAIPEM SPA

Modular Reactor and Process for Carbon-Dioxide Extraction

The present invention relates to a reactor and a process suitable for extracting carbon dioxide from carbon dioxide-containing gas stream. The reactor is based on a two module system where absorption occurs in one module and desorption occurs in the other module. The absorption and desorption modules in the system include at least one gas-liquid membrane (GLM) module and at least one direct gas-liquid contact (DGLC) module. The carbon dioxide extraction may be catalyzed by carbonic anhydrase.

Owner:NOVOZYMES AS

Process and installation for the fractionation of air into specific gases

InactiveUS20060213224A1Improve conversion performanceSolidificationLiquefactionHydration reactionCooling tower

Owner:CO2 SOLUTION

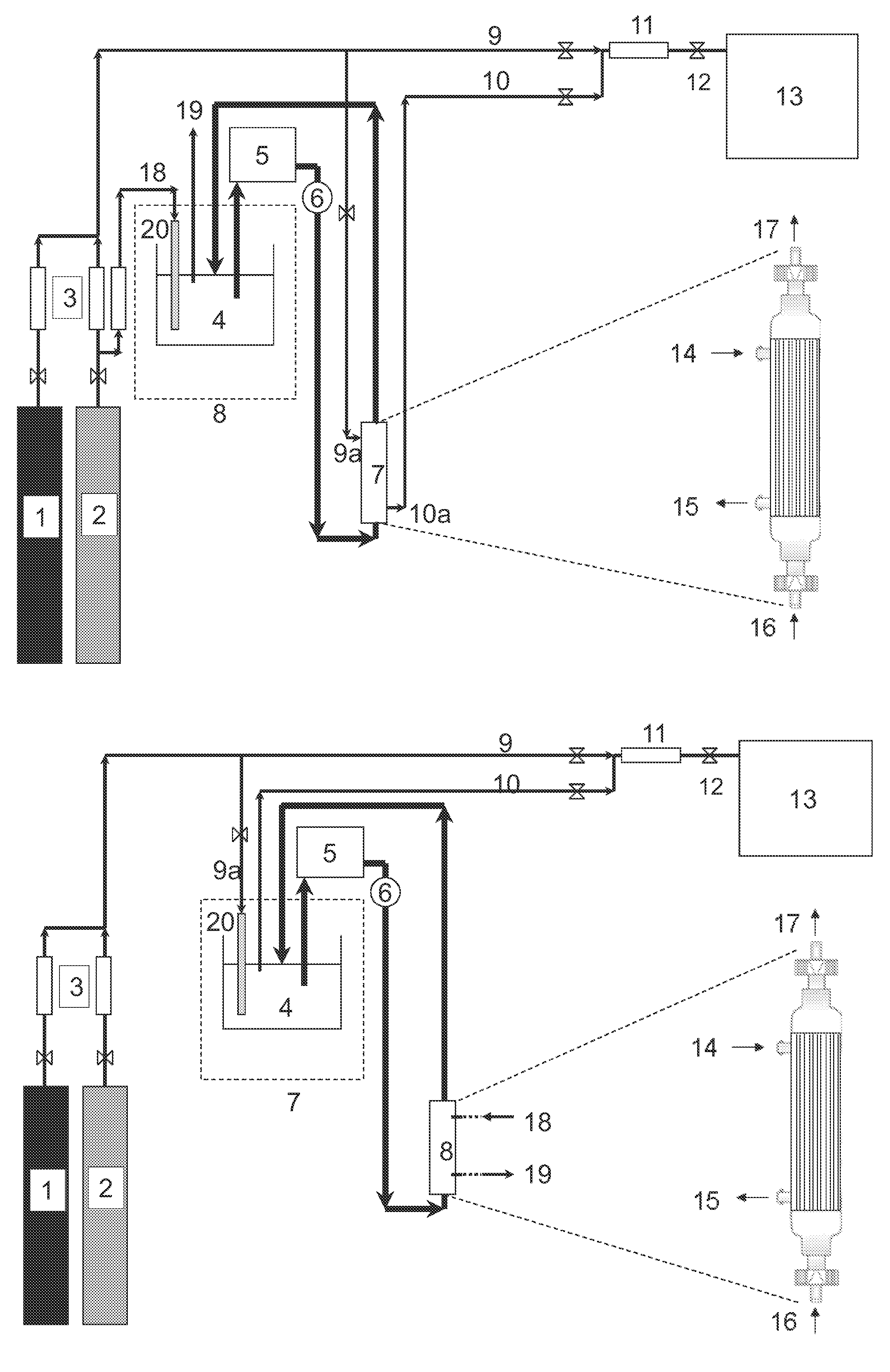

Biological Clean Fuel Processing Systems and Methods

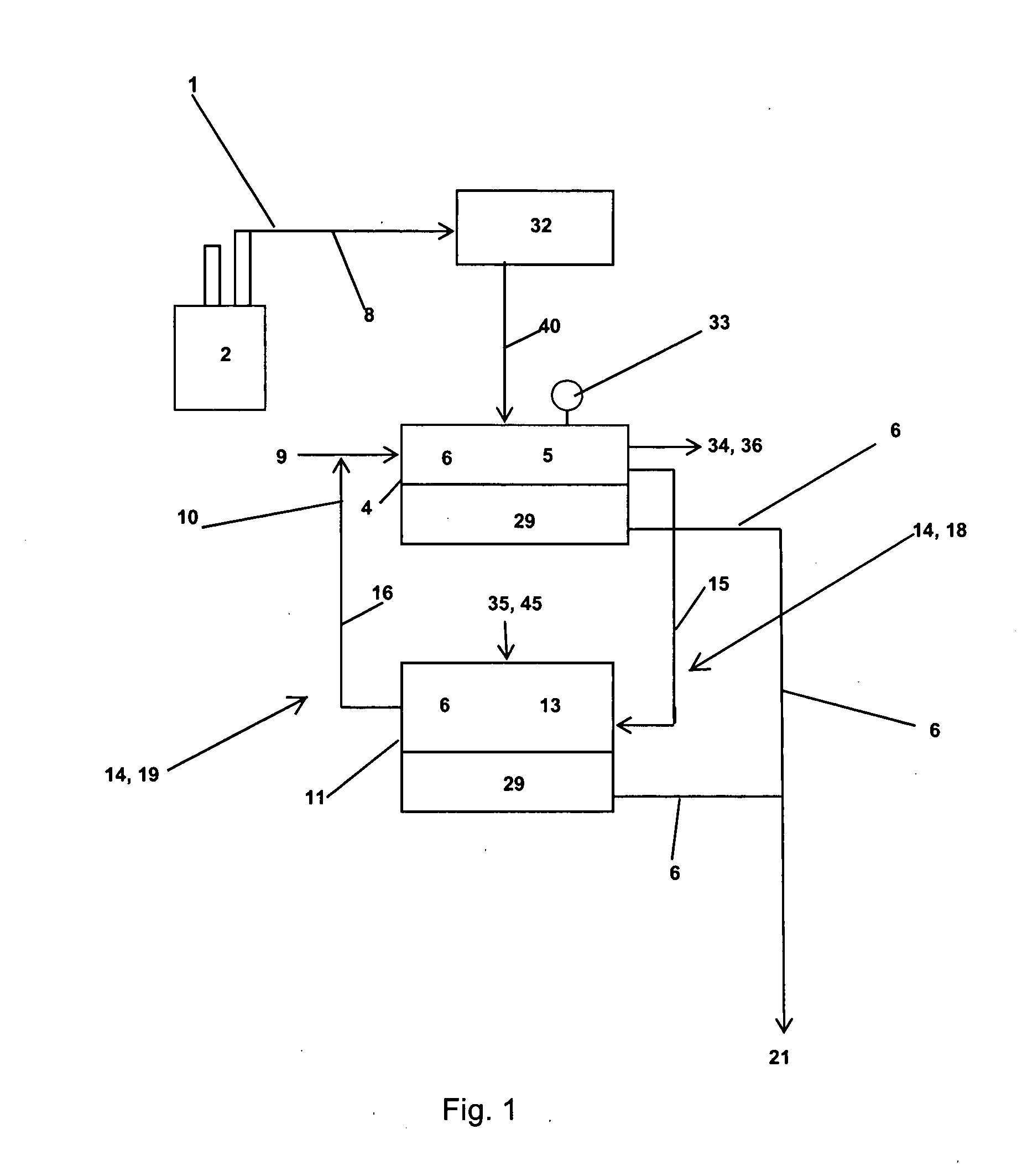

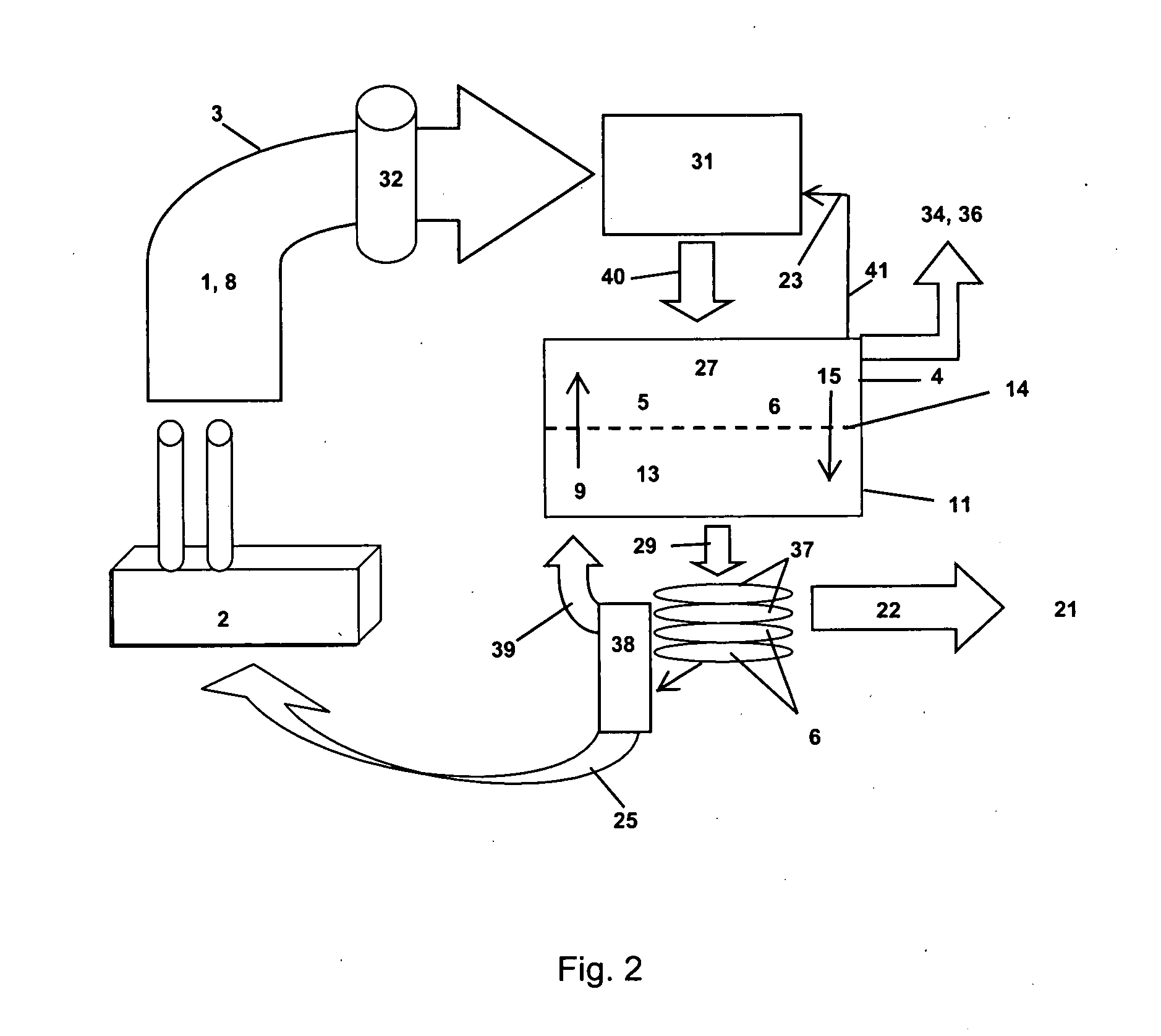

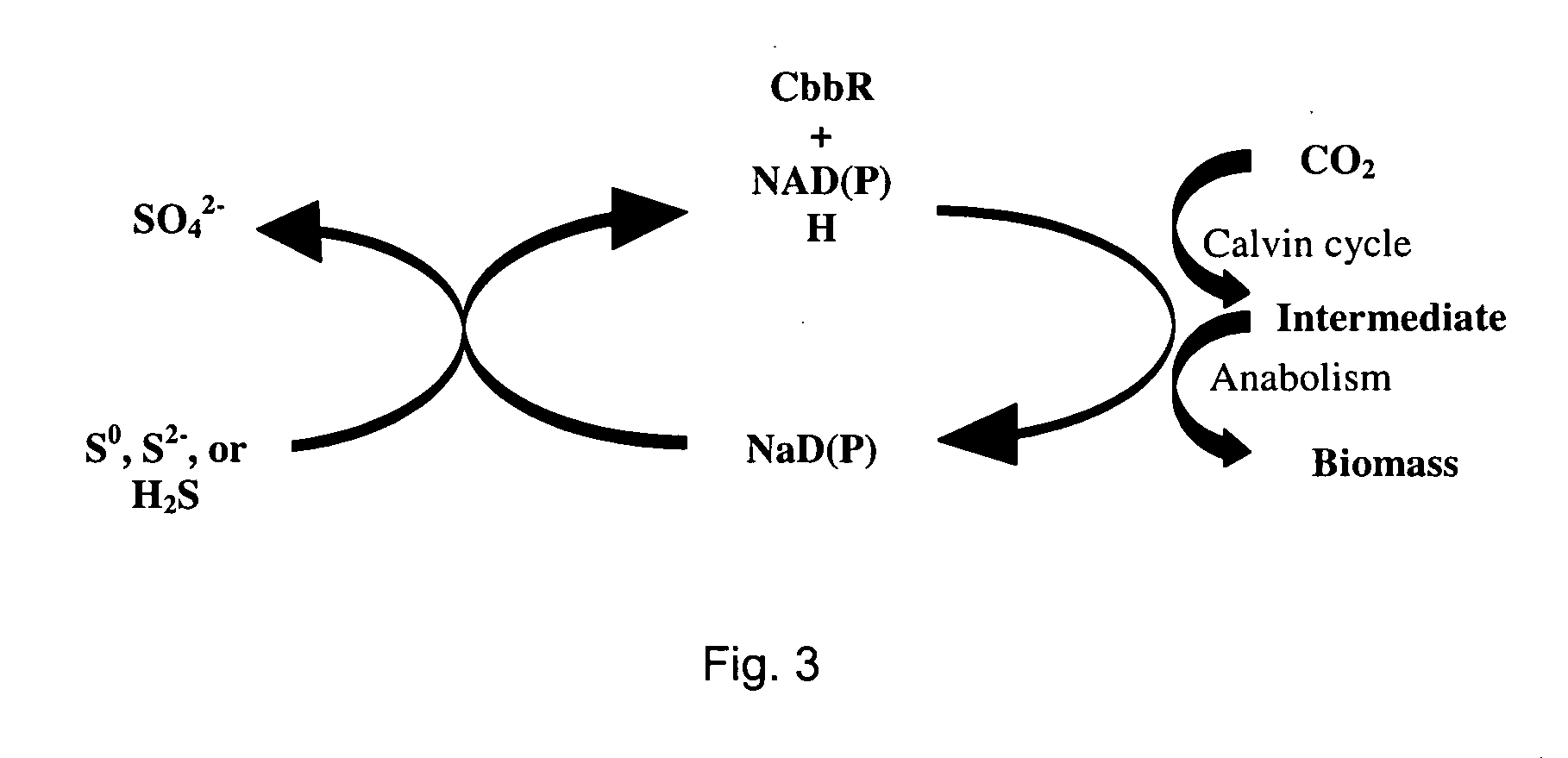

InactiveUS20120003705A1Reduce carbon emissionsImprove planting efficiencyBacteriaBiofuelsSulfate-reducing bacteriaFuel treatment

Methods and systems to achieve clean fuel processing systems in which carbon dioxide emissions (1) from fossil fuel consumption sources (2) may be processed in at least one processing reactor (4) containing a plurality of chemoautotrophic bacteria (5) which can convert the carbon dioxide emissions into biomass (6) which may then be used for various products (21) such as biofuels, fertilizer, feedstock, or the like. Sulfate reducing bacteria (13) may be used to supply sulfur containing compounds to the chemoautotrophic bacteria (5).

Owner:WESTERN RES INST INC

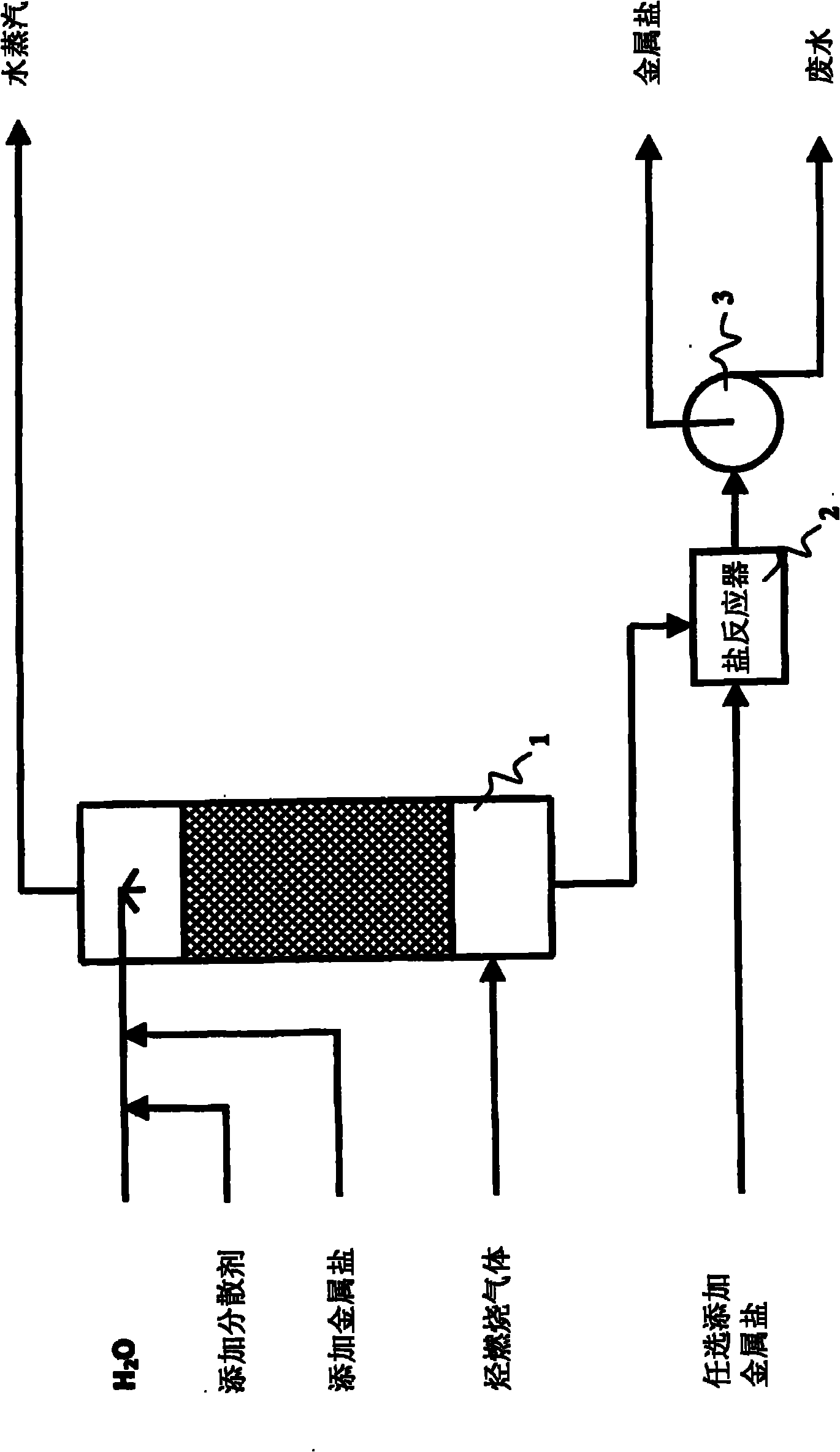

Methods, processes and apparatus of sequestering and environmentally coverting oxide(s) of carbon and nitrogen

InactiveUS20090087898A1Effectively and efficiently removed from a combustion exhaustEffectively and efficiently convertedBioreactor/fermenter combinationsNitrogen compoundsSulfateNitrogen

The instant invention presents improved means for sequestering COX and / or NOX in the aqueous phase of a gas scrubber. The instant invention presents means for the scrubbing of COX and / or NOX gas by chemically assimilating at least one of COX and NOX. The instant invention presents means for concentrating the COX and / or the NOX in the aqueous phase by creating a metal salt comprising the COX and / or the NOX. To control salt deposition, the instant invention presents means of chemical dispersion so that salt deposition can be controlled and the aqueous phase can become an efficient and effective carrier of the COX and / or the NOX. Means of controlling sulfide and sulfate emissions are presented incorporating sulfur consuming bacteria.

Owner:CLEARVALUE TECH

Gas purification apparatus and process using biofiltration and enzymatic reactions

InactiveUS20070048856A1Reduce the amount requiredGas treatmentDispersed particle separationHydrogenBicarbonate Ion

The invention provides a gas purification apparatus for purifying effluent gas by treating VOCs and the CO2 gas, comprising a biofiltration chamber containing micro-organisms for degrading the VOCs and producing a partially cleansed gas containing CO2 gas by-product; and an enzymatic chamber comprising an enzyme capable of catalyzing the hydration of the CO2 gas by-product into bicarbonate ions and hydrogen ions, to produce an ion rich solution and a purified gas. Additionally, a gas purification process is provided.

Owner:FPINNOVATIONS INC +1

Heat-Stable Carbonic Anhydrases and Their Use

The present invention relates to use of heat-stable carbonic anhydrase in CO2 extraction, e.g., from flue gas, natural gas or biogas. Furthermore, the invention relates to isolated polypeptides having carbonic anhydrase activity at elevated temperatures and isolated polynucleotides encoding the polypeptides. The invention also relates to nucleic acid constructs, vectors, and host cells comprising the polynucleotides.

Owner:NOVOZYMES AS

Triphasic process for gas effluent treatment

InactiveUS7579185B2Bioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseProduct gas

A triphasic bioreactor for physico-chemically treating a gas is disclosed. The triphasic bioreactor comprises a reaction chamber with a liquid and biocatalysts in suspension in the liquid, for catalyzing a reaction between the gas and the liquid to obtain a treated gas and a solution containing a reaction product. A gas bubbling means is provided in the reaction chamber for bubbling the gas to be treated into the liquid thereby dissolving the gas into the liquid and increasing a pressure inside the reaction chamber. The bioreactor further comprises a liquid inlet in fluid communication with the reaction chamber for receiving the liquid and filling the reaction chamber, a liquid outlet in fluid communication with the reaction chamber for releasing the solution and a gas outlet in fluid communication with the reaction chamber to release the treated gas. The bioreactor further comprises a retention device to retain the biocatalysts in the reaction chamber. The invention also concerns a process using the triphasic bioreactor. The triphasic bioreactor may advantageously be used for removing carbonic dioxide from a CO2-containing gas.

Owner:CO2 SOLUTION

Process and installation for the fractionation of air into specific gases

InactiveUS7514056B2Improve conversion performanceBioreactor/fermenter combinationsSolidificationHydration reactionCooling tower

In order to reduce incoming atmospheric carbon dioxide levels in compressed air prior to cryogenic distillation, a water spray cooling tower equipped with biocatalytic packing, or fed with absorptive reagents, is used to convert gaseous carbon dioxide into bicarbonate ions which dissolve in the cooling water. The hydration reaction and refrigeration occur synergistically. The bicarbonate ions are subsequently removed from the solution using the heat from the compressed air in a regenerator re-boiler unit, and then fed to a percolation cooling tower for releasing CO2 and cooling.

Owner:CO2 SOLUTION

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS8110395B2Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsLiquid degasificationCombustion systemLiquid medium

Owner:THE TRON GRP

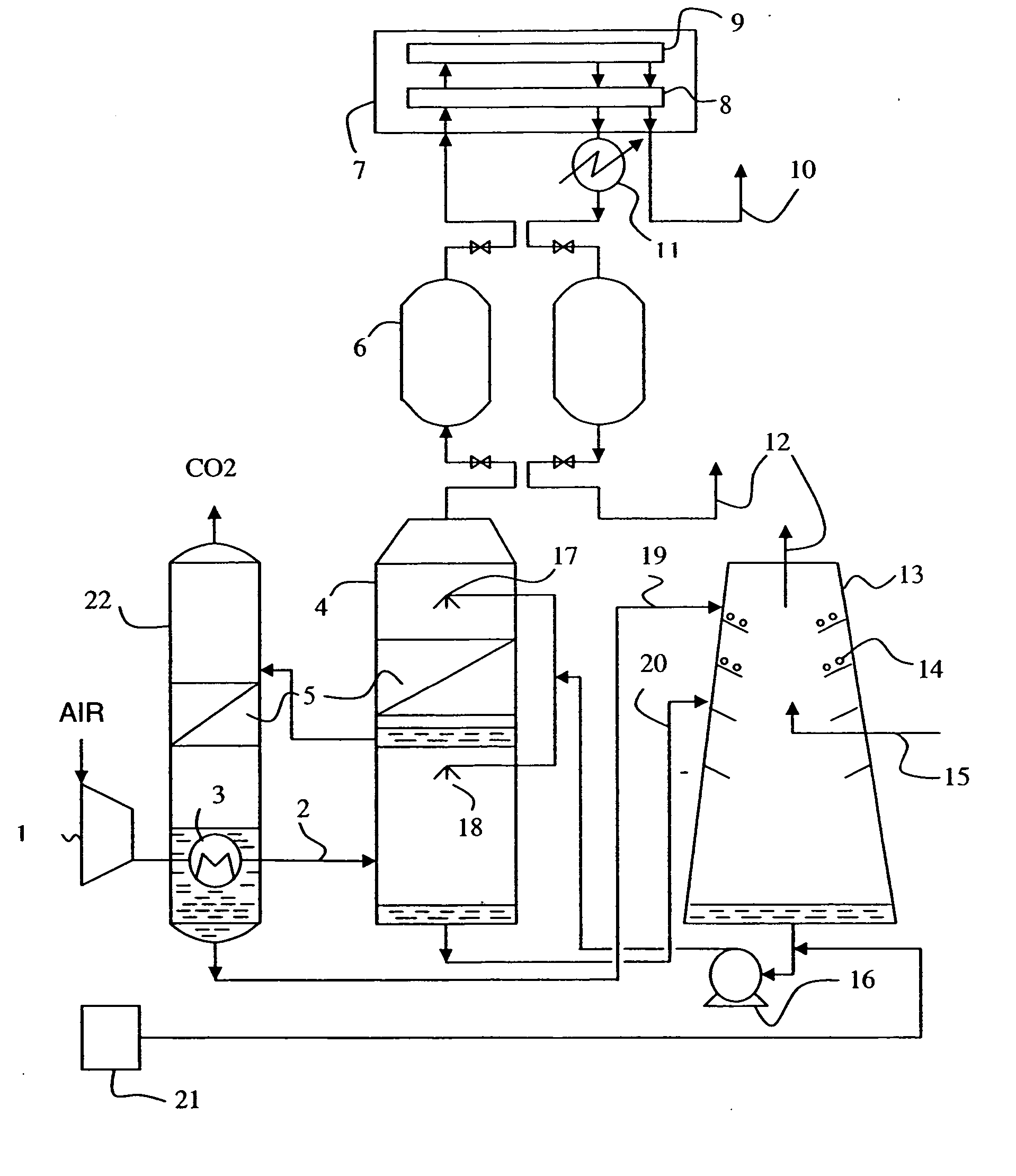

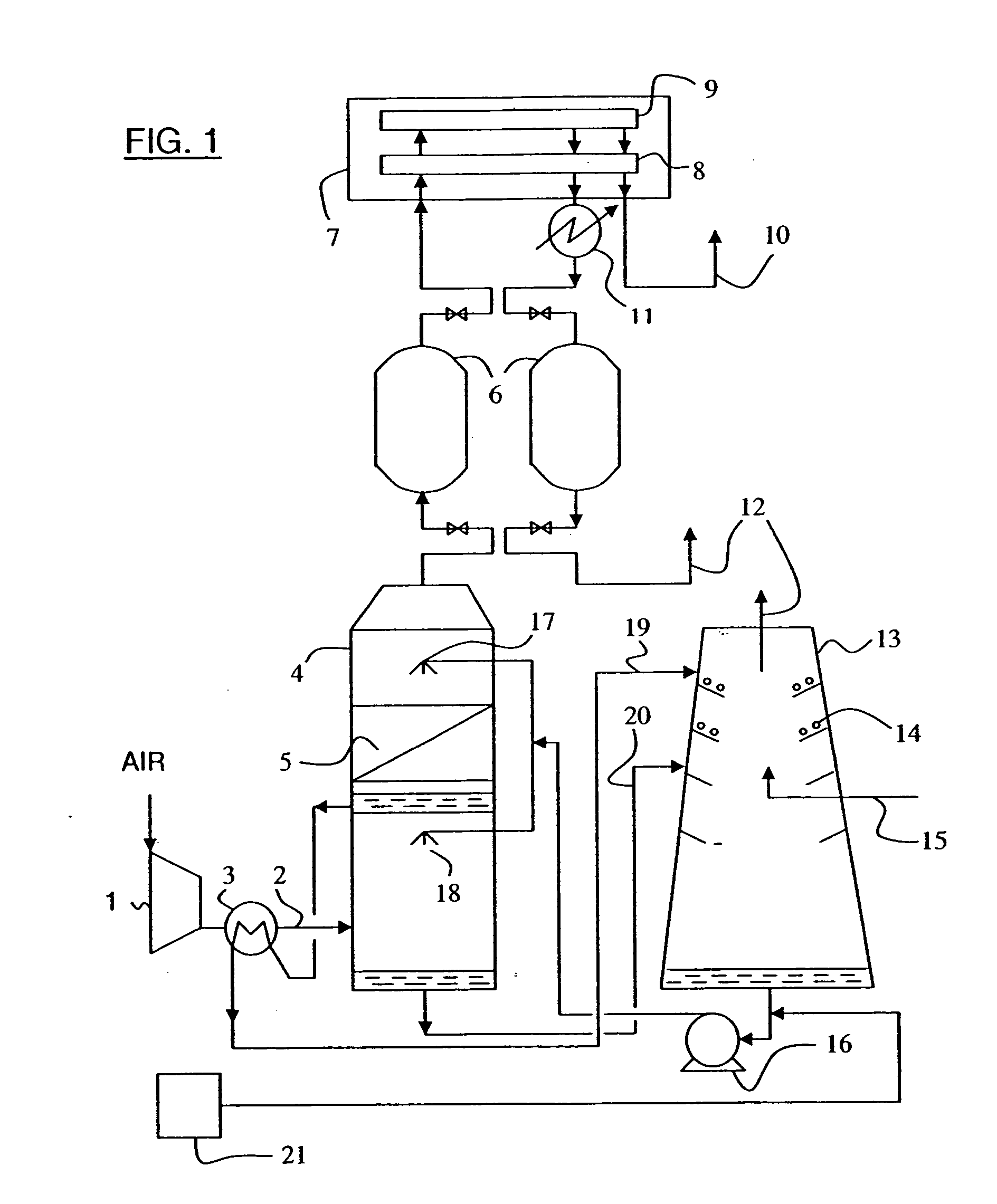

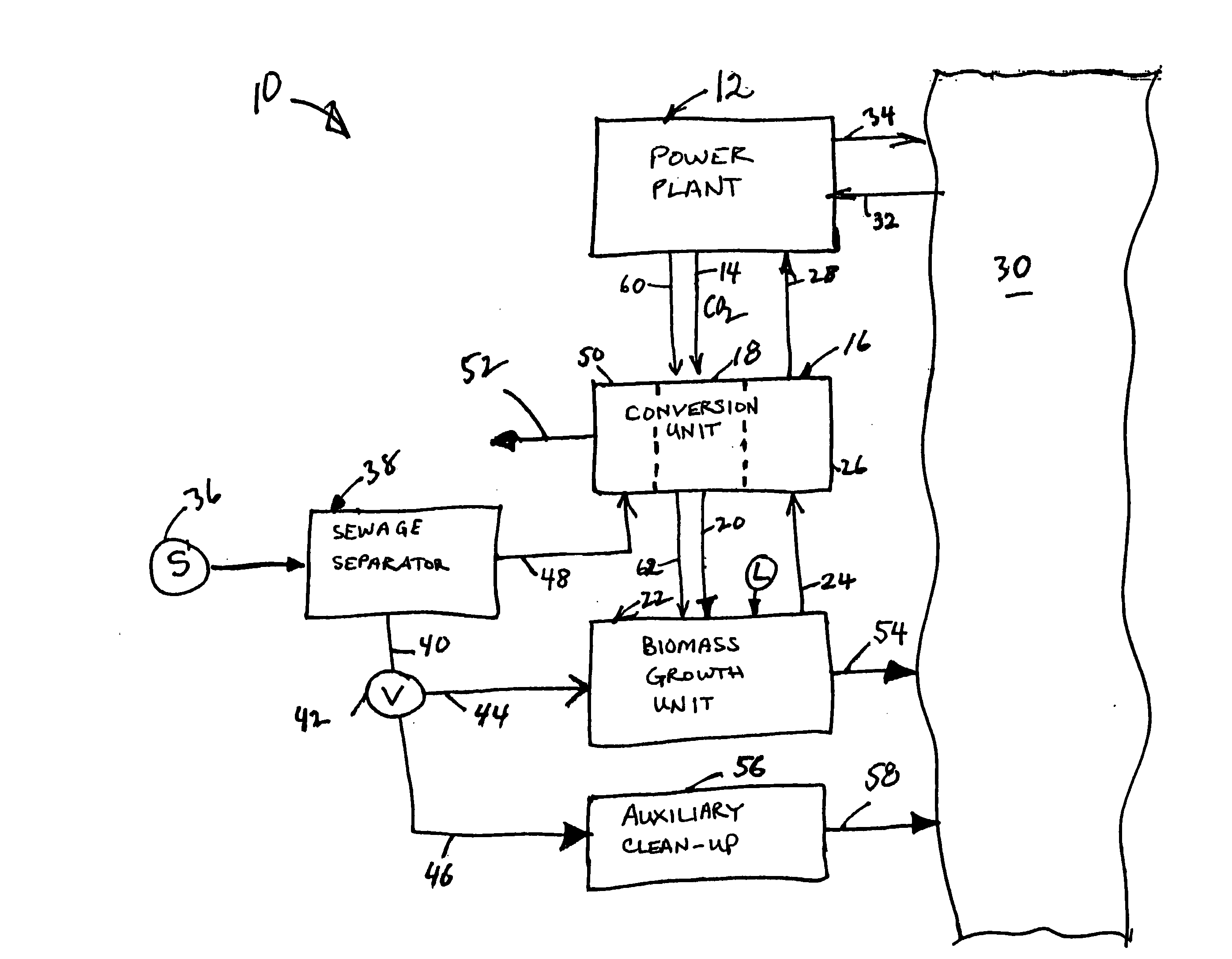

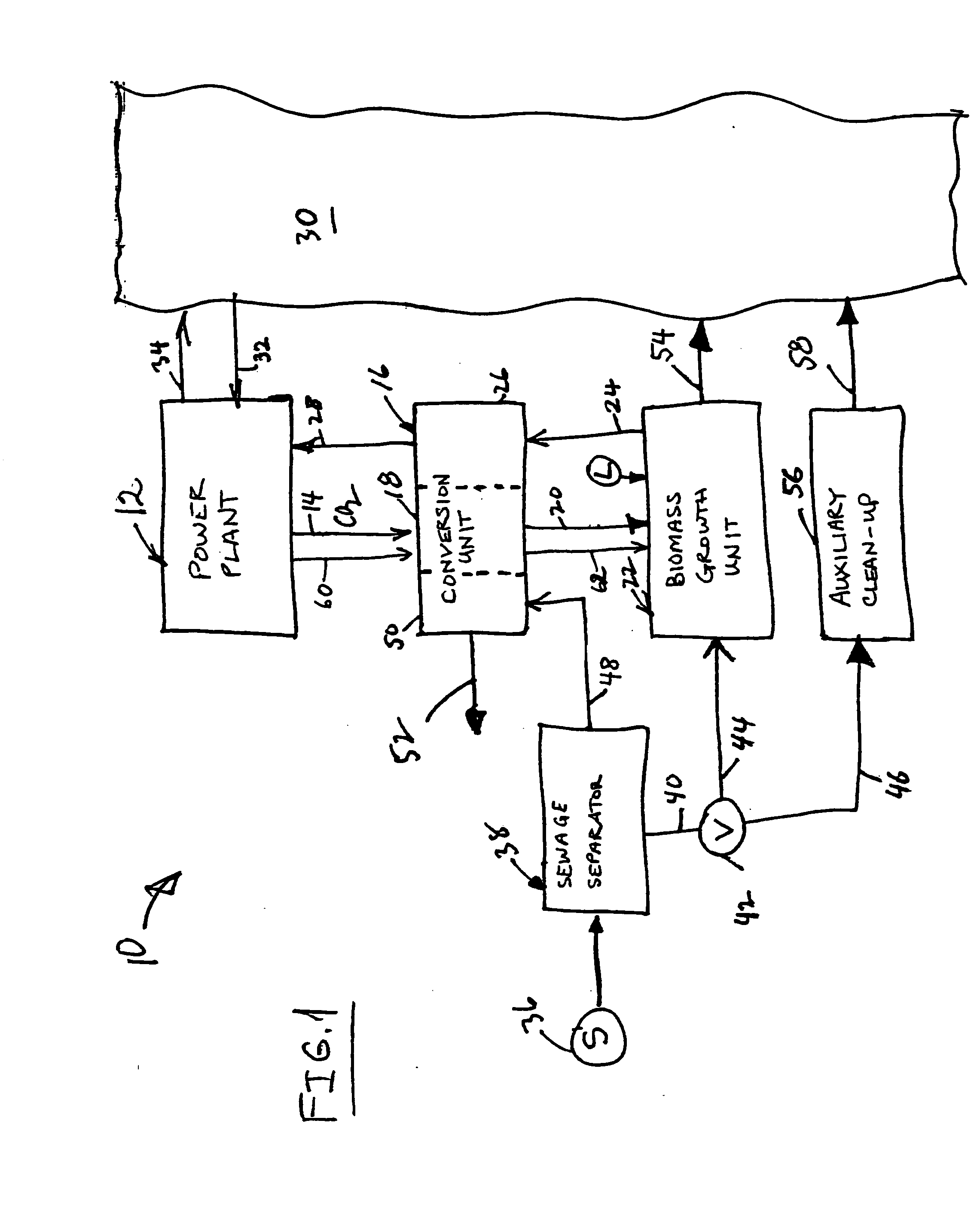

Integrated power plant, sewage treatment, and aquatic biomass fuel production system

InactiveUS20100003741A1Increased biomass generation rateReduce carbon dioxide emissionsBioreactor/fermenter combinationsBiological substance pretreatmentsWater useEngineering

Two waste products, nitrate-rich sewage wastewater and power plant CO2 emissions, are combined and converted into a renewable, biomass energy source, which supplies the fuel to the power plant. The power plant, wastewater treatment facility, and biomass growth unit are preferably located on one site and arranged for convenient transfer of the CO2 and wastewater to the biomass growth unit; harvesting, processing and return of biomass from the growth unit as fuel to the power plant; and discharge of the de-nitrated wastewater into the same body of water used as the heat sink by the power plant, e.g., a lake, river, or sound. The present invention thus provides an integrated approach to minimization of CO2 emissions and nitrate discharge while achieving improved efficiency in the generation and harvesting of the biomass.

Owner:FROMSON HOWARD A

Method for culturing microalgae by utilizing flue gas of coal fired power plant

ActiveCN102061261AHuge societyGreat economyUnicellular algaeDispersed particle separationPtru catalystProcess engineering

The invention relates to a method for culturing microalgae by utilizing flue gas of a coal fired power plant, comprising the following steps of: firstly, introducing flue gas to a CO removing tower, and leading the trace amount of CO and NO to generate CO2 and N2 under the catalysis of active semicoke; leading the flue gas from the CO removing tower to enter a desulfurizing tower again, oxidizingSO2 in the flue gas into SO3 under the catalysis action of active semicoke by utilizing O2 contained in the flue gas, and absorbing the SO3 on a catalyst; leading the flue gas to enter a denitrifyingtower after passing through the desulfurizing tower, oxidizing the NO in the flue gas into NO2 under the catalysis of active semicoke by utilizing the O2 contained in the flue gas, and absorbing the NO2 on the catalyst; and introducing the purified flue gas to a microalgae culturing device, fixing the CO2 in the flue gas by oily microalgae and then passing through a flue gas-flue gas heat exchanger, and finally, exhausting the residual flue gas through a chimney. In the method, the flue gas of a thermal power plant is taken as one of raw materials for microalgae culture, high-quality oily microalgae is obtained as oil-producing materials, not only the environment is governed, but also fuel is produced, therefore, the method has very important social, economic and environmental benefits.

Owner:OCEAN UNIV OF CHINA

Device and method for trapping carbon resources in atmosphere

ActiveCN103418235AOffset total annual emissions growthAchieve negative growthProductsCarbon compoundsBiosphereCarbon storage

Disclosed are a device and method for trapping carbon resources in the atmosphere. The method includes the following steps: (1), transferring gaseous CO2 in the atmosphere into the biosphere to form solid organic carbon compounds through photosynthesis of rank vegetation, trapping CO2 in the atmosphere, and converting the CO2 into organic carbon compounds through microorganisms or enzyme, (2), trapping CO2 in the atmosphere in a physical method, (3), trapping CO2 in the atmosphere in a chemical method, (4), trapping CO2 in the atmosphere in a physicochemical method, and (5), carrying out carbon storage and sealing storage on the carbon resources trapped from the atmosphere to achieve negative growth of atmospheric CO2, reduce partial pressure of atmospheric CO2 gas, adjust the greenhouse effect and solve relevant environmental problems, putting the stored carbon products into global carbon trading, and carrying out technical control over the cyclic process of carbon cycle, carbon conversion, carbon storage, carbon sealing storage and carbon utilization so that people can use carbon sources fully and reasonably. Manual cultivation and planting of the rank vegetation are new power for carbon cycles on the earth.

Owner:雷学军

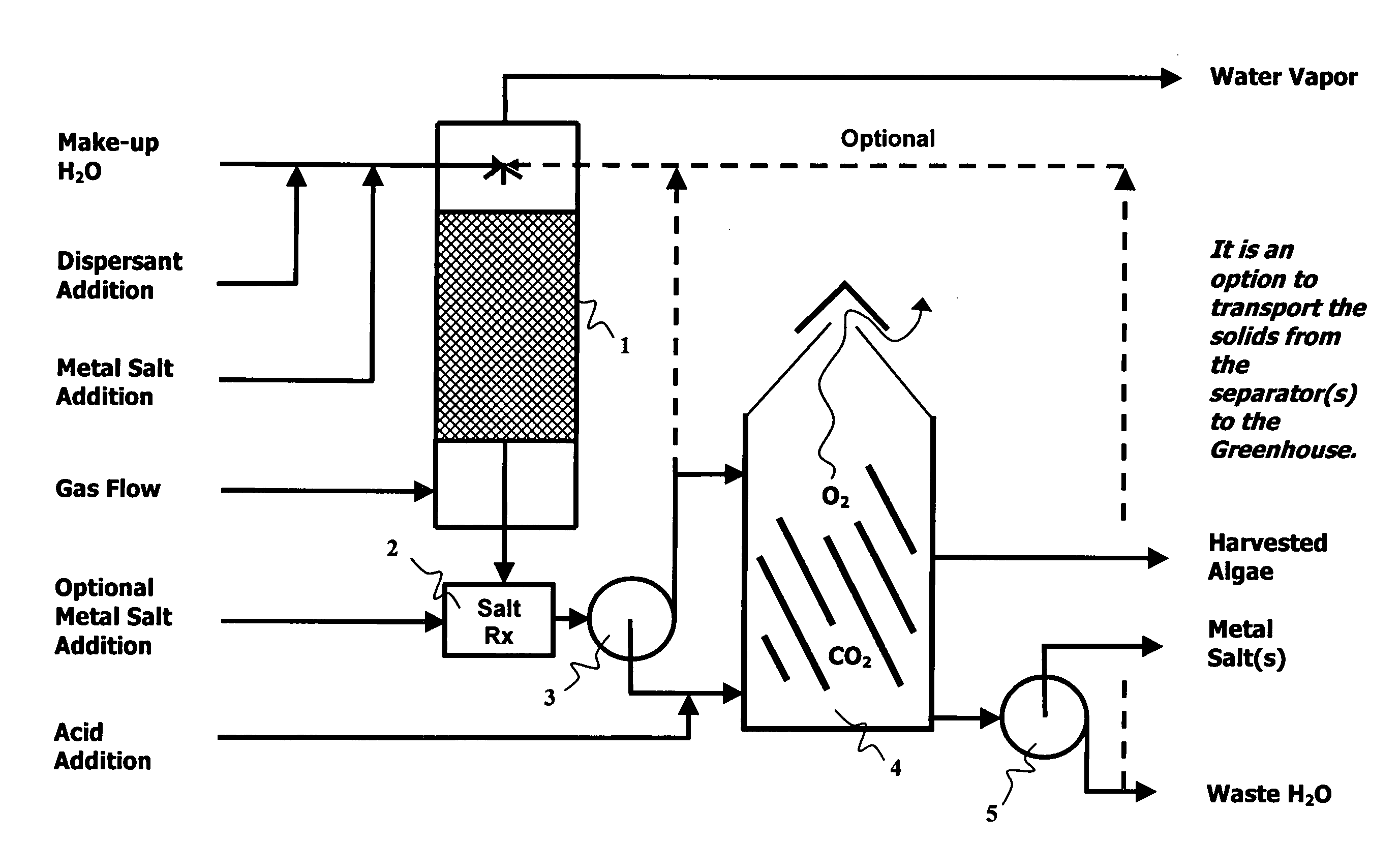

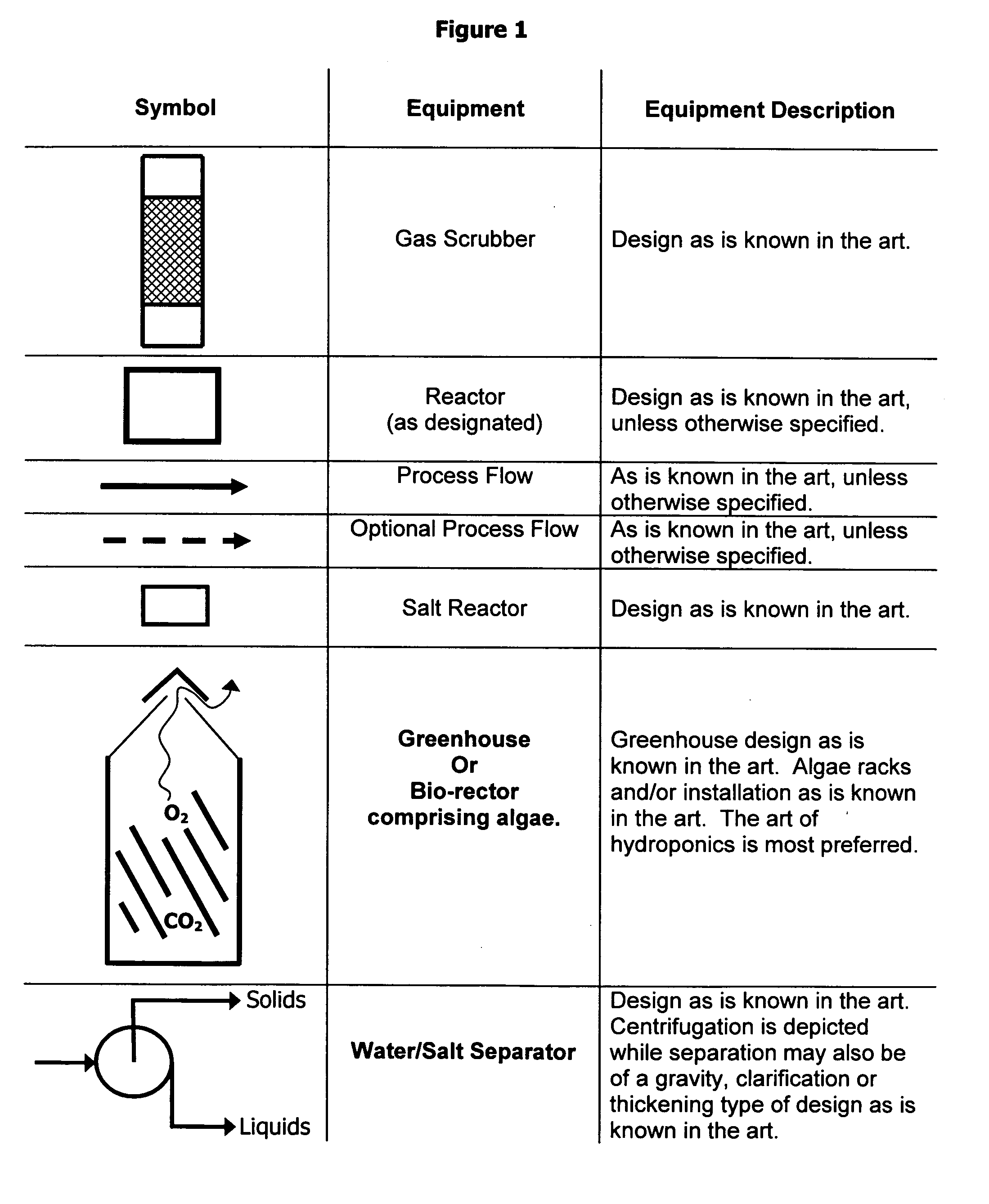

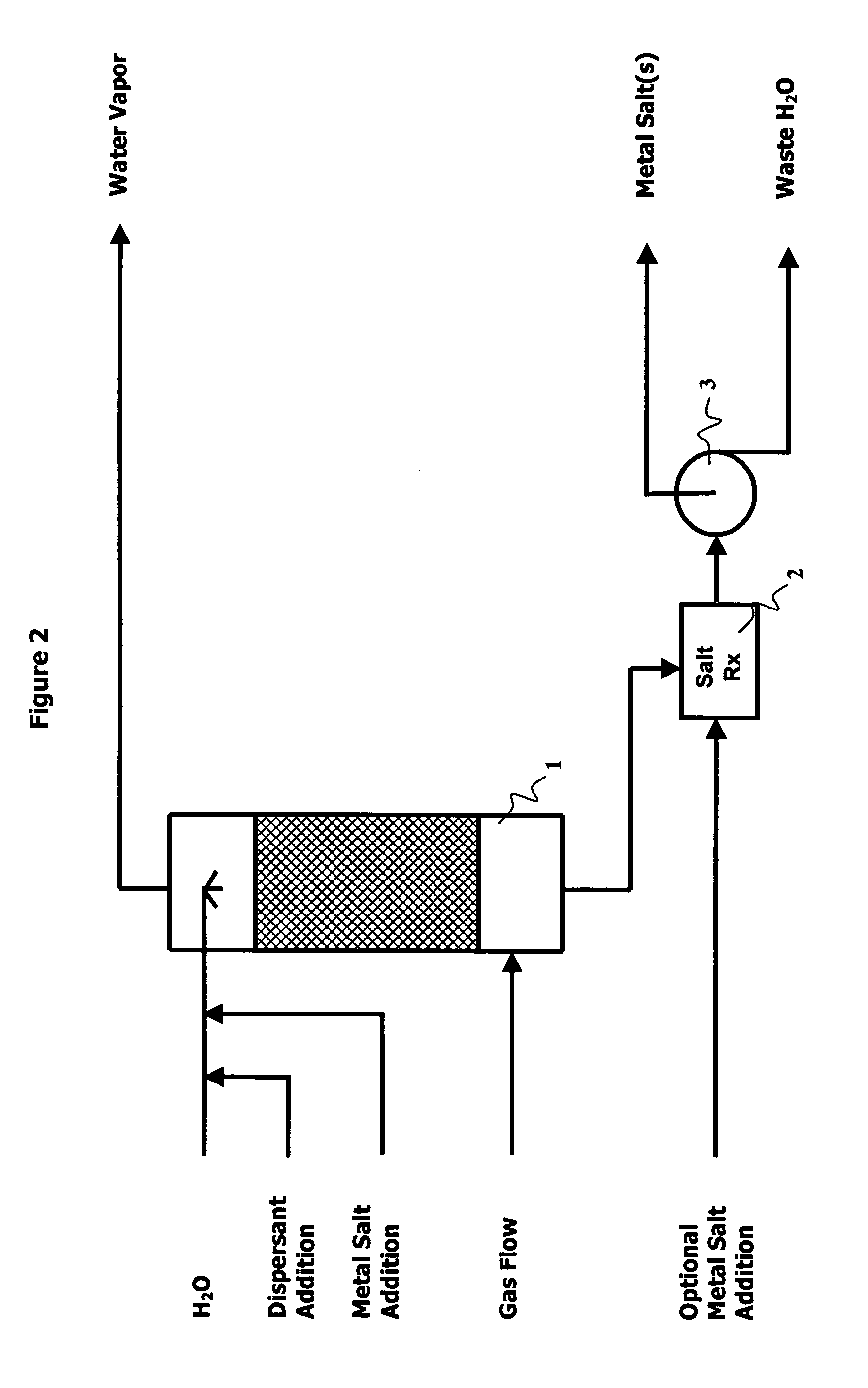

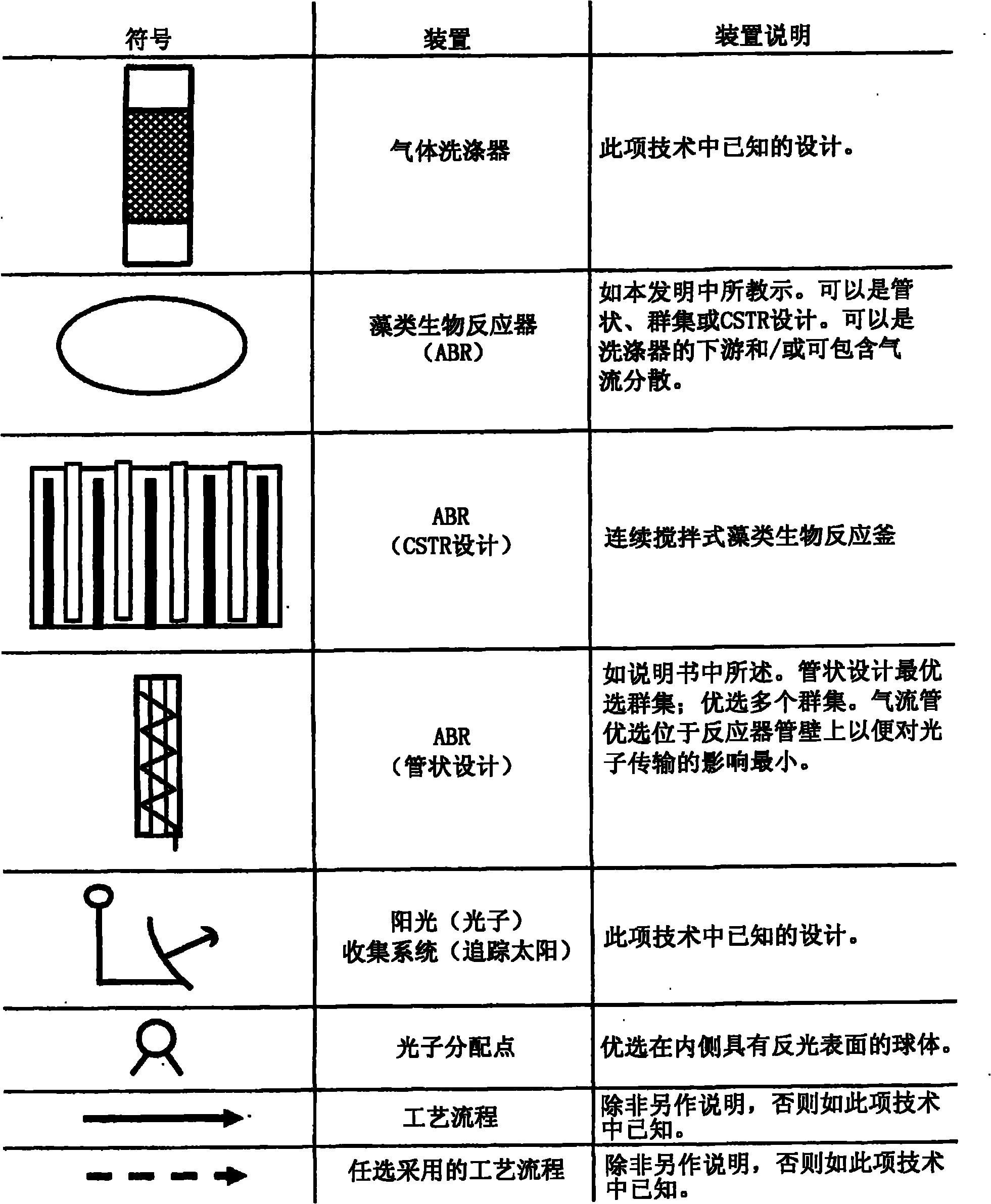

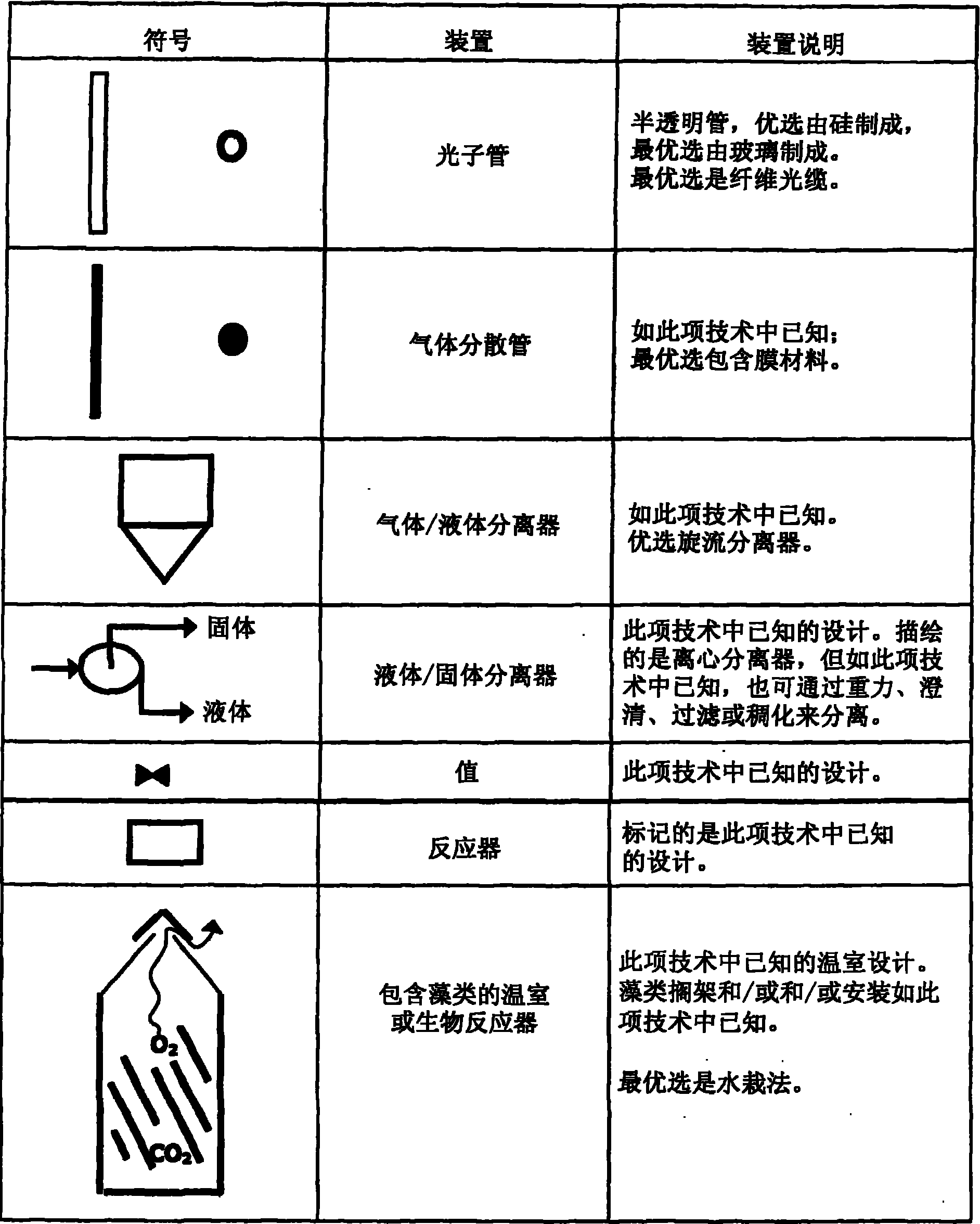

Means for sequestration and conversion of COx and NOx, CONOx

InactiveCN101918110AInexpensive and safe to removeBroad appealBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSulfide

The instant invention presents means for sequestering COx and NOx; further comprising algae means to convert COx into oxygen (O2), as well as biological means to convert sulfides into elemental sulfur. The instant invention comprises algae, heterotrophs, facultative bacteria and Thiobacillus. The instant invention comprises means of light (photon) transfer. Fiber optics is a means of photon transfer to provide photons to a biological reactor. The instant invention comprises the photon depth adsorption capability of algae in biological reactor means. The instant invention comprises means of energy management so that the instant invention may be used in most any environment, wherein a photon (light) source is available and can comprise a means of photon source generation when a light source is not available.

Owner:理查德·艾伦·哈斯

Diesel exhaust gas scrubbing method for carbon dioxide removal

InactiveUS20090162922A1Minimize impactReducing carbon dioxideCombination devicesGas treatmentExhaust fumesDiesel exhaust

Systems and methods for removing carbon dioxide from gas, e.g., diesel exhaust gas, are provided. The systems involve uptake of carbon dioxide by algae in water to which the gas is exposed.

Owner:CARBON CAPTURE CORP

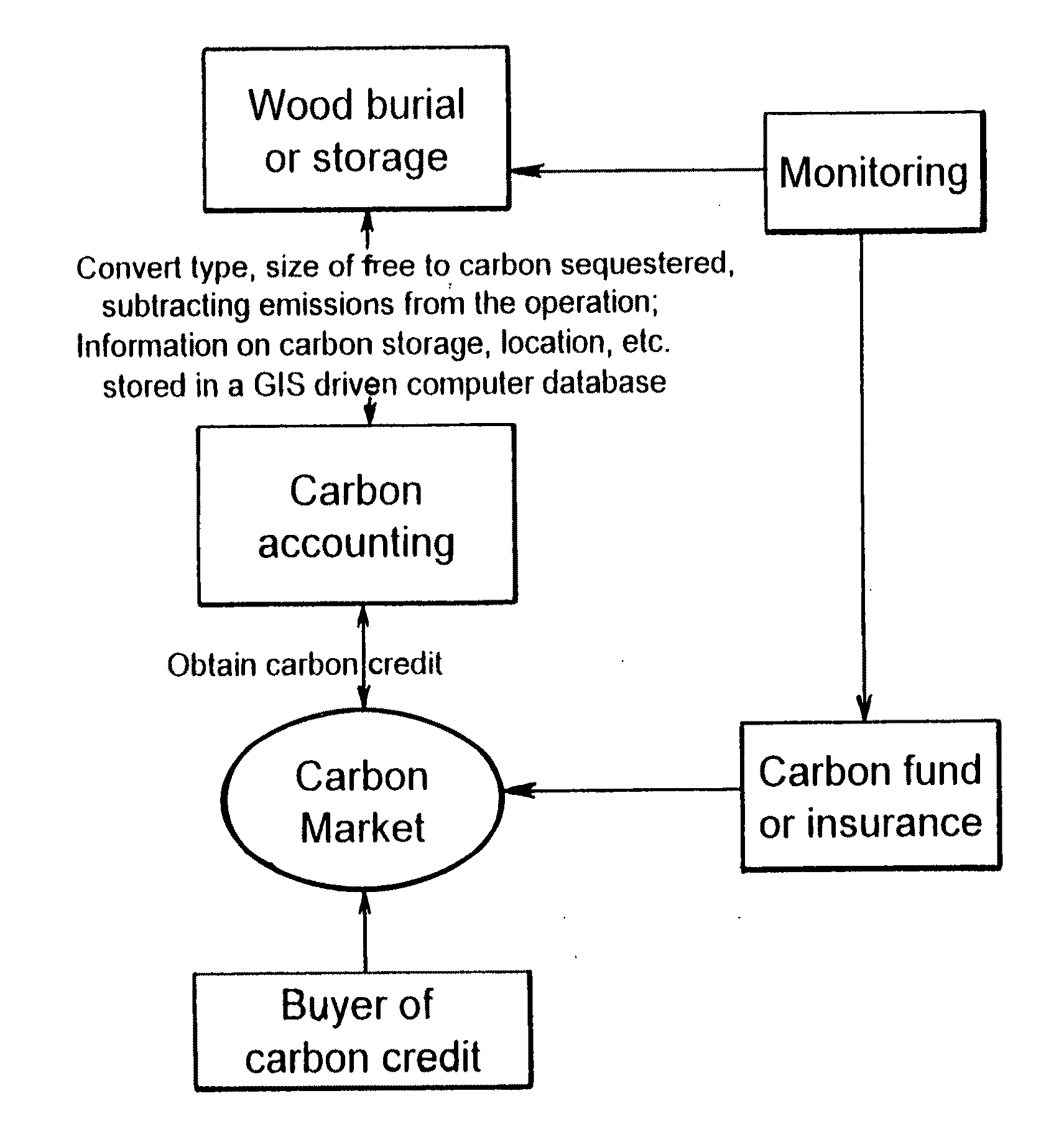

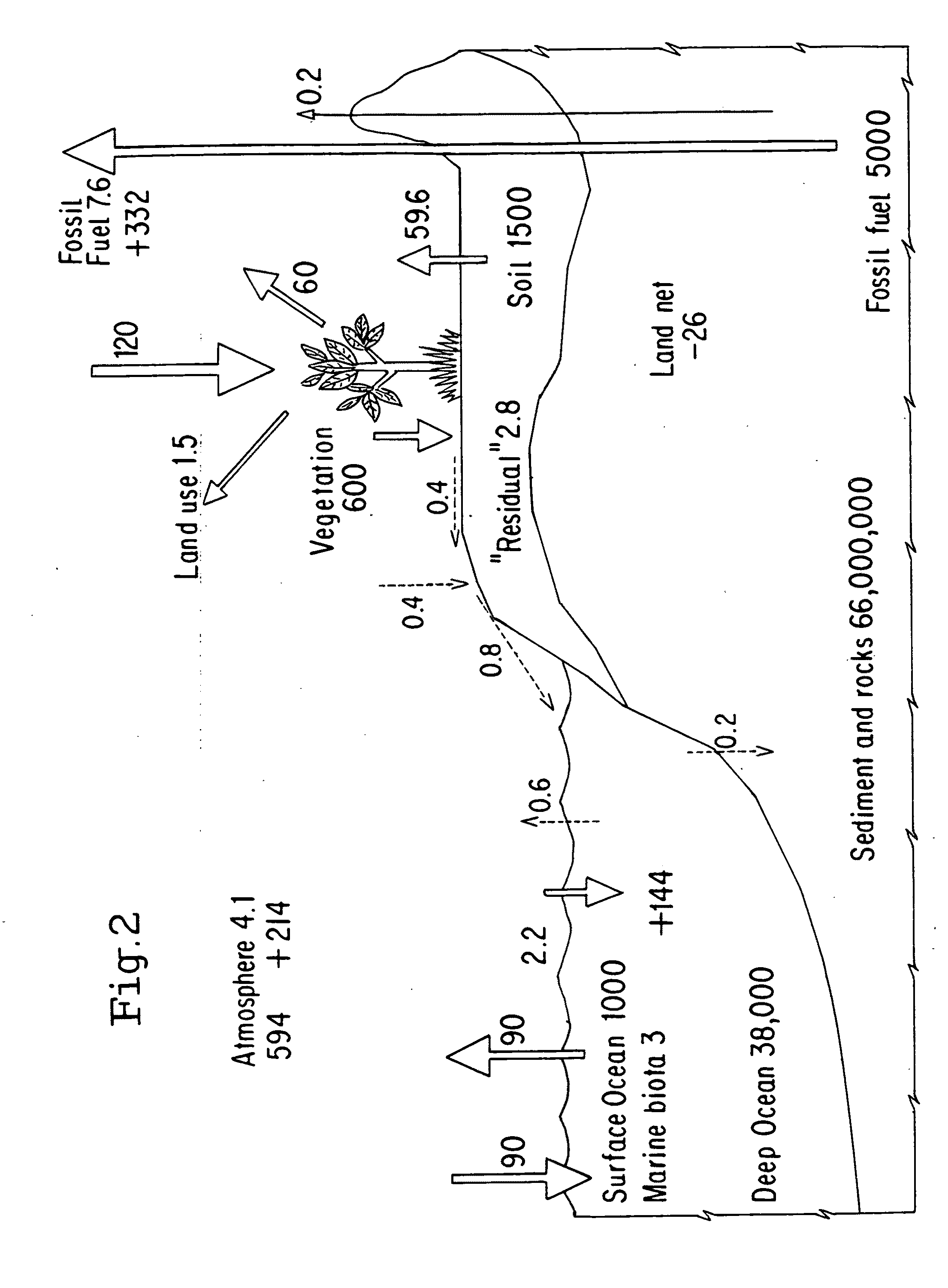

Carbon sequestration via wood burial and storage

InactiveUS20100145716A1Reduce decompositionLow techHydrogen sulfidesDispersed particle separationAbove groundLiving tree

To mitigate global climate change, a portfolio of strategies will be needed to keep the atmospheric CO2 concentration below a dangerous level. Here a carbon sequestration strategy is proposed in which certain dead or live trees are harvested via collection or selective cutting, then buried in trenches or stowed away in above-ground shelters. The largely anaerobic condition under a sufficiently thick layer of soil will prevent the decomposition of the buried wood. Because a large flux of CO2 is constantly being assimilated into the world's forests via photosynthesis, cutting off its return pathway to the atmosphere forms an effective carbon sink.

Owner:ZENG NING

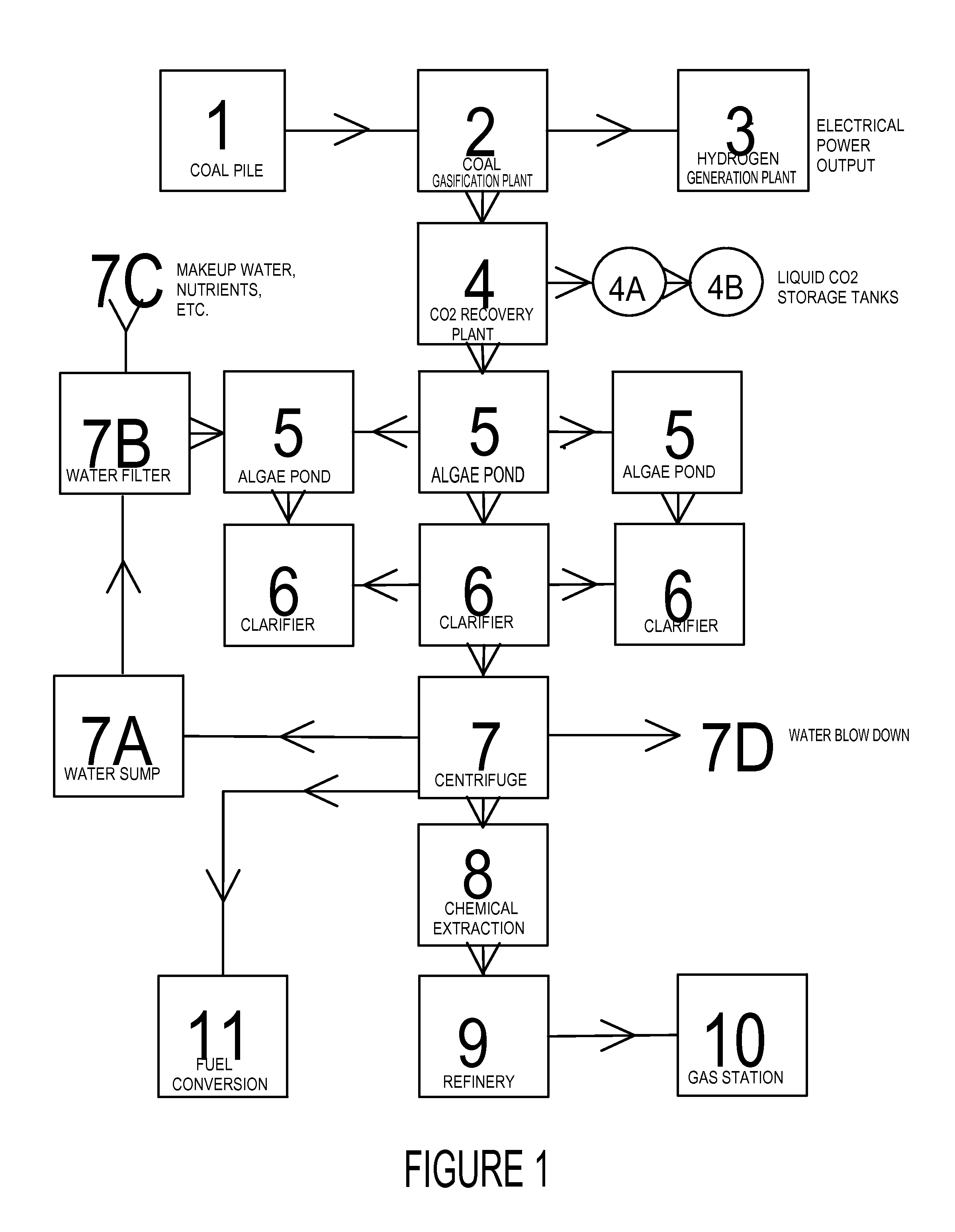

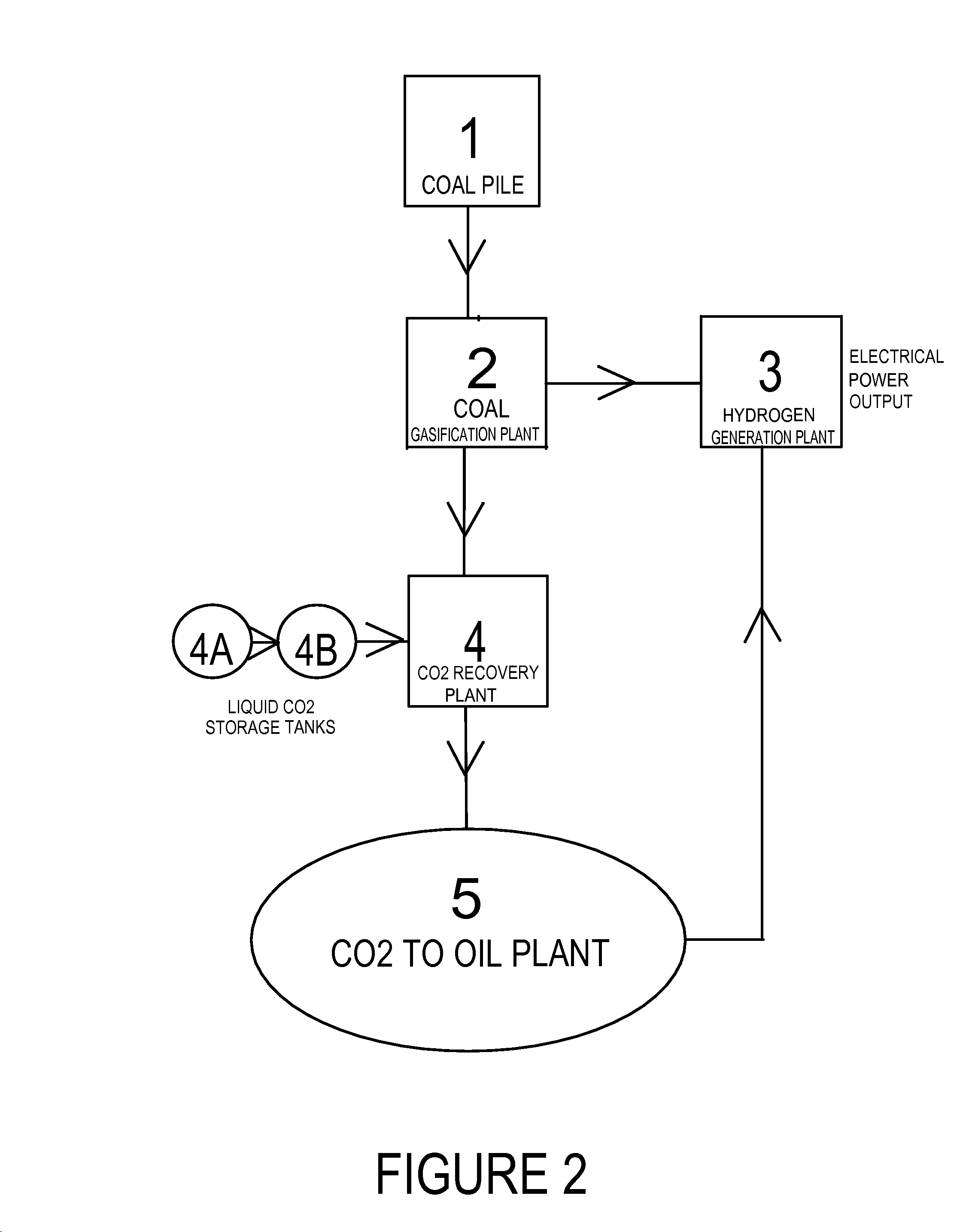

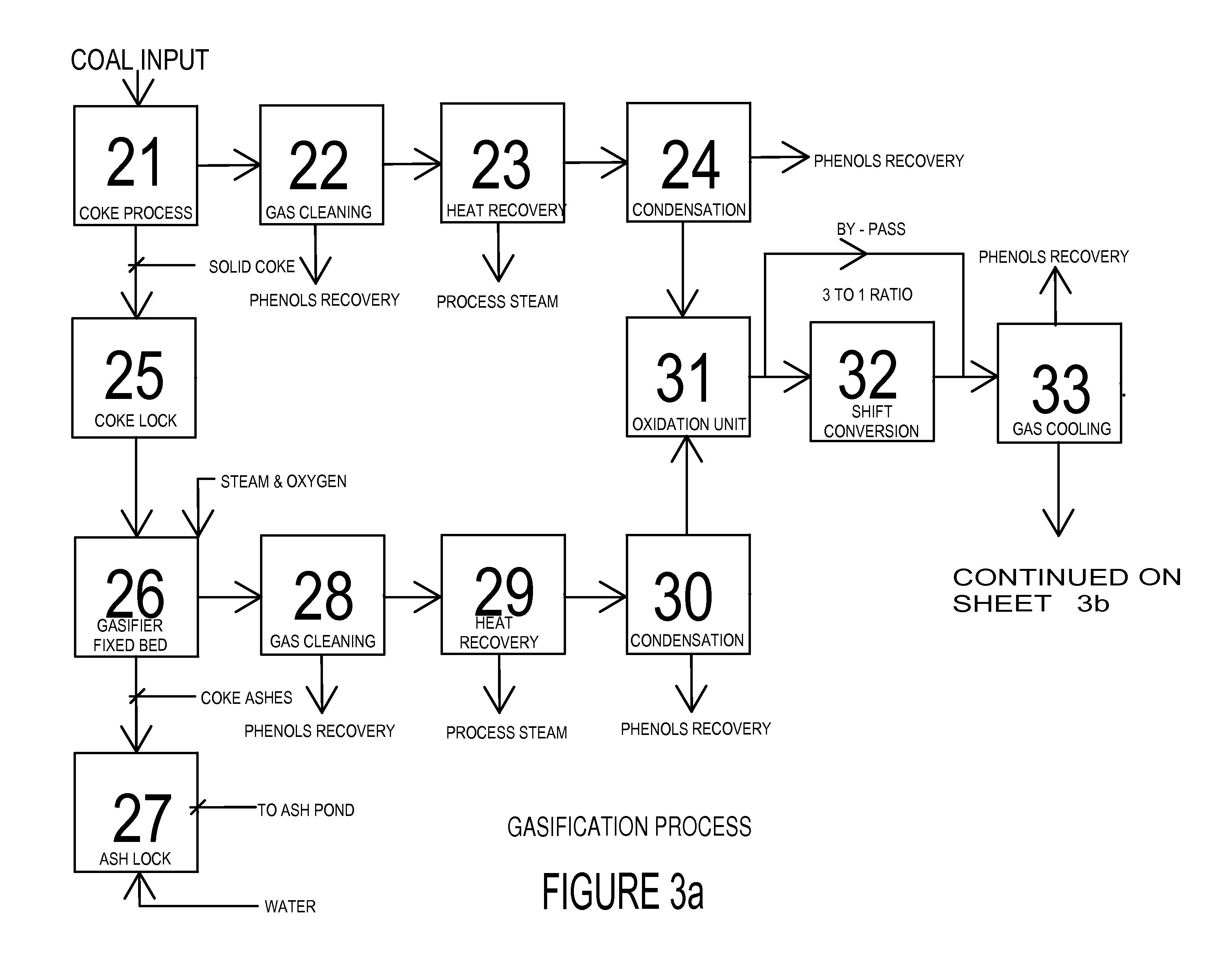

Method for capture carbon & storage (CCS process) from coal fuel gas and the storage as biofuels: oil, gasoline, biodiesel, jet fuel, ethanol, and methane

A Capture Carbon Storage (CCS) Process for the economical capture of carbon dioxide from coal fuel gas, and the storage of the carbon dioxide as lipid oil or the use of the environmentally begin oil for transportation. The lipid oil may be refined into gasoline, biodiesel fuel, jet fuel, ethanol, and methane which provide a renewable energy resource for the United State's future energy needs. It is a new fuel form which has been both chemically and physically altered to reduce the emissions of carbon dioxide. It is a coal cleaning / upgrading process which produces a refined fuel, Hydrogen, that may be used to produce electricity and an environmentally begin biofuel for transportation. The renewable fuel will produce no carbon foot print at the internal combustion engine's exhaust pipe. The CCS Process will produce a 100% reduction in carbon dioxide (CO2) emissions into the atmosphere and thereby, stop the Global Warming.

Owner:HEICHBERGER ALBERT NORMAN

Triphasic process for gas effluent treatment

InactiveUS20070128713A1Bioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseBioreactor

Owner:CO2 SOLUTION

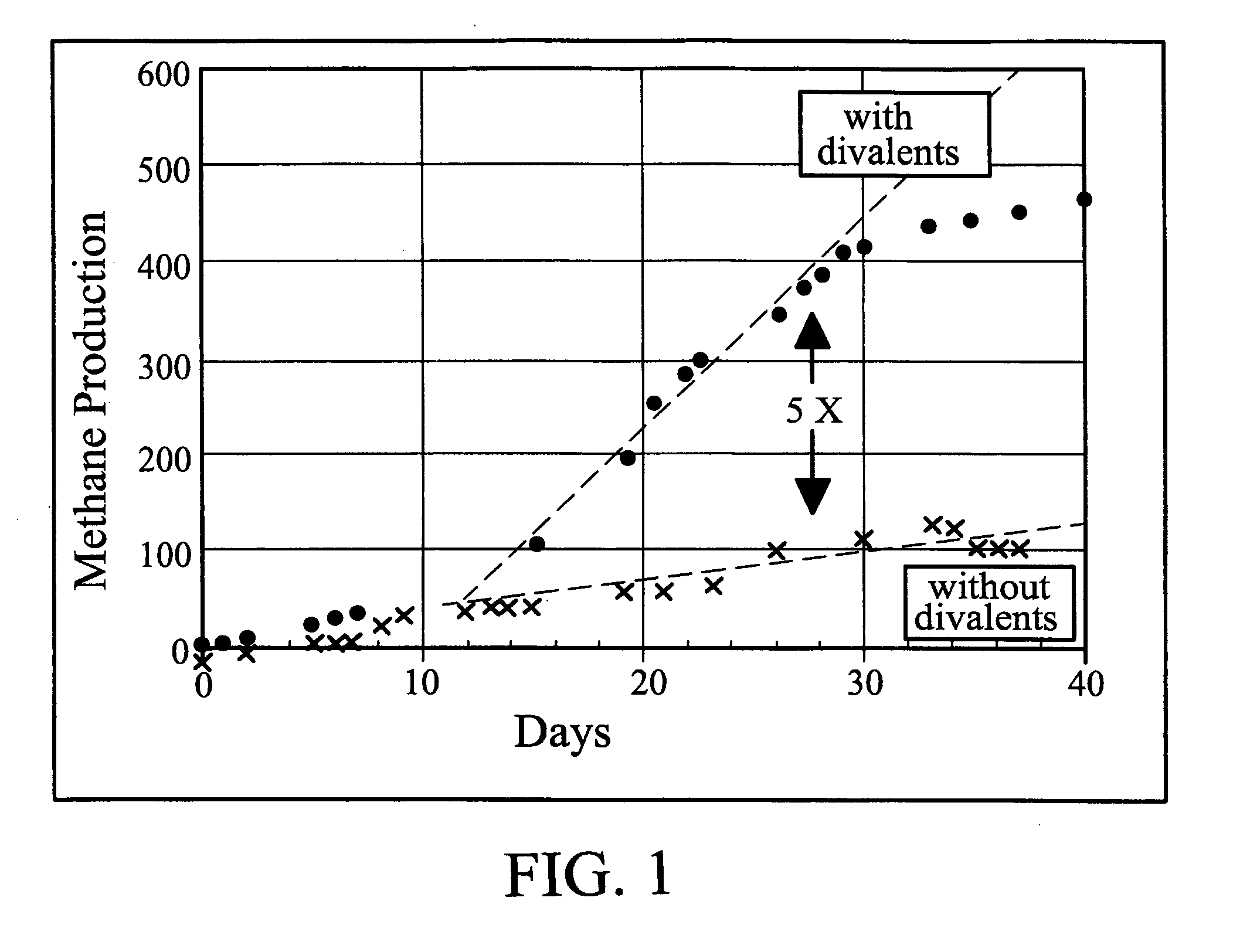

Biological methane production from coal, manure, sludge, wastes, or other carbonaceous feedstocks with simultaneous sequestration of co2

ActiveUS20100093049A1Reduce capacityReduce gas contentProductsGas treatmentParticulatesAlkaline earth metal

The present invention provides a method for generating methane from a carbonaceous fuel source with simultaneous sequestration of carbon dioxide, the method comprising anaerobically incubating a particulate alkaline earth metal salt in contact with a particulate and / or dissolved carbonaceous feedstock in a neutral or alkaline aqueous culture medium containing a culture of methanogenic bacteria consortia and collecting methane generated therefrom. At least a portion of carbon dioxide produced during the incubation reacts with the alkaline earth metal salt to form an alkaline earth metal carbonate, thereby sequestering the carbon dioxide.

Owner:UCHICAGO ARGONNE LLC

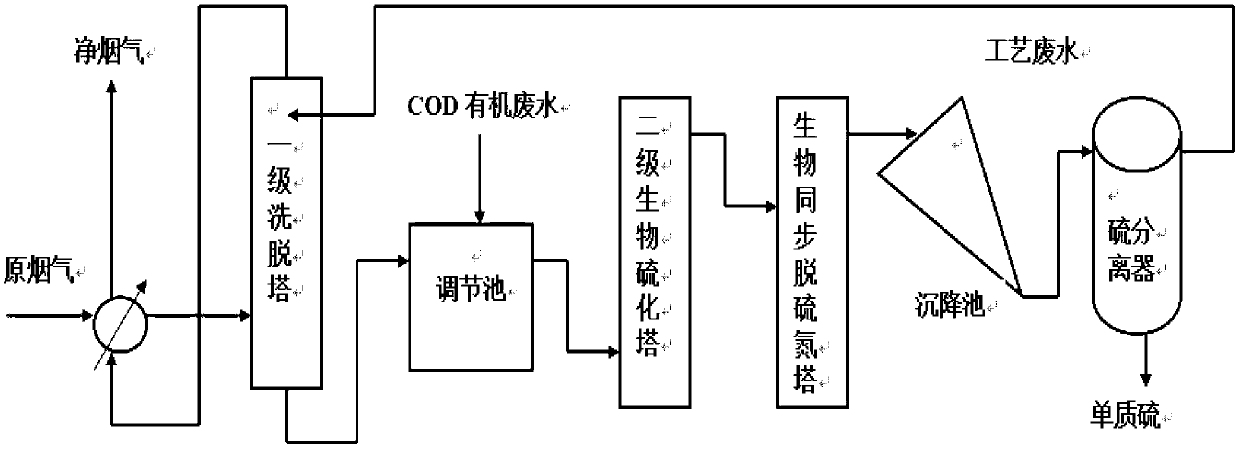

Method and device for synchronously removing sulfur dioxide and nitric oxide by flue gas biological method

InactiveCN102989272AEasy to handleLow costProductsNitrogen preparationVulcanizationChemical oxygen demand

The invention relates to a method and a device for synchronously removing sulfur dioxide and nitric oxide by a flue gas biological method. The device is formed by connecting a primary eluting tower, an adjusting tank, a secondary biological vulcanization tower, a biological synchronous desulfurization and denitrification tower, a sedimentation tank and a sulfur separator in series. A flue gas purification treatment technology has low inflowing air requirements, is not afraid of dust and heavy metal and does not need strict pre-treatment. Corresponding microorganisms are added into a biological flora to effectively remove heavy metal. Meanwhile, a synchronous desulfurization and denitrification flora is autotrophic bacteria and has certain removing effect on CO2. An operation condition is moderate and the equipment does not need to be antiseptic. Besides, an external substance such as COD (Chemical Oxygen Demand) organic wastewater, only few microorganism nutrient substances and supplementing alkali for adjusting and controlling a pH (Potential of Hydrogen) value in the eluting tower need to be added; and a temperature needed by a rear-end biological reaction is maintained through heat obtained by front-end heat exchange. In a process, large-sized power consumption equipment is not needed; and the device and the method have the advantages that electric power consumption and water consumption are low compared with a conventional treatment process. Compared with the conventional cost, the cost of the whole process is 1 / 3 that of the conventional process, and the industrial production can be realized.

Owner:TIANJIN UNIV

Popular searches

Biochemistry cleaning apparatus Biomass after-treatment Energy based wastewater treatment Liquid hydrocarbon mixture production Photobioreactors Enzymology/microbiology apparatus Tissue/virus culture apparatus Biological synthesis Biological water/sewage treatment Specific use bioreactors/fermenters

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com